Process for controlling oxidation of nitrogen and metals in circulating fluidized solids contacting process

a fluidized solids and oxidation control technology, applied in the direction of catalytic naphtha reforming, catalytic cracking, naphtha reforming, etc., can solve the problems of increasing the environmental pollution of the regenerator flue gas, reducing catalyst selectivity, and reducing the concentration of refining "catalyst poisons, etc., to reduce the atmosphere and minimize the deactivation of catalysts from vanadium and sodium.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0002] Field of the Invention

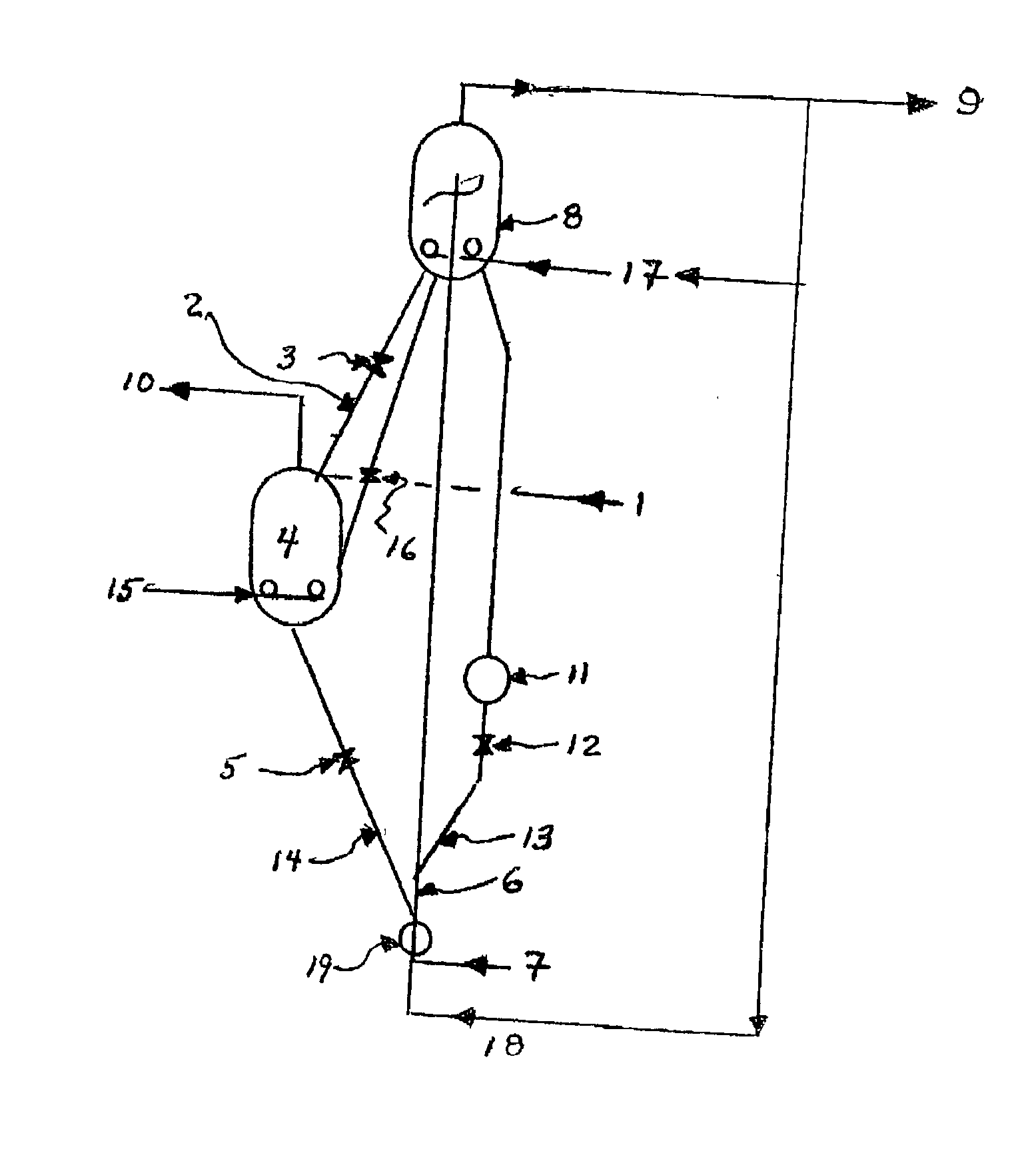

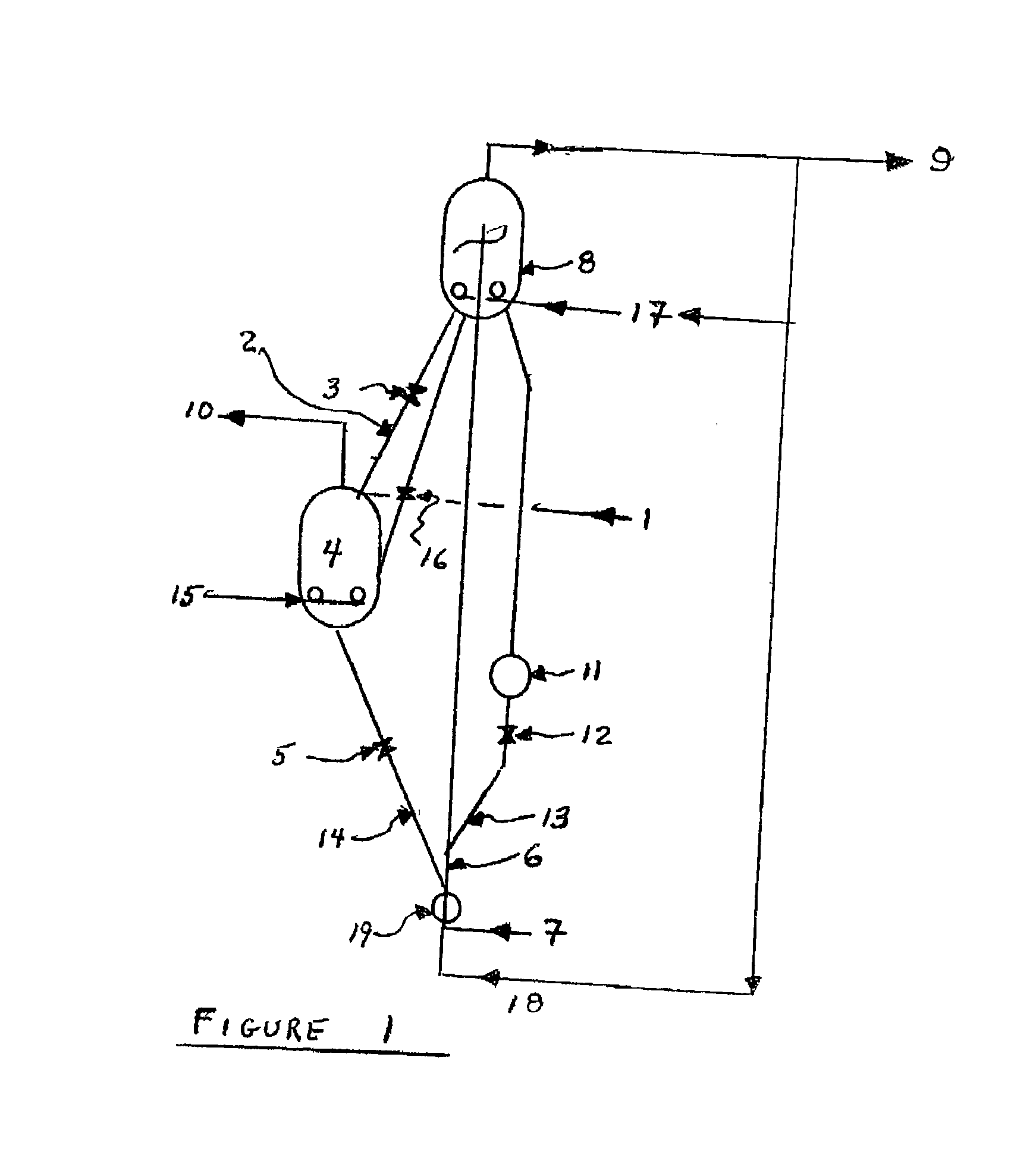

[0003] This invention relates to an improved circulating fluid particulate solids contacting process for upgrading hydrocarbon feedstocks containing metals, such as vanadium, and / or nitrogen, in which certain regenerator design and operating conditions are employed to (1) reduce the nitrogen oxides (NOx) emissions in regenerator flue gas and / or (2) permit operating with an increased equilibrium solids vanadium level over and above the current state of the art. This invention also relates to an improved fluid catalytic cracking (FCC) process for processing gas oils and residual oils, in which certain FCC unit (FCCU) catalyst regenerator design and operating conditions are employed to reduce the nitrogen oxides (NOx) emissions in the catalyst regenerator flue gas and / or permit operating with an increased equilibrium catalyst vanadium level.

[0004] Background of the Invention

[0005] The Fluid Catalytic Cracking (FCC) Process, for converting petroleum-derived ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com