Patents

Literature

100 results about "Babbitt" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Babbitt metal or bearing metal, is any of several alloys used for the bearing surface in a plain bearing. The original Babbitt alloy was invented in 1839 by Isaac Babbitt in Taunton, Massachusetts, United States. He disclosed one of his alloy recipes but kept others as trade secrets. Other formulations were developed later. Like other terms whose eponymous origin is long since deemphasized (such as diesel engine or eustachian tube), the term babbitt metal is frequently styled in lowercase. It is preferred over the term "white metal", because the latter term may refer to various bearing alloys, lead- or tin-based alloys, or zinc die-casting metal.

Laser quick repair process method for large rotary machine bearing bush

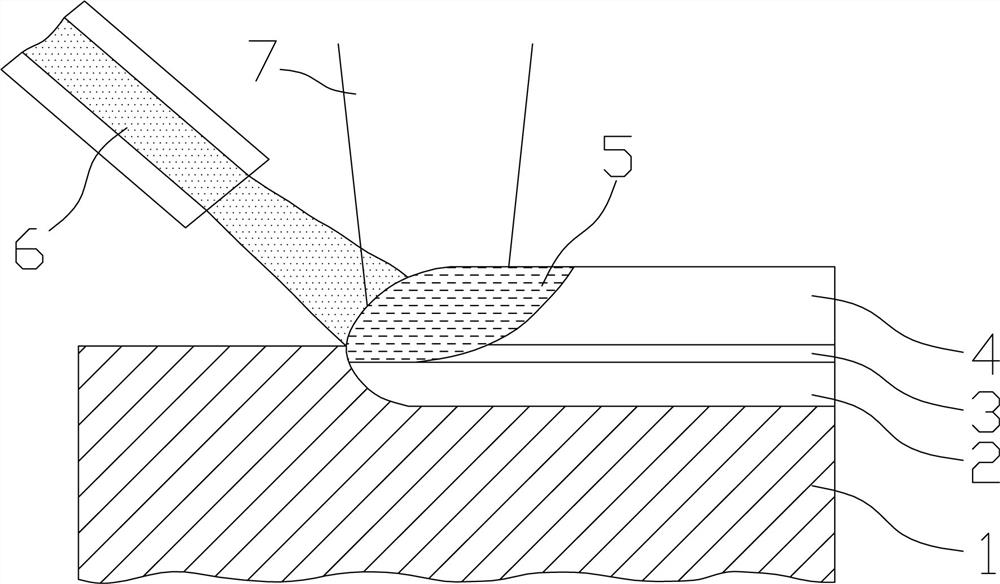

InactiveCN103451650ASmall dilutionDense tissueMetallic material coating processesSlagHigh energy laser beam

The invention relates to the technical field of laser cladding, in particular to a laser quick repair process method for a large rotary machine bearing bush. According to the laser quick repair process method, a layer of purpose-made powdered materials capable of meeting operating requirements is arranged on the surface of a part in advance; then, high-energy laser beams are used for quick scanning processing on the coating; the powdered materials arranged in advance melt instantaneously and solidify; base metal below the coating melts into a thin layer along with the coating, molecular or atomic interdiffusion quickly occurs in a quite narrow area in a boundary between the thin layer and the coating, and solid metallurgical bonding is formed at the same time; a substrate is extremely little affected by heat under a rapid heating condition and does not deform. The laser quick repair process method for the large rotary machine bearing bush achieves the effect that a local and whole-area Babbitt metal laser cladding layer is formed on the substrate made of cast steel and bronze alloy, a Babbitt metal layer which is 1.0-15 mm is formed as required, and metallurgical bonding between Babbitt metal and various substrates is realized; the laser cladding layer is low in dilution, compact in structure and free of delaminating, air holes, slag inclusion, cracks and other quality defects.

Owner:岳阳大陆激光技术有限公司

Method for preparing babbitt alloy from residue containing silver of copper anode slime

InactiveCN102312097AEasy to separateLow costProcess efficiency improvementElectrolytic agentAntimony potassium tartrate

The invention relates to a method for preparing a babbitt alloy from residue containing silver of copper anode slime. The method comprises the following steps:1, adding sodium carbonate, powdered carbon and borax according to the mass of the residue containing silver, and uniformly mixing; 2, melting to obtain a crude alloy containing lead; 3, preparing an electrolyte from fluosilicic acid, lead fluorosilicate, stannous oxide and potassium antimonyl tartrate, and adding with gelatin and ethyl naphthol; 4, treating the crude alloy as an anode and a stainless steel plate as a cathode, and taking the cathode plate (the stainless steel plate) and peeling cathode products each 12h; and 5, adding lead, antimony and copper or tin, antimony and copper to the cathode products, and melting to obtain the lead-based or tin-based babbitt alloy. The method which has the advantages of short flow, low cost, and strong practicality and allows the lead-based or tin-based babbitt alloy to be prepared from the residue containing silver of the copper anode slime is especially suitable for anode slime processing in electrolyzing electronic wastes with regenerated copper, and has the characteristics of simple and feasible operation, and high recovery rate of valuable metals.

Owner:广东省资源综合利用研究所

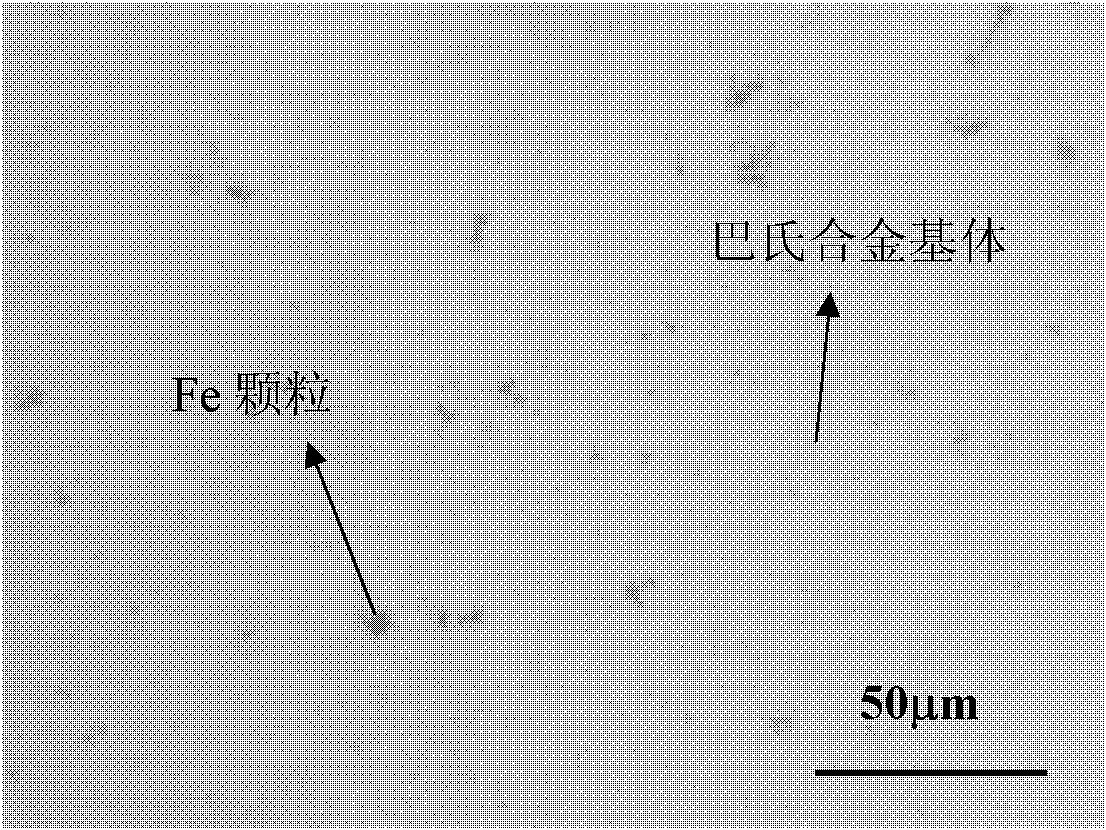

Stannum-based composite babbit metal and method for preparing welding wire

InactiveCN102248320AArc welding apparatusWelding/cutting media/materialsSolderabilityUltrasonic atomization

The invention relates to stannum-based composite babbit metal. The stannum-based composite babbit metal comprises 1 to 10 weight percent of magnetic particles and the balance of babbit metal matrix, wherein the babbit metal matrix comprises 5 to 13 weight percent of Sb, 1 to 10 weight percent of Cu and the balance of Sn. A method for preparing a welding wire from the composite babbit metal comprises the following steps of: mixing babbit metal powder and the magnetic particles uniformly; heating the mixture to 450 to 500 DEG C under the protection of a soldering flux; stirring and casting in the magnetic field; and preparing a wire material of 0.1 to 3 mm from the alloy by an extruding and drawing process. The babbit metal powder is prepared by the following steps of: mixing 5 to 13 weightpercent of Sb, 1 to 10 weight percent of Cu and the balance of Sn; heating the mixture to a melting state; and under the protection of nitrogen, preparing babbit metal powder from the molten liquid by using ultrasonic atomization equipment. The stannum-based composite babbit metal refines alloy crystal particles, improves wear resistance and obviously improves wettability and weldability on a steel matrix under the action of magnetic field.

Owner:SOUTHEAST UNIV

Composite material for sliding bearing and preparation method thereof

InactiveCN1800668AImprove tribological propertiesImprove carrying capacityBearing componentsReflex reflectorsElectricityCarbon nanotube

The invention relates to a composite sliding bearing material and relative preparation method. It comprises a common babbit and carbon nanometer pipe. Wherein, the common babbit is the basic material and the carbon nanometer pipe is a reinforced element. Said common babbit is lead or tin alloy. The preparation method comprises: the common babbit basic material and the carbon nanometer pipe reinforced element are compounded via electric deposition. The electric deposition method comprises following steps: (1) processing plating-before process on the common sliding bearing steel back; (2) plating in the plating solution in the electric plating groove. The plating-before process is using 10g / L metal cleaning solution to wash in ultrasonic for several minutes to be washed via tap water. And the plating solution comprises the components as: Sn(BF4)2: 8-12g / L; Pb(BF4)2: 3-6g / L; HBF: 350-420g / L; glutin: 4g / L and carbon nanometer pipe: 0.5-1g / L. the invention ahs high carrying ability, long service life, and simple producing method.

Owner:GUANGDONG UNIV OF TECH

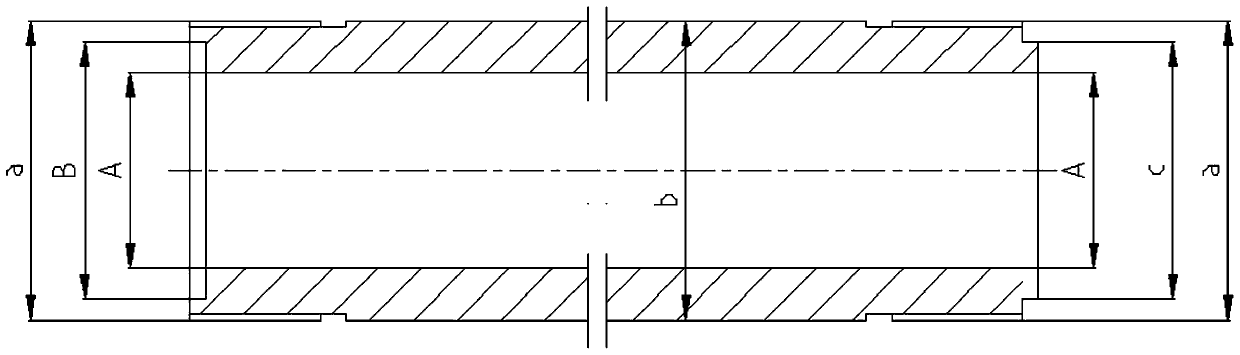

Centrifugal casting method of bearing bushes

InactiveCN103866225AStrong physical propertiesHigh dimensional accuracyHot-dipping/immersion processesMolten casting coatingPre treatmentCasting defect

The invention discloses a centrifugal casting method of bearing bushes. The centrifugal casting method comprises the following steps: preprocessing steel brushes; dipping the steel brushes with tin; melting tin-based bearing Babbitt alloys; casting; checking and the like. The products cast by the method are high in size precision, small in machining allowance and few in casting defects. The method has the advantages that the working efficiency is improved and the cost is reduced and plays a role of guiding actual production.

Owner:SUZHOU JIEDERUI PRECISION MACHINERY

High-plasticity tin-based Babbitt alloy

The invention discloses a high-plasticity tin-based Babbitt alloy and relates to a tin-based Babbitt alloy. In the invention, the problems of low high-temperature strength and low plasticity of the conventional medium / high-plasticity tin-based Babbitt alloys are solved. The high-plasticity tin-based Babbitt alloy comprises the following components in percentage by mass: 0.05 to 1.5 percent of Gd, 6 to 10 percent of Sb, 1 to 6 percent of Cu, 0.5 to 1 percent of Ag and the balance of Sn. In the invention, the addition of Gd into the Babbitt alloy can improve the plasticity of the alloy. Compared with the conventional tin-based Babbitt alloy, under the same test condition, the coefficient of elongation is improved by 10 to 20 percent, the strength at room temperature is improved by 8 to 18 percent, the strength at a high temperature of 200 DEG C is improved by 12 to 20 percent, and the wear resistance is improved by over 35 percent. The high-plasticity tin-based Babbitt alloy can be used as a bearing bush material and also can be drawn into wires which can be used as deposition materials.

Owner:HARBIN INST OF TECH

Pouring technology for bearing alloy

InactiveCN105642874AQuality improvementPouring process method is simpleMolten metal conveying equipmentsAlloySlow cooling

The invention discloses a pouring technology for bearing alloy. The pouring technology comprises the steps of 1, fully stirring alloy liquid before pouring, leaving the alloy liquid to stand for 2-4 minutes and clearing dross, wherein the pouring temperature of tin-antimony alloy ranges from 400 DEG C to 440 DEG C; 2, preheating all pouring tools to 150-200 DEG C before pouring and taking out dies preheated to 270-300 DEG C; 3, in the pouring process, guaranteeing that the temperature of the inner surfaces of the dies is always higher than the temperature of a steel shell bearing bush surface because the temperature decides the condensation direction of the liquid alloy; 4, for completing the pouring process, placing a die base on a platform before pouring, immediately pouring molten babbitt metal into an iron ladle preheated to 270-300 DEG C for carrying out casting after preparation work is completed, controlling the speed to be low at the initial stage of pouring, gradually increasing the speed and cooling the alloy through quenching and slow cooling after pouring is completed.

Owner:CHONGQING XUXINYUE NC MACHINERY CO LTD

Method for thermally spraying Babbitt-metal coating on surface of crosshead

InactiveCN103014589AHigh bonding strengthReduce oxideMolten spray coatingMetal coatingPhysical chemistry

The invention relates to a method for thermally spraying Babbitt metal coating on the surface of a crosshead, comprising the following steps: (1) decontaminating the surface of the crosshead; (2) sandblasting and roughing the decontaminated surface of the crosshead; (3) thermally spraying nickel and aluminum on the roughed surface of the crosshead to form a priming coating; and (4) thermally spraying Babbitt metal work coating to cover the nickel-aluminum priming coating. Due to the characteristics of the Babbitt metal, the Babbitt-metal coating formed on the surface of the crosshead by thermally spraying the Babbitt metal can be well used as an anti-friction coating. The crosshead coated with the Babbitt metal on the surface can be used for an air cylinder to store oil and reduce the coefficient of friction. The hardness of the crosshead is lower than that of the cylinder material, and the crosshead can be used as a friction pair.

Owner:上海大豪纳米材料喷涂有限公司

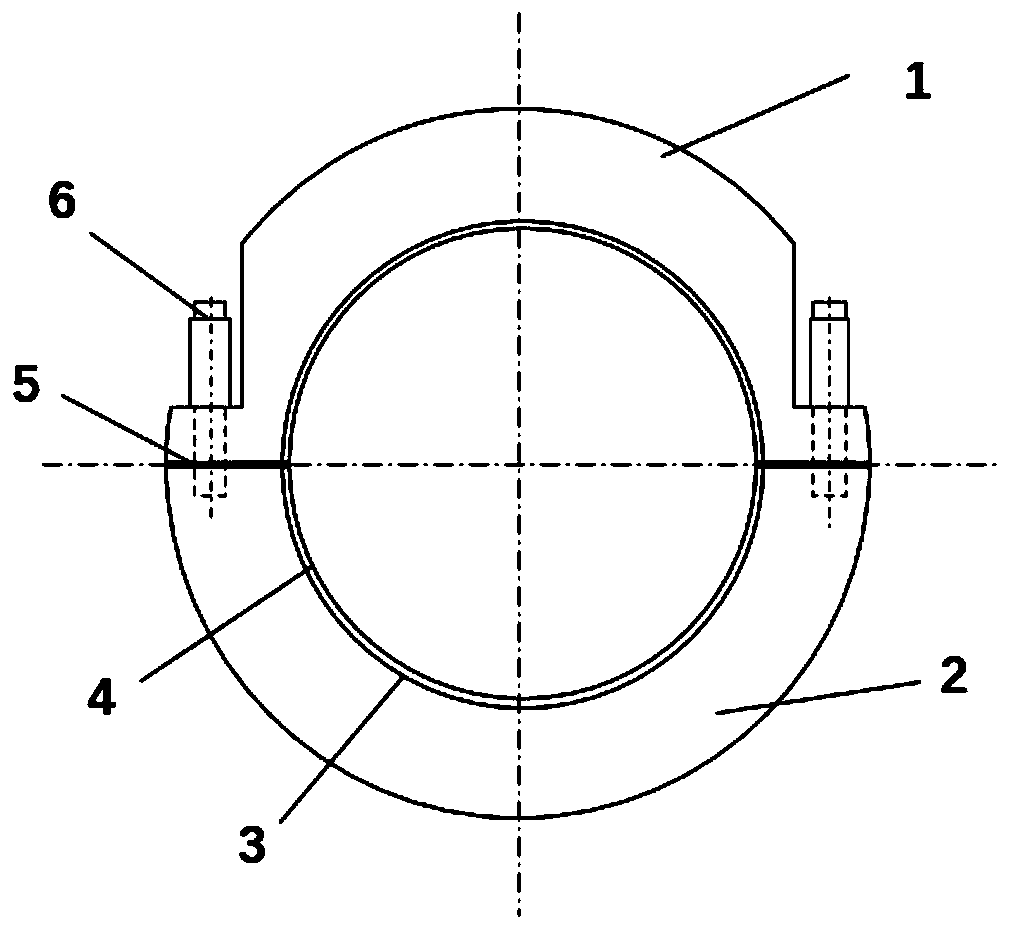

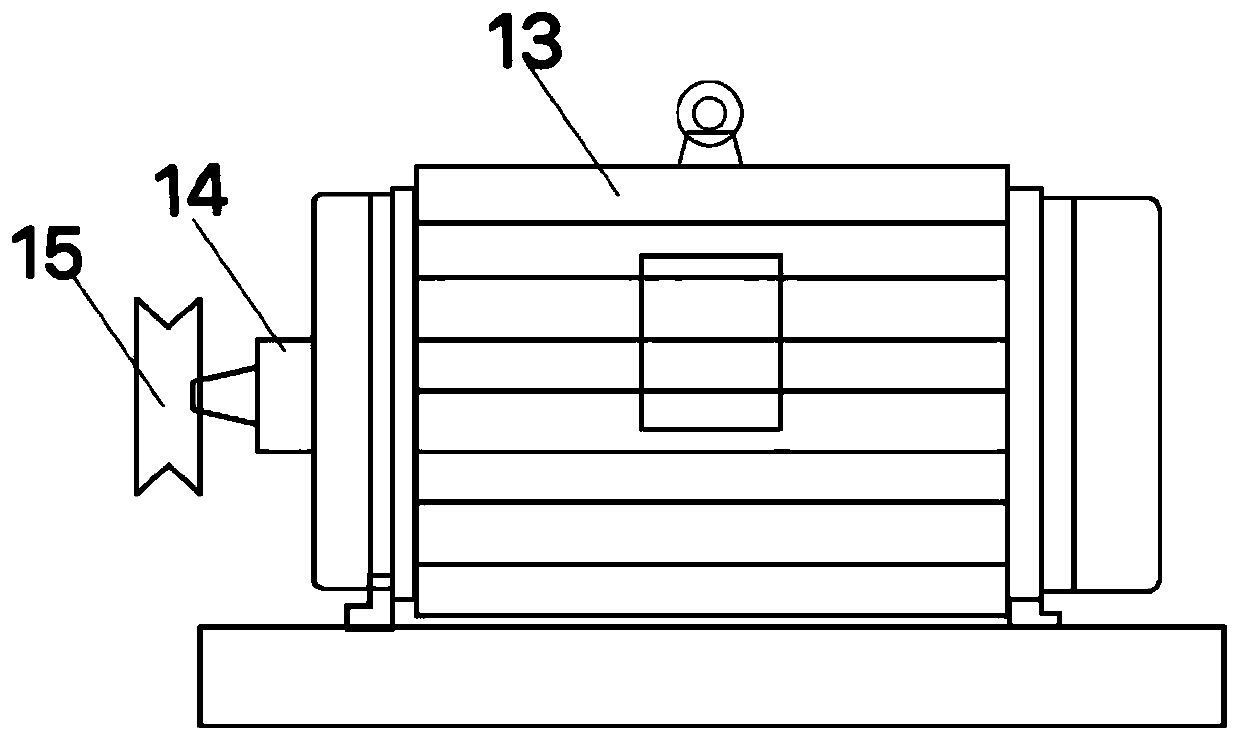

Method and equipment for manufacturing Babbitt alloy bearing bush

ActiveCN111001924AReduce consumptionThe solution to the problem of slow heatingNon-electric welding apparatusSlider bearingMechanical engineering

The invention relates to the technical field of manufacturing of sliding bearings, in particular to a method and equipment for manufacturing a Babbitt alloy bearing bush. The manufacturing method of the Babbitt alloy bearing bush comprises the following steps: the Babbitt alloy sleeve is arranged in the bearing bush assembly part in a sleeving mode, the Babbitt alloy sleeve and the bearing bush assembly part relatively rotate and rub to enable the outer layer of the Babbitt alloy sleeve to be molten, and welding of the Babbitt alloy sleeve and the bearing bush assembly part is completed. The Babbitt alloy sleeve and the bearing bush assembly part are welded in a rotary friction mode, the rotary friction self-heat-production speed is high, a large amount of energy consumption caused by traditional overall heating is reduced, the energy-saving effect is obvious, the problem that a traditional bearing bush base body heating mode is slow in temperature rise is solved, the production efficiency can be greatly improved, and the beneficial effects of saving energy, reducing emission, saving materials, improving quality, improving efficiency, protecting the environment and the like are achieved.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

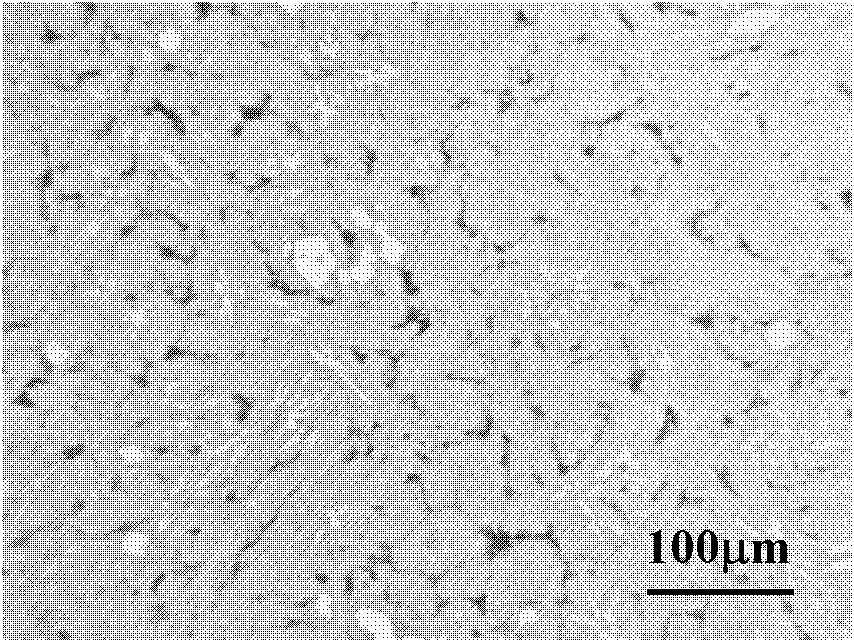

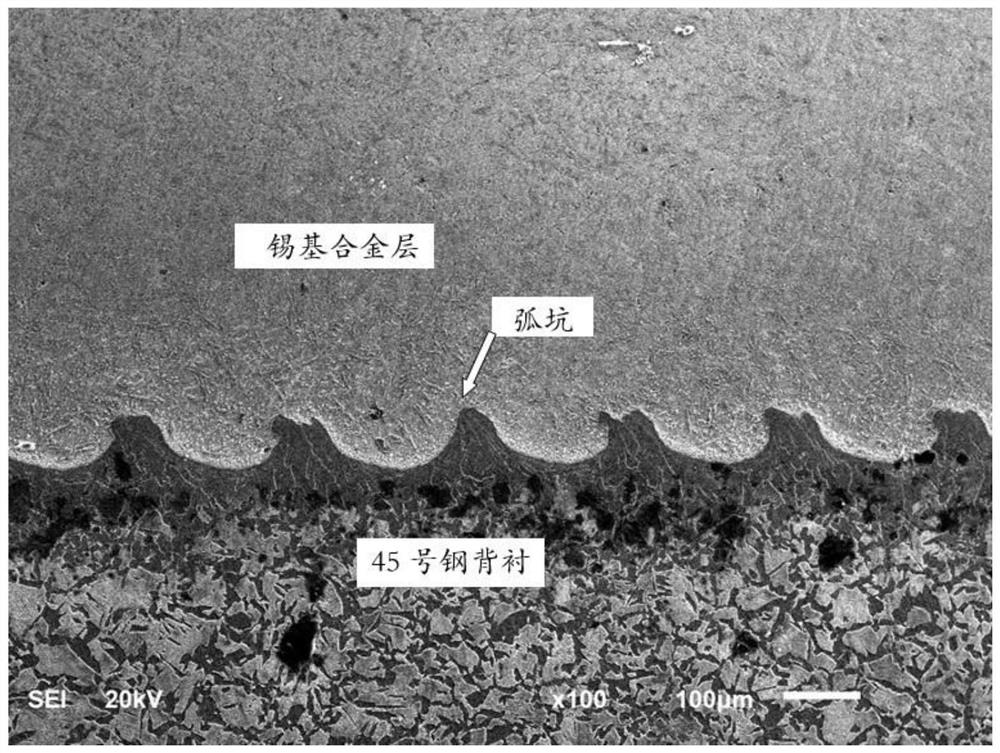

Preparation method for babbit metal layer of sliding bearing

InactiveCN107598134AHigh bonding strengthFastening shrinkage cavityGearingCylindersRoughcastCrystallite

The invention discloses a preparation method for a babbit metal layer of a sliding bearing. Before a bearing blank is subjected to tinning, the bearing blank is preheated to be 300-500 DEG C firstly,thus tin liquid can better permeate into a base body of the bearing blank, and the combining strength of the babbit metal layer is improved. Additionally, when the babbit metal layer begins to be solidified and treelike crystal appears, the bearing blank is subjected to rapid forced cooling through cooling water, and thus grains near the combining layer of the babbit metal layer are refined; and after refining, the combining layer is more firm, shrinkage holes in the combining layer are greatly reduced, and thus the strength and the combing strength of the babbit metal layer can be greatly improved.

Owner:XIAN UNIV OF TECH

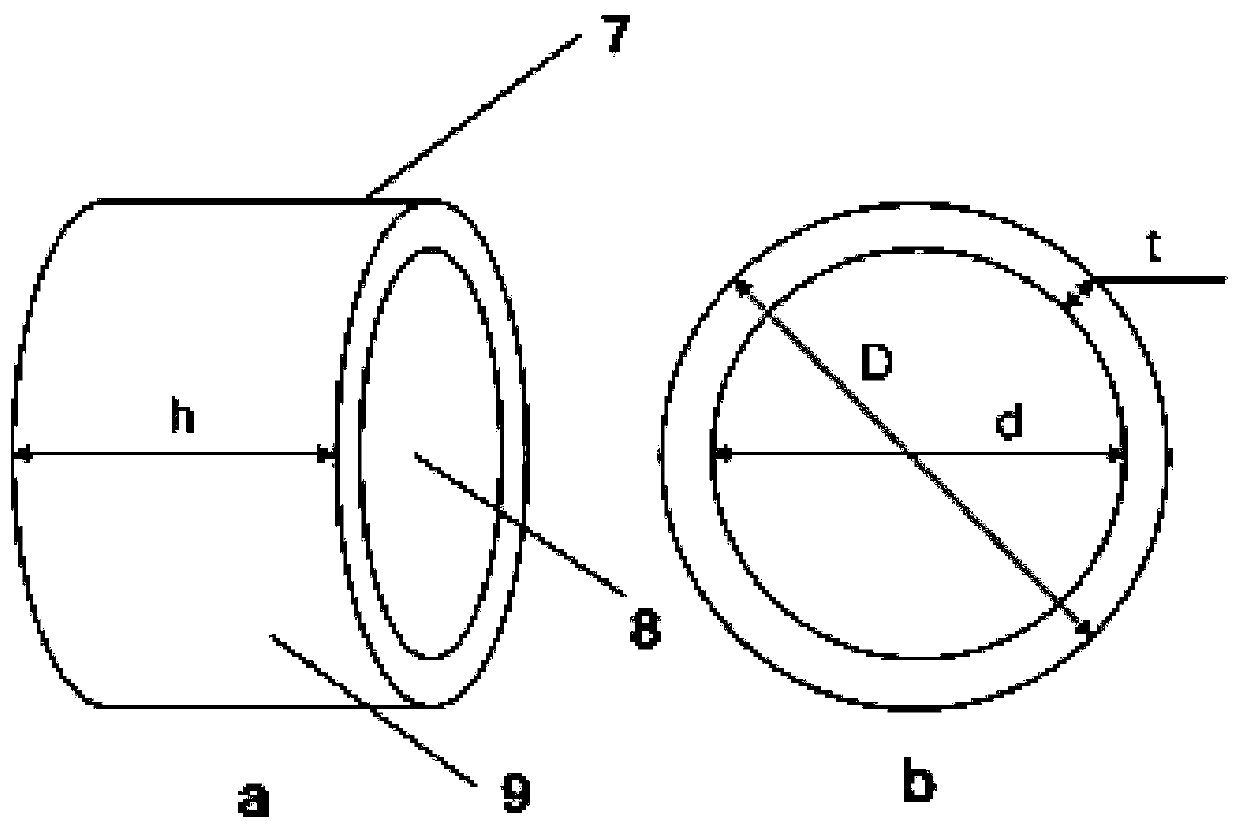

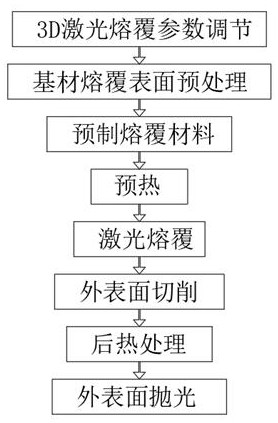

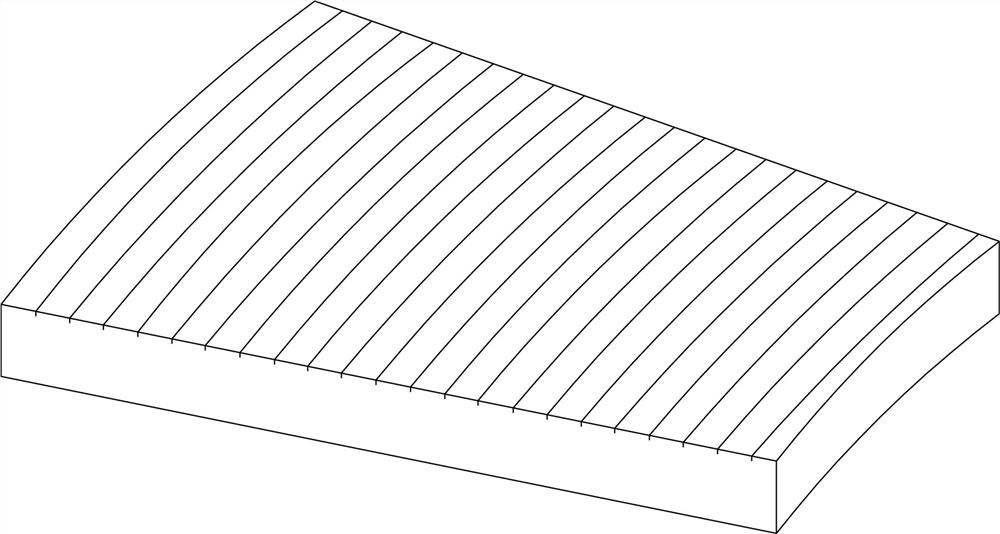

3D laser cladding additive manufacturing process based on bearing bush alloy layer

InactiveCN112536447AHigh degree of automationSimple processAdditive manufacturing apparatusWorking environmentAlloy

The invention relates to the technical field of laser cladding, in particular to a 3D laser cladding additive manufacturing process based on a bearing bush alloy layer. The process comprises the following steps: 1, adjusting 3D laser cladding parameters; 2, pretreating the cladding surface of a base material; 3, presetting a cladding material; 4, preheating; 5, carrying out laser cladding; 6, cutting the outer surface; 7, carrying out post-heat treatment; and 8, polishing the outer surface. According to the laser cladding additive manufacturing process for the bearing bush alloy layer, a traditional bearing bush alloy casting production process is replaced, laser cladding is directly adopted for the bearing bush alloy layer, and tin-based babbitt metal powder is cladded layer by layer to the designed thickness, so that the problems that the traditional bearing bush alloy casting process is complex in procedure, unstable in product quality, high in production cost, high in labor intensity, poor in working environment and the like are solved, and the beneficial effects of simplified procedure, good product quality, stable product quality, low production cost, high automation degree,environmental friendliness, sanitation and the like are achieved.

Owner:SHENKE SLIDE BEARING

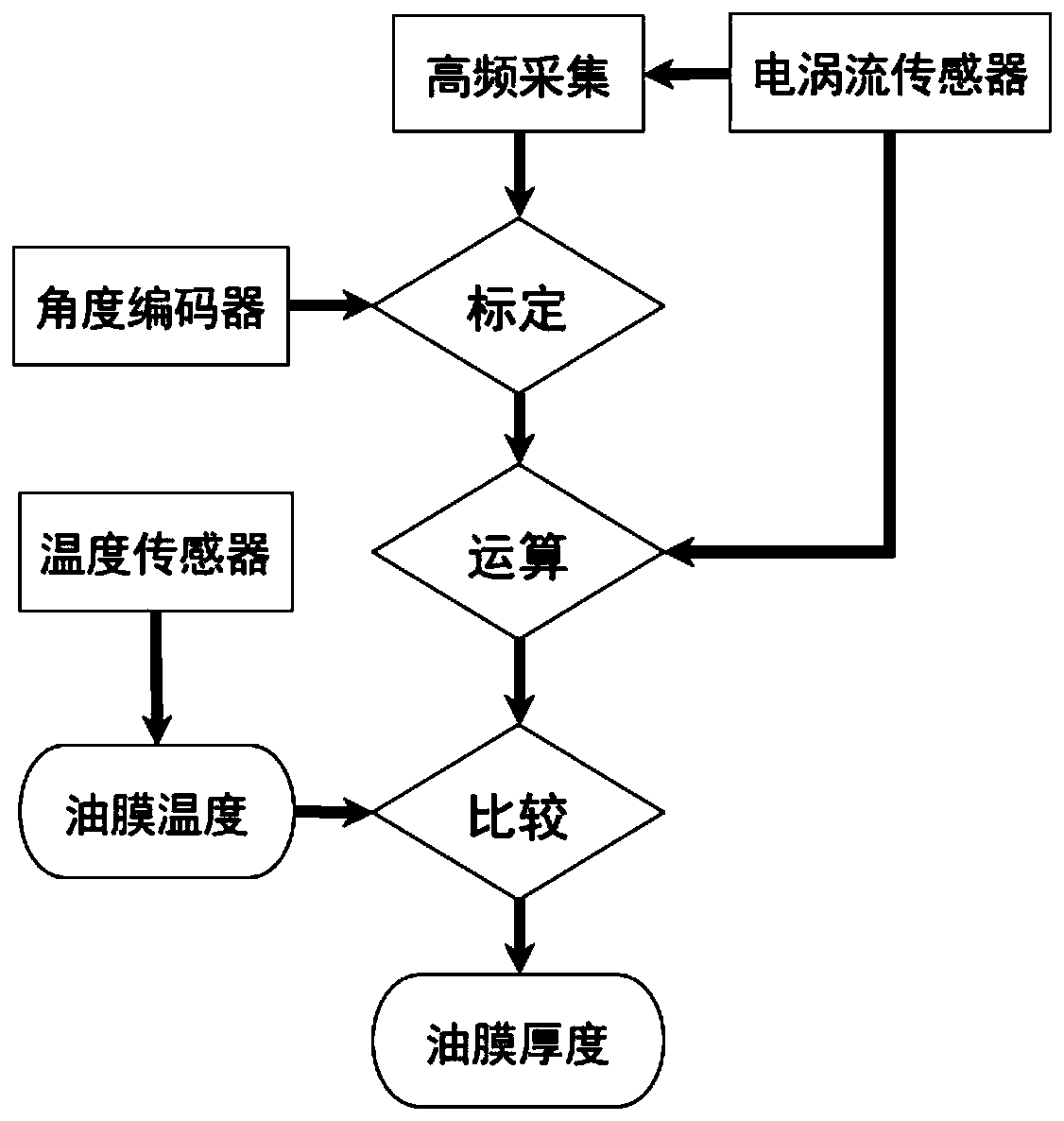

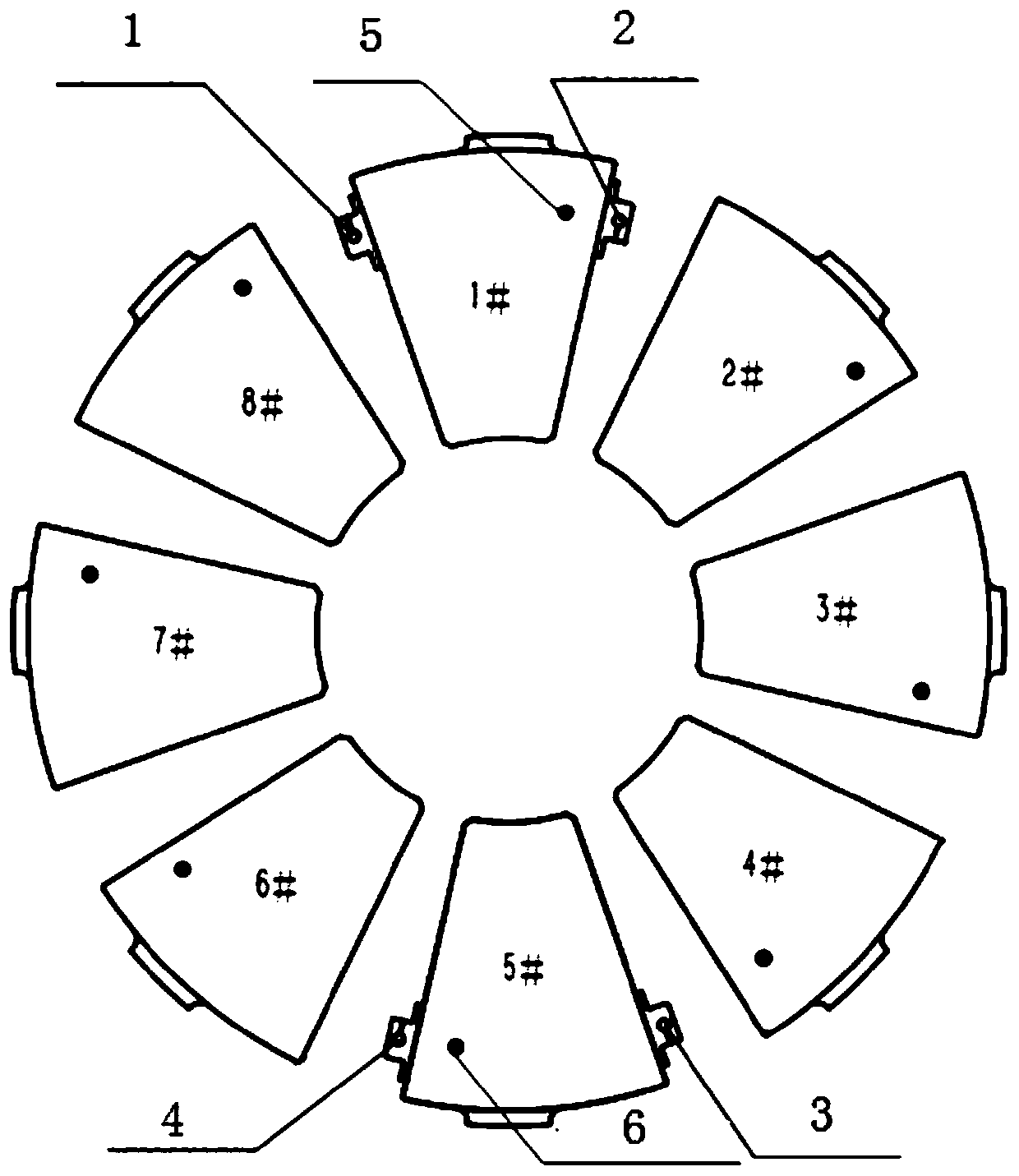

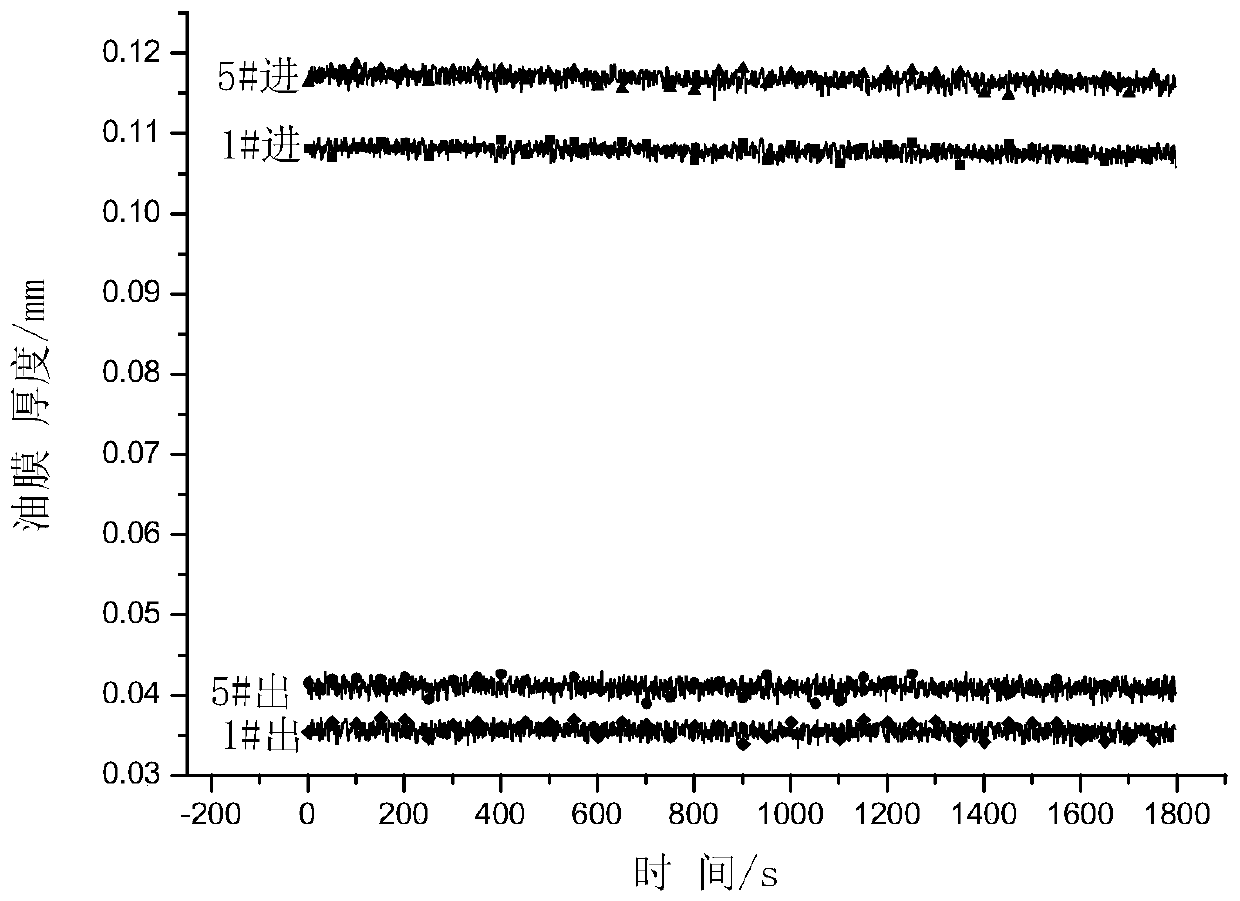

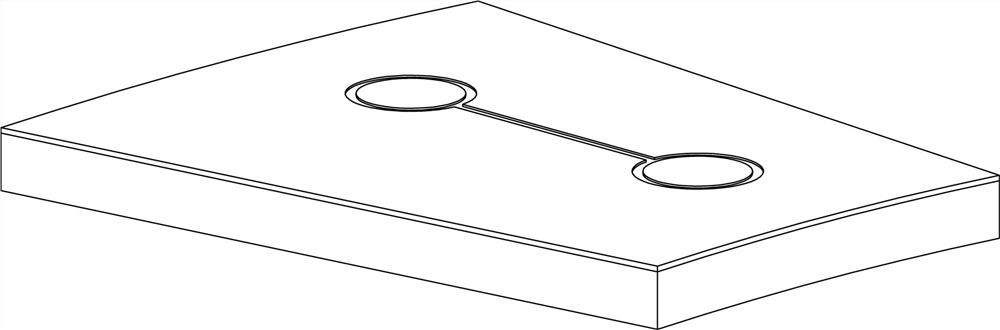

Oil film thickness measuring method of thrust bearing-babbitt metal tile for water turbine

ActiveCN111336909AReduce the number of layoutsReduce complexityUsing electrical meansElectrical/magnetic thickness measurementsWater turbineThrust bearing

The invention provides an oil film thickness measuring method of a thrust bearing-babbitt metal tile for a water turbine. According to the method, the thickness of the oil film is measured through eddy current displacement sensors installed at the oil inlet end and the oil outlet end of the fan-shaped babbitt metal tile. In the prior art, an eddy current displacement sensor is used for measuring the thickness of an oil film; the characteristic of zero drift of eddy current exists, namely the characteristic of difficulty in calibration. According to the invention, the angle measurement encoderis adopted, a plurality of zero points are adopted for rotation through high-speed collection and processing, a plurality of factors influencing the measurement precision of the eddy current displacement sensor are eliminated, the eddy current zero point selection problem in the measurement process of a hydraulic turbine set is solved, initial calibration is completed, and the oil film thickness measurement of the babbitt metal thrust bearing is realized. By establishing the function relationship between the oil film thickness at the oil inlet end and the oil outlet end of the thrust bearing and the oil film temperature, the measurement and calculation of the whole set of thrust bearing oil film are completed, and the arrangement number of sensors and the complexity of system hardware arereduced.

Owner:DALIAN SANHUAN COMPOSITE MATERIAL TECH DEV

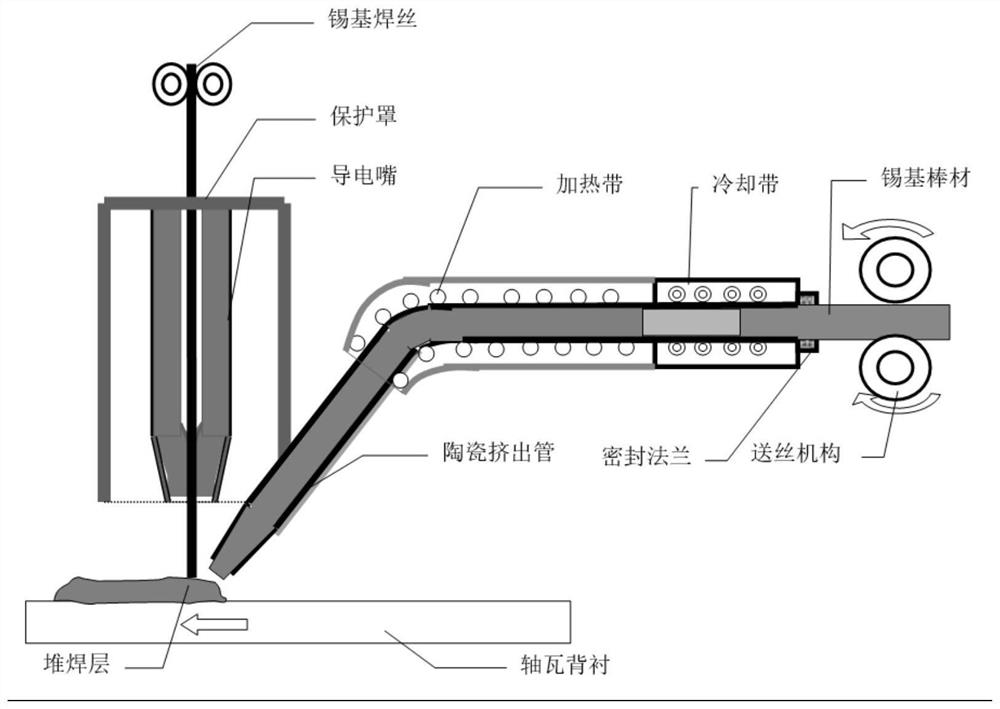

Sliding bearing bush material and preparation method thereof

ActiveCN112222575AIncrease productivityImprove bindingElectrode supporting devicesWelding accessoriesSlider bearingSemi solid

The invention discloses a sliding bearing bush material and a composite additive preparation process thereof. The bearing bush material is sequentially composed of a backing, a bonding layer and an anti-friction layer, the backing is made of medium-low carbon steel, the bonding layer and the anti-friction layer are both made of tin-based babbitt metal, and the bonding layer is made of tin-based babbitt metal with low Sb and Cu content. The bonding layer and the anti-friction layer are sequentially prepared by using a method of combining MIG welding and semi-solid extrusion. The specific preparation method comprises the steps that an MIG welding gun and a semi-solid slurry extrusion pipe keep a fixed angle, when the welding gun conducts MIG welding on the backing, the semi-solid extrusion pipe extrudes semi-solid materials to the same backing position at the same time, in this way, the bonding layer and the anti-friction layer are deposited on the surface of the backing in sequence, andtherefore the bearing bush material is prepared. The method is high in efficiency, the tool cost and the machining allowance can be greatly reduced, and good welding quality is achieved.

Owner:JIANGSU UNIV OF SCI & TECH

Thrust pad repairing method based on laser cladding process

PendingCN112981395ALow heat inputSmall amount of thermal deformationAdditive manufacturing apparatusIncreasing energy efficiencyTinningEngineering

The invention aims at providing a thrust pad repairing method based on a laser cladding process. The deformation amount in the thrust pad repairing process is effectively controlled, the problems of hole shrinkage and shelling of a babbitt metal layer are thoroughly solved, the design size of a thrust pad is recovered, the use performance of the thrust pad is improved, the service life of the thrust pad is prolonged, and extremely high economical efficiency is achieved. The thrust pad repairing method comprises the following steps: removing an original babbitt metal layer of the thrust pad, preparing the babbitt metal layer on the surface of a steel billet through laser cladding, carrying out ultrasonic flaw detection, milling, carrying out dye penetrant inspection and grinding. According to the method, the thrust pad which fails in service is remanufactured, and the use performance of the thrust pad is recovered and improved through a new additive manufacturing method. Compared with pouring and oxyacetylene welding processes, the manufacturing process of the babbitt metal layer is greatly simplified, the steel billet preheating and tinning processes are omitted, and the quality of the babbitt metal layer, the combination condition of the babbitt metal layer and the steel billet, the deformation amount of the steel billet and the labor environment are effectively improved.

Owner:CHINA YANGTZE POWER

Large-scale Babbitt bearing casting machine

InactiveCN105772696AEfficient rust removalEfficient degreasingCasting cleaning apparatusMolten metal conveying equipmentsMechanical equipmentLayer removal

The invention discloses a large-scale Babbitt bearing casting machine and aims to provide casting mechanical equipment in the field of metal casting. The casting machine comprises a base, damping pads, two clamping pinchers, a painting device, and a vibrator, wherein the two clamping pinchers are horizontally arranged oppositely and fixedly connected in a middle groove formed in the base; the painting device is fixedly connected to a foundation; the vibrator is fixedly connected with a plane which is arranged on the base; the amount of the damping pads is six, and the damping pads are all arranged on the bottom face of the base. According to the technical scheme of the large-scale Babbitt bearing casting machine, wind pressure is used as the power, by means of the wiggle, rotation and reciprocating rectilinear movement of painting tools in the painting device, operations such as rust removal, oxide layer removal, degreasing and tin coating can be conducted efficiently; vibration casting is adopted, and the casting quality is improved. By means of the large-scale Babbitt bearing casting machine, casting efficiency can be improved effectively, and the working conditions of workers can be largely improved and labor intensity of the workers can be largely relieved; the casting machine is simple in structure, convenient to repair and low in equipment investment.

Owner:KUNMING UNIV

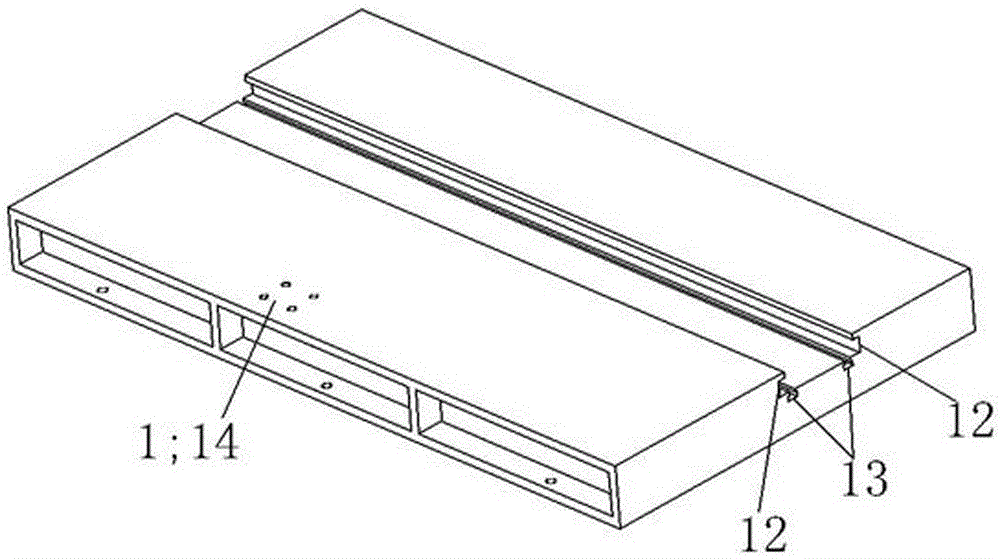

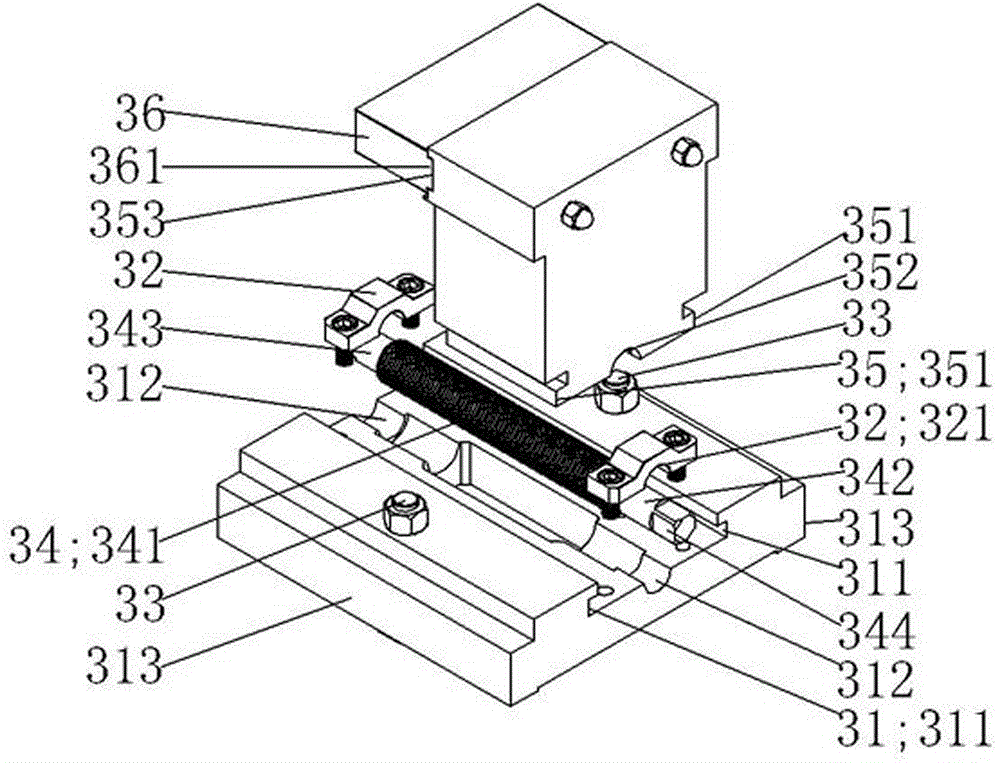

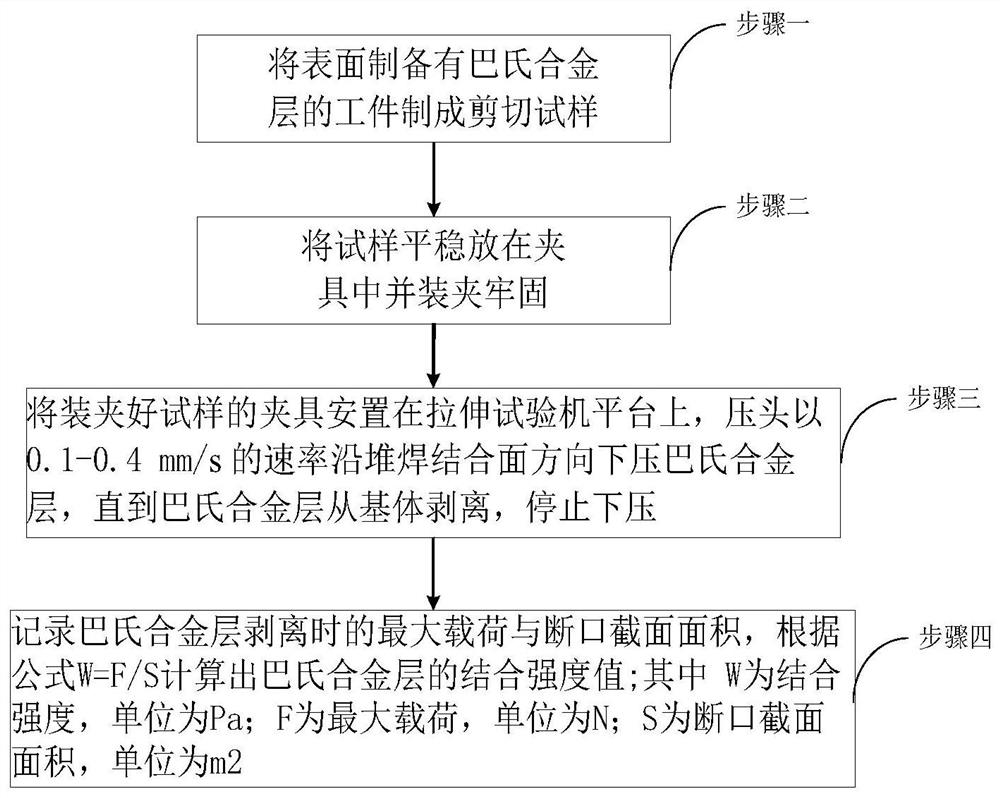

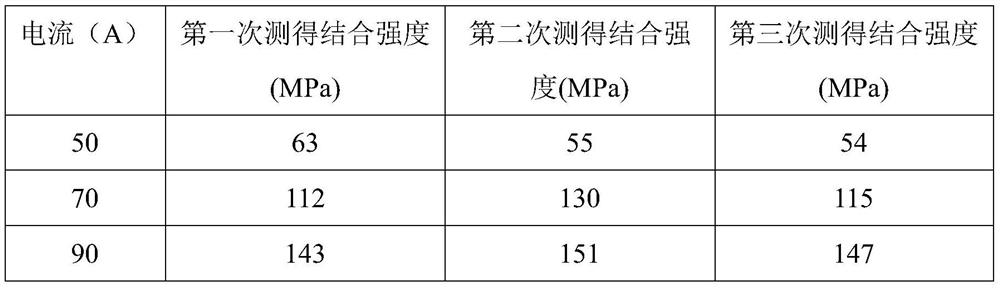

Method for detecting bonding strength of babbitt metal and matrix

PendingCN112326550APrecise Binding Strength DataAccurate dataUsing mechanical meansMaterial analysisQualitative analysisTensile testing

The invention discloses a detection method for detecting the bonding strength of babbitt metal and a matrix. The method comprises the following steps of: preparing a matrix with a babbitt metal layerprepared on the surface into a shear sample, stably placing the sample in a clamp, performing firm clamping, placing the clamp with the clamped sample on a tensile testing machine platform, pressing the babbitt metal layer downwards along the direction of a surfacing bonding surface at a speed of 0.1mm / s-0.4mm / s by a pressure head until the babbitt metal layer is stripped from the matrix, and stopping pressing; and recording the maximum load and the sectional area of a fracture during stripping of the babbitt metal layer, and calculating the bonding strength value of the babbitt metal layer according to the formula W=F / S. The method can be used for quantitatively measuring the bonding strength of the babbitt metal and the matrix, overcomes the defects of large error and incapability of quantitative rating in qualitative analysis, can acquire precise and visual bonding strength data, and has the advantages of short analysis period, easy sample processing, simple operation, low detectioncost, precise data, high sensitivity and the like.

Owner:JIANGSU UNIV OF SCI & TECH

Coated guided pad for saw blades

InactiveUS20090205470A1Improve wear resistanceReduce coefficient of frictionMetal sawing devicesCross-cut reciprocating sawsElectroless nickelWear resistance

Guide pads with electroless nickel coatings provide a better wear resistance and a lower coefficient of friction than the Babbitt guide pad material. The unexpected benefit is that when the electroless nickel coating comes into contact with the rotating saw blade body the damage to the pad or saw blade or both is substantially reduced. Also the effect of hydraulic erosion or third body erosion is minimal. With a nickel boron coating on a set of guide pads made of AMS-5069-1018 steel, at least 600 hours of use was achieved without failure of the pad or damage to the saw blade body

Owner:UCT COATINGS

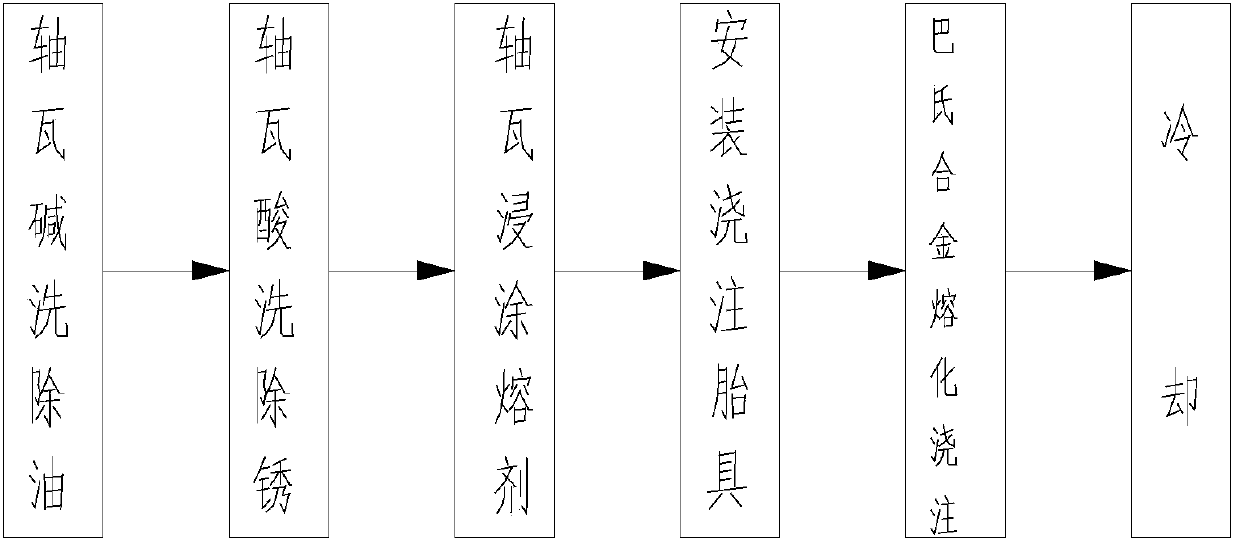

Babbitt metal casting solvent, preparation method and Babbitt metal casting method

The invention discloses a Babbitt metal casting solvent, a preparation method and a Babbitt metal casting method. The Babbitt metal casting solvent comprises the following components: zinc chloride, stannous chloride dihydrate, copric chloride dihydrate, technical hydrochloric acid and water. The preparation method of the solvent comprises the following steps: calculating the working volume of a solvent pot; calculating the needed amount of each component; adding the components according to the above order; stirring and blending; heating to 200-250 DEG C, wherein the heating time is determined according to the thickness of a cast bearing concave tile, and heating is performed for 1-2 minutes for every millimeter in thickness; arranging a water dropper on the solvent pot to uniformly adding water into the solvent. A Babbitt metal casting process comprises: alkali cleaning of a bearing bush, acid washing of the bearing bush, solvent dip-coating of the bearing bush, installation of a pouring mold, melting and pouring of Babbitt metal, and cooling. The Babbitt metal casting solvent has the remarkable characteristics of simple process, saving in time and materials, low cost and good bonding quality.

Owner:JIANGXI COPPER

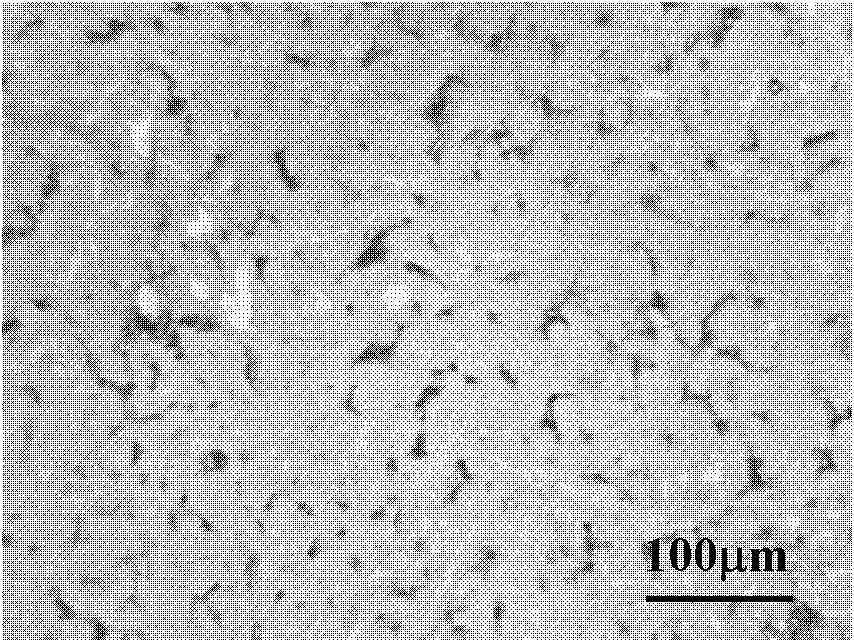

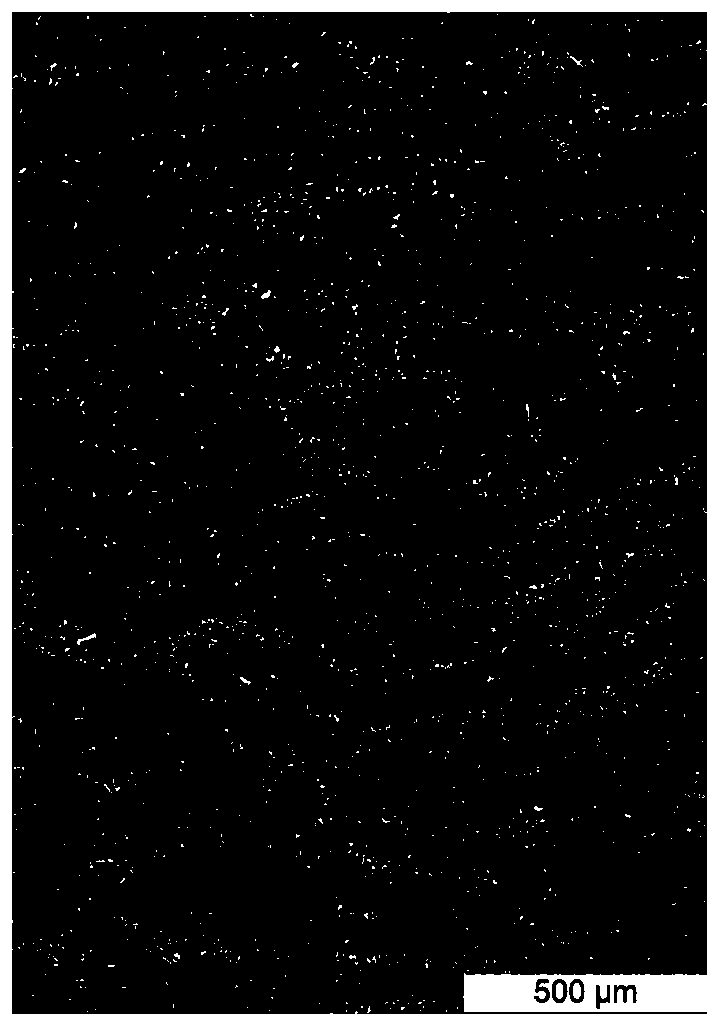

A laser additive manufacturing method for tin-based babbitt alloy components

ActiveCN107803501BImprove performanceReduce structural complexityAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingMetallurgy

A laser additive manufacturing method for a tin-based babbitt alloy component, and the invention belongs to the related field of additive manufacturing. The invention solves the problems of segregation, low forming precision, complicated process, high energy consumption and difficulty in forming products with complicated shapes when the casting method is used to manufacture babbitt alloy products. The invention adopts selective laser melting to prepare babbitt alloy. The babbitt alloy obtained by selective laser melting not only has compact structure, uniform composition and precise size, but also can produce products with complex shapes. High power laser, which promotes good forming of babbitt alloy. The process flow is simple, the energy consumption is low, and products of any shape can be formed, which fills the gap in the additive manufacturing of tin-based babbitt alloy components.

Owner:UNIV OF SCI & TECH BEIJING

Sn matrix babbitt alloy and preparing method and purpose thereof

ActiveCN111471889ASelf-lubricatingReduce coefficient of frictionBearing componentsSmelting processIngot

The invention discloses a Sn matrix babbitt alloy and a preparing method and a purpose thereof. The alloy comprises, by mass percent, 5 to 15% of antimony, 6 to 12% of copper, 3 to 9% of nickel, 1 to3% of graphite and 61 to 85% of tin. The Sn matrix babbitt alloy has the self lubricating effect, the friction coefficient is low, the preparing method of the Sn matrix babbitt alloy is provided, thecharacteristic that a Cu-Ni solid solution generated by mechanical alloying is large in proportion is used, upward floating of small-granularity graphite in the smelting process is restrained, composition segregation is avoided, meanwhile, affinity of the Cu-Ni solid solution and a copper base phase in a casting ingot can be used, continuity of graphite and a matrix can be reinforced, binding strength of the graphite and the matrix can be improved, and whole falling of the graphite in the use process can be prevented.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD +1

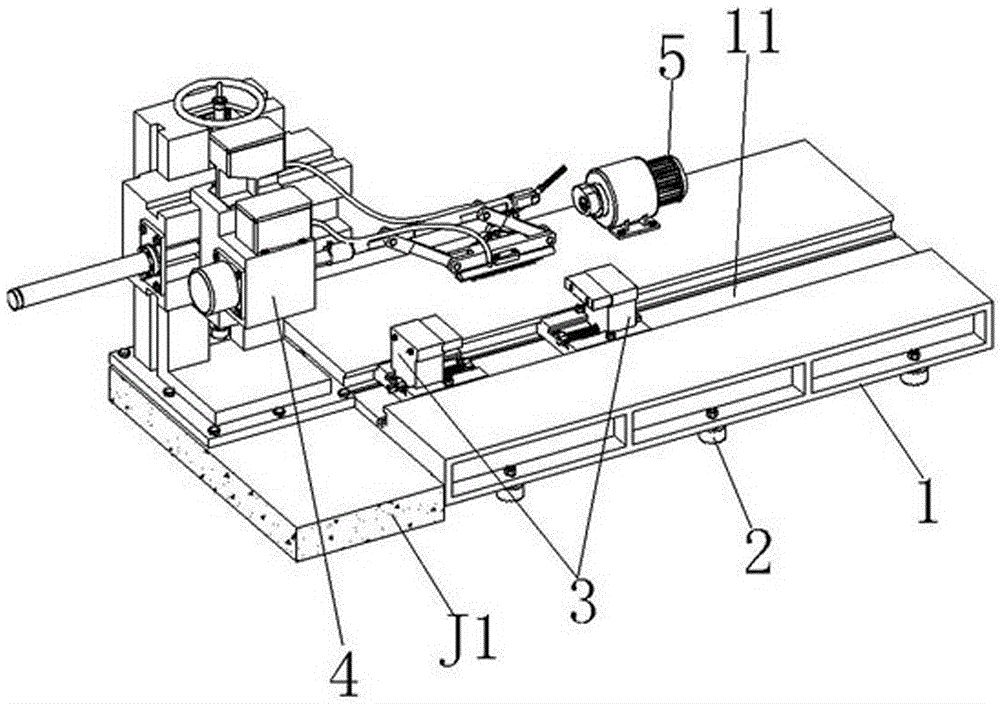

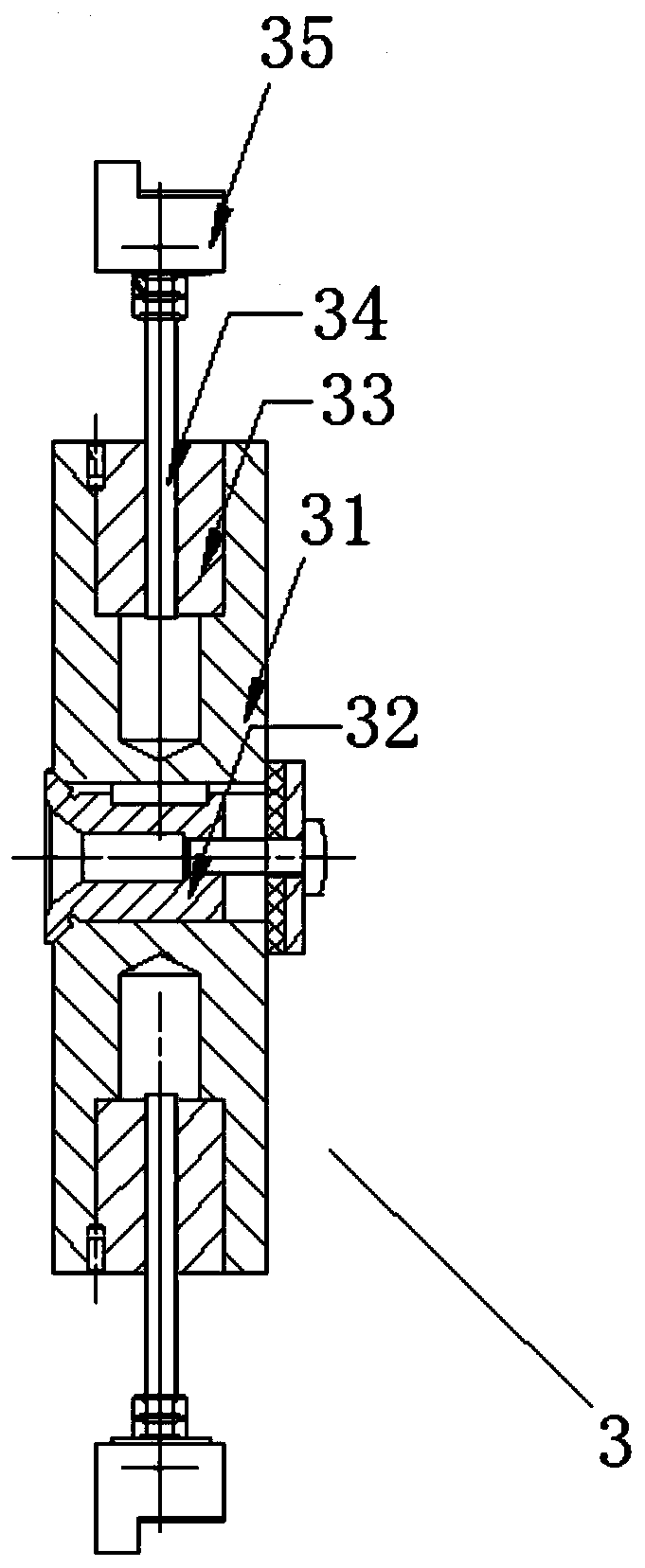

Structure for ensuring requirement for high coaxiality of large-diameter precision pipe body workpiece and method

The invention discloses a structure for ensuring the requirement for high coaxiality of a large-diameter precision pipe body workpiece and a method. The structure includes an adjustable center supportand a center frame, the adjustable center support includes a support body, a center support body, a support rod, support blocks and the like, and the support blocks are arranged on the center frame with the included angle being 120 degrees. The adjustable center support can realize the requirement of clamping of the pipe body workpiece in jacking and clamping manners, clearance-free fit with an inner hole of the workpiece can be achieved, and the clamping accuracy is improved; as for the support blocks, radial size adjustment can be realized, so that the use range of the tool is widened, andthe manufacturing quantity and cost are reduced; a workpiece thickness wall measuring method is used for calibrating and adjusting the clamped workpiece, the coaxiality of the axis of the inner hole of the workpiece and the main axis of a machine tool before finish turning is achieved, and the design requirement for high coaxiality with the inner hole when the sizes of all parts of an outer circleare subjected to finish turning is met; and the characteristics of a Babbitt alloy material are used, the machine tool accessory center frame is modified, the centering accuracy can be effectively improved, system errors caused by original center frame bearing gaps are eliminated, and the processing accuracy requirement is ensured.

Owner:上海电气上重碾磨特装设备有限公司

Metallurgical roller

The invention discloses a metallurgical roller. The metallurgical roller comprises, by weight, from 40 to 50 parts of nodular cast iron, from 35 to 60 parts of manganese steel, from 20 to 40 parts of brass, from 5 to 12 parts of aluminum oxide, from 6 to 15 parts of silicon dioxide and from 3 to 8 parts of babbit metal. The metallurgical roller has the advantages that the hardness and the tenacity of the metallurgical roller are superior to those of a conventional metallurgical roller, and the metallurgical roller cannot deform under the condition of local high temperature, and is adaptable to wide application.

Owner:WUXI ZHONGCAI NEW MATERIAL

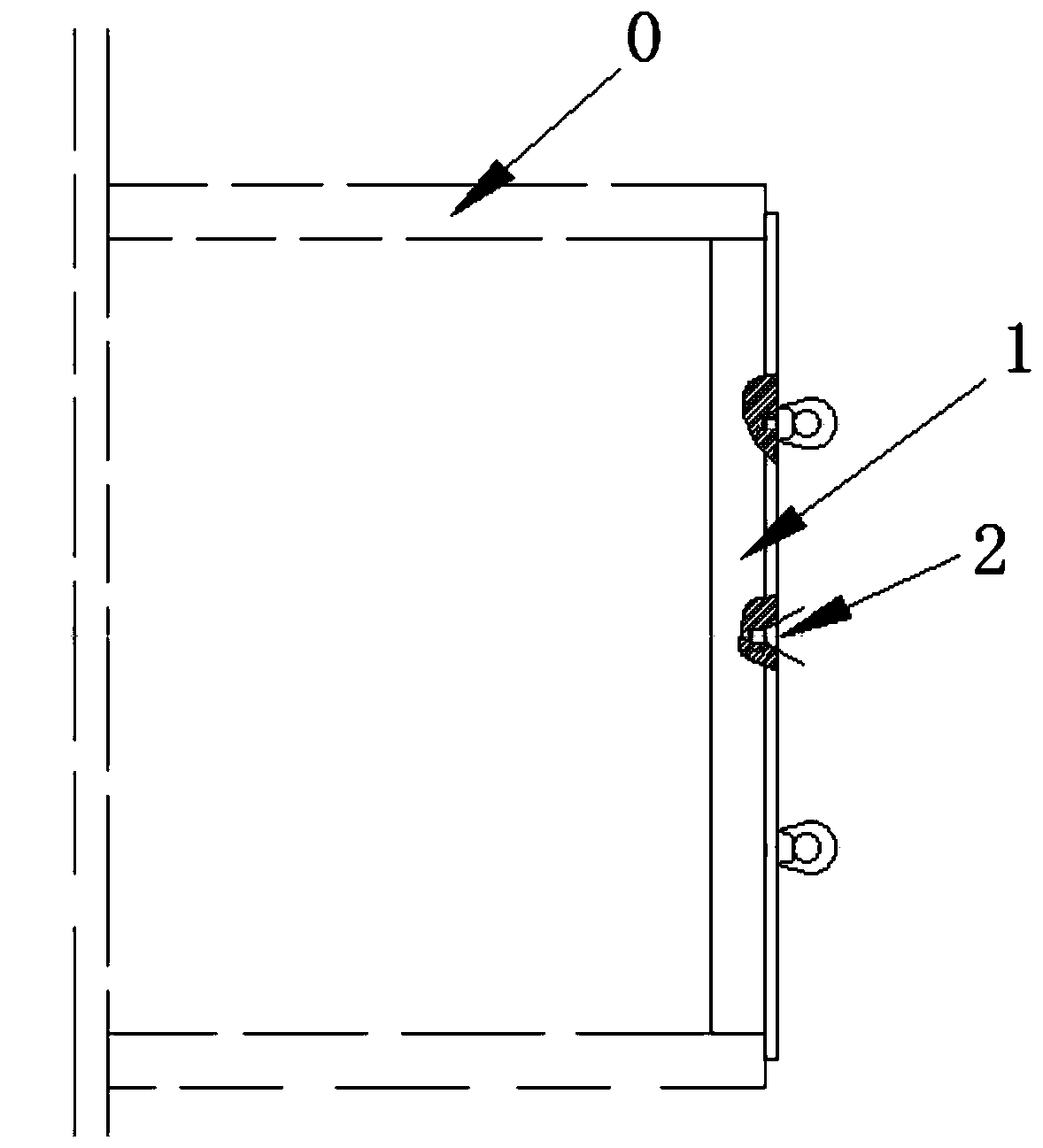

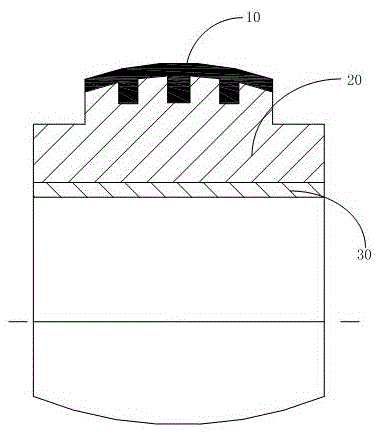

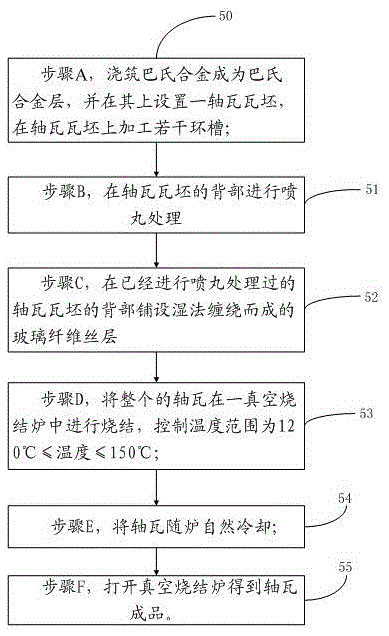

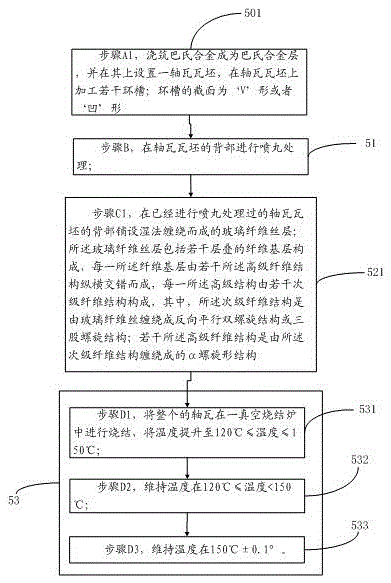

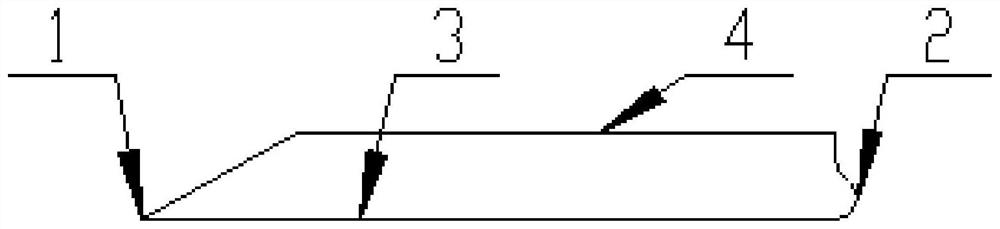

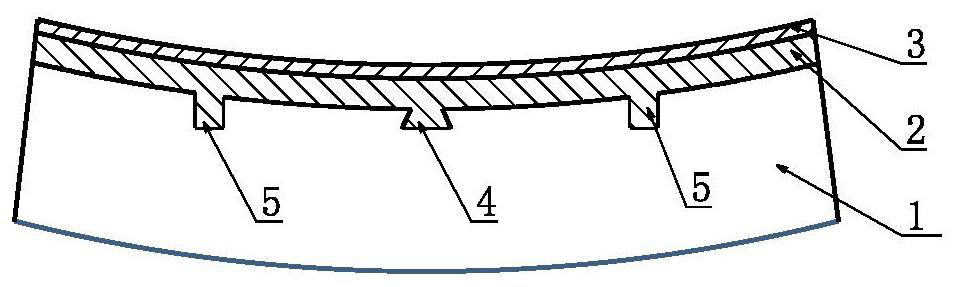

Plain bearing bush insulation structure, bearing bush and manufacturing technology of bearing bush

InactiveCN105485170AImprove insulation performanceGuaranteed uptimeShaftsBearing componentsGlass fiberManufacturing technology

The invention discloses a plain bearing bush insulation structure, a bearing bush and a manufacturing technology of the bearing bush. According to the technical scheme of the bearing bush and the manufacturing technology of the bearing bush, the bearing bush insulation structure with a babbitt metal layer poured is included; a V-shaped groove is further included; or, a fiber glass filament layer of 1 mm to 2 mm is arranged.; or, a teflon layer is arranged on the outer surface of the fiber glass filament layer; or, a primary fiber structure is composed of a plurality of secondary fiber structures, and a plurality of stacked filter base layers are included. The defects that a traditional insulation bearing is isolated from a bearing bush through teflon film pasting to cut off a shaft current path, consequently, an insulation film is quite prone to being damaged in the mounting and maintaining process, the repair technology adopted after damage is quite complex, a dedicated tool is needed, and consequently, maintaining difficulty, equipment scraping and the like are caused are overcome. The plain bearing bush insulation structure, the bearing bush and the manufacturing technology of the bearing bush are suitable for insulation plain bearing bushes adopted in various projects, and especially suitable for insulation of plain bearing bushes of matched large rotary machines in the industries such as mines, electric power, coal mines, metallurgy, traffic, chemical engineering, water conservancy, machine tools and chips.

Owner:HUNAN CHONGDE IND TECH

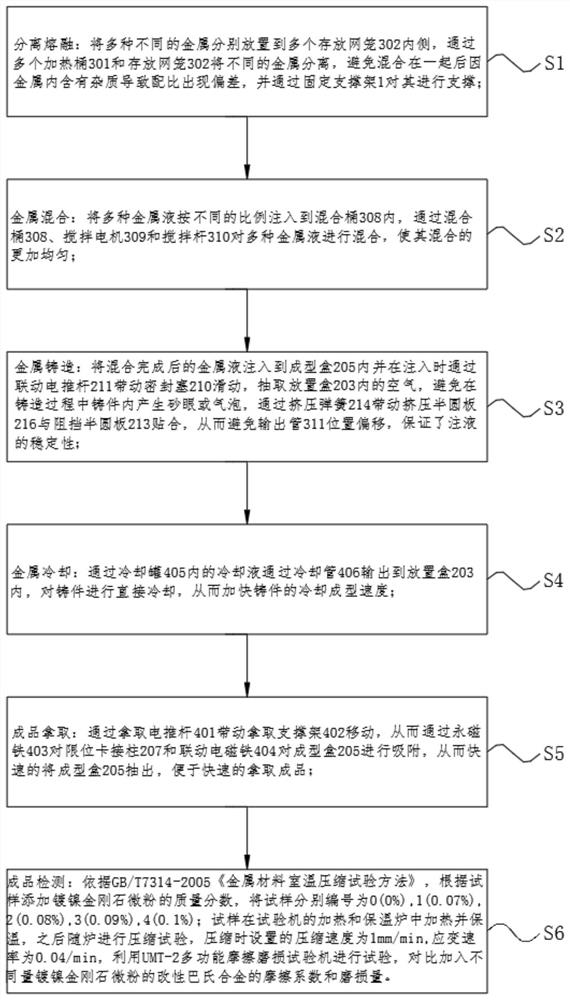

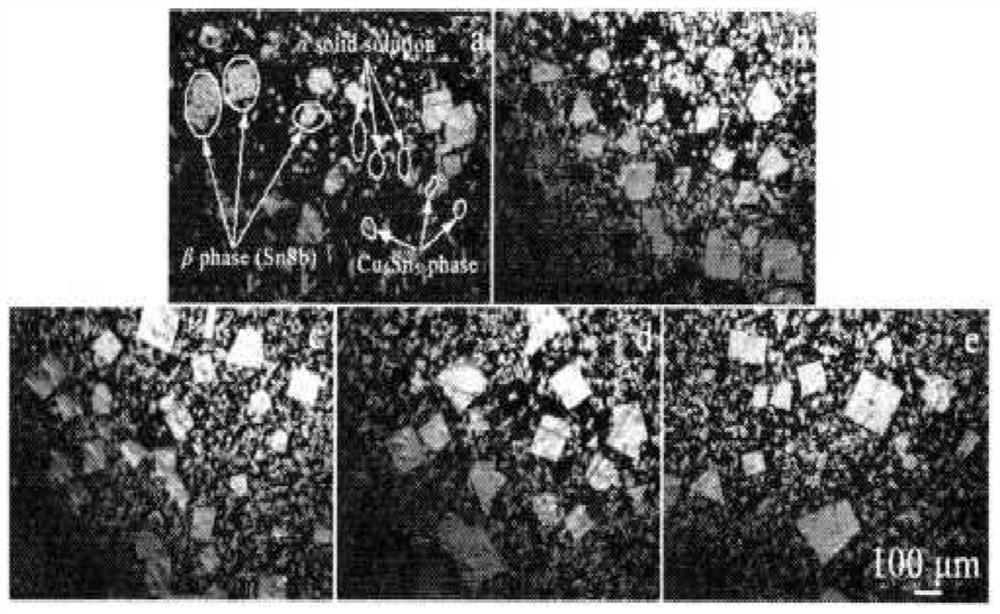

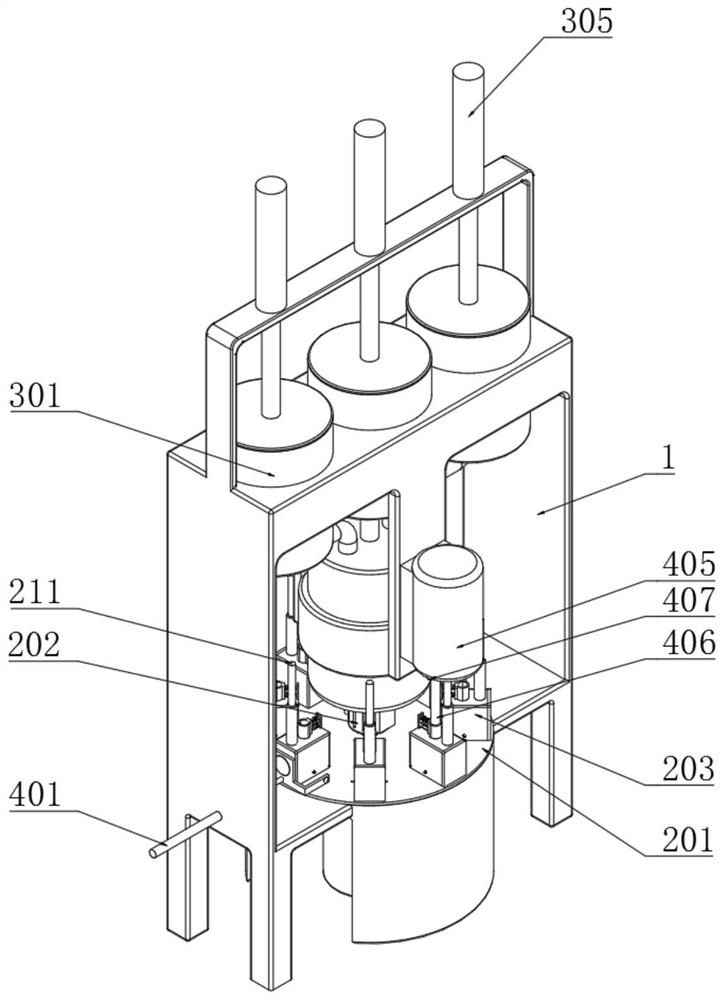

Nickel-plated diamond micro-powder enhanced babbitt metal and preparation process

PendingCN113441680AScientific and reasonable structureEasy to useRotary stirring mixersFoundry mouldsMetal impuritiesMolten metal

The invention discloses nickel-plated diamond micro-powder enhanced babbitt metal and a preparation process. The preparation process comprises the steps of S1, separating and melting; S2, metal mixing; S3, metal casting; S4, metal cooling; and S5, finished product taking. According to the nickel-plated diamond micro-powder enhanced babbitt metal and the preparation process, multiple kinds of metal are separated and molten, the situation that the final proportion is affected by metal impurities is avoided, and therefore the stability of the proportion is guaranteed; various molten metal is mixed through a mixing barrel, so that the mutual mixing uniformity of the molten metal is guaranteed, the situation of metal precipitation is avoided, and the product quality is guaranteed; vacuum extraction is carried out on a forming box, so that the situation of sand holes in products is avoided; castings are directly and rapidly cooled, so that the forming speed of the castings is increased; and a taking electric push rod drives a taking supporting frame to directly and rapidly take the products, so that rapid collection of the products is facilitated, the production speed of the products is increased through multi-step treatment, and the quality of the products is guaranteed.

Owner:NANJING TIN REFINING CO LTD

Babbitt metal wire and preparation technology thereof

The invention discloses a Babbitt metal wire and a preparation technology thereof, and relates to the technical field of mechanical materials. The Babbitt metal wire comprises the following raw material ingredients in parts by weight: 7-18% of Sb, 3-8% of Cu, 0.0001-0.005% of Au, 0.0001-0.01% of Ni and the balance of Sn and trace elements including Cr, Mo and W. A raw material ingredient proportion of the Babbitt metal wire is regulated, the trace elements are added, the flexibility and the metallographic structure of the Babbitt metal which is finally smelted can be greatly improved, a situation that the Babbitt metal is free from a fracture phenomenon when the Babbitt metal is pulled to form wires can be guaranteed, and the flexibility and the strength of the Babbitt metal wire are improved.

Owner:SHENZHEN XINGHONGTAI TIN

Method for producing low-lead tin-based babbitt metal by using tin refining slag

The invention relates to a method for producing low-lead tin-based babbitt metal by using tin refining slag. The method comprises the following steps: (1) adding crude tin refining copper-sulfur-removed slag, crude tin refining arsenic-antimony-aluminum-removed slag, tin calcine, limestone and river sand into a reduction smelting furnace according to a certain material ratio; (2) the produced crude tin with high copper and antimony content is subjected to centrifugal iron removal, and an iron removal agent is used for deep iron removal; (3) high-copper-and-antimony-content crude tin with the iron content smaller than or equal to 0.01% is fed into a high-temperature vacuum distillation separation furnace, arsenic, lead and bismuth are removed, and a high-copper-antimony-content crude tin alloy is produced; and (4) elements such as copper and antimony are added into the high-copper-antimony crude tin alloy according to the tin-based babbitt alloy element requirements, and a low-lead tin-based babbitt alloy product is produced. The method disclosed by the invention is simple in process operation condition, high in mechanical automation degree, short in flow, environment-friendly in production process, small in smelting waste residue generation amount, free of generation of highly toxic substances, namely arsenic and aluminum residues, and high in tin smelting recovery rate.

Owner:柳州华锡有色设计研究院有限责任公司

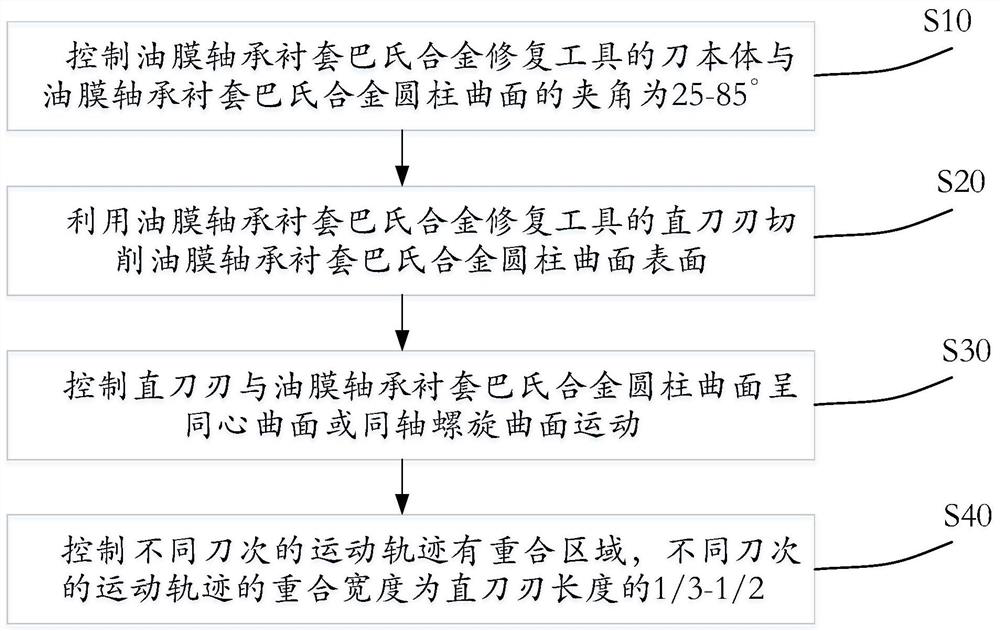

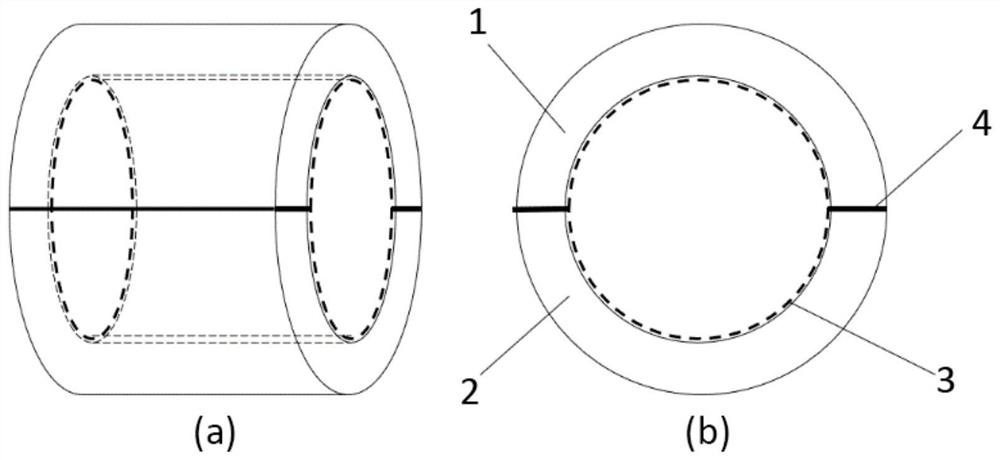

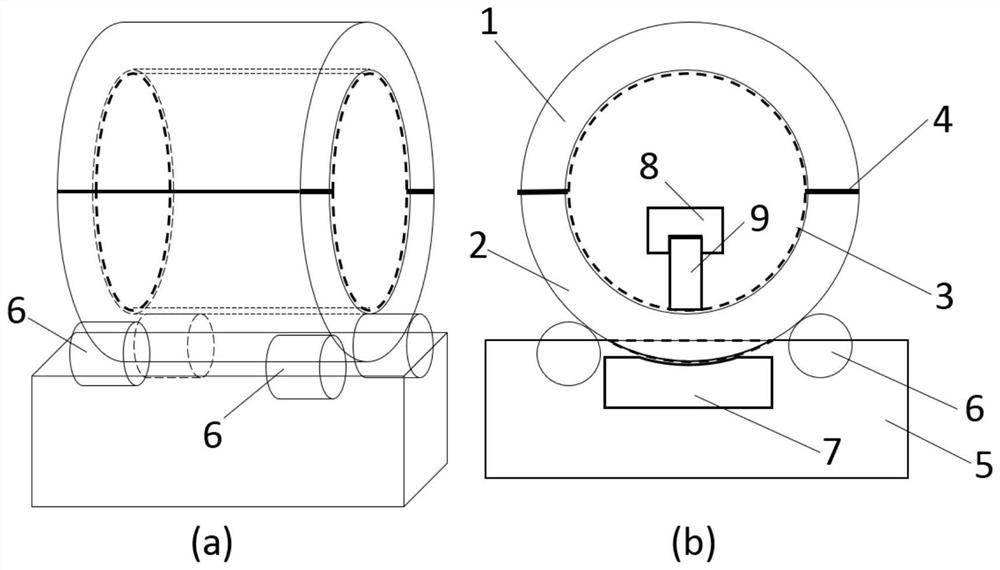

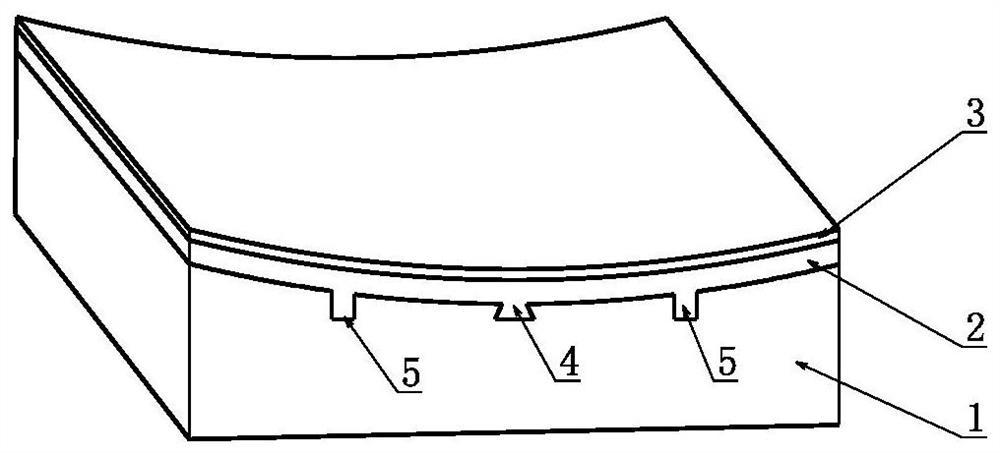

Oil Film Bearing Bushing Babbitt Repair Tool and Method

The invention relates to an oil film bearing lining babbitt metal repairing tool. The oil film bearing lining babbitt metal repairing tool comprises a tool body. A tool back, a straight cutting edge,a first edge part and a second edge part are arranged at the outer end of the tool body. The tool back is opposite to the straight cutting edge. The first edge part is opposite to the second edge part. One end of the first edge part is connected with the tool back, and the other end of the first edge part is connected with the straight cutting edge. One end of the second edge part is connected with the tool back, and the other end of the second edge part is connected with the straight cutting edge. The invention further relates an oil film bearing lining babbitt metal repairing method. The included angle between the tool body and an oil film bearing lining babbitt metal cylinder hook face is controlled to range from 25 degrees to 85 degrees. The straight cutting edge is utilized for cutting the surface of the oil film bearing lining babbitt metal cylinder hook face. The straight cutting edge and the oil film bearing lining babbitt metal cylinder hook face are controlled to move in theform of a concentric hook face or a coaxial spiral hook face. According to the oil film bearing lining babbitt metal repairing tool and method, a fatigue layer on an oil film bearing lining babbitt metal structure can be rapidly repaired.

Owner:SHOUGANG JINGTANG IRON & STEEL CO LTD

Device and method for quickly manufacturing babbitt metal bearing bush

ActiveCN111940865AEfficient preparation methodReduce energy consumptionWelding/cutting auxillary devicesAuxillary welding devicesElectrical connectionEngineering

The invention relates to the technical field of bearing bush manufacturing, in particular to a device and a method for quickly manufacturing a babbitt metal bearing bush. The device for quickly manufacturing the babbitt metal bearing bush comprises a rack, a rotating unit, an electrode unit and a power supply unit, The rotating unit comprises two rotating shafts arranged in the rack in parallel, each rotating shaft is sleeved with at least one wheel, and the wheels are tangent to the outer surface of the bearing bush and drive the bearing bush to rotate in the circumferential direction of thebearing bush; the electrode unit comprises a first electrode and a second electrode, and the first electrode and the second electrode are electrically connected through the power supply unit; and thefirst electrode is in contact with the arc surface of the outer surface of the bearing bush in an attached mode, and the second electrode is arranged in an inner cavity of the bearing bush and is opposite to the first electrode. By means of the device and the method for quickly manufacturing the babbitt metal bearing bush, according to the Joule law, the contact position of a cast ingot and the inner surface of the bearing bush is molten to the inner surface of the bearing bush; and along with circumferential rotation of the bearing bush, molten babbitt metal is solidified and welded to the inner surface of the bearing bush.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

Connecting coating for casting babbitt metal on bearing bush and preparation process of connecting coating

The invention discloses a connecting coating for casting babbitt metal on a bearing bush and a preparation process of the connecting coating. The connecting coating with a thickness of 150-500 micronsis prepared on a bottom bush by adopting a thermal spraying mode, and the connecting coating is copper with the purity of more than or equal to 99.5%. The process comprises the following specific steps: (1) deoiling and decontaminating the surface of the bottom bush; (2) performing sand blasting and texturing; and (3) spraying copper wires or copper powder to form the connecting coating with a certain thickness. According to the connecting coating prepared through the method, quality of the subsequent casting process can be guaranteed, and bonding strength between the babbitt metal and the bottom bush is improved. Compared with a common tinning process at present, the process has a series of remarkable advantages of low cost, low energy consumption, no pollution, simplicity in operation and the like.

Owner:MIN OF WATER RESOURCES HANGZHOU MACHINERY DESIGN INST

Large generator set bearing alloy casting and welding matching method

The invention discloses a large generator set bearing alloy casting and welding matching method. According to the method, casting and welding are combined, the problems of composition segregation, multiple surface defects and the like caused in the large generator set bearing alloy casting process are solved, the defects of large tile blank deformation and low production efficiency caused by welding are overcome, the production efficiency and the product quality of a large generator set bearing alloy can be improved, the defective rate and the repair rate are reduced, and the method is particularly suitable for producing and manufacturing the Babbitt metal on the surface of the thin-wall tile blank with grooves and high precision requirements.

Owner:HARBIN ELECTRIC MASCH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com