Energy-saving heat supply system with function of reducing temperature of heat supply return water

A technology of return water temperature and heating system, which is applied in heating systems, hot water central heating systems, and household heating, etc. Low grade can not be fully utilized and other problems, to achieve the effect of saving investment costs, improving energy utilization rate, reducing the amount of drift water

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

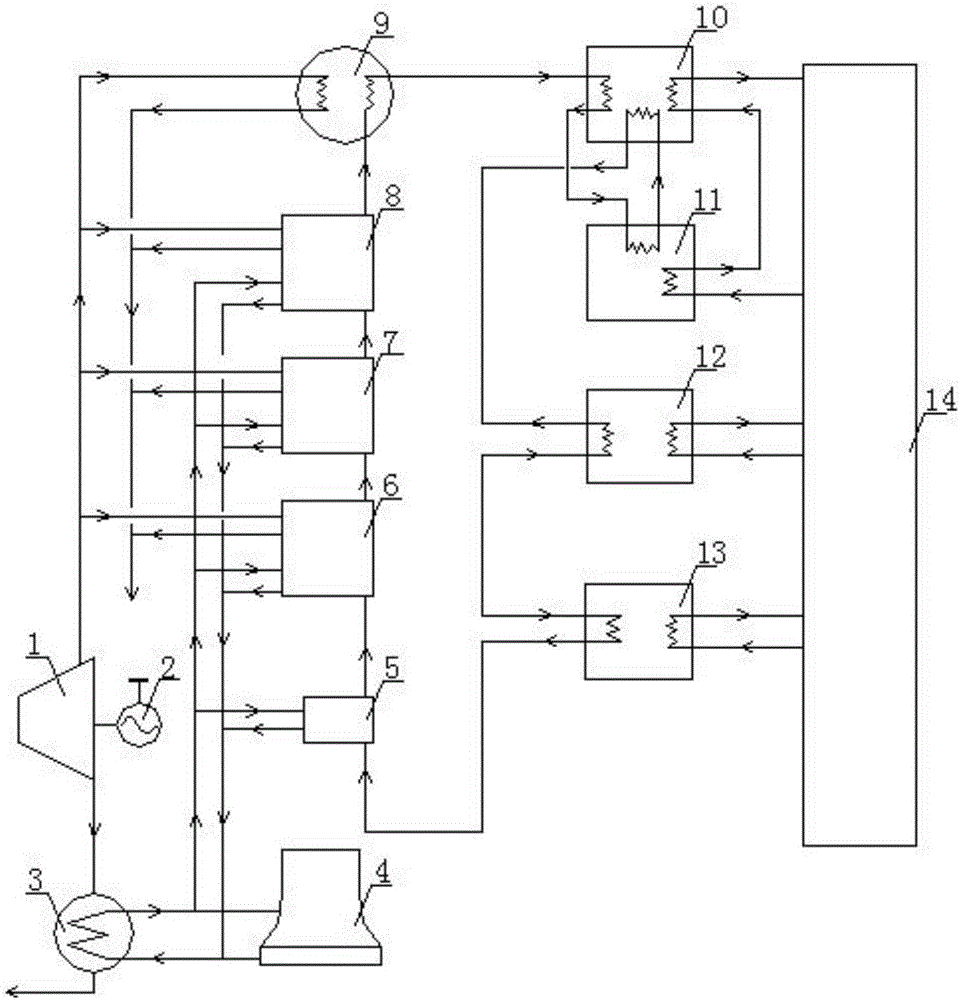

[0033] On the heating station side of the community, the 110°C hot water output from the primary heating pipe network of the thermal power plant enters the absorption heat pump 10 as the driving heat source, and enters the heat exchanger 11 to exchange heat with the return water of the secondary heating pipe network after cooling down. After that, it enters the evaporator of the absorption heat pump 10 as a low-temperature heat source, and the return water temperature of the primary heating pipe network is reduced to 15°C; the return water of the user-side circulating water first enters the heat exchanger 11 for a heat exchange from 40°C to 45°C, and then enters the The condenser side of the absorption heat pump 10 performs the second heat exchange from 45°C to 50°C and returns to the user side;

[0034] The compression refrigerator 12 installed on the heating station side of the community uses the return water of the primary heating pipe network at 15°C discharged from the abs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com