Patents

Literature

677 results about "Liquid slag" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

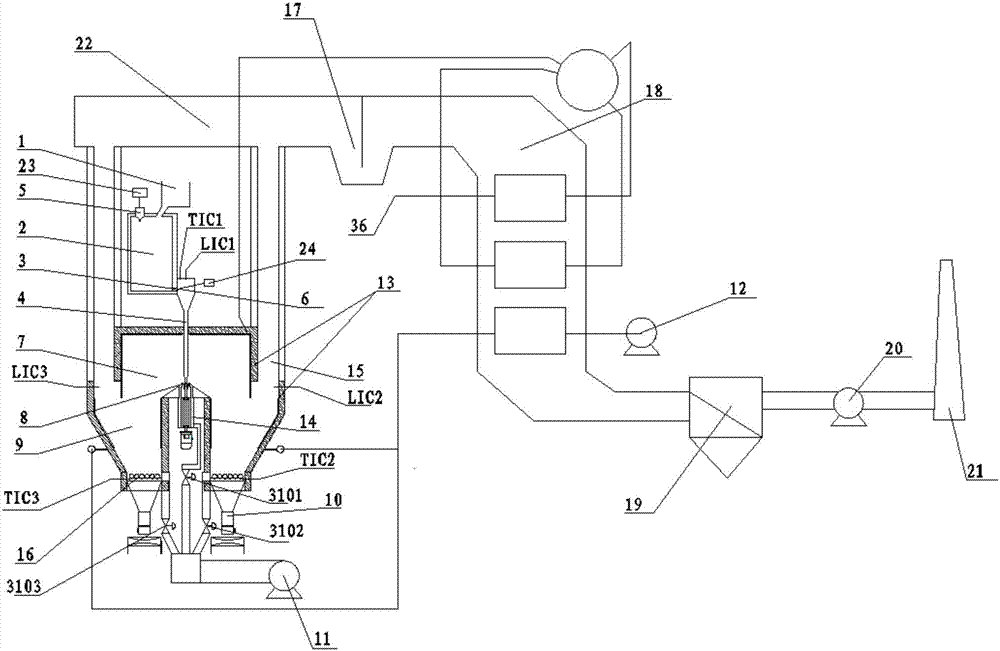

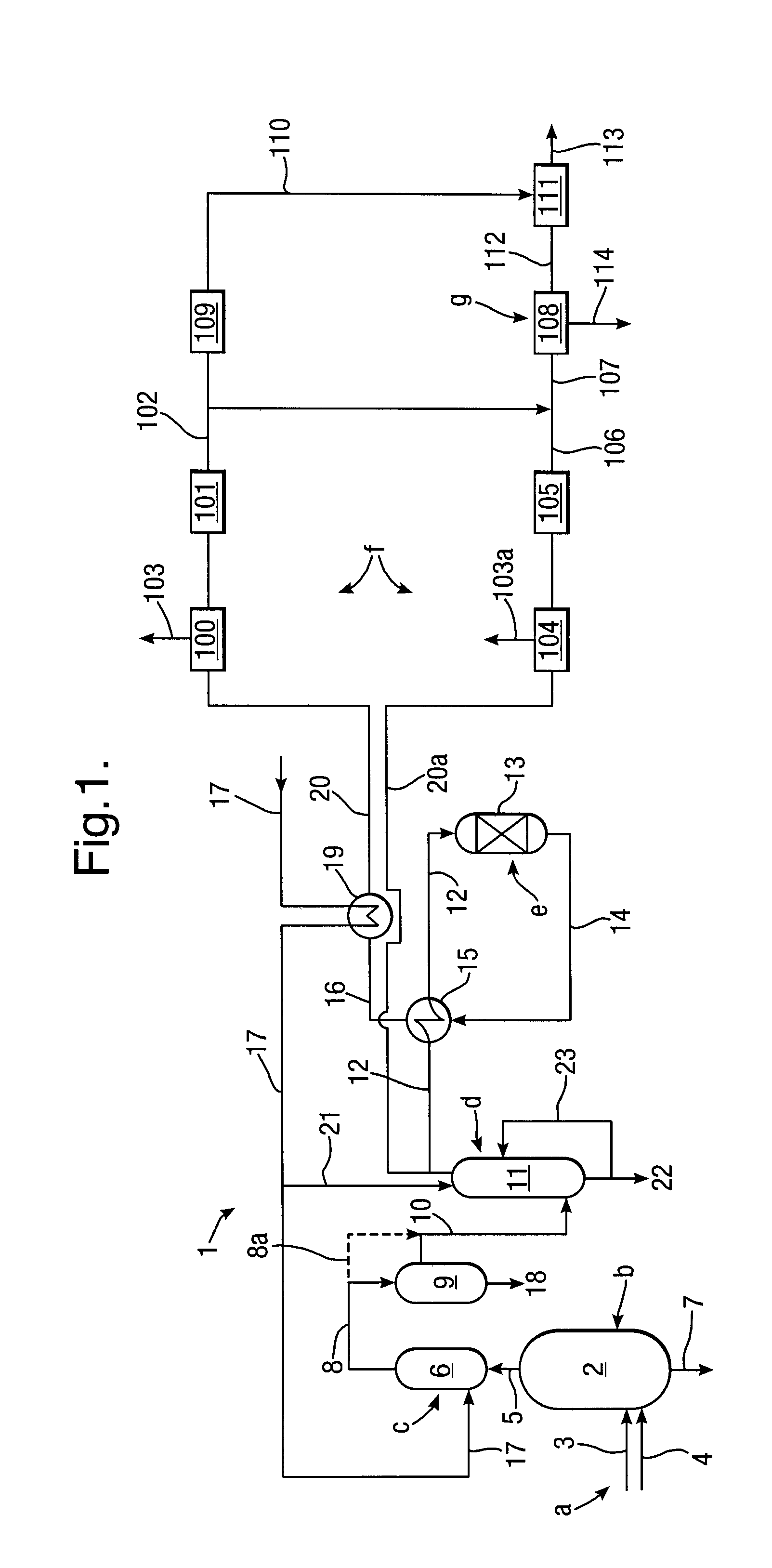

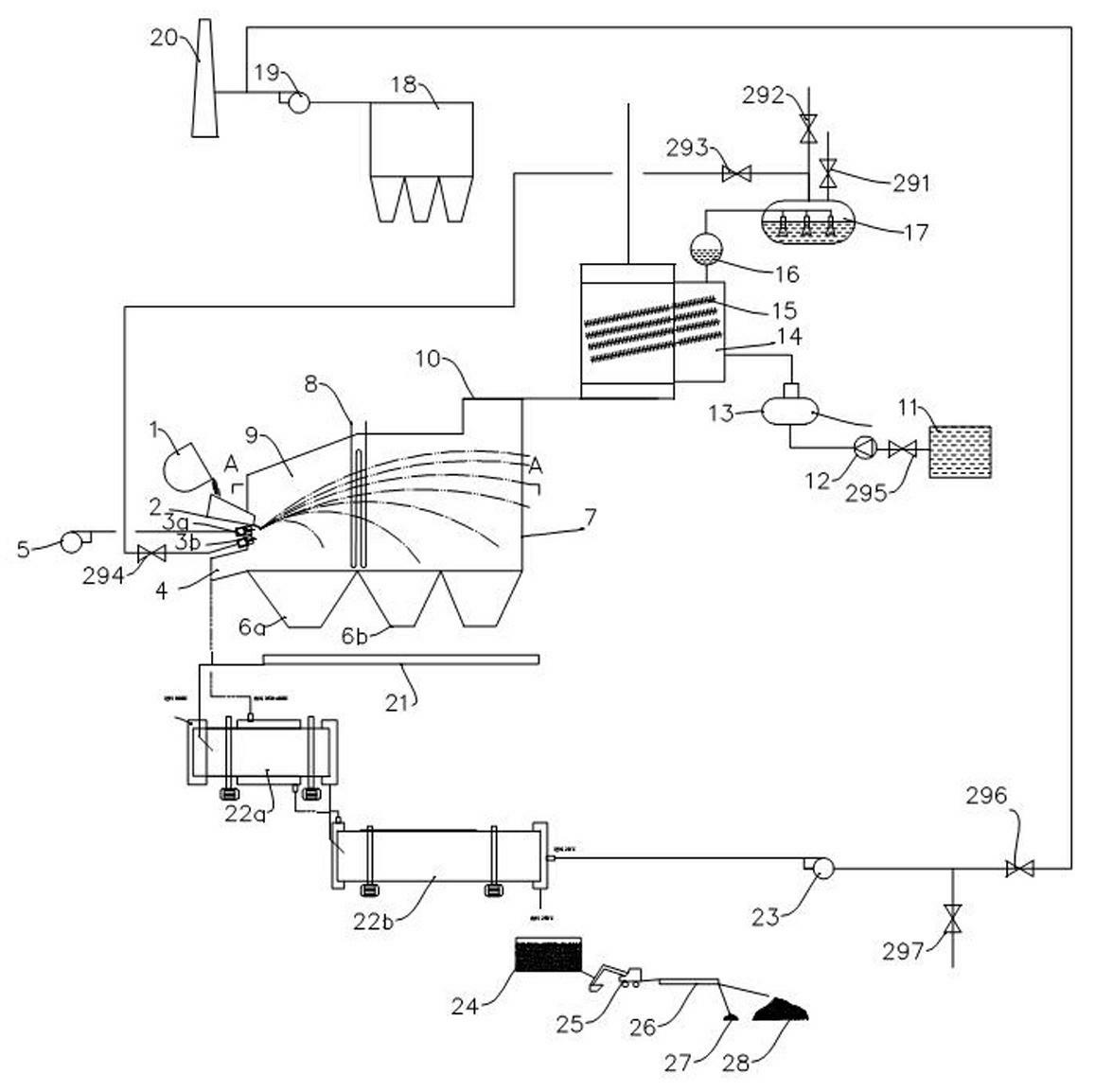

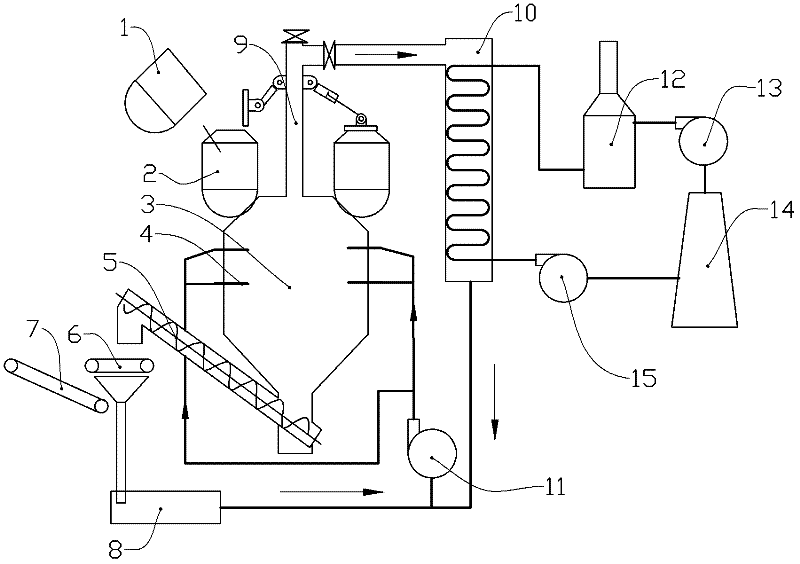

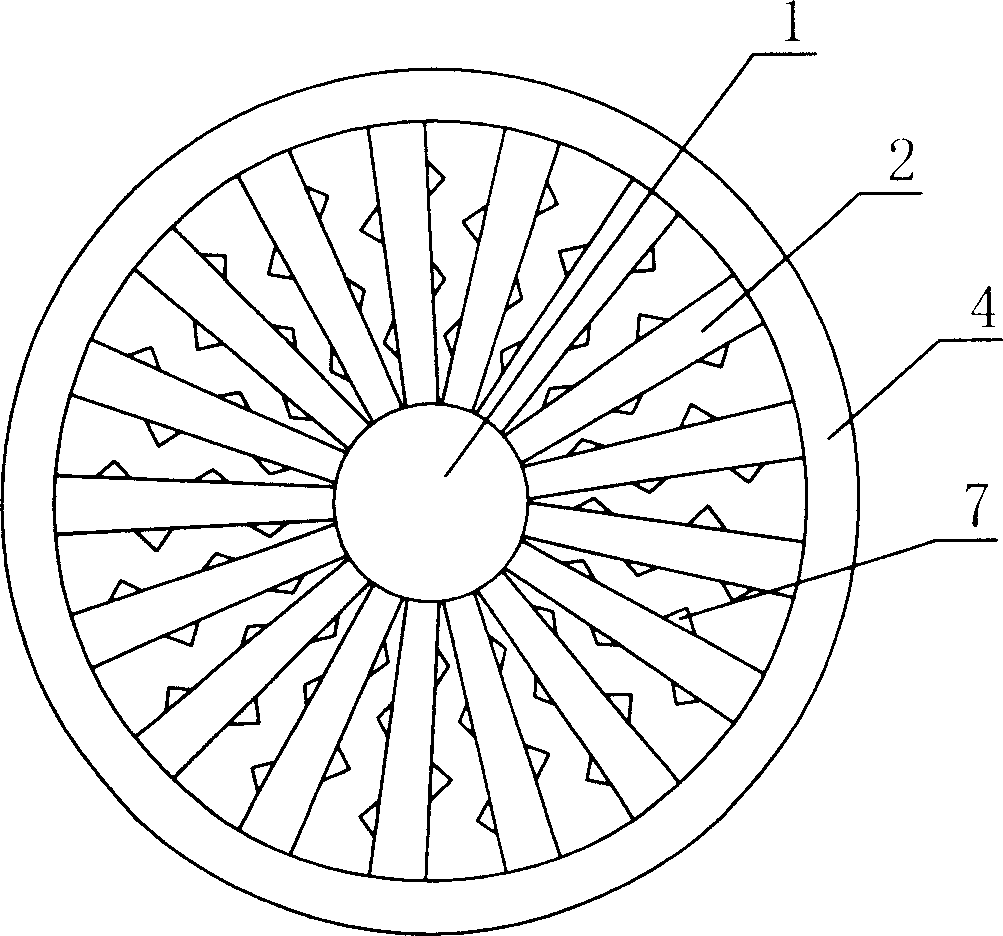

System and control method for liquid slag dry type centrifugal pelletizing and waste heat recycling

ActiveCN106939363AGuaranteed uptimeIncrease the level of automationIncreasing energy efficiencyWaste heat treatmentLiquid slagWater resources

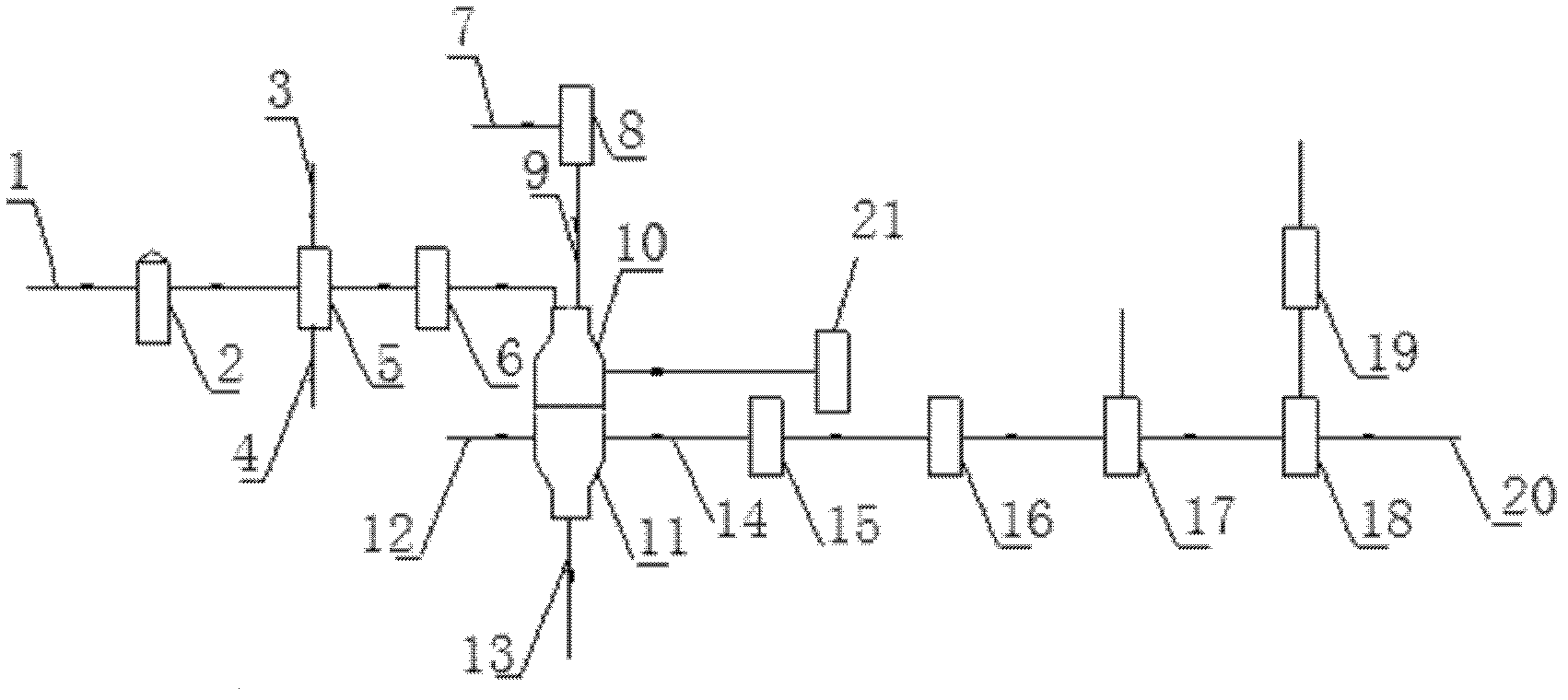

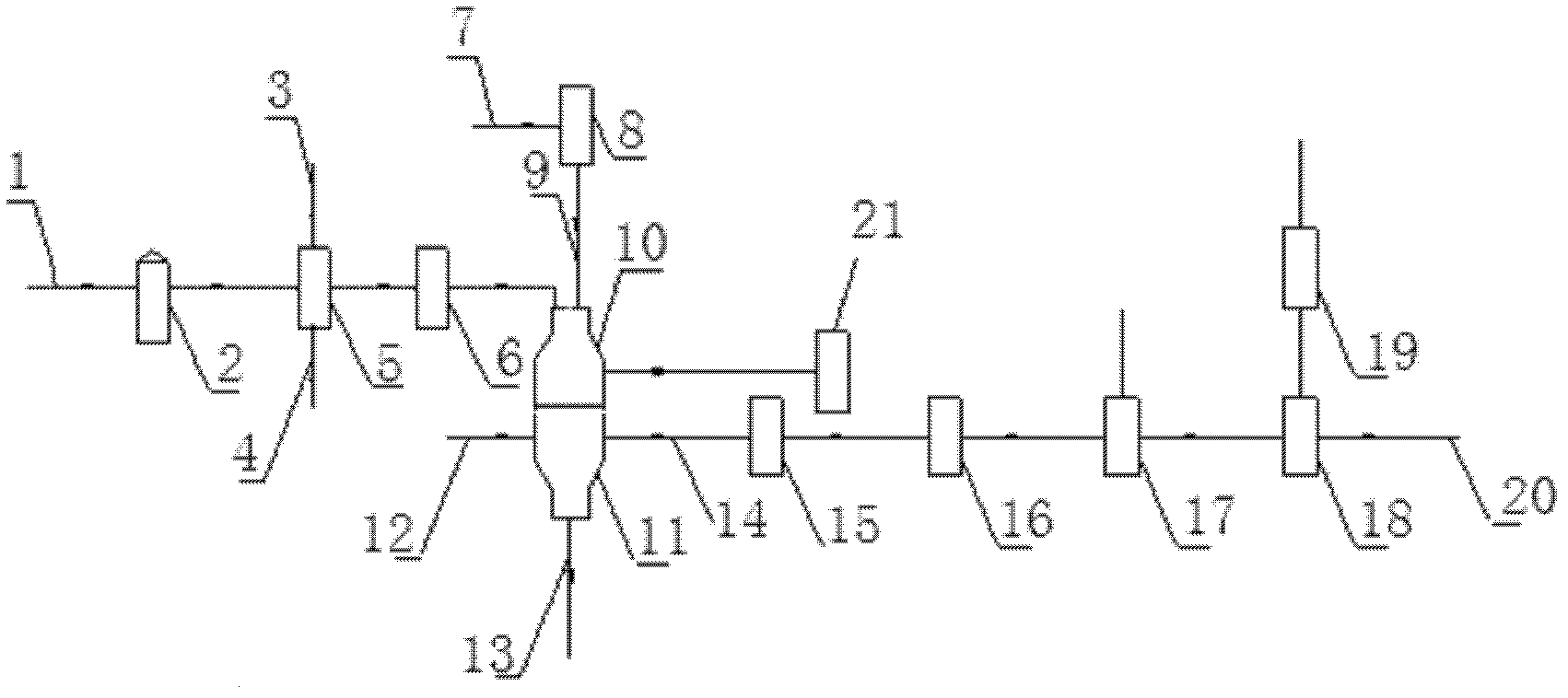

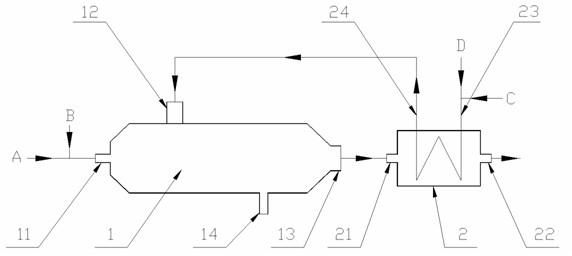

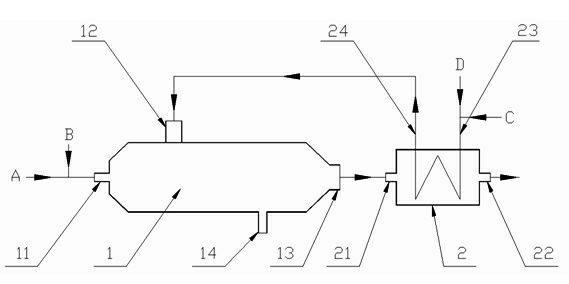

The invention discloses a system and control method for liquid slag dry type centrifugal pelletizing and waste heat recycling. The system comprises a liquid slag draining unit, a liquid slag temporary storage and flow control unit, a liquid slag pelletizing and waste heat recycling unit, and a waste heat utilizing unit. By the adoption of the system and the control method, the temperature and flow of liquid slag entering a pelletizing bin, the liquid slag pelletizing particle size and the moving bed slag discharging temperature can be strictly controlled, thus, the overall technological requirements of the technology are met, and the effect that the system for liquid slag dry type centrifugal pelletizing and waste heat recycling and utilizing operates safely and reliably is guaranteed. All high-quality waste heat resources contained in the high-temperature liquid slag are not wasted, no water resource is consumed, environment pollution is avoided, and the urgent requirements of the current iron and steel industry for energy saving and emission reduction can be met.

Owner:XI AN JIAOTONG UNIV

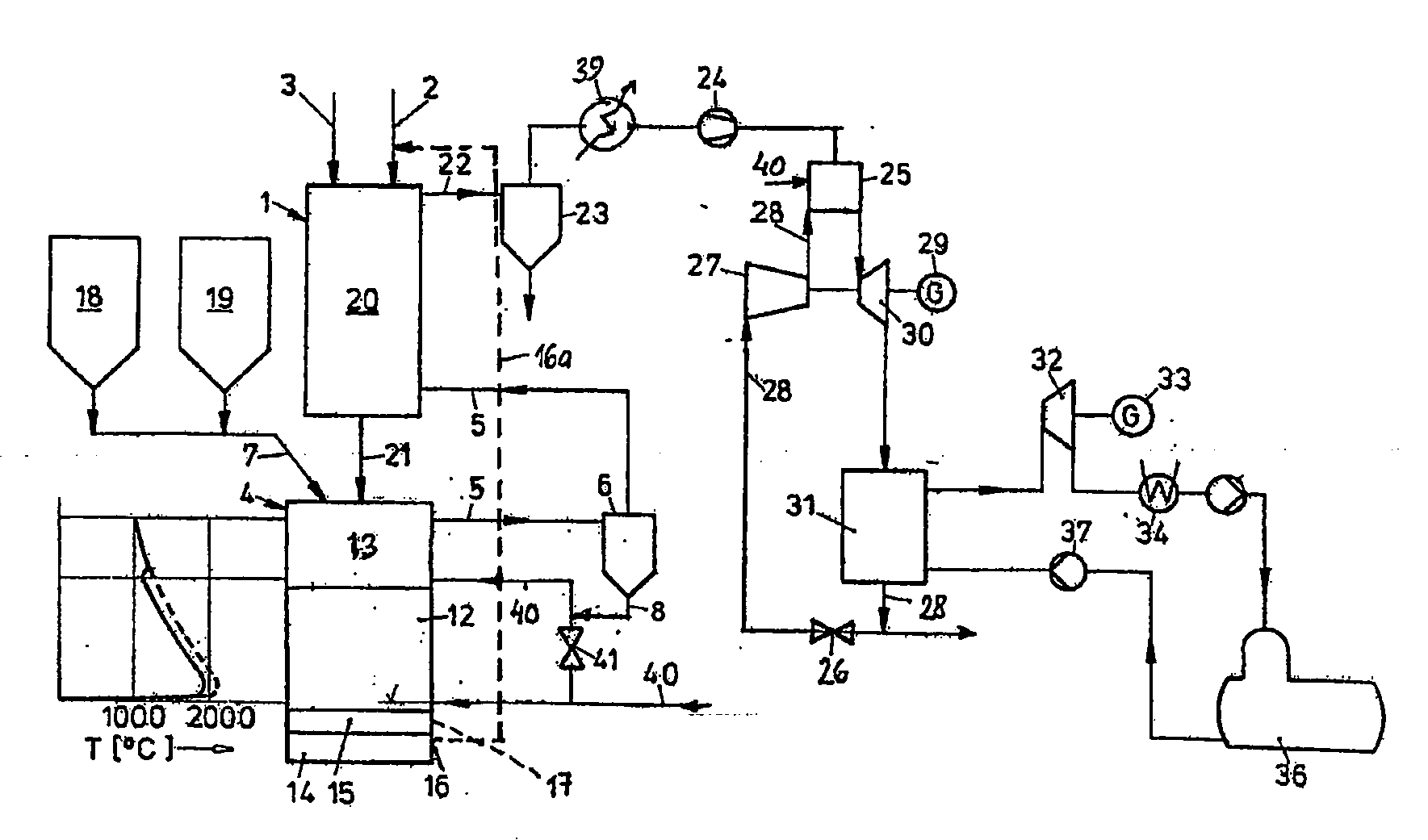

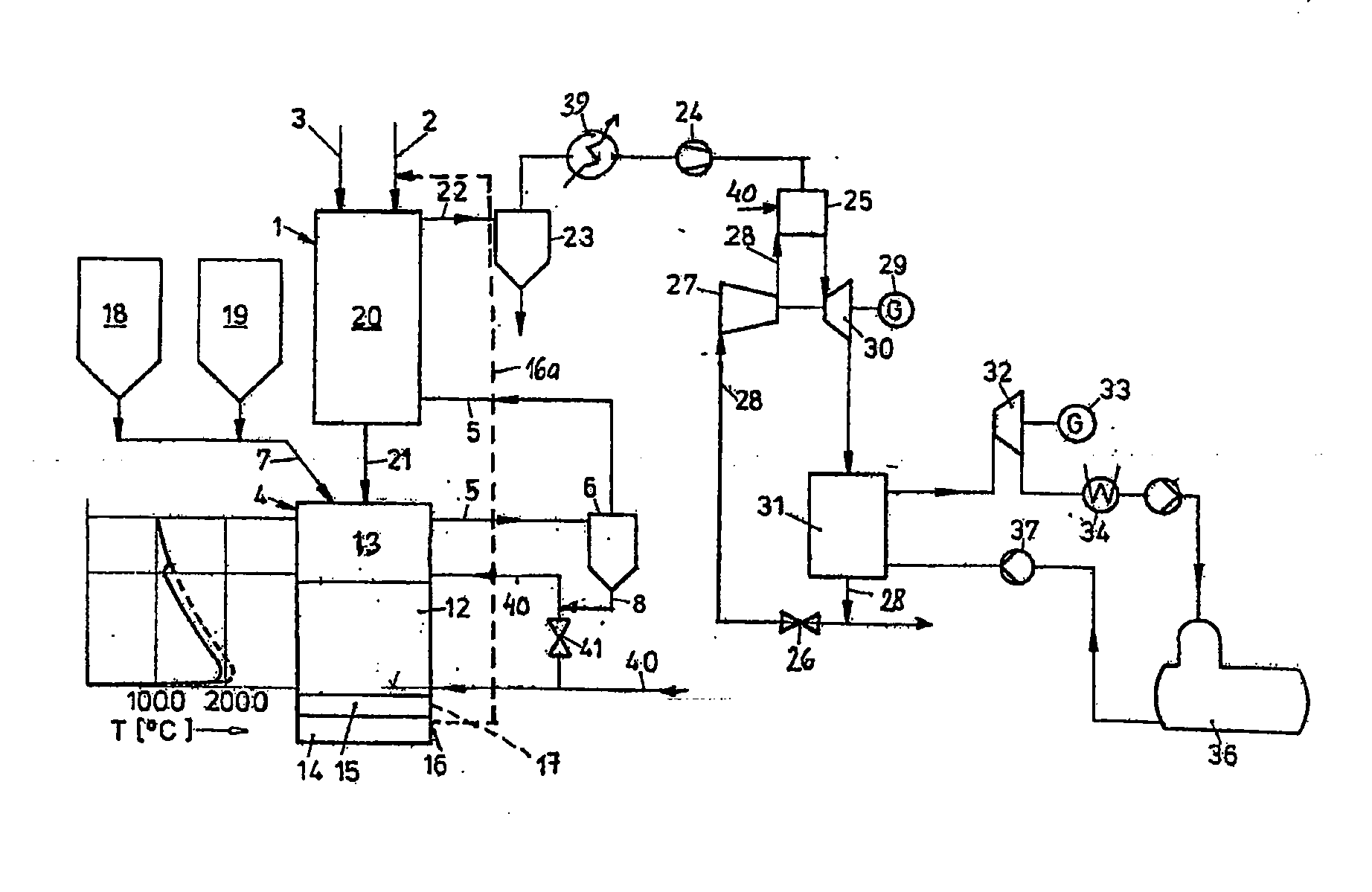

Process and installation for generating electrical energy in a gas and steam turbine (combined cycle) power generating plant

InactiveUS20100031668A1Small possible occurrenceIncreased carbon dioxide contentCombustion enginesGas turbine plantsCombustion chamberWater vapor

A process for generating electrical energy in a gas and steam turbine (combined cycle) power generating plant with a gasification gas produced from carbon carriers and oxygen-containing gas. Carbon carriers are gasified in a gassing zone with oxygen or a gas containing a large amount of oxygen. Gasification gas produced is passed through a desulfurizing zone containing a desulfurizing agent. Used desulfurizing agent is fed into the gassing zone and drawn off after the formation of a liquid slag. Desulfurized gasification gas is burned in a combustion chamber. The resulting combustion gases H2O and CO2 are introduced into the gas turbine for energy generation. Downstream of the gas turbine, the combustion gases are separated in a steam boiler into water vapor and carbon dioxide. The water vapor is subsequently introduced into a steam turbine. The carbon dioxide is at least partially returned to the combustion chamber for setting the temperature.

Owner:SIEMENS VAI METALS TECHNOLOGIES GMBH & CO

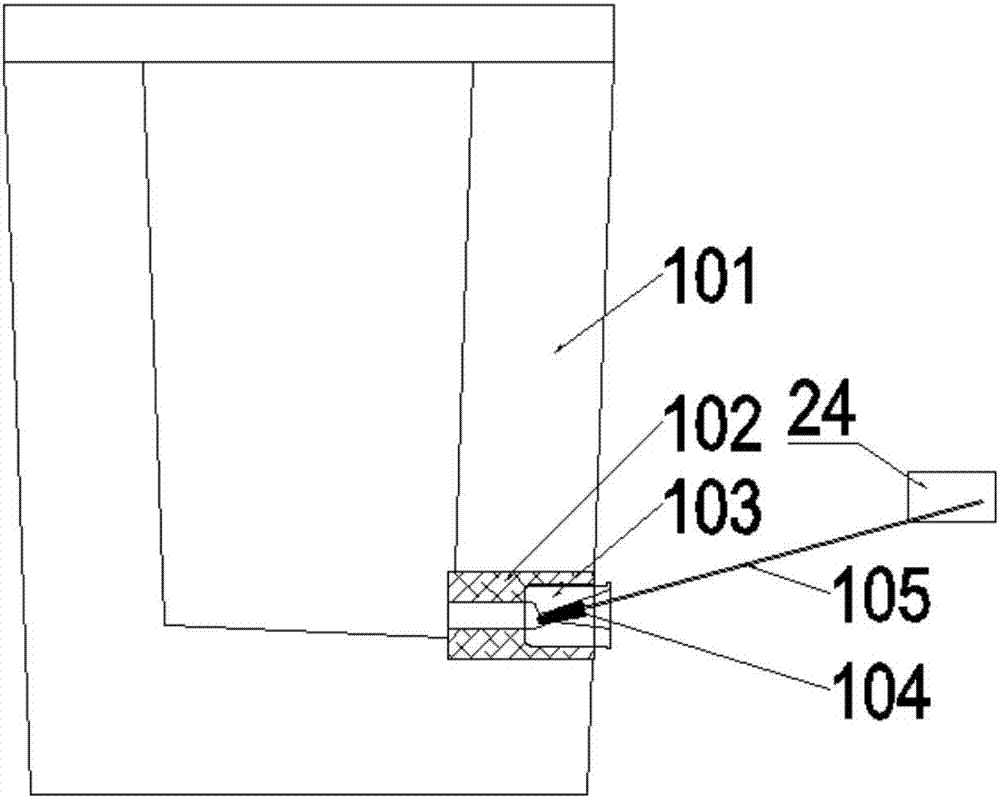

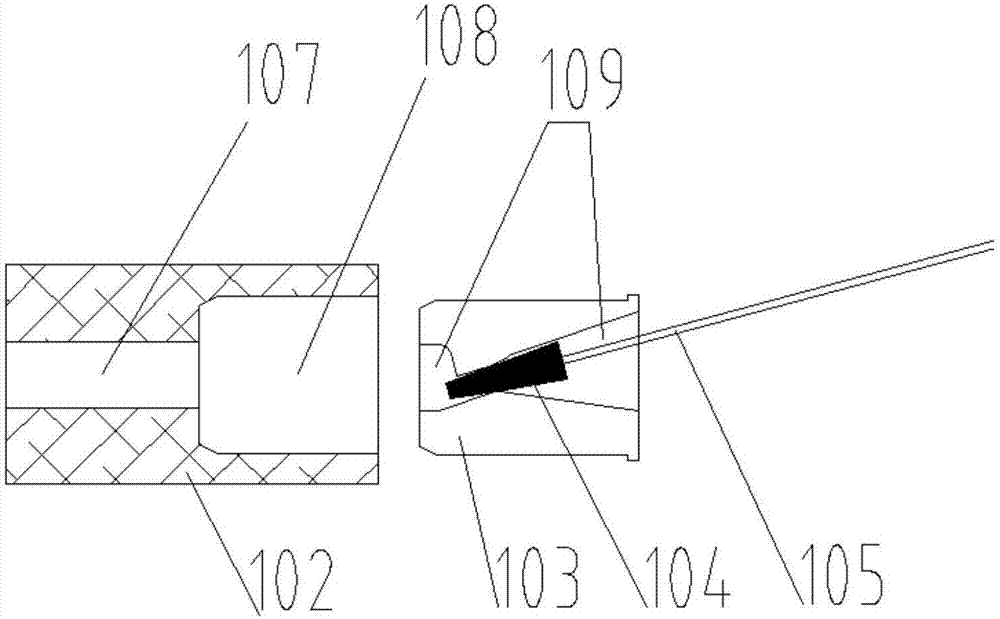

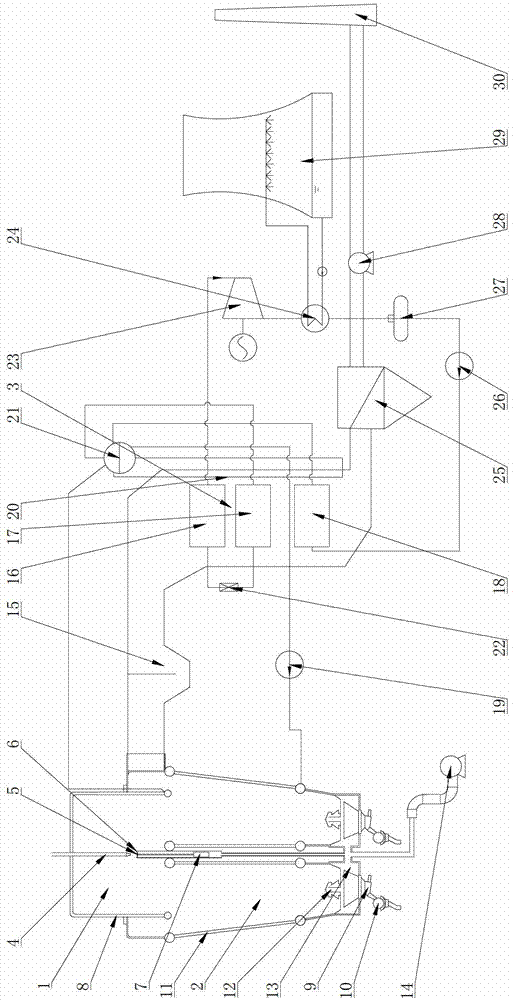

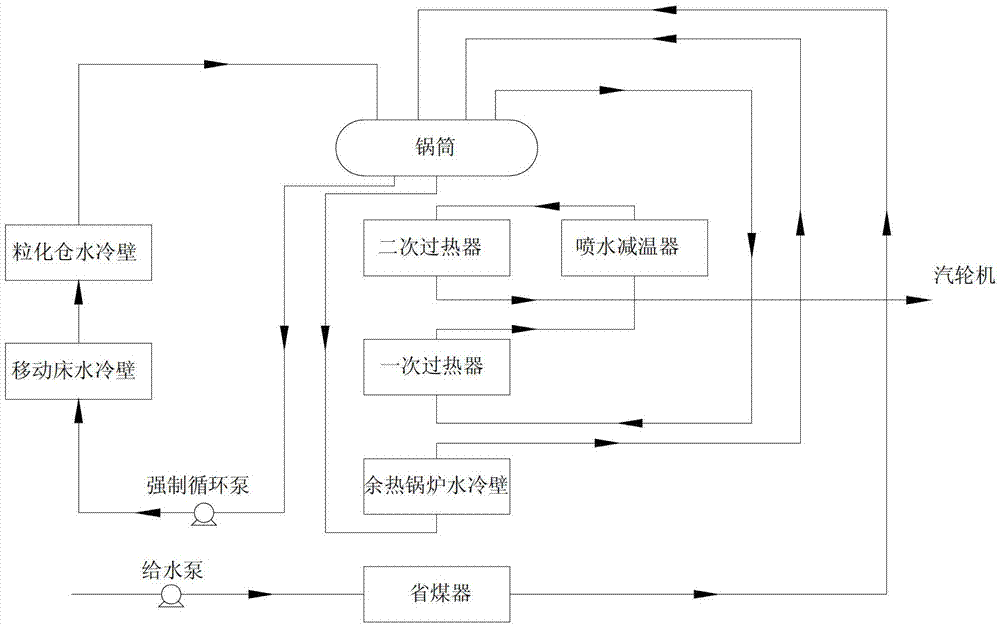

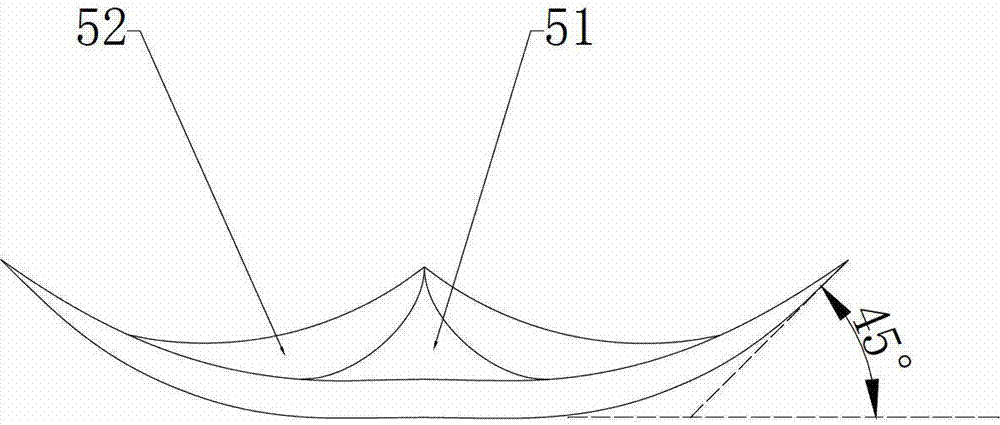

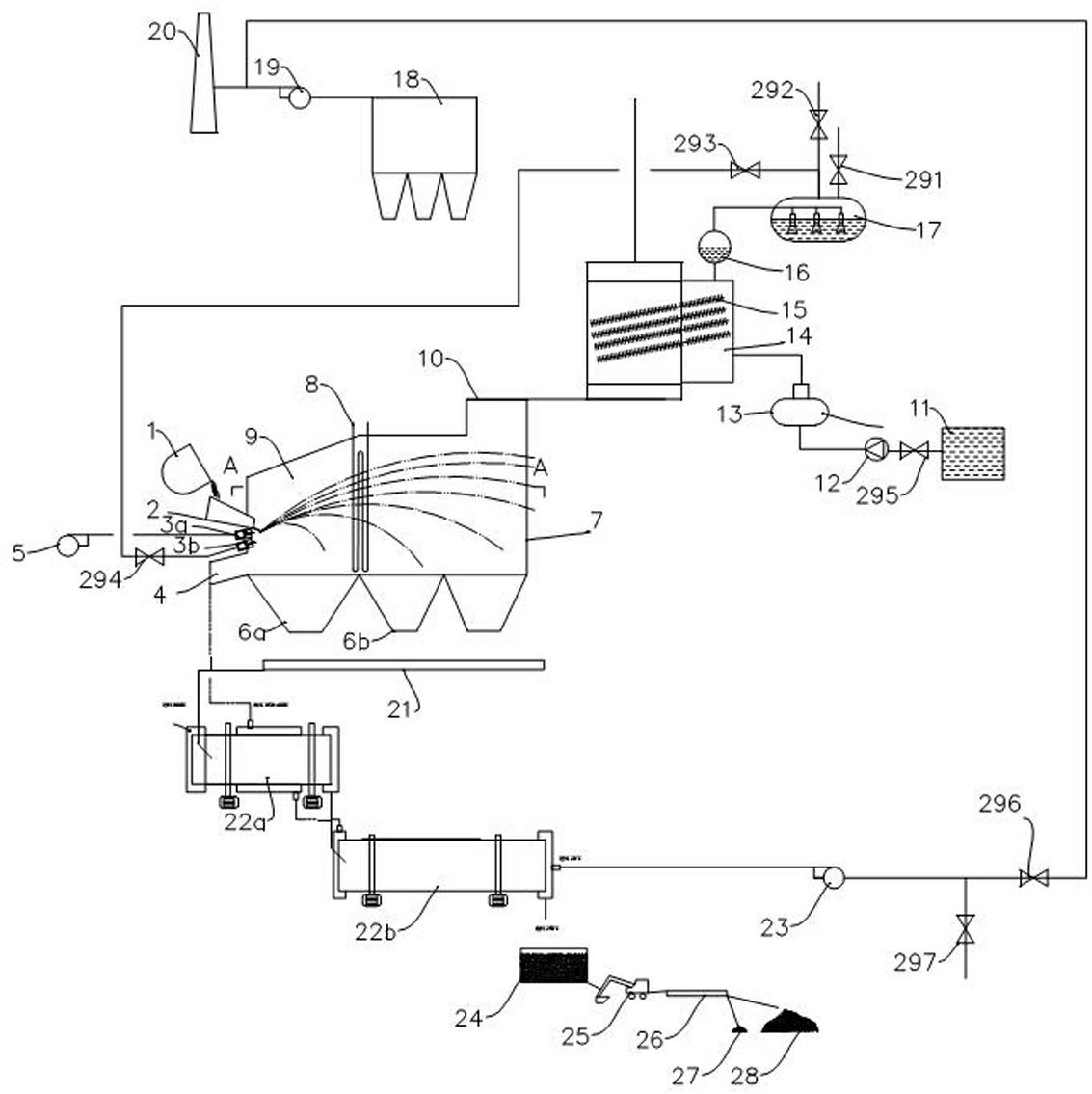

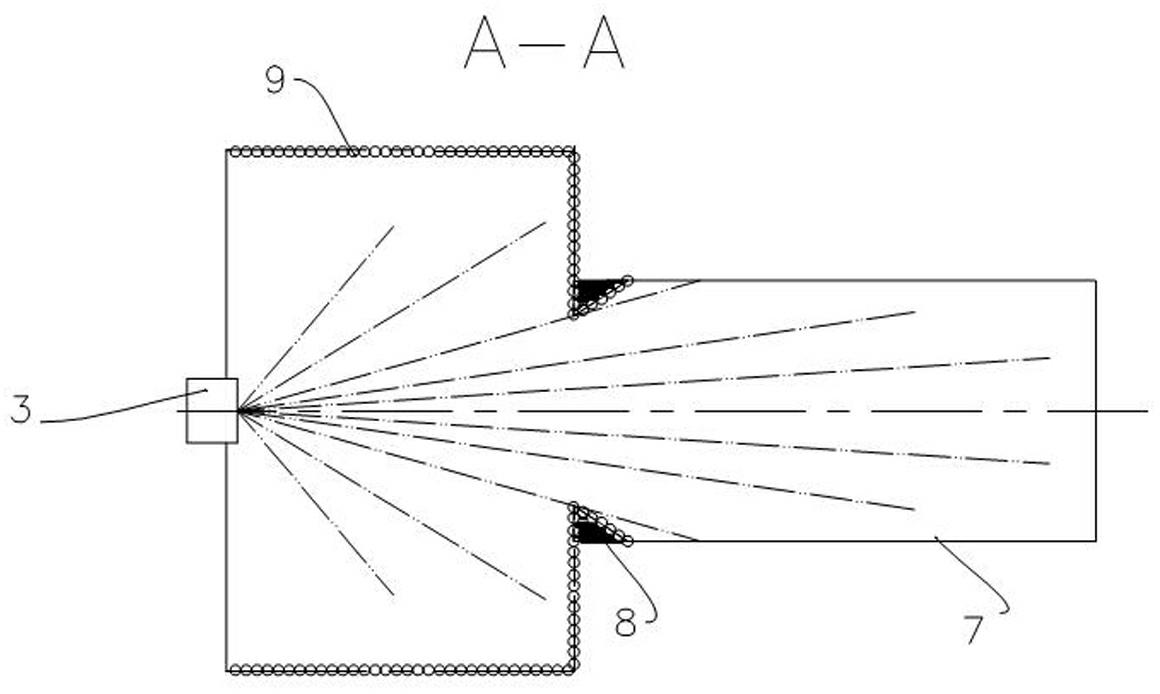

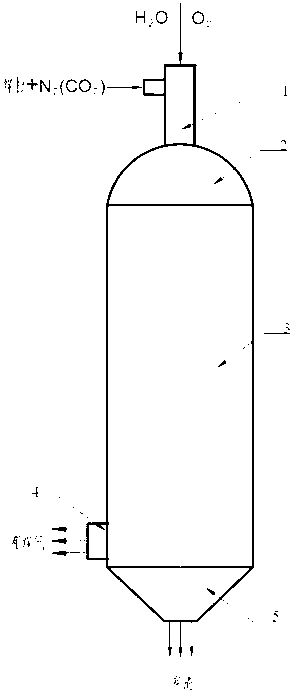

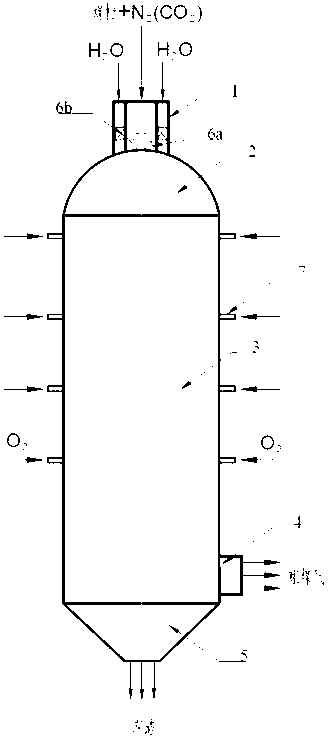

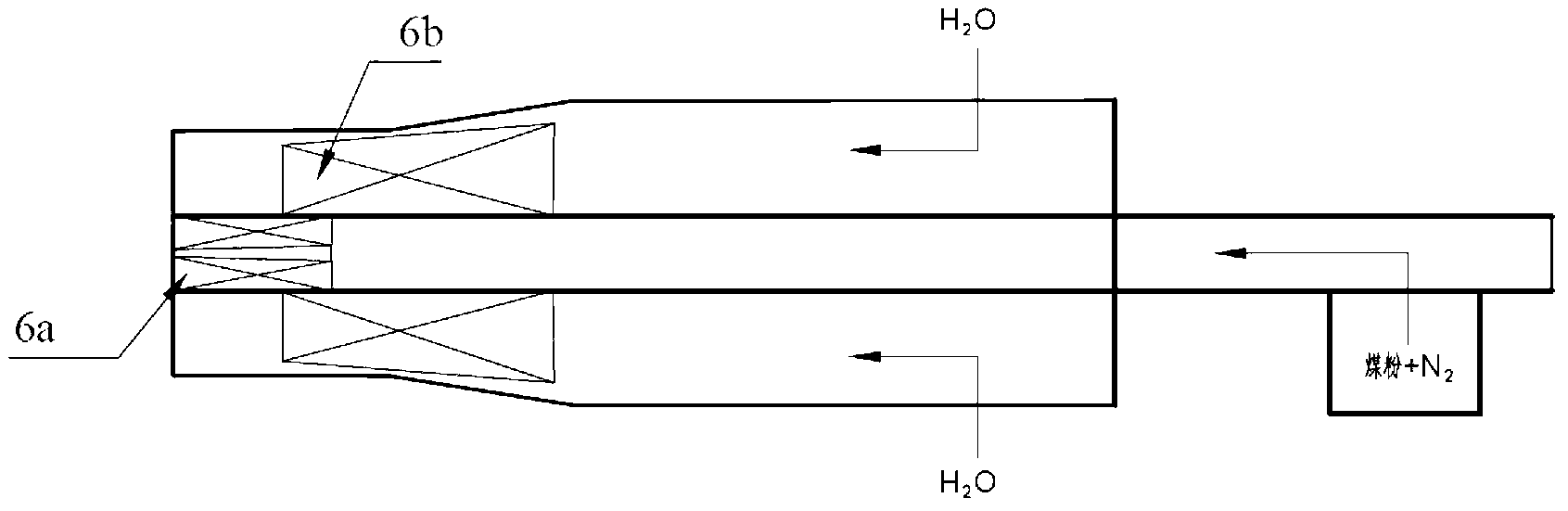

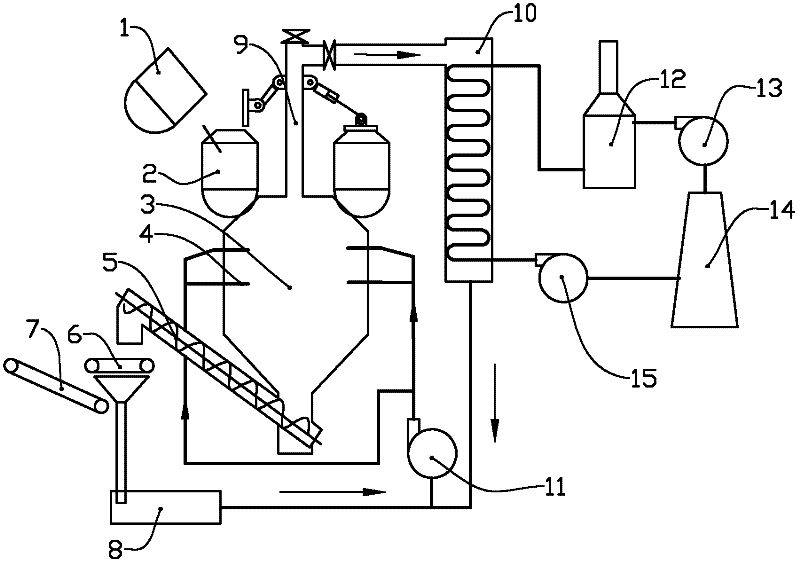

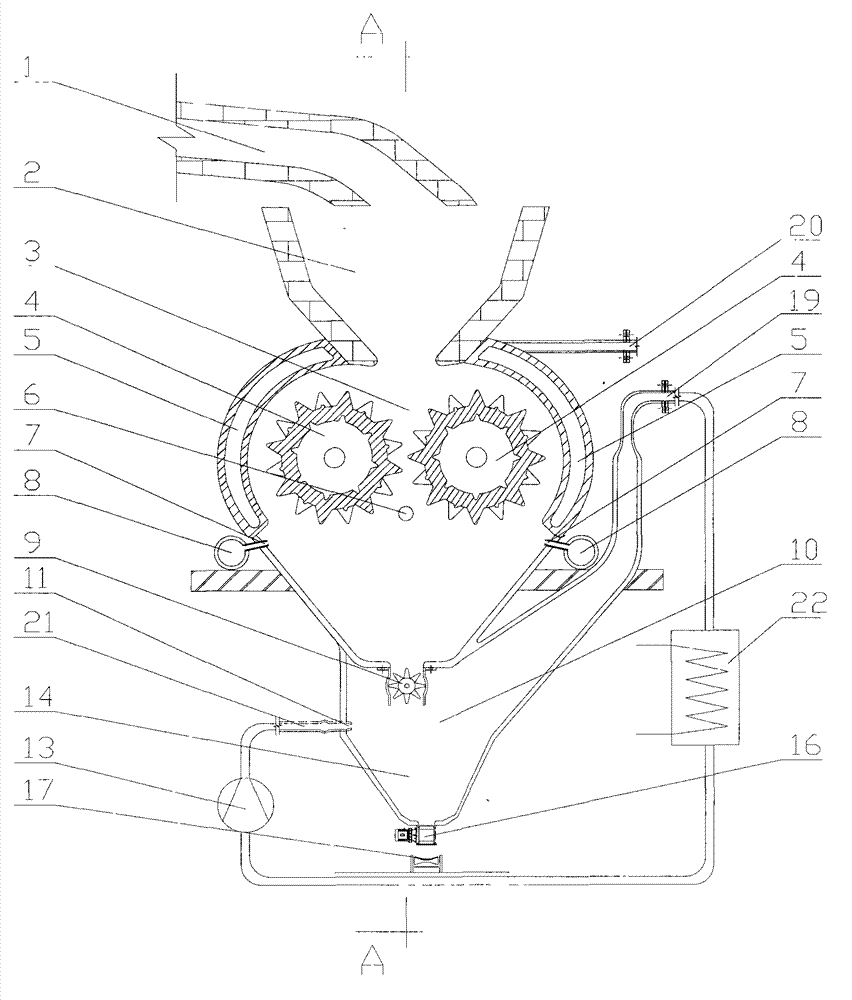

Afterheat recovery system and method of dry granulating liquid slag

ActiveCN102827969AEasy to diluteImprove granulation effectIncreasing energy efficiencyRecycling and recovery technologiesRecovery methodLiquid slag

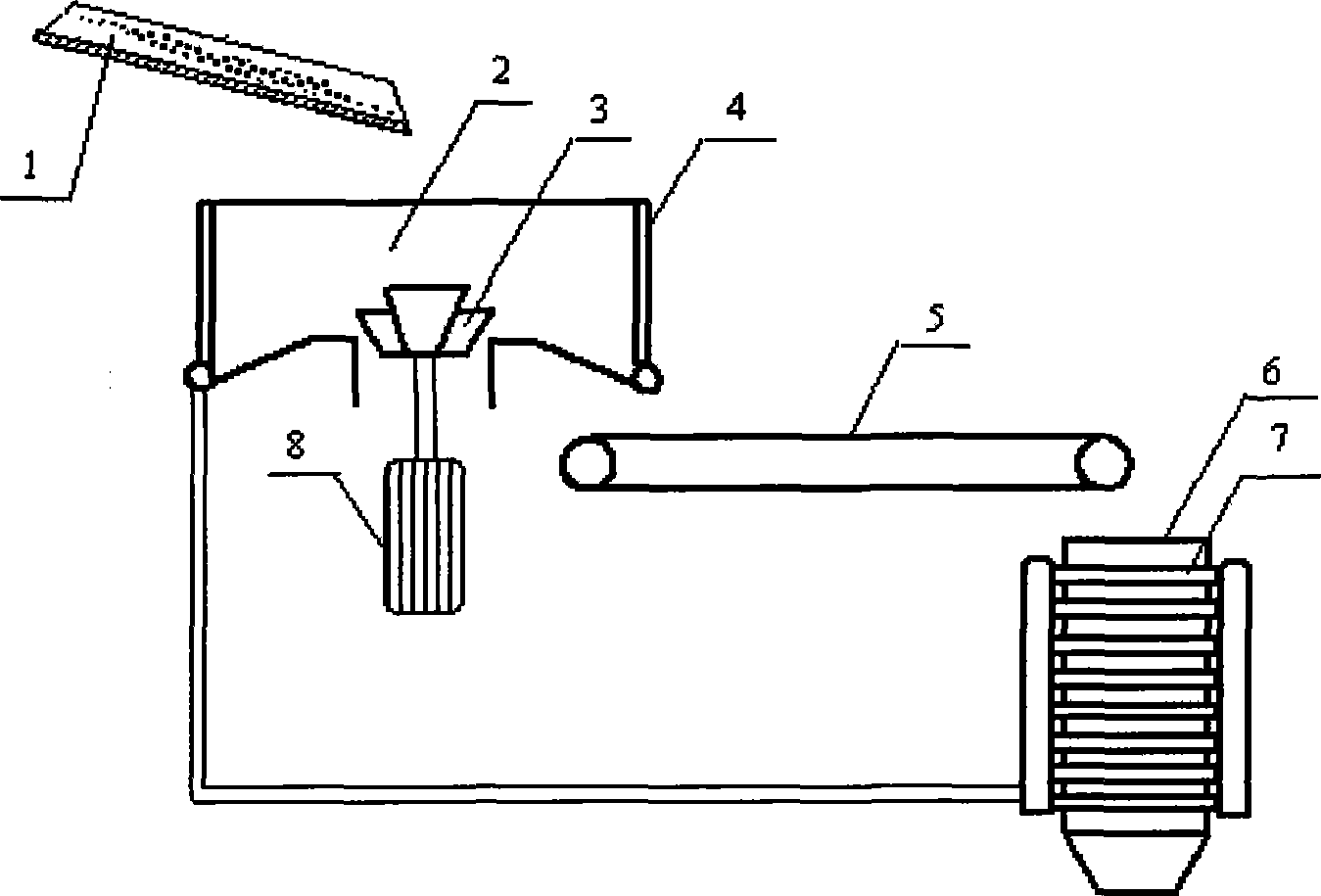

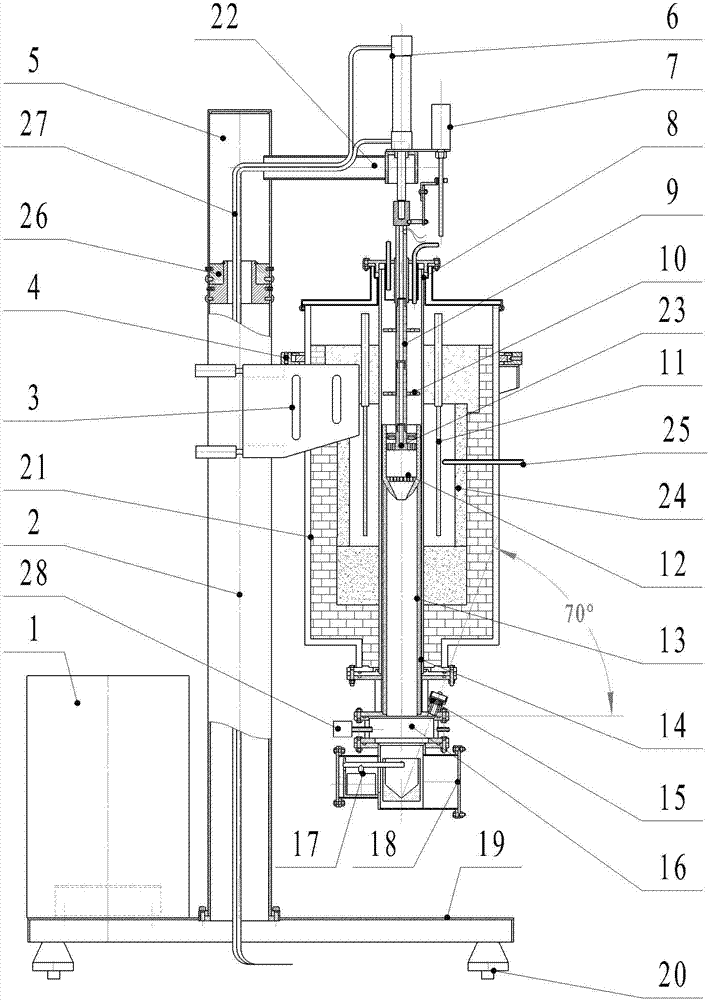

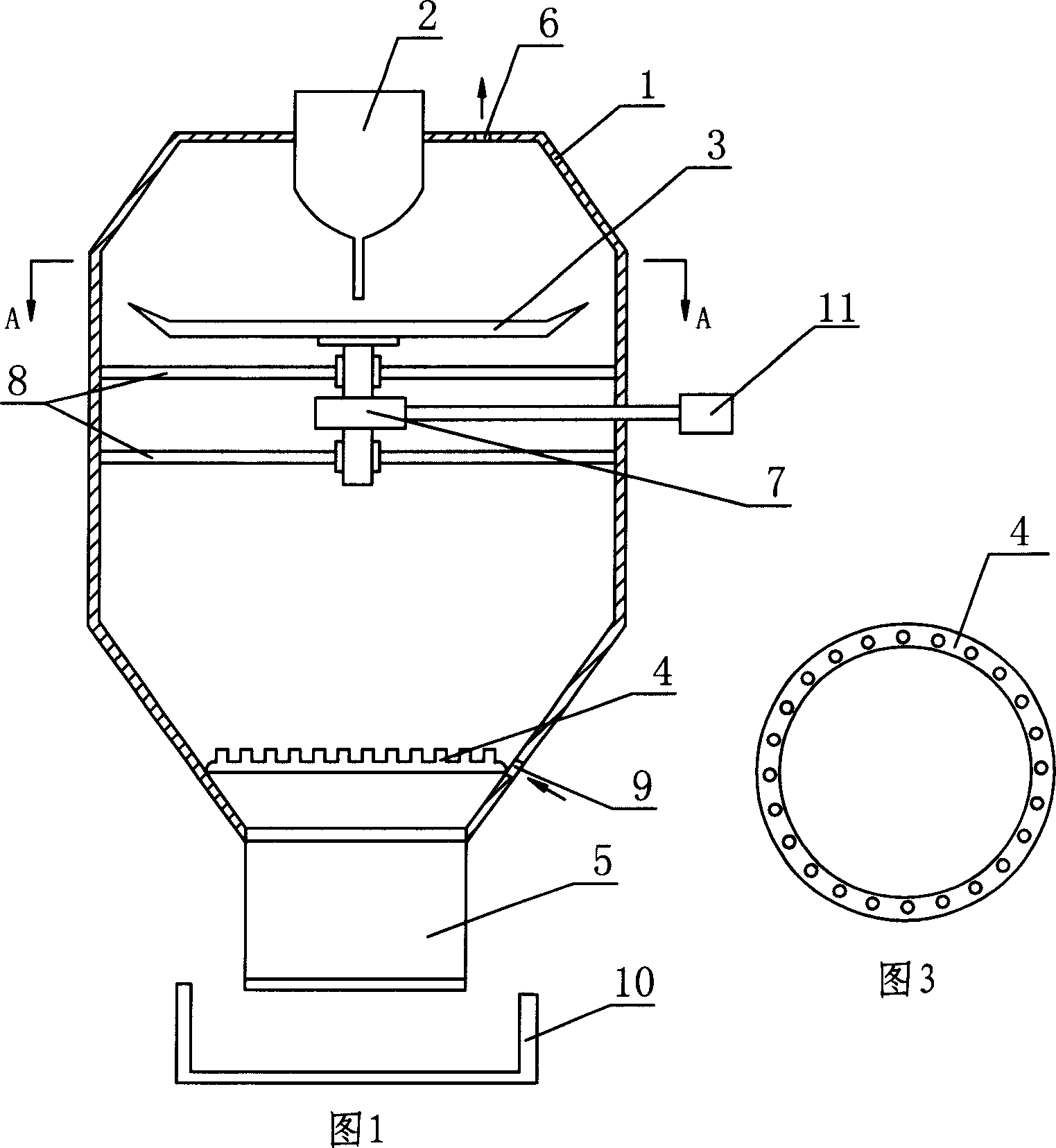

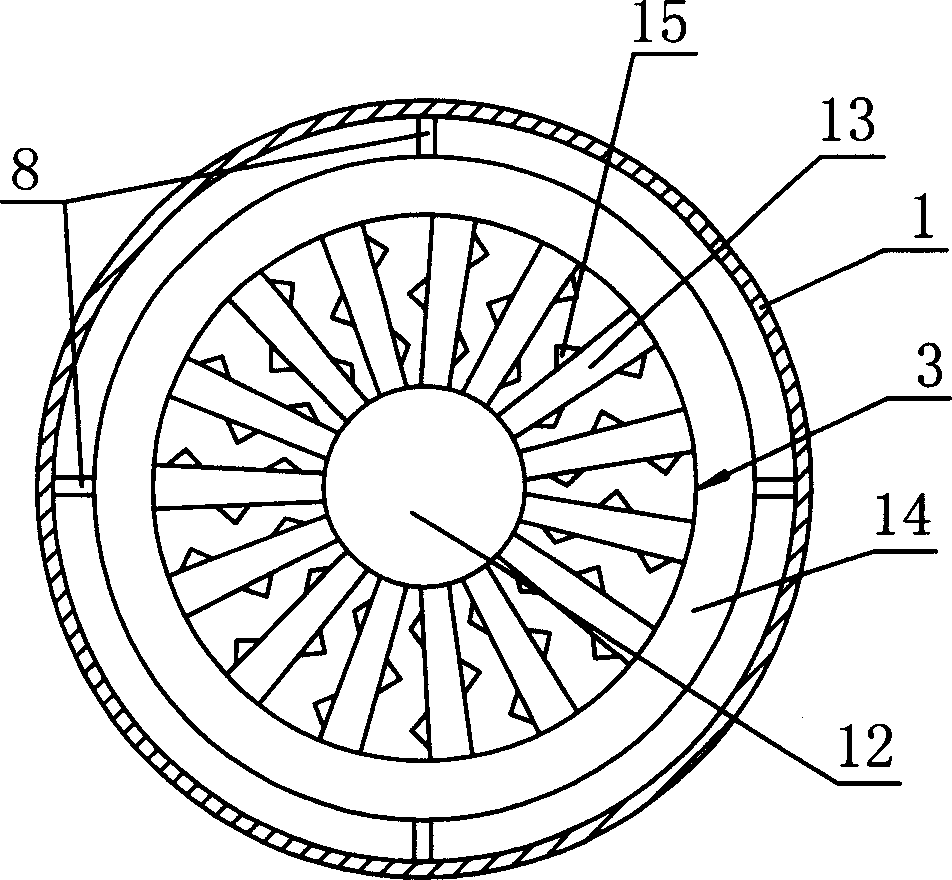

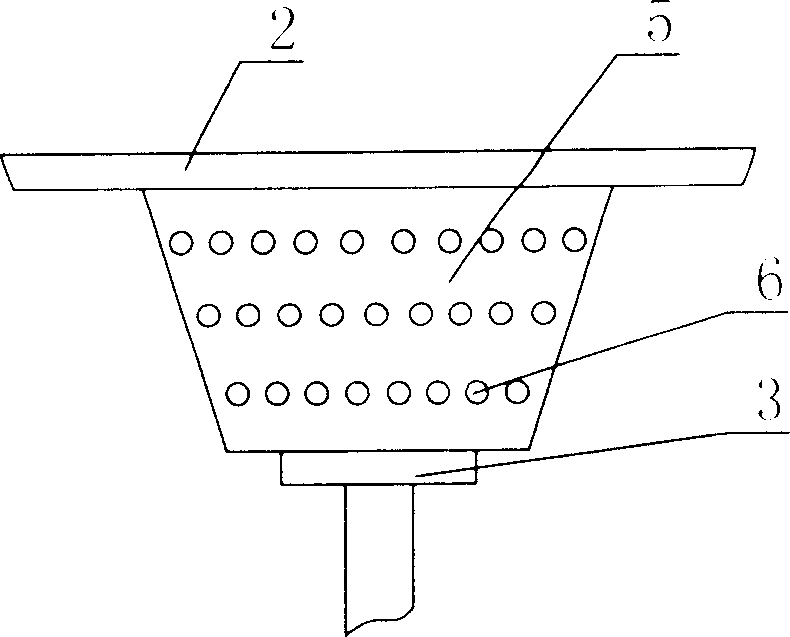

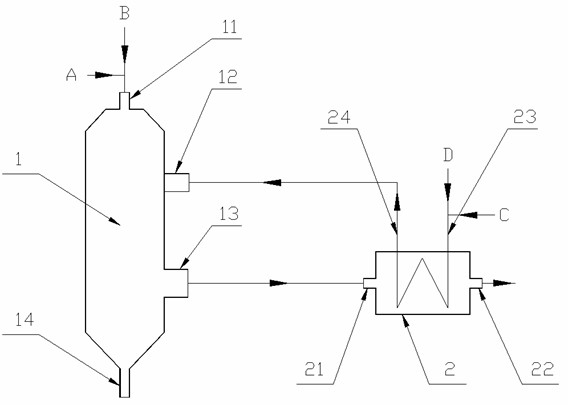

The invention discloses an afterheat recovery system and an afterheat recovery method of dry granulating liquid slag. The system comprises a granulating cabin, a moving bed and an afterheat recovery system, the inner surface of the granulating cabin is provided with a granulating cabin water cooling wall, the center of the top of the granulating cabin is provided with a slag pipe, the slag pipe extends into the granulating cabin, the lower part of the tail end of the slag pipe is provided with a centrifugal granulator, the centrifugal granulator is connected with a motor arranged at the lower part of the centrifugal granulator, the lateral side of the centrifugal granulator is provided with an air supply pipeline, an annular air opening is formed between the centrifugal granulator and the air supply pipeline, the lower part of the granulating cabin is provided with the moving bed, the inner surface of the moving bed is provided with a moving bed water cooling wall, the top of the moving bed is provided with an air outlet, the bottom of the moving bed is provided with a slag discharge device, an air inlet device is arranged above the slag discharge device, the afterheat recovery system comprises a primary dust remover, an afterheat boiler, a secondary dust remover, an exhaust fan and a chimney which are connected in sequence, and the primary dust remover is connected with the air outlet arranged at the top of the moving bed. The system and the method effectively solve the problems of heat recovery and furnace slag granulation of equipment such as a blast furnace.

Owner:XI AN JIAOTONG UNIV +1

System for recovering sensible heat of blast furnace slag

ActiveCN101418950AReduce consumptionAchieve recyclingRecycling and recovery technologiesProcess efficiency improvementLiquid slagHeat energy

The invention relates to a blast furnace slag sensible heat recovery system, which belongs to the technical field of residual heat energy recovery. The recovery system comprises a revolving cup, a slag particle catcher, and an exhaust-heat boiler, wherein the slag particle catcher is cylindrical and the middle part of the slag particle catcher is provided with the double-layer revolving cup; the double-layer revolving cup is connected with an electric motor; the periphery of the slag particle catcher is provided with a water screen which is connected with the exhaust-heat boiler through a pipeline; an outlet on the lower end of the slag particle catcher and the upper part of the exhaust-heat boiler are provided with a slag conveying belt; high-temperature liquid slag enters the revolving cup which rotates at a high speed through a slag chute and is thrown away along the tangential direction of the revolving cup, and the slag are crushed into slag particles in the process; the slag particles dash against the water screen of the slag particle catcher, are solidified on the water screen, slide to the bottom of the slag particle catcher, and are conveyed to the exhaust-heat boiler through the conveying belt; and the amount of heat of the slag particles is transmitted to water in the pipeline, the water is vaporized to generate vapor; and the cooled slag is discharged from the bottom of the exhaust-heat boiler.

Owner:NORTHEASTERN UNIV

High-sodium low-fluorine continuous casting mould fluxes and preparation method thereof

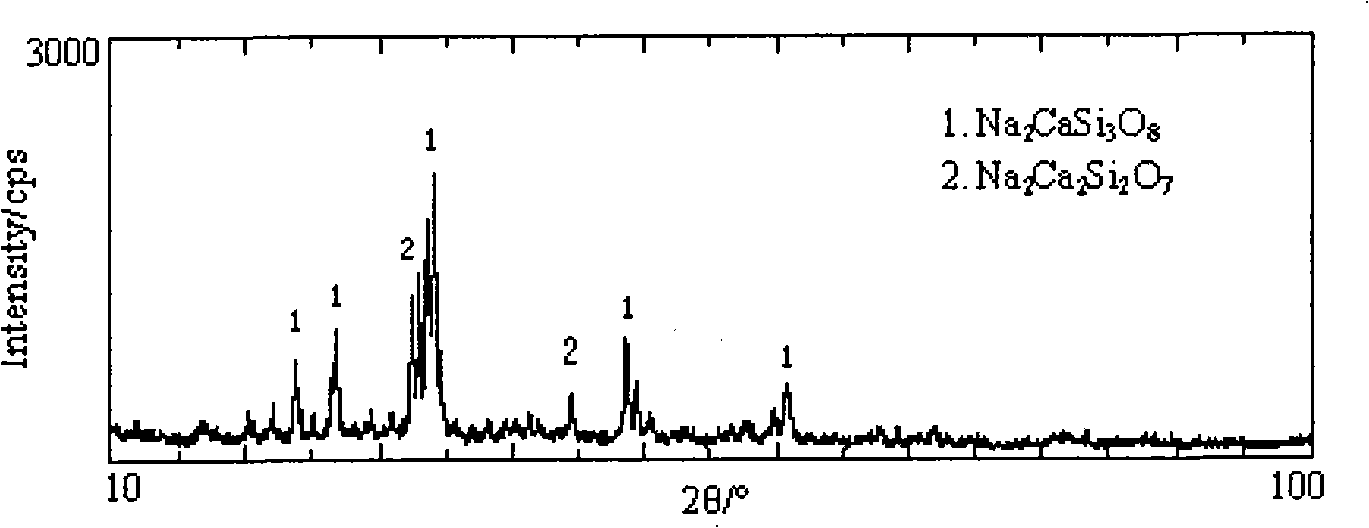

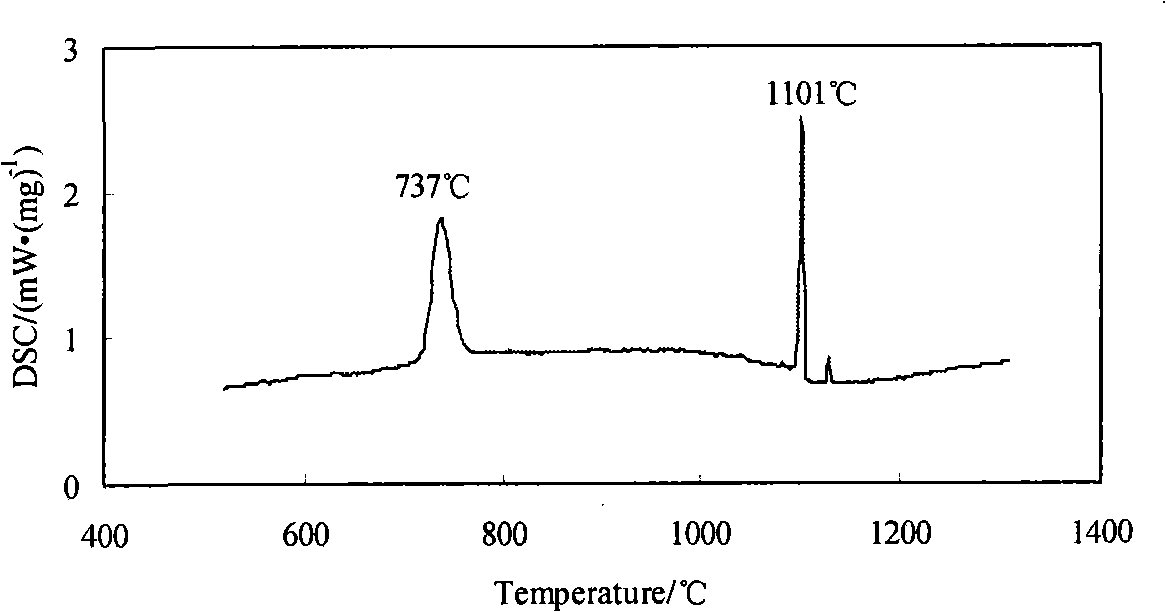

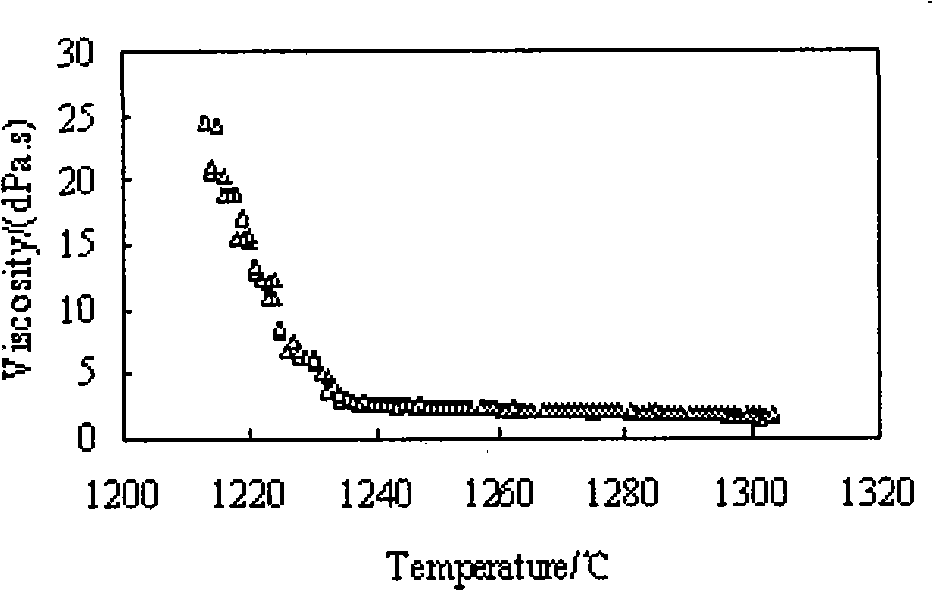

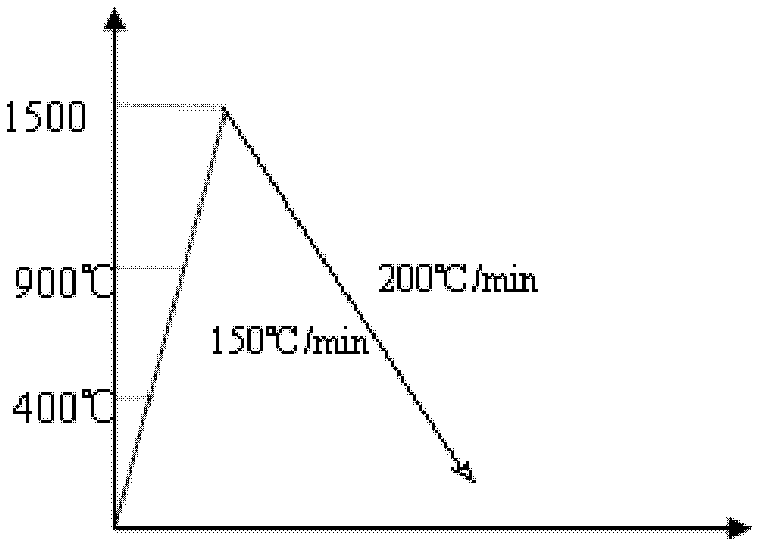

The invention relates to high-sodium low-fluorine covering slag, which is prepared from raw materials of wollastonite, limestone, quartz sand, fluorite, bauxite, manganese carbonate, magnesia, hydrous borax, industrial soda, lithium carbonate, and carbonaceous materials, and the chemical components of the covering slag meets the following weight percentage: more than 30 and less than 34 percent of CaO, more than 30 and less than 38 percent of SiO2, more than 12 and less than 25 percent of Na2O, less than 4 percent of MgO, less than 8 percent of MnO, less than 4 percent of B2O3, less than 1.5 percent of Li2O, less than 4 percent of Al2O3, less than 2 percent of F, more than 4 percent and less than 10 percent of C, and the balance being impurities. In the covering slag, the ratio of sigma CaO to the SiO2 is controlled to between 0.8 and 1.15 to ensure that the fused mass of the covering slag does not separate out crystals at high temperature and liquid slag in a slag film can lubricate a casting blank. Aiming at that the content of fluorine has adverse influence on environment and equipment, the invention adopts high-sodium low-fluorine continuous casting covering slag which not only can meet the requirement of coordinated control of heat transfer and lubrification of a continuous casting covering slag for crack sensitive steel to cast casting blank with good surface quality, but also can reduce the fluorine content in air and secondary cooling water, thus the air pollution is reduced and the corrosion of fluorine-contained water to equipment is reduced.

Owner:CHONGQING UNIV

Protective slag of large-profile round billet continuous-casting crystallizer and method for preparing same

The invention discloses a protective slag of a large-profile round billet continuous-casting crystallizer and a method for preparing same. The protective slag comprises the following components by weight percentage: 27-33% of SiO2, 24-30% of CaO, 1-3% of MgO, not more than 2% of Fe2O3, 5-10% of Al2O3, 4-9% of Na2O, 1-4% of F, 0.5-2.5% of MnO and 15-20% of C (solid). The components of the protective slag of the continuous casting crystallizer are selected according to the regions of fake siliceous lime in a three-element system CaO-SiO2-Al2O3; out of the components for composing the protectiveslag, the CaO is taken as a main alkaline material, the SiO2 is taken as a main acid material, the Na2O, the CaF2 and the Li2O are taken as main flux agents, and the carbon component is taken as a framework material and a fusing speed controlling agent. By organic combination of the basic materials and the flux agents, the chemical components of the protective slag are adjusted, so as to adjust the physico-chemical indexes of the protective slag, such as fusing temperature, viscosity, crystallization performance, absorbing and including capability, heat conducting capability and the like and meet the requirements of keeping normal slag consumption, thickness of liquid slag layer and reasonable heat conducting amount under a special profile condition, thus ensuring the thickness of the billet shell at the outlet end of the crystallizer and realizing non-gluing continuous casting production.

Owner:HENAN TONGYU METALLURGY MATERIALS GRP

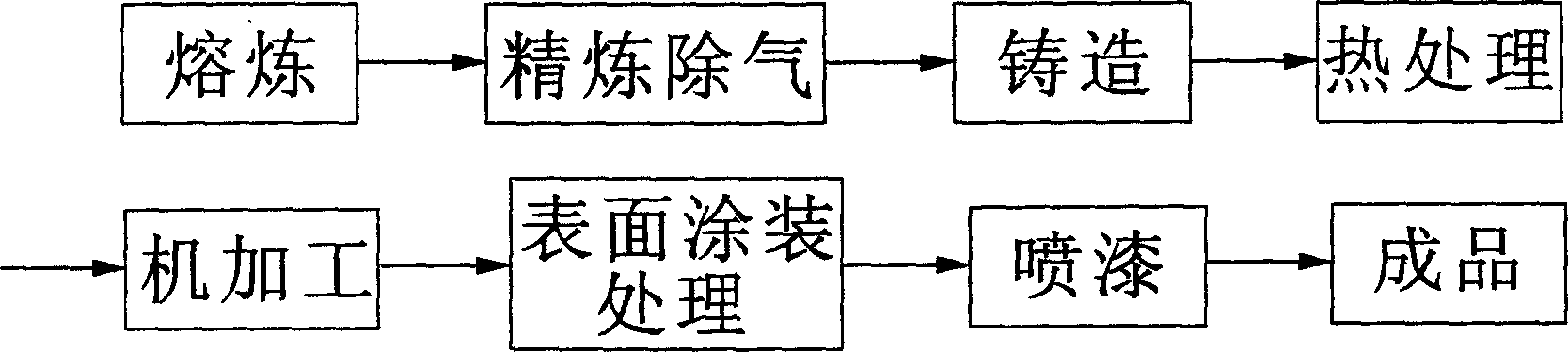

Magnesium alloy auto hub and its producing method

This invention relates to a kind of automobile hub of magnesium alloy and producing metho. It belongs to the die-casting technology of non-ferrous metal. The main raw material is magnesium alloy ingot. After preheating and drying, it is put in pot and melted under high temperature. Adding master alloy, mixing it fully. The following steps are refining and degassing, casting, heat treatment, machining, surface painting, drying, japanning. During the process, the degassing can reach standard easily. Magnesium liquid slag-removing is easy.

Owner:WUXI DAIKA WHEEL HUB MFG

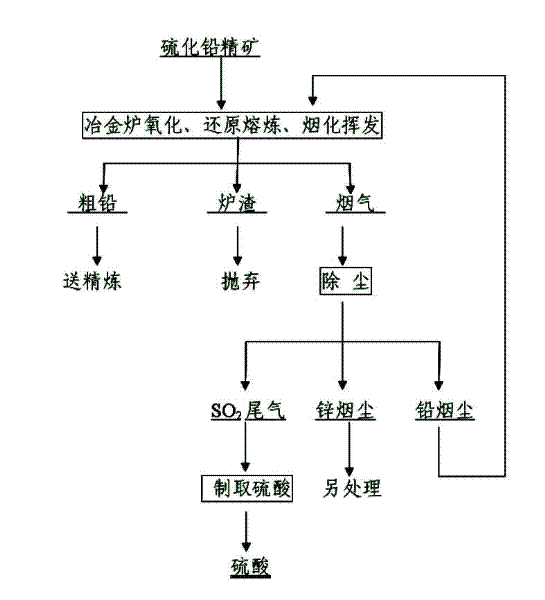

One-step oxidation smelting, reduction smelting and slag fuming and volatilization methods for lead sulfide concentrate

The invention relates to non-ferrous metal metallurgy technology, in particular to the pyrometallurgy technology of lead sulfide concentrate. The process method is to successively carry out three smelting processes of oxidation smelting, reduction smelting and fuming volatilization in the same metallurgical furnace to smelt lead sulfide concentrate, and smelt crude lead, zinc fume and discardable slag in one step. In the oxidation smelting stage, after the feed reaches the set amount, the lead oxide slag is not released, and the high-temperature liquid slag is directly used in the furnace to transfer to the reduction stage of the lead oxide slag, and the smoke generated by oxidation smelting and reduction smelting is returned to the furnace for smelting. After the reduction is completed, all the crude lead is released, and the high-temperature liquid slag remains in the furnace, and it enters the slag fuming stage, and the zinc fume dust from the slag fuming is recovered and enters the next smelting cycle. The heat of the slag in the invention is fully utilized, and the energy-saving effect is obvious. The raw material preparation of the method is simple, the reducing agent only needs ordinary anthracite, and part of the fuel that needs to be supplemented in the reducing section and the fuming section is pulverized coal, which is low in value and easy to obtain.

Owner:YUNNAN TIN GROUP HLDG

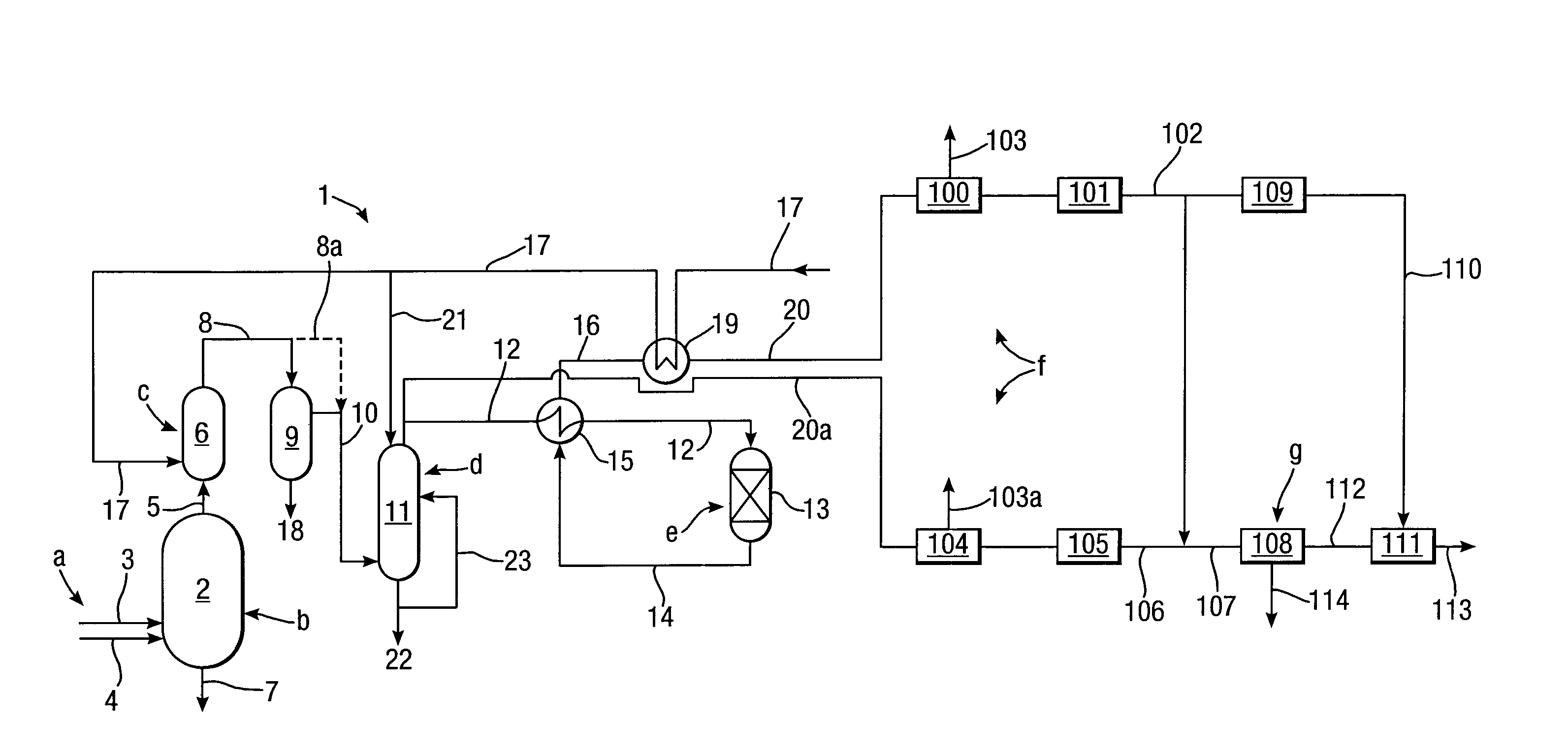

Solid carbonaceous feed to liquid process

ActiveUS20080182912A1Gasifier mechanical detailsCombustible gas catalytic treatmentAlkanePartial oxidation

A process to prepare a paraffinic hydrocarbon from a solid carbonaceous feedstock, preferably coal by performing the following steps,(a) feeding an oxygen comprising gas and the carbonaceous feedstock to a burner positioned horizontal and firing into a reactor vessel,(b) performing a partial oxidation of the carbonaceous feedstock in said burner to obtain a stream of hot synthesis gas which flows upwardly relative to the burner and a liquid slag which flows downwardly relative to the burner,(c) cooling the hot synthesis gas by first cooling the gas to a temperature of between 500 and 900° C. by injecting a gaseous or liquid cooling medium into the synthesis gas and subsequently second cooling the gas in to below 500° C. by directly contacting with water,(d) separating solids from the cooled synthesis gas by means of a water scrubbing process step,(e) performing a water shift reaction on at least part of the scrubbed synthesis gas,(f) separating sulphur compounds, carbon dioxide and other possible impurities from the shifted gas to obtain a purified synthesis gas, and(g) performing a Fischer-Tropsch synthesis using the purified synthesis gas of step (f) to obtain a synthesis product comprising paraffinic hydrocarbons.

Owner:AIR PROD & CHEM INC

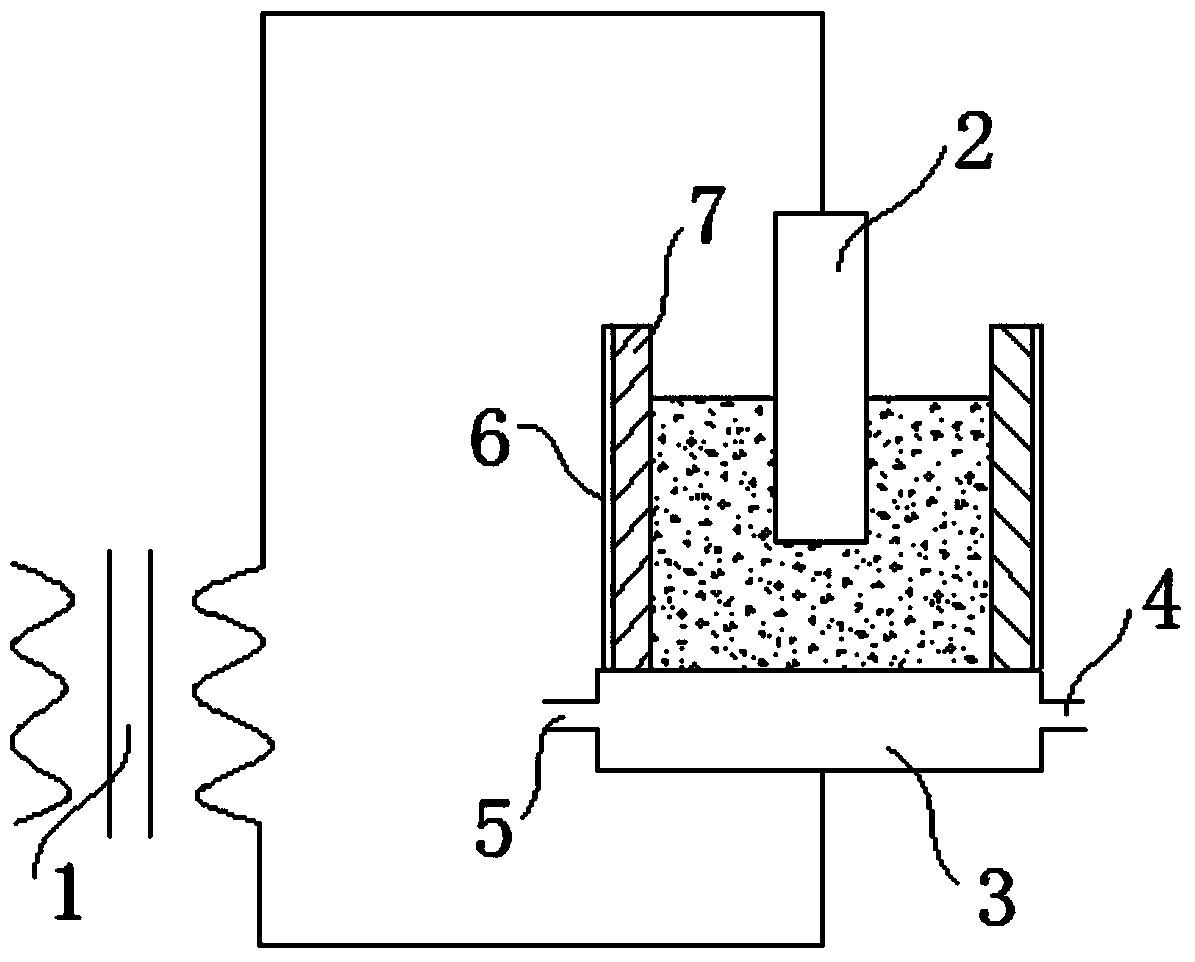

Treatment device of liquid slag

ActiveCN102443662ASlit height can be adjustedImprove granulation effectRecycling and recovery technologiesProcess efficiency improvementLiquid slagMaterials science

The invention relates to a treatment device of liquid slag. The treatment device comprises a slag pot and a launder and is characterized by further comprising a granulating heat exchange bin, a nozzle, a heat exchanger, a cooling device and an ash conveyor; the slag pot is arranged on the launder; the nozzle and the launder are arranged at the entrance of the granulating heat exchange bin; the nozzle is arranged under the launder; the granulating heat exchange bin is provided with an air inlet and an air outlet; an ash bucket is arranged at the bottom of the granulating heat exchange bin. Perfect function settings enable the afterheat recovery effect of the device to be better.

Owner:无锡市东方环境工程设计研究所

Crystallizer protective slag for effectively controlling carbon steel cracks in compact strip production (CSP)

The invention discloses crystallizer protective slag for effectively controlling carbon steel cracks in a compact strip production (CSP). The crystallizer protective slag comprises the following chemical components in percentage by mass: 35 to 38 percent of CaO, 28 to 31 percent of SiO2, 1 to 3 percent of Al2O3, 1 to 2 percent of MgO, 0.5 to 1.5 percent of Fe2O3, 10 to 11.5 percent of F, 9 to 11.5 percent of Na2O, 1.5 to 3.5 percent of MnO, 5 to 8 percent of fixed carbon, and the balance of inevitable trace elements. Through the crystallizer protective slag for controlling the carbon steel cracks in the CSP, the alkalinity is improved by 0.04 to 0.09, the alkalinity is controlled to be 1.20 to 1.25, the constraint that the alkalinity cannot be more than 1.16 in the field is broken, the viscosity is controlled to be 0.08 to 0.09Pa.S, and the melting point is from 1,155 to 1,185 DEG C; capabilities of dissolving and absorbing inclusions are improved, and heat transfer is retarded by reducing a vitreous body, so that an aim of reducing longitudinal cracks is fulfilled; and by adjusting the proportioned carbon and controlling the thickness of a liquid slag layer, bonding steel leakage caused by high crystallization temperature and deteriorated lubricating performance due to over high alkalinity of the protective slag is relieved.

Owner:GANSU JIU STEEL GRP HONGXING IRON & STEEL CO LTD

Dry pulverized coal cyclone entrained flow bed gasification furnace and gasification method thereof

InactiveCN102796566AImprove carbon conversionImprove conversion rateCombined combustion mitigationGranular/pulverulent flues gasificationCycloneWater vapor

The invention relates to a dry pulverized coal cyclone entrained flow bed gasification furnace and a gasification method thereof, which belong to the technical field of coal gasification device. The dry coal dust cyclone entrained flow bed gasification furnace comprises a top nozzle, a furnace roof, a gasification chamber, an exhaust port and a bottom slag discharge port. The top nozzle is an annular channel structure with inner, outer swirl vanes, at least one layer of a tangential O2 nozzle is arranged on the lateral wall of the gasification chamber. Pulverized coal gas flow and vapor are fed through a top nozzle in a whirling way, and the pulverized coal gas flow rotating downwards is formed in the near-wall area. The pulverized coal particles are subjected to film type gasification on a liquid slag film formed on the surface of the furnace wall under the centrifugal action of the high-speed rotation gas flow. The service life of the nozzle is effectively prolonged, the residing time of the pulverized coal in the furnace is increased, and the carbon conversion efficiency is increased; liquid slags reside on the wall surface, so as to effectively protect the wall surface; the multiple layers of the tangential O2 nozzles are arranged to effectively disperse heat load and the work reliability of the gasification furnace is increased.

Owner:TSINGHUA UNIV +1

Blast furnace slag waste heat recycling system

InactiveCN102392085AHigh" activityGuaranteed normal operationIncreasing energy efficiencyWaste heat treatmentLiquid slagEvaporation

The invention discloses a blast furnace slag waste heat recycling system, comprising a liquid slag transport tank, a liquid slag fixing tank, a seal flush slag tank, a flush slag water nozzle, a spiral slag removal unit, a water granulated slag dehydration unit, a water granulated slag transport belt, a flush slag water sedimentation basin, a flush slag steam discharge pipe, a dividing wall type heat exchanger, a flush slag water pump, an evaporation boiler, a generator, a steam condenser, a generating water circulation water pump, and a compressed air repressing unit. According to the invention, the present blast furnace slag water quenching technology can be kept, high activity of the products of the water granulated slag can be kept, and normal running of the industrial chain of the application channel of the water granulated slag can be guaranteed; and the recycling of the steam waste heat by using low water quantity to flush slag can be realized.

Owner:SHANDONG IRON & STEEL CO LTD

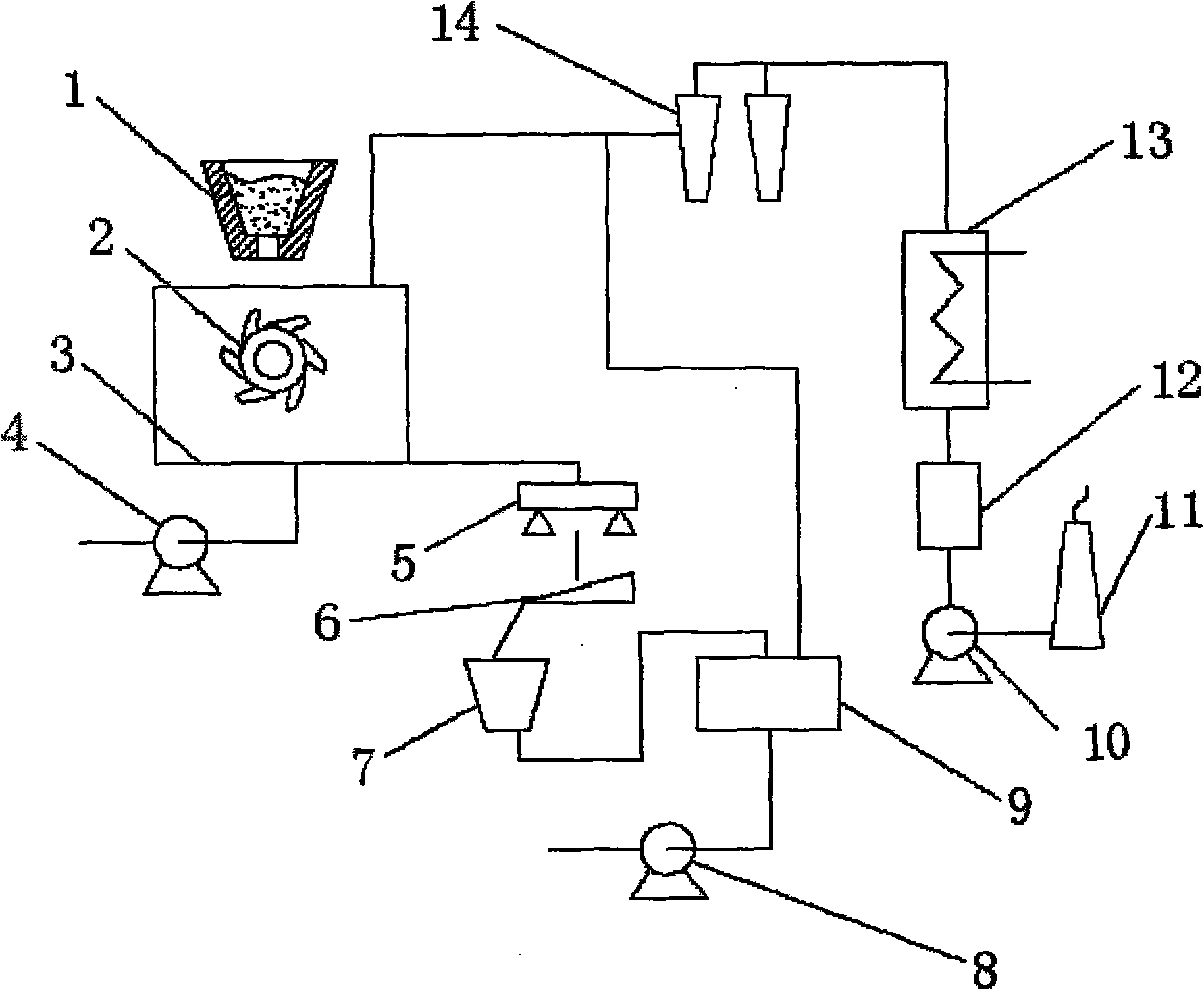

Recovery method of steel slag residual heat and system thereof

ActiveCN101551199AReduce consumptionEliminate pollutionProcess efficiency improvementWaste heat treatmentRecovery methodFluidized bed

The invention discloses a recovery method of steel slag residual heat and system thereof. The system is composed of a steel slag flow distributor, a water-cooling granulation wheel, a first fluidized bed, a weigher, a vibration sieve, a hot slag particles bunker, a second fluidized bed, a dedusting device, a blower and a residual heat boiler in sequence. The method is that, pouring high-temperature liquid slag into the steel slag flow distributor, the steel slag flown out of the steel slag flow distributor falling onto the water-cooling granulation wheel and being crushed and throwing out to fall into the first fluidized bed for exchanging heat with air, hot slag particles discharged from the first fluidized bed is stored in the hot slag particles bunker after going through the weigher and the vibration sieve, and discharging when the temperature is cooled to 350 DEG by a heat exchanger of the second fluidized bed. High-temperature air discharged from the first fluidized bed and the second fluidized bed enters the residual heat boiler for exchanging heat after dedusting. The invention can reduce energy consumption in steel production, graining effect of the steel slag is good, which is benefit for following degradation of free CaO and magnetic separation of wasted steel.

Owner:HANGZHOU BOILER GRP CO LTD

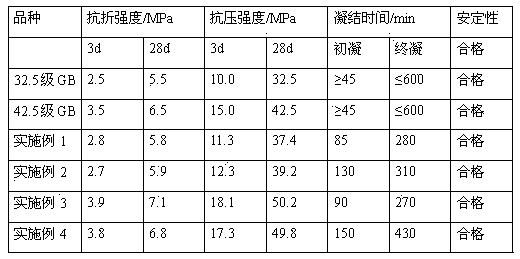

Portland blast furnace slag cement and preparation method thereof

The invention relates to a portland blast furnace slag cement and a preparation method thereof. The portland blast furnace slag cement is prepared from the following raw materials by weight percent: 12%-30% of at least one of slag, coal gangue, boiling slag, liquid slag, cinerite, kiln dust and crushed tile, 10%-42% of mineral waste residue, steel slag or silicomanganese slag, 0-12% of limestone, 2%-8% of gypsum, 0-10% of zeolite, 0-17% of boiling slag, 0-10% of coal ash, and 10%-50% of silicate series cement. The preparation method comprises steps of putting the slag, mineral waste residue, gypsum, zeolite, boiling slag, and coal ash into a pulverizer to be smashed, grinding by a ball mill to achieve the fineness of 0.08mm, sieving by a square hole sieve with 2% left, and then mixing with the silicate series cement. The portland blast furnace slag cement has the advantages of having a simple preparation method, needing no cement clinker, guaranteeing the strength and stability of the cement, fully using industrial residue resources like slag and mineral waste residue, lowering production cost, and reducing the pollution of industrial residue to the environment.

Owner:LIAONING PETROCCHEM VOCATIONAL & TECH COLLEGE

ASP medium thickness slab high drawing speed plate blank low-carbon steel continuous casting functional protective material

The invention discloses an ASP medium thickness slab high drawing speed plate blank low-carbon steel continuous casting functional protective material which comprises the components by weight percent:1.0-1.5% of Li2O, 3.0-5.0% of MgO, 0.7-1.5% of Fe2O3, 0.93-0.97% of CaO / SiO2 and the rest of SiO2, CaO, Al2O3, Na2O, F and K2O. The material solves the problems that high drawing speed plate blank continuous casting low-carbon steel has a thin liquid slag layer, poor lubrication, breakout by sticking, casting blank surface slag inclusion and sticky residue quality in the prior art. Protective slag has good spreadability, heat preservation and melting property in a crystallizer; the four sides inside the crystallizer are stable and even in capacity of heat transmission; the thickness of the liquid slag layer is 8-12mm; furthermore, the protective material has fewer slag strips, good lubricating property of the protective slag, prevents the breakout by sticking, and has no slag inclusion and sticky residue on the surface of casting blank as well as good casting blank surface quality.

Owner:HENAN XIBAO METALLURGICAL MATERIALS GROUP

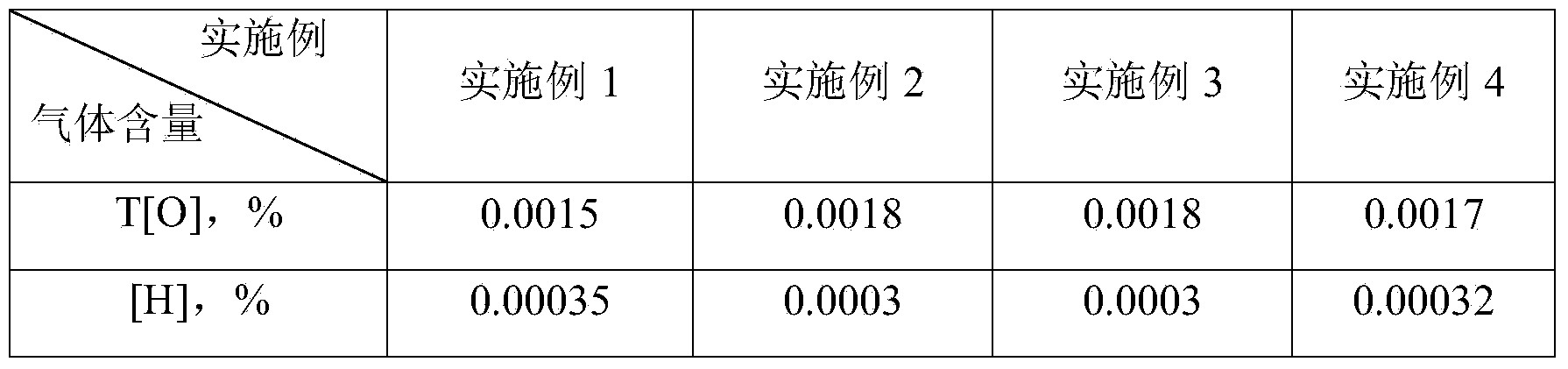

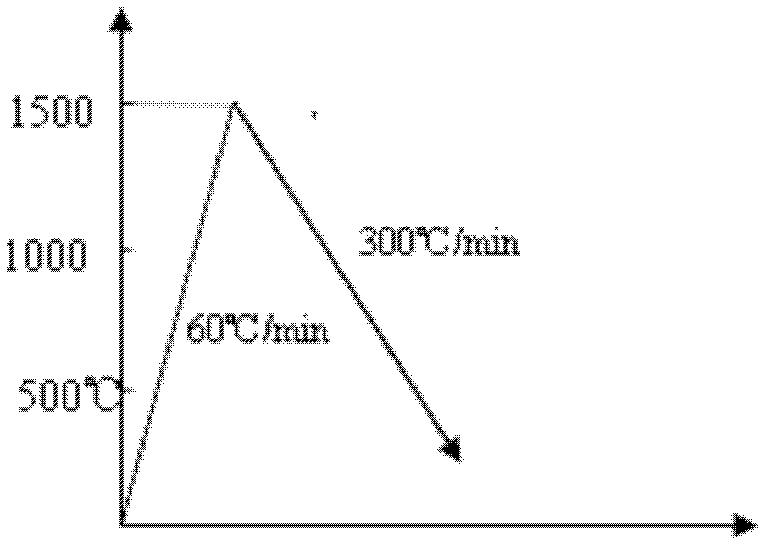

New slag system for synchronously controlling hydrogen-oxygen content of electroslag ingot and preparation method thereof

The invention discloses a new slag system for synchronously controlling the hydrogen-oxygen content of an electroslag ingot and a preparation method thereof, belonging to the technical field of an electroslag remelting slag system. The slag system comprises the following components in percentage by weight: 43-47% of CaF2, 18-22% of CaO, 4-6% of Al2O3, 8-12% of MgO, 14-16% of Ce2O3 and 4-6% of La2O3. The preparation method comprises the steps of proportionally preparing slag charge according to the components of the slag system and the weight percentage requirements, wherein the slag charge comprises limestone, dolomite, fluorite, bauxite, cerium oxide powder and lanthanum oxide powder; pre-melting the mixed slag charge at 1,600 DEG C, wherein the pre-melting process is performed by use of an Fe-Al electrode in an electroslag melting device; pouring the liquid-state slag charge into a steel mould; after the product is cooled, breaking and packaging. By adopting the new slag system and preparation method disclosed by the invention, the oxygen content increase of the electroslag ingot in the electroslag remelting process can be controlled to be less than 0.0008%, and the hydrogen content increase can be controlled to be less than 0.0003%, thereby achieving an aim of synchronously controlling the hydrogen content and oxygen content in the electroslag ingot.

Owner:ANHUI FUKAI STAINLESS STEEL

Technique for heating liquid steel scoria

InactiveCN101220399APut an end to the problem of serious pollution of the environmentReduce the difficulty of subsequent processingRecycling and recovery technologiesLiquid slagLiquid steel

The invention discloses a thermal-braise technique for liquid steel slag, which pours liquid steel slag into a thermal-braise tank directly for treatment, and the specific working procedure is: extending the bottom of the thermal-braise tank equally with dry steel slag with the thickness of 190 to 230 mm, pouring the produced liquid steel slag while making steel into the thermal-braise tank, the amount of the poured liquid steel slag is 10 to 12 percent of the gross cubage of the thermal-braise tank; spraying water into the thermal-braise tank immediately after the liquid steel is poured into the tank to ensure the surface of the liquid steel slag to form crust immediately; the manipulator looses the crusted steel slag until the liquid slag appears, and then restarts the water-spraying procedure to loose the steel slag; the final part is temperature-reducing procedure, and opens the cover to discharge the slag after aerating for 25 to 35 minutes. The technique of the invention finishes the whole process from liquid steel slag to steel slag grain in the thermal-braise tank, which primarily puts an end to the problem that liquid steel slag pollutes environment seriously, furthermore, the fine crushing degree of steel slag finally formed by the technique of the invention is excellent, and the self-crushing effect of steel slag in the fine crushing process is excellent, thereby leading the metal recovery rate of the steel slag to be improved about 18 percent compared with the prior art.

Owner:山东济钢泰航合金有限公司

Method and system for jointly and circularly generating electricity by gasifying municipal garbage at high temperature

ActiveCN102359729APromote resource utilizationMeet incineration pollution emission standardsUsing liquid separation agentBiofuelsFuranResource utilization

The invention relates to a method and a system for jointly and circularly generating electricity by gasifying municipal garbage at a high temperature. The method comprises the following steps of taking high-temperature gasification of a combustion furnace as a main technological approach, gasifying organic components in household garbage when a combustion temperature under a pure oxygen combustion environment reaches 1000 DEG C to 1250 DEG C, and melting inorganic components. The technical schemes of the method and the system provided by the invention have high resource utilization of the garbage, can efficiently recover the resource and energy source in the household garbage, recover valuable metals and liquid slag in ash slag, fundamentally solve the secondary pollution problem of dioxin and heavy metal, reduces the emission value of highly toxic secondary pollutants such as dioxin, furans (PCDD / Fs), heavy metals and the like close to zero emission, and meet the more strict pollutants emission standard of combustion of household garbage.

Owner:BEIJING AEROSPACE PROPULSION INST

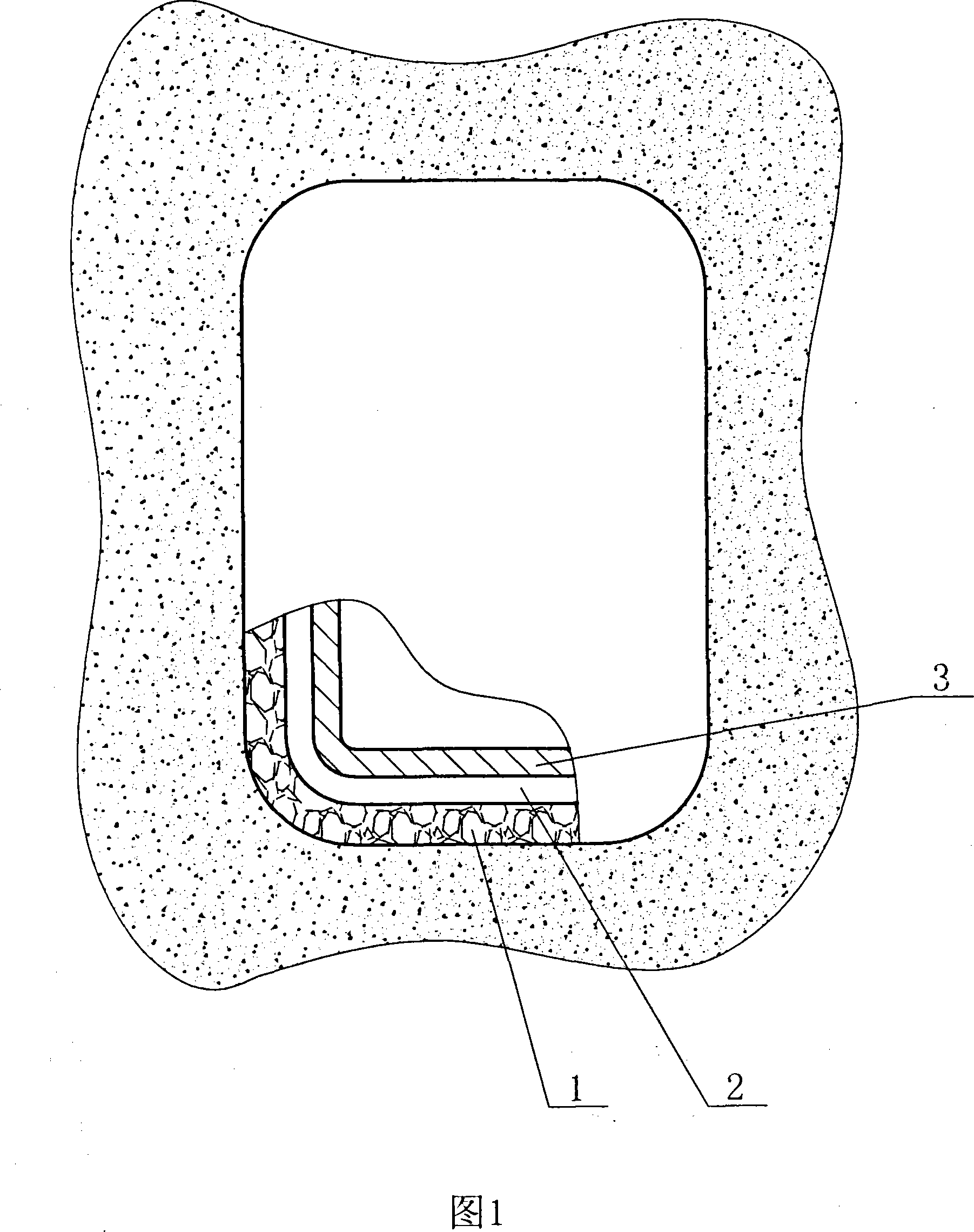

Experiment device for testing softening and dropping point of sinter

ActiveCN103713007AEasy to operateMeet testing needsInvestigating phase/state changeFurnace temperatureGas cylinder

The invention relates to an experiment device for testing a softening and dropping point of a sinter. The device is composed of a large current transformer, a furnace body fixing column, a tray, a furnace body adjusting frame, a rotary column, a pressurized gas cylinder, a displacement sensor, a furnace top sealing furnace cover, a pressurized graphite compression strut, an anti-radiation graphite cover, a molybdenum disilicide heater, a graphite crucible, a high pure graphite sleeve, a sealed alundum tube, a pinhole camera, an air inlet channel fixing sleeve, a dropping crucible weighing device, a dropping crucible device, a furnace body chassis, furnace body castors, a heating furnace body, a cantilever beam, a sample temperature thermocouple, a alumina hollow ball member, a furnace temperature control thermocouple, a rotary column circular sleeve, a pressurized gas cylinder pipeline and a pressure transmitter. The large current transformer is adopted to supply power for the molybdenum disilicide heater; the pinhole camera is used to observe a dropping process of high temperature liquid slag iron; the dropping crucible weighing device is arranged; the crucible is assembled and disassembled in a manner of laterally opening the door; and the position of the heating furnace body is adjusted by the furnace body adjusting frame, so that the device is flexible, accurate and convenient for operations.

Owner:NORTHEASTERN UNIV

Pouring slag for continuously casting cast steel plate (CSP) sheet billet high-carbon steel

The invention discloses pouring slag for continuously casting cast steel plate (CSP) sheet billet high-carbon steel. During the continuous casting of the CSP sheet billet high-carbon steel, phenomena of binding cold steel, clotting pouring slag and slagging badly do not occur basically when silicon iron is used; the pouring slag has low alkalinity and proper viscosity; after the silicon iron is oxidized quickly, the silicon iron and other components of the pouring slag form acidic slag with alkalinity of 0.5 to 0.7 quickly; and under an acidic slag system, a network limiting body, namely silicon dioxide has high content, so that the viscosity of liquid slag formed by the pouring slag which uses a large number of fusing agent materials such as sodium fluoride, flousper powder, white alkali, cryolite and the like is not ultralow, the liquid slag forms uniform slag membranes between a primary solidification billet shell and the wall of a crystallizer and has long viscous time, and stable, continuous and good lubricating effect is provided during pouring of the CSP high-carbon steel.

Owner:XIXIA LONGCHENG METALLURGICAL MATERIALS CO LTD

Recycling method of casting slag

InactiveCN103333980AConducive to earlyReduce the amount addedManufacturing convertersRecycling and recovery technologiesLiquid slagIron levels

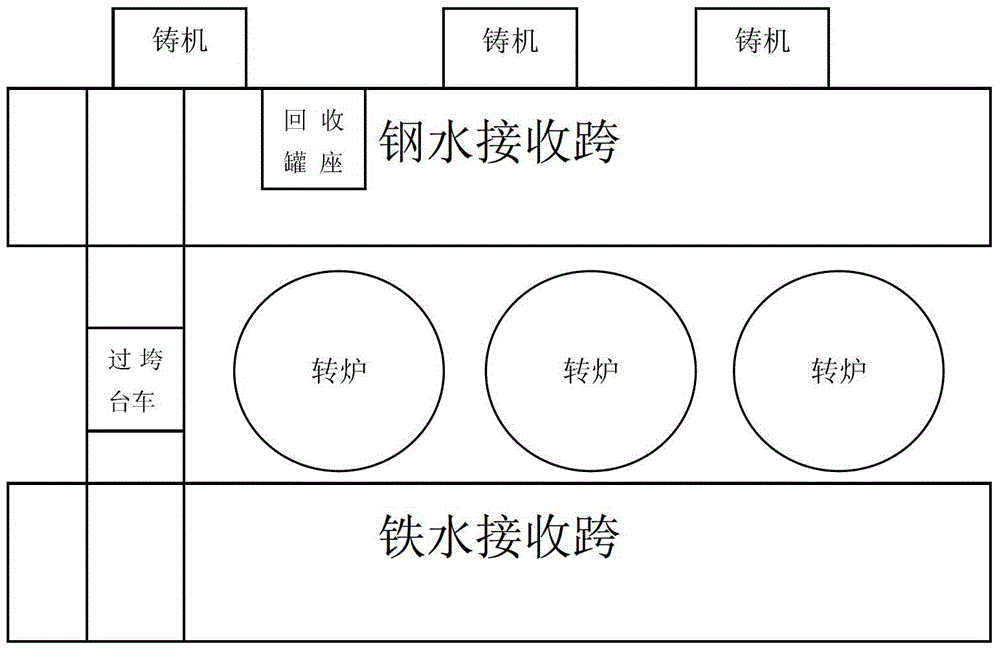

The invention relates to a recycling method of casting slag, which comprises the steps that headroom control of a molten iron level in a molten iron jar requires that a distance from a jar port to the level is greater than 500mm; the molten iron jar is fixed at a recycling jar seat by a cross trolley and a molten steel receiving span sequentially; the continuous casting slag is collected by the molten iron jar; the waiting time of the molten iron jar does not exceed 2h; the molten iron jar passes through the cross trolley vehicle and the molten steel receiving span sequentially; molten iron in the molten iron jar is added to converters; converter smelting adopts single-slag operation; and finally molten steel is produced. The recycling method has the advantages that liquid slag recycling is limited by a production rhythm, so that about 10 jars of slag can be recycled every day; the continuous casting liquid slag is recycled to the molten iron jar and then added to the converters, and the liquid slag contains a part of free CaO and Al2O3, so that a part of slag and CaO can be provided; early melting of pre-slag of the converters is facilitated; the adding quantity of lime is reduced; the remnant molten steel after casting is recycled; and the production cost is saved.

Owner:ANGANG STEEL CO LTD

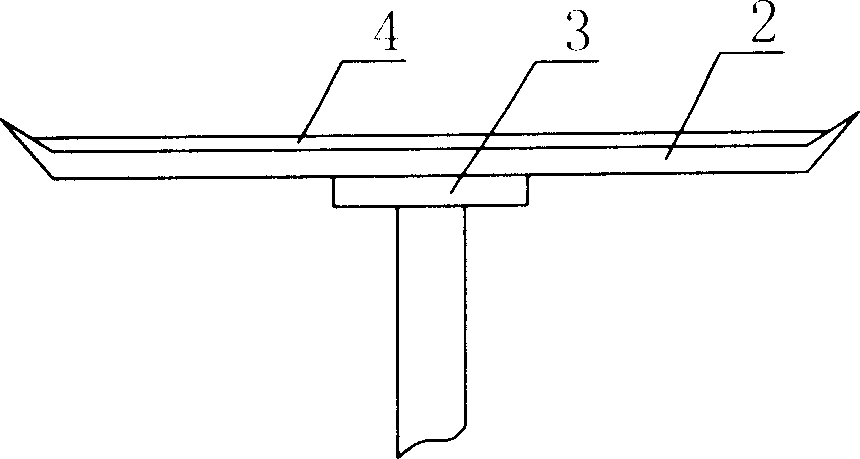

Liquid blast furnace slag heat recovering apparatus and method

InactiveCN1888082ASmall granularityEfficient recyclingOther heat production devicesRecycling and recovery technologiesRecovery methodLiquid slag

The liquid blast furnace slag heat recovering apparatus includes one sealed cylindrical container with top gas outlet, one liquid slag gate on the top of the container, one pelletizing unit comprising motor and its driving system inside the container, and one cooling-gas injecting unit. The heat recovering method includes leading liquid blast furnace slag through the gate into the container, pelletizing the liquid slag with the pelletizing unit, heat exchange between the falling blast furnace slag grains and the cooling gas, and exhausting the cooling gas, which is compressed air or nitrogen, after heat exchange through the gas outlet for reuse. The present invention has effective heat exchange.

Owner:CHONGQING UNIV

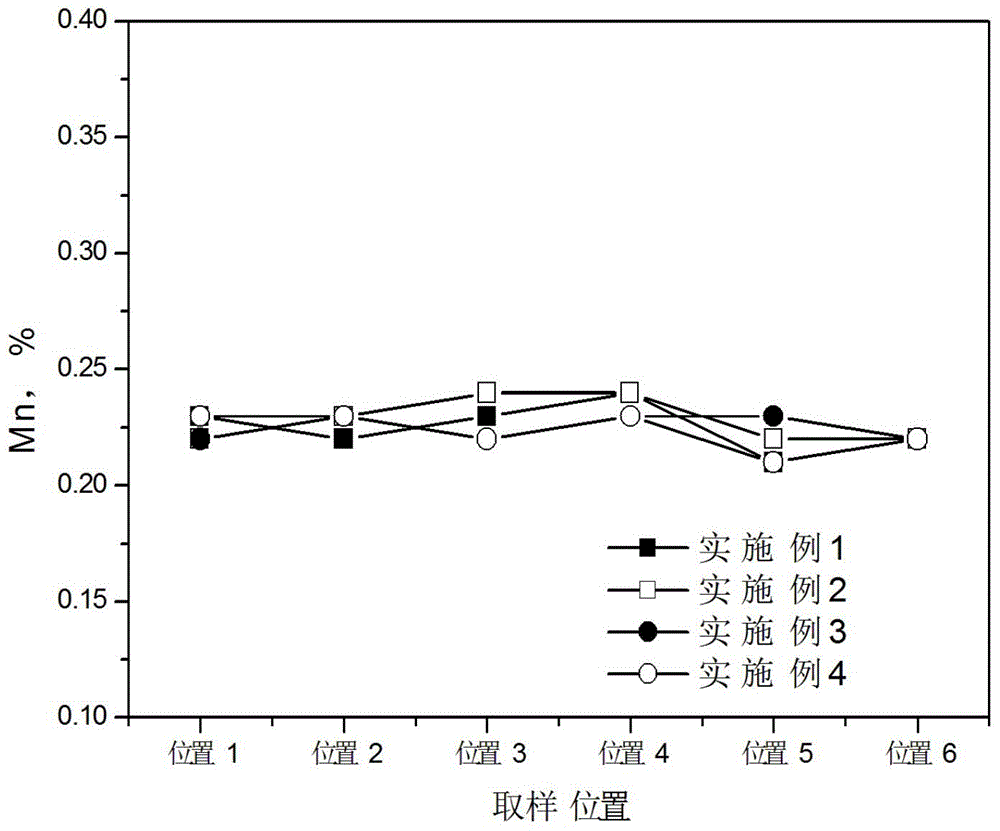

Using method of electroslag remelting refining slag by efficiently using returned slag

ActiveCN104561570AReduce manufacturing costStable remelting processLiquid slagElectro-slag remelting

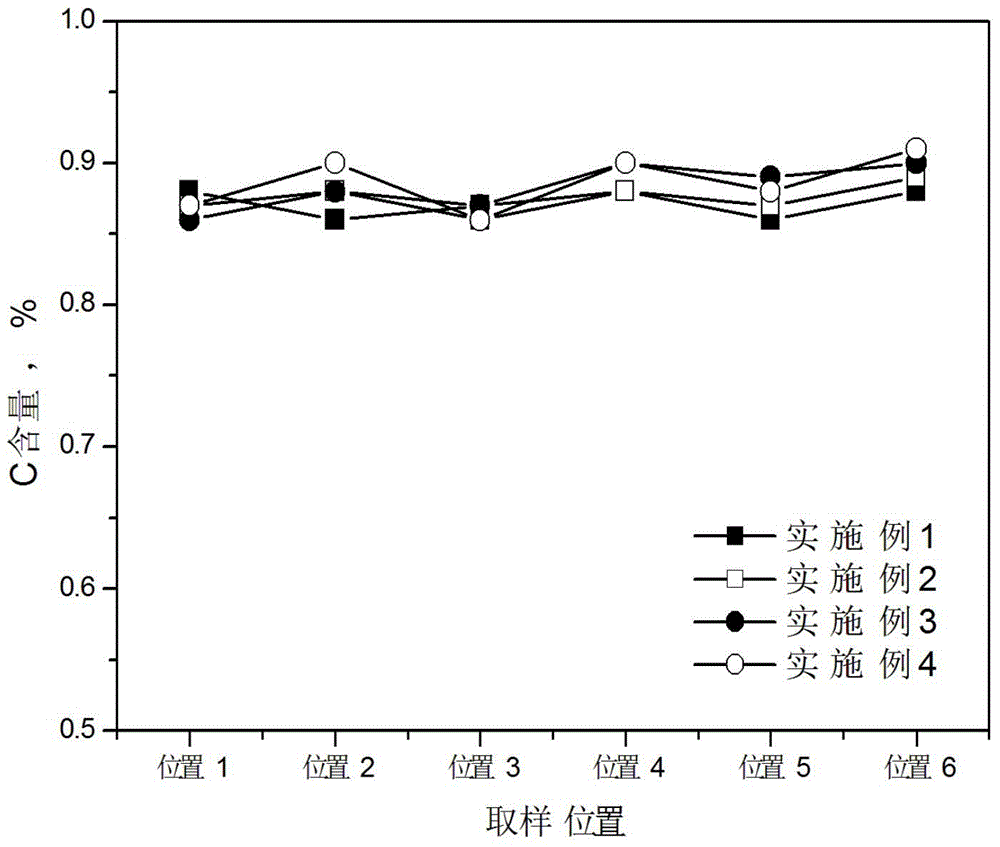

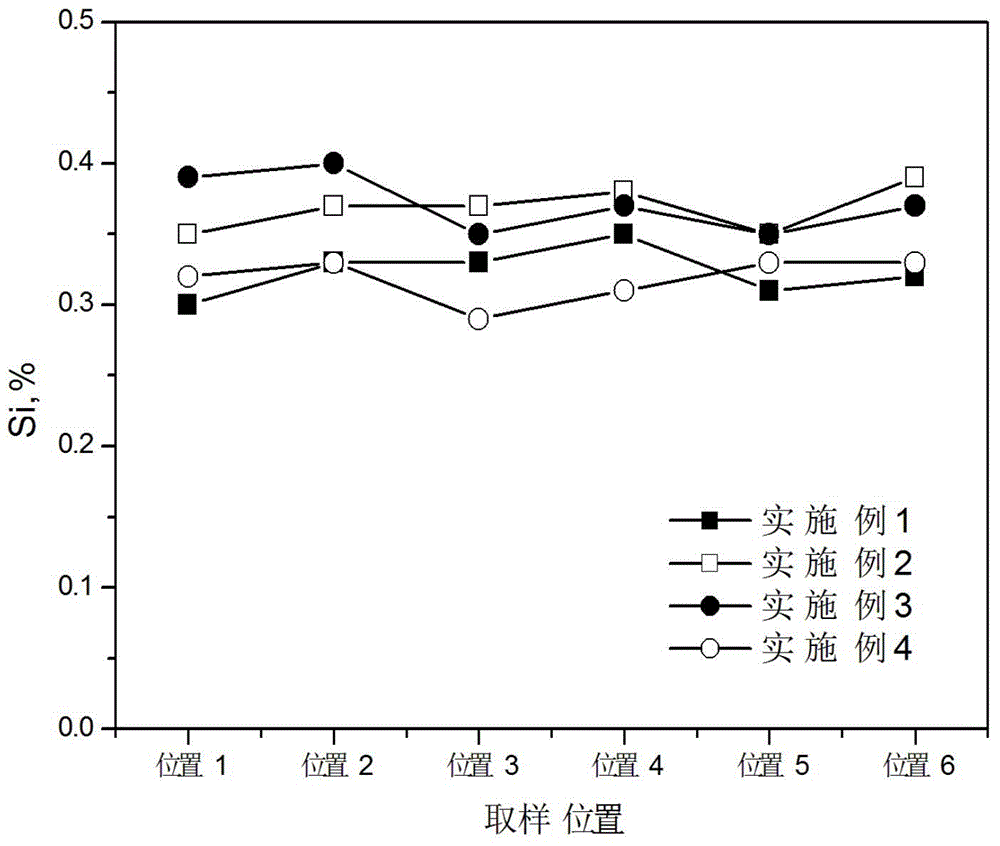

The invention discloses a using method of electroslag remelting refining slag by efficiently using returned slag and belongs to the technical field of electroslag remelting refining slag. The electroslag remelting refining slag is prepared from the following components in percentage by mass: 50-80% of electroslag remelting refining slag, 16-35% of fluorite, 4-10% of aluminum oxide powder and 0-5% of lime. A preparation method comprises the following steps: after uniformly mixing a novel slag system formed by the components, pre-melting in a slagging furnace; and then, crushing liquid slag by virtue of an air quenching method. The using method comprises the following steps: roasting the electroslag remelting refining slag prepared by using the returned slag; and then by using coke as an arc striking agent, doping aluminum metallic particles into the electroslag remelting refining slag, wherein the slagging time is controlled at 30 minutes. The remelting technical process of electroslag remelting refining slag is stable, and a steel ingot is good in surface quality and uniform in chemical component distribution. The cost of the slag system is **yuan / ton which is lowered by 55-78%, so that the efficient utilization of the returned slag is realized.

Owner:ANHUI FUKAI STAINLESS STEEL

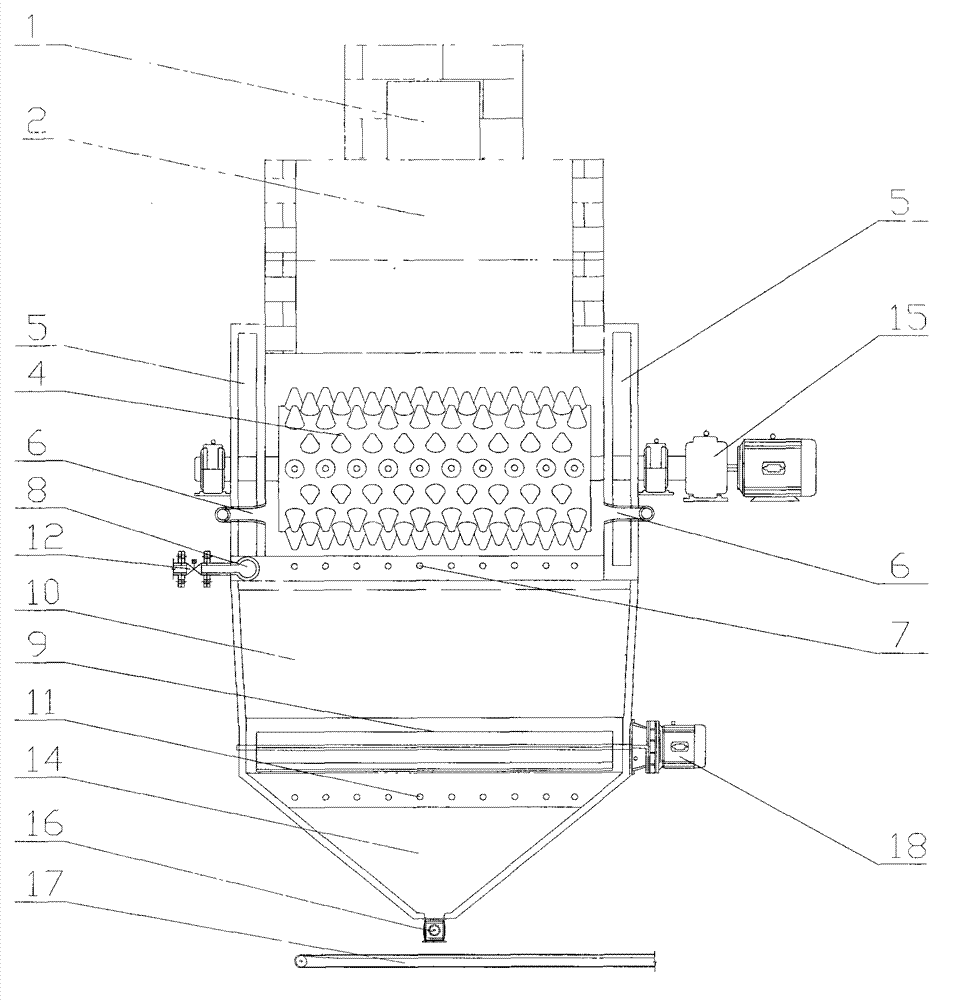

Blast furnace slag granulation and waste heat recovery device

ActiveCN102888473AReduce consumptionReduce pollutionRecycling and recovery technologiesProcess efficiency improvementWaste heat recovery unitMechanical crushing

The invention discloses a blast furnace slag granulation and waste heat recovery device which mainly comprises a slag sliding port (1), a liquid slag bucket (2), a quick cooling cavity (3), a star-shaped slag dumping wheel (9) and an air cooling cavity (10), wherein the quick cooling cavity (3) is further divided into an upper granulation wheel set part and a lower water quenching part; and the quick cooling cavity (3) is connected with the air cooling cavity (10) through the star-shaped slag dumping wheel (9). The invention has the following advantages: water resources can be greatly saved, pollution to the surrounding environment can be reduced, most or even all of cooling water can be changed into steam for use, and steam condensate can be further recovered and used; and meanwhile, the waste heat of heat circulating air obtained through air cooling can be recovered by a waste heat boiler. Mechanical crushing and water quenching processes are further used, thereby ensuring the quality of slag granules. The blast furnace slag granulation and waste heat recovery device is simple in structure and reasonable in design and can ensure that the liquid blast furnace slag is effectively granulated, thereby ensuring that the heat of the liquid blast furnace slag can be sufficiently and effectively recovered.

Owner:潼关中金冶炼有限责任公司

Mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect

The invention relates to a mold powder capable of effectively controlling peritectic steel thick slab narrow face depression defect. The mold powder comprises the following elements by weight percent: 38.02 to 40.1 percent of Cao, 28.8 to 30.02 percent of SiO2, 9.9 to 10.5 percent of CaF2, 9.06 to 9.5 percent of Na2O, 1.55 to 1.93 percent of MgO, 1.5 to 1.93 percent of AL203, 0.01 to 0.037 percent of Li2O and 0.035 to 0.053 percent of MnO. The mold powder has good lubricating property and spreadability. Because of the high melting speed, the invention can complement the quick consumption of liquid slag in time; because of the high alkalinity, the invention has strong absorbing and mixing capability; and because of the proper viscosity and the reasonable crystallization temperature, the invention plays an important role in uniformity. When the mold powder is applied to the casting of peritectic steel thick slab, the slag entrapment defect caused by crystallizer liquid level fluctuation is reduced greatly, the heat transmission uniformity is improved greatly and the surface quality of casting blank is good.

Owner:SHOUGANG CORPORATION

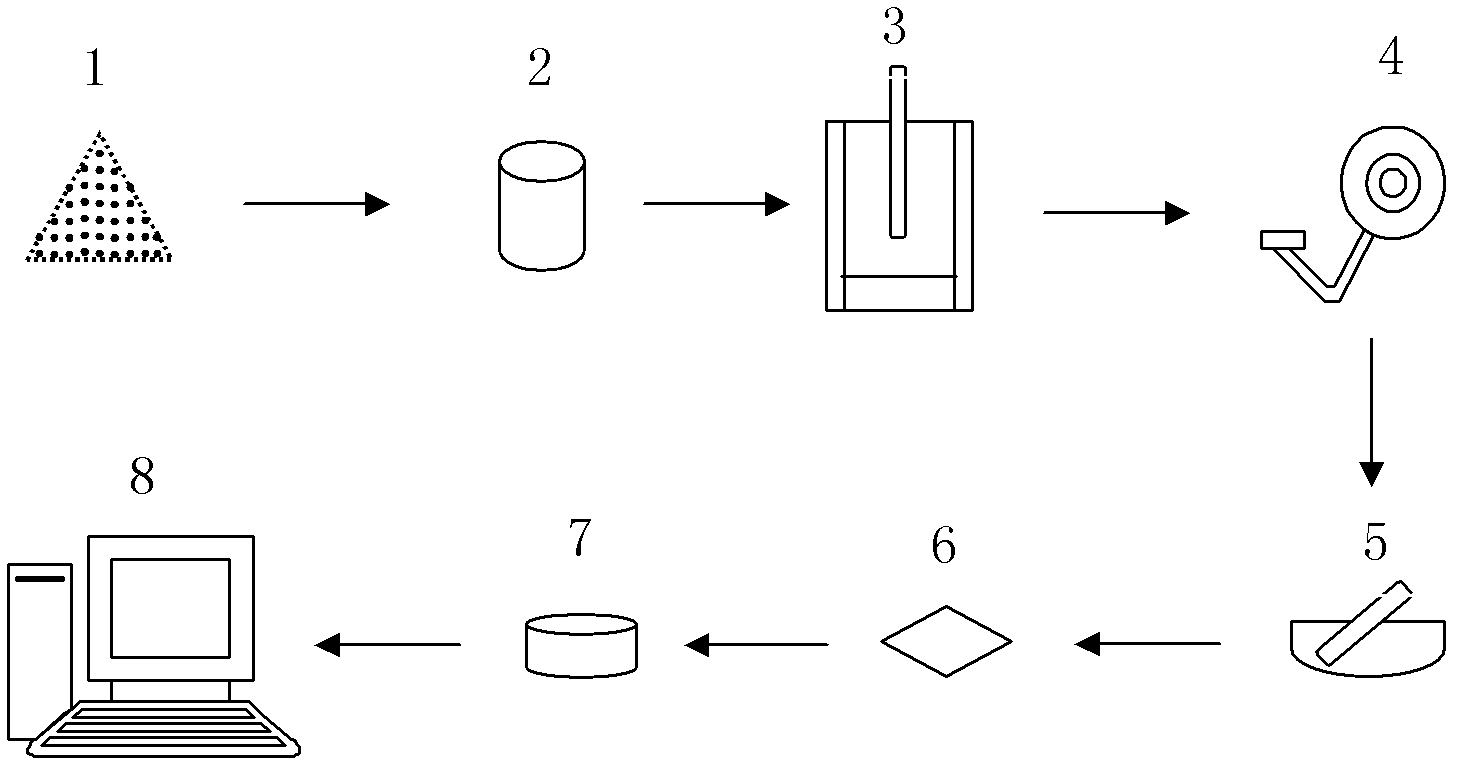

Method for determining melting behavior and melting point of slag-like material

ActiveCN102495096AThe test result is accurateDynamic and intuitive testing processInvestigating phase/state changeMetallurgical slagTemperature testing

The invention relates to a method for determining a melting behavior and a melting point of a slag-like material, belonging to the technical field of detection of metallurgical slag-like material. The process comprises slag sample preparation, slag sample formation, high-temperature laser sample filling, experimental parameter setting, melting process observation and data and image processing. The method provided by the invention has the advantages that the defect of low accuracy of the slag column deformation method, i.e. the hemisphere point temperature testing method, in the traditional melting point testing can be overcome, and the limitations of difficulties in control of the stability of testing conditions and high testing costs in the method of slag melting in liquid steel can be eliminated. The initial melting temperature of the slag sample from the solid phase to the liquid phase and the melting temperature of the slag sample to the full liquid phase can be captured promptly so as to accurately determine the melting point of the slag sample; and the liquid phase nucleation, growth and other melting changes and behaviors of the slag sample in the heating process can also be analyzed, the direct theoretical basis and technical support can be provided for the curing of liquid slag and the control of metallurgical reaction in the steel-making and iron-making process, and different characteristics of different slag samples in the melting process can be used as an important means for evaluation of high-temperature properties of different slag samples.

Owner:SHOUGANG CORPORATION

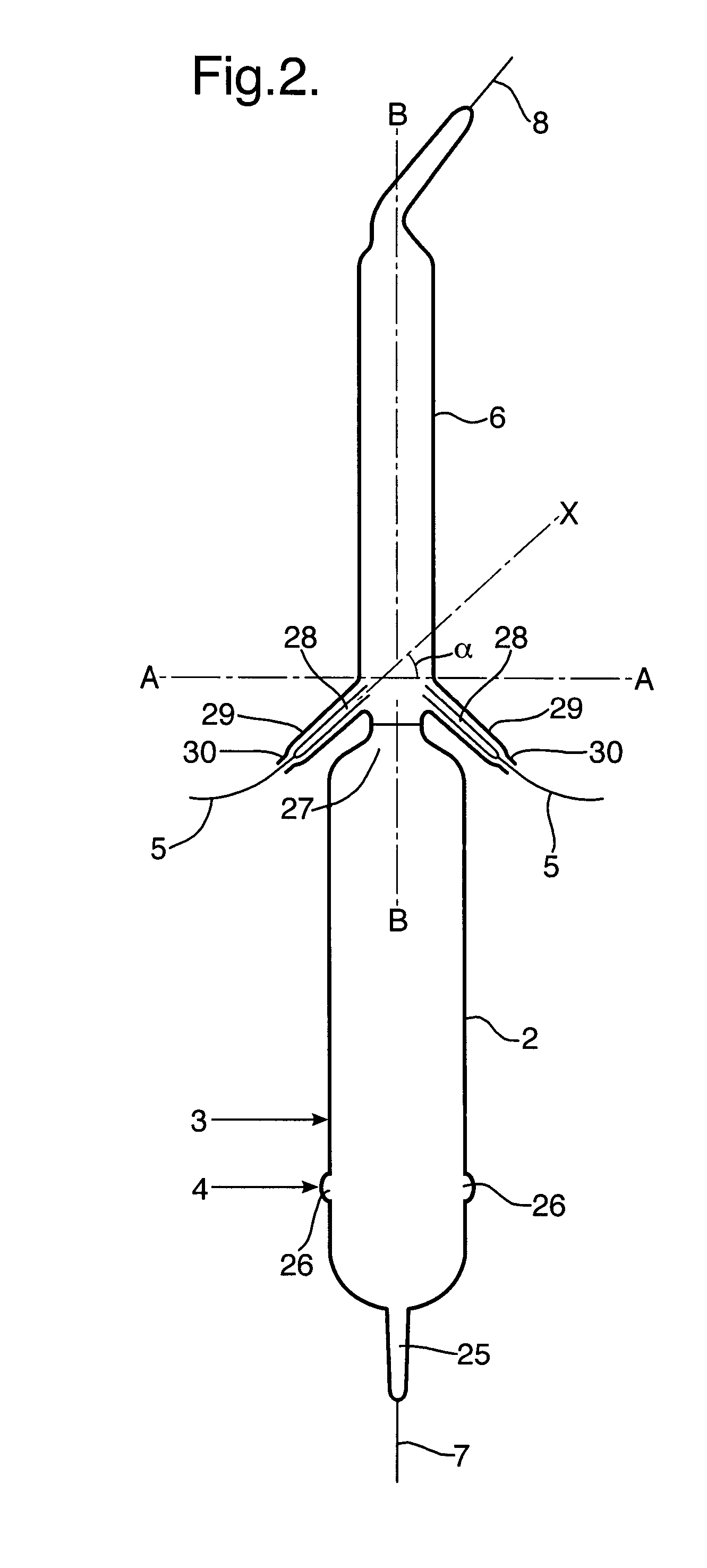

Liquid blast furnace slag pelletizing method and apparatus for heat recovering process

InactiveCN1888081AGuaranteed heat effectHigh activityOther heat production devicesRecycling and recovery technologiesLiquid slagProduct gas

The present invention is liquid blast furnace slag pelletizing method and apparatus for heat recovering process, and features that the liquid slag blast furnace discharges in downward flow is crushed into grains with the pelletizing apparatus in high speed rotation to produce centrifugal force of throwing the liquid slag. Crushing the liquid slag into relatively homogeneous fine grains can ensure the effective heat exchange between slag and gas. The pelletizing apparatus is one wheel spoke type disc or cup structure capable of ensure the effective recovering of heat from the liquid blast furnace slag.

Owner:CHONGQING UNIV

Slag for liquid pouring of electroslag

InactiveCN101890492AReduce manufacturing costReduce production processProcess efficiency improvementMelting tankHearth

The invention discloses slag for liquid pouring of electroslag, which belongs to the technical field of electroslag metallurgy. The slag comprises the following main components in percentage by weight: 35 to 45 percent of CaF2, 15 to 25 percent of CaO, 20 to 30 percent of Al2O3, 7 to 13 percent of SiO2 and 2 to 8 percent of MgO. A production method for the slag comprises the following steps of: putting raw materials, namely fluorite, industrial alumina, lime, quartz sand and magnesia, in a slag hearth; electrifying to arc and slag; after completely melting the slag, standing for 3 to 5 minutes and then cutting electricity; and leaning the hearth to pour the liquid slag into a slag disk (protective atmosphere) and cooling the liquid slag to obtain the slag. The slag has the advantages of changing the specific relation between a temperature parameter and electrical efficiency in the traditional electroslag remelting process, greatly enhancing the heat distribution capability between a control slag pool and a molten pool, providing the electrical efficiency and the thermal efficiency of a system, reducing the depth of the molten pool and contributing to obtaining uniform and fine tissues; moreover, the slag has the characteristic of continuous casting, and improves the production efficiency.

Owner:SHENYANG DONGDA MATERIAL ADVANCED PREPARATION TECH ENG RES CENT +1

Cyclone melting device and method for fly ash preheating

InactiveCN102620299AImprove leaching rateLow melting slag collection rateIncinerator apparatusThermodynamicsLiquid slag

The invention discloses a cyclone melting device and a cyclone melting method for fly ash preheating, particularly relates to a device and a method for fly ash melting treatment. The device comprises a cyclone furnace and a fly ash preheater, wherein a smoke outlet of the cyclone furnace is connected with a hot smoke inlet of the fly ash preheater, and a working medium outlet of the fly ash preheater is communicated with a secondary air tangential inlet of the cyclone furnace. The method comprises the steps as follows: mixing the primary air with coal powders; spraying into the front end of the cyclone furnace from a primary air inlet of the cyclone furnace; carrying fly ashes into the fly ash preheater through the secondary air for the combustion of the coal powders through adopting the pneumatic transmission technology, enabling high-temperature smoke generated by combustion in the cyclone furnace to enter the fly ash preheater for heating the secondary air and the fly ashes, enabling the fly ashes after heated through the high-temperature smoke to enter the cyclone furnace, quickly heating the fly ashes to reach the fly ash melting temperature, rotating the secondary air in the cyclone furnace at a high speed, throwing the fly ashes to the wall surface of the cyclone surface under the action of a centrifugal force, quickly melting the fly ashes through the high-temperature wall surface, and discharging the molten fly ashes in the form of liquid slags from a liquid deslagging hole at the bottom of the cyclone furnace.

Owner:NANJING XINYE ENERGY TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com