Ultrahigh strength hot-rolled complex phase steel plate and production method thereof

A production method and ultra-high-strength technology, applied in the field of hot-rolled steel plate rolling, can solve the problems of low grade, achieve good extension flangeability, reduce the difference in mechanical properties, and excellent hole expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

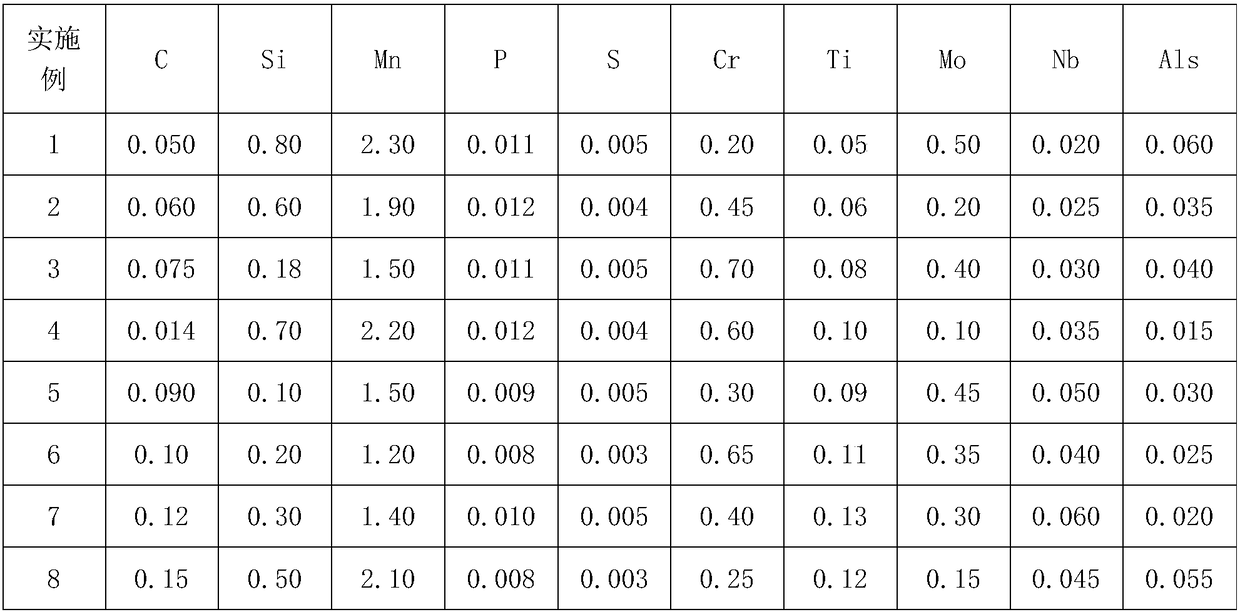

[0037] Ultra-high-strength hot-rolled multiphase steel plate and its production method, the chemical composition percentages of the hot-rolled multiphase steel plate are: C: 0.05% to 0.15%, Si: 0.1% to 0.8%, Mn: 1.2% to 2.3%, P≤0.012% , S≤0.005%, Cr: 0.20%~0.70%, Mo: 0.10%~0.50%, Nb: 0.02%~0.06%, Ti: 0.05%~0.13%, Als: 0.015%~0.060%, the rest are Fe and unavoidable impurities.

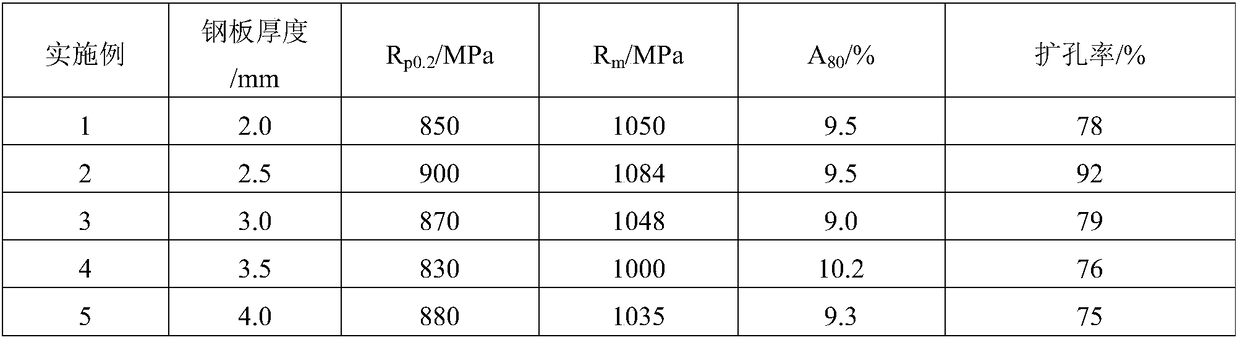

[0038] The production method of ultra-high-strength hot-rolled multi-phase steel plate, through two-stage controlled rolling and three-stage controlled cooling, the tensile strength can reach above 980MPa, and the microstructure is ferrite and bainite with a small amount of martensite and residual Austenitic multiphase steel plate.

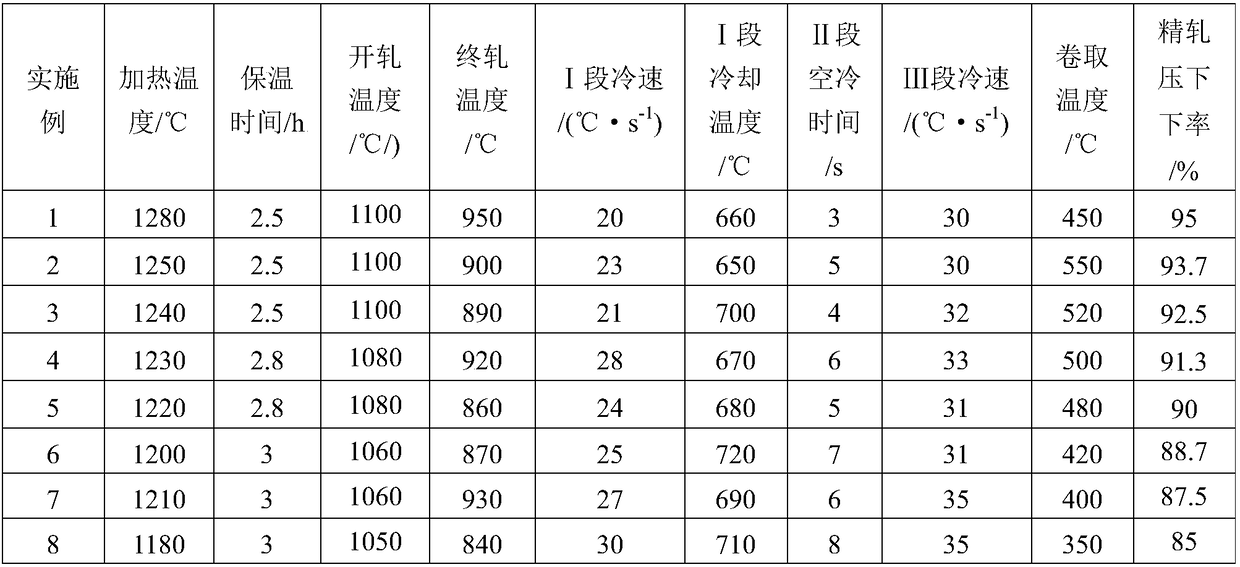

[0039] The continuous casting slab of the above composition is heated to 1180-1280°C, and the slab is rolled in multiple passes on the rolling mill. The thickness of the intermediate slab is 35-45mm, preferably 40mm. The temperature is 840-950°C, and the cooling after rol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com