Laboratory staged hydraulic fracturing test method for large-size natural rock

A technology of hydraulic fracturing and test method, which is applied in the direction of applying stable tension/pressure to test the strength of materials, etc. It can solve the problems of segmental hydraulic fracturing test failure, large difference in physical and mechanical properties, and poor cementation effect. Achieve the effect of optimizing production increase, good cementation, and avoiding liquid stringing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

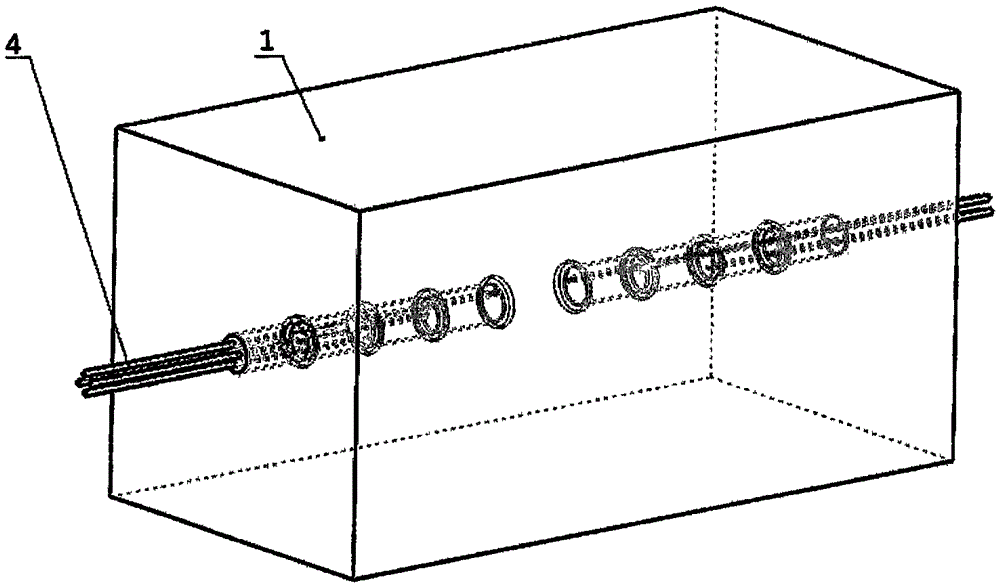

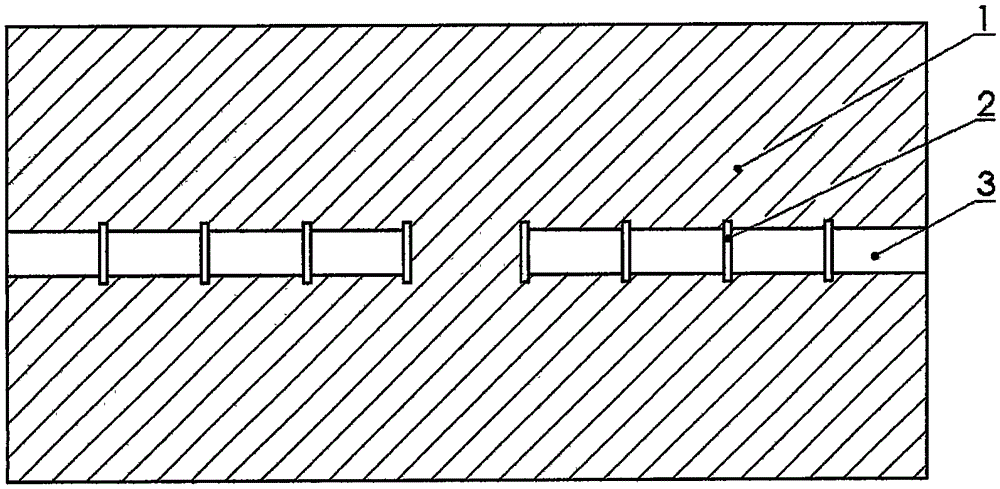

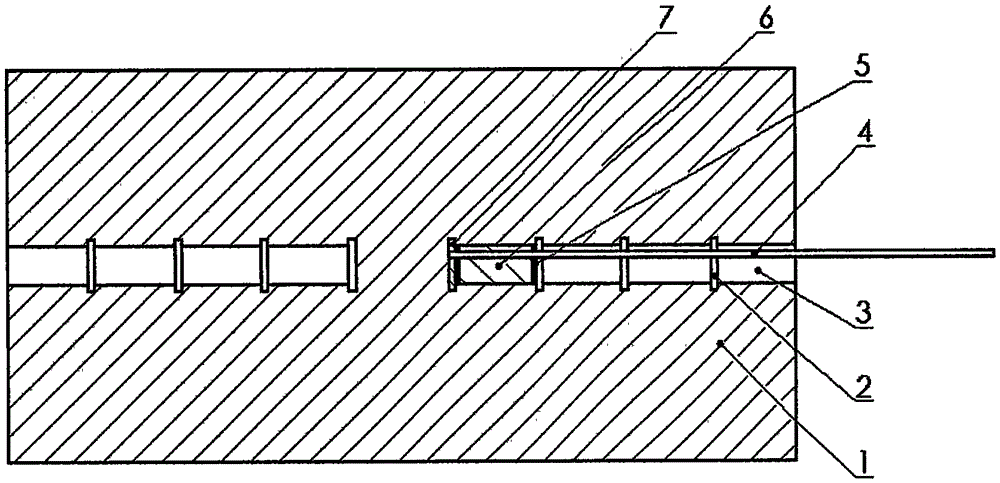

[0032] Example: figure 1 It is an overall effect diagram of an embodiment of a laboratory segmented hydraulic fracturing test method for large-scale natural rock blocks according to the present invention; figure 2 for figure 1 The cross-sectional view of the standard test piece after the drilling and grooving is completed in the shown embodiment; image 3 for figure 1 Sectional view of a standard specimen for fixing a fracturing stage liquid injection pipeline in the shown embodiment; Figure 4 for figure 1 Schematic diagram of the partition with holes and the arrangement of holes thereof in the shown embodiment; Figure 5 for figure 1 An exploded view of the grooving tool in the illustrated embodiment.

[0033] A kind of test method for large-scale natural rock block laboratory staged hydraulic fracturing, comprising the following steps:

[0034] 1. Preparation and primary processing of standard test pieces

[0035] According to the physical and mechanical properties...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com