Patents

Literature

31results about How to "Long continuous service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

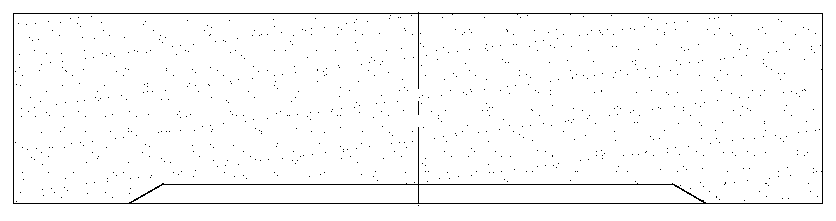

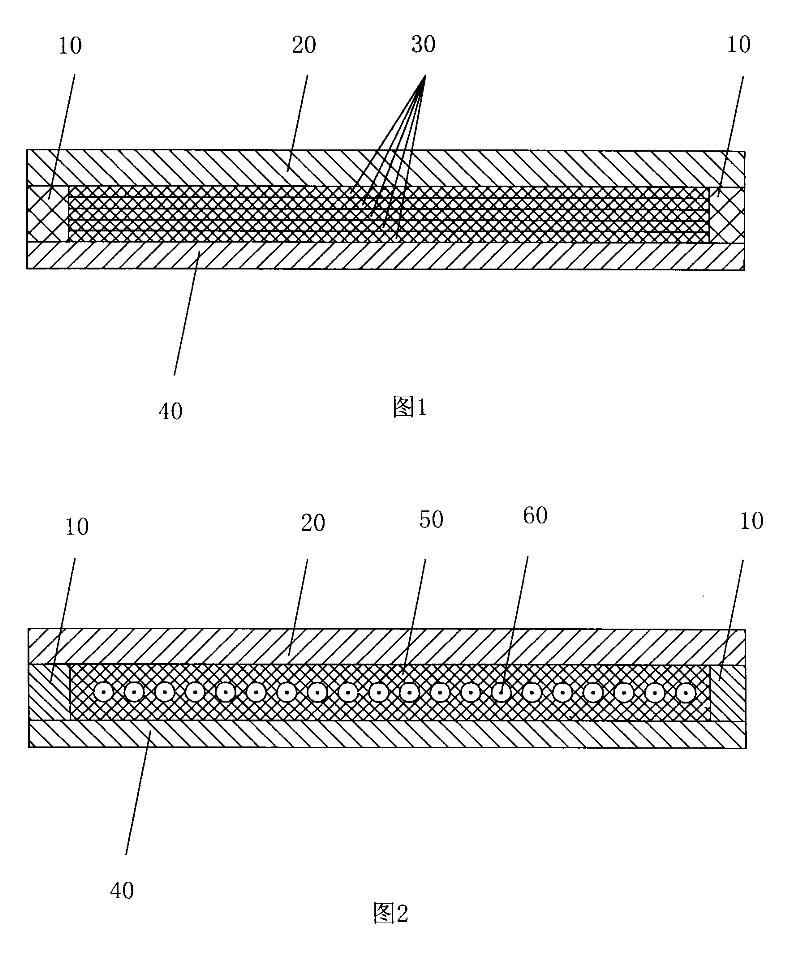

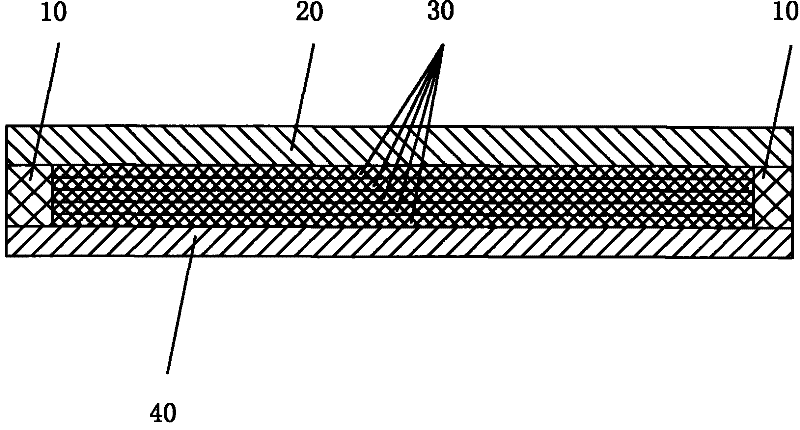

Phase-change fire resistant conveyer belt

InactiveCN101428705AHeat-resistant temperature adjustableSimple production processConveyorsAdhesive beltHeat resistance

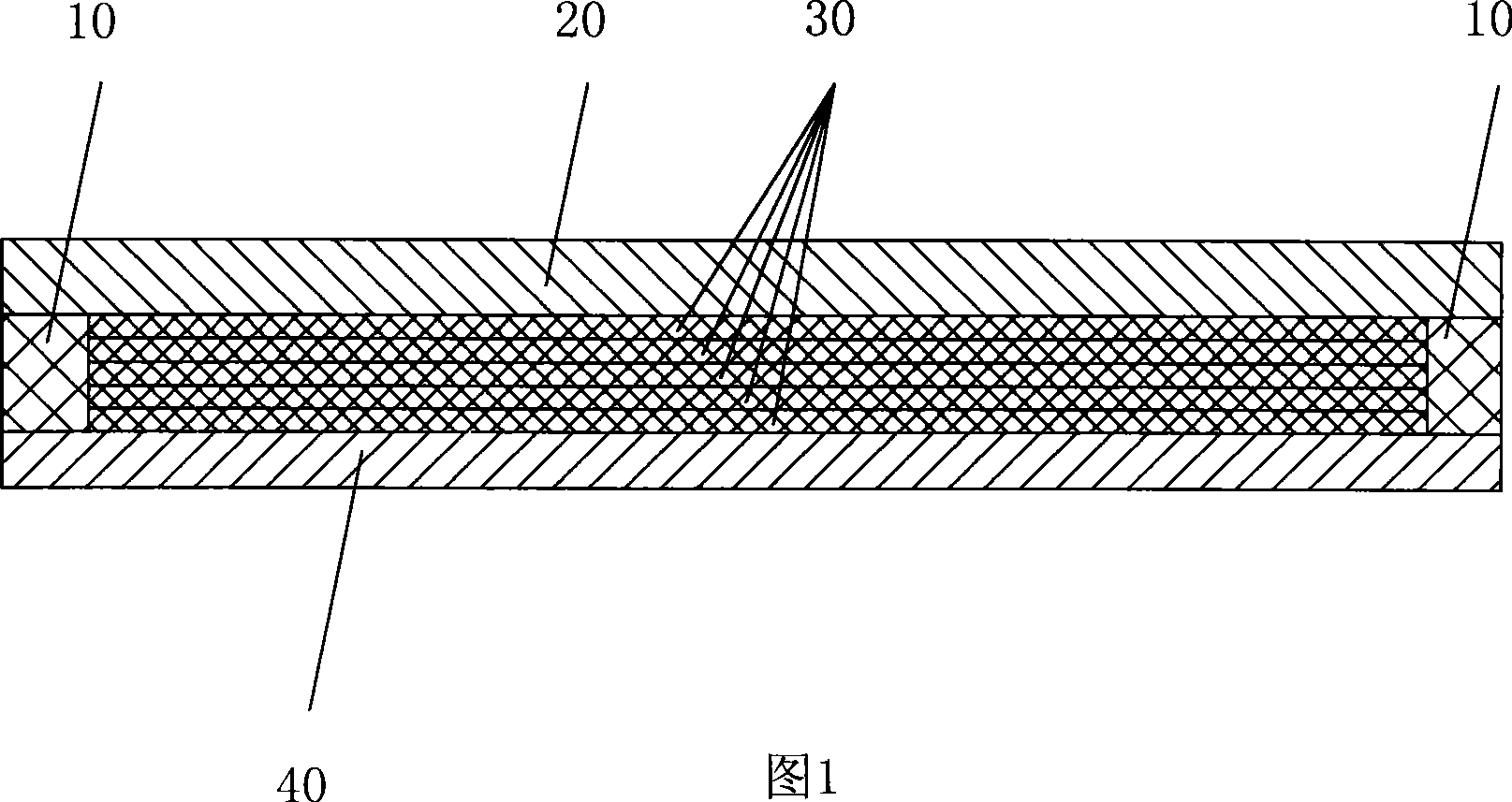

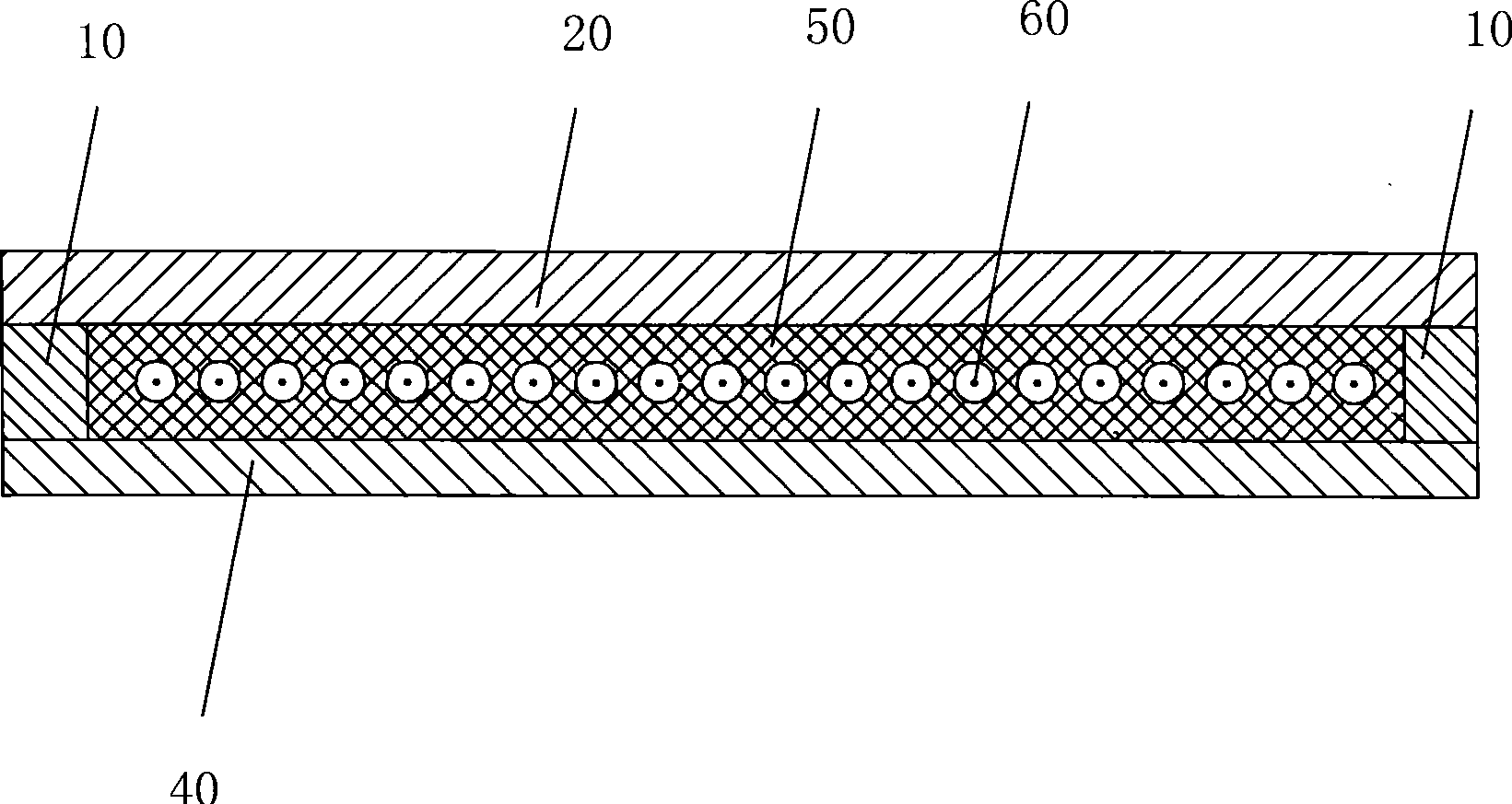

The invention belongs to the technical field of conveyer belts, in particular to a phase transition high-temperature resistant conveyer belt. The section of the conveyer belt is characterized in that side adhesives are arranged at the two ends of a fabric core layer or a steel wire rope layer; the steel wire rope layer is formed by enwrapping coil adhesive in the space outside the steel wire rope; a non-working surface adhesive is arranged at the lower end of the side adhesive and fabric coil layer or the steel wire rope layer; and a working surface adhesive is arranged at the upper end of the side adhesive and fabric coil layer or the steel wire rope layer. The invention realizes the adjustable heat-resistance temperature of an adhesive belt, and also realizes 250 to 500 DEG C temperature resistance performance. The invention has the advantages of simple production process, simple structure, and lower cost; can be popularized to the fields of the metallurgy industry, the electrical power industry and the building materials industry, and the application range is wide.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

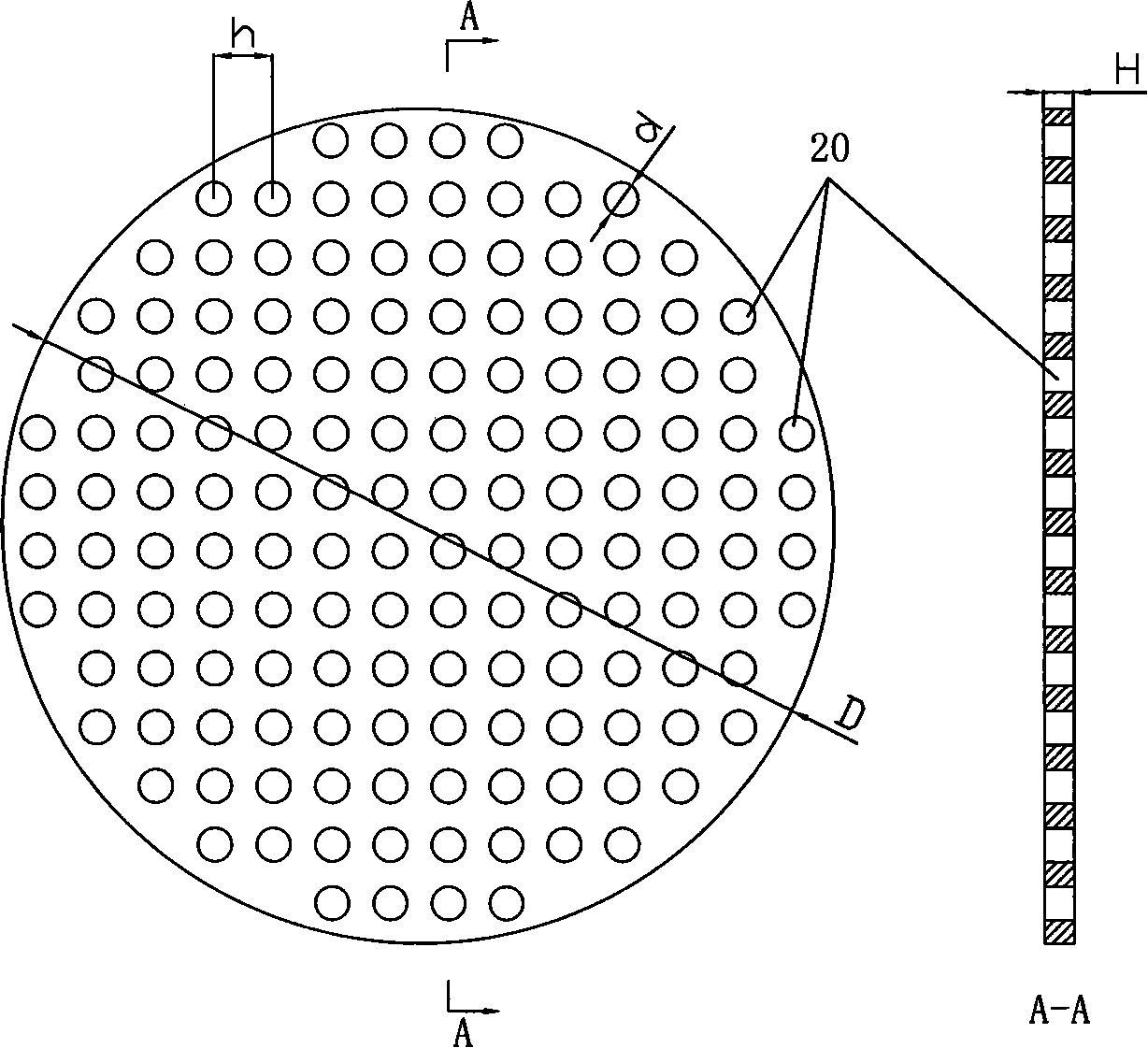

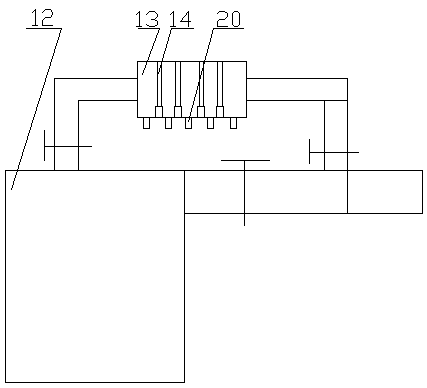

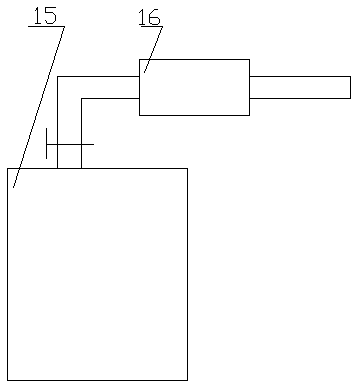

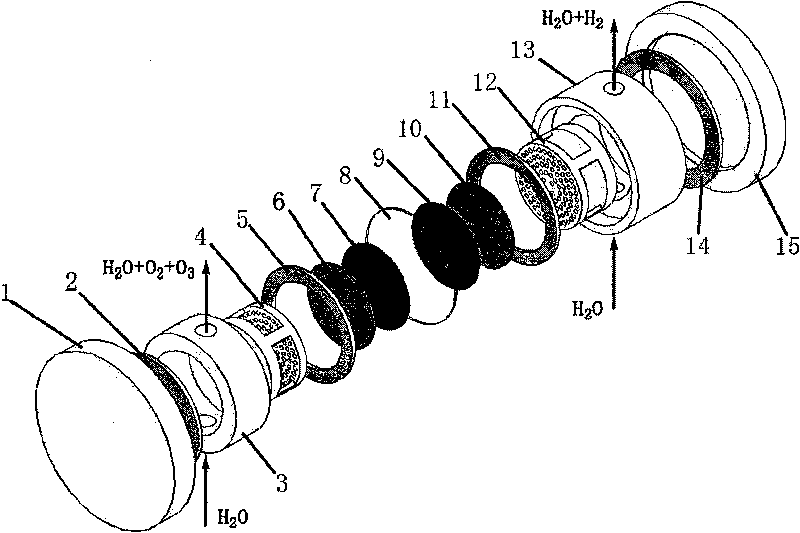

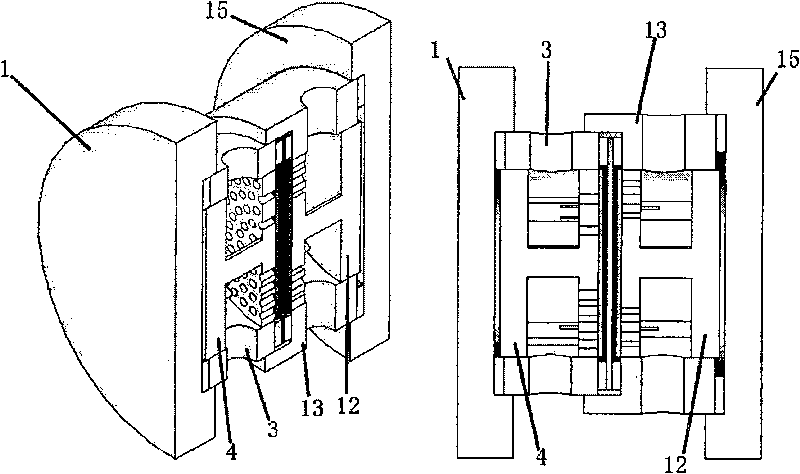

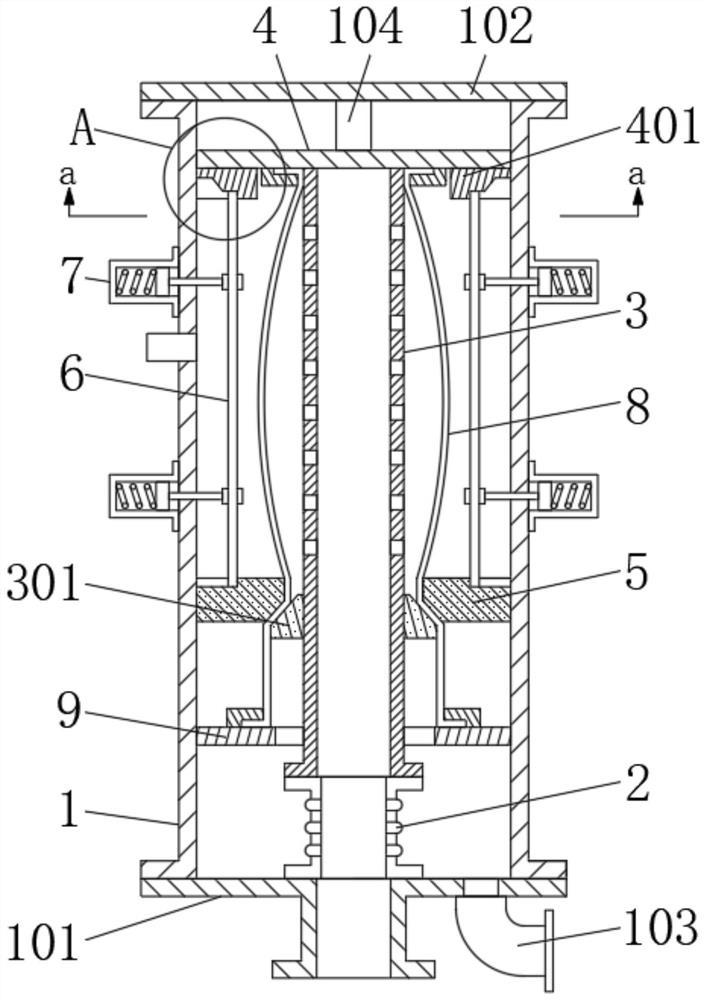

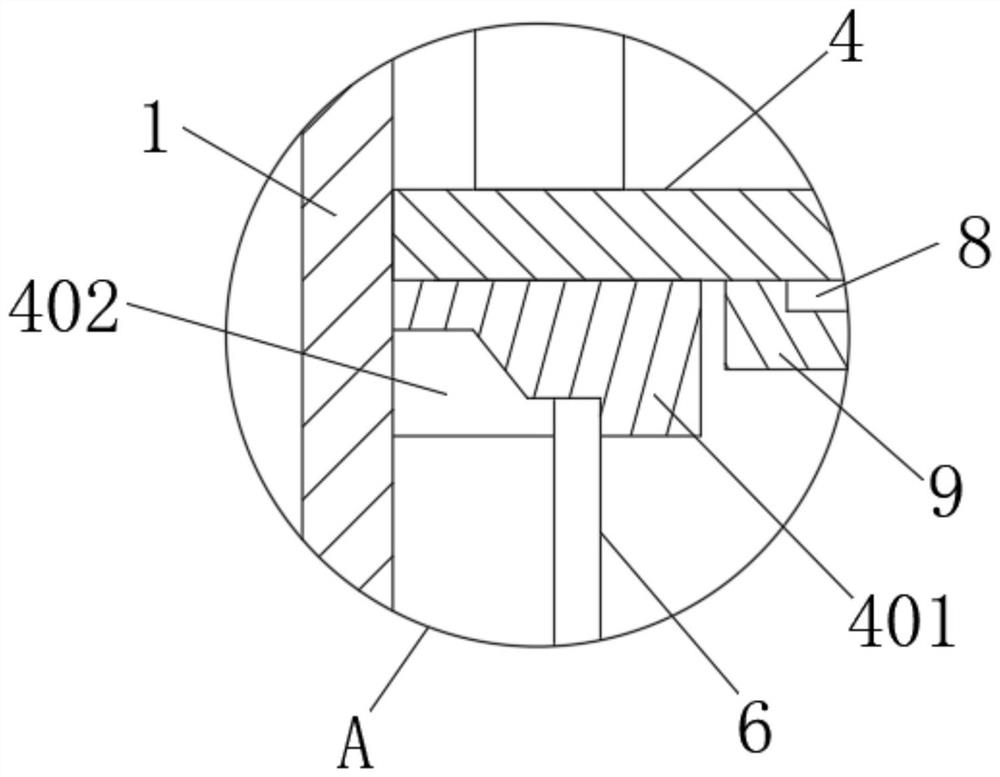

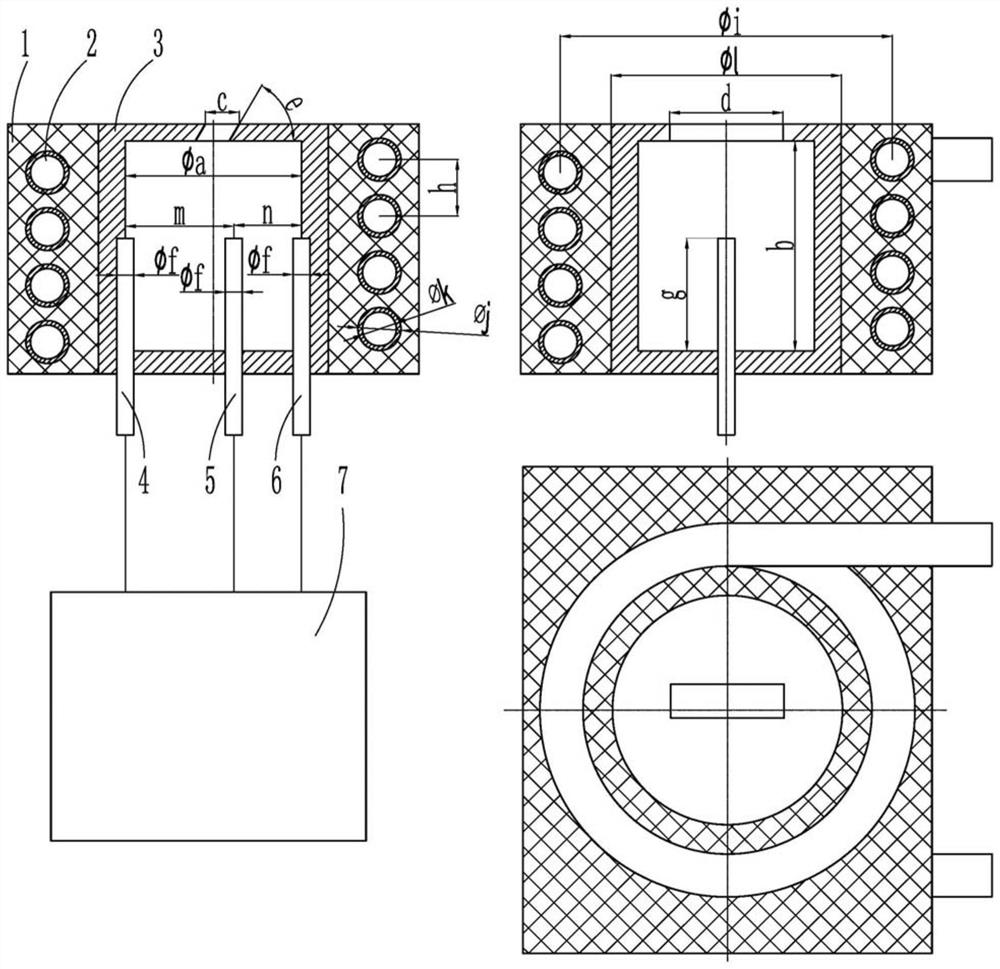

Electrolytic ozone generator and preparation technique for cathode catalysis layer thereof

InactiveCN101250710ALong continuous service lifeImprove current efficiencyElectrolysis componentsContinuous useDiamond electrodes

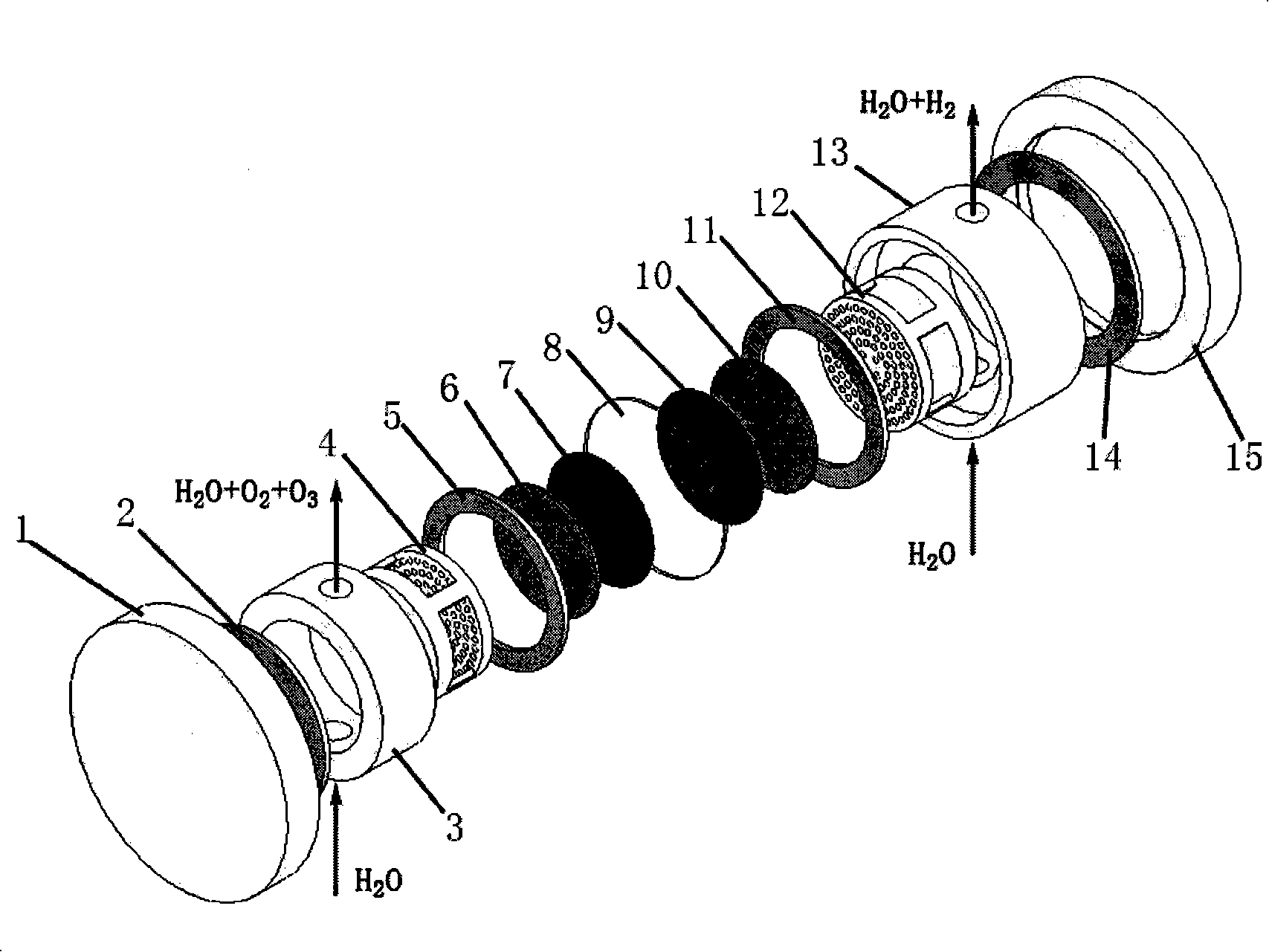

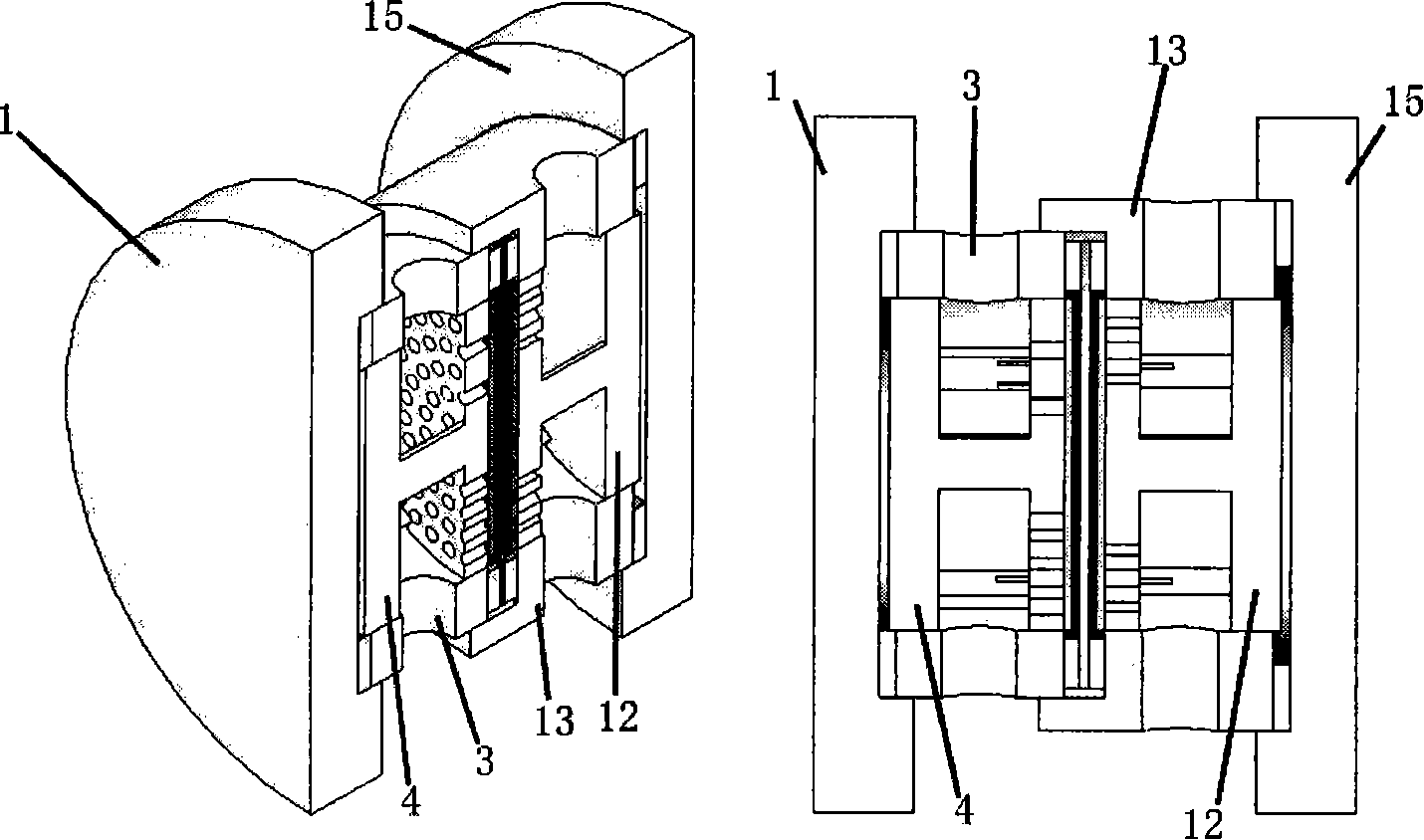

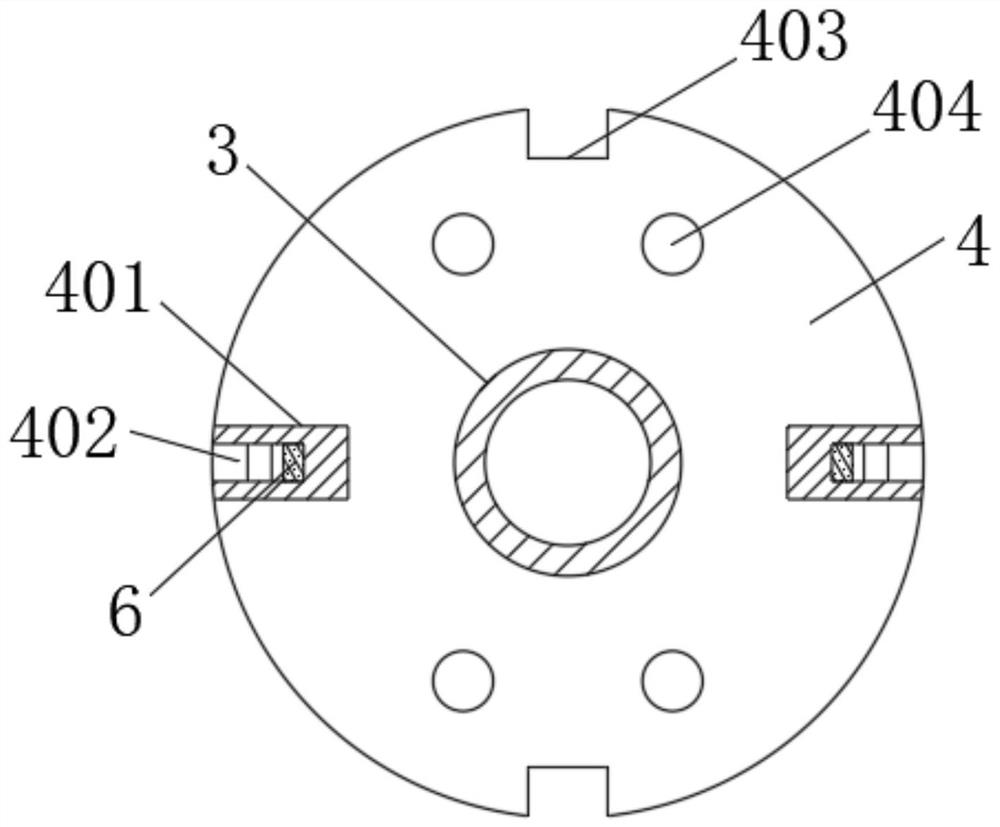

The invention relates to an electrolytic type ozone generator and a process for preparing a cathode catalyst layer of the electrolytic type ozone generator. The electrolytic type ozone generator comprises a round Nafion film, a round anode component and a round cathode component which are arranged on two axial sides of the Nafion film. The electrolytic type ozone generator adopts a diamond electrode which is doped with porous boron as an anode, the cathode catalyst layer adopts a process for preparing platinum-on-carbon and an electrolysis chamber for preparing ozone is optimally designed, not only the performance is greatly increased, but also the current efficiency of a borocarbon electrode to produce the ozone is greatly increased, the current efficiency can reach 30% under room temperature to the maximum, and the continuous service life of the electrodes can be greatly prolonged compared with lead dioxide electrodes which are used in a large number at present.

Owner:SHAANXI UNIV OF SCI & TECH

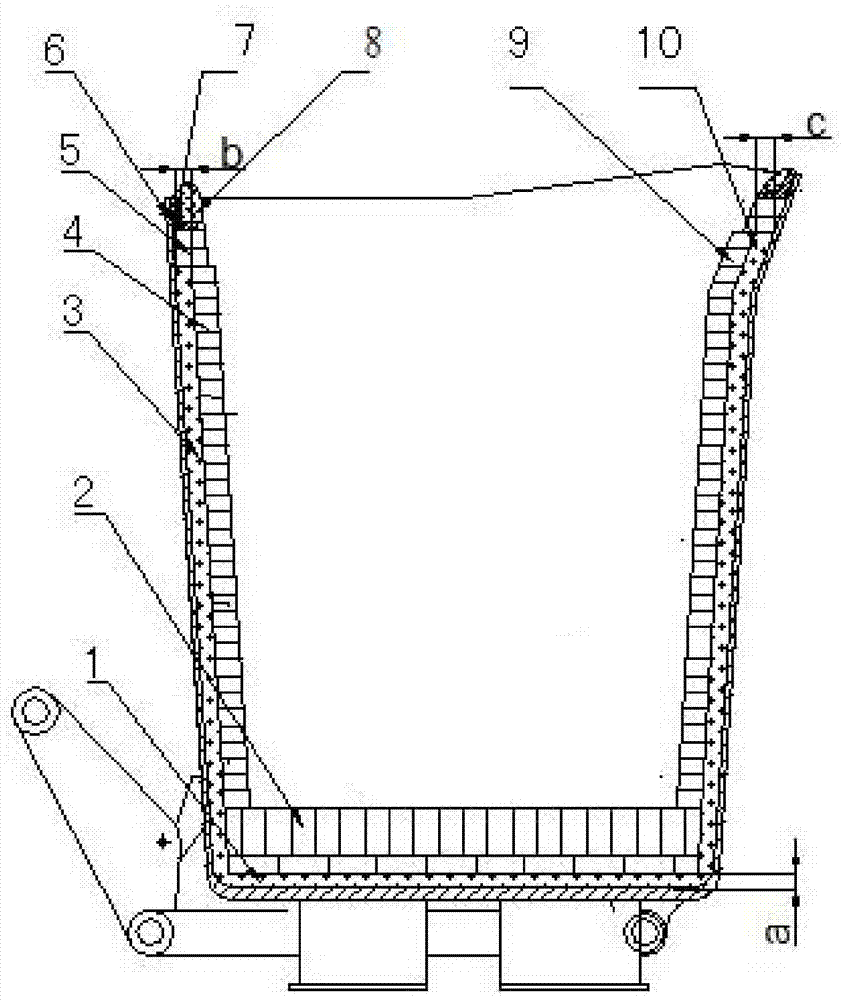

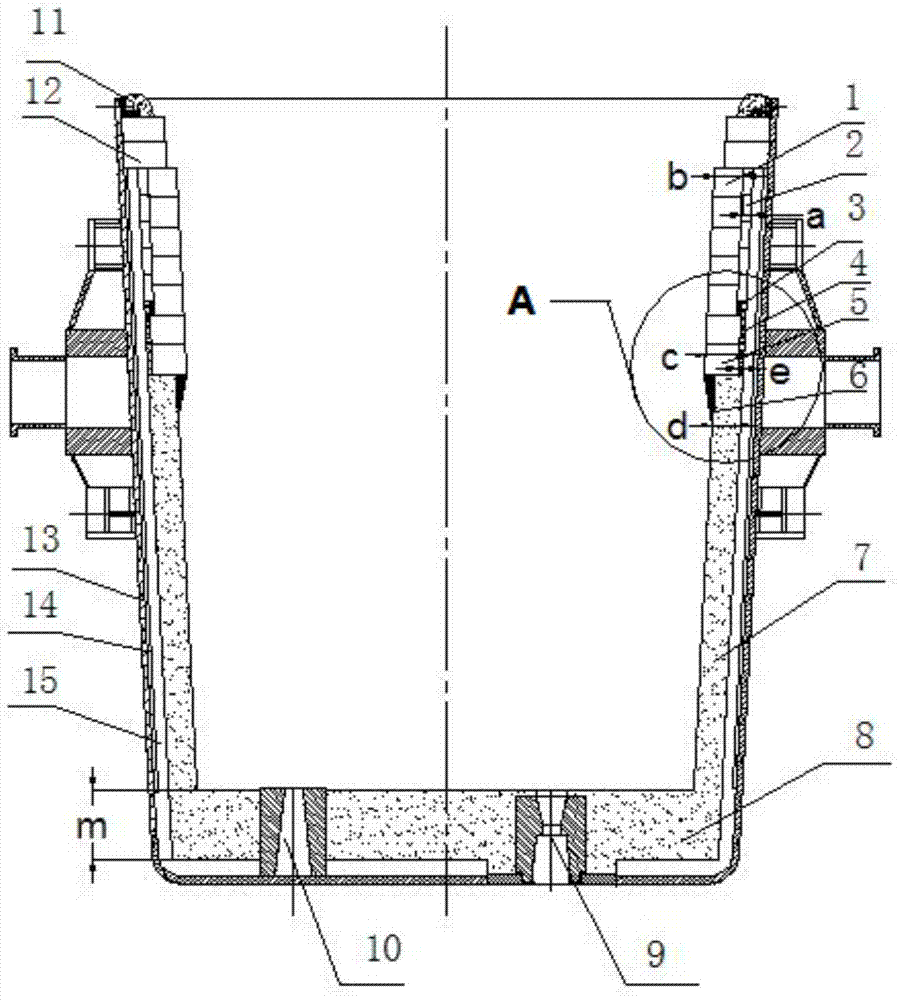

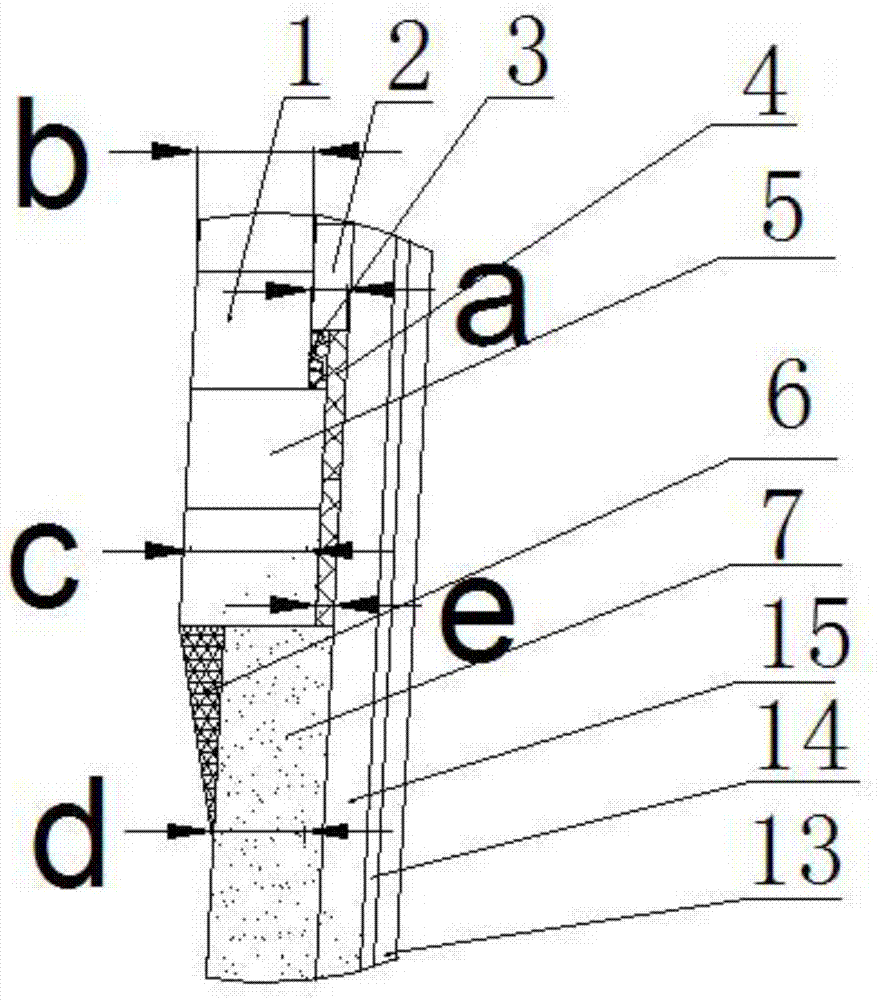

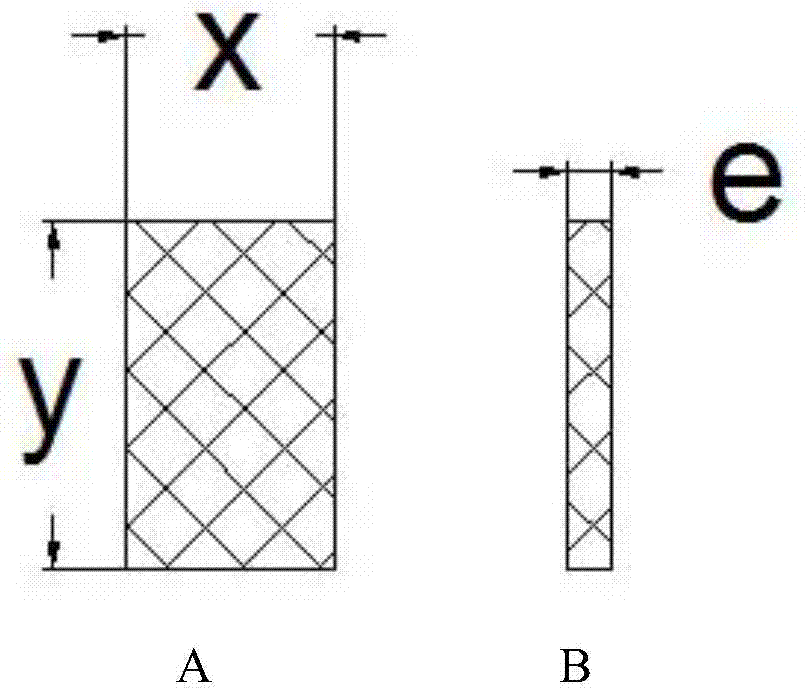

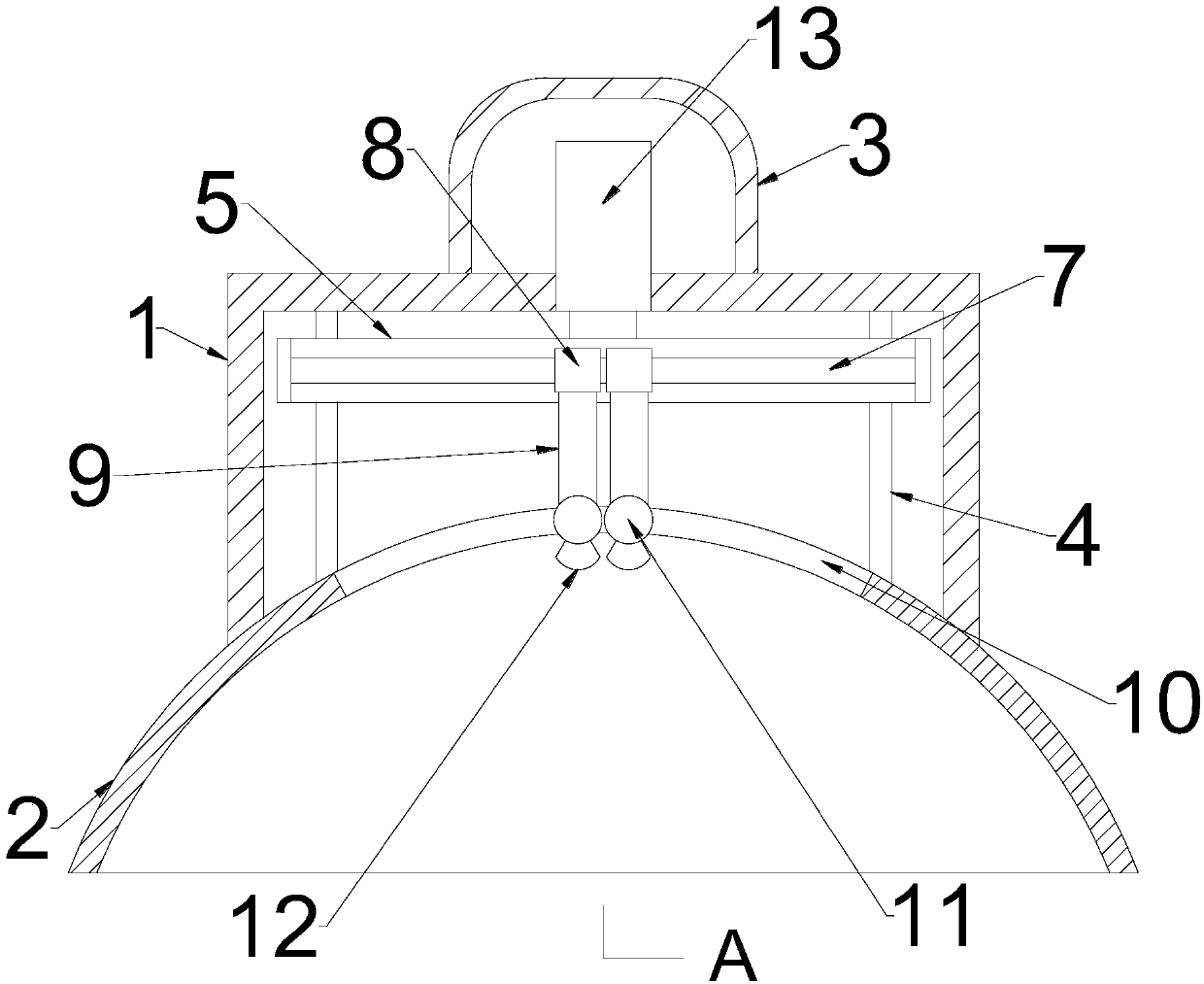

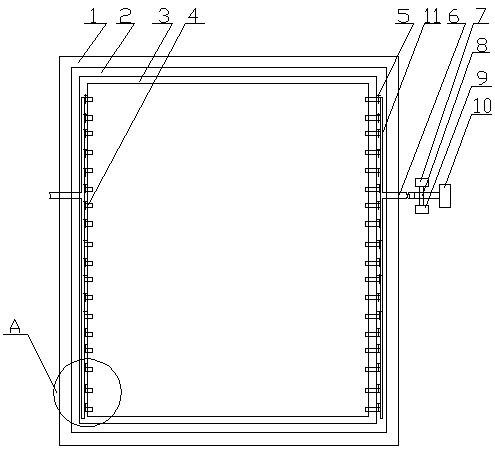

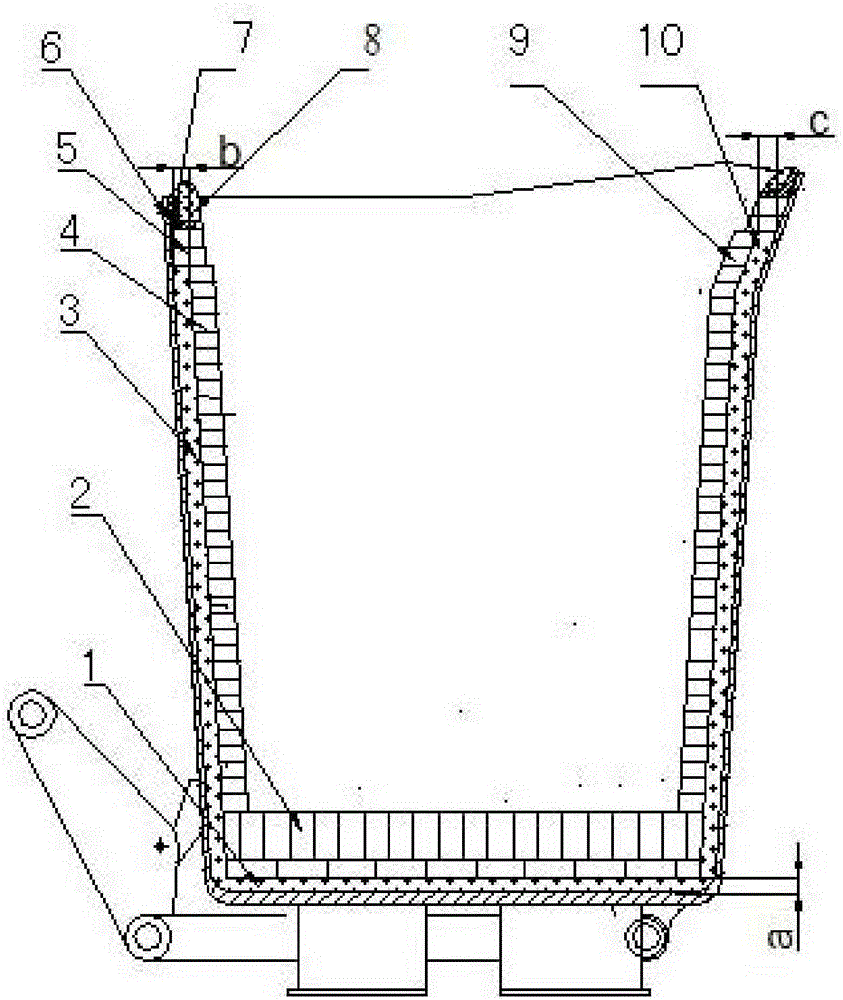

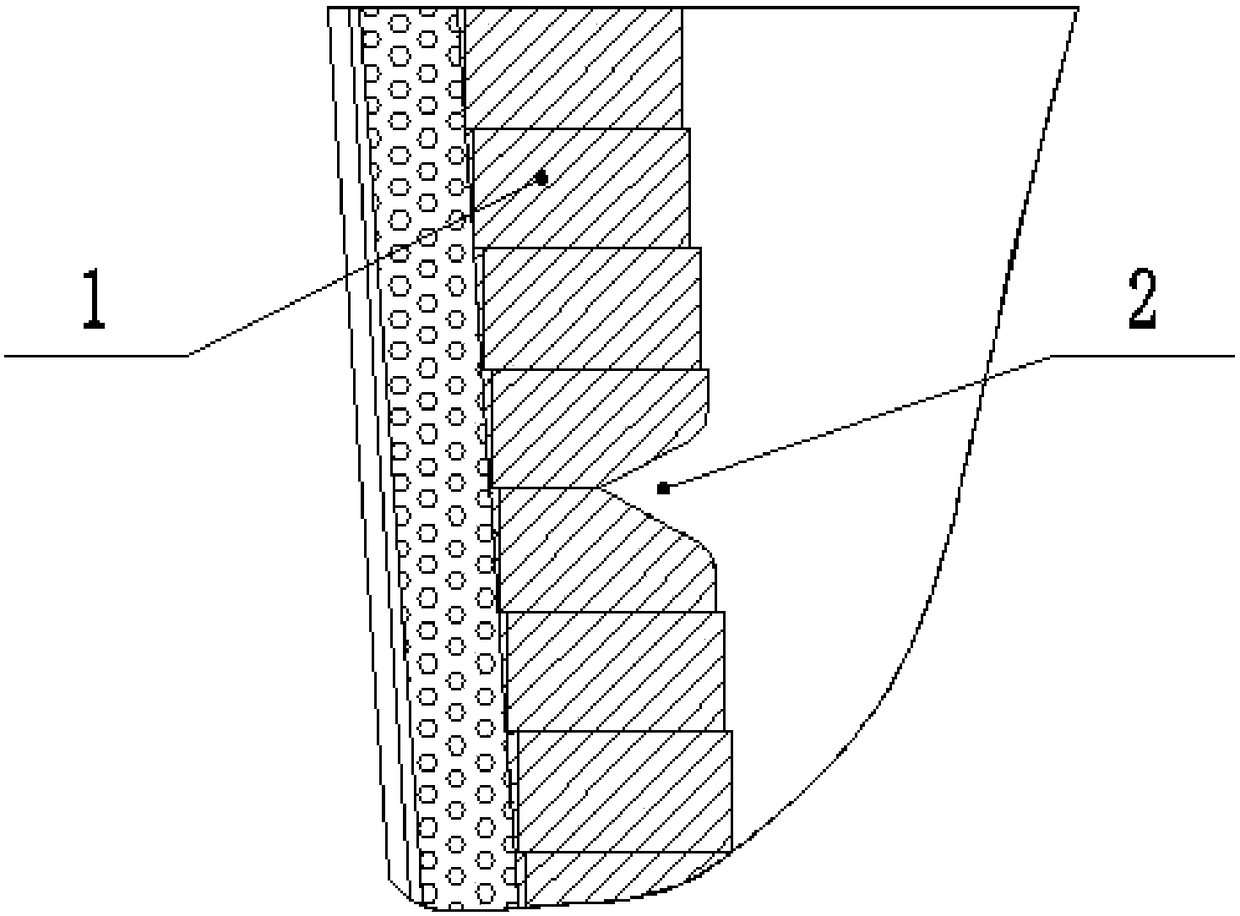

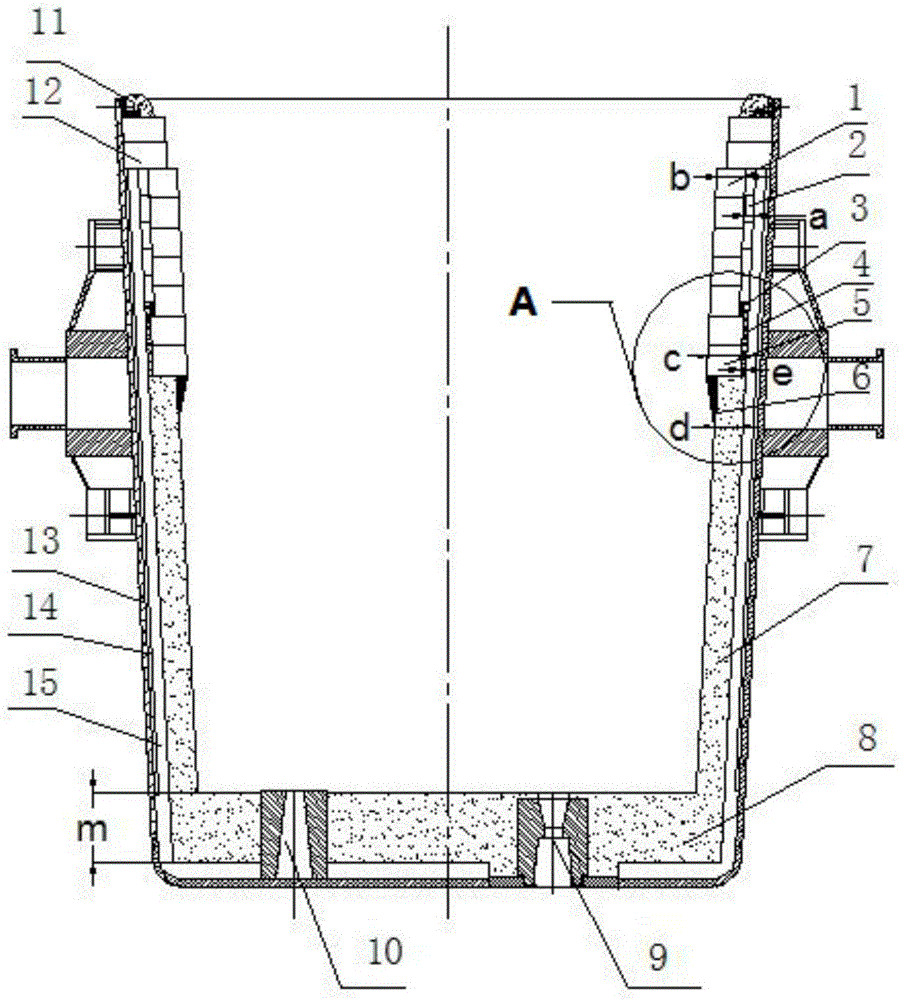

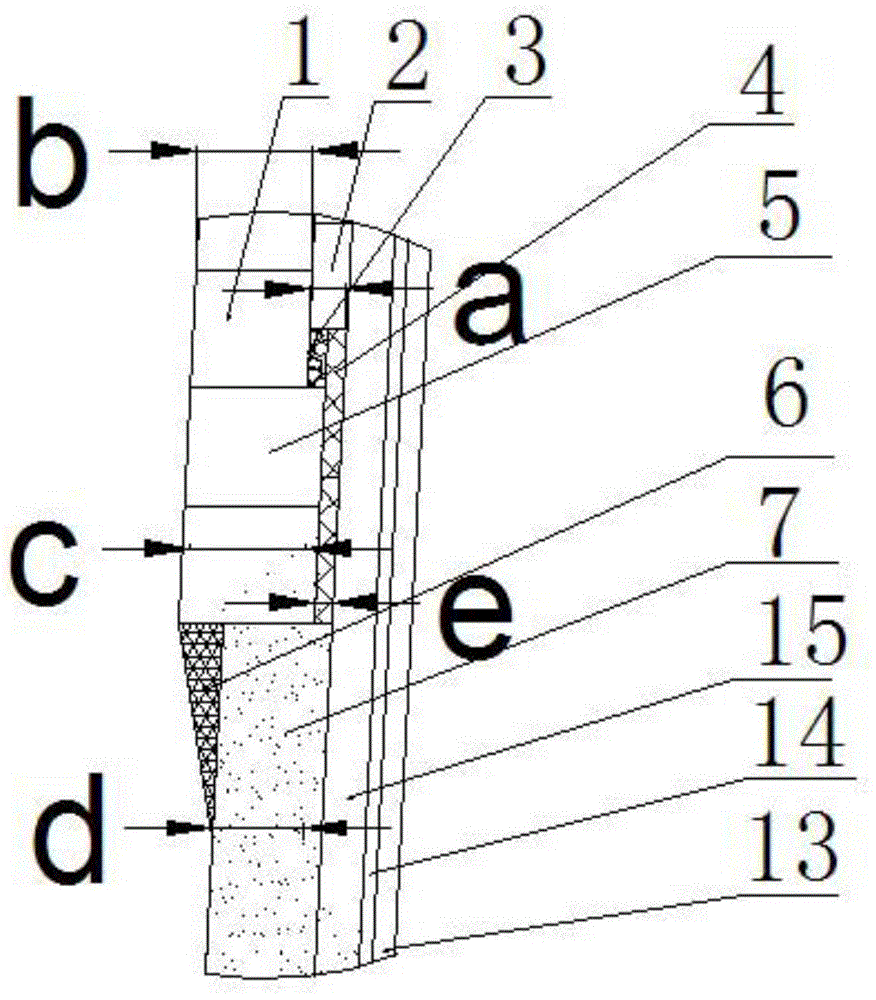

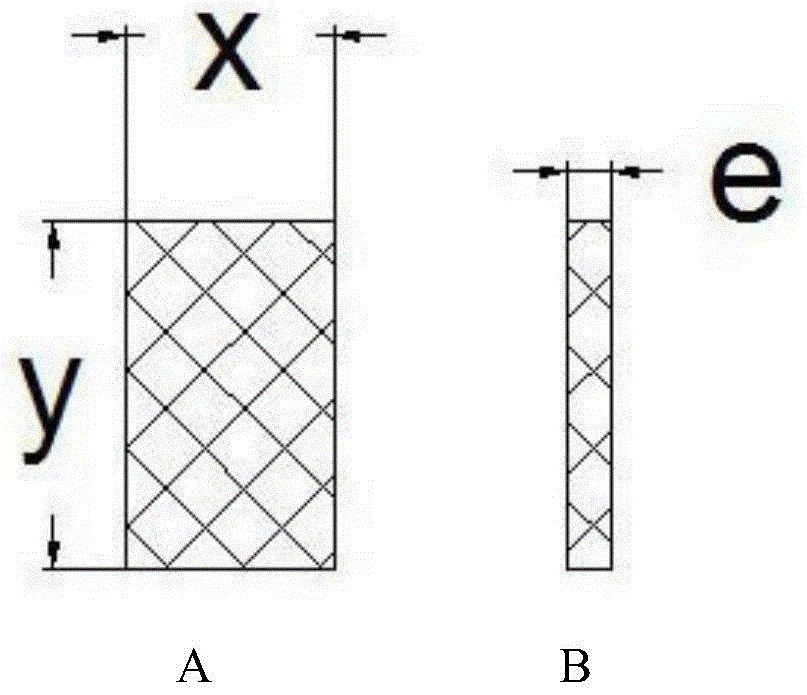

Ladle permanent lining and manufacturing method thereof

ActiveCN103785820AExtended service lifeSolve the problem of seeping steelMelt-holding vesselsBrickRefractory

The invention relates to a ladle permanent lining and a manufacturing method of the ladle permanent lining, and belongs to the technical field of ferrous metallurgy ladle lining fireproof material. The ladle permanent lining is laid on the inner wall of a shell (6) of a ladle and sequentially comprises a ladle bottom permanent lining (1), a ladle wall permanent lining (3) and a ladle nozzle permanent lining (10) from bottom to top. The ladle permanent lining is characterized in that the ladle permanent lining is manufactured by minimum-inflation artesian flow castable in a segmented casting mode, an overall casting forming die is not used, and the ladle permanent lining and a bricked working lining are constructed synchronously. The technological process of repairing and laying the ladle lining is simplified, the problem that in the prior art, the bricked working lining leaks steel because the high-aluminum artesian flow castable shrinks in the hardening process is solved, compared with the prior art, the service life of the ladle working lining is prolonged by 150 furnace round-200 furnace round, and the cost of ladle fireproof material is reduced by over 15%.

Owner:LAIWU IRON & STEEL GRP

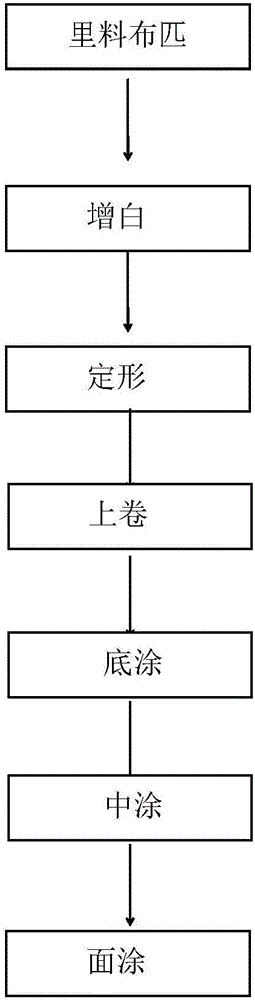

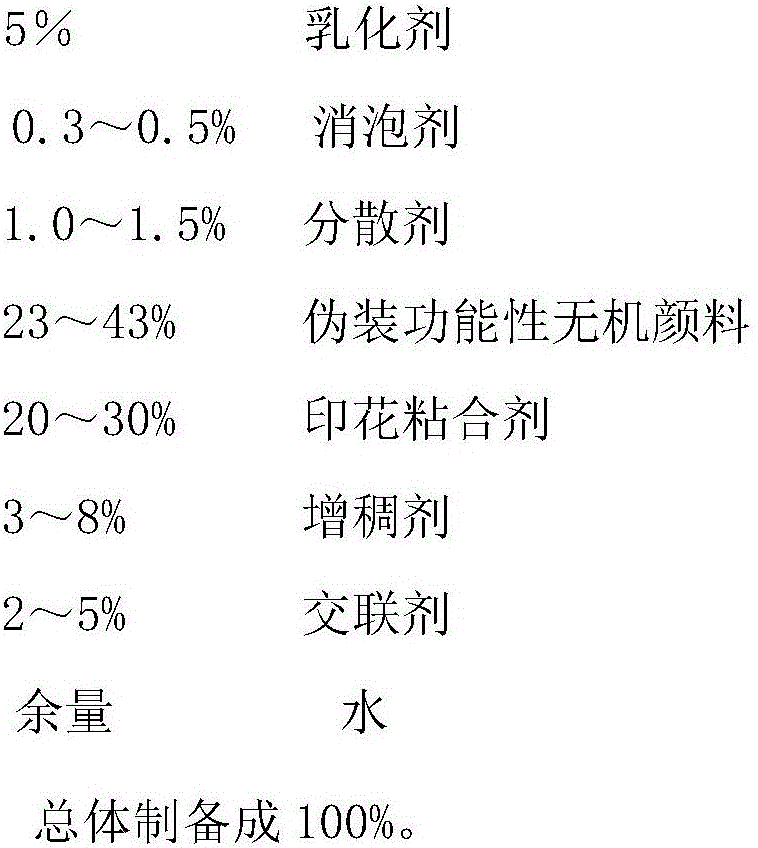

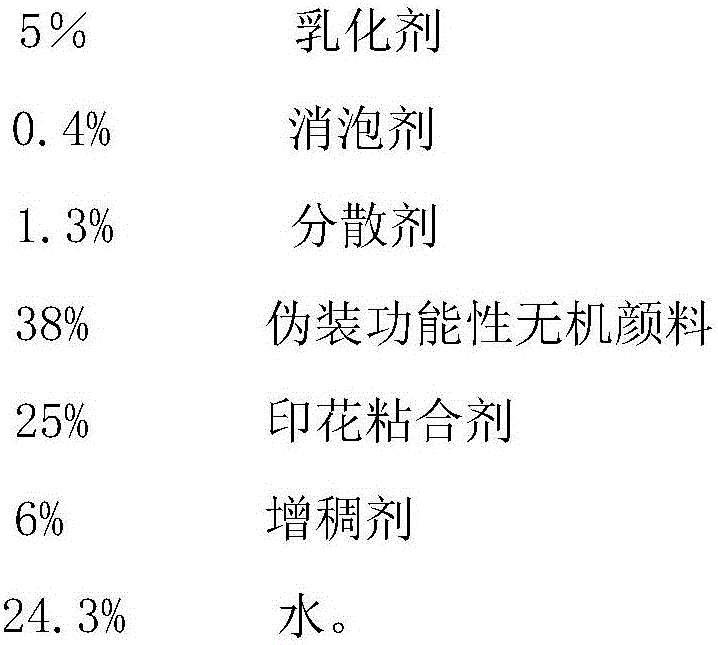

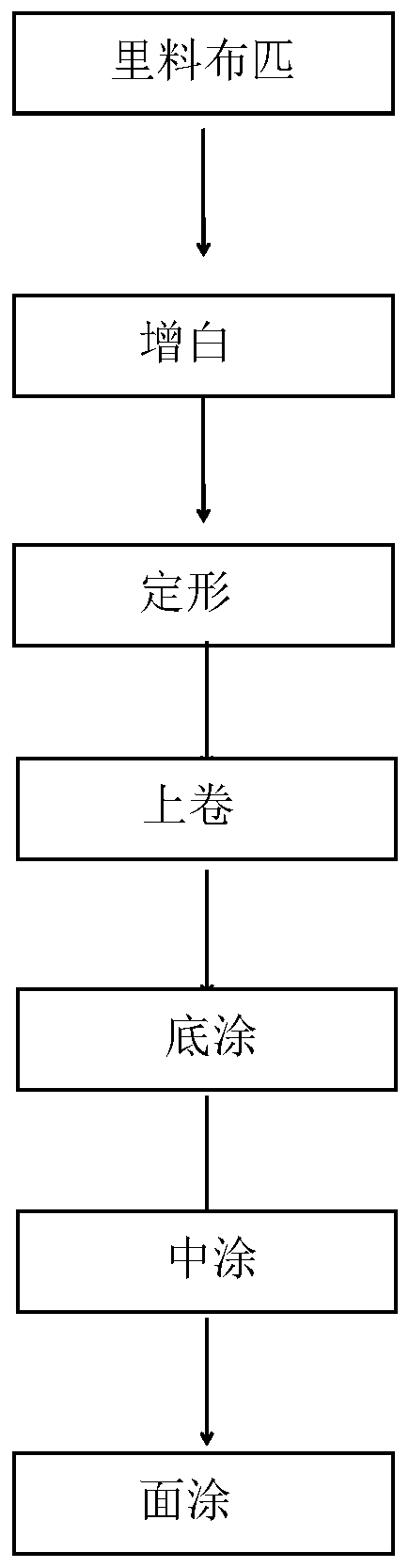

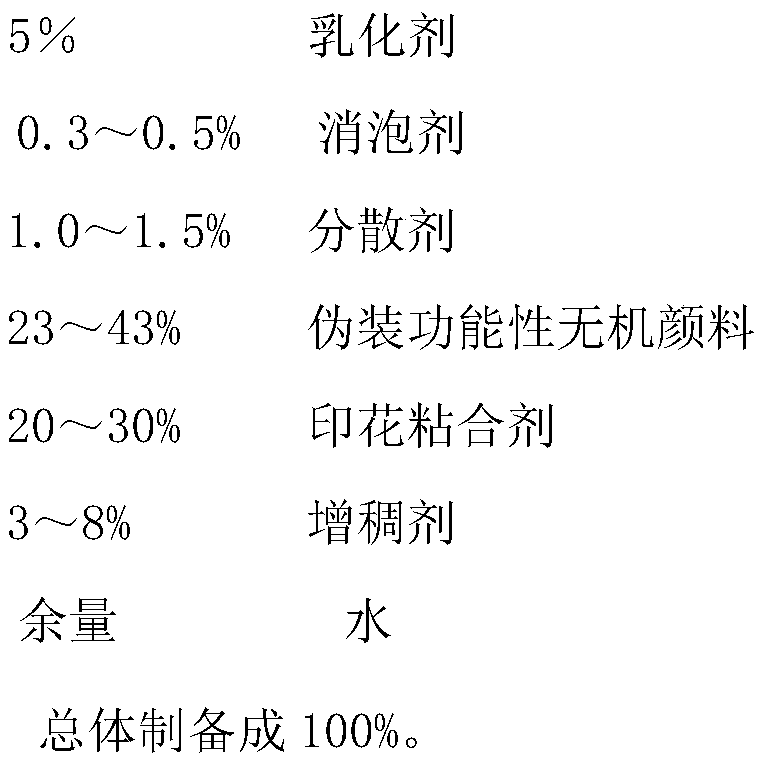

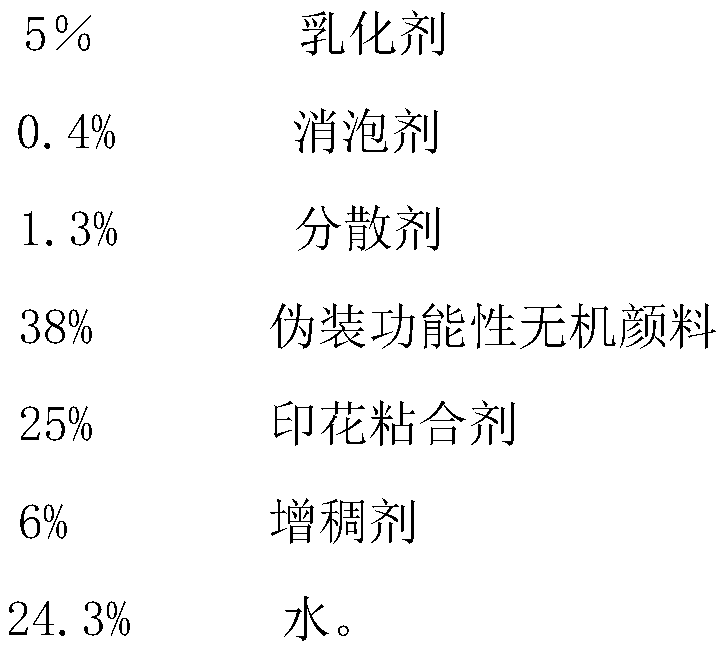

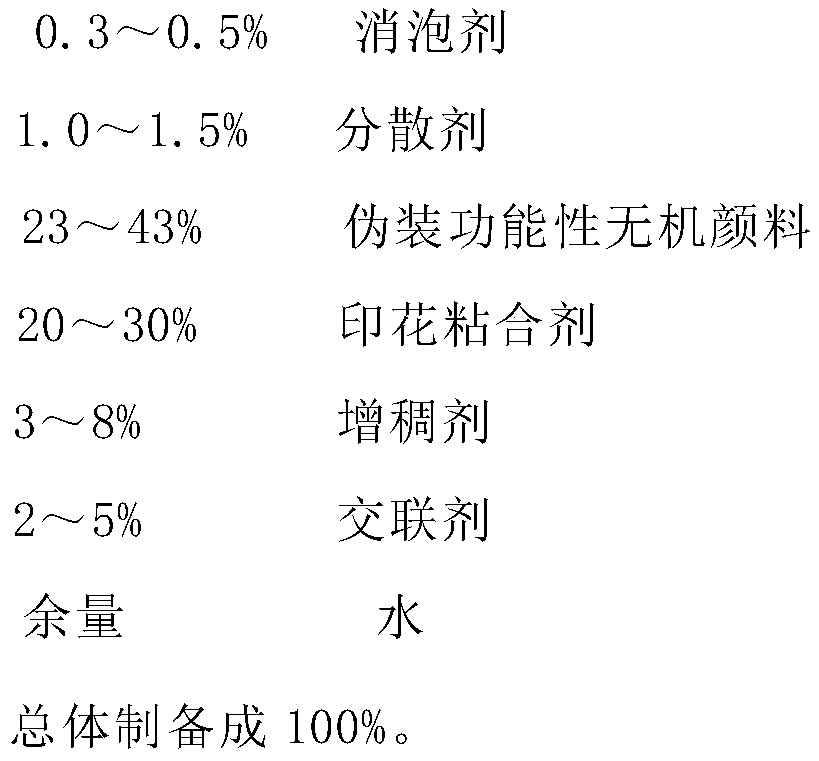

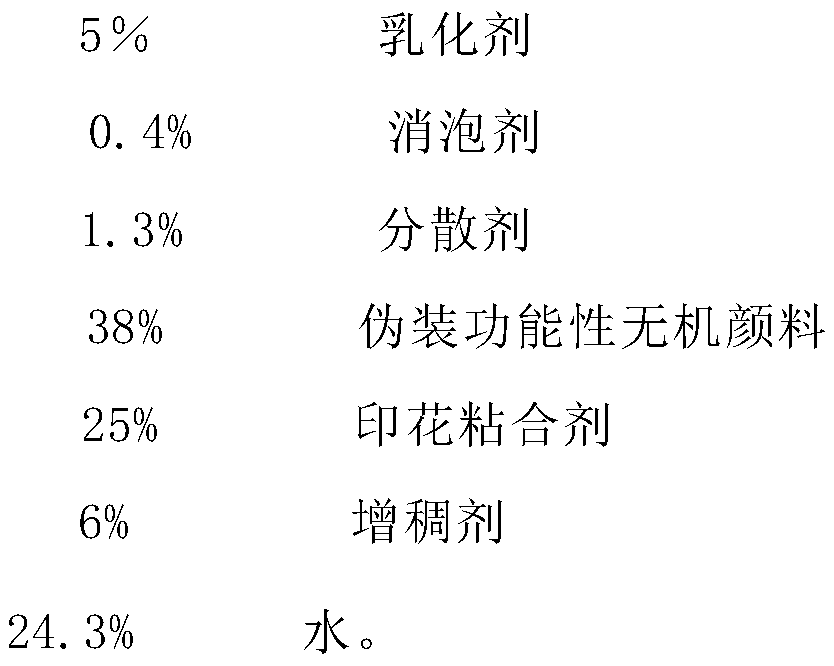

Coating special for counterreconnaissance device fabric and manufacturing method thereof and fabric

ActiveCN106192479AReduce pollutionReconnaissance weakenedDyeing processProtective garmentOrganic dyeAdhesive

The invention provides a coating special for a counterreconnaissance device fabric and a manufacturing method thereof and the fabric. The coating can be an inorganic printing coating. The coating comprises, by mass percentage, 5% of emulsifier, 0.3-0.5% of antifoaming agent, 1.0-1.5% of dispersing agent, 23-43% of disguised functional inorganic pigment, 20-33% of coating printing adhesive, 3-8% of thickener, and the balance water; and finally the coating with a mass percent of 100% is obtained. The coating achieves functions of visual reconnaissance prevention and near infrared surveillance prevention. The coating is an inorganic coating, and the problems that the environmental pollution is caused by previous printing of a camouflage fabric through an organic dye for clothes, tents and weapons and coating printing easily leads to aging and short service life are solved. Besides, in the printing production process, ageing color development and alkaline removal flooding treatment do not need to be performed, and compared with a conventional dye printing method, the coating generates fewer harmful substances and is lower in environmental pollution.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

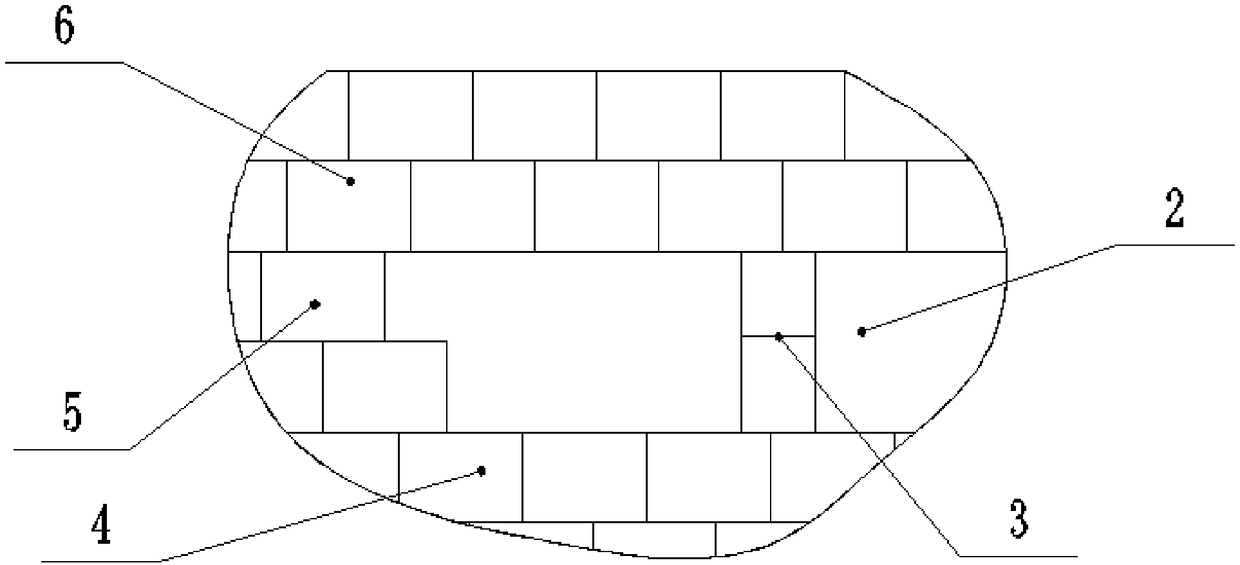

Steel ladle composite working lining and repairing method for slag line position thereof

The invention relates to a steel ladle composite working lining and a repairing method for a slag line position thereof. The steel ladle composite working lining comprises a steel ladle shell, a permanent lining insulating refractory plate and permanent lining castable are arranged on the inner wall of the steel ladle shell, the upper portion of the permanent lining castable at the ladle bottom is provided with ladle bottom working lining castable, ladle wall working lining castable, a slag line part, single-ring ladle opening bricks and ladle edge castable from bottom to top, and water gap seat bricks and air permeable seat bricks are arranged in the ladle bottom working lining castable; the slag line part is arranged to be divided into an inner ring and an outer ring, and the inner ring comprises slag line bottom inner ring bricks and slag line inner ring alumina-magnesia-carbon bricks from bottom to top; the outer ring comprises slag line bottom outer ring bricks and slag line outer ring magnesia-carbon bricks from bottom to top. When the slag line position of the steel ladle composite working lining is subjected to the first minor repair, the second minor repair and the first medium repair, the used slag line bottom inner ring bricks and the slag line inner ring alumina-magnesia-carbon bricks are reserved, only the slag line bottom outer ring bricks and the slag line outer ring magnesia-carbon bricks are dismantled and replaced, and therefore the consumption of the working lining slag line magnesia-carbon bricks is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

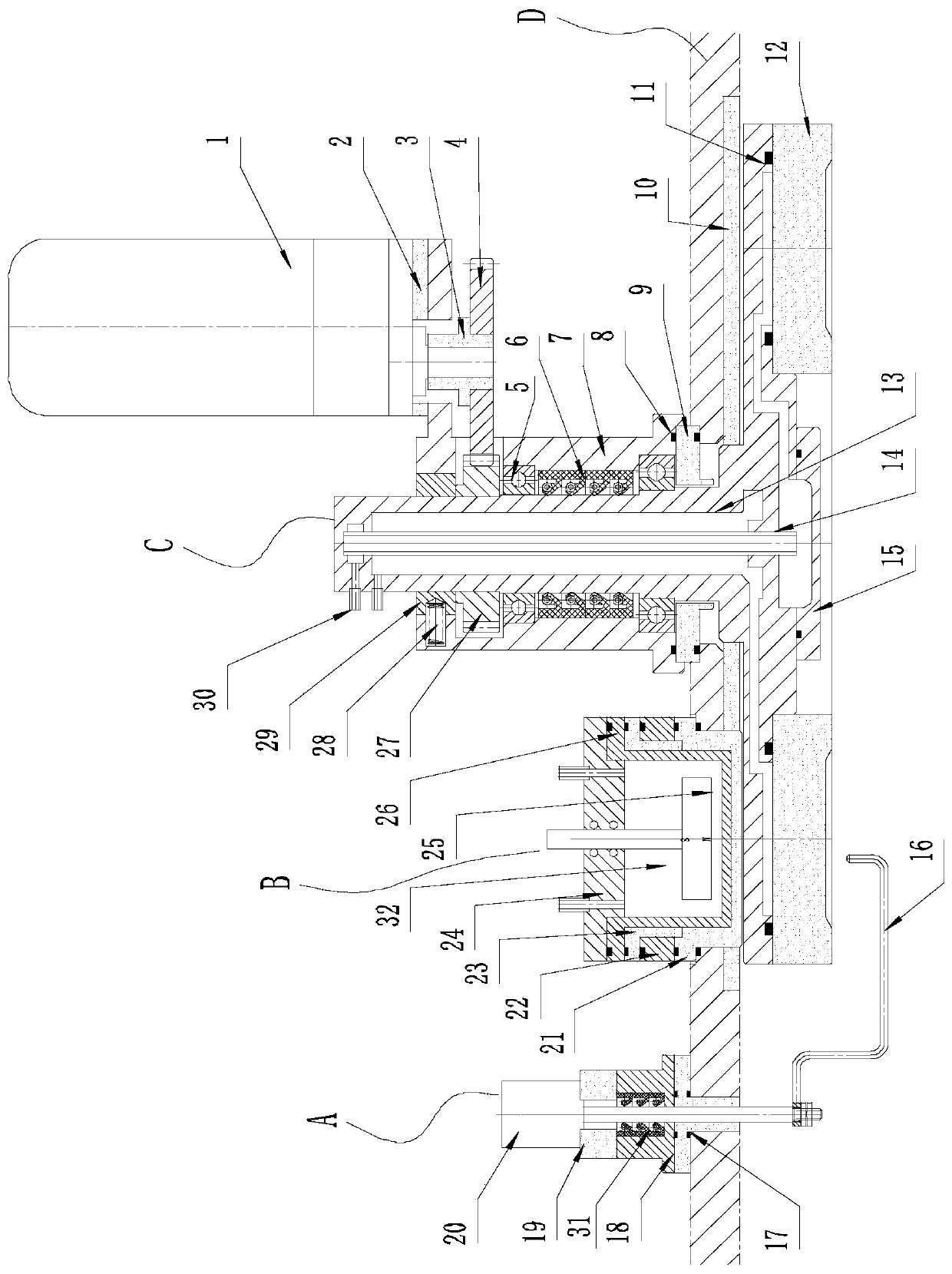

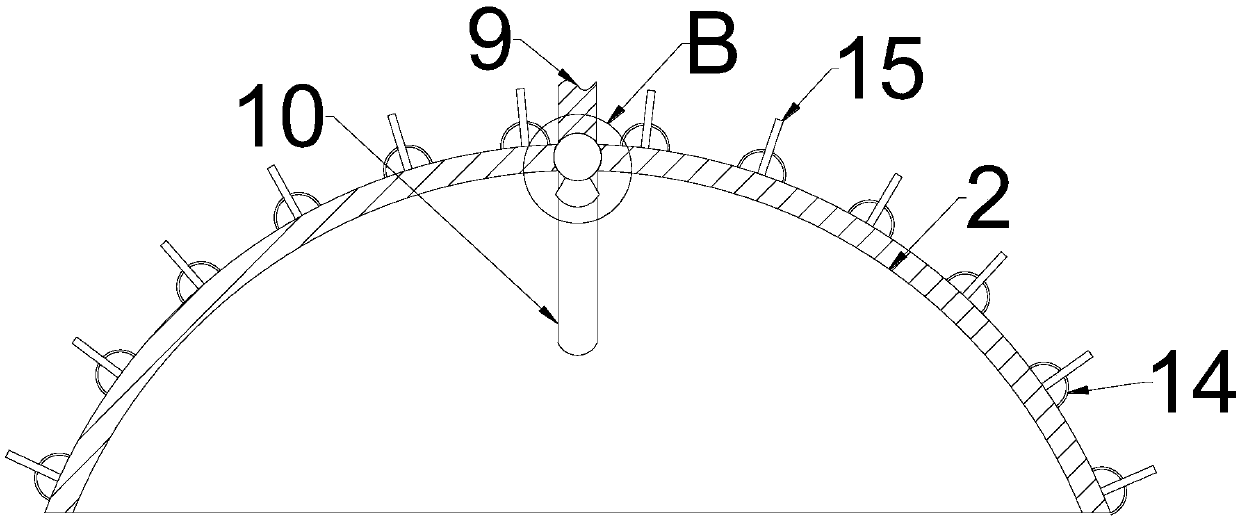

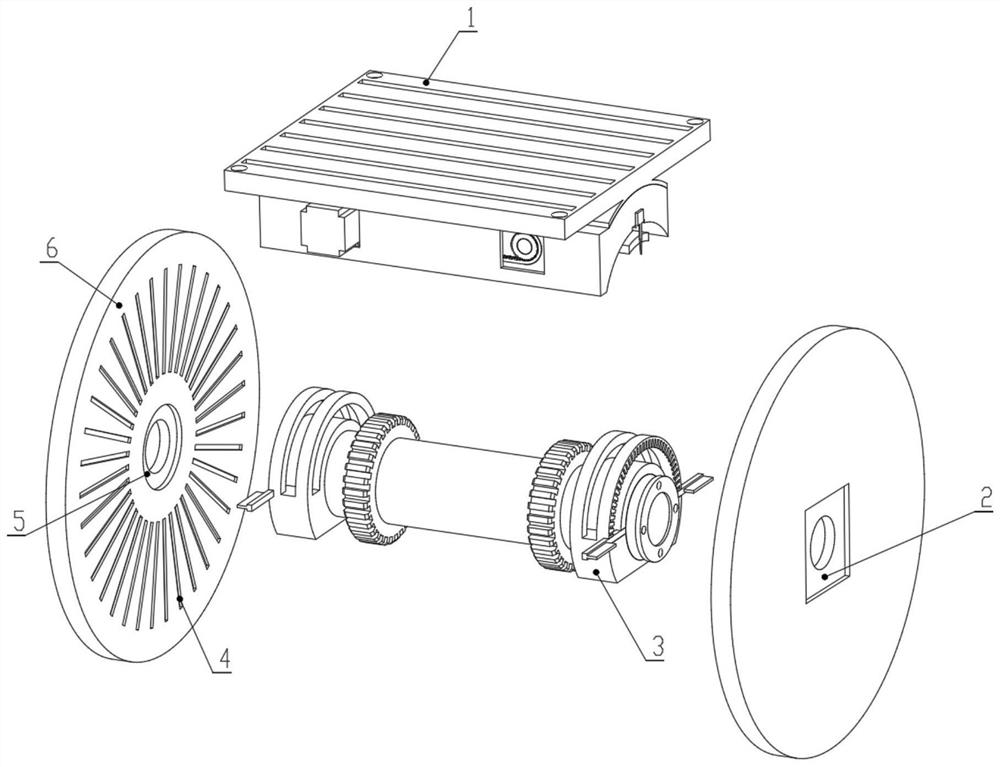

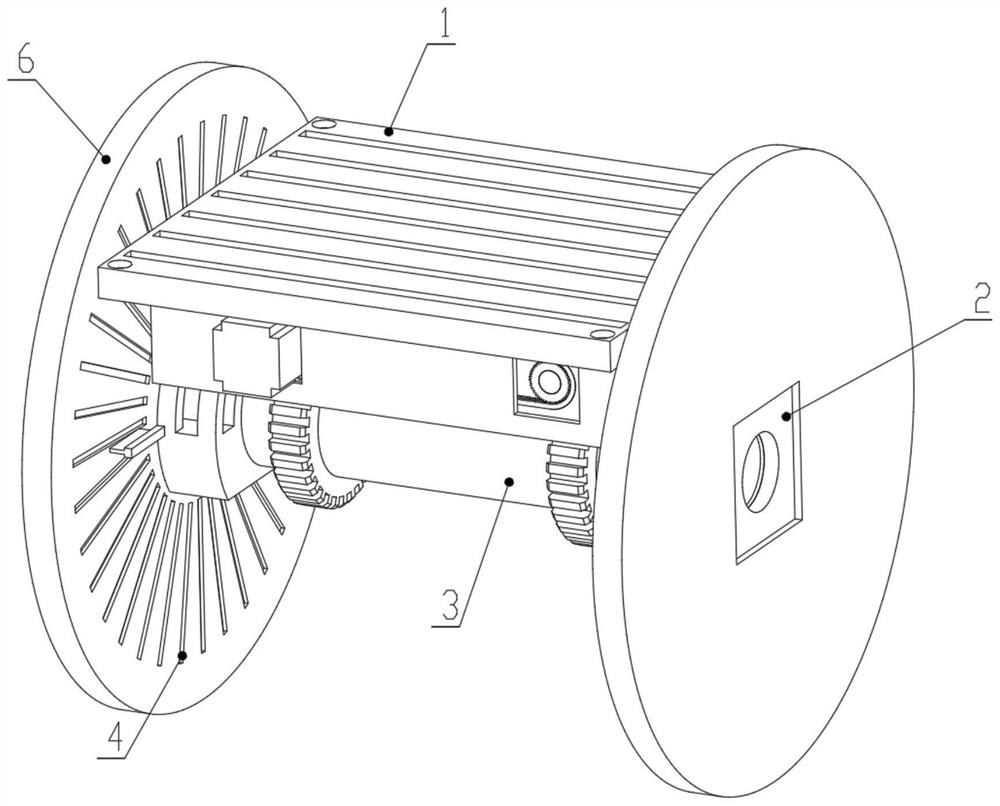

Rotary long-service-life multi-arc target and using method thereof

ActiveCN111424247AStable controlGood coating effectVacuum evaporation coatingSputtering coatingPhysicsContinuous use

The invention discloses a rotary long-service-life multi-arc target and a using method thereof. The rotary long-service-life multi-arc target comprises an arc striking device, an anode device and a rotary electric arc target device, the rotary electric arc target device comprises an annular arc target material and a target material rotation driving mechanism, the annular arc target material is arranged at the output end of the target material rotation driving mechanism, and the arc striking device and the anode device are arranged on the outer sides of the two opposite faces of the annular arctarget material correspondingly. The using method of the rotary long-service-life multi-arc target comprises the following steps: of driving the annular arc target material to continuously rotate through the target material rotation driving mechanism, taking an area between the arc striking device and the anode device as a sputtering area in the rotating process, exciting the surface of the annular arc target material in the sputtering area to sputter a required coating material by using the arc striking device and the anode device which are fixed, and continuously coating a workpiece or a base material passing through the sputtering area. By means of the rotary long-service-life multi-arc target and the using method, the continuous service life of the target material can be effectively prolonged, the target material can be well applied to a continuous coating and long-time working production line, and meanwhile the coating effect is improved.

Owner:ZHAOQING KERUN VACUUM EQUIP

Easy-in-dimming heat-radiating streetlamp

InactiveCN109654410AReduce the impactLong continuous service lifeMechanical apparatusLighting heating/cooling arrangementsHeat conductingEngineering

The invention discloses an easy-in-dimming heat-radiating streetlamp which comprises a lamp shell, a lamp cover and LED lamps slidably mounted on the lamp cover through a sliding ball. A sliding groove is formed in the lamp cover, and the sliding ball is slidably arranged in the sliding groove and driven to slide on the sliding groove through a slider driving structure. Distance among the LED lamps can be controlled and adjusted through an electric extensible push rod, illumination range or illumination intensity can be adjusted and controlled according to needs through two groups of the LED lamps, and impact of shadows on sight line can be reduced by designing multiple groups LED lamps; by designing multiple heat conducting cavities and heat conducting pieces, heat radiation is ensured effectively on the basis of the LED lamps, and continuous service life of a lamp set is prolonged.

Owner:覃天

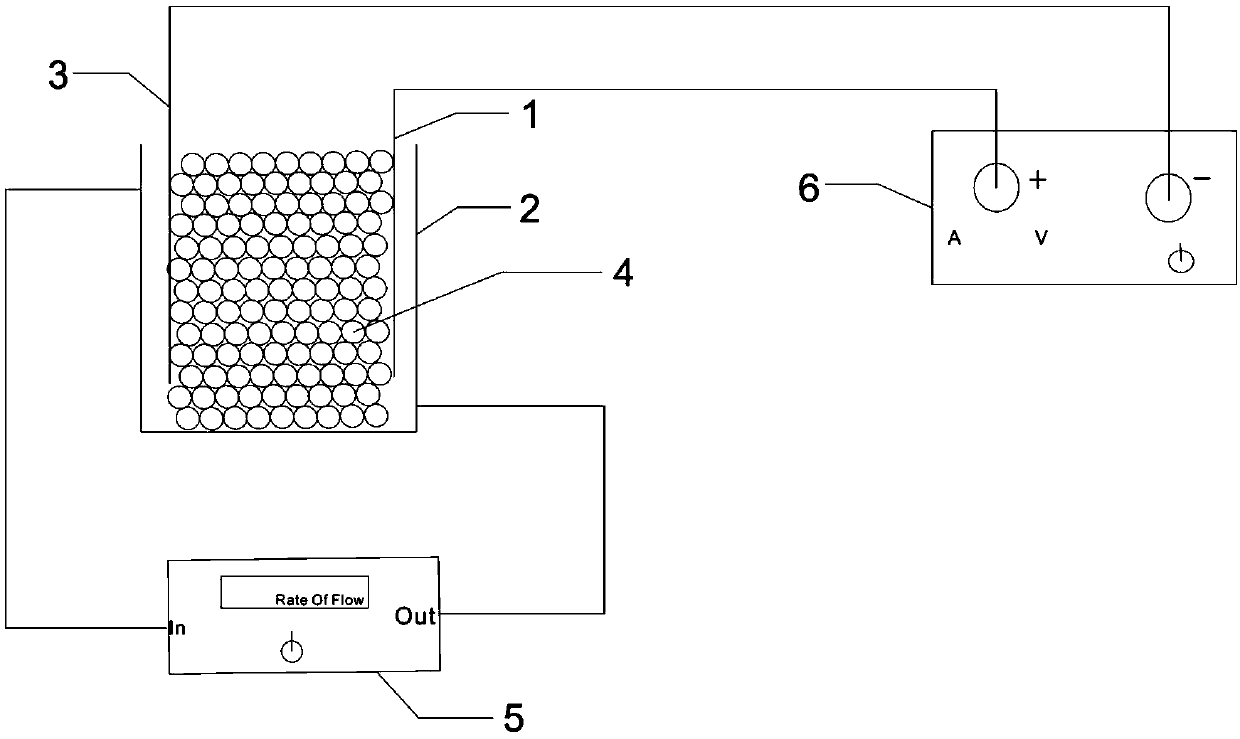

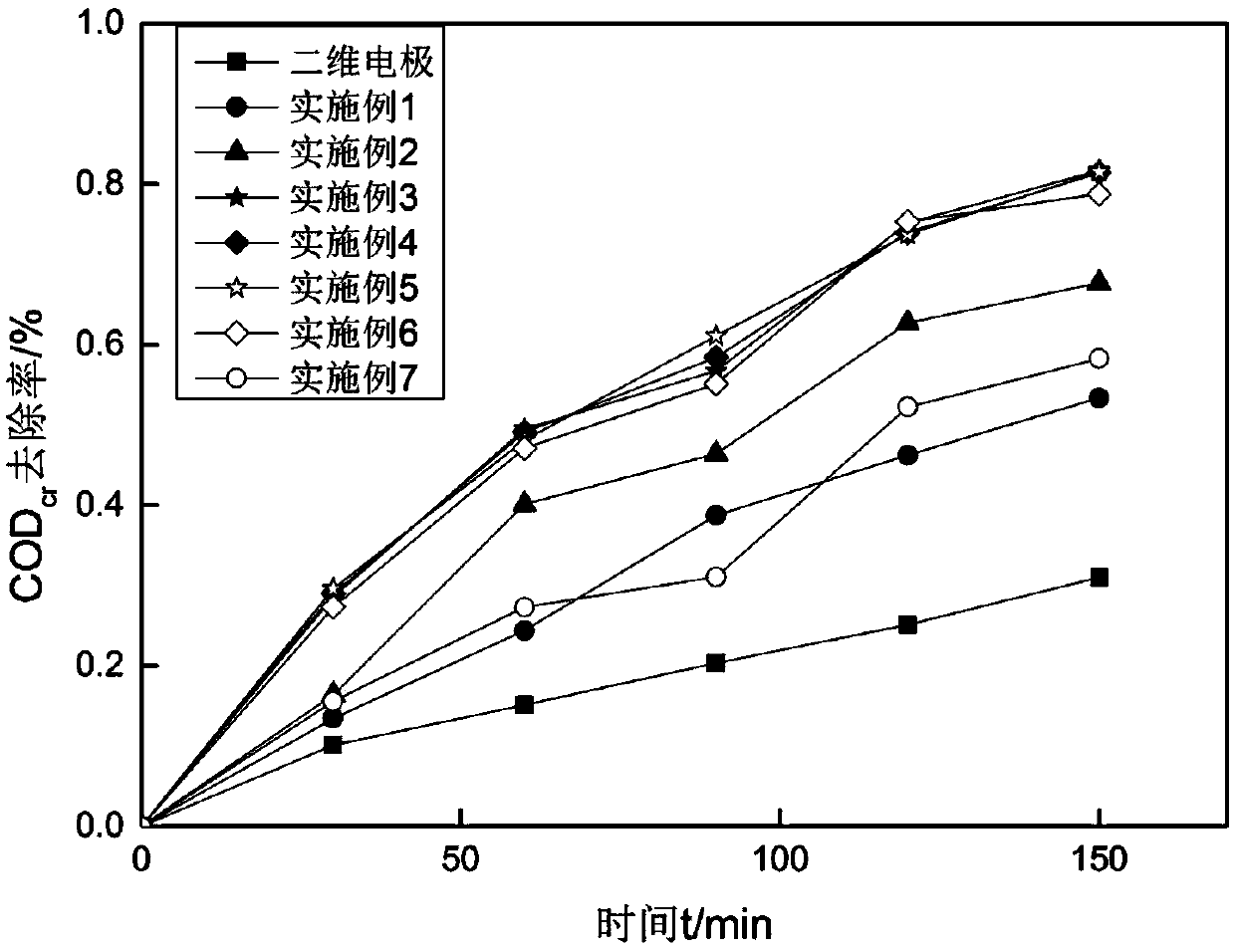

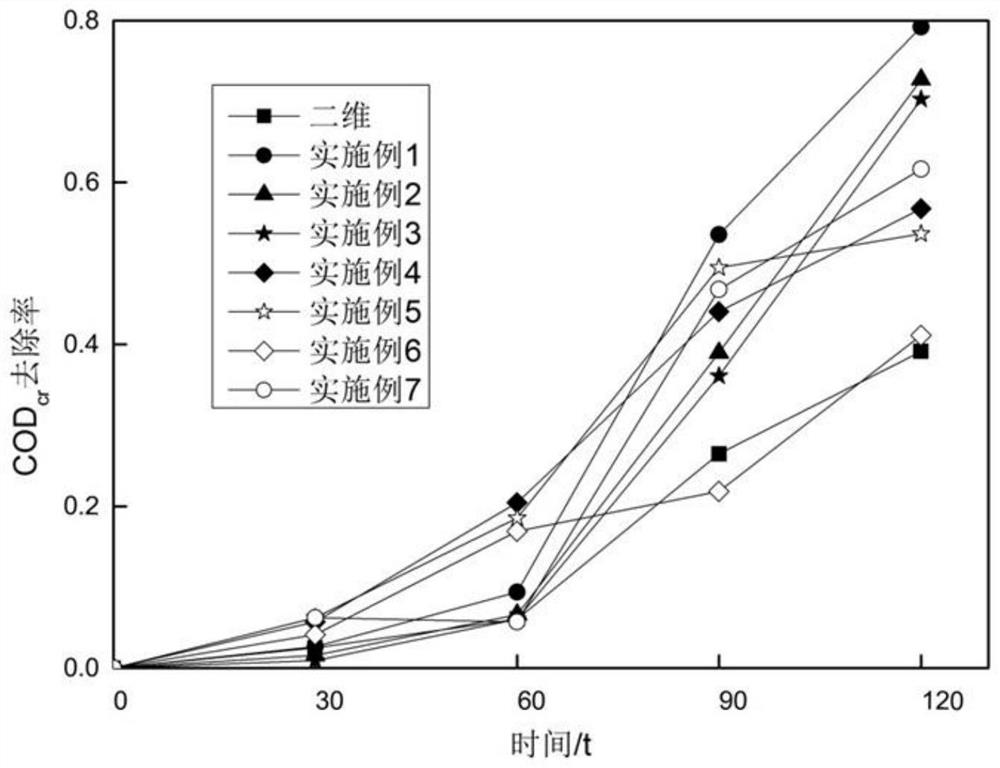

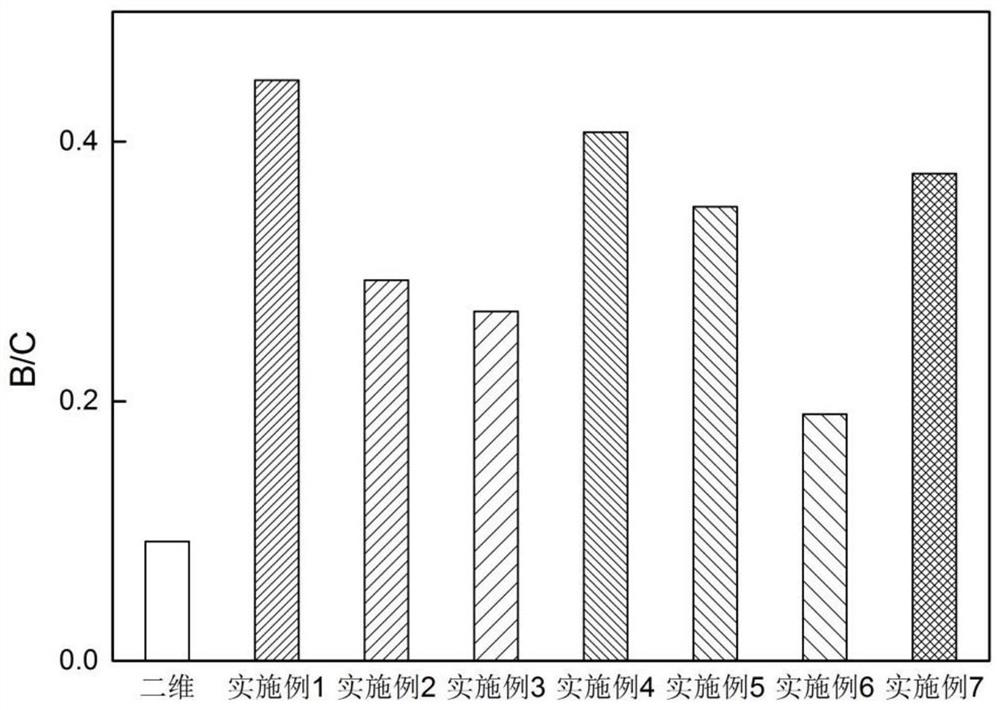

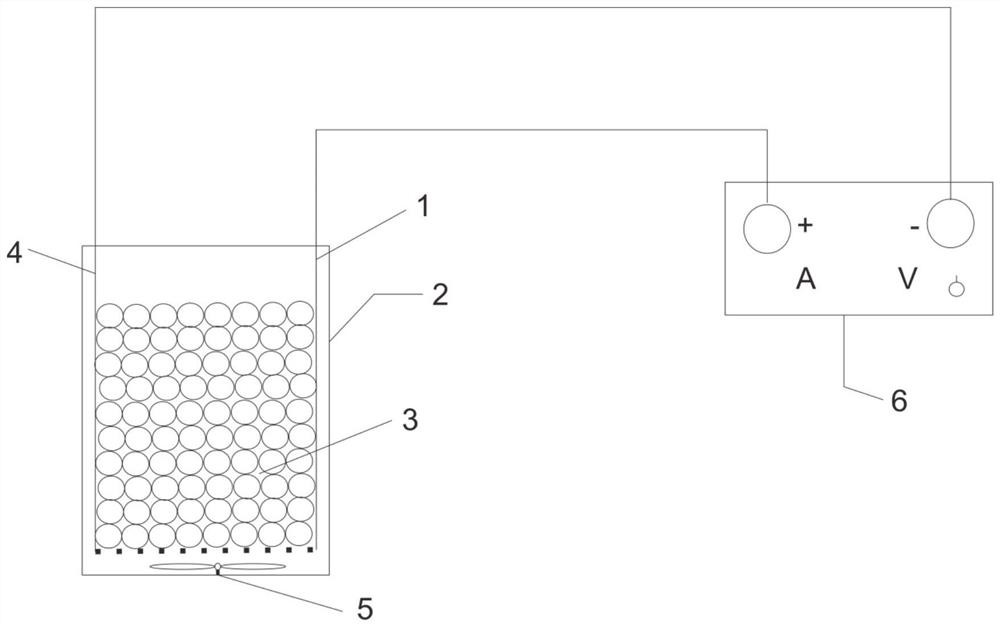

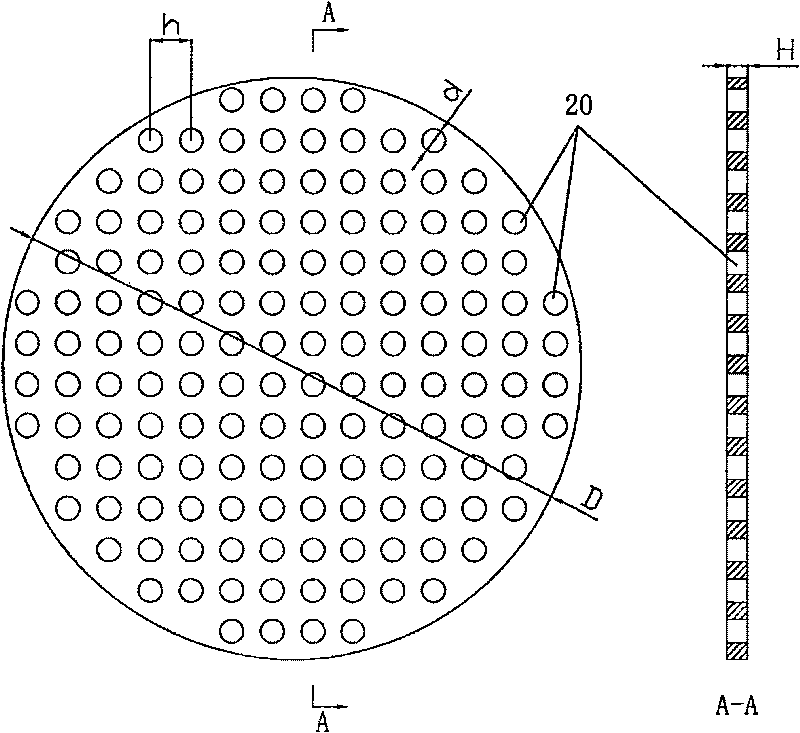

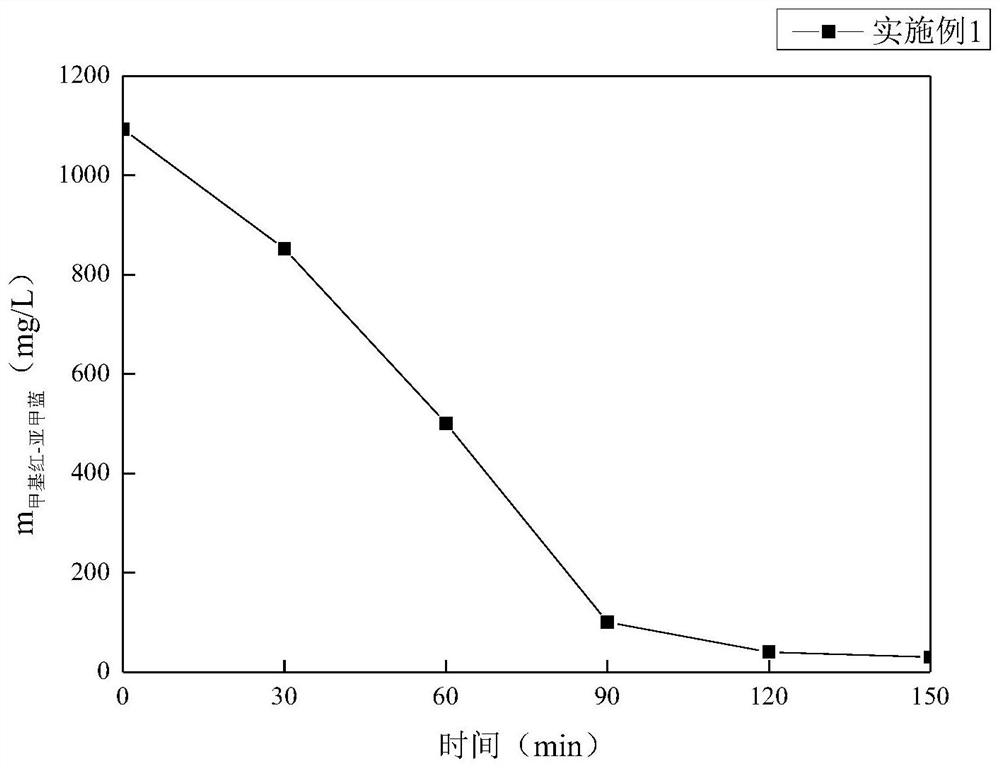

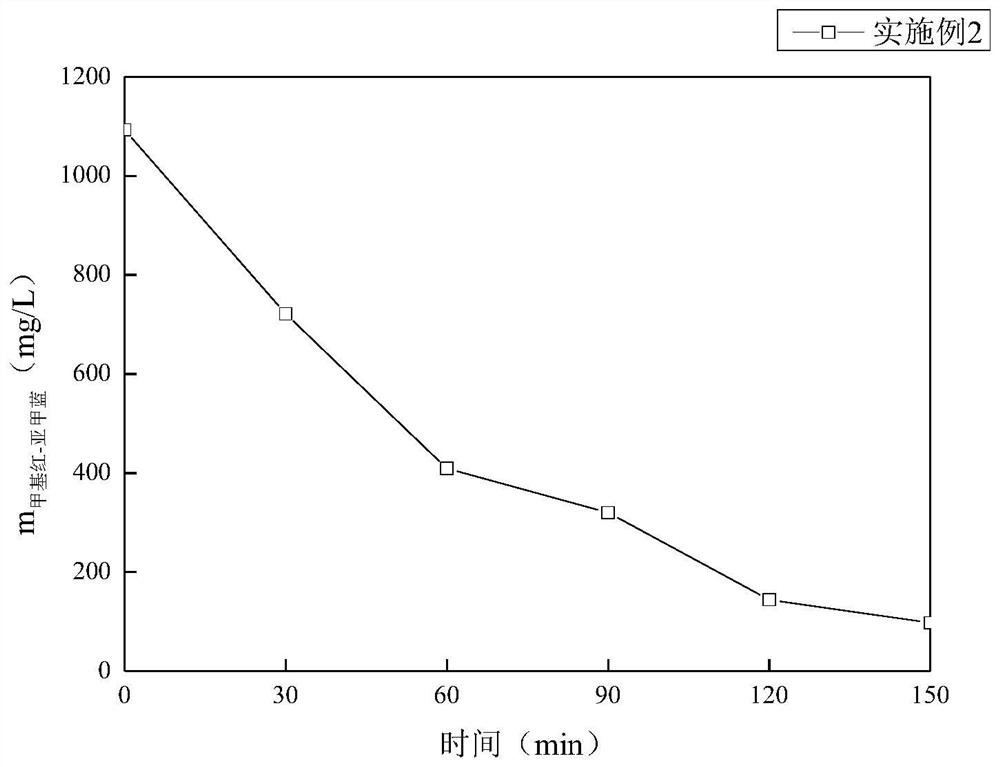

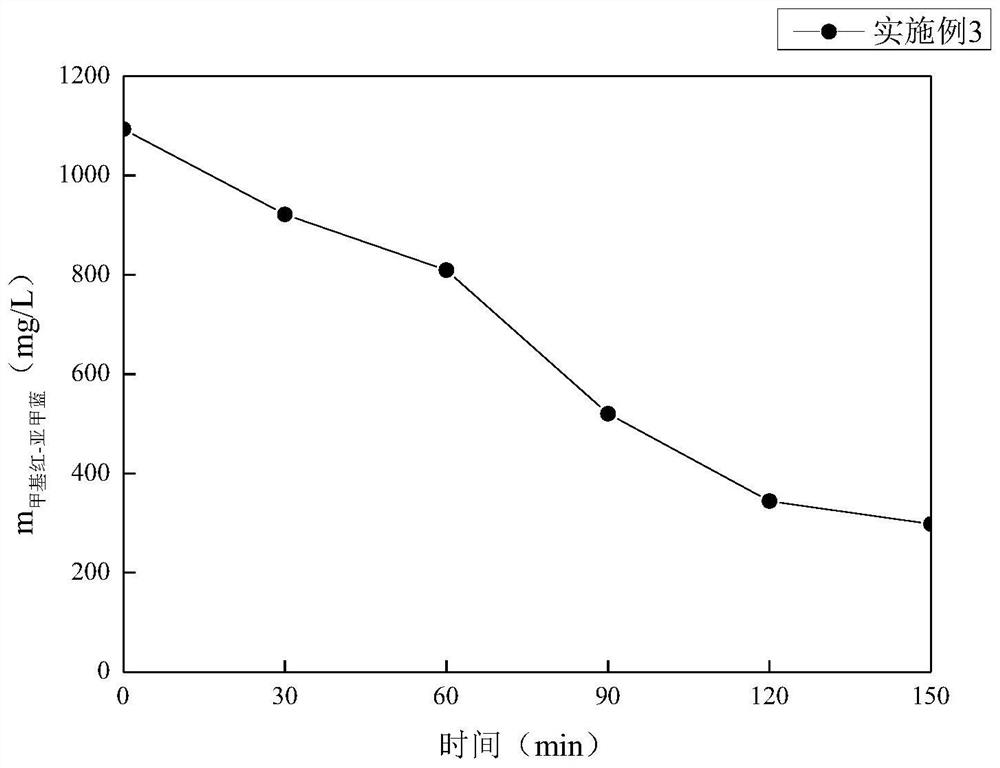

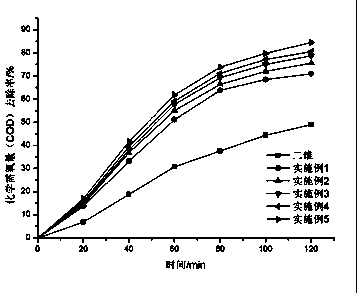

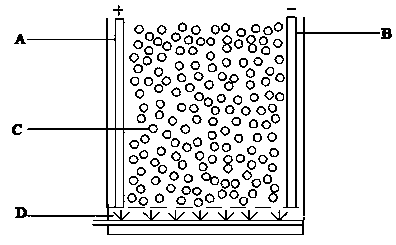

Carbon ceramic shell-core-type three-dimensional particle electrode and preparing method thereof

ActiveCN109626514AHigh catalytic activityLong continuous service lifeWater/sewage treatment using germicide/oligodynamic-processPeristaltic pumpChemical oxygen demand

The invention discloses a carbon ceramic shell-core-type three-dimensional particle electrode and a preparing method thereof. The carbon ceramic shell-core-type three-dimensional particle electrode comprises a three-dimensional electrocatalytic oxidation device composed of an anode plate, an electrolytic cell, a cathode plate, a carbon ceramic shell-core-type three-dimensional particle electrode body, a peristaltic pump and a power source, the carbon ceramic shell-core-type three-dimensional particle electrode body is placed in the electrolytic cell, the two sides of the stacked carbon ceramicshell-core-type three-dimensional particle electrode body are attached to the anode plate and the cathode plate, the anode plate is connected to an a positive electrode of a power source, the cathodeplate is connected to a negative electrode of the power source, and the electrolytic cell is connected with the peristaltic pump through a guide pipe. The carbon ceramic shell-core-type three-dimensional particle electrode comprises 15-30 wt% of argil, coal powder the bulk density of which is 0.45-0.5 t / m<3> and metal salt which accounts for 1-9 wt% of the coal powder. The carbon ceramic shell-core-type three-dimensional particle electrode is high in catalytic activity and low in unit chemical oxygen demand energy dissipation, active components do not easily get lost, the service life is longeven after continuous use, the preparing process is simple, the price is low, the applicability is strong, and the carbon ceramic shell-core-type three-dimensional particle electrode is particularlysuitable for wastewater difficult to degrade biochemically.

Owner:东莞市晶昱环保设备工程有限公司

A special coating for anti-reconnaissance equipment fabric and its production method and fabric

ActiveCN106192479BReduce pollutionReconnaissance weakenedDyeing processProtective garmentTextile printerOrganic dye

The invention provides a coating special for a counterreconnaissance device fabric and a manufacturing method thereof and the fabric. The coating can be an inorganic printing coating. The coating comprises, by mass percentage, 5% of emulsifier, 0.3-0.5% of antifoaming agent, 1.0-1.5% of dispersing agent, 23-43% of disguised functional inorganic pigment, 20-33% of coating printing adhesive, 3-8% of thickener, and the balance water; and finally the coating with a mass percent of 100% is obtained. The coating achieves functions of visual reconnaissance prevention and near infrared surveillance prevention. The coating is an inorganic coating, and the problems that the environmental pollution is caused by previous printing of a camouflage fabric through an organic dye for clothes, tents and weapons and coating printing easily leads to aging and short service life are solved. Besides, in the printing production process, ageing color development and alkaline removal flooding treatment do not need to be performed, and compared with a conventional dye printing method, the coating generates fewer harmful substances and is lower in environmental pollution.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

An intelligent whole-process temperature-controlled steam curing kiln

ActiveCN105946107BAvoid product qualityEasy to control intelligentlyCeramic shaping apparatusTemperature controlProcess engineering

Owner:HENAN DINGLI POLE TOWER

Phase-change fire resistant conveyer belt

InactiveCN101428705BHeat-resistant temperature adjustableSimple production processConveyorsAdhesive beltHeat resistance

The invention belongs to the technical field of conveyer belts, in particular to a phase transition high-temperature resistant conveyer belt. The section of the conveyer belt is characterized in that side adhesives are arranged at the two ends of a fabric core layer or a steel wire rope layer; the steel wire rope layer is formed by enwrapping coil adhesive in the space outside the steel wire rope; a non-working surface adhesive is arranged at the lower end of the side adhesive and fabric coil layer or the steel wire rope layer; and a working surface adhesive is arranged at the upper end of the side adhesive and fabric coil layer or the steel wire rope layer. The invention realizes the adjustable heat-resistance temperature of an adhesive belt, and also realizes 250 to 500 DEG C temperature resistance performance. The invention has the advantages of simple production process, simple structure, and lower cost; can be popularized to the fields of the metallurgy industry, the electrical power industry and the building materials industry, and the application range is wide.

Owner:ZHEJIANG SOUTHEAST RUBBER CORP

A kind of iron ladle permanent lining and preparation method thereof

The invention relates to a ladle permanent lining and a manufacturing method of the ladle permanent lining, and belongs to the technical field of ferrous metallurgy ladle lining fireproof material. The ladle permanent lining is laid on the inner wall of a shell (6) of a ladle and sequentially comprises a ladle bottom permanent lining (1), a ladle wall permanent lining (3) and a ladle nozzle permanent lining (10) from bottom to top. The ladle permanent lining is characterized in that the ladle permanent lining is manufactured by minimum-inflation artesian flow castable in a segmented casting mode, an overall casting forming die is not used, and the ladle permanent lining and a bricked working lining are constructed synchronously. The technological process of repairing and laying the ladle lining is simplified, the problem that in the prior art, the bricked working lining leaks steel because the high-aluminum artesian flow castable shrinks in the hardening process is solved, compared with the prior art, the service life of the ladle working lining is prolonged by 150 furnace round-200 furnace round, and the cost of ladle fireproof material is reduced by over 15%.

Owner:LAIWU IRON & STEEL GRP

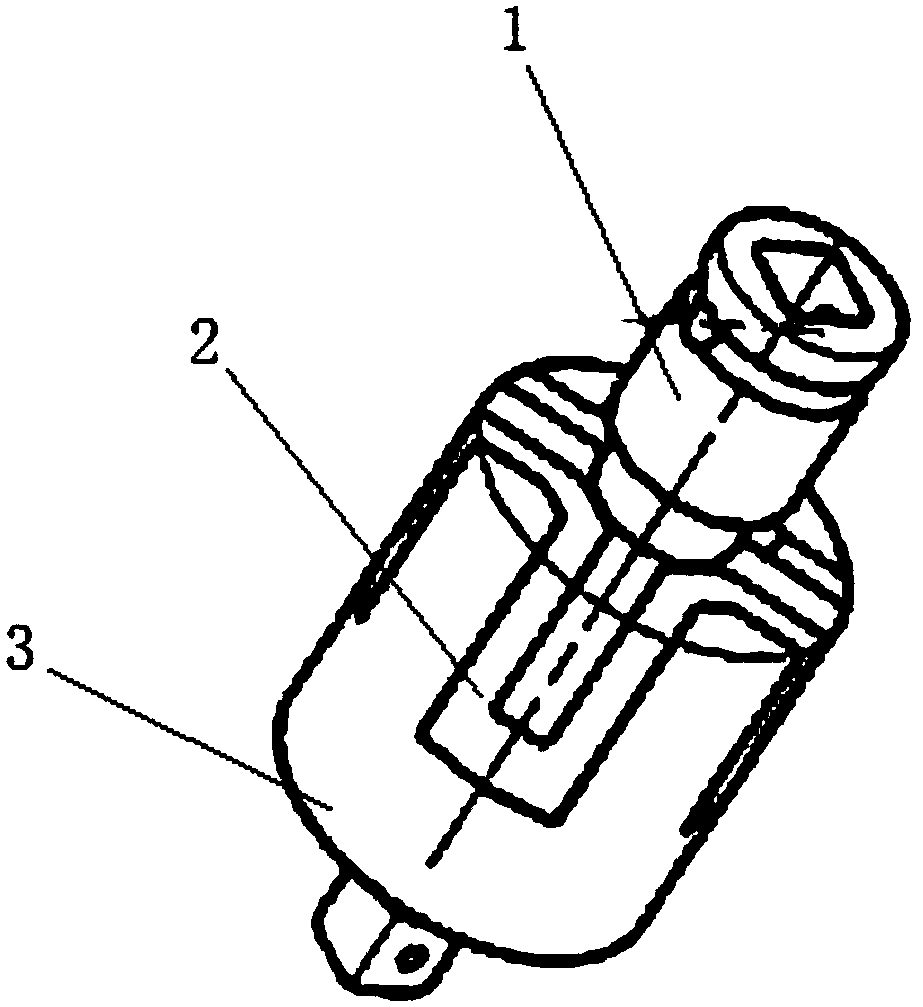

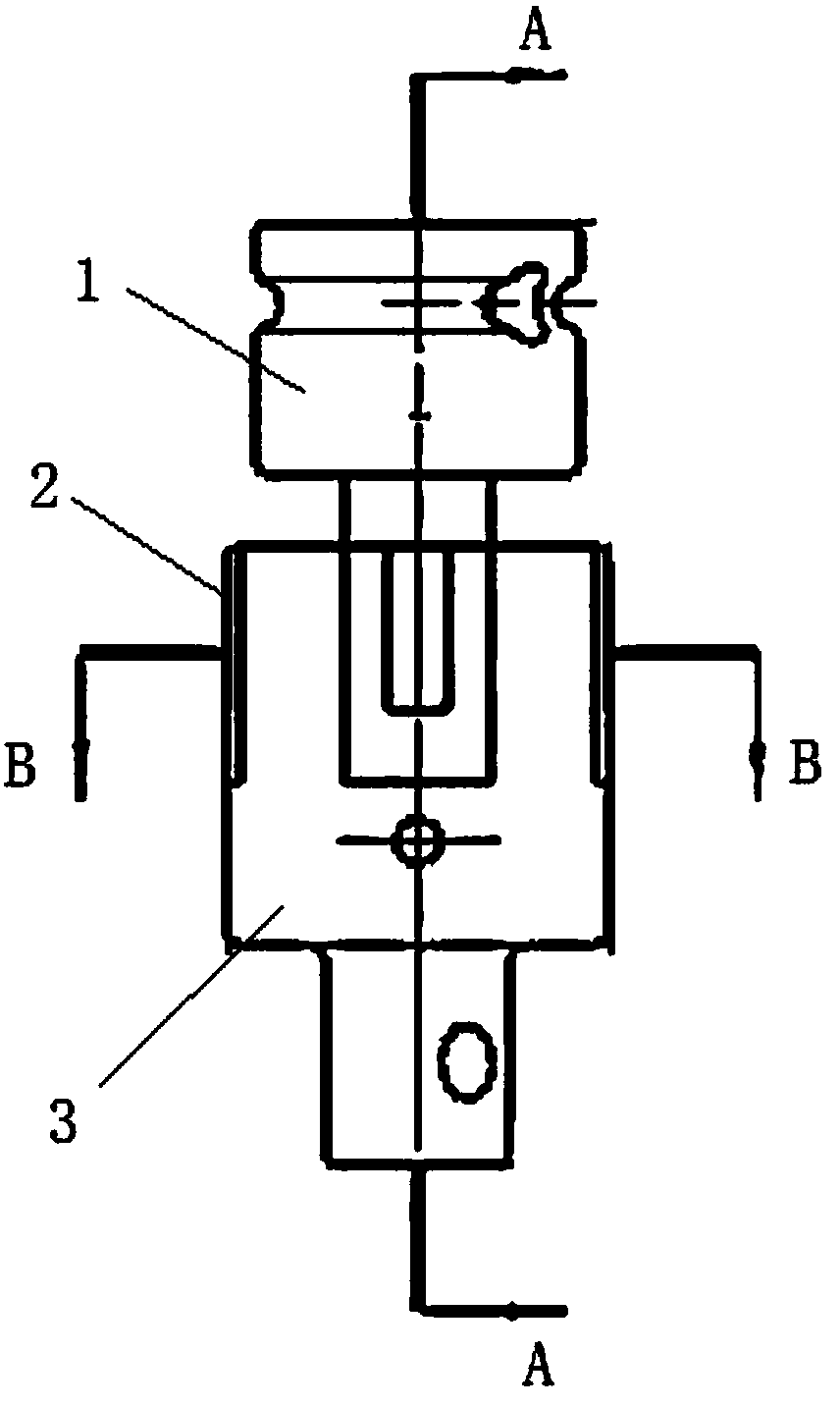

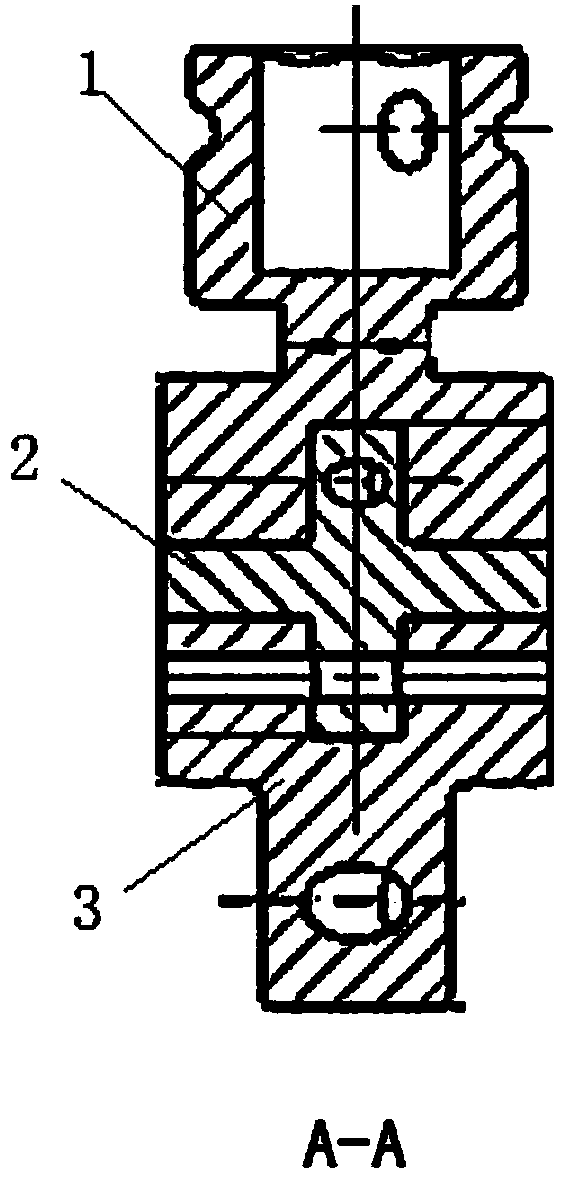

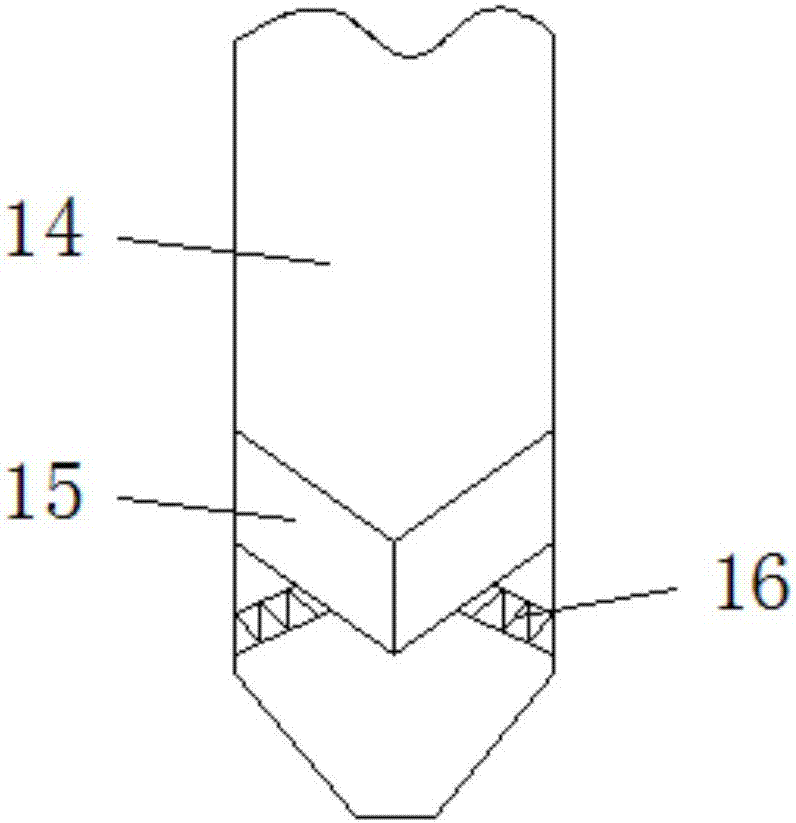

Insulating sleeve structure for new energy vehicle battery assembling

PendingCN108565079AHigh withstand voltageLong continuous service lifeInsulating bodiesContinuous useNew energy

The present invention discloses an insulating sleeve structure for new energy vehicle battery assembling. The structure comprises: a first adapter, wherein the upper portion of the first adapter is circular and is provided with a square standard slot, and the lower portion of the first adapter is provided with a cross-shaped plug; a middle insulation connection body, wherein the outer surface of the middle insulation connection body is provided with a first cylindrical structure, the middle portion of the first cylindrical structure comprises a cross-shaped plug, and the external portion of the first cylindrical structure is provided with four grooves with inclination angles of 45 degrees; and a second adapter, wherein the outer surface of the upper half portion of the second adapter is provided with a second cylindrical structure, the external portion of the second cylindrical structure comprises four stand columns with inclination angels of 45 degrees, and the lower half portion of the second adapter is a standard square head. The insulating sleeve structure is simple and reasonable, and convenient to install and use. the middle insulation connection body only bears the pressureload and does not load the torsion load so as to ensure that the insulation sleeve can bear large torque load, the insulating sleeve structure is high in withstand voltage, long in service life, goodin insulation effect and safe and reliable.

Owner:SHANGHAI SK SPECIAL MACHINERY CO LTD

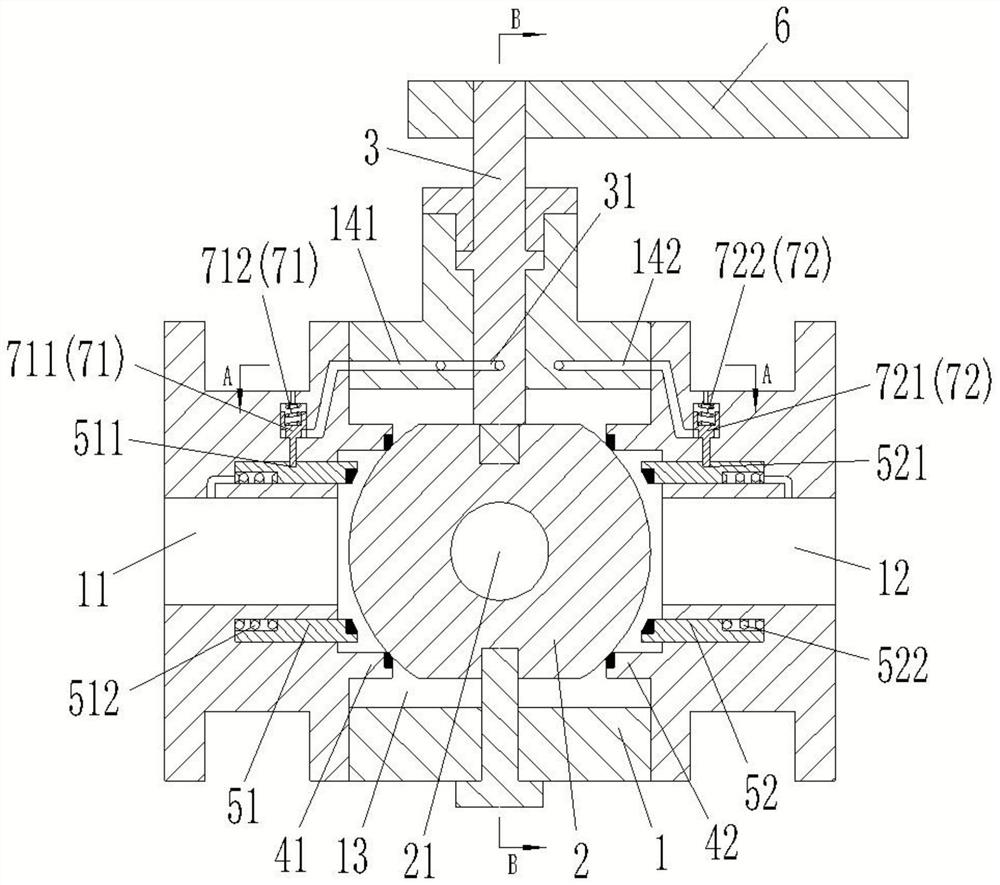

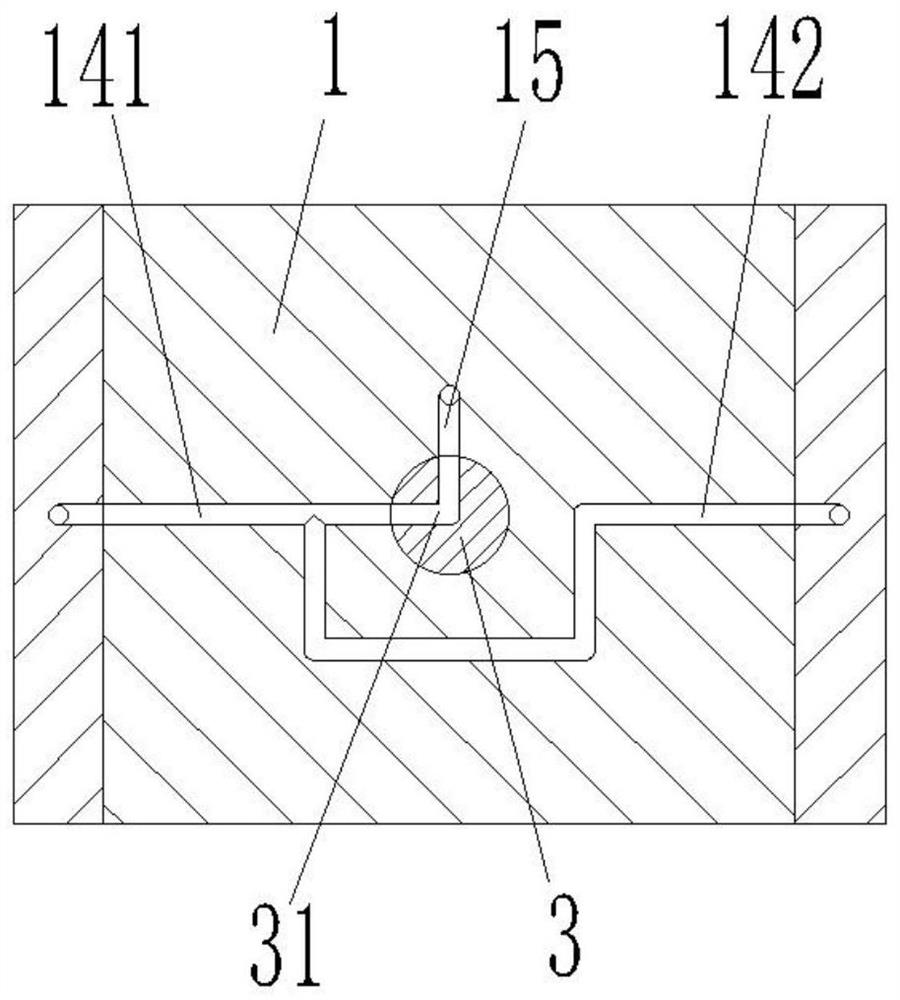

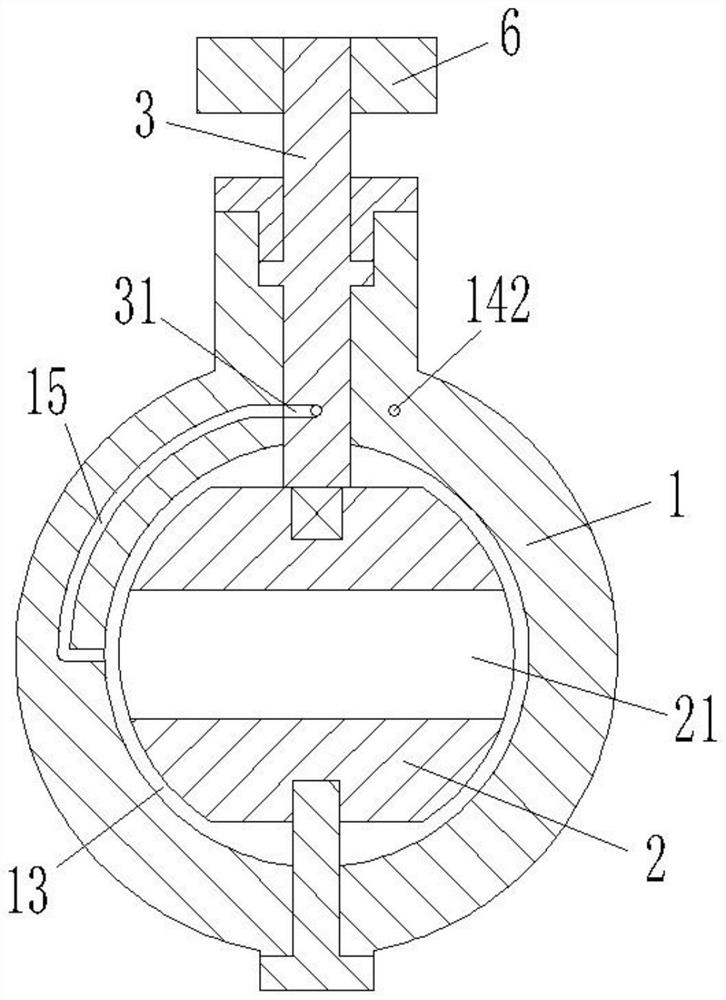

Ball valve

InactiveCN113217659AImprove leak-proof performanceImprove reliabilityPlug valvesValve housingsDrive shaftInlet valve

The invention belongs to the technical field of pipeline valves and discloses a ball valve. The ball valve comprises a valve body, a valve ball, a driving shaft, a first inlet valve seat, a first outlet valve seat, a second inlet valve seat and a second outlet valve seat; the first inlet valve seat and the first outlet valve seat are located at the inlet position and the outlet position in the valve body respectively and form normal contact sealing with the valve ball; the second inlet valve seat and the second outlet valve seat are located at the inlet position and the outlet position in the valve body respectively and form selective contact sealing with the valve ball; and when the sealing between the first inlet valve seat and / or the first outlet valve seat and the valve ball fails, the second inlet valve seat and the second outlet valve seat respectively move relative to the valve body and respectively form contact sealing with the valve ball. According to the ball valve provided by the invention, double-seal switching can be achieved, the anti-leakage effect is improved, and the ball valve has the longer service life.

Owner:任林赟

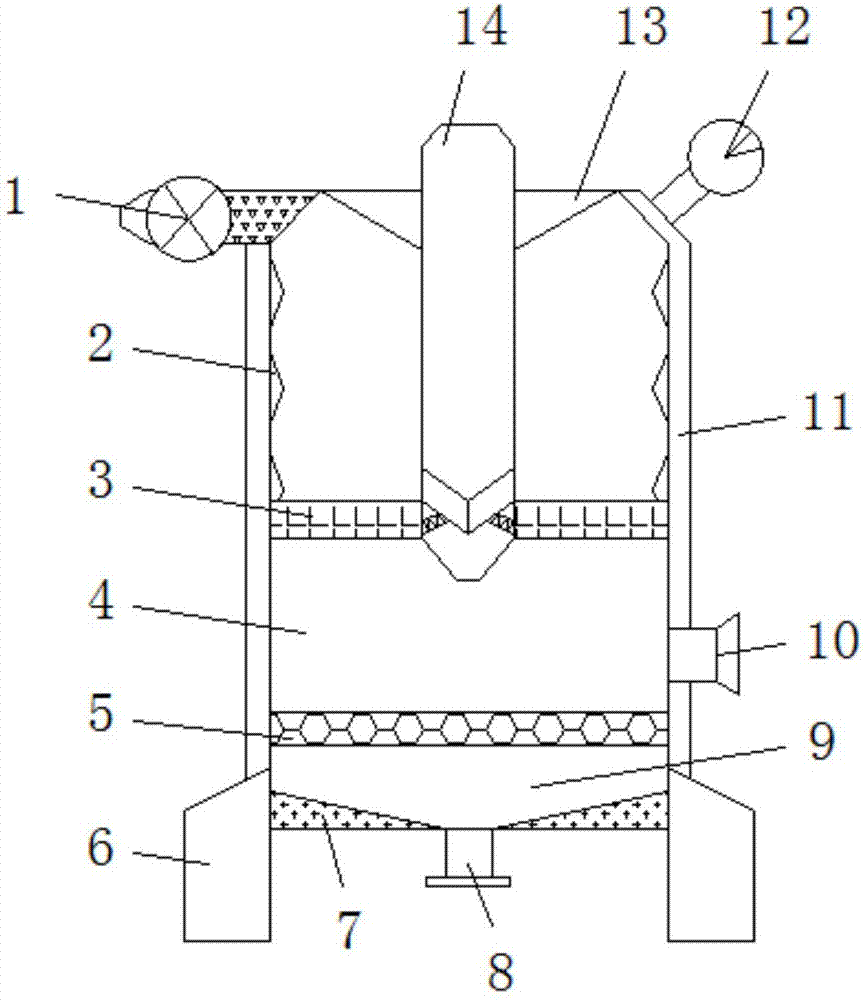

Efficient straw gasification furnace

InactiveCN107573969AFlow state is stableImprove collection efficiencyCombustible gas productionArchitectural engineering

The invention discloses an efficient straw gasification furnace, which comprises a furnace body, wherein one side of the top of the furnace body is provided with a deflation valve, and the other sideis provided with a barometer; the middle position of the top of the furnace body is provided with a feeding pipe; the inner surface wall of the feeding pipe is provided with a one-way valve rod; the bottom of the one-way valve rod is provided with a limiting spring; the inner top plate of the furnace body is provided with a buffer layer; the outer surface of the furnace body is provided with a vacuum layer; the inner surface wall of the furnace body is welded with a stream guiding block; the inner surface wall of the furnace body is provided with a clapboard and a filter plate; the bottom of the furnace body is welded with a dust collection cabin; two sides of the bottom of the dust collection cabin are provided with sloping benches; the bottom of the dust collection cabin is welded with ablow-off pipe; one side of the furnace body is welded with a gas pipe; two sides of the bottom of the furnace body are welded with brackets. In the efficient straw gasification furnace, a gasification device has the advantages of simple and reasonable integral structure design, stable and sealing connection, safe and convenient dust discharge and high practicality, and the operation burden of people is lowered.

Owner:CHENGDU ZHONGFU LIXIANG TECH

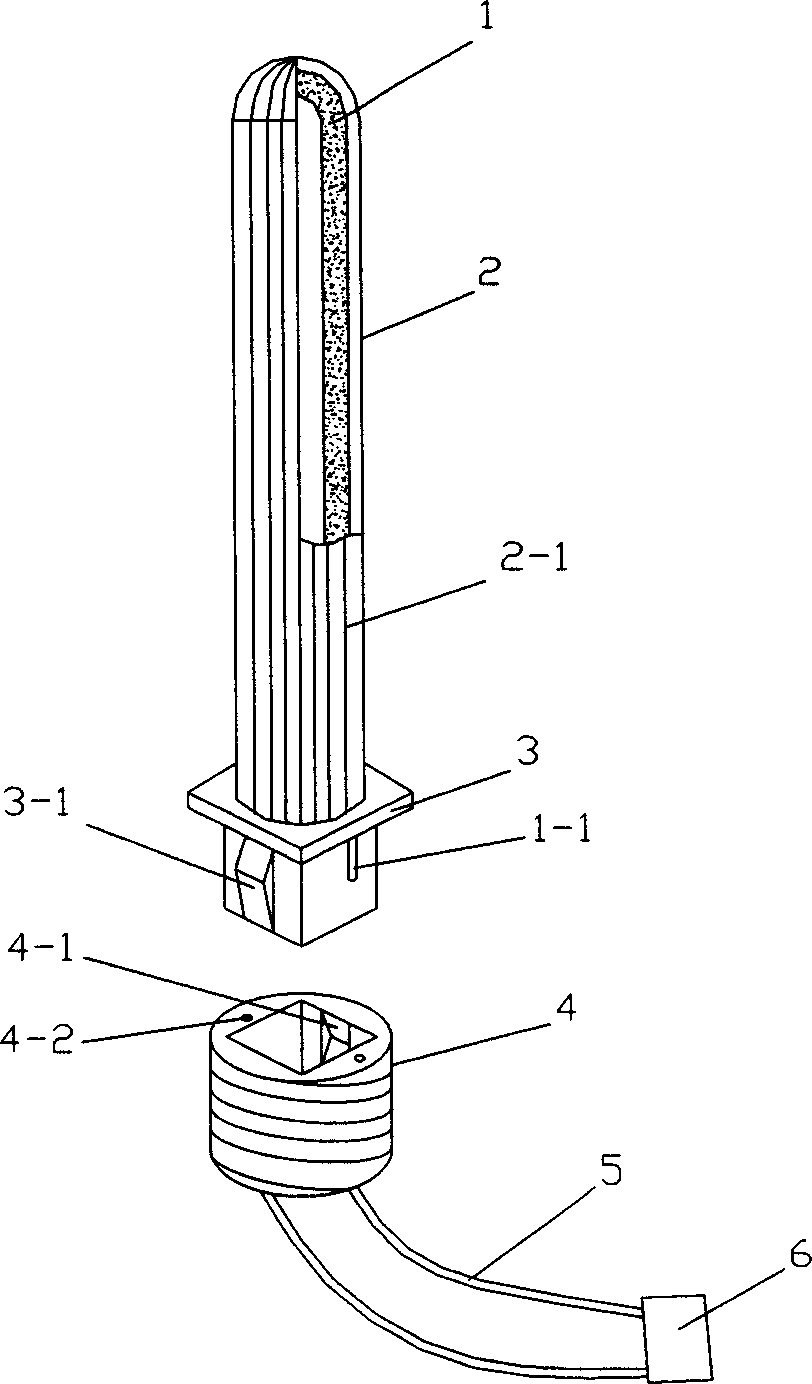

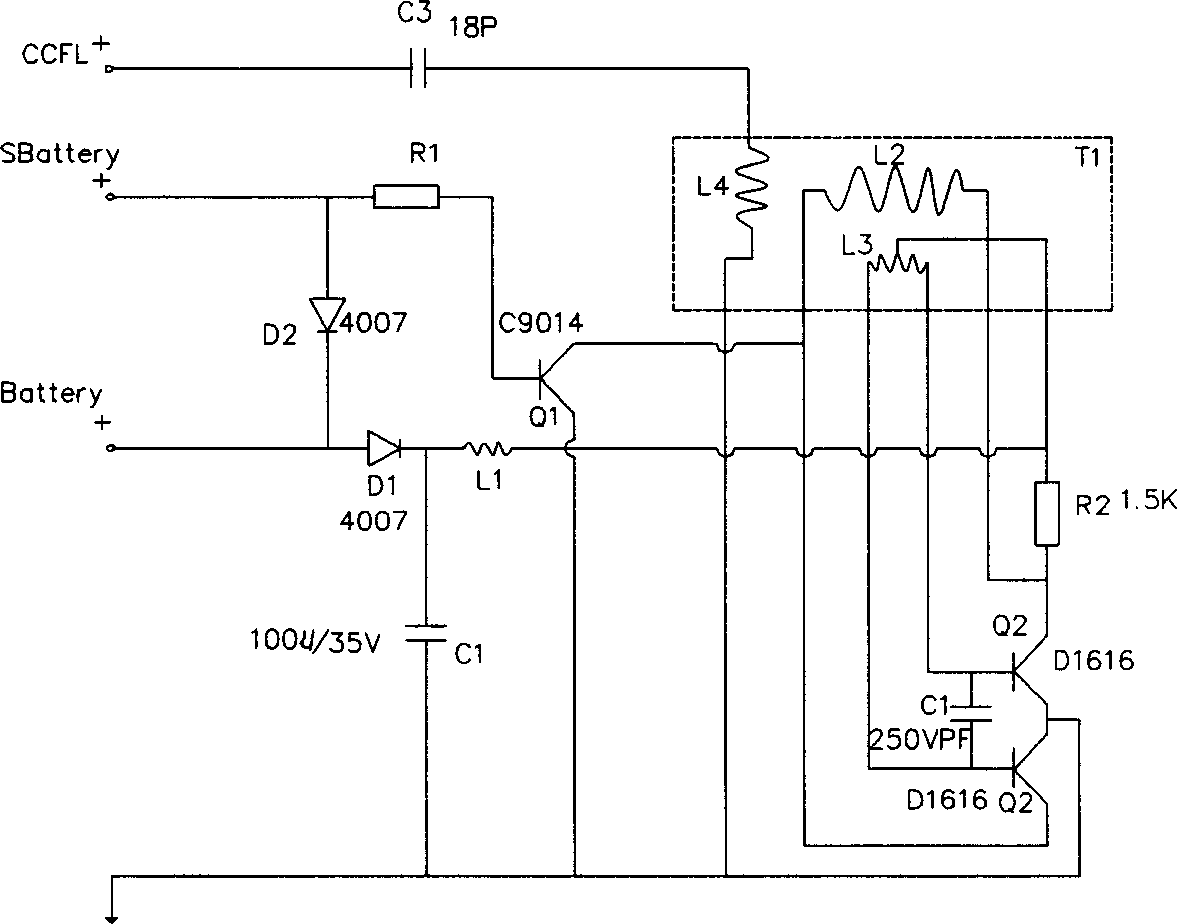

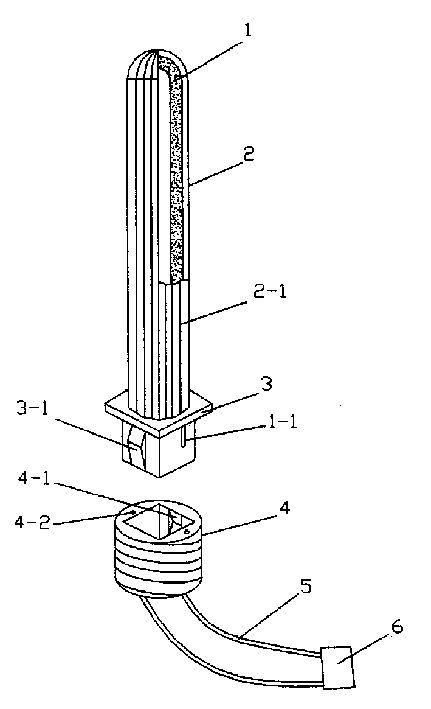

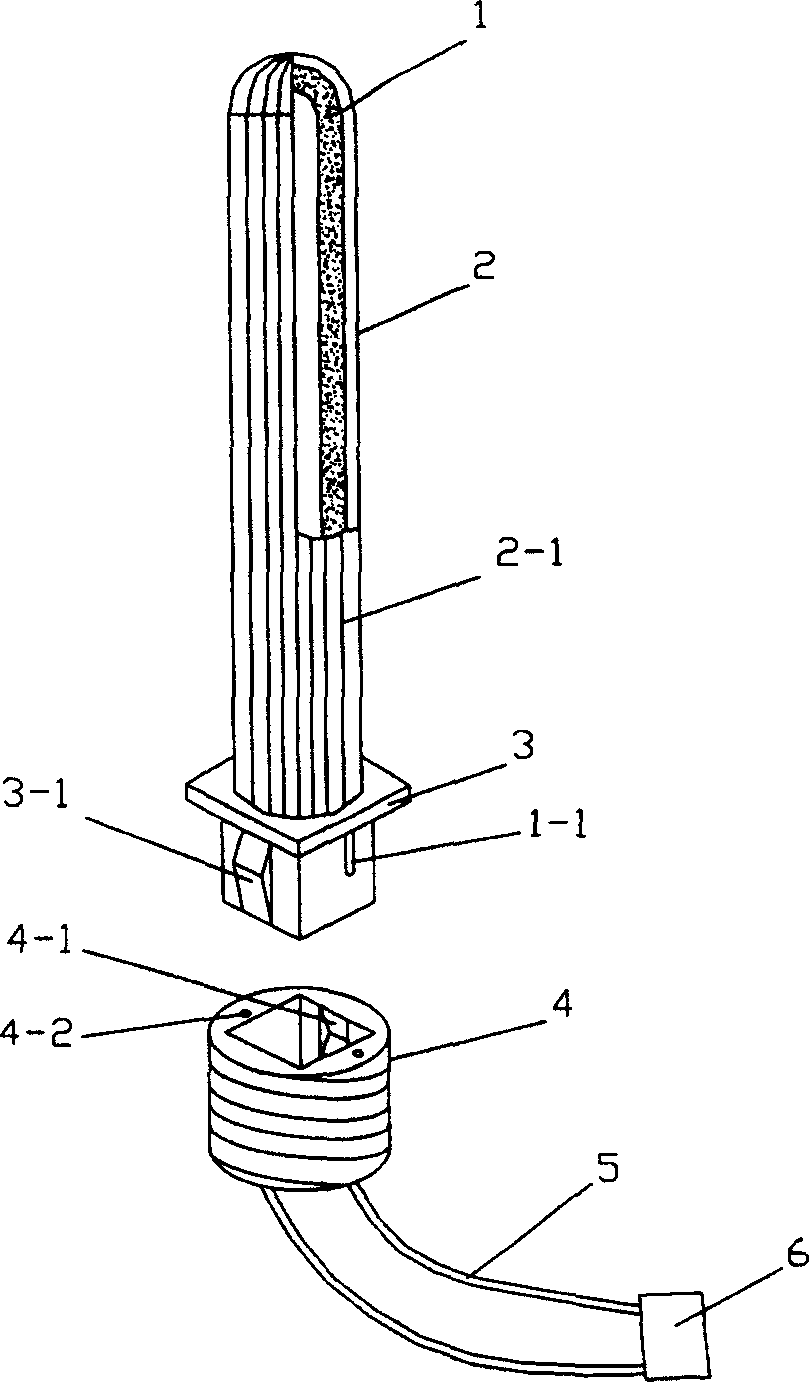

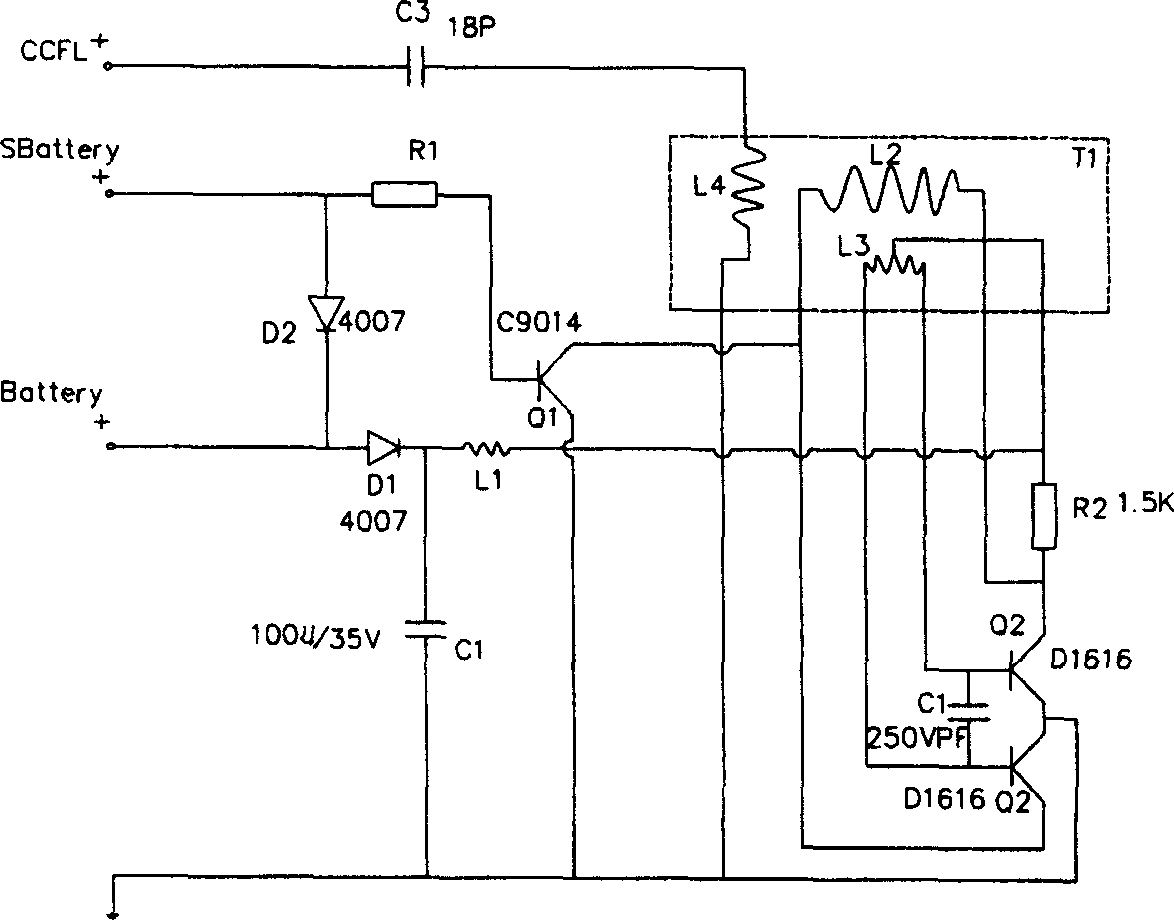

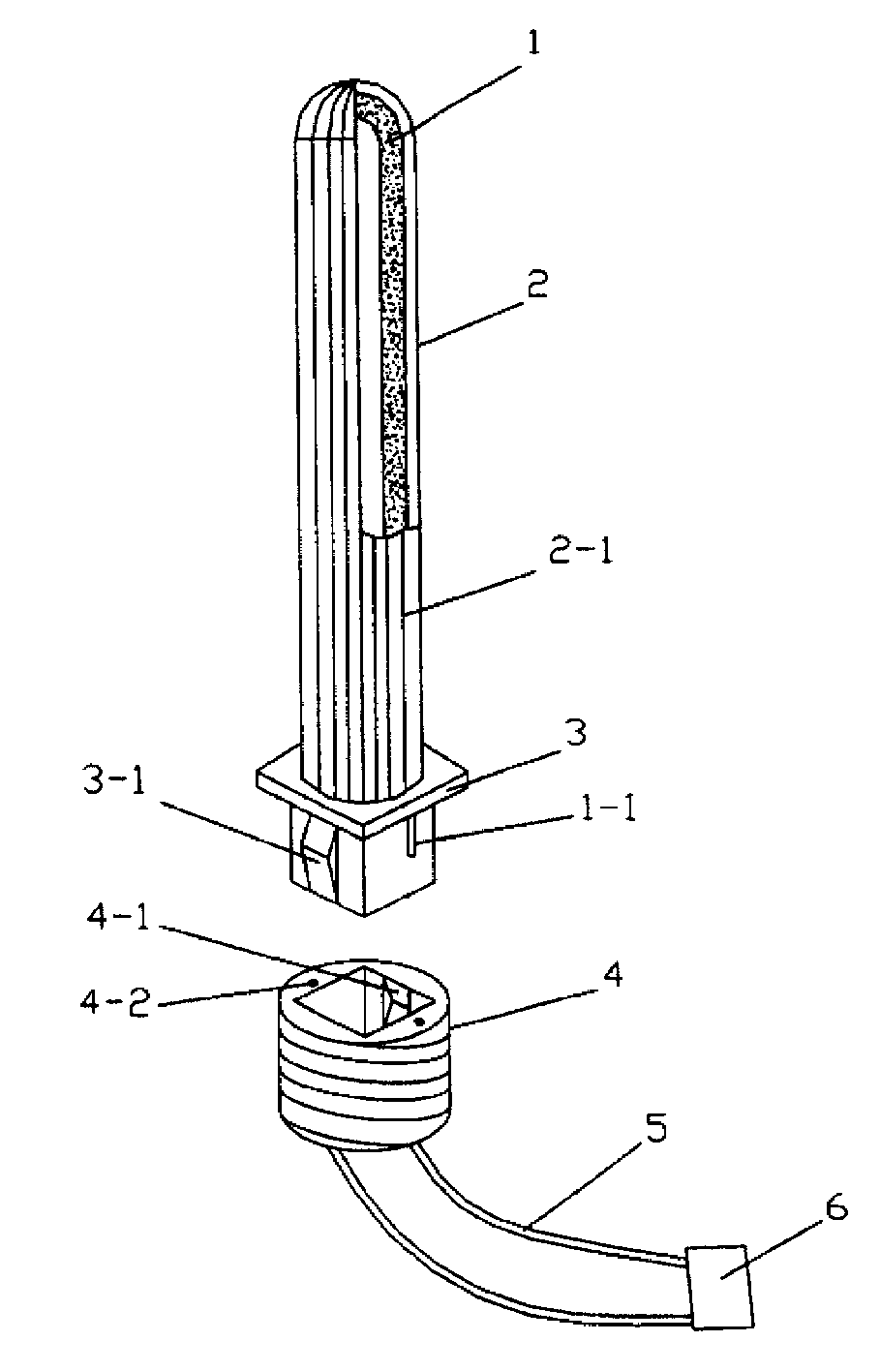

Cold cathode light-source and use thereof

InactiveCN1438446ALong continuous service lifeThere will be no burning problemBatteries circuit arrangementsElectric powerLuminous intensityCold cathode

The invention provides a kind of cold cathode light tube, it includes cold cathode light tube, lamp holder, control circuit. The cold cathode light tube is set o the lamp holder, the lamp holder connects with the control circuit; the cold cathode source is used as the lamp-house of the lamp, it connects with the solar battery and transforms the solar energy into electric energy.

Owner:李仲吉 +1

Electrode material for three-dimensional electrode and preparation method and application thereof

ActiveCN114477377AImprove applicabilityImprove stabilityWater treatment parameter controlWater contaminantsChemical oxygen demandContinuous use

The invention relates to the field of electrocatalytic oxidation, and discloses a method for preparing an electrode material for a three-dimensional electrode, the method comprises the following steps: impregnating an alumina matrix in an impregnation liquid containing metal ions, and sequentially drying and roasting the alumina matrix after the impregnation is completed, and the roasting is carried out under the protection of an inert atmosphere. The electrode material prepared by the method provided by the invention has the advantages of high applicability, good stability, high catalytic activity, low energy consumption per unit chemical oxygen demand, difficult loss of active components, long continuous service life and the like, can be regenerated and reused for multiple times, and is suitable for large-scale industrial production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

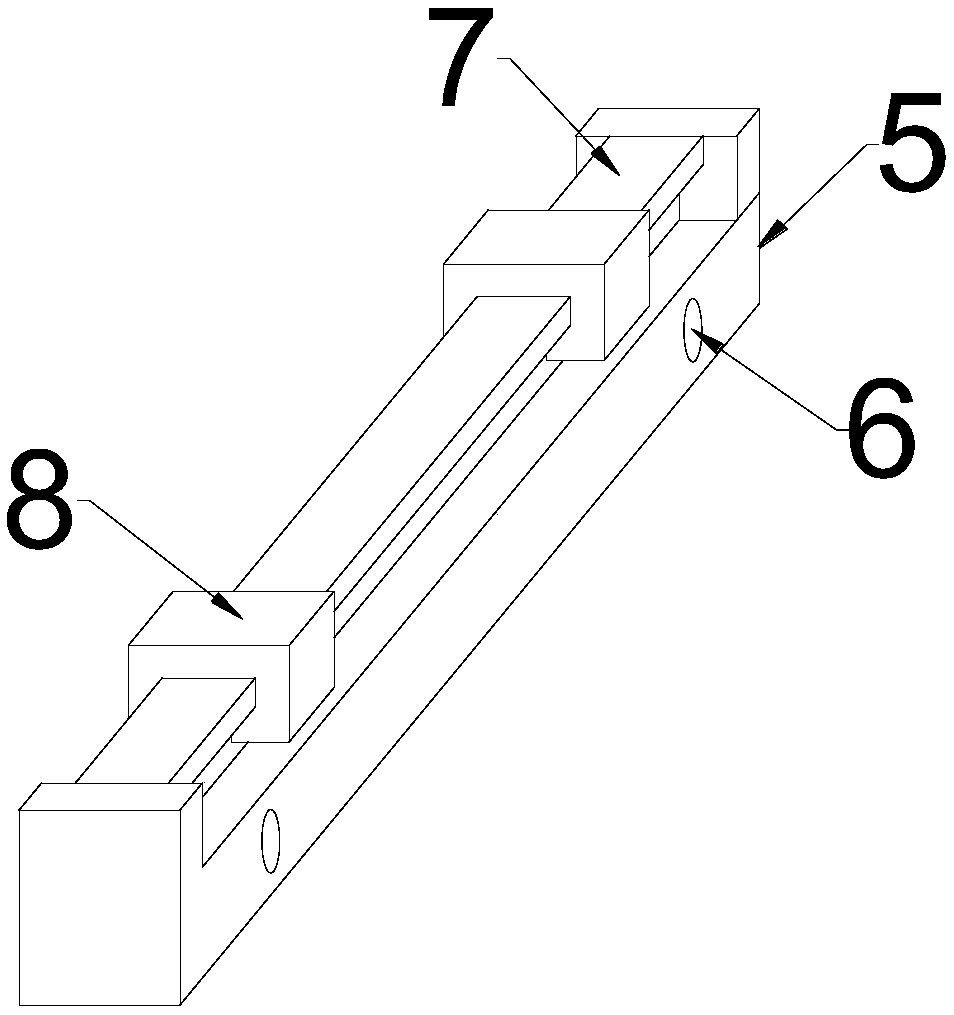

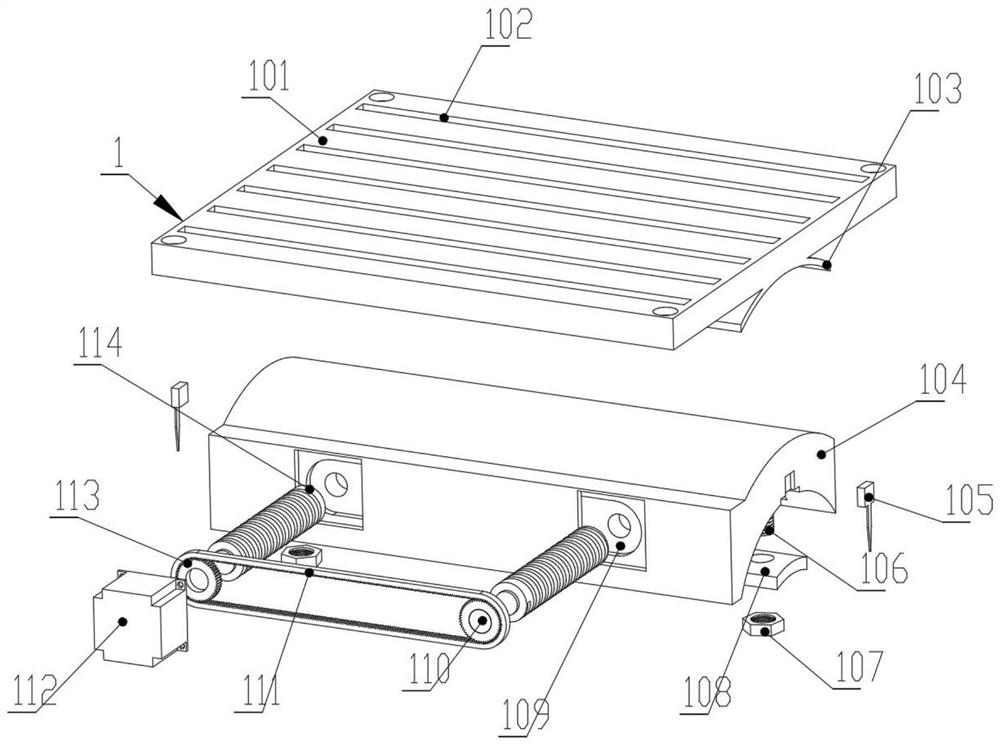

A Mechanical Clamping Mechanism That Can Accurately Adjust Clamping Angle

ActiveCN111633617BHigh precisionImprove stabilityWork benchesMechanical energy handlingElectric machineryEngineering

The invention discloses a mechanical clamping mechanism capable of precisely adjusting the clamping inclination angle, which includes a positioning mechanism, a motor slot, a supporting mechanism, a dial, an insertion slot and a limit card seat, and the side end surface of the support mechanism passes through the insertion slot The symmetrical rotation snaps into the limited card seat. The present invention can drive two sets of connecting worms to rotate through the fixed motor when adjusting the angle of the clamping workpiece. When the connecting worms rotate, since the connecting worms and the connecting worm gears are meshed, the positioning mechanism can be driven to turn over at the top of the supporting mechanism. , so as to accurately adjust the angle of the workpiece flipping and clamping, and the adjustment method of thread engagement can effectively improve the accuracy and stability of the subsequent adjustment of the clamping angle. The perimeter is programmed, which further improves the accuracy of angle adjustment when clamping the workpiece, reduces the error of manual adjustment, and improves efficiency.

Owner:中泓智能科技(河北)有限公司

An anti-reconnaissance and camouflage functional inorganic pigment, inorganic printing paint and fabric

ActiveCN106436377BImprove absorbing performanceImprove light fastnessDyeing processProtective garmentUltravioletManganese

The invention provides a counterreconnaissance pretending functional inorganic pigment, an inorganic printing coating and a fabric; the counterreconnaissance pretending functional inorganic pigment includes mixtures of any several types of titanium chrome yellow, titanium manganese brown, cobalt blue, titanium cobalt green, titanium nickel yellow, copper eriochrome black or iron eriochrome black; after adding the emulgator, the dispersing agent, the flame retardant, and water or solvent type PU glue and others, the reflectivity of near infrared ray corresponding to the color block required and the lightness L, a, and b values can be obtained; moreover, more metal elements are applied to improve the wave absorbing effect and also improve the fastness , and guarantee no color fading under the ultraviolet irradiation for thousands of hours. The front face of the fabric layer using the coating can be coated with digital camouflage pattern; the opposite face can be coated through the coating; the dual-faced coating can make that the static water pressure resistance index is over double to the fabric in the past; thus the fabric has higher waterproof and wet penetration, and the overall performance is better.

Owner:ZHEJIANG SHENGFA TEXTILE PRINTING & DYEING

Vanadium nano electrothermal material

PendingCN111304590AImprove securityGuaranteed reservesMaterial nanotechnologyVacuum evaporation coatingSputteringVanadium atom

The invention provides a vanadium nano electrothermal material, belongs to the technical field of branch nanomaterials of new material large classes, and particularly provides a vanadium nano electrothermal material body mainly formed by vanadium. The nanomaterial is formed in the manner that vanadium, nickel, tungsten and chromium at the mass percent of 40%-80%-10%-30%-5%-16%-0%-15% are embed-plated on base materials with different sizes and shapes such as the pipe shape, the plate shape, the piece shape, the strip shape and the round shape made of quartz glass, ceramic and other materials with specially-treated surfaces through sputtering. The thickness of a film is 5,000-20,000 nanometers, the material has the properties that the electrothermal conversion rate is high, heating is extremely rapid, the heating surface temperature is high, the durability is long, the material is resistant to scratching and does not disengage, the power is not attenuated, and the magnetic radiation is low, and power can be supplied through 10 V-220 V alternating and direct currents. The material is prepared into various heating assemblies and designed into various novel electric appliances and equipment, the beneficial effects that instant heating is achieved, the cost performance is high, energy is saved, and environmental friendliness is achieved are achieved, use is easy, and the applicationrange is wide. The vanadium nano electrothermal material fills up the blank of the world in the field of electrothermal heating application and has extremely high use value and broad application prospects.

Owner:彭文婷

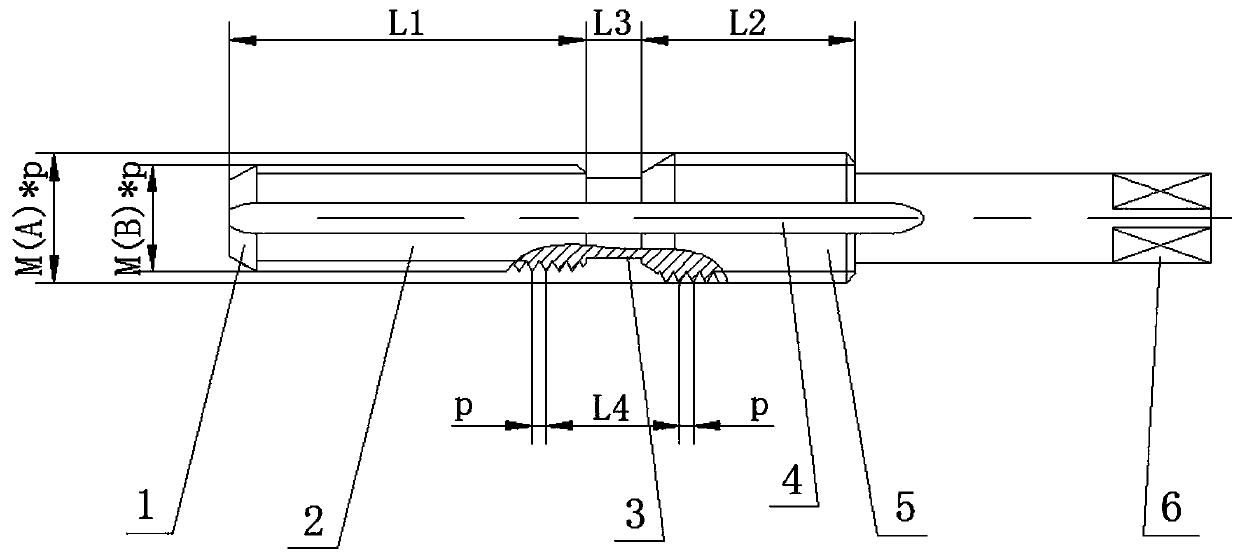

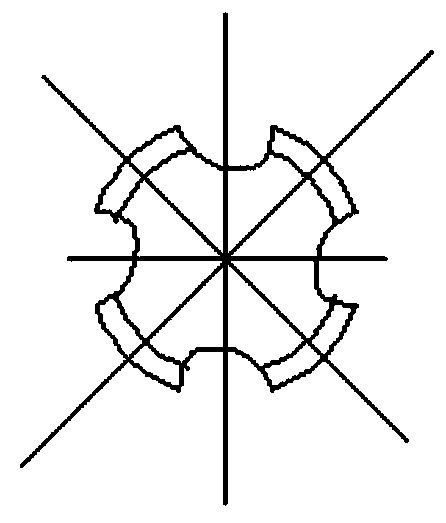

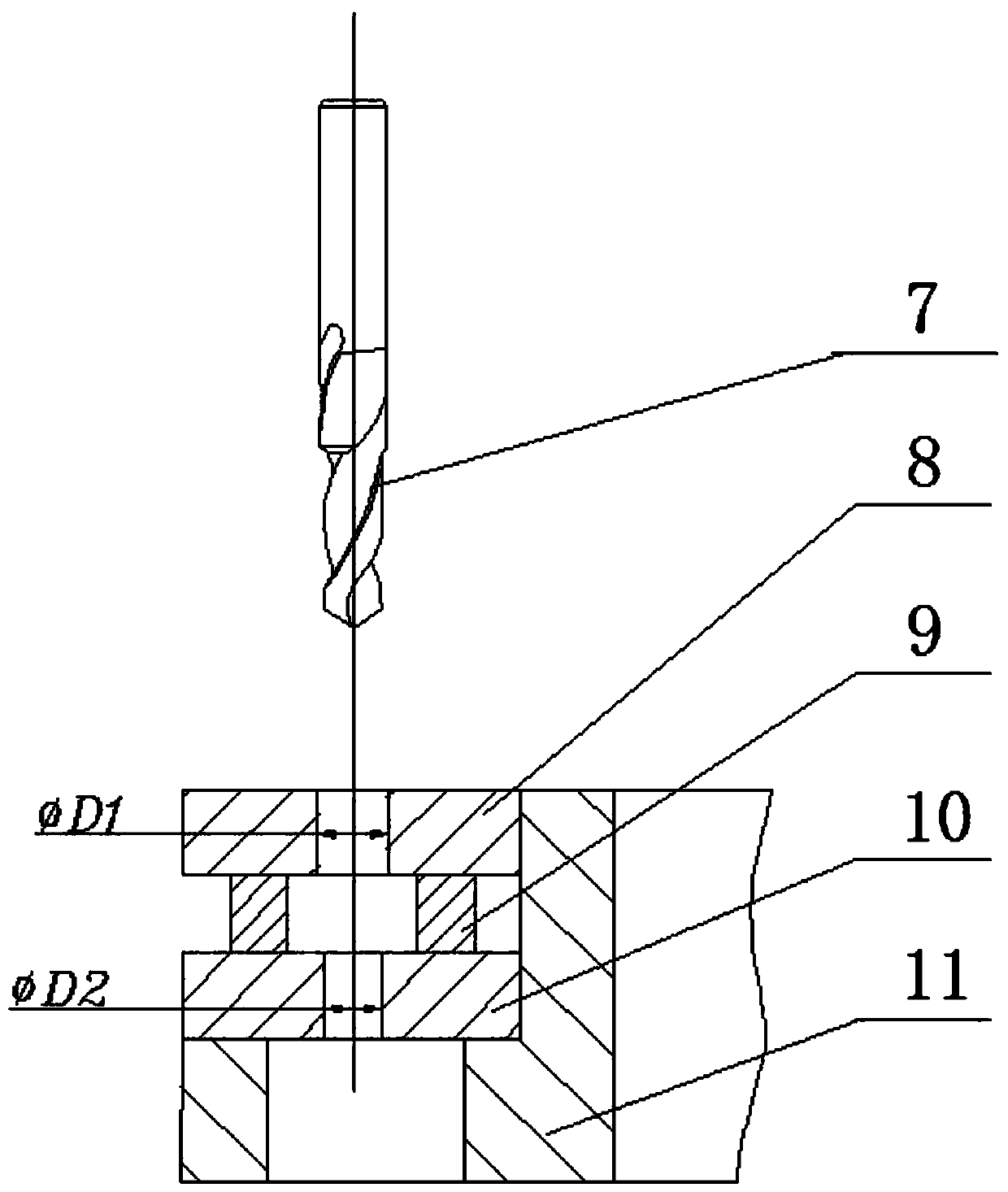

Holder assembly double threaded hole machining method and double-order single-screw tap used for same

PendingCN110614479AImprove concentricity differenceQuality improvementThread cutting toolsFluteScrew thread

The invention discloses a double-order single-screw tap used for holder assembly double threaded hole machining. The tap comprises a first section part and a second section part which are connected into an integral formed structure; the first section part comprises a first-order tap, a tool withdrawal groove and a second-order tap which are connected into an integral formed structure; the front end of the first-order tap is provided with a front blade B, and the outer circumference of the first-order tap is provided with a first-order thread; the front end of the second-order tap is provided with a front blade A, and the outer circumference of the second-order tap is provided with a second-order thread; and the outer circumferences of the first section part and the second section part areprovided with flutes, and the rear part of the second section part is provided with a cutter handle. According to the tap, controllable batch machining of a machine tool is realized, the serious quality problems that double threaded holes are different in concentricity and not uniform in perpendicularity are solved, and the quality of the machined same set of matched products is guaranteed to be 100% qualified, which cannot be guaranteed by manual thread machining; and in particular, when threaded holes of a holder are more, the production mode of a matched supporting column is changed from traditional single selecting and matching to standardized batch production.

Owner:WAFANGDIAN METALLURGICAL BEARING GRP CO LTD

Electrolytic ozone generator and preparation technique for cathode catalysis layer thereof

InactiveCN101250710BLong continuous service lifeImprove current efficiencyElectrolysis componentsDiamond electrodesElectrolysis

The invention relates to an electrolytic type ozone generator and a process for preparing a cathode catalyst layer of the electrolytic type ozone generator. The electrolytic type ozone generator comprises a round Nafion film, a round anode component and a round cathode component which are arranged on two axial sides of the Nafion film. The electrolytic type ozone generator adopts a diamond electrode which is doped with porous boron as an anode, the cathode catalyst layer adopts a process for preparing platinum-on-carbon and an electrolysis chamber for preparing ozone is optimally designed, notonly the performance is greatly increased, but also the current efficiency of a borocarbon electrode to produce the ozone is greatly increased, the current efficiency can reach 30% under room temperature to the maximum, and the continuous service life of the electrodes can be greatly prolonged compared with lead dioxide electrodes which are used in a large number at present.

Owner:SHAANXI UNIV OF SCI & TECH

Adsorption material, preparation method thereof, dye wastewater treatment method and application of adsorption material and dye wastewater treatment method

PendingCN114471446AEasy to prepareLow priceOther chemical processesWater contaminantsContinuous usePhysical chemistry

The invention relates to the technical field of adsorption separation, and discloses an adsorption material, which comprises an alumina matrix, and polyacrylamide and metal cations loaded on the alumina matrix. The adsorption material provided by the invention is high in adsorption efficiency, large in unit adsorption capacity and long in continuous service life, and has the advantages that the preparation method is simple, the adsorption material can be regenerated and repeatedly used for multiple times, and the performance is still stable after the adsorption material is repeatedly used for multiple times. The method is especially suitable for adsorption treatment of dye wastewater, the treated wastewater can reach the discharge or biochemical treatment standard, and the method is suitable for industrial large-scale production and application.

Owner:CHINA PETROLEUM & CHEM CORP +1

A method for repairing the circular seam of the ladle slag line

The invention relates to a repair mode for a circumferential weld in a ladle slag line part. The minimum residual thickness permitted by a circumferential weld is h, the residual thickness of a slag line brick on the upper part of the circumferential weld is greater than or equal to 150mm, and the thinnest part of the circumferential weld is opened and the thickness h1 is measured first; if h1 is greater than or equal to h, smearing repair is adopted; if h1 is smaller than h, repair is performed by adopting a mending method by replacing a damaged part; the mending method by replacing the damaged part comprises the following steps of: S1, removing the part of the circumferential weld, the thickness of which is smaller than h, along the circumferential weld, and in the removing process, setting a plurality of pivot points between upper available bricks and lower available bricks; S2, thoroughly cleaning and smoothly modifying the lower surfaces of the upper available bricks and the upper surfaces of the lower available bricks; S3, performing bricklaying by using repair bricks; S4, closing the circumferential weld; and S5, baking the repaired ladles according to a bake curve which is slightly modified for later use. According to the repair mode provided by the invention, the circumferential weld part is only removed and repaired, so that the integral structure of a ladle refractory material is retained to the maximum extent, and therefore, the consumption of the ladle refractory material of steel per ton is reduced, and the repair mode is energy-saving, low-carbon and environmental-friendly.

Owner:北京利尔高温材料股份有限公司

A kind of preparation method of hydroxycitronellal

ActiveCN108892607BRaw materials are easy to getHigh catalytic activityOrganic compound preparationPreparation by dehydrogenationPtru catalystAlkali metal oxide

The invention provides a method for preparing hydroxycitronellal, which comprises the steps of preparing a solid dehydrogenation catalyst; the preparation of the solid dehydrogenation catalyst: adopts zeolite as a carrier to support the dehydrogenation catalyst. The zeolite supports an alkali metal oxide, and the alkali metal oxide can be K 2 O, Rb 2 O, Cs 2 Any one of O, preferably K 2 O, Cs 2 O, the mass ratio of the loading amount of the alkali metal oxide to the zeolite is: 0.001˜0.01:1, preferably 0.006˜0.008:1. The invention has simple process and high efficiency; the loaded solid dehydrogenation catalyst has easy-to-obtain raw materials, high catalytic activity and low reaction temperature.

Owner:SHANDONG NHU PHARMA

Rubber container airbag-type water hammer absorber for waterway pipe network

PendingCN113700967AExpansion protectionLong continuous service lifePipe elementsMarine engineeringSlide plate

The invention relates to the field of water hammer elimination equipment, and discloses a rubber container airbag-type water hammer absorber for a waterway pipe network. The rubber container airbag-type water hammer absorber comprises a pipe body, wherein an upper sliding plate movably sleeves the top of an inner cavity of the pipe body; a through hole is formed in the upper sliding plate; a hammer suction pipe is fixedly connected to the middle of the bottom end of the pipe body; a bottom flange of the hammer suction pipe is connected with a compensation pipe; the compensation pipe communicates with the waterway pipe network; and the bottom of the inner cavity of the pipe body is fixedly sleeved with a lower annular plate located above the compensation pipe. Through the structural design that the hammer suction pipe and the upper sliding plate in the pipe body can move downwards as a whole, a passive sealing block on the hammer suction pipe and a positioning sealing ring fixedly sleeving the the side wall of the inner cavity of the pipe body are matched to clamp a rubber container airbag, so that normal pipeline water hammer elimination is not affected, and when water pressure generated by a water hammer is too large, the passive sealing block can move downwards to be separated from the positioning sealing ring, so that water drainage and pressure relief are carried out, and the expansion of the rubber container airbag is effectively protected.

Owner:宫兆旭

Cold cathode light-source and use thereof

InactiveCN1245587CLong continuous service lifeThere will be no burning problemMechanical apparatusBatteries circuit arrangementsCold cathodeEngineering

The invention provides a kind of cold cathode light tube, it includes cold cathode light tube, lamp holder, control circuit. The cold cathode light tube is set o the lamp holder, the lamp holder connects with the control circuit; the cold cathode source is used as the lamp-house of the lamp, it connects with the solar battery and transforms the solar energy into electric energy.

Owner:李仲吉 +1

A Plasma Synthetic Jet Generator with Controllable Cavity Temperature and Its Application

A plasma synthetic jet generator with controllable cavity temperature and its application. The nozzle includes: a heat conduction support structure, a heat pipe, a cavity, electrodes and a DC high-voltage pulse power supply; wherein the electrodes include an anode, a cathode and an excitation electrode; The cavity, the electrode and the DC high-voltage pulse power supply constitute a plasma synthetic jet generator; the heat management component includes the heat-conducting support structure and heat pipes; the DC high-voltage pulse power supply and the electrode are connected through wires ; The electrode forms a high-frequency arc under the excitation of the DC high-voltage pulse power supply. In one excitation cycle, the arc heats the gas in the cavity, and sprays it into the main flow through the oblique hole in the cavity, and the high-temperature gas is ejected Afterwards, the density in the cavity decreases and the temperature rises, and the mainstream gas is sucked into the cavity through the oblique hole of the cavity to form a working cycle; the heat management component conducts the high temperature of the cavity to the cold end of the heat pipe, which can The temperature in the cavity is lowered, thereby increasing the density in the cavity. The invention greatly improves the momentum of jet flow ejected from the plasma synthetic jet flow generator.

Owner:CHINA ACAD OF AEROSPACE AERODYNAMICS

Bipolar three-dimensional electrode catalyst packing and preparation method thereof

InactiveCN102764660BExtended service lifeImprove distributionWater/sewage treatment by electrochemical methodsMetal/metal-oxides/metal-hydroxide catalystsChemical oxygen demandActive component

Owner:HUNAN NORMAL UNIVERSITY

Ladle composite working lining and method for repairing slag line parts thereof

The invention relates to a steel ladle composite working lining and a repairing method for a slag line position thereof. The steel ladle composite working lining comprises a steel ladle shell, a permanent lining insulating refractory plate and permanent lining castable are arranged on the inner wall of the steel ladle shell, the upper portion of the permanent lining castable at the ladle bottom is provided with ladle bottom working lining castable, ladle wall working lining castable, a slag line part, single-ring ladle opening bricks and ladle edge castable from bottom to top, and water gap seat bricks and air permeable seat bricks are arranged in the ladle bottom working lining castable; the slag line part is arranged to be divided into an inner ring and an outer ring, and the inner ring comprises slag line bottom inner ring bricks and slag line inner ring alumina-magnesia-carbon bricks from bottom to top; the outer ring comprises slag line bottom outer ring bricks and slag line outer ring magnesia-carbon bricks from bottom to top. When the slag line position of the steel ladle composite working lining is subjected to the first minor repair, the second minor repair and the first medium repair, the used slag line bottom inner ring bricks and the slag line inner ring alumina-magnesia-carbon bricks are reserved, only the slag line bottom outer ring bricks and the slag line outer ring magnesia-carbon bricks are dismantled and replaced, and therefore the consumption of the working lining slag line magnesia-carbon bricks is reduced.

Owner:SHANDONG IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com