Blast furnace blowing-in burdening method

A technology for batching and blast furnace opening, which is applied to blast furnaces, blast furnace details, furnaces, etc., can solve problems such as unfavorable heating hearths, sleepers do not calculate the volume, and cannot verify the charging volume error in real time, and achieves a refinement of the coke ratio gradient. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

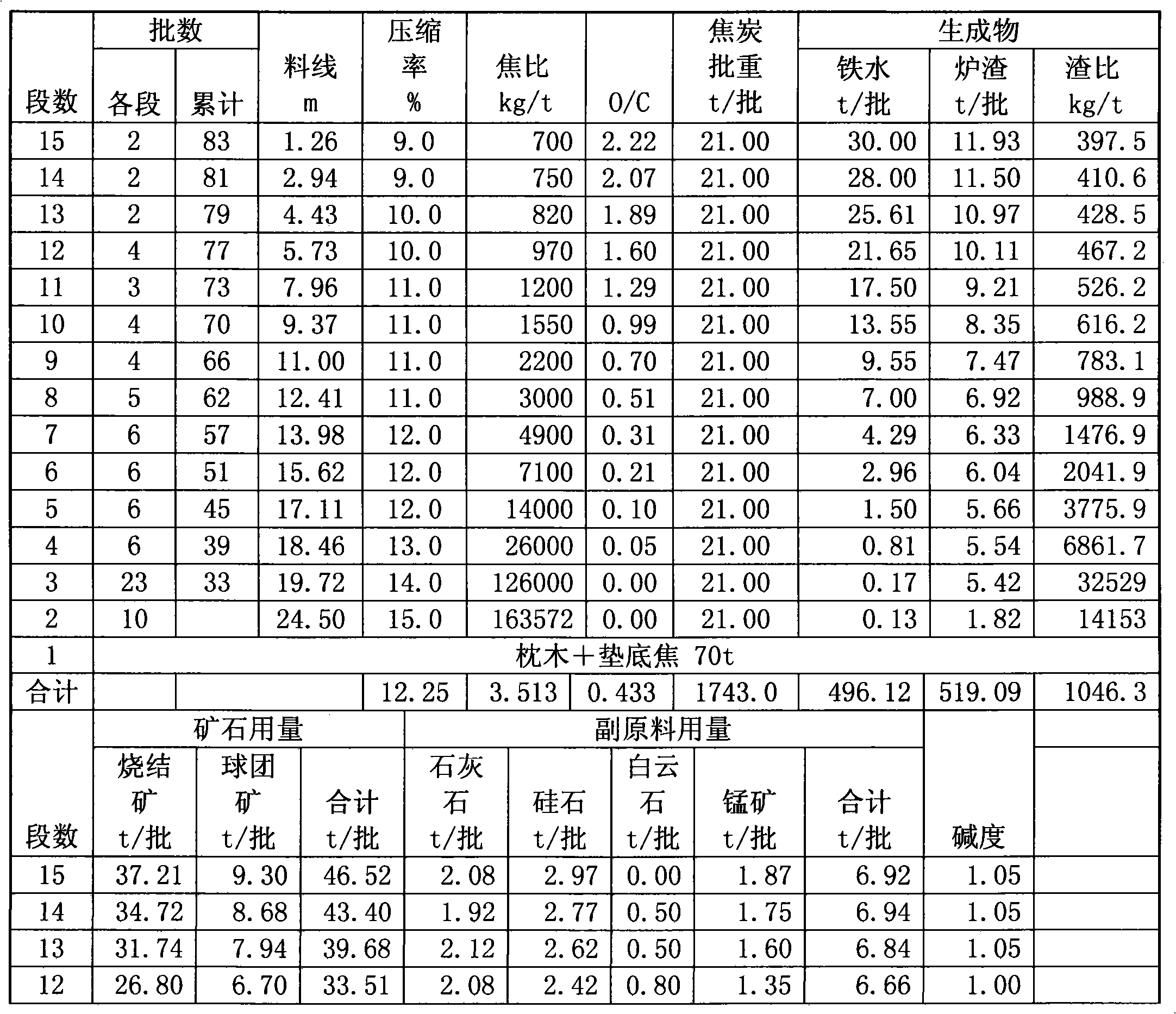

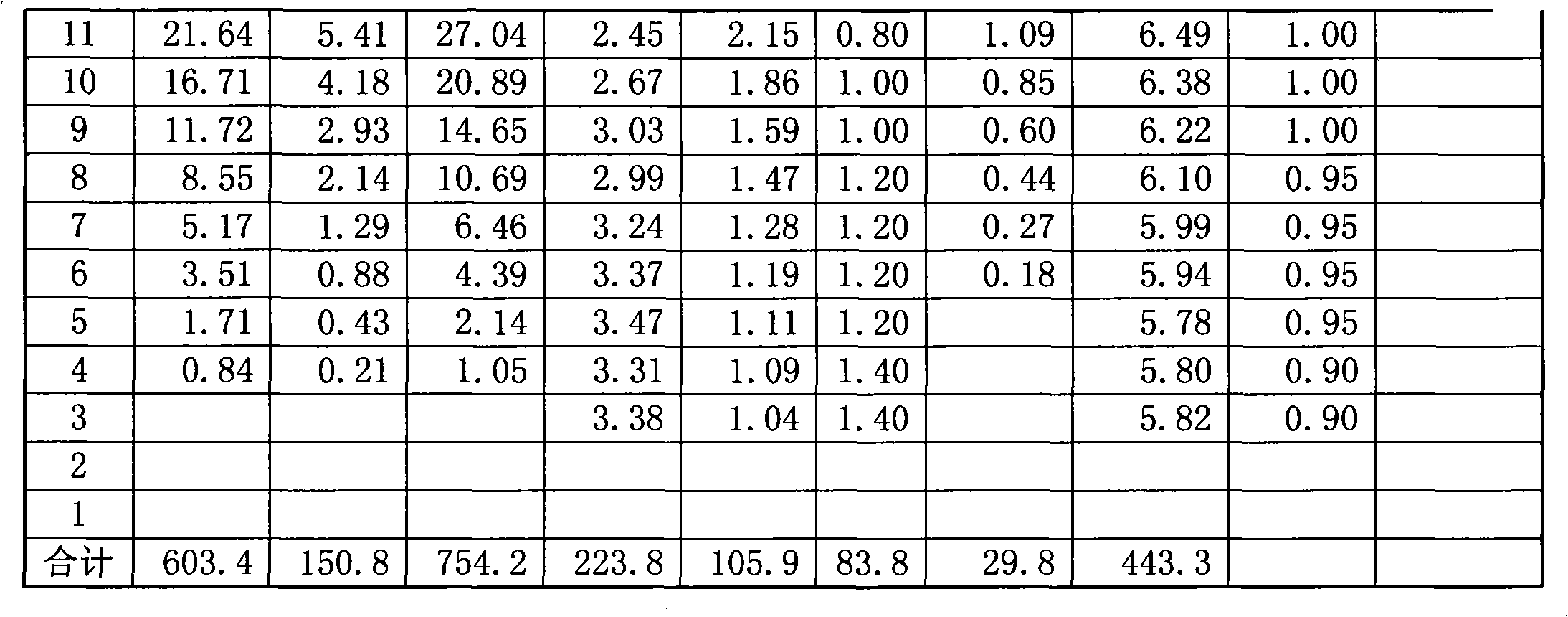

[0034] With furnace capacity 4038m 3 Take the blast furnace as an example.

[0035] The invention makes up for the shortcomings of the previous batching methods by changing and improving the batching and charging methods, and achieves the purpose of smoothly opening the newly-built blast furnace and quickly reaching production.

[0036] For this reason, according to the raw material and fuel conditions and the goal to be achieved after the furnace is opened, the blast furnace is divided into 15 sections from the bottom to the top of the furnace. The first section is the sleepers and the bottom material, which are filled to the center line of the tuyere. The second segment is the net coke, and the filled volume is from the upper part of the sleeper, that is, the center line of the tuyere, to the full filling of the hearth. The 13th paragraphs from paragraph 3 to paragraph 15 are all normal materials, which are equivalent to the previous transitional materials and normal materials.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com