Patents

Literature

184 results about "Diamond electrodes" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

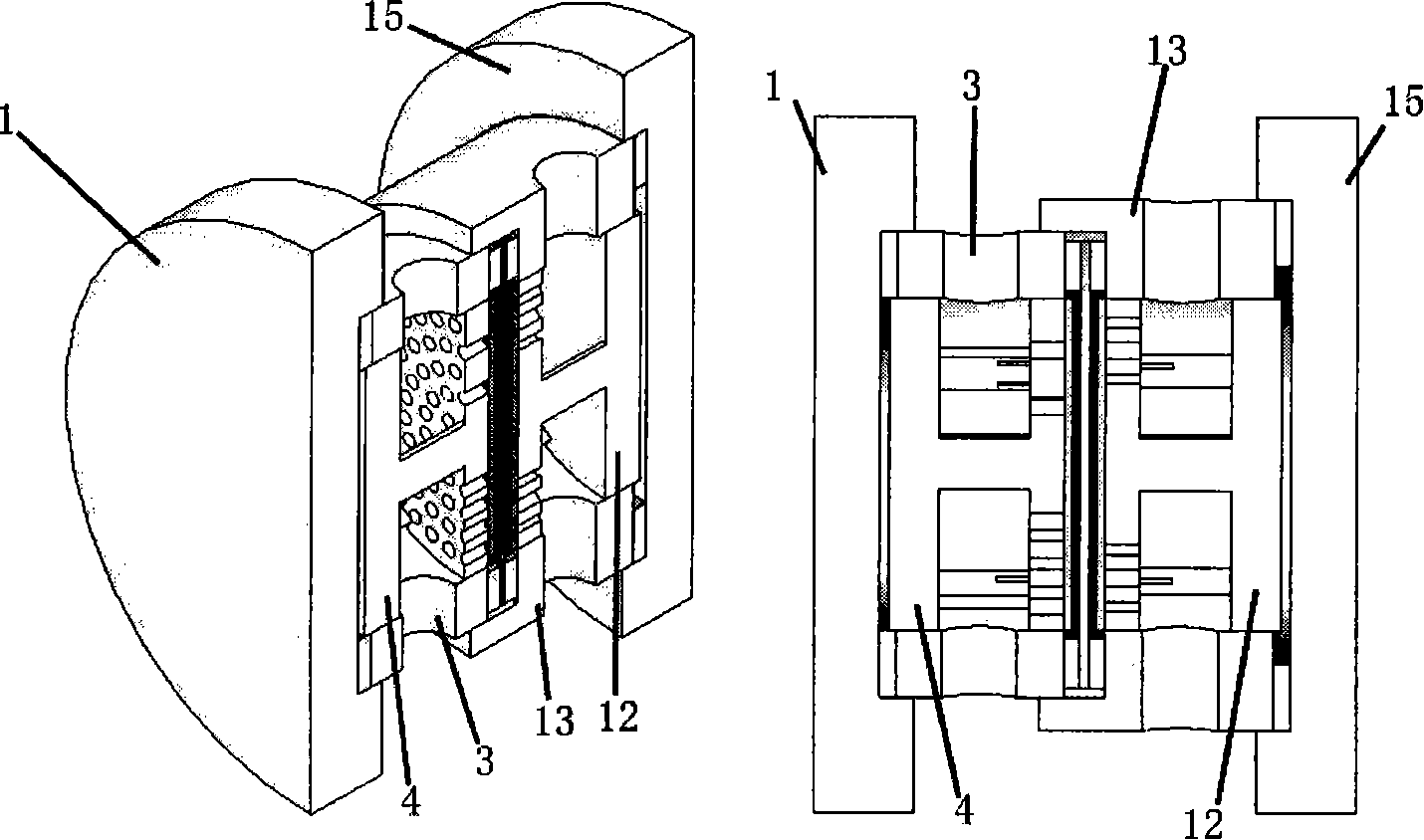

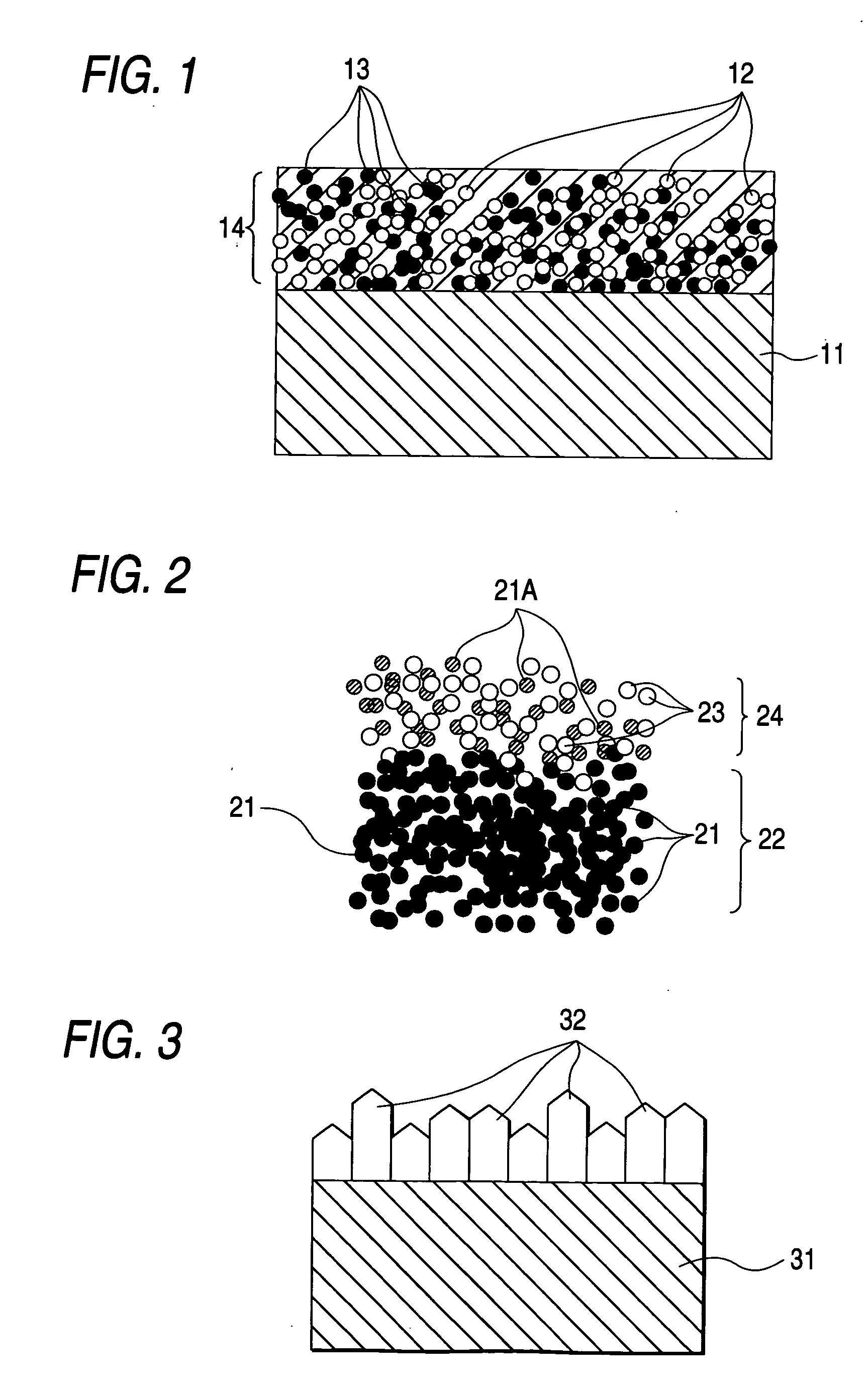

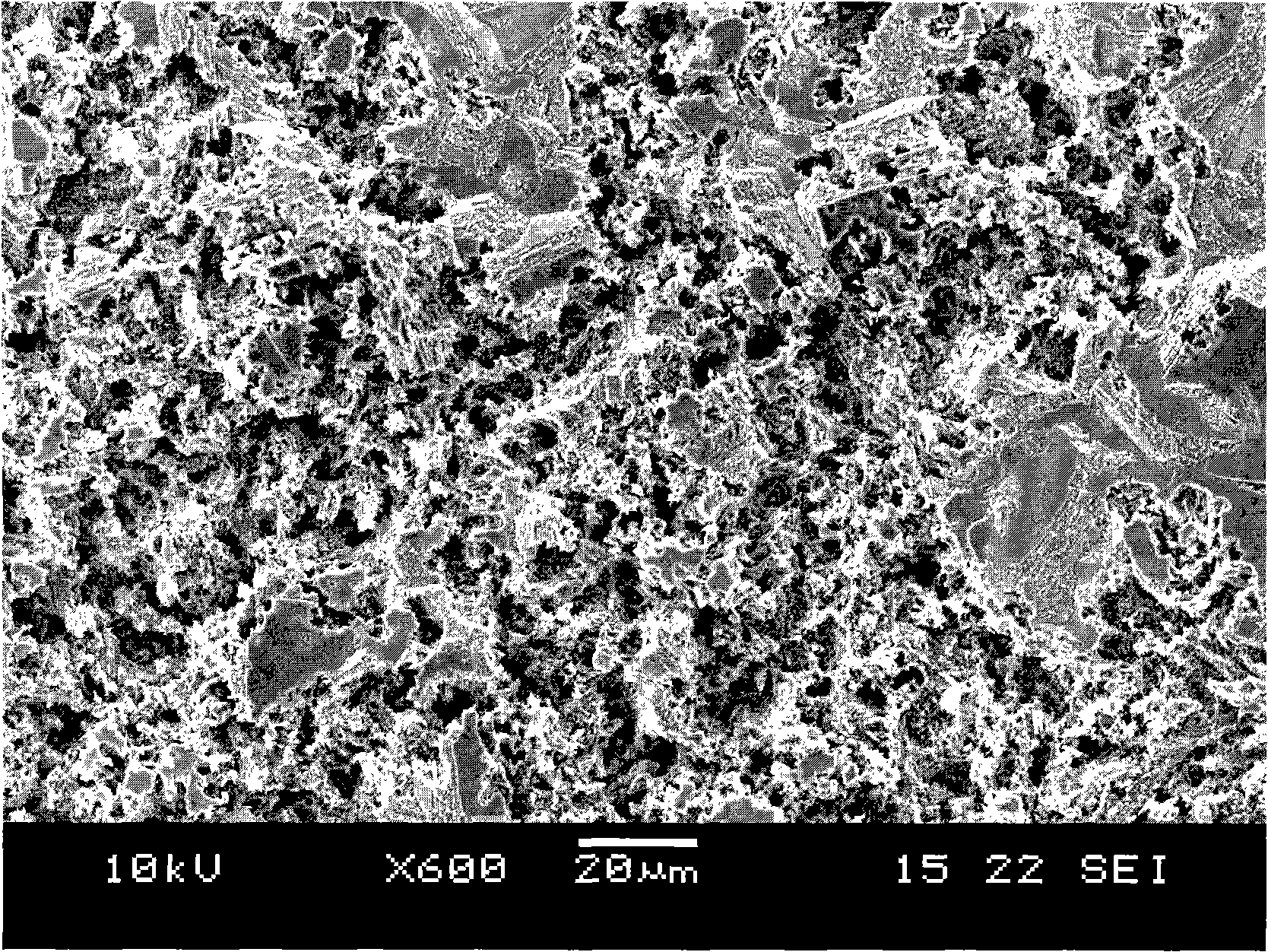

High-specific-surface-area boron-doped diamond electrode and preparation method and application thereof

ActiveCN106435518AHigh activityLarge electrochemical reaction interfaceWater contaminantsWater/sewage treatmentElectrochemical biosensorDiamond electrodes

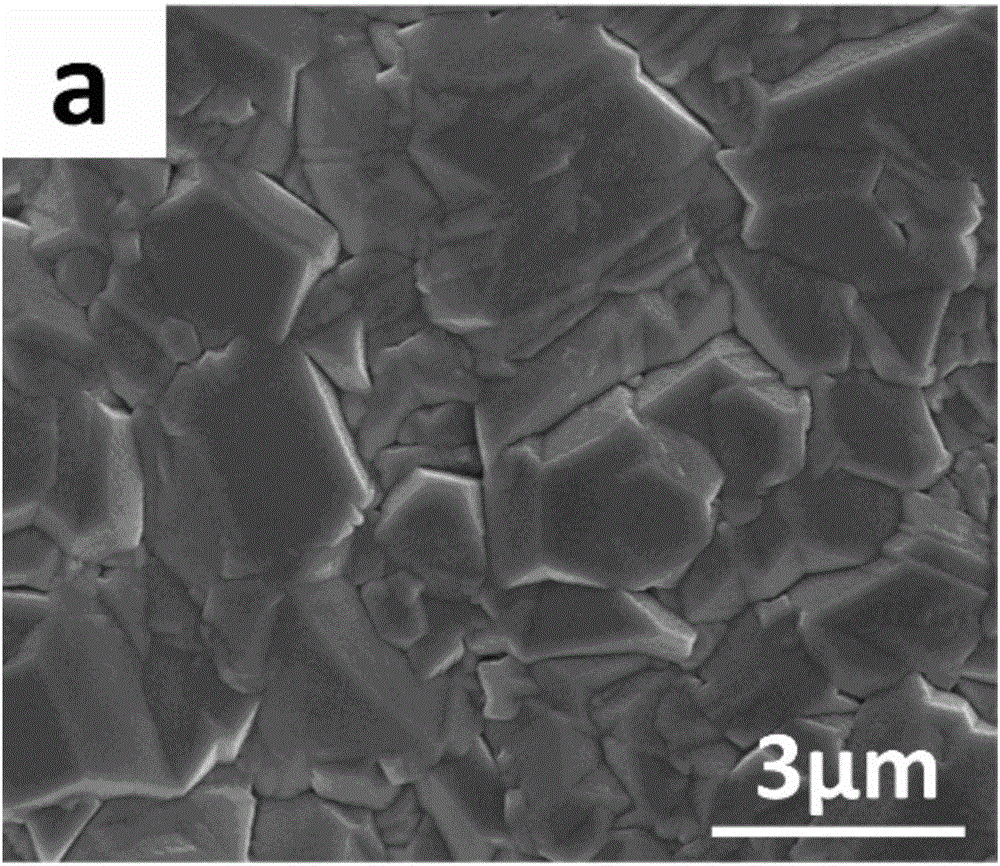

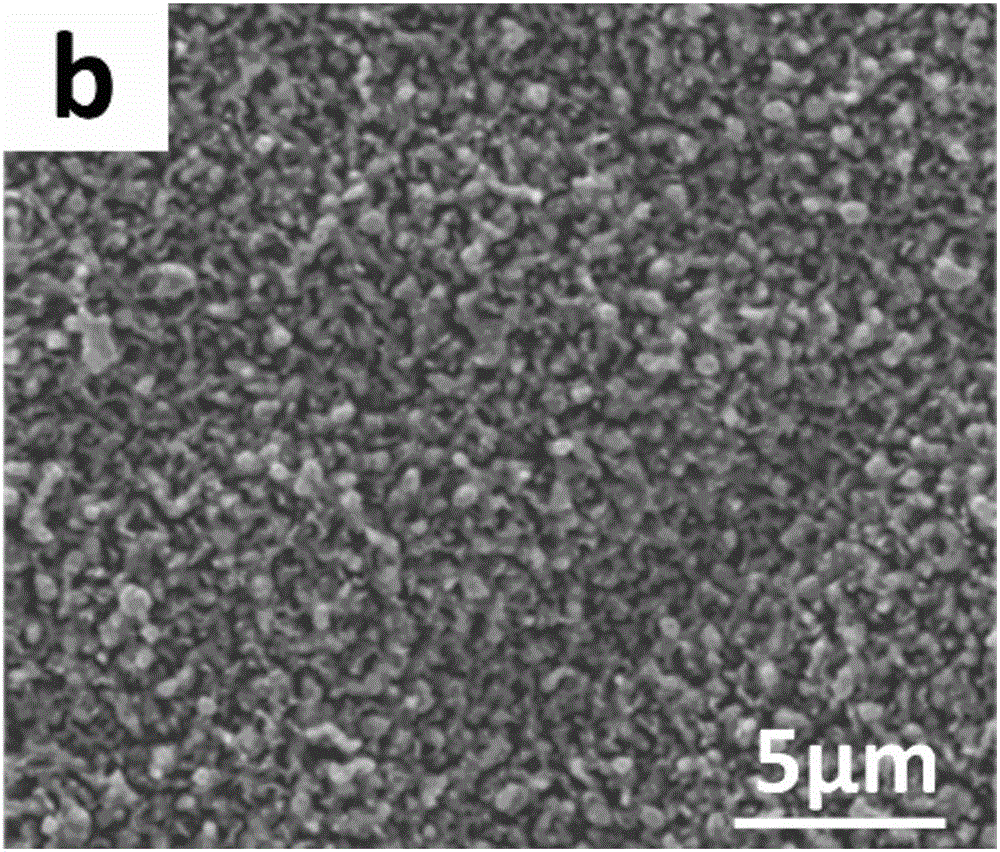

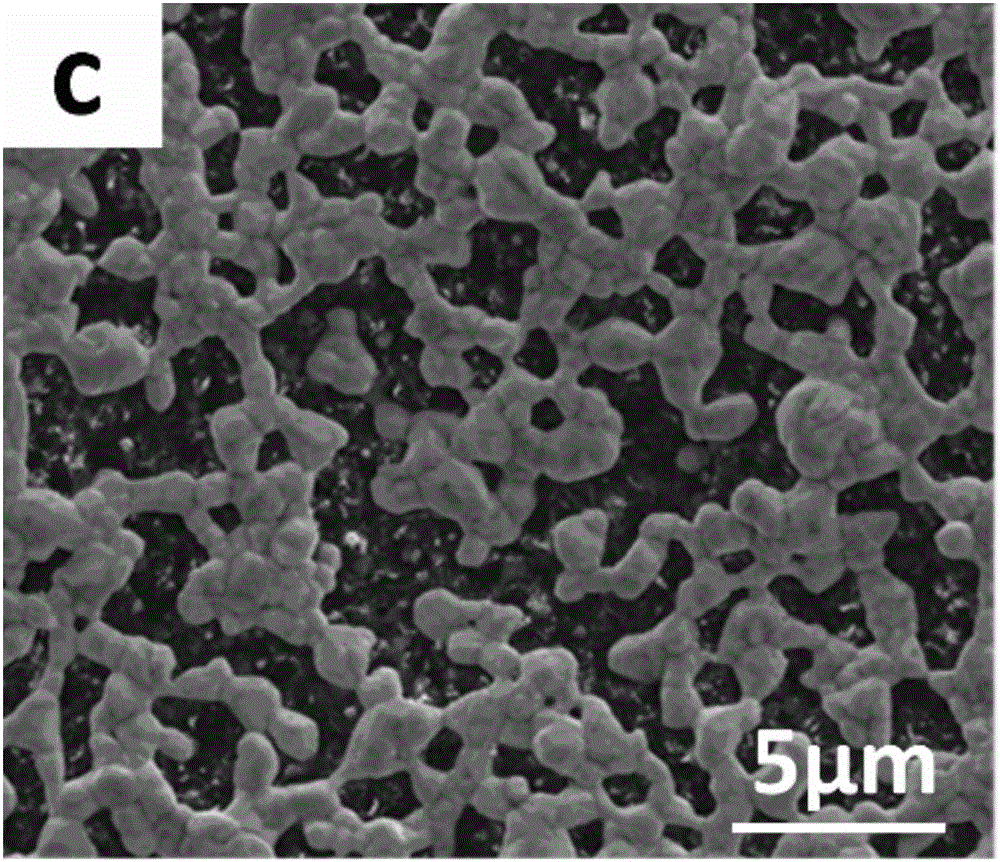

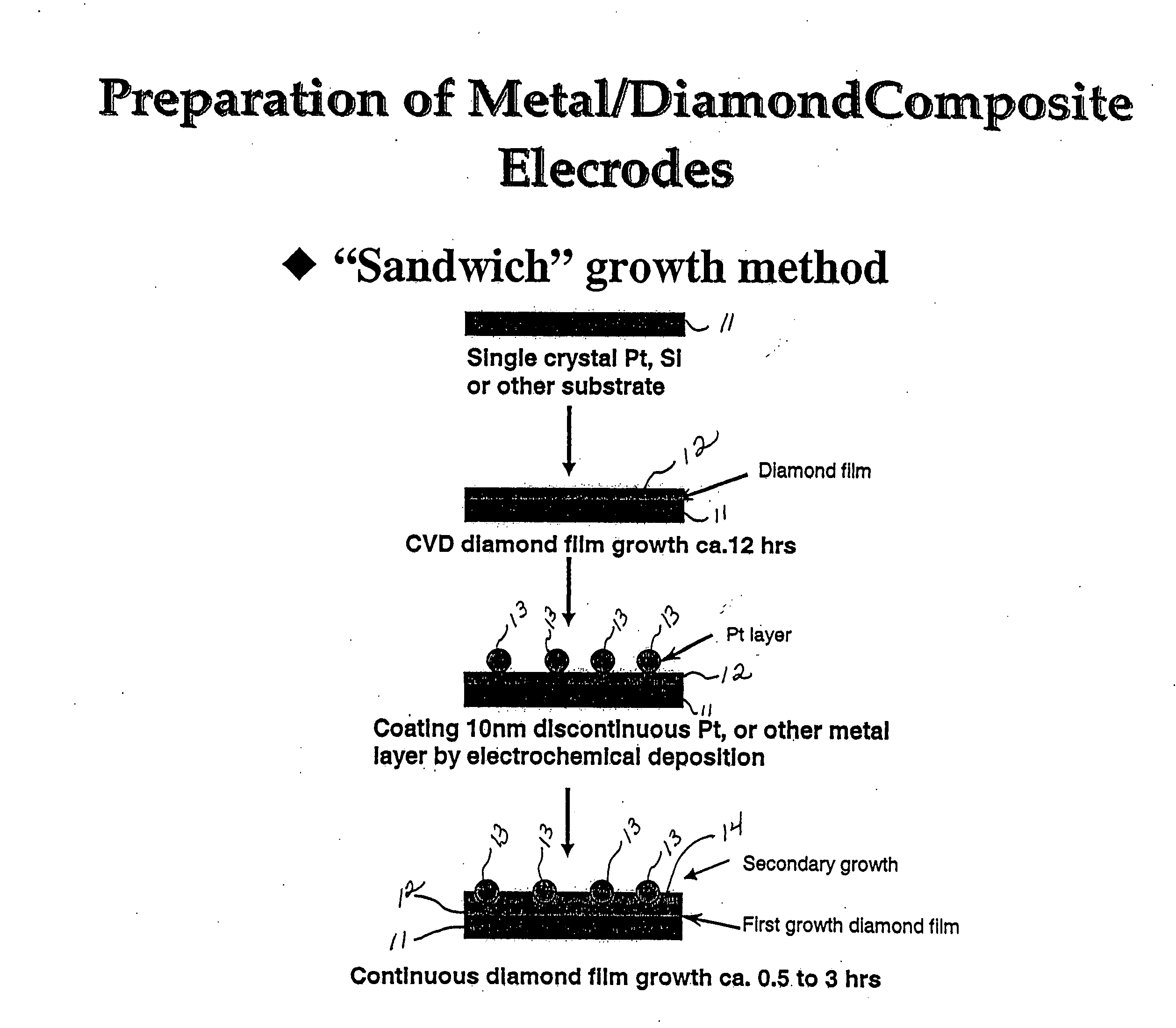

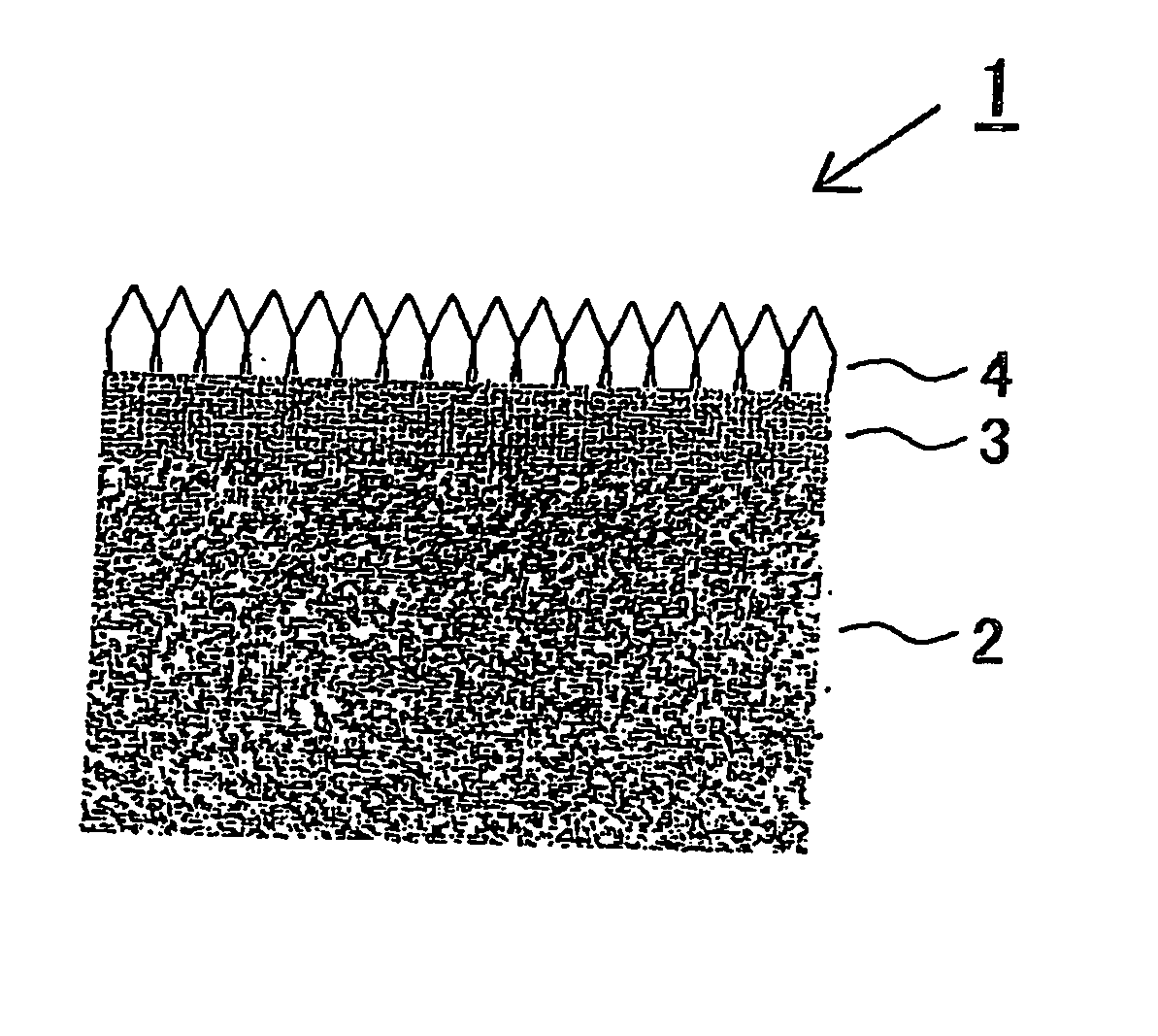

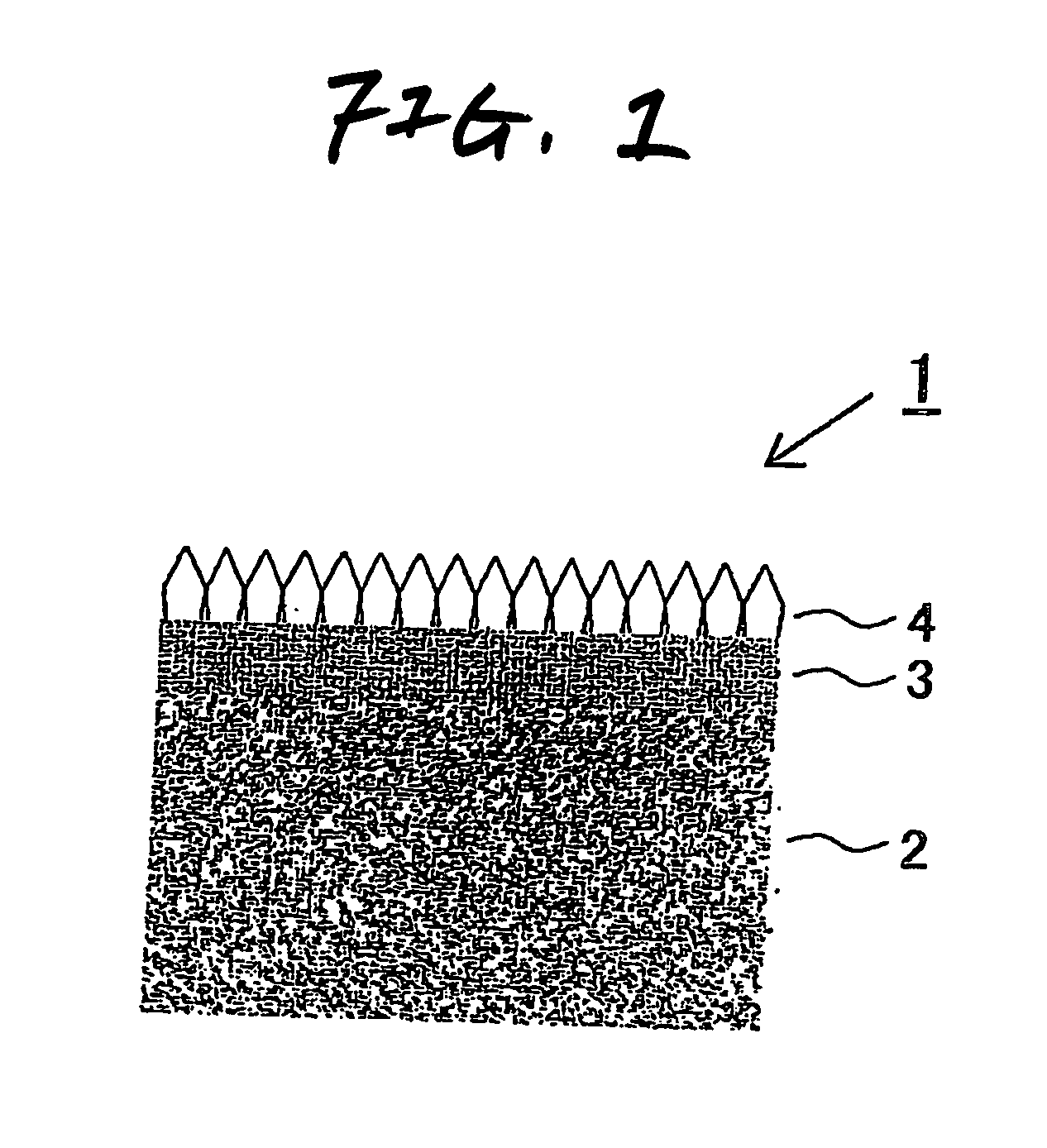

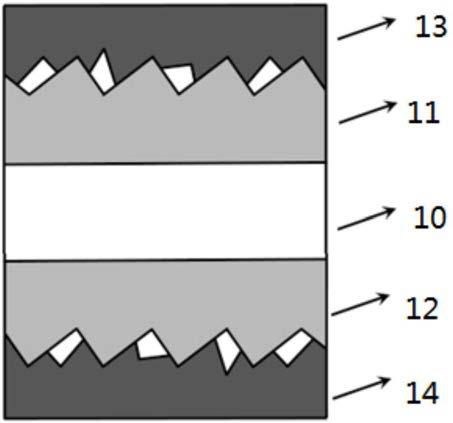

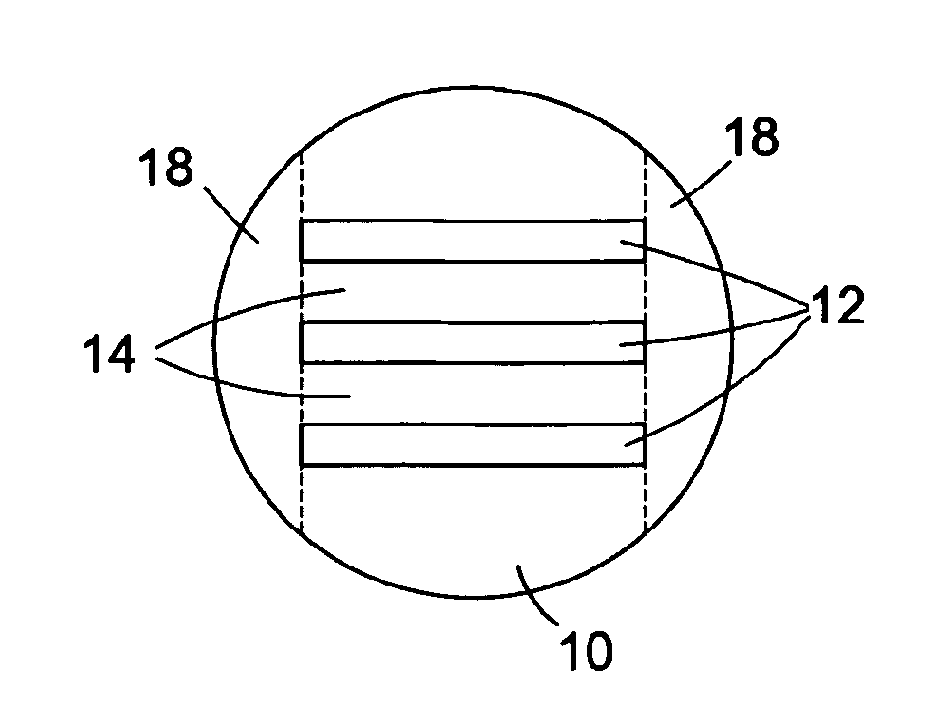

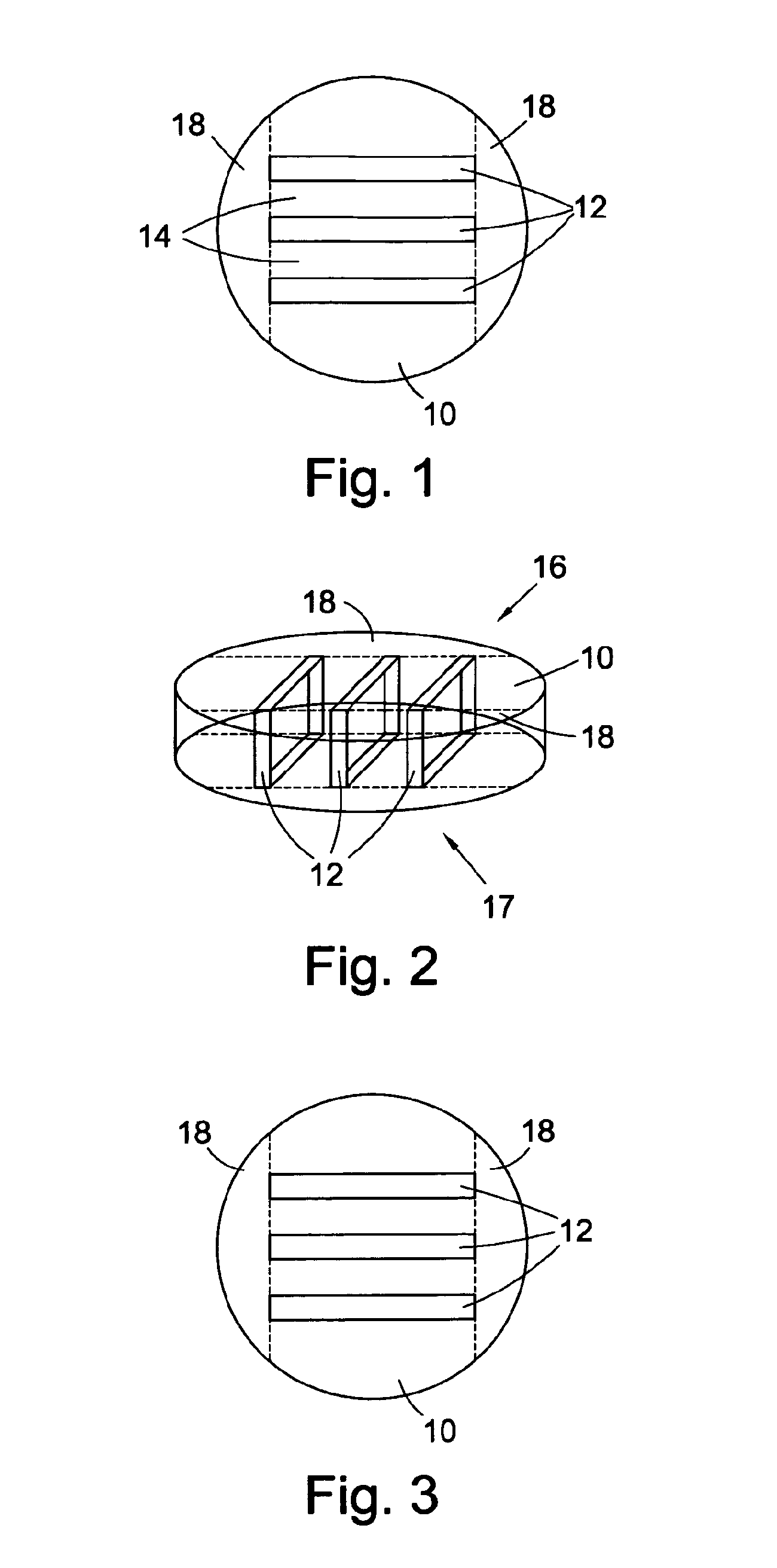

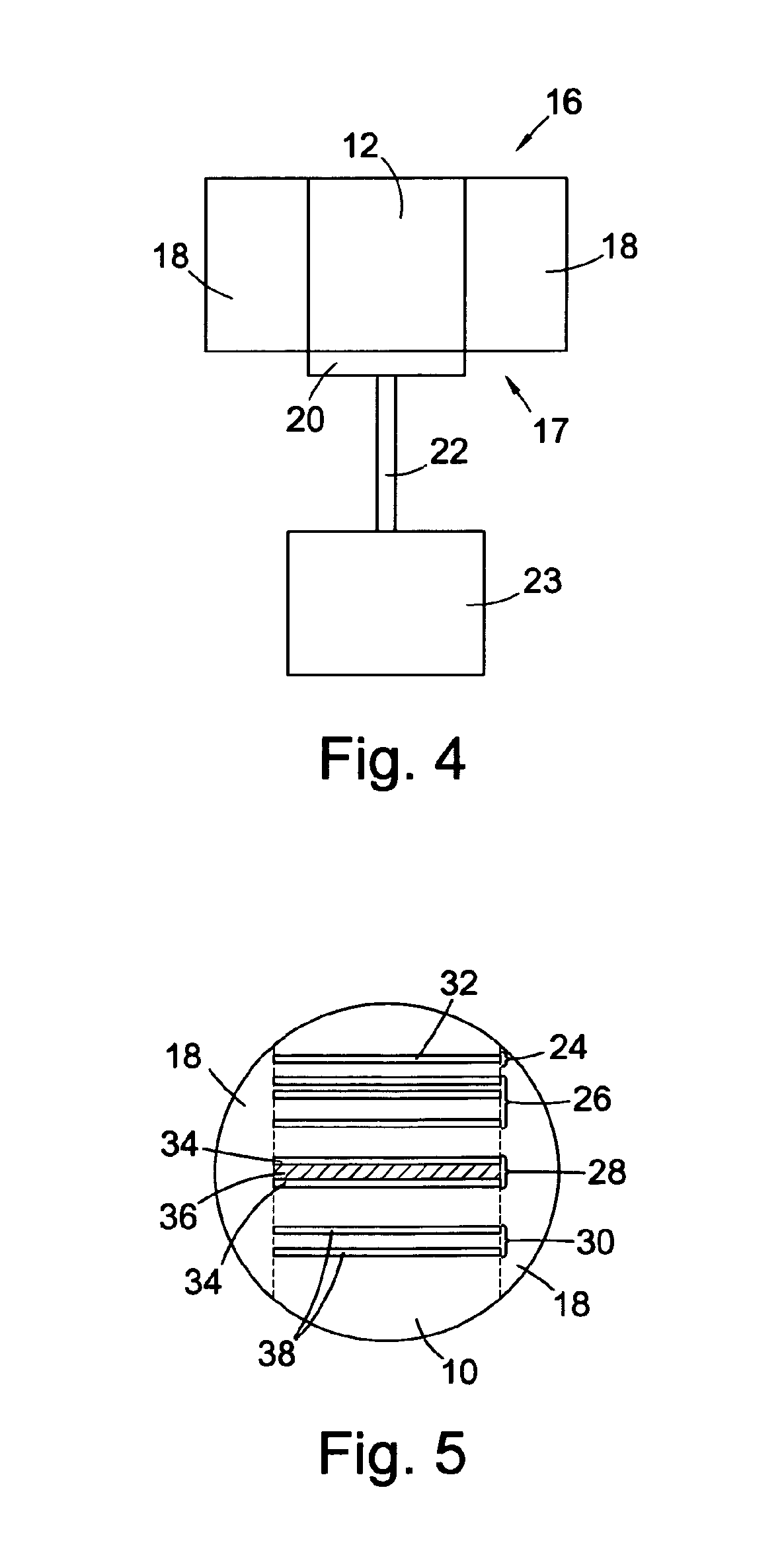

The invention discloses a high-specific-surface-area boron-doped diamond (BDD) electrode which comprises an electrode substrate. A boron-doped diamond layer is arranged on the surface of the electrode substrate. Or, a transition layer is arranged on the surface of the substrate, and then a boron-doped diamond layer is arranged on the surface of the transition layer. Metal particles are distributed in the diamond layer, and tiny holes and / or pointed cones are distributed on the surface of the diamond layer. Compared with a traditional plate electrode, the boron-doped diamond electrode contains a large number of tiny holes and pointed cones and has the extremely high specific surface area, and the large current intensity is provided through the low current intensity; and meanwhile, due to the different electrode configurations of the substrate and modification of surface graphene and / or carbon nano tubs (CNT), the mass transfer process can be greatly improved, the current efficiency and the electrochemical property are greatly improved, and the BDD electrode with high electrocatalytic activity and high using efficiency is prepared. The electrode can be widely applied in the fields of electrochemical wastewater purification treatment, electrochemical biosensors, strong oxidant electrochemical synthesis, electrochemical detection and the like.

Owner:NANJING DAIMONTE TECH CO LTD

Electrically conductive diamond electrodes

InactiveUS20060175953A1From normal temperature solutionsUltra-high pressure processesHydrogenDiamond electrodes

An electrically conductive diamond electrode and process for preparation thereof is described. The electrode comprises diamond particles coated with electrically conductive doped diamond preferably by chemical vapor deposition which are held together with a binder. The electrodes are useful for oxidation reduction in gas, such as hydrogen generation by electrolysis.

Owner:MICHIGAN STATE UNIV

Conductive diamond electrode and process for producing the same

ActiveUS20070031694A1Improvement in substrate stabilityExcellent in economical efficiencyMachining electrodesWater/sewage treatmentDiamond electrodesNiobium

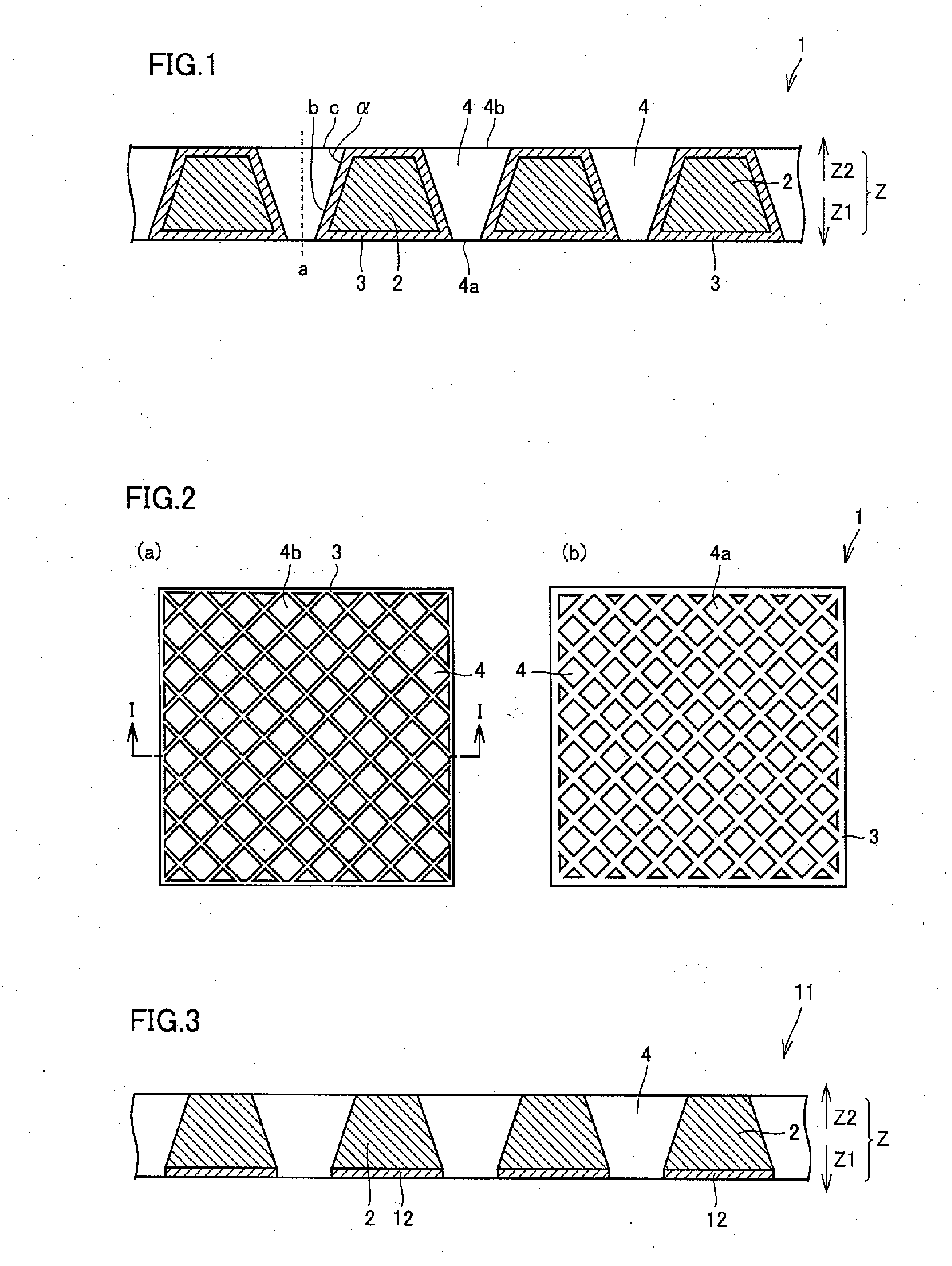

The present invention provides a conductive diamond electrode having: a conductive substrate; a coating layer formed on a surface of the conductive substrate, the coating layer containing one of a metal and an alloy each including at least one of niobium and tantalum; and a conductive diamond layer formed on a surface of the coating layer, and a process for producing the conductive diamond electrode.

Owner:DE NORA PERMELEC LTD

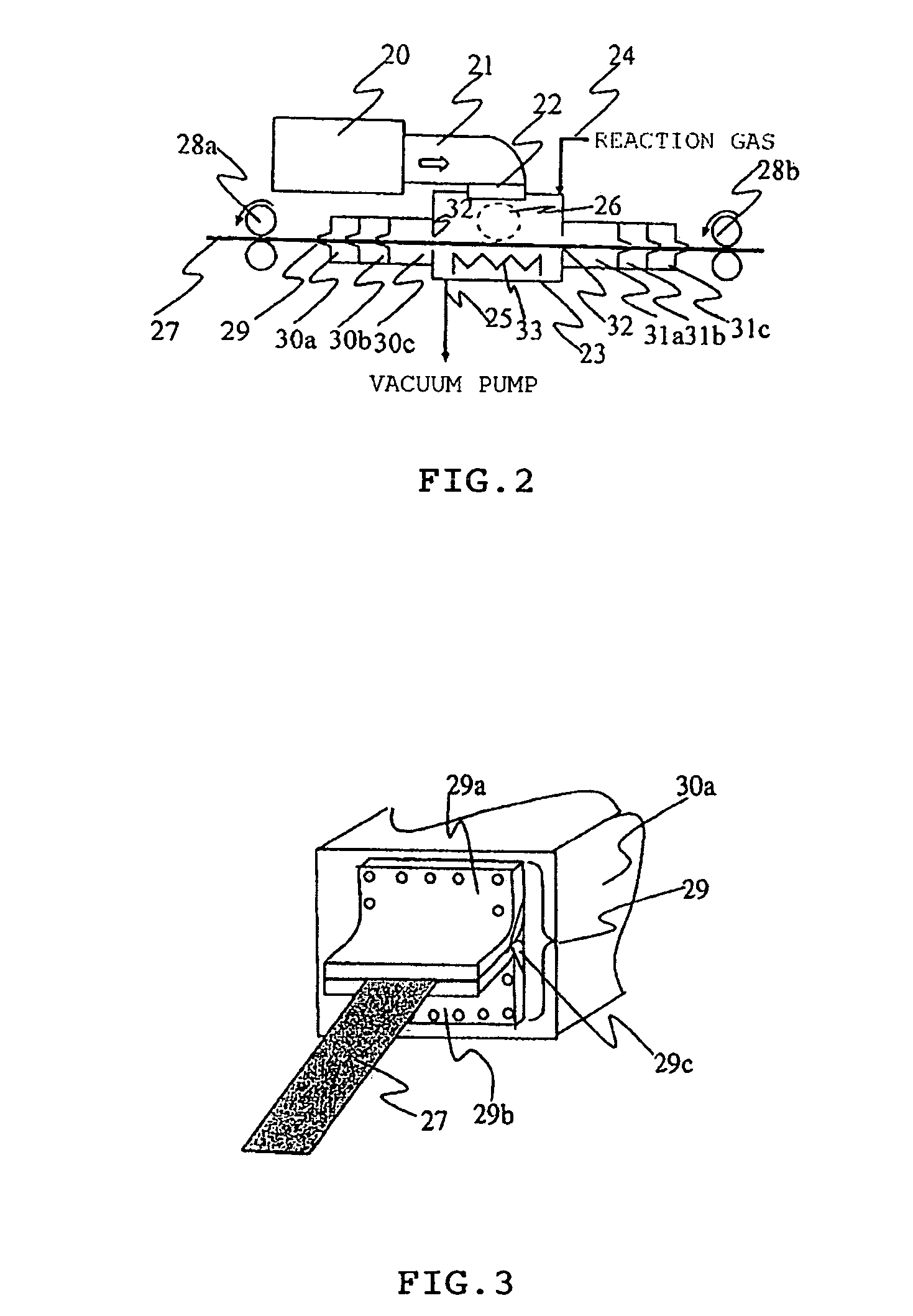

Method for production of diamond electrodes

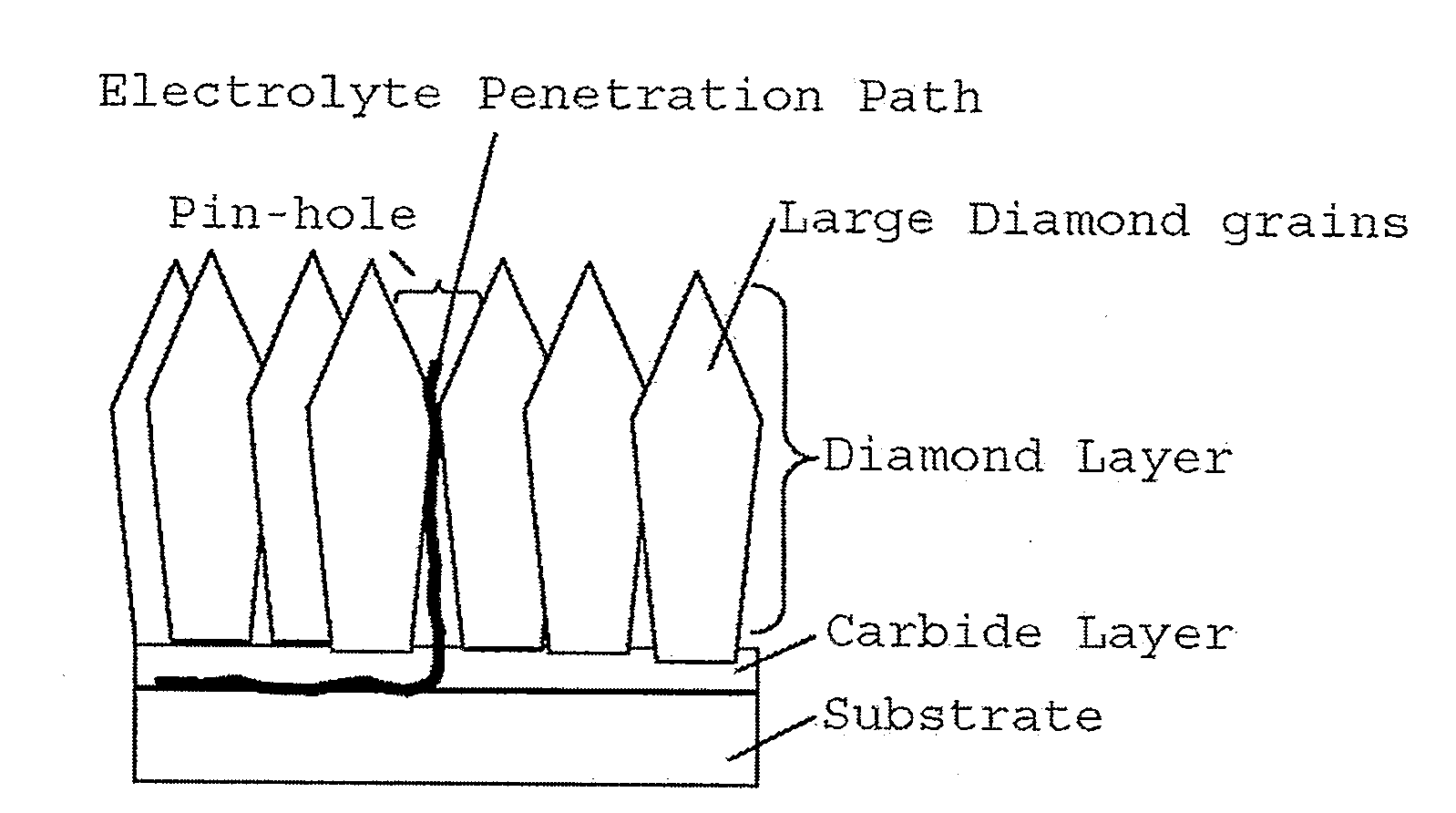

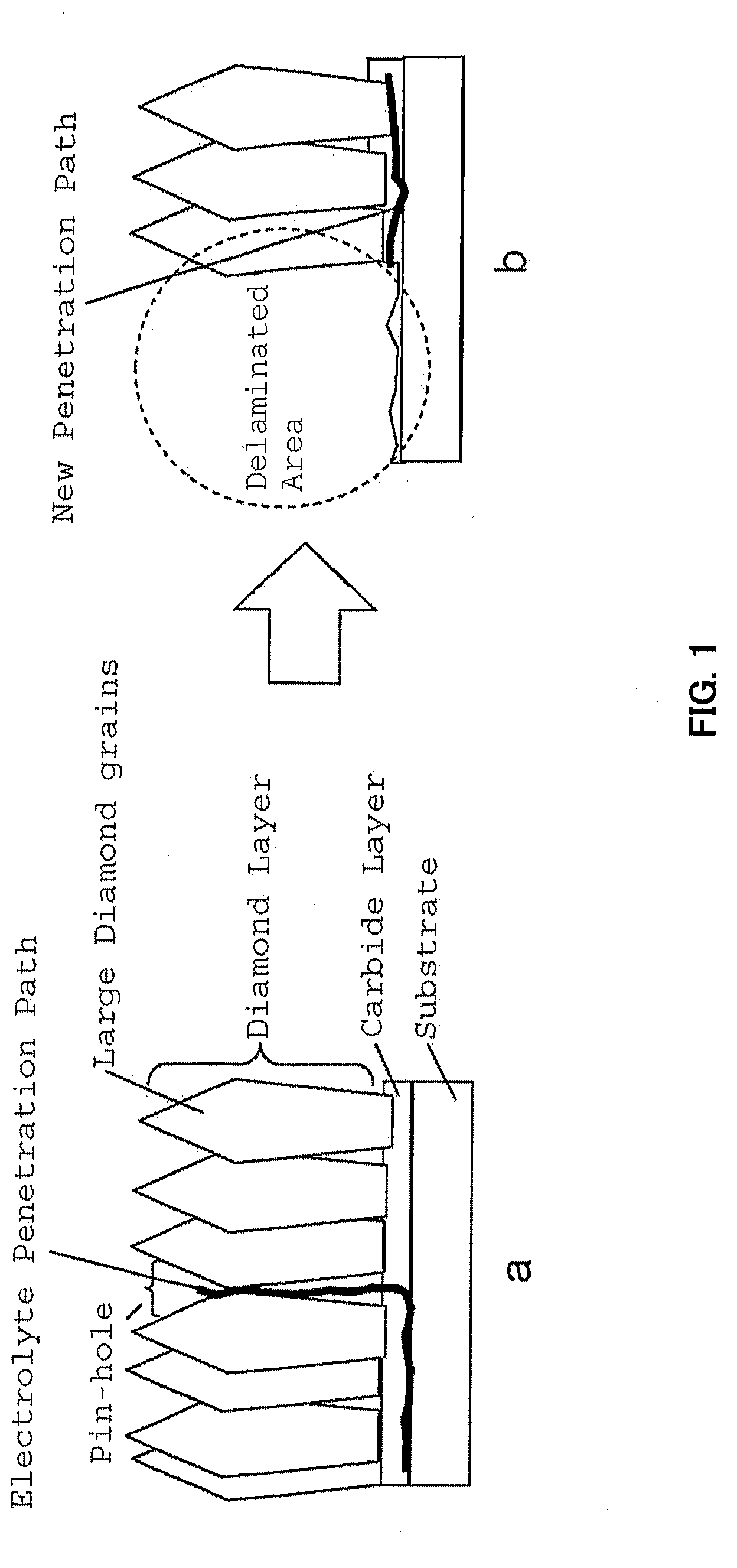

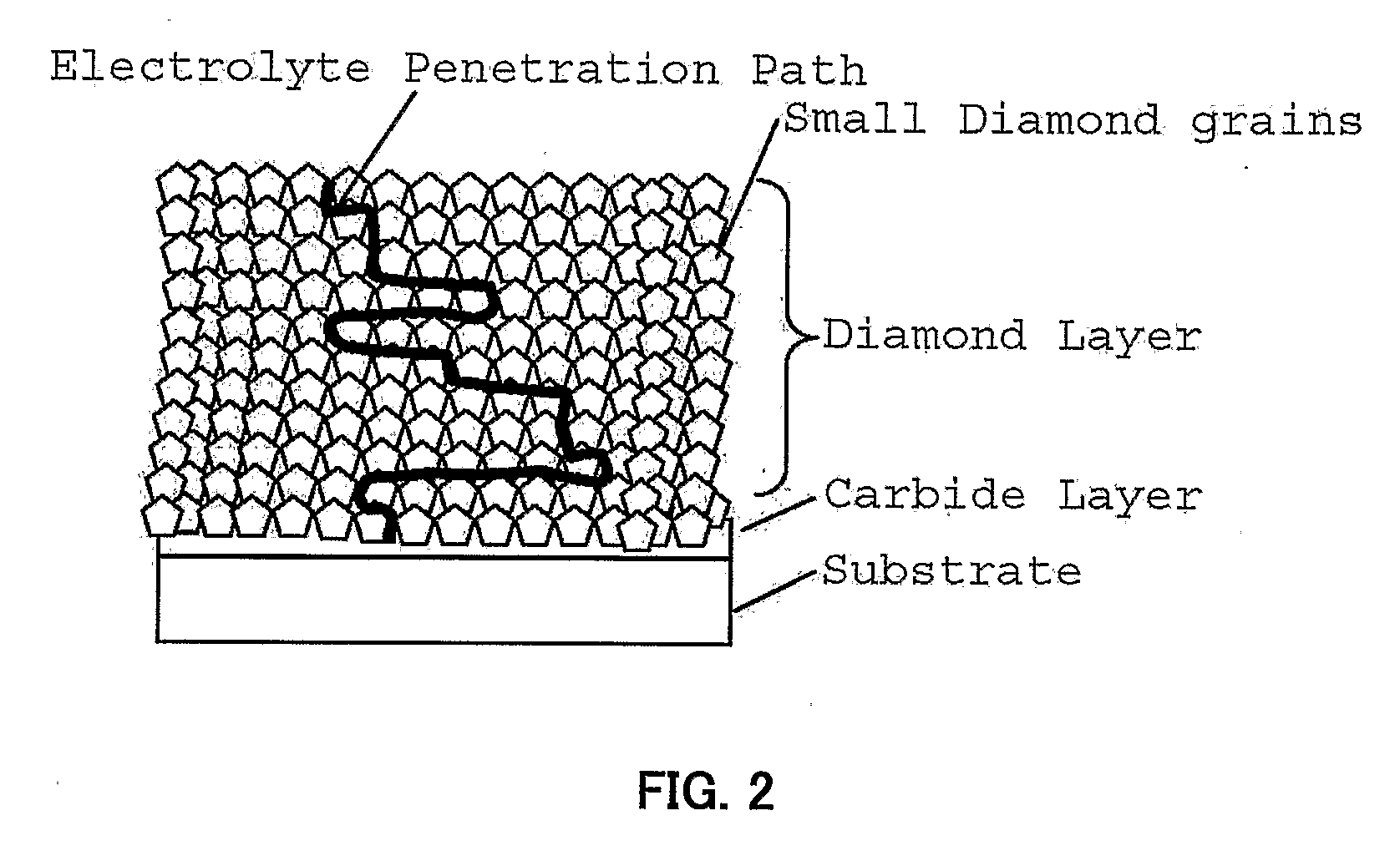

InactiveUS20090324810A1Reduced stabilityReduced life-timeSpecial surfacesChemical vapor deposition coatingElectrochemical responseDiamond electrodes

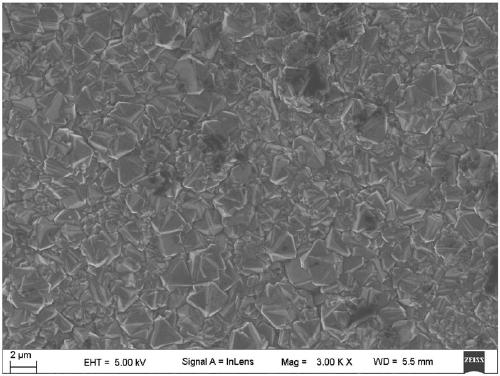

The invention is related to the method for production of diamond electrode with improved stability for use in electrochemical reaction. The method concerns to the production of diamond electrodes where the diamond layer is composed of small sized grain, avoiding the delamination problems found in conventional diamond electrodes.

Owner:EBARA CORP +1

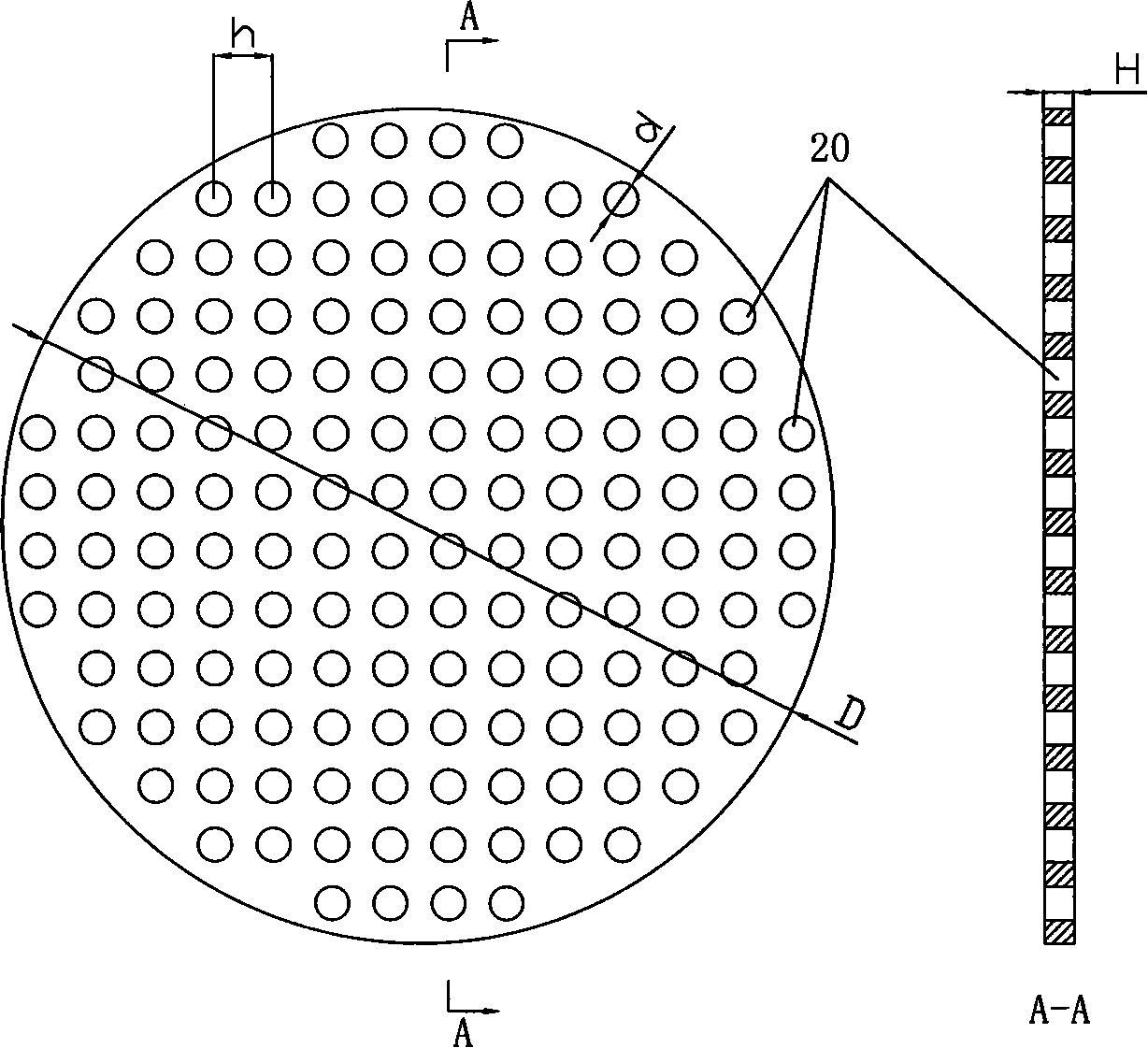

Diamond electrode, method for producing same, and electrolytic bath

InactiveUS20090301865A1Low production costImprove electrolysis efficiencyCellsElectrode shape/formsDiamond electrodesSilicon

A diamond electrode includes a conductive silicon substrate having a plurality of pores. The diamond electrode also includes a conductive diamond covering the conductive silicon substrate. The inner wall surfaces of the plurality of pores are at an angle of 60° to 85° with respect to a substrate of the conductive silicon substrate.

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

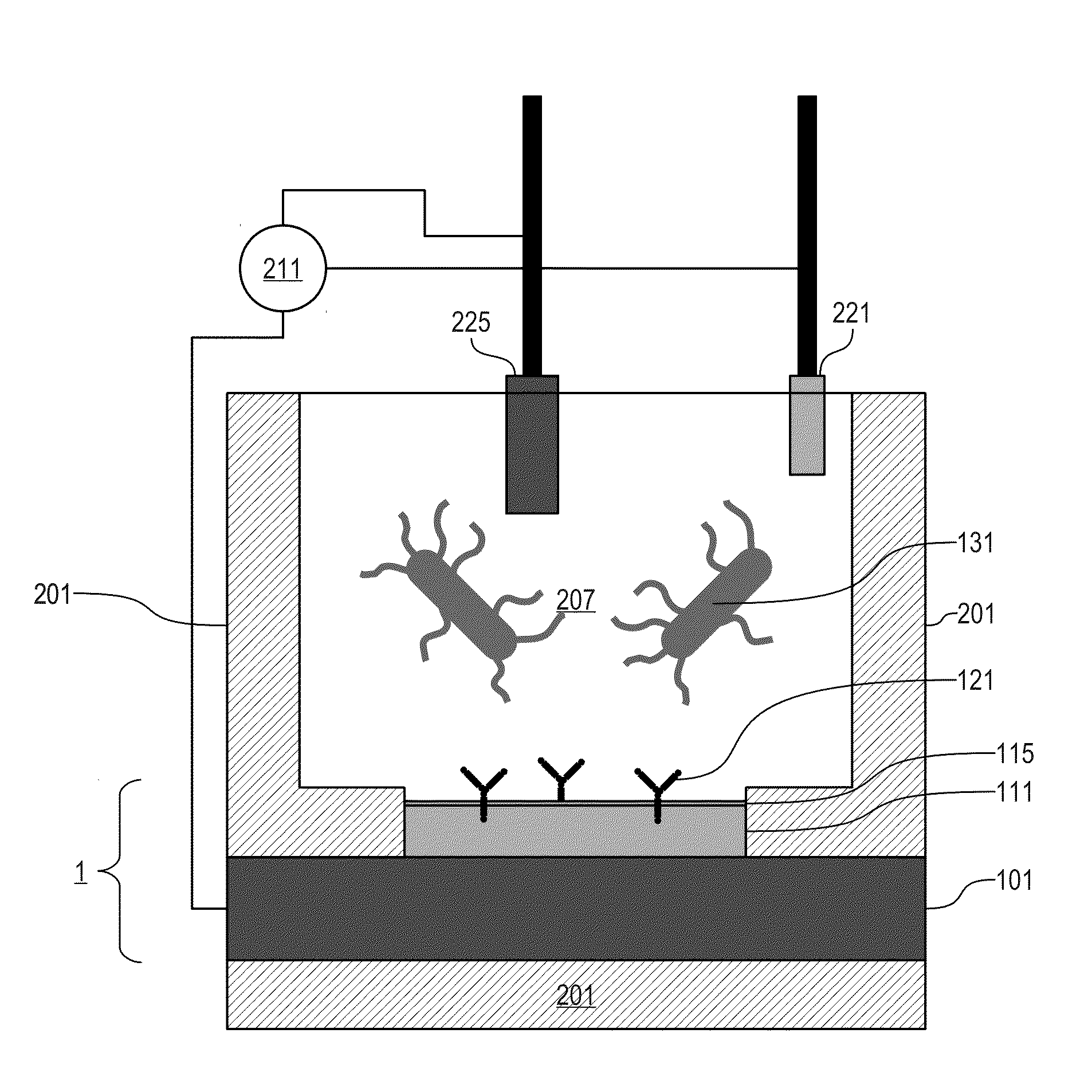

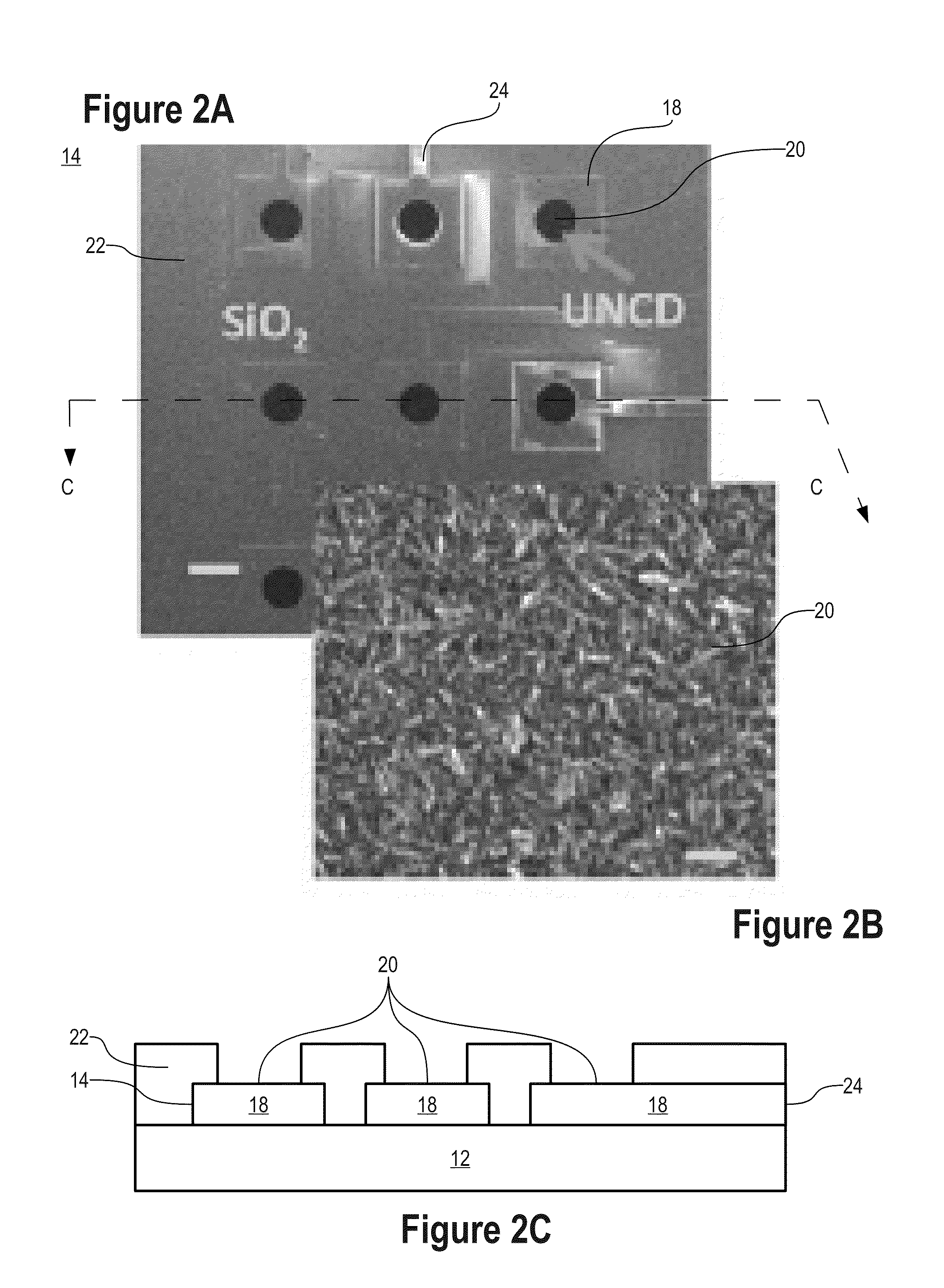

Electroanalytical sensor based on nanocrystalline diamond electrodes and microelectrode arrays

ActiveUS20130213823A1Addressing Insufficient SensitivityHigh signal voltageImmobilised enzymesBioreactor/fermenter combinationsDiamond electrodesSpectroscopy

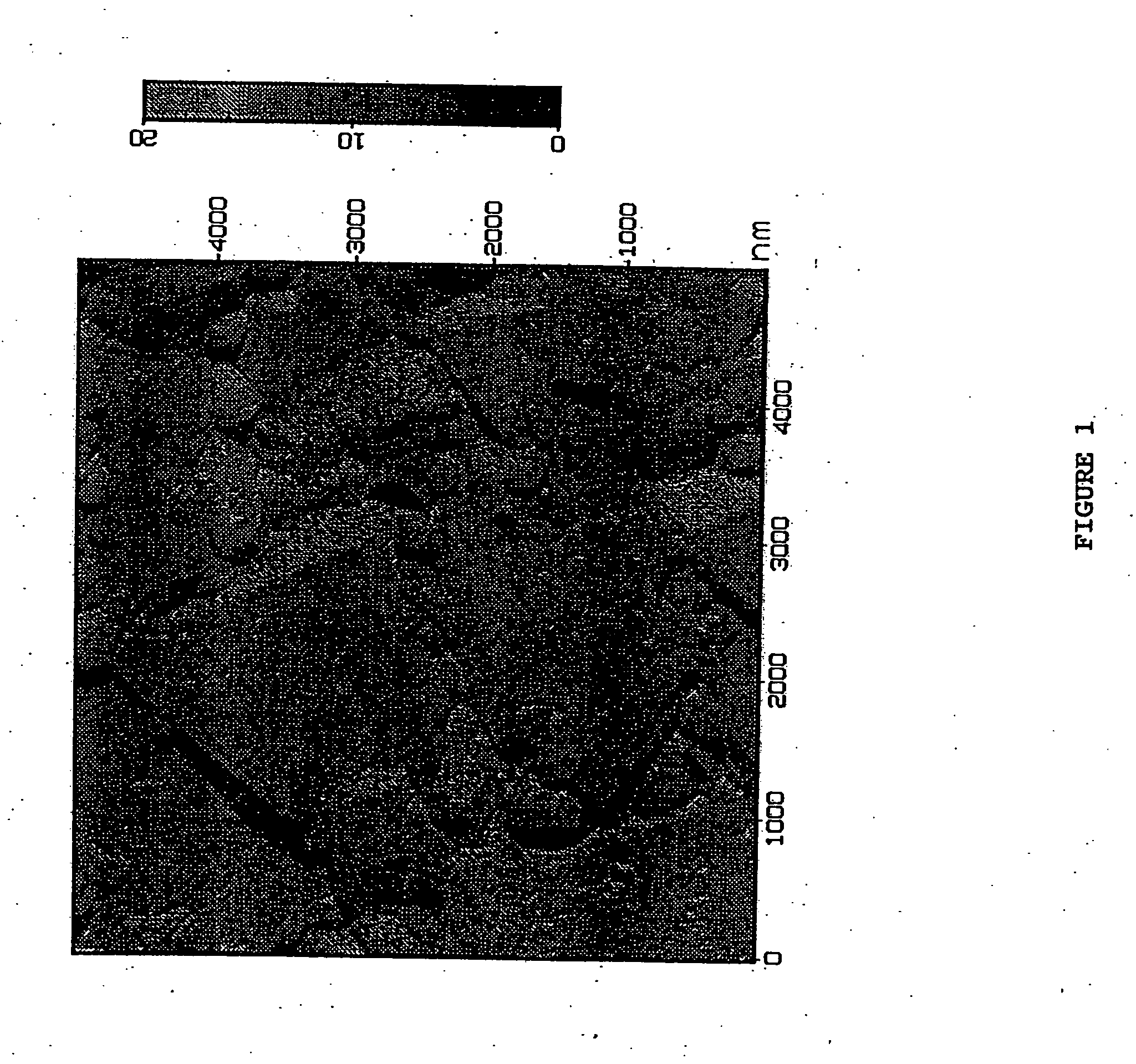

A diamond electrode and a diamond microelectrode array for biosensors and electroanalytical applications, such as electrochemical impedance spectroscopy (EIS), are disclosed. The electrode comprises a layer of ultra-smooth conductive nanocrystalline diamond (NCD) having a resistivity of >0.05 Ωcm and a surface roughness of <20 nm Ra. Preferably, the diamond layer comprises boron or nitrogen-doped ultrananocrystalline diamond (UNCD) having an average grain size <10 nm and a surface roughness <10 nm Ra. It may be patterned to define a microelectrode array with a plurality of individually addressable electrodes, each having a diameter in the range from 100 nm to 100 μm. The surface of each microelectrode is hydrogen-terminated before bio-functionalization, i.e. modifying with sensing molecules for detection of a specific biological or chemical target and coating with a blocker for reducing non-specific binding. These diamond electrodes exhibited substantial increases in sensitivity, selectivity and signal reproducibility, e.g. for detection of E. coli K12 using EIS.

Owner:JOHN CRANE INC

Conductive diamond electrode and process for producing the same

ActiveUS7273536B2Increased durabilityMachining electrodesSurface reaction electrolytic coatingDiamond electrodesAlloy

A conductive diamond electrode including an electrode substrate comprising a material selected from the group consisting of a valve metal and an alloy based on the valve metal, at least a surface of the metal or alloy having been subjected to plasticization processing, or heat treatment in vacuum or inert atmosphere; and a conductive diamond film formed on the plasticization processed surface of the electrode substrate. When the electrode substrate is subjected to plasticization processing and heat treatment, peeling resistance of the conductive diamond film is improved, thereby an electrode life is prolonged.

Owner:DE NORA PERMELEC LTD

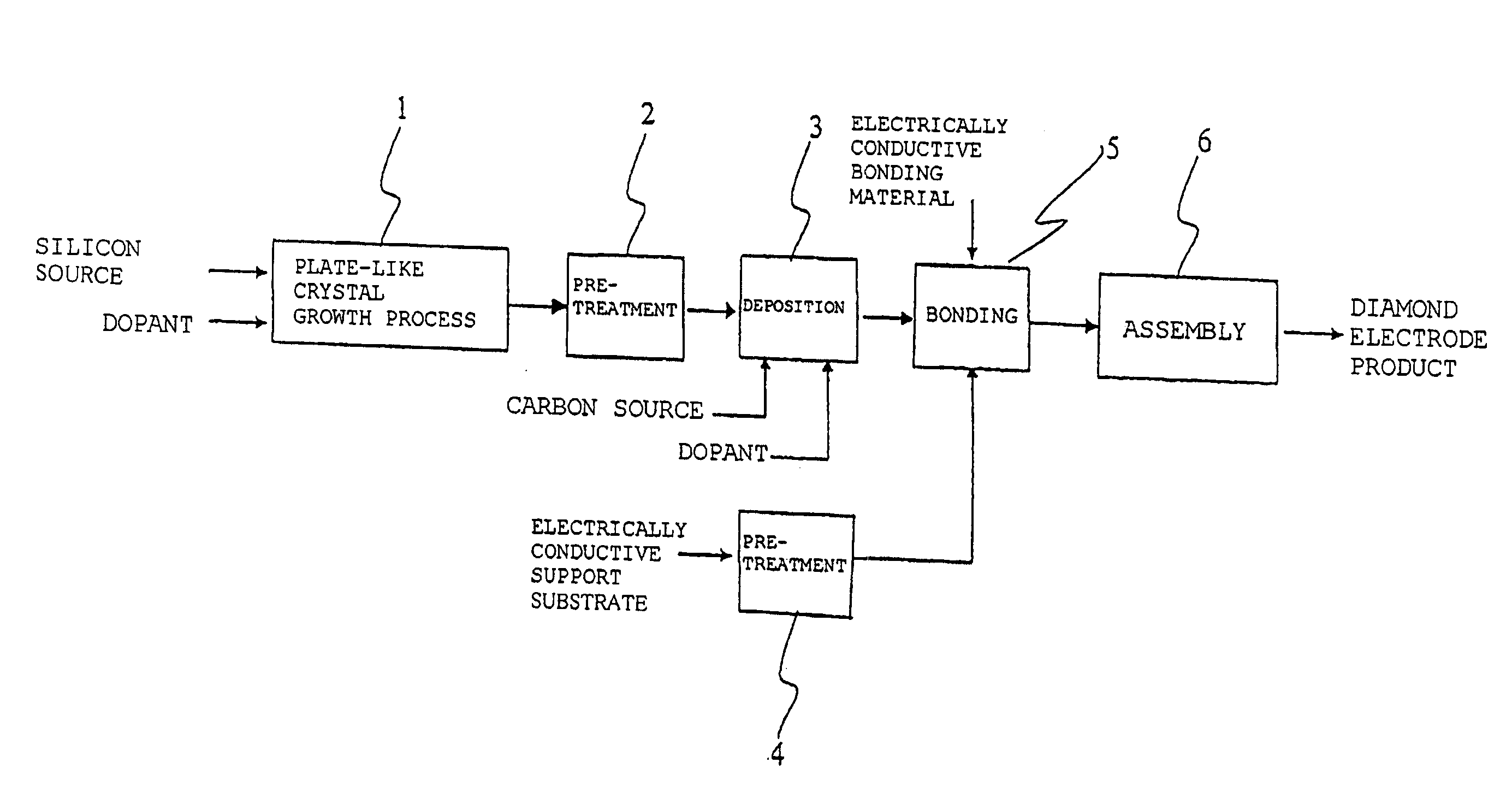

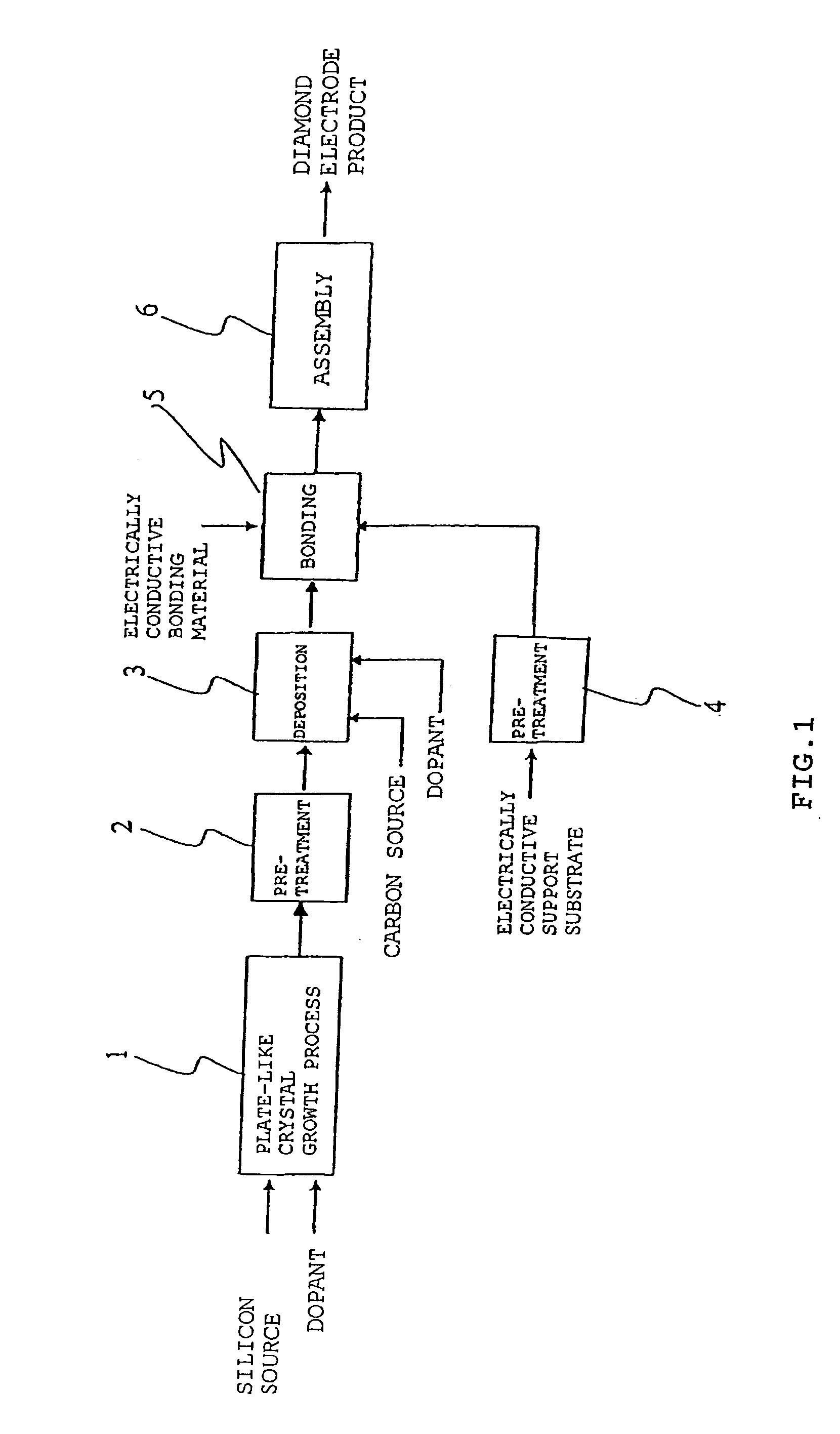

Diamond film-forming silicon and its manufacturing method

InactiveUS20060216514A1Polycrystalline material growthFrom chemically reactive gasesDiamond electrodesGas phase

The present invention intends to provide a diamond-coated silicon to be used in an industrially applicable diamond electrode. A diamond-coated silicon comprising a silicon substrate having a thickness of 500 μm or less is coated at least partially with electrically conductive diamond. The silicon substrate having a thickness of 500 μm or less is manufactured by the plate-like crystal growth process, and then the silicon substrate is coated with the electrically conductive diamond by the chemical vapor deposition process to manufacture the diamond-coated silicon. The diamond-coated silicon is flexible and can be stuck to an electrically conductive support substrate, and thereby a large area electrode and a three-dimensional electrode structure can be readily obtained.

Owner:EBARA CORP

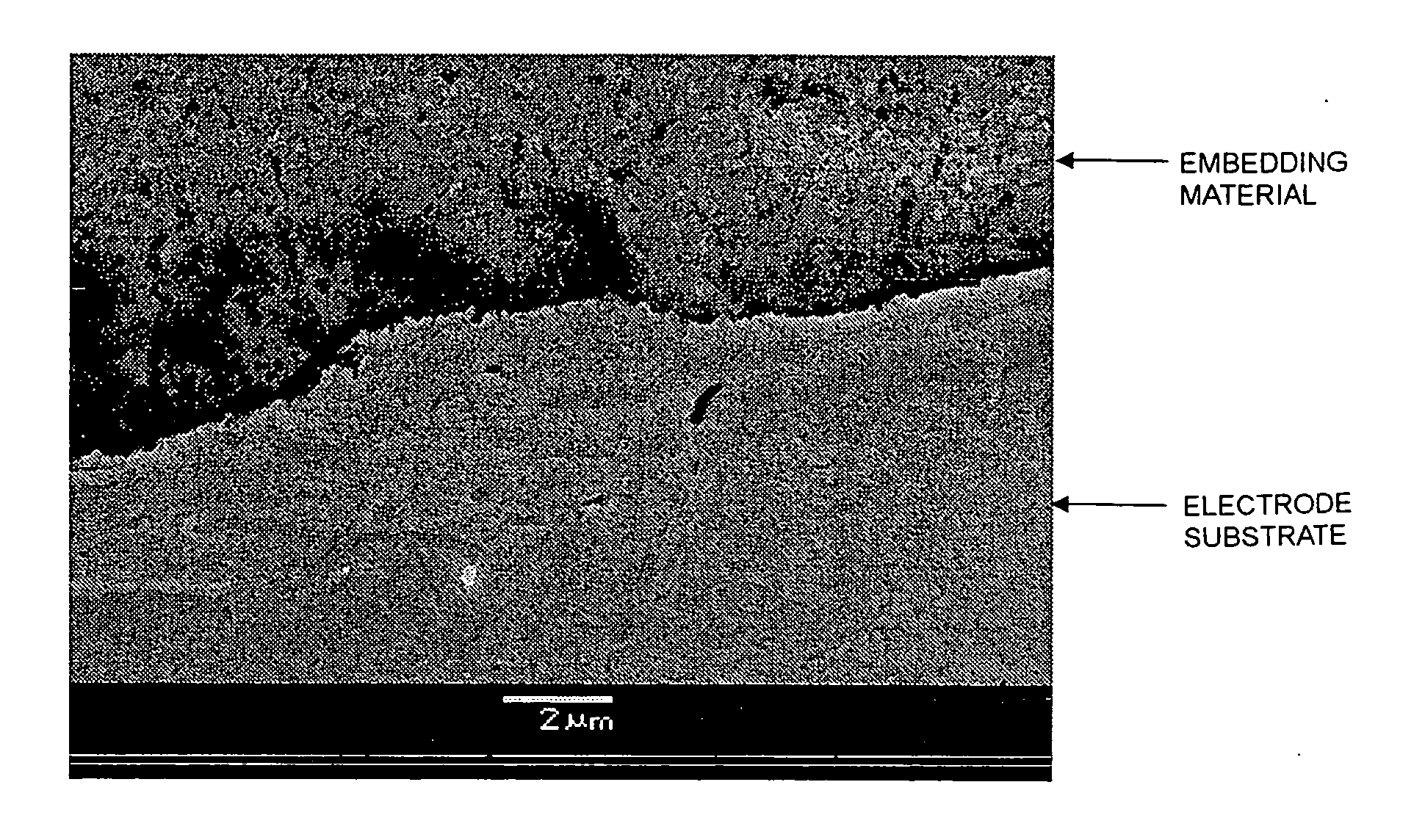

Conductive diamond electrode and process for producing the same

ActiveUS20050186345A1Increased durabilityMachining electrodesLiquid separation by electricityElectrical resistance and conductanceDiamond electrodes

A conductive diamond electrode including an electrode substrate comprising a material selected from the group consisting of a valve metal and an alloy based on the valve metal, at least a surface of the metal or alloy having been subjected to plasticization processing, or heat treatment in vacuum or inert atmosphere; and a conductive diamond film formed on the plasticization processed surface of the electrode substrate. When the electrode substrate is subjected to plasticization processing and heat treatment, peeling resistance of the conductive diamond film is improved, thereby an electrode life is prolonged.

Owner:DE NORA PERMELEC LTD

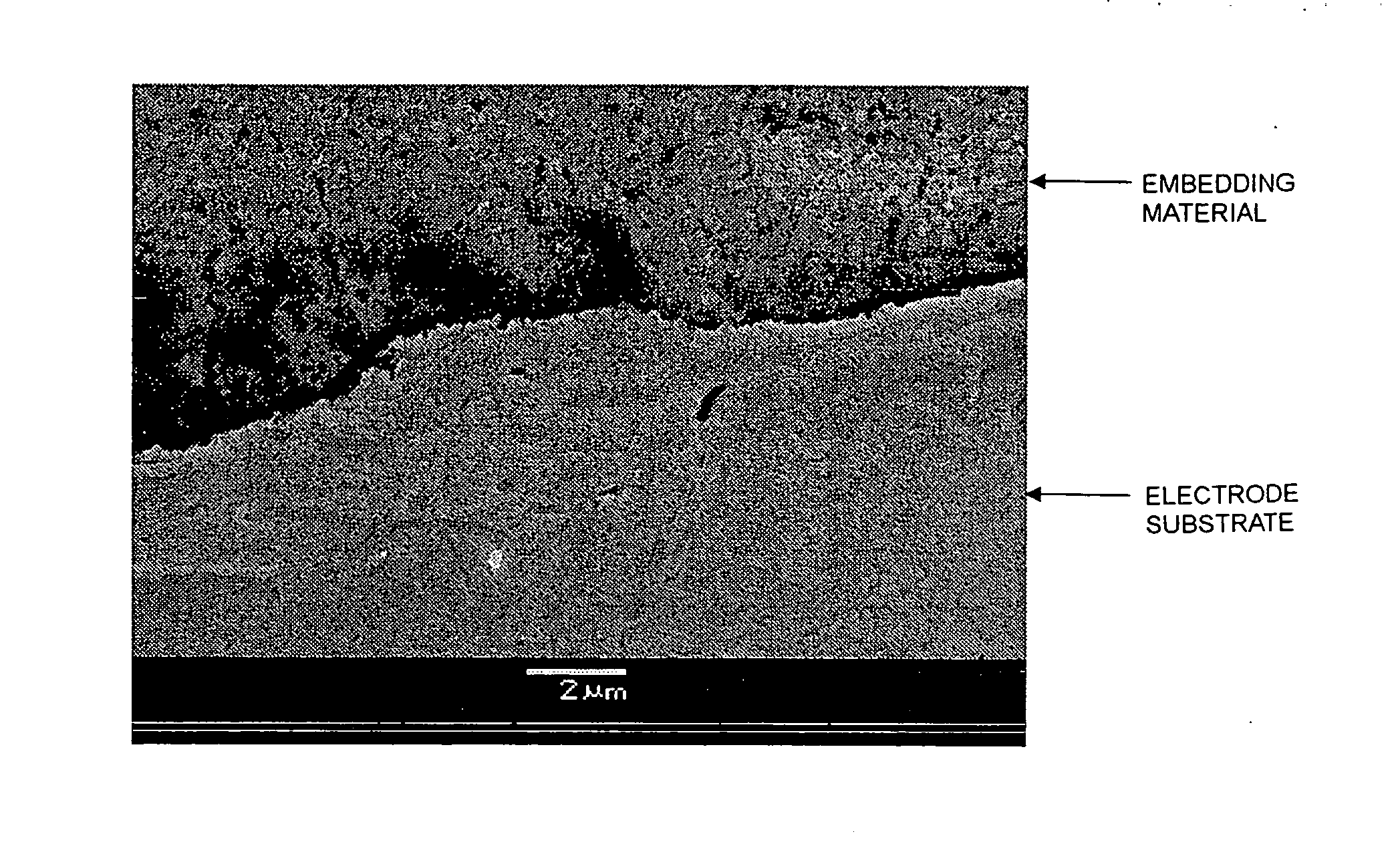

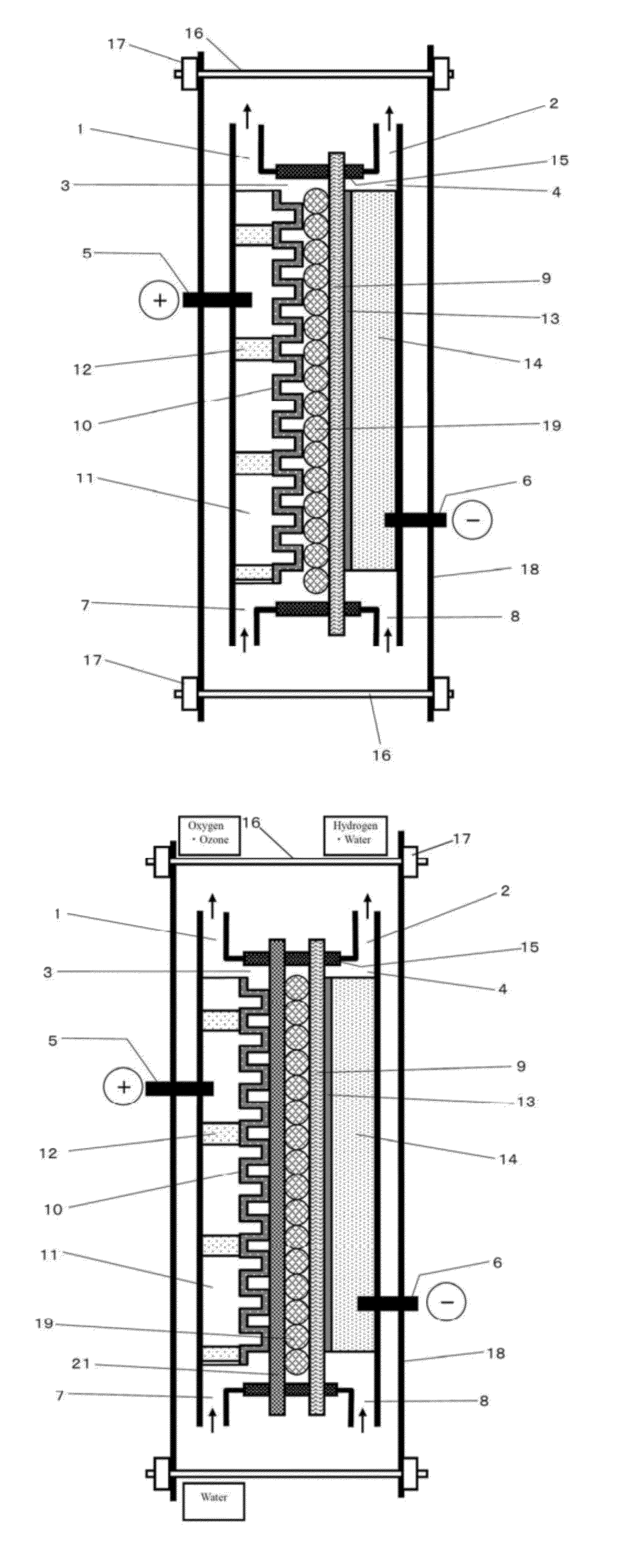

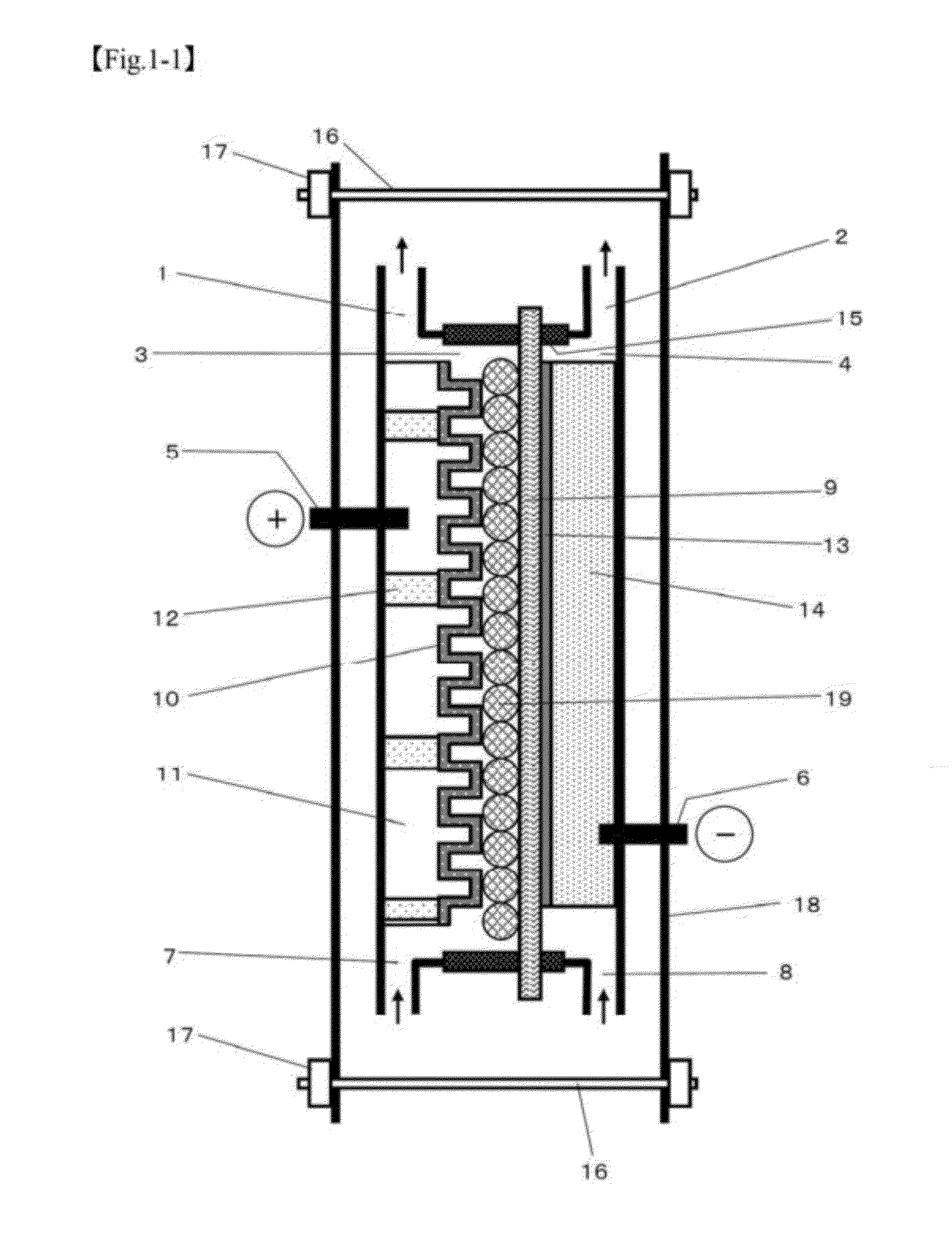

Electrolytic ozone generator and preparation technique for cathode catalysis layer thereof

InactiveCN101250710ALong continuous service lifeImprove current efficiencyElectrolysis componentsContinuous useDiamond electrodes

The invention relates to an electrolytic type ozone generator and a process for preparing a cathode catalyst layer of the electrolytic type ozone generator. The electrolytic type ozone generator comprises a round Nafion film, a round anode component and a round cathode component which are arranged on two axial sides of the Nafion film. The electrolytic type ozone generator adopts a diamond electrode which is doped with porous boron as an anode, the cathode catalyst layer adopts a process for preparing platinum-on-carbon and an electrolysis chamber for preparing ozone is optimally designed, not only the performance is greatly increased, but also the current efficiency of a borocarbon electrode to produce the ozone is greatly increased, the current efficiency can reach 30% under room temperature to the maximum, and the continuous service life of the electrodes can be greatly prolonged compared with lead dioxide electrodes which are used in a large number at present.

Owner:SHAANXI UNIV OF SCI & TECH

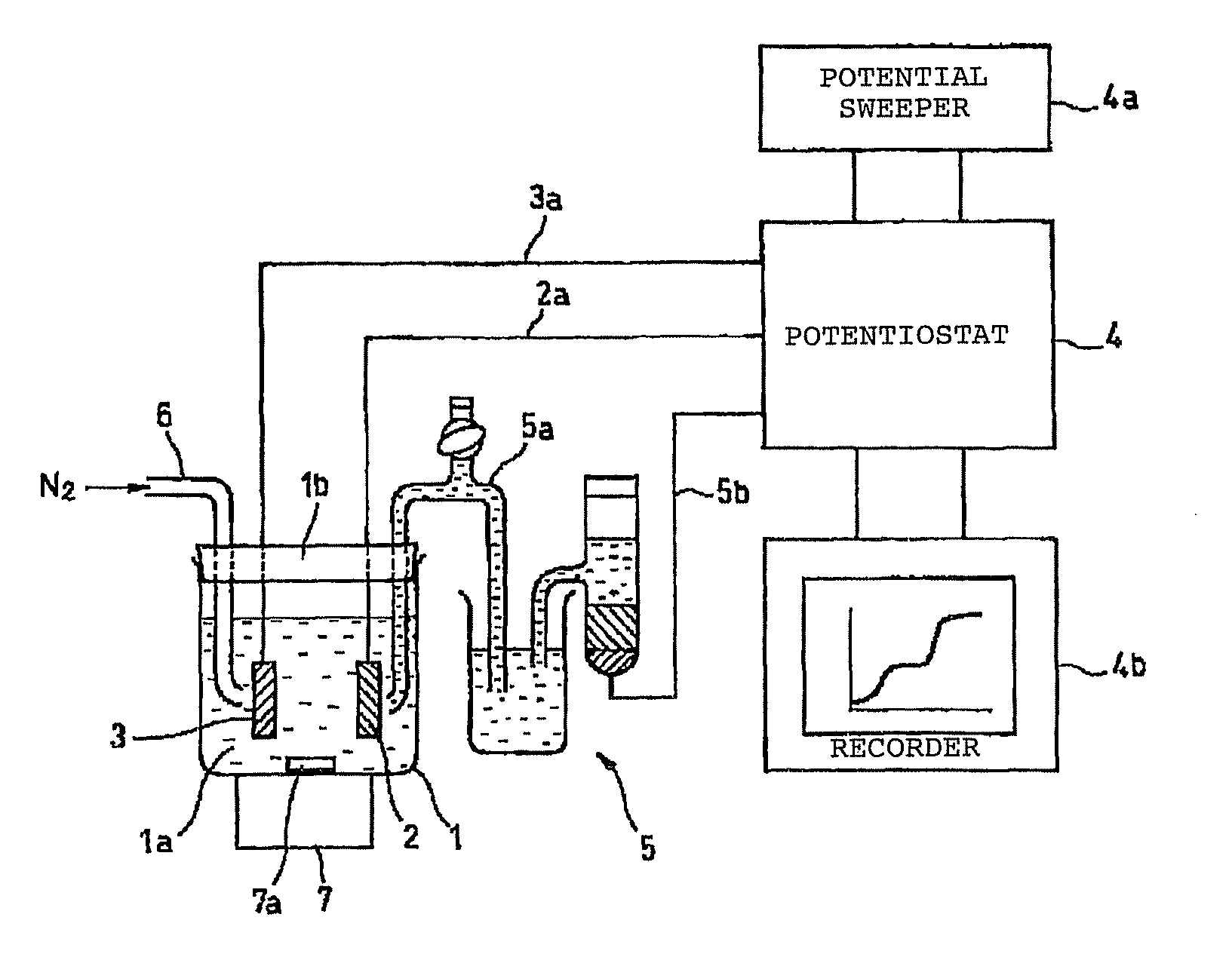

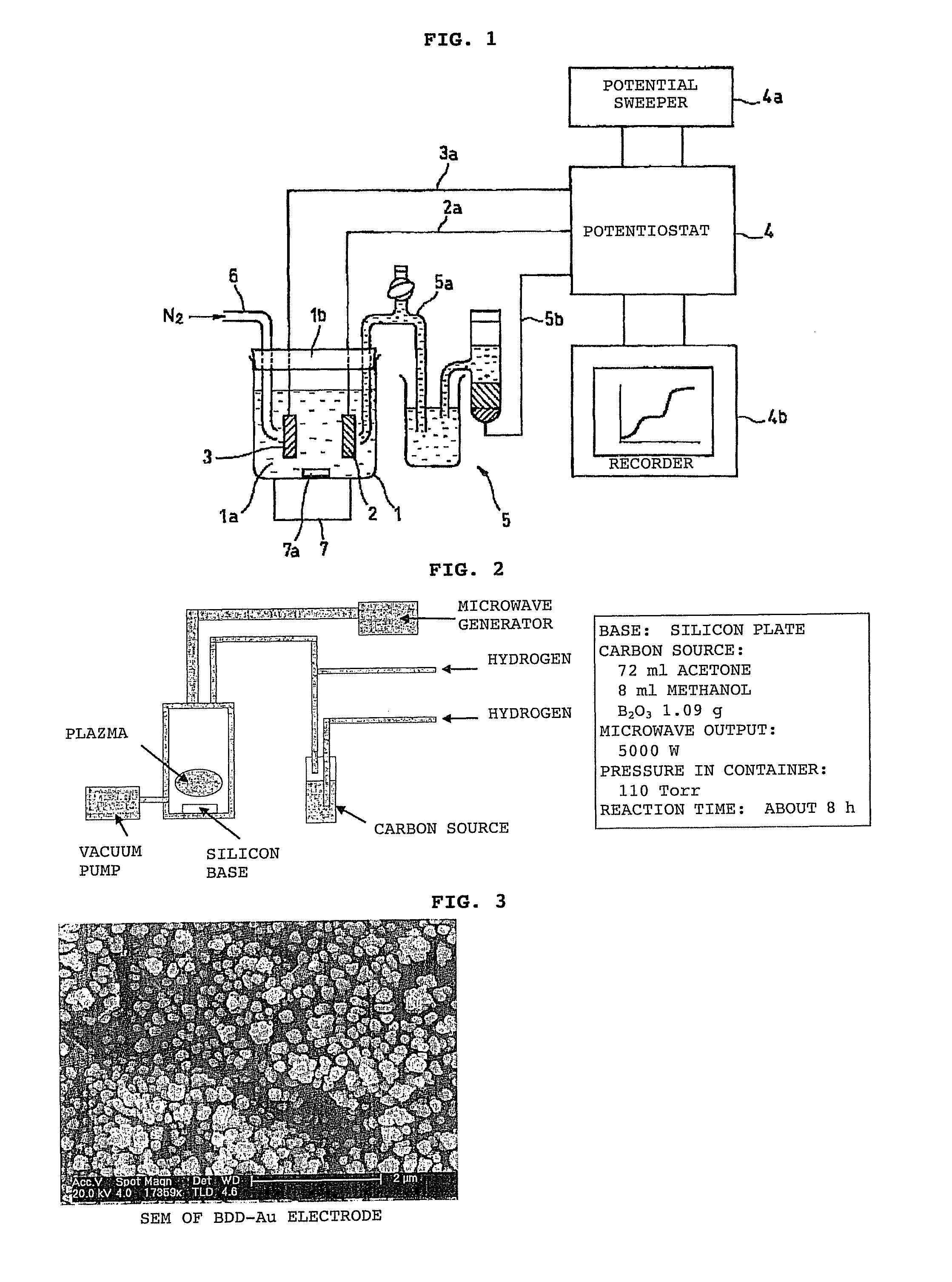

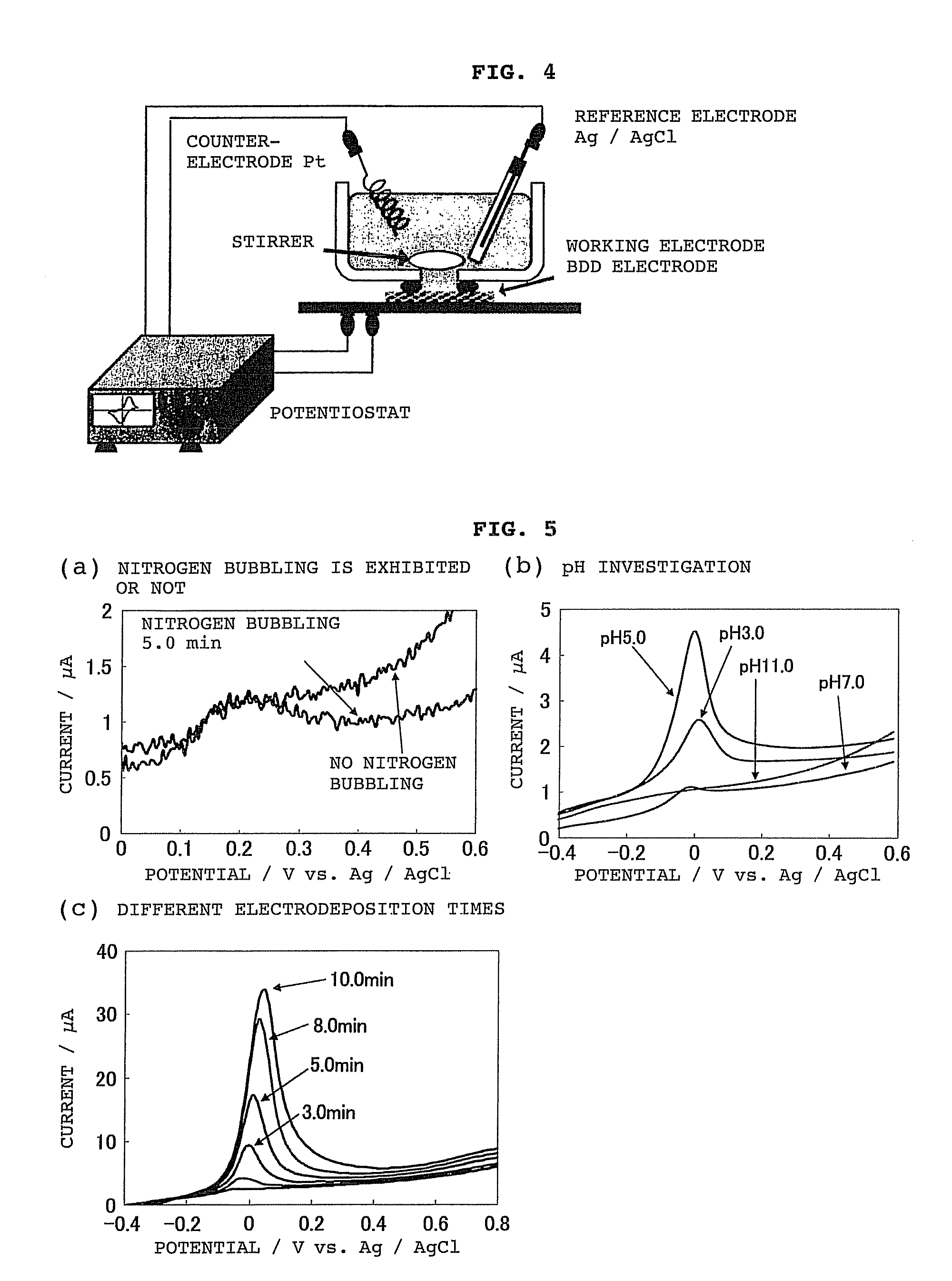

Electrochemical analysis method using boron-doped electroconductive diamond electrode

InactiveUS7883617B2Easy for quantitative analysisMaximum accuracyCellsWeather/light/corrosion resistanceElectrolytic agentPotential change

Owner:KEIO UNIV

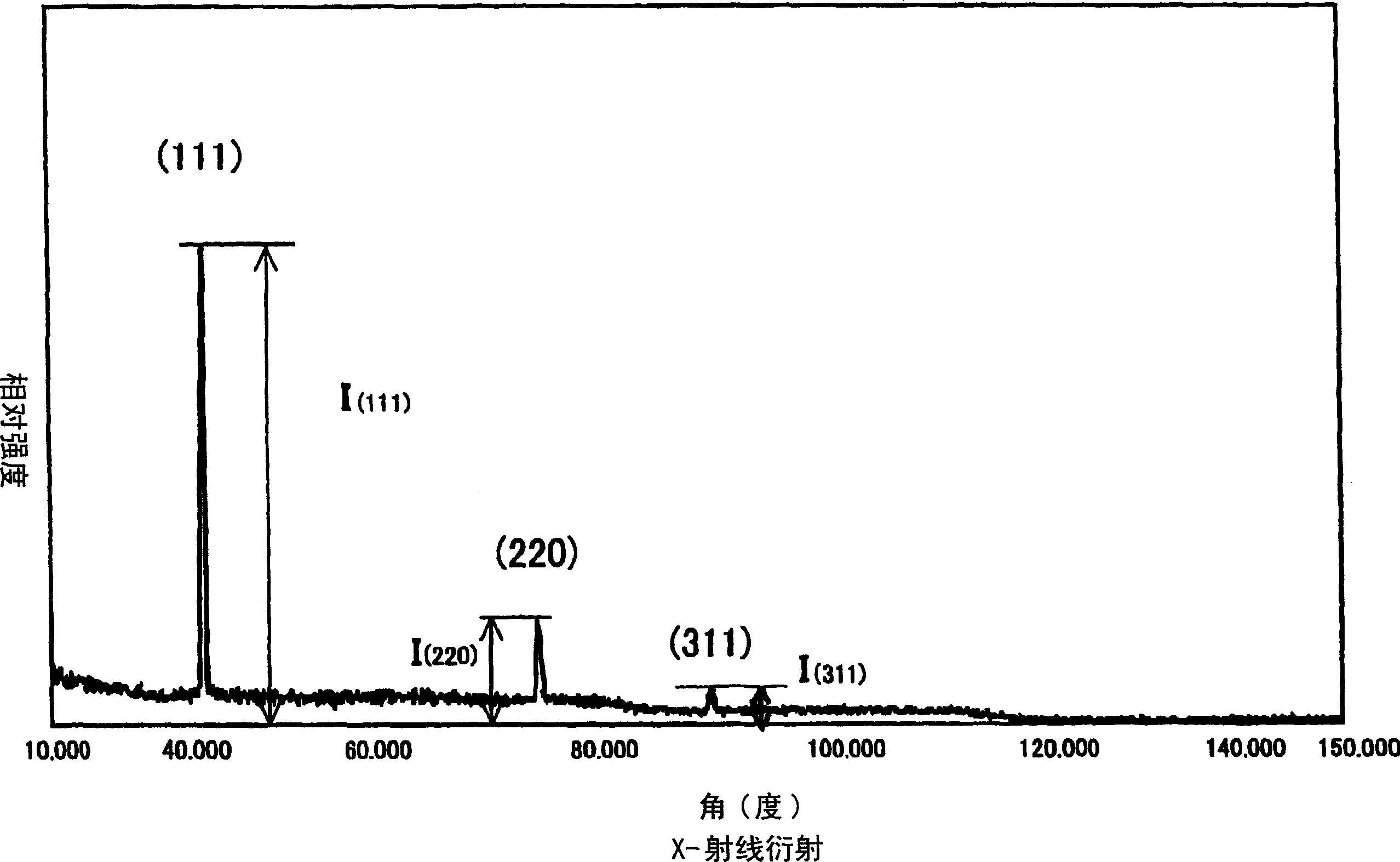

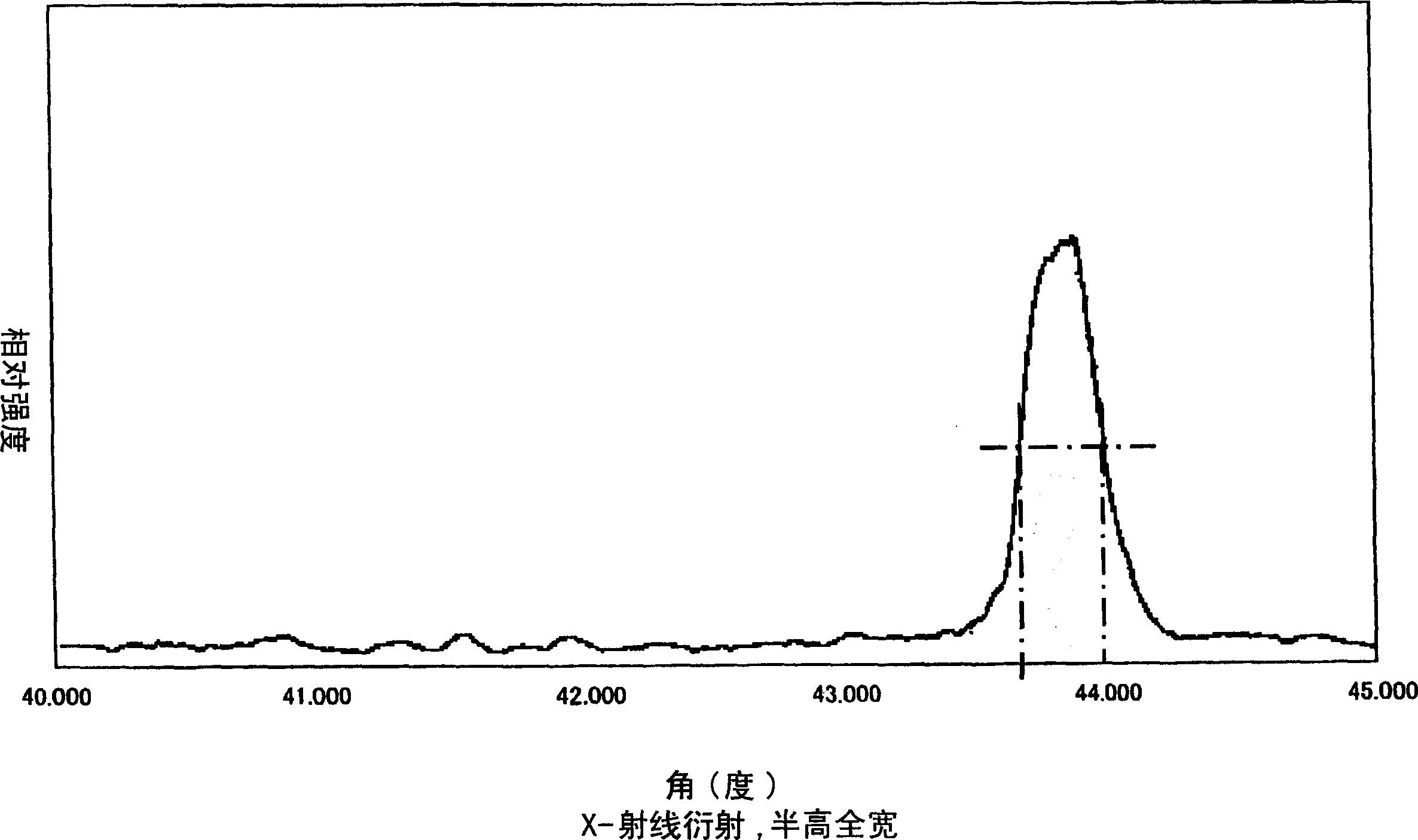

Diamond-coated electrode and method for producing same

InactiveCN1735716AGood electrolyte peel strengthLower resistanceElectrodesElectrical resistance and conductanceDiamond electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

Conductive diamond electrode and process for producing the same

ActiveUS20060066203A1Avoid corrosionIncreased durabilityMachining electrodesCell electrodesElectrolytic agentDiamond electrodes

A conductive diamond electrode including a conductive substrate comprising a carbonaceous material, a conductive diamond catalyst layer formed on a surface of the conductive substrate, and a carbon fluoride formed on an exposed portion present on the surface of the conductive substrate. The formed carbon fluoride prevents the conductive substrate from contacting with an electrolytic solution, thereby suppressing corrosion of the substrate. A long life of the electrode can be attained.

Owner:DE NORA PERMELEC LTD

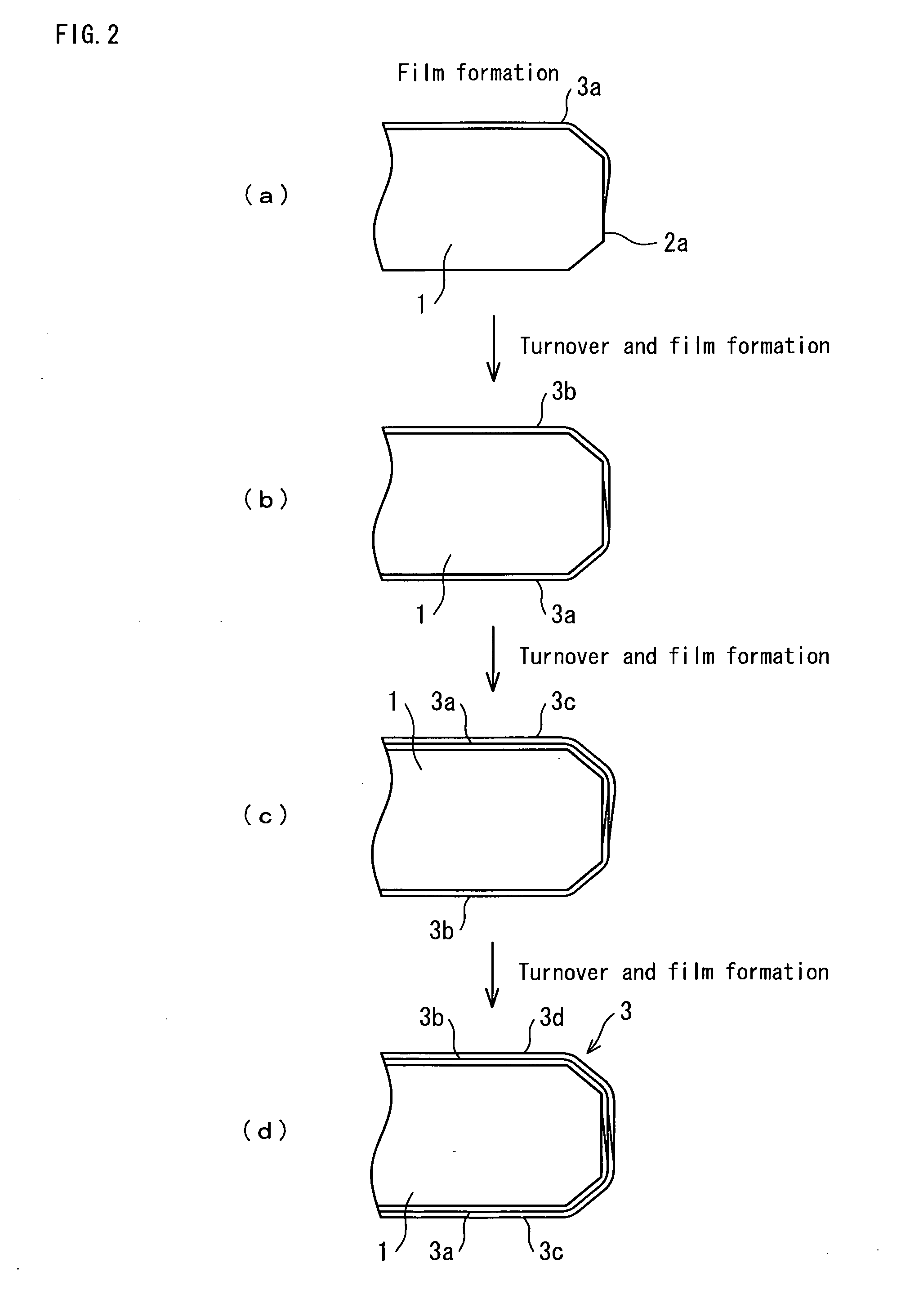

Diamond electrode and method for manufacturing diamond electrode

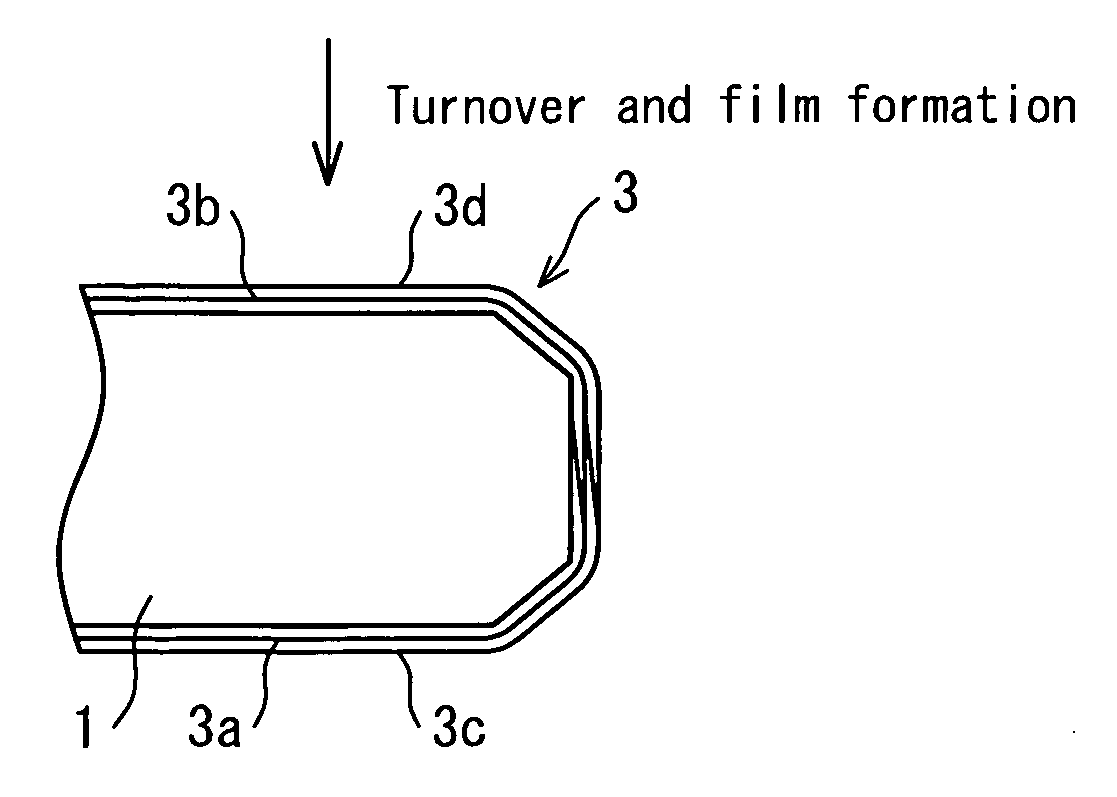

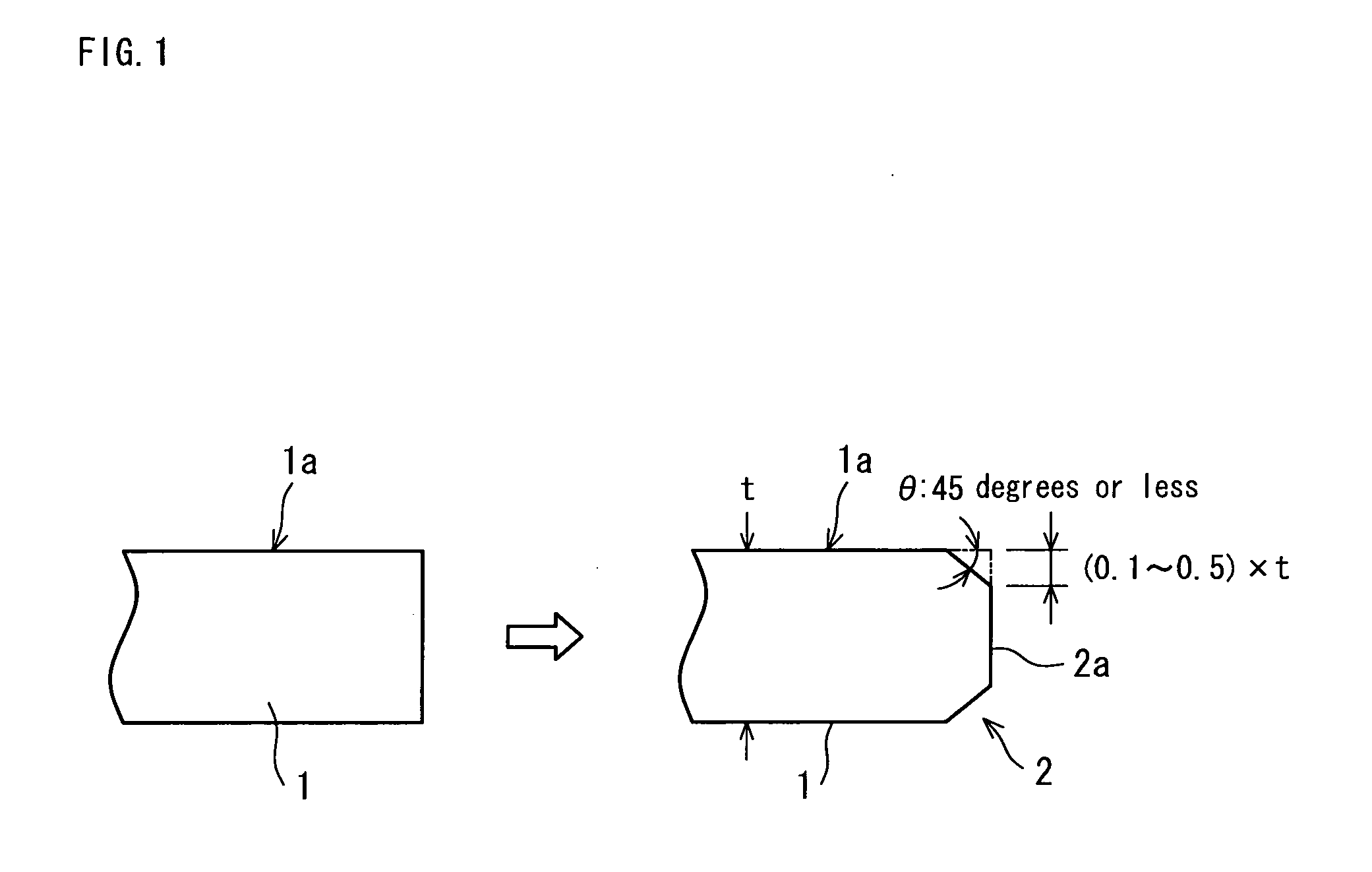

InactiveUS20110247929A1Inhibit deteriorationIncreasing the thicknessMachining electrodesNon-insulated conductorsOxidation resistantDiamond electrodes

A diamond electrode having an oxidation resistant diamond film which will not separate from the electrode during electrolysis with highly oxidizing materials. The thickness of the diamond film is 20 pm or more and the diamond film should preferably cover opposite side surfaces of a substrate in such a manner as to also cover end surfaces 2a of the substrate. The surfaces of the substrate are covered with a plurality of diamond layers to form the film using repeated steps of forming separate diamond layers with each diamond layer having a thickness of 10 to 30 pm on one of the surfaces of the substrate and then forming a diamond layer having a thickness of 10 to 30 pm on the other surface of the substrate. Thus, it is possible to form a nonporous surface of diamond layer and prevent deterioration of an electrode caused by the separation of a diamond film.

Owner:KURITA WATER INDUSTRIES LTD +1

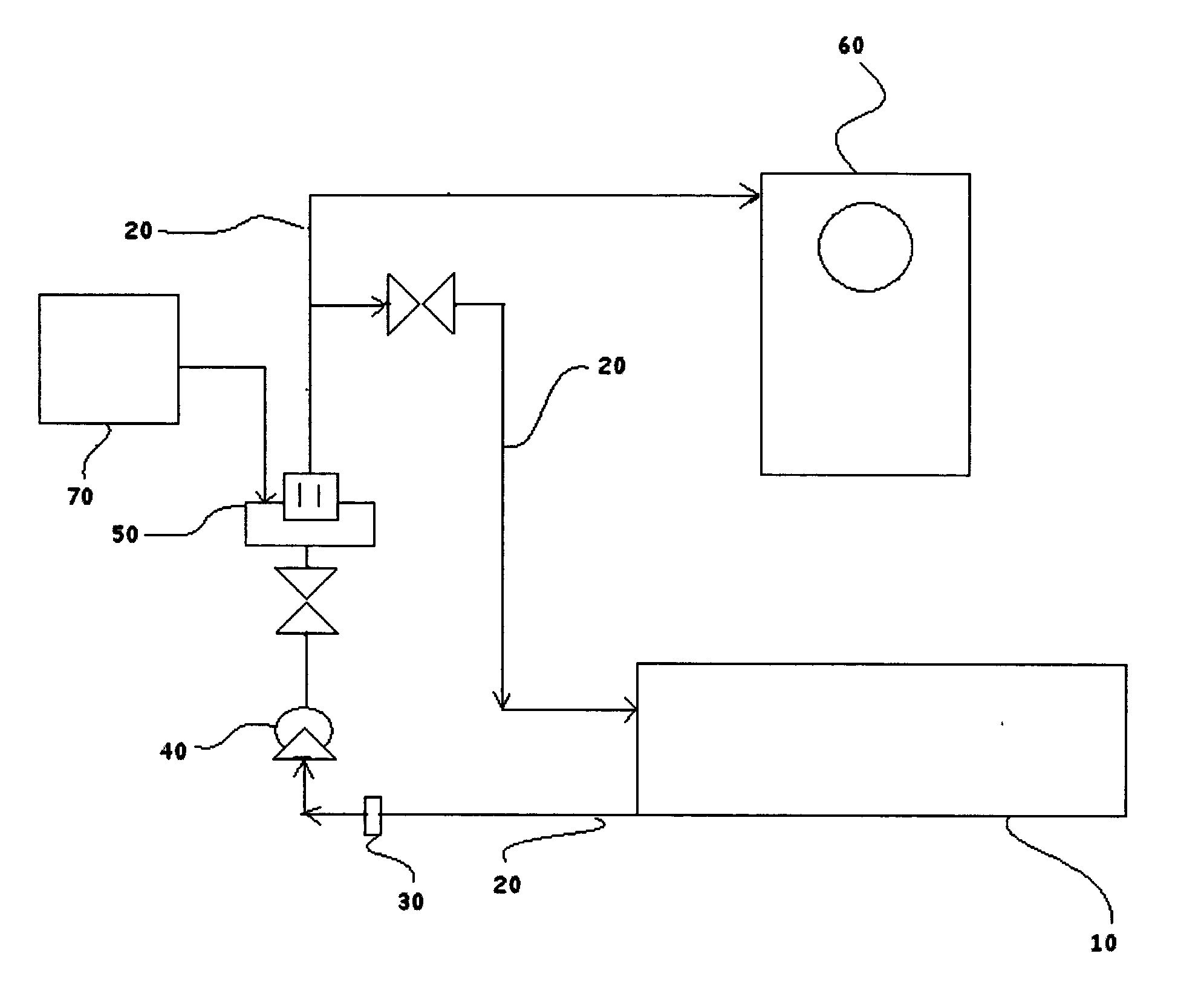

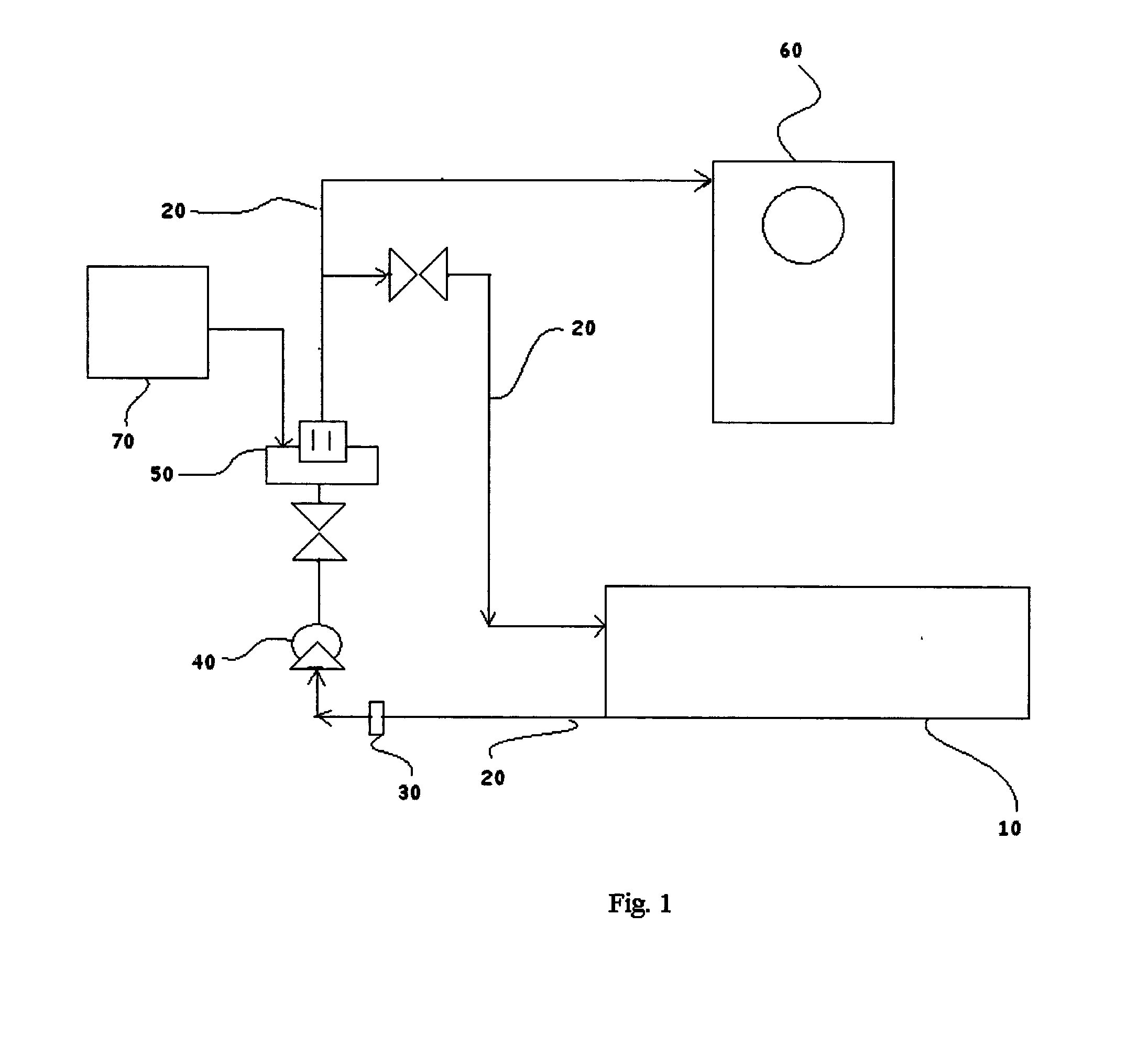

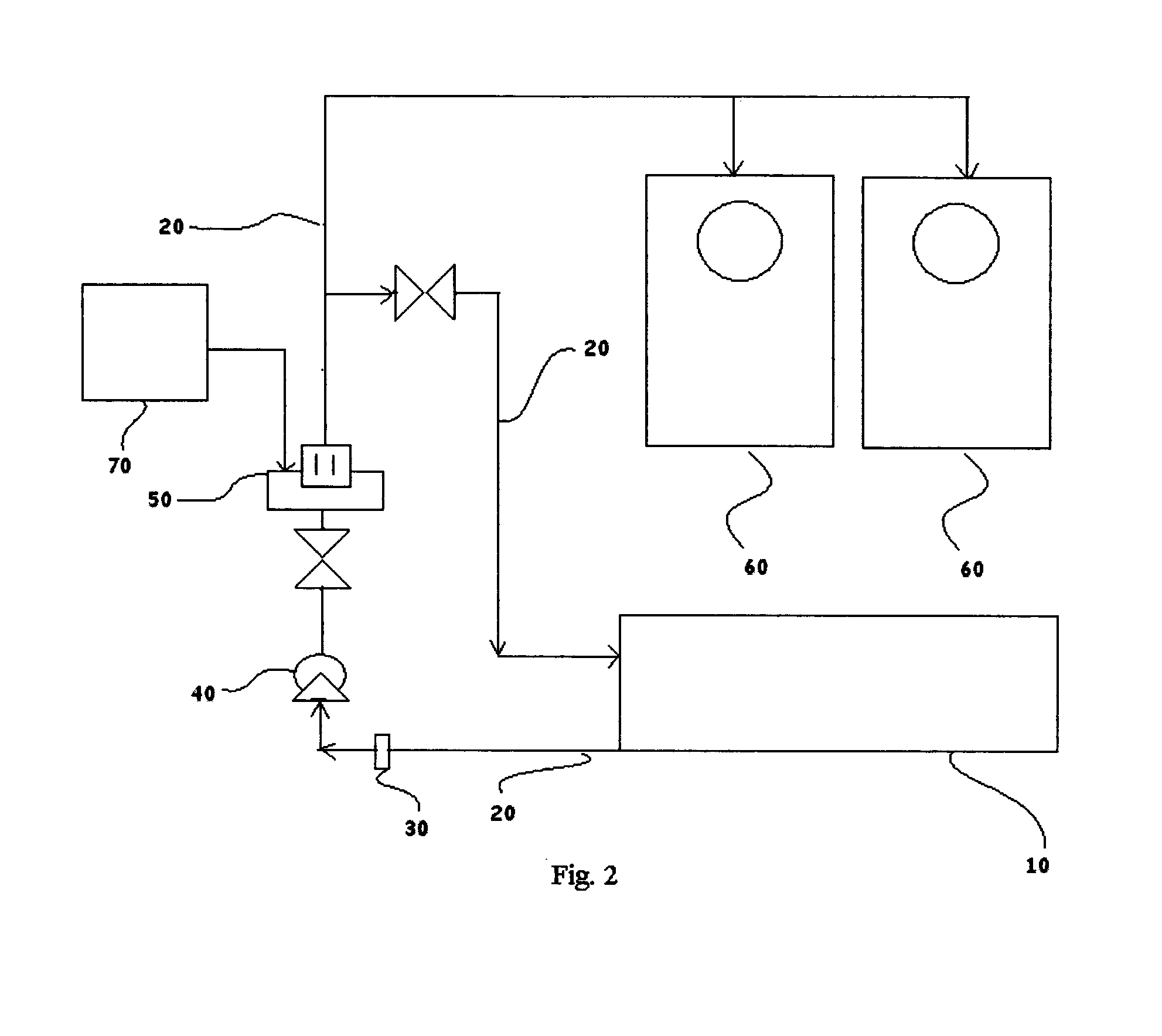

System and a Method for Washing, Cleaning, Disinfecting and Sanitizing Laundry Using Electrolytic Cell Having Boron-Doped Diamond Electrode

InactiveUS20130125316A1Unique propertyImprove efficiencyWater treatment parameter controlElectrolysis componentsElectrochemical responseDiamond electrodes

The invention relates to a system and a method for washing, cleaning, disinfecting and sanitizing laundry using electrolyte solution containing mixed oxidants generated in-situ using electrochemical reaction. More particularly the present invention relates to a system and a method for washing, cleaning, disinfecting and sanitizing laundry at a pH between 6.5 to 10.5 and at a temperature below 50° C. using in-situ mixed oxidants generated by passing electrolyte solution through electrolytic cell having boron-doped diamond electrode.

Owner:XH2O SOLUTIONS PRIVATE

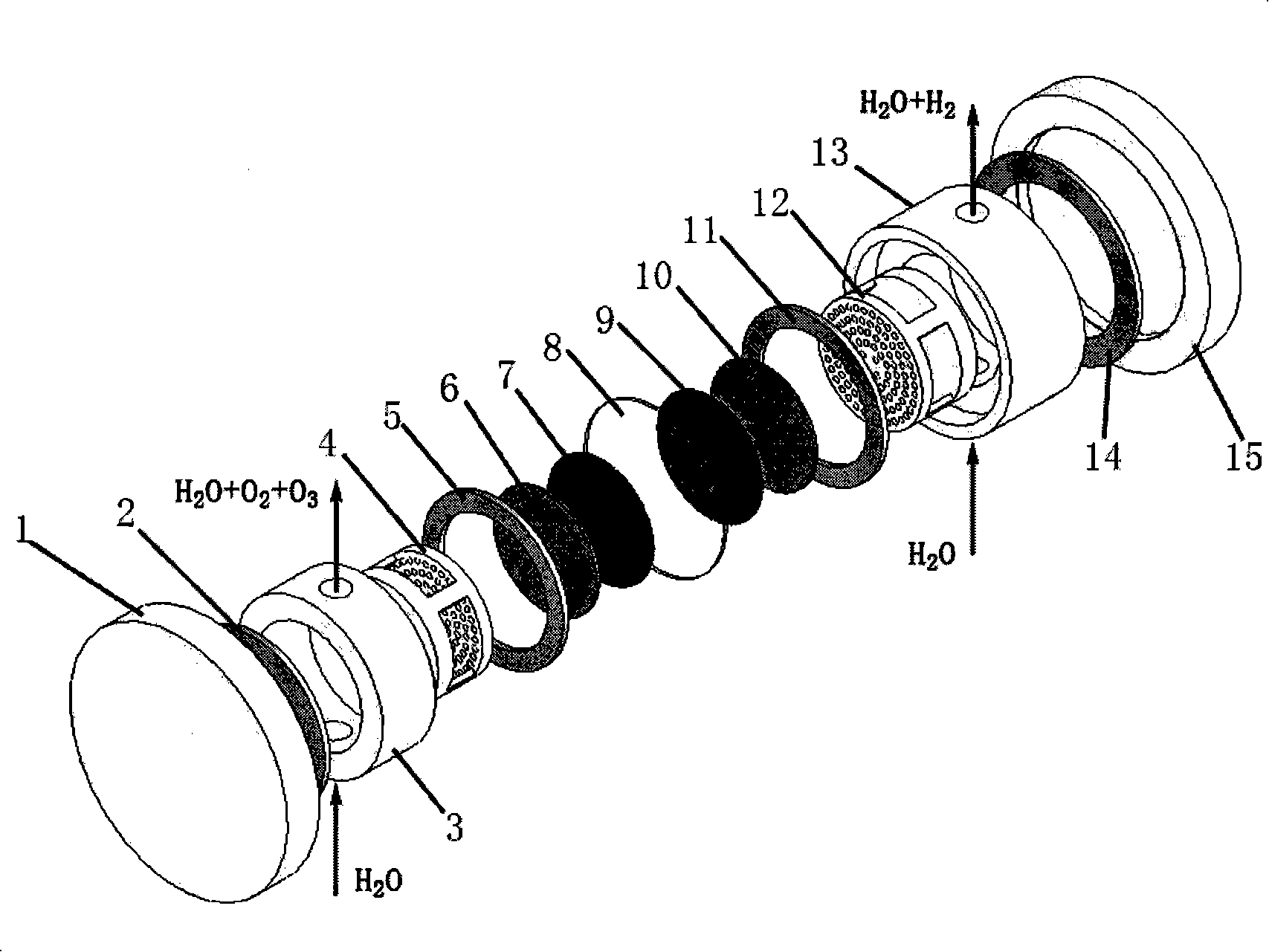

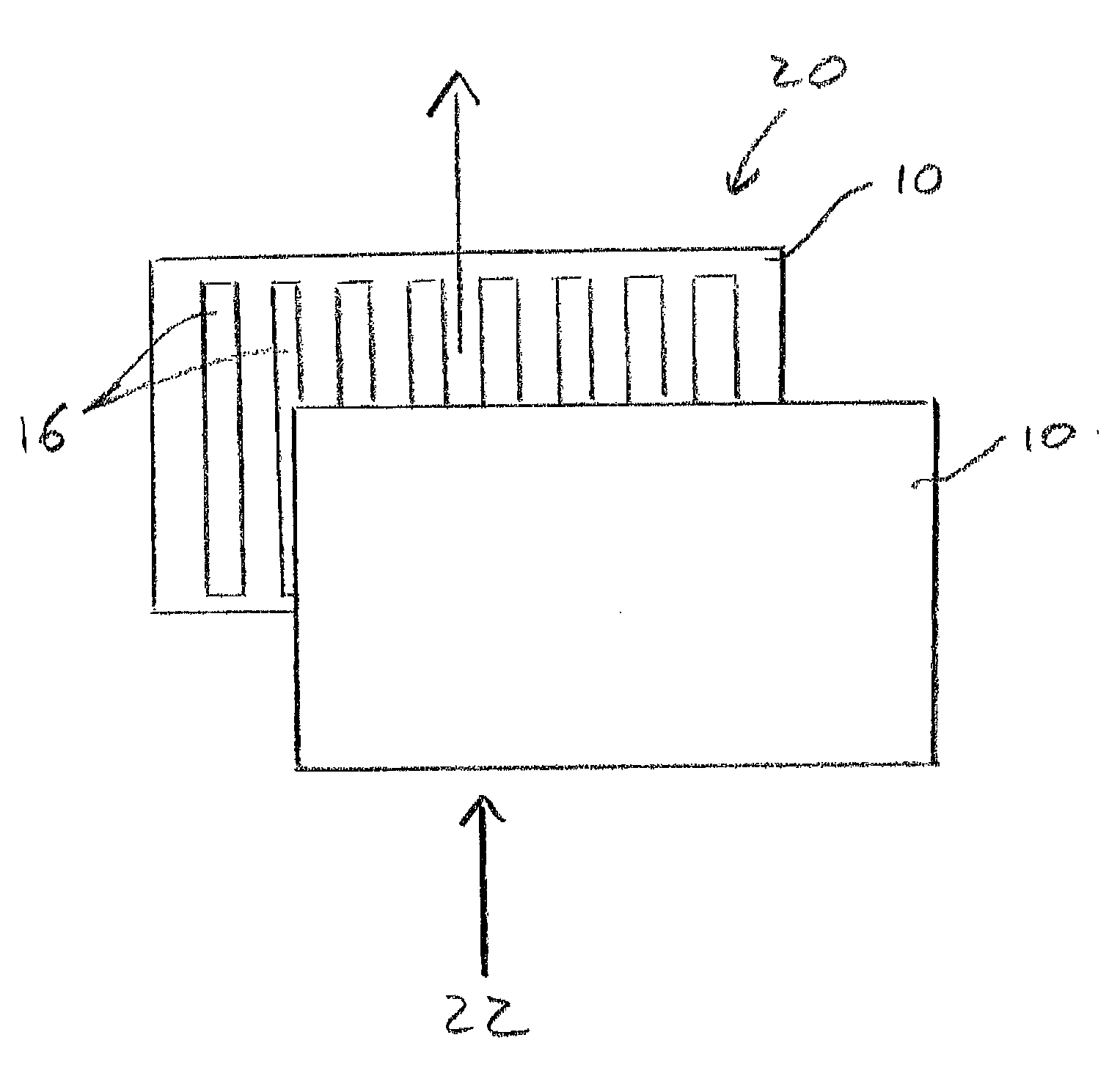

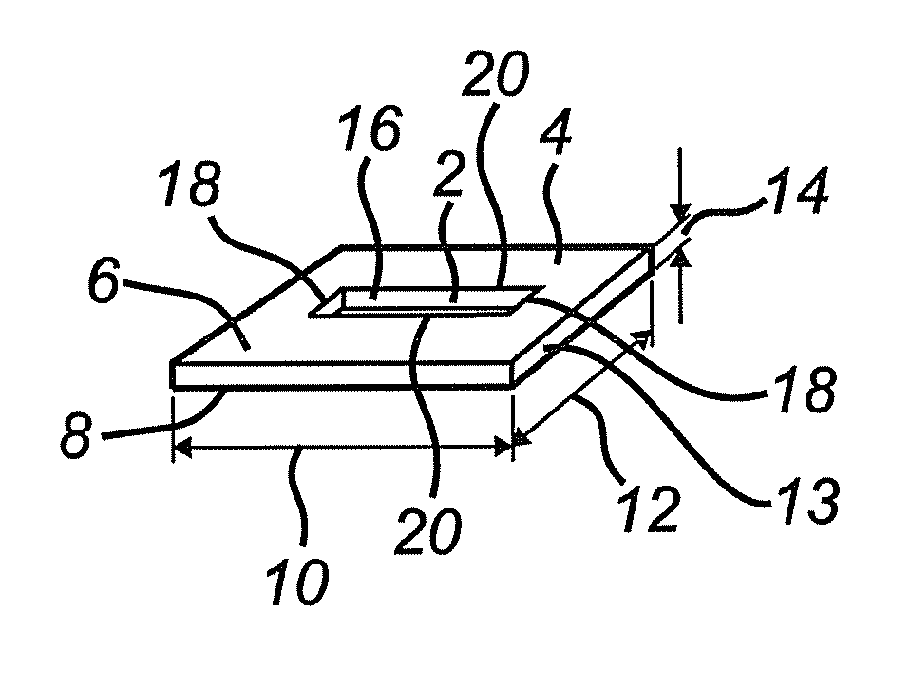

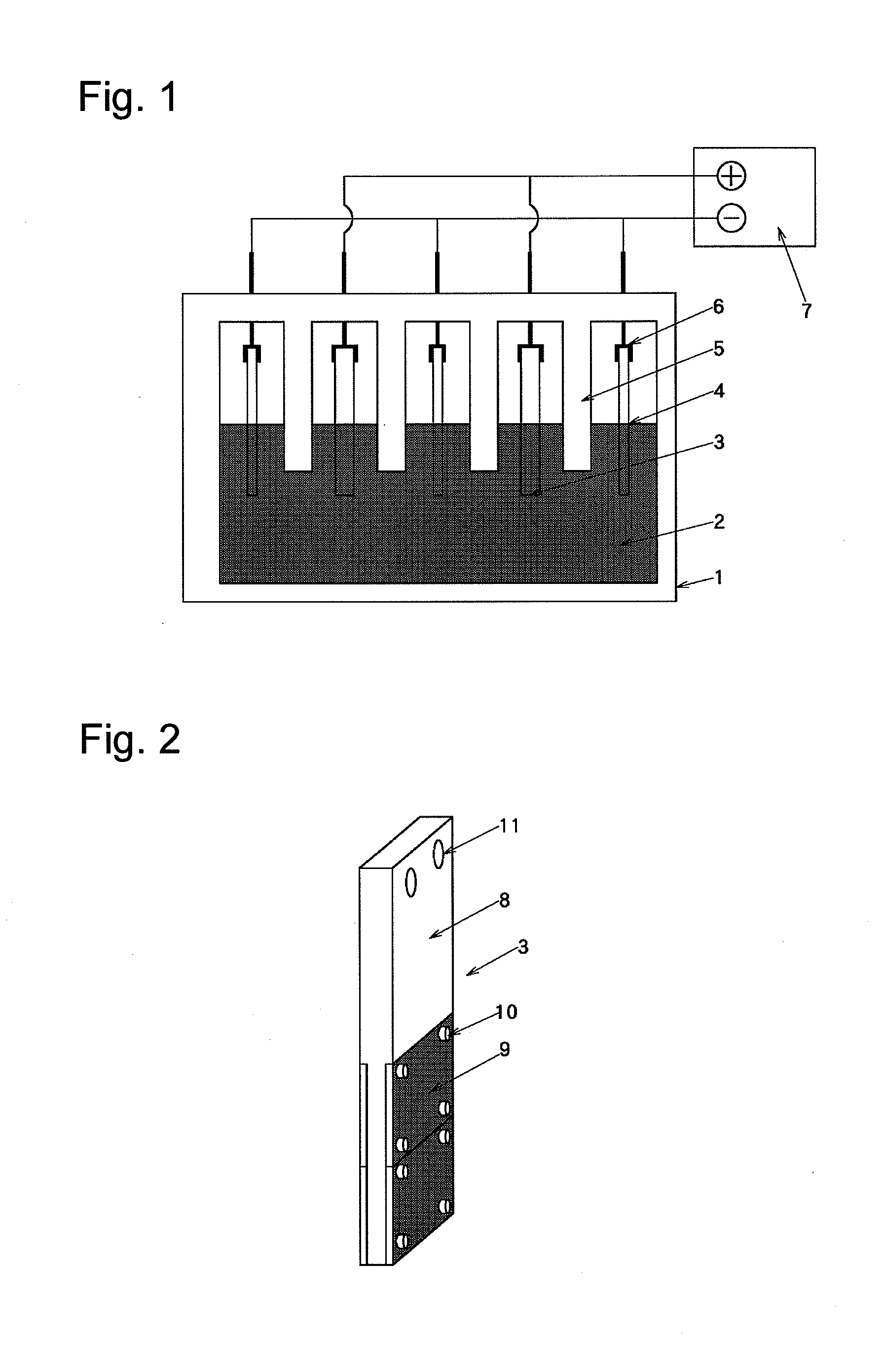

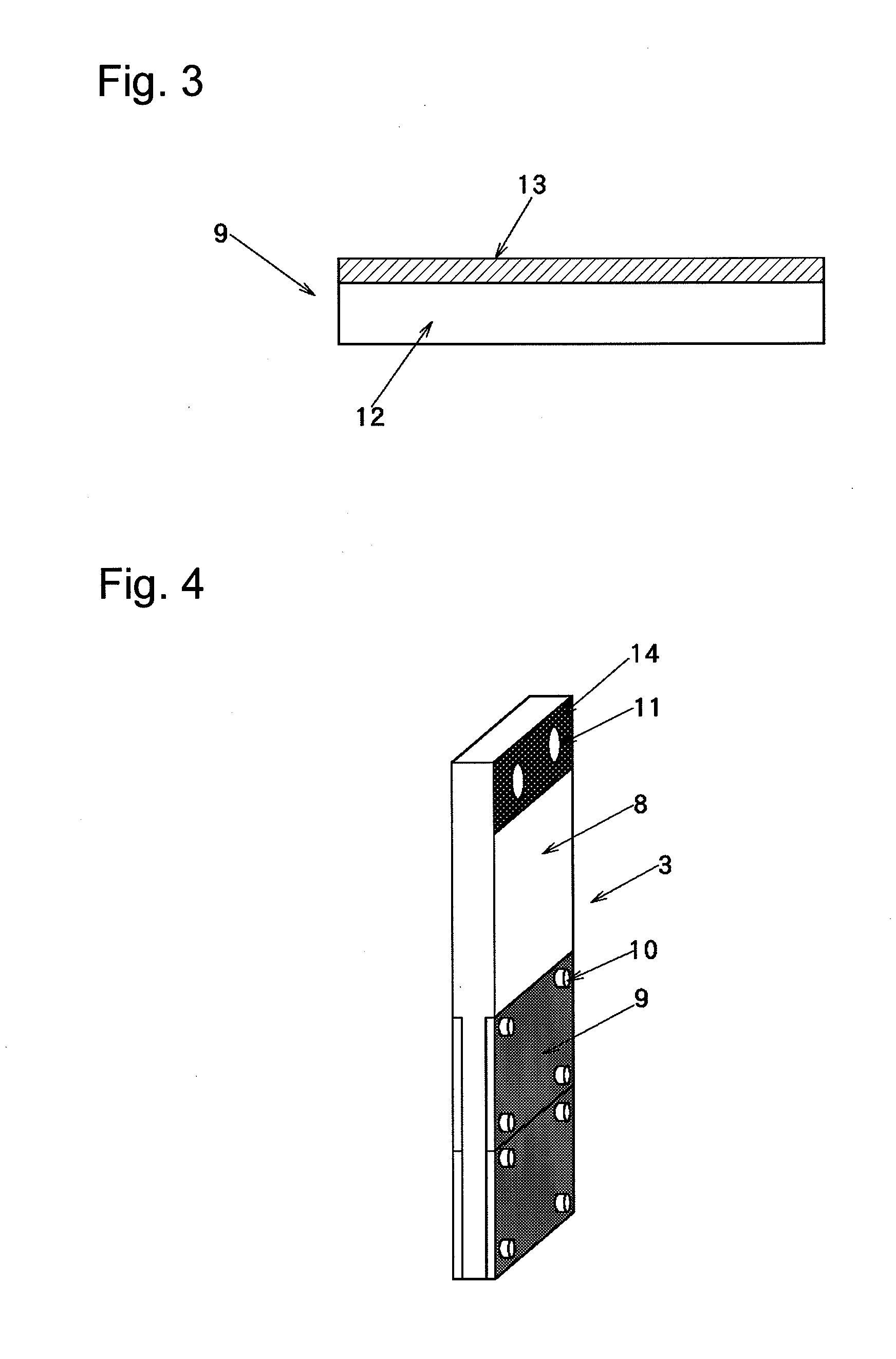

Method for the production of a diamond electrode, and diamond electrode

ActiveUS20100170783A1Smooth connectionSimple processMachining electrodesCell electrodesDiamond electrodesConductive materials

A method for producing a diamond electrode comprising synthetically produced and electrically conductive (doped) diamond particles, which are embedded into a support layer of electrically non-conductive material. The doped diamond particles are introduced as a single layer between two films that form the support layer, the films then being permanently connected to each other and the diamond particles being exposed on both sides of the support layer.

Owner:PRO AQUA DIAMANTELEKTRODEN PRODN

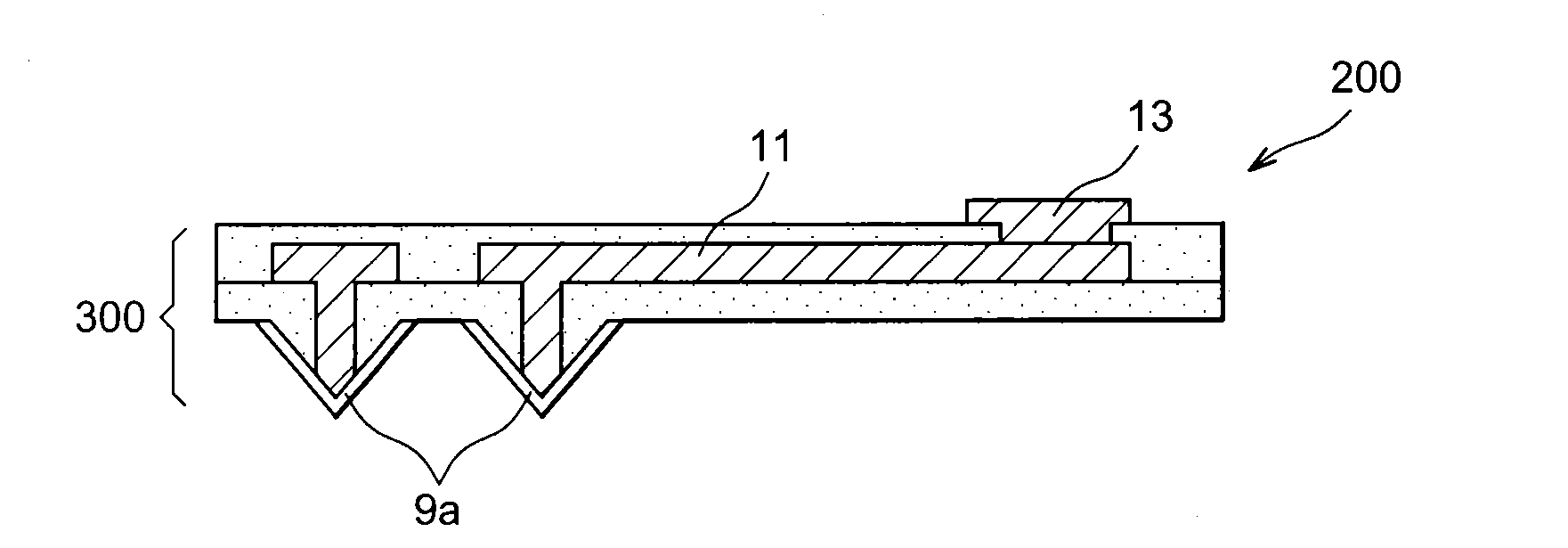

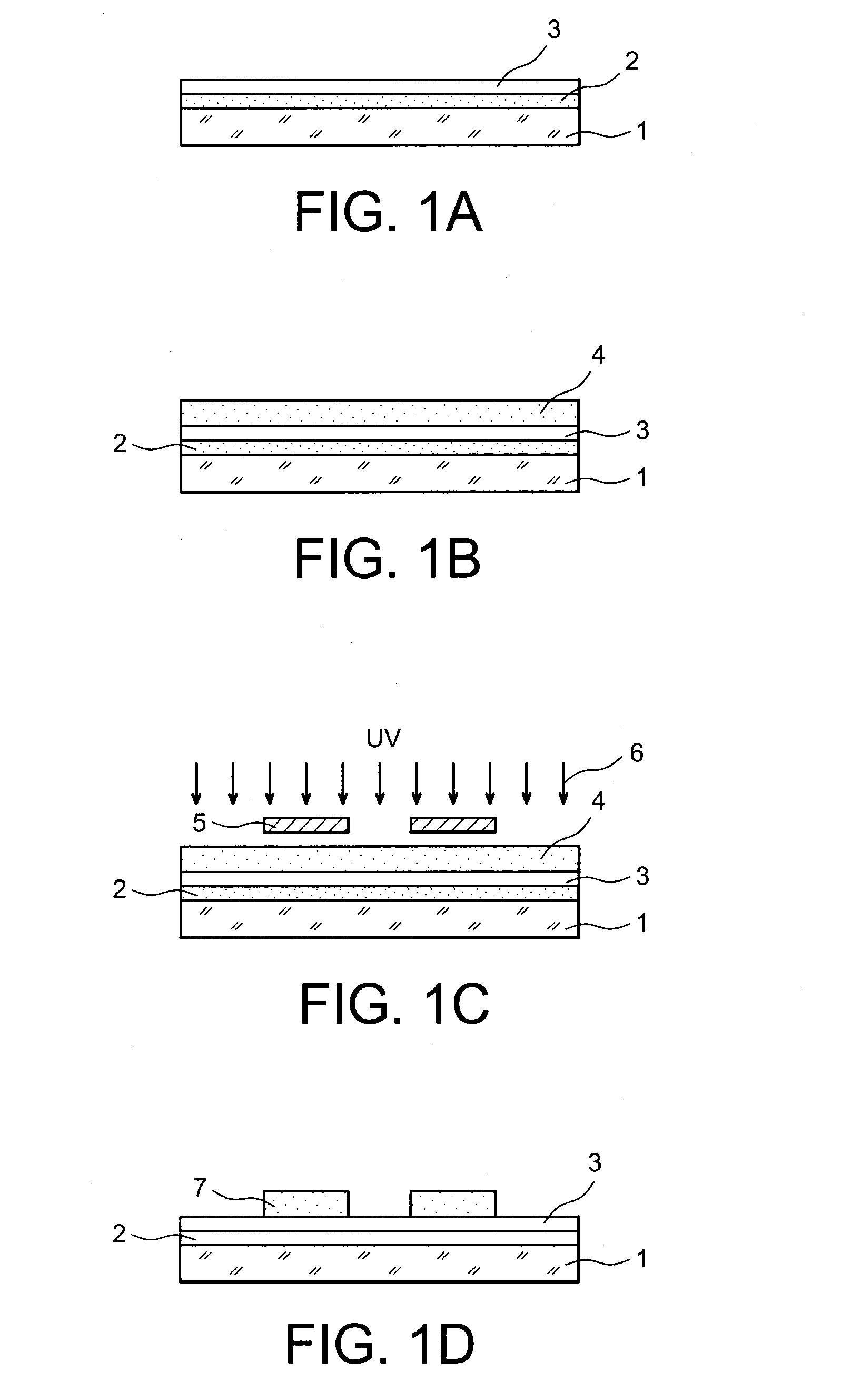

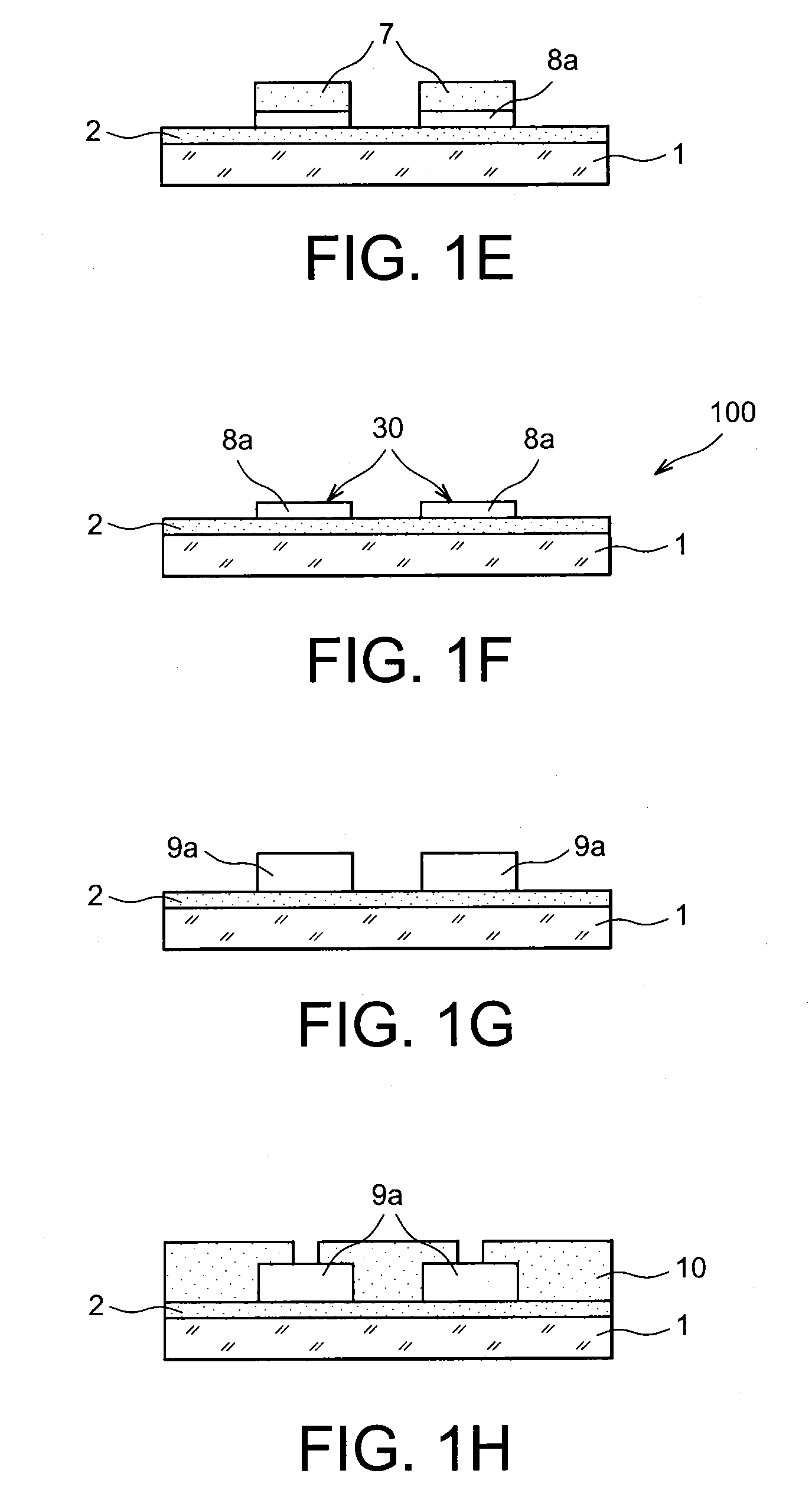

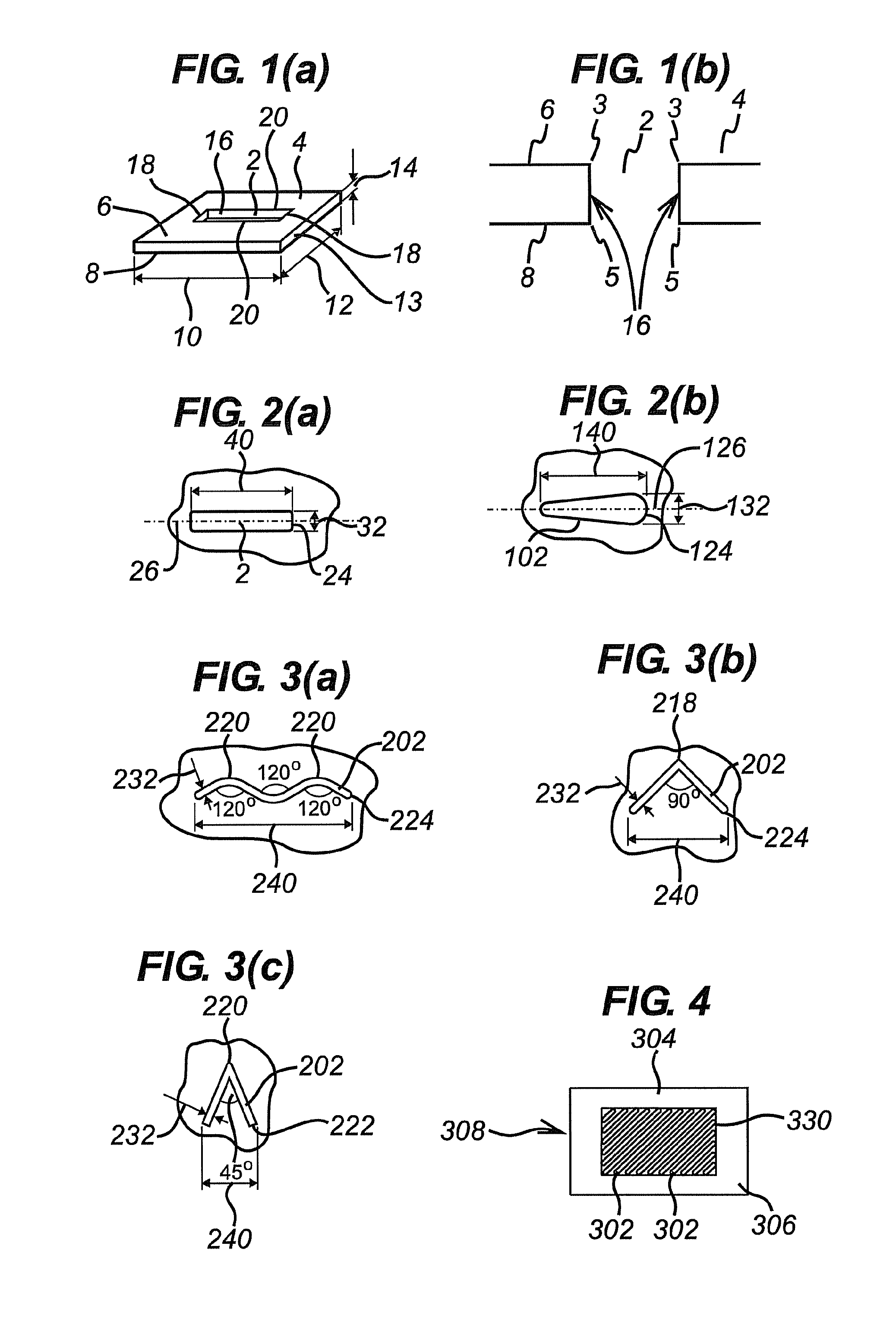

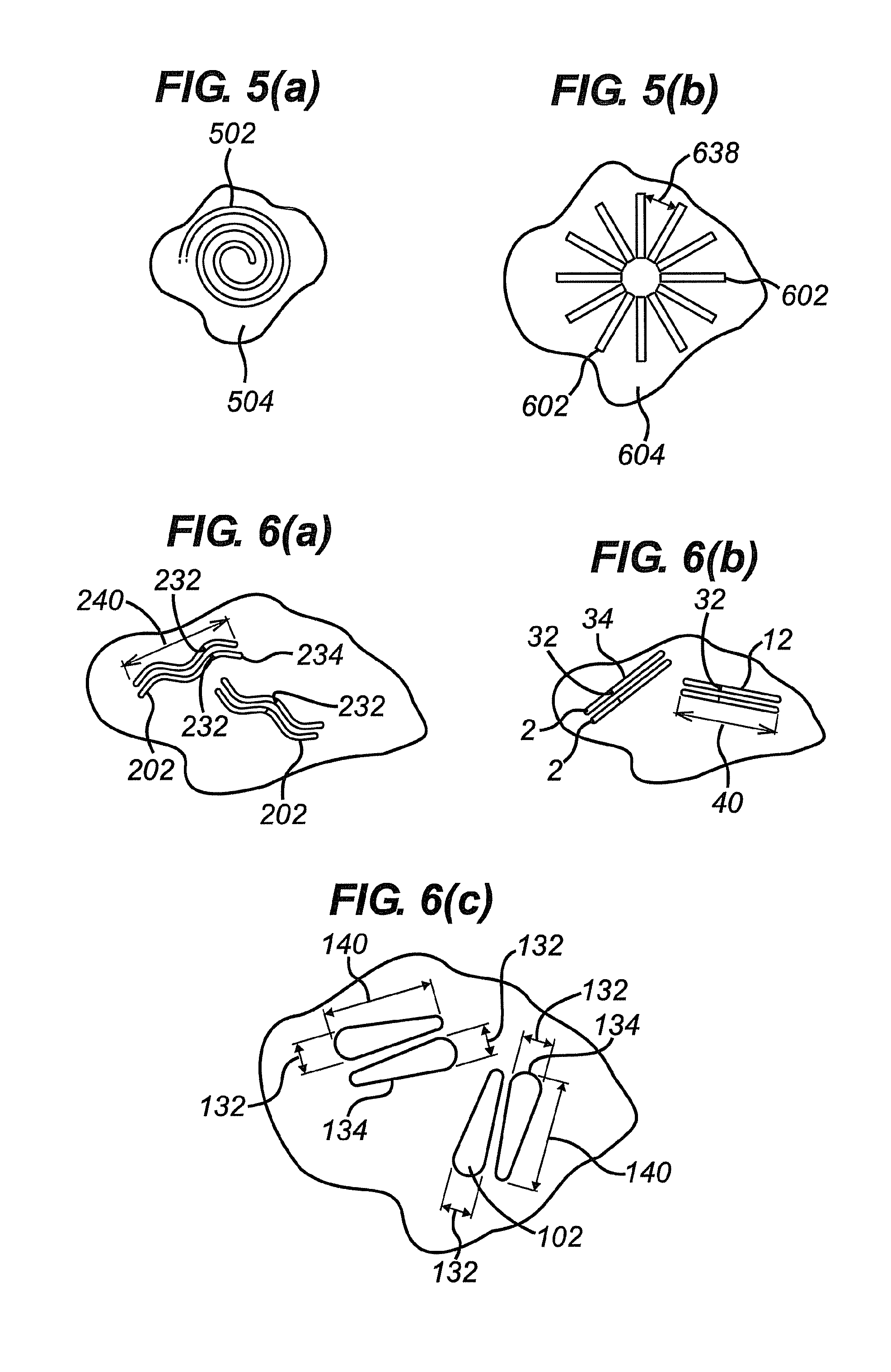

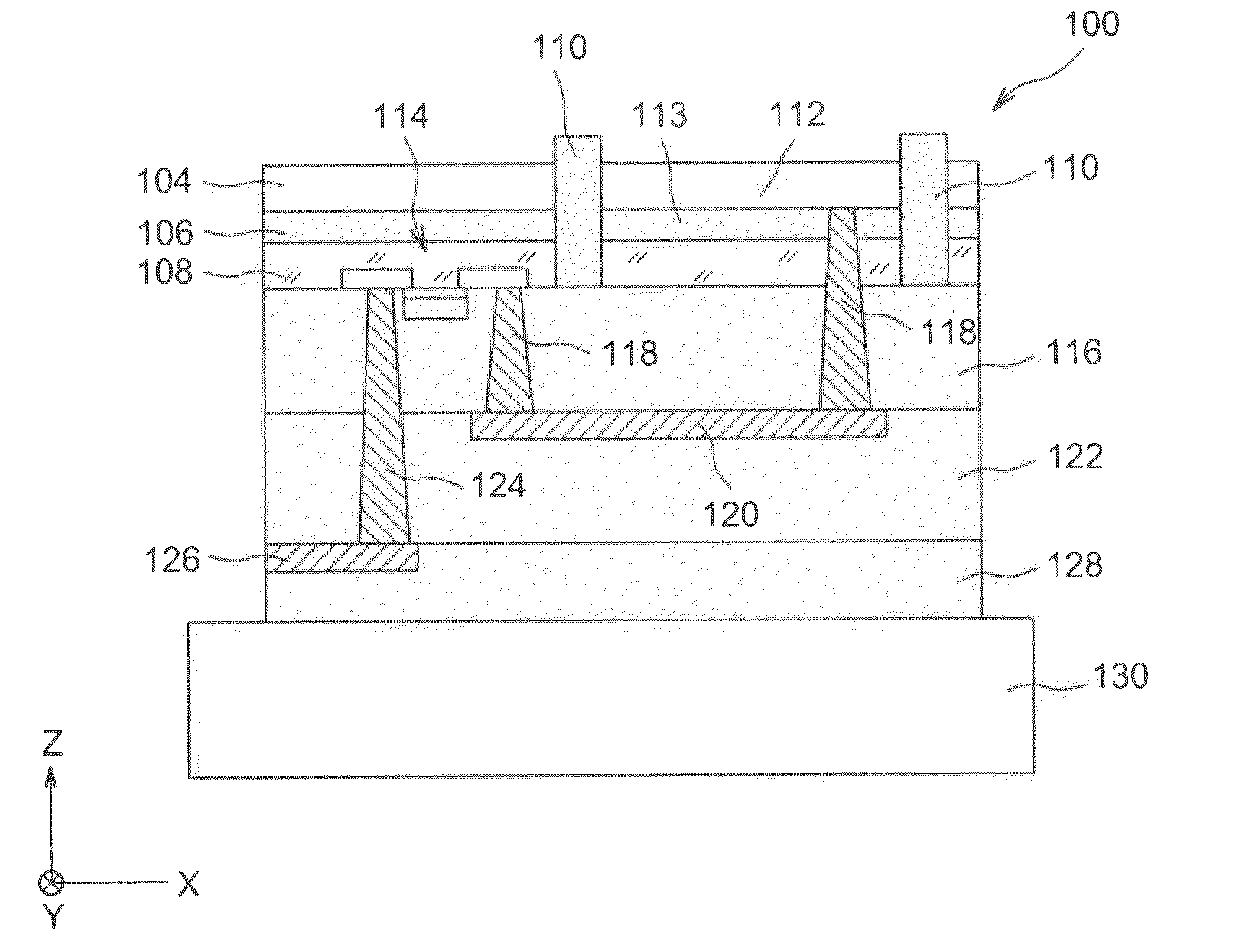

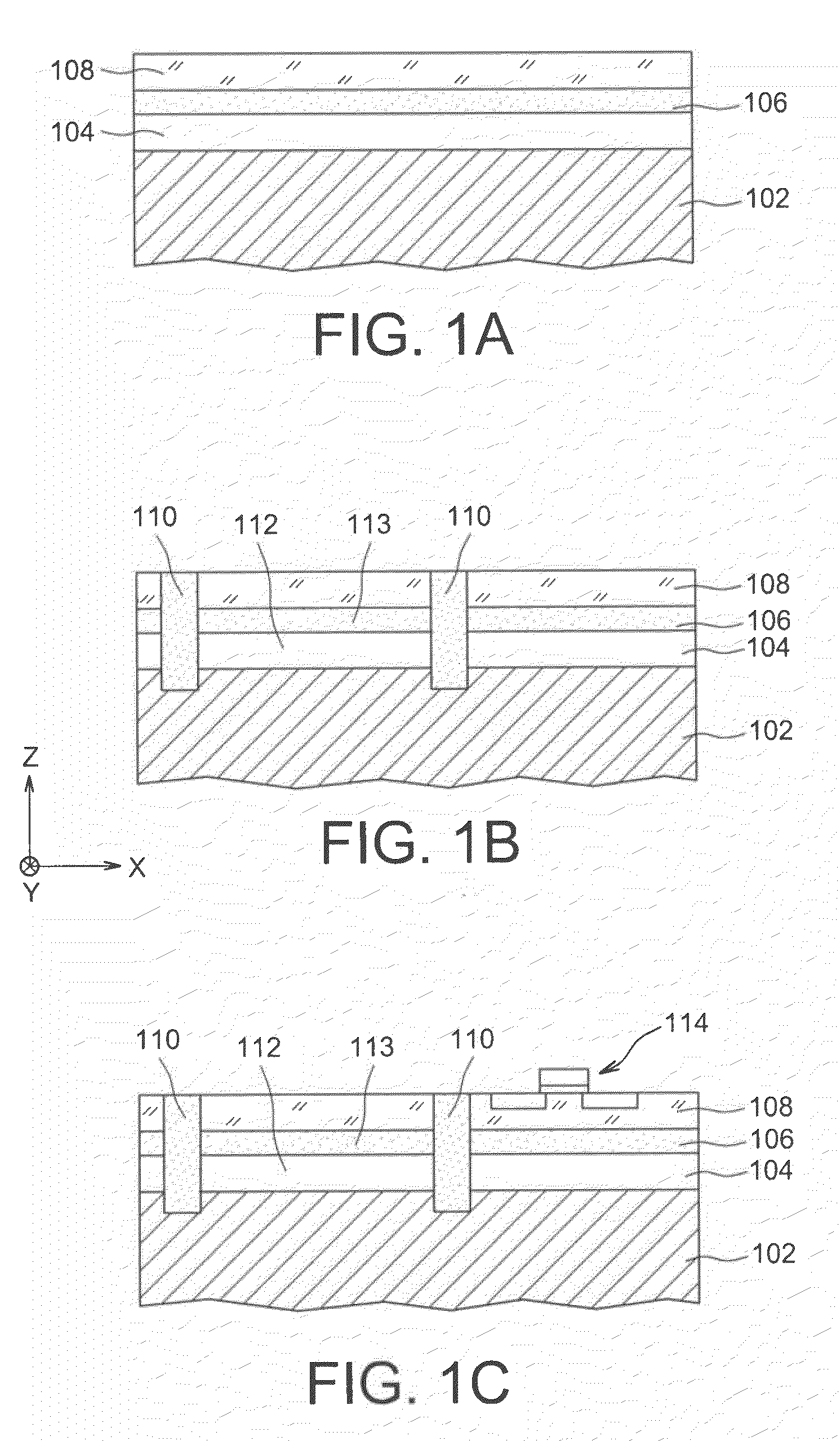

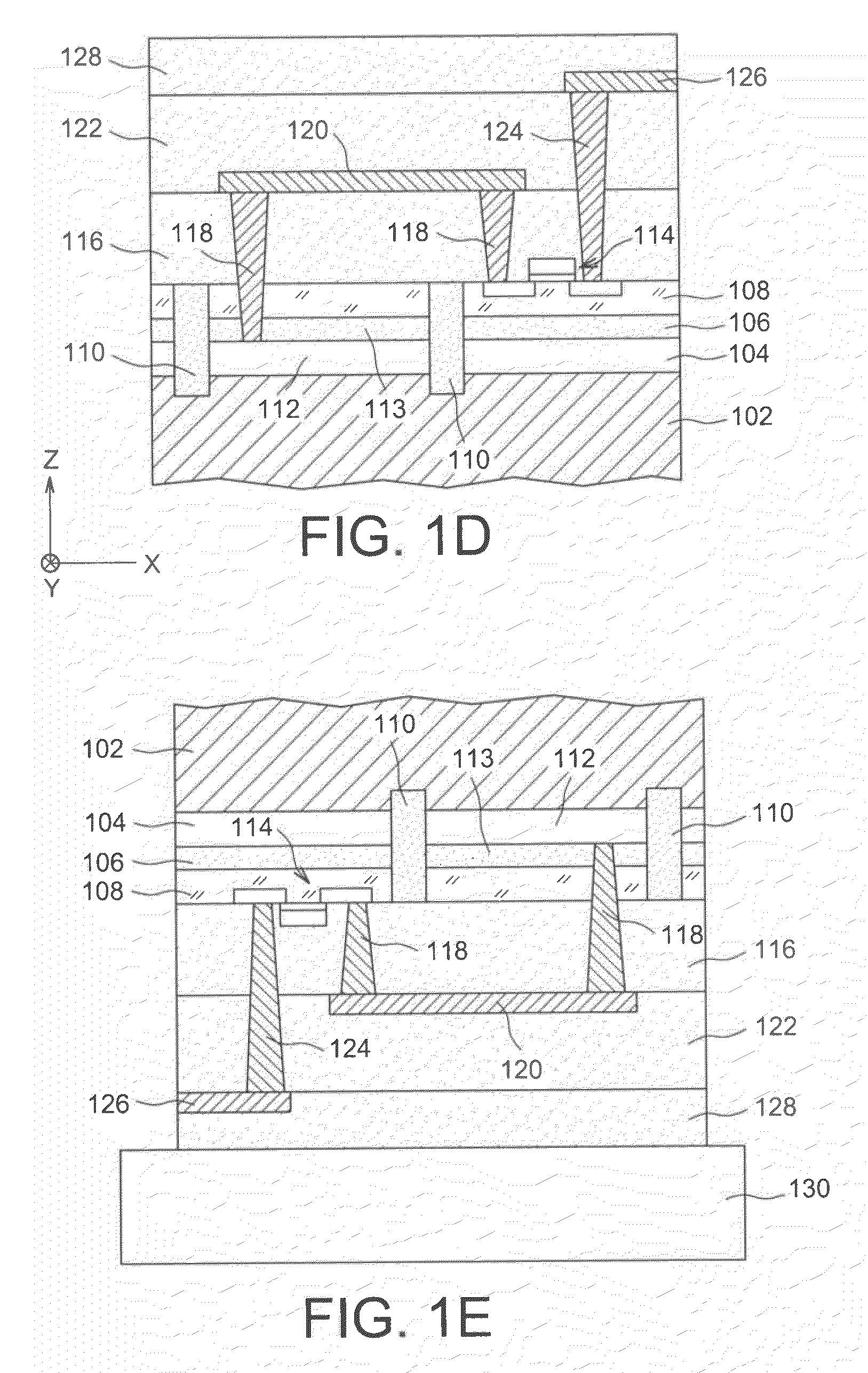

Method for manufacturing a flexible intraocular retinal implant having doped diamond electrodes

ActiveUS20130228547A1Good biocompatibilityIncrease contactHead electrodesSemiconductor/solid-state device manufacturingDiamond electrodesRetinal implant

A method for manufacturing an intraocular retinal implant including: providing a mold capable of supporting growth of a layer of doped diamond, the mold including, on one face, elements all depressed or all projecting with respect to the surface of the face, and constituting a pattern cavity for the electrodes of the implant which it is desired to obtain; producing the doped diamond electrodes by growing a layer of doped diamond in all or part of a space occupied by the pattern cavity elements; forming a first insulating layer on the face of the mold including the pattern cavity; producing interconnection lines by depositing an electrically conductive material at least in spaces not covered by the first insulating layer; forming a second insulating layer on the mold face including the pattern cavity, the second layer covering the interconnection lines, the first and second insulating layers forming a flexible plate of the implant; removing the mold.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES +1

Diamond electrode, method for producing same, and electrolytic cell

InactiveUS7951274B2Low production costEasy to produceCellsElectrode shape/formsDiamond electrodesSilicon

Owner:SUMITOMO ELECTRIC HARDMETAL CORP

Diamond electrodes for electrochemical devices

InactiveUS20150060267A1Reduce the effective areaImprove electrochemical activityElectrode shape/formsSpecial surfacesDiamond electrodesElectrical battery

A bulk boron doped diamond electrode comprising a plurality of grooves disposed in a surface of the bulk boron doped diamond electrode. The bulk boron doped diamond electrode is formed by growing a bulk boron doped diamond electrode using a chemical vapour deposition technique and forming a plurality of grooves in a surface of the bulk boron doped diamond electrode. According to one arrangement, the plurality of grooves are formed by forming a pattern of carbon solvent metal over a surface of the bulk boron doped diamond electrode and heating whereby the carbon solvent metal dissolves underlying diamond to form grooves in the surface of the bulk boron doped electrode. The invention also relates to an electrochemical cell comprising one or more grooved bulk boron doped diamond electrodes. The or each bulk boron doped diamond electrode is oriented within the electrochemical device such that the grooves are aligned in a direction substantially parallel to a direction of electrolyte flow.

Owner:ELEMENT SIX LTD

Boron doped diamond electrode and preparation method thereof

The invention provides a boron doped diamond electrode. The boron doped diamond electrode comprises an electrode substrate, transition layers and boron doped diamond film layers; the transition layersare arranged on one side or the two sides of the electrode substrate; the boron doped diamond film layers are arranged on the transition layers; the transition layers are made of one or more of titanium diboride, niobium diboride, tantalum diboride and wolfram diboride; and the electrode substrate is made of titanium, niobium, tantalum or wolfram. According to the boron doped diamond electrode, materials such as the titanium diboride are used to form the transition layers between the electrode substrate and boron doped diamond films, so that a loose carbide layer is effectively prevented frombeing formed on the surface of a metal substrate, binding force between the boron doped diamond films and the substrate is increased, and the boron doped diamond films are high in quality, are denseand have no holes; the boron doped diamond electrode is used for treating an anode of high concentrated organic wastewater by an electrochemical advanced oxidation method; the corrosion resistance ishigh; the working life of the electrode is long; and the treatment efficiency is high. The invention further provides a preparation method of the boron doped diamond electrode.

Owner:SHENZHEN INST OF ADVANCED TECH

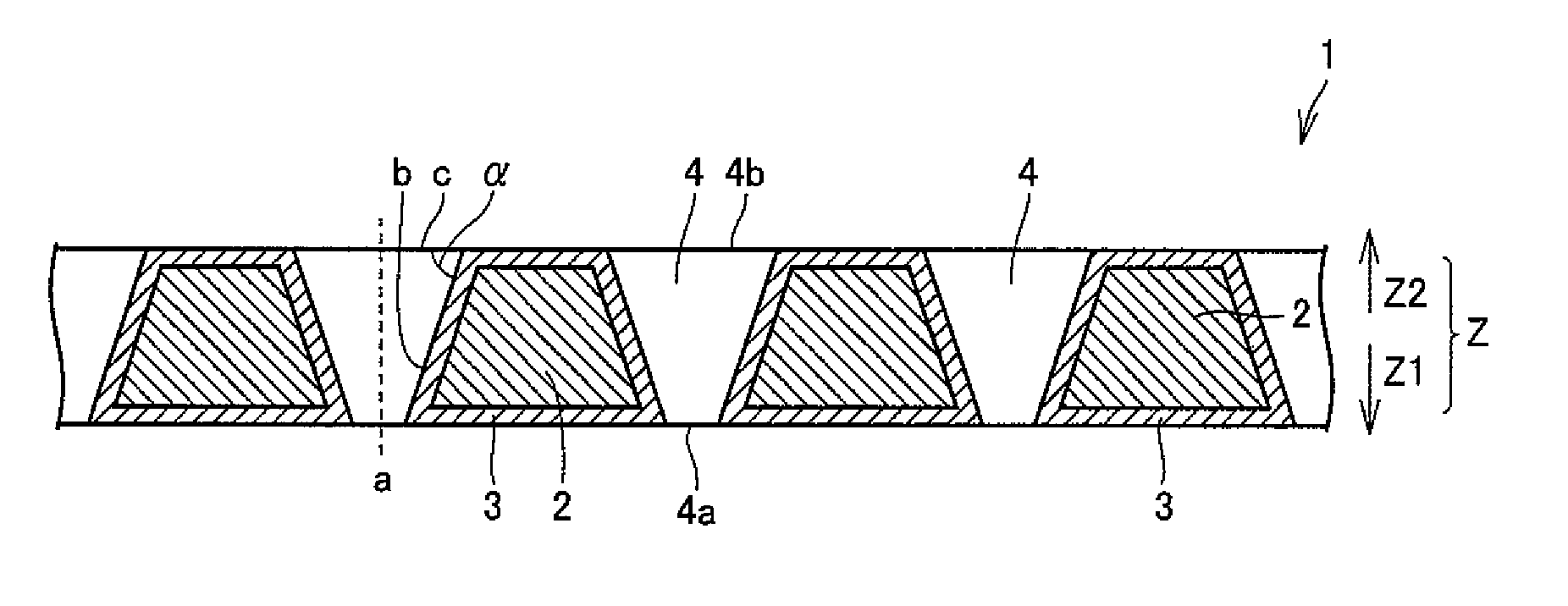

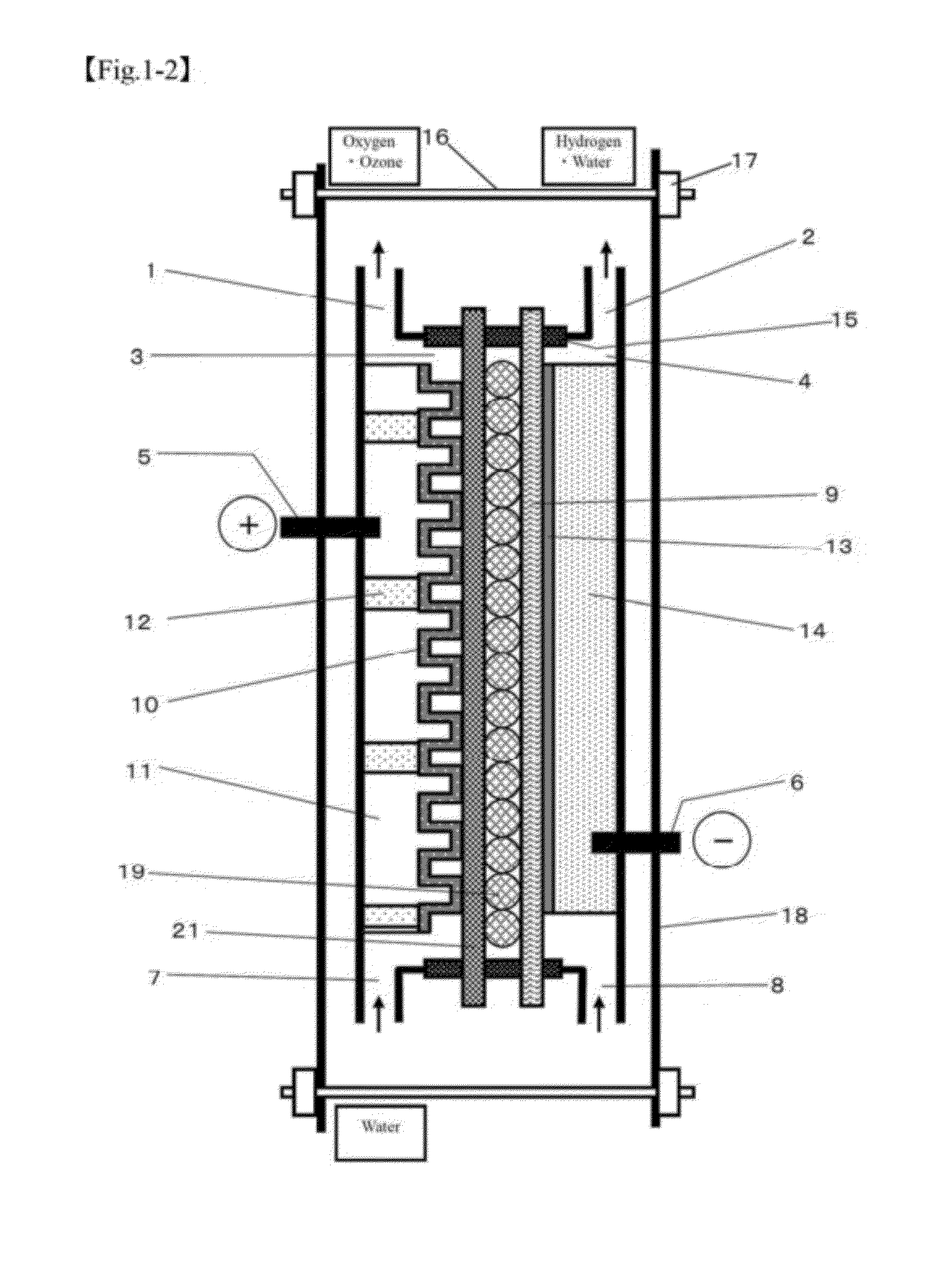

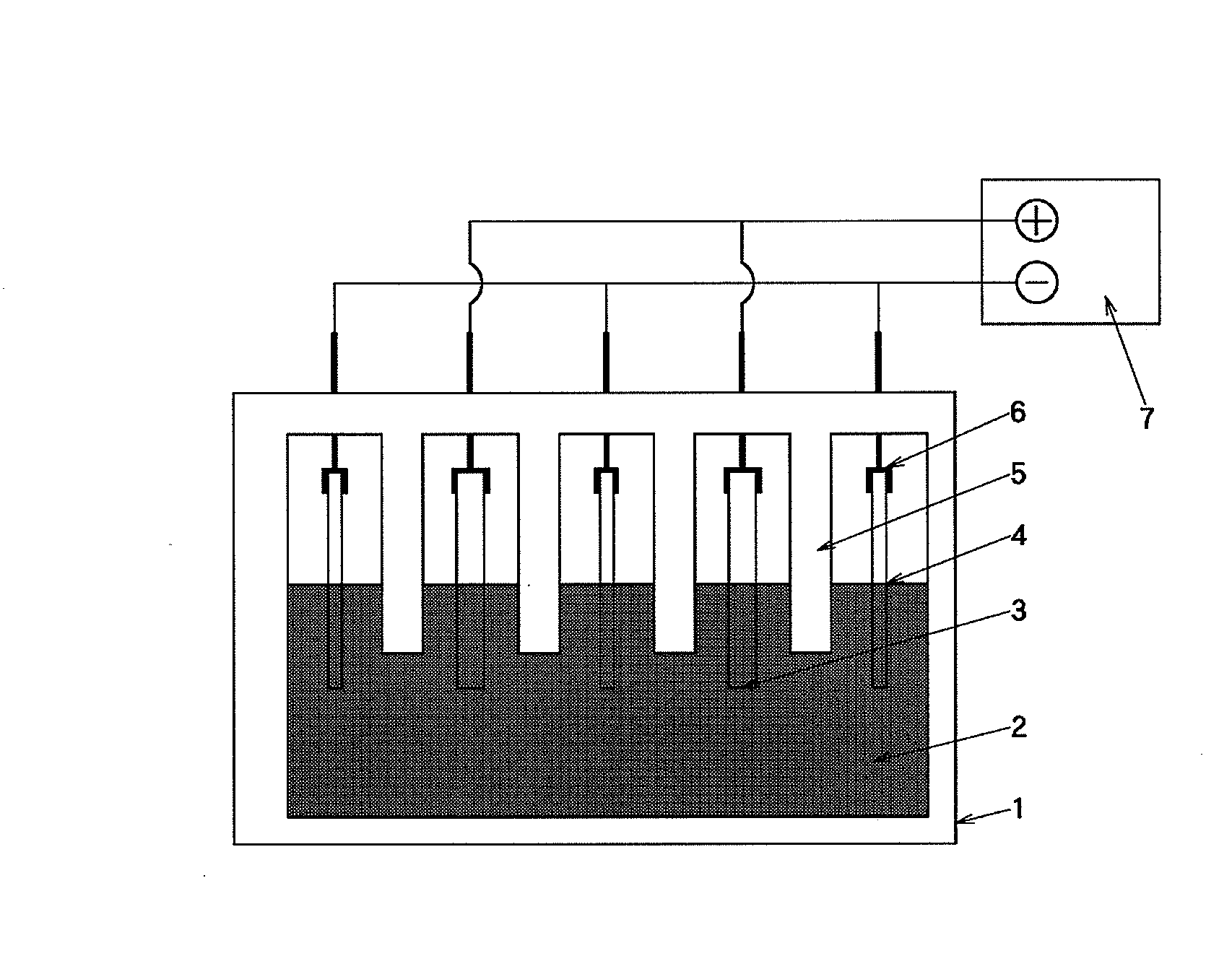

Ozone generator

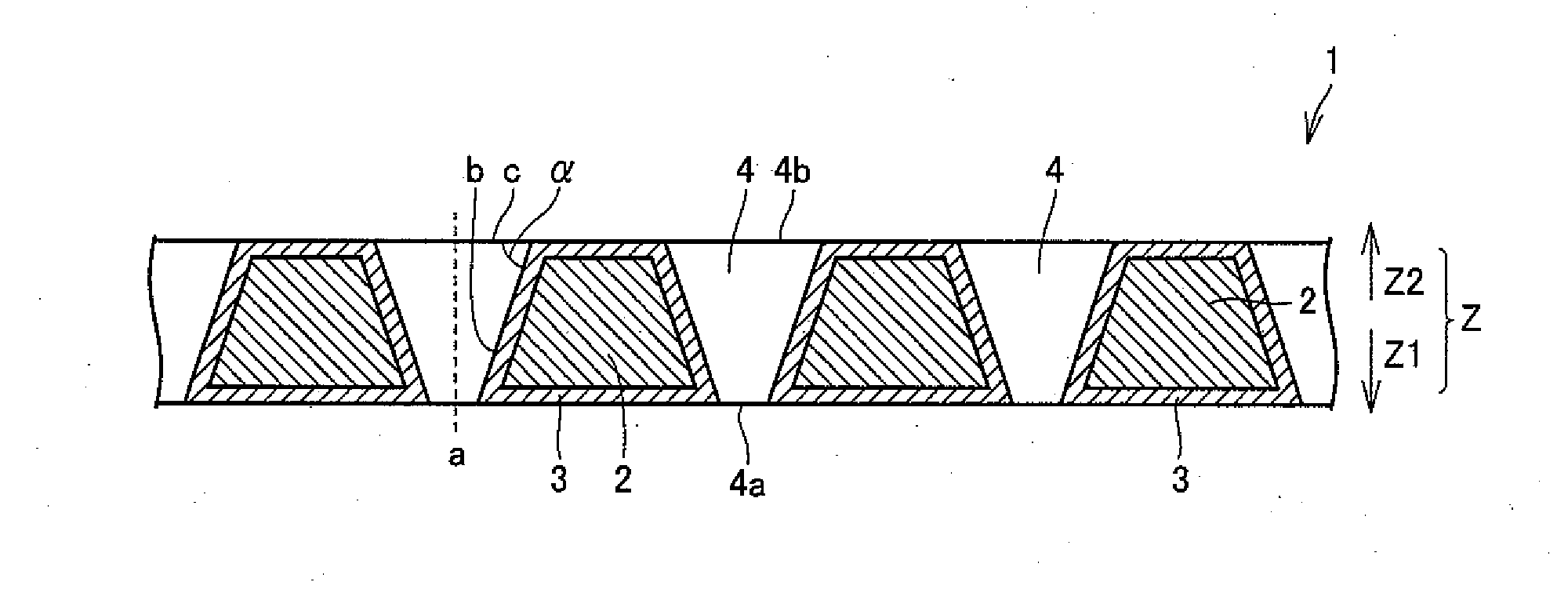

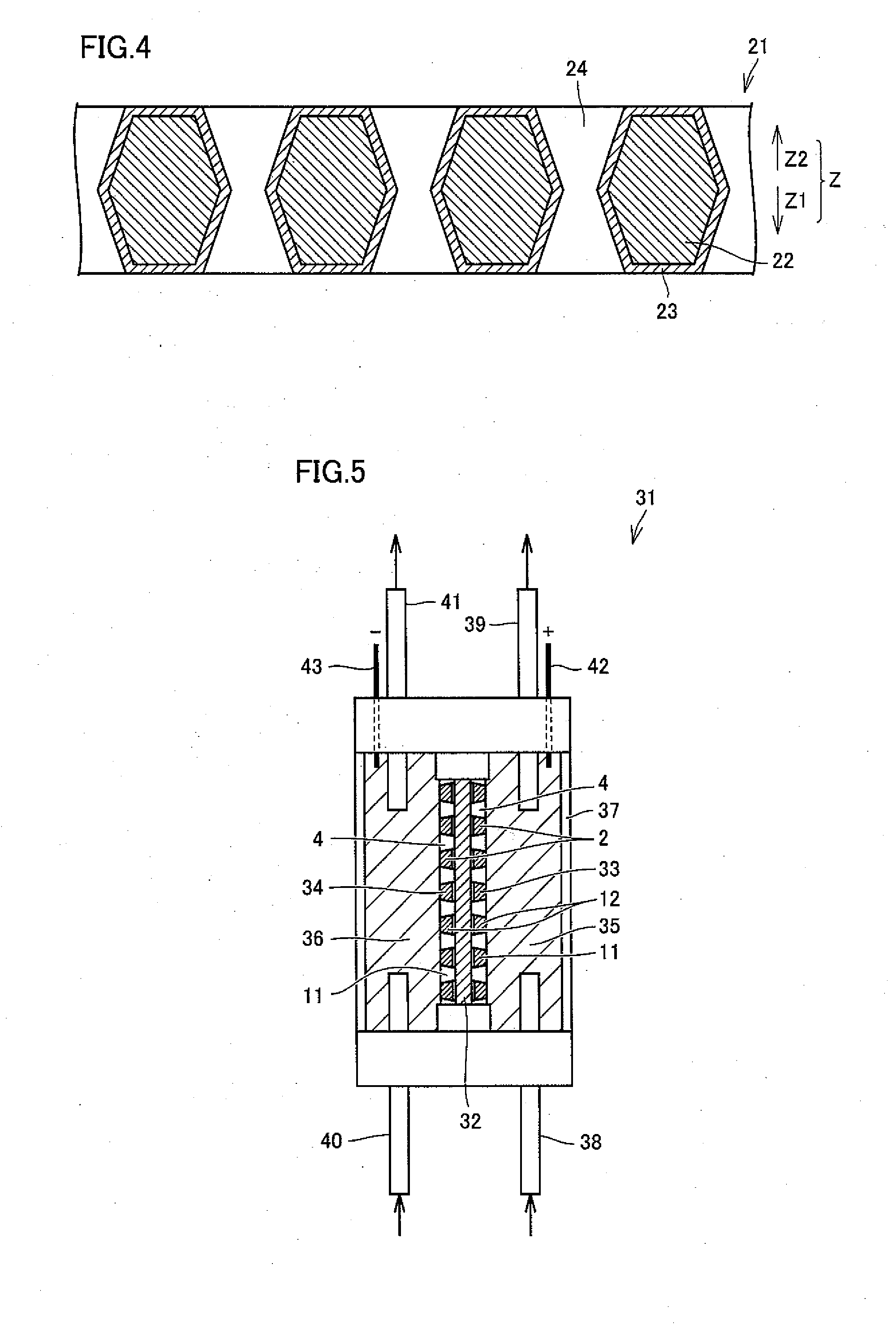

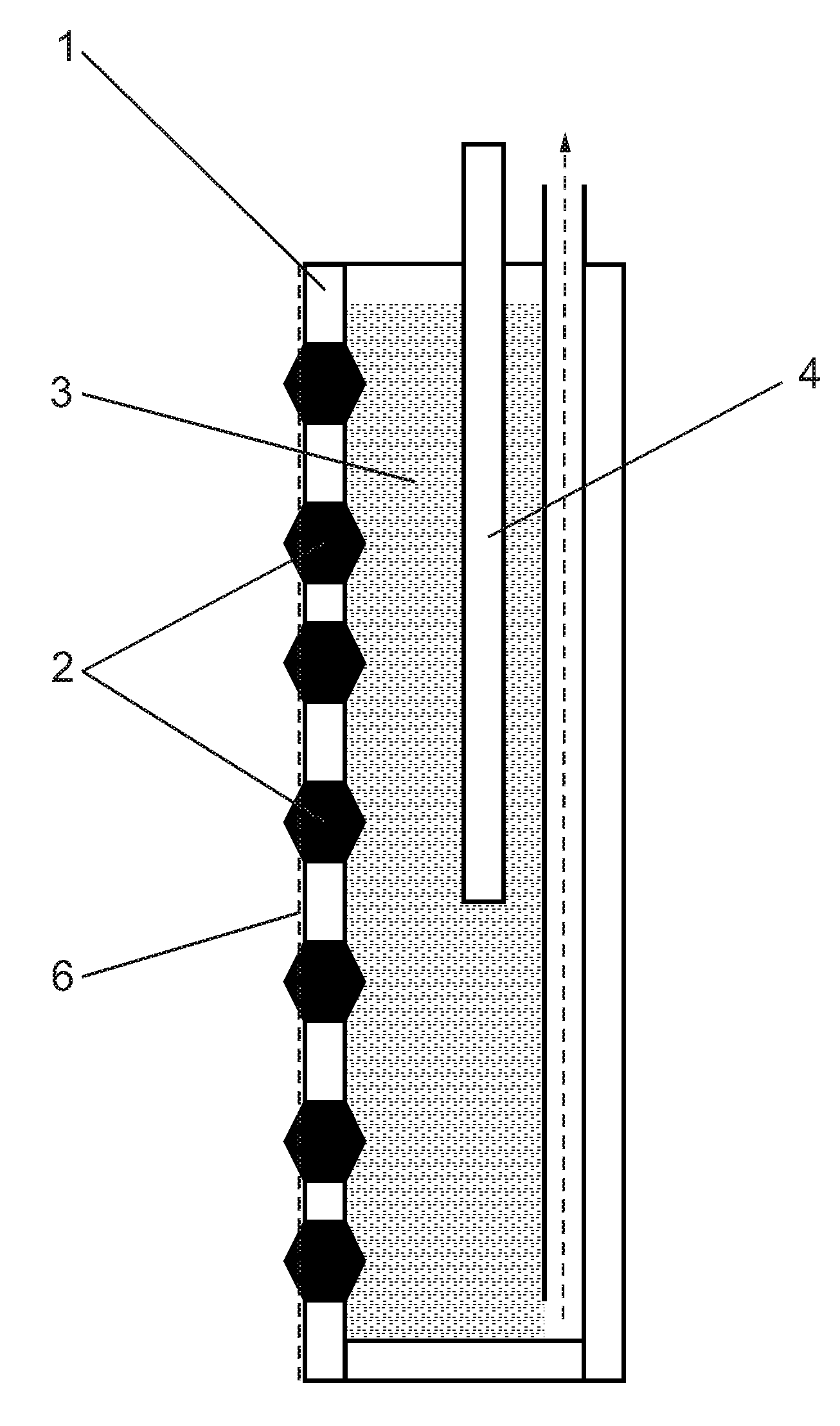

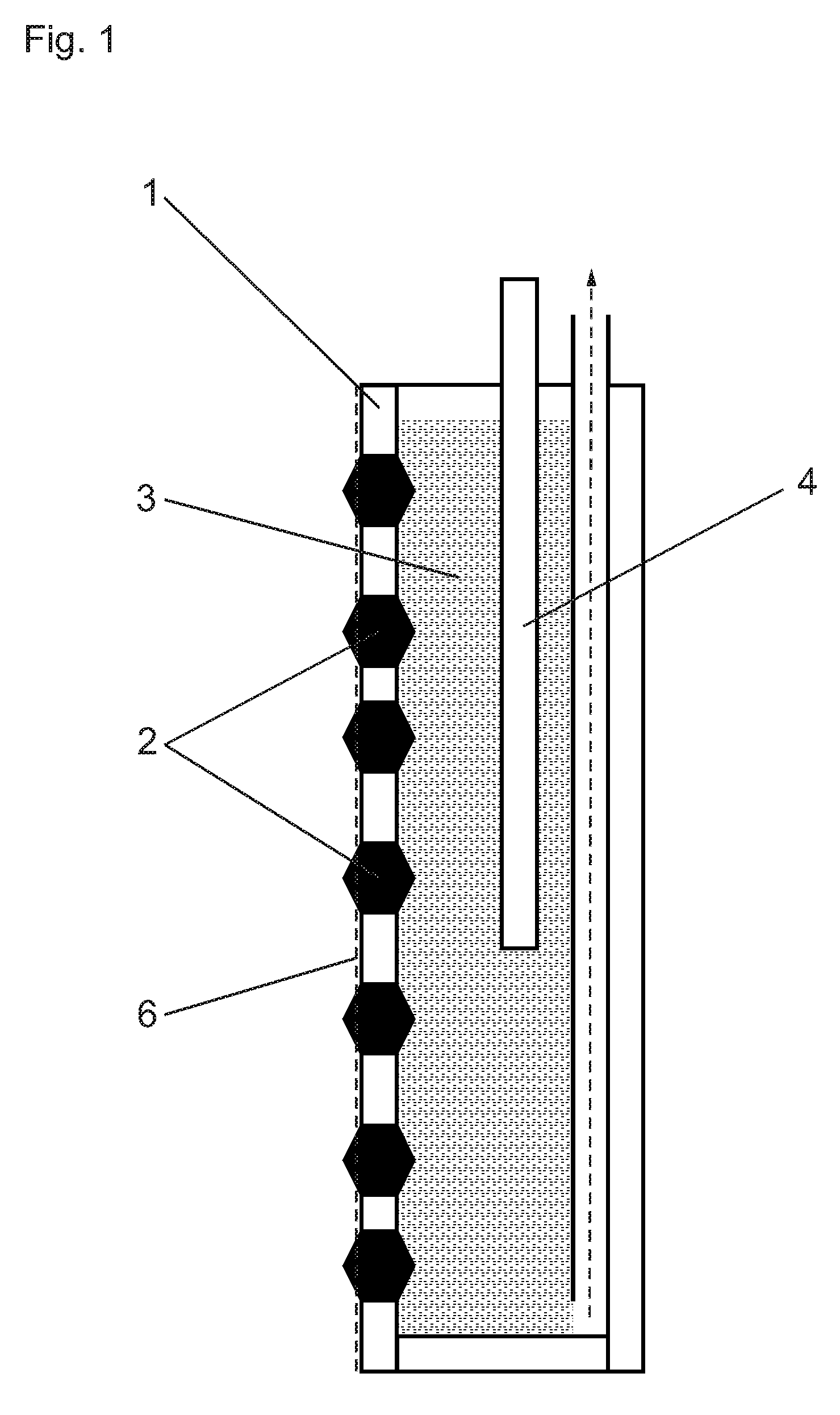

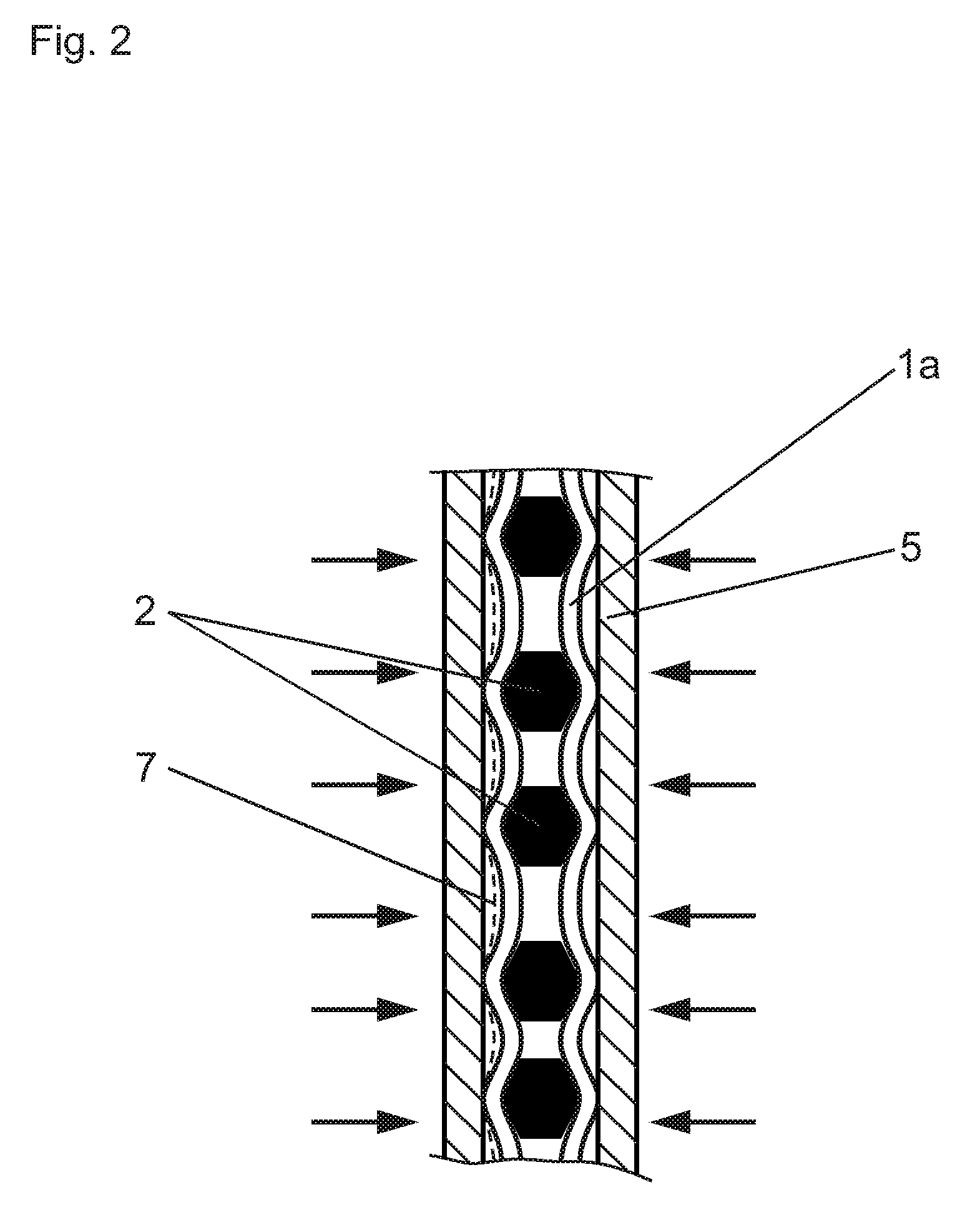

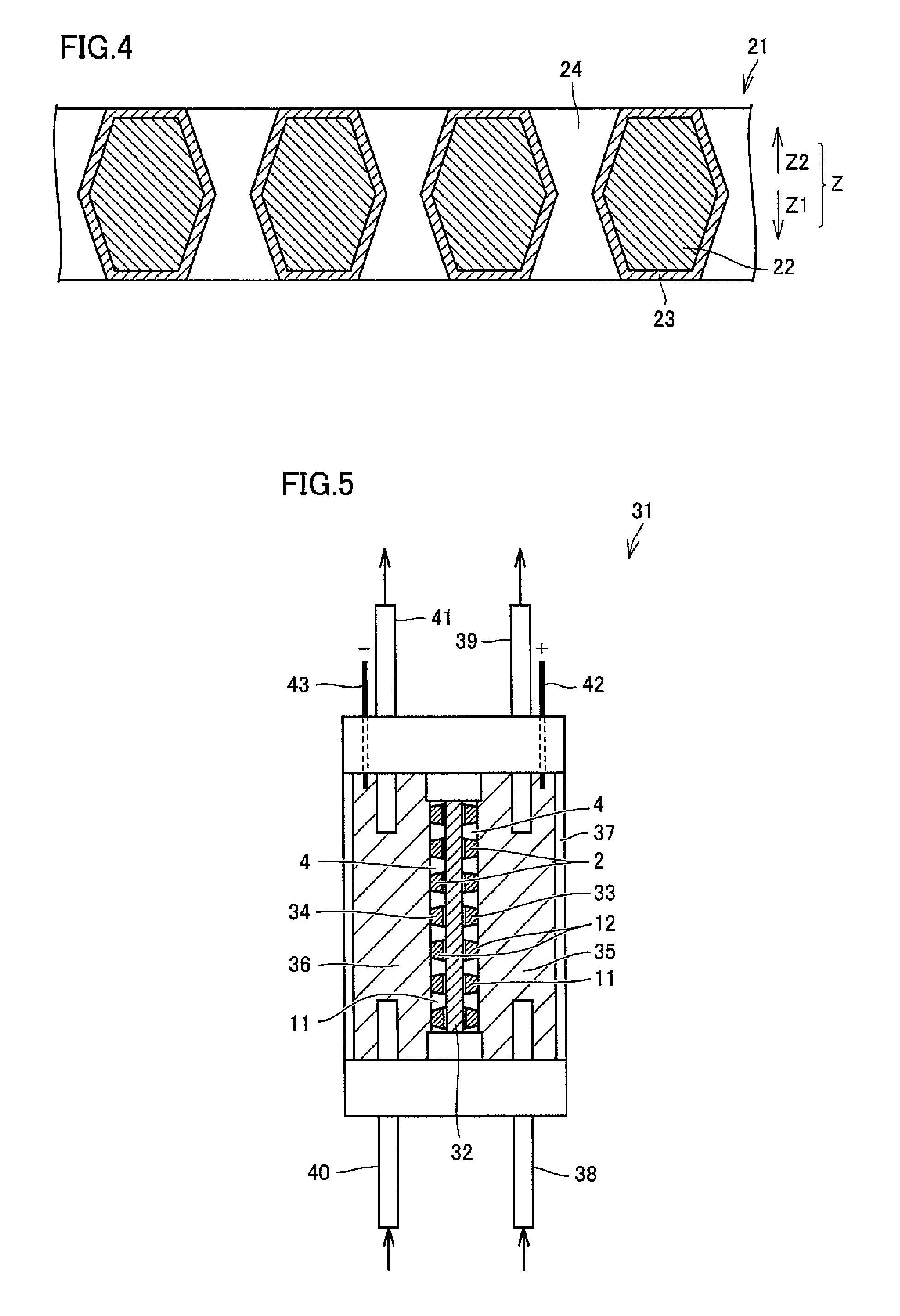

ActiveUS20120168302A1Long to produceStable productionCellsOrganic diaphragmsHydrogenDiamond electrodes

The present invention provides an ozone generator comprising an anode and a cathode provided on each side of a fluororesin type cation exchange membrane, the anode being a conductive diamond electrode having conductive diamond on the surface, wherein water is supplied to an anode compartment, DC current is supplied between the anode and the cathode to electrolyze water to evolve ozone from the anode compartment and hydrogen from a cathode compartment, the conductive diamond electrode comprising a substrate having a plurality of convexo-concave and a conductive diamond film coated on the surface of the substrate is applied as the conductive diamond electrode, and a close packed layer of ion exchange resin particles or the fluororesin type cation exchange membrane with notch is closely adhered to the surface of the anode side of the fluororesin type cation exchange membrane.

Owner:DE NORA PERMELEC LTD

Diamond electrode for electrolysis

InactiveUS20040206624A1Multiple component coatingsWater/sewage treatment using germicide/oligodynamic-processDiamond electrodesElectrolysis

A diamond electrode having a prolonged life by combining a conventional diamond electrode having a relatively short life with other components is provided. A diamond electrode for electrolysis includes an electrode substrate, at least the surface of which comprises Magneli phase titanium oxide, and conductive diamond supported as an electrode catalyst on a surface of the electrode. The electrode catalyst may contain a titanium oxide powder. Magneli phase titanium oxide improves conductivity without forming a stable oxide layer on the substrate surface.

Owner:DE NORA PERMELEC LTD

Diamond electrode

ActiveUS8361289B2Reduce manufacturing costShort lifeCellsPhotography auxillary processesWater useElectrolysis

An electrode comprising an electrically conducting diamond plate wherein the diamond plate comprises at least one elongate aperture and having an aperture edge length per unit working area of the diamond plate of greater than about 4 mm / mm2, electrolysis cells comprising such electrodes, methods of treating water using such electrolysis cells and a method of production of ozone are disclosed.

Owner:FRANKE COFFEE SYST AMERICAS LLC

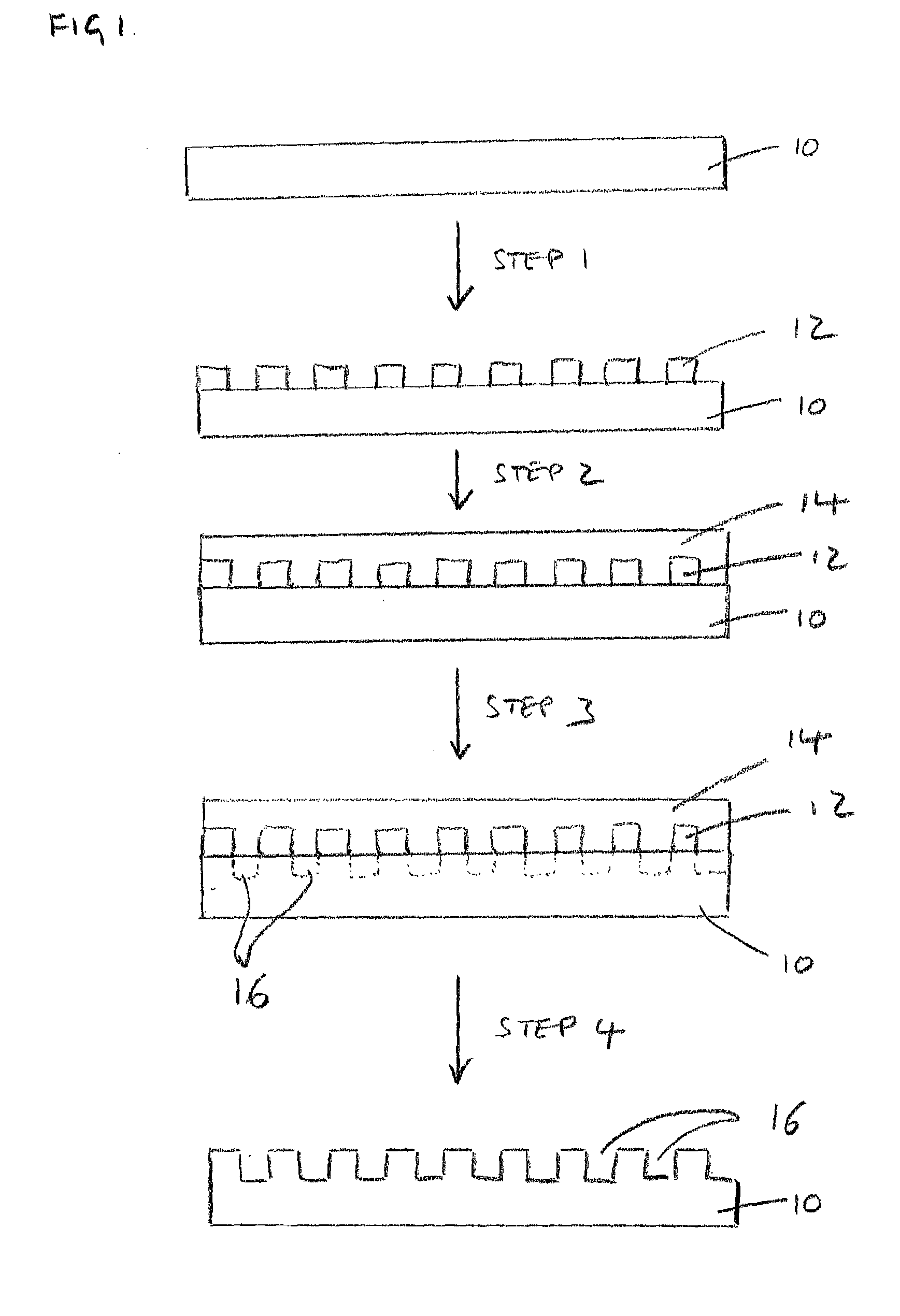

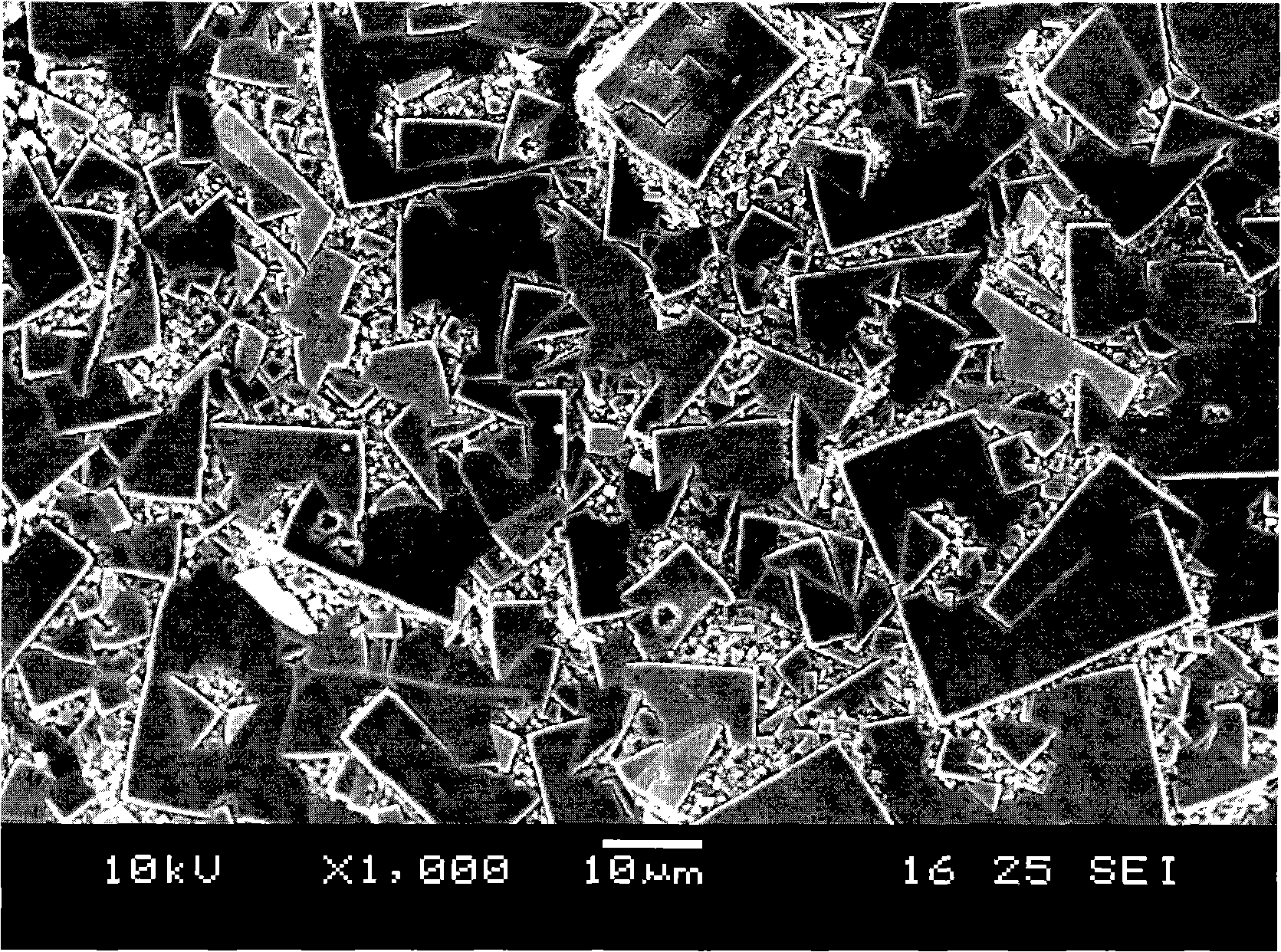

Method for preparing high specific surface diamond electrode

InactiveCN101358356ALarge specific surface areaSave raw materialsChemical vapor deposition coatingElectrodesDiamond electrodesContact method

The invention belongs to the field of diamond electrode preparation. A preparation method of the high-specific surface diamond electrode is characterized by comprising the following steps: (1) the metal electrode is cleaned; (2) conductive diamond film is prepared; (3) solid etching material is prepared on the surface of the conductive diamond film; (4) the diamond film surface is corroded through a plasma auxiliary solid contact method; (5) residual solid etching material on the diamond film surface is dissolved by acid solution, to obtain the high-specific surface diamond electrode. The preparation method has the advantages of large-area preparation, easy operation, short time in preparation, etc.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

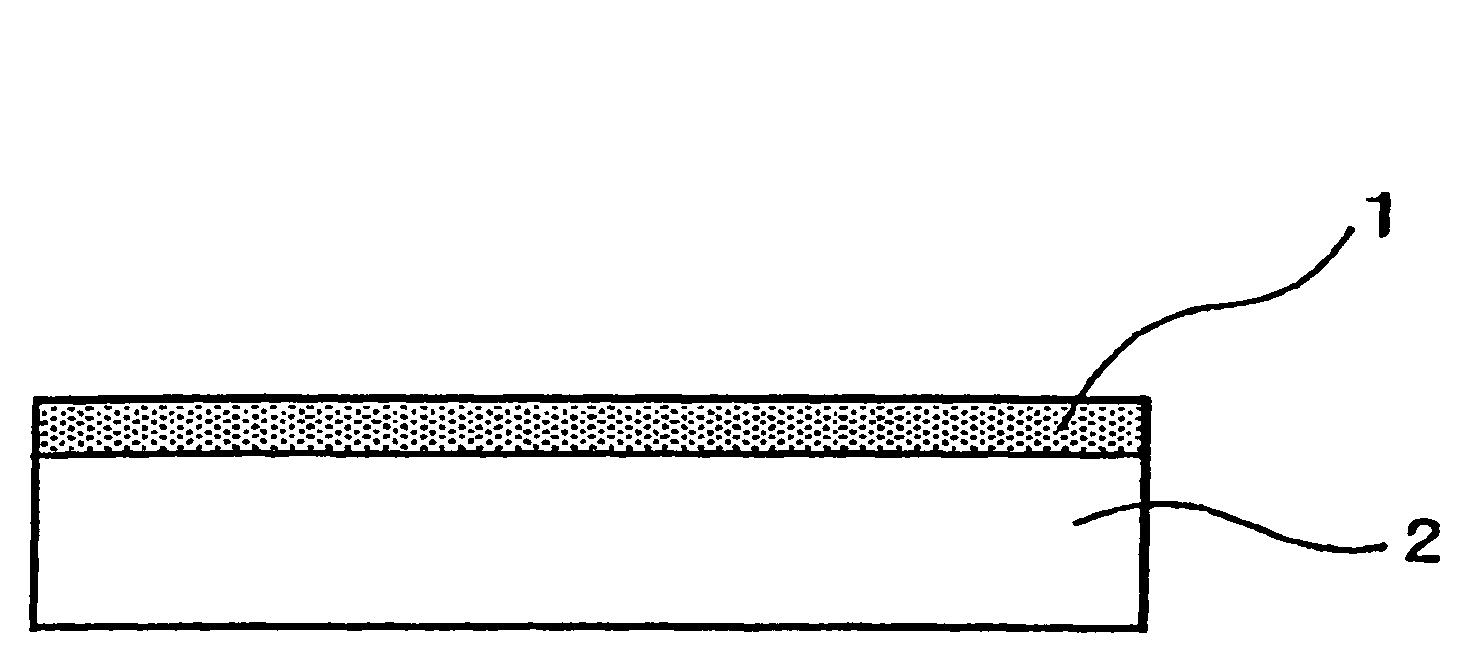

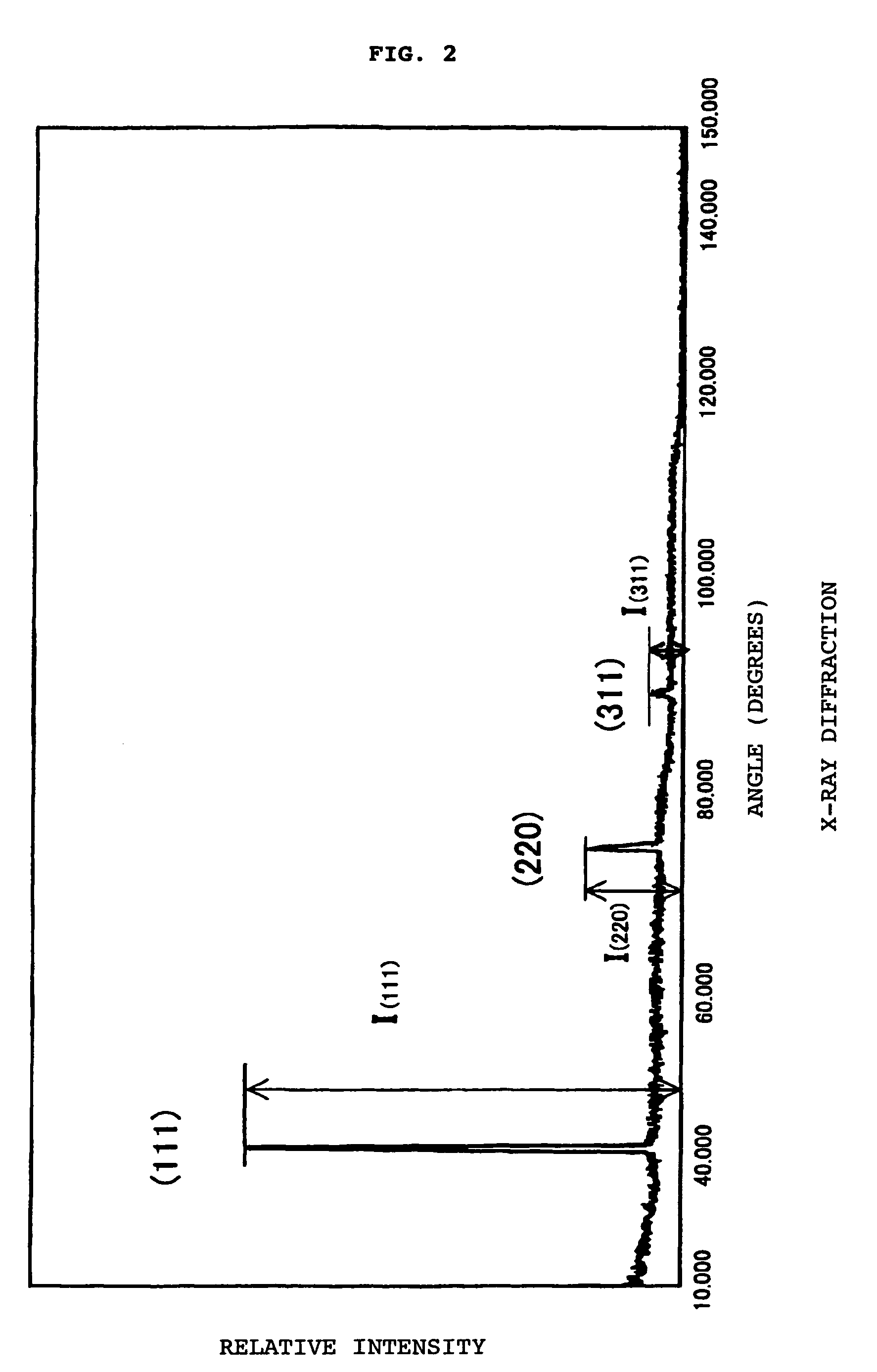

Diamond-coated electrode and method for producing same

InactiveUS7314540B2Lower resistanceImprove adhesionPhysical/chemical process catalystsUltra-high pressure processesElectrical resistance and conductanceDiamond electrodes

A diamond electrode having a sufficiently low resistance is disclosed which is realized by increasing the amount of boron added thereto. A method for producing a high-performance, high-durability electrode is also disclosed by which adhesiveness between a diamond coating and a substrate and separation resistance during electrolysis are sufficiently increased. An electrode composed of a substrate and a diamond layer coating the substrate is characterized in that the electrode is composed of a base coated with diamond and the diamond contains boron in such an amount that the boron concentration is not less than 10,000 ppm but not more than 100,000 ppm. The base is preferably made of an insulating material.

Owner:SUMITOMO ELECTRIC IND LTD

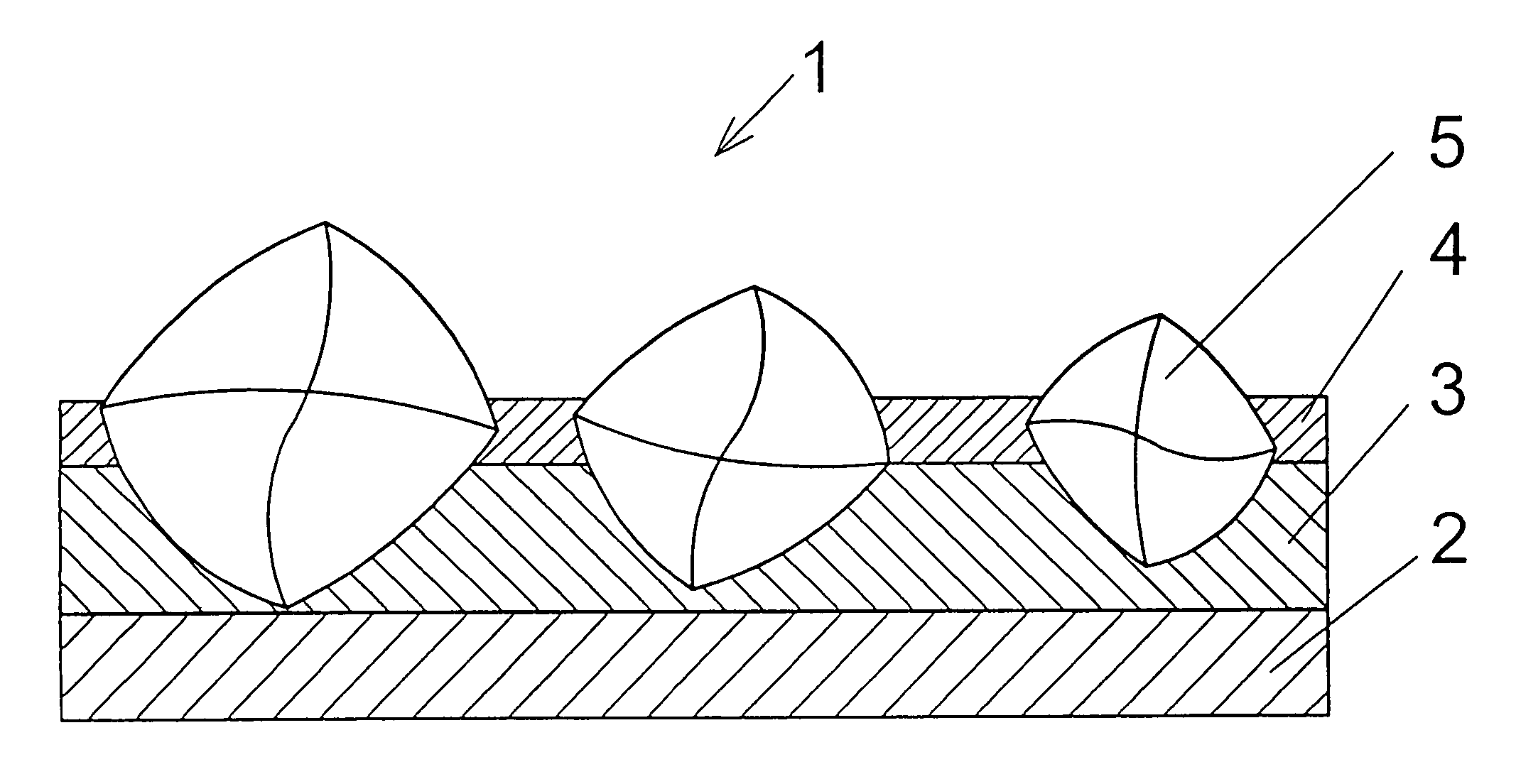

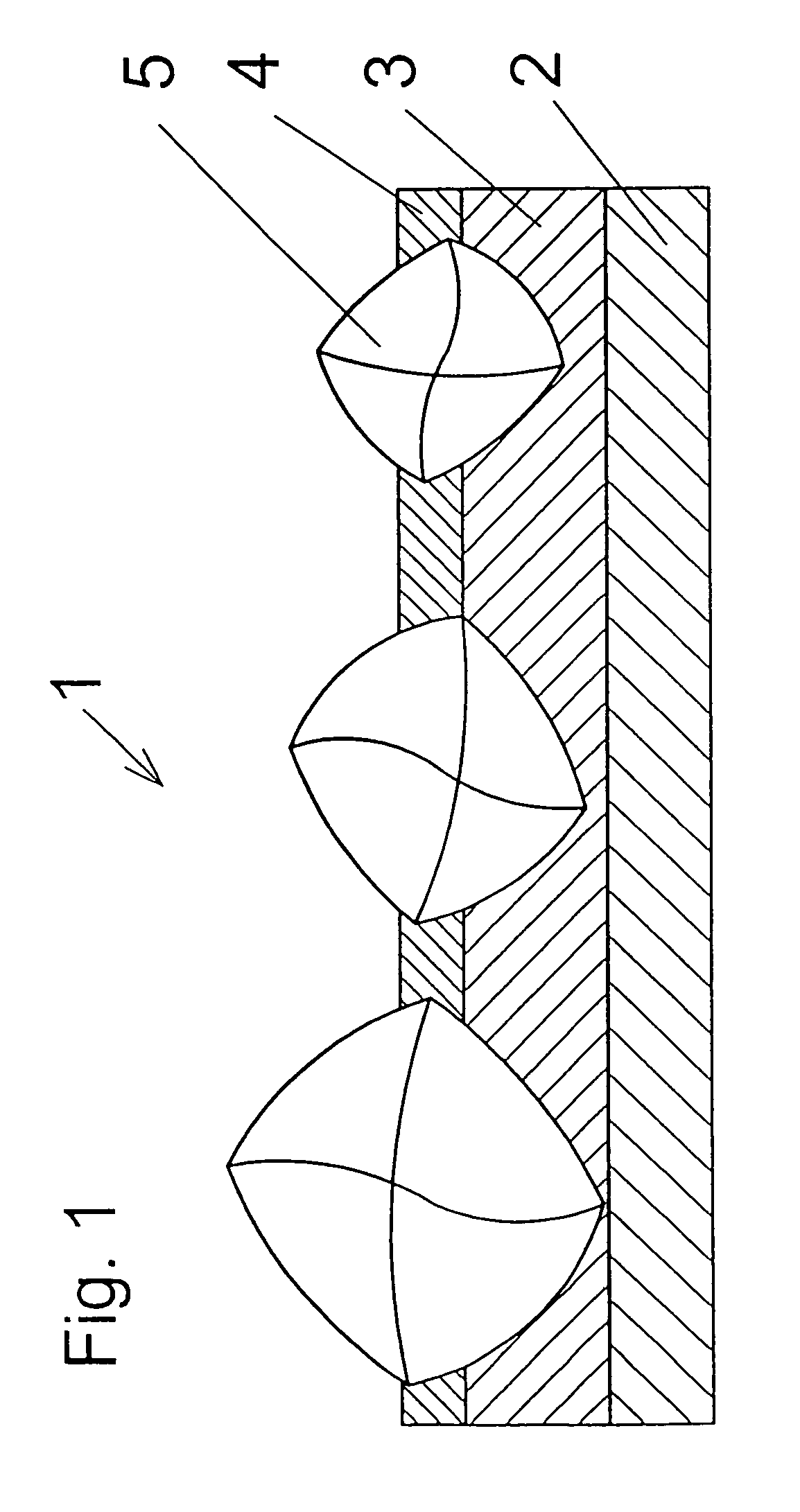

Diamond electrode and method for production thereof

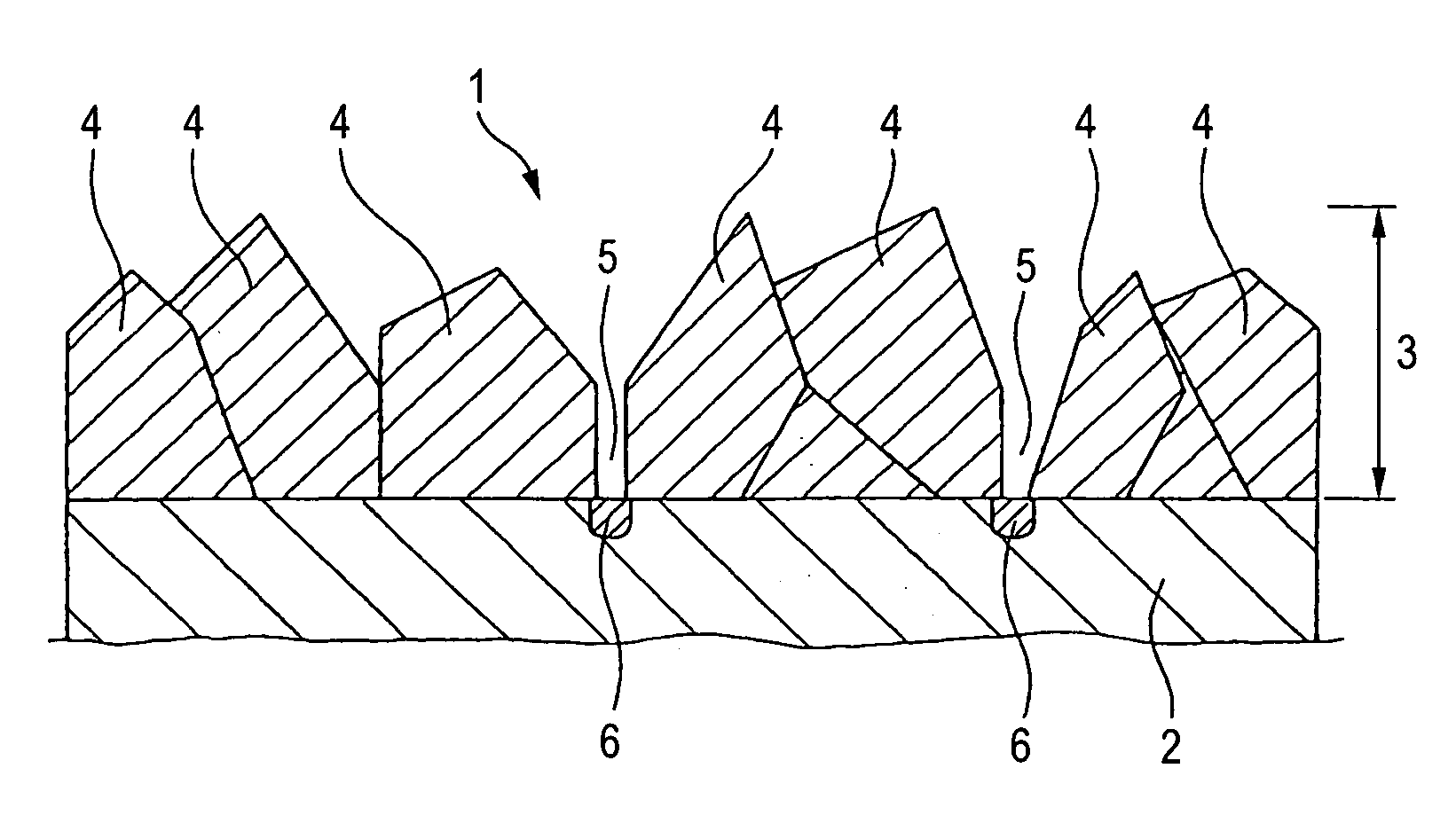

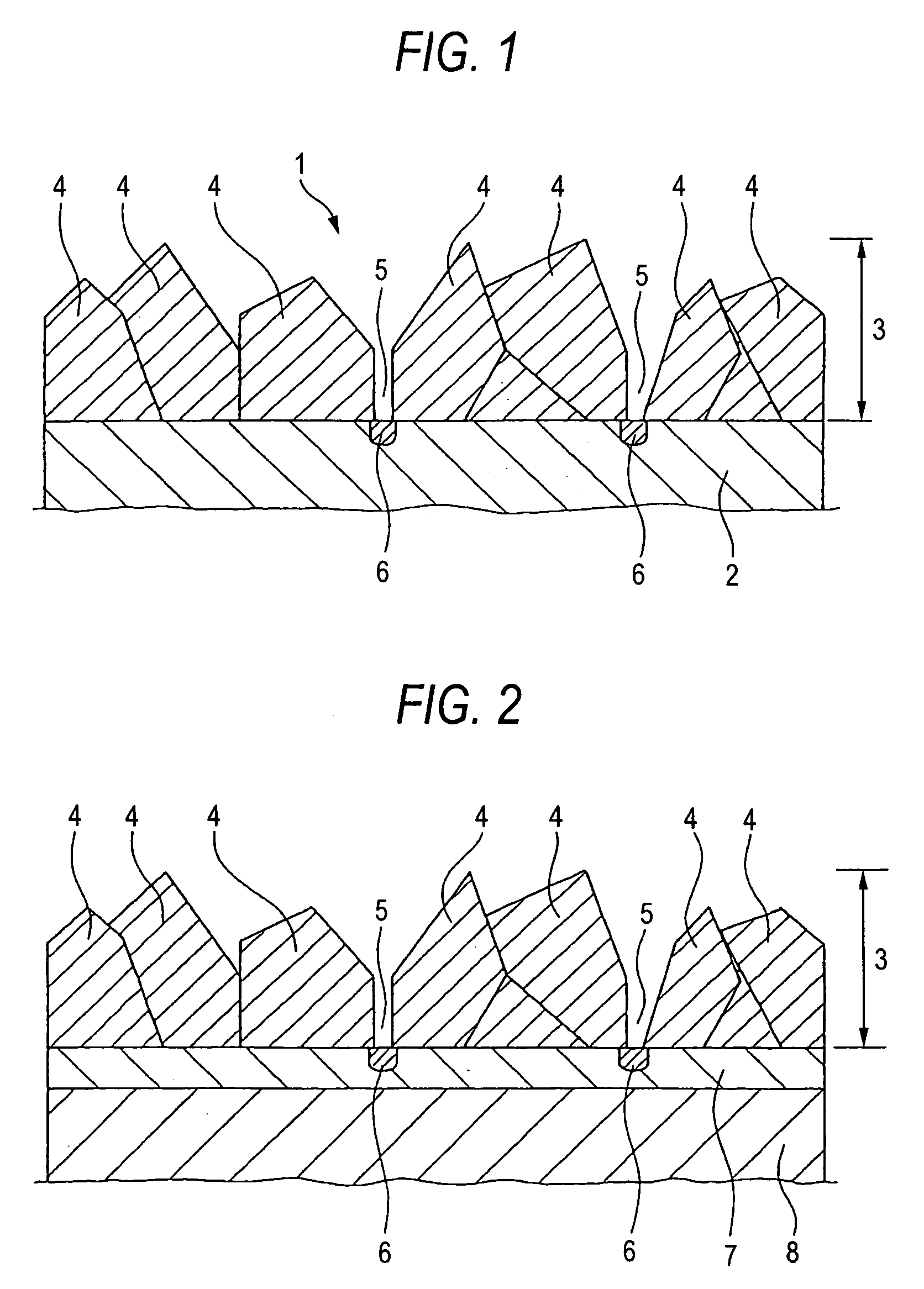

InactiveUS7455754B2Reduce deliveryHigh mechanical strengthMachining electrodesVacuum tubesDiamond electrodesMetal alloy

The invention relates to a diamond electrode with synthetically produced, electrically conductive (doped) diamonds. The surface has diamond particles (5) embedded in a metal or metal alloy layer so as to produce a conductive connection to the metal or metal alloy.

Owner:PRO AQUA DIAMANTELEKTRODEN PRODN

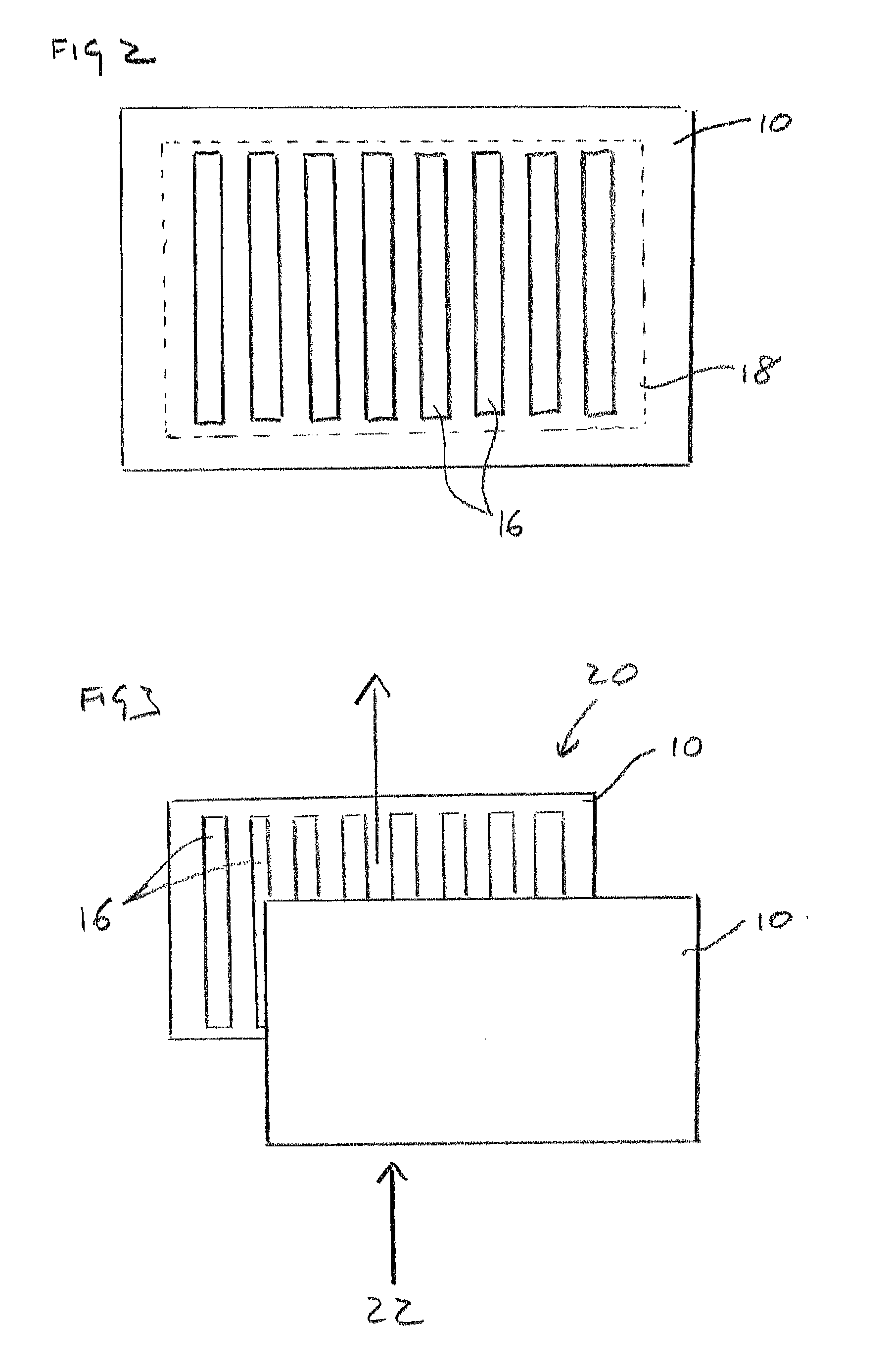

Diamond based electrochemical sensors

InactiveUS20130327640A1Improve Sensing PerformanceHigh aspect ratioMaterial electrochemical variablesElectrodesDiamond electrodesAdamite

A diamond based electrochemical band sensor comprising: a diamond body; and a plurality of boron doped diamond band electrodes disposed within the diamond body, wherein at least a portion of each of the plurality of boron doped diamond band electrodes is doped with boron to a level suitable to achieve metallic conduction, the boron doped diamond electrodes being spaced apart by non-conductive intrinsic layers of diamond, wherein the diamond body comprises a front sensing surface with the plurality of boron doped diamond band electrodes being exposed at said sensing surface and extending in an elongate manner across said surface, and wherein each boron doped diamond electrode has a length / width ratio of at least 10 at the front sensing surface.

Owner:ELEMENT SIX TECH LTD

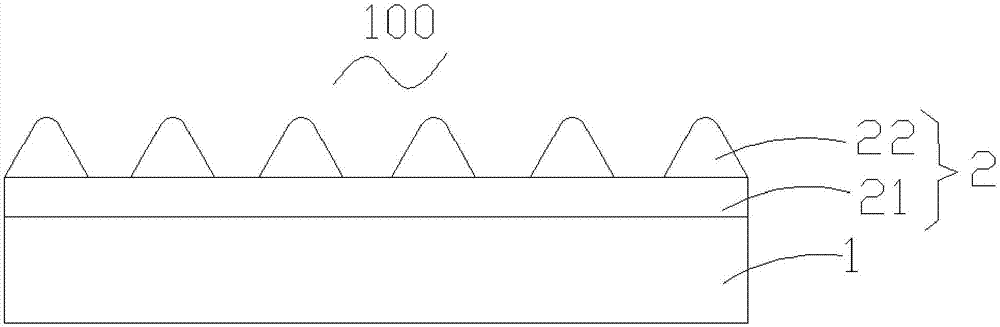

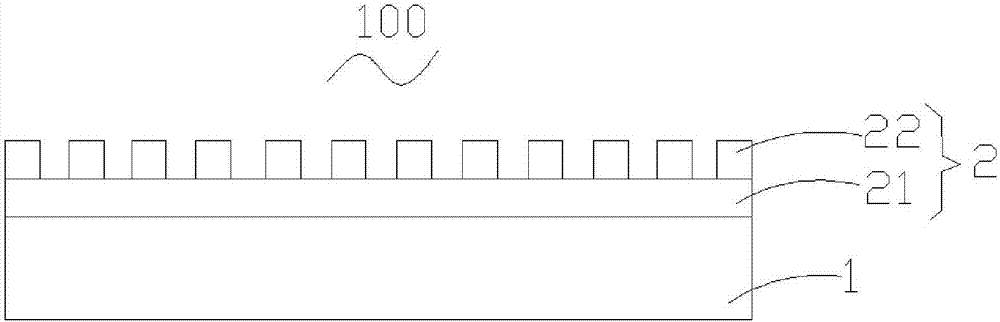

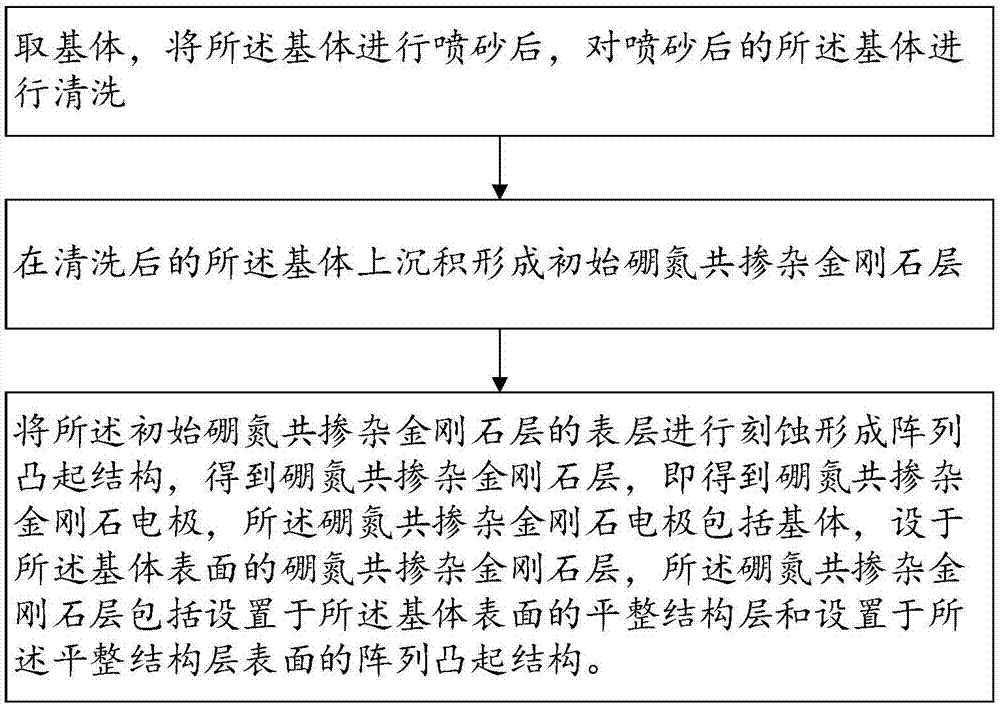

Boron-nitrogen co-doped diamond electrode and preparation method and application thereof

PendingCN107964669AHigh hydrogen evolutionHigh oxygen evolution potentialElectrolytic organic productionChemical vapor deposition coatingDiamond electrodesSurface layer

The invention provides a boron-nitrogen co-doped diamond electrode comprising a matrix and a boron-nitrogen co-doped diamond layer arranged on the surface of the matrix. The boron-nitrogen co-doped diamond layer comprises a flat structure layer arranged on the surface of the matrix and an array protrusion structure arranged on the surface of the flat structure layer. According to the boron-nitrogen co-doped diamond electrode, the surface layer of the boron-nitrogen co-doped diamond layer is arranged to be the array protrusion structure, so that the specific surface area and active sites of theboron-nitrogen co-doped diamond layer are increased, and therefore the capacity of the electrode to conduct carbon dioxide electro-catalytic reduction is improved; and finally, the accumulation amount of the carbon dioxide in the atmosphere is reduced, and resource utilization of waste is achieved, and the practicability is high. The invention further provides a preparation method of the boron-nitrogen co-doped diamond electrode. According to the preparation method of the boron-nitrogen co-doped diamond electrode, the technology is simple, the cost is low, the boron-nitrogen co-doped diamondelectrode having an excellent carbon dioxide electro-catalytic reduction performance can be prepared, and the service life of the boron-nitrogen co-doped diamond electrode in severe environments is long.

Owner:SHENZHEN INST OF ADVANCED TECH

Biological sensor measuring electrochemical and / or electrical and diamond electrode and electronic integrated circuit

InactiveUS20110162962A1Reduce noiseSmall sizeImmobilised enzymesBioreactor/fermenter combinationsElectricitySemiconductor materials

A biological sensor for electrochemical and / or electrical measurement, including at least:a measurement electrode, able to make electrochemical and / or electrical measurements, and including a part of a doped diamond layer of a substrate comprising a stack including a dielectric layer placed between the doped diamond layer and a semiconductor material layer;an electronic circuit for amplifying and / or processing at least one electrical signal intended to be issued by the measurement electrode, electrically connected to the measurement electrode and made in a portion of the semiconductor material layer.

Owner:COMMISSARIAT A LENERGIE ATOMIQUE ET AUX ENERGIES ALTERNATIVES

Conductive diamond electrode structure and method for electrolytic synthesis of fluorine-containing material

ActiveUS20080314759A1Improve productivityLow production costCellsMachining electrodesDiamond electrodesMolten salt

The present invention provides a conductive diamond electrode structure for use in electrolytic synthesis of a fluorine-containing material with a fluoride ion-containing molten salt electrolytic bath, which comprises: a conductive electrode feeder; and a conductive diamond catalyst carrier comprising a conductive substrate and a conductive diamond film carried on a surface thereof, wherein the conductive diamond catalyst carrier is detachably attached to the conductive electrode feeder at a portion to be immersed in the electrolytic bath. Also disclosed is an electrolytic synthesis of a fluorine-containing material using the conductive diamond electrode structure.

Owner:DE NORA PERMELEC LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com