Patents

Literature

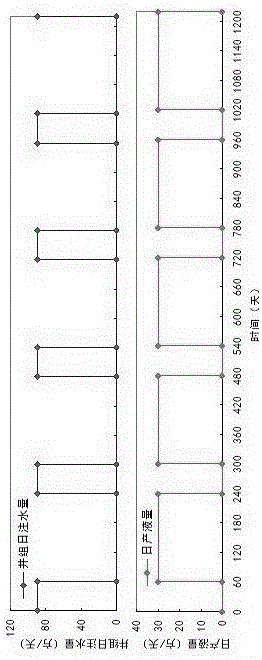

184 results about "Type fracture" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

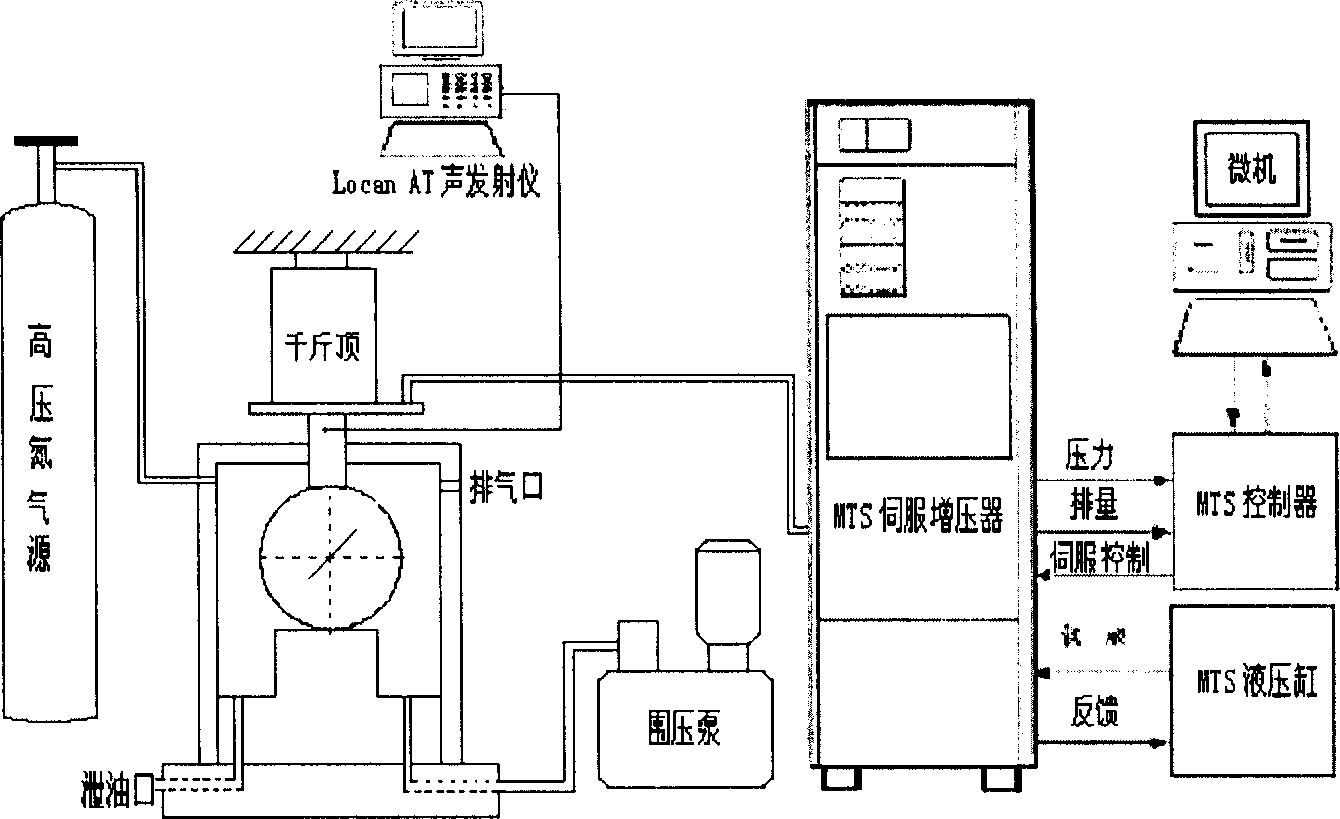

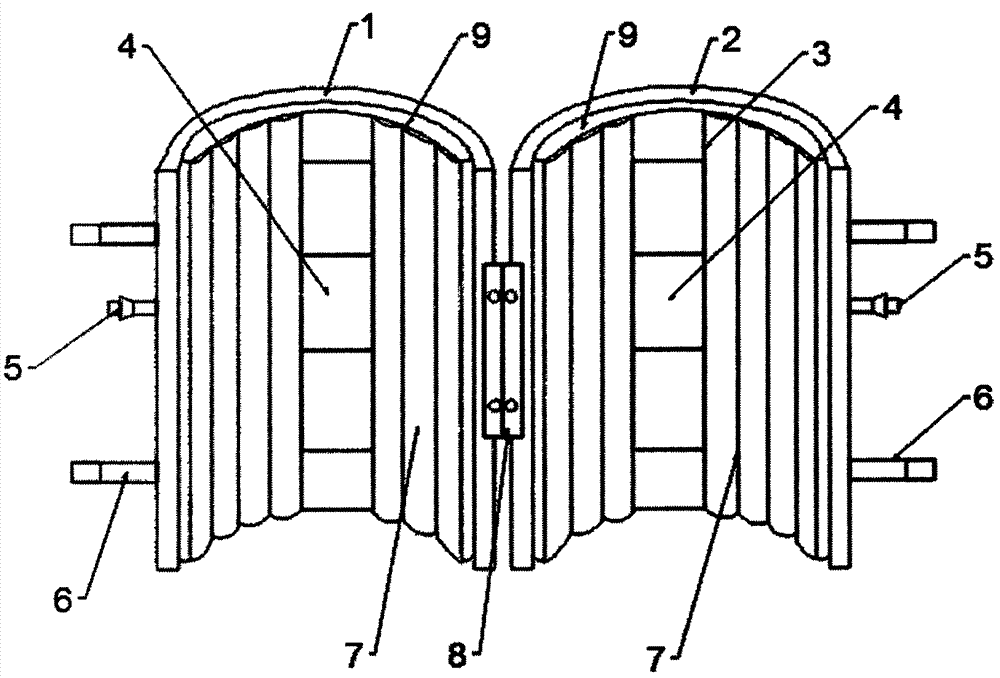

Oil-gas well hydraulically-created-fracture expansion visualization experiment method and oil-gas well hydraulically-created-fracture expansion visualization experiment device

ActiveCN103485759AFor the purpose of visualizationSurveyEarth material testingEpoxyHigh pressure water

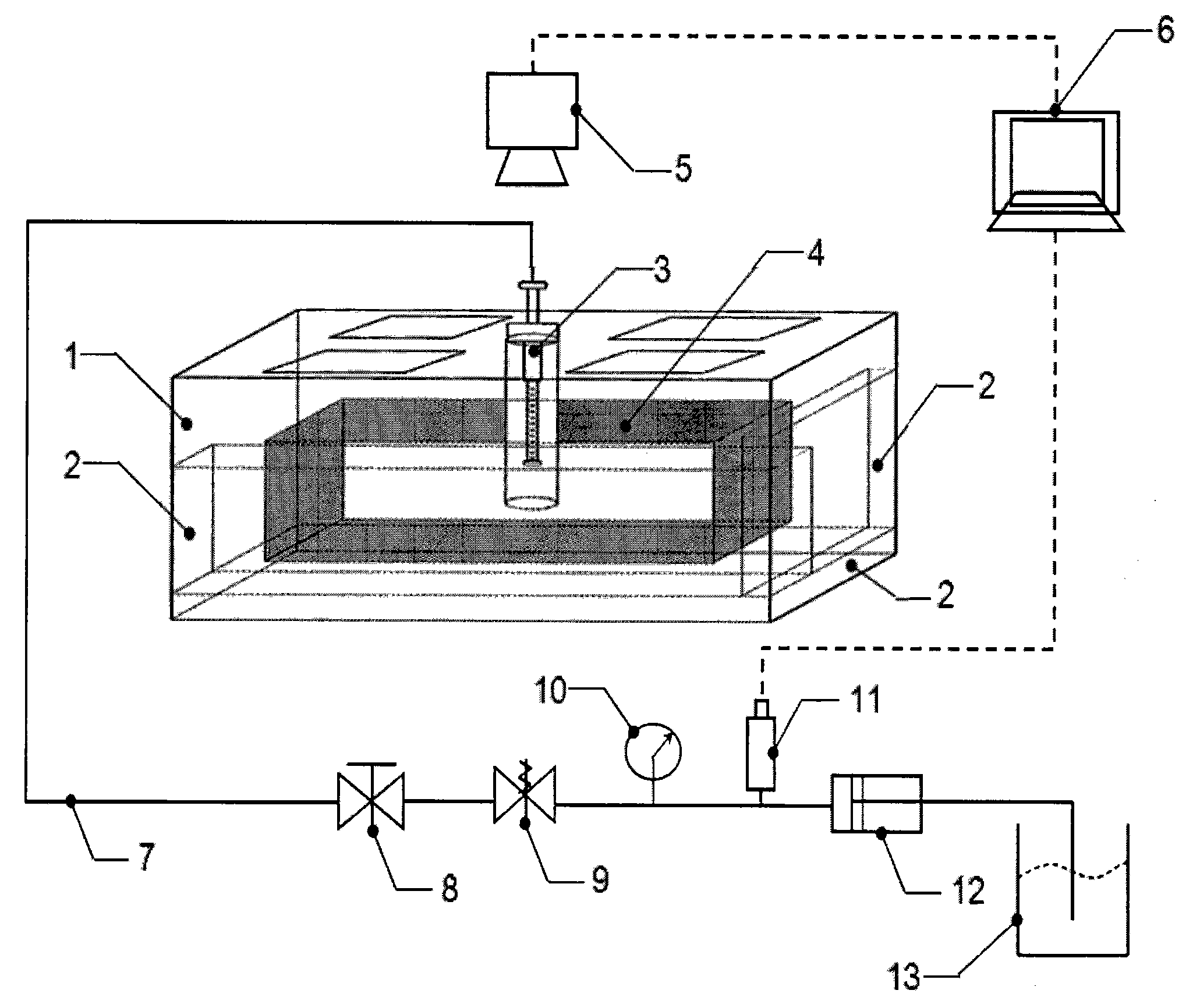

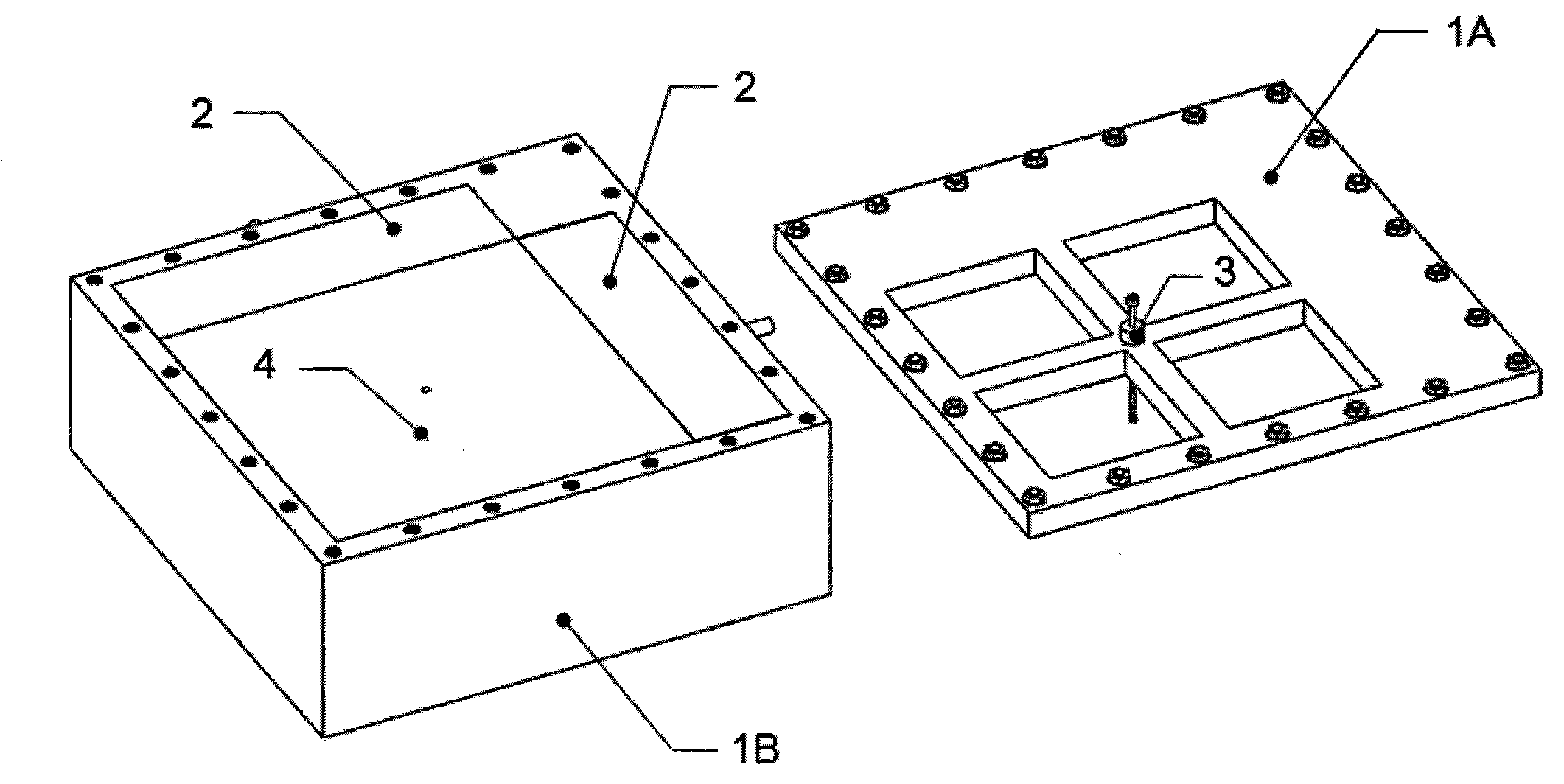

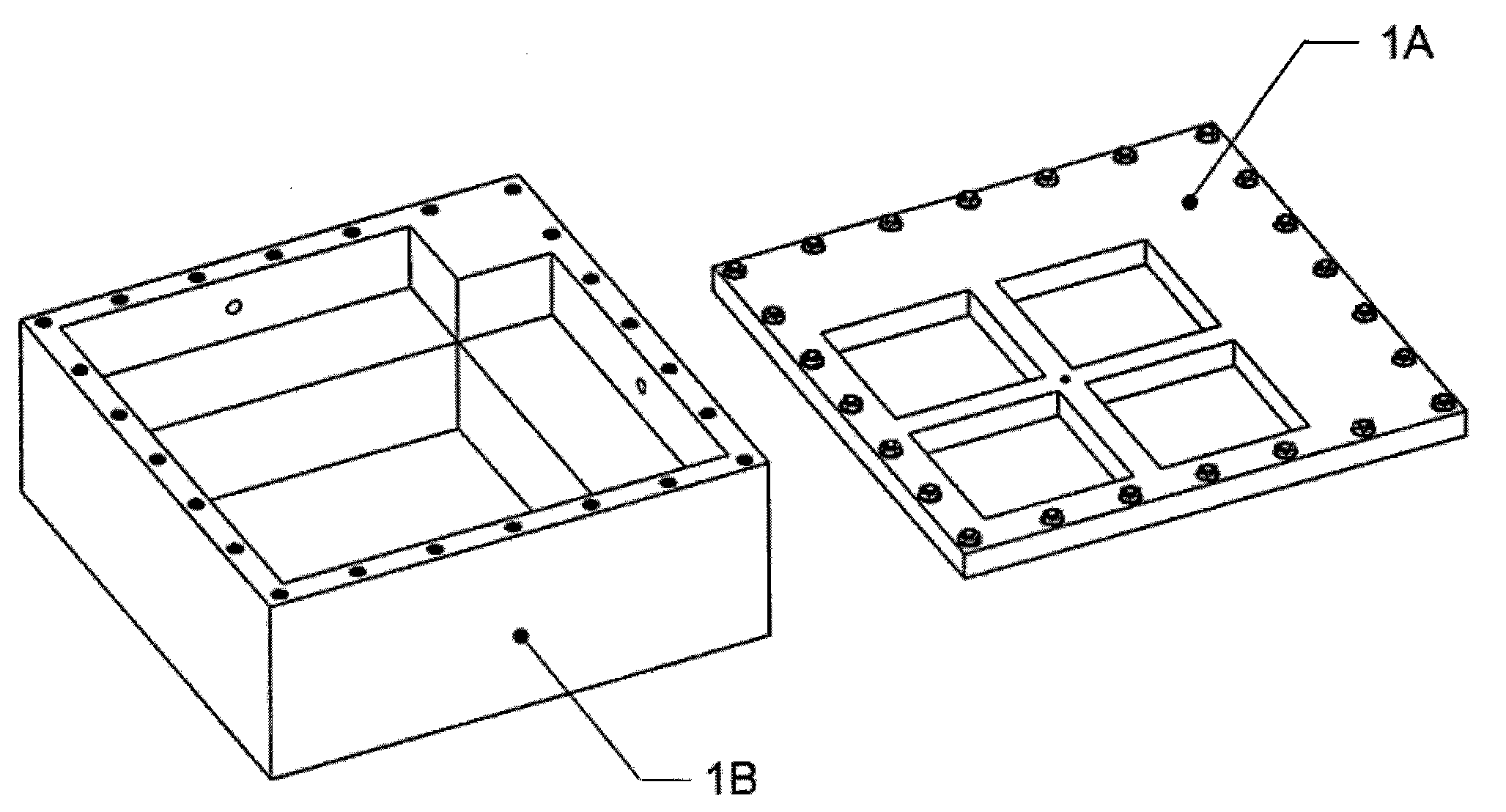

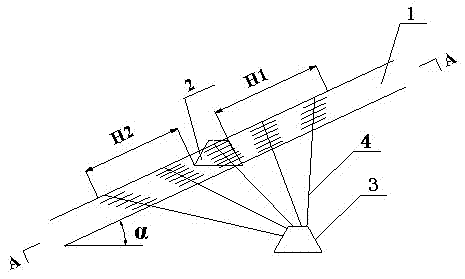

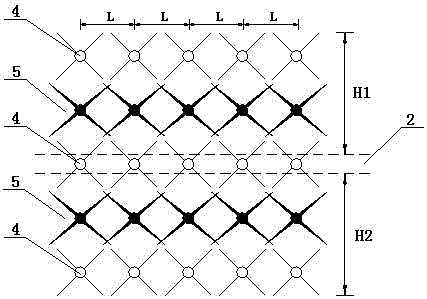

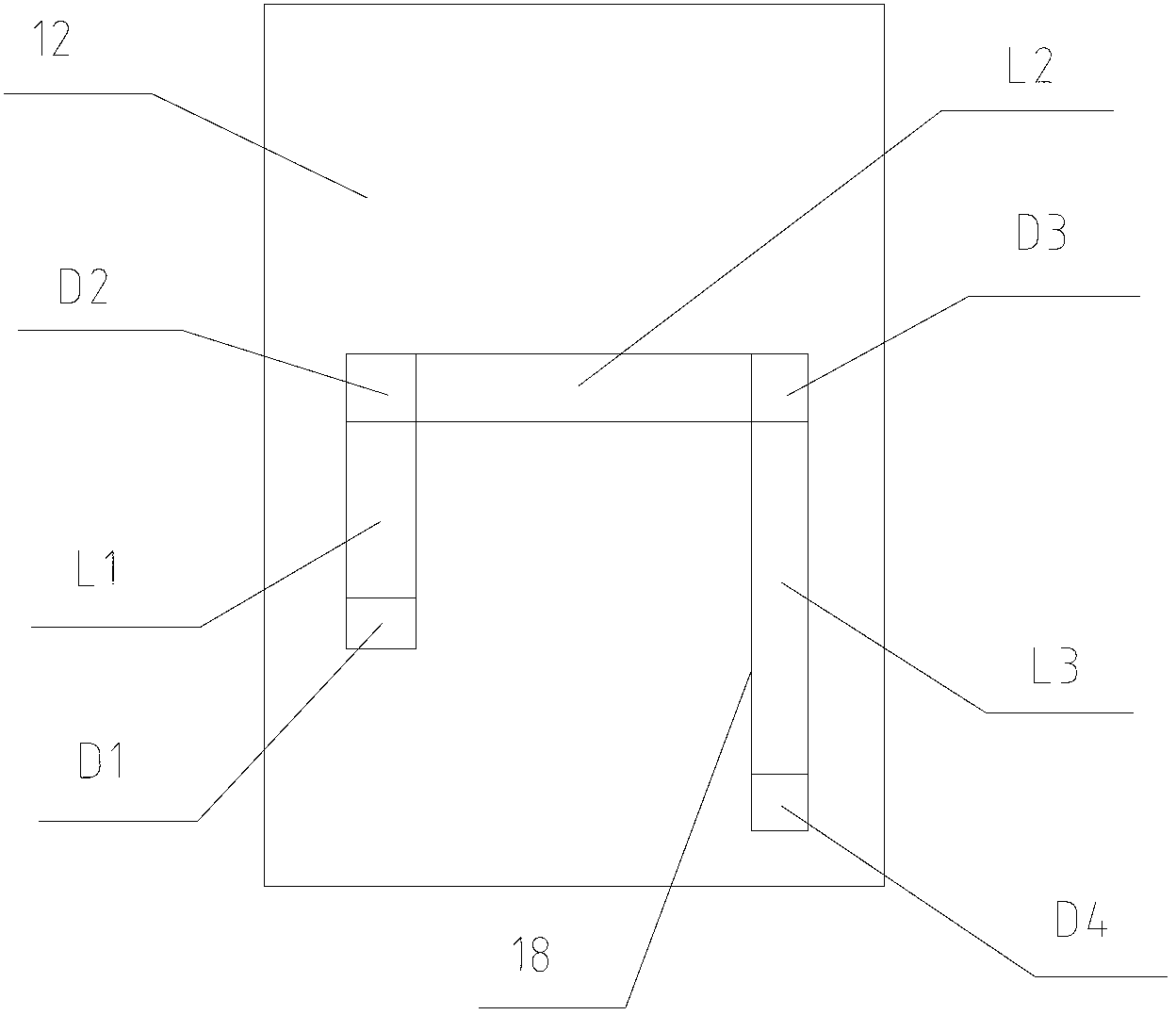

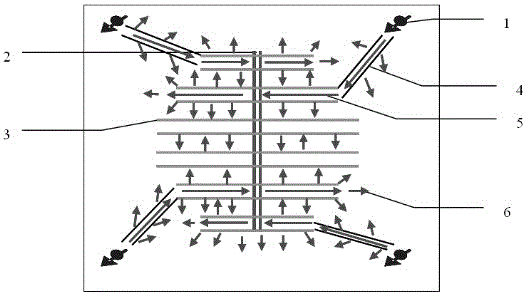

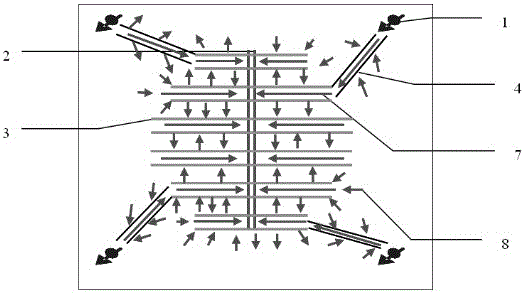

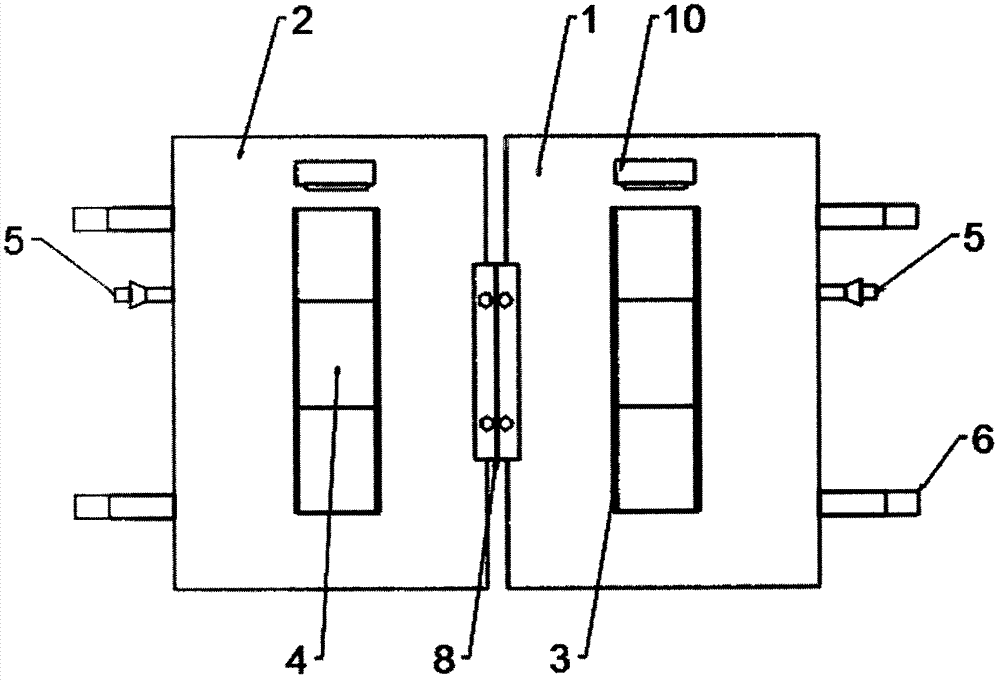

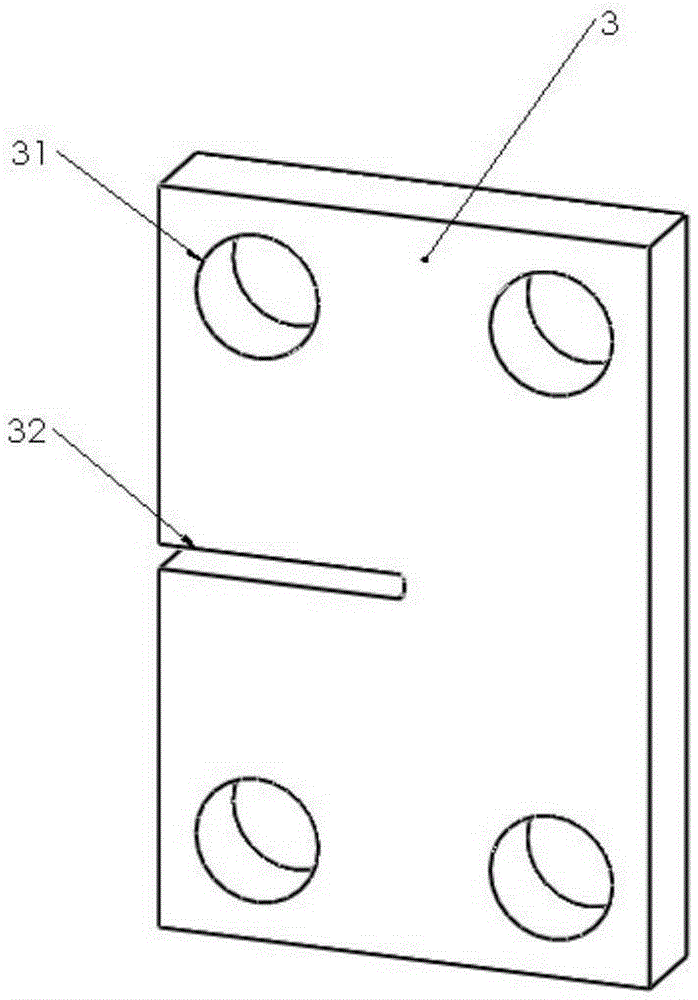

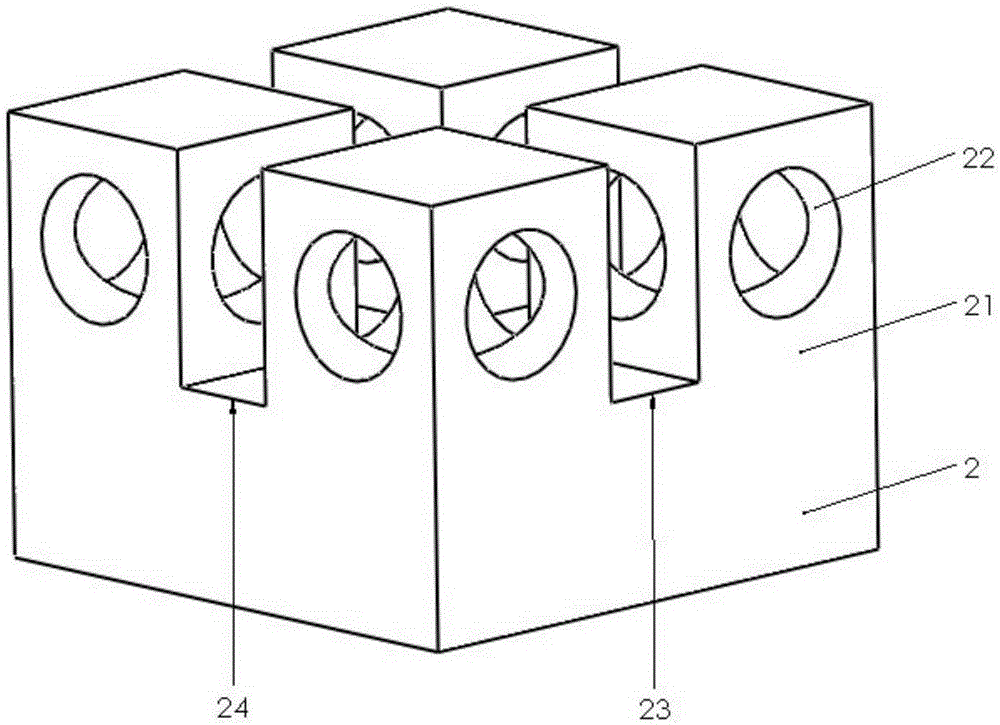

The invention relates to an oil-gas well hydraulically-created-fracture expansion visualization experiment method and an oil-gas well hydraulically-created-fracture expansion visualization experiment device. The device is composed of a rock sample chamber, a crustal loading unit, a simulation fracturing string, a high-speed camera, a high-pressure pumping unit, a data measuring and collecting unit and the like, and four transparent observation ports are formed on a top cover of the rock sample chamber. The method includes firstly, preparing a flat-plate-type rock sample, performing high-pressure-water cutting to preform a natural fracture, and filling the natural fracture with epoxy resin to form a filled-type fracture; secondly, performing water saturation on the rock sample for 3-5 days, and using epoxy resin to wrap the rock sample after water saturation; thirdly, loading three-axis stress on the rock sample, drilling a borehole under the condition that the three-axis stress is applied on the rock sample, and mounting the simulation fracturing string; finally, connecting a high-pressure pipeline with a constant-flux pump, pumping fracturing liquid, recording a fracture expansion path by the high-speed camera, and measuring pumping pressure changes by a pressure transmitter. By the method and the device, the hydraulically-created-fracture expansion path can be visualized on a plane, and a novel experiment method is provided for studying on a hydraulically-created-fracture expansion mechanism.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

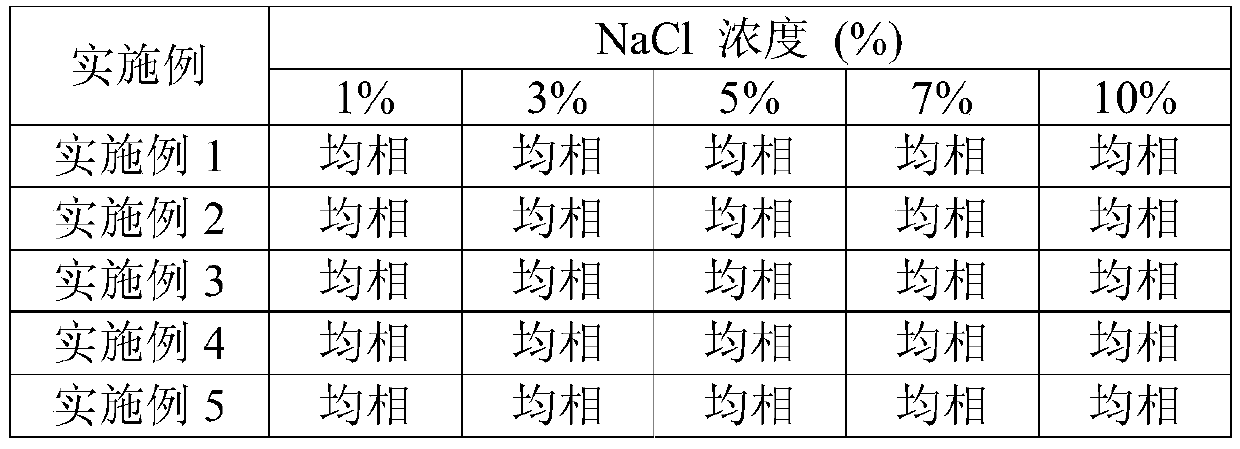

Microemulsion-type fracture acidizing cleanup additive, and preparation method and application thereof

InactiveCN102127414APerformance is not affectedGood compatibilityDrilling compositionType fracturePetrochemical

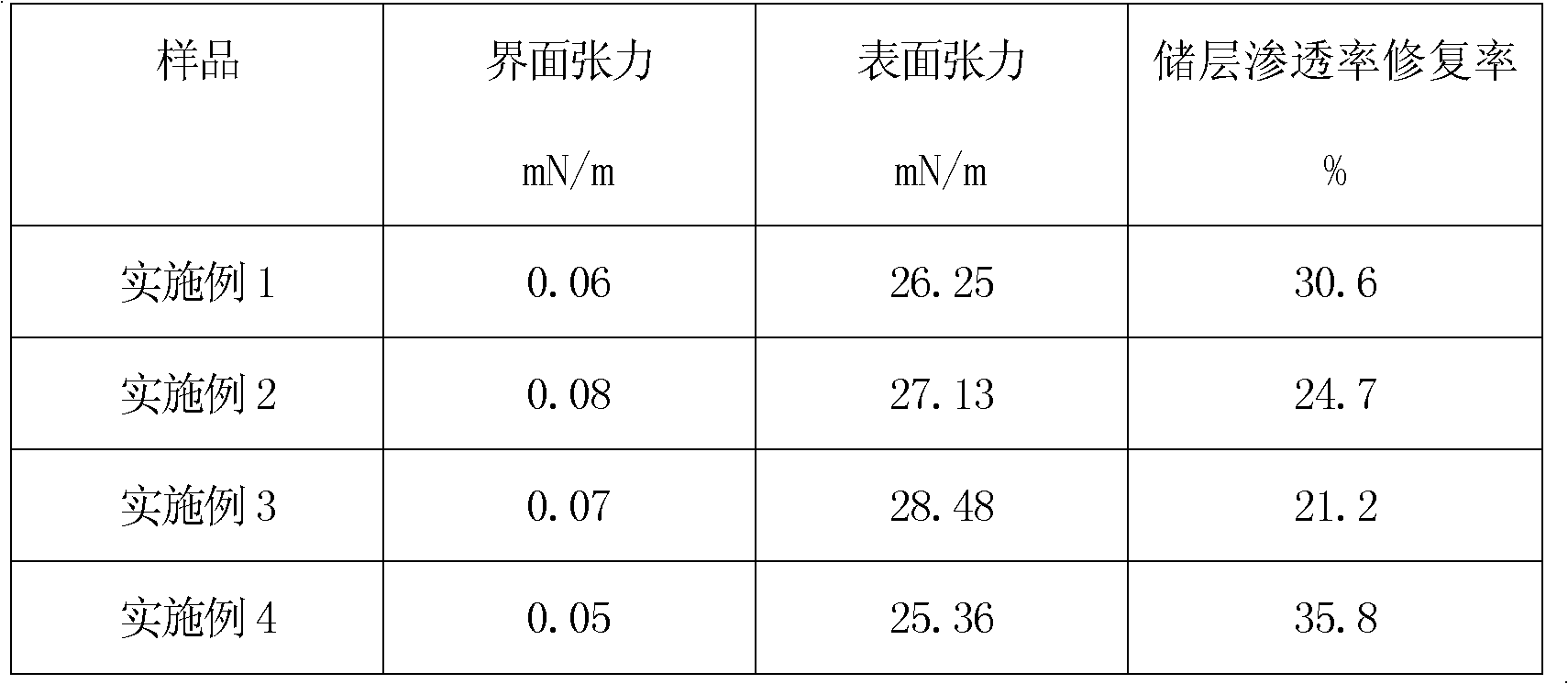

The invention relates to a microemulsion-type fracture acidizing cleanup additive, and a preparation method and application thereof, belonging to the technical field of petrochemical industry. The microemulsion-type fracture acidizing cleanup additive is prepared from the following components in percentage by weight:5-10% of surfactant, 2-8% of cosurfactant, 35-45% of oil phase, 35-45% of water phase and 3-10% of inorganic electrolyte. The microemulsion-type fracture acidizing cleanup additive provided by the invention has a function of restoring reservoir permeability; and compared with the existing cleanup additive system, the microemulsion-type fracture acidizing cleanup additive provided by the invention can reduce the degree of reservoir damage, which is caused by incompatibility of water locks, residues and formation fluids in the wellbore area of an oil well in the fracture acidizing process of an oil and gas well, by more than 50%.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on soft and high-outburst coal seam

InactiveCN102900460AIncrease the speed of excavationIncrease extraction concentrationGas removalStress distributionType fracture

The invention discloses a method for performing through-going seam cutting, pressure relief, permeability enhancement and quick tunneling on a soft and high-outburst coal seam, and in particular is applied to quick tunneling in a coal seam which is high in outburst danger and a laneway is difficult to support in a coal mine. The method comprises the following steps of: forming a network type fractured net by high-pressure jet flow seam cutting, pressure relief and permeability enhancement technologies, and enhancing an effect of extracting strip-type coal seam gas on a coal laneway subjected to through-going drilling and pre-extraction; and forming a network type filling region by pressing and injecting filling materials, so that the strength and stress distribution of a coal body are improved, the coal laneway is easy to maintain in the tunneling process, a phenomenon that the gas rushes out of a tunneled laneway is avoided, gas accidents are eliminated in the tunneling process, and an aim of safely and quickly tunneling the laneway is fulfilled.

Owner:CHINA UNIV OF MINING & TECH

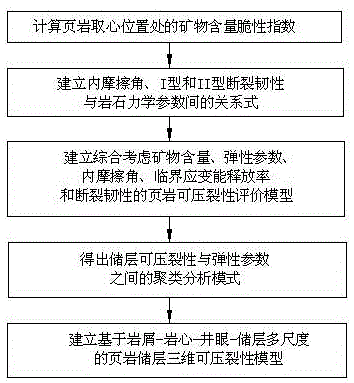

Debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method

ActiveCN105156103ALarge capacityQuantification of fracabilityBorehole/well accessoriesType fractureWell placement

The invention relates to a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing evaluation method. The method comprises the steps of: (S1) calculating mineral content brittleness indexes in a shale coring position; (S2) building relations among an internal friction angle, I type and II type fracture toughness and rock mechanical parameters; (S3) building shale fracturing evaluation models comprehensively considering a mineral content, elastic parameters, the internal friction angle, a critical strain energy release rate and the rapture toughness; (S4) applying a support vector machine algorithm to obtain a cluster analysis mode between a reservoir fracturing performance and the elastic parameters; and (S5) applying the cluster analysis mode and a reservoir three-dimensional elastic parameter data body to obtain a debris-core-borehole-reservoir multiscale shale reservoir three-dimensional fracturing model. The method can be applied to obtain the fracturing performance of any space position in a shale reservoir, so that the well position selection blindness is prevented, and the fracturing modification effect and the after-pressing yield are improved.

Owner:SOUTHWEST PETROLEUM UNIV +1

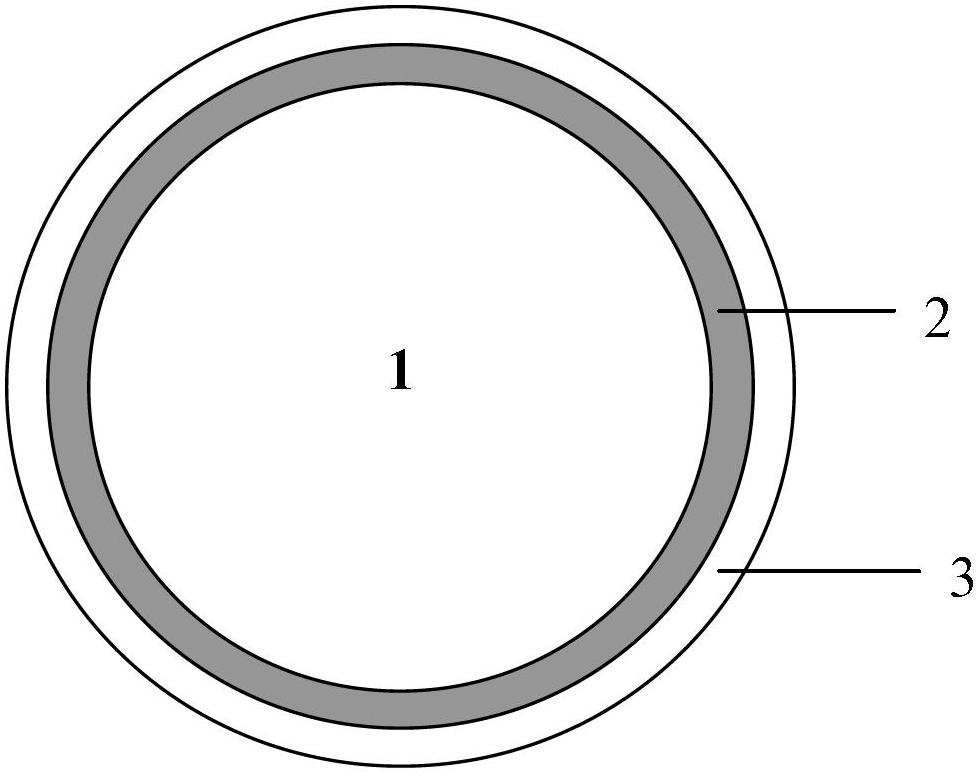

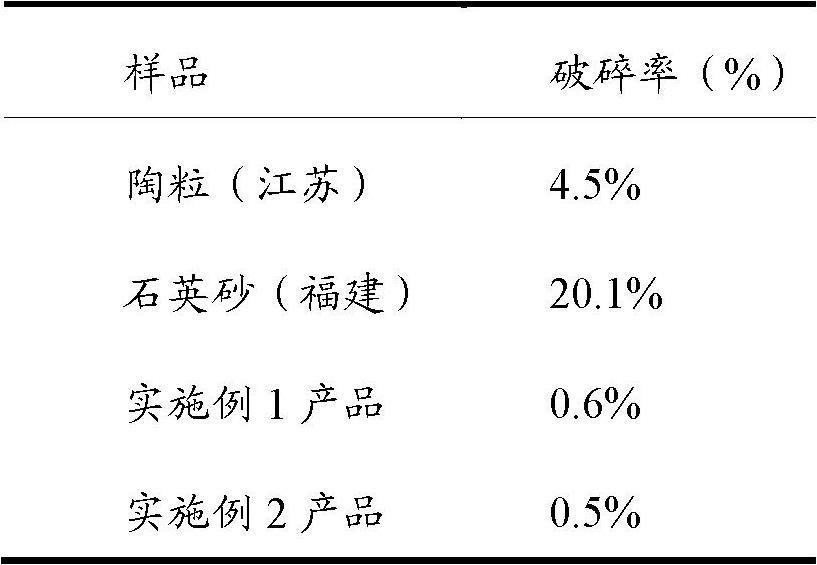

Sustained-release gel-breaking type fracturing propping agent and preparation method thereof

The invention discloses a sustained-release gel-breaking type fracturing propping agent for fracturing an oilfield. The propping agent sequentially comprises a base material, a medicament carrying layer and a sustained release layer from inside to outside, wherein the medicament carrying layer comprises a gel breaking agent and a filling agent, and the sustained release layer comprises a film forming material and a pore forming agent. The invention further provides a preparation method of the sustained-release gel-breaking type fracturing propping agent. In an actual application, the sustained-release gel-breaking type fracturing propping agent disclosed by the invention can enter the stratum along with fracturing fluid, and the gel breaking agent can be released slowly under the stratum conditions; and as the propping dosage is great, the gel breaking agent is distributed uniformly, and gel breaking can be realized to the greatest extent. Simultaneously, a chemical material coating the gel breaking agent can be stilly firmly coated on matrix particles, thus the problems of breaking, reflux and stratum embedding of the propping agent can be reduced.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Volume fracturing and energy replenishing method for low-yield horizontal well in dense oil reservoir

ActiveCN105952430AIncreased discharge volumeEfficient SupplementFluid removalType fractureFracturing fluid

The invention provides a volume fracturing and energy replenishing method for a low-yield horizontal well in a dense oil reservoir. A sectional fracturing pipe column is lowered into a first section for refracturing of the horizontal well, and packing between a target transformation well section and other well sections is achieved; plugging removing fluid is squeezed in at a small displacement, and the purpose of cleaning the zone nearby a hole of a shaft, the zone nearby the shaft, the wall of a deep fracture and a microfracture channel is achieved; a large amount of low-friction-drag oil flooding type fracturing fluid is injected at a large displacement; temporary plugging agents at different scales are added, and secondary bridge plugging of the zone nearby the shaft and fracture far ends is achieved; energy replenishing type fracturing fluid carrying a combined-particle-size supporting agent is injected in a pumped mode, and a main support fracture network system is obtained; after fracturing is finished, the well is closed for 1-2 days of diffusion, then backwashing is carried out with open flow, the sectional fracturing pipe column is uplifted to a next section, and sectional volume fracturing repeated transformation and energy replenishing are completed; sand washing is carried out for well completion, and production is restored. In the repeated transformation process, volume fracturing and energy replenishing are integrated, the fluid seepage distance is shortened, and remaining oil in fractures and the well is utilized; deep energy in the oil reservoir is effectively replenished, and the formation pressure level is increased.

Owner:PETROCHINA CO LTD

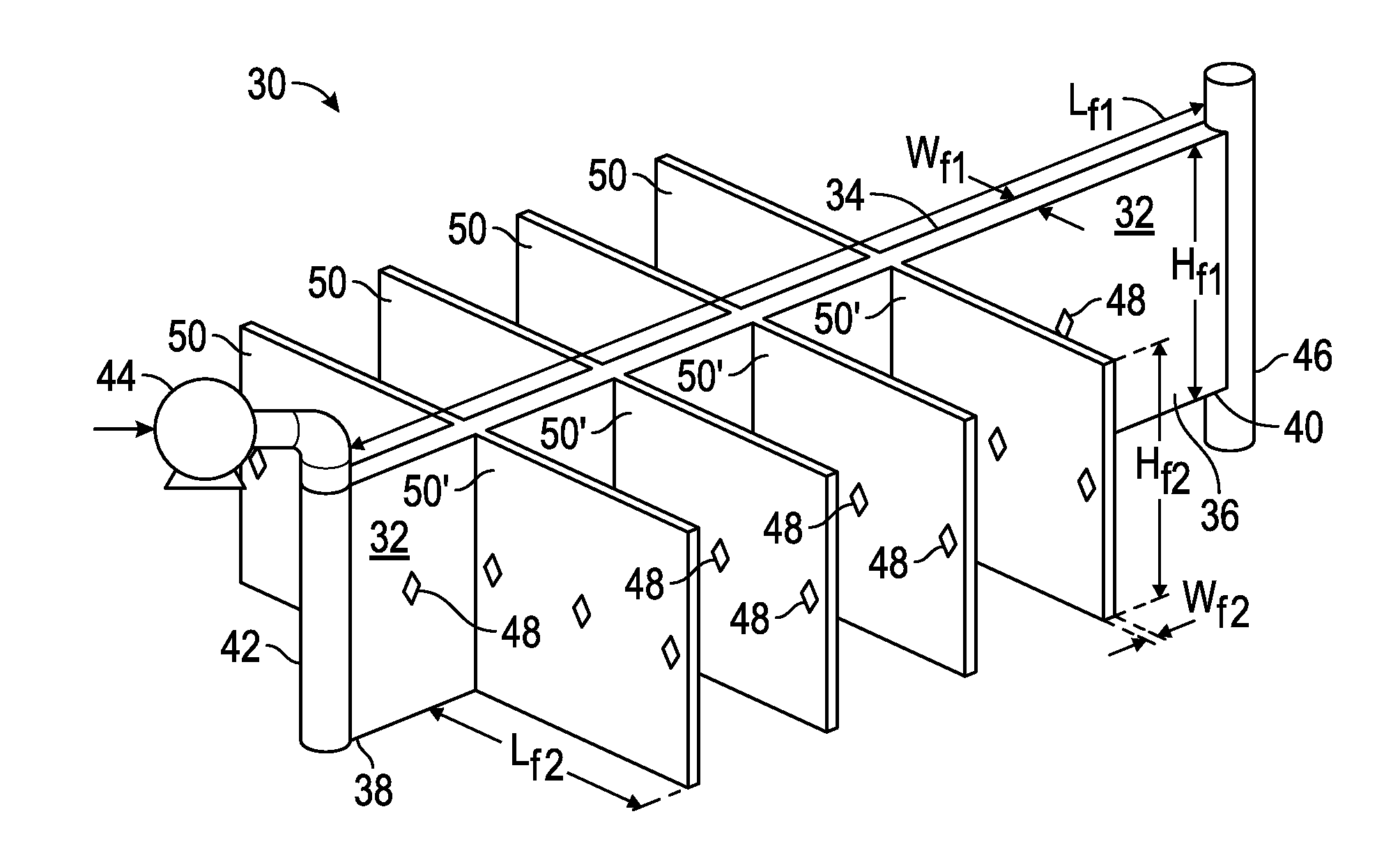

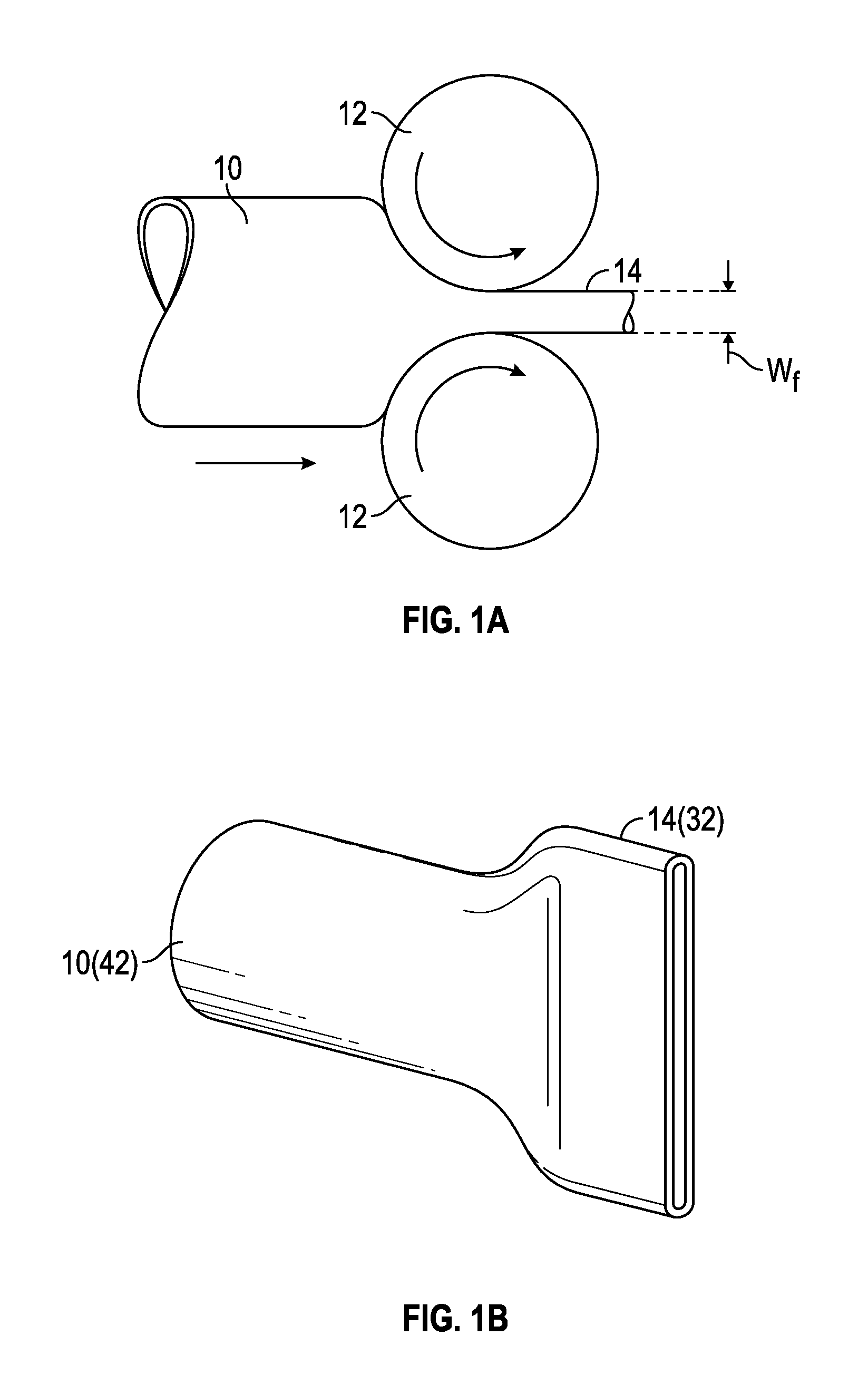

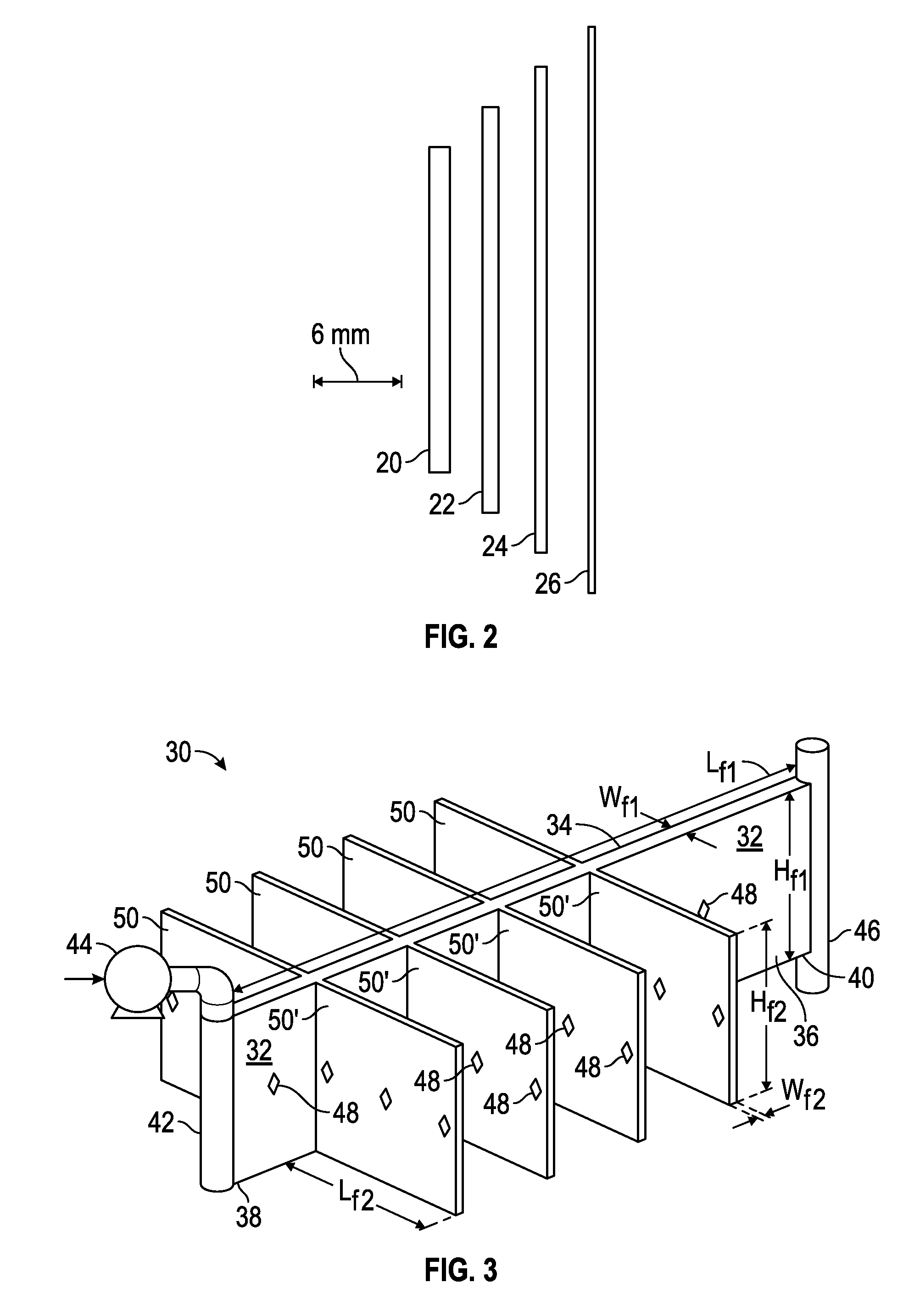

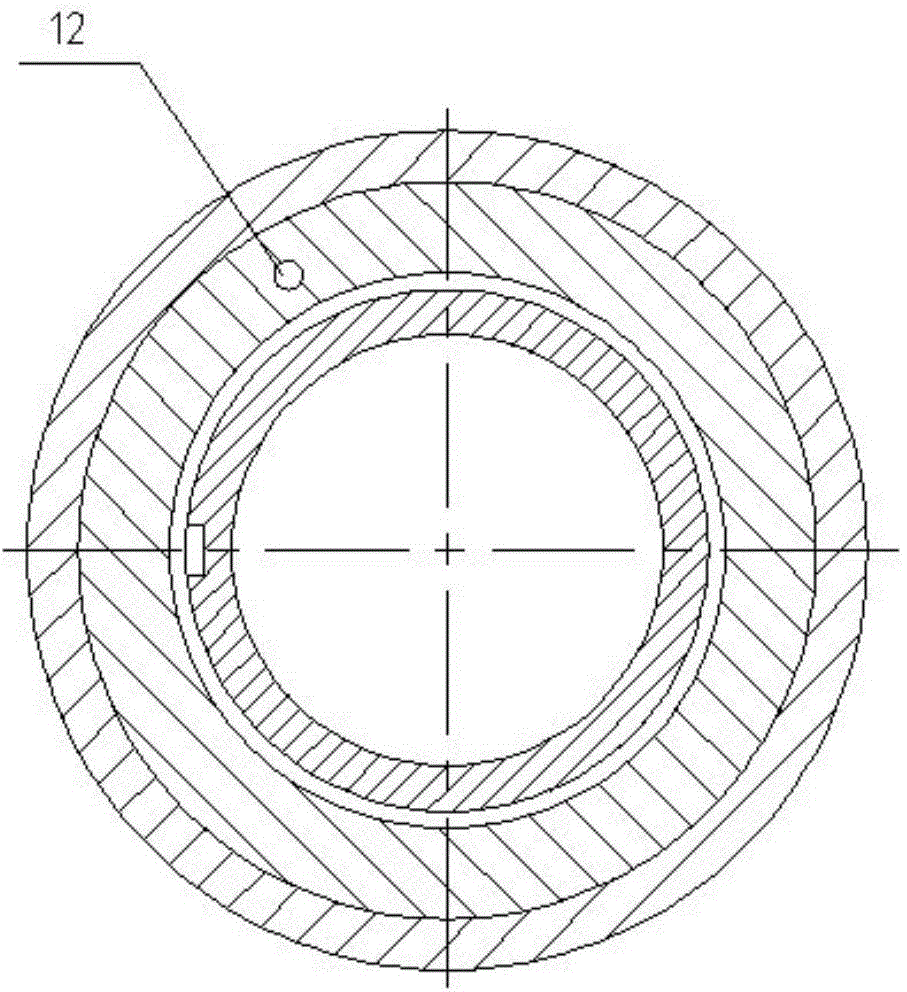

Shale fracture flow simulation apparatus

An apparatus having conduits, flattened tubing or pipes of varying widths, heights and / or lengths may simulate a network of fractures that may be used to experimentally evaluate the flow of treatment fluids (e.g. fracturing fluids) within narrow, shale-type fractures. The tubing or pipes each have an interior space with a height and a width, and in one non-limiting embodiment the ratio of height / width is at least 10. The conduits may be constructed of flattened tubing or constructed from components designed and engineered to have the correct height / width ratio. The apparatus may be used to empirically develop diversion principles, more precise numeric models and the parameter relationships that control fluid diversion, secondary fracture initiation and the development of complex fracture networks.

Owner:BAKER HUGHES INC

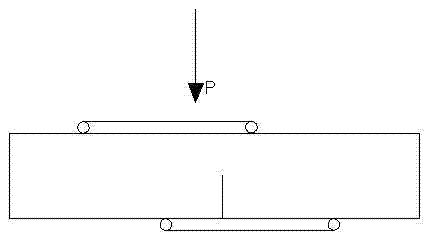

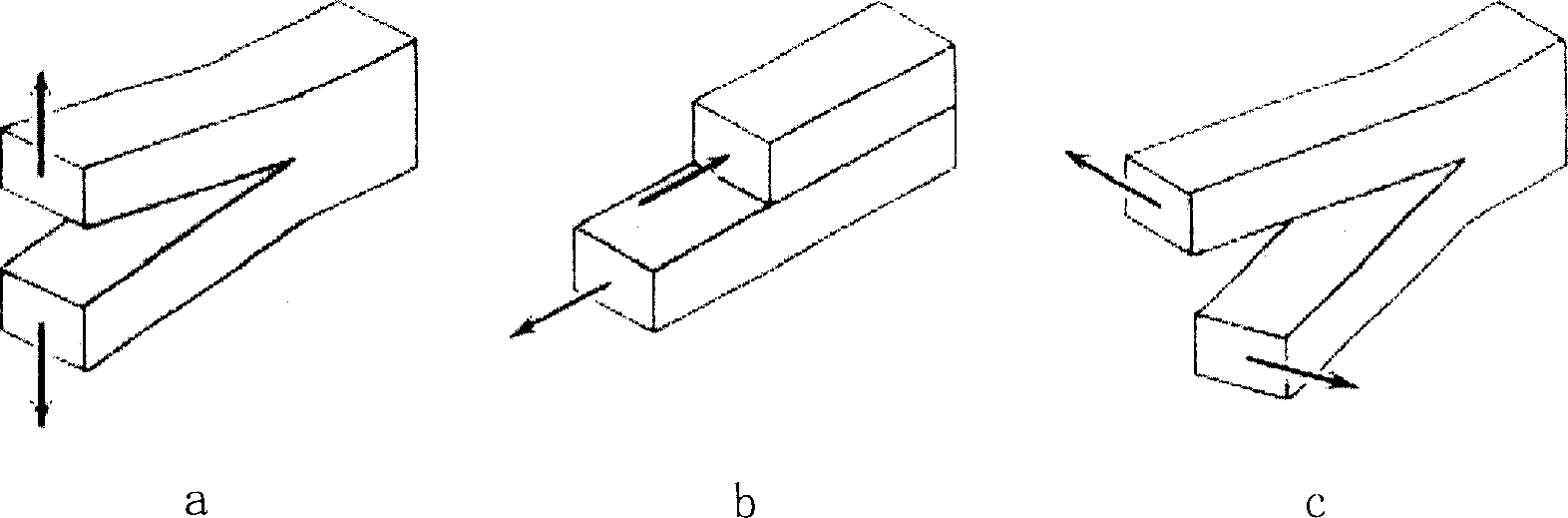

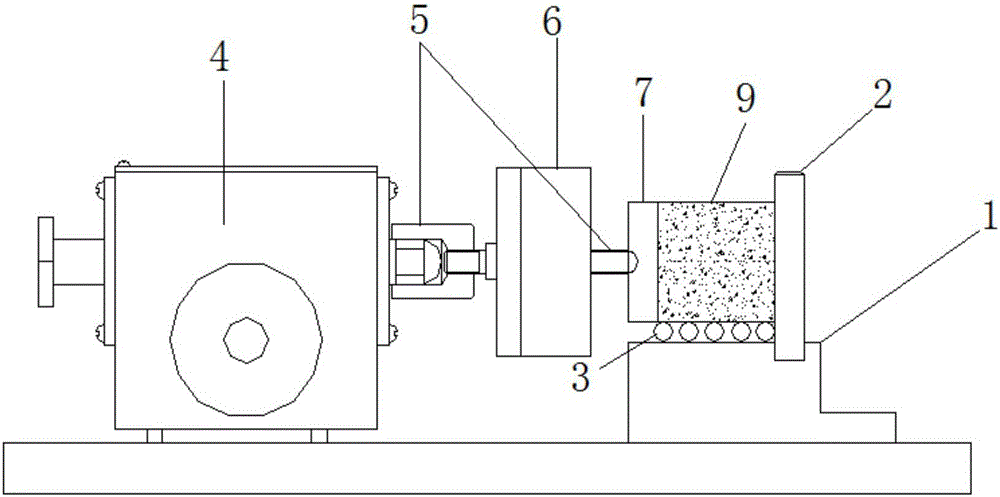

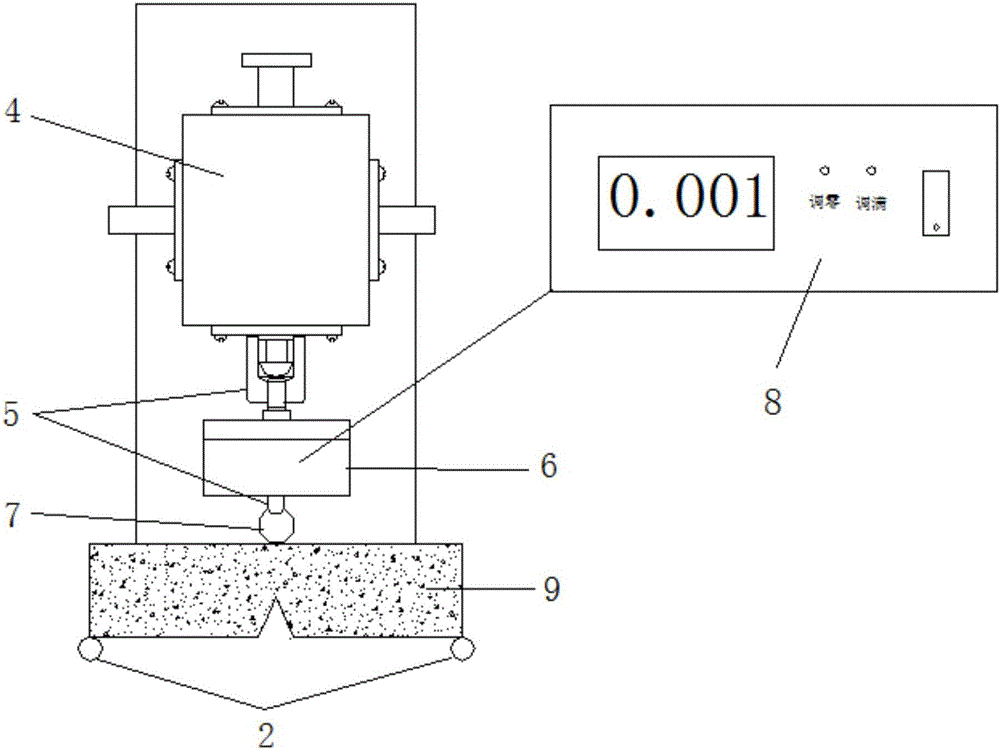

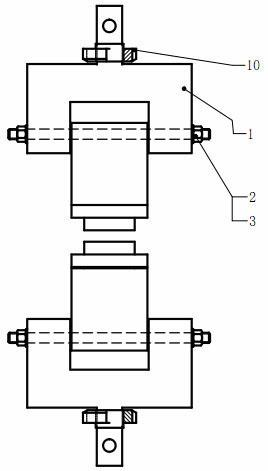

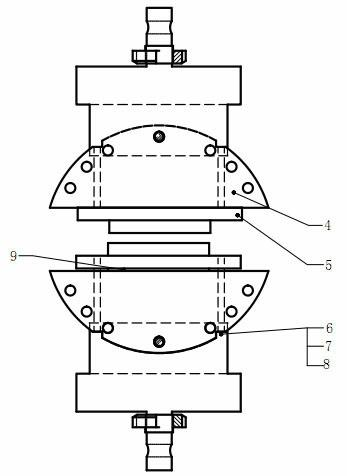

Testing device and method of soil body II-type fracture damage

ActiveCN102128742AThe test data is accurate and reliableFacilitate mechanical analysisStrength propertiesType fractureTest sample

The invention discloses a testing device of soil body II-type fracture damage. A front stop iron and a thrust providing device are respectively connected to two ends of a base, and the front stop iron or the thrust providing device is in sliding connection with the base; the power output part of the thrust providing device is connected with one end of a load sensor, and the other end of the load sensor is connected with a thrust plate; the signal output ends of the load sensor and a displacement sensor are both connected to a computer; the load sensor detects a load applied to a test sample; and the displacement sensor detects the deformation of the test sample in a test. The invention has the beneficial effects that the loading state of the test sample in the whole testing process is kept as a pure II-type, and the damage to the test sample is II-type fracture damage, thereby ensuring that the test data is accurate and credible, and facilitating the later mechanical analysis.

Owner:昌泰建设集团有限公司

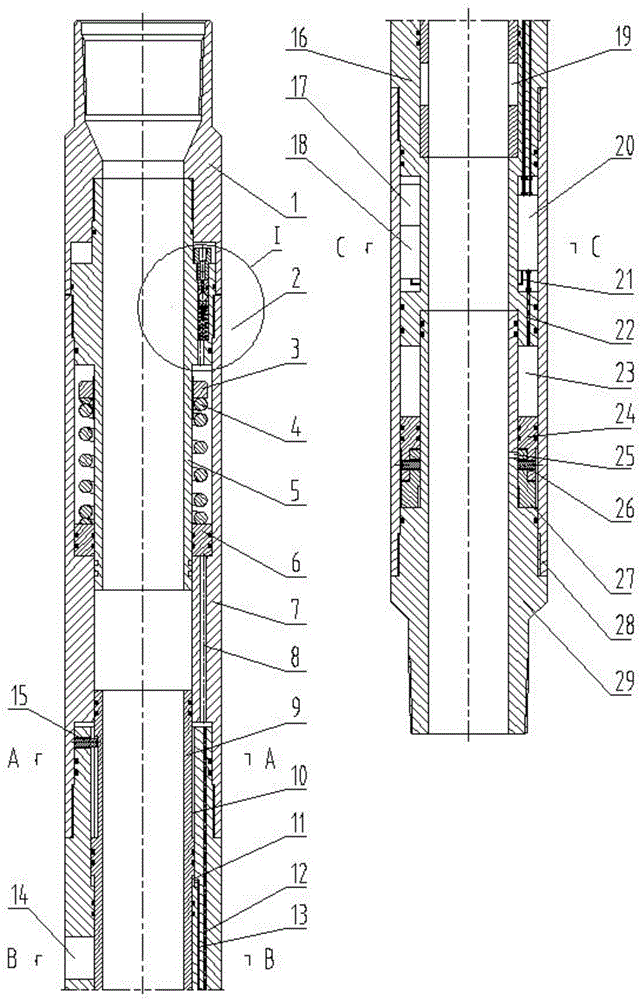

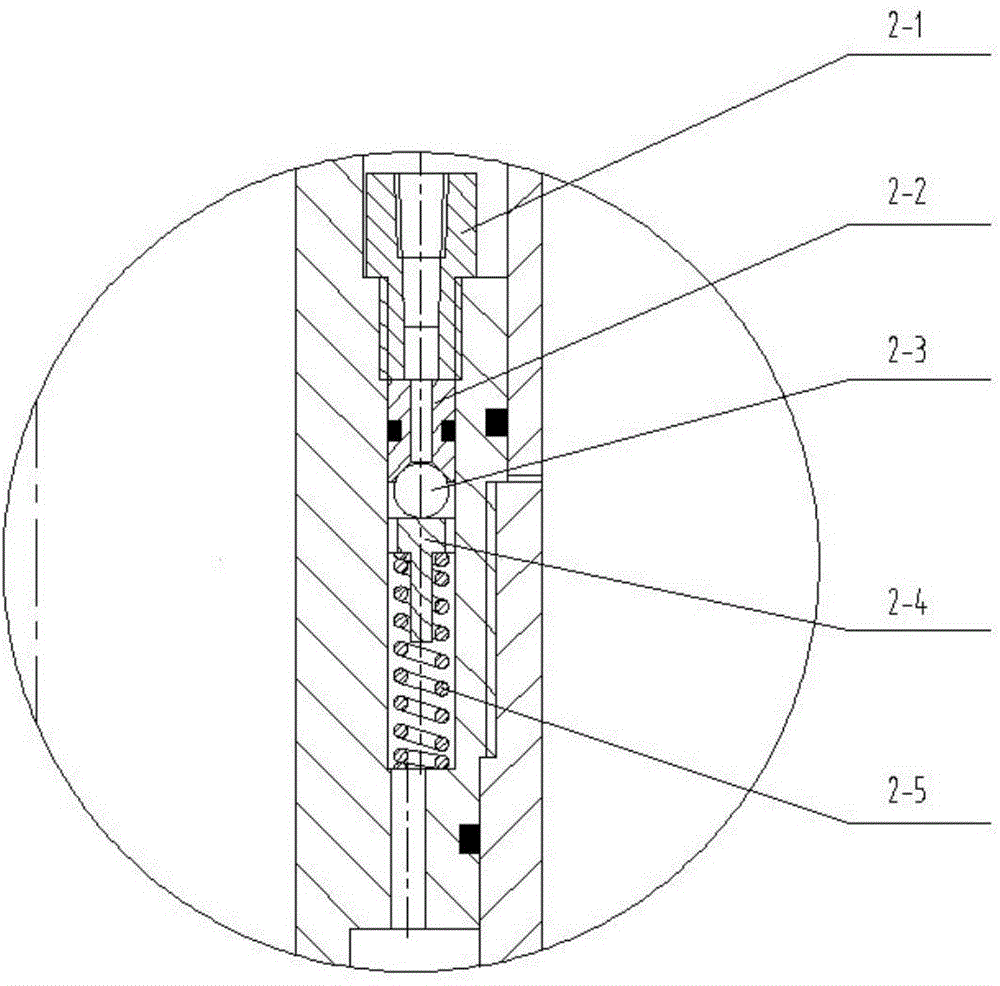

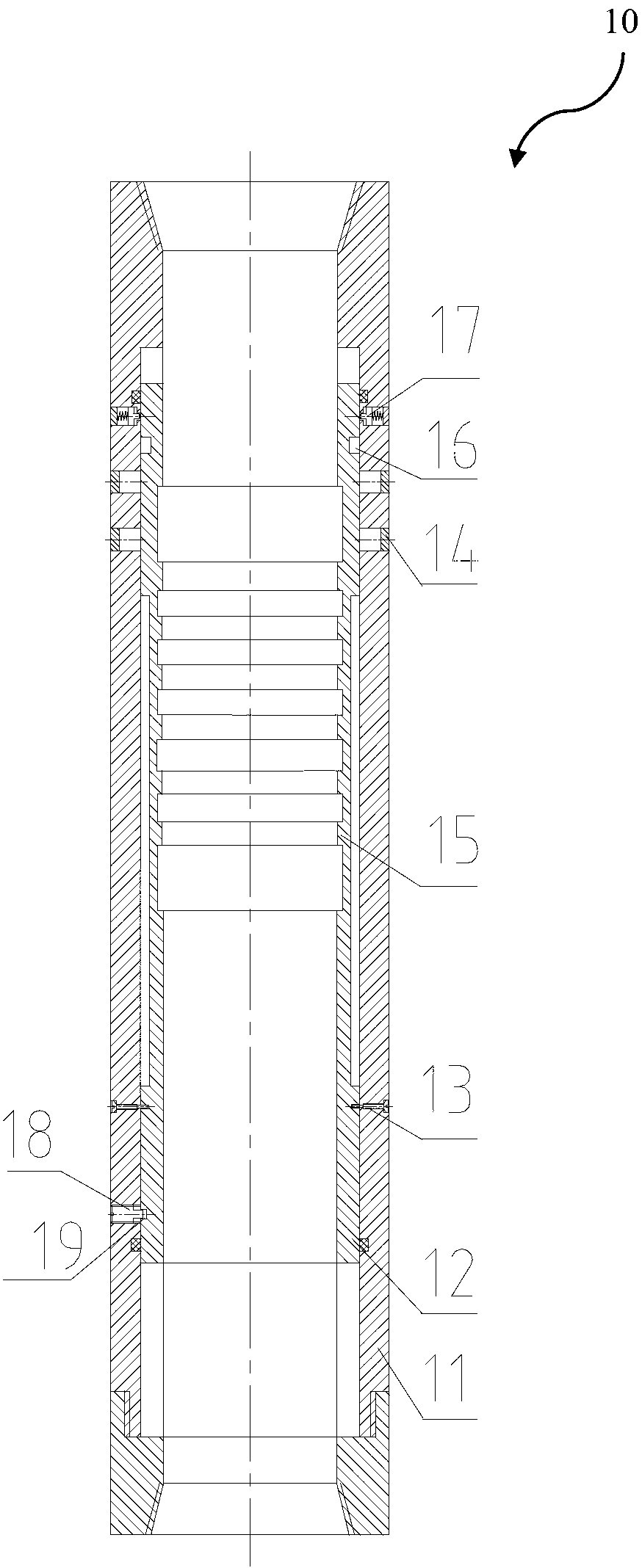

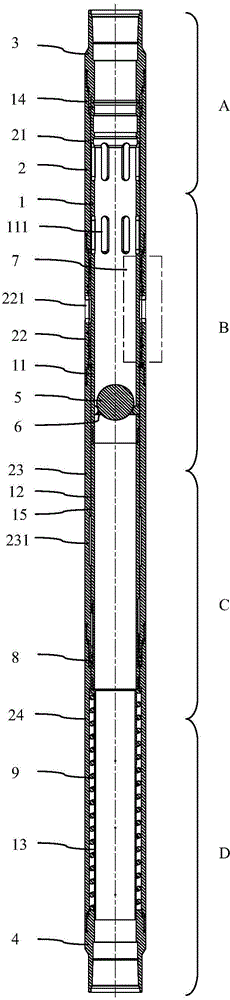

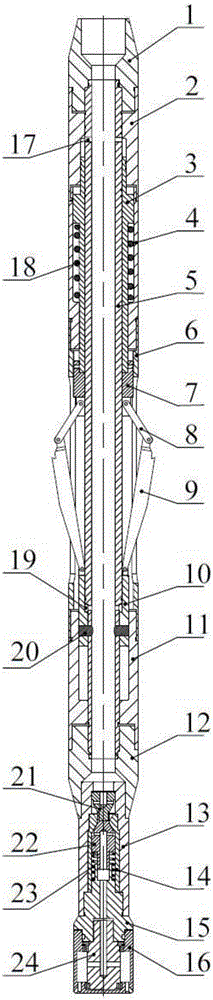

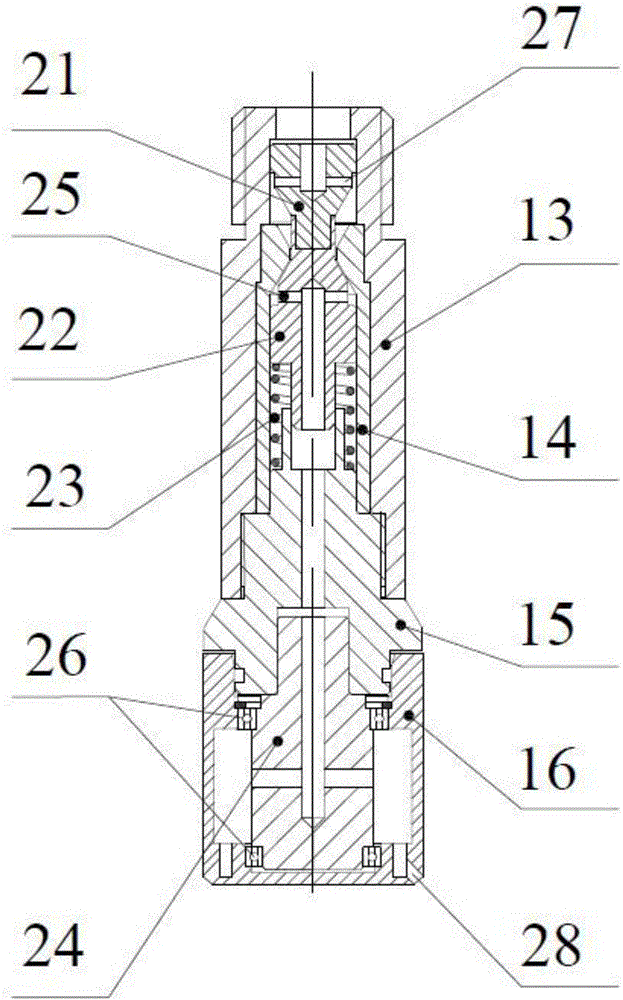

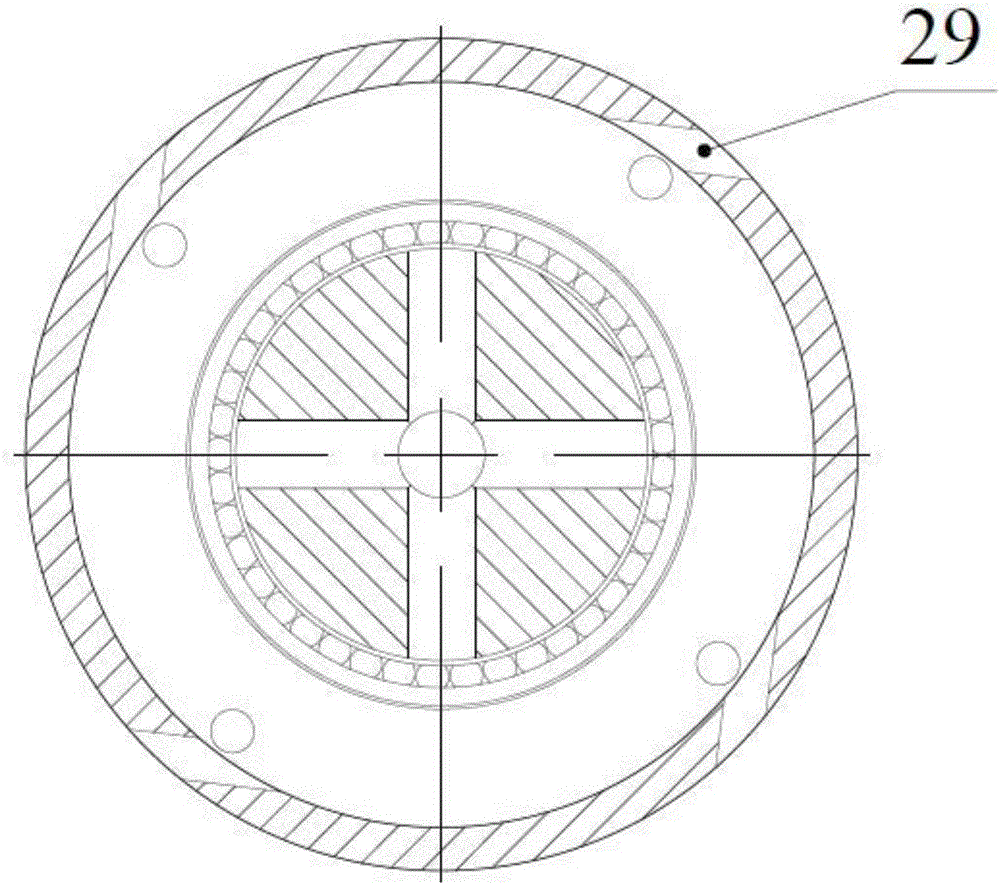

Electric-hydraulic dual-control energy storage type fracturing well completion switch and switch control method

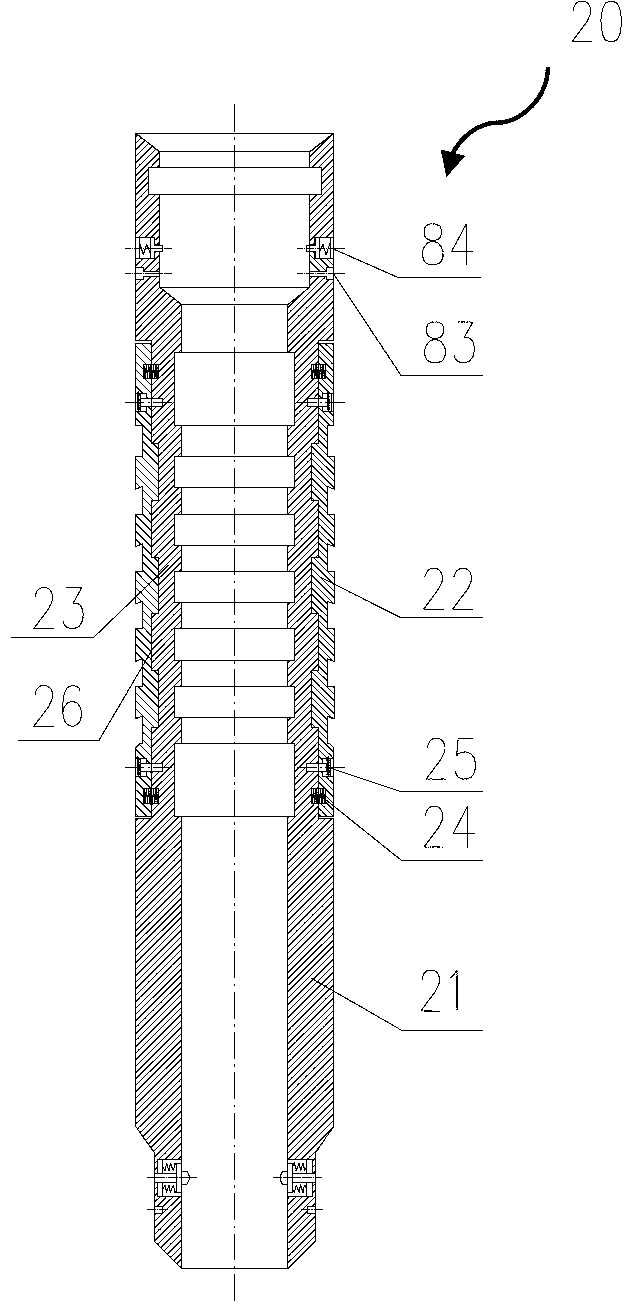

ActiveCN105003226AGood for moving up and downGuaranteed reliabilityFluid removalWell/borehole valve arrangementsType fracturePressure transmission

The invention discloses an electric-hydraulic dual-control energy storage type fracturing well completion switch. The electric-hydraulic dual-control energy storage type fracturing well completion switch comprises an upper joint, a center pipe, a pressure transmission outer tube, a slide sleeve outer tube, an outer sheath and a lower joint which are sequentially connected from top to bottom, wherein an energy storage device is arranged on the center pipe; a slide sleeve system is arranged inside the slide sleeve outer tube; a hydraulic transmission system is arranged inside the slide sleeve outer tube and the outer sheath; each of the center pipe, the pressure transmission outer tube and the slide sleeve outer tube is provided with communicated pressure transmission holes; and the energy storage device, the slide sleeve system and the hydraulic transmission system are communicated through the pressure transmission holes. A control driving system is also arranged between the lower half part of the slide sleeve outer tube and the outer sheath. The electric-hydraulic dual-control energy storage type fracturing well completion switch solves the problems that during the conventional ball injection slide sleeve staged fracturing, due to the existence of a ball seat, the layering stage number is limited; the oil well yield is influenced; and the late-period control production and the selective production cannot be realized, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

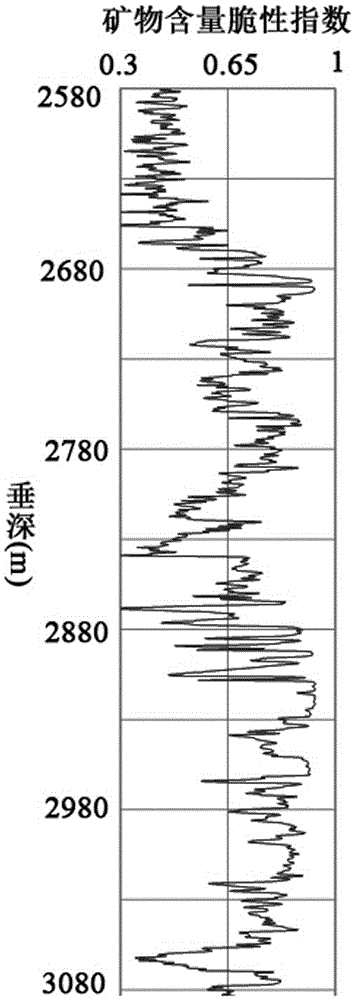

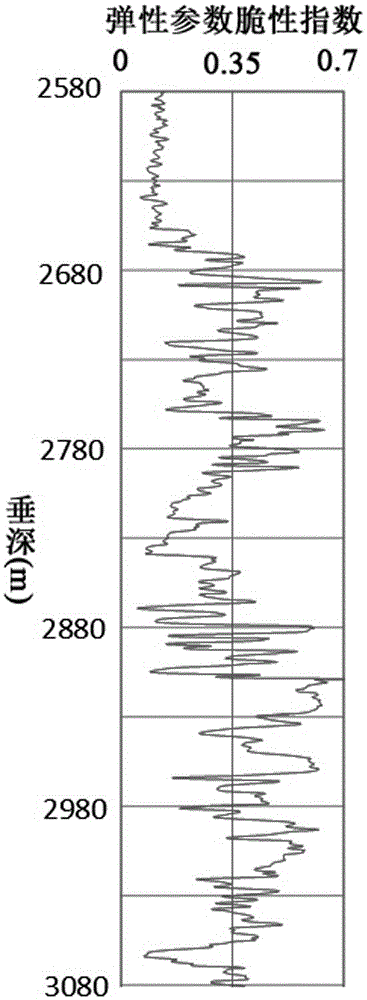

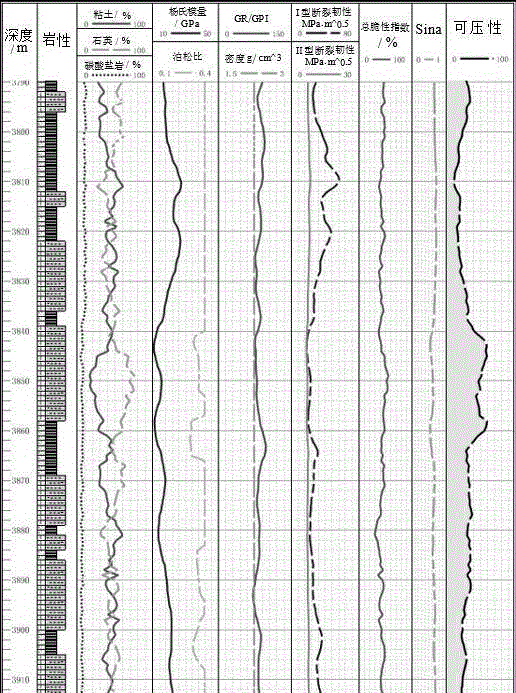

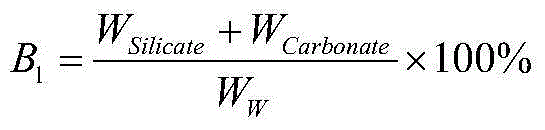

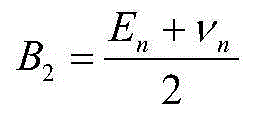

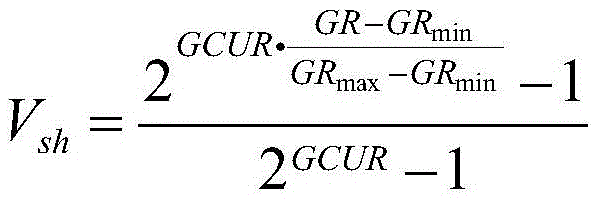

Method utilizing logging information for determining optimal perforation layer for SRV fracturing

InactiveCN105114047AConvenient and efficient calculationComputationally efficientFluid removalType fractureReservoir volume

The invention discloses a method utilizing logging information for determining the optimal perforation position for SRV (Stimulated Reservoir Volume) fracturing. The method comprises the following steps: (A) calculating mineral friability index B1 by using conventional logging information, elemental capture spectroscopy logging information and natural gamma spectroscopy logging information; (B) calculating dynamic Young modulus E and dynamical poisson ratio v of each layer section by using acoustic logging information and calculating a mechanical friability index B2 of each layer section; (C) calculating total friability index BTot of the layer sections; (D) calculating confining pressure Pc; (E) calculating rock tensile strength St of the layer sections; (F) calculating an I type fracture toughness value KIC and an II type fracture toughness value KIIC of the each layer section; (G) calculating an inner friction angle of each layer section by using logging information; (H) calculating the reservoir compressibility index Frac of each layer section; and (I) selecting a layer section with a high reservoir compressibility index Frac as the optimal SRV fracturing perforation layer. The method is capable of conveniently and efficiently calculating the compressibility index of each layer section by directly using the logging information, so as to provide decision basis for selecting the optimal SRV fracturing perforation layer and promoting exploitation of shale reservoirs.

Owner:SOUTHWEST PETROLEUM UNIV

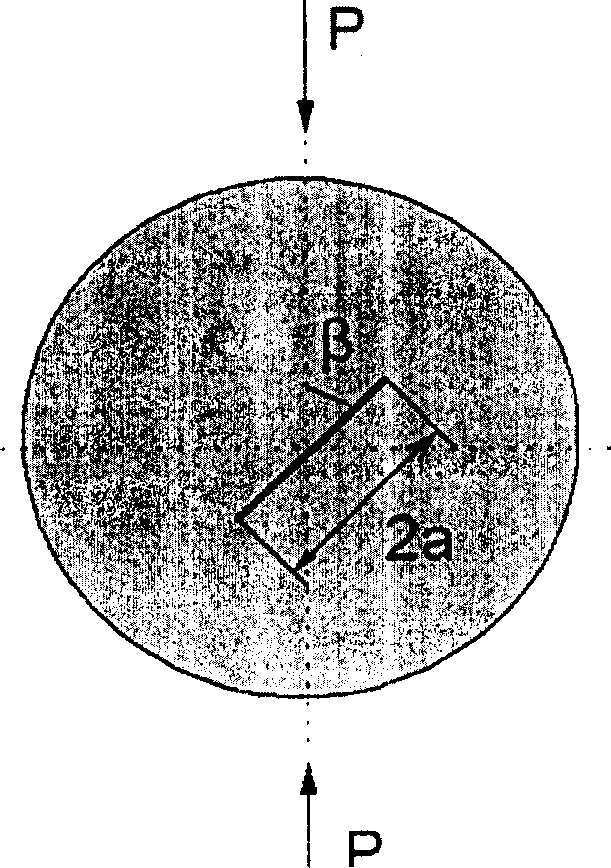

Method for computing rock II-type fracture toughness

InactiveCN1818608AImprove forecast accuracyEffective distributionPreparing sample for investigationInvestigating material hardnessType fractureHydraulic fracturing

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

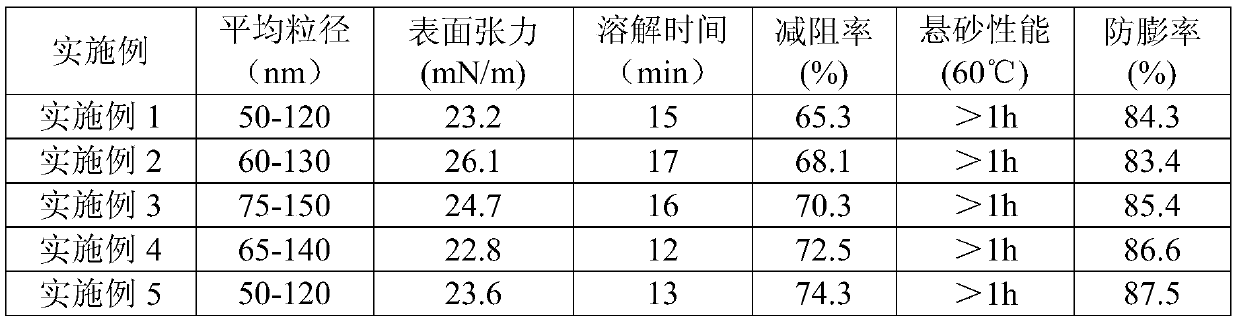

Nanoscale Pickering emulsion type fracturing fluid and preparing method thereof

The invention provides nanoscale Pickering emulsion type fracturing fluid and a preparing method thereof. The method includes the steps that a water-soluble monomer, two functional monomers, water-soluble polymeric emulsifier and inorganic salt are mixed and dissolved in deionized water to form a water phase; oil-soluble emulsifier and oil are mixed to form an oil phase; the water phase and the oil phase are mixed and heated, nitrogen is introduced, nano particles and an initiating agent are added to initiate polymerization, high-speed dispersion is combined with high-pressure homogenization or high-pressure microjet to disperse a mixed solution into dispersion fluid, the dispersion fluid is diluted to prepare the nanoscale Pickering emulsion type fracturing fluid. The fracturing fluid has good capacity of reducing resistance, aiding discharge, stabilizing clay, suspending sand and reducing surface activity, can effectively reduce usage of clay stabilizer and a discharge aiding agent, reduces operation cost, shortens work time and improves the fracturing efficiency. The stability of the fracturing fluid is effectively improved by the introduced nano particles.

Owner:PETROCHINA CO LTD

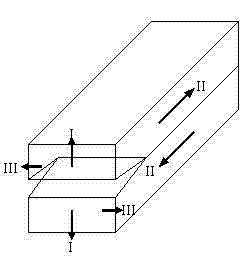

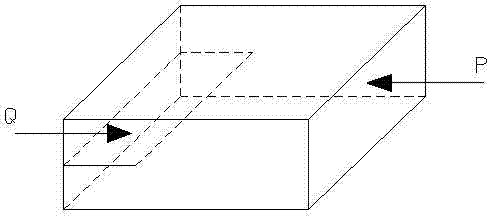

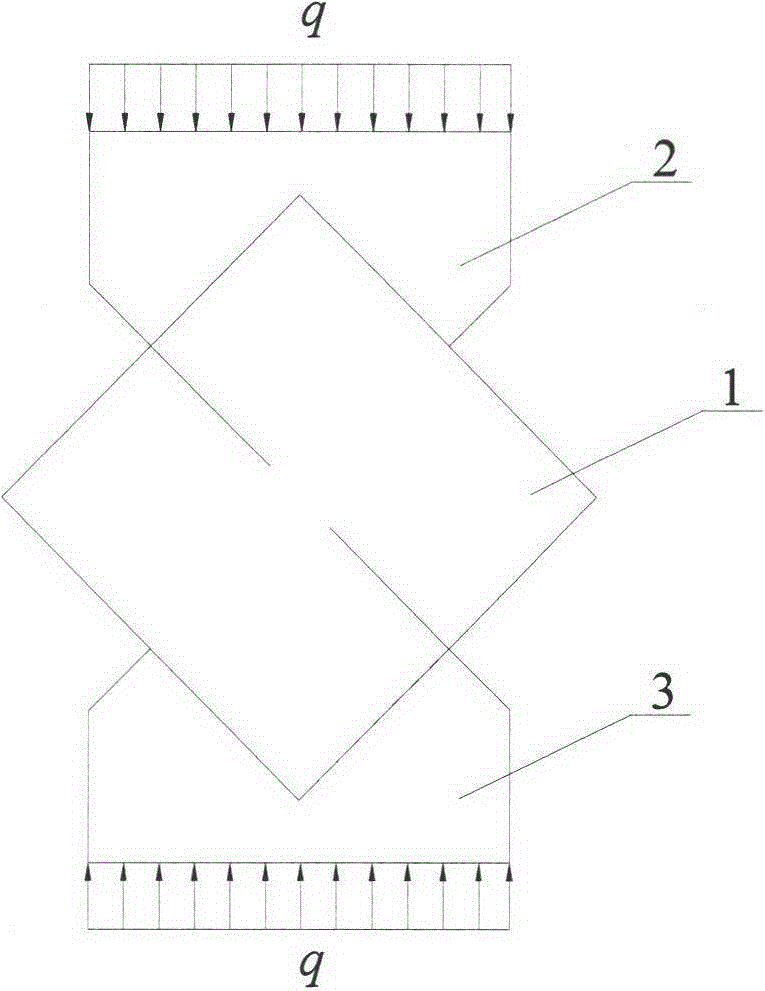

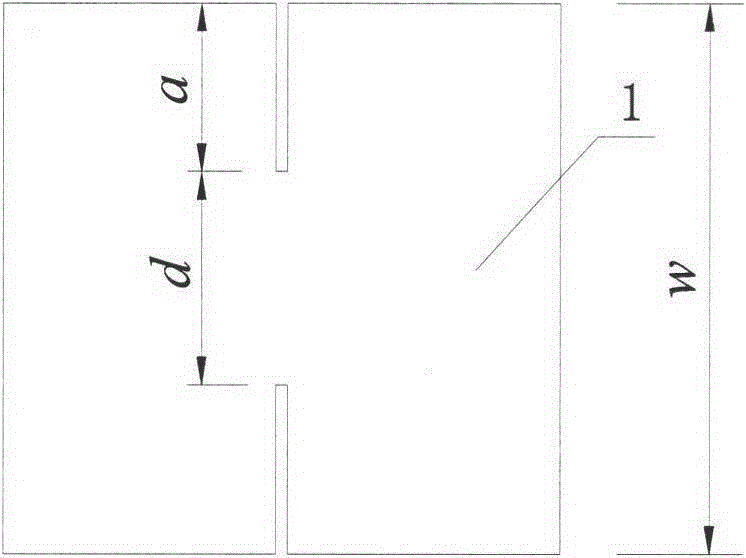

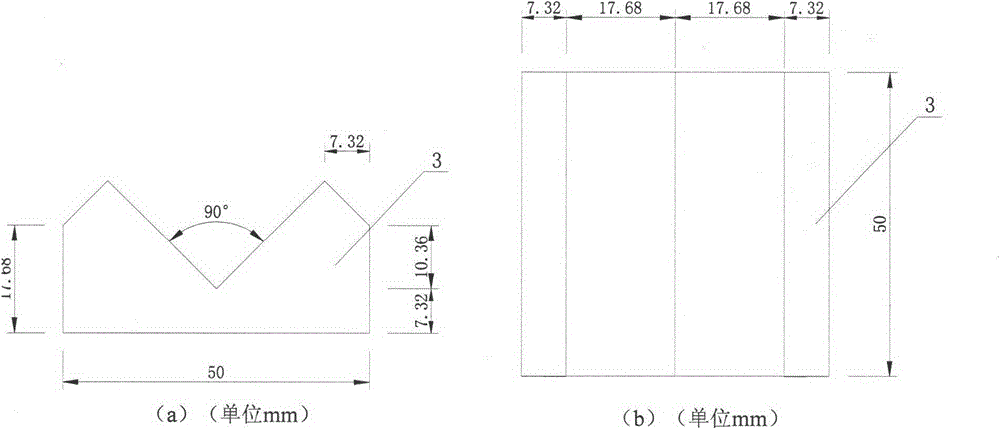

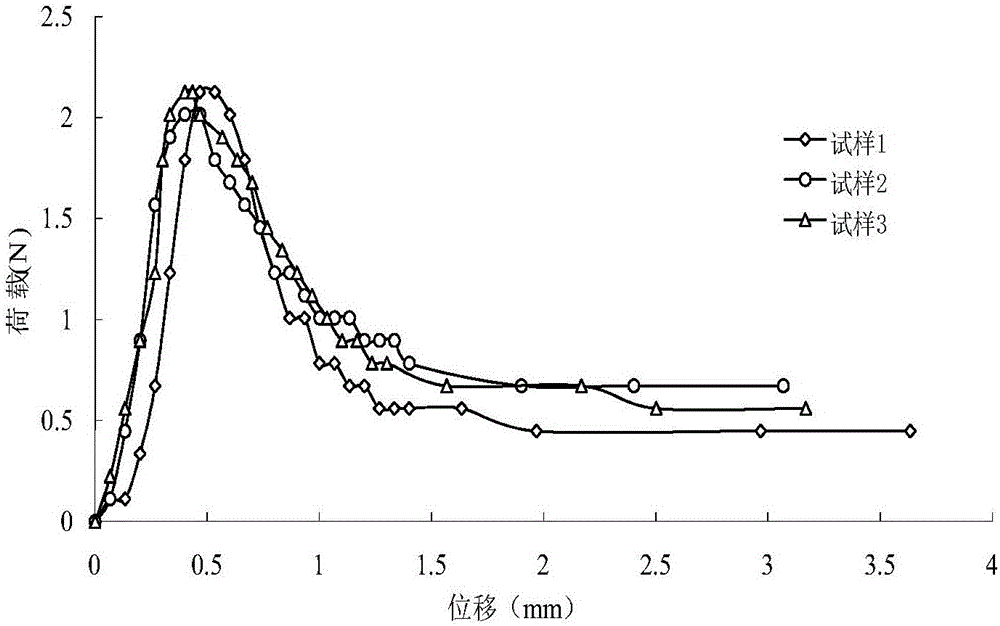

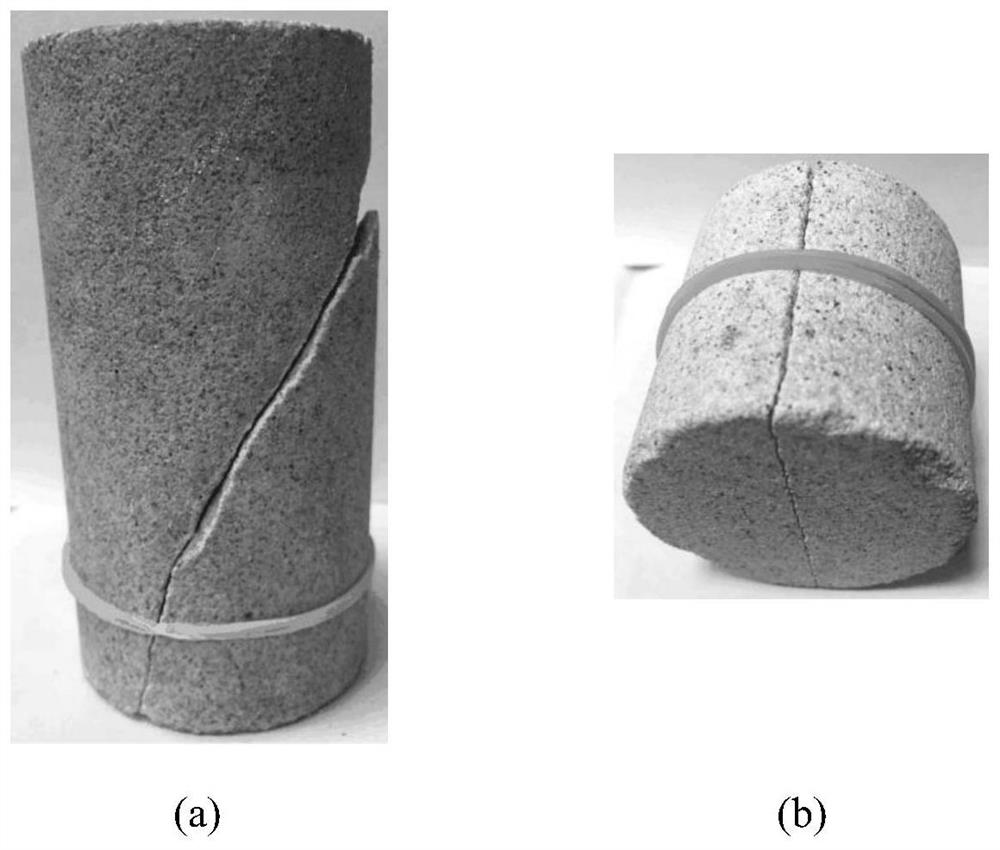

New rock II-type fracture toughness test method

InactiveCN104833590AEnables Mode II Fracture Toughness TestingIncrease the tensile stressPreparing sample for investigationMaterial strength using steady shearing forcesType fractureRock sample

The invention relates to a new rock II-type fracture toughness test method. According to the invention, on the basis of an original shear box test, by means of adjustments of the stress state of a loaded mould and arrangement of a sample to eliminate rotation tendency of the sample, generation of an excessive tensile stress on a crack tip is inhibited, thereby achieving rock II-type fracture toughness test. A test model includes a square rock sample and two steel loading moulds. Straight cracks are pre-formed on the middle parts of the two sides of the square rock sample, wherein the lengths and the widths of the two straight cracks are equal to each other. The two straight cracks are arranged symmetrically. The loading moulds can achieve 45-degree loading of the sample with a loading end surface being flat and smooth. The widths of two contact surfaces between the loading moulds and the square rock sample are both half of the side length of the sample. An upper end and a lower end of the whole system are subjected to a uniform load. The method enables processing of the rock sample and the loading moulds to be more convenient, is simplified in test process, ensures accuracy of test data, is suitable for the II-type fracture toughness test of various rocks, and provides basis for researching the II-type fracture of rocks and a problem of composite fracture mainly comprising II-type fracture.

Owner:吴礼舟

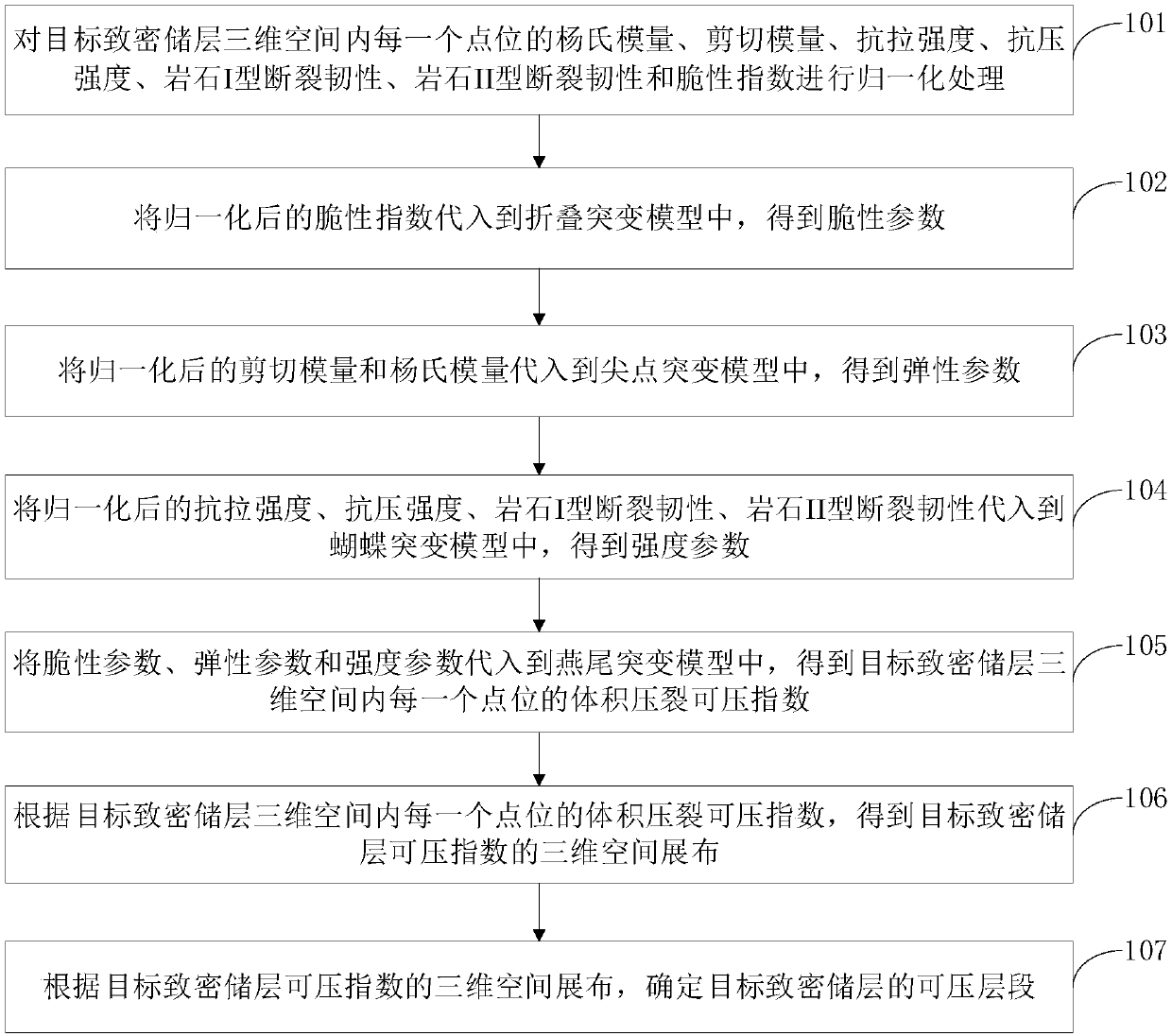

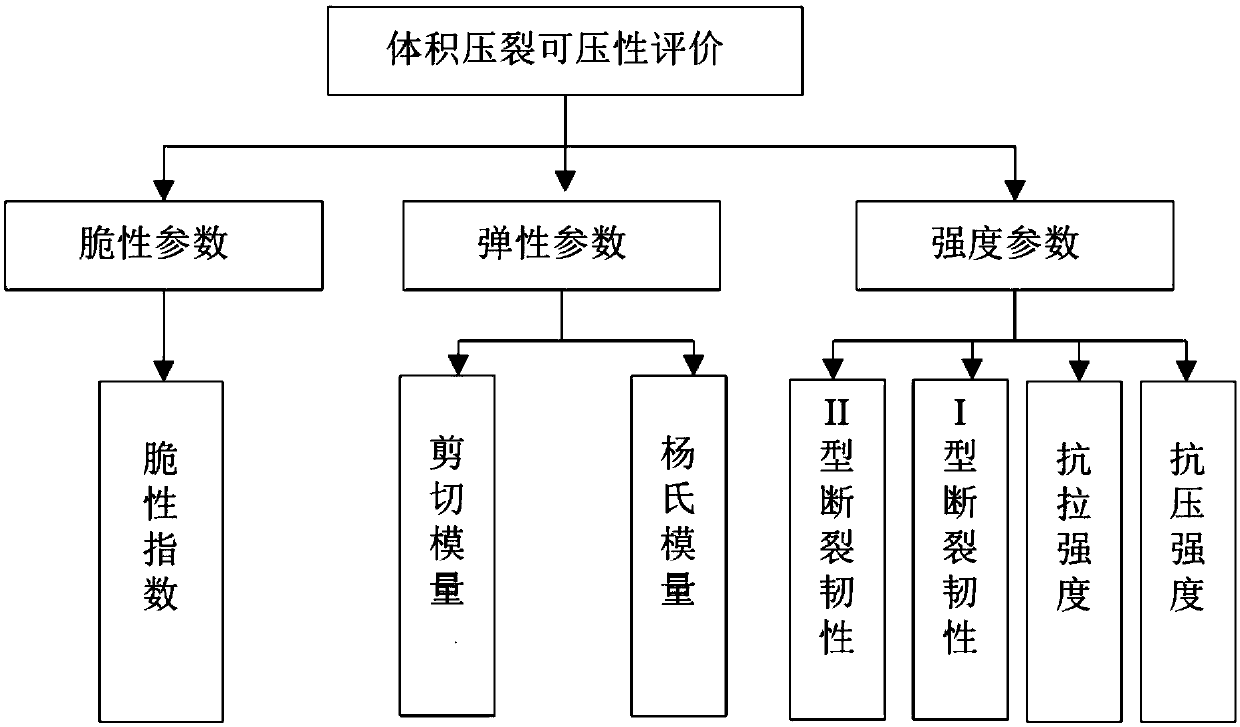

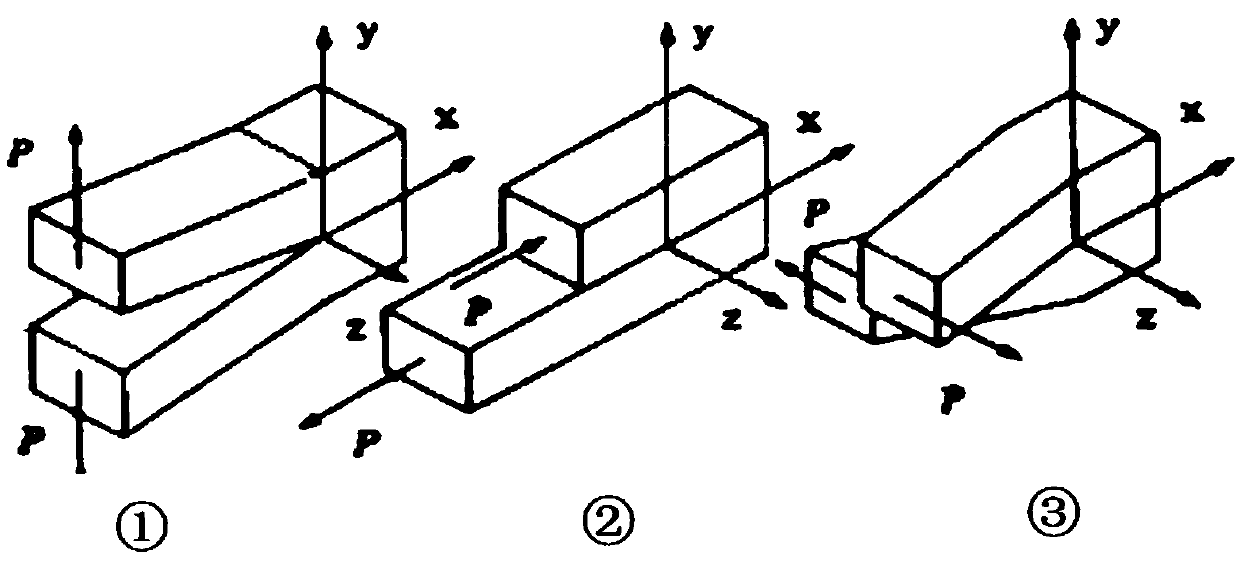

Tight reservoir volume fracturing compressibility evaluation method

ActiveCN108681635AAddress subjectivitySolve the problem of incomplete consideration of parametersDesign optimisation/simulationSpecial data processing applicationsYoung's modulusCompressibility

The invention discloses a tight reservoir volume fracturing compressibility evaluation method and belongs to the field of oil-gas field development technology. According to the tight reservoir volumefracturing compressibility evaluation method, the Young modulus, shear modulus, tensile strength, compressive strength, rock I-type fracture toughness, rock II-type fracture toughness and brittlenessindexes of each point location in a target tight reservoir three-dimensional space obtained after normalization are substituted into different catastrophic models, brittleness parameters, elasticity parameters and strength parameters are obtained through calculation, then the brittleness parameters, the elasticity parameters and the strength parameters are utilized to construct a volume fracturingcompressibility evaluation model, a volume fracturing compressibility coefficient of each point location in the target tight reservoir three-dimensional space is obtained through calculation, and three-dimensional spatial distribution of compressibility indexes of a target tight reservoir is acquired to determine compressible layer sections of the target tight reservoir. Therefore, quantitative evaluation of tight reservoir volume fracturing compressibility is realized, and the problems that in the prior art, the subjectivity of weight determination is excessively high, and parameters are notconsidered comprehensively are solved.

Owner:PETROCHINA CO LTD

Sliding sleeve type fracturing module, device including the module and method of using the device

ActiveCN102839944AUnlimited quantityRealize staged fracturingFluid removalWell/borehole valve arrangementsType fractureMechanical engineering

Owner:CHINA PETROLEUM & CHEM CORP +1

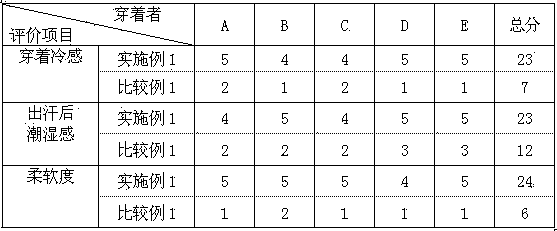

Cool sweat-absorbent quick-drying knitted fabric and application thereof

Owner:TORAY FIBER RES INST(CHINA) CO LTD

Cohesive-soil strain-control-type I-type fracture toughness tester and testing method

InactiveCN105865924AIngenious ideaUnique structurePreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureTest sample

The invention discloses a cohesive-soil strain-control-type I-type fracture toughness tester and a testing method. The tester comprises an installing table. A motor is arranged on the installing table, and is connected with a stretchable connecting rod, and a sensor is connected to the front end of the connecting rod, and is connected with a pushing rod; a base is arranged on the installing table, sliding rails are arranged on the base, tested samples are arranged on the sliding rails, a pair of stopping rods are fixedly connected to the base, one faces of the tested samples are connected with the stopping rods, the other faces of the tested samples are connected with the pushing rod, and initial fissures are formed in the tested samples. According to the cohesive-soil strain-control-type I-type fracture toughness tester, as the tested samples lie flatly to be subjected to a fracture test, the gravity influence is eliminated; as the tested samples are put onto the sliding rails, the influence of friction force is eliminated.

Owner:NANJING UNIV

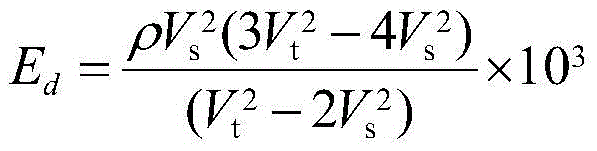

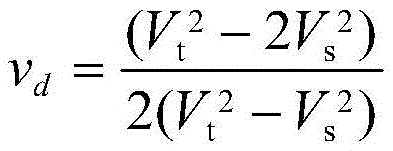

Shale reservoir high brittleness optimization method

The invention discloses a shale reservoir high brittleness optimization method. The method successively includes the following steps: (A) calculating the dynamic Young modulus Ed and the dynamic Poisson's ratio vd of rocks in each section of a reservoir; (B) calculating the I type fracture toughness KIC of the rocks in each section of the reservoir; (C) calculating the brittleness index BI of the rocks in each section of the reservoir by utilizing results of a step (A) and a step (B); and (D) selecting out a layer section with the large brittleness index as a high brittleness layer section. The brittleness of shale reservoir rocks is affected by rock mechanics parameters of a shale and the anti-brittle failure capacity of the shale, the method defines that the brittleness index BI represents the brittleness of the rocks in each section; and a high brittleness shale section can be directly selected out through calculation of the brittleness index BI of the rocks in each section. The method can accurately select out the high brittleness section suitable for fracture in the shale reservoir, and then provides an effective guide for increasing production of the shale reservoir, so that hydraulic fracturing construction in the shale reservoir has pertinence and effectiveness.

Owner:SOUTHWEST PETROLEUM UNIV

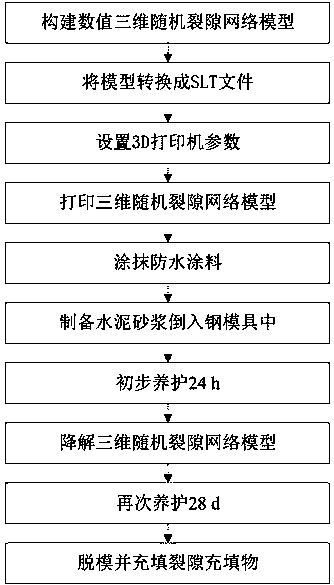

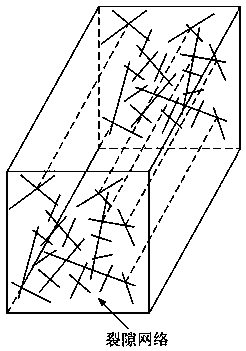

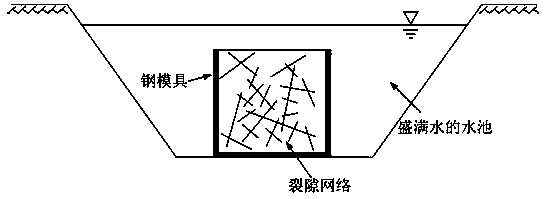

Filling type fracture network rock test piece preparing method based on 3D printing technology

InactiveCN109648693AEfficient manufacturing methodEffective WaysAdditive manufacturing apparatusPreparing sample for investigationType fractureEngineering

The invention relates to a filling type fracture network rock test piece preparing method based on the 3D printing technology, and belongs to the related technical field of construction, hydraulic engineering, mining and other underground project tests. According to the filling type fracture network rock test piece preparing method based on the 3D printing technology, firstly, a three-dimensionalrandom fracture network model is constructed; the obtained model is converted into an SLT file; the SLT file is guided into a 3D printer; the 3D printer is used for printing the three-dimensional random fracture network model; the outer surface of the model is coated with a waterproof coating; the three-dimensional random fracture network model is placed in a steel die, cement mortar is poured into the steel die containing the three-dimensional random fracture network model, and uniform vibration is conducted; and a cement mortar test piece and the steel die are placed in a standard curing boxtogether; then the three-dimensional random fracture network model is degraded; and the degraded test piece is placed in the standard curing box again to be cured, the cured test piece three-dimensional random fracture is filled with needed materials, and finally a filling type fracture network rock test piece is obtained.

Owner:KUNMING UNIV OF SCI & TECH

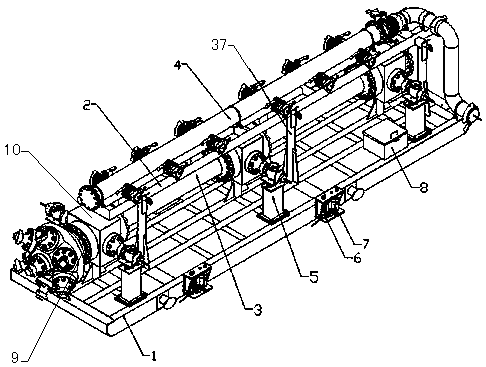

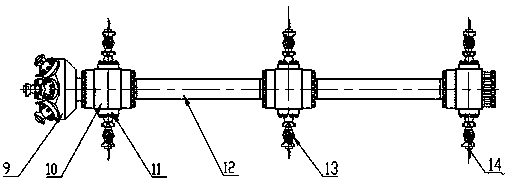

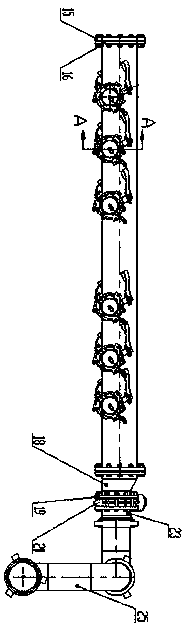

Flange type fracturing combination manifold device with damping device

InactiveCN109025944AReduce shockConvenient lifting fracturing manifoldFluid removalType fractureHigh pressure

The invention relates to a well fracturing device, in particular to a flange type fracturing combination manifold device with a damping device. A high pressure manifold pry is in a square frame shape,the high pressure manifold pry and a low pressure manifold are connected through a combination support, the low pressure manifold pry is connected with a low pressure manifold, the high pressure manifold pry and the high pressure manifold are connected through a bolt type four way joint and a fixing support connected with the bolt type four way joint, a fracturing head is connected to the front end of the bolt type four way joint, the bottom of the damping device is connected with the high pressure manifold pry, the upper portion of the damping device is connected with the bolt type four wayjoint, four hydraulic jack supports are connected with the two ends of the side faces of the high pressure manifold pry, and hydraulic jacks are arranged on the hydraulic jack supports. High and low pressure fracturing solutions are conveyed to a well mouth and a fracturing truck respectively, vibration of the fracturing vehicle and impact caused by vibration on a high pressure component in the manifold can be sufficiently absorbed.

Owner:中石化四机石油机械有限公司 +1

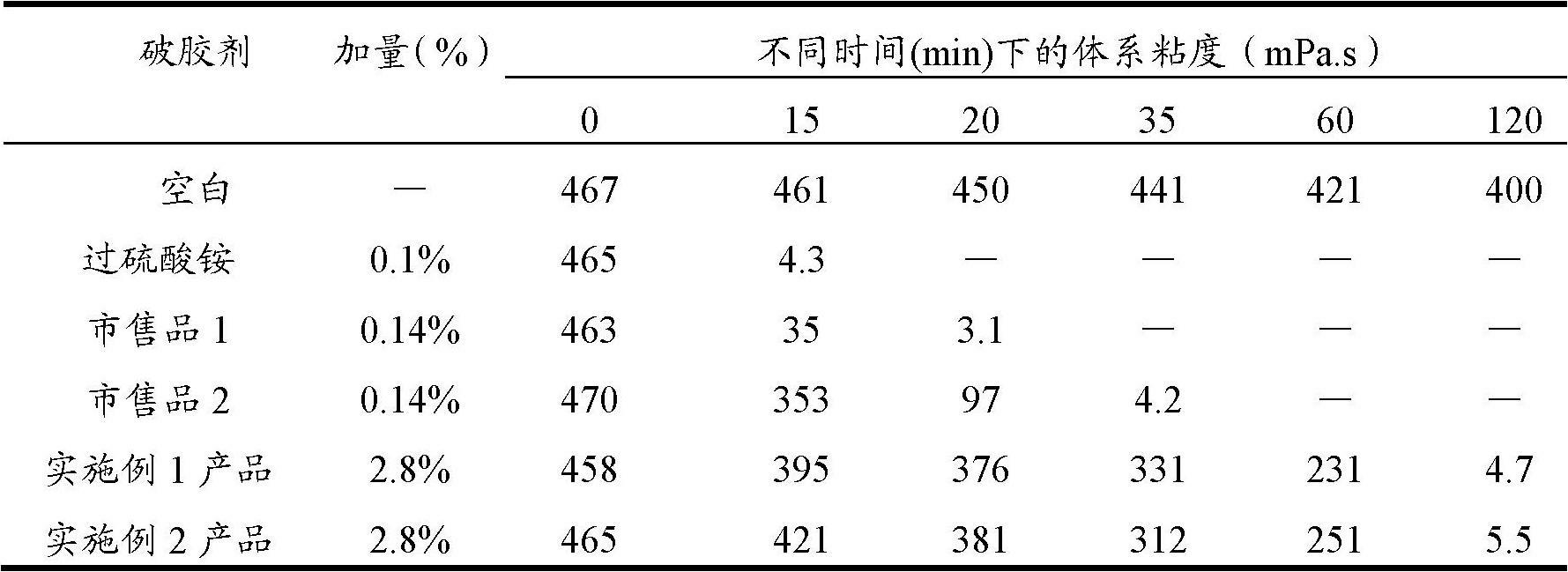

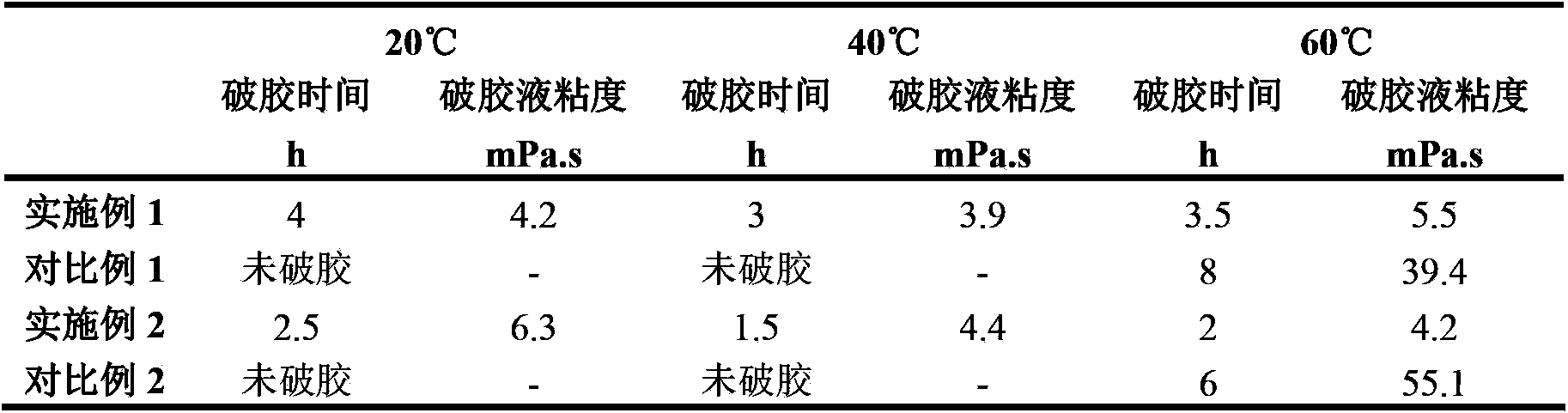

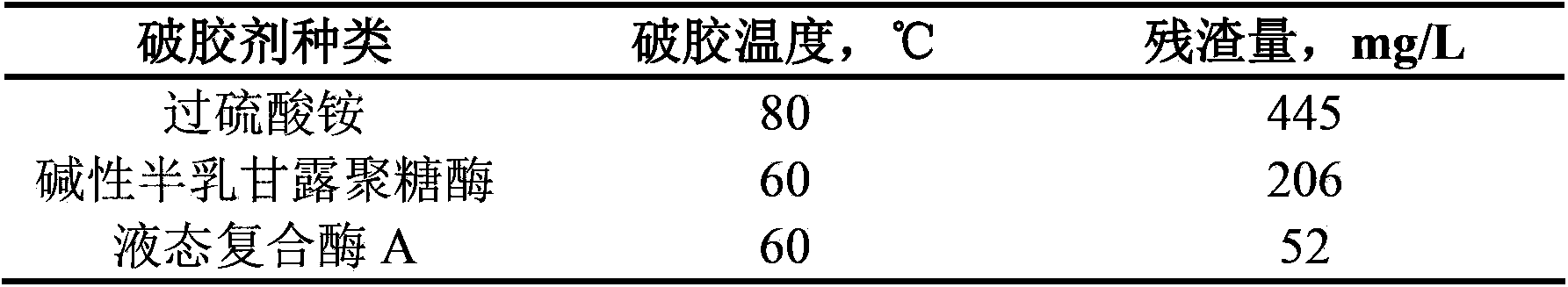

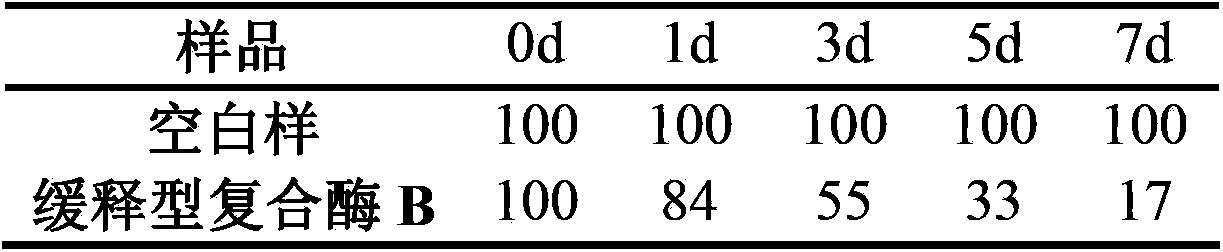

Combined-type fracturing fluid bio-enzyme gel breaker and application method thereof

ActiveCN103911140AImprove gel breaking efficiencyReduce harmFluid removalDrilling compositionType fractureProteinase activity

The invention provides a combined-type fracturing fluid bio-enzyme gel breaker and an application method thereof, and the combined-type fracturing fluid bio-enzyme gel breaker comprises a slow-release compound enzyme B and / or a liquid compound enzyme A; the slow-release compound enzyme B is prepared from a slow releasing material B2 and a compound enzyme solution B1 by granulation, the slow releasing material B2 and the compound enzyme solution B1 respectively account for 70-80wt% and 20-30wt% of the total weight of granulation materials; the compound enzyme solution B1 in the slow-release compound enzyme B comprise, by volume, 70%-80% of a galactomannan enzyme liquid, 10%-15% of a cellulase liquid and 10%-15% of a protease liquid; the liquid compound enzyme A comprise, by volume, 5%-20% of the galactomannan enzyme liquid, 0.10%-5.0% of the cellulase liquid, 0.10%-5.0% of the protease liquid and 70-90% of water. According to the combined-type fracturing fluid bio-enzyme gel breaker and the application method thereof, efficient gel breaking of a middle and low temperature oil deposit fracturing fluid can be realized, the gel breaking is long in aging, fracturing residues can be reduced, and damages of the fracturing fluid to stratum can be reduced.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fractured reservoir horizontal well injection-production asynchronous exploitation method

InactiveCN106437642AEfficient developmentReduce moisture contentFluid removalType fractureAsynchronous operation

The invention provides a fractured reservoir horizontal well injection-production asynchronous exploitation method. The method comprises the steps that 1, area selecting and well selecting are conducted, specifically, a reservoir stratum with developed natural micro-fractures is selected, fractured water breakthrough in the multi-section fractured horizontal well production process is achieved through waterflooding extraction, and when the average increasing amount of the water content every day is larger than or equal to 1.5%, remaining oil within a horizontal well controlled area is used for an injection-production asynchronous oil extraction horizontal well; 2, the oil extraction horizontal well is closed, 80-100 cubic meters of water is injected into a water injection well, and the oil extraction horizontal well is closed; 3, the water injection well is closed, then, the oil extraction horizontal well is opened for oil extraction, the injected water entering matrix rock blocks is preserved, and the equal amount of crude oil replacing the injected water enters a fracture system, flows into a shaft and is extracted; and 4, the next round of water injection is started, the step 2 and the step 3 are repeated, and injection-exploitation asynchronous operation is conducted for 8-10 periods. According to the fractured reservoir horizontal well injection-exploitation asynchronous exploitation method, on the basis of the seam-net type fractures, the contact area of the injected water and the fractures is enlarged, the oil-water replacement amount is further increased, the reservoir overall imbibitions yield-increasing effect is improved, and accordingly the purposes of decreasing the water content of the fractured water breakthrough horizontal well, increasing the liquid amount and the oil amount, and supplementing the stratum energy are achieved.

Owner:PETROCHINA CO LTD

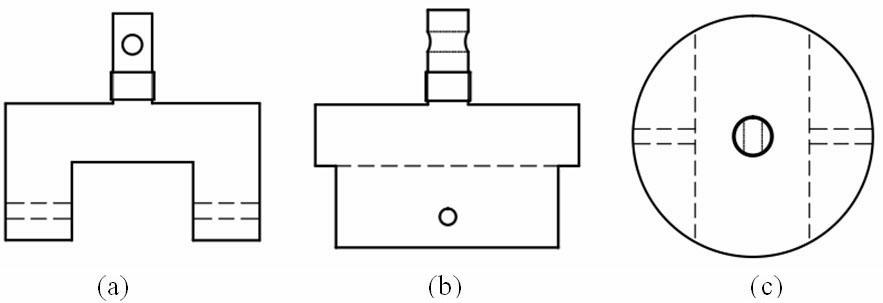

Clamp for mixed fracture test of dual-phase material interface

The invention belongs to the technical field of a material detection, and particularly relates to a clamp for mixed fracture test of a dual-phase material interface. The clamp is divided into an upper part and a lower part that are symmetric to each other; each of the upper part and the lower part consists of a pulling rod, a semiround plate and a sample table; the sample table is connected with the semiround plate by bolts; the semiround plate is connected with the pulling rod by a bolt; a plurality of round holes are symmetrically arranged at the edge of the semiround plate; and the upper pulling rod and the lower pulling rod are fixedly connected with an upper force-applying system and a lower force-applying system of a pulling machine respectively. The clamp can be used together with a universal mechanic tensile testing machine; a sample with a pre-crack is fixed on the clamp; subsequently the clamp can be rotated so as to apply the pull forces of different angles to the sample; the critical fracture strength of the interface crack can be calculated according to a force-displacement curve. The clamp can be used for conveniently determining the situations of the I-type mixed fracture mode and the II-type mixed fracture mode under different tensile loading angles, and is also applicable to determinine the I-type fracture situation of the dual-phase material interface.

Owner:FUDAN UNIV

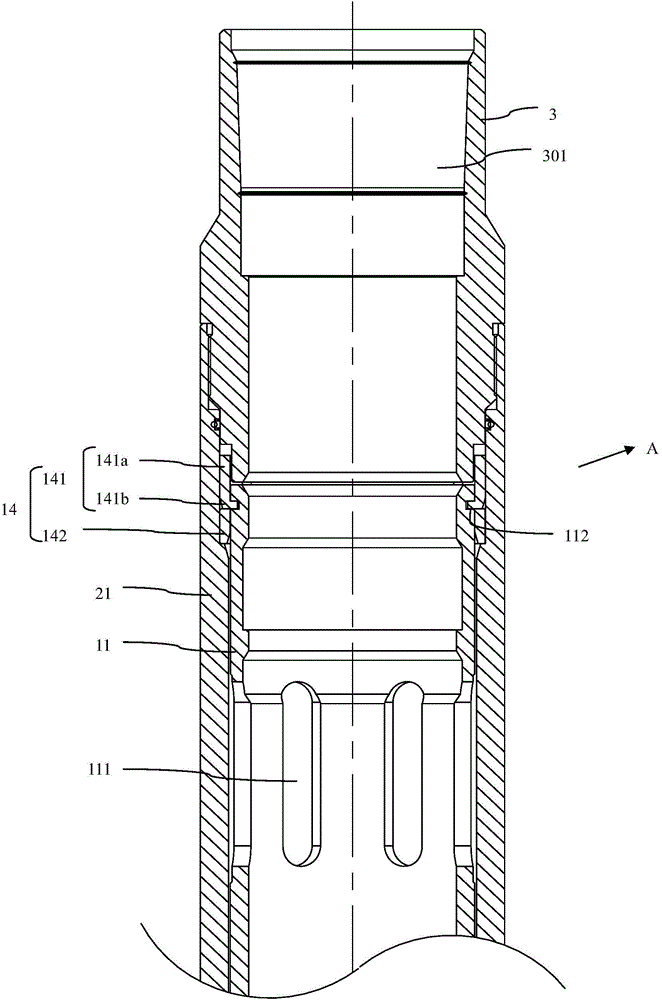

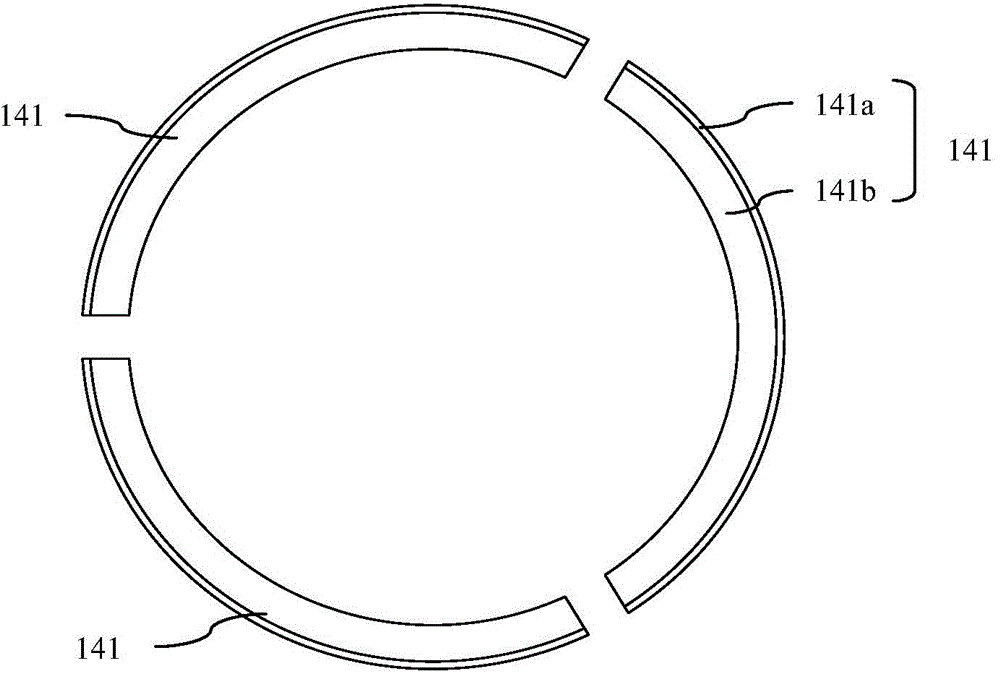

Ball seat assembly and ball-pitching sliding sleeve type fracturing device

ActiveCN105840163AReduce construction costsHigh degree of automationFluid removalWell/borehole valve arrangementsType fractureBall release

The invention relates to a ball seat assembly and a ball-pitching sliding sleeve type fracturing device. The ball-pitching sliding sleeve type fracturing device comprises an inner sleeve, and outer sleeve, a fracturing ball, and the ball seat assembly. The inner sleeve is slidably sleeved in the outer sleeve. The inner sleeve and the outer sleeve are respectively provided with fracturing windows. The inner sleeve slides to open or close the fracturing window. The inner side surface of the outer sleeve is provided with a fracturing ball releasing groove. The fracturing ball is pitched on the ball seat assembly. When the ball seat assembly moves to the fracturing ball releasing groove, the fracturing ball generates thrust under the action of external forces, to push a plurality of ball seat supports to move outward along a radial direction, and the fracturing ball passes through the ball seat assembly and falls into a next section of the ball-pitching sliding sleeve type fracturing device. Using the ball-pitching sliding sleeve type fracturing device can realize an objective of fracturing an infinite layer section by just pitching a ball, and construction cost is reduced and yield of a single well is increased. The device solves defects in the prior art of range limitation of a fracturing sliding sleeve and influence of sliding of the inner sleeve after a shear pin is cut off.

Owner:PETRO KING ENERGY TECH HUIZHOU CO LTD

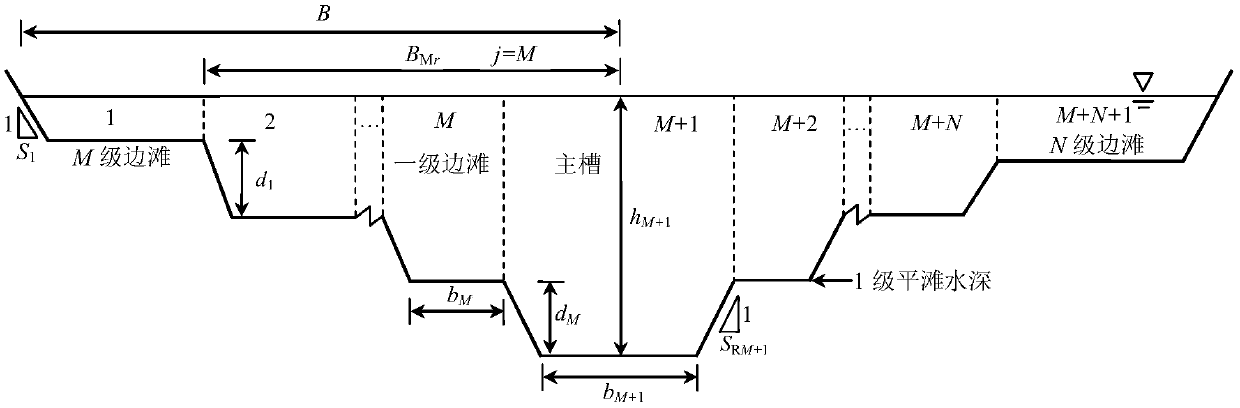

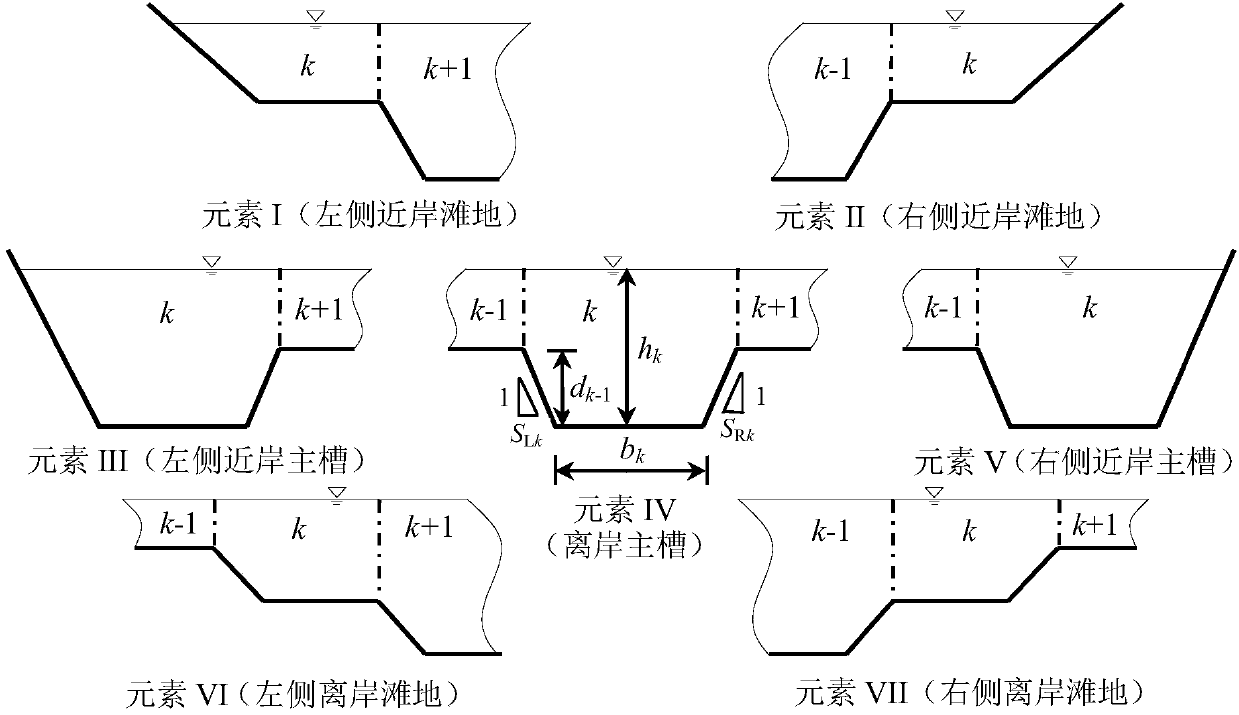

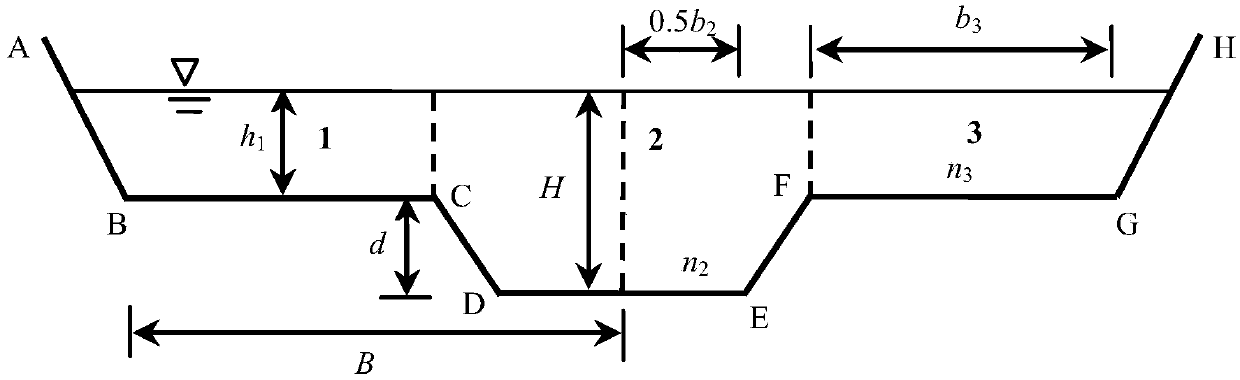

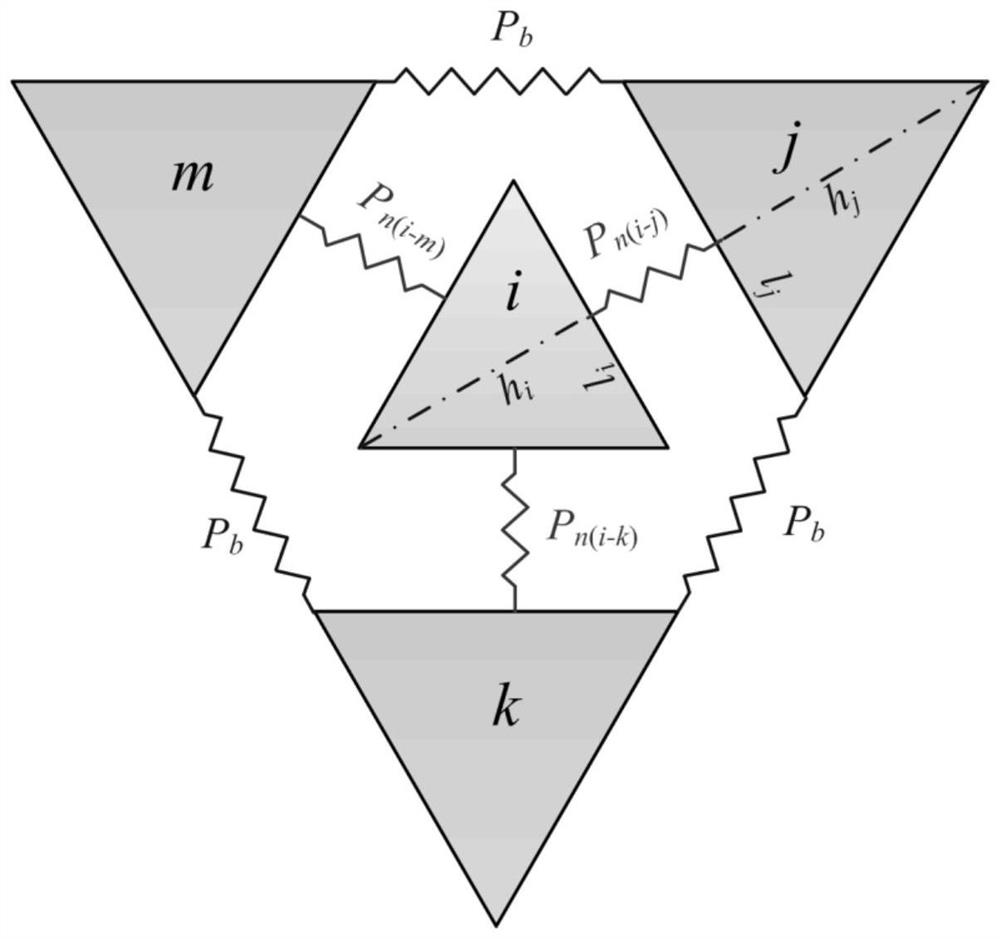

Universal method for deducing and solving multistage composite type fracture surface water level flow relationship

ActiveCN107816009AHigh precisionShorten the timeHydraulic engineering apparatusStream regulationType fractureShear stress

The invention provides a universal method for deducing and solving the multistage composite type fracture surface water level flow relationship. The method includes the following steps that firstly, measured data of a target fracture surface are acquired, the fracture surface is divided into M+N+1 sub-fracture surfaces, and the M+N+1 sub-fracture surfaces are further classified as seven composition elements; resistance dividing is performed on the sub-fracture surfaces, f<k>=f<bk>+f<vk>, wherein f<vk>=4lambda<k>C<D>D<k>m<k>h<k> is a resistance coefficient generated due to plant dragging, and the Manning coefficient (please see the formula in the specification) of the sub-fracture surfaces is calculated, the apparent shear stress of each element is calculated, the momentum balance relationof the sub-fracture surfaces is built, and therefore the matrix equation of three diagonal coefficient matrixes is obtained; and the matrix equation is solved in a chasing method, the fracture surfaceaverage flow speed of the sub-fracture surfaces is obtained, and therefore the water level flow relationship of the sub-fracture surface is obtained. The method has a unified expression, Excel or programming can be conveniently adopted for performing calculation, and the universal method can be applied to deducing and solving of the water level flow relationship of the multi-stage composite typefracture surface including a two-stage composite type fracture surface, and is a calculation method easy and convenient in calculation and high in precision.

Owner:云南省水利水电勘测设计院有限公司

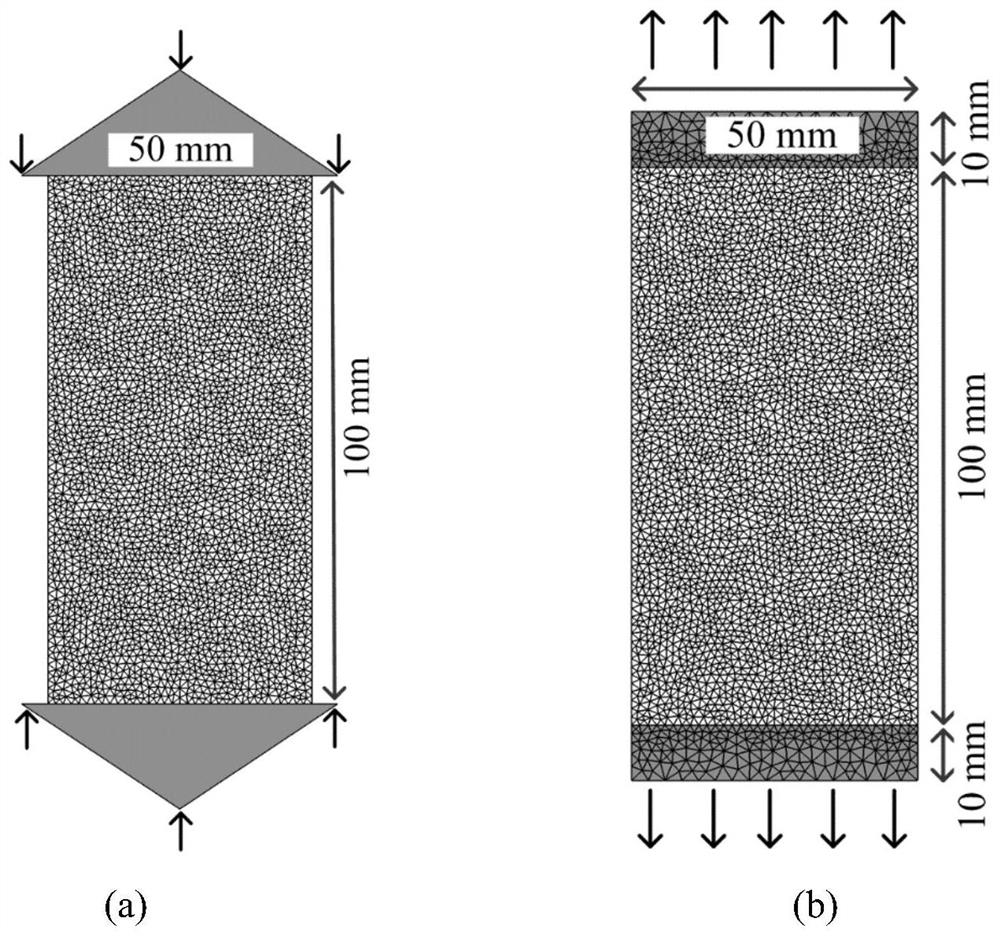

Finite element-discrete element coupling numerical simulation program (FDEM) input parameter rapid calibration method

ActiveCN112362520AAccurately determine correctnessEasy accessStrength propertiesUniaxial compressionType fracture

The invention discloses a finite element-discrete element coupling numerical simulation program (FDEM) input parameter rapid calibration method. The method comprises the following steps of (1) acquiring rock macroscopic physical and mechanical parameters through uniaxial compression, Brazilian splitting and triaxial compression indoor tests; (2) calibrating a joint penalty value Pf by adopting a uniaxial compression simulation test pre-peak stage curve; (3) calibrating normal contact stiffness Pn based on algorithm improvement and single joint unit compression-shear failure; (4) calibrating II-type fracture energy GII by adopting a uniaxial compression simulation test whole process curve; (5) calibrating I-type fracture energy GI by adopting a direct tensile test; (6) calibrating tangential contact stiffness Pt by adopting the uniaxial compression simulation test again; and (7) checking the reliability of the calibrated parameters by adopting triaxial compression, Brazilian splitting and direct shear simulation tests. The calibration method provided by the invention is high in efficiency, eliminates the dependence of parameter values on a grid size, and can be suitable for engineering scale simulation.

Owner:WUHAN UNIV

Combined type fracture restorer

The invention relates to the fracture restorer technical field, and specifically relates to a combined type fracture restorer; the left cavity of a nut is screwed with a forward spinning screw rod; the right cavity of the nut is screwed with a backward spinning screw rod; a compaction rod is plugged in a second through hole; the top and bottom of a first press block are respectively connected with a boss; one side, far away from the second through hole, of the boss is connected with a third straight rod; the first press block and a second press block are arranged on two sides of a Kirschner wire. The combined type fracture restorer can be freely mounted / dismounted according to needs, can restore long bone fractures and arms and legs surrounding fractures, and different parts can be combined so as to realize long bone linear mode restoration and joint surrounding fracture right angle mode restoration; the combined type fracture restorer is simple and easy to operate, and needs no special training; the parts are simple in design and easy to use, and no special training is needed; the combined type fracture restorer is low in cost, and suitable for primary hospitals.

Owner:唐佩福

Horizontal well staged fracturing sliding sleeve opening-closing tool

InactiveCN105971559AOvercome irreversible difficultiesImprove reliabilityConstructionsCleaning apparatusType fractureForeign matter

The invention relates to a horizontal well staged fracturing sliding sleeve opening-closing tool which mainly comprises an upper connector, a lower connector, a compression spring, a spring sleeve, a connection sleeve, a core shaft, a protective sleeve, a clamping jaw, a spray head and the like. The two ends of the core shaft are connected with the upper connector and the lower connector respectively. The upper connector and the lower connector can be in threaded connection with a coiled tubing. The upper connector and the lower connector can also be connected with the spray head. The clamping jaw can be opened through hydraulic force, an opening-closing type fracturing sliding sleeve is opened and closed through the clamping jaw, and the clamping jaw can be retracted through resilience of the spring after the opening-closing action is finished. Even though on the condition that the clamping jaw cannot be normally retracted when a sand clamp or the spring loses efficacy, hydraulic force can also be used for clipping a safety pin to retract the clamping jaw in a forced mode, and the reliability of the tool is greatly improved. In addition, settling sand in the fracturing sliding sleeve can be removed by rotating the spray head, foreign matter such as sand gravels can be effectively prevented from limiting sliding of the sliding sleeve, and operation success rate is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Self-radiating-type fracture nursing splint

InactiveCN107349043APlay a role in coolingHeat dissipationFractureTherapeutic coolingType fractureMedicine

The invention discloses a self-radiating-type fracture nursing splint which comprises strip-shaped air bags, a first splint body and a second splint body. The first splint body and the second splint body are connected and fixed through a hinge, and the left side of the first splint body and the right side of the second splint body are provided with a plurality of binding belts correspondingly. The cross sections of the first splint body and the second splint body are each in an arc shape, and the inner sides of the first splint body and the second splint body are each provided with an arc-shaped large cushion body. The multiple strip-shaped air bags are distributed on the upper surfaces of the large cushion bodies at equal intervals, and the interiors of the strip-shaped air bags communicate with the large cushion bodies. A one-way air inlet valve is installed on each large cushion body, hollow-out grooves are formed in the middles of the first splint body and the second splint body, and long-strip-shaped installation frames matched with the splint bodies in shape are arranged in the hollow-out grooves. The installation frames are internally provided with a plurality of tightly-arranged semiconductor-refrigerating chips from top to bottom, and the multiple semiconductor-refrigerating chips arranged in the middles of the splint bodies achieve the cooling and radiating effects, so that when wearing the splint, a patient does not feel stuffiness, the use comfort of the patient is increased, and recovery of the patient is facilitated.

Owner:杨露萍

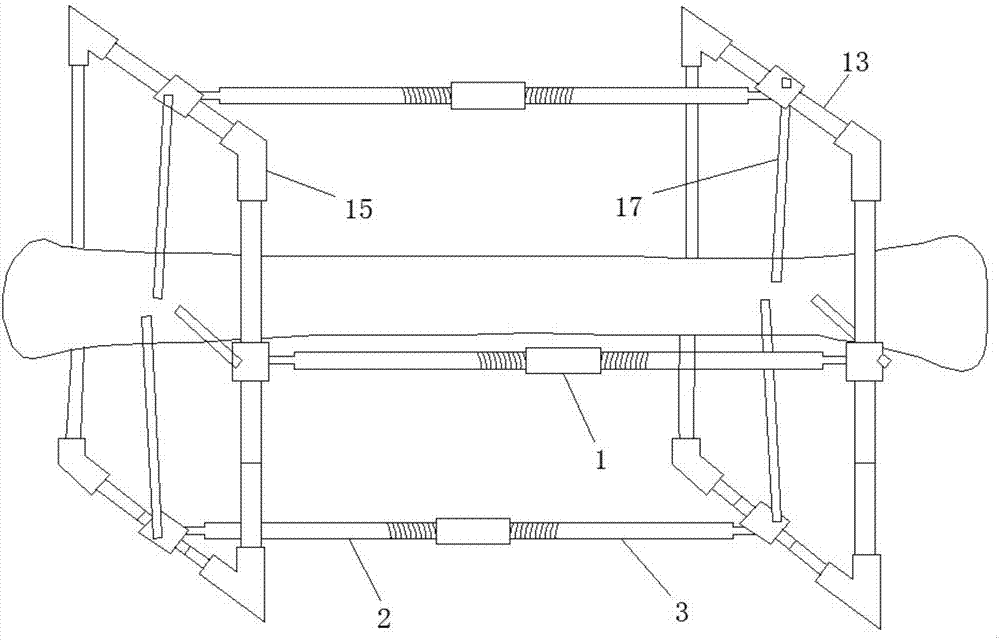

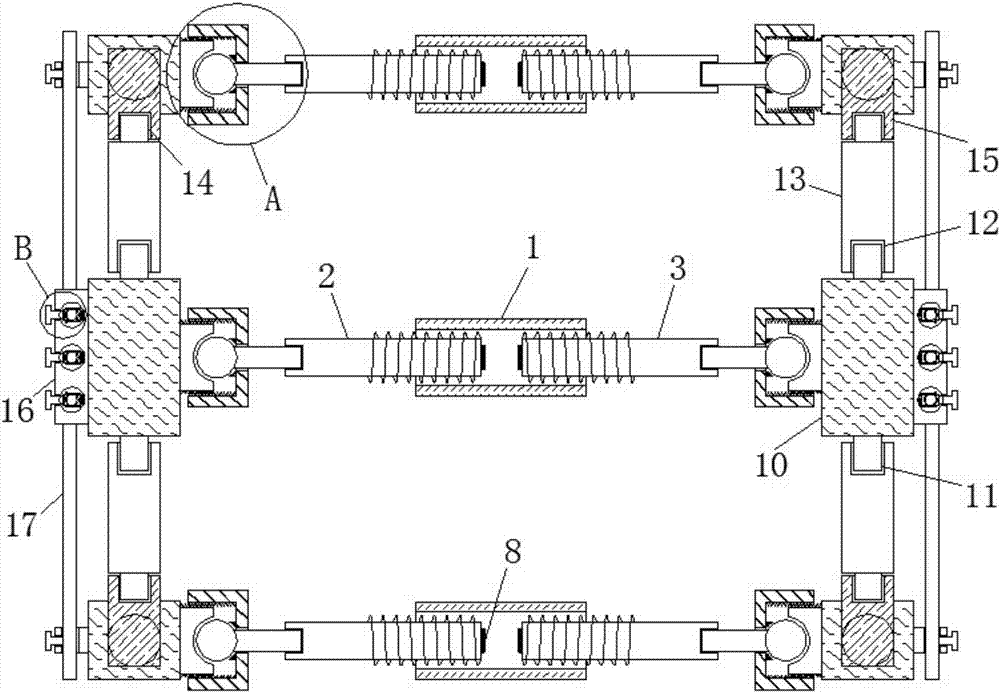

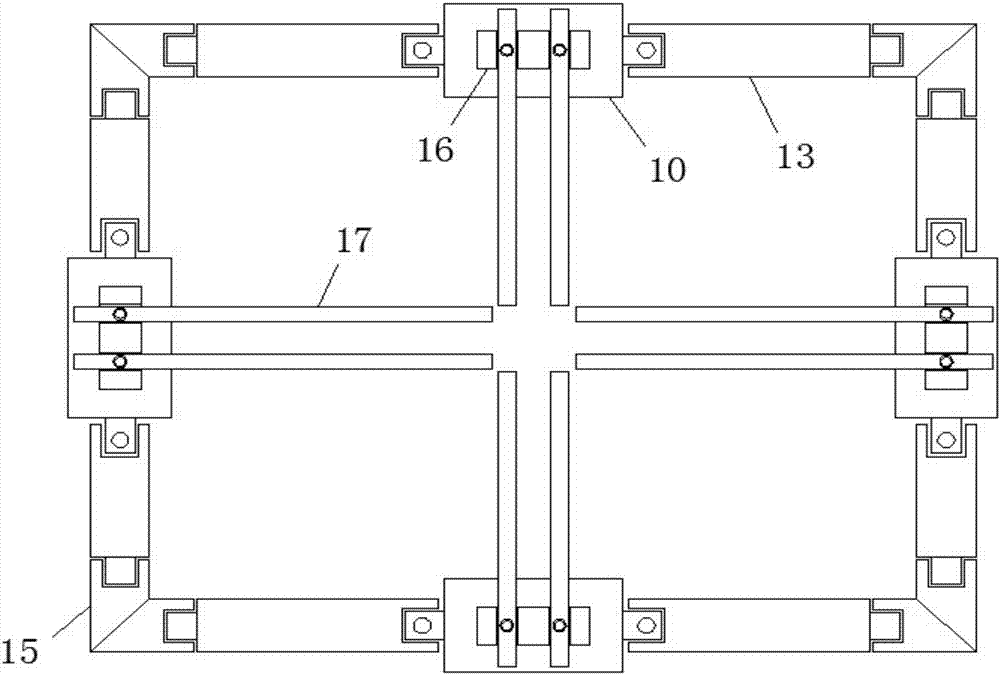

Composite type fracture test loading device

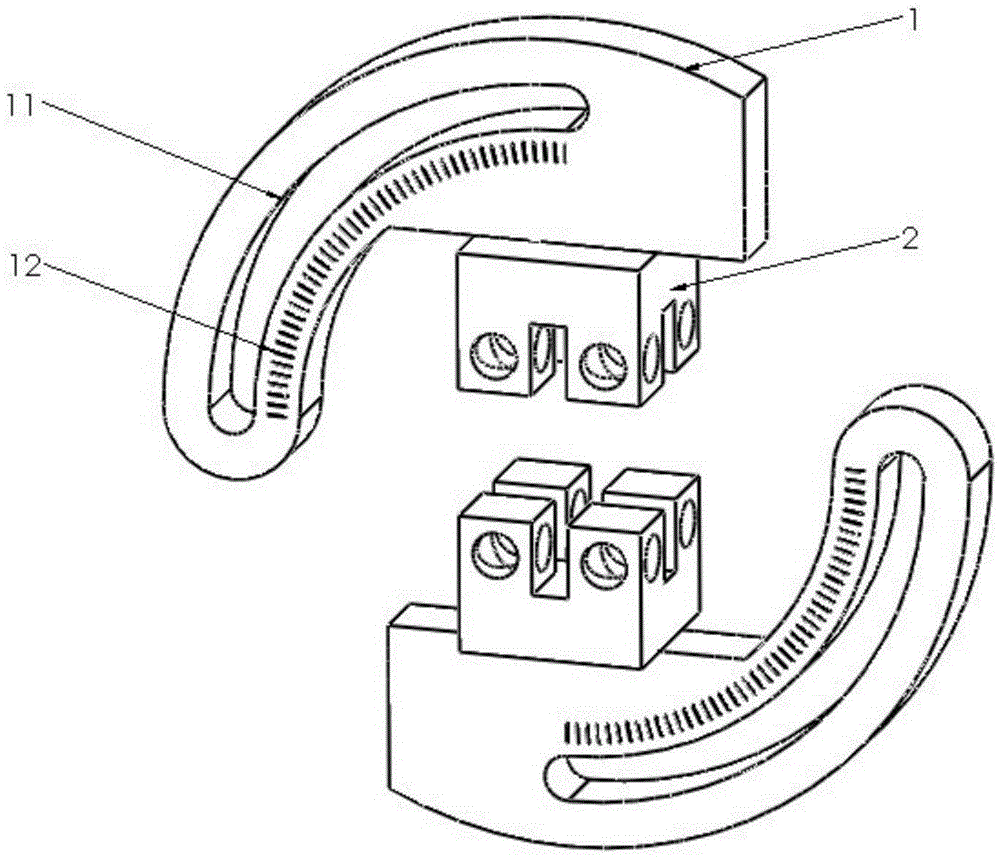

ActiveCN105403450AAvoid adjustmentAvoid the disadvantages of inconvenient clamping and disassemblyMaterial strength using tensile/compressive forcesCruciformType fracture

The invention relates to a composite type fracture test loading device including a pair of C-shaped arc plates which face each other in the vertical direction and are coplanar; each C-shaped arc plate is provided with a circular arc chute for fixing the C-shaped arc plate on a testing machine through positioning bolts; the inner walls of the C-shaped arc plates also are respectively fixedly provided with cross fixing parts facing each other in the vertical direction; the cross-shaped parts are each provided with a cross-shaped groove for clamping a specimen, each cross-shaped groove comprises a first clamping groove and a second clamping groove vertically crossed with each other, and each cross-shaped fixing part surface is divided into four convex stand columns by the cross-shaped groove, each stand column is provided with fixing holes having two axes perpendicular to each other and corresponding to connecting holes on the specimen, and each fixing hole is internally provided with a bolt for connecting the specimen and fixing the specimen in the cross-shaped groove. The I / II type and I / III type composite fracture test loading is achieved, and the test loading device having simple structure and continuously adjustable angle is provided for studies of fracture properties of materials.

Owner:GUILIN UNIV OF ELECTRONIC TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com