Patents

Literature

7197results about How to "Improve air tightness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

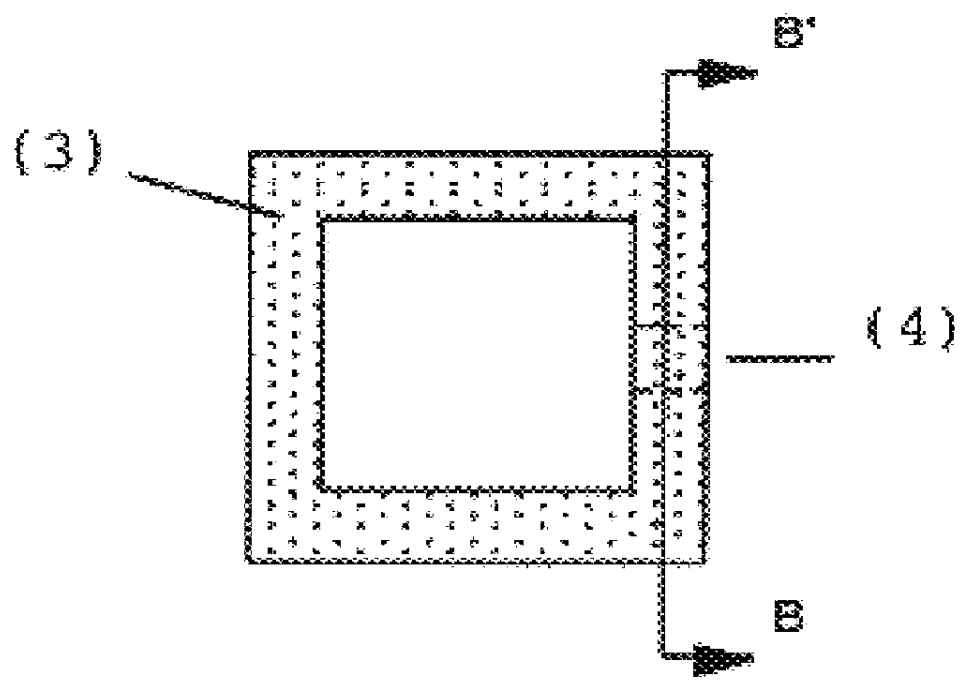

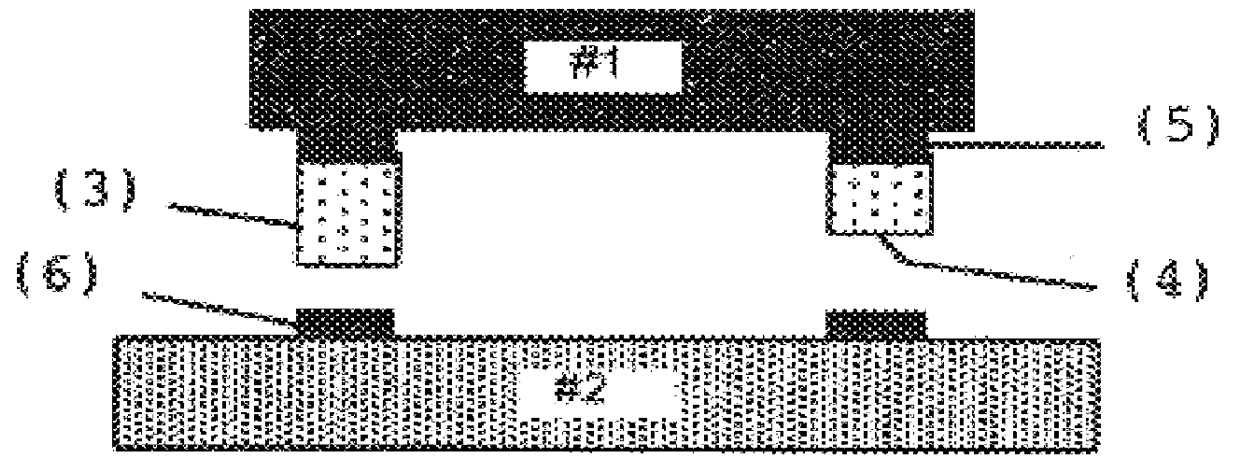

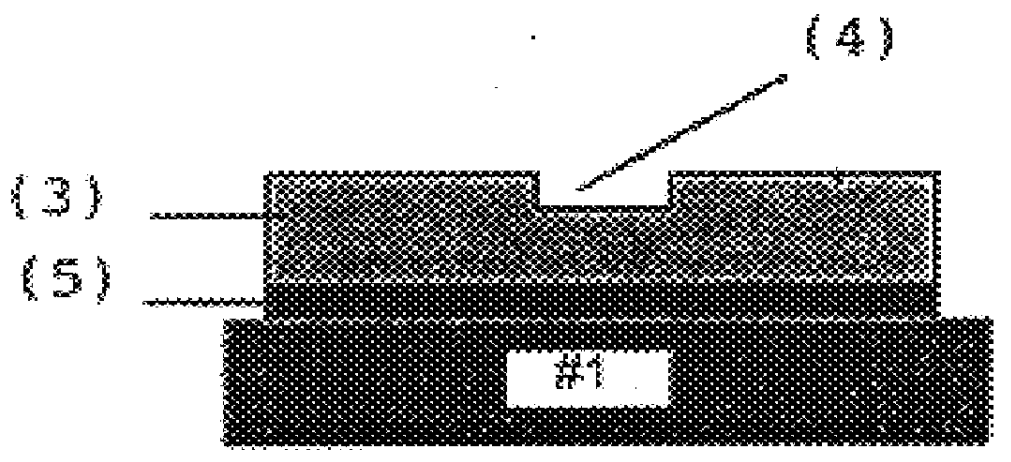

Method of fabrication of a microstructure having an internal cavity

InactiveUS6297072B1Easy to manufactureImprove air tightnessAcceleration measurement using interia forcesDecorative surface effectsInternal cavityMicrostructure

A method of fabricating a microstructure having an inside cavity. The method includes depositing a first layer or a first stack of layers in a substantially closed geometric configuration on a first substrate. Then, performing an indent on the first layer or on the top layer of said first stack of layers. Then, depositing a second layer or a second stack of layers substantially with said substantially closed geometric configuration on a second substrate. Then, aligning and bonding said first substrate on said second substrate such that a microstructure having a cavity is formed according to said closed geometry configuration.

Owner:CP CLARE +1

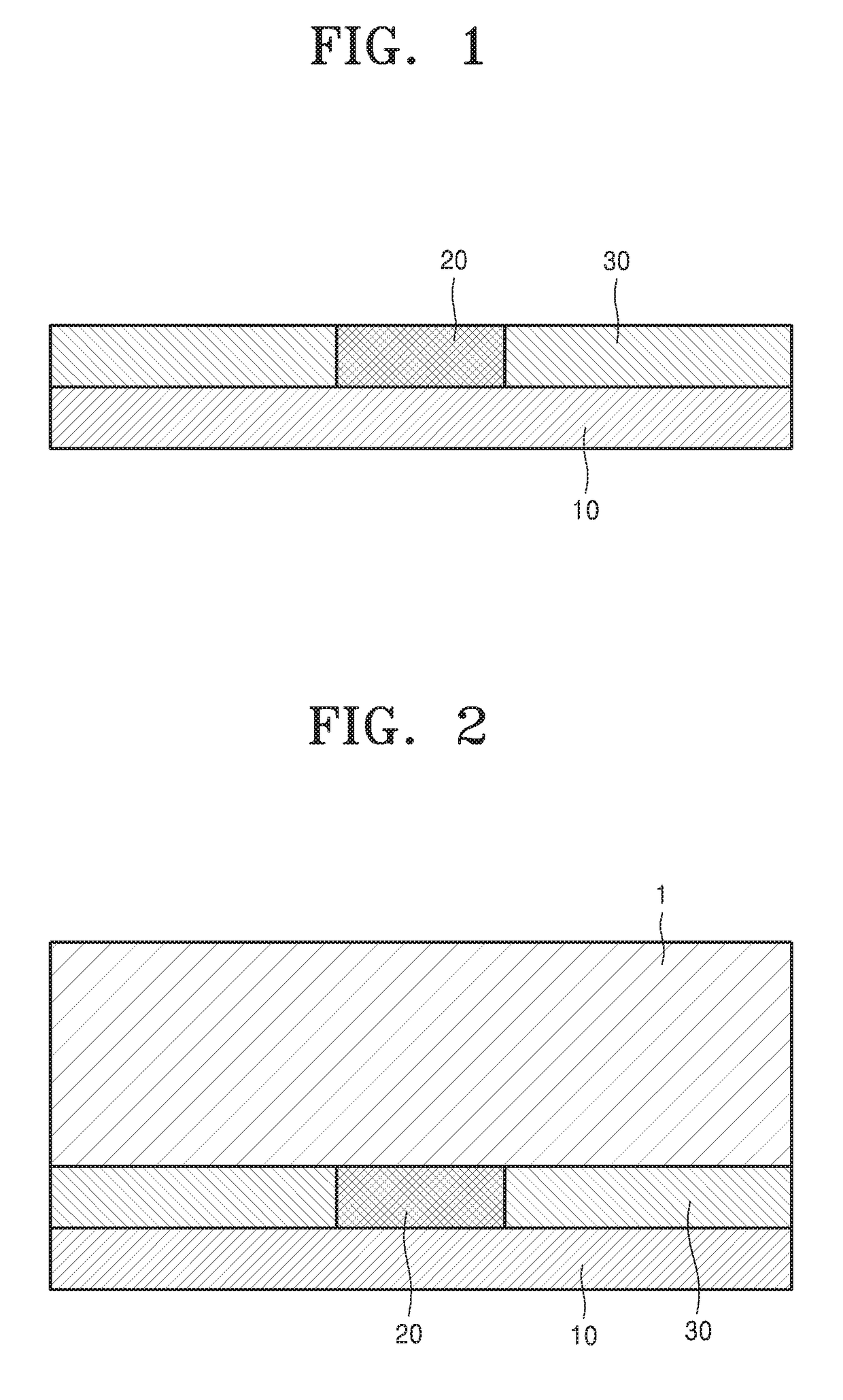

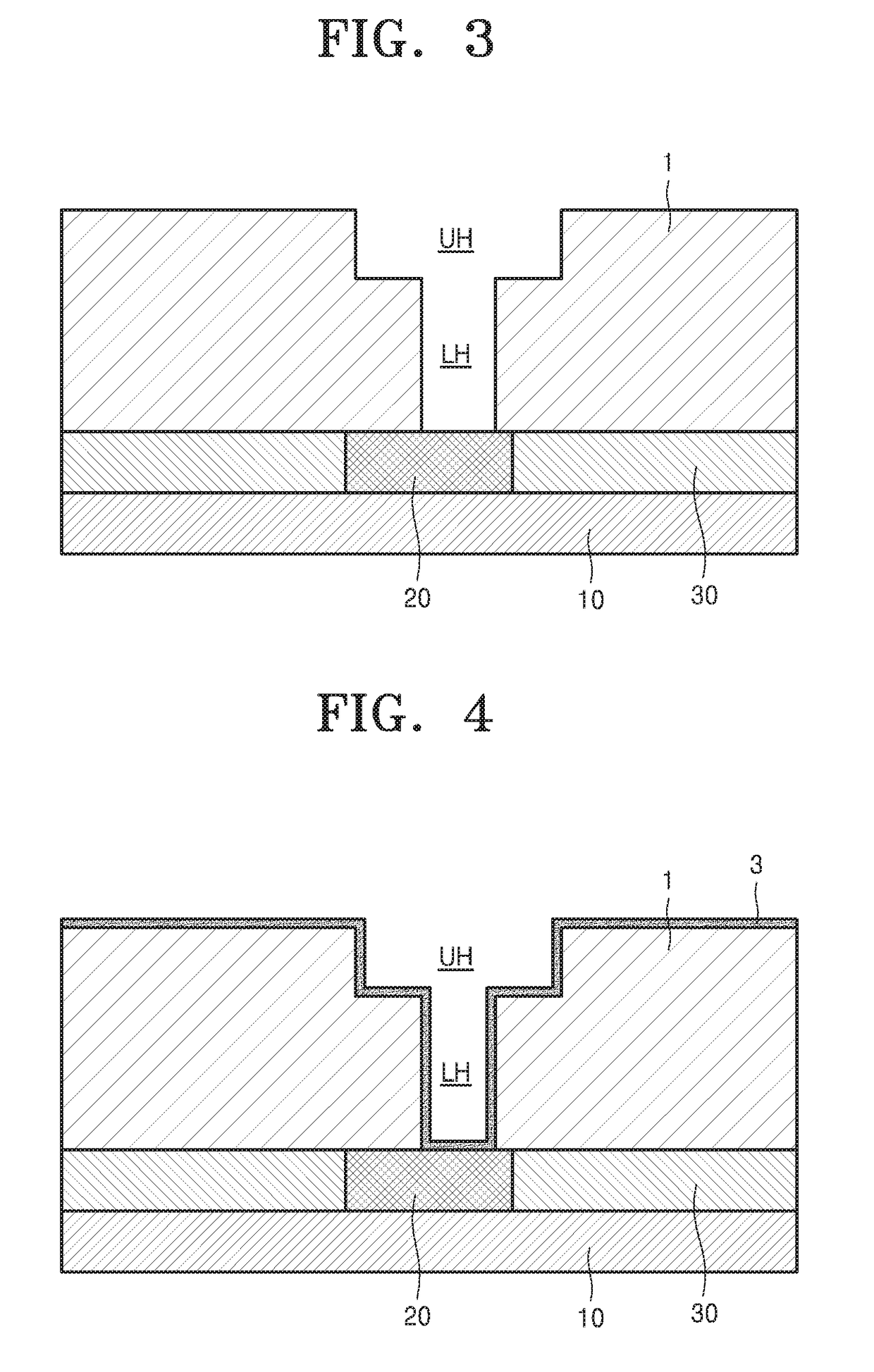

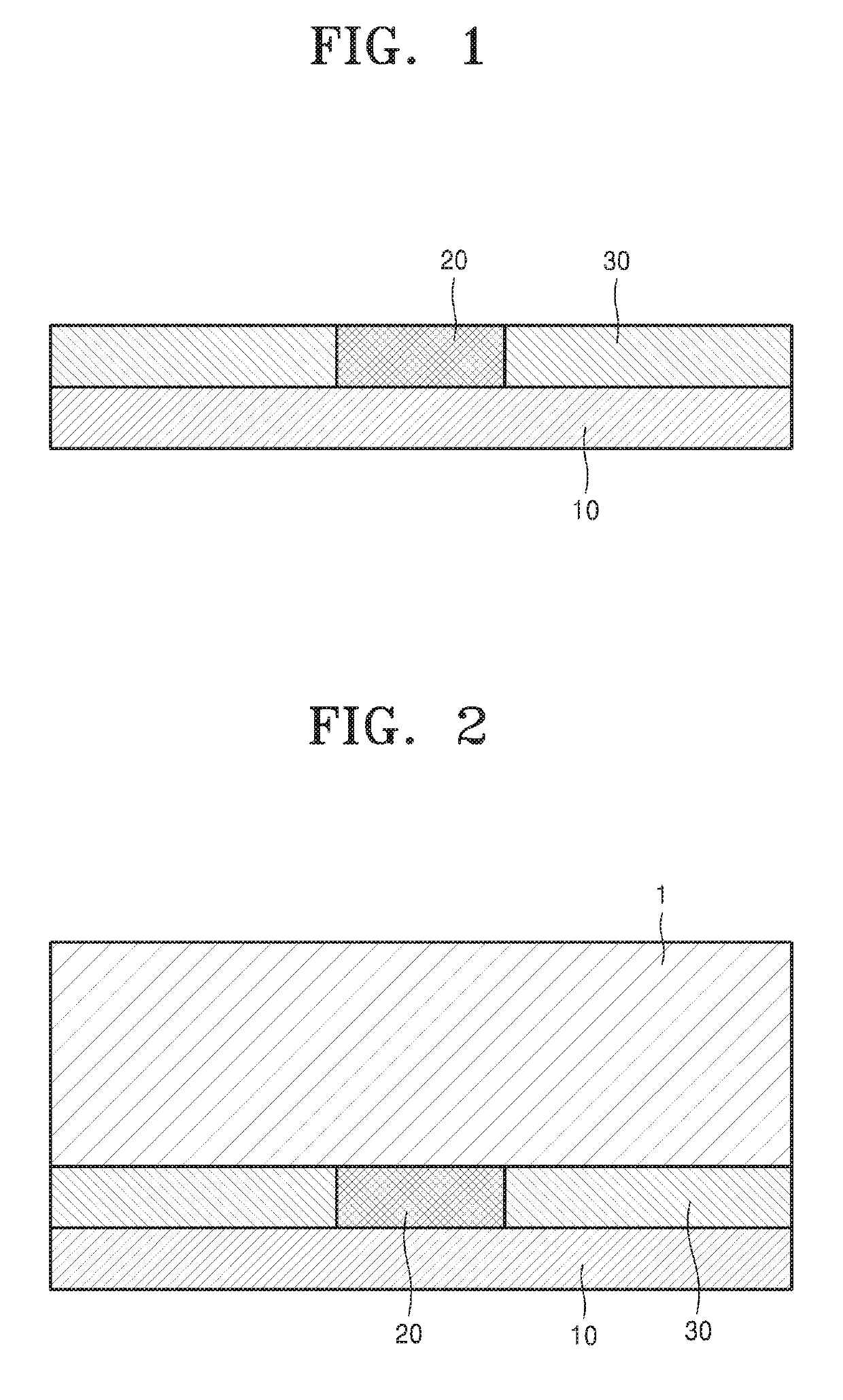

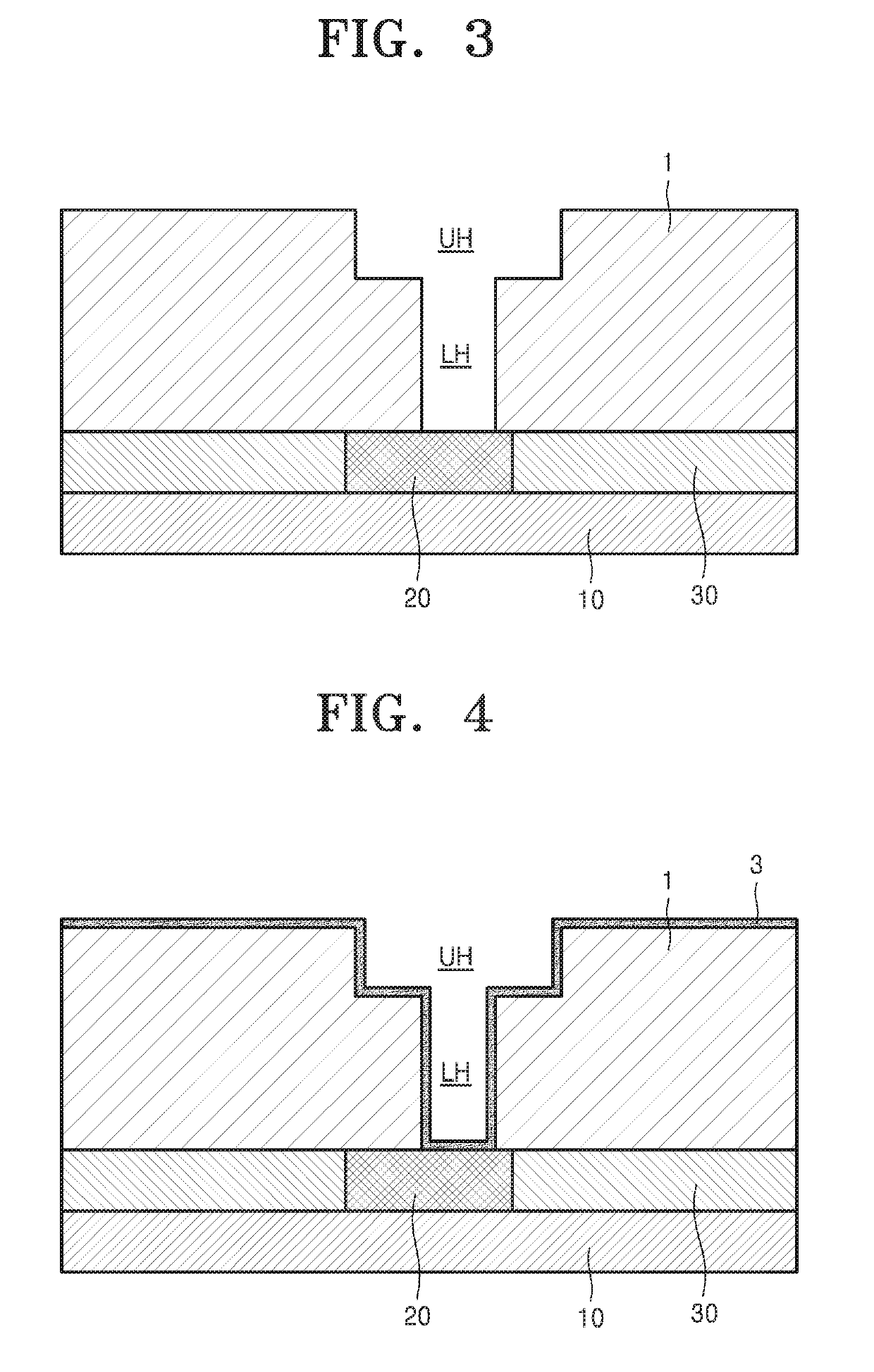

Method of forming metal interconnection and method of fabricating semiconductor apparatus using the method

ActiveUS20170338192A1Improve air tightnessSemiconductor/solid-state device detailsSolid-state devicesInterconnectionFiller metal

A semiconductor manufacturing method includes depositing a low-k dielectric layer, forming a trench in the low-k dielectric layer, forming a barrier layer in the trench, filling a metal on the barrier layer, planarizing the metal, and forming a capping layer on the planarized metal, wherein the capping layer includes at least two layers.

Owner:ASM IP HLDG BV

Method of forming metal interconnection and method of fabricating semiconductor apparatus using the method

ActiveUS10249577B2Improve air tightnessSemiconductor/solid-state device detailsSolid-state devicesInterconnectionFiller metal

A semiconductor manufacturing method includes depositing a low-k dielectric layer, forming a trench in the low-k dielectric layer, forming a barrier layer in the trench, filling a metal on the barrier layer, planarizing the metal, and forming a capping layer on the planarized metal, wherein the capping layer includes at least two layers.

Owner:ASM IP HLDG BV

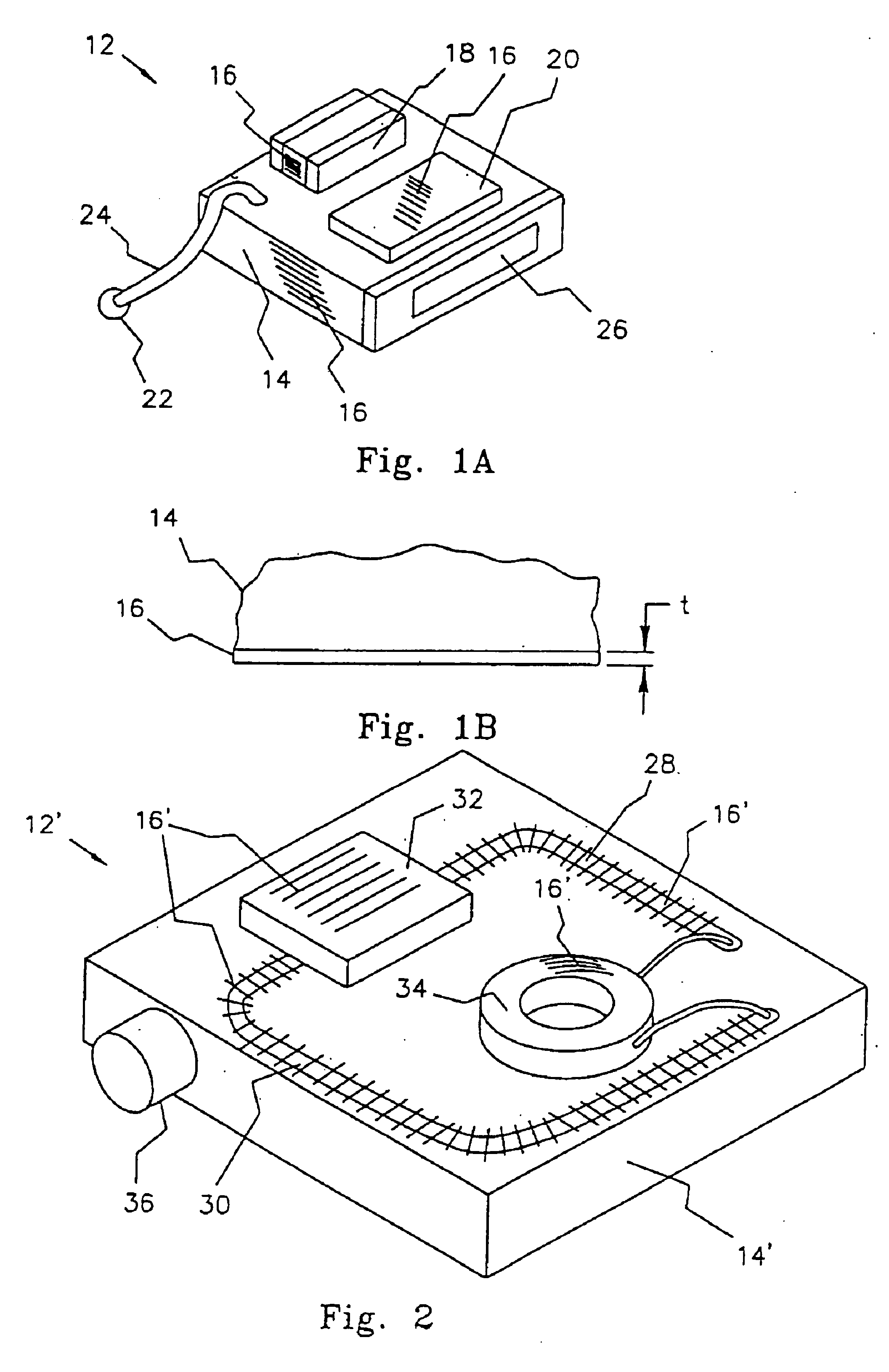

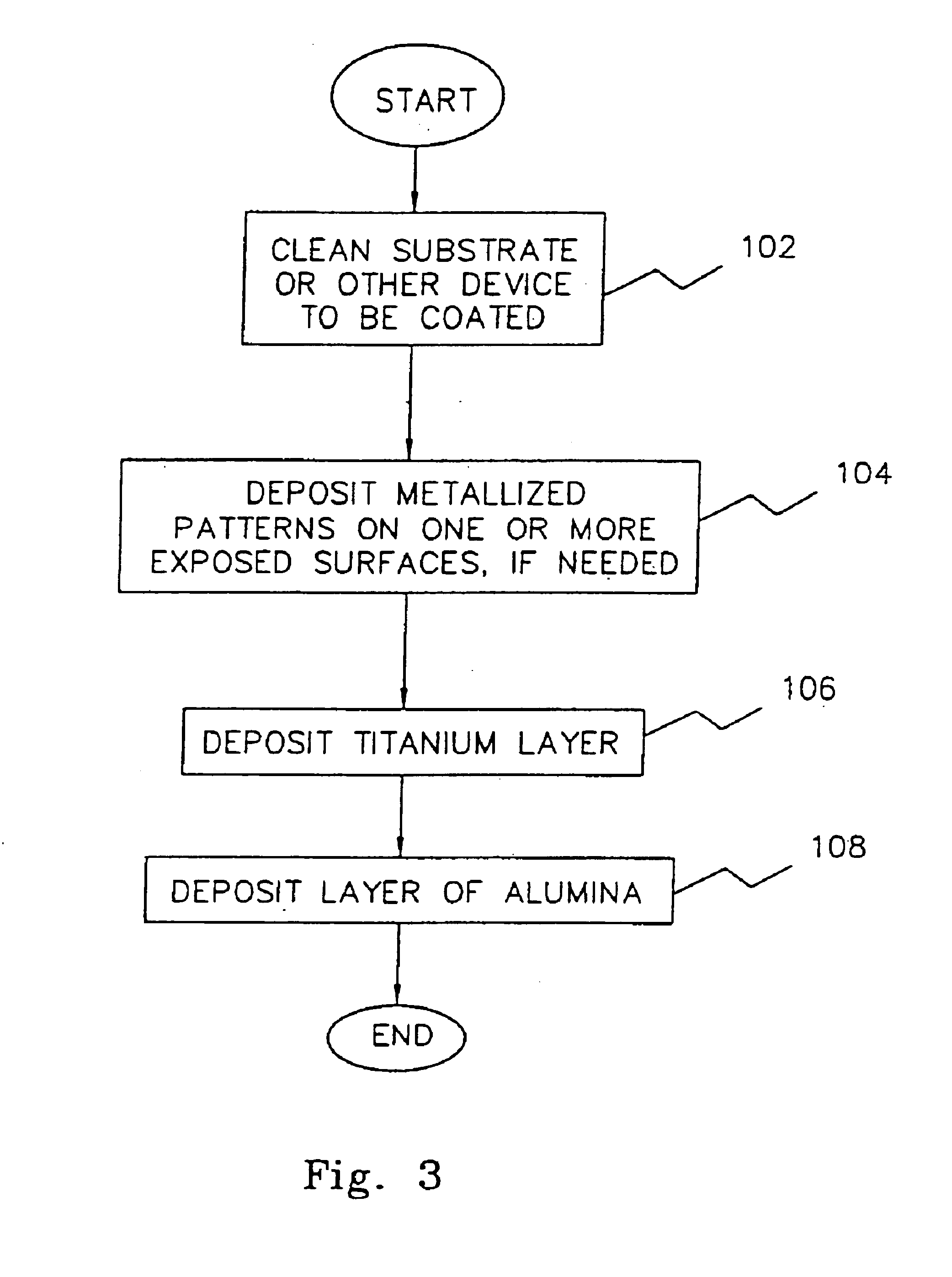

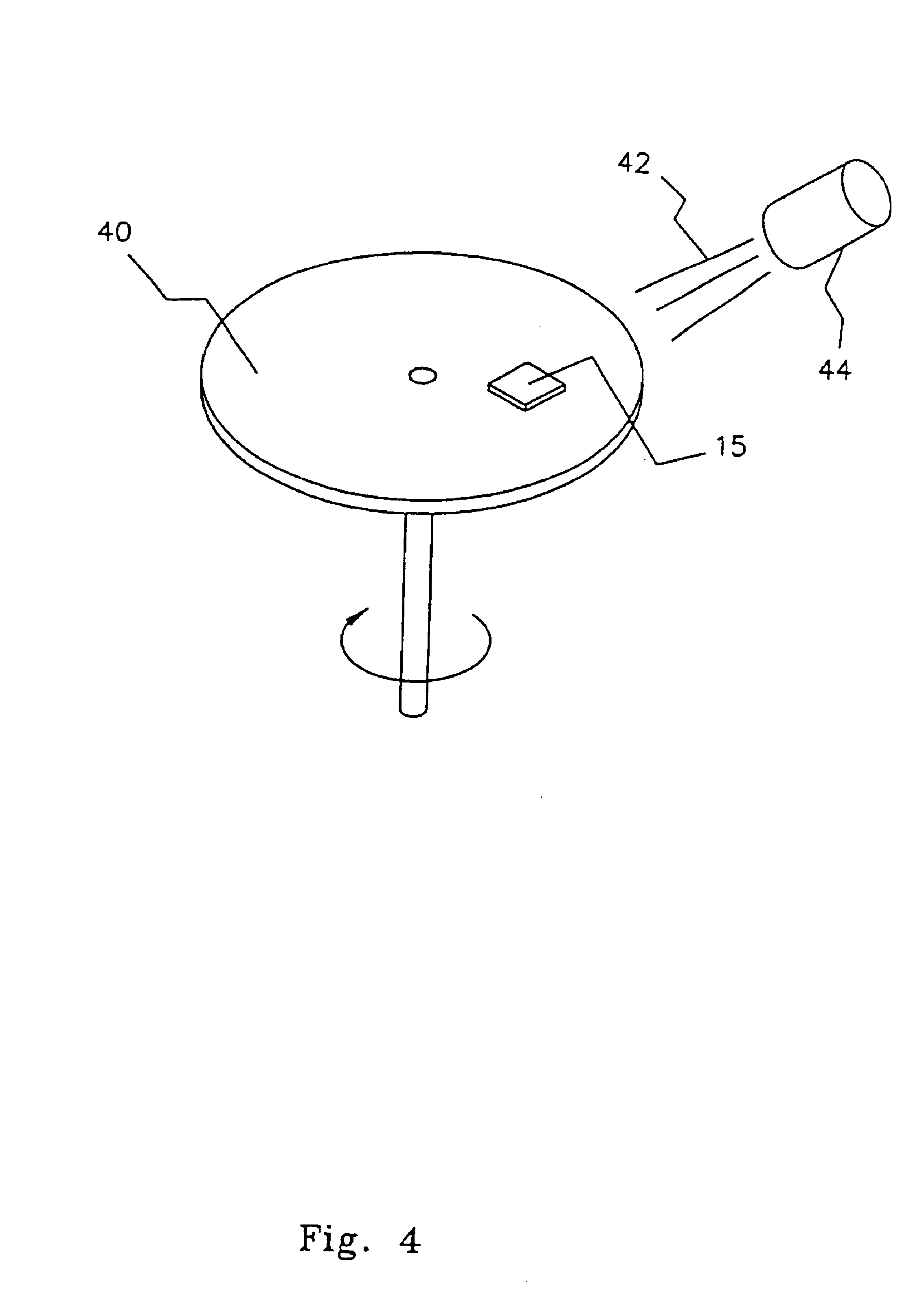

Alumina insulation for coating implantable components and other microminiature devices

InactiveUS6844023B2Efficient use ofImprove insulation performanceElectrotherapyVacuum evaporation coatingBiocompatible coatingThin layer

A protective, biocompatible coating or encapsulation material protects and insulates a component or device intended to be implanted in living tissue. The coating or encapsulation material comprises a thin layer or layers of alumina, zirconia or other ceramic, less than 25 microns thick, e.g., 5-10 microns thick. The alumina layer(s) may be applied at relatively low temperature. Once applied, the layer provides excellent hermeticity, and prevents electrical leakage. Even though very thin, the alumina layer retains excellent insulating characteristics. In one embodiment, an alumina layer less than about 6 microns thick provides an insulative coating that exhibits less than 10 pA of leakage current over an area 75 mils by 25 mils area while soaking in a saline solution at temperatures up to 80° C. over a three month period.

Owner:MEDTRONIC MIMIMED INC

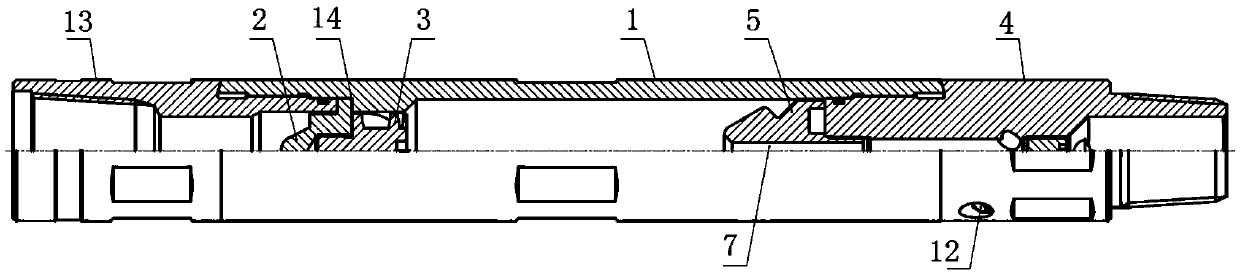

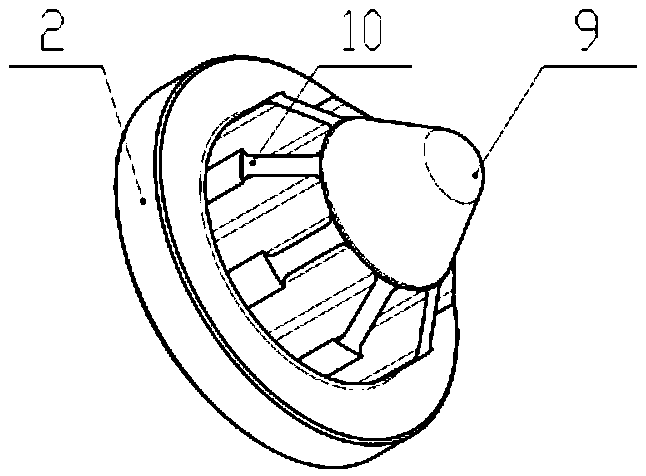

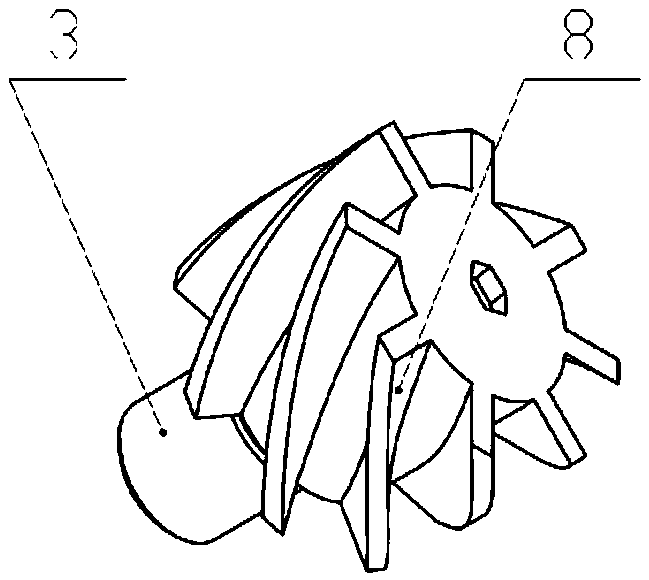

Downhole gas-liquid separation device and working method thereof

ActiveCN105536299AReduce in quantitySimple structureLiquid degasificationSeparation devicesEngineeringProduct gas

A downhole gas-liquid separation device comprises a barrel-shaped body, and a positioning wheel is fixedly installed in the body. A rotatable swirling wheel is installed on the positioning wheel and provided with spiral wheel blades, and the positioning wheel is provided with fluid channels. A lower connector is connected to the body, a diverting joint is arranged at the inner end, located in an inner cavity of the body, of the lower connector, a gas outlet channel is formed in the center of the diverting joint in a coaxial mode, and the outer side of the diverting joint is provided with liquid drainage channels. An interval is formed between the swirling wheel and the diverting joint. The downhole gas-liquid separation device is small in part number, simple in structure and lower in cost; the swirling wheel is driven to rotate when liquid passes through the swirling wheel to enable the liquid to generate centrifugal force and swirlingly flow in the inner cavity in the mode of being attached to the wall, the liquid in gas is gathered to the center, and then the liquid and the gas flow out through the liquid drainage channels formed in the outer side and the gas outlet channel formed in the center respectively, so that gas and liquid separation is achieved; accordingly, the liquid sent to a motor does not contain the gas, damage to the motor is avoided, and the service life of the motor is prolonged.

Owner:JEREH ENERGY SERVICES

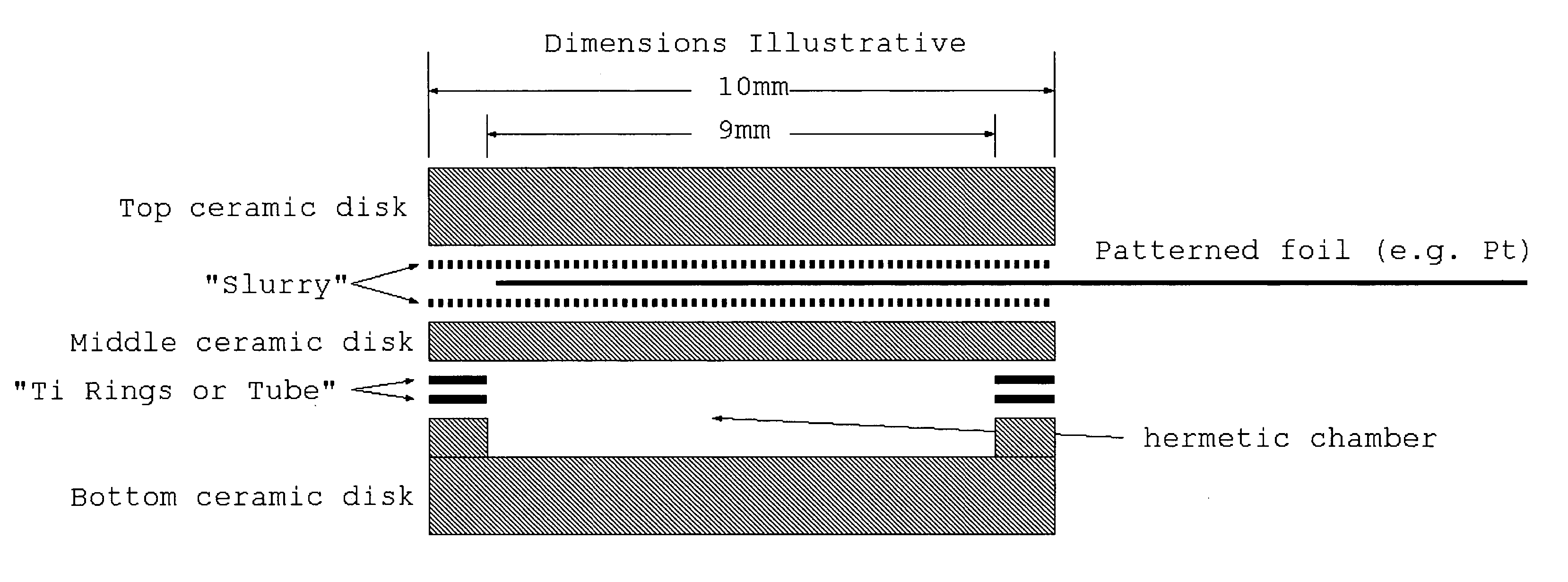

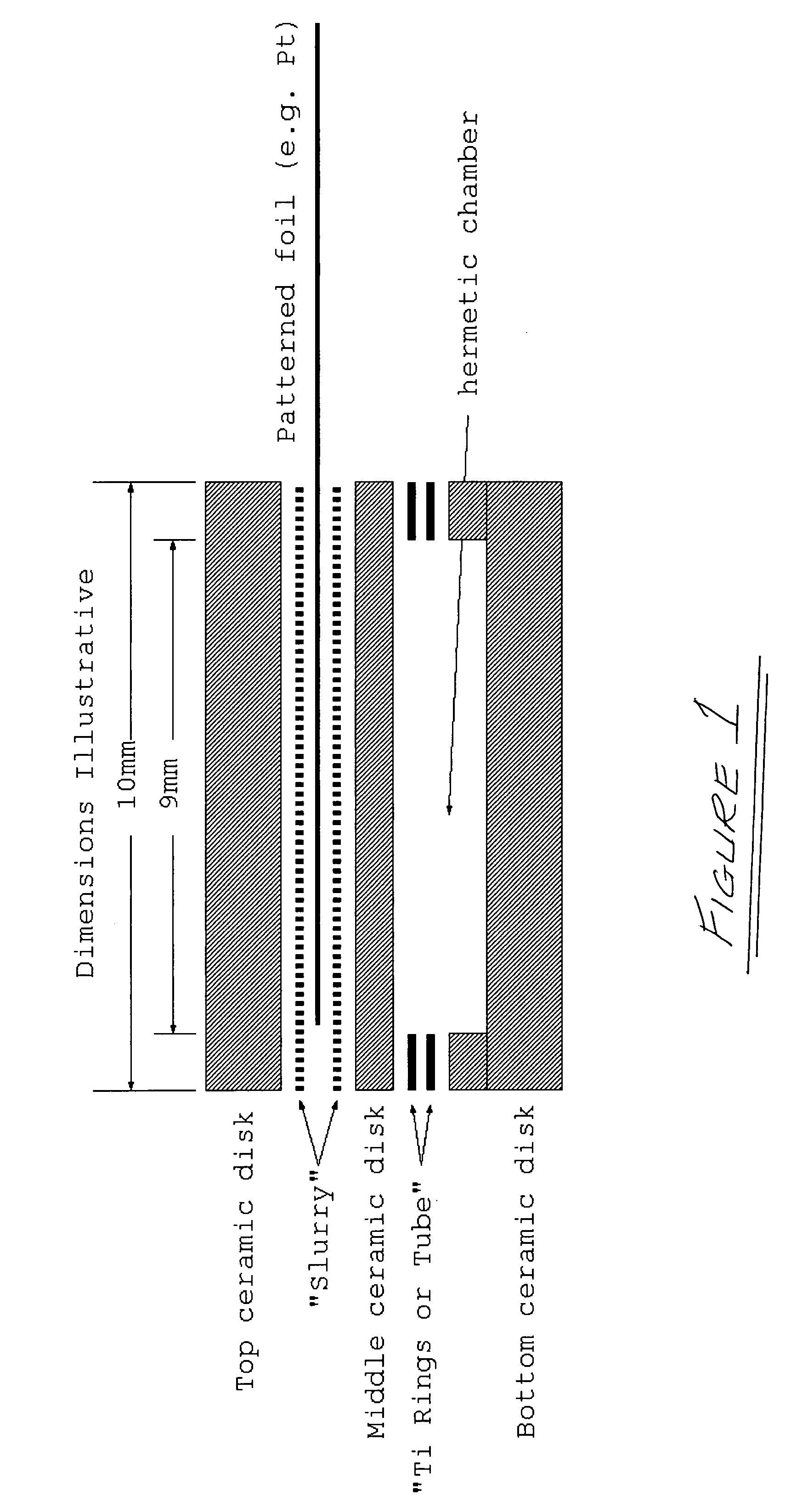

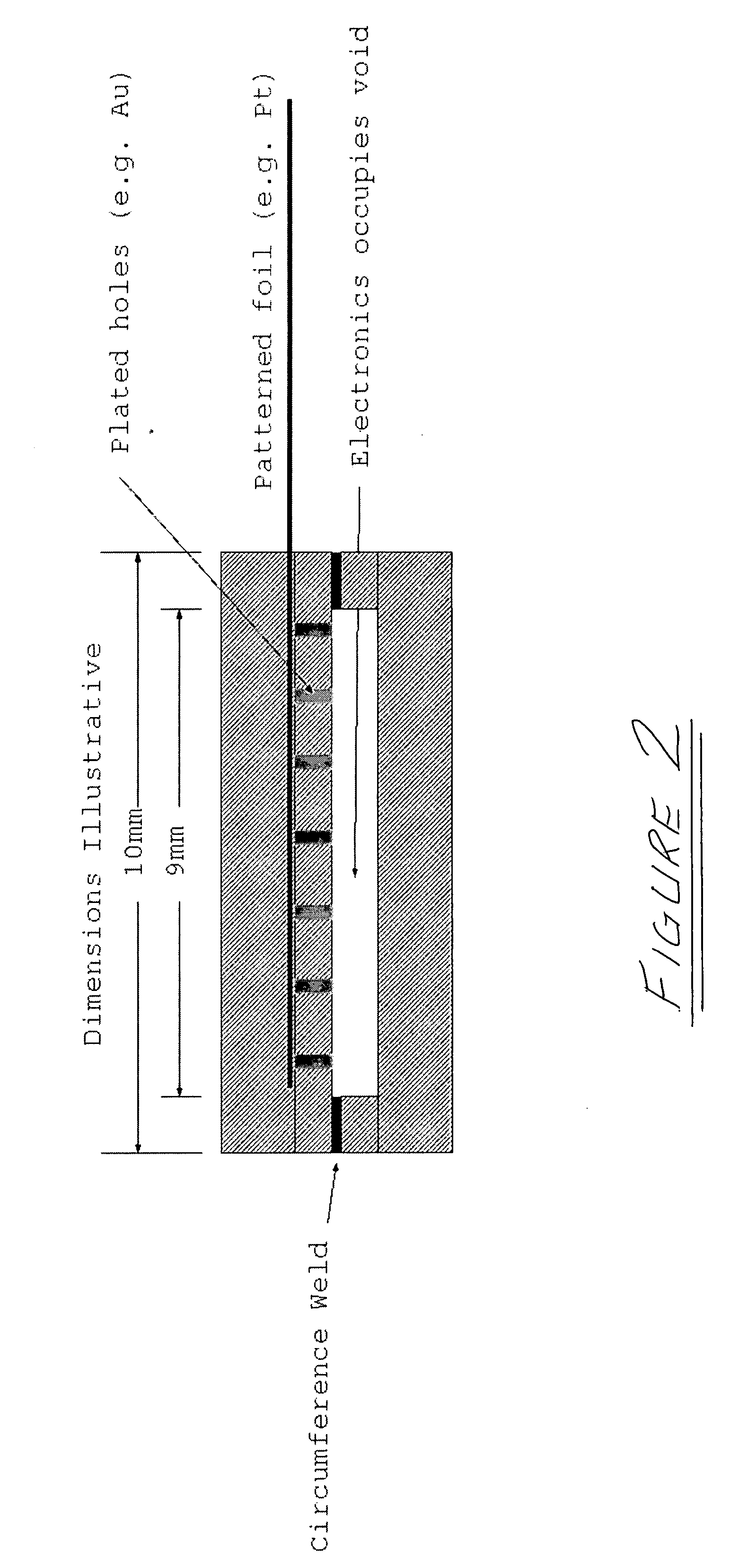

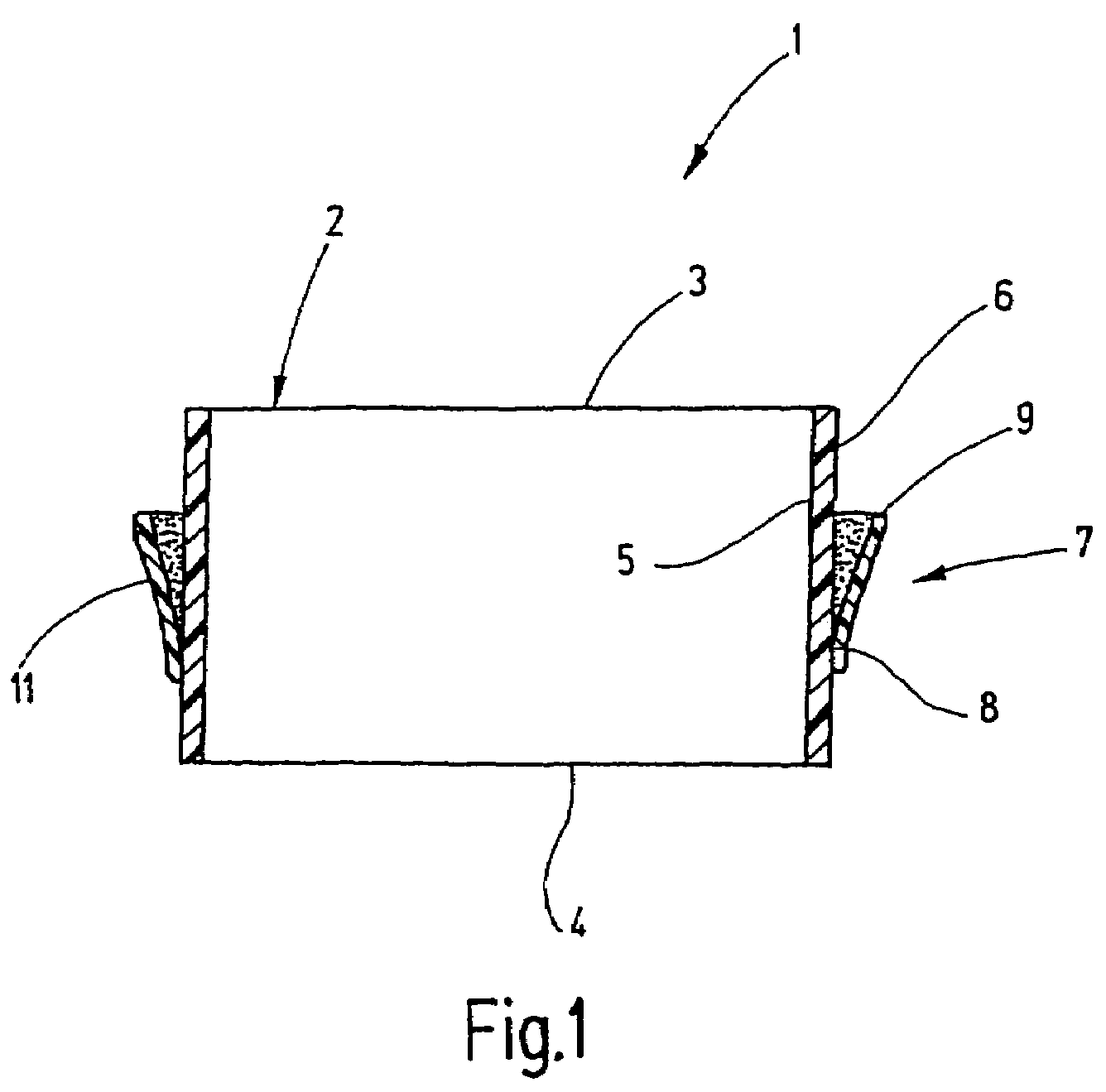

Method for fabrication of hermetic electrical conductor feedthroughs

InactiveUS20070277374A1High bonding strengthComplicated in fabrication procedurePrinted circuit assemblingLine/current collector detailsOxide ceramicPlatinum

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

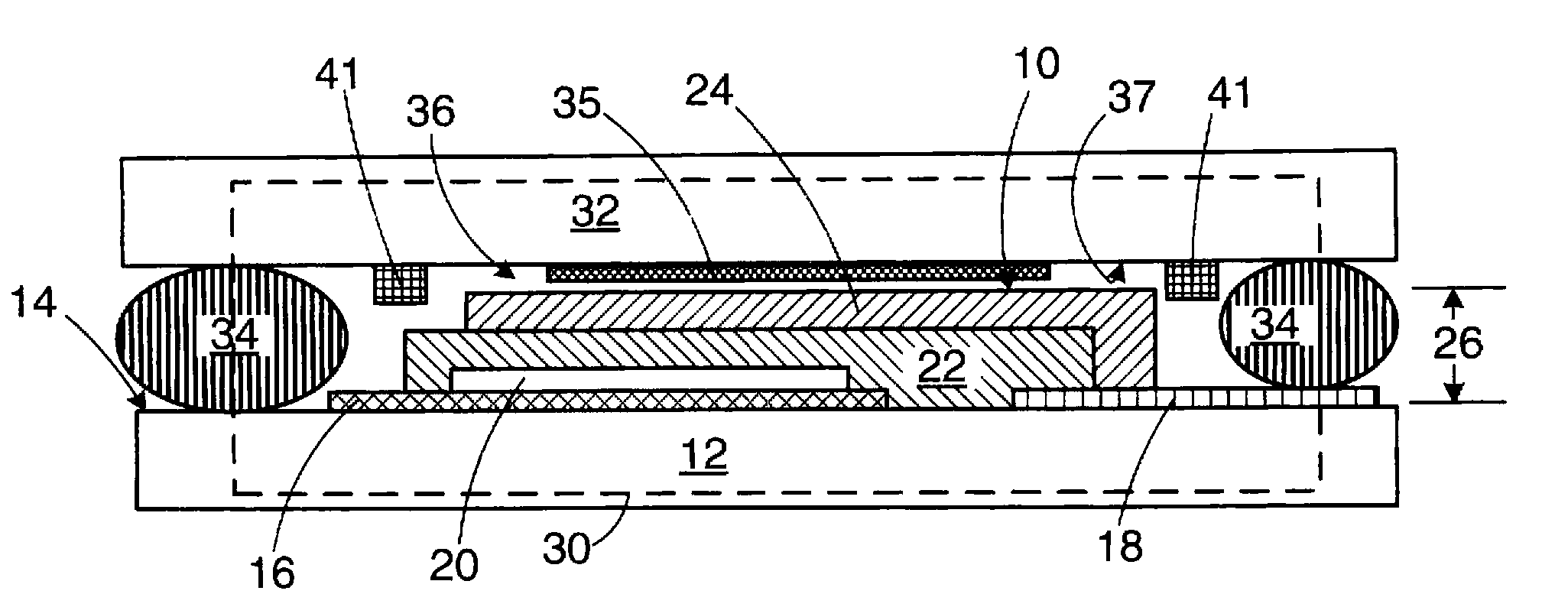

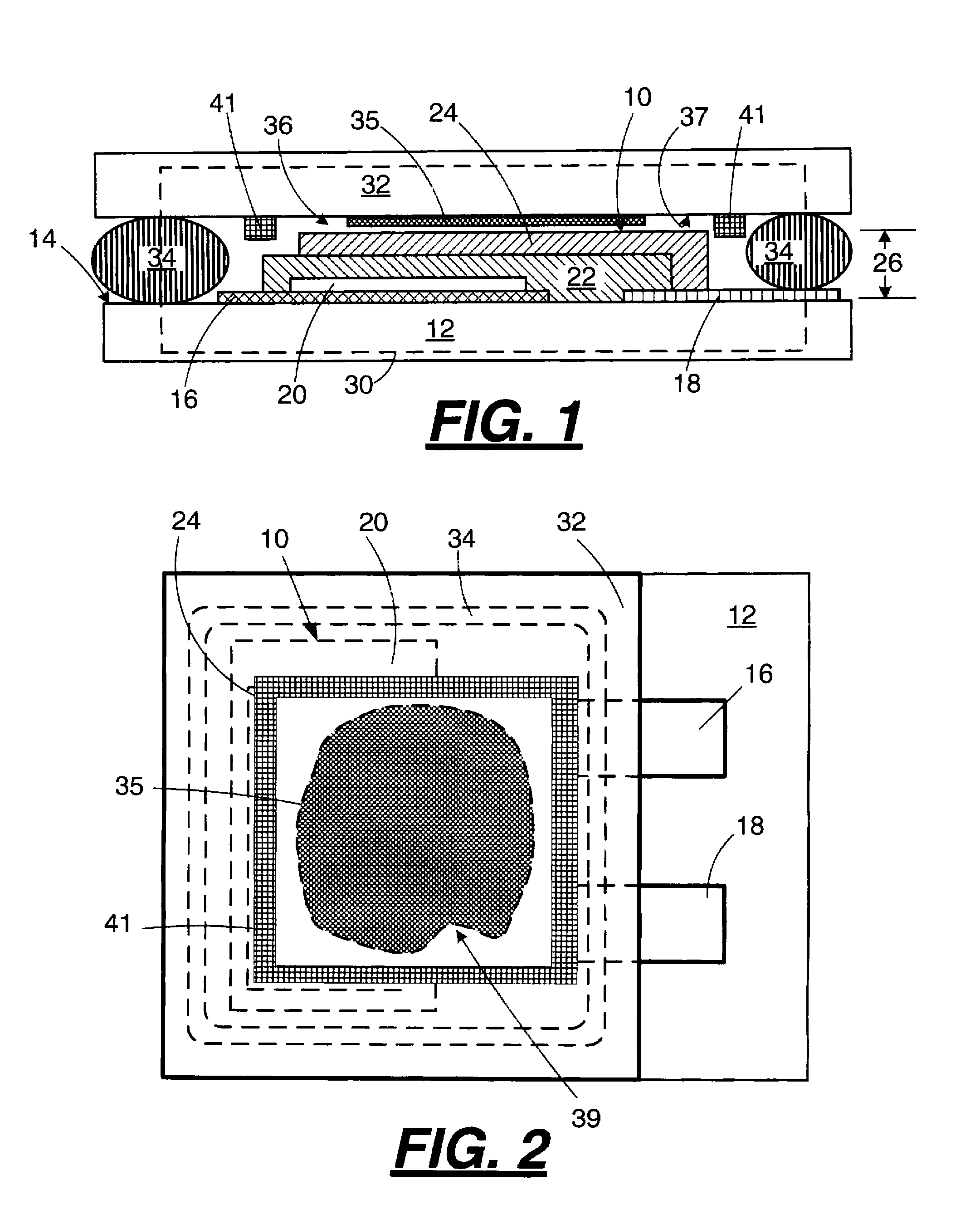

Getters for thin film battery hermetic package

InactiveUS20080003493A1Expand on chargeImprove hermetic sealingSolid electrolytesFinal product manufactureGetterEngineering

A method for improving the useful life of a thin film lithium-ion battery containing a solid electrolyte and an anode that expands on charging and long life batteries made by the method. The method includes providing a hermetic barrier package for the thin film battery that includes an anode expansion absorbing structure and at least one film getter.

Owner:OAK RIDGE MICRO ENERGY

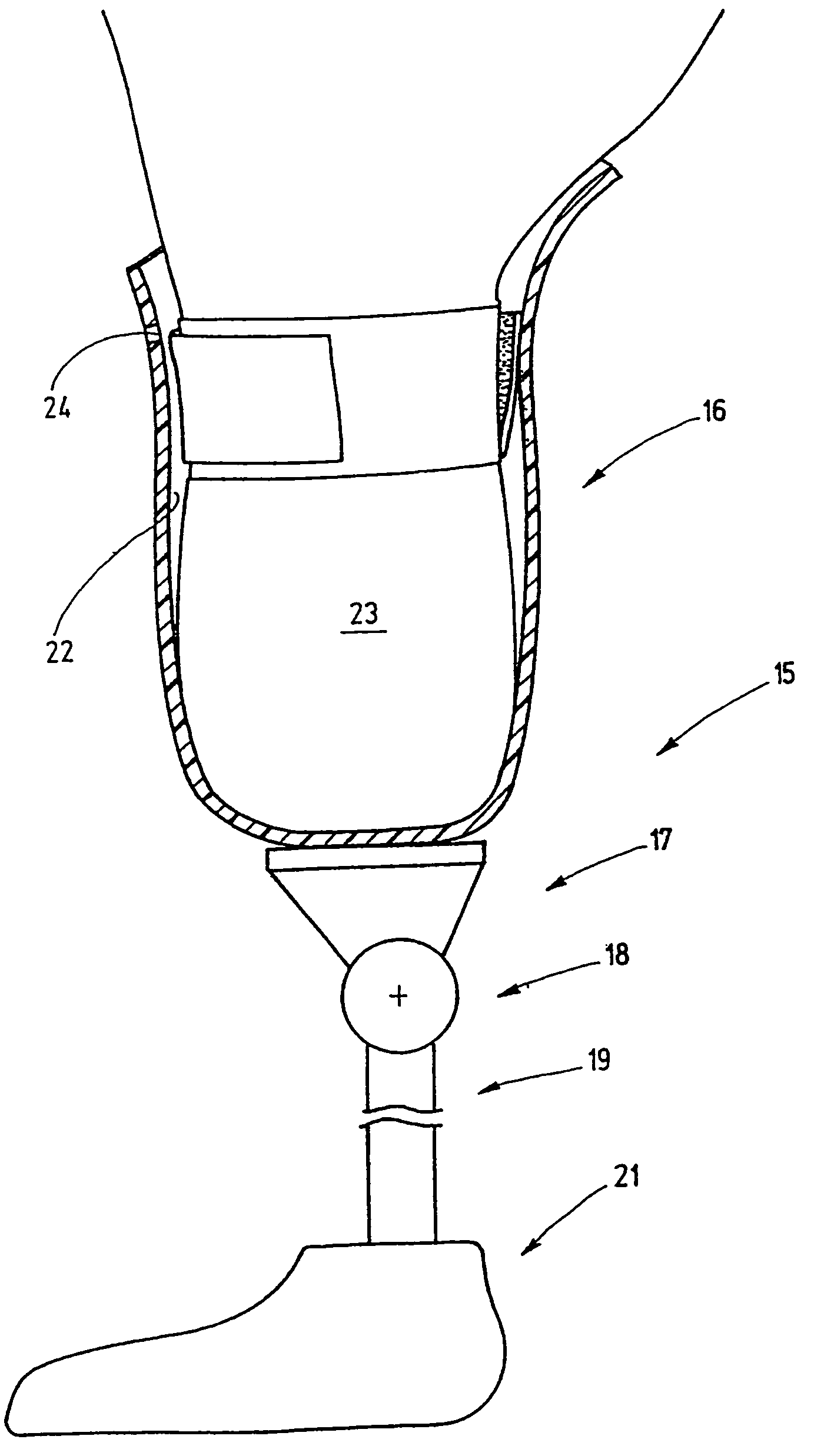

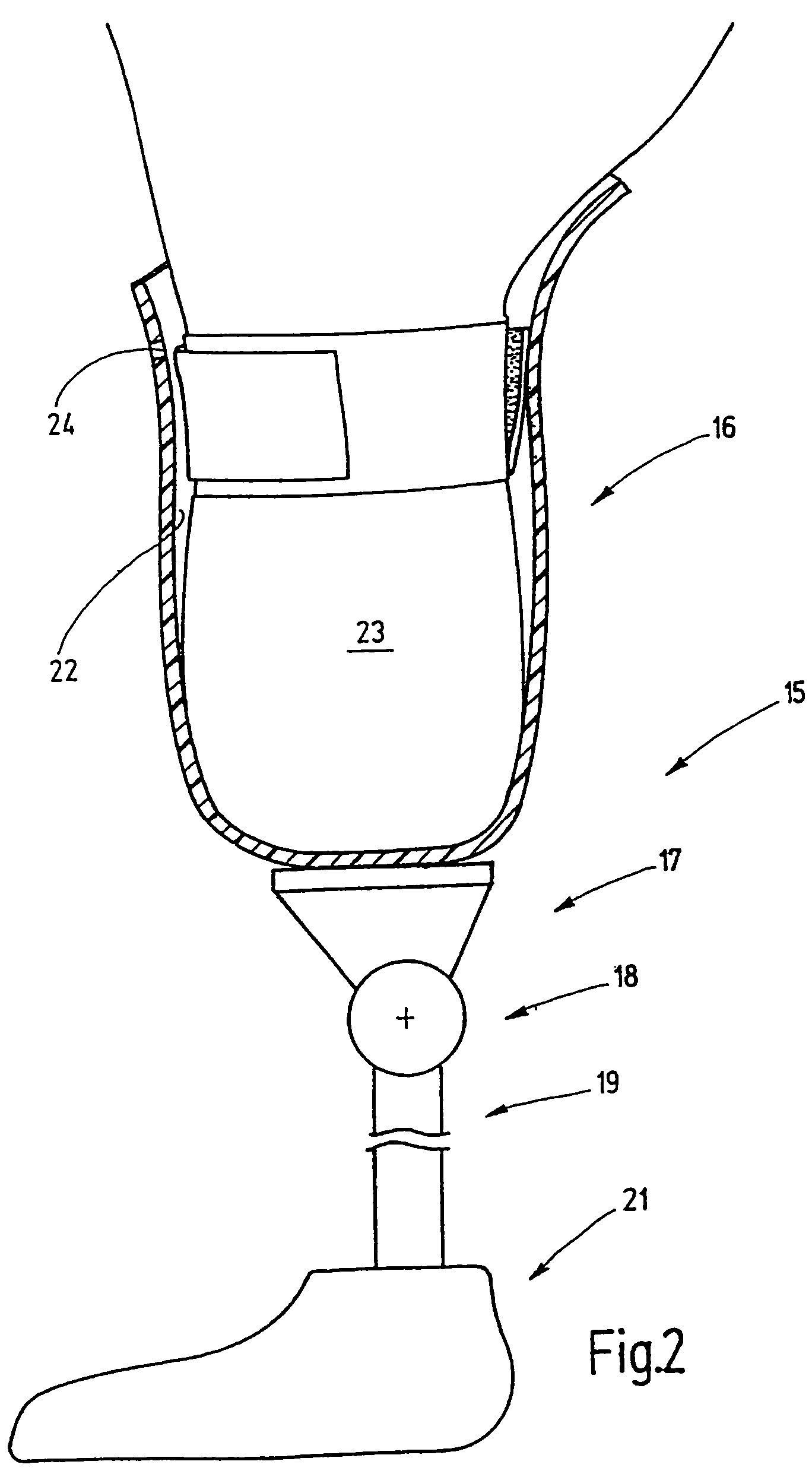

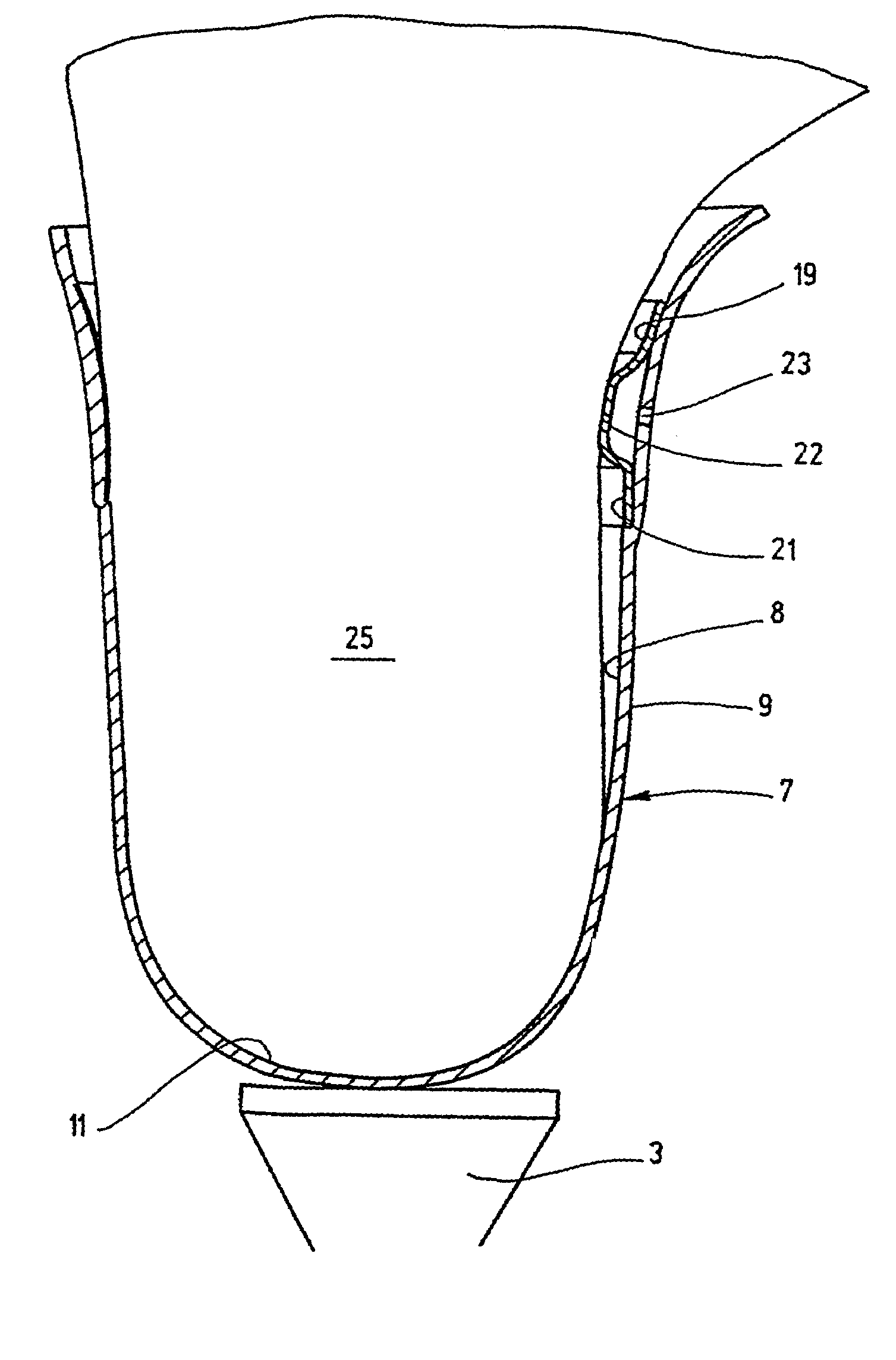

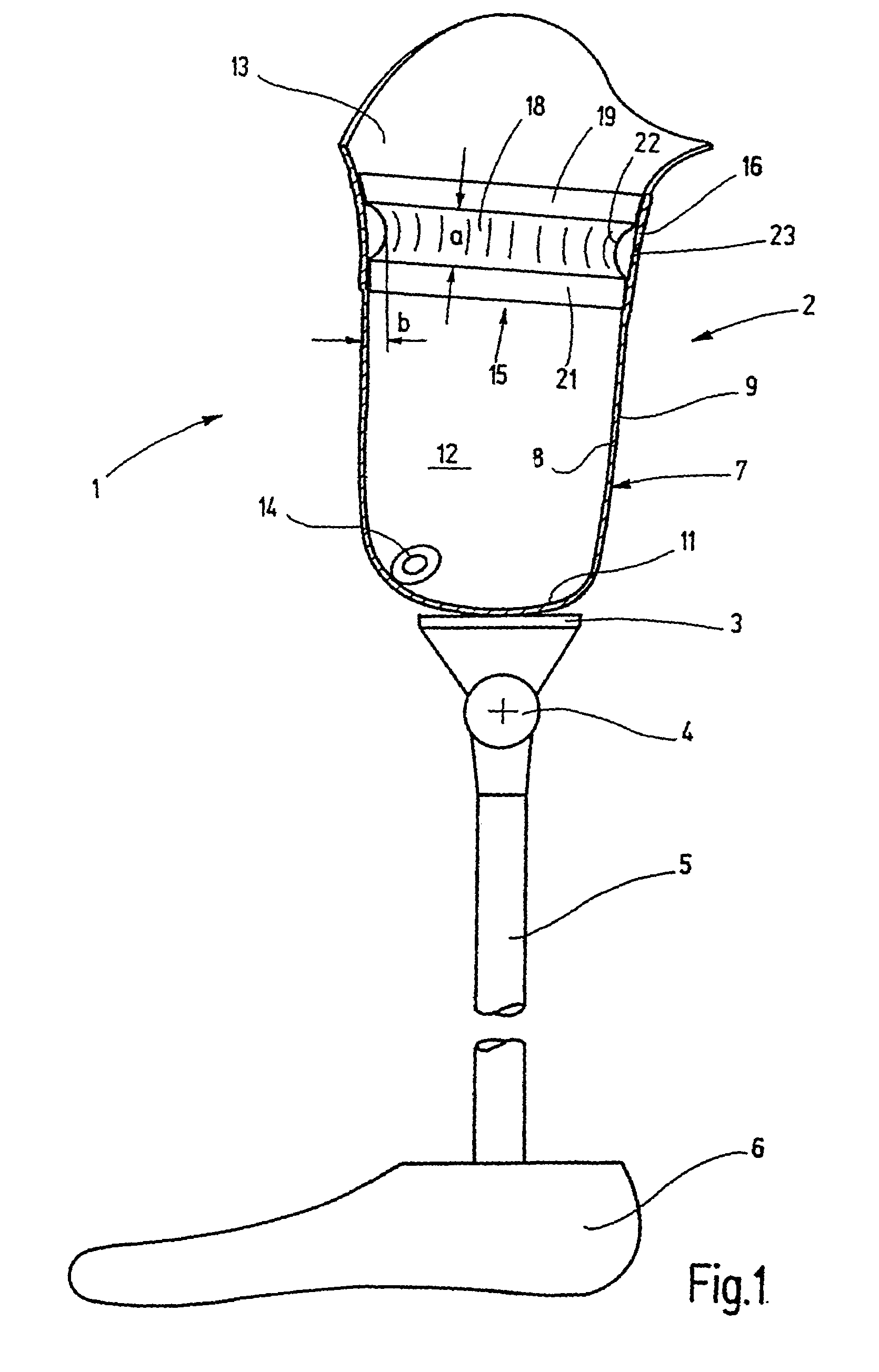

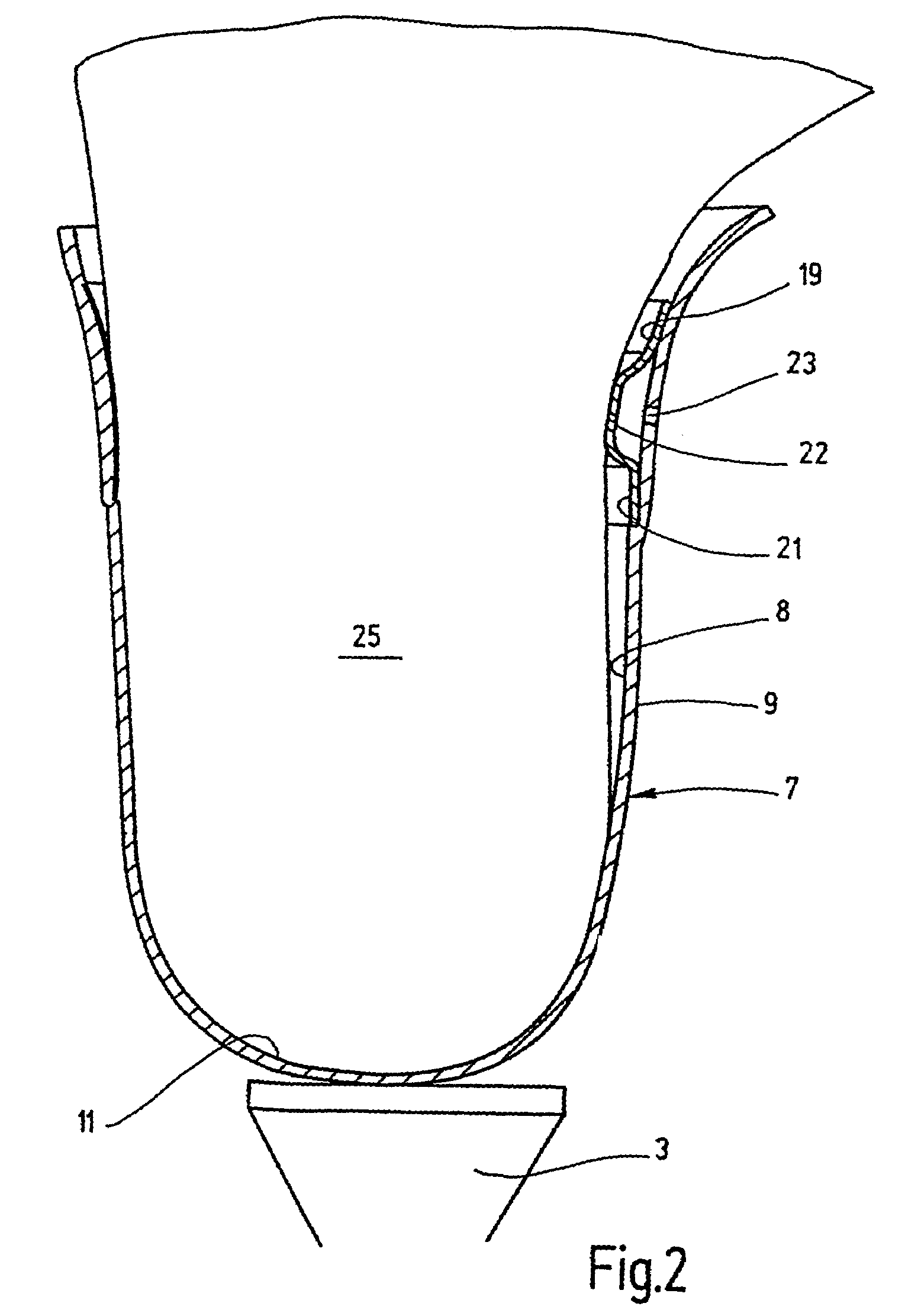

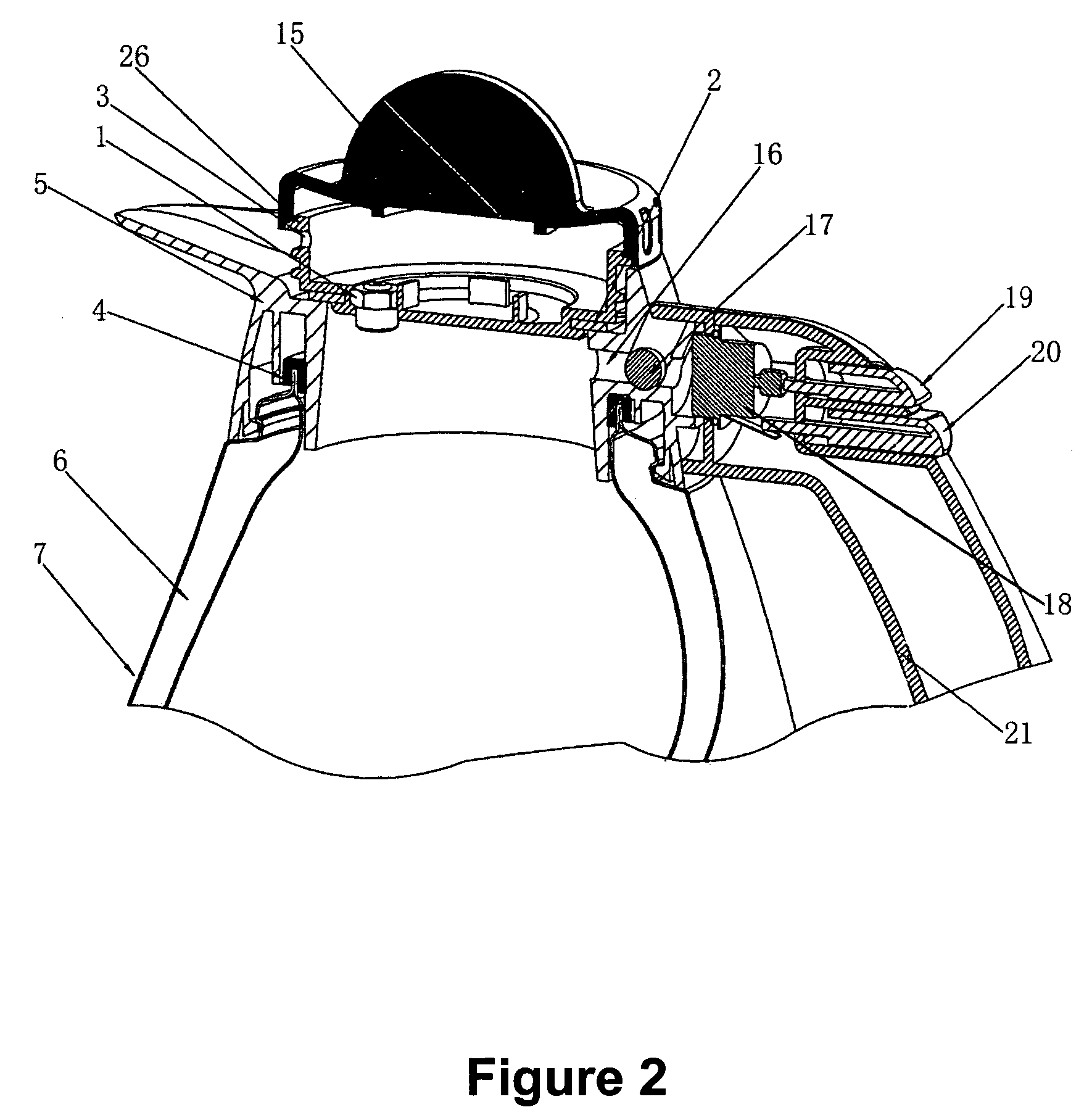

Seal arrangement for residual limb prosthetic socket

A prosthetic socket seal includes at least one radially projecting sealing lip which jointly with a base subtends an annular gap. This annular gap is vented on a proximal side by the external atmosphere, resulting in creation of a pressure gradient at the sealing lip that produces stronger compression of the sealing lip against the prosthetic socket with increasing partial vacuum on a distal side of the sealing lip.

Owner:KAUPTHING BANK

Sealing sleeve for sealing residual limb in a prosthetic socket

InactiveUS7169188B2Improve air tightnessEasy to compressAnkle jointsJoint implantsResidual limbProsthetic socket

A prosthetic socket is fitted at a distance from its distal end with an annular chamber. This annular chamber is closed by a contour-conforming sealing wall facing the inner side of the prosthetic socket, said wall being designed to hermetically rest against the outer side of a residual limb. The space between the contour-conforming wall and the hard prosthetic socket is vented to atmosphere, whereby self-enhancing compression by the sealing wall against a residual limb arises when a partial vacuum arises in the distal prosthetic socket between the wall and the distal end. A liner having a sealing wall also is disclosed.

Owner:KAUPTHING BANK

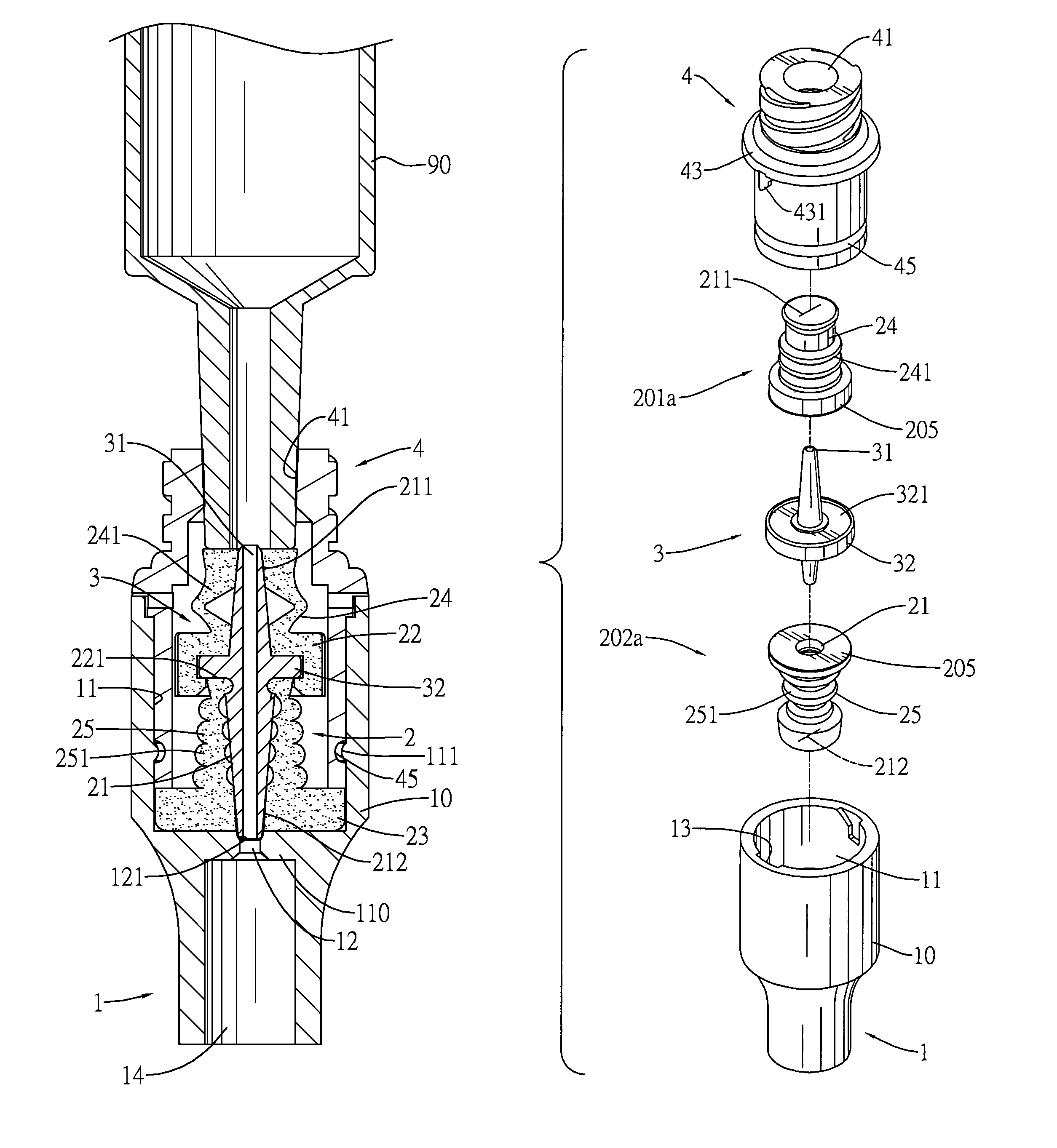

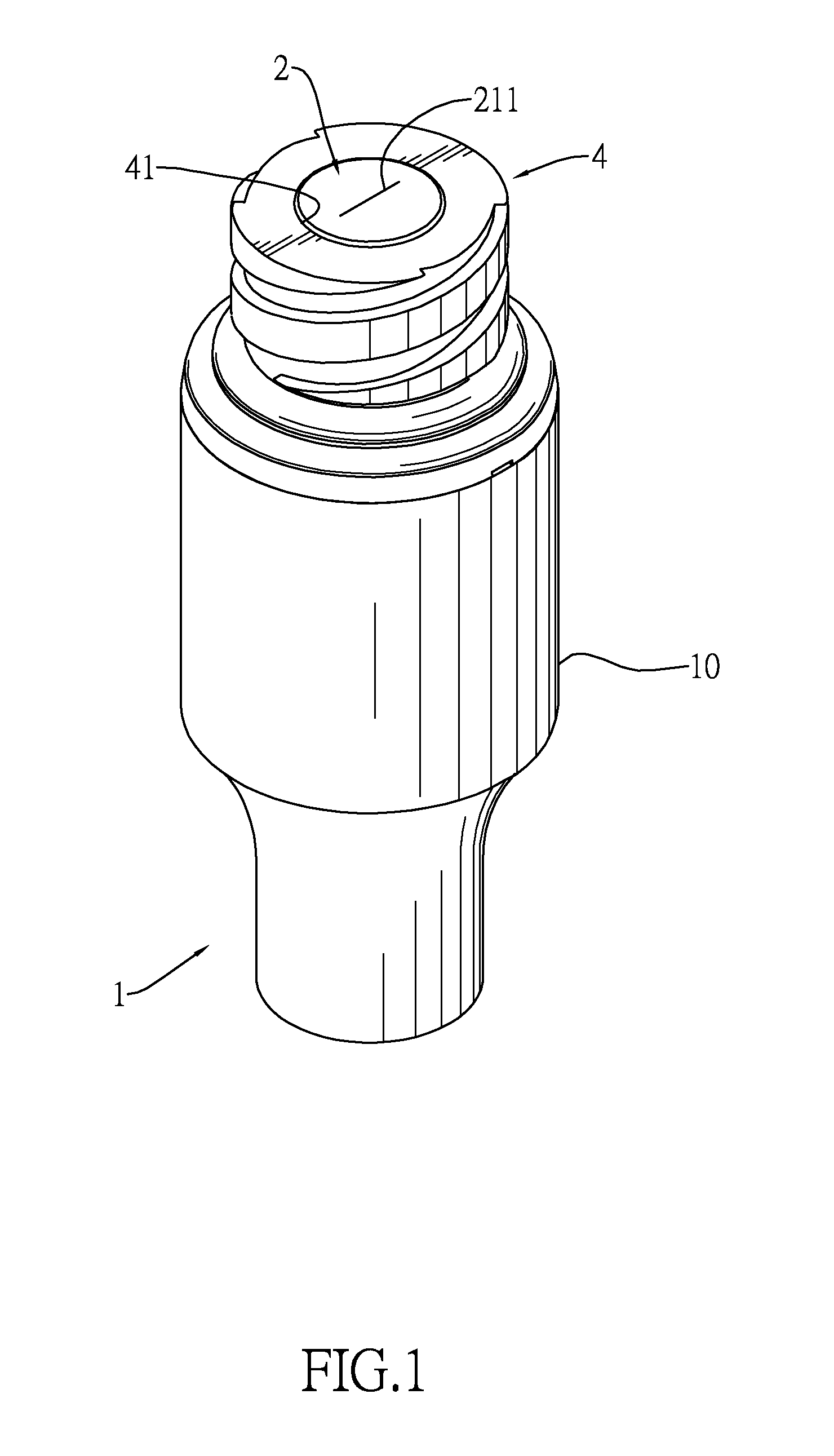

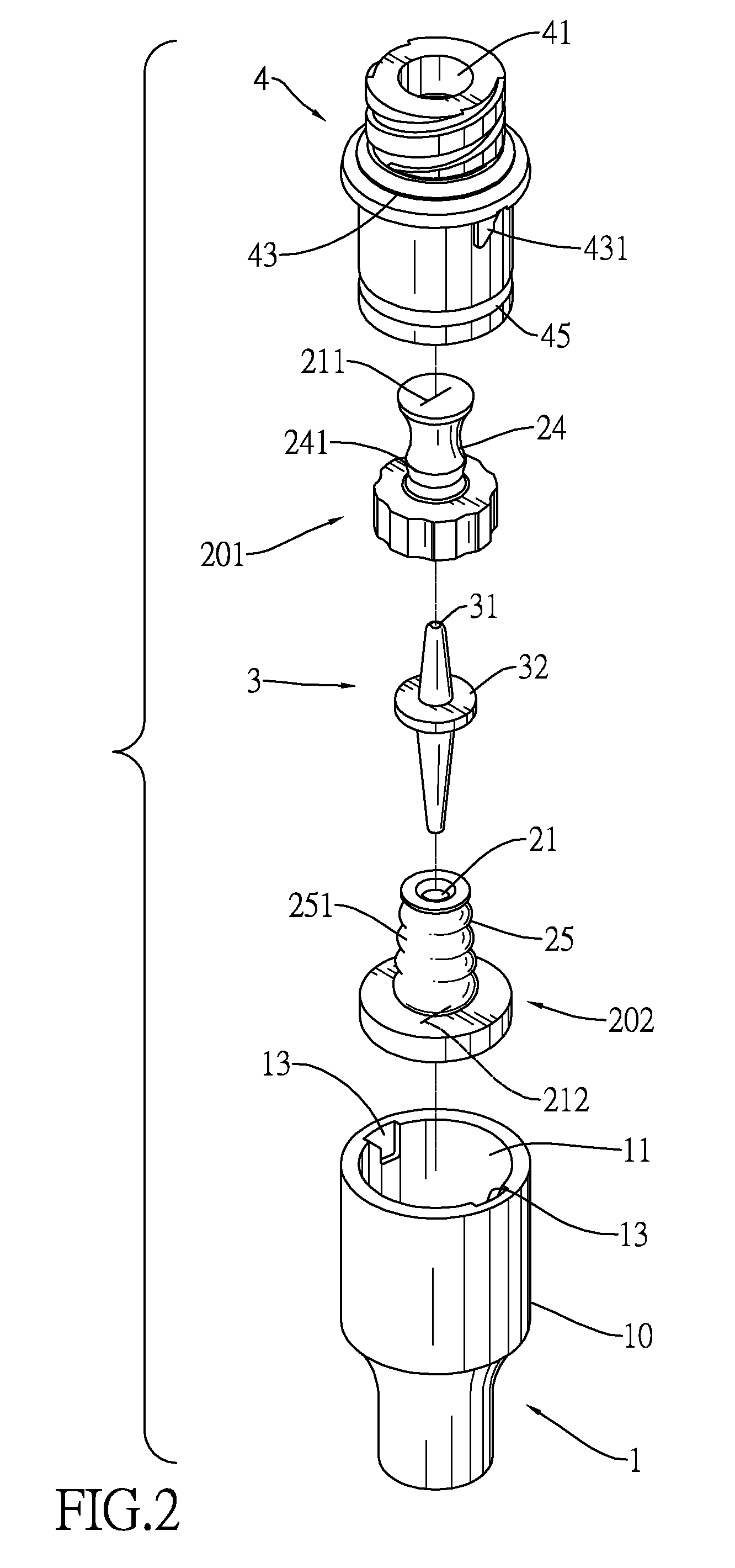

Needle-less syringe adapter

ActiveUS8277424B2Improve air tightnessPrevent backflowJet injection syringesInfusion devicesCatheterBiomedical engineering

A needle-less syringe adapter has a tube, a resilient valve, a piercing member and an injection member. The tube has a body has a cavity and an outlet hole. The resilient valve is mounted in the cavity and has a chamber, a top slit and a bottom slit. The piercing conduit is mounted in the chamber, is driven to move when the resilient valve is compressed, selectively extends out through the top and bottom slits and has a through hole defined through the piercing conduit. The injection member is mounted on the tube and is selectively sealed by the resilient valve. The needle-less syringe adapter has excellent hermetical characteristics to prevent air infiltration and backflow of bloody and liquid medicine in a patient's blood vessel.

Owner:SKILL PARTNER

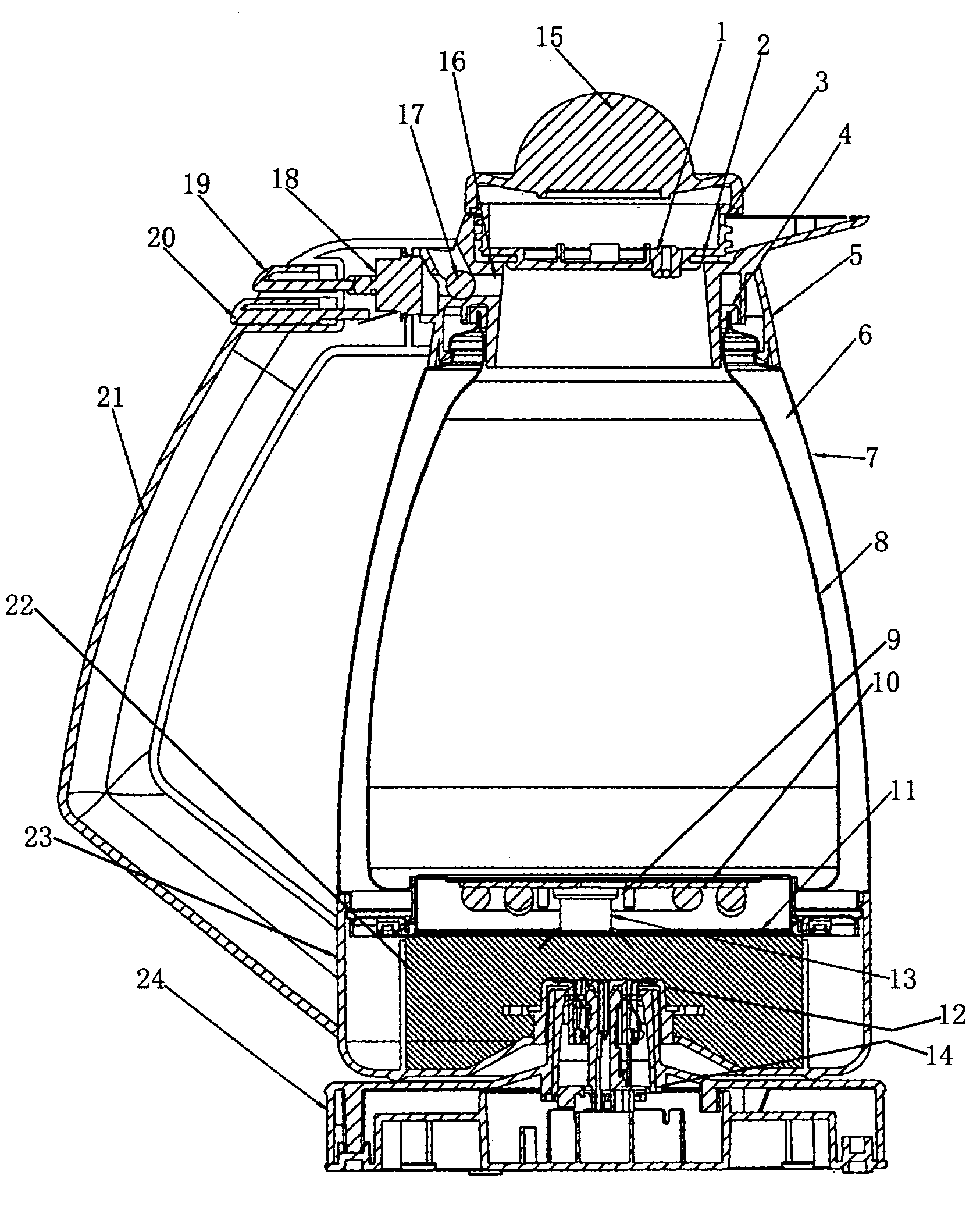

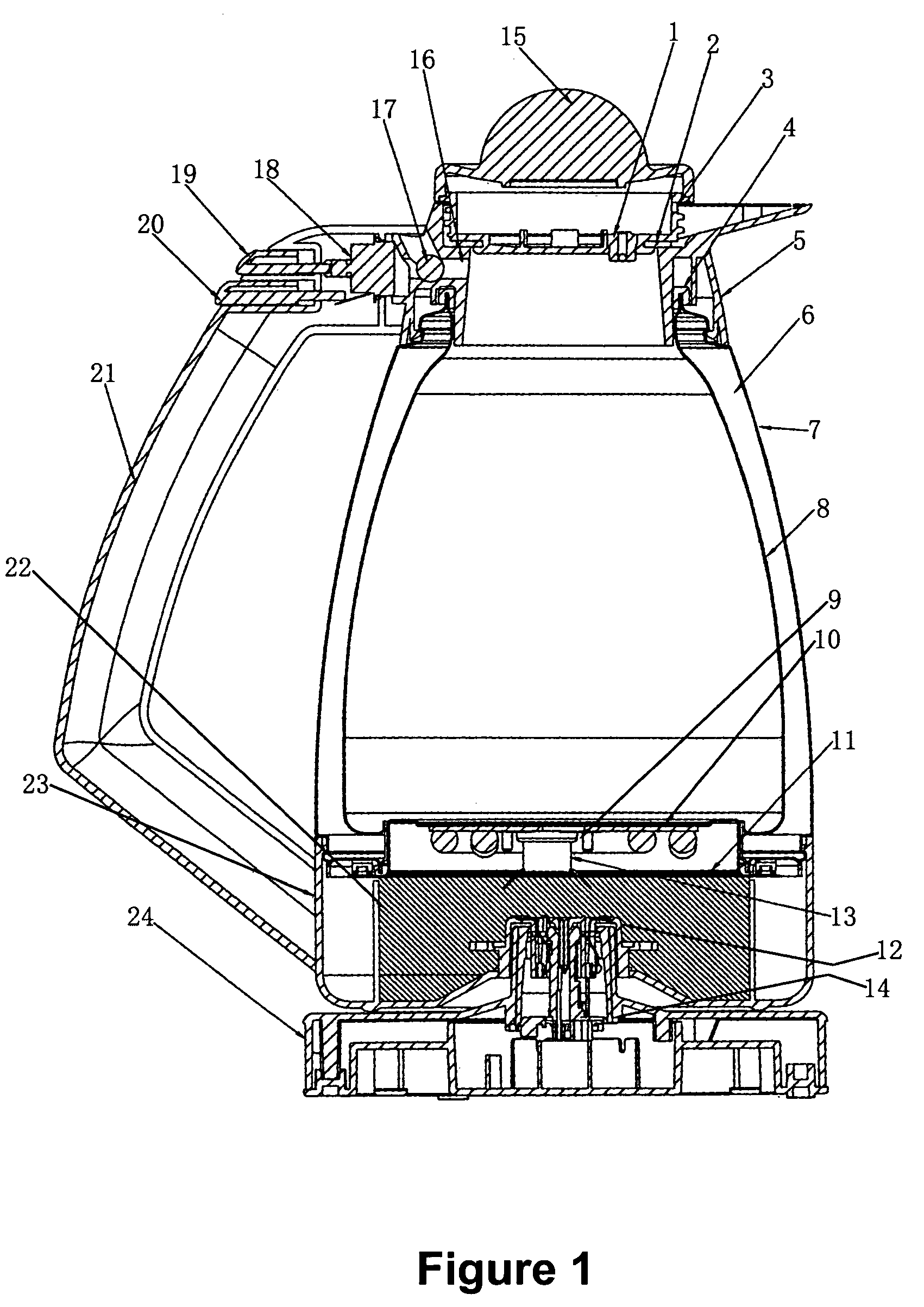

Electric thermos jug

InactiveUS7091455B2Improve air tightnessEasy to useCooking-vessel materialsDomestic cooling apparatusElectricityWater quality

Owner:FUNG SHIU PO

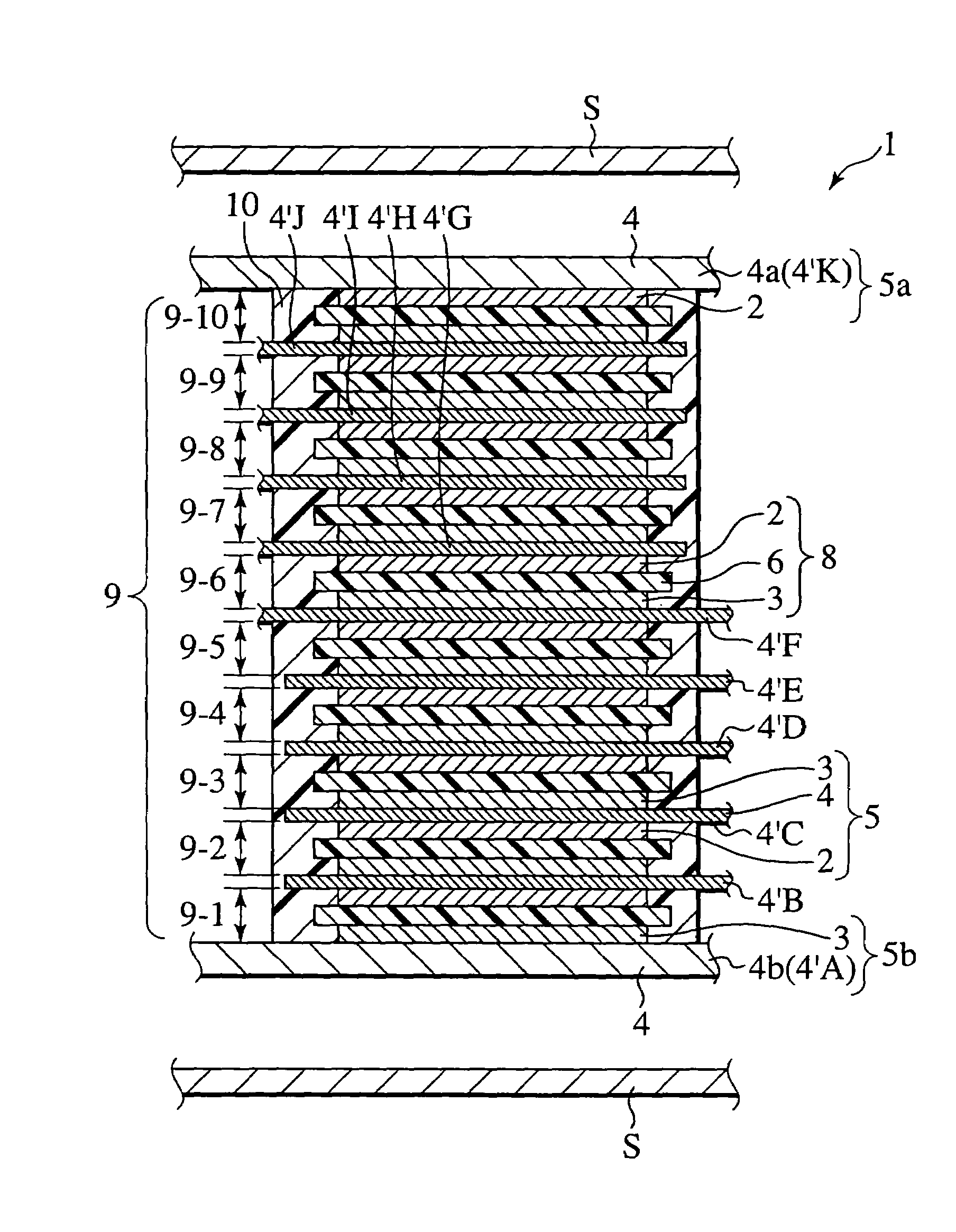

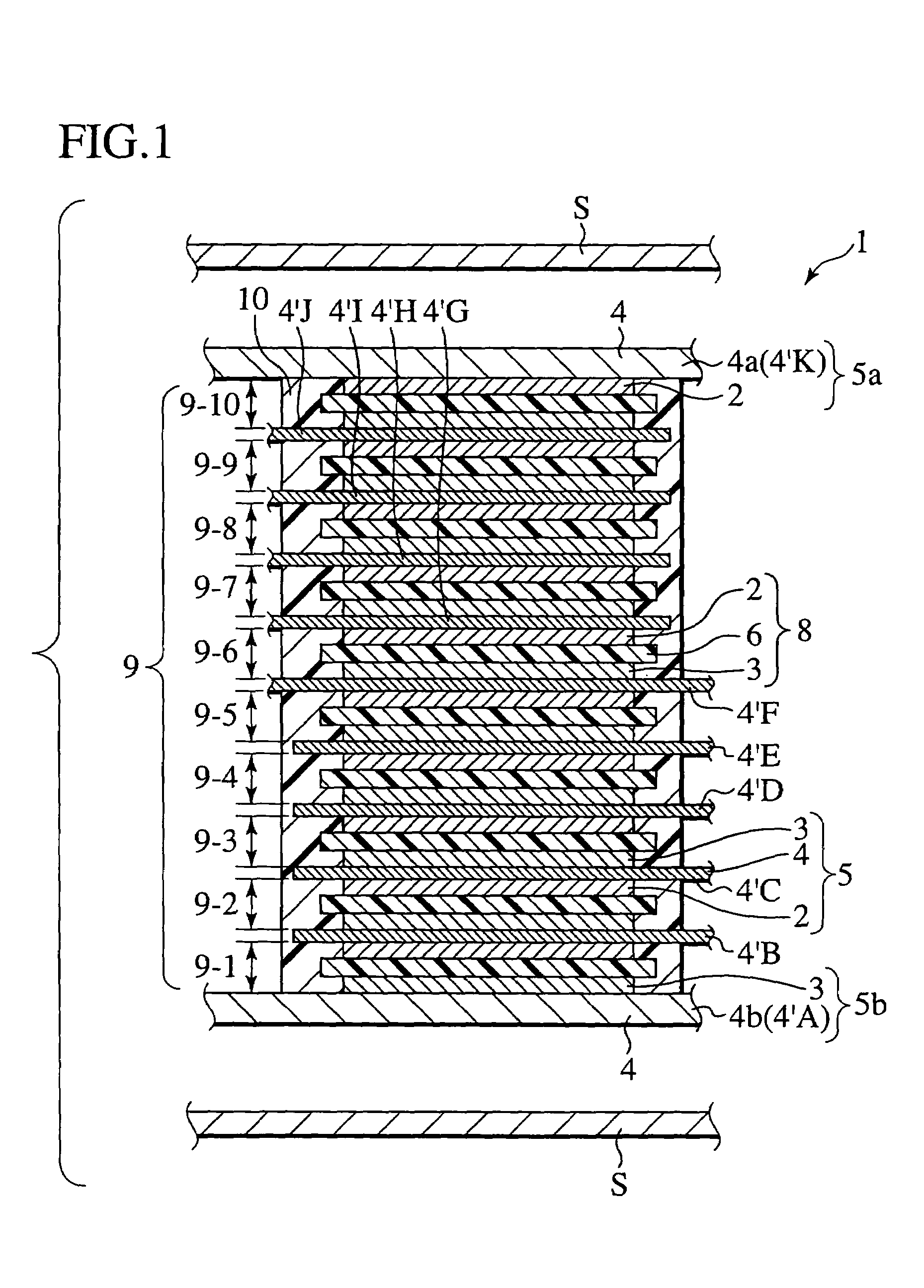

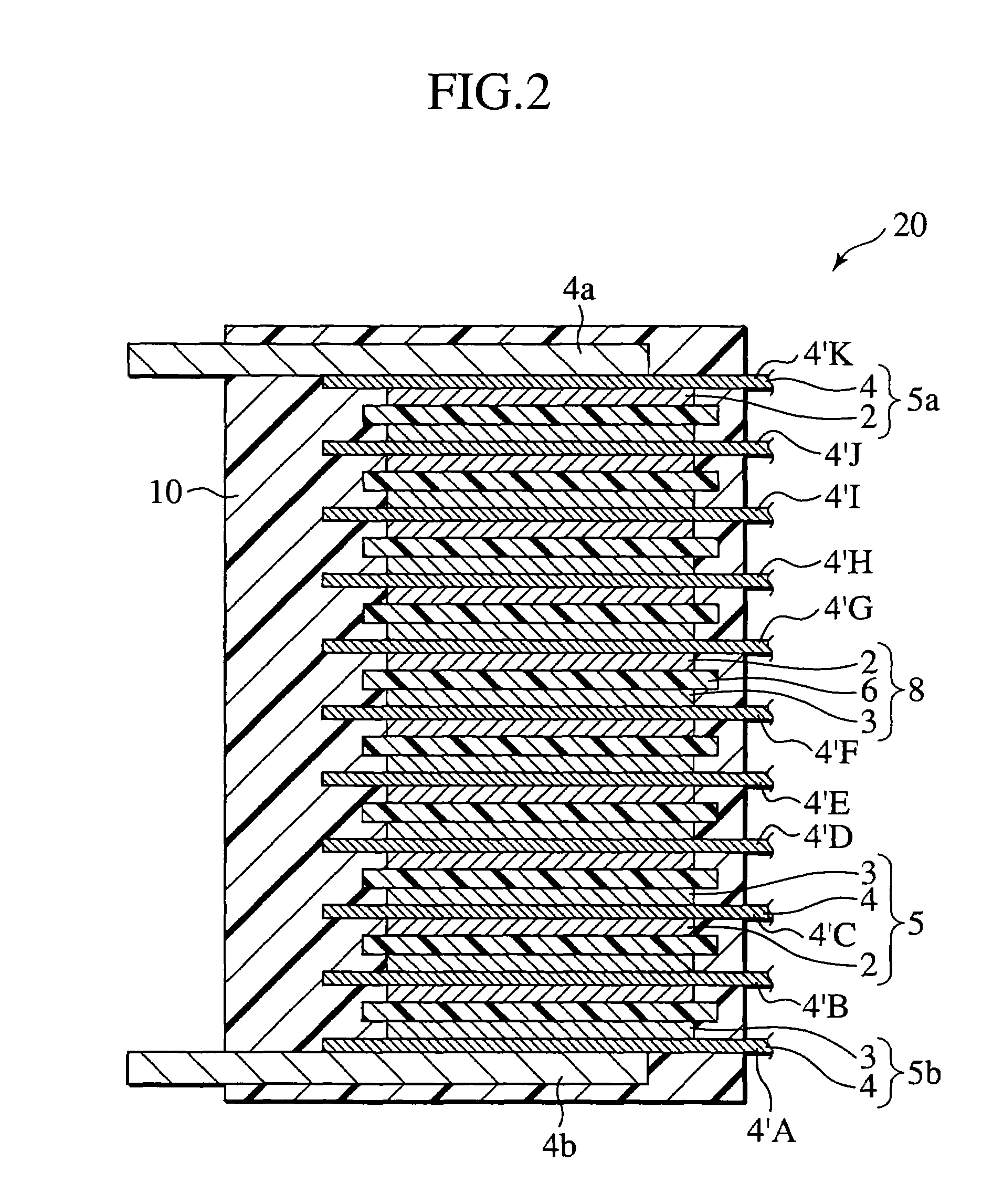

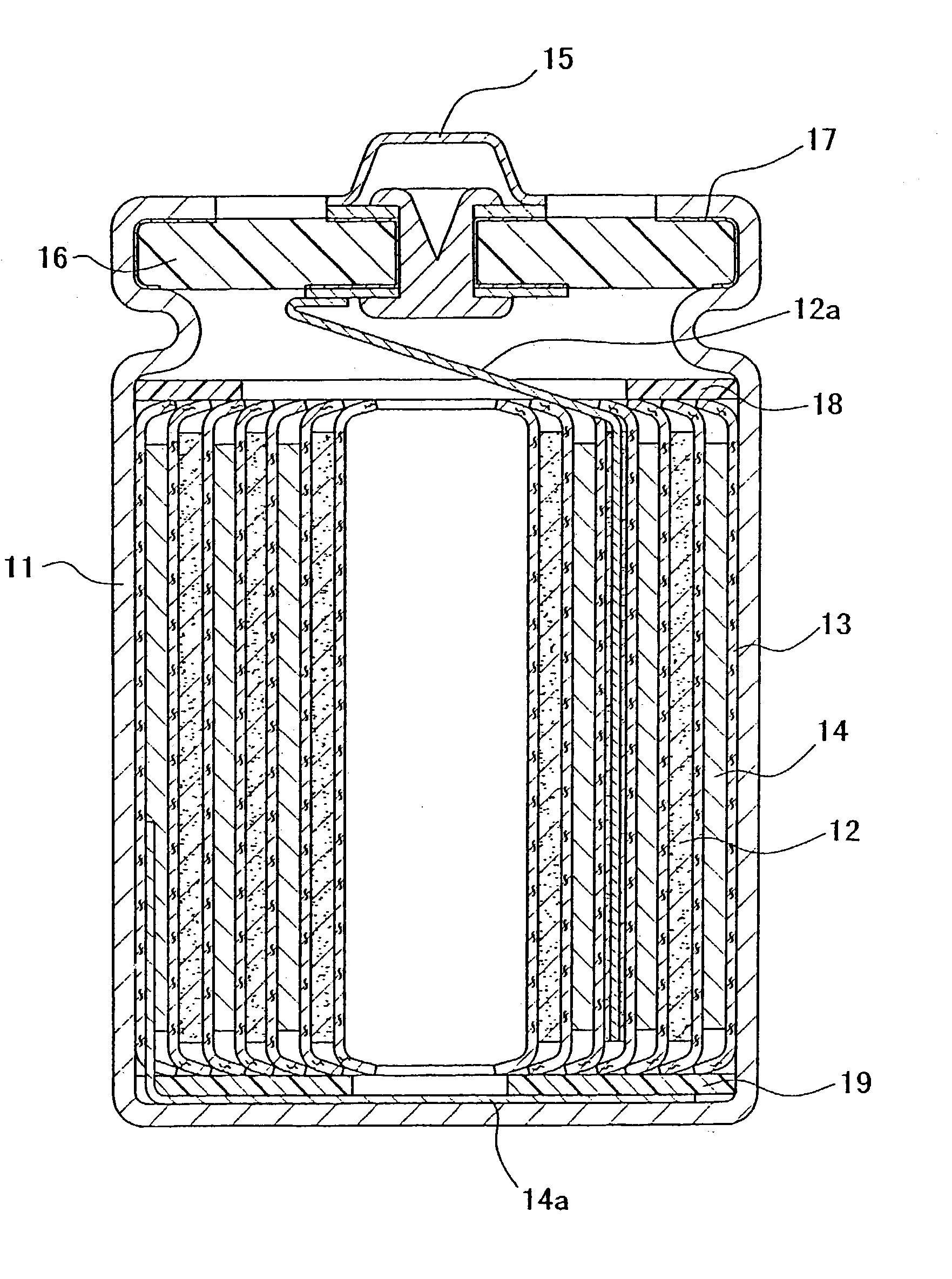

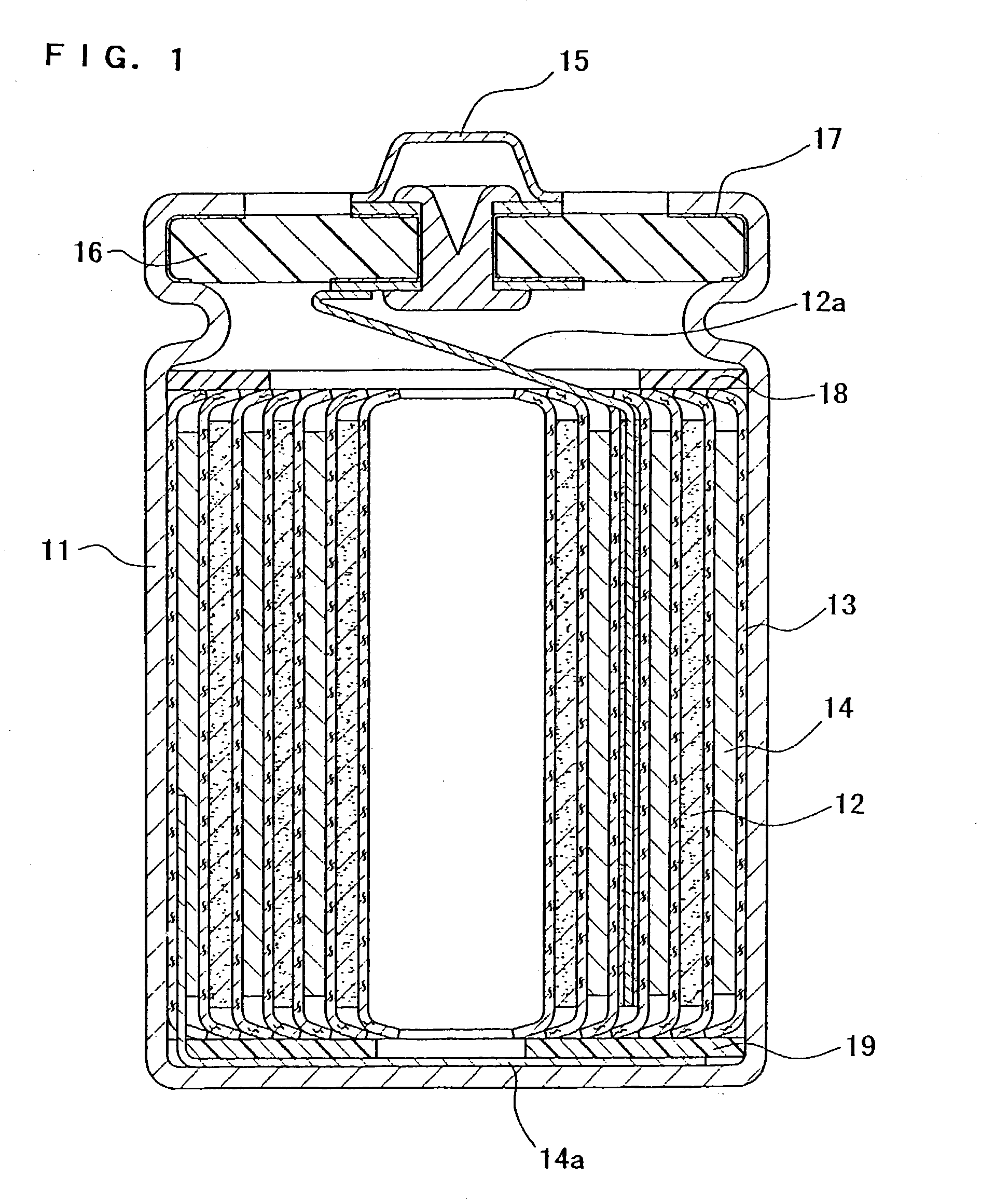

Bipolar battery and method for manufacturing the same

ActiveUS7320846B2Improve gas tightnessImprove vibration proof and impact resistanceFuel cells groupingFinal product manufactureCurrent collectorElectrical and Electronics engineering

A bipolar battery includes a bipolar electrode and an electrolyte layer. The bipolar electrode includes a current collector, a positive electrode layer formed on one surface of the current collector, and a negative electrode layer formed on the other surface of the current collector. The bipolar electrode is sequentially laminated to provide connection in series via the electrolyte layer to form a stack structure. The positive electrode layer, the negative electrode layer and the electrolyte layer are potted with a resin portion.

Owner:NISSAN MOTOR CO LTD

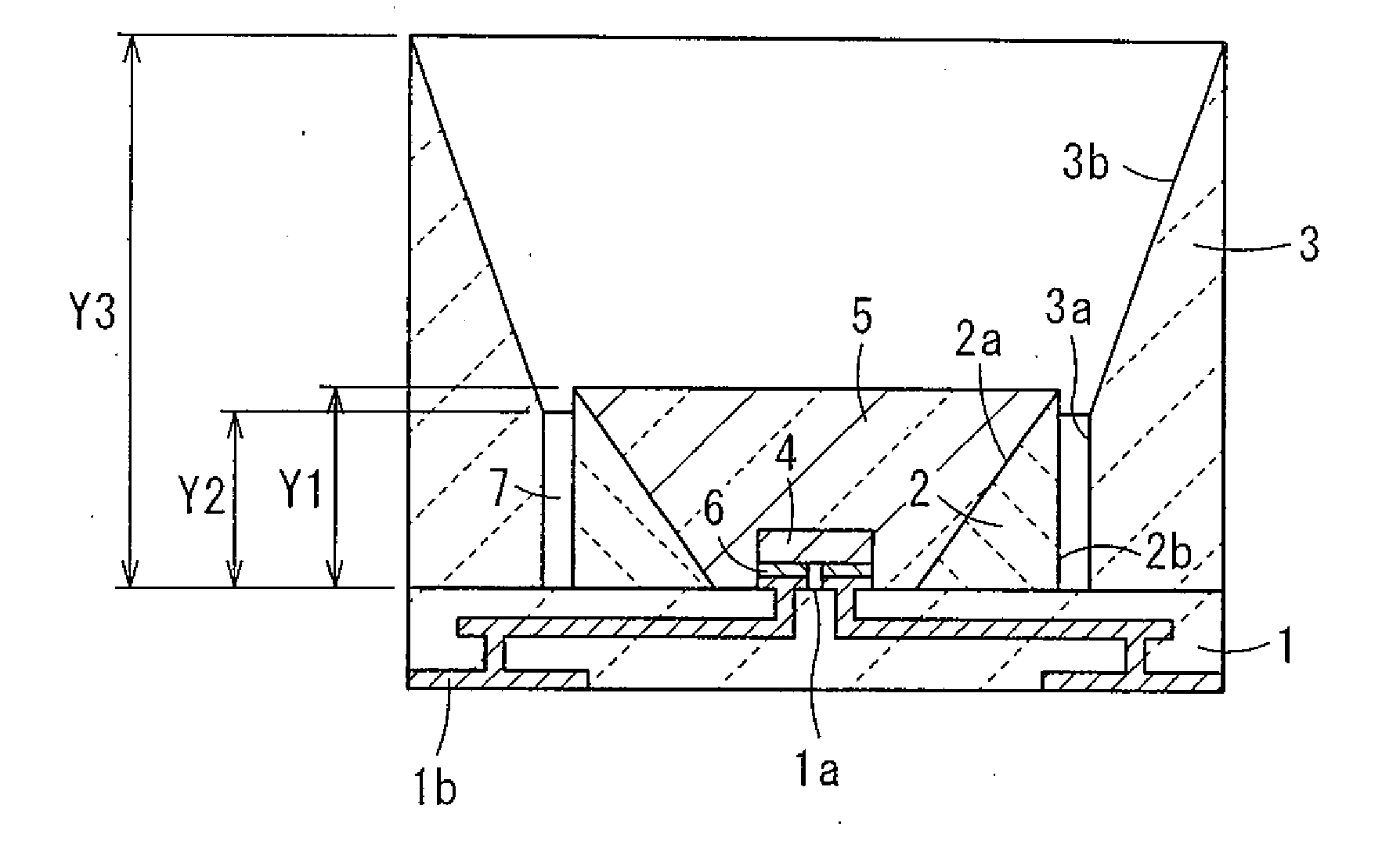

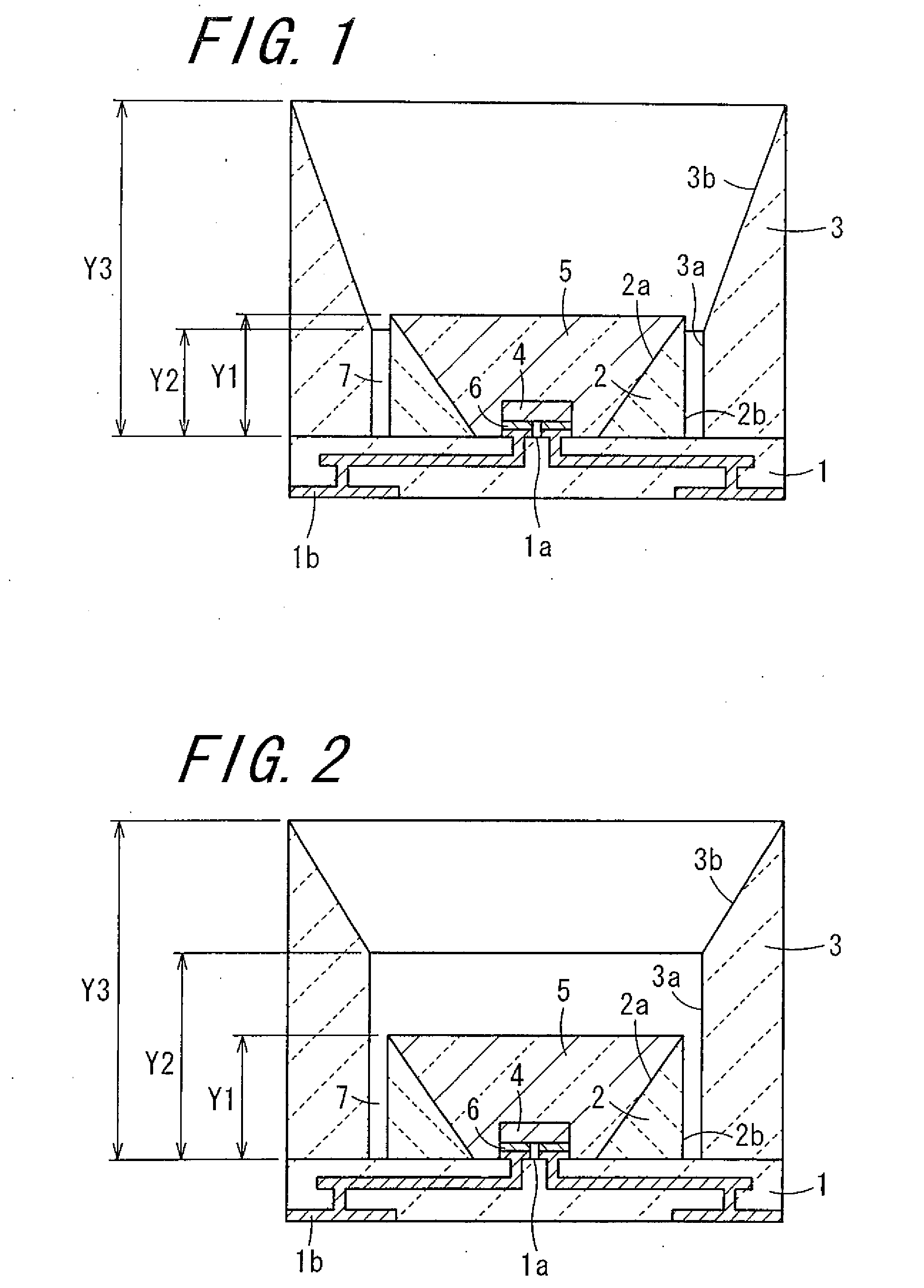

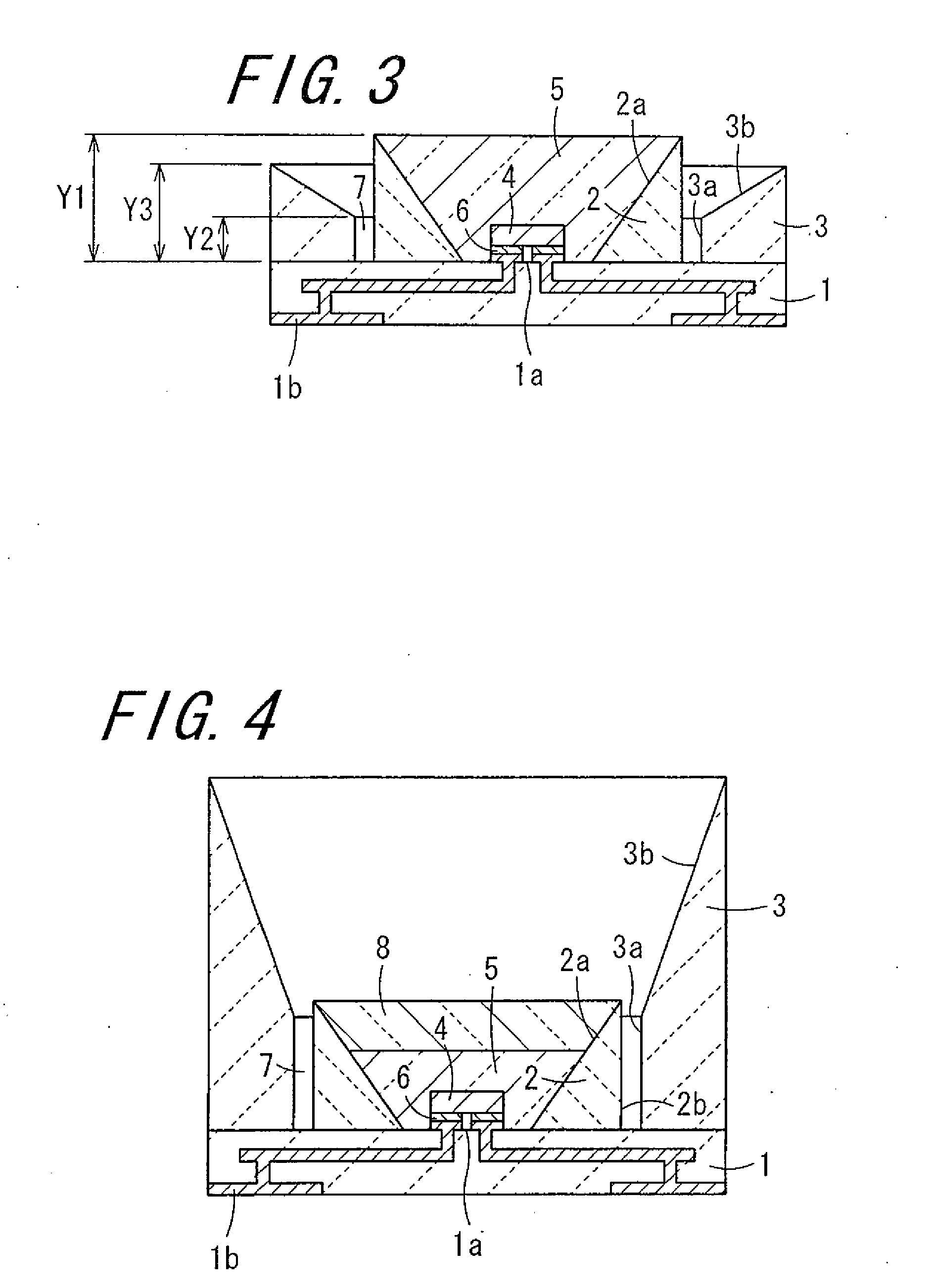

Package For Light-Emitting Device, Light-Emitting Apparatus, and Illuminating Apparatus

ActiveUS20090296367A1Excellent hermeticityImprove air tightnessSolid-state devicesSpectral modifiersEngineeringLight emitting device

A package includes a base body having a mounting portion for mounting a light-emitting device, a frame-shaped first reflection member attached to the upper surface of the base body, an inner peripheral surface of which is shaped into a first light reflecting surface and surrounds the mounting portion, and a frame-shaped second reflection member attached to the upper surface of the base body, with a spacing secured between an inner peripheral surface of the second reflection member and an outer peripheral surface of the first reflection member, the inner peripheral surface surrounding the first reflection member and having a second light reflecting surface at a location above an upper end of the first reflection member.

Owner:KYOCERA CORP

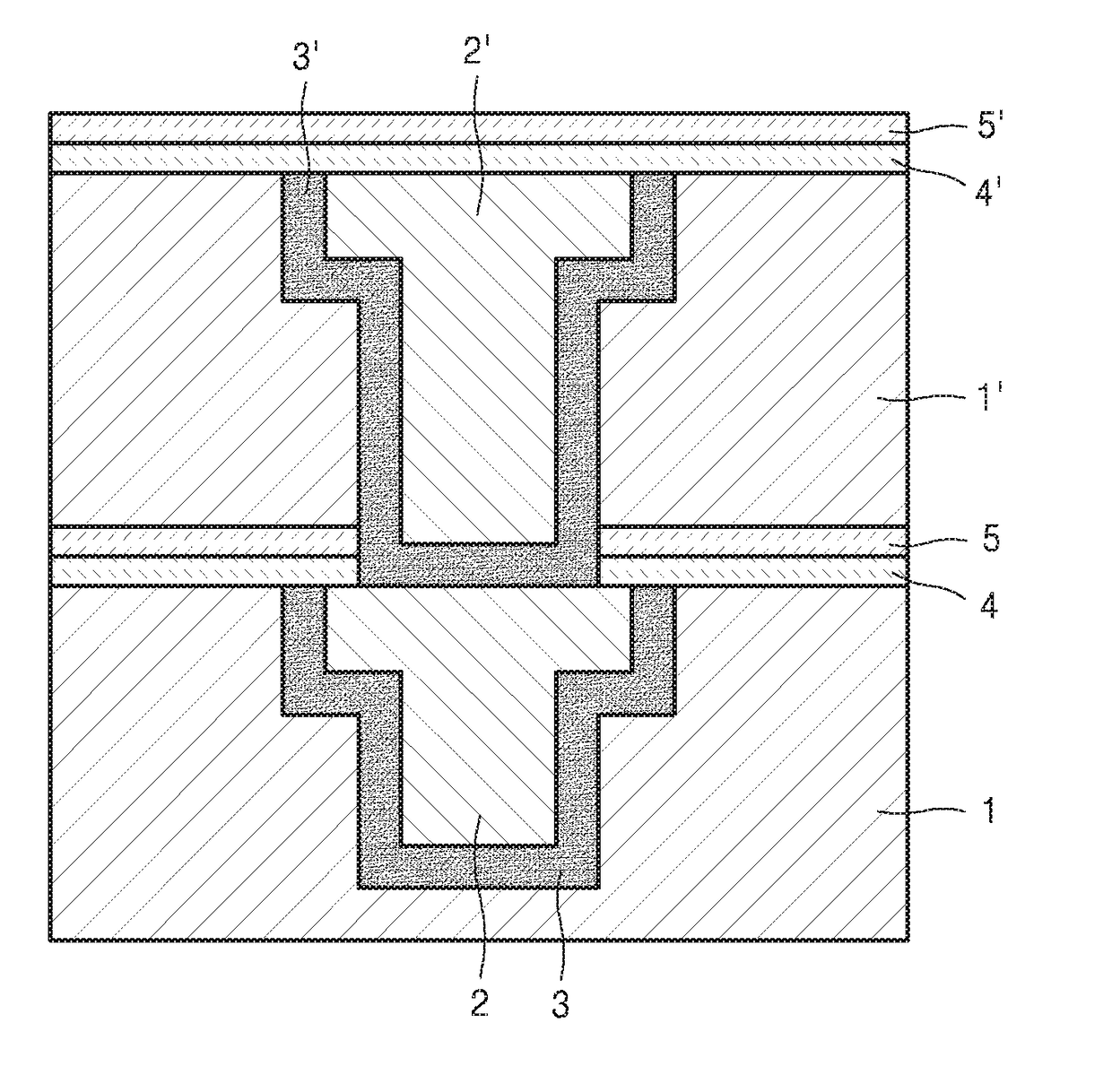

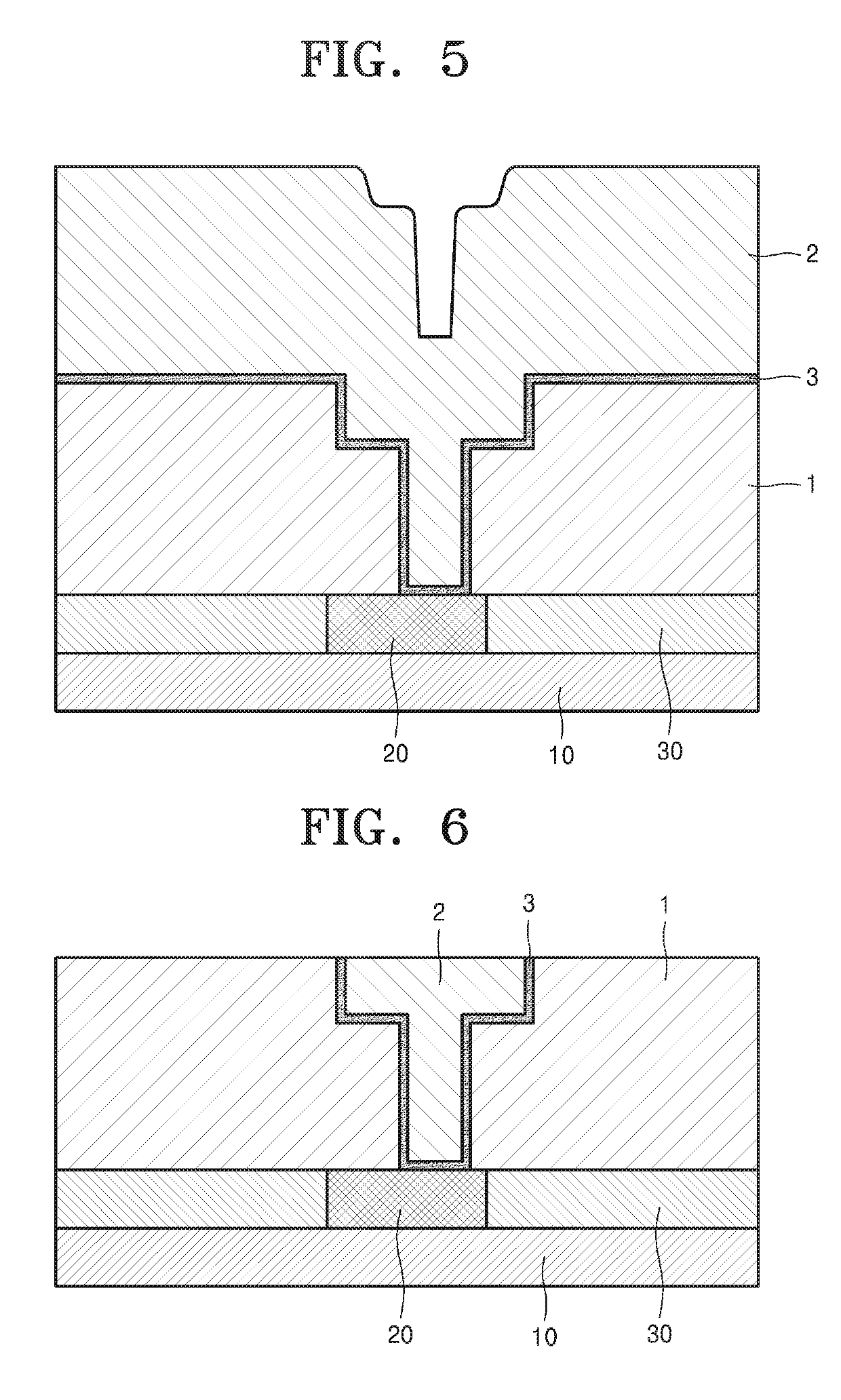

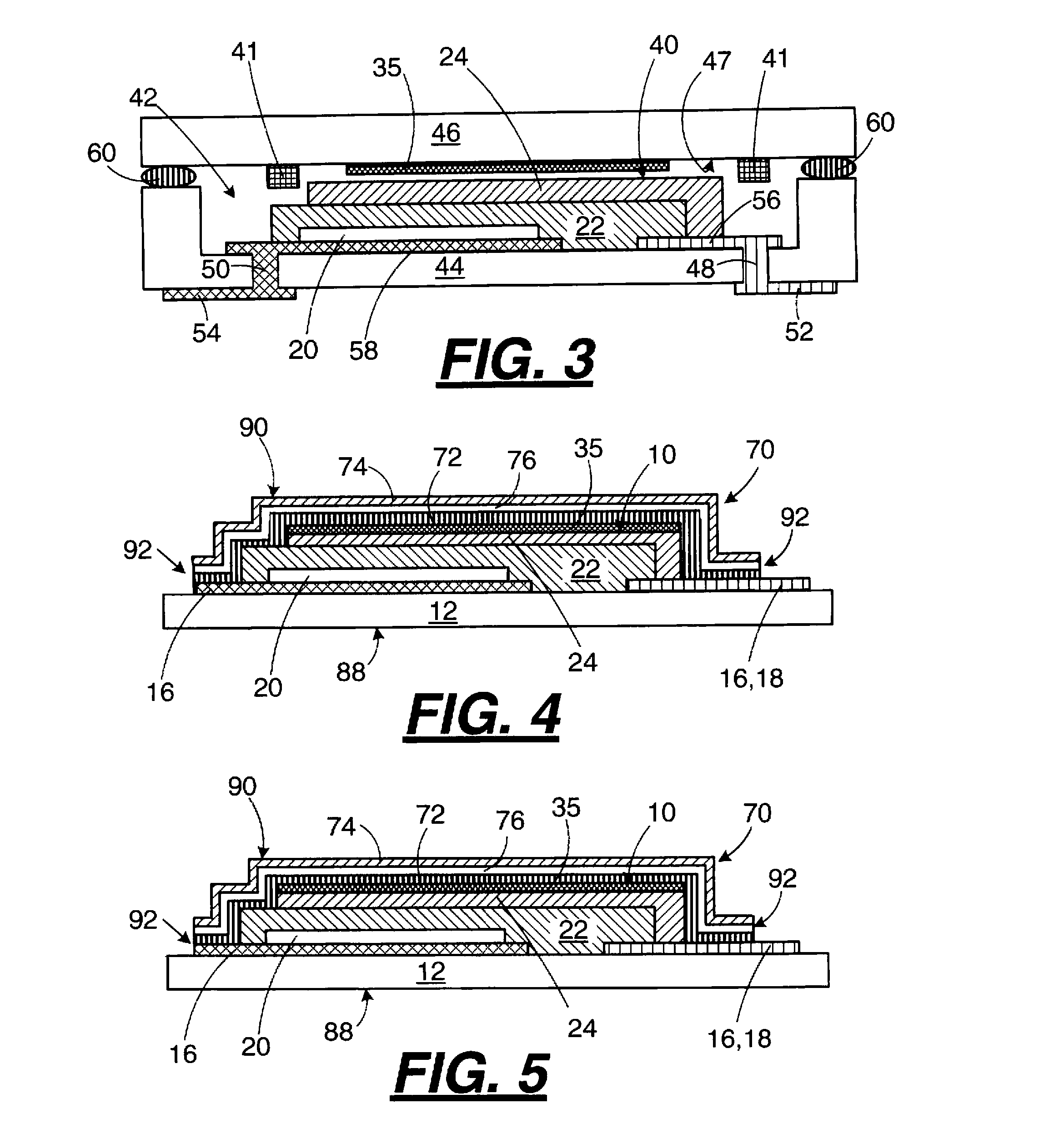

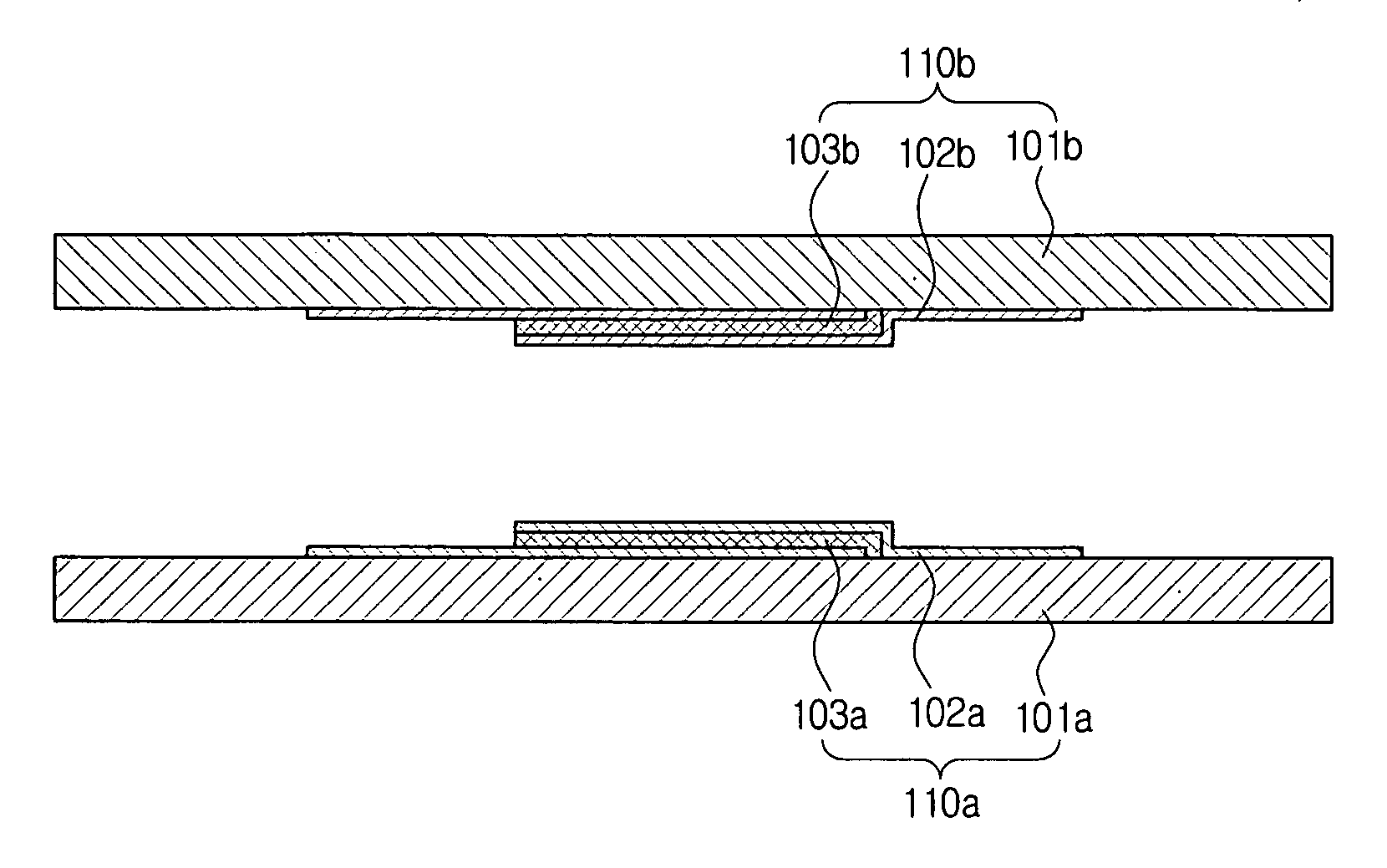

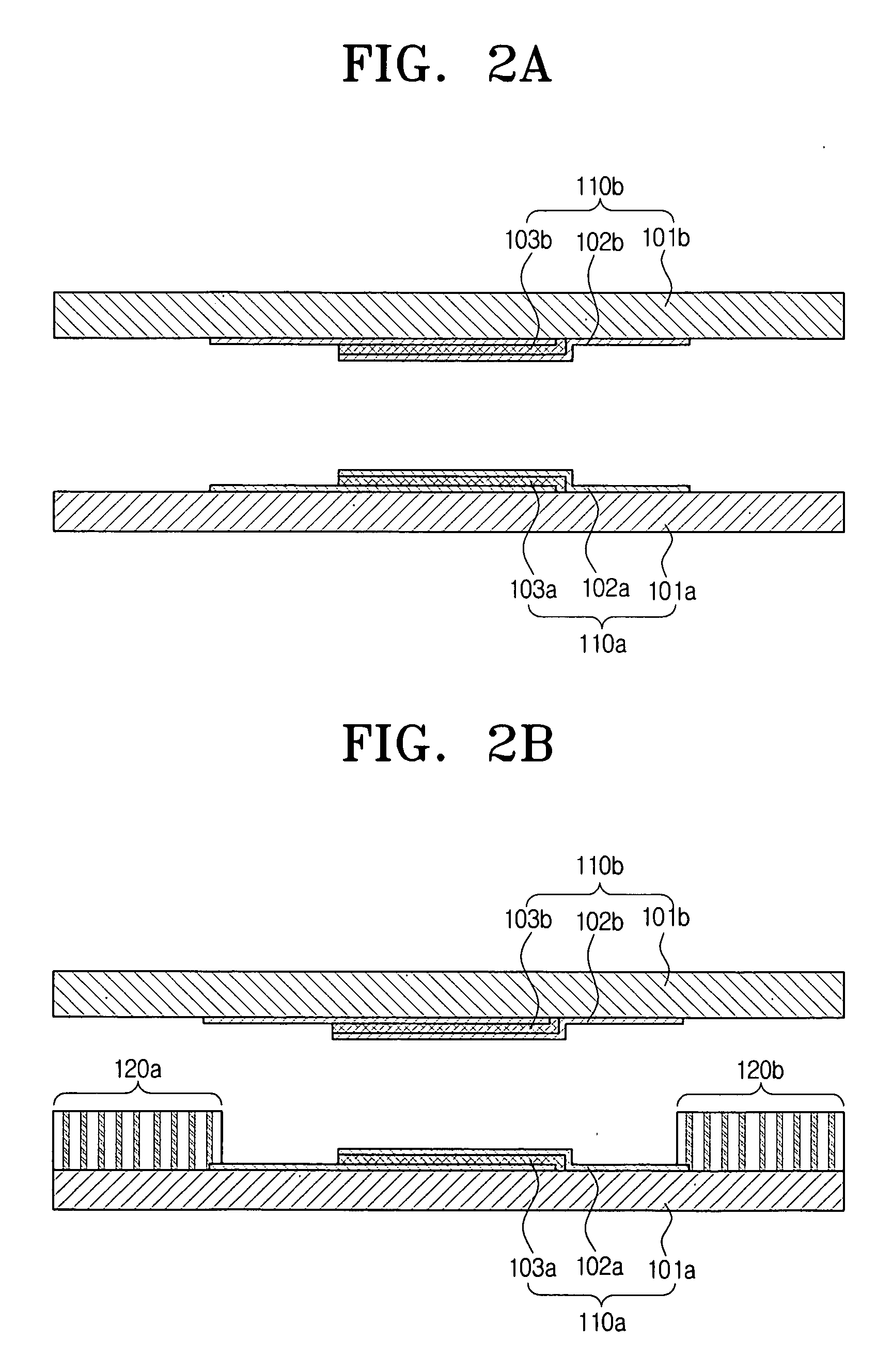

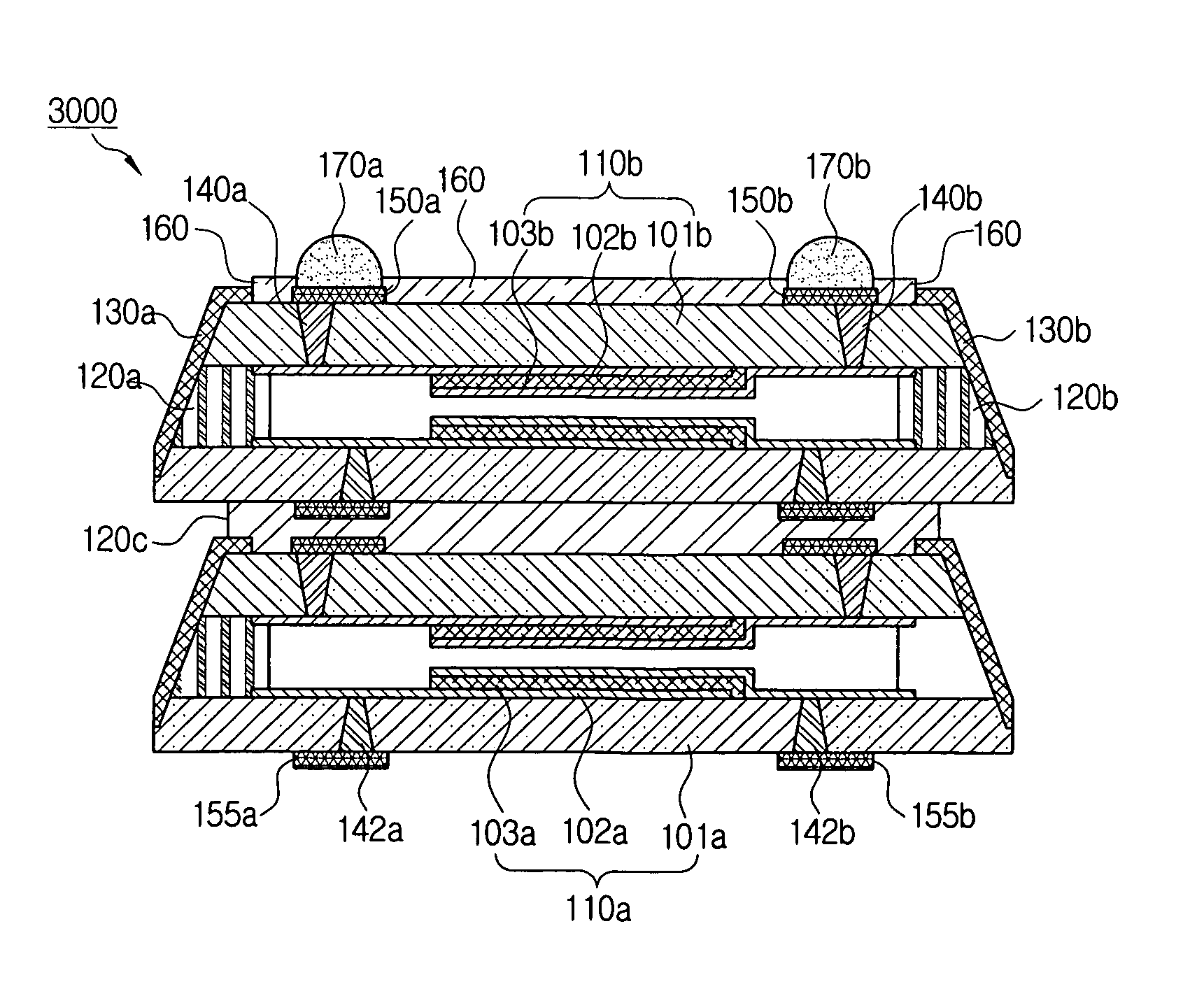

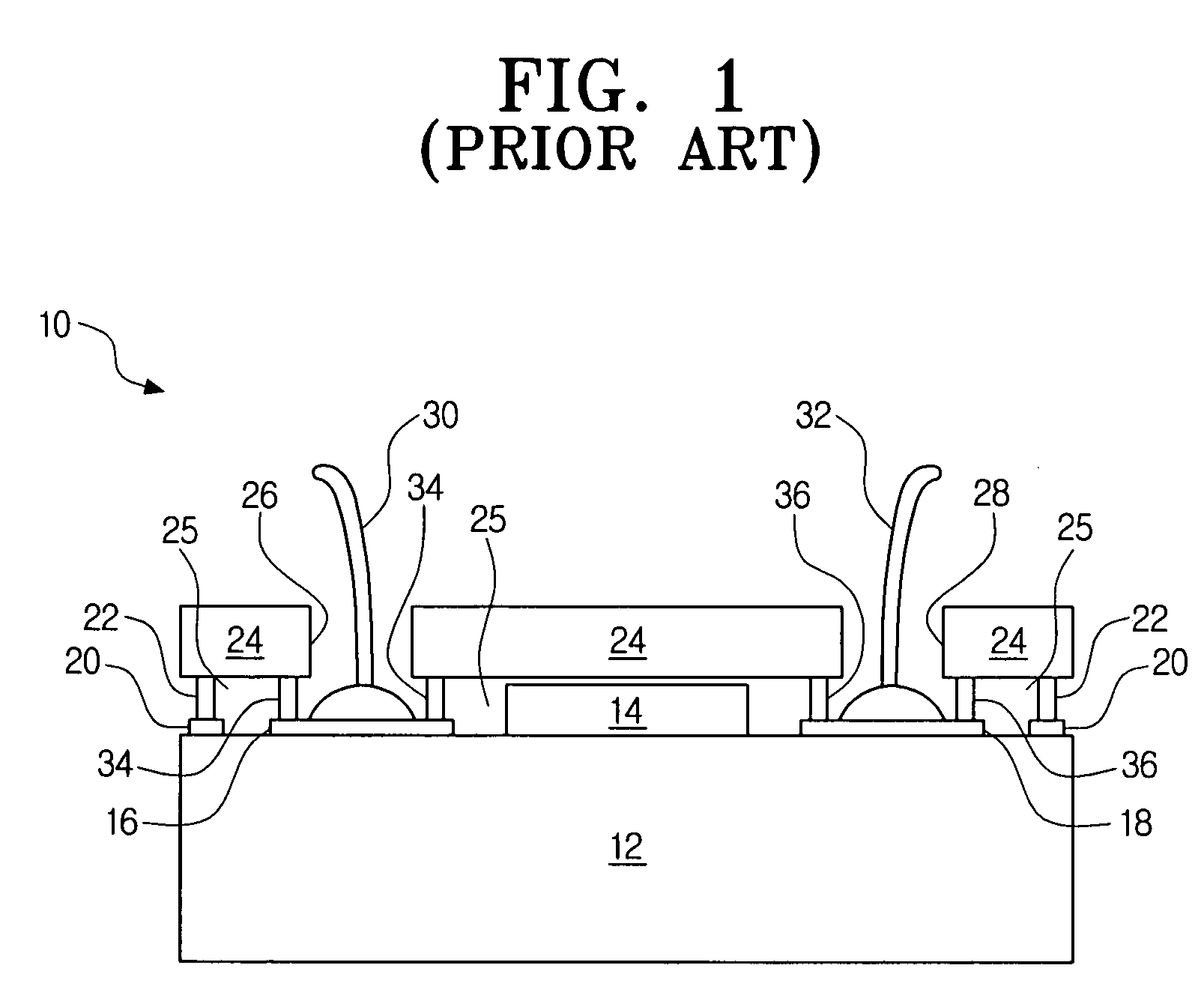

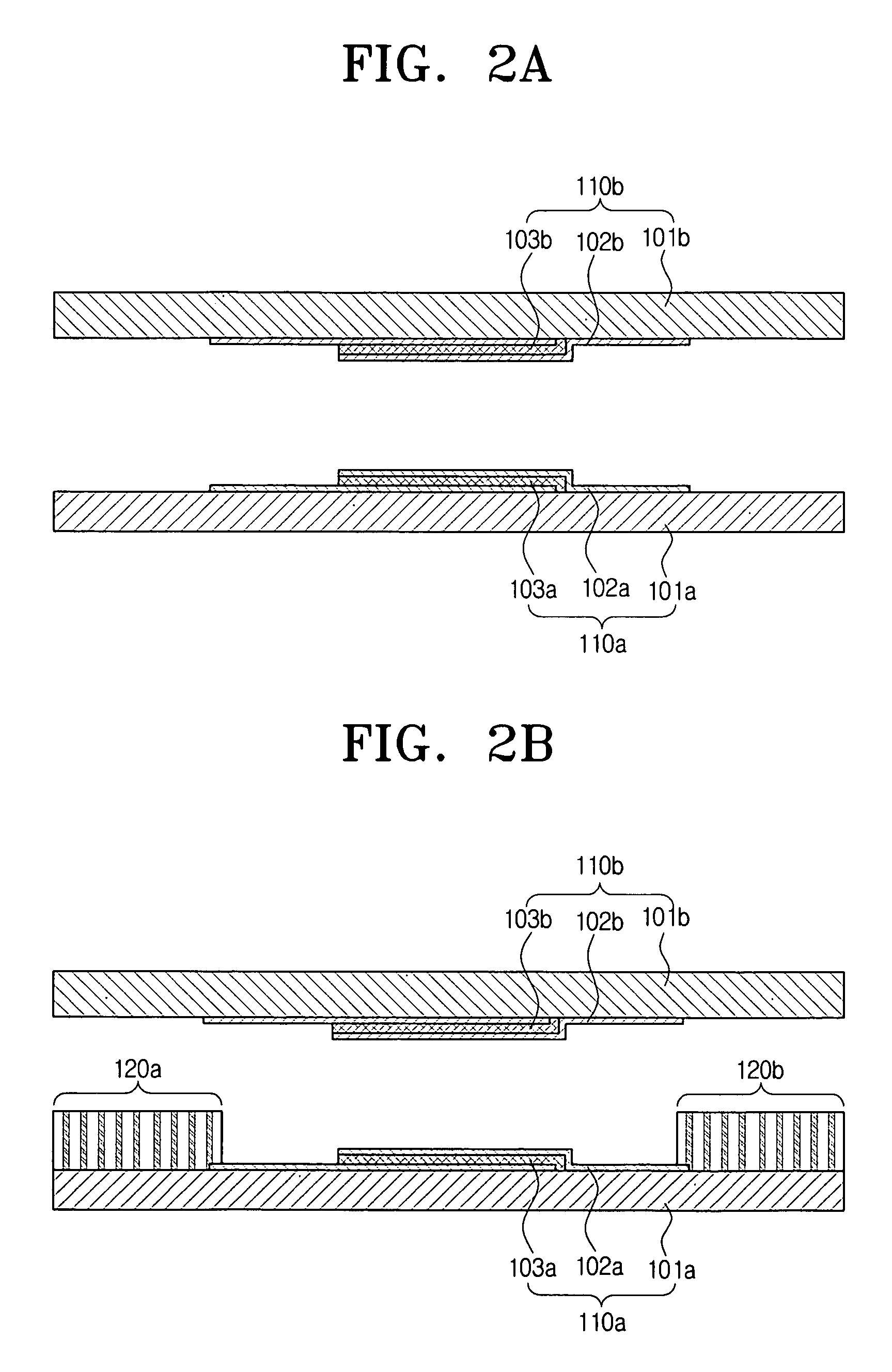

Micro-package, multi-stack micro-package, and manufacturing method therefor

ActiveUS20070012655A1Improving hermetical sealingAvoid damageSemiconductor/solid-state device detailsSolid-state devicesEngineeringElectrical and Electronics engineering

A micro package, a multi-stack micro package, and a manufacture method therefor are provided. A micro package according to the present invention includes a device substrate for mounting a devices, being a circuit module; a protection cap for protecting the device; bonding substances which, formed by patterning on predetermined areas on the device substrate, bond the device substrate and the protection cap; layers formed on a portion of the device substrate and a portion of the protection cap and exterior sides of the bonding substances; vias which are formed by etching away another portion of the protection cap, and electrically connected to an upper surface of the device substrate through the bonding substances; under barrier metals (UBMs) formed on the vias; and solder bumpers, being connection terminals for an external signal, formed on the UBMs. As stated above, the present invention has advantages of guaranteeing the hermetical sealing since the above layers prevent moisture absorption from outside at the same time of lowering possibility of damages to the device inside the package since the processing temperature drops below 150° upon wafer bonding due to the use of the polymer substance as a bonding substance.

Owner:SAMSUNG ELECTRONICS CO LTD

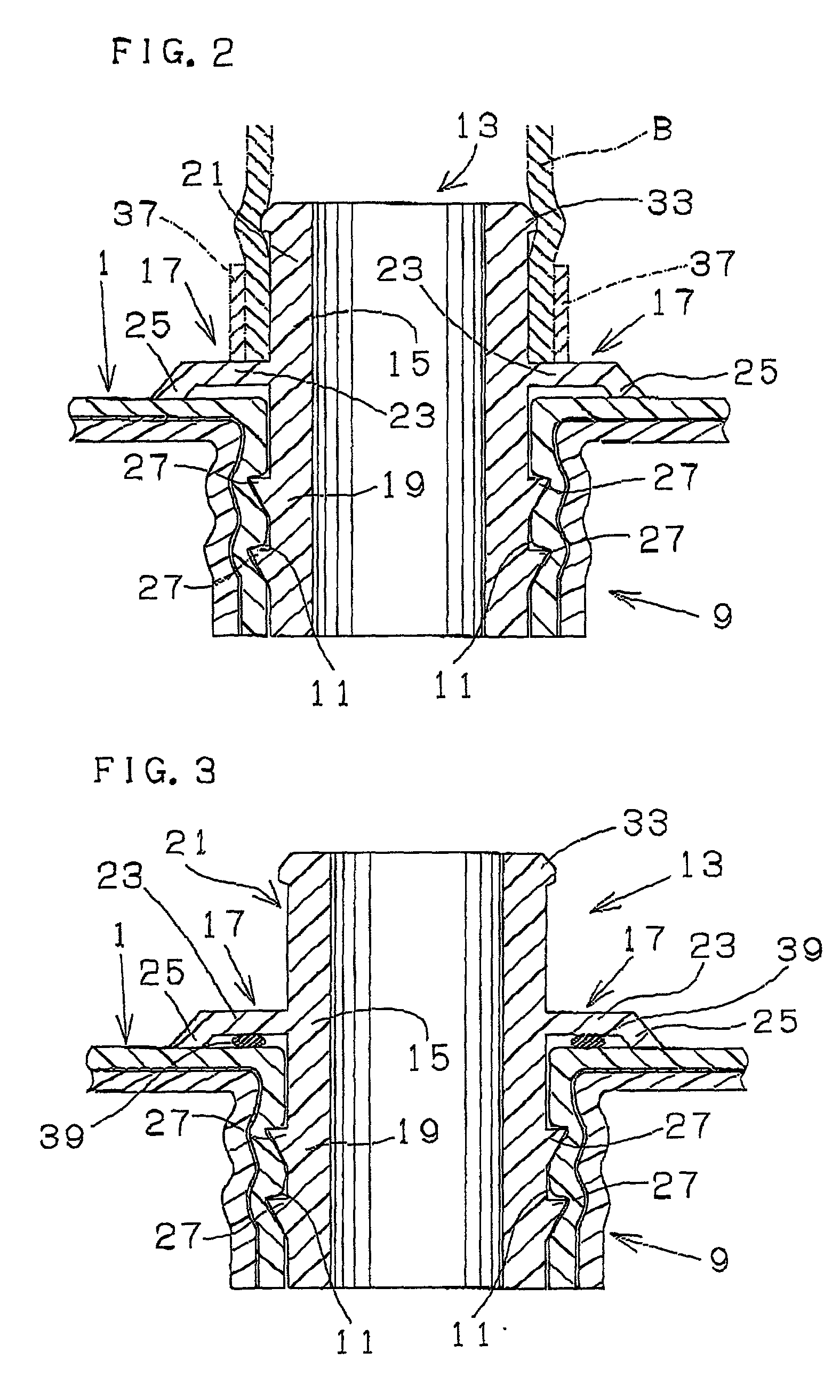

Structure for connecting tubular member to fuel tank

InactiveUS20020130515A1Improve penetration resistanceAvoid DimensionsLarge containersUnderstructuresFuel tank

An cylindrical convex portion of which opposite ends are open is integrally formed onto a fuel tank made of RDPE therewith so as to inwardly extend in the fuel tank, to provide an opening thereon. A press-fit portion of a filler hose connecting pipe made of PA as a tubular member is press-fitted in the cylindrical convex portion to connecting the tubular member to the fuel tank. At least one annular projection is provided on the outer peripheral surface of the press-fit portion of the tubular member so as to bite in the inner peripheral surface of the cylindrical connvex portion. A face of the annular projection in direction axially of one end of tubular member is formed so as to extend outwardly and inclinedly with respect to the axial direction of the tubular member form one end toward the other end thereof.

Owner:SUMITOMO RIKO CO LTD

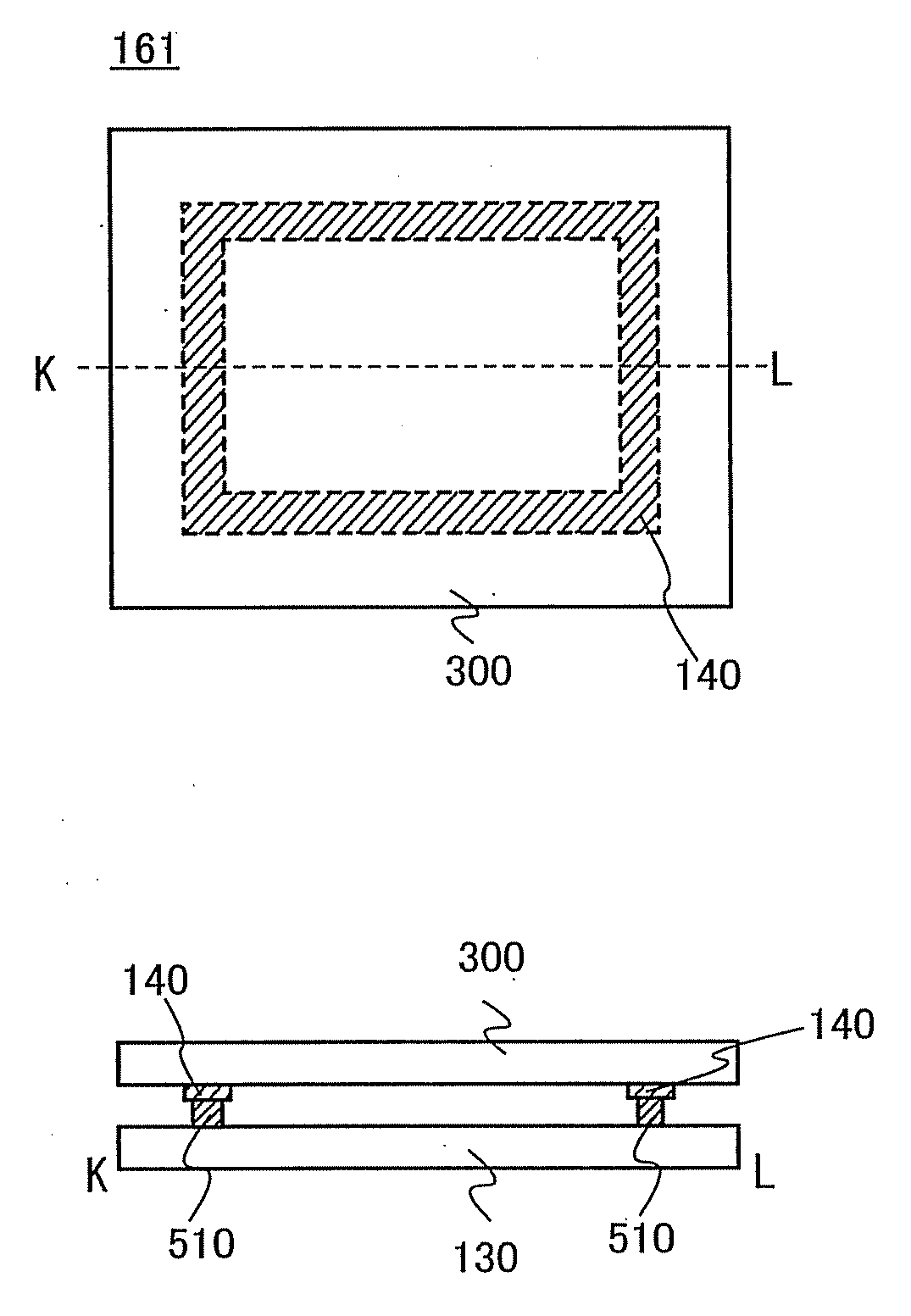

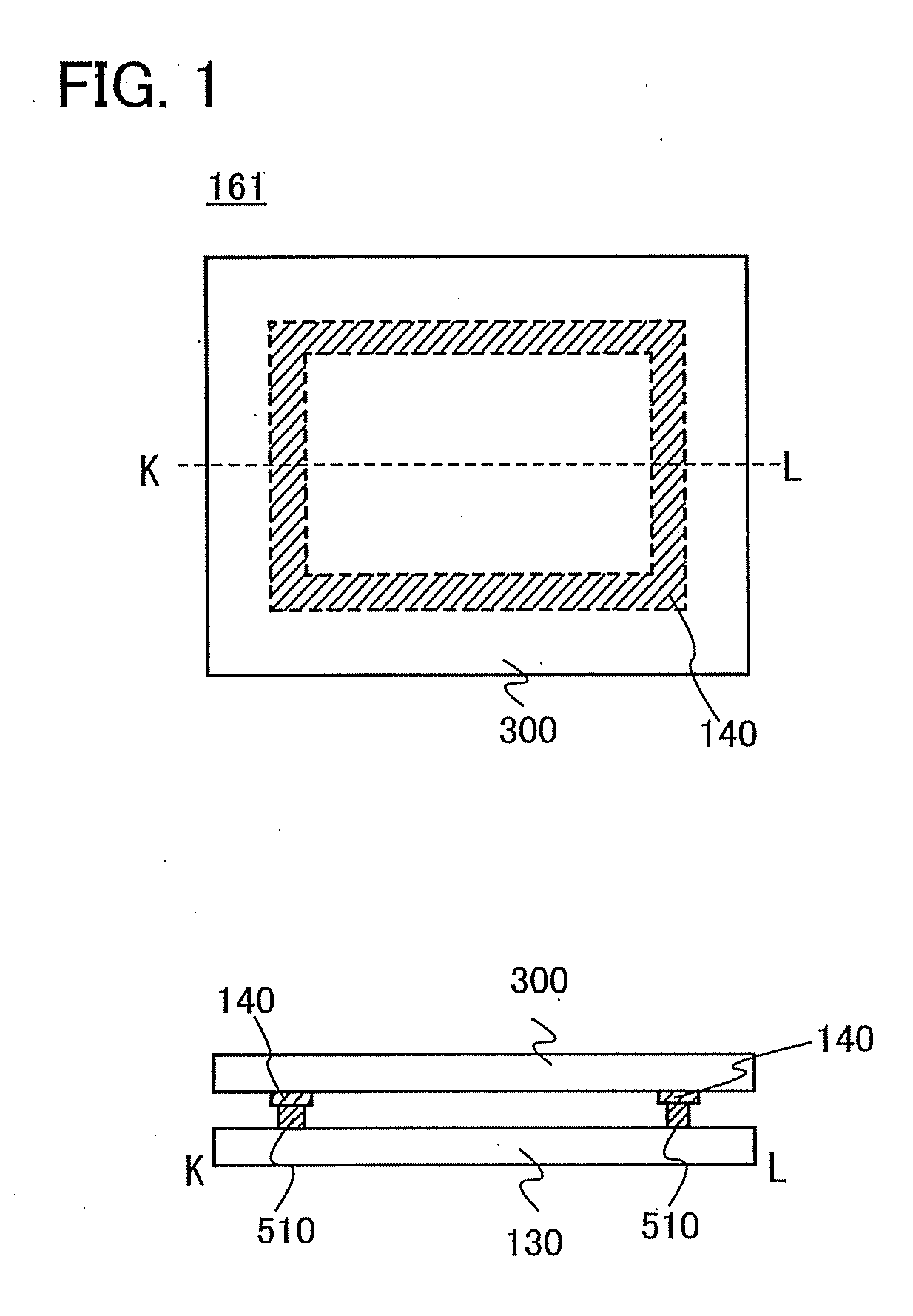

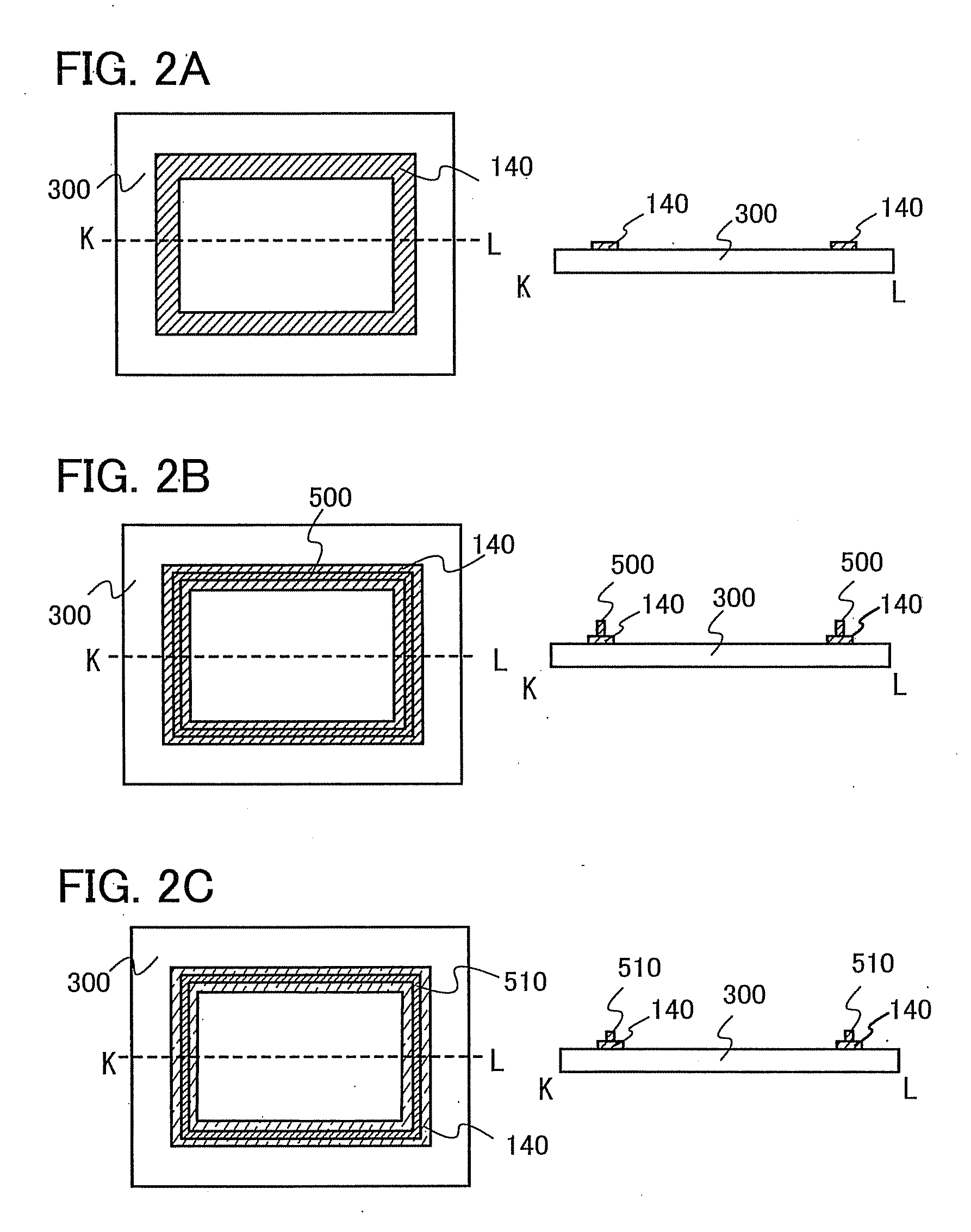

Method of manufacturing light-emitting device

ActiveUS20120318023A1Improve reliabilityImprove air tightnessGlass reforming apparatusFritLaser light

A method of manufacturing a sealed structure with excellent hermeticity and a method of manufacturing a light-emitting device sealed with the sealed structure. In the methods of manufacturing a sealed structure and a light-emitting device using a glass frit layer, a first step of forming a buffer layer for preventing a crack generated in a substrate and the glass frit layer by laser light irradiation, a second step of forming the glass frit layer to overlap with the buffer layer over the substrate, and a third step of welding the substrates by irradiating the glass frit layer or the buffer layer with laser light are performed, whereby a sealed structure with high hermeticity and a reliable light-emitting device sealed with the sealed structure can be manufactured. By applying the method of manufacturing a light-emitting device especially to an organic EL element, a highly reliable light-emitting device can be obtained.

Owner:SEMICON ENERGY LAB CO LTD

Endoscope optical system device and endoscope with the same

InactiveUS20100022841A1Bright and clear imageInhibition formationSurgeryEndoscopesAdhesiveMoisture permeability

Out of optical elements that are provided to the top end side of an inserting portion of an endoscope, a first optical element arranged closest to an observation object side and a second optical element joined hermetically to the first optical element via an air layer are joined at joined surfaces by a first adhesive. Also, peripheries of end portions of the joined surfaces are covered with a second adhesive whose moisture permeability is lower than the first adhesive.

Owner:FUJIFILM CORP

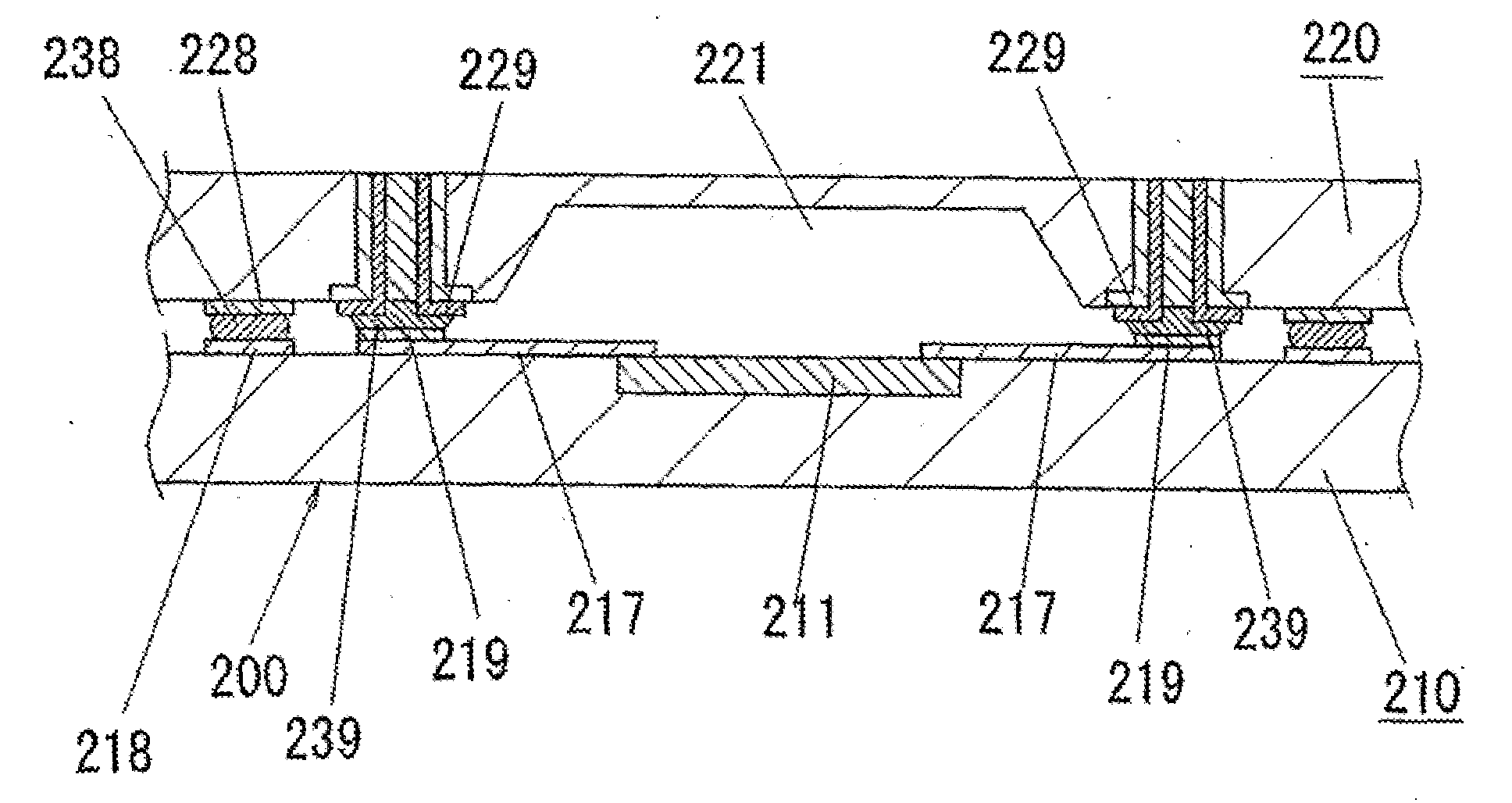

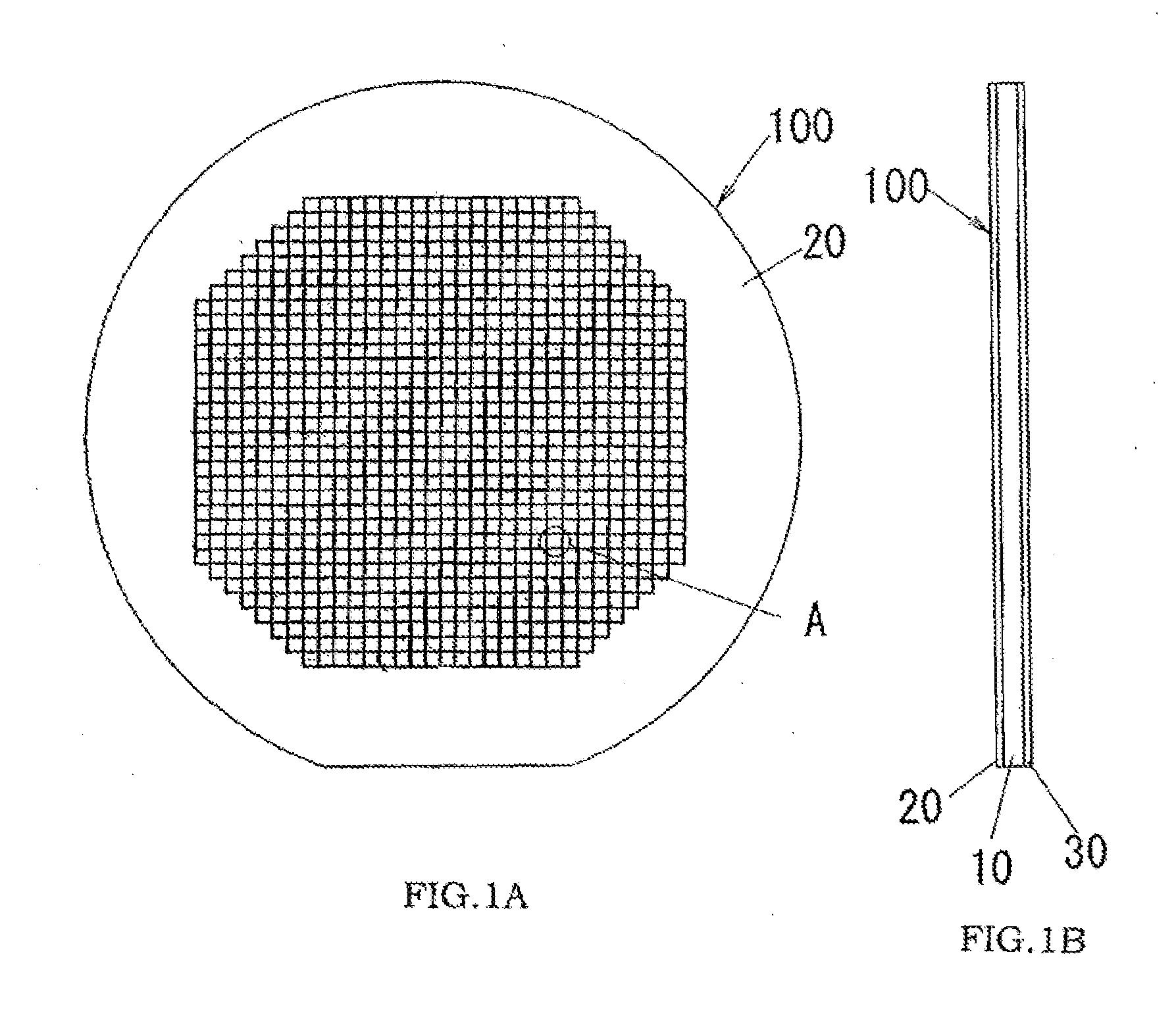

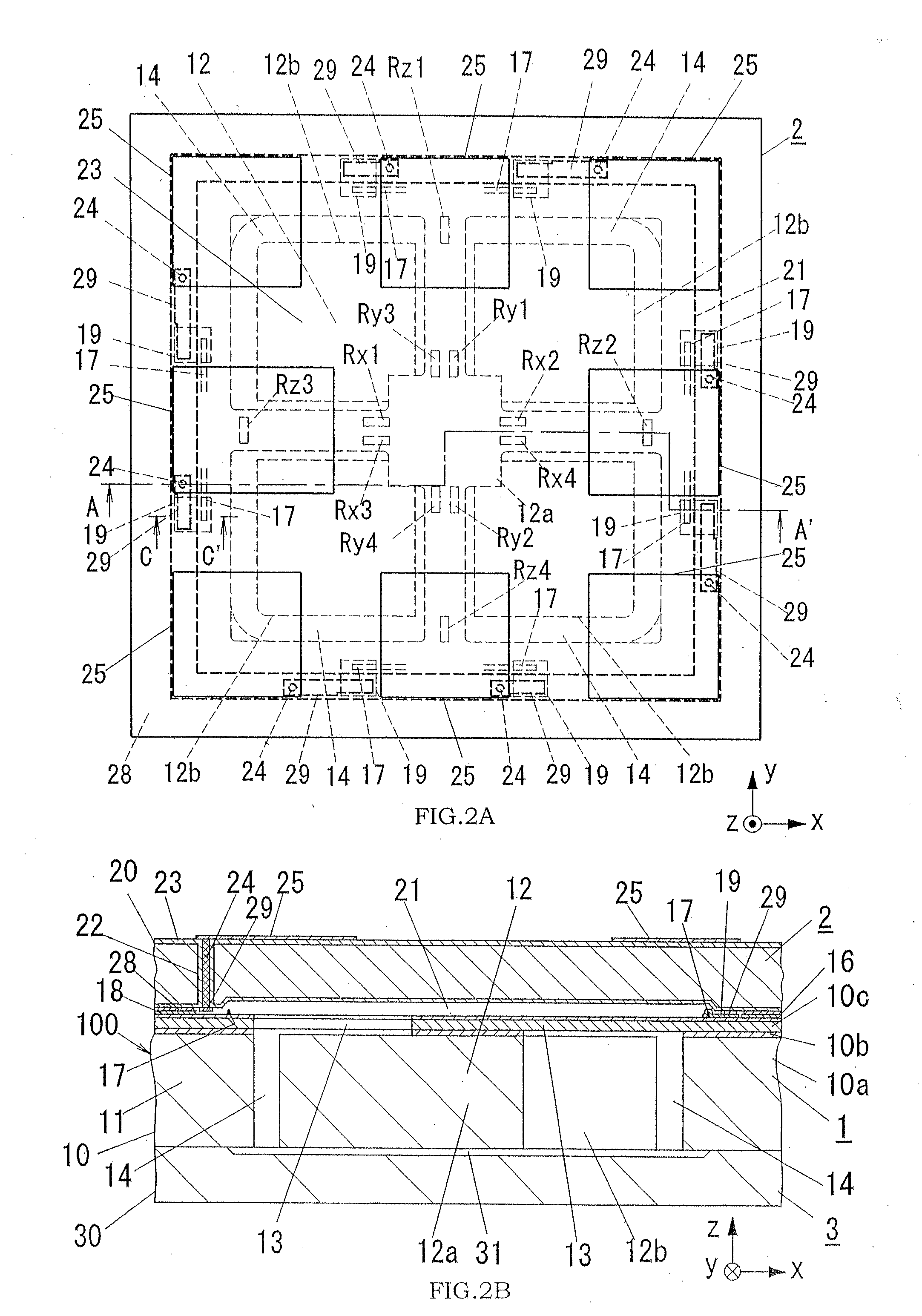

Wafer level package structure, and sensor device obtained from the same package structure

InactiveUS20090267165A1Little changeReducing atmosphereAcceleration measurement using interia forcesSemiconductor/solid-state device testing/measurementDiffusionGyroscope

A wafer level package structure with a plurality of compact sensors such as acceleration sensors and gyro sensors is provided. This package structure is composed of a semiconductor wafer with plural sensor units, and a pair of package wafers bonded to both surfaces of the semiconductor wafer. Each of the sensor units has a frame having an opening, a movable portion held in the opening to be movable relative to the frame, and a detecting portion for outputting an electric signal according to a positional displacement of the movable portion. Since the semiconductor wafer is bonded to each of the package wafers by a solid-phase direct bonding without diffusion between a surface-activated region formed on the frame and a surface-activated region formed on the package wafer, it is possible to prevent that variations in sensor characteristics occur due to residual stress at the bonding interface.

Owner:MATSUSHITA ELECTRIC WORKS LTD

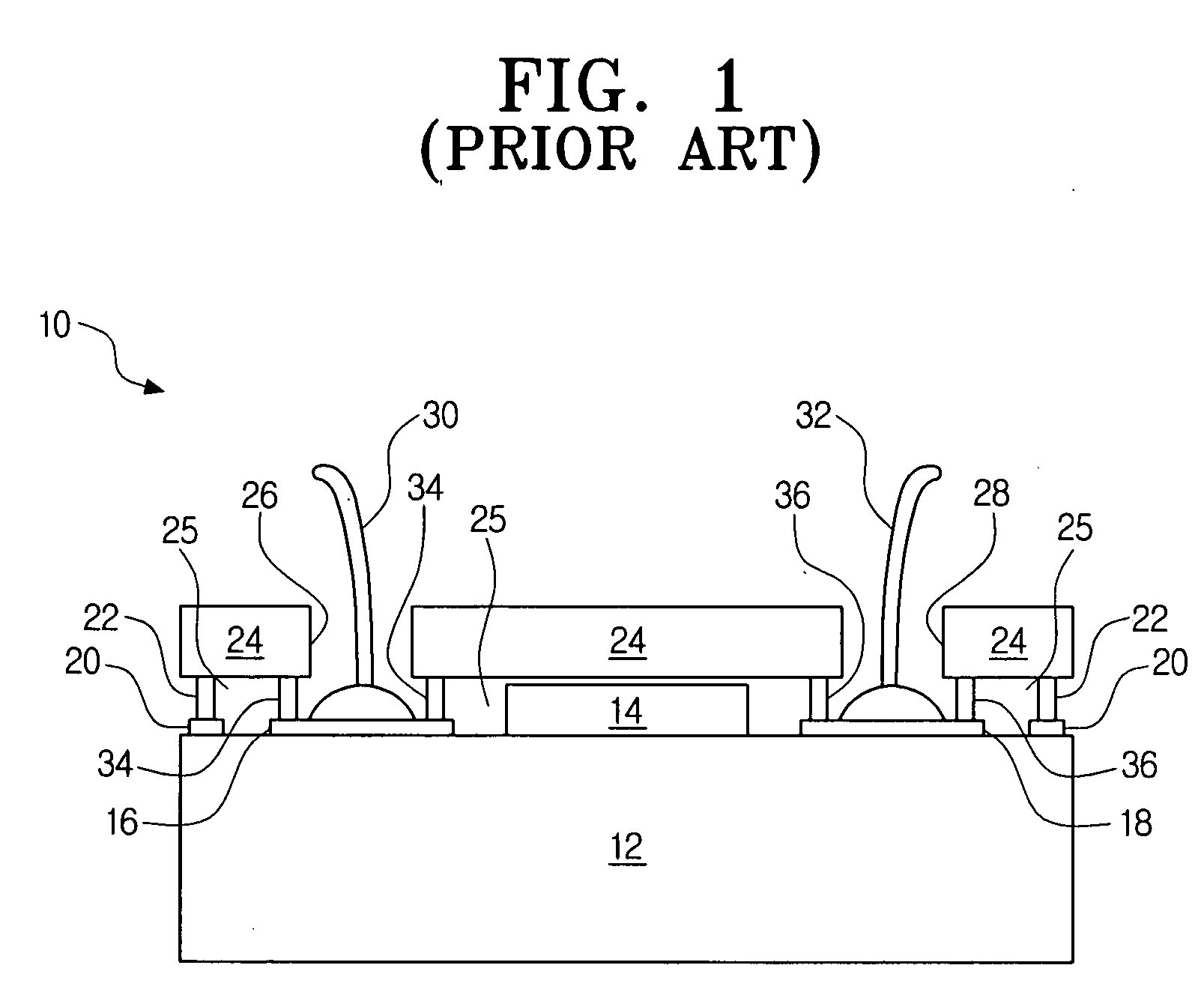

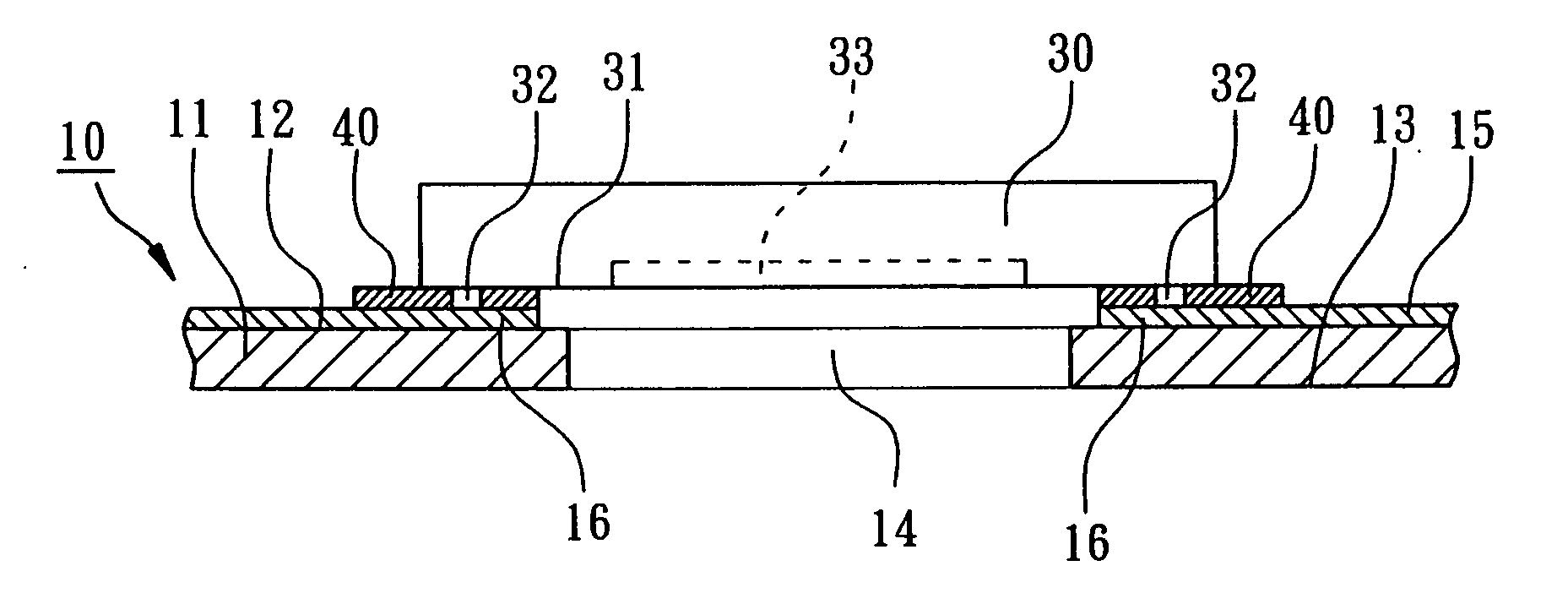

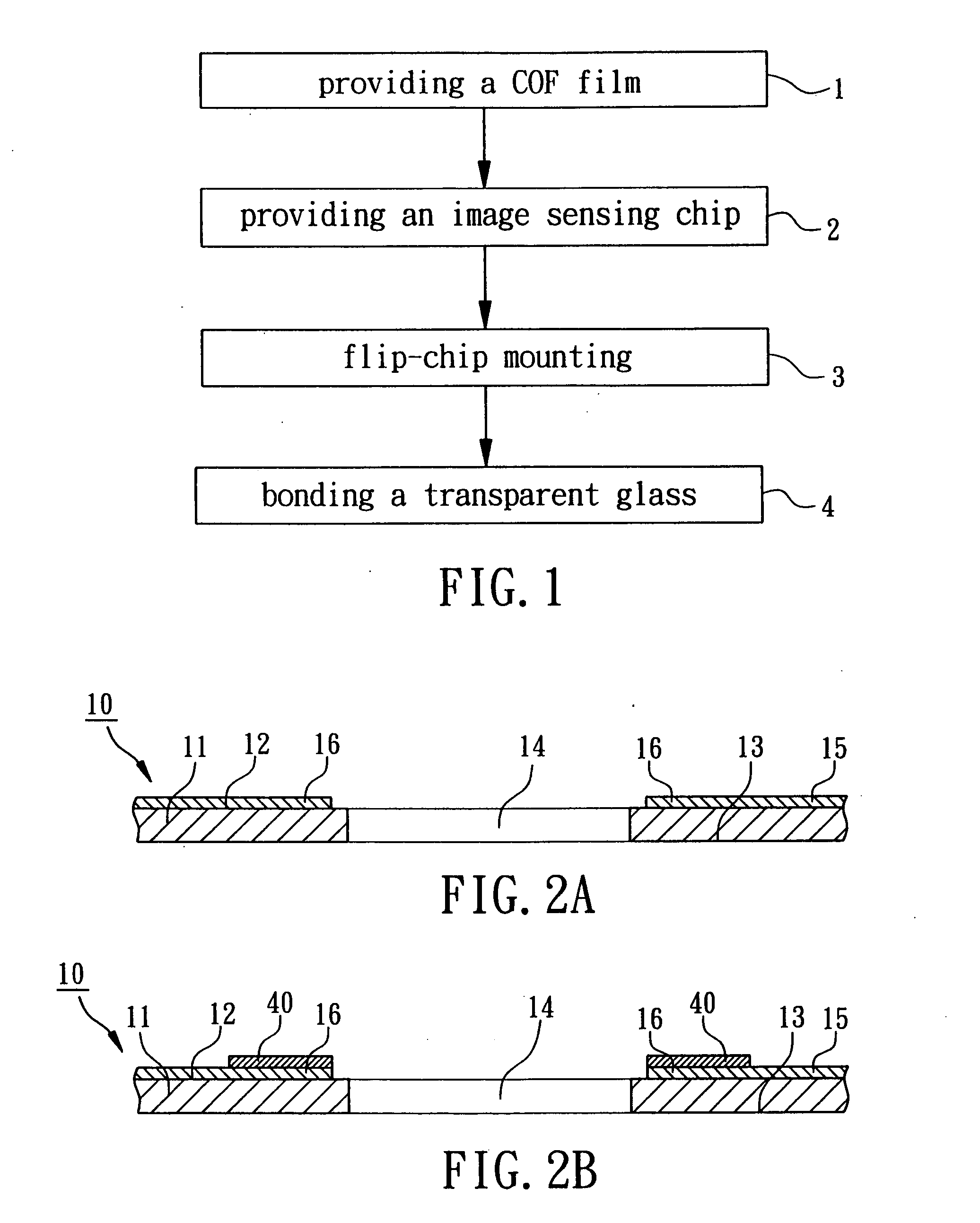

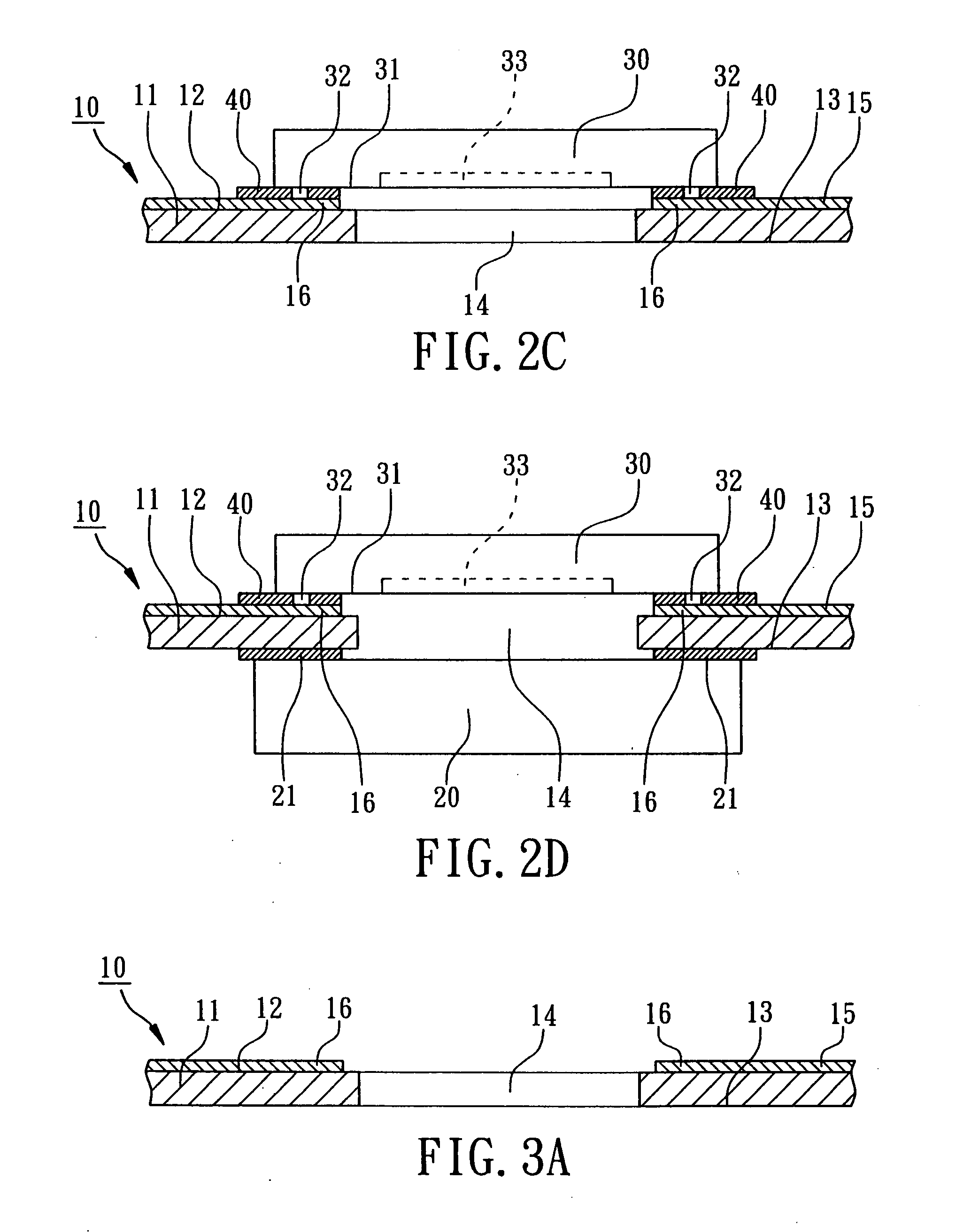

Chip-on-film package for image sensor and method for manufacturing the same

InactiveUS20050104186A1Simplify filling materialWell formedSemiconductor/solid-state device detailsSolid-state devicesChip on filmFilling materials

A chip-on-film (COF) package and method for image sensor has been disclosed. According to the method a COF film with opening is provided. The COF film has an upper surface, a lower surface and at least an opening. An image sensing chip is flip-chip mounted on the upper surface of the COF film. A transparent glass is bonded to the lower surface of the COF film. The opening is clipped by the transparent glass and the image sensing chip to form a hermetic space. The active surface of the image sensing chip includes an image sensing region toward the transparent glass through the opening and is sealed in the hermetic space by a limited filling material in order to prevent the image sensing region of the image sensing chip from contamination by means of COF tape packaging method.

Owner:ADVANCED SEMICON TECH

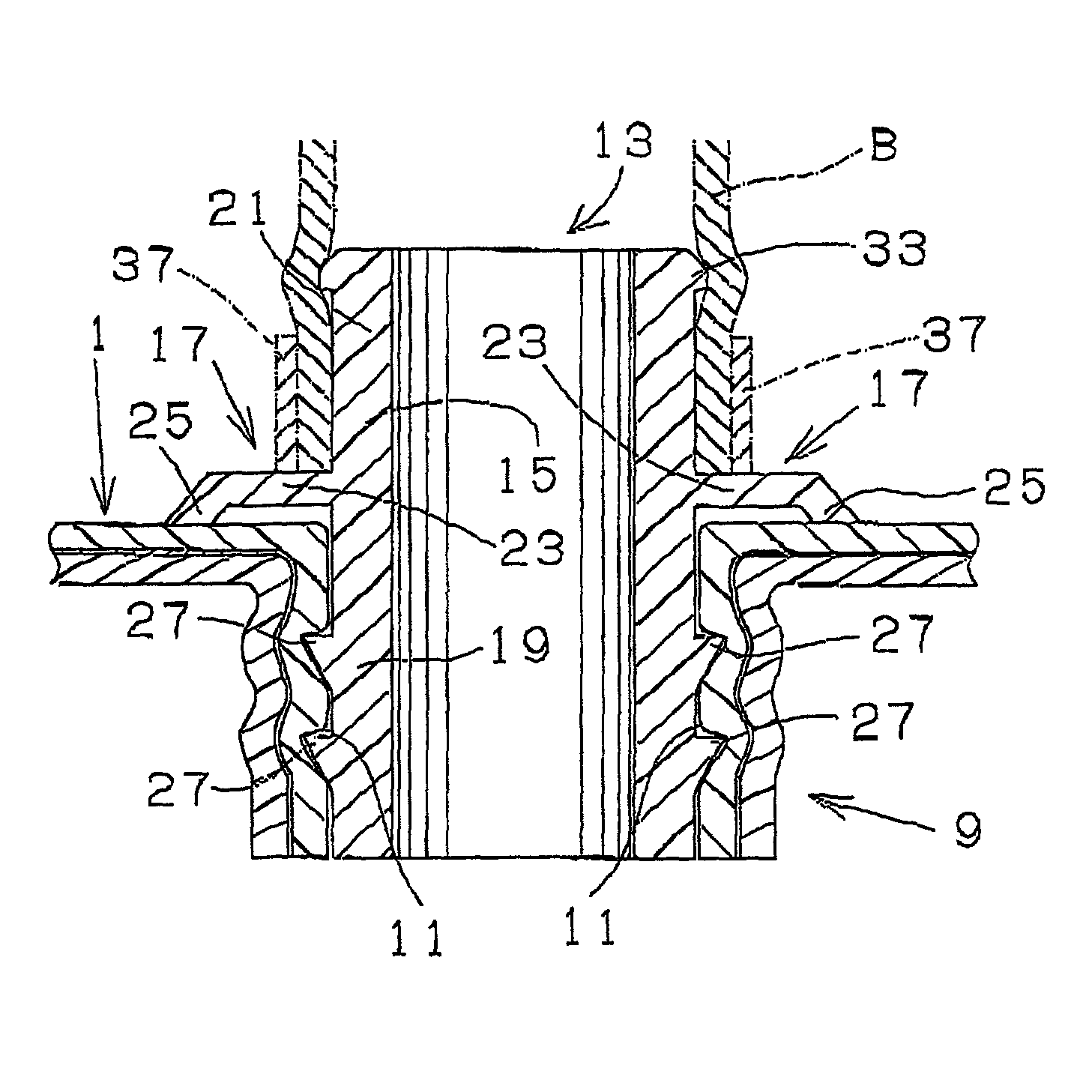

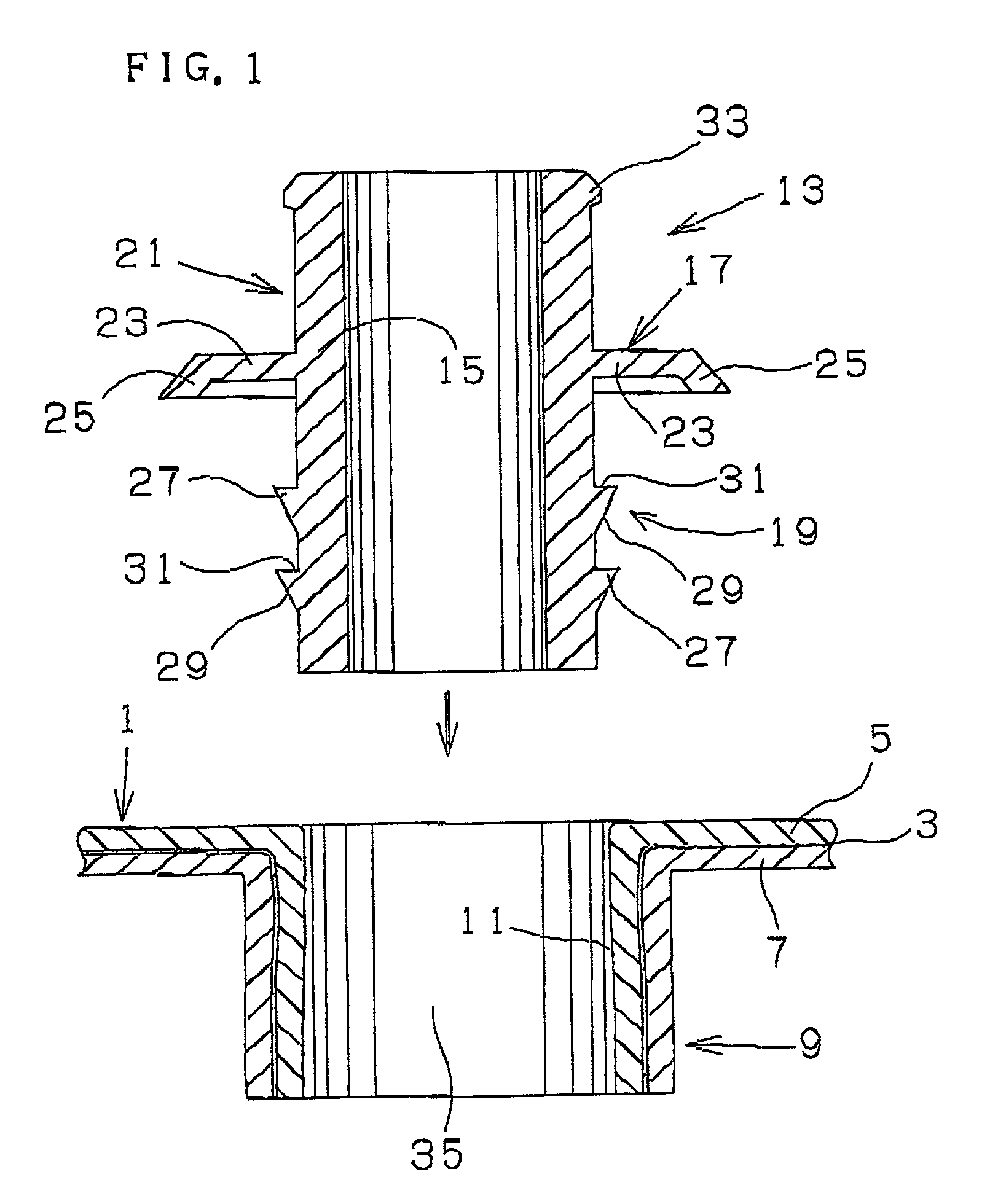

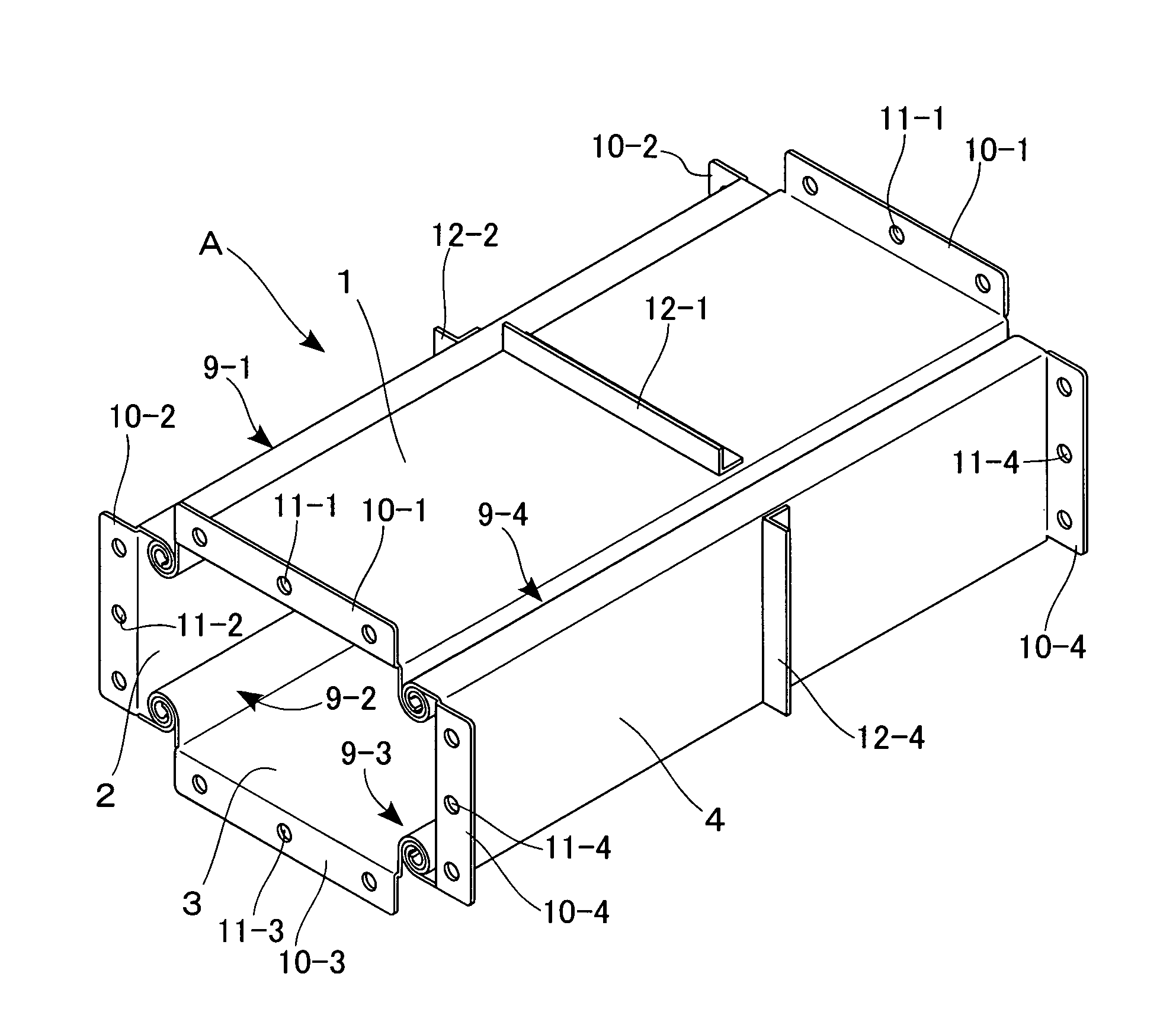

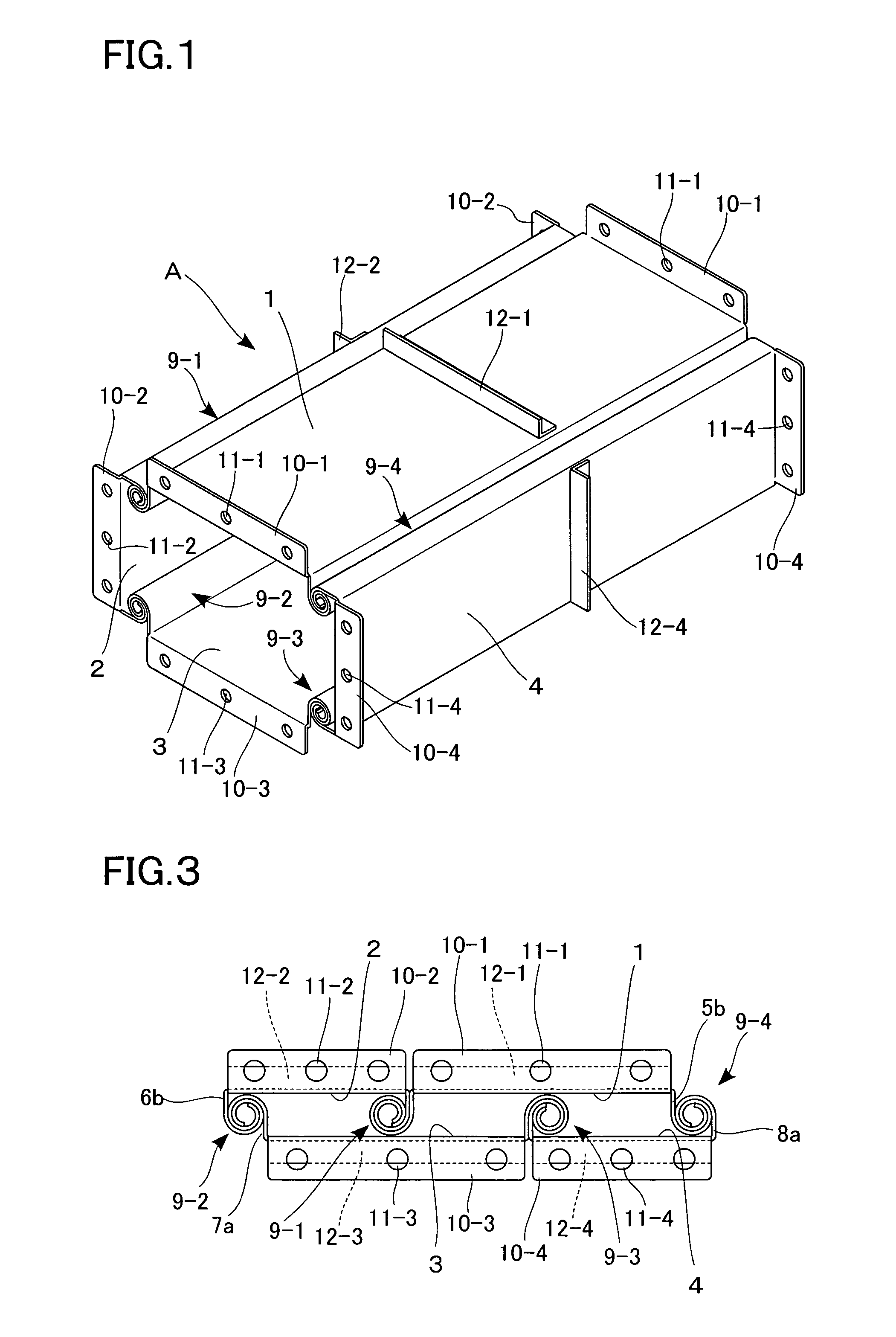

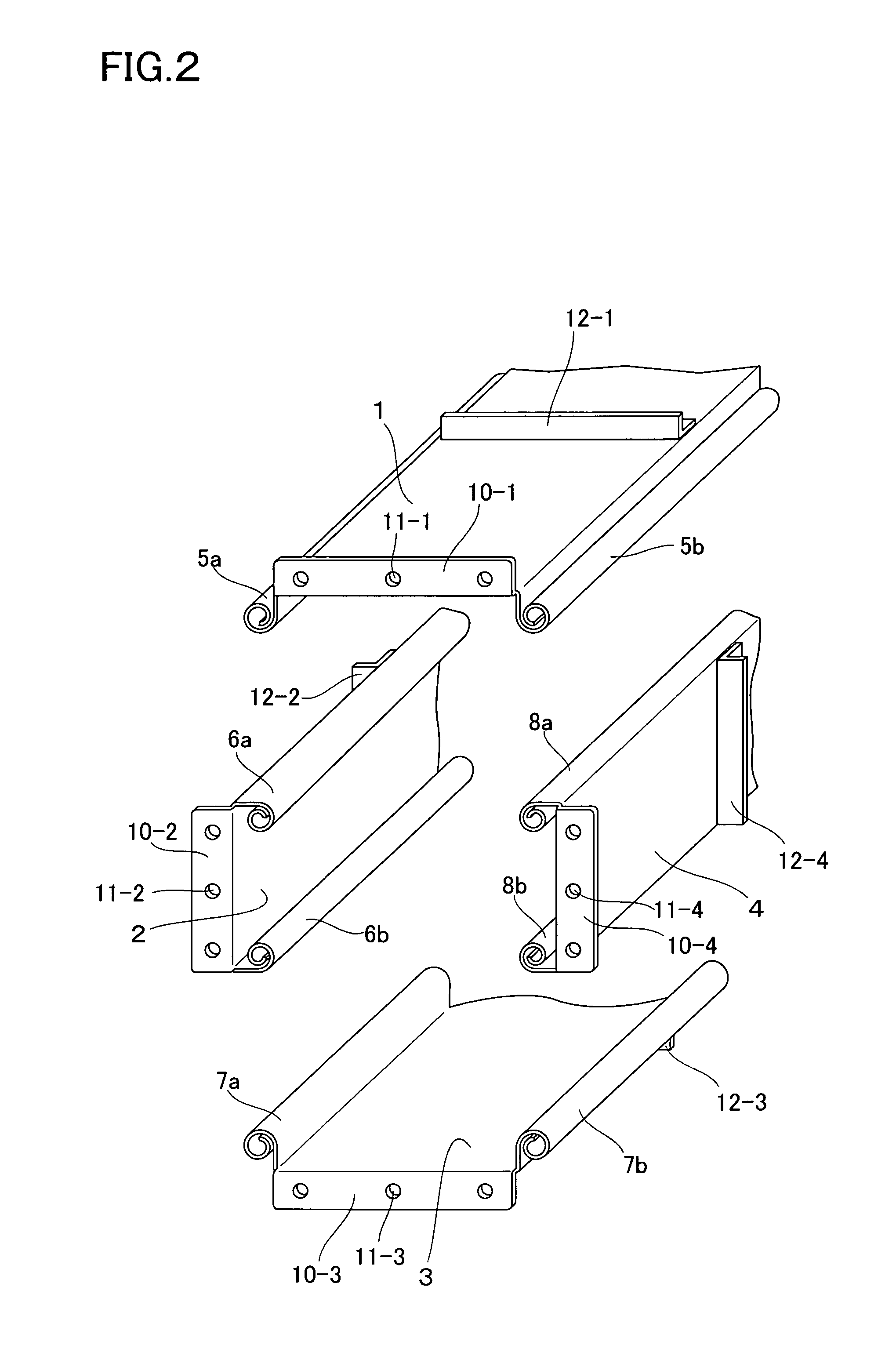

Duct unit for air-conditioner

InactiveUS6957670B1Reduce capacitySufficient workspaceDucting arrangementsFlanged jointsMetal sheetStructural engineering

An object of the present invention is to provide an air-conditioning duct unit capable of being made compact when transported to largely reduce the cost of transport inside and outside a building as well as the cost of transportation by a truck.A duct unit A of the present invention has upper and lower wall portions 1 and 3 and right and left wall portions 2 and 4 formed of metal sheets, and spin locks curved into a curled shape, the spin locks being provided on the wall portions 1 to 4 at two side edges of the same along the longitudinal direction. One of the pair of spin locks provided on each adjacent pair of the wall portions is inserted in the other to form one of lock joints 9-1 to 9-4 rotatably. The wall portions 1 to 4 are linked so that the duct unit A can be changed in shape. Consequently, the duct unit can be folded so as to be flattened.

Owner:FUJI KUUCHOU KOUGYOU CO LTD

Micro-package, multi-stack micro-package, and manufacturing method therefor

ActiveUS7285865B2Improve air tightnessAvoid damageSemiconductor/solid-state device detailsSolid-state devicesPOLYMER SUBSTANCEMoisture absorption

A micro package, a multi-stack micro package, and a manufacture method therefor are provided. A micro package according to the present invention includes a device substrate for mounting a devices, being a circuit module; a protection cap for protecting the device; bonding substances which, formed by patterning on predetermined areas on the device substrate, bond the device substrate and the protection cap; layers formed on a portion of the device substrate and a portion of the protection cap and exterior sides of the bonding substances; vias which are formed by etching away another portion of the protection cap, and electrically connected to an upper surface of the device substrate through the bonding substances; under barrier metals (UBMs) formed on the vias; and solder bumpers, being connection terminals for an external signal, formed on the UBMs. As stated above, the present invention has advantages of guaranteeing the hermetical sealing since the above layers prevent moisture absorption from outside at the same time of lowering possibility of damages to the device inside the package since the processing temperature drops below 150° upon wafer bonding due to the use of the polymer substance as a bonding substance.

Owner:SAMSUNG ELECTRONICS CO LTD

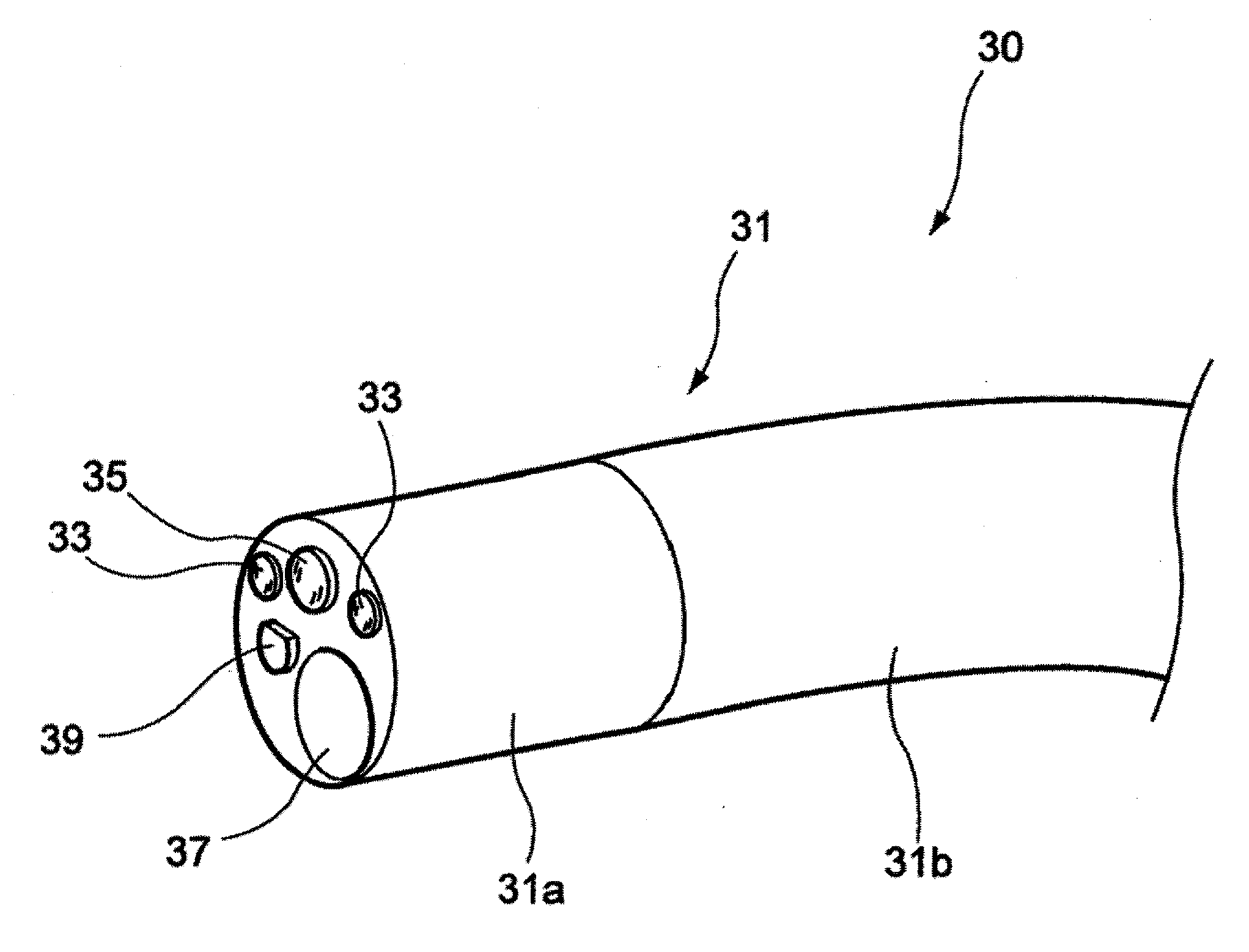

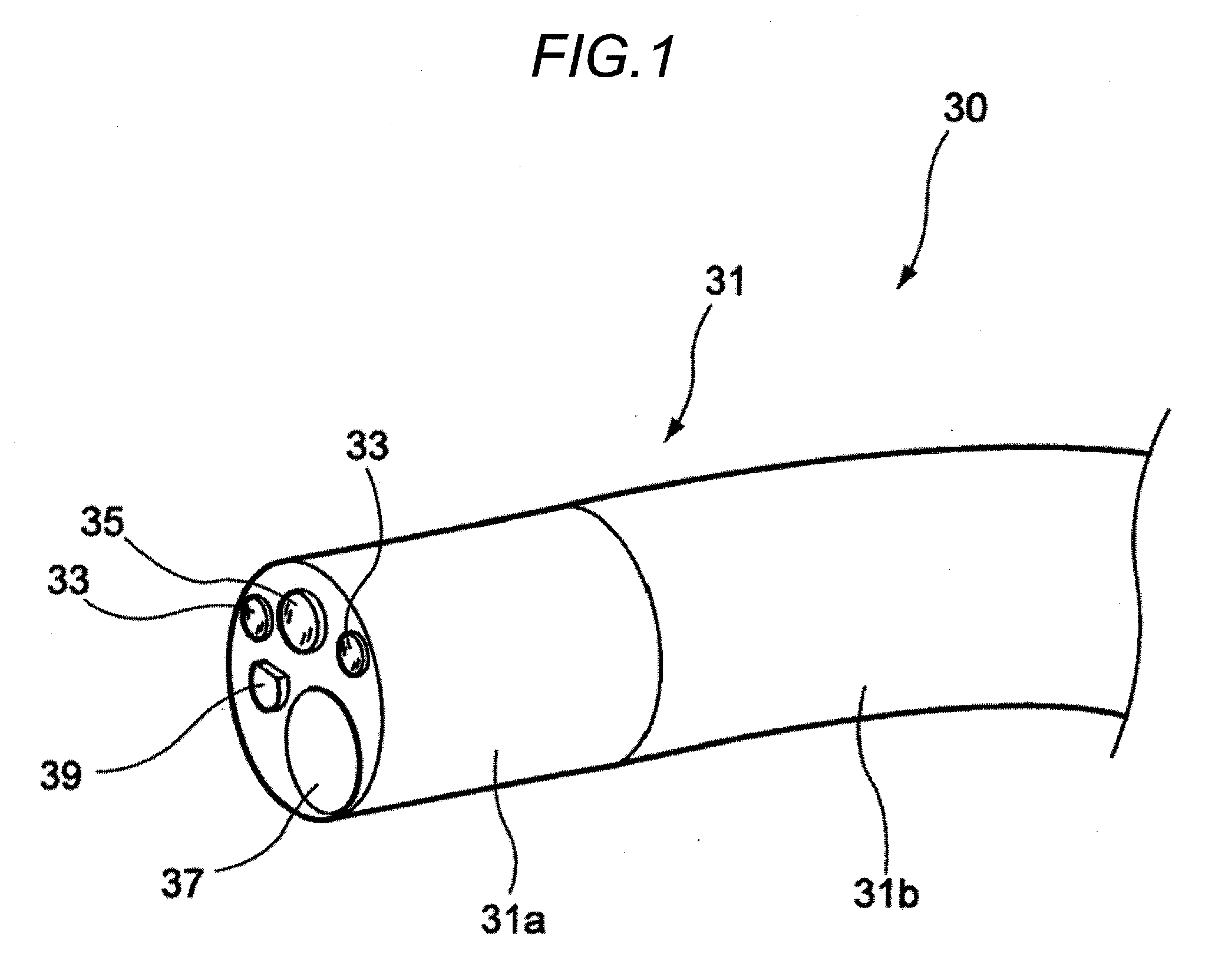

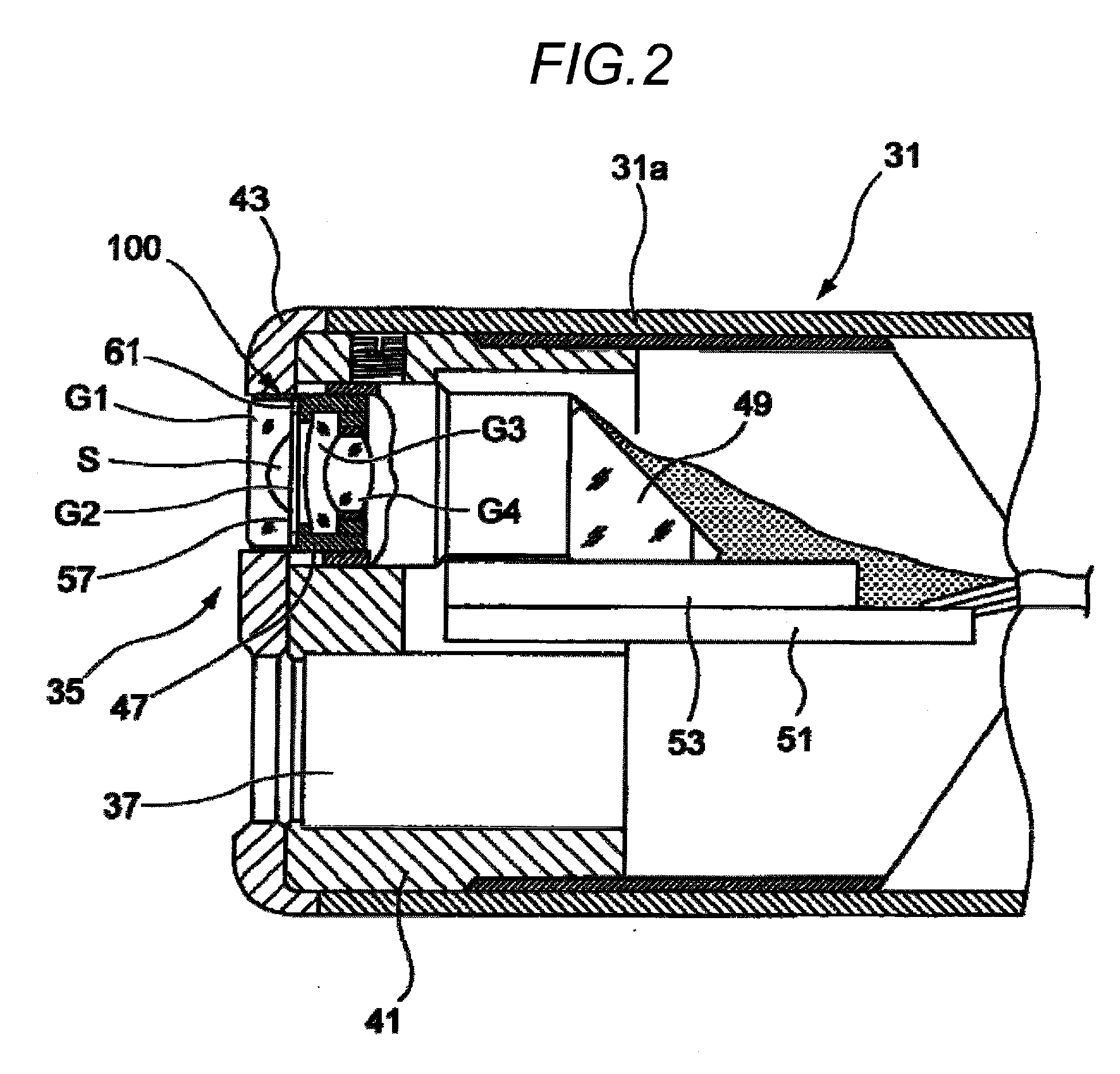

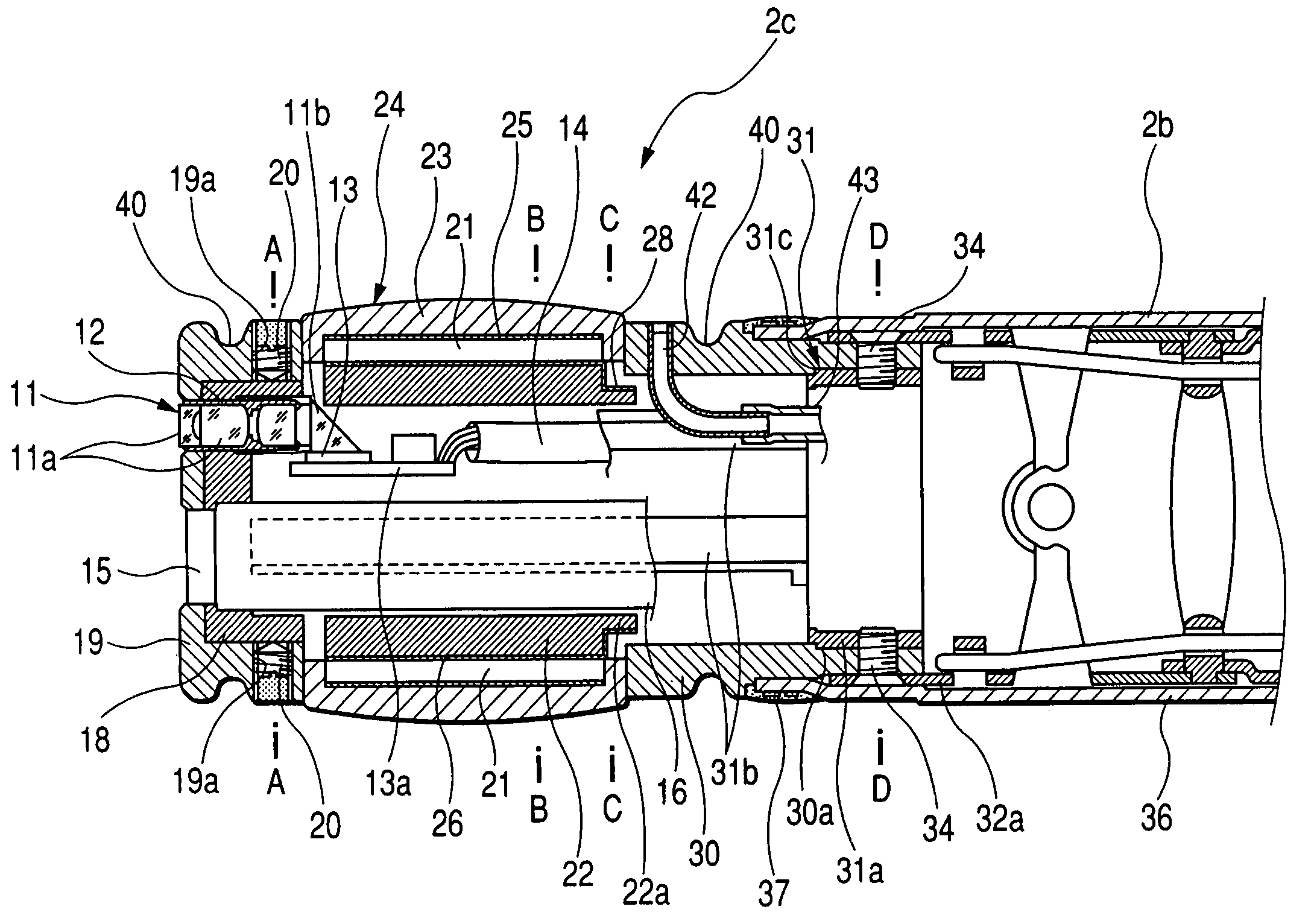

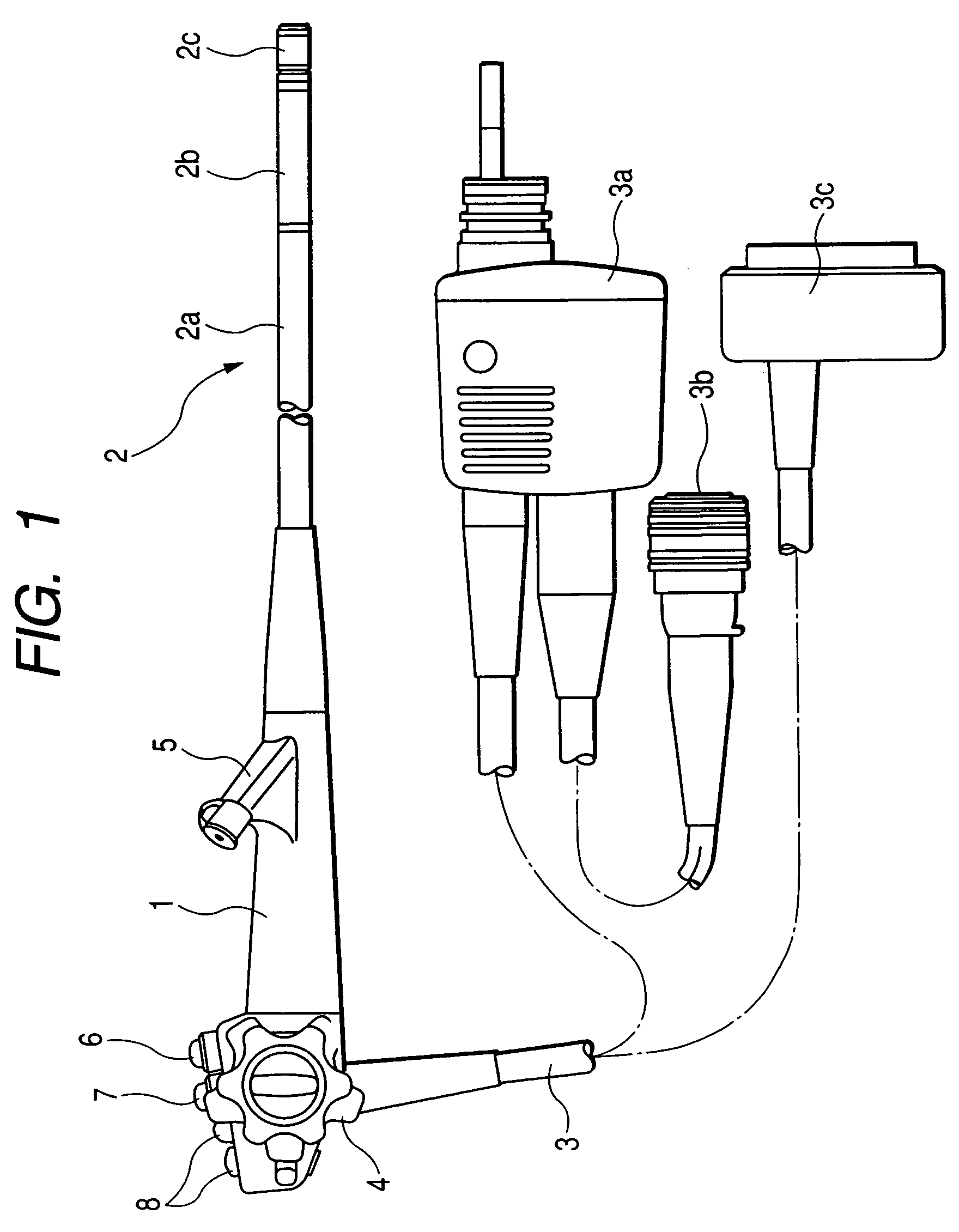

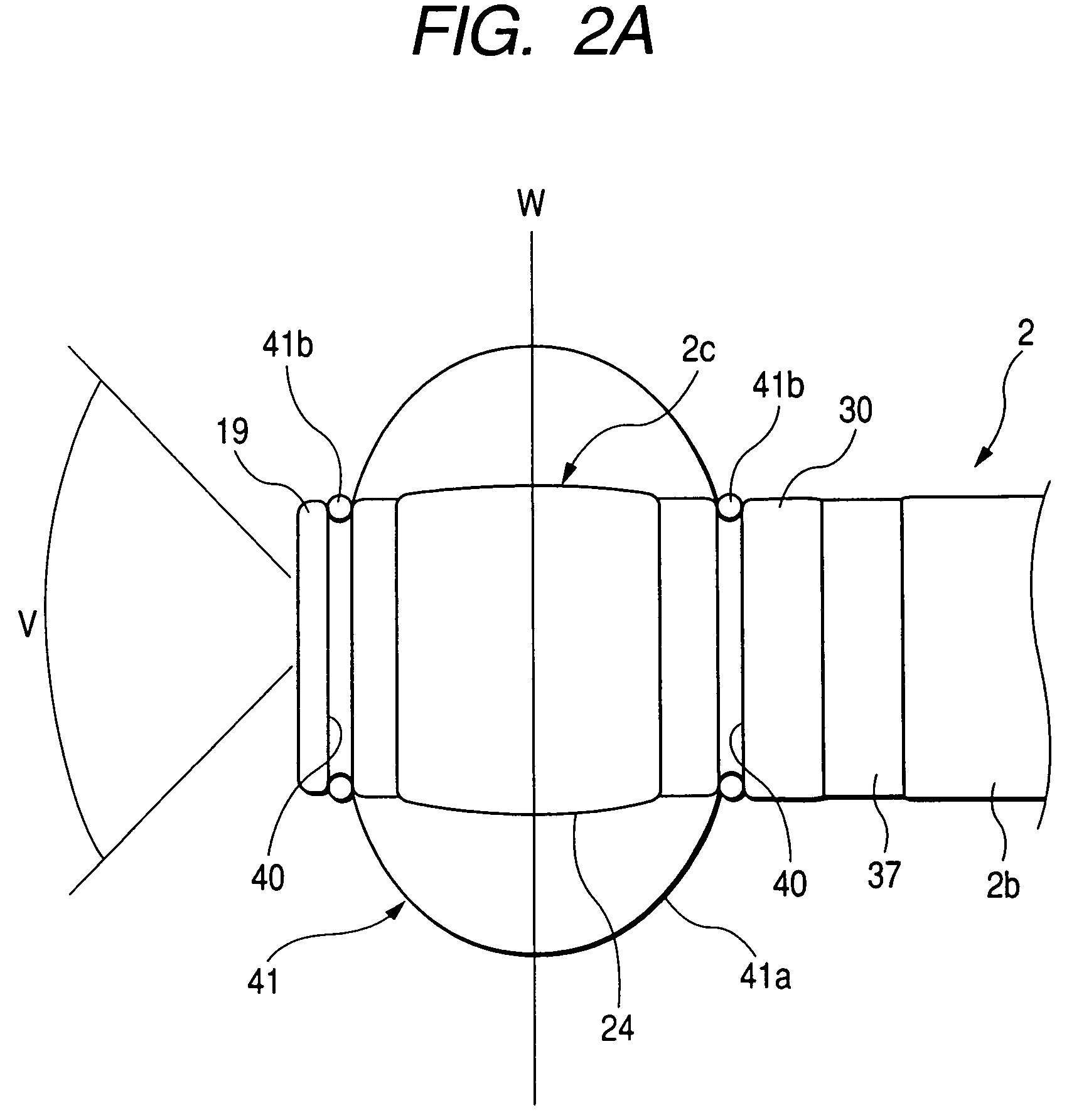

Ultrasonic endoscope

InactiveUS7569012B2Effective functionLarge caliberUltrasonic/sonic/infrasonic diagnosticsSurgeryMedicineObservation unit

An ultrasonic endoscope comprises an insertion portion comprising a distal hard portion which has: an endoscopic observation unit; and an ultrasonic observation unit having ultrasonic transducers arranged circumferentially on an outer circumferential section of the distal hard portion, wherein the ultrasonic observation unit comprises an ultrasonic-wave transmission / reception unit having an tunnel-shaped path which has an inner circumferential surface formed as a backing layer; a distal block is arranged on a distal side in an axial direction of the distal hard portion with respect to a location where the ultrasonic-wave transmission / reception unit is arranged, and distal ends of respective members constituting the endoscopic observation unit are fixed to the distal block; and part of the members which constitute the endoscopic observation unit are fitted so as to be partially protruded from an inside diameter of the tunnel-shaped path toward an outer circumferential side thereof.

Owner:FUJI PHOTO OPTICAL CO LTD

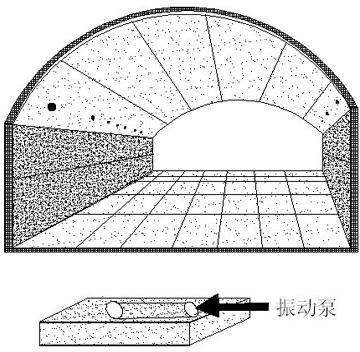

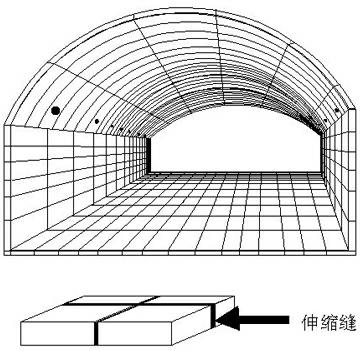

Composite fire-proof material with high refractoriness under load for coke ovens as well as furnace-building process and products thereof

InactiveCN102584294AImprove bindingWaste heat can be recovered for power generationCoke oven brickworkEnergy inputAdhesiveRefractory

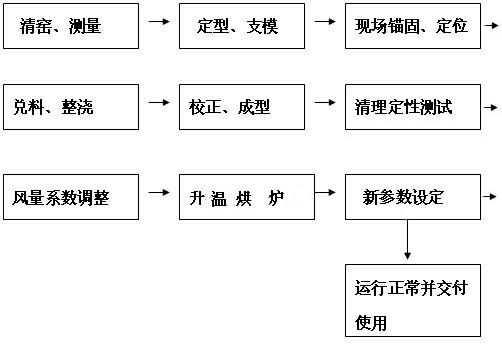

The invention discloses a composite fire-proof material with high refractoriness under load for coke ovens. The preparation method of the material comprises the following steps of: evenly mixing and crushing 40%-60% of Al2O3, 15%-30% of SiC micro powder, less than 2% of Fe2O3, 5%-10% of Si micro powder and 1%-3% of cement as an additive; adding 3%-5% of Al(H2PO4)3 as an adhesive and stirring and mixing evenly; and pouring the mixture to a working region in 20-30 minutes. The furnace-building process comprises the following steps of: cleaning a kiln, measuring, molding, positioning and supporting a mould, adding materials, pouring and correcting, cleaning, starting for warming up and testing. The coke ovens newly built by pouring is characterized in that the top of the chamber of the furnace is fan-shaped, the chamber of the furnace is built by on-site seamless overall vibration pouring according to the process above with the furnace-building materials above, afterheat of the furnace can be recycled for power generation and no chemical residues exist. The furnace is short in charring time and higher in coke recovery and can be started and used at any time between the normal temperature and 1550 DEG C.

Owner:GUIYANG DONGJIBOYU REFRACTORY MATERIALS

Compound Sealing Method for Vacuum Glass

ActiveUS20120321822A1Excellent brazeabilityPrevent annealingClimate change adaptationSoldering apparatusThermal shockBrazing

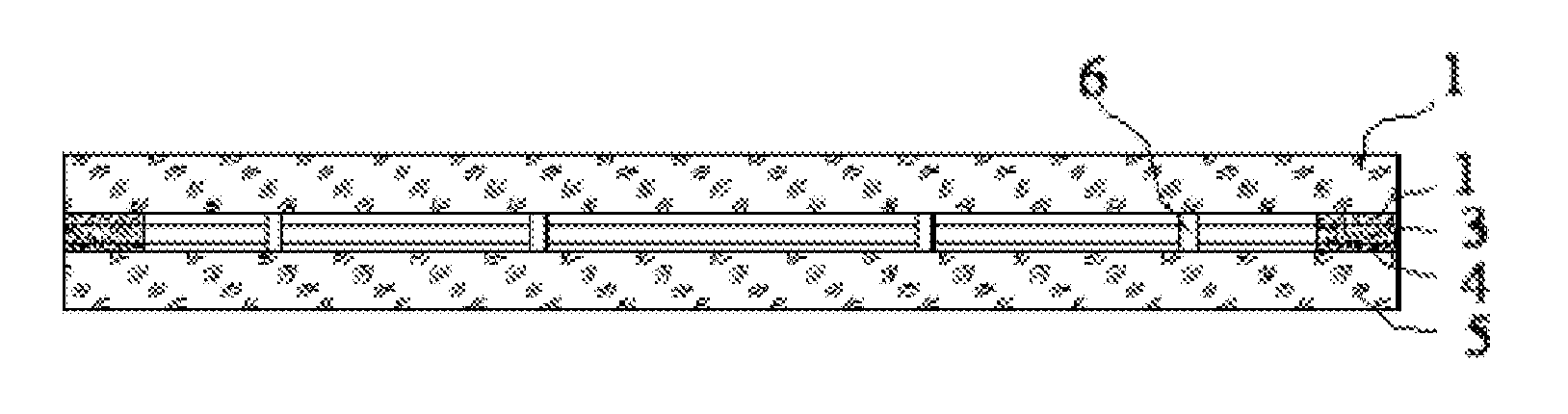

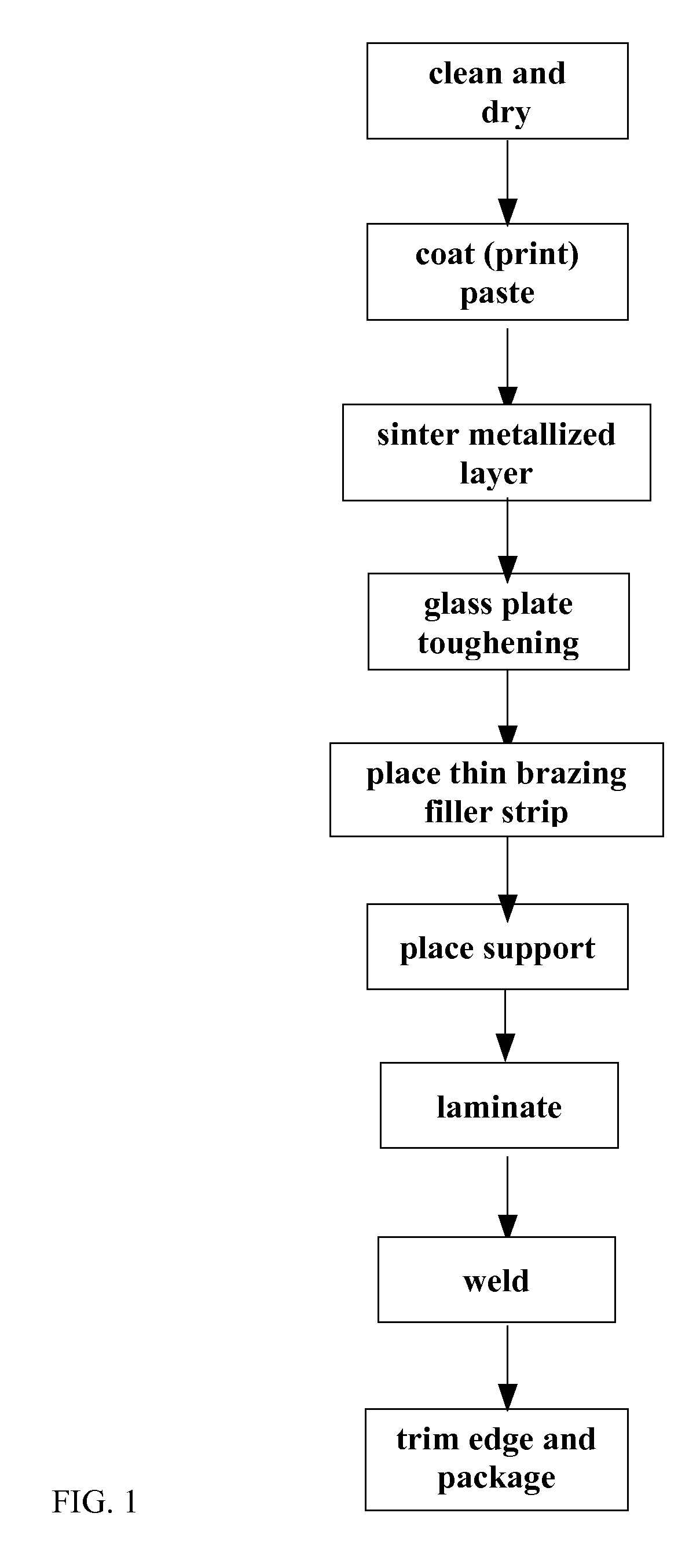

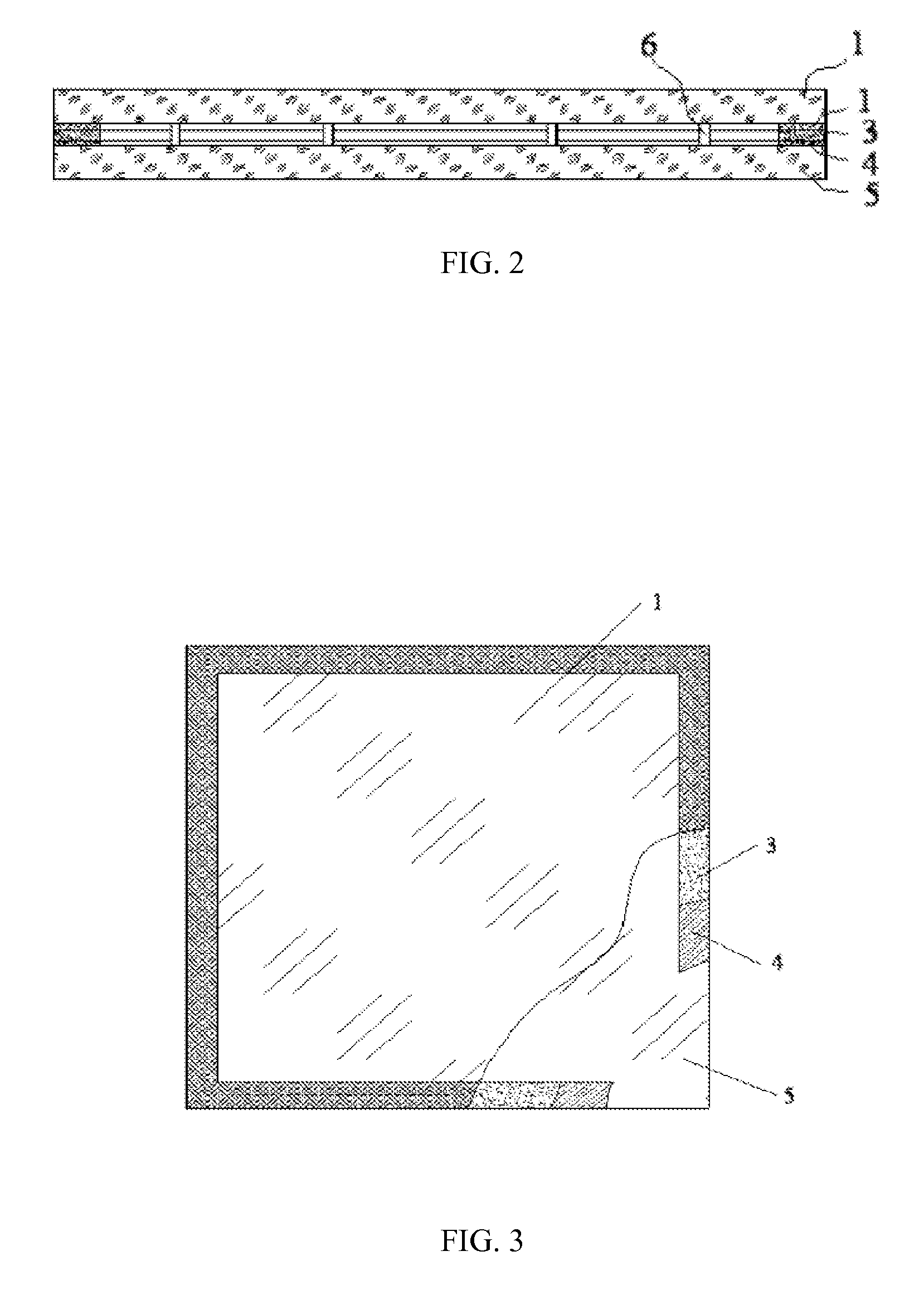

The invention relates to a compound sealing method for glass plates, which is characterized by realizing the air-tight joint between compounded glass plates in a preset position by using a metal brazing technology. The invention provides a brand new technological method for the compound sealing between glass plates. The method has the advantages of firm connection in sealing positions, high air tightness, favorable thermal shock resistance and the like, and the annealing of toughened glass are avoided because of a lower brazing temperature used, thereby providing convenience to the processing of toughened vacuum glass, toughened insulated glass and other toughened compound glass products

Owner:LUOYANG LANDGLASS TECH CO LTD

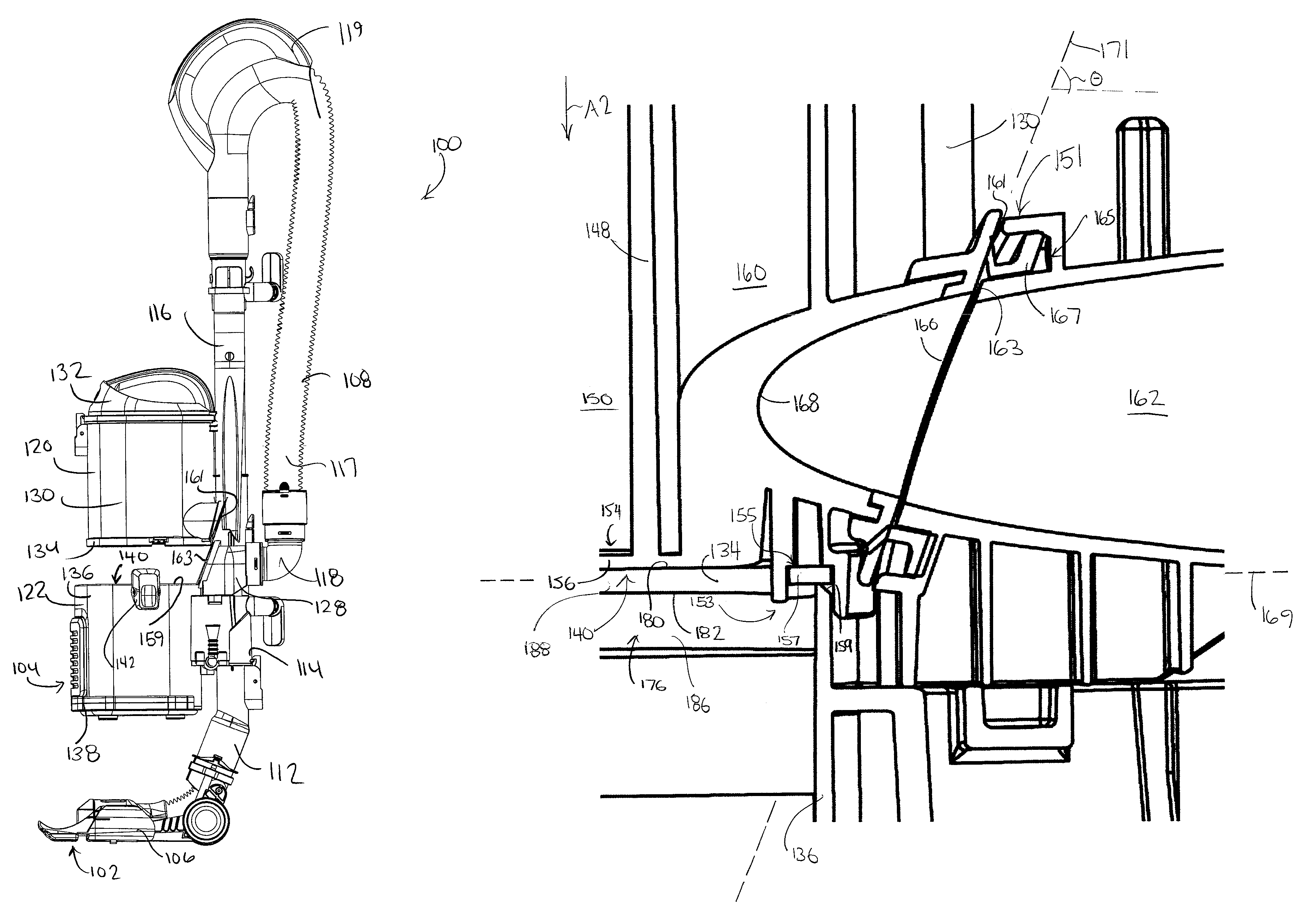

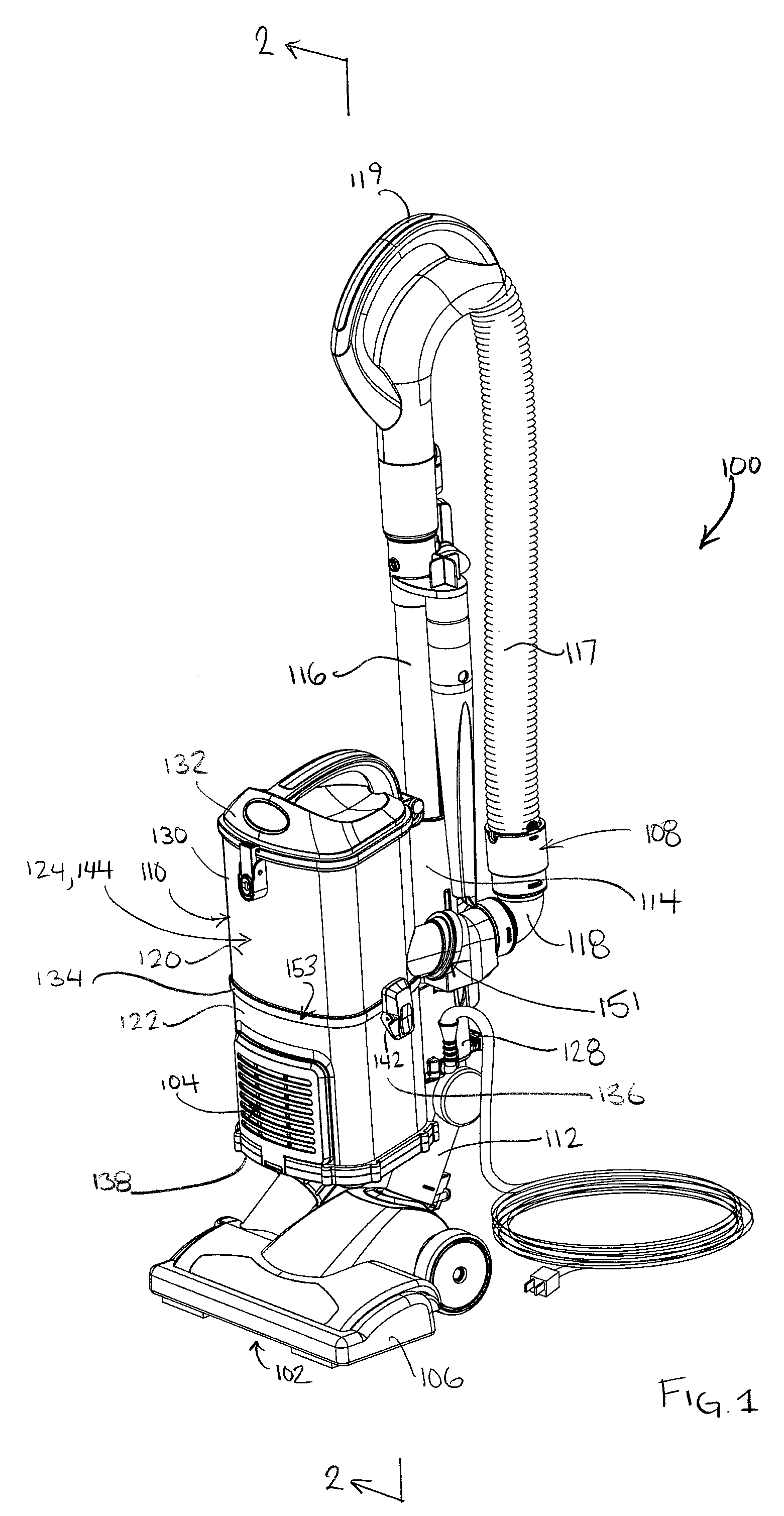

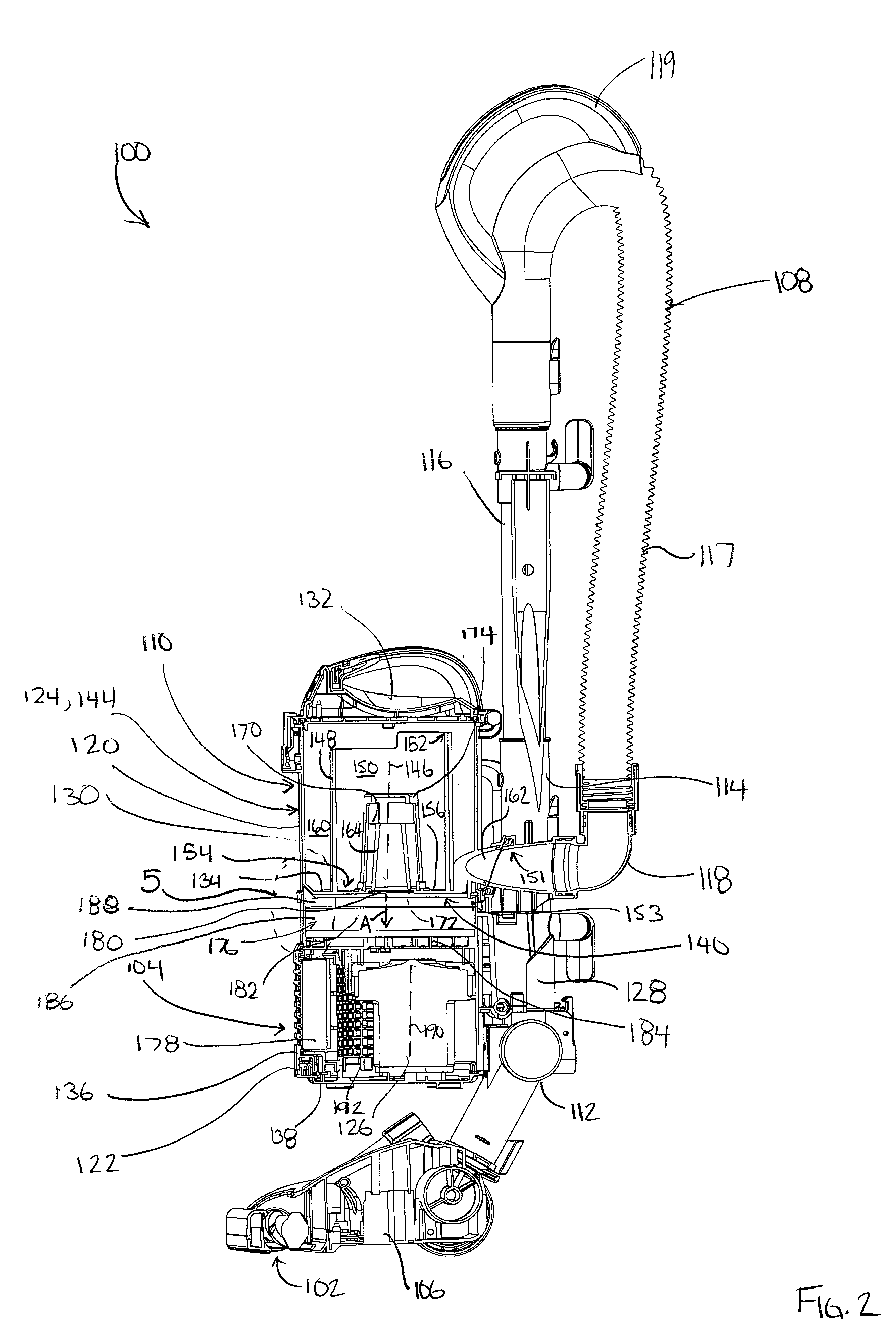

Seal construction for a surface cleaning apparatus

ActiveUS8296900B2Weight increaseReduce the use effectCleaning filter meansCombination devicesCycloneSurface cleaning

A surface cleaning apparatus comprises an air flow passage extending from a dirty air inlet to a clean air outlet. A suction motor positioned in the air flow passage. A cyclone is removably mounted to the surface cleaning apparatus and positioned in the air flow path. The cyclone has a cyclone air inlet and a cyclone air outlet. The cyclone is mountable to the surface cleaning apparatus in a mounting direction. An air inlet seal is positioned in a first plane and seals the cyclone air inlet to the airflow passage. An air outlet seal is positioned in a second, non-orthogonal plane and seals the cyclone air outlet to the airflow passage. The air inlet seal and the air outlet seal are concurrently sealed by movement of the cyclone in the mounting direction.

Owner:OMACHRON INTPROP

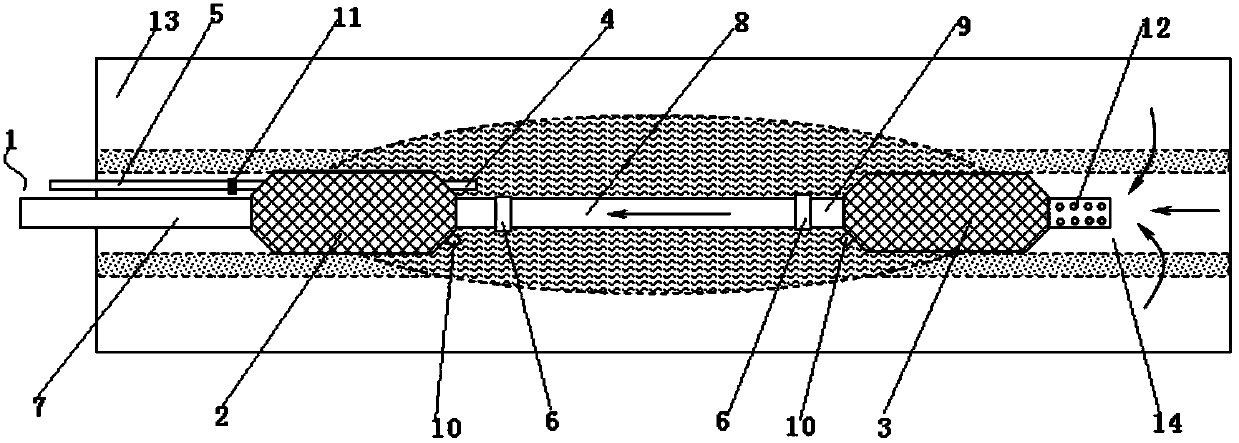

Under-pressure grouting hole sealing device and method for gas extraction drill air bag blocking

The invention relates to an under-pressure grouting and hole sealing device and method for gas extraction drill air bag blocking. The device is characterized in that the device comprises an extraction pipe, a first tip air bag, a second tip air bag, a slurry outlet pipe and a grouting pipe, wherein the extraction pipe is composed of a first extraction pipe body, a second extraction pipe body and a third extraction pipe body, the first extraction pipe body is sleeved with the first tip air bag, a one-way needle valve is arranged on the first tip air bag, the slurry outlet pipe with a one-way check valve arranged inside penetrates through the first tip air bag, the outer end of the slurry outlet pipe is communicated with the grouting pipe, the third extraction pipe body is sleeved with the second tip air bag, a one-way needle valve is arranged on the second tip air bag, the two ends of the second extraction pipe body are connected with one end of the first extraction pipe body and one end of the third extraction pipe body respectively, the tip of the other end of the third extraction pipe body is provided with a plurality of sieve holes which allow gas to inflow, and the first tip air bag and the second tip air bag are filled with expansion agents in advance. The device and the method can be widely applied to permanent hole sealing for coal mine underground gas extraction hole drilling.

Owner:NORTH CHINA INST OF SCI & TECH

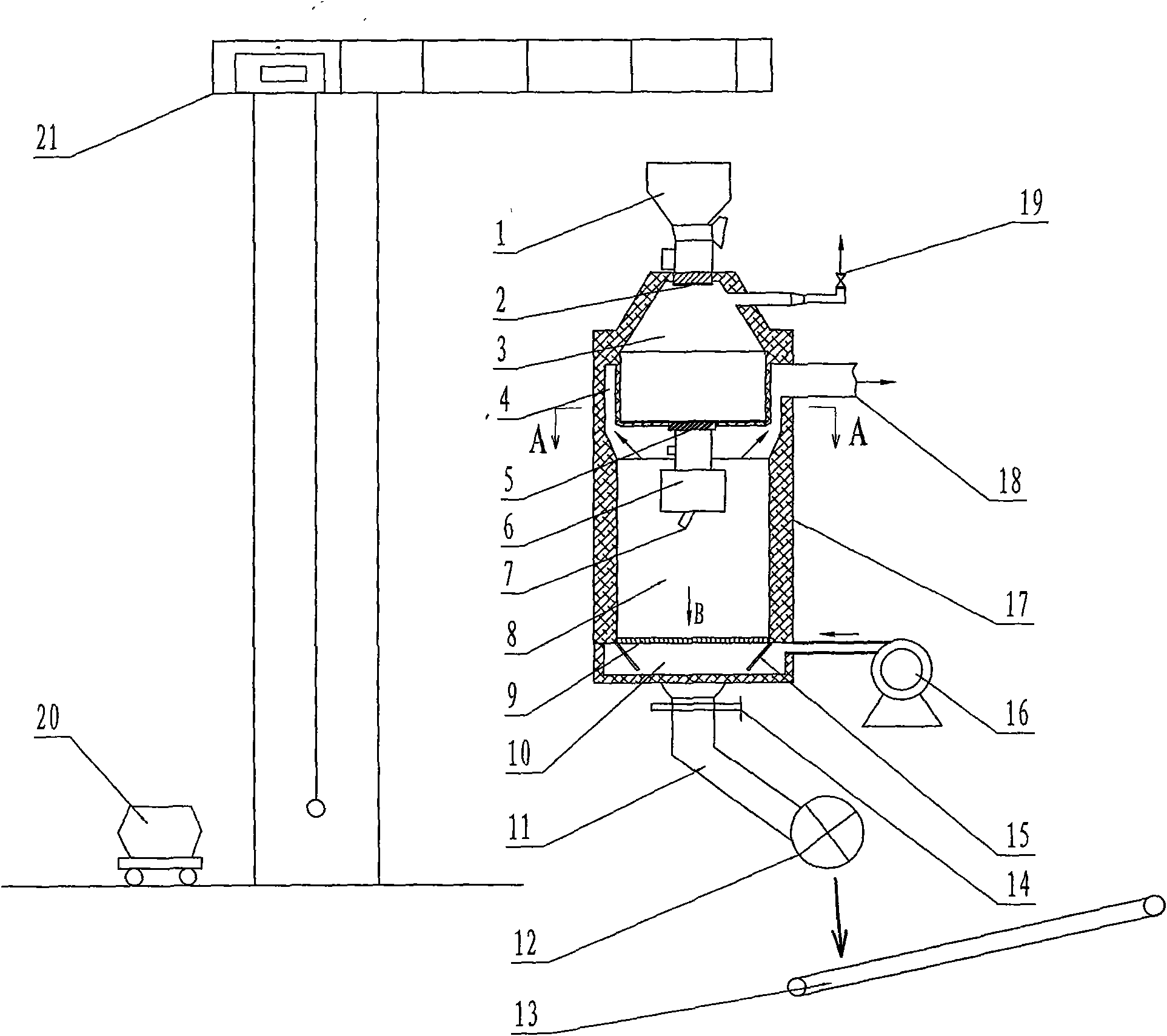

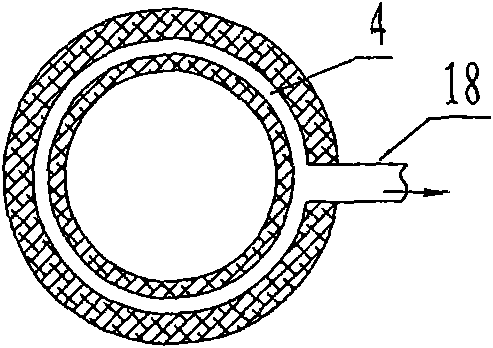

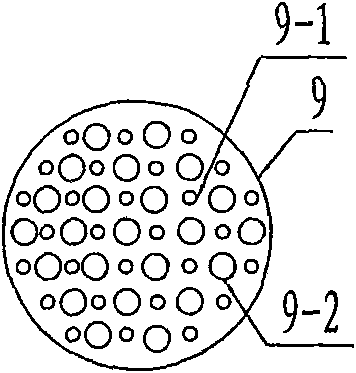

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

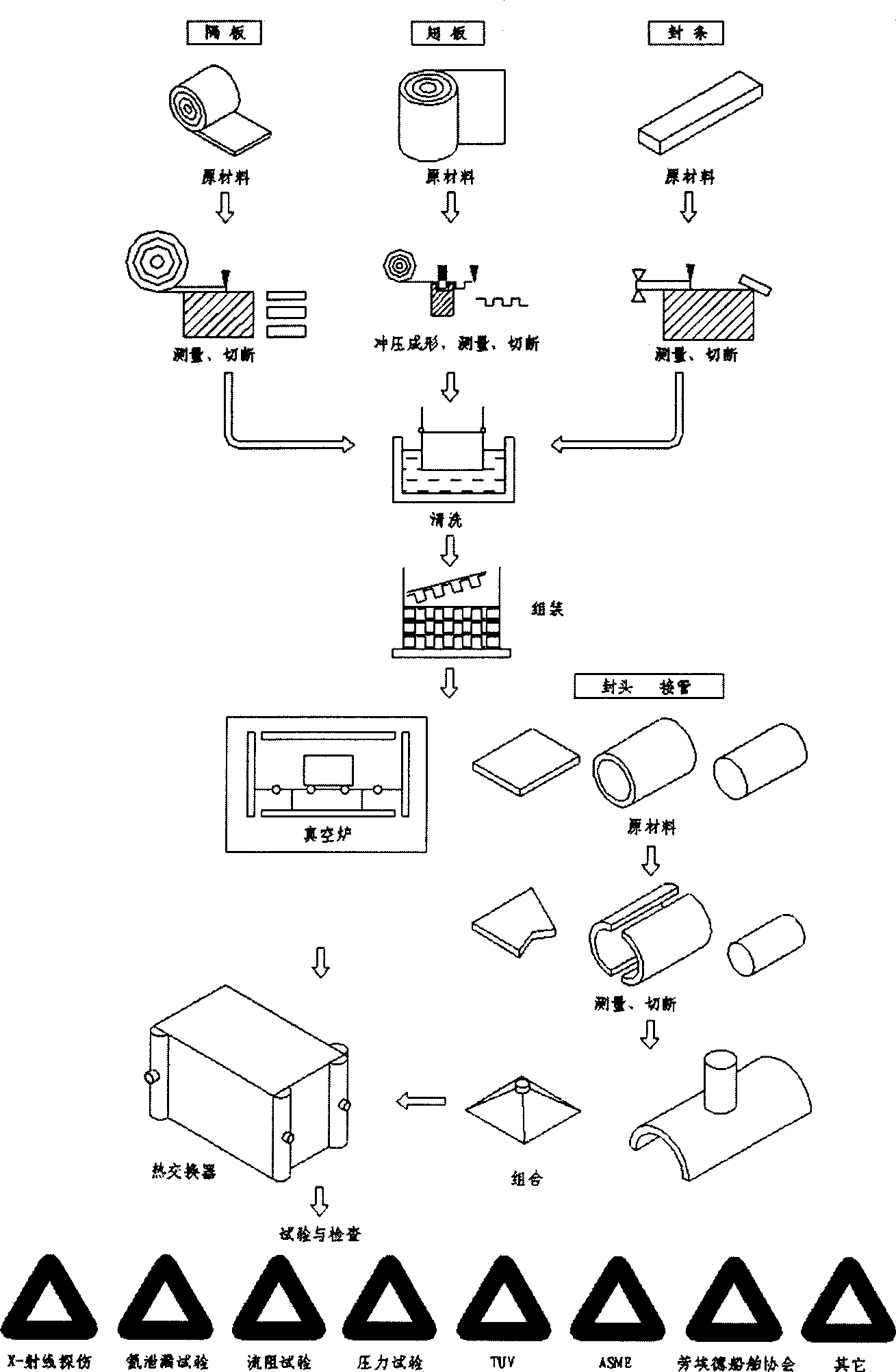

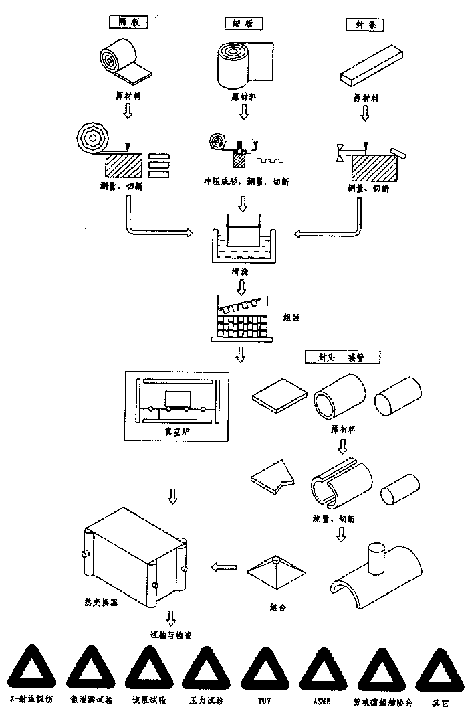

Manufacture of fine-type stainless steel plate heat exchanger

InactiveCN1375374AImprove wettabilityIngredients evenly distributedSoldering apparatusX-rayHigh pressure water

The production method of austenitic stainless steel plate fin heat exchanger includes the following steps: part preparation: partition, sealing strip, fin, sealing head and connecting pipe preparation; cleaning before welding; acid pickling to remove oil, dirt and oxide, and using high-pressure water to wash; element assembling and holding; vacuum braze welding, adopting argon arc welding to weldscaling head and connecting pipe, making general assembly; test and inspection, making x-ray inspection, helium leak detection, flow resistance test, pressure test, TUV, ASME and other test and inspection. Said invented process raise the production quality of said stainless steel plate fin heat exchanger, tensile-strength of connector and its service life.

Owner:NANJING UNIV OF TECH

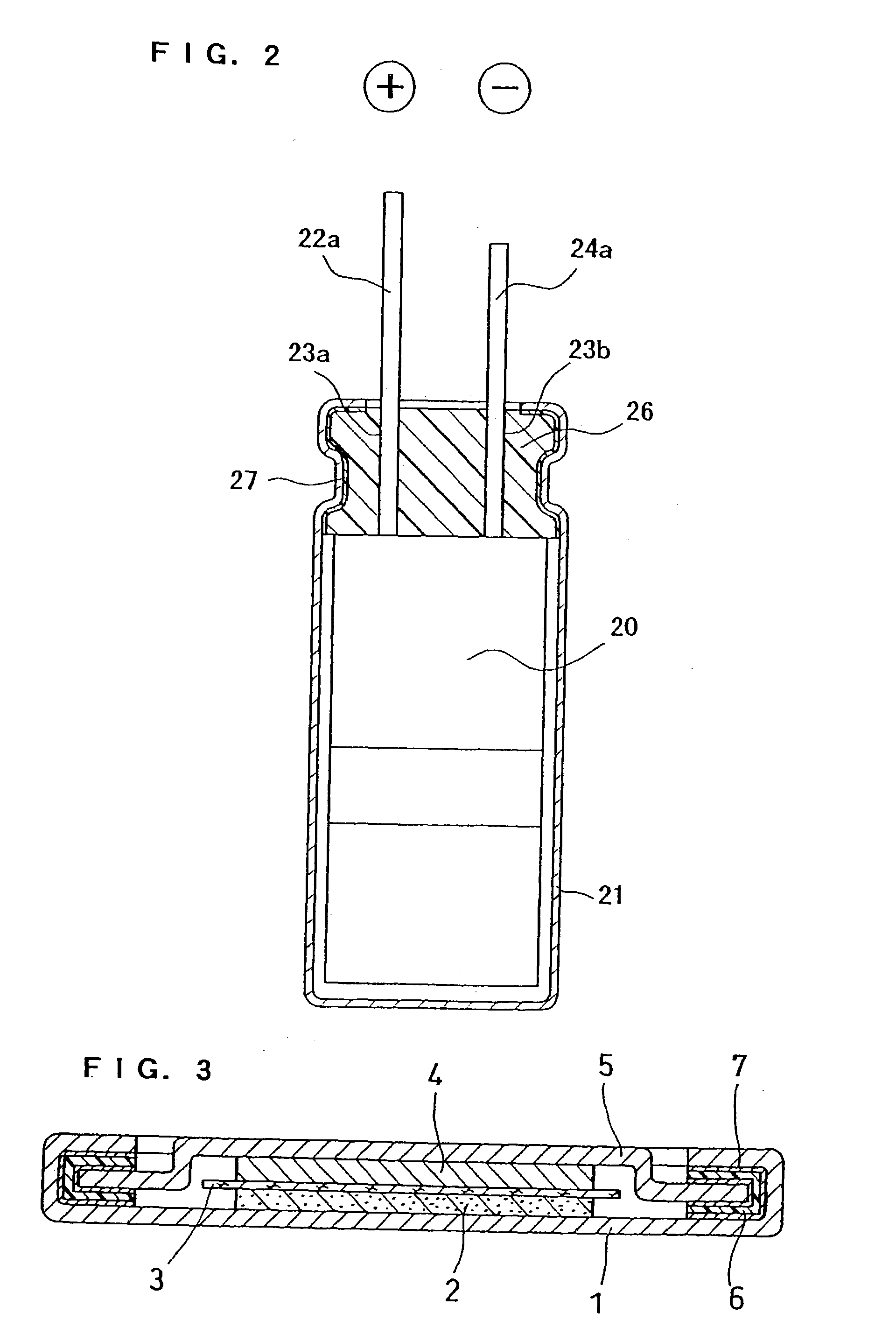

Sealing material for electrochemical element and electrochemical element containing the same

InactiveUS20030148179A1Good flexibilityReduction factorPrimary cell to battery groupingHybrid capacitor separatorsElectrochemistrySealant

In order to give excellent hermeticity in a broad temperature range to an electrochemical device, a sealant comprising a rubber component and a tackifier is used, the rubber component comprising at least one of butyl rubber and polyisobutylene rubber, the tackifier comprising at least one selected from the group consisting of a terpene resin, an aliphatic petroleum resin and an alicyclic petroleum resin.

Owner:PANASONIC CORP

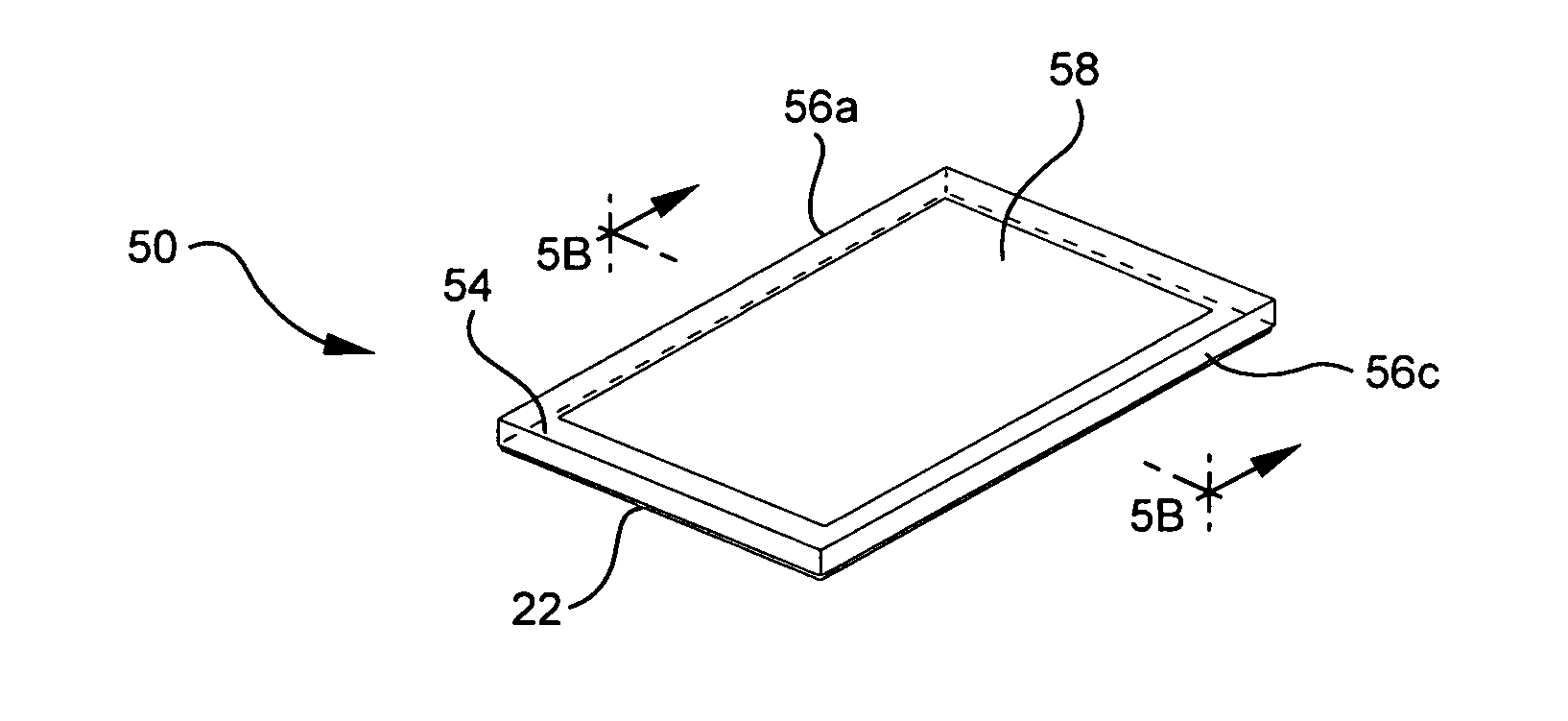

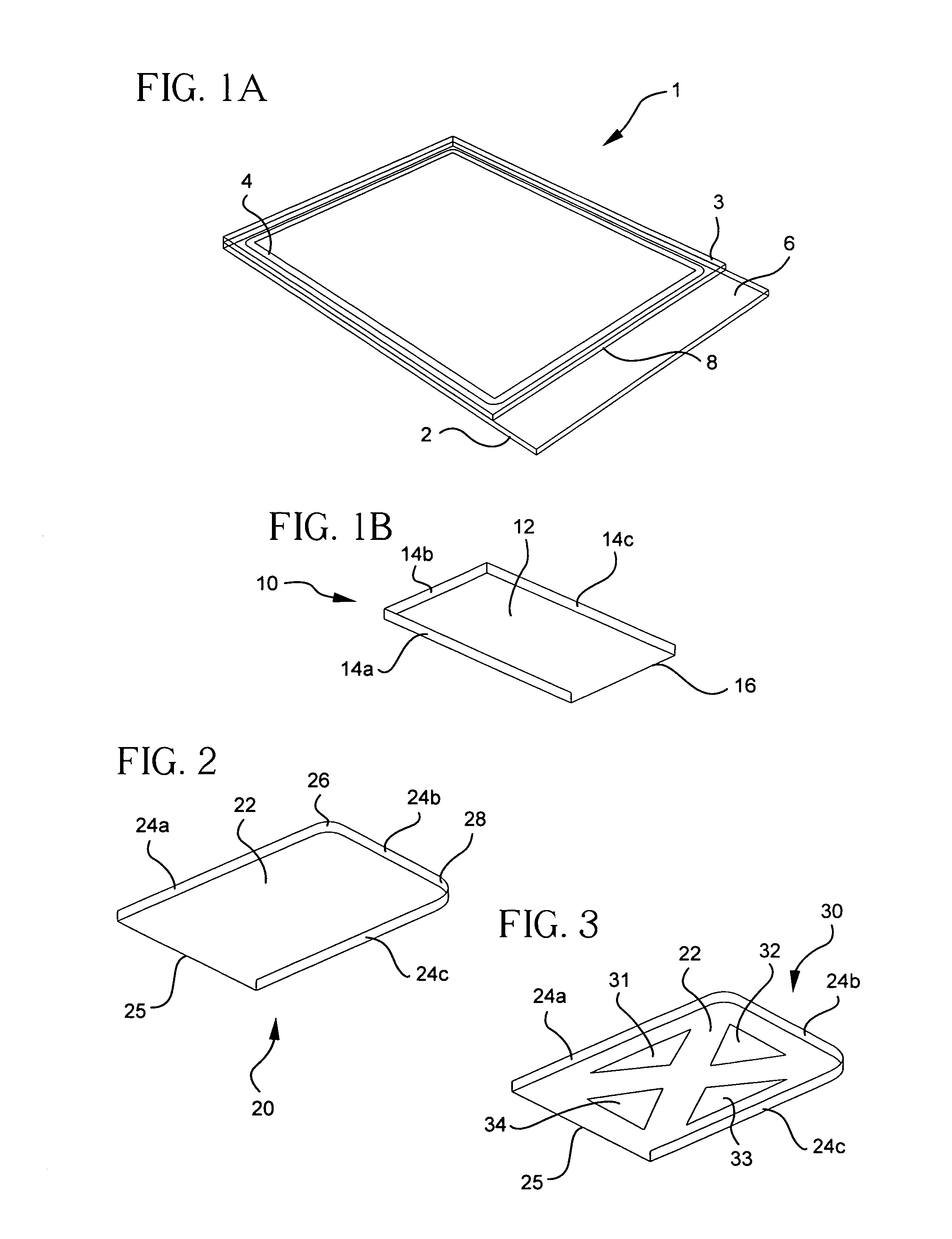

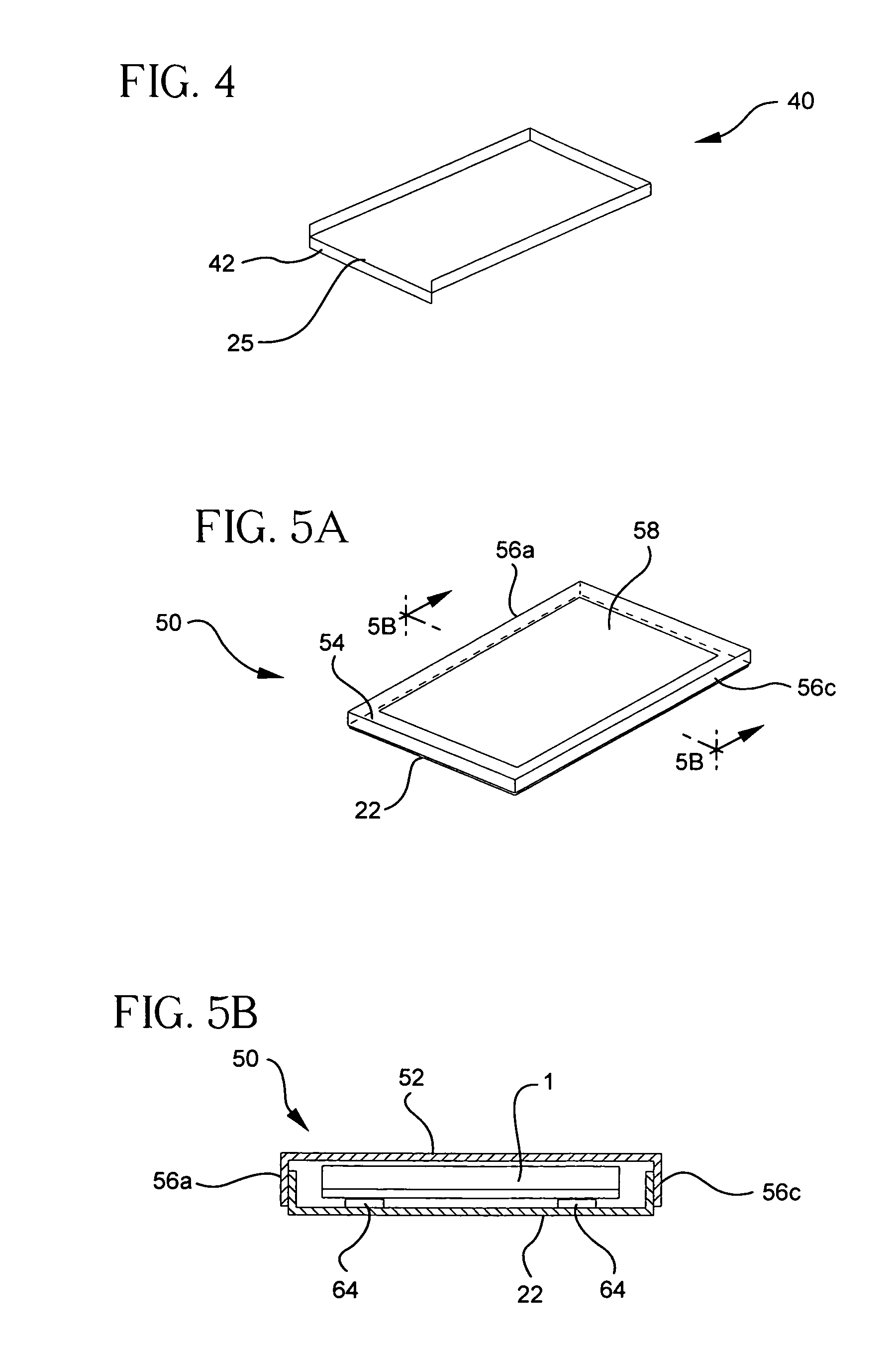

Bezel packaging for sealed glass assemblies and a glass assembly therefor

InactiveUS20110019351A1Reduce the likelihood of failureImprove integrityPlanar light sourcesStatic indicating devicesLeading edgeInter layer

Methods and assemblies related to frame or bezel packaging of a sealed glass assembly, such as a fit-sealed OLED device, such as an OLED display panel. The frame or bezel packaging may have one or more of (a) rounded or chamfered corners, (a) a cover, (b) a reinforced lead edge, (c) openings or cutouts in the back panel to conserve material and lighten the bezel, and (d) a shock absorbent intermediate layer of low modulus of elasticity material applied between the sealed glass assembly and the back and / or sides of the frame or bezel. The frame or bezel design may include a gap between the sealed glass assembly and the back panel of the bezel. The gap may be filled at least in part with low modulus of elasticity backing material. The glass package may have one or more of (a) rounded or chamfered corners, (b) rounded or chamfered edges, (c) a low modulus of elasticity material applied around its periphery or portions of its periphery, such as on the corners only, (d) a shortened lead end, and (e) a thickened lead end.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com