Patents

Literature

295 results about "Fracture test" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fracture test. Macro- or microscopic examination of a fractured surface to determine characteristics such as grain pattern, composition, or the presence of defects. A test designed to evaluate fracture stress.

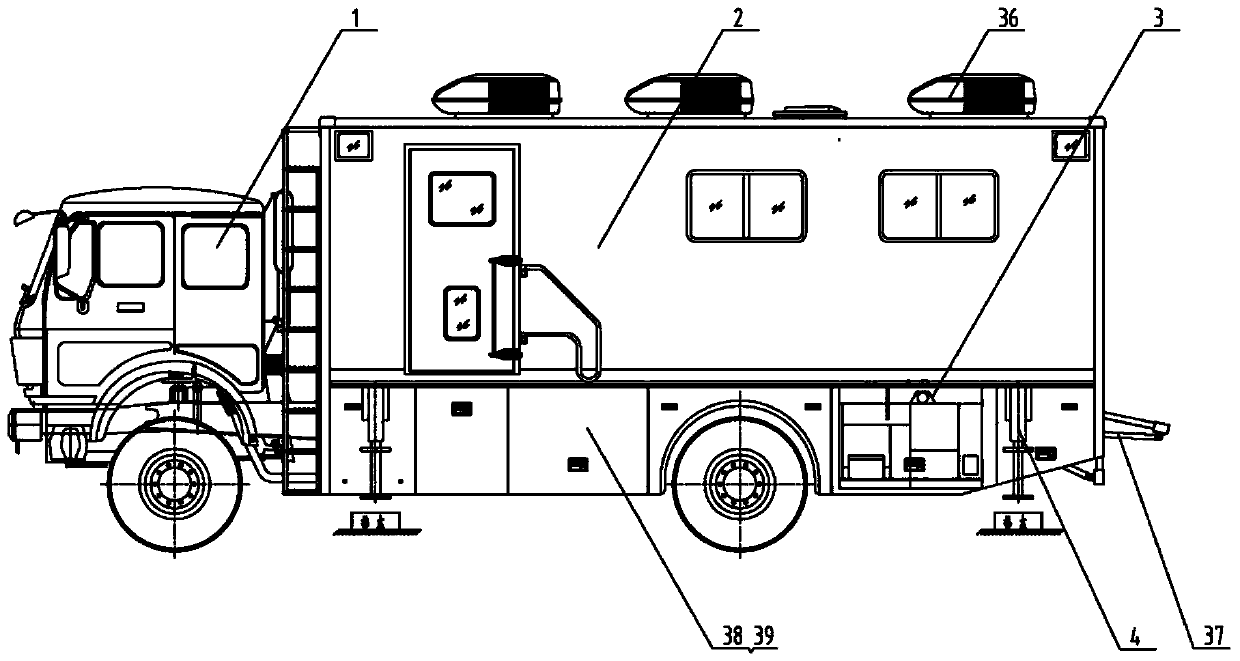

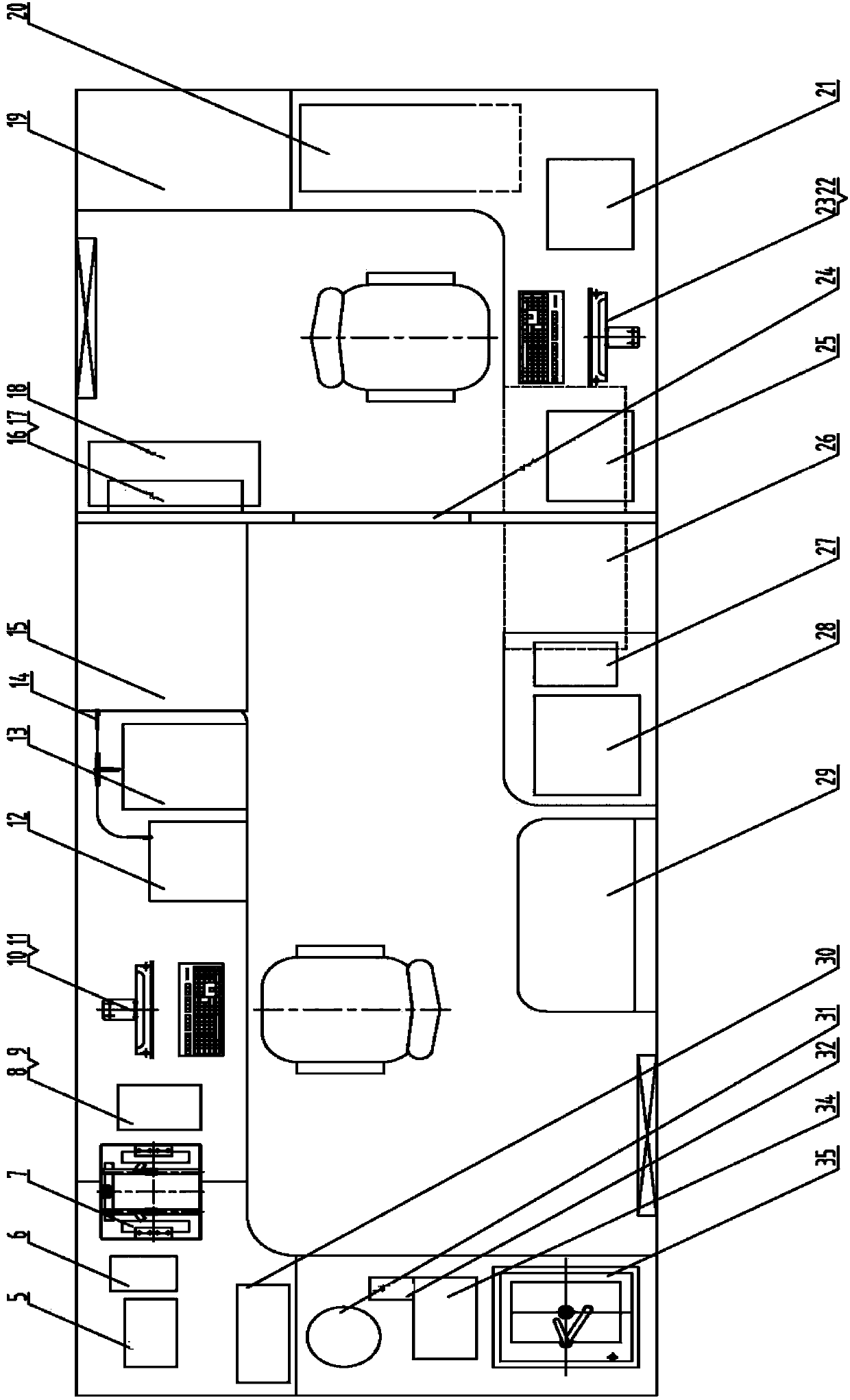

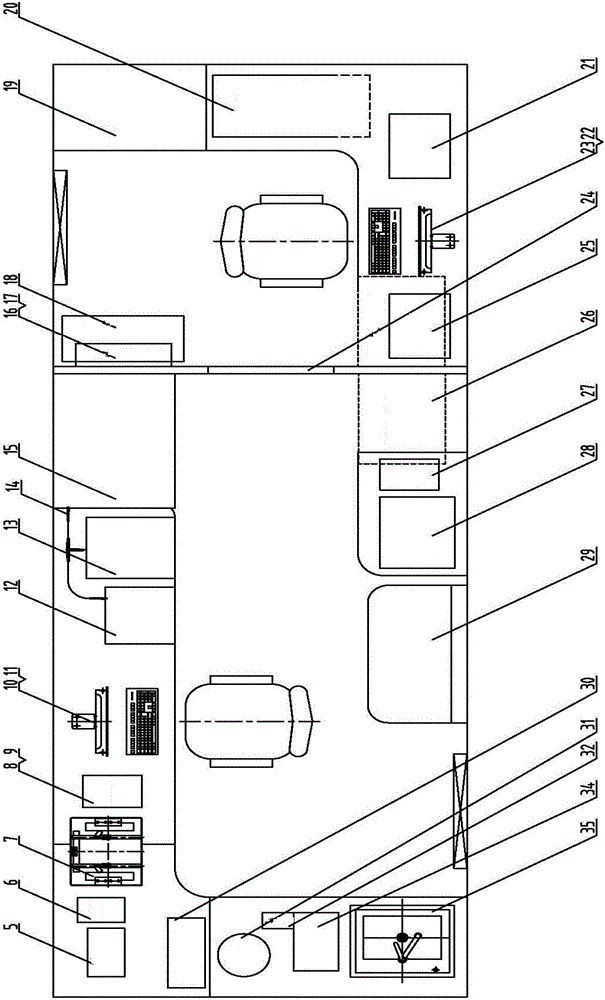

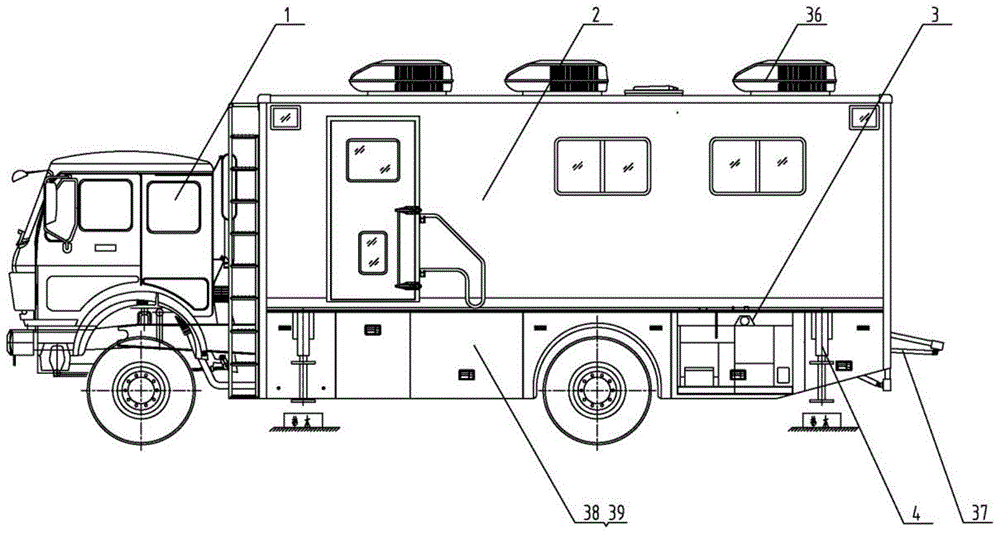

Online fracturing test vehicle

ActiveCN104369687AGuaranteed shock absorptionEasy to useFluid removalItem transportation vehiclesOnline testFracturing fluid

The invention relates to an online fracturing test vehicle. The online fracturing test vehicle comprises a chassis, a shelter, a back protection device, a skirt edge box, a heating system and an automatic leveling device, wherein the shelter is mounted at the upper part of the chassis; the back protection device is mounted at the back end of the chassis; the skirt edge box and a generator are mounted at the side of the chassis; the automatic leveling device is mounted at four corners of the bottom of the chassis; the heating system is mounted at the top of the chassis; the shelter is integrated with an experiment instrument for a fracturing fluid test and a support agent analysis evaluation test; and the experiment instrument for the fracturing fluid test and the support agent analysis evaluation test is mounted on the chassis provided with the shelter, so that the online test can be performed on spot, the detecting accuracy and preciseness can be improved, and the detecting efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

An online testing vehicle for fracturing

ActiveCN104369687BImprove accuracyHigh precisionFluid removalItem transportation vehiclesOnline testFracturing fluid

The invention relates to an online fracturing test vehicle. The online fracturing test vehicle comprises a chassis, a shelter, a back protection device, a skirt edge box, a heating system and an automatic leveling device, wherein the shelter is mounted at the upper part of the chassis; the back protection device is mounted at the back end of the chassis; the skirt edge box and a generator are mounted at the side of the chassis; the automatic leveling device is mounted at four corners of the bottom of the chassis; the heating system is mounted at the top of the chassis; the shelter is integrated with an experiment instrument for a fracturing fluid test and a support agent analysis evaluation test; and the experiment instrument for the fracturing fluid test and the support agent analysis evaluation test is mounted on the chassis provided with the shelter, so that the online test can be performed on spot, the detecting accuracy and preciseness can be improved, and the detecting efficiency is improved.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

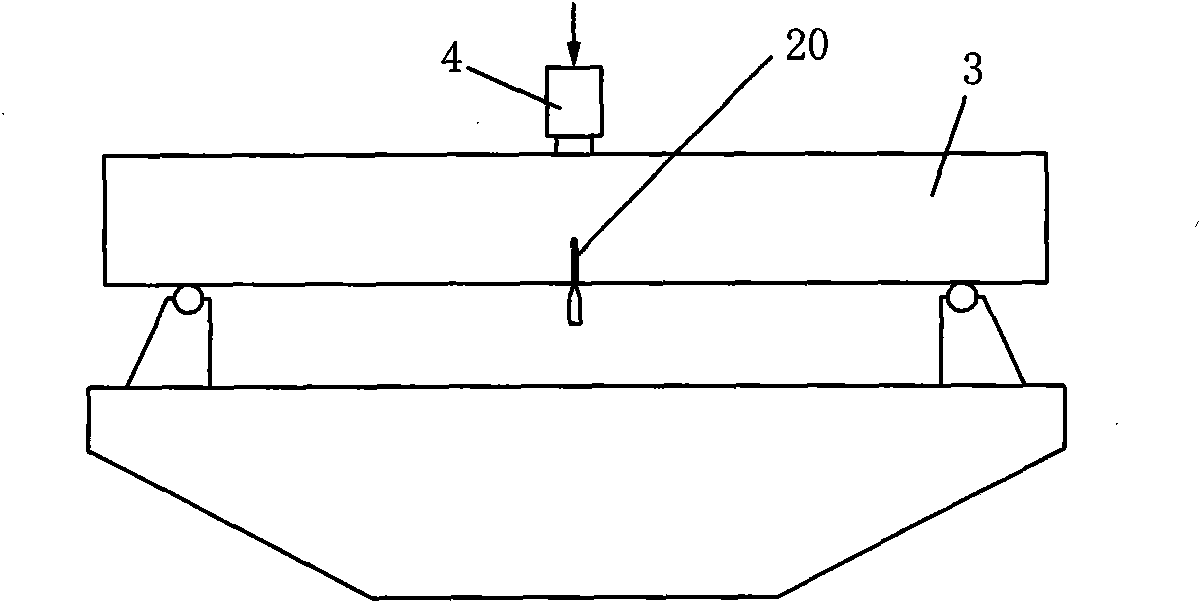

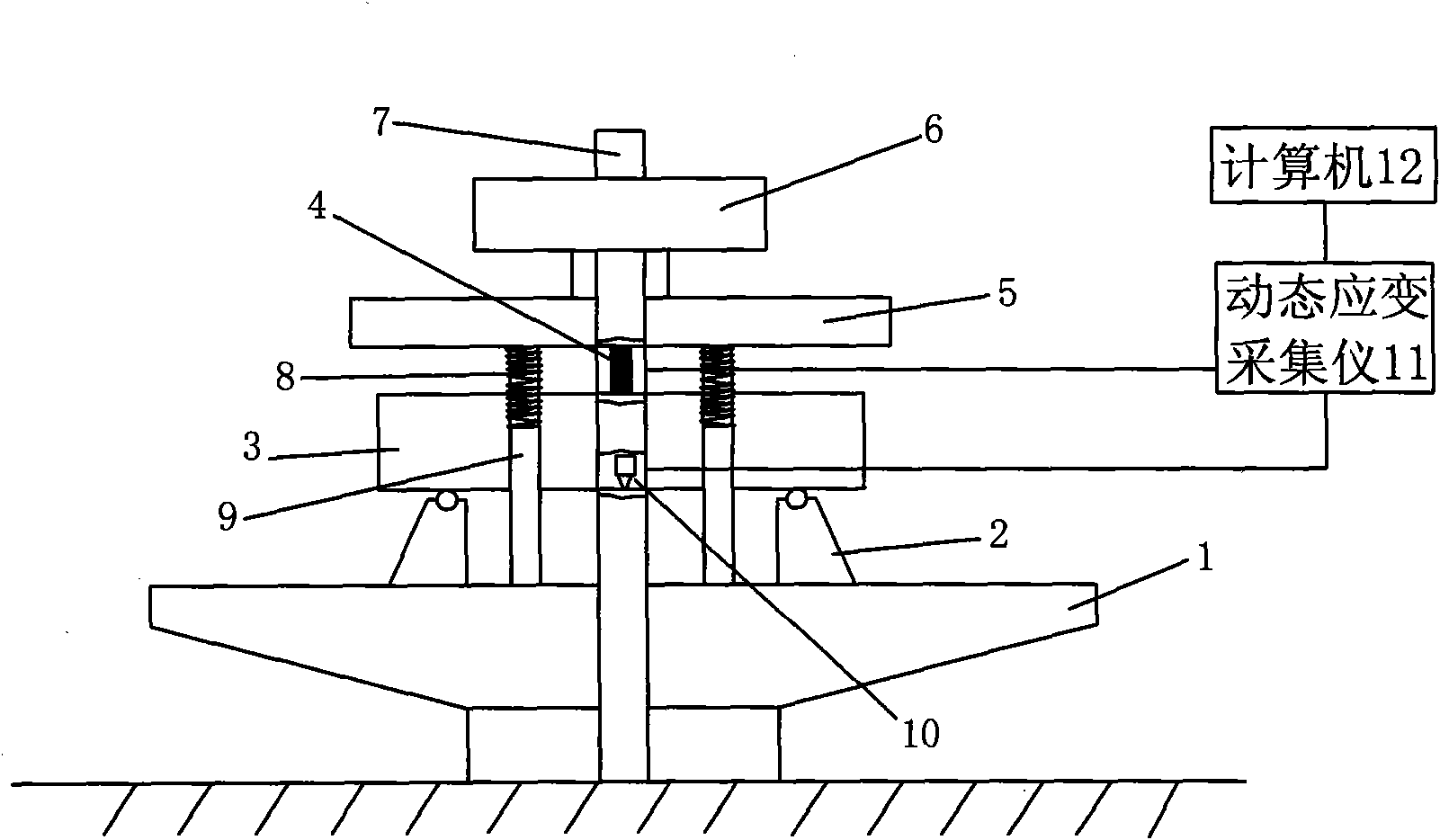

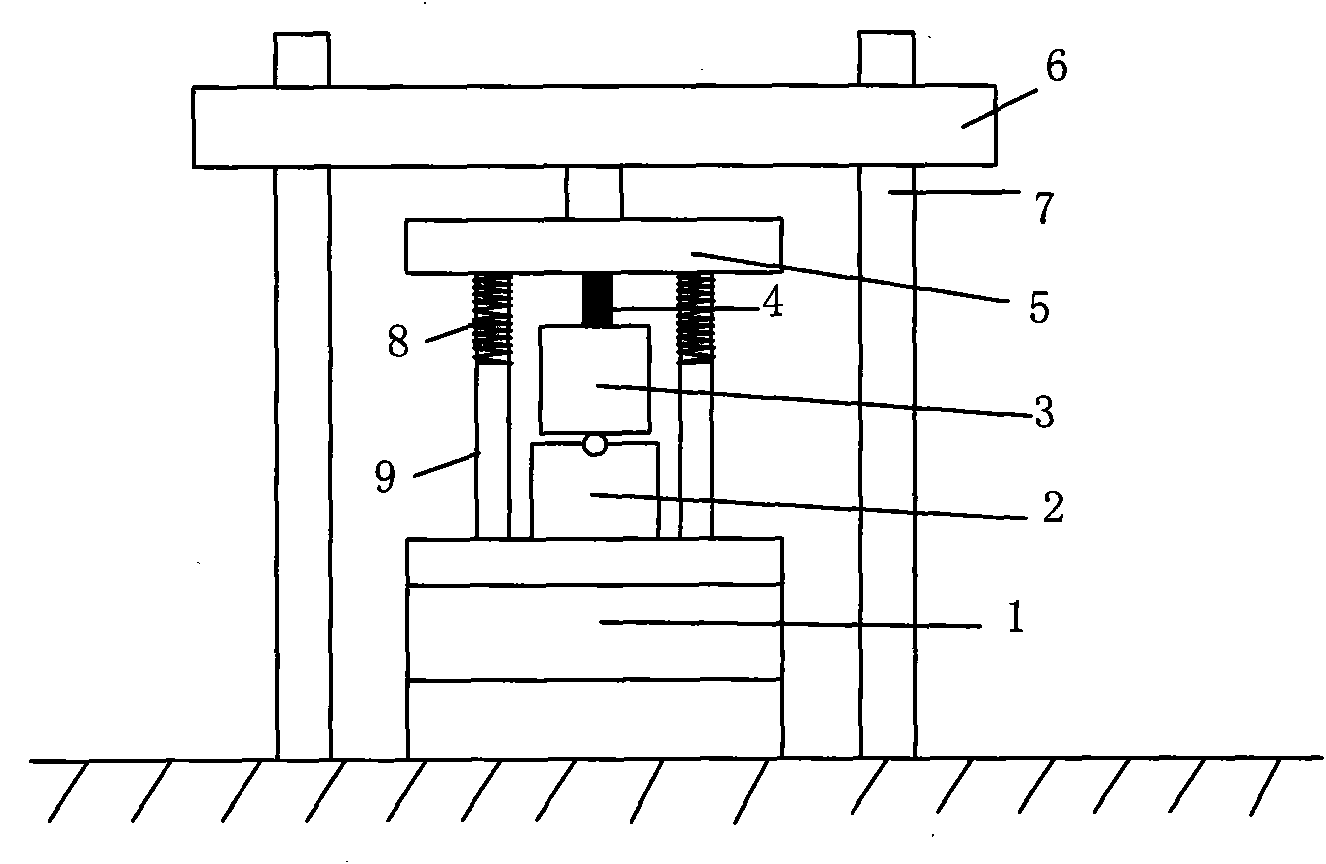

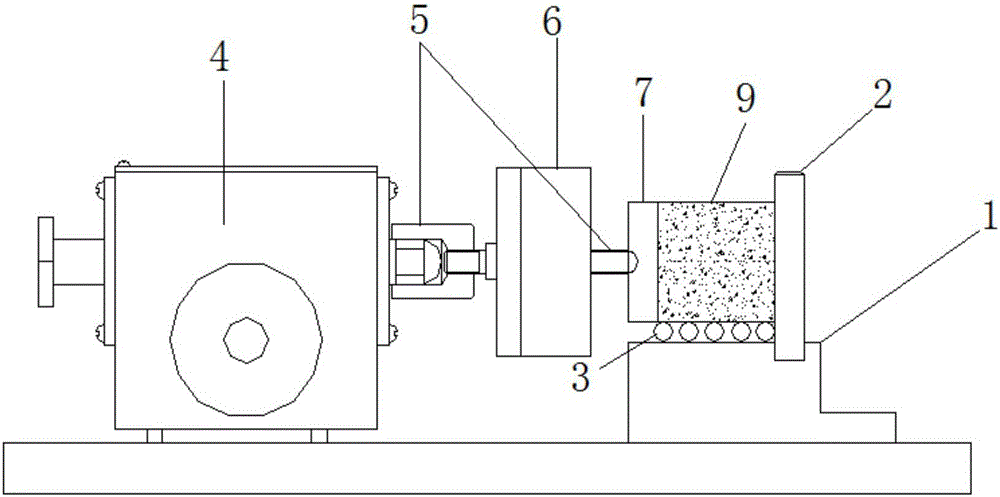

Concrete fracture test system and test method thereof

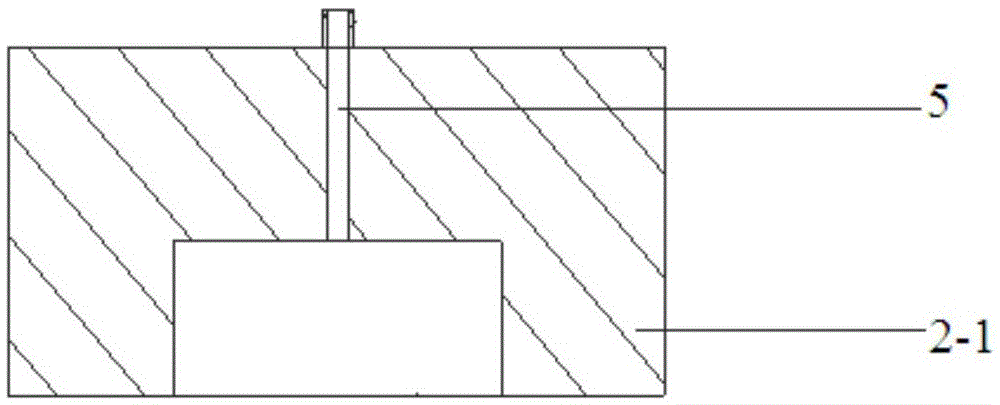

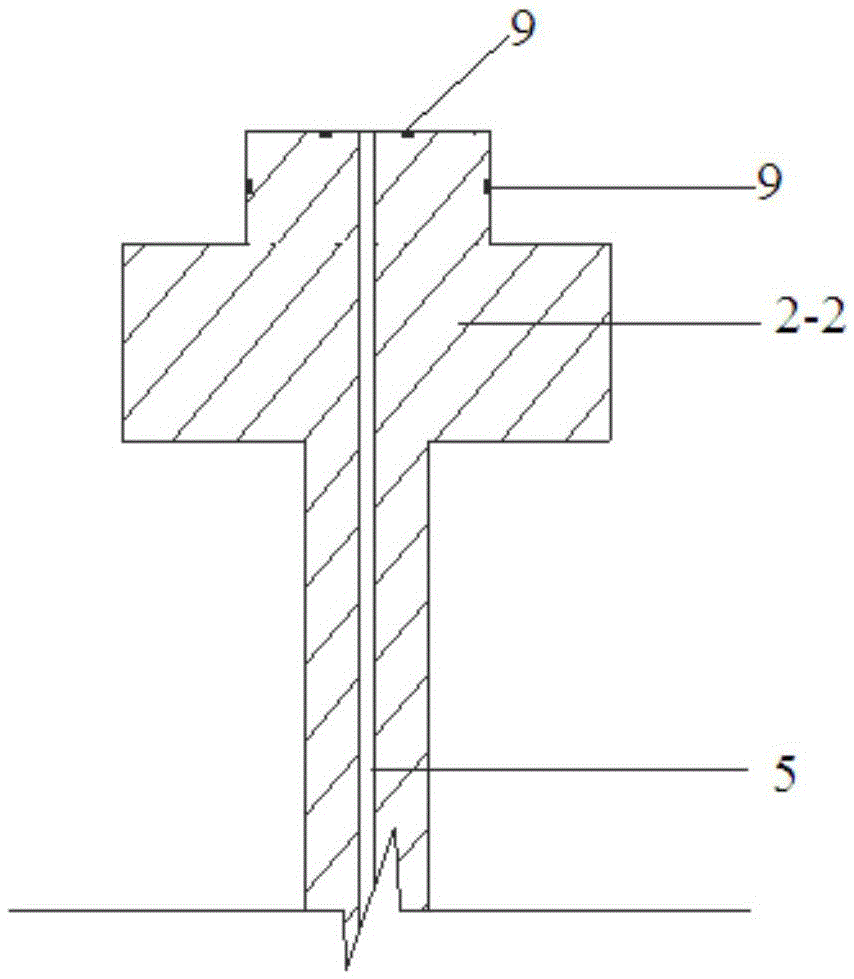

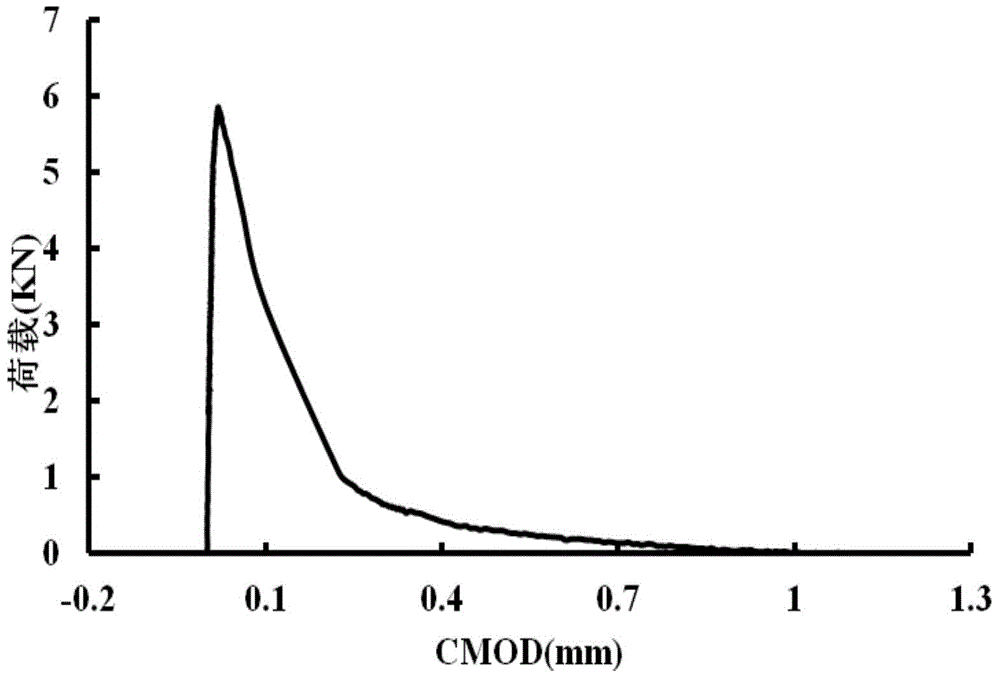

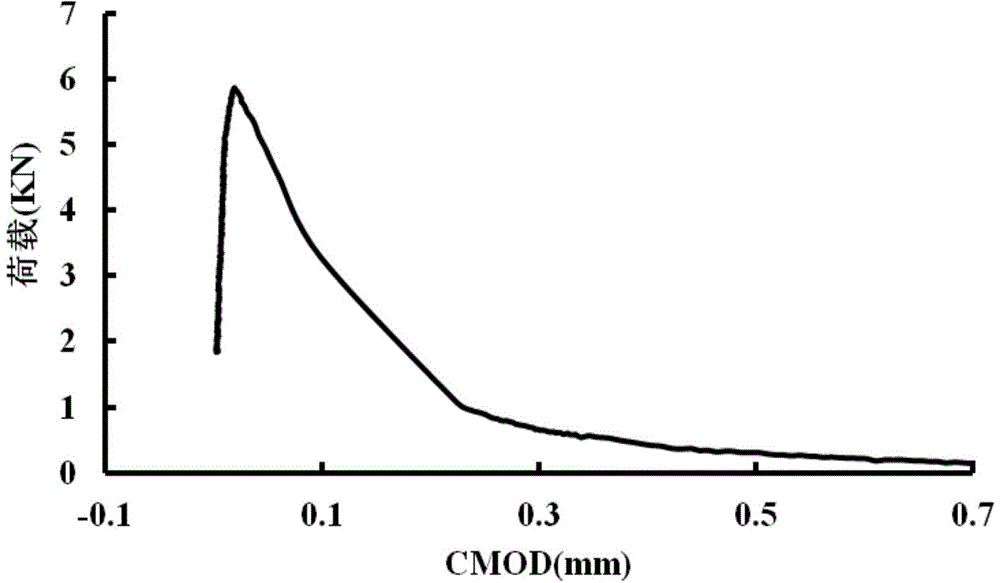

InactiveCN101975701ASmall loadMeet load rate requirementsMaterial strength using steady bending forcesContact pressureData acquisition

The invention relates to a concrete fracture test system and a test method thereof, and belongs to the technical field of concrete material performance test. The system comprises a measurement system and a data acquisition and processing system; a support for supporting a concrete test piece and even cushion posts symmetrically positioned on the surrounding side of the concrete test piece are arranged on a pressure tester platform of the measurement system; and springs which extend out of the tops of the cushion posts and are higher than pressure sensors are sleeved on the cushion posts. The method comprises the following steps of: when a top plate moves relative to the platform by adopting the system, making the top plate contact the springs and then contact the pressure sensors; when the top plate is contacted with the pressure sensors, controlling the load loaded onto the concrete test piece to be continuously loaded with low loading rate till the concrete test piece cracks, destabilizes and is damaged; and meanwhile, acquiring a load signal and a crack opening displacement signal and transmitting the signals to a computer. The system and the method can acquire a fine load-displacement curve so as to calculate an accurate concrete double-K fracture parameter.

Owner:胡少伟

Method for visually monitoring fracture crack

InactiveCN101968348AFor the purpose of visualizationUsing fluid meansFracturing fluidRoom temperature

The invention relates to a method for visually monitoring a fracture crack, which comprises the steps of: with a room-temperature cured type fluid material as a fraction fluid, injecting the fluid material into a wellbore hole simulator of a core sample, filling the fluid material into the crack and fully filling into the crack when the core sample is fractured to generate the crack; and after the fluid material is cured to form a simulated crack, taking the simulated crack out and observing the form of the simulated crack. The prepared concrete core sample is subjected to a fracture test in an experiment room by selecting silicon oil and fluid silicon gel as the fracture fluid, and after the fracture fluid is filled into the fracture crack and cured, the silicon gel simulated crack is taken out, and the expansion form of the crack can be represented by observing the form of the simulated crack, therefore, the method for visually monitoring the fracture crack achieves the purpose of visualization.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

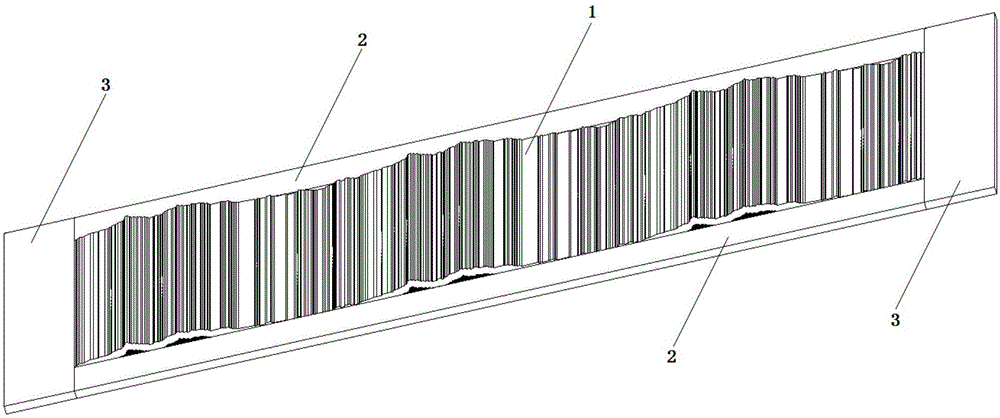

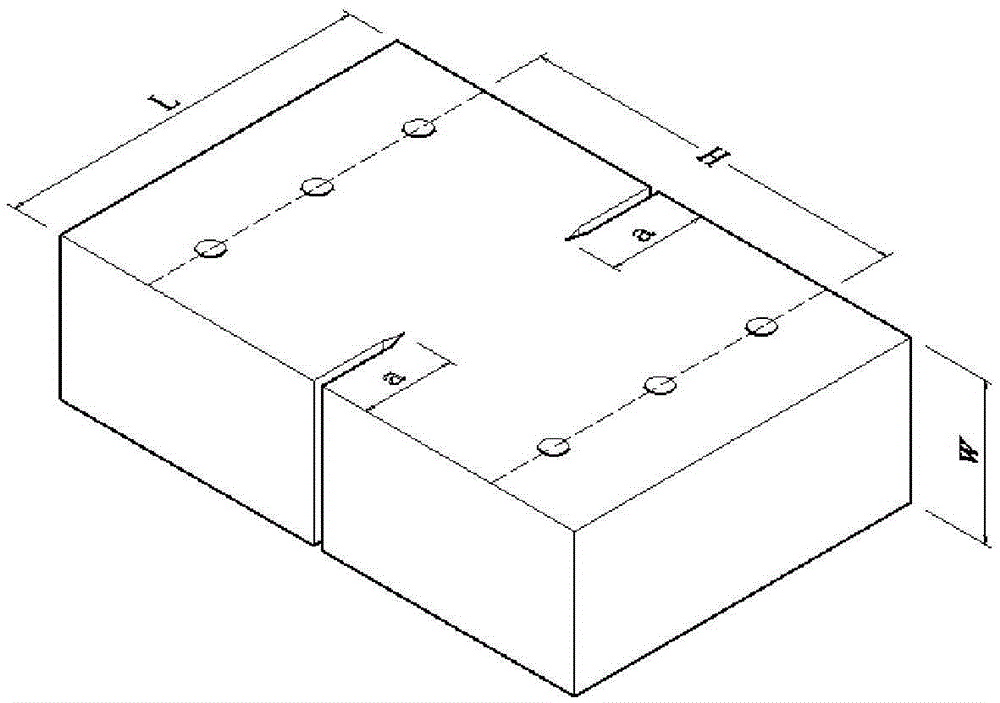

Manufacturing method of simulation fracture for fractured rock mass seepage test

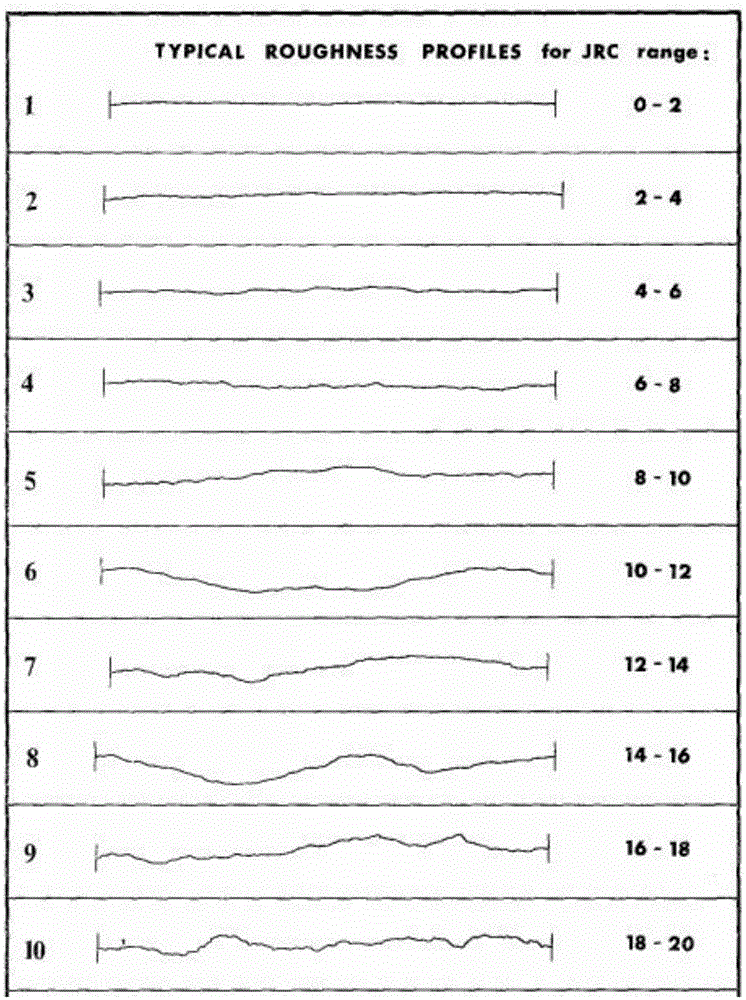

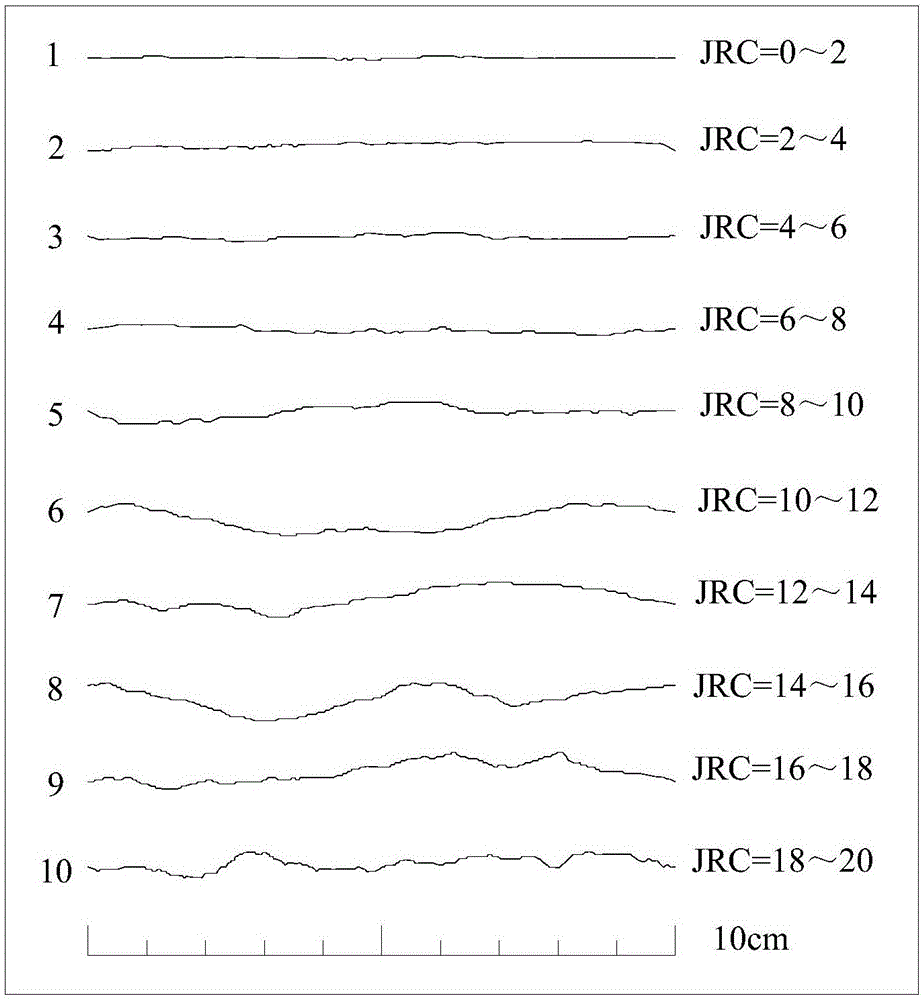

InactiveCN105158039AOvercome limitationsHigh precisionPreparing sample for investigationPermeability/surface area analysisComputer Aided DesignSurface roughness

The invention discloses a manufacturing method of a simulation fracture for a fractured rock mass seepage test. The manufacturing method comprises the steps of drawing a fracture digitized profile curve, constructing a fracture three-dimensional model, making a fracture plate through 3D (three-dimensional) printing, making a fracture test piece casting model and performing casting and maintenance of a fracture test piece, specifically, through digitizing a rock structural surface joint roughness profile curve, drawing the fracture three-dimensional model on the basis of CAD (Computer Aided Design) software, making the fracture plate satisfying JRC value fluctuation by adopting a 3D printing technology, making the fracture test piece casting model by combining the fracture test piece, forming by using cement mortar to cast, and making the fracture test piece by performing maintenance in a cement test piece maintenance box for 28 days. The manufacturing method has the beneficial effects: the manufacturing method of rock rough fracture analogue simulation which is easy in observing, simple in manufacturing, convenient in testing, convenient for adjusting fracture opening, and capable of truly and accurately reflect rock mass fracture structural surface roughness is provided, the working procedures are simple and clear, the manufacturing duration is short, economy and efficiency are realized, the accuracy is high, and the adaptability is good.

Owner:HOHAI UNIV

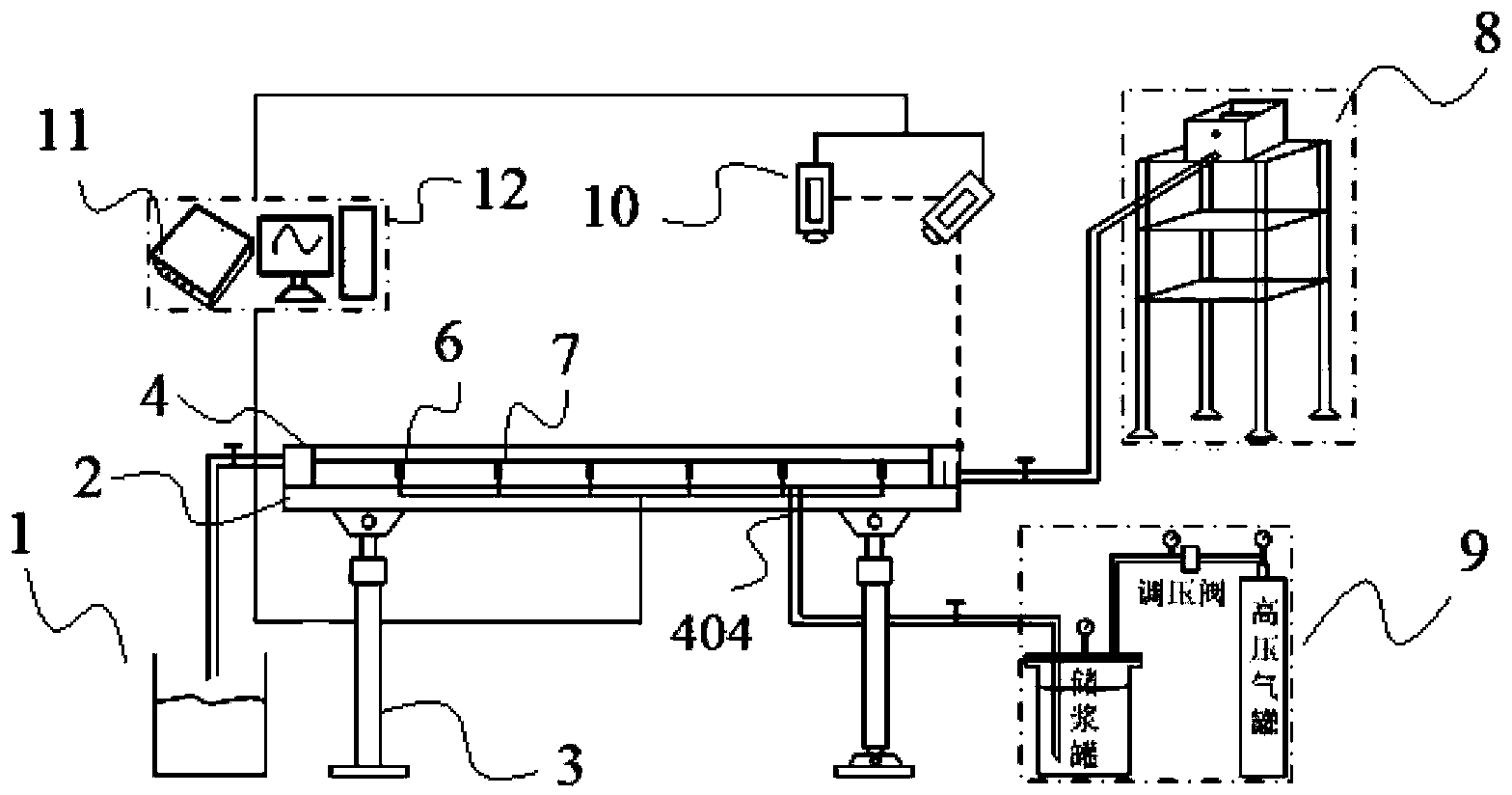

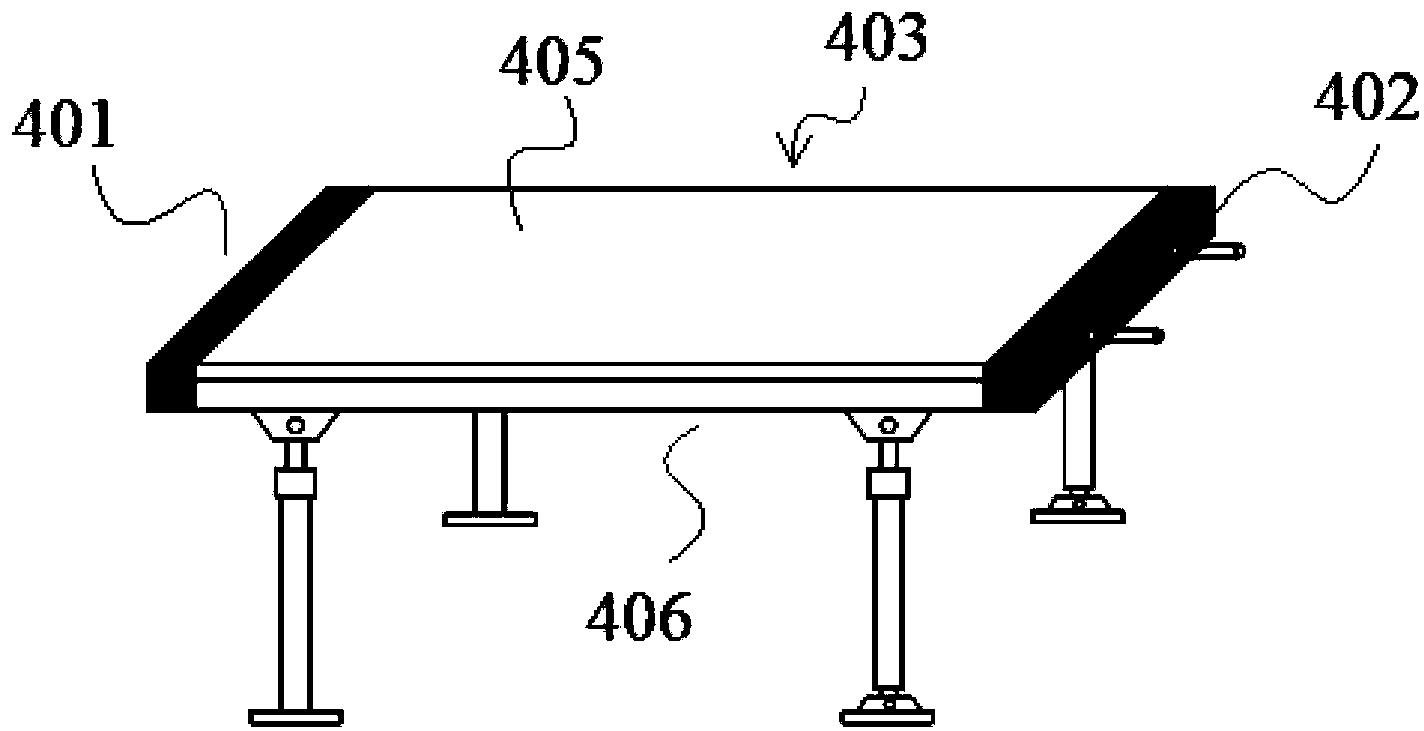

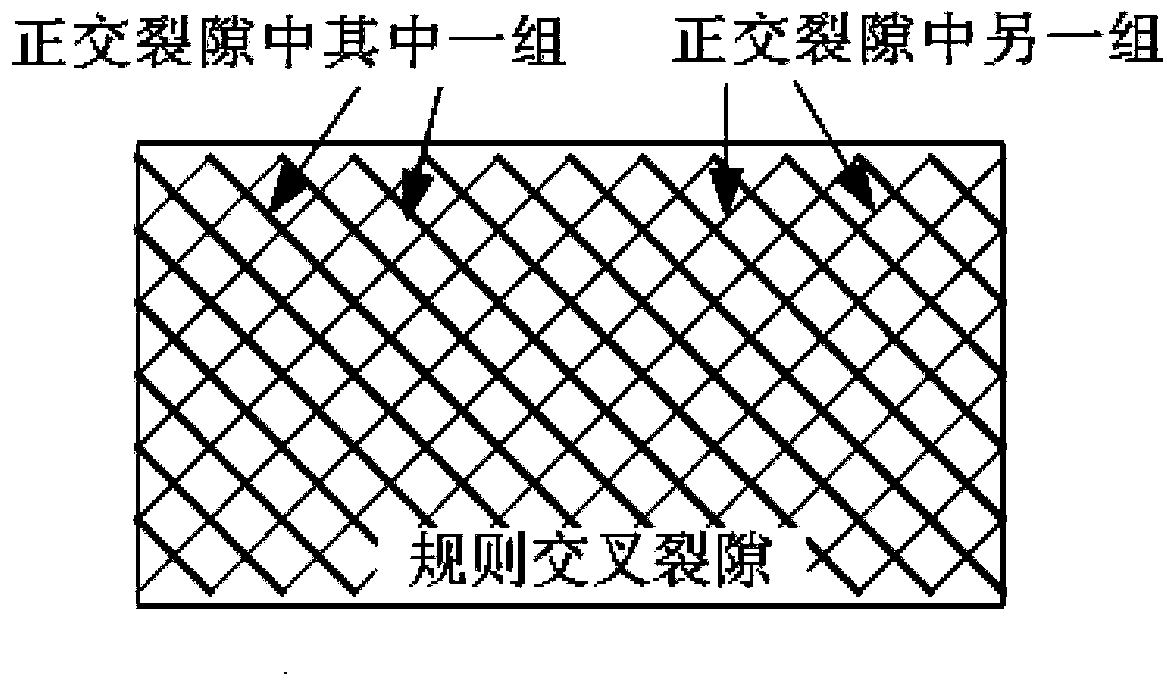

Visual intersected fracture flowing water grouting test device and method

ActiveCN103411751ARealize grouting simulation testRealize analysisHydrodynamic testingSlurryAtmospheric pressure

The invention discloses a visual intersected fracture flowing water grouting test device and method. The visual intersected fracture flowing water grouting test device comprises a grout collection device and further comprises an intersected fracture platform. The intersected fracture platform comprises supporting frames, an intersected fracture test room arranged on the supporting frames, intersected fractures arranged on the inner wall of the intersected fracture test room, flow sensors arranged inside the intersected fracture test room, and pressure sensors arranged inside the intersected fracture test room. The visual intersected fracture flowing water grouting test device further comprises a flowing water supply device used for injecting water for the intersected fracture test room and an air pressure grouting device used for grouting for the intersected fracture test room, and the intersected fracture test room is connected with the grout collection device. The visual intersected fracture flowing water grouting test device and method can achieve grouting simulation test and analysis under the conditions of the intersected fractures and flowing water.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

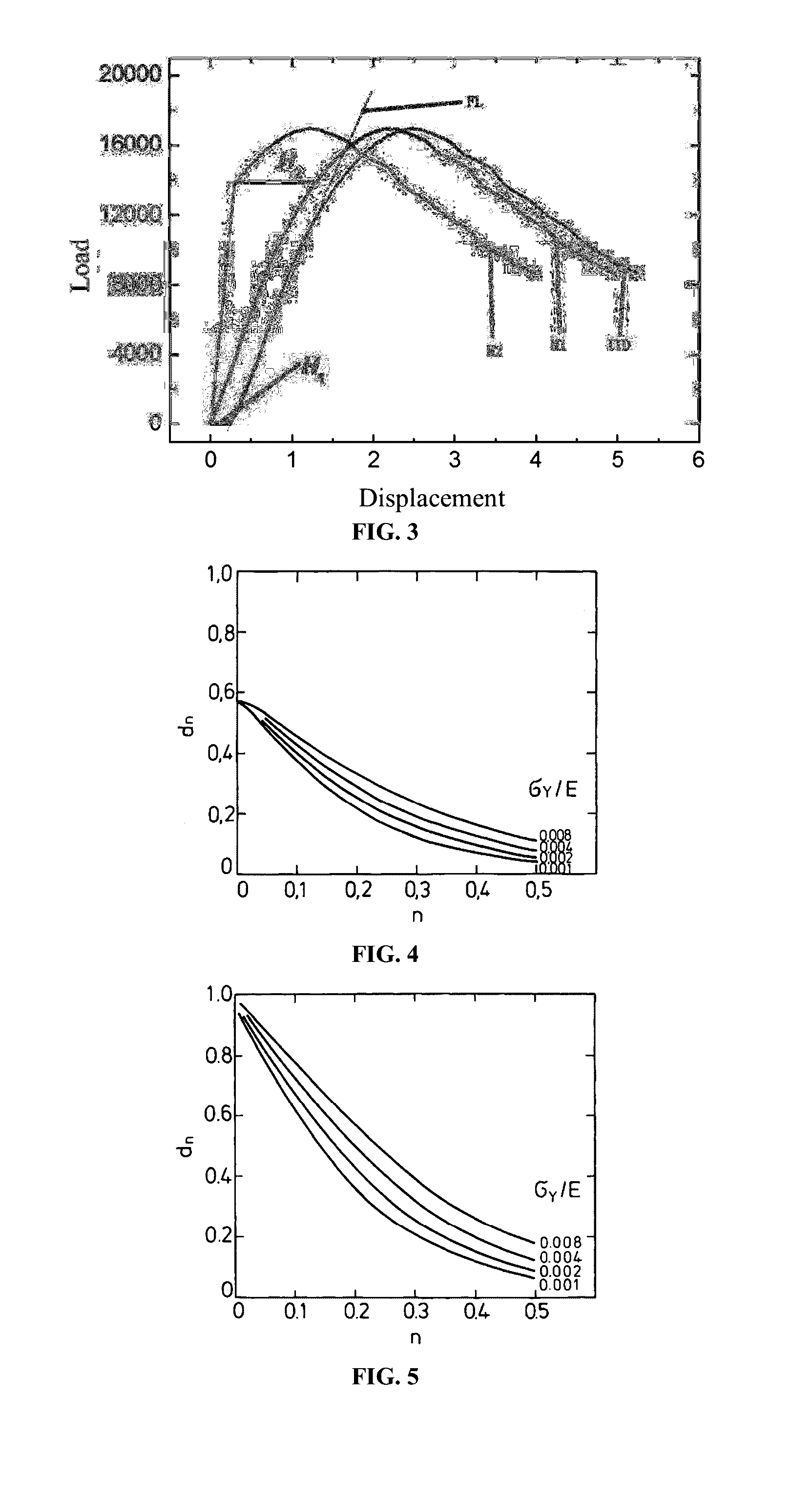

A method of measurement and determination on fracture toughness of structural materials at high temperature

ActiveUS20160299046A1Material strength using tensile/compressive forcesInvestigating material ductilityEquivalent weightFracture test

Disclosed is a method of measurement and determination on fracture toughness of structural materials at high temperature, comprising: preliminary assessing the ductility of a material based on a high-temperature uniaxial tensile test and the fracture characteristic; designing and manufacturing a CT specimen; conducting a monotonic loading fracture test on the CT specimen at high temperature; modifying a load-displacement curve output by a testing machine; determining a passivation coefficient M for the crack of the structural material; reversely recursing instant load-displacement data pairs corresponding to the instant crack length; calculating a J_R crack extension resistance curve of the tensile test; examining the validity of the J_R crack extension resistance curve and the fracture toughness JIC; calculating the fracture toughness per equivalent of the structural material KIC. The present invention overcomes the difficulty of placing an extensometer inside a high-temperature furnace.

Owner:EAST CHINA UNIV OF SCI & TECH +1

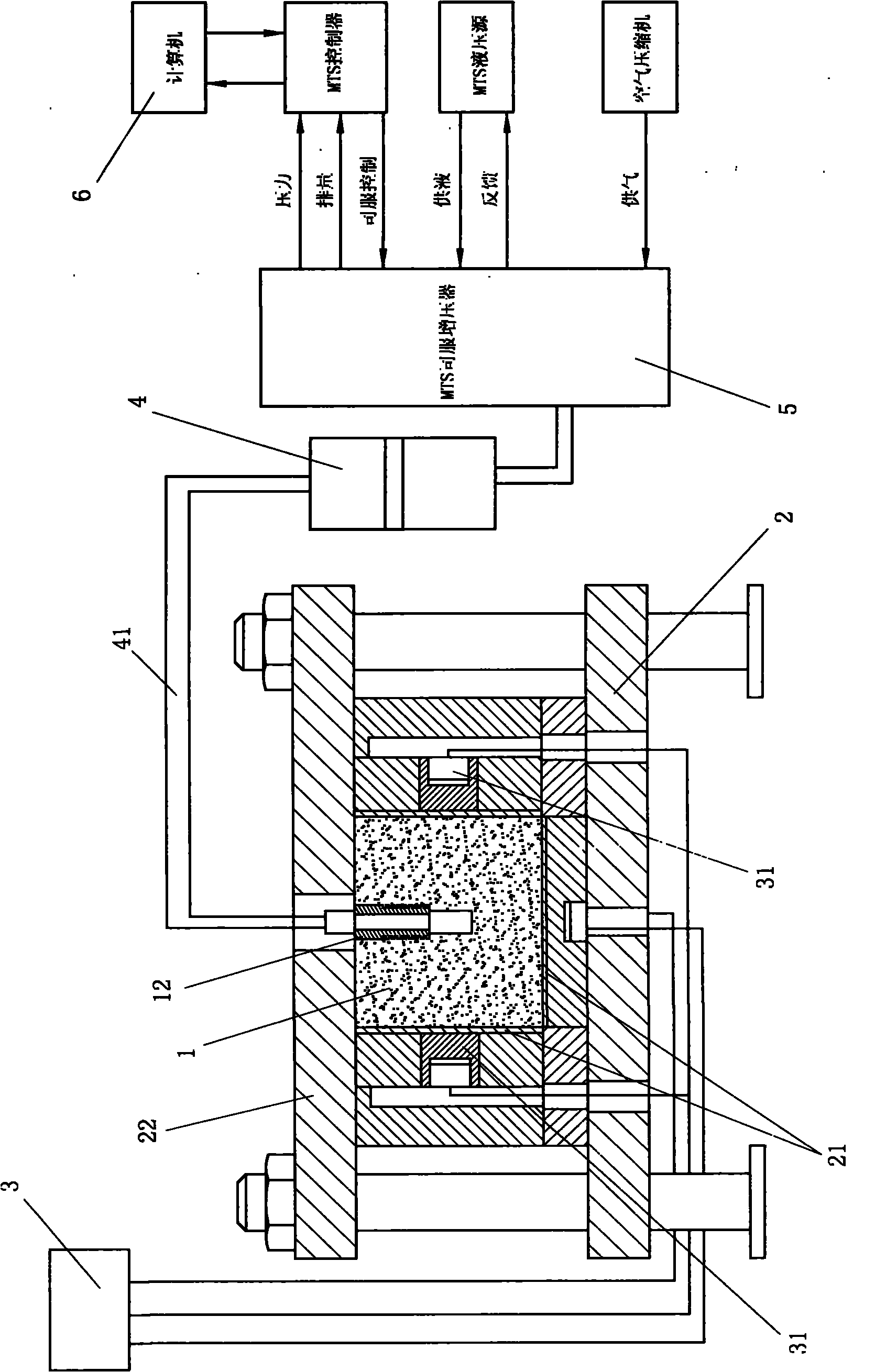

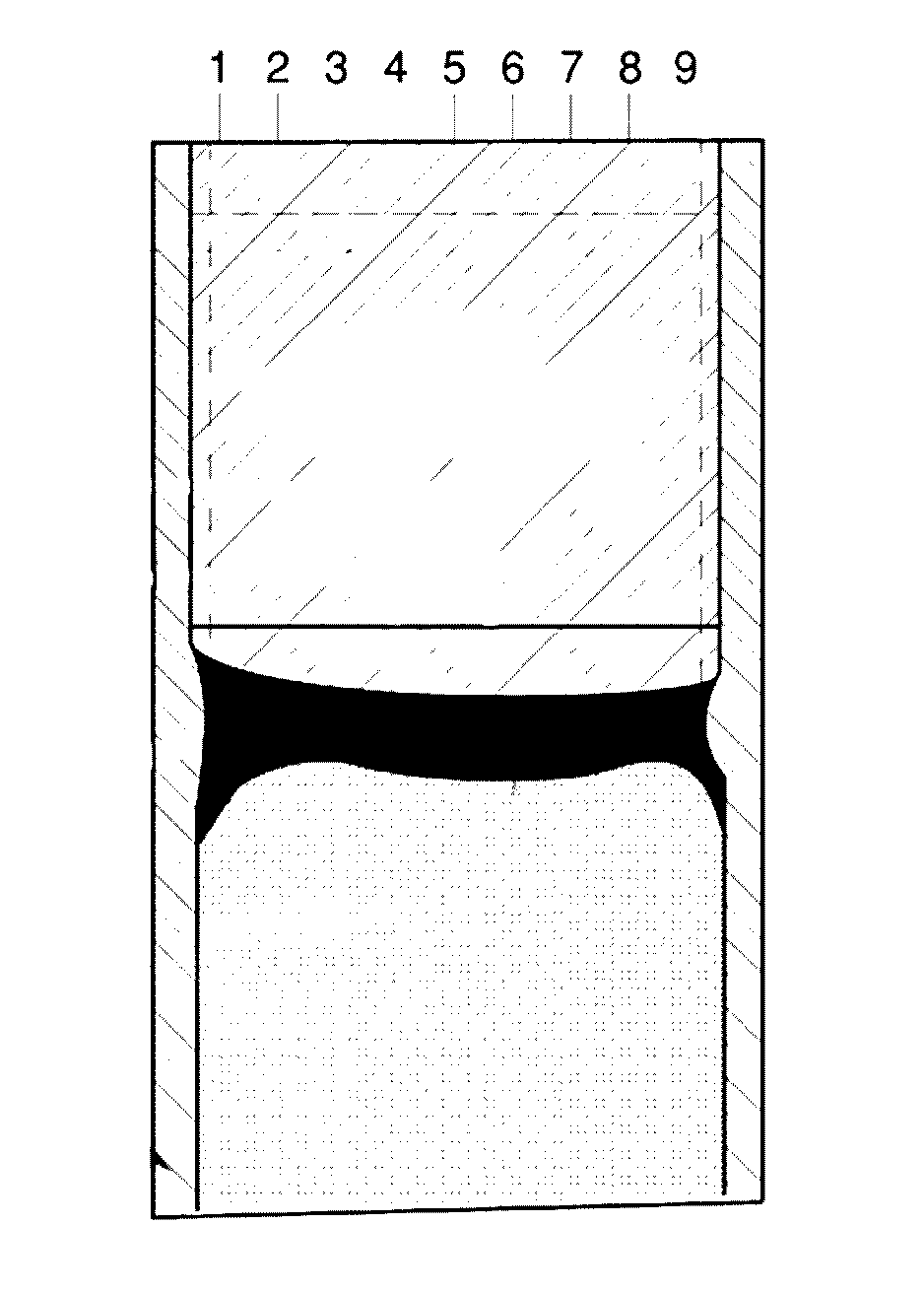

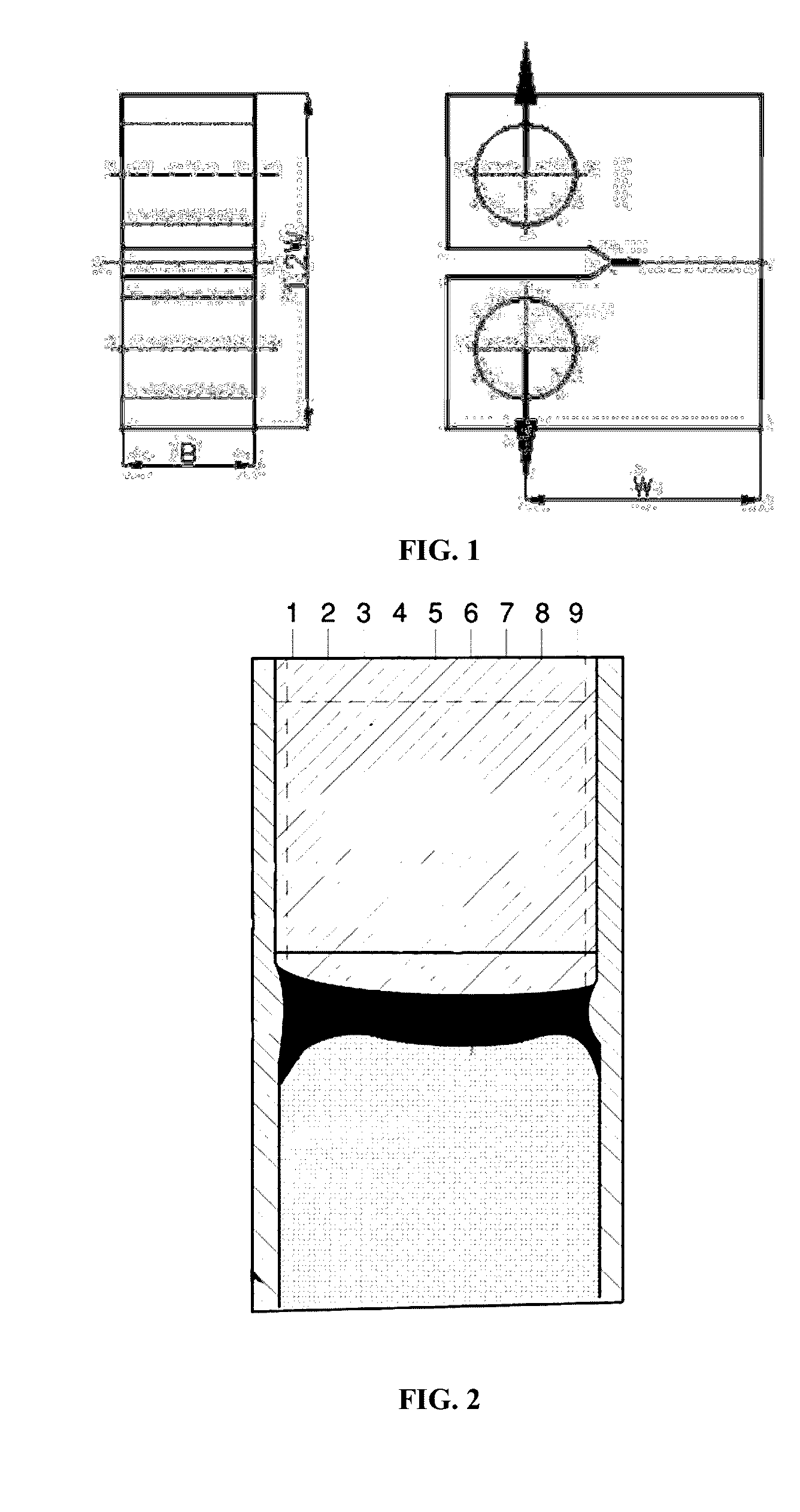

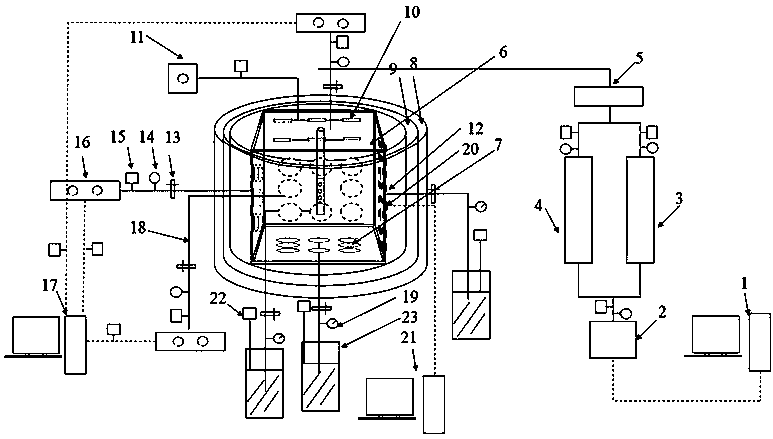

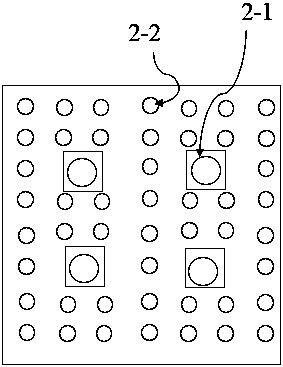

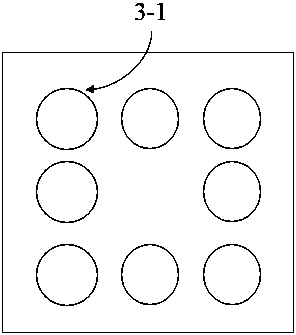

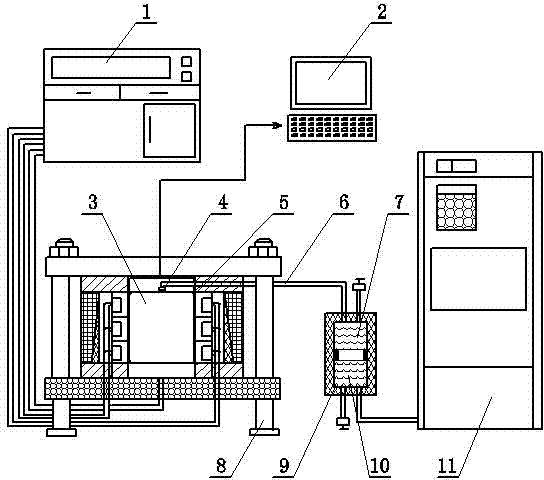

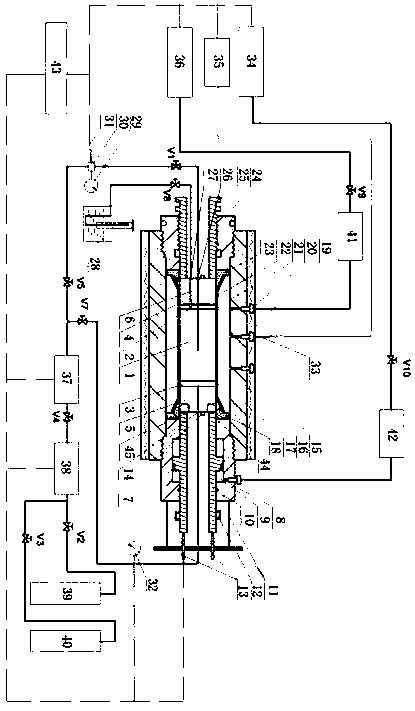

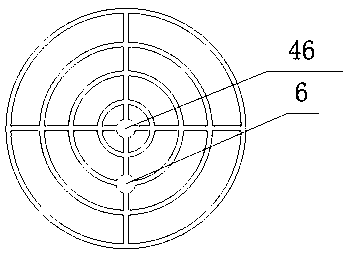

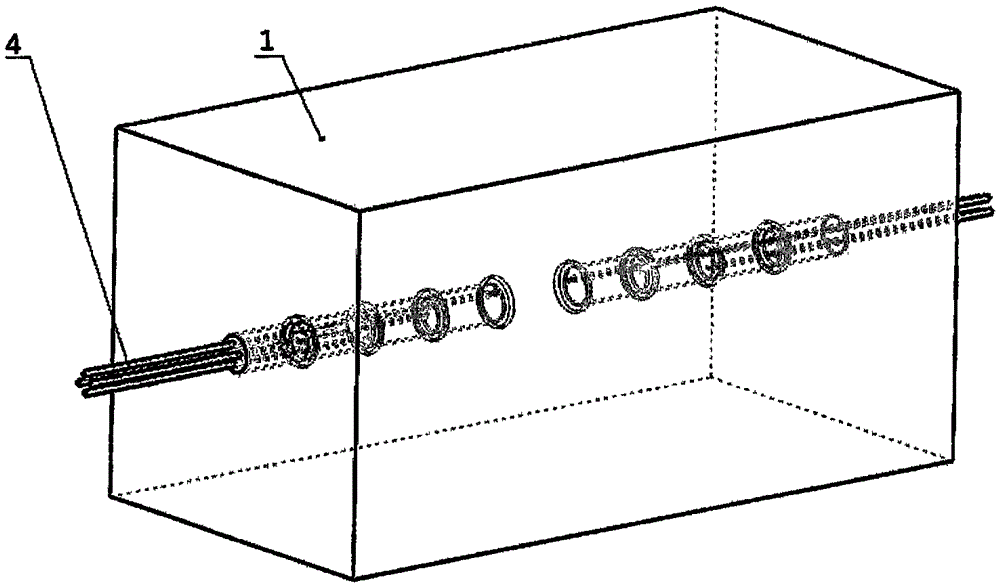

Hydraulic fracturing simulation experimental device and method of hot dry rock enhanced type geothermal system

InactiveCN107893652AAccurate calculation of hydraulic fracturing heat transfer efficiencySimulation is accurateSurveyFluid removalHydraulic fracturingHigh pressure

The invention relates to a hydraulic fracturing simulation experimental device and method of a hot dry rock enhanced type geothermal system. A hot dry rock high-pressure and high-temperature generating environment is simulated, precise stress is applied to a rock core by designing a multistage piston, the permeability of hot dry rock fluid is maintained by adopting a pressureproof and temperature-resistant perforated plate, the hot dry rock fluid is externally connected to a fluid collection chamber through a flow guiding groove, and meanwhile an adjustable sound emission probe is embedded into a true-triaxial high-pressure axe to monitor a sound emission event happening when a fracture expands in the hydraulic fracturing process, integrated collection of information of rock hydraulic fracturing, sound emission, heat energy recovery efficiency and the like under the triaxial confining pressure condition can be achieved by utilizing the device, and therefore the fracture initiation andexpanding situations of the hot dry rock hydraulic fracture can be studied. The hydraulic fracturing simulation experimental device and method have the beneficial effects that warming and heat preservation effects are good, a sealed part is simple to replace and convenient to maintain, a sound emission embedded part can be adjusted according to the requirements for the probe sizes, in addition, the whole device further has the characteristics that operation is convenient, and the protection and maintenance period is short, and the device is an important technological innovation at the aspect of dry hot rock enhanced type geothermal system hydraulic fracturing testing device detection.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Physical simulation method of coal-bed gas well hydraulic fractures

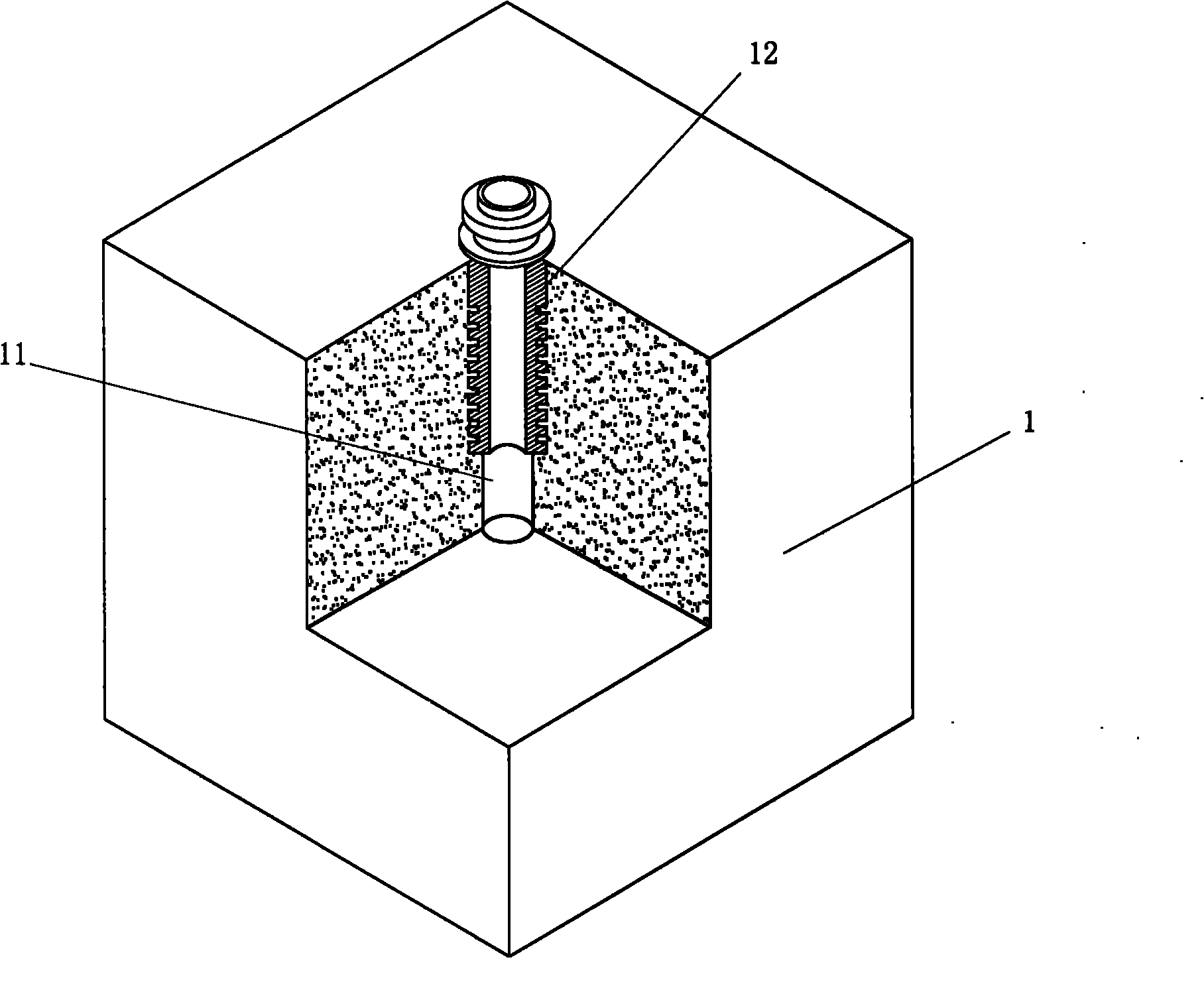

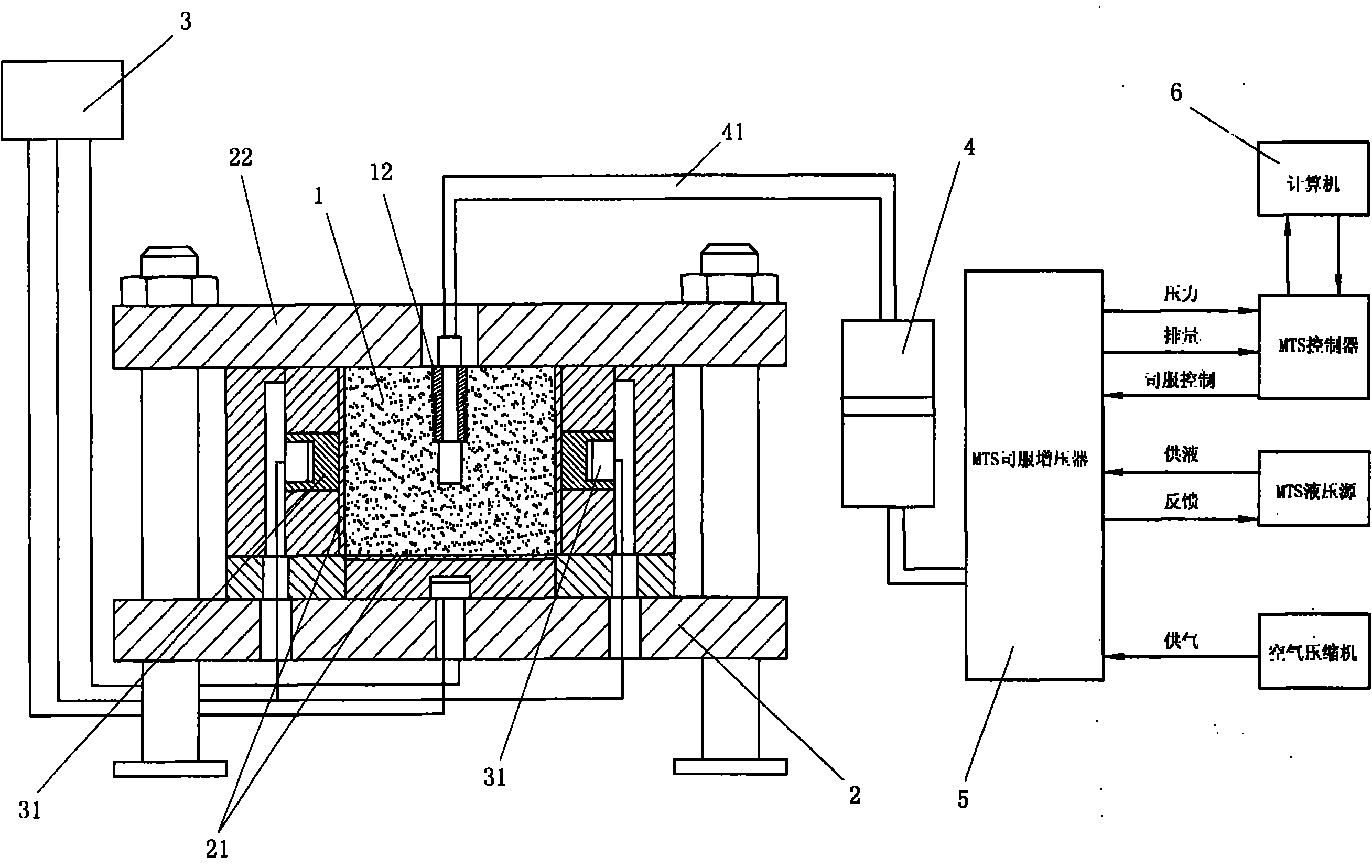

The invention discloses a physical simulation method of coal-bed gas well hydraulic fractures. According to the method, a real three-shaft fracture simulating test frame is arranged, a fracture test piece with a wellbore hole simulator is placed in the real three-shaft fracture simulating test frame, and sound transmitting probes tightly adhere to the eight corners of the fracture test piece respectively through plastic cement and are connected with sound transmitting receivers through acoustic emission signal amplifiers; a hydraulic pressure stabilizer is connected to the exterior of the real three-shaft fracture simulating test frame; the top of the wellbore hole simulator is connected with an oil and water separator through a fracturing liquid pipeline, guar glue hydraulic fracturing liquid is added to the upper portion of the oil and water separator, and oil is added to the lower portion of the oil and water separator; a control panel is connected to the bottom of the oil and water separator. With the physical simulation method of coal-bed gas well hydraulic fractures, generation and development of fractures in the test piece can be detected in real time in the hydraulic fracturing physical simulation process in a laboratory, the three-dimensional characteristic analysis of the fractures is paid attention to, the method is not confined to observation on the extension of the fractures on the surface of the fracture test piece, and the extension process of the fractures can be better reflected.

Owner:CHINA UNIV OF MINING & TECH

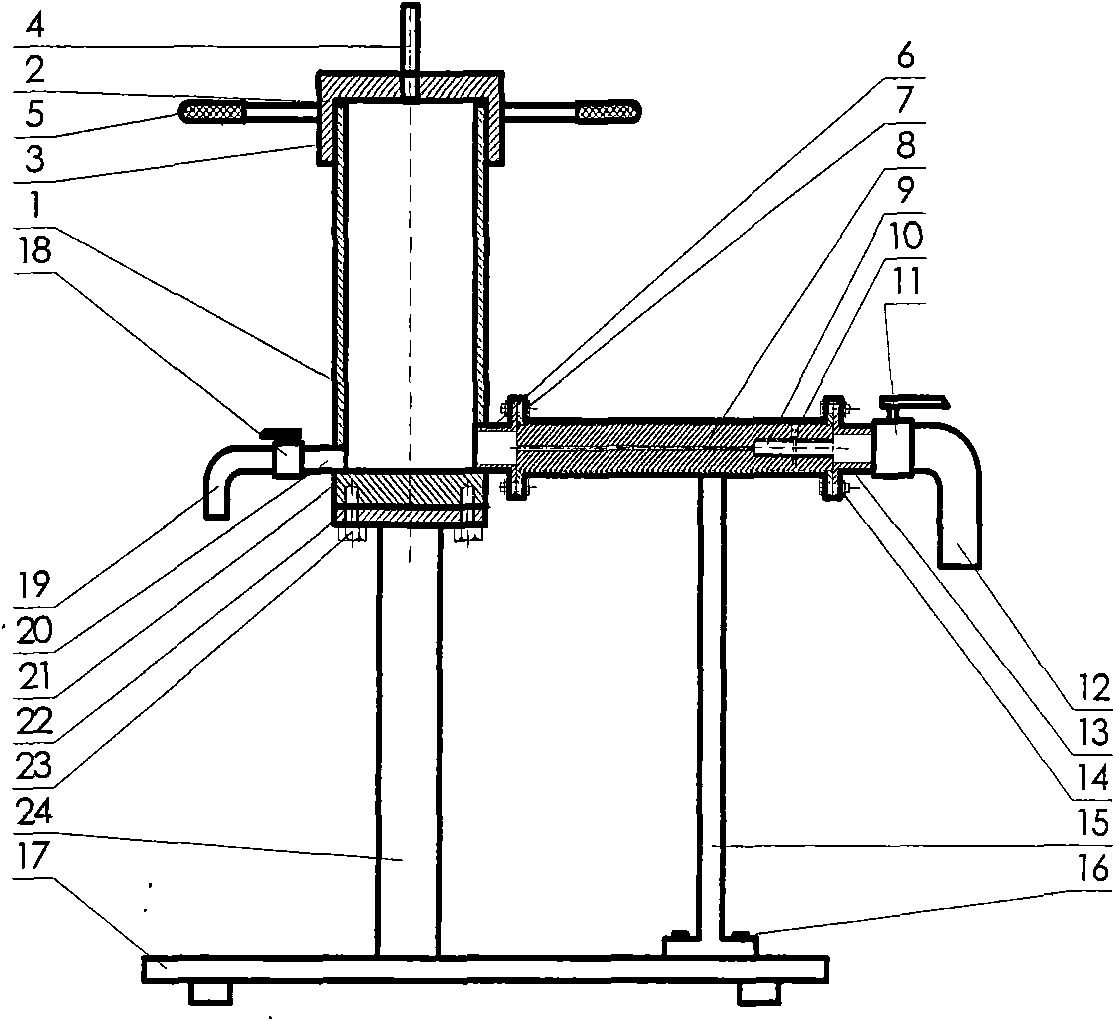

Simulation fracture plugging test device and test method

InactiveCN101672172APrevent critical leaksIngenious and reasonable structureSealing/packingStudy methodsHigh pressure

The invention relates to a simulation fracture plugging test device and a test method used in drilling operation in oil-gas fields, which can estimate fracture plugging materials with longer fracturedepth and a plugging drilling fluid or completion fluid system, and truly reflect the plugging effect of fracture leakage loss with depth. The test device consists of a fracture test module and a highpressure container. The technical scheme thereof is as follows: the upper end of the high pressure container is provided with an O-shaped seal ring of the high pressure container; the top part of anupper cover is provided with a needle check valve; the needle check valve is connected with the quick joint of the high pressure gas pipe of a nitrogen bottle; the high pressure container is connectedonto an upright post by a bottom cover and a bottom cover connecting flange; the fracture test module is located by a module locating sleeve, and is fixed by a module connecting fastening bolt; and aplugging fluid outlet pipeline is connected with a plugging fluid outlet connecting flange. The invention has the advantages of reasonable simulation fracture structure, stable and reliable high pressure sealing and working, convenient operation of test device, and the like, and can provide important test device and research method for customizing a production field plugging scheme.

Owner:SOUTHWEST PETROLEUM UNIV

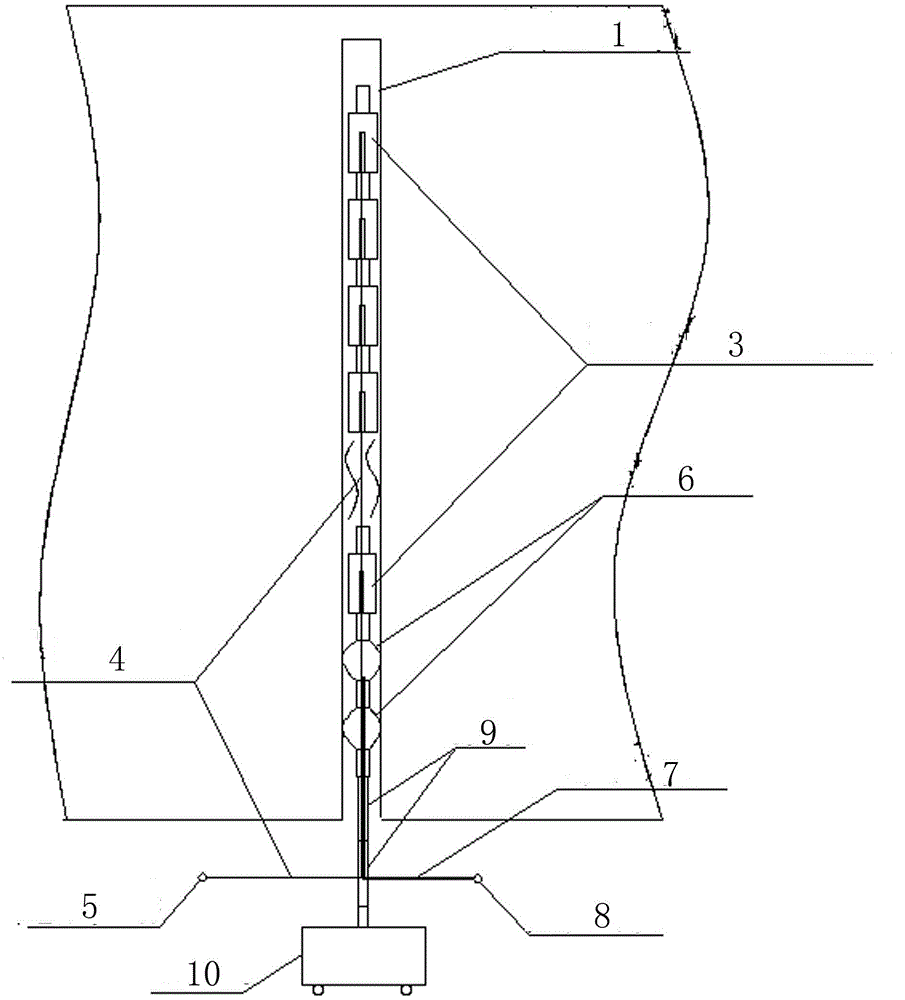

Liquid CO2 phase transition multipoint fracturing and permeability increasing method

ActiveCN105201481AImprove breathabilityImprove acceleration performanceFluid removalGas removalHigh pressureFracture test

The invention discloses a liquid CO2 phase transition multipoint fracturing and permeability increasing technology used in a coal seam, mainly solving a series of problems of poor coal seam permeability and difficult gas extraction. The method comprises the following steps: forming fracturing test drill holes in a coal seam, arranging liquid CO2 fracturing pipes in the fracturing test drill holes in a series connection mode, connecting two hole packers at the back surfaces of the liquid CO2 fracturing pipes, and pushing the liquid CO2 fracturing pipes and hole packers into the fracturing test drill holes by a push rod, wherein the liquid CO2 fracturing pipes are connected by conductive leads and connected with an exploder for a mine at the outer part of the test drill holes; and after the above arrangement, carrying out hole packing, heating the multiple liquid CO2 fracturing pipes by virtue of the exploder for a mine to convert a CO2 liquid into a high-pressure CO2 gas in short time, impacting coal to generate fracture, thus improving extraction efficiency of gas. The invention also comprises selection of an arrangement distance and time for the liquid CO2 fracturing drill holes and extraction drill holes.

Owner:SHANXI JINMEI GRP TECH RESEACH INST

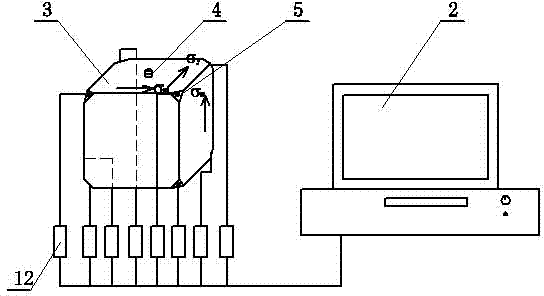

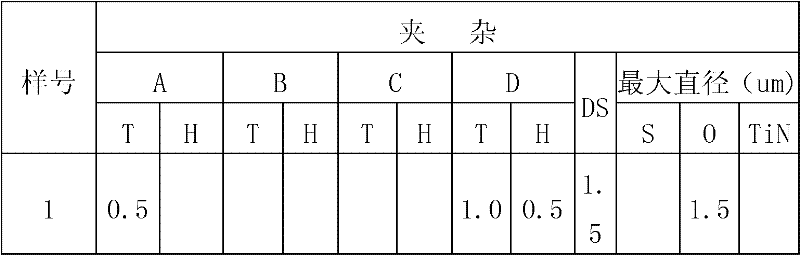

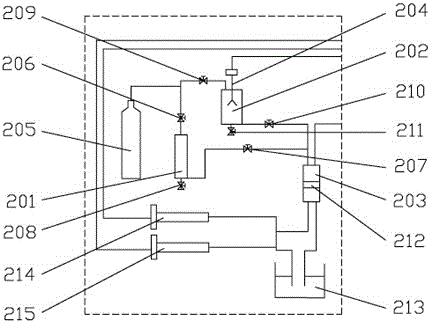

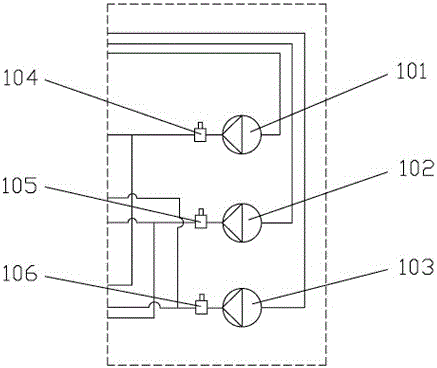

Supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography

InactiveCN110057739AMonitor pressureRich researchPermeability/surface area analysisEngineeringHigh pressure

The invention discloses a supercritical carbon dioxide fracture-creepage-seepage test device for high-temperature high-pressure coal petrography. The device comprises a triaxial cell, a supercriticalcarbon dioxide generator system, an axle load and confining pressure loading system, an acoustic emission monitoring system, a temperature rise control system, a deformation-pressure monitoring systemand a permeability measuring system. The device is capable of realizing the supercritical carbon dioxide fluid fracture test of coal petrography under high temperature and high pressure, monitoring and recording the temperature and pressure changes of supercritical carbon dioxide and characteristics of fracture cracking and extension in the supercritical carbon dioxide fracture process in real time, monitoring and recording the axial and radial deformations of coal petrography samples in real time, directly and effectively measuring the DH4 permeability of the coal petrography before and after the fracture without unloading the coal petrography sample stress, and measuring the CH4 permeability of the coal petrography after the fracture under the action of creepage. The measurement methodis high in precision, intuitional and high in automation degree, and the device is simple in structure.

Owner:TAIYUAN UNIV OF TECH

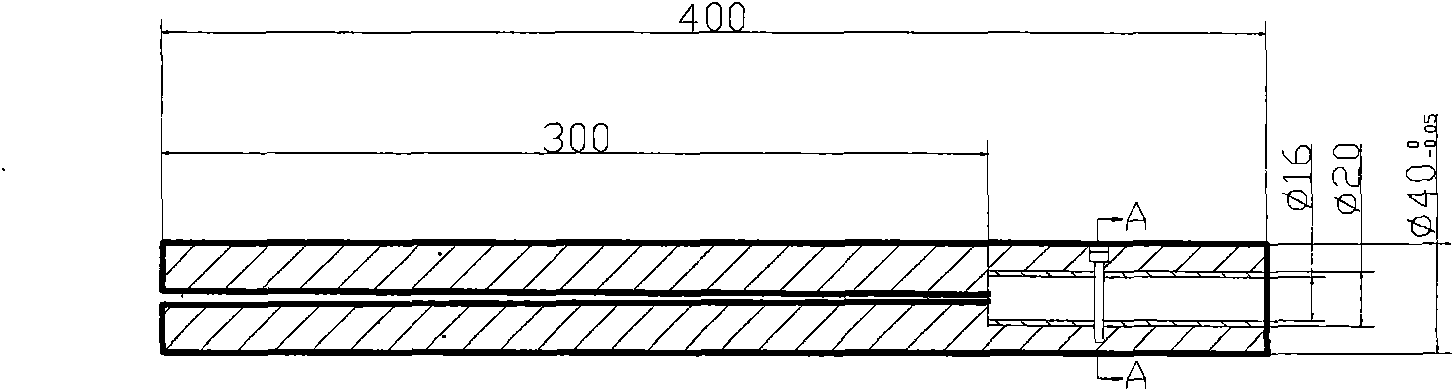

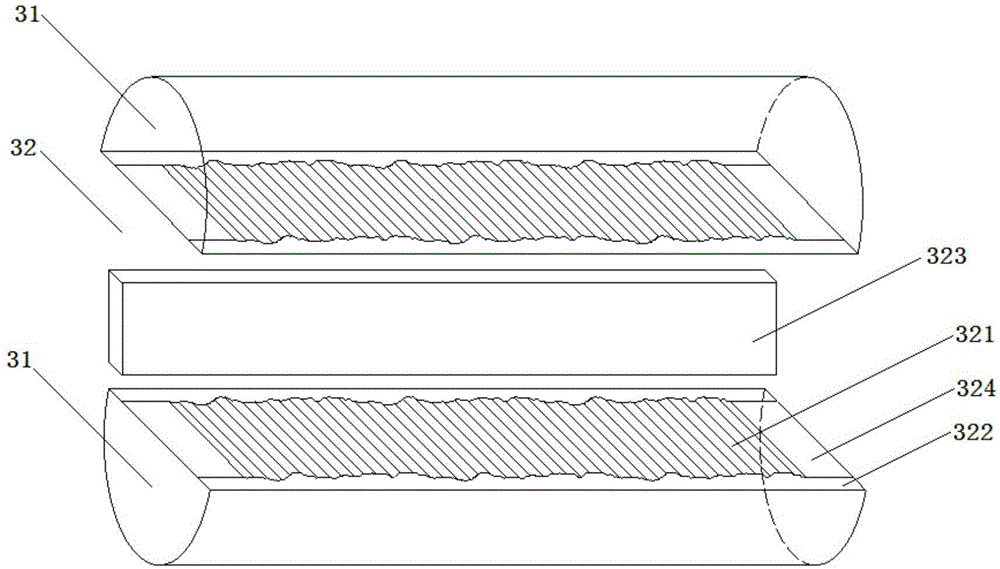

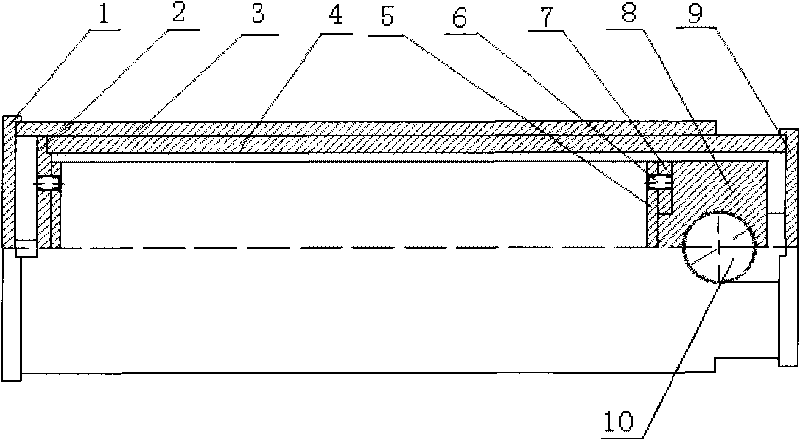

Recyclable coarse fracture high velocity seepage testing apparatus

InactiveCN105158141AEasy to processAccurate and convenient reflectionPermeability/surface area analysisWater volumeEngineering

The invention discloses a recyclable coarse fracture high velocity seepage testing apparatus which comprises a water tank, a water supply pipe, a water inlet end cap, a fracture test piece, a water outlet end cap and a return pipe which are sequentially connected and a water pressure sensor; the water supply pipe is sequentially provided with a booster pump and a pressure regulating valve, both the water inlet end cap and the water outlet end cap are provided with horizontal seams for water diversion; the fracture test piece comprises a test piece main body and a fracture main body located in the test piece main body, the fracture main body comprises a fracture, smooth flat grooves and rubber gaskets, the smooth flat grooves are distributed at two sides of the fracture along the axial direction of the fracture, the rubber gaskets are used for filling the smooth flat grooves to seal the two sides of the fracture, the two ends of axial length of the fracture are connected with the horizontal seams, and the fracture aperture is regulated through changing rubber gaskets of different thicknesses; the water pressure sensor extends into the fracture through a probe for measuring flowing water pressure of the fracture, the process of coarse rock mass fracture high velocity seepage is accurately, conveniently and truly reflected, the working procedures are simple and clear, the water volume calculation is simple, used water is recyclable, and the fracture aperture is controllable.

Owner:HOHAI UNIV

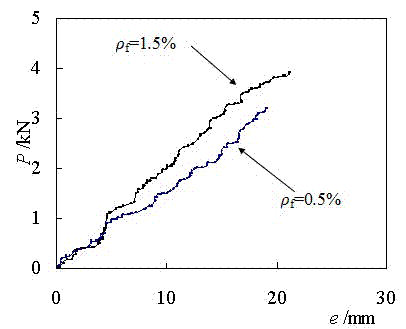

Testing method of steel fiber reinforced concrete fracture test crack initiation load

ActiveCN103760036AReduce test costsLower requirementMaterial strength using steady bending forcesStress intensity factorClassical mechanics

The invention relates to a testing method of steel fiber reinforced concrete fracture test crack initiation load, and belongs to the technical field of concrete cracking parameter testing. The testing method provided by the invention is characterized in that when a steel fiber reinforced concrete coped beam specimen cracks, a stress intensity factor of a prefabrication crack front edge achieves concrete fracture toughness, and the steel fibre blocking action is not exerted; the stress intensity factor generated by external load and concrete cracking toughness(i)K( / i) IC are equal, the external load value which is corresponding to a numerical value (i)K( / i)IC of the stress intensity factor generated by the external load can be used for determining the crack initiation load according to the curve relation graph of the external load and the stress intensity factor (i)K generated by the external load (img file='2014100081259100004dest_path_image002.TIF'wi='8'he='21' / )( / i)-(i)P( / i) curve relational graph. The testing method provided by the invenytion has the advantages that the required equipment, analyzing and processing method are simple, the cost is low, and the precision is high.

Owner:YELLOW RIVER INST OF HYDRAULIC RES YELLOW RIVER CONSERVANCY COMMISSION

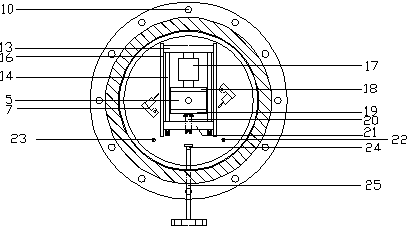

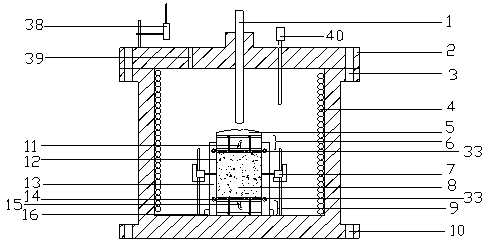

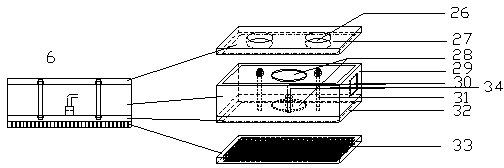

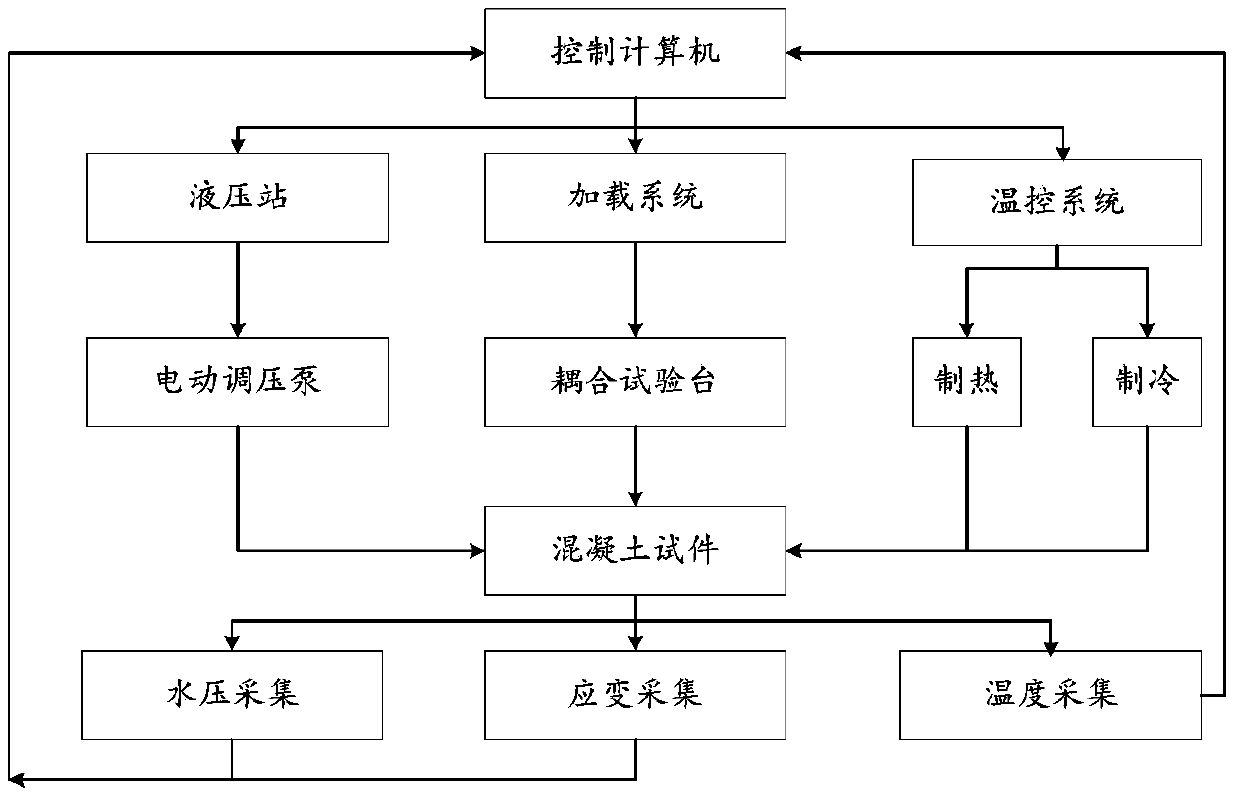

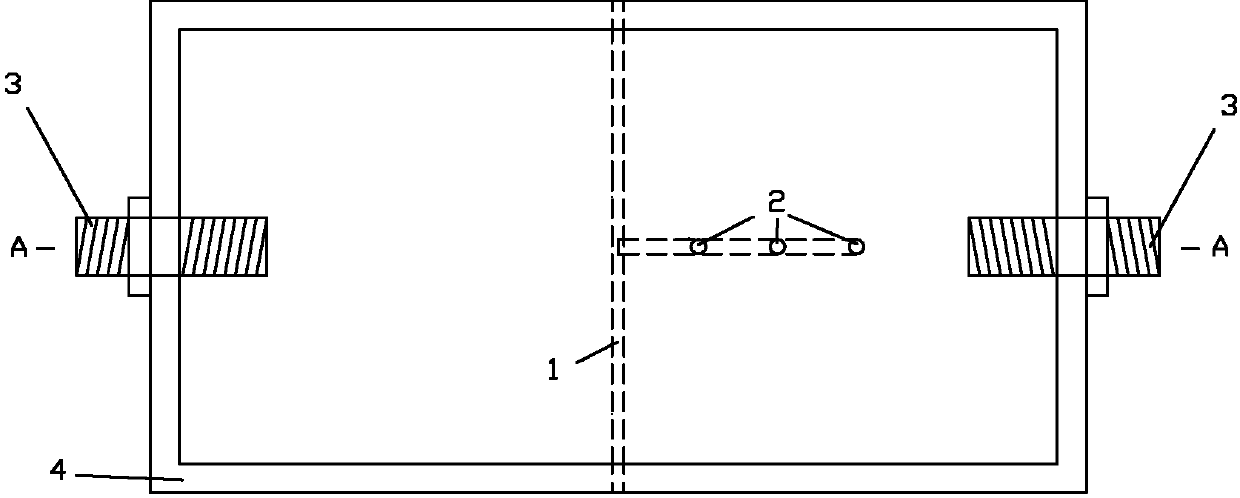

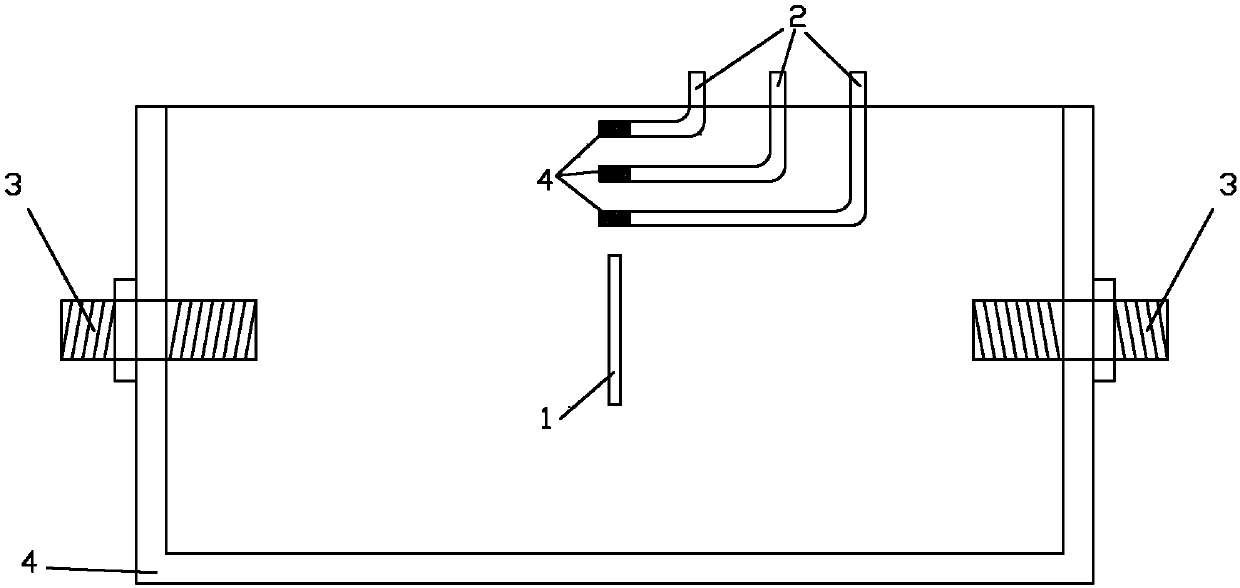

Testing device for simulating concrete test piece hydraulic fracture under multi-field coupling condition

ActiveCN103383325AStudy hydraulic fracturing propertiesMaterial strength using tensile/compressive forcesSteel framePipe

The invention relates to a testing device for simulating concrete test piece hydraulic fracture under a multi-field coupling condition. The testing device is characterized in that a large cylindrical pressure chamber is manufactured specifically, copper pipes are arranged on the inner wall of the pressure chamber, and the copper pipes are connected with an external refrigerating and heating system to control the temperature in the pressure chamber. A set of steel frame clamp manufactured specifically is fixed on a base plate of the pressure chamber, and a test piece is placed in the steel frame clamp. Water pressure is exerted on the test piece through a steel external member at the bottom of the test piece and a water permeable copper plate, and water is guided out from a steel external member on the upper portion of the test piece and the water permeable copper plate through a water pipe. Fracture water pressure and environment temperature simulation is added on the basis of a conventional three-shaft test. The device overcomes the defect that a traditional hydraulic fracture test can not simulate temperature environment change, can reflect a testing theory of the hydraulic fracture truly and is suitable for test research on concrete test piece hydraulic fracture under the water solid thermal coupling condition. The testing device has good market transformation prospects and is suitable for popularization.

Owner:HOHAI UNIV

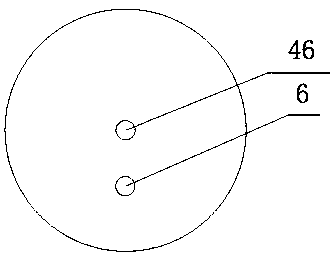

Testing system for simulating hydraulic fracture of concrete members under high water pressure

ActiveCN103389247AOvercoming Water Sealing ProblemsAdjustable water temperatureMaterial strength using tensile/compressive forcesStructural engineeringPipe

The invention discloses a testing system for simulating hydraulic fracture of concrete members under high water pressure. The system comprises a specimen mould system and a water-solid thermal coupling testing system, the specimen moulding system comprises a casting mould and a water-sealing clamp, a simulation initial crack, which vertically runs through the casting mould, is arranged on the center position of the casting mould, a water pressure measuring elbow pipe is horizontally arranged above the simulation initial crack, one end of the water pressure measuring elbow pipe is embedded into the casting mould in a position which is opposite to the simulation initial crack, and the other end of the water pressure measuring elbow pipe stretches out of the casting mould and is connected to the water-solid thermal coupling testing system. The defects that the concrete wedge fracture specimen cannot be sealed under high water pressure in the conventional fracture tests and important data such as fracture aperture, water pressure and water temperature during the test process cannot be measured when a cylinder concrete specimen is adopted in the tests are overcome, the water sealing problem of the hydraulic fracture tests under high water pressure is solved, data such as the change and strain of water pressure in the crack during the fracture process can be measured in real time, and the test system is closer to the real situation.

Owner:HOHAI UNIV

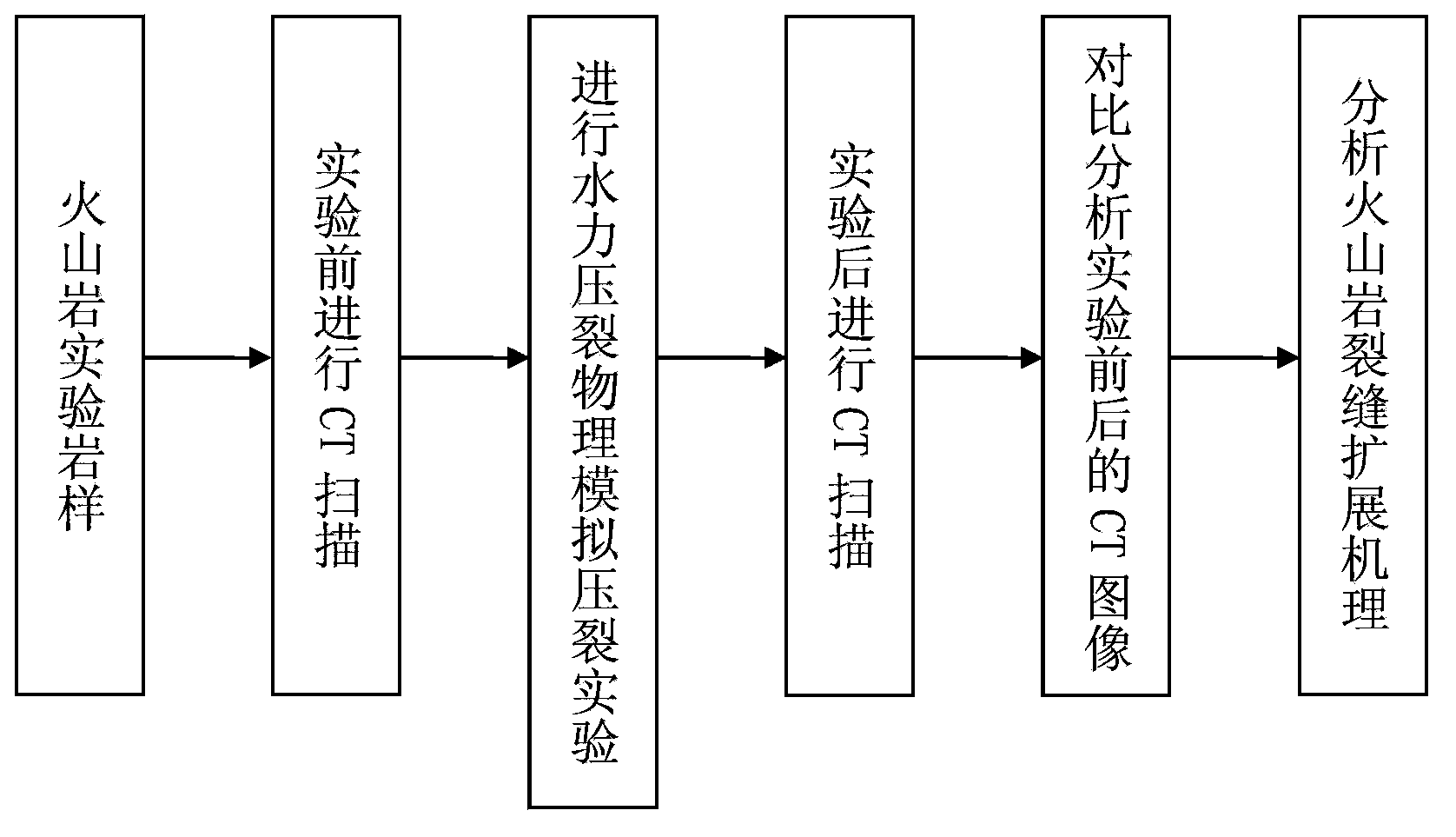

Method for carrying out fracture CT (Computed Tomography) scanning and monitoring on fracture initiation and extension of large-size volcanic hydraulic fracture

ActiveCN103573251AObserve the extended formObserve the law of crack initiation and expansionConstructionsVolcanic GasesComputed tomography

The invention provides a method for carrying out fracture CT (Computed Tomography) scanning and monitoring on initiation and extension of a large-size volcanic hydraulic fracture, which belongs to the field of volcanic gas reservoir and fracturing during oil and gas field development. The method is characterized in that CT scanning is respectively carried out on a rock sample of a volcanic before and after a hydraulic fracture physical modeling fracture test, and the monitoring on the large-size volcanic hydraulic fracture and intuitive analysis on a fracture initiation and extension rule of the hydraulic fracture can be realized through comparing changes of the rock sample before and after the test. According to the method provided by the invention, a fracture initiation and extension process of each scanning cross-section fracture can be clearly and intuitively reflected under the situations of different primary stress differences before and after fracturing, rock pore, development degree of a natural fracture and discharge capacity and viscosity of a fracturing liquid, and an important role is played in researching a fracturing fracture initiation and extension mechanism which adapt to characteristics of multiple fractures and fractured-vuggy reservoir of the volcanic.

Owner:CHINA PETROLEUM & CHEM CORP +1

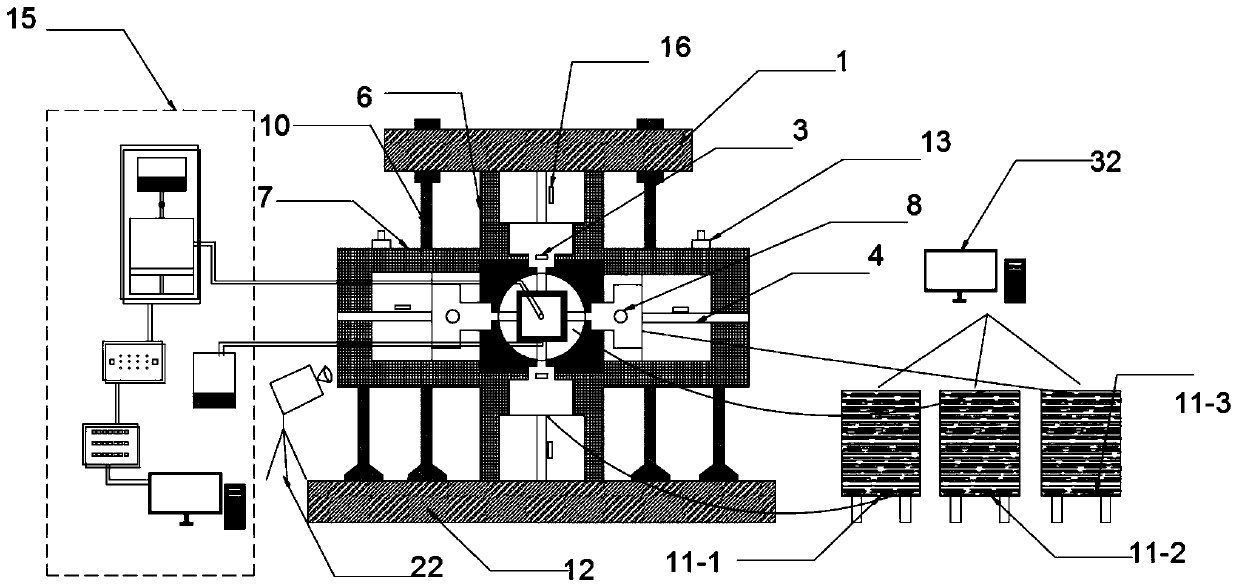

Visual true triaxial hydraulic fracturing test device and method

InactiveCN110987638AMeet testing needsSimple and fast operationMaterial strength using tensile/compressive forcesAxial pressureFracturing fluid

The invention discloses a visual true triaxial hydraulic fracturing test device and a visual true triaxial hydraulic fracturing test method. The visual true triaxial hydraulic fracturing test device comprises a vertical axial pressure loading system, a horizontal stress loading system, a confining pressure loading system and the like, wherein a hydraulic loading system adopts high-transparency oilto perform flexible servo loading on six surfaces of a rock sample, and a hydraulic loading system is mounted on a flexible loading surface to realize hydraulic fracture; in order to ensure the sealing performance of a cylinder body of a pressure chamber, oil leakage prevention elastic rubber sleeves are fixed at the contact parts of the vertical axial pressure loading system, the horizontal stress loading system and the pressure chamber; a water pressure loading system realizes hydraulic fracture through carrying out water injection on the flexible loading surface, and fracturing fluid is collected by means of a rigid water guide base plate; and a high-speed camera is used for collecting the crack propagation process of the sample in the visual pressure chamber. In addition, the visual true triaxial hydraulic fracturing test device can further complete a hydraulic fracturing test of a cylindrical sample under the condition of false triaxial loading, and meet the test requirements ofrock samples with different shapes.

Owner:SHANDONG UNIV +1

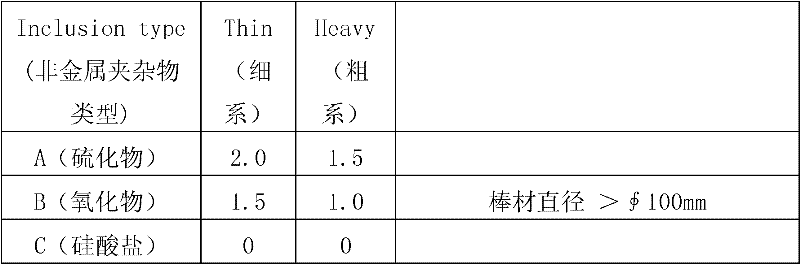

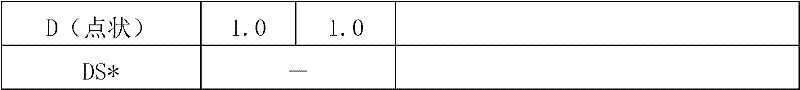

Smelting method of high-carbon chromium bearing steel

The invention relates to a smelting method of high-carbon chromium bearing steel, which is used for solving the phenomena of distribution and congregation of B non-metal inclusions in steel by controlling slag system and inclusions through controlling the Ti content in the refining process, carrying out slag exchange during refining mildly stirring and adding carbonized rice hull. The smelting method comprises the specific steps of: in EAF (electric arc furnace) process, controlling [S] in molten supernatant being less than or equal to 0.030% during burdening; in EAF tapping process, inhibiting the oxidizing slag flowing into a steel ladle and using low-Ti-content alloy; in LF (ladle furnace) process, carrying out online slag sample analysis (carrying out first LF analysis before hoistingthe ladle), and controlling the alkalinity of the low-alkalinity slag to be 2.0-3.0 with buhrstone according to the slag sample analysis before pouring the slag out of LF furnace; after VD (vacuum degassing) furnace vacuum treatment, carrying out online slag sample analysis to control hydrogen being less than or equal to 1.5ppm and no larger than 2.0ppm; after VD furnace vacuum treatment, closingthe cover and stirring mildly for 15-20 minutes; and in die casting process, using FZ-2 covering slag and adding an inlet heating agent after casting. According to the invention, by bluing fracture test measurement, the content of low-multiple inclusions is less than or equal to 2.5mm / dm<2>, the maximum length of single inclusion is less than or equal to 3mm; and the coarse system rating in B inclusions is less than or equal to 1.0.

Owner:宝钢特钢有限公司

Pressure-limited and discharge-quantity-unlimited fracturing method for increasing shale gas crack transforming size

ActiveCN107476790AGood effectImproving net fracturing uplift is limitedFluid removalLiquid ratioReservoir evaluation

The invention discloses a pressure-limited and discharge-quantity-unlimited fracturing method for increasing the shale gas crack transforming size. The pressure-limited and discharge-quantity-unlimited fracturing method comprises the steps that (1) reservoir evaluation before fracturing and real-time evaluation of the fracturing construction earlier stage are conducted; (2) a layered small testing fracturing test is conducted on a straight well guiding well; (3) simulation analysis is conducted through software MEYER; (4) normal fracturing construction is conducted, and in the construction midway, one-time or two-time instantaneous pump stopping is conducted; (5) the wellhead construction anticipated pressure is derived reversely through the well bottom pressure; (6) as long as the wellhead construction pressure is lower than the anticipated pressure of the step (5), the discharge quantity is increased to enable the wellhead pressure to approximate the anticipated value; and (7) if the wellhead construction pressure after the discharge quantity is increased still does not reach the anticipated pressure, the construction sand-liquid ratio is increased. According to the pressure-limited and discharge-quantity-unlimited fracturing method for increasing the shale gas crack transforming size, the various problems caused by using a discharge-quantity-limited method can be solved, so that the actual after-fracturing transforming size of a shale reservoir is increased, and the complexity of man-made cracks is improved.

Owner:CHINA PETROLEUM & CHEM CORP +1

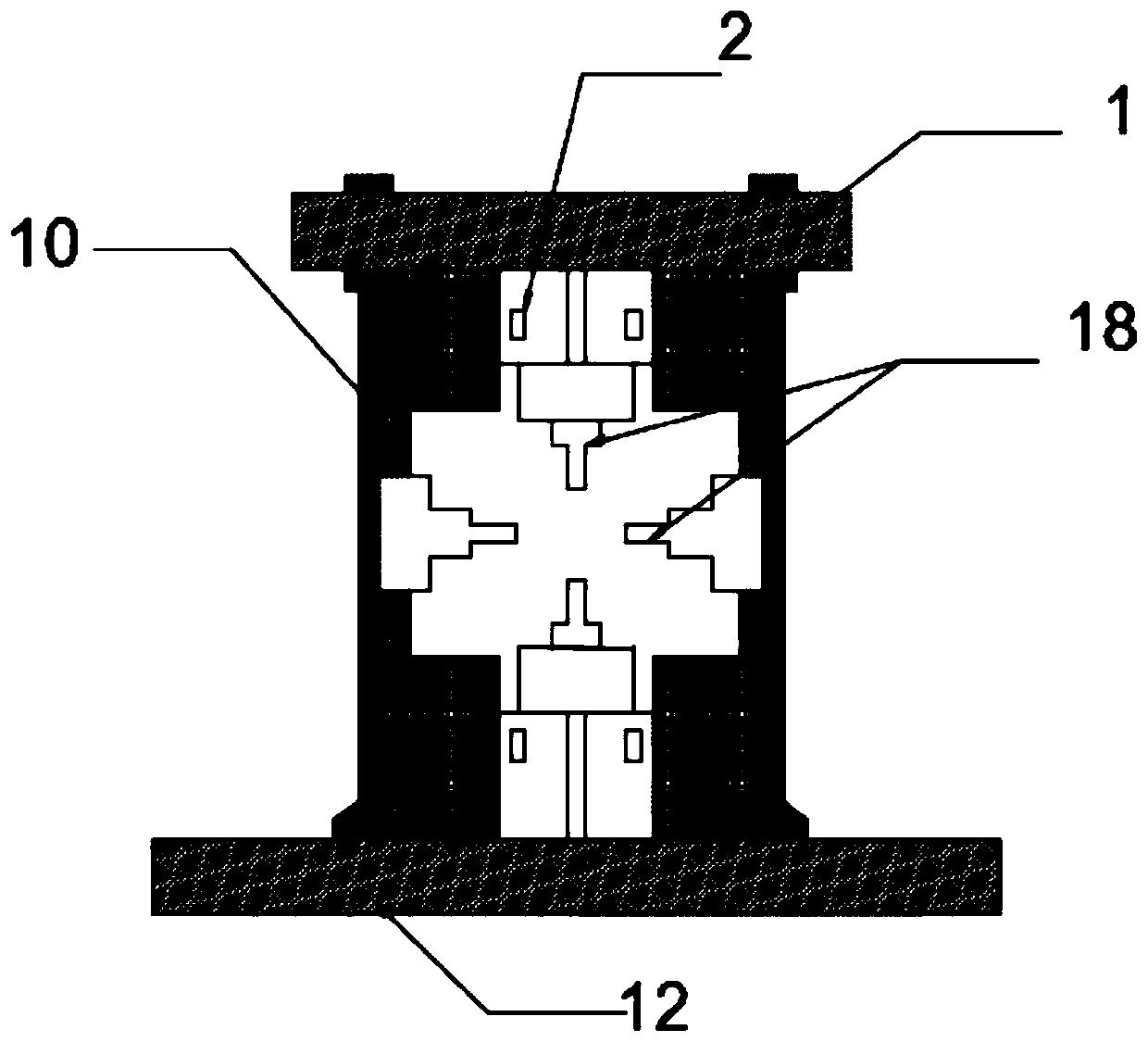

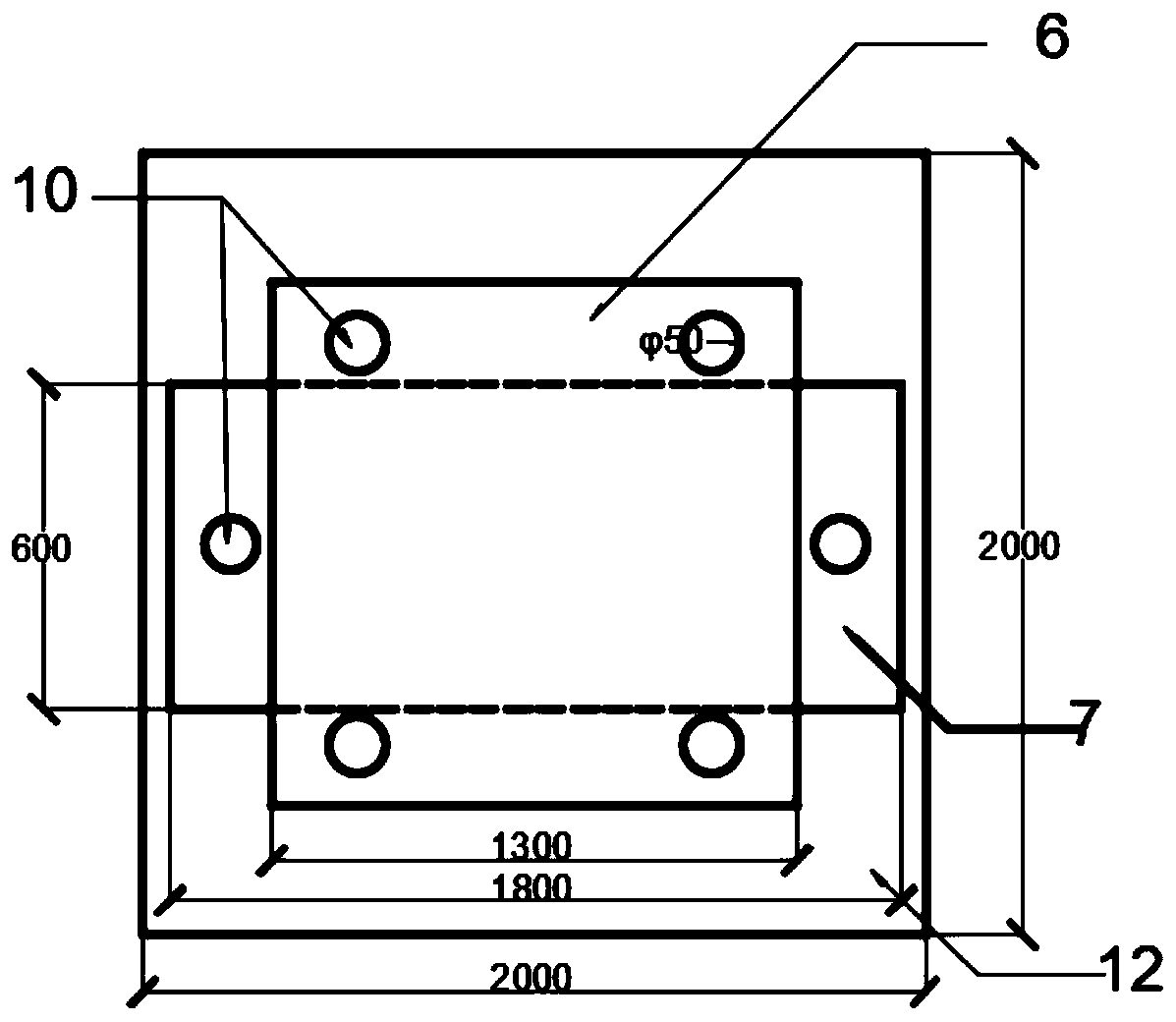

True tri-axial hydraulic fracture test machine and test method

InactiveCN106644734AImprove heat resistanceImprove insulation performanceMaterial strength using tensile/compressive forcesFracturing fluidEngineering

The invention relates to a true tri-axial hydraulic fracture test machine which comprises a confining pressure system, an injection system and a true tri-axial test stand, wherein the injection system comprises a fracturing solution container I, a fracturing solution container II and a piston container, and a stirring mechanism is mounted in the fracturing solution container II. A test method comprises the following steps: injecting clear water and an additive into the fracturing solution container II according to a certain proportion, and starting the stirring mechanism to stir; injecting a fracturing solution into a cavity body above a piston plate in the piston container by utilizing pressure; respectively applying confining pressures onto three axial directions of a downhole rock core simultaneously through three high-pressure advection pumps; draining into a cavity body under the piston plate in the piston container through a constant-pressure constant-speed plunger pump I and / or a constant-pressure constant-speed plunger pump II; injecting the fracturing solution into the rock core to start to fracture and taking out the downhole rock core after the end of fracturing to observe fracture expansion condition. The true tri-axial hydraulic fracture test machine provided by the invention has the benefits that the technical scheme is simple and easy to understand, the operation is convenient and fast, the unified control of the confining pressure system and the injection system can be realized, and the fracturing solution is convenient to replace.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

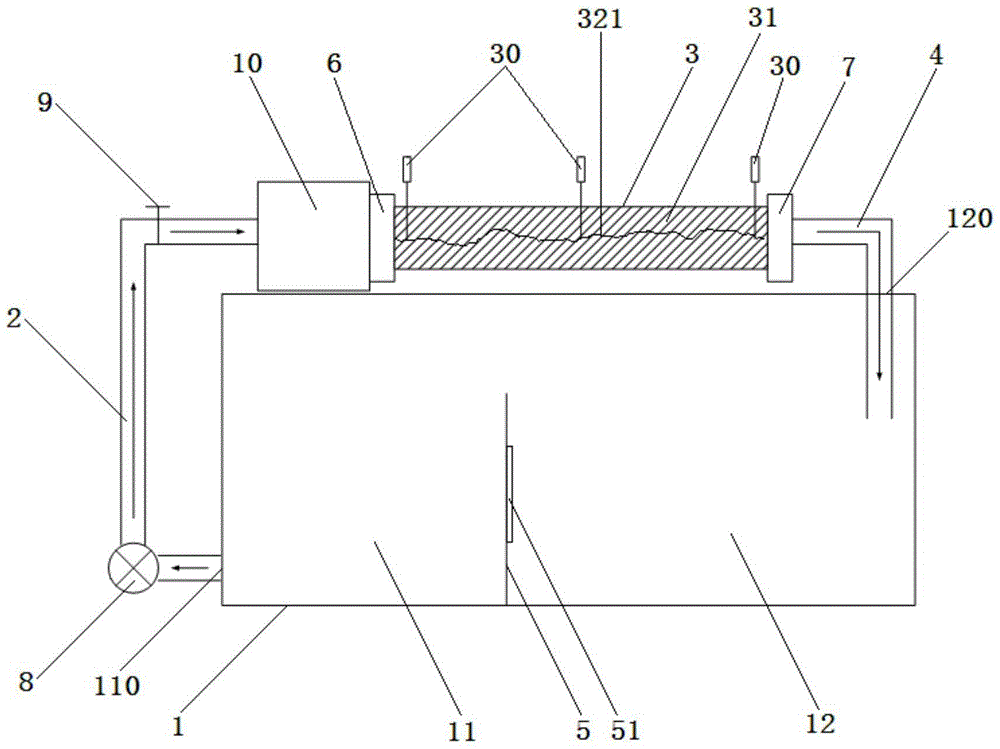

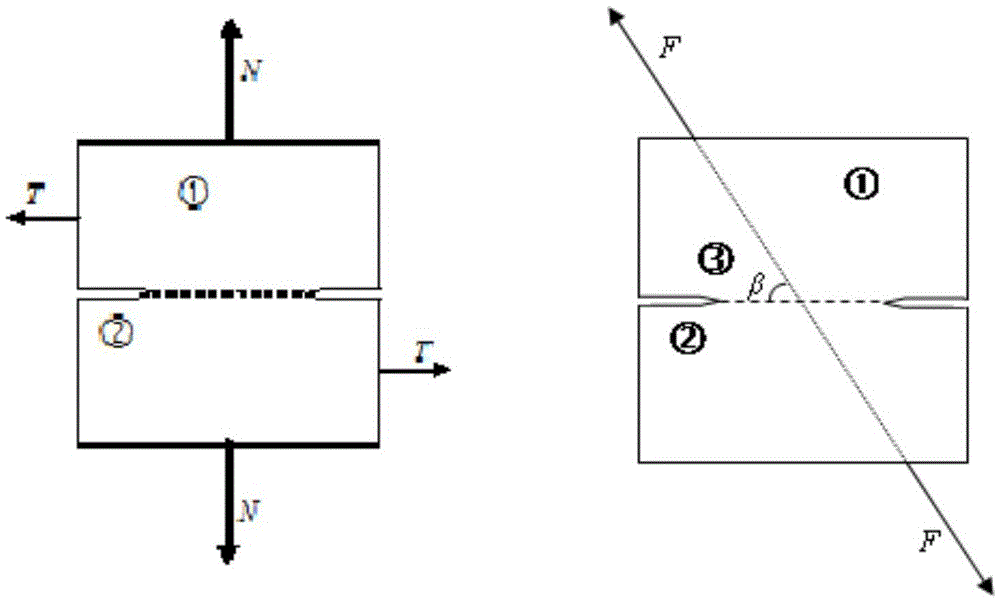

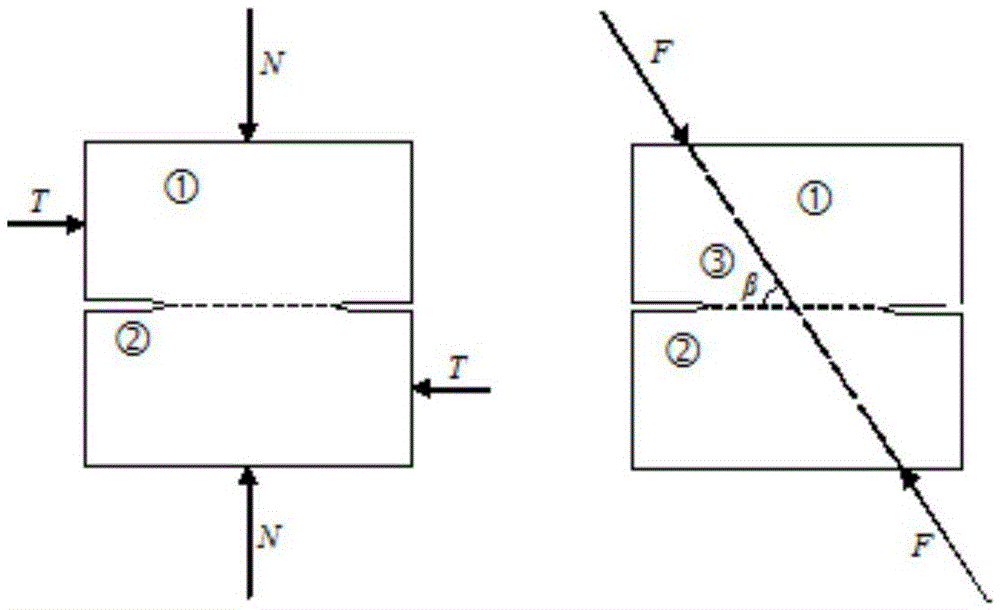

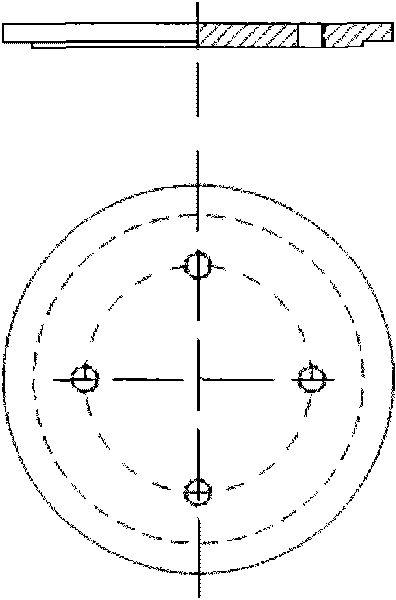

Soil body two-dimensional fracture testing method and device

ActiveCN105486583AGood continuous distributionGood shear forceMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesFracture testingData acquisition

The invention discloses a soil body two-dimensional fracture testing method and device. In the testing method, loading clamps are combined in different forms according to different fracture testing types; the loading clamps are installed on a power loading device according to required loading angles. Loading rods are connected with the external power loading device, and starting and loading modes of the loading rods are controlled by a computer and a data acquisition system. The testing device comprises a sample, a loading plate I and a loading plate II, wherein a loading clamp is formed by the loading plate I and the loading plate II which are completely identical. Each loading plate comprises a clamp body, a loading rod installing hole, a compression-shear assisting plate, a sample fixing hole, a sample clamping plate, a pull-shear assisting plate and the corresponding loading rod, and the compression-shear assisting plates and the pull-shear assisting plates are detachable. The testing device can simultaneously achieve compression-shear type '-I-II type', shear type 'II type', pull-shear type 'I-II type' and stretching type 'I type' fracture testing.

Owner:重庆山渝道科技有限公司

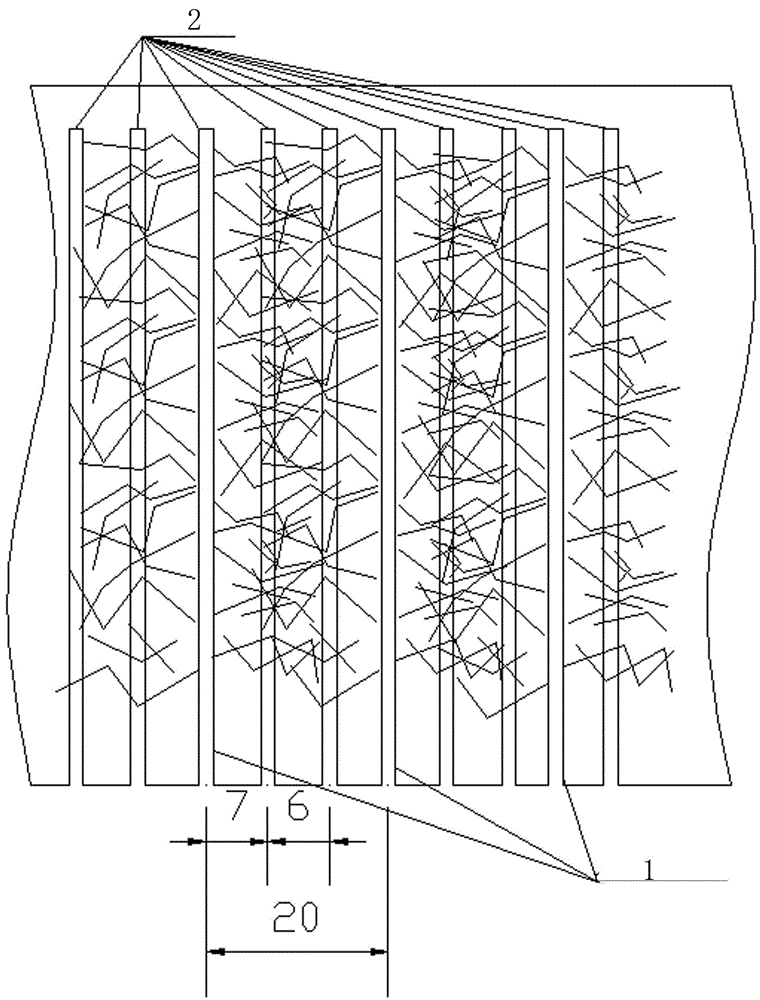

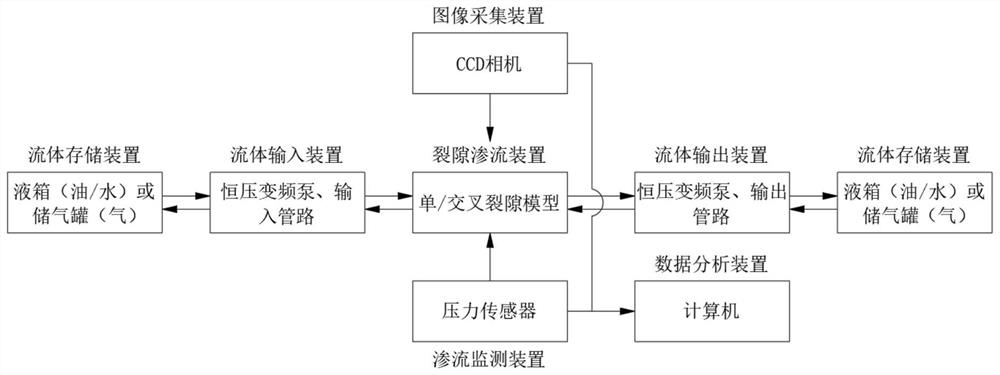

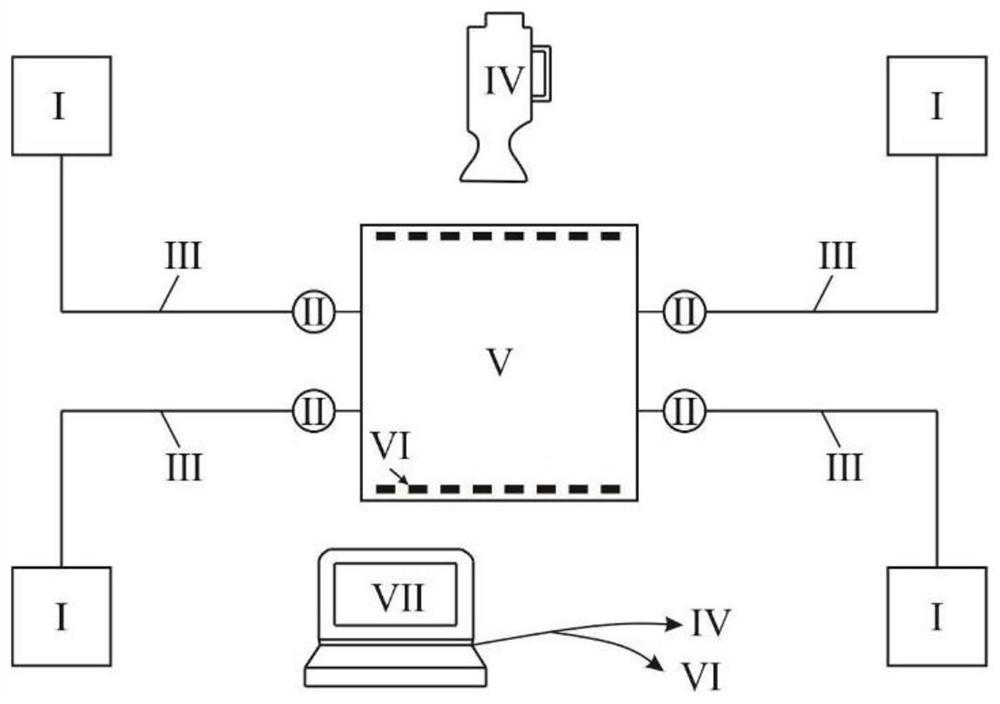

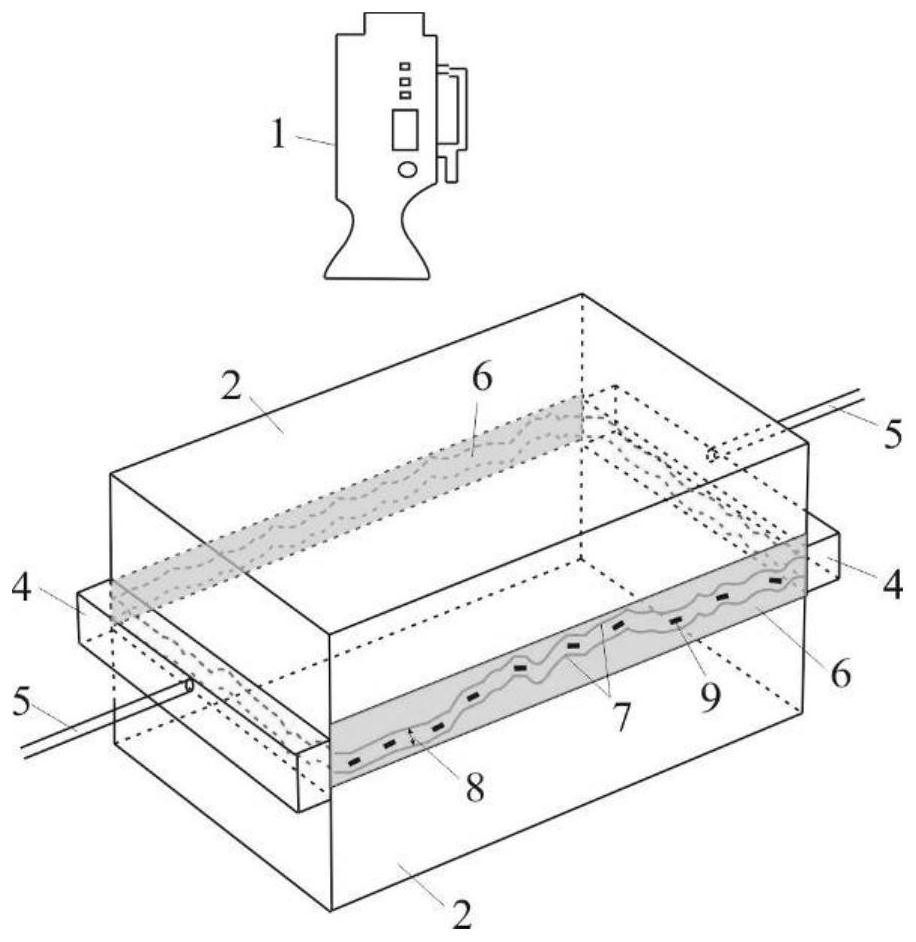

Visual test method and system for simulating rough single-cross fracture multiphase seepage

ActiveCN111811995AWide coverageComprehensive coverageSurface/boundary effectMaterial analysis by optical meansModel sampleVisual test

The invention provides a visual test method and system for simulating rough single-cross fracture multiphase seepage, wherein the test method comprises the following steps: S10, collecting a rock masssample on site, carrying out the statistics of the roughness of a fracture surface, and determining fractal characteristic parameters; S20, outputting a three-dimensional rough fracture model grid file; S30, preparing transparent or opaque three-dimensional rough fracture model samples with different roughness; S40, assembling a test device according to a single-fracture or cross-fracture test object; S50, simulating a fluid displacement process under the action of pressure difference, and carrying out a rough fracture medium multiphase displacement test; S60, collecting test data; and S70, arranging and analyzing the multiphase seepage characteristics of the rough fractured medium. The displacement mechanism of multiphase fluid in the fractures with different roughness and opening degrees can be systematically studied, and certain guiding significance is achieved for study of the water seal mechanism of a rough fractured rock mass of an underground water seal oil depot.

Owner:CHINA UNIV OF GEOSCIENCES (BEIJING)

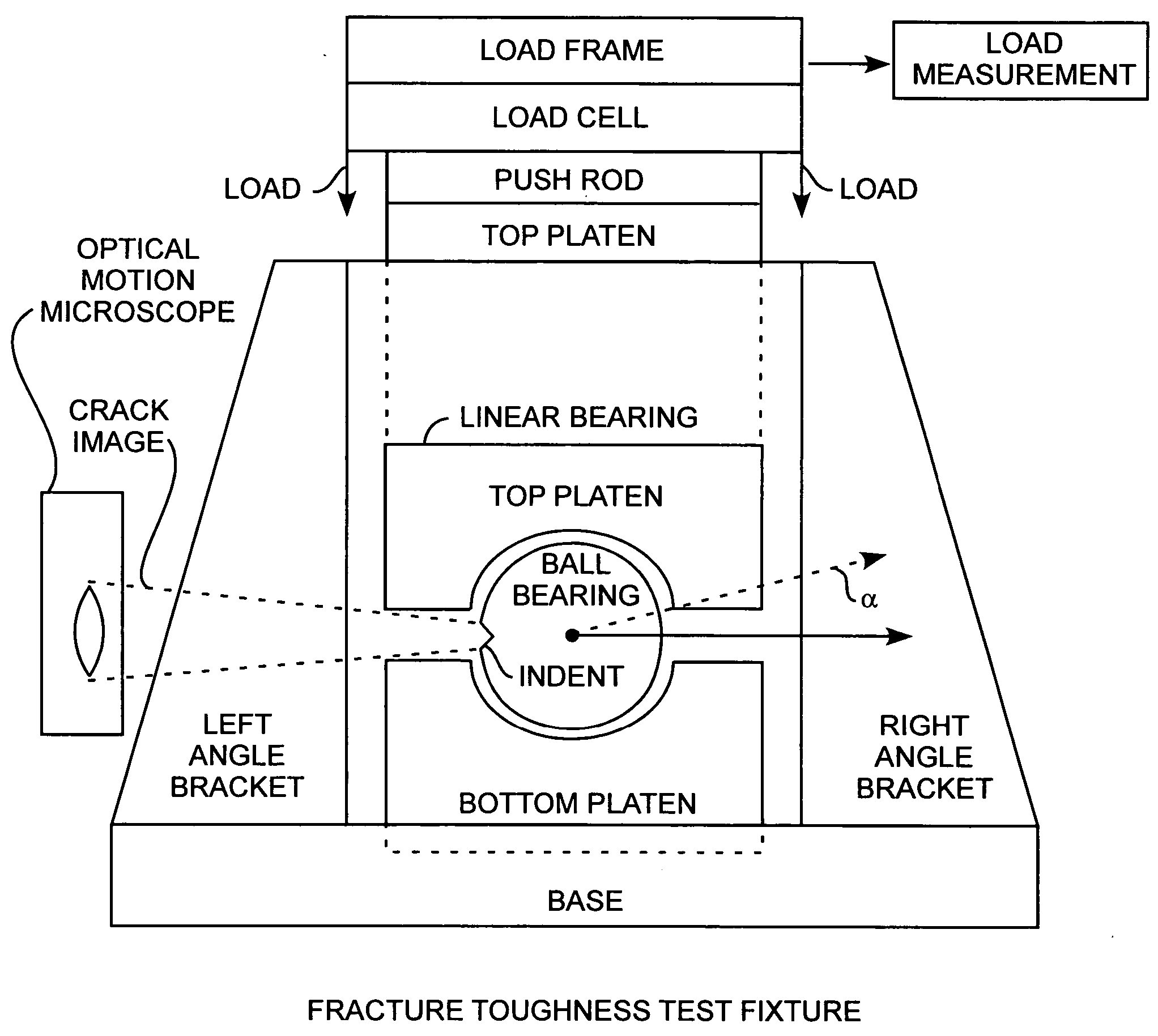

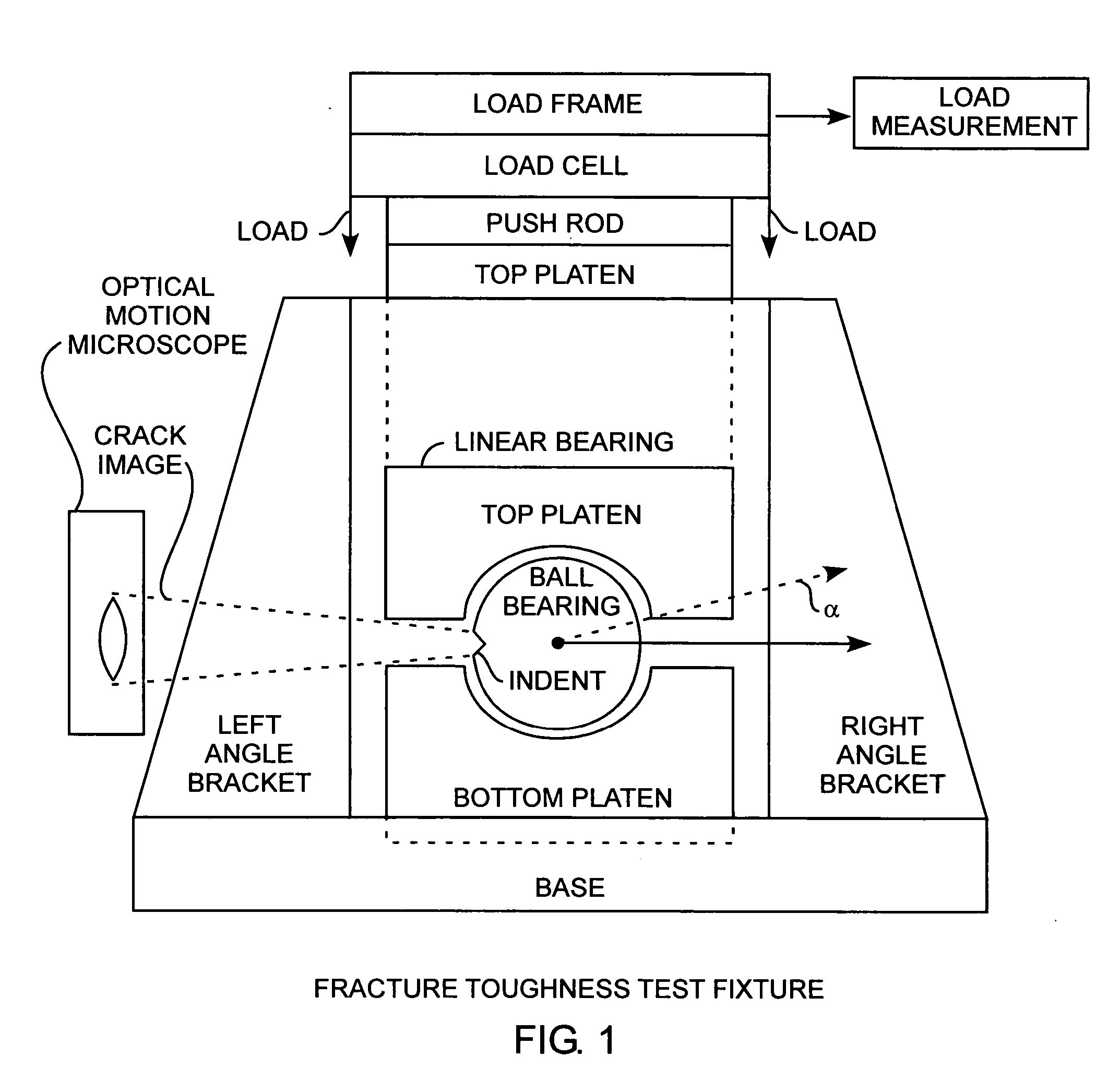

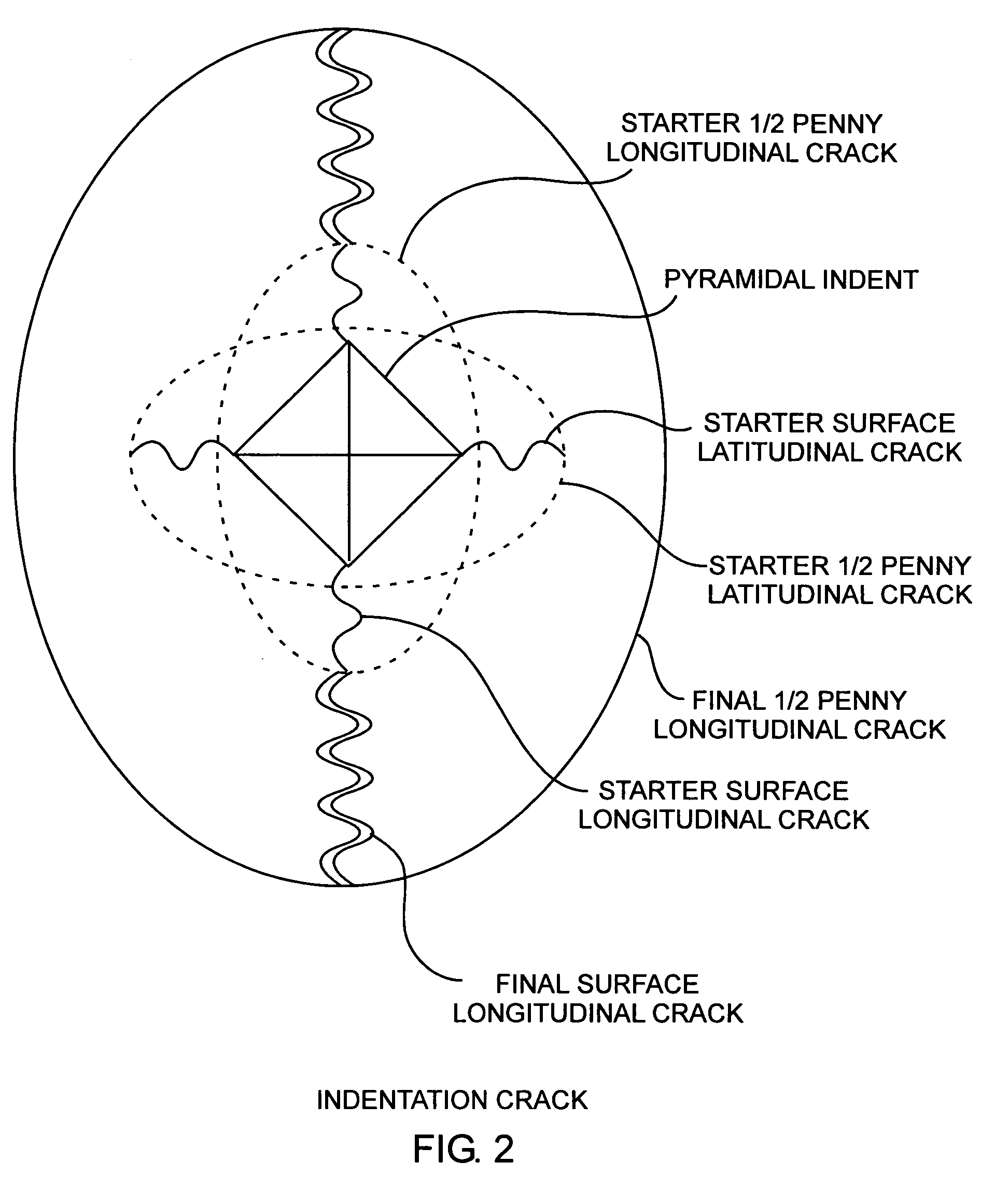

Ceramic ball bearing fracture test method

ActiveUS20050066741A1Machine bearings testingMaterial strength using tensile/compressive forcesBall bearingCrazing

A mechanical test method prescribes compressing brittle balls in spherical conforming opposing platens producing equatorial bulging, tensile stresses, and resulting indentation crack growth that is imaged for providing direct measurement of the fracture toughness of brittle balls, such as, silicon-nitride balls used in hybrid bearings as well as conventional steel ball bearings, with measurement errors being immune to characterizing the dimensions and positioning of the precrack indentations, so that, the test method is accurate, repeatable, and robust.

Owner:THE AEROSPACE CORPORATION

Hydraulic fracturing test apparatus based on conventional testing machine for rock mechanics, rock specimen and hydraulic fracturing testing method

InactiveCN105628507AReduce processing stepsLow costPreparing sample for investigationMaterial strength using tensile/compressive forcesWater channelAxial compression

The invention provides a hydraulic fracturing test apparatus based on a conventional testing machine for rock mechanics. The hydraulic fracturing test apparatus comprises a lower pressing head and an upper pressing head. The lower pressing head is arranged on a triaxial base plate, and an axial compression bar acts on the upper pressing head. Both the upper pressing head and the lower pressing head are designed with pressure water channels. The hydraulic fracturing test apparatus is characterized by further comprising a leak-proof sleeve and a permeable plate; the leak-proof sleeve sleeves the rock specimen to prevent pressure water from mixing with confining oil in a triaxial chamber, and the upper end and the lower end of the leak-proof sleeve are respectively fixed to the upper pressing head and the lower pressing head; the permeable plate is distributed with pressure water permeable holes and is arranged between the rock specimen at the pressure water outlet end and the upper pressing head; one of the upper pressing head and the lower pressing head is a pressing head combination combined by an acting pressing head acting on the rock specimen and an adapting pressing head, and the acting pressing head is connected with the adapting pressing head through a tongue-and-groove insertion structure. The invention further provides the rock specimen for the apparatus and the hydraulic fracturing testing method utilizing the hydraulic fracturing test apparatus based on the conventional testing machine for rock mechanics to achieve hydraulic fracturing tests on the conventional test machine for rock mechanics.

Owner:SICHUAN UNIV

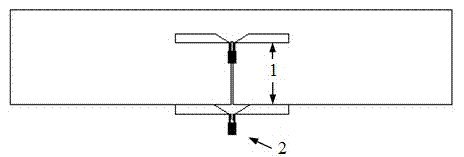

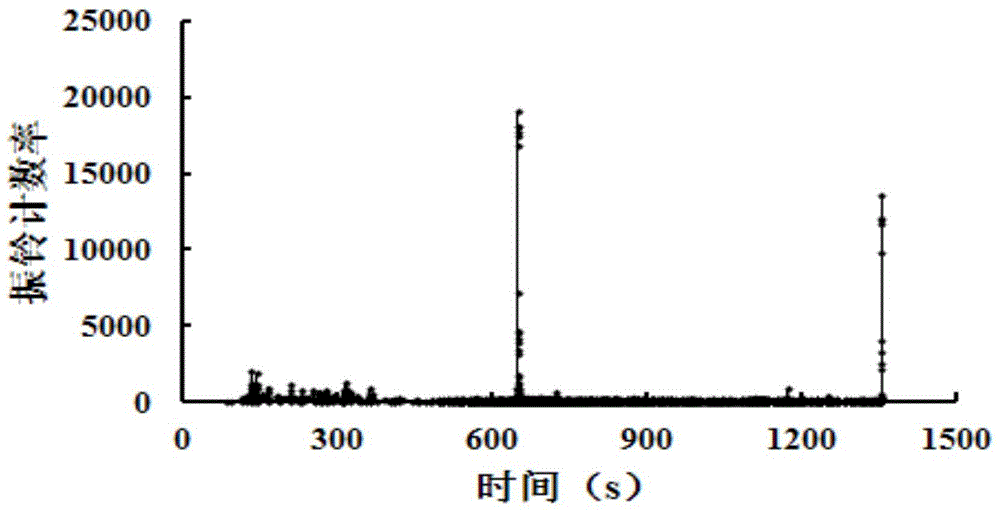

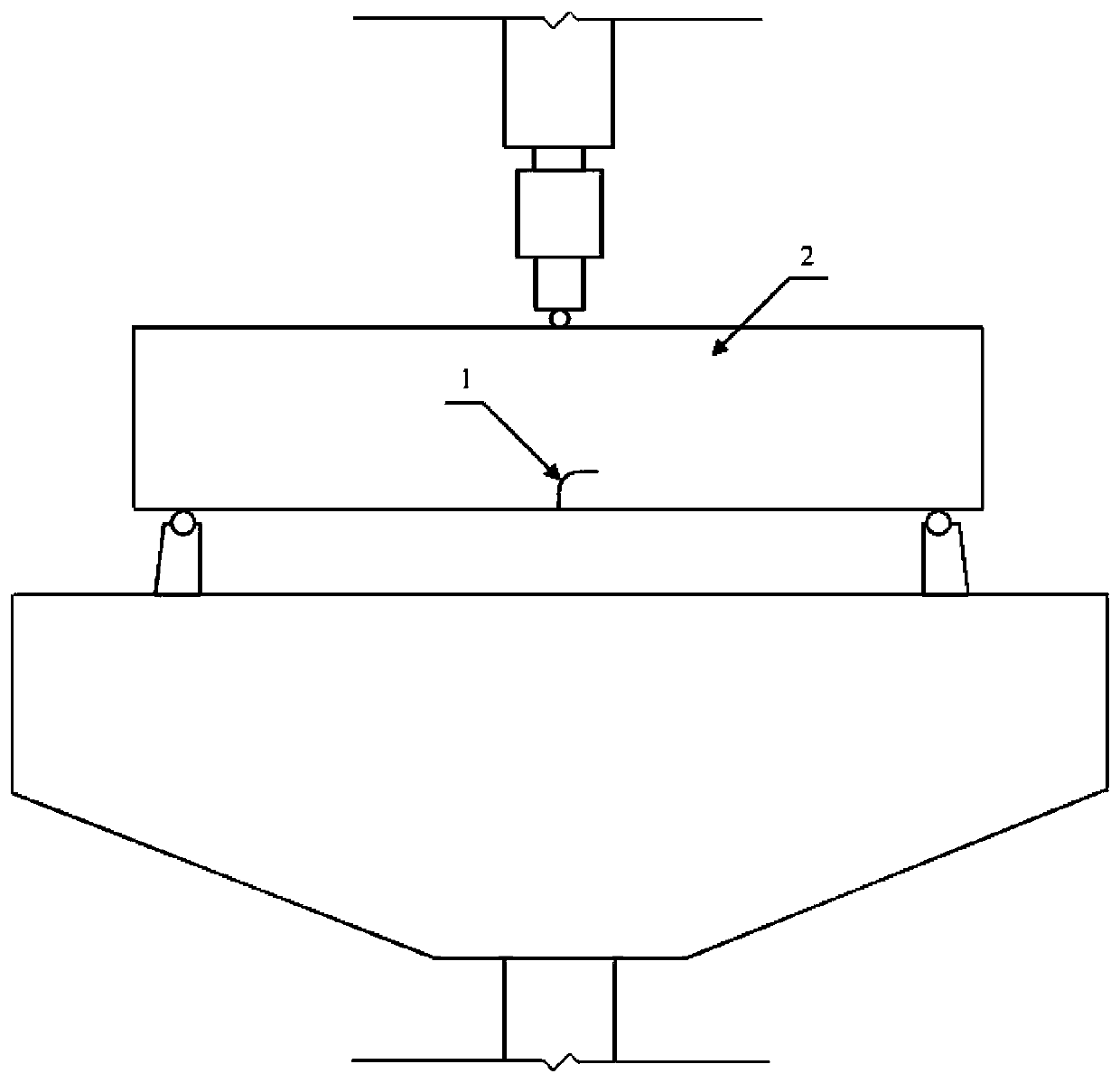

Cracking load determination method of concrete fracture test based on acoustic emission technique

InactiveCN104964882AAccurately determineAnalysing solids using sonic/ultrasonic/infrasonic wavesMaterial strength using steady bending forcesConcrete beamsAcoustic emission

The invention discloses a cracking load determination method of a concrete fracture test based on an acoustic emission technique. A three-point bending concrete beam is measured, an acoustic emission sensor and a load sensor are adopted, the acoustic emission sensor is connected with an acoustic emission collection device, and the load sensor is connected with a load-strain collection device. The cracking load determination method comprises the following steps of pasting the acoustic emission sensor on the surface of the three-point bending concrete beam, and putting the load sensor in a position, to which load is applied, of the three-point bending concrete beam, wherein the acoustic emission sensor is perpendicular to the surface of the three-point bending concrete beam; applying load to the three-point bending concrete beam, and recording the load as cracking load of the three-point bending concrete beam when the interior of the three-point bending concrete beam begins to crack. According to the cracking load determination method of the concrete fracture test based on the acoustic emission technique, the cracking load of the concrete fracture test can be more precisely determined.

Owner:NANJING HYDRAULIC RES INST

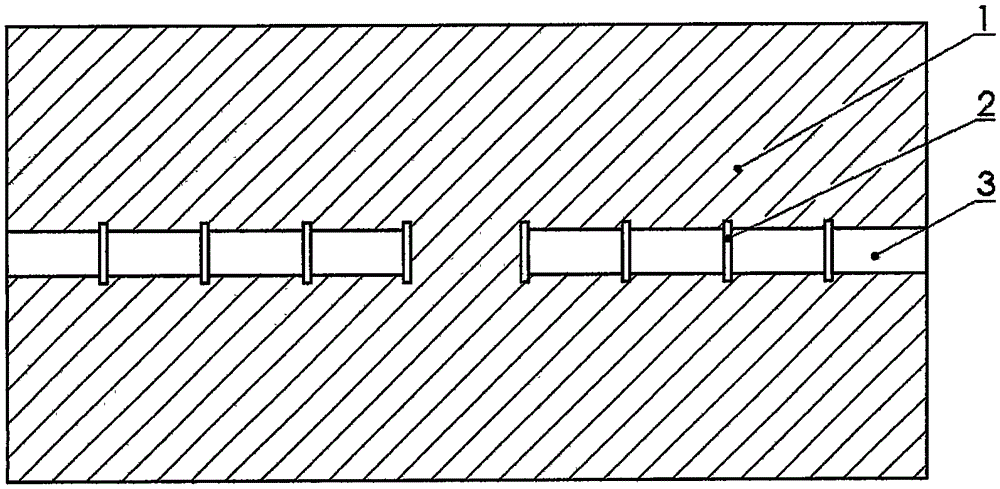

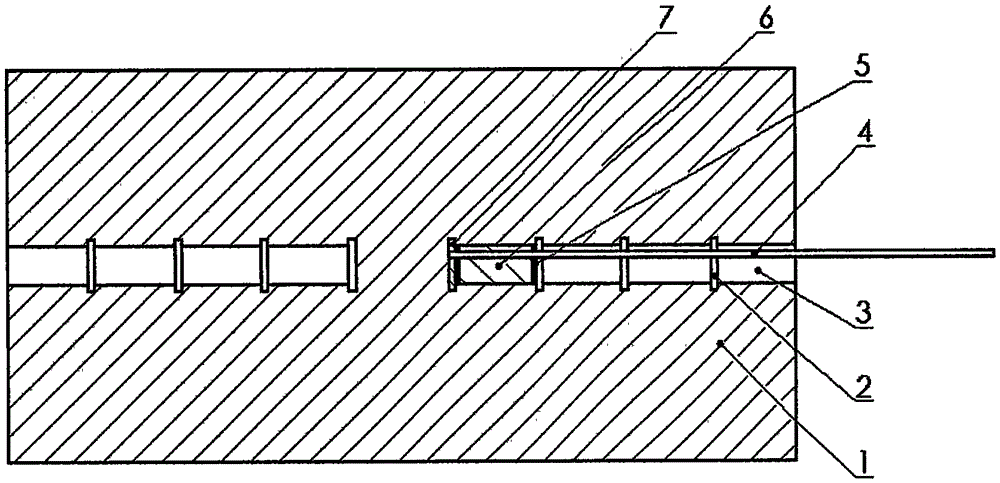

Laboratory staged hydraulic fracturing test method for large-size natural rock

ActiveCN105675399AImprove cementing performanceAvoid bleedingMaterial strength using tensile/compressive forcesHydraulic fracturingLarge size

The invention discloses a laboratory staged hydraulic fracturing test method for large-size natural rock. The method comprises the following steps: 1) selecting natural rock, processing the rock into a standard-size test piece, drilling a hole of desired depth in an end face of the test piece, and cutting multiple ring grooves in the drill-hole, wherein a cavity between the ring grooves is a glue injection cavity; 2) placing a liquid injection pipe at a predetermined ring groove, filling the ring groove with coarse sand, filling the glue injection cavity with glue, sealing two ends of glue with foraminous separator plates until the glue is solidified; 3) repeating the Step 2; 4) placing the standard test piece onto a test rack, connecting the liquid injection pipe, applying three-dimensional confining pressure, and carrying out a staged fracturing test; and 5) unloading three-dimensional confining pressure off the standard test piece, dismounting the liquid injection pipe, and sectioning the standard test piece to observe the internal fracture morphology so as to end the test. The method provided by the invention can be adopted to carry out a staged fracturing test on natural rock under laboratory conditions so as to obtain fracture morphology under experimental conditions.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

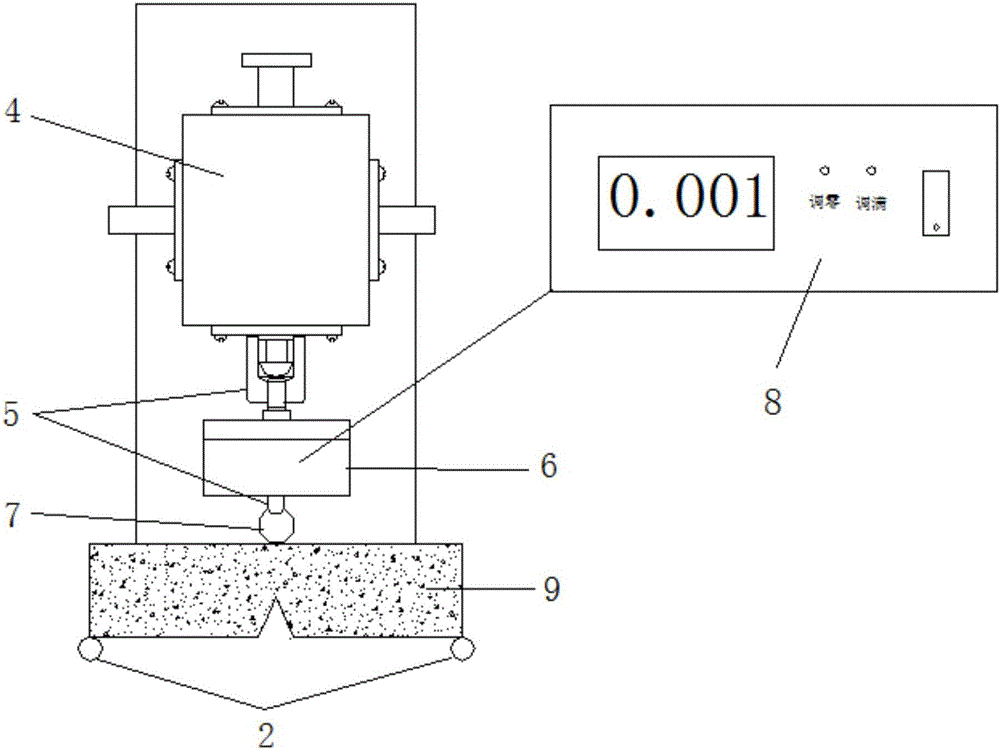

Cohesive-soil strain-control-type I-type fracture toughness tester and testing method

InactiveCN105865924AIngenious ideaUnique structurePreparing sample for investigationMaterial strength using tensile/compressive forcesType fractureTest sample

The invention discloses a cohesive-soil strain-control-type I-type fracture toughness tester and a testing method. The tester comprises an installing table. A motor is arranged on the installing table, and is connected with a stretchable connecting rod, and a sensor is connected to the front end of the connecting rod, and is connected with a pushing rod; a base is arranged on the installing table, sliding rails are arranged on the base, tested samples are arranged on the sliding rails, a pair of stopping rods are fixedly connected to the base, one faces of the tested samples are connected with the stopping rods, the other faces of the tested samples are connected with the pushing rod, and initial fissures are formed in the tested samples. According to the cohesive-soil strain-control-type I-type fracture toughness tester, as the tested samples lie flatly to be subjected to a fracture test, the gravity influence is eliminated; as the tested samples are put onto the sliding rails, the influence of friction force is eliminated.

Owner:NANJING UNIV

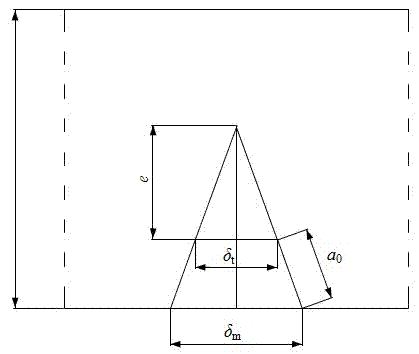

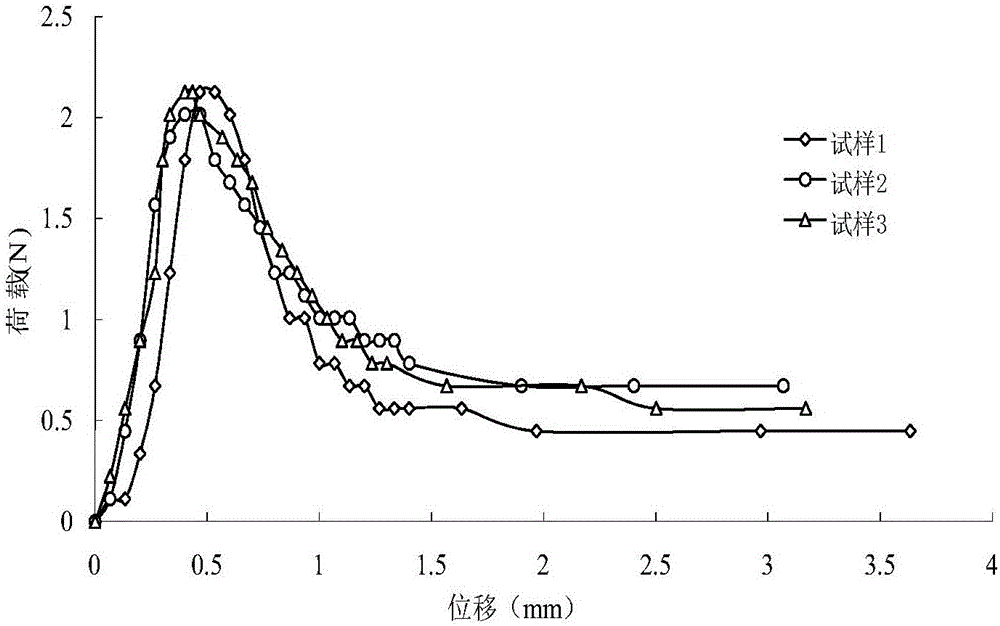

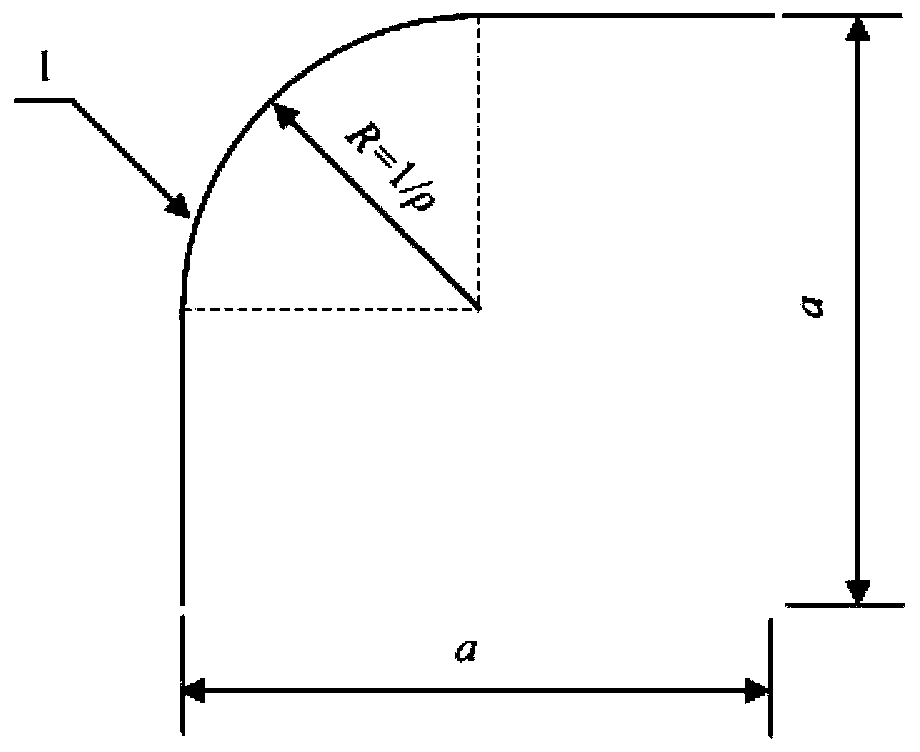

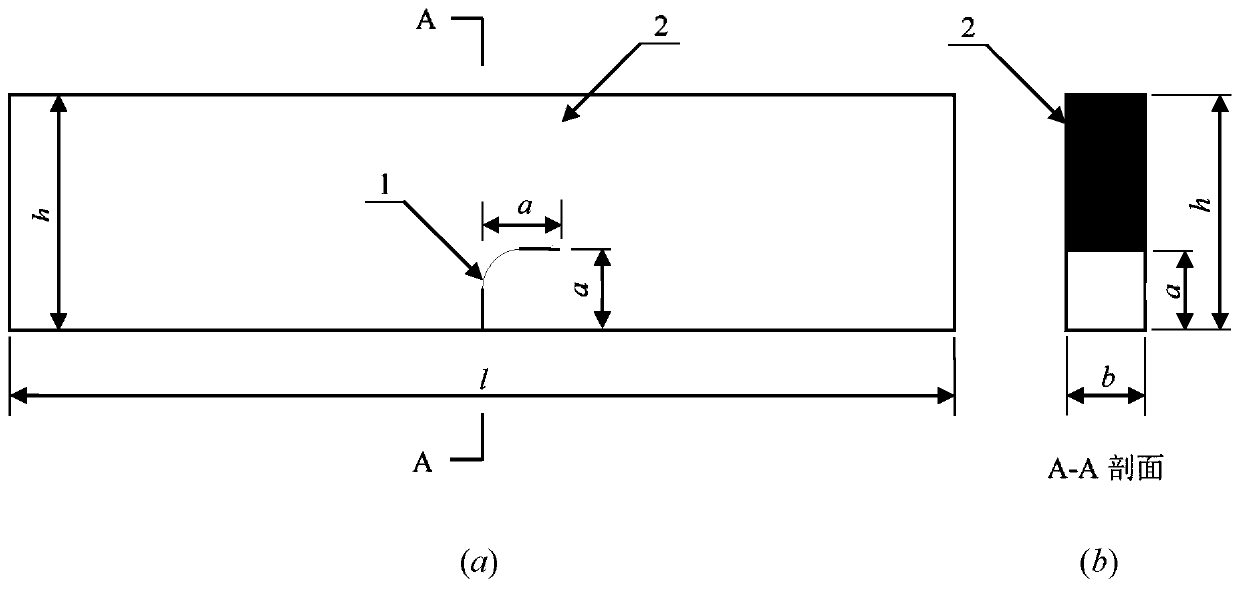

Method of determining load-displacement complete curve of concrete I-II composite cracks

InactiveCN109916739AAccurate and effective verificationMaterial strength using steady bending forcesEngineeringFracture test

The invention provides a method of determining a load-displacement complete curve of concrete I-II composite cracks, which belongs to the technical field of concrete fracture test. In the new test method, a right-angled broken line crack is cut in the midspan of the traditional three-point bending beam concrete specimen, an improved three-point bending beam concrete specimen is obtained, the crackhas the same lengths in a horizontal direction and a vertical direction, and the break point is subjected to arc treatment; the initial crack height ratio a / h is 0.2 to 0.5, and the value of the curvature pho of the arc has a range of 1 / a to 15 / a; and the test adopts three-point loading, load is applied to the midspan of the improved three-point bending beam concrete specimen by a test machine, apredetermined loading scheme is realized, and a load-displacement complete curve is obtained. The initial crack tip of the test piece has large KII / KI, the load-displacement complete curve can be tested under simple test operation, a numerical value simulation result can be verified accurately and effectively, and a certain reference value is provided for testing accuracy of the concrete I-II composite fracture analysis model and the numerical value analysis theory.

Owner:DALIAN UNIV OF TECH

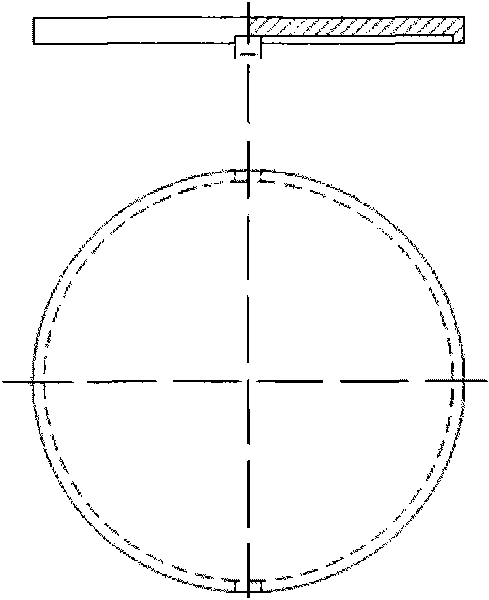

Device and method for measuring I-type creep fracture toughness and fracture toughness of rock

InactiveCN101710042ASimple test operationGuaranteed accuracyInvestigating material ductilityFracture testEnvironmental geology

The invention relates to a device and a method for measuring the I-type creep fracture toughness and the fracture toughness of rock. A rock single axle tensile creep fracture test and a conventional fracture test are carried out on the device for measuring the I-type creep fracture toughness and the fracture toughness of rock, thus the I-type creep fracture toughness and the fracture toughness of rock are measured. The measuring method comprises the steps of: transferring a pressure applied by the exterior into a tensile force of the interior of a rock test piece so as to realize the single axle tension of the rock test piece. The invention enables the operation of the indoor measuring method of rock fracture toughness to be simpler, guarantees the accuracy of the measured data of the test and has rather high precision, therefore having excellent using and popularizing values.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com