Patents

Literature

701 results about "Bond properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A property bond is a bond that posts the value of tangible property, such as real estate, in order to obtain a pre-trial release from jail. In some cases, the value of the property may need to be twice as high as the bail amount in order for a property bond to be accepted. A property bond is not allowed in every state.

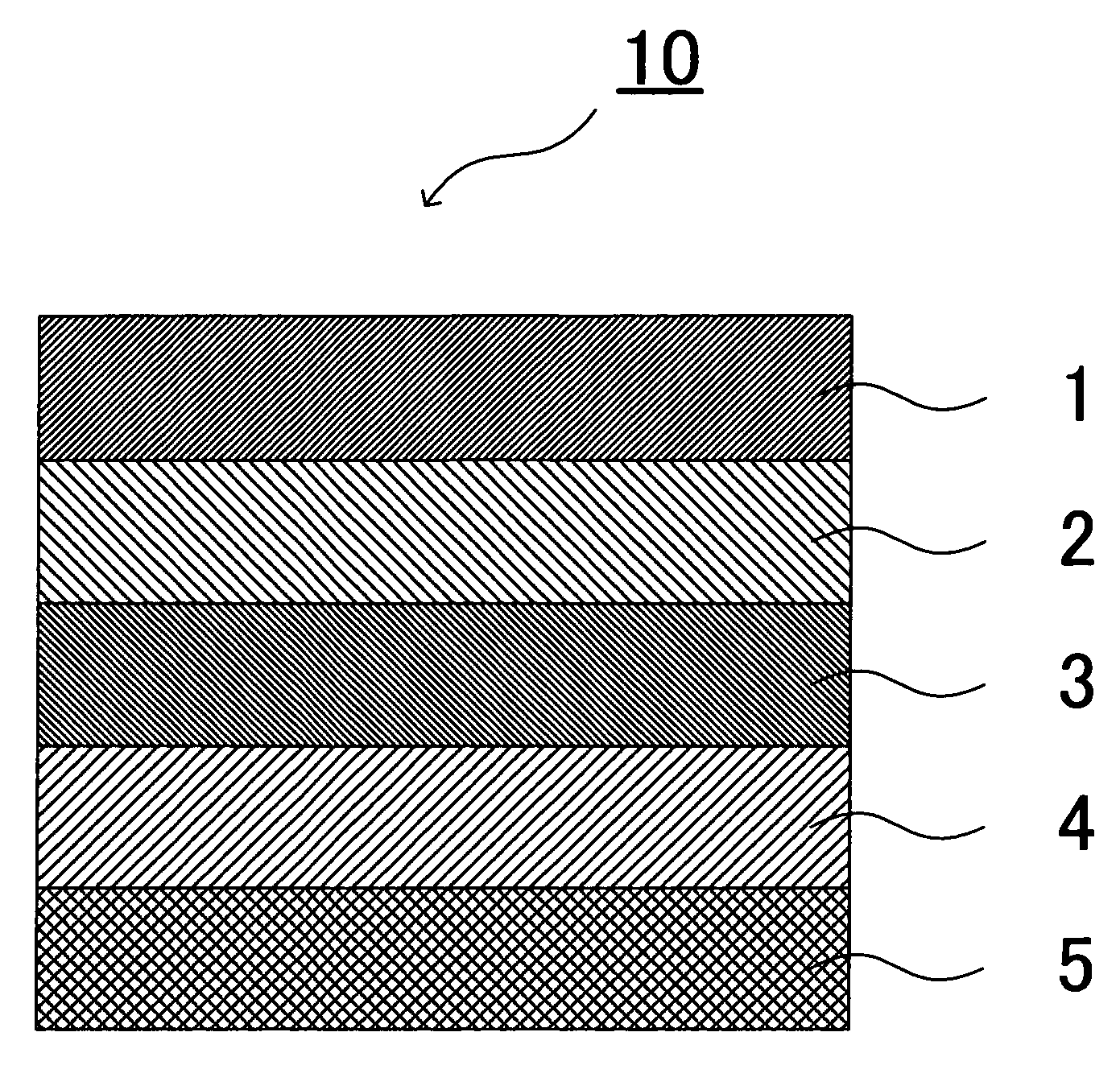

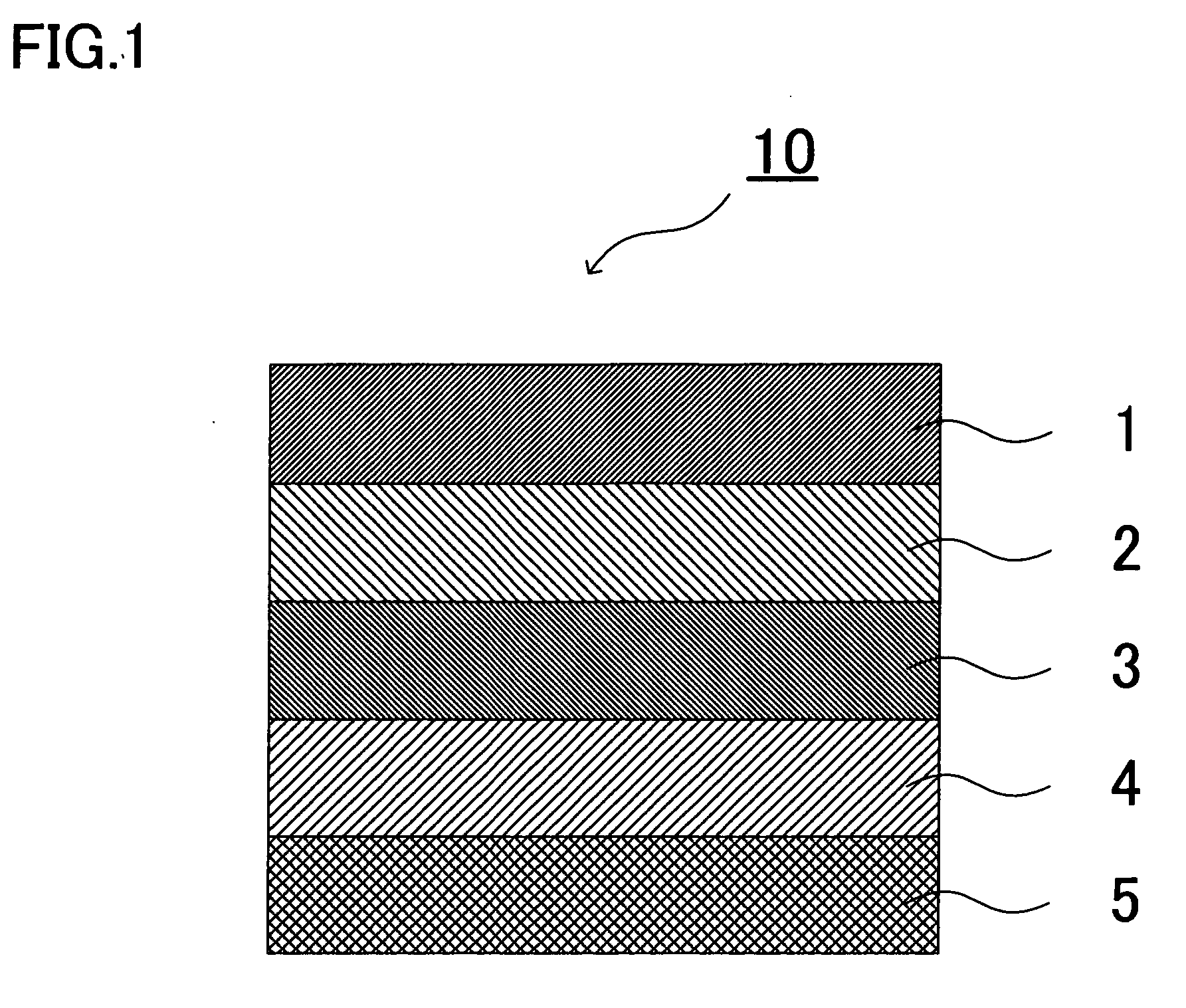

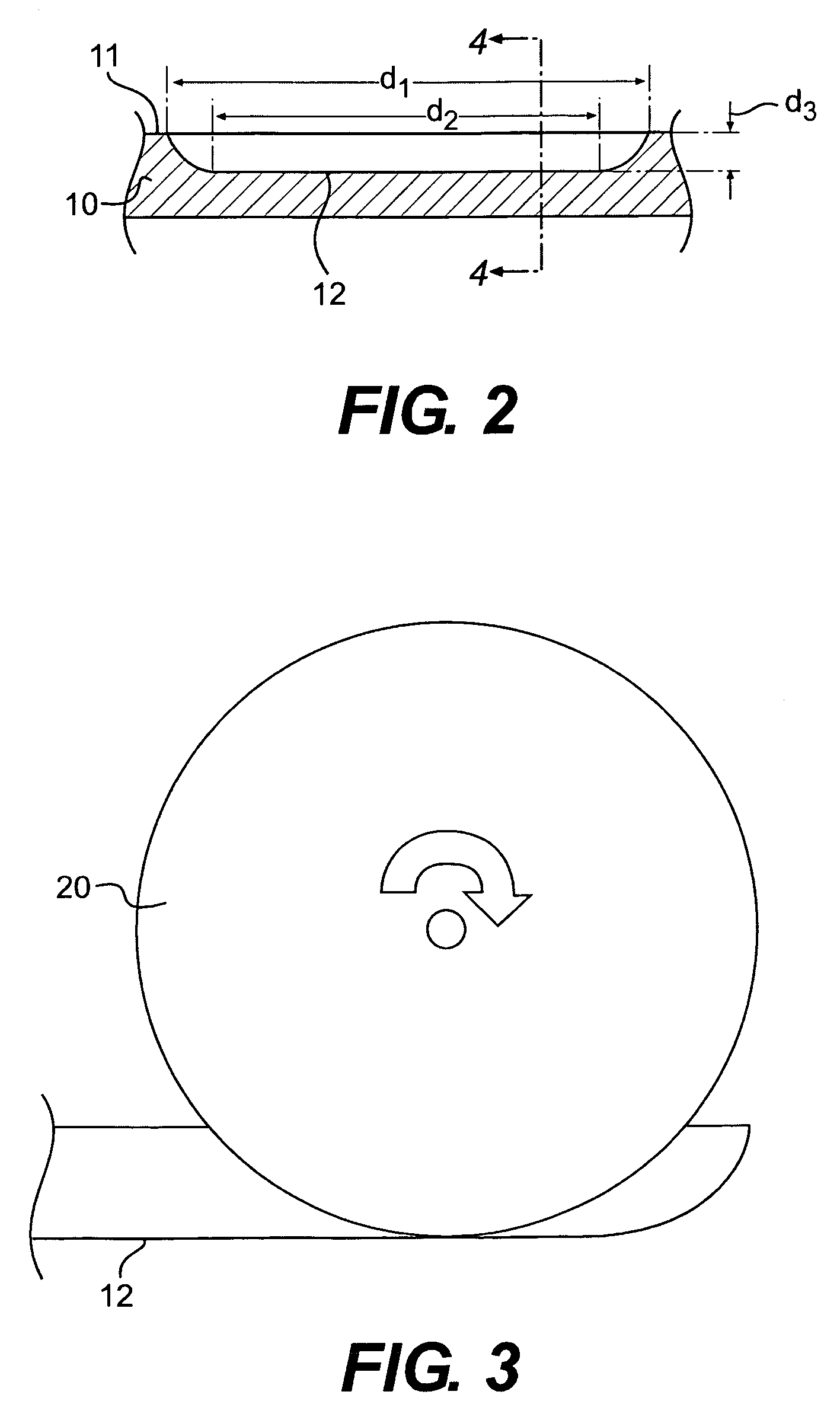

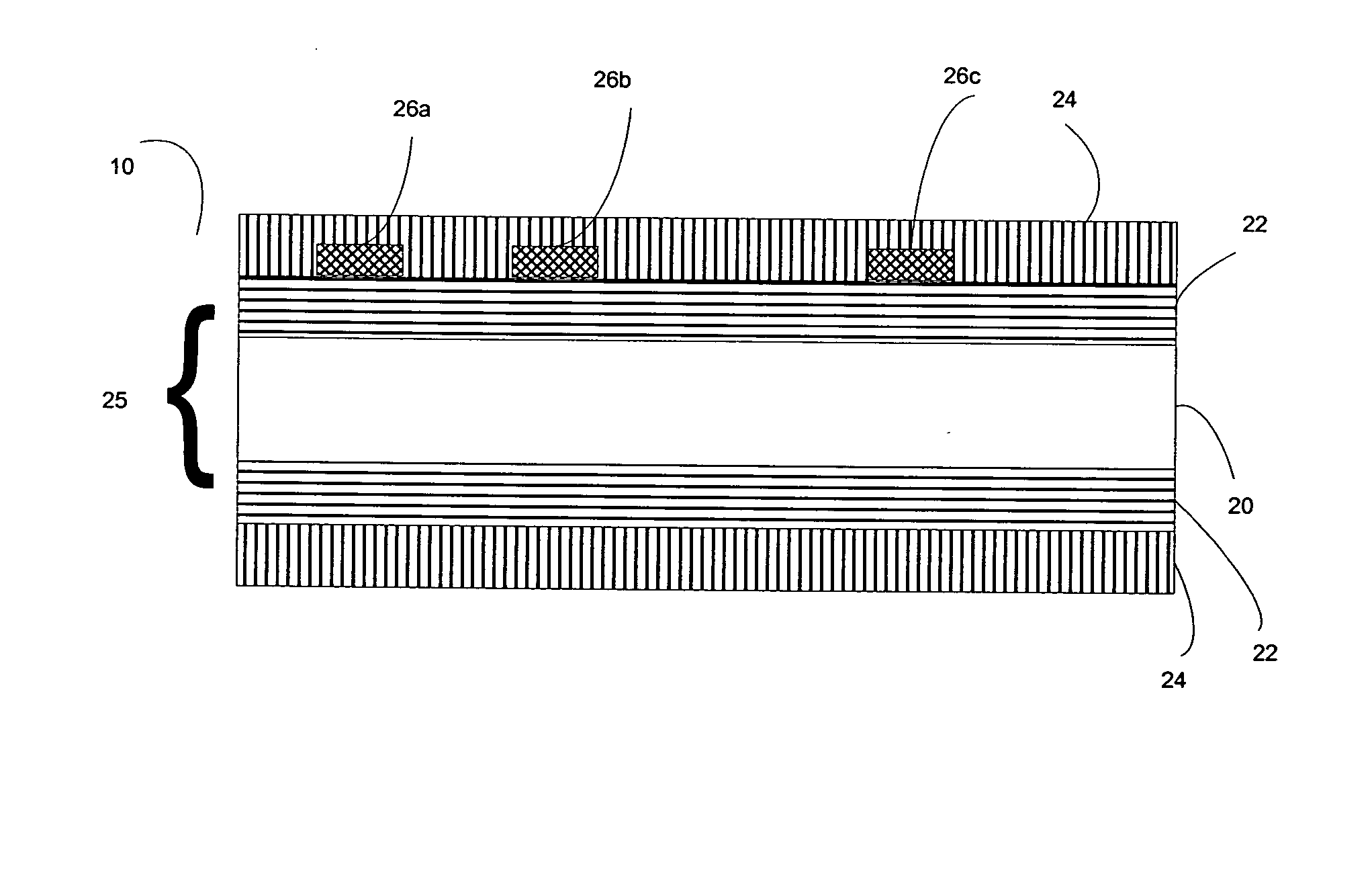

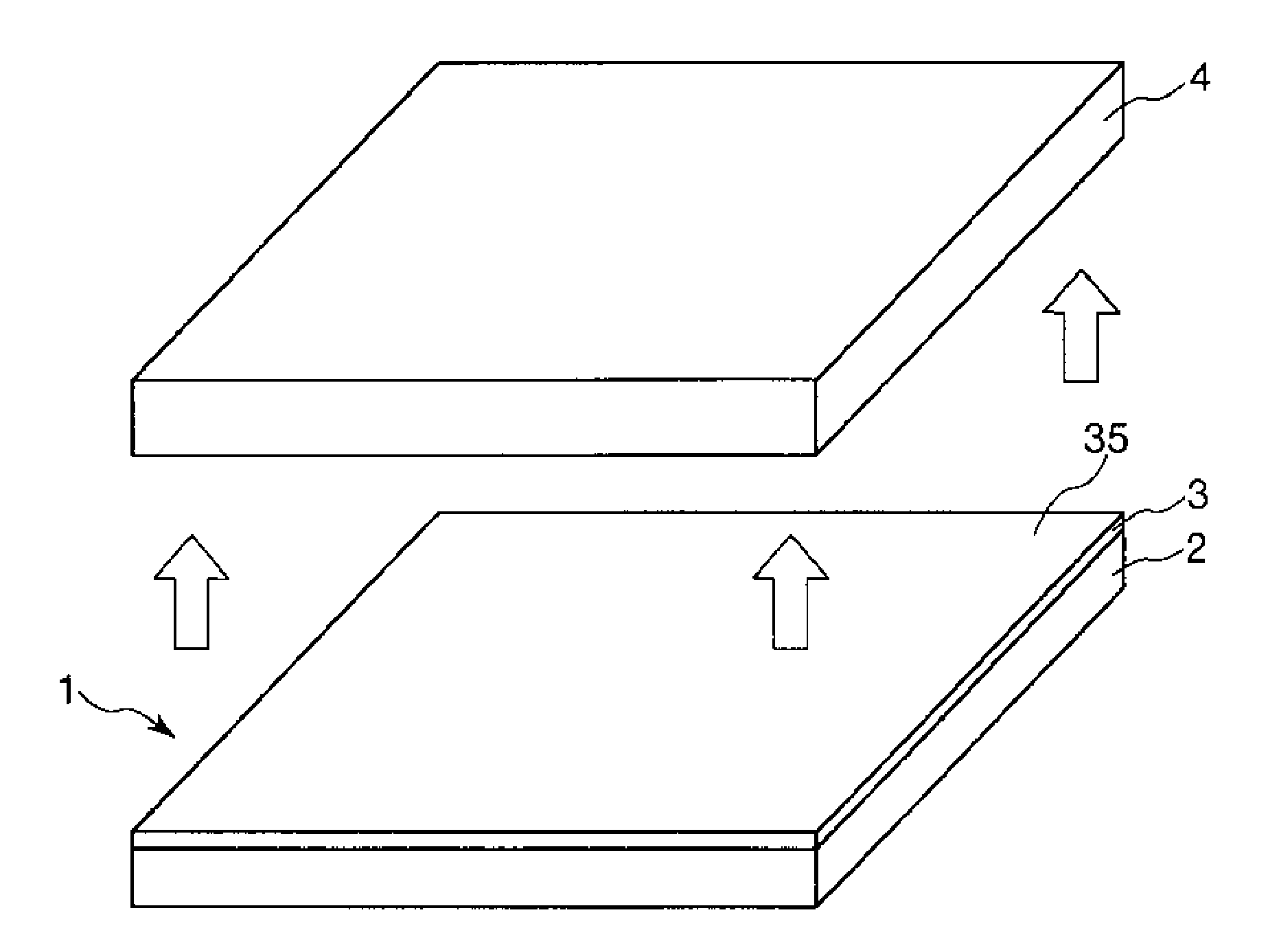

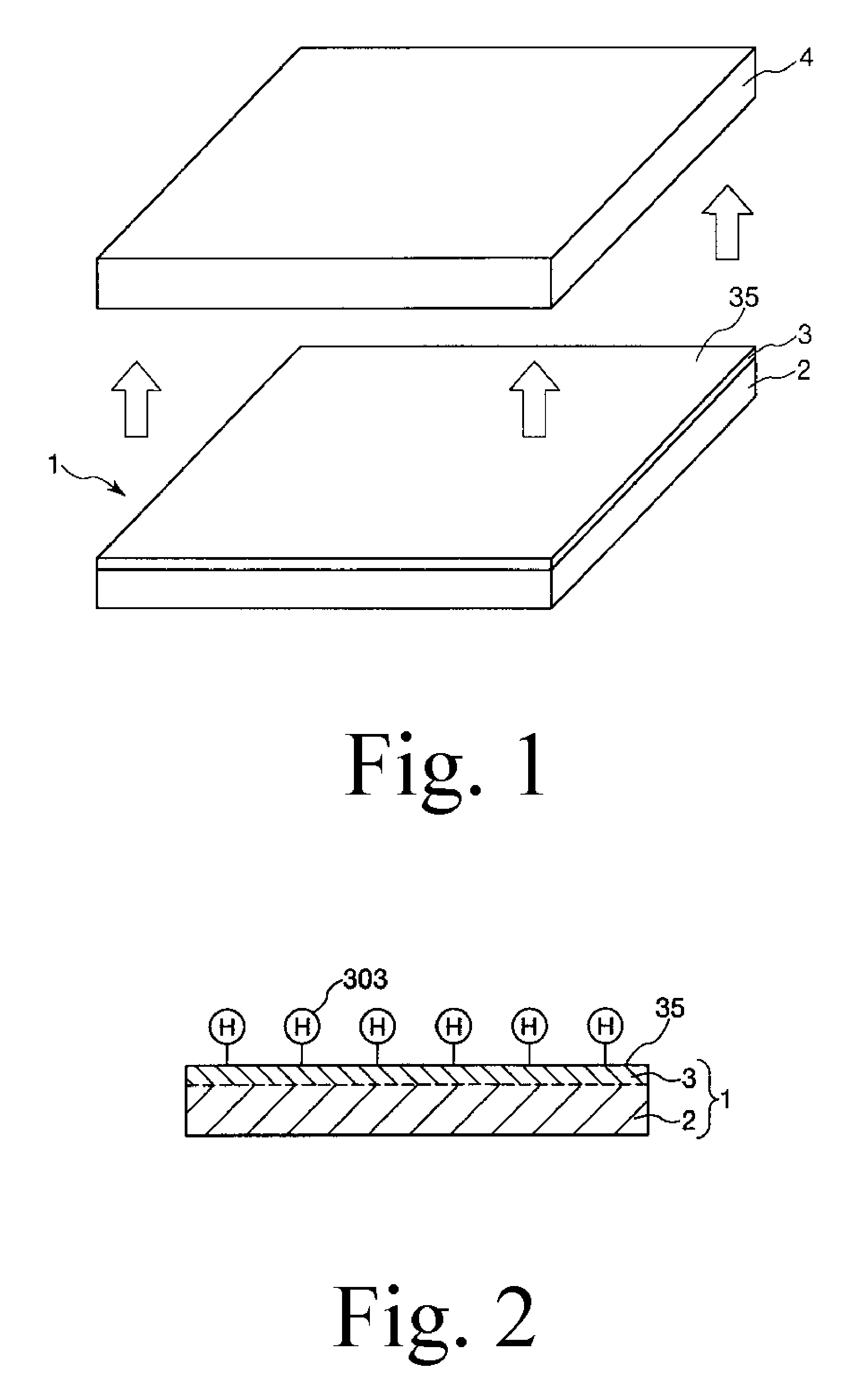

Filler sheet for solar cell module, and solar cell module using the same

InactiveUS20060201544A1High strengthLow costPV power plantsSynthetic resin layered productsPolyolefinEngineering

A main object of the invention is to provide a filler sheet for a solar cell module which is excellent in various properties such as strength, endurance, weatherability, heat resistance, water resistance, light resistance, wind pressure resistance, hailstorm resistance, and vacuum laminating suitability, and has very good thermal melting / bonding property without being affected by production conditions and others, and which makes it possible to produce a solar cell module, suitable for various use purposes, stably at low costs; and a solar cell module using the same. In order to attain the object, the invention provides, as a filler sheet for solar cell element, a filler sheet made of a resin film produced by a resin composition comprising a copolymer of an α-olefin and an ethylenic unsaturated silane compound, or a modified or condensed body thereof, and one or more selected from the group consisting of a light resisting agent, an ultraviolet absorbent and a thermal stabilizer; and a filler sheet made of a resin film produced by a resin composition comprising a maleic anhydride modified polyolefin.

Owner:DAI NIPPON PRINTING CO LTD

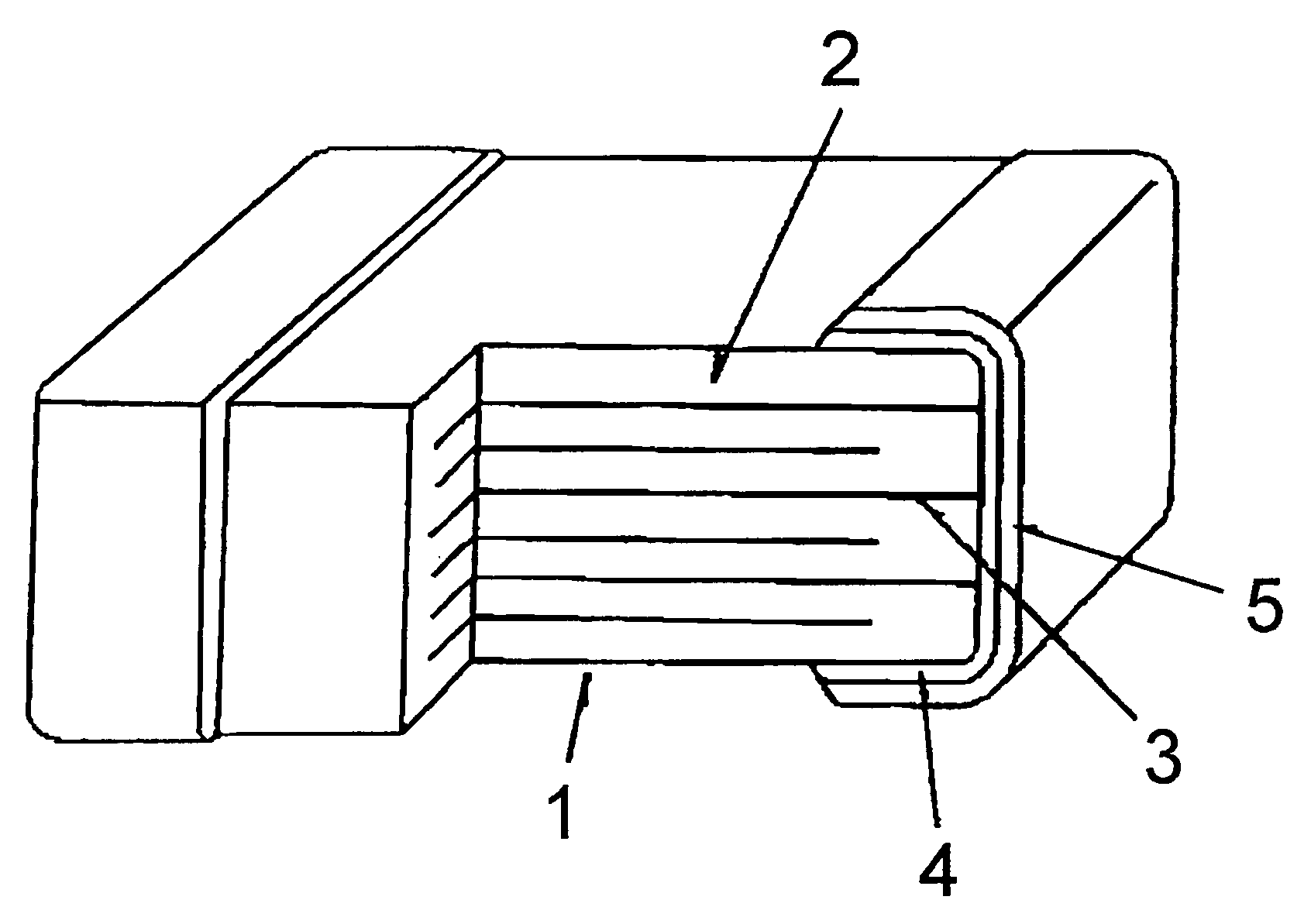

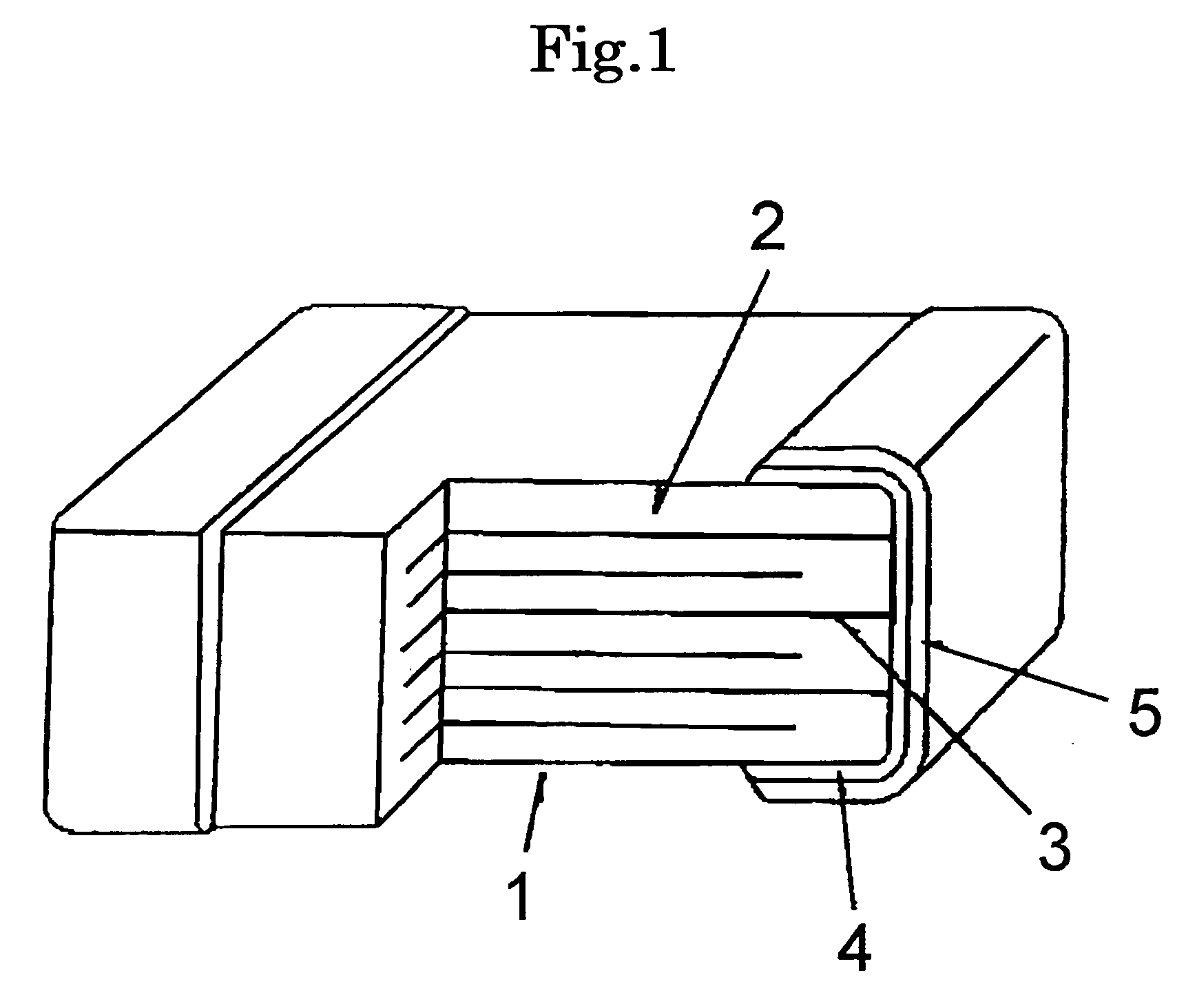

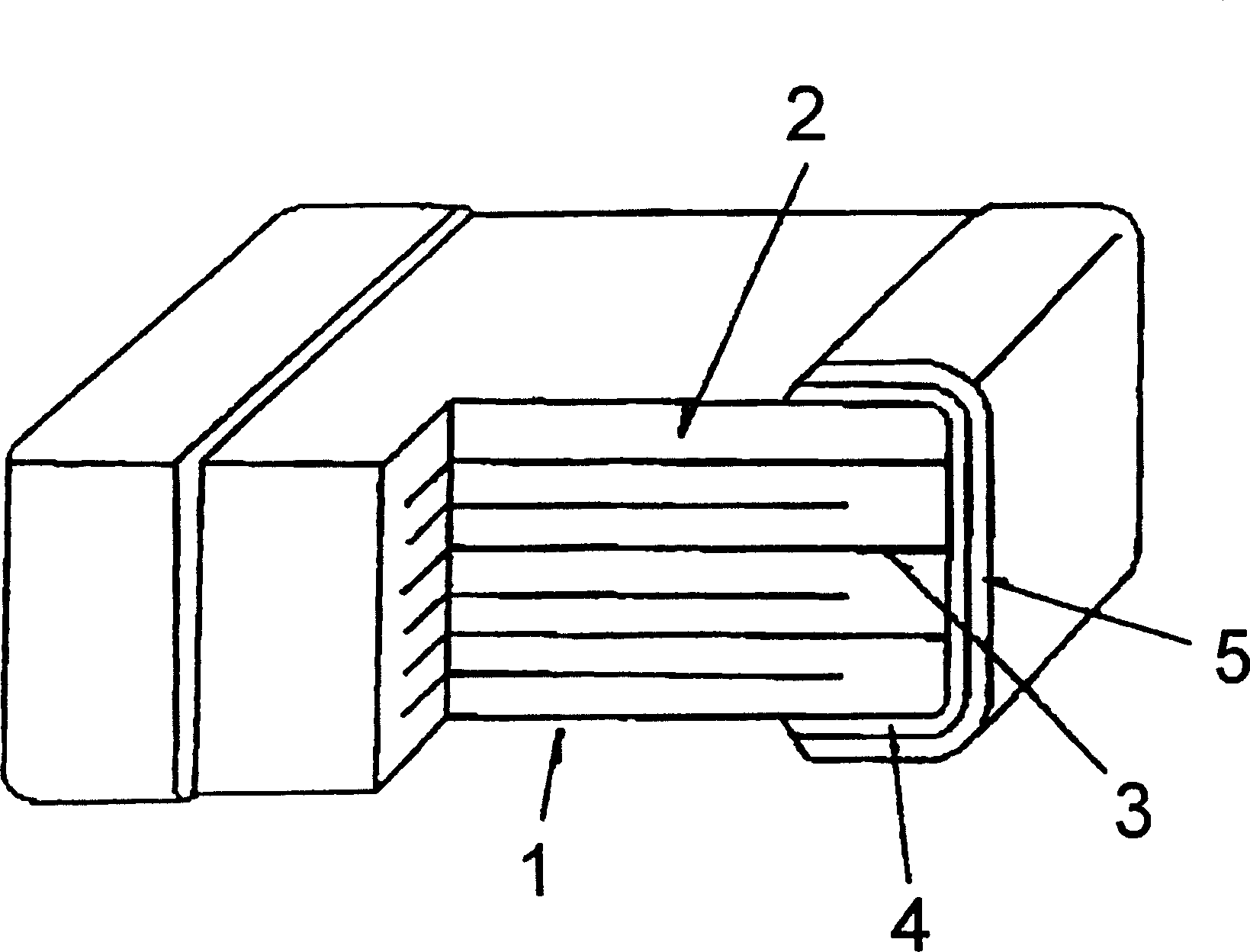

Electronic part with external electrode

ActiveUS20060044098A1High melting pointImprove adhesionFixed capacitor electrodesConductive materialConductive pasteBond properties

The present invention is intended to solve the problem of a conventional thermosetting conductive paste with respect to bonding-property between an internal electrode(s) and an external electrode(s) so as to provide a multilayer ceramic electronic part suitable for its mounting on a substrate and for its plating-treatment. The present invention relates to a multilayer ceramic electronic part, characterized in that it has an external electrode(s) formed from a thermosetting conductive paste comprising conductive particles having a high melting point, metal powder having a melting point of 300° C. or less and a resin(s).

Owner:NAMICS CORPORATION +1

Coated conductive particle coated conductive particle manufacturing method anisotropic conductive material and conductive connection structure

InactiveUS20060154070A1Improve connection reliabilityMetal-working apparatusCoupling contact membersConductive materialsBond properties

An objective of the invention is to provide a coated conductive particle having superior connection reliability, a method for manufacturing such coated conductive particle, an anisotropic conductive material and a conductive-connection structure. A coated conductive particle comprising a particle having a surface made of conductive metal and an insulating particles to coat the surface of the particle having the surface made of conductive metal there with, wherein the insulating particles are chemically bonded to the particle having the surface made of conductive metal via a functional group (A) having a bonding property to the conductive metal so that a single coating layer is formed.

Owner:SEKISUI CHEM CO LTD

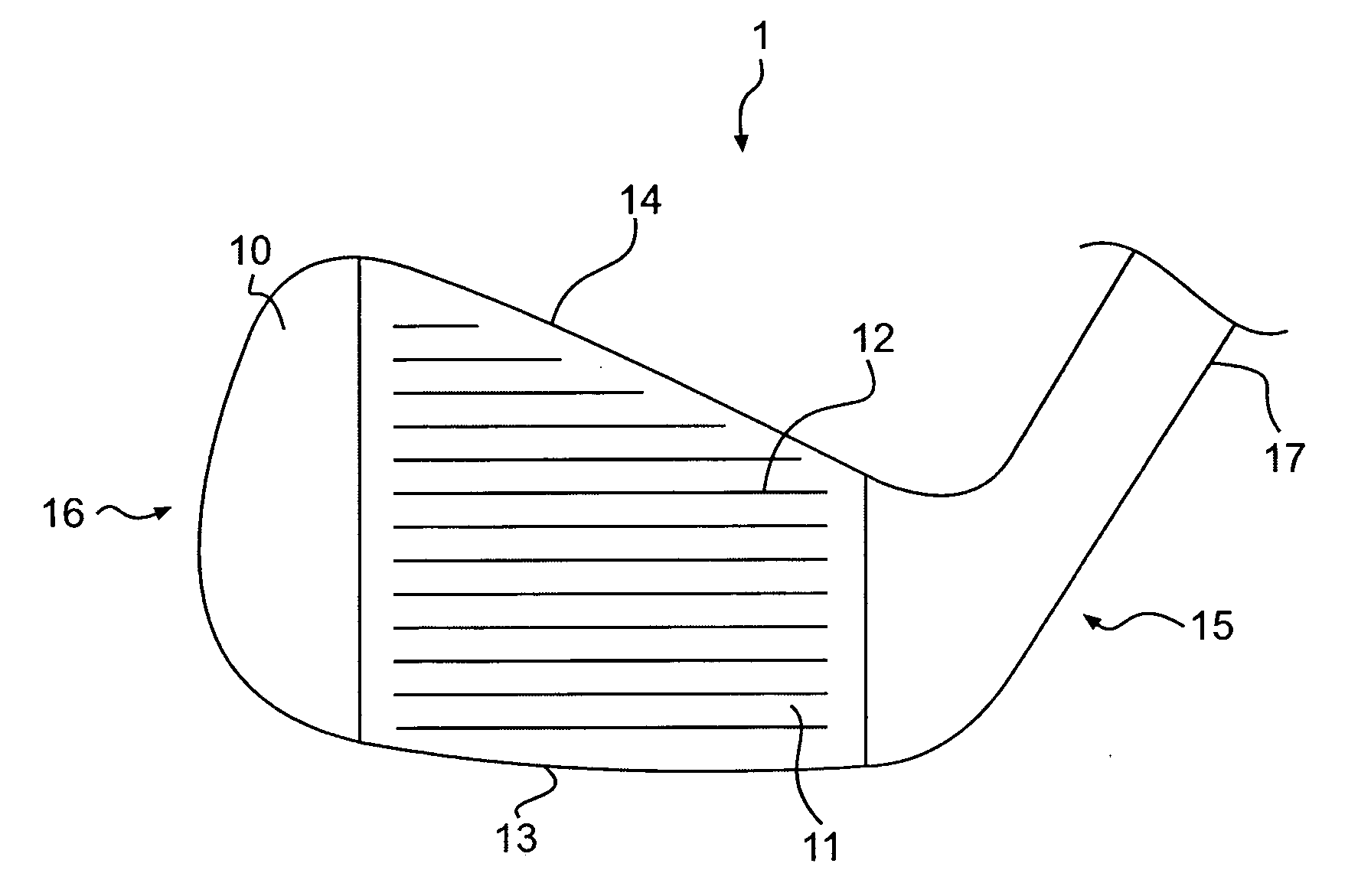

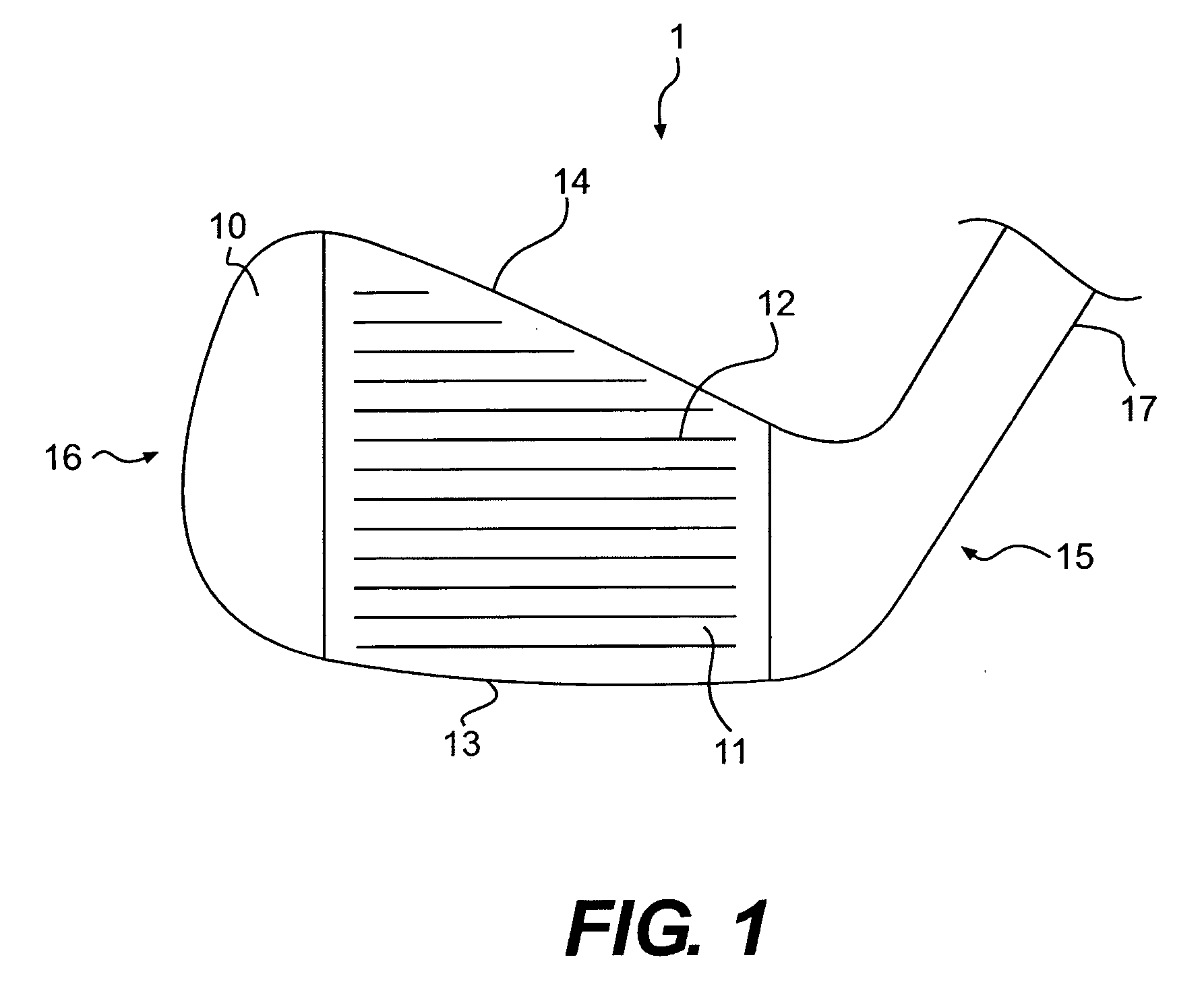

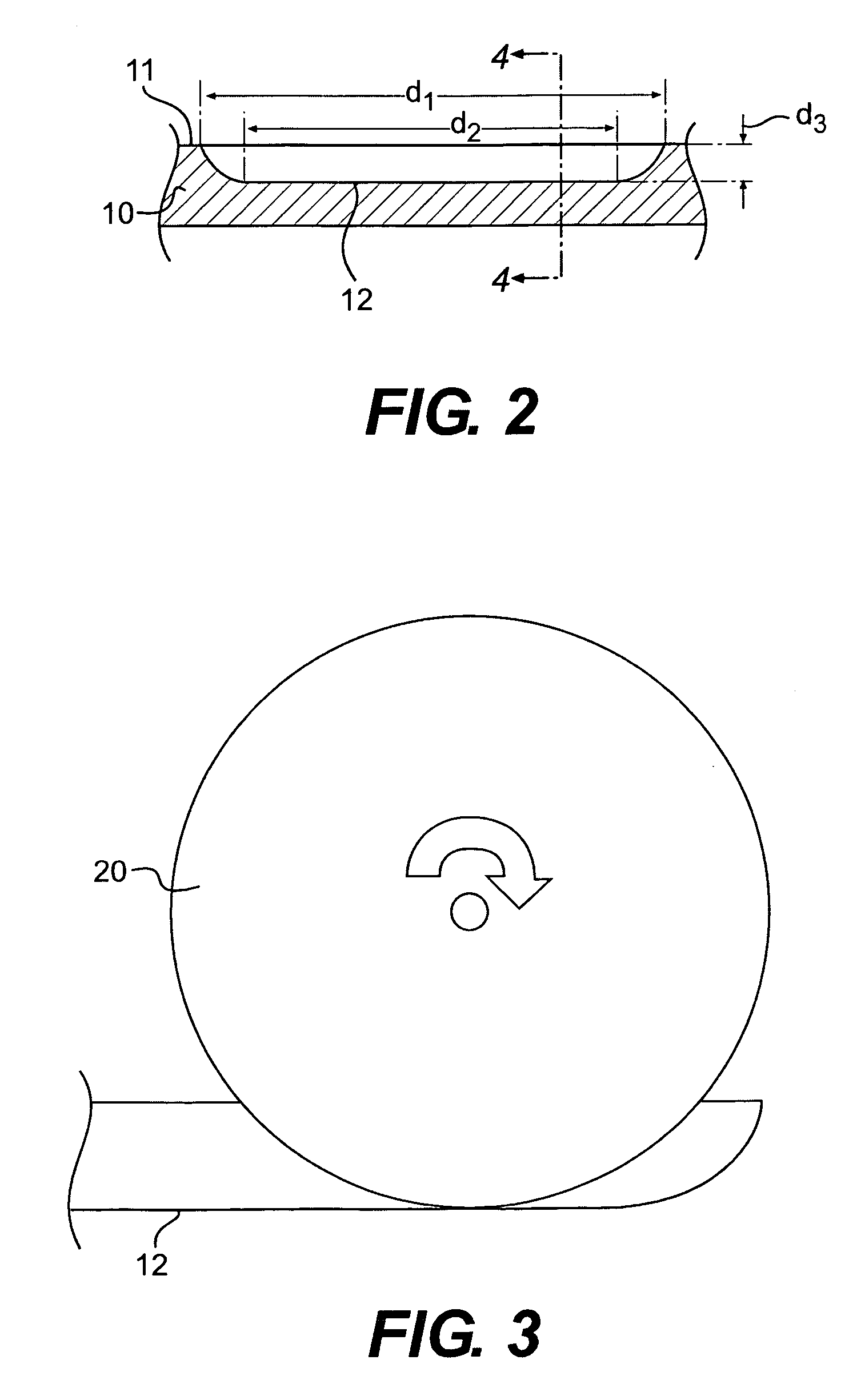

Golf club head

InactiveUS7846039B2Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face is disclosed and claimed. The face is formed by explosion welding, allowing materials having substantially different properties to be uniformly joined. Explosion welding allows the materials to be joined together via a cold-working process, allowing them to joined without losing their pre-bonded properties. Thus, the golf club head have a hard, wear resistant material as the ball-impacting face surface explosion welded to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face also allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

Epoxy resin composite, and preparation method thereof and using method thereof

This invention supply a epoxide resin combination and its preparation method, and its application as filling material of railway plate type orbit convex shape block platform. It takes ethoxyline resin, pigment, padding, curing agent and other accessory ingredient as main ingredient. This ethoxyline resin combination possess good construction usability, good cement bond property, appropriate elasticity and syntheses mechanical property, and has performance of ultraviolet radiation proof, moisture-proof.

Owner:ZHEJIANG HANGMO SYNTHETIC MATERIAL

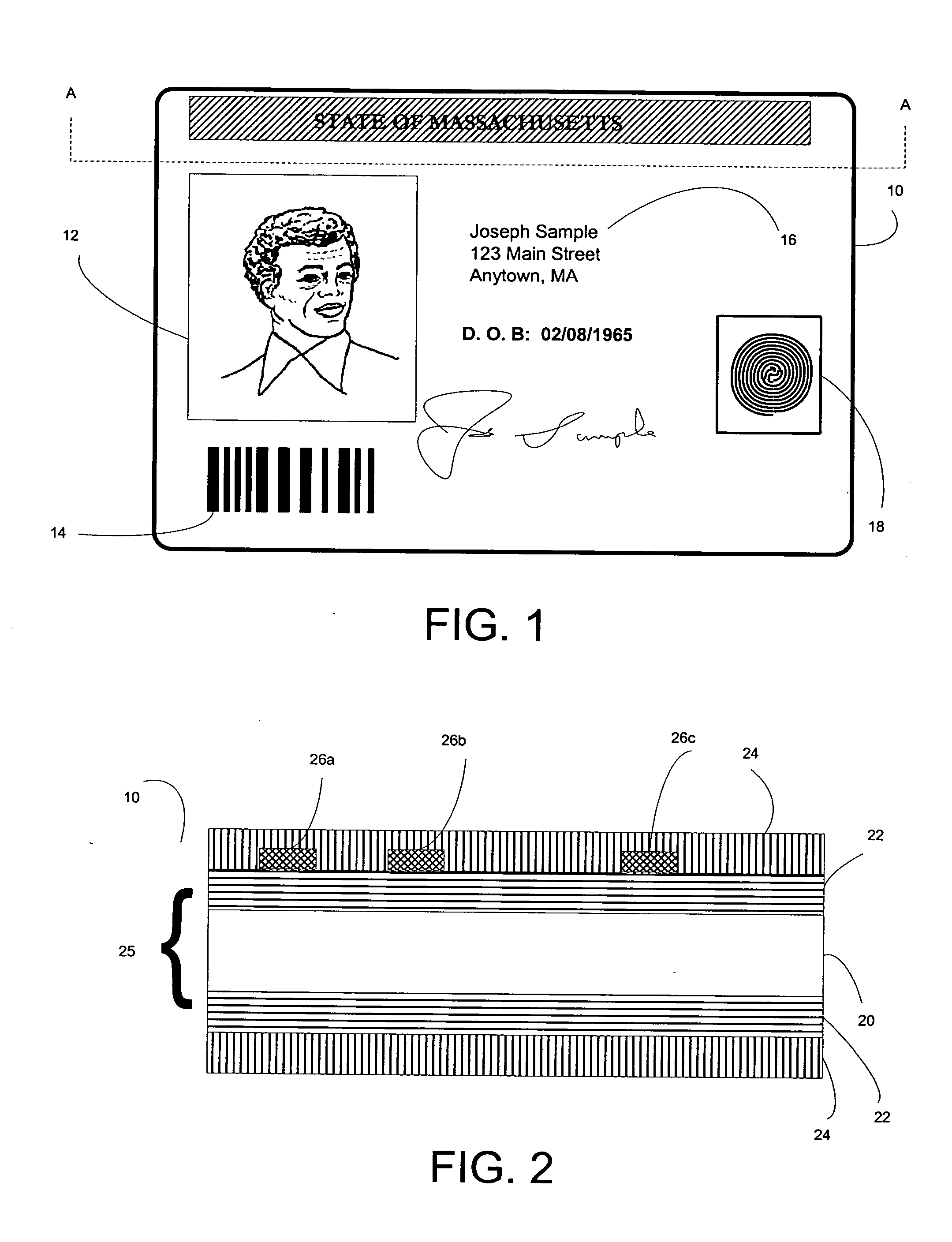

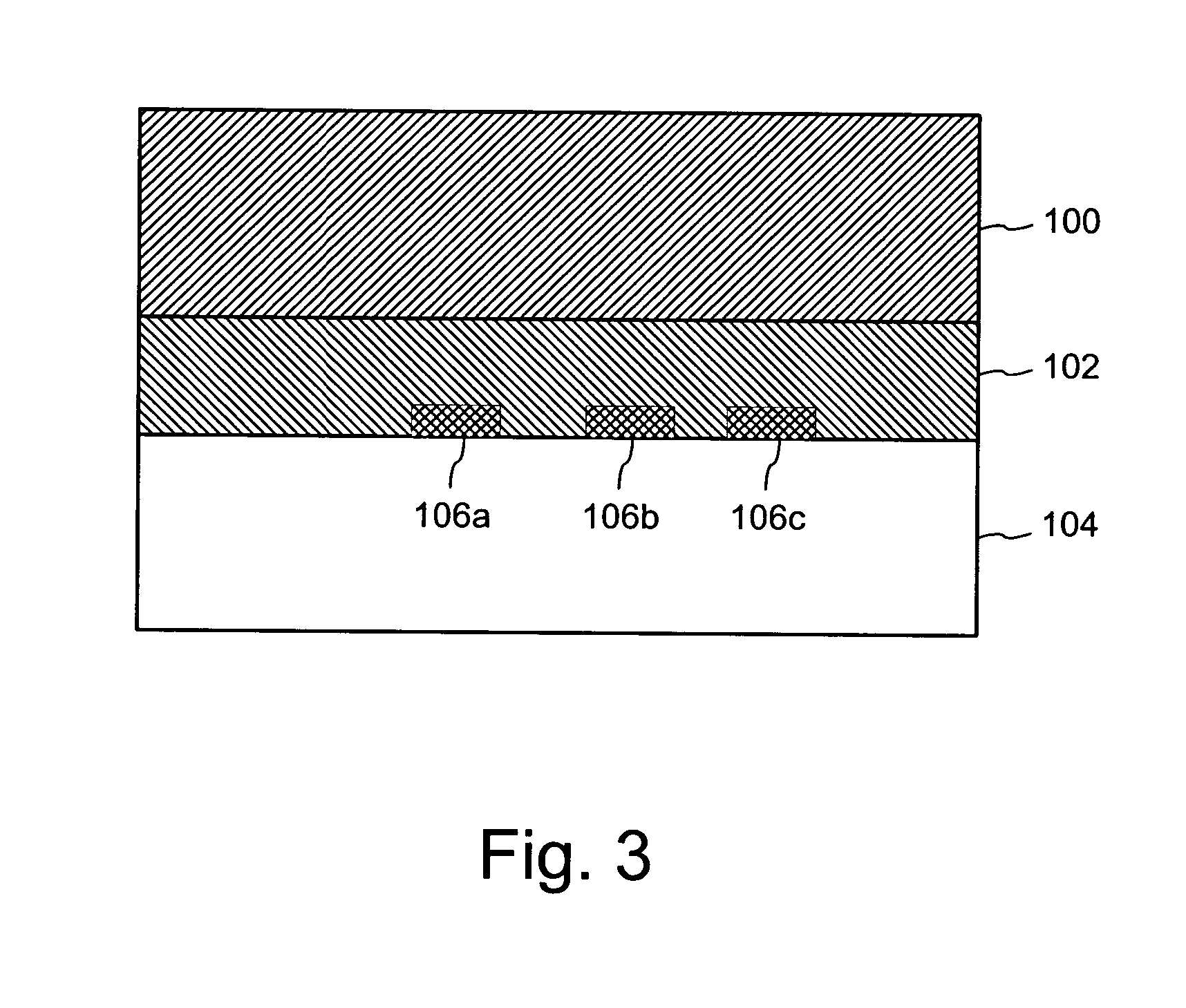

Document laminate formed from different polyester materials

InactiveUS20050084693A1Reduce adverse effectsImproved safety and durabilityRecord carriersDecorative surface effectsPolyesterAdhesive

A polyester laminate for an identification document is formed from different polyester materials. One of the polyester materials, such as PCTA, provides a durability property. Another of the polyester materials, such as PETG, provides a layer having a surface with a bonding property for bonding directly to a core without adhesive. The polyester material with the bonding property is selected to enable direct bonding to a printed core layer of TESLIN or polyester through a roll to roll or platen press process.

Owner:L 1 SECURE CREDENTIALING

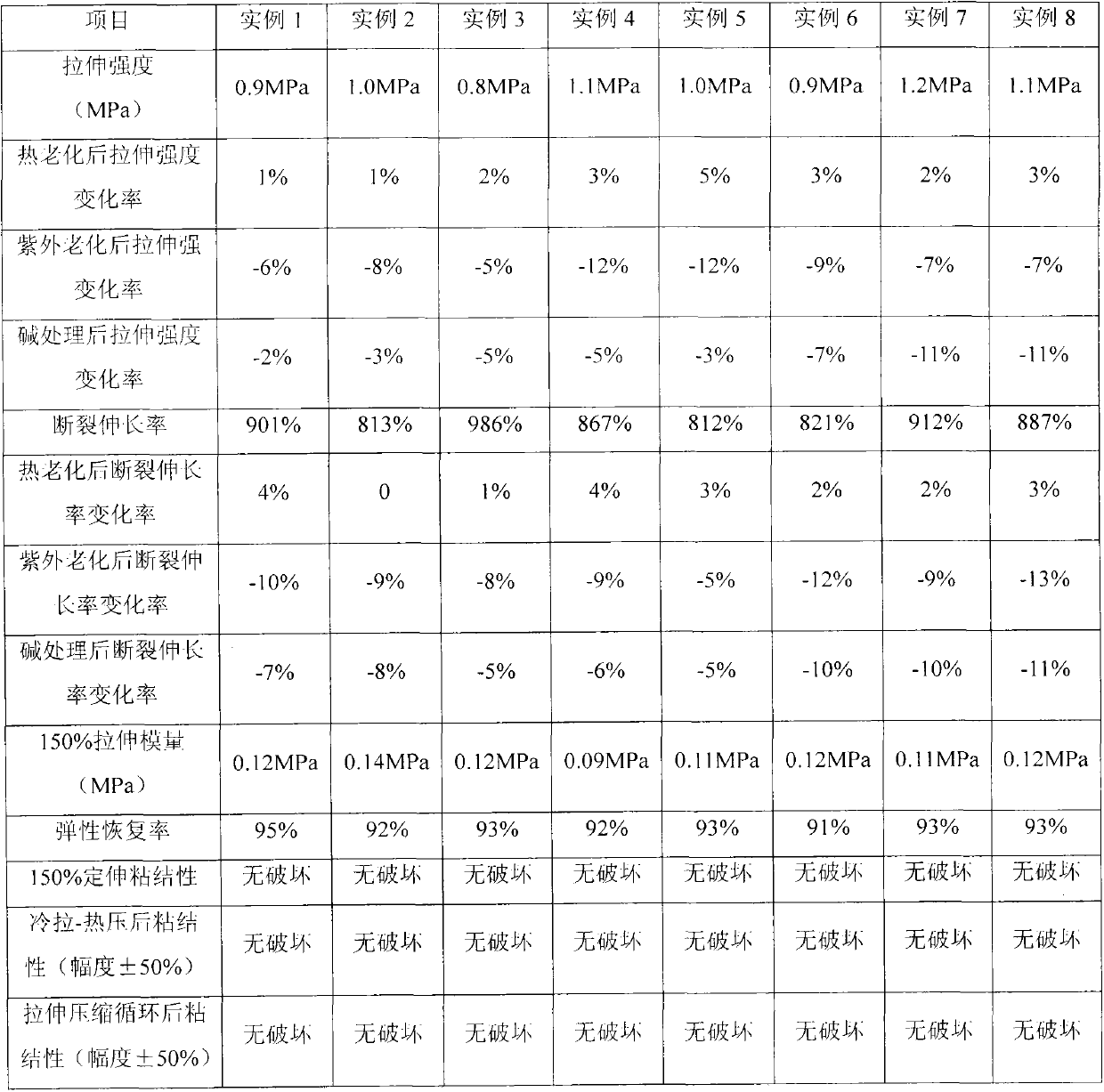

Polyurethane caulking material for expansion joints of ballastless track of high speed railway

ActiveCN103992633AImprove displacement abilityModerate mechanical strengthLow temperature curingBond properties

A polyurethane caulking material for expansion joints of a ballastless track of a high speed railway is disclosed. The caulking material is prepared from two parts A and B. the part A is composed of the following raw materials, by weight, 100 parts of isocyanate and its prepolymer, 10-150 parts of a plasticizer, 5-150 parts of a solid filler, 1-20 parts of a diluents, 1-5 parts of an adhesion promoter, 0-10 parts of a thixotropic agent and 1-3 parts of a water-removal agent. The part B is composed of the following raw materials, by weight, 10-20 parts of modified polyhydric alcohol, 1-5 parts of a diluent, 2-30 parts of a plasticizer, 5-30 parts of a solid filler, 0-5 parts of a thixotropic agent, 0.5-2 parts of an antifoaming agent, 0.1-1 part of an anti-aging agent and 0-0.01 part of a catalyst. The mass ratio of the part A to the part B is 4:1-10:1. The polyurethane caulking material has advantages of good low-temperature curing performance, high displacement capability, low tensile modulus, good bond property and excellent endurance quality and fatigue resistance, and is suitable for expansion joints of a ballastless track of a high speed railway as well as expansion joints of roads and airfield runways.

Owner:RAILWAY ENG RES INST CHINA ACADEMY OF RAILWAY SCI +2

Golf club head

InactiveUS20070010346A1Feel goodImprove wear resistanceGolf clubsRacket sportsMulti materialWear resistant

A golf club head having a multi-material face is disclosed and claimed. The face is formed by explosion welding, allowing materials having substantially different properties to be uniformly joined. Explosion welding allows the materials to be joined together via a cold-working process, allowing them to joined without losing their pre-bonded properties. Thus, the golf club head have a hard, wear resistant material as the ball-impacting face surface explosion welded to a softer material, allowing the multi-material face to be joined to a soft body material such that the body can be bent and customized. The multi-material face also allows for improved playing characteristics by allowing the club designer to use a thinner face and lighter body material while still providing improved face wear resistance and durability.

Owner:ACUSHNET CO

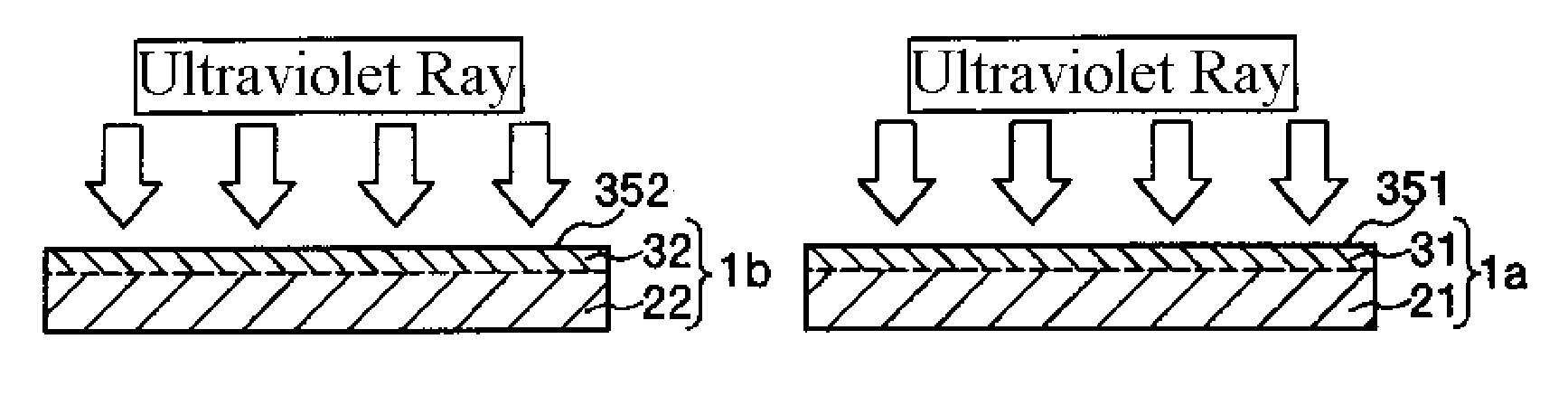

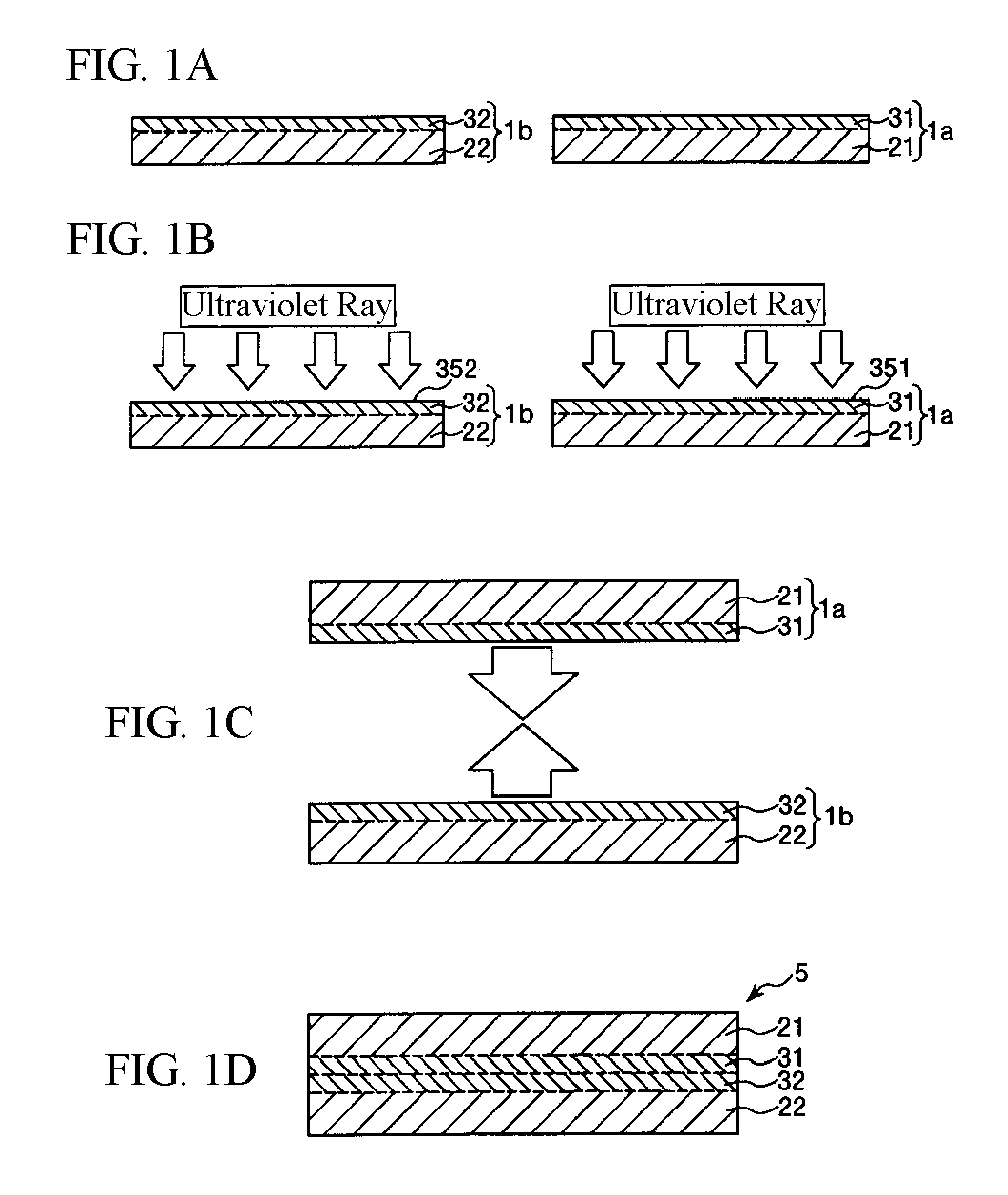

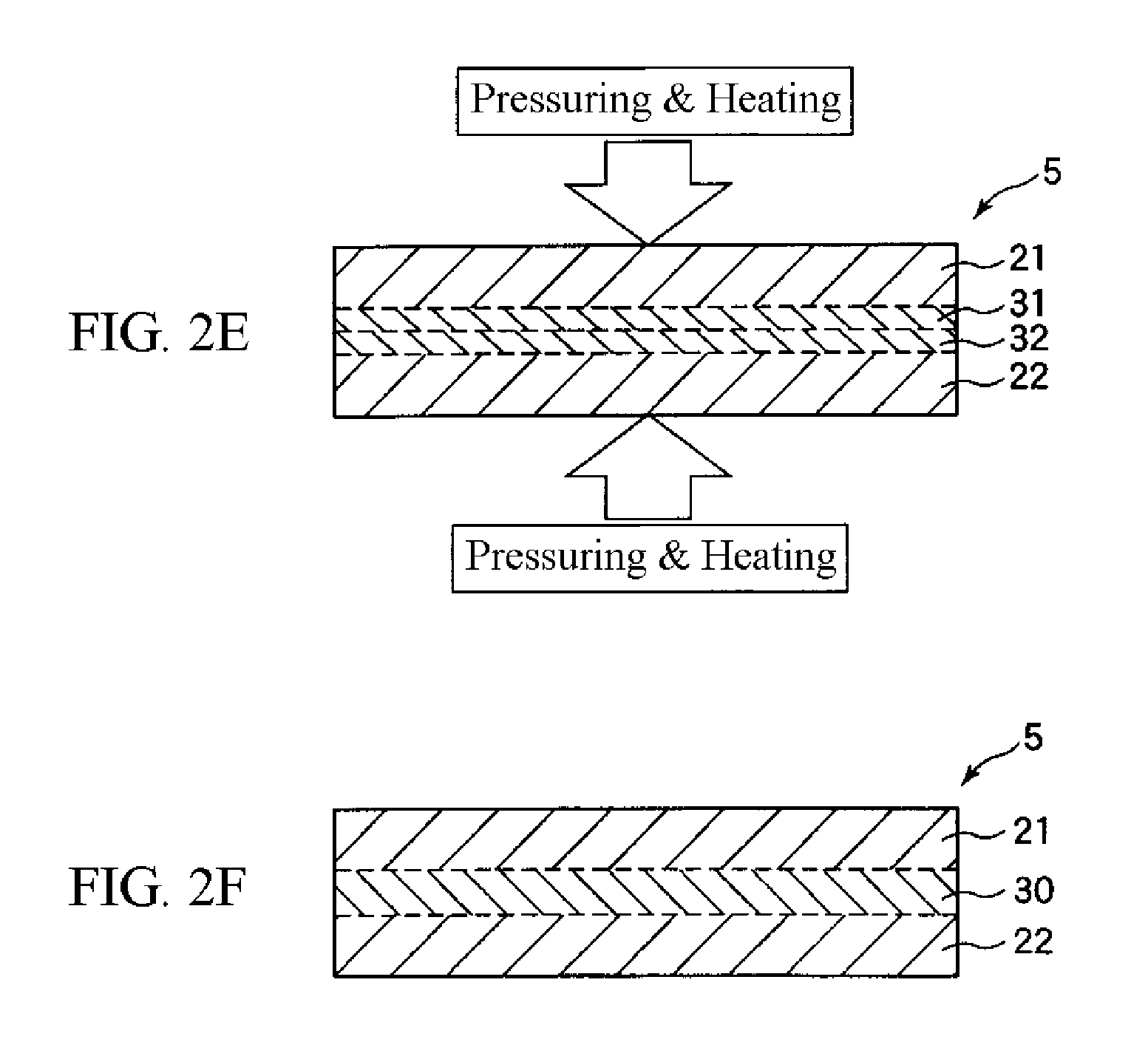

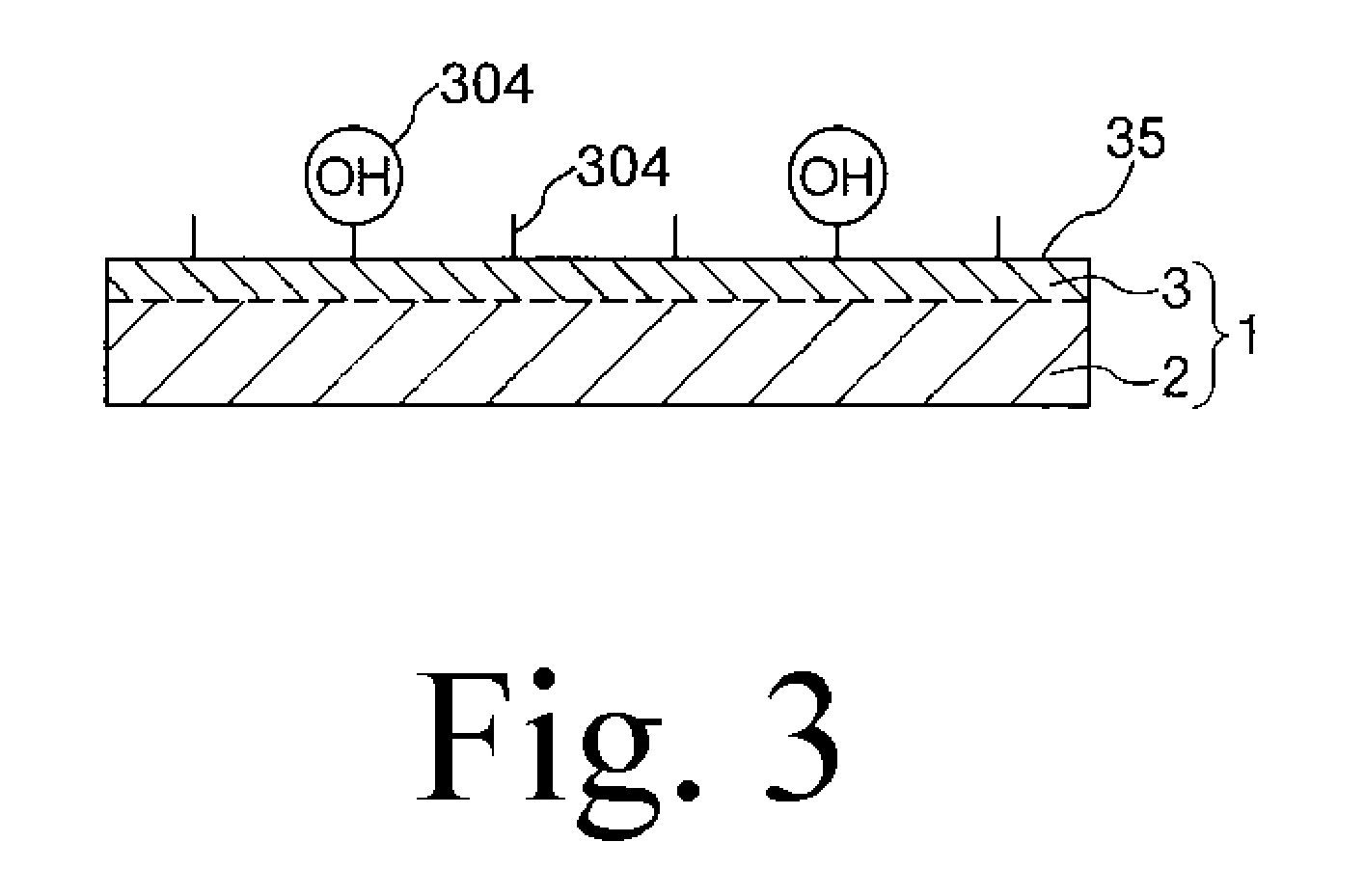

Bonded body and bonding method

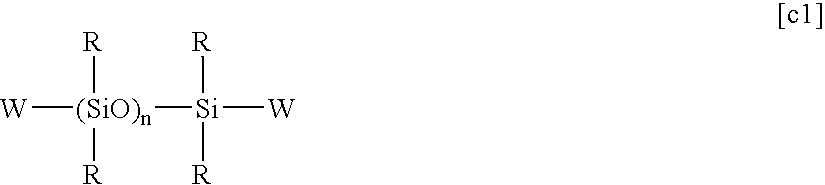

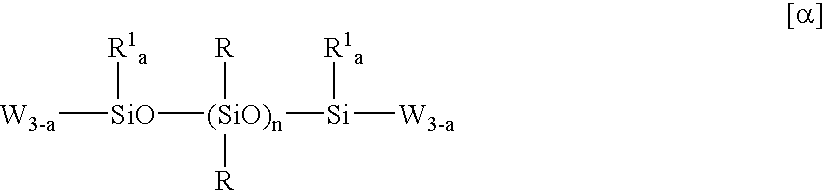

InactiveUS20100151231A1High dimensional accuracyEffective combinationSynthetic resin layered productsLaminationBond propertiesSilicon

A bonded body according to the present invention comprises a first object comprised of a first substrate and a first bonding film formed on the first substrate and a second object comprised of a second substrate and a second bonding film formed on the second substrate. The first and second bonding films contain a Si-skeleton constituted of constituent atoms containing silicon atoms and elimination groups bonded to the silicon atoms of the Si-skeleton. The Si-skeleton includes siloxane (Si—O) bonds. The constituent atoms are bonded to each other. When an energy is applied to at least a part region of the surface of each of the first and second bonding films, the elimination groups existing in the vicinity of the surface within the region are removed from the silicon atoms of the Si-skeleton so that each region develops a bonding property with respect to the other film to thereby bond the first and second objects together through the first and second bonding films.

Owner:SEIKO EPSON CORP

Electronic part with external electrode

InactiveCN1723514AResolve articulatedSolve the problem of jointnessFixed capacitor electrodesFixed capacitor dielectricConductive pasteBond properties

The present invention is intended to solve the problem of a conventional thermosetting conductive paste with respect to bonding-property between an internal electrode(s) and an external electrode(s) so as to provide a multilayer ceramic electronic part suitable for its mounting on a substrate and for its plating-treatment. The present invention relates to a multilayer ceramic electronic part, characterized in that it has an external electrode(s) formed from a thermosetting conductive paste comprising conductive particles having a high melting point, metal powder having a melting point of 300 DEG C or less and a resin(s).

Owner:PANASONIC CORP +1

Method and materials for bonding electrodes to interconnect layers in solid oxide fuel cell stacks

ActiveUS20070111069A1Reliable electrical connectionStrong adhesive bondFuel cells groupingFuel cell auxillariesBond propertiesElectrical integrity

A method and related bonding compositions for use in assembling a solid oxide fuel cell (“SOFC”) stack having thermally and chemically stable and electrically conductive bonds between alternating fuel cells and interconnect components in the stack. The improved method and materials allow for the assembly of solid oxide fuel cells having a stronger and more reliable bond with good electrical contact in situ between the SOFC interconnect layers (plates) and the electrodes. The bonding materials and method according to the invention provide good electrical performance while maintaining the mechanical and electrical integrity of SOFC stacks without requiring excessive mechanical compression of the stack as exemplified by prior art systems. The preferred bonding agents comprise a primary phase that provides the electrical conduction path during fuel cell operation, as well as the mechanical strength necessary to insure a reliable connection between the interconnect and the relevant anode or cathode surfaces of the fuel cell. Secondary phases can be added in small amounts to the primary phase to improve adhesion. An exemplary method according to the invention also contemplates various different steps for pre-treating the surfaces of the interconnect plates and electrodes to improve their surface bonding properties.

Owner:CUMMINS ENTERPRISE LLC

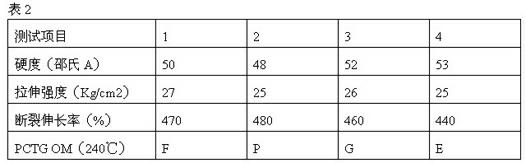

Preparation method of thermoplastic elastomer (TPE) alloy material for polyethylene terephthalate (PBT) bonding encapsulation

InactiveCN102181169AHigh strengthHigh modulusPolyethylene terephthalate glycolPolyethylene terephthalate

The invention discloses a thermoplastic elastomer (TPE) alloy material for polyethylene terephthalate (PBT) bonding encapsulation and a preparation method thereof. The TPE alloy material is characterized by comprising the following components in part by weight: 30 to 40 parts of TPE, 10 to 30 parts of plasticizer, 15 to 30 parts of engineering plastic, 10 to 15 parts of compatilizer, 10 to 15 parts of filler and 0.02 to 0.1 part of auxiliary agent. The invention provides the TPE alloy material which has specific bonding property to PBT, is simple and convenient to process, is energy-saving and environment-friendly and can be widely applied to food contact and skin contact.

Owner:深圳市塑源实业有限公司

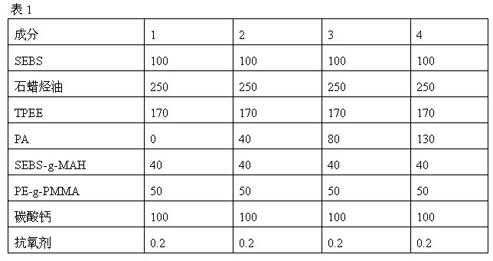

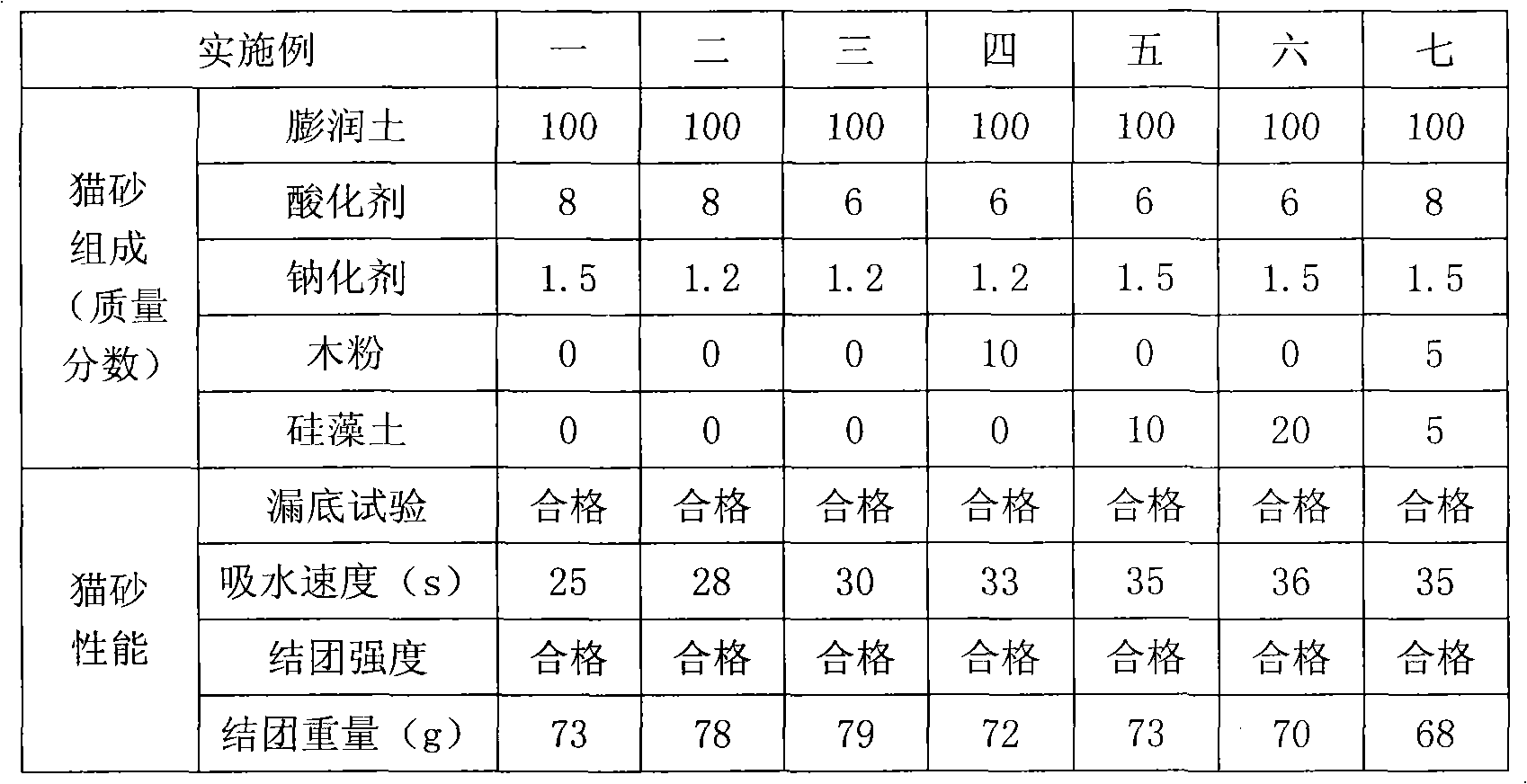

Method for producing bentonite cat litter

The invention discloses a method for producing bentonite cat litter by calcium-based bentonite. The method comprises the following steps of: grinding, acidification, sodium-modification, forming, drying and the like. In method, the calcium-based bentonite crude ores are used as a starting point, the bentonite slices are acidified and corroded by an acidifier so as to greatly increase a specific surface area of the bentonite, a sodium-modification agent is used for sodium-modification of the acidified calcium-based bentonite so as to improve a water absorption rate and bonding property of the bentonite, other additives such as wood flour and diatomite are added so as to adjust indexes, such as density and whiteness, of the cat litter, and finally the bentonite undergoes granulation, drying, screening and the like to form the bentonite cat litter having the advantages of quick water absorption, large amount of water absorption, high whiteness and high strength. The method has the advantages of good quality of the bentonite cat litter prepared by the method, simple process and low cost.

Owner:INNER MONGOLIA UNIVERSITY

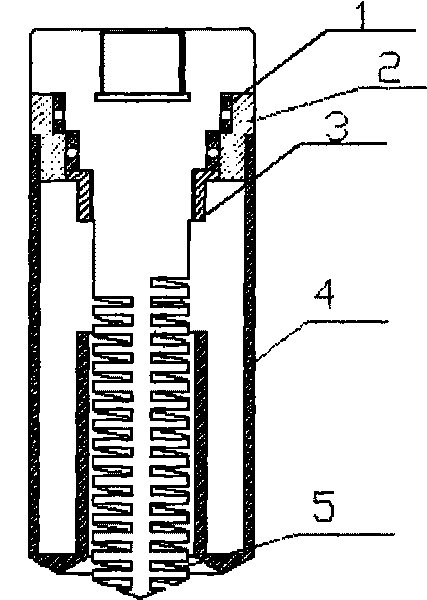

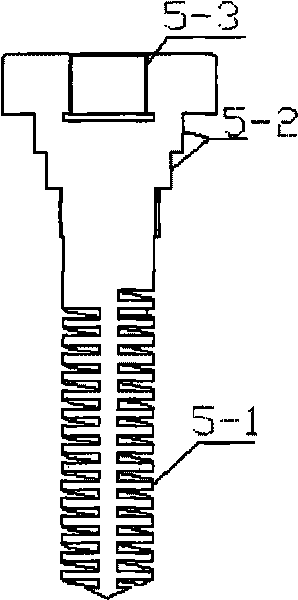

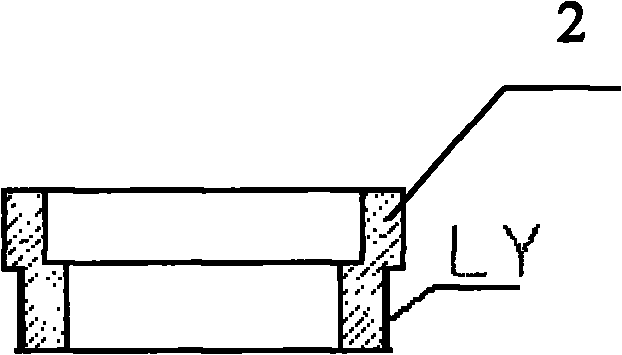

Moon lunar soil shallow layer drilling and coring method

InactiveCN101694424ASolving the Coring ProblemTechnological innovationWithdrawing sample devicesSoil scienceRock core

The invention relates to a moon lunar soil shallow layer drilling and coring method, which relates to a moon unconsolidated formation lunar soil drilling exploration sampling method. The invention adopts a drill head to conduct center-drilling hole aiming at the characteristics that the moon shallow layer lunar soil is loose sand without bonding property, as the drilling deep-going of the drill bit, drilled dry loose rock cores are led to core collect through a coring cannula on the periphery of the drill bit, the lower portion of a screw thread drill bit of a drilling tool which uses the method of the invention is a drill bit vane, an upper bearing seat and a bearing are statically connected in a matching way, a connecting sleeve and a bearing are fixedly connected, the coring cannula is connected with screw threads of the connecting sleeve through the upper end of an outer pipe hole, and is sleeved on the periphery of the threaded rod drill bit, and the inner pipe hole of the coring cannula integrates rock cores. The moon lunar soil shallow layer drilling and coring method has innovative technology and outstanding technical effect, improves the maximum coring rate of 3.07% of the traditional drilling inner-tube coring method to 95%, comprehensively solves the difficult problems of coring in loose sand grain layers, and supplies a feasible moon lunar soil shallow layer drilling and coring method and an application drilling tool for lunar exploration geologic research.

Owner:WUHAN DIDA CHANGJIANG BIT

Tei Coat for Organopolysiloxane Antifouling Coat, Composite Coats, and Ships and Underwater Structures Covered with the Composite Coats

InactiveUS20090042042A1Big burden to solveWell formedAntifouling/underwater paintsSynthetic resin layered productsEpoxyBond properties

Disclosed is a tie coat which is formed on a surface of a base or an undercoating film prior to formation of an organopolysiloxane-based antifouling coating film and is formed from a moisture-curing organopolysiloxane-based composition comprising (b1) organopolysiloxane having condensing functional groups at both ends of a molecule and / or (b2) a curing composition formed by subjecting the component (b1) and an extender pigment selected from the group consisting of silica, calcium carbonate, talc, mica, clay, kaolin and barium sulfate to contact treatment with heating or without heating. Also disclosed is a composite coating film wherein on a surface of the above tie coat is formed a finish coat formed from a three-pack type organopolysiloxane-based curing composition comprising (c1) a main agent comprising the component (b1), (c2) a curing agent component comprising tetraalkoxysilicate or its condensate and (c3) a curing accelerator component comprising a metallic compound. Further disclosed is a composite coating film wherein an epoxy-based sealer coat, the tie coat and the finish coat are formed in this order on a surface of an old antifouling coating film (G). There is provided by the invention a tie coat capable of forming a composite coating film having excellent interlaminar bond property. The composite coating film is favorably formed on a surface of a base, an undercoating film, an old antifouling coating film or the like, has excellent interlaminar bond strength and antifouling property and is preferably used for coating outer surfaces of ships, submerged parts of marine structures, water supply / drainage channels of atomic power plant, etc.

Owner:CHUGOKU MARINE PAINTS

Coated conductive particle coated conductive particle manufacturing method anisotropic conductive material and conductive connection structure

InactiveUS7291393B2Improve connection reliabilityLiquid surface applicatorsMetal-working apparatusBond propertiesConductive materials

An objective of the invention is to provide a coated conductive particle having superior connection reliability, a method for manufacturing such coated conductive particle, an anisotropic conductive material and a conductive-connection structure.A coated conductive particle comprising a particle having a surface made of conductive metal and an insulating particles to coat the surface of the particle having the surface made of conductive metal there with, wherein the insulating particles are chemically bonded to the particle having the surface made of conductive metal via a functional group (A) having a bonding property to the conductive metal so that a single coating layer is formed.

Owner:SEKISUI CHEM CO LTD

Far infrared negative ion functional non-woven fabric and preparation method thereof

InactiveCN103757820AHeat resistantCorrosion resistanceSynthetic resin layered productsNon-woven fabricsPolyethylene glycolCis-Butenedioic Acid

The invention discloses a far infrared negative ion functional non-woven fabric. The far infrared negative ion functional non-woven fabric consists of a top surface layer, a back face layer and a fiber cotton layer clamped between the top surface layer and the back face layer, wherein the top surface layer and the back face layer are made of a non-woven fabric material. The non-woven fabric is prepared from the following raw materials in parts by weight through a melt blowing method: 100 parts of isotactic polypropylene, 3-4 parts of tourmaline, 2-3 parts of aluminum oxide, 1-2 parts of zinc oxide, 12-15 parts of tributyl phosphate, 1-2 parts of titanium dioxide, 6-8 parts of dibutyl maleate, 2-3 parts of 3-aminopropyltrimethoxysilane, 2-3 parts of polyethylene glycol, 3-4 parts of urea, 2-3 parts of grassleaf sweelflag rhizome, 1-2 parts of lily, 2-3 parts of kudzuvine root and 4-5 parts of aid. The non-woven fabric has far infrared, negative ions, antibacterial and deodorization functions. Due to the adoption of the isotactic polypropylene, the non-woven fabric has the characteristics of heat resistance, corrosion resistance, nontoxicity and no odor, is high in tensile strength and bonding property, does not produce dust or scrap, and has the functions of perfuming and health care.

Owner:芜湖跃飞新型吸音材料股份有限公司

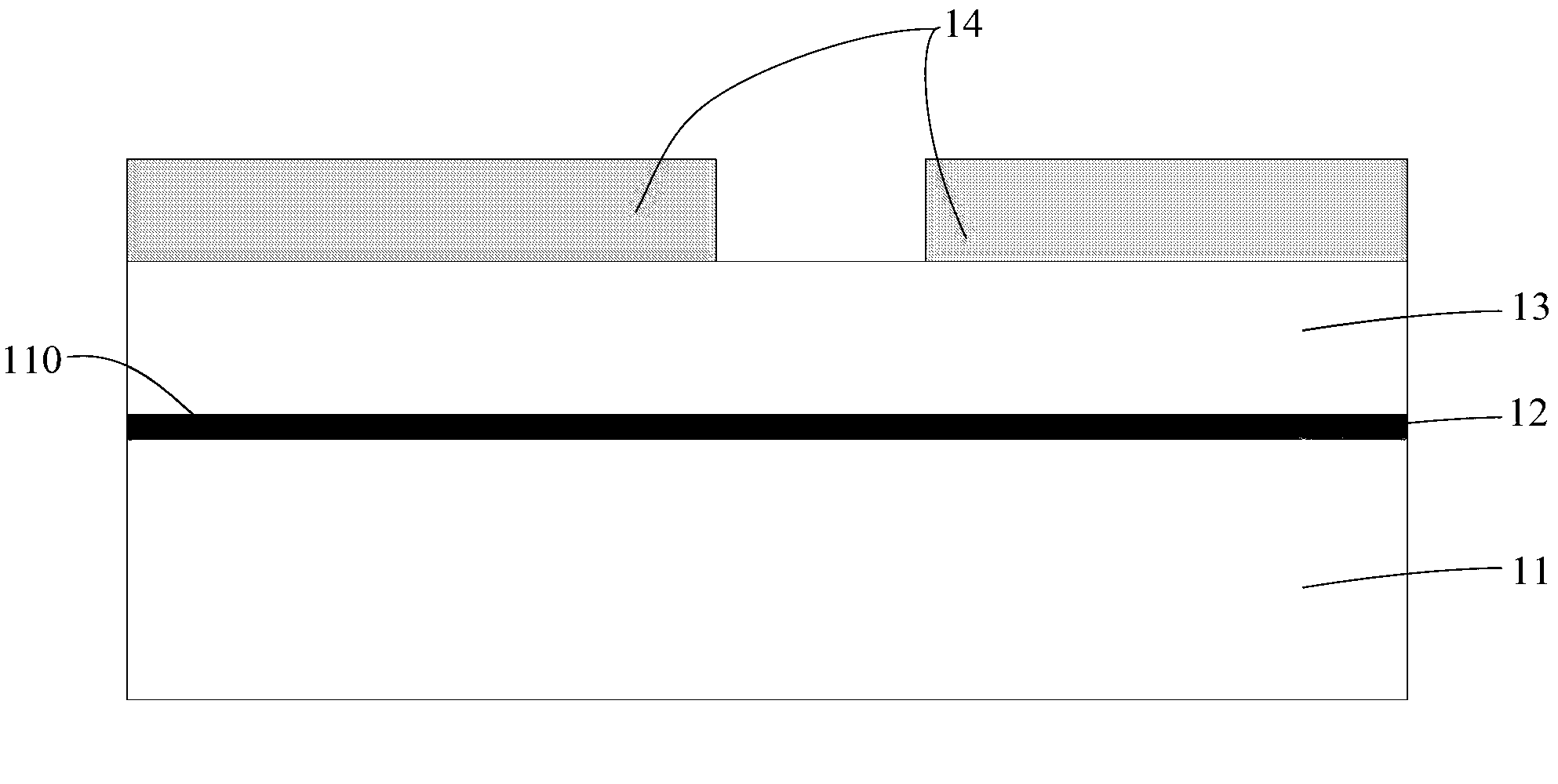

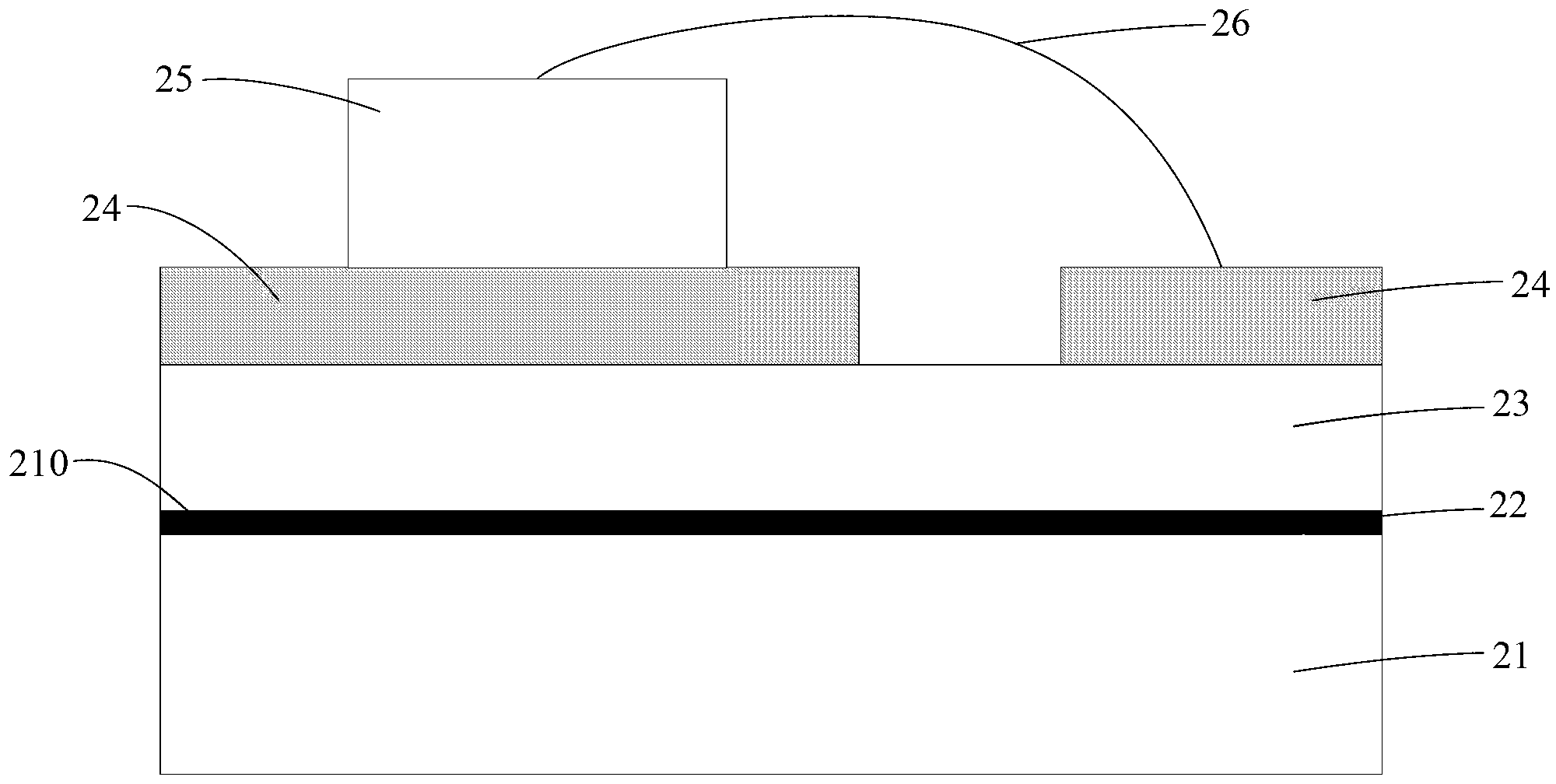

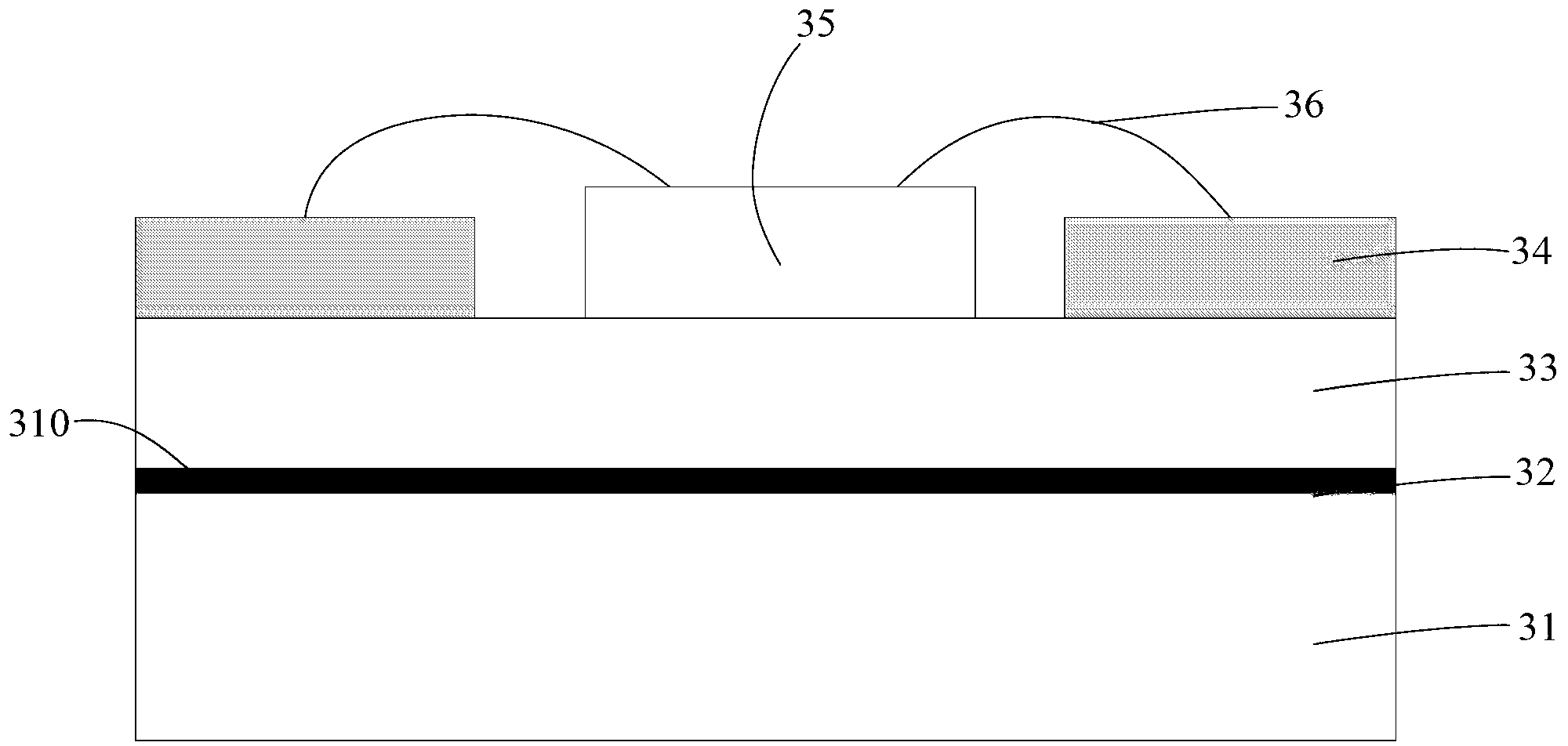

Metal ceramic composite substrate and manufacturing method for same

InactiveCN103079339AHigh thermal conductivityImprove bindingSolid-state devicesPrinted circuit manufactureComposite substrateBond properties

The invention is applied to the field of substrates, provides a metal ceramic composite substrate and a manufacturing method for the same, and aims to solve the problems of low thermal conductivity of a metal substrate and low bonding properties of a metal ceramic composite substrate in the prior art. The metal ceramic composite substrate comprises a metal substrate, a ceramic layer, a metal line layer and a metal ceramic transition layer, wherein the ceramic layer is arranged on the metal substrate; the metal line layer is arranged on the surface of the ceramic layer; the metal ceramic transition layer is formed on the metal substrate, and is connected with the ceramic layer; the ceramic layer is positioned between the metal ceramic transition layer and the metal line layer; the metal ceramic transition layer consists of metal and metal nitrides; and the ceramic layer consists of a ceramic thin film. The ceramic layer is used for improving the thermal conductivity of the substrate, and the metal ceramic transition layer is arranged to improve the bonding properties between the ceramic layer and the metal substrate to improve bonding reliability.

Owner:SHENZHEN HOYOL OPTO ELECTRONICS

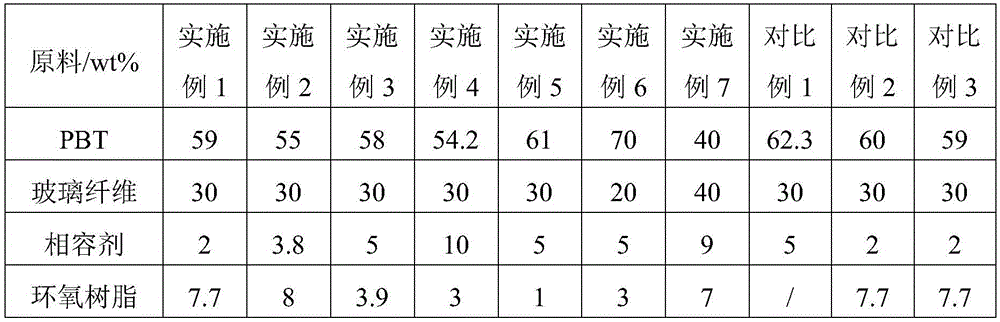

A kind of PBT material with good epoxy resin adhesion and preparation method thereof

Owner:上海日之升科技有限公司

Geopolymer composite material for 3D printing and preparation method and application thereof

ActiveCN106082898ASave energyEnvironmentally friendlyAdditive manufacturing apparatusSolid waste managementAdditive ingredientSlag

A geopolymer composite material for 3D printing and a preparation method and application thereof are disclosed. The geopolymer composite material comprises the following ingredients (by weight): 20-25% of water-quenched granulated blast furnace slag powder, 10-15% of ground steel slag, 0-5% of fly ash, 33-45% of tailings machine-made sand, 3-5% of a composite activator, 2.5-3% of a high-molecular polymer, 1-3% of a volume stabilizer, 1-2% of a thixotropic agent, 0.05-0.1% of an antifoaming agent and 13.9-12.45% of mixing water. The above ingredients are fully and uniformly stirred and then the mixture is subsequently pumped into a 3D printer for construction. The geopolymer composite material has good caking property, strong stability and has good pump-out morphology maintaining capability and bond property. Printed buildings have good morphology and volume stability, and houses and buildings have good overall stability and use security.

Owner:CHINA STATE CONSTRUCTION ENGINEERING CORPORATION

Bonding sheet, bonding method and bonded body

InactiveUS20090081424A1High dimensional accuracyImprove reliabilityNon-macromolecular adhesive additivesSolid-state devicesSpecific functionBond properties

A bonding sheet having a bonding film that can be firmly bonded to an object with high dimensional accuracy and efficiently bonded to the object at a low temperature, a bonding method which is capable of efficiently bonding such a bonding sheet and the object at a low temperature, and a bonded body formed by firmly bonding the bonding sheet and the object with high dimensional accuracy and therefore being capable of providing high reliability are provided. The bonding sheet is adapted to be bonded to an object. The bonding sheet includes a functional substrate having a specific function and a surface, and a bonding film provided on the side of the surface of the functional substrate, the bonding film containing metal atoms, oxygen atoms bonded to the metal atoms, and leaving groups each bonded to at least one of the metal and oxygen atoms, and having a surface. When energy is applied to at least a predetermined region of the surface of the bonding film, the leaving groups, which exist in the vicinity of the surface within the region, are removed from the bonding film so that the region develops a bonding property with respect to the object.

Owner:SEIKO EPSON CORP

Manufacturing technique of digitally customizing orthopedic implants

InactiveCN103150442AFit closelyReduced chance of internal fixation failureSpecial data processing applicationsGraphicsBond properties

The invention discloses a manufacturing technique of digitally customizing an orthopedic implant, which comprises the steps of scanning a fracture part of a fracture patient, obtaining injured fracture data, introducing the injured fracture data into 3D (three dimensional) medical finite element simulation software for processing, obtaining a 3D figure of the fracture part, reconstructing and resetting fracture part, introducing 3D figure data after medical 3D reconstruction and resetting into 3D industrial design software, designing a primary orthopedic implant according to a surgical requirement and experience, obtaining 3D figure data of the primary orthopedic implant, introducing the 3D figure data of the primary orthopedic implant into the 3D medical finite element simulation software to conduct virtual assembly with the fracture part after the medical 3D reconstruction and resetting, confirming a position and a direction of a screw hole of the primary orthopedic implant according to a resetting condition of the fracture part, introducing 3D figure data of a final orthopedic implant into a quick forming machine to accumulate to a practical orthopedic implant, and obtaining the finished orthopedic implant. The manufacturing technique can design specially and achieve high-precision resetting and internal fixation according to different fracture shapes, and the manufactured orthopedic implant is good in surface bonding property and reasonable in thickness.

Owner:CHANGZHOU WASTON MEDICAL APPLIANCE CO LTD

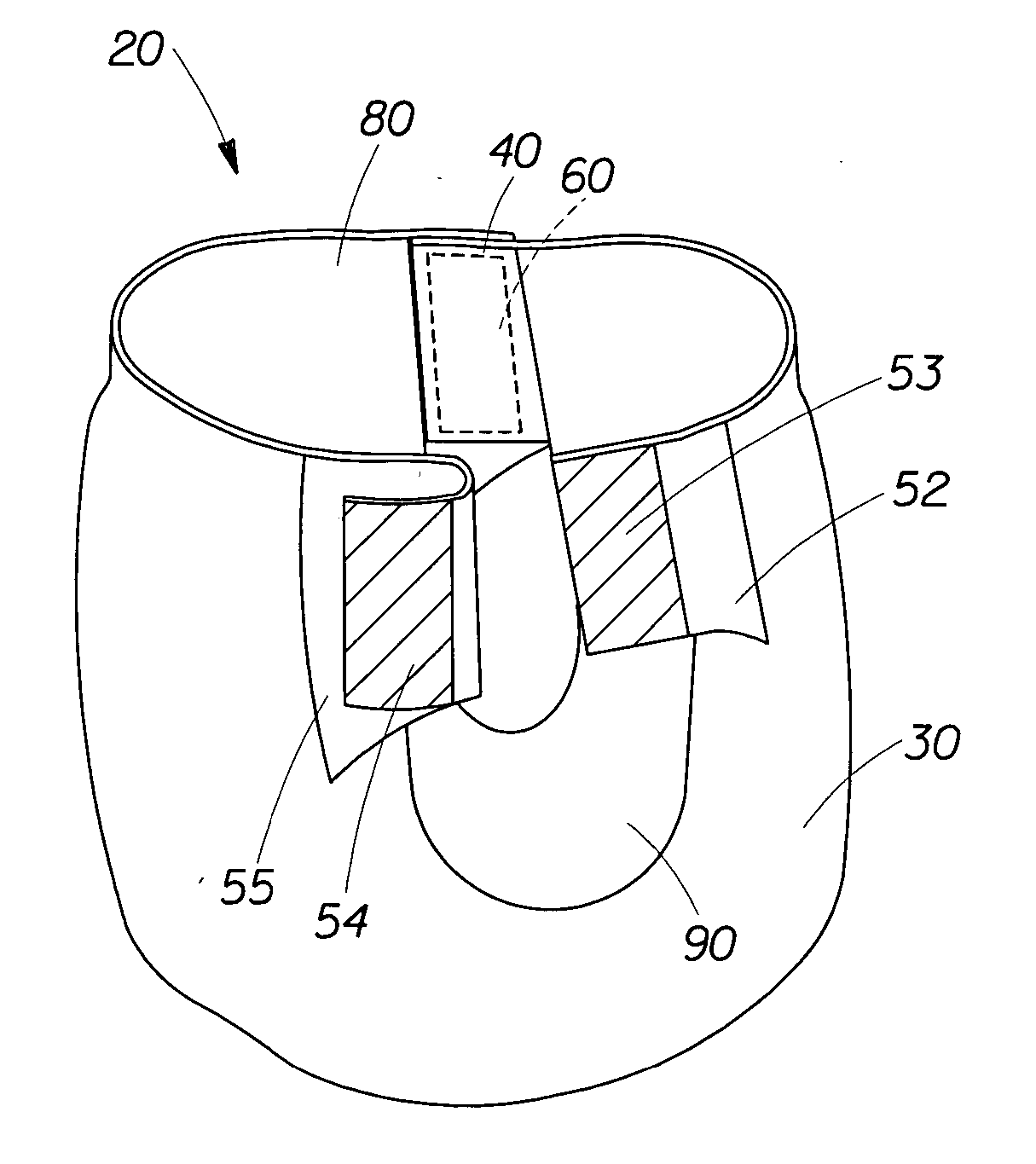

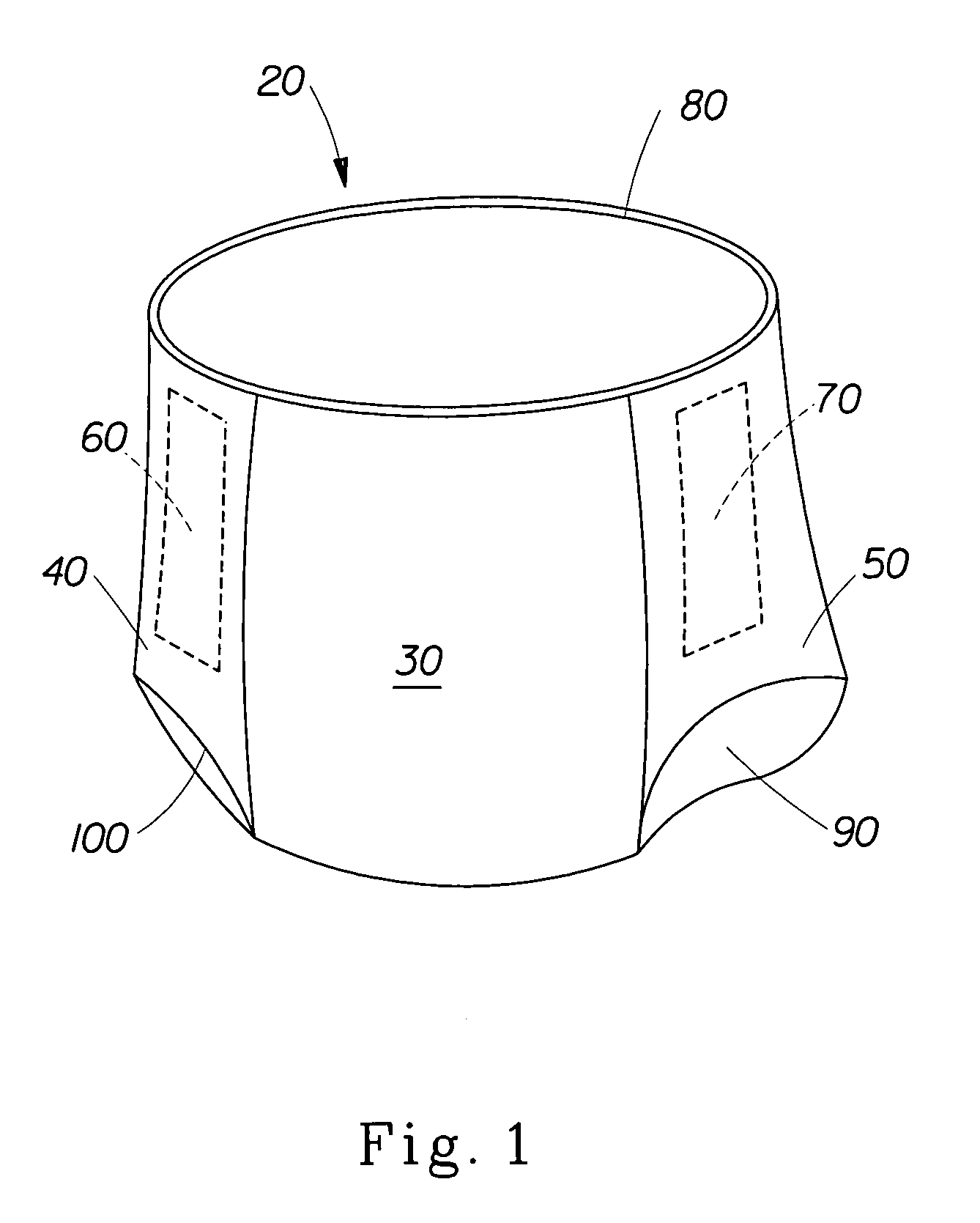

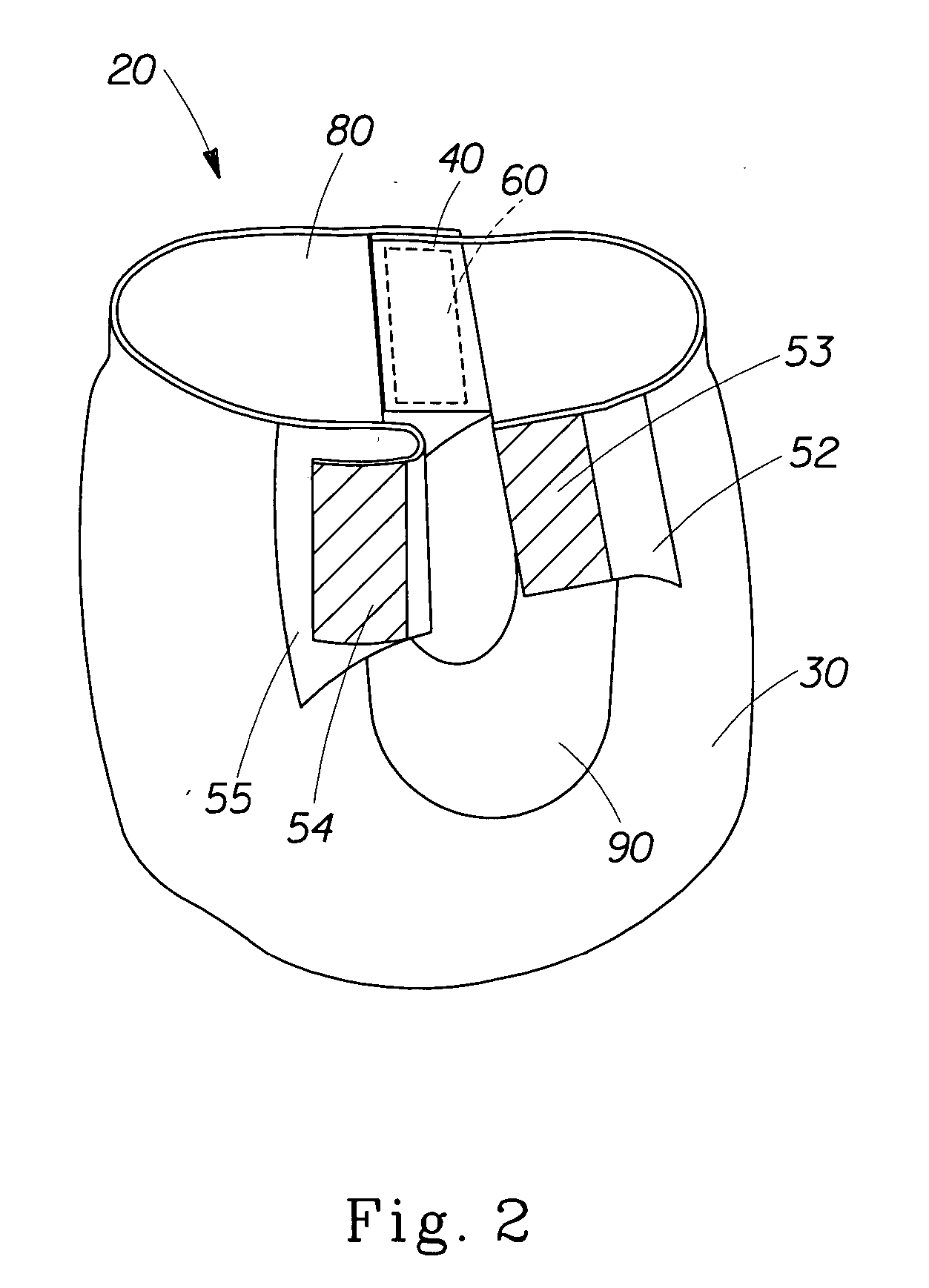

Pant-like disposable garment having improved fastener systems

Disposable pant like garments are disclosed. Pant like garments of the present invention generally comprise a main absorbent portion and a pair of side portions. One or more sections of the pant-like garments are provided with one or more cohesive areas which allow for cohesive fastening and refastening of portions of the garment. The cohesives chosen may have the same properties or may be of the selective adhesive type. Pant like garments may be provided with cohesive fasteners and not other types of refastening means. In other variations, cohesive fasteners may be supplemented with one or more frangible bonds. Also disclosed are side portions having cohesive areas which may be converted in use from an abutting facing relationship to an overlapping facing relationship. Multiple cohesive areas of varying types for providing differential bond properties during use are also disclosed.

Owner:THE PROCTER & GAMBLE COMPANY

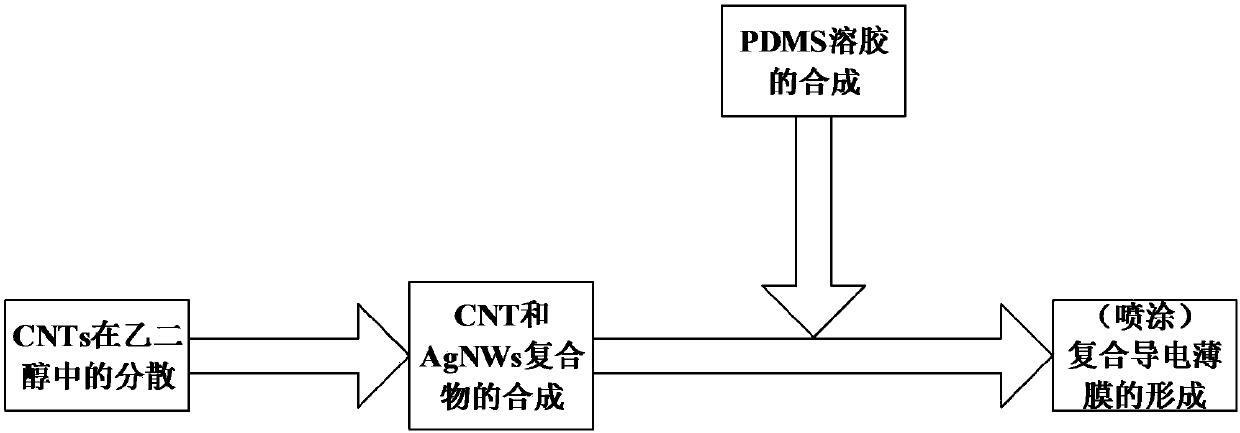

Flexible stress sensor based on carbon nanotube and silver nanowire composite conductive film

The invention discloses a flexible stress sensor based on a carbon nanotube and silver nanowire composite conductive film, which belongs to the technical field of flexible stress sensor. First, CNTs is dispersed in ethylene glycol, and AgNWs is synthesized in the dispersed solution. Then, the synthesized compound is transferred to a PDMS flexible substrate by means of spray coating to prepare a CNTs-AgNWs composite conductive film conductive electrode. Finally, a flexible stress sensor with high stability is obtained through packaging with a layer of PDMS flexible substrate. The compound of CNTs and AgNWs is chemically synthesized using the ethylene glycol dispersion of carbon nanotubes, which improves the bonding property of CNTs and AgNWs, and greatly improves the stability and responsiveness of the flexible stress sensor. The compounding of CNTs and AgNWs improves conductivity, saves energy and greatly widens the application of the flexible stress sensor in flexible electronics without changing the original flexibility, ductility and transparency.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

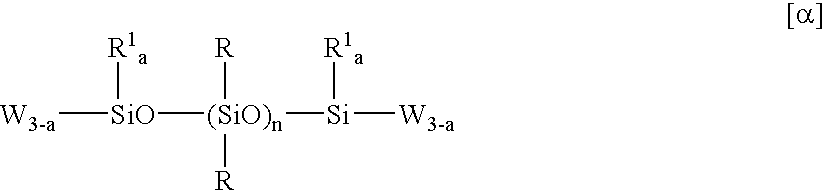

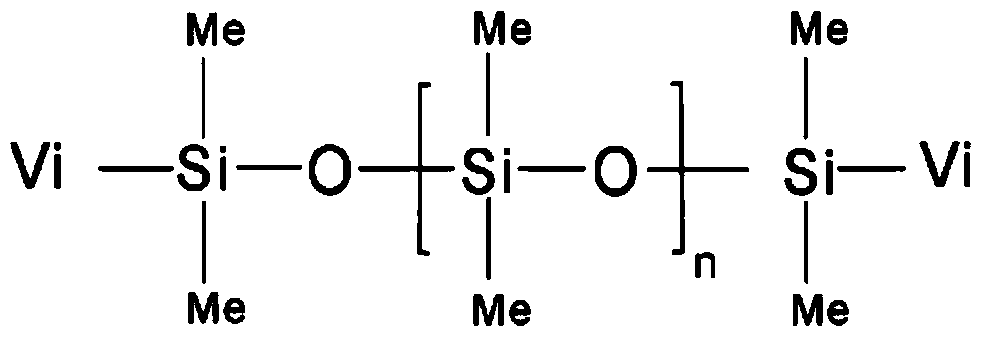

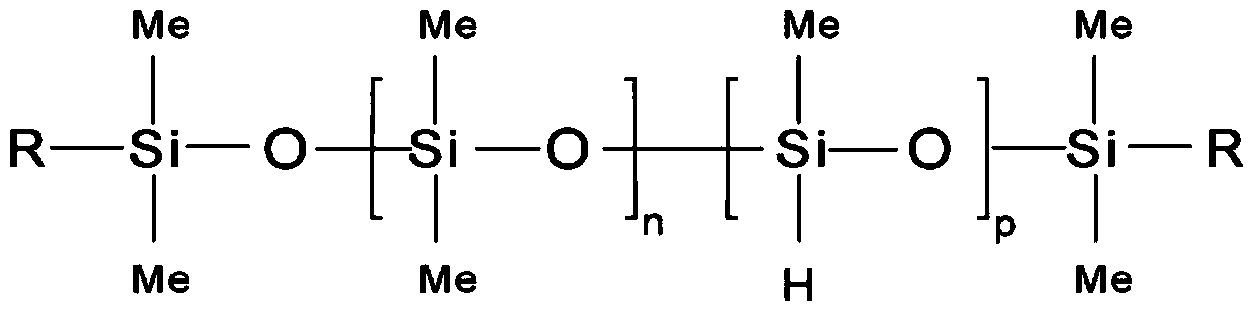

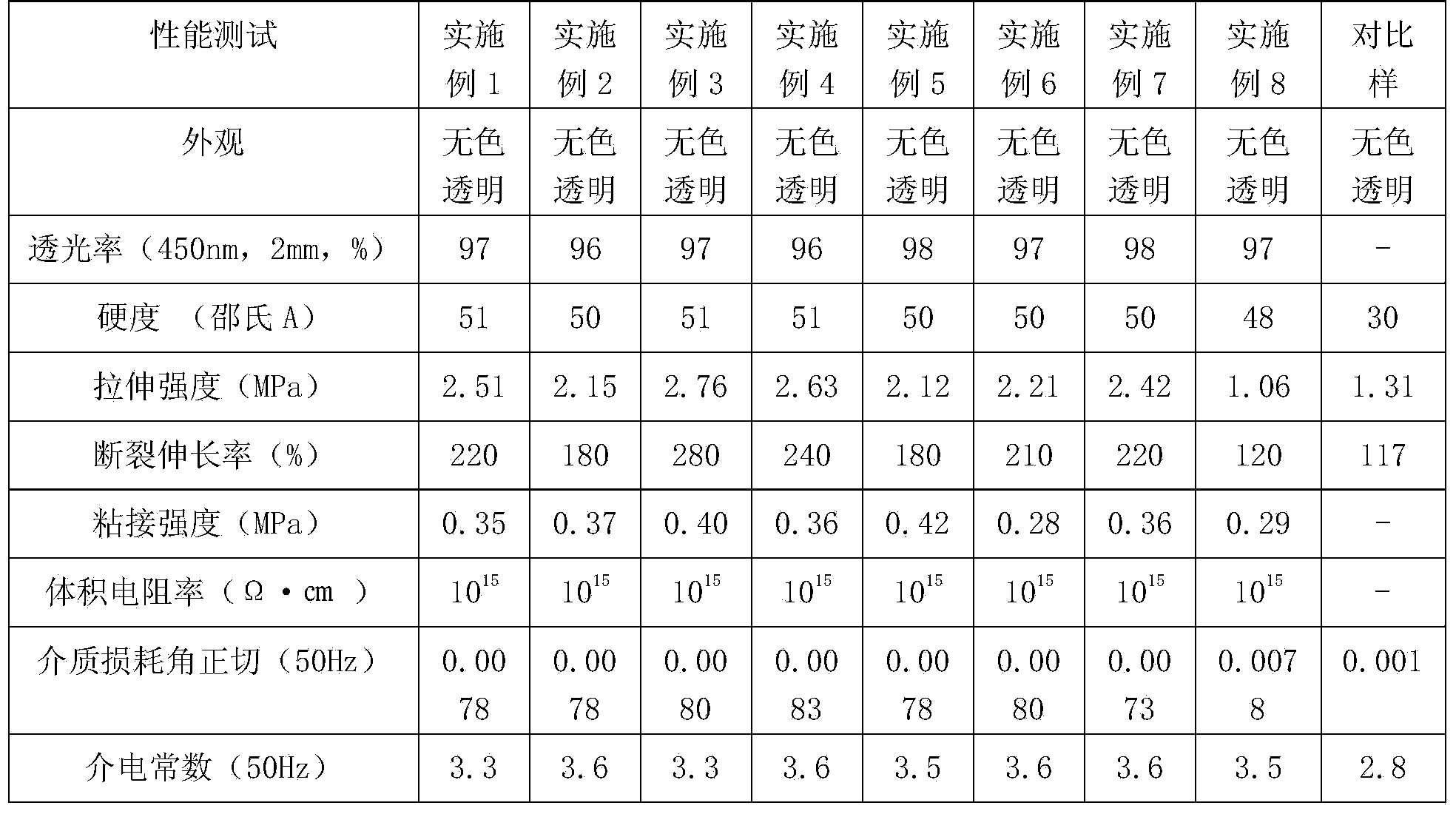

High-strength bonding room temperature curing organosilicone potting adhesive for LED (light-emitting diode) and preparation method of adhesive

ActiveCN103589387AIncrease cross-linking pointImprove mechanical propertiesMacromolecular adhesive additivesSemiconductor devicesAdhesiveBond properties

The invention discloses a high-strength bonding room temperature curing organosilicone potting adhesive for an LED (light-emitting diode), which comprises a component A and a component B. The component A is prepared by uniformly mixing terminal vinyl silicone oil, hydrogen silicone oil and methyl vinyl MO silicon resin at a weight ratio of 100:(8-100):(15-50). The component B is prepared by uniformly mixing terminal vinyl silicone oil, methyl vinyl MO silicon resin, a catalyst and a tackifier at a weight ratio of 100:(15-50):(0.02-3):(2-24). With the adoption of the methyl vinyl MO silicon resin and the tackifier, namely a hydrogenous cyclosiloxane compound containing epoxy groups and siloxane groups, the mechanical properties, a bonding property and optical properties of the room temperature curing potting adhesive are effectively improved, and a provided preparation technology has concise steps, does not require demanding equipment and therefore, is suitable for industrial production.

Owner:GUANGZHOU JOINTAS CHEM

Hot melt adhesive special for random copolymerization polypropylene multiunit tube and manufacture method thereof

InactiveCN101245228ALow melting pointImprove liquidityTubular articlesGraft polymer adhesivesElastomerPolymer science

Owner:合诚技术股份有限公司

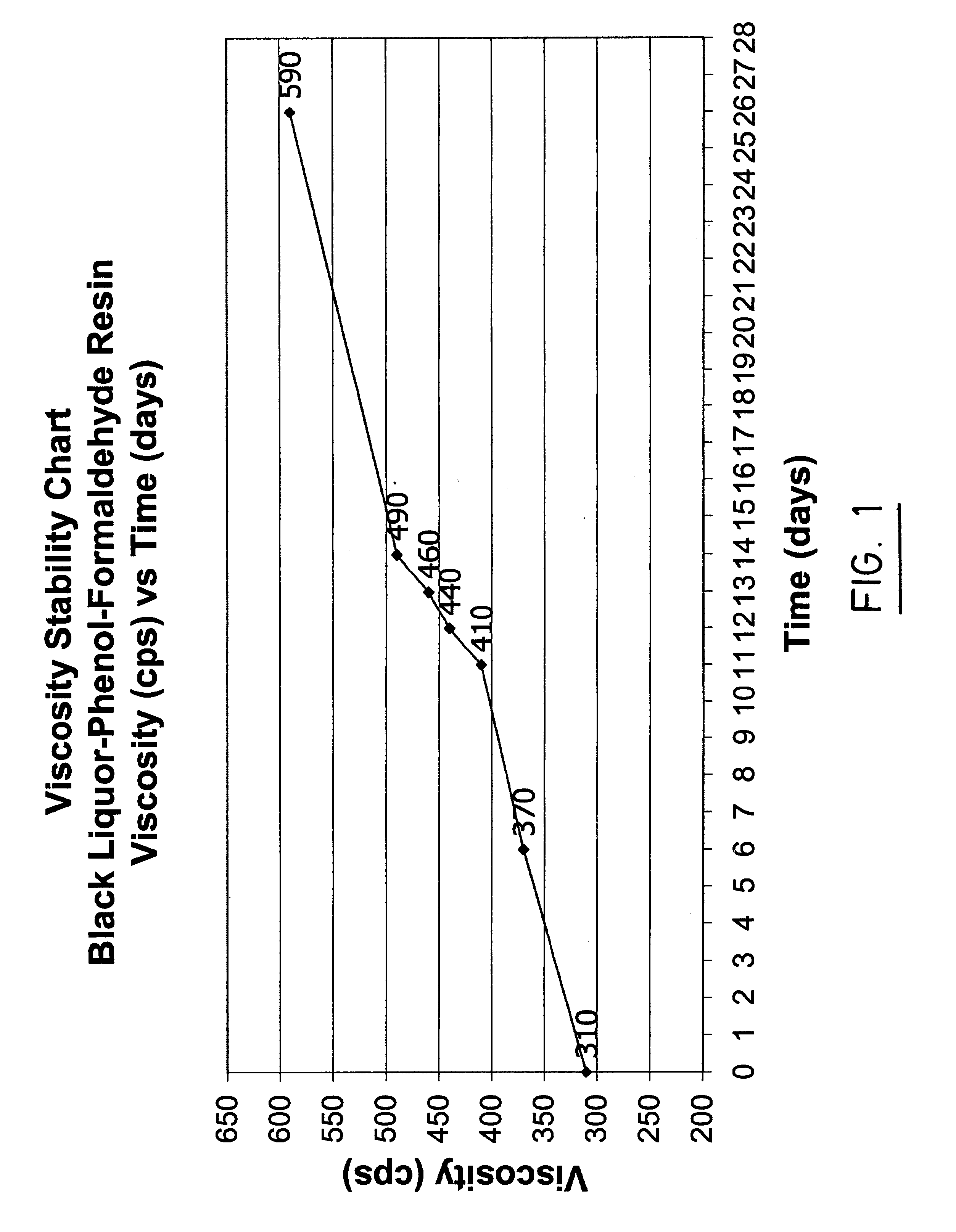

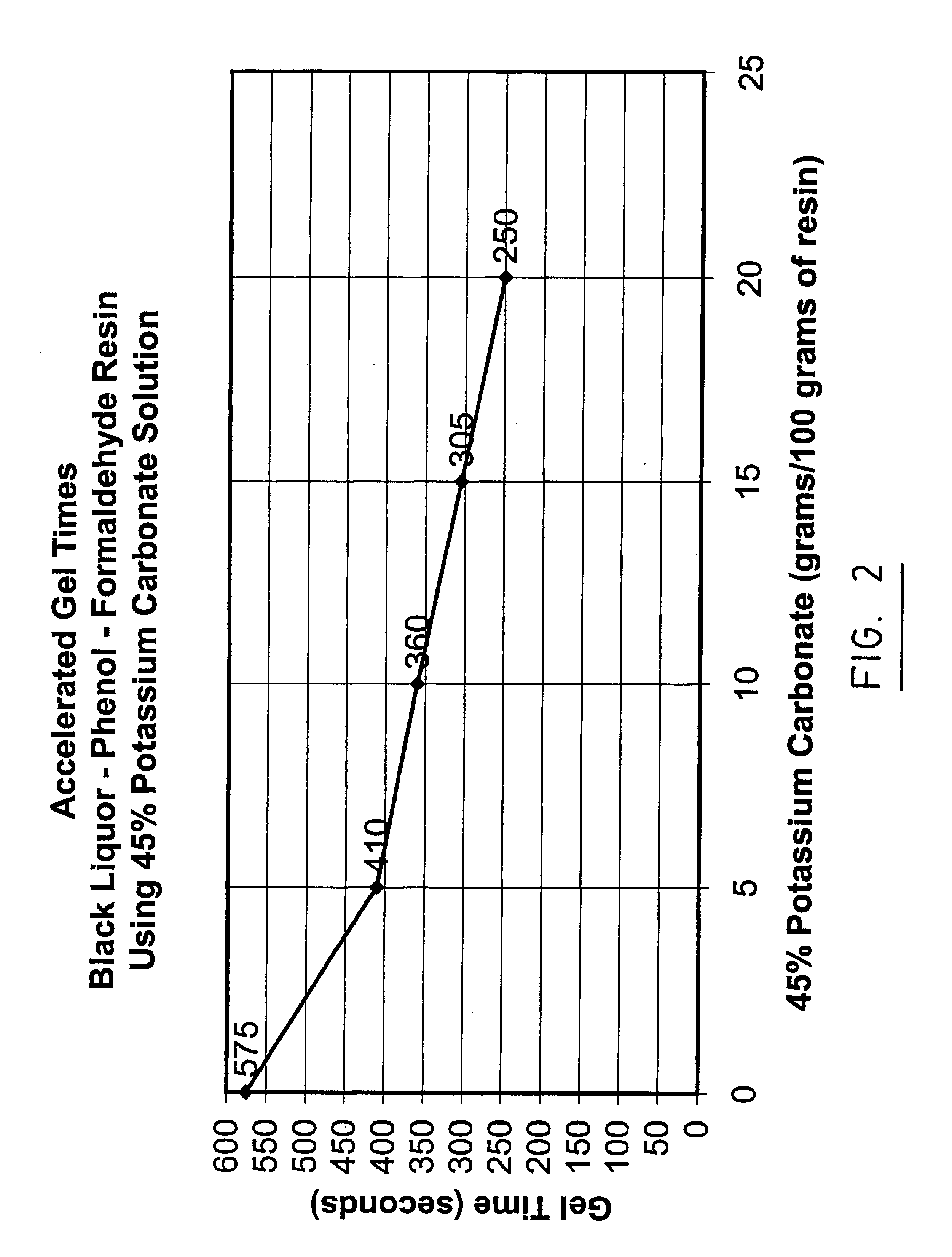

Process for preparing a black liquor-phenol formaldehyde thermoset resin

Owner:CASCADES CANADA INC

Graphene-modified building coating material

ActiveCN103740158AImprove adhesionHigh contrast ratioPolyurea/polyurethane coatingsFiberCarbon fibers

The present invention discloses a graphene-modified building coating material, which comprises a solvent, a commonly used additive and a main film forming substance, and further comprises graphene for modification, wherein the amount of the added graphene is 0.001-20% of the weight of the building coating material, the building coating material can further be added with the auxiliary additive, and the amount of the added auxiliary additive is 0-8% of the weight of the building coating material. According to the present invention, graphene is added to the existing building coating material so as to modify the water resistance mechanical strength of the building coating material and increase adhesion of the building coating material and the substrate, the contrast ratio and the scrubbing resistance; the bamboo carbon fibers are added to the building coating material so as to provide effects of bacterial inhibition, antibacterial and anti-ultraviolet light, such that the building coating material has the characteristic of green environmental protection; and the bone glue is added to the building coating material so as to improve bonding property and increase adhesion.

Owner:NINGBO MORSH TECH

Core/shell type organosilicone-modified acrylate emulsion and preparation method and application thereof

InactiveCN105601799AUniform appearanceImprove stabilityLiquid repellent fibresEmulsionEmulsion polymerization

The invention relates to a core / shell type organosilicone-modified acrylate emulsion and a preparation method and application thereof. The core / shell type emulsion is prepared through polymerization based on the core / shell emulsion polymerization technology and is prepared from, by weight, 500-850 parts of acrylate mixed monomers, 150-500 parts of organosilicone monomers, 10-50 parts of an emulsifying agent, 5-12 parts of an initiating agent, 5-50 parts of a crosslinking agent and 1000-4000 parts of water, wherein acrylate mixed monomers are composed of methyl methacrylate, butyl acrylate and acrylic acid at the mass ratio of (1.0-3.5):(6.5-9.0):(0.15-0.75), and a seed emulsion in the core / shell emulsion polymerization technology is obtained through polymerization of the acrylate mixed monomers. The core / shell type emulsion is good in stability, the mean grain size is 170 nm or so, and an emulsion film has an excellent film-forming property, an excellent bonding property, low surface energy and good waterproofness.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

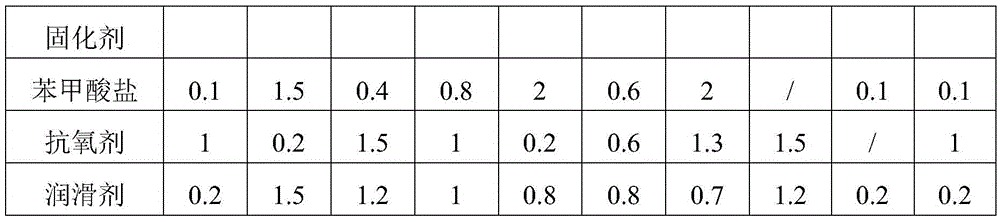

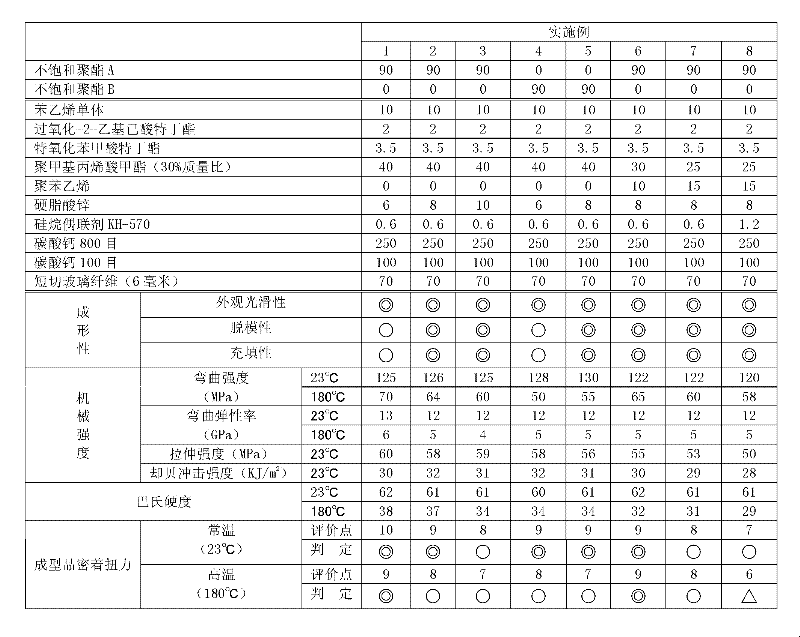

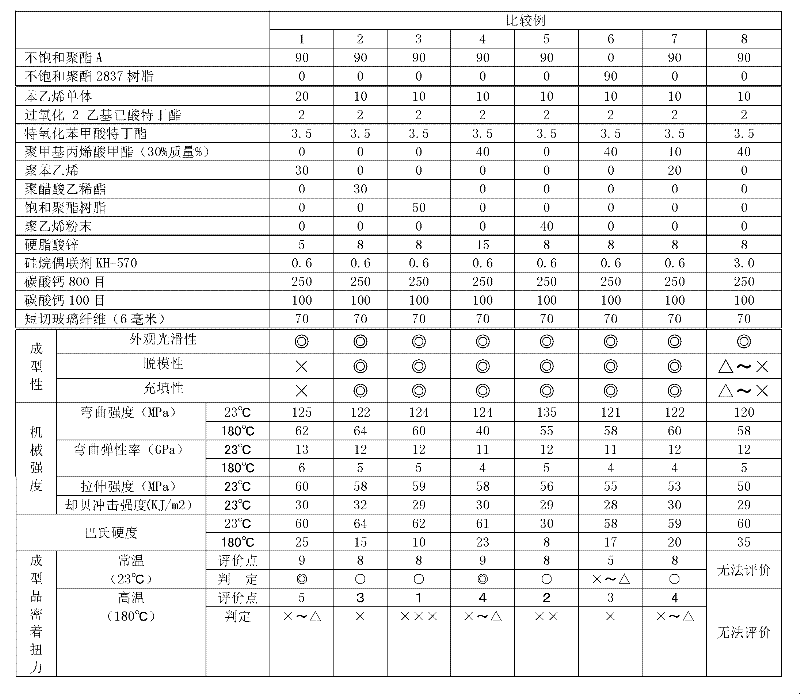

Unsaturated polyester bulk molding compound as well as method and application thereof

The invention relates to the technical field of a bulk molding compound for metal bonding, and specifically relates to an unsaturated polyester bulk molding compound as well as a method and application of the bulk molding compound. The bulk molding compound is prepared from the following raw materials in parts by weight: 8-20 parts of unsaturated polyester, 5-15 parts of low shrink agent, 55-70 parts of inorganic filler, 0.8-1.8 parts of internal demolding agent, 6-20 parts of fiber-reinforced material, 0.3-0.7 parts of curing agent, 0-3 parts of styrene, and 0.05-0.3 part of coupling agent. According to the invention, after the bulk molding compound (BMC) is molded, fast setting is realized and the appearance is excellent; and when used for electric tool and motor loop sealing and other fields, the bulk molding compound has excellent bonding property and torsion to the metal surface at normal temperature and high temperature, excellent resistance to impact, and excellent voltage withstand performance, conforms to the reliability required by product use, and fills up the blank of the field.

Owner:SHANGHAI SHOWA HIGHPOLYMER CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com