Nickel-plated diamond micro-powder enhanced babbitt metal and preparation process

A nickel-plated diamond, babbitt alloy technology, used in manufacturing tools, casting molding equipment, metal processing equipment, etc., can solve problems such as actual mixing ratio deviation, product blisters or voids, product abnormality, etc., to accelerate the molding speed. , to avoid metal precipitation, to ensure the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

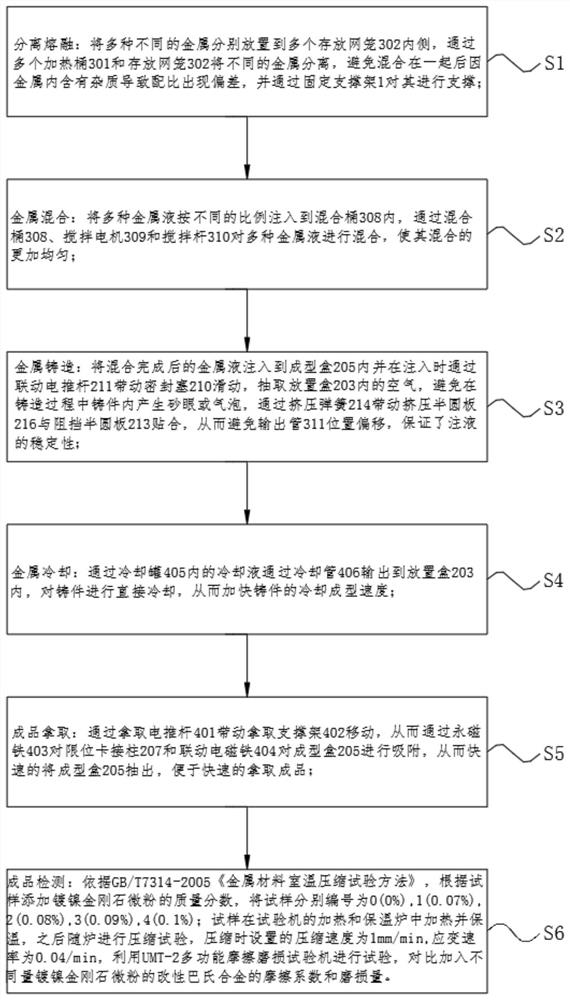

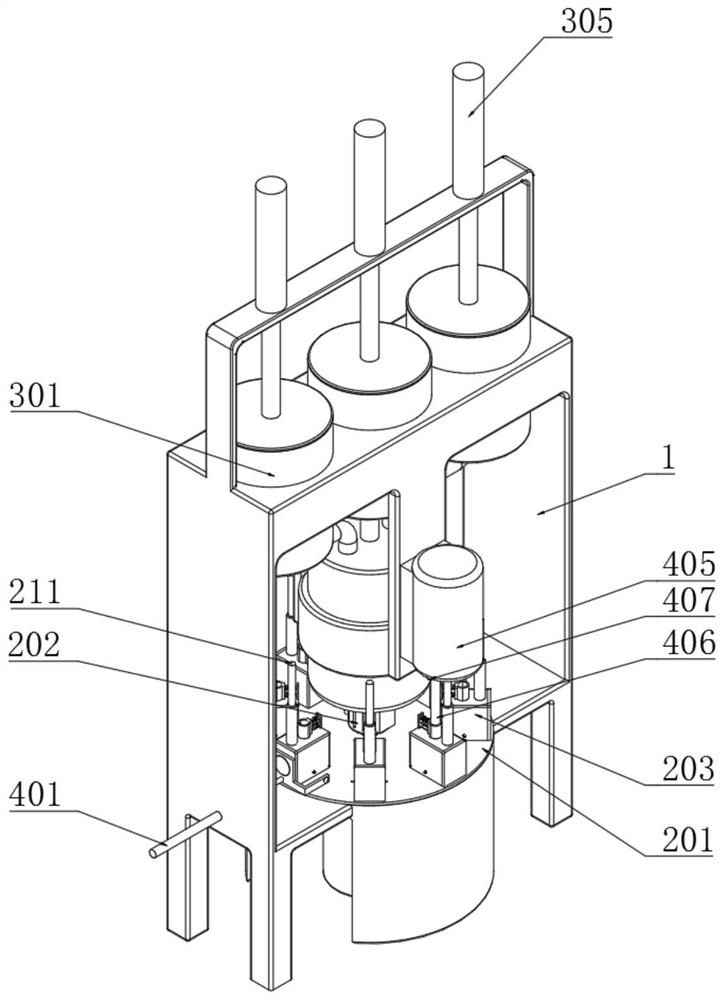

[0052] Example: such as Figure 1-9 As shown, the present invention provides a kind of technical scheme, a kind of preparation technology of nickel-plated diamond micropowder reinforced babbitt alloy, comprises the steps:

[0053] S1: Separation and melting: Place a variety of different metals inside multiple storage cages 302, separate the different metals through multiple heating barrels 301 and storage cages 302, and avoid mixing them together due to impurities in the metals. There is a deviation in the ratio, and it is supported by a fixed support frame 1;

[0054] S2: Metal mixing: inject various metal liquids into the mixing tank 308 in different proportions, and mix the various metal liquids through the mixing tank 308, stirring motor 309 and stirring rod 310 to make the mixing more uniform;

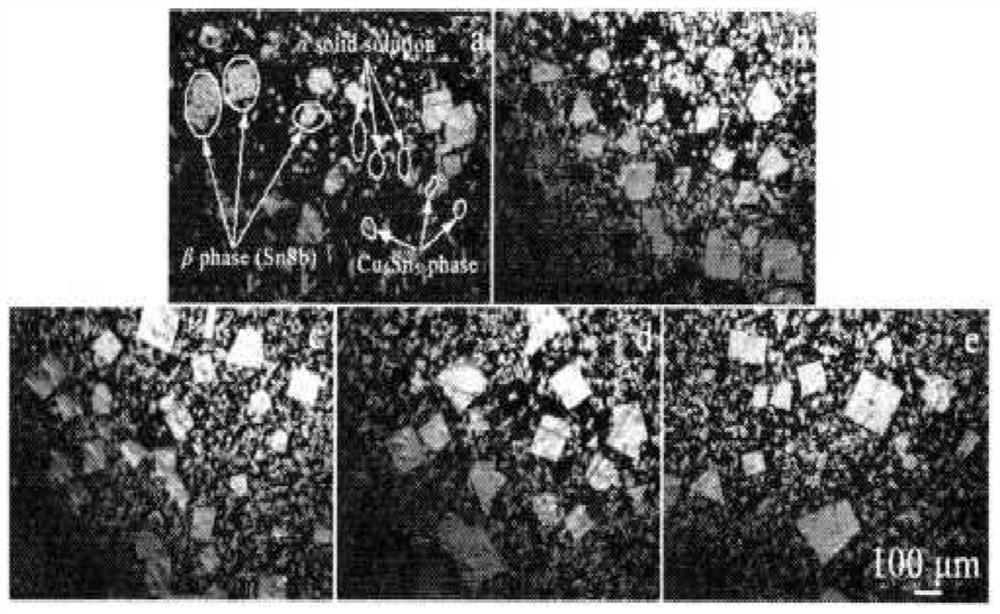

[0055] S3: Metal casting: inject the mixed metal liquid into the forming box 205, and drive the sealing plug 210 to slide through the linkage electric push rod 211 during injecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com