Patents

Literature

253results about How to "Excellent hole expandability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

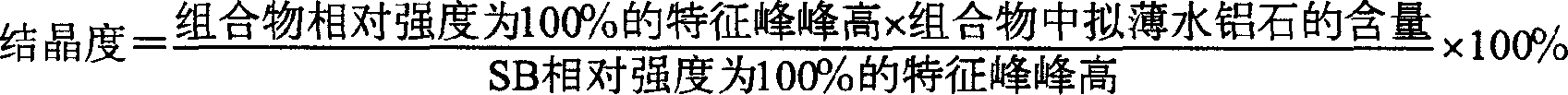

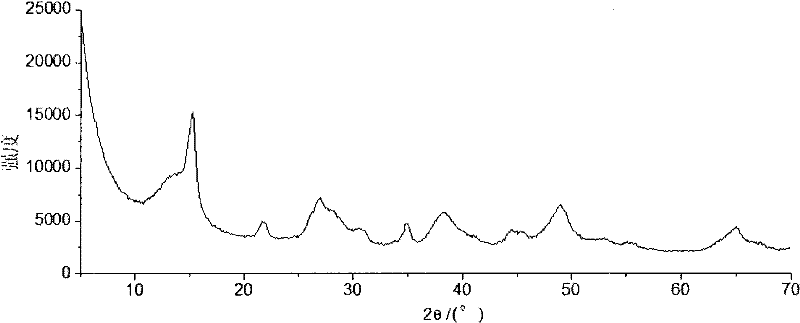

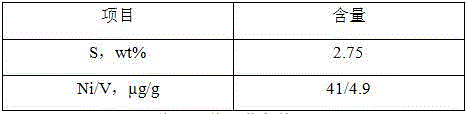

Quasi-thin empholite composition containing organic reaming agent

ActiveCN1611300AReduce crystallinityLarge hole volumeCatalyst activation/preparationRefining to eliminate hetero atomsDiasporeResidual oil

The present invention relates to a pseudothin diaspore composition containing organic pore-expanding agent. Said composition contains 92-99.5 wt% of pseudothin diaspore and 0.5-8 wt% of organic pore-expanding agent, in which the crystallinity of pseudothin diaspore is 10-70%. In the pseudothin diaspore composition provided by said invention the organic pore-expanding agent content is low, after high-temperature calcination the alumina with large pore capacity and large pore diameter can be obtained. Said alumina can be used as carrier material for preparing hydrodemetalization catalyst for heavy oil, residual oil and short residuum specially.

Owner:CHINA PETROLEUM & CHEM CORP +1

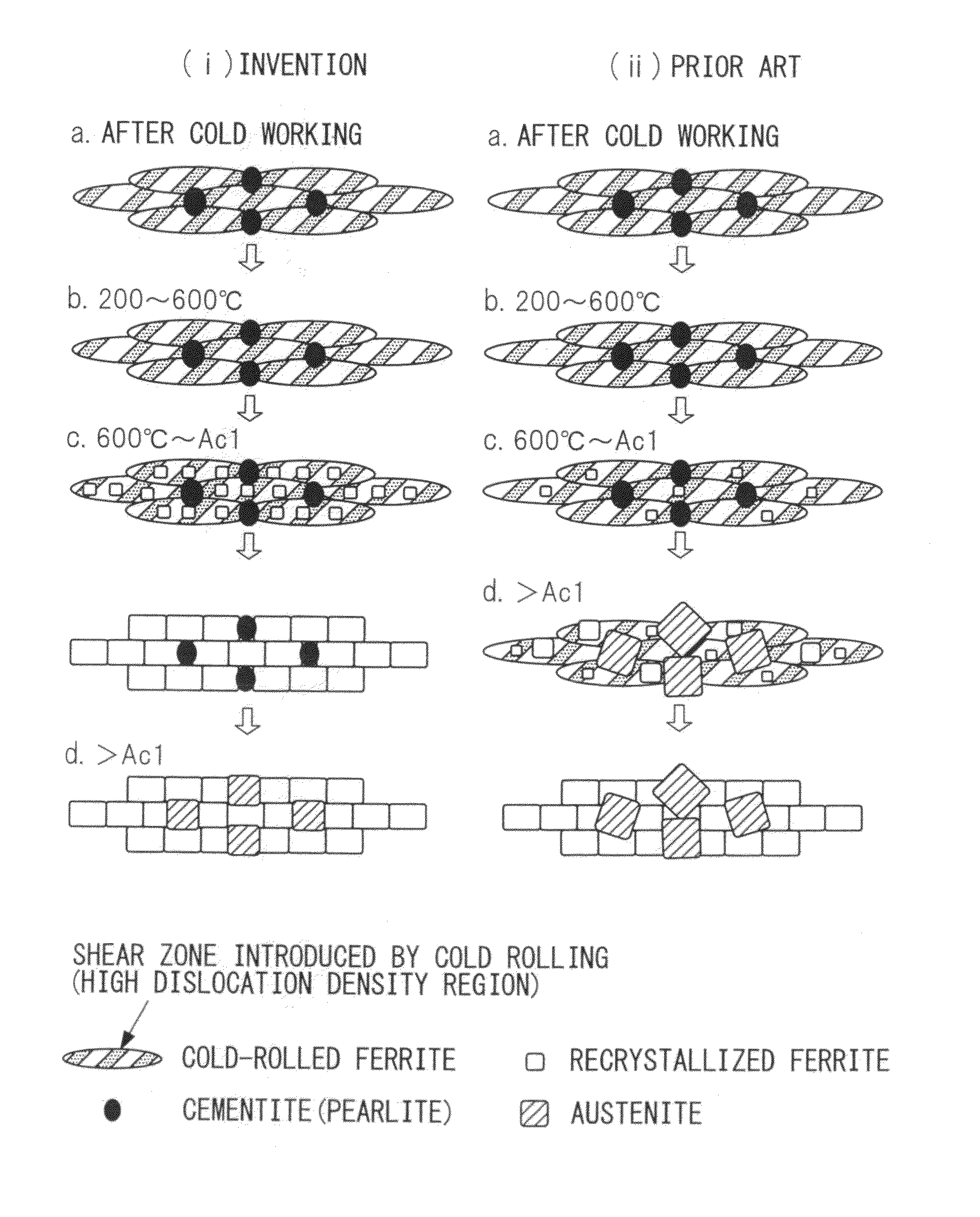

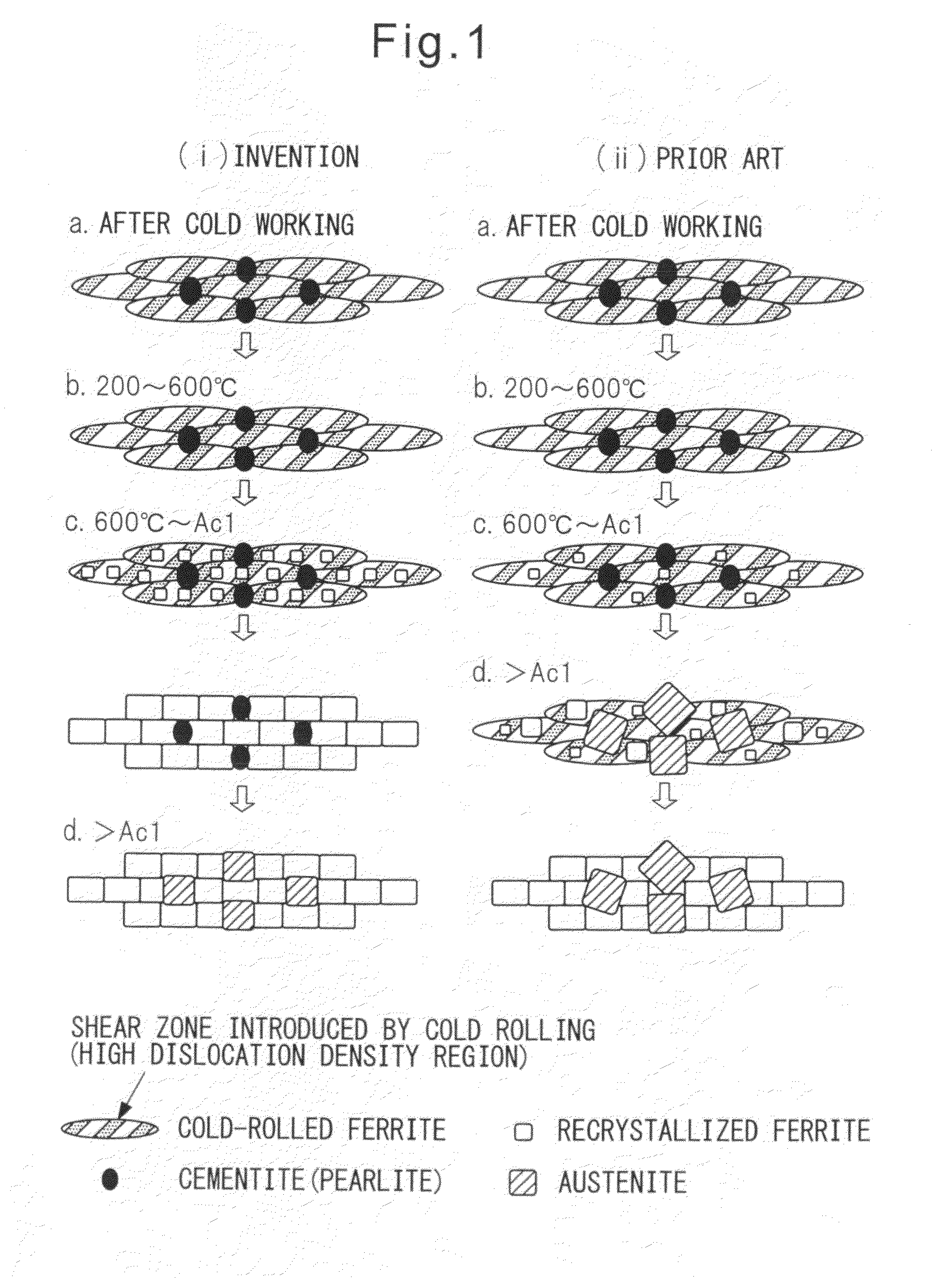

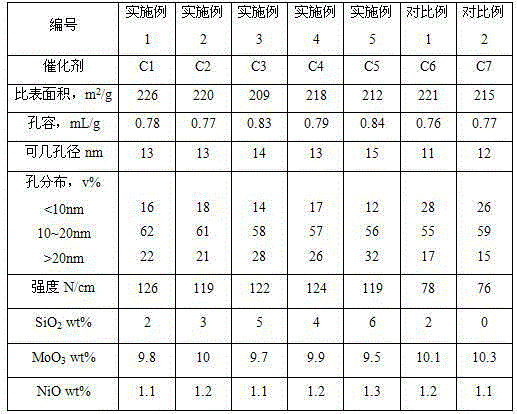

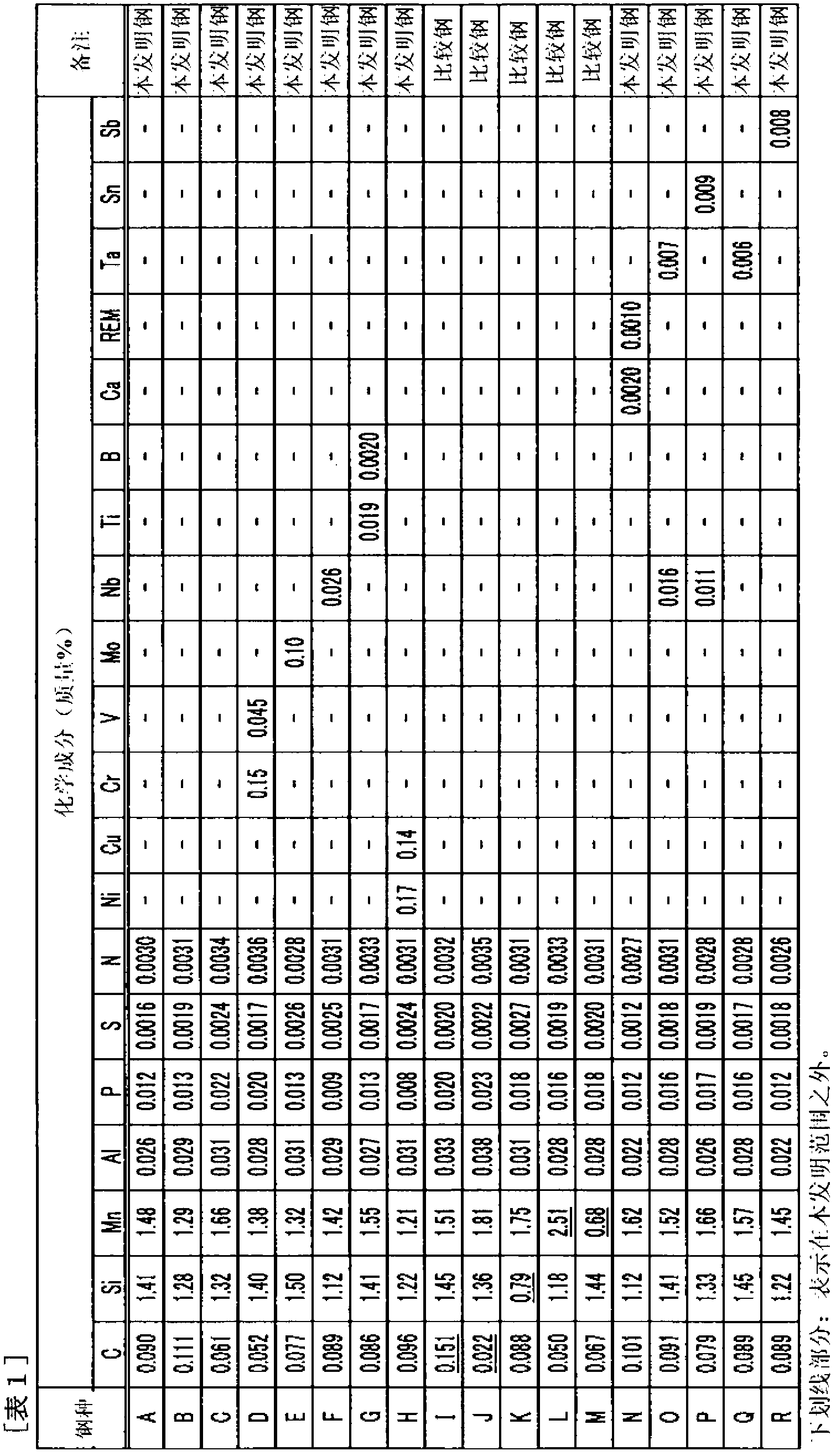

High Strength Thin-Gauge Steel Sheet Excellent in Elongation and Hole Expandability and Method of Production of Same

InactiveUS20080000555A1High strengthHigh elongationFurnace typesMetal rolling arrangementsSectilityHigh intensity

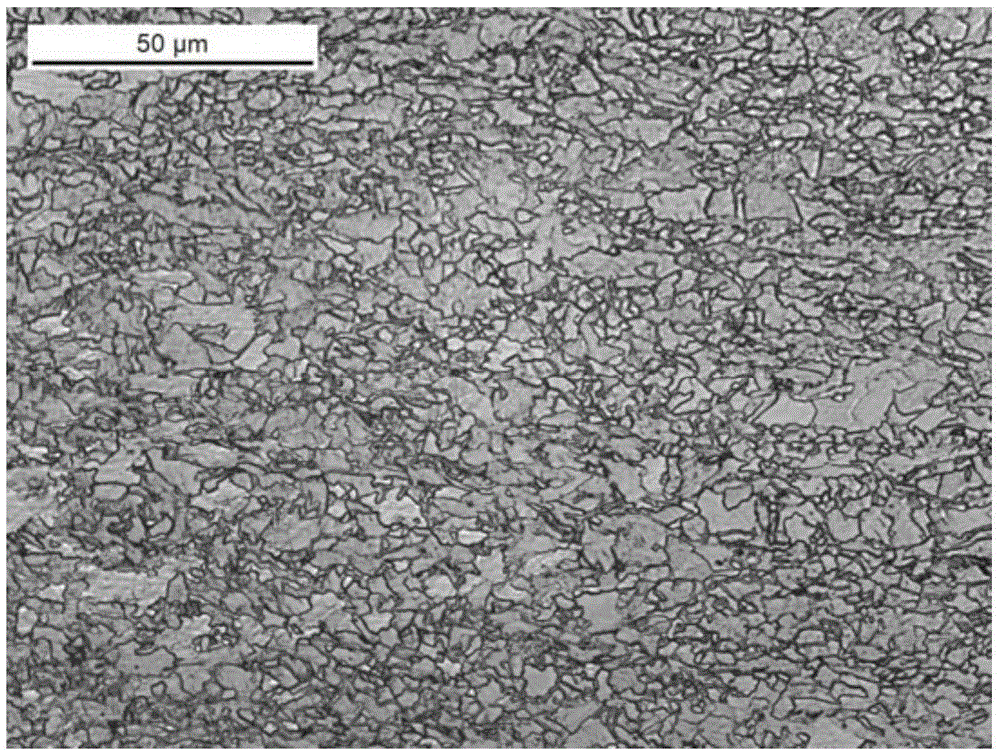

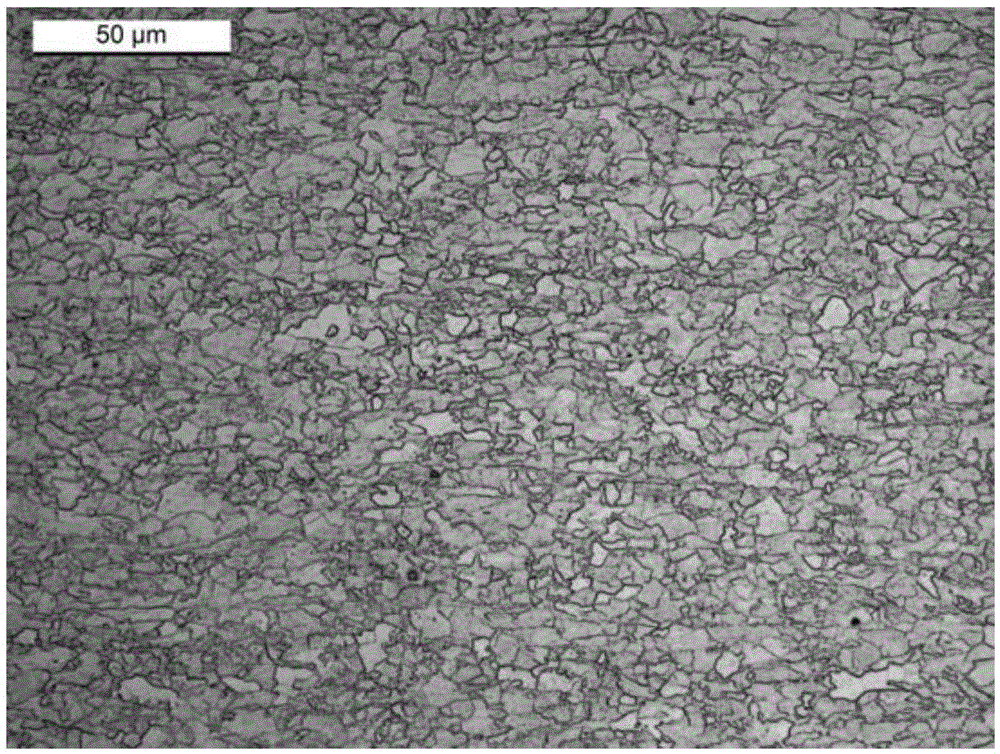

The present invention provides high strength thin-gauge steel sheet with excellent elongation and hole expandability having a tensile strength of 500 MPa or more and a method of production of high strength thin-gauge steel sheet with excellent elongation and hole expandability enabling production of this on an industrial scale, that is, high strength thin-gauge steel sheet comprised of, by mass %, C: 0.03 to 0.25%, Si: 0.4 to 2.0%, Mn: 0.8 to 3.1%, P≦0.02%, S≦0.02%, Al≦2.0%, N≦0.01%, and a balance of Fe and unavoidable impurities and having a microstructure comprised of ferrite with an area fraction of 10 to 85% and residual austenite with a volume fraction of 1 to 10%, an area fraction of 10% to 60% of tempered martensite, and a balance of bainite.

Owner:NIPPON STEEL CORP

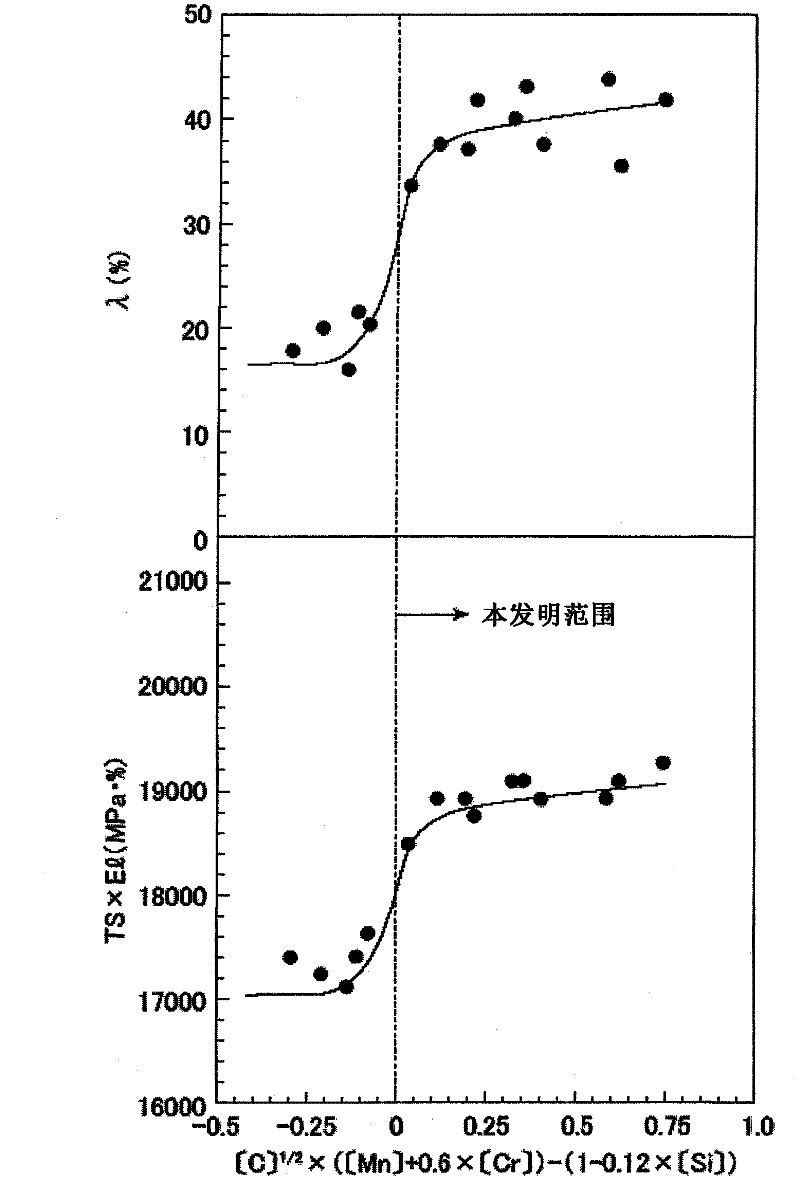

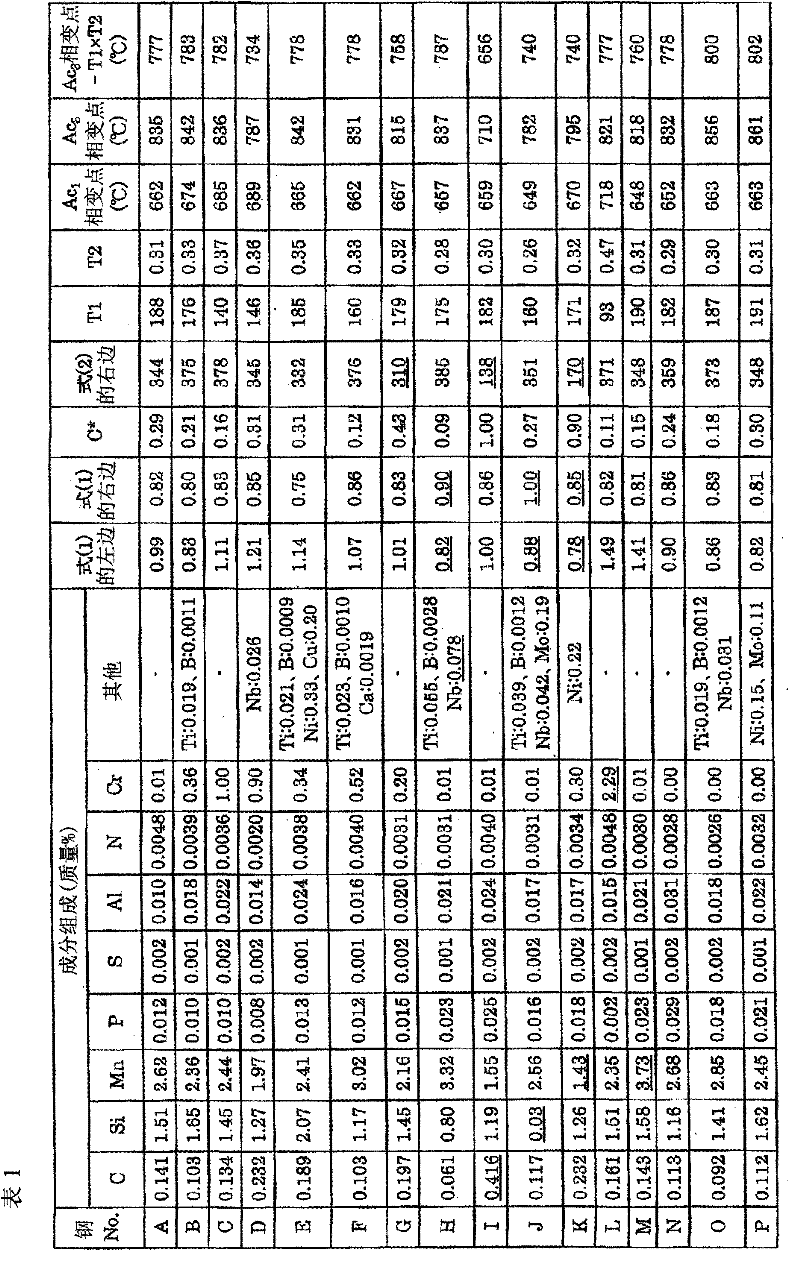

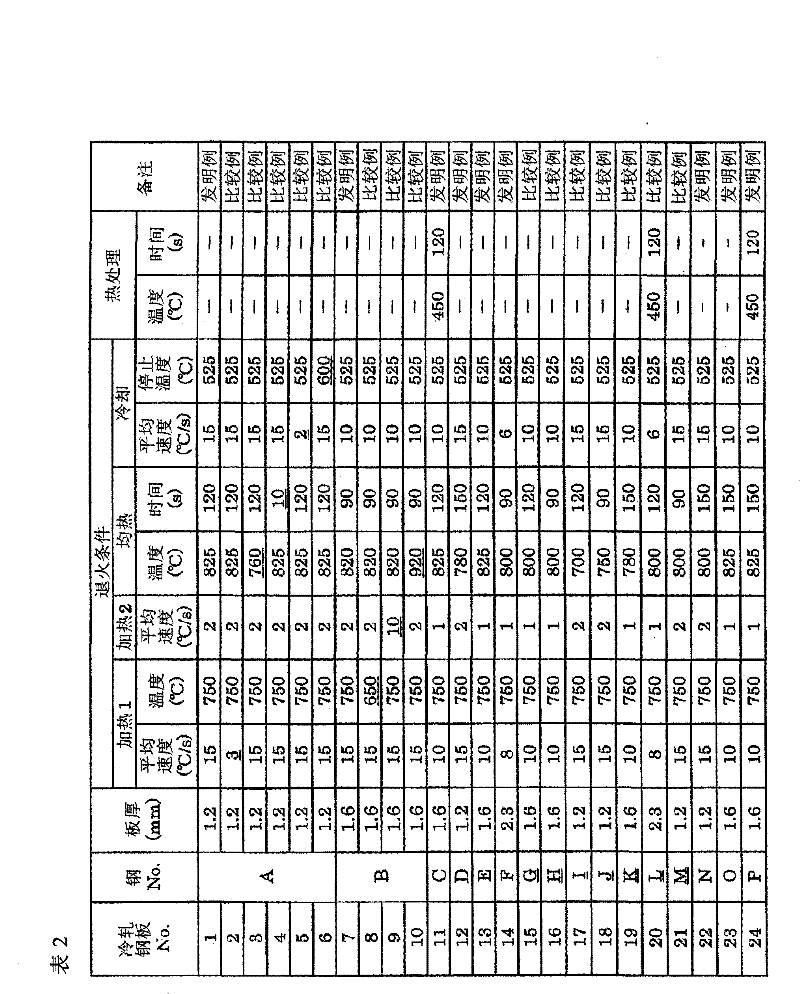

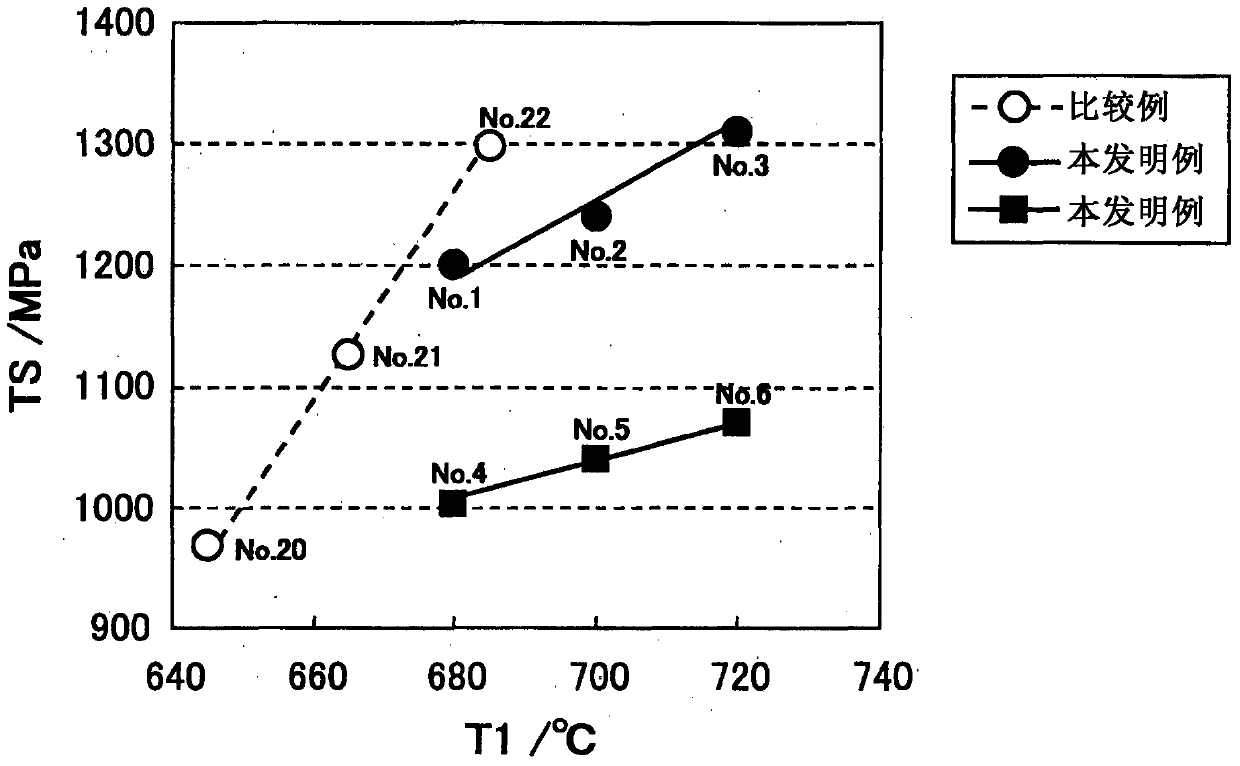

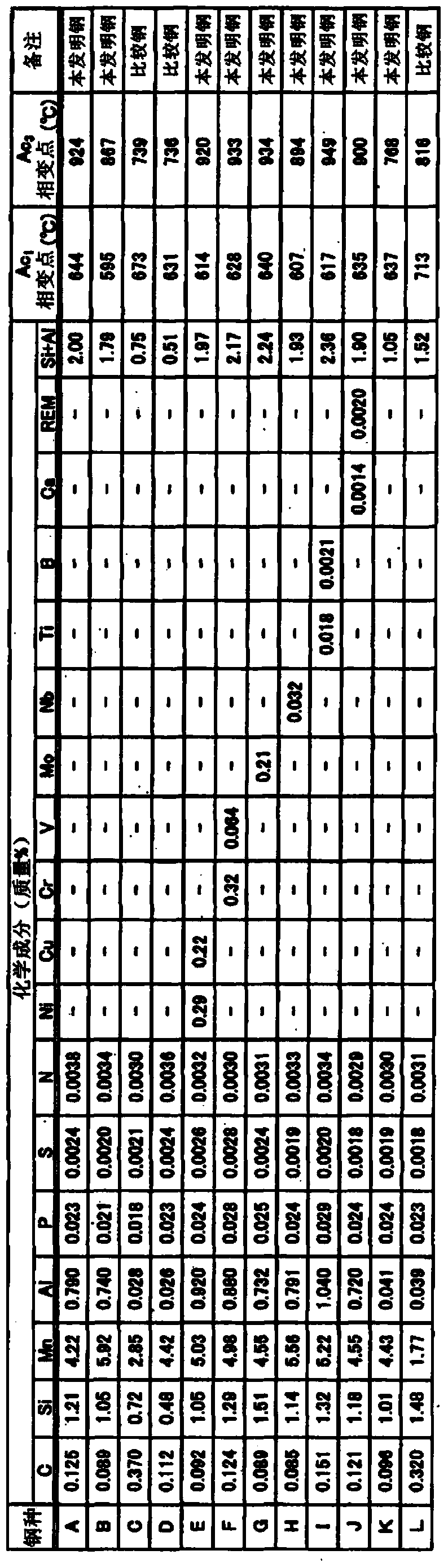

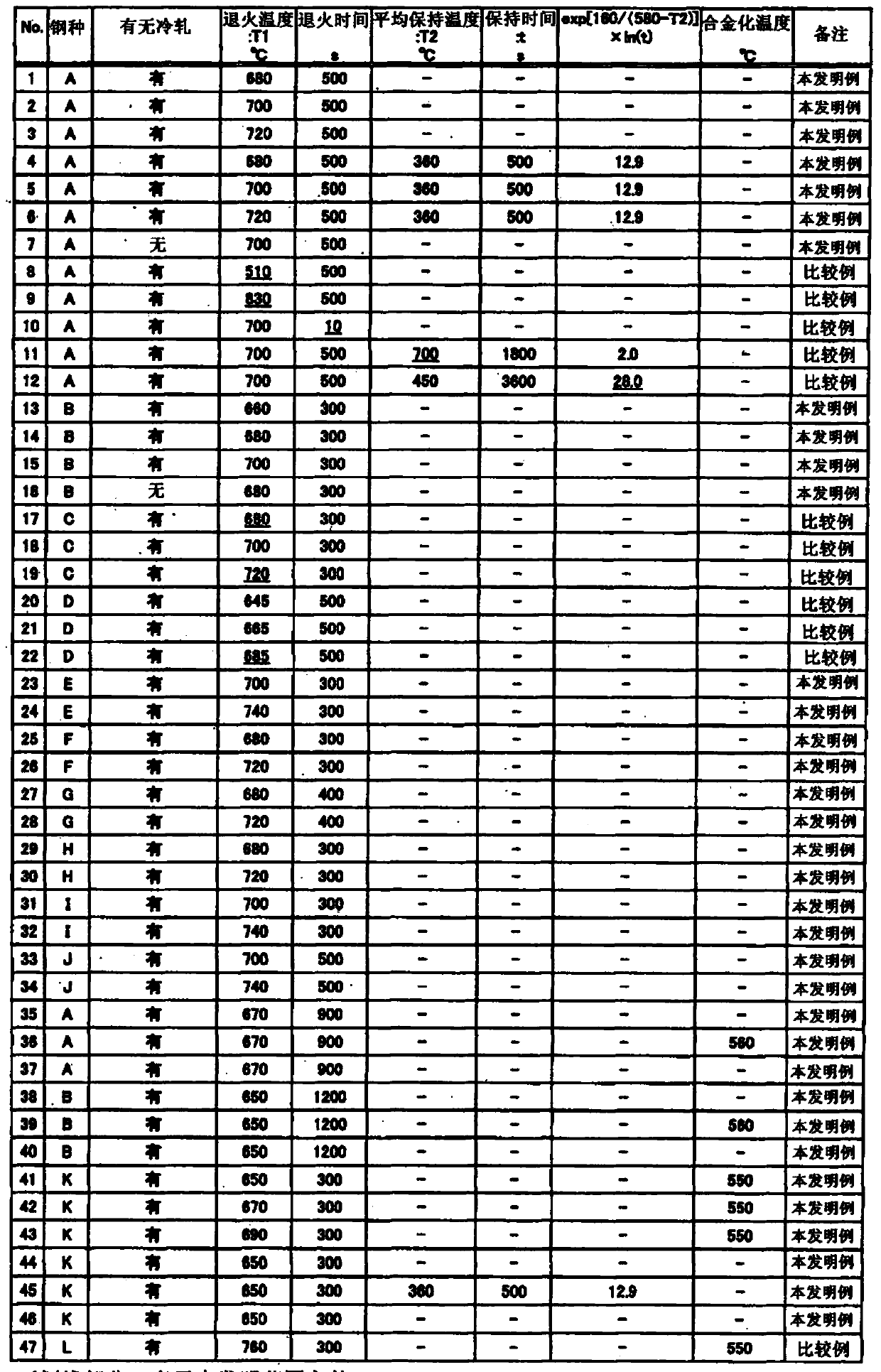

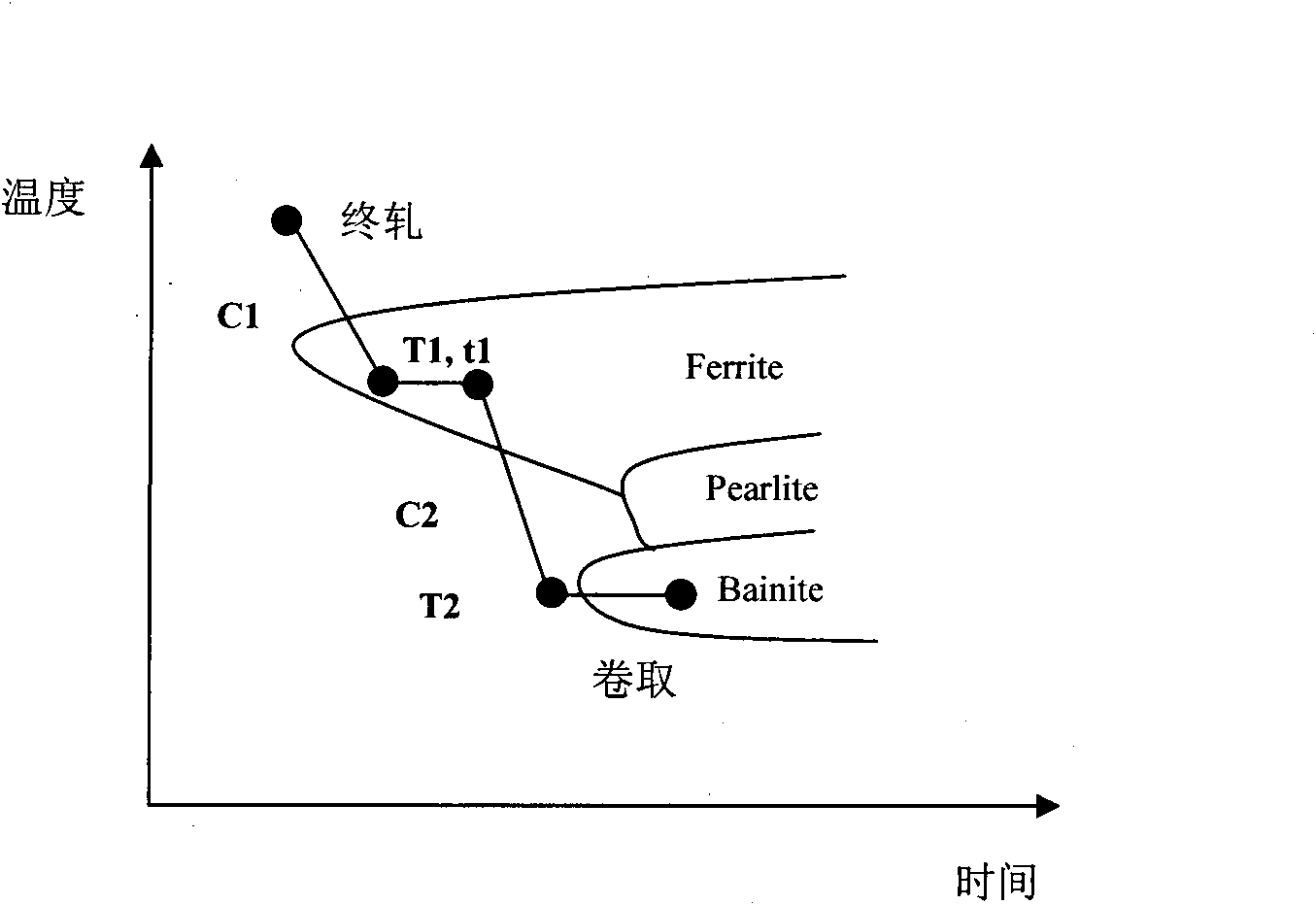

High-strength cold-rolled steel sheet having excellent workability, molten galvanized high-strength steel sheet, and method for producing same

ActiveCN102227511AExcellent hole expandabilityImprove bending performanceHot-dipping/immersion processesFurnace typesUltimate tensile strengthMartensite

The invention provides a high-strength cold-rolled steel sheet having a TS of 1,180 MPa or greater and excellent workability, such as stretch flange workability and bendability. Also provided are a molten galvanized high-strength steel sheet, and a method for producing the same. The high-strength cold-rolled steel sheet having excellent workability has a composition that comprises, by mass%, C: 0.05 to 0.3, Si: 0.5 to 2.5, Mn: 1.5 to 3.5, P: 0.001 to 0.05, S: 0.0001 to 0.01, Al: 0.001 to 0.1, N: 0.0005 to 0.01, and Cr: 1.5 or less (including 0) and satisfies formulas (1) and (2), with the balance being Fe and inevitable impurities. The steel sheet has a microtexture wherein there is a ferrite phase and a martensite phase, the percentage of the texture total surface area occupied by martensite phase is 30% or greater, (the surface area occupied by martensite phase) / (surface area occupied by ferrite phase) exceeds 0.45 but is less than 1.5, and the average particle diameter of the martensite phase is 2 microns or larger. [C]1 / 2*([Mn]+0.6*[Cr])> / =1-0.12*[Si] (1), and 550-350*C*-40*[Mn]-20*[Cr]+30*[Al]> / =340 (2), wherein C*=[C] / (1.3*[C]+0.4*[Mn]+0.45*[Cr]-0.75).

Owner:JFE STEEL CORP

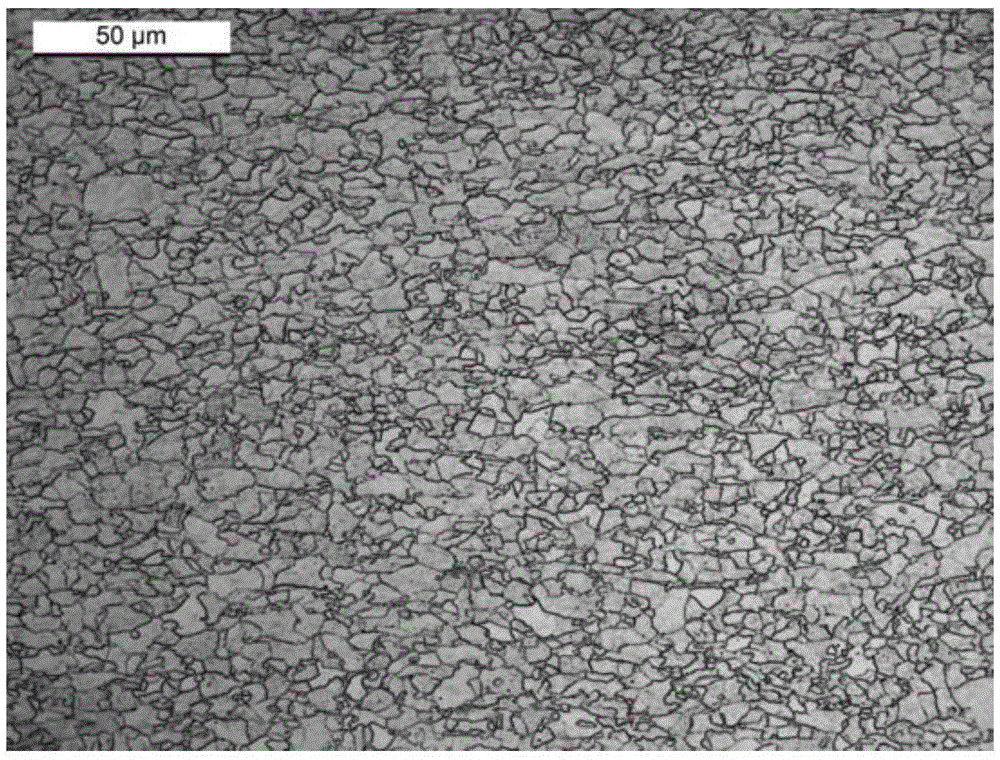

Macroporous aluminium oxide carrier and its preparing method

The present invention is macroporous alumina carrier and its preparation process. The carrier has pore volume of 0.9-1.3 ml / g, pore volume rate of pores smaller than 20 nm in 55-85 %, pore volume rate of 20-100 nm diameter pores in 7-25 %, and pore volume rate of pores greater than 100 nm in 7-25 %. The preparation process of the carrier includes forming and roasting pseudo-thin diasphore composition containing organic pore expanding agent. The preparation process of the present invention has relatively low organic pore expanding agent consumption and high pore expanding effect. The prepared macroporous alumina carrier is used in catalyst for hydrogenating and demetallating heavy and residual oil, especially decompression residual oil with high metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

780 MPa hot-rolled high-strength steel with high hole expansion ratio and manufacturing method thereof

The invention provides a 780 MPa hot-rolled high-strength steel with high hole expansion ratio and a manufacturing method thereof. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio comprises the following chemical components in percentage by mass: more than or equal to 0.03 percent and less than or equal to 0.07 percent of C, less than or equal to 0.2 percent of Si, more than or equal to 1.0 percent and less than or equal to 2.0 percent of Mn, less than or equal to 0.02 percent of P, less than or equal to 0.005 percent of S, more than or equal to 0.02 percent and less than or equal to 0.05 percent of Al, less than or equal to 0.005 percent of N, more than or equal to 0.08 percent and less than or equal to 0.20 percent of Ti, more than or equal to 0.15 percent and less than or equal to 0.25 percent of Mo, less than or equal to 0.003 percent of O and the balance of Fe and inevitable impurity elements, wherein Ti / Mo is more than or equal to 0.25 and less than or equal to 1.5, and (Ti-3.42N) / 4+Mo / 8 is more than or equal to 0.03 percent and less than or equal to 0.07 percent. The 780 MPa hot-rolled high-strength steel with high hole expansion ratio is obtained through smelting, casting, high-temperature heating, hot rolling and reeling processes, and is more than or equal to 750 MPa in yield strength, more than or equal to 780 MPa in tensile strength, more than or equal to 20 percent in extensibility, more than or equal to 70 percent in hole expansion ratio when the thickness is 3-6 mm.

Owner:BAOSTEEL ZHANJIANG IRON & STEEL CO LTD +1

Alumina carrier and its preparation method and hydrogenation catalyst and its preparation method

ActiveCN102259033AImproved ability to remove and accommodate metalsExcellent hole expandabilityCatalyst carriersMetal/metal-oxides/metal-hydroxide catalystsBoehmiteChemistry

The invention provides an alumina carrier, wherein the average pore diameter of the alumina carrier is 25-35nm; the most probable pore diameter is 21-30nm; and the volume of pores with diameters of 10-60nm is 95-99.8% of the volume of total pores. The invention also provides a preparation method of the alumina carrier, comprising the steps of carrying out molding, drying and roasting on a mixture containing hydrated alumina and water, wherein the hydrated alumina contains pseudo-boehmite and ammonium aluminium carbonate hydroxide. The invention also provides a hydrogenation catalyst containing the alumina carrier and a preparation method thereof. The pore diameters of the alumina carrier provided by the invention are increased, therefore, the abilities of removing and accommodating metals of the hydrogenation catalyst containing the alumina carrier are improved and the hydrogenation catalyst is suitable for hydrogenation and demetalization treatments of inferior residual oil with higher metal content.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and method of production of same

InactiveUS20070190353A1High strengthImprove adhesionHot-dipping/immersion processesPretreated surfacesMartensite transformationAdditive ingredient

The present invention provides a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and a method of production of the same, that is, a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability containing C: 0.01 to 0.3%, Si: 0.005 to 0.6%, Mn: 0.1 to 3.3%, P: 0.001 to 0.06%, S: 0.001 to 0.01%, Al: 0.01 to 1.8%, and N: 0.0005 to 0.01% and having a metal structure of ferrite and, by area rate, 5% to 60% of tempered martensite and a method of production of the same comprising hot rolling, then cold rolling a slab including the above ingredients, heating the sheet in the hot dip galvanization heating process to Ac1 l to Ac3+100° C., holding it there for 30 seconds to 30 minutes, then cooling it by a 1° C. / s or higher cooling rate to 450 to 600° C., hot dip galvanizing it at that temperature, then cooling it at a 1° C. / s or higher cooling rate to the martensite transformation point or lower in temperature, holding it there at 200° C. to 500° C. for 1 second to 5 minutes, then cooling it at a 5° C. / s or higher cooling rate to 100° C. or less.

Owner:NIPPON STEEL CORP

High-strength steel plate with excellent formability and stability of material properties, and method for manufacturing same

ActiveCN103502496AExcellent hole expansion and material stabilityImprove fuel efficiencyHot-dipping/immersion processesFurnace typesAusteniteFormability

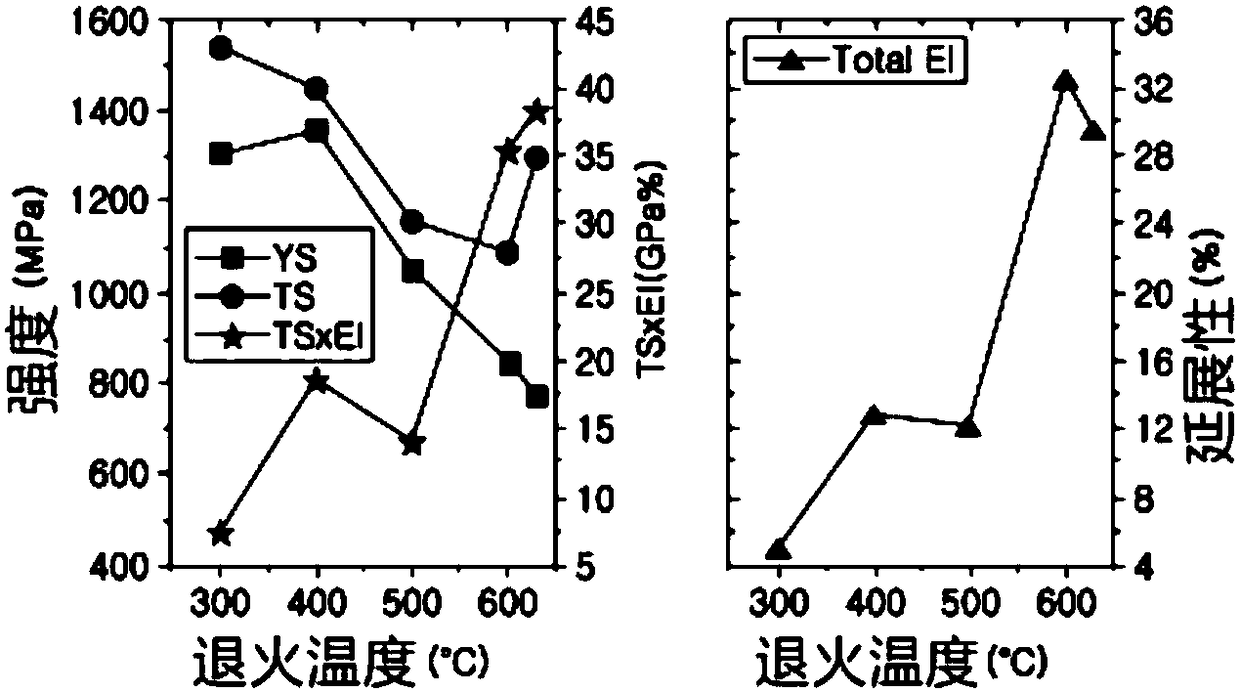

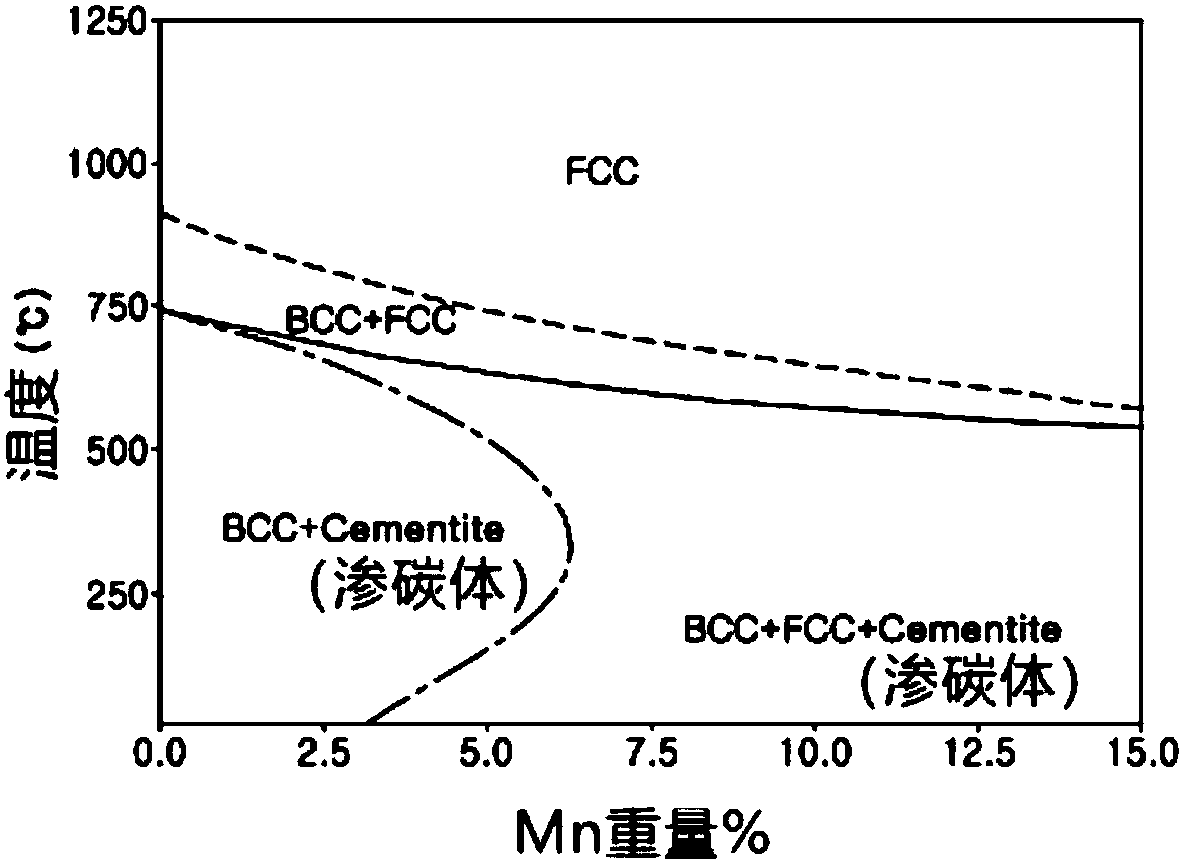

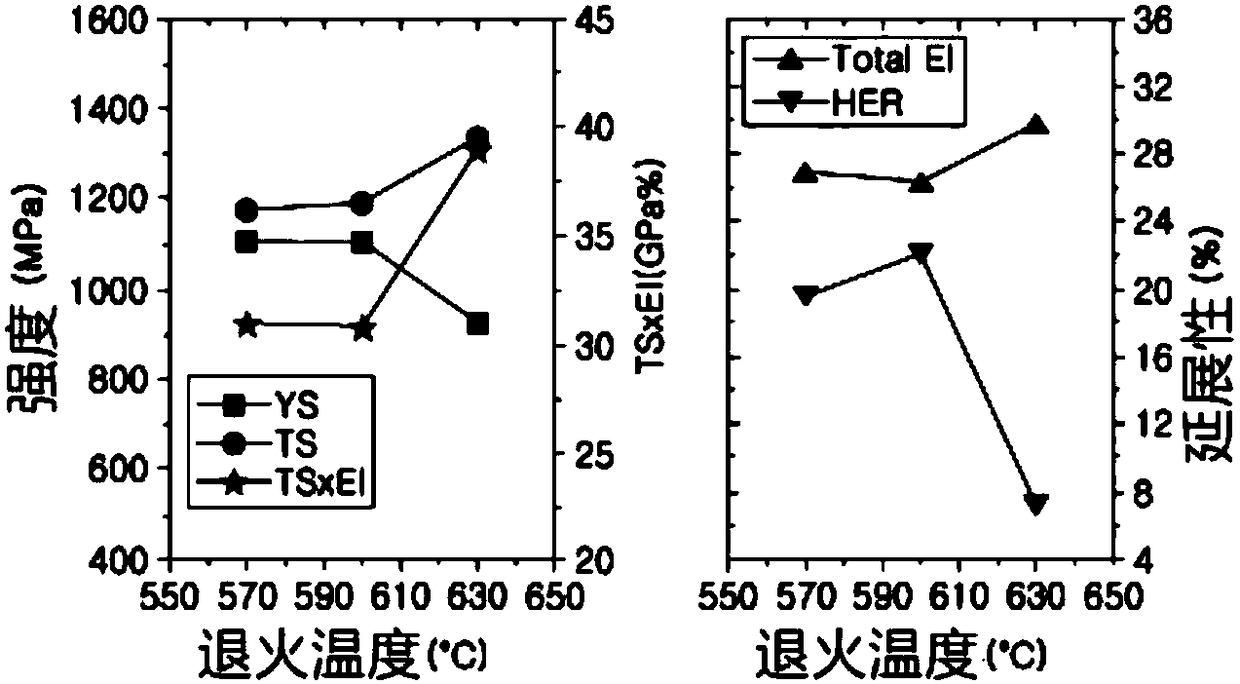

Provided is a high-strength steel plate having excellent hole expandability as well as stability of material properties, and a method for manufacturing the same, the high-strength steel plate having a TS of at least 780 MPa and a TS*EL of at least 22,000 MPa DEG % in a low-C steel composition. The high-strength steel plate having excellent formability and stability of material properties has an ingredient composition including, in terms of mass%, 0.03%-0.25% C, 0.4%-2.5% Si, 3.5%-10.0% Mn, 0.1% or less P, 0.01% or less S, 0.01%-2.5% Al, 0.008% or less N, and Si+Al at least 1.0%, the remainder being Fe and unavoidable impurities, the steel structure having, by area ratio, 30%-80% ferrite, 0%-17% martensite, and, by volume ratio, 8% or more of residual austenite, and the average crystalline particle diameter of the residual austenite being 2[mu]m or less.

Owner:JFE STEEL CORP

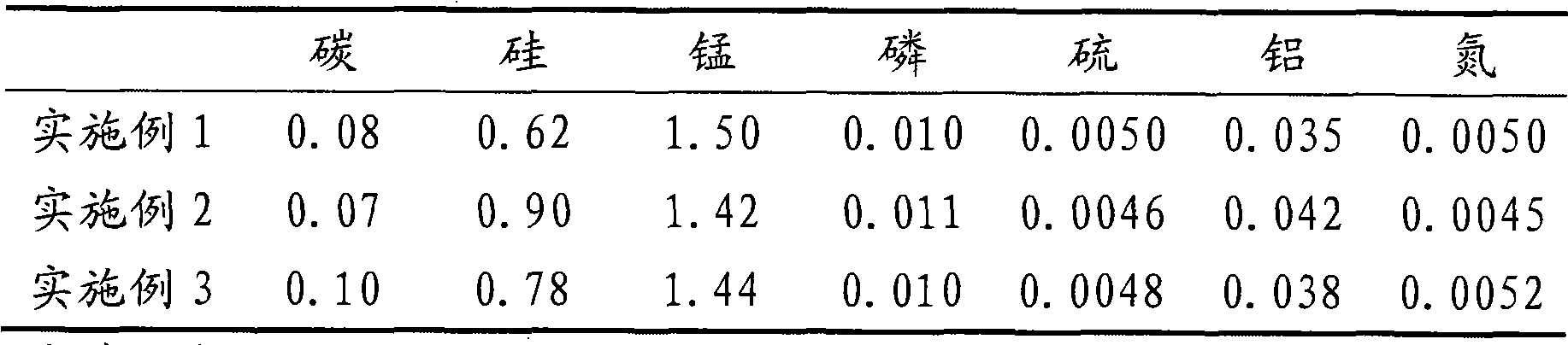

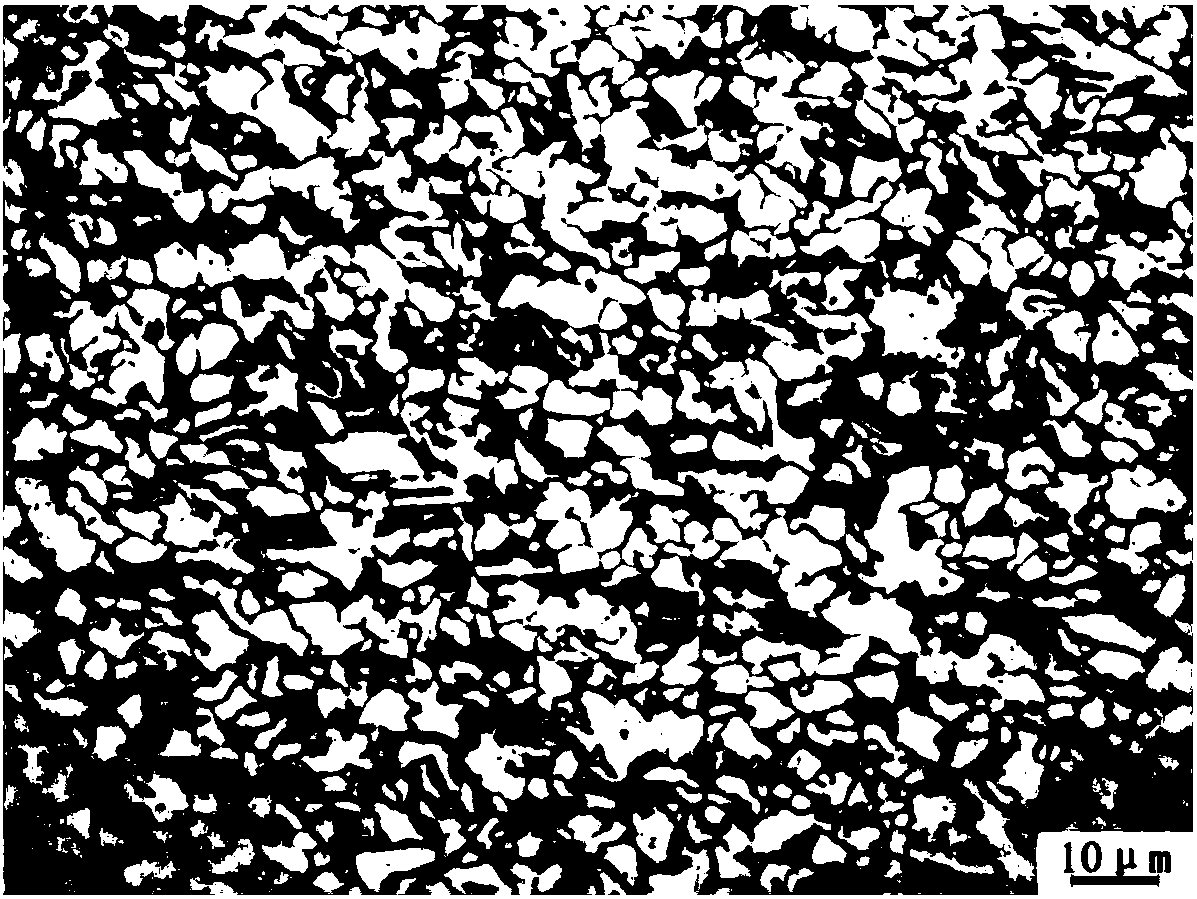

High tensile strength hot rolled ferrite bainite dual phase steel and preparation method thereof

ActiveCN101643880AExcellent hole expandabilityGood molding effectTemperature control deviceManganeseImpurity

The invention relates to a hot rolled ferrite bainite dual phase steel of which tensile strength is not less than 490MPa and a preparation method thereof. The dual phase steel comprises the followingcomponents by weight percent: 0.05-0.15% of carbon, 0.5-1.0% of silicon, 1.0-1.5% of manganese, 0.02% or less of phosphorus, 0.010% or less of sulfur, 0.03-0.05% of aluminum, 0.0060% or less of nitrogen and the balance Fe and impurities. The preparation method of the dual phase steel comprises the following steps: performing hot rolling treatment to steel ingot, treating by subsection cooling technology and finally reeling the obtained steel. The dual phase steel of the invention has high tensile strength, good chambering performance and formability and cheap cost; in addition, the productionprocess is simple, no precious alloy element is needed to add and different strength levels can be obtained by controlling the process. The hot rolled ferrite bainite dual phase steel of the inventioncan widely and mainly used for the forming of complex shape parts such as automobile wheels, suspension parts and the like.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE

High-strength steel sheet and galvanized steel sheet having very good balance between hole expansibility and ductility, and also excellent in fatigue resistance, and methods of producing the steel sheets

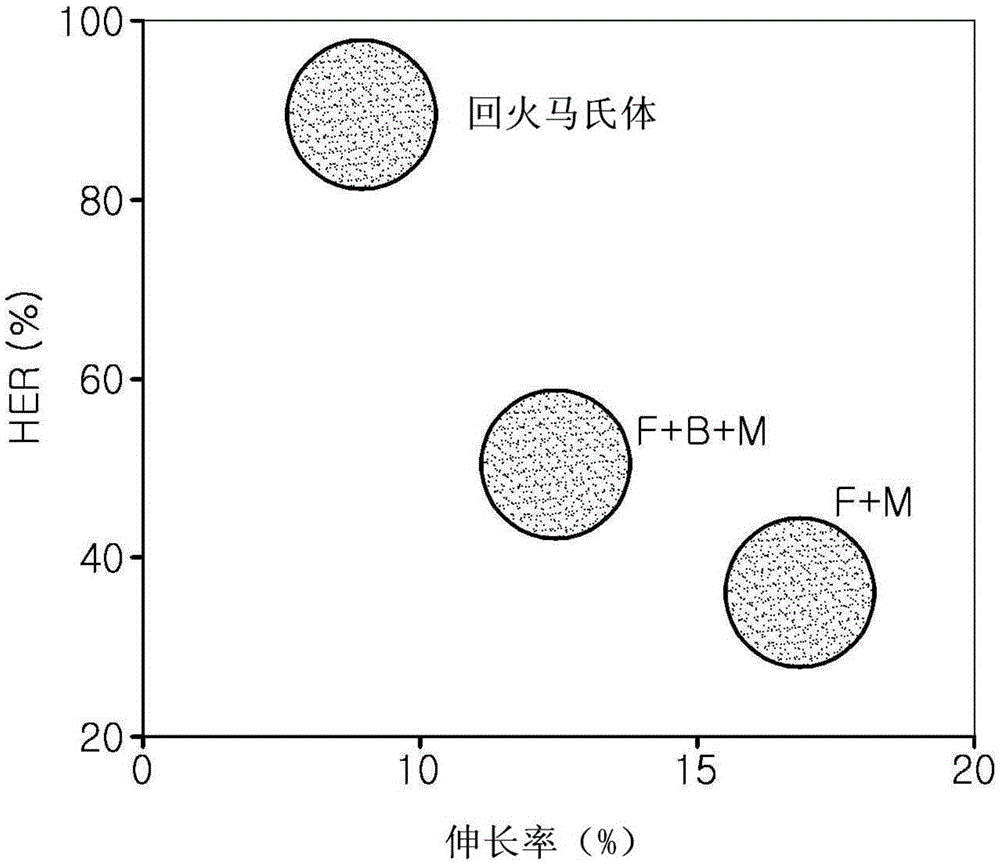

ActiveUS20110024004A1Improve ductilityExcellent hole expandabilityHot-dipping/immersion processesFurnace typesCrystal orientationHome appliance

The invention is directed to providing, for application in automobiles, construction materials, household appliances and the like, high-strength sheets excellent in formability properties such as hole expansibility and ductility, and also in fatigue resistance, characterized in comprising, in specified contents expressed in mass %, C, Si, Mn, P, S, Al, N and O and a balance of iron and unavoidable impurities, and having a steel sheet structure composed mainly of ferrite and hard structures, a crystal orientation difference between some ferrite adjacent to hard structures and the hard structures of less than 9°, and a maximum tensile strength of 540 MPa or greater.

Owner:NIPPON STEEL CORP

High-strength cold-rolled steel sheet of excellent bending workability and hole-expanding property, hot-dip galvanized steel sheet and manufacturing method thereof

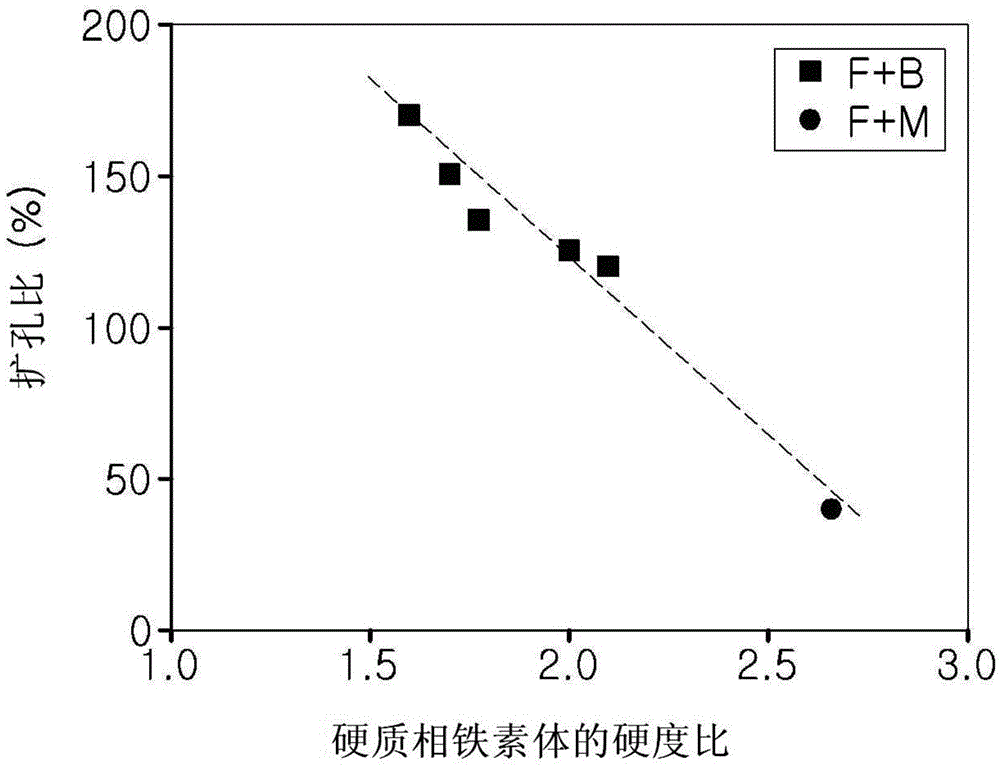

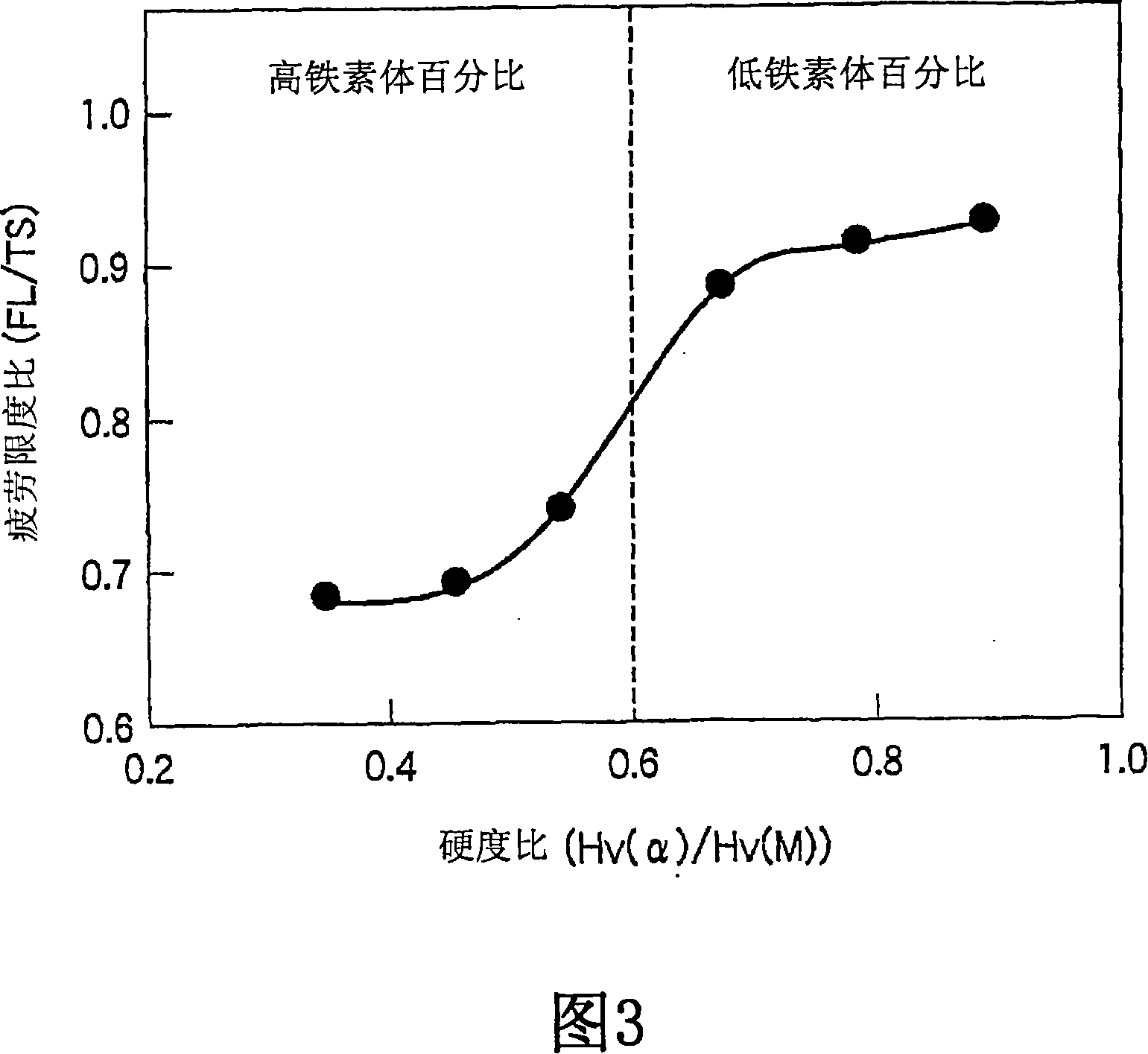

InactiveCN105734410AEasy to processExcellent hole expandabilityHot-dipping/immersion processesHardness ratioFine structure

The invention relates to a high-strength cold-rolled steel sheet of excellent bending workability and hole-expanding property. The high-strength cold-rolled steel sheet comprises the following components in weight percentage: 0.06 to 0.1% of C, 0.05 to 0.5% of Si, 2.0 to 2.5% of Mn, 0.001 to 0.10% of P, 0.010% or less of S, 0.01 to 0.10% of soluble Al, 0.010% or less of N, more than one selected from 0.003 to 0.08% of Ti and Nb, the balance of Fe and impurities. The fine structure of the steel material is composed of 40% or less of martensite, 30 to 40% of bainite and 20 to 30% of ferrite in area percentage. The hardness ratio of bainite to ferrite is over 0.7. The ferrite contains precipitates, wherein the density of the precipitates is 1.5*10<6> per mm2 and the size of the precipitates is smaller than 10 nm. In this way, the hardness ratio of bainite to ferrite is 2 or less.

Owner:POHANG IRON & STEEL CO LTD

Zinc hot dip galvanized composite high strength steel plate excellent in formability and bore-expanding characteristics and method for production thereof

ActiveCN1930316AGood formabilityExcellent hole expandabilityHot-dipping/immersion processesFurnace typesMartensite transformationSheet steel

The present invention provides a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability and a method of production of the same, that is, a hot dip galvanized composite high strength steel sheet excellent in shapeability and hole enlargement ability containing C: 0.01 to 0.3%, Si: 0.005 to 0.6%, Mn: 0.1 to 3.3%, P: 0.001 to 0.06%, S: 0.001 to 0.01%, Al: 0.01 to 1.8%, and N: 0.0005 to 0.01% and having a metal structure of ferrite and, by area rate, 5% to 60% of tempered martensite and a method of production of the same comprising hot rolling, then cold rolling a slab including the above ingredients, heating the sheet in the hot dip galvanization heating process to Ac 1 to Ac 3 +100°C, holding it there for 30 seconds to 30 minutes, then cooling it by a 1°C / s or higher cooling rate to 450 to 600°C, hot dip galvanizing it at that temperature, then cooling it at a 1°C / s or higher cooling rate to the martensite transformation point or lower in temperature, holding it there at 200°C to 500°C for 1 second to 5 minutes, then cooling it at a 5°C / s or higher cooling rate to 100°C or less.

Owner:NIPPON STEEL CORP

Hot dip galvanized high strength steel sheet having excellent plating adhesion and hole expansibility, and its production method

InactiveCN1910301AImprove adhesionExcellent hole expandabilityHot-dipping/immersion processesFurnace typesMartensite transformationSheet steel

The present invention provides hot dip galvanized high strength steel sheet excellent in plating adhesion and hole expandability and a method of production of the same, that is, hot dip galvanization steel sheet excellent in plating adhesion and hole expandability containing, by mass%, C: 0.08 to 0.35%, Si: 1.0% or less, Mn: 0.8 to 3.5%, P: 0.03% or less, S: 0.03% or less, Al: 0.25 to 1.8%, Mo: 0.05 to 0.35%, and N: 0.010% or less and having a balance of Fe and unavoidable impurities, said hot dip galvanized high strength steel characterized in that the steel sheet has a metal structure having ferrite, bainite, by area percent, 0.5% to 10% of tempered martensite, and, by volume percent, 5% or more of residual austenite, and a method of production comprising annealing by a continuous annealing process at 680 to 930 DEG C in temperature, then cooling to the martensite transformation point or less, then hot dip galvanizing the steel during which heating the steel to 250 to 600 DEG C, then hot dip galvanizing it.

Owner:NIPPON STEEL CORP

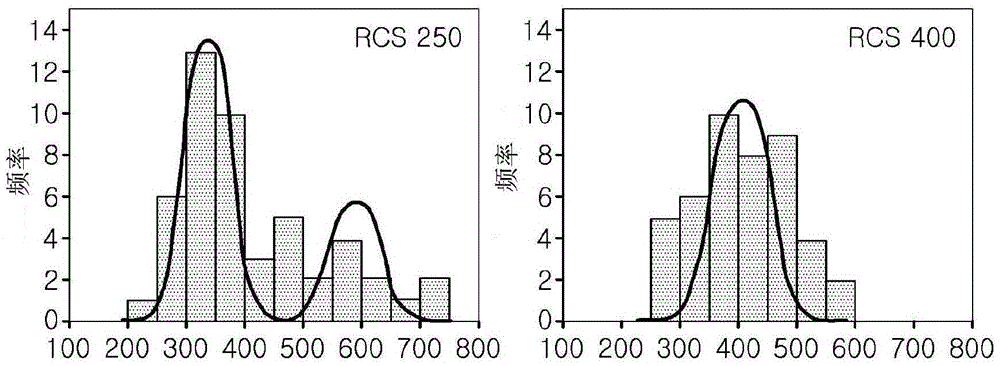

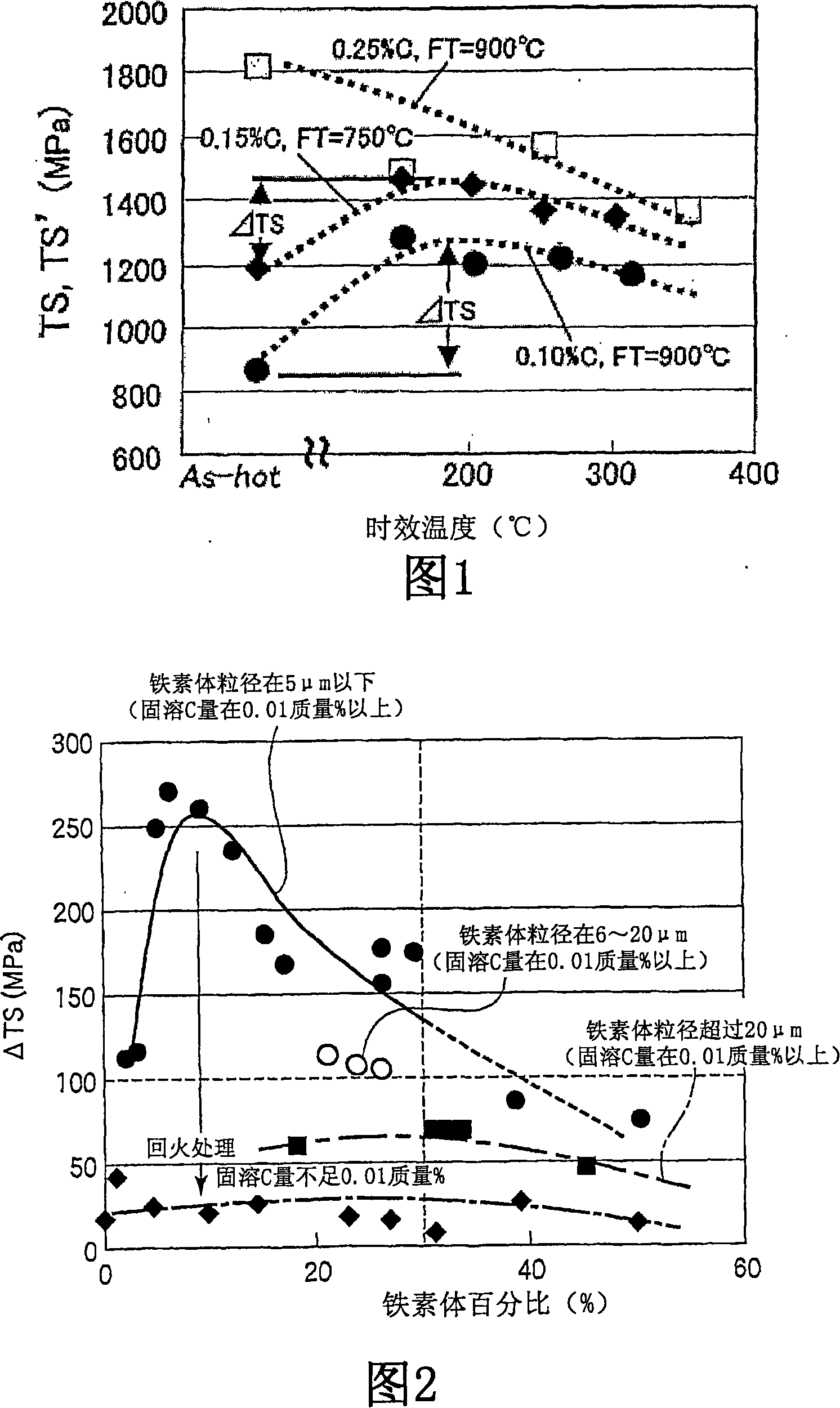

Hot-rolled steel sheet, method for production thereof and molded article formed from hot-rolled steel sheet

InactiveCN101151391AExcellent strain age hardening propertiesGood stamping performanceFurnace typesHeat treatment furnacesSheet steelSolid solution

A hot-rolled steel sheet which comprises 0.01 to 0.2% by mass of C, 2.0% by mass or less of Si and 3.0% by mass or less of Mn and has a martensite phase as the main phase and a ferrite phase as a second phase, the ferrite phase containing ferrite having a grain size of 20 [mu]m or less in such an amount that the area ratio of ferrite becomes 1 to 30% (inclusive) and also containing 0.01% by mass or more of solid solution carbon. The steel sheet has excellent press workability, and exhibits excellent strain ageing property, that is, can be markedly increased in its tensile strength by a heat treatment, after press forming, at a temperature around that for a conventional baking finish, and thus can be suitably used as a steel sheet for an automobile. Further, fatigue characteristics after the strain ageing treatment are improved by hardening the ferrite phase.

Owner:JFE STEEL CORP

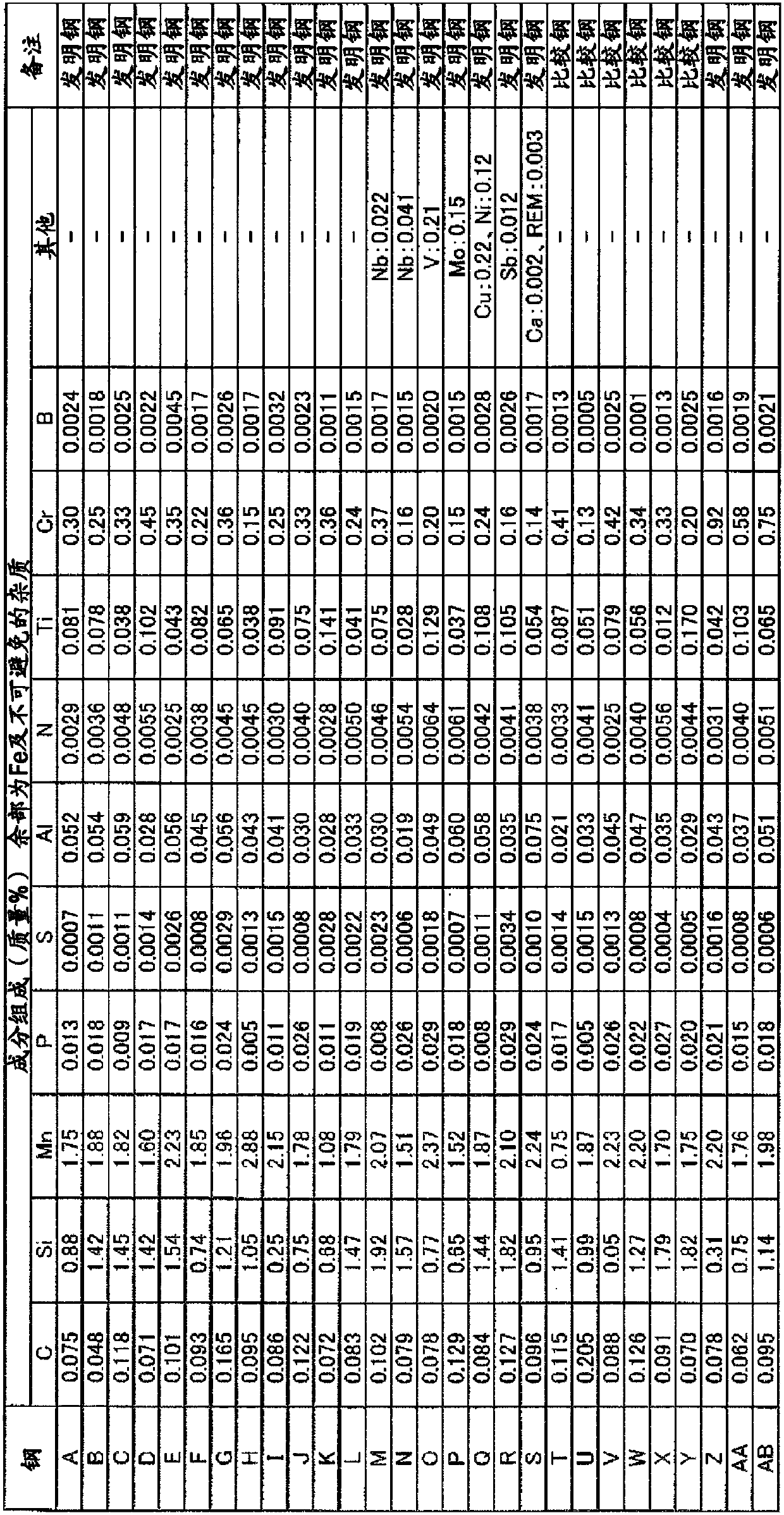

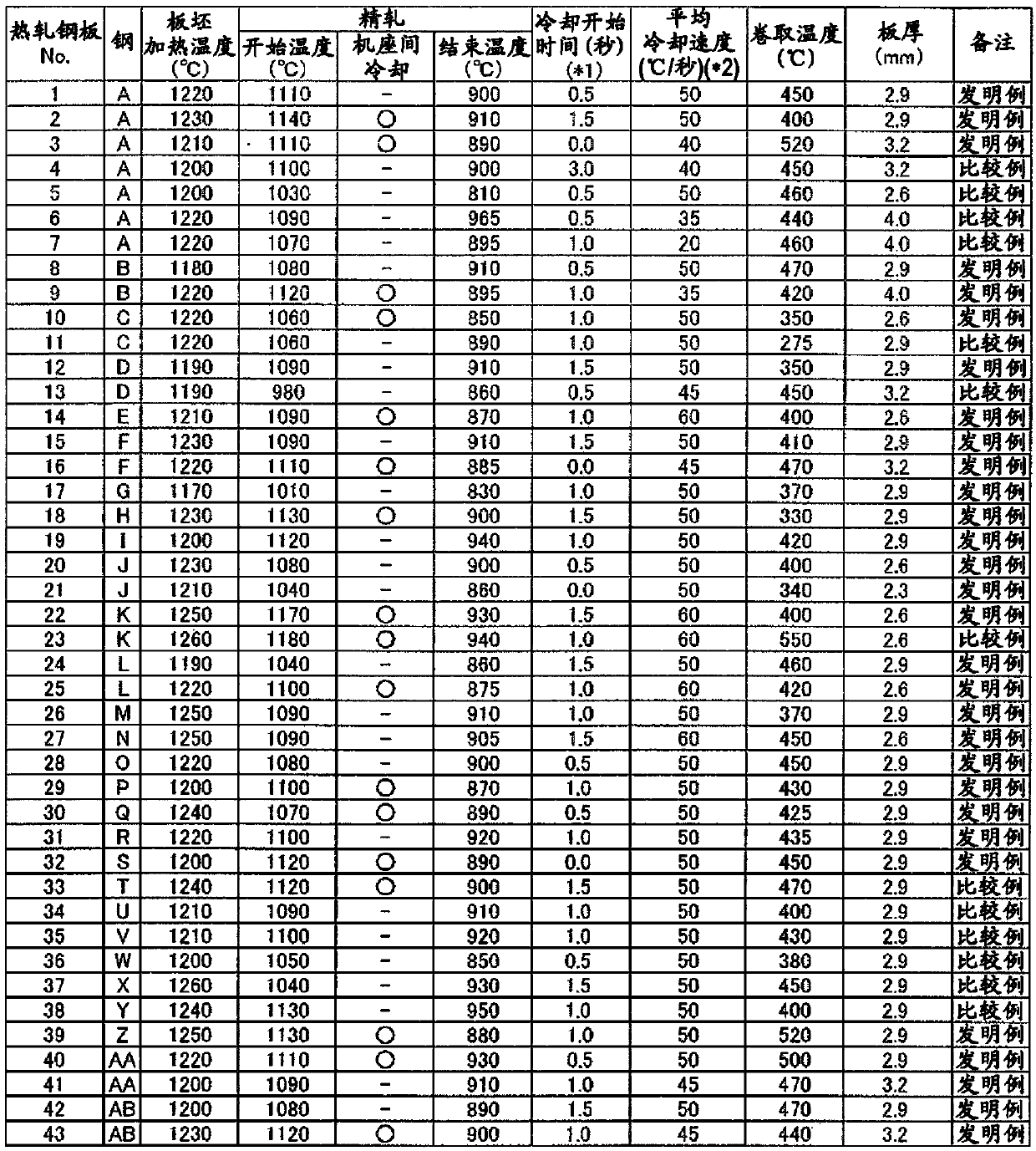

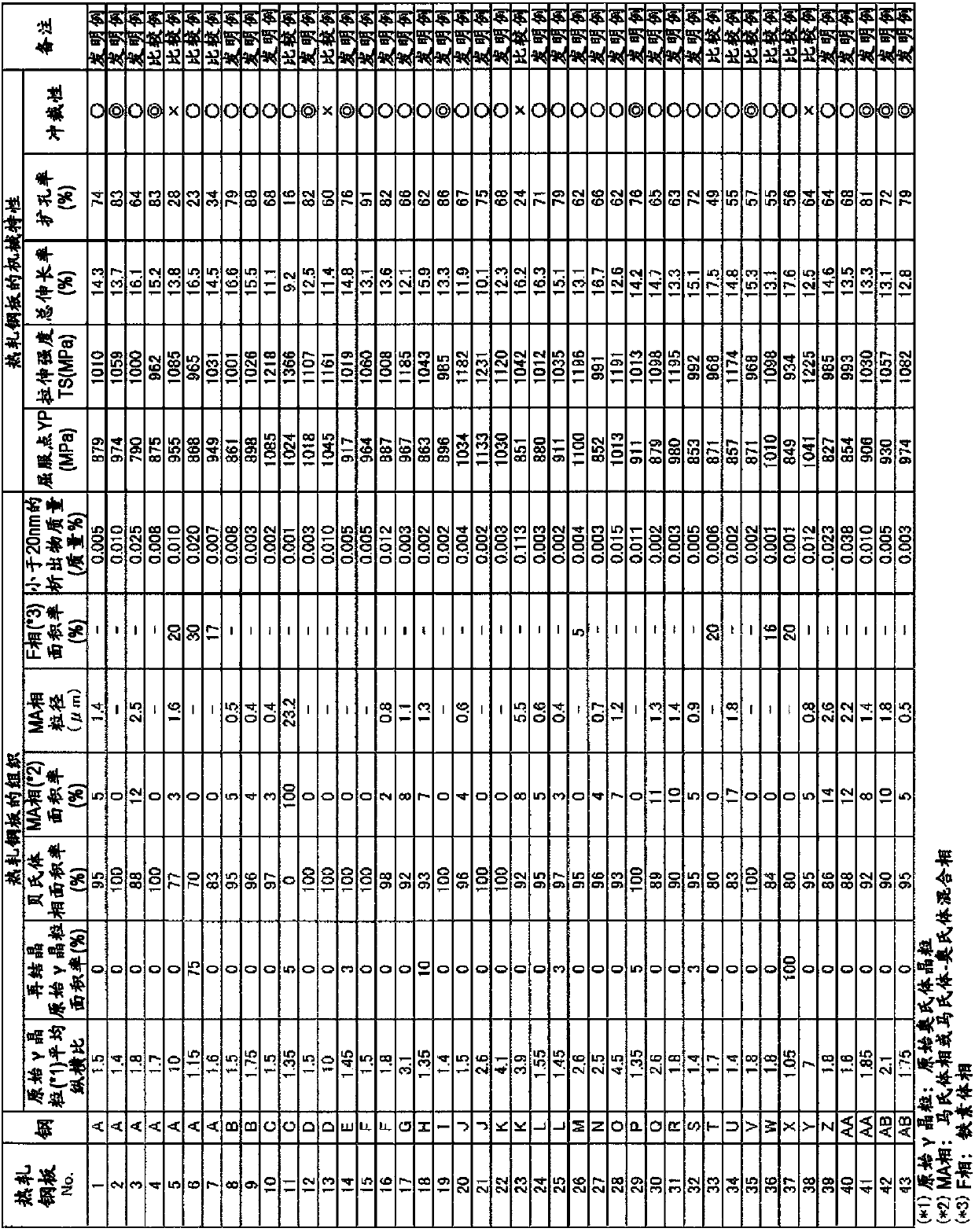

High strength hot rolled steel sheet and manufacturing method for same

InactiveCN107849663AImprove punching effectExcellent hole expandabilityFurnace typesHeat treatment furnacesAustenite grainSheet steel

Provided is a high strength hot rolled steel sheet having superior punchability and hole expandability and a tensile strength TS of at least 980 MPa and a manufacturing method for same. The high strength hot rolled steel sheet has a structure with specified amounts of C, Si, Mn, P, S, Al, N, Ti, Cr and B as a component composition and that comprises a main phase that is a bainite phase with an area ratio of at least 85%, a second phase that is a martensite phase or a martensite-austenite mixed phase with an area ratio of at most 15% and a ferrite phase that is the remainder, wherein the average grain size in the second phase is at most 3.0 [mu]m and furthermore, the average aspect ratio of the prior austenite grains is 1.3-5.0 and the area ratio of recrystallized prior austenite grains tounrecrystallized prior austenite grains is at most 15%, and wherein deposits under 20 nm in diameter are at most 0.10 mass%.

Owner:JFE STEEL CORP

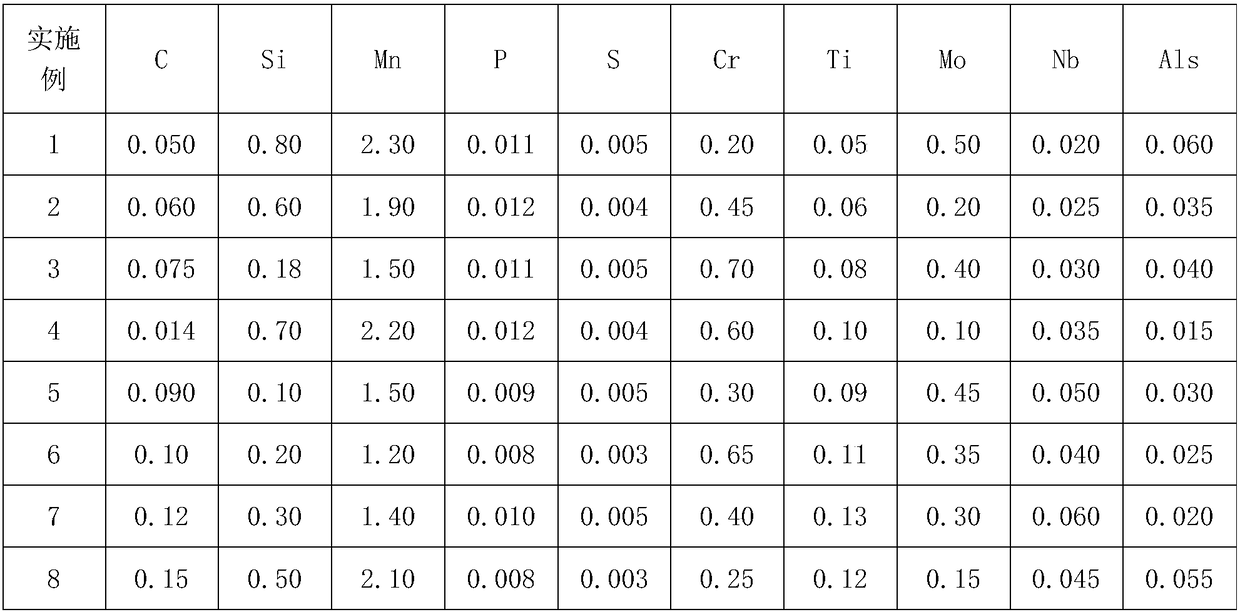

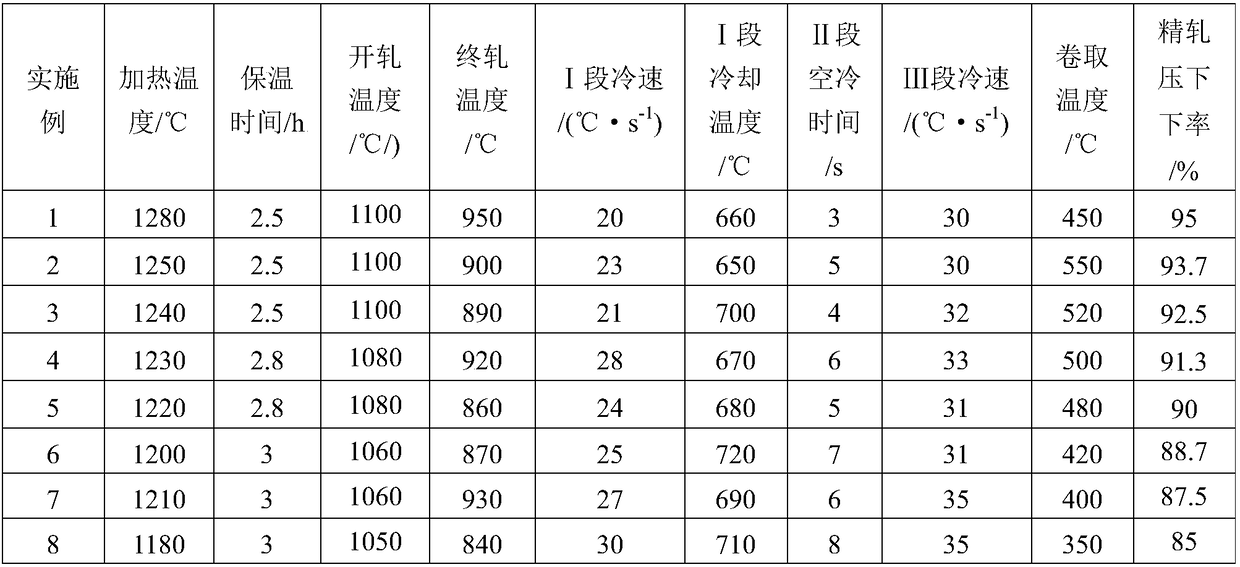

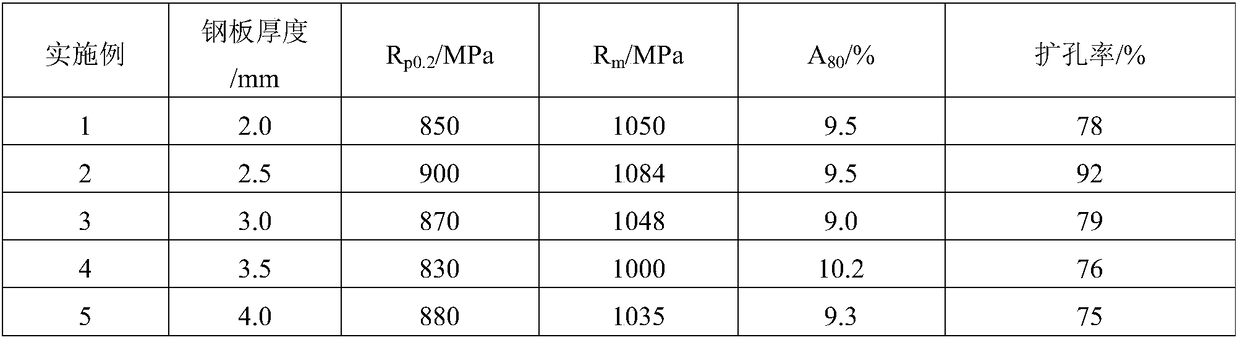

Ultrahigh strength hot-rolled complex phase steel plate and production method thereof

ActiveCN109023036AReduce the difference in mechanical propertiesReduces sensitive points for crackingChemical compositionImpurity

The invention relates to an ultrahigh strength hot-rolled complex phase steel plate and a production method thereof. The ultrahigh strength hot-rolled complex phase steel plate comprises the followingchemical components of, by weight percentage, 0.05-0.15% of C, 0.1-0.8% of Si, 1.2-2.3% of Mn, no more than 0.012% of P, no more than 0.005% of S, 0.20-0.70% of Cr, 0.10-0.50% of Mo, 0.02-0.06% of Nb, 0.05-0.13% of Ti, 0.015-0.060% of Als and the balance Fe and inevitable impurities. The ultrahigh strength hot-rolled complex phase steel plate has the advantages that by controlling rolling and cooling, the effects of fine-grain strengthening, phase transformation strengthening and precipitation strengthening are comprehensively utilized, and the purposes that the high-strength performance of materials is maintained, the microhardness difference between two phases is reduced through precipitation strengthening, and the performance of chambering is improved are achieved.

Owner:ANGANG STEEL CO LTD

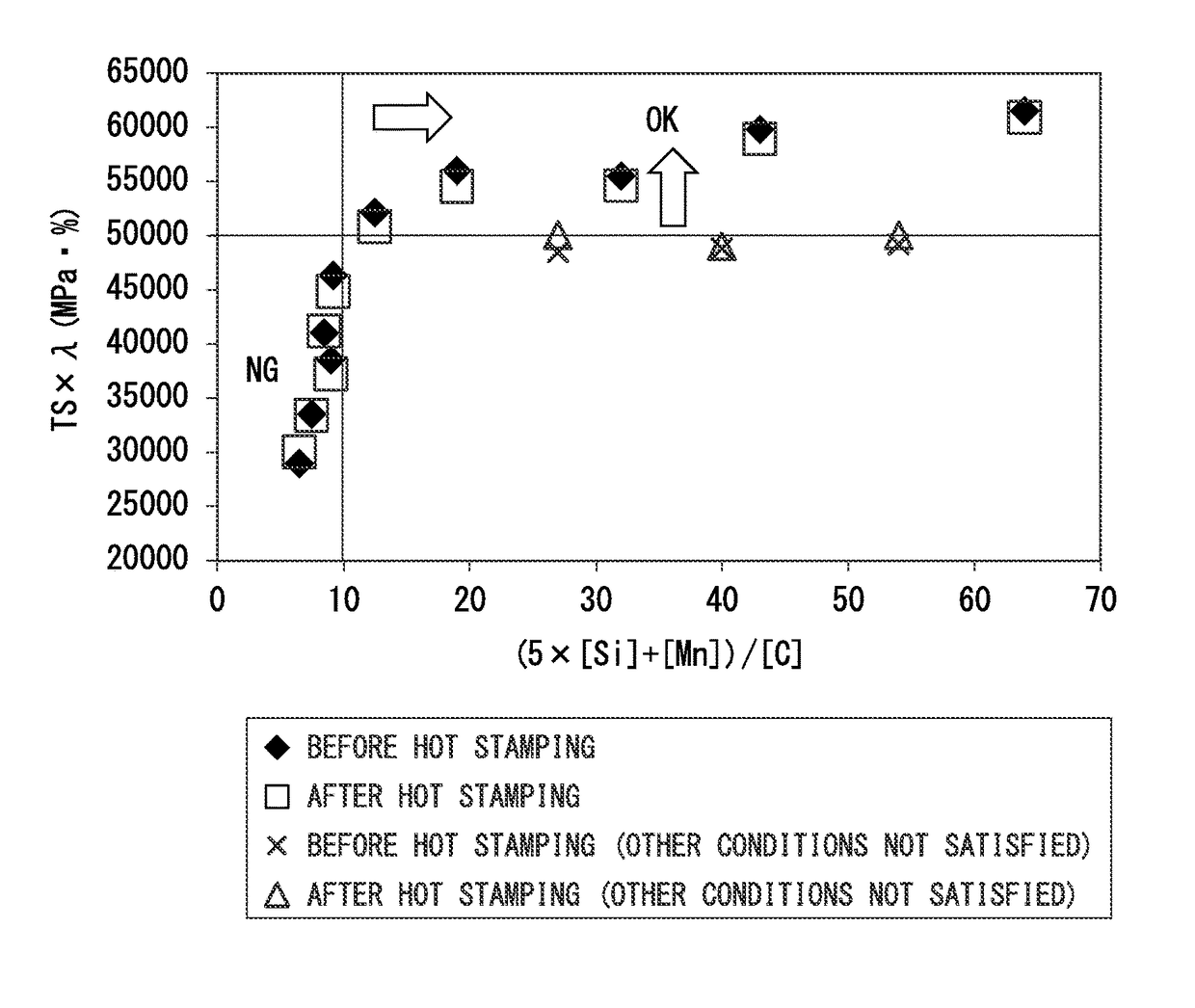

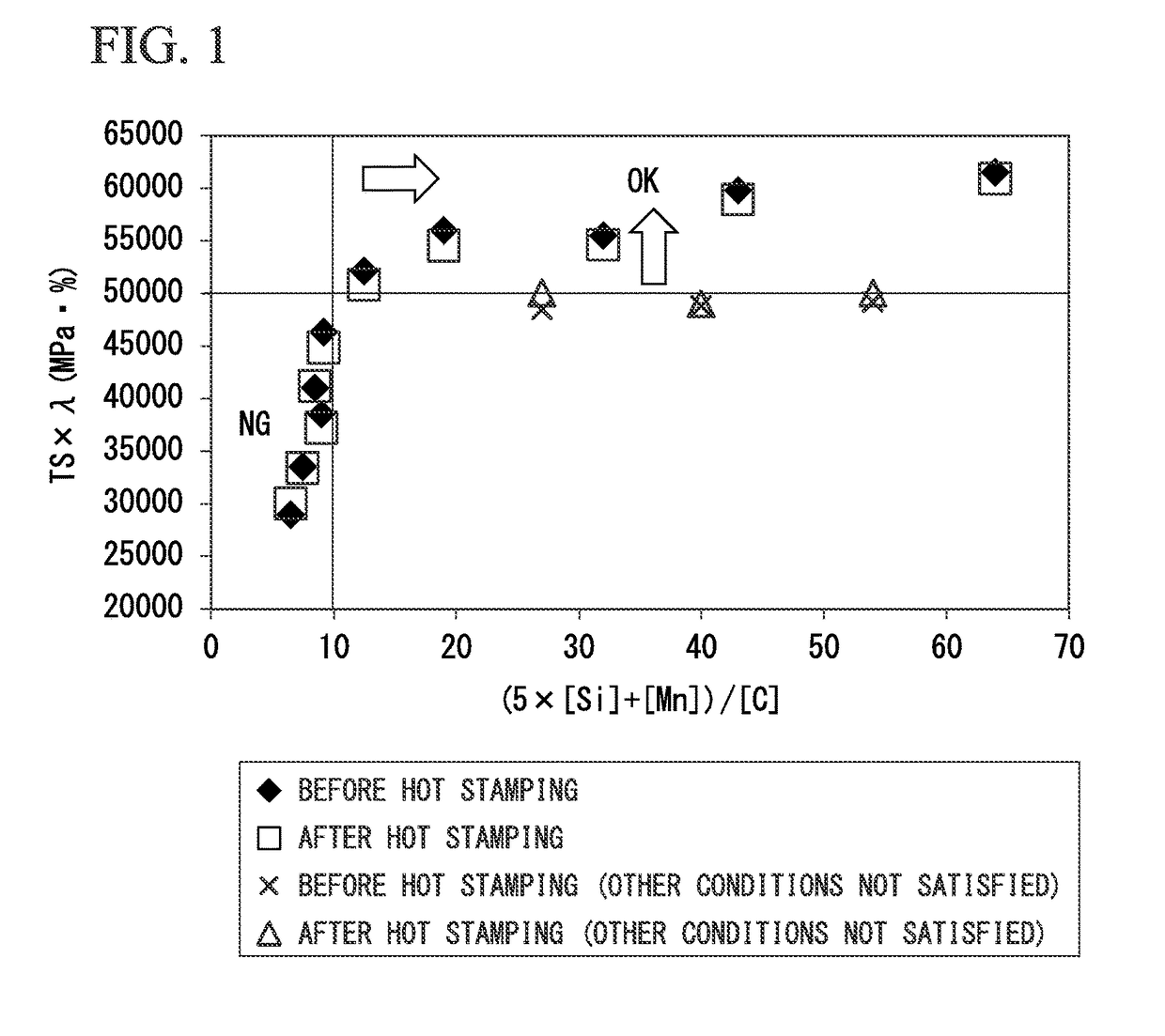

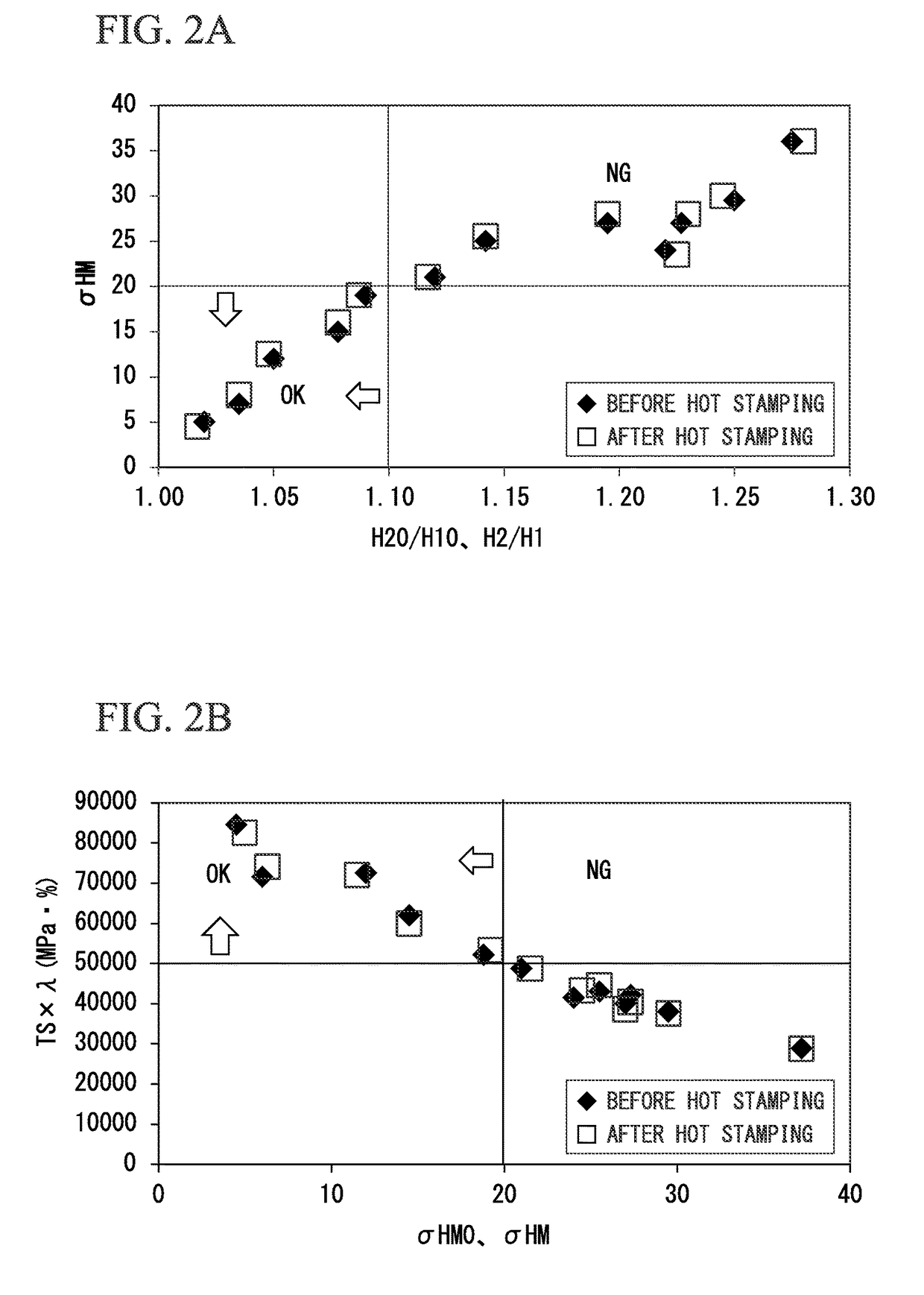

Hot stamp molded article, and method for producing hot stamp molded article

ActiveCN104040011AExcellent hole expandabilityHot-dipping/immersion processesFurnace typesHot stampingUnit mass

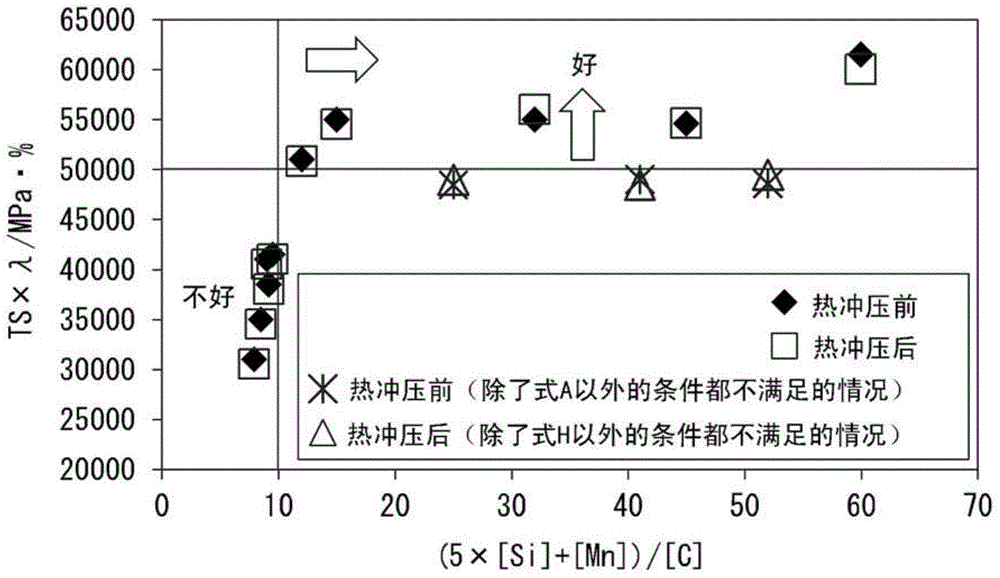

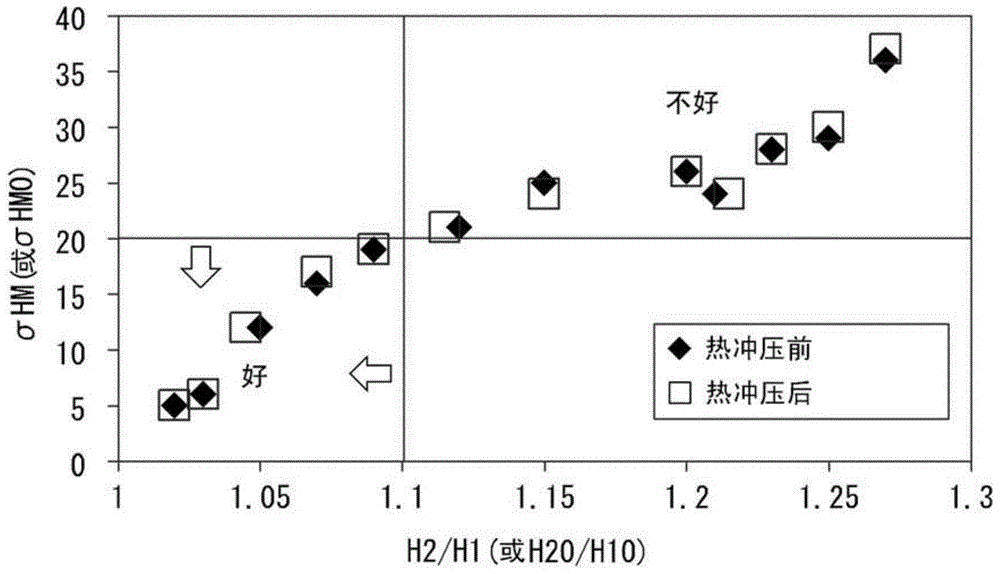

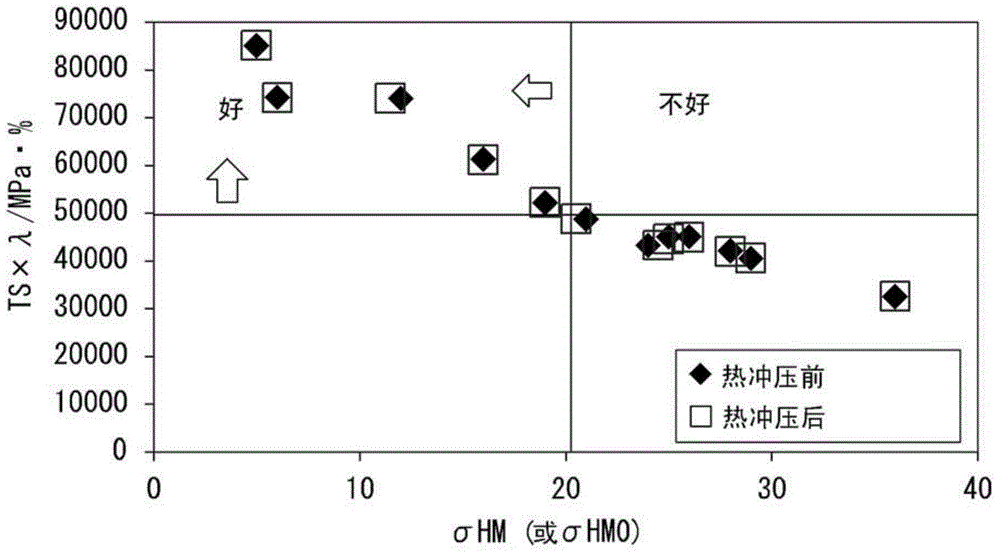

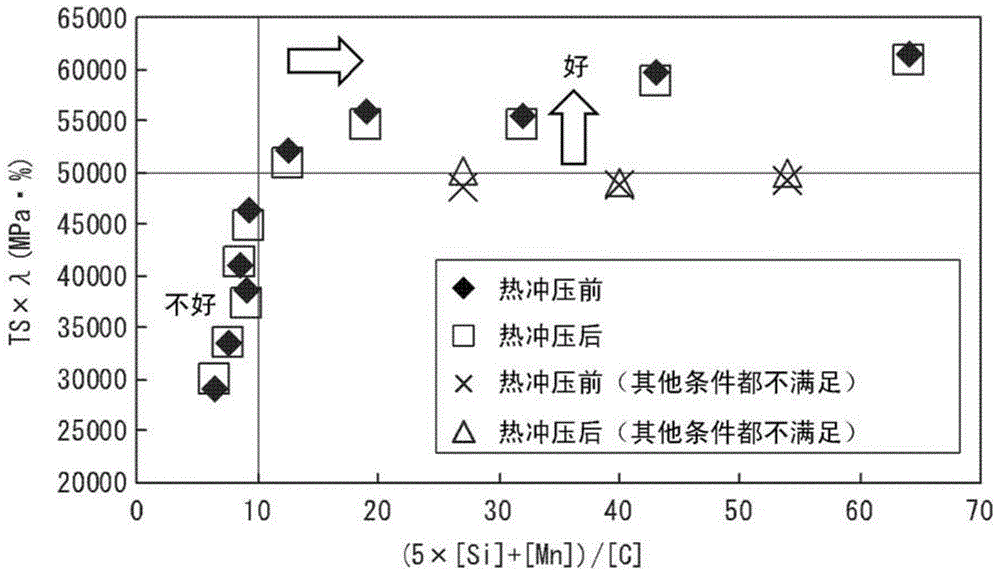

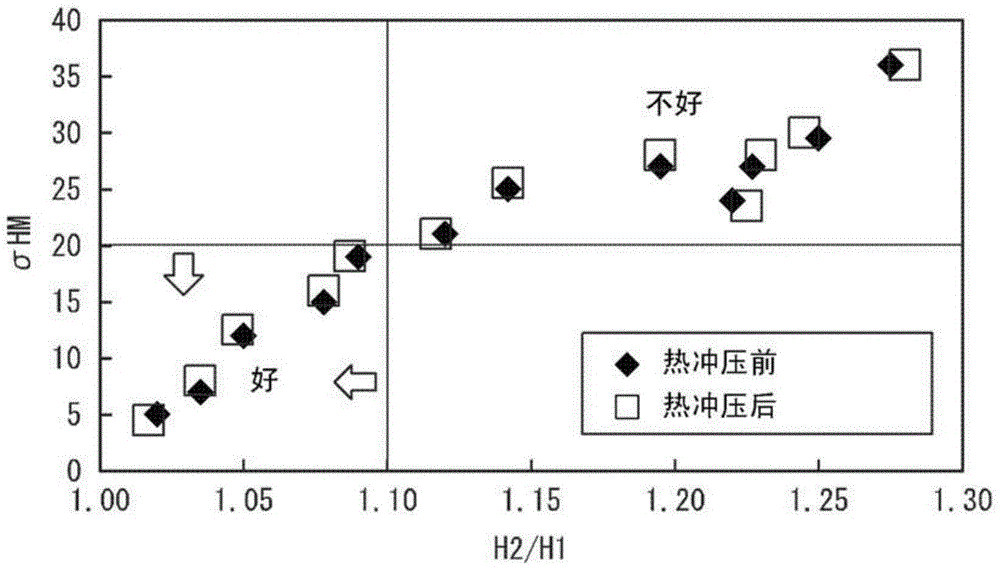

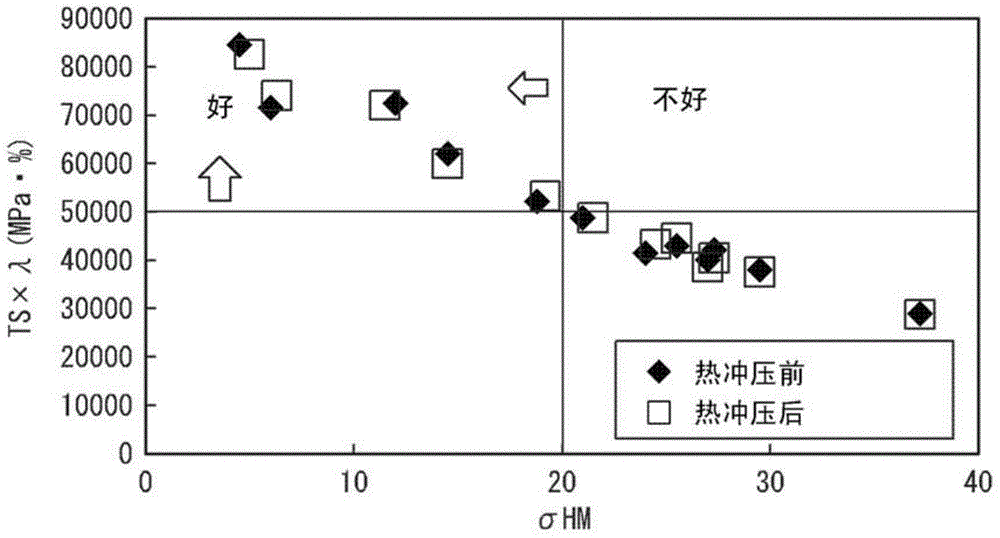

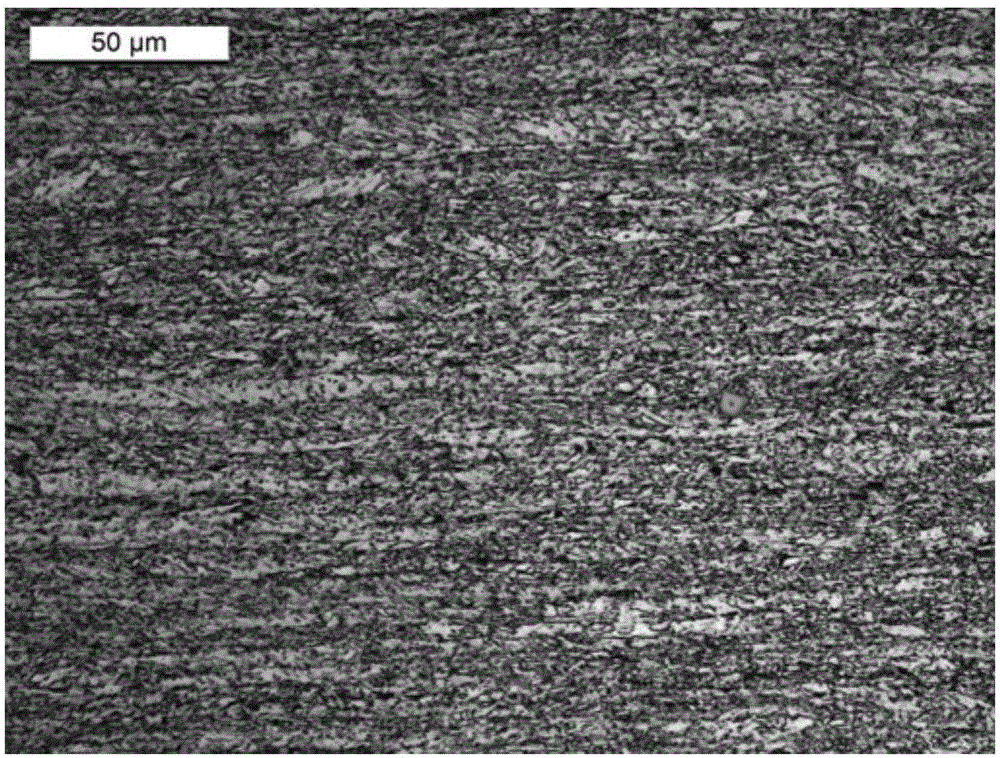

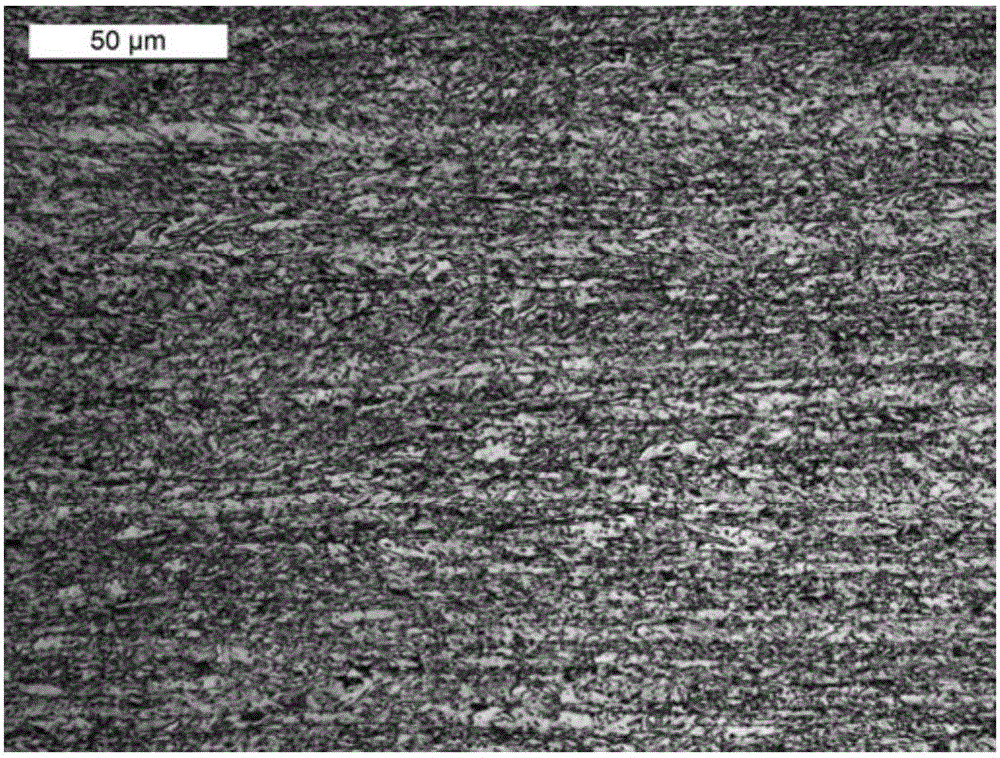

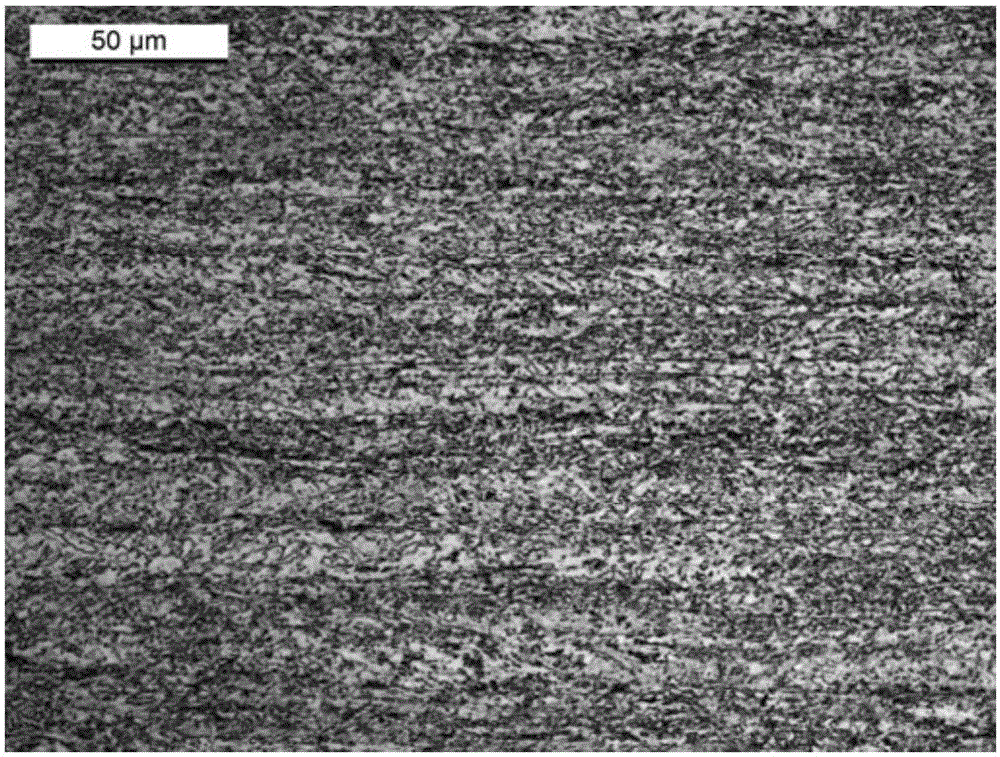

When the carbon content, silicon content and manganese content of this hot stamp molded article are expressed as [C], [Si] and [Mn], respectively, in terms of unit mass%, a relationship of (5 × [Si] + [Mn]) / [C] > 11 holds; and the metal structure after hot stamping contains ferrite at 40% to 90% and martensite at 10% to 60% by area ratio, and the sum of the area ratio of ferrite and the area ratio of martensite is at least 60%. Furthermore, the hardness of the martensite, as measured by a nanoindenter, satisfies H2 / H1 < 1.10 and sigmaHM < 20, and TS × lambda, which is the product of the tensile strength (TS) and hole expansion rate (lambda), is at least 50000 MPa.%.

Owner:NIPPON STEEL CORP

Hot stamp molded article and method for producing same

ActiveCN104040008AExcellent hole expandabilityHot-dipping/immersion processesFurnace typesManganeseHardness

A hot stamp molded article is characterized in that when the carbon content (mass%), silicon content (mass%) and manganese content (mass%) are expressed as [C], [Si] and [Mn], respectively, a relationship of (5*[Si] + [Mn]) / [C] > 10 holds, and if the metal structure contains martensite at 80% or more by area ratio, and further contains one or more of perlite at 10% or less by area ratio, retained austenite at 5% or less by volume ratio, ferrite at 20% or less by area ratio, and bainite at less than 20% by area ratio, TS lambda, which is the product of the tensile strength (TS) and hole expansion rate (lambda), is at least 50000 MPa.%, and the hardness of the martensite, as measured by a nanoindenter, satisfies H2 / H1 < 1.10 and sigmaHM < 20.

Owner:NIPPON STEEL CORP

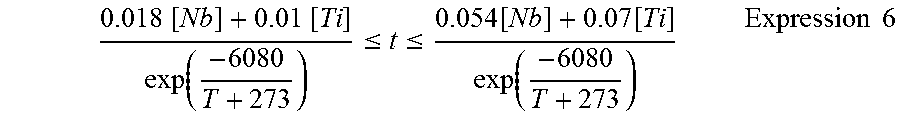

1180 MPa-grade precipitation strengthened hot rolled ultra-high-strength steel and manufacturing method thereof

Provided are 1180 MPa-grade precipitation strengthened hot rolled ultra-high-strength steel and a manufacturing method thereof. The steel is prepared from, by weight, C 0.10-0.20%, Mn 1.5-2.0%, P smaller than or equal to 0.015%, S smaller than or equal to 0.005%, Al 0.02-0.08%, N smaller than or equal to 0.005%, O smaller than or equal to 0.003%, Ti 0.10-0.20%, Nb 0.03-0.06%, V 0.20-0.40% and the balance Fe and inevitable impurities, and meanwhile the conditions required to be met are as follows: the sum of Nb and Ti is greater than or equal to 0.16% but is smaller than or equal to 0.23%, and (Ti-3.42N-3S) / 4+V / 4.24+Nb / 7.74 is greater than or equal to 0.065% but is smaller than or equal to 0.15%. The microstructure of the steel is ferrite, bainite and nanoscale precipitation carbide, wherein the equivalent grain size of the ferrite is smaller than or equal to 5 microns, the width of bainite battens is smaller than or equal to 0.5 micron, the tensile strength of the bainite battens is greater than or equal to 1180 MPa, the elongation is greater than or equal to 15%, the hole expansion rate is greater than or equal to 30%, and excellent strength, plasticity and burring matching are shown.

Owner:BAOSHAN IRON & STEEL CO LTD

Cold-rolled steel sheet and method for manufacturing same

ActiveCN107429369AExcellent punching fatigue propertiesHigh elongationHot-dipping/immersion processesFurnace typesChemical compositionMartensite

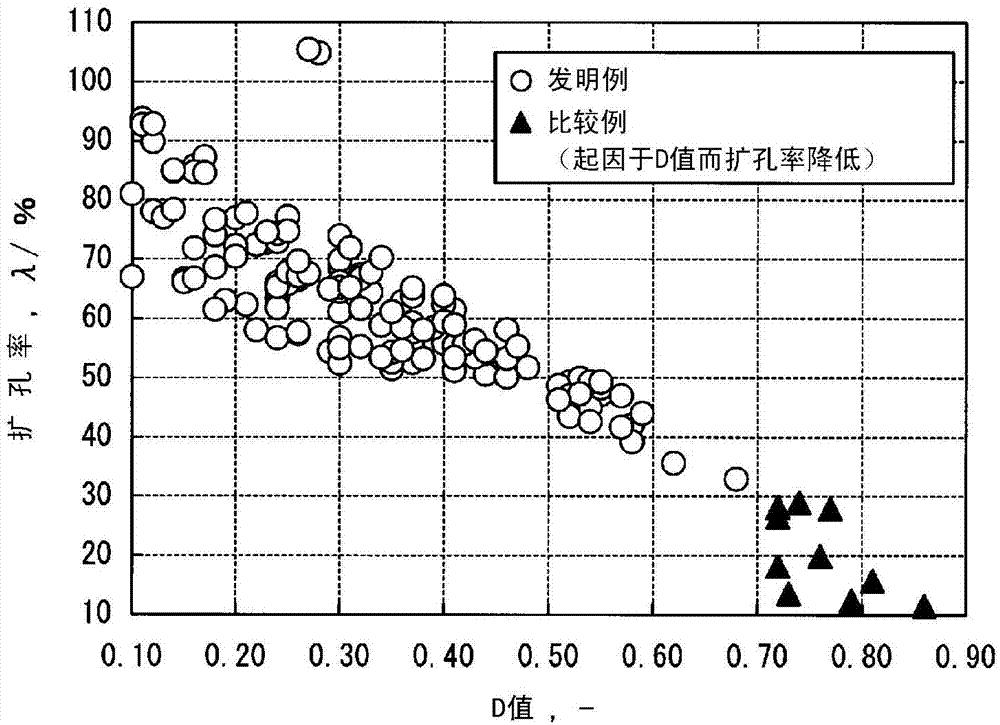

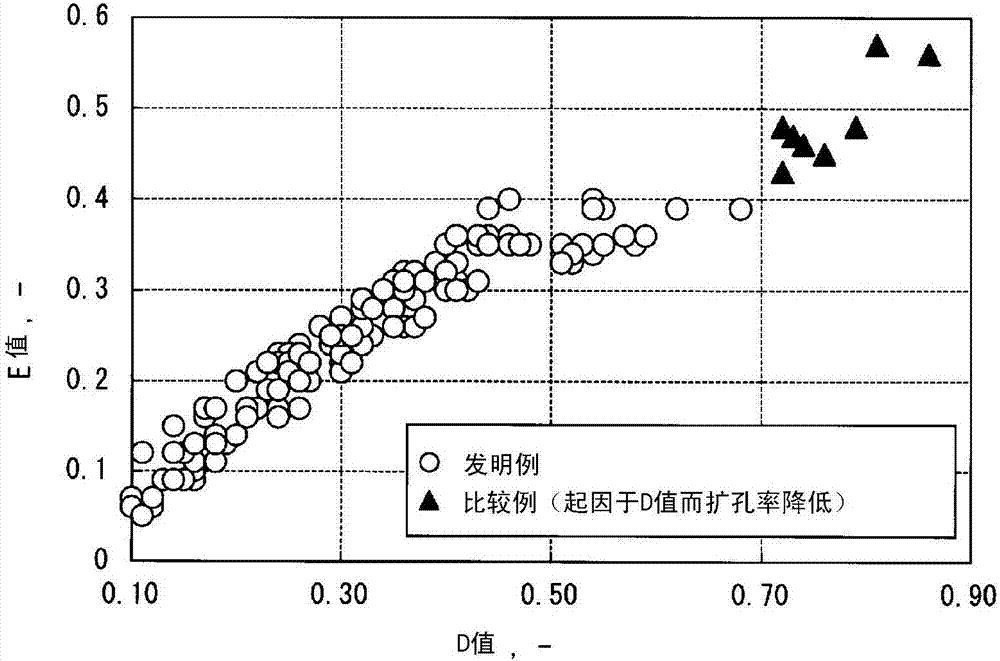

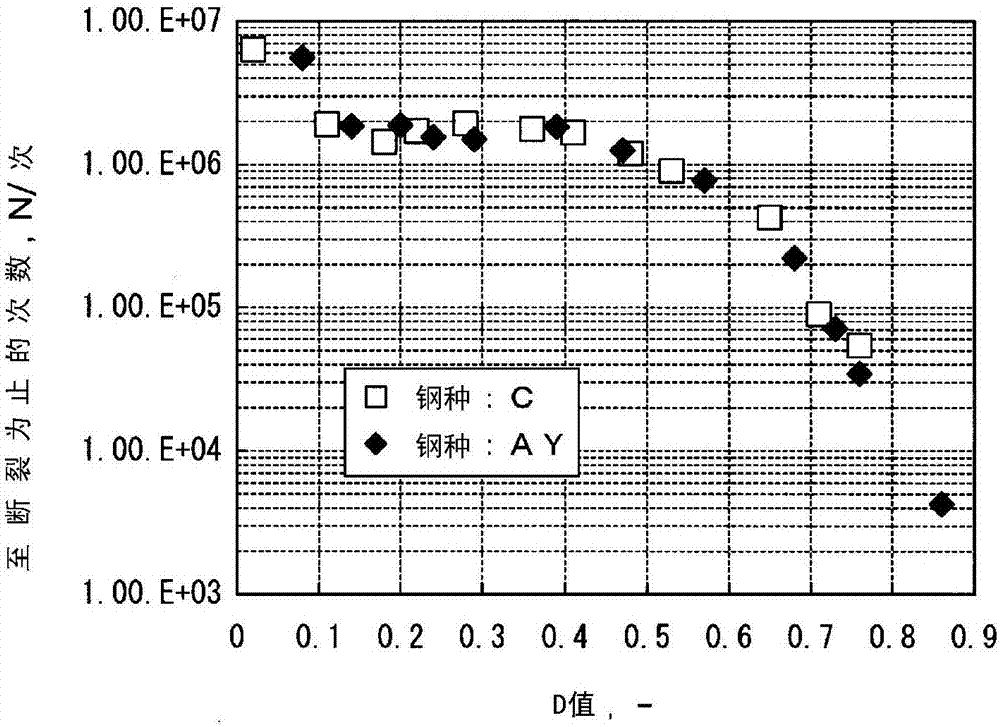

This cold-rolled steel sheet has a predetermined chemical composition, and has a metallographic structure containing, by area fraction, 40.0% to below 60.0% of polygonal ferrite, 30.0% or more of bainitic ferrite, 10.0-25.0% of retained austenite, and 15.0% or less of martensite. In the retained austenite, the proportion of retained austenite having an aspect ratio of 2.0 or less, a major axis length of 1.0 microns or less, and a minor axis length of 1.0 microns or less is 80.0% or more. In the bainitic ferrite, the proportion of bainitic ferrite which has an aspect ratio of 1.7 or less, and in which the average crystallographic misorientation is 0.5 degrees to below 3.0 degrees in a region surrounded by grain boundaries having a crystallographic misorientation of 15 degrees or more, is 80.0% or more. The connectivity D value between the martensite, the bainitic ferrite, and the retained austenite is 0.70 or less.

Owner:NIPPON STEEL CORP

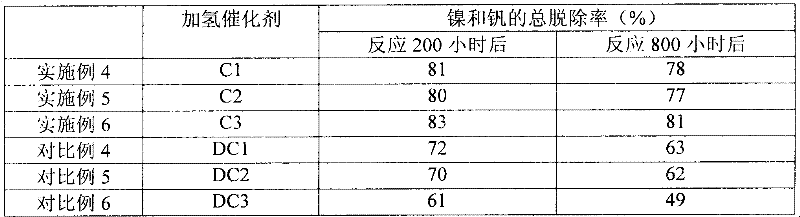

Hydrogenation and metal removing catalyst preparation method

ActiveCN106669707AExcellent hole expandabilityPore expansion effect, the content of the increased carrier macropore is goodHeterogenous catalyst chemical elementsCatalyst activation/preparationAir atmosphereMetal catalyst

The invention discloses a hydrogenation and metal removing catalyst preparation method, which comprises: (1) impregnating a physical pore expanding agent by using a silicon-containing solution, carrying out mixing kneading on the physical pore expanding agent, pseudo-boehmite, an auxiliary extrusion agent and a glue solvent after the impregnating to form a plastic body, extruding strips, drying, calcining the dried material in a nitrogen atmosphere, and then calcining in an air atmosphere to produce a silica-containing alumina carrier; and (2) impregnating the carrier by using a hydrogenation activity component impregnating liquid, drying the material, and calcining to prepare the hydrogenation and metal removing catalyst. According to the present invention, the catalyst prepared through the method has advantages of high mechanical strength, suitable pore structure, high catalytic activity, and high activity stability.

Owner:CHINA PETROLEUM & CHEM CORP +1

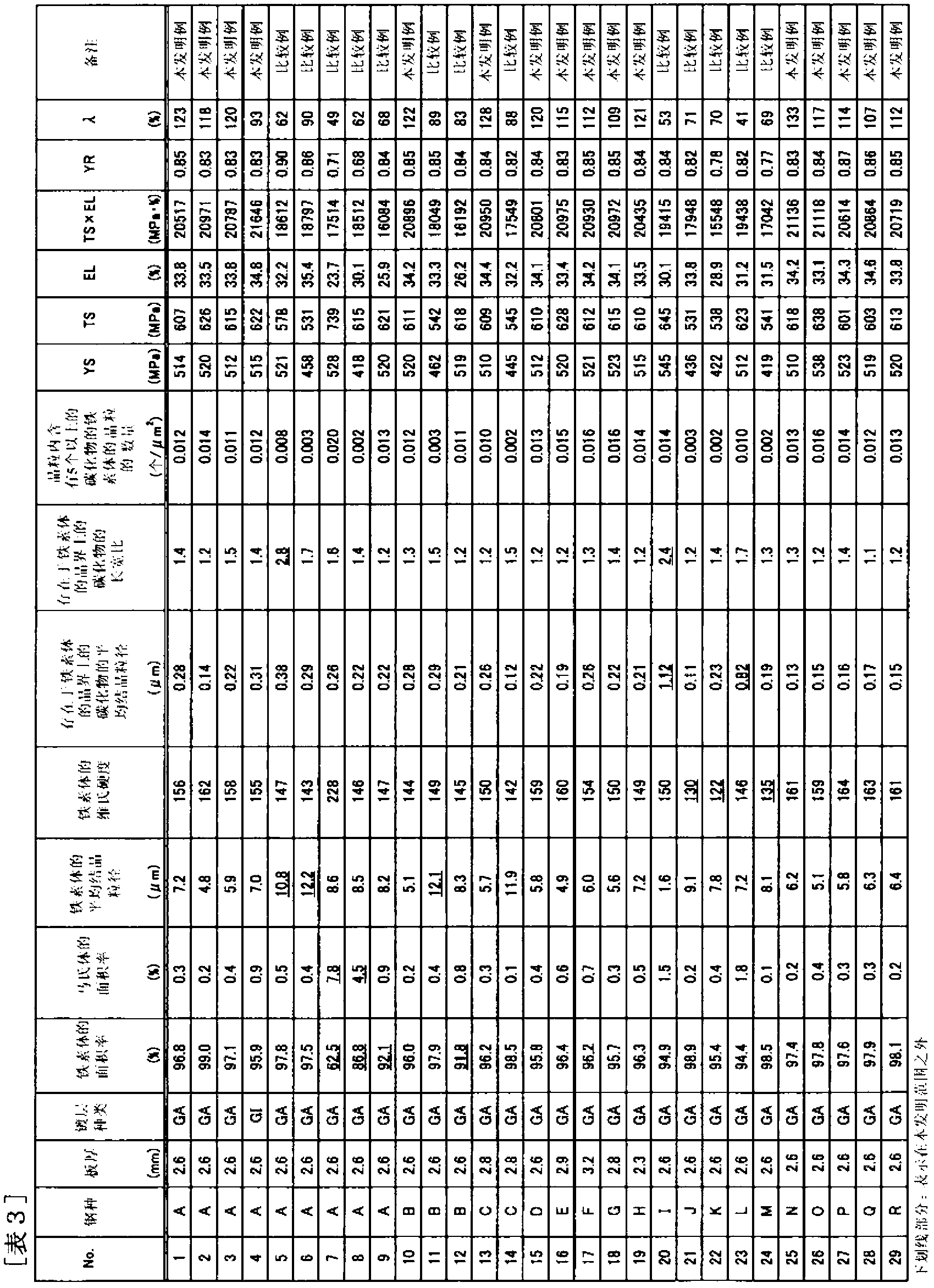

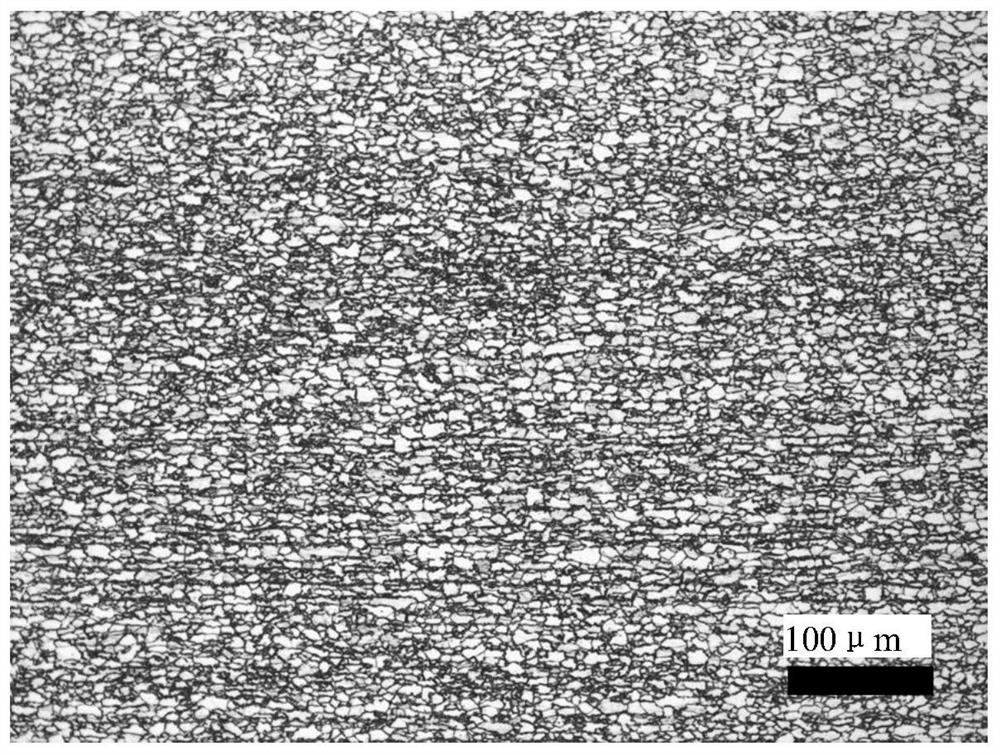

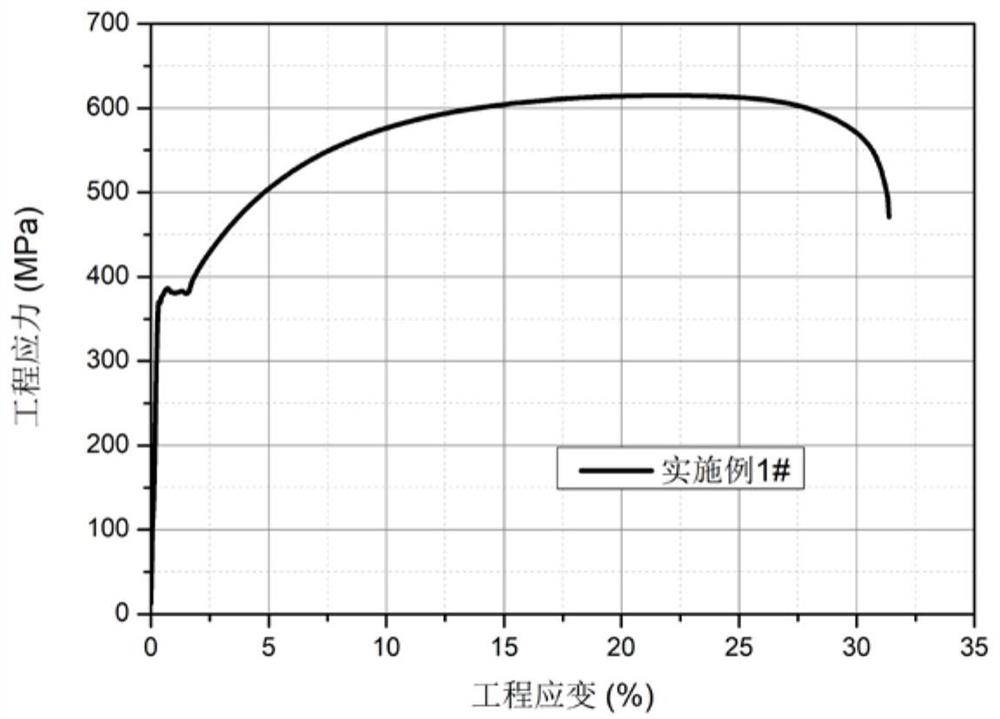

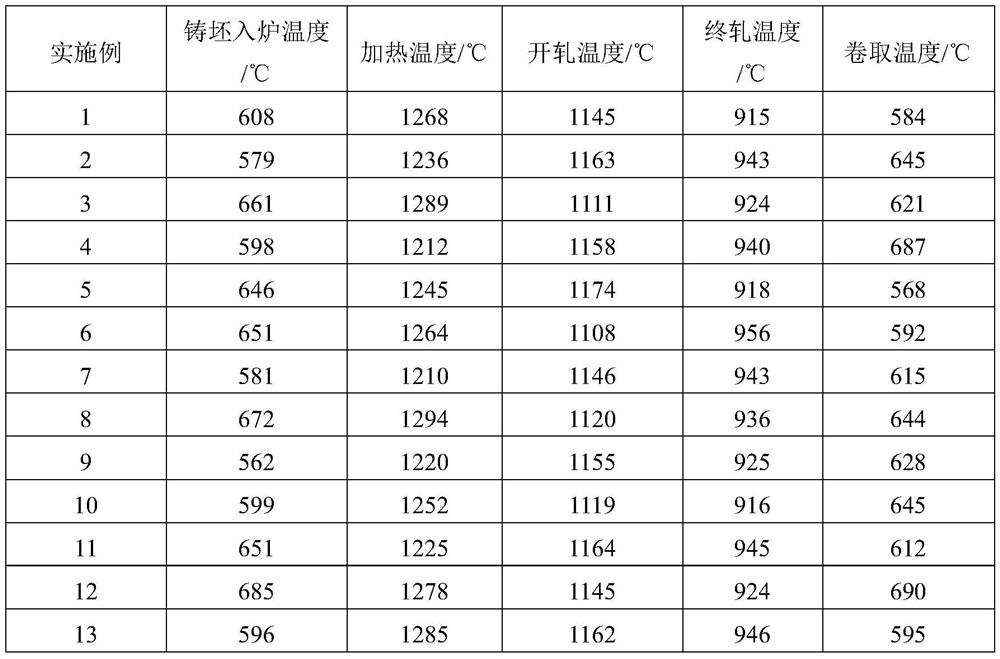

High yield ratio high-strength hot-dip galvanized steel sheet with excellent ductility and hole expansion properties, and manufacturing method thereof

ActiveCN103003460AHigh strengthHigh yield ratioHot-dipping/immersion processesPretreated surfacesSheet steelCarbide

Disclosed is a high yield ratio hot-dip galvanized steel sheet with excellent ductility and hole expansion properties and having a tensile strength: TS) of 590 MPa or greater; also disclosed is a manufacturing method thereof. The disclosed high yield ratio high-strength hot-dip galvanized steel sheet with excellent ductility and hole expansion properties contains, by mass%, C: between 0.04% and 0.13%, Si: between 0.9% and 2.3%, Mn: between 0.8% and 2.4%, P: less than 0.1%, S: .01% or less, Al: between 0.01% and 0.1%, N: 0.008% or less, with the remainder consisting of iron and inevitable impurities. The composition is 94% or more ferrite and 2% or less martensite by area ratio, the average grain size of the ferrite is 10[mu]m or less, the Vickers hardness of the ferrite is 140 or greater, the average grain size of the carbides present on the ferrite grain boundaries is 0.5[mu]m or less, and the aspect ratio of the carbides present on the ferrite grain boundaries is 2.0 or less.

Owner:JFE STEEL CORP

High-ductility and high-formability cold-rolled DH590 steel and production method thereof

The invention discloses high-ductility and high-formability cold-rolled DH590 steel and a production method thereof. The steel comprises 0.08%-0.14% of C, 1.2%-2.2% of Mn, 0.35%-0.75% of Si, 0.02%-0.50% of Al, 0.03%-0.45% of Cr, 0.02%-0.25% of Mo, 0-0.01% of P, 0-0.01% of S, 0-0.03% of Nb and the balance iron and inevitable impurities. The heating temperature of a casting blank is 1200-1300 DEG C,the initial rolling temperature is 1100-1180 DEG C, the final rolling temperature is higher than or equal to 910 DEG C, and the coiling temperature is 550-700 DEG C; the cold rolling reduction rate is 50%-90%; the continuous annealing temperature is 750-850 DEG C, the annealing time is 10-600S, the slow cooling outlet temperature is 660-730 DEG C, the rapid cooling rate is higher than 20 DEG C / S,the rapid cooling outlet temperature is 300-420 DEG C, the overaging temperature is 300-420 DEG C, and the overaging time is 30-3600S; and the finishing elongation is 0.3%-0.6%. A finished steel plate has high ductility and high formability.

Owner:ANGANG STEEL CO LTD

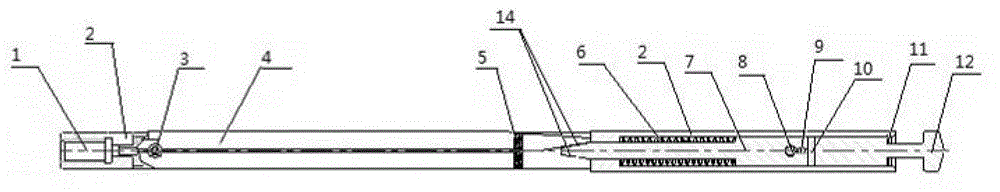

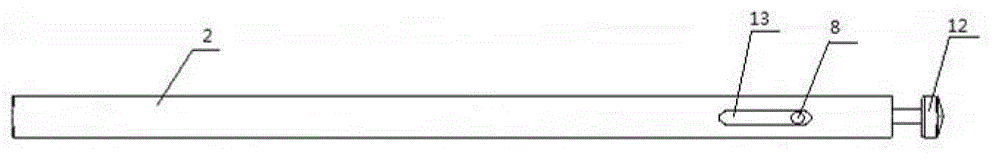

Method and device for supporting weak adhesion bond soft rock roadway

InactiveCN102943681ASimple structureExcellent hole expandabilityDrill bitsAnchoring boltsSolid structureEngineering

The invention discloses a method and device for supporting a weak adhesion bond soft rock roadway. The method includes that step 1, a drilling machine is adopted for drilling holes; step 2, a reamer bit and a drilling stem are connected, and the bottom of a drilled hole is chambered; step 3, an anchoring agent and an anchor rod are placed in the drilled hole, the anchor rod and the drilling machine are connected, the drilling machine drives the anchor rod to rotate and stir the anchoring agent, after the anchoring agent is solidified, a chambering portion is full with the anchoring agent to form a solid structure in a reverse wedge shape, and the solid structure is used for fixing an anchoring section of the anchor rod; and step 4, a tray is arranged on top of the drilled hole, a nut is used for screwing a free end of the anchor rod tightly, and pre-tightening torsion meets design value. The device is a chambering reamer bit comprising a casing, a cutter and a cutter control device, wherein one end of the casing is a connector, the cutter is connected with the bottom of the connector in pivoted mode, and the cutter control device is connected with the cutter and controls the cutter to be screwed out from the casing or withdrawn. By means of the device and method, an effect of the anchor rod is good.

Owner:TIANDI SCI & TECH CO LTD

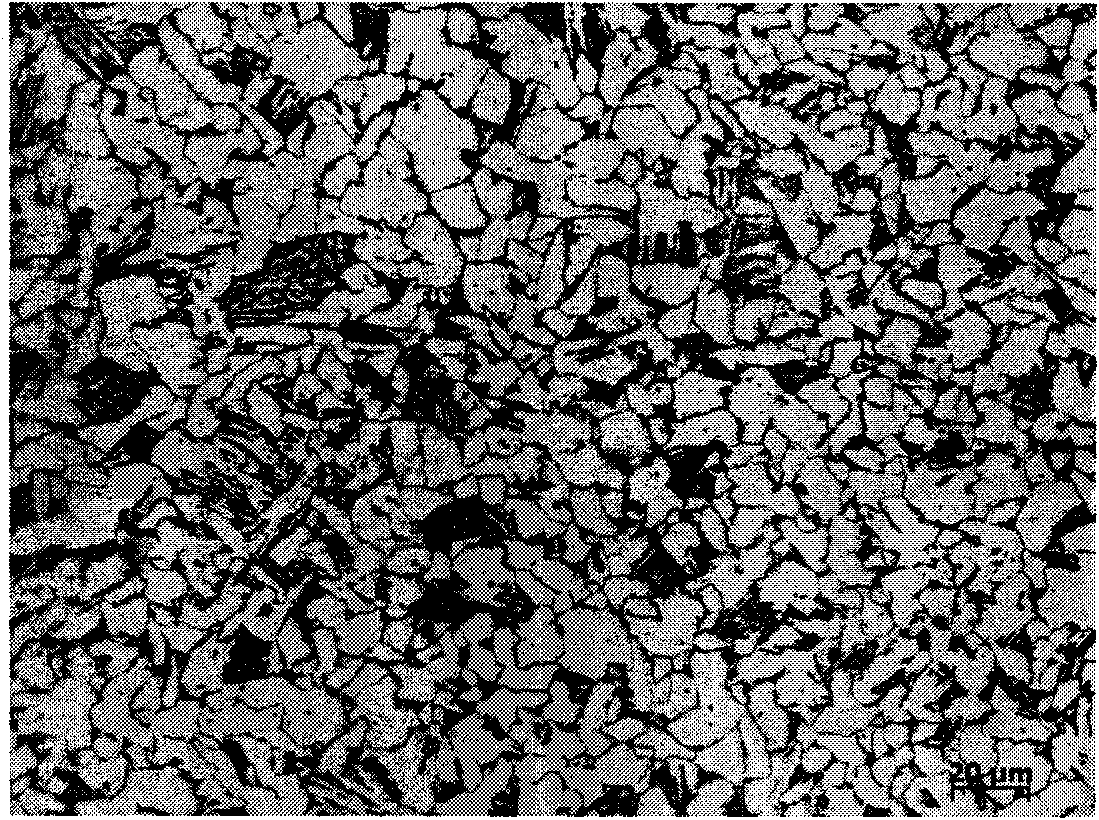

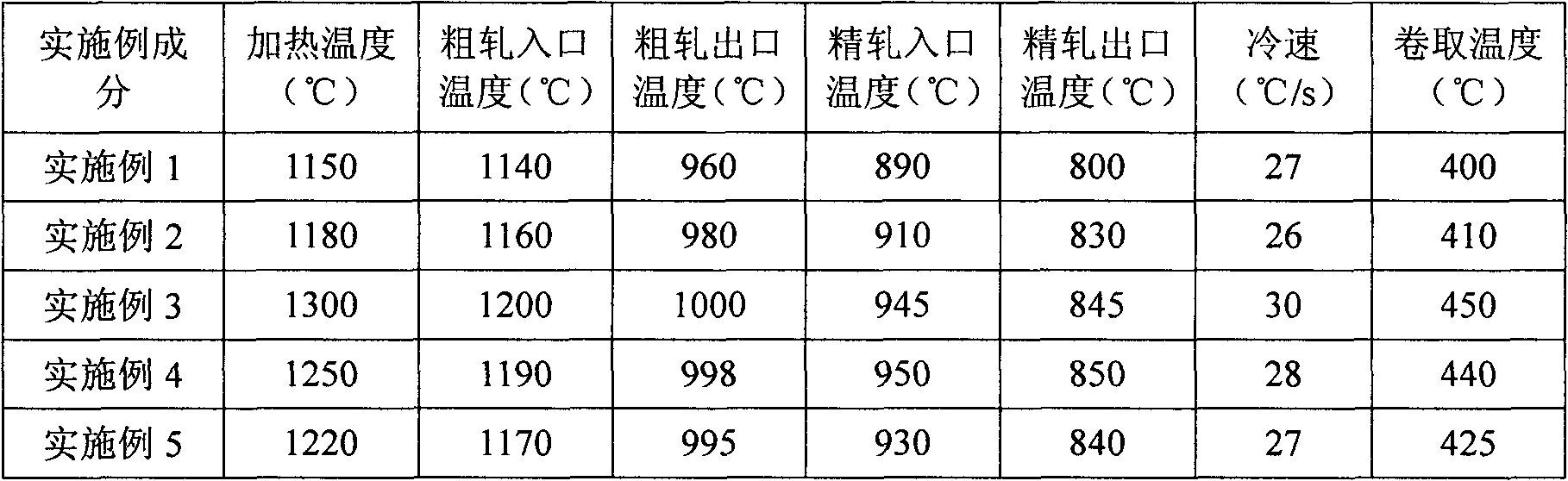

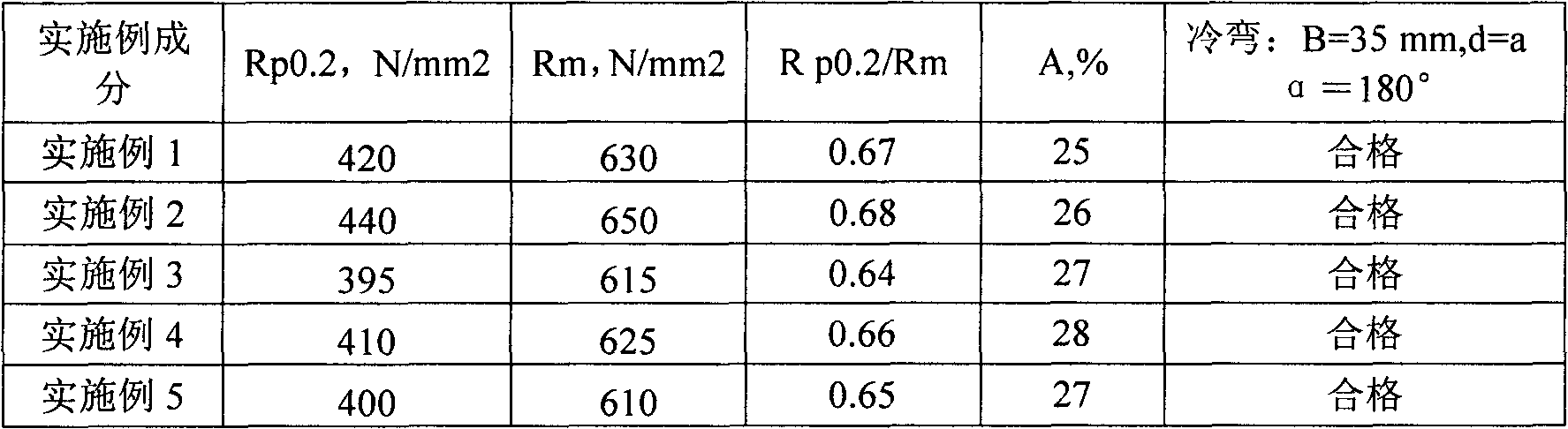

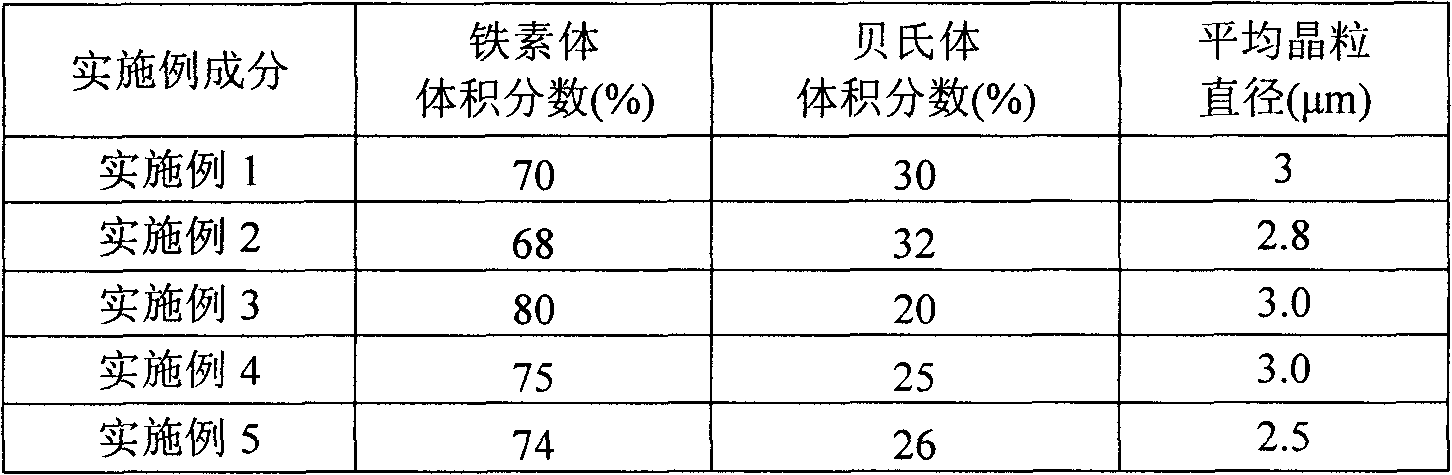

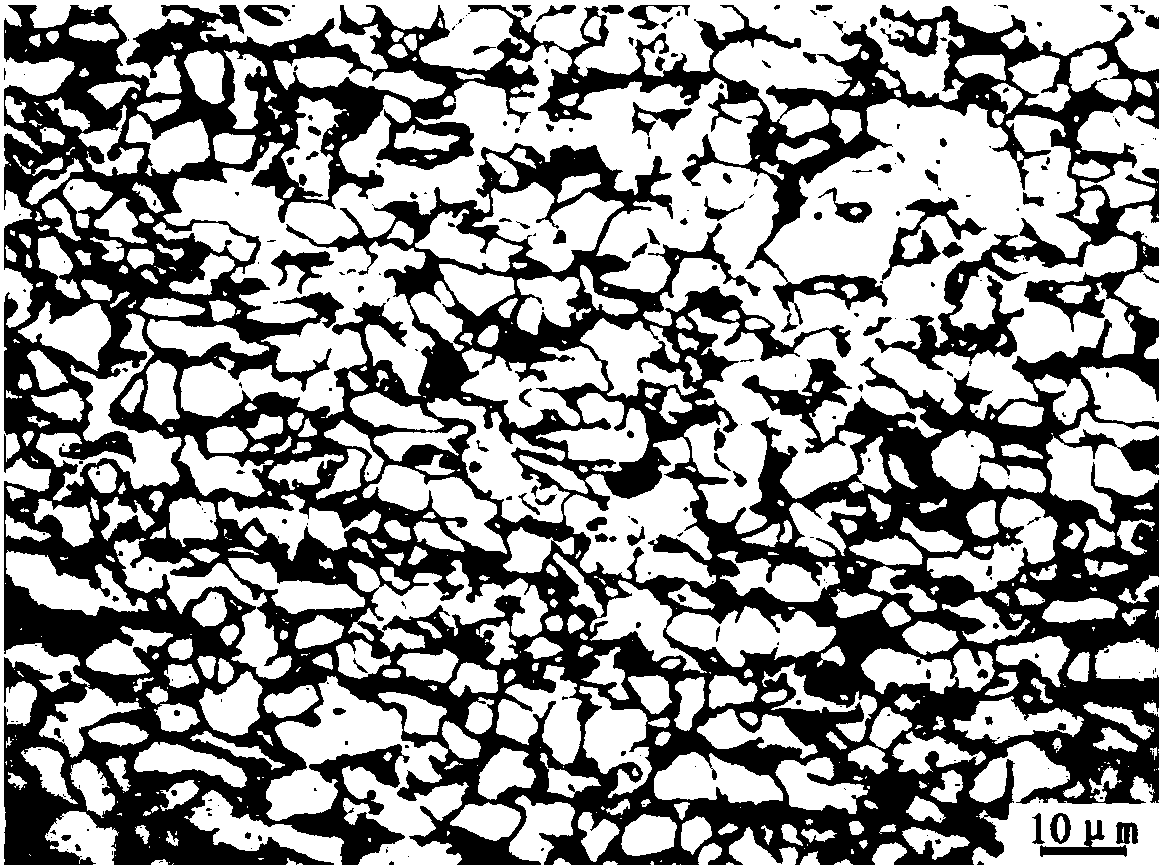

Ultrafine-grain hot-rolling dual phase steel plate for automobile and production method thereof

InactiveCN102719735ALow costImprove performanceTemperature control deviceChemical constituentsImpurity

The invention discloses an ultrafine-grain hot-rolling dual phase steel plate for automobiles and a production method thereof. The chemical constituent of the steel plate comprises, by mass, 0.07%-0.09% of C, 0.2%-0.5% of Si, 1.3%-1.5% of Mn, 0.03%-0.05% of Nb, less than 0.02% of P, and less than 0.01% of S, and the balance being iron and ineluctable impurities, wherein the volume fraction of ferrite is between 60% and 80%, the volume fraction of bainite is between 20% and 40%, the average grain diameter is between 2-3 mu m. The production method comprises that: continuous casting blanks are heated to 1150-1300 DEG C and insulated for 2-3 h. The rolling temperature is between 1100-1200 DEG C and the finishing temperature>950 DEG C during rough rolling. During finish rolling, the initial rolling temperature is between 890-950 DEG C and the final rolling temperature>800 DEG C. A laminar flow cooling technology is utilized and rapid cooling is carried out. The cooling speed is controlled between 25-35 DEG C / s and coiling is carried out when the temperature is between 400-450 DEG C finally. The steel plate and the production method thereof have the advantages of low cost without adding noble metals such as Cr, Mo; simple technology without subsection cooling, easy production control; uniform and consistent product performance and good formability. The steel plate and the production method thereof are mainly used for stamping workpieces of automobile wheels and girders.

Owner:ANGANG STEEL CO LTD

Cold rolled steel sheet and manufacturing method thereof

ActiveUS9605329B2Excellent hole expandabilityGood molding effectHot-dipping/immersion processesFurnace typesUnit massHardness

When the amount of C, the amount of Si and the amount of Mn are respectively represented by [C], [Si] and [Mn] in unit mass %, the cold rolled steel sheet satisfies a relationship of (5×[Si]+[Mn]) / [C]>10, the metallographic structure contains, by area ratio, 40% to 90% of a ferrite and 10% to 60% of a martensite, further contains one or more of 10% or less of a pearlite by area ratio, 5% or less of a retained austenite by volume ratio and 20% or less of a bainite by area ratio, the hardness of the martensite measured using a nanoindenter satisfies H20 / H10<1.10 and σHM0<20, and TS×λ representing the product of TS that is a tensile strength and λ that is a hole expansion ratio is 50000 MPa·% or more.

Owner:NIPPON STEEL CORP

Ultra-high strength steel plate having excellent formability and hole-expandability, and method for manufacturing same

ActiveCN108350546AGood physical and mechanical propertiesHigh yield strengthHot-dipping/immersion processesFurnace typesUltimate tensile strengthSteel plates

The present invention relates to an ultra-high strength steel plate for an automobile and, more specifically, to an ultra-high strength steel plate having excellent formability and hole-expandability,and a method for manufacturing the same.

Owner:浦项股份有限公司

Hot-rolled steel sheet

ActiveUS20180037980A1Excellent peel resistanceExcellent hole expandabilityHot-dipping/immersion processesFurnace typesChemical compositionHot rolled

A hot-rolled steel sheet includes a chemical composition represented by, in mass %, C: 0.010% to 0.100%, Si: 0.30% or less, Cr: 0.05% to 1.00%, Nb: 0.003% to 0.050%, Ti: 0.003% to 0.200% and others, wherein a proportion of grains having an intragranular misorientation of 5° to 14° in all grains is 20% or more by area ratio, the grain being defined as an area which is surrounded by a boundary having a misorientation of 15° or more and has a circle-equivalent diameter of 0.3 μm or more.

Owner:NIPPON STEEL CORP

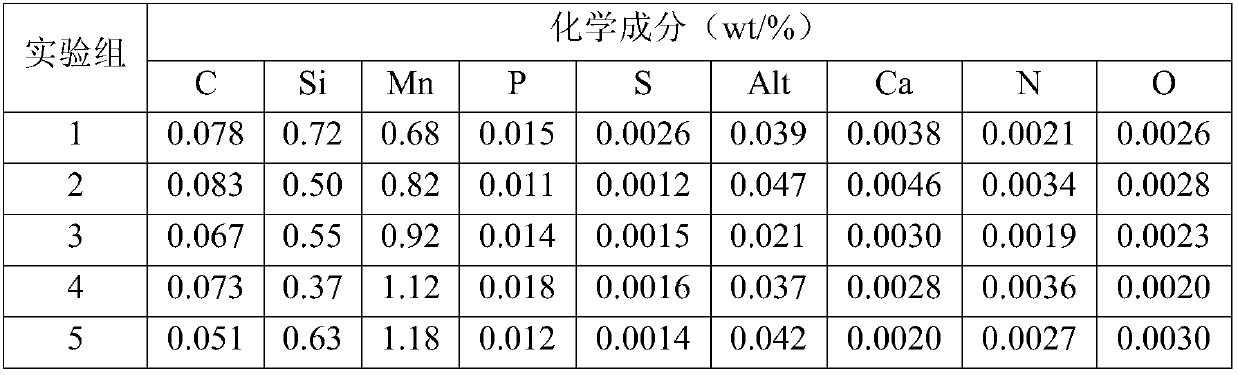

450MPa economical type high-surface-quality highly-reamed steel and preparation method thereof

The invention discloses 450MPa economical type high-surface-quality highly-reamed steel and a preparation method thereof, and belongs to the technical field of ferrous metallurgy and calendaring. The450MPa economical type high-surface-quality highly-reamed steel comprises, by weight, 0.045-0.085% of C, 0.30-0.80% of Si, 0.60-1.30% of Mn, 0.010-0.020% of P, 0-0.003% of S, 0.010-0.050% of Alt, 0.0010-0.0050% of Ca, 0-0.0050% of N, 0-0.0040% of O, and the balance Fe and inevitable impurities, wherein C*Mn*104 is smaller than or equal to 0.10, {P+10*S}*102 is smaller than or equal to 0.04, and Ca / S is greater than or equal to 0.3. The preparation method comprises the following steps of smelting, continuous casting, heating, rough rolling, hot box coiling, finish rolling, laminar cooling, coiling, slow cooling, acid pickling and coiling. The 450MPa economical type high-surface-quality highly-reamed steel has the characteristics of being low in cost and excellent in performance, and can meet the requirements of steel for car chassis and complex stamping parts.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

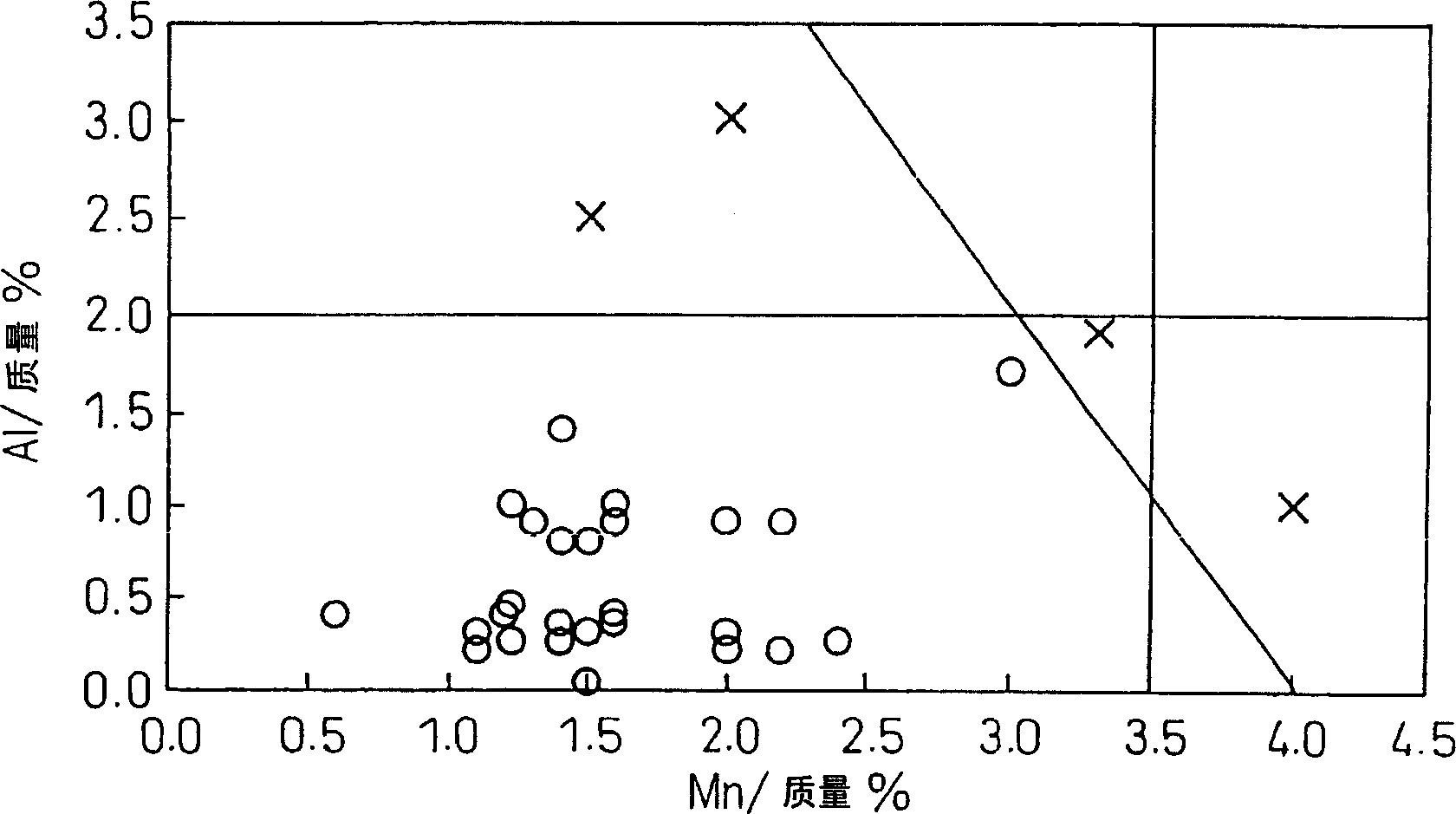

High strength thin steel sheet excellent in hole expansibility, ductility and chemical treatment characteristics, and method for production thereof

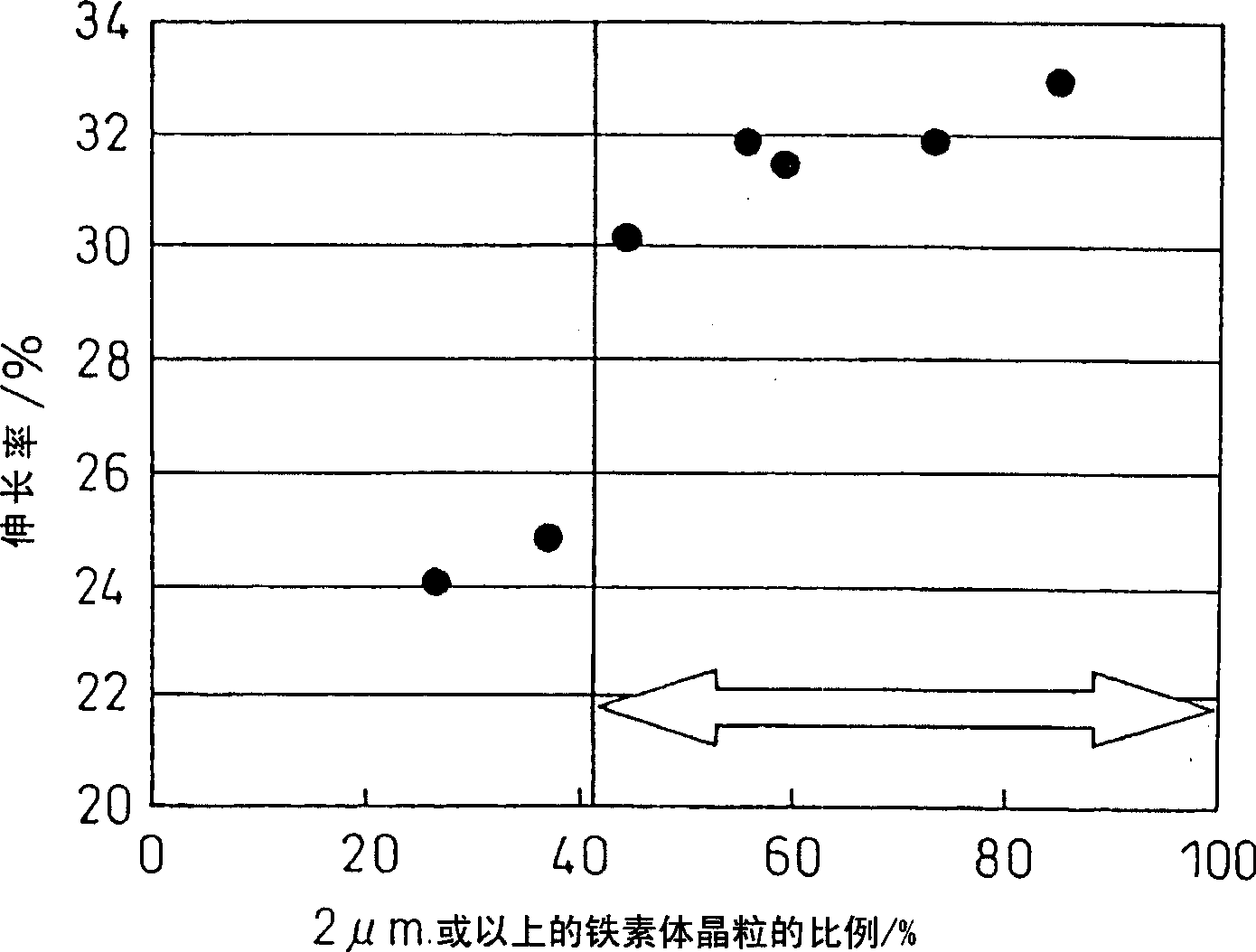

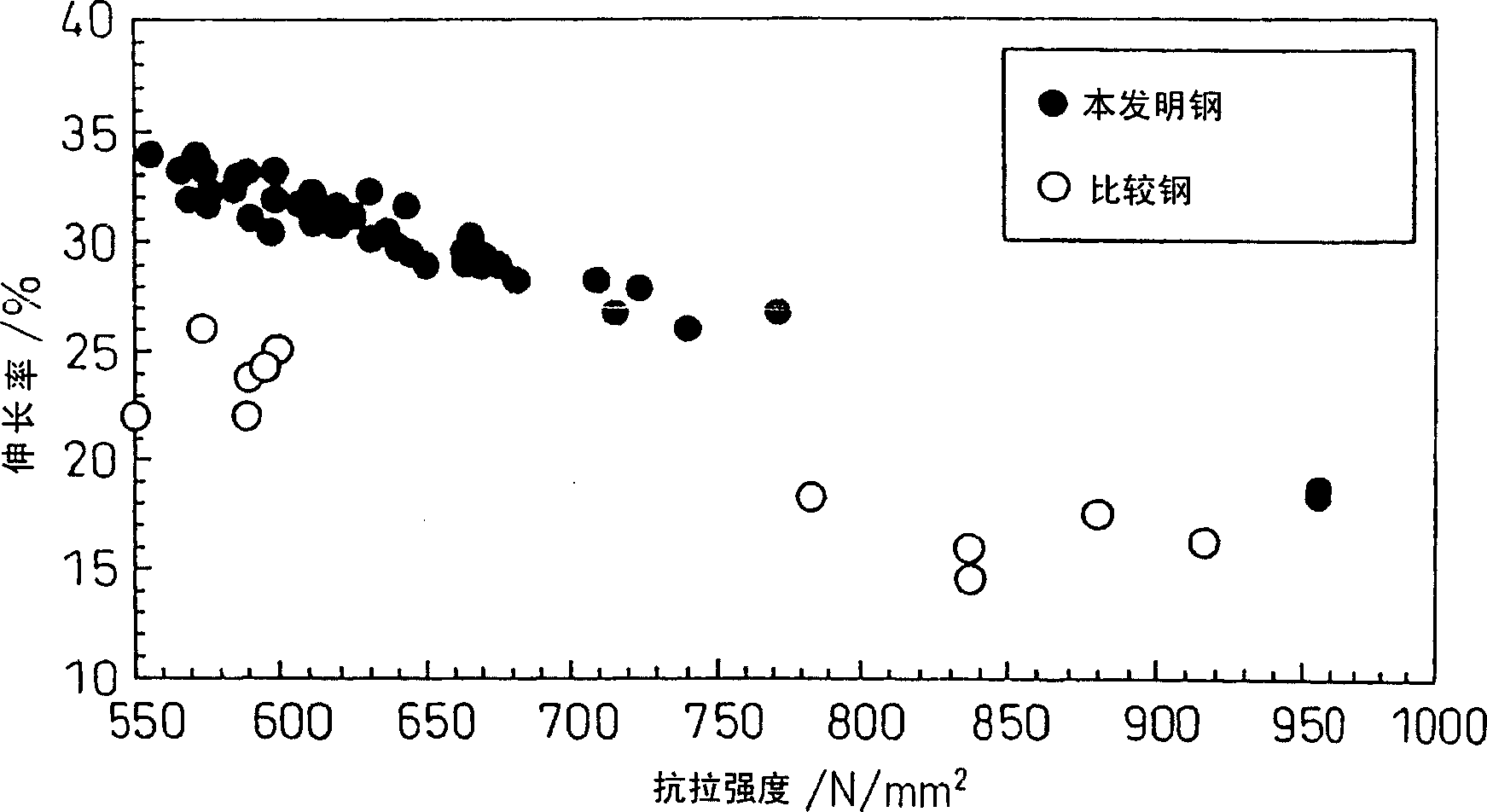

ActiveCN1732281ALow ductilityImprove ductilityFurnace typesMetal rolling arrangementsChemical treatmentChemical composition

This invention Provides a hot-rolled high strength thin steel sheet which is excellent in hole expansibility, ductility and chemical treatment characteristics. Said steel sheet has a chemical composition, in mass %: C: 0.02 to 0.08 %, Si: 0.50 % or less, Mn: 0.50 to 3.50 %, P: 0.03 % or less, S: 0.01 % or less, Al: 0.15 to 2.0 %, and the balance: Fe and inevitable impurities, with the proviso that the formula: Mn + 0.5 X Al < 4 is satisfied, and has a metal structure wherein ferrite having a particle size of 2 Mum or more accounts for 40 area % or more. The thin steel sheet has a tensile strength of 590 N / mm<2> or more.

Owner:NIPPON STEEL CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com