Patents

Literature

68results about How to "Increase cross-linking point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low permanent compression deformation thermoplastic polyurethane elastomer

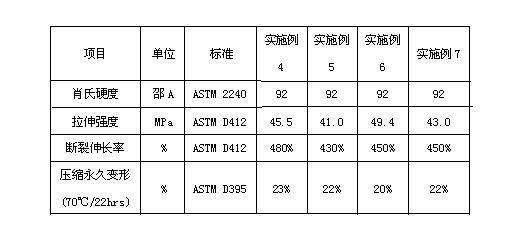

The invention discloses a low permanent compression deformation thermoplastic polyurethane elastomer, which is characterized in that: a certain amount of short-chain alcohol with the molar mass of 100-600g and the functionality of more than 2 is added into a chain extender; and due to the crosslinking of the short-chain alcohol, the elasticity, strength and permanent compression deformation resistance of a product are improved.

Owner:烟台美瑞化学材料有限公司

Gelatin hydrogel and preparation method and application thereof

InactiveCN107236135AIncrease satietyIncrease the amount of double bondsAerosol deliverySurgeryCross-linkUltraviolet lights

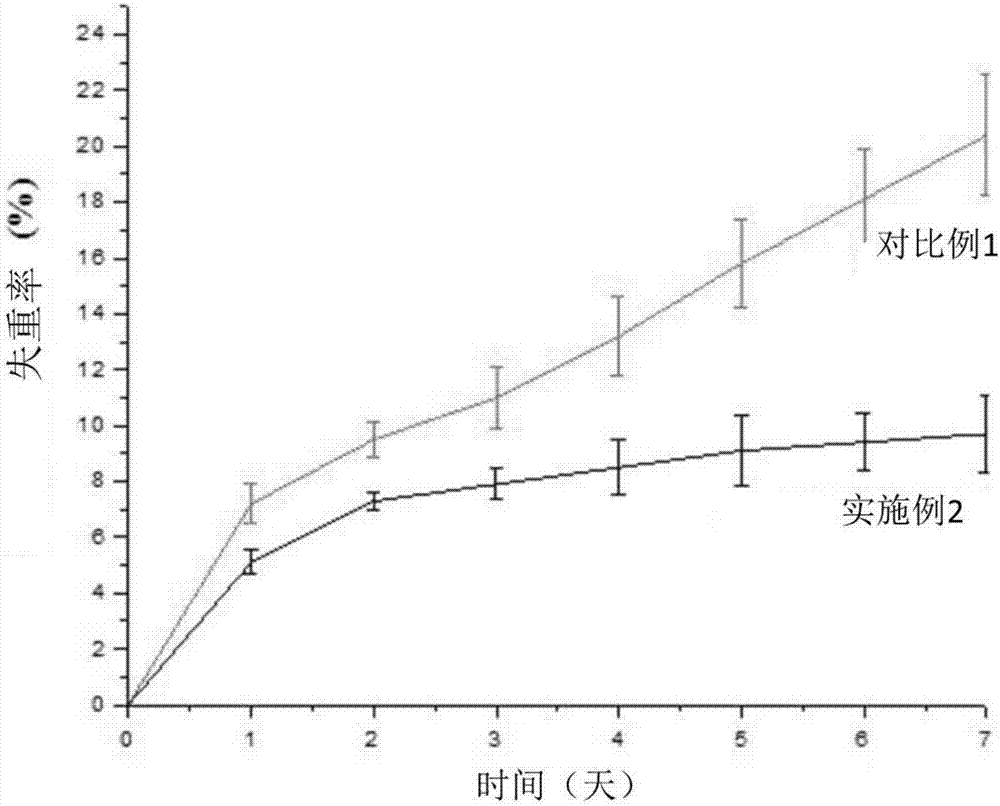

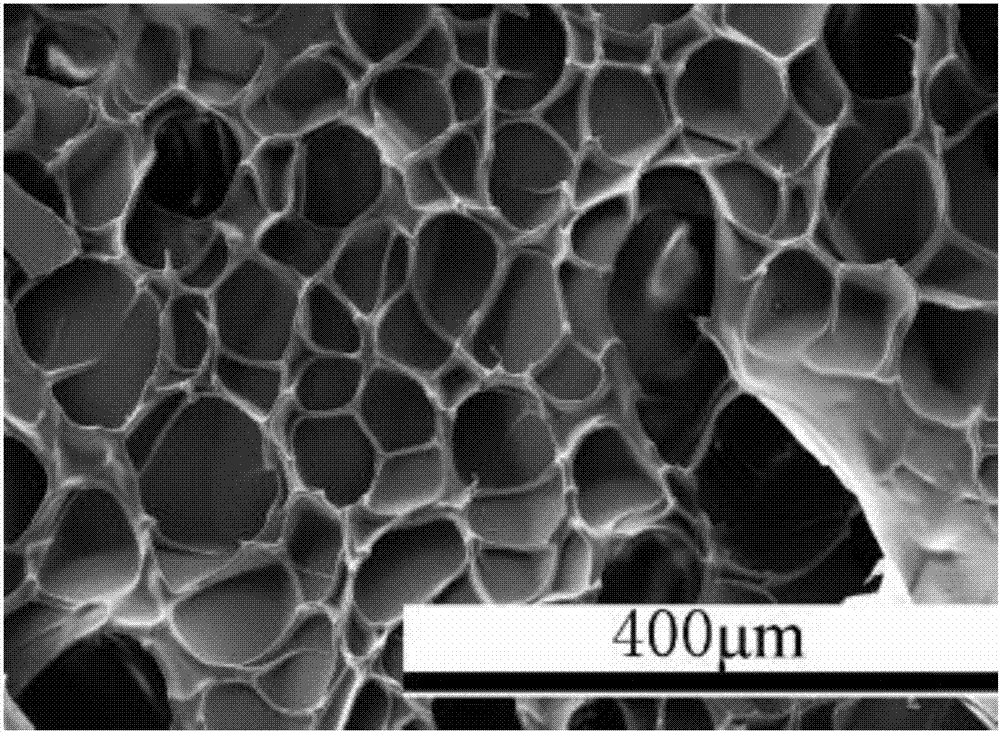

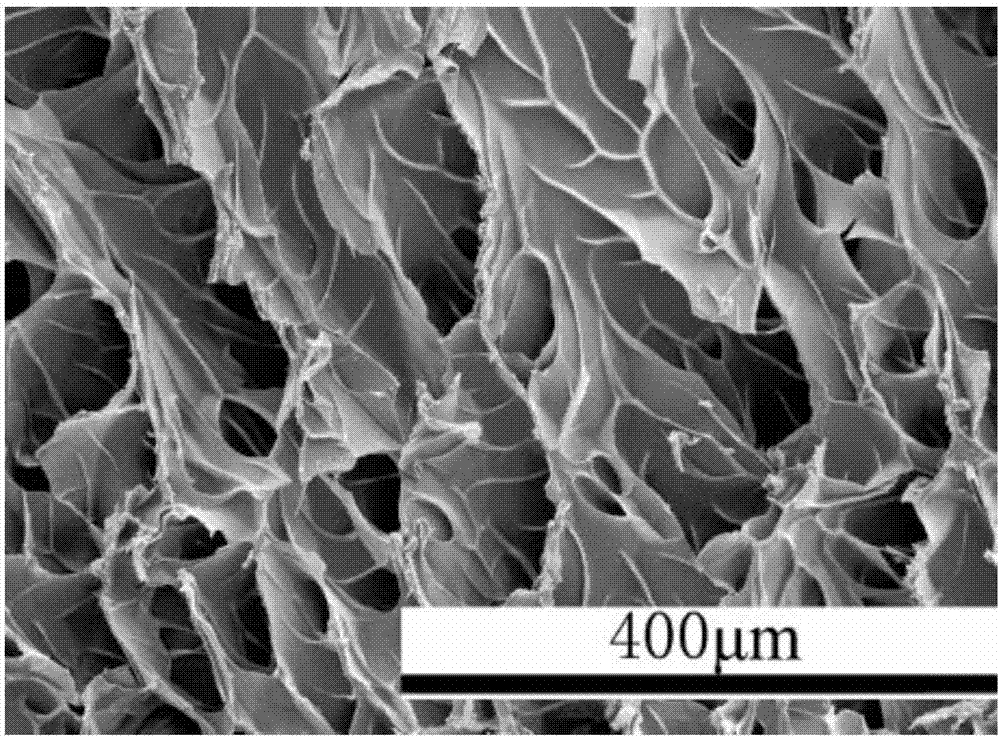

The invention discloses gelatin hydrogel, which is of a water molecule filled porous three-network structure, wherein the first network is a cross-linked network between the modified gelatin; the second network is a cross-linked network between polyethylene glycol diacrylate; the third network is a cross-linked network between the modified gelatin and the polyethylene glycol diacrylate. The invention also discloses a preparation method of the gelatin hydrogel. By using an ultraviolet light catalytic crosslinking technology, the modified gelatin is cross-linked with the polyethylene glycol diacrylate; the gelatin hydrogel is obtained through preparation. The gelatin hydrogel provided by the invention has the advantages that the elasticity modulus and the degrading performance of the support frame can be regulated and controlled through changing the modification degree of the modified gelatin and the addition quantity of the polyethylene glycol diacrylate; the structure regulation can be better performed according to the requirements of different tissue engineering support frames; the proper space and the intensity can be provided for the growth of the cells; the ordered space structure is formed.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

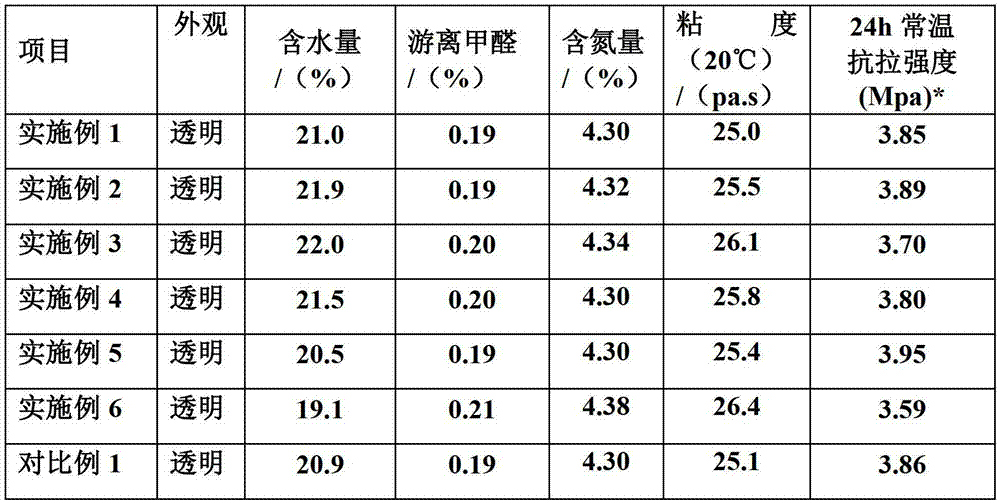

Furan resin for casting and preparation method thereof

InactiveCN102863600AEffective combinationReduce dosageFoundry mouldsFoundry coresFurfuryl alcoholMaterials science

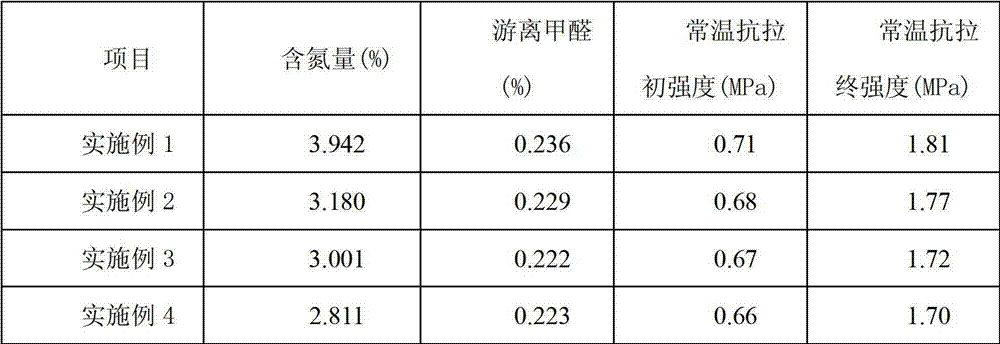

The invention relates to a furan resin for casting and a preparation method thereof. The furan resin comprises, by weight, 15 to 35 parts of formaldehyde, 5 to 10 parts of urea, 60 to 90 parts of furfuryl alcohol and 5 to 40 parts of lignin. According to the furan resin for casting and the preparation method thereof, the lignin is used for modifying the furfuryl alcohol, the cost is lowered, simultaneously the content of free formaldehyde is lowered to a certain extent, and the initial strength and final strength are improved to a certain extent.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

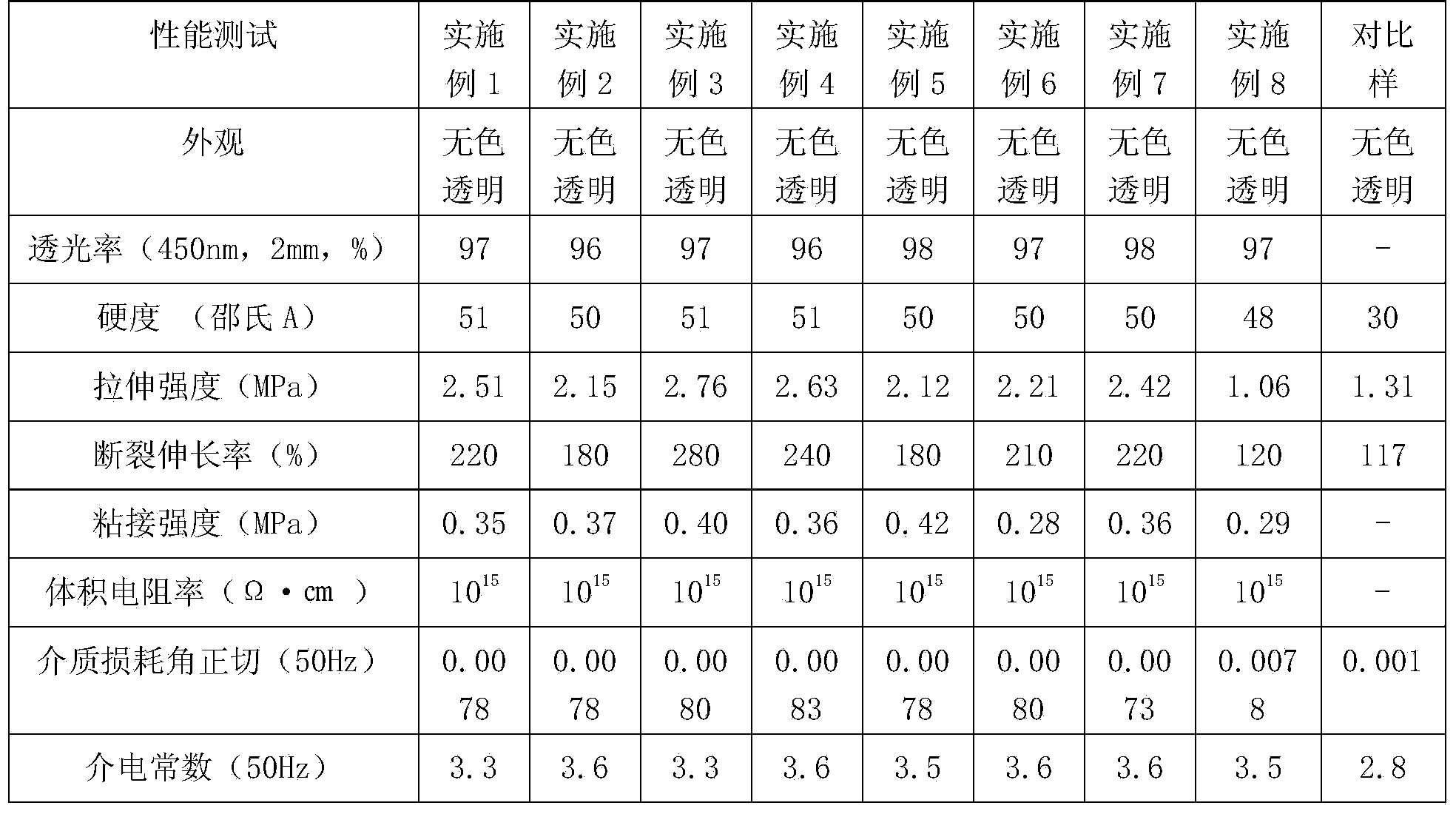

High-strength bonding room temperature curing organosilicone potting adhesive for LED (light-emitting diode) and preparation method of adhesive

ActiveCN103589387AIncrease cross-linking pointImprove mechanical propertiesMacromolecular adhesive additivesSemiconductor devicesAdhesiveBond properties

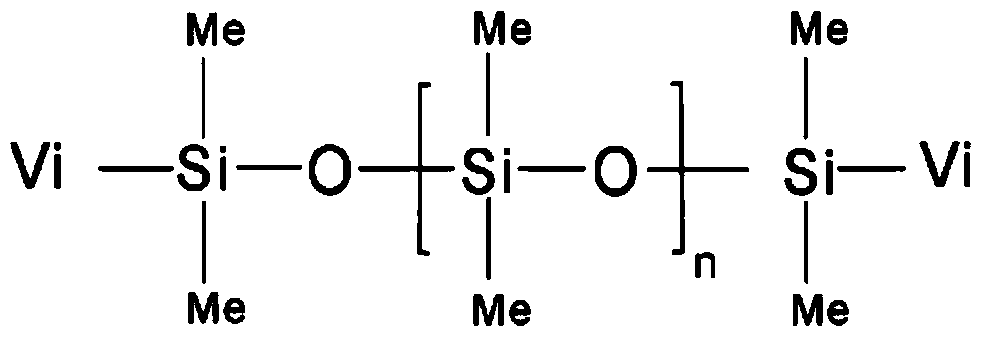

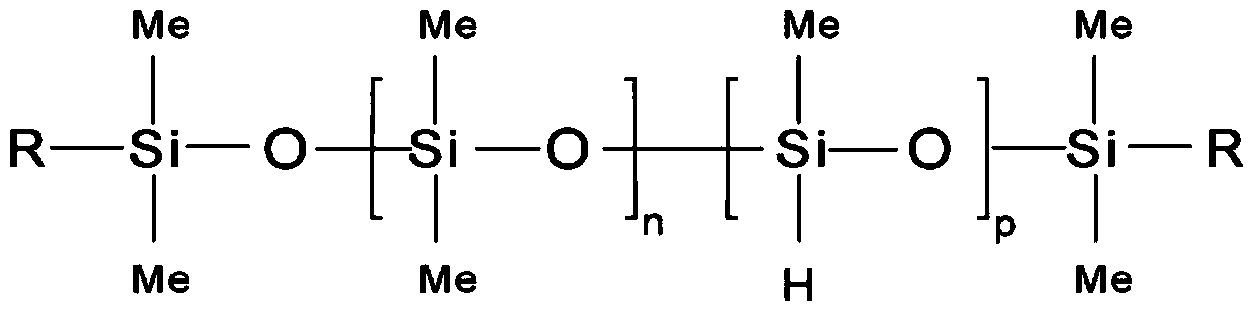

The invention discloses a high-strength bonding room temperature curing organosilicone potting adhesive for an LED (light-emitting diode), which comprises a component A and a component B. The component A is prepared by uniformly mixing terminal vinyl silicone oil, hydrogen silicone oil and methyl vinyl MO silicon resin at a weight ratio of 100:(8-100):(15-50). The component B is prepared by uniformly mixing terminal vinyl silicone oil, methyl vinyl MO silicon resin, a catalyst and a tackifier at a weight ratio of 100:(15-50):(0.02-3):(2-24). With the adoption of the methyl vinyl MO silicon resin and the tackifier, namely a hydrogenous cyclosiloxane compound containing epoxy groups and siloxane groups, the mechanical properties, a bonding property and optical properties of the room temperature curing potting adhesive are effectively improved, and a provided preparation technology has concise steps, does not require demanding equipment and therefore, is suitable for industrial production.

Owner:GUANGZHOU JOINTAS CHEM

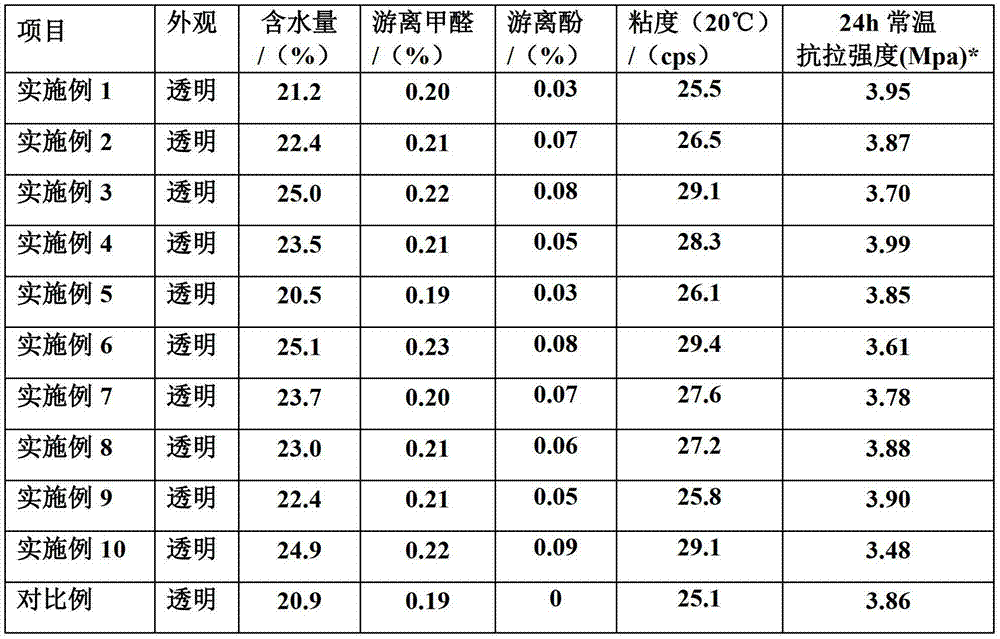

Preparation method of novel modified furan resin for casting

The invention discloses a preparation method of novel modified furan resin for casting. The method is characterized by comprising the following steps of: (1) dissolving 100 parts by weight of saccharides and 0.1-40 parts by weight of urea into 30-200 parts by weight of water; adding 5-60 parts by weight of acid into a mixture to react for 0.5-10 hours at the temperature of 60-105 DEG C; cooling to 30-90 DEG C; regulating a pH value to 7.5-10 and adding 0.1-40 parts by weight of formaldehyde; raising the temperature to 60-100 DEG C to react for 0.5-6 hours; and removing 3-300 parts by weight of water to obtain viscous liquid; and (2) using the viscous liquid obtained in the step (1) as a partial furfuryl alcohol substitute and preparing the novel modified furan resin for casting according to the conventional process of furan resin for casting, wherein the using amount of the viscous liquid is equivalent to the weight of furfuryl alcohol to be substituted and accounts for 1-20 percent of the total weight of a furan resin synthetic raw material for casting. The method is simple, feasible and environmentally-friendly, and a reticulate structure of the resin is formed during curing, so that the intensity of furan resin sand for casting can be improved.

Owner:SUZHOU XINGYE MATERIALS TECH

Method for producing self-hardened furan resin for casting by modifying furfuryl alcohol through pentose compound

ActiveCN102861867AReduce dosageReduce contentFoundry mouldsFoundry coresFuranUltimate tensile strength

The invention relates to a preparation method of self-hardened furan resin for casting, in particular to a method for producing the self-hardened furan resin for casting by partially modifying furfuryl alcohol through a pentose compound. The method comprises the following steps of: taking the furfuryl alcohol and the pentose compound in a weight ratio of (50-60): (5-35) as raw materials to prepare a furfuryl alcohol modified component to replace a large amount of the furfuryl alcohol needed by the prior art, so that the use amount of the furfuryl alcohol is reduced; compared with the traditional production of the furan resin, the preparation method provided by the invention has the advantages that the production cost is reduced, the damages to an environment are reduced and the large-scale production is easy to realize; meanwhile, pentose compound molecules contain an aldehyde group and a polyhydroxy structure; and in a process of preparing the furan resin, the cross-linking point of resin curing is increased, a net-shaped structure is easy to form in a curing process of the resin, the strength of resin sand is improved and the content of free formaldehyde can be effectively reduced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Preparation method for modified foundry furan resin

ActiveCN103113547AIncrease cross-linking pointHigh strengthFoundry mouldsFoundry coresViscous liquidFuran

The invention discloses a preparation method for modified foundry furan resin, which is characterized by comprising the following steps of: (1) dissolving 100 parts by weight of saccharides in 40-200 parts by weight of water, and then adding 0.1-50 parts by weight of phenols and 5-50 parts by weight of acid, reacting for 0.5-10 hours in a temperature condition of 70-100 DEG C, cooling to 30-90 DEG C, adding pH value to 7.5-10, adding 0.1-20 parts by weight of formaldehyde, heating to 60-100 DEG C and reacting for 0.5-6 hours, and then removing 5-280 parts by weight of water to obtain a viscous liquid; and (2) taking the viscous liquid obtained in the step (1) as a part of furfuryl alcohol substitutes, and preparing foundry furan resin according to the conventional process for foundry furan resin; wherein the dosage of the viscous liquid is equivalent to the weight of the substituted furfuryl alcohol, and is 1-20% of the total weight of the synthetic materials of foundry furan resin.

Owner:SUZHOU XINGYE MATERIALS TECH

Organic silicon modified styrene-acrylic emulsion type pressure sensitive glue with high steric hindrance and low residual, and preparation method and application thereof

InactiveCN104356980AImprove cohesionImprove high temperature aging resistance and water resistanceFilm/foil adhesivesEster polymer adhesivesEmulsionOrganosilicon

The invention belongs to the technical field of a pressure sensitive adhesive for packing of electronic products, and discloses organic silicon modified styrene-acrylic emulsion type pressure sensitive glue with high steric hindrance and low residual, and a preparation method thereof. The method comprises the following steps: firstly synthesizing a polyacrylate seed emulsion, then introducing organic silicon by using the after dripping technique, and processing heated glue films to urge the cross-linking of carboxyl and hydroxyl to obtain the organic silicon modified styrene-acrylic emulsion type pressure sensitive glue with low residual. The siloxane with larger steric hindrance is used, so that side effects of hydrolysis and autocondensation of the organic silicon in a polyreaction process are reduced, the gel rate is reduced, the conversion rate is increased, and the stability of emulsion is improved. The glue films are heated and processed, so that the cohesion of the pressure sensitive glue is further improved. Through adoption of the method, a complex working procedure of additionally adding cross-linking agents for improving the cohesion is avoided, the disadvantages that the cross-linking agents are additionally added for modifying and improving the cohesion, and the initial adhesion and the peeling strength of the pressure sensitive glue can be sacrificed at the same time are overcome, and water resistance, high temperature resistance and aging resistance are improved.

Owner:GUANGZHOU CHEM CO LTD CHINESE ACADEMY OF SCI +1

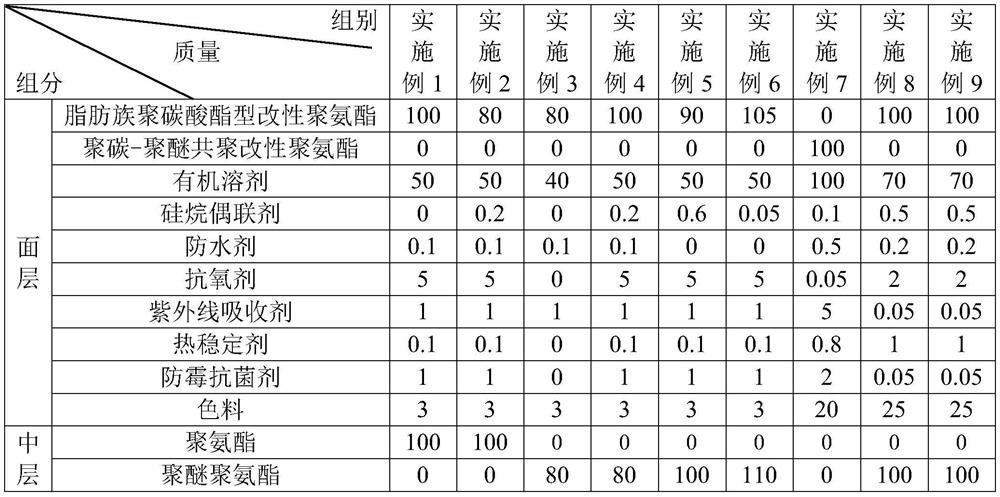

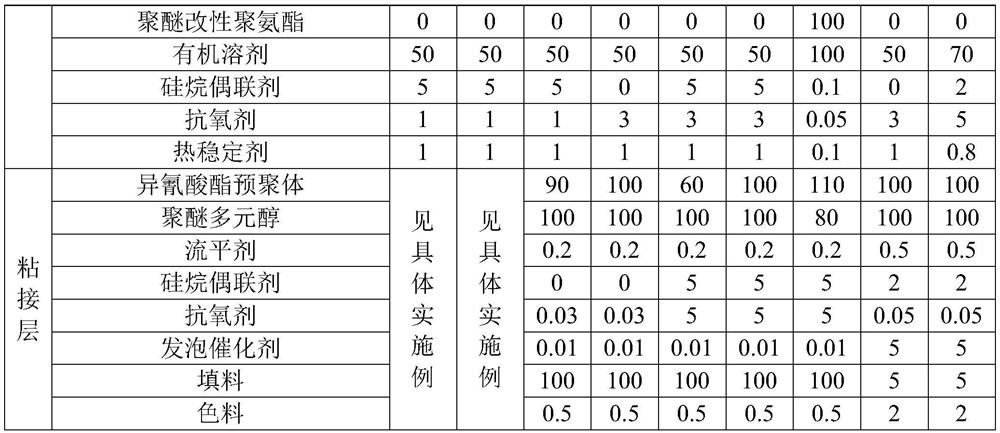

PU automobile leather easy to clean and preparation method thereof

The invention discloses a PU automobile leather easy to clean and a preparation method thereof. The PU automobile leather easy to clean comprises a base cloth, a bonding layer, a middle layer, a surface layer, a first surface layer and a second surface layer which are arranged in sequence; the first surface layer comprises the following components of 5-95 parts of hydrophobic aliphatic self-matting polycarbonate polyurethane, 5-95 parts of hydrophobic aliphatic polyurethane gloss surface treatment agent, 0.5-8 parts of isocyanate cross-linking agent, 3-8 parts of silane coupling agent, 0.1-2 parts of leveling agent and 1.1-15 parts of other auxiliaries in parts by weight; the total amount of the hydrophobic aliphatic polyurethane gloss surface treatment agent and the hydrophobic aliphaticself-matting polycarbonate polyurethane is 100 parts; the second surface layer comprises the following components of 40-75 parts of side-chain fluorine-containing vinyl silicone resin, 2-25 parts of polysilazane, 3-20 parts of hydrogen containing silicone oil, 30-70 parts of organic solvents, 0.5-18 parts of adhesive agent, 0.001-1 parts of platinum catalyst, 0.5-10 parts of accelerator, 8-40 parts of packing and 0.1-2 parts of wear-resistant agent in parts by weight. The PU automobile leather easy to clean has the advantages that the PU automobile leather easy to clean is easy to clean, and meanwhile, the PU automobile leather easy to clean possesses excellent hydrolysis resistance, wear resistance and weather resistance.

Owner:浙江康成新材料科技有限公司

Weather-proof and water-proof cable sheathing material

InactiveCN105255076AGood weather resistanceImprove pollutionPlastic/resin/waxes insulatorsInsulated cablesPolyvinyl chloridePolymethyl methacrylate

The invention discloses a weather-proof and water-proof cable sheathing material. The weather-proof and water-proof cable sheathing material comprises raw materials as follows: polyvinylidene fluoride, polymethyl methacrylate, polyvinyl chloride, acrylonitrile-styrene-butyl acrylate copolymer, nitrile rubber, nano titanium dioxide, nano silica, carbon nano tubes, mica powder, zinc stearate, calcium stearate, zinc oxide, stearic acid, dibutyl phthalate, acetyl trihexyl citrate, triethyl citrate, coumarone resin, an anti-ageing agent, polyvinyl butyral and a silane coupling agent. The weather-proof and water-proof cable sheathing material has high strength, good water resistance and weather resistance and excellent processing performance.

Owner:ANHUI LAND GRP

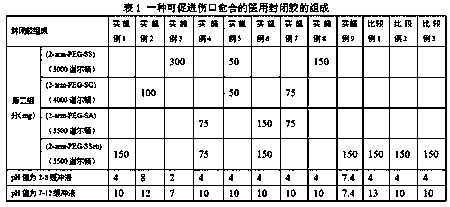

Sizing agent for carbon fiber

InactiveCN101982602AIncrease cross-linking pointImprove the interface bonding strengthCarbon fibresFiberCarbon fibers

The invention discloses a sizing agent for a carbon fiber, belonging to the fields of organic chemistry and fiber materials. The sizing agent is an epoxy water emulsion added with an aqueous curing agent, wherein the aqueous curing agent is modified epoxy amine curing agent, namely an amidated amine curing agent obtained by a reaction between a mono-fatty acid and an epoxy amine curing agent, a polyamide curing agent obtained by a reaction between a dimer acid and an epoxy amine curing agent and a curing agent obtained by a reaction between an epoxy amine curing agent and epoxy resin; the epoxy emulsion uses bisphenol A epoxy resin as the main body, and the epoxy equivalent is 200-500; the amount of the aqueous curing agent is 10% to 40% of theoretical one, and the theoretical amount should be calculated as follows: W=(Namine / NEP)*100, wherein Namine is the amine hydrogen equivalent of the curing agent, NEP is the epoxy equivalent of the epoxy resin, and W is the theoretical amount of the curing agent required by 100 grams of epoxy resin. The sizing agent is safe and healthy, the stability and the bundling performance are further improved, and the interface bonding strength of the composite material is enhanced.

Owner:BEIJING UNIV OF CHEM TECH

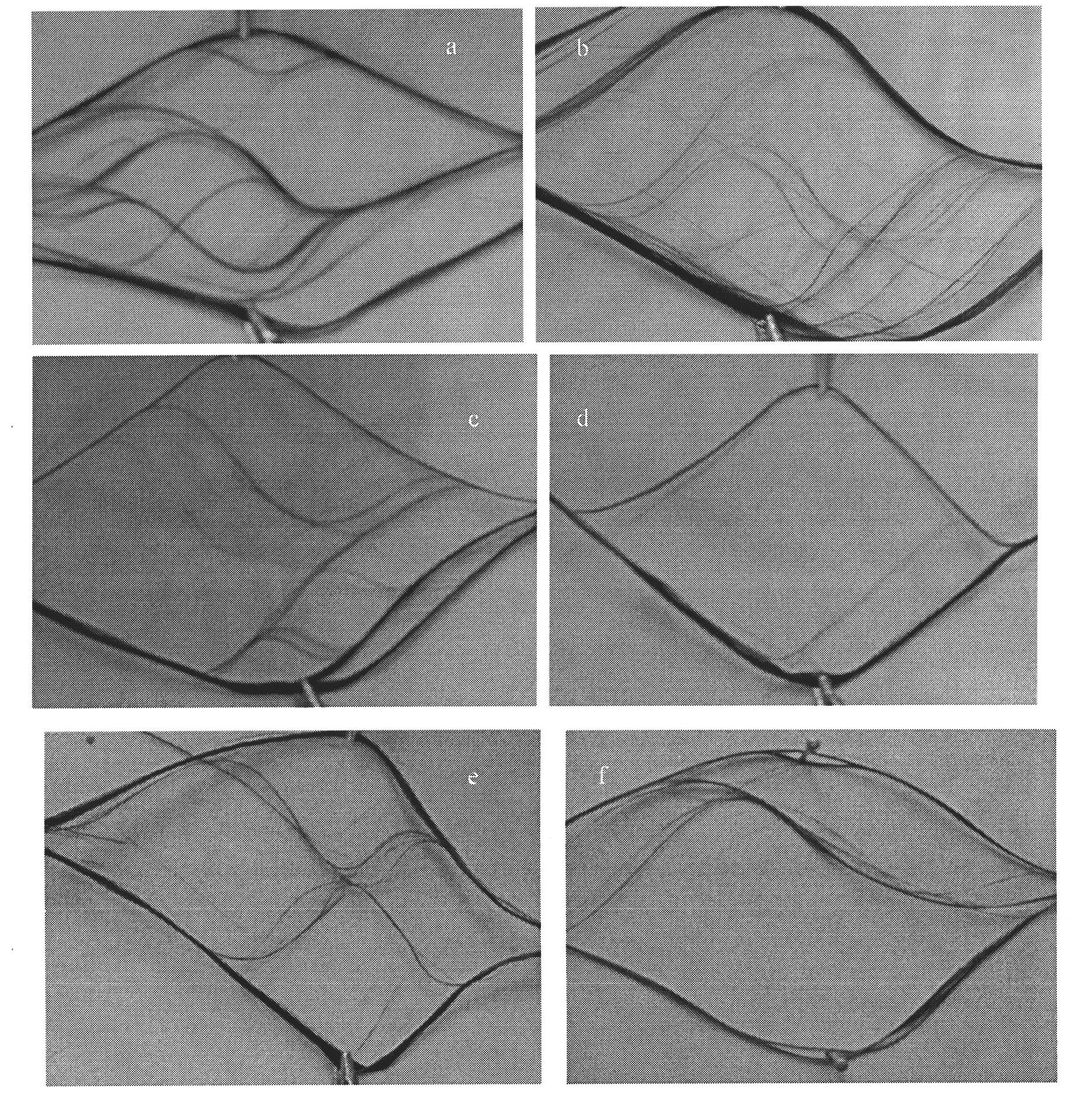

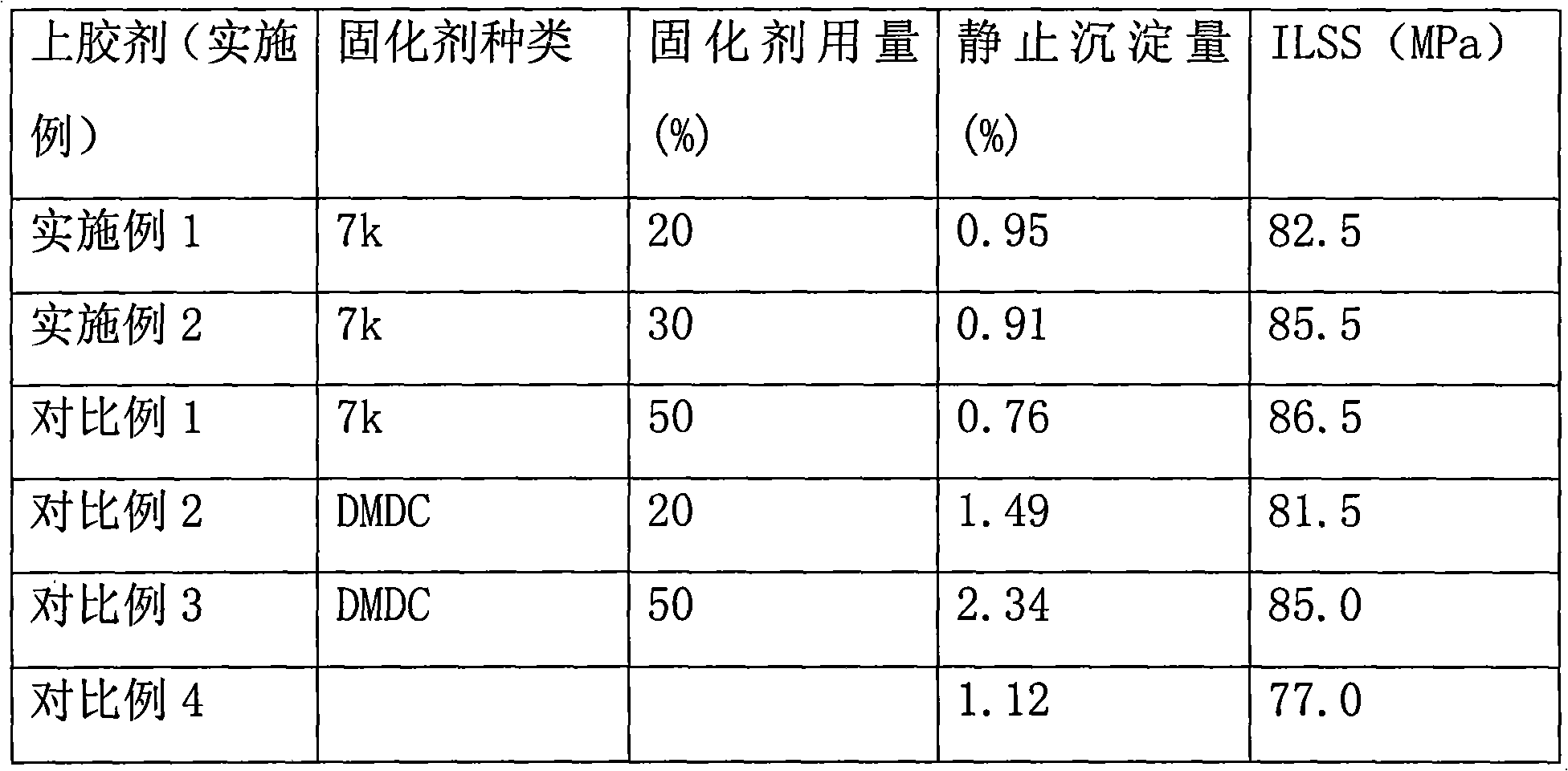

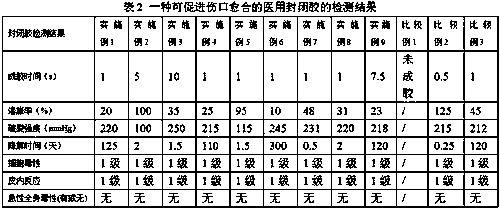

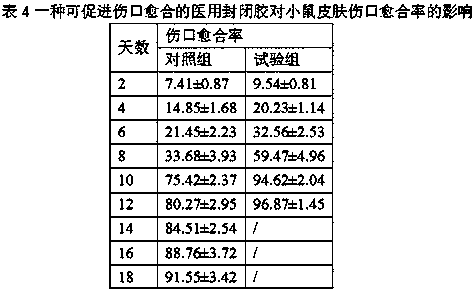

Medical sealing glue capable of promoting wound healing and preparation method thereof

ActiveCN109568641AImprove mechanical propertiesStrong mechanical propertiesSurgical adhesivesPharmaceutical delivery mechanismWound healingMedicine

The invention discloses in-situ crosslinking shaping medical sealing glue capable of promoting wound healing and a preparation method thereof. The medical sealing glue has the gelling time being 1 to10s, the swelling degree being 0 to 100 percent, the cracking intensity being 100 to 250mmHg and the degradation time being 0.5 to 300 days. The medical sealing glue is prepared from two ingredients through being physically mixed by a mixing tool and then being subjected to covalent cross-linking; a first ingredient is a nucleophilic ingredient; a second ingredient is an electrophilic ingredient.The medical nucleophilic ingredient contains exosomes or hyaluronic acid and chitosan, so that the medical sealing glue has the effect of promoting the wound healing; the antibacterial and anti-infection effects are achieved.

Owner:SHANDONG BRANDEN MEDICAL DEVICE

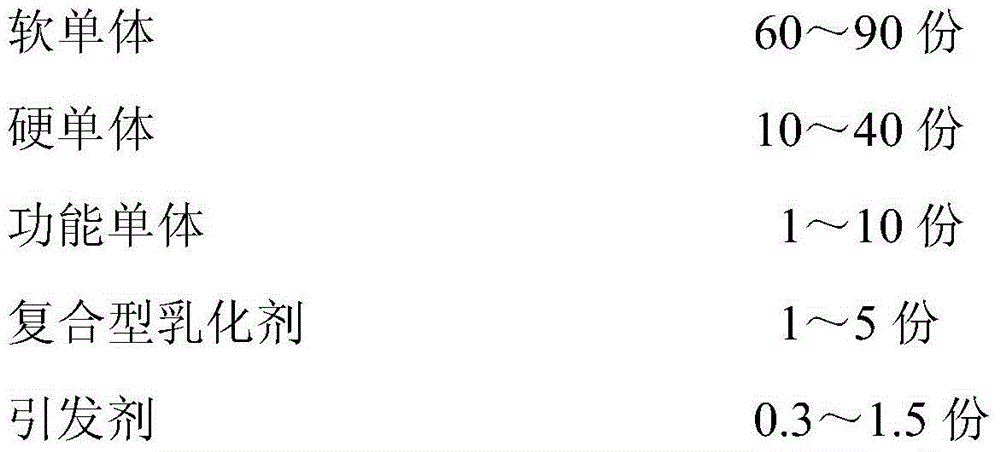

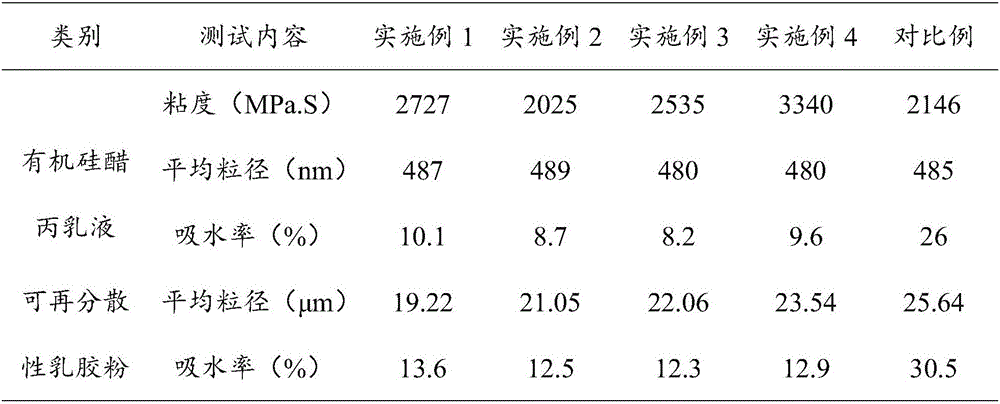

Organosilicon vinyl acetate-acrylic emulsion and preparation method thereof and redispersible emulsion powder prepared from organosilicon vinyl acetate-acrylic emulsion

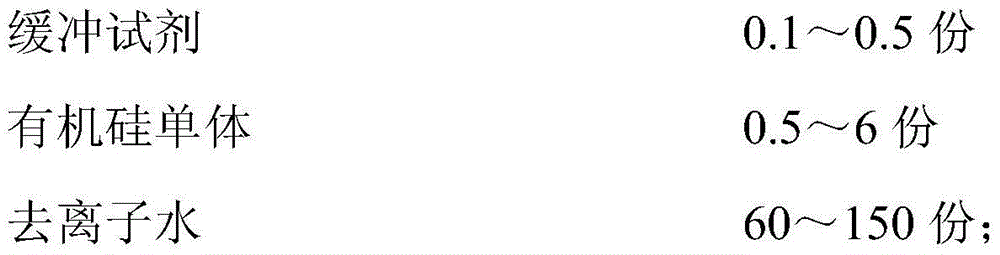

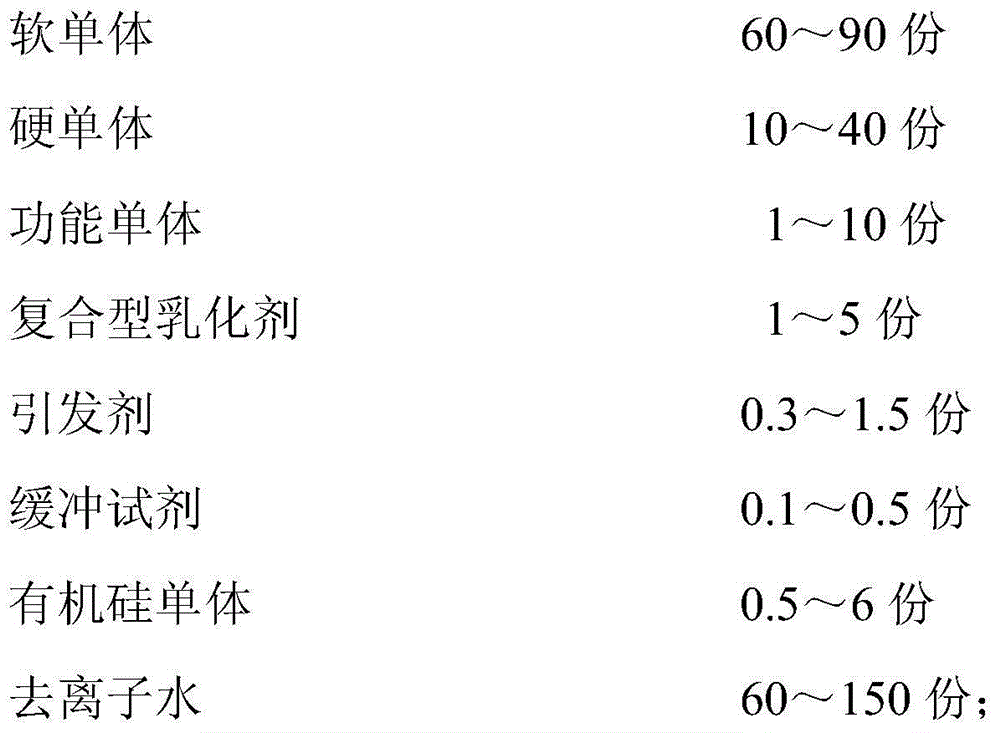

The invention discloses organosilicon vinyl acetate-acrylic emulsion and a preparation method thereof and redispersible emulsion powder prepared from the organosilicon vinyl acetate-acrylic emulsion. The emulsion is prepared from, by mass, 60-80 parts of vinyl acetate, 12-30 parts of butyl acrylate, 5-15 parts of a functional monomer, 1-6 parts of a crosslinking monomer, 0.2-3 parts of a silane coupling agent, 3-10 parts of protective colloid, 0.2-5 parts of an emulsifying agent, 0.2-0.6 part of a buffering agent, 0.2-0.6 part of a redox initiator and 90-120 parts of water. According to the organosilicon vinyl acetate-acrylic emulsion, by adopting a pre-emulsification method, the emulsion stability is greatly improved, the gelation phenomenon caused by instability of the emulsion in the polymerization process is effectively reduced, and the emulsion preparation success rate is increased; by introducing the crosslinking monomer, the functional monomer and the silane coupling agent into macromolecular chains of a polymer, crosslinking points on the polymer are increased, and a dense three-dimensional net is formed during the film forming process, so that the water resistance is improved, and then the application property of the redispersible emulsion powder in the application fields of building mortar, building waterproof paint and the like is promoted.

Owner:YOUNGWOO CHEMTECH

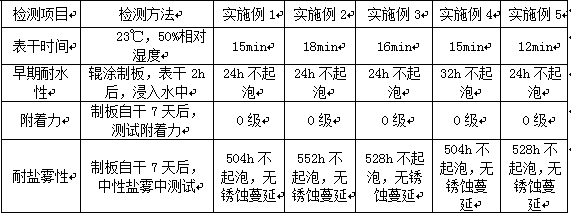

Black waterborne automotive chassis paint and preparation method thereof

ActiveCN109321099AImprove anti-corrosionSmall smellAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention belongs to the technical field of paint and specifically relates to black waterborne automotive chassis paint and a preparation method thereof. The black waterborne automotive chassis paint is prepared from the following raw materials of 20 to 25% of self-emulsification acrylic modified epoxy ester resin, 20 to 25% of waterborne epoxy ester dispersoid, 0.5 to 1.0% of a waterborne drier, 0.01 to 0.5% of graphene, 1 to 2% of carbon black, 5 to 10% of compound zinc phosphate, 10 to 15% of barium sulfate, 1 to 2% of a corrosion inhibitor, 1 to 2% of an environment-friendly solvent, 0.1 to 0.2% of a neutralizing agent, 0.2 to 0.5% of a defoaming agent, 0.4 to 0.6% of a leveling agent, 0.3 to 0.5% of a base material wetting agent, 15 to 39.5% of deionized water and 0.5 to 1.0% of athickening agent. The black waterborne automotive chassis paint disclosed by the invention has very low smell; meanwhile, the product has the advantages of good dryness, good early water resistance and excellent salt spray resistance property.

Owner:河南中垣新材料科技有限公司

Method for producing self-hardening furan resin for casting with pentose compound instead of furfuryl alcohol

The invention relates to a method for producing self-hardening furan resin for casting, in particular to a method for producing self-hardening furan resin for casting by taking a pentose compound as a raw material to substitute for part of furfuryl alcohol. According to the method, 5-35 parts of pentose compound and 50-60 parts of furfuryl alcohol are used as raw materials combination to replace a large quantity of furfuryl alcohol required in the prior art, so that the using quantity of the furfuryl alcohol is reduced. Compared with the traditional method for producing furan resin, the method provided by the invention has the advantages that production cost is lowered, harm to environments is reduced, and the method is favorable to large scale production; and meanwhile, in the preparation process of the furan resin, an aldehyde and polyhydroxy structure in the molecule of the pentose compound is utilized to increase resin curing crosslinking points and facilitate the formation of a reticular structure in the curing process of the resin, the strength of resin sand is improved, and the content of free formaldehyde can be effectively reduced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

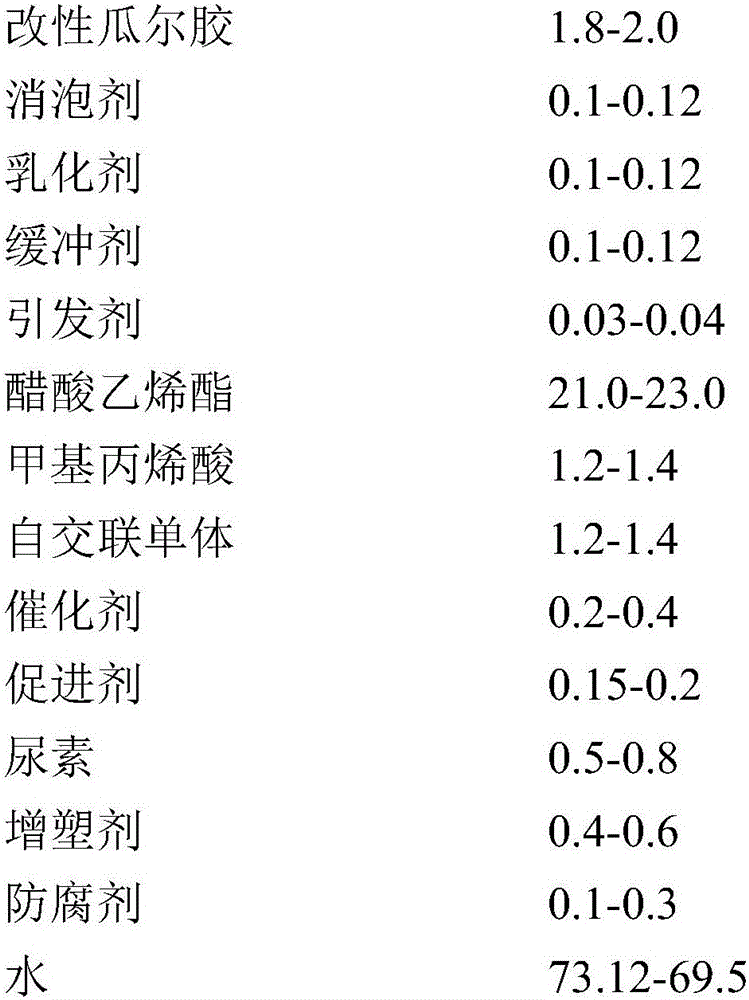

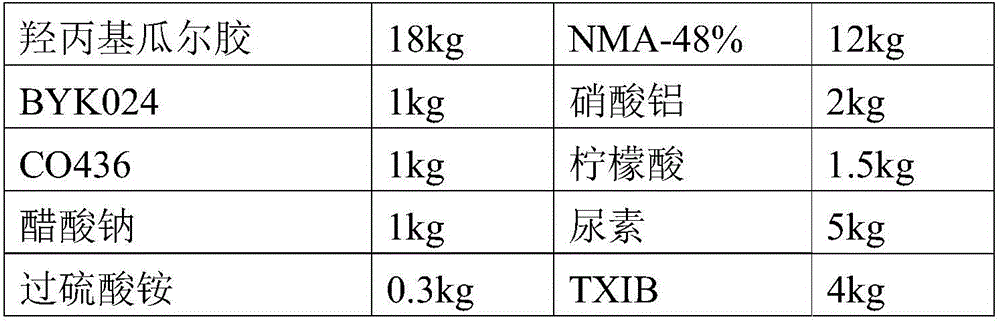

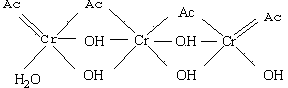

Guar gum modified vinyl acetate low-solid and high-viscosity pressing plate adhesive and preparation method thereof

InactiveCN106010303AHigh degree of branchingIncrease the number ofNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveCross-linkAdhesive

The invention discloses a guar gum modified vinyl acetate low-solid and high-viscosity pressing plate adhesive and a preparation method thereof. Main components of the guar gum modified vinyl acetate low-solid and high-viscosity pressing plate adhesive comprise tap water, modified guar gum, a de-foaming agent, a buffering agent, an emulsifier, an initiator, methacrylic acid, vinyl acetate, a self-cross-linking monomer, a plasticizer, a catalyst and a preservative. The modified guar gum is used as protective colloid; almost primary hydroxyl and secondary hydroxyl on a straight chain in a guar gum molecular structure are located at the outer side so that a hydrogen bond combining area is the largest; a process of increasing the amount of the polymerization initiator at an initial period and directly dropwise adding the monomer to polymerize is adopted and the homogeneous nucleation quantity is increased, so that the quantity of latex particles in a system is increased and a low-solid and high-viscosity adhesive product is prepared.

Owner:顶立新材料科技股份有限公司

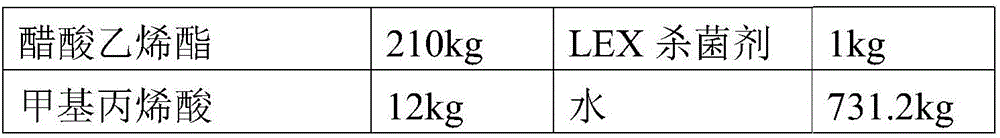

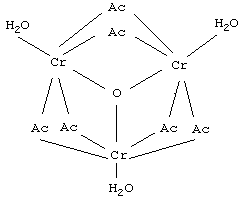

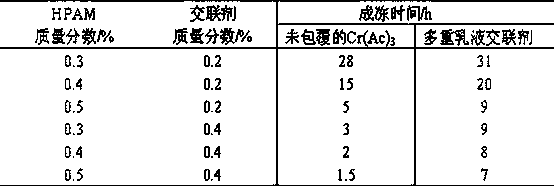

Preparation method of W/O/W type multiple emulsion delaying chromium sol cross-linking system

The present invention relates to a preparation method of a W / O / W type multiple emulsion delaying chromium sol cross-linking system. The preparation method comprises: (A) adding an emulsifier Span-80 and residual oil to diesel fuel, and uniformly stirring so as to be adopted as an oil phase for spare; (B) preparing a cross-linking agent with a mass fraction of 8-10% (calculated as CrCl3), weighing CrCl3.6H2O and CH3COONa.3H2O, dissolving to make the ratio of n(Cr<3+>) to n(Ac<->) in the obtained solution be 1:3 , and then preparing a solution with a volume fraction of 2% so as to be adopted as a water phase for spare; (C) mixing the prepared oil phase and the prepared water phase according to a volume ratio of 3:7, and emulsifying to form a primary emulsion; (D) preparing polyacrylamide into a 2000 ppm aqueous solution, wherein the ratio of the emulsifier mSpan-80 to the emulsifier mTween-80 in the aqueous solution is 7:3, and the Span-80 and the Tween-80 is 1.0-2.0% of the mass of the aqueous solution; (E) carrying out mixing emulsification the primary emulsion and the polyacrylamide solution according to a volume ratio of 1-7:1-3; and (F) adjusting the pH value of the prepared emulsion to 7-10. With the preparation method of the present invention, the cross-linking time can be delayed, and the gelation time can achieve 480 h.

Owner:NORTHEAST GASOLINEEUM UNIV

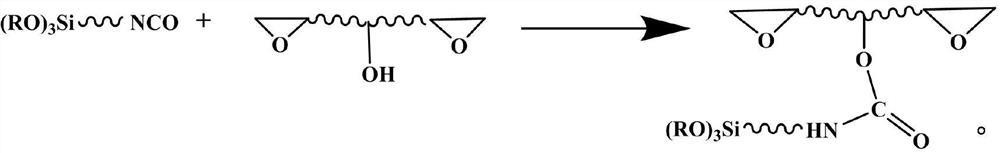

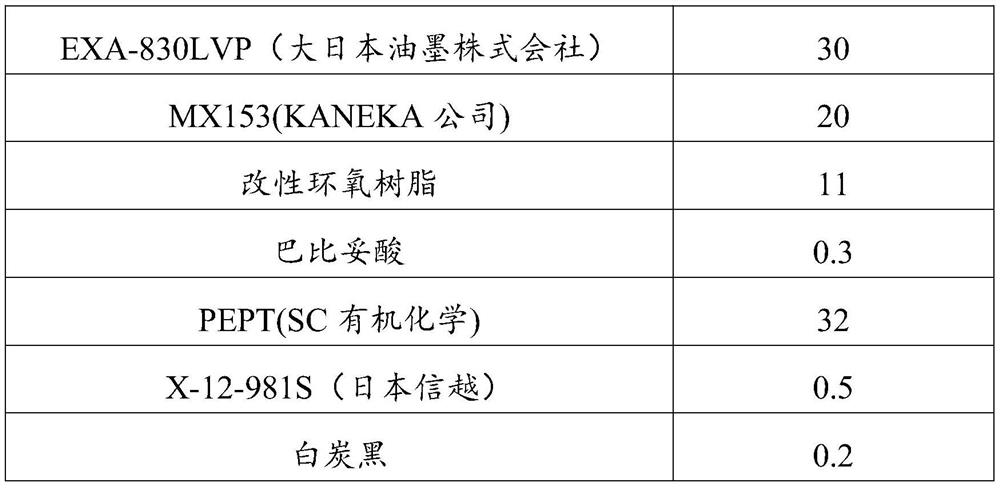

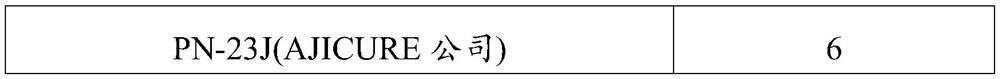

High-adhesion low-modulus epoxy adhesive and preparation method thereof

PendingCN112646525AImprove hydrophobicityDoes not affect epoxy valueNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceFirming agent

The invention discloses a high-adhesion low-modulus epoxy adhesive which comprises the following components in parts by weight: 15-55 parts of epoxy resin, 5-35 parts of modified epoxy resin, 0.1-6 parts of a stabilizer, 10-50 parts of a curing agent, 1-10 parts of an accelerant, 0.1-0.5 part of white carbon black and 0.1-10 parts of a coupling agent. The modified epoxy resin added into the high-adhesion low-modulus epoxy adhesive is isocyanate silane coupling agent modified epoxy resin, an amide structure is generated through hydroxyl reaction in the epoxy resin, and an organic chain and a silane structure are introduced, so that the hydrophobicity of the epoxy resin and the adhesion performance of the epoxy resin to the surface of a base material are improved, especially for glass and metal interfaces, and meanwhile, the epoxy value of the epoxy resin itself is not affected, and the curing reaction of the epoxy resin itself is not affected.

Owner:YANTAI DARBOND TECH

Vacuum electroplating UV photo-curing primer and preparation method thereof

InactiveCN111793409AIncrease cross-linking pointImprove adhesionPolyurea/polyurethane coatingsEpoxy resin coatingsPolyesterPolymer science

The invention relates to the technical field of vacuum electroplating, in particular to a vacuum electroplating UV photocuring prime coat and a preparation method thereof. The vacuum electroplating UVphoto-curing prime coat is prepared from the following components by weight percentage: 10-20 parts of epoxy acrylic resin, 10-15 parts of polyester acrylate and 10-15 parts of polyurethane acrylic resin; 0.3 to 0.5 part of an adhesion promoter; 15 to 25 parts of an active monomer diluent; 3-5 parts of a photoinitiator; and 30 to 40 parts of a cosolvent; and the adhesion promoter is vinyl trimethoxy silane. In the present application, an adhesion promoter is added into the vacuum electroplating UV photocuring prime coat; vinyl trimethoxy silane is subjected to a double bond addition reactionin the presence of a photoinitiator, and is copolymerized or grafted into a prepolymer, alkoxy and silica bonds are introduced, and the alkoxy increases the crosslinking point of the prepolymer duringcrosslinking and curing, so that the crosslinking density is improved, and the effect of improving the adhesive force of a cured coating is achieved.

Owner:上海蓝宝涂料有限公司

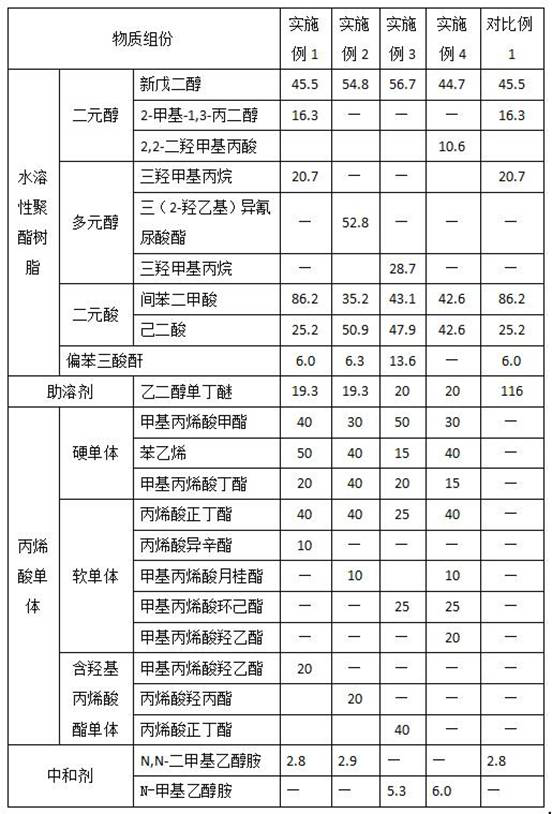

High-branching-degree water-based saturated polyester modified acrylic resin, preparation method thereof and water-based gloss oil for metal

PendingCN113603835AReduce usageIncrease the degree of branchingCoatingsMonomer compositionOrganic acid

The invention discloses a high-branching-degree water-based saturated polyester modified acrylic resin which is characterized by comprising the following components in parts by mass: 100 parts of water-based polyester resin, 80-95 parts of acrylate monomer, 6-15 parts of cosolvent, 1-2 parts of neutralizer, 0.8-1.2 parts of initiator and a proper amount of deionized water, wherein the water-based polyester resin is obtained by carrying out high-temperature esterification dehydration on polyol and organic acid and / or anhydride, and the acrylate monomer consists of a hard monomer, a soft monomer and a hydroxyl-containing acrylic monomer. According to the method, the characteristics that a large amount of solvent is used and control is not easy in oil free radical graft polymerization are avoided, the modified resin with high branching degree and high cross-linking point can be simply prepared, and the prepared product has excellent chemical resistance, wear resistance and high-temperature cooking resistance.

Owner:清远慧谷新材料技术有限公司

High wear resistant automobile foot pad material

The invention relates to a high wear resistant automobile foot pad material prepared from the following raw materials by weight: 35-40 parts of ethylene-propylene-diene monomer, 30-35 parts of polyurethane, 15-22 parts of a nano-filler, 8-10 parts of carbon black, 3-4 parts of glass fibers, 3-4 parts of dioctyl phthalate, and 2-3 parts of paraffin oil. An automobile foot pad provided by the invention adopts the ethylene-propylene-diene monomer and polyurethane as base rubber; by addition of the nano-filler and the glass fibers for compositing, a traditional reinforcing method using a large amount of carbon black is changed; the novel nano-filler is used for increasing the crosslinking points of rubber; meanwhile, the bonding points of carbon black, the nano-filler and rubber are significantly increased due to good dispersity of the filler, a space network structure is formed, and the strength, wear resistance and aging resistance of the rubber are effectively enhanced.

Owner:合肥凯大新型材料科技有限公司

High-temperature curing high-strength solid epoxy adhesive toughened by butyronitrile and preparation method thereof

InactiveCN101638567BLow viscosityImprove insulation performanceCarboxyl rubber adhesivesEpoxy resin adhesivesSilanesUltimate tensile strength

The invention discloses a high-temperature curing high-strength solid epoxy adhesive toughened by butyronitrile, which is characterized by comprising the following raw materials in parts by weight: 5-40 parts of carboxy-terminated butadiene nitrile liquid rubber, 100 parts of solid epoxy resins, 3-10 parts of liquid epoxy resins, 3-10 parts of multifunctional epoxy resins, 0-3 parts of catalysts,1-5 parts of silane coupling agents and 5-10 parts of curing agents. The preparation method comprises the following steps: adding the carboxy-terminated butadiene nitrile liquid rubber, the solid epoxy resins, the liquid epoxy resins, the multifunctional epoxy resins and the catalysts in the above raw materials into a reaction kettle to react, controlling the acid value below 1.0, finally adding the silane coupling agents to be mixed with the curing agents and obtaining the solid adhesive after cooling. The adhesive has high bond strength and insulating property in the temperature range from minus 50 DEG C to 200 DEG C, has excellent water-proof and oil-proof properties and is mainly used for adhesive bonding among metals when high-temperature curing is required, in particular being used for consolidating the high-speed railway track structures.

Owner:YANTAI DARBOND TECH

Multi-armed polyglutamic acid taking beta-cyclodextrin as nucleus and injectable hydrogel and preparation method thereof

The invention relates to a multi-armed polyglutamic acid taking beta-cyclodextrin as a nucleus and an injectable hydrogel and a preparation method thereof. The method comprises the steps that multi-aminated beta-cyclodextrin is synthesized first, multiple grafting reaction initiating loci are introduced, L-glutamate-N-carboxylic acid anhydride ring opening polymerization is initiated, hydroformylation modification is conducted on the multi-armed poly(L-glutamic acid), and the obtained product serves as a first component of the hydrogel; meanwhile, the poly(L-glutamic acid) subjected to amination modification serves as a second component, the two components are mixed according to a certain proportion, and the glutamic acid-based hydrogel is obtained through crosslinking in a Schiff base reaction, wherein the gelation time ranges from 20 s to 400 s. The hydrogel has the advantages that the hydrogel has good biocompatibility and biodegradability and can adapt to different shapes; in addition, due to the fact that beta-cyclodextrin is introduced, crosslinking points can be increased, improvement of the mechanical strength of the hydrogel is promoted, and loading and release control can be conducted on hydrophobic drugs. Therefore, the hydrogel has wide application prospects in the fields of tissue engineering, regenerative medicine, controlled drug release and the like.

Owner:SHANGHAI UNIV

Water-based acrylic resin anti-corrosive insulation coating and preparation method of anti-corrosive insulation coating

InactiveCN109233500AImprove water resistanceAccelerated corrosionAnti-corrosive paintsEpoxy resin coatingsWater basedZinc phosphate

The invention provides a water-based acrylic resin anti-corrosive insulation coating and a preparation method of the anti-corrosive insulation coating. The preparation method comprises the following steps: 1) octamethylcyclotetrasiloxane and divinyl-tetramethyl-disiloxanc are mixed under a nitrogen atmosphere in the presence of an initiator and placed at a temperature of 100 to 170 DEG C to obtaina premix X1; 2) epoxy resin and the premix X1 and a modified accelerator are stirred in the presence of a solvent to obtain a modified epoxy resin X2; 3) the water-based acrylic resin, the modified epoxy resin X2, a filler, azodiisobutyronitrile and water are mixed and ground to obtain a water-based acrylic resin anti-corrosive insulation coating, wherein the filler comprises at least calcium carbonate and zinc phosphate. Good resistance to water and corrosion is achieved.

Owner:CHANGSHA XIAORU INFORMATION TECH CO LTD

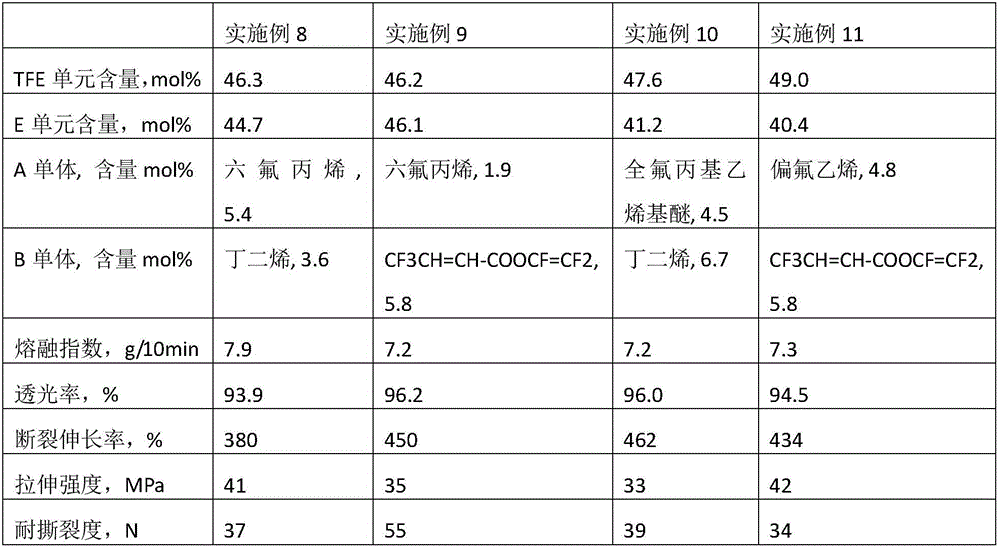

Cross-linkable ethylene-tetrafluoroethylene copolymer and synthetic method thereof

The invention relates to a cross-linkable ethylene-tetrafluoroethylene copolymer and a synthetic method thereof. A polymer is prepared from tetrafluoroethylene, ethylene, a monomer A and a monomer B through copolymerization, wherein the monomer A is a compound containing one double bond, and the monomer B is a compound containing two double bonds; and by virtue of proper crosslinking, the ethylene-tetrafluoroethylene copolymer can be endowed with relatively high radiation resistance, toughness, abradability, tensile strength and tear strength. The invention further provides a preparation method of the cross-linkable ethylene-tetrafluoroethylene copolymer and a cross-linkable copolymer composition. By controlling a polymerization process, too many low polymers can be reduced, and excellent performance of the polymer can be maintained.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

High-speed compounding and online peeling polyurethane transfer adhesive and preparation method thereof

InactiveCN109825239AHigh molecular weightImprove temperature resistancePolyureas/polyurethane adhesivesPolyesterPolyol

The invention discloses a high-speed compounding and online peeling polyurethane transfer adhesive which comprises a component A and a component B. The component A comprises, in weight percent, 30-70%of polymers A1, 1-10% of polymers A2, 20-60% of polyisocyanate, 0.5-2% of coupling agents and 0.1-1% of leveling agents, the polymers A1 is one of polyether polyol and polyester polyol or mixture ofthe polyether polyol and the polyester polyol, the functionality of the polyether polyol is 2, the polymers A2 is one of polyester polyol and polyether polyol or mixture of the polyester polyol and the polyether polyol, and the functionality of the polyester polyol is larger than or equal to 3. The component B comprises, in weight percent, 5-25% of amine chain extenders, 0.1-1% of amine catalystsand the balance water. The invention further provides a preparation method of the high-speed compounding and online peeling polyurethane transfer adhesive. The high-speed compounding and online peeling polyurethane transfer adhesive is used for production of transfer aluminized paper, high-speed compounding and online peeling can be achieved, improvement of production speed is facilitated, energyconsumption and production cost are reduced, and the adhesive has high bending resistance and good heat resistance and anti-sticking property and is safe and environmentally friendly.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

Novel additive for leather pickling procedure

InactiveCN106811557AAvoid damageAvoid pollutionTanning treatmentPre-tanning chemical treatmentOrganic acidSulfonate

The invention provides a novel auxiliary agent used in leather pickling process and usage of the novel auxiliary agent. This additive contains organic acid compounds, fatty alcohol polyoxyethylene ether surfactants, alkylbenzene sulfonate surfactants and calcium and magnesium ion chelates. This additive is used in the pickling process of the leather industry, which can effectively improve the absorption of chromium, reduce the use of chromium powder, and at the same time improve the yield and tensile strength of leather. In the low pH value, it can avoid the damage of high mechanical action to the leather surface, and can also improve the firmness, fineness and softness of the leather grain. Especially it has obvious effect on skin samples that have not been deashed in the previous process.

Owner:QINGDAO SENMEIKE CHEM TECH CO LTD

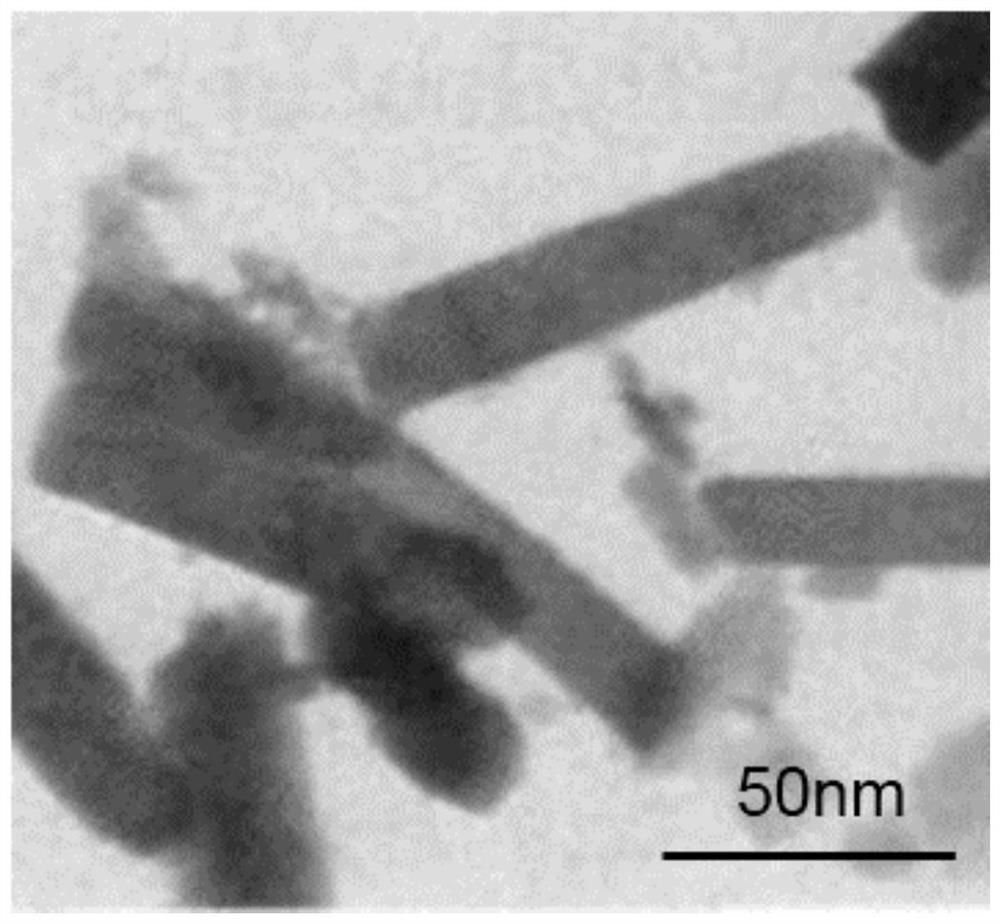

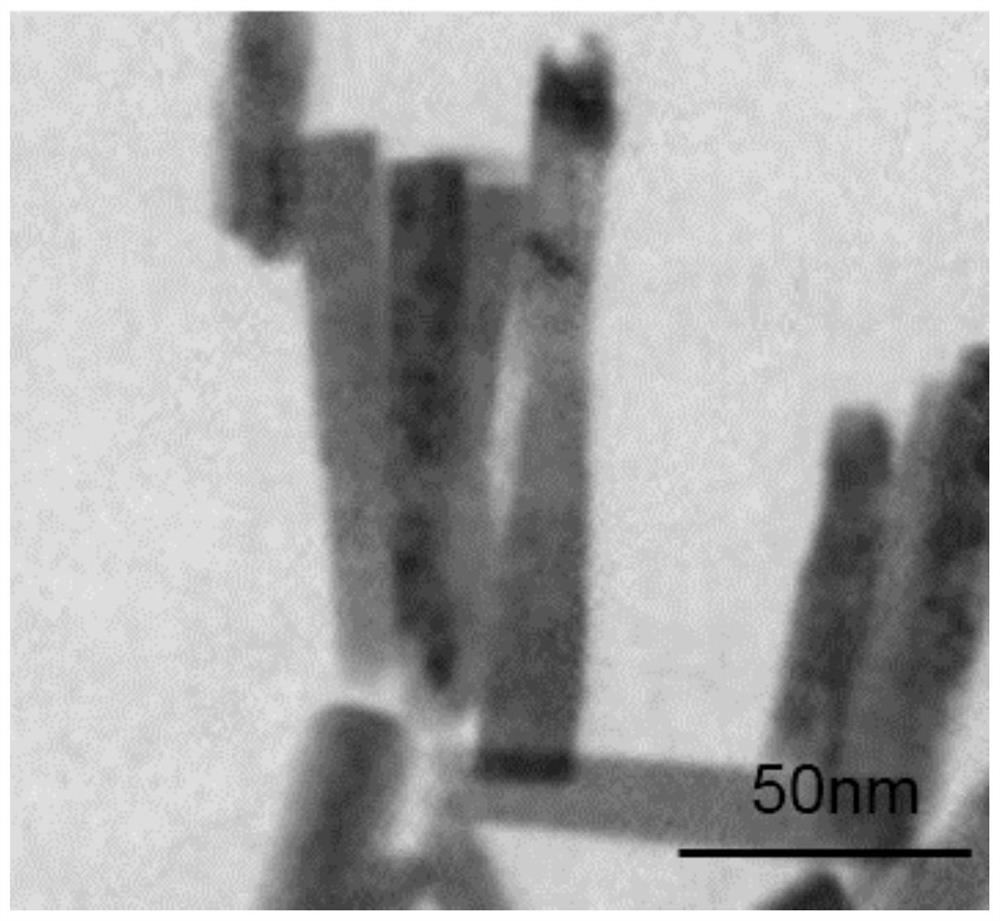

Cross-linking agent, preparation method and application thereof

ActiveCN113025300AIncrease cross-linking pointFacilitate cross-linkingFluid removalDrilling compositionBoronic acidCross linker

The invention provides a cross-linking agent, a preparation method and application thereof. The cross-linking agent is prepared by grafting boric acid ester and titanate onto surface-modified nano rod-shaped aluminum oxide. The invention further provides application of the cross-linking agent in tight sandstone reservoir fracturing with the well temperature not higher than 140 DEG C. The cross-linking agent provided by the invention can improve the cross-linking efficiency with the guanidine gum, greatly reduce the dosage of the guanidine gum, reduce the cost and relieve the damage to a reservoir, and has the advantages of higher temperature resistance, simple preparation process, low cost of raw materials and wide sources of raw materials.

Owner:PETROCHINA CO LTD

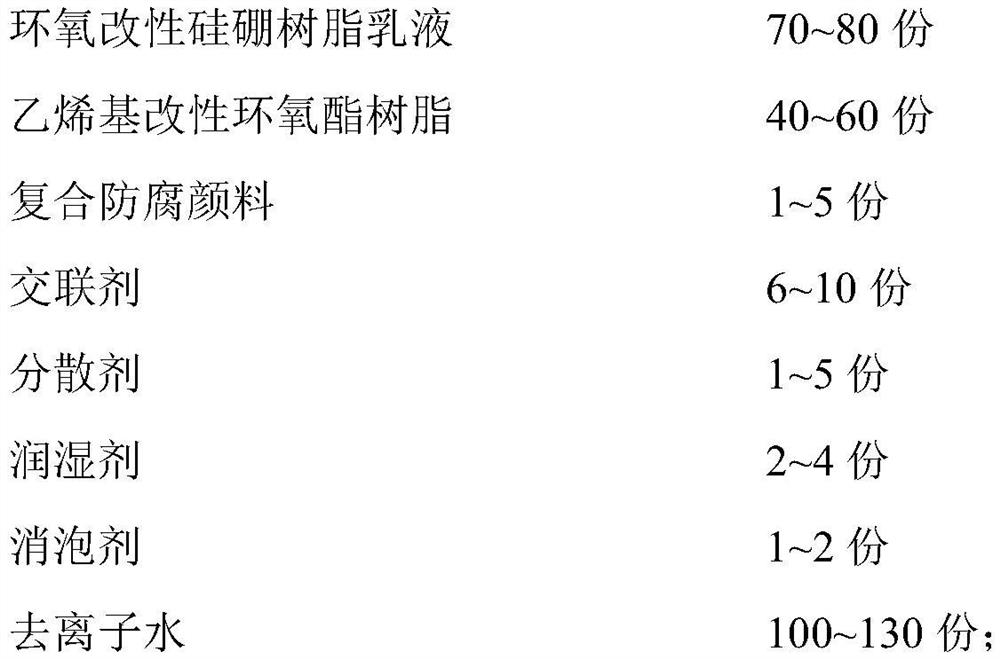

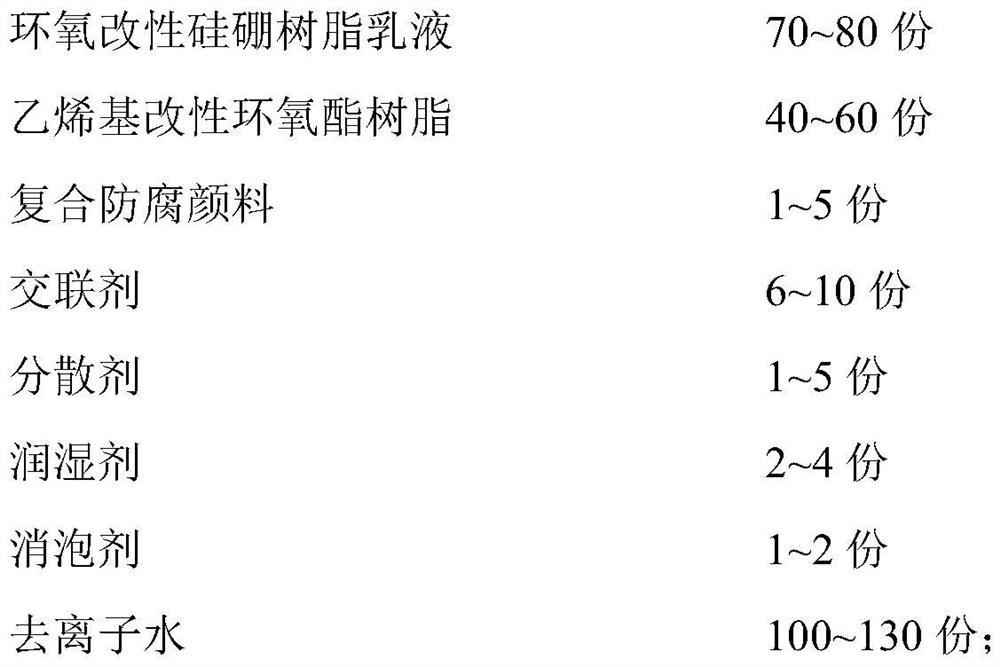

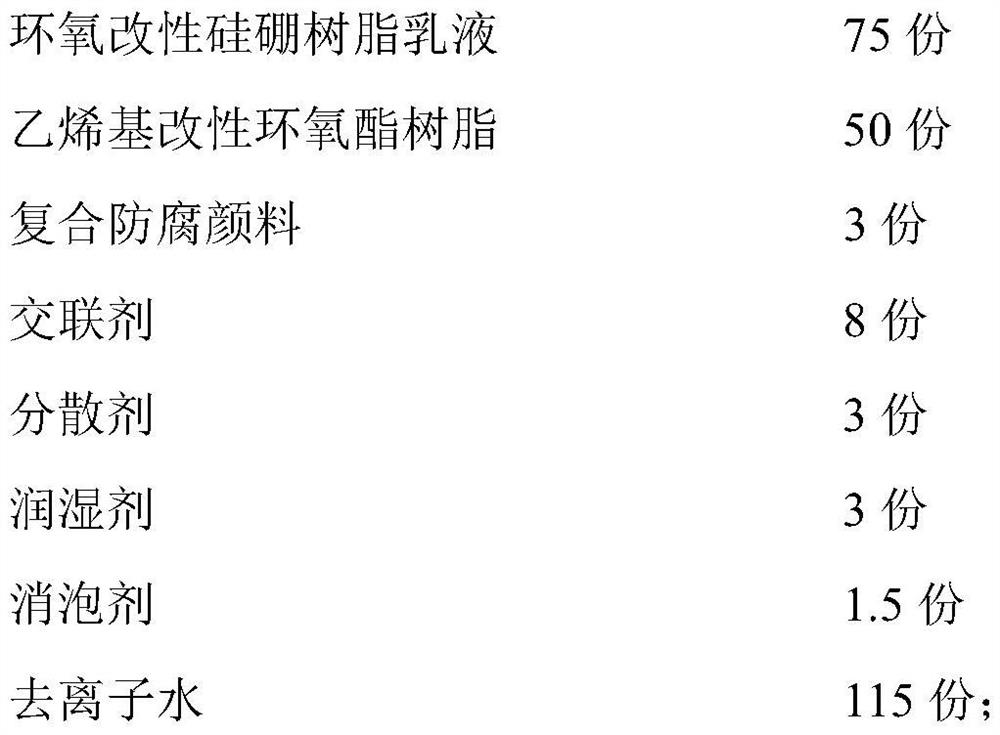

High-temperature-resistant anti-corrosion water-based coating and preparation method thereof

InactiveCN113150688AAvoid breakingGood adhesionFireproof paintsAnti-corrosive paintsEpoxyALUMINUM PHOSPHATE

The invention relates to the technical field of coatings, in particular to a high-temperature-resistant anti-corrosion water-based coating and a preparation method thereof. The water-based coating is prepared from 70-80 parts of epoxy modified silicon-boron resin emulsion, 40-60 parts of vinyl modified epoxy ester resin, 1-5 parts of composite anti-corrosion pigment, 6-10 parts of cross-linking agent, 1-5 parts of dispersing agent, 2-4 parts of wetting agent, 1-2 parts of defoaming agent and 100-130 parts of deionized water. The composite anti-corrosion pigment is a hydroxyl-terminated hyperbranched poly (amine-ester) modified graphene oxide / nano aluminum phosphate composite anticorrosive pigment. The water-based coating has excellent high-temperature-resistant and anti-corrosion effects and is high in adhesive force and hardness, and meanwhile the preparation process is easy to operate and low in cost.

Owner:东莞大宝化工制品有限公司 +2

Method for preparing self-solidified furan resin for casting by amyl saccharide compound instead of furfuryl alcohol

ActiveCN102887984AReduce dosageReduce contentFoundry mouldsFoundry coresFuranUltimate tensile strength

The invention relates to a preparation method of self-solidified furan resin for casting, and particularly relates to a preparation method for preparing the self-solidified furan resin for casting by amyl saccharide compound part instead of furfuryl alcohol as a material. According to the method disclosed by the invention, 5-35 parts of amyl saccharide compounds and 50-60 parts of furfuryl alcohol are combined as materials to replace a large quantity of furfuryl alcohol required in the prior art, so that the dosage of the furfuryl alcohol is reduced. Compared with the production of the traditional furan resin, the preparation method has the advantages that the production cost is reduced, the harm on the environment is reduced, and large-scale production is facilitated. Meanwhile, an aldehyde group and a polyhydroxy structure contained in an amyl saccharide compound molecule are utilized; a resin curing crosslinked point is increased in a process of preparing the furan resin; the situation that the resin forms a mesh structure in a curing process is facilitated; the strength of resin sand is improved, and the content of free formaldehyde can be effectively reduced.

Owner:JINAN SHENGQUAN GROUP SHARE HLDG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com