Patents

Literature

43results about How to "Reduce the difficulty of subsequent processing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

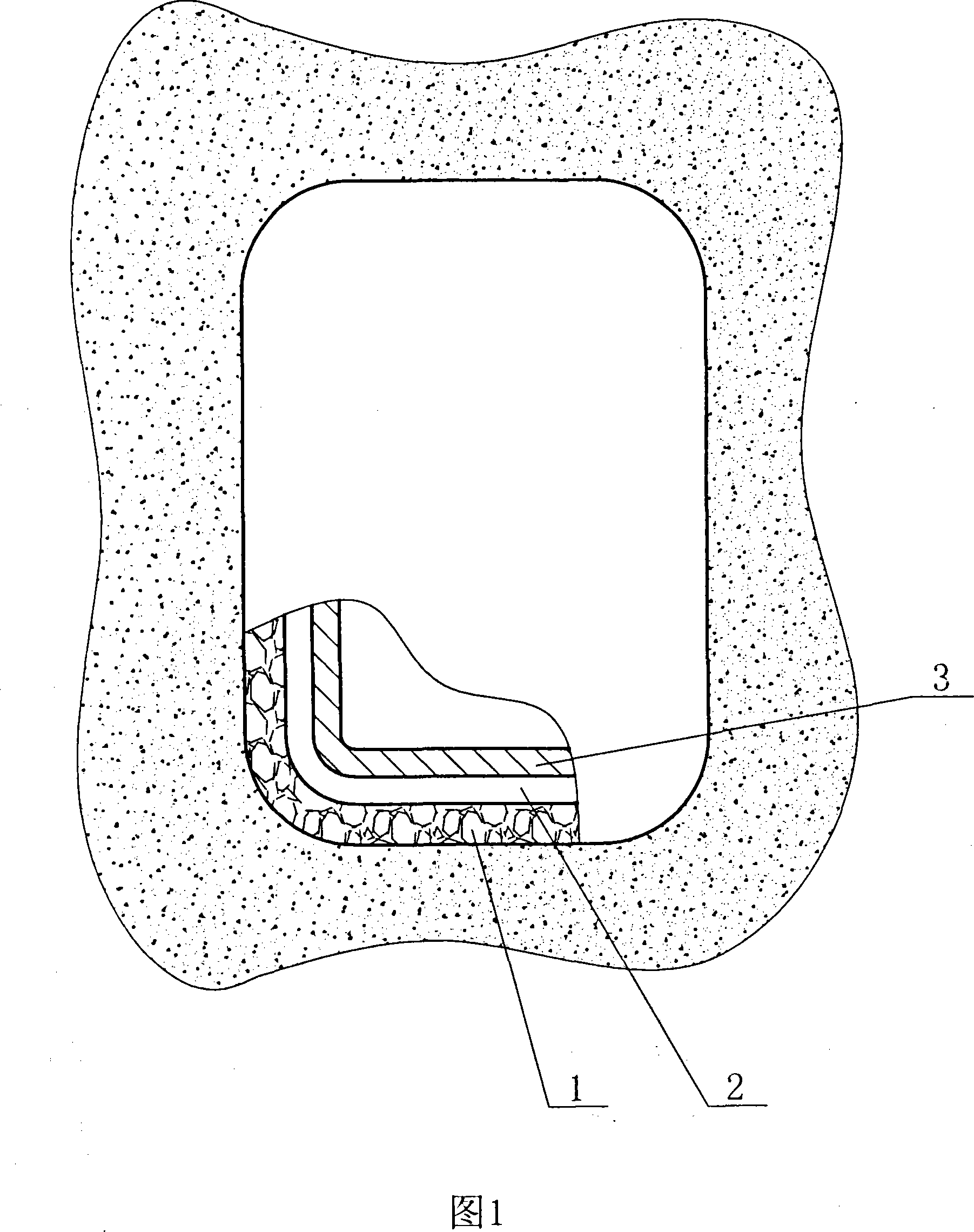

Technique for heating liquid steel scoria

InactiveCN101220399APut an end to the problem of serious pollution of the environmentReduce the difficulty of subsequent processingRecycling and recovery technologiesLiquid slagLiquid steel

The invention discloses a thermal-braise technique for liquid steel slag, which pours liquid steel slag into a thermal-braise tank directly for treatment, and the specific working procedure is: extending the bottom of the thermal-braise tank equally with dry steel slag with the thickness of 190 to 230 mm, pouring the produced liquid steel slag while making steel into the thermal-braise tank, the amount of the poured liquid steel slag is 10 to 12 percent of the gross cubage of the thermal-braise tank; spraying water into the thermal-braise tank immediately after the liquid steel is poured into the tank to ensure the surface of the liquid steel slag to form crust immediately; the manipulator looses the crusted steel slag until the liquid slag appears, and then restarts the water-spraying procedure to loose the steel slag; the final part is temperature-reducing procedure, and opens the cover to discharge the slag after aerating for 25 to 35 minutes. The technique of the invention finishes the whole process from liquid steel slag to steel slag grain in the thermal-braise tank, which primarily puts an end to the problem that liquid steel slag pollutes environment seriously, furthermore, the fine crushing degree of steel slag finally formed by the technique of the invention is excellent, and the self-crushing effect of steel slag in the fine crushing process is excellent, thereby leading the metal recovery rate of the steel slag to be improved about 18 percent compared with the prior art.

Owner:山东济钢泰航合金有限公司

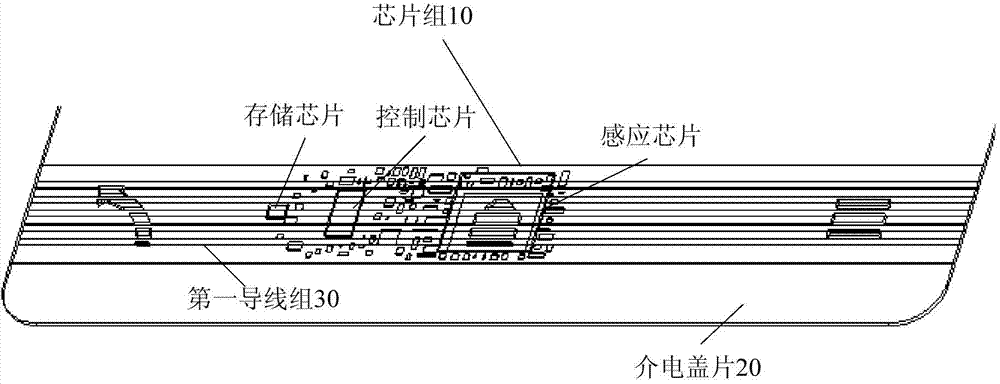

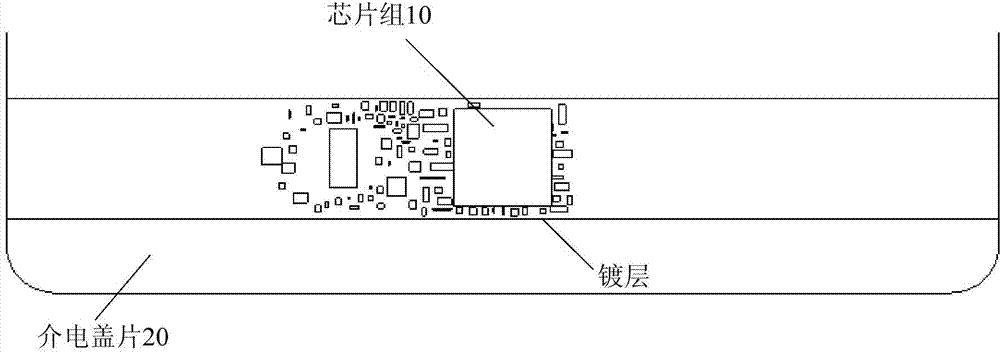

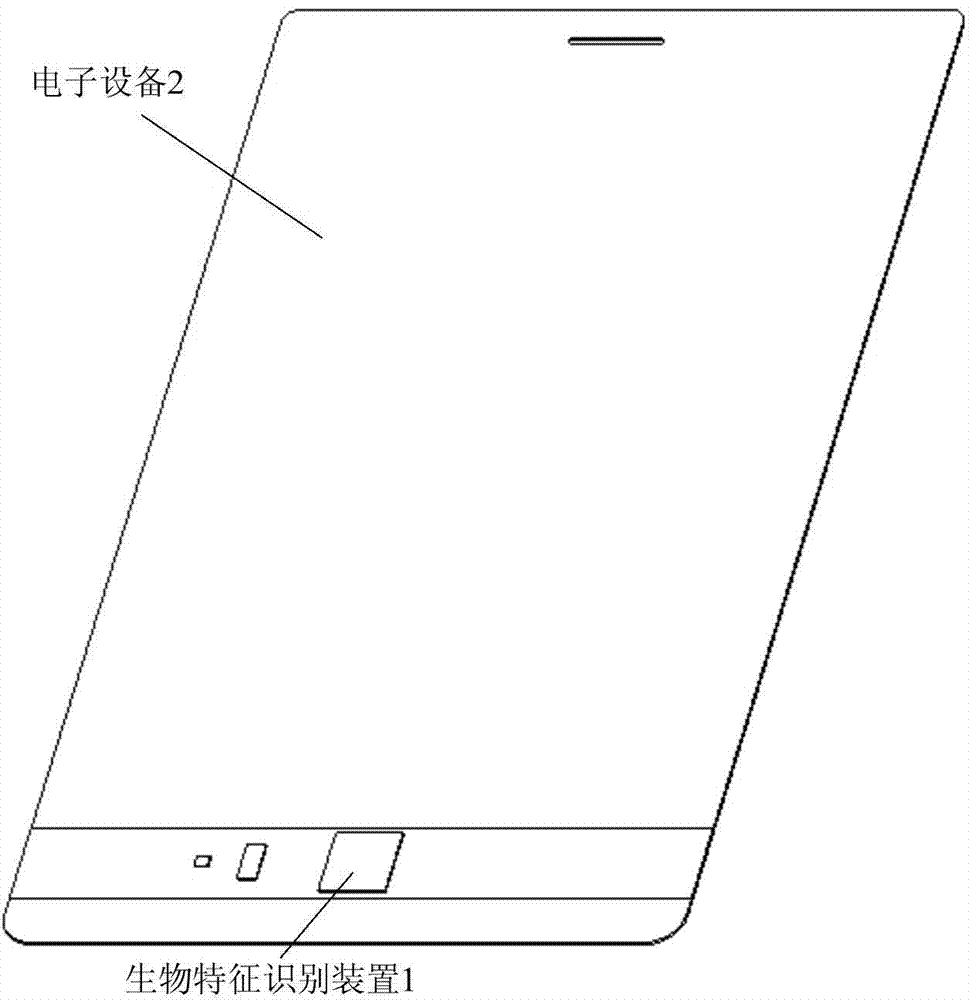

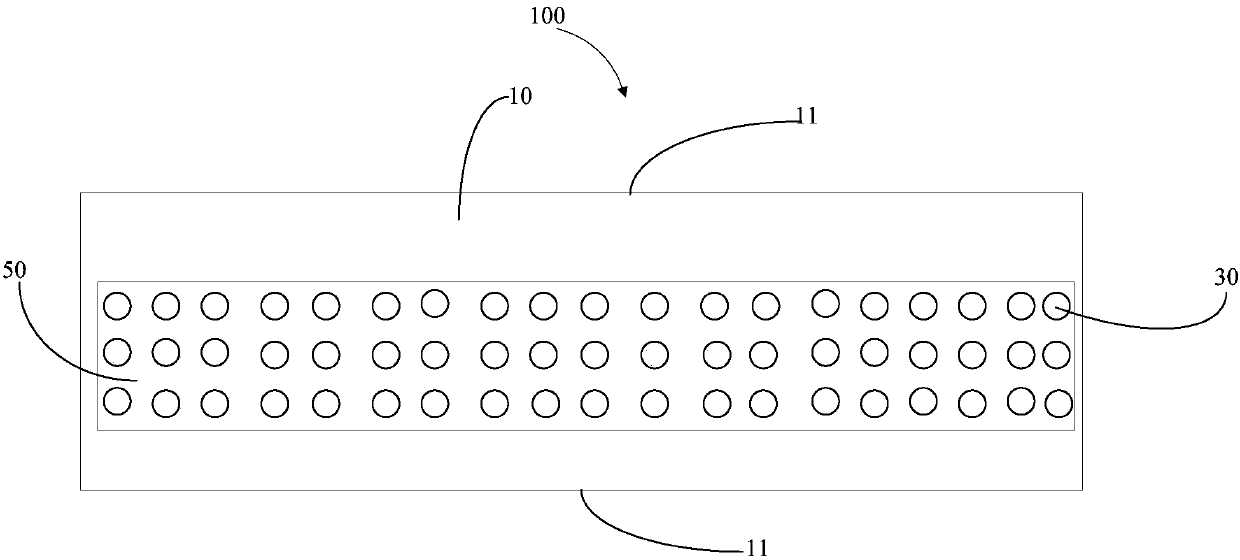

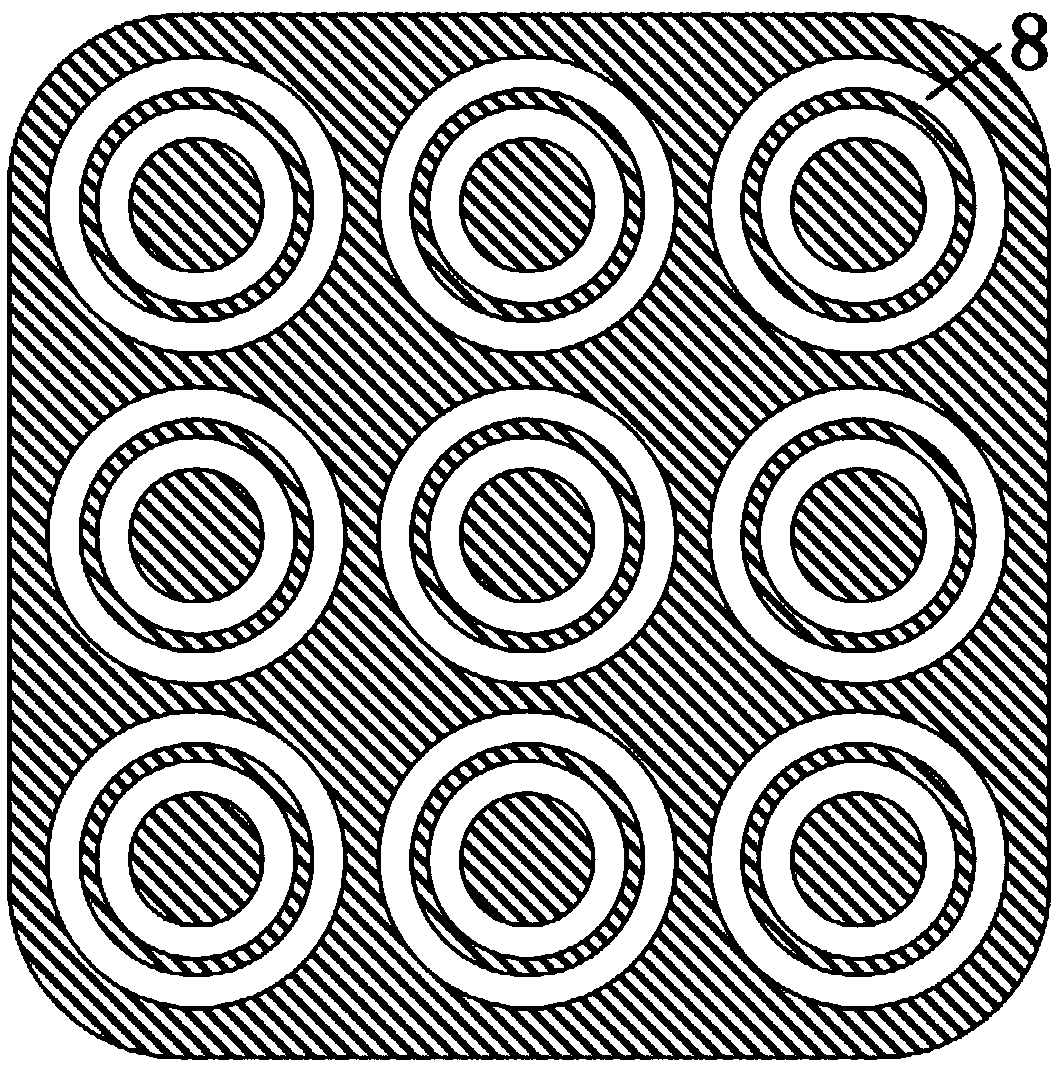

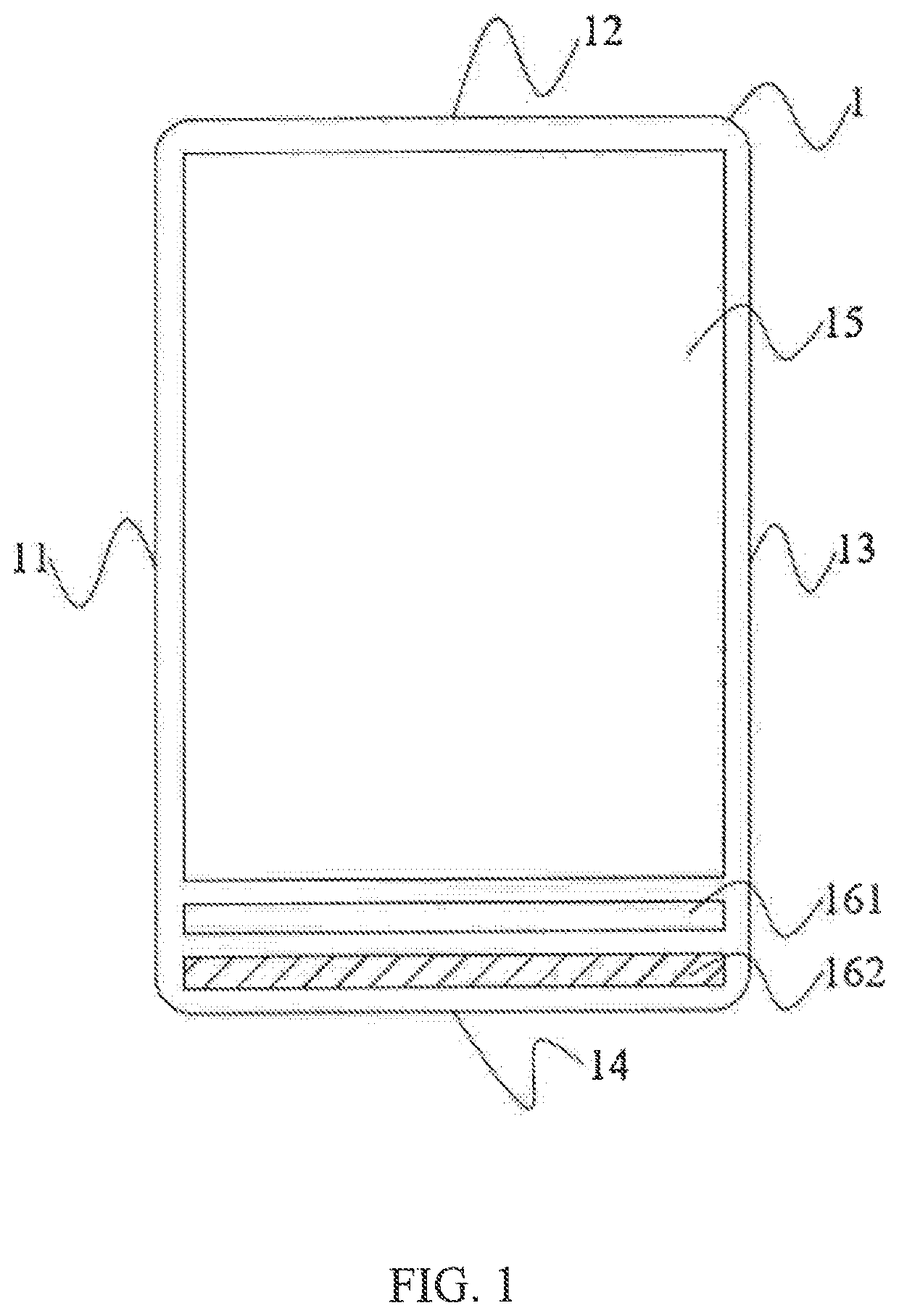

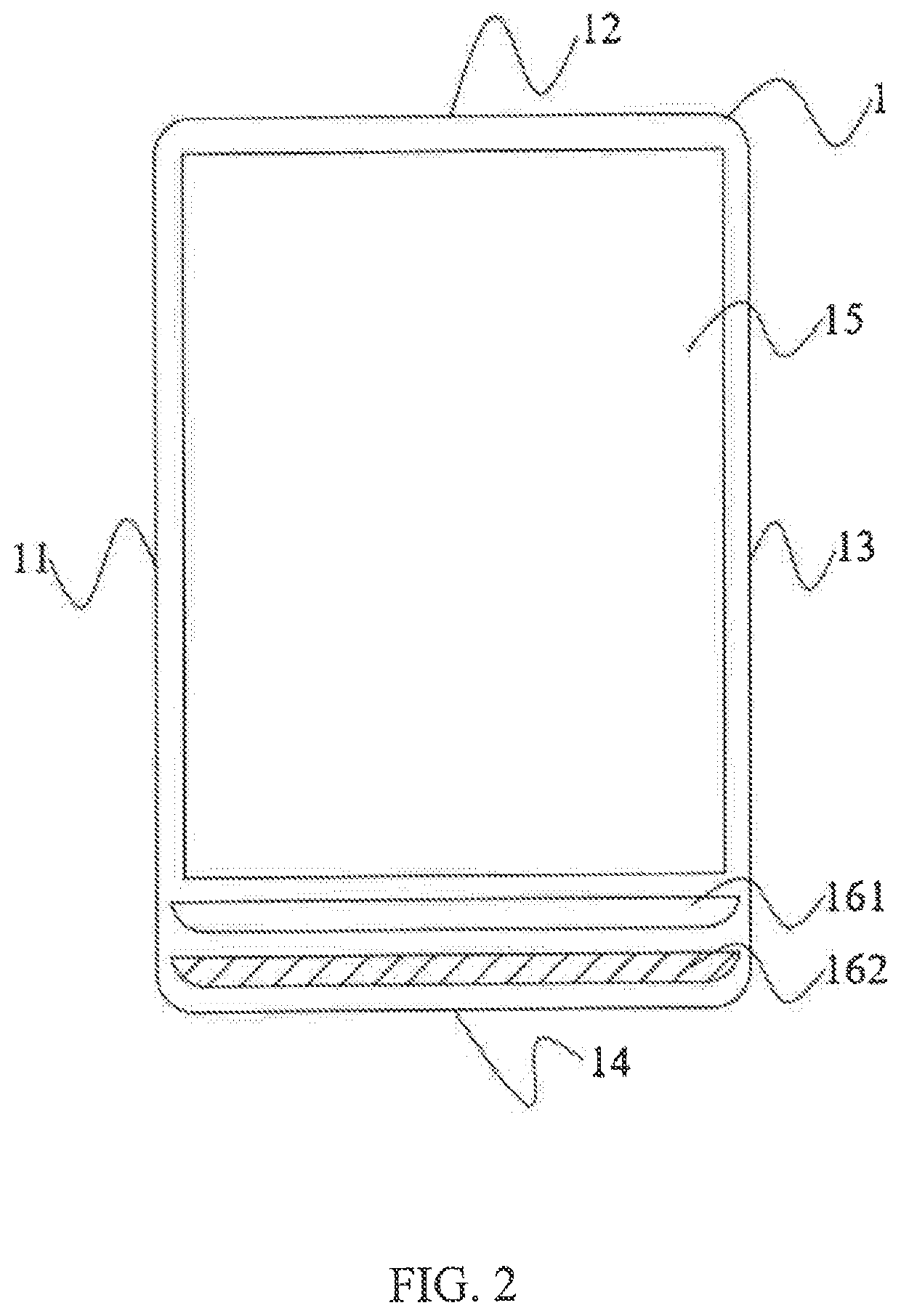

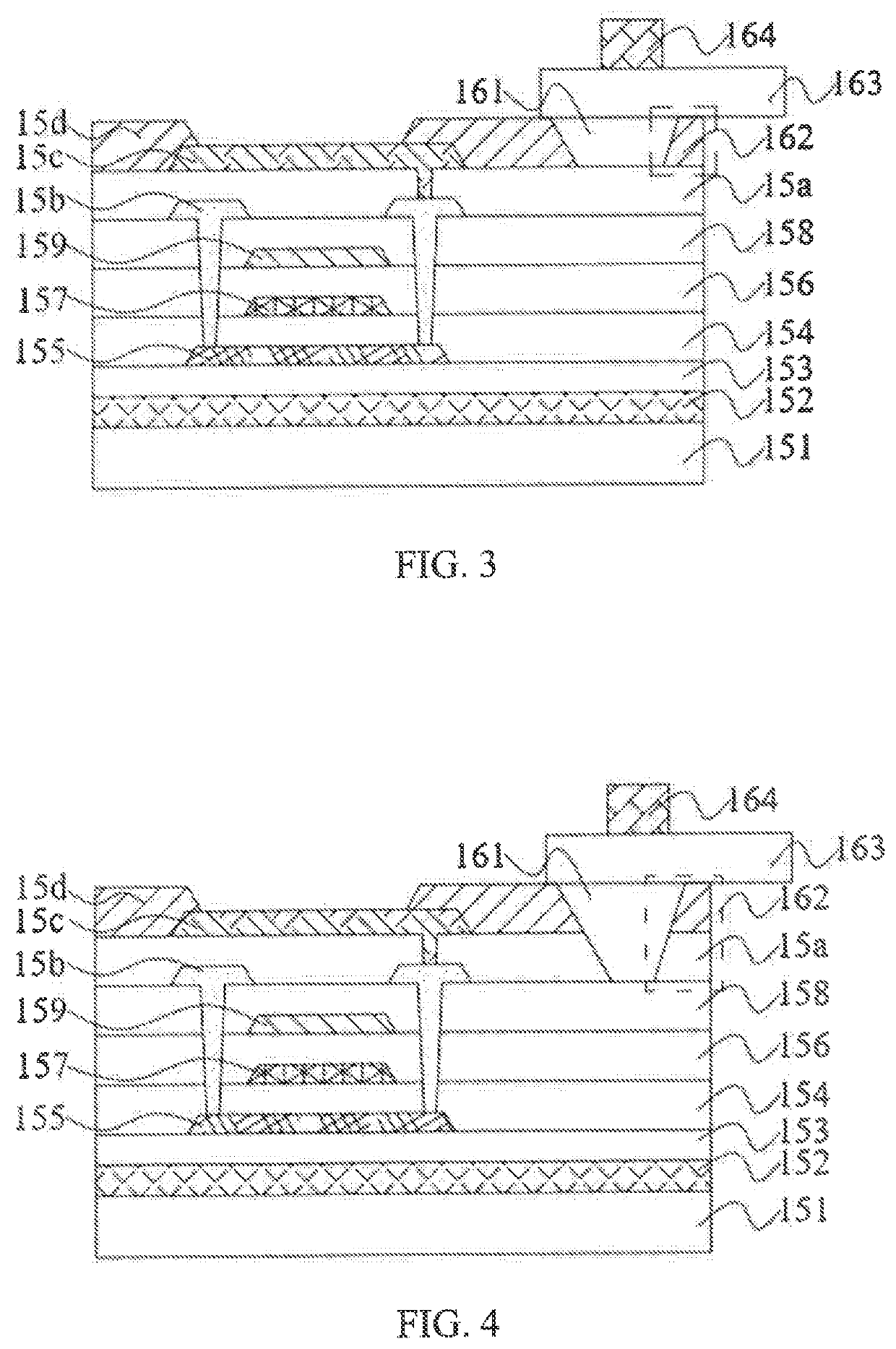

Biometric feature recognition device and electronic equipment

ActiveCN103793688AImprove integration densityReduce manufacturing costAutomatic exchangesPrint image acquisitionElectricityVolumetric Mass Density

The invention provides a biometric feature recognition device and electronic equipment with the biometric feature recognition device. The biometric feature recognition device comprises a chip set, a dielectric cover plate which is placed on the chip set and a first wire set which is placed on the dielectric cover plate. The first wire set is connected with the chip set, and the first wire set provides pulse signals for a finger when the finger of a user makes contact with the biometric feature recognition device. The biometric feature recognition device has the advantages that integration density is high, and subsequent processing difficulty is low; the device can be manufactured to be of an ultrathin structure, so that the ornamental value is high; in addition, the inside of the biometric feature recognition device can be protected, and thus the degree of safety is high.

Owner:SHENZHEN GOODIX TECH CO LTD

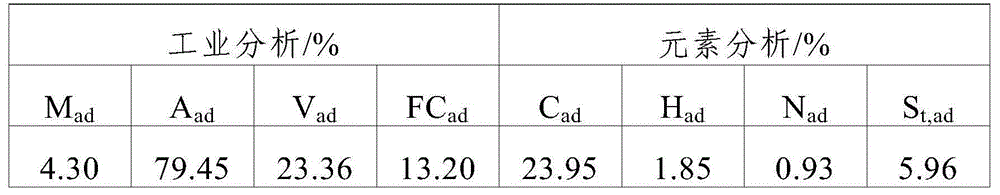

Catalyst for pyrolysis of oil shale as well as preparation method and use method of catalyst

InactiveCN103878031AIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisMetallic sulfide

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

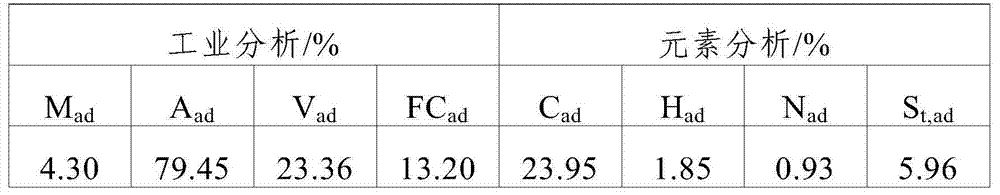

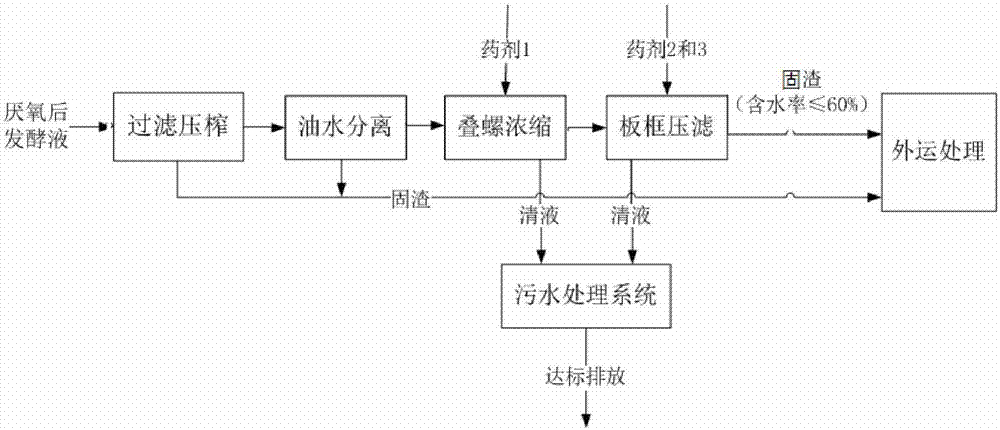

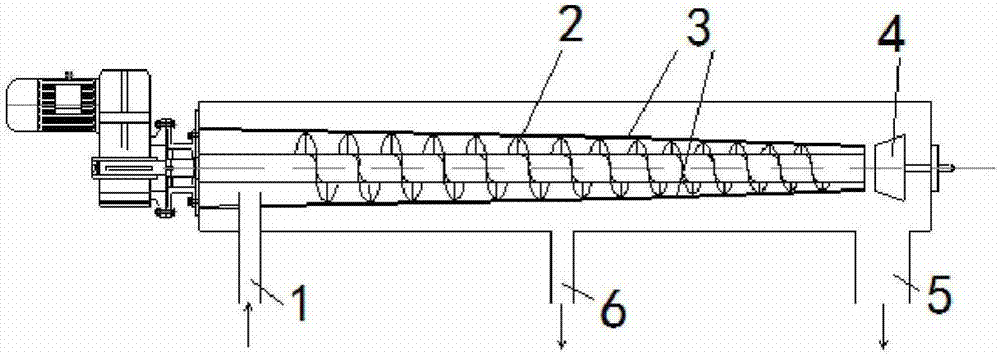

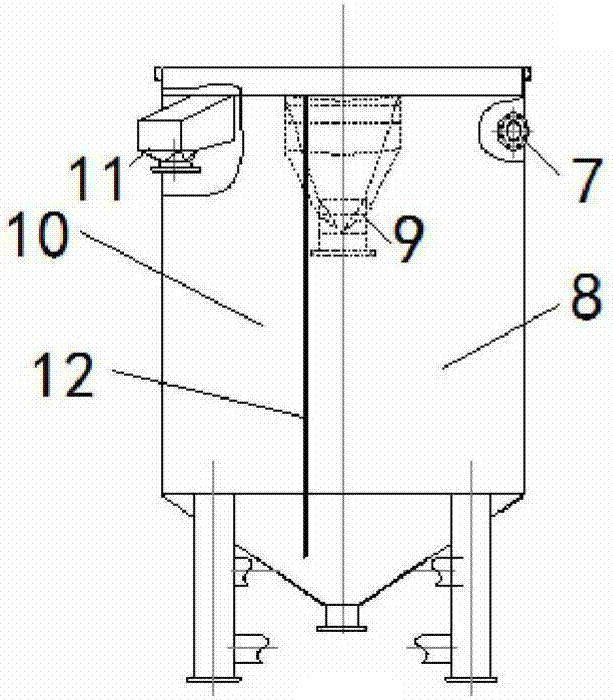

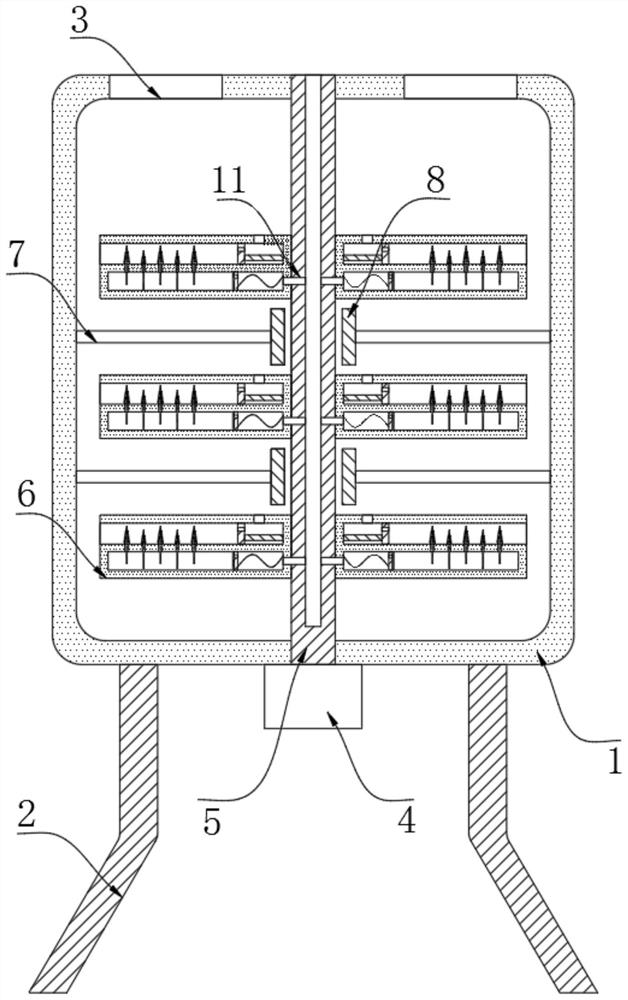

Solid-liquid separation method and device for multi-material anaerobic fermentation liquid containing kitchen wastes

PendingCN108002599AReduce workloadReduce filter areaFatty/oily/floating substances removal devicesTreatment involving filtrationPlunger pumpMulti material

The invention discloses a solid-liquid separation method and device for multi-material anaerobic fermentation liquid containing kitchen wastes and belongs to the technical field of kitchen waste treatment. A first discharging hole of a filter press is connected with a feeding hole of an oil-water separation tank by virtue of a pipeline; an overflow port of the oil-water separation tank is connected to a first conditioner by virtue of a pipeline; a submersible sewage pump is arranged in the first conditioner; the discharging hole of the submersible sewage pump is connected with a feeding hole of a multi-disk screw thickener; a second discharging hole of the multi-disk screw thickener is connected to a second conditioner by virtue of a pipeline; the second conditioner is connected with a feeding hole of a plunger pump by virtue of a pipeline; a discharging hole of the plunger pump is connected with a feeding hole of a plate-and-frame filter press; a residue outlet collection bucket of the plate-and-frame filter press is connected with the feeding hole of a residue delivery screw; the discharging hole of the residue delivery screw is connected with a residue box. Aiming at the material characteristics, the problems generated during operation of the original anaerobic fermentation liquid solid-liquid separation equipment with participation of kitchen wastes are gradually solved, the operating stability is improved, the treatment effect is ensured, the operating cost is reduced, secondary pollution is reduced, and the solid residues obtained by solid-liquid separation meet the national standard.

Owner:BMEI +1

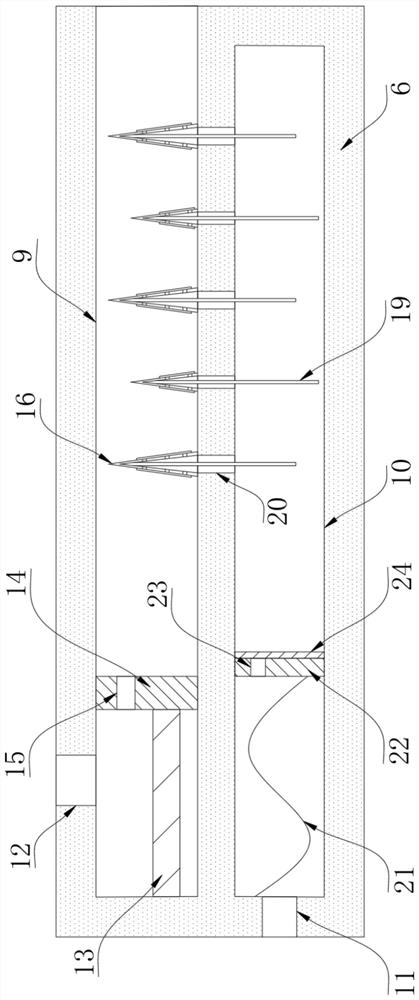

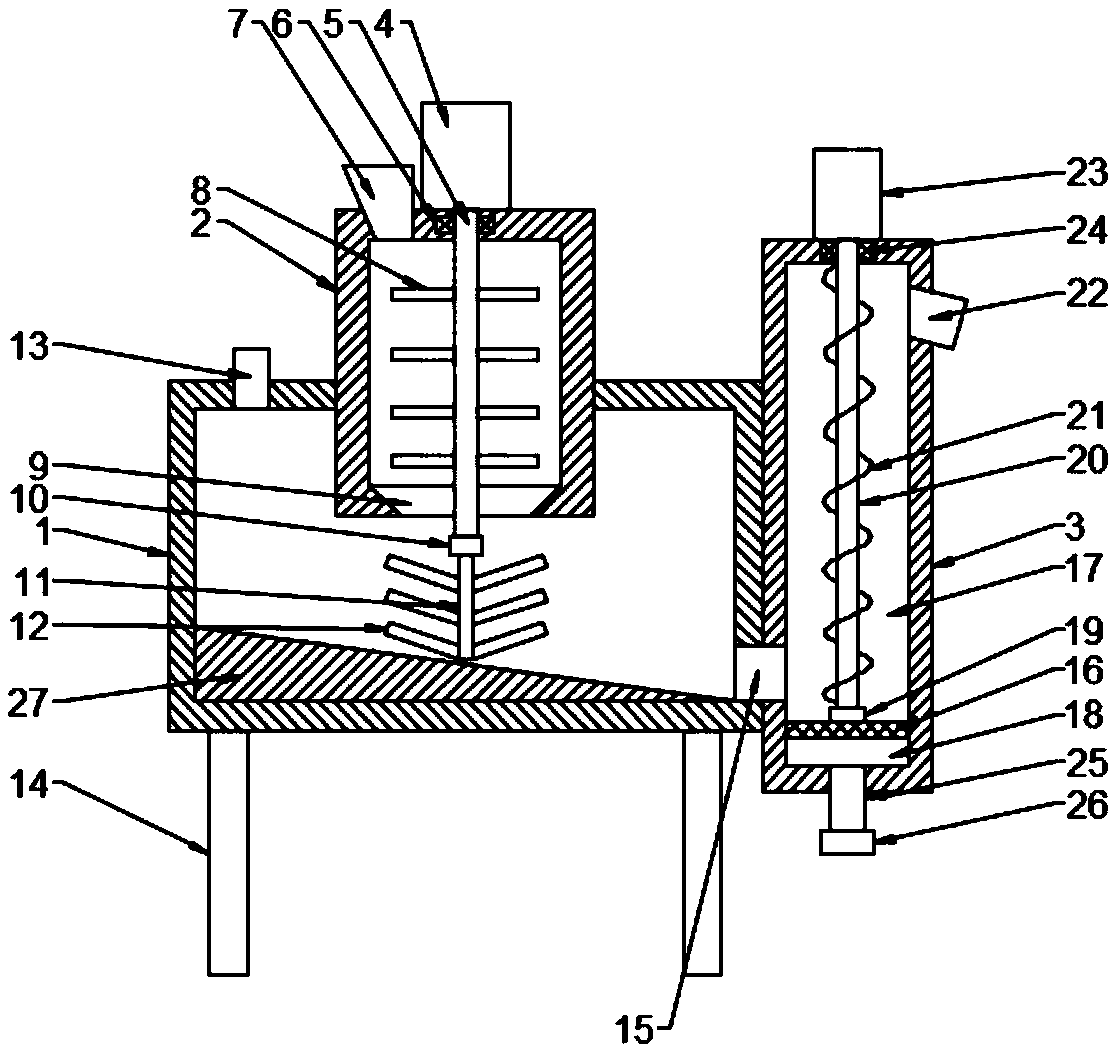

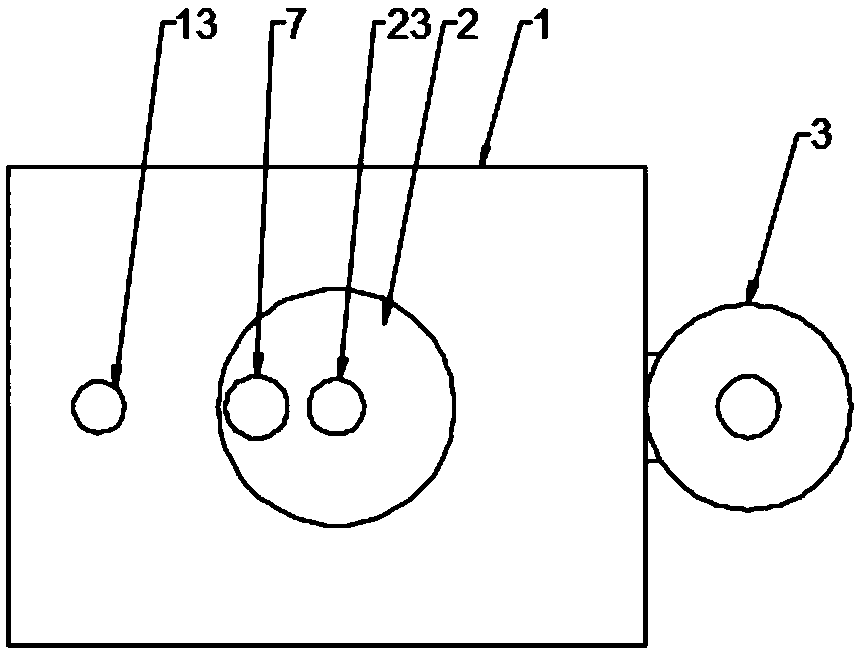

Mixing and defoaming equipment for water paint processing

InactiveCN112742240AImprove stirring and mixing effectReduce the difficulty of subsequent processingRotary stirring mixersTransportation and packagingReciprocating motionElectric machinery

The invention discloses a mixing and defoaming equipment for water paint processing. The mixing and defoaming equipment comprises a stirring box, a support is fixed to the bottom of the stirring box, a discharging opening is formed in the upper end of the stirring box, a motor is fixed to the bottom of the stirring box, a rotating shaft is fixed to an output shaft of the motor, and a plurality of stirring blades are fixed to the circumferential side wall of the rotating shaft; a plurality of fixing rods are fixed to the inner wall of the stirring box, a magnetic block is fixed to the end of each fixing rod, and a bubble removing groove is formed in the side wall of each stirring blade. The equipment has the advantages that by arranging a telescopic rod and the magnetic blocks, in the rotating and stirring process of the stirring blades, the telescopic rod does reciprocating telescopic motion under the action of the magnetic blocks, so that a push plate does reciprocating motion, and raw materials in the center of the stirring box enter the bubble removing groove from the inner inlet and are conveyed to the edge position of the stirring box; the raw materials at the center and the edge positions are exchanged, so that the stirring and mixing effects are improved.

Owner:武汉积墨包装印刷有限公司

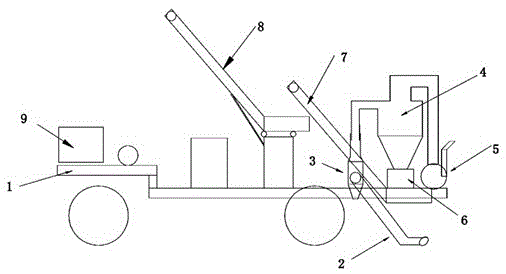

Moving type bulk pepper collecting equipment

InactiveCN105600512AReduce generationEnvironmentally friendlyGas current separationLoading/unloadingEngineeringHigh pressure

The invention discloses moving type bulk pepper collecting equipment, which comprises a carrying vehicle body, wherein a feeding pipeline, a stone removing and rotating device, a cyclone separator, a high-pressure fan, a wind closer and a chain plate conveyor are arranged on the carrying vehicle body; the outlet end of the feeding pipeline is connected with the stone removing and rotating device; the stone removing and rotating device is connected with the cyclone separator; the upper end of the cyclone separator is connected with the high-pressure fan; the lower end of the cyclone separator is connected with the wind closer; the wind closer is connected with the chain plate conveyor. The moving type bulk pepper collecting equipment has the advantages that the pepper bulk loading is realized; a woven bag is not used in the whole process; the labor consumption and the work intensity of people are reduced.

Owner:新疆晨曦椒业有限公司

Split type bearing bush centrifugal casting method

ActiveCN102581248AGuarantee molding qualityReduce internal stressBearing componentsMolten stateMaterials preparation

The invention discloses a split type bearing bush centrifugal casting method, which includes the steps of molten-state antifriction material preparation, bush billet treatment, centrifugal casting and subsequent machining. A bush billet is formed by fixing two fastened half bushes, and a bush billet treatment process includes the steps: machining annular grooves coaxial to the bush billet on two end faces of the bush billet, enabling each of two side walls of each annular groove to be low inside and high outside, arranging a spacer on a jointing face of the two half bushes which are integrally fastened, and enabling the spacer to extend along the axis of the bush billet to form a partition with the radial length along the bush billet not smaller than the radial thickness of a lining formed by pre-casting. Subsequent machining of the split type bearing bush centrifugal casting method only needs to turn two end faces of a bush body formed after casting, two split half bushes naturally form two bearing bushes without machining of a slotting machine or a sawing machine, Babbitt metal is low in internal stress generated by means of subsequent machining and is firm in jointing with the bush billet, bearing bush forming quality can be guaranteed, subsequent machining difficulty is low, workload is less and machining cost is low.

Owner:重庆新承航锐科技股份有限公司

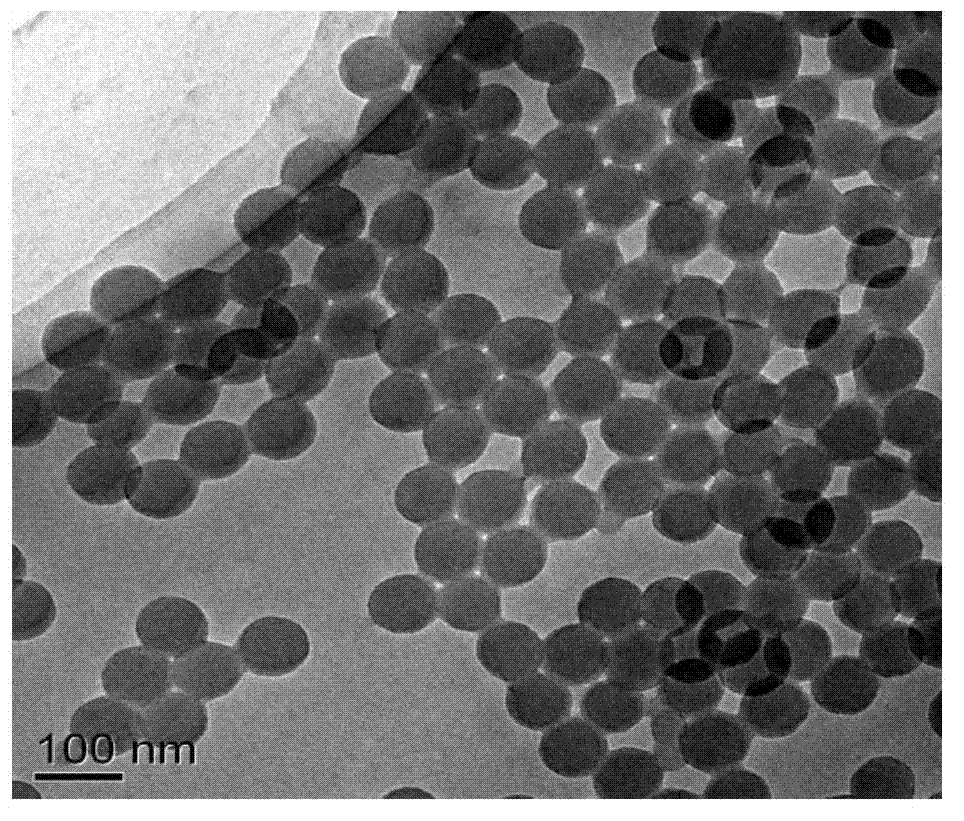

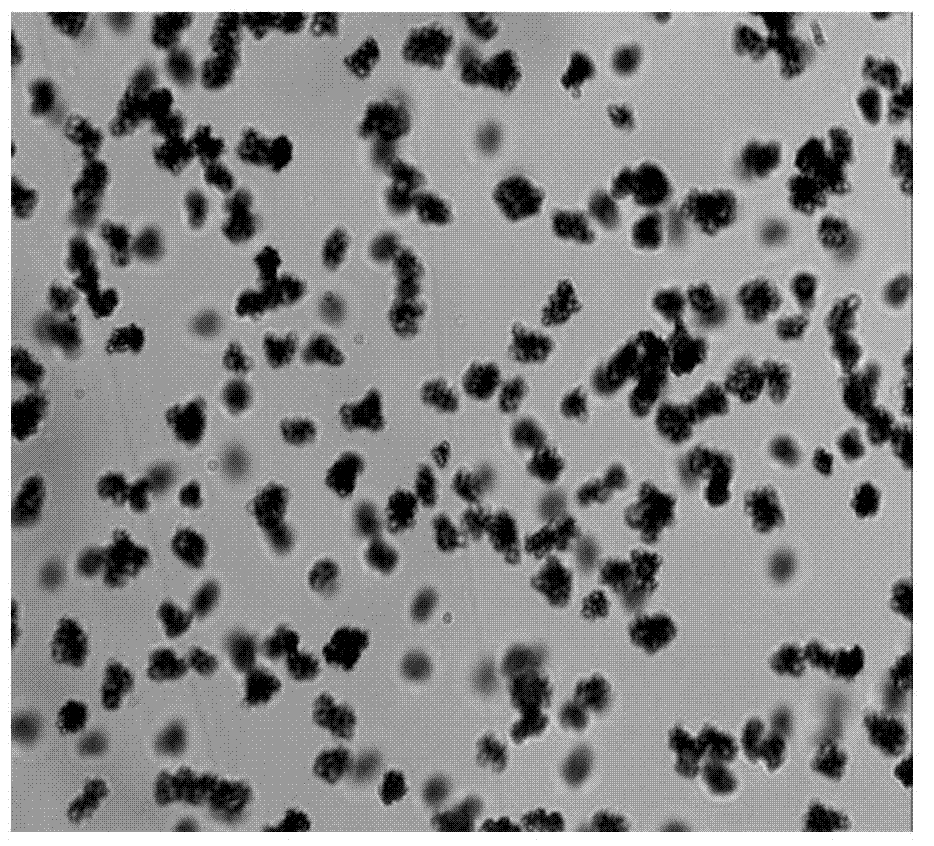

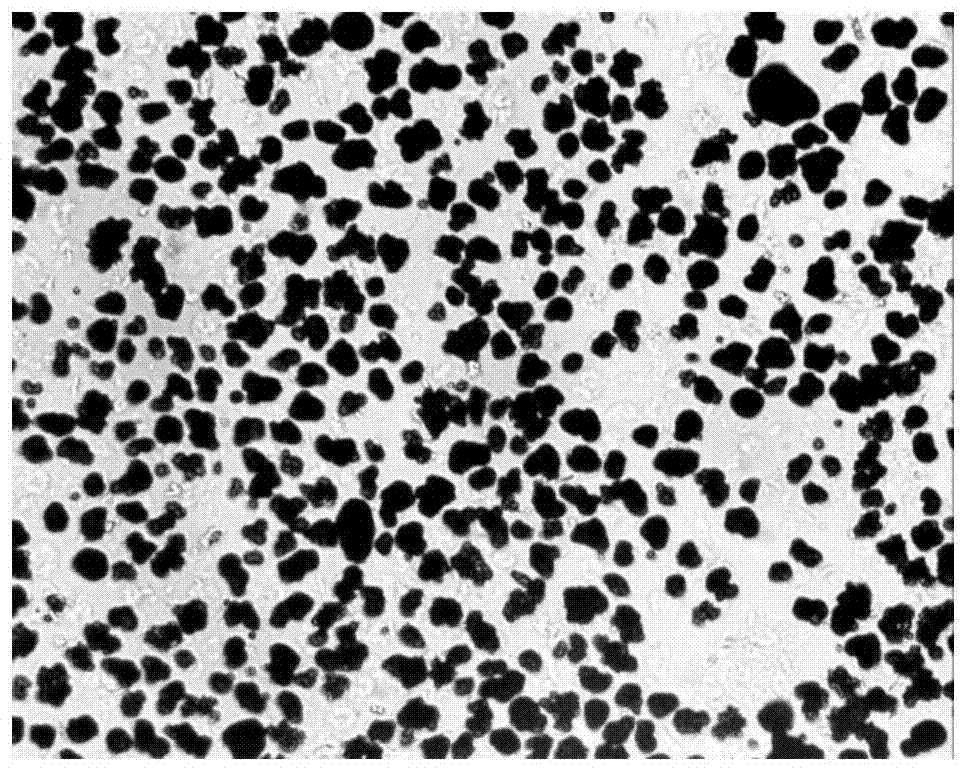

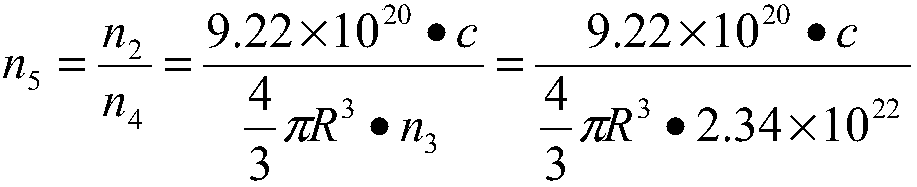

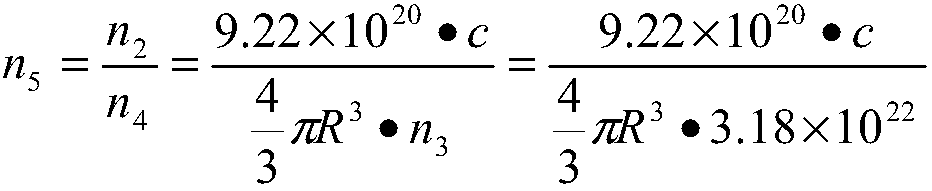

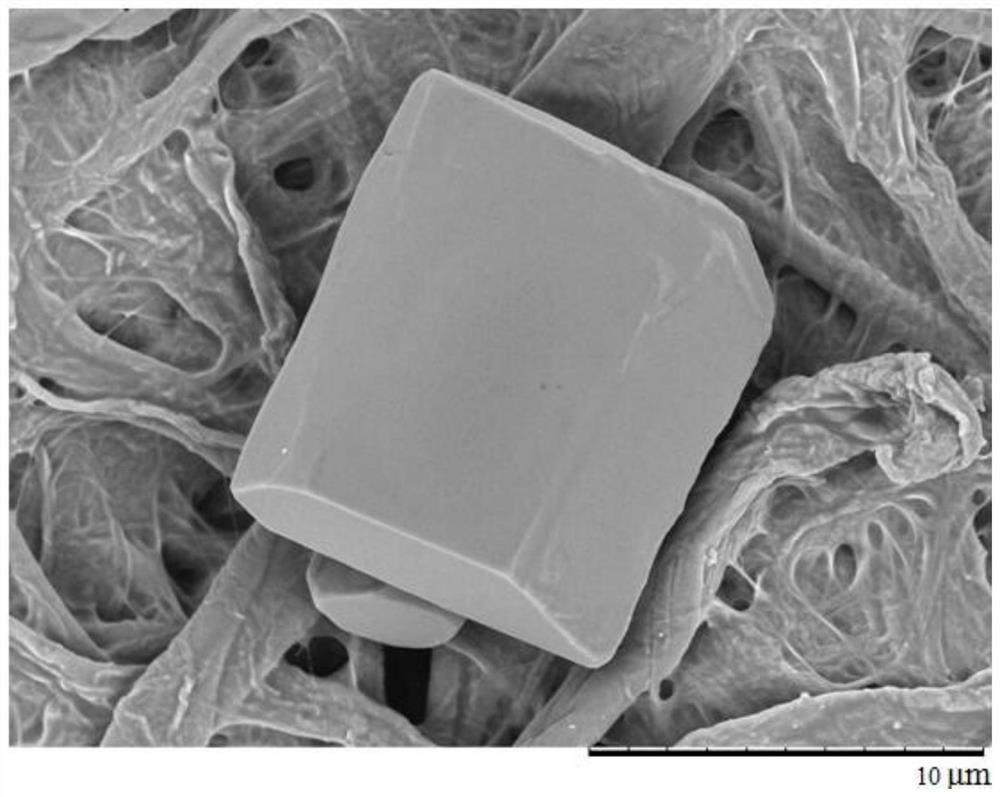

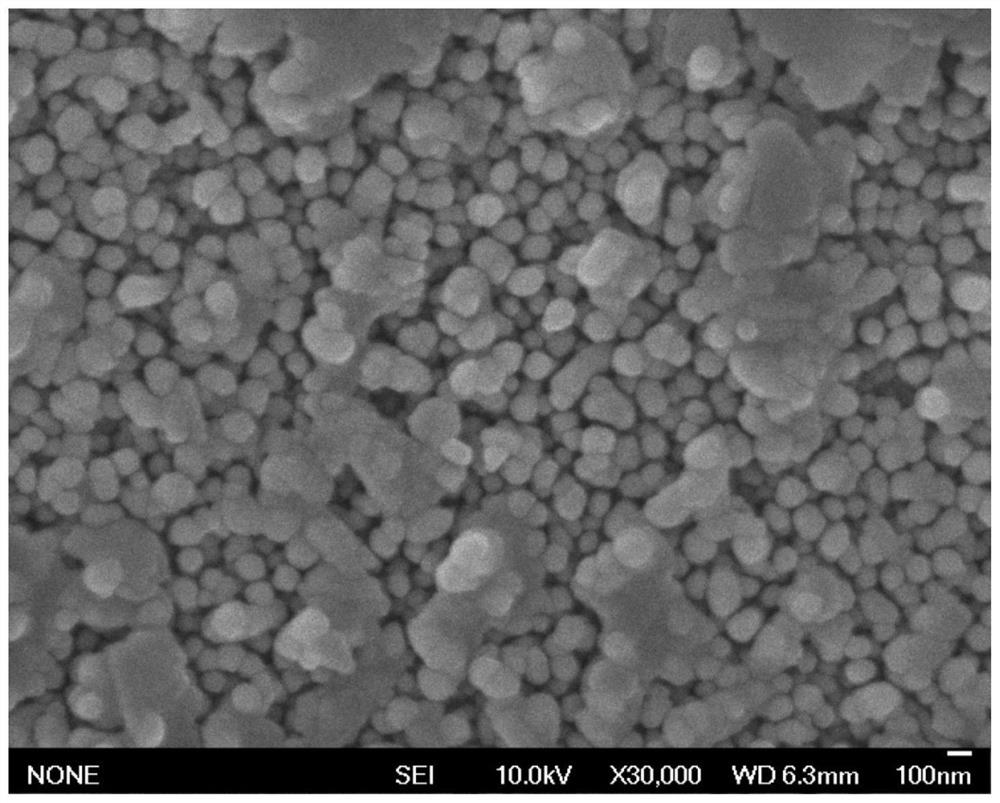

Method for preparing chemical carbon powder by coagulation on basis of modified latex particles and modified pigment emulsion

InactiveCN102809905AParticle size controllableNarrow size distributionDevelopersEmulsionLatex particle

The invention relates to a method for preparing chemical carbon powder by coagulation on the basis of modified latex particles and modified pigment emulsion. The method includes uniformly dispersing the modified latex particles with sulfonic groups fixed on surfaces, modified pigment particles coated with high polymers, wax dispersion liquid, anionic surfactants and nonionic surfactants in a disperse system at first; then adding flocculating agents into the system to remove stabilization so that the latex particles are coagulated to form micelle, and enabling the pigment particles and wax dispersion particles to coat inside the micelle when the latex particles are coagulated to form the micelle; and finally, performing thermal treatment to obtain chemical carbon powder particles with controllable sizes, approximately spherical shapes and uniform particle diameters.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

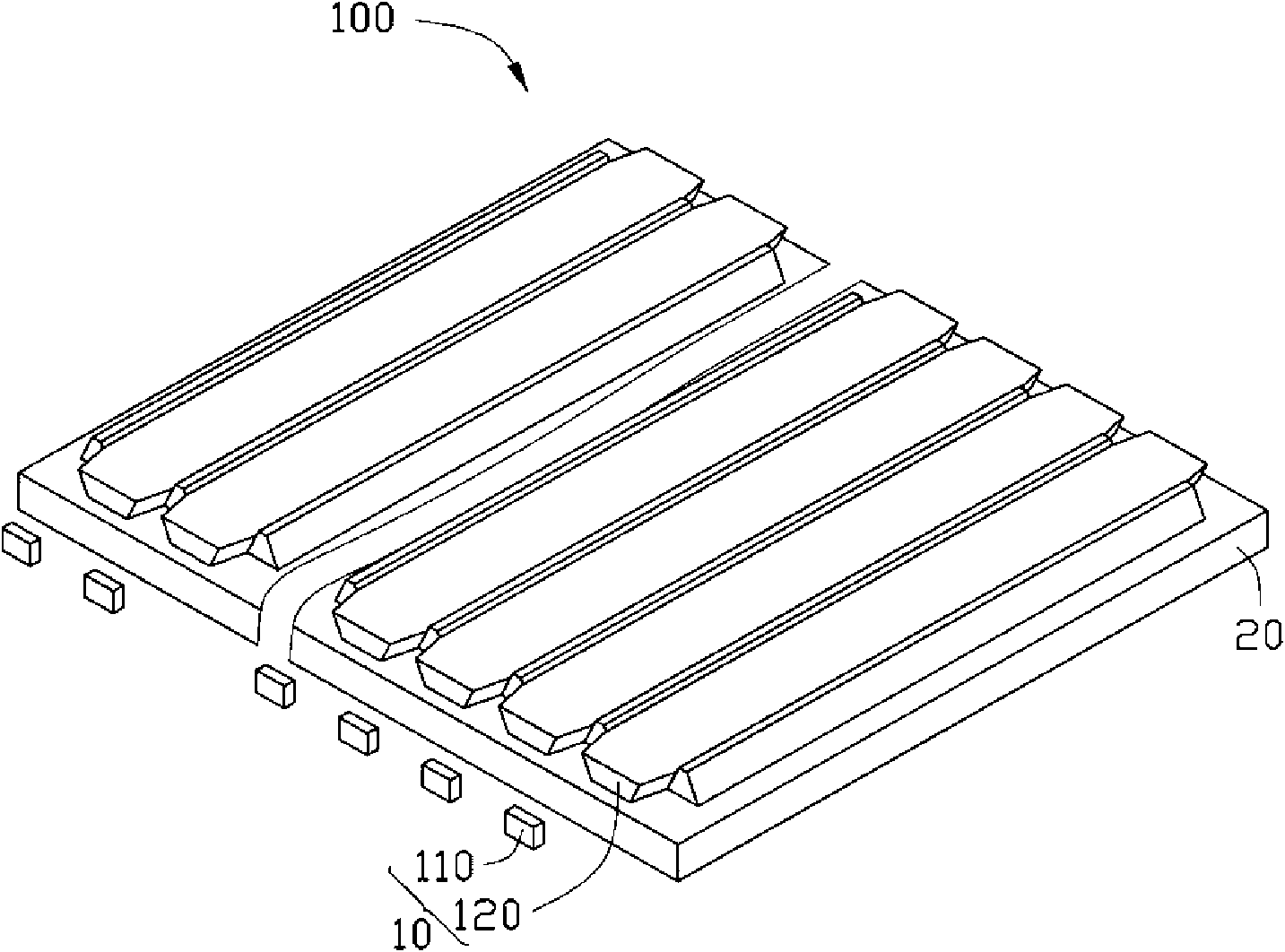

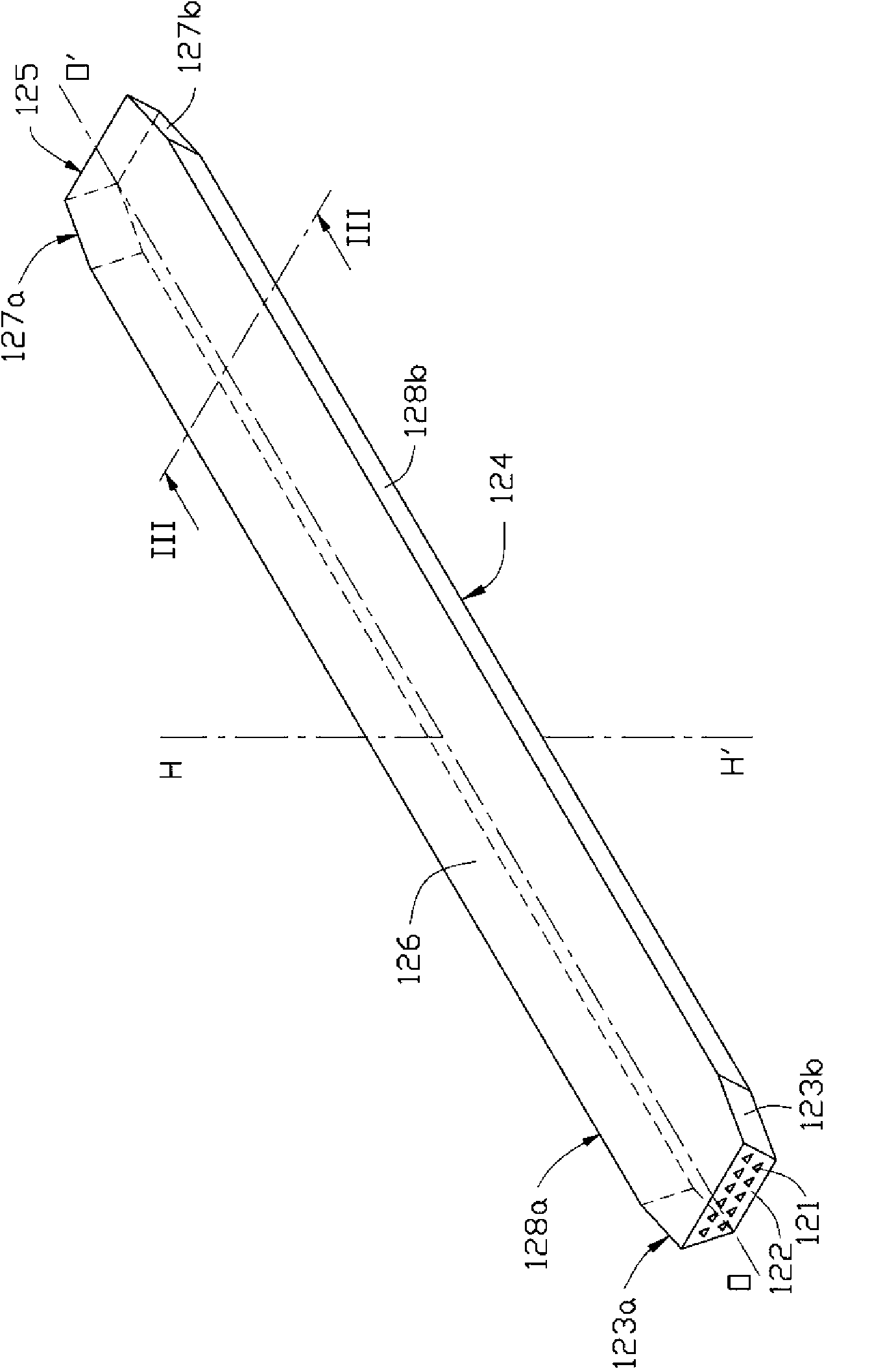

Backlight module

InactiveCN101592824AMeet needsAvoid makingOptical light guidesNon-linear opticsLiquid-crystal displayLight guide

The invention discloses a backlight module, which comprises a frame and a plurality of backlight units. Each backlight unit comprises a light source and a light guide plate, wherein the light guide plate comprises an incident face opposite to the light source, a bottom face and an exit face opposite to the bottom face; the incident face is connected with the bottom face and the exit face; and the cross section, in a direction perpendicular to the exit face and parallel to the incident face, of the light guide plate is an inverse trapezium. The frame comprises a plurality of accommodating spaces which are matched with the plurality of the light guide plates for accommodating the plurality of the light guide plates. As the plurality of the light guide plates are tightly accommodated in the plurality of the accommodating spaces of the frame, the backlight module meets the requirements of a large-sized liquid crystal display on a large-sized backlight module, avoids making a large-sized light guide plate by using a large mold or forming machine at the same time, and reduces difficulties in subsequent processing.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Ceramic composite material, manufacturing method thereof, and wavelength converter

PendingCN107797312AHigh light conversion efficiencyPrevent direct transmissionNon-linear opticsNoble gasCeramic composite

Provided is a ceramic composite material, comprising a ceramic body. The ceramic body is luminescent ceramic in structure of cerium doped with garnet. Cerium is used as an optical active center of theceramic composite material. The ceramic composite material also includes a plurality of ion implantation components which are arranged at interval and distributed uniformly. The ion implantation component is formed and is held in the ceramic body through an ion implantation method. The internal of the ion implantation component is pores and / or solid particles. The pores contain at least one of hydrogen, nitrogen or rare gases. The solid particles are oxide particles whose optical absorption coefficient is lower than 0.01 cm<-1>. The invention also discloses a manufacturing method of the ceramic composite material, and a wavelength converter including the ceramic composite material. The ceramic composite material has relatively high light conversion efficiency.

Owner:APPOTRONICS CORP LTD

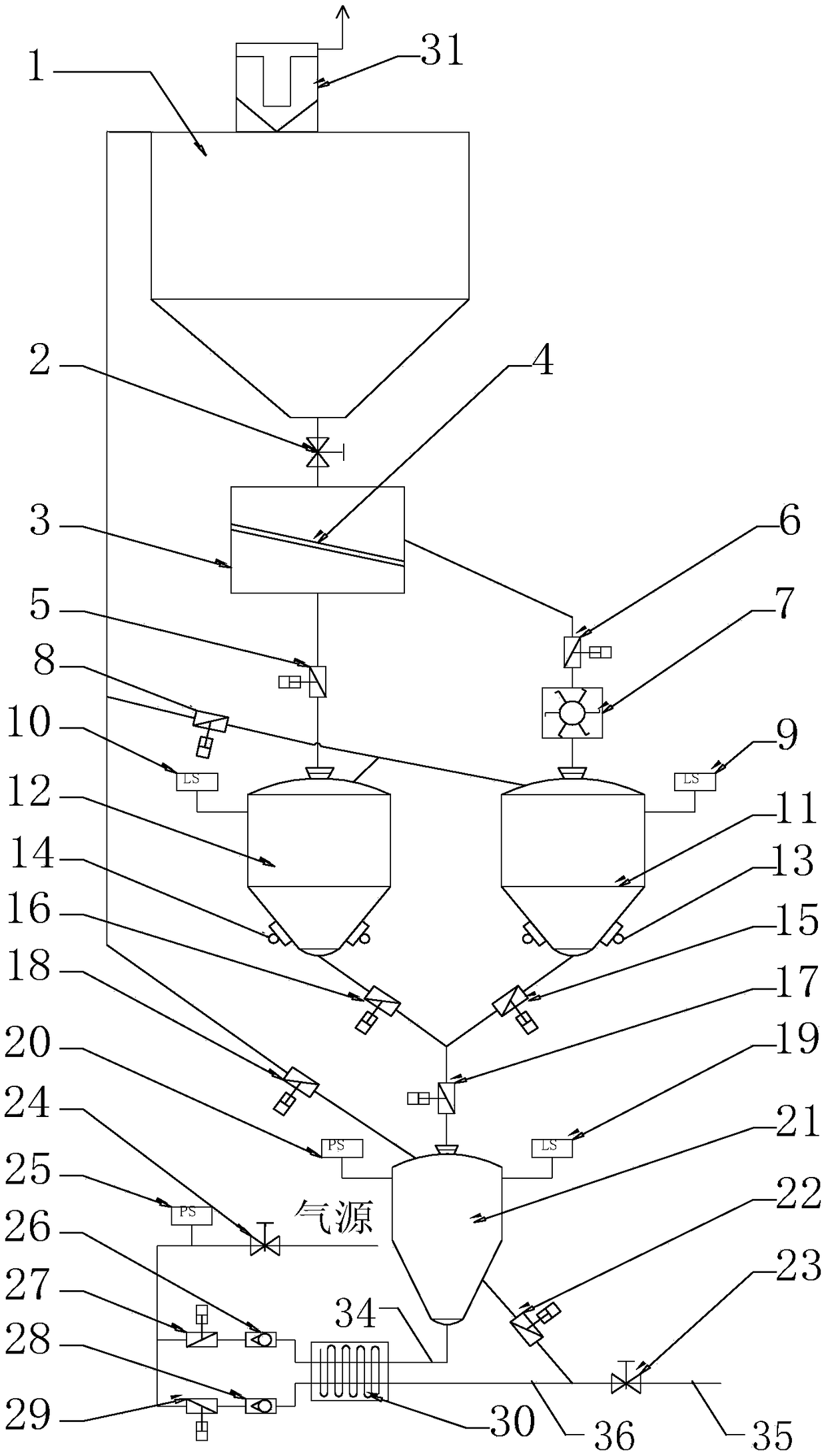

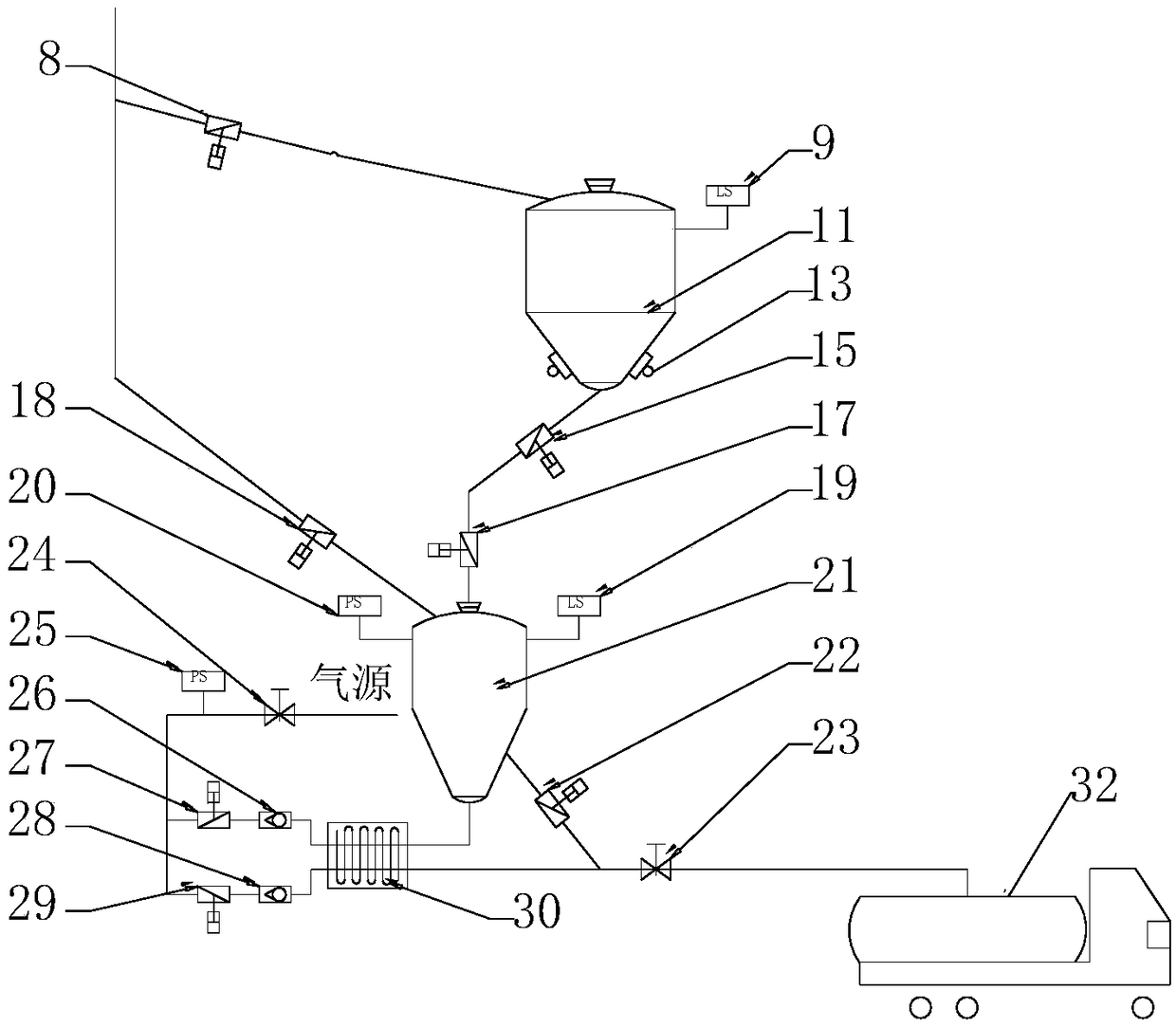

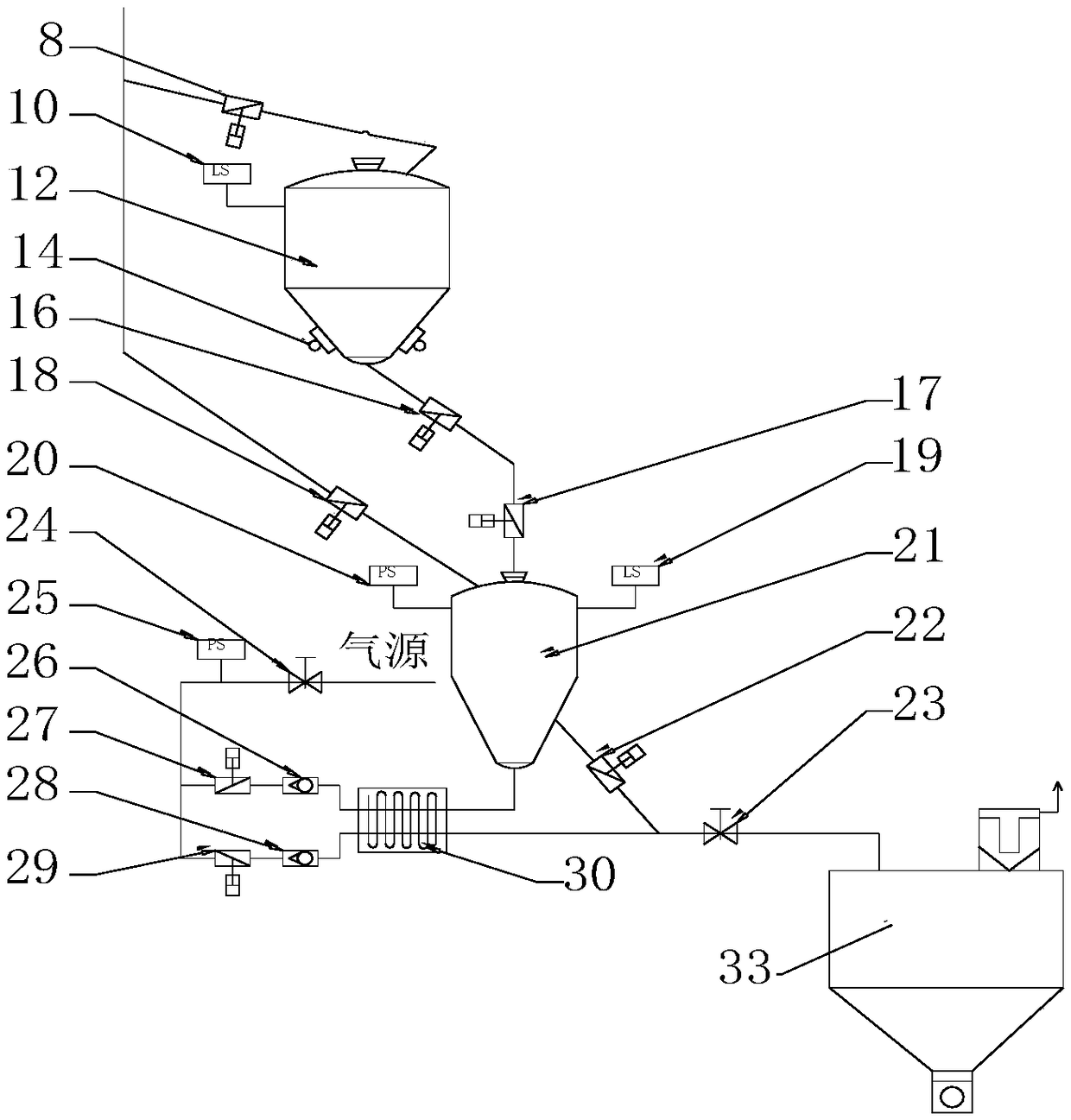

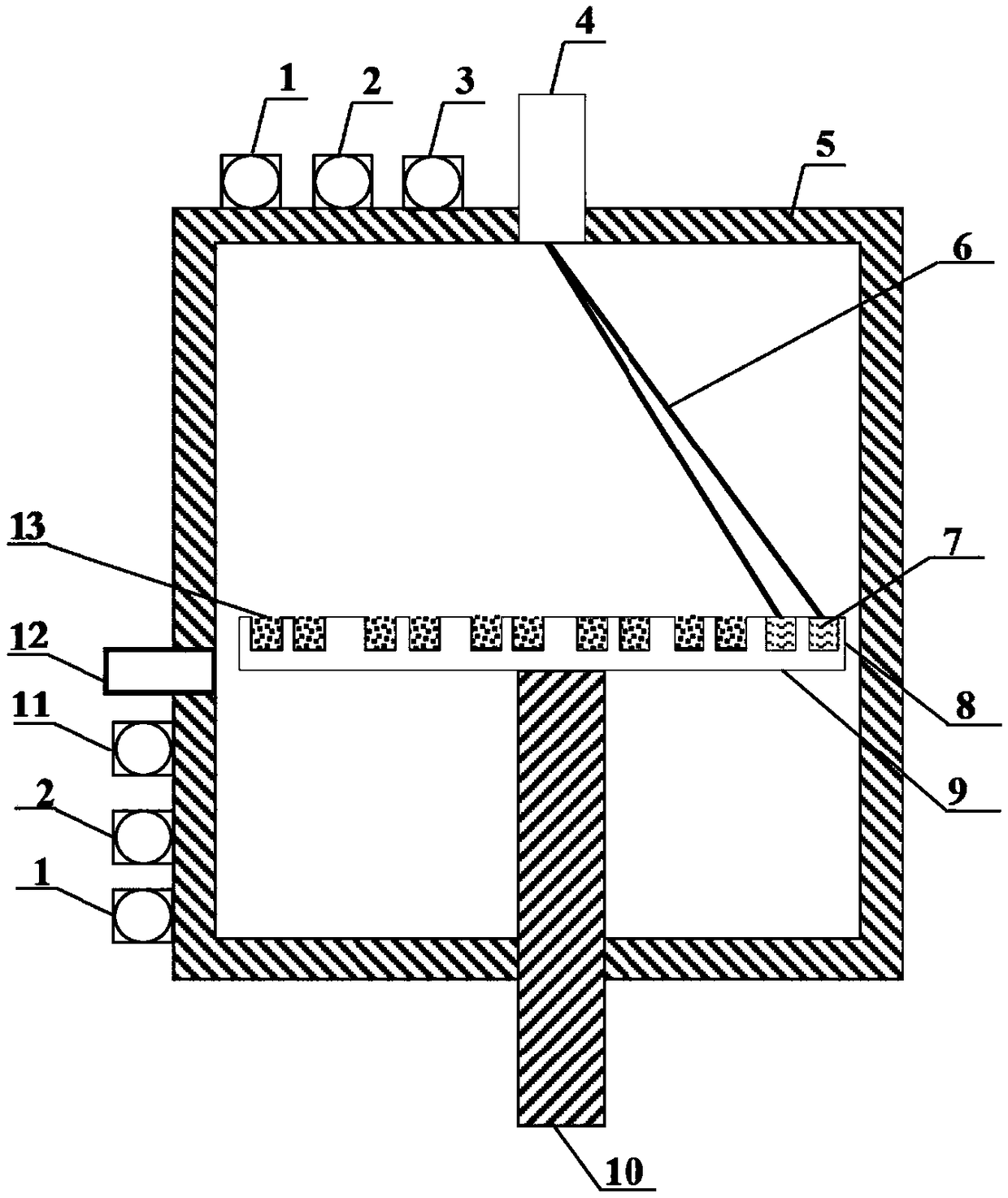

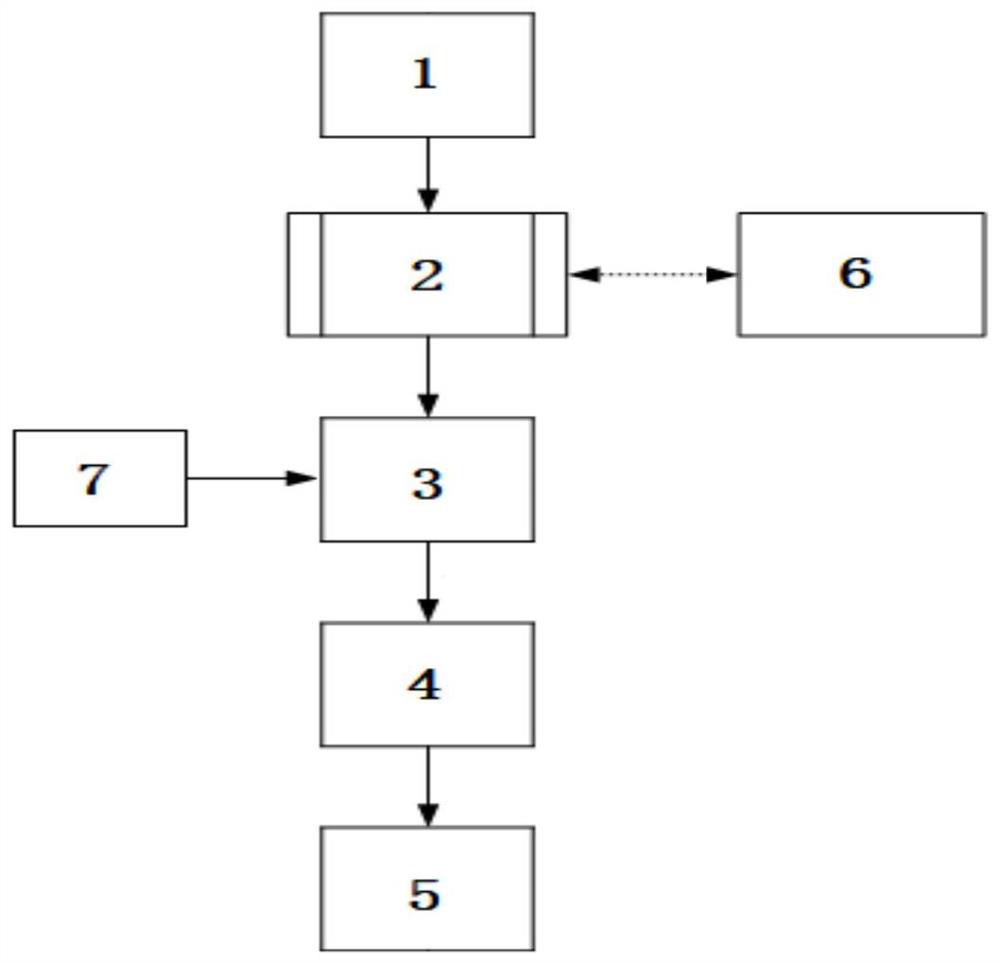

Metallurgical fly ash closed collection and treatment and transportation system and technology

InactiveCN108928651ADelay wearReduce transportation energy consumptionLoading/unloadingTemperature UnitMaterial storage

The invention discloses a metallurgical fly ash closed collection and treatment and transportation system and technology. The metallurgical fly ash closed collection and treatment and transportation system comprises a fly ash main storage unit, a filter storage unit, a fluidized variable temperature unit, a pneumatic transportation unit and a diffusing unit. The fly ash main storage unit is used for storing fly ashes. The filter storage unit includes a filter module, a coarse material storage module and a fine material storage module, the filter module is used for performing vibration screening on the fly ashes, the fine material storage module is used for fine materials, and the coarse material storage module is used for grinding and storage of coarse materials. The fluidized variable temperature unit is used for heating and dehydrating, cooling or pressurized fluidizing on fine materials and / or the coarse materials. The pneumatic transportation unit is used for transporting the fly ashes to subsequent equipment. The diffusing unit is used for ensuring the pressure balance between the fly ash main storage unit, the filter storage unit and the fluidized variable temperature unit. The metallurgical fly ash closed collection and treatment and transportation system can realize the functions of fly ash collection, screening, grinding, heating, cooling, pressurized fluidizing, storing, pneumatic transporting and the like in a closed system.

Owner:武汉钢铁有限公司

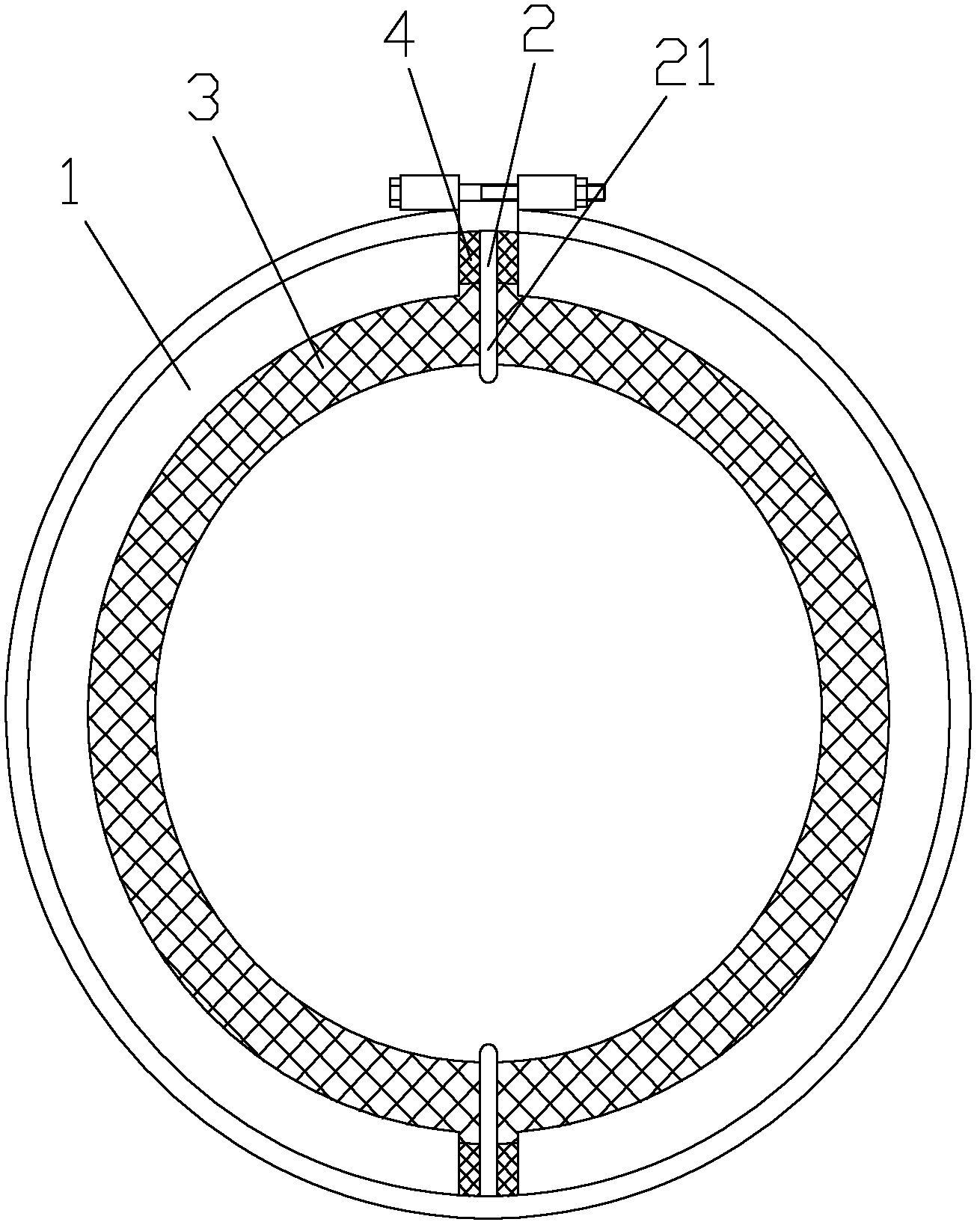

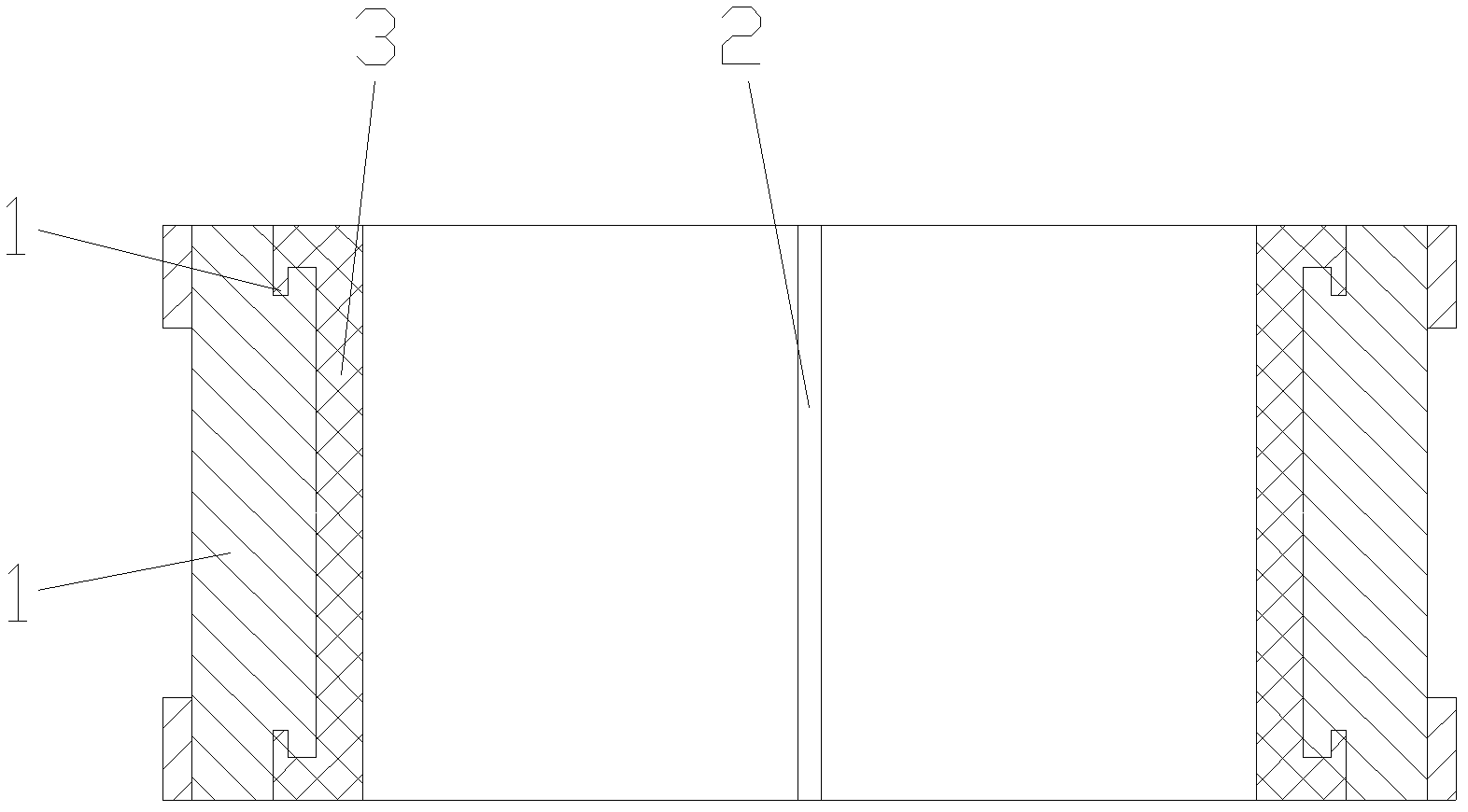

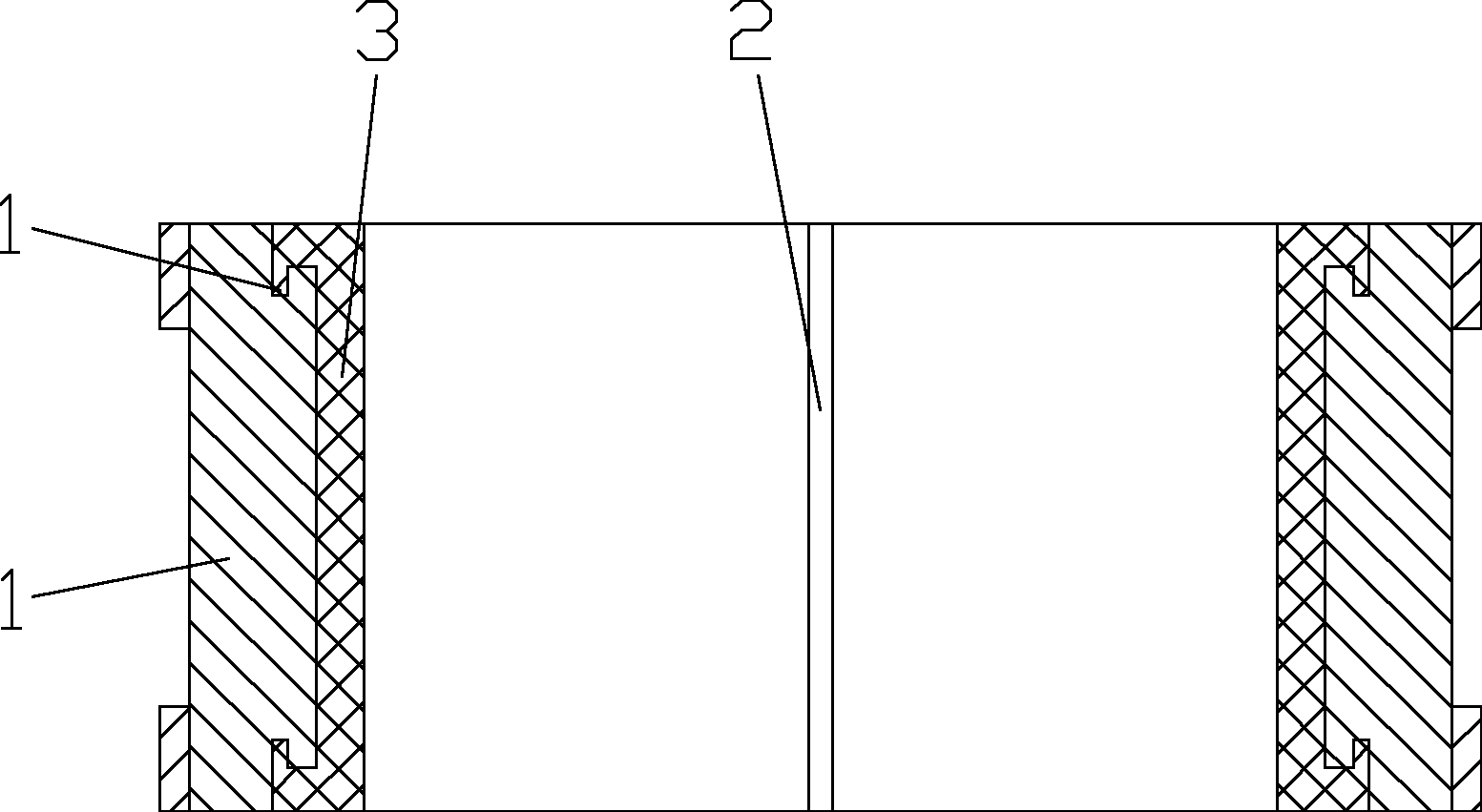

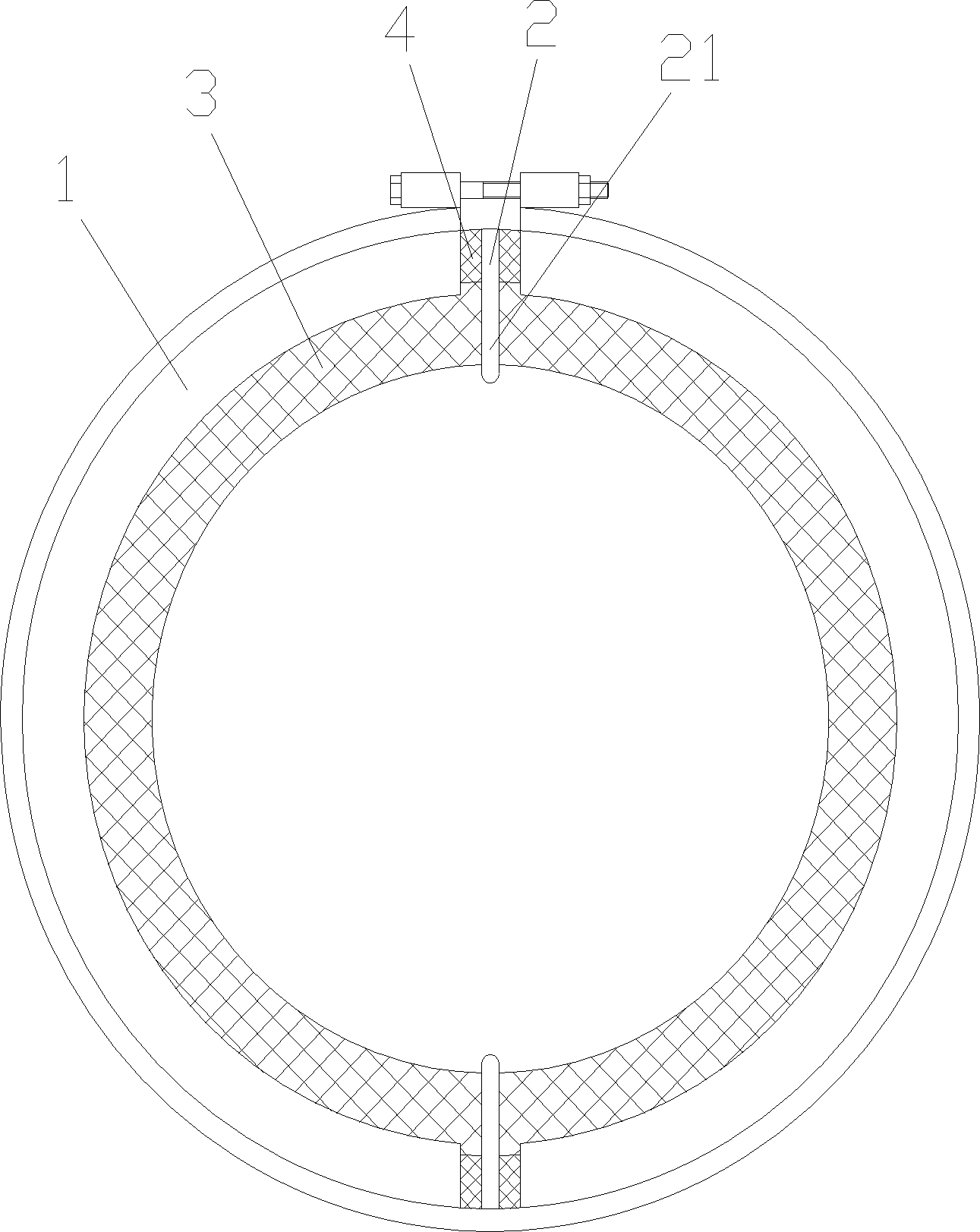

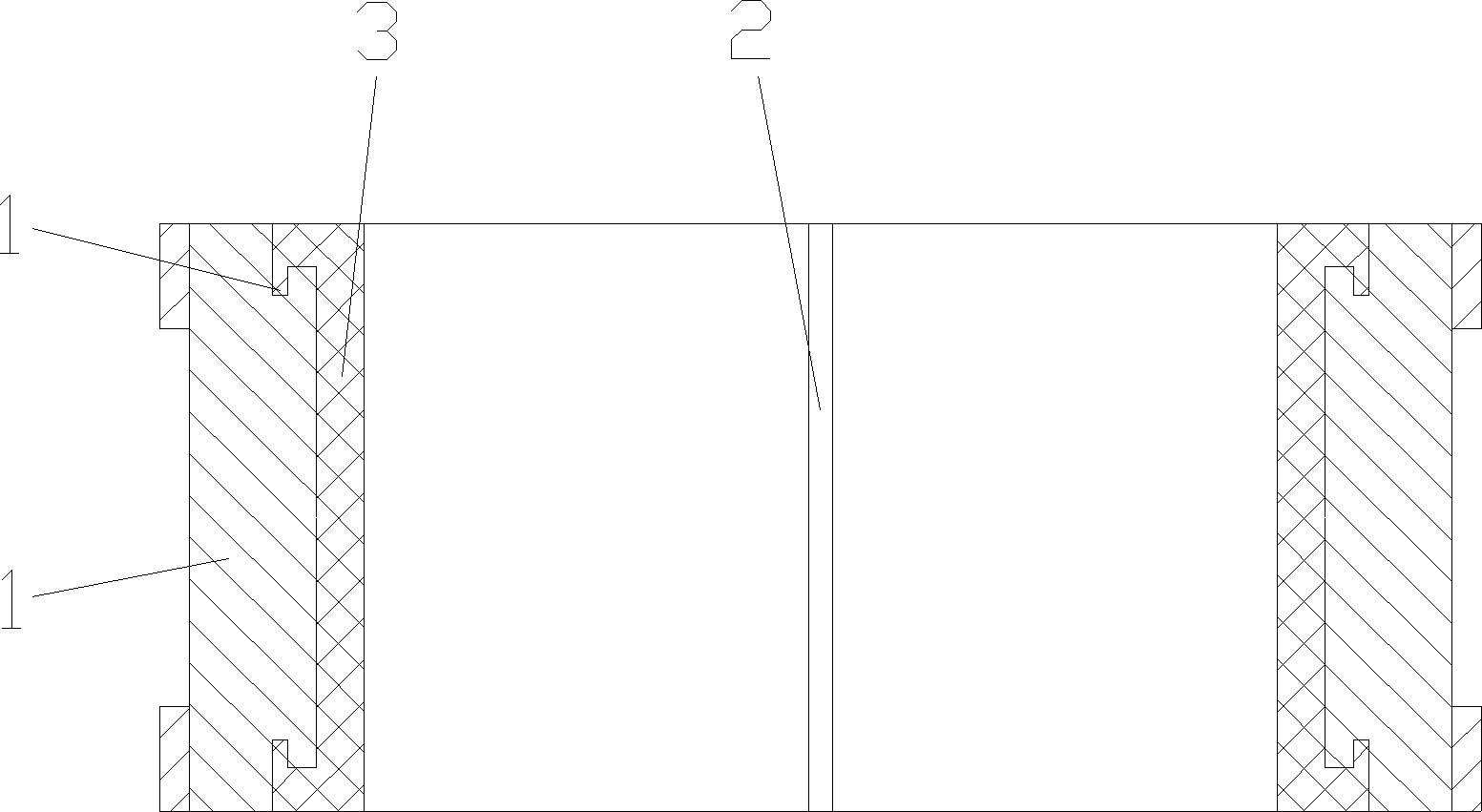

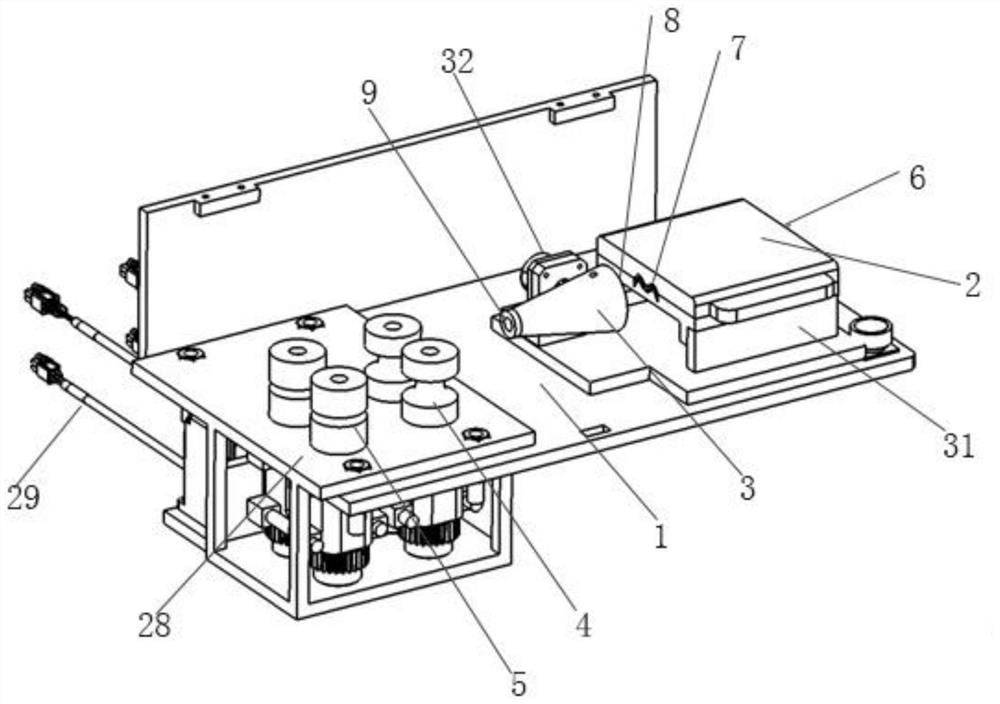

Preparation method and device for refractory rare metal annular target materials

InactiveCN108796456ASimple processLow costVacuum evaporation coatingSputtering coatingMaterials preparationWater cooling

The invention relates to a preparation method and device for refractory rare metal annular target materials, and belongs to the technical field of metal target material preparation. The device comprises a furnace body, a vacuum system, an inflation valve, an electronic gun and a water cooling mould. The furnace body is divided into a furnace room and an electronic gun room. The vacuum system is connected with the furnace room and the electronic gun room. The inflation valve is connected with the furnace room and the electronic gun room. The water cooling mould is arranged in the furnace room.An electronic gun is arranged above the water cooling mould. The water cooling mould is a mold provided with multiple annular water cooling grooves. By means of the technical scheme, the preparation process of the refractory rare metal target materials can be simplified, the subsequent processing difficulty can be lowered, and the production efficiency and purity of products can be improved.

Owner:QINGDAO BLUE LIGHT NEW MATERIAL CO LTD

Catalyst for pyrolysis of oil shale, preparation method and application method thereof

InactiveCN103878031BIncrease lytic activityHigh cracking rateOrganic-compounds/hydrides/coordination-complexes catalystsSpecial form destructive distillationCatalytic pyrolysisLiquid fuel

The invention discloses a catalyst for pyrolysis of oil shale. The catalyst is prepared from the following raw materials by weight percentage: 2-8% of a molecular sieve, 1-5% of activated clay, 10-60% of organic cobaltate, 5-20% of metal sulfide, 8-30% of glycerate, and 15-35% of paraffin; the organic cobaltate is one or more of cobalt acetate, cobalt oxalate, cobalt naphthenate and cobalt neocaprate; the metal sulfide is molybdenum sulfide and / or nickel sulfide. The invention further discloses a preparation method of the catalyst and a use method of the catalyst. According to the catalyst disclosed by the invention, the pyrolysis efficiency of the oil shale can be improved, the distribution of pyrolysis products of the oil shale is improved, more light products are produced, and components of gasoline and diesel oil can be separated through rectification. According to the preparation method and use method of the catalyst, which are disclosed by the invention, the catalytic pyrolysis and microwave heating are combined, so that the utilization efficiency of energy source can be improved, the composition and process performance of liquid fuel are improved, and the following processing difficulty is reduced.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

Agricultural machinery straw crushing device based on water-washing silt removal technology

InactiveCN108617291AImprove cleanlinessImprove convenienceCuttersCleaning using liquidsAgricultural engineeringMachining time

The invention discloses an agricultural machinery straw crushing device based on a water-washing silt removal technology. The agricultural machinery straw crushing device comprises a cleaning box, a crushing box and a separating box, wherein the top end of the cleaning box is embedded with the crushing box; the bottom end of the crushing box is provided with a communicating hole; the center of thetop end surface of the crushing box is provided with a first motor; the inner cavity of the crushing box is provided with a crushing shaft; the bottom end of the crushing shaft penetrates through thecommunicating hole and is fixedly connected with a stirring rod through a connecting sleeve; the right side end of the cleaning box is fixedly connected with the separating box; the bottom part of the inner cavity of the separating box is provided with a separating net which separates the inner cavity of the separating box into a discharge chamber and a drainage chamber; and the interior of the discharge chamber is provided with a rotating shaft which is sleeved by an auger. According to the invention, through embedding of the crushing box on the cleaning box, two processes of crushing and cleaning are integrated together, and convenience in processing is greatly improved, so non-processing time is reduced, and processing efficiency is improved; and water stirred in the cleaning box is utilized to completely clean silts in crushed straw, and cleanness of straw can be effectively guaranteed, so the difficulty of subsequent processing is reduced, and the quality of processing is improved.

Owner:汪培杰

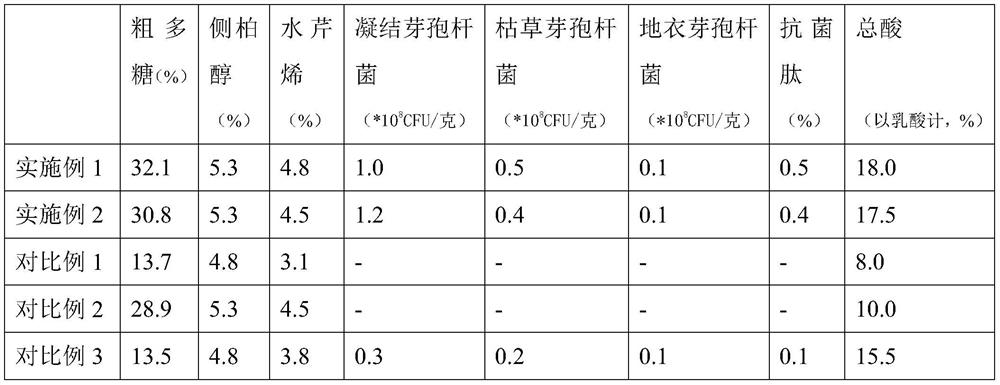

Animal health-care traditional Chinese medicine additive as well as preparation method and application thereof

PendingCN113907192AImprove non-specific immunityIncrease production levelsFood processingDigestive systemBacillus licheniformisPhellandrene

The invention discloses an animal health-care traditional Chinese medicine additive and a preparation method and application thereof, the additive is prepared by mixing and fermenting folium artemisiae argyi in the earlier stage of flowering with wheat bran, molasses and a fermentation strain, and the fermentation strain is a mixed strain of saccharomyces cerevisiae, bacillus coagulans, bacillus subtilis, bacillus licheniformis and aspergillus niger. The preparation method of the additive mainly comprises the following steps: performing sealed fermentation on a mixture to obtain a fermented product, performing water extraction and alcohol extraction on the fermented product, performing alcohol degradation and centrifugal separation on squeezed juice to obtain an extractum mixture, performing normal-temperature vacuum drying on the pasty mixture, and crushing to obtain the animal health-care traditional Chinese medicine additive. The additive is rich in natural phellandrene with a hormone-like effect, natural platycladus orientalis alcohol with an antibiotic-like effect, various small peptides, crude polysaccharides, probiotic flora and metabolites thereof, can improve the flora microecological balance of animal digestive tracts, improve animal endocrine and improve the disease resistance of animals, can be flexibly added and applied to animal feeding, and has a wide application prospect. And the feeding production performance index is improved.

Owner:HUNAN SINOWEST ANIMAL NUTRITION GRP

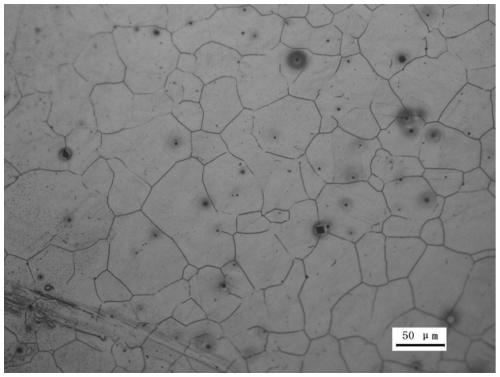

Sucrose seed crystal and preparation method thereof

ActiveCN111808999AUniform particle sizeThe surface of the seed crystal is smoothSugar productsClimate change adaptationHigh sucroseSeed crystal

The invention belongs to the field of sugar industry, and discloses a sucrose seed crystal and a preparation method thereof. The preparation method comprises the steps: dissolving cane sugar in waterto prepare a sugar solution with the mass concentration of 50%-70%, and then concentrating the sugar solution at the temperature of -10 DEG C to 4 DEG C to obtain a concentrated sugar solution with the cane sugar mass concentration of 82%-90%; and adding ethanol into the concentrated sugar solution, treating for 5-120 s under an ultrasonic condition, filtering, collecting, dispersing and preserving to obtain the sucrose seed crystal. According to the method, the seed crystal is prepared under the low-temperature condition, sucrose conversion can be avoided, and the seed crystal quality is improved. The obtained seed crystal is uniform in granularity and smooth in surface. The reduction of treatment difficulty of subsequent procedures is facilitated and improvement of the quality of sucrosecrystal products is facilitated.

Owner:GUANGDONG PROVINCIAL BIOENGINEERING INST (GUANGZHOU SUGARCANE IND RES INST)

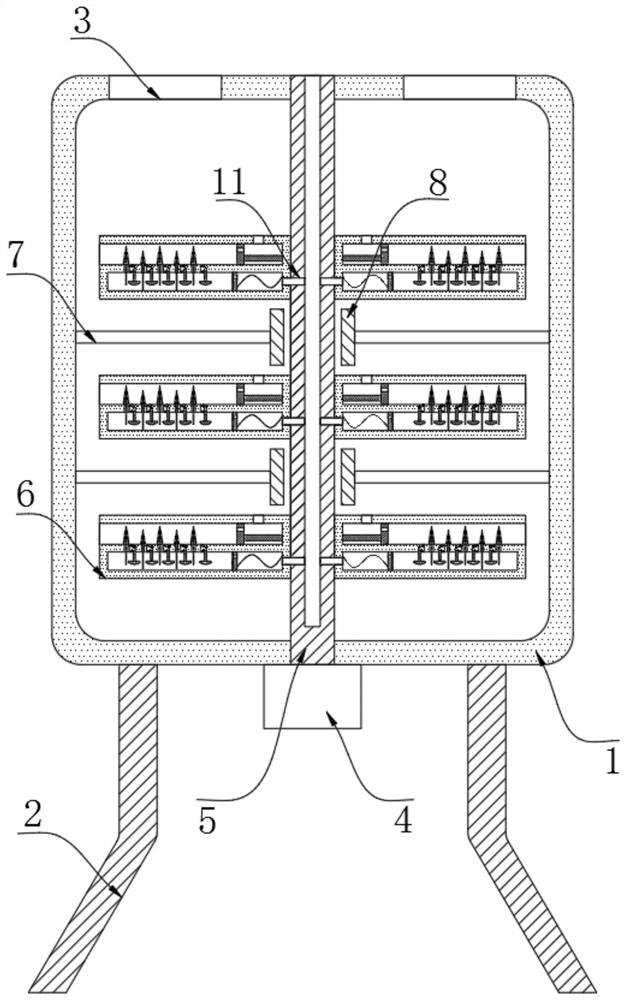

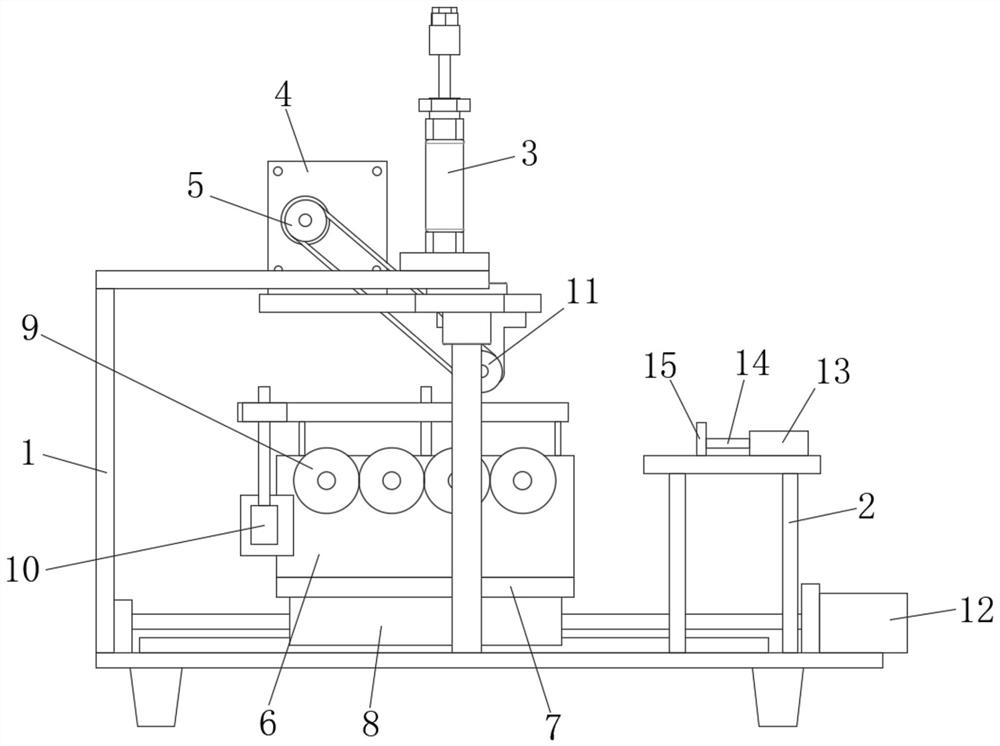

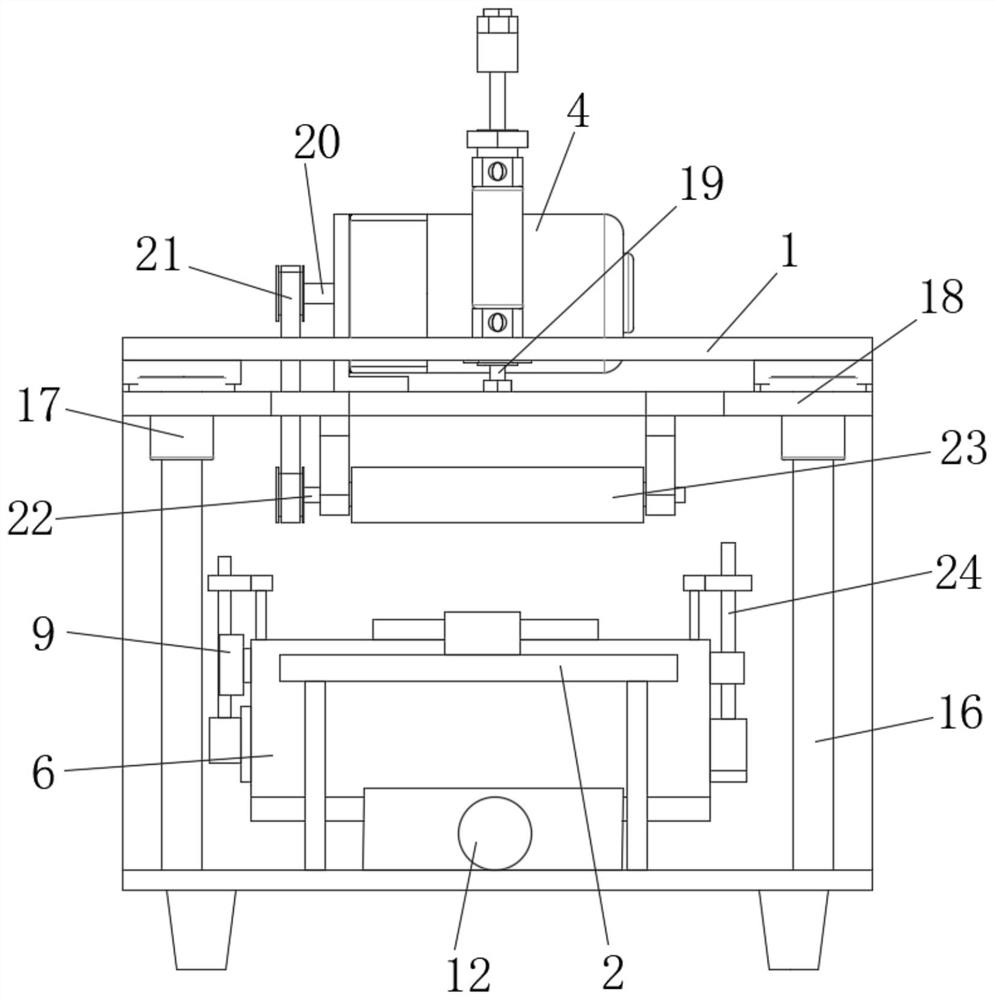

A fish scale removal device

ActiveCN111972470BAvoid damageReduce the difficulty of subsequent processingFish washing/descalingEngineeringZoology

The invention discloses a device for removing fish scales. By setting a first roller and a second roller, the second roller performs descale treatment on the lower surface of fish products while rotating, and the first motor passes through the first rotating shaft. Drive the first runner to rotate, and the first runner drives the second runner to rotate through the belt, so that the second runner drives the first roller to rotate through the second rotating shaft, so that the first roller rotates while the fish The fish scale treatment is carried out on the upper surface of fish products, and the descale treatment of fish products is completed through the cooperation of the first roller and the second roller, and in the process of removing fish scales, through the first press plate and the second press plate, The position of the fish product can be fixed, and the fish product will not collide with the first roller and the second roller due to other external forces such as gravity or centrifugal force, thereby avoiding damage to the surface of the fish product due to external force Cause damage or damage to internal organs, which reduces the difficulty of subsequent processing of fish products.

Owner:WUHAN POLYTECHNIC UNIVERSITY

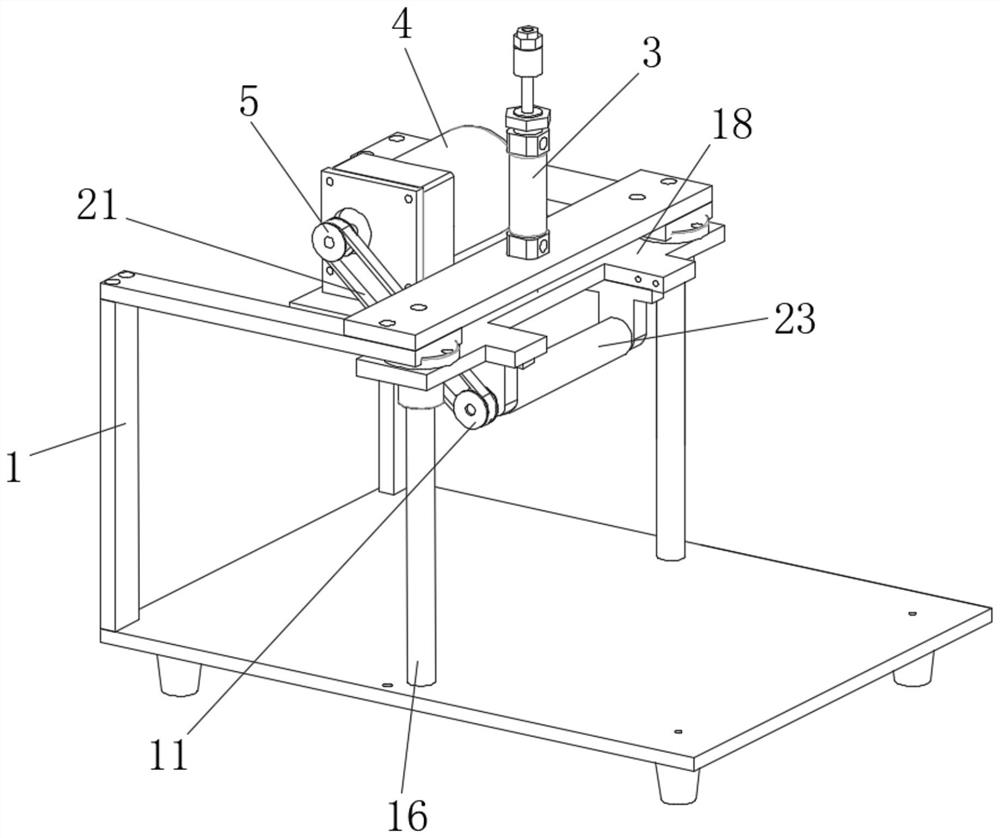

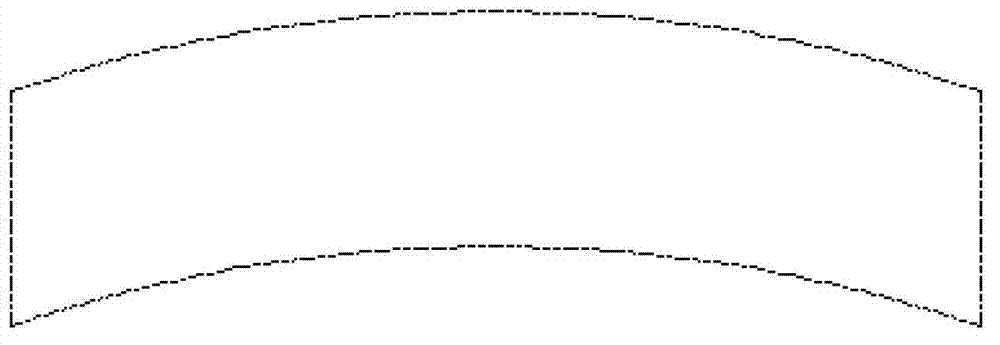

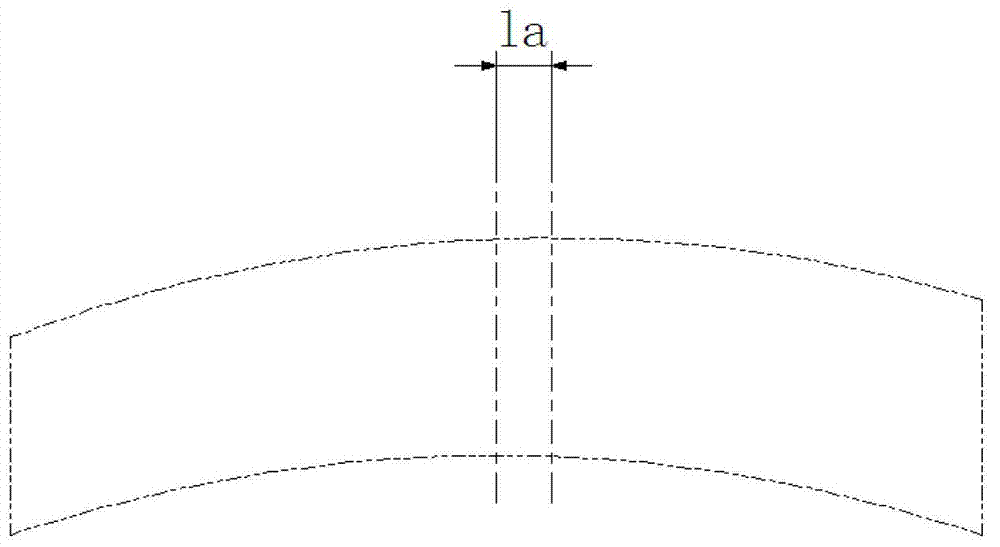

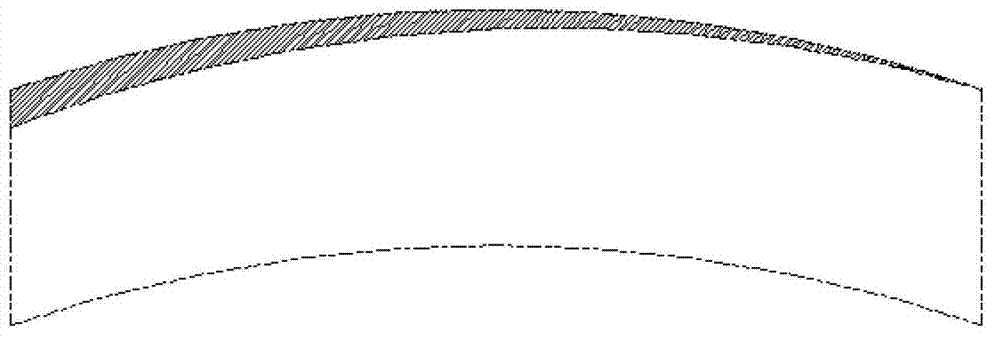

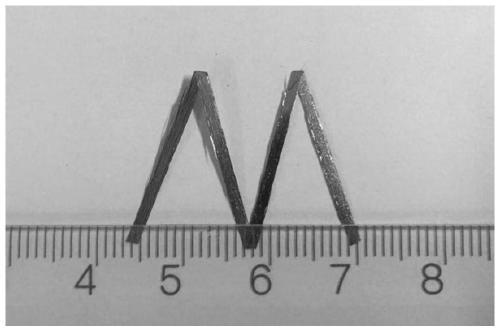

Manufacturing method for blank of length-unequal arc sheet metal part

The invention discloses a manufacturing method for a blank of a length-unequal arc sheet metal part. The manufacturing method comprises the steps that the length-unequal arc sheet metal part is subjected to sheet metal spreading treatment by analytical software to obtain an approximate eccentric unequal side arc sheet whose arc sides R are equal; and a coil material is adopted as a raw material and manufacturing is performed on a blanking mould by adopting a mandarin duck type two-step dislocation blanking method. With the adoption of the manufacturing method of the blank of the length-unequal arc sheet metal part, an unequal side arc blank capable of being used for manufacturing the length-unequal arc sheet metal part can be manufactured on the basis of the existing blanking mould processing equipment; the processing allowance is small; the difficulty in subsequent processing can be reduced; the production efficiency can be improved; the material can be saved; the cost can be lowered; and the improvement on competitiveness of an enterprise is facilitated.

Owner:宁波沪荣汽车部件有限公司

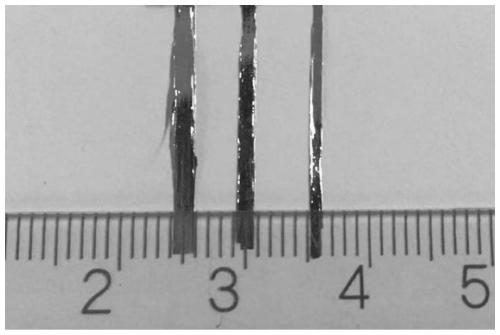

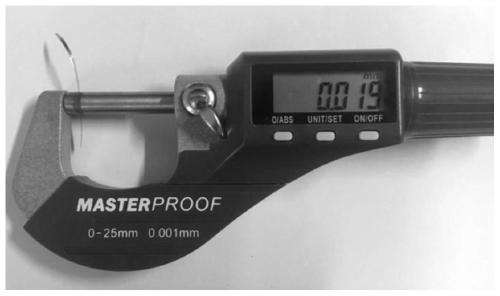

Fe-based soft magnetic alloy and preparation method of soft magnetic alloy strip

InactiveCN109797344ALow costEliminate high temperature annealing process stepsMagnetic materialsMagnetizationToughness

The invention relates to a Fe-based soft magnetic alloy. The Fe-based soft magnetic alloy is prepared from the components: FeNiCo<c>B<d>Si<e>, wherein atomic percentage comprises that a is greater than or equal to 76 and less than or equal to 82, b is greater than or equal to 2 and less than or equal to 4, c is greater than or equal to 2 and less than or equal to 4, d is greater than or equal to 8 and less than or equal to 12, e is greater than or equal to 2 and less than or equal to 8, and a requirement of a+b+c+d+e=100 is met; the Fe-based soft magnetic alloy is an amorphous-nanocrystal biphasic structure, the average grain size d<c> of the amorphous-nanocrystal biphasic structure meets that d<c> is greater than or equal to 26nm and less than or equal to 33nm, the coercive force H<c> meets that H<c> is greater than or equal to 3.9A / m and less than or equal to 4.2 A / m, and the saturation magnetization meets that M<s> is greater than or equal to 166emu / g and less than or equal to171em / g. Compared with the prior art, raw materials used in the Fe-based soft magnetic alloy are common Fe, Ni, Co and immediate alloys Fe-B and Fe-Si, rare metals similar to Nb are not contained, the cost is low, the preparation process is simple, and good toughness is achieved.

Owner:SHANGHAI UNIVERSITY OF ELECTRIC POWER

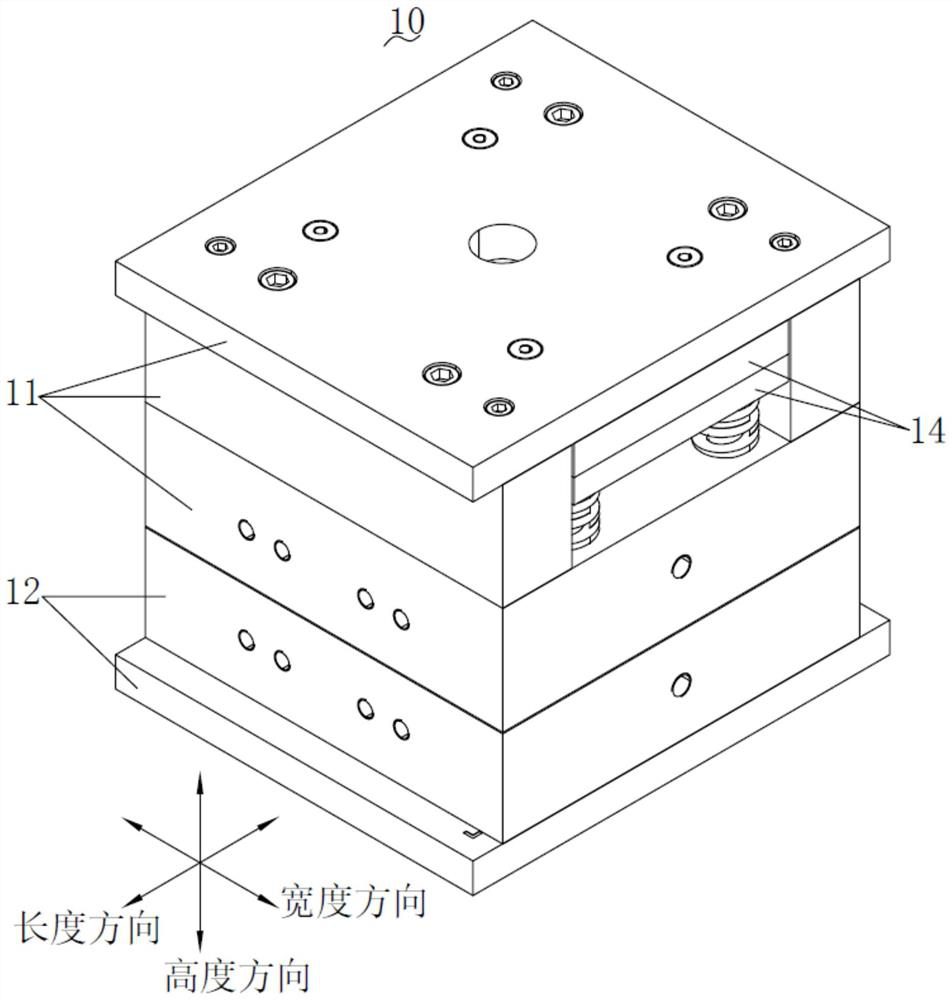

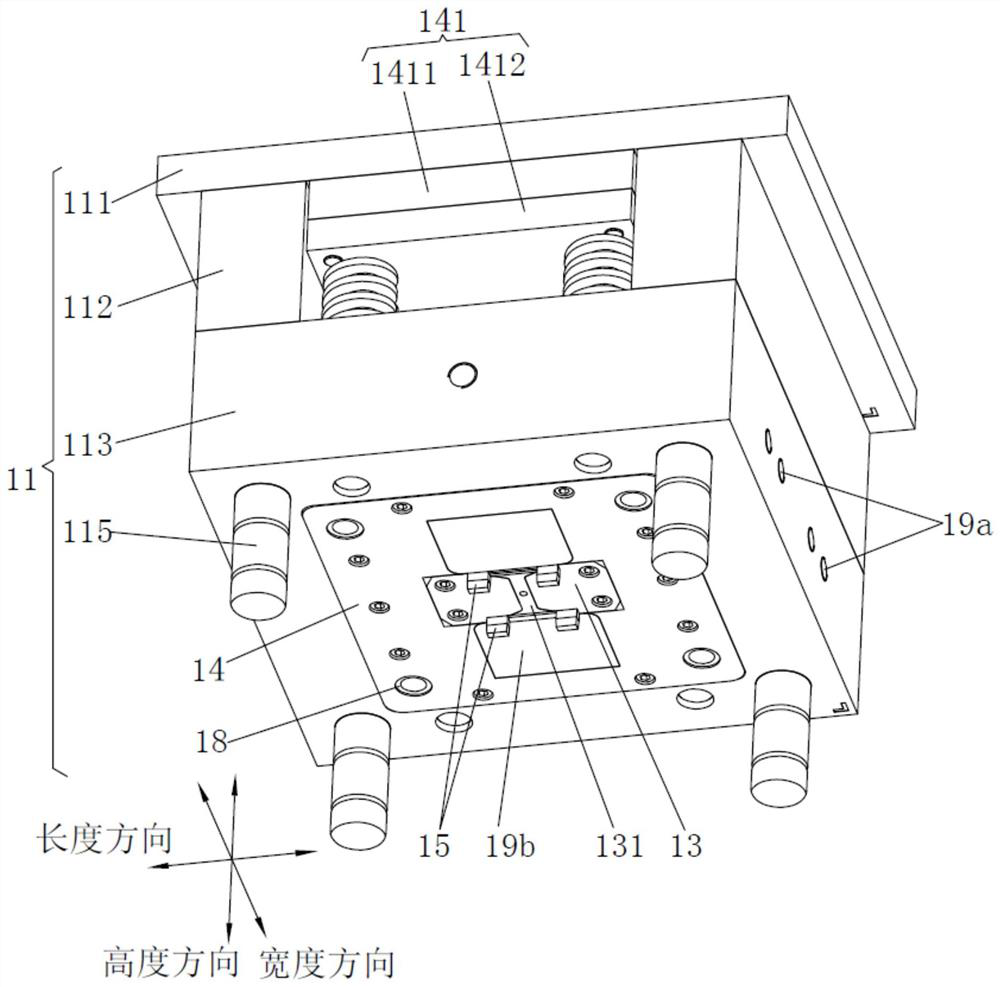

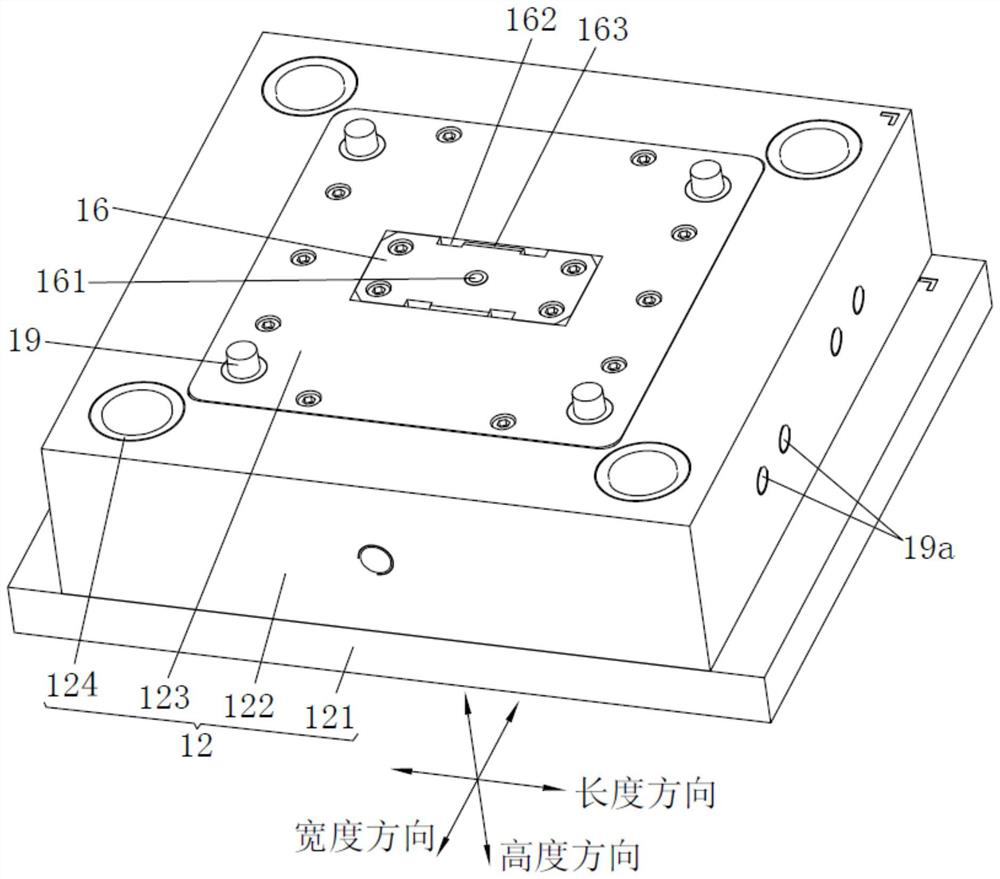

In-mold cutting injection mold and use method thereof

PendingCN113977878AEliminate operational difficultyIncrease productivityMaterials scienceCutting tool

The invention provides an in-mold cutting injection mold and a use method thereof. The in-mold cutting injection mold comprises a fixed mold and a movable mold, wherein the movable mold and the fixed mold are connected to form a mold cavity. The in-mold cutting injection mold further comprises a drainage opening plate, wherein the drainage opening plate is arranged on the movable mold, and a drainage opening communicated with the mold cavity is formed in the drainage opening plate; an ejection mechanism which is movably arranged on the movable mold; and a cutting tool, wherein one end of the cutting tool is connected with the ejection mechanism, and the other end of the cutting tool is located at the connecting position of the drainage opening plate and the mold cavity, and the cutting tool is driven by the ejection mechanism to cut the drainage opening material at the connecting position of the drainage opening plate and the mold cavity. Through the arrangement of the cutting tool and the driving of the ejection mechanism, the drainage opening material connected with the injection molding product is automatically cut off in the mold, so that the operation difficulty of manual cutting off is eliminated, and the production efficiency is improved; and meanwhile, the drainage opening material is cut off when the injection molding product is not completely cooled and hardened, and breaking marks on the injection molding product are eliminated.

Owner:SHENZHEN SOUTH POLE OPTOELECTRONICS TECH

Split type bearing bush centrifugal casting method

ActiveCN102581248BGuarantee molding qualityReduce internal stressBearing componentsMaterials preparationMolten state

The invention discloses a split type bearing bush centrifugal casting method, which includes the steps of molten-state antifriction material preparation, bush billet treatment, centrifugal casting and subsequent machining. A bush billet is formed by fixing two fastened half bushes, and a bush billet treatment process includes the steps: machining annular grooves coaxial to the bush billet on two end faces of the bush billet, enabling each of two side walls of each annular groove to be low inside and high outside, arranging a spacer on a jointing face of the two half bushes which are integrally fastened, and enabling the spacer to extend along the axis of the bush billet to form a partition with the radial length along the bush billet not smaller than the radial thickness of a lining formed by pre-casting. Subsequent machining of the split type bearing bush centrifugal casting method only needs to turn two end faces of a bush body formed after casting, two split half bushes naturally form two bearing bushes without machining of a slotting machine or a sawing machine, Babbitt metal is low in internal stress generated by means of subsequent machining and is firm in jointing with the bush billet, bearing bush forming quality can be guaranteed, subsequent machining difficulty is low, workload is less and machining cost is low.

Owner:重庆新承航锐科技股份有限公司

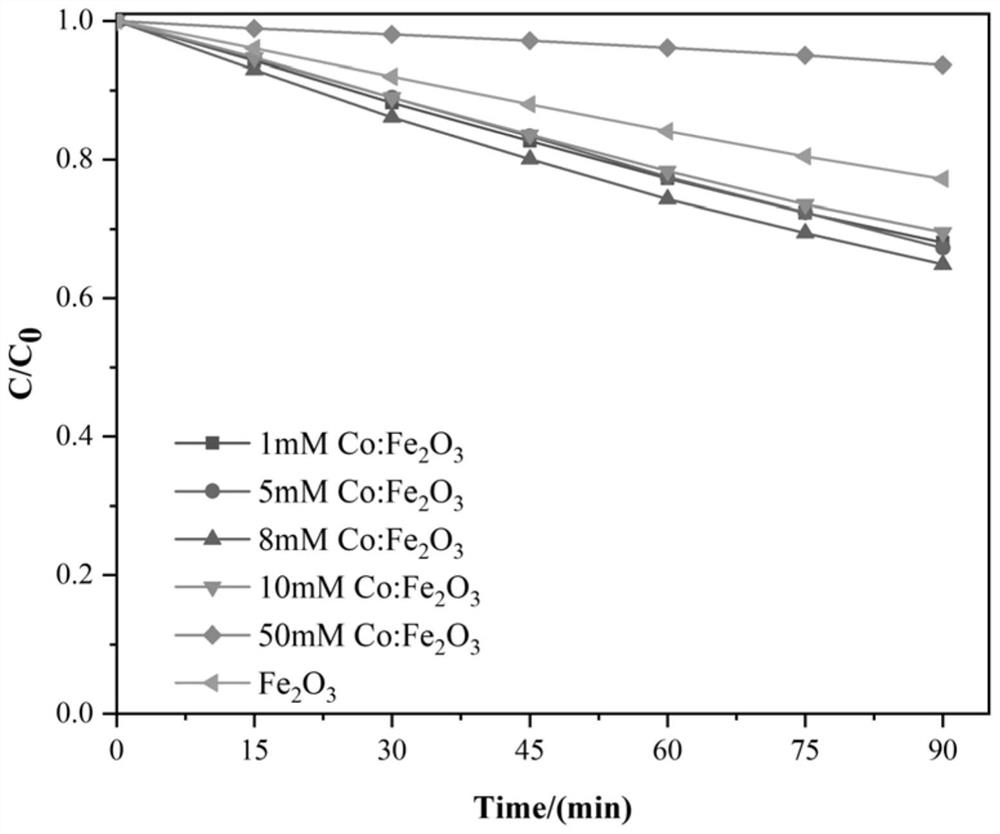

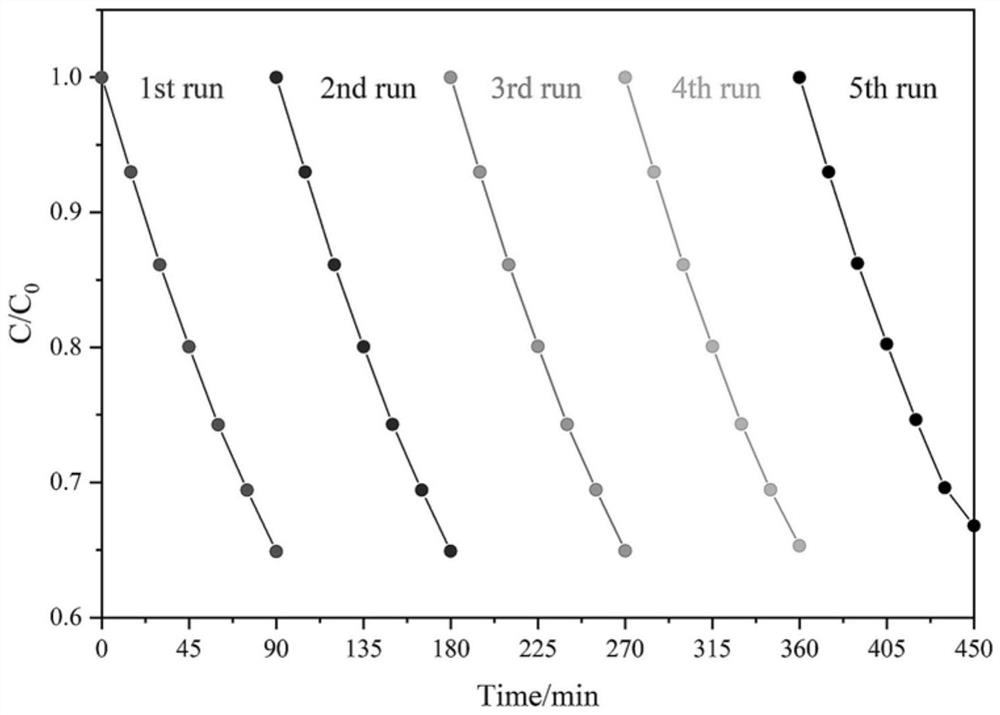

Anode material applied to photoelectric degradation of tetracycline and preparation method of anode material

ActiveCN114044559AAchieve recyclingAchieve degradationWater/sewage treatment by irradiationWater treatment compoundsSodium nitrateMaterials science

The invention relates to the field of materials for degrading tetracycline substances, and in particular, relates to an anode material applied to photoelectric degradation of tetracycline, wherein the anode material comprises ferric chloride hexahydrate, sodium nitrate, a cobalt chloride hexahydrate mixed solution and fluorine-doped SnO2 electrically conductive glass. The invention provides the anode material applied to the photoelectric degradation of tetracycline, the Co:alpha-Fe2O3 anode material is prepared in a Co doping mode, and the recombination rate of an electron-hole pair of alpha-Fe2O3 is effectively reduced. Under the condition of illumination, the Co:alpha-Fe2O3 anode material can degrade tetracycline hydrochloride at a relatively low voltage, so that the degradation cost is reduced, and the safety of the degradation process is improved. Besides, the Co:alpha-Fe2O3 anode material grows on the FTO, and after the degradation process is completed, the Co:alpha-Fe2O3 anode material can be recycled without filtering operation, so that the difficulty of the subsequent treatment process is reduced, and the burden of the material on the structure of the next unit is reduced.

Owner:DONGGUAN UNIV OF TECH

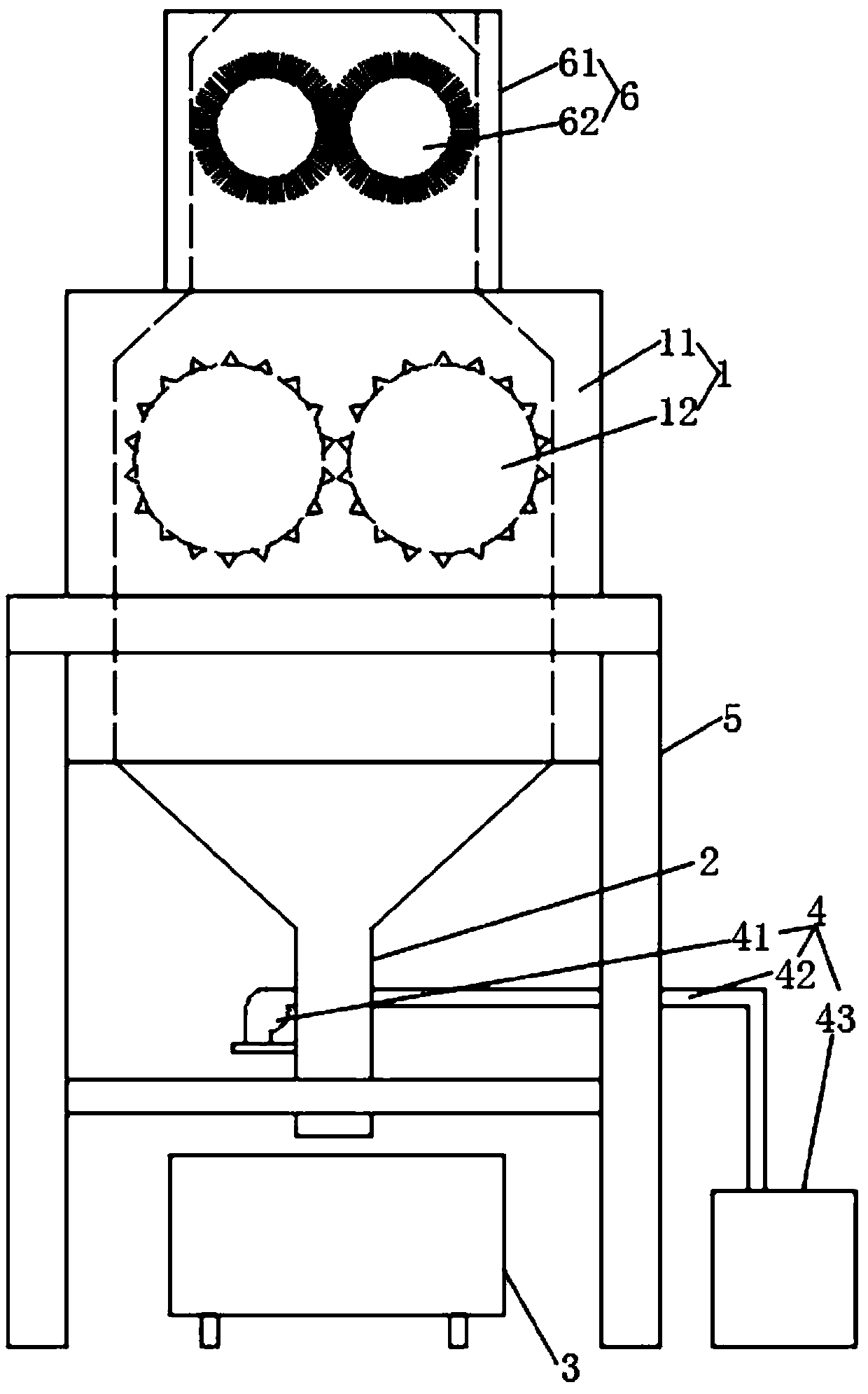

Plastic product crushing and cleaning device

InactiveCN109624142ASimple structureEasy to useGas current separationPlastic recyclingCrusherEngineering

The invention relates to the processing of plastic products, in particular to aplastic product crushing and cleaning device. Theplastic product crushing and cleaning device comprises a machine frame,a crusher, a dischargechannel and a collecting trough; themachine frame is a hollow frame body; the crusher is installed at the upper end of themachine frame, the upper end of the crusher is a feedingopening,andthe lower end of the crusher is a discharge opening; a feed cleaning device is connected to the feedopening; the discharge channel is vertically disposed under the crusher, and the discharge opening of the crusher is connected and communicates with the upper end of the discharge channel; and the collection trough is placed below the discharge channel. The plastic product crushing and cleaning device has the advantages thatthe structure issimple, operation and use areconvenient, plastic products can be pre-cleaned before crushing, the difficulty of subsequent processing isreduced, and trouble and effort are saved.

Owner:松滋市隆鑫塑料制品有限公司

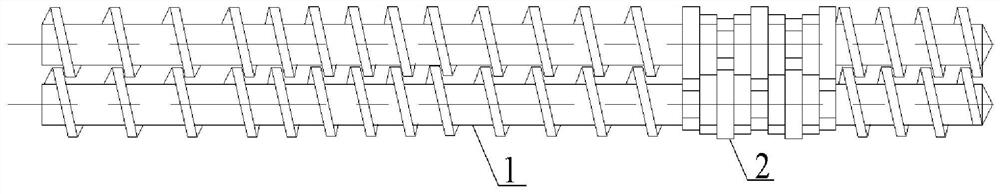

A wear-resistant screw of a twin-screw extruder and its processing technology

ActiveCN109093975BImprove wear resistanceWear adaptationMolten spray coatingAlloy coatingMachining process

With increase of amount of filler in extruded materials, abrasion to a screw rod of a double-screw extruder is increasingly serious, and as a kneading block is a main component for shearing and extruding materials, it is very urgent to solve the problem about abrasion. The invention provides an abrasion-resistance screw rod of a double-screw extruder. The kneading block of the screw rod comprisesa steel base, silicon nitride ceramic bars and an alloy coating, concave pits are evenly distributed in the outer surface, parallel to the axis direction of the screw rod, of the steel base; the halfportions of the silicon nitride ceramic bars in the length direction are located in the concave pits, the other half portions of the silicon nitride ceramic bars in the length direction are exposed outside the surface of the steel bar, the alloy coating completely covers the surface of the steel base, and the top ends of the silicon nitride ceramic bars are exposed outside the alloy coating. According to the abrasion-resistance screw rod, the problem about abrasion to the screw rod of the double-screw extruder can be effectively solved.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY +1

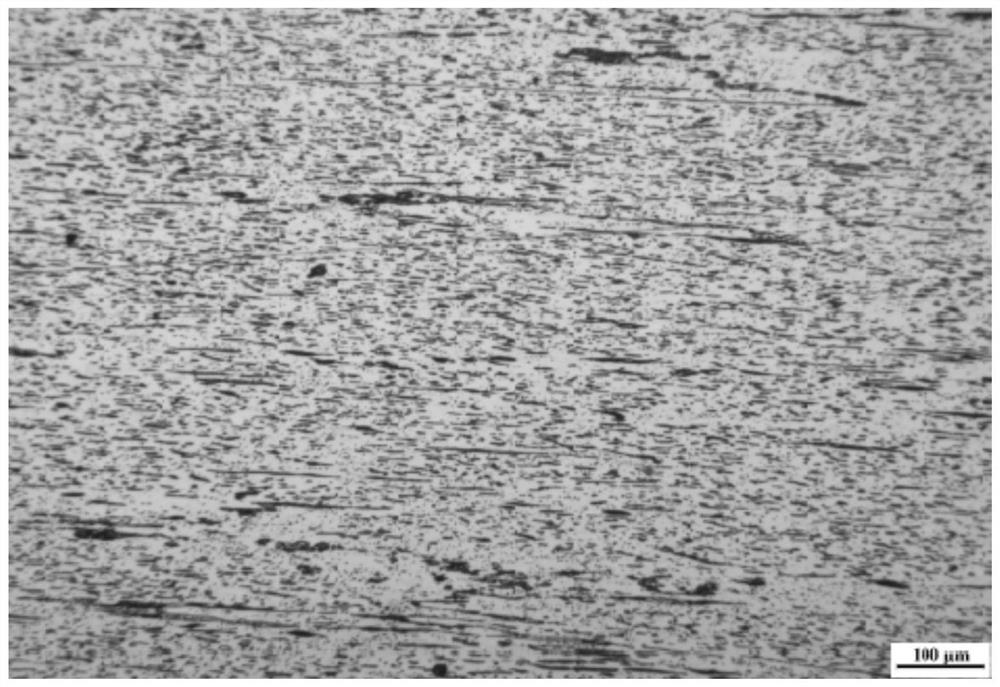

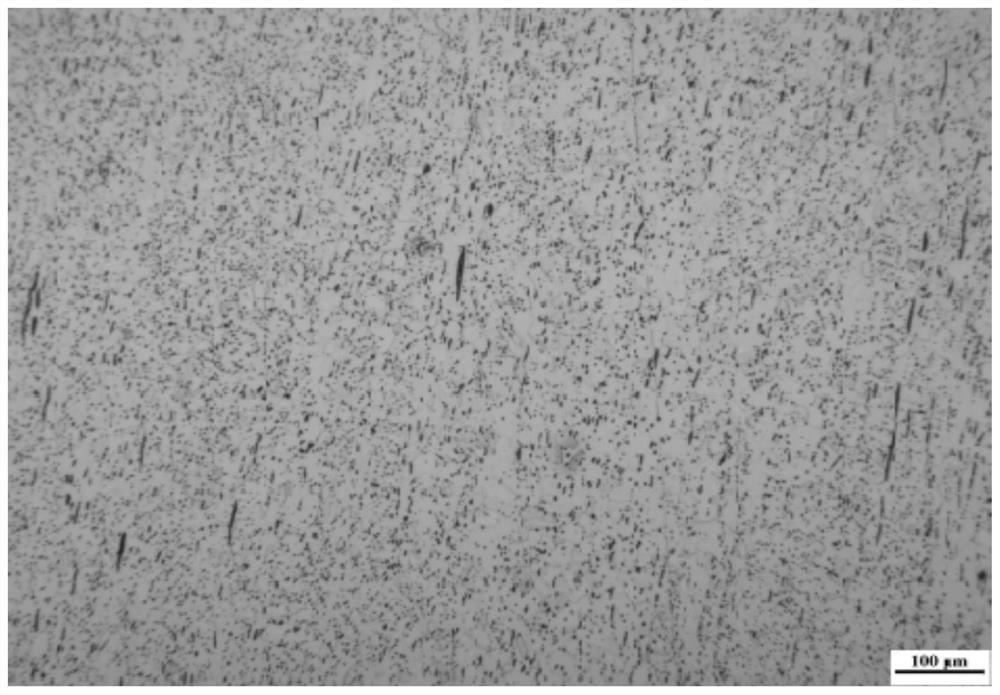

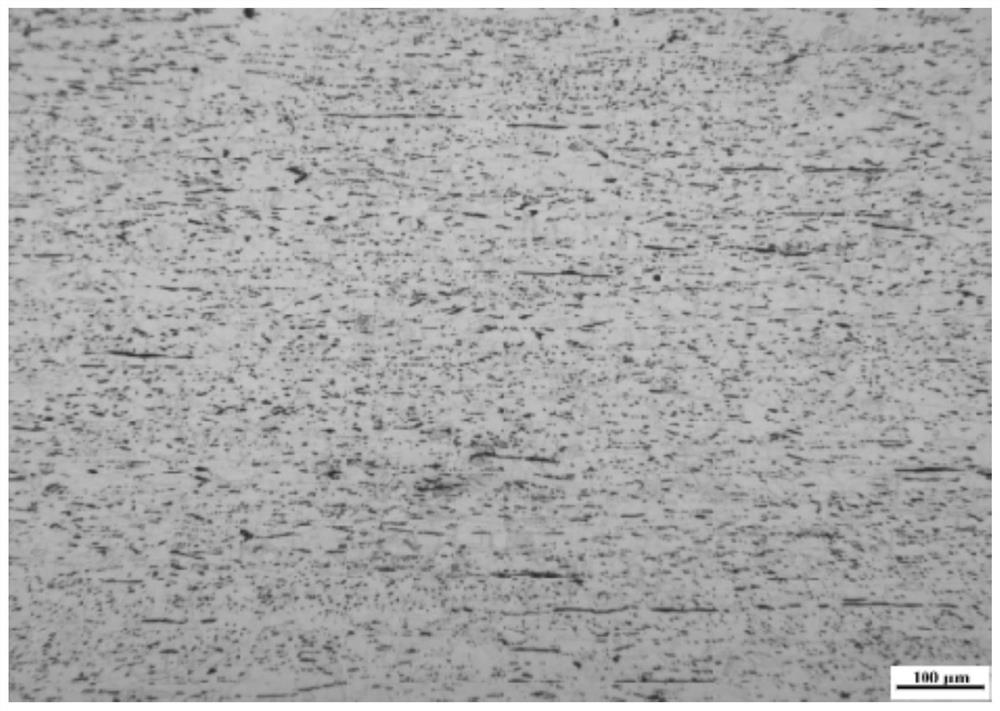

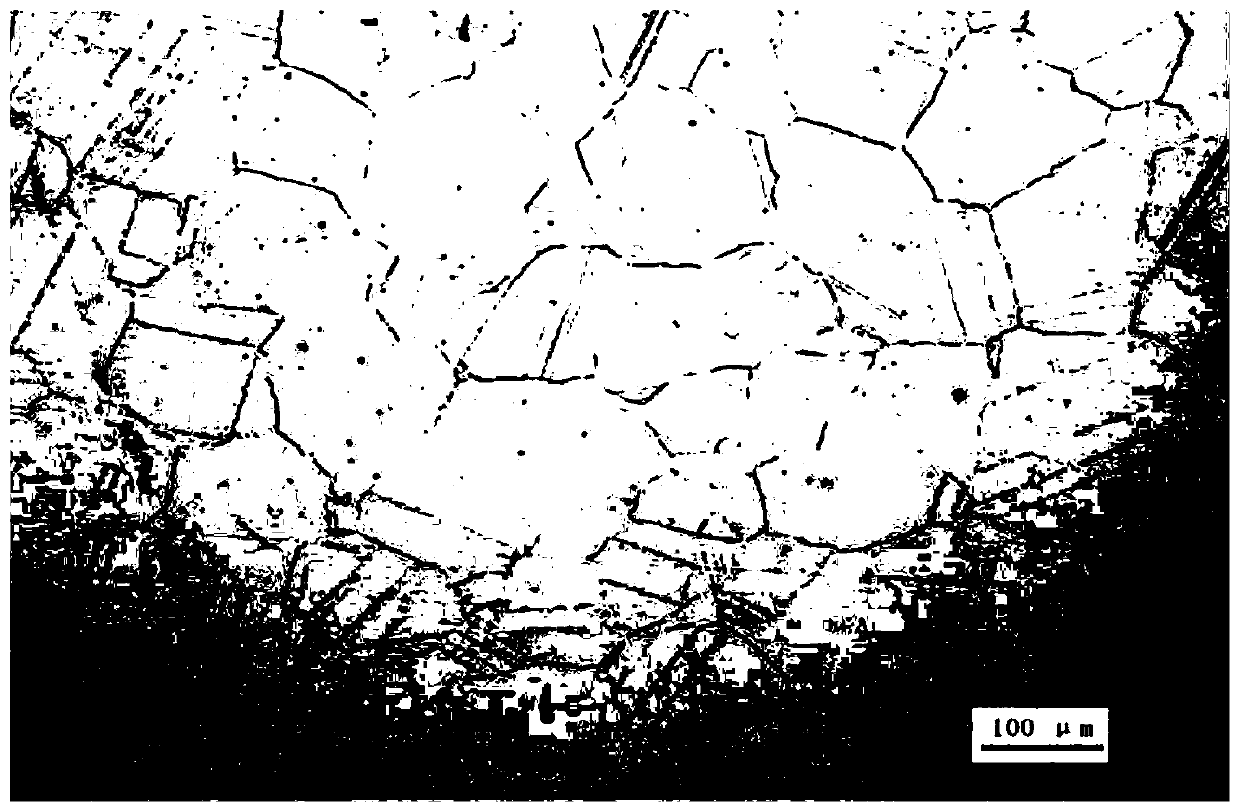

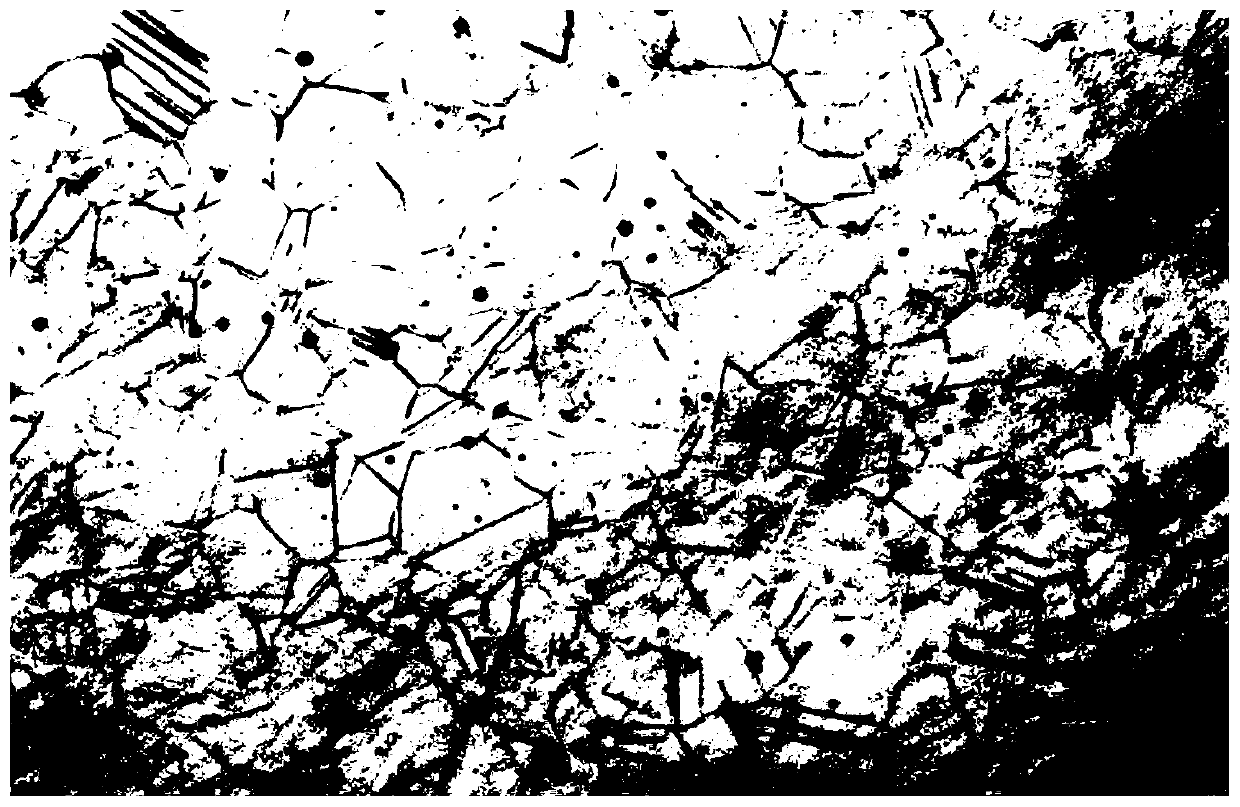

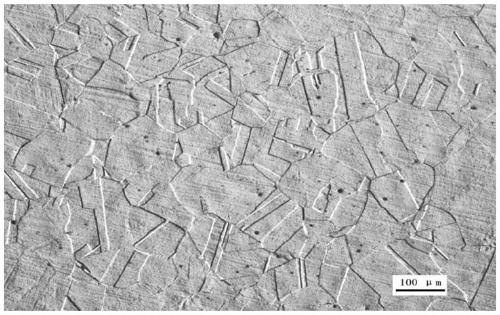

An optimized forging process for gh6783 alloy bar

ActiveCN106834642BImprove plasticityPromote continuous dissolution and precipitationFurnace typesHeat treatment furnacesTemperature controlProcess engineering

The invention discloses an optimized forging process for GH6783 alloy rods. By improving the heating process, adopting stepwise temperature control and staged forging, the purpose of improving the plasticity of the alloy and making the forged β phase evenly distributed can be achieved. The technical scheme of the present invention is as follows: the forging process of the GH6783 alloy bar is as follows: ingot heating→first fire forging→intermediate fire forging→final fire forging→bar finishing→bar performance inspection→bar finishing→rod Material performance inspection; through the over-aging treatment between 820 ° C and 880 ° C during the heating process of the ingot, the plasticity of the GH6783 alloy steel ingot is improved, and the refinement and uniform distribution of the forged β phase are promoted by step temperature control forging. The advantages of the present invention are: firstly, through the overaging treatment at 820°C to 880°C, the plasticity of the alloy is greatly improved, and the difficulty of subsequent processing is reduced; secondly, the stepwise temperature-controlled forging is used to promote the continuous dissolution and precipitation of the β phase, Further make the β phase evenly and finely distributed.

Owner:FUSHUN SPECIAL STEEL SHARES

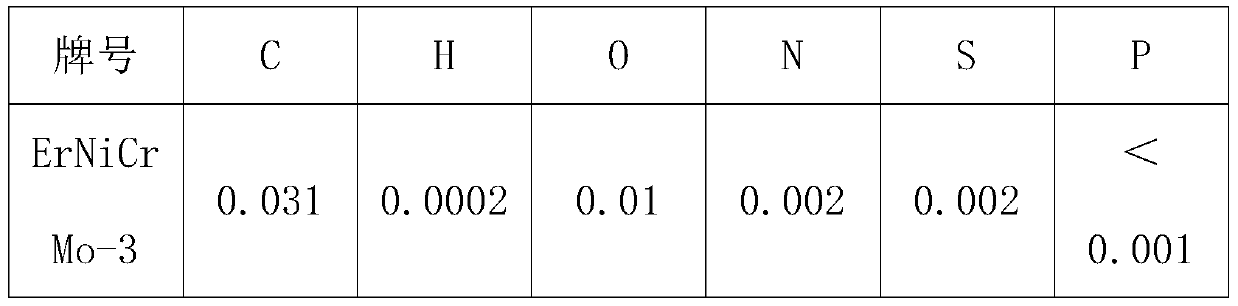

Application of a nickel-molybdenum master alloy in the preparation of ernicrmo-3 alloy

The invention discloses a preparation method of an nickel-molybdenum intermediate alloy. The method comprises the following steps of a, taking 30%-60% of nickel and 40%-70% of molybdenum according tothe weight ratio; b, filling a crucible with a part of nickel, filling the crucible with carbon, then filling the crucible with the rest nickel, and filling an alloy bin with molybdenum, a small amount of the nickel-magnesium alloy and the carbon; c, vacuumizing the crucible to be less than or equal to 5 pa, carrying out heating and smelting, heating at the speed of 2-5 kw / 5 min to 25 kw when thetemperature is below 25kw, then heating at the speed of 5 kw / 10 min to 30kw; carrying out refining for 10 minutes, carrying out standing for 5 minutes until the air pressure in the crucible reaches 0.07 Mpa, adding molybdenum in the alloy bin into the crucible, raising the power to 20 kw, carrying out refining for 4 minutes and standing for 1 minute after the materials in the crucible are completely melted until the liquid surface is clarified, carrying out power failure, closing the valve and adding the nickel-magnesium alloy, carrying out heating after the nickel-magnesium alloy is added, pouring the mixture into a mold when the liquid surface is clarified and the temperature is proper, and the mixture is cooled for 20 minutes and discharged out of the crucible.

Owner:BAOJI TITANIUM IND

Organic light-emitting diode display panel

InactiveUS20210175313A1Reduce the difficulty of subsequent processingAvoid normal displayPrinted circuit aspectsSolid-state devicesAnisotropic conductive filmFlexible electronics

An organic light-emitting diode display panel, including a display area, a non-display area. A plurality of different film layers are disposed in the display area and the non-display area. A flexible printed circuit board is disposed in the non-display area. An anisotropic conductive film is configured to attach the display panel with the flexible printed circuit board. A barrier is disposed on a side of the display panel adjacent to the non-display area. A barrier covers one or more different film layers, and is configured to prevent the anisotropic conductive film from overflowing from an edge of the non-display area.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Application of a nickel-manganese master alloy in the preparation of ernicr-3 alloy

Owner:BAOJI TITANIUM IND

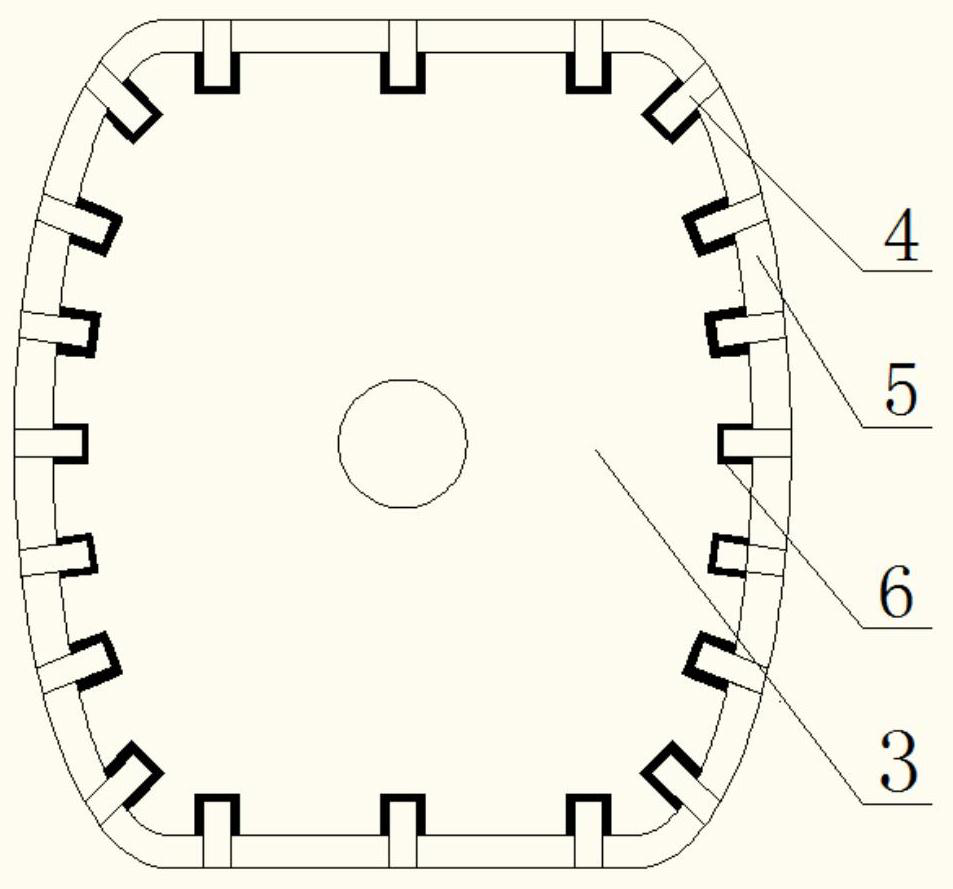

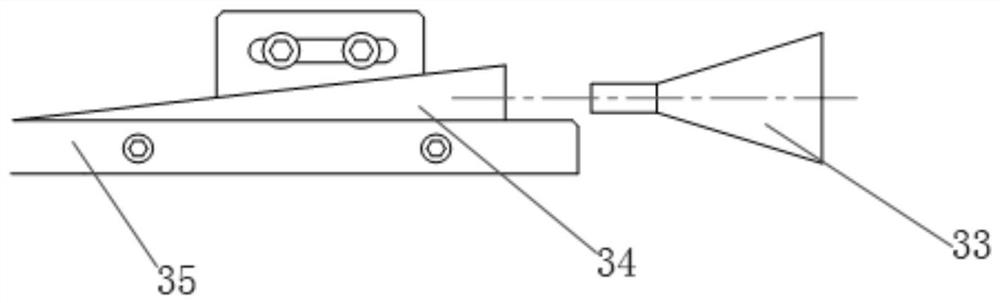

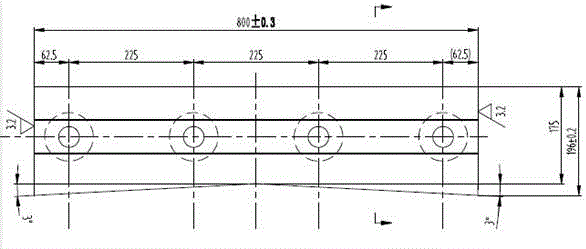

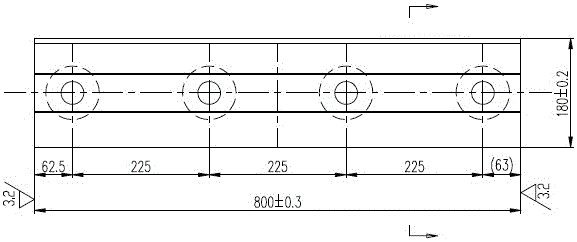

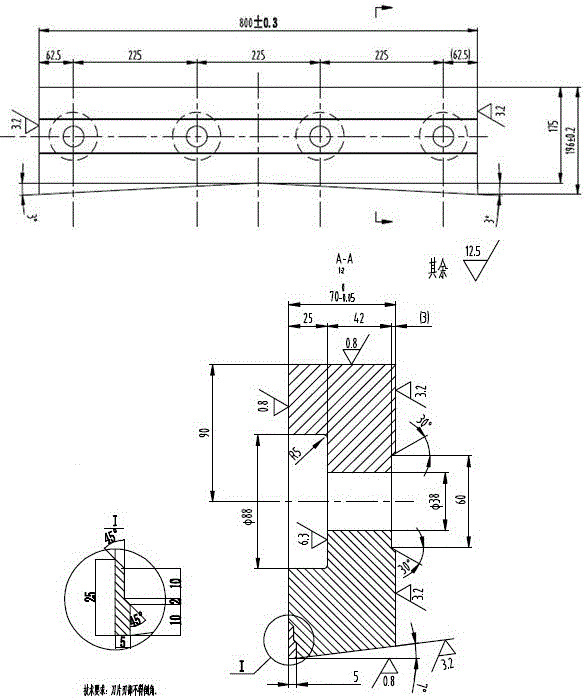

Filter stick material pre-folding and collecting device

PendingCN114176253AComply with workmanship standardsImprove appearance qualityTobacco smoke filtersEngineeringPower apparatus

The filter stick material pre-folding and collecting device comprises a rack, a paper guide device, a conical barrel, a first-stage forming wheel and a second-stage forming wheel are sequentially installed on the rack from upstream to downstream, a paper guide channel is formed in the paper guide device, and the paper guide channel is gradually shrunk from the inlet end to the outlet end; a conical channel is formed in the conical barrel, the large opening end of the conical channel faces the paper guide device, and the small opening end of the conical channel faces the first-stage forming wheel; the first-stage forming wheel and the second-stage forming wheel are each composed of a fixed wheel and a separation wheel, the distance between the fixed wheels and the separation wheels is the wheel distance, the wheel distance of the first-stage forming wheel is larger than the wheel distance of the second-stage forming wheel, and the diameter of the small opening end of the conical channel is larger than the wheel distance of the first-stage forming wheel. The first-stage forming wheel and the second-stage forming wheel are driven by a power device to rotate. The bundling device can enable the end face hole of the cooling base rod to meet the technological standard, the roundness index meets the technological standard, and the cigarette rejecting amount is reduced by more than 50%.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Laser compound manufacturing rod wire cold shear blade

InactiveCN106119839AReduce removalReduce manufacturing costMetallic material coating processesCobalt based alloyCast iron

The invention mainly solves a rod wire cold shear blade laser manufacturing structure and a manufacturing flow and a method. The gradient cladding is performed for a cobalt base alloy material under a shear blade shear surface stress point, and the cladding quantity of the cobalt base alloy is gradually reduced according to a shear force transfer descending path, so that the blade life is prolonged, and the cost consumption is reduced. In order to reduce deformation generated by laser cladding, the removing quantity of a working layer surface of the laser clad cobalt base material is reduced, so that the blade function is realized, and the manufacturing cost is reduced; and in the shear blade laser cladding process, a shear blade is fixed on a platform manufactured by gray cast iron for dispersing heat and stress generated in the machining process to effectively limit deformation and reduce subsequent machining difficulty.

Owner:北京中航华晟激光技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com