A mold for making rock-like samples with non-penetrating fractures

A rock sample, non-penetrating technology, applied in the field of rock mechanics, can solve the problems of high processing difficulty, crack angle error, and high processing accuracy requirements, so as to reduce the manufacturing difficulty and cost, reduce the mechanical property error, and ensure the manufacturing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

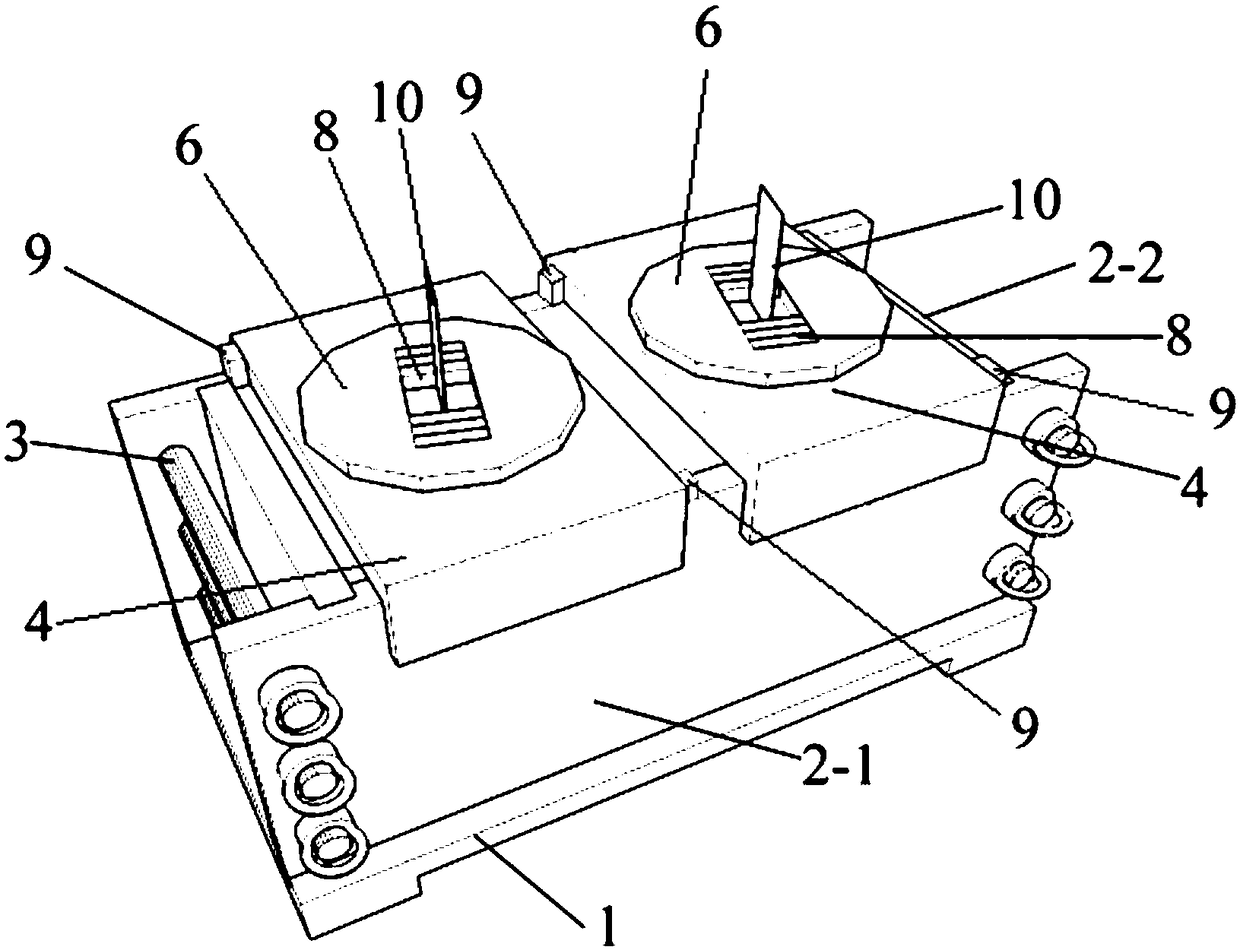

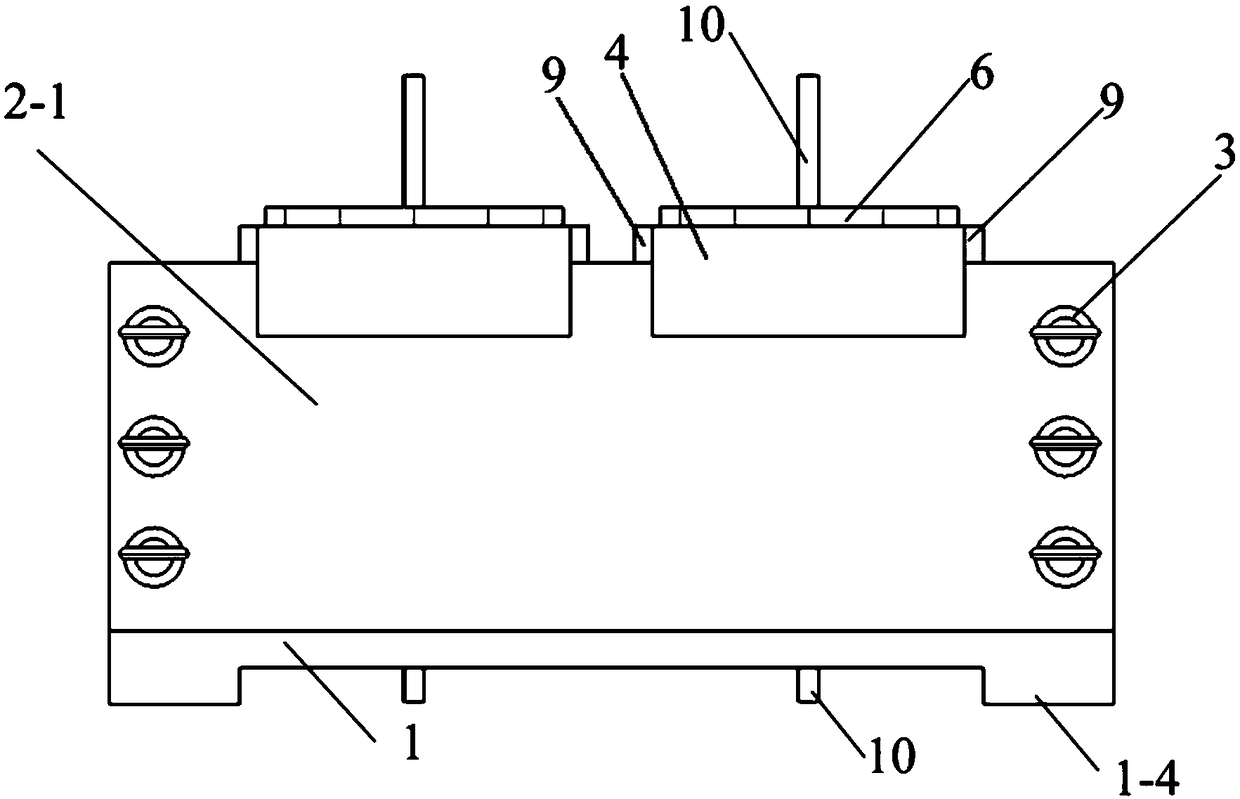

[0042] In this embodiment, the schematic diagram of the structure of the mold for making a rock-like sample containing non-penetrating cracks is as follows figure 1 as shown, figure 2 for figure 1 The front view of the mold includes bottom plate 1, side plate, fixing bolt 3, slit prefabricated sheet 10, cover plate 4, first slit angle adjustment block 5, second slit angle adjustment block 6, positioning bar 8 and cover plate positioning Item 9.

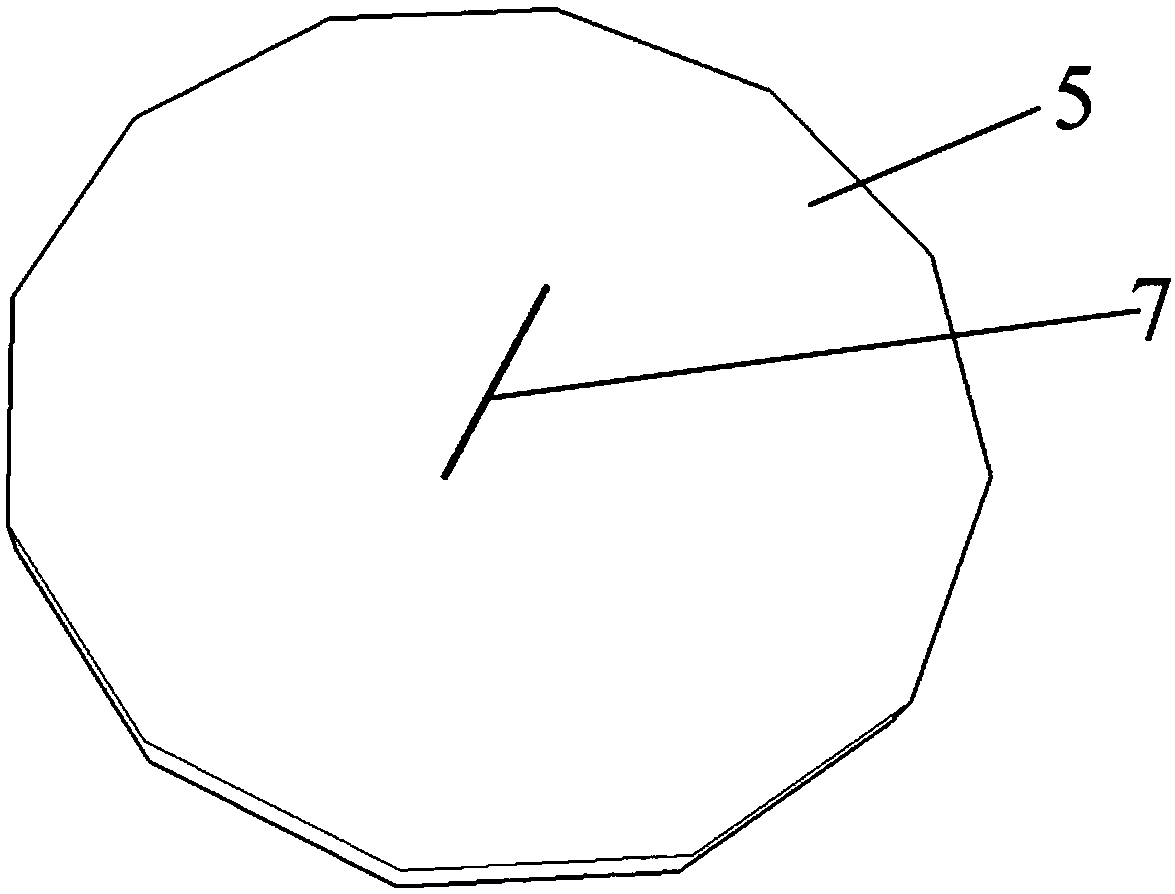

[0043] The structural schematic diagram of the first slit angle adjustment block is shown in image 3 , the first slit angle adjustment block 5 is a positive twelve prism platform, the first slit angle adjustment block is provided with a fixing seam 7, and the shape and size of the fixing seam 7 match the shape and size of the slit prefabricated sheet 10; The structural schematic diagram of the second crack angle adjustment block is shown in Figure 4 , the second slit angle adjustment block 6 is made up of a first regular prism ...

Embodiment 2

[0051] In this embodiment, the structure of the mold for making rock-like samples containing non-penetrating fractures is similar to figure 1 , the mold includes a bottom plate 1, a side plate, a fixing bolt 3, a slit prefabricated sheet 10, a cover plate 4, a first slit angle adjustment block 5, a second slit angle adjustment block 6, a positioning bar 8 and a cover plate positioning member 9.

[0052] The first slit angle adjustment block 5 is a regular pentagonal prism, the first slit angle adjustment block is provided with a fixing seam 7, the shape and size of the fixing seam 7 match the shape and size of the slit prefabricated sheet 10; Two slit angle adjustment blocks 6 are made up of the first regular prism stand 6-1 and the second regular prism stand 6-2, the cross-sectional area of the first regular prism stand 6-1 is greater than the cross-section of the second regular prism stand 6-2 Area, and the cross section of the first regular prism stand 6-1, the cross sect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com