Patents

Literature

186results about How to "High withstand voltage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

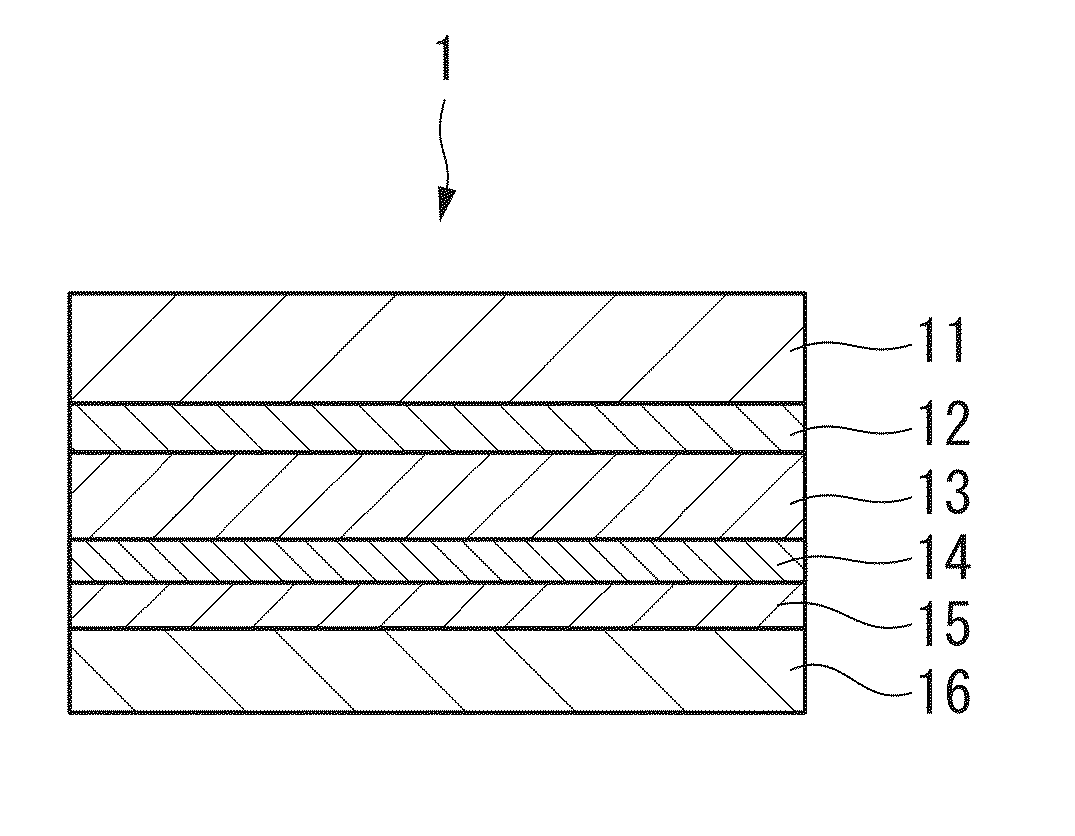

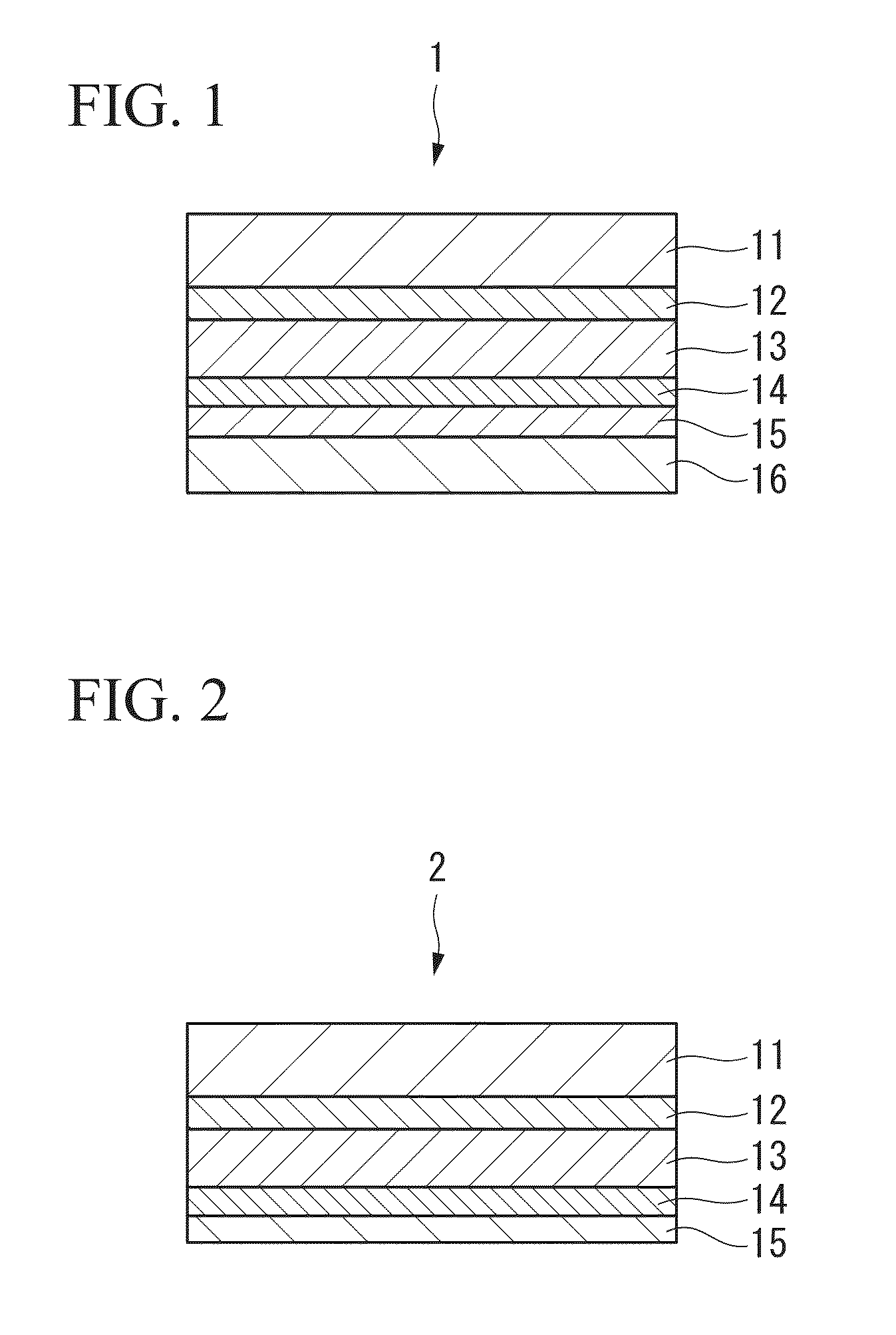

Lithium ion battery exterior material

ActiveUS20130209868A1Improve pressure resistanceImprove moisture resistanceSynthetic resin layered productsSpecific condition cell workingElastomerPolyolefin

A lithium ion battery exterior material, includes: a base material layer, and a sequentially laminated adhesive layer, aluminum foil layer provided with a corrosion prevention treated layer, and an adhesive resin layer on one surface of the base material layer; wherein, the adhesive resin layer contains an acid-modified polyolefin resin and a miscible elastomer dispersed in the acid-modified polyolefin at a dispersed phase size of 1 nm to less than 1 μm.

Owner:TOPPAN PRINTING CO LTD

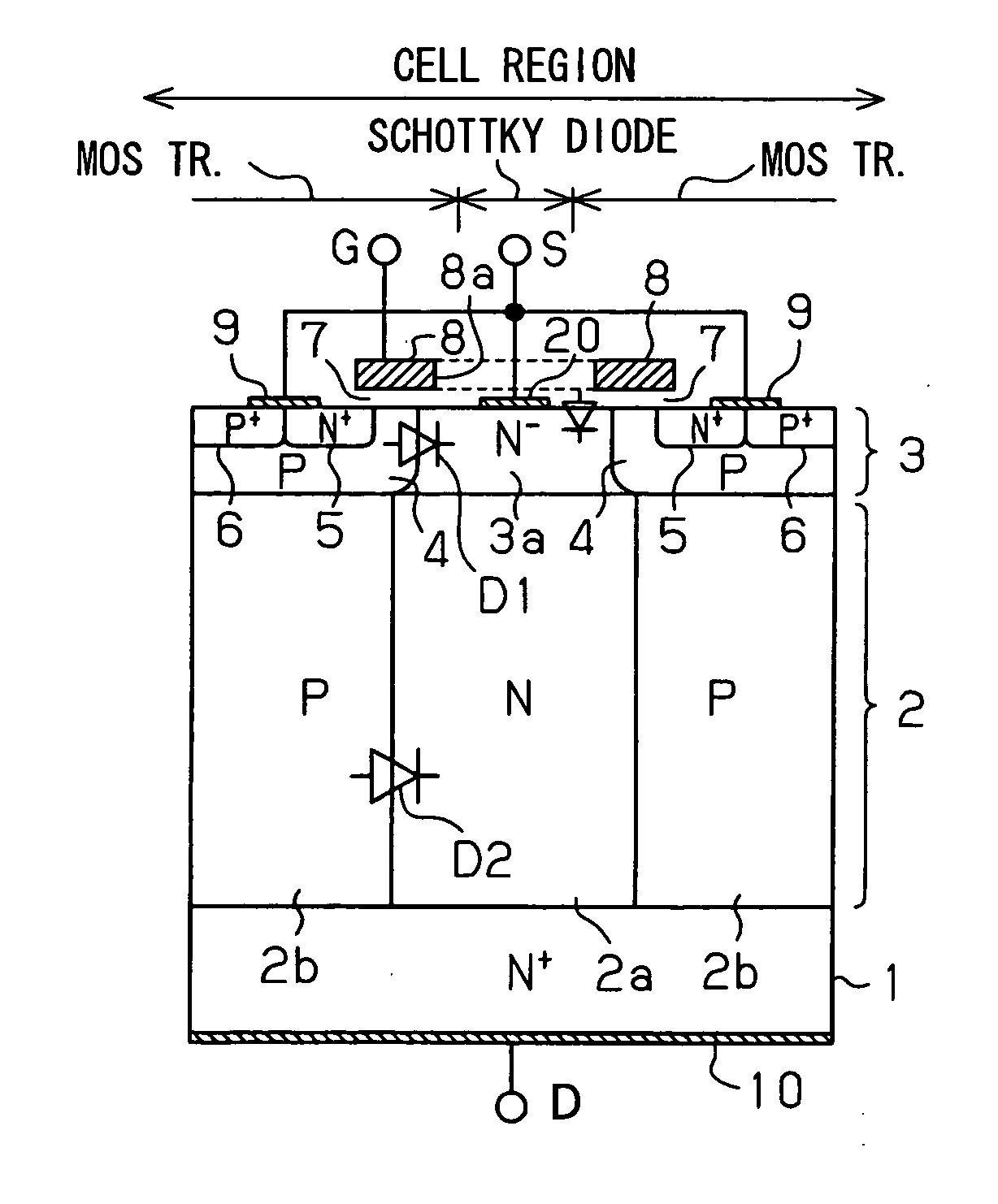

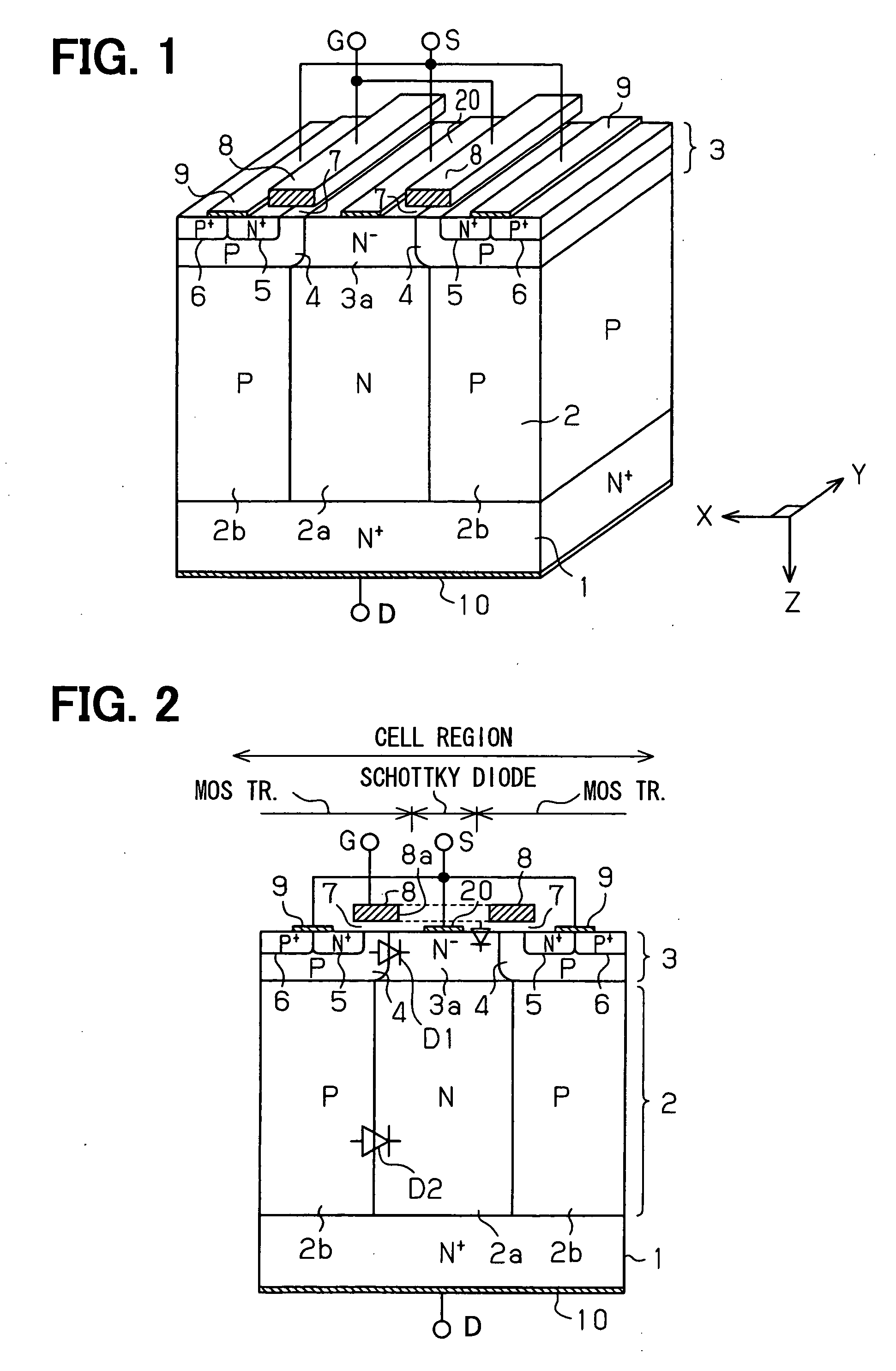

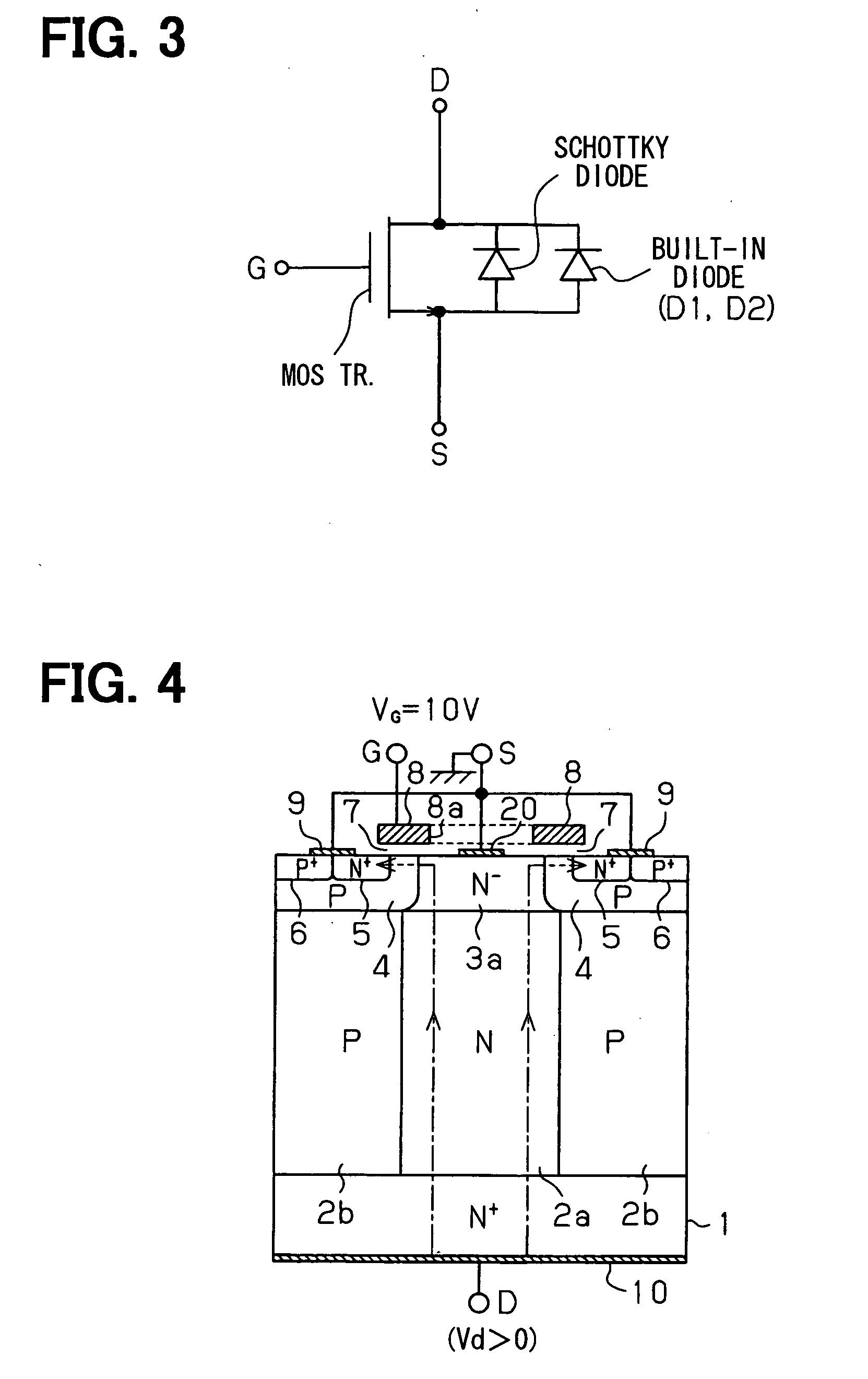

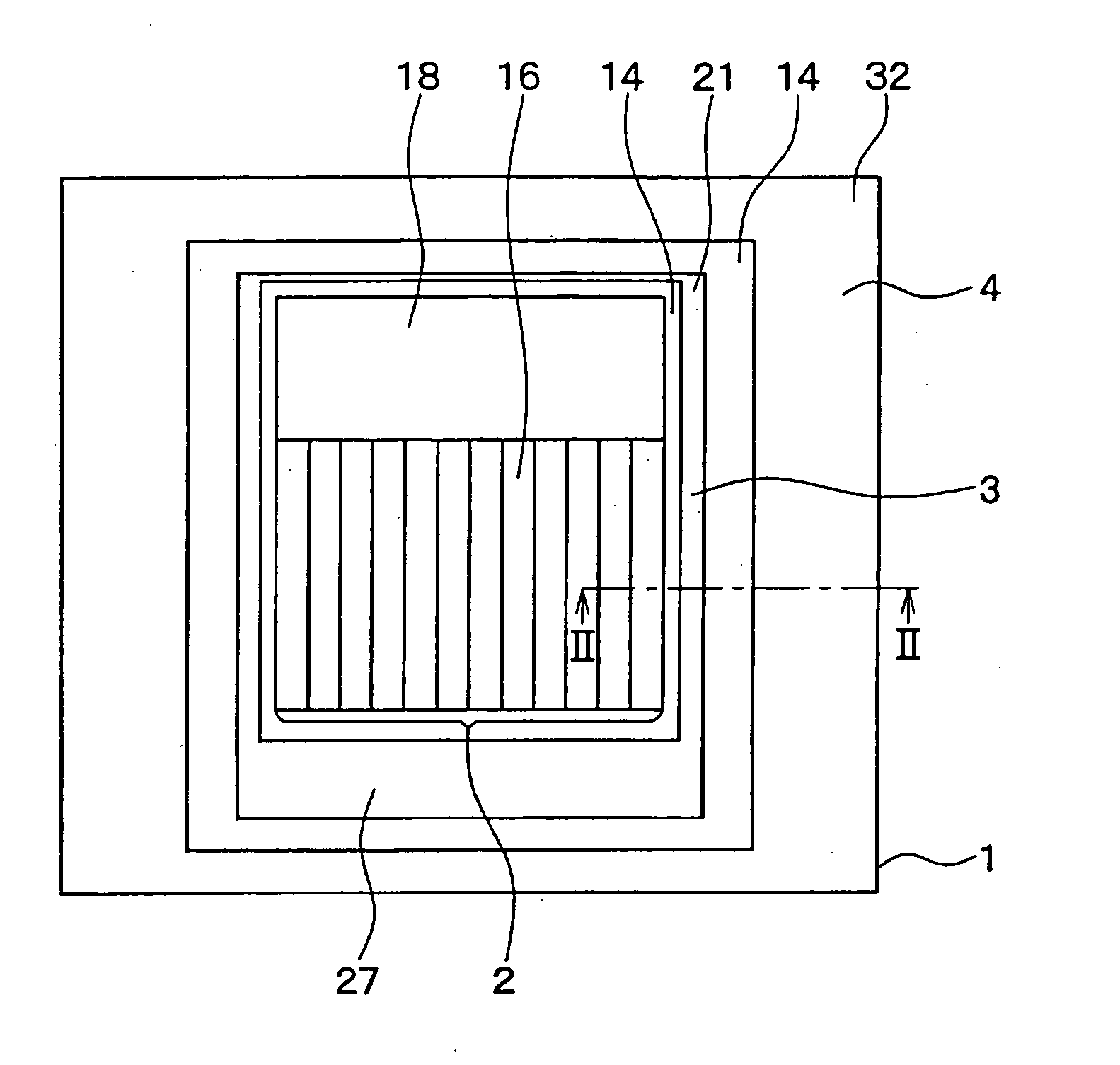

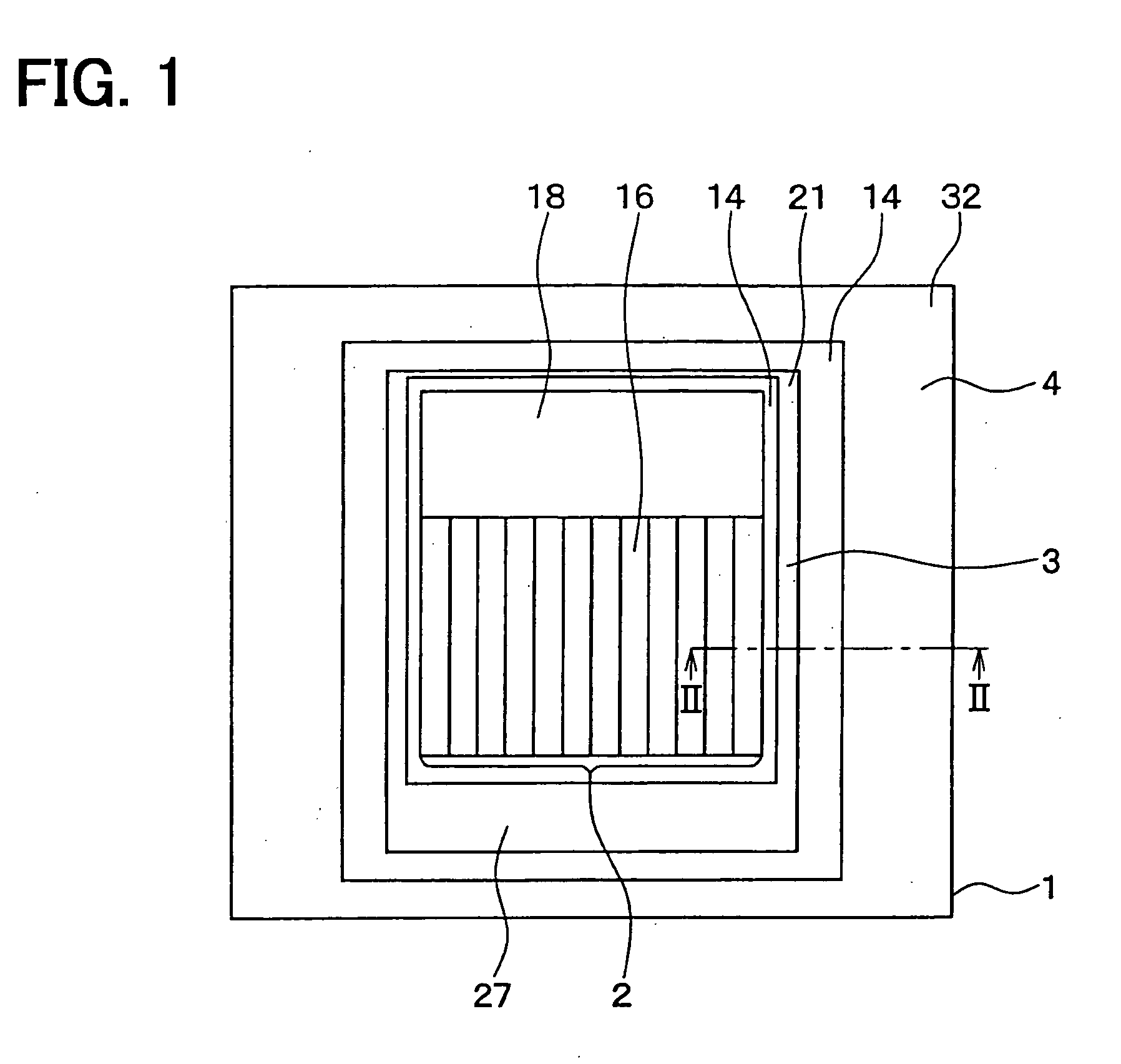

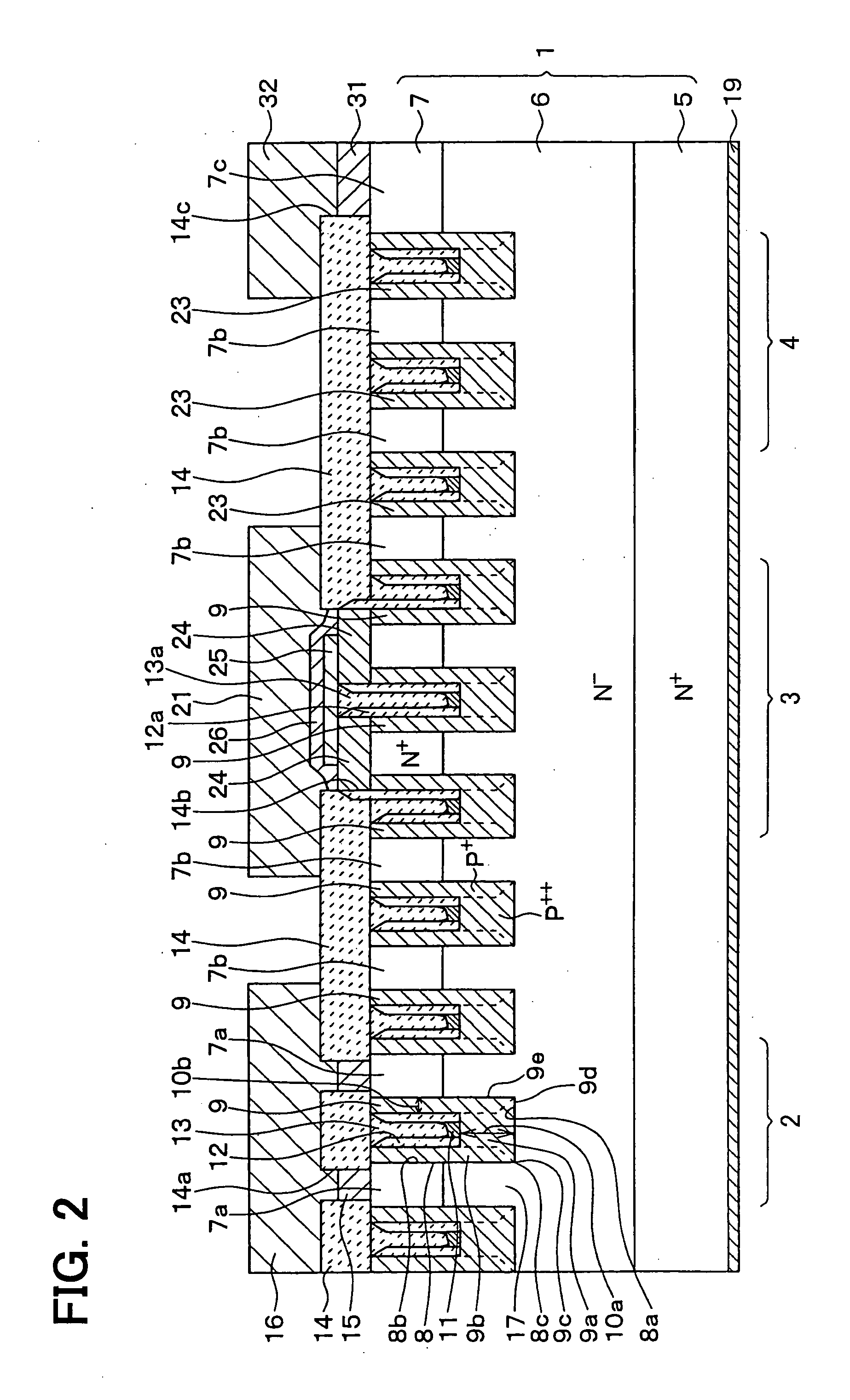

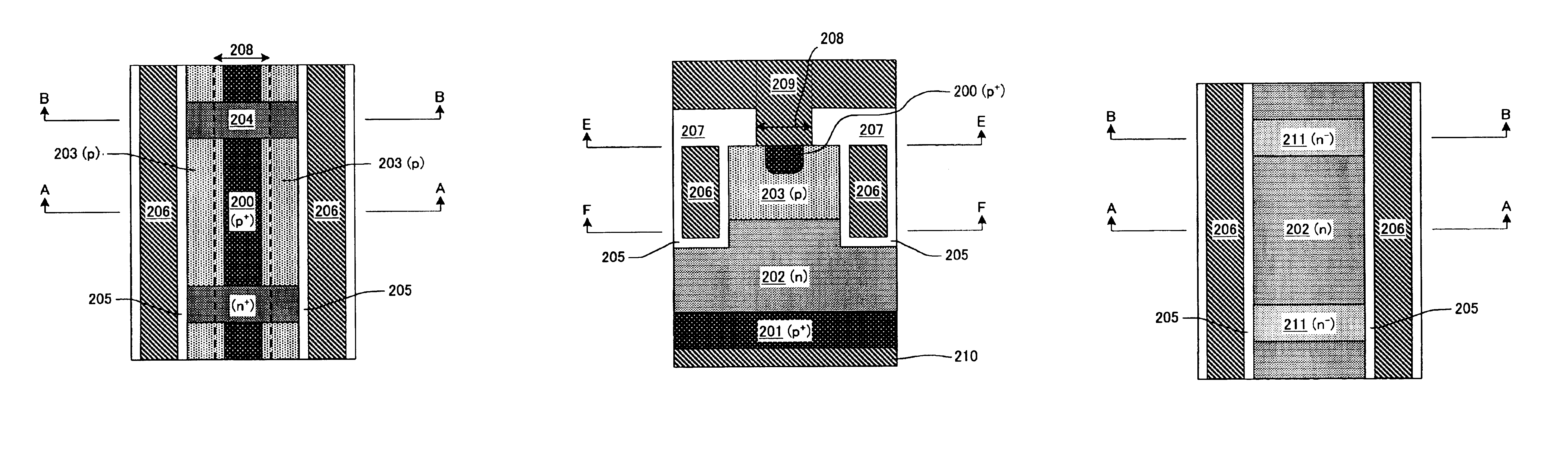

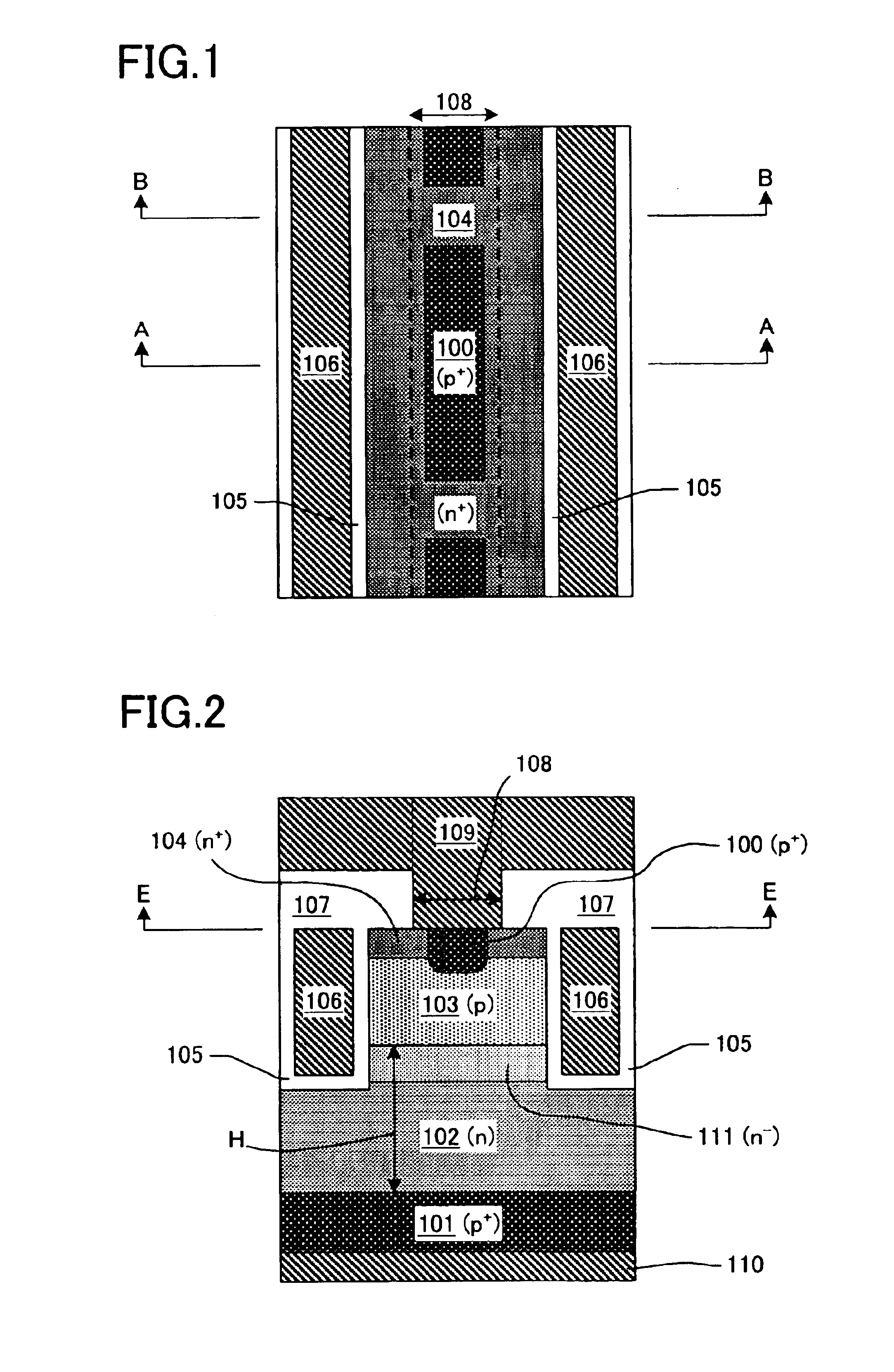

Semiconductor device having super junction MOS transistor and method for manufacturing the same

InactiveUS20070120201A1High withstand voltageLow lossTransistorSolid-state devicesElectrical conductorSchottky barrier

A semiconductor device having a super junction MOS transistor includes: a semiconductor substrate; a first semiconductor layer on the substrate; a second semiconductor layer on the first semiconductor layer; a channel forming region on a first surface portion of the second semiconductor layer; a source region on a first surface portion of the channel forming region; a source contact region on a second surface portion of the channel forming region; a gate electrode on a third surface portion of the channel forming region; a source electrode on the source region and the source contact region; a drain electrode on a backside of the substrate; and an anode electrode on a second surface portion of the second semiconductor layer. The anode electrode provides a Schottky barrier diode.

Owner:DENSO CORP

Silicon carbide semiconductor device and method for manufacturing the same

InactiveUS20050258454A1Input resistance of becomes lowHigh withstand voltageTransistorSemiconductor/solid-state device detailsSemiconductorDevice material

A manufacturing method of a silicon carbide semiconductor device includes the steps of: preparing a semiconductor substrate including a silicon carbide substrate, a drift layer and a first semiconductor layer; forming a plurality of first trenches in a cell portion; forming a gate layer on an inner wall of each first trench by an epitaxial growth method; forming a first insulation film on the surface of the semiconductor substrate; forming a gate electrode on the first insulation film for connecting to the gate layer electrically; forming a source electrode on the first insulation film for connecting to the first semiconductor layer in the cell portion; and forming a drain electrode connected to the silicon carbide substrate electrically.

Owner:DENSO CORP +1

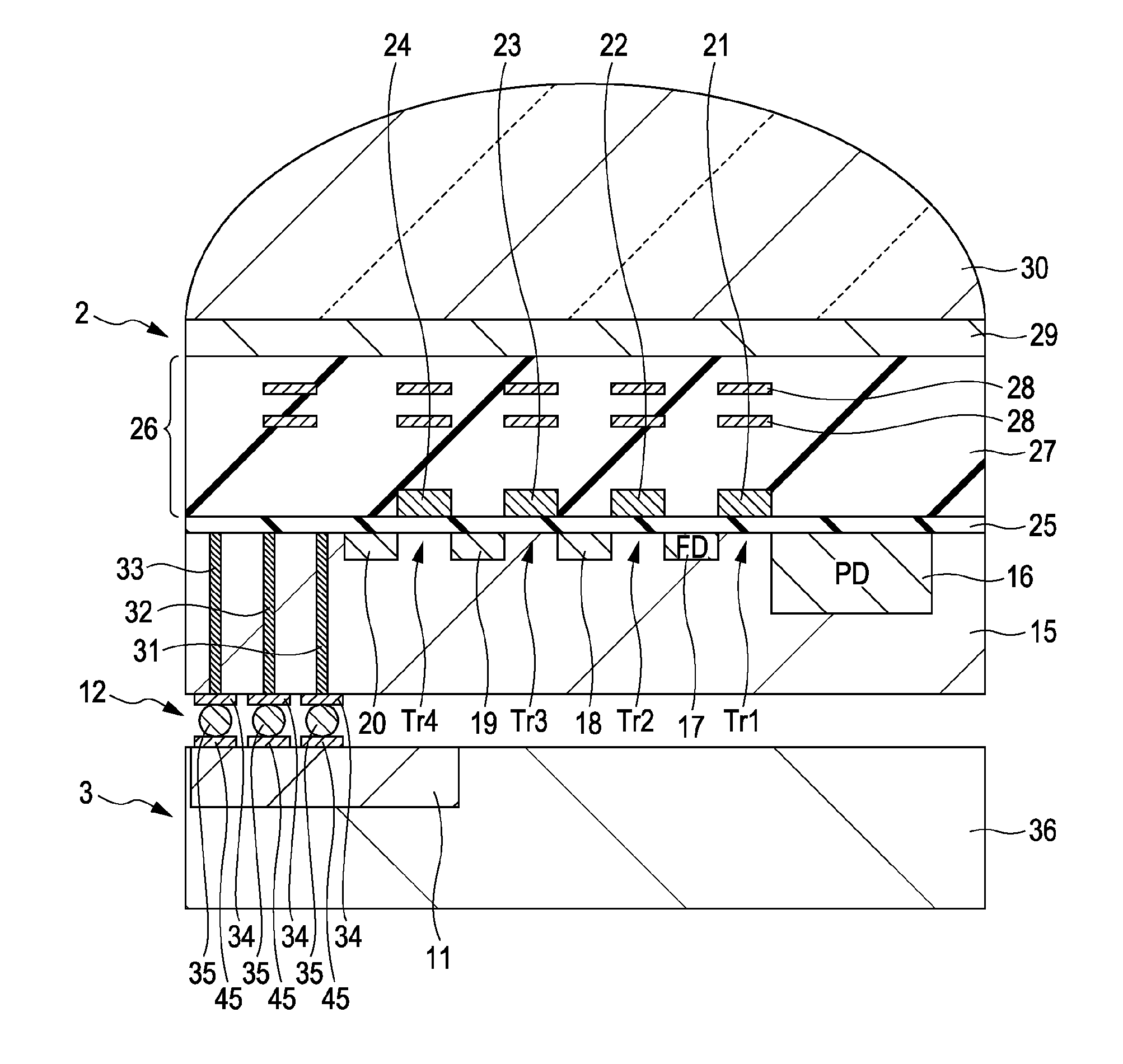

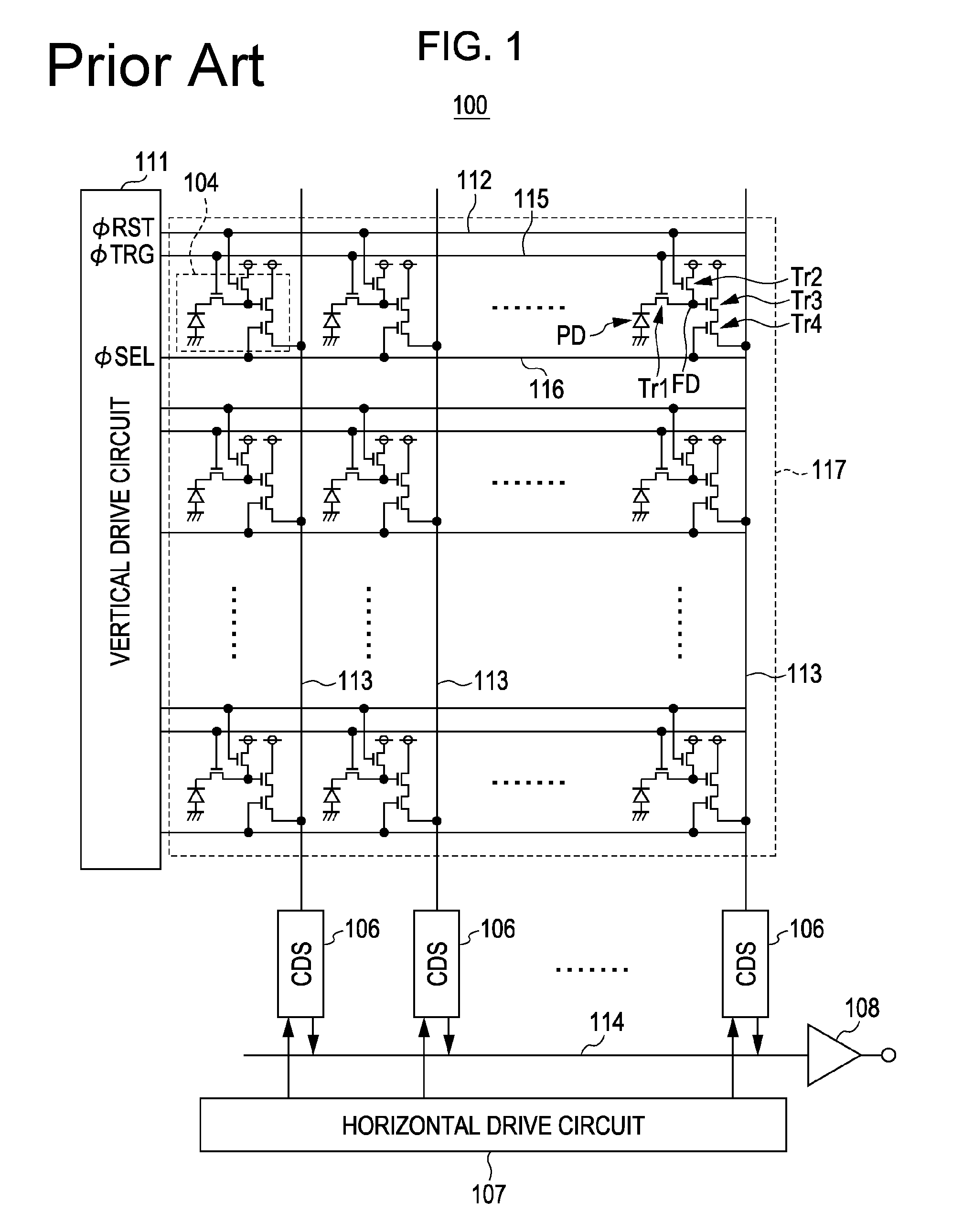

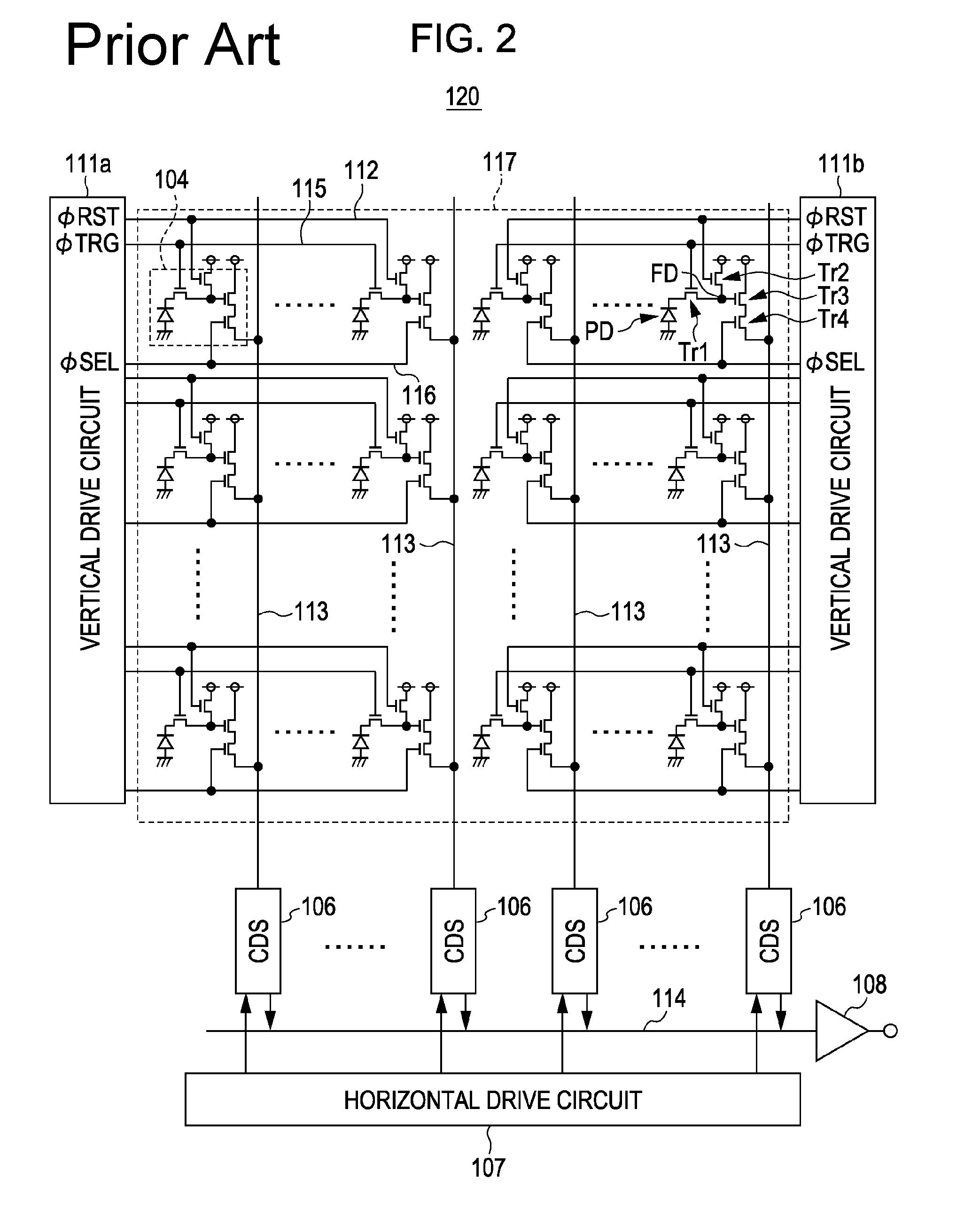

Solid-state imaging device with stacked sensor and processing chips

ActiveUS8854517B2Pixel blurring reducedIncrease speedTelevision system detailsTelevision system scanning detailsLight sensingTransistor

A solid-state imaging device includes a first chip including a plurality of pixels, each pixel including a light sensing unit generating a signal charge responsive to an amount of received light, and a plurality of MOS transistors reading the signal charge generated by the light sensing unit and outputting the read signal charge as a pixel signal, a second chip including a plurality of pixel drive circuits supplying desired drive pulses to pixels, the second chip being laminated beneath the first chip in a manner such that the pixel drive circuits are arranged beneath the pixels formed in the first chip to drive the pixels, and a connection unit for electrically connecting the pixels to the pixel drive circuits arranged beneath the pixels.

Owner:SONY CORP

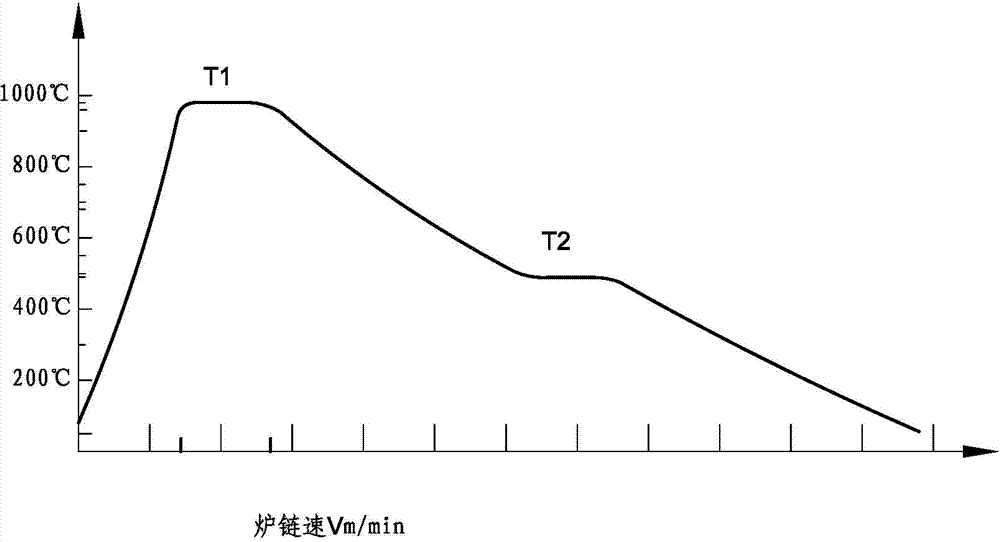

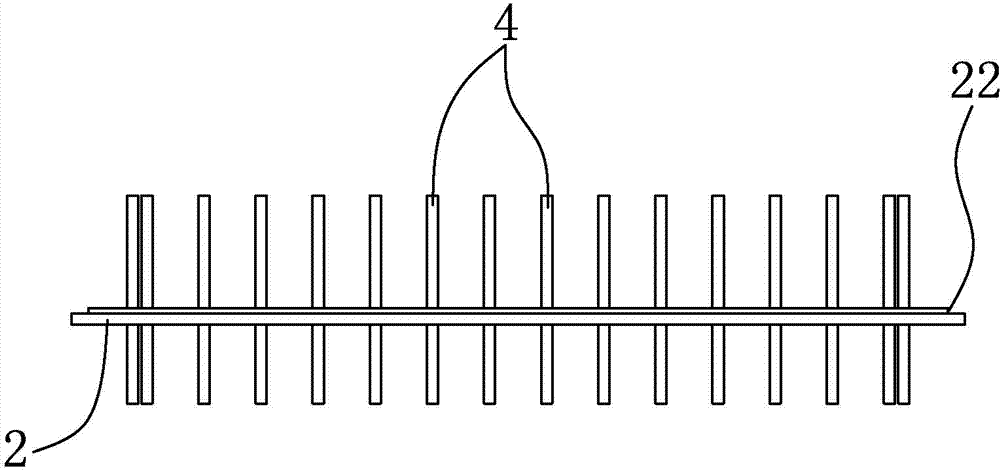

Press fit method for high-voltage-resistant PCB with thick copper plate

InactiveCN105472912AMeet reliabilityImprove liquidityMultilayer circuit manufactureCircuit laminationHigh resistanceVitrification

The invention discloses a press fit method for a high-voltage-resistant PCB with a thick copper plate. The method includes the following steps: S1, cutting, i.e., cutting an outer-layer copper foil, a polyimide medium, pure-glue prepreg and a polyimide copper-clad plate according to required dimensions; S2, inner-layer pattern making; and S3, conducting press fit after plate lamination, the press fit including the first heating stage at the temperature of 100-140 DEG C, the second heating stage at the temperature of 140-180 DEG C, the third heating stage at the temperature of 180-220 DEG C, a warm-keeping stage, the first cooling stage at the temperature of 220-150 DEG C and the second cooling stage at the temperature of 150-100 DEG C. Conventional FR-4 prepreg is replaced by a polyimide material that has higher glass transition temperature and exhibits higher resistance to voltage, so a PCB with a thick copper plate is made to have the excellent resistance to voltage, and polyimide having high glass transition temperature can effectively ensure that resin is fully filled among lines during press fit. Moreover, press fit parameters can be adjusted and the operating time of a high-temperature and high-voltage stage can be prolonged, thus helping polyimide materials to fully fill line gaps in a high-temperature and high-voltage condition.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

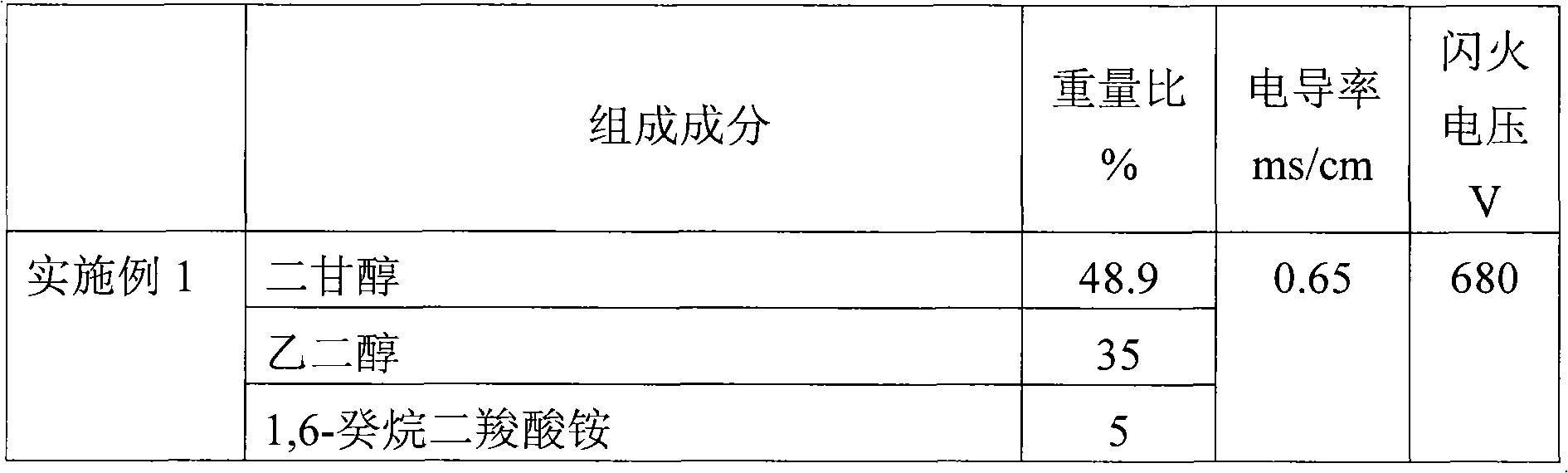

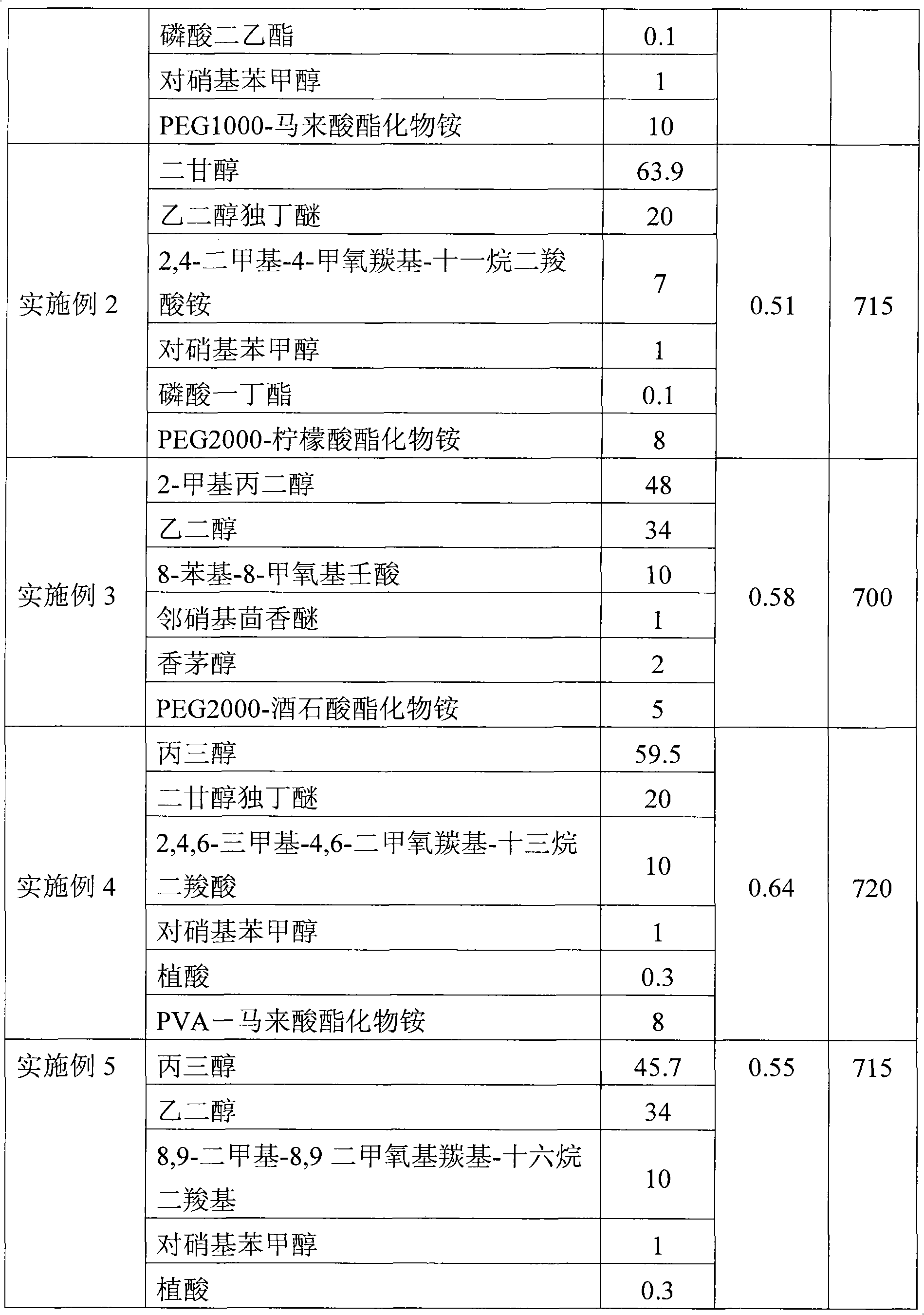

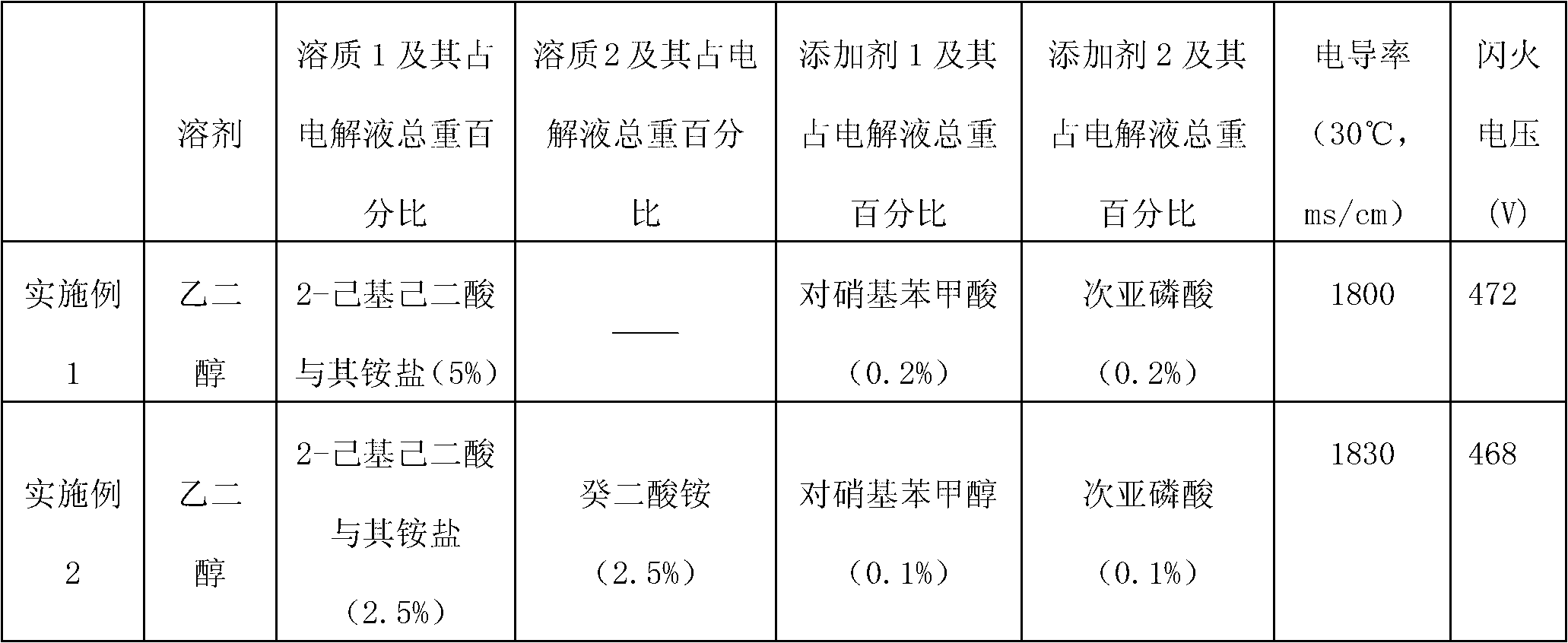

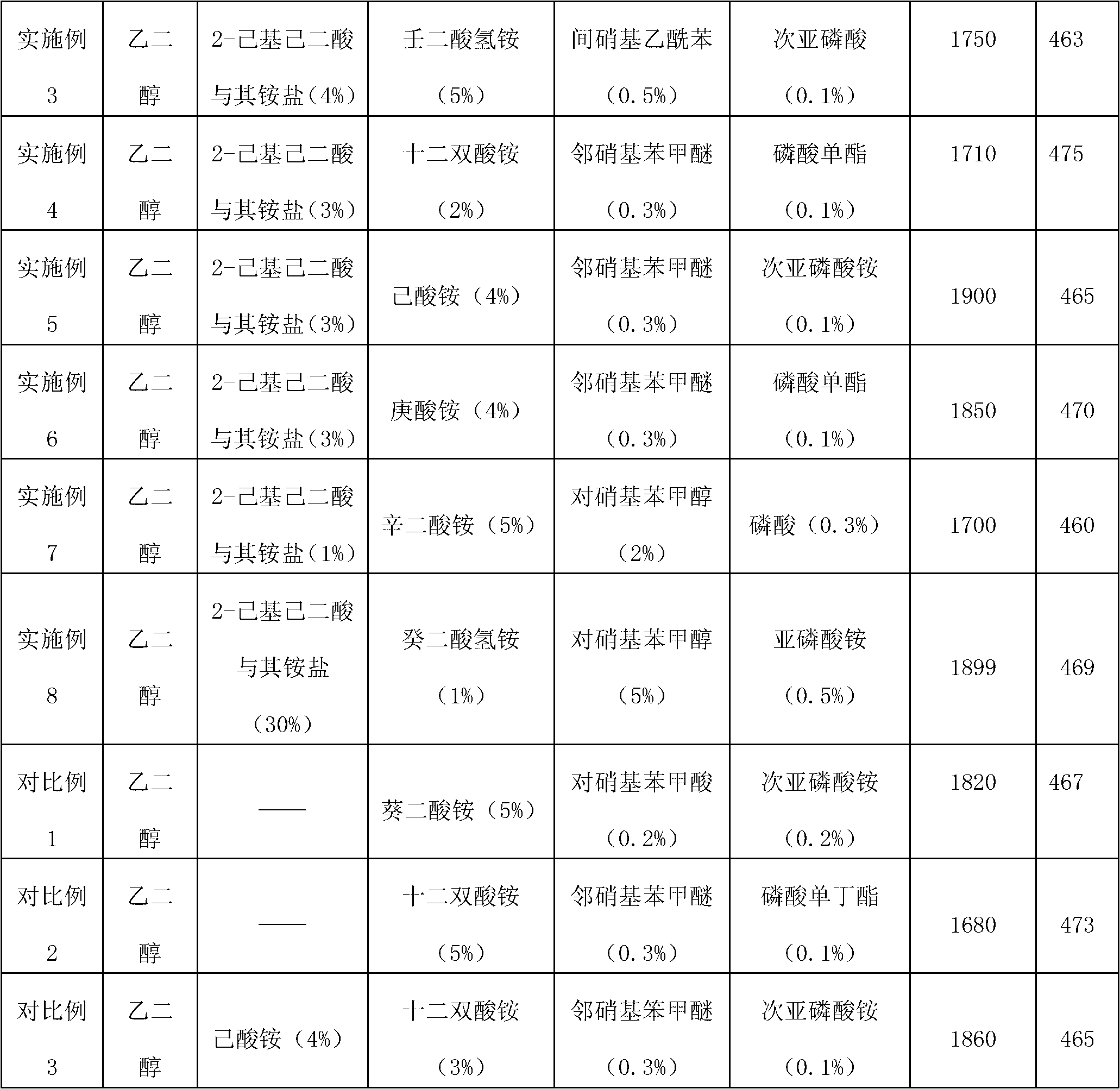

Electrolyte for driving ultrahigh voltage large-sized aluminium electrolytic capacitor and solute thereof

ActiveCN101866752AIncrease the flash voltageImprove conductivityElectrolytic capacitorsSolventEsterification reaction

The invention provides an electrolyte for driving an ultrahigh voltage large-sized aluminium electrolytic capacitor and a solute thereof. The solute of the electrolyte for driving the ultrahigh voltage large-sized aluminium electrolytic capacitor is a high-molecular solute, and the preparation process comprises the following steps of: uniformly mixing a polyalcohol polymer with hydroxyl at a tail end and a saturated or unsaturated binary or polybasic acid according to a certain proportion; adding a certain amount of catalyst; carrying out condensation and esterification reaction at certain temperature under the condition of decompression, cooling, and separating an ester, wherein the total number of carbon atoms positioned on a main chain of the ester is 15 or more than 15; and dissolving the ester into a solvent to prepare a solution with certain concentration, then introducing ammonia so that the pH of the solution reaches a certain range, and stopping introducing the ammonia so that the ester reacts with the ammonia to form ester ammonium salt, wherein the ester ammonium salt is the high-molecular solute used for the electrolyte. The aluminium electrolytic capacitor has very high voltage resistance, larger ripple current bearing and high reliability and finished product ratio when using the electrolyte prepared by the solute.

Owner:RESEARCH INSTITUTE OF TSINGHUA UNIVERSITY IN SHENZHEN +1

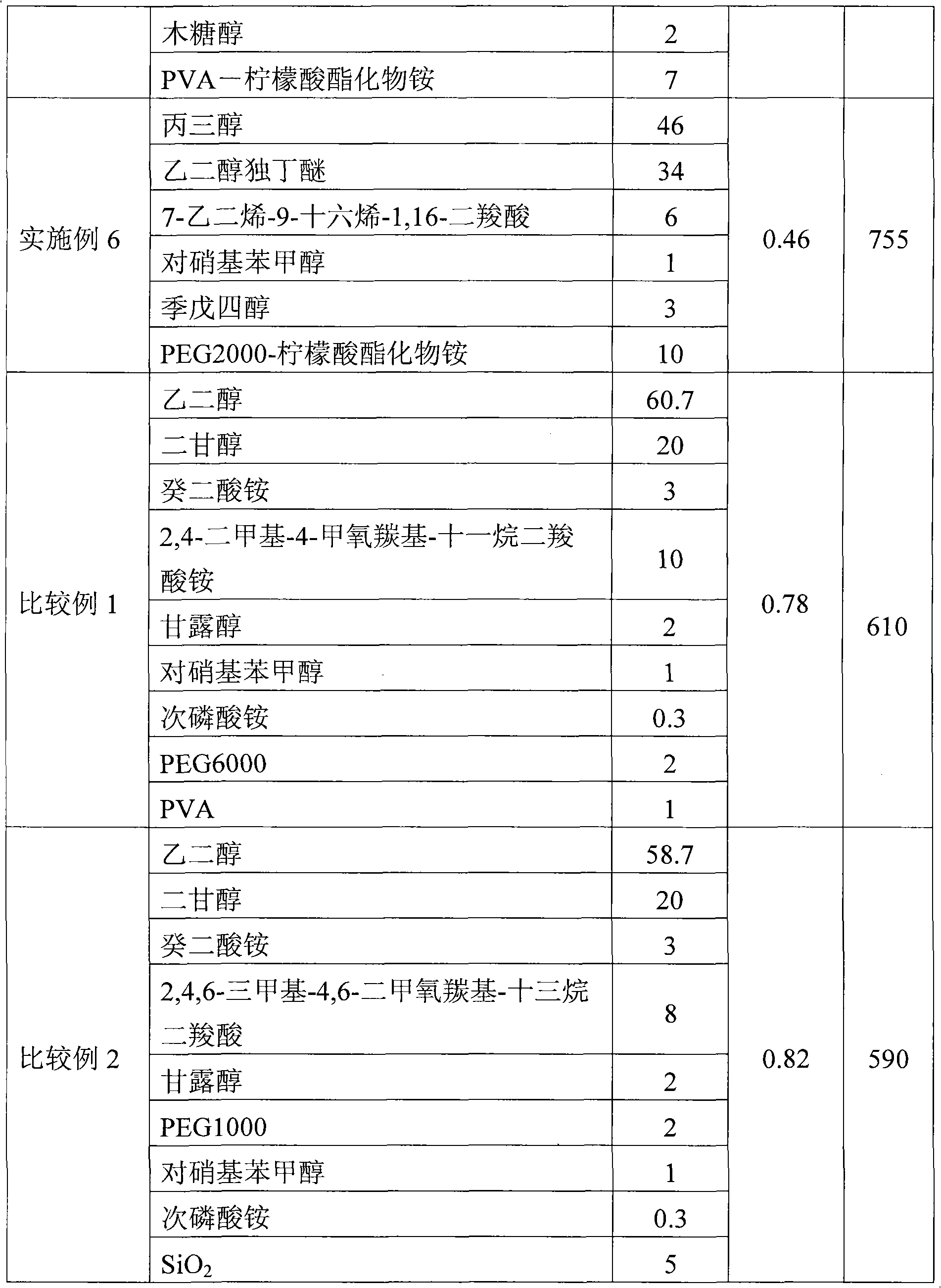

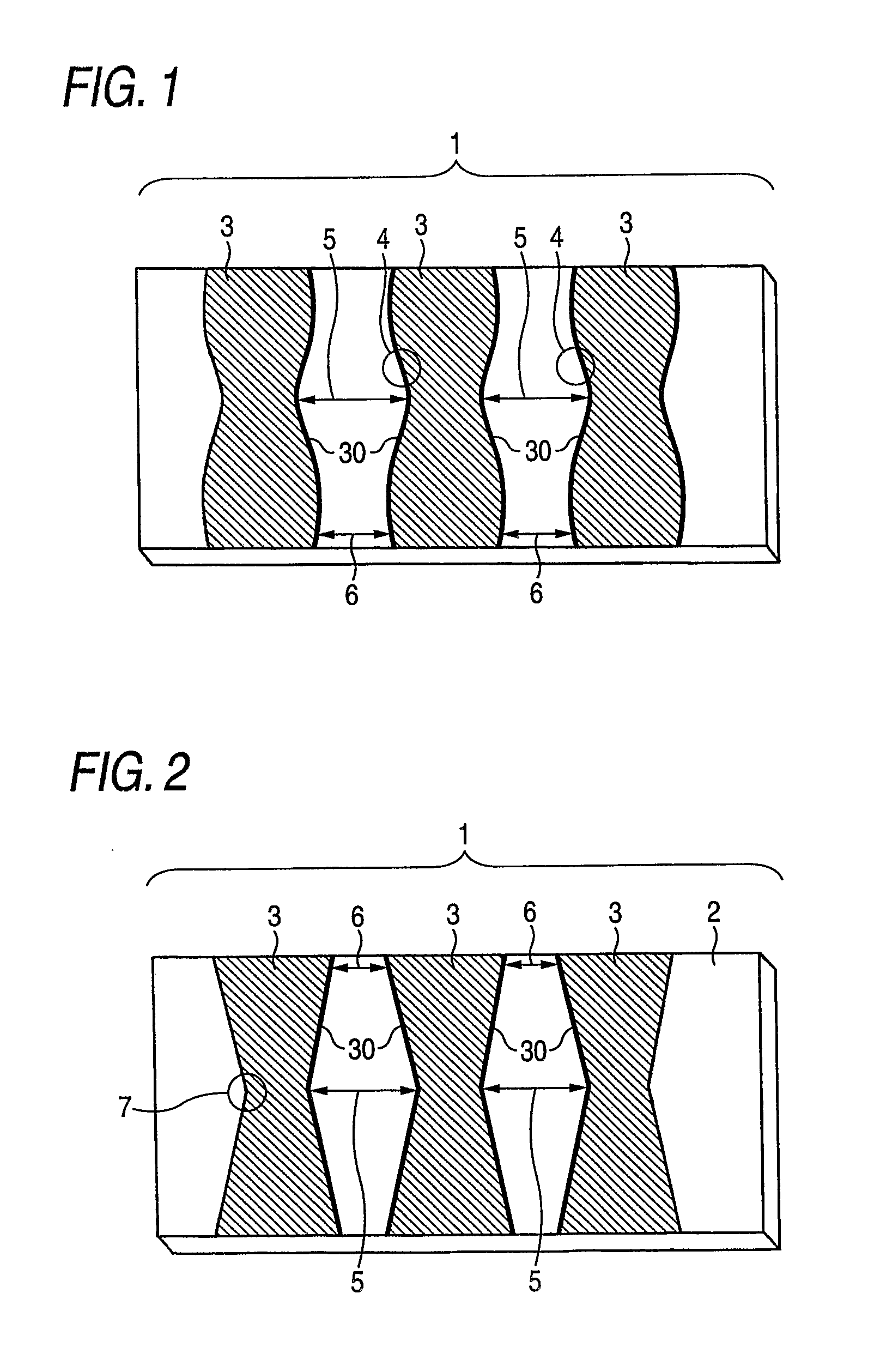

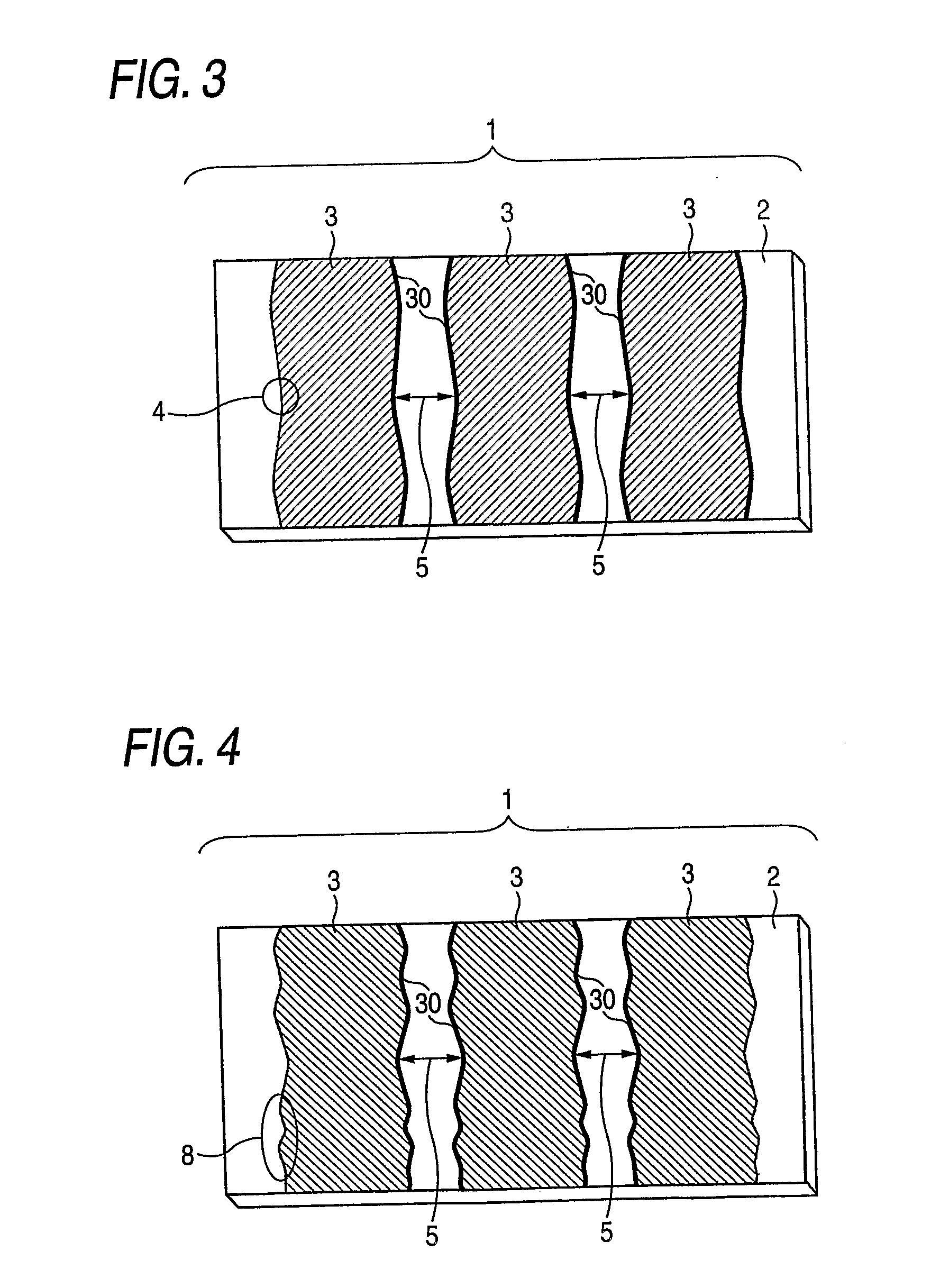

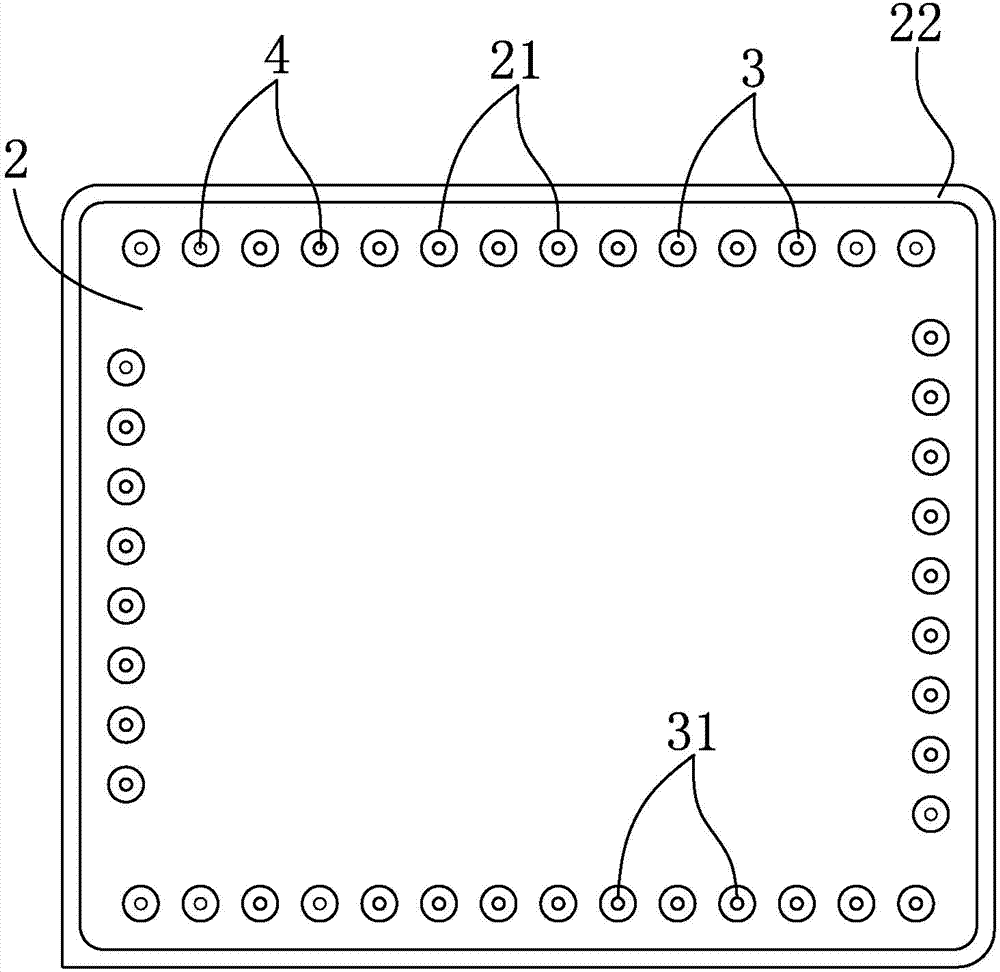

Multi-Layer Capacitor and Mold Capacitor

InactiveUS20080030922A1High withstand voltageDownsizing be hinderMultiple fixed capacitorsFixed capacitor electrodesDielectric substrateElectrical and Electronics engineering

A mulitilayer A capacitor includes a plurality of dielectric substrates (2) which are layered; a pair of terminal electrodes formed on the plurality of dielectric substrates; a plurality of internal electrodes (3) arranged on each of the dielectric substrates and having outer edges (30) opposed apart by a predetermined interval, wherein at least one of the internal electrodes (3) is arranged apart from the adjacent internal electrode (3) by the maximum interval (5) at the center of the outer edges (30).

Owner:PANASONIC CORP

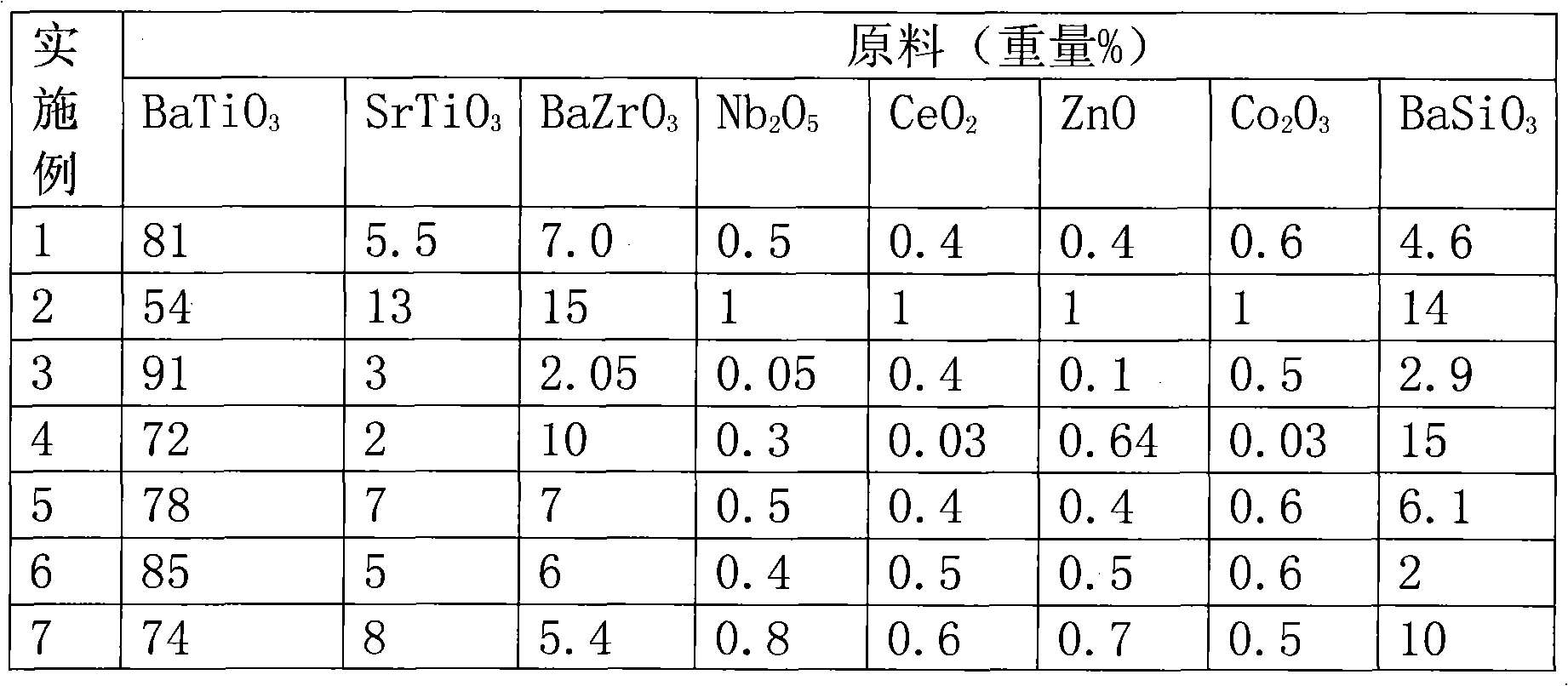

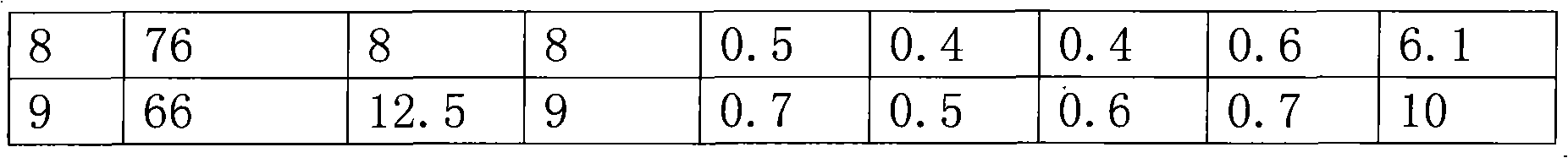

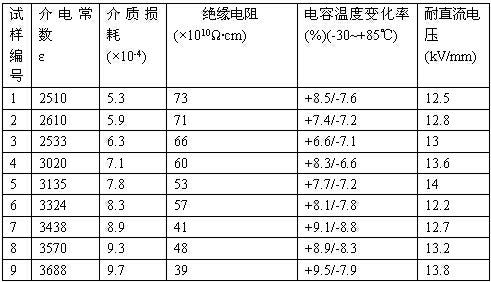

Dielectric medium of ceramic capacitor and preparation method thereof

The invention provides a dielectric medium of a ceramic capacitor, which is prepared from the following raw materials in percentage by weight: 54 to 91 percent of BaTiO3, 2 to 13 percent of SrTiO3, 2 to 15 percent of BaZrO3, 0.05 to 1 percent of Nb2O5, 0.03 to 1.0 percent of CeO2, 0.1 to 1.0 percent of ZnO, 0.03 to 1.0 percent of Co2O3, and 2 to 15 percent of BaSiO3. The invention also provides apreparation method of the dielectric medium of the ceramic capacitor. The dielectric medium of the ceramic capacitor has high dielectric constant and high withstand voltage, generates no pollution tothe environment in the process of preparation and use, and can reduce the cost of the ceramic capacitor, so the dielectric medium is suitable for preparing monolithic ceramic capacitors and multilayer chip ceramic capacitors.

Owner:汕头高新区松田实业有限公司

Production method of high specific energy super capacitor carbonaceous electrode material

InactiveCN101295587ASmall specific surface areaHigh bulk densityElectrolytic capacitorsHigh energyChemical dehydration

The invention discloses a preparation method for the carbon electrode material of a high-energy-density super capacitor which is characterized by pre-carbonizing a refinery coke or other form bodies rich in carbon for 0.5 to 5 hours under the temperature of 400 to 900 DEG C; then carrying out ball milling on the refinery coke or other form bodies rich in carbon to 4 to 30 Mum; then carrying out dipping and mixing with KOH at a weight percentage ratio of 1: 3 to 1: 6 (or simultaneously adding the metal salt of 5 to 20wt percent); after physical dehydration, chemical dehydration and activating hole making by being cooperated with catalyzing are carried out on the matters respectively under the temperatures of 100 to 250 DEG C, 300 to 500 DEG C and 700 to 1000 DEG C, then surface chemical treatment in an H2 atmosphere is carried out on the matters under the temperature of 500 to 900 DEG C to manufacture the carbon electrode material. The invention adopts the pre-carbonizing or the combining technology of catalyzing chemical cooperated with activation to manufacture the carbon electrode material; the invention has higher energy density and power density compared with the existing carbon electrode material as the power storage principle of the invention is different from a double electric layer power storage principle.

Owner:EAST CHINA UNIV OF SCI & TECH

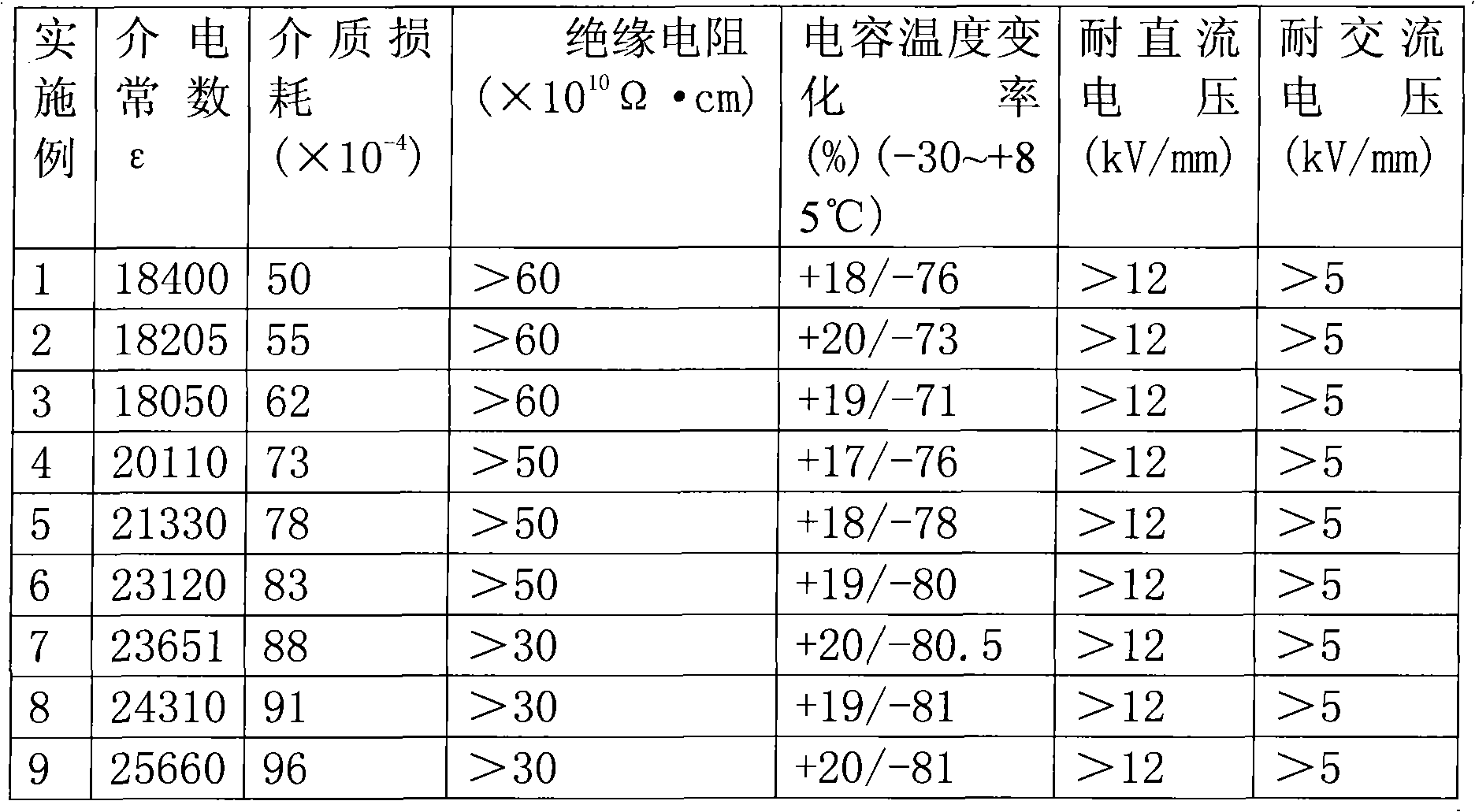

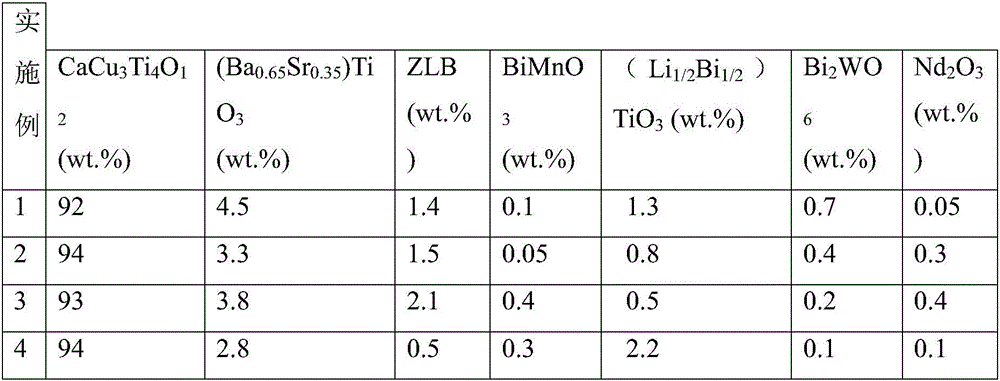

Low-temperature-sintered giant-dielectric ceramic capacitor dielectric and preparation method thereof

InactiveCN105777109AHigh dielectric constantHigh withstand voltageFixed capacitor dielectricDielectricCapacitance

The invention relates to the technical field of inorganic nonmetallic materials, in particular to low-temperature-sintered giant-dielectric ceramic capacitor dielectric with the low capacitor temperature change rate.The low-temperature-sintered giant-dielectric ceramic capacitor dielectric is prepared from 88 wt%-96 wt% of CaCu3Ti4O12, 0.01 wt%-7.0 wt% of (Ba0.65Sr0.35)TiO3, 0.01 wt%-6 wt% of Bi2WO6, 0.01 wt%-0.6 wt% of Nd2O3, 0.1 wt%-4 wt% of SiO2-Li2O-B2O3 glass powder (ZLB), 0.01 wt%-0.5 wt% of BiMnO3 and 0.5 wt%-4 wt% of (Li(1 / 2)Bi(1 / 2))TiO3.The lead-free cadmium-free giant-dielectric ceramic capacitor dielectric with the low capacitor temperature change rate is prepared by adopting the ordinary chemical raw materials of capacitor ceramic, and the sintering temperature of the capacitor ceramic can be greatly lowered.

Owner:JIANGSU UNIV

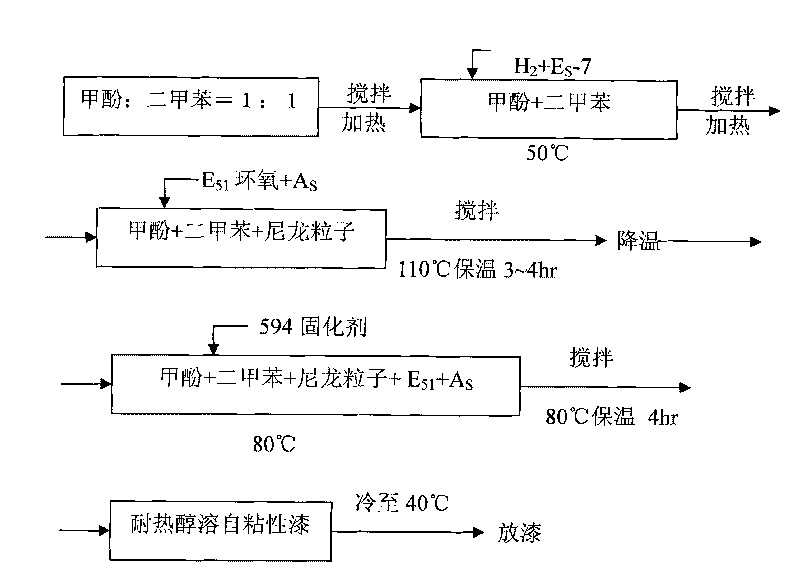

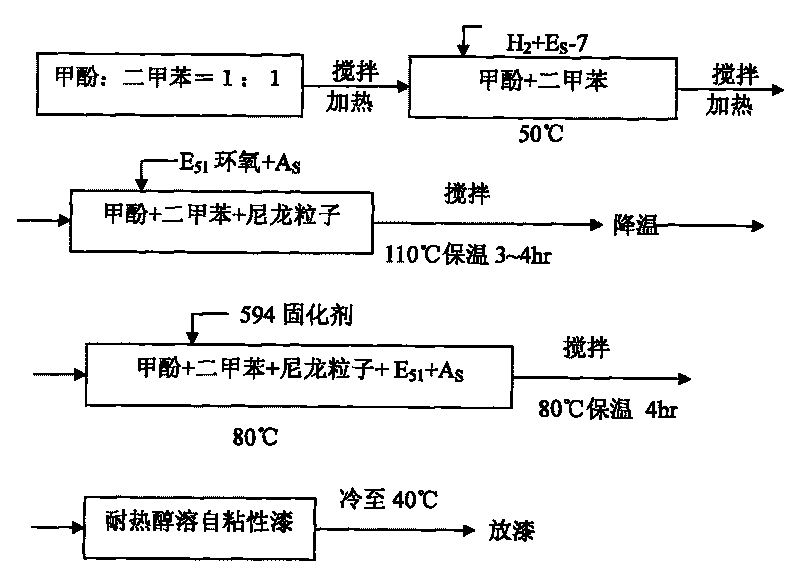

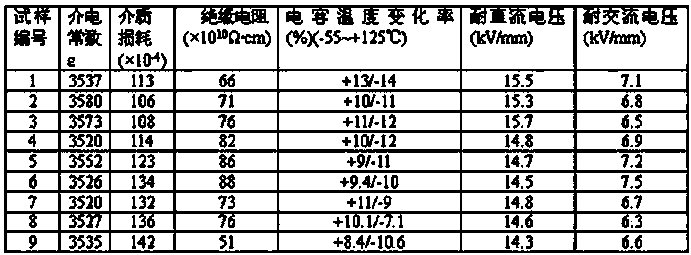

Heat resistant alcohol-soluble self-bonding paint used for self-bonding insulated winding wire and manufacturing method thereof

InactiveCN101724339AHigh withstand voltageGood high frequency performancePlastic/resin/waxes insulatorsPolyamide coatingsEpoxyCresol

The invention relates to a heat resistant alcohol-soluble self-bonding paint used for self-bonding insulated winding wire and manufacturing method thereof. The self-bonding paint contains the following components by weight percent: 35-45% of cresol, 35-45% of dimethylbenzene, 5-20% of H2 nylon, 3-7% of Es-7 nylon, 0.1-1% of AS resin, 0.1-2% of E51 epoxy resin and 0.01-0.1% of 594 curing agent. Compared with the prior art, the invention is simple in technology, the heat resistant alcohol-soluble self-bonding paint obtained by adopting the invention is coated outside a three-layer insulated winding wire to form a self-bonding three-layer insulated winding wire, and unframed coil formed by the winding wire has high withstand voltage and good high frequency performance and accords with the development trend of the current information industry.

Owner:上海旌缘科技股份有限公司

Low temperature sintering high voltage ceramic capacitor dielectric

The present invention relates to technical field of inorganic non-metal materials, particularly to a low temperature sintering high voltage ceramic capacitor dielectric, wherein the formula of the dielectric comprises, by weight, 60-91% of BaTiO3, 1-13% of SrTiO3, 2-15% of BaZrO3, 0.05-2% of Nb2O5, 0.1-1.5% of ZnO, 0.03-2.0% of Co2O3, 0.5-6% of ZnB2O4 glass powder, and 0.5-4% of BaCu(B2O5). According to the present invention, the conventional ceramic capacitor dielectric preparation method is adopted, and ordinary capacitor ceramic chemical raw materials are utilized to prepare the lead-free and cadmium-free high dielectric high voltage ceramic capacitor dielectric so as to substantially reduce a sintering temperature of the ceramic capacitor; and the dielectric is suitable for preparation of monolithic ceramic capacitors and multi-layer ceramic capacitors, wherein a ceramic capacitor cost can be substantially reduced, a withstand voltage can be increased, an application range of the ceramic capacitor can be broadened, and no environment pollution is generated during preparation and use processes.

Owner:JIANGSU UNIV

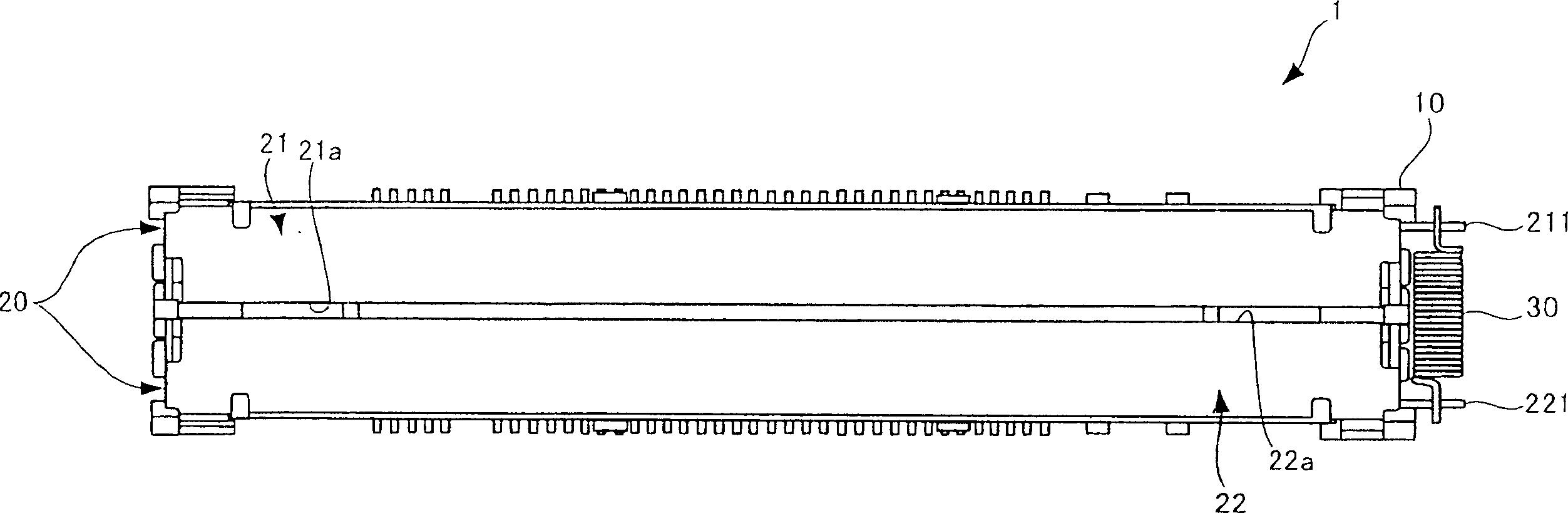

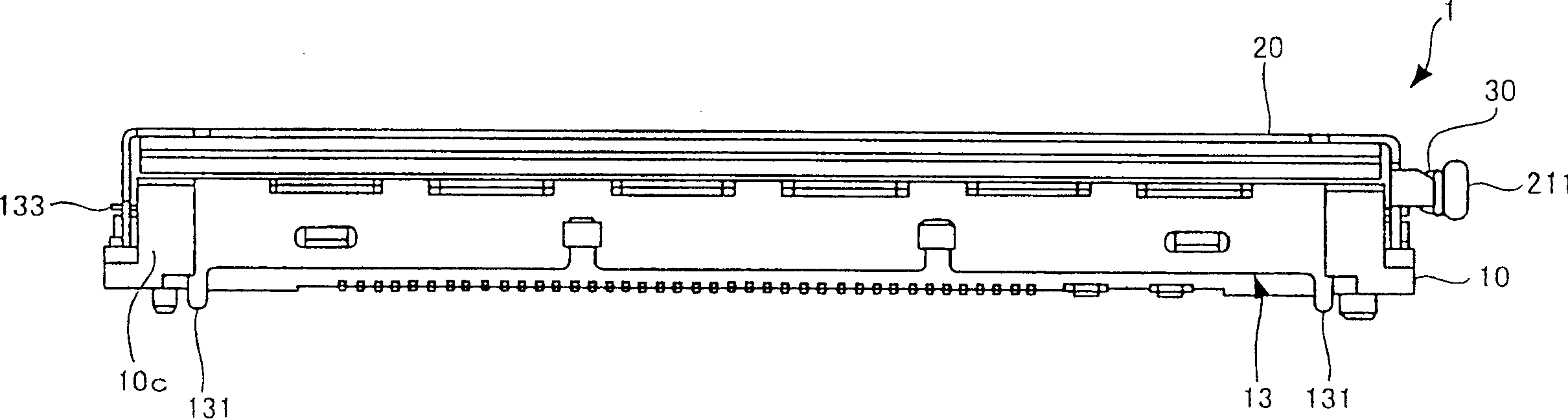

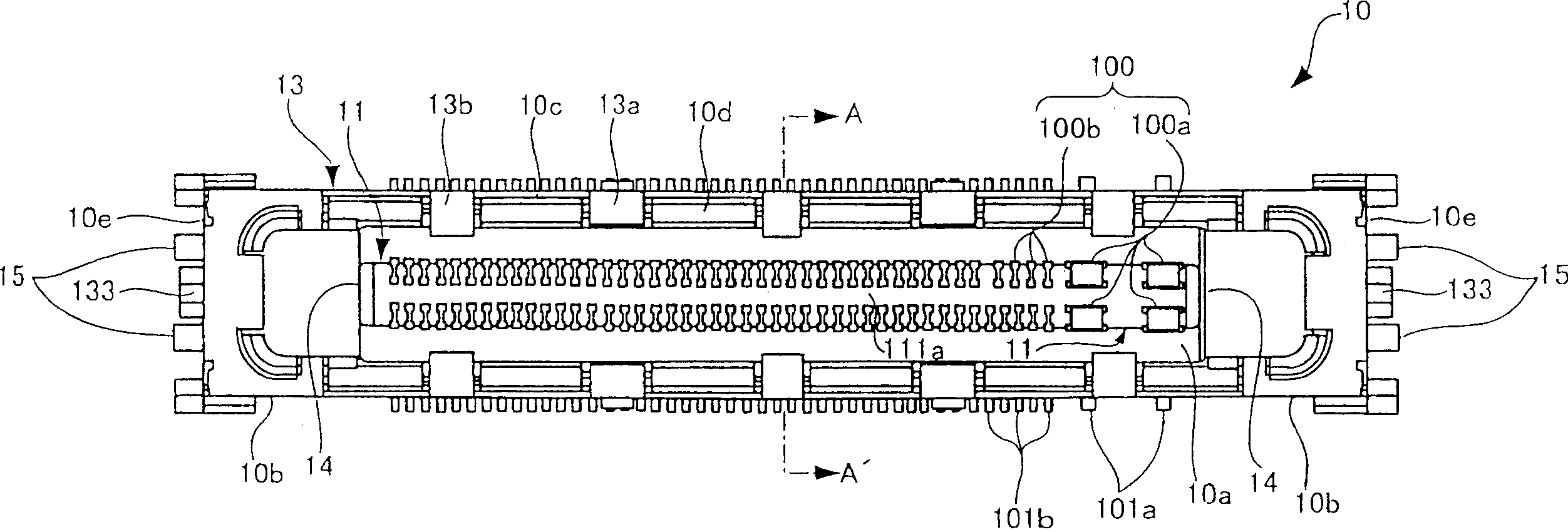

Electrical connector with shutter

InactiveCN1499675AAvoid deformationHigh withstand voltageCouplings bases/casesCoupling protective earth/shielding arrangementsForeign matterEngineering

To prevent the adhesion of the foreign matters to the contacts and also to prevent damage to the electronic circuit of the connected equipment by the electrostatic discharge, in the electric connector with a shutter equipped with a housing having an engagement part arranged with a plurality of contacts and a pair of shutter members covering the engagement part of the housing in free opening and shutting. The pair of shutter members are made of metal and are energized in the direction of the edges approaching each other, and in the state of the edges approached together, cover the engaging part, and release the engagement part when the edges are separated. The housing is equipped with a shield member 13 that surrounds the surroundings of the housing and has a protrusion 133 that is clipped by the pair of shutter members when the edges come close.

Owner:TYCO ELECTRONICS JAPAN GK

Low-loss high-voltage ceramic capacitor dielectric

InactiveCN102627456ALow costNo pollution in the processFixed capacitor dielectricDielectricMetallic materials

The invention relates to the technical field of inorganic nonmetallic materials, in particular to a low-loss high-voltage ceramic capacitor dielectric. By adopting a conventional ceramic capacitor dielectric preparation method and using common chemical raw materials for capacitor ceramic, a lead-free and cadmium-free low-loss high-voltage ceramic capacitor dielectric is prepared and the sintering temperature of the capacitor ceramic can be reduced. The dielectric is suitable for preparing monolithic ceramic capacitors or chip multi-layer ceramic capacitors, the cost of the ceramic capacitors can be greatly reduced, the withstand voltage can be improved and the losses can be reduced to expand the application scope of the ceramic capacitors, the safety of the ceramic capacitors can be greatly improved and the environment is not polluted during preparation and use at the same time.

Owner:JIANGSU UNIV

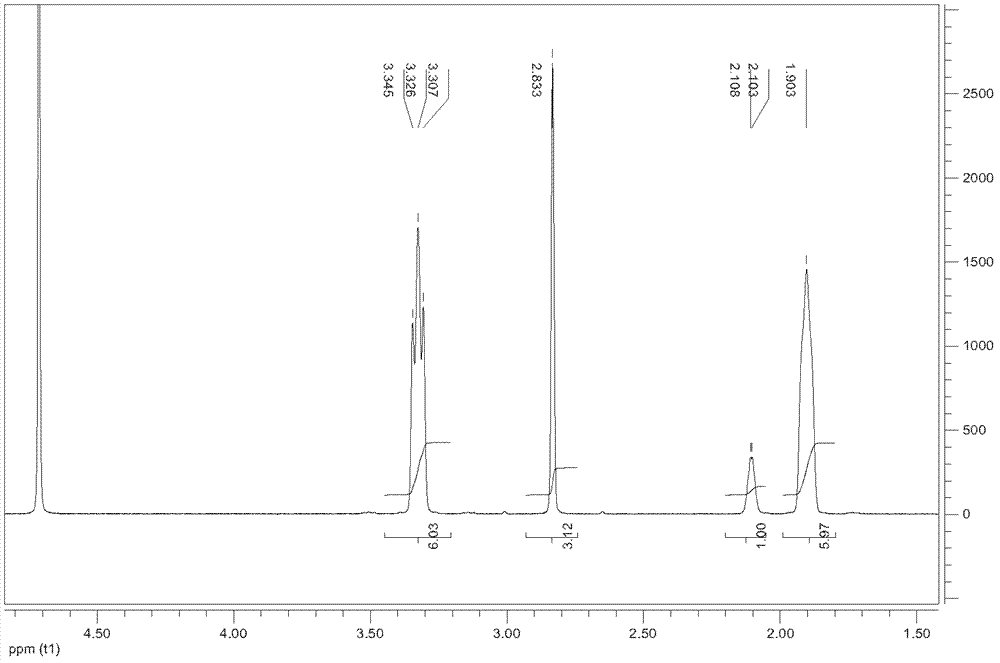

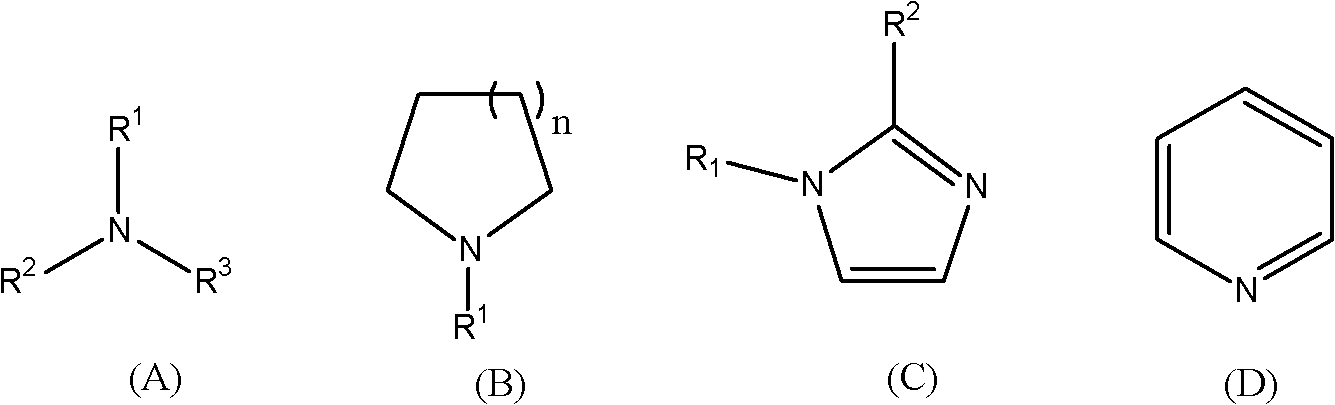

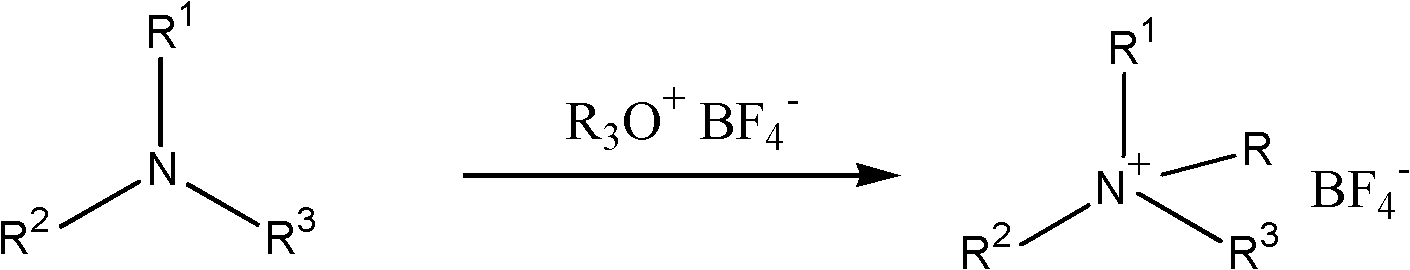

Preparation process, electrolyte and electrochemical element of electrolytic salt

InactiveCN102789903AImprove long-term reliabilityHigh withstand voltageElectrolytic capacitorsSupercapacitorSolvent

The invention relates to a preparation process, an electrolyte and an electrochemical element of electrolytic salt. Polycyclic tertiary amine serves as a raw material, the electrolytic salt is prepared through a quaternarization reaction, the electrolyte is composed of the electrolytic salt and a nonaqueous solvent, and the electrochemical element uses the electrolyte. The supercapacitor organic electrolyte of the electrolytic salt prepared by the preparation process can meet requirements of a supercapacitor for electrochemical and chemical stability; a series of the polycyclic tertiary amine is subjected to the simple quaternarization reaction, a series of the electrolytic salt with high purity is prepared, the process cost is low, and the target product yield is high; and the device investment is low, the operation is easy, the yield is high, the post treatment is simple and large-scale production is suitable.

Owner:EAST CHINA UNIV OF SCI & TECH

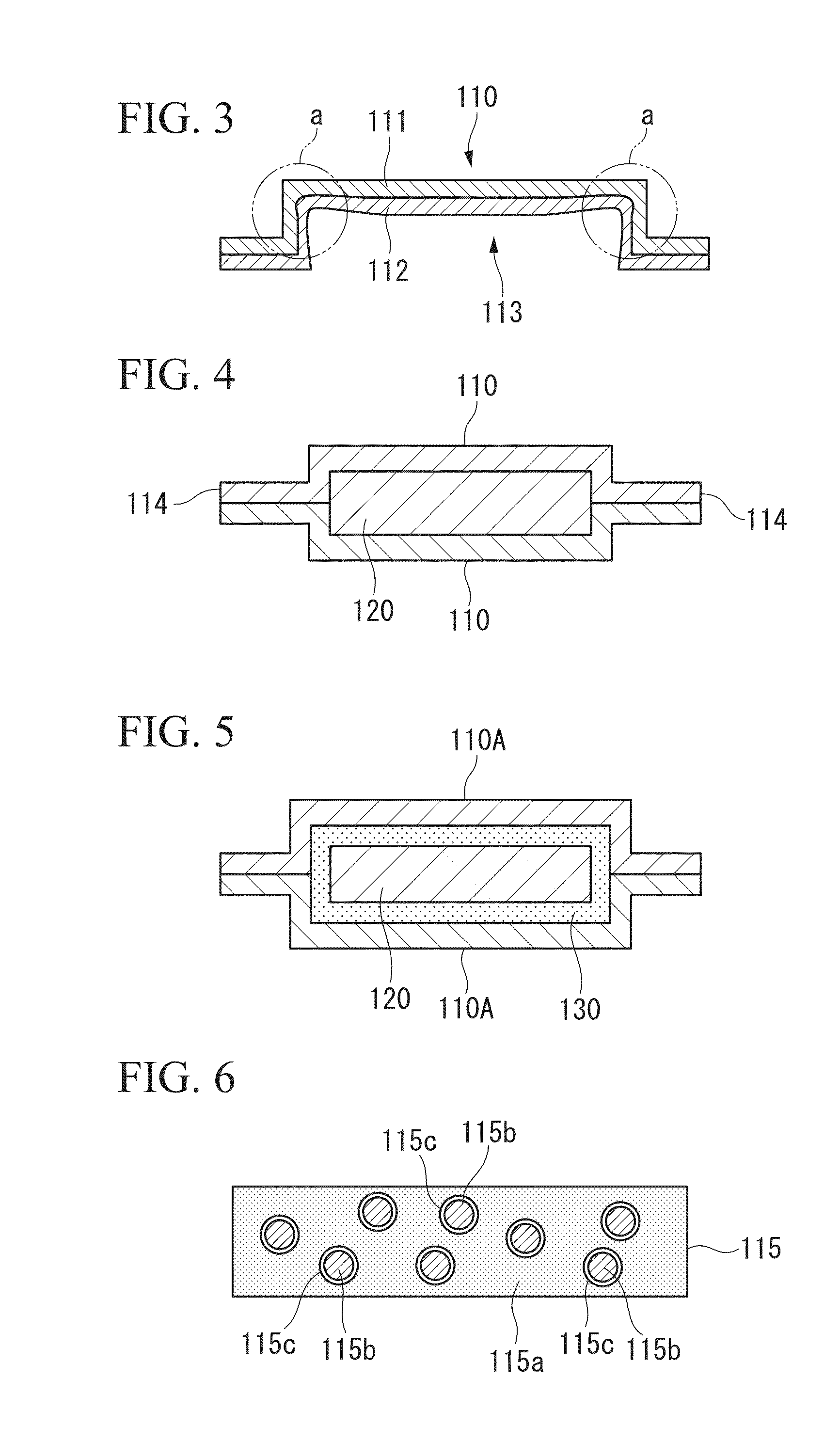

Solid electrolytic capacitor

ActiveCN102473526AHigh withstand voltageIncrease capacitySolid electrolytic capacitorsCapacitor electrolytes/absorbentsElectrolysisOptoelectronics

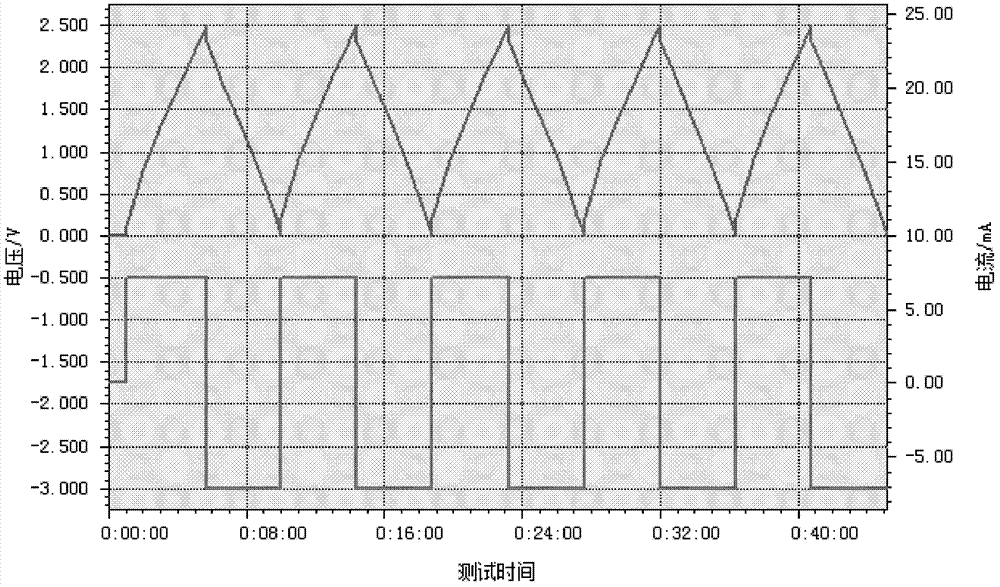

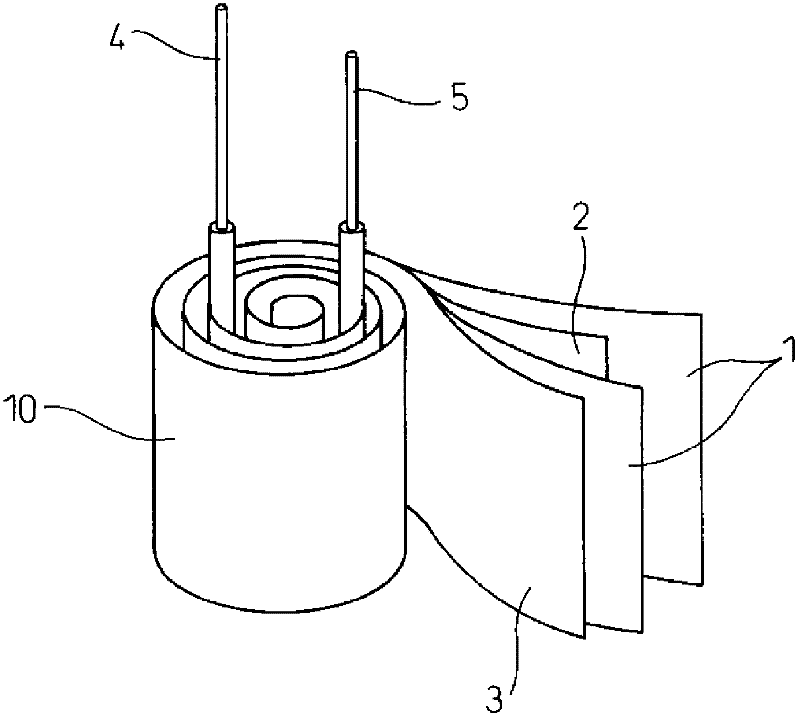

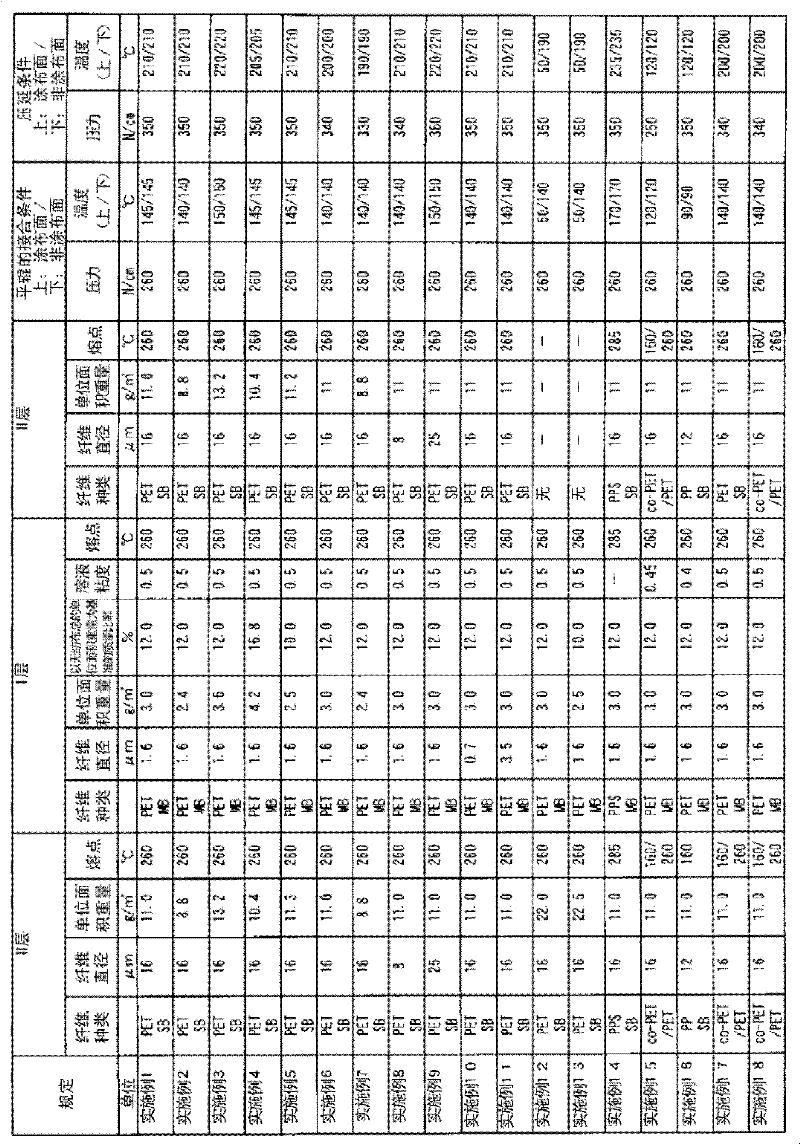

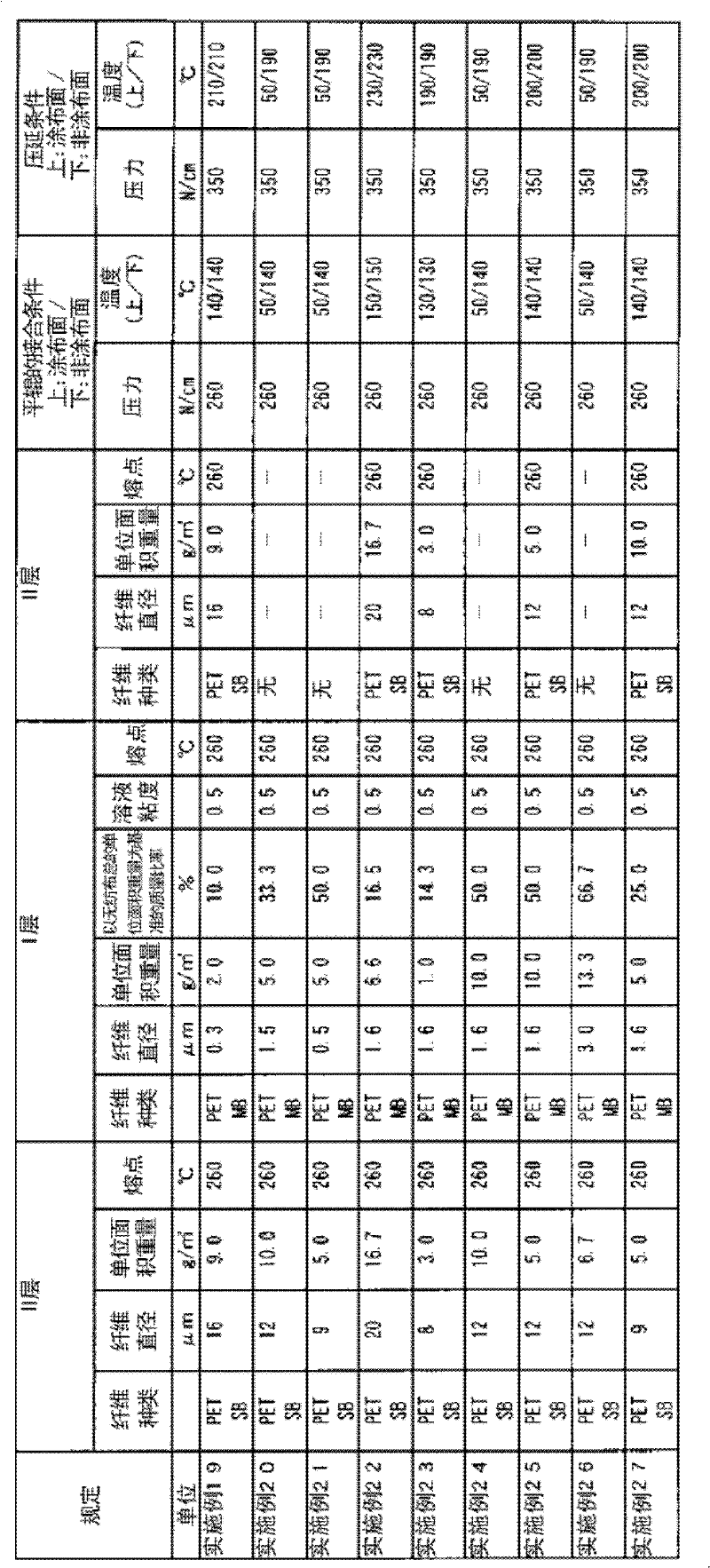

Provided is a high-performance solid electrolytic capacitor that can be produced with stability. The solid electrolytic capacitor is a capacitor comprising an anode foil, a cathode foil, and separators arranged between the anode foil and the cathode foil. The anode foil, the cathode foil, and the separators are wound around so as to have the separator intervene between the anode foil and the cathode foil. The anode foil has a dielectric oxide-film layer, and the separators comprise a solid electrolyte and a nonwoven fabric that holds the solid electrolyte. The nonwoven fabric, which composes the separator, is a laminated nonwoven fabric having at least two nonwoven fabric layers, and the laminated nonwoven fabric comprises: a nonwoven fabric layer (layer I) composed of extra-fine fiber with a fiber diameter of 0.1-4 [mu]m; and a nonwoven fabric layer (layer II) composed of thermoplastic resin fiber with a fiber diameter of 6-30 [mu]m.

Owner:ASAHI KASEI KK

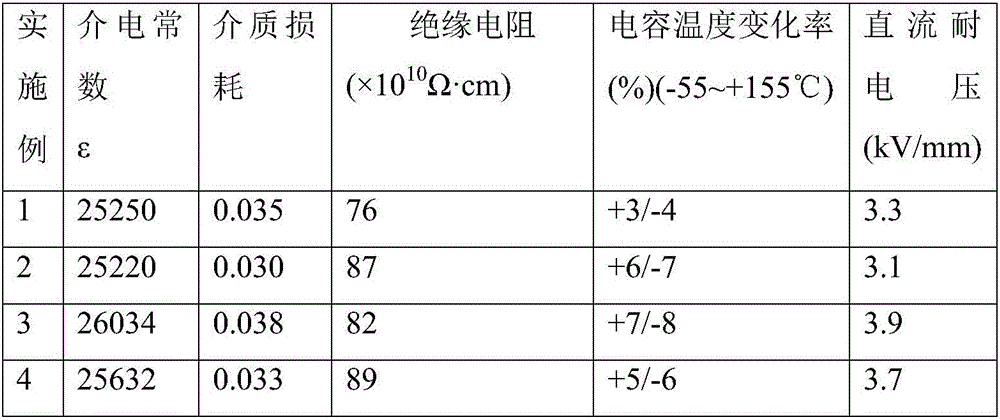

Low temperature coefficient crystal boundary layer ceramic capacitor medium and preparation method thereof

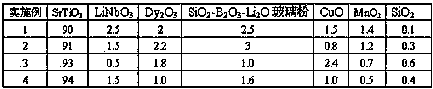

The invention relates to the technical field of inorganic non-metal materials, and particularly discloses a low temperature coefficient crystal boundary layer ceramic capacitor medium and a preparation method thereof. The medium formula comprises the following components in percentage by weight: 88 to 96 percent of SrTiO3, 0.1 to 4 percent of LiNbO3, 0.05 to 4 percent of Dy2O3, 0.03 to 3.0 percent of SiO2-B2O3-Li2O glass powder, 0.1 to 4 percent of CuO, 0.01 to 1 percent of SiO2, and 0.03 to 2.0 percent of MnO, wherein SrTiO3, LiNbO3 and SiO2-B2O3-Li2O glass powder are respectively compounded by conventional chemical raw materials through a solid phase method. According to the invention, a conventional ceramic capacitor medium preparation method and a one-time sintering technological method are adopted, the common capacitor ceramic chemical raw material is adopted to prepare the lead-free and cadmium-free low temperature coefficient crystal boundary layer ceramic capacitor medium, the sintering temperature of capacitor ceramic can be also lowered, and the medium is applicable to the preparation of monolithic ceramic capacitors and monolayer chip ceramic capacitors.

Owner:JIANGSU UNIV

Glass insulator

ActiveCN102881386AStable physical propertiesStable chemical propertiesLead-in/lead-through insulatorsAlternating currentMetal

The invention discloses a glass insulator used for encapsulation connection between the metal end cover and the metal conductive columns of the wiring terminal of a compressor. The glass insulator comprises the components with the weight percentage as follows: 92-94 percent of SiO2, 3-4 percent of Al2O3, 0.5-1 percent of Bi2O3, 0.5-1 percent of TiO2 and 1.5-2.5 percent of SrO, preferably, 93 percent of SiO2, 33.3 percent of Al2O3, 0.7 percent of Bi2O3, 0.8 percent of TiO2 and 2.2 percent of SrO. The glass insulator not only has favorable insulating performance and avoids flashover generated during operation, but also has low probability of generation of crackle under the long-term action of the alternating current of the metal columns, therefore an explosion hazard of the compressor is avoided, and the glass insulator is suitable for widely applied in the wiring terminal of the compressor.

Owner:JIANGSU CHANGRONG ELECTRICAL APPLIANCE CO LTD

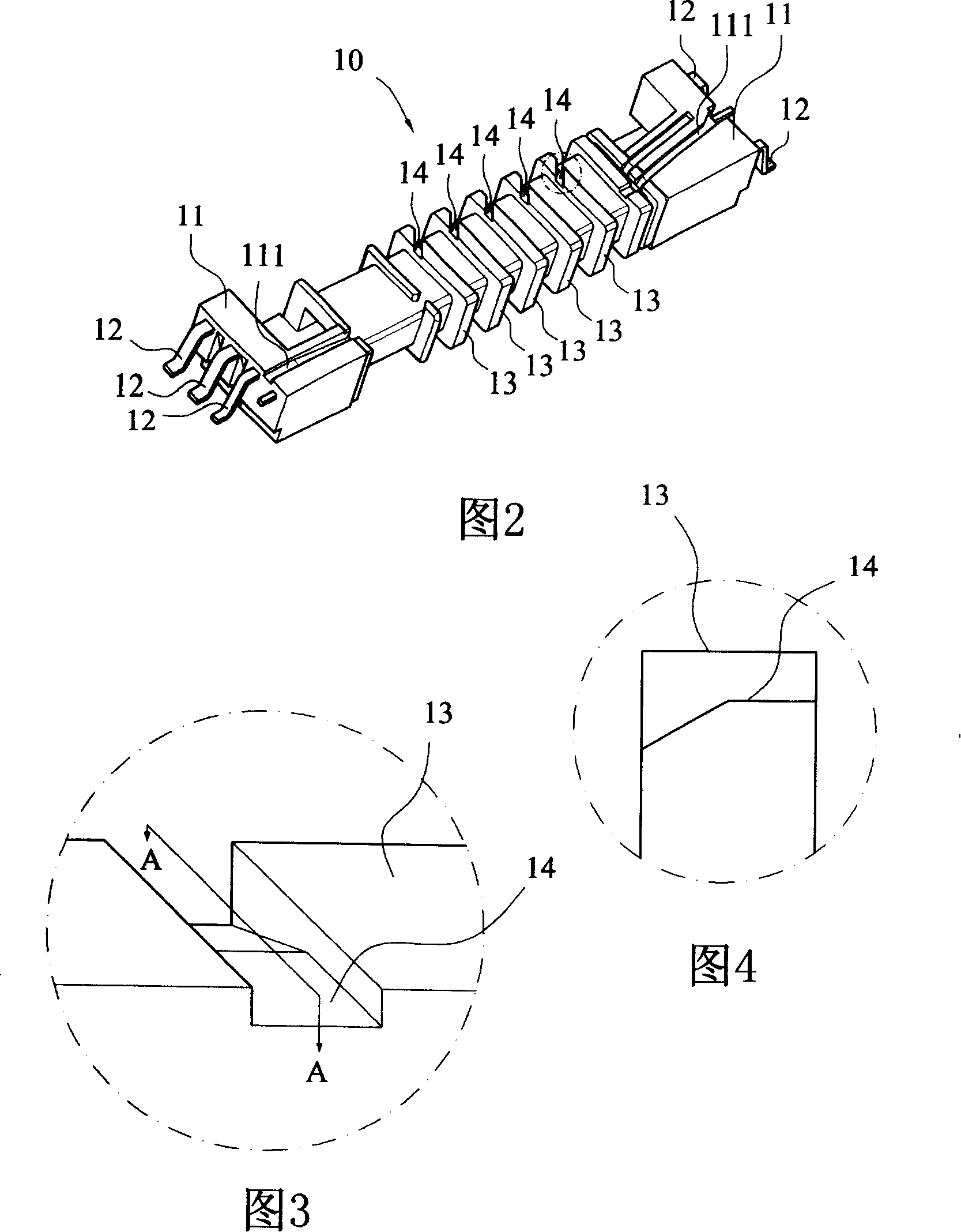

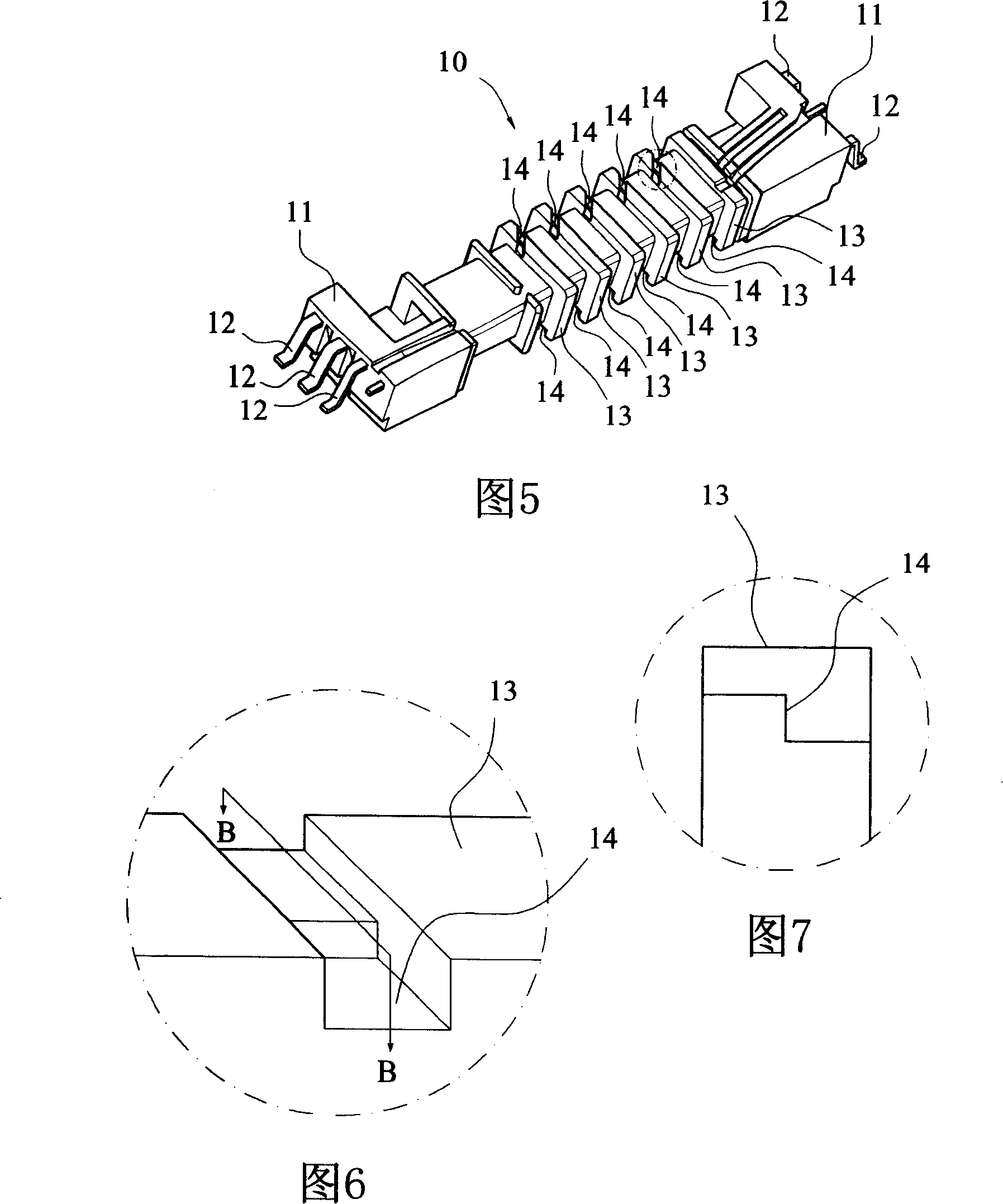

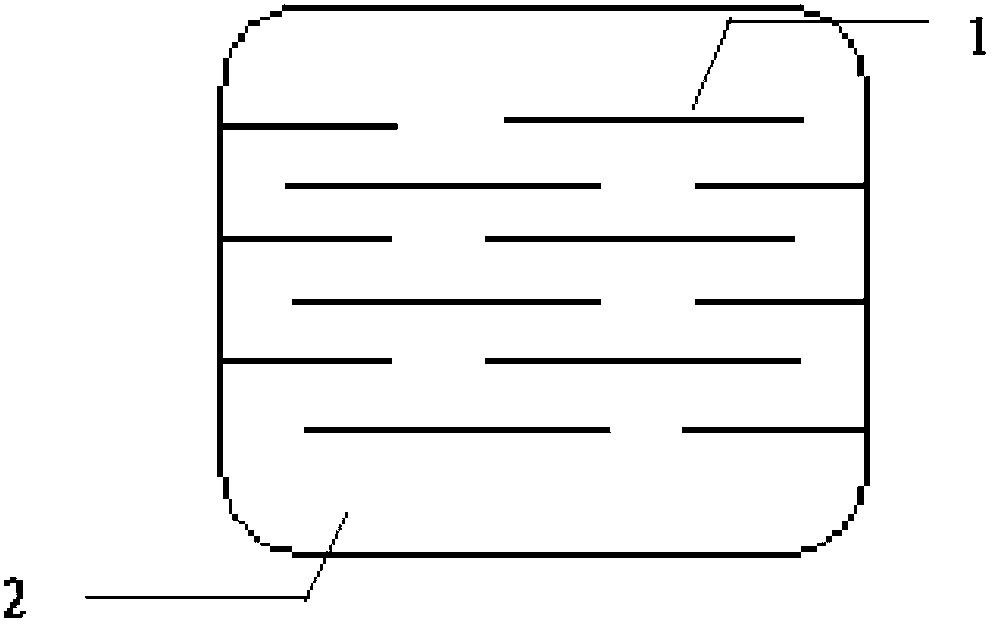

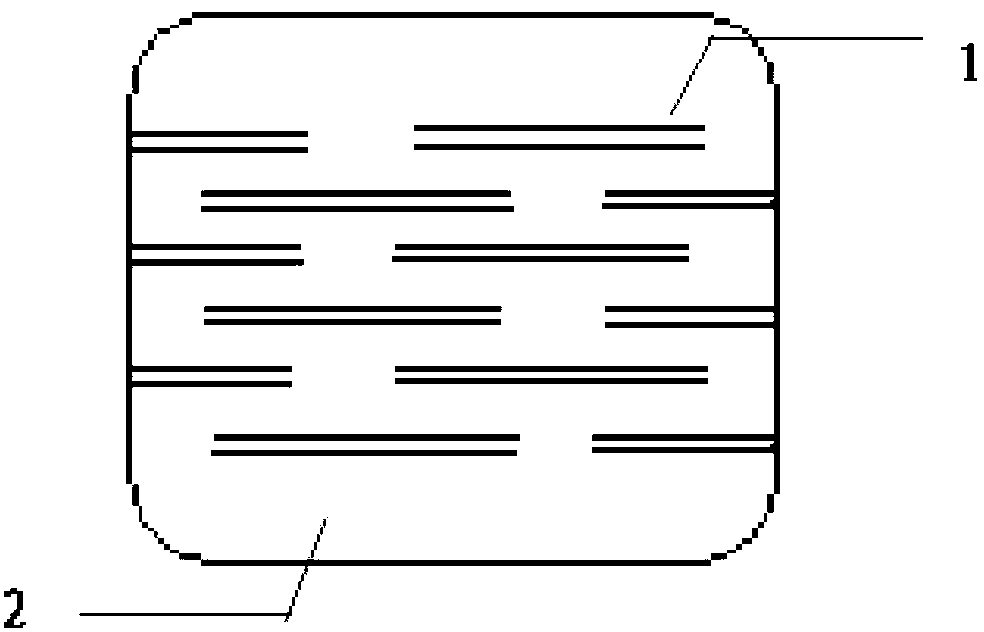

Bobbin bracket structure of transformer

InactiveCN101211692AIncrease coil trace distanceHigh withstand voltageTransformers/inductances coils/windings/connectionsCoils manufactureEngineeringBobbin

The invention discloses a structure for transformer bobbin bracket, which takes a shape of a hollow pipe body. A plurality of separators are arranged on the transformer bobbin bracket and at least one trans-line groove is arranged on the separator and used for providing space for the coil to cross the separator; the trans-line groove is designed to be slantingly tangent with the separator so as to increase the laying distance of the coil, and the depth of the trans-line groove presents a slant shape or ladder shape which is higher at one side and lower at the other side to ensure that the line of the coil enters at a higher position and goes out at a lower position when the lines of the coil are laid so as to increase the relative distance between two neighboring groups of coils of the separator, thereby effectively increasing the withstanding voltage of the separator of the bobbin bracket and relatively shortening the thickness of the separator of the bobbin bracket so as to further shorten the size of the transformer.

Owner:TDK TAIWAN

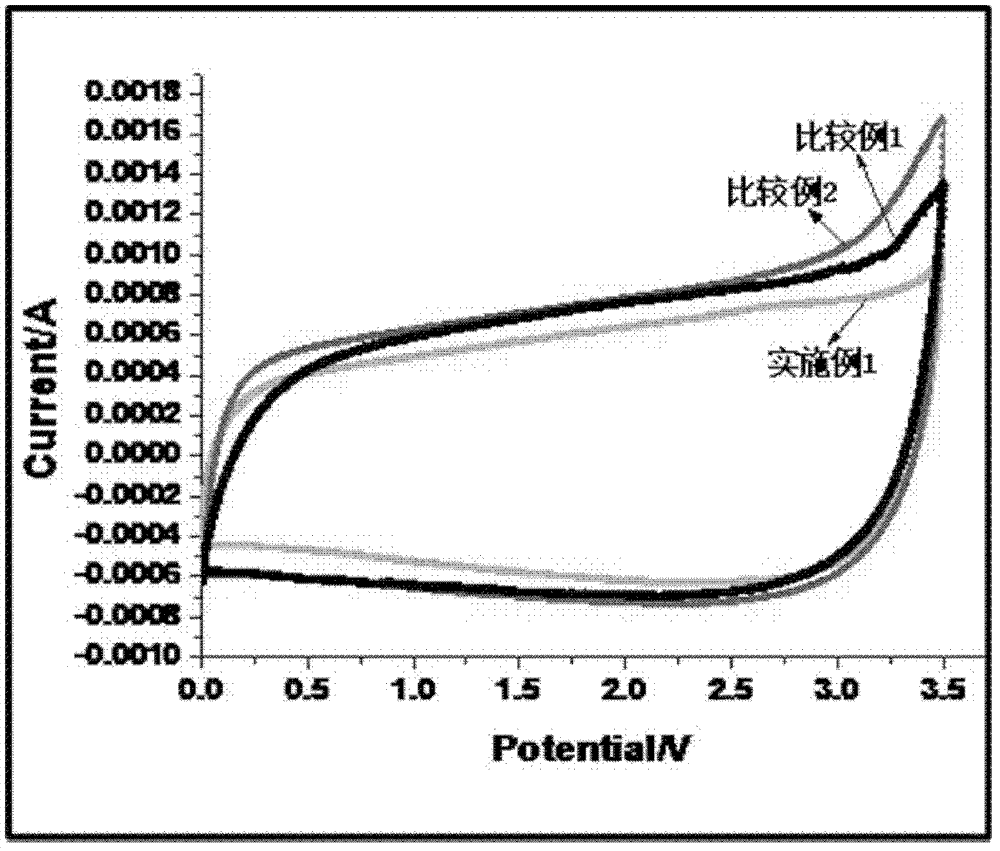

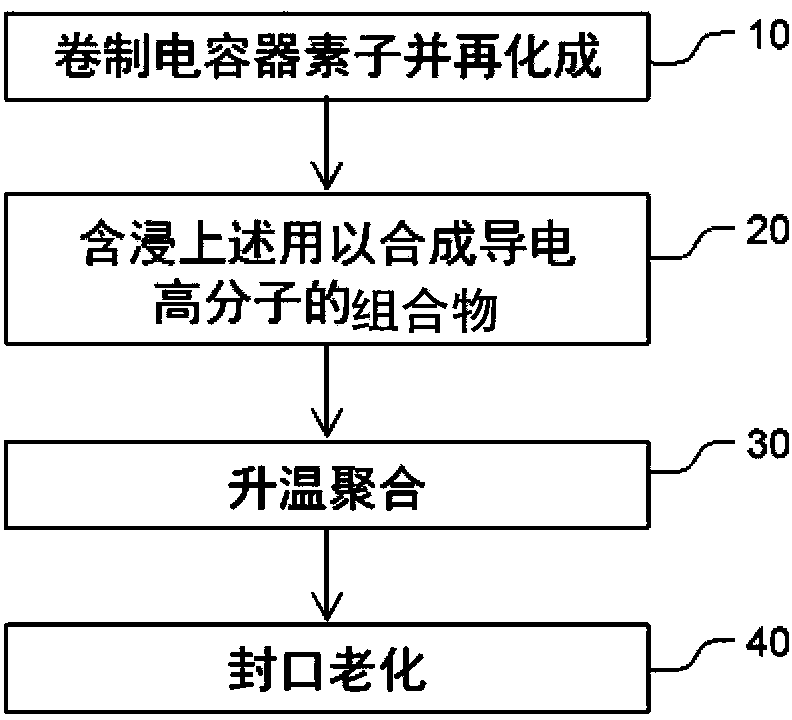

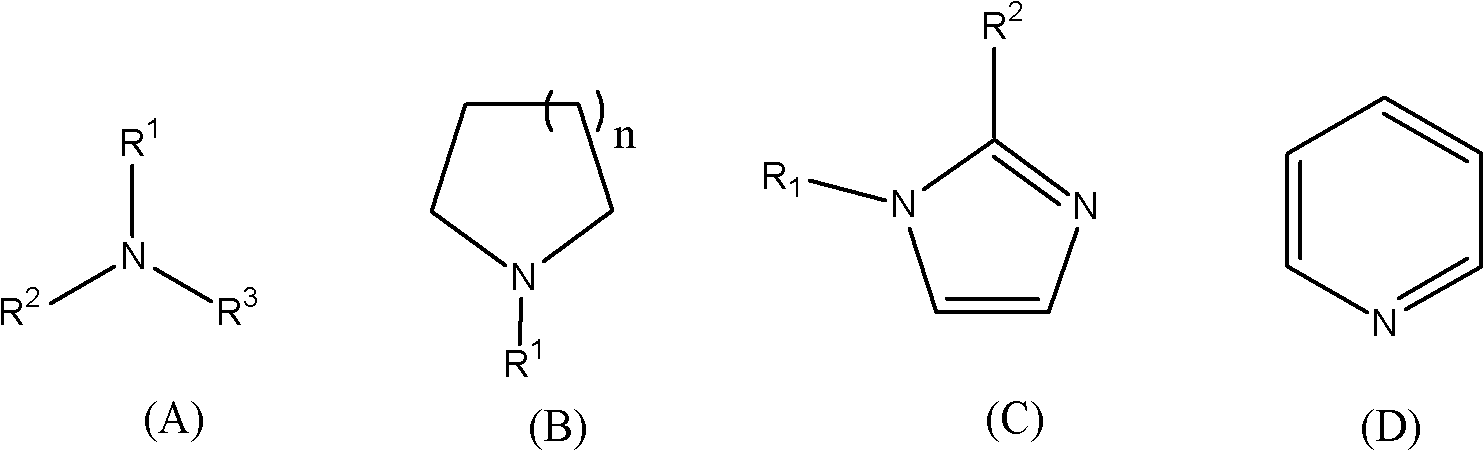

Electrolyte mixture, composition for conductive polymer synthesis and conductive polymer solid electrolytic capacitor formed by using the same

InactiveCN103578769AImprove conductivityHigh withstand voltageSolid electrolytic capacitorsCapacitor electrolytes/absorbentsCapacitanceElectrolysis

The invention discloses an electrolyte mixture, a composition for conductive polymer synthesis and conductive polymer solid electrolytic capacitor formed by using the same. The electrolyte mixture includes a conductive polymer and a nitrogen-containing polymer. The nitrogen-containing polymer includes a cyclic nitrogen-containing polymer, a polymer with primary amine group, a polymer with secondary amine group, a polymer with tertiary amine group, a polymer with quaternary ammonium group, or a combination thereof. The interface impedance between the conductive polymer and the oxide film can be facilitated by additionally providing the cyclic nitrogen-containing polymer, and the filming performance of the conductive polymer can be improved, the conductivity of the conductive polymer can be improved, and by applying the cyclic nitrogen-containing polymer to the solid electrolytic capacitor, the capacitance, the reliability, the voltage resistance performance, and the thermal resistance performance of the solid electrolytic capacitor can be improved, the dissipation factor value, the 120kHz equivalent series resistor, and the service lifetime can be reduced.

Owner:IND TECH RES INST

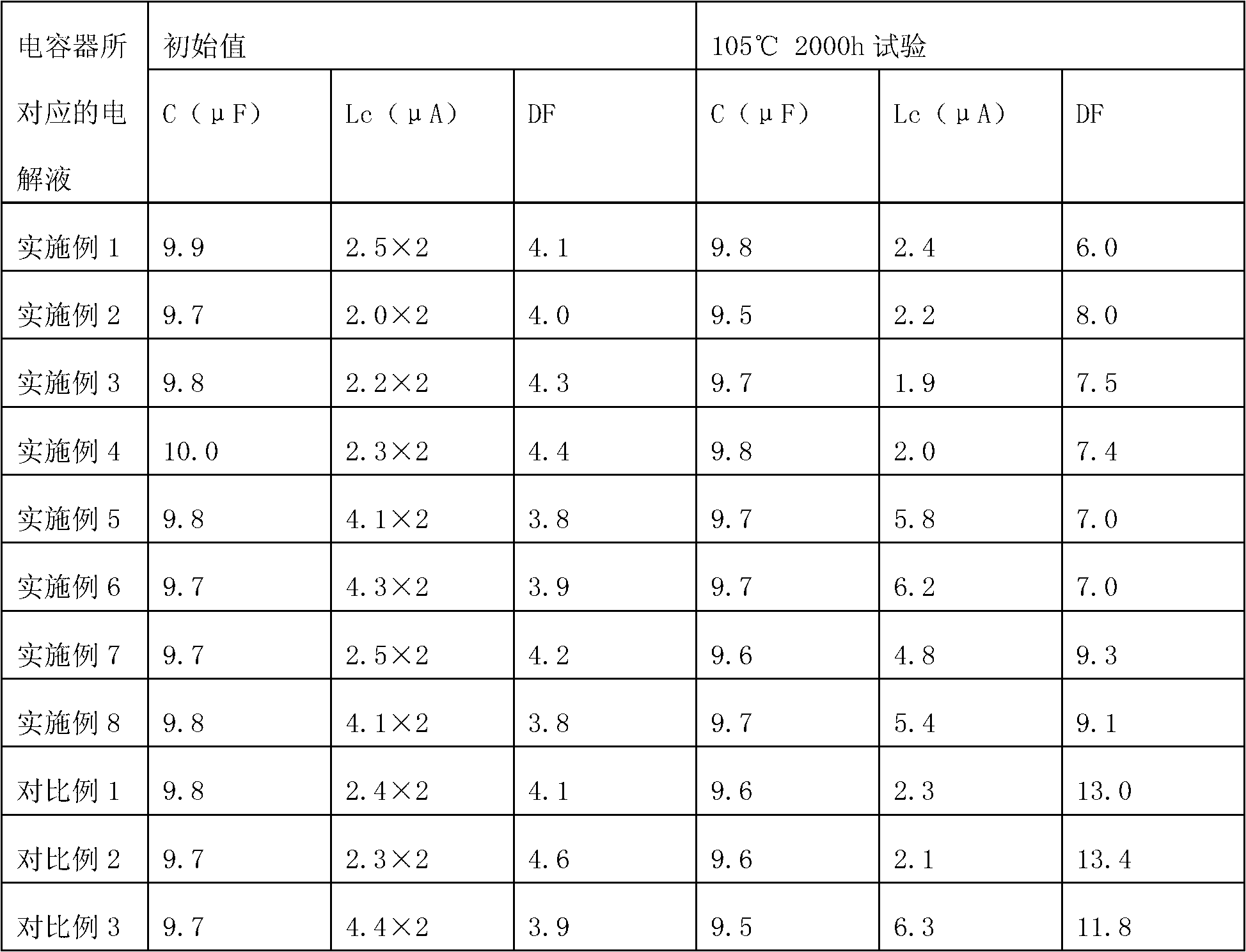

Aluminum electrolytic capacitor electrolyte and aluminum electrolytic capacitor

ActiveCN102842430AIncrease the flash voltageImprove thermal stabilityLiquid electrolytic capacitorsOrganic solventThermal stability

The invention aims at providing aluminum electrolytic capacitor electrolyte with excellent heat stability. Meanwhile the invention also provides an aluminum electrolytic capacitor prepared by the electrolyte. The electrolyte comprises following components of organic solvent and 2-hexyl ammonium adipate or combination of 2-hexyl ammonium adipate and ammonium salt of the 2-hexyl ammonium adipate. The electrolyte has better heat stability.

Owner:SHENZHEN CAPCHEM TECH

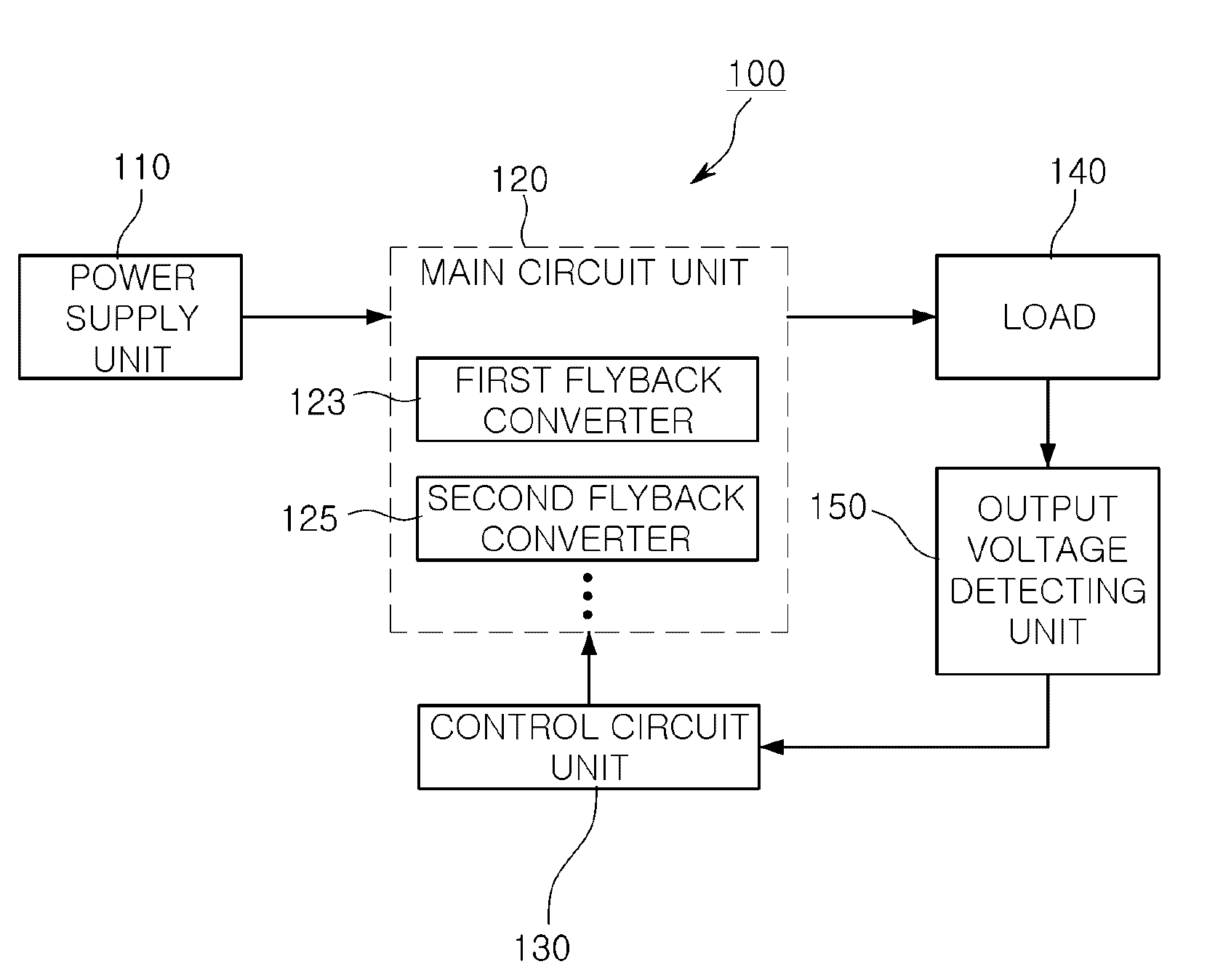

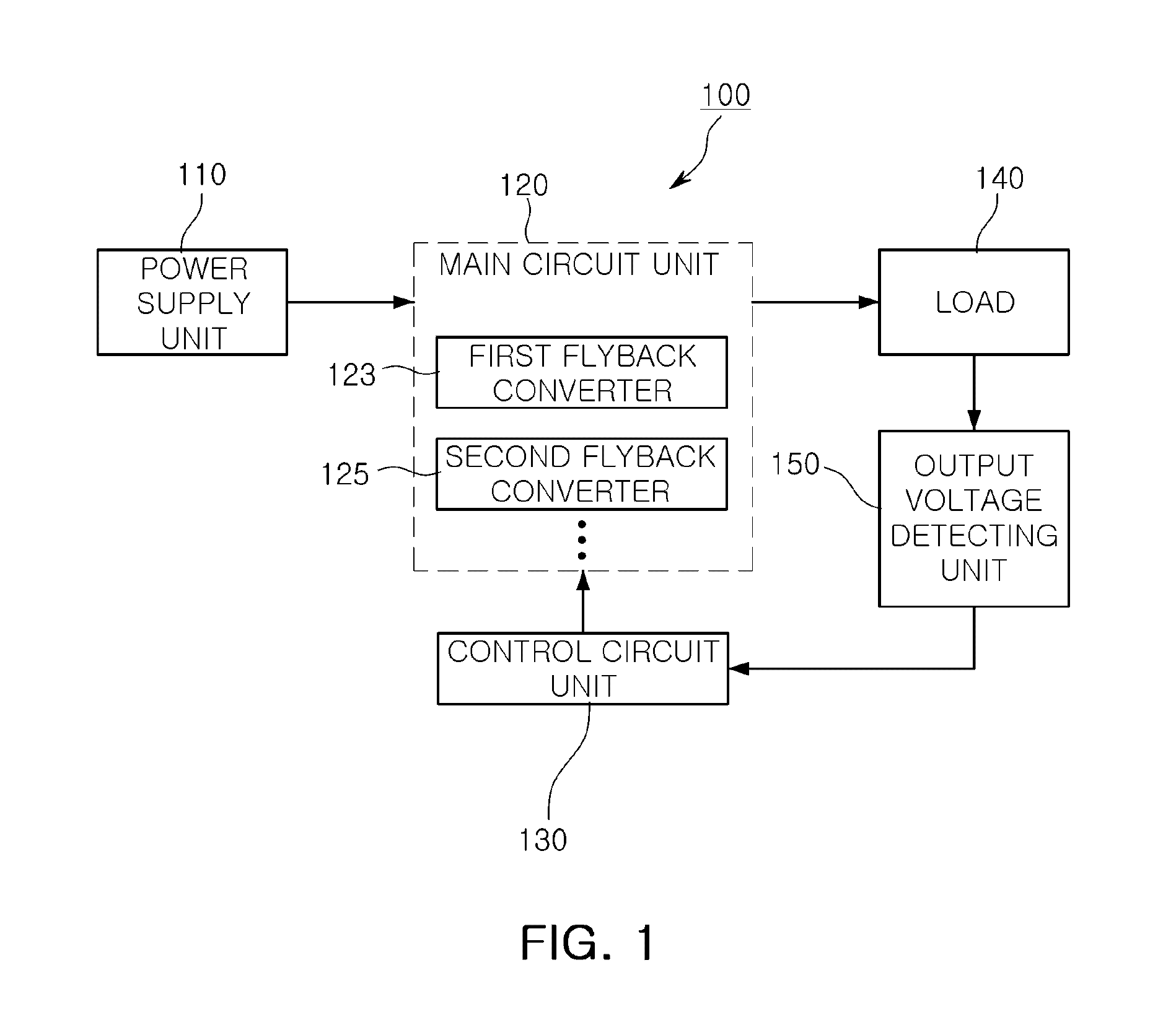

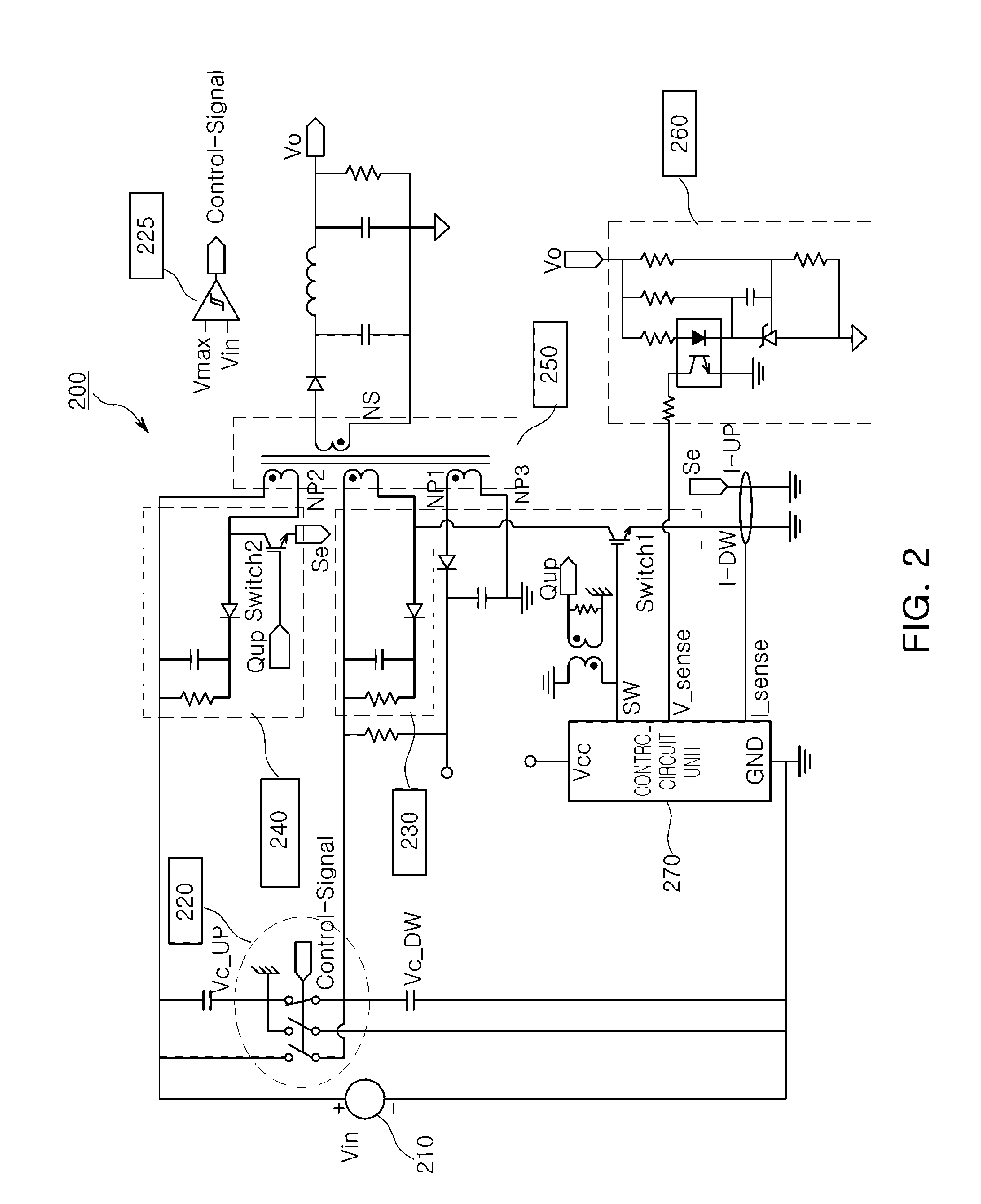

Power supplying apparatus, method of operating the same, and solar power generation system including the same

InactiveUS20130286699A1Effectively direct current (DC)High withstand voltageEnergy industryApparatus with intermediate ac conversionVoltage rangeEngineering

There are provided a power supplying apparatus, a method of operating the same, and a solar power generation system including the same. The power supplying apparatus includes: a power supply unit generating a direct current (DC) input signal; a main circuit unit including a plurality of flyback converter circuits connected to the power supply unit to generate a DC output signal; and a control circuit unit controlling an operation of the main circuit unit, wherein the control circuit unit connects the plurality of flyback converter circuits to each other in series or in parallel according to a level of the DC input signal. Therefore, even in the case in which the level of the DC input signal is high, a circuit maybe configured using a circuit device having a low withstand voltage range and damage and deterioration of the circuit device may be prevented.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD +1

Preparation method of high-purity alkylammonium tetrafluoroborate for super capacitor

ActiveCN102432474AHigh purityHigh yieldOrganic compound preparationElectrolytic capacitorsHalogenTetrafluoroborate

The invention discloses a preparation method of high-purity alkylammonium tetrafluoroborate for a super capacitor, characterized by reacting tertiary amine with tetrafluoroborate alcoxylonium salt at a certain temperature to obtain corresponding alkylammonium tetrafluoroborate, and purifying to obtain the high-purity alkylammonium tetrafluoroborate. The method has the advantages of simple operation steps, good selectivity, high conversion rate, high product purity, and no halogen ions, and can satisfy the requirements of a high performance super capacitor. The use of the prepared alkylammonium tetrafluoroborate as an electrolyte in the super capacitor can achieve the advantages of high product capacity, low internal resistance, and reduced capacity fade at a high temperature.

Owner:锦州凯美能源有限公司

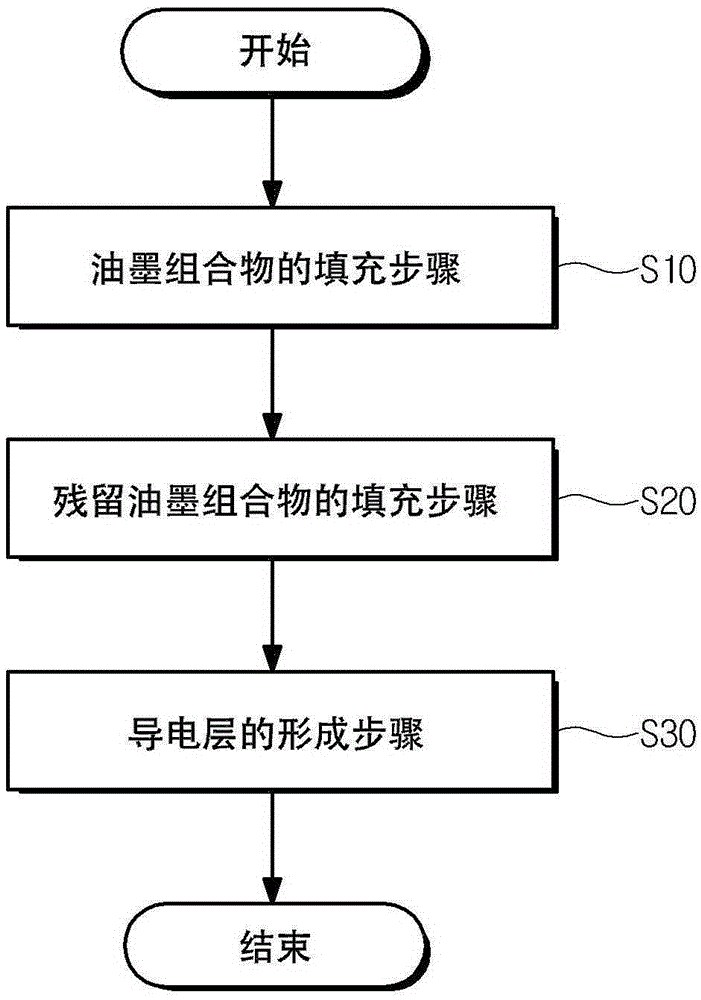

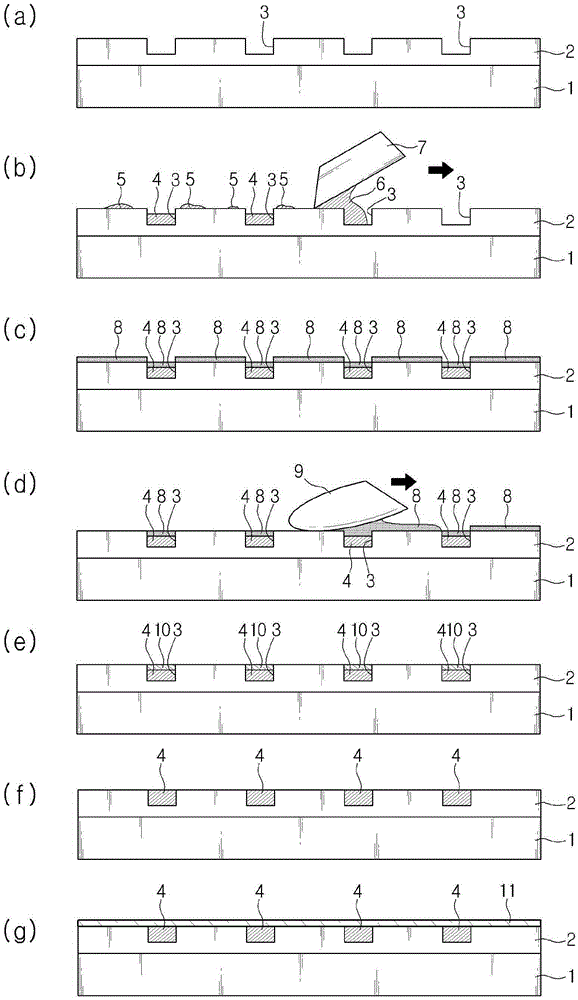

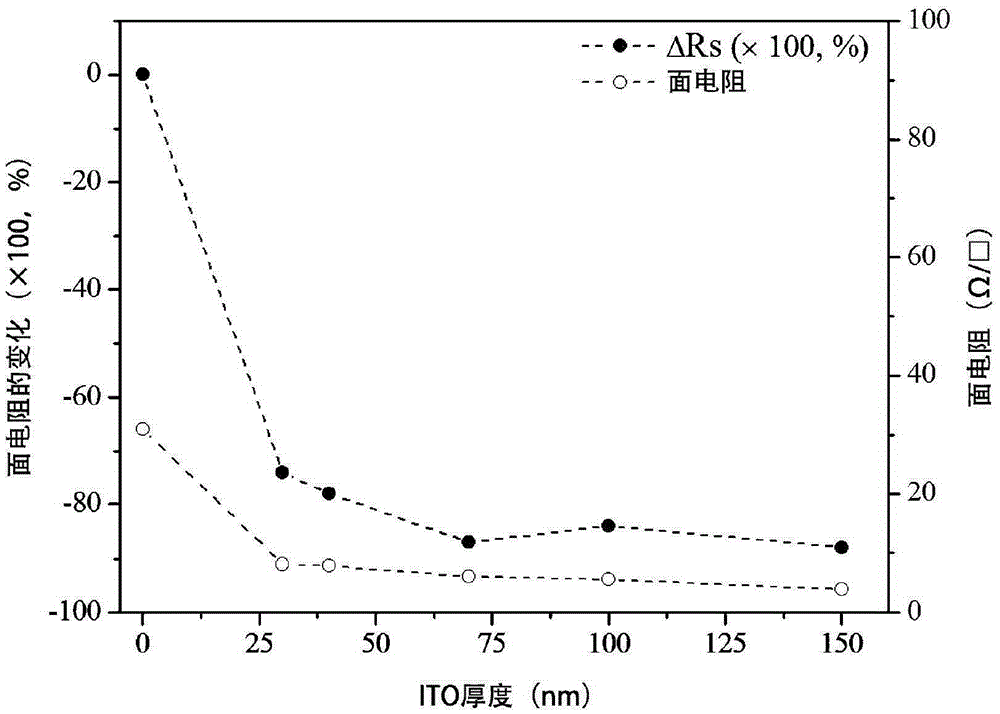

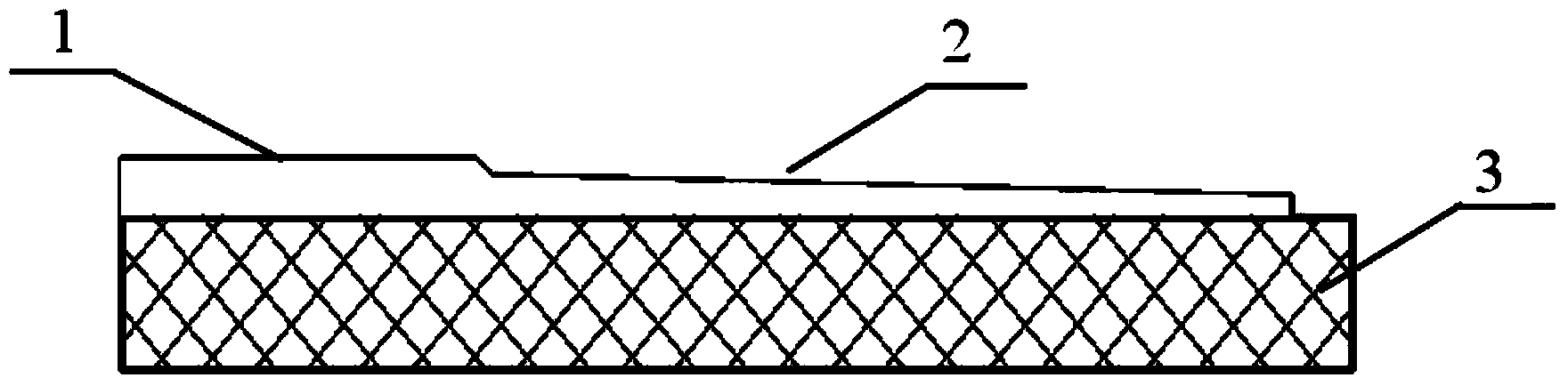

Method for manufacturing hybrid transparent electrode and hybrid transparent electrode

InactiveCN105393314AImprove conductivityImprove transmittanceConductive layers on insulating-supportsDuplicating/marking methodsConductive materialsPolymer chemistry

The present invention relates to a method for manufacturing a hybrid transparent electrode and a hybrid transparent electrode, the method comprising: an ink composition filling step for filling a conductive metal ink composition into a groove on a base material having the groove; a remaining ink composition filling step of forming an electrode pattern by filling the groove with the conductive metal ink composition remaining on the surface of the base material, as the conductive metal ink composition is filled in the groove; and a conductive layer forming step of forming a conductive layer comprising a conductive material on top of the electrode pattern.

Owner:INKTEC CO LTD

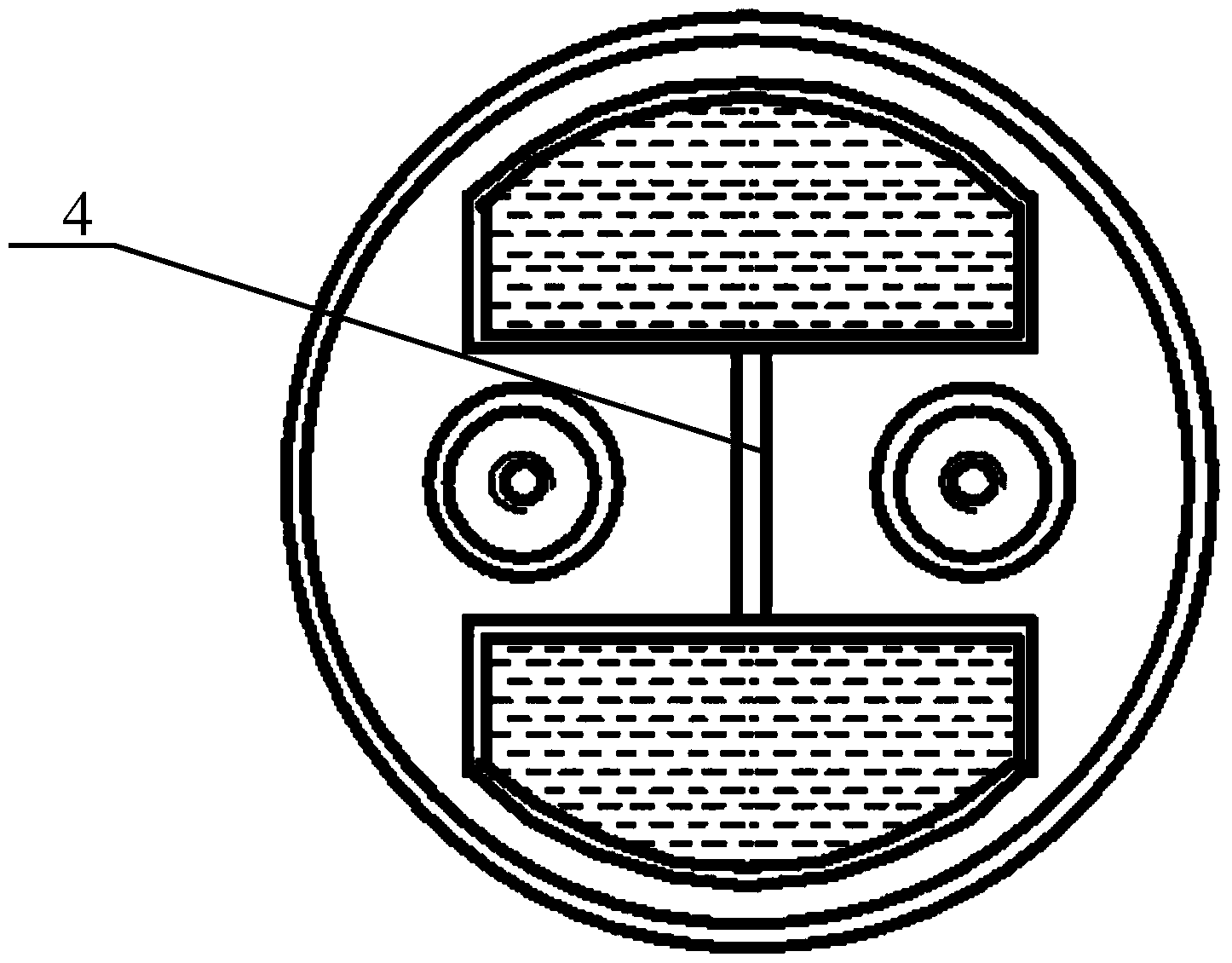

Trapezoidal evaporation metalizing polypropylene film capacitor

InactiveCN104252969AHigh withstand voltageImprove self-healing abilityMultiple fixed capacitorsFixed capacitor electrodesEvaporationOxidation resistant

The invention relates to the technical field of capacitors, and discloses a trapezoidal evaporation metalizing polypropylene film capacitor, which comprises a casing, capacitor cores, a leading-out terminal and a leading-out electrode, wherein the capacitor core comprises a high temperature-resistant polypropylene film, the polypropylene film is evaporated with a metal aluminum layer as an electronic moving area under the high-vacuum environment, the moving area is of a trapezoidal structure, the edge of the moving area is thickened and evaporated with a pure zinc layer as a thickening area, the evaporation trapezoidal square resistance in the moving area is controlled to 30-50 ohms, the square resistance in the thickening area is controlled to 2-4 ohms, and two to three capacitor cores are parallelly connected in the capacitor. The capacitor has the advantages that the voltage resistant property is high, the loss is little, the effective current can be withstood, the impact capacity is high, the temperature rise is low, the self equivalent serial resistance of the capacitor is little, the anti-oxidizing capacity is high, the safety and reliability are high, the service life is long, the storage is easy, the heat radiating property is good, and the cost is low.

Owner:宁国市裕华电器有限公司

Method for preparing high voltage-resisting chip type ceramic capacitor

ActiveCN103000369AHigh withstand voltageReduce manufacturing costFixed capacitor electrodesFixed capacitor dielectricMetallurgyCeramic capacitor

The invention provides a method for preparing a high voltage-resisting chip type ceramic capacitor and relates to the technical field of electronic information materials and elements. The method comprises the procedures of dispersing of ceramic slurry, curtain coating of ceramic membranes, printing of inner electrode, staggered lamination, uniform pressing, cutting, plastic removal, sintering, chamfering, end coating and silver electrode firing, wherein a solvent for the ceramic slurry adopts methylbenzene and ethanol, during printing of inner electrode, the inner electrode is made of a silver palladium alloy which is sintered at a low temperature, during end coating, the end electrode is made of silver (Ag), particularly, during dispersing of ceramic slurry, ceramic powder adopts Ba-Ti-Nd based ceramic powder, particle sizes of the Ba-Ti-Nd based ceramic powder are within a range of 0.22-0.95mu m of spherical or approximately spherical bodies, and the solvent for the ceramic slurry adopts a mixture of the methylbenzene and the ethanol in a proportion of (1-2.5):1. By the aid of the method for preparing the high voltage-resisting chip type ceramic capacitor, the high-frequency high voltage-resisting chip type ceramic capacitor can be manufactured effectively, and simultaneously, the manufacturing cost can be reduced effectively.

Owner:BEIJING YUANLIU HONGYUAN ELECTRONICS TECH

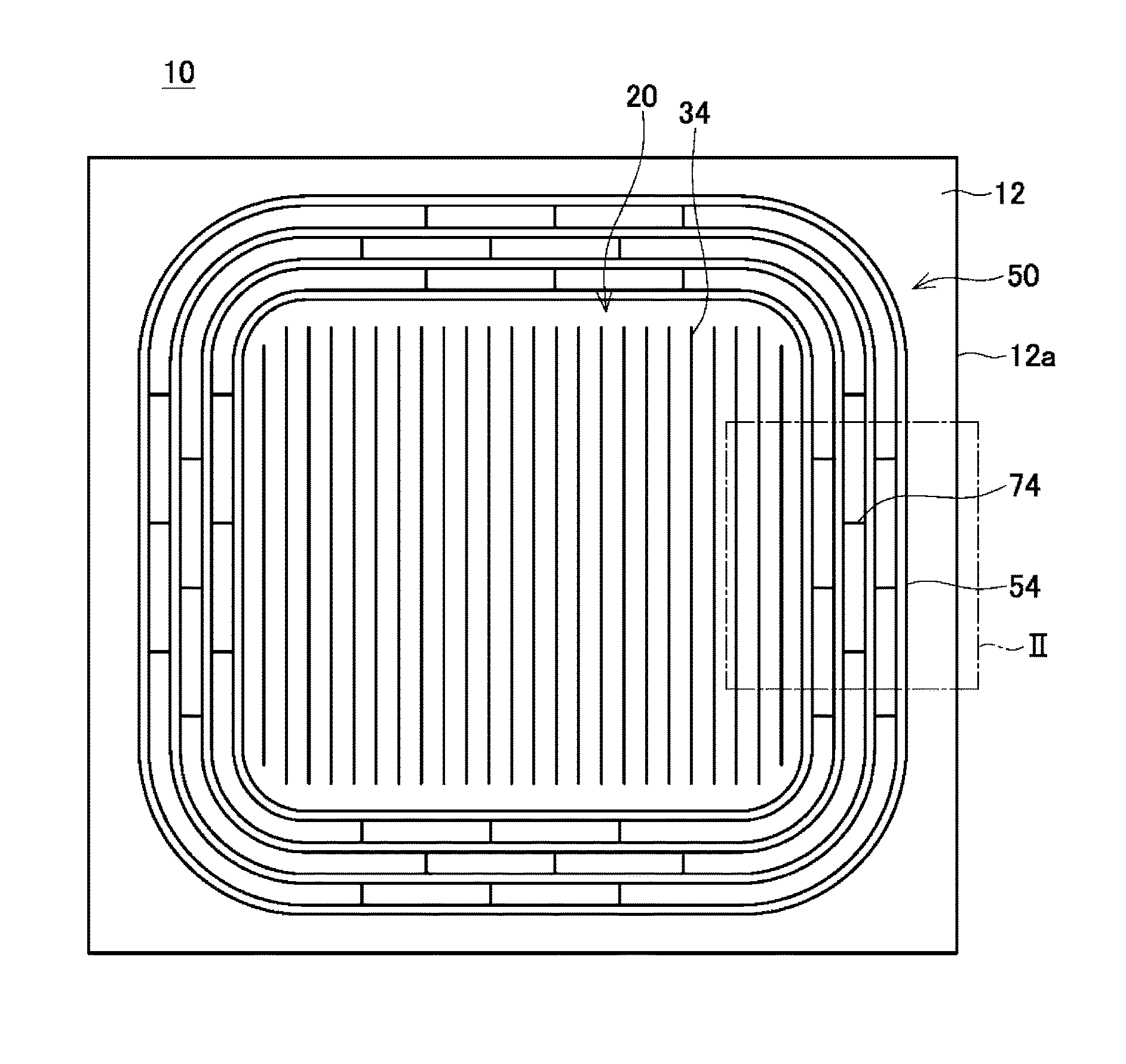

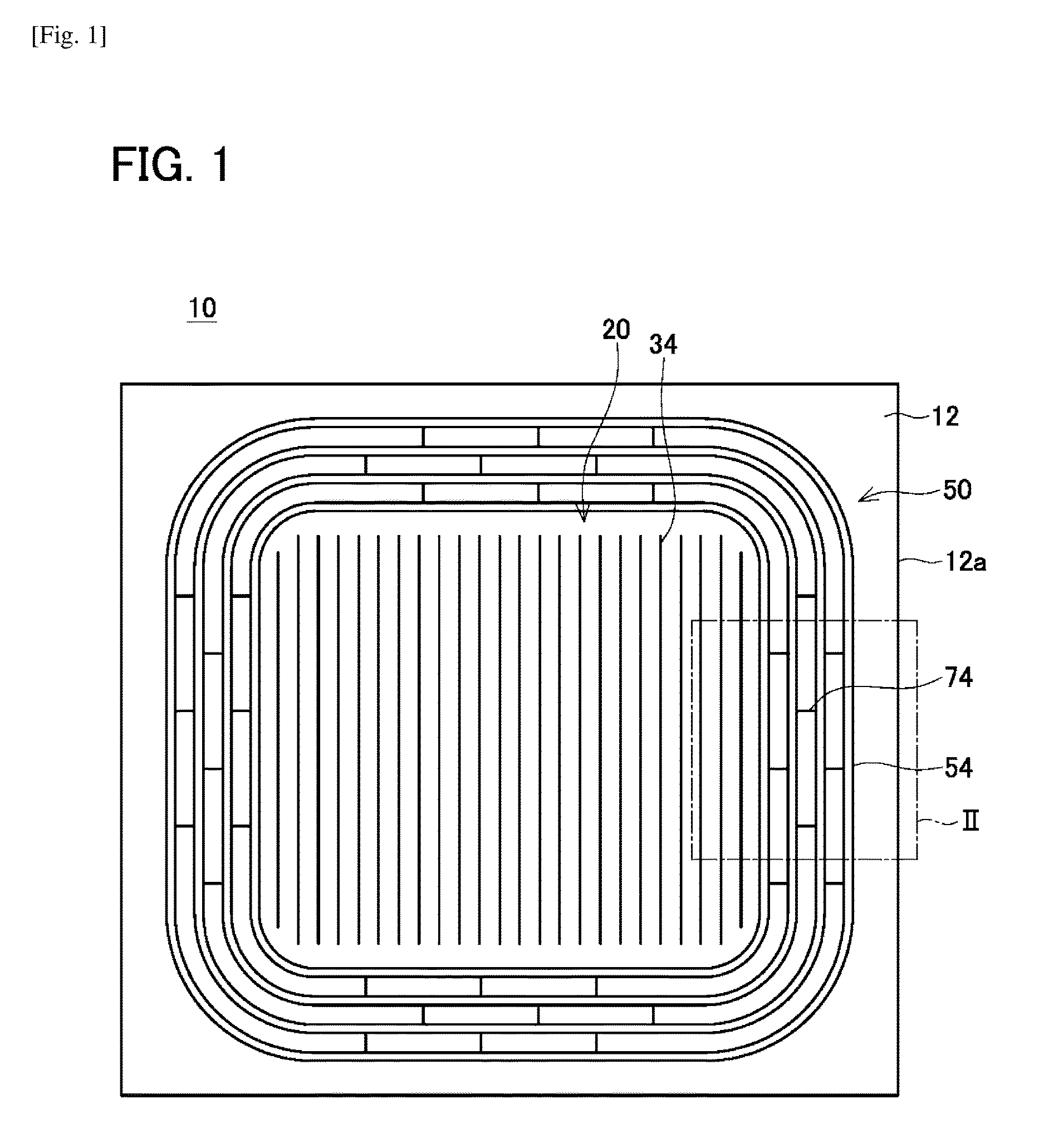

Insulated gate type semiconductor device

ActiveUS20170011952A1High withstand voltageEasily depletedSemiconductor/solid-state device manufacturingSemiconductor devicesEngineeringSemiconductor

An insulating gate type semiconductor device being capable of easily depleting an outer periphery region is provided. The insulating gate type semiconductor device includes: first to fourth outer periphery trenches formed in a front surface of a semiconductor substrate; insulating layers located in the outer periphery trenches; fifth semiconductor regions being of a second conductive type and formed in ranges exposed to bottom surfaces of the outer periphery trenches; and a connection region connecting the fifth semiconductor region exposed to the bottom surface of the second outer periphery trench to the fifth semiconductor region exposed to the bottom surface of the third outer periphery trench. A clearance between the second and third outer periphery trenches is wider than each of a clearance between the first and second outer periphery trenches and a clearance between the third and fourth outer periphery trenches.

Owner:TOYOTA JIDOSHA KK

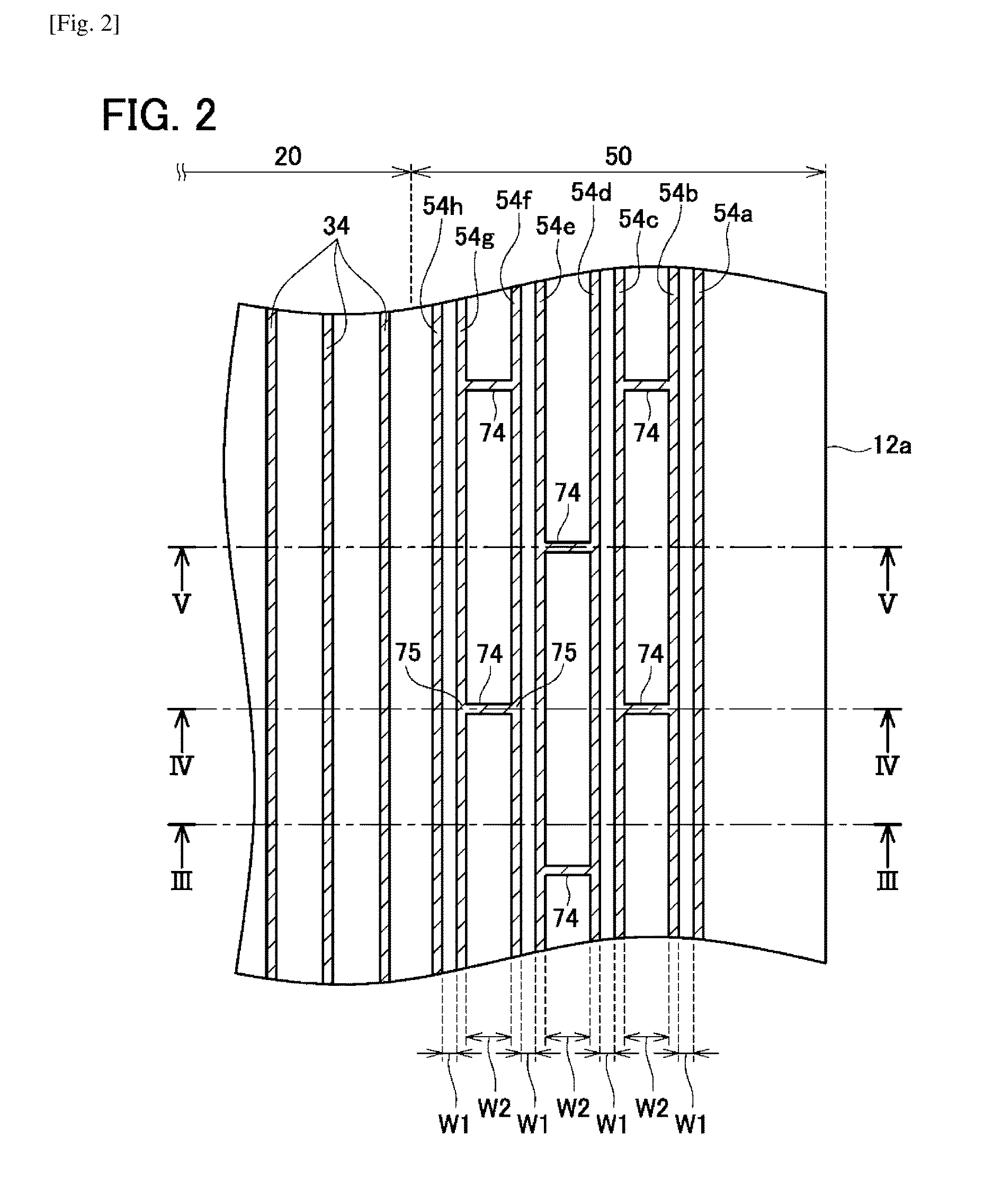

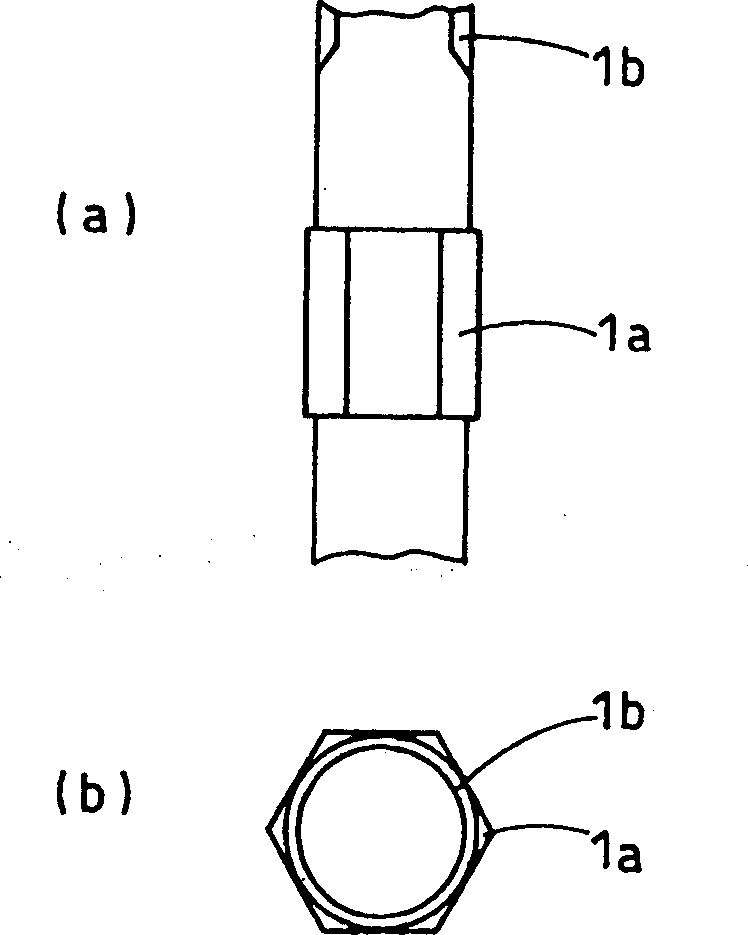

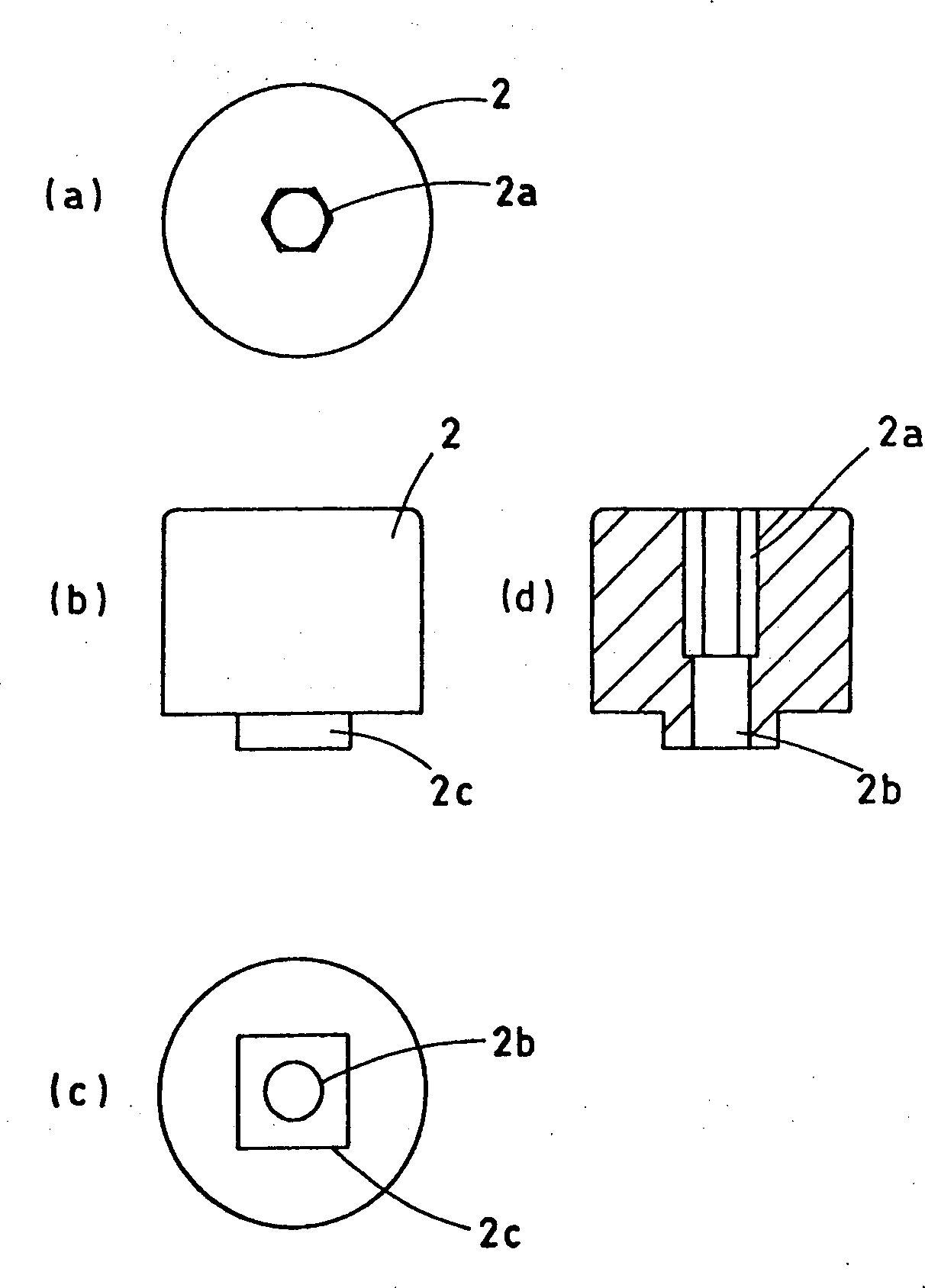

Terminal equipment of electric appliance

InactiveCN1360321APrevent rotationAvoid damageElectrically conductive connectionsFixed capacitor housing/encapsulationTerminal equipmentConvex side

The present invention relates to a terminal device for an electronic apparatus, which includes an external lead out rod having a convex side part on the center; an insulation terminal seat consists of an outer insulation terminal seat and an inner insulation terminal seat, wherein one has a concave part and the other has a convex part and the two parts forms a concavo-convex part, and a counter boring for preventing the external lead out rod from rotating is formed on the outer insulation terminal seat; a casing of a through hole that the convex part of the insulation terminal seat goes into the outer terminal seat to prevent rotating; a fixing mechanism for fixing the external lead out rod on the casing through said insulation terminal seat; a concavo-convex part sets an inner terminal seat and an outer terminal seat in and out of the through hole of the casing. The terminal device is satisfactory in rotation preventing function to the rotational torque at a terminal part and is satisfactory in setup work by preventing deterioration of the functions of the terminal part, caused by human error and by making it into a structurally simple constitution, and is high in operability, and is capable of price reduction, too.

Owner:PANASONIC CORP

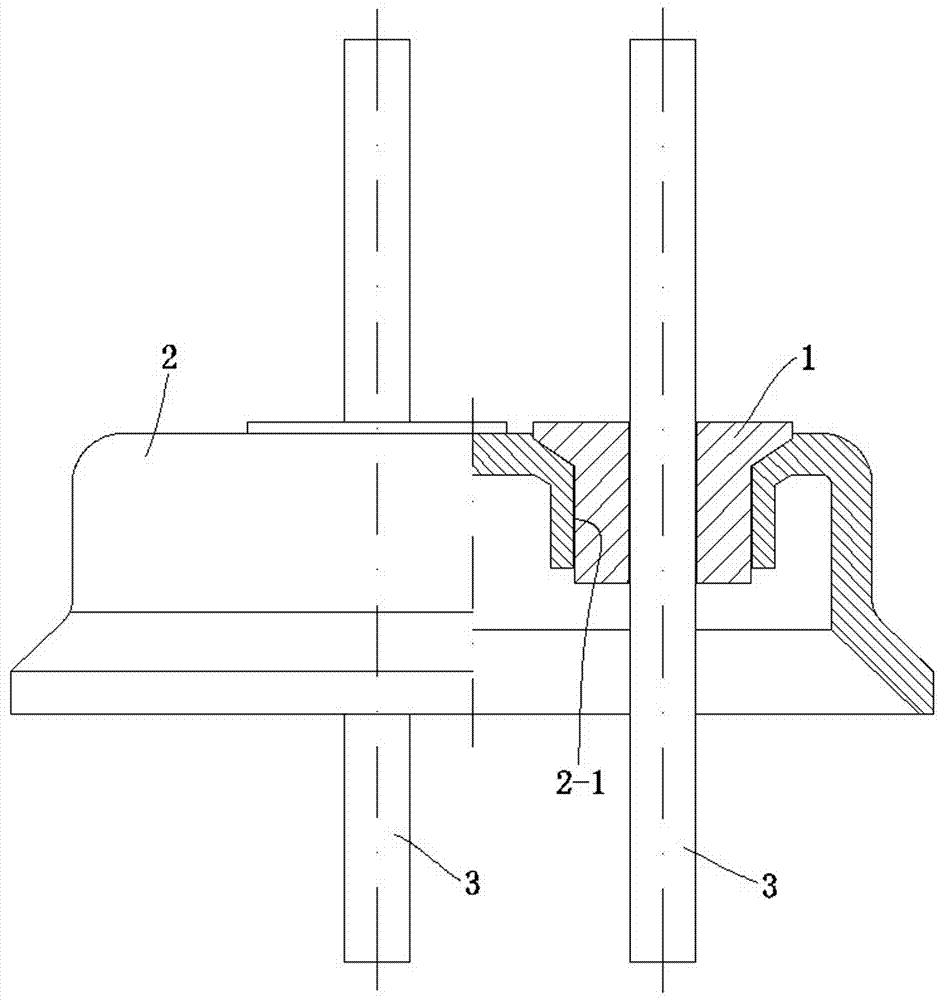

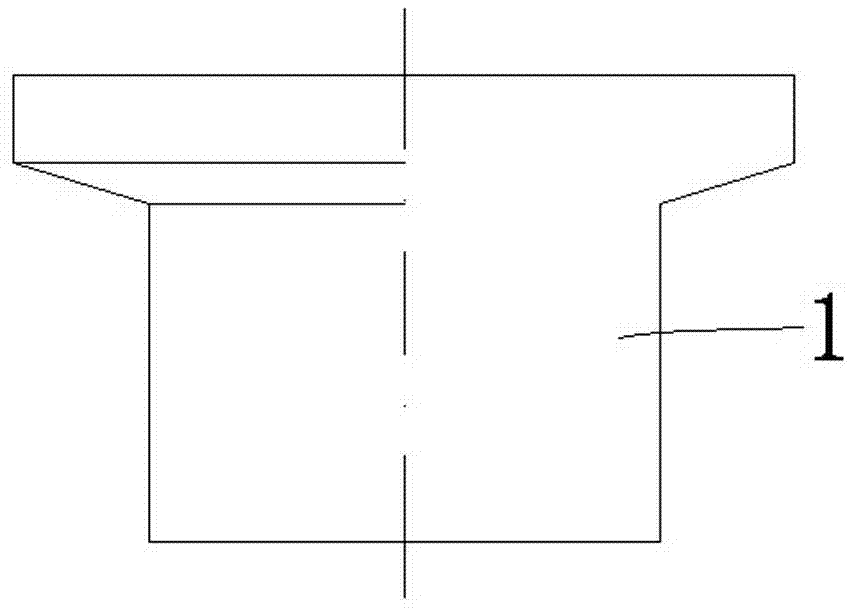

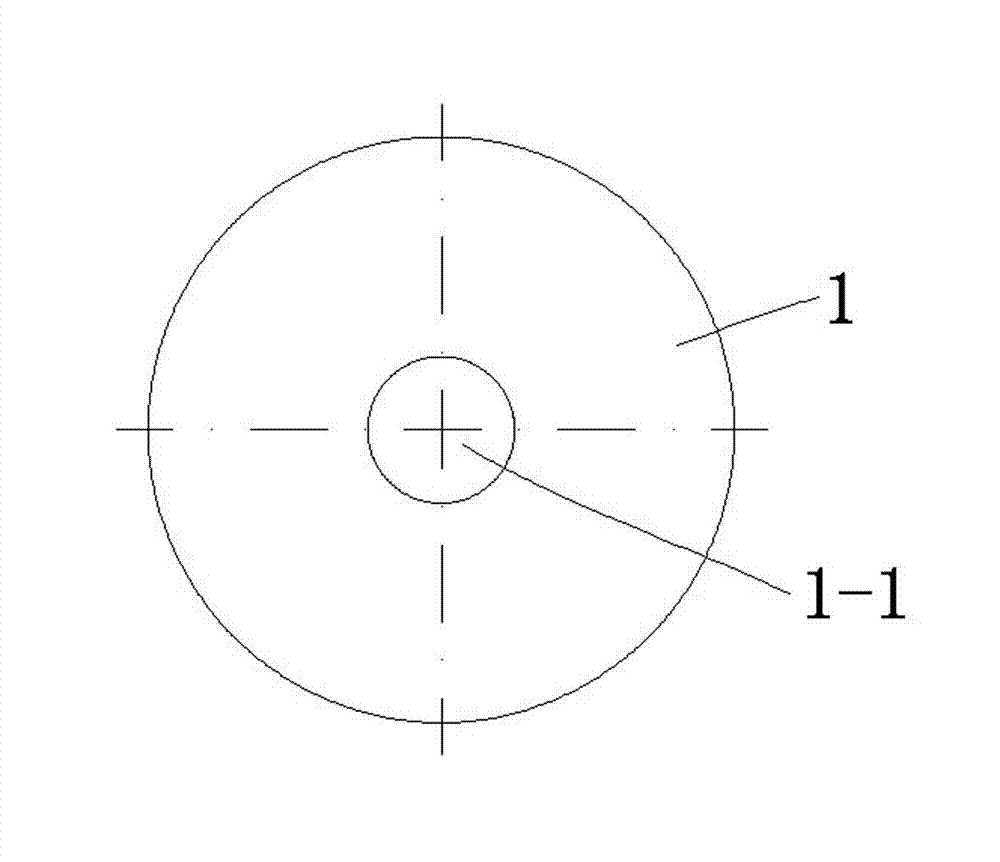

Machining method of metal packaging shell of large-scale and large-power integrated circuit

ActiveCN102832140AImprove air tightnessHigh withstand voltageSemiconductor/solid-state device manufacturingComputer moduleEngineering

The invention relates to a machining method of a metal packaging shell of a large-scale and large-power integrated circuit. The shell comprises a base and an outer cover, wherein the base is composed of a base plate, a plurality of glass blanks and a plurality of terminal pins; a plurality of first through holes for holding the terminal pins and the glass blanks are formed on the base plate; and the terminal pins are arranged inside the first through holes on the base plate through the glass blanks. When the base and the outer cover are machined well, required elements such as integrated circuits and modules are installed on the base; and the outer cover is welded with the base; the integrated circuits, the modules and the like are fixed on the base of the metal shell, and are connected with external tested devices through leading-out terminals of the terminal pins, thereby accomplishing the output, input and detection and control functions of system signals. The outer cover is welded with the base; the integrated circuits and the modules are sealed inside the metal shell, so that both the functions of signal output, detection and control are achieved, and the internal circuit is prevented from being influenced by various external severe environments.

Owner:中国电子科技集团公司第四十研究所

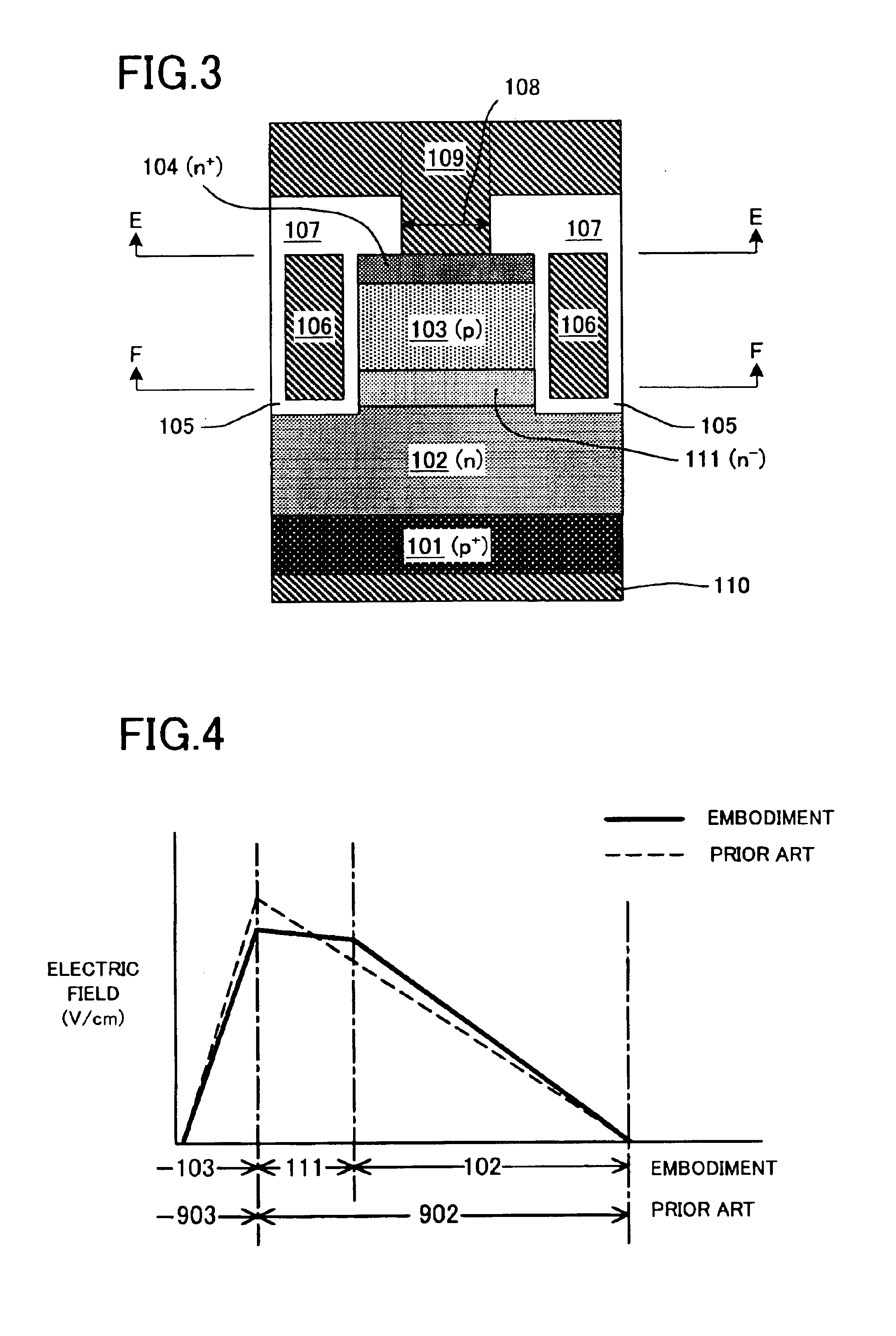

High withstand voltage field effect semiconductor device with a field dispersion region

ActiveUS6921941B2High withstand voltageLow net impurity concentrationTransistorSemiconductor/solid-state device manufacturingBody regionElectric field

It is intended to provide a high withstand voltage field effect type semiconductor device that relaxes electric fields in a semiconductor substrate without thickening thickness of a drift region and achieves withstand-ability against high voltage without sacrificing ON-voltage, switch-OFF characteristics, and miniaturization. A field effective type semiconductor device comprises emitter regions 100, 104 and gate electrodes 106 and the like on a surface (upper surface in FIG. 2), a collector region 101 and the like on the other surface (lower surface in FIG. 2), wherein N− field dispersion regions 111 of low impurity concentration are arranged between P body regions 103 facing to gate electrodes 106 and an N drift region 102 below P body regions 103. Thereby, electric field between collector and emitter is relaxed and high withstand voltage field effect type semiconductor device is realized. Another field dispersion region can be arranged between the N drift region 102 and P+ collector region 101 below the N drift region 102.

Owner:TOYOTA JIDOSHA KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com