Patents

Literature

44results about How to "Reducing atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

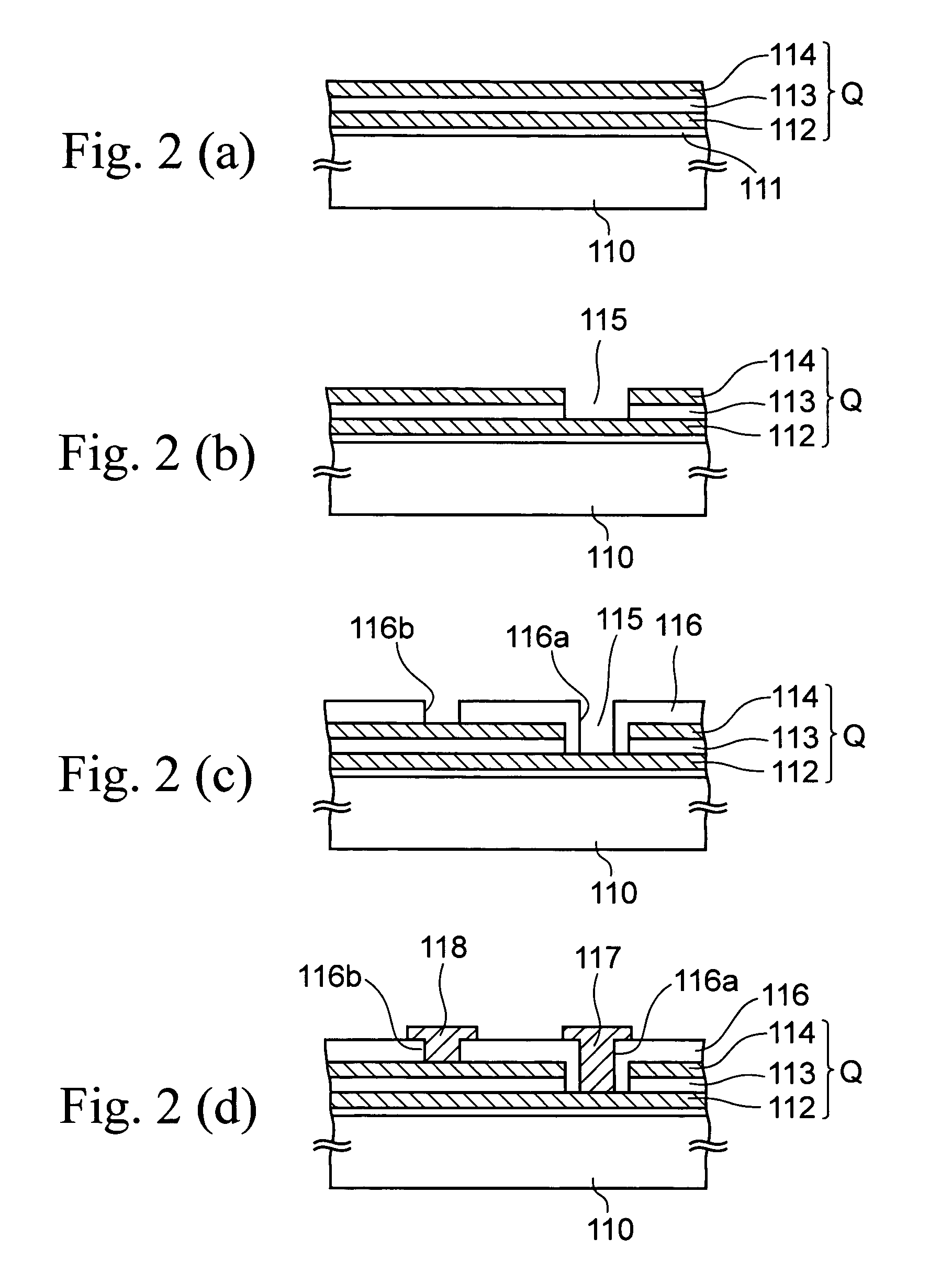

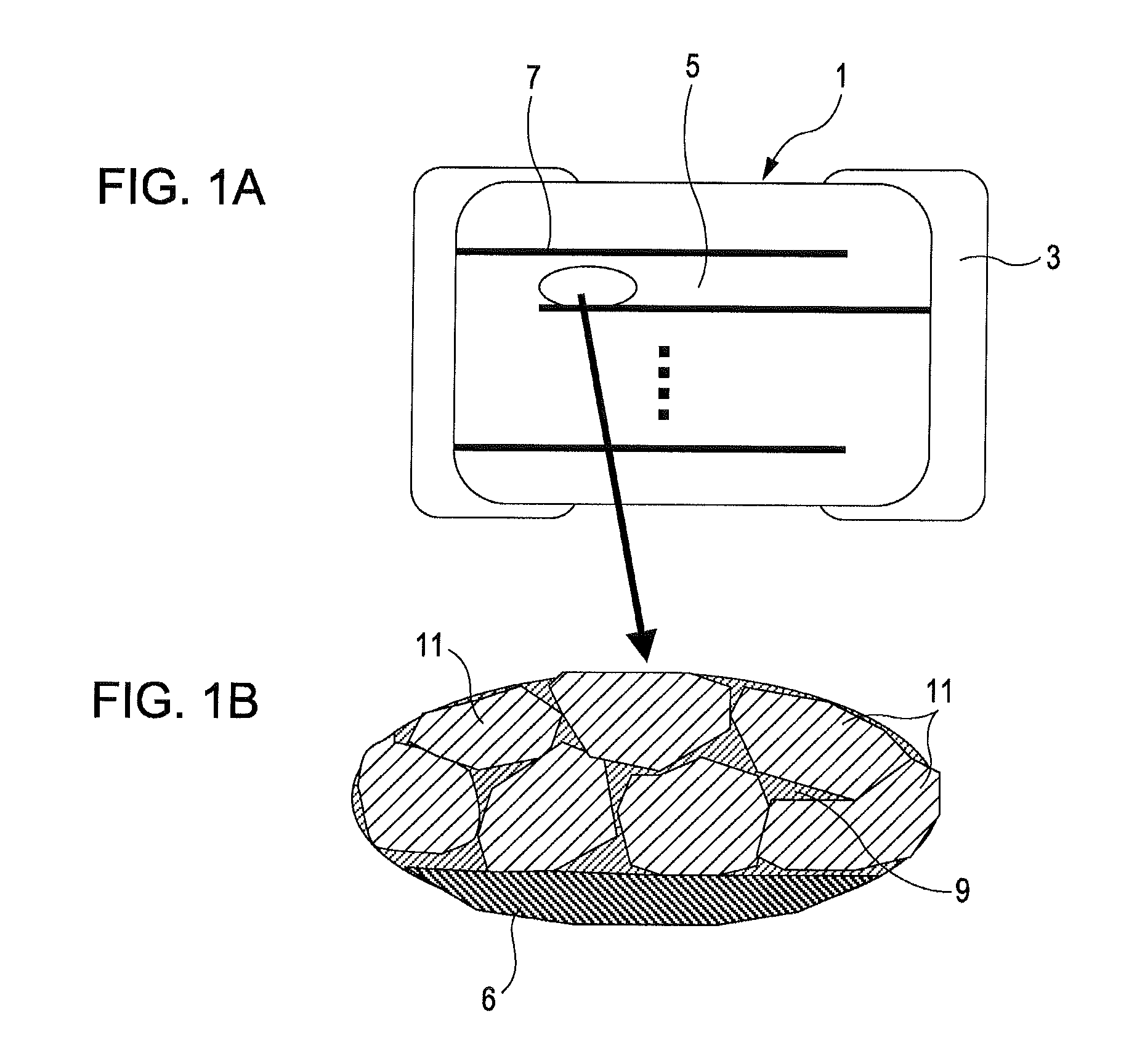

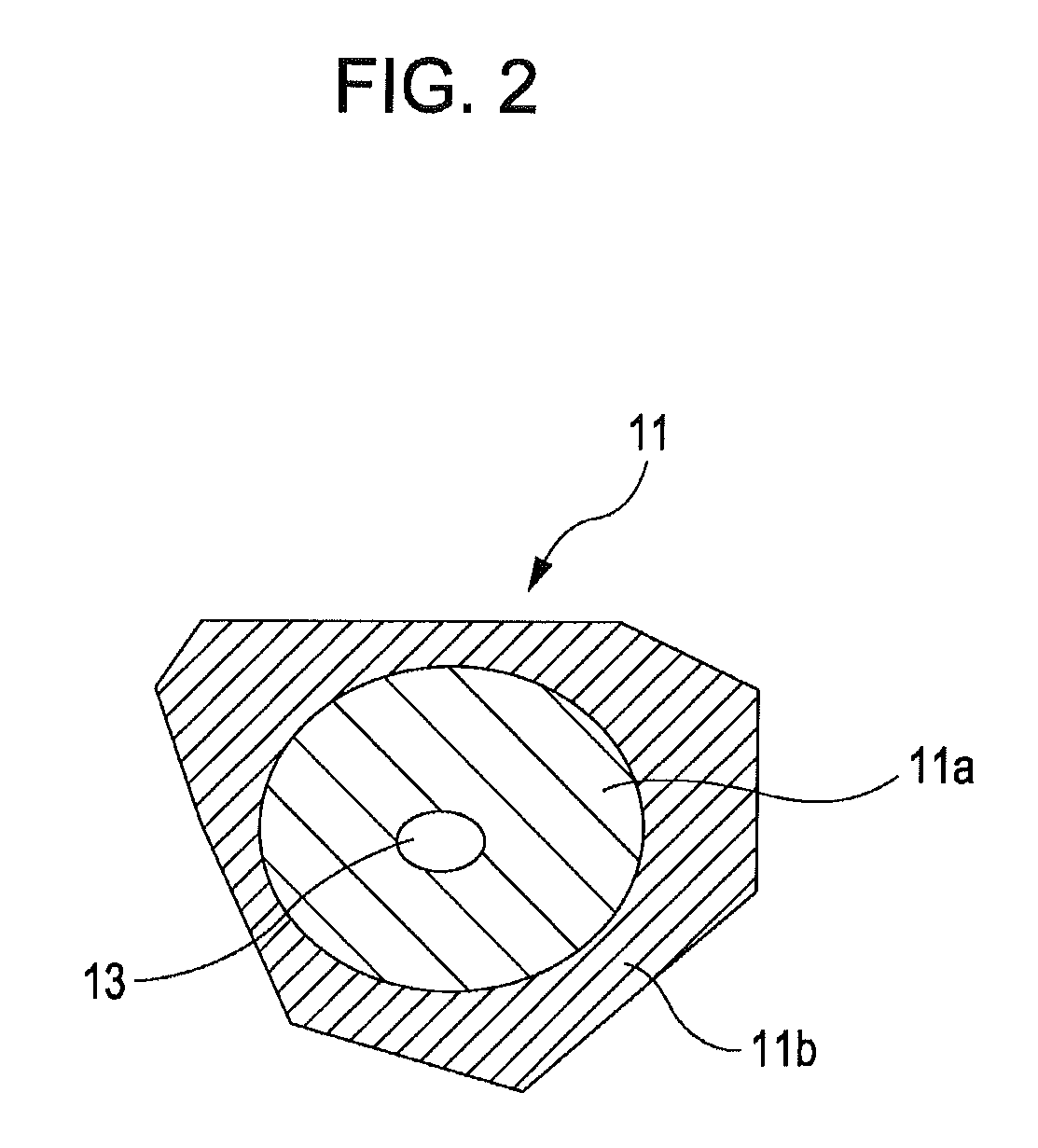

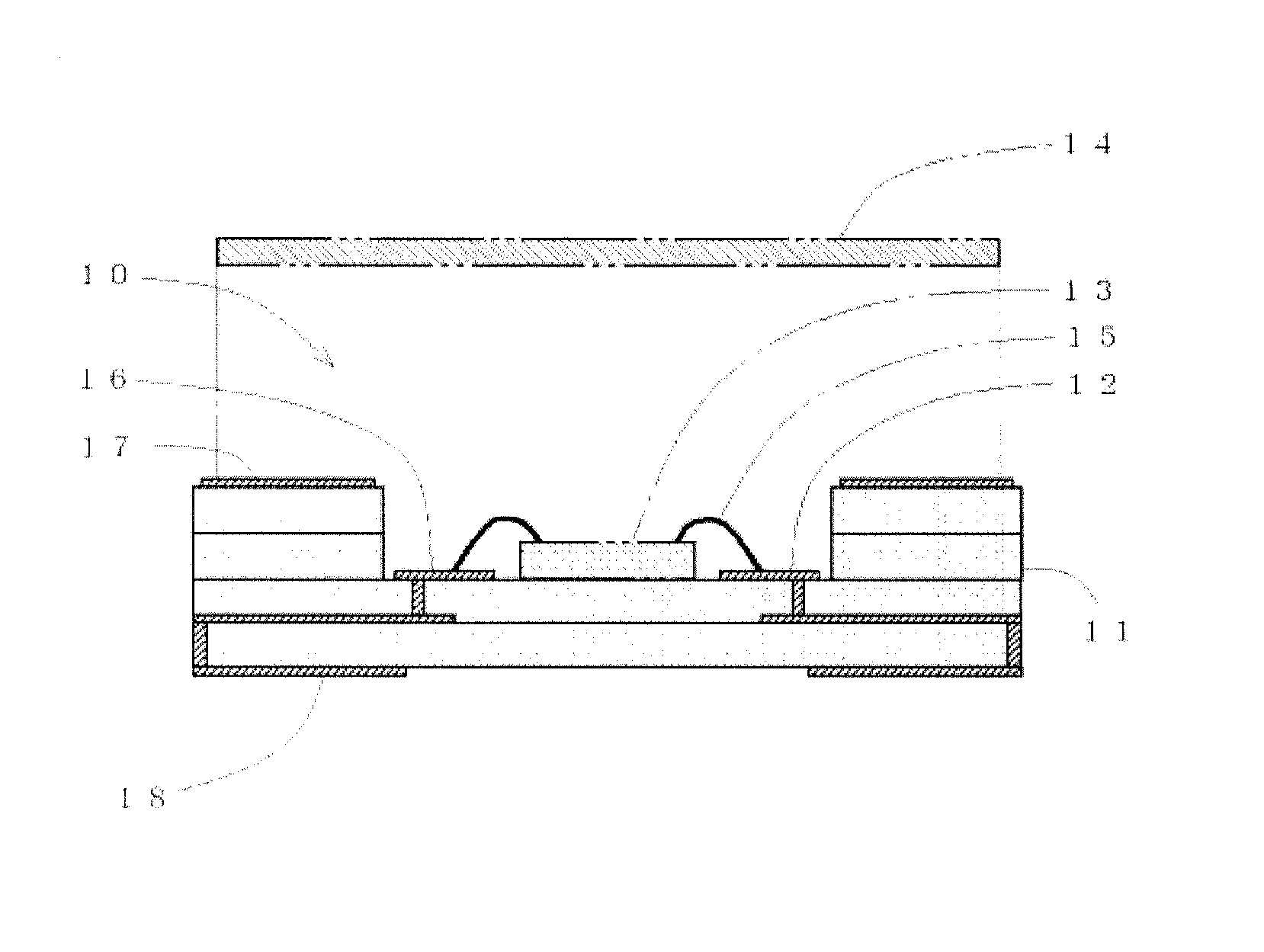

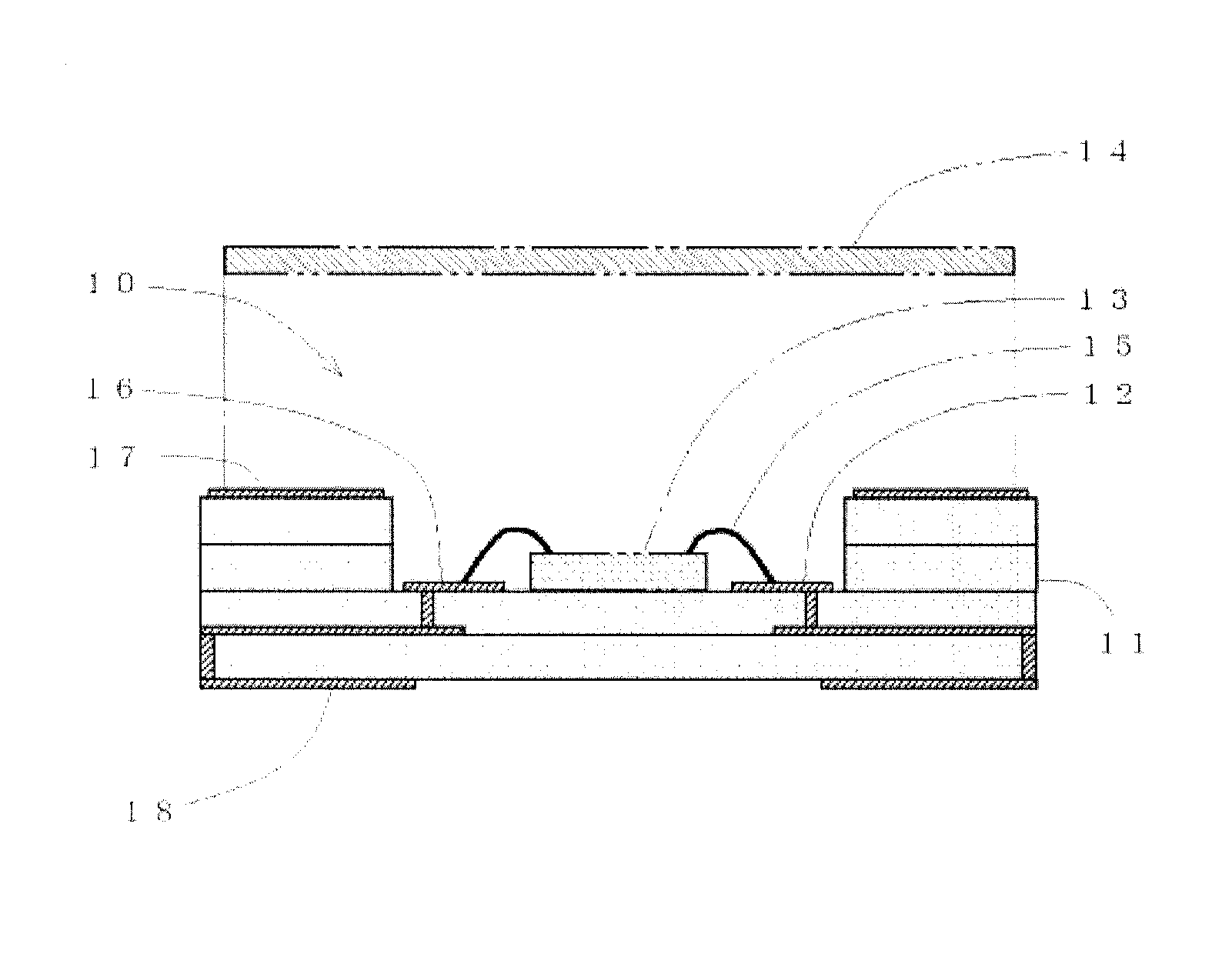

Wafer level package structure, and sensor device obtained from the same package structure

InactiveUS20090267165A1Little changeReducing atmosphereAcceleration measurement using interia forcesSemiconductor/solid-state device testing/measurementDiffusionGyroscope

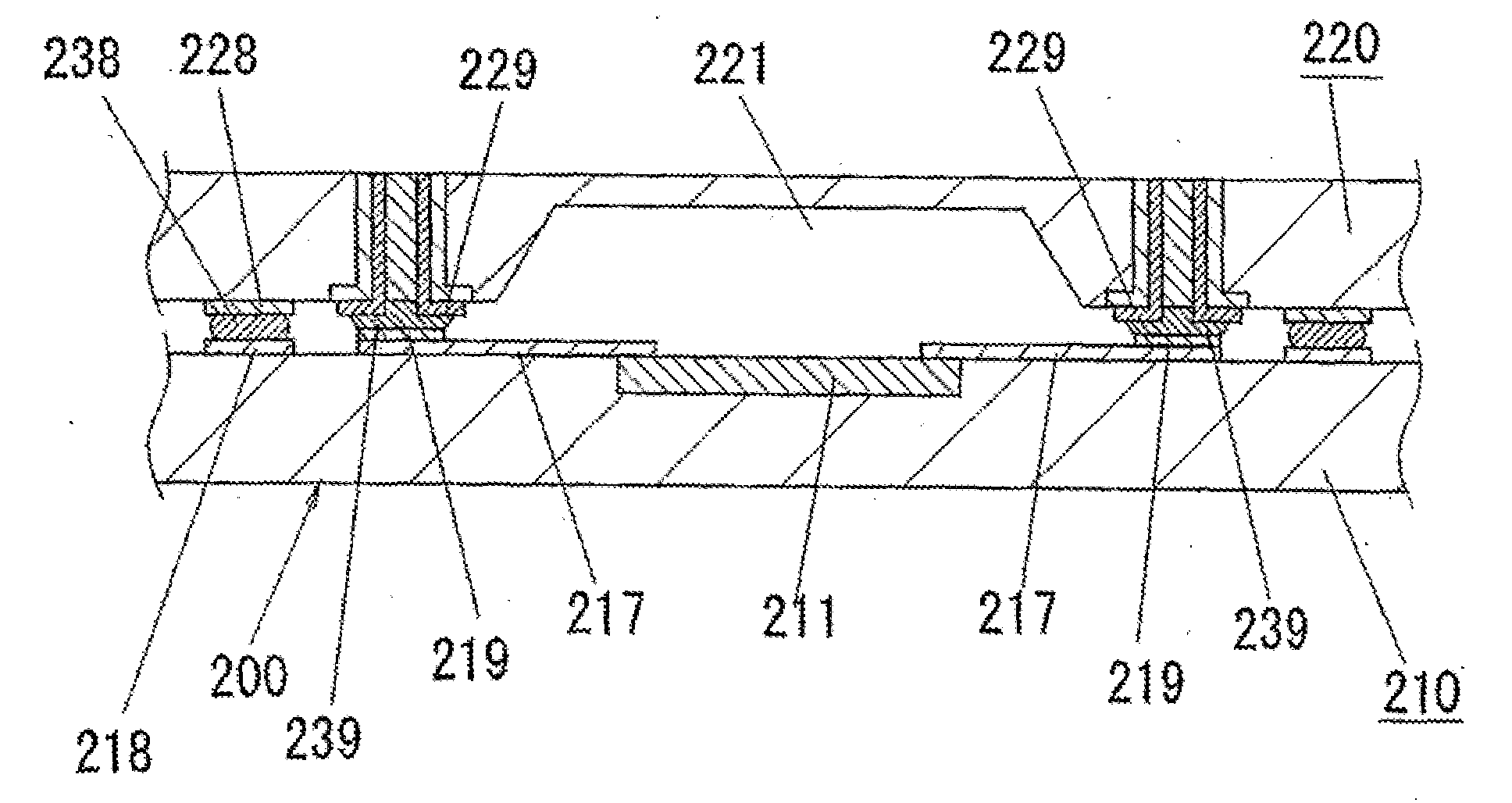

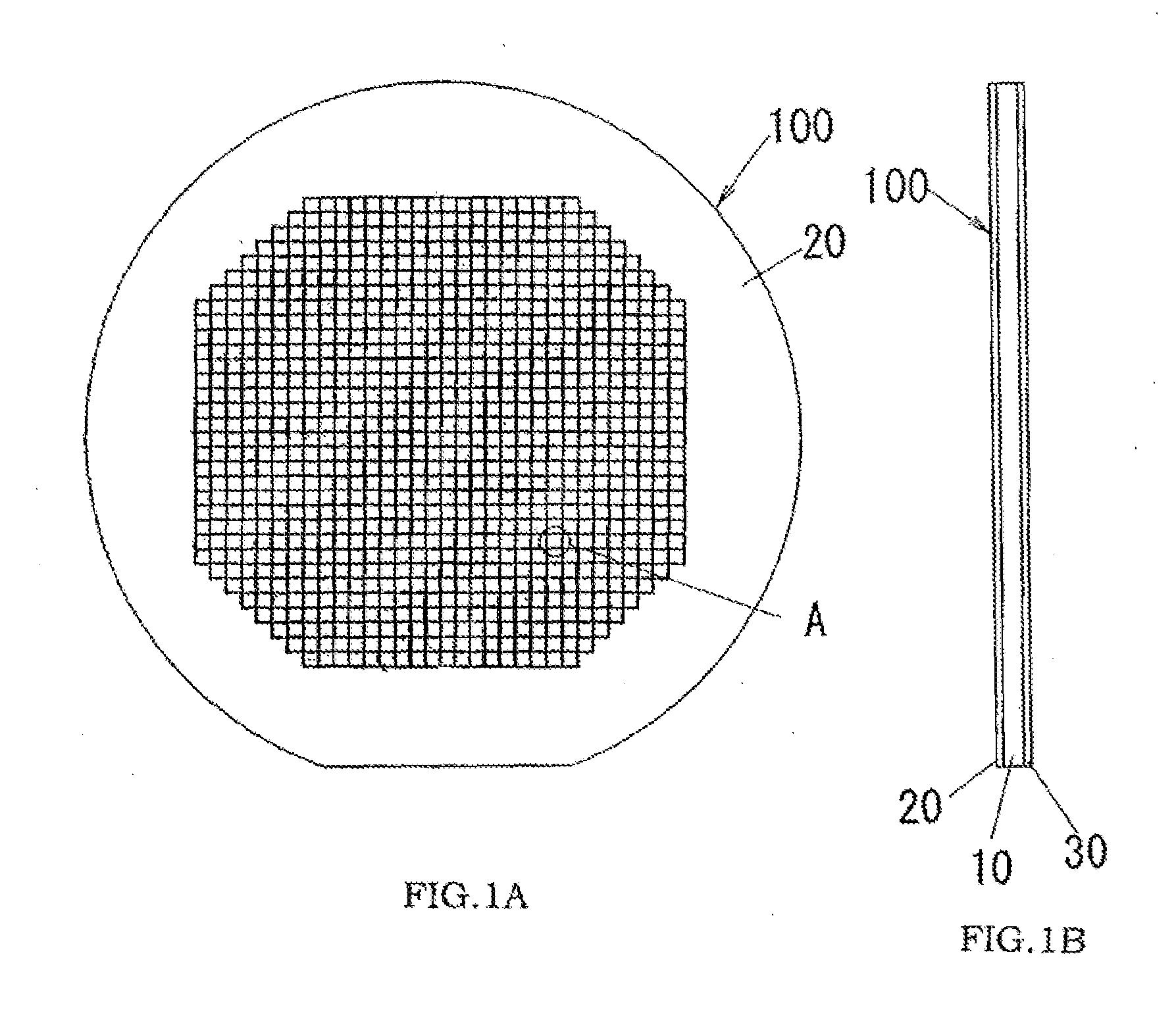

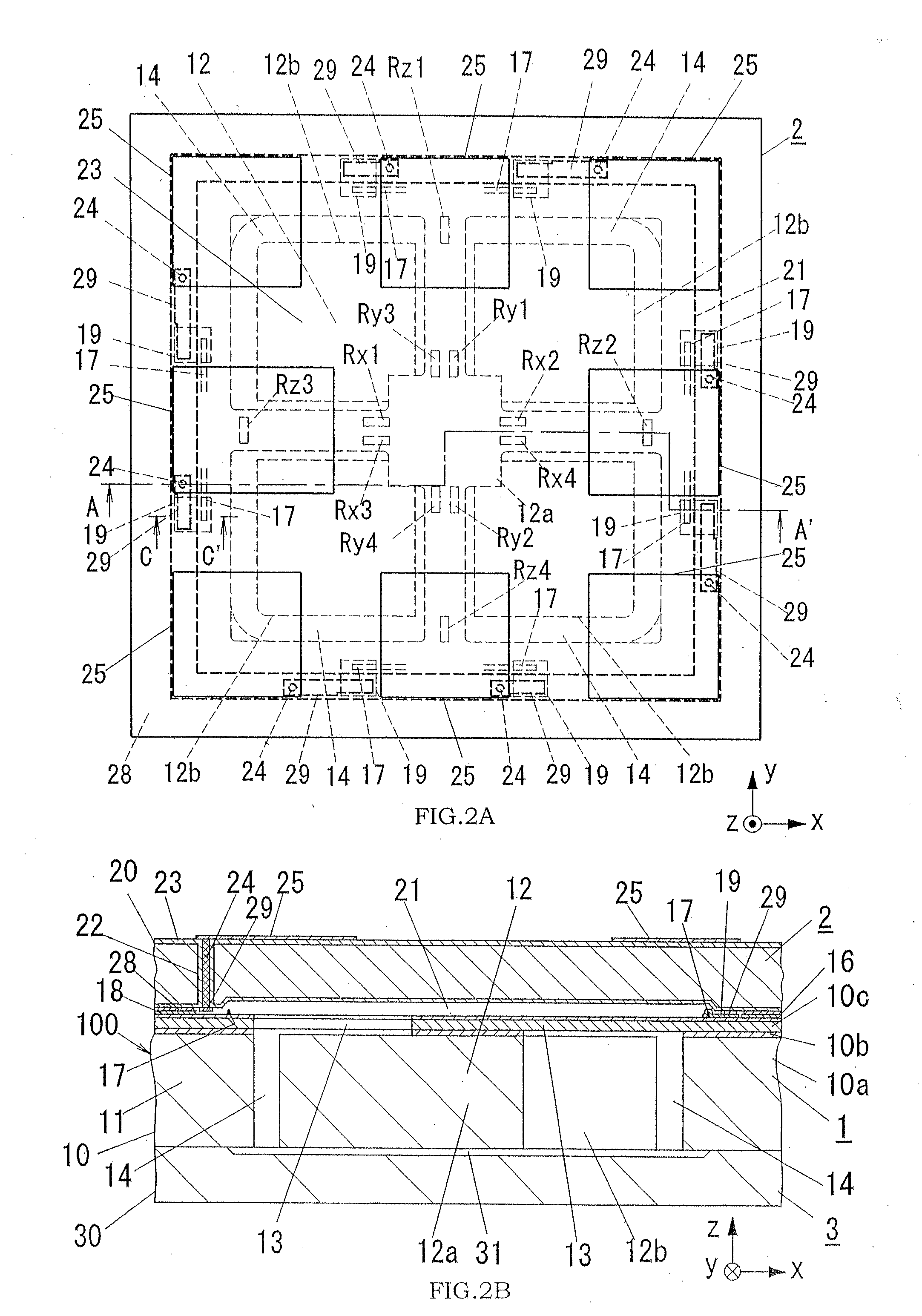

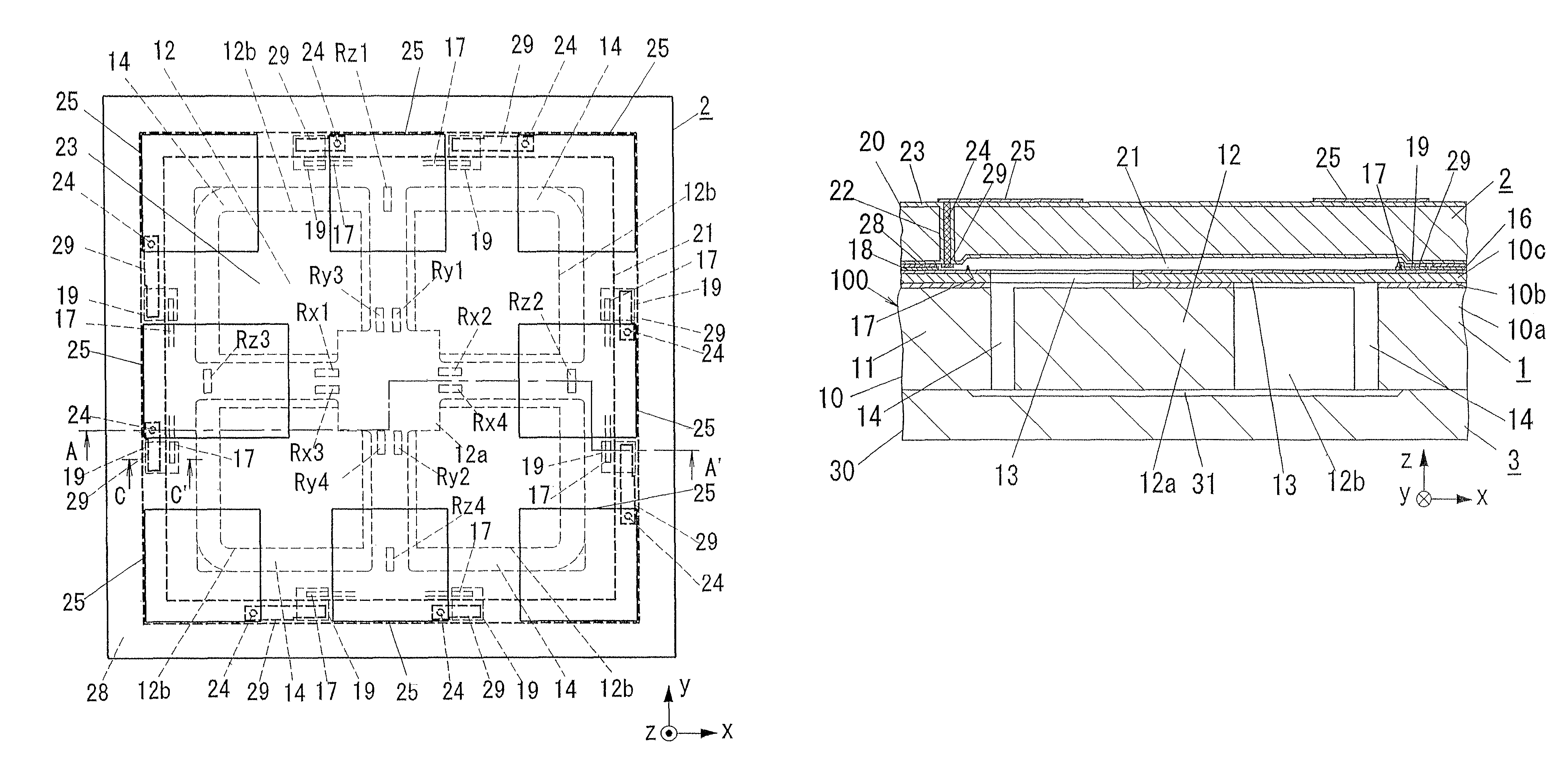

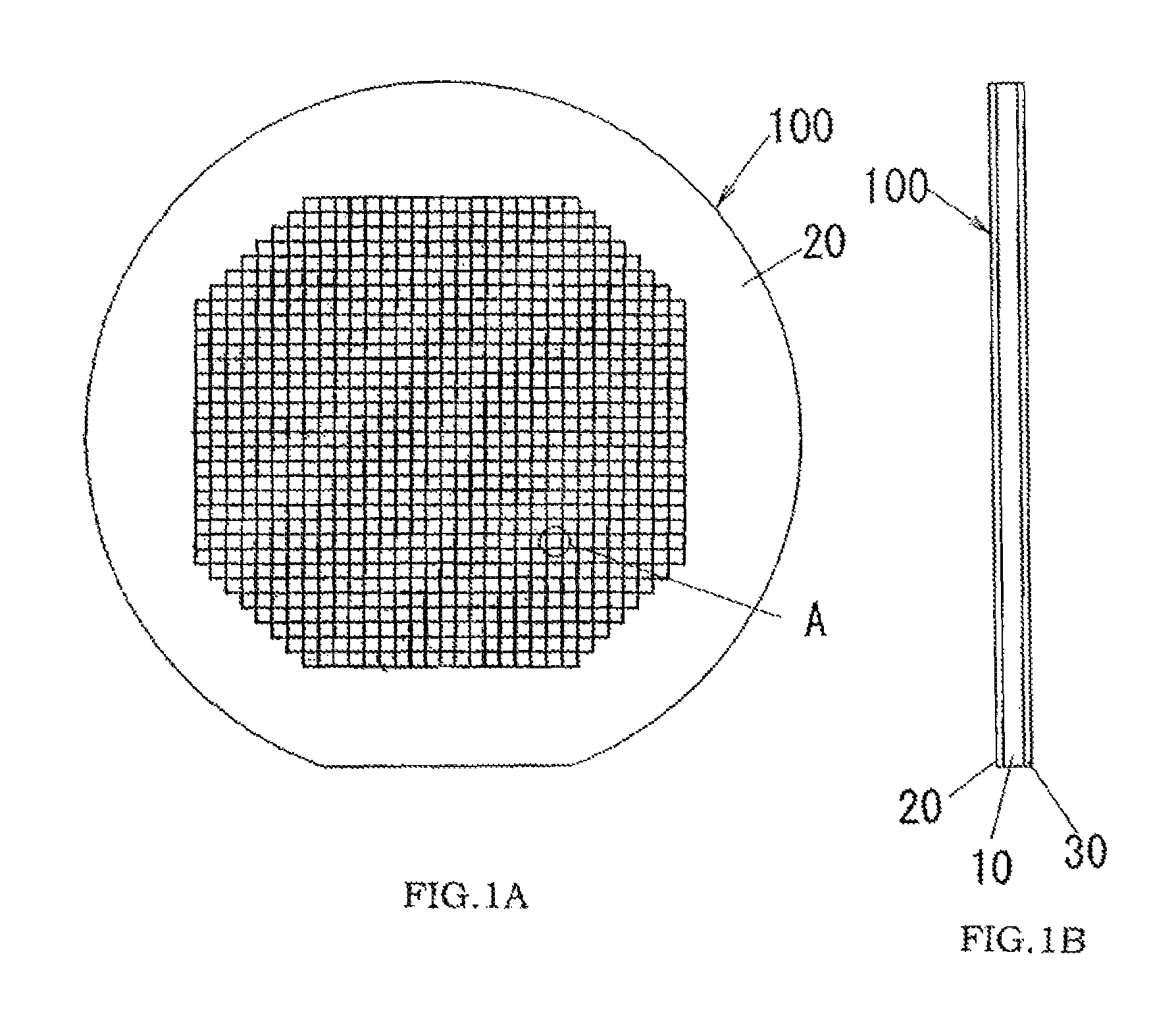

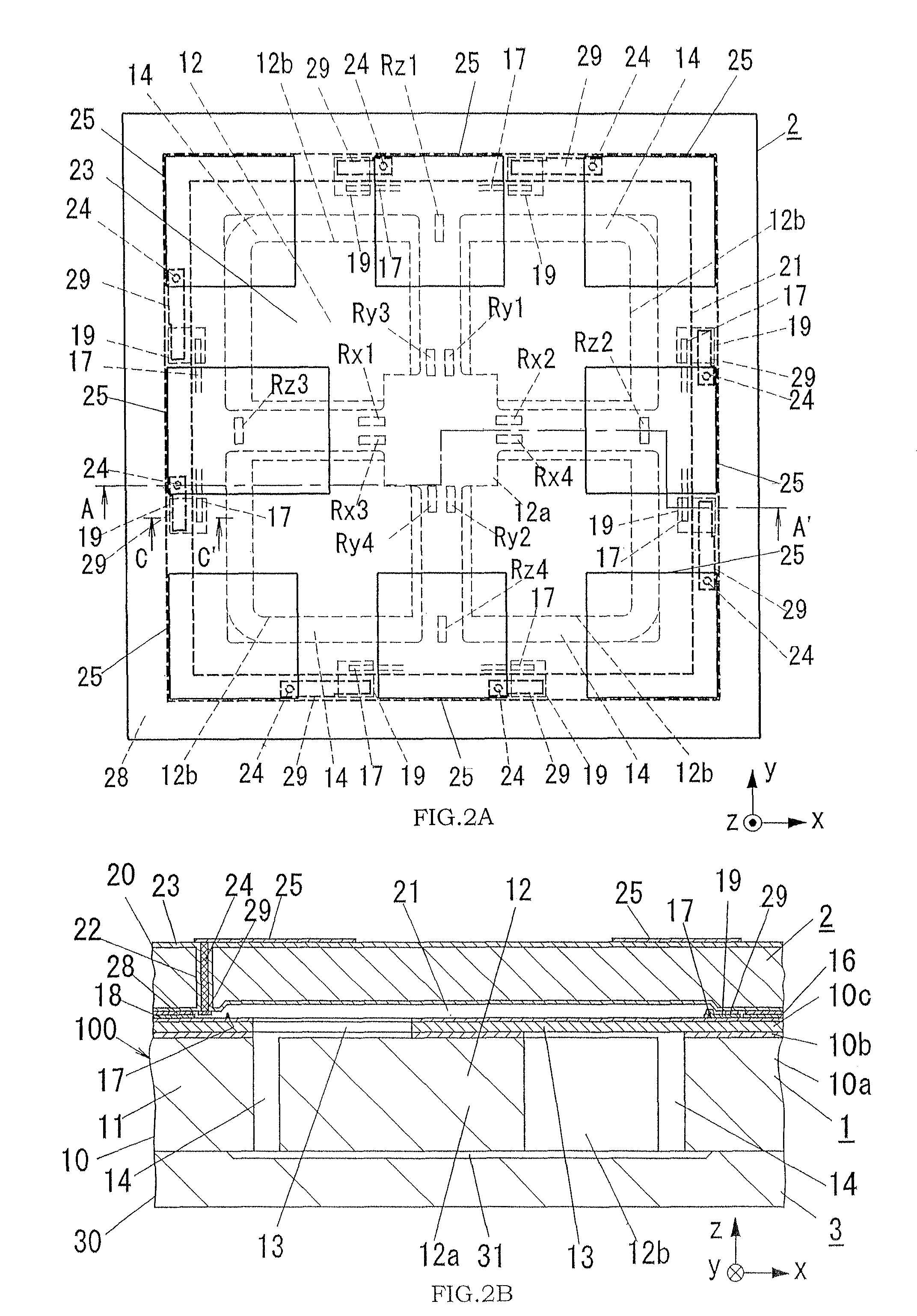

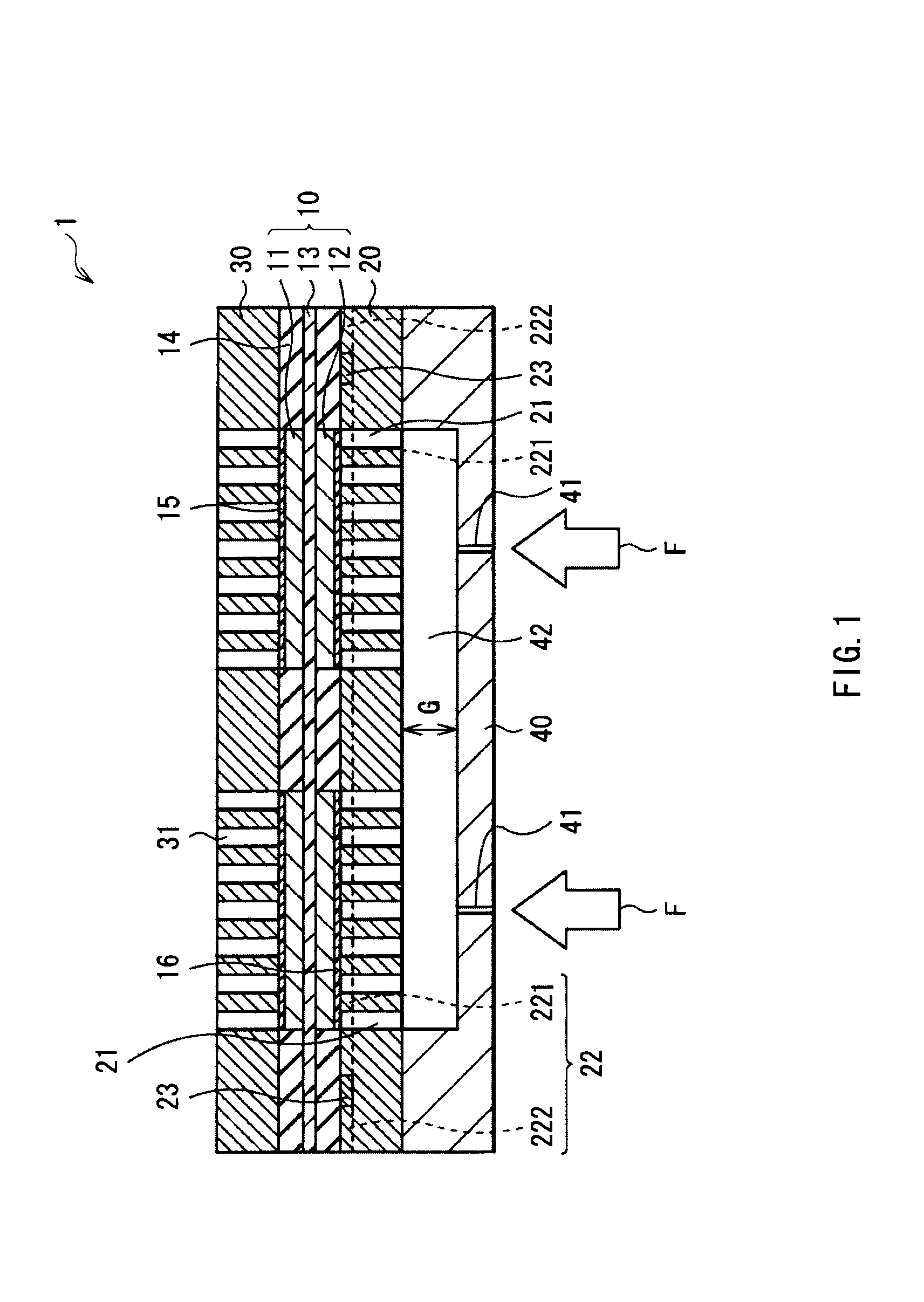

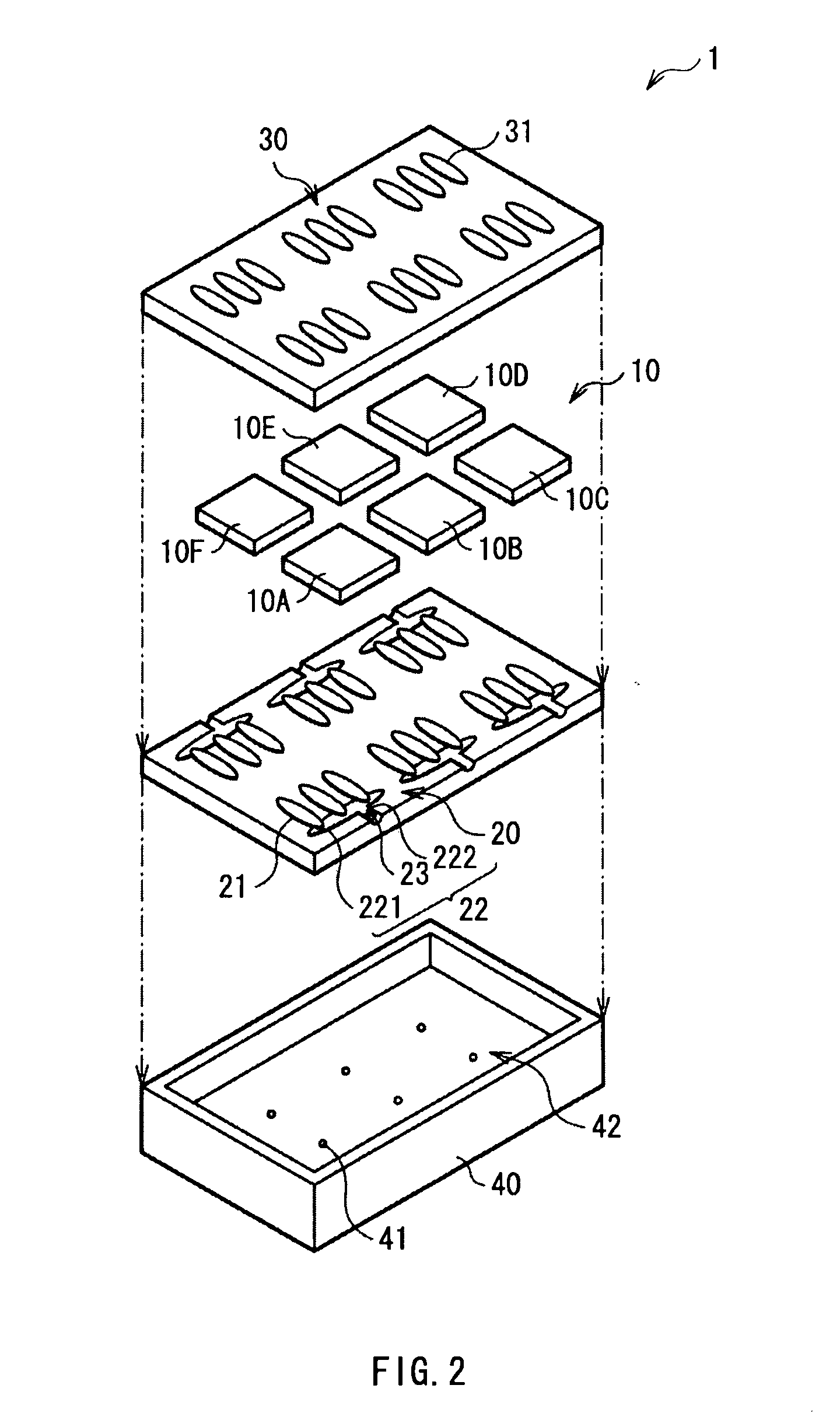

A wafer level package structure with a plurality of compact sensors such as acceleration sensors and gyro sensors is provided. This package structure is composed of a semiconductor wafer with plural sensor units, and a pair of package wafers bonded to both surfaces of the semiconductor wafer. Each of the sensor units has a frame having an opening, a movable portion held in the opening to be movable relative to the frame, and a detecting portion for outputting an electric signal according to a positional displacement of the movable portion. Since the semiconductor wafer is bonded to each of the package wafers by a solid-phase direct bonding without diffusion between a surface-activated region formed on the frame and a surface-activated region formed on the package wafer, it is possible to prevent that variations in sensor characteristics occur due to residual stress at the bonding interface.

Owner:MATSUSHITA ELECTRIC WORKS LTD

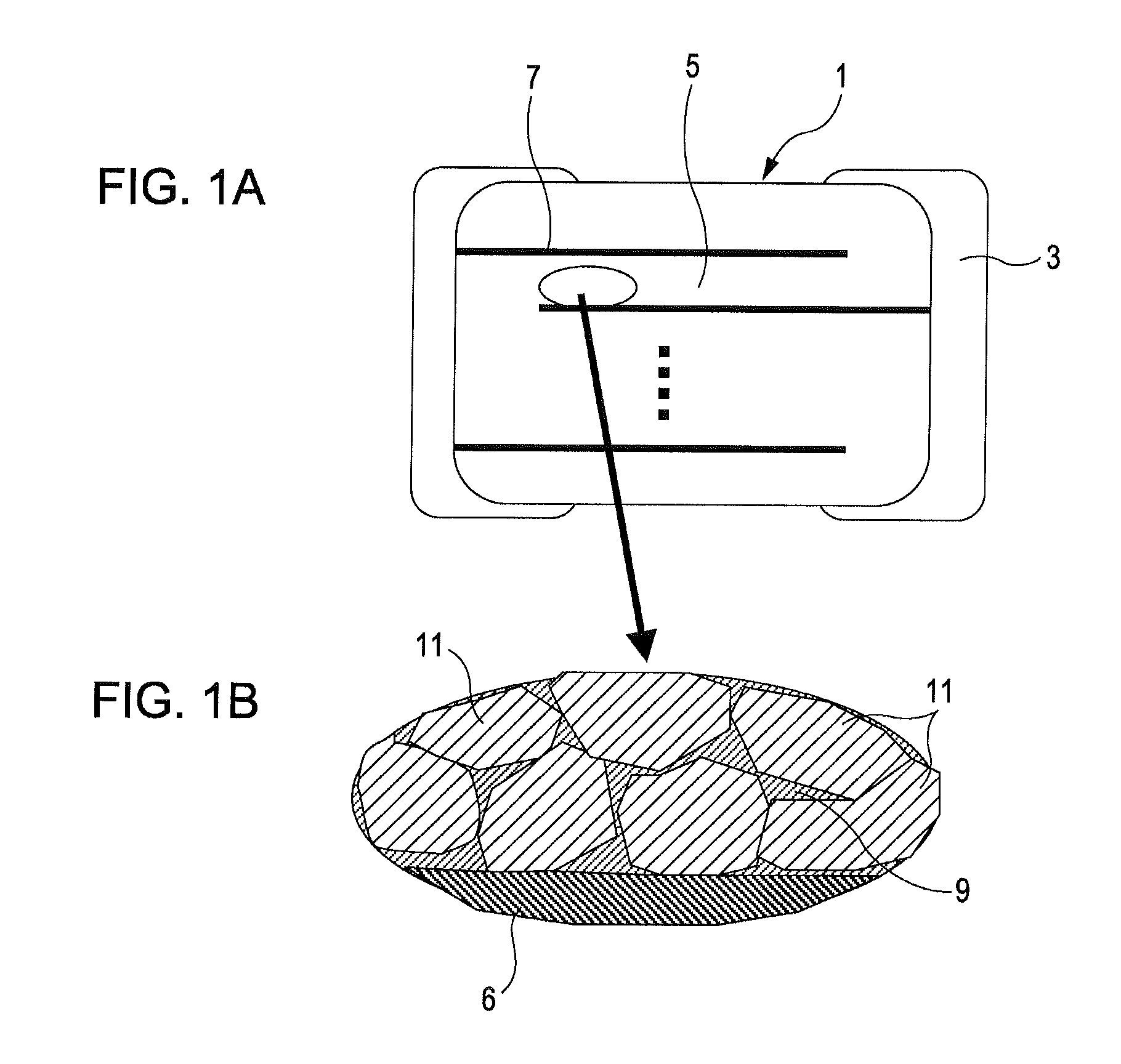

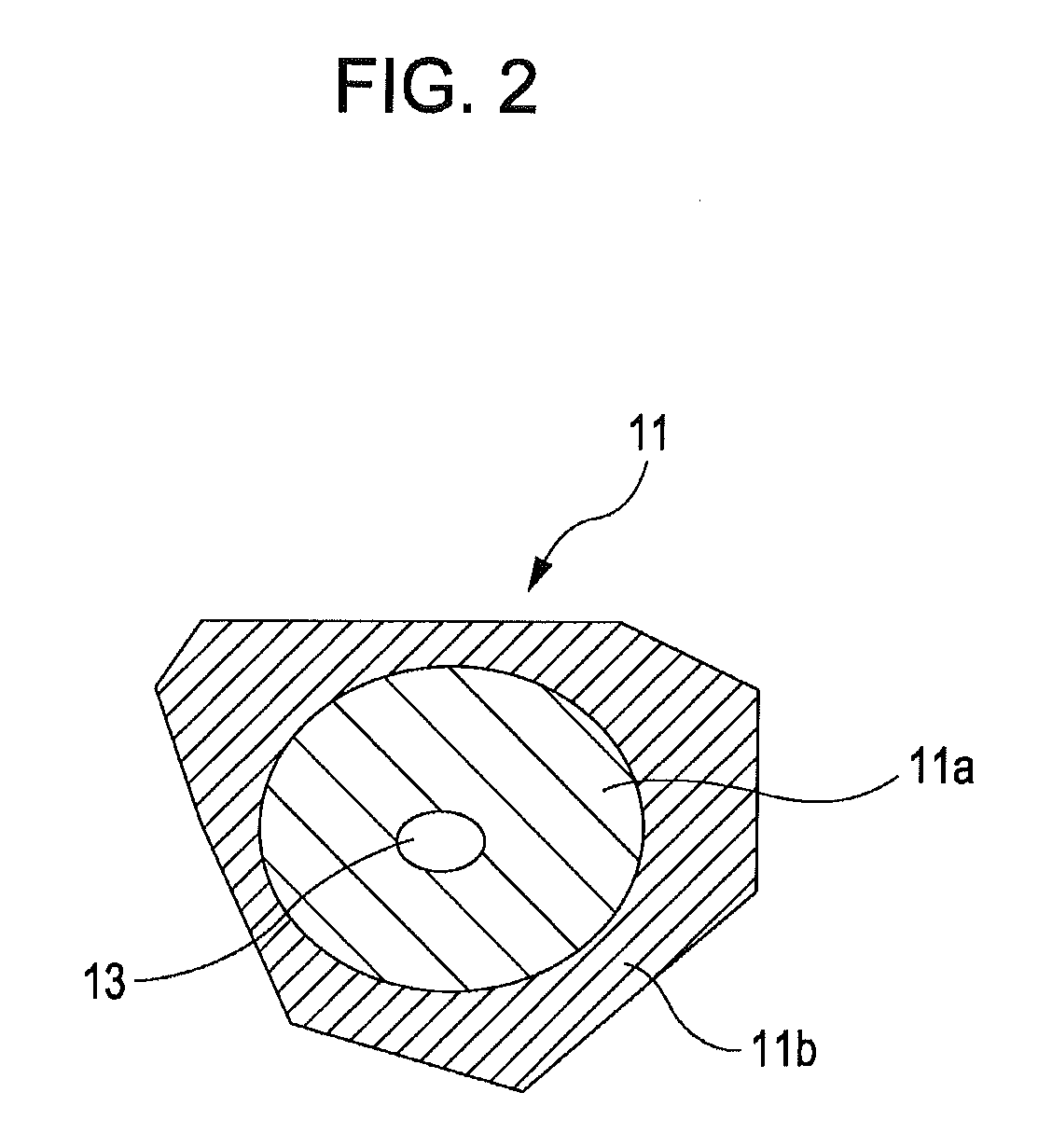

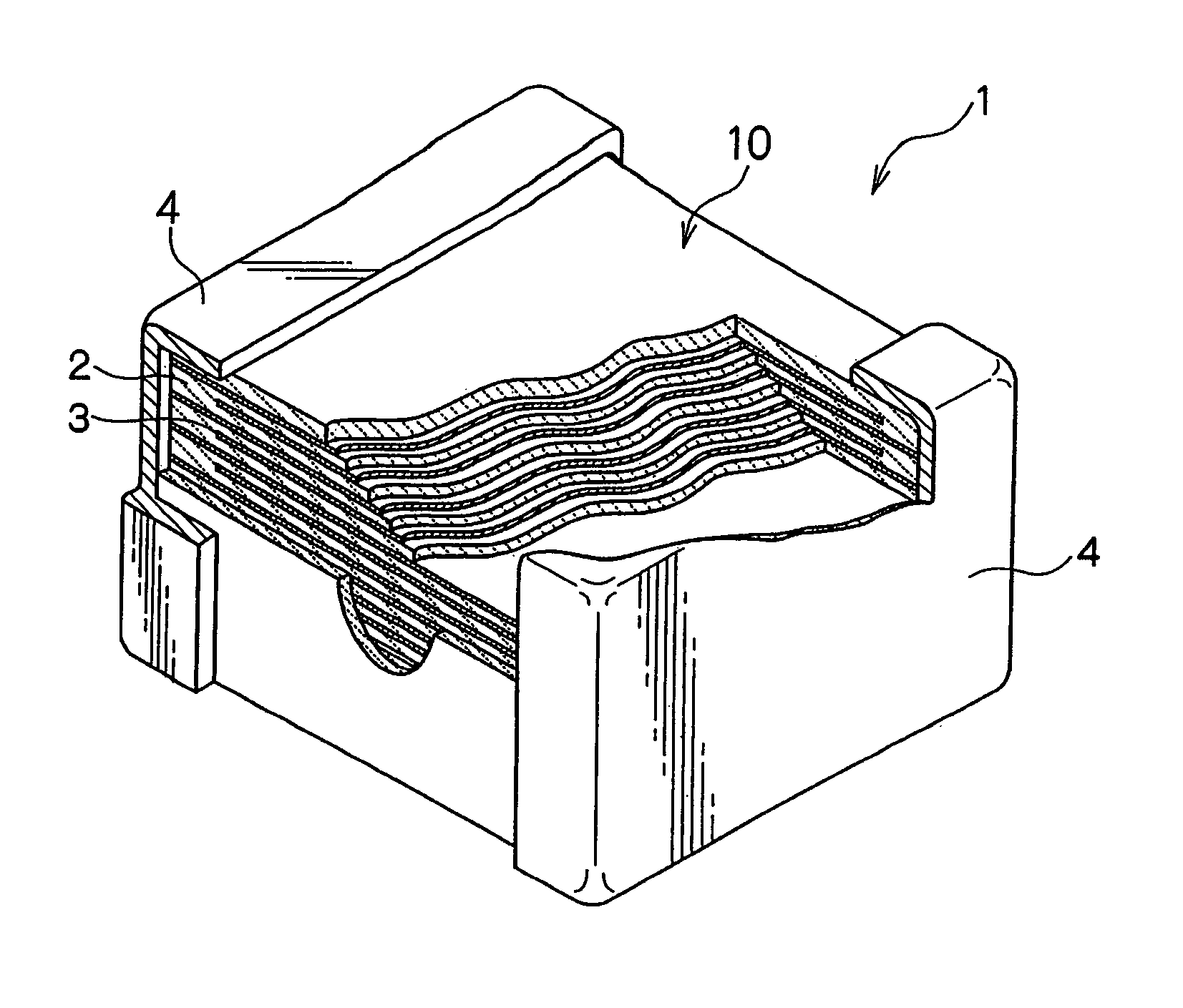

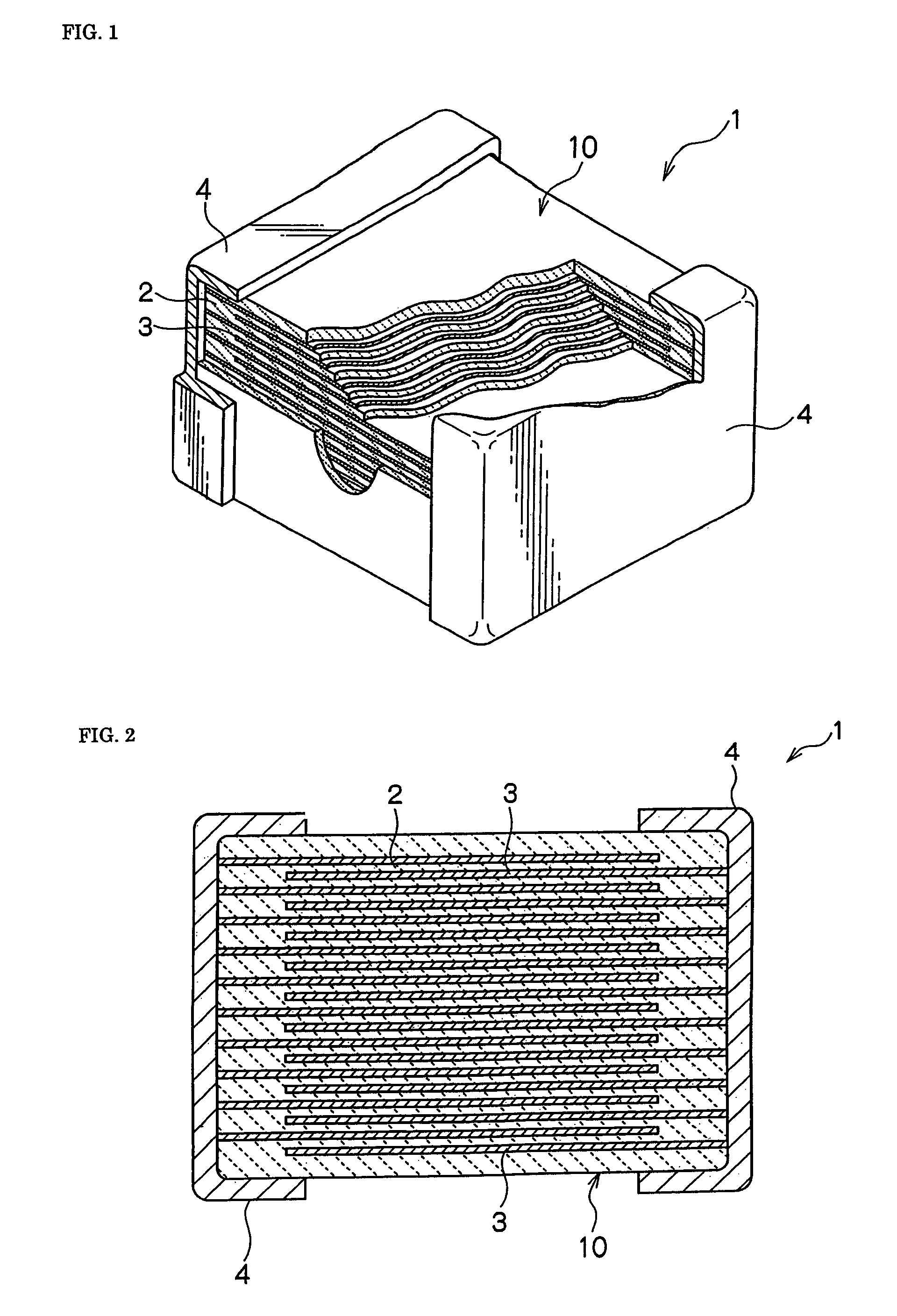

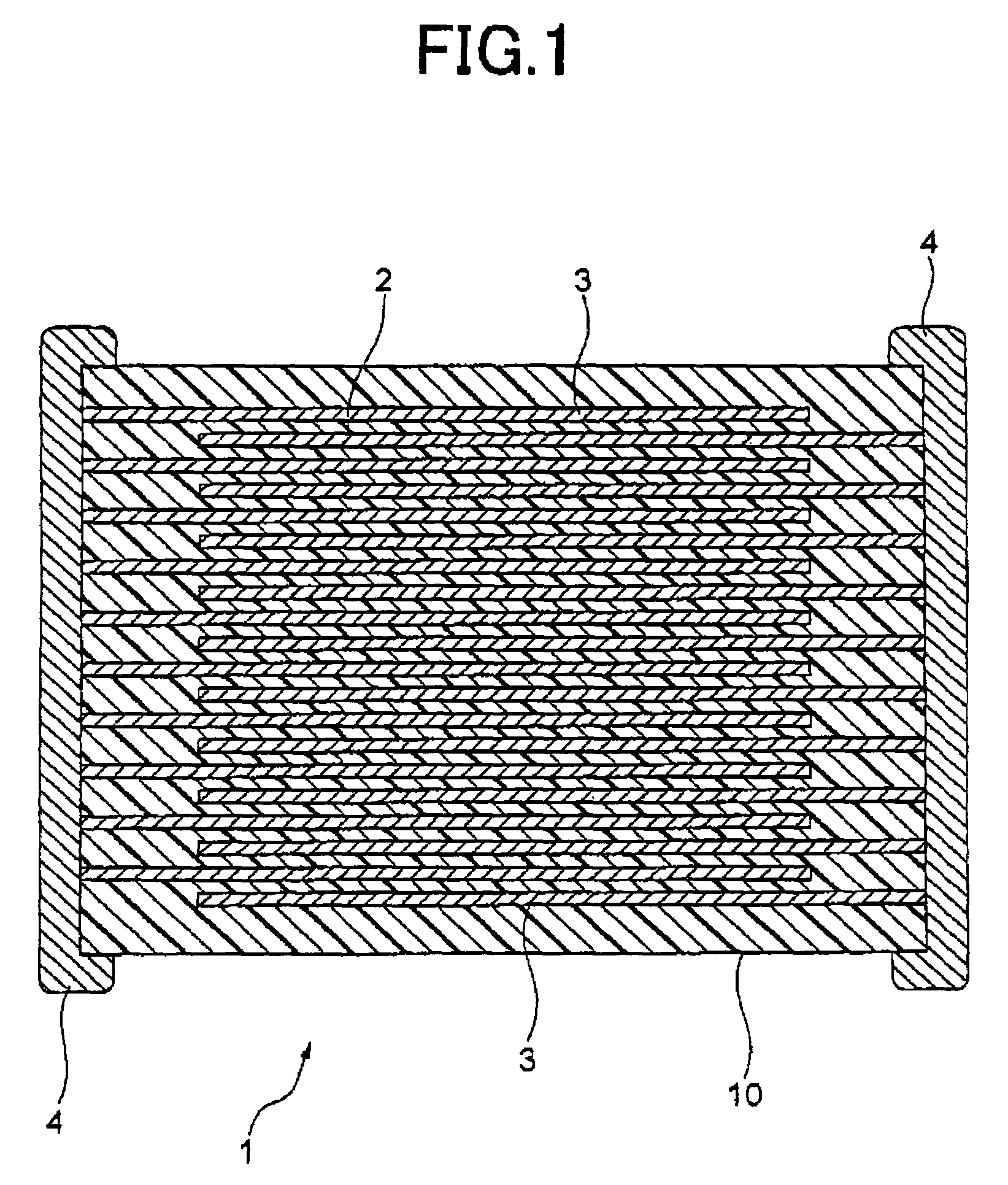

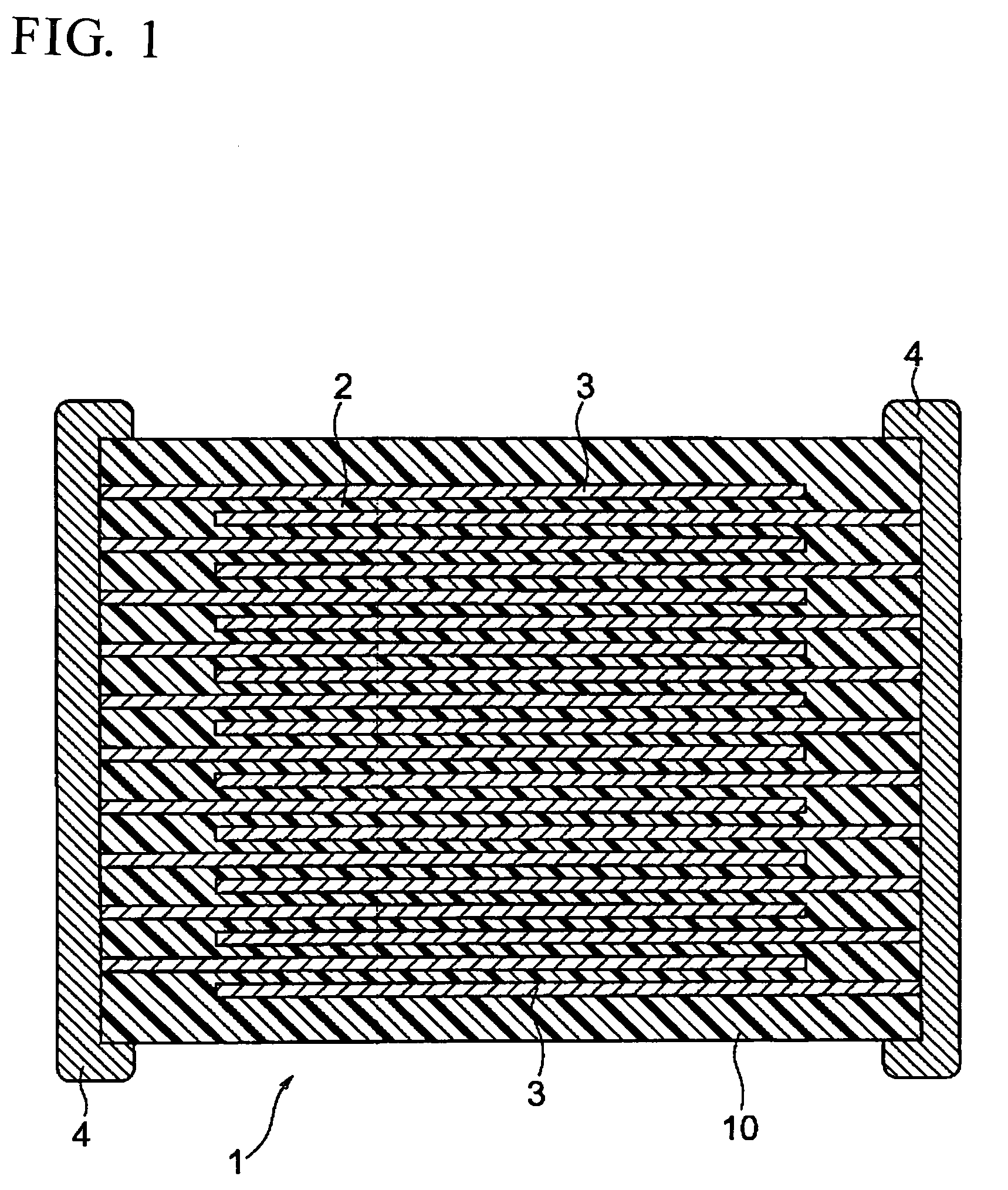

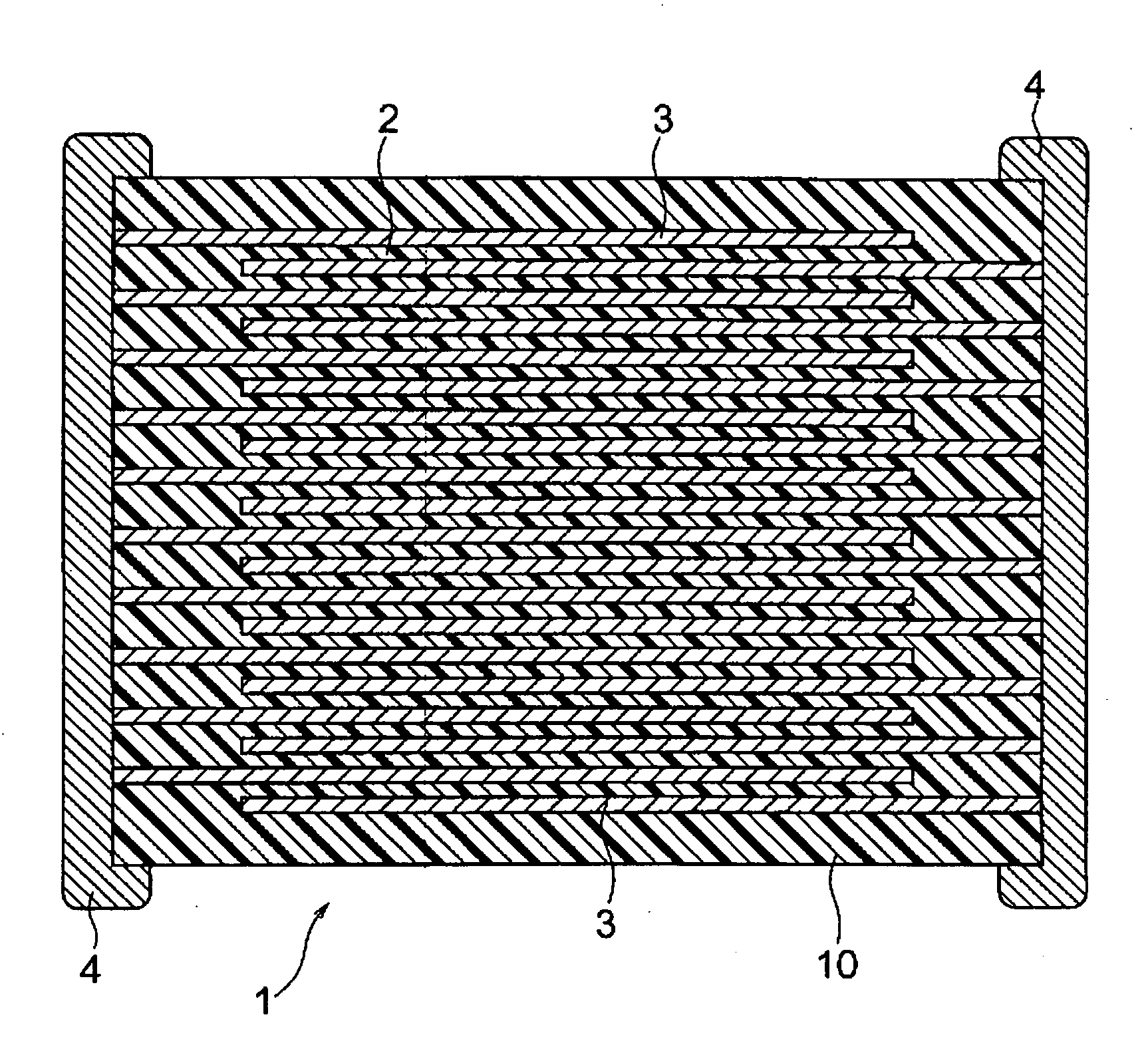

Multilayer ceramic capacitor

InactiveUS20080266751A1Low reliabilityReducing atmosphereFixed capacitor dielectricStacked capacitorsMetallurgyDielectric layer

A multilayer ceramic capacitor includes a plurality of ceramic dielectric layers, a plurality of inner electrode layers and and external electrodes. The ceramic dielectric layers includes barium titanate crystal grains having pores inside. The inner electrode layers are between the ceramic dielectric layers. The external electrodes are electrically connected to the inner electrode layers. The barium titanate crystal grains each have a core-shell structure which include a core and a shell around the core. The the pores are mainly formed in the cores.

Owner:KYOCERA CORP

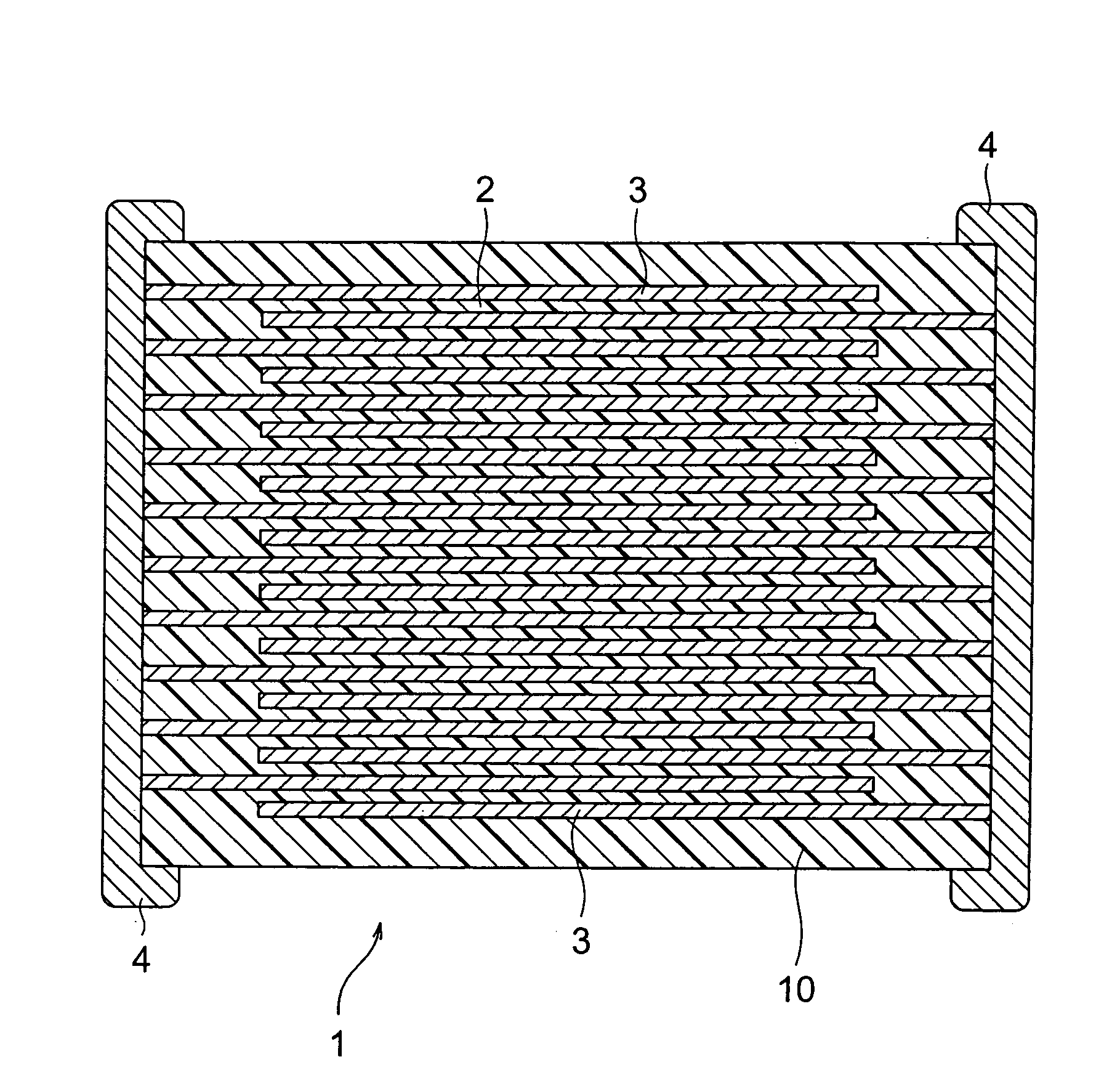

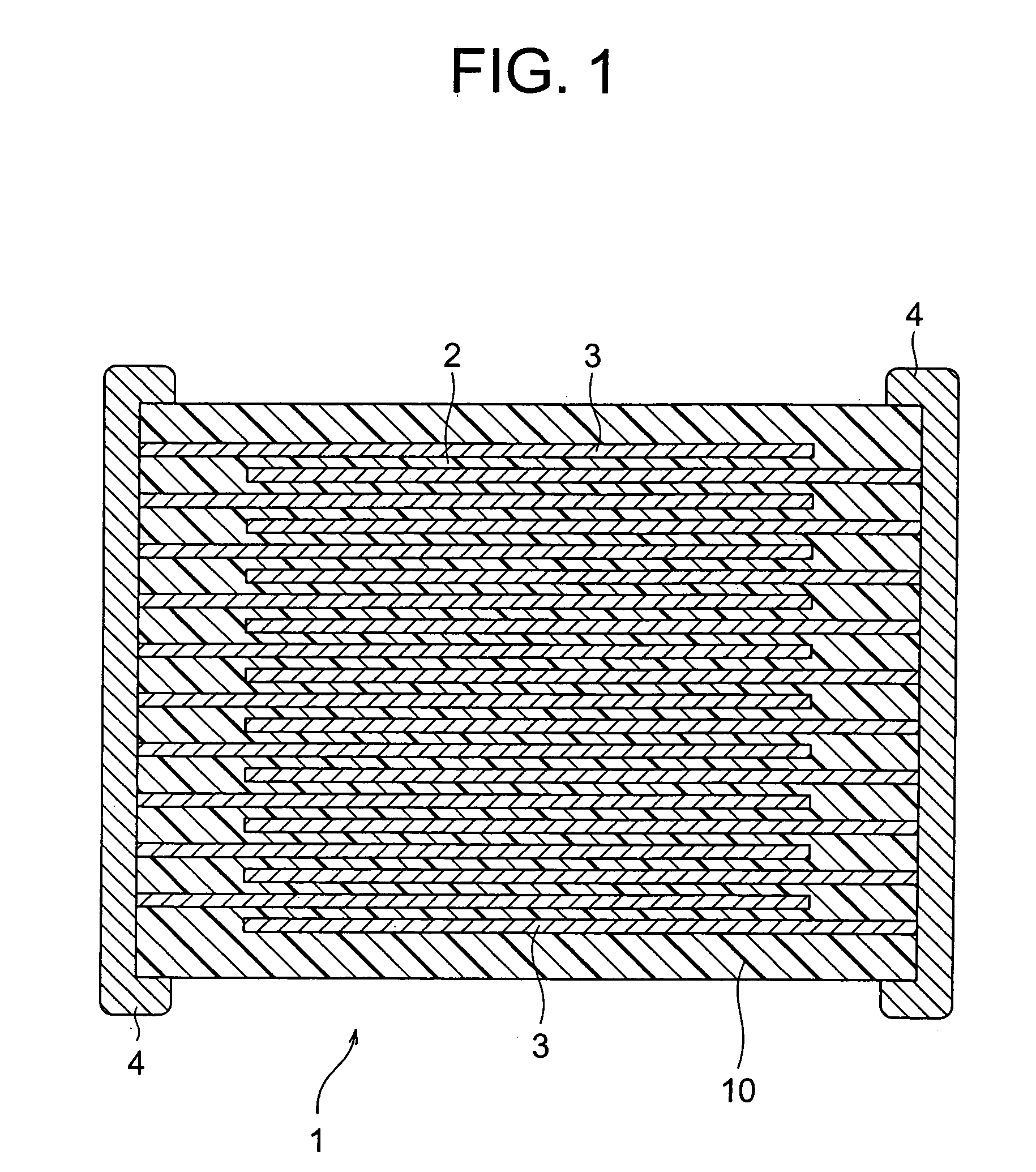

Dielectric ceramic composition and electronic device

ActiveUS7262146B2High specific permittivityReducing atmosphereLayered productsFixed capacitor dielectricBarium titanateMaterials science

A dielectric ceramic composition, comprising a main component including barium titanate; a first subcomponent including at least one kind selected from MgO, CaO, BaO and SrO; a second subcomponent functioning as a sintering auxiliary agent; a third subcomponent including at least one kind selected from V2O5, MoO3 and WO3; a fourth subcomponent including an oxide of R1 (note that R1 is at least one kind selected from Sc, Er, Tm Yb and Lu); a fifth subcomponent including CaZrO3 or CaO+ZrO2; and an eighth subcomponent including an oxide of A (note that A is at least one kind selected from a cation element group having an effective ionic radius at the time of 6 coordination of 0.065 nm to 0.085 nm); wherein a ratio of the eighth subcomponent with respect to 100 moles of the main component is 0 to 4 moles (note that 0 mole and 4 moles are excluded, and the value is in terms of an A oxide).

Owner:TDK CORPARATION

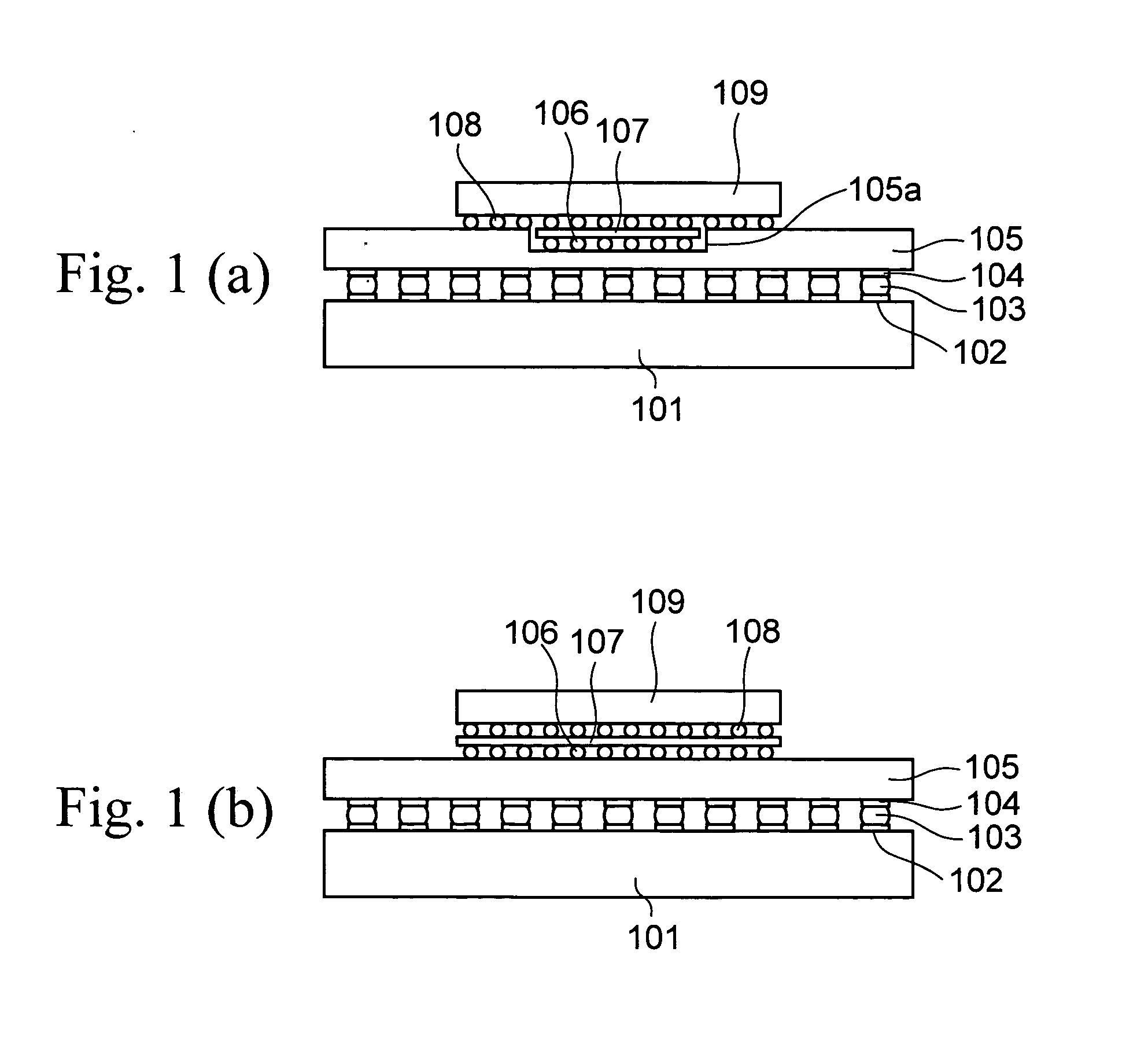

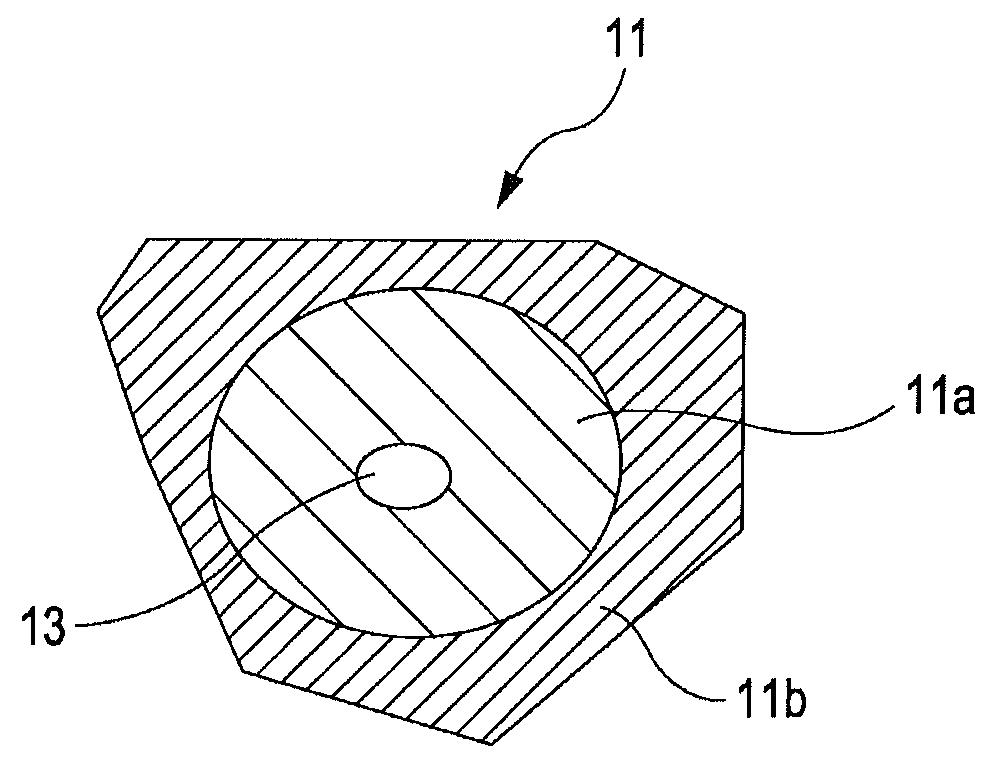

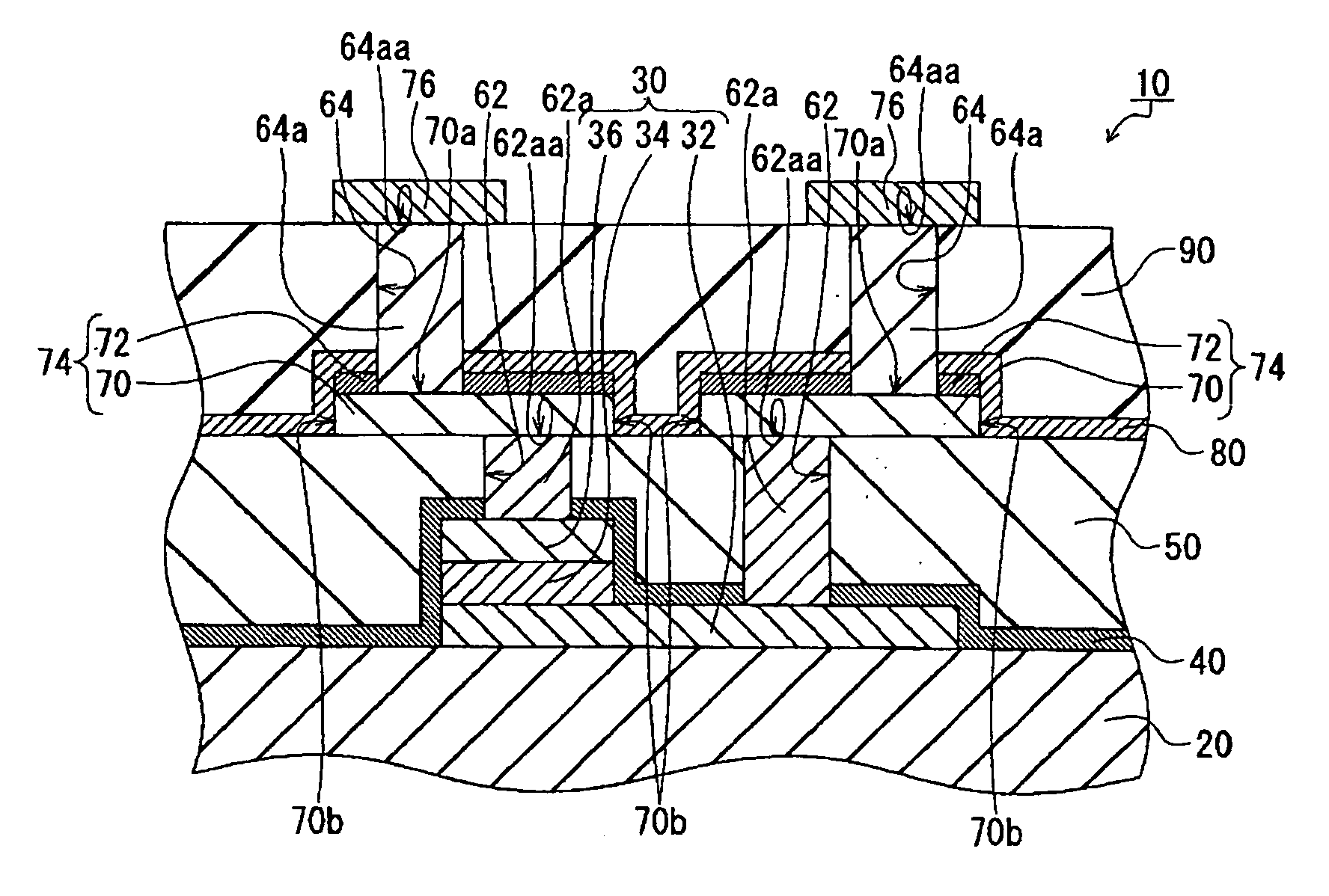

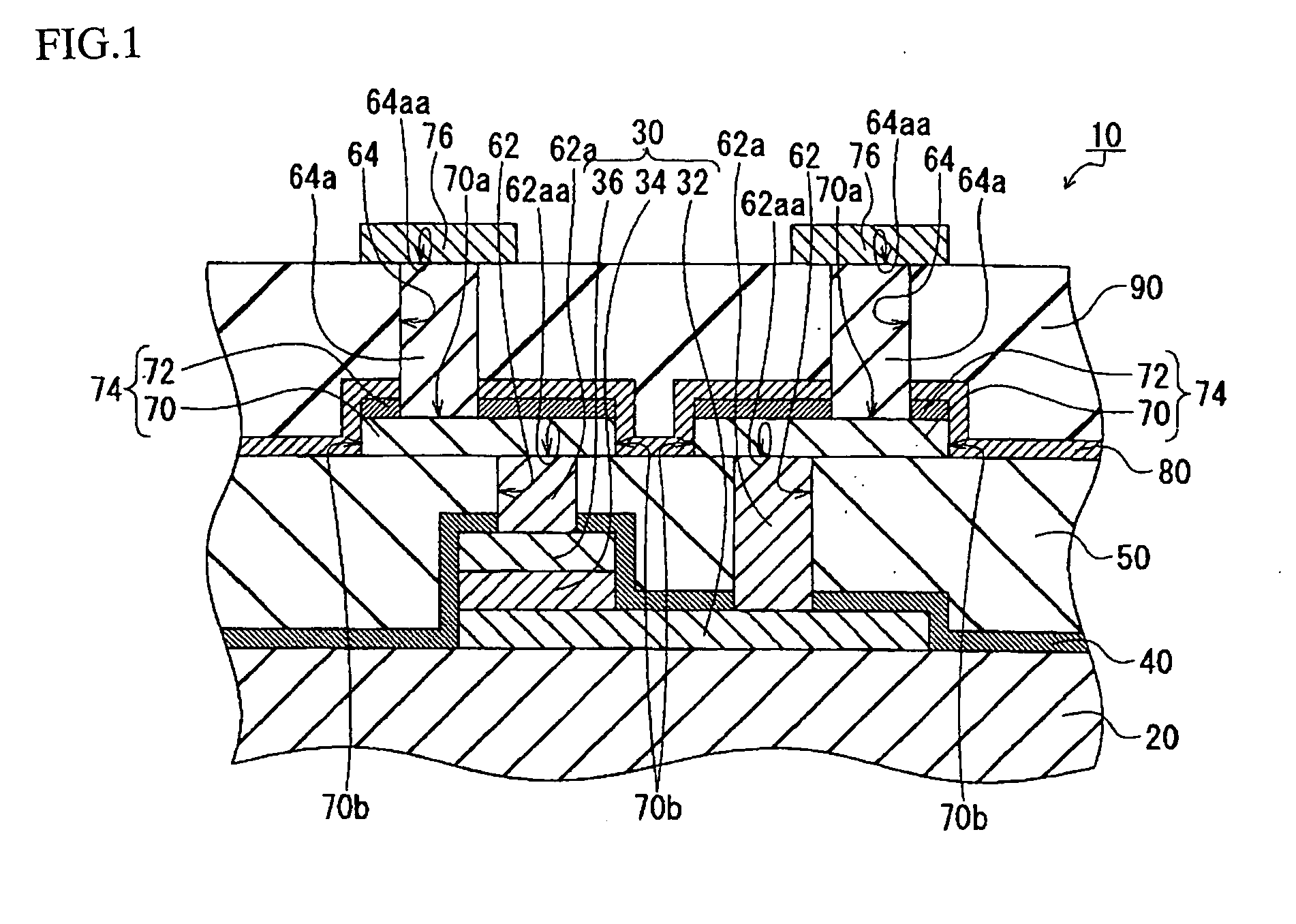

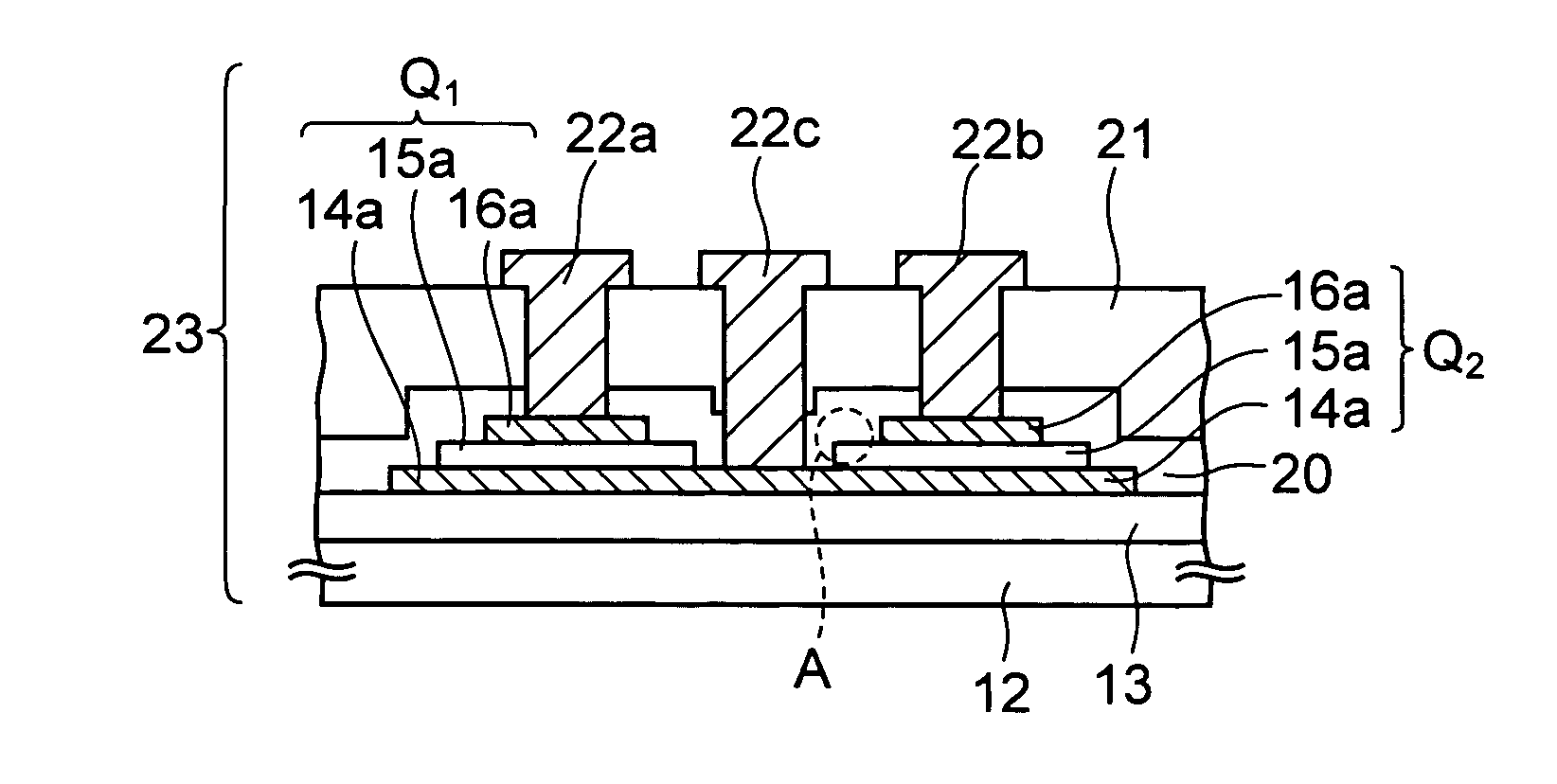

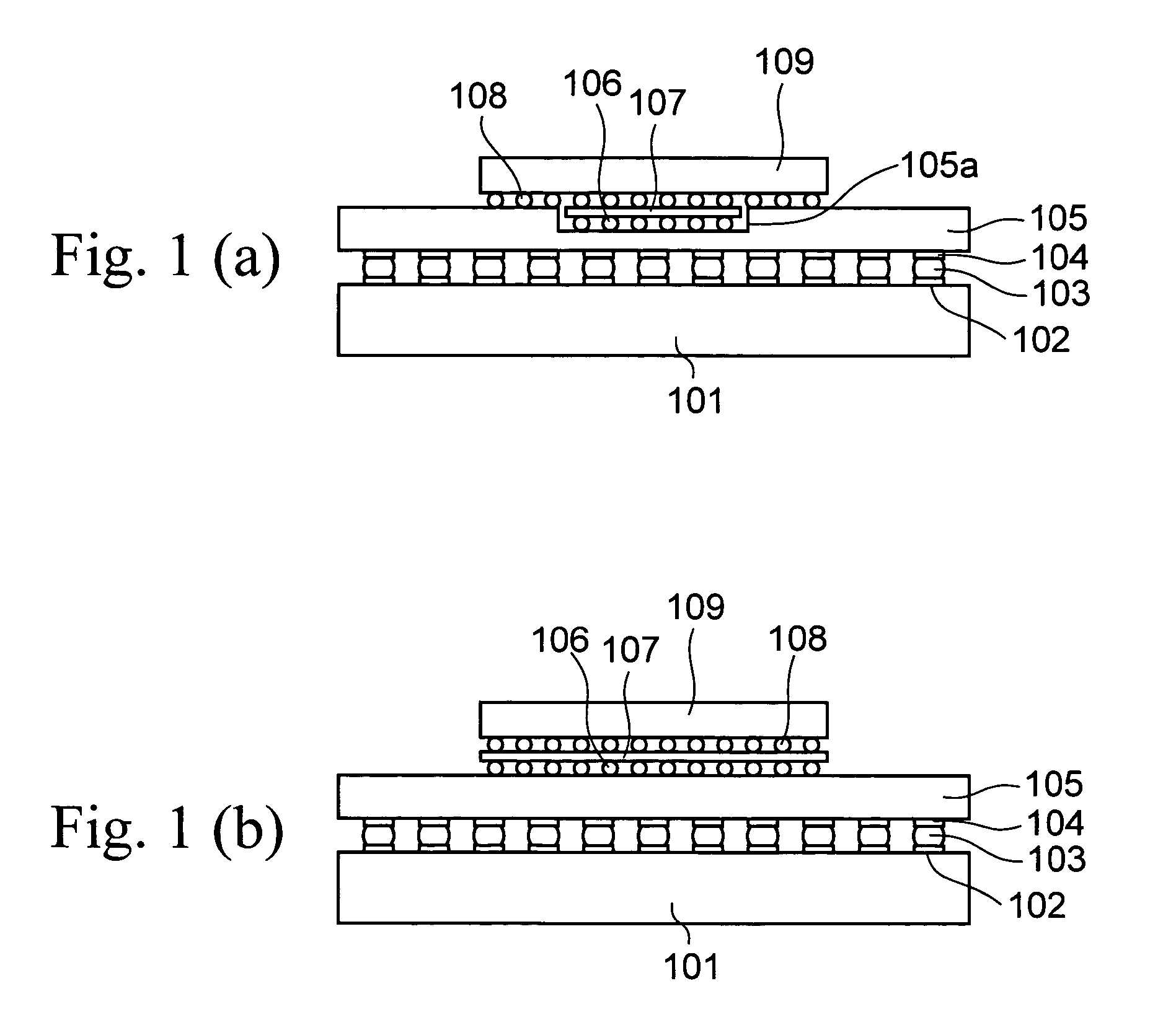

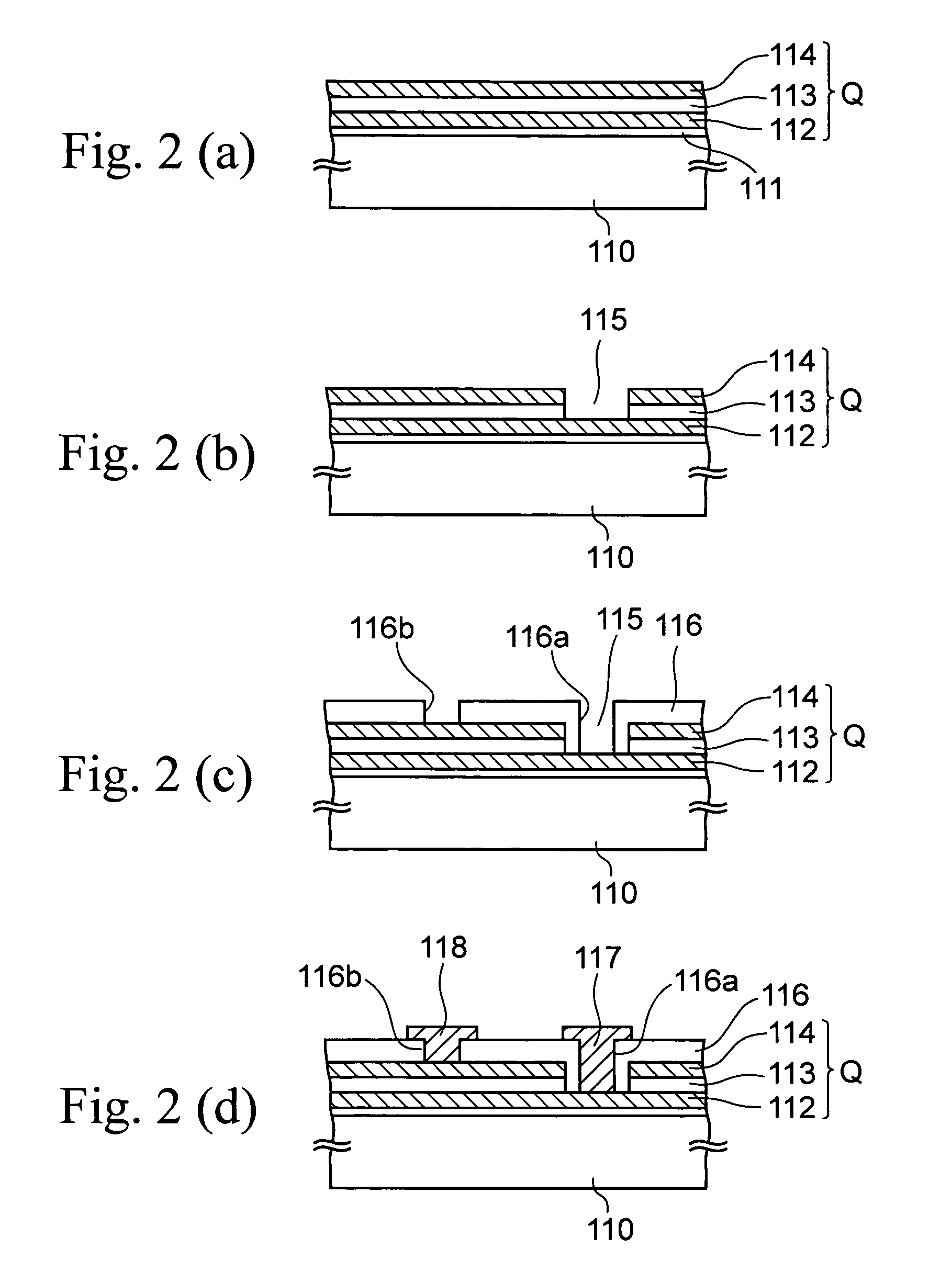

Capacitive element, method of manufacture of the same, and semiconductor device

InactiveUS20070034989A1Shorten the connection distanceAvoiding characteristicThin/thick film capacitorSemiconductor/solid-state device detailsDielectricCapacitance

A capacitive element is characterized by including: a base (12); a lower barrier layer (13) formed on the base (12); capacitors (Q1 and Q2) made by forming a lower electrode (14a), capacitor dielectric layers (15a), and upper electrodes (16a) in this order on the lower barrier layer (13); and an upper barrier layer (20) covering at least the capacitor dielectric layers (15a) and the lower barrier layer (13).

Owner:FUJITSU LTD

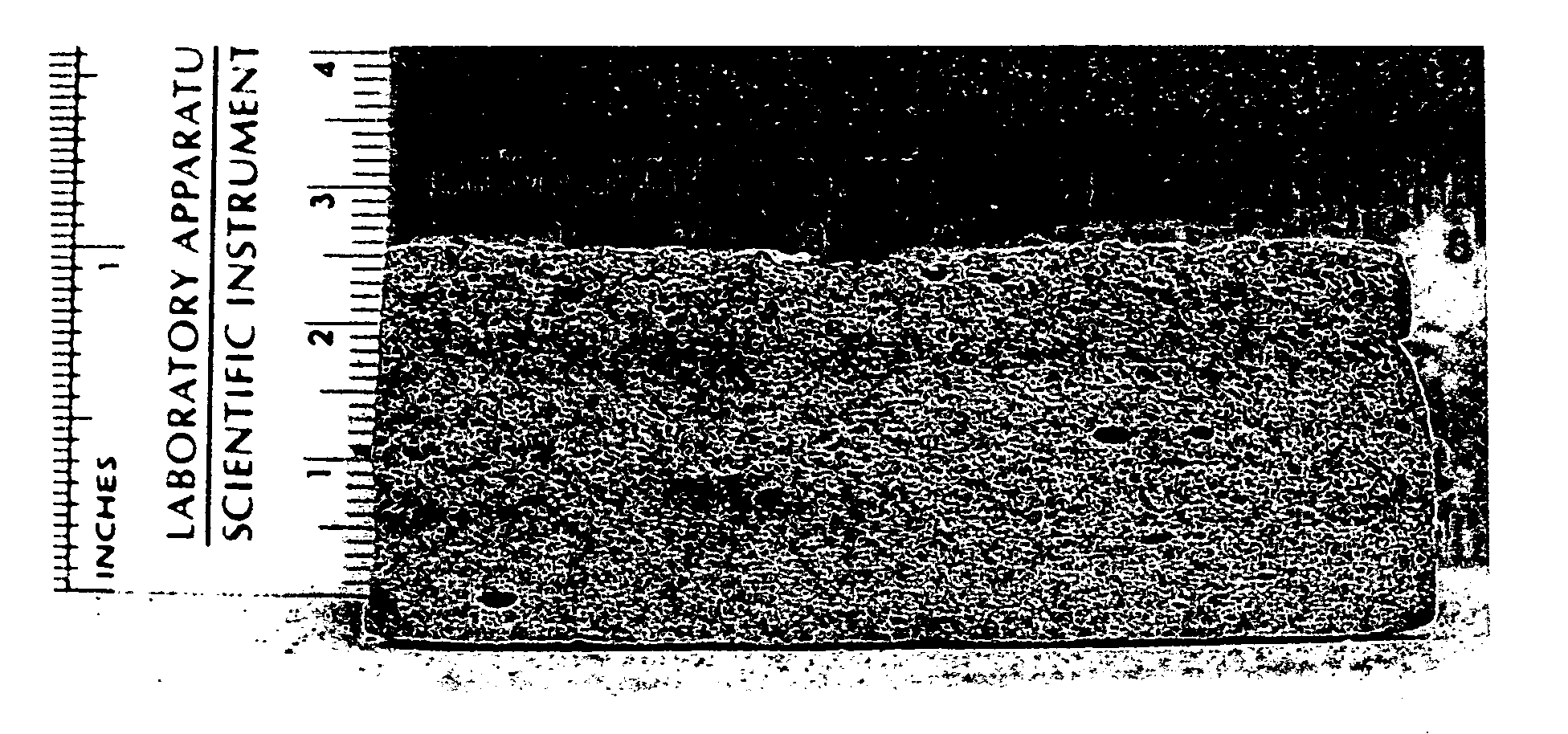

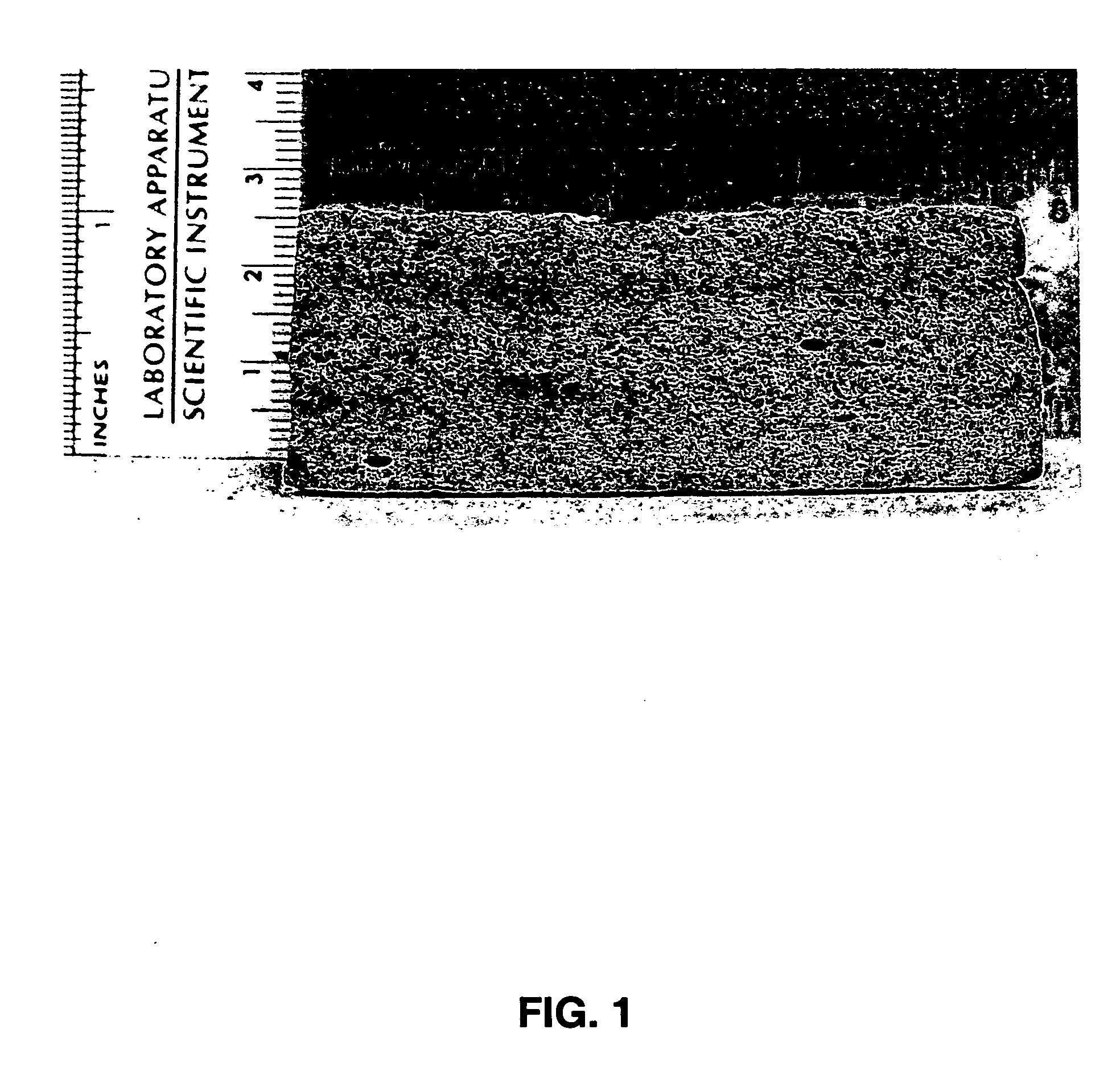

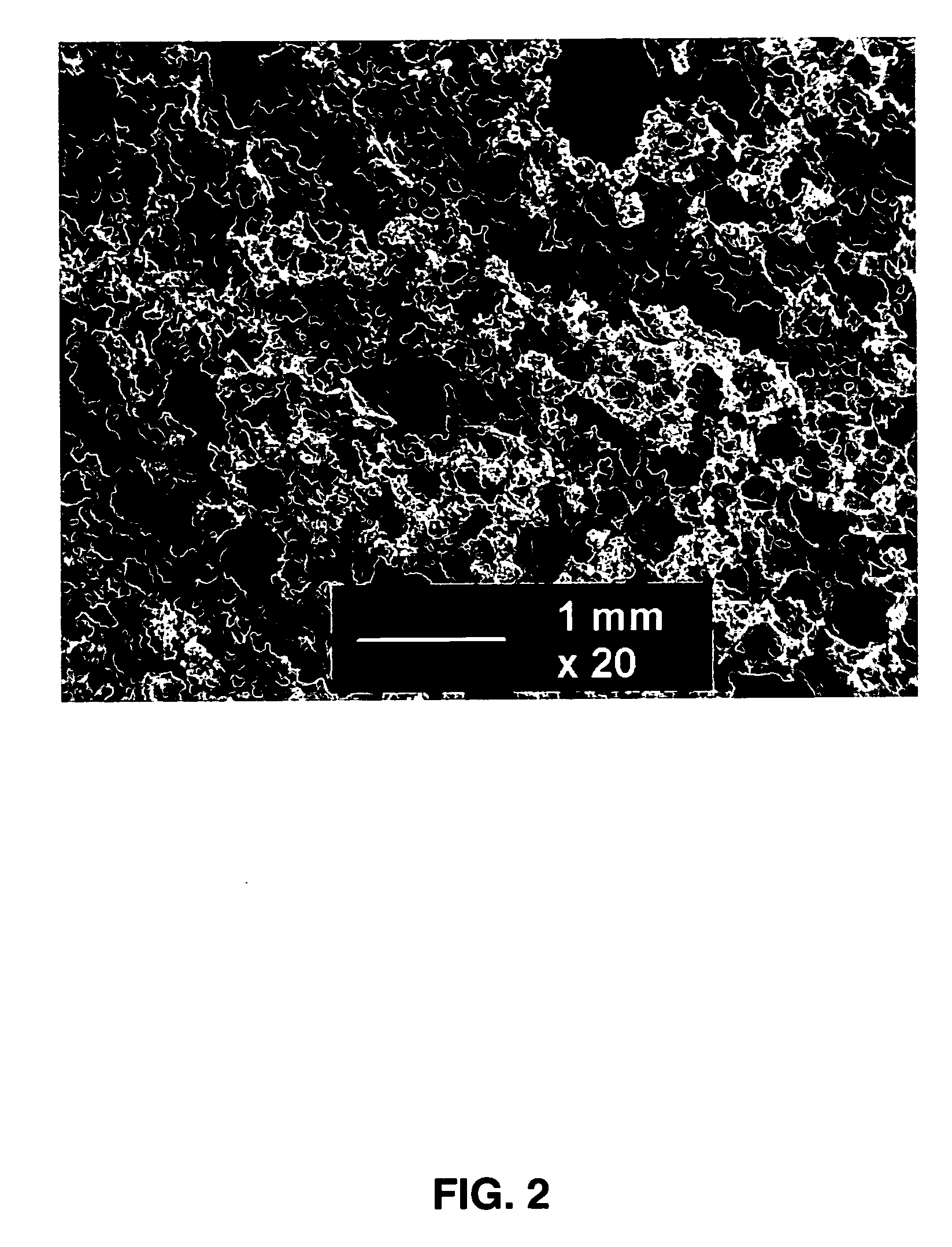

High porosity metal biporous foam

InactiveUS20070081911A1Reducing atmosphereTransportation and packagingMetal-working apparatusCopperMetal powder

An environmentally friendly process for producing metal biporous foam by using filamentary metal powders such as nickel or copper. The filamentary metal powders are initially wet when combined with a suitable foam former such as methylcellulose. Because the filamentary metal powder is wet, it does not extract water from the foam structure thereby ensuring a highly porous metal foam having both high macroporosity and microporosity.

Owner:INCO

Multilayer ceramic capacitor

InactiveUS7652870B2Low reliabilityReducing atmosphereFixed capacitor dielectricStacked capacitorsMetallurgyBarium titanate

A multilayer ceramic capacitor includes a plurality of ceramic dielectric layers, a plurality of inner electrode layers and and external electrodes. The ceramic dielectric layers includes barium titanate crystal grains having pores inside. The inner electrode layers are between the ceramic dielectric layers. The external electrodes are electrically connected to the inner electrode layers. The barium titanate crystal grains each have a core-shell structure which include a core and a shell around the core. The the pores are mainly formed in the cores.

Owner:KYOCERA CORP

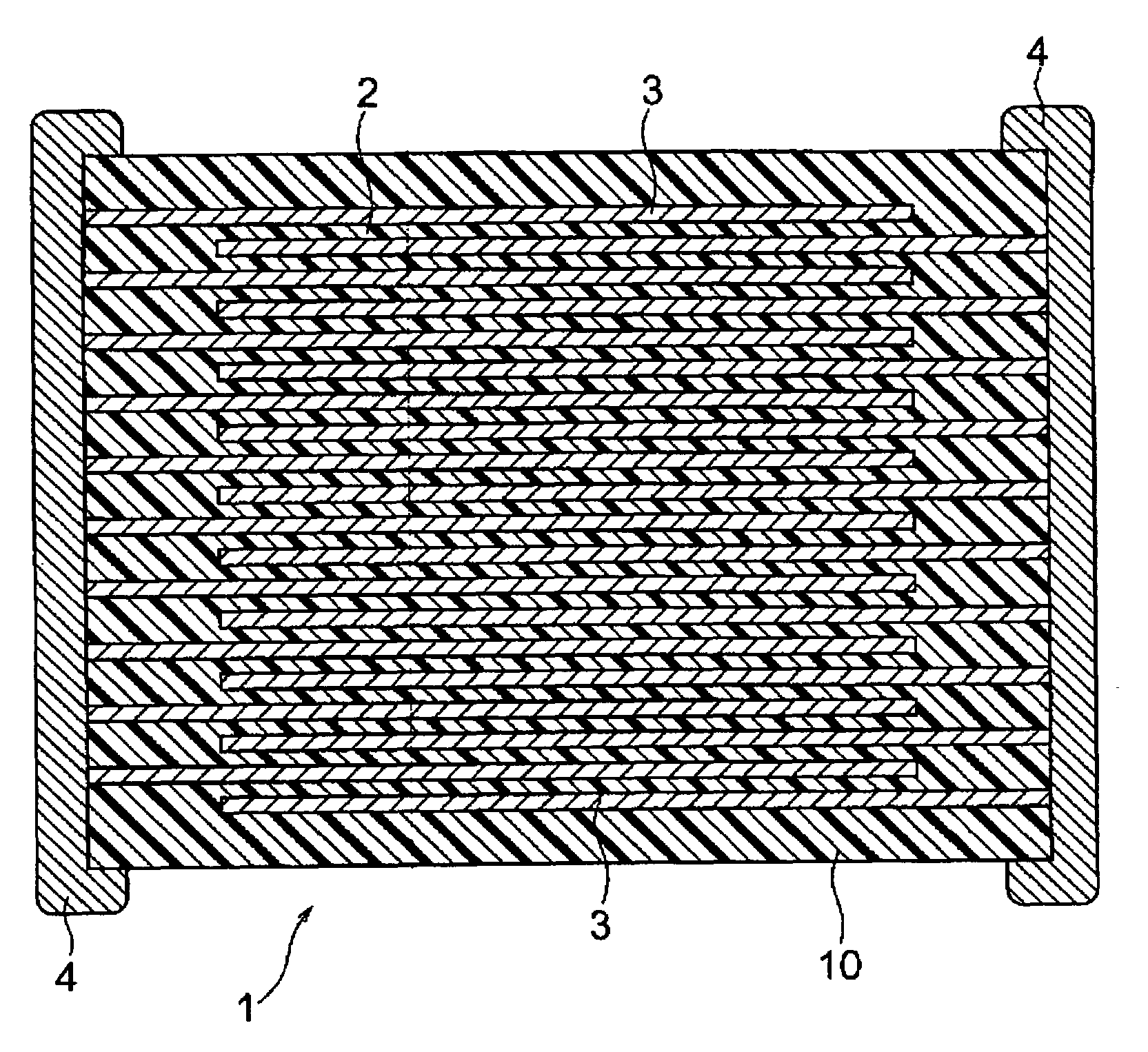

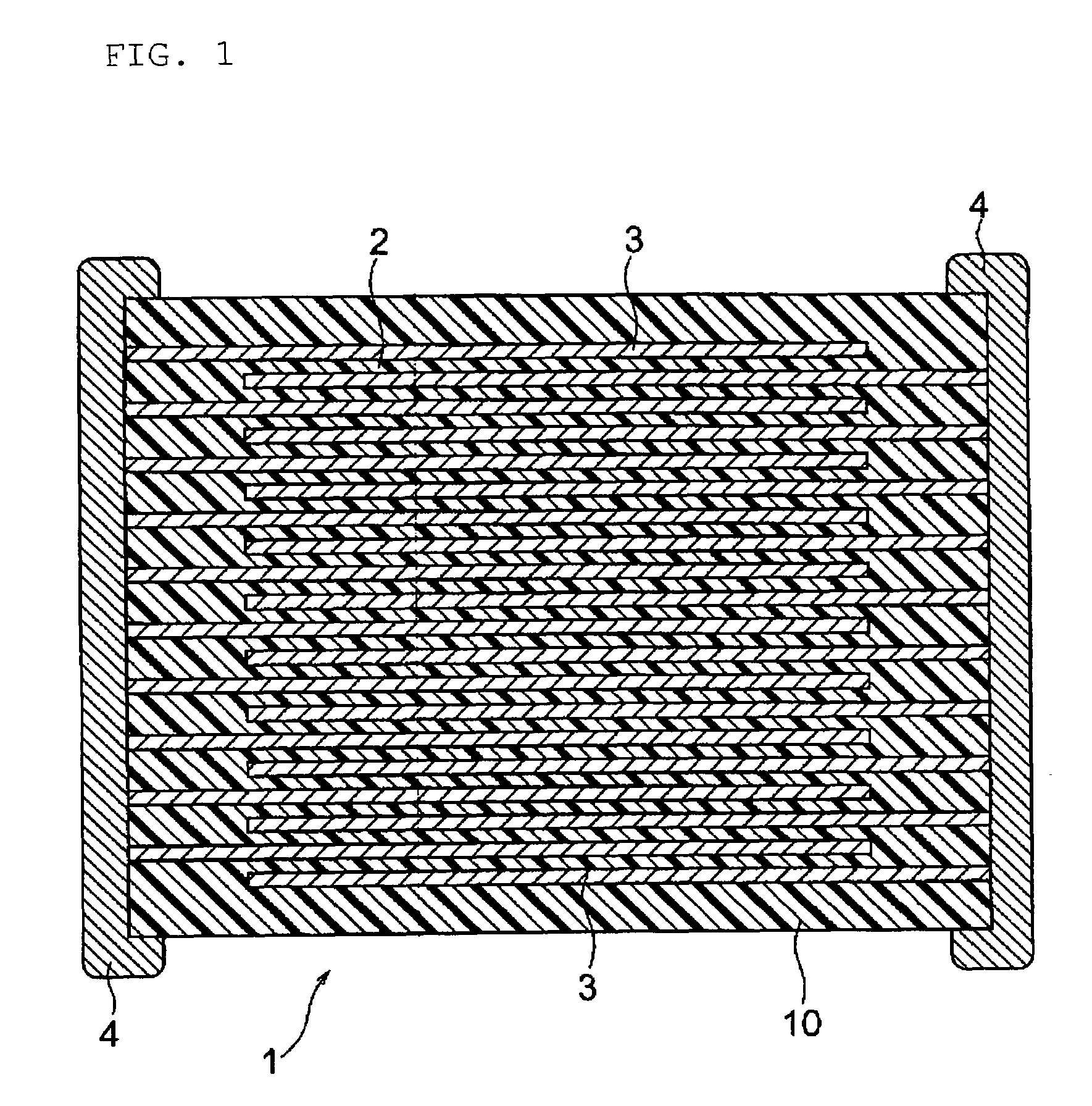

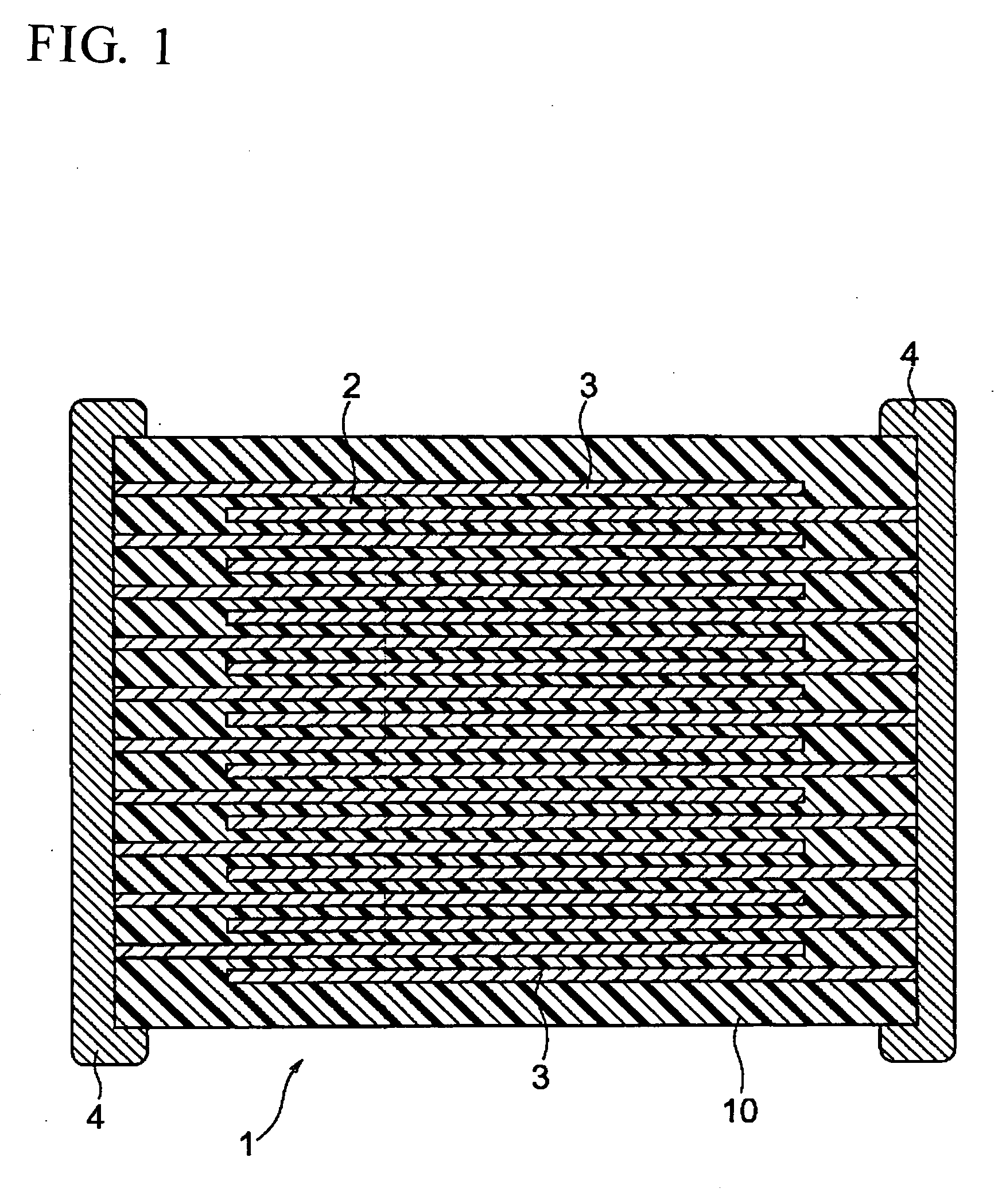

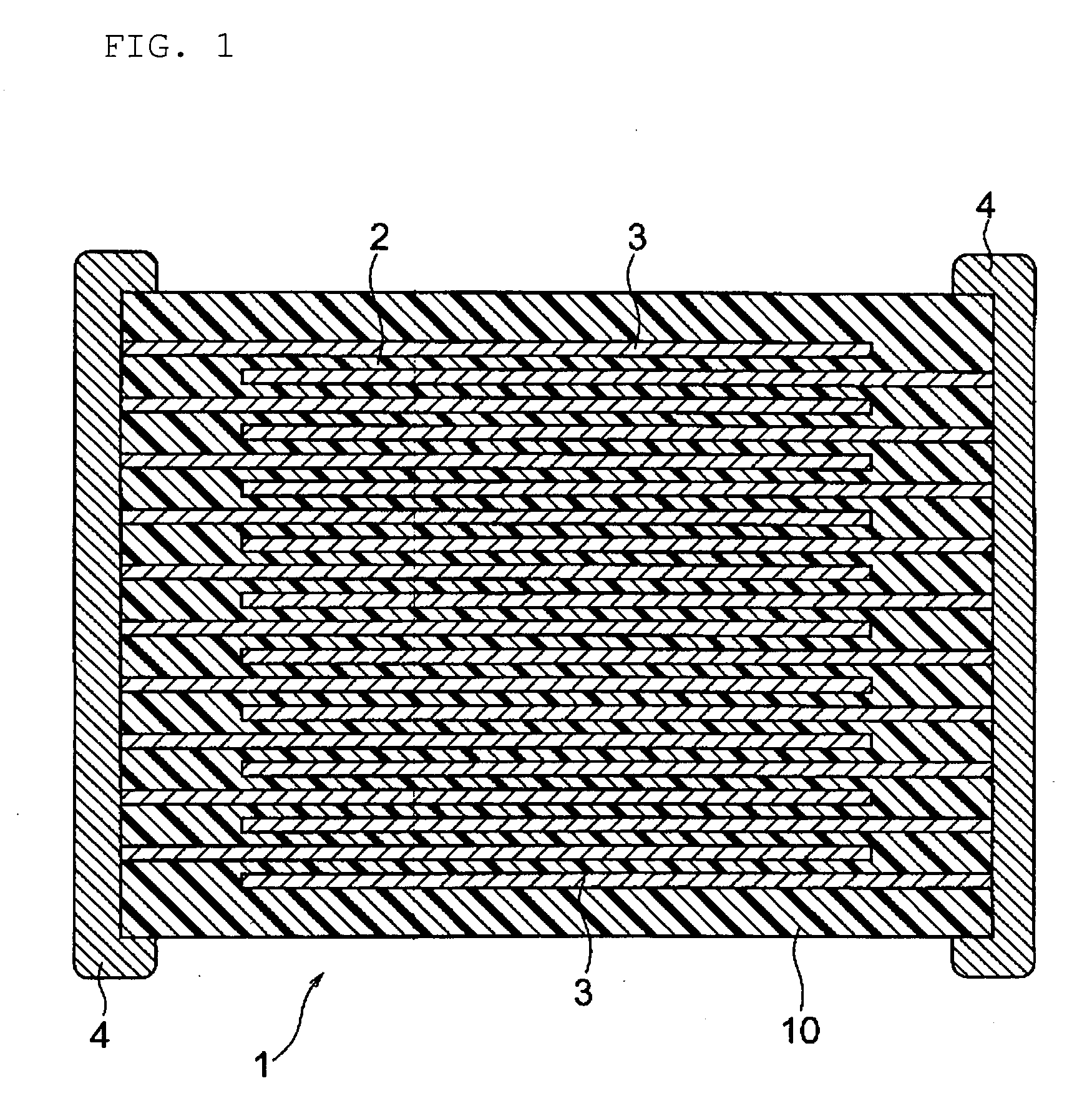

Laminated ceramic capacitor

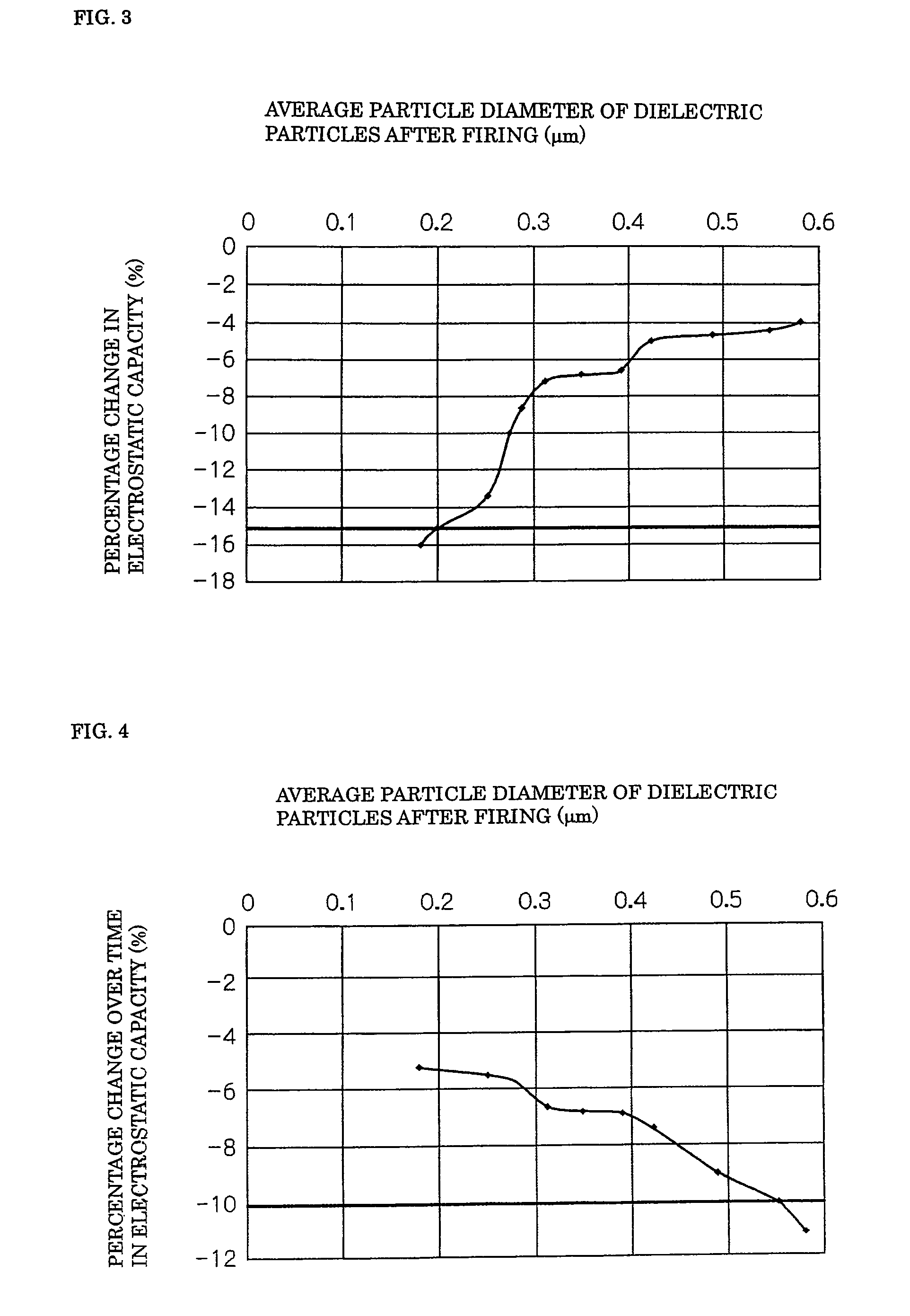

ActiveUS7898793B2Small amount of changeImprove featuresFixed capacitor dielectricCeramicsBarium titanateCeramic capacitor

A multilayer ceramic capacitor having a laminate including alternately stacked dielectric layers of a sintered compact composed of crystal particles of a dielectric porcelain composite and internal-electrode layers. The dielectric porcelain composite comprises a primary constituent containing barium titanate; a first accessory constituent composed of at least one of MgO, CaO, BaO, and SrO; a second accessory constituent containing silicon oxide as a major constituent; a third accessory constituent composed of at least one of V2O5, MoO3, and WO3; a fourth accessory constituent composed of an oxide of R1 (wherein R1 is at least one of Sc, Er, Tm, Yb, and Lu); a fifth accessory constituent composed of CaZrO3 or a combination of CaO and ZrO2; and a sixth accessory constituent composed of an oxide of R2 (wherein R2 is at least one of Y, Dy, Ho, Tb, Gd, and Eu).

Owner:TDK CORPARATION

Dielectric ceramic composition and electronic device

ActiveUS7580242B2Extended service lifeReducing atmosphereFixed capacitor dielectricStacked capacitorsMaterials scienceOxide

Owner:TDK CORPARATION

Dielectric ceramic composition and electronic device

ActiveUS20060160693A1High specific permittivityLarge capacityEdge grinding machinesFixed capacitor dielectricDielectricElectron

A dielectric ceramic composition comprising a predetermined main component and a fifth subcomponent including an oxide of A (note that A is at least one king selected from a cation element group having an effective ionic radius of 0.065 nm to 0.085 nm at the time of 6 coordination); and the dielectric ceramic composition comprises a plurality of crystal grains including Ca elements and, when assuming that an average value of a concentration of entire Ca exiting in said respective crystal grains is grain Ca concentration, at least unevenness exists in said grain Ca concentration between said crystal grains and it is 5% or higher in a CV value.

Owner:TDK CORPARATION

Dielectric ceramic composition and electronic device

A dielectric ceramic composition having a main ingredient including a dielectric oxide expressed by the formula {(Me1-xCax)O}m.(Zr1-yTiy)O2, where the symbol Me indicating the name of the element in said formula is at least one of Sr, Mg, and Ba and where the symbols m, x, and y indicating the molar ratios of the formulation in the formula are in relationships of 0.995≦m≦1.020, 0<x≦0.15, and 0≦y≦1.00, a first sub ingredient including an oxide of R (where R is a rare earth element), a second sub ingredient including an oxide of Mg, and a third sub ingredient including an oxide of Mn, wherein the ratios of the sub ingredients with respect to 100 moles of the main ingredient are first sub ingredient: 0.1 to 6 moles (value converted to oxide of R), second sub ingredient: 0.1 to 5 moles (value converted to oxide of Mg), and third sub ingredient: 0.1 to 2.5 moles (value converted to oxide of Mn), said dielectric ceramic composition further having as a fourth sub ingredient an oxide of A (where A is at least one type of element selected from the group of anionic elements having an effective ion radius at the time of hexacoordination of 0.065 nm to 0.085 nm).

Owner:TDK CORPARATION

Dielectric ceramic composition and electronic device

ActiveUS7358208B2High specific permittivityThin layerEdge grinding machinesFixed capacitor dielectricDielectricElectron

A dielectric ceramic composition comprising a predetermined main component and a fifth subcomponent including an oxide of A (note that A is at least one king selected from a cation element group having an effective ionic radius of 0.065 nm to 0.085 nm at the time of 6 coordination); and the dielectric ceramic composition comprises a plurality of crystal grains including Ca elements and, when assuming that an average value of a concentration of entire Ca exiting in said respective crystal grains is grain Ca concentration, at least unevenness exists in said grain Ca concentration between said crystal grains and it is 5% or higher in a CV value.

Owner:TDK CORPARATION

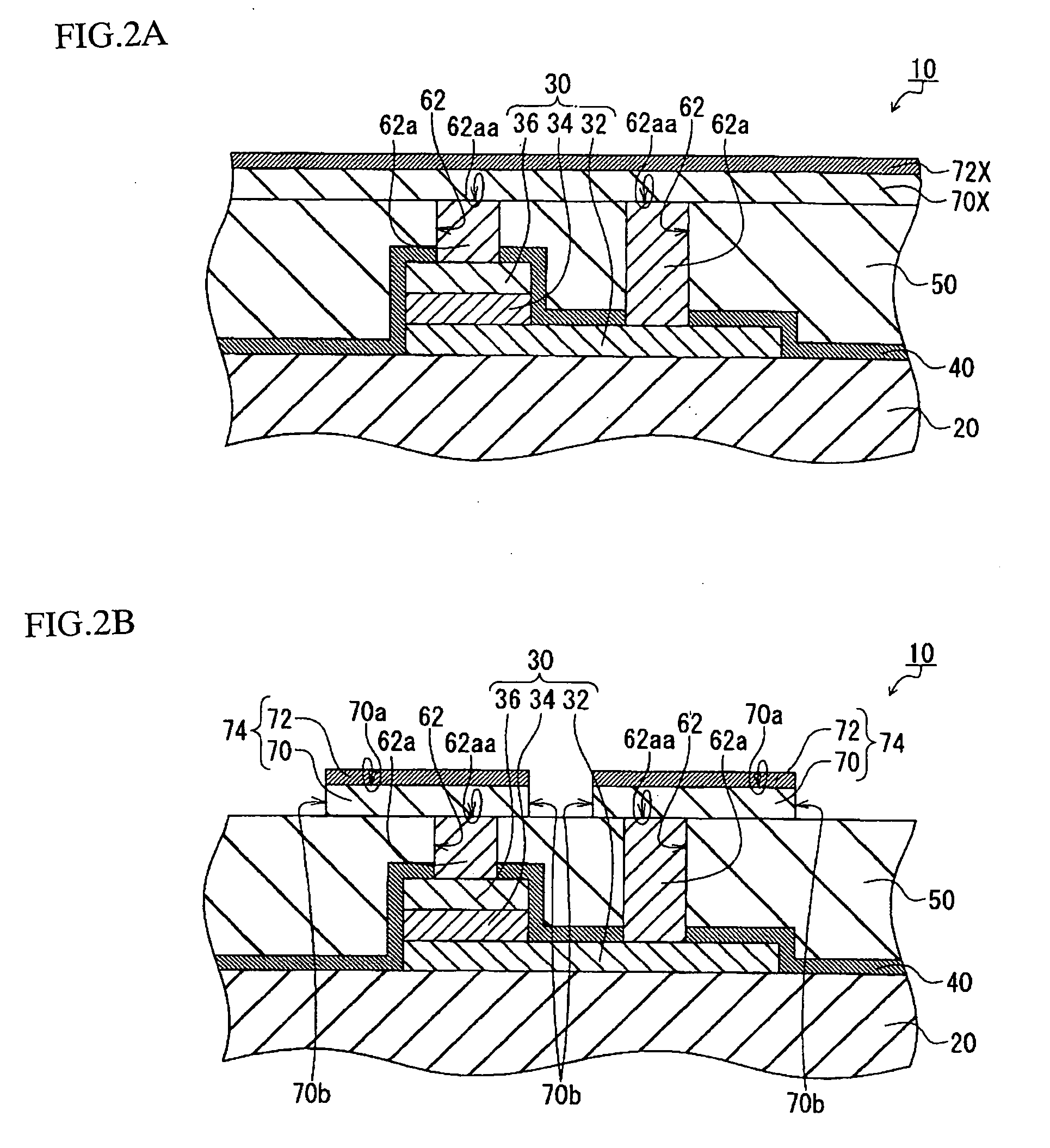

Ferroelectric memory and method for manufacturing the same

InactiveUS20060102942A1Blocking phenomenonDeterioration of characteristic can be preventedSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringFerroelectric capacitor

The ferroelectric memory includes a ferroelectric capacitor structure having a ferroelectric layer and formed on a first insulating film, a first barrier film formed to cover the ferroelectric capacitor structure and the first insulating film, a second insulating film formed on the first barrier film, a first buried contact formed to pass through the second insulating film and the first barrier film, a first wiring layer formed on the second insulating film, an oxide film formed on the first wiring layer, a second barrier film formed to cover the oxide film, the first wiring layer and the second insulating film, a third insulating film formed on the second barrier film, a second buried contact formed to pass through the third insulating film, the second barrier film and the oxide film, and a second wiring layer formed on the third insulating film.

Owner:LAPIS SEMICON CO LTD

Dielectric ceramic composition and electronic device

ActiveUS20080297979A1Improve withstand pressure (breakdown voltage)Good specific permittivityFixed capacitor dielectricStacked capacitorsMaterials scienceOxide

A dielectric ceramic composition comprising BamTiO2+m (note that “m” satisfies 0.99≦m≦1.01) and BanZrO2+n (note that “n” satisfies 0.99≦n≦1.01), an oxide of Mg, an oxide of R (note that R is at least one selected from Sc, Y, La, Ce, Pr, Nd, Pm, Sm, Eu, Gd, Tb, Dy, Ho, Er, Tm, Yb and Lu), an oxide of at least one element selected from Mn, Cr, Co and Fe, and an oxide of at least one element selected from Si, Li, Al, Ge and B. With respect to 100 moles of said BamTiO2+m, 35 to 65 moles of BanZrO2+n, 4 to 12 moles of an oxide of Mg, 4 to 15 moles of an oxide of R, 0.5 to 3 moles of an oxide of Mn, Cr, Co and Fe, and 3 to 9 moles of an oxide of Si, Li, Al, Ge and B are included therein.

Owner:TDK CORPARATION

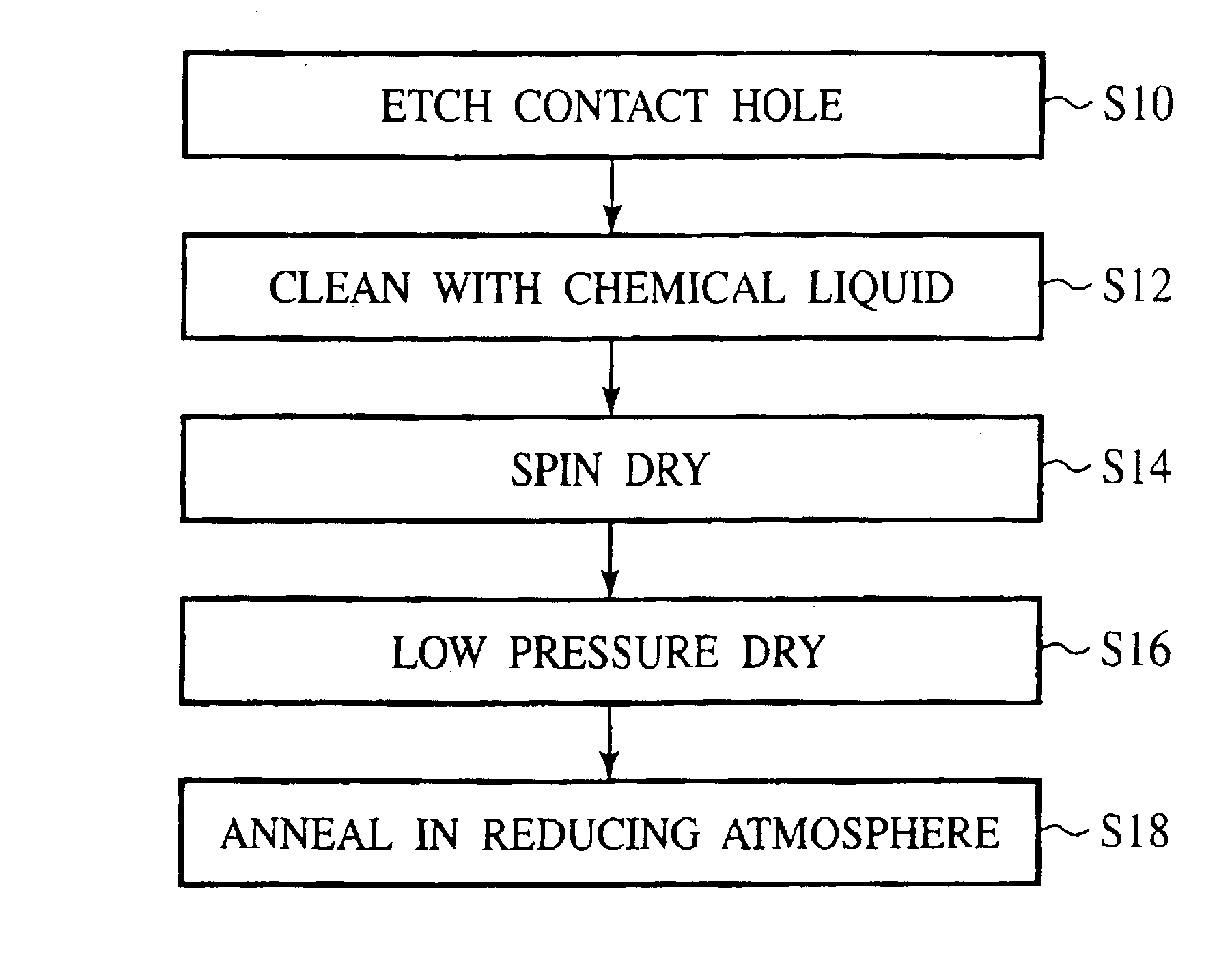

Cross reference to related application

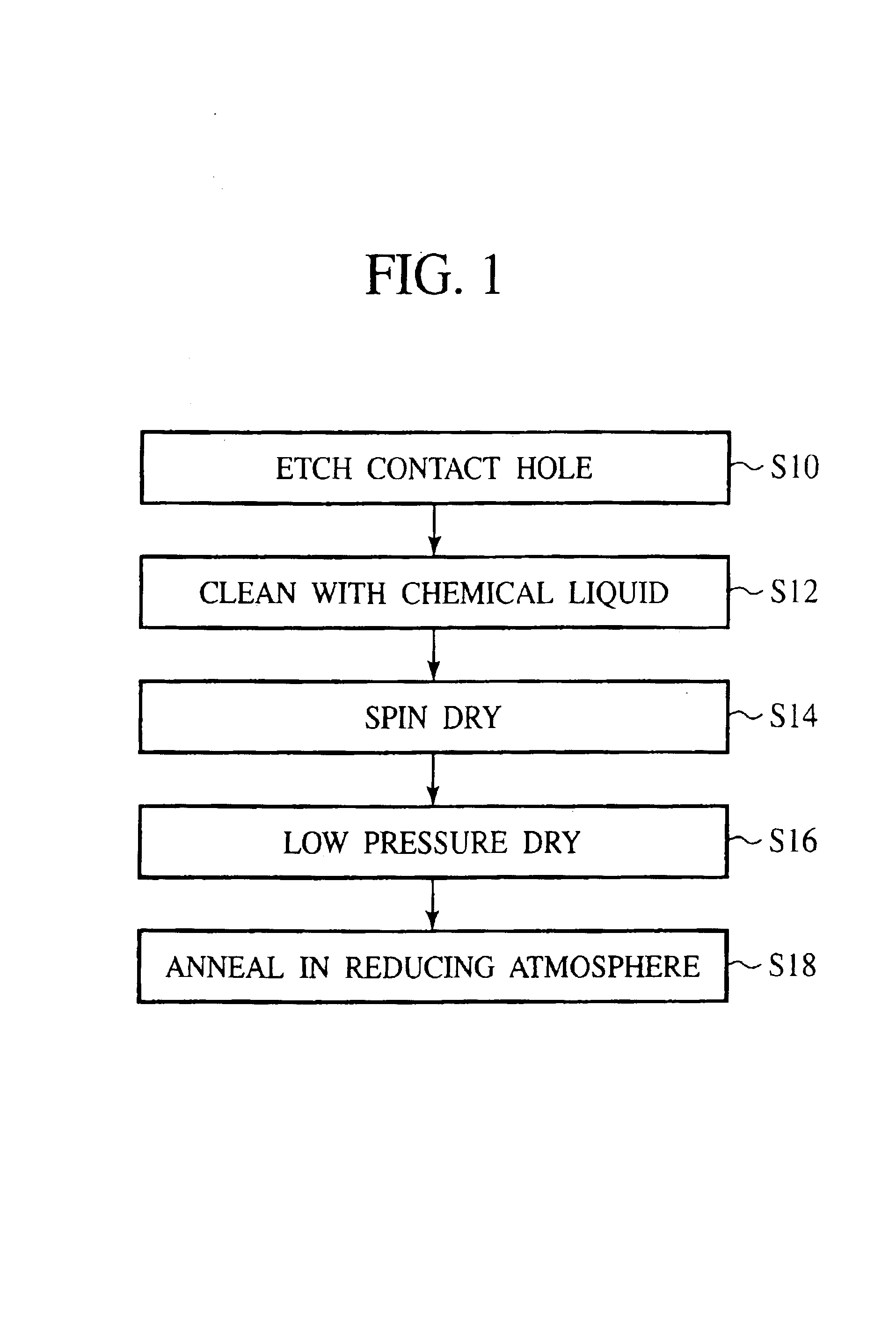

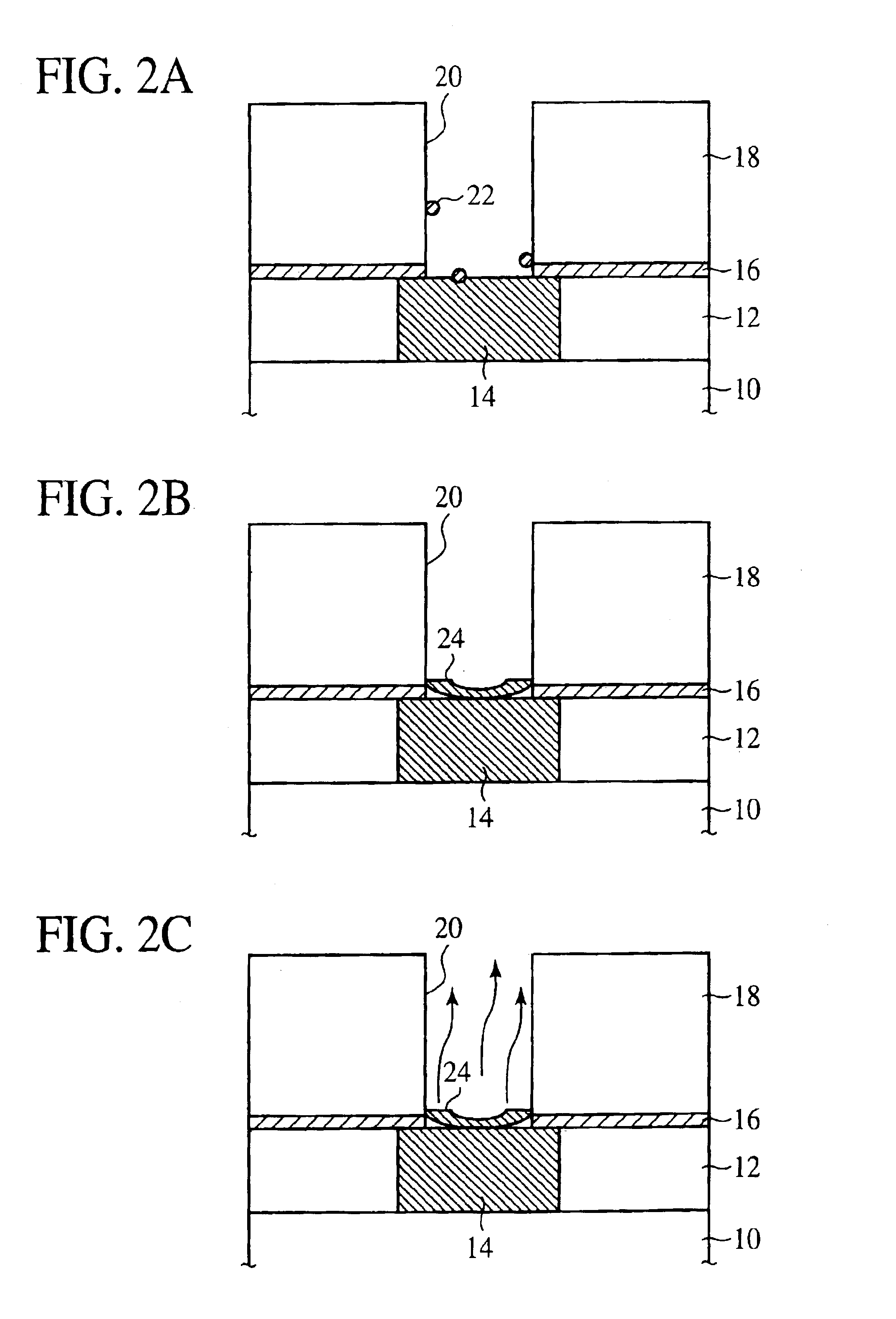

ActiveUS6930045B2High stability and reliabilityGuaranteed high stability and reliabilitySemiconductor/solid-state device manufacturingEngineeringContact hole

The method comprises the step of forming a diffusion preventing film 16 and an insulation film 18 on an insulation film 12 formed on a substrate 10 and having a Cu interconnection layer 14 buried in; the step of forming a contact hole 20 in the insulation film 18 down to the Cu interconnection layer 14; the step of cleaning the substrate 10 with the contact hole 20 formed with a chemical liquid; the step of drying the substrate 10 cleaned with the chemical liquid; and the step of annealing the dried substrate in a reducing atmosphere.

Owner:FUJITSU SEMICON LTD

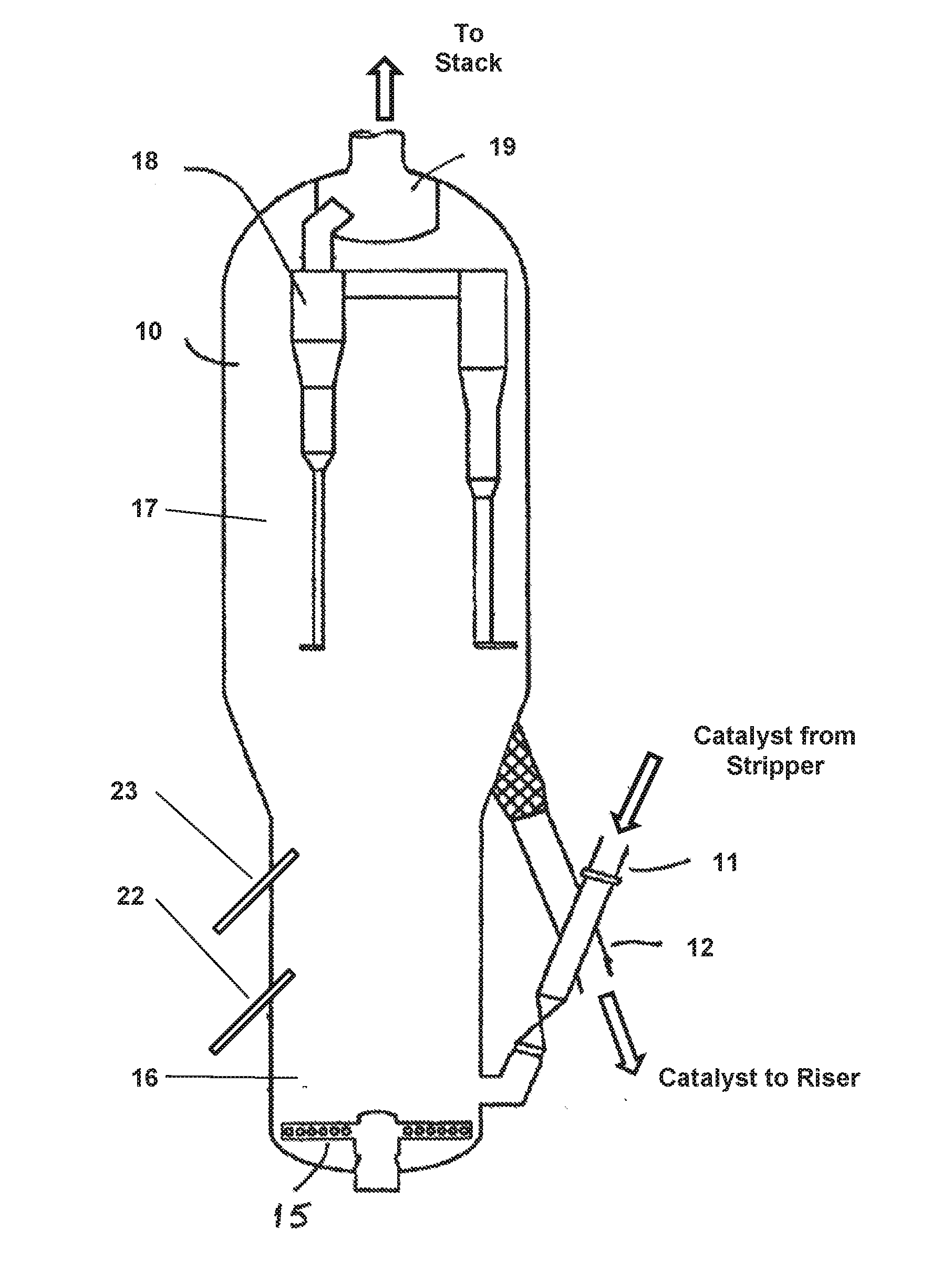

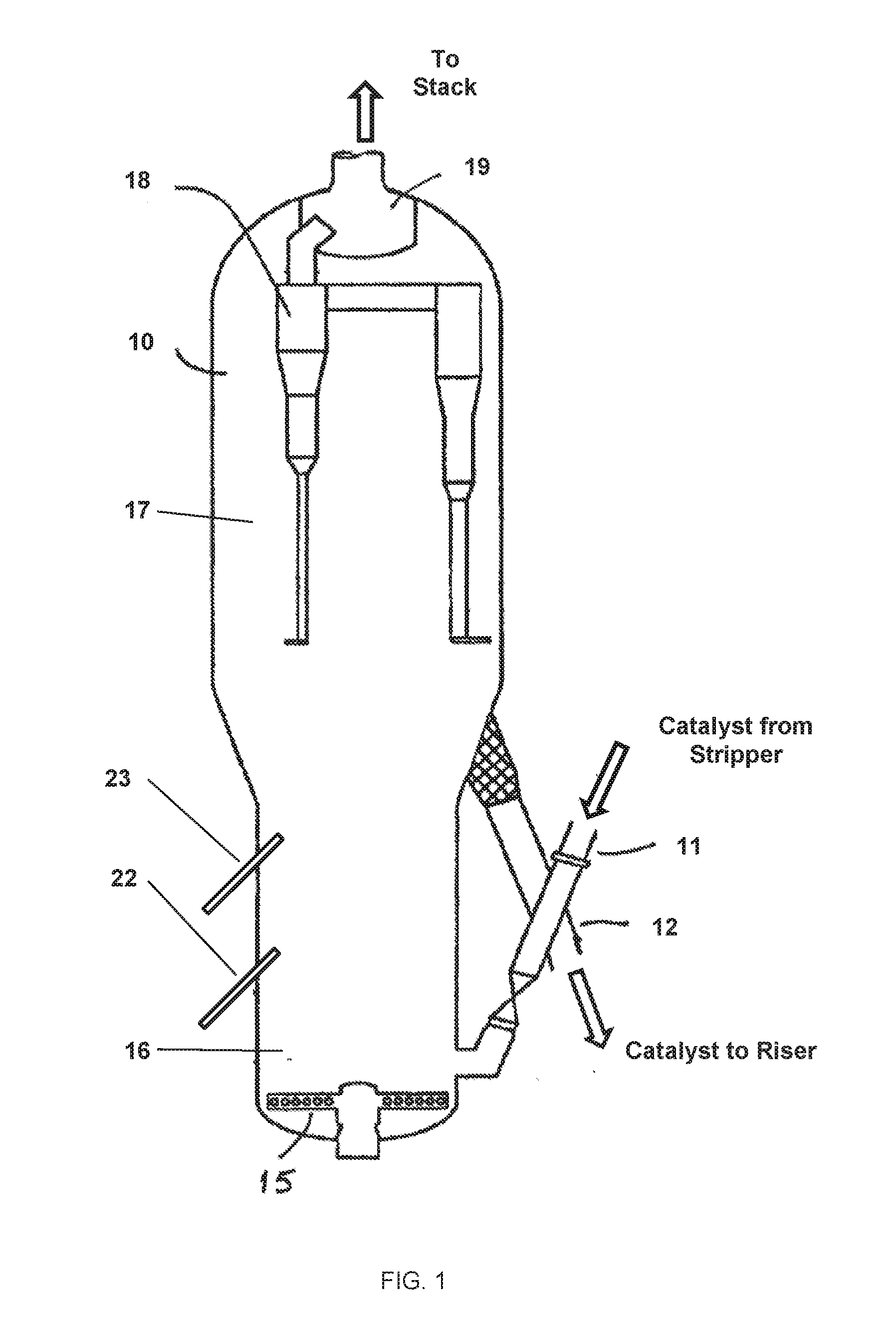

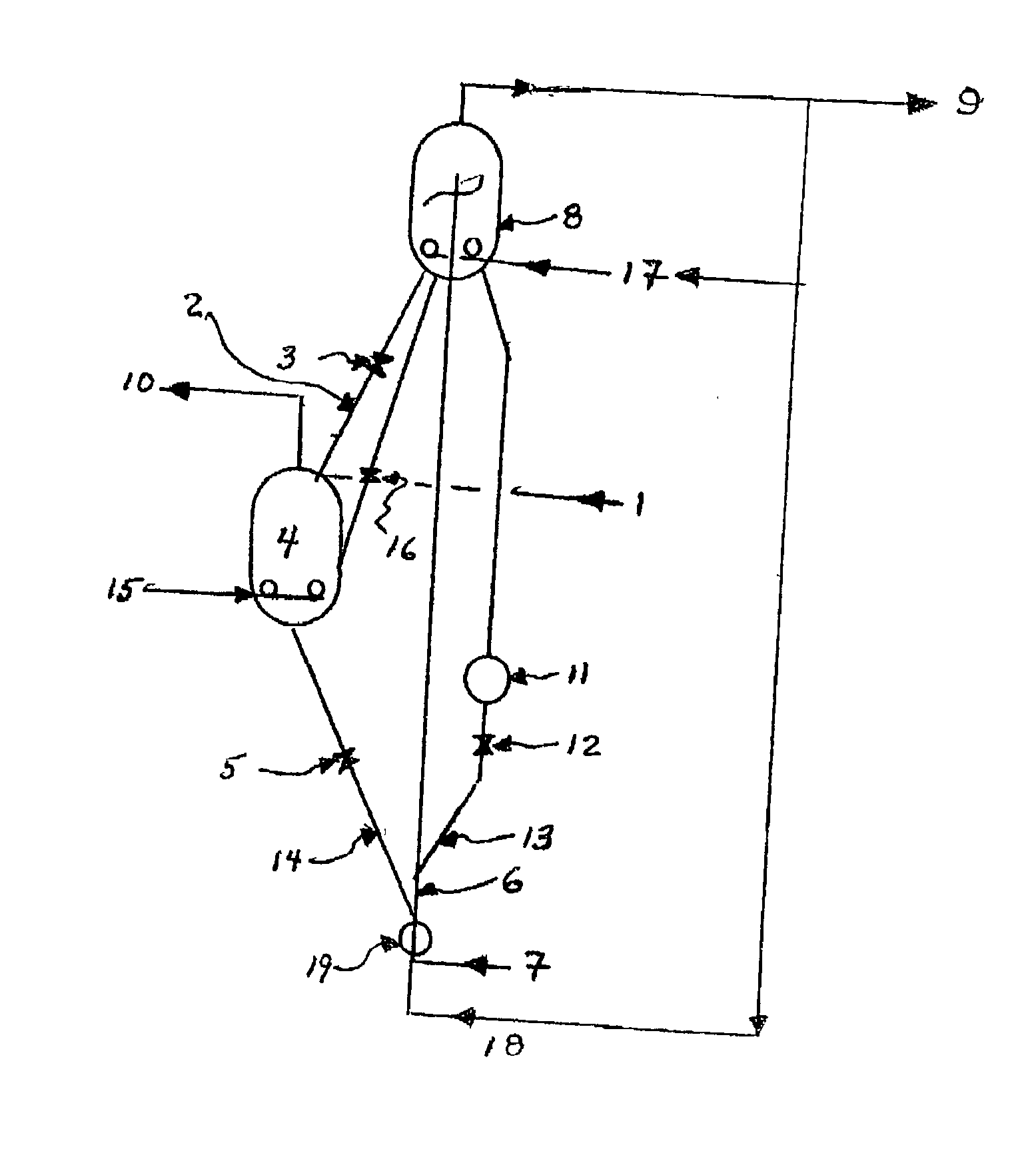

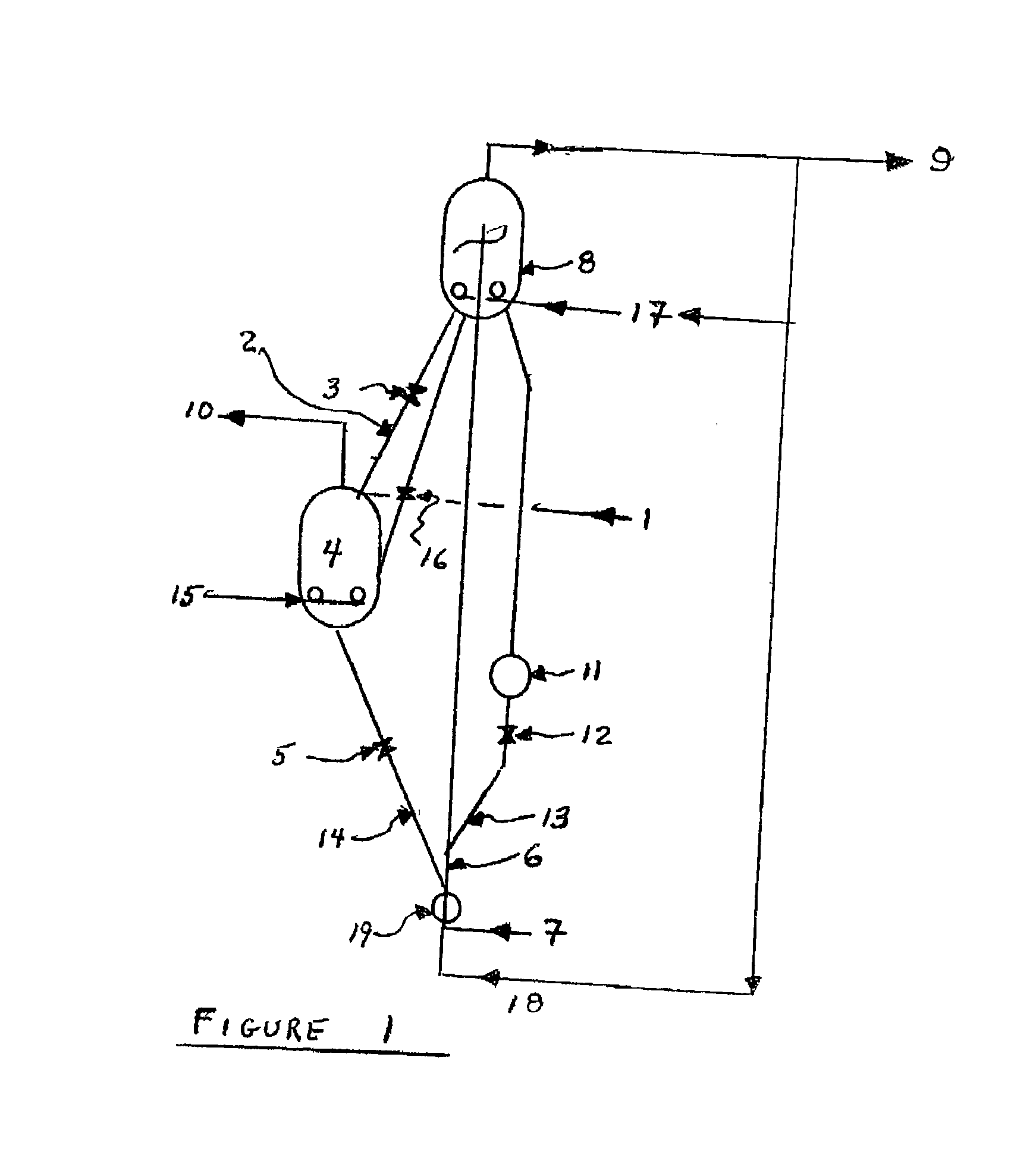

Fluid catalytic cracking with supplemental heat

InactiveUS20160362613A1Improve cooling effectEmission reductionCatalytic crackingEthylene productionLiquid productCombustion

A potentially heat-deficient fluid catalytic cracking process for effecting a bulk boiling point conversion of a high boiling point petroleum feed to lower boiling products in which the overall enthalpy balance between the endothermic cracking and exothermic regeneration is maintained by combustion of a supplemental fuel in the middle or upper region of the dense bed in the regenerator (including the region immediately above the dense phase bed). There is a direct economic benefit from operation of the cracking process in this way since the preferred supplemental fuel is methane (natural gas) which is currently a low cost fuel while liquid products are higher value. Use of natural gas as a supplemental fuel will allow re-optimization of the catalyst and operations separately from the heat balance demand.

Owner:EXXON RES & ENG CO

Electronic component element housing package

ActiveUS20130240262A1Increase bending strengthGreat bond strengthSemiconductor/solid-state device detailsSolid-state devicesManganese oxideMetal

An electronic component element housing package is produced by firing a ceramic substrate for housing an electronic component element and a metal layer for bonding to the ceramic substrate to form an electrical path, simultaneously in a reducing atmosphere. The ceramic substrate comprises alumina (Al2O3), a partially stabilized zirconia by forming solid solution with yttria (Y2O3) and a sintering agent. The sintering agent comprises magnesia (MgO), and at least 1 type selected from silica (SiO2), calcia (CaO), or manganese oxides (MnO, MnO2, Mn2O3, Mn3O4).

Owner:SUMITOMO METAL SMI ELECTRONICS DEVICES

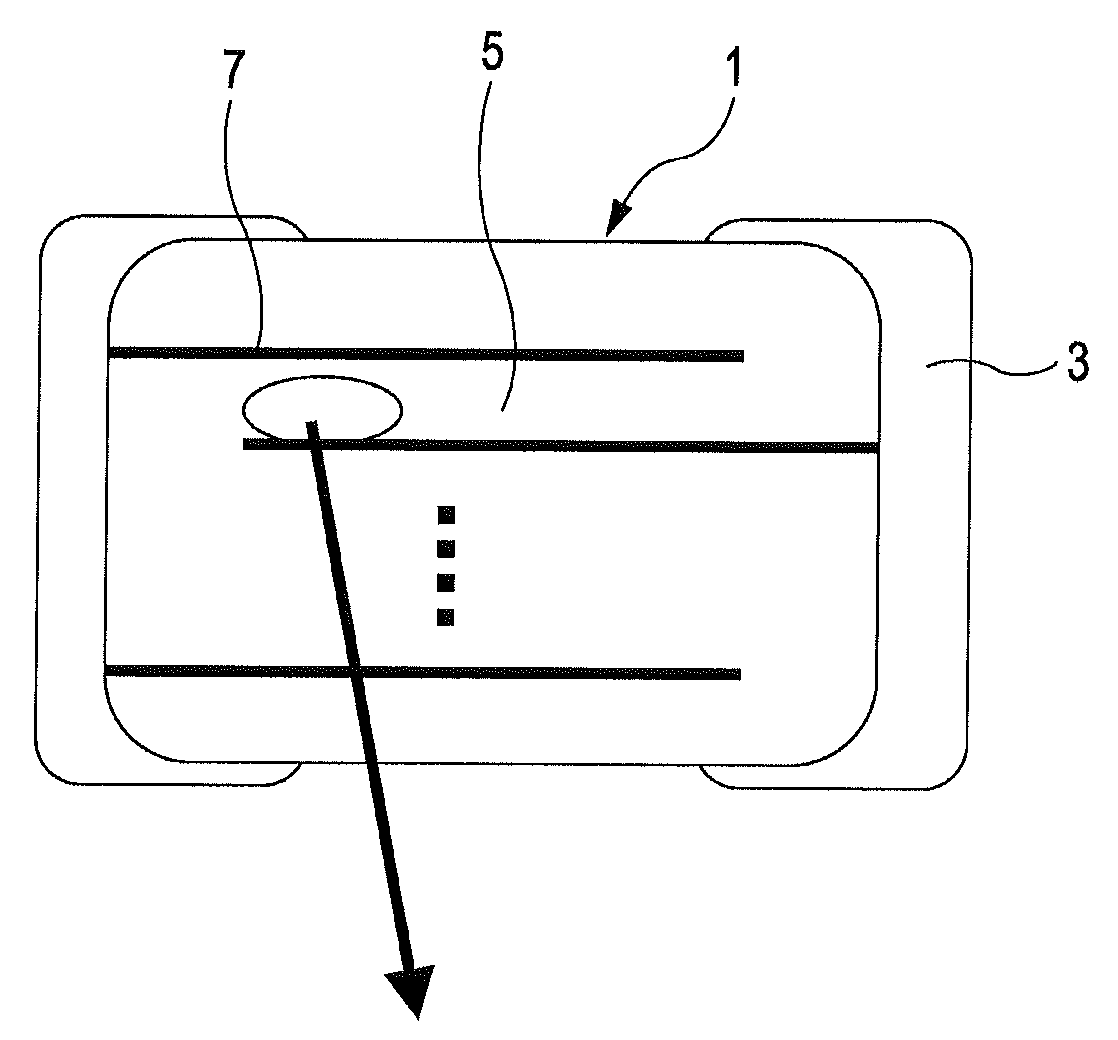

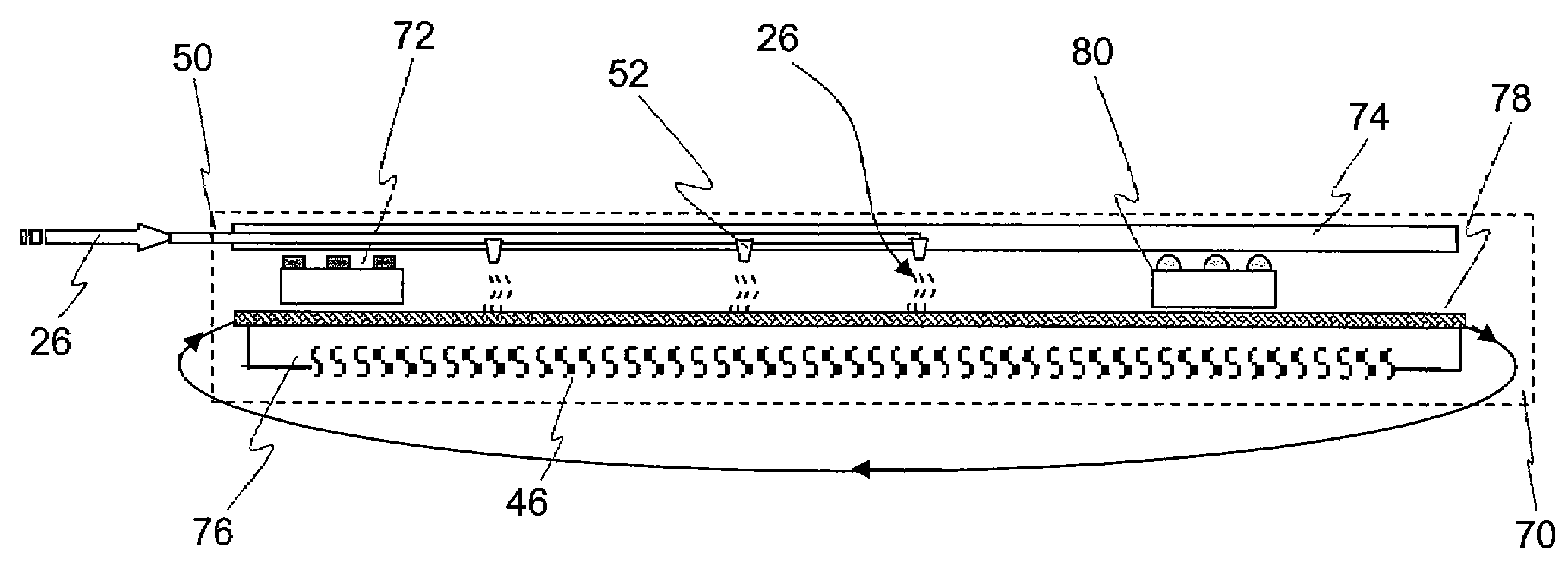

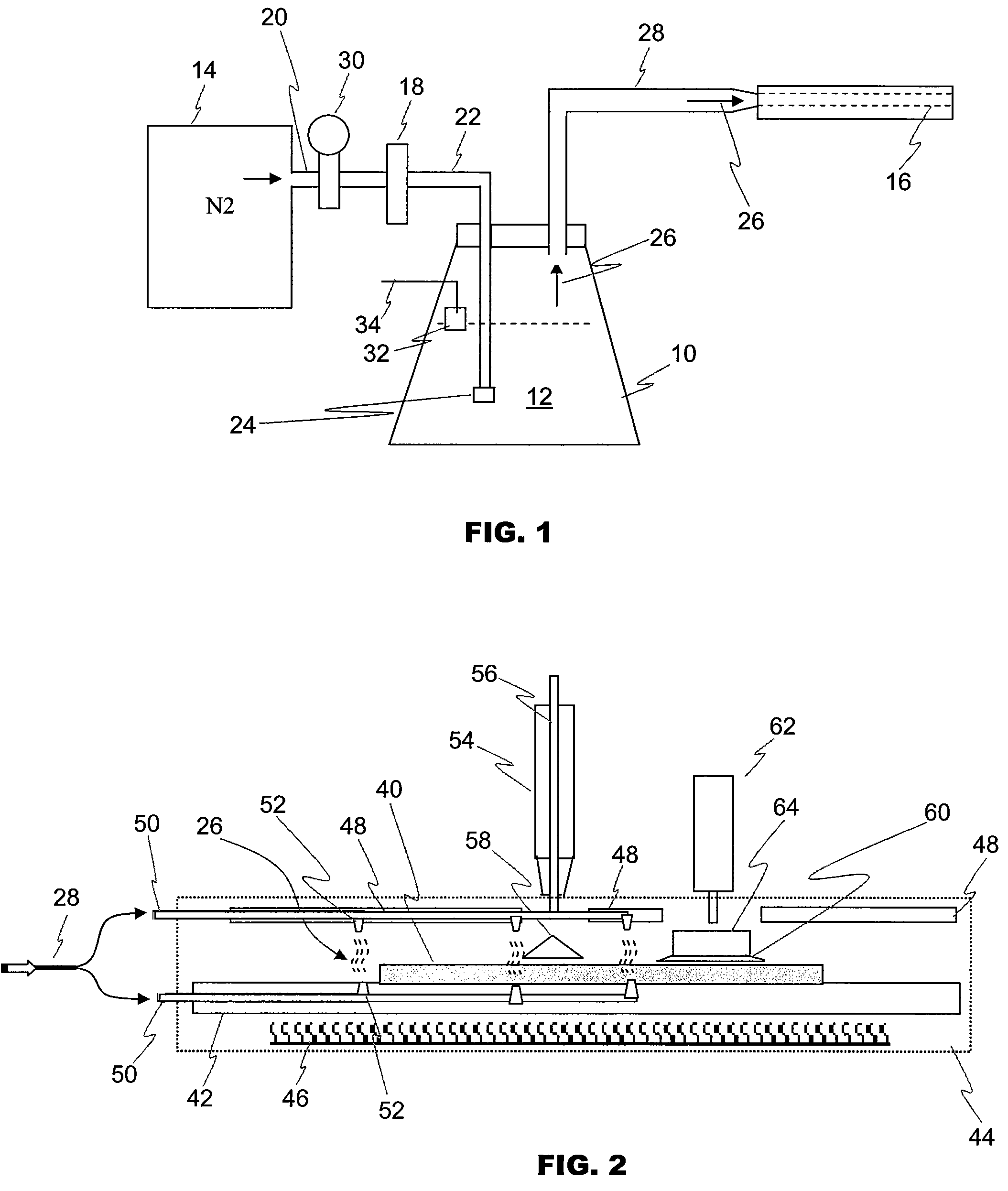

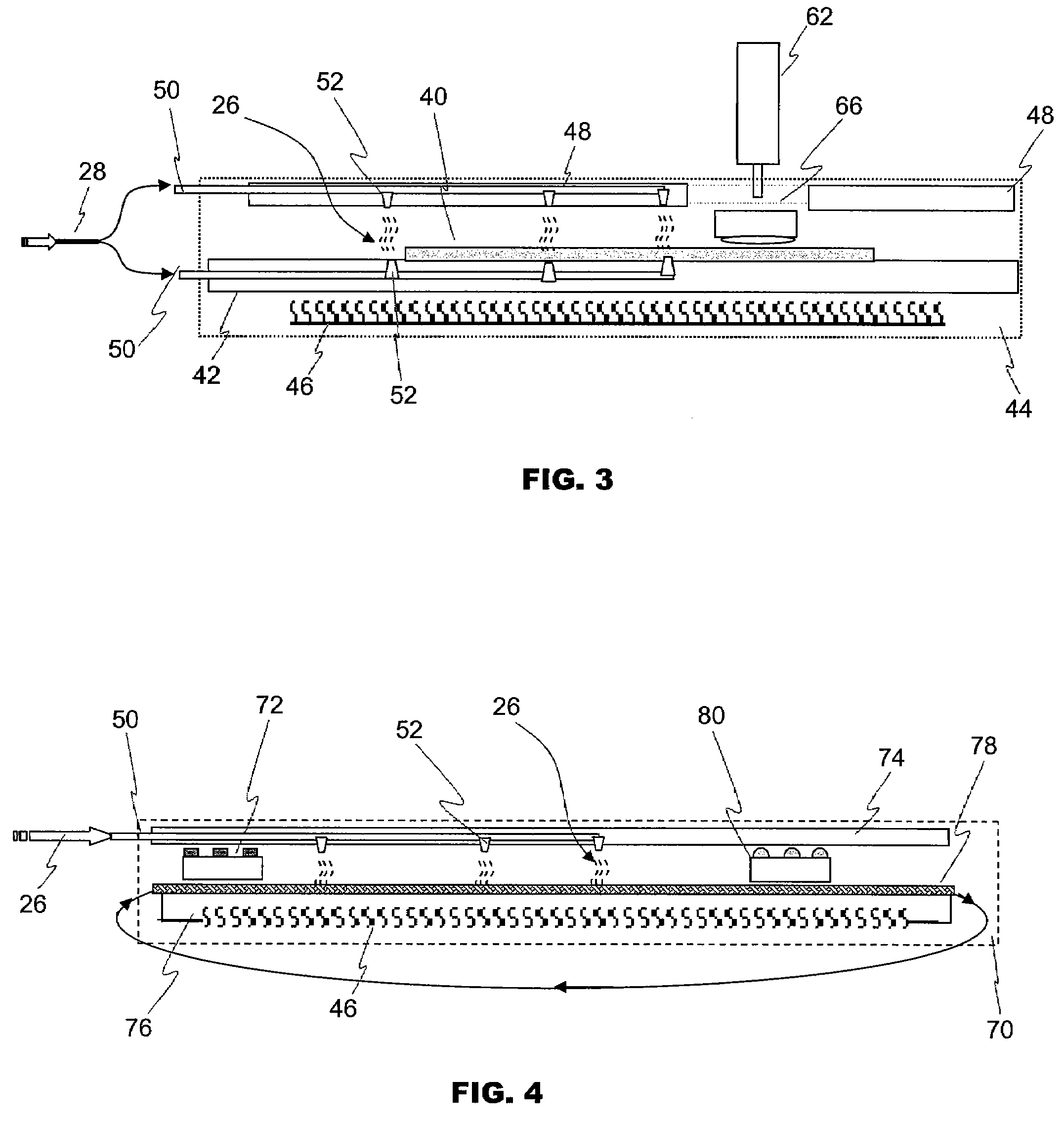

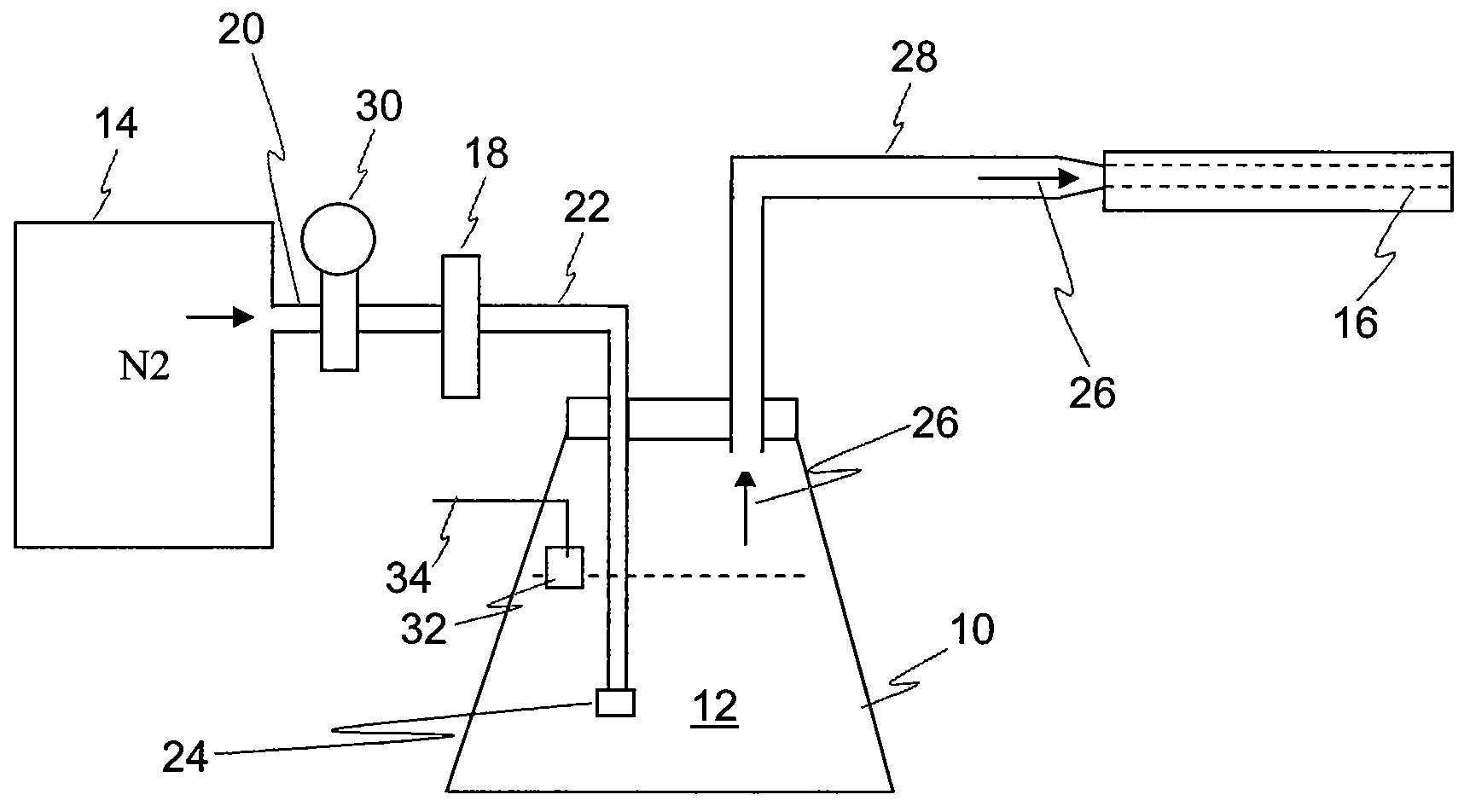

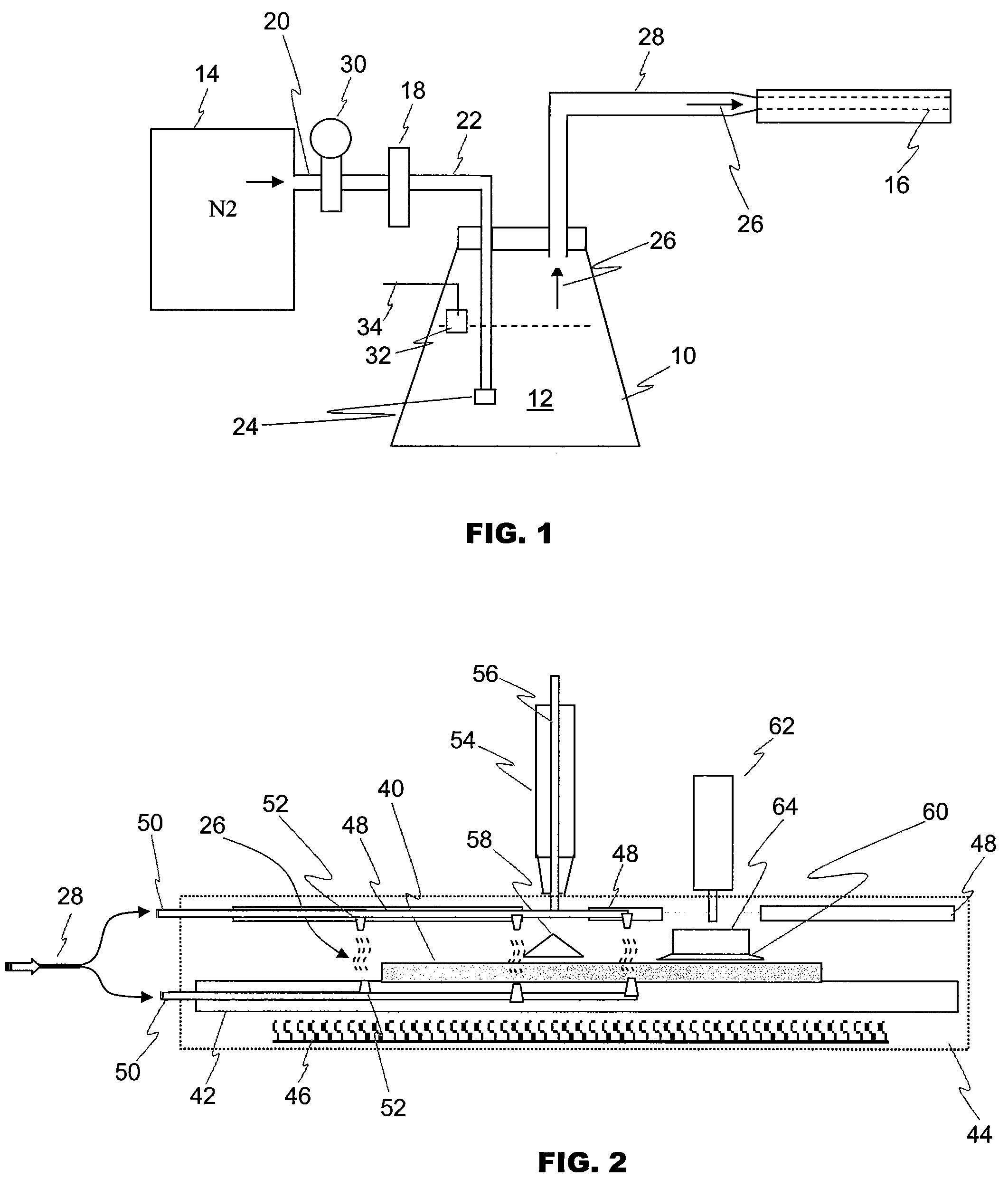

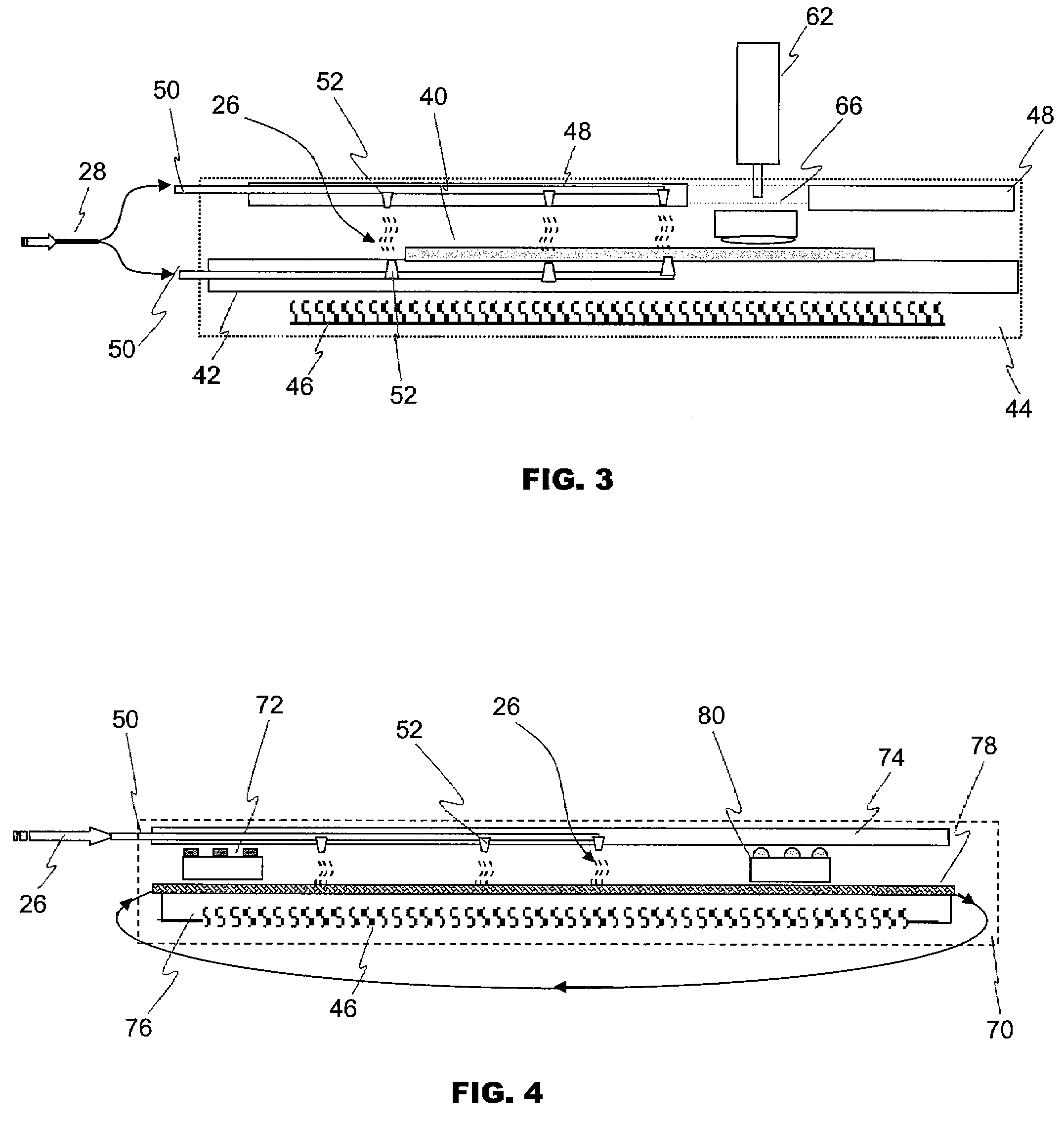

Manufacturing process and apparatus therefor utilizing reducing gas

ActiveUS7648901B2Reduce usageReducing atmosphereSoldering apparatusSemiconductor/solid-state device manufacturingProduct gasGlycollic acid

A manufacturing process and apparatus therefore are provided for processing an electronic device comprising oxidizable material during processing. The electronic device is located inside a chamber and is heated a processing temperature with a heater. A reductive atmosphere is created in the chamber by supplying a gas comprising glycolic acid vapor while processing the electronic device at the processing temperature.

Owner:ASM ASSEMBLY AUTOMATION LTD

Process for controlling oxidation of nitrogen and metals in circulating fluidized solids contacting process

InactiveUS20030075480A1Reducing atmosphereMinimize deactivationCatalytic crackingCatalytic naphtha reformingParticulatesFlue gas

A fluidized particulate solids contacting process for reducing regenerator flue gas NOx emissions and / or permitting operating with an increased equilibrium solids vanadium level, which process may be an FCC process or a fluidized particulate solid hydrocarbon treating process, wherein spent FCC catalyst or other spent solid is in a regenerator with an oxygen-containing regeneration gas under catalyst (solid) regeneration conditions which include a combination of at least a regeneration temperature and an oxygen level in the regeneration gas which is effective to burn off the spent solid a majority of carbonaceous deposits thereon, while substantially preventing the formation of NOx, and thereby produce a regenerated solid having a carbon level reduced from that of the spent solid and a flue gas; maintaining the regenerated solid in a fluidized state with a fluidizing media that substantially prevents any further oxidation or regeneration; and returning the fluidized regenerated solid to the reactor (contactor) used in the process.

Owner:BAR PROCESSES JOINT VENTURE

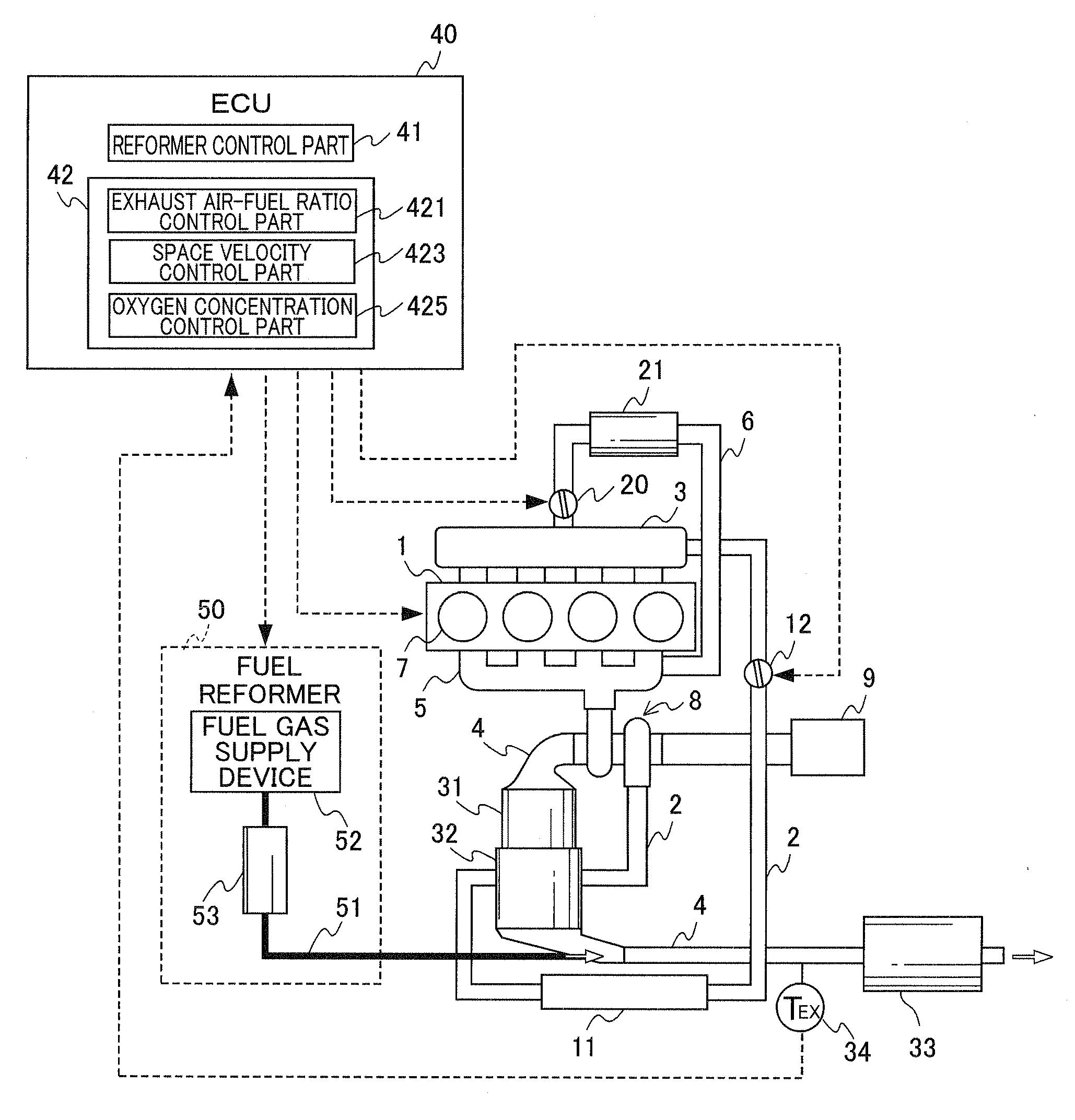

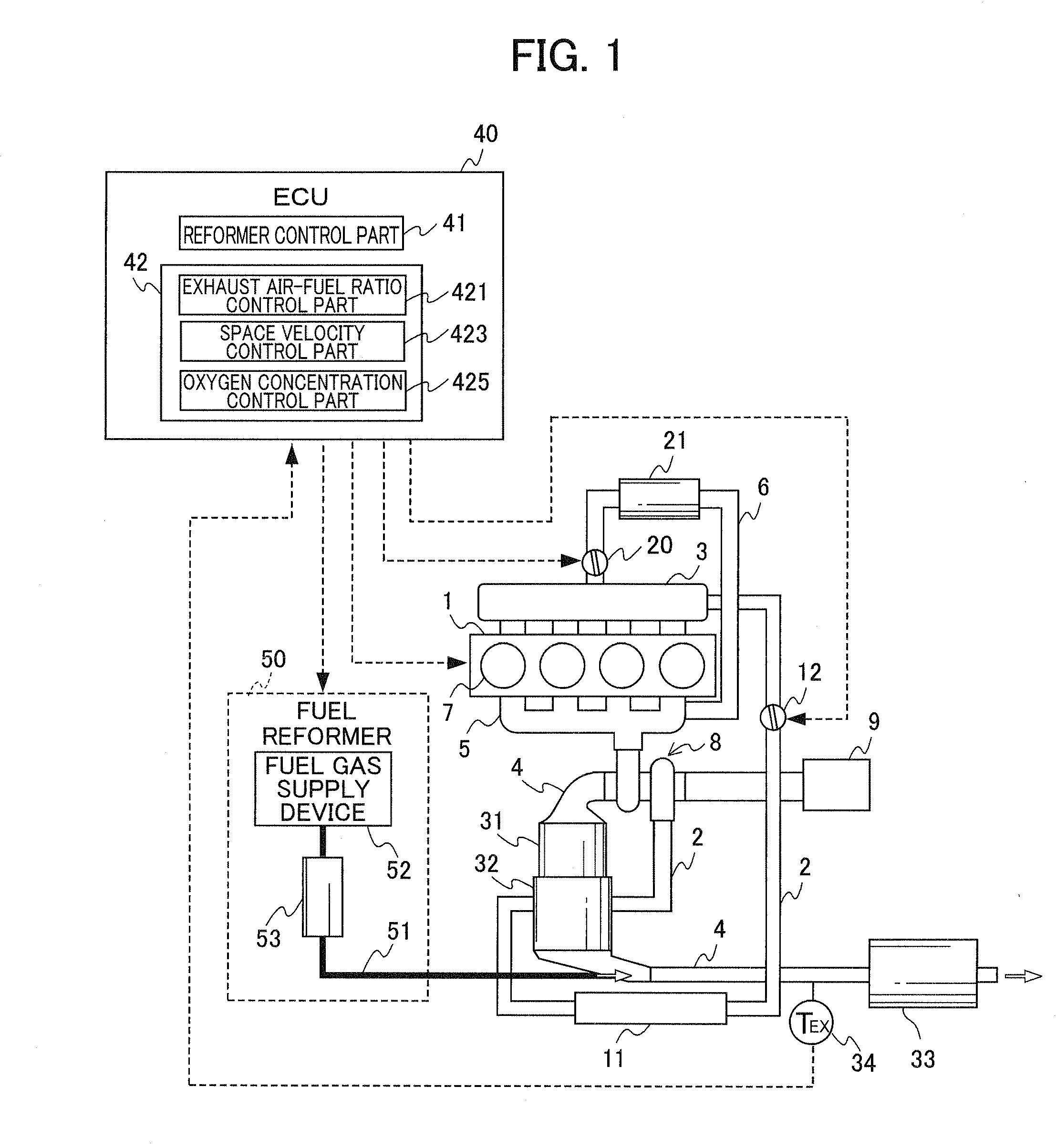

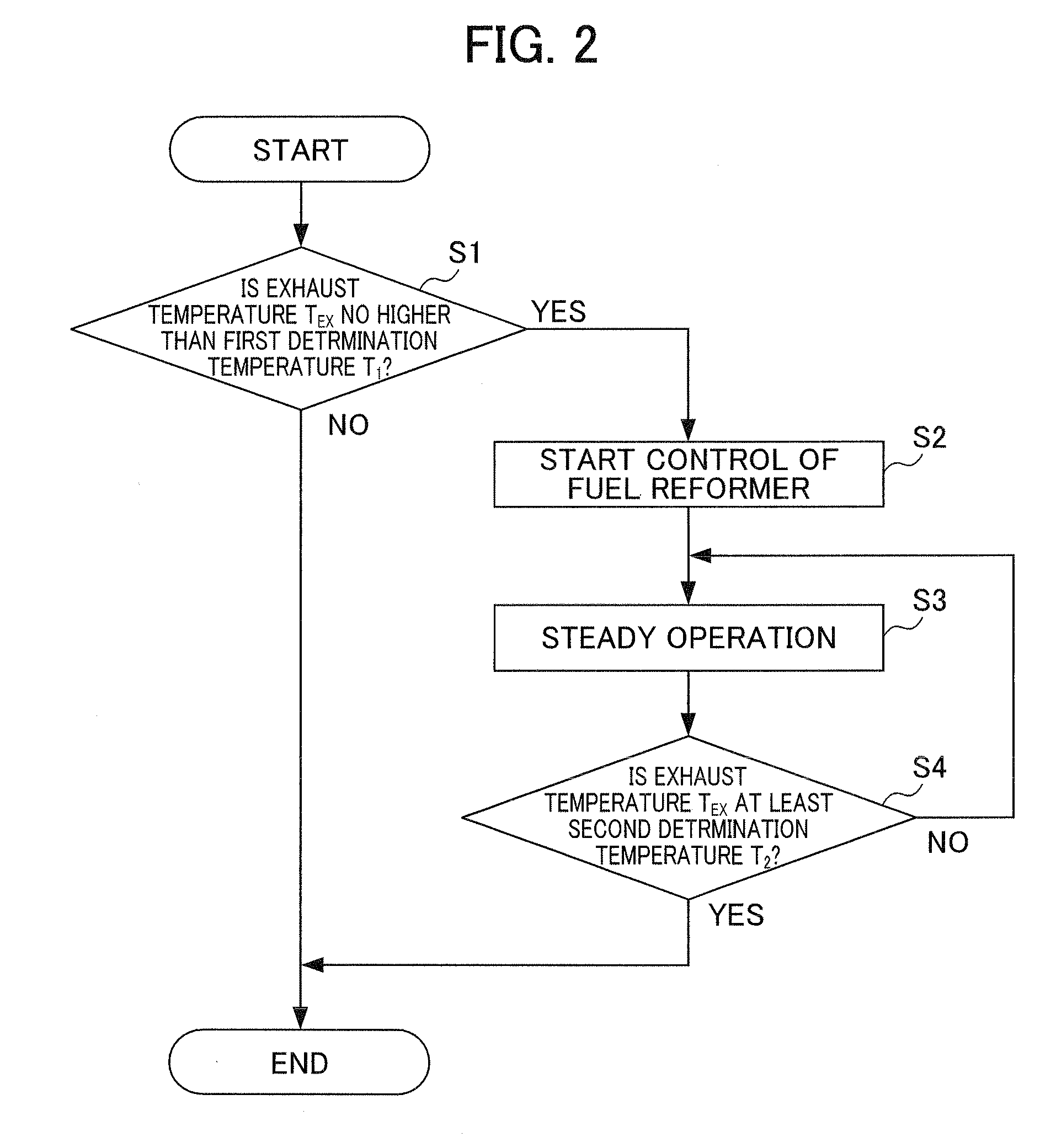

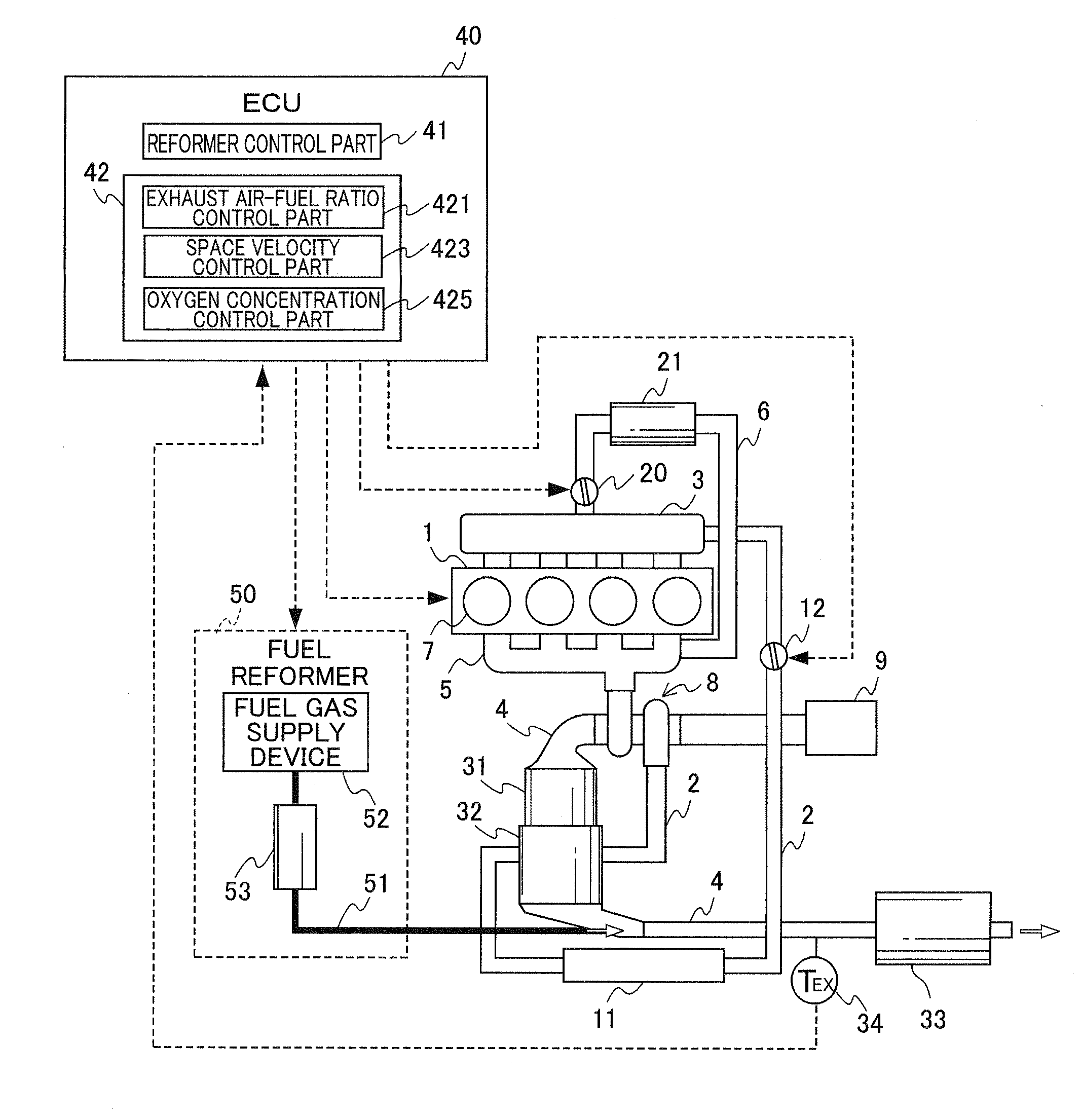

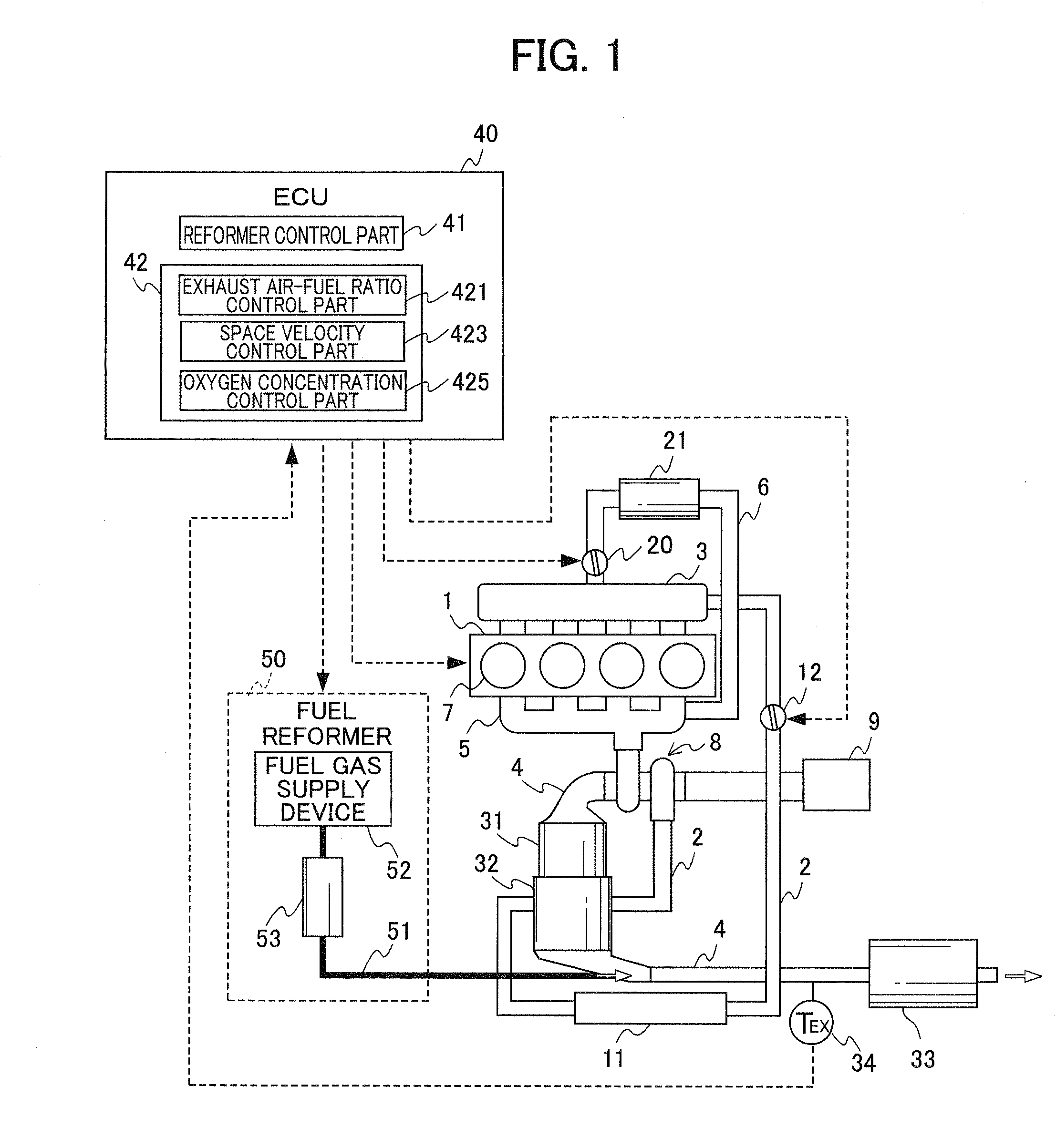

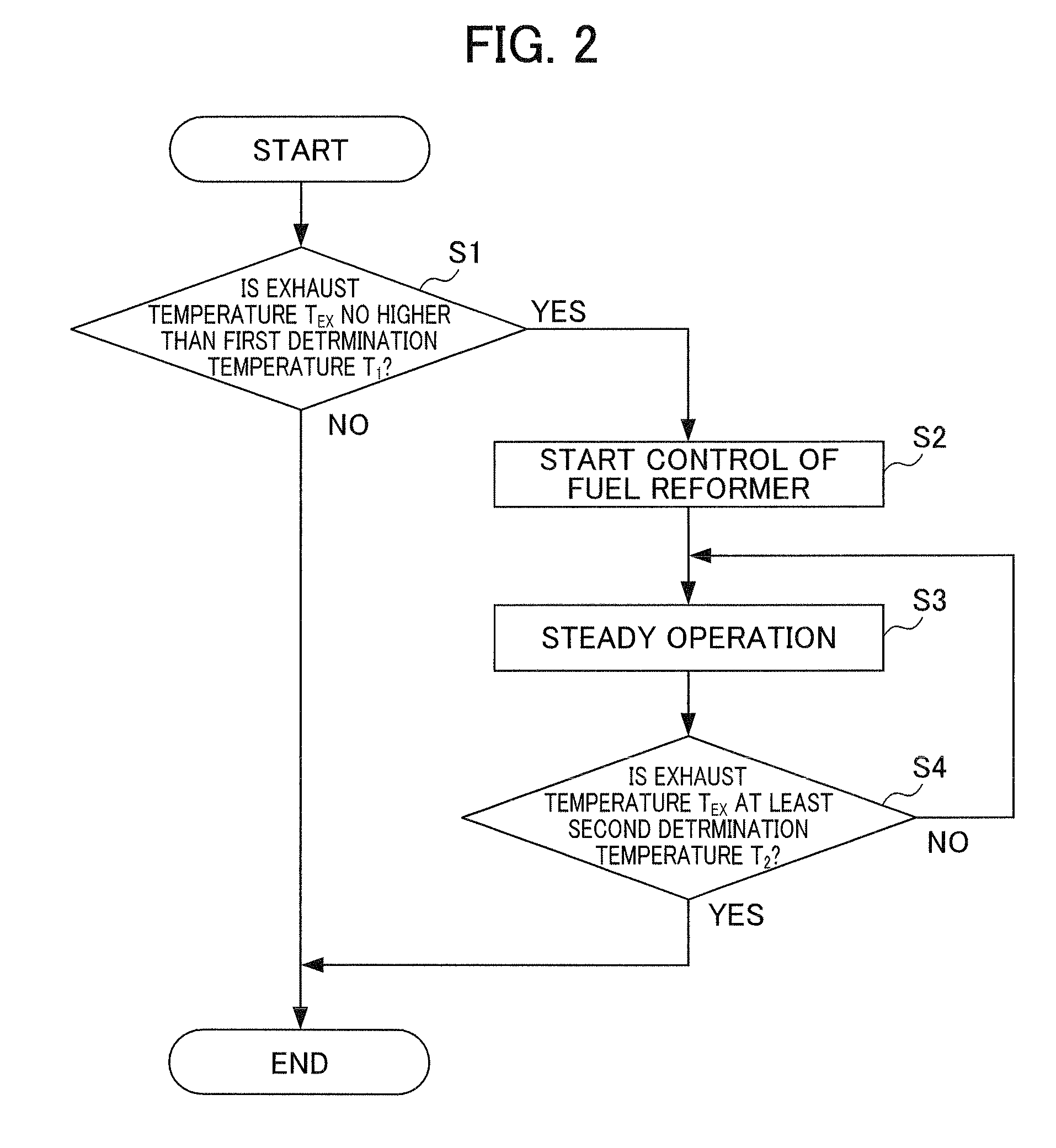

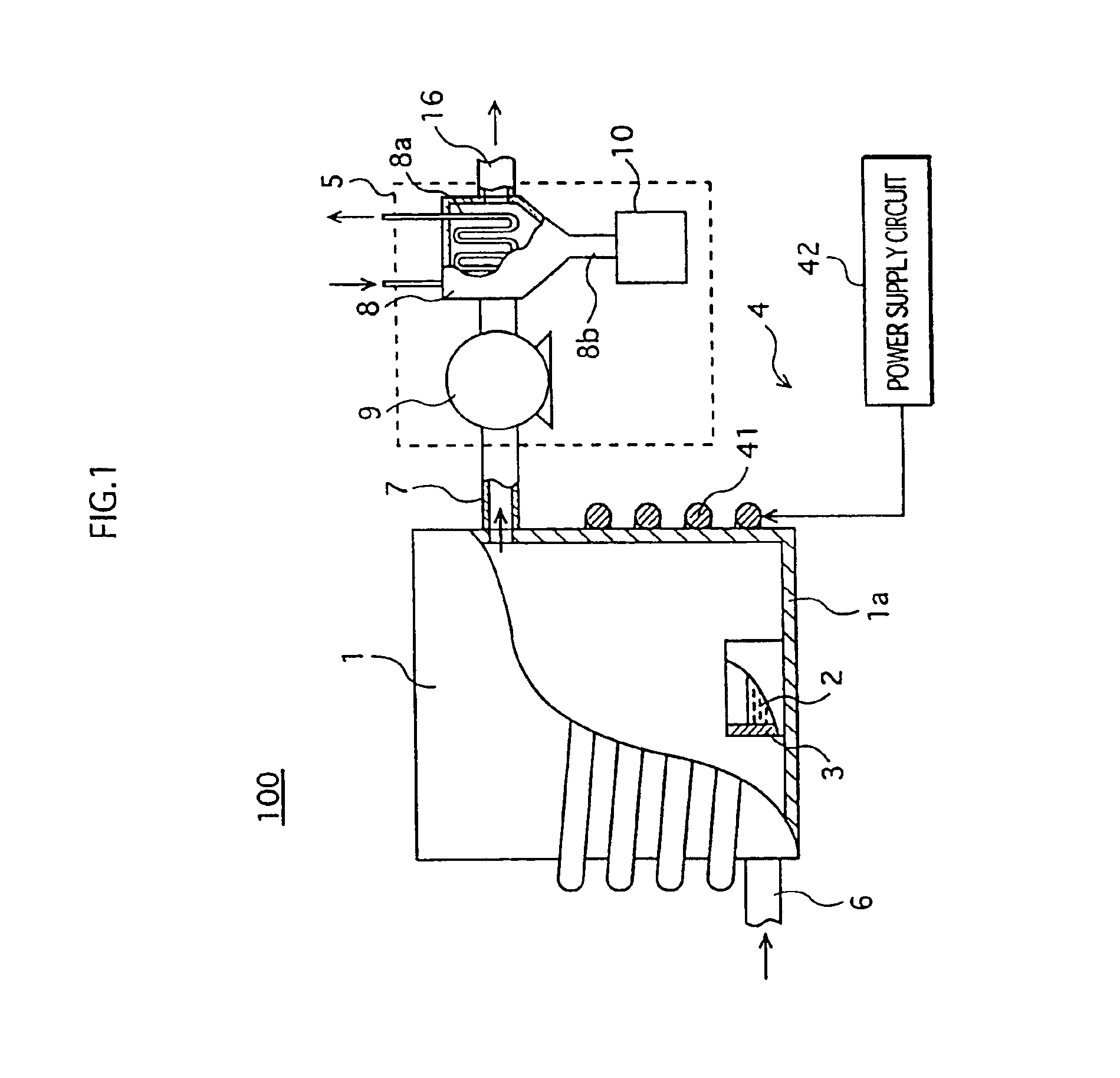

Exhaust purification device for internal combustion engine

InactiveUS20100257845A1Reduce and purify NOxReducing atmosphereInternal combustion piston enginesExhaust apparatusHydrogenProcess engineering

An exhaust purification device for an internal combustion engine is provided that can promote the reduction of NOx in a NOx purification catalyst from immediately after startup of the internal combustion engine. The exhaust purification device includes: a fuel reformer that is provided separately from exhaust plumbing 4, reforms fuel and produces a reducing gas that contains carbon monoxide, hydrogen and hydrocarbons, and supplies the reducing gas upstream of the NOx purification catalyst into the exhaust path; an exhaust gas temperature sensor 34 that detects a temperature TEX of the exhaust flowing in the exhaust plumbing 4; and a reformer control part 41 that starts supply of the reducing gas to the exhaust plumbing 4 by starting control of the fuel reformer 50 in a case where the temperature TEX thus detected by this exhaust gas temperature sensor 34 is no higher than a predetermined first determination temperature T1, and stops the supply of reducing gas to the exhaust plumbing 4 by stopping control of the fuel reformer 50 in a case where the temperature detected by the exhaust gas temperature sensor 34 is at least a second determination temperature T2, which is higher than the first determination temperature.

Owner:HONDA MOTOR CO LTD

Manufacturing process and apparatus therefor utilizing reducing gas

ActiveUS20080078145A1Reduce usageReducing atmosphereSoldering apparatusSemiconductor/solid-state device manufacturingProduct gasGlycollic acid

A manufacturing process and apparatus therefore are provided for processing an electronic device comprising oxidizable material during processing. The electronic device is located inside a chamber and is heated a processing temperature with a heater. A reductive atmosphere is created in the chamber by supplying a gas comprising glycolic acid vapor while processing the electronic device at the processing temperature.

Owner:ASM ASSEMBLY AUTOMATION LTD

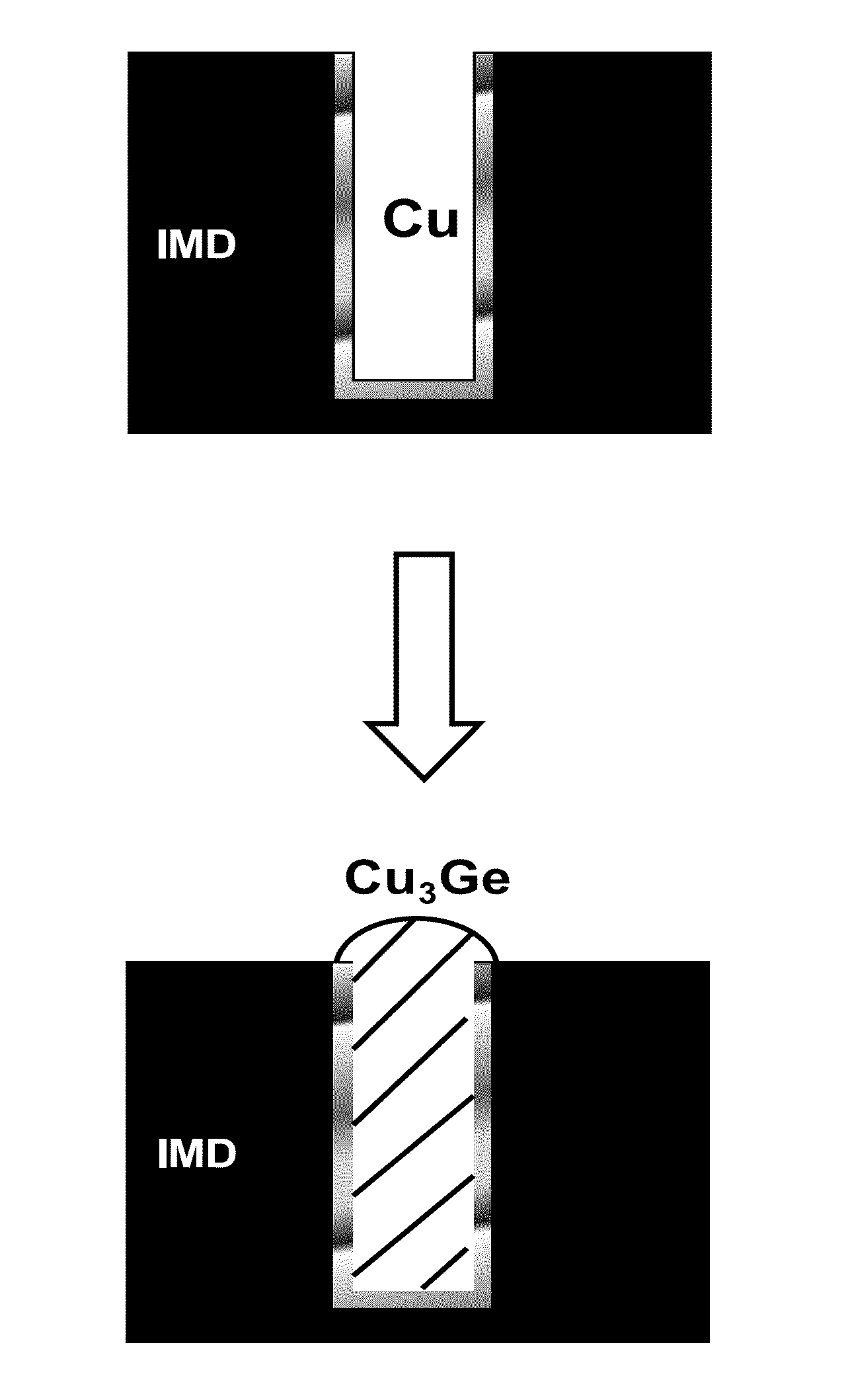

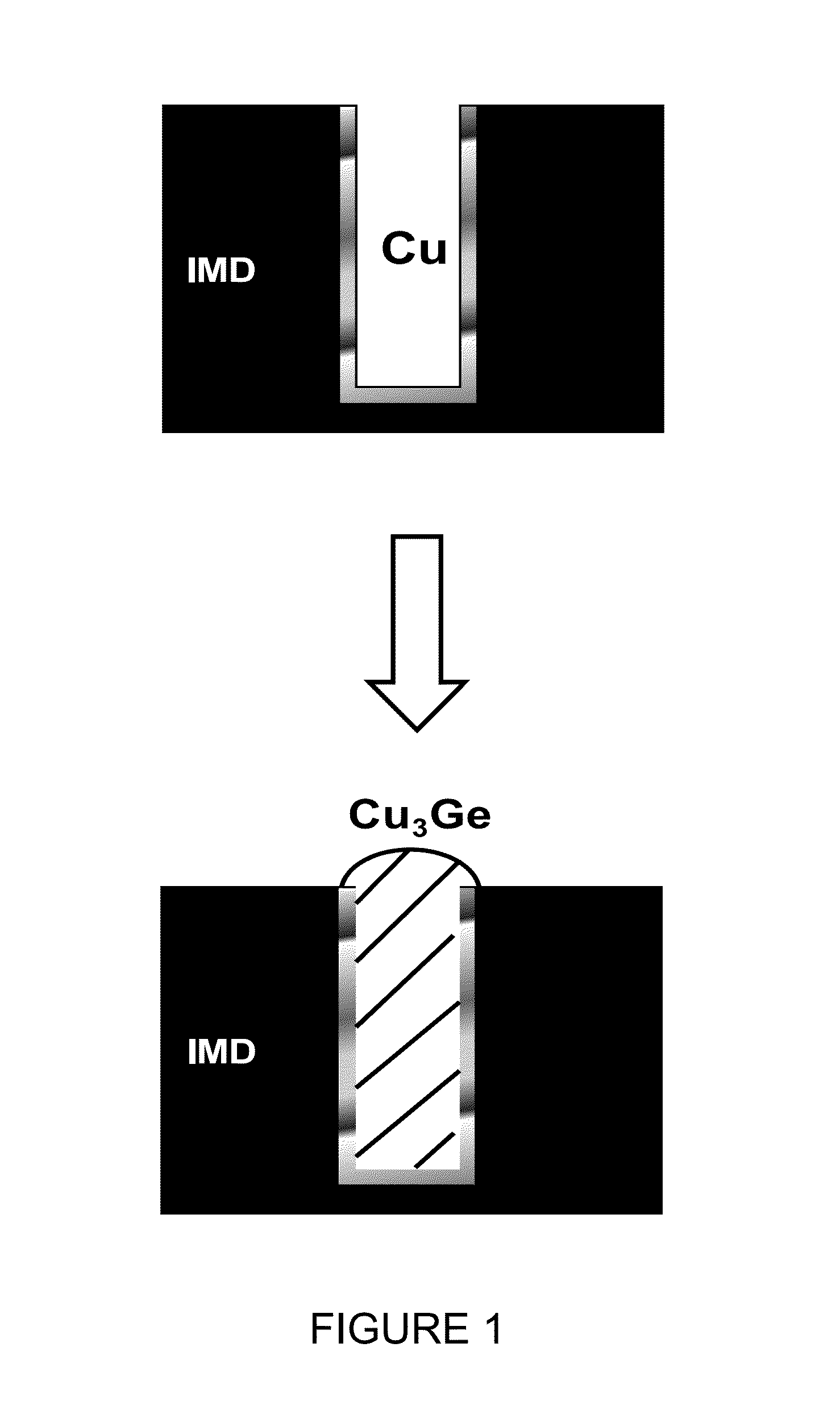

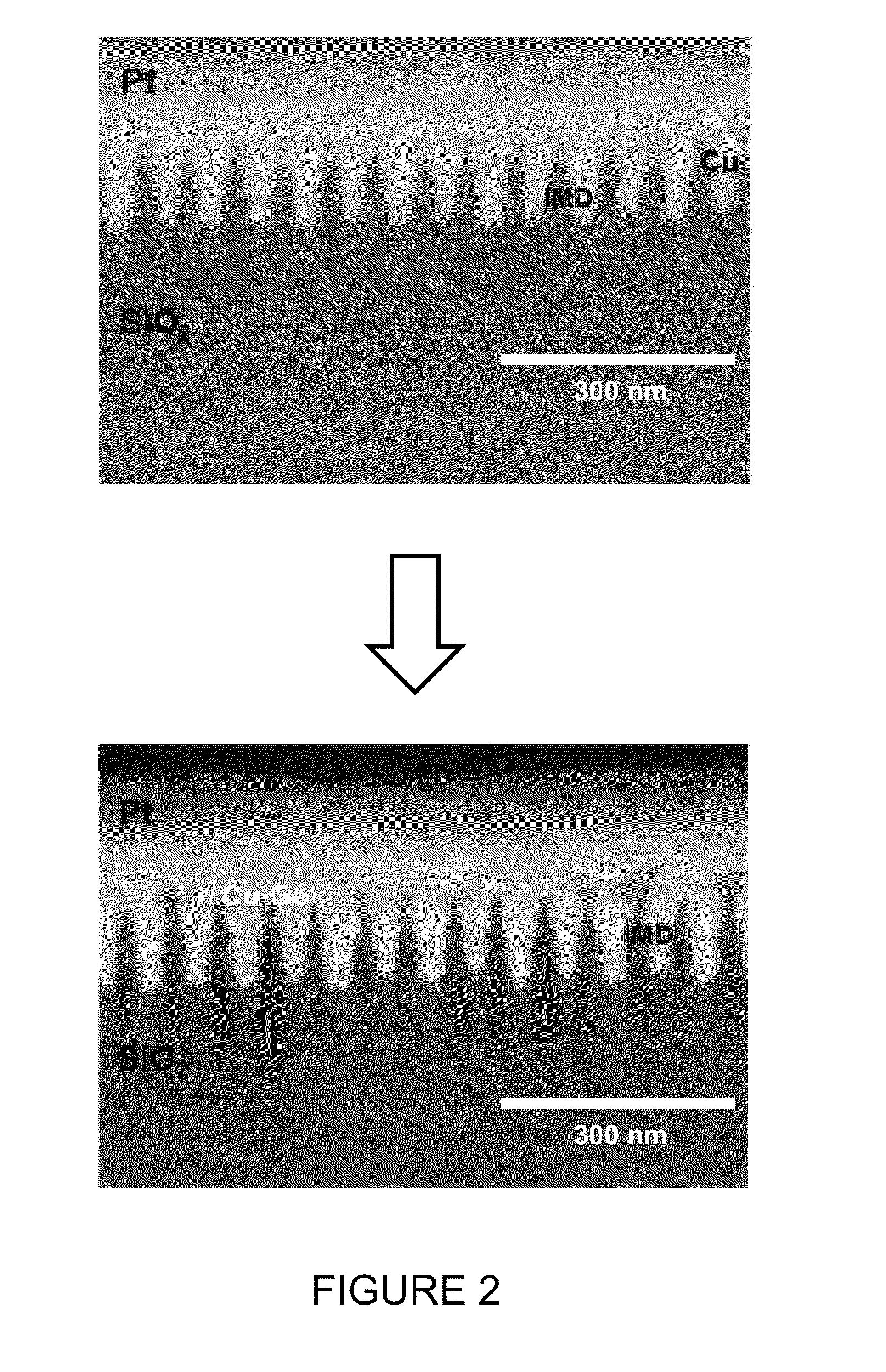

Method for Manufacturing Germanide Interconnect Structures and Corresponding Interconnect Structures

ActiveUS20150130062A1Low resistivityFacilitating solid vapor reactionSemiconductor/solid-state device detailsSolid-state devicesMetallurgyGermanide

Method for forming an interconnect structure, comprising the steps of: forming a recessed structure in a dielectric material on a substrate; at least partially filling said recessed structure with a metal chosen from the group consisting of copper, nickel and cobalt; introducing the substrate in a CVD reactor; bringing the substrate in the CVD reactor to a soak temperature and subsequently performing a soak treatment by supplying a germanium precursor gas to the CVD reactor at the soak temperature, thereby substantially completely converting the metal in the recessed structure to a germanide.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

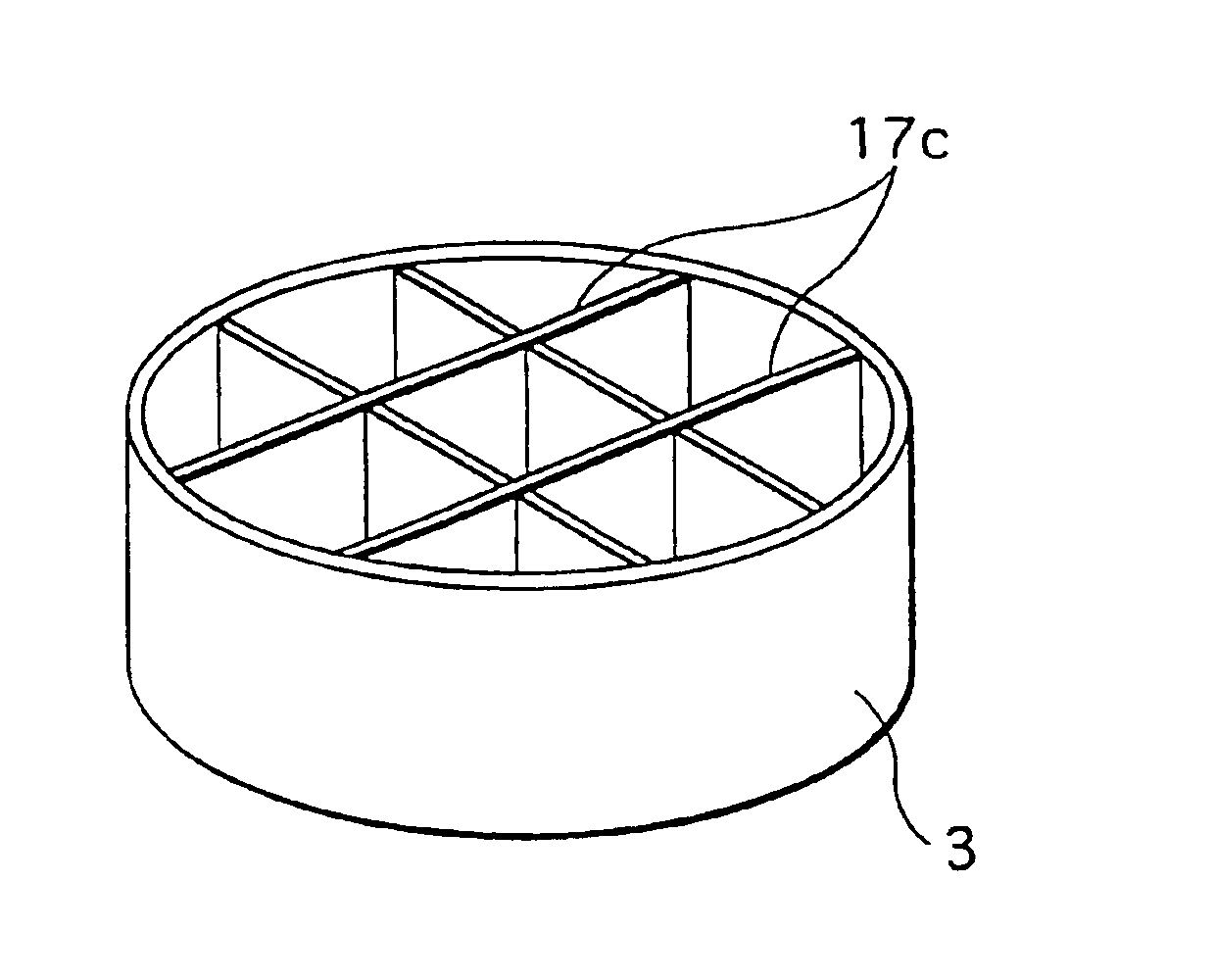

Wafer level package structure, and sensor device obtained from the same package structure

InactiveUS8067769B2Little changeReducing atmosphereAcceleration measurement using interia forcesSemiconductor/solid-state device testing/measurementDiffusionGyroscope

A wafer level package structure with a plurality of compact sensors such as acceleration sensors and gyro sensors is provided. This package structure is composed of a semiconductor wafer with plural sensor units, and a pair of package wafers bonded to both surfaces of the semiconductor wafer. Each of the sensor units has a frame having an opening, a movable portion held in the opening to be movable relative to the frame, and a detecting portion for outputting an electric signal according to a positional displacement of the movable portion. Since the semiconductor wafer is bonded to each of the package wafers by a solid-phase direct bonding without diffusion between a surface-activated region formed on the frame and a surface-activated region formed on the package wafer, it is possible to prevent that variations in sensor characteristics occur due to residual stress at the bonding interface.

Owner:MATSUSHITA ELECTRIC WORKS LTD

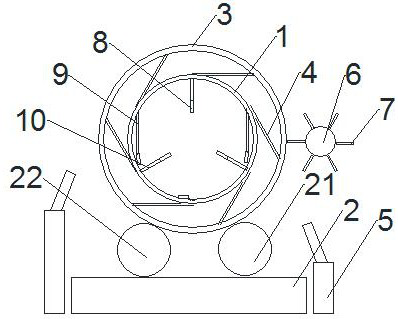

Rotary kiln for reducing ferronickel ore

PendingCN113073164AControl incomplete combustionImprove recovery rateRotary drum furnacesAir volumeAir blower

The invention discloses a rotary kiln for reducing a ferronickel ore, comprising a barrel and a driving support device. The barrel is sequentially provided with a preheating section, a drying dehydrating section, a reducing section, a smelting section and a cooling section in the material moving direction; the reducing section is provided with an air inlet; and the drying dehydrating section and / or the preheating section are / is provided with an air outlet. An air blower is arranged at the air inlet of the reducing section of the rotary kiln for reducing the ferronickel ore, the air inlet amount can be adjusted according to needs, incomplete combustion of pulverized coal is controlled, the reducing atmosphere of the kiln tail is achieved, and the metal reduction rate is increased. When the temperature of the rotary kiln needs to be increased, air is continuously blown into the rotary kiln, so that combustible gas in flue gas is combusted. Besides, the air outlet is formed in the drying dehydration section and / or the preheating section, an exhaust fan can be arranged at the air outlet, convection is formed between the air inlet and the air outlet, high-temperature flue gas generated by reduction smelting is fully utilized for preheating and drying raw ore, and energy consumption is greatly reduced.

Owner:河南省煜晟镍业有限责任公司

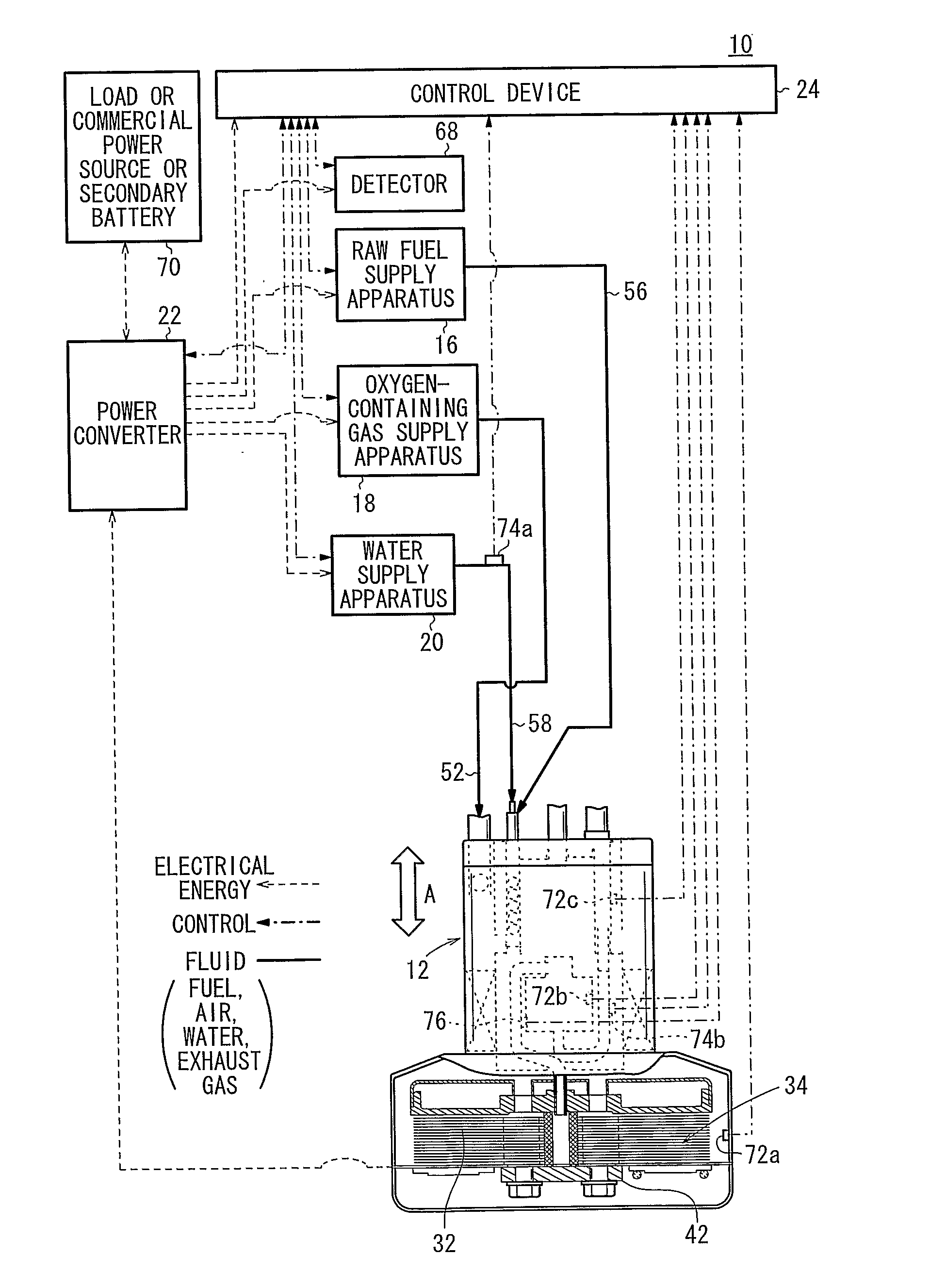

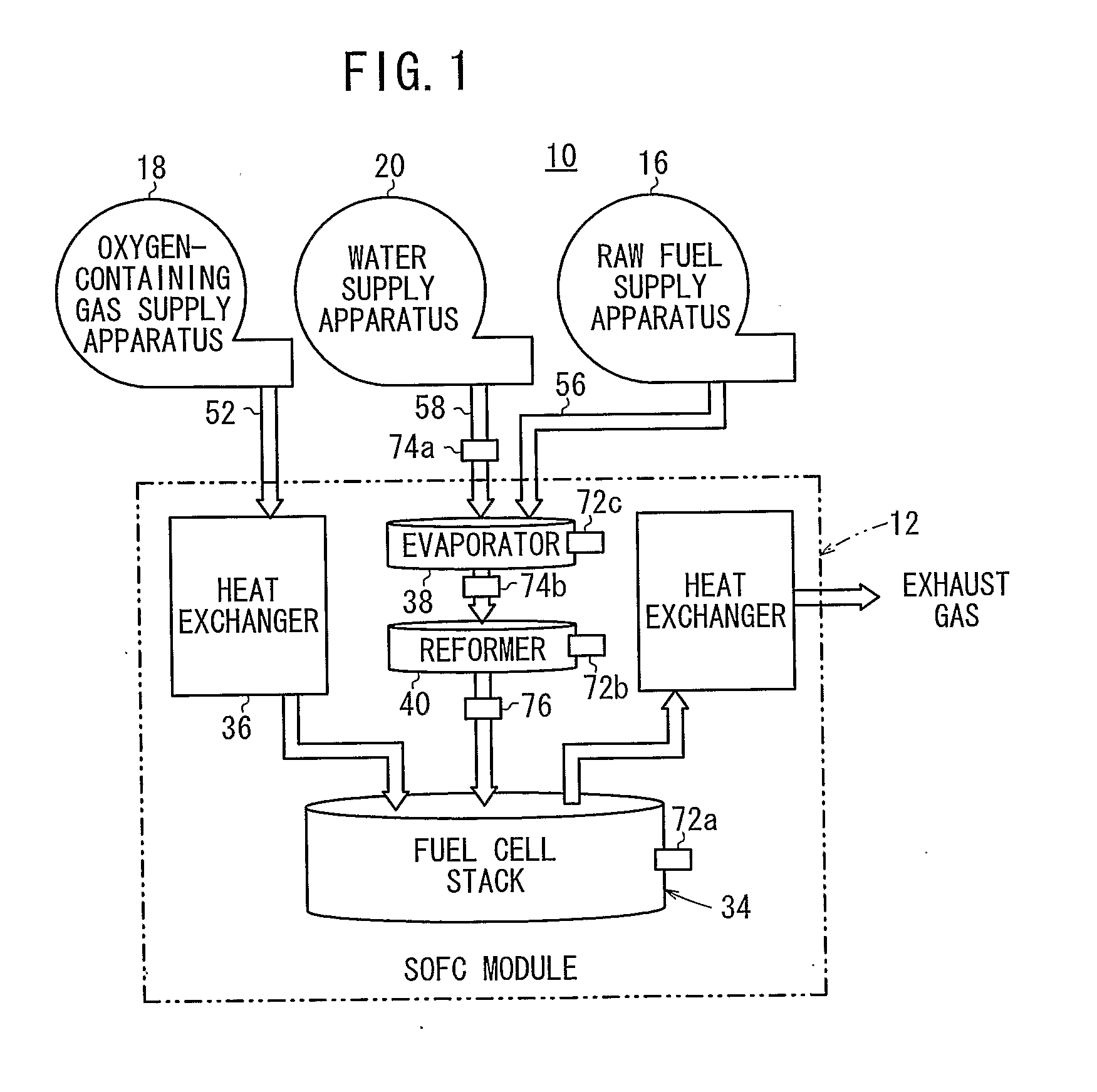

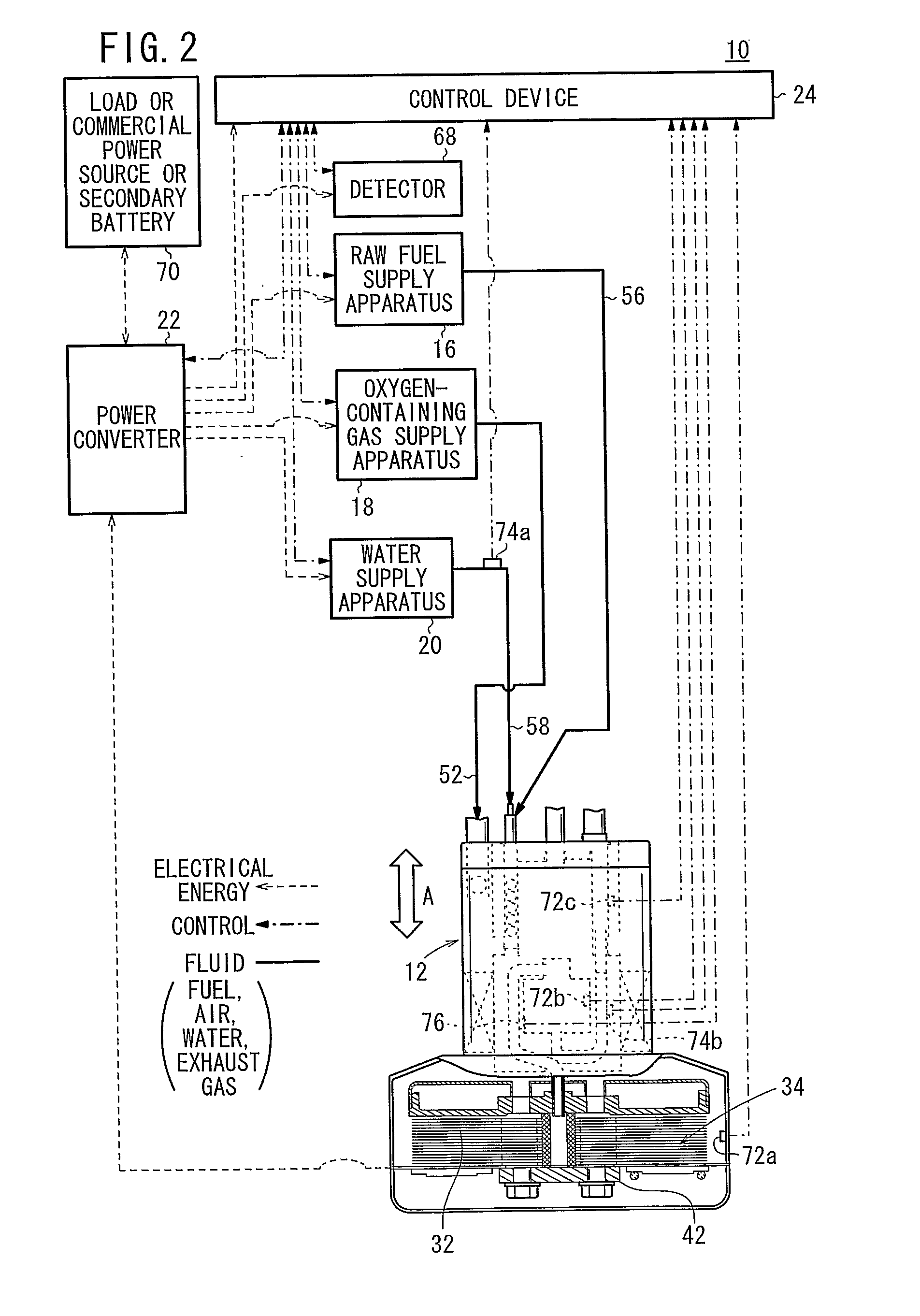

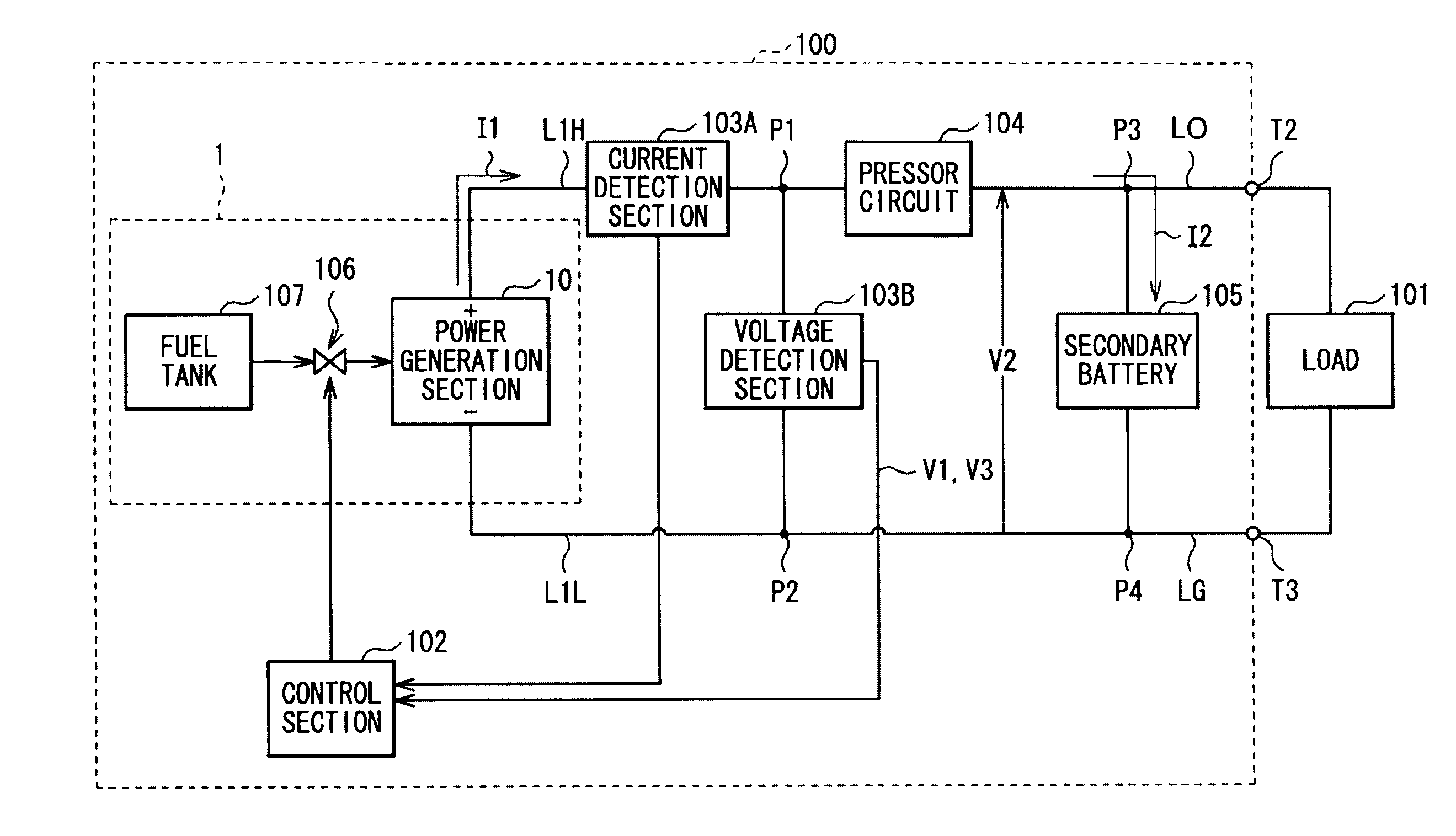

Fuel Cell System and Method of Operating the fuel Cell System

InactiveUS20130034782A1Reduce energy consumptionReducing atmosphereFuel cell heat exchangeFuel cellsWater vapor

A method of operating a fuel cell system includes the steps of temporarily supplying a raw fuel to an electrode surface of an anode at the time of starting operation of the fuel cell system, supplying water vapor to the electrode surface of the anode at least based on any of the temperature of a fuel cell stack and the temperature of an evaporator after stopping the supply of the raw fuel, and supplying a fuel gas to the electrode surface of the anode by supplying the raw fuel and the water to the evaporator at least based on any of detection results of the pressure of the water supplied to the evaporator, the flow rate of the water supplied to the evaporator), the pressure of the water vapor discharged from the evaporator, and the flow rate of the water vapor discharged from the evaporator.

Owner:HONDA MOTOR CO LTD

Exhaust purification device for internal combustion engine

InactiveUS8549845B2Reduce and purify NOxReducing atmosphereInternal combustion piston enginesExhaust apparatusHydrogenExternal combustion engine

An exhaust purification device for an internal combustion engine is provided that can promote the reduction of NOx in a NOx purification catalyst from immediately after startup of the internal combustion engine. The exhaust purification device includes: a fuel reformer that is provided separately from exhaust plumbing 4, reforms fuel and produces a reducing gas that contains carbon monoxide, hydrogen and hydrocarbons, and supplies the reducing gas upstream of the NOx purification catalyst into the exhaust path; an exhaust gas temperature sensor 34 that detects a temperature TEX of the exhaust flowing in the exhaust plumbing 4; and a reformer control part 41 that starts supply of the reducing gas to the exhaust plumbing 4 by starting control of the fuel reformer 50 in a case where the temperature TEX thus detected by this exhaust gas temperature sensor 34 is no higher than a predetermined first determination temperature T1, and stops the supply of reducing gas to the exhaust plumbing 4 by stopping control of the fuel reformer 50 in a case where the temperature detected by the exhaust gas temperature sensor 34 is at least a second determination temperature T2, which is higher than the first determination temperature.

Owner:HONDA MOTOR CO LTD

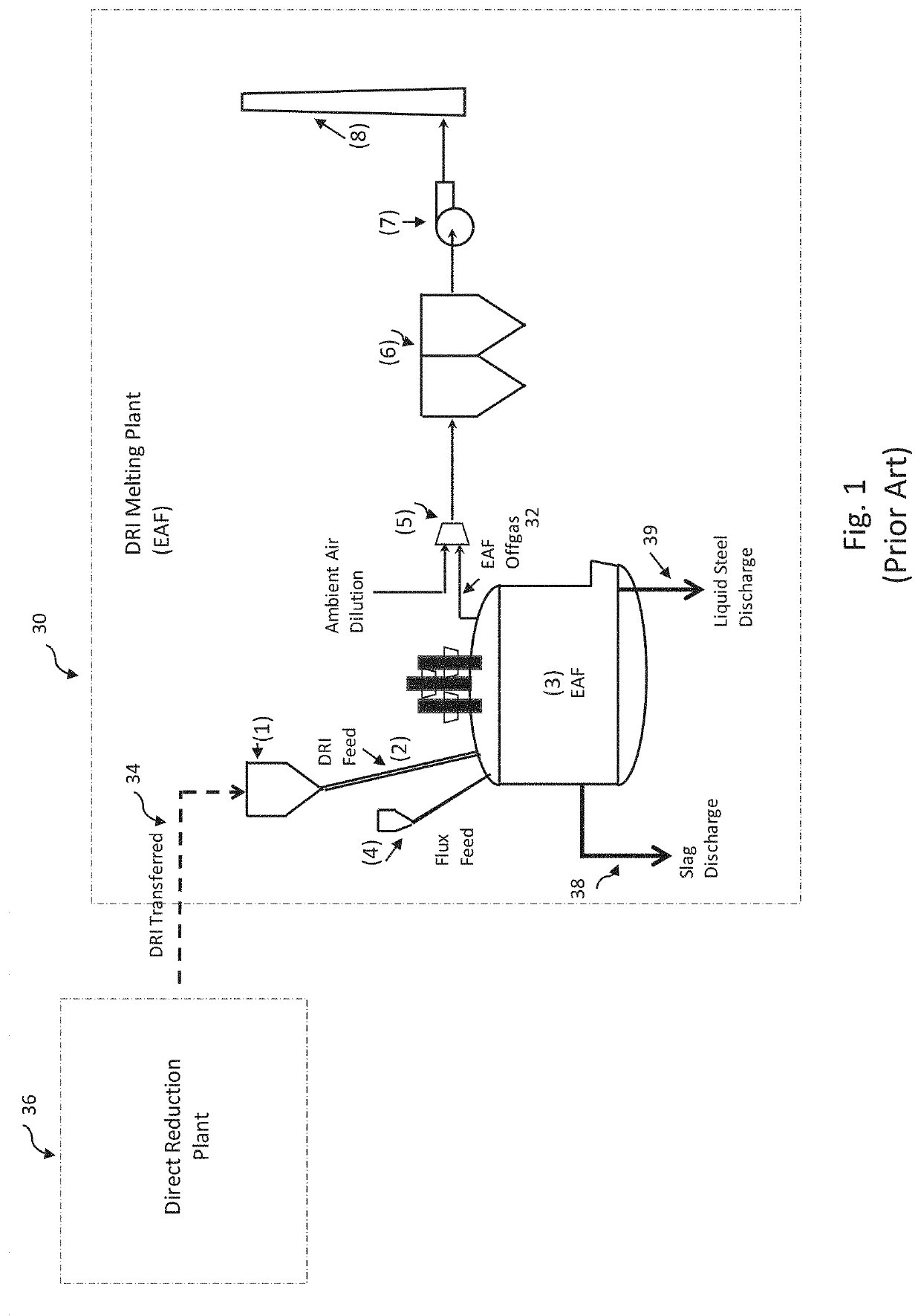

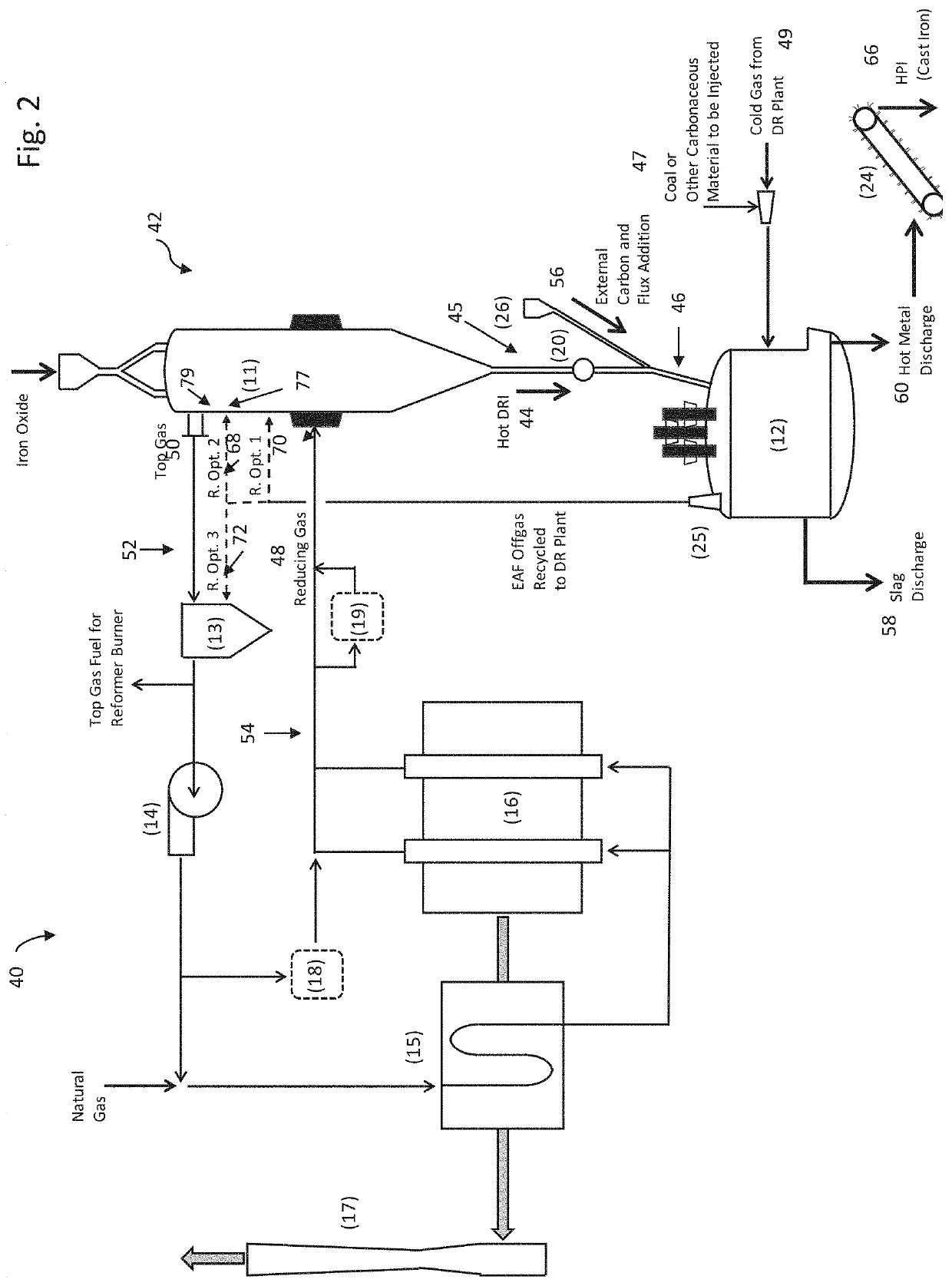

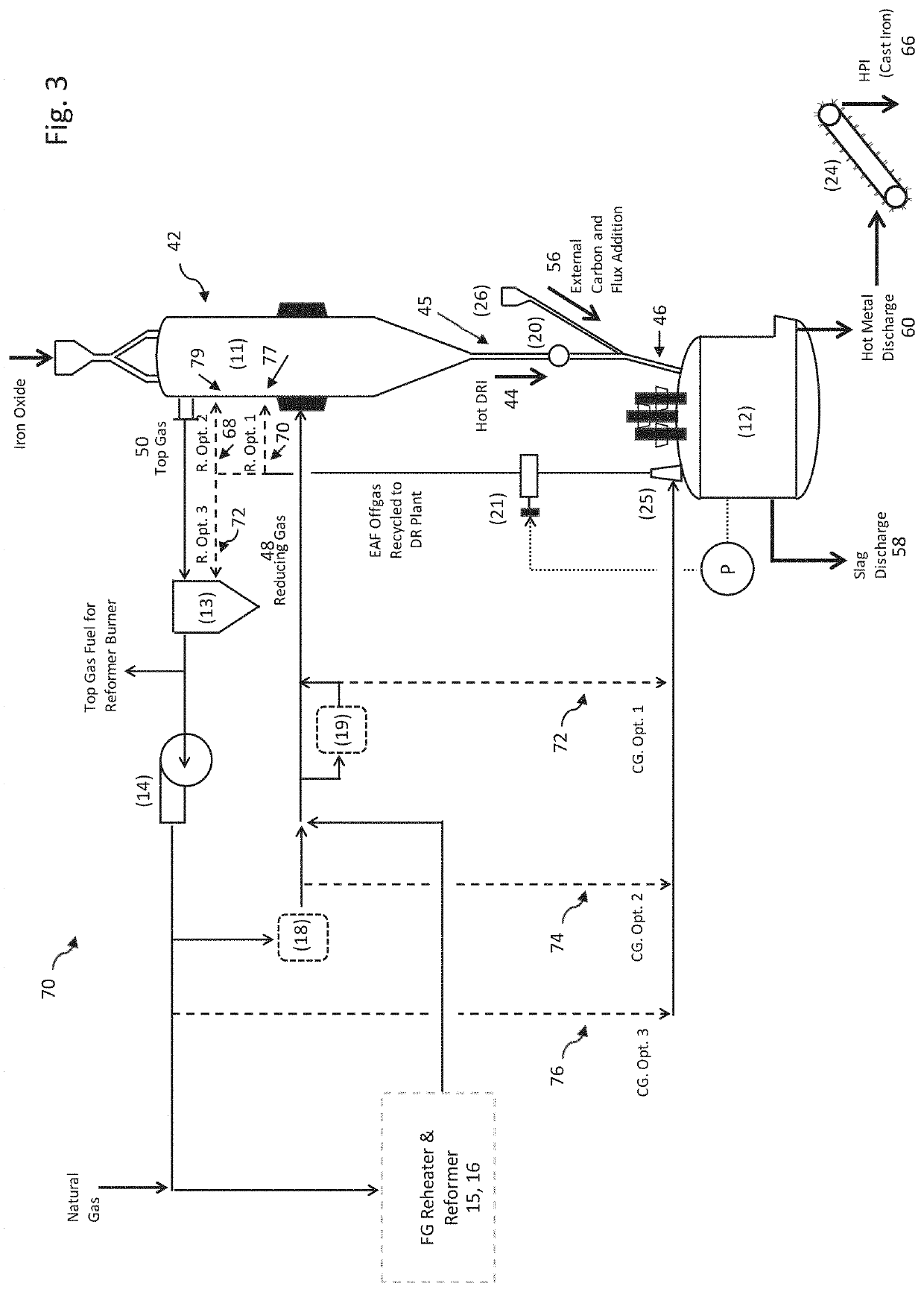

Integration of dr plant and electric dri melting furnace for producing high performance iron

PendingUS20210301359A1Speed up the processImprove energy efficiencyExhaust gas handlingProcess efficiency improvementProcess engineeringShaft furnace

A direct reduction process comprises providing a shaft furnace of a direct reduction plant to reduce iron oxide with reducing gas; providing a direct reduced iron melting furnace; and coupling a discharge chute between a discharge exit of the direct reduced shaft furnace and an inlet of the direct reduced iron melting furnace; wherein direct reduced iron and the reducing gas from the shaft furnace flow through the discharge chute and the reducing gas controls the melting furnace atmosphere to reducing environment.

Owner:MIDREX TECH INC

Capacitive element, method of manufacture of the same, and semiconductor device

InactiveUS7439199B2Shorten the connection distanceAvoiding characteristicFixed capacitor electrodesThin/thick film capacitorCapacitanceDielectric

A capacitive element is characterized by including: a base (12); a lower barrier layer (13) formed on the base (12); capacitors (Q1 and Q2) made by forming a lower electrode (14a), capacitor dielectric layers (15a), and upper electrodes (16a) in this order on the lower barrier layer (13); and an upper barrier layer (20) covering at least the capacitor dielectric layers (15a) and the lower barrier layer (13).

Owner:FUJITSU LTD

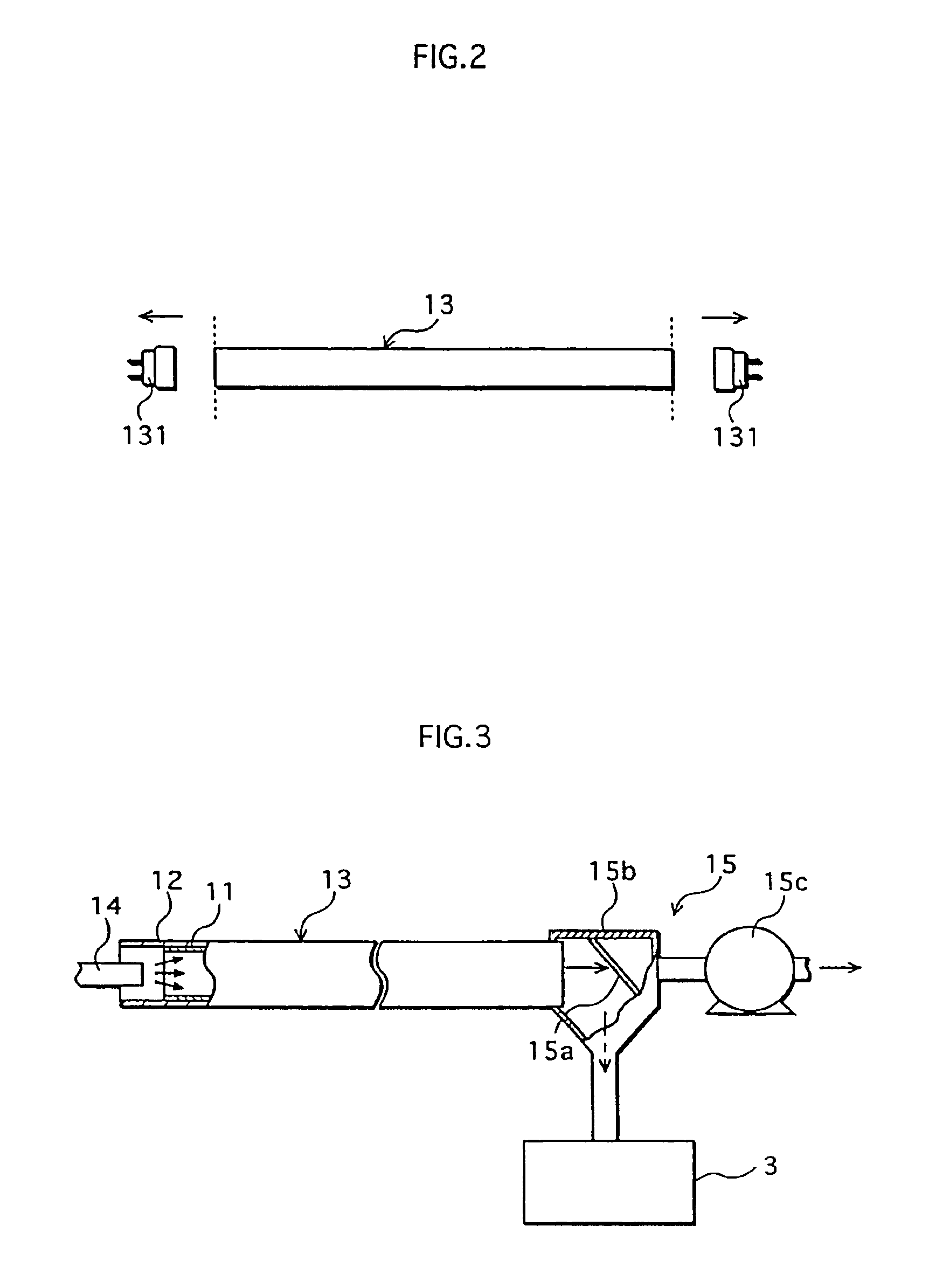

Mercury recovery apparatus

InactiveUS6866814B2Reduce thermal degradationFacilitate separationUsing liquid separation agentSolid waste disposalEnvironmental chemistryFluorescent lamp

Both ends of a bulb of a waste fluorescent lamp are cut off, a phosphor layer formed on an interior surface of the bulb is detached, so that mercury-containing phosphor powder can be obtained. The mercury-containing phosphor powder is subjected to a heating and reducing process with the dry-method, by mixing an organic reducing agent with the phosphor powder and heating the mixture, to vaporize and separate mercury from the phosphor powder. The vaporized mercury is then cooled and condensed, to collect mercury.

Owner:PANASONIC CORP

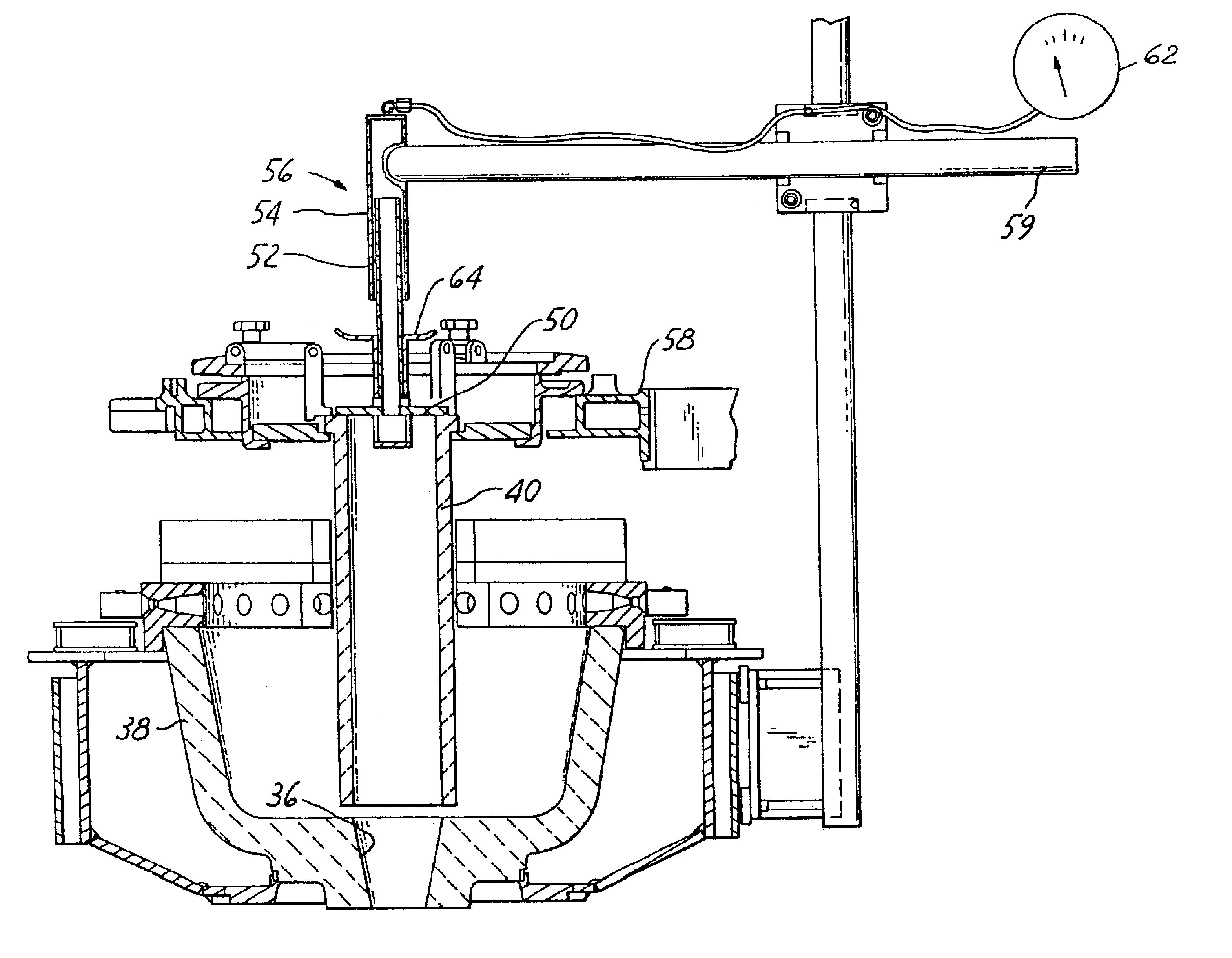

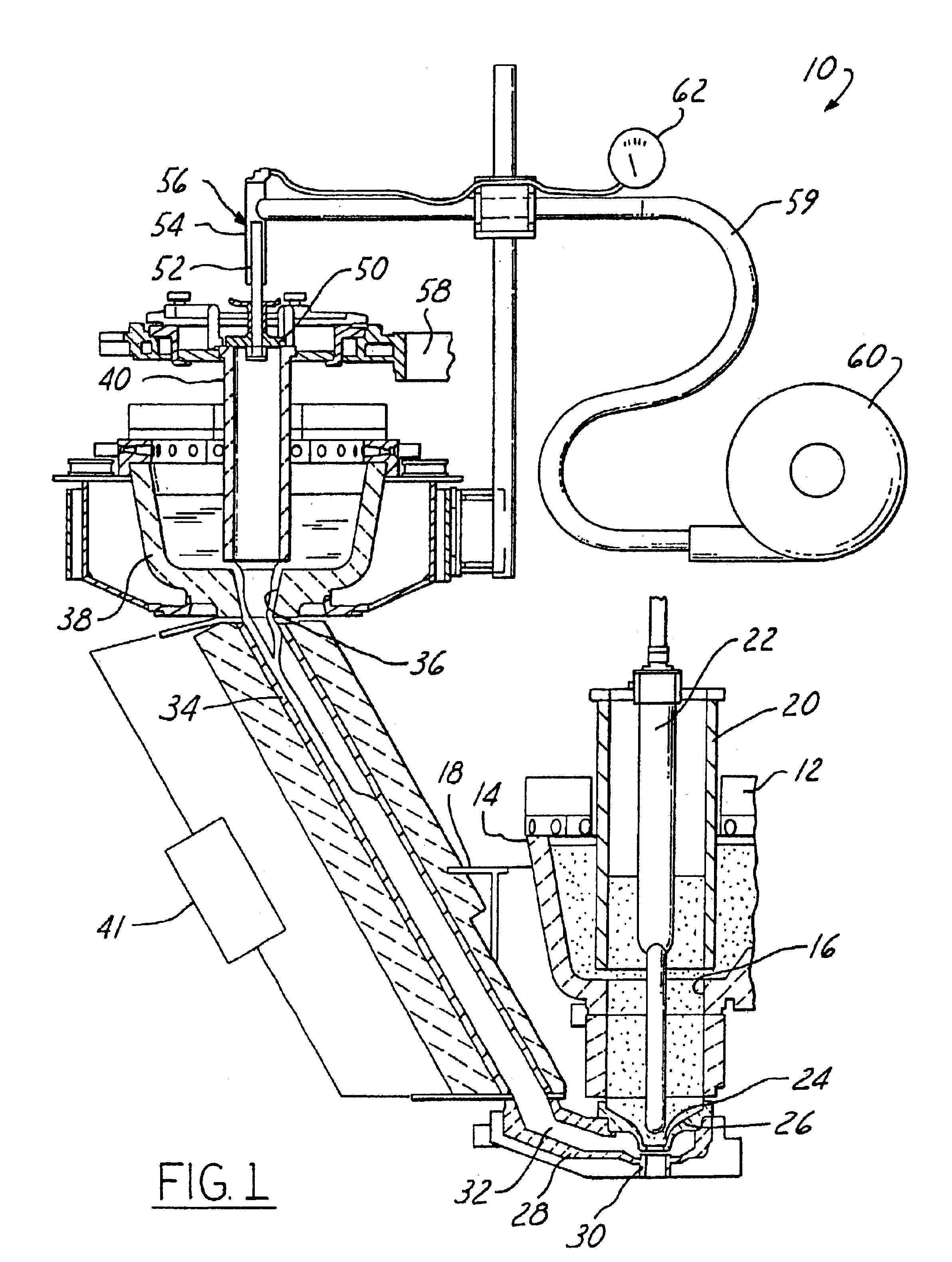

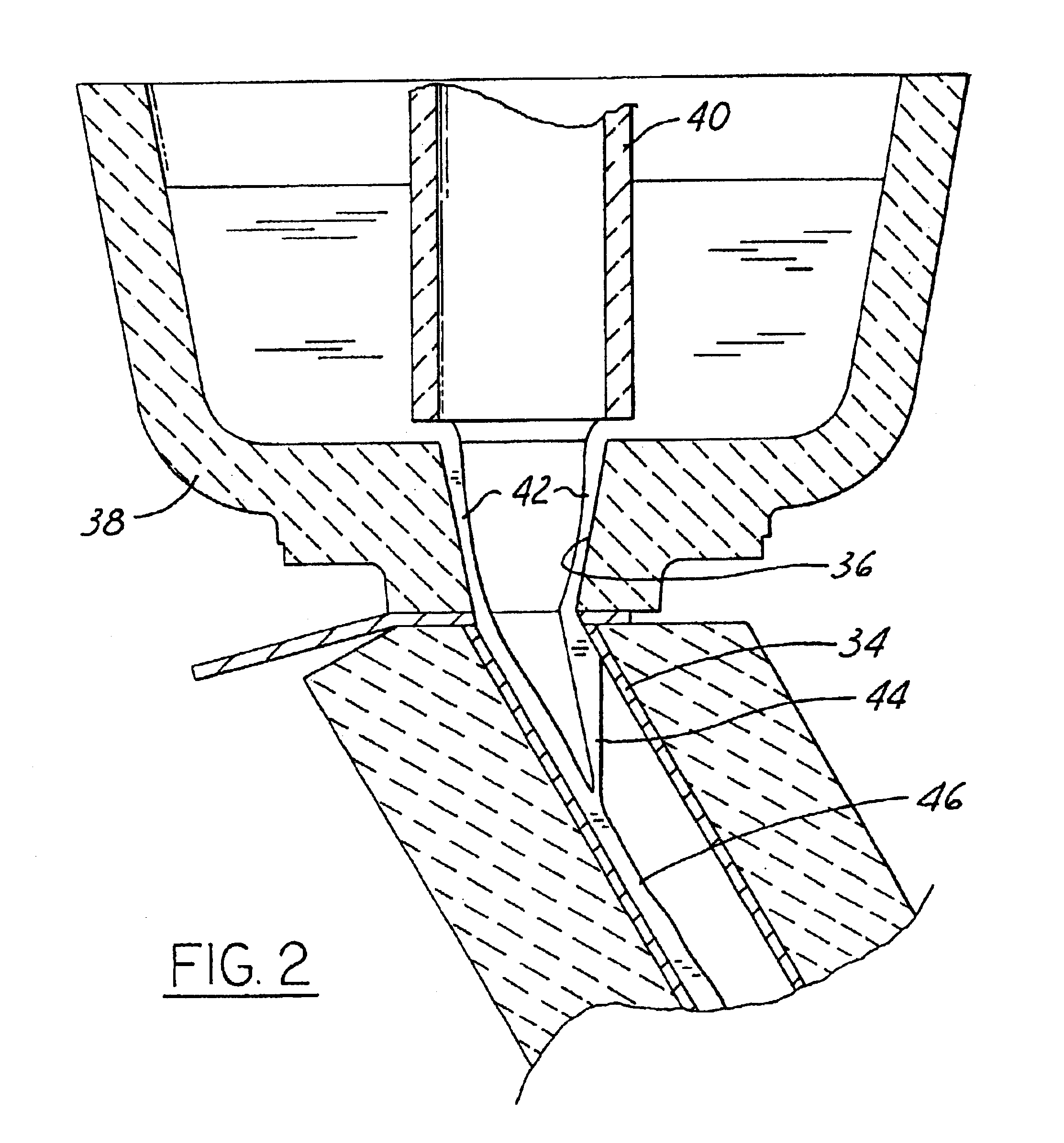

Method and apparatus for delivering a cased glass stream

InactiveUS6848272B2Prevent penetrationReducing atmosphereGlass furnace apparatusGlass forming apparatusRefractoryAmbient pressure

Apparatus for forming a cased glass stream having an inner core glass surrounded by an outer casing glass that includes a spout for delivering core glass from a first source through a first orifice. A second orifice is vertically spaced beneath and aligned with the first orifice, and is surrounded by an annular chamber that communicates with the second orifice through a gap between the first and second orifices. A tube delivers casing glass from the outlet opening of a casing glass spout to the annular chamber in such a way that glass flows by gravity through the orifices from the first and second sources to form the cased glass stream. A hollow tube within the casing glass spout is positioned with respect to the spout outlet opening for metering flow of casing glass through the outlet opening and delivery tube to the annular chamber surrounding the orifices. The interior of the hollow tube is coupled to a source of gas under pressure so as to maintain the tube interior, and the interior of the thin fall of casing glass through the spout outlet opening, at a pressure above ambient pressure surrounding the casing glass spout. This elevated gas pressure within the casing glass fall reverses the pressure differential between the interior and exterior of the spout outlet opening, so that any tendency for air to migrate through the refractory material surrounding the outlet opening and into the casing glass fall is eliminated.

Owner:OWENS-BROCKWAY GLASS CONTAINER INC

Fuel cell, fuel cell system, and electronic device

InactiveUS20100248052A1Inhibition is effectiveIncrease blockingReactant parameters controlFuel cell detailsFuel cellsVaporization

A fuel cell with which deterioration of an anode electrode is able to be inhibited by an inexpensive means while generated carbon dioxide is removed, a fuel cell system including the same, and an electronic device including the same are provided. The fuel cell includes: a power generation section having an electrolyte between a cathode electrode and an anode electrode; an anode side platy member provided on the anode electrode side of the power generation section; a fuel vaporization chamber; a through hole that is formed in the anode platy member and gives passage between the anode electrode and the fuel vaporization chamber; a carbon dioxide exhaust section that guides carbon dioxide generated in the power generation section to each side face of the anode platy member or the fuel vaporization chamber; and a valve provided in the carbon dioxide exhaust section.

Owner:SONY CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com