Trapezoidal evaporation metalizing polypropylene film capacitor

A polypropylene film and capacitor technology, applied in the field of capacitors, can solve the problems that the shell hardness of large-volume capacitors cannot meet the requirements of use, the low current bearing capacity of aluminum electrolytic capacitors, and the installation tolerance tolerance, etc., to achieve low cost, long service life, and durability. high voltage effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further specifically described below in conjunction with the accompanying drawings and specific embodiments.

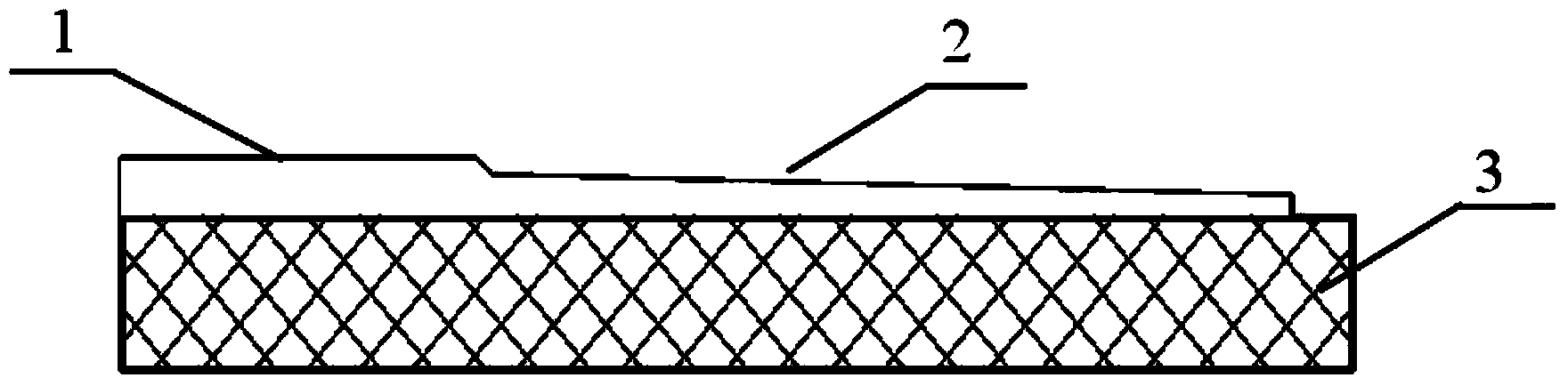

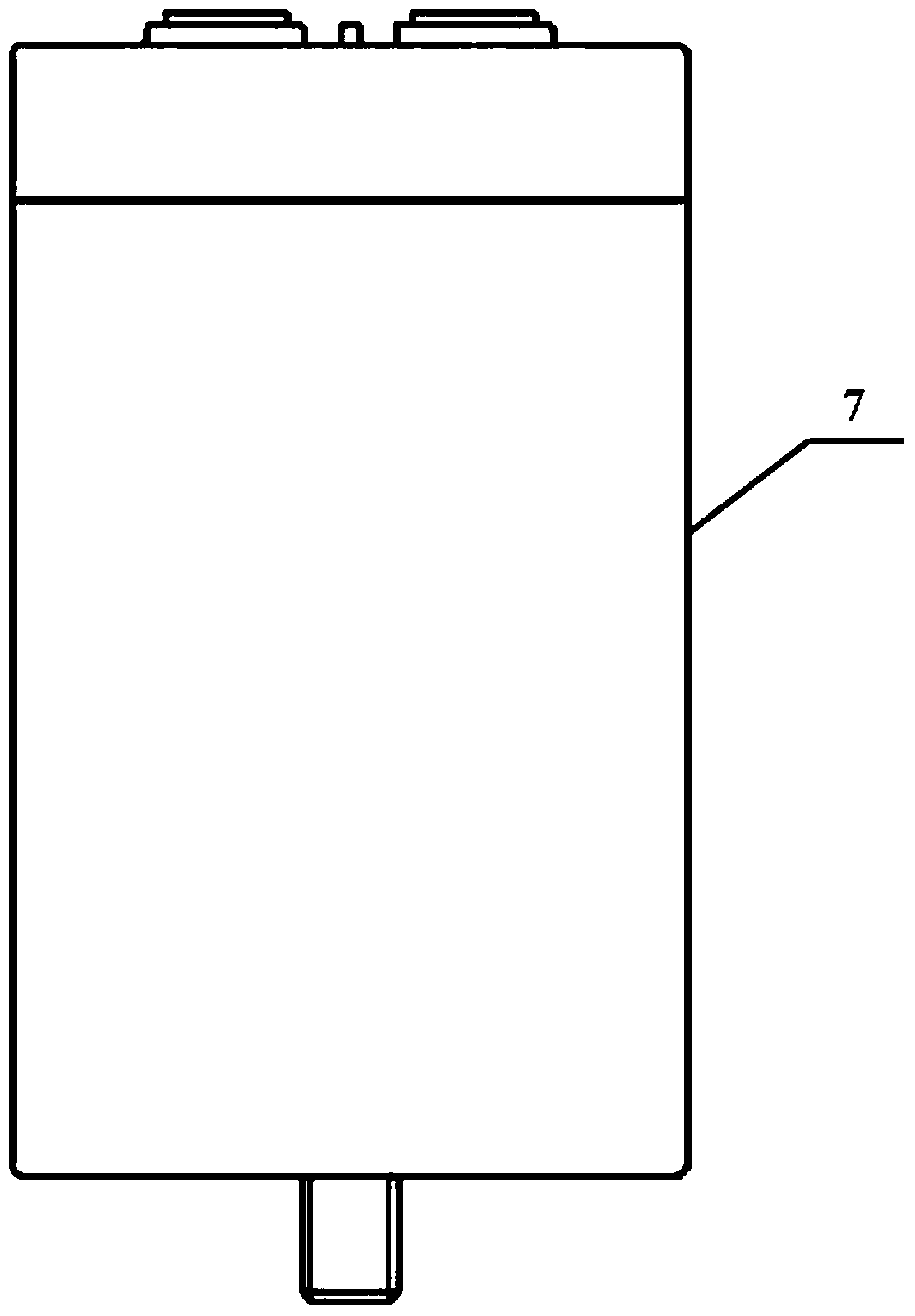

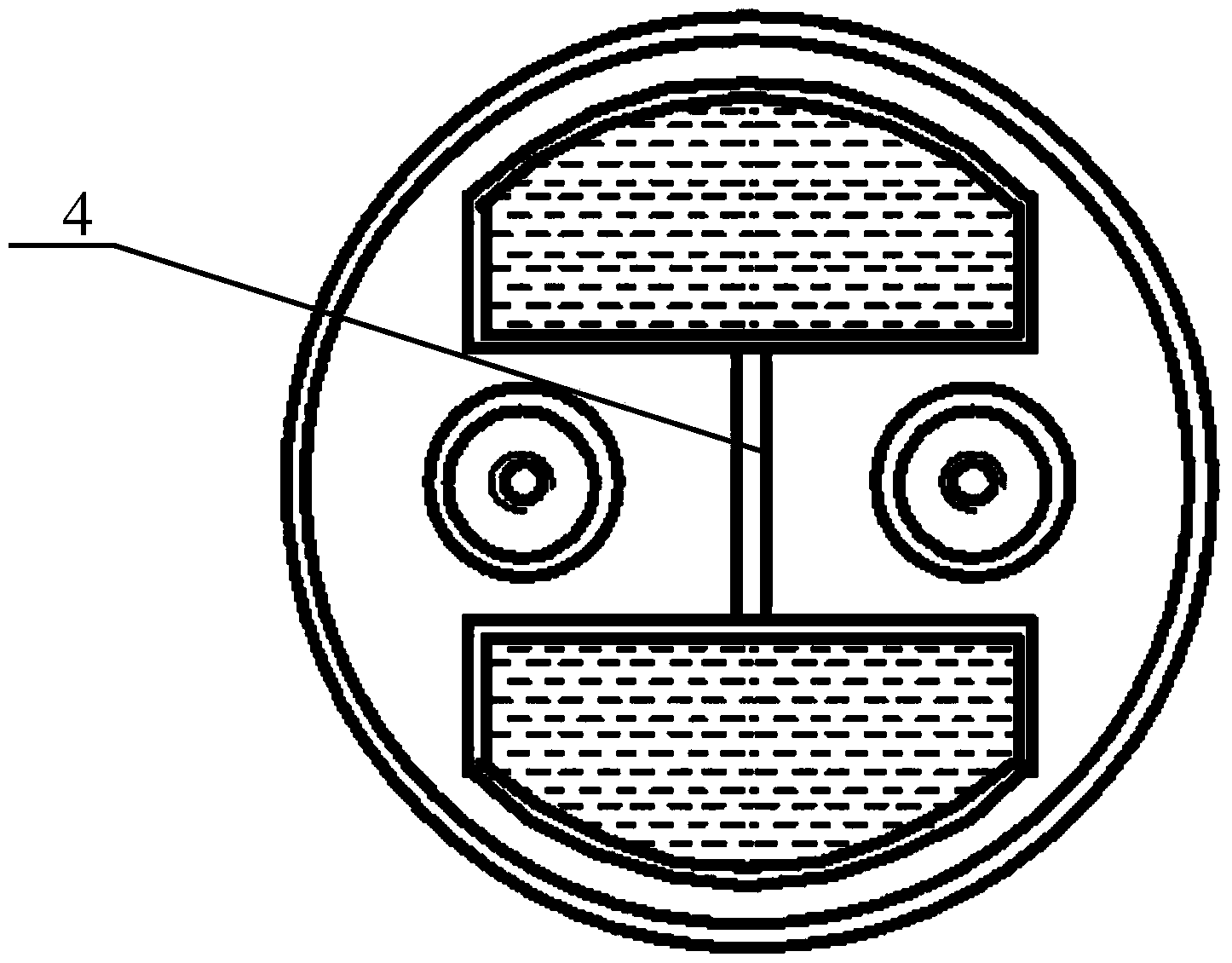

[0023] Such as figure 1 , figure 2 , image 3 As shown, a trapezoidal vapor-deposited metallized polypropylene film capacitor includes a shell 7, a capacitor core, a lead-out terminal 6 and a lead-out electrode. The capacitor core includes a high-temperature-resistant polypropylene film 3, and the polypropylene film 3 is placed in a high-vacuum environment. A layer of metal aluminum is evaporated on the bottom as the active area 2 of the electrode. The active area 2 is evaporated in a trapezoidal evaporation mode with high square resistance. The resistance of the vapor-deposited trapezoidal square is controlled at 30-50 ohms, and the resistance of one square in the thickened area is controlled at 2-4 ohms; the inside of the capacitor adopts a parallel design of 2-3 capacitor cores.

[0024] In this em...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com