Patents

Literature

804results about "Exhaust gas handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

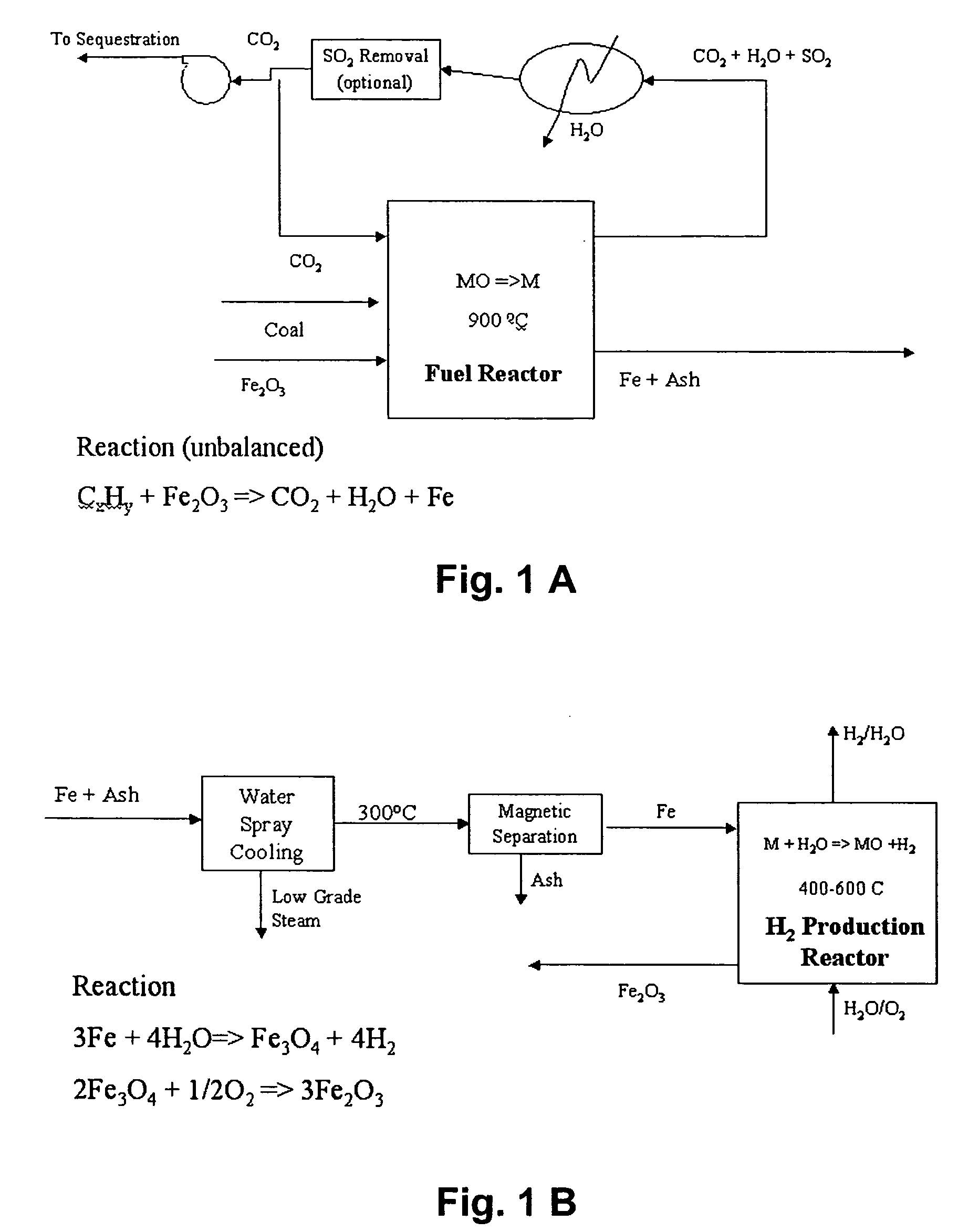

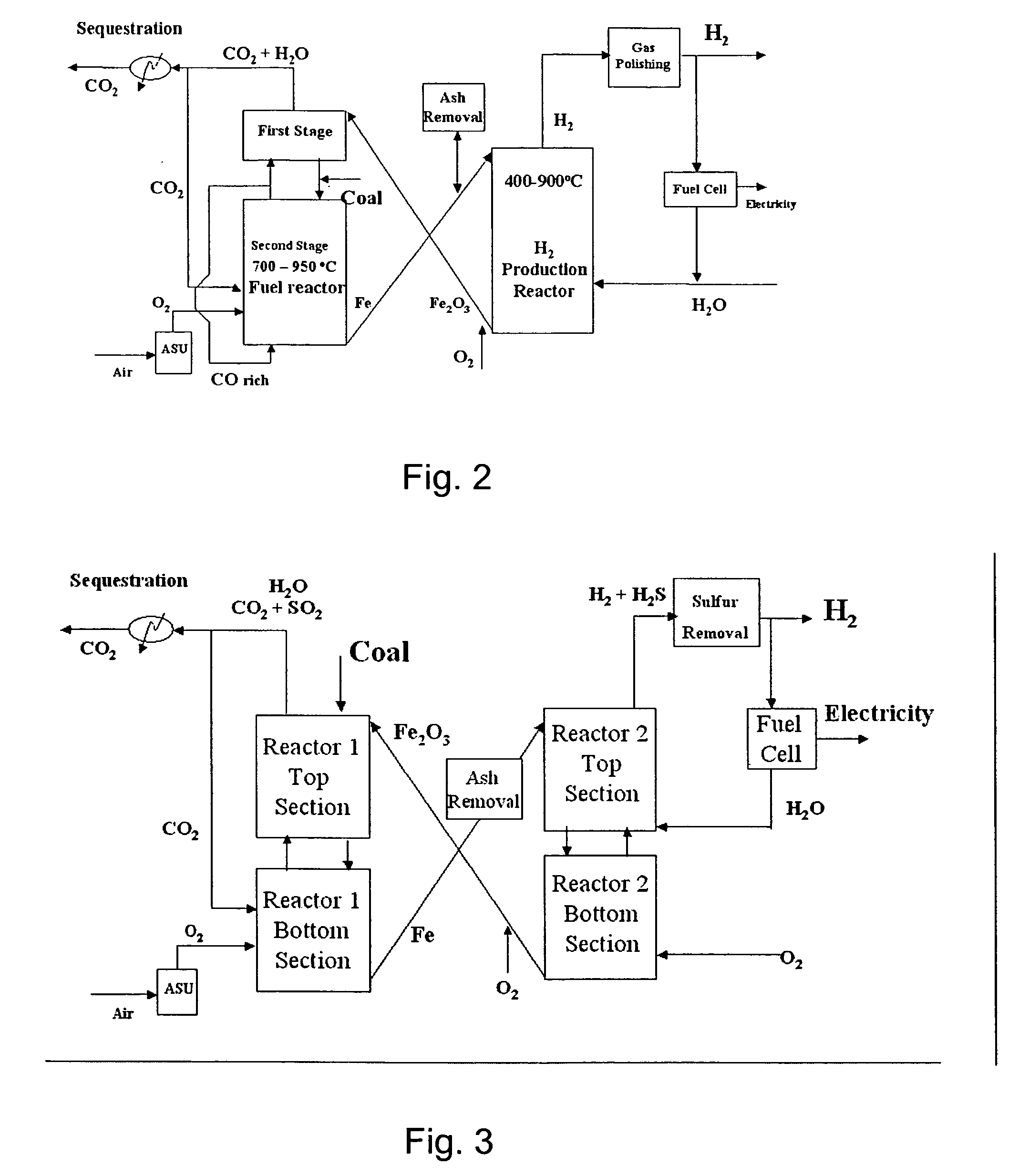

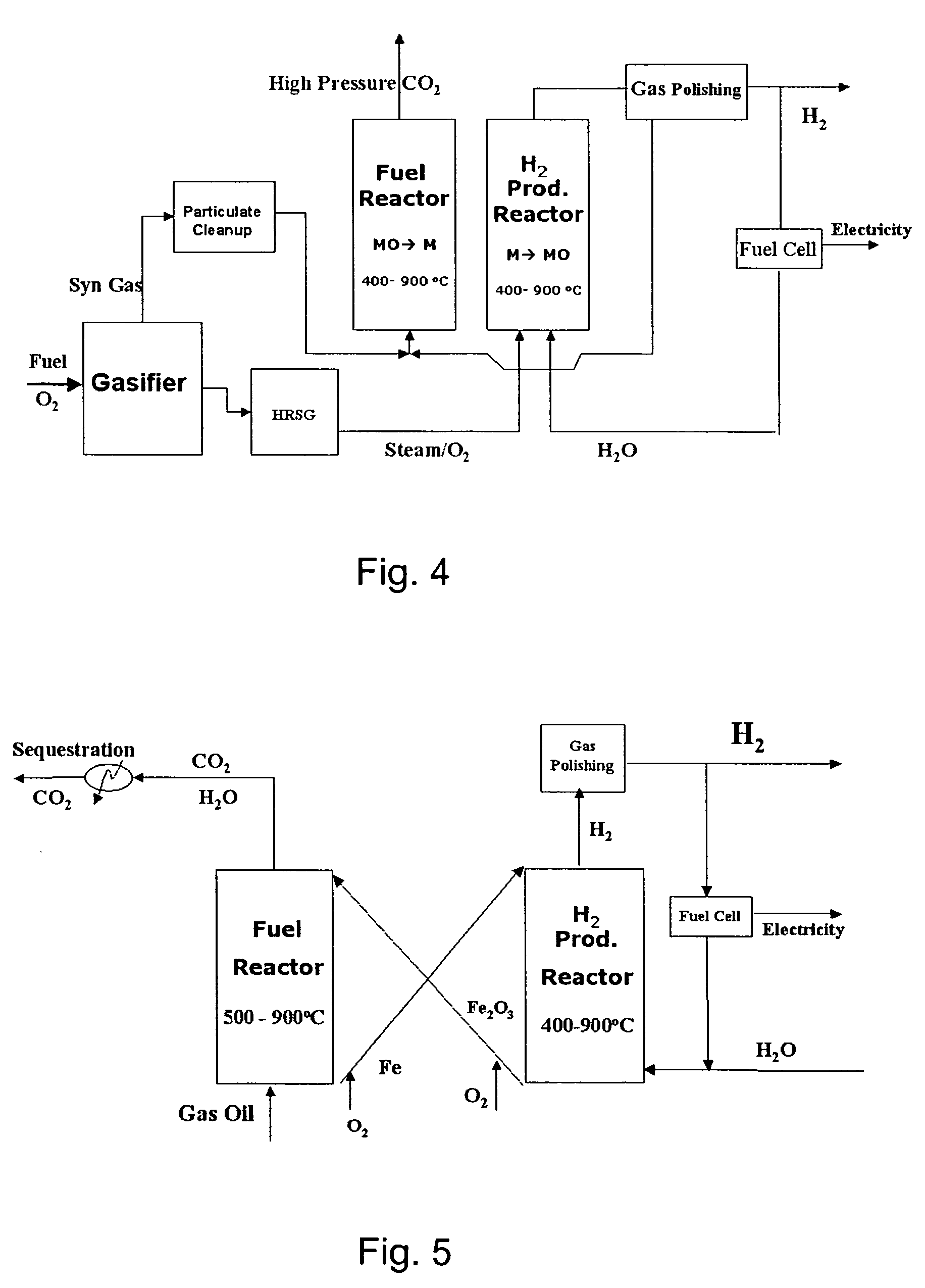

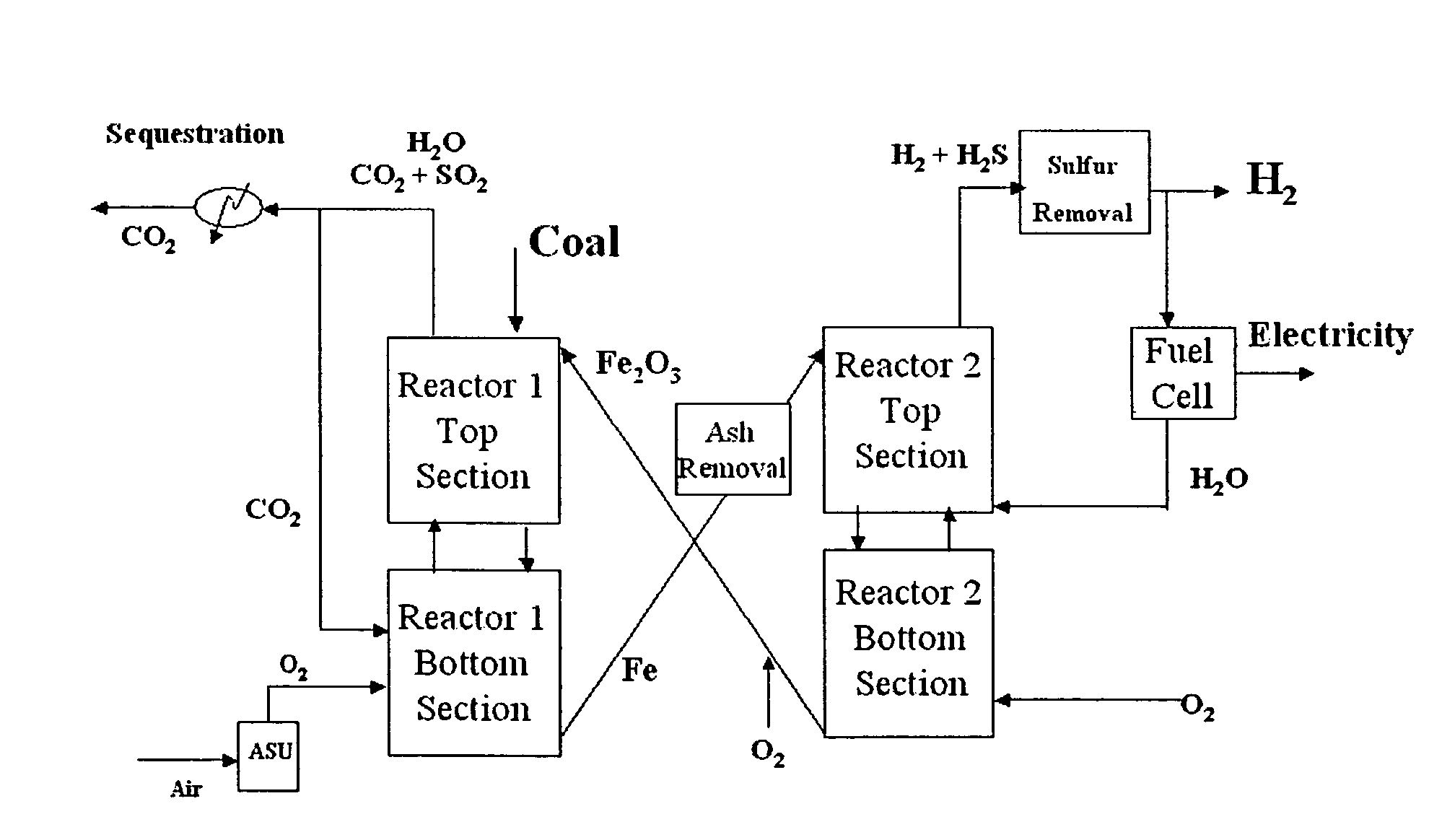

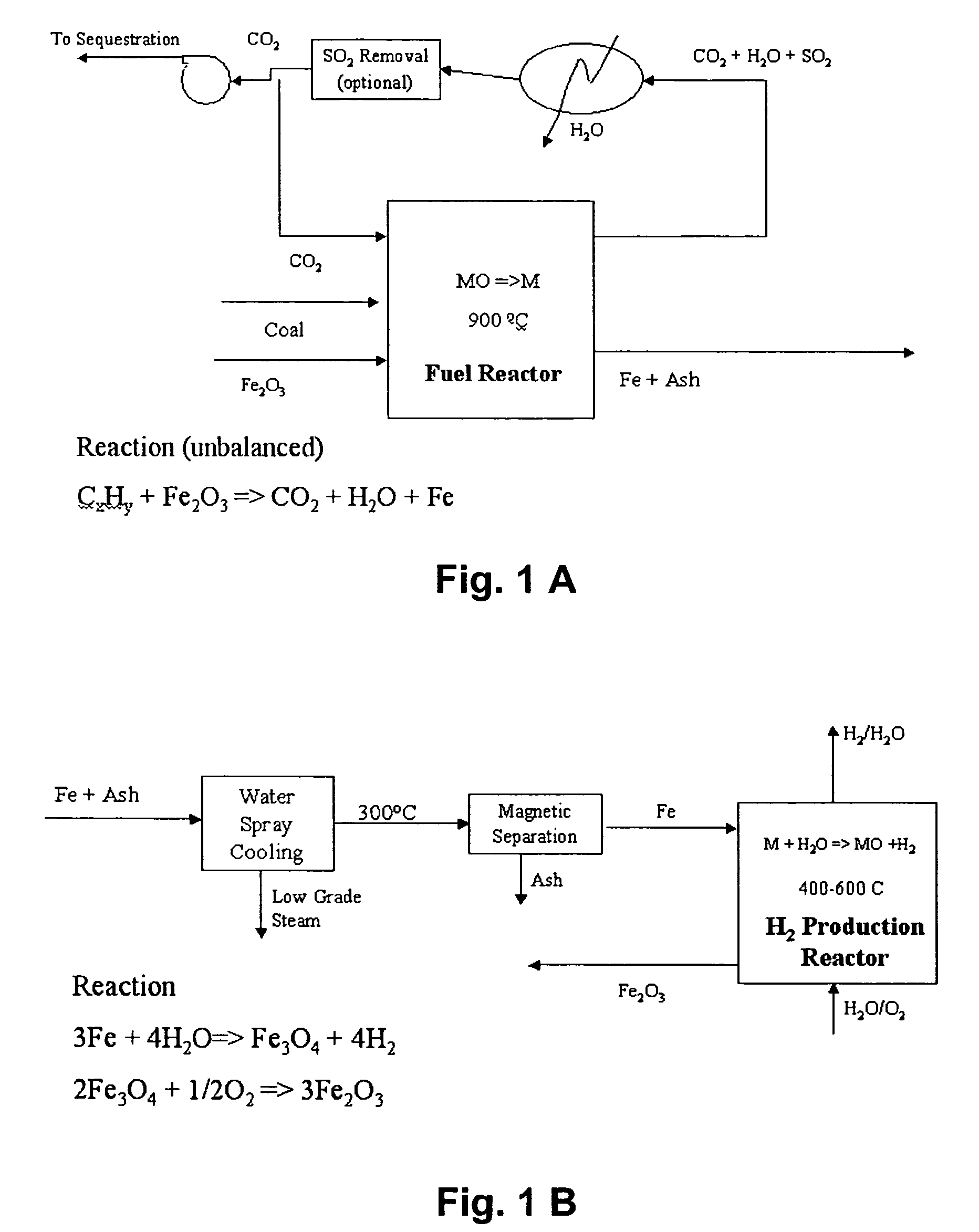

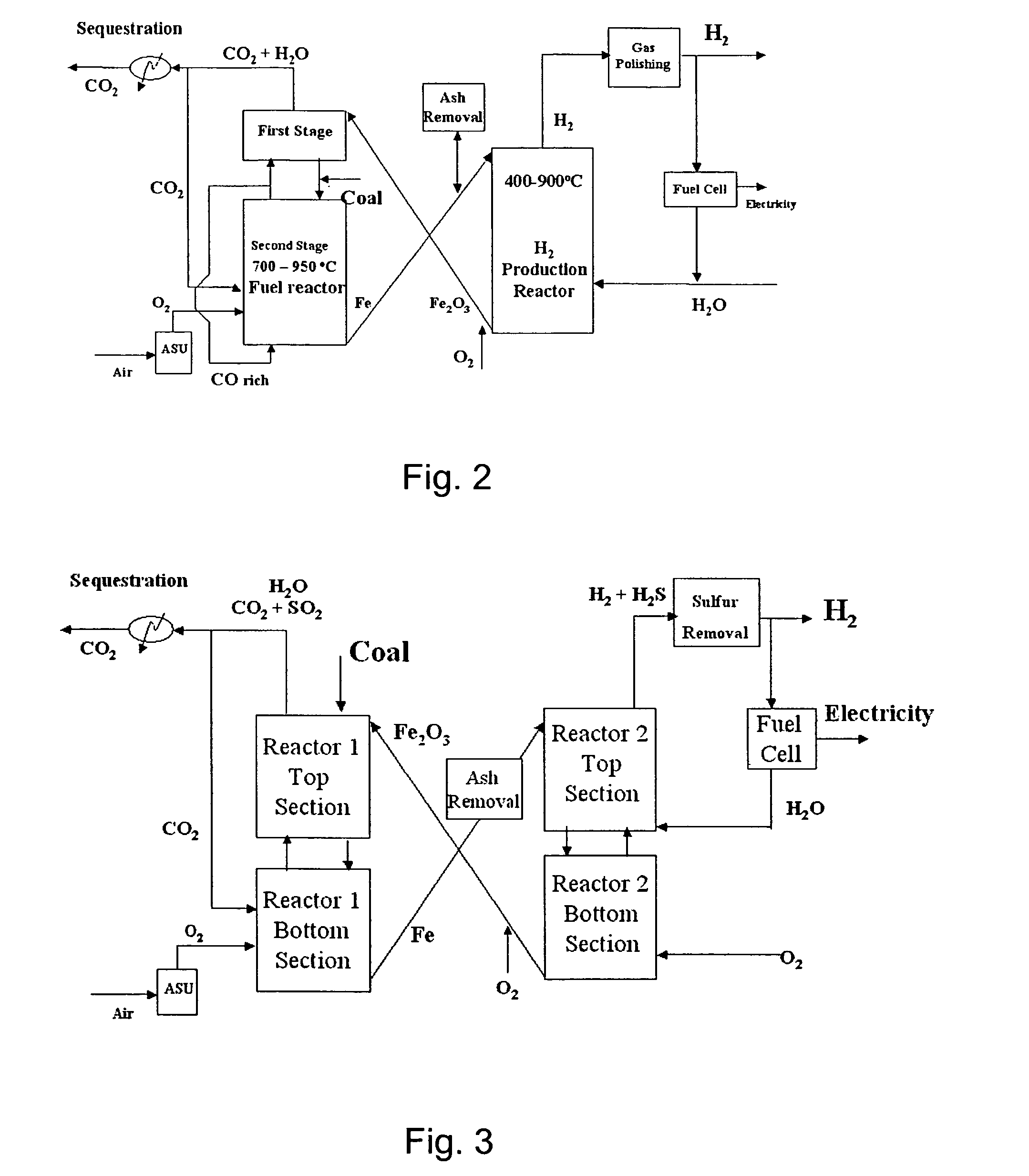

Combustion looping using composite oxygen carriers

ActiveUS20050175533A1Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

Combustion looping using composite oxygen carriers

ActiveUS7767191B2Increase surface areaImprove energy conversion efficiencyHydrogen productionIndirect carbon-dioxide mitigationHydrogenCombustion

A method for producing hydrogen gas is provided and comprises reducing a metal oxide in a reduction reaction between a carbon-based fuel and a metal oxide to provide a reduced metal or metal oxide having a lower oxidation state, and oxidizing the reduced metal or metal oxide to produce hydrogen and a metal oxide having a higher oxidation state. The metal or metal oxide is provided in the form of a porous composite of a ceramic material containing the metal or metal oxide. The porous composite may comprise either a monolith, pellets, or particles.

Owner:OHIO STATE INNOVATION FOUND

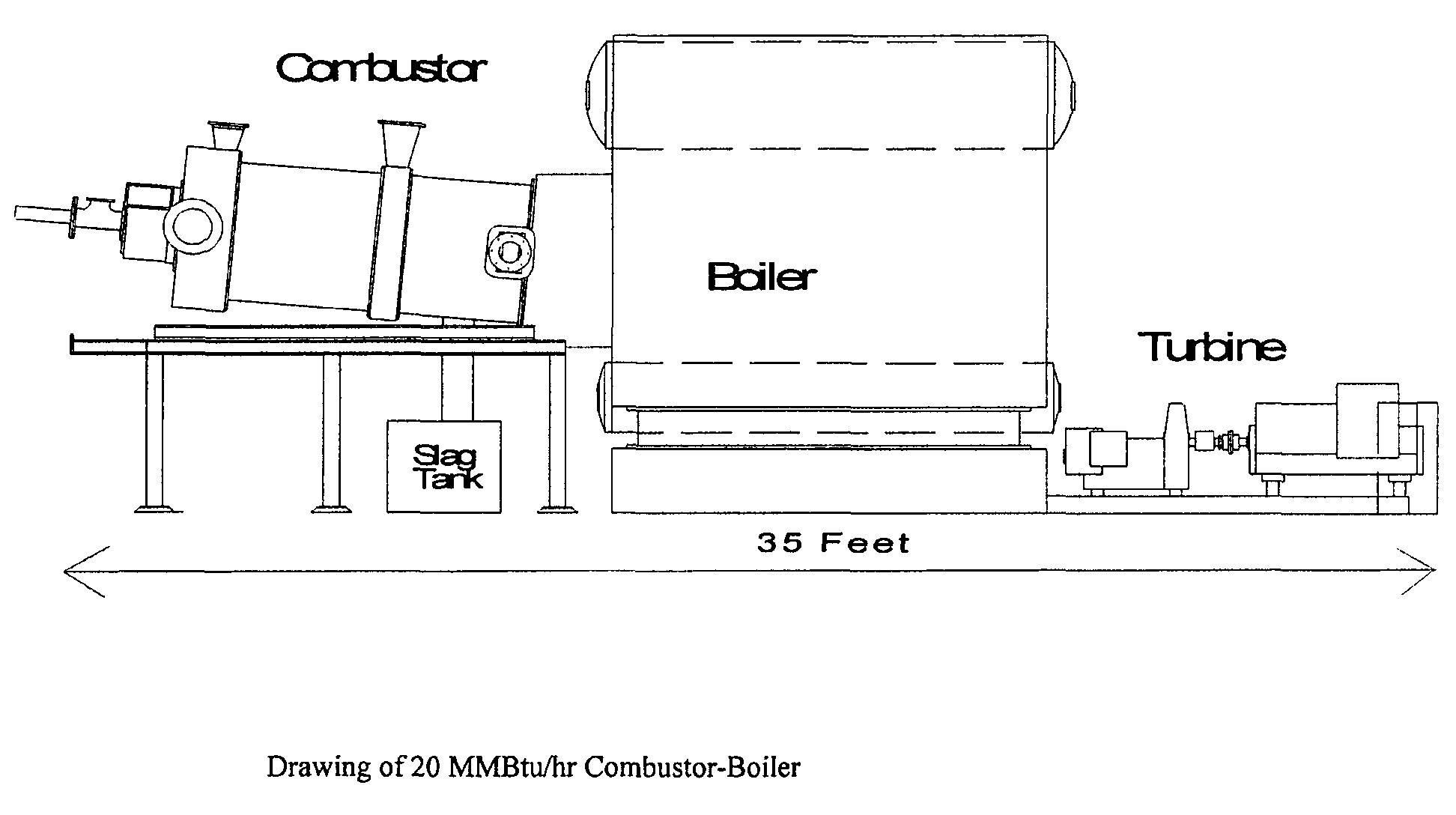

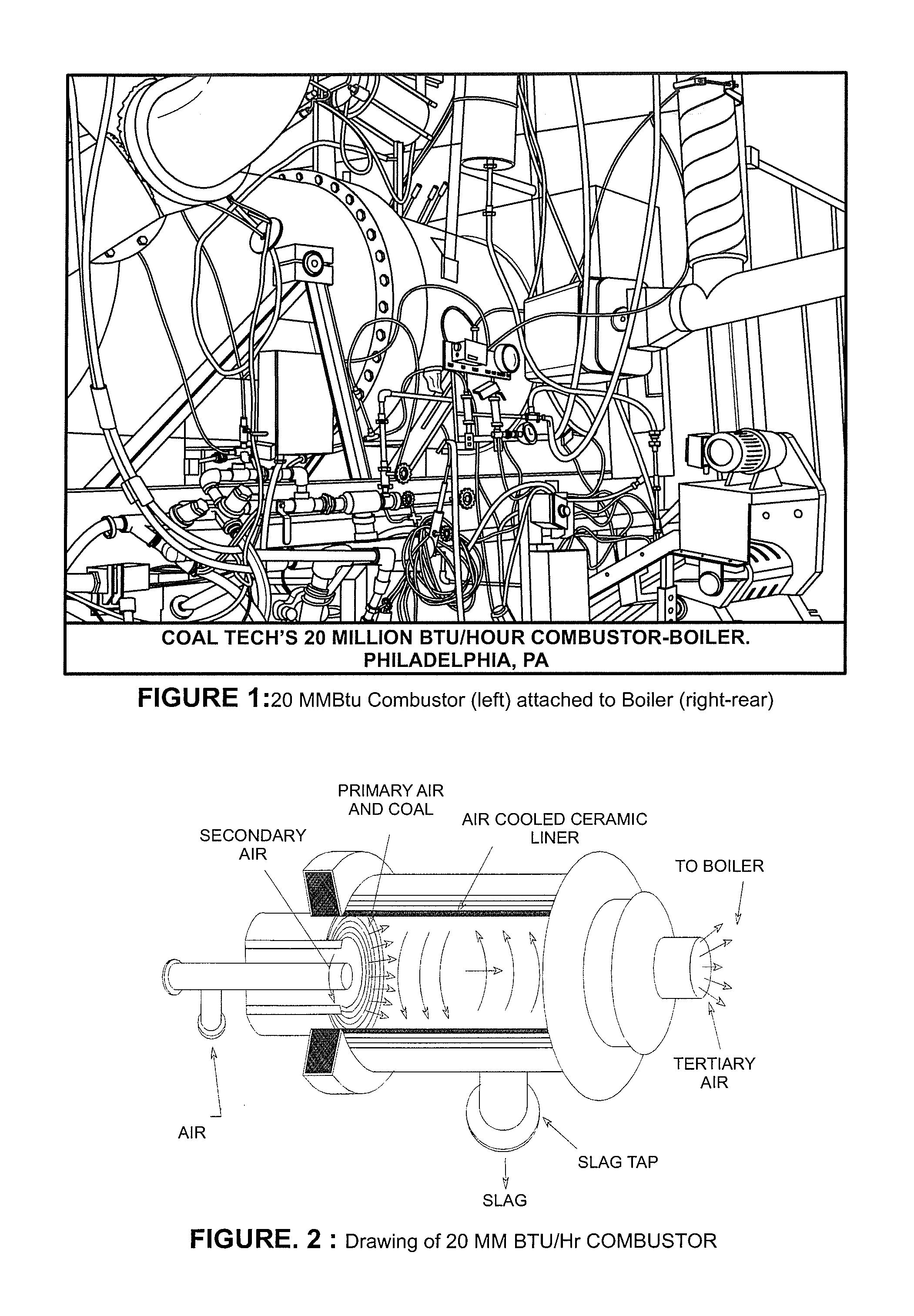

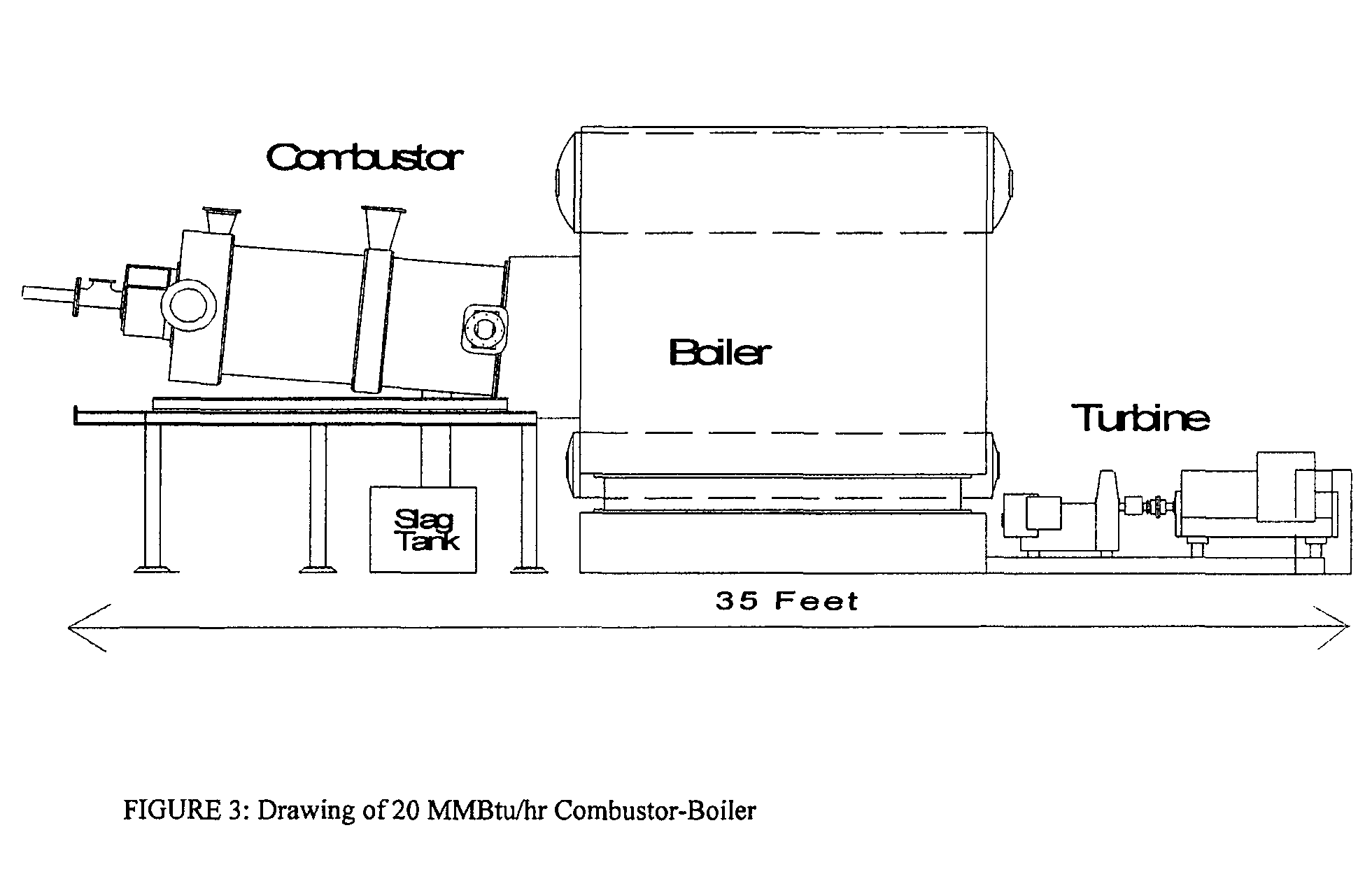

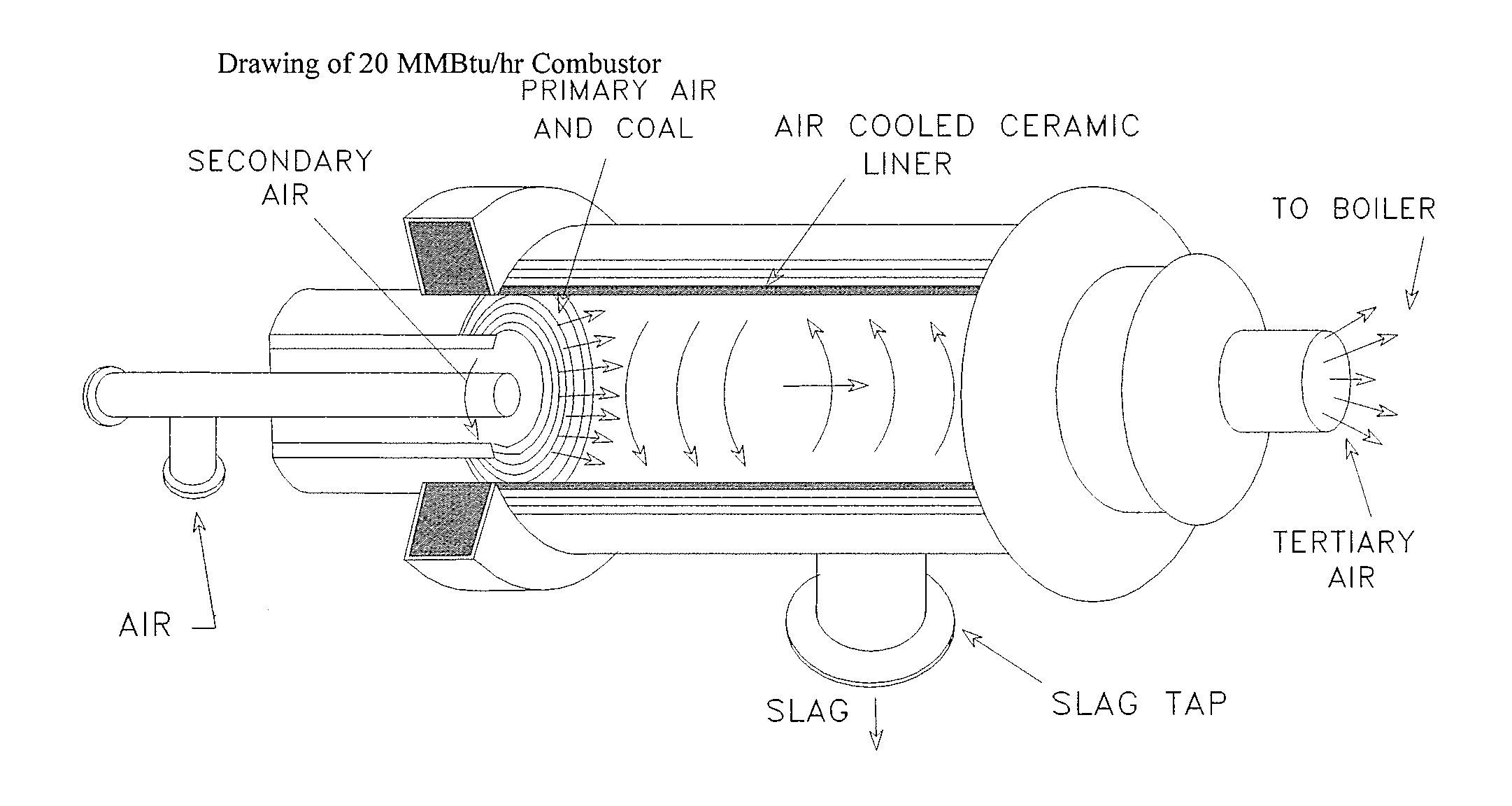

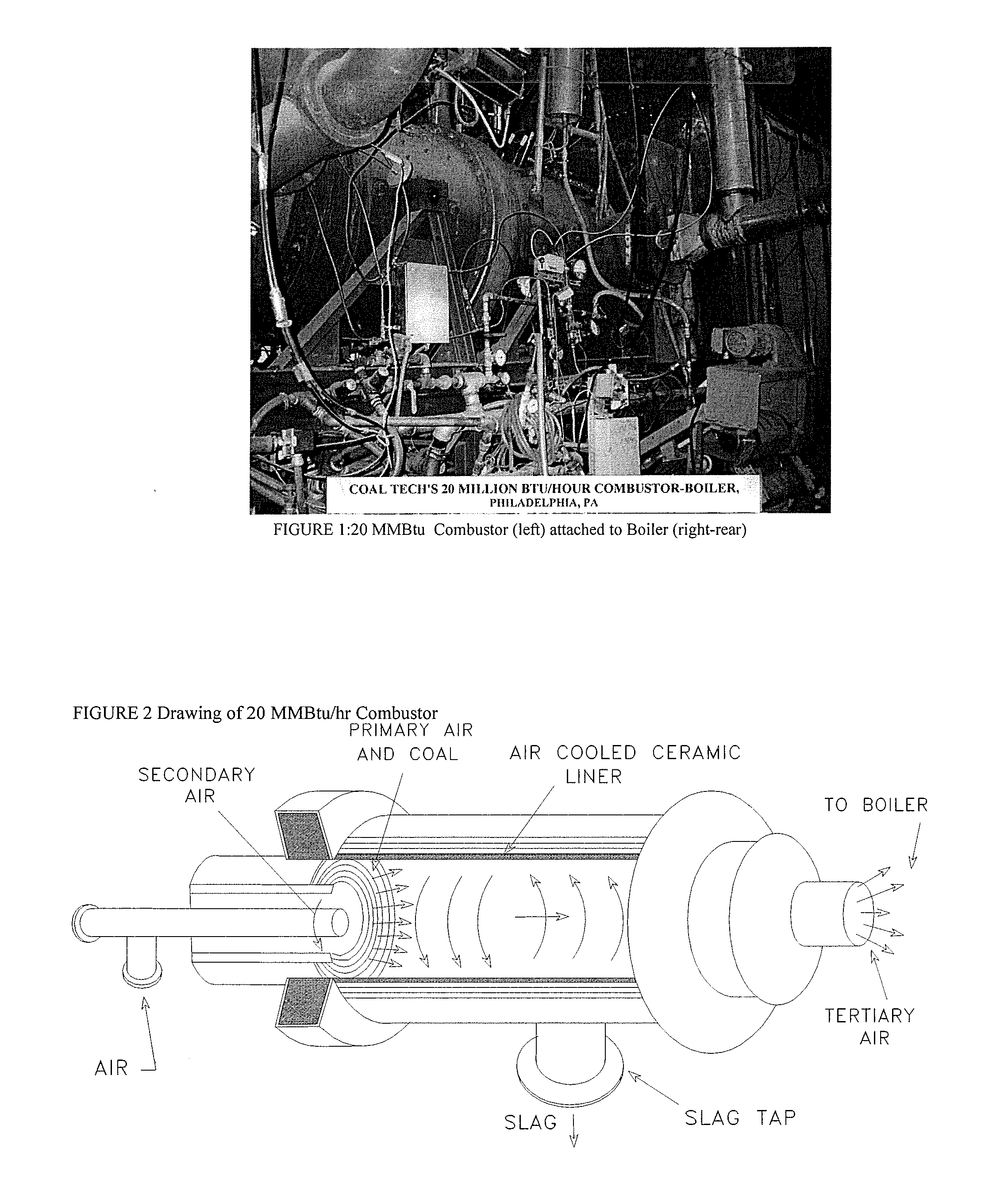

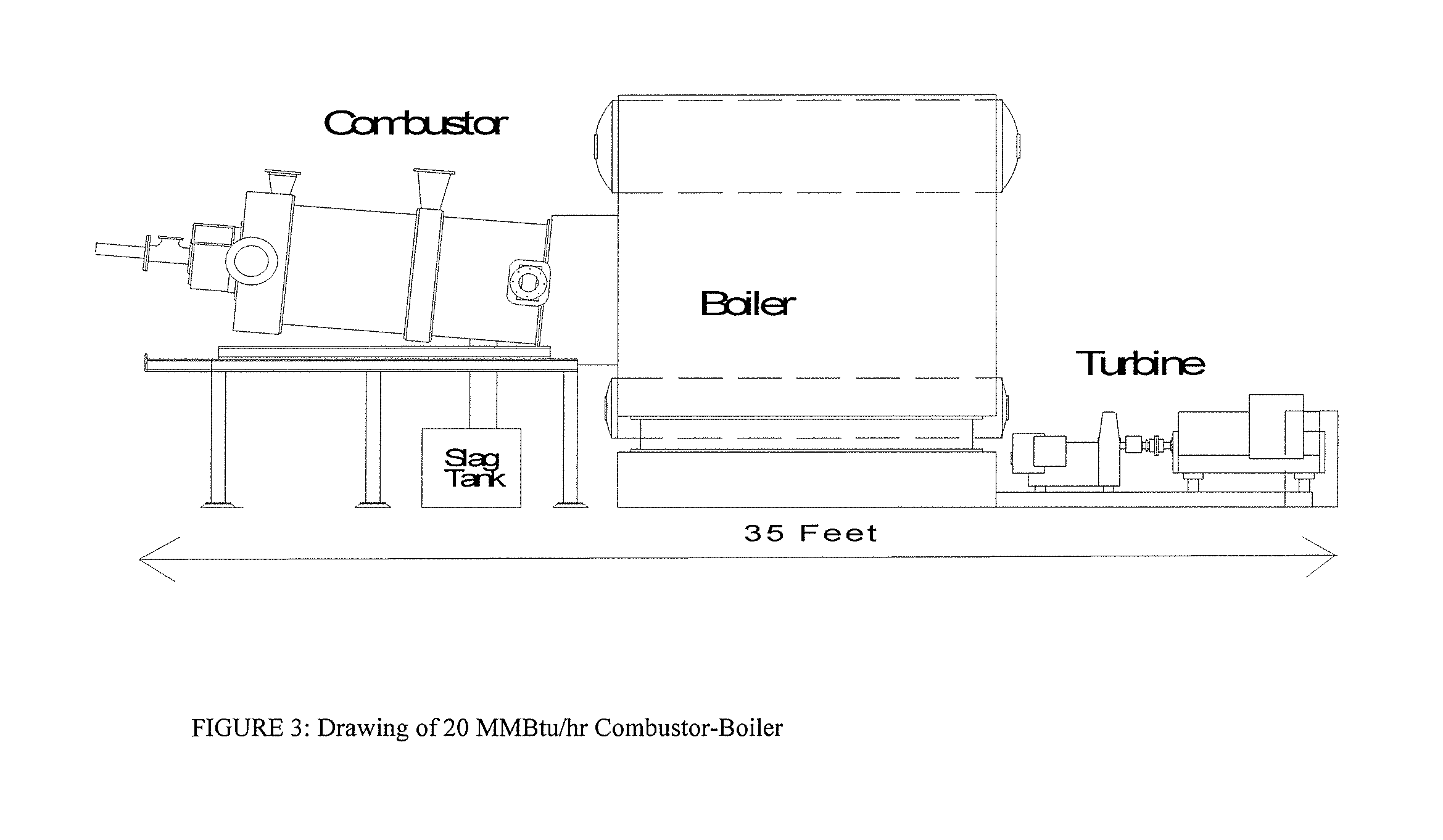

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and CO2 sequestration

InactiveUS8337613B2Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsCombustorEnvironmental remediation

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

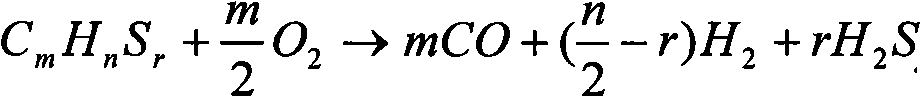

Process for production of elemental iron

InactiveUS7931731B2Easy to processIsotope separationHydrogen/synthetic gas productionPartial oxidationFerric

A process to prepare elemental iron by contacting an iron ore feed with a reducing gas at a pressure of between 1 and 10 bar to obtain iron and an off-gas includes preparing the reducing gas by performing the following steps: (a) partially oxidizing a mixture comprising a solid or liquid carbonaceous fuel and oxygen at a pressure of between 10 and 80 bar, thereby obtaining a gas comprising H2 and CO; (b) removing CO2 and H2S from the gas obtained in step (a) to obtain an intermediate gas comprising H2 and CO; (c) supplying the intermediate gas obtained in step (b) to a H2-selective membrane to obtain a H2-rich permeate gas and a CO-rich retentate; and (d) heating H2-rich permeate to obtain a heated H2-rich permeate as the reducing gas.

Owner:SHELL OIL CO

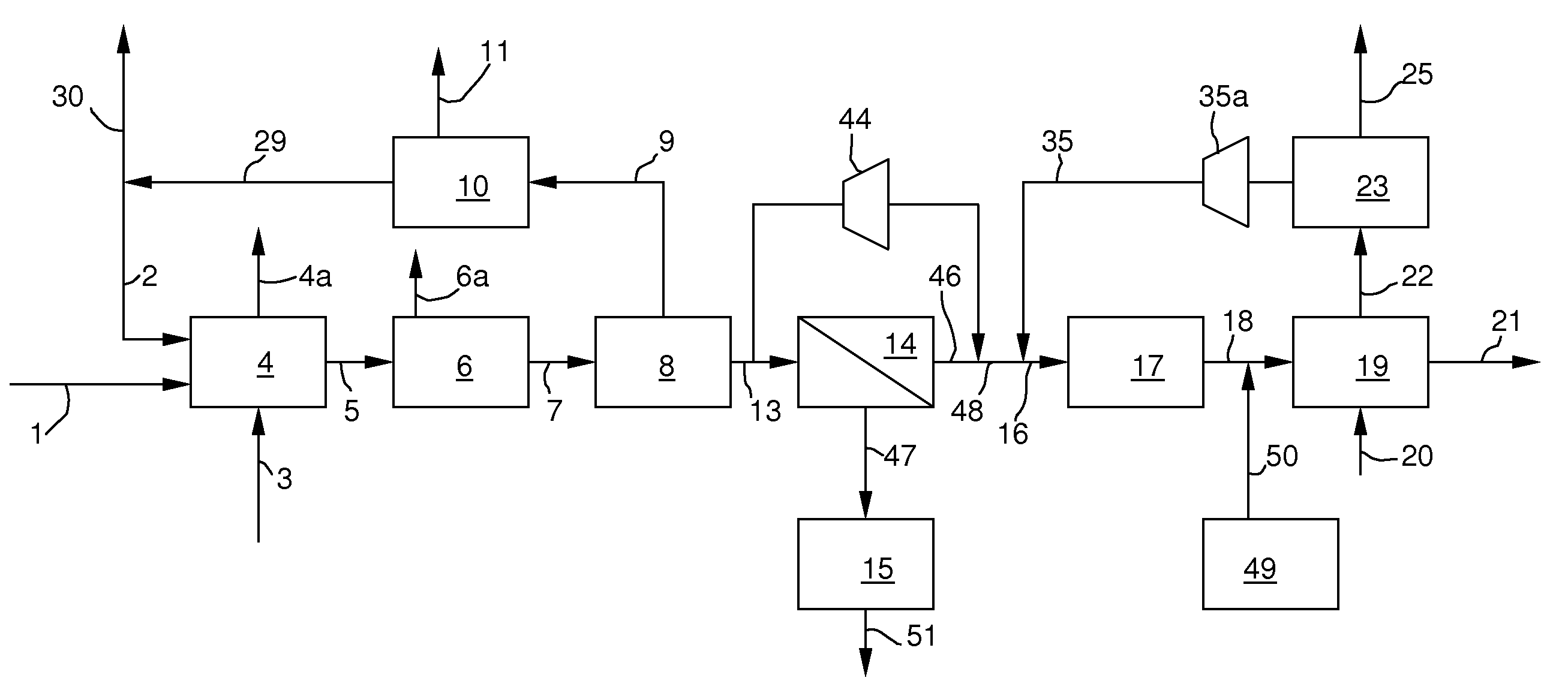

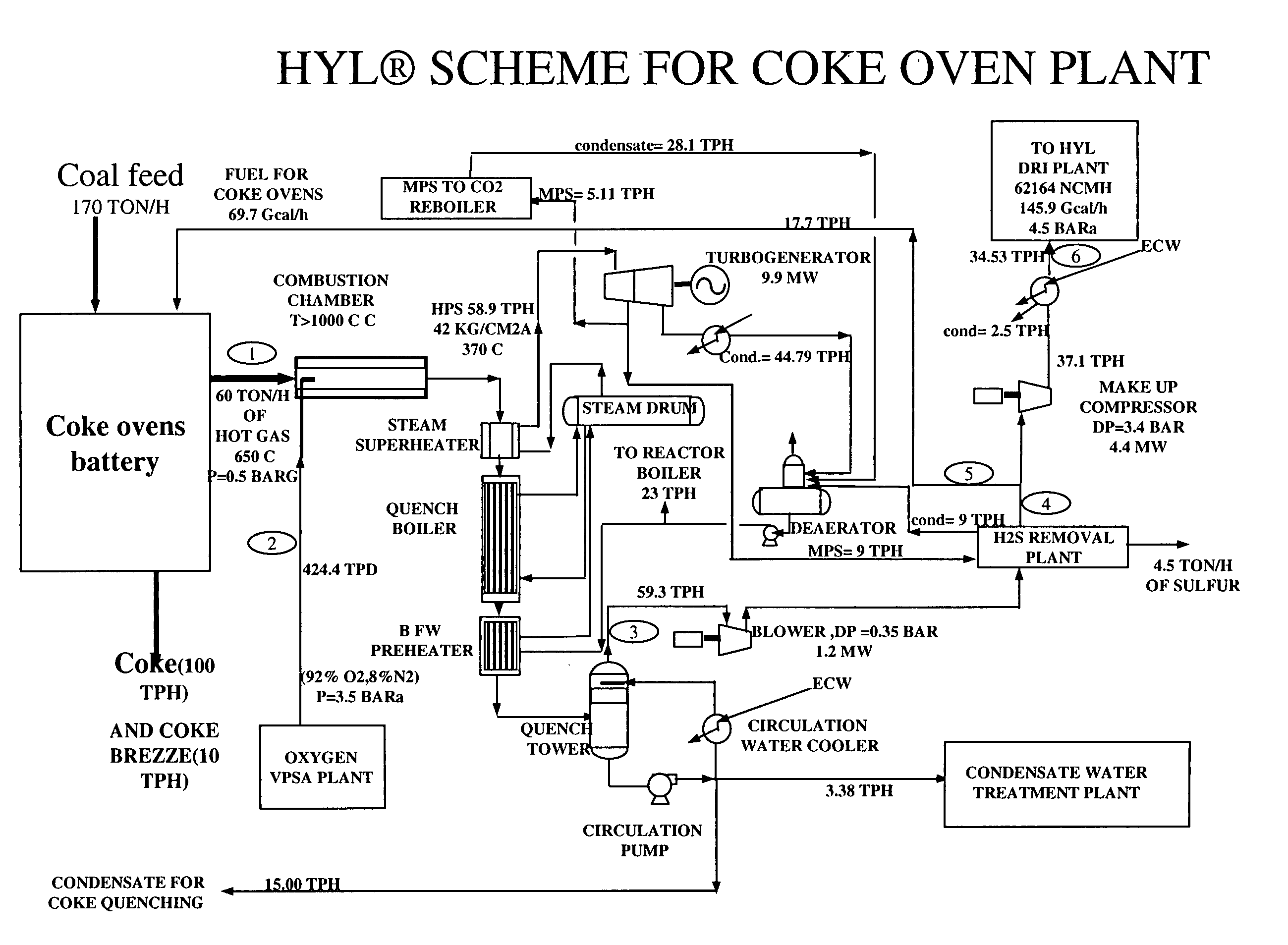

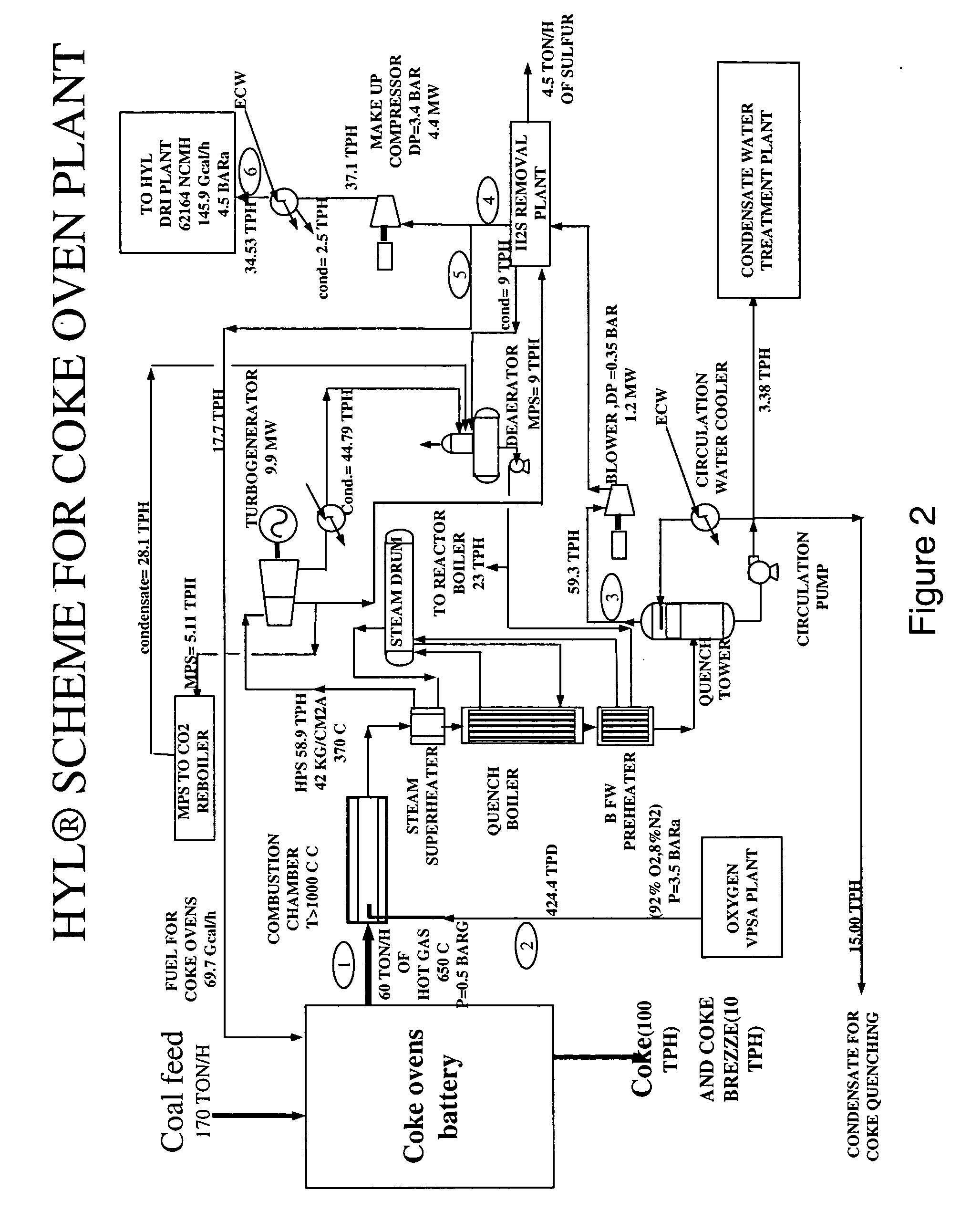

Method and apparatus for producing clean reducing gases from coke oven gas

InactiveUS20060027043A1Avoiding complex and expensiveOxygen/ozone/oxide/hydroxideHydrogen separationProcess engineeringCoke oven

A process and system for producing reducing gases are disclosed, wherein volatile components derived from coal are transformed into reducing gases suitable for utilization as synthesis gas, as a reducing agent for the direct reduction of iron ores and / or as a clean fuel.

Owner:HYLSA SA DE CV

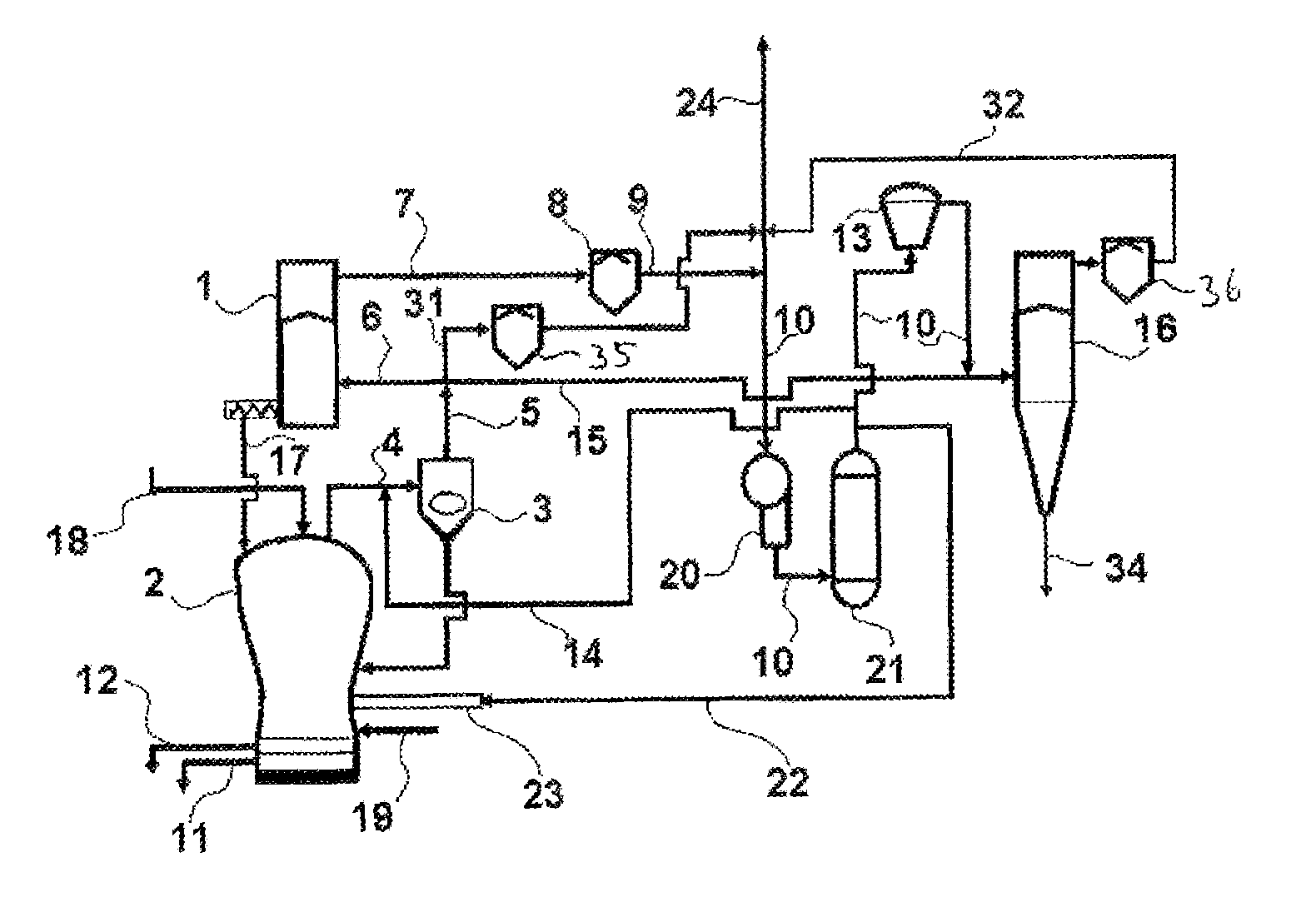

Method and system for energy-optimized and CO2 emission-optimized iron production

InactiveUS8419825B2Emission reductionIncrease profitBlast furnace detailsExhaust gas handlingProcess engineeringProduct gas

A process for energy- and emission-optimized iron production and an installation for carrying out the process. A first partial amount of a generator gas produced in a melter gasifier is used as a first reducing gas in a first reduction zone. A second partial amount is fed to at least one further reduction zone as a second reducing gas. In addition, after CO2 scrubbing, a partial amount of top gas removed from the first reduction zone is admixed with the generator gas after the latter leaves the melter gasifier, for cooling the generator gas.

Owner:PRIMETALS TECH AUSTRIA GMBH

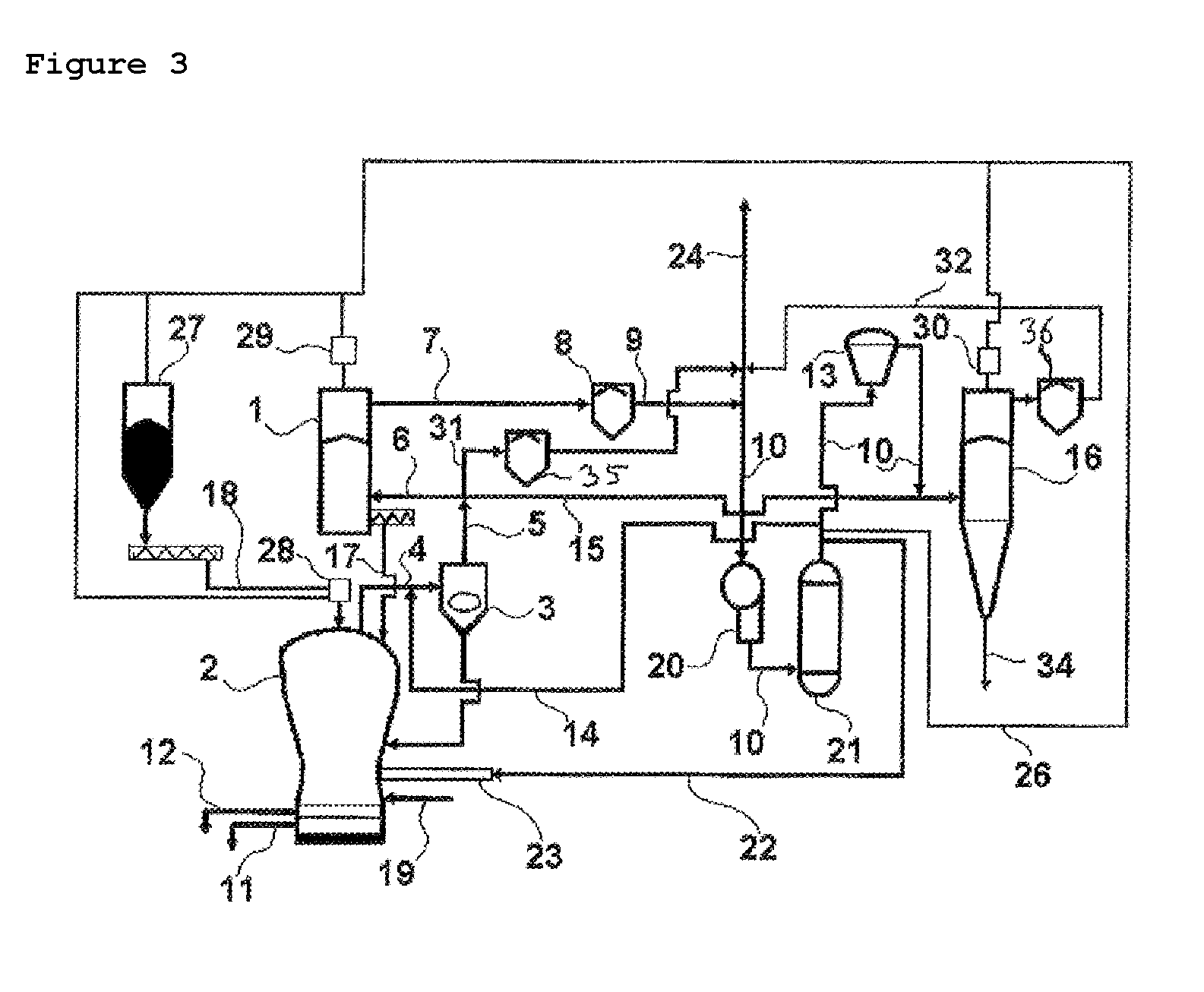

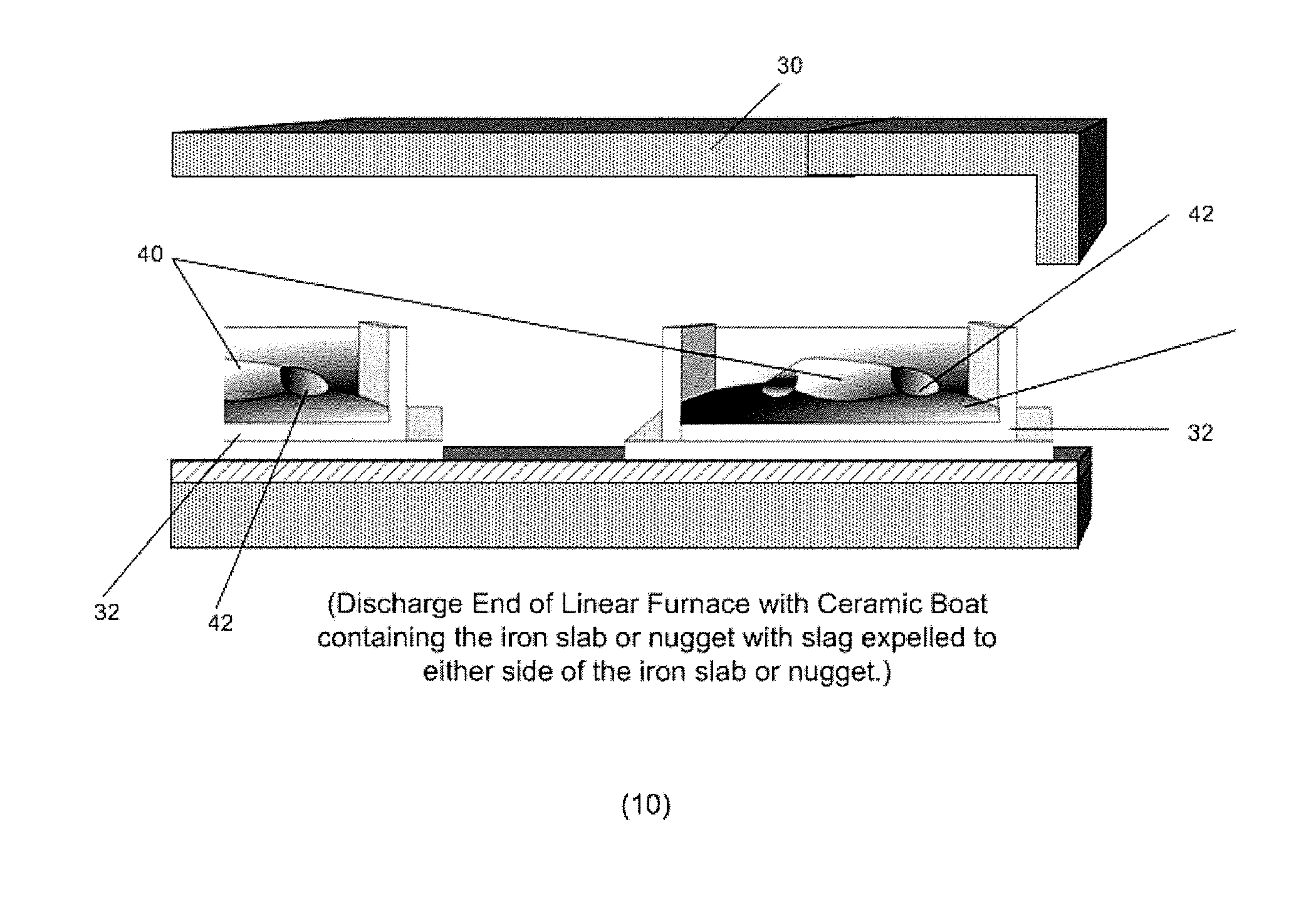

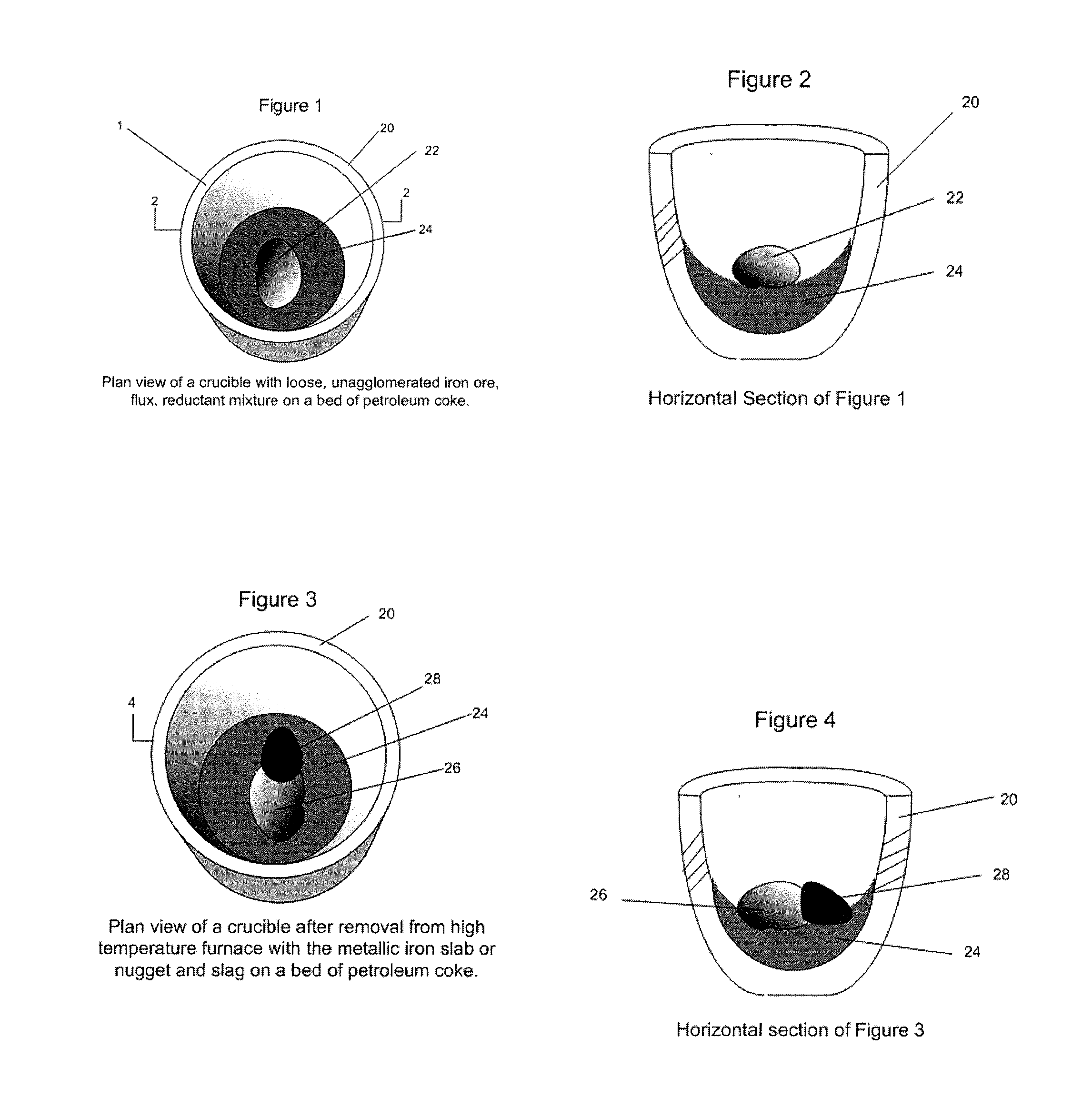

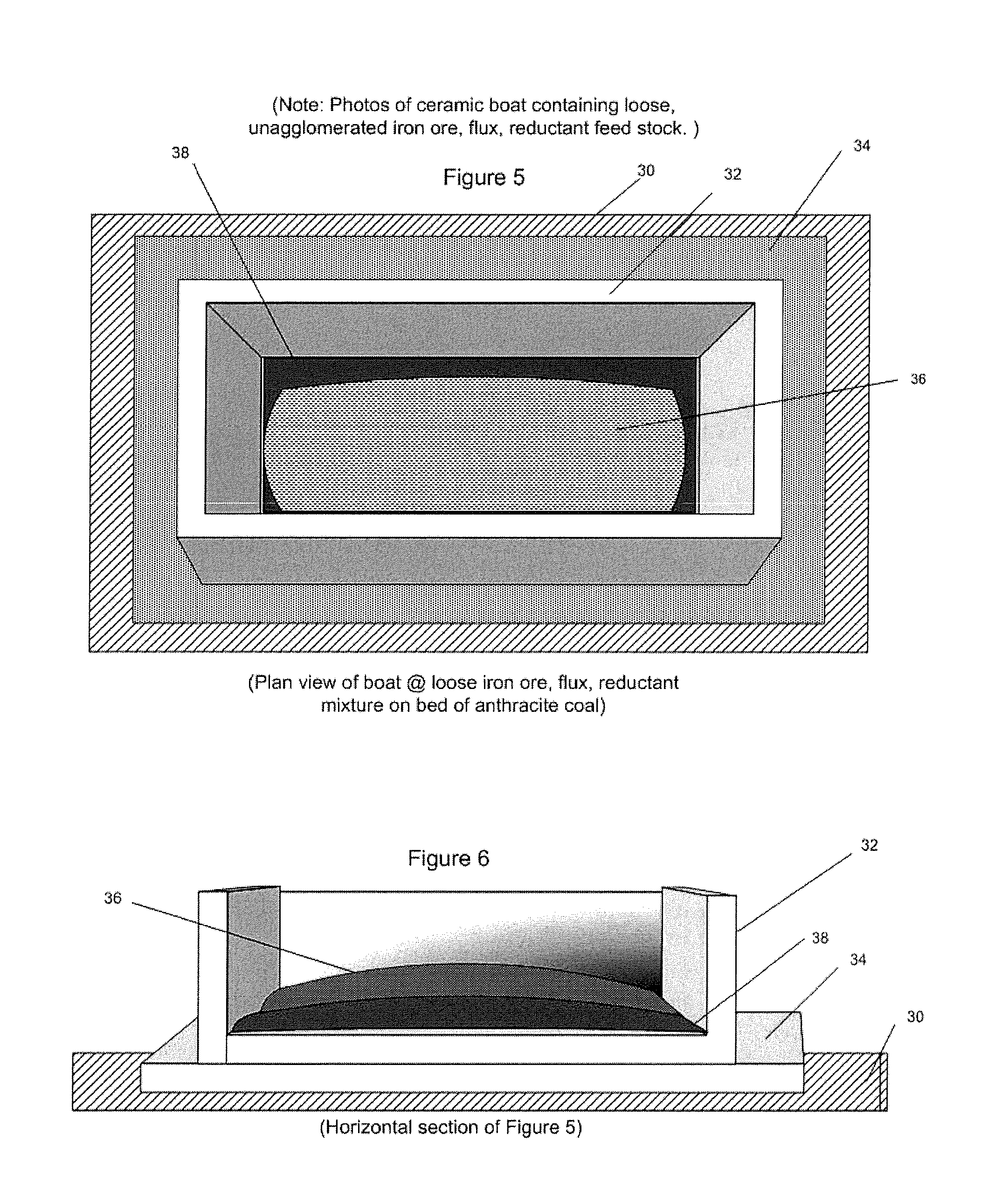

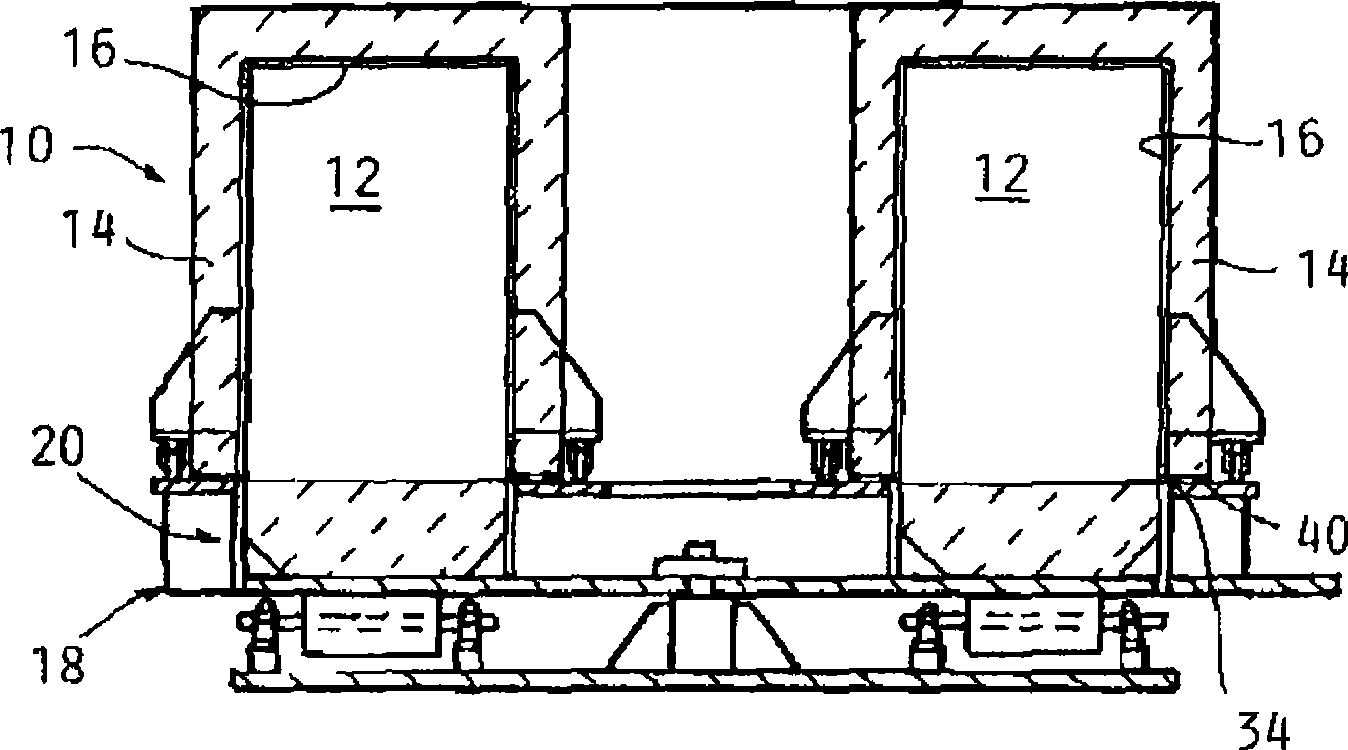

Direct Production of Iron Slabs and Nuggets From Ore Without Pelletizing or Briquetting

ActiveUS20130081516A1Lower cost of capitalReduce operating costsExhaust gas handlingGas emission reductionParticulatesIronstone

Metallic iron is produced from a composition formed from a mixture of iron ore particles and particles of a reductant made of a biomass material, a coal or coke in a particulate form together with a flux and is processed in a loose, un-agglomerated non-pelletized, non-briquetted form in a reducing furnace to produce metallic iron directly from the ore. An excess of biomass or coal or coke reductant can be used to provide CO and H that can be recovered as a synthetic gas and converted to electrical or other energy. Metallic iron nuggets or slabs can be produced from manganiferous ores or concentrates. Manganese can be caused to enter the nugget or slab or the slag by adjusting the furnace temperature. Titaniferous ores or concentrates can be used to produce metallic iron slabs or nuggets and a titanium-rich slag.

Owner:SIMMONS JOHN J

Direct reduced iron discharge system and method

InactiveUS6214086B1No loss in metallizationWide range of sizesMolten spray coatingNuclear energy generationEngineeringDirect reduced iron

A method and apparatus for simultaneously supplying varying proportions of hot and cold direct reduced iron(DRI) material from a source of hot DRI for melting, storage, briquetting, or transport. The system uses gravity to transport hot DRI material from a reduction furnace to a furnace discharge section, which transports desired amounts to a cooling receptacle and to a hot DRI vessel. The cooling section of the apparatus is connected to the furnace discharge section through a dynamic seal leg. The hot section is also connected to the furnace discharge section through separate a dynamic sealing leg and can feed a surge vessel, a briquetter, a storage vessel or a melting furnace. The method of operation is also disclosed.

Owner:IDREX INT BV ROTTERDAM ZURICH BRANCH

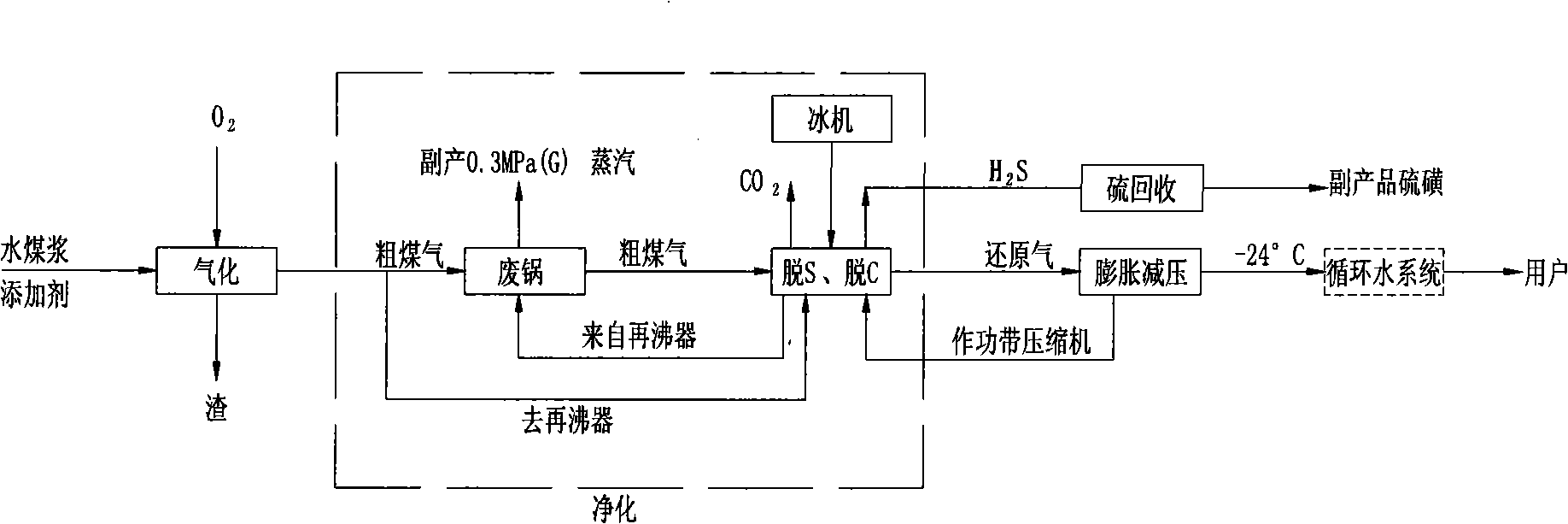

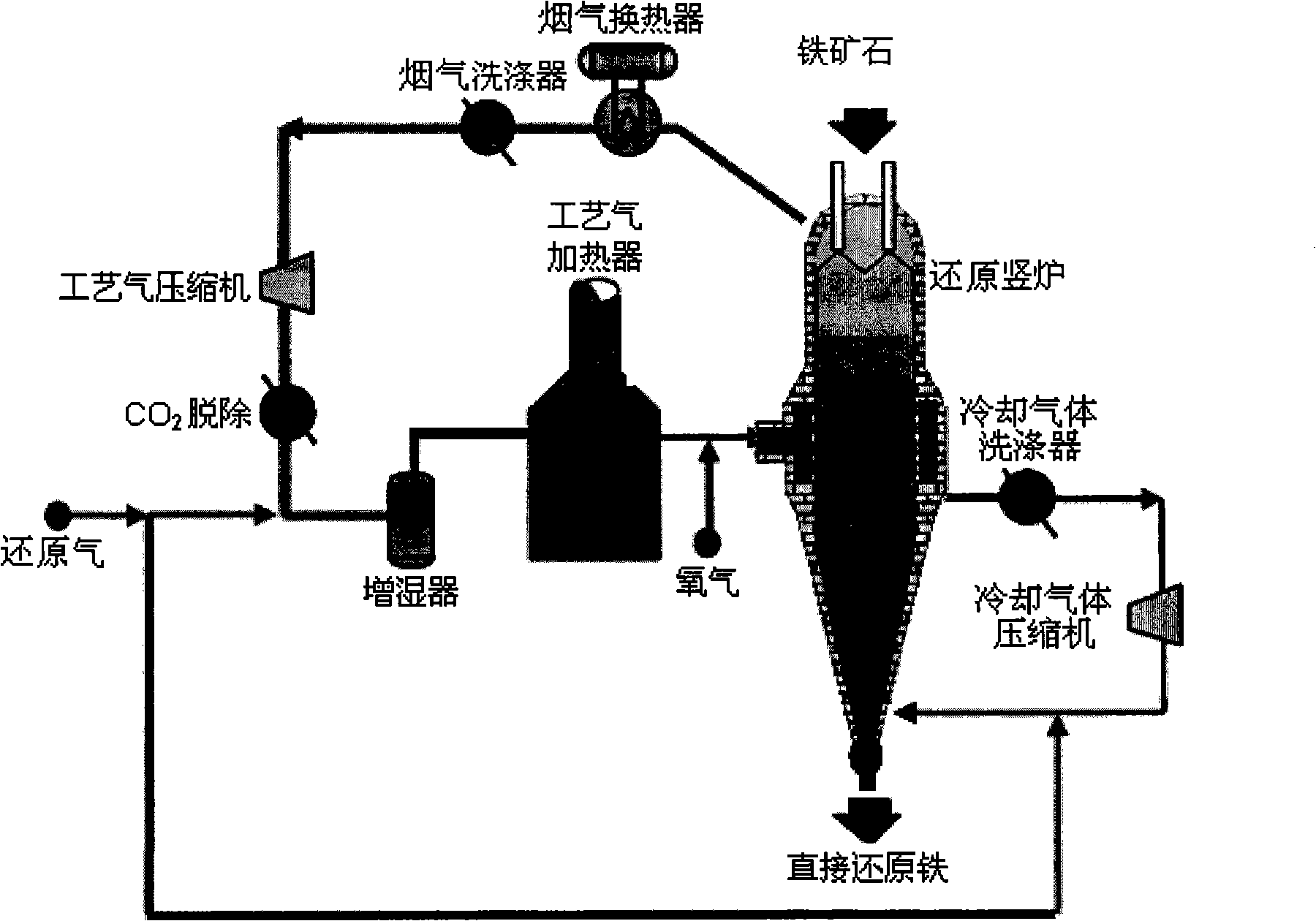

Coal reducing gas direct reduction metallurgical process in gas-based shaft kiln and system

ActiveCN101358258ASimple structureReduce processing costsExhaust gas handlingShaft furnaceGas heaterProduct gas

The invention discloses a coal-derived reducing gas base shaft furnace direct reduction metallurgical method and a system thereof. Reducing gases with CO and H2 serving as the main components are prepared from coal through a coal-derived reducing gas system, and are treated by the reducing reaction with iron ore through a direct reduction metallurgical system. The reducing gases are mainly used as the reducing agents of the reducing flow, the cooling agents of the cooling flow and the fuel of the direct reducing metallurgical system. The reducing flow is composed of a reducing shaft furnace, a furnace top gas heat exchanger, a furnace top gas shock chilling / scrubbing system, a process gas recycle compressor, a compressor secondary cooler, a CO2 absorber, a process gas humidifier, a process gas heater, etc. The conical part of the lower part of the shaft furnace is the cooling zone of the shaft furnace direct reduction metallurgical furnace. The cooling gases are sprayed in from the conical region of the lower part of the shaft furnace direct reduction metallurgical furnace, and flow upwards across the metallurgical furnace. The hot cooling gases flow away the cooling region and then are cooled, compressed and recycled. The system is simple in structure and low in process cost.

Owner:JIANGSU PROVINCE METALLURGICAL DESIGN INST

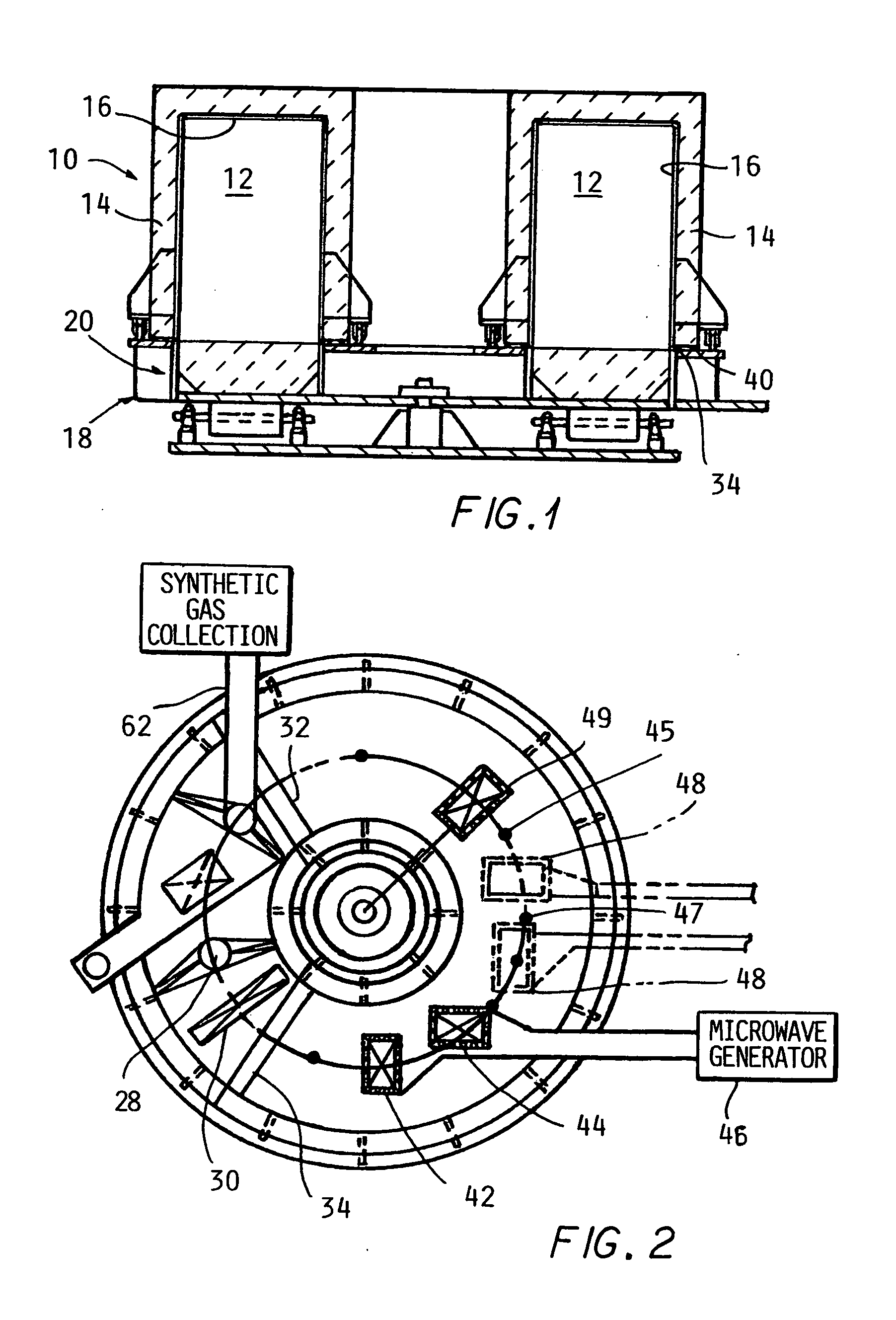

Method and Apparatus For Coproduction of Pig Iron and High Quality Syngas

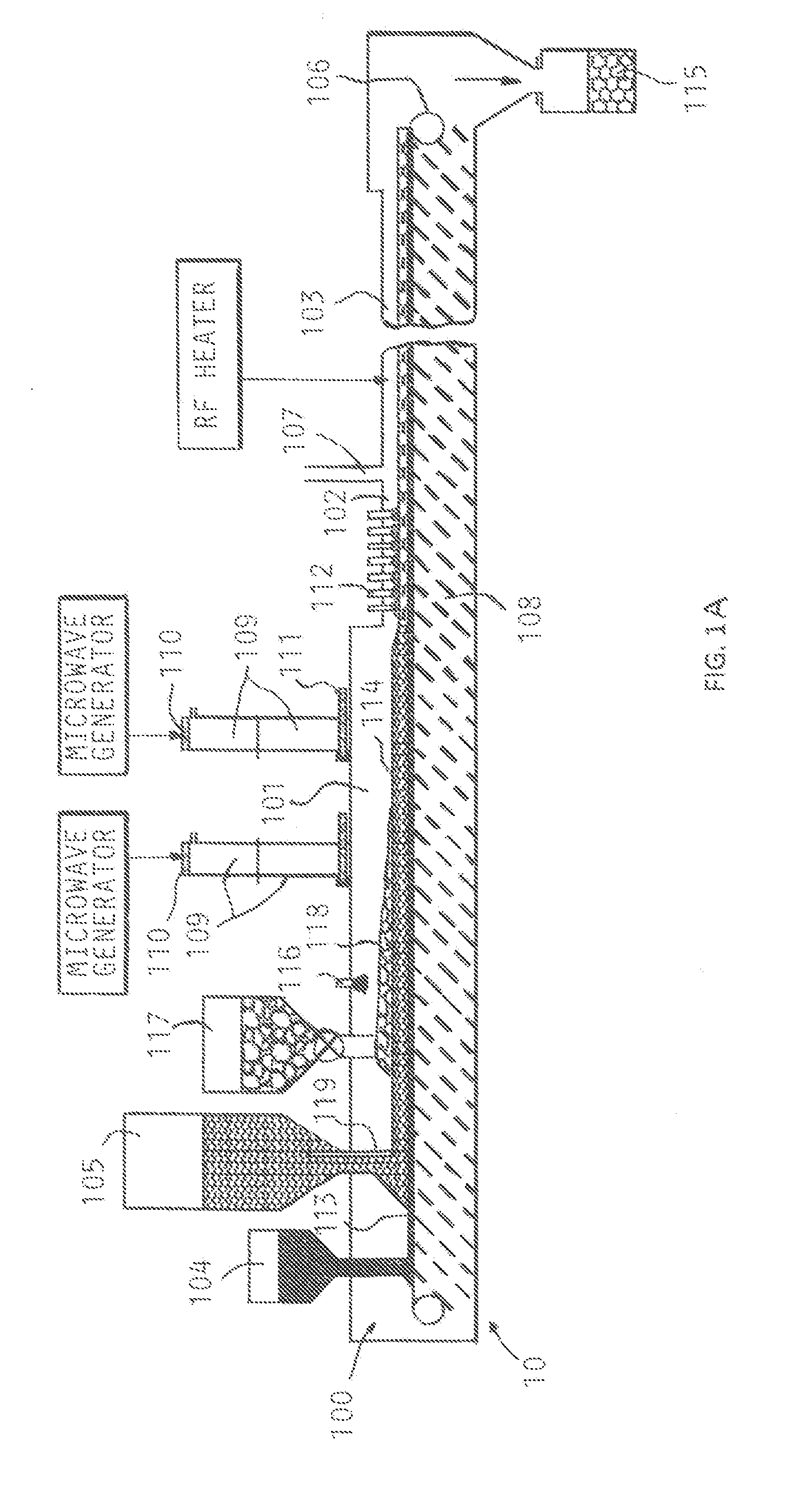

ActiveUS20120031232A1Improve microwave absorption performanceHeating up fastBlast furnace detailsCharge manipulationSludgeLiquid fuel

Combined microwave heating and plasma / electric arc heating is utilized in several processes and apparatus which involve co-production of pig iron and high quality syngas, biomass to liquid fuel production, coal to liquid fuel production, co-gasification of biomass and coal, municipal solid waste treatment, waste-to-energy (agriculture waste, ASR and PEF), EAF dust and BOF sludge treatment to recover zinc and iron, hazardous bottom ash vitrification, and bromine, chlorine and sulfur removal / recycling.

Owner:HUANG XIAODI +1

Slagging coal combustor for cementitious slag production, metal oxide reduction, shale gas and oil recovery, enviromental remediation, emission control and co2 sequestration

InactiveUS20110173139A1Reduce transportationMinimize disfiguringNitrogen compoundsSulfur compoundsMaterials scienceChar

Systems, methods and processes teach by specific examples how the cost of sequestering carbon dioxide (CO2) can be totally offset and turned into profits during coal powered electricity generation from revenue and co-benefits. The process is provided whereby fly ash-carbon mixtures, or de-volatilized coal char, or anthracite coal culm is co-fired in an air-cooled, slagging combustor with limestone or similar slag fluxing materials converts the ash into cementitious slag with properties similar to ground granulated blast furnace slag.

Owner:ZAUDERER BERT

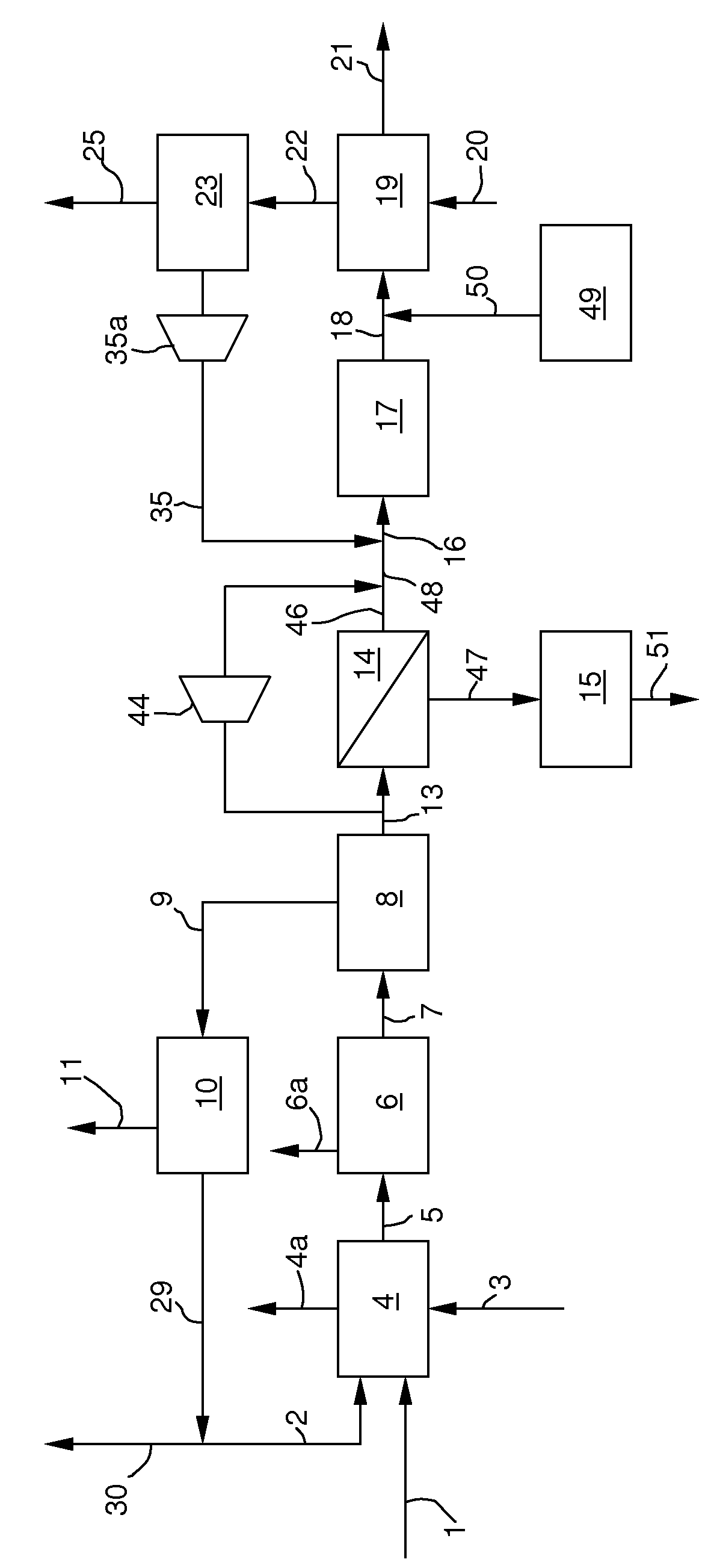

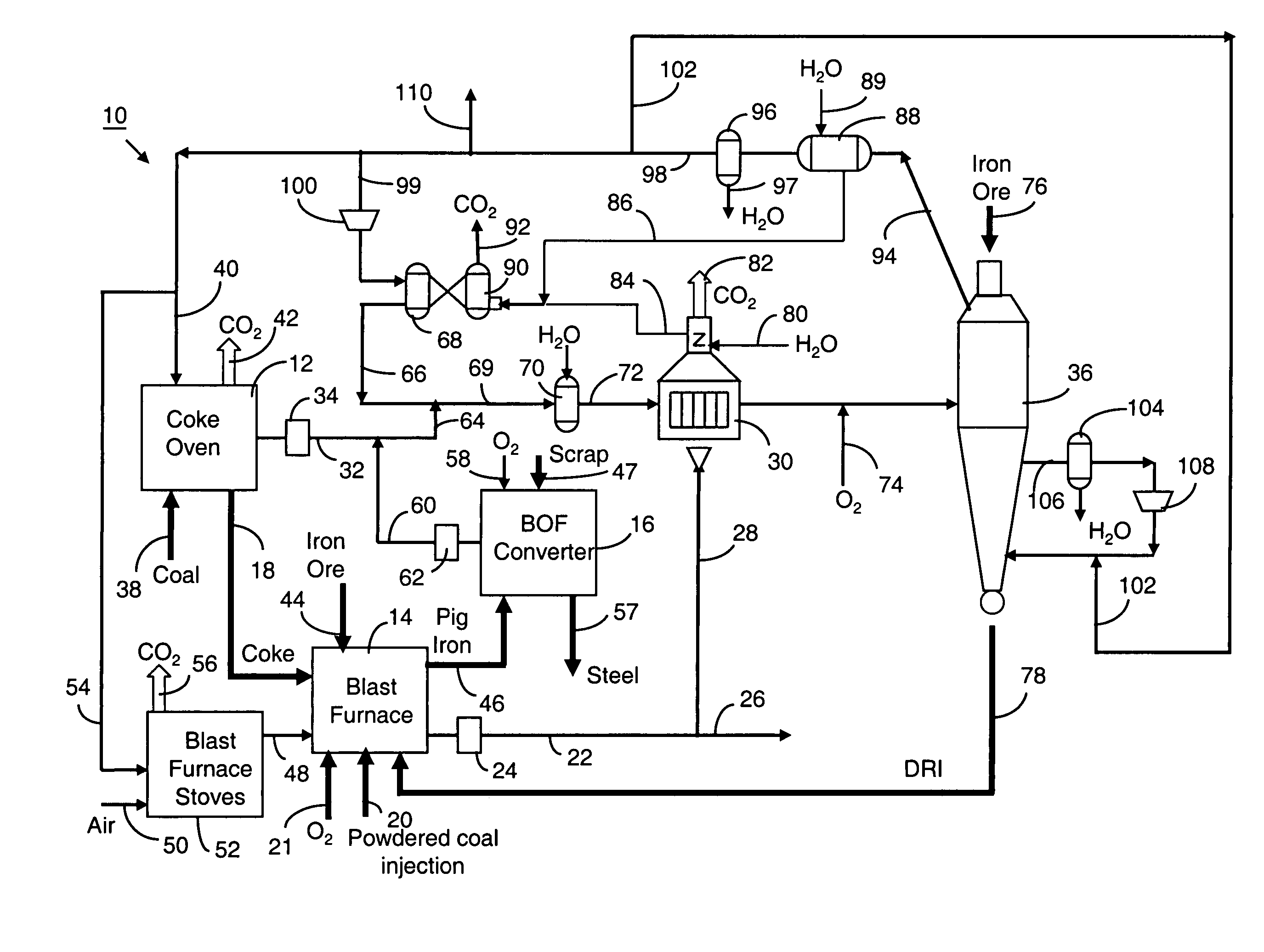

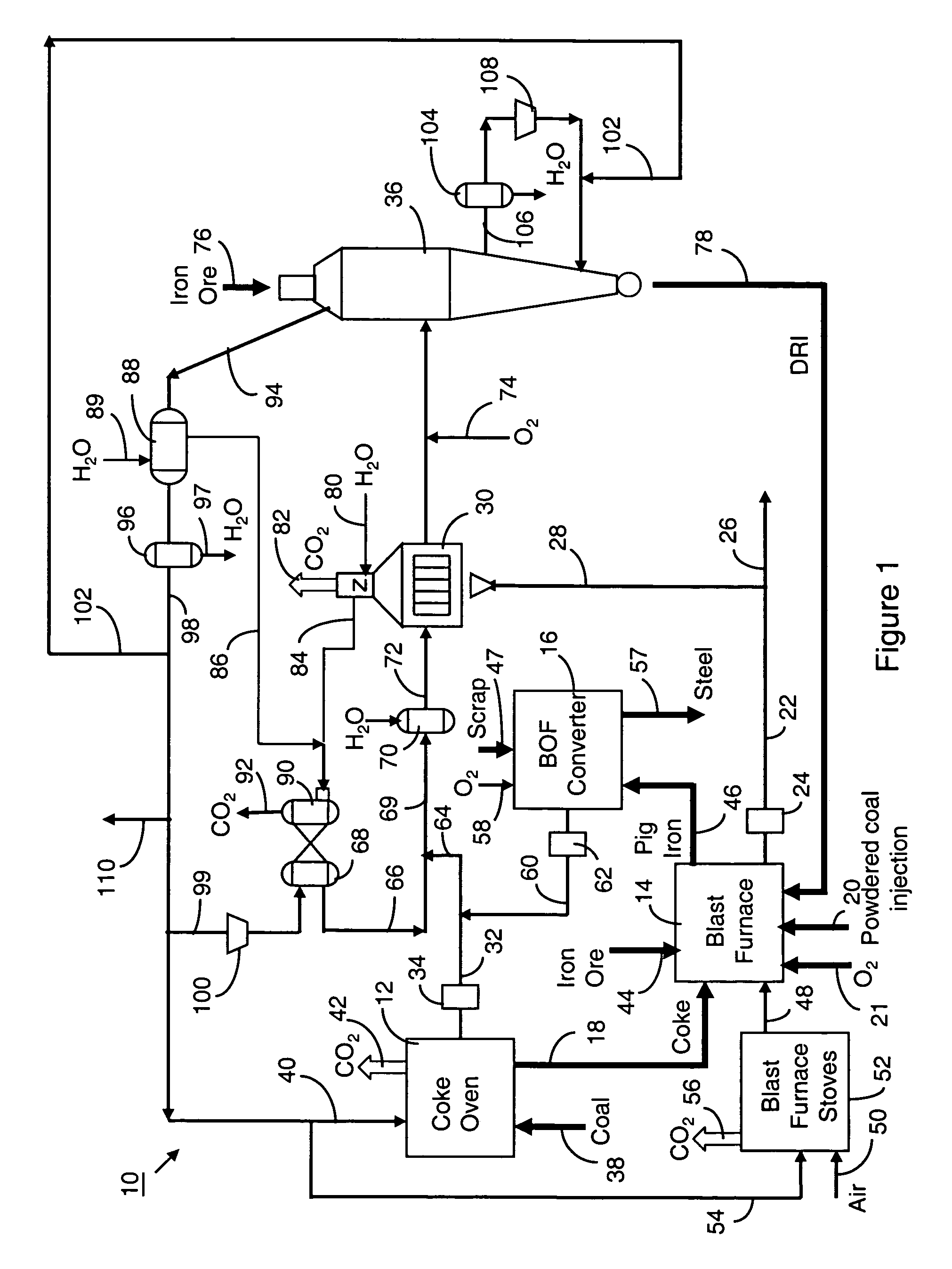

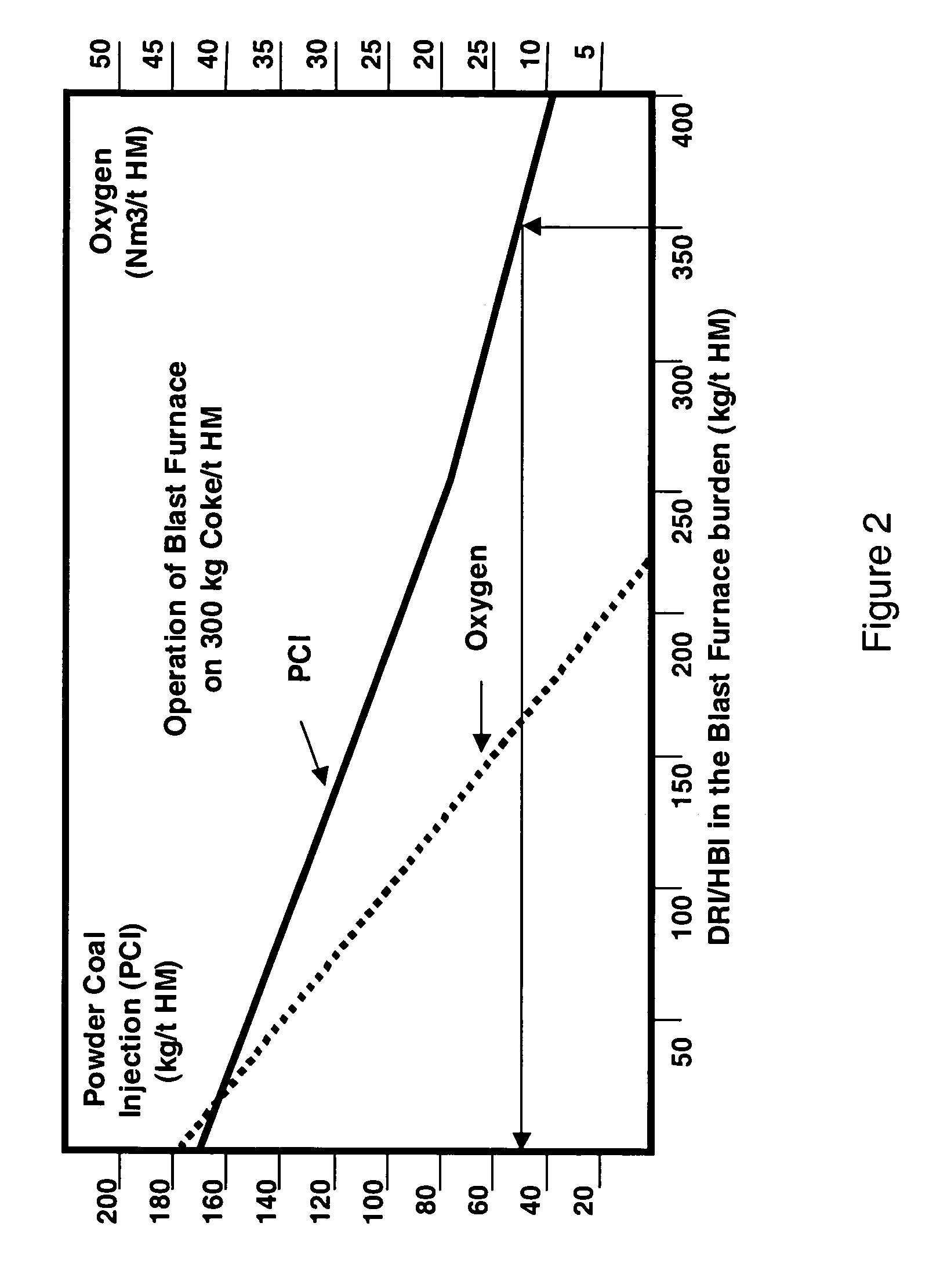

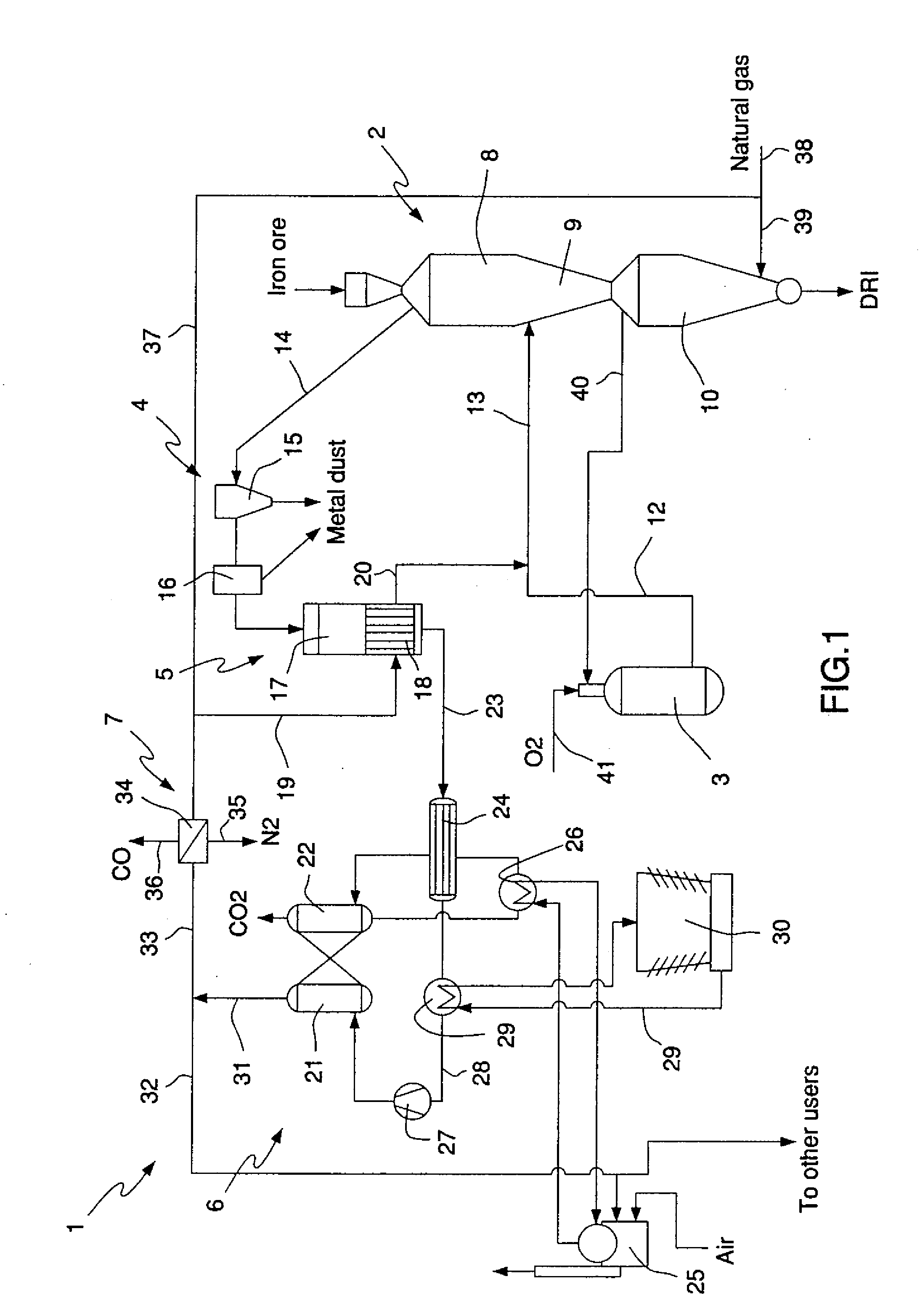

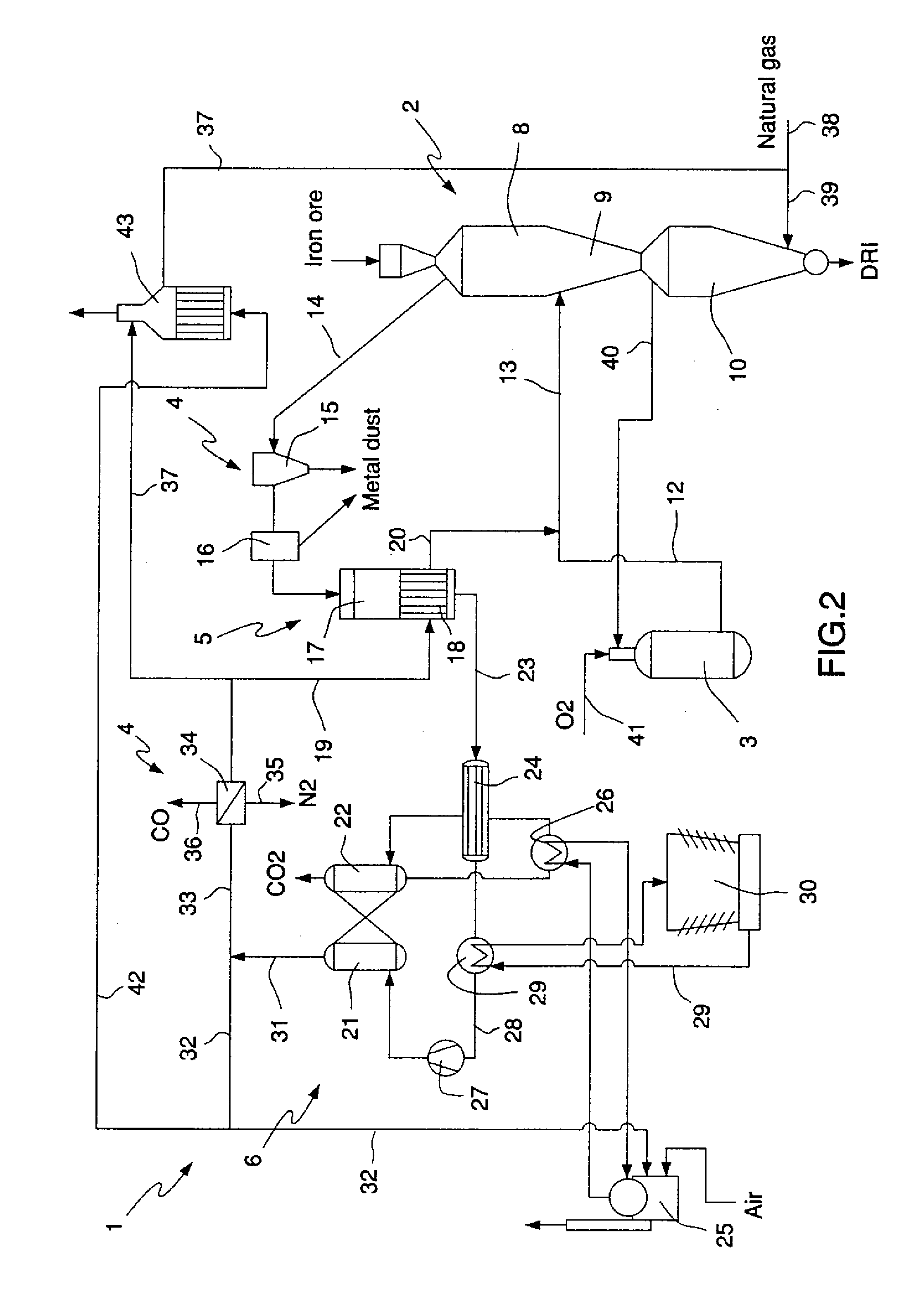

Method and apparatus for improved use of primary energy sources in integrated steel plants

ActiveUS6986800B2Increase productionReduction of fossil fuel specific consumptionBlast furnace detailsManufacturing convertersChemical agentFossil fuel

A method and an integrated steel plant wherein, instead of using coke oven gases, converter gases and blast furnace top gases available as fuel for power generation or other heating purposes, these gases are more efficiently utilized as chemical agents for direct reduction of iron ores producing DRI.DRI is charged to blast furnaces increasing production of crude steel without increasing the capacities of the coke oven plant and blast furnaces and without changes in the quality of the crude steel, or, if production rate is maintained, the fossil fuels specific consumption is significantly reduced.Utilisation of primary fossil energy according to the invention also reduces the specific CO2 emissions per ton of crude steel. The specific CO2 emission in conventional integrated mills is about 1.6 tons of CO2 per ton of crude steel.

Owner:HYLSA SA DE CV

Method for the direct reduction of iron oxides to metallic iron utilizing coke oven gas or the like

A process for reducing iron ore particles in a moving bed reduction reactor comprising an upper reduction zone and a lower discharge zone, wherein the coke oven gas, preferably forming all the make-up for the reducing gas circulating through and reacting in said reduction zone, is first fed to said discharge (cooling) zone and thereafter said coke oven gas, conditioned by the DRI in the lower zone, is withdrawn from the reactor and fed preferably into the recycled reducing gas for injection into the reduction zone of the reactor. Heavy hydrocarbons and other components of coke oven gas which may otherwise cause fouling, corrosion, or deposits in the direct reduction plant are removed from coke oven gas by catalytic and / or adsorptive action of the DRI present in said lower zone, before being externally transferred to the reduction zone of the reduction reactor.

Owner:HYL TECH

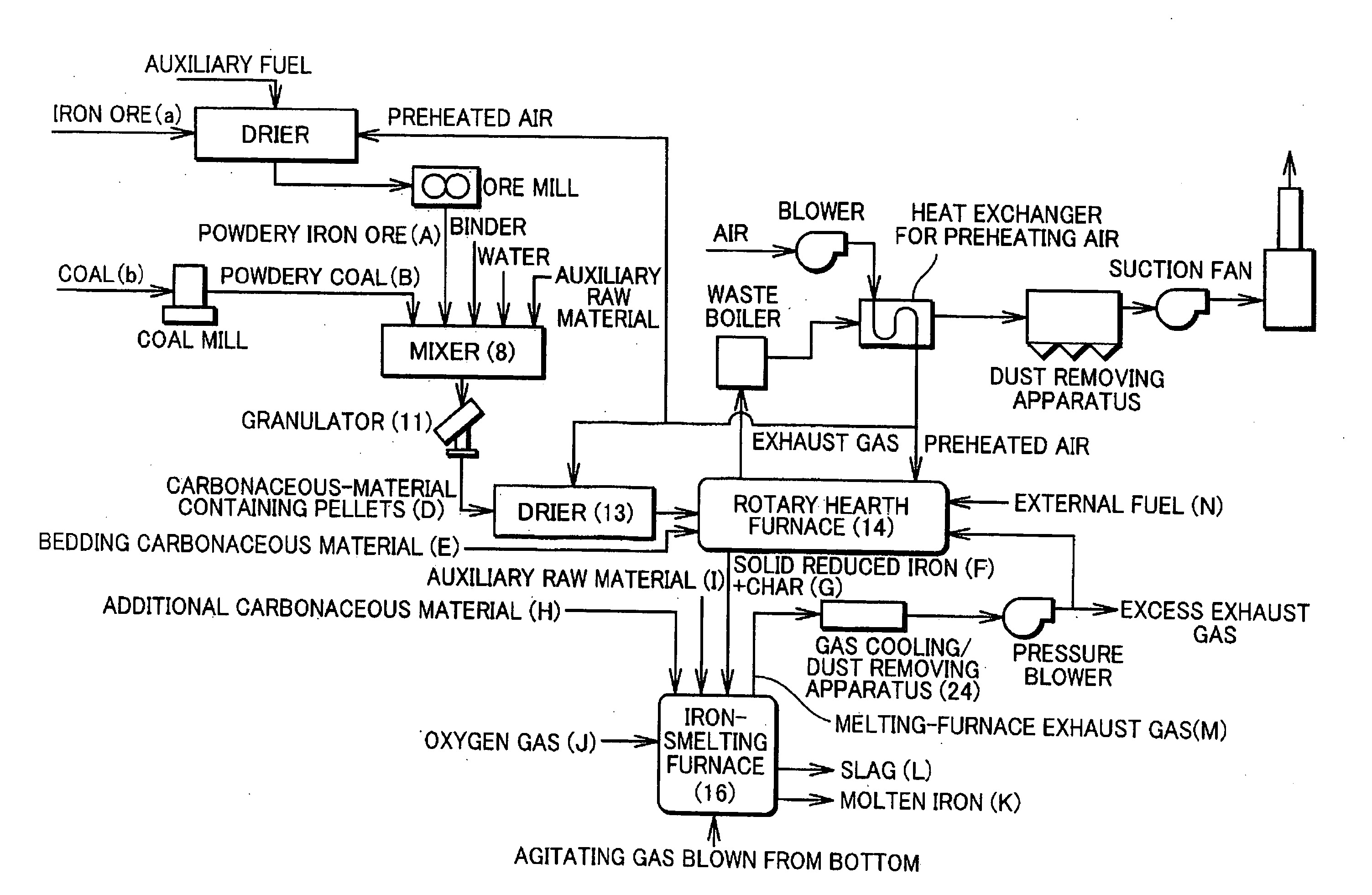

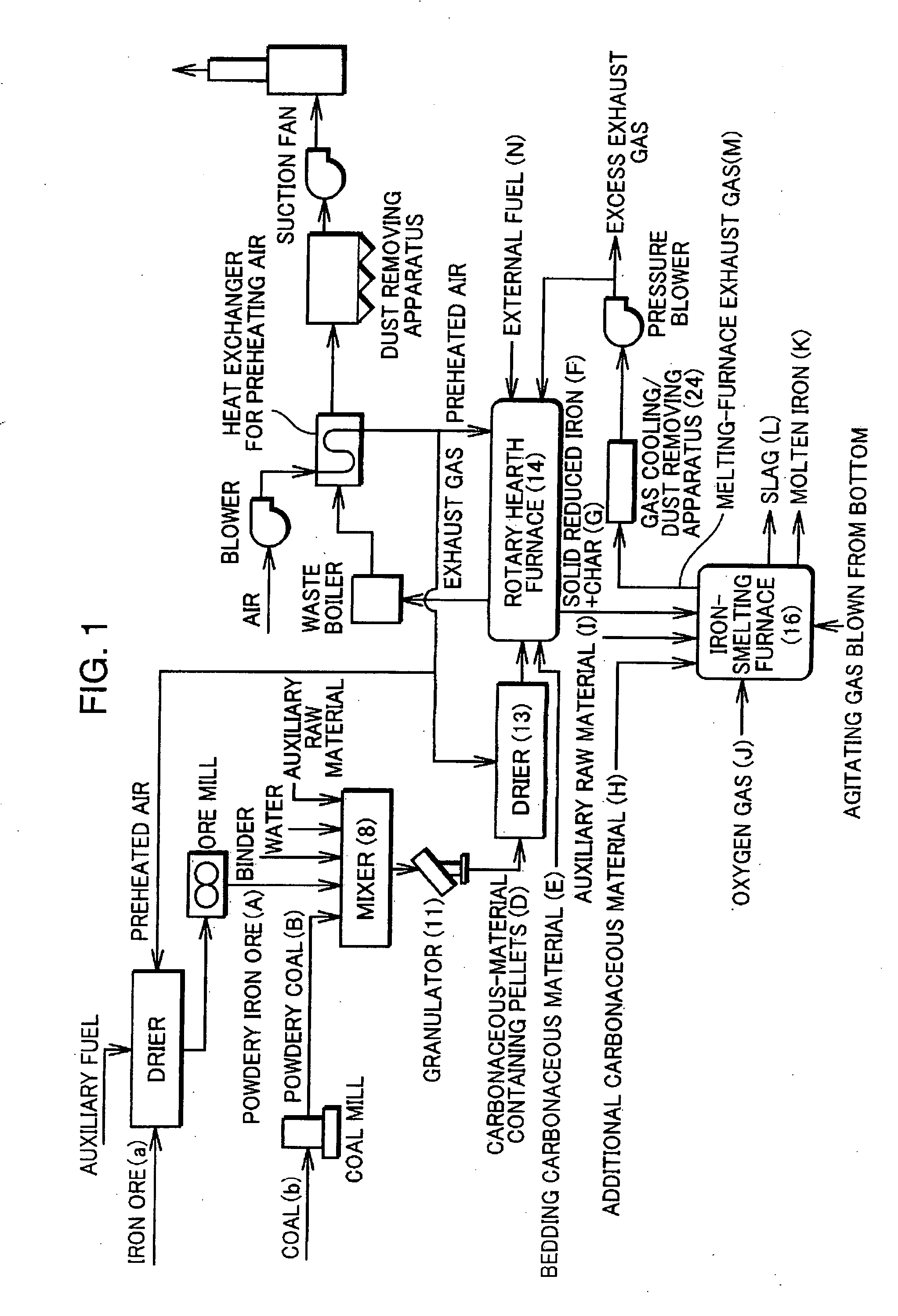

Process for Producing Molten Iron and Apparatus Therefor

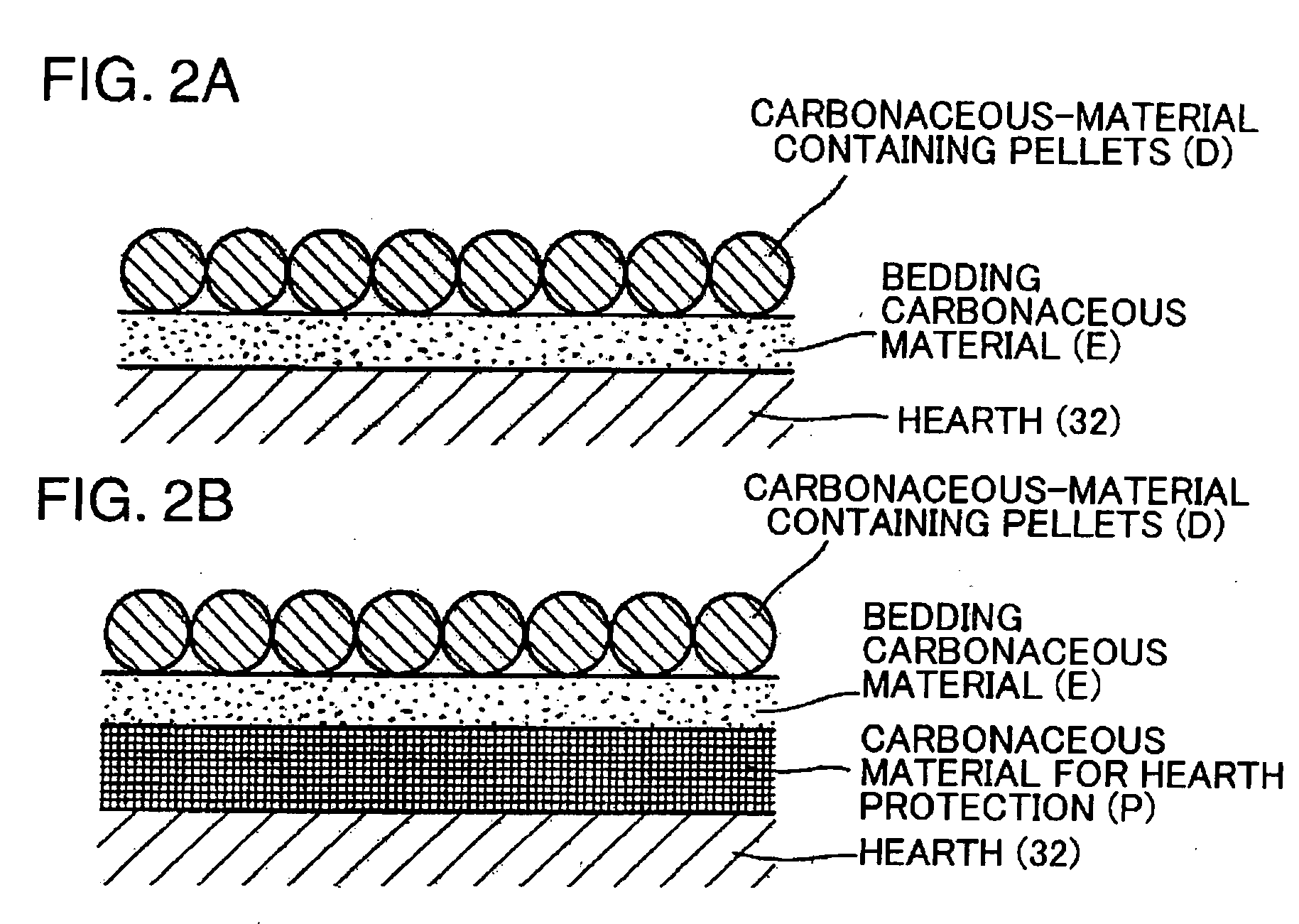

A bedding carbonaceous material is charged onto a hearth of a rotary hearth furnace, carbonaceous-material containing pellets containing powdery iron ore and powdery coal are placed on the bedding carbonaceous material, and the hearth is caused to pass inside the rotary hearth furnace to heat and reduce the carbonaceous-material containing pellets to solid reduced iron and to heat and dry the bedding carbonaceous material by distillation into char. Subsequently, the solid reduced iron and the char are charged into an iron-melting furnace without being substantially cooled, and an oxygen gas is blown into the iron-melting furnace to melt the solid reduced iron, thereby obtaining molten iron. At least a part of an exhaust gas from the iron-melting furnace is used as a fuel gas for the rotary hearth furnace after being cooled and having dust removed.

Owner:KOBE STEEL LTD

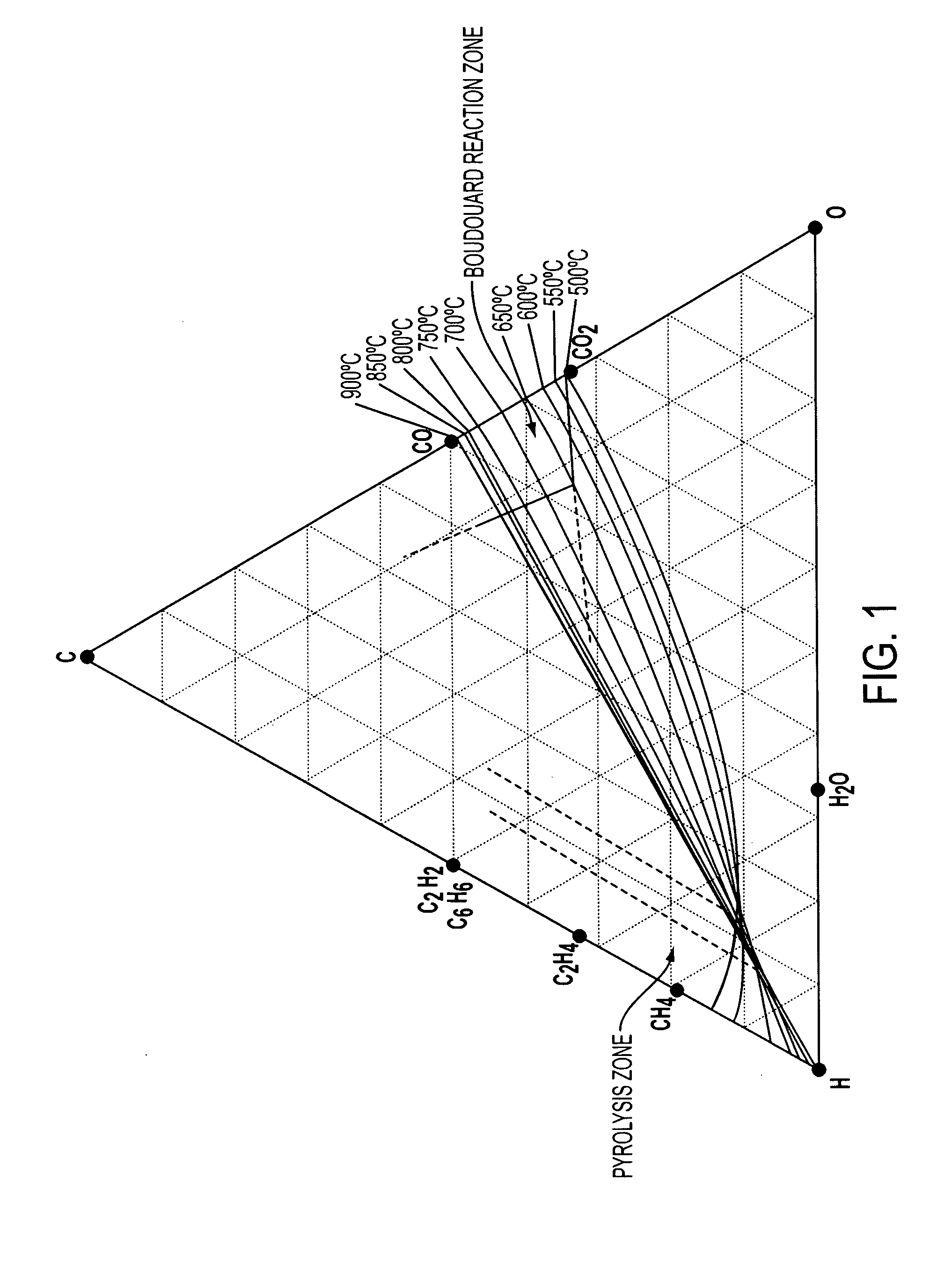

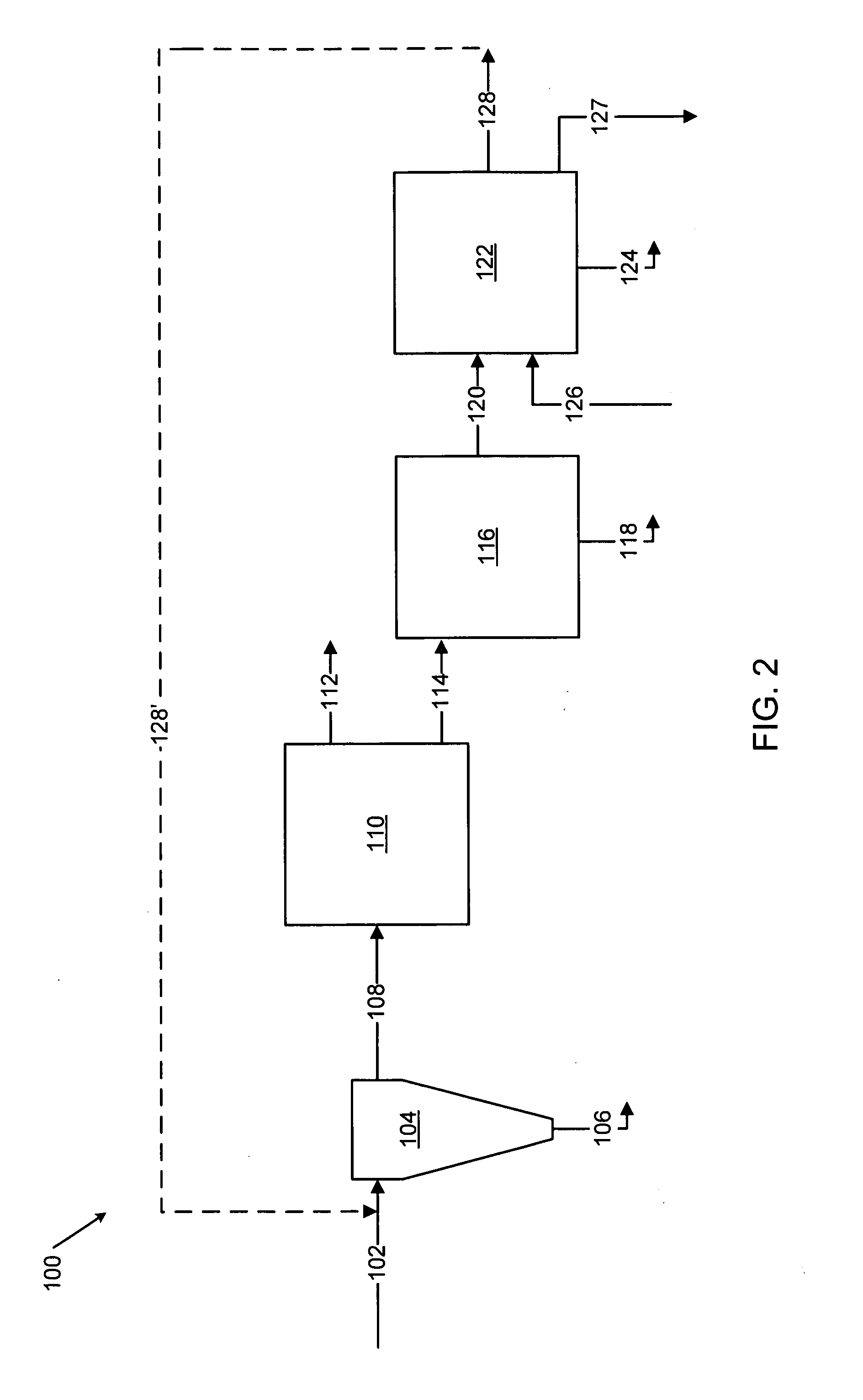

Methods for treating an offgas containing carbon oxides

ActiveUS20150059527A1Cheap sourceIncrease valueMaterial nanotechnologyPigmenting treatmentParticulatesSolid carbon

A method of treating an offgas includes purifying the offgas to remove particulate matter, water, undesirable gaseous components and inert gases to produce a dried carbon oxide gas feedstock, and converting at least a portion of carbon oxides in the dried carbon oxide gas feedstock into solid carbon. In other embodiments, a method includes passing a dried carbon oxide gas feedstock through a multi-stage catalytic converter. A first stage is configured to catalyze methane-reforming reactions to convert methane into carbon dioxide, carbon monoxide and hydrogen with residual methane. A second stage is configured to catalyze the Bosch reaction and convert carbon oxides and hydrogen to solid carbon and water.

Owner:SEERSTONE

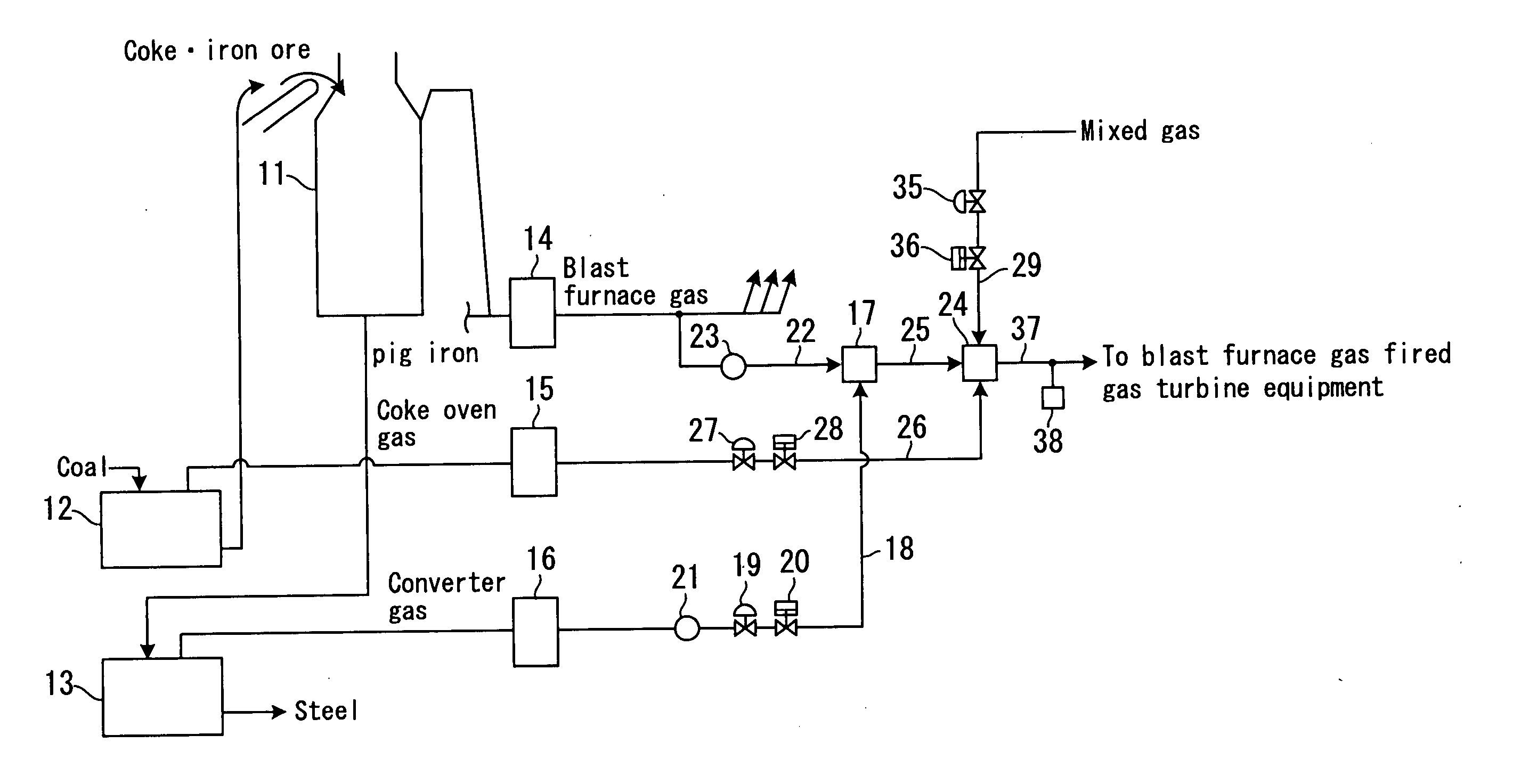

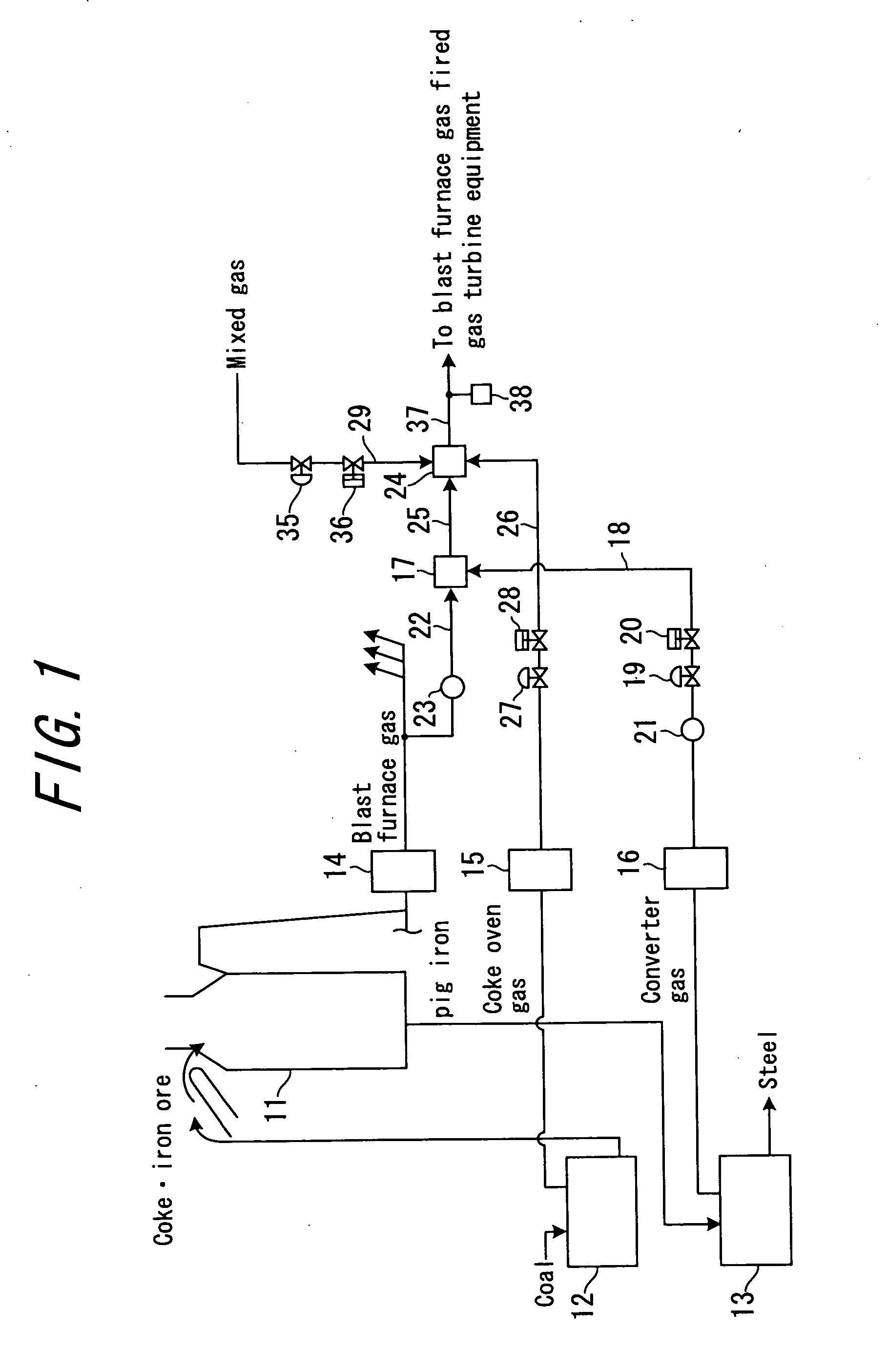

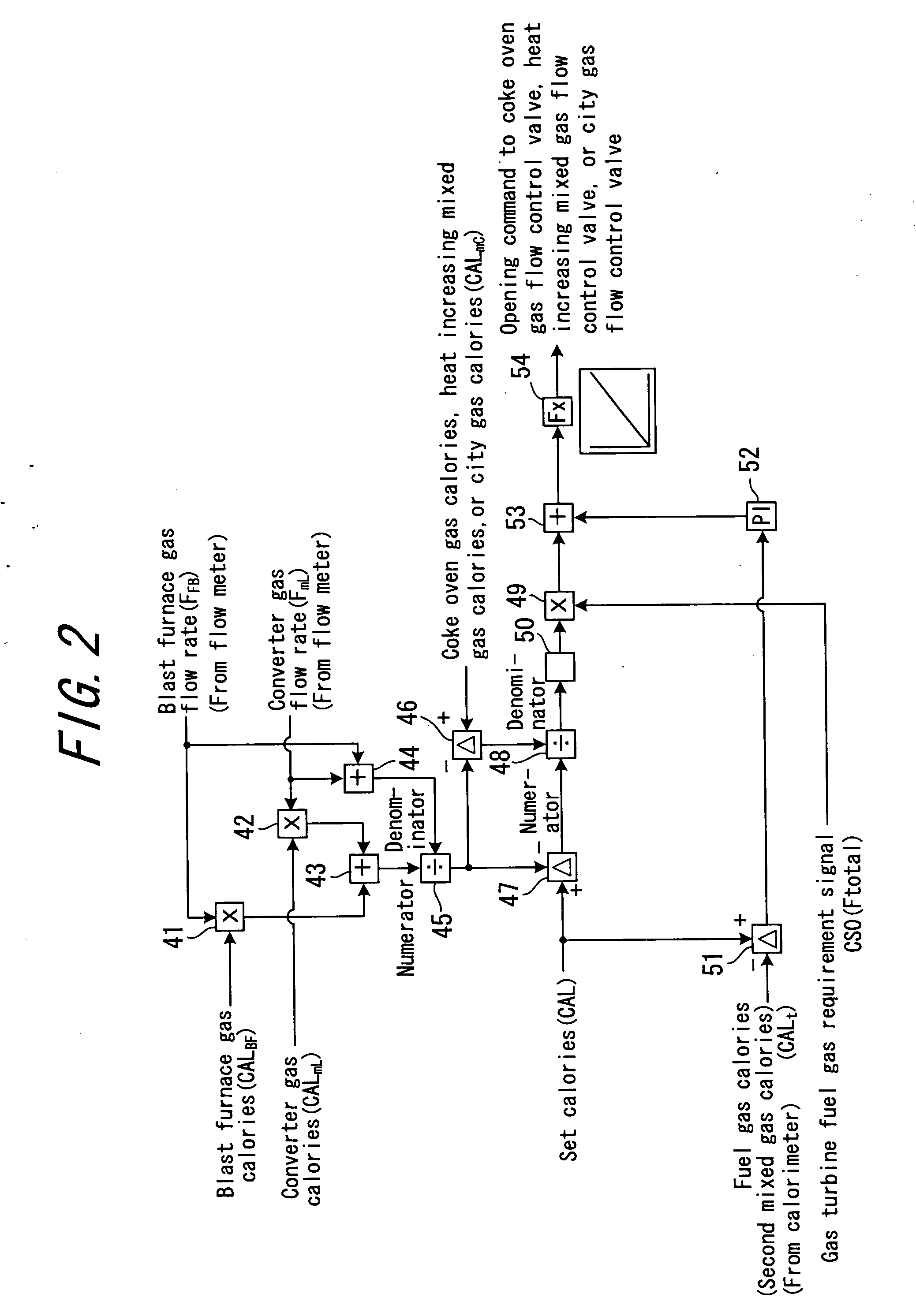

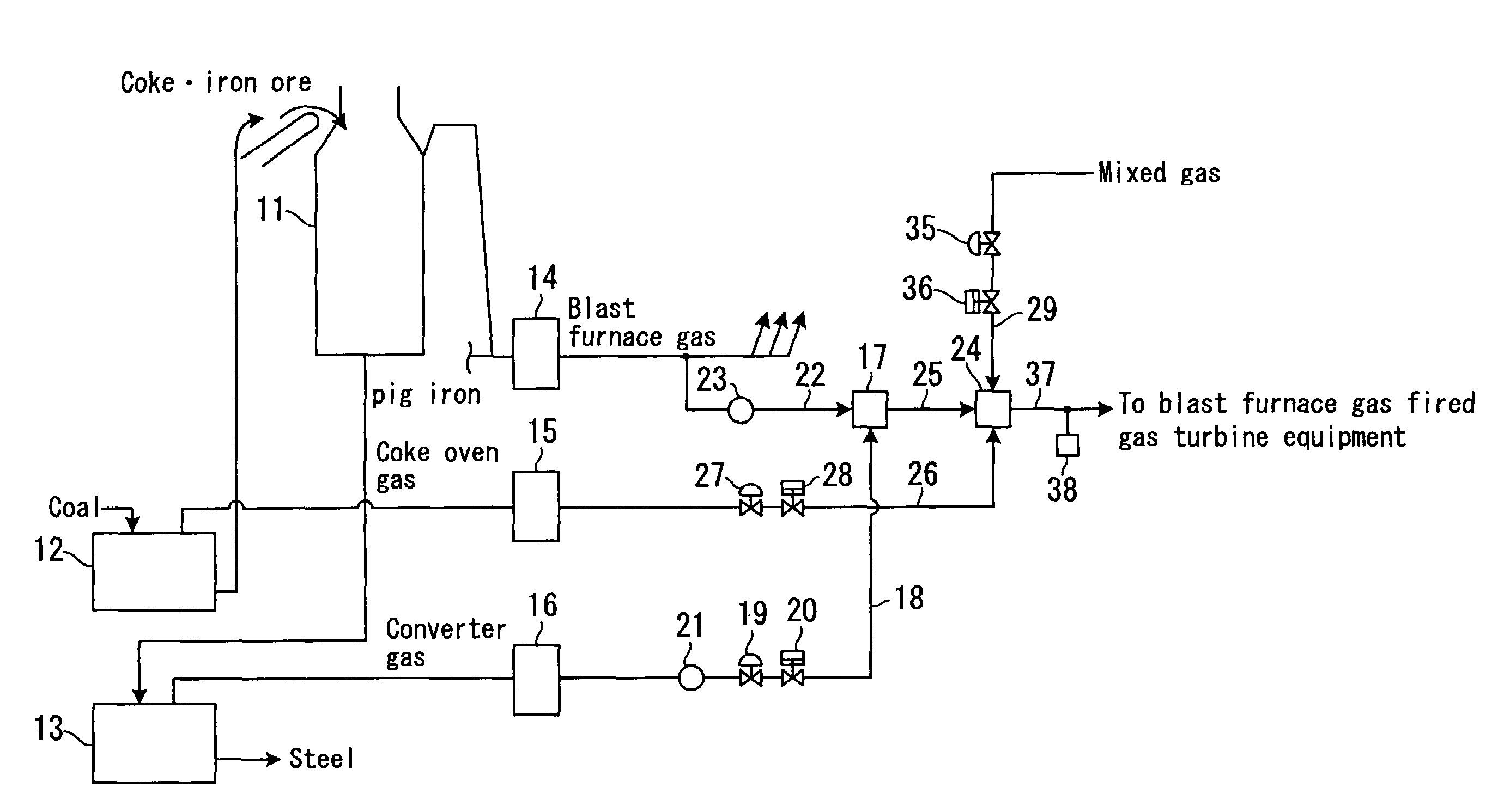

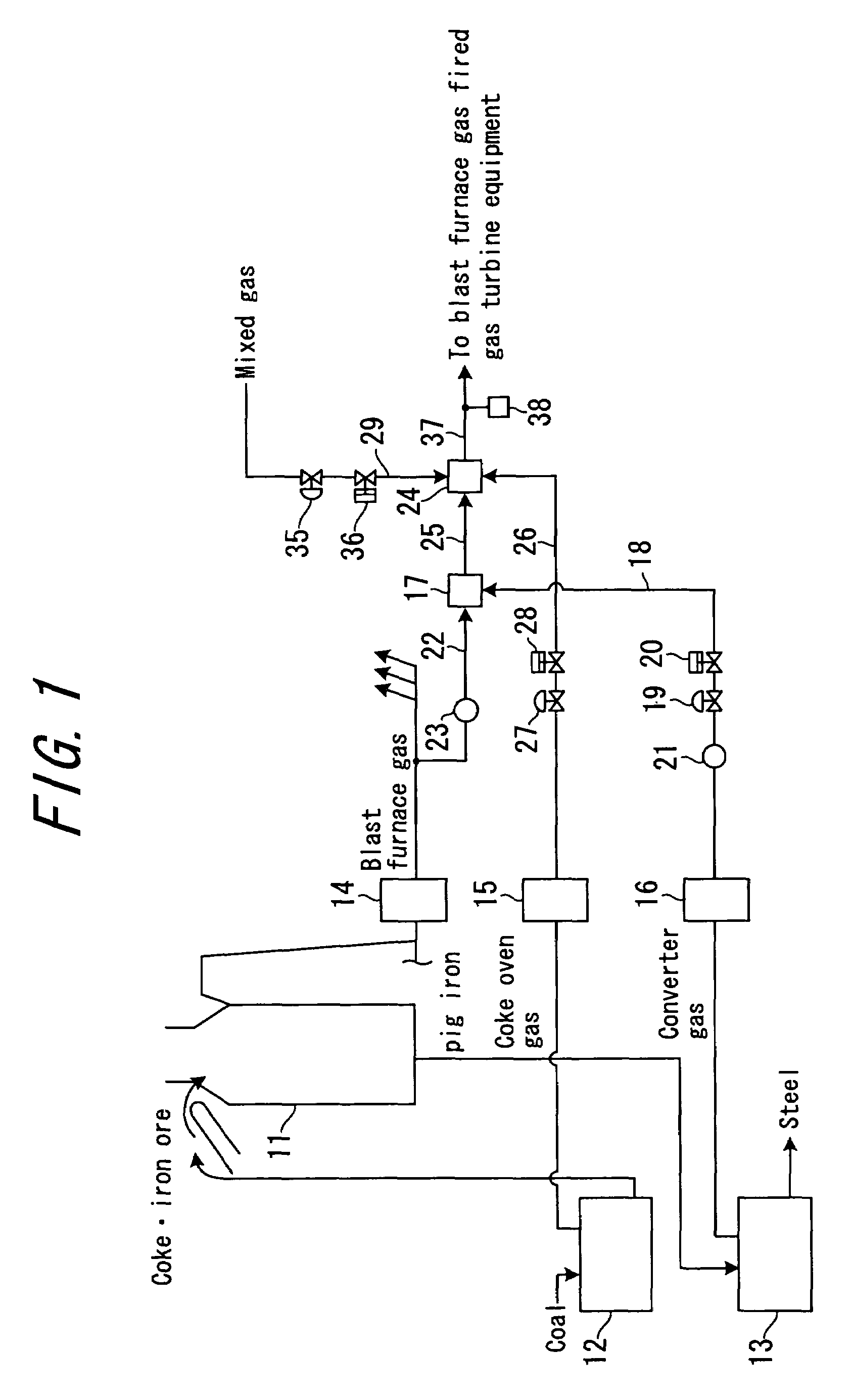

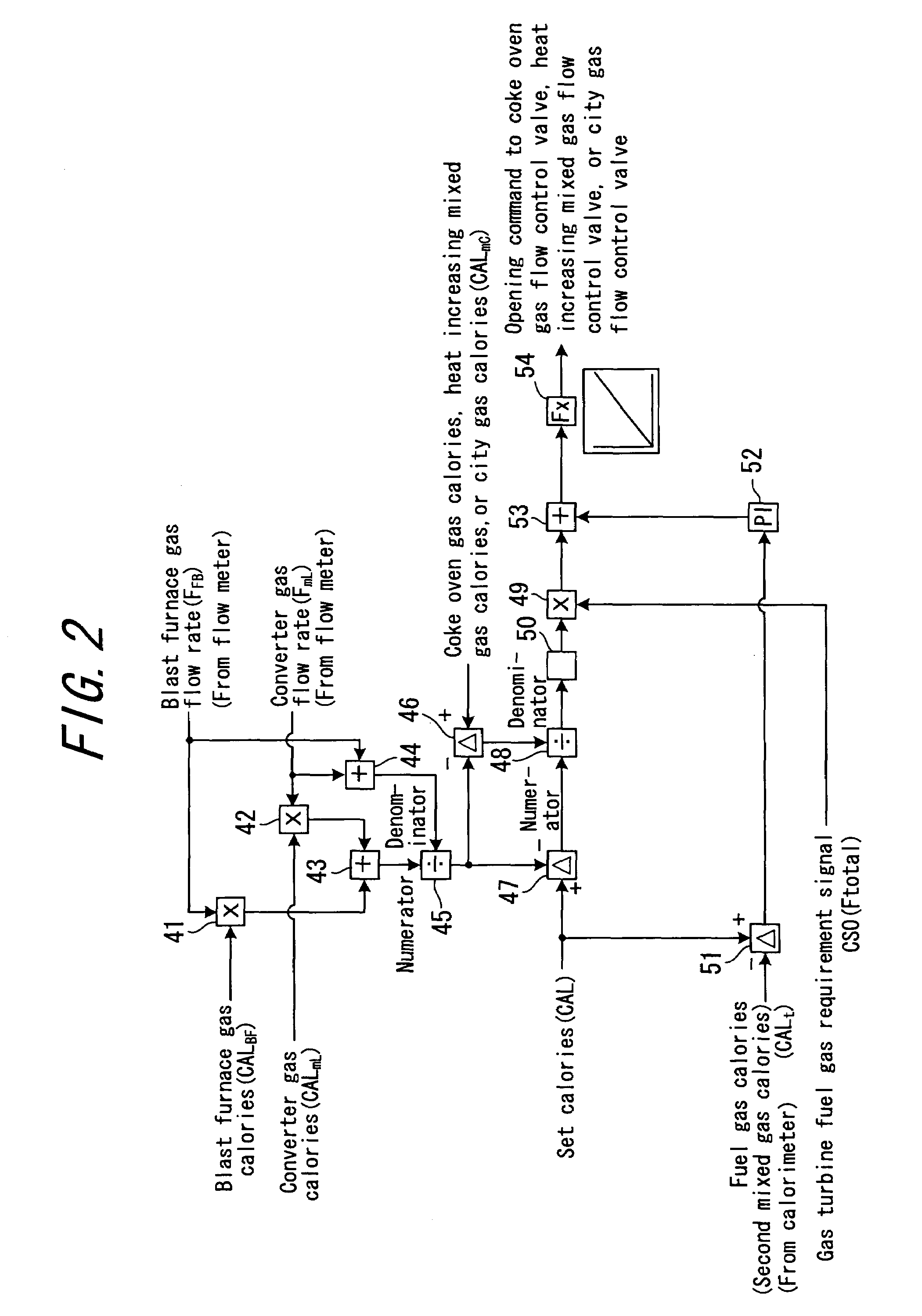

Fuel gas calorie control method and device

ActiveUS20060234171A1Excessive mixingEasy to controlBurnersGas modification by gas mixingMixed flowEngineering

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

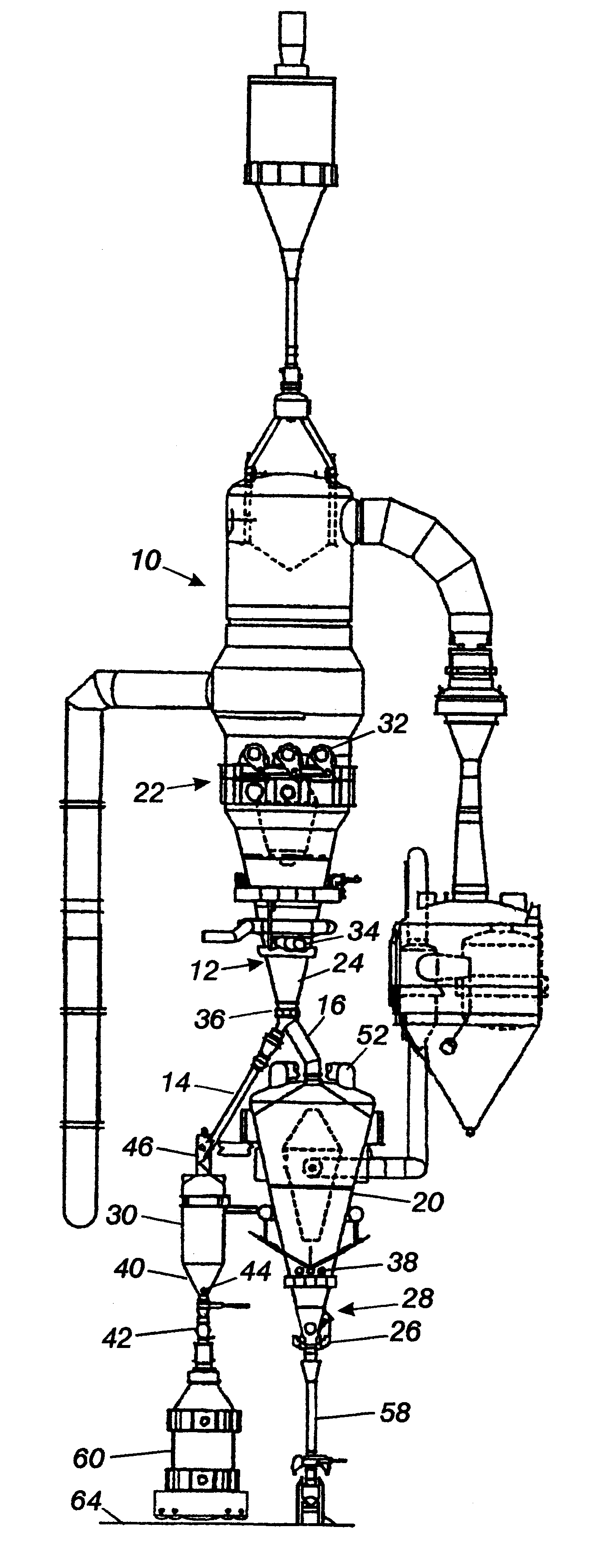

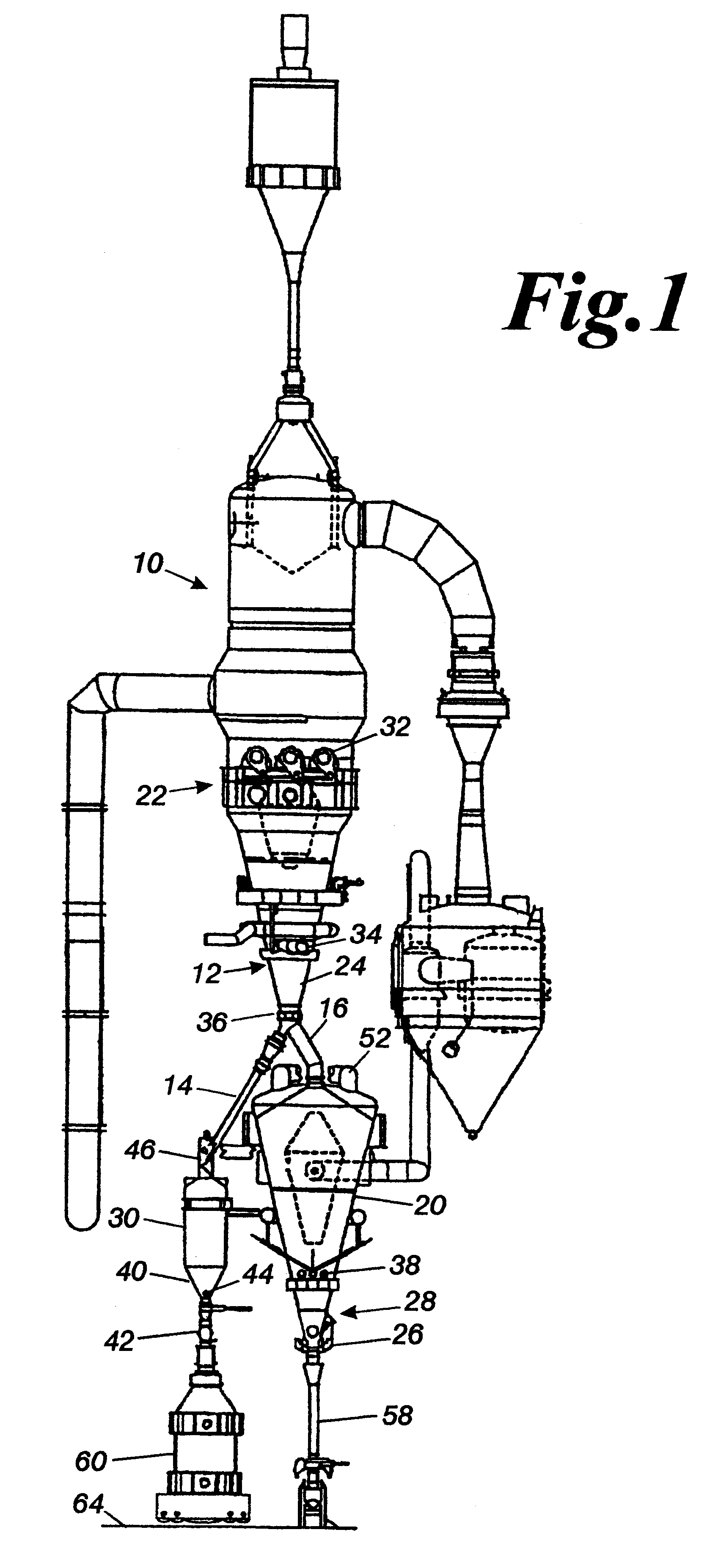

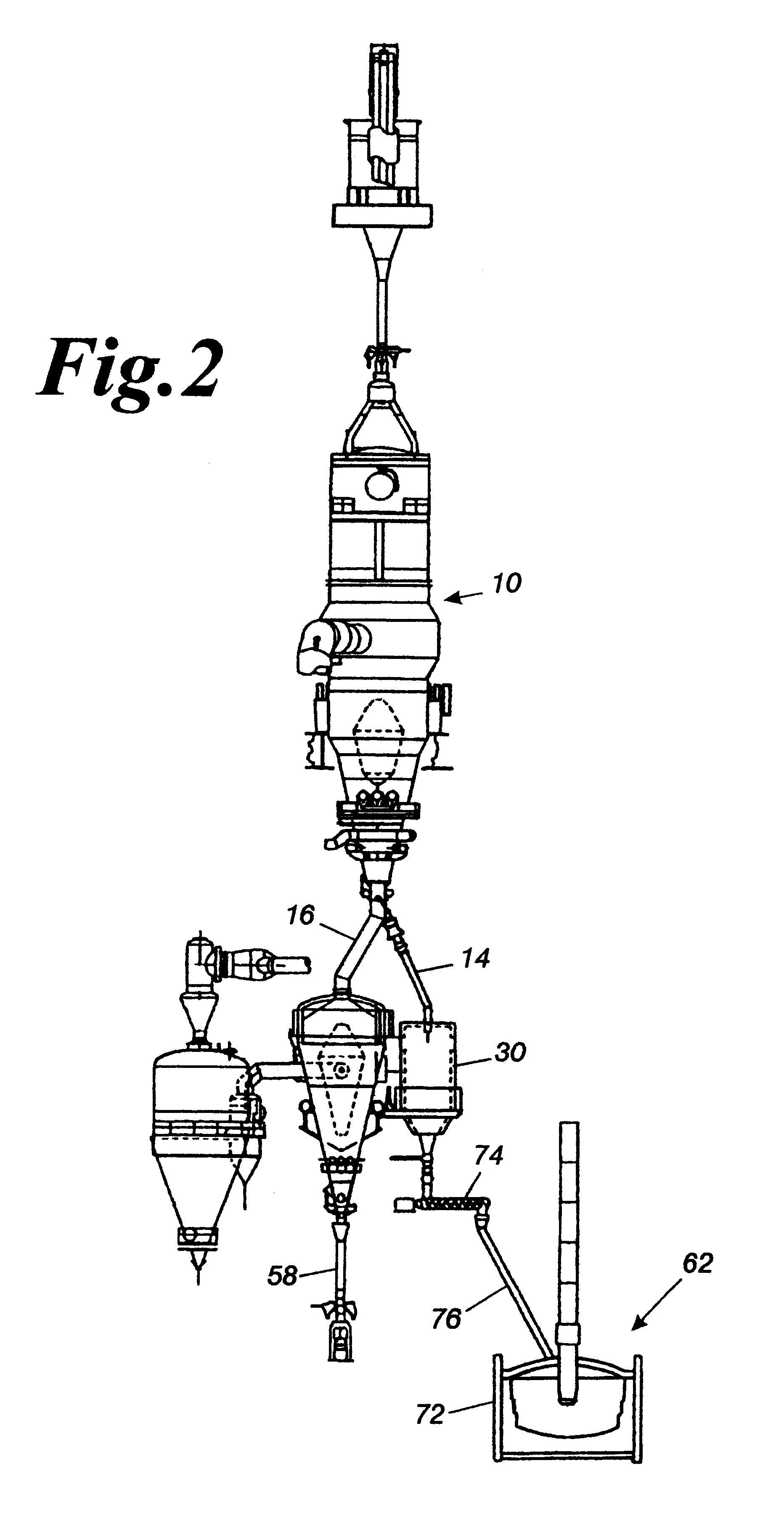

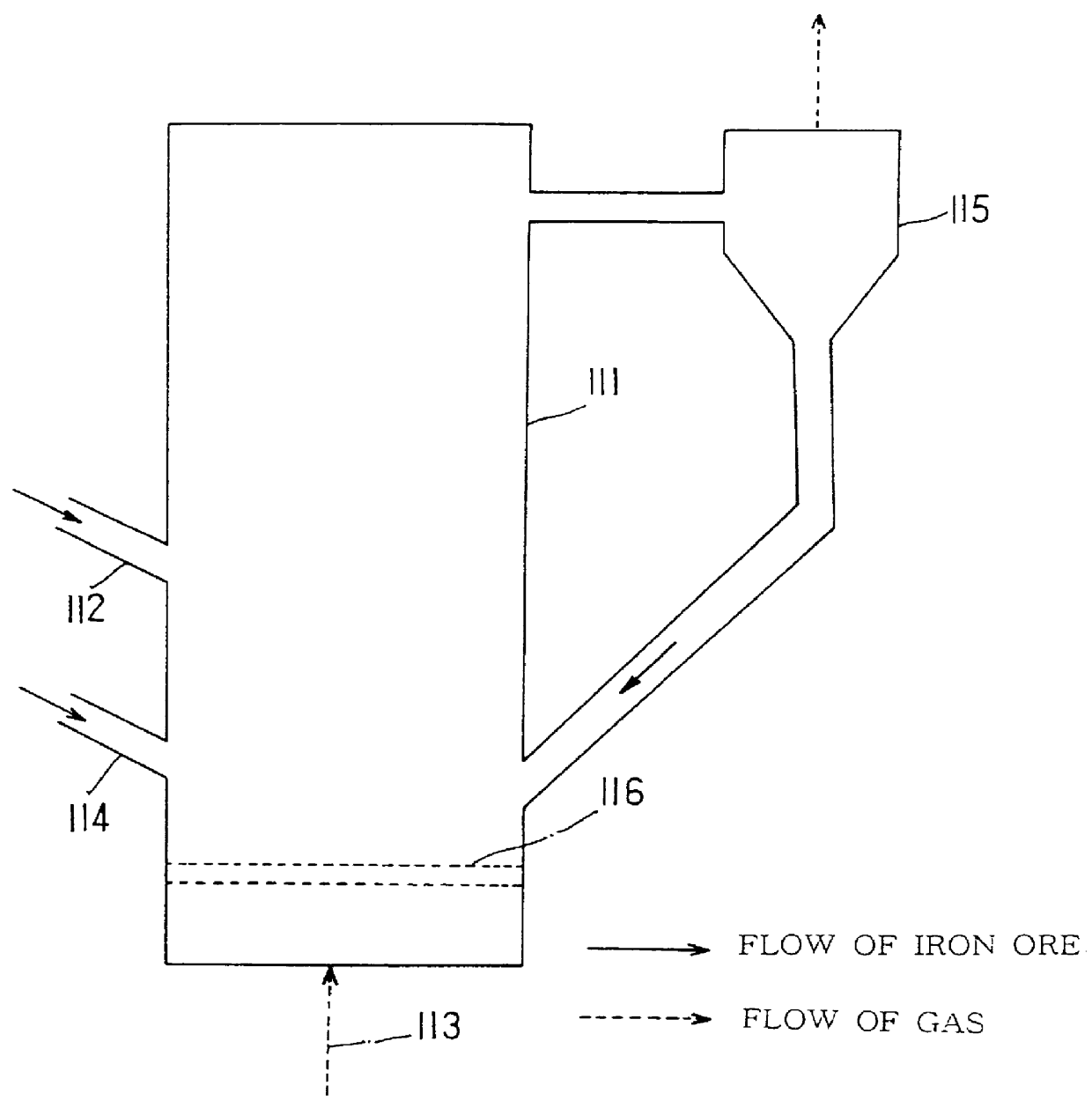

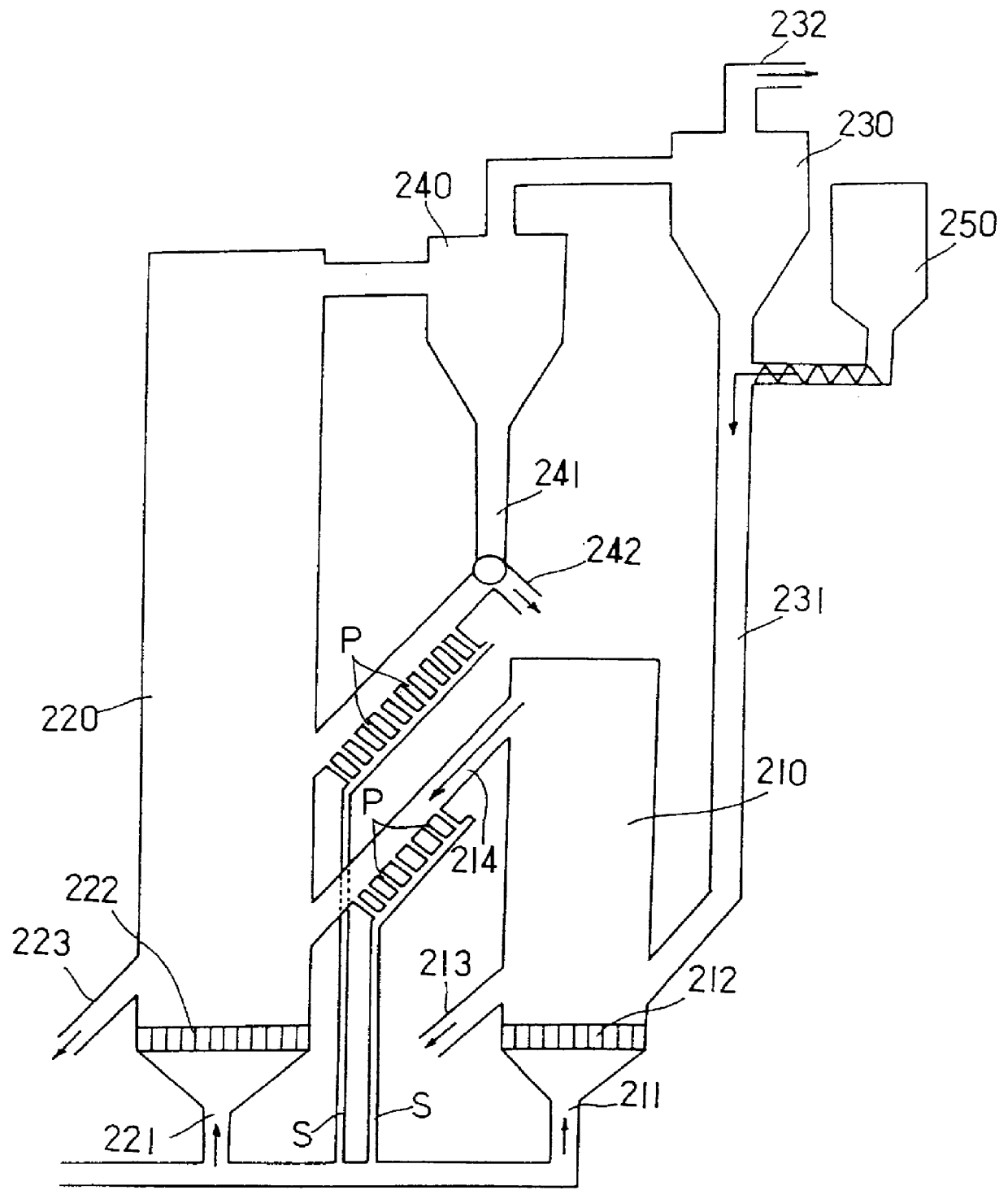

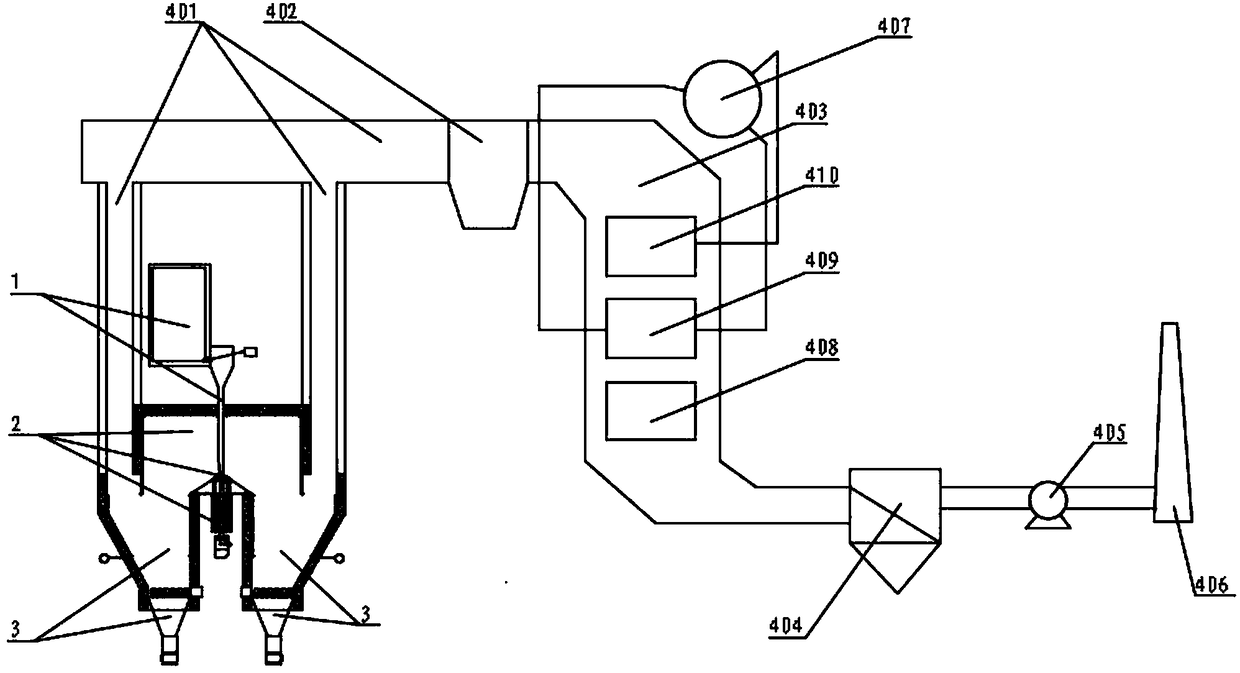

3-Stage fluidized bed reducing apparatus for reducing fine iron ore

InactiveUS6110413AReduce probabilityReduce consumption rateBlast furnace detailsExhaust gas handlingIronstoneExhaust gas

PCT No. PCT / KR97 / 00275 Sec. 371 Date Aug. 20, 1998 Sec. 102(e) Date Aug. 20, 1998 PCT Filed Dec. 19, 1997 PCT Pub. No. WO98 / 28449 PCT Pub. Date Jul. 2, 1998A 3-stage fluidized bed type iron ore reducing apparatus having X shaped circulating tubes is disclosed for forming a gas pore fluidizing layer of a fine iron ore, and for drying / pre-heating it to reduce it, so that the gas utilization rate and the reducing rate can be improved, as well as decreasing the gas consumption rate. The present invention relates to a 3-stage fluidized bed type iron ore reducing apparatus having X shaped circulating tubes comprising: a shaft type single type first fluidized bed furnace where a raw fine iron ore is dried and pre-heated in a bubbling fluidization state; a first cyclone for collecting fine iron ore particles from a exhaust gas of said first fluidized bed type furnace; a shaft type single type second fluidizing bed furnace where the dried and pre-heated fine iron ore is pre-reduced in a bubbling fluidization state; a second cyclone for separating the fine iron ore particles from a exhaust gas from said second fluidizing bed type furnace so as to re-circulate them; a twin type third fluidized bed furnace consisting of a first reaction furnace and a second reaction furnace, for separating the pre-reduced iron ore from said second fluidized bed type furnace into coarse particles and medium / fine particles so that the coarse particles and medium / fine particles ore finally reduced in separate reactors in bubbling fluidization states; and a third cyclone for separating fine iron ore particles from the exhaust gas of said second reaction furnace of said third fluidized bed type furnace so as to re-circulate them to said first reaction furnace.

Owner:POHANG IRON & STEEL CO LTD +2

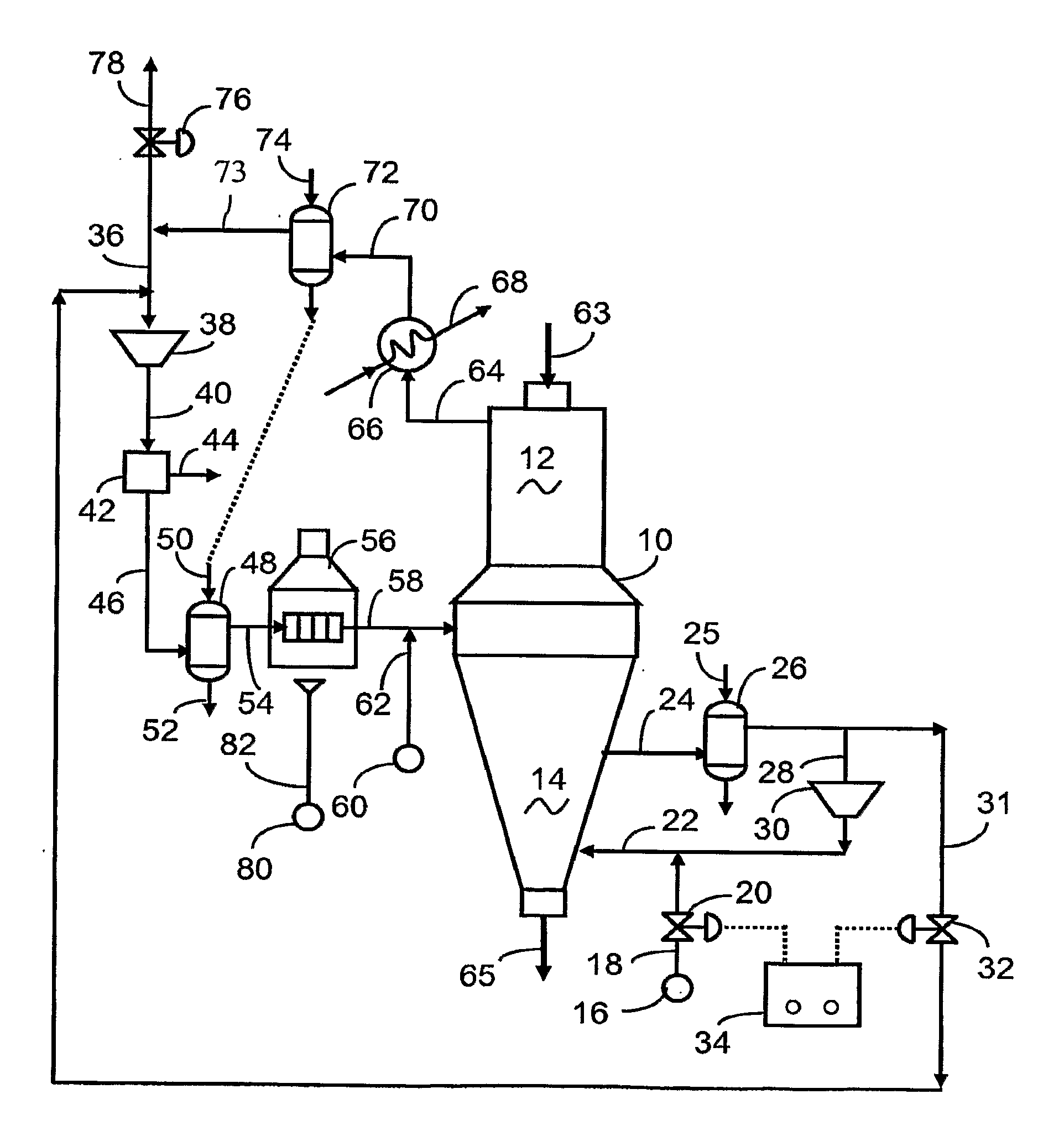

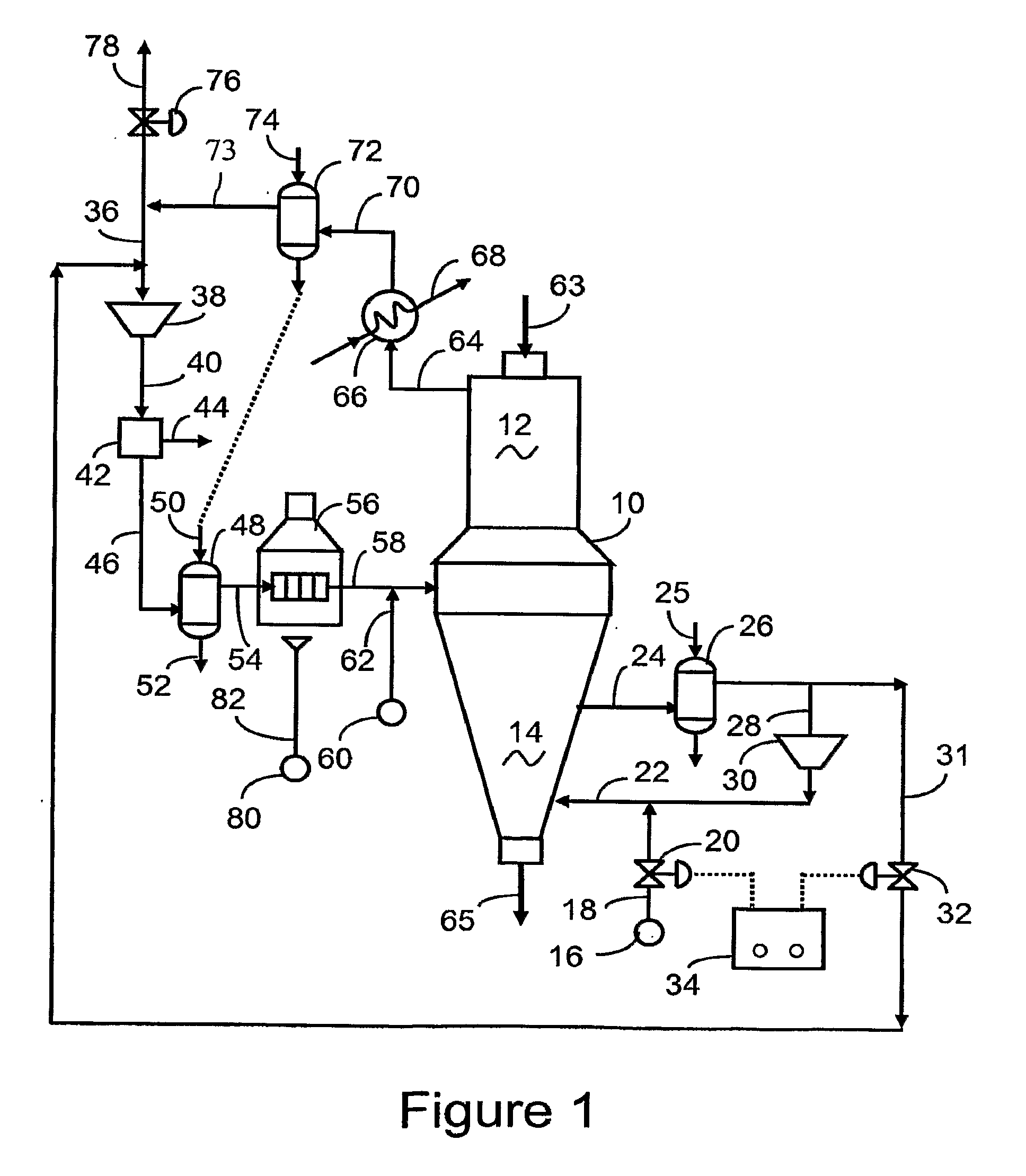

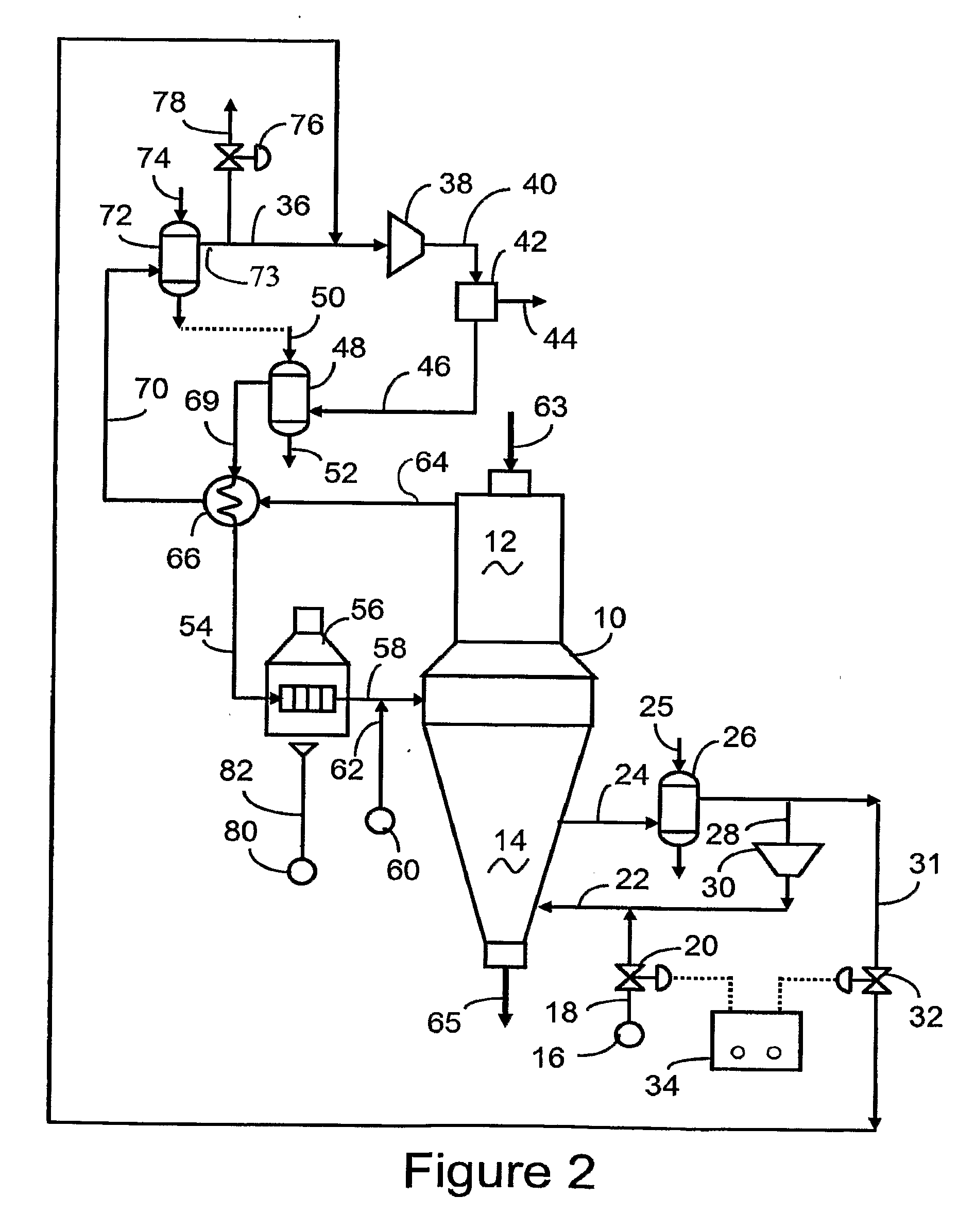

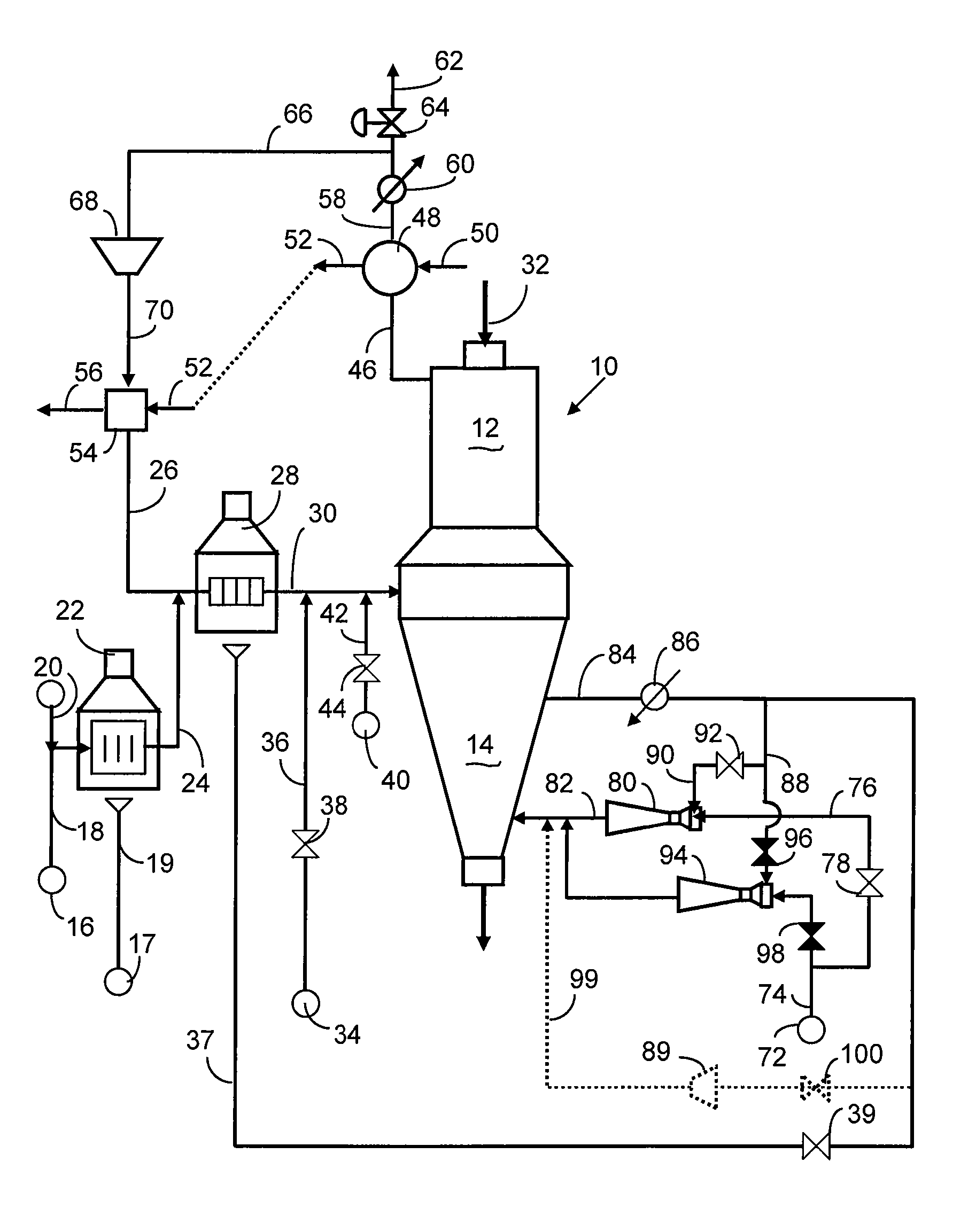

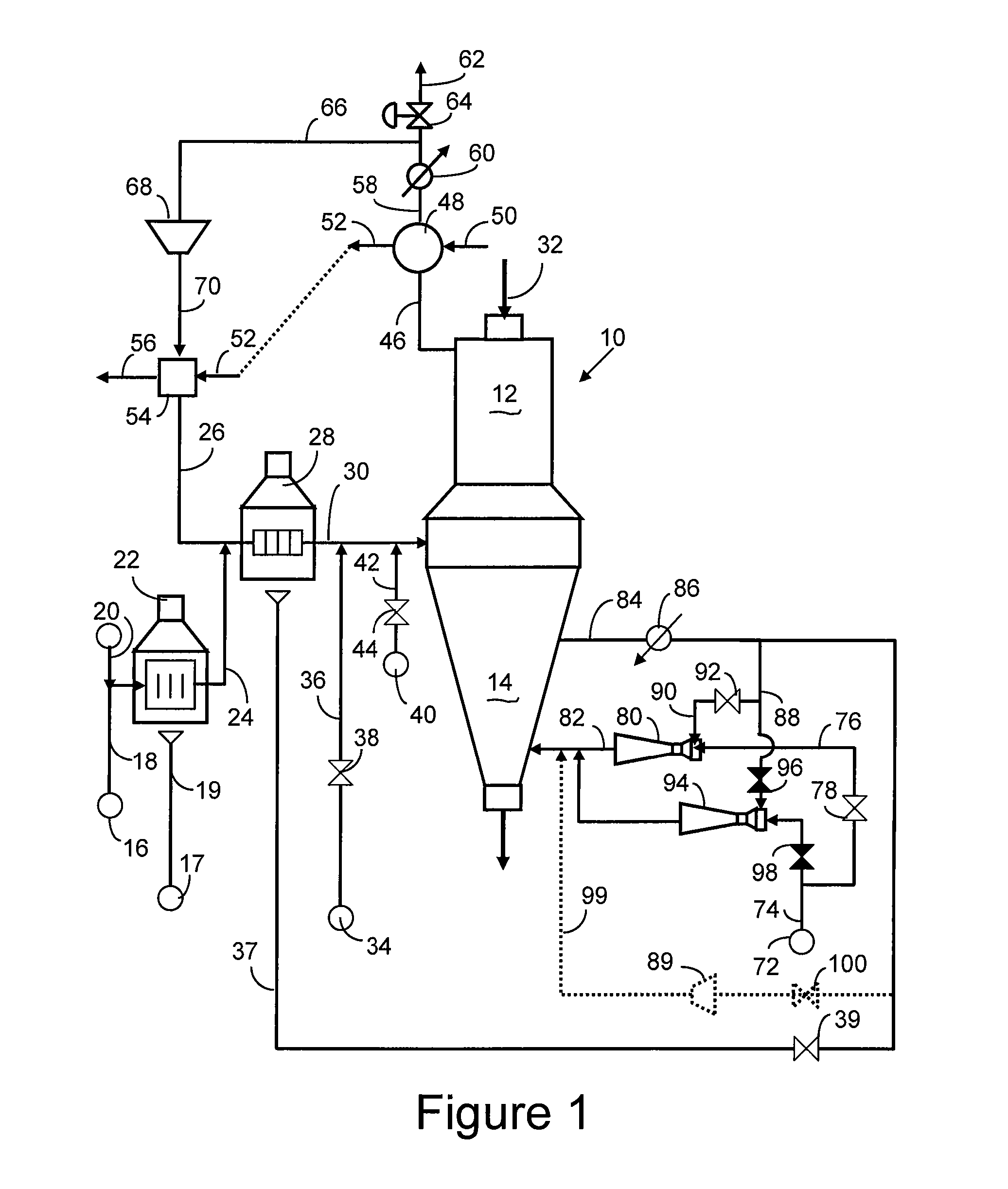

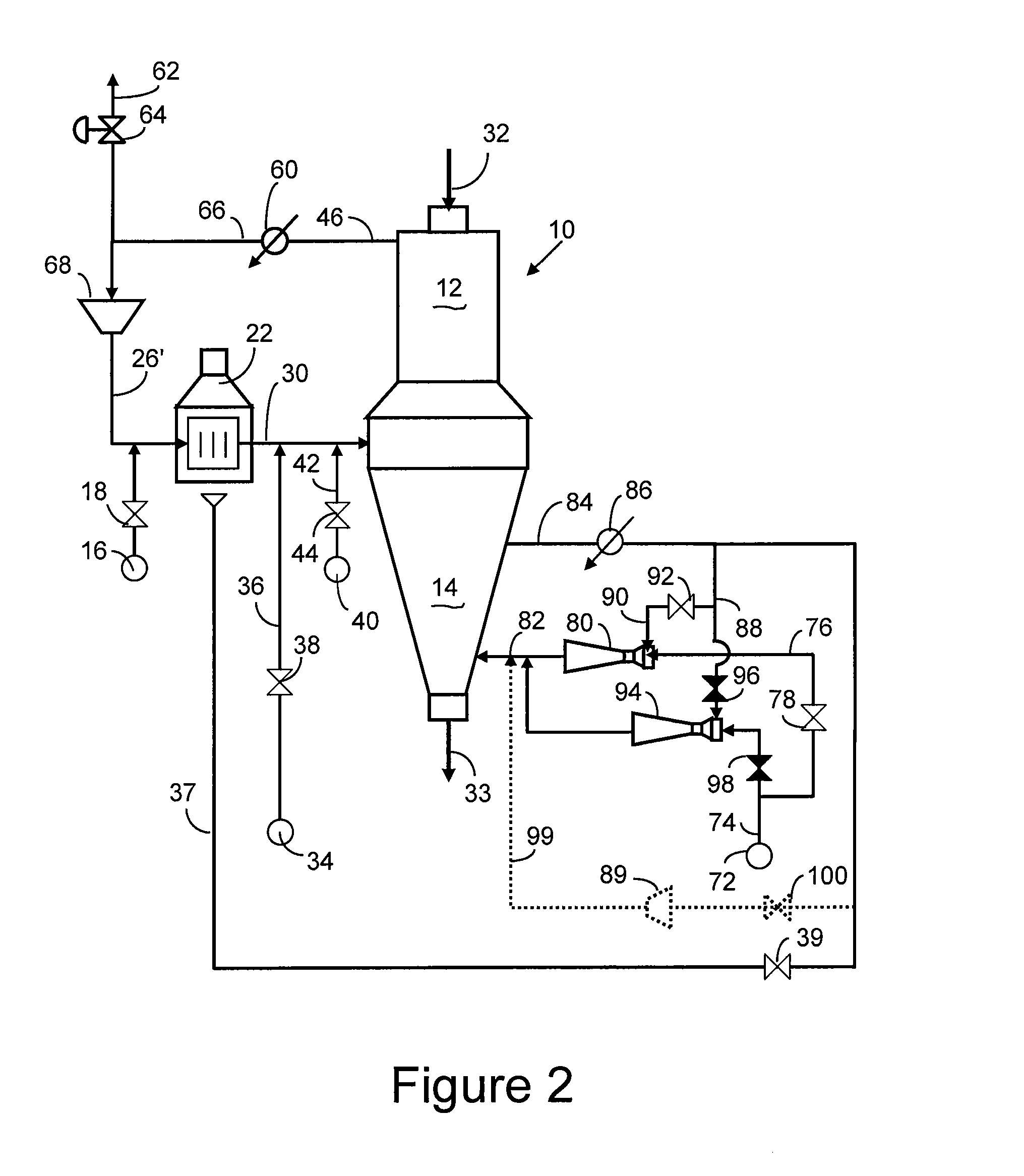

Method and Apparatus for Producing Direct Reduced Iron

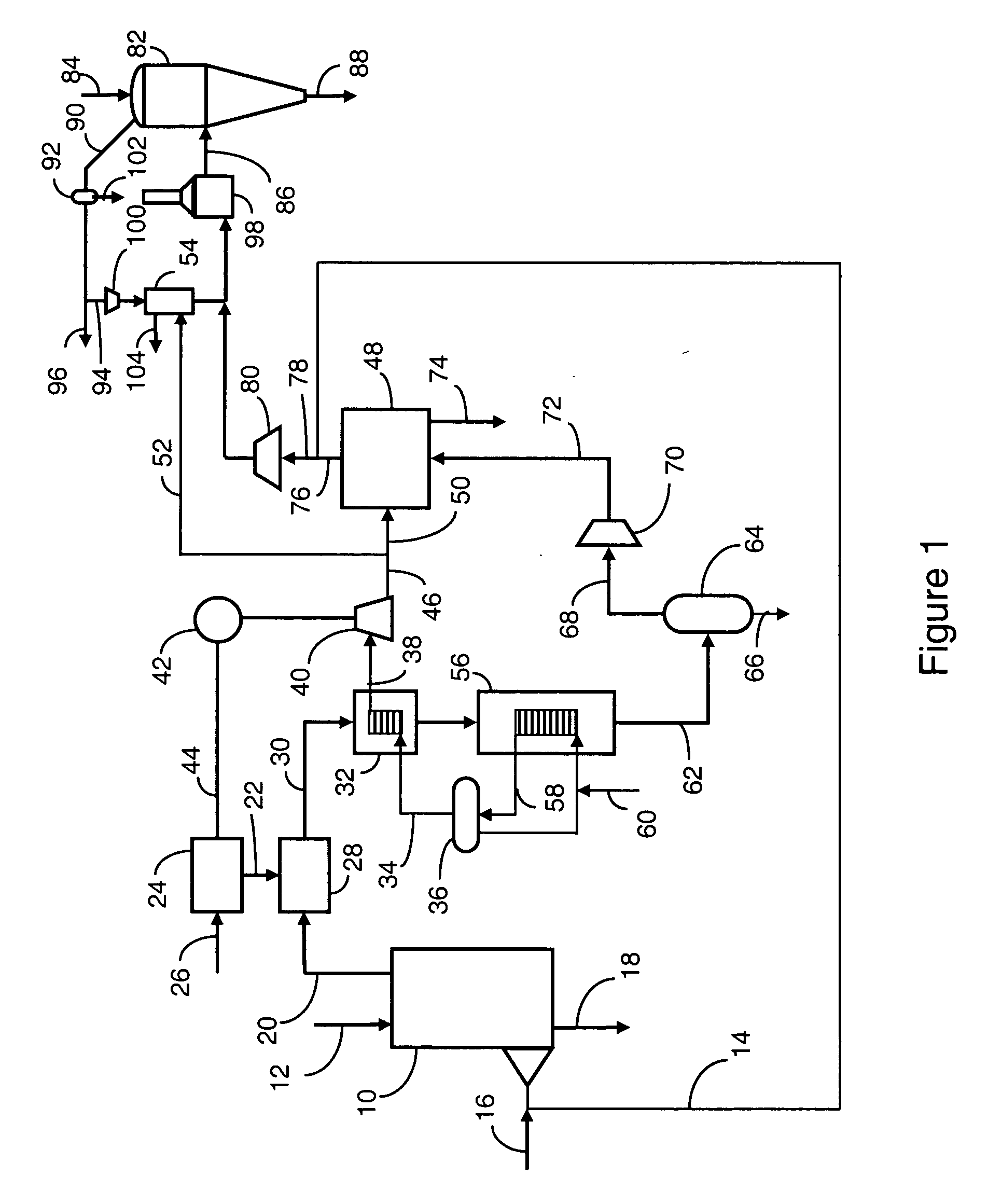

ActiveUS20070245855A1Cutting costsLess-expensive equipmentBlast furnace detailsManufacturing convertersElectricityGas cooler

A direct reduction process for producing direct reduced iron (DRI) in a reduction reactor having a reduction zone for reducing iron-oxides-containing particles, such as iron ore pellets, to DRI by reaction of said iron oxides with a high temperature reducing gas, and a cooling zone for lowering the temperature of the DRI produced in said reduction zone, wherein a stream of cooling gas, usually natural gas, is circulated through said cooling zone, a portion of said cooling gas is withdrawn from the cooling zone, cooled and cleaned in a gas cooler and a portion of the cooled gas is recycled to said reduction zone by means of an ejector utilizing the high-pressure natural gas make-up feed as the ejector's motive fluid. Using an ejector for recycling the cooling gas instead of using a mechanical compressor provides significant savings in electricity and in capital, operational and maintenance costs. A direct reduction plant having a DRI cooling zone which uses at least one ejector in recycling at least a portion of cooling gas to the cooling zone.

Owner:HYL TECH SA DE CV

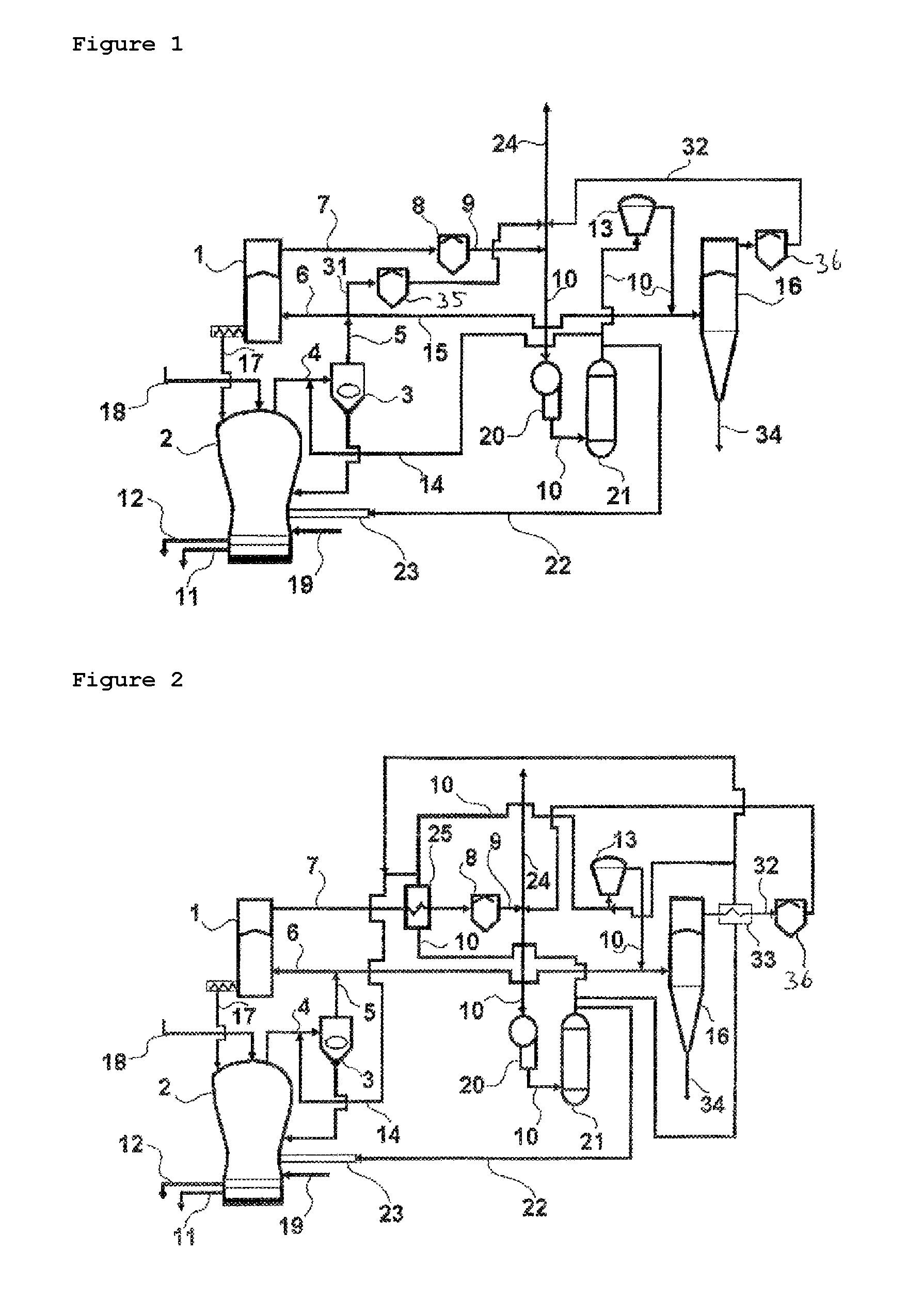

Process for production of direct reduced iron

InactiveUS20110247457A1High strengthLow levelGas treatmentExhaust gas handlingNitrogen gasMaterials science

The present invention relates to a process for the direct reduction of iron ore performed by means of a plant comprising a gravitational furnace (2) having at least one iron ore reduction zone (8) in the upper part thereof, and at least one carbon deposition zone (9) and one reduced metal product cooling zone (10) in the lower part thereof, and means for feeding a reducing gas mixture into the reactor in correspondence to the with the reduction zone, means for recycle exhaust or reactor off gas from the reactor to syngas and mixing the recycled gas with natural gas to form a reducing gas mixture. According to the invention a in first reformation step (5) unreacted carbon monoxide CO and steam present in the reactor off gas is reformed to carbon dioxide and hydrogen following the water gas shift reaction CO+H20=CO2+H2, in a secondary reformation step the de-watered reactor off gas comprising mainly of carbon dioxide and hydrogen is processed to remove carbon dioxide, and in a third reformation step physical separation of both nitrogen and carbon oxide CO from the reducing syngas is carried out to bring down the levels of CO and any existing other gases in the recycled gas to as low level as possible such that recycled reducing gas is as close to pure hydrogen H2 as possible.

Owner:LOUSSAVAARA KIIRUNAVAORA AB

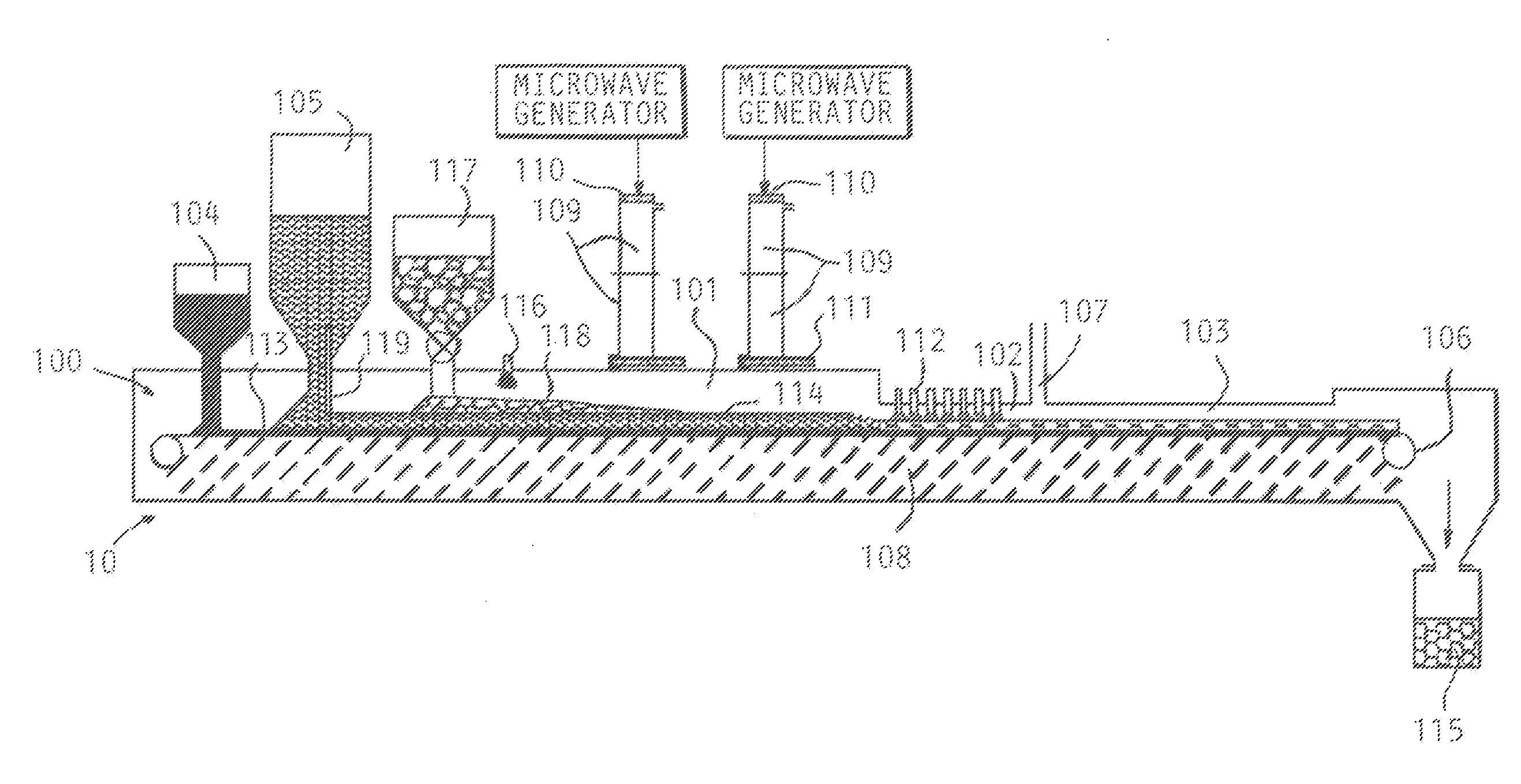

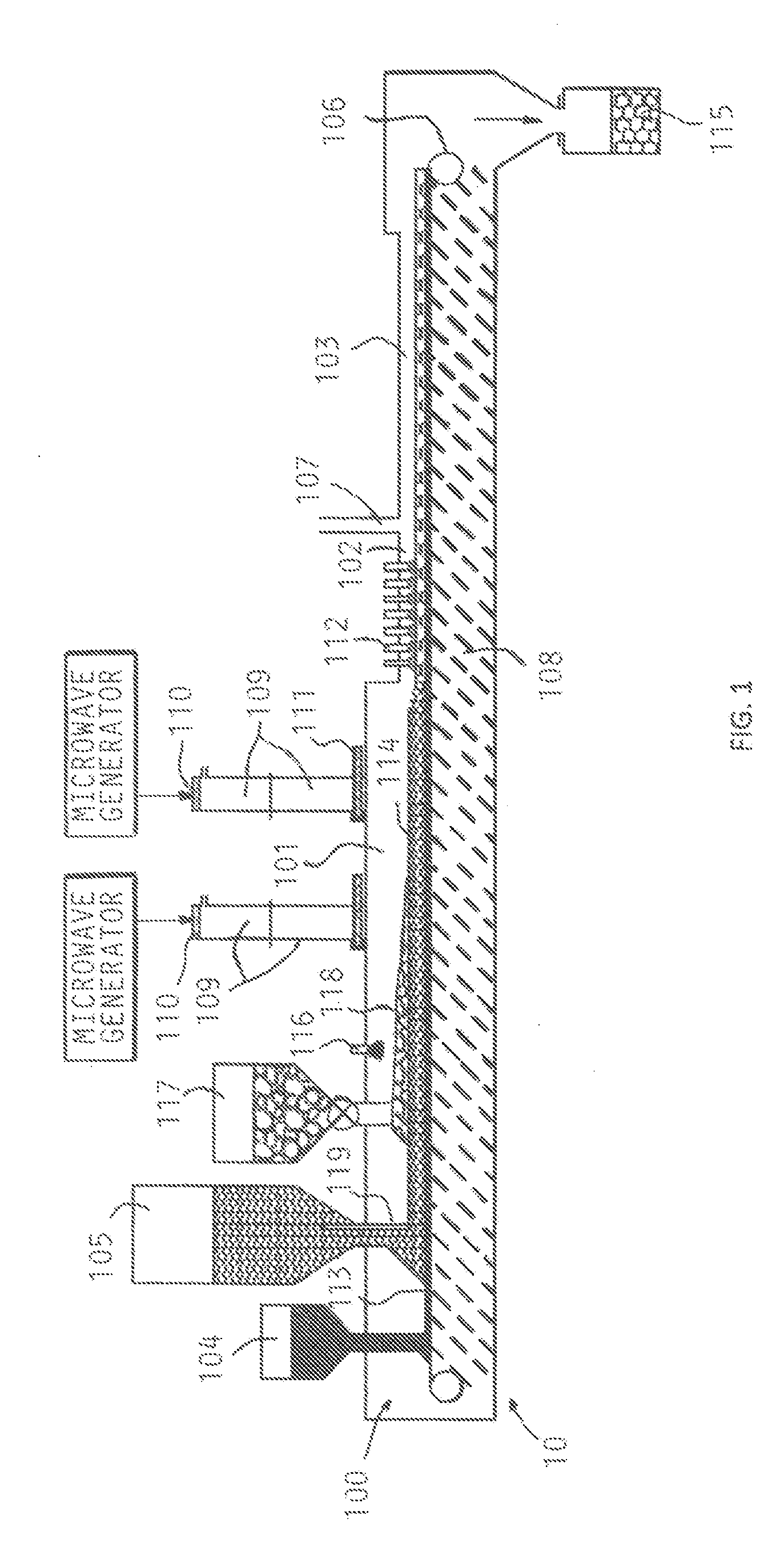

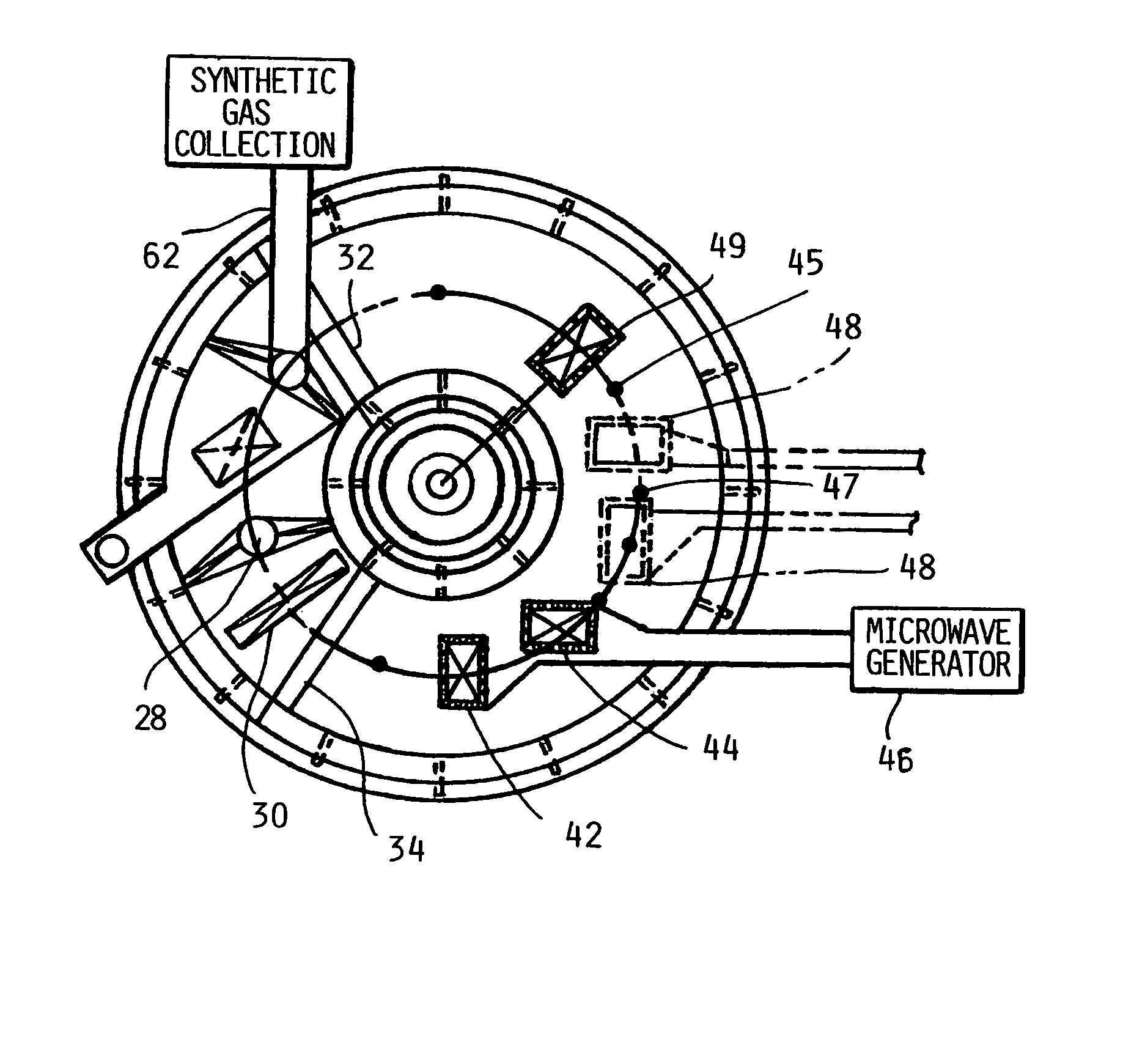

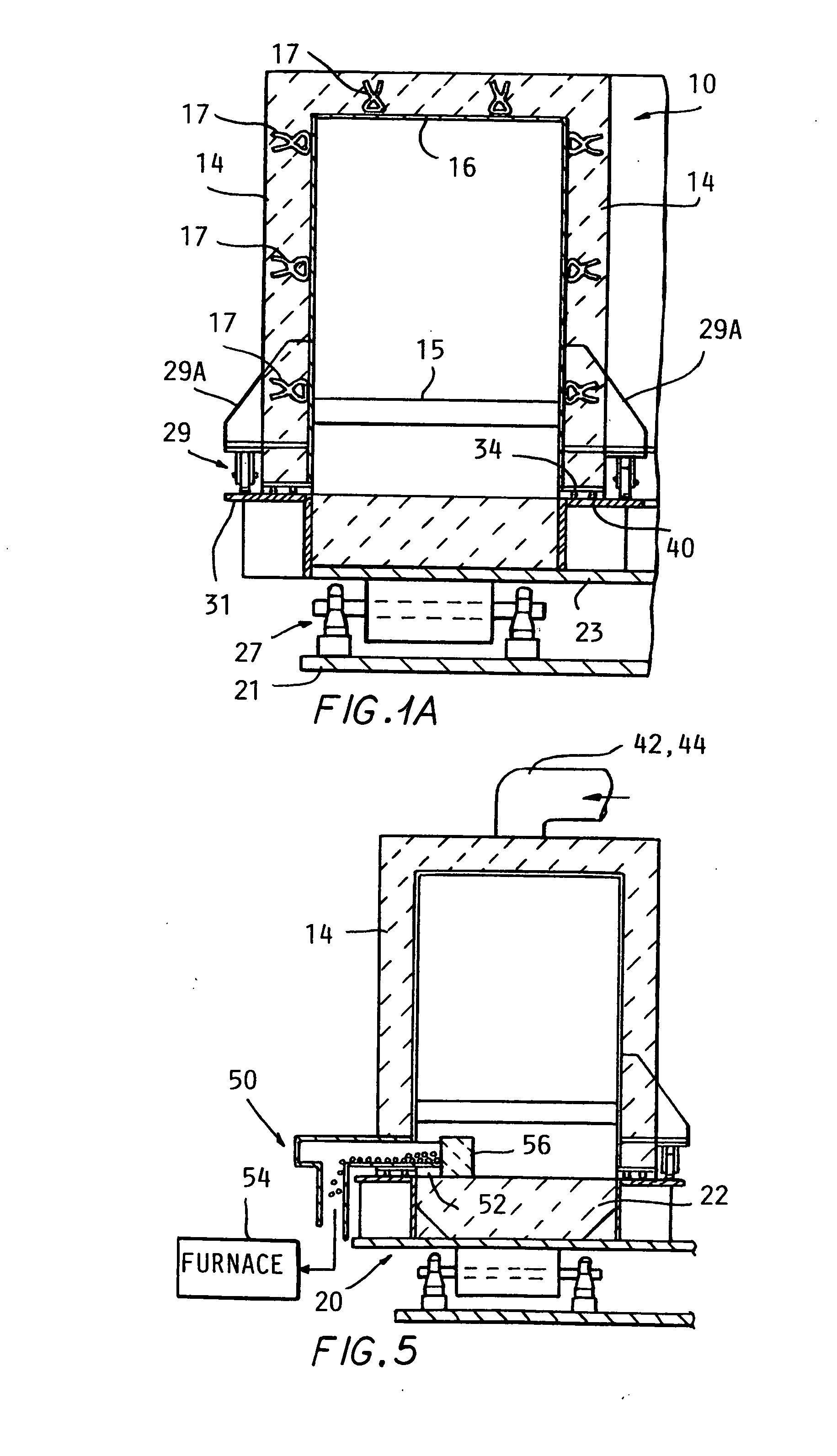

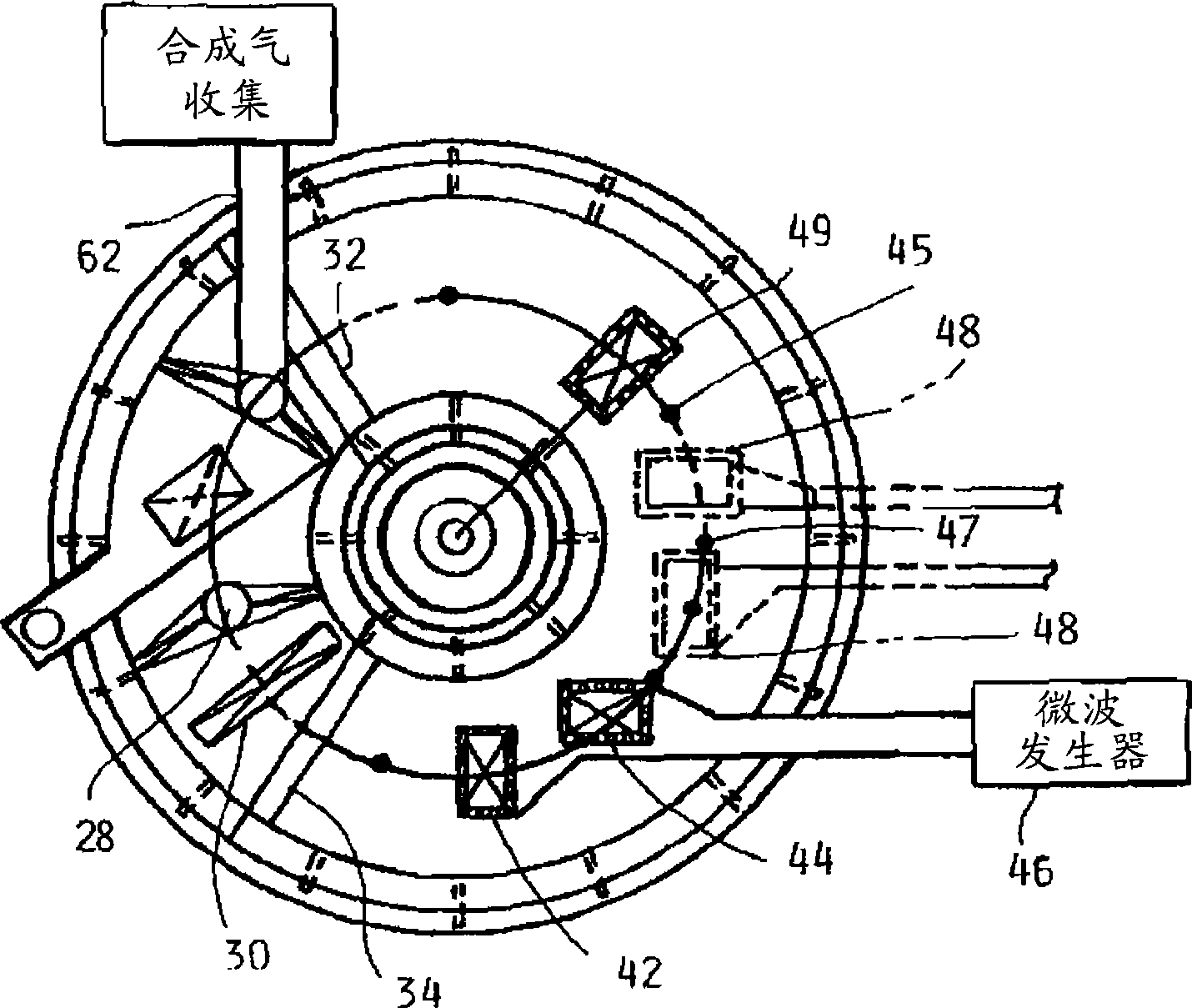

Microwave heating method and apparatus for iron oxide reduction

A method and apparatus for reducing iron oxides using microwave heating in a furnace chamber which is sealed against the entrance of air reduces the energy required and produces a low temperature reduction and allows the recovery of combustible synthetic gas as a byproduct of the process. Avoidance of the reduction of sulfur, phorphorus and silica is also insured, as is the need to reduce the silica content of the feed material prior to reducing the ore. A continuous rotary hearth furnace, a rotary kiln, a linear conveyor and vertical shaft furnace chamber configurations are described. A secondary heating zone can also be included to process the reduced iron into iron nuggets or liquid metallic iron.

Owner:HWANG JIANN YANG +1

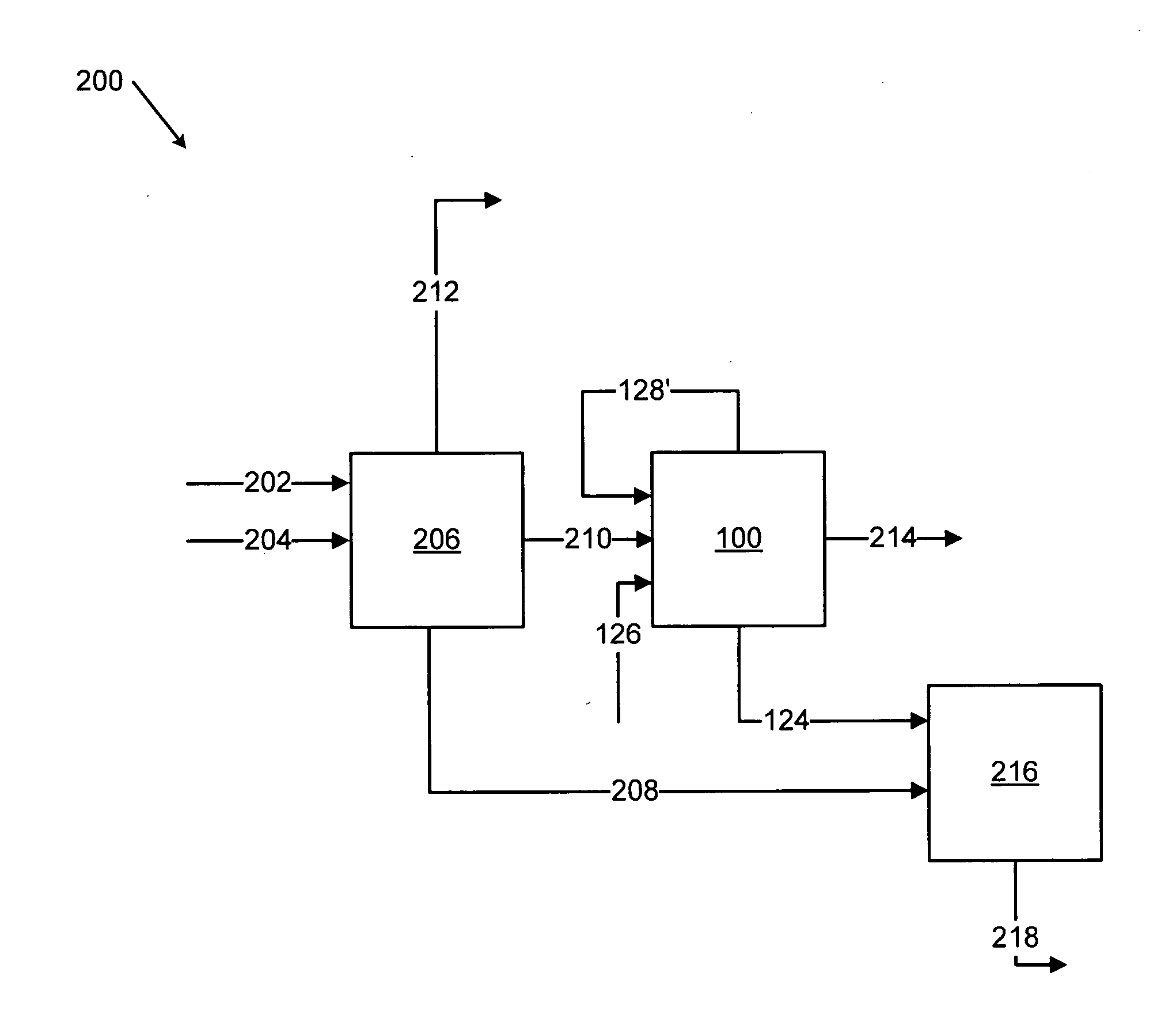

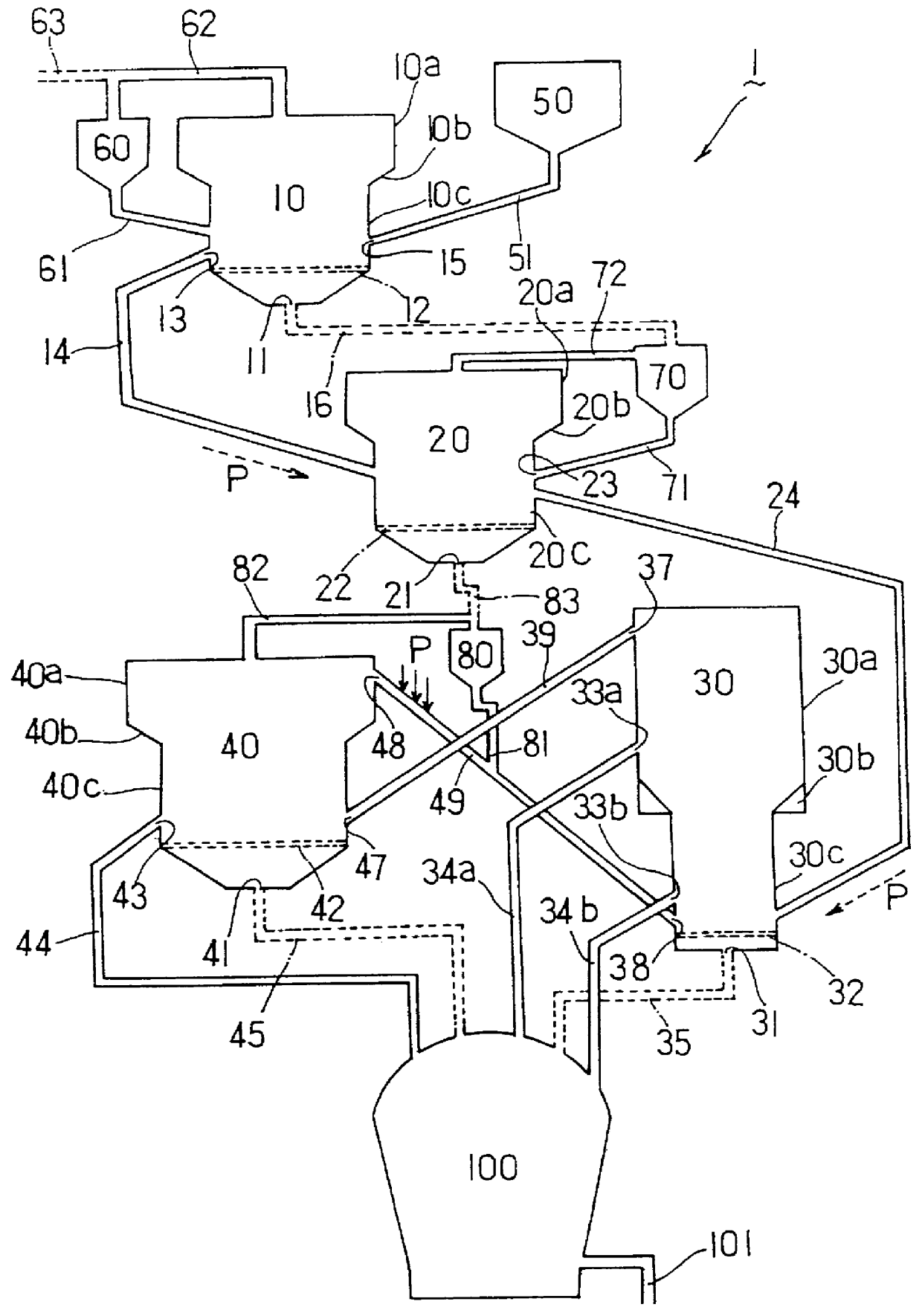

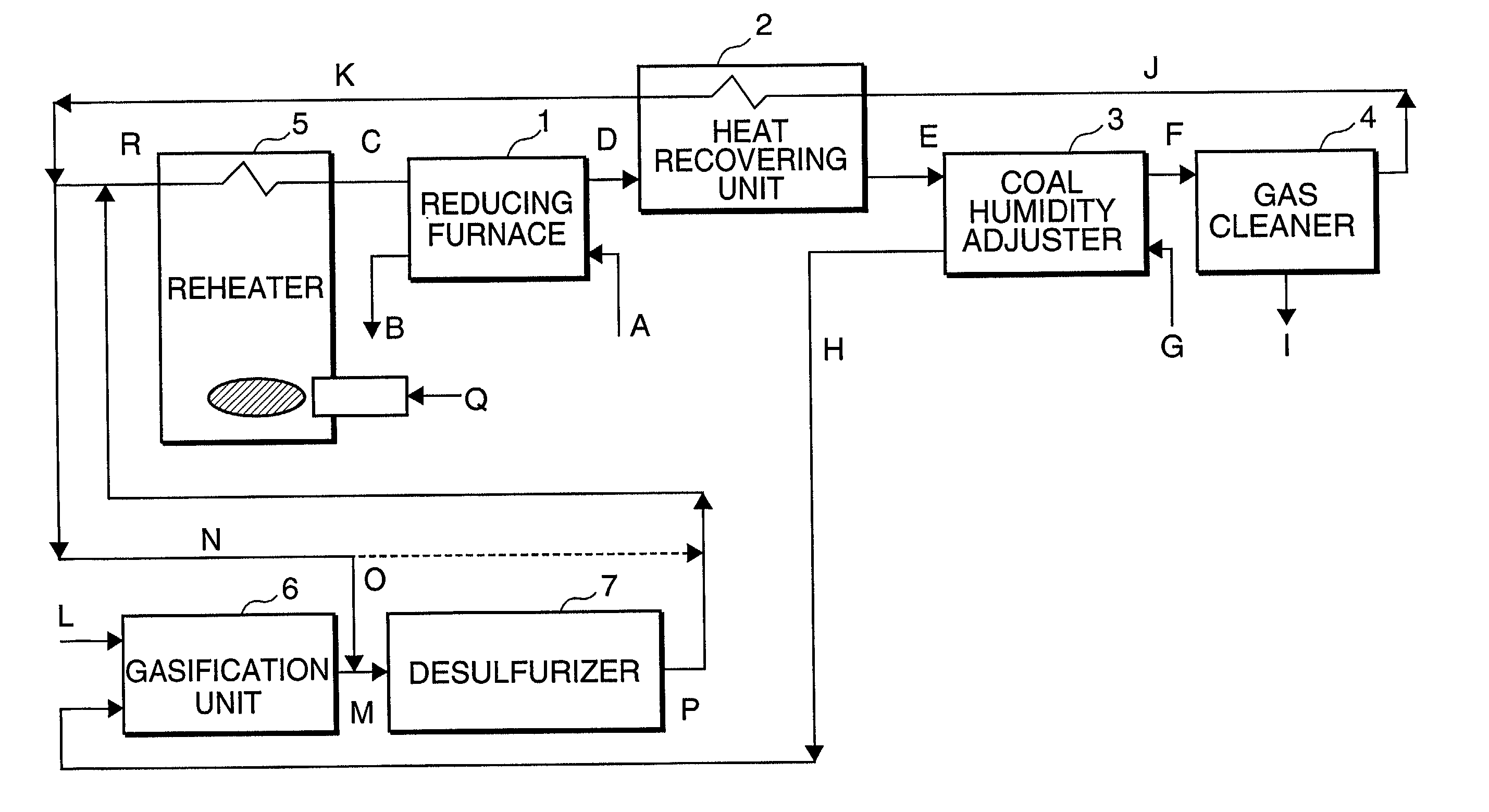

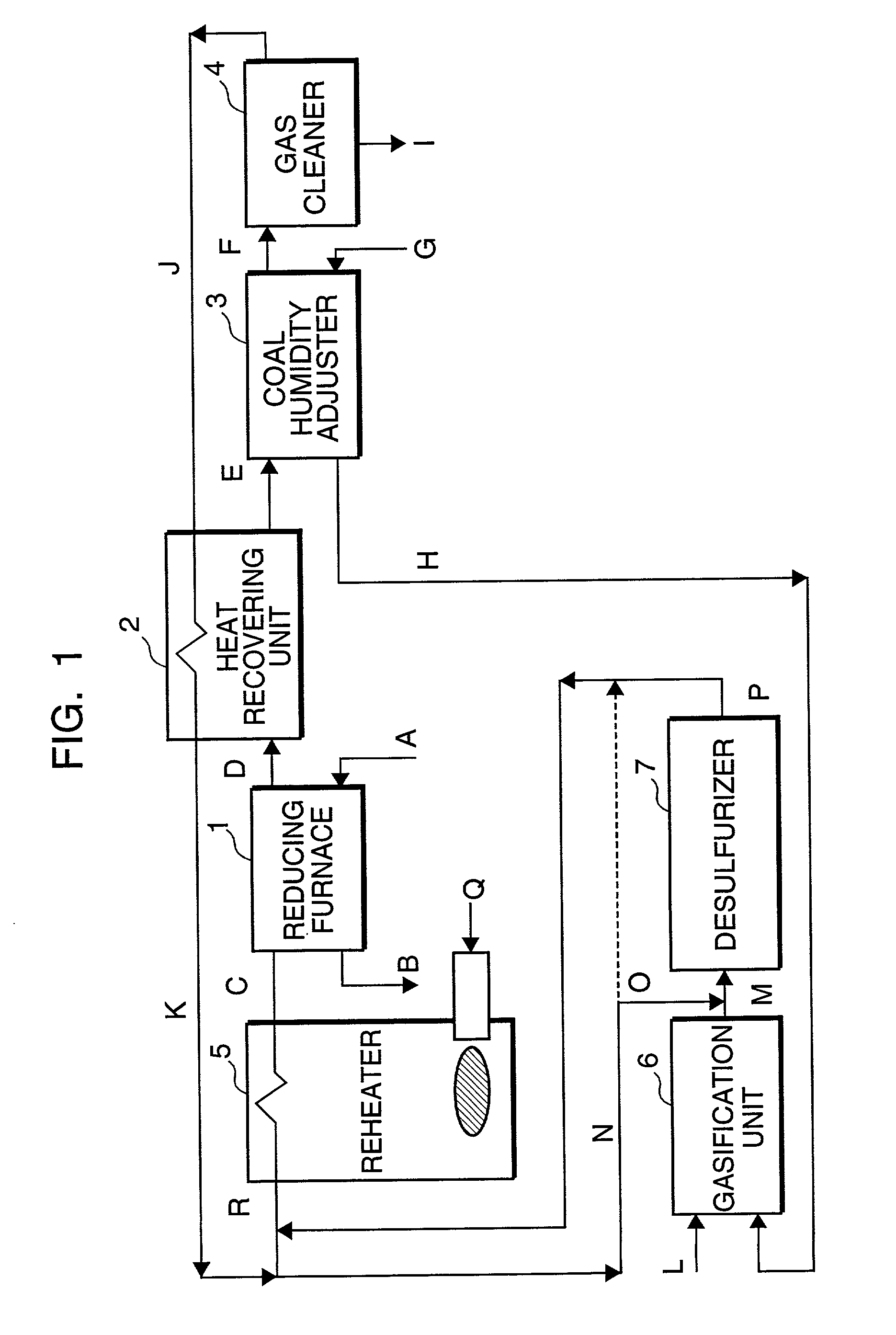

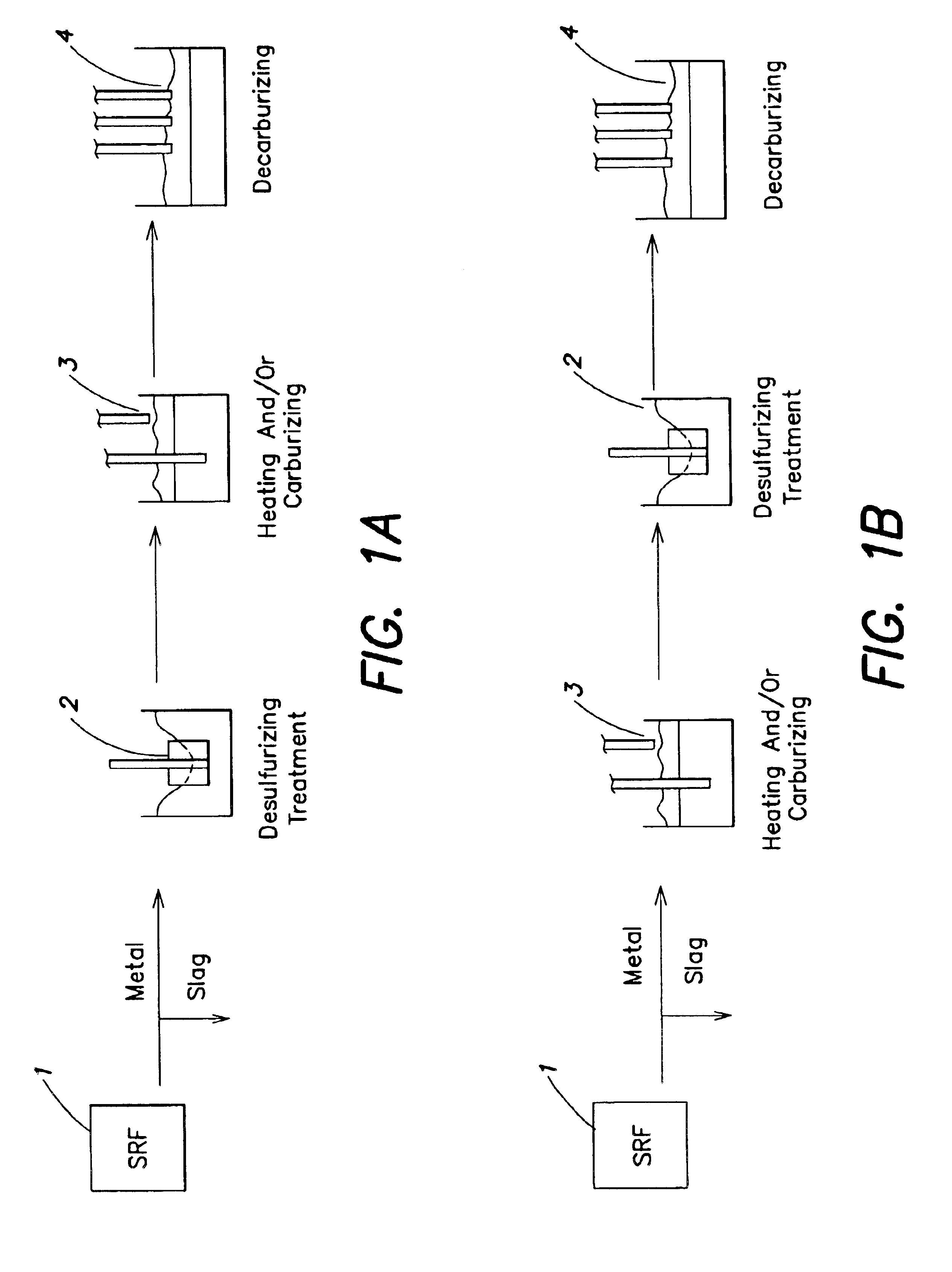

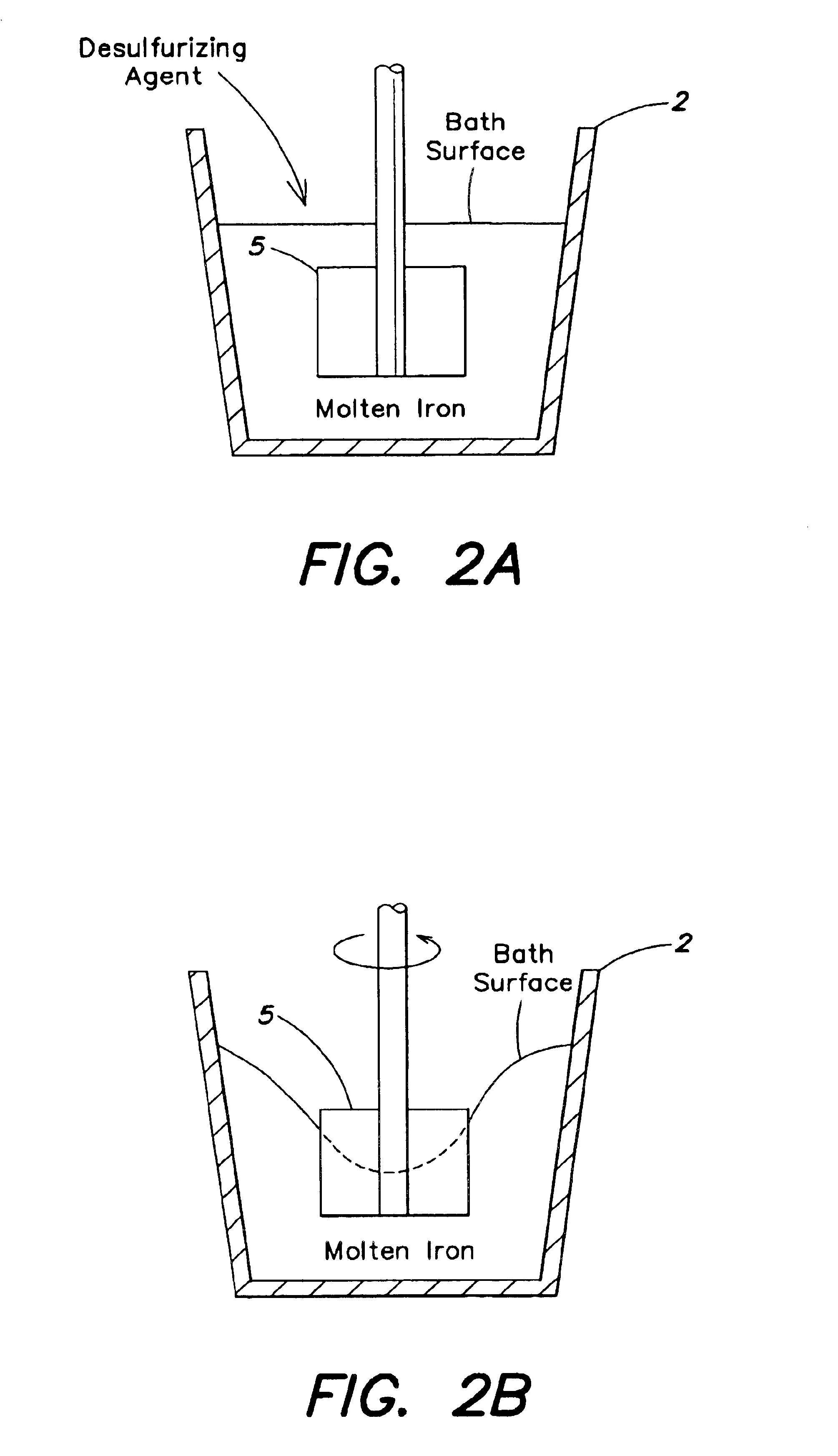

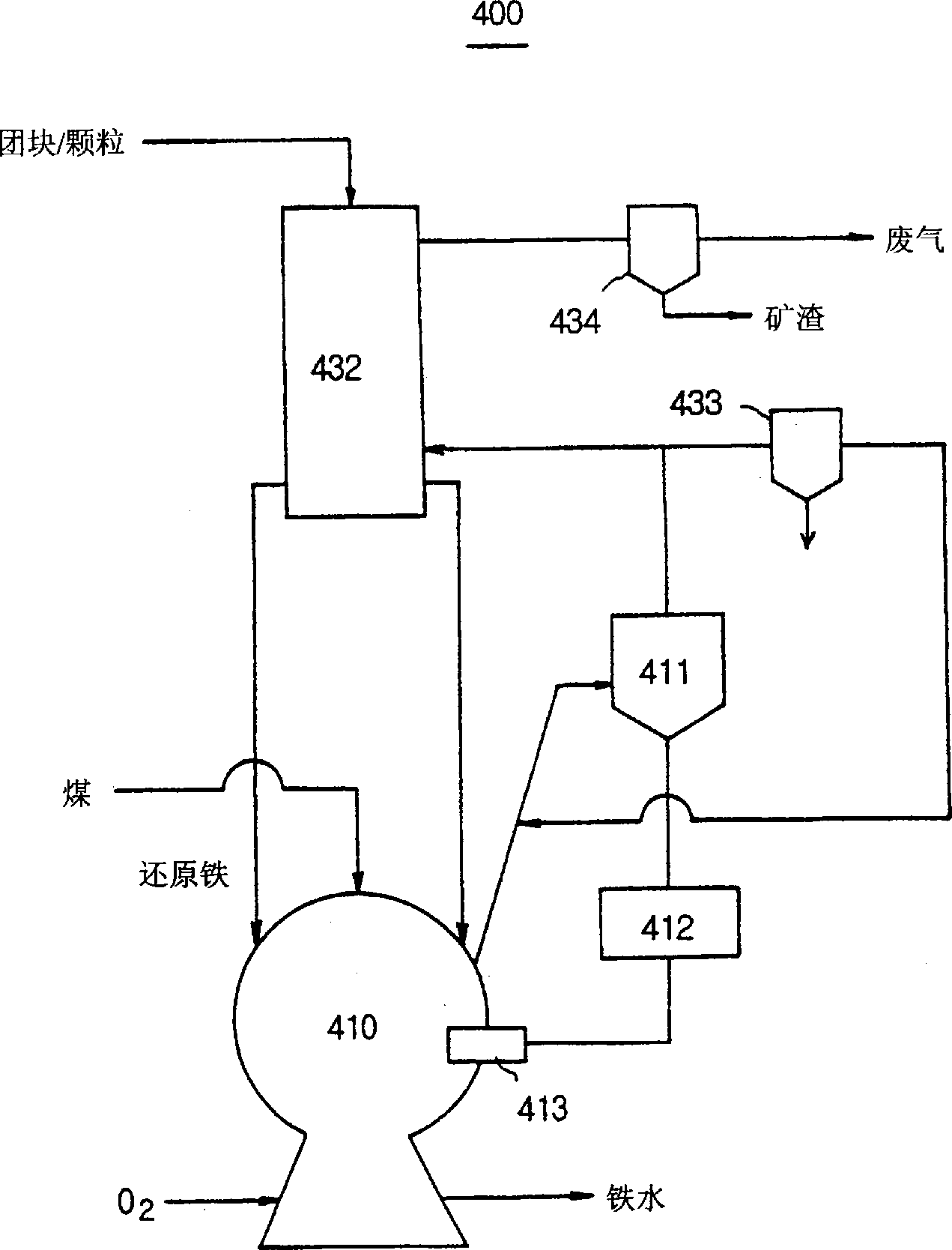

Method of producing direct reduced iron with use of coal-derived gas

InactiveUS20020078795A1Efficient use ofLow degreeTuyeresBell-and-hopper arrangementProduct gasCoal gasifier

In a method of producing direct reduced iron with use of a coal-derived gas, coal is heated to lower the moisture thereof, and the moisture-lowered coal is gasified in a coal gasification furnace to produce a coal-derived gas containing a reducing gas. The reducing gas is then utilized to reduce iron ore in an iron ore reducing furnace. With use of an exhaust gas from the iron ore reducing furnace, the coal is heated in the step of heating coal.

Owner:KOBE STEEL LTD +1

Fuel gas calorie control method and device

ActiveUS7396228B2Calorie controlEasy to controlBurnersTurbine/propulsion fuel supply systemsMixed flowProduct gas

Calories of a first mixed gas are predicted by calculations based on the mixed flow rate of a blast furnace gas and the mixed flow rate of a converter gas measured by flow meters, and preset blast furnace gas calories and converter gas calories; the flow rate ratio of the mixed flow rate of a coke oven gas to a gas turbine consumed fuel gas flow rate is calculated based on the predicted calories, set calories, and preset coke oven gas calories; the mixed flow rate required value of the coke oven gas is calculated based on the flow rate ratio and a gas turbine fuel gas requirement signal corresponding to the gas turbine consumed fuel gas flow rate; and the opening of a coke oven gas flow control valve provided in a fuel gas production system is controlled, based on the mixed flow rate required value, to control the mixed flow rate of the coke oven gas.

Owner:MITSUBISHI POWER LTD

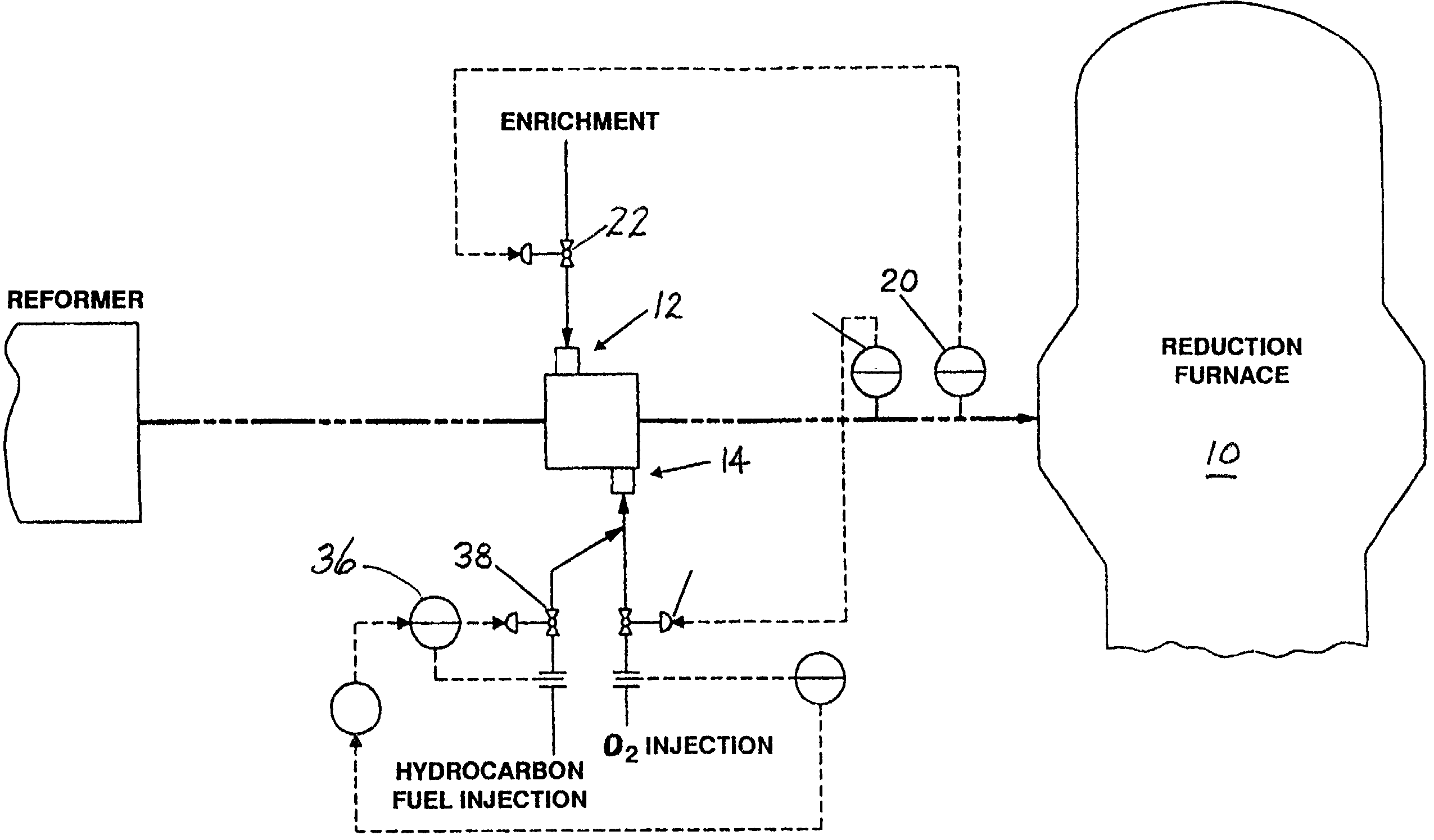

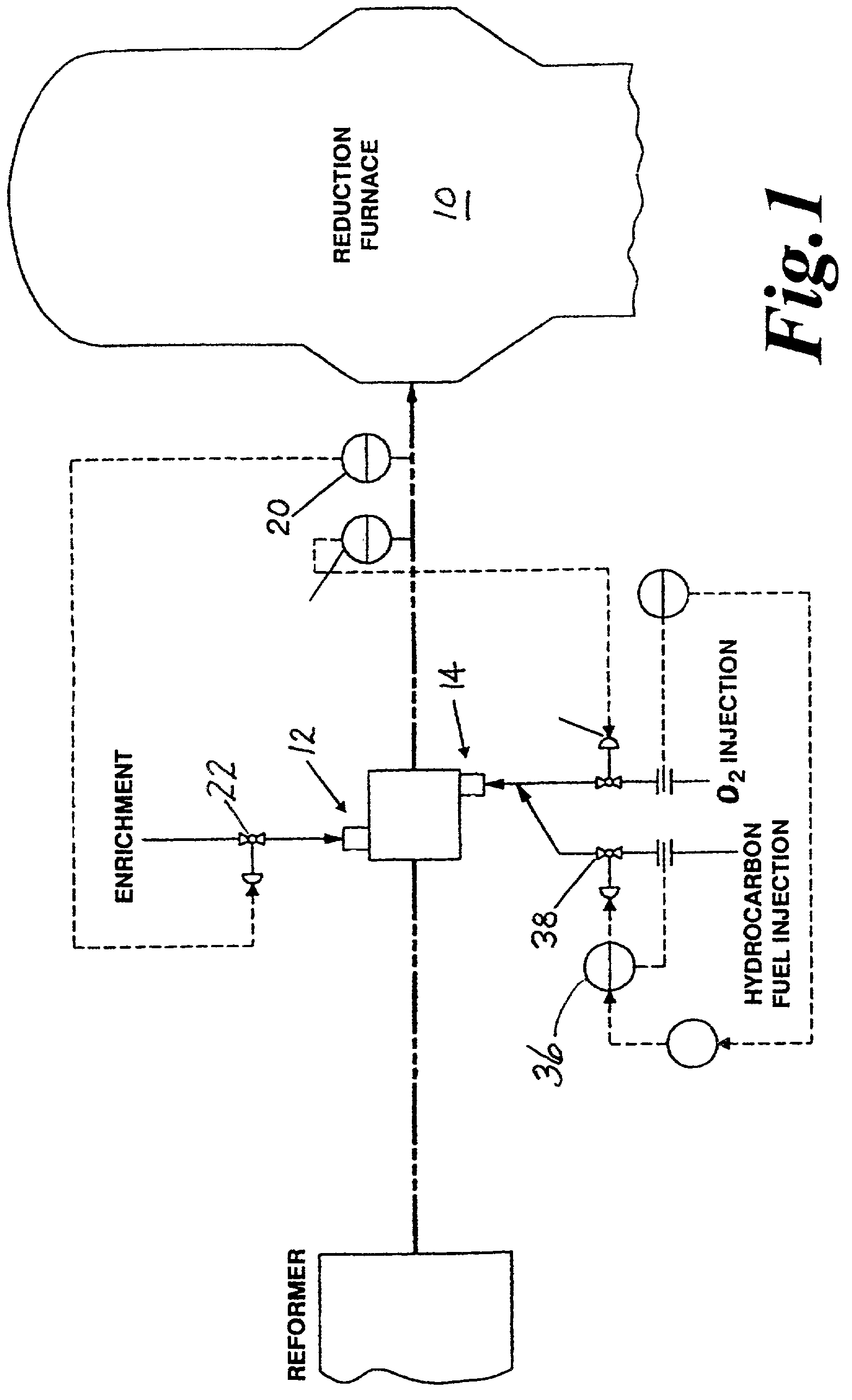

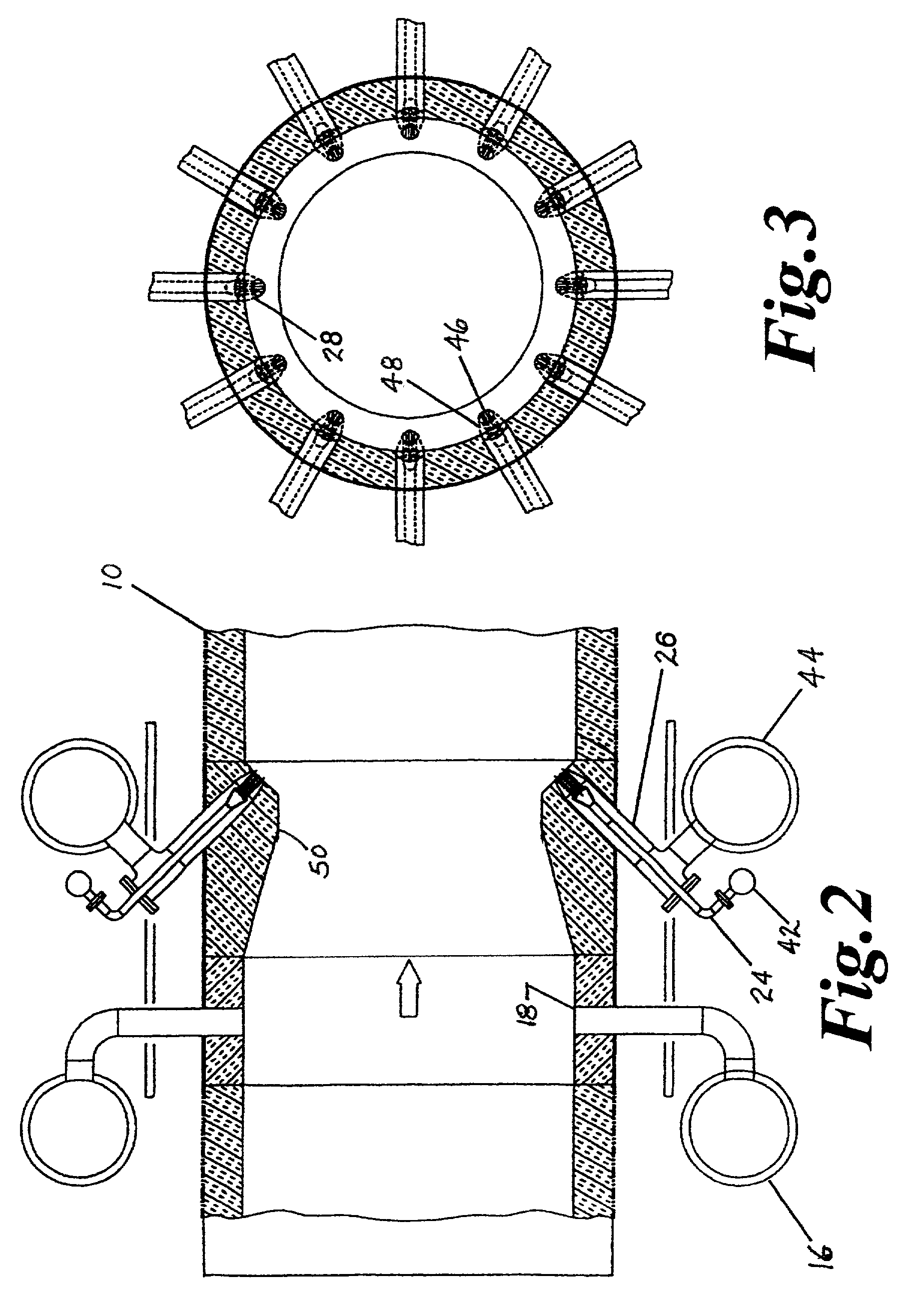

Apparatus and method for optimizing the use of oxygen in the direct reduction of iron

InactiveUS20020007699A1Increase volumeQuality improvementHydrogenChemical industryHydrogen contentProcess engineering

An apparatus and method for adjusting the parameters of a reducing gas stream prior to introduction into a direct reduction furnace, such parameters including temperature of the gas stream, and amount of hydrocarbon, carbon monoxide, and hydrogen contained in the reducing gas. The apparatus is placed in-line with the reducing gas recycle loop of a direct reduction furnace, which has an enrichment section which introduces hydrocarbon components to the main stream, and an oxygen / fuel injection system, located downstream from the enrichment section, which injects a shrouded stream of oxygen and hydrocarbon gas into the reducing gas stream. Temperature, carbon monoxide content, and hydrogen content of the reducing gas are adjusted by controlling the flow of oxygen and the ratio of hydrocarbon to oxygen injected in the oxygen / fuel injection system. Hydrocarbon content of the reducing gas is adjusted primarily by controlling the flow rate of the enrichment section.

Owner:MIDREX TECH INC

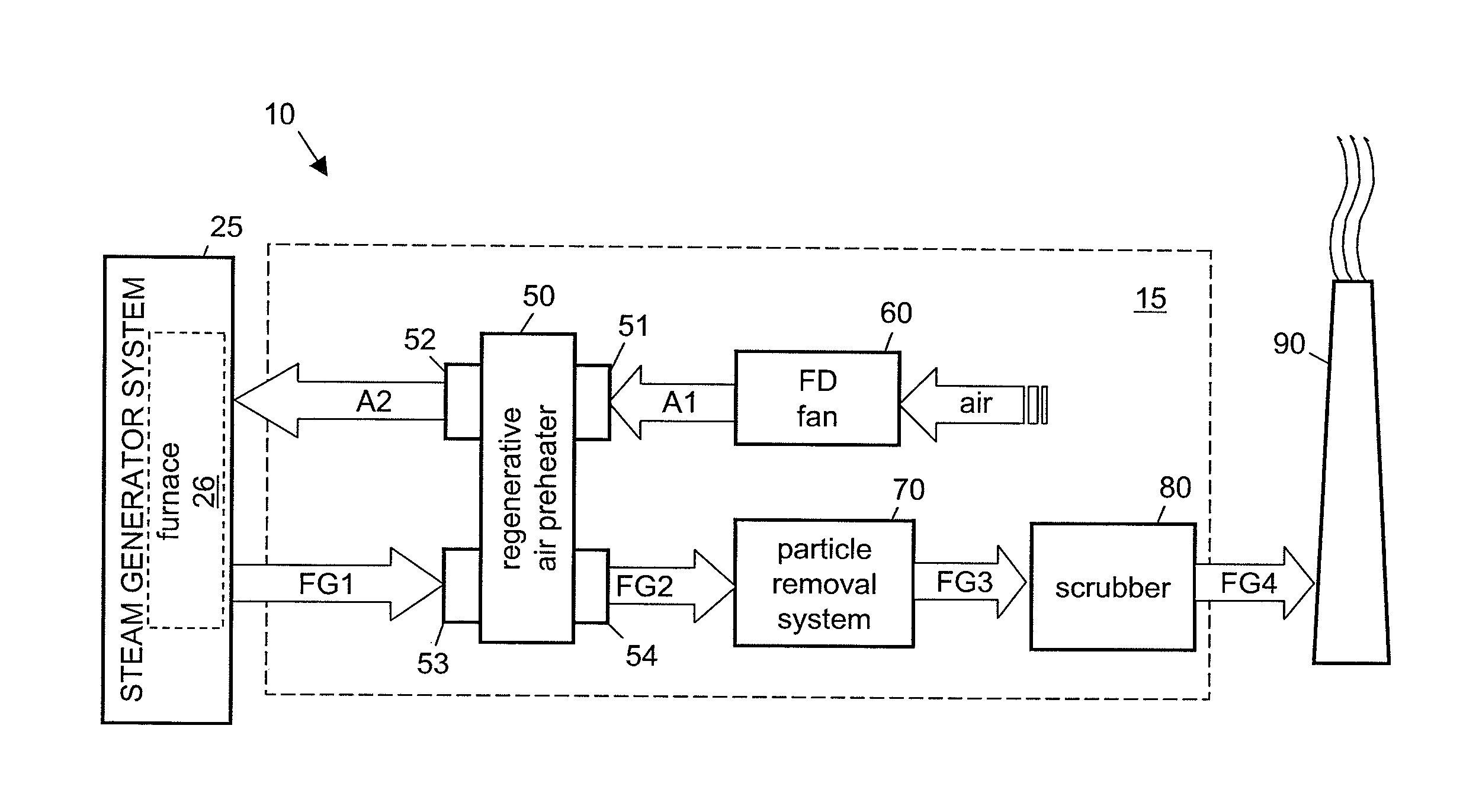

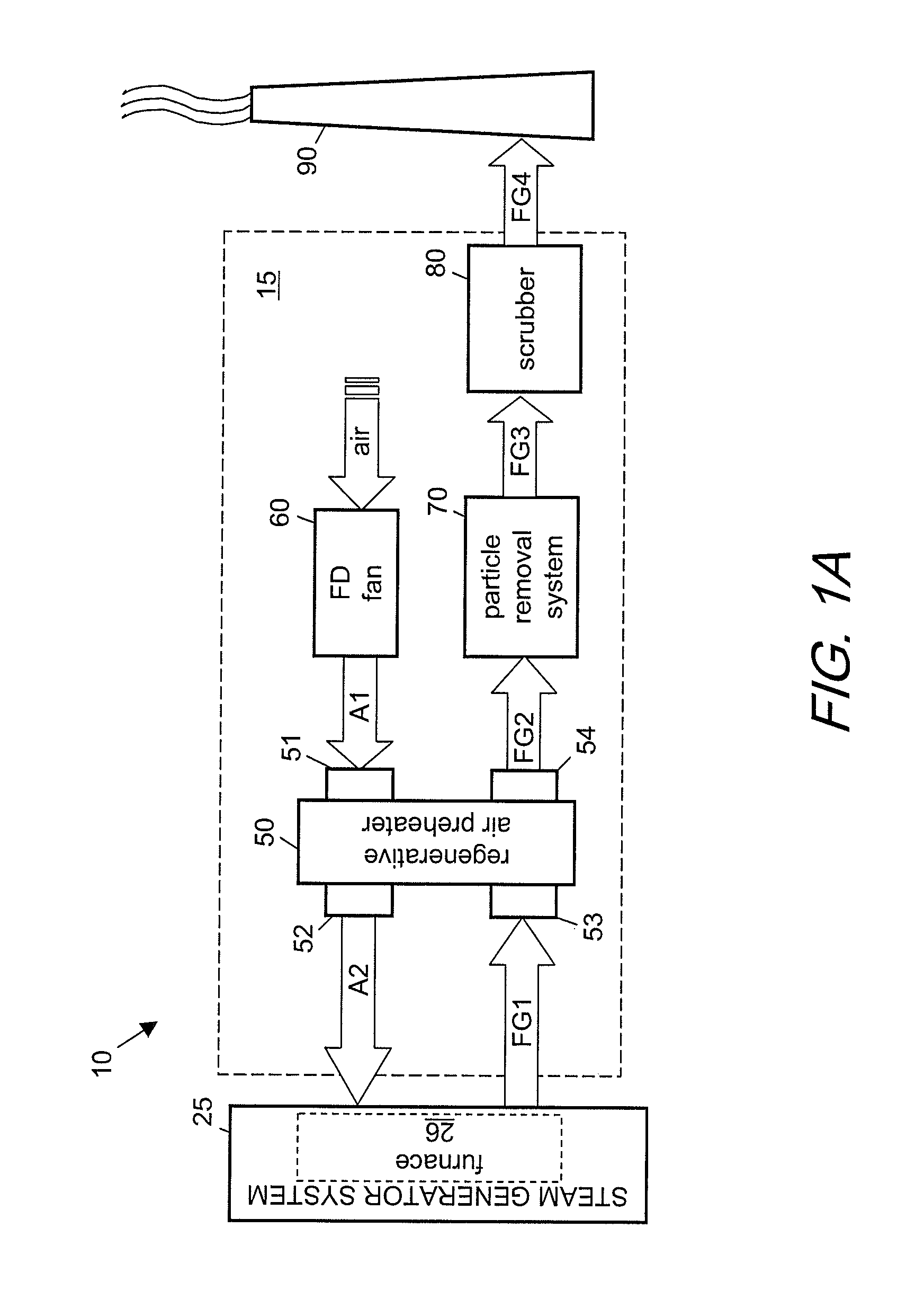

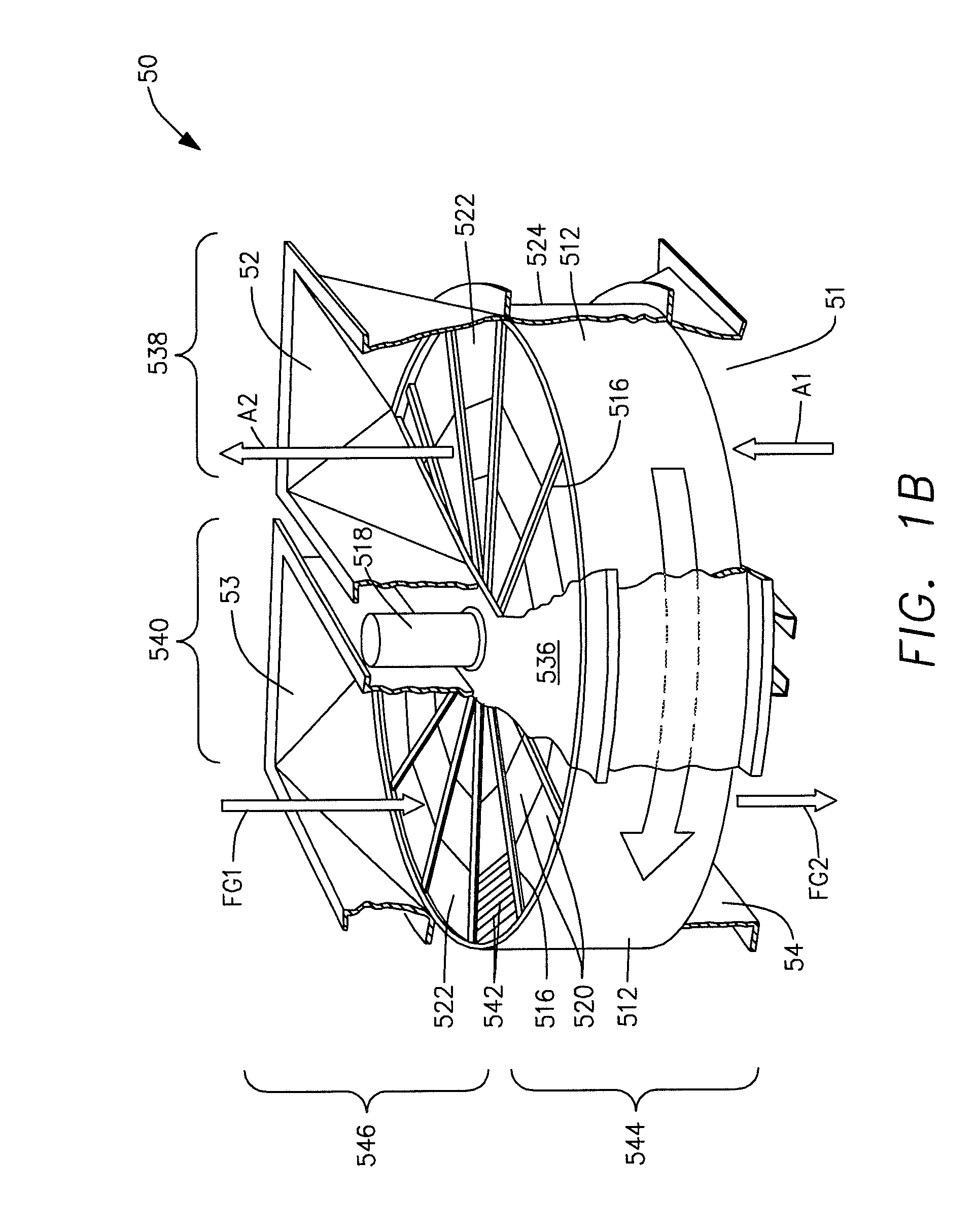

Exhaust processing and heat recovery system

InactiveUS20110073023A1Reduce accumulationImprove thermal efficiencyBurnersBlast furnace detailsThermal energyAir preheater

A thermally efficiency regenerative air preheater 250 extracts more thermal energy from the flue gas exiting a solid fuel fired furnace 26 by employing an alkaline injection system 276. This mitigates acid fouling by selectively injecting different sized alkaline particles 275 into the air preheater 250. Small particles provide nucleation sites for condensation and neutralization of acid vapors. Large particles are injected to contact and selectively adhere to the heat exchange elements 542 and neutralize liquid acid that condenses there. When the deposit accumulation exceeds a threshold, the apparatus generates and utilizes a higher relative percentage of large particles. Similarly, a larger relative percentage of small particles are used in other cases. Mitigation of the fouling conditions permits the redesign of the air preheater 250 to achieve the transfer of more heat from the flue resulting in a lower flue gas outlet temperature without excessive fouling.

Owner:ALSTOM ENERGY TECH AG

Microwave heating method and apparatus for iron oxide reduction

The present invention discloses a method and apparatus for reducing iron oxides using microwave heating in a furnace chamber which is sealed against the entrance of air reduces trie energy required and produces a low temperature reduction and allows the recovery of combustible synthetic gas as a byproduct of the process. Avoidance of the reduction of sulfur, phorphorus and silica is also insured, as is the need to reduce the silica content of the feed material prior to reducing the ore. A continuous rotary hearth furnace, a rotary kiln, a linear conveyor and vertical shaft furnace chamber configurations are described. A secondary heating zone can also be included to process the reduced iron into iron nuggets or liquid metallic iron.

Owner:J·Y·黄 +1

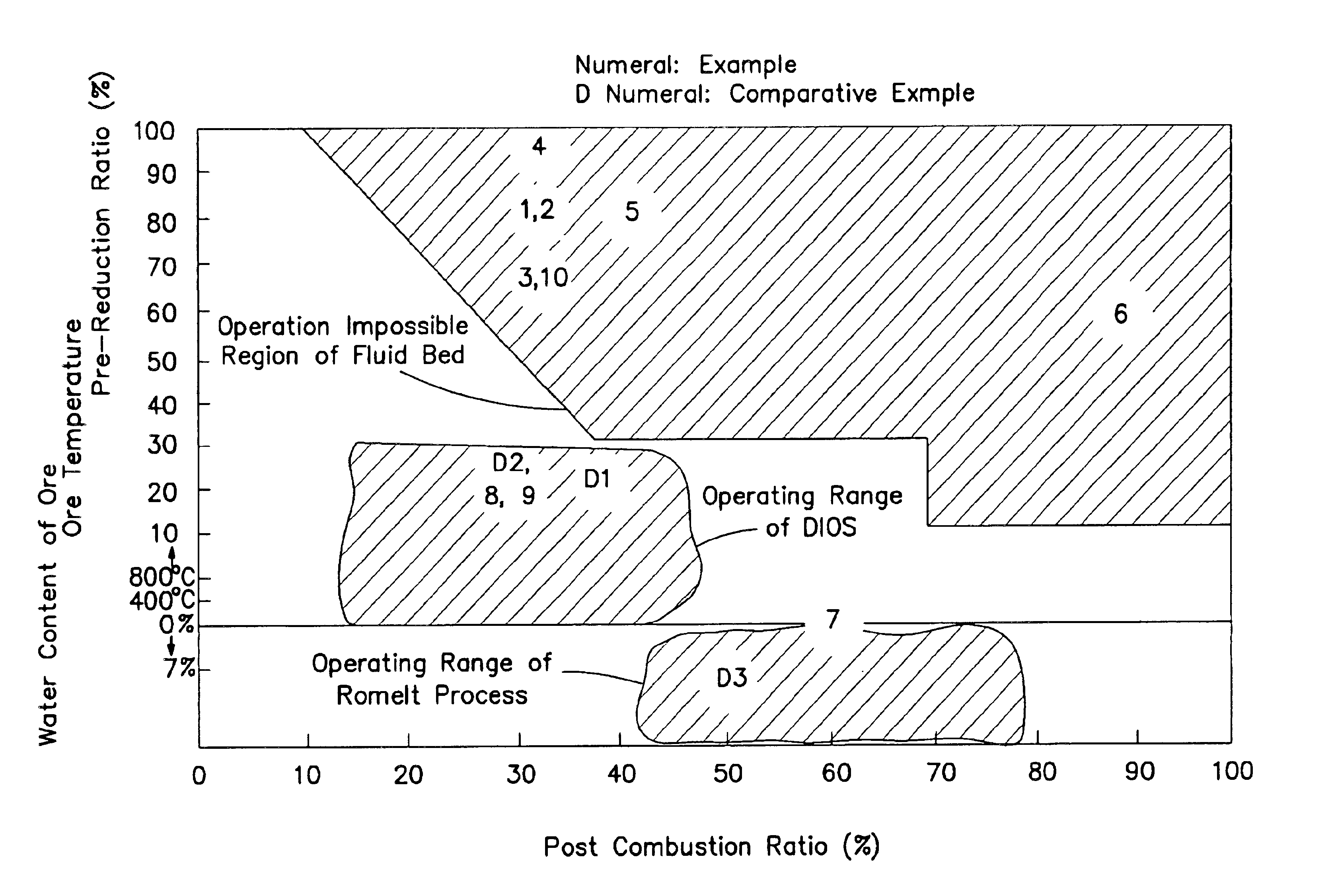

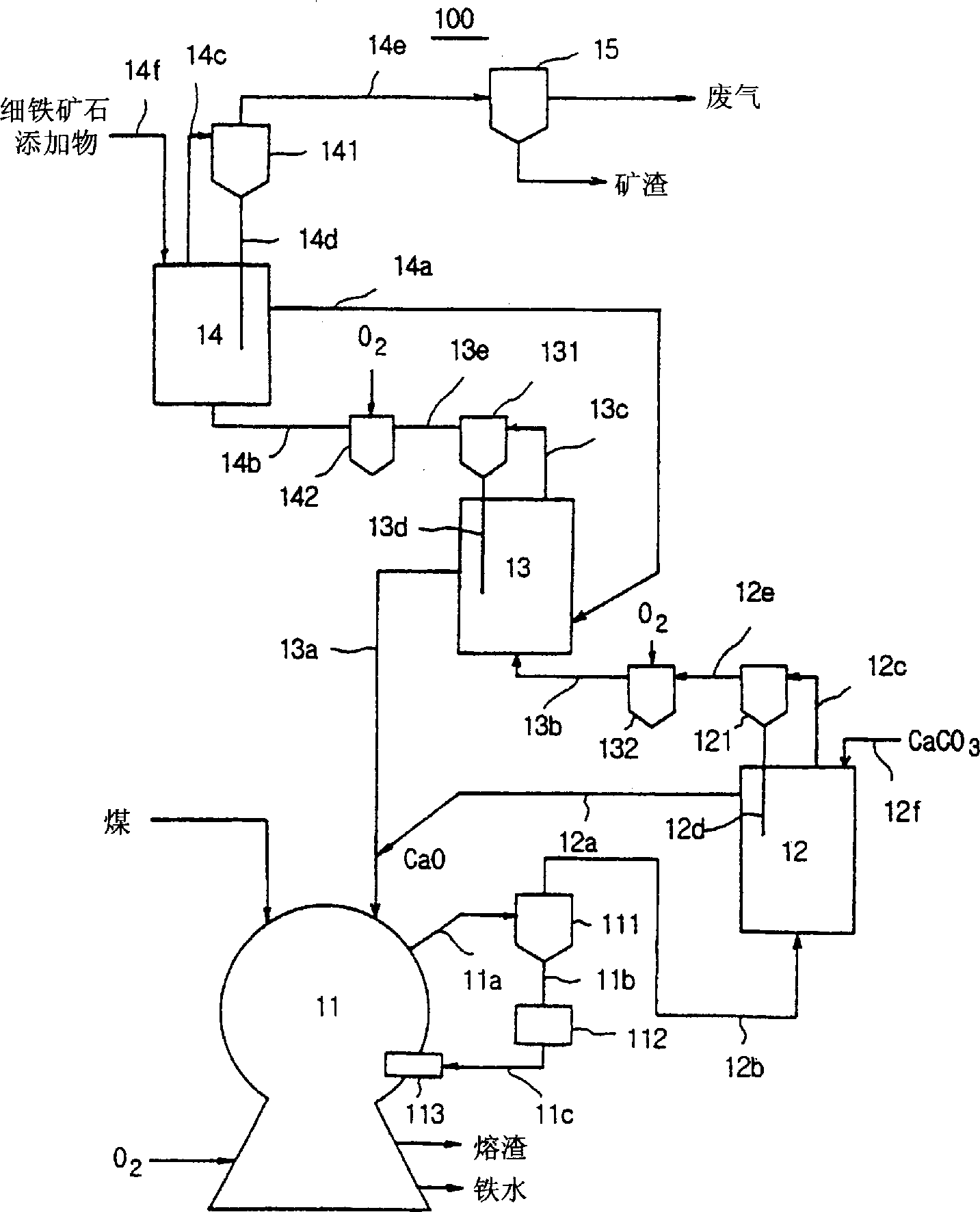

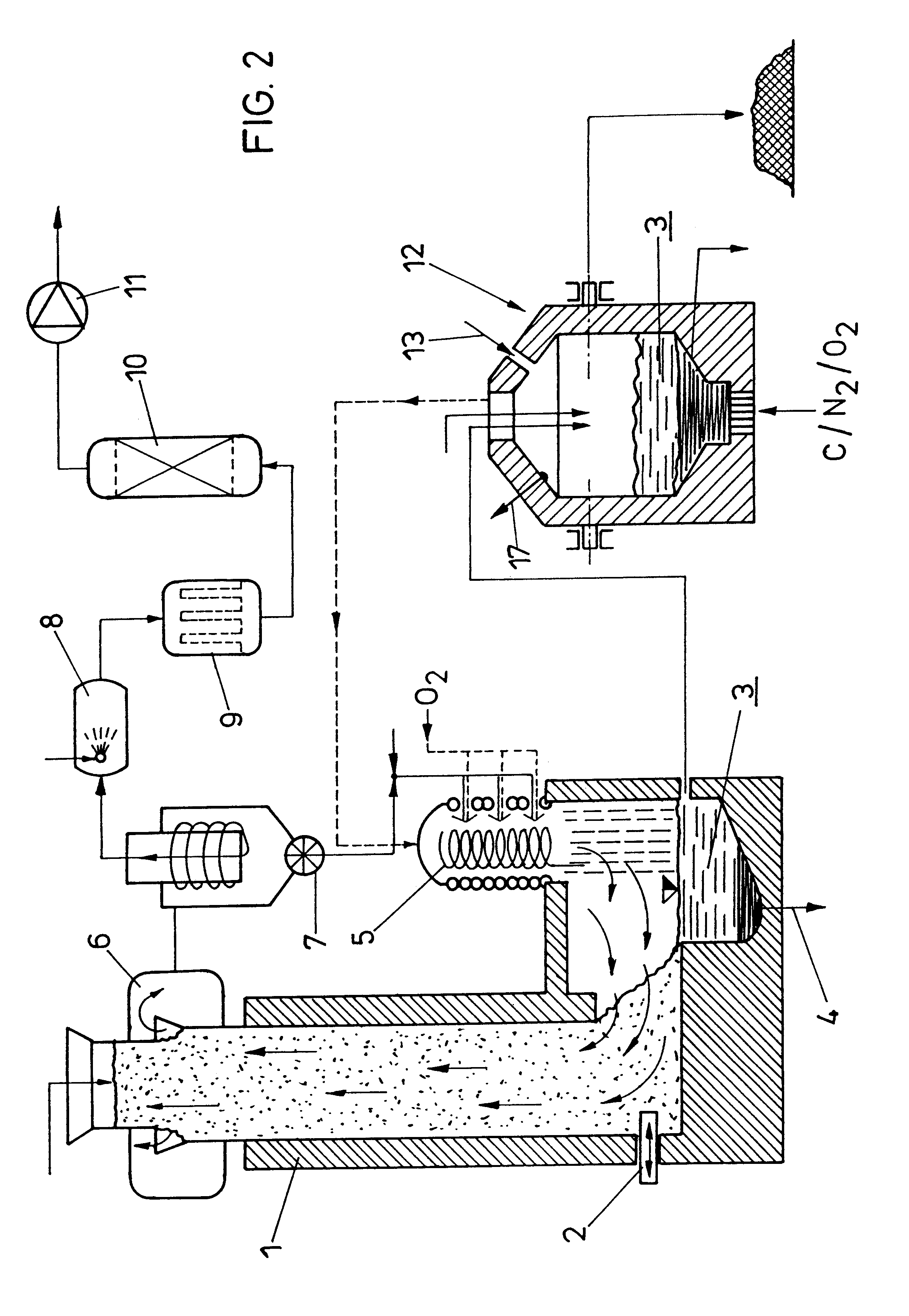

Smelting reduction method

InactiveUS6837916B2Increase carbonReduce equipment costsRotary drum furnacesManufacturing convertersOxygenMetal

A smelting reduction method comprising (a) charging a carbonaceous material and an ore into a reacting furnace to directly contact the carbonaceous material and the ore; (b) reducing the ore until at least a part of the ore is metallized, the resultant reduced ore containing at least a part of metallized metal being produced; (c) charging the carbonaceous material and the ore containing at least a part of the metallized metal from step (b) into a smelting furnace having a metal bath; and (d) blowing a gas containing 20% or more of oxygen into the metal bath in the smelting furnace to produce molten iron.

Owner:NIPPON KOKAN KK

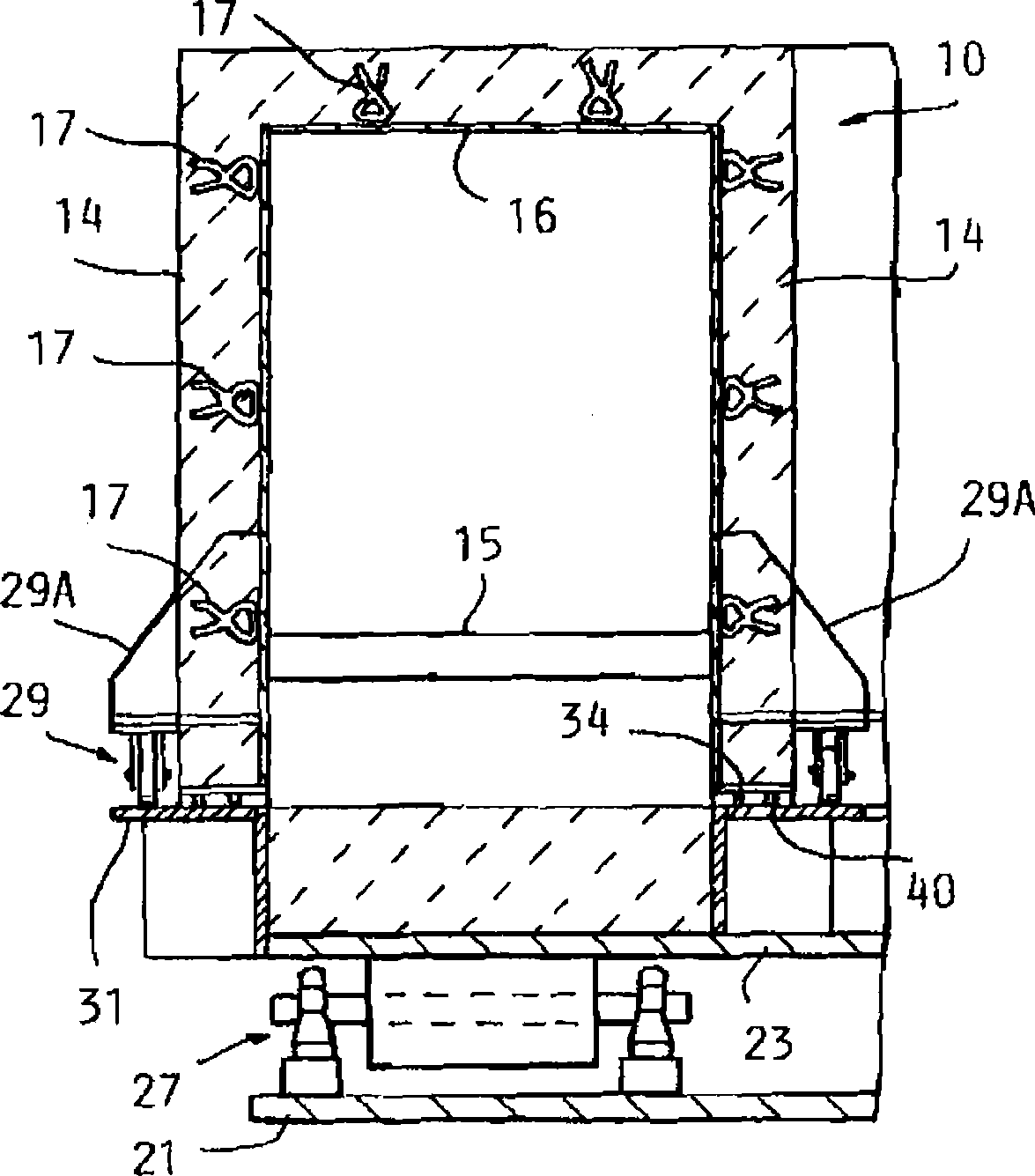

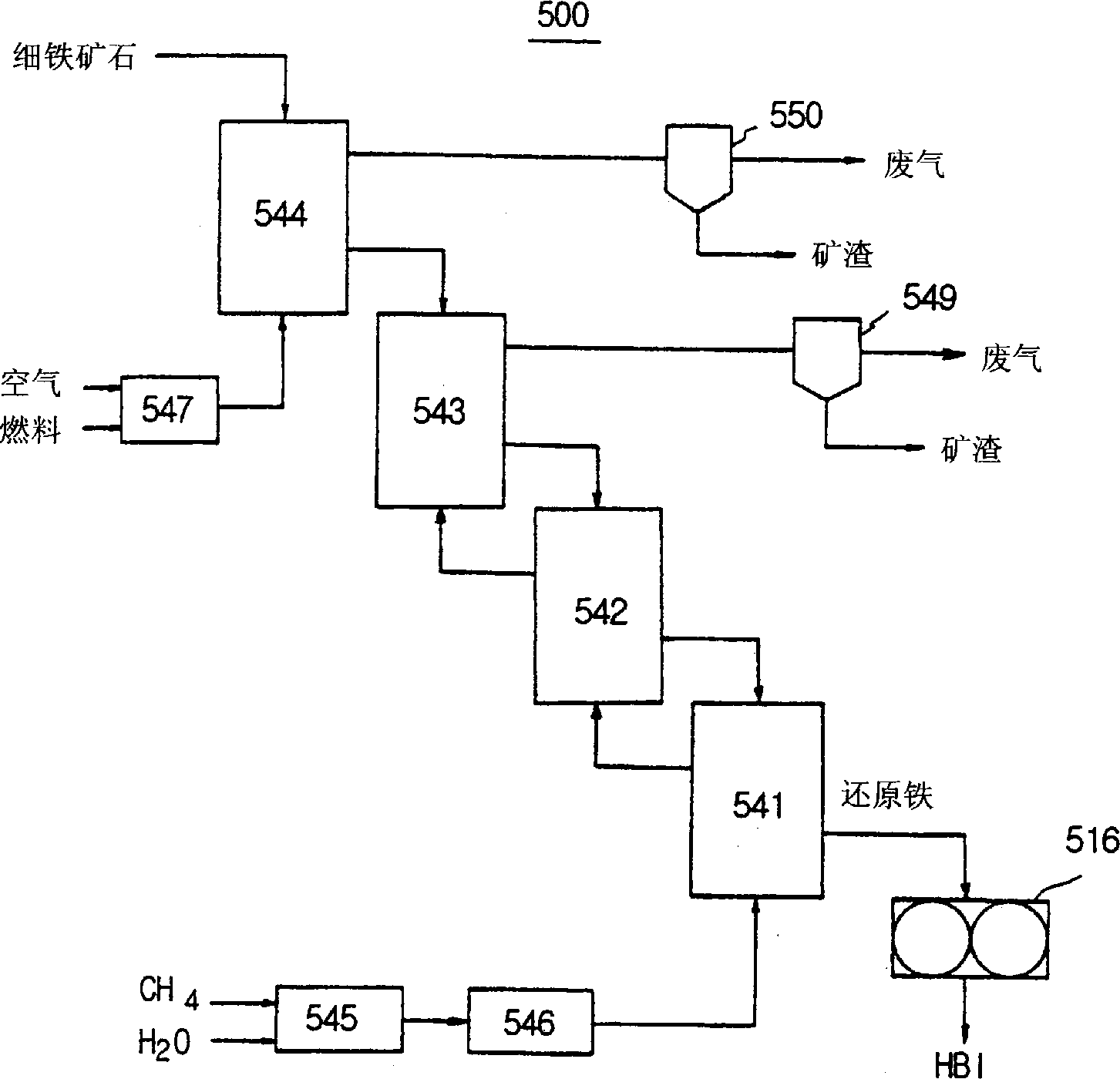

Apparatus for manufacturing molten pig iron and reduced iron by utilizing fluidized bed, and method therefor

An apparatus and a method for manufacturing molten pig iron by using a fine iron ore are disclosed. Coal is used to produce a reducing gas, and a fine iron ore is used to produce a molten iron and a reduced iron in a simple and efficient manner. The apparatus for manufacturing a molten iron by directly using coal as the fuel according to the present invention is characterized as follows. A high temperature reducing gas is sent from a melter-gasifier for a fluidized bed lime stone calcining furnace to calcine lime stone. Then the reducing gas is supplied to a second fluidized bed reducing furnace so as to manufacture a reduced iron directly. An off-gas from the second fluidized bed reducing furnace is supplied to a first fluidized bed reducing furnace disposed above the second fluidized bed reducing furnace to pre-heat and pre-reduce the fine iron ore. The calcined lime stone and the finally reduced iron are supplied to a melter-gasifier to manufacture a molten pig iron.

Owner:POHANG IRON & STEEL CO LTD +2

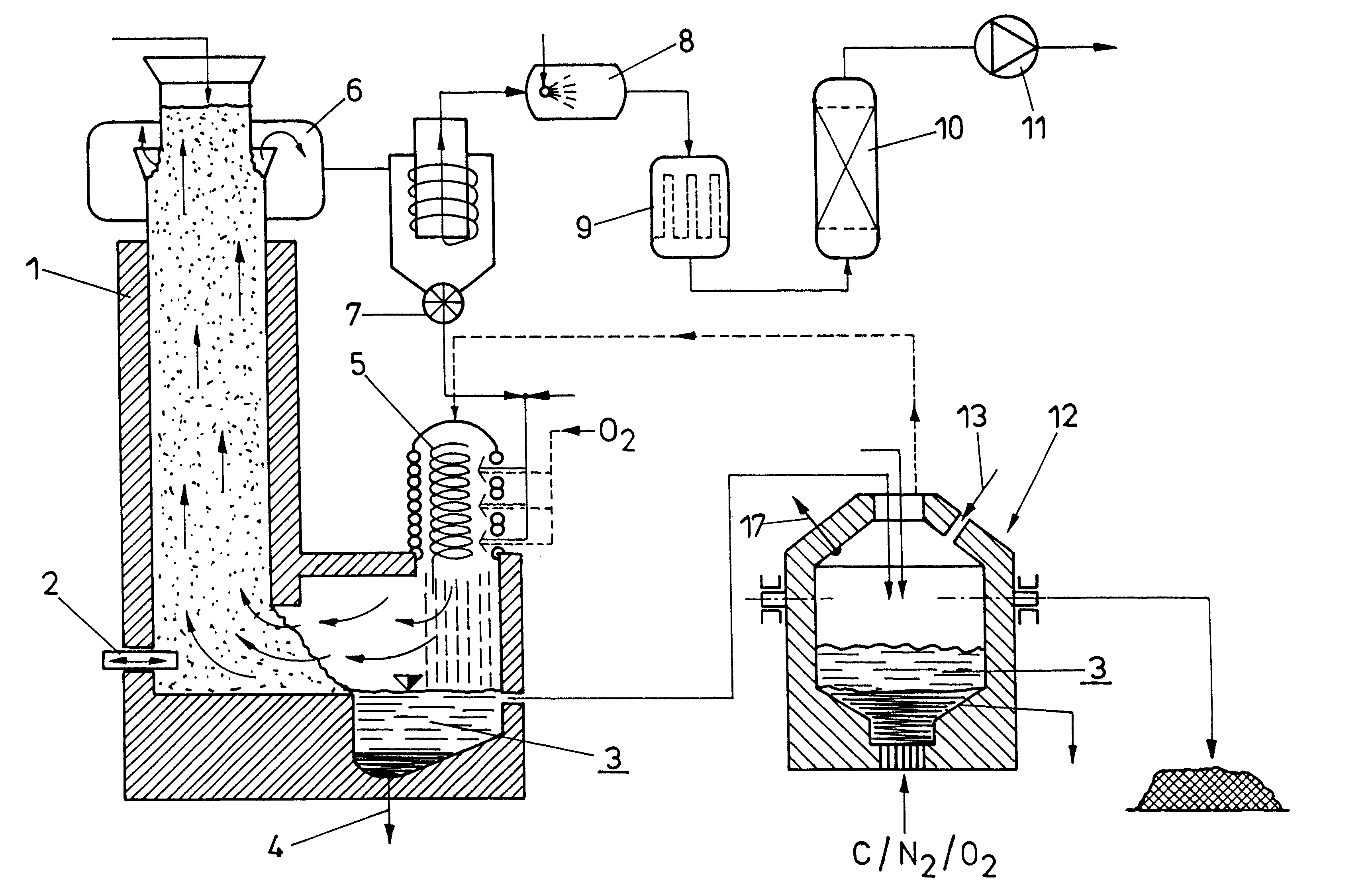

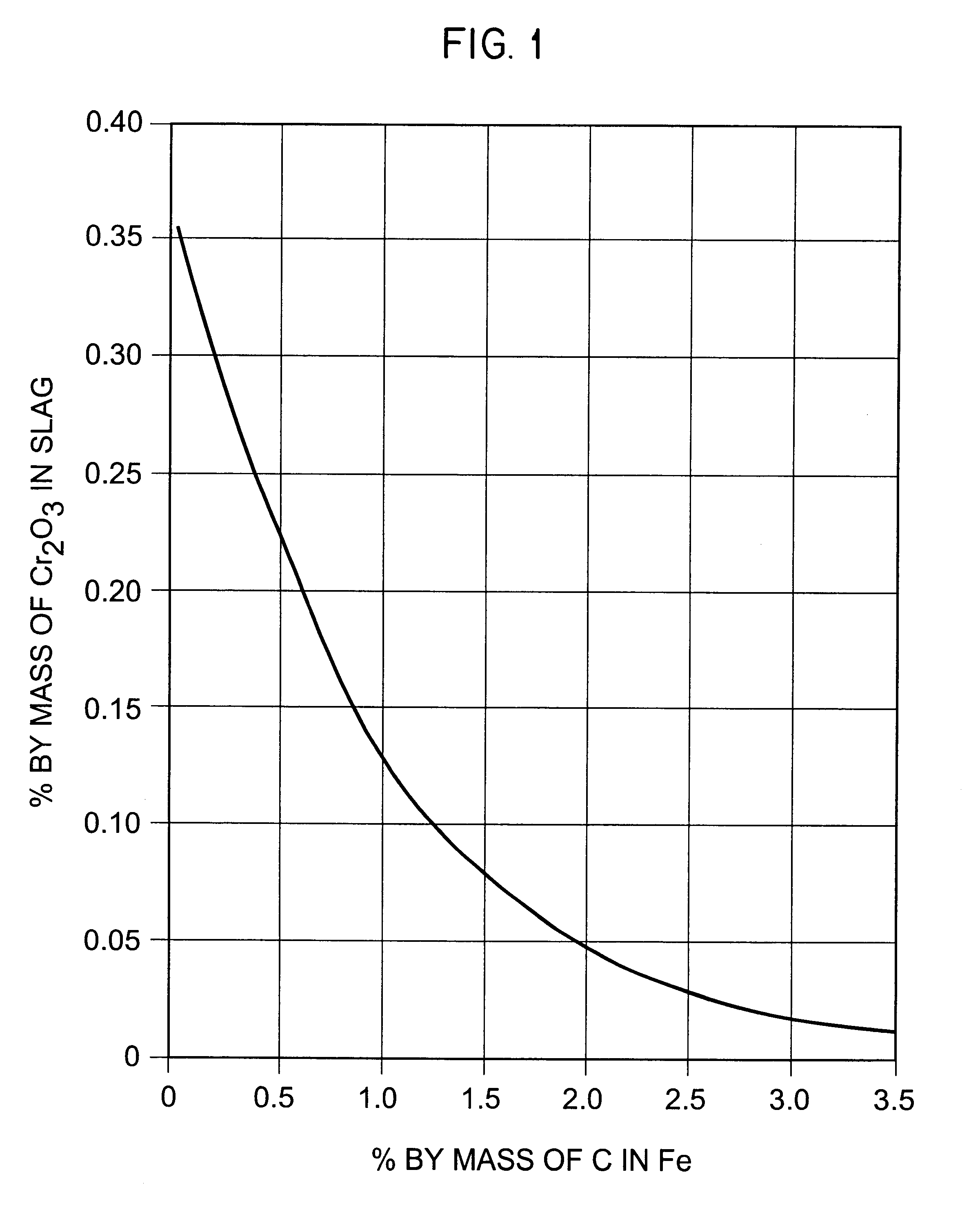

Process for producing pozzolanes, synthetic blast furnace slags, belite or alite clinkers, or pig iron alloys from oxidic slags

InactiveUS6395054B1Little structural expenditureOperational securityGlass furnace apparatusGlass shaping apparatusAlloyBelite

A process that produces pozzolanes, synthetic blast furnace slags, belite, or alite clinkers, as well as pig iron alloys, from oxidic liquid slag. The oxidic liquid slag is reduced above an iron bath in a reactor containing submerged tuyeres. Carbon is blown through the submerged tuyeres and into the iron bath to maintain the iron bath at a carbon content of between 2.5 wt % and 4.6 wt %.

Owner:HOLCIM

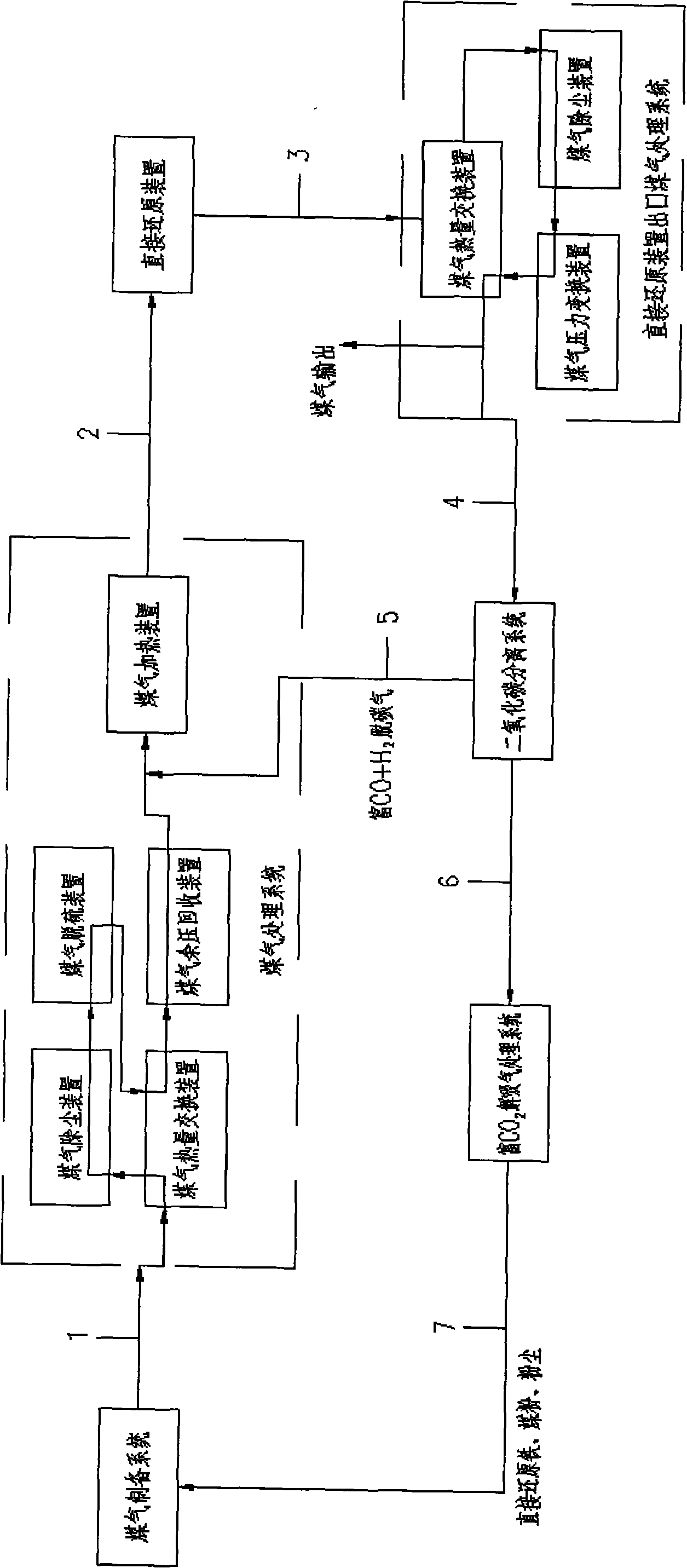

Recycling method of outlet gas in direct reduction process using gas as reducing gas

ActiveCN101638702AReduce displacementEconomical and energy-savingCombustible gas chemical modificationExhaust gas handlingDesorptionHigh carbon

The invention discloses a recycling method of outlet gas in a direct reduction process using gas as reducing gas, in particular to a method for recycling CO2 in outlet gas in a direct reduction process using gas as reducing gas. The method comprises the following treating steps: after outlet gas of a direct reduction device is treated by an outlet gas treating system of the direct reduction device, the outlet gas enters a CO2 separating system for decarburization treatment to obtain CO2 enriched desorption gas and CO+H2 enriched decarburizing gas, wherein after the CO2 enriched desorption gasis treated by a treating system of the CO2 enriched desorption gas, and the CO2 enriched desorption gas is sent back to a gas preparing system or the CO2 enriched desorption gas used as a transport carrier of direct reduction iron, high-carbon carrier or dust is sent back to the gas preparing system. The method achieves the purpose of CO2 emission reduction, also reduces the quantity of consumed coal required by reducing iron ore per unit mass and saves the cost.

Owner:CISDI ENG CO LTD

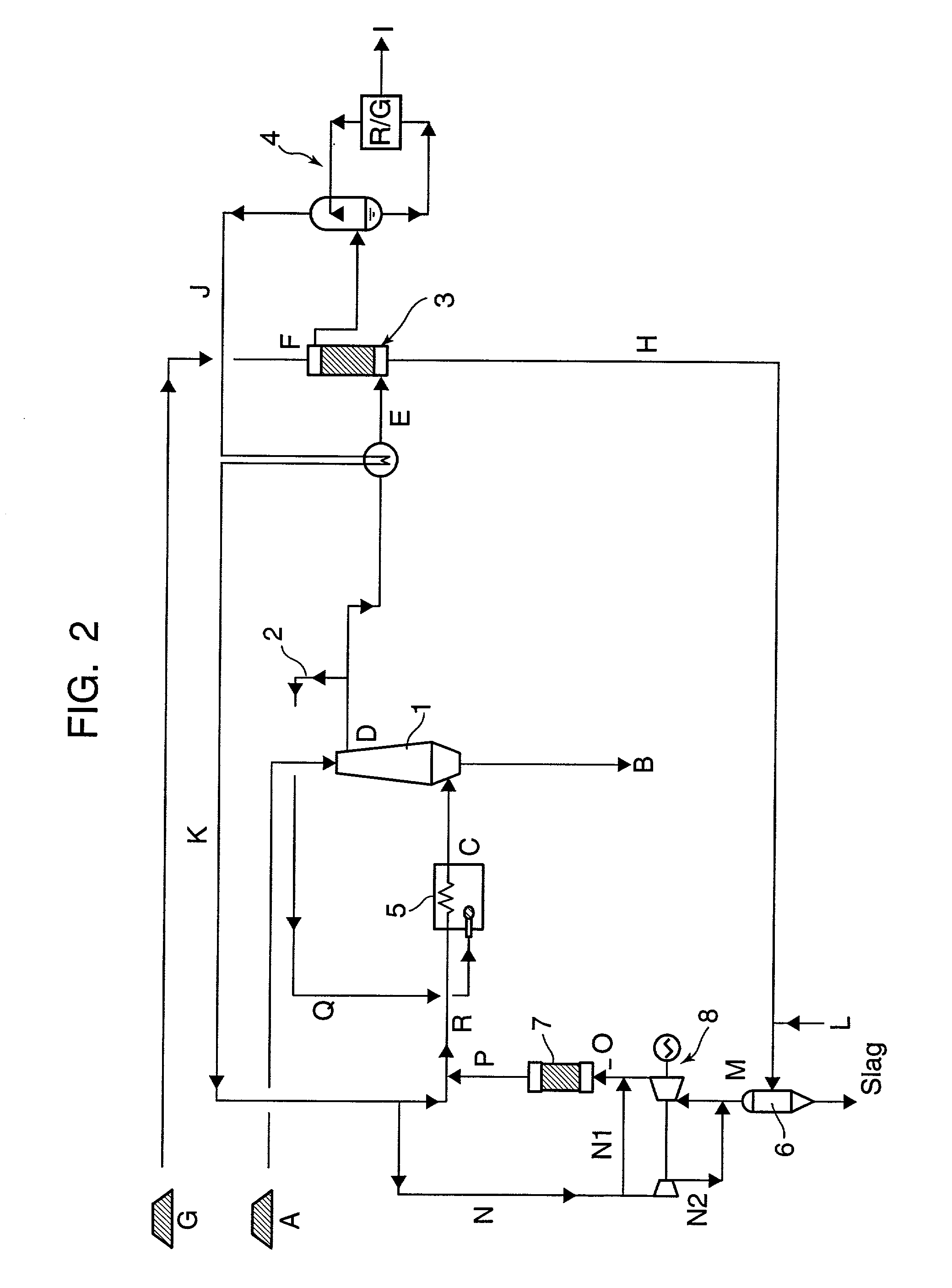

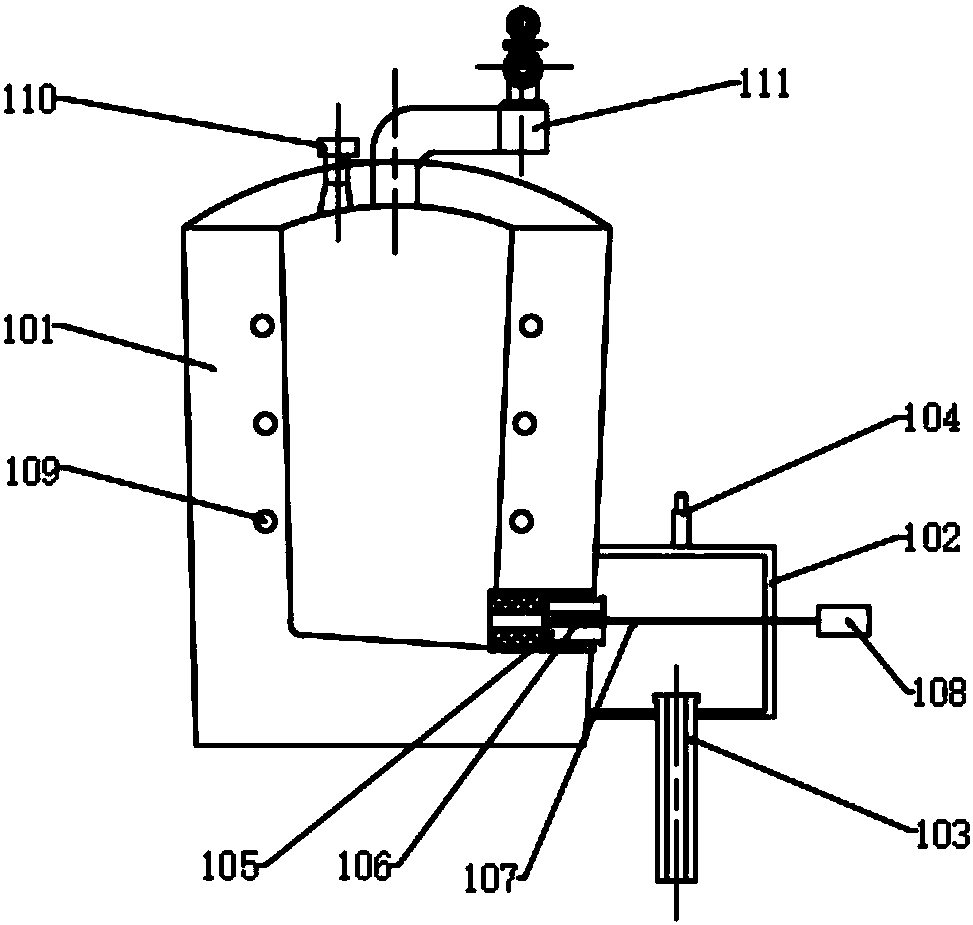

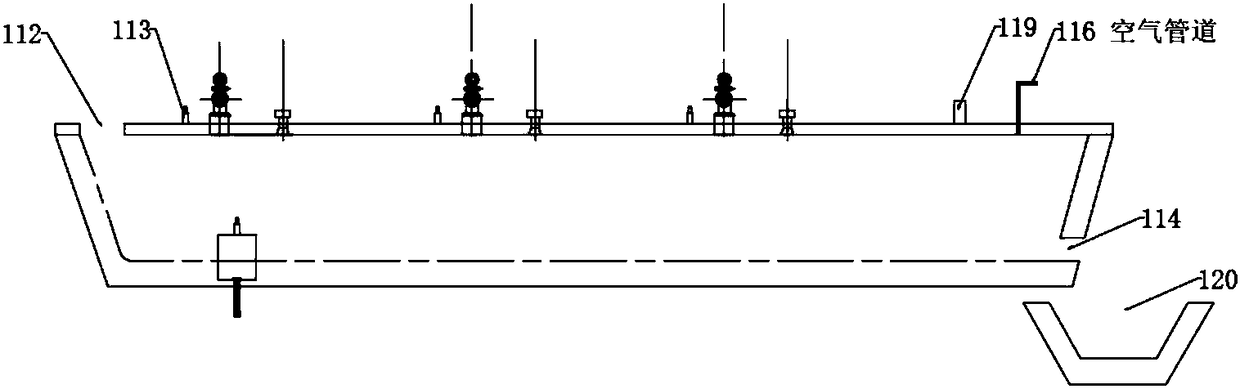

Liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions

ActiveCN108330233AEnsure structural stabilityGuaranteed operational safetyExhaust gas handlingRecycling and recovery technologiesMetallurgyIron industry

The invention discloses a liquid molten slag dry-type centrifugal granulation and afterheat recycle system having molten slag buffer-storage and flow control functions. The system comprises a molten slag buffer-storage and flow control unit, a granulation unit, a mobile bed unit and an afterheat utilization unit; the molten slag buffer-storage and flow control unit is arranged at the upper part ofthe granulation unit and is used for buffer-storage of the liquid molten slag and controlling the flow rate and speed of the liquid molten slag falling to the granulation unit; the granulation unit is used for granulating the falling liquid molten slag; the mobile bed unit is arranged at the lower part of the granulation unit and is used for cooling and temporarily storing the granulated molten slag; hot air inside the granulation unit and the mobile bed unit communicates with the afterheat utilization unit; and the afterheat utilization unit comprises a hot air flue, a primary dust collector, an afterheat boiler, a secondary dust collector, an exhaust fan and a chimney which are arranged in sequence. The system disclosed by the invention does not use water resources, is free of environmental pollution, can effectively recycle high-quality afterheat resources contained in the high-temperature liquid molten slag, and can meet the urgent requirements of energy conservation and emissionreduction of the present steel and iron industry.

Owner:XI AN JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com