Patents

Literature

5420 results about "Metal particle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

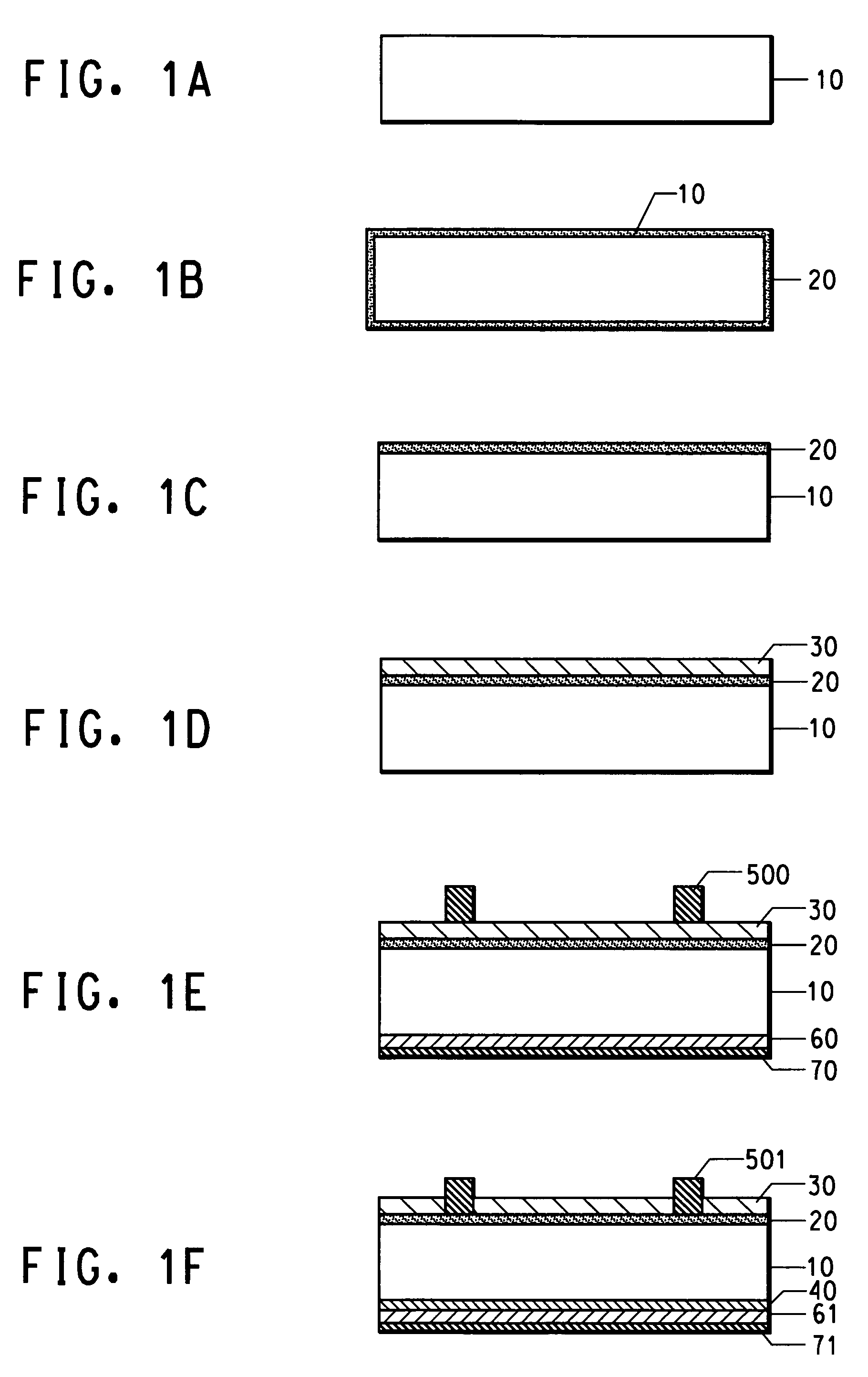

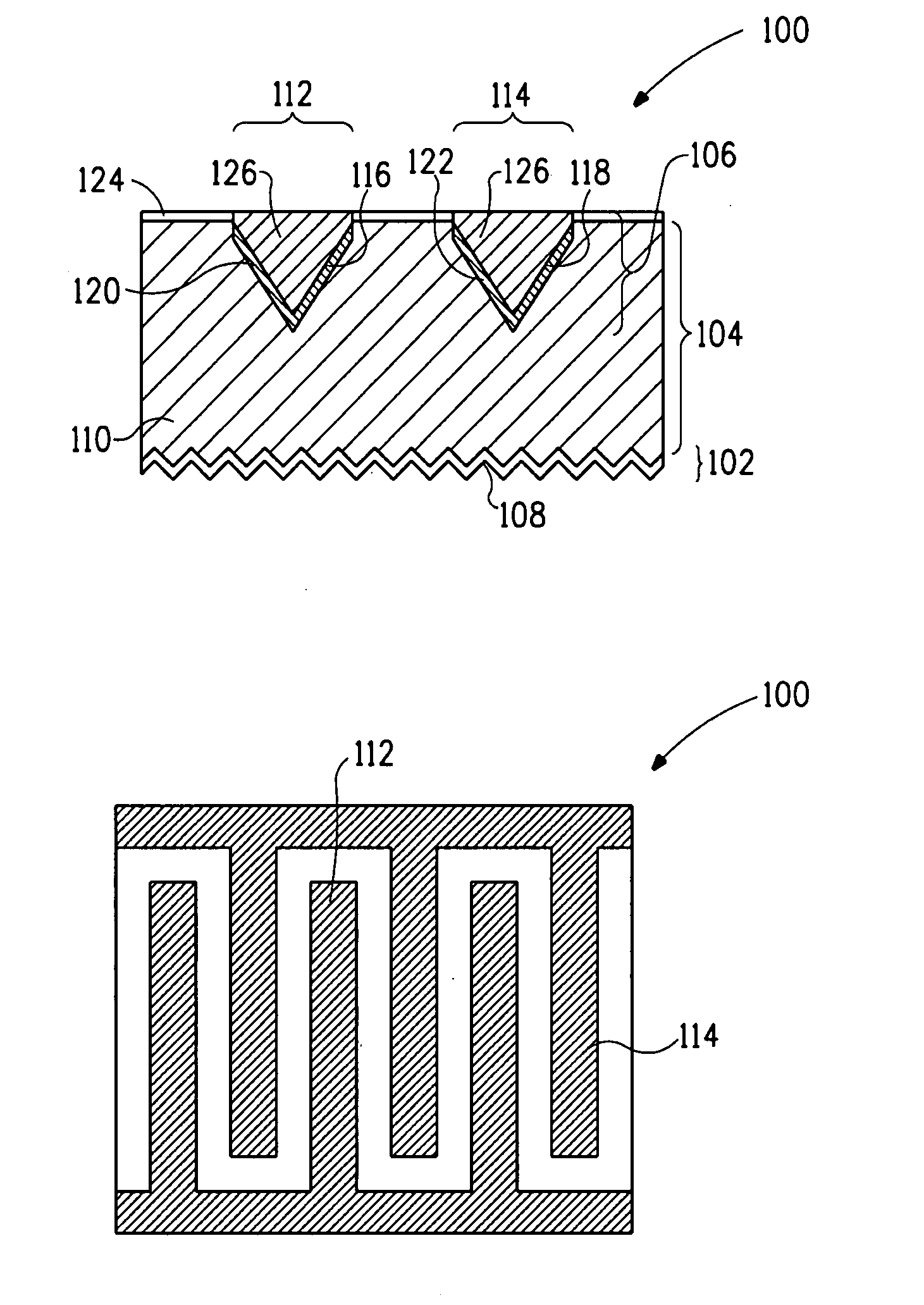

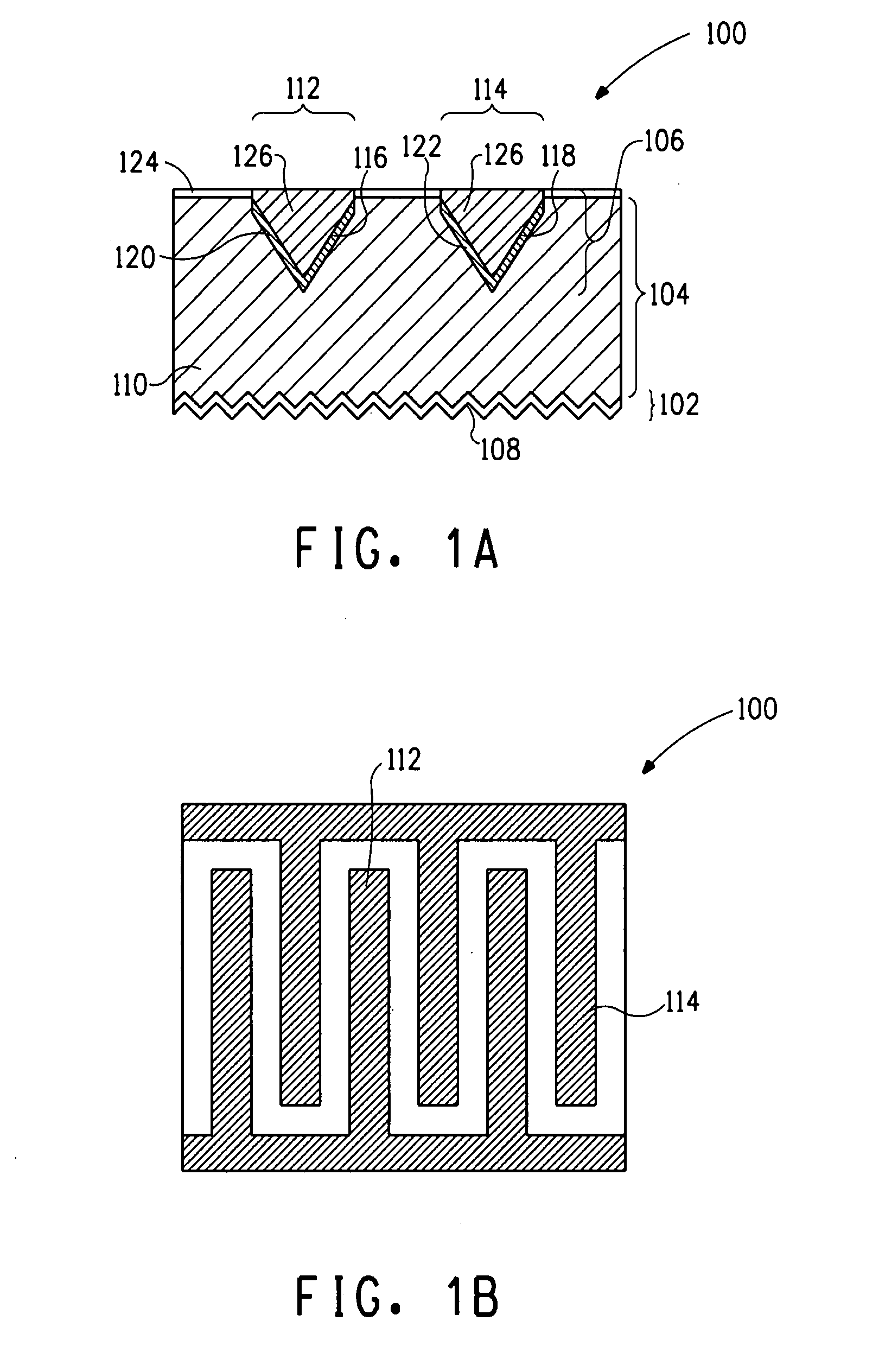

Film forming method, semiconductor device, manufacturing method thereof and substrate processing apparatus therefor

InactiveUS8785311B2Solid-state devicesSemiconductor/solid-state device manufacturingSemiconductor materialsSilanes

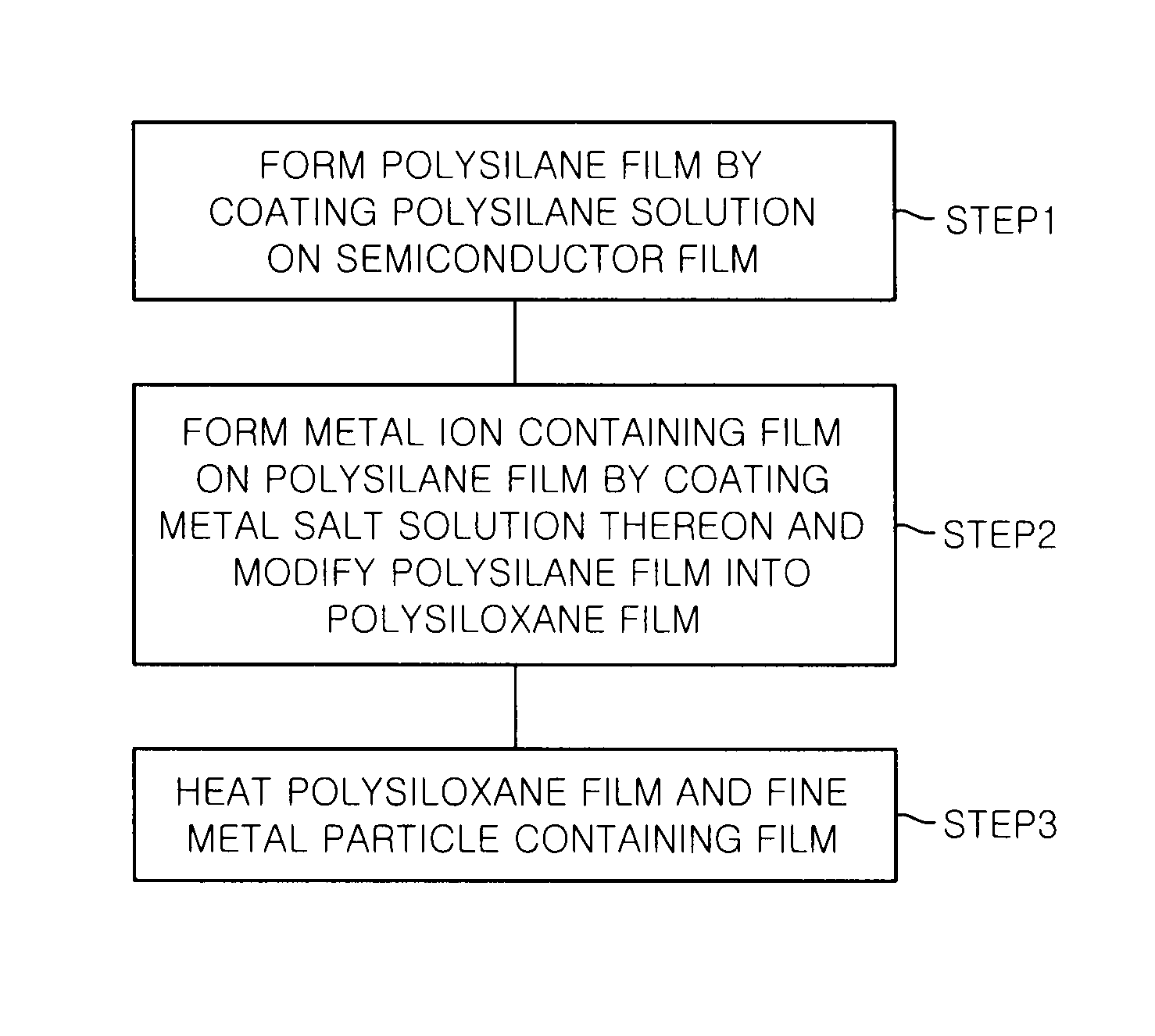

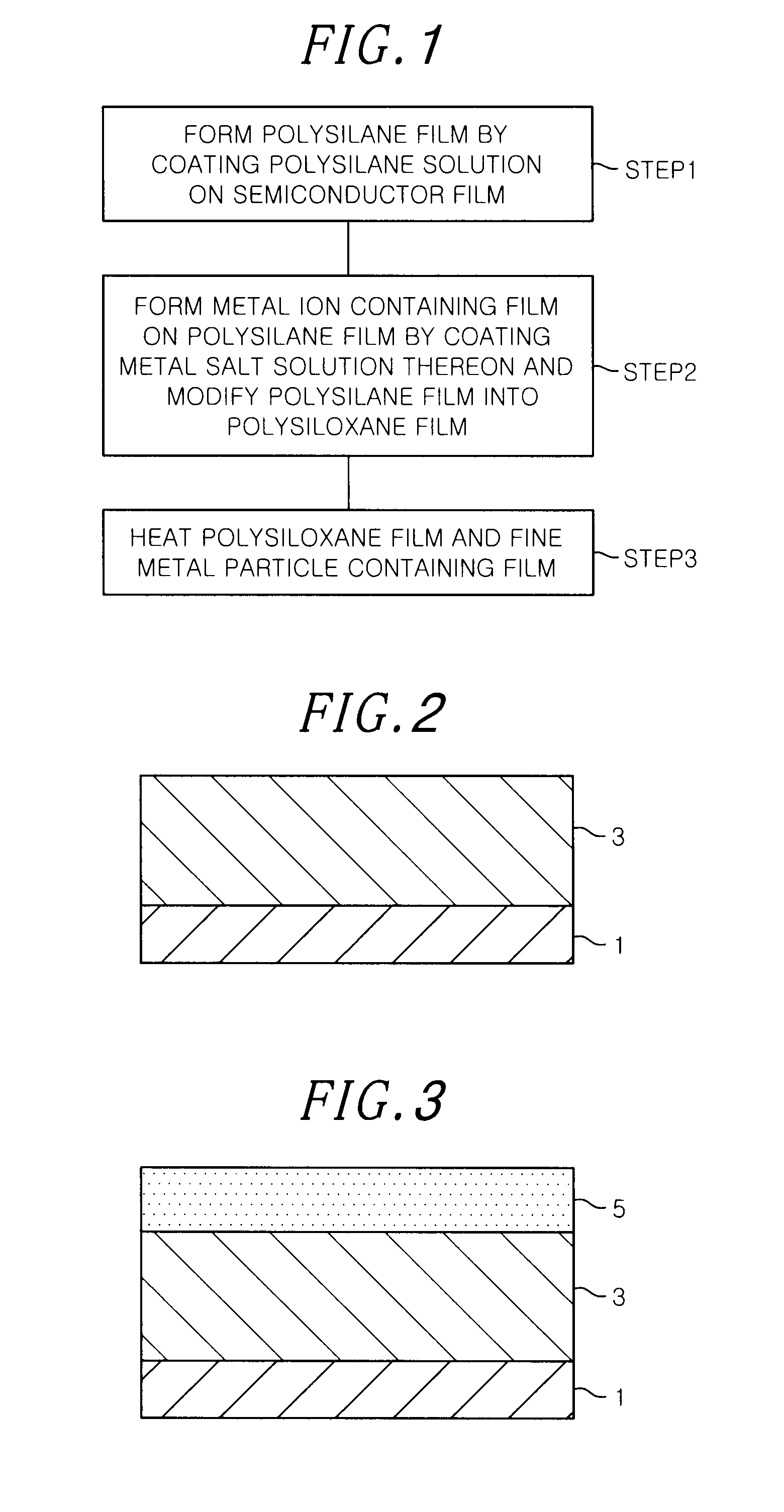

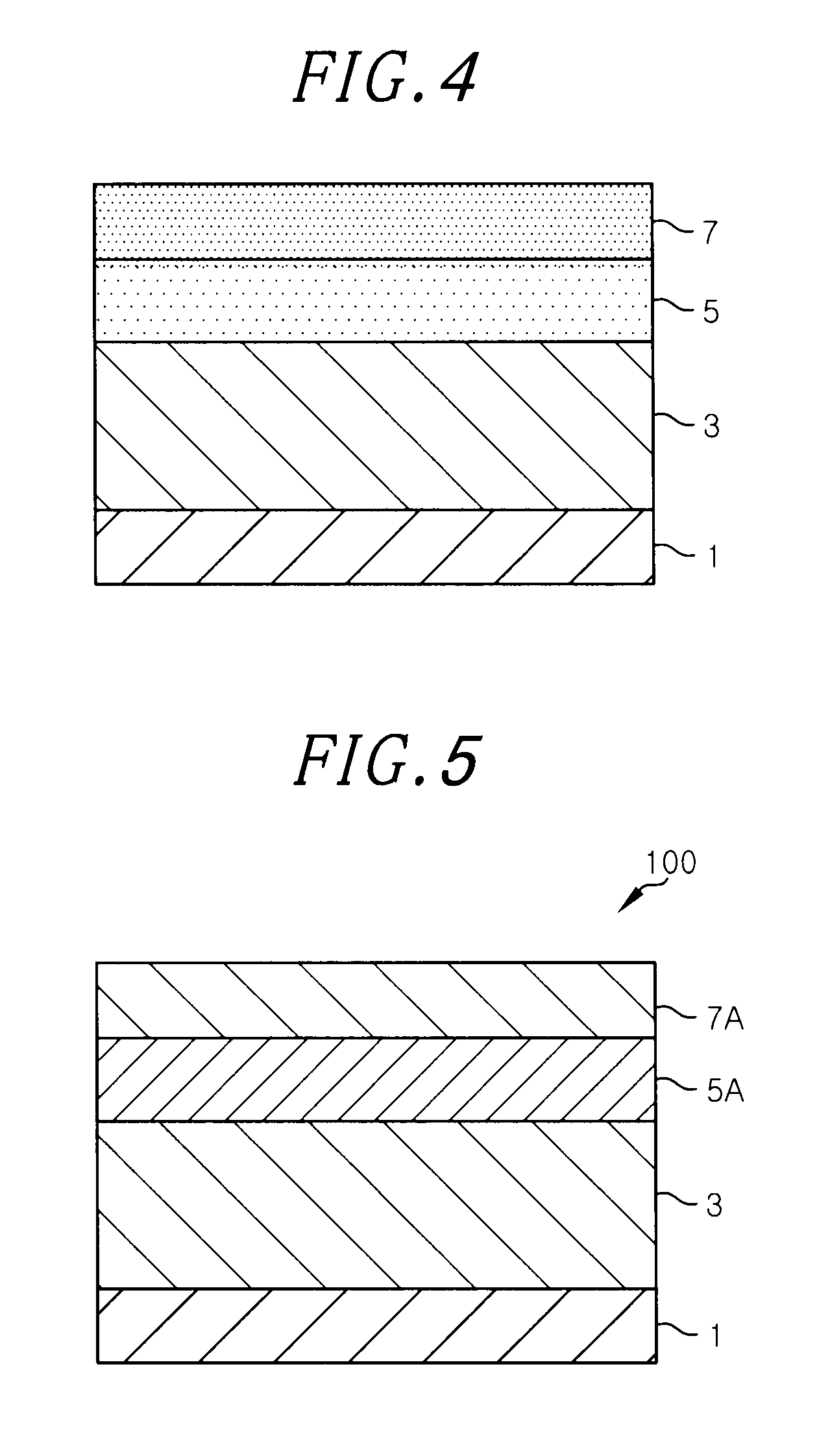

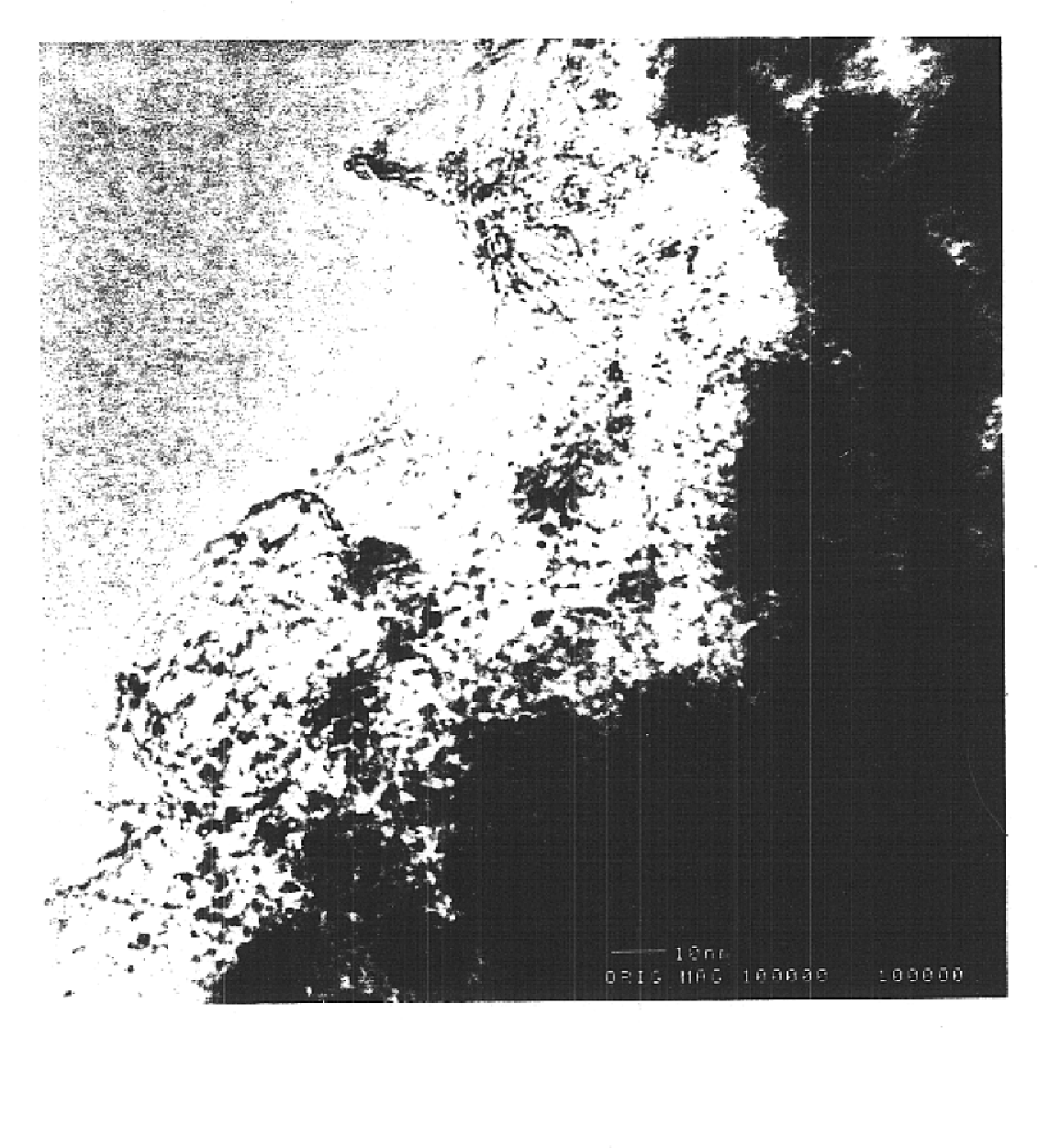

In a method for forming a stacked substrate of a MOS (Metal Oxide Semiconductor) structure including an oxide film serving as a gate insulating film formed on a semiconductor material layer having a film or substrate shape; and a conductive film serving as a gate electrode formed on the oxide film, a polysilane film on the semiconductor material layer is formed by coating a polysilane solution on a surface of a substrate to which the semiconductor material layer is exposed. A film containing metal ions is formed on the polysilane film by coating a metal salt solution thereon, and the polysilane film and the film containing metal ions are respectively modified into a polysiloxane film and a film containing fine metal particles to form the stacked substrate.

Owner:TOKYO ELECTRON LTD

Catalytic growth of single-wall carbon nanotubes from metal particles

InactiveUS6692717B1Material nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Owner:RICE UNIV

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

The present invention is directed to an electroconductive thick film composition comprising: (a) electroconductive metal particles selected from (1) Al, Cu, Au, Ag, Pd and Pt; (2) alloy of Al, Cu, Au, Ag, Pd and Pt; and (3) mixtures thereof; (3) glass frit wherein said glass frit is Pb-free; dispersed in (d) an organic medium, and wherein the average diameter of said electroconductive metal particles is in the range of 0.5-10.0 μm. The present invention is further directed to an electrode formed from the composition as detailed above and a semiconductor device(s) (for example, a solar cell) comprising said electrode.

Owner:SOLAR PASTE LLC

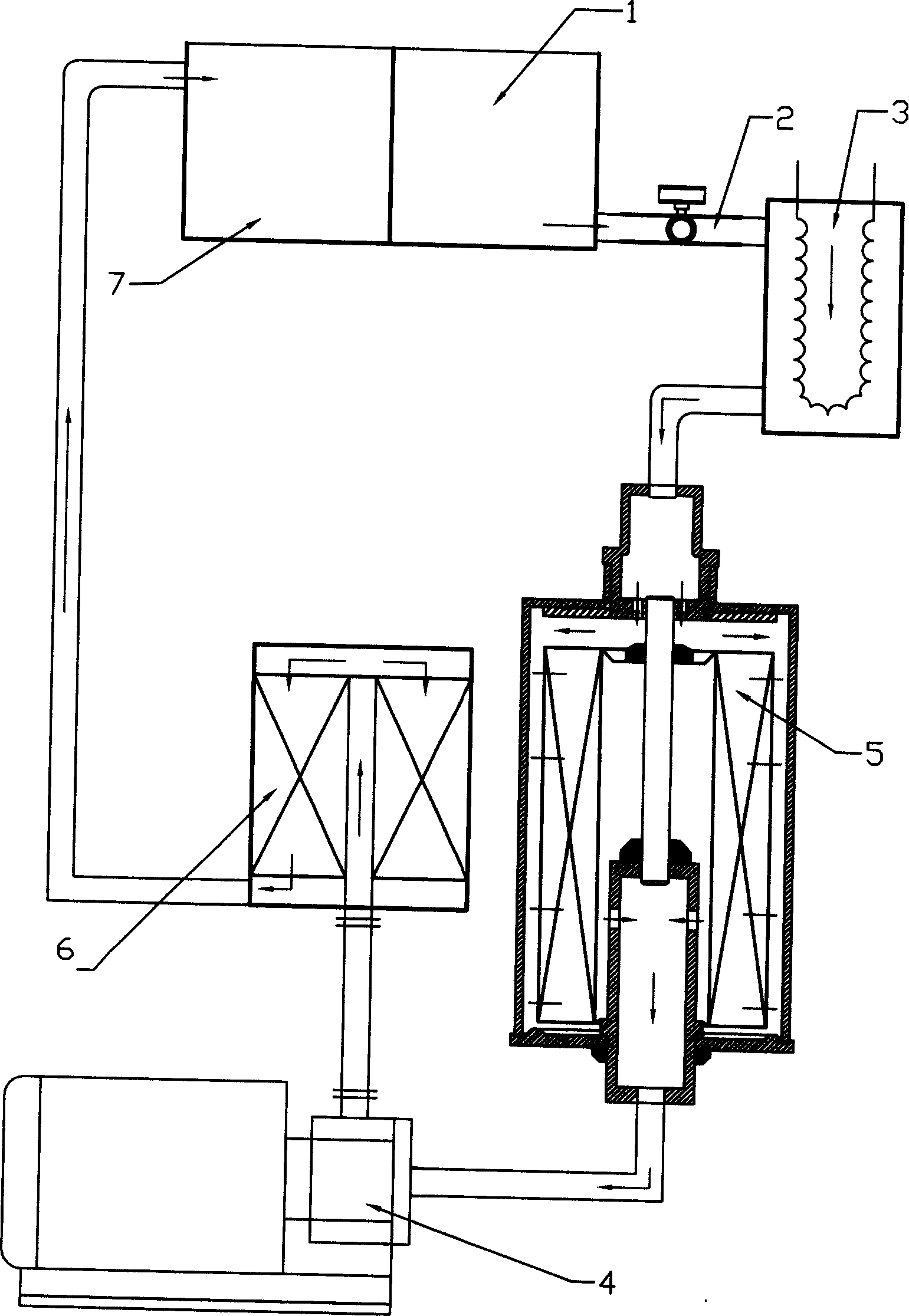

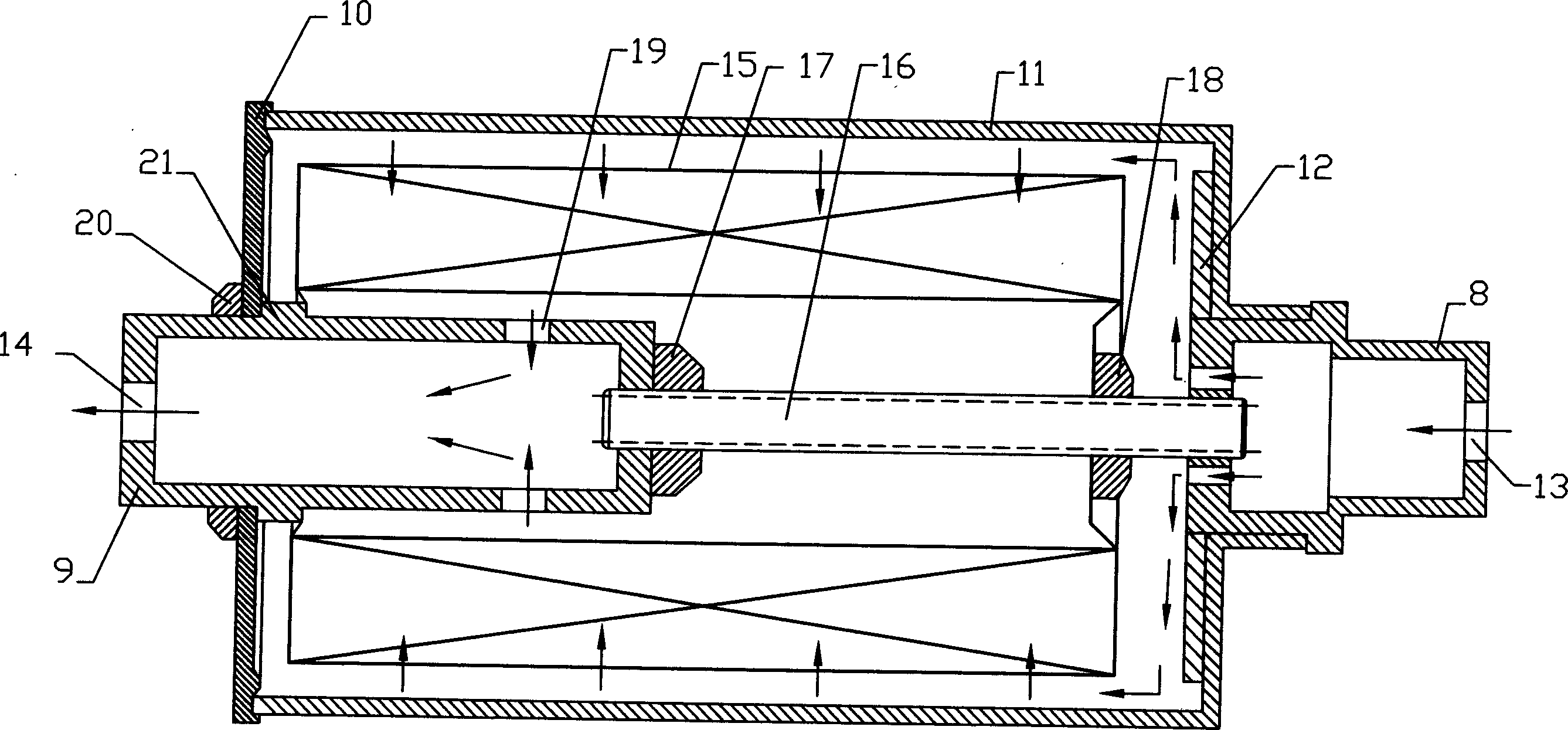

Method and system for purifying hydraulic-oil

InactiveCN1546198AEasy to installEasy to operateFiltration circuitsLubricant compositionControl systemFuel tank

The invention refers to a method and system for purifying the hydraulic pressure oil in hydraulic pressure machine. The method includes magnetism absorbing step which absorbs the metal particles in the hydraulic oil through magnetism structure onto the magnetism structure and a filter step blocking the impurities in the sift filter core, and finishes the first grade filter, and the second filter step with a sorption filter; the system includes: forward oil boxes connected in series, oil heater, magnetism filter, oil pump, sorption filter, backwards oil boxes and electric control system. Each device is connected through oil pipes and valves, all of which are set in a mobile machine box, moves the box, the purification to hydraulic pressure oil of different locations can be carried on conveniently.

Owner:邝念曾

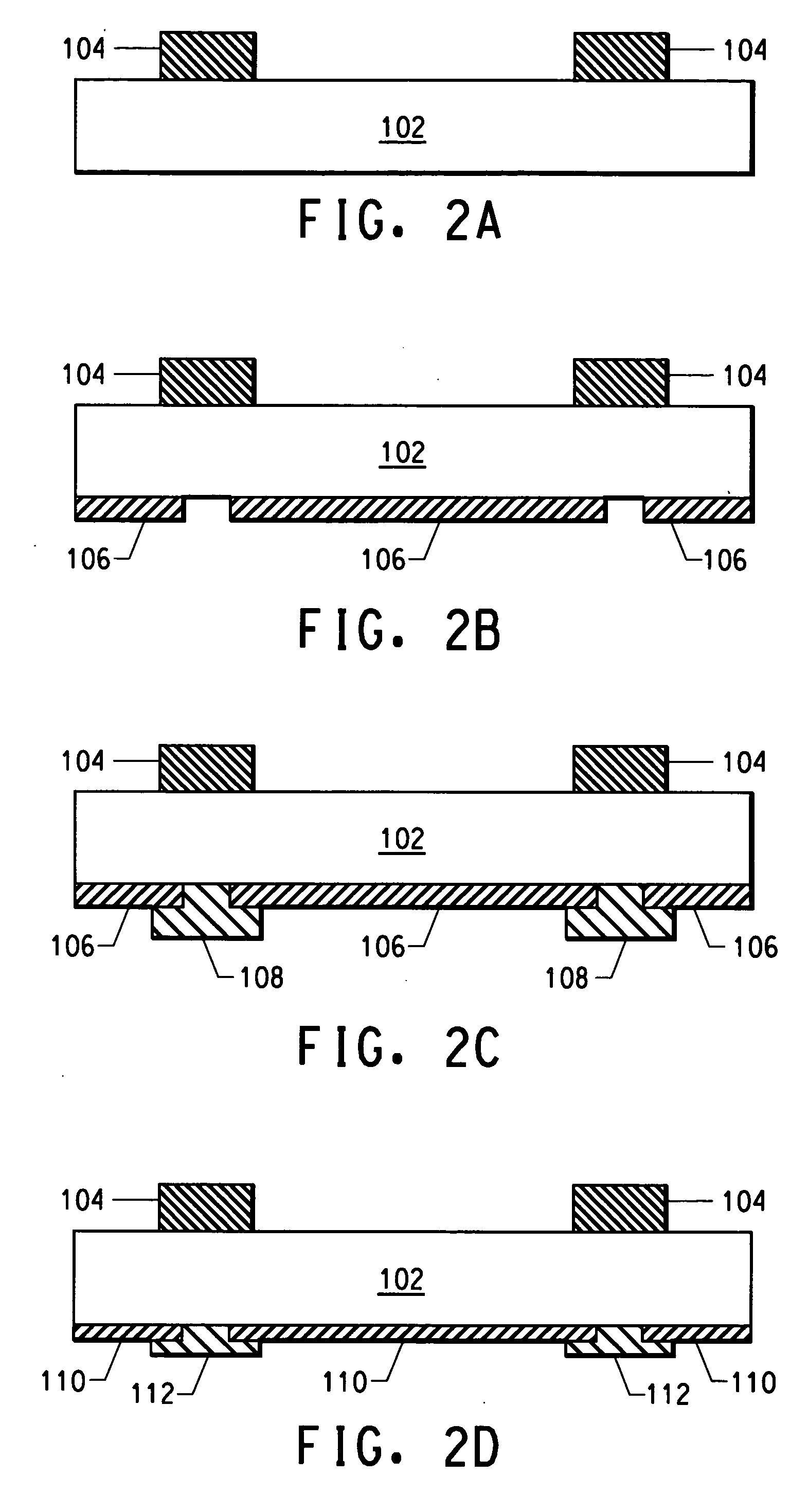

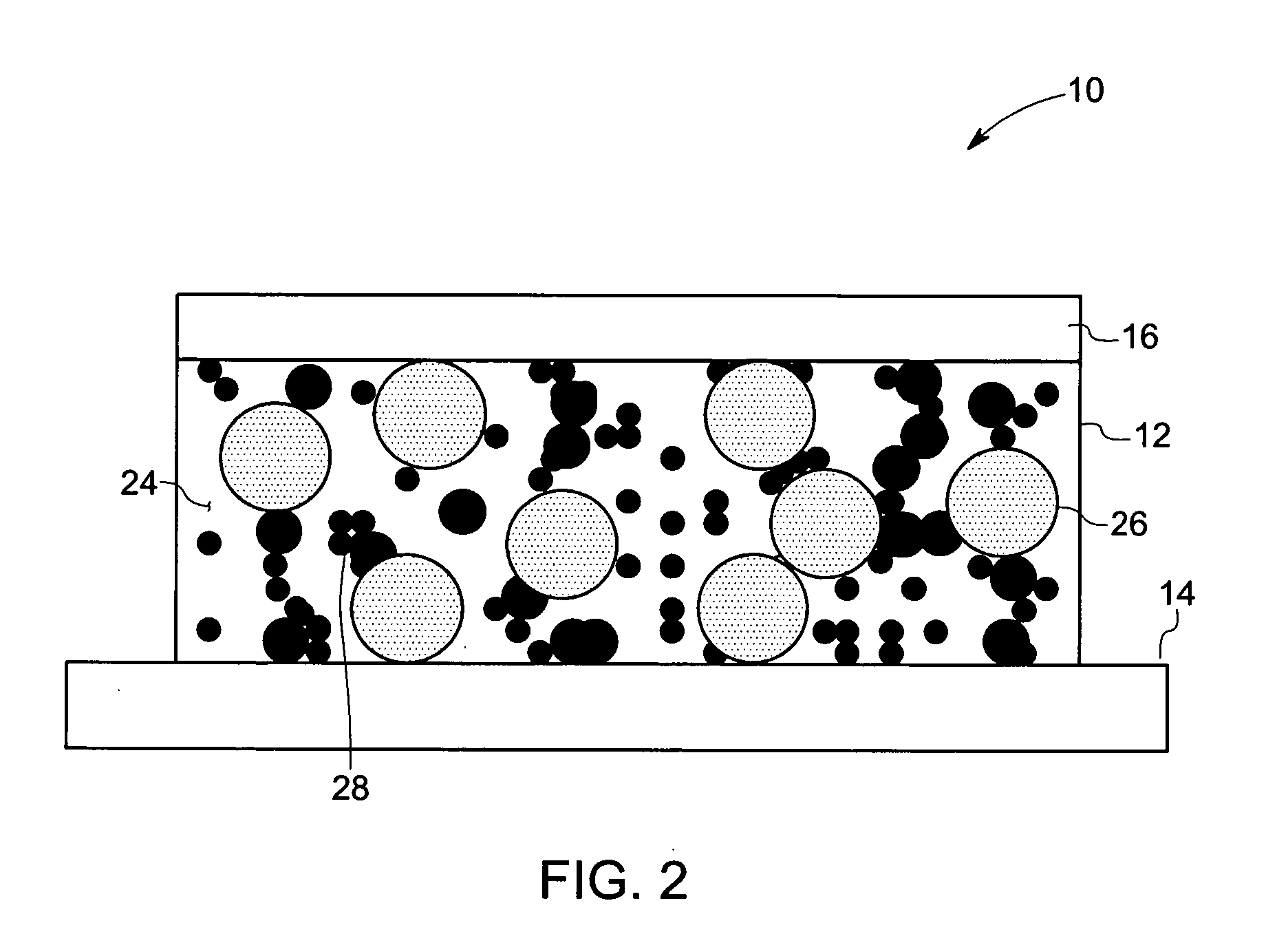

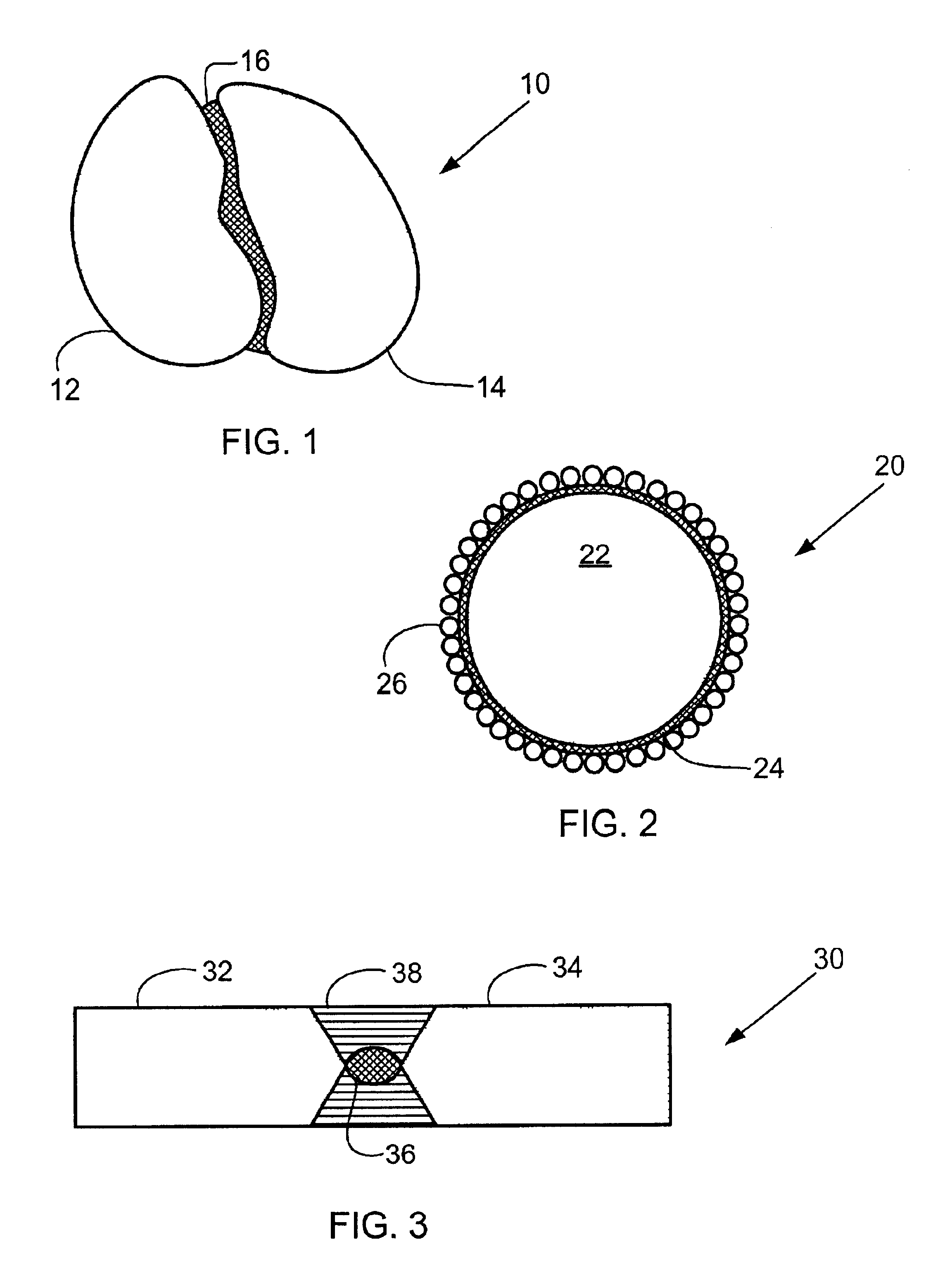

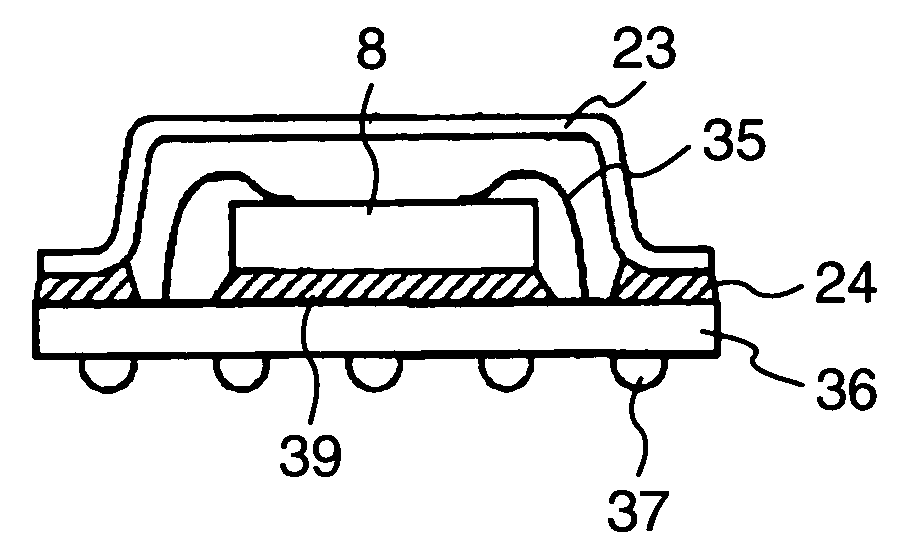

Semiconductor chip assembly with embedded metal particle

InactiveUS7009297B1Enhancing mechanical supportImprove protectionSemiconductor/solid-state device detailsSolid-state devicesSemiconductor chipMetal particle

A semiconductor chip assembly includes a semiconductor chip that includes a conductive pad, a conductive trace that includes a routing line and a metal particle, a connection joint that electrically connects the routing line and the pad, and an encapsulant. The routing line extends laterally beyond the metal particle towards the chip, and the chip and the metal particle are embedded in the encapsulant and extend vertically beyond the routing line in the same direction.

Owner:BRIDGE SEMICON

Electrically conductive adhesives

InactiveUS20070131912A1Material nanotechnologyNon-macromolecular adhesive additivesElastomerMetal particle

The present invention provides an electrically conductive adhesive composition having cured low modulus elastomer and metallurgically-bonded micron-sized metal particles and nano-sized metal particles. The low modulus elastomer provides the mechanical robustness and reliability by relieving the stresses generated; and the metallurgically-bonded micron-sized metal particles and nano-sized metal particles provide a continuous conducting path with minimized interface resistance. Addition of nano-sized metal particles lowers the fusion temperature and allows the metallurgical-bonding to occur at manageable temperatures.

Owner:GENERAL ELECTRIC CO

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

Owner:SOLAR PASTE LLC

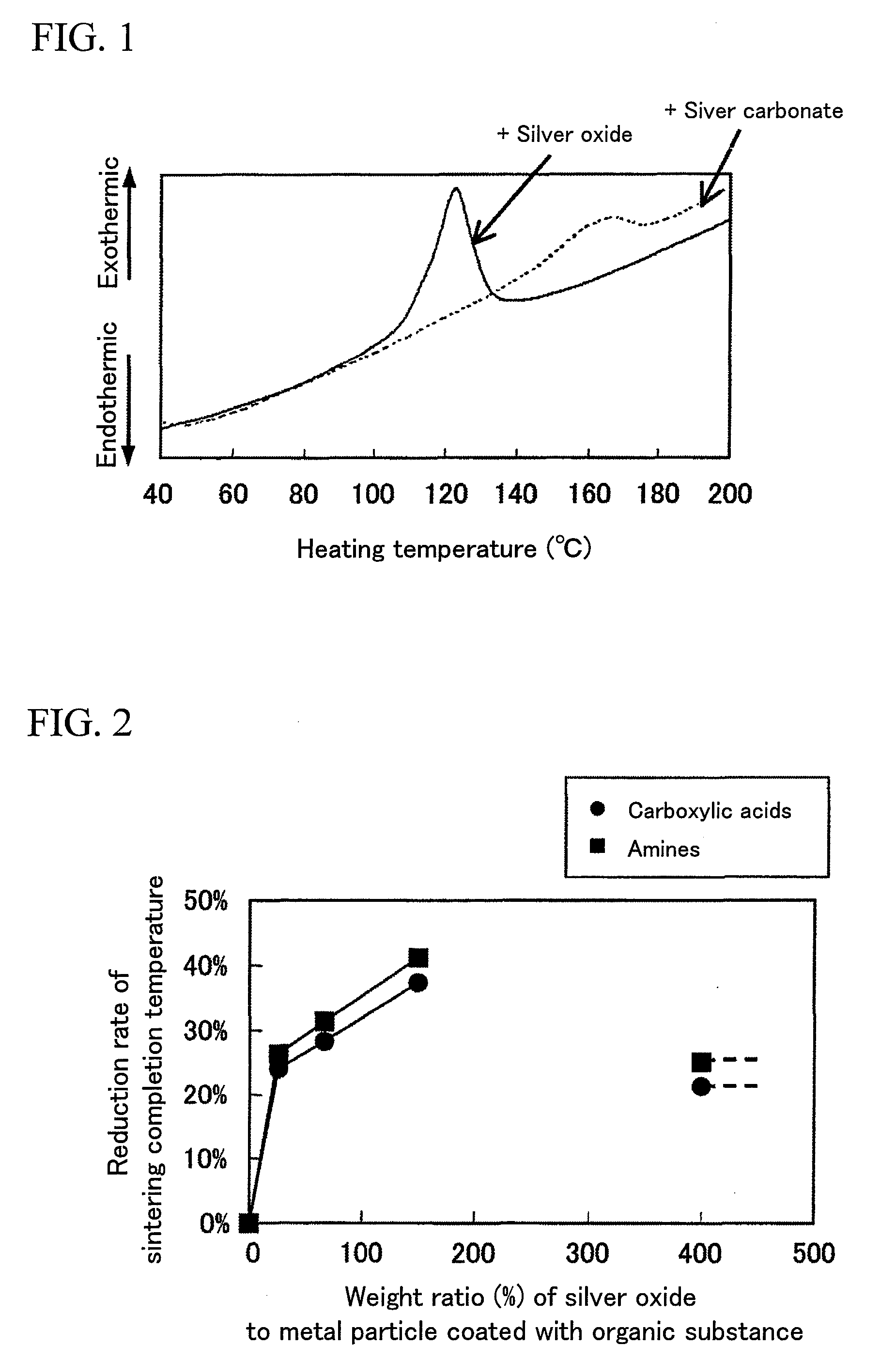

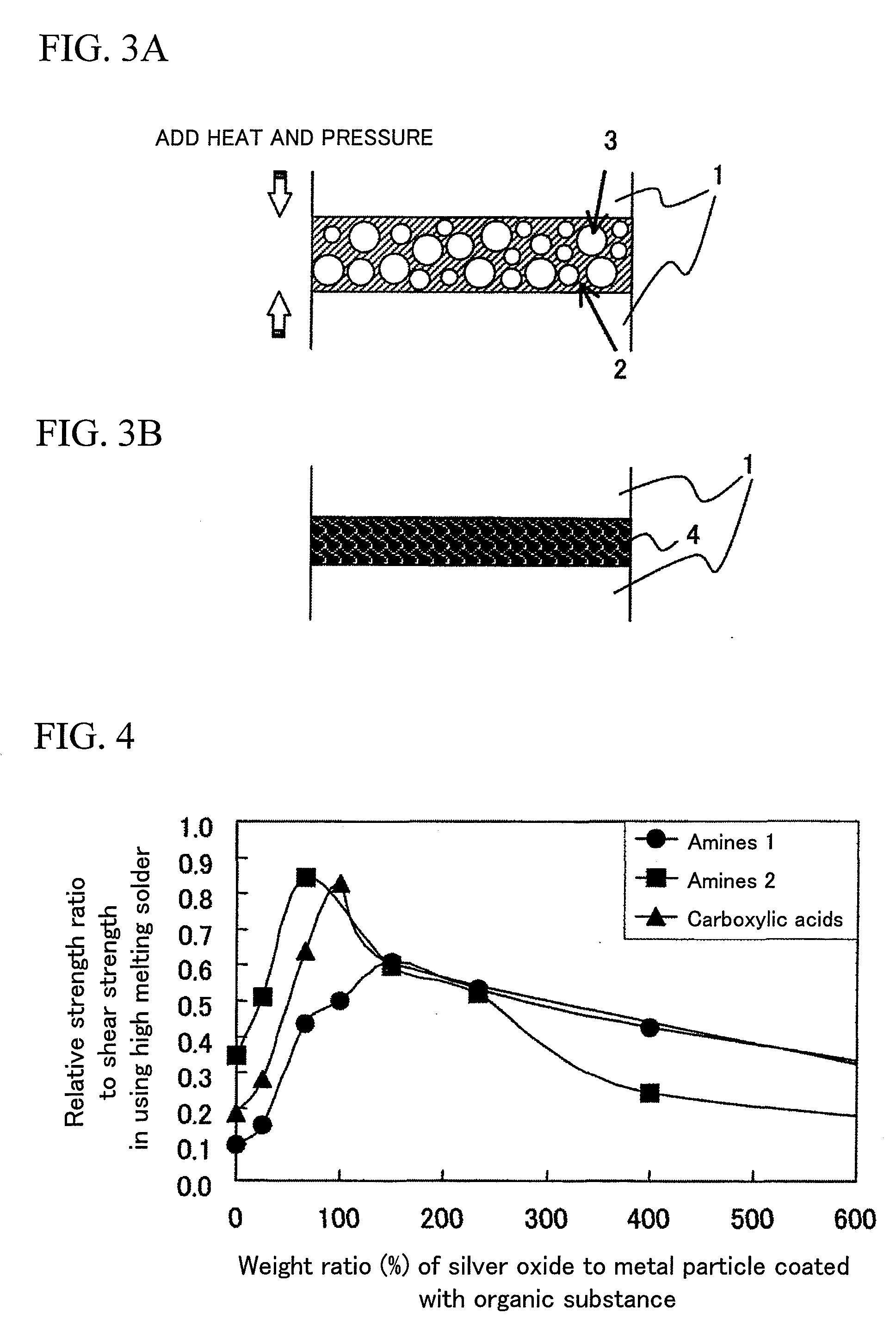

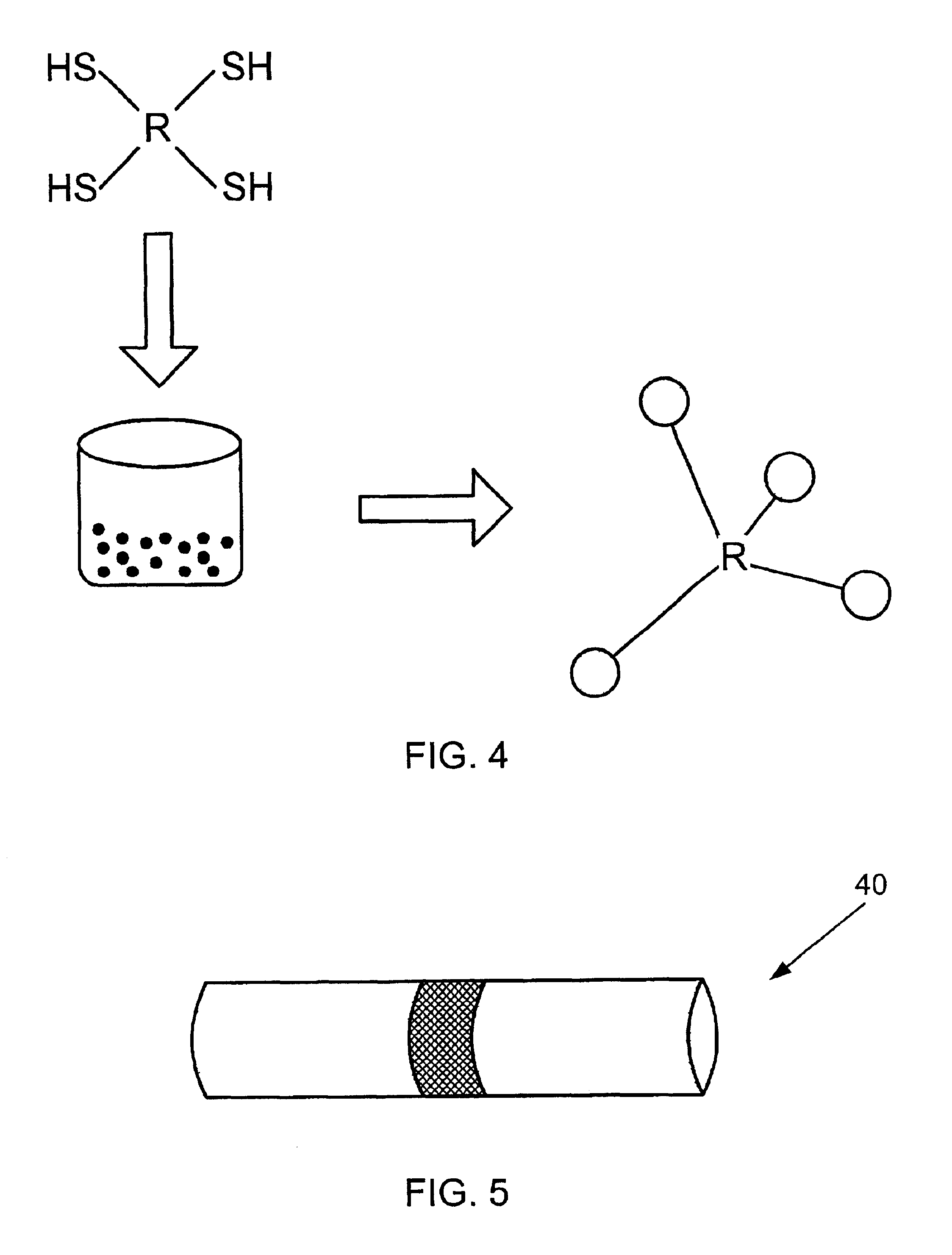

Conductive sintered layer forming composition and conductive coating film forming method and bonding method using the same

InactiveUS20080160183A1Low heating temperatureShorten heating timeSemiconductor/solid-state device detailsConductive materialHeating timeConductive coating

There is provided a conductive sintered layer forming composition and a conductive sintered layer forming method that can lower heating temperature and shorten heating time for a process of accelerating sintering or bonding by sintering of metal nano-particles coated with an organic substance. The conductive sintered layer forming composition may be obtained by utilizing a phenomenon that particles may be sintered at low temperature by mixing silver oxide with metal particles coated with the organic substance and having a grain size of 1 nm to 5 μm as compared to sintering each simple substance. The conductive sintered layer forming composition of the invention is characterized in that it contains the metal particles whose surface is coated with the organic substance and whose grain size is 1 nm to 5 μm and the silver oxide particles.

Owner:HITACHI LTD

Surface-enhanced spectroscopy-active sandwich nanoparticles

Surface-enhanced Raman spectroscopy (SERS) uses nanoscale metal particles (SERS-active particles) or surface roughness to enhance the Raman signal of Raman-active analytes contacting the surface. SERS sandwich particles contain SERS-active particles sandwiching a Raman-active substance and serve as optical tags. Preferably, the particles are rod-shaped, with each layer (SERS-active and Raman-active) formed as a distinct stripe of the particle. These freestanding particles can be derivatized with surface ligands capable of associating with analytes of interest in, for example, a biological sample. The acquired Raman spectrum of the particle encodes the identity of the ligand. Because of the simplicity and intensity of Raman spectra, highly multiplexed assays are capable using SERS particles with different Raman-active species.

Owner:BECTON DICKINSON & CO +1

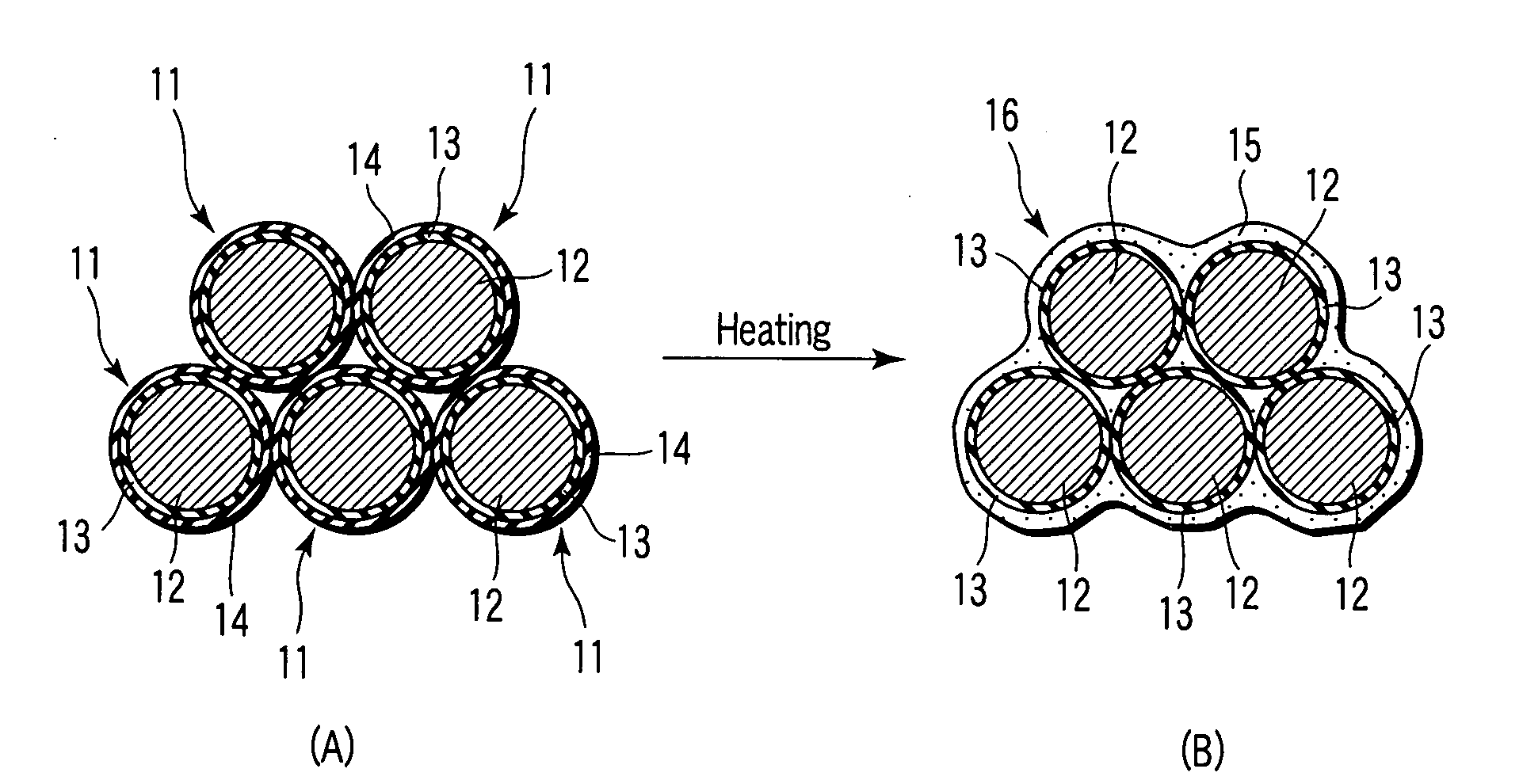

Insulating magnectic metal particles and method for manufacturing insulating magnetic material

ActiveUS20080029300A1Magnetic/electric field screeningMetal-working apparatusMetal particleMaterials science

An insulating magnetic metal particle includes a magnetic metal particle containing at least one metal selected from the group consisting of Co, Fe, and Ni and having a diameter of 5 to 500 nm, a first inorganic insulating layer made of an oxide that covers the surface of the magnetic metal particle, and a second inorganic insulating layer made of an oxide that produces a eutectic crystal by reacting together with the first inorganic insulating layer at the time of heating them, the second inorganic insulating layer being coated on the first inorganic insulating layer. A thickness ratio of the second inorganic insulating layer with respect to the first inorganic insulating layer is set so that the first inorganic insulating layer remains on the surface of the magnetic metal particle after producing the eutectic crystal.

Owner:KK TOSHIBA

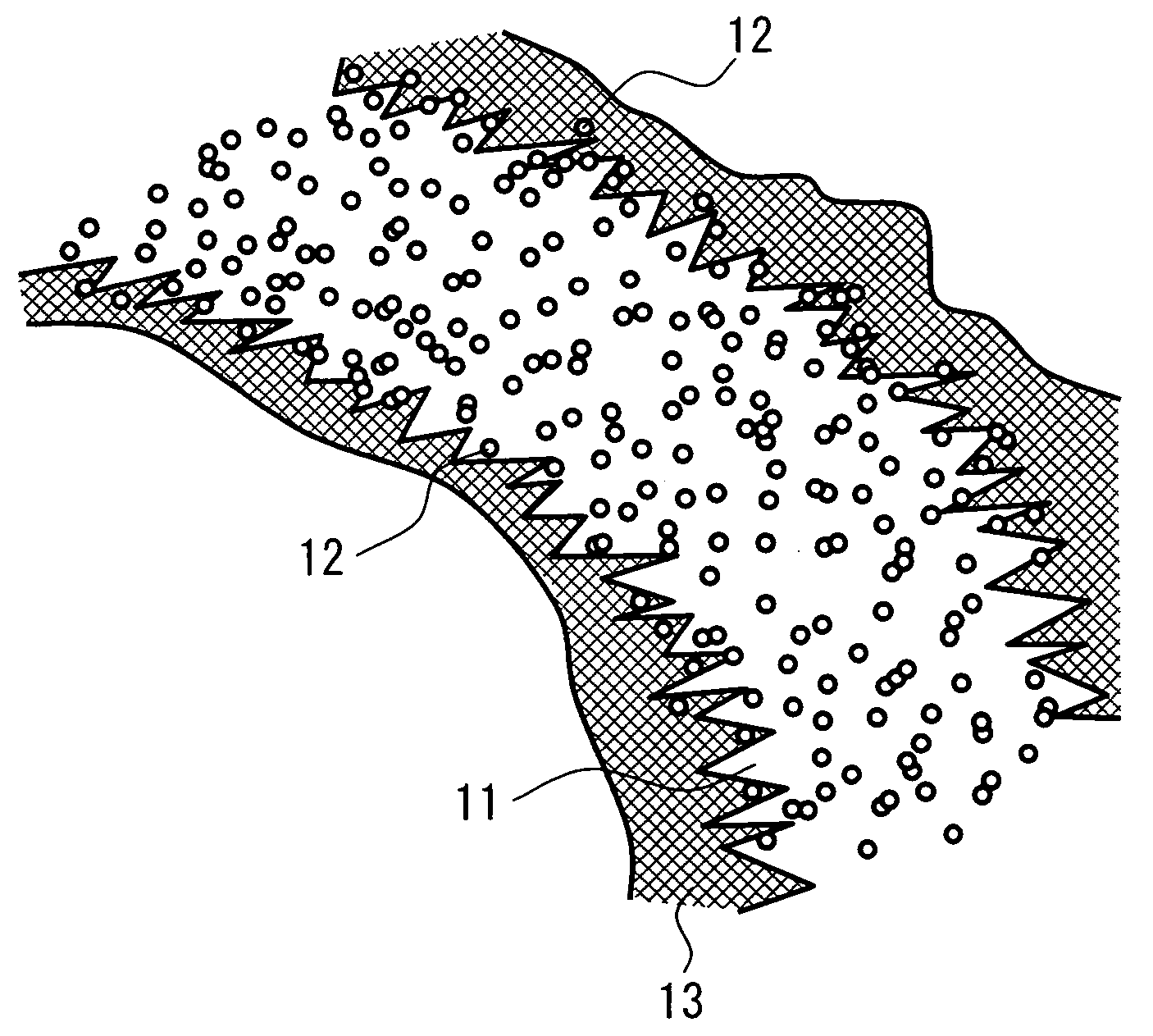

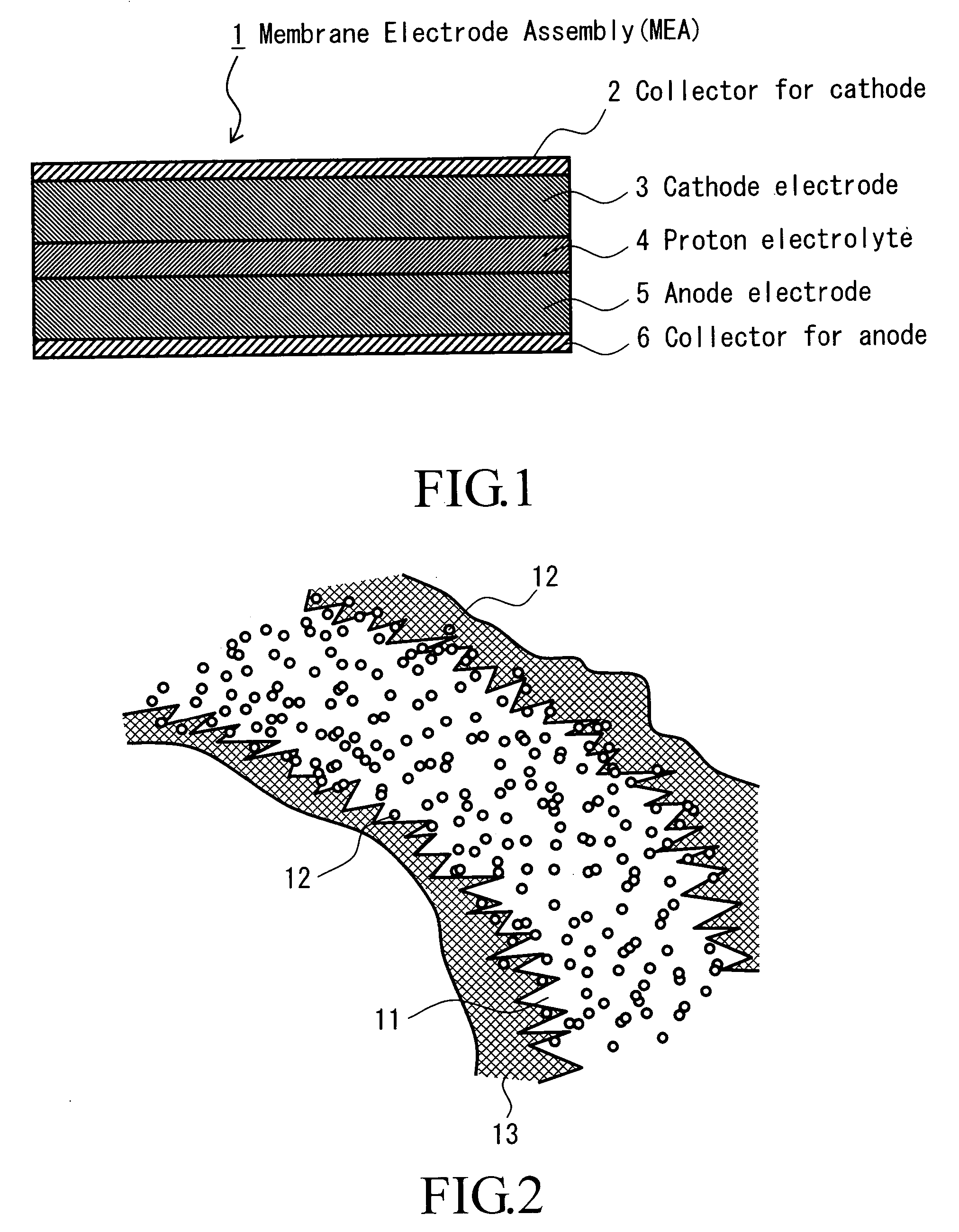

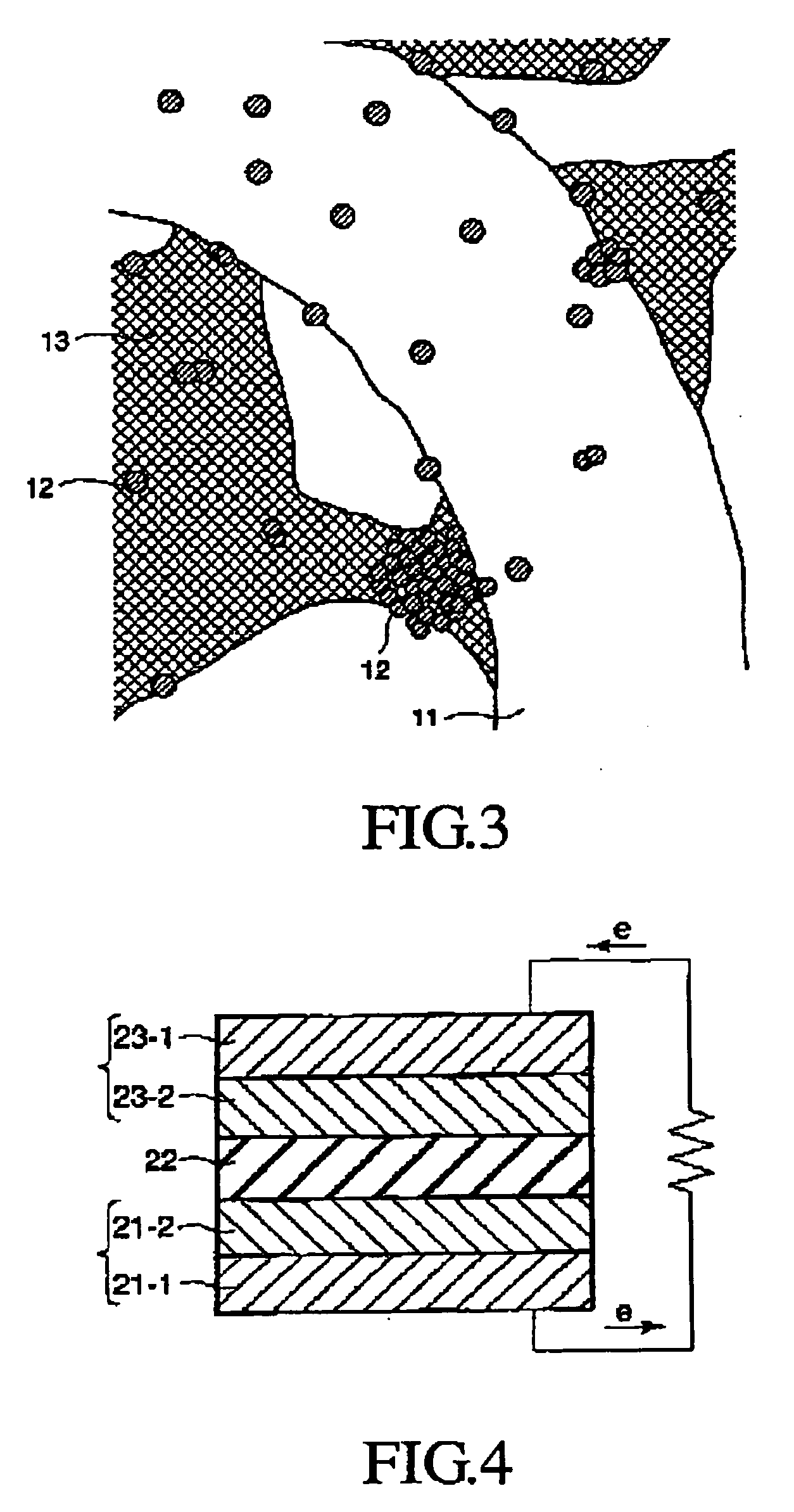

Manufacturing methods of catalysts for carbon fiber composition and carbon material compound, manufacturing methods of carbon fiber and catalyst material for fuel cell, and catalyst material for fuel cell

The carbon fibers of this invention is characterized in that irreducible inorganic material particles in a mean primary particle size below 500 nm and reducible inorganic material particles in a mean primary particle size below 500 nm were mixed by pulverizing and then, the mixture was heat treated under the reducing atmosphere and metal particles in a mean particle size below 1 μm were obtained, and the mixed powder of the thus obtained metal particles with the irreducible inorganic material particles are included in the carbon fibers.

Owner:KK TOSHIBA

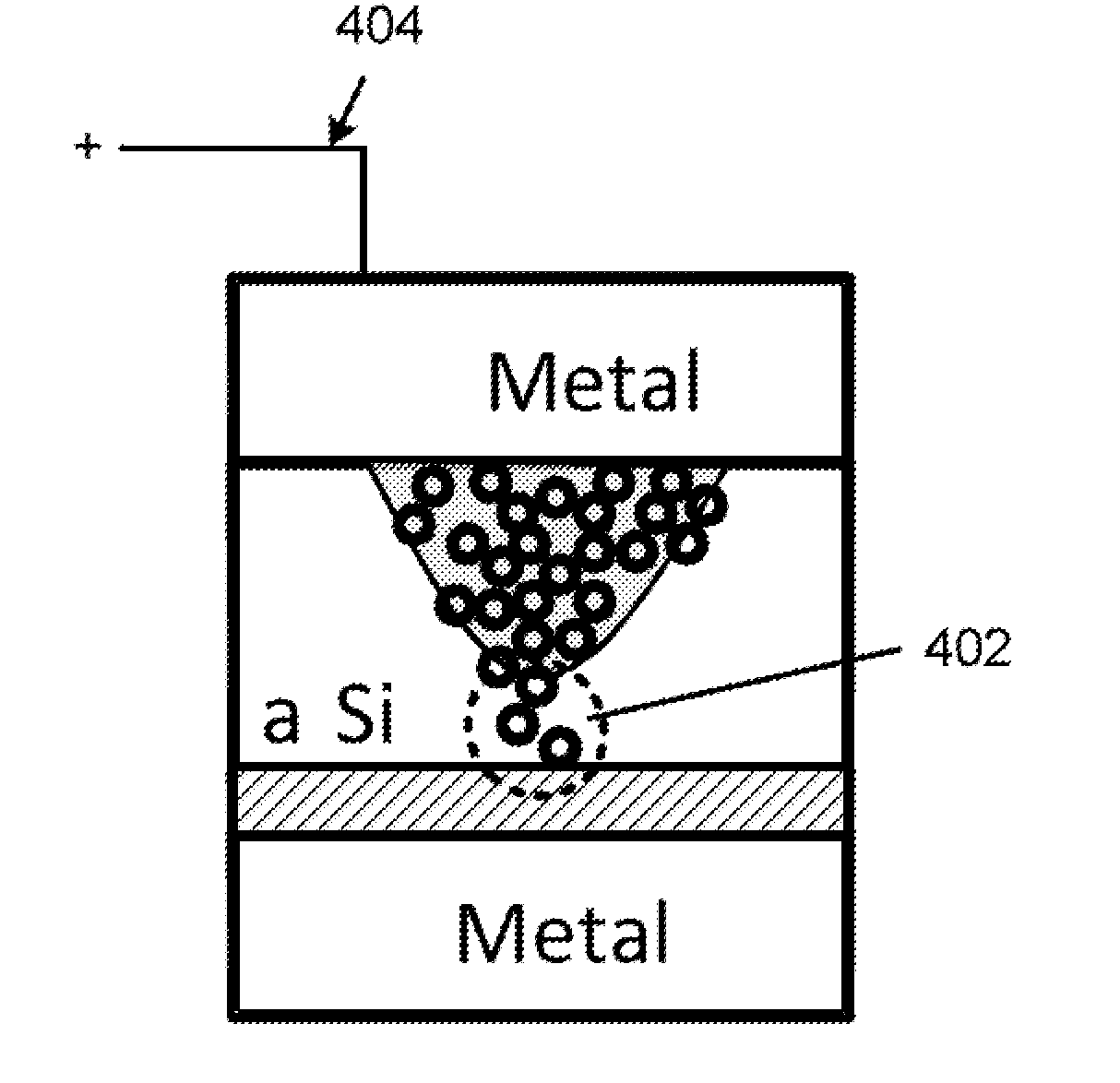

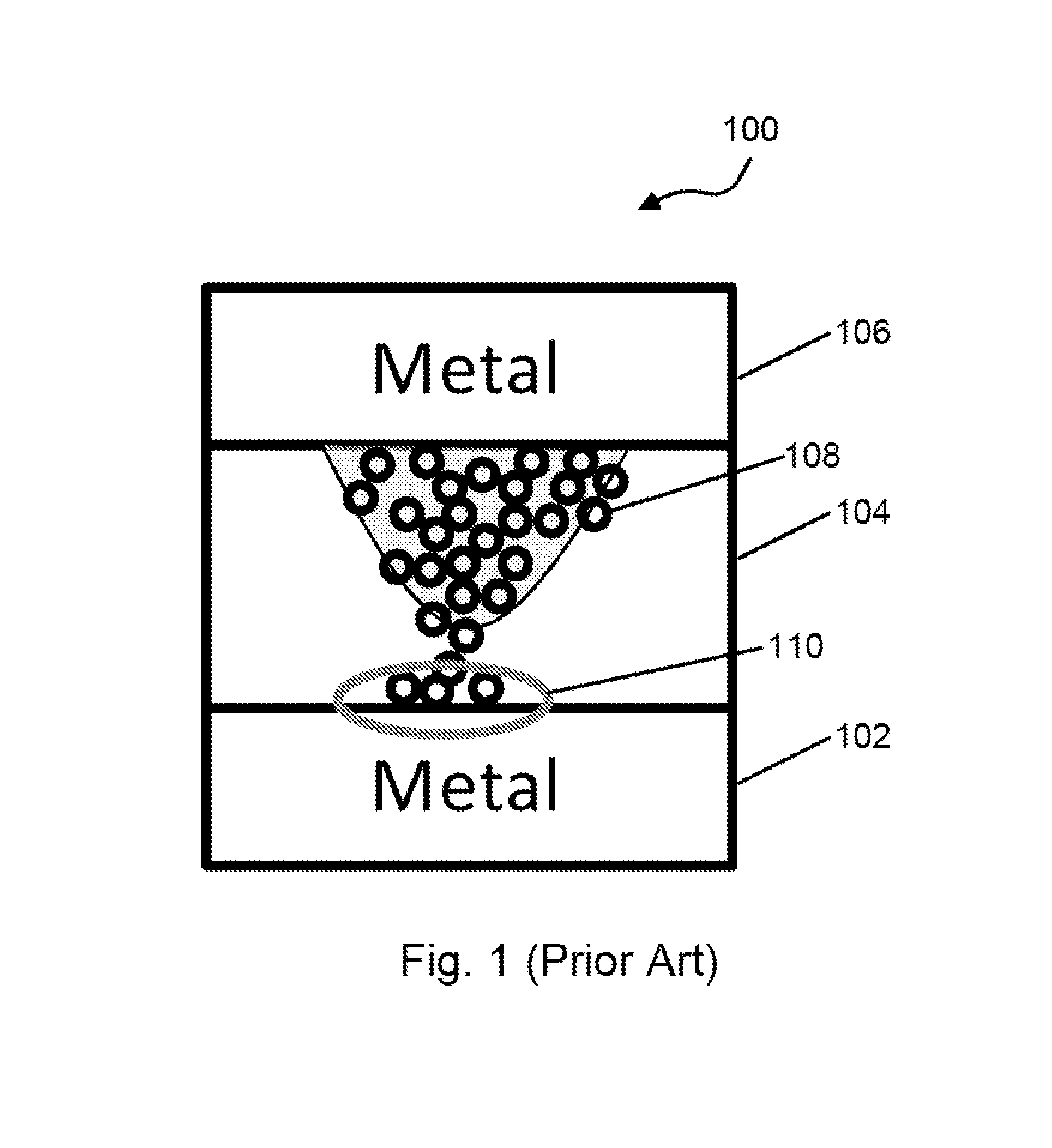

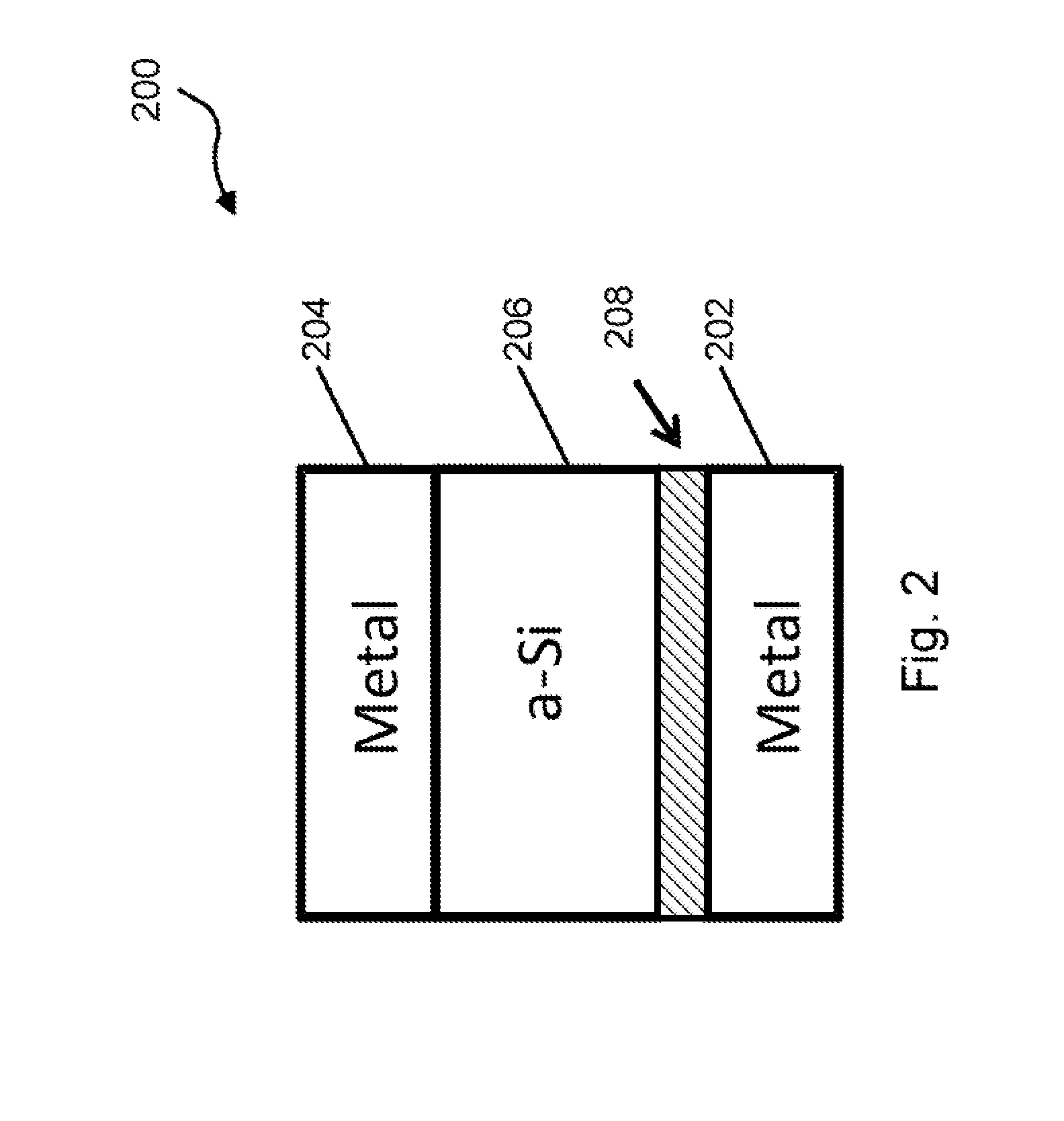

Device switching using layered device structure

ActiveUS20120043519A1Total current dropImproved switchingSolid-state devicesDigital storageElectricityElectrical resistance and conductance

A resistive switching device. The device includes a first electrode comprising a first metal material overlying the first dielectric material and a switching material comprising an amorphous silicon material. The device includes a second electrode comprising at least a second metal material. In a specific embodiment, the device includes a buffer material disposed between the first electrode and the switching material. The buffer material provides a blocking region between the switching material and the first electrode so that the blocking region is substantially free from metal particles from the second metal material when a first voltage is applied to the second electrode.

Owner:CROSSBAR INC

Metal nanowires, method for producing the same, and transparent conductor

InactiveUS20100078197A1Increased durabilityTransparencyMaterial nanotechnologyNon-insulated conductorsMetal particleNanometre

Owner:FUJIFILM CORP

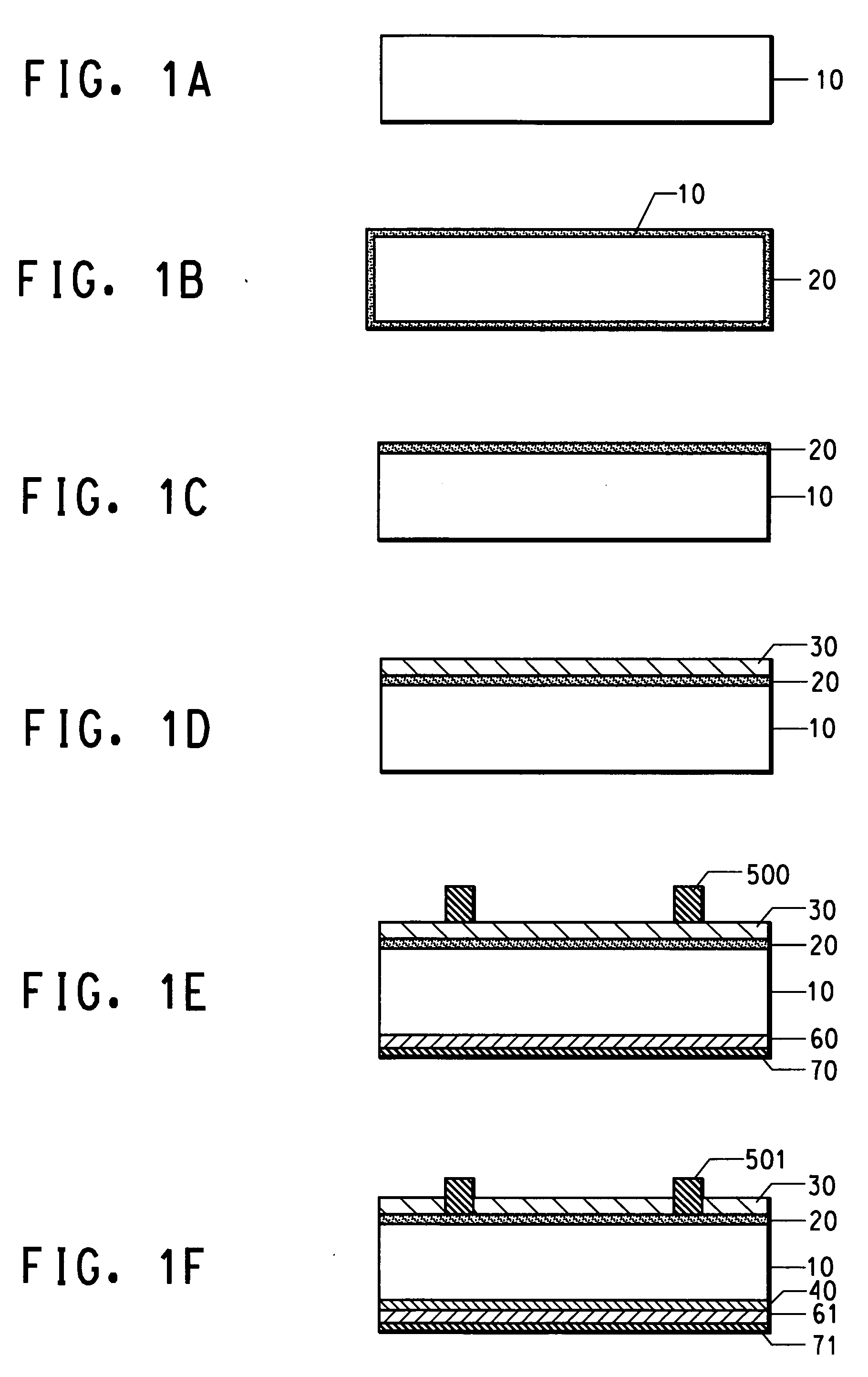

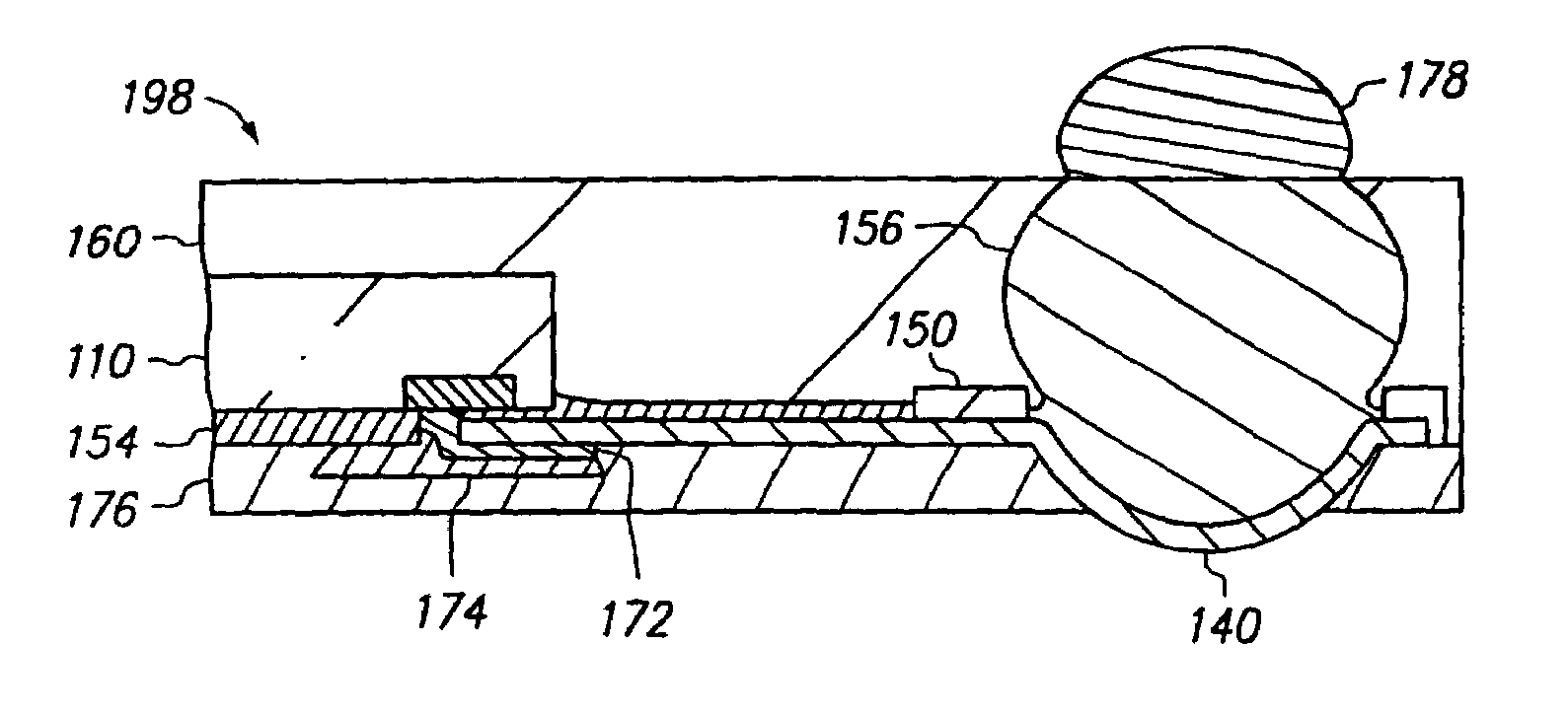

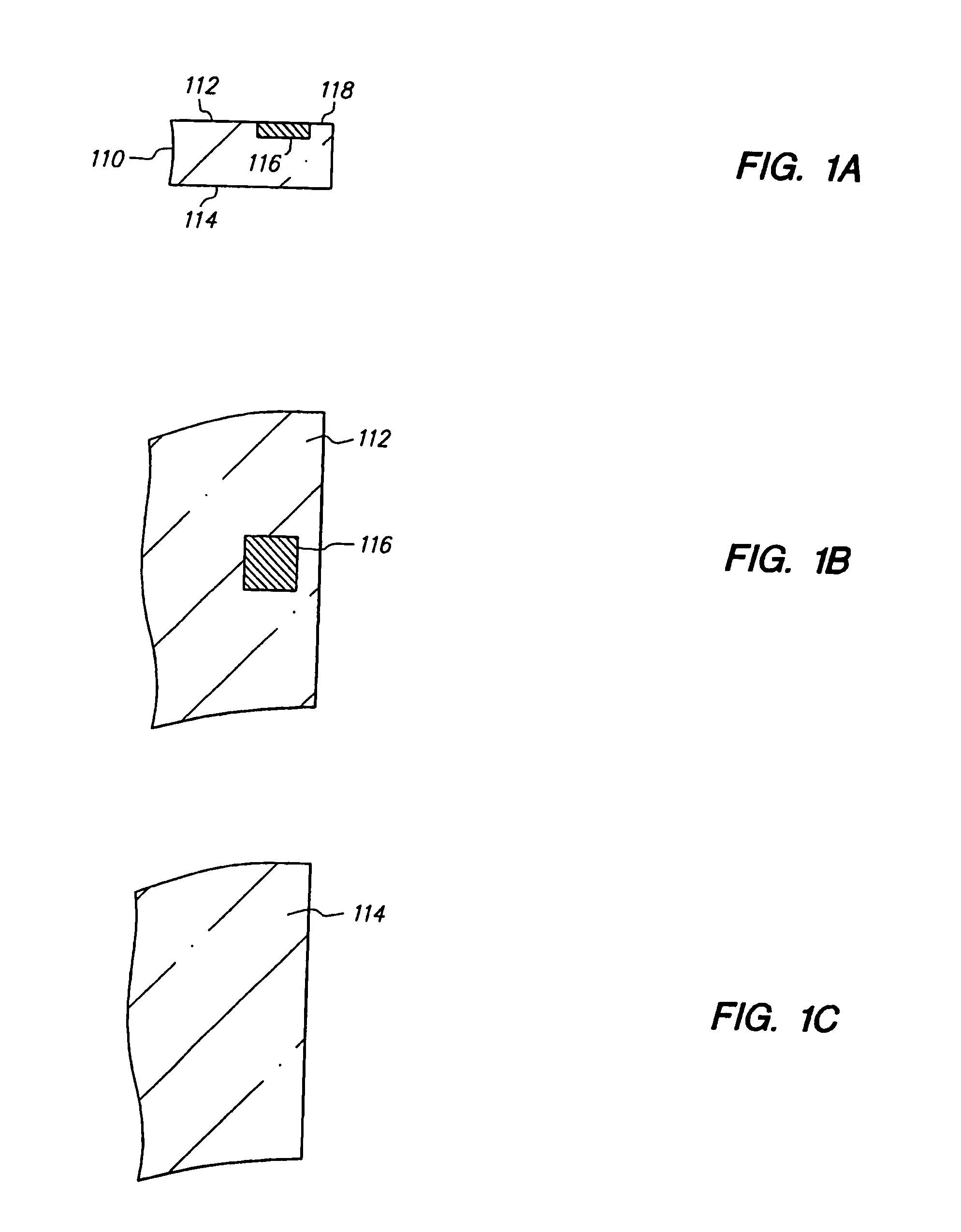

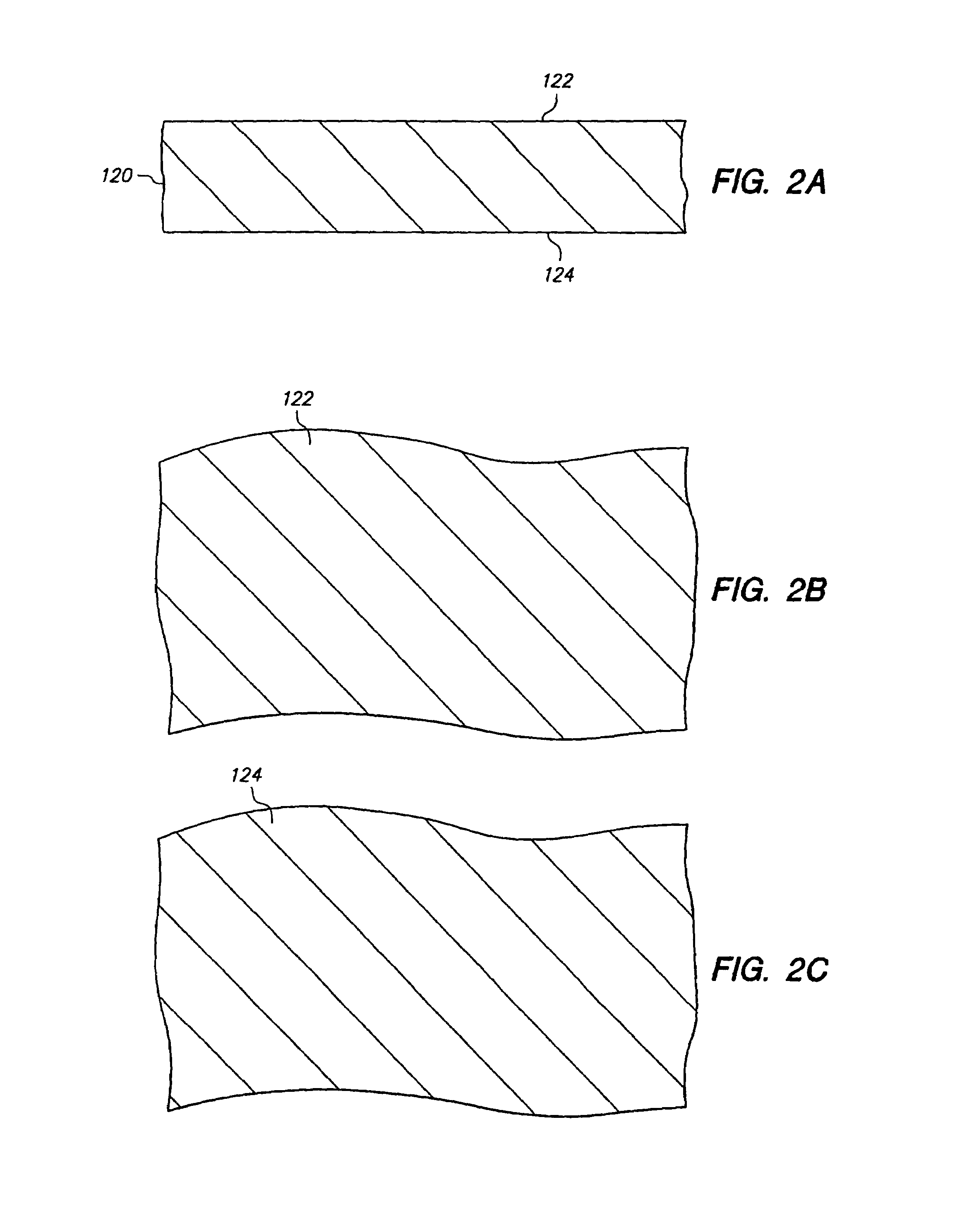

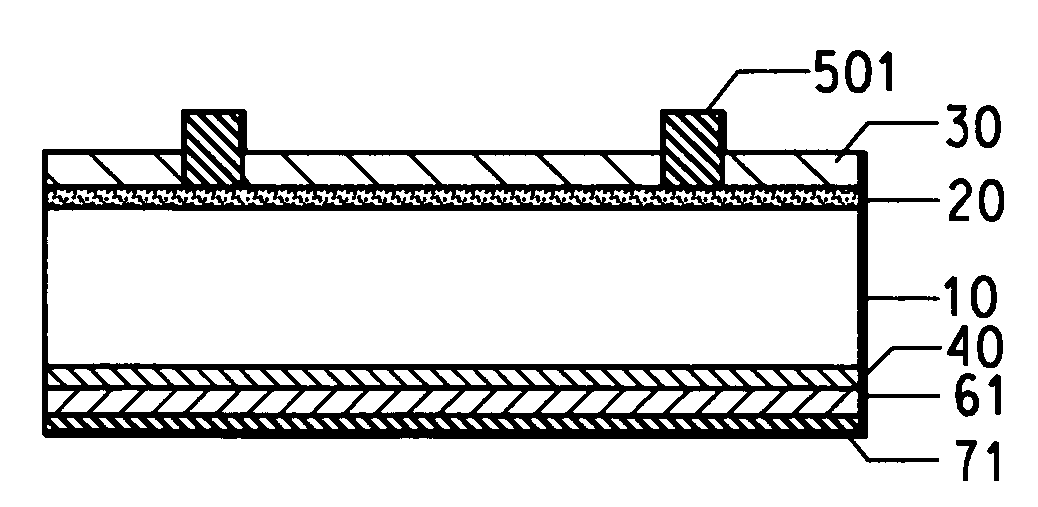

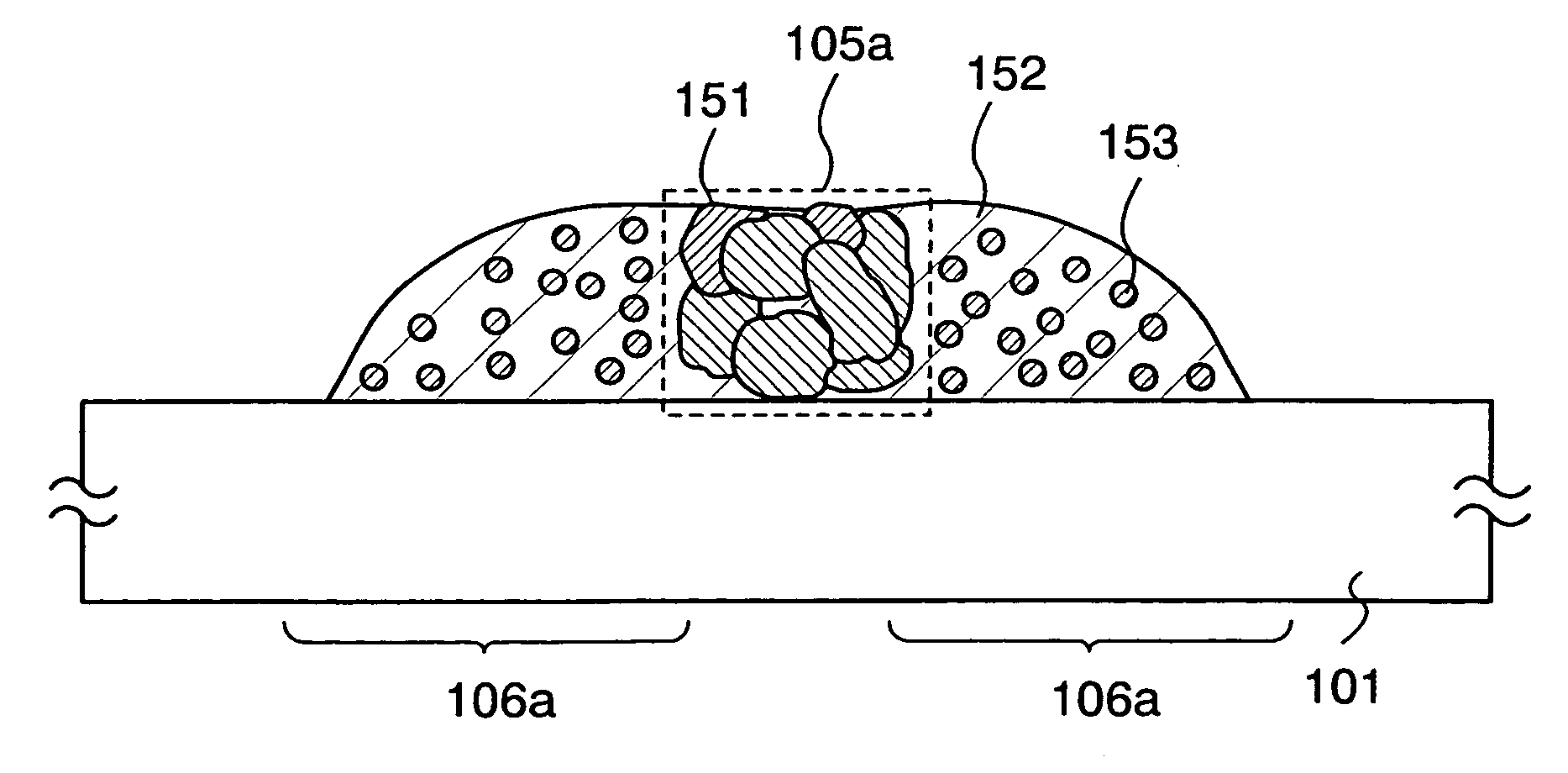

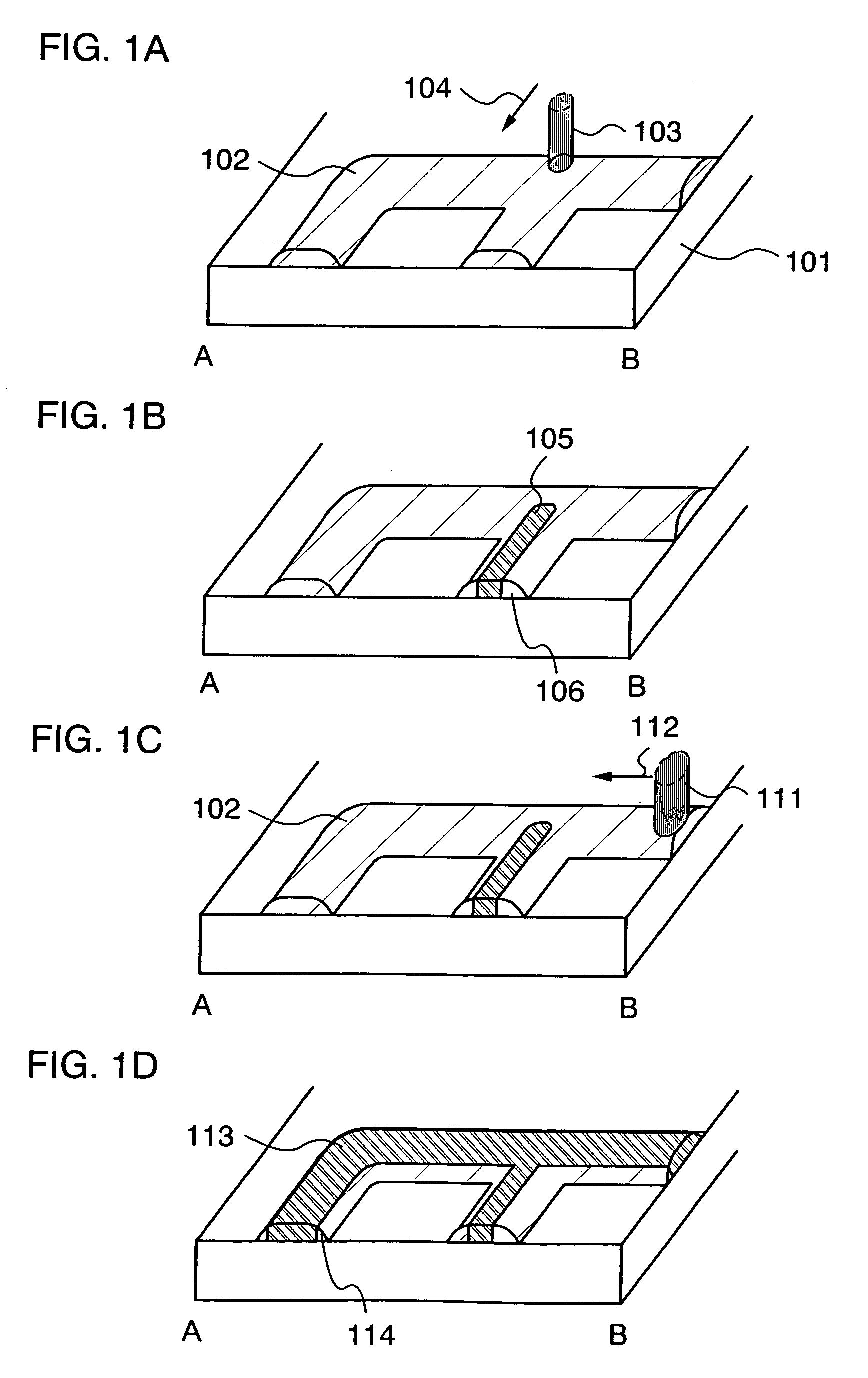

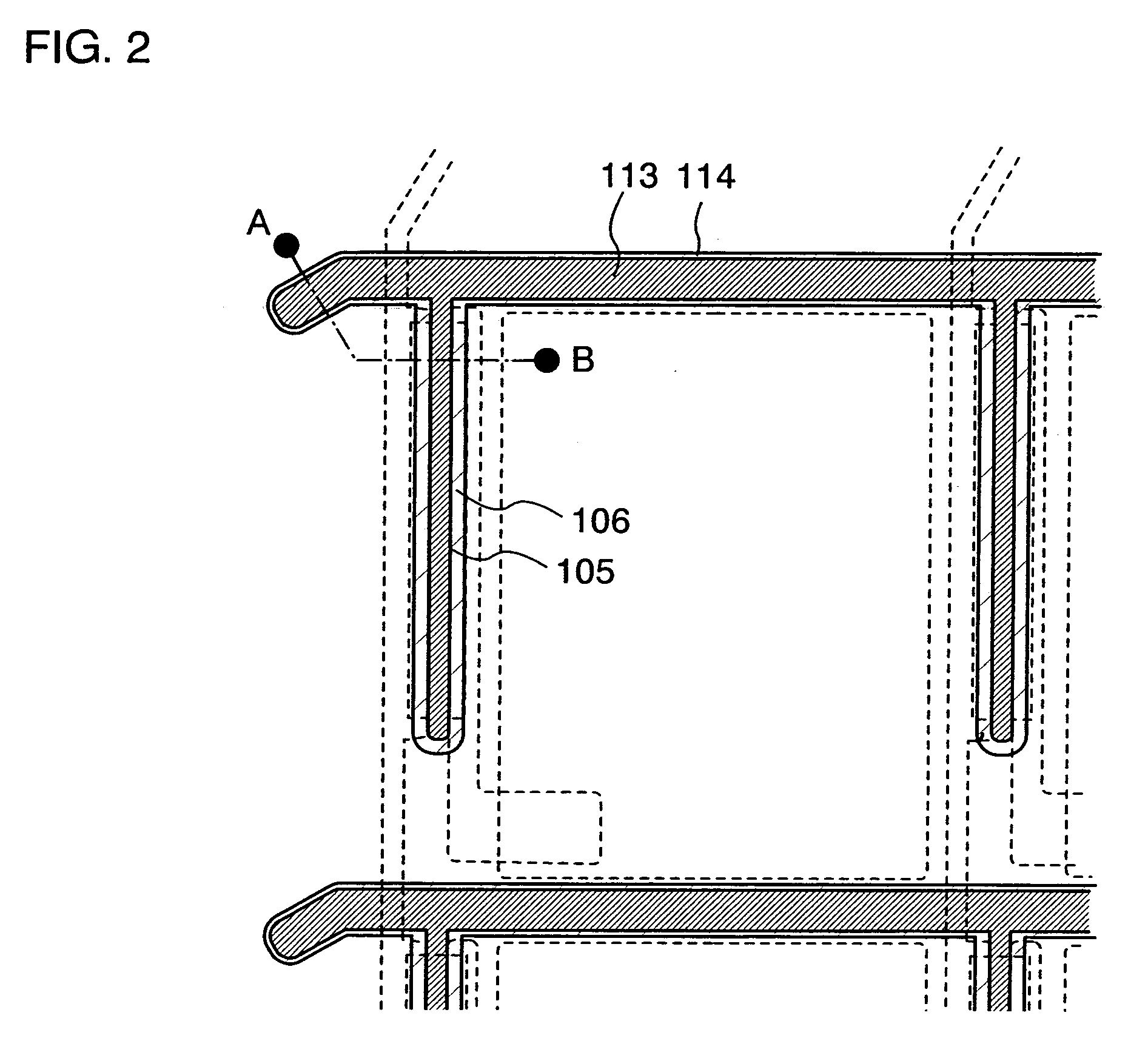

Wiring substrate, semiconductor device and manufacturing method thereof

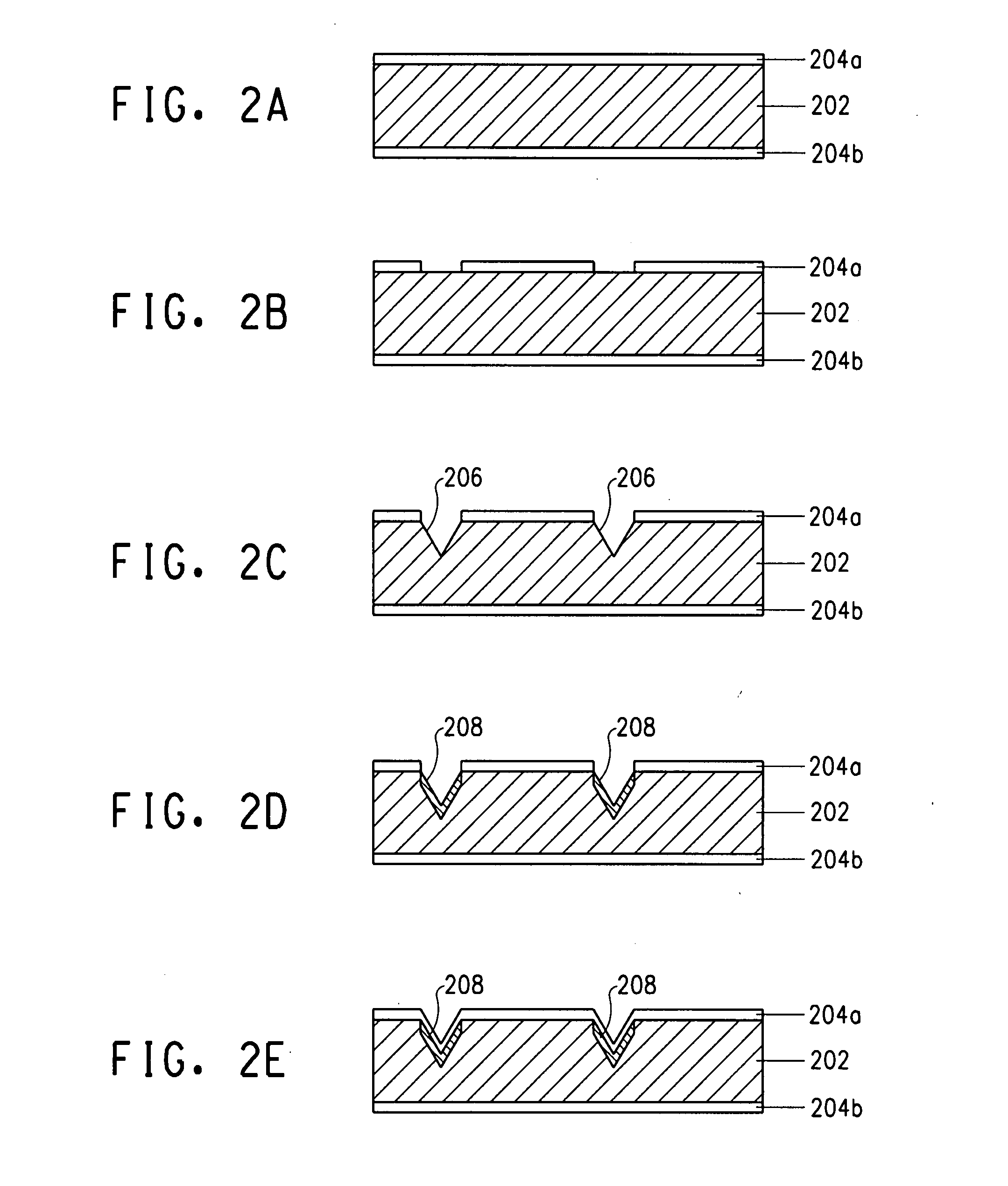

InactiveUS20050276912A1Low costImprove throughputFinal product manufacturePrinted circuit aspectsDevice materialLaser light

The present invention provides a method for forming a wiring having a minute shape on a large substrate with a small number of steps, and further a wiring substrate formed by the method. Moreover, the present invention provides a semiconductor device in which cost reduction and throughput improvement are possible due to the small number of steps and reduction of materials and which has a semiconductor element with a minute structure, and further a manufacturing method thereof. According to the present invention, a composition including metal particles and organic resin is irradiated with laser light and a part of the metal particles is baked to form a conductive layer typified by a wiring, an electrode or the like over a substrate. Further, a semiconductor device having the baked conductive layer as a wiring or an electrode is formed.

Owner:SEMICON ENERGY LAB CO LTD

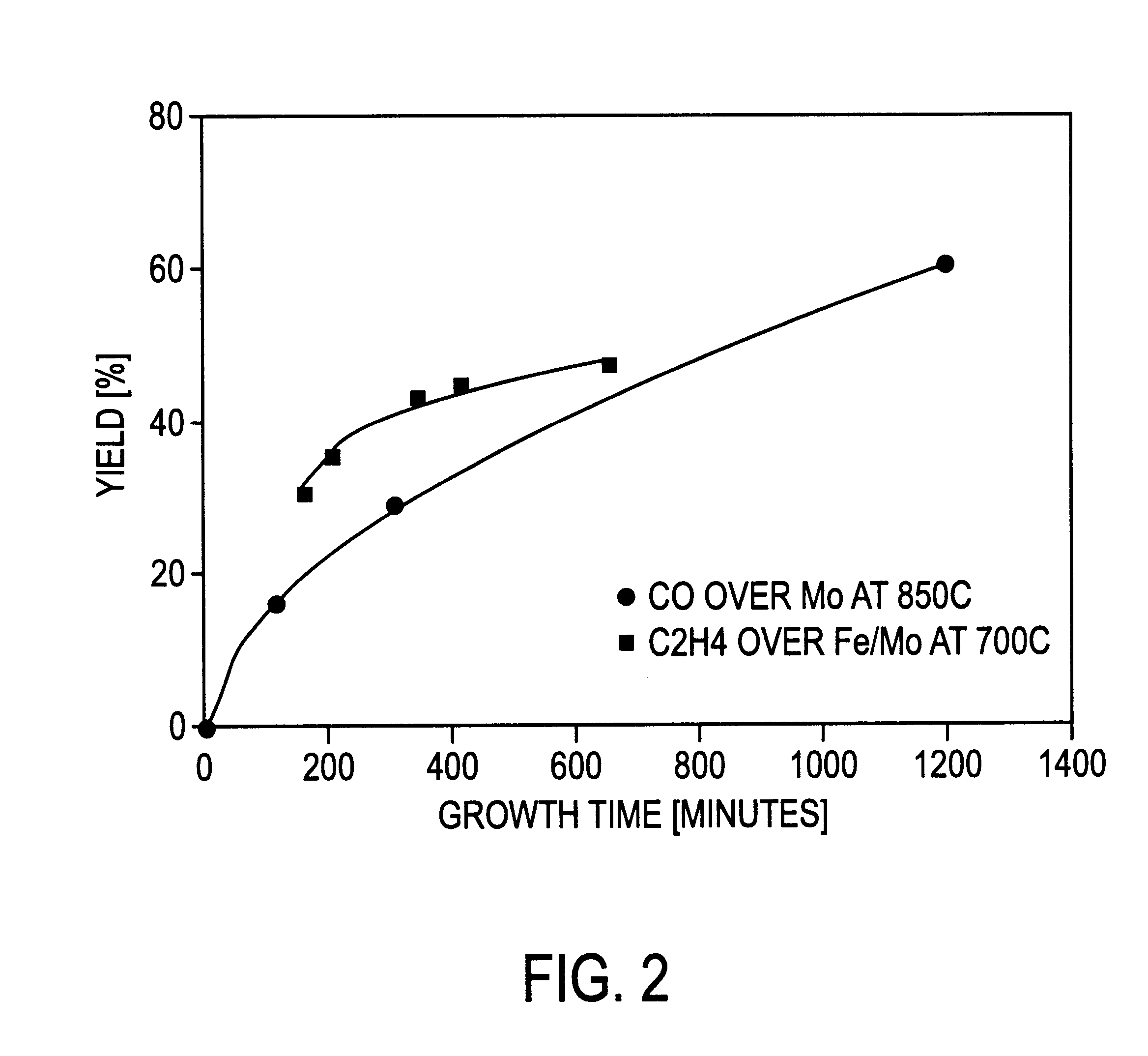

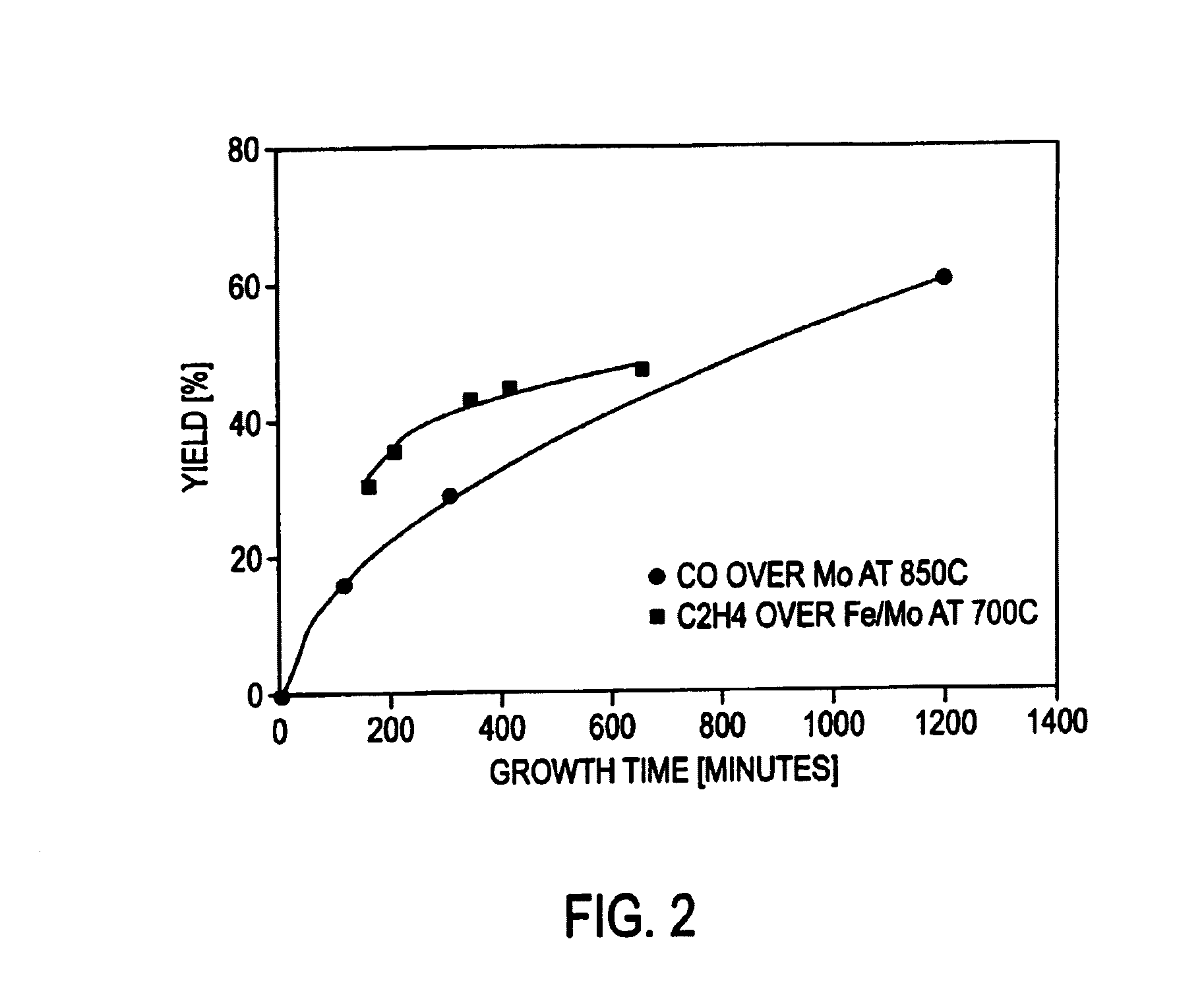

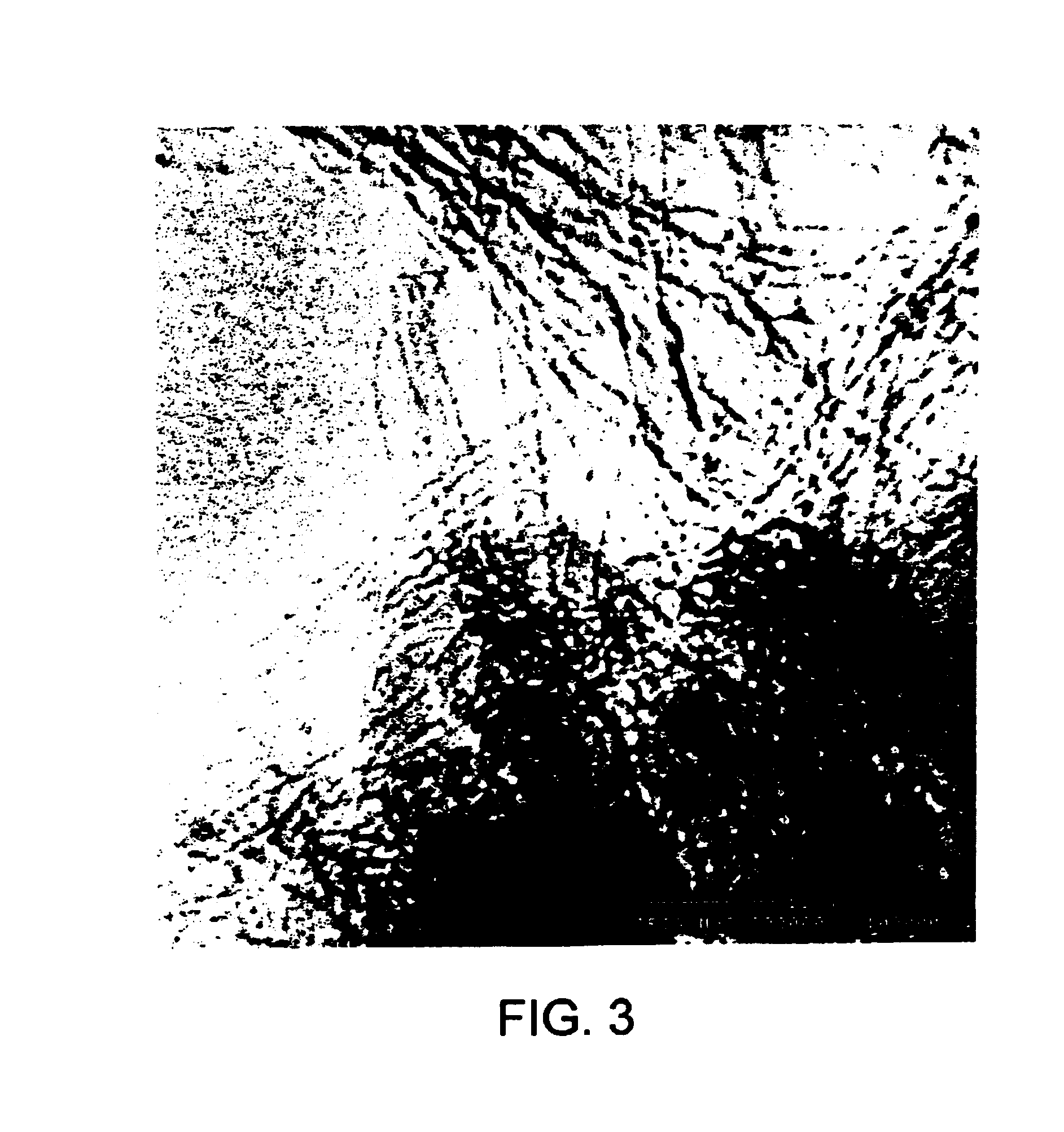

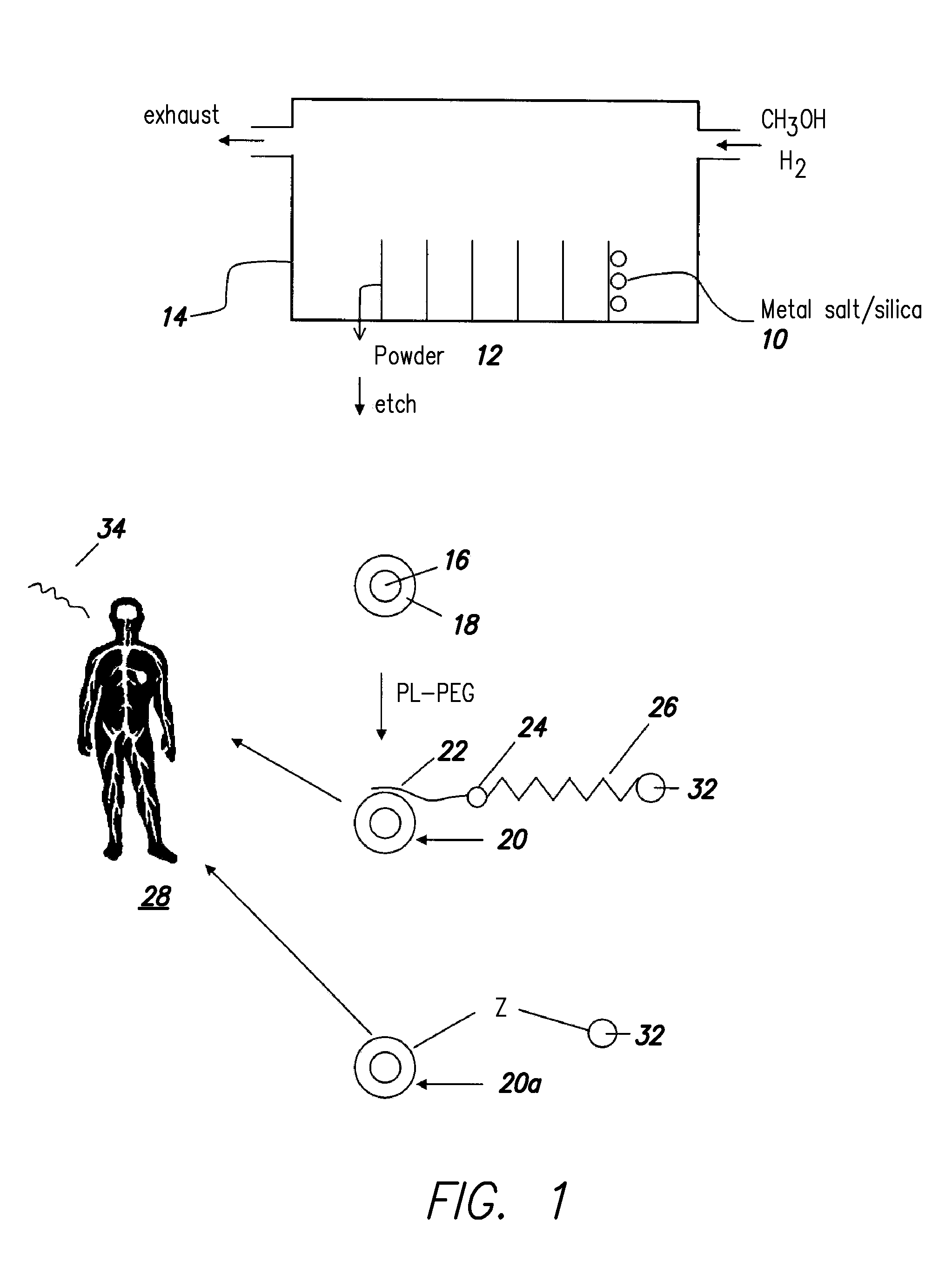

Catalytic growth of single- and double-wall carbon nanotubes from metal particles

InactiveUS7125534B1Improve productivityImprove scalabilityMaterial nanotechnologyFibre chemical featuresMetal catalystCatalytic decomposition

Single-walled carbon nanotubes have been synthesized by the catalytic decomposition of both carbon monoxide and ethylene over a supported metal catalyst known to produce larger multi-walled nanotubes. Under certain conditions, there is no termination of nanotube growth, and production appears to be limited only by the diffusion of reactant gas through the product nanotube mat that covers the catalyst. The present invention concerns a catalyst-substrate system which promotes the growth of nanotubes that are predominantly single-walled tubes in a specific size range, rather than the large irregular-sized multi-walled carbon fibrils that are known to grow from supported catalysts. With development of the supported catalyst system to provide an effective means for production of single-wall nanotubes, and further development of the catalyst geometry to overcome the diffusion limitation, the present invention will allow bulk catalytic production of predominantly single-wall carbon nanotubes from metal catalysts located on a catalyst supporting surface.

Owner:RICE UNIV

Paste for back contact-type solar cell

InactiveUS20080230119A1Reduce contact resistanceExcellent electrical propertiesFinal product manufactureConductive materialFritMetal alloy

Disclosed is a paste for a back contact-type solar cell that includes: (a) electrically conductive particles containing silver particle and added particles selected from the group consisting of (i) metal particles selected from the group consisting of Mo, Tc, Ru, Rh, Pd, W, Re, Os, Ir and Pt particles, (ii) a metal alloy containing the metal particles, and (iii) particles loaded with the metal particles, (b) glass frit, and (c) a resin binder.

Owner:EI DU PONT DE NEMOURS & CO

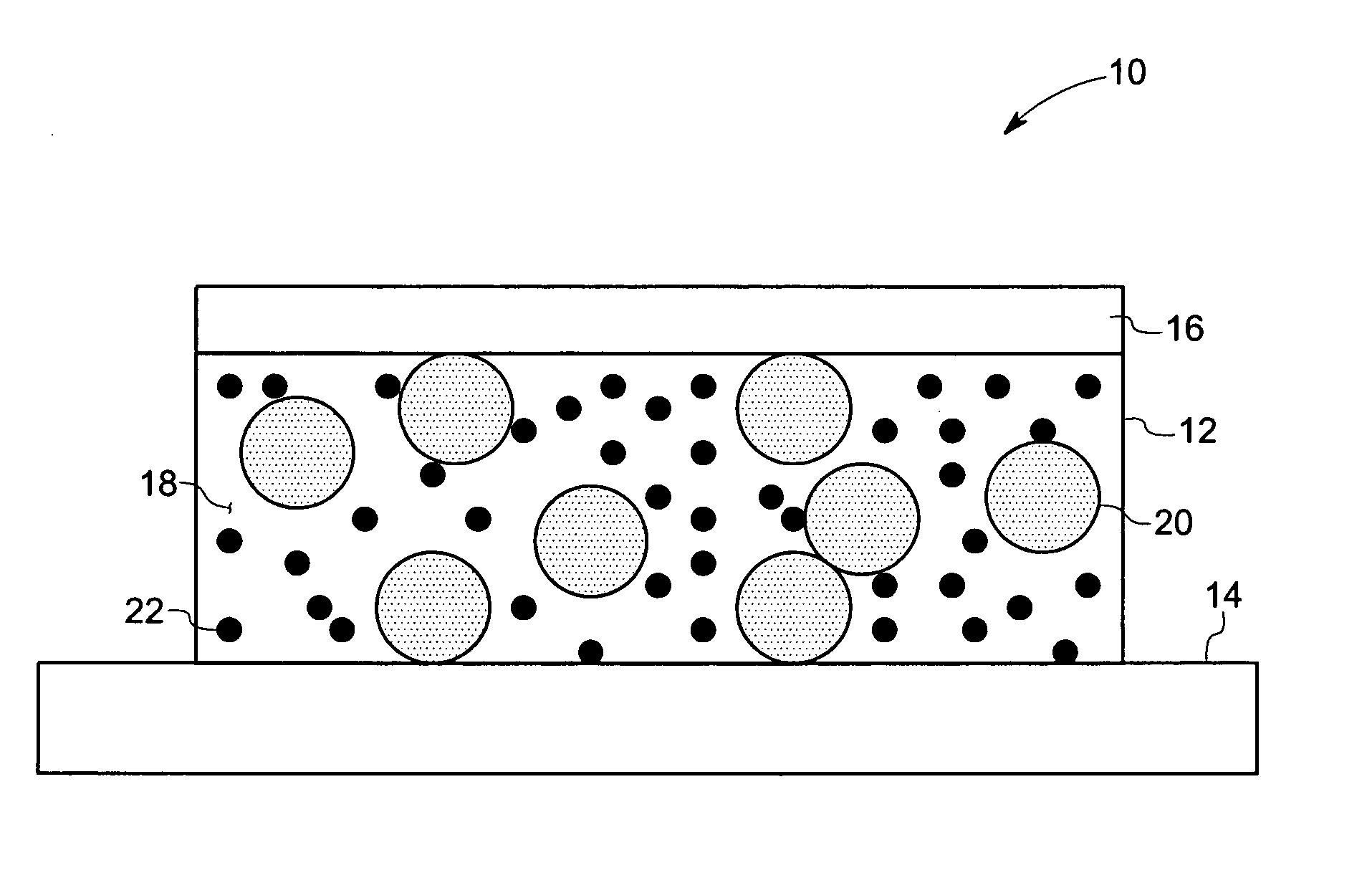

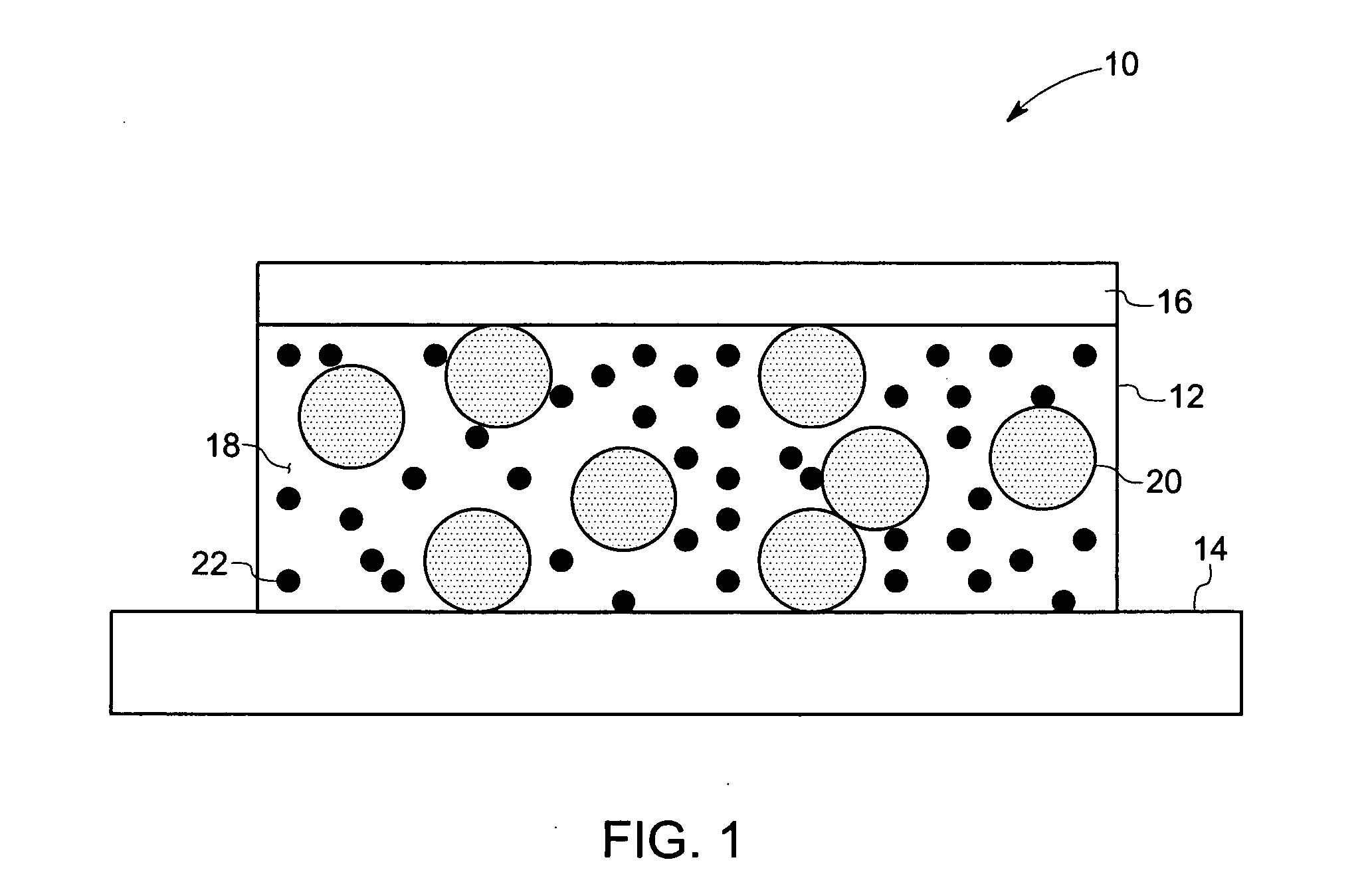

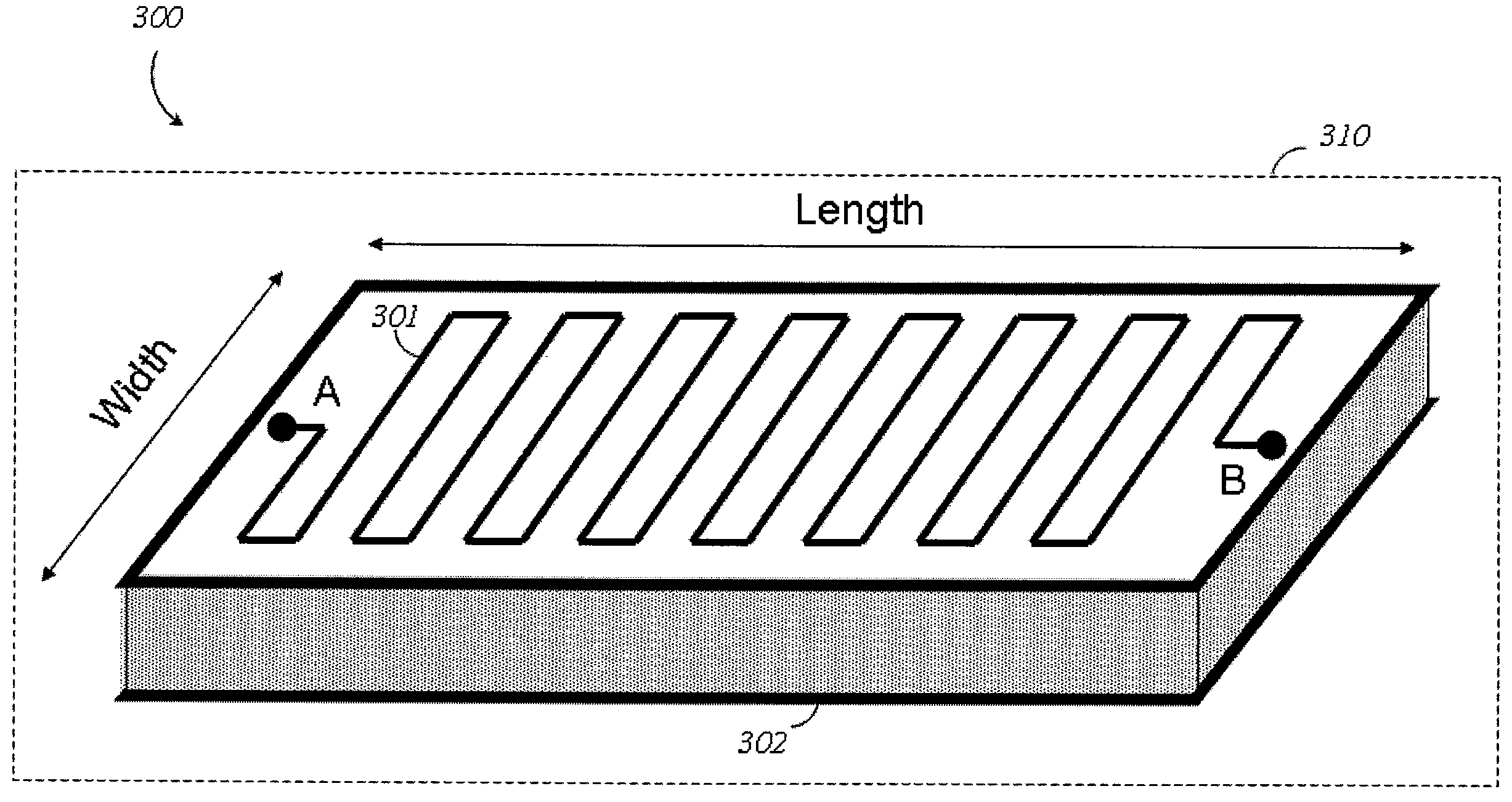

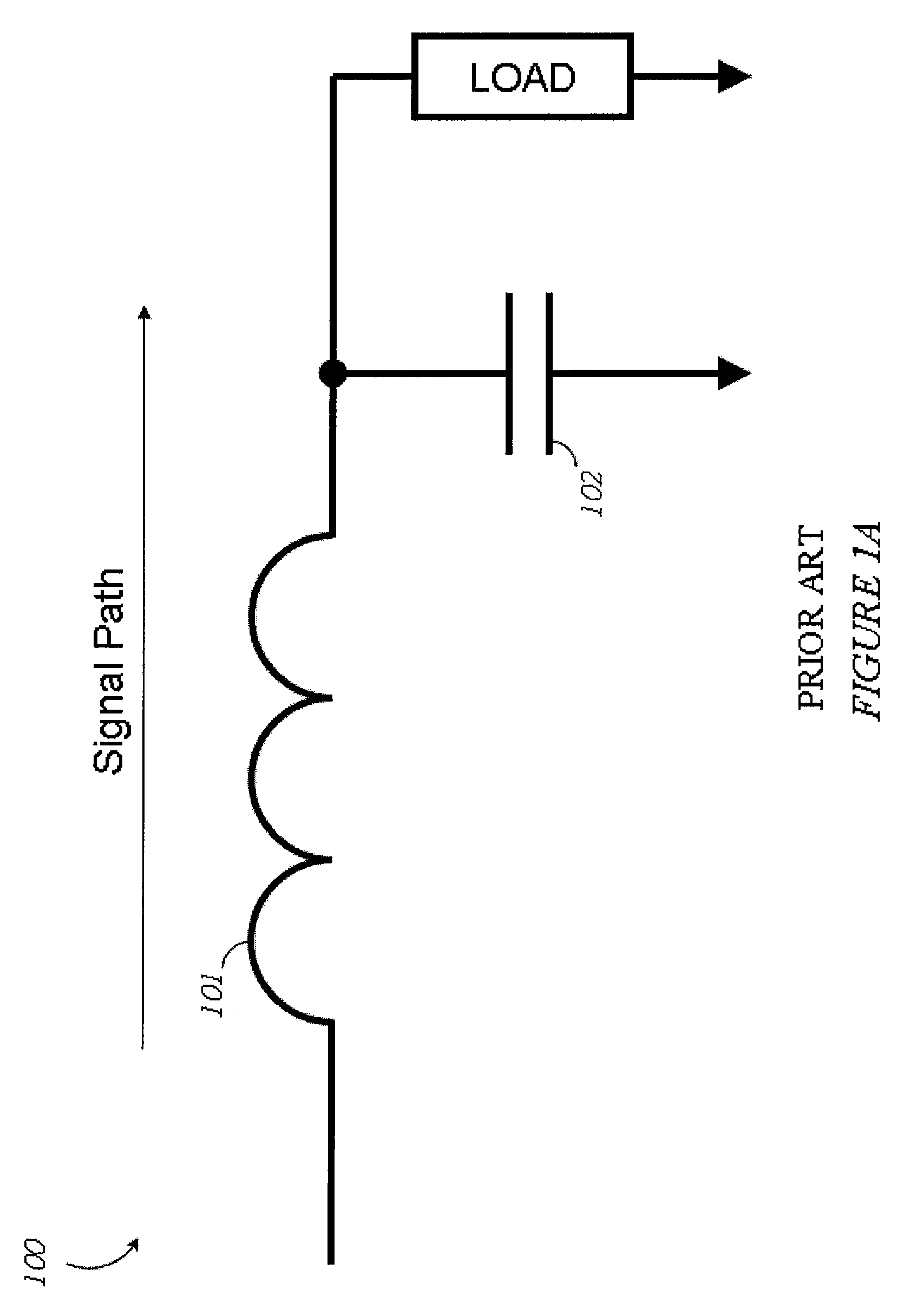

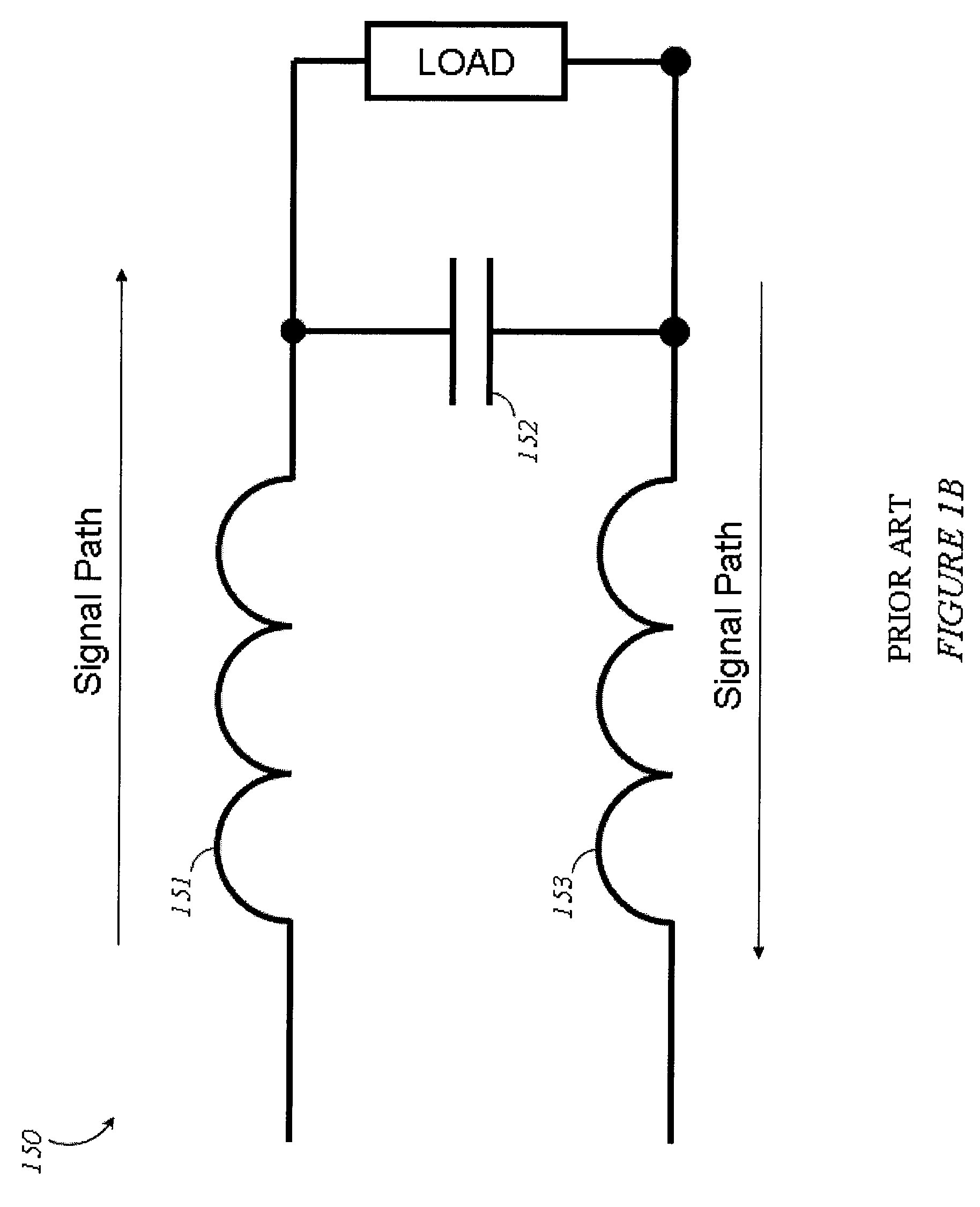

Systems, methods, and apparatus for electrical filters and input/output systems

ActiveUS20090102580A1Multiple-port networksCross-talk/noise/interference reductionEpoxyDielectric substrate

An electronic filtering device includes continuous trace on a dielectric substrate and a dissipation layer communicatively coupled to the trace. The dissipation layer may include disconnected metal particles, which may be embedded in a substrate, for example in an epoxy. The continuous trace may be meandering, for example crenulated, coil or spiral signal path. At least a second continuous trace may be spaced from the first by the substrate, and conductively coupled by a via. The electronic filtering device may be used in one or more printed circuit boards (PCBs) that form stages of an input / output system.

Owner:D WAVE SYSTEMS INC

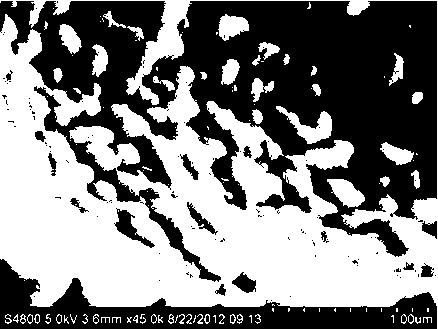

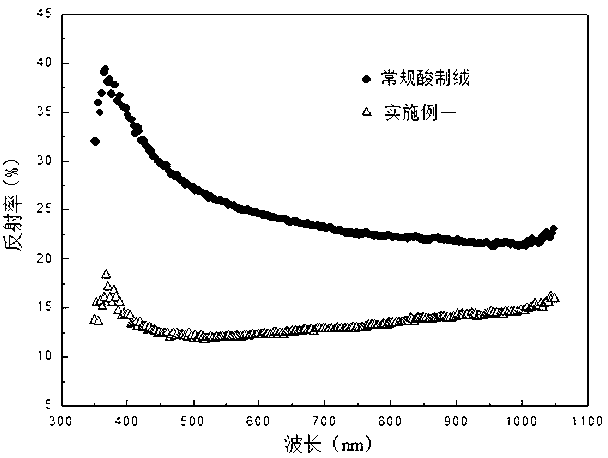

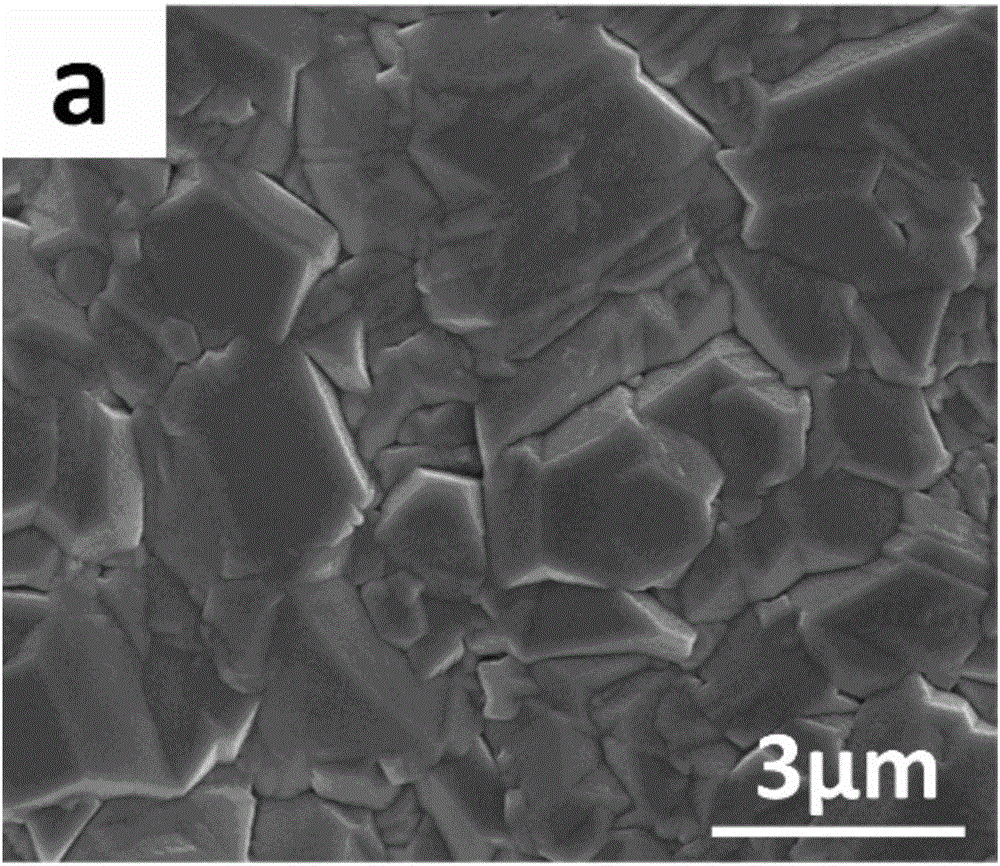

Textured structure of crystalline silicon solar cell and preparation method thereof

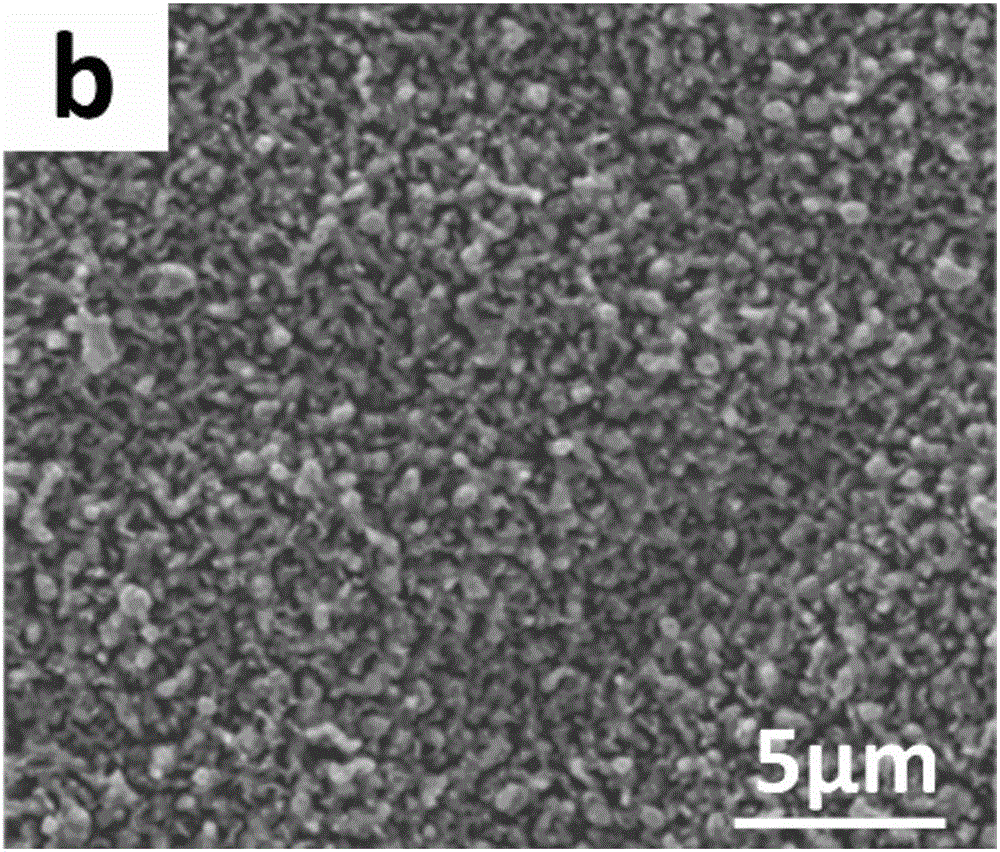

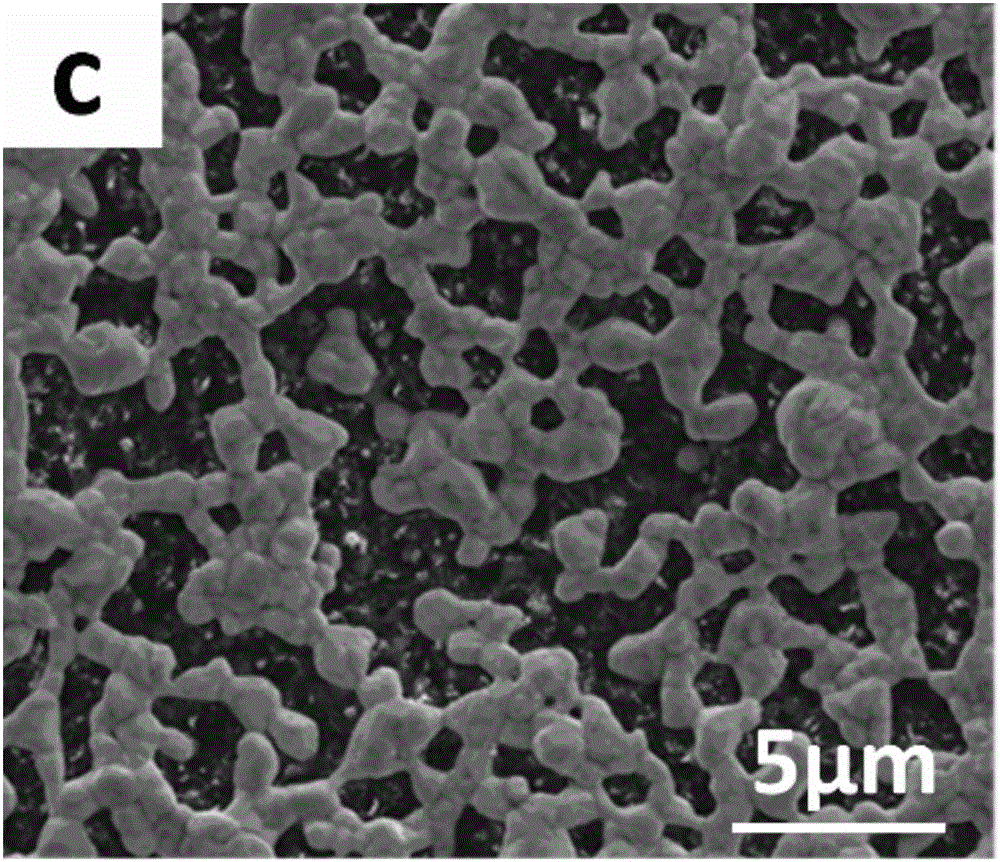

ActiveCN103219428AImprove conversion efficiencySimple manufacturing methodPhotovoltaic energy generationSemiconductor devicesMicrometerSpins

The invention discloses a preparation method of a textured structure of a crystalline silicon solar cell. The method includes the steps of (1) cleaning and texture preparation, (2) soaking a silicon wafer in a solution containing metal ions to enable the surface of the silicon wafer to be coated with a layer of metal nanometer particles, (3) corroding the surface of the silicon wafer to form a nanometer-grade texture, (4) cleaning to remove the metal particles, (5) carrying out microstructure amendment etching in second chemical corrosive liquid, and (6) cleaning and spin-drying. As is proved by a test, the size of the textured structure is between 100nm-500nm; the textured structure is of a nanopore shape with a large hole diameter and a small depth, or a nanometer pyramid with edge angles, or of a nanometer pit shape structure with an edge angle nanometer cone body or with an edge angle; and compared with a nanometer-micrometer composite textured structure disclosed in CN102610692A, the textured structure enables conversion efficiency of a cell piece to be improved by about 0.2%-0.5%, and an unexpected effect is achieved.

Owner:SUZHOU UNIV +1

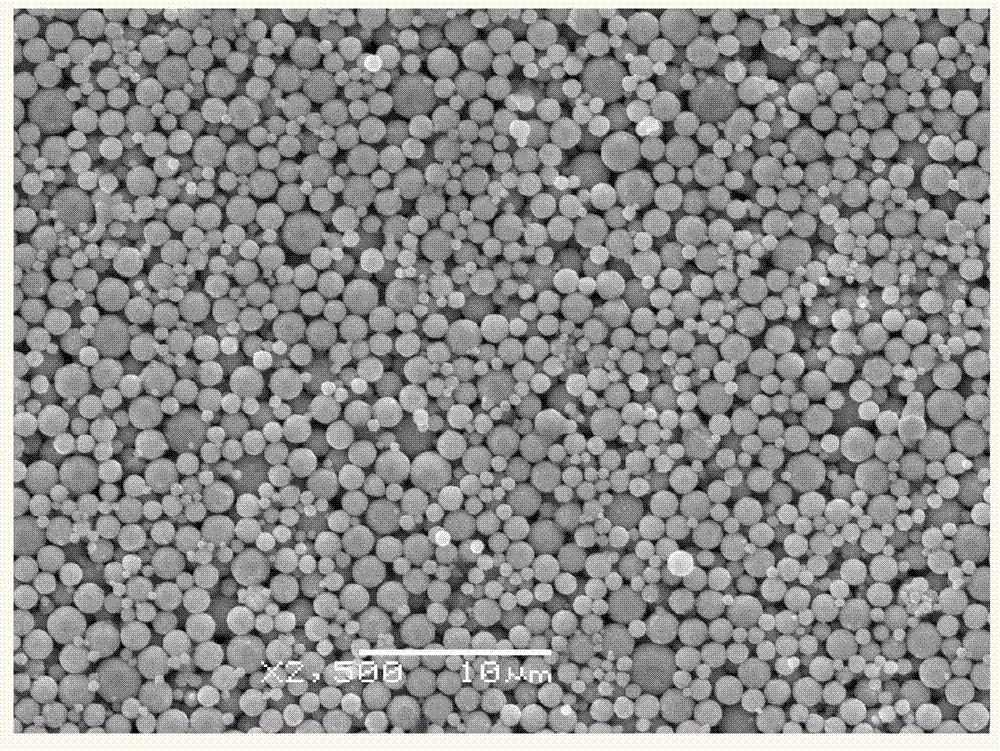

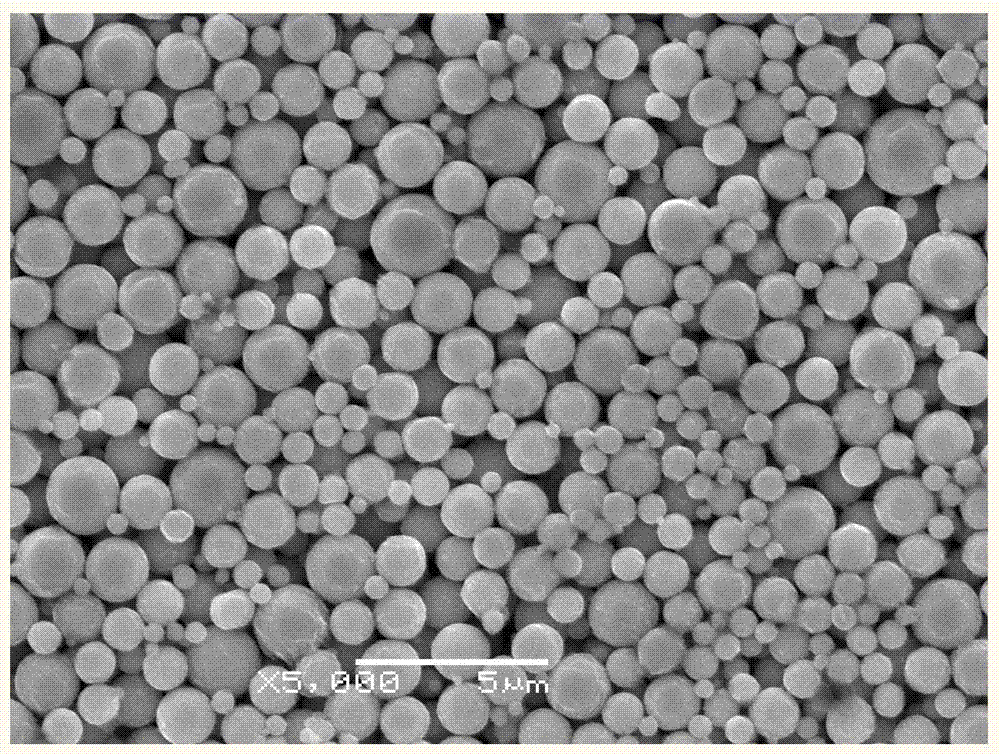

Metal powder for 3D printer and preparing method thereof

ActiveCN103785860AHigh sphericityUniform compositionAdditive manufacturing apparatusTransportation and packagingDispersityMetal particle

Owner:JIANGSU BOQIAN NEW MATERIALS CO LTD

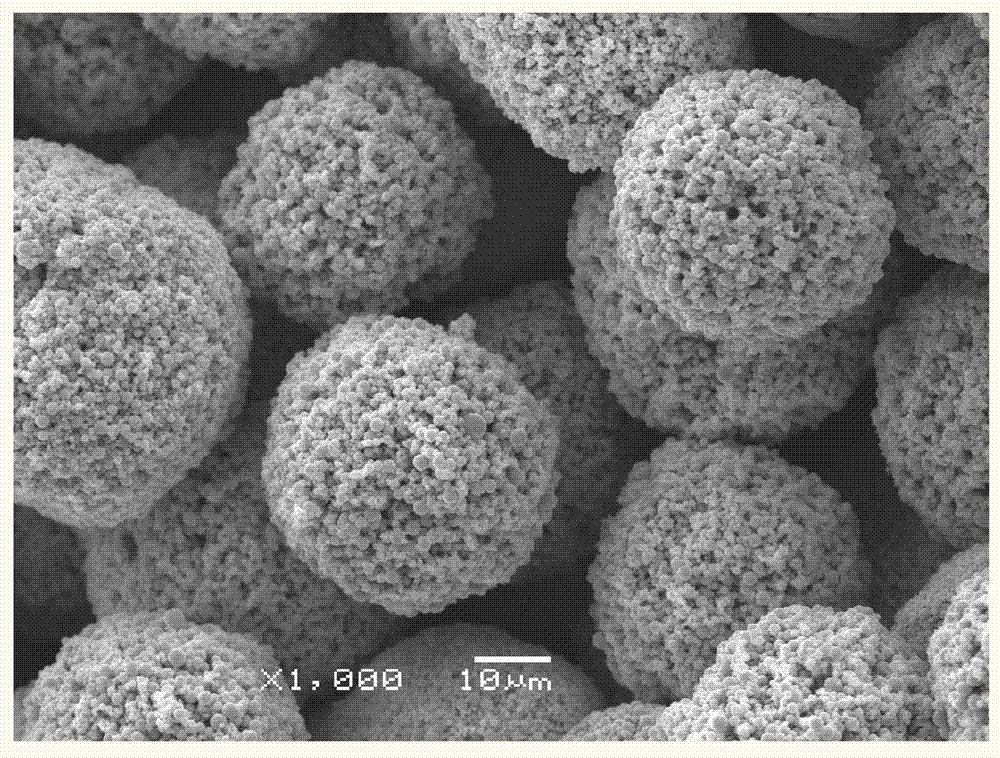

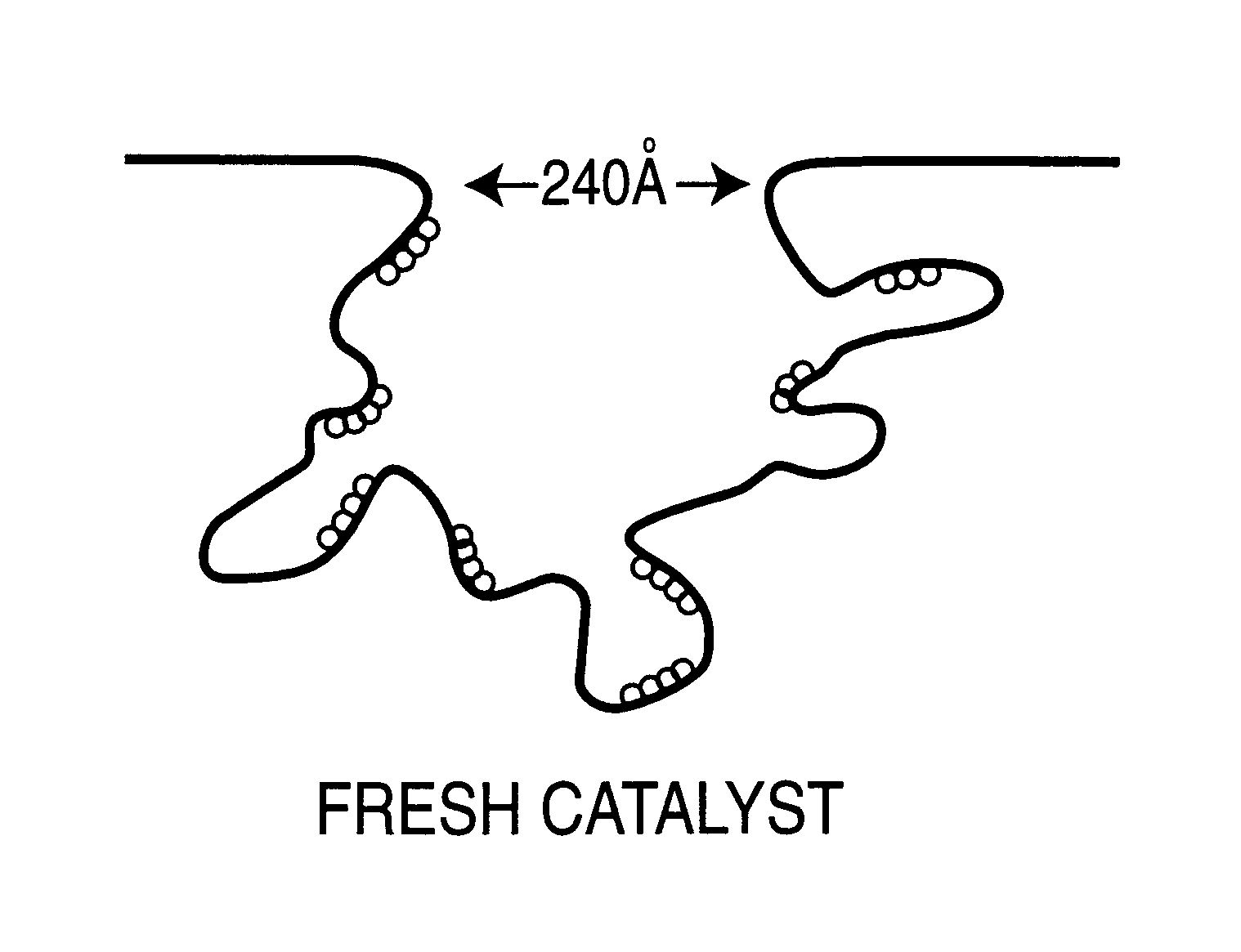

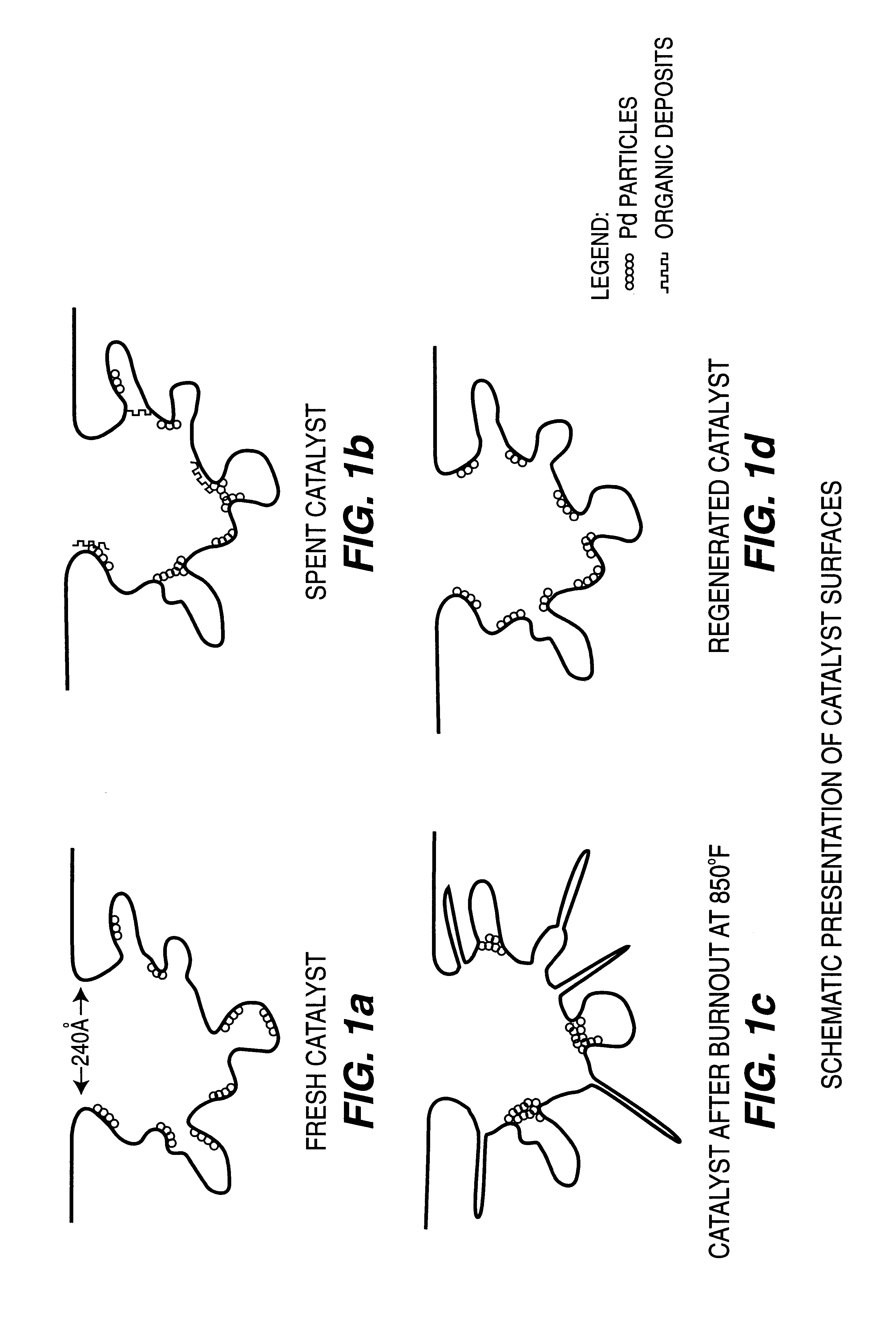

Regeneration of used supported noble metal catalysts

InactiveUS6740615B2Efficient removalImproves expositionHydrogen peroxideOther chemical processesPalladium catalystMetal particle

A method for regenerating used supported noble metal catalysts, which method includes solvent cleaning the used catalyst by contact with a suitable organic liquid cleaning solvent such as alcohols, ketones and such to remove organic deposits from the catalyst, followed by drying and calcining at elevated temperature to remove any remaining organic deposits from the catalyst, then treating the catalyst with an organo-metallic complex forming agent having ionization constant pK1 greater than about 2.5, such as glycolic acid and the like. The organic-metallic complex forming agent acts to break down large clusters of noble metal particles such as palladium (Pd) and redistributes the metal particles on the catalyst support such as alumina (Al2O3) in the same or other larger pores, so as to increase catalyst surface area and catalytic activity to provide a catalytic activity level at least 80% or even exceeding that of the fresh catalyst. This regeneration method is particularly useful for regenerating used supported palladium catalysts utilized for hydrogenation of ethyl anthraquinone (EAQ) for producing hydrogen peroxide (H2O2) product.

Owner:POROCEL INT LLC +1

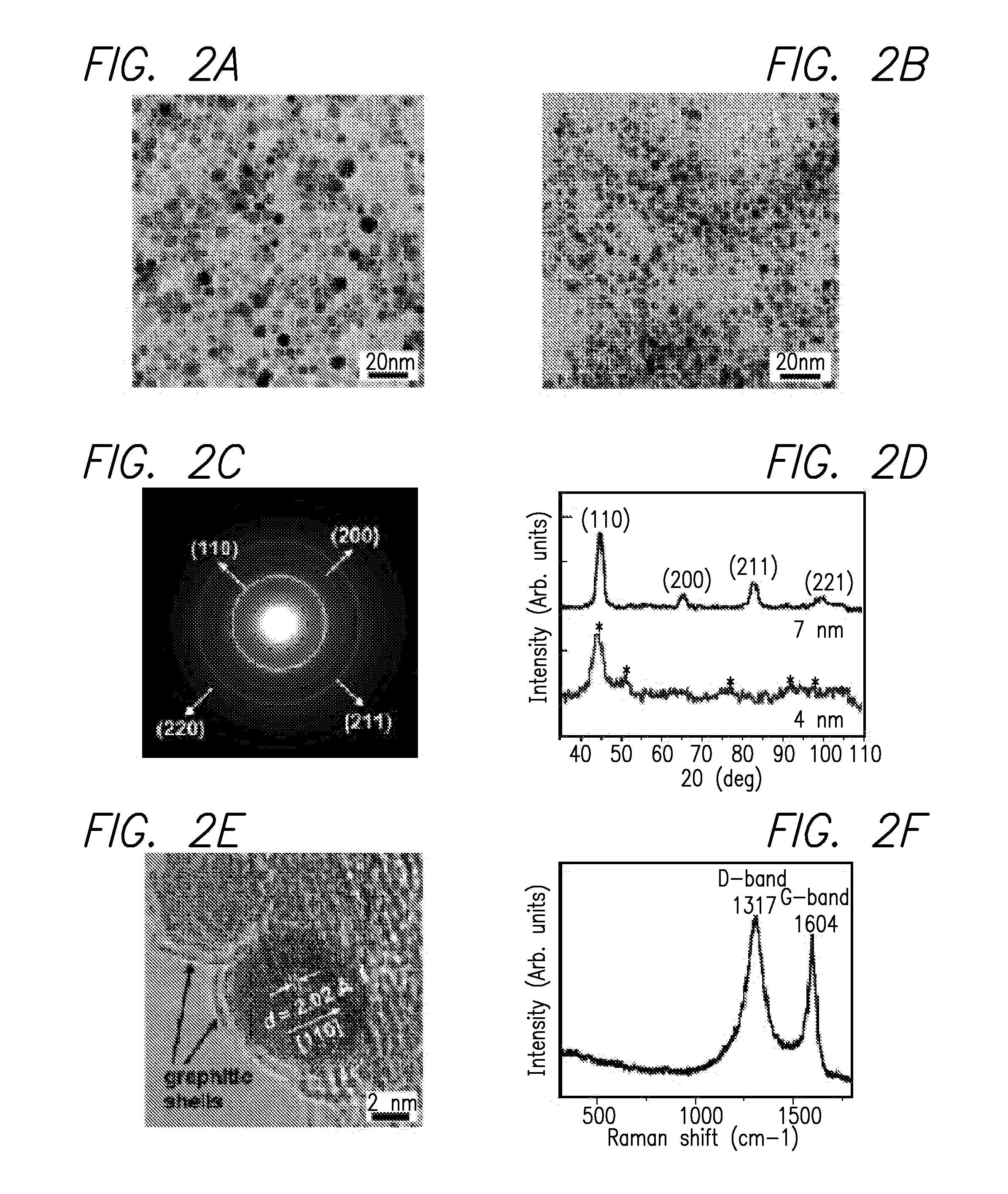

Multifunctional metal-graphite nanocrystals

InactiveUS20080213189A1High resolutionShrink tumorPowder deliveryInorganic active ingredientsMRI contrast agentPolyethylene glycol

Disclosed are nanocrystals comprising metals and metal alloys, which are formed by a process that results in a layer of graphite in direct contact with the metallic core. The nanocrystals may be used in vivo as MRI contrast agents, X-ray contrast agents, near IR (NIR) heating agents, drug delivery, protein separation, catalysis etc. The nanocrystals may be further functionalized with a hydrophilic coating, e.g., phospholipid-polyethylene glycol, which improves in vivo stability. The process comprises chemical vapor deposition of metals adsorbed onto silica as a fine powder, in conjunction with a carbon containing gas, which coats the metal particles. The silica is then etched away. Preferred metals include iron, gold, cobalt, platinum, ruthenium and mixtures thereof, e.g., FeCo and AuFe. The process permits control of the alloy compositions, size, and other characteristics.

Owner:THE BOARD OF TRUSTEES OF THE LELAND STANFORD JUNIOR UNIV

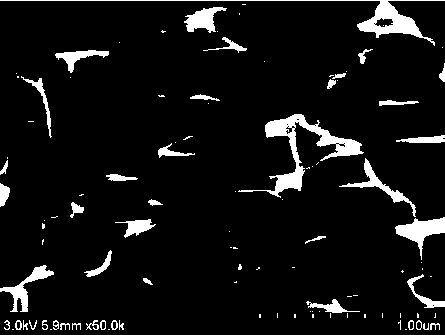

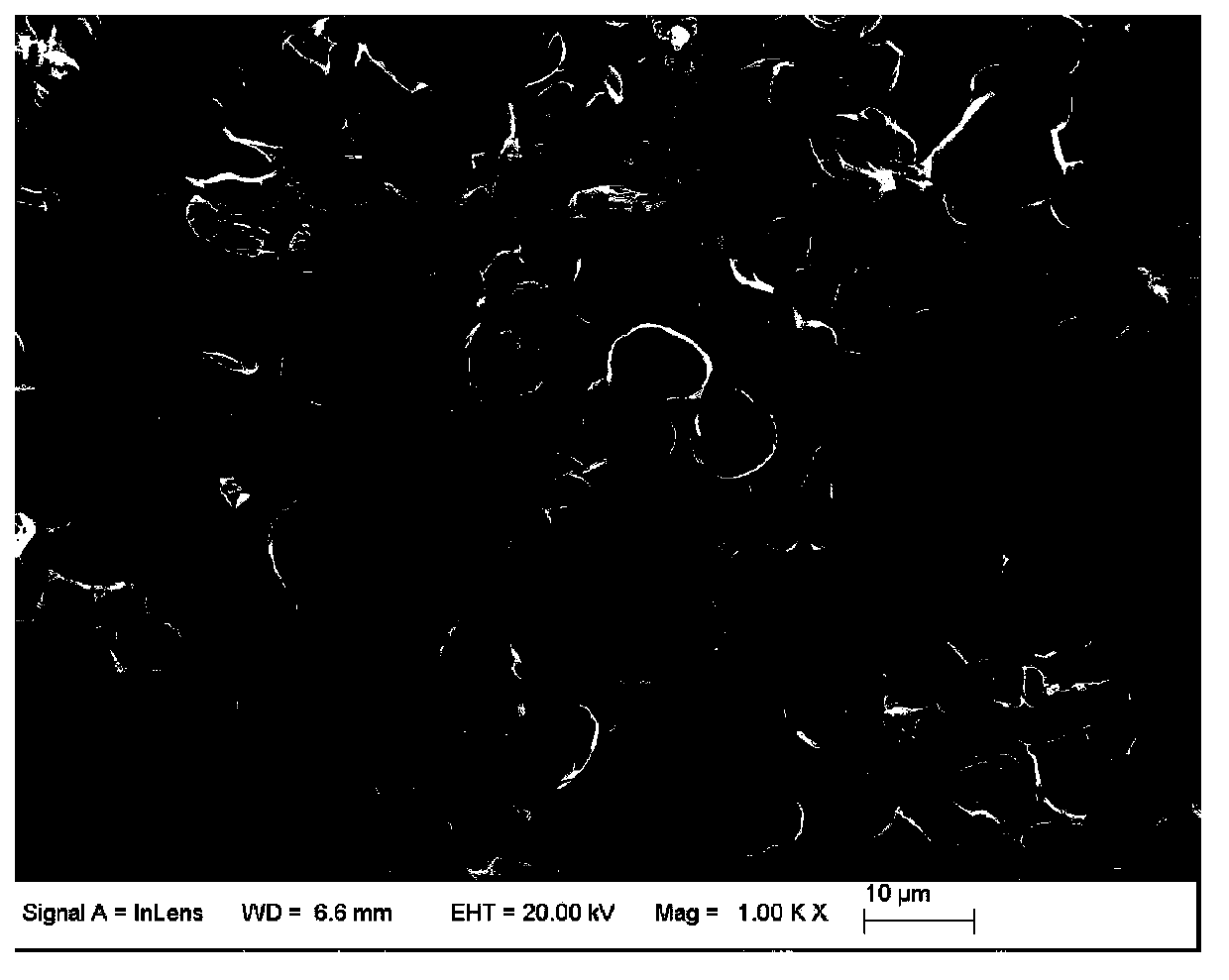

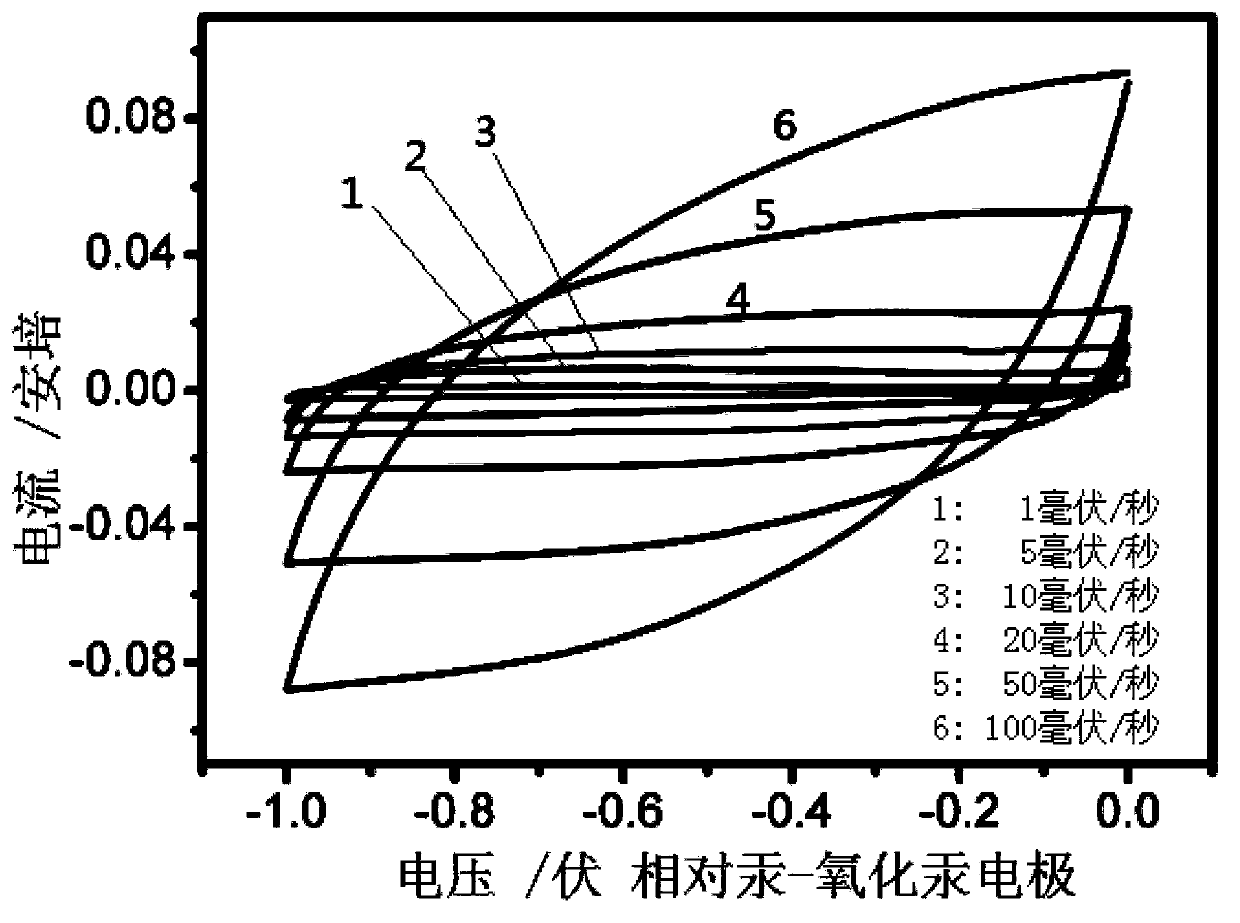

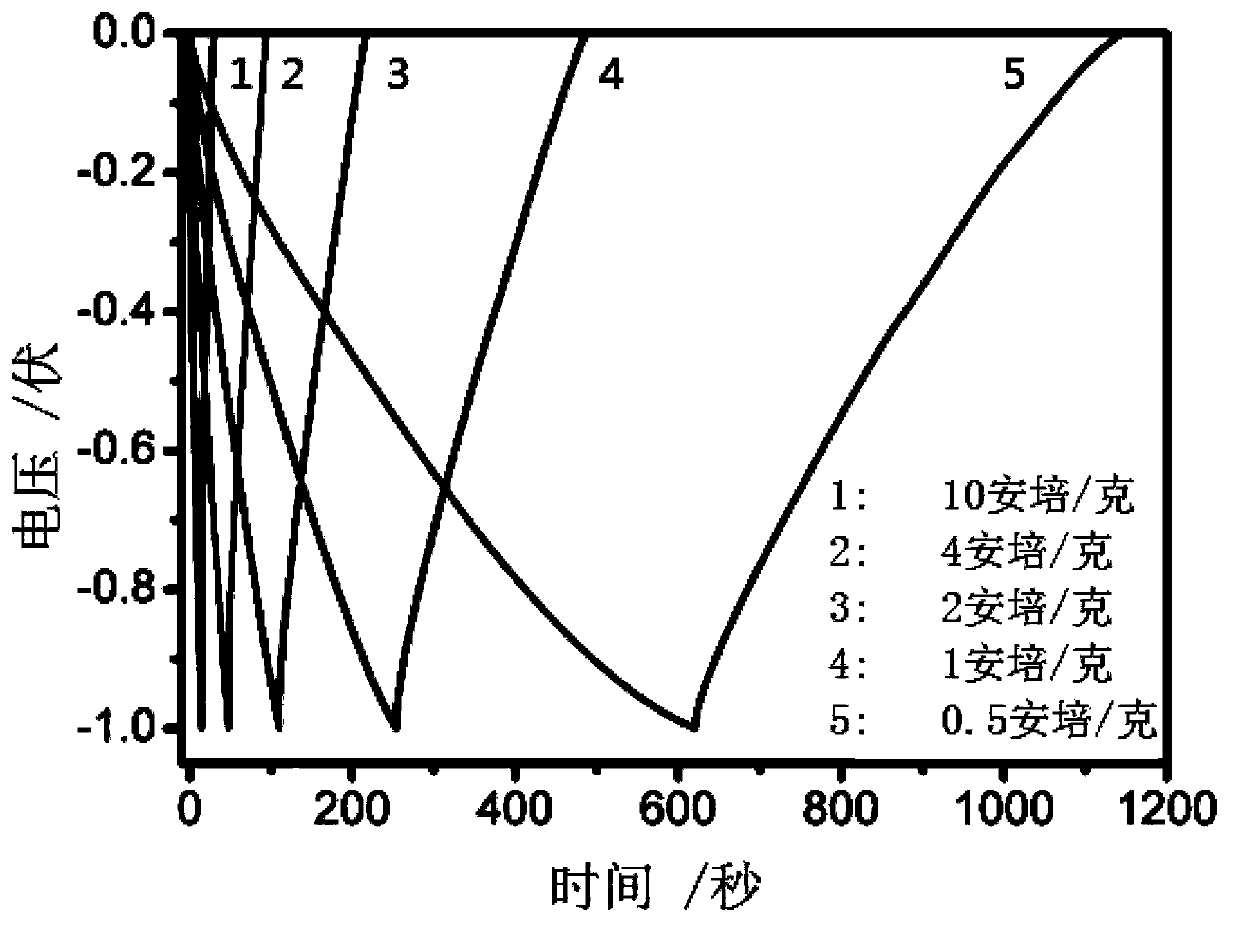

High-specific-surface-area boron-doped diamond electrode and preparation method and application thereof

ActiveCN106435518AHigh activityLarge electrochemical reaction interfaceWater contaminantsWater/sewage treatmentElectrochemical biosensorDiamond electrodes

The invention discloses a high-specific-surface-area boron-doped diamond (BDD) electrode which comprises an electrode substrate. A boron-doped diamond layer is arranged on the surface of the electrode substrate. Or, a transition layer is arranged on the surface of the substrate, and then a boron-doped diamond layer is arranged on the surface of the transition layer. Metal particles are distributed in the diamond layer, and tiny holes and / or pointed cones are distributed on the surface of the diamond layer. Compared with a traditional plate electrode, the boron-doped diamond electrode contains a large number of tiny holes and pointed cones and has the extremely high specific surface area, and the large current intensity is provided through the low current intensity; and meanwhile, due to the different electrode configurations of the substrate and modification of surface graphene and / or carbon nano tubs (CNT), the mass transfer process can be greatly improved, the current efficiency and the electrochemical property are greatly improved, and the BDD electrode with high electrocatalytic activity and high using efficiency is prepared. The electrode can be widely applied in the fields of electrochemical wastewater purification treatment, electrochemical biosensors, strong oxidant electrochemical synthesis, electrochemical detection and the like.

Owner:NANJING DAIMONTE TECH CO LTD

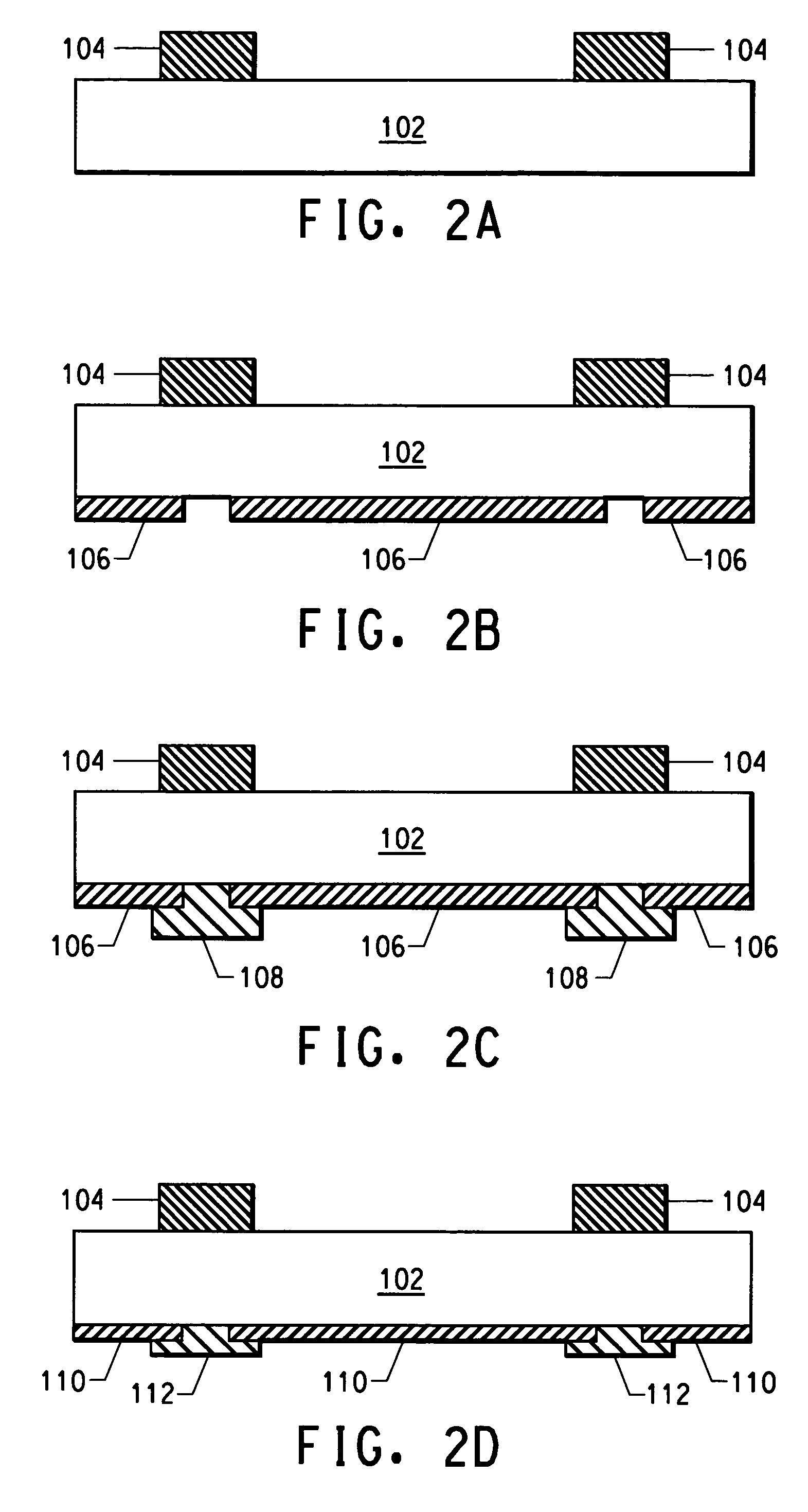

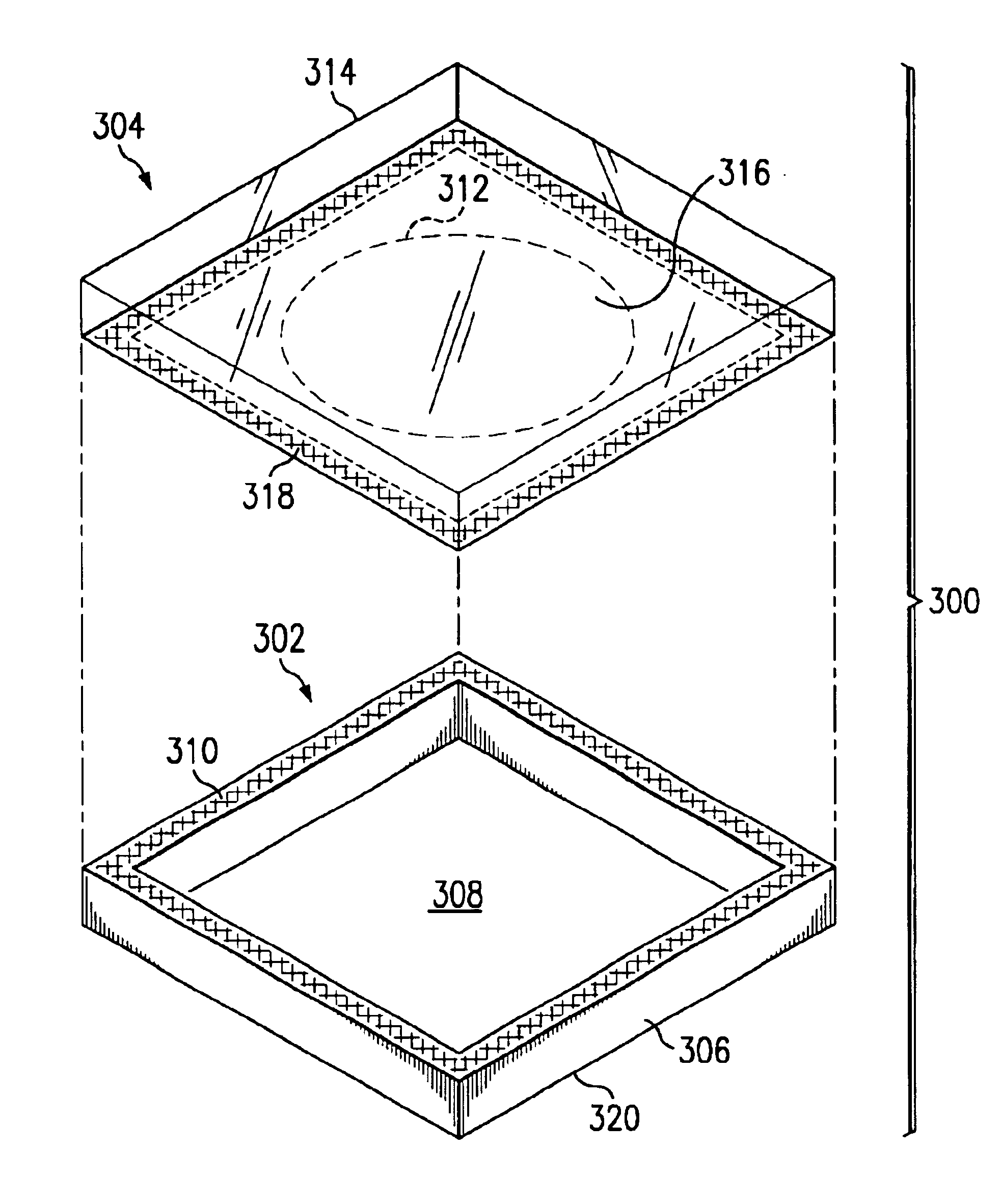

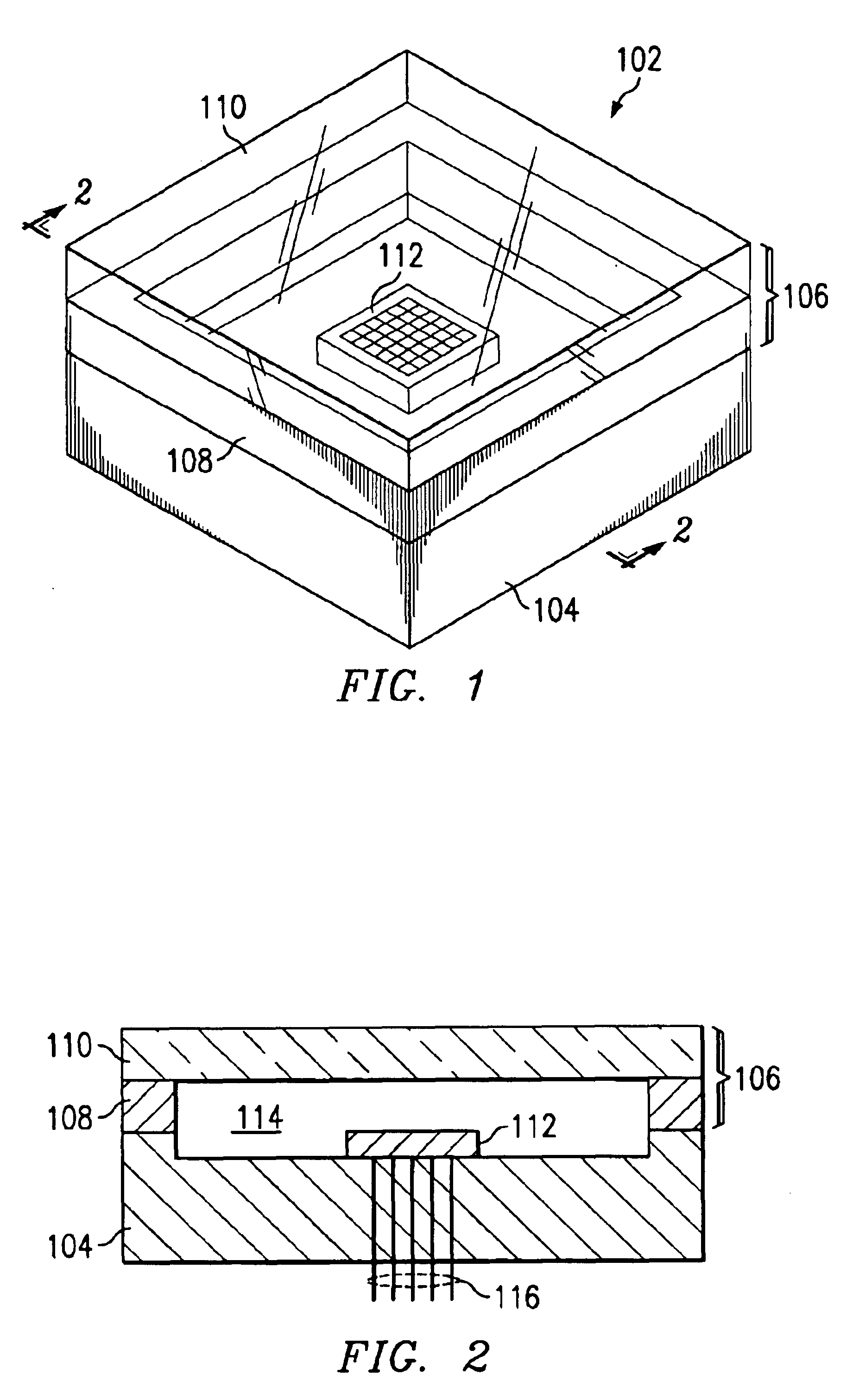

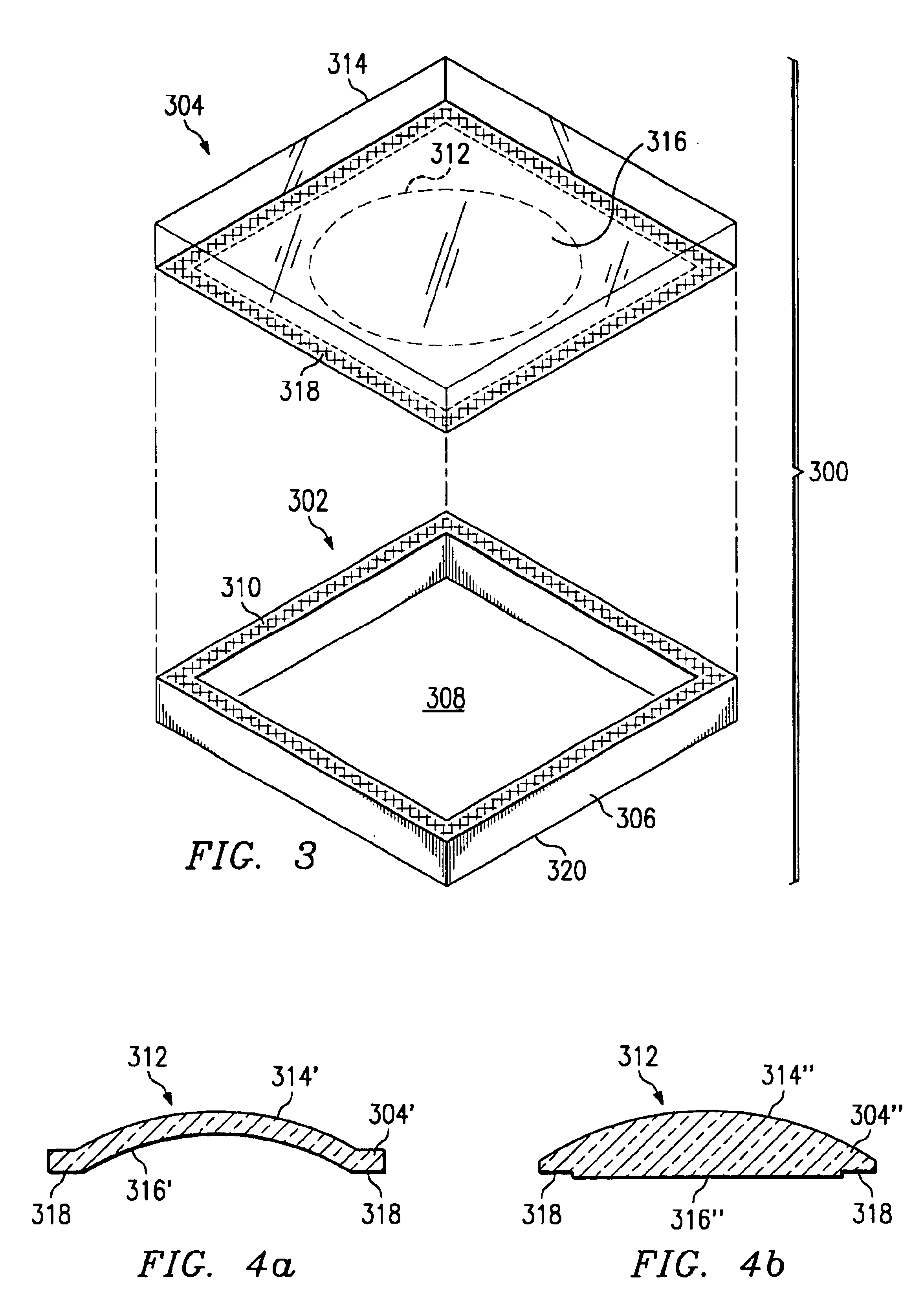

Hermetically sealed micro-device package using cold-gas dynamic spray material deposition

InactiveUS6924974B2Digital data processing detailsSemiconductor/solid-state device detailsMetal coatingMetal framework

A cover assembly for welding to a package base to form a hermetically sealed micro-device package. The cover assembly includes a sheet of a transparent material having a window portion. A built-up metallic frame adheres to the sheet and circumscribes the window portion, the frame having been deposited as follows: First, powdered metal particles are sprayed onto a prepared area of the sheet using a gas jet at a temperature below the fusing temperature of the particles, the jet having a velocity sufficient to cause the particles to merge with one another upon impact with the sheet and with one another to form an initial continuous metallic coating adhering to the prepared area of the sheet. Next, successive metal particles are applied over the initial coating using the jet to form the frame incorporating the initial continuous metallic coating as its base and having an predetermined overall thickness.

Owner:ASTRAVAC GLASS INC

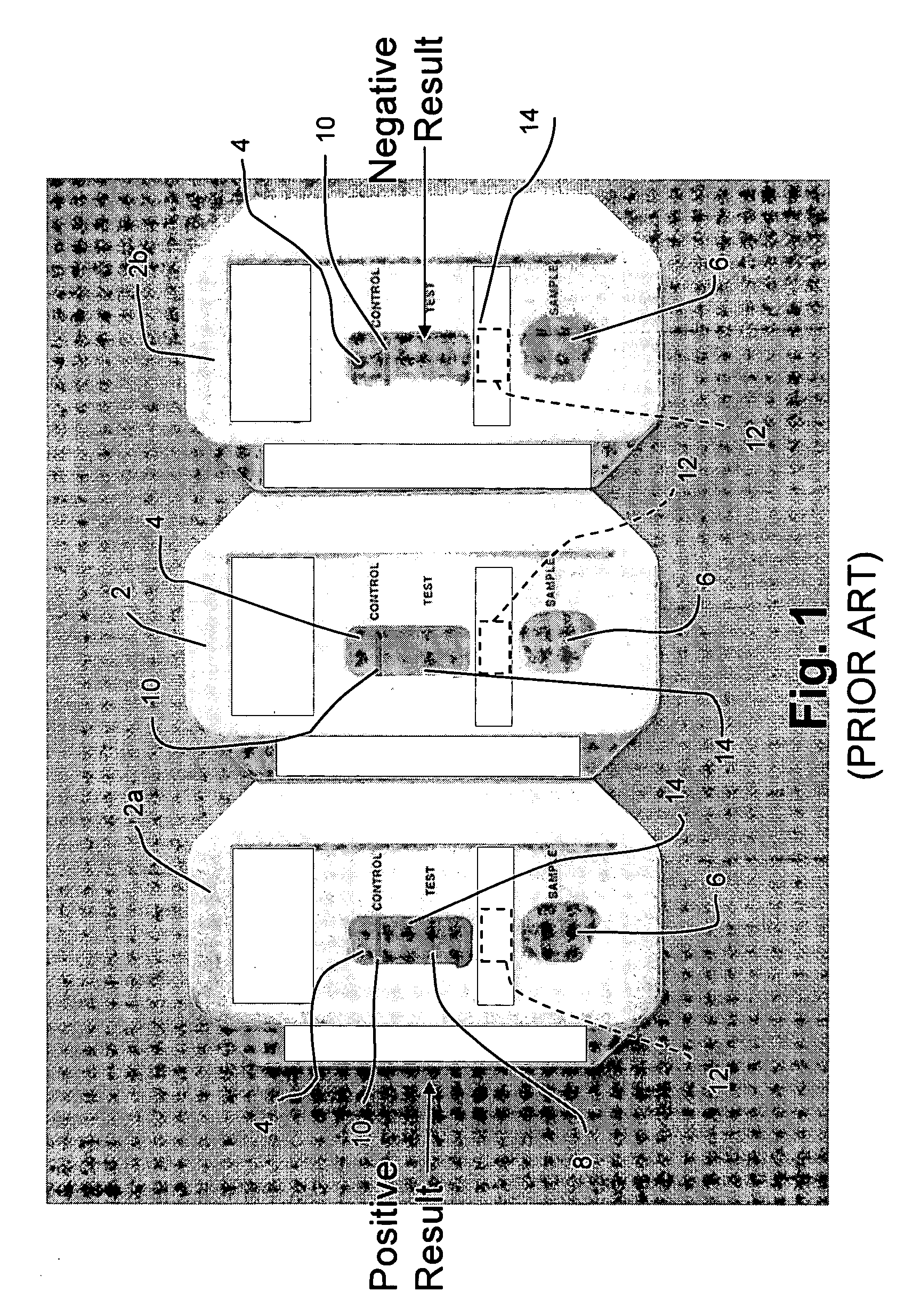

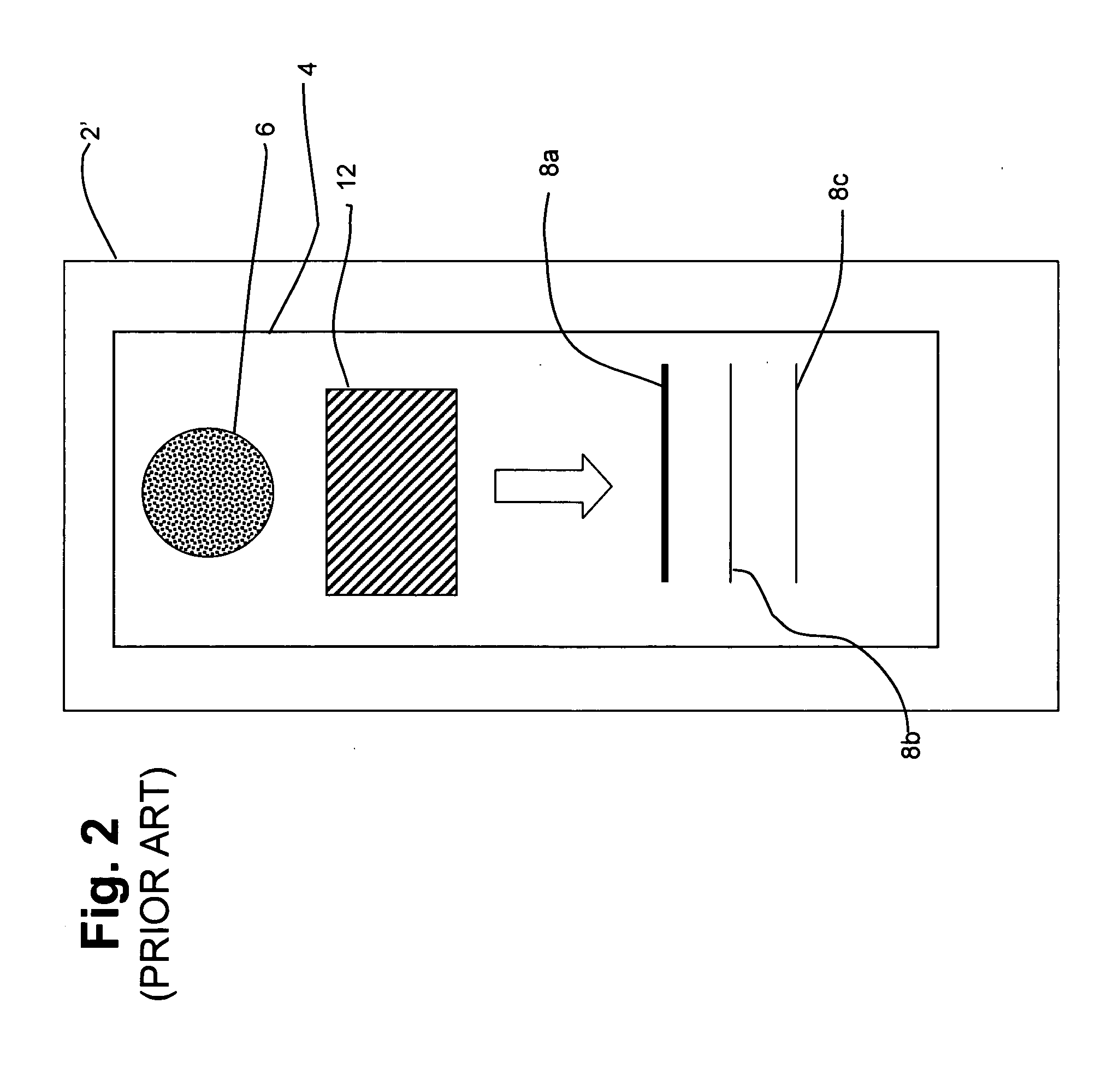

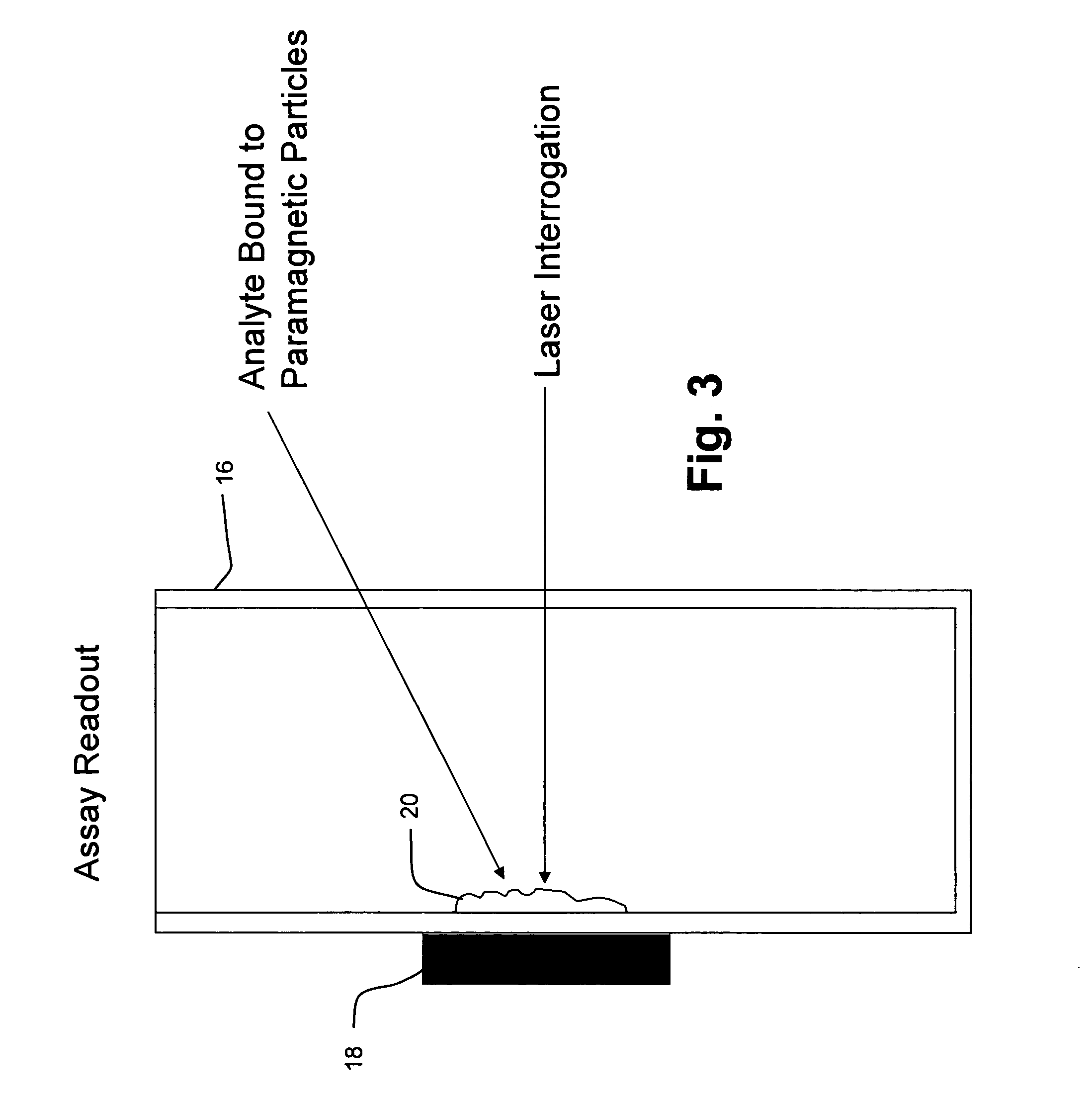

System and method for Raman spectroscopy assay using paramagnetic particles

ActiveUS20060240572A1Easy to measureRadiation pyrometryMaterial analysis by optical meansAnalyteCompound (substance)

A Raman spectroscopy technique allows an analyte, a paramagnetic particle, and a spectral enhancement particle to combine in solution and for the combination product to be localized by a magnetic field for analysis. The spectral enhancement particle may be comprised of an active SERS metal particle with or without a material coating. The spectral enhancement particle may function as a reporter for the presence of the analyte or merely increase the magnitude of the Raman spectrum of the analyte. The technique is applicable to both immunoassays and chemical assays. Multiple spectral enhancement particle reporters may be measured in a single assay that can detect multiple analytes using the SERS effect.

Owner:UNIVERSITY OF WYOMING

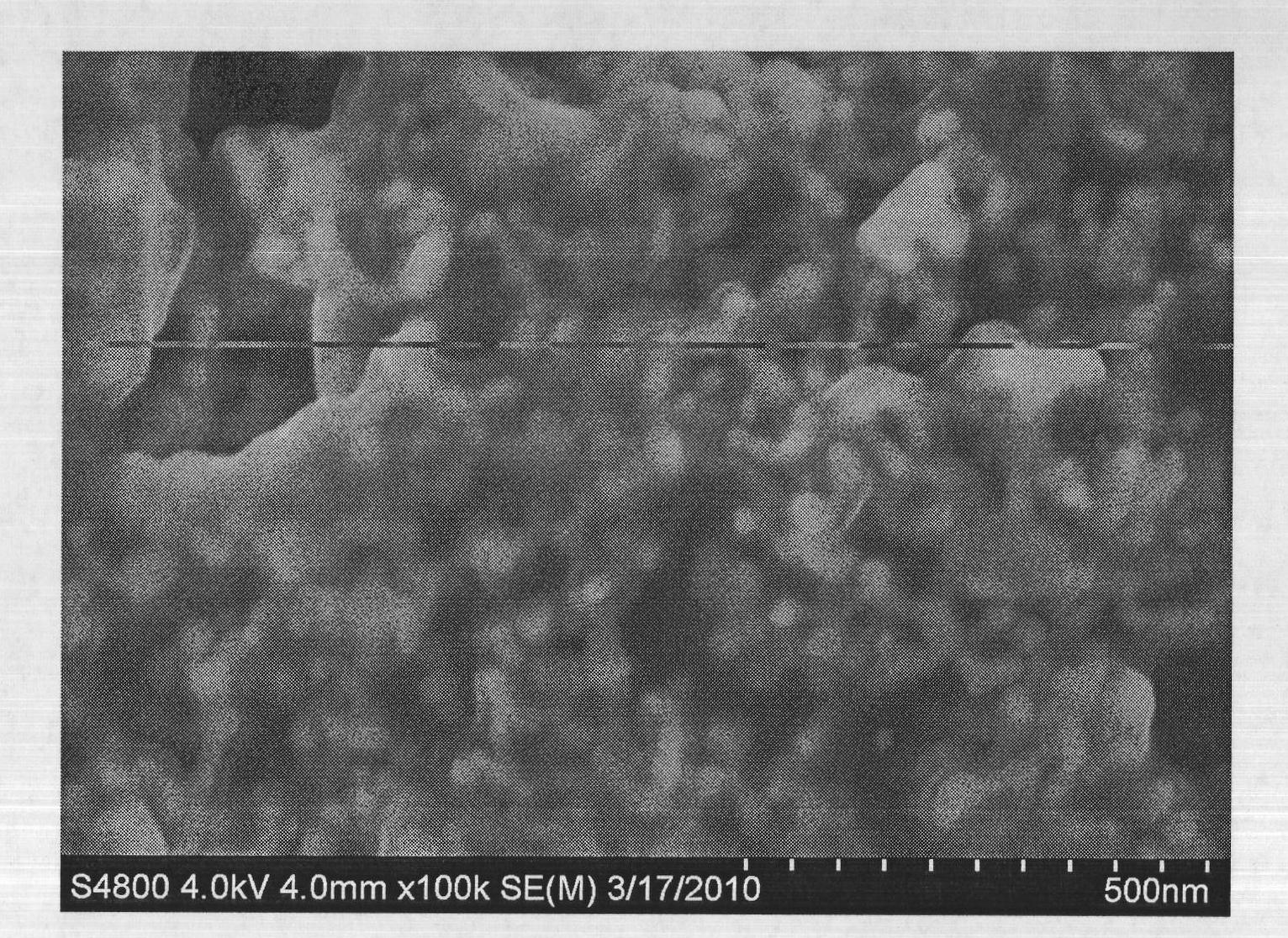

Preparation method of nitrogen-doped porous-structure carbon material

ActiveCN103964412AImprove the reduction catalytic activityHigh nitrogen contentMaterial nanotechnologyPhysical/chemical process catalystsCapacitanceMetal particle

The invention discloses a preparation method of a nitrogen-doped porous-structure carbon material and belongs to the technical field of inorganic material preparation. The preparation method utilizes a micromolecular carbon-containing compound as a raw material and comprises the following steps of based on the weight of the raw material, adding 0-400wt% of an inorganic base, 0-400wt% of an organic nitrogen-containing compound and 0-50wt% of a metal or metal oxide or inorganic metal salt into the raw material, carrying out uniform dispersion, and carrying out a reaction process in an inert gas protective atmosphere at a temperature of 400-900 DEG C for 0.5-12h so that the nitrogen-doped porous-structure carbon material having micropores, mesopores and macropores is obtained. The preparation method has simple processes, can be controlled easily, and realizes one-step combination of porous structure, functionalization nitrogen doping and metal particle modification. The nitrogen-doped porous-structure carbon material having high nitrogen content has a large capacitance value and good cycle performances, can be used as an oxygen reduction reaction catalyst having high activity, high selectivity and high stability and has a very large application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Lower-temperature sintered conductive ink

ActiveCN101805538AIncrease base rangeReduce consumptionInksMetallic pattern materialsAdhesivePreservative

The invention discloses a low-temperature quickly sintered conductive ink for use in ink jet printing, which comprises 1 to 70 weight percent of nano metal particles, 0.1 to 10 weight percent of dispersant, 25 to 98 weight percent of solvent and 0.01 to 36 weight percent of additive, wherein the additive is one or a mixture of two or more of a surfactant, a reducer, a defoamer, an adhesive, a preservative and a humectants. Compared with the prior art, the low-temperature sintered conductive ink can reduce sintering temperature and keep the high conductivity of a wire. For example, at a sintering temperature of 150 DEG C, the conductive ink can make the resistance of a silver wire reach 10 to 7ohm.m. Therefore, the conductive ink can enlarge the range of substrates to which the conductive ink is applied in ink jet printing and reduce energy consumption, and has a great significance for the cost control and environmental protection of manufacturers.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Nanoscale metal particles and method of preparing same

A process of preparing individually-isolated, carbon-coated nanoscale metal particles is disclosed. The process is effected by sonicating a mixture of a metal carbonyl and a hydrocarbon solvent that is selected so as to polymerize during sonication. Air-stable and aqueous solution-stable, carbon-coated nanoscale metal particles and a process of preparing same are also disclosed.

Owner:BAR ILAN UNIV

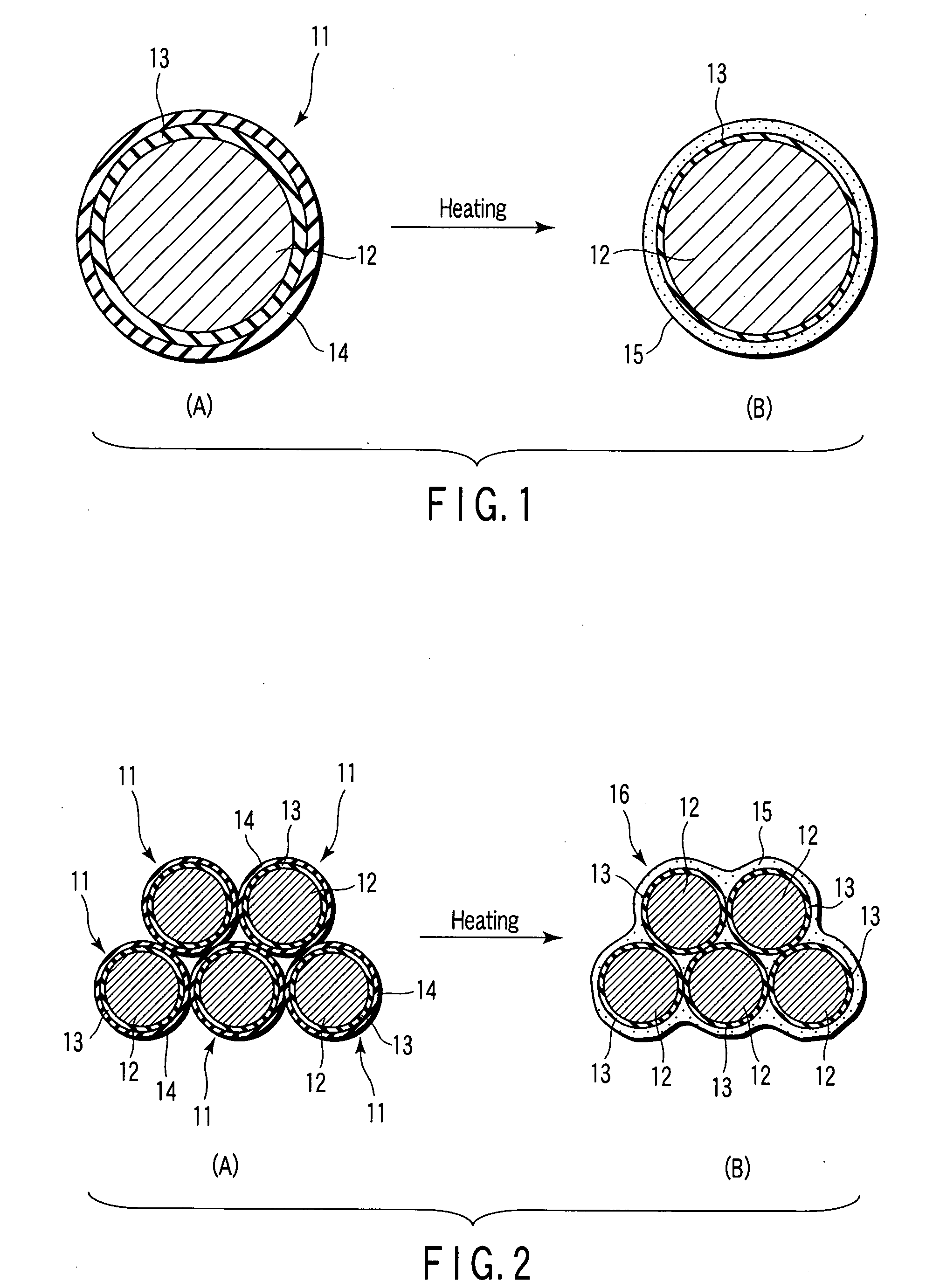

Conductive composite particle, method of manufacturing the same, electrode using the same, lithium ion secondary battery

In a manufacturing method of a conductive composite particle, a conductive composite particle is manufactured that is formed of an active material particle having a region capable of electrochemically inserting and desorbing lithium and a carbon layer joined to the particle surface. In the carbon layer, fine metal particles are dispersed. This method has the following three steps. In the first step, a polymer material containing the metal element composing the fine metal particles is prepared. In the second step, the active material particle surface is coated with the polymer material containing the metal element. In the third step, a carbon layer having a porous structure including a fibrous structure is formed as the surface layer section from the polymer material by a treatment where the active material particle coated with the polymer containing the metal element is heated in an inert atmosphere to carbonize the polymer material.

Owner:PANASONIC CORP

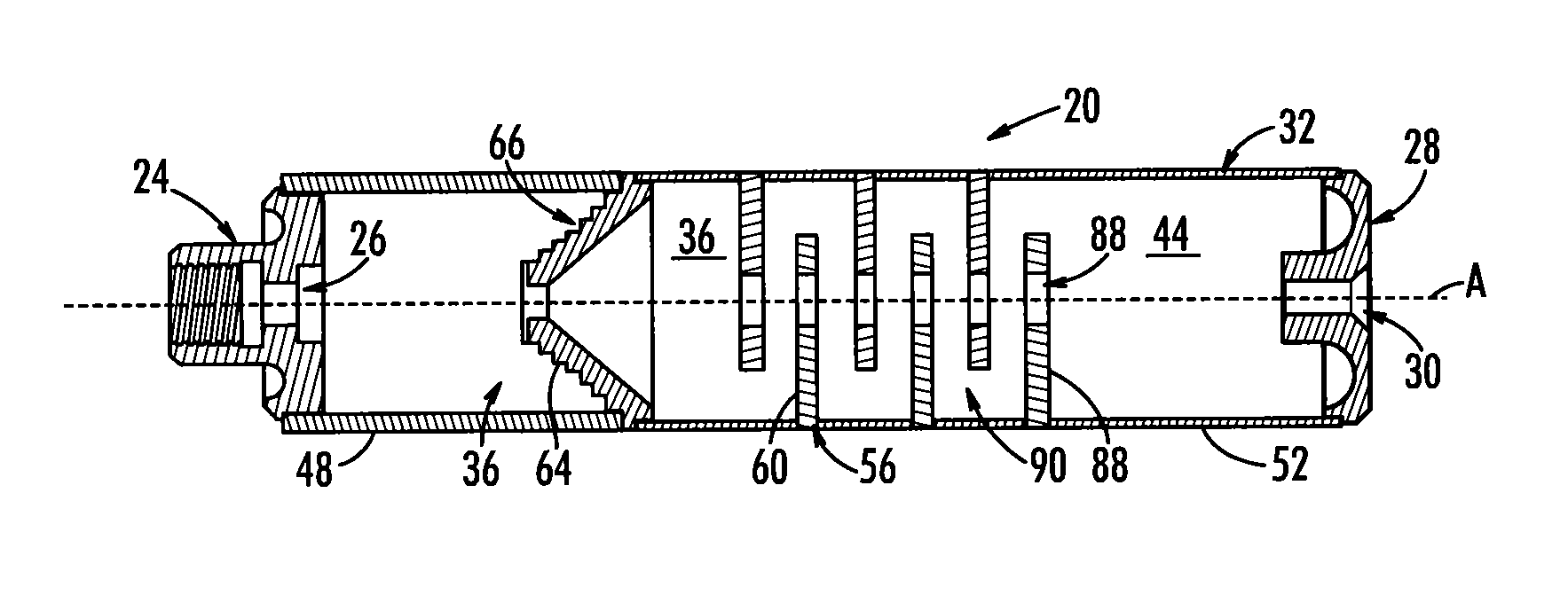

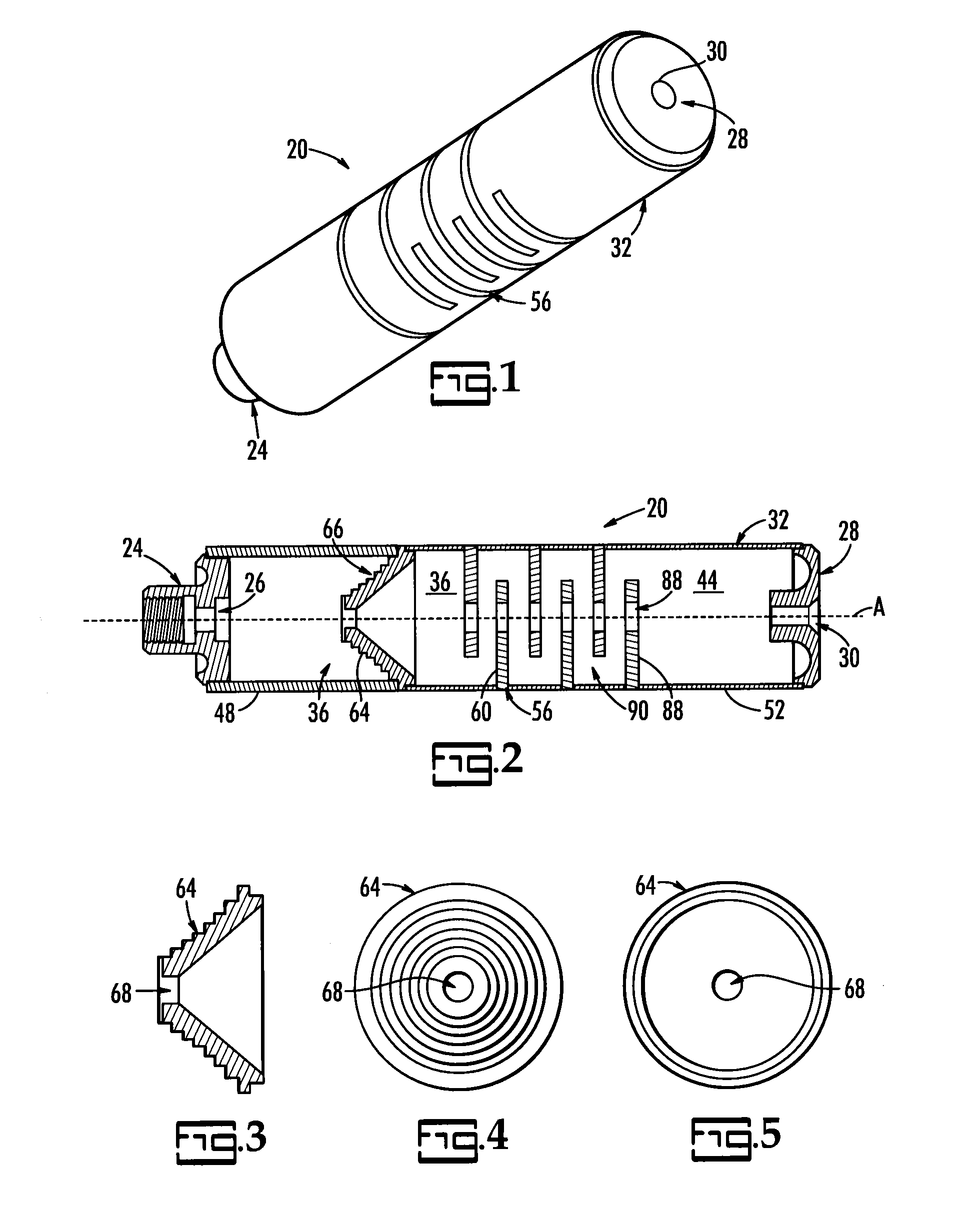

Sound suppressor

A sound suppressor suppresses sound and flash by creating interacting paths of gas. While a first portion of the gas follows a first path through the suppressor, a second portion of the gas is diverted radially from the first path to a second path and then repeatedly made to cross the first path by a series of baffles with alternating radial passages so that the two portions of gas interfere and interact with each other, and therefore quickly give up much of their kinetic energy before they exit the suppressor. Preferably, the baffles defining the second path impart a swirl to the second portion of gas to cause the present suppressor to flush itself of carbon and metal particles. The interaction of the two portions also accelerates completion of combustion of the gas to thereby reduce flash.

Owner:FN AMERICA +1

Solder foil semiconductor device and electronic device

InactiveUS20060061974A1NovelSemiconductor/solid-state device detailsSolid-state devicesDevice materialMetal particle

A solder foil formed from a material comprising particles of Cu, etc. as metal particles and Sn particles as solder particles by rolling is suitable for solder bonding at a high temperature side in temperature-hierarchical bonding, and semiconductor devices and electronic devices produced by use of such solder bonding have distinguished reliability of mechanical characteristics, etc.

Owner:RENESAS ELECTRONICS CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com