Furan resin for casting and preparation method thereof

A furan resin and lignin technology, which is used in casting and molding equipment, casting molds, manufacturing tools, etc., can solve the problems of firm combination of lignin and furan resin, strength reduction, etc., to improve strength, reduce dosage, and increase cross-linking points. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

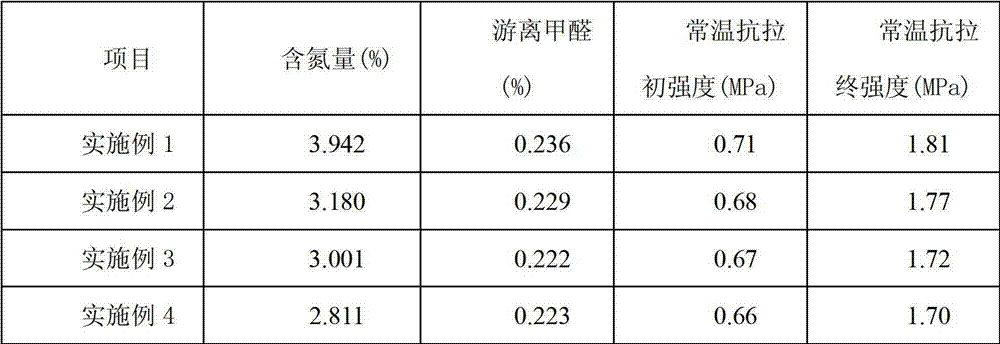

Embodiment 1

[0022] Add 774Kg of furfuryl alcohol into the reaction kettle, start stirring, adjust the pH to 8.5 with 15% sodium hydroxide solution, add 56Kg of lignin, raise the temperature to 70°C for 2 hours, cool down, adjust the pH to 6.5 with 20% oxalic acid solution, and Carry out dehydration, and stop dehydration until the water content of the resin is below 1.0%, to obtain 794Kg of lignin-modified furfuryl alcohol component for use.

[0023] Add 316Kg of formaldehyde (concentration 37%) into the reaction kettle, start stirring, add 72Kg of urea in one step, after the urea dissolves, adjust the pH value to 7.8 with alkaline solution, raise the temperature to 85°C and react for 1 hour; add lignin modified furfuryl alcohol component 294Kg and then react for 1 hour; adjust the pH value of the material system to 3.7, and react at a reaction temperature of 95°C for 1.5 hours; add 18Kg of two-step urea, adjust the pH value of the material system to 7.5, and react at 75°C for 1 hour, then ...

Embodiment 2

[0025] Add 837Kg of furfuryl alcohol into the reaction kettle, start stirring, adjust the pH to 9.0 with 15% sodium hydroxide solution, add 93Kg of lignin, raise the temperature to 70°C for 2 hours, cool down, adjust the pH to 7.5 with 20% oxalic acid solution, and put it under vacuum Dehydration is carried out until the water content of the resin is below 1.0%, and the dehydration is stopped to obtain 886Kg of lignin-modified furfuryl alcohol components for use.

[0026] Add 243Kg of formaldehyde (concentration 37%) to the reaction kettle, start stirring, add 60Kg of urea in one step, after the urea dissolves, adjust the pH value to 8.4 with alkaline solution, raise the temperature to 90°C and react for 2 hours; add lignin modified furfuryl alcohol component 286Kg to react for another 2 hours; adjust the pH value of the material system to 4.2, and react at a reaction temperature of 90°C for 2 hours; add 15Kg of two-step urea, adjust the pH value of the material system to 7, an...

Embodiment 3

[0028] Add 867Kg of furfuryl alcohol into the reaction kettle, start stirring, adjust the pH to 11.0 with 15% sodium hydroxide solution, add 153Kg of lignin, raise the temperature to 78~80°C for 2 hours, cool down, adjust the pH to 7.5 with 20% oxalic acid solution, vacuum Dehydration is carried out under the state, and the dehydration is stopped until the water content of the resin is below 1.0%, and 979Kg of the lignin-modified furfuryl alcohol component is obtained for use.

[0029] Add 223Kg of formaldehyde (concentration 37%) to the reaction kettle, start stirring, add 60Kg of urea in one step, after the urea dissolves, adjust the pH value to 8.8 with alkaline solution, raise the temperature to 85°C and react for 1.5 hours; add the lignin-modified furfuryl alcohol component 279Kg and then react for 1.5 hours; adjust the pH value of the material system to 4.6, and react at a reaction temperature of 95°C for 1 hour; add 15Kg of two-step urea, adjust the pH value of the mater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com