Patents

Literature

154results about How to "No heat loss" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

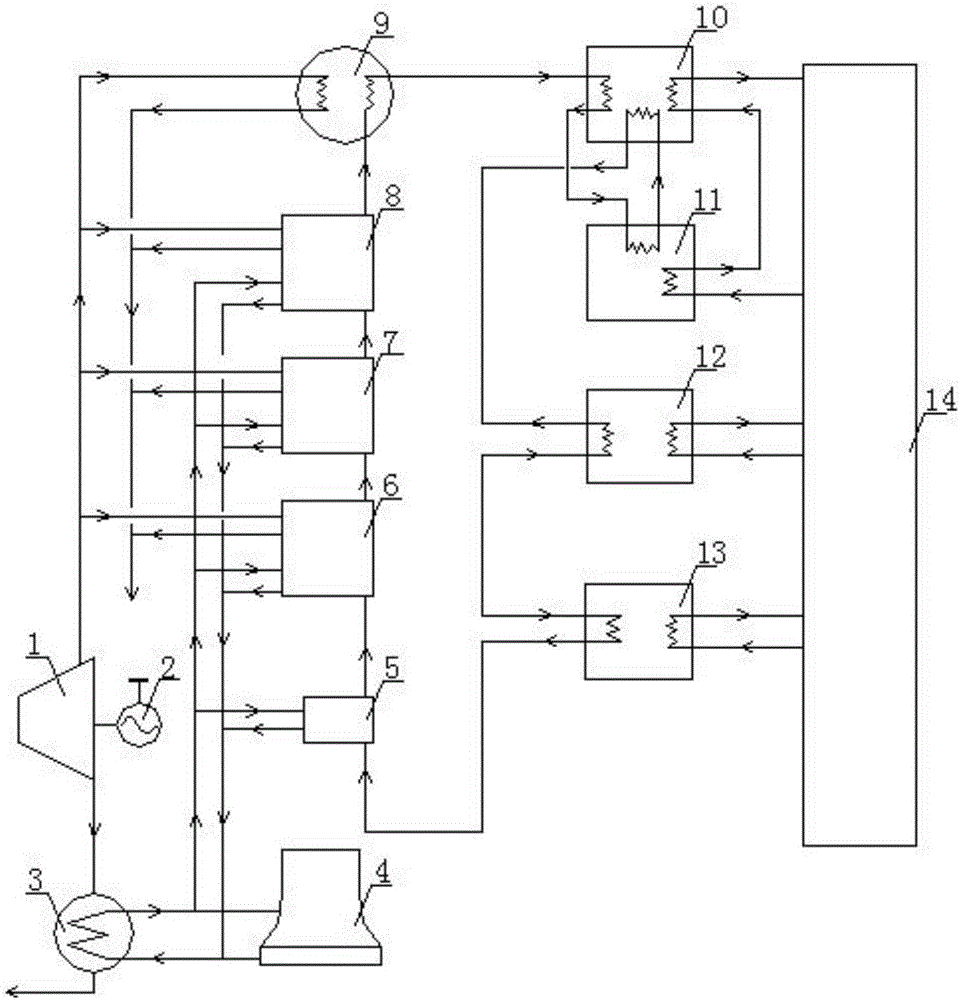

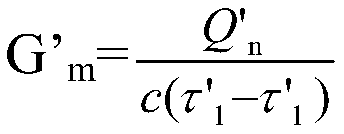

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

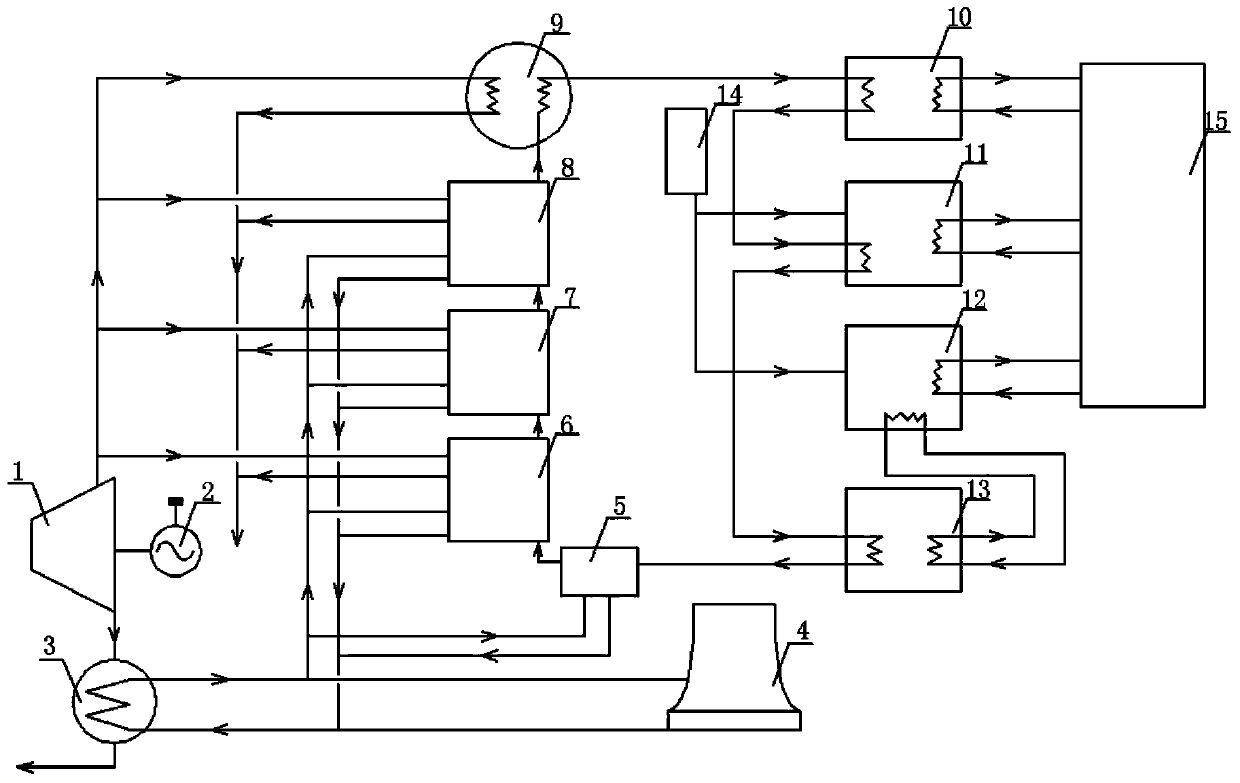

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

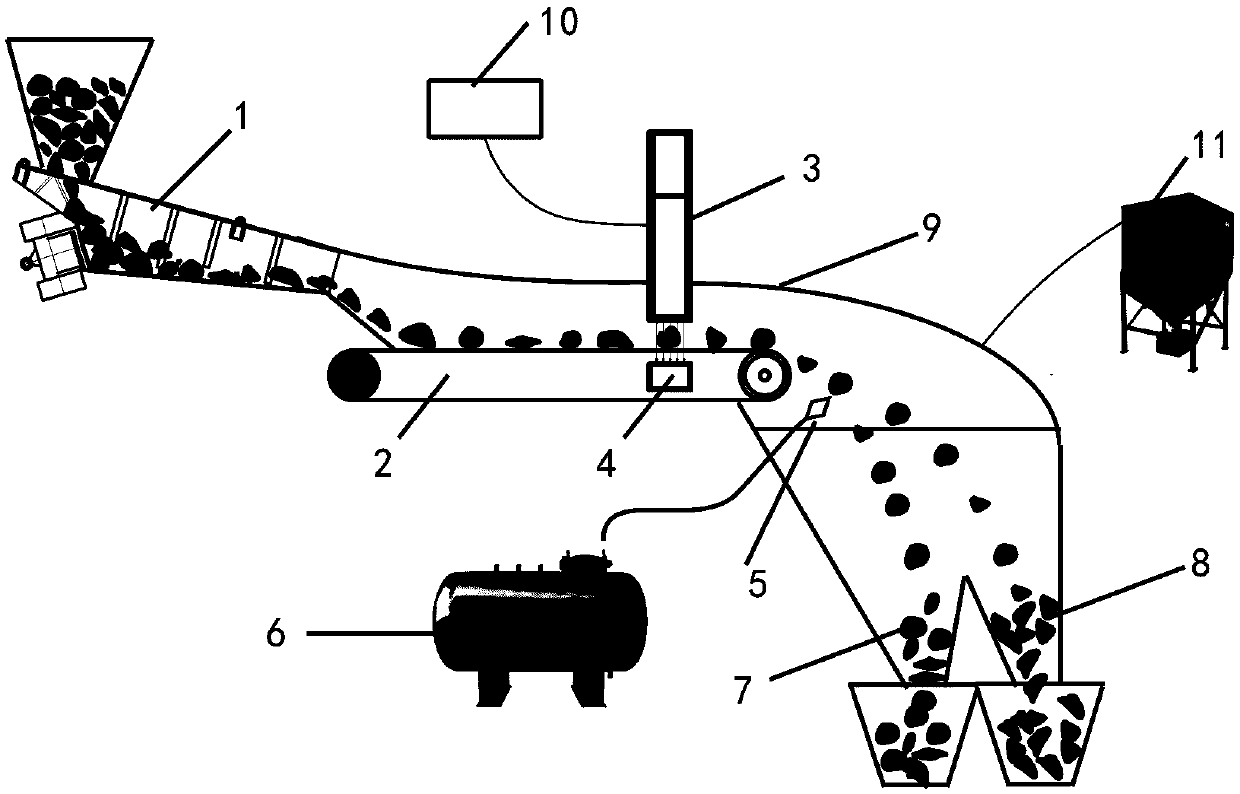

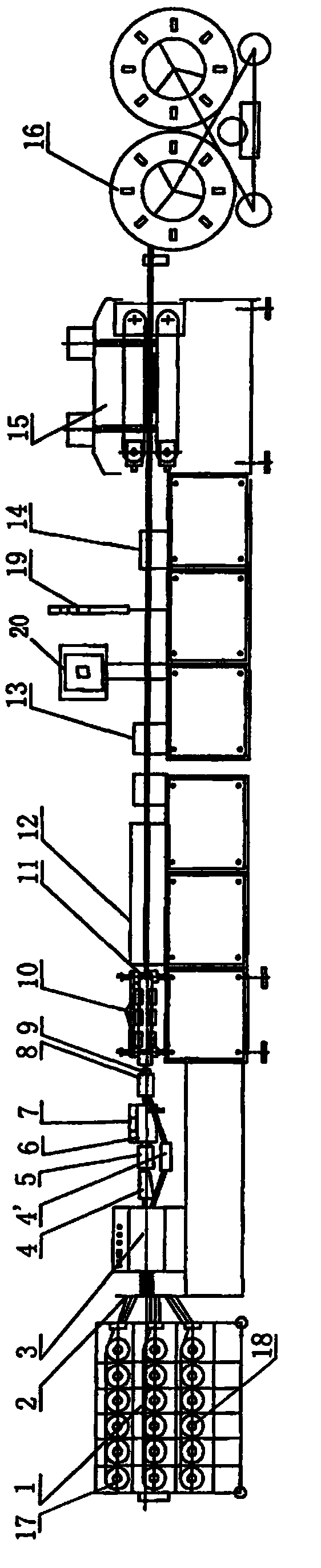

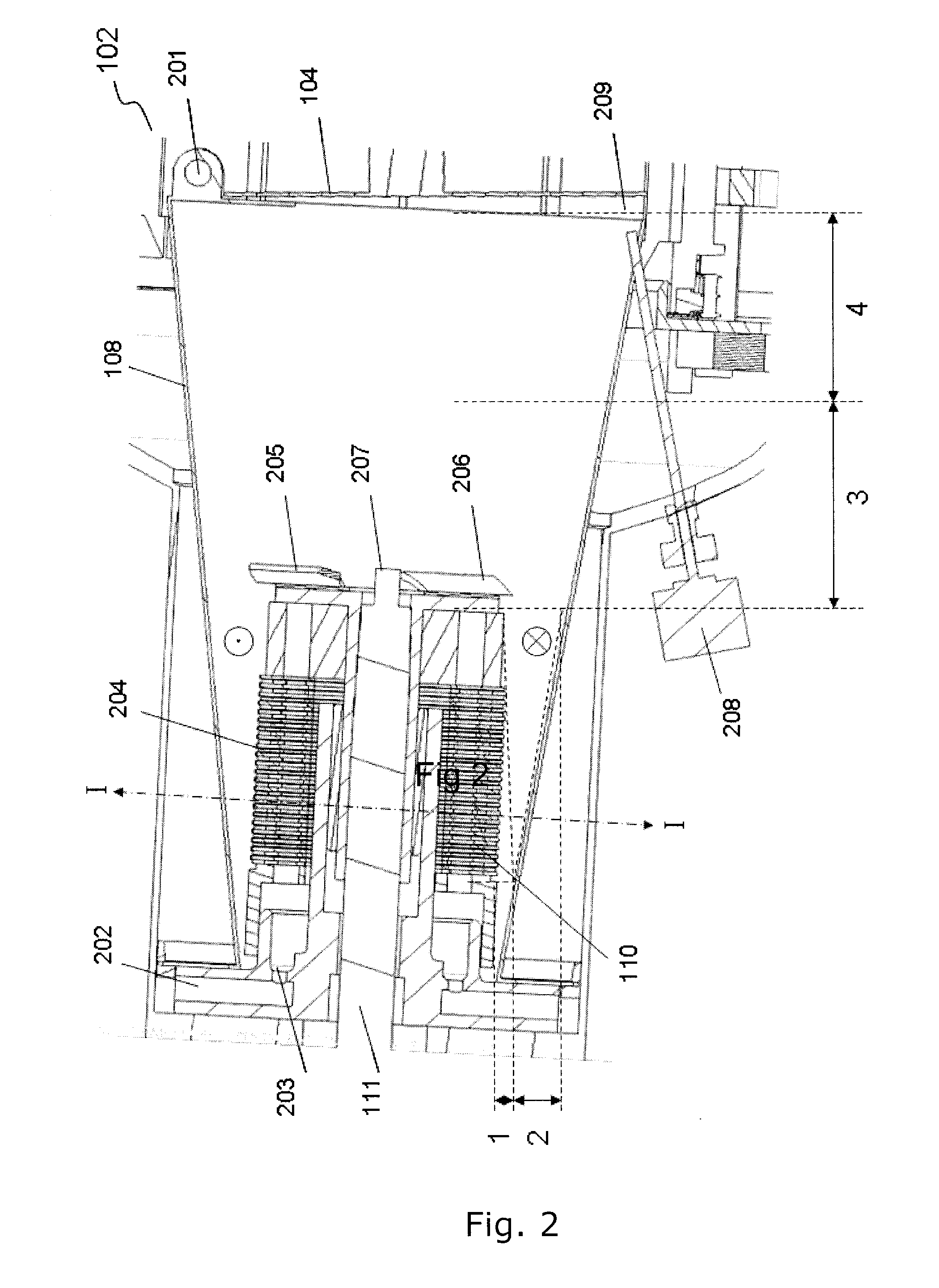

Telligent dry separator (TDS)

InactiveCN105499154AReduce in quantityLess-associative articulation pointSortingDust controlElectric control

The invention discloses a telligent dry separator (TDS). The telligent dry separator is characterized in that an intelligent identification method is adopted for establishing corresponding analysis models according to different characteristics of coal quality, through big data analysis, digitalized identification is conducted on coal and gangue, and finally the gangue is discharged through an intelligent execution system. The telligent dry separator (TDS) comprises four major systems, namely a feeding system, a material distribution system, an identification device and an execution mechanism, and three auxiliary systems, namely an air supplying system, a dedusting system and an electric control system. By means of the telligent dry separator (TDS), separation precision can be improved, the lower separation limit can be further lowered, and a condition is created for achieving the effect that all block raw materials ranging from 3mm to 300 mm adopt the intelligent dry separation process. Compared with traditional cleaning equipment, the telligent dry separator (TDS) has the advantages that on the aspect of construction investment, a system can be simplified, investment can be reduced, and the construction period can be shortened; on the aspect of separation effects, precision can be guaranteed, the heat value can be raised, and no coal slime is generated; on the aspect of production cost, consumption can be lowered, maintenance can be reduced, and manual work can be decreased.

Owner:TIANJIN MEITENG TECH CO LTD

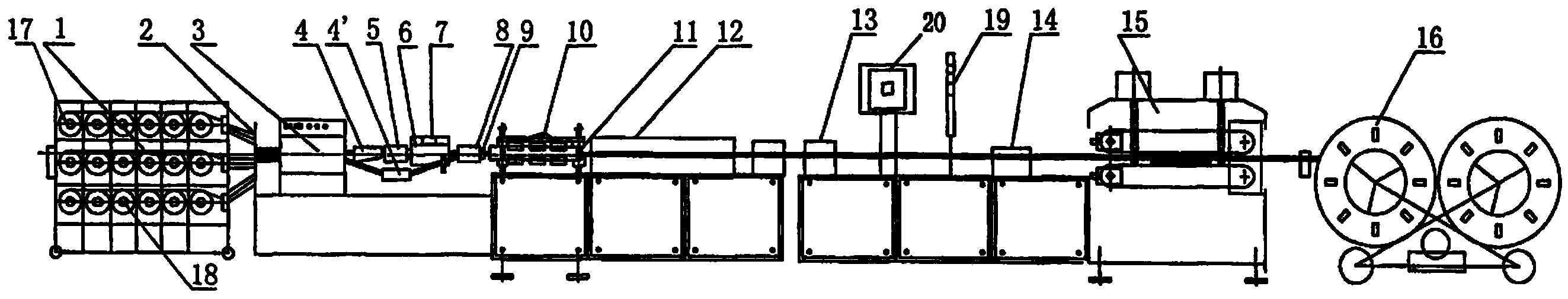

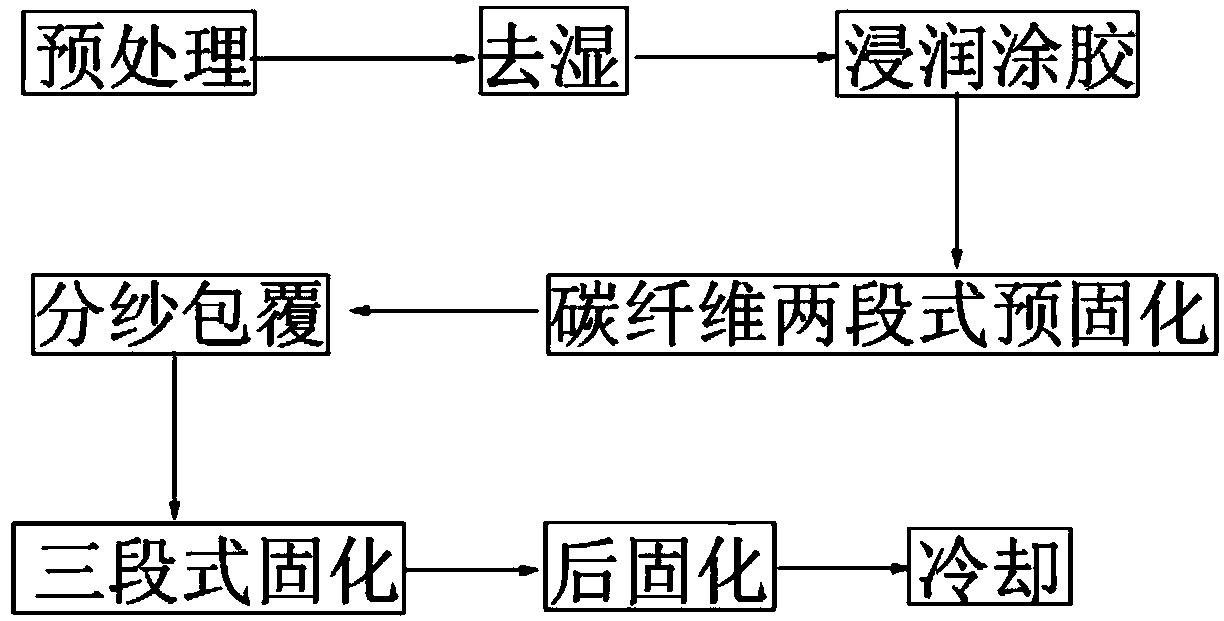

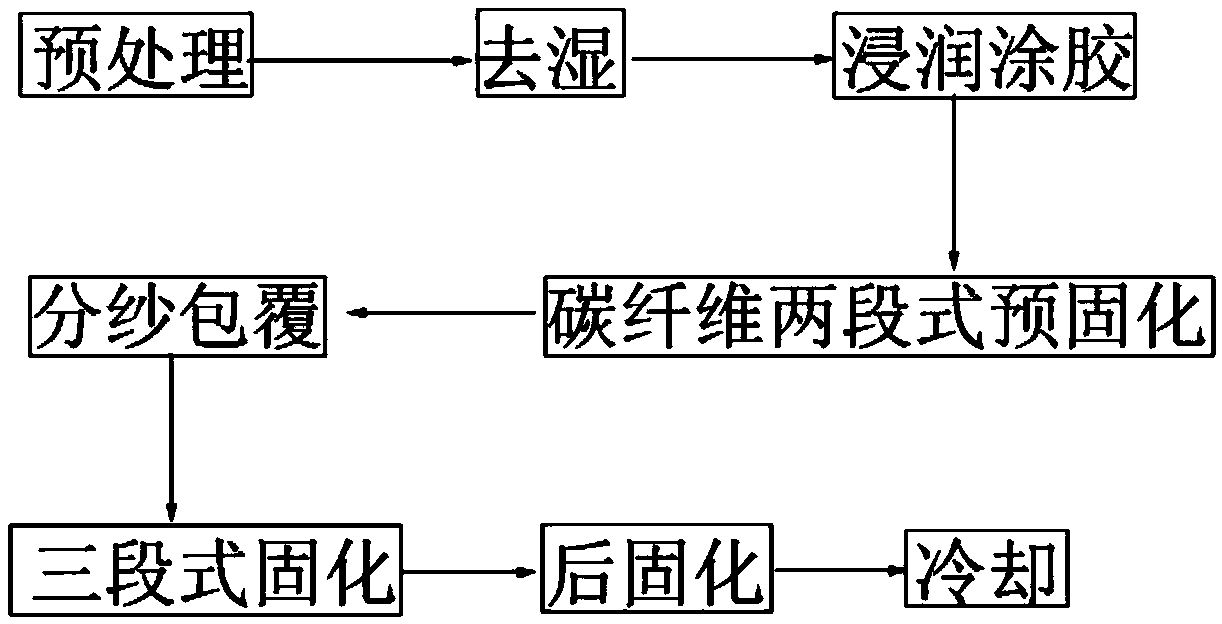

Electric transmission line carbon fiber composite core manufacturing method

InactiveCN103413629AImprove conductivityImprove performanceCable/conductor manufactureElectric power transmissionBasalt fiber

An electric transmission line carbon fiber composite core manufacturing method mainly includes the following steps of conducting preprocessing, dehumidification and glue infiltration, pre-hardening carbon fibers in a two-section heating mode, enabling high-strength glass fibers or basalt fibers to cover a pre-hardened carbon fiber core according to certain rules, hardening the carbon fiber core covered by the high-strength glass fibers or the basalt fibers in a three-section mode, and conducting post curing and cooling, wherein consumed epoxy resin is high-temperature-resistant special type pultrusion epoxy resin which is prepared by adding modified anhydride compounds in the glue infiltration process. The electric transmission line carbon fiber composite core manufacturing method has the advantages that the carbon fibers are preformed in a pultrusion mode to be in a semi-hardened state after being infiltrated, heating temperature sections are controlled so that the carbon fiber core with excellent performance can be obtained, particularly, heating and hardening are conducted in the three-section mode in the final covering and forming process, therefore, the rigidity of final products is ensured, the smoothness of production and production efficiency are improved, and the carbon fiber composite core produced through combination can completely meet the requirements of electric power transmission.

Owner:SUZHOU SUYUE NEW MATERIAL

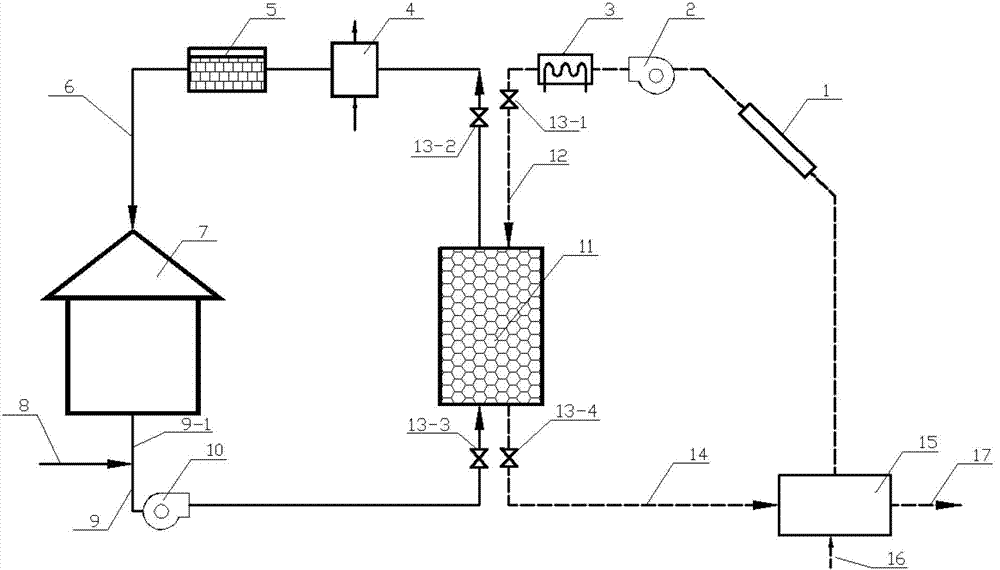

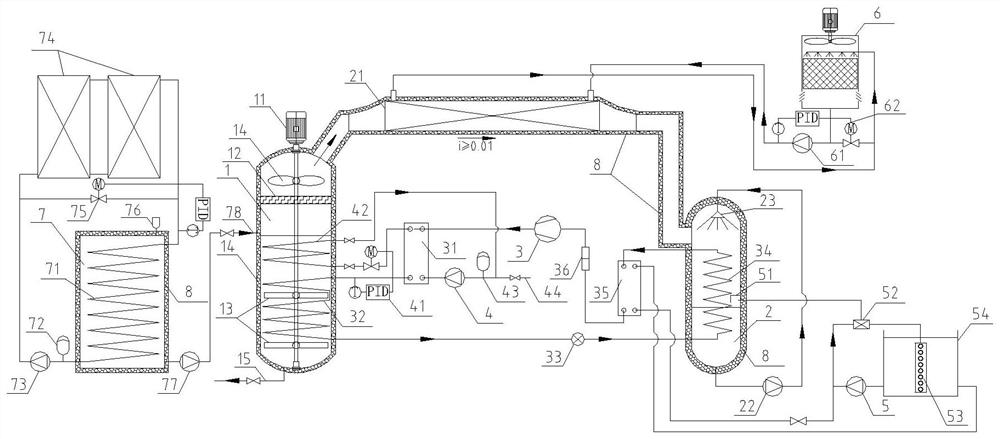

Energy-saving heat supply system for decreasing temperature of heating return water and recovering waste heat of thermal power plant

InactiveCN104197397AImprove energy efficiencyImprove heating efficiencyCentral heating with accumulated heatLighting and heating apparatusCogenerationDirect combustion

The invention relates to an energy-saving heat supply system for decreasing temperature of heating return water and recovering waste heat of thermal power plant and aims to solve the problems such that waste heat of a cooling column in a power plant cannot be fully utilized, and energy for direct combustion of coal and natural gas is greatly wasted. According to the system, the waste heat of the cooling column in the power plant is recovered, return heat of a heating primary network is borrowed, and energy saving is significantly effective. An absorbing heat pump is driven to work by combustion of coal or natural gas, heat in return water of a primary network of a combined heat and power generation heating pipeline is borrowed, heating area can be effectively enlarged, and the waste heat of the cooling column in the power plant is delivered to an urban heat network place. A temperature difference between supply and return waters is 108 DEG C, along with another temperature difference generated by electric power, and overall heating temperature difference is up to 160-180 DEG C. Delivery efficiency of a pipeline network is greatly improved, great significance to continuously increasing urban energy conservation is achieved, and related cyclic energy consumption of the primary network is decreased to less than one fourth of the original consumption.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

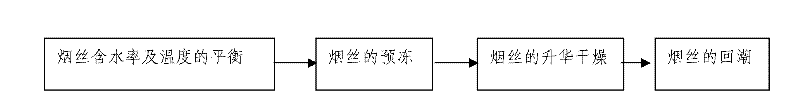

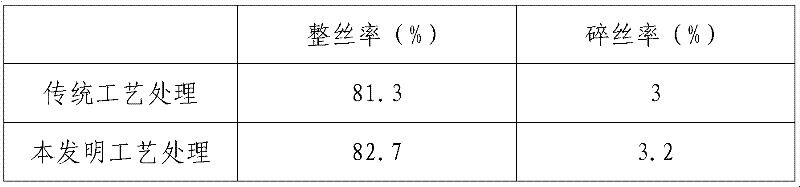

Tobacco shred drying method

InactiveCN102511913AGood quality characteristicsImprove stabilityTobacco preparationDrying timeVacuum chamber

The invention discloses a tobacco shred drying method. The moisture content of cut tobacco shreds is balanced to 20-24%, and the temperature is balanced to 10-30 DEG C. The balanced tobacco shreds are quickly frozen to be under the temperature of -40 DEG C to -35 DEG C at a cooling rate of -0.06 DEG C / min to -1.0 DEG C / min and maintained for 1-4 hours. Pre-frozen tobacco shreds are placed into a vacuum chamber to be dried, wherein absolute pressure in the vacuum chamber is 50-70 Pa, the temperature of a heating plate is 20-40 DEG C, and drying time is 0.5-4 hours. Finally, the moisture content of tobacco shreds is regained to 11-13%. By means of the method, quality characteristics and original shape of raw materials can be maintained well, and the phenomena including surface hardening, fragrance loss and the like caused by surface precipitation of soluble matter contained in the tobacco shreds are avoided. The method is simple and low in energy consumption, can improve smoking quality of the tobacco shreds remarkably, and has good application prospect.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

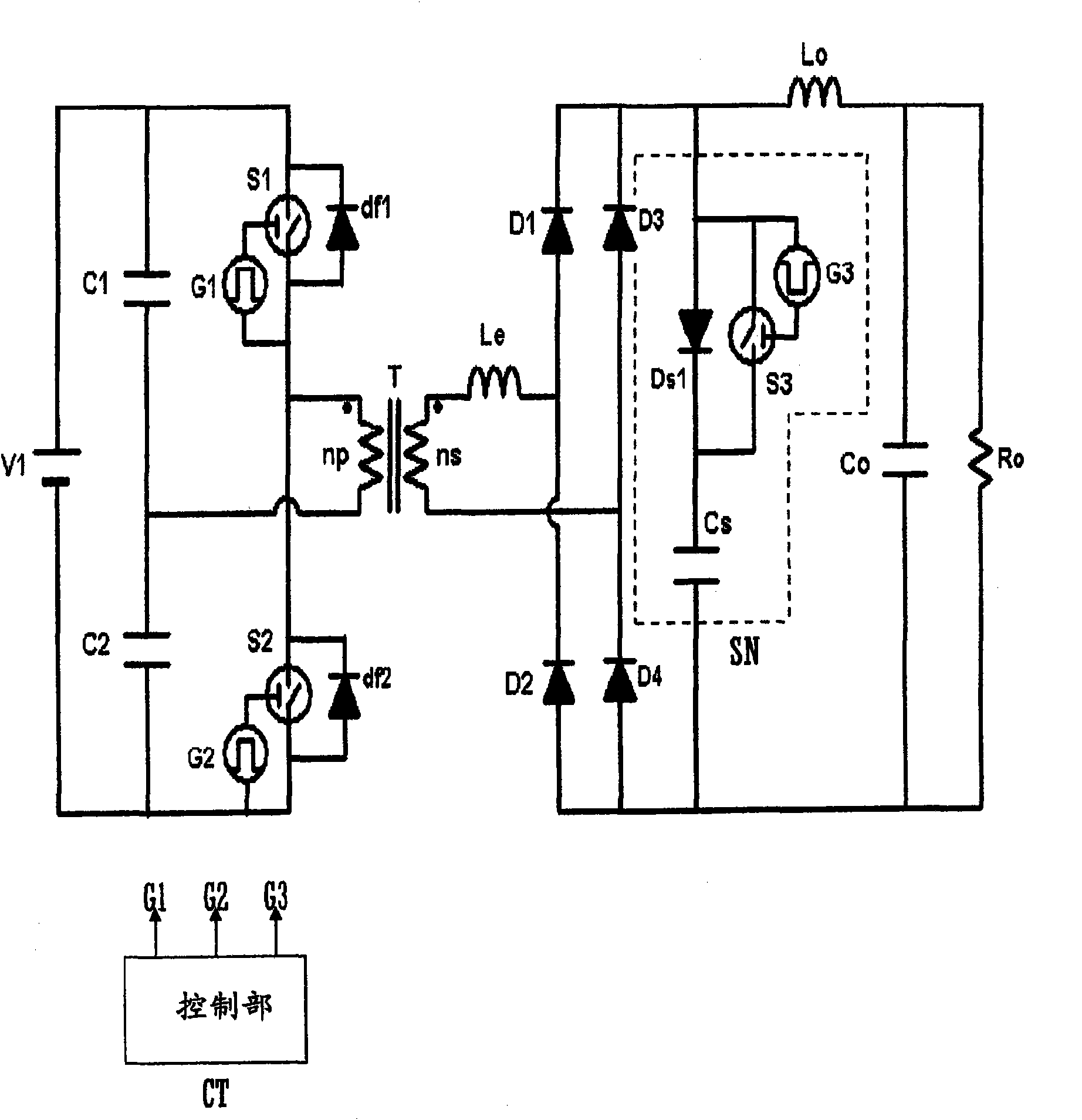

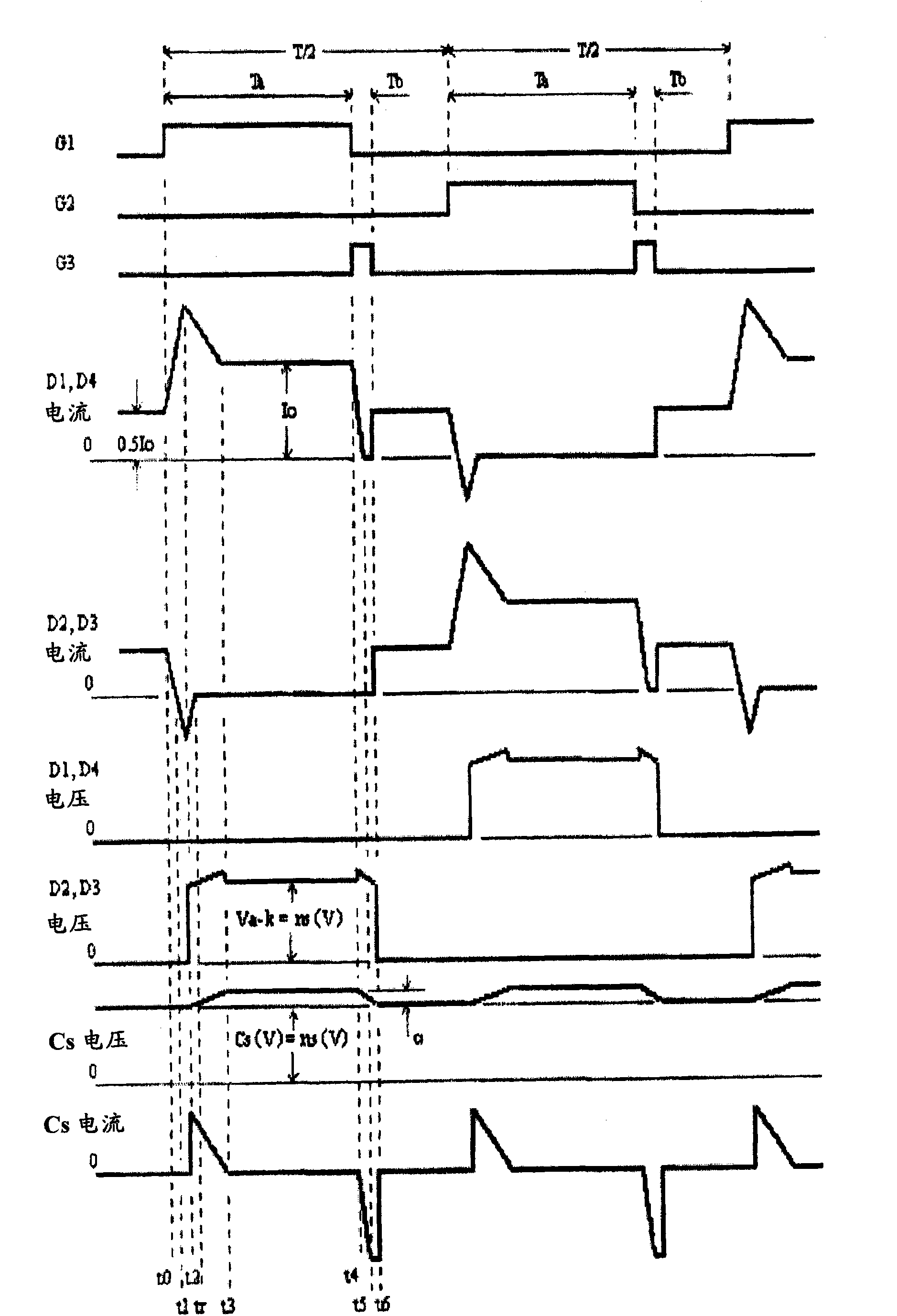

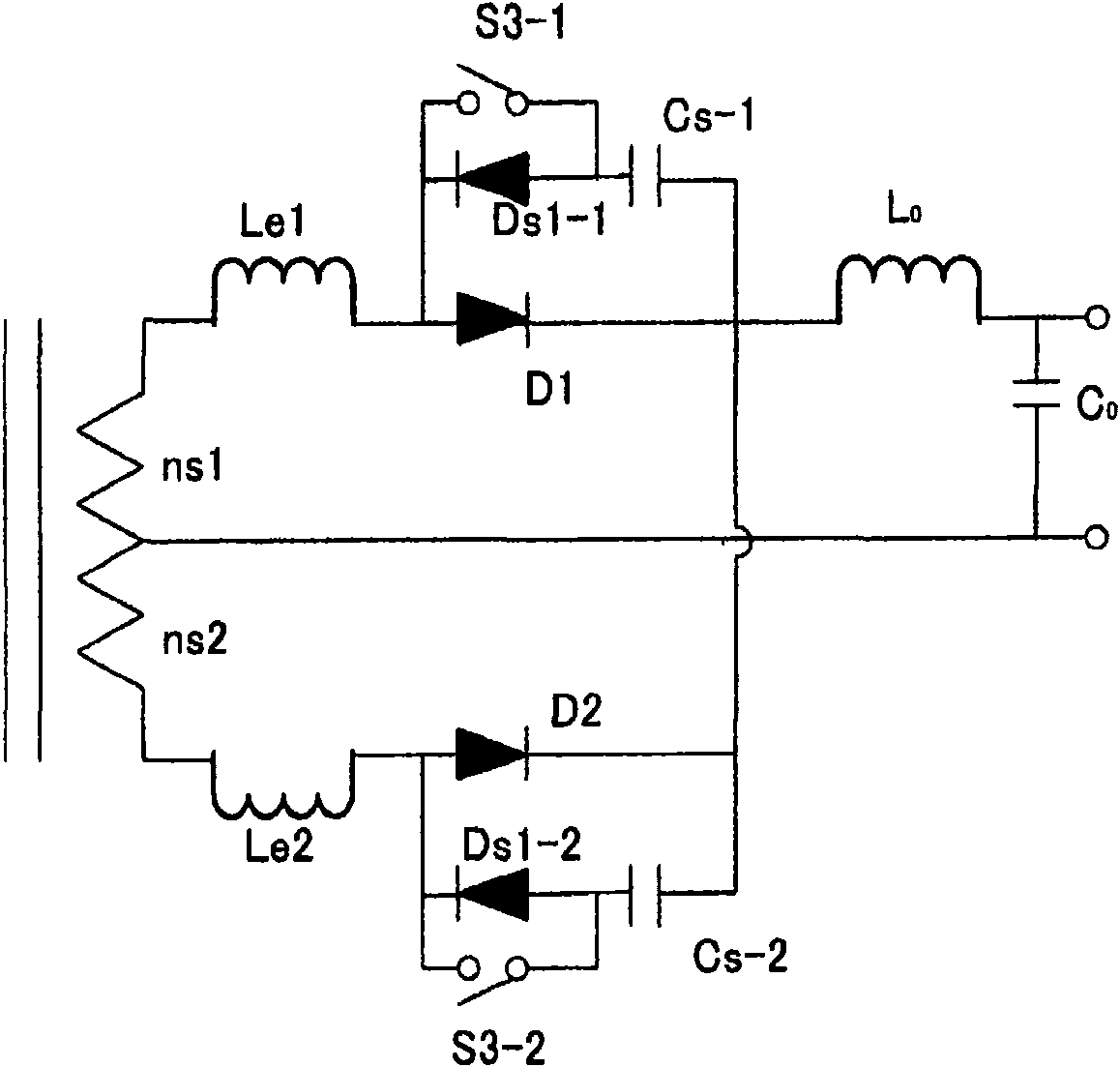

Dc-dc converter circuit

ActiveCN101842971ANo heat lossImprove efficiencyEfficient power electronics conversionApparatus with intermediate ac conversionSnubber capacitorDc dc converter

A DC-DC converter circuit comprises a switching circuit for switching a DC power supply with a primary switch element, a transformer having primary winding to which the output from the switching circuit is applied and secondary winding for outputting a voltage transformed at a predetermined transformation ratio, and a secondary diode for rectification connected with the secondary winding of the transformer. The circuit further comprises a regenerative snubber circuit, which is connected between the rectification outputs of the secondary diode and includes a series circuit of a discharge prevention diode and a snubber capacitor and a switch element for regeneration connected in parallel with the discharge prevention diode, and a control section for turning on the switch element for regeneration for a predetermined time from the off timing of the primary switching element. The predetermined time is set to a time for substantially discharging the snubber capacitor due to a reverse recovery time when the secondary diode is turned off.

Owner:SANSHA ELECTRIC MFG

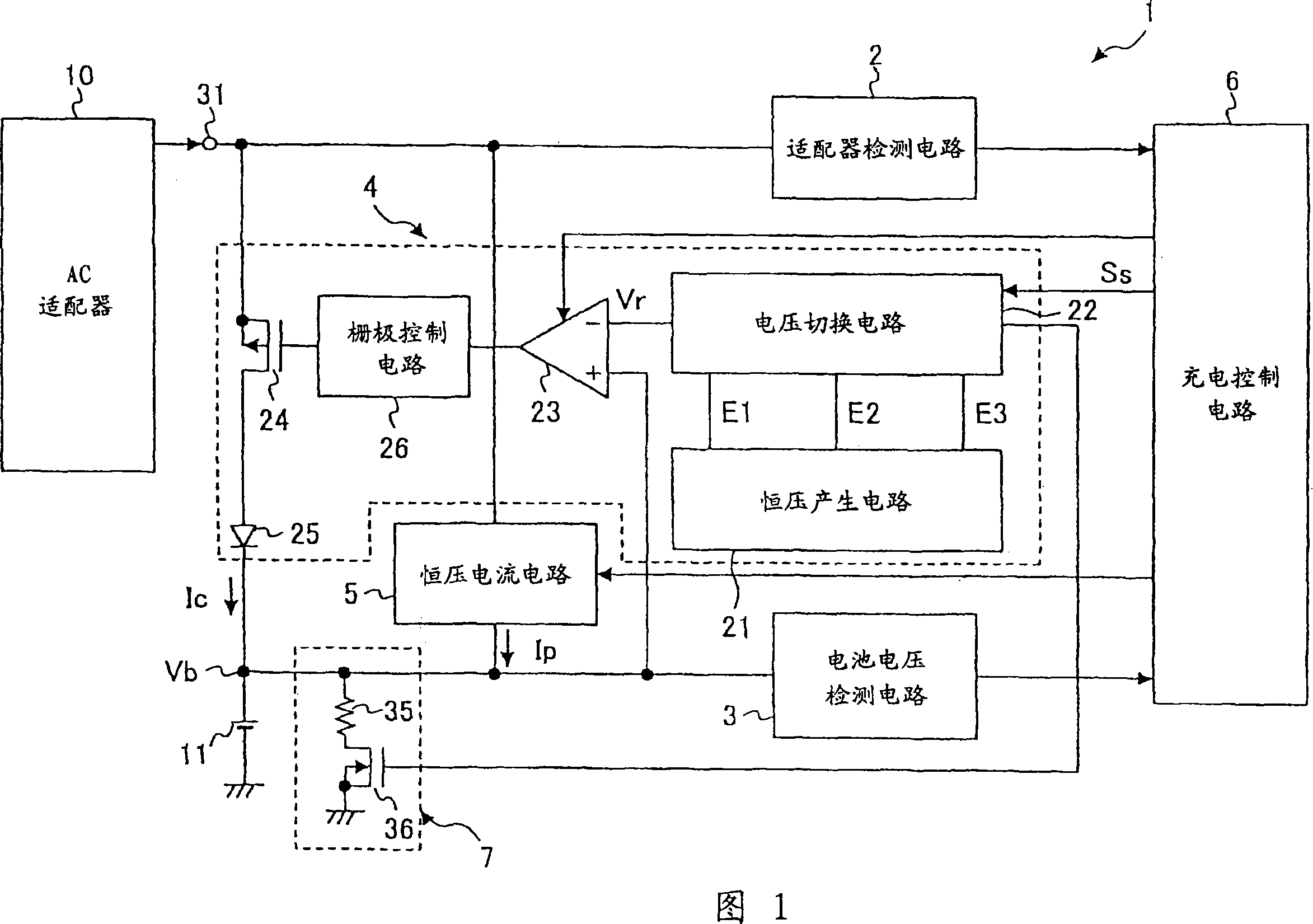

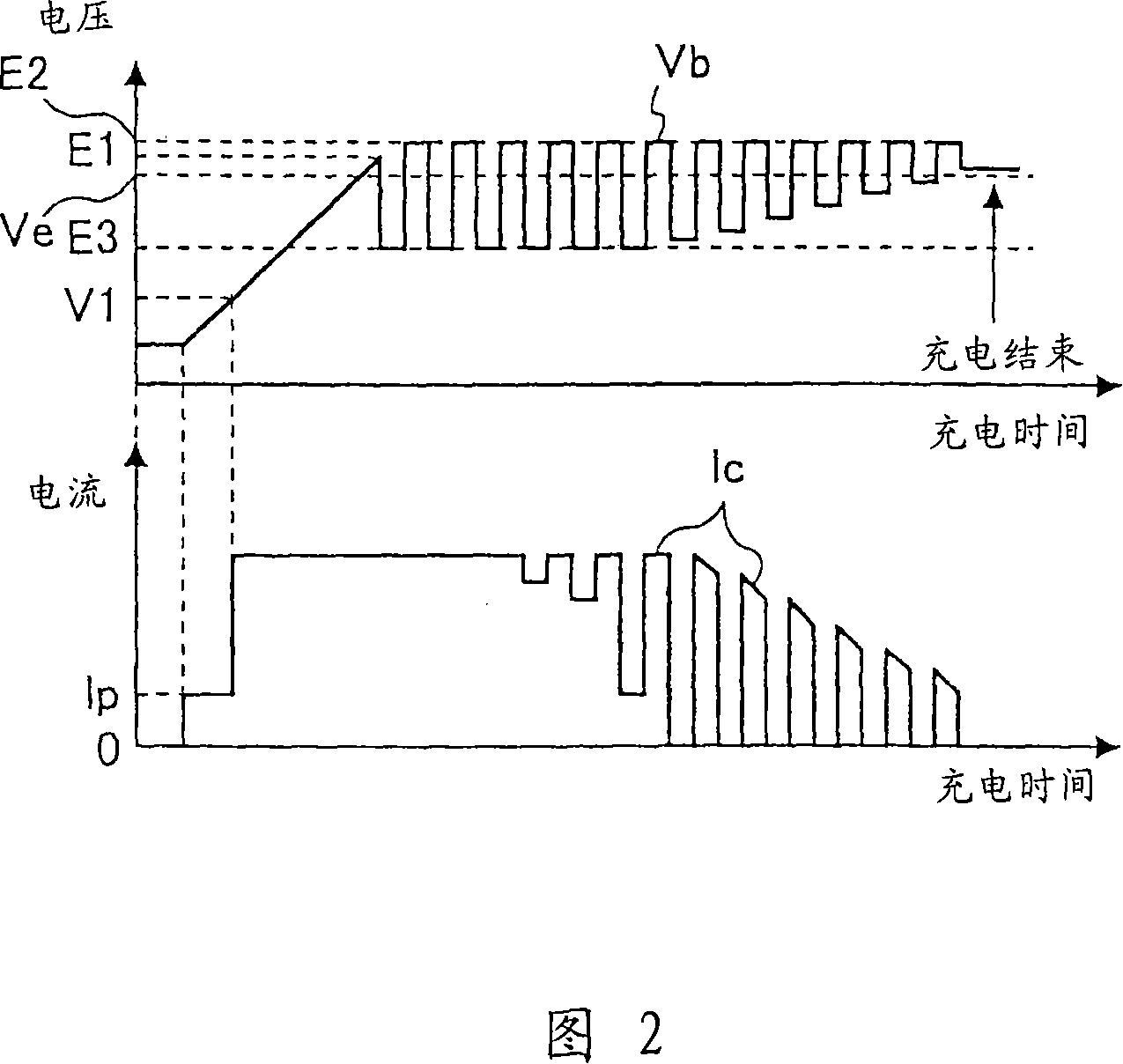

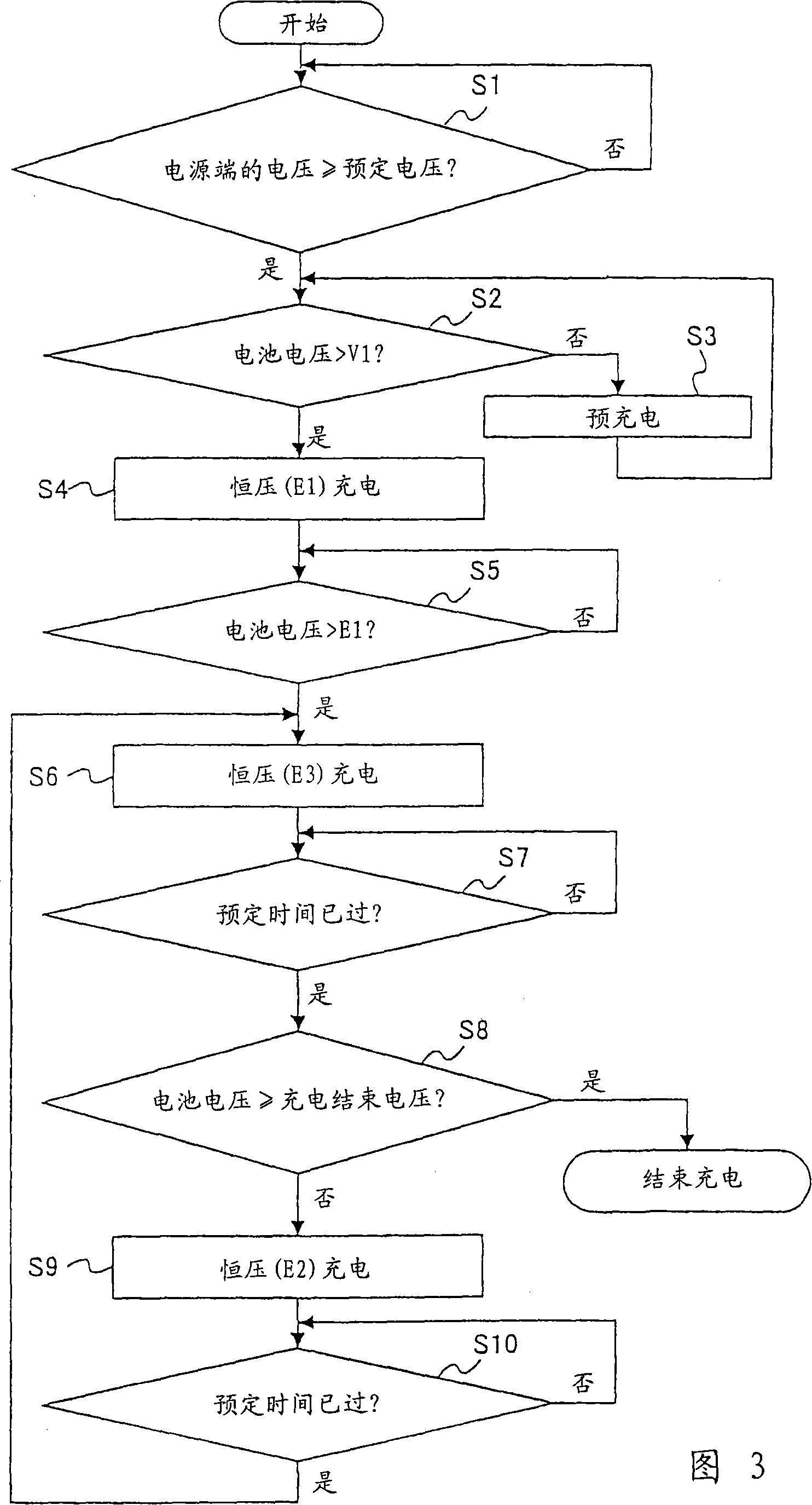

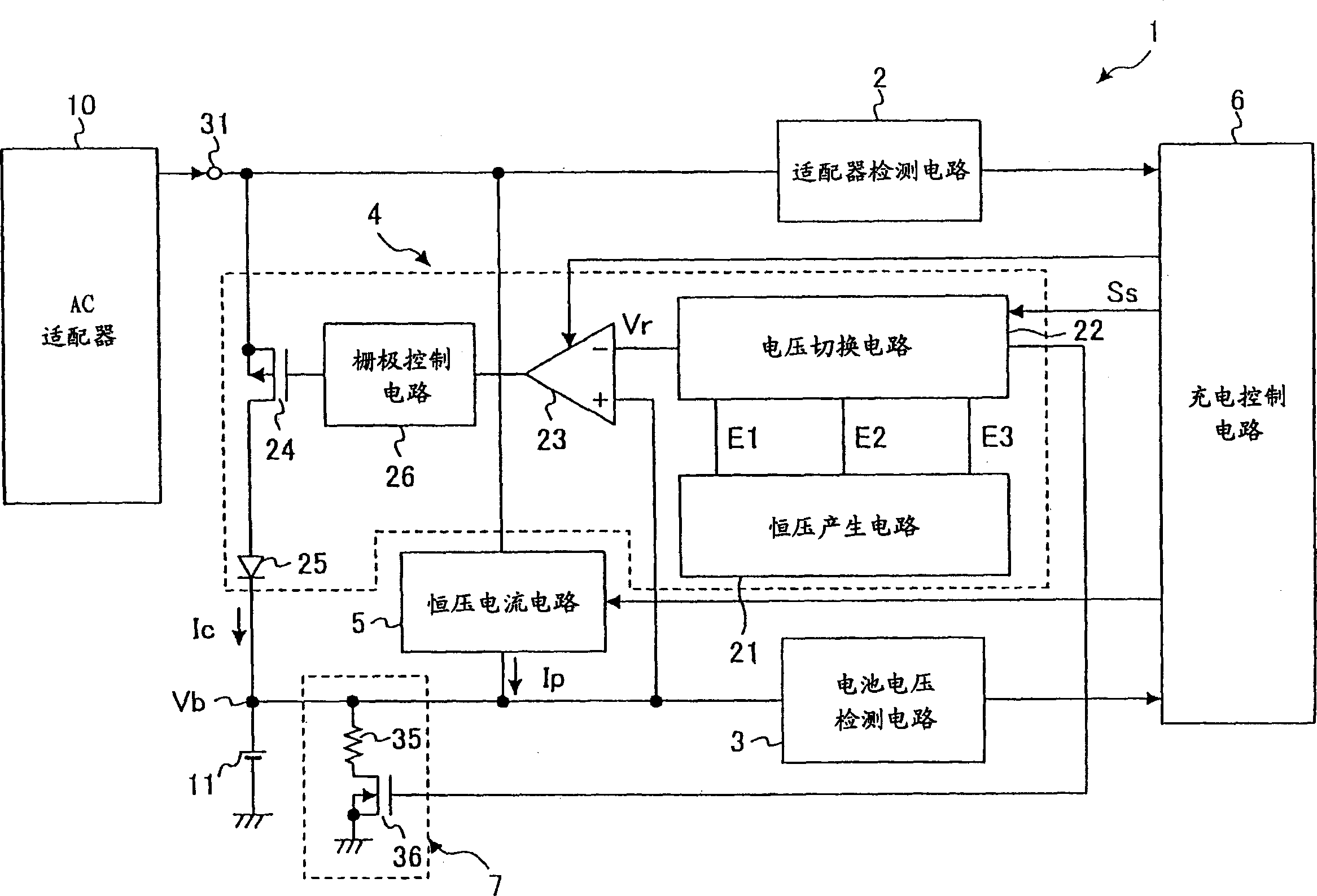

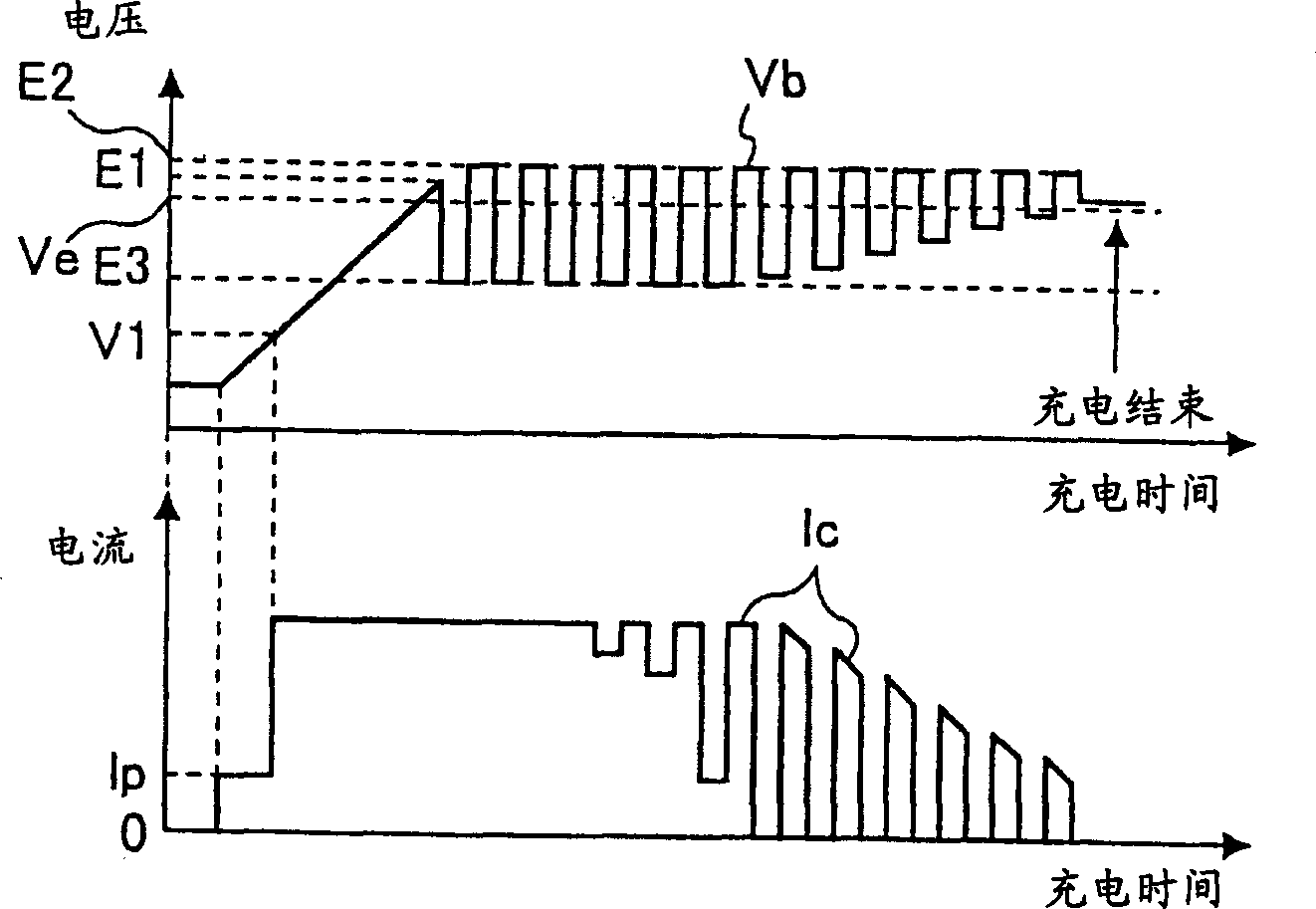

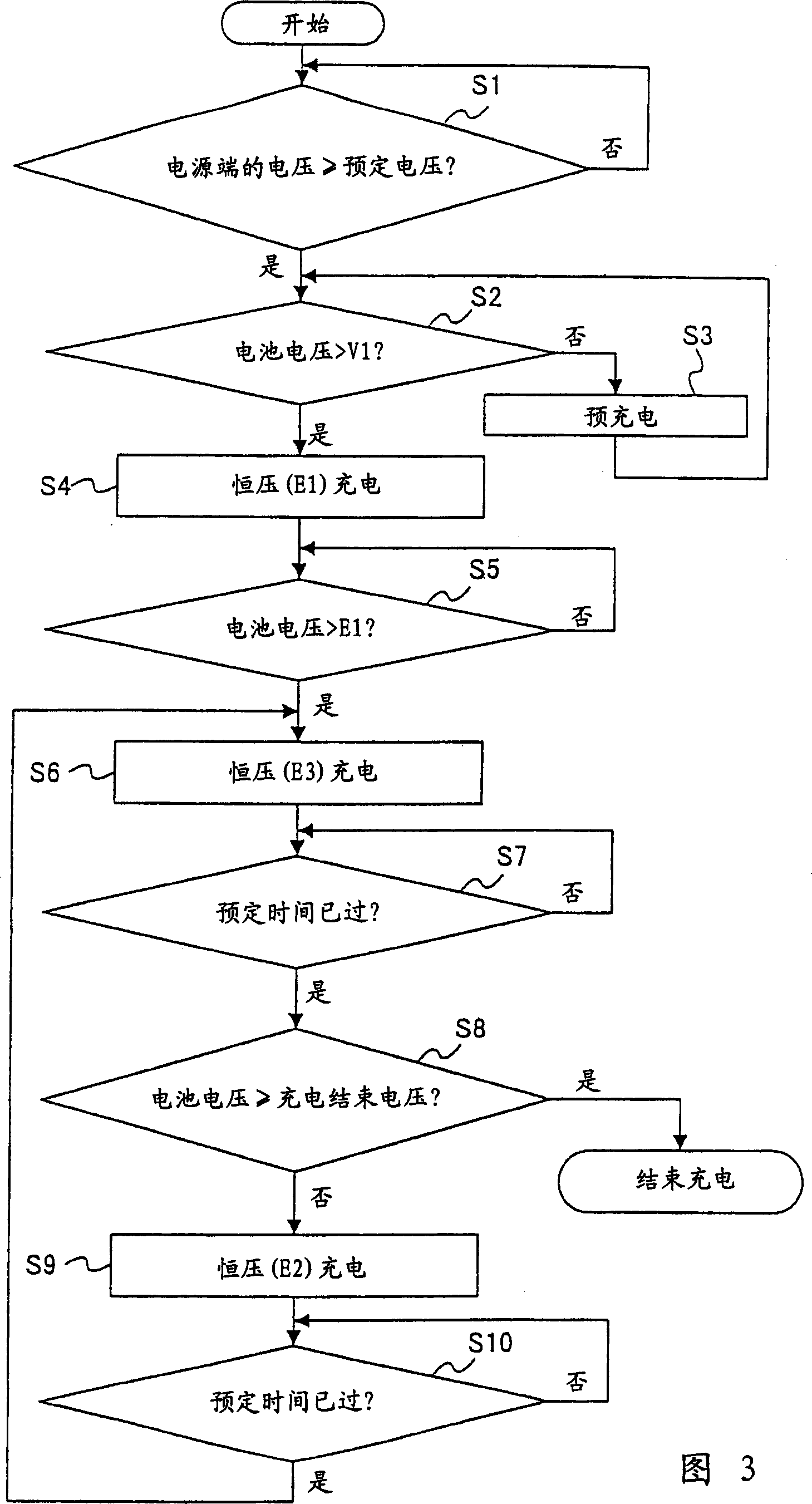

Charging circuit for secondary battery

InactiveCN101123365ANo heat lossNo energy lossBatteries circuit arrangementsSecondary cells charging/dischargingCharge currentCharge control

A charging circuit for a secondary battery includes a constant-voltage circuit part outputting one of a plurality of predetermined constant voltages and charges the secondary battery by applying the constant voltage thereto, a detection circuit part detecting a battery voltage of the secondary battery, and a control circuit part controlling the selection of the constant-voltage in response to the detected battery voltage. Another charging circuit includes a constant-current circuit part outputting, to the secondary battery, one of two predetermined constant currents, a constant-voltage circuit part charging the secondary battery by applying a predetermined constant voltage thereto, a battery voltage detection circuit part detecting a battery voltage of the secondary battery, a charge current detection circuit part outputting a predetermined charge completion signal, and a charge control circuit part stopping operations of the constant-current circuit part and constant-voltage circuit part when receiving the charge completion signal.

Owner:RICOH KK

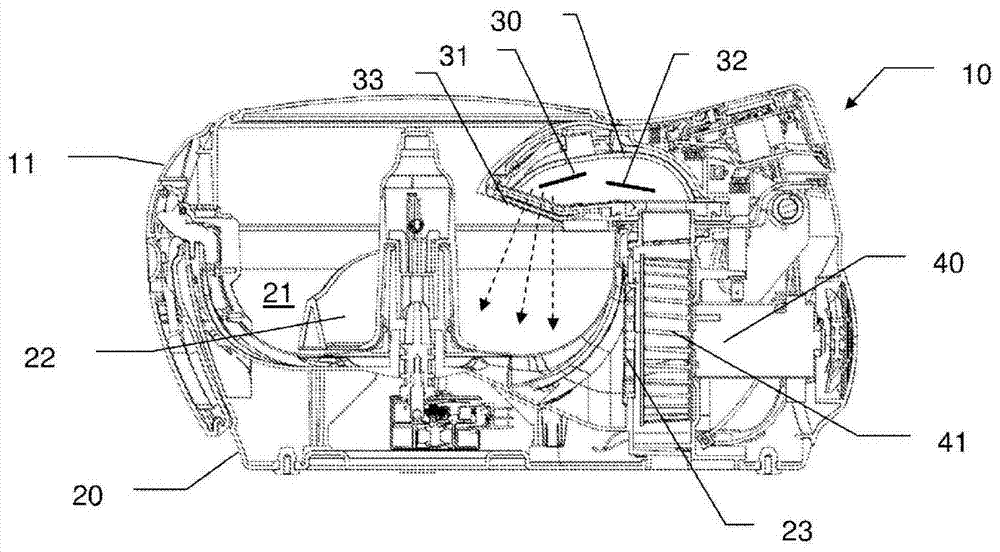

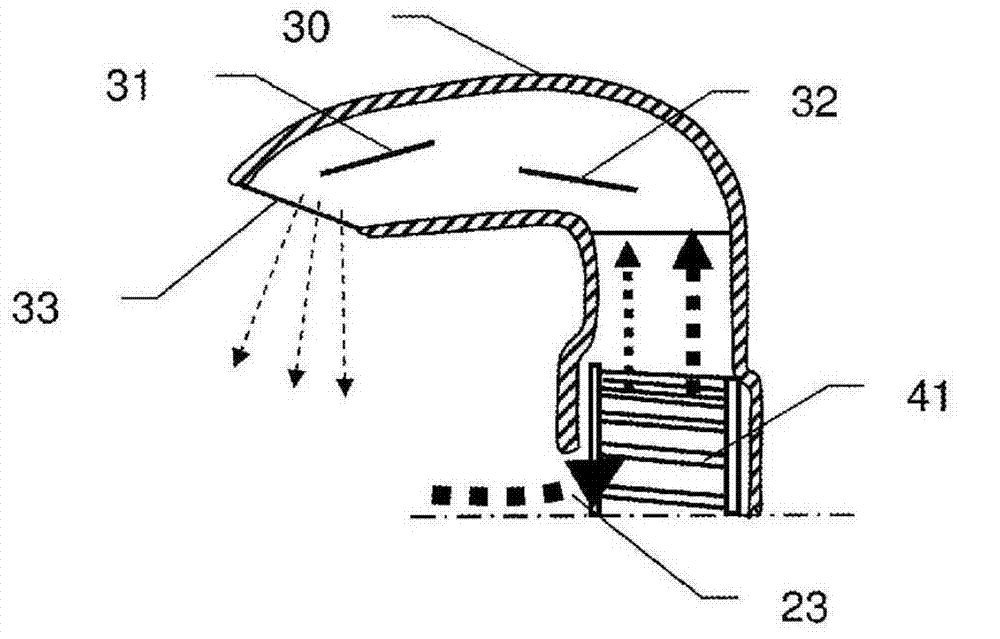

Electric cooking apparatus having an air flow

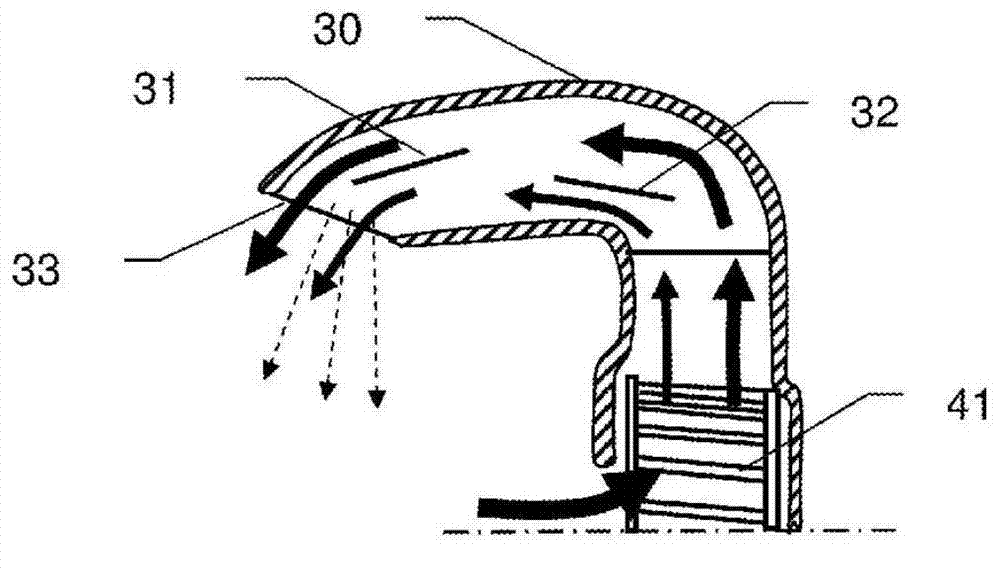

ActiveCN104736025AReduce cooking timeNo heat lossDomestic stoves or rangesLighting and heating apparatusElectricityProcess engineering

The invention relates to an electric apparatus (10) for cooking and / or reheating food, including: a housing (20) having a cooking tray (21) arranged such as to receive the food to be cooked and / or reheated, a circuit for heating by ventilation, including a ventilation sleeve (30) having an outlet (33) arranged such as to direct an air flow onto the food to be cooked and / or reheated, and the heating means arranged in the ventilation sleeve (30) such as to heat the air flow by radiation and by convection, characterized in that at least a portion of the heating means is arranged relative to the outlet (33) of the ventilation sleeve (30) such that the heat radiation produced by said portion of the heating means directly heats the food to be cooked and / or reheated.

Owner:SEB SA

Electric dry oven capable of saving energy and reducing emission

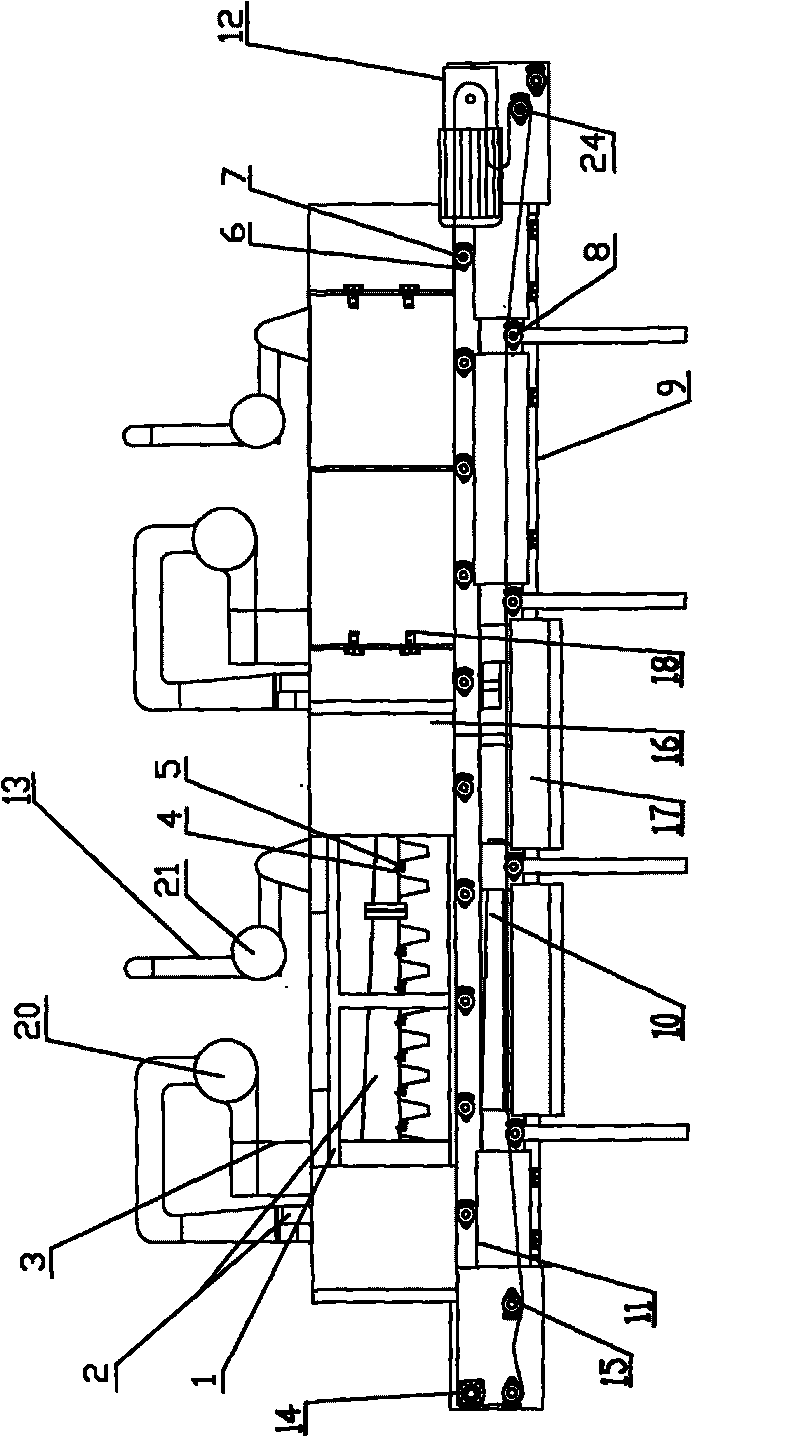

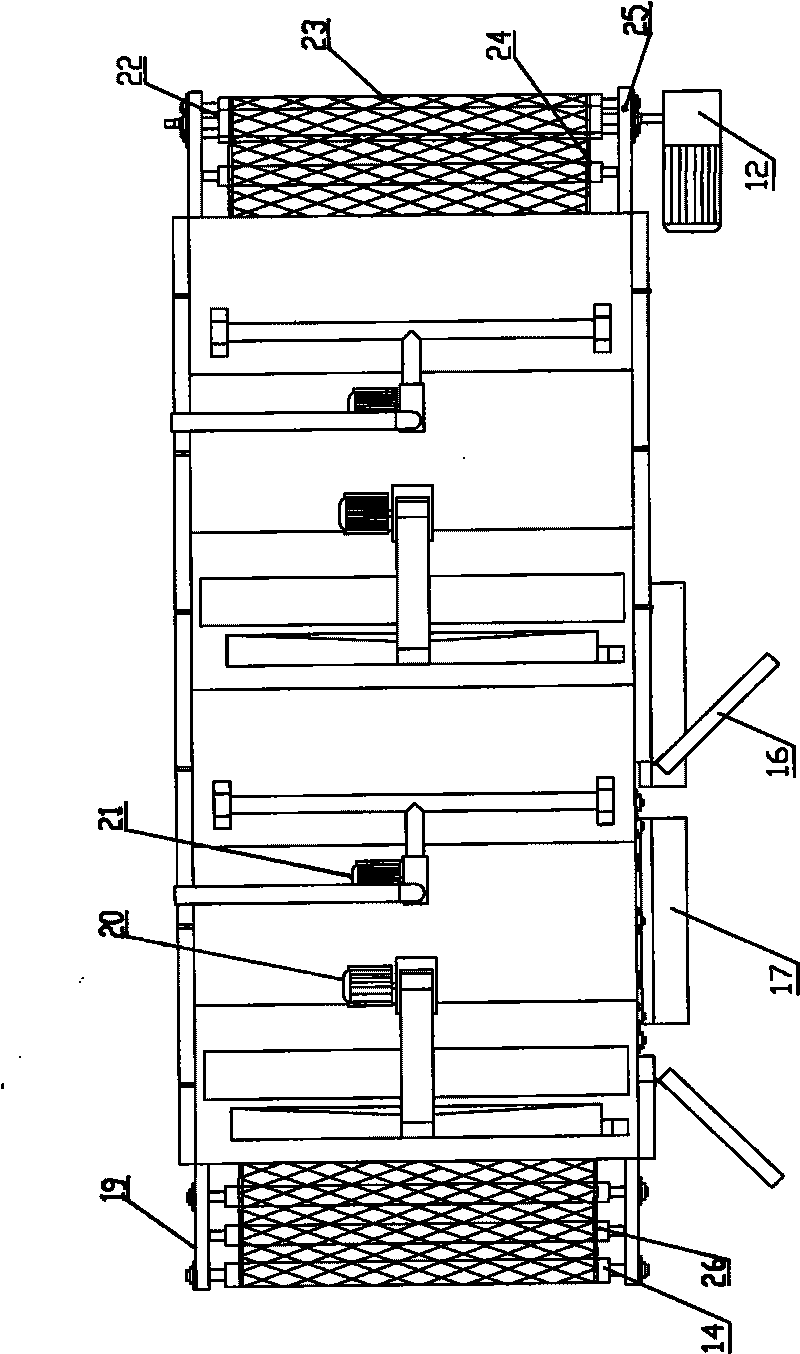

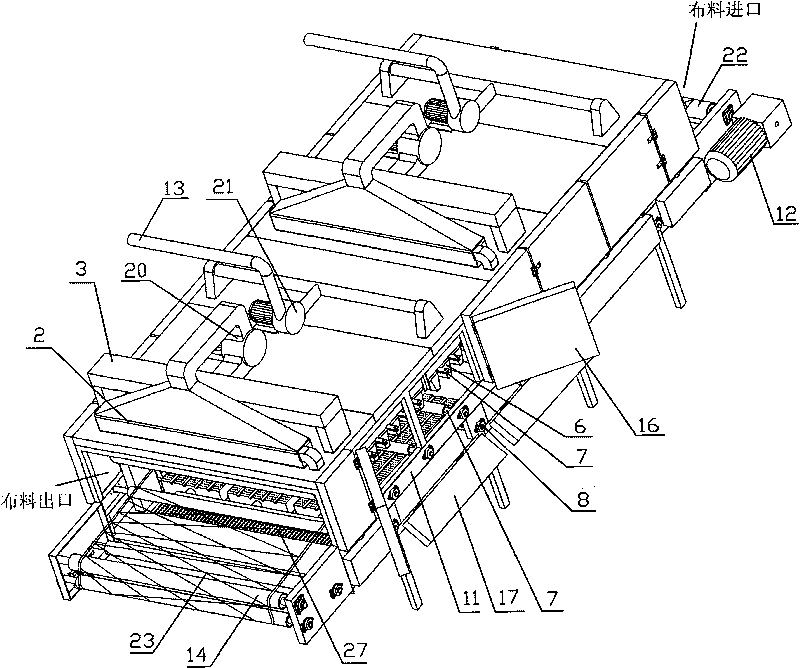

InactiveCN101706195AIdeal temperature controlIdeal energy savingDrying solid materials with heatDrying gas arrangementsElectricityEngineering

An electric dry oven capable of saving energy and reducing emission of the invention relates to a textile drying device used in the dyeing, coating, flocking and stretching production lines of the textile industry. The electric dry oven comprises an oven frame, a circulating fan, a circulating upper air duct, a circulating lower air duct, a circulating outtake, heating pipe clamps, medium-wave infrared radiation heating pipes, an upper tape guide roller, a lower tape guide roller, a bearing, needle board chain guide rails or mesh belts, a reduction electric motor, a carrier roller beam and an air outlet filter board, wherein a plurality of groups of the heating pipe clamps are arranged in the oven frame, a plurality of the medium-wave infrared radiation heating pipes are separately arranged at the heating pipe clamps, the needle board chain guide rails or mesh belts are arranged on a drive roller, a driven roller, the upper tape guide roller and the lower tape guide roller, one end of the lower part of the oven frame is provided with the reduction electric motor, the output shaft of the reduction electric motor is connected with the drive roller; the circulating upper air duct is arranged on the upper part of the inside of the oven frame, the circulating lower air duct is arranged on the lower part of the upper tape guide roller in the oven frame; and the circulating fan is arranged on the top of the oven frame and the air intake of the circulating fan is communicated with the circulating outtake on the top of the oven frame.

Owner:李丹

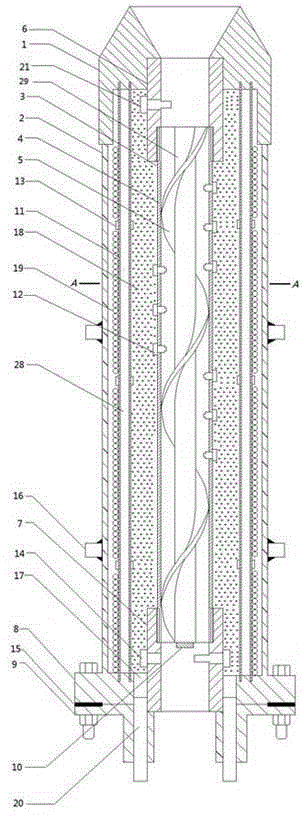

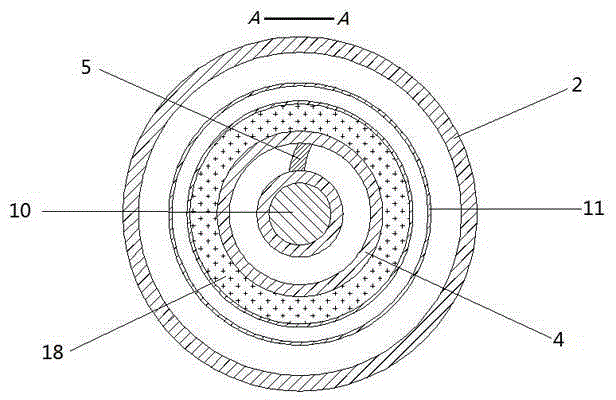

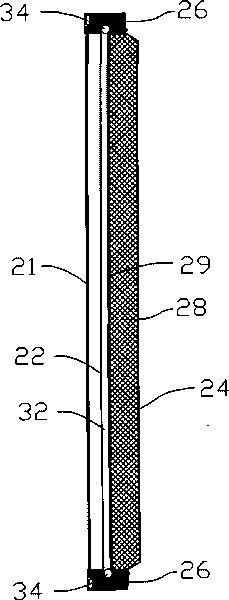

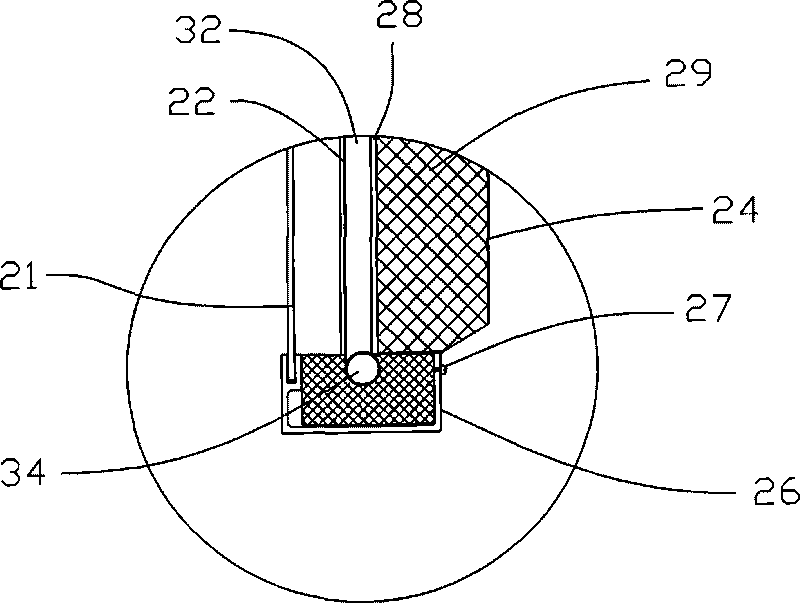

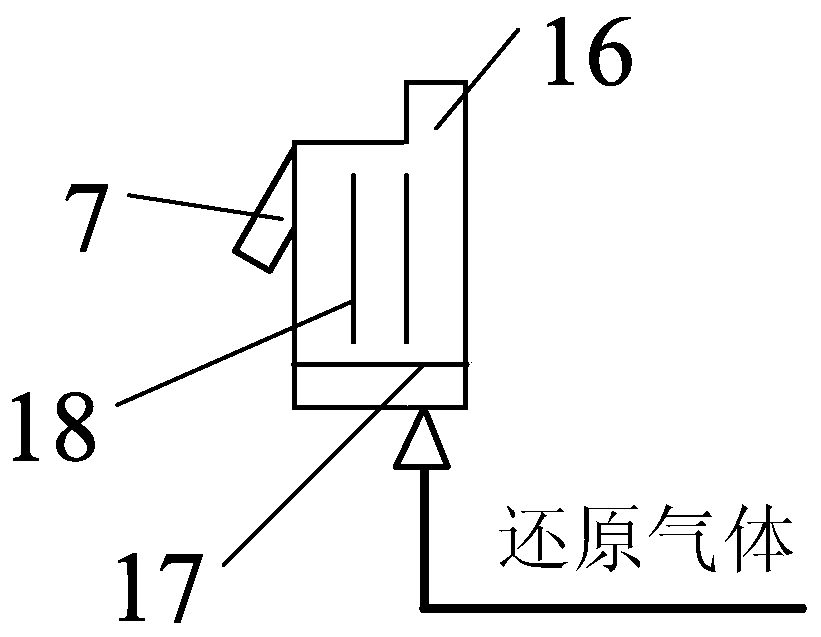

Soft measurement method based on variable-boundary segmentation energy balance, multifunctional wet steam measuring needle and wet steam heat absorption measurement and control device

ActiveCN103185735AGuaranteed absorptionNo heat lossMaterial heat developmentMaterial moisture contentElectricityProcess mechanism

The invention relates to a soft measurement method based on variable-boundary segmentation energy balance, a multifunctional wet steam measuring needle and a wet steam heat absorption measurement and control device. The multifunctional wet steam measuring needle is characterized by consisting of an electric heating rod, an electric heating rod sleeve with uniform and screw pitch-equal convex spiral ribs, a multifunctional wet steam measuring needle outer wall tube, a front sensor seat and a rear sensor seat. The wet steam heat absorption measurement and control device consists of an isothermal sleeve, temperature measuring points distributed on the inner wall and the outer wall of the isothermal sleeve at equal distances and computer online measurement and control equipment. The multifunctional wet steam measuring needle is put in the wet steam heat absorption measurement and control device and is wholly pressed and fixed by an outer sleeve, an outer sleeve flange cover and an outer sleeve flange disc; based on the flowing and heating process mechanism analysis of wet steam in the structure, a soft measurement model and an online calibration model of measurement results are established; and the whole equipment is simple in structure and is suitable for various measurement fields in relation to wet steam two-phase flow, in particular to the measurement of exhaust steam humidity of a condensing turbine.

Owner:杨善让

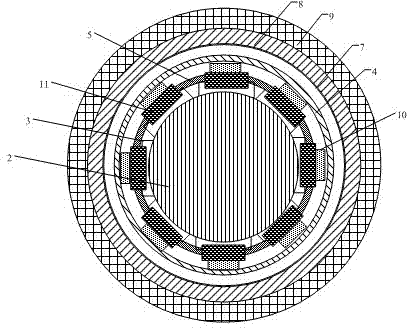

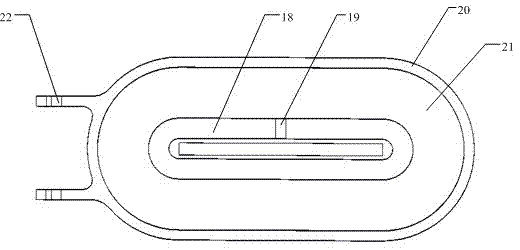

Offshore type superconducting wind power generator

ActiveCN102412640ALarge capacityReduce volumeMagnetic circuit rotating partsMagnetic circuit stationary partsElectrical resistance and conductanceElectric machine

The invention relates to an offshore type superconducting wind power generator which is suitable for offshore areas. The offshore type superconducting wind power generator comprises a stator system, a rotor system and a cooling system, wherein a rotor coil subassembly of the rotor system comprises a magnet framework, high-temperature superconducting coils and a coil fastening piece; the magnet framework is in an annular runway shape and the hollow part of the magnet framework is a refrigeration medium flow channel; an annular groove is arranged on the side face of the magnet framework and double layers of the high-temperature superconducting coils are wound through the groove and the outer parts of the high-temperature superconducting coils are provided with the coil fastening piece for preventing the high-temperature superconducting coils from being loosened outwards; meanwhile, one end of the coil fastening piece is provided with a current lead wire connector so as to enable the coil fastening piece to conveniently penetrate through a high-temperature superconducting current lead wire; and the cooling system is used for cooling the rotor system to realize the closed loop cooling work. The offshore type superconducting wind power generator provided by the invention has the advantages of high single-machine capacity, small volume and light weight, namely high power density; a rotor coil of the rotor system is made of the high-temperature superconducting material so that the rotor coil does not have resistance heating loss and the efficiency of a motor is high.

Owner:DONGFANG ELECTRIC CORP LTD

Charging circuit for secondary battery

InactiveCN1507686ANo heat lossNo energy lossBatteries circuit arrangementsElectric powerCharge currentCharge control

A charging circuit for a secondary battery includes a constant-voltage circuit part outputting one of a plurality of predetermined constant voltages and charges the secondary battery by applying the constant voltage thereto, a detection circuit part detecting a battery voltage of the secondary battery, and a control circuit part controlling the selection of the constant-voltage in response to the detected battery voltage. Another charging circuit includes a constant-current circuit part outputting, to the secondary battery, one of two predetermined constant currents, a constant-voltage circuit part charging the secondary battery by applying a predetermined constant voltage thereto, a battery voltage detection circuit part detecting a battery voltage of the secondary battery, a charge current detection circuit part outputting a predetermined charge completion signal, and a charge control circuit part stopping operations of the constant-current circuit part and constant-voltage circuit part when receiving the charge completion signal.

Owner:RICOH KK

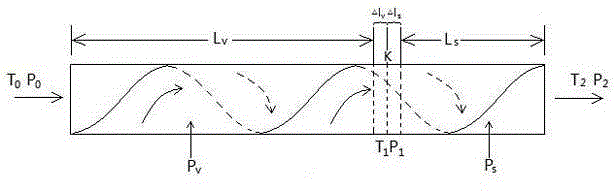

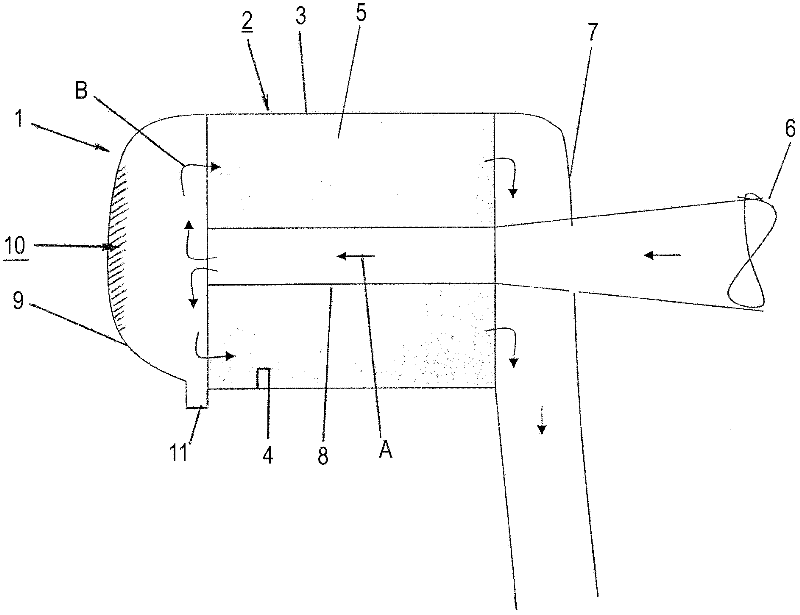

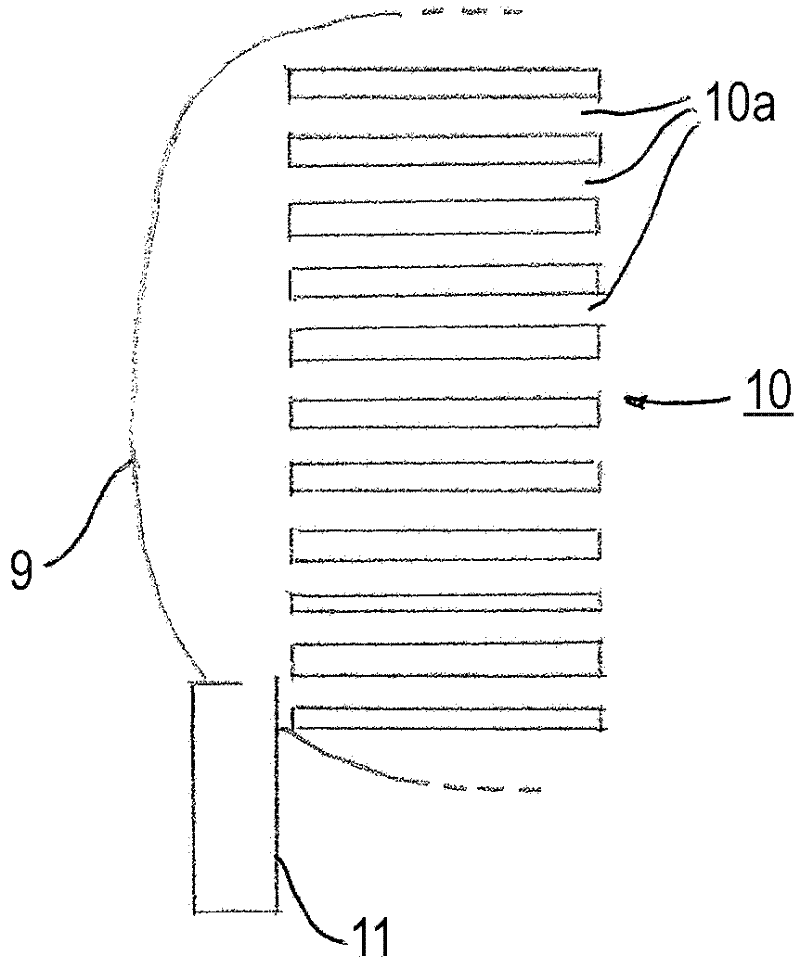

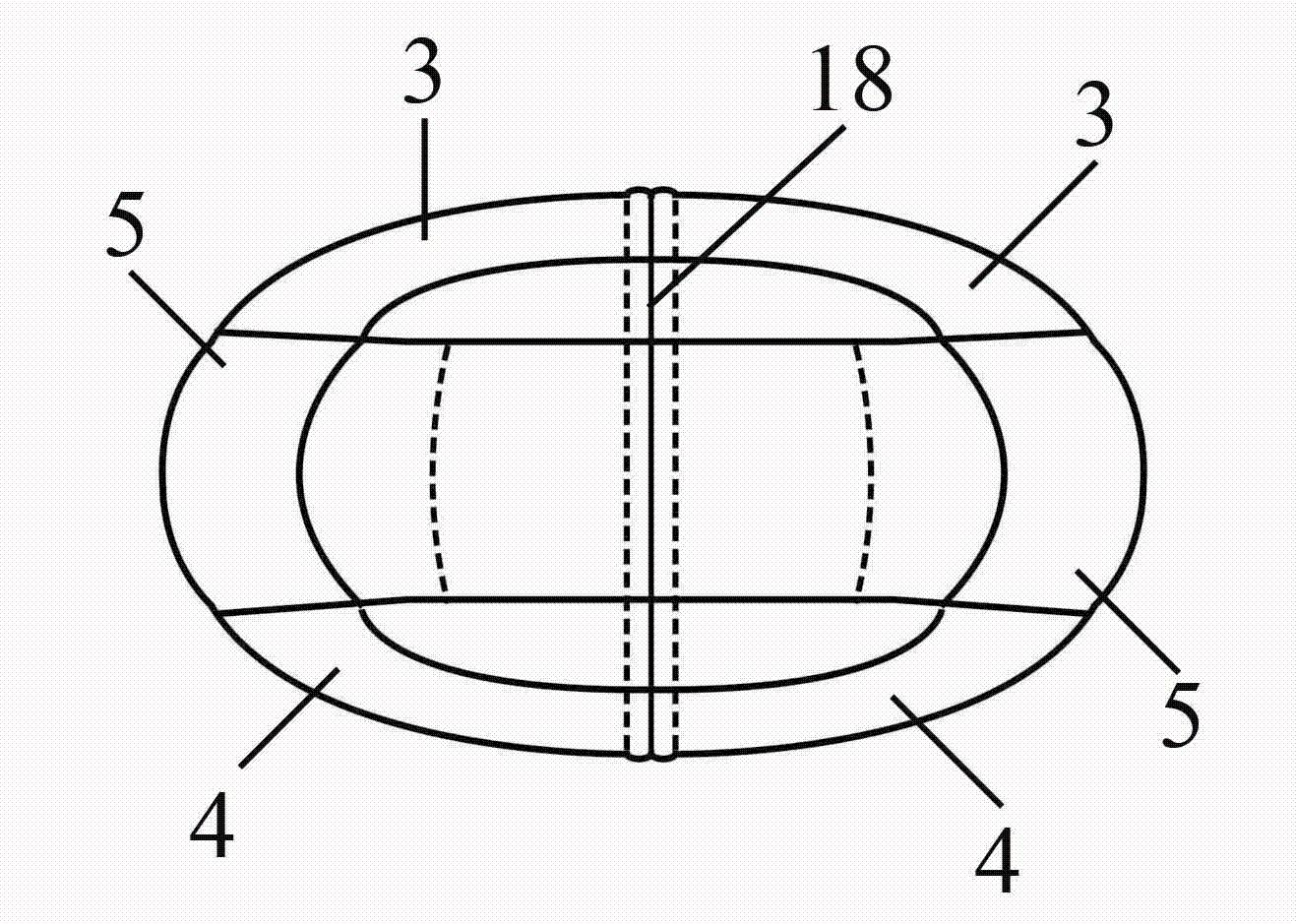

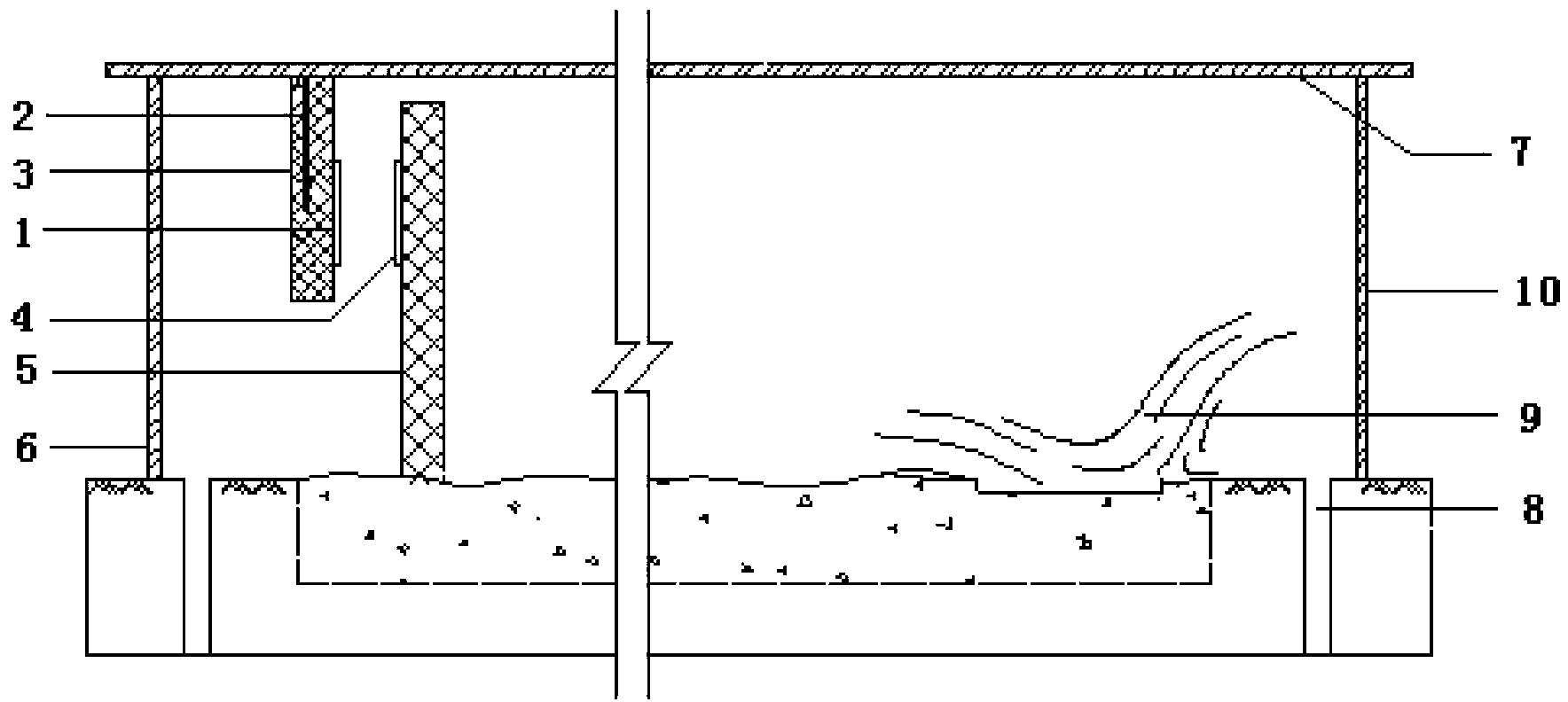

Exhaust-gas aftertreatment device

ActiveCN102465746ALess quantityWell mixedInternal combustion piston enginesSilencing apparatusExhaust fumesExhaust gas emissions

The present invention relates to an exhaust-gas aftertreatment device for an internal combustion engine, wherein said device (1) comprises a catalytic converter (2), wherein the catalytic converter (2) comprises a tubular member (3) which defines a volume (4) within which a catalytic converter substrate (5) is located, and wherein the volume (4) with the catalytic converter substrate (5) communicates with an inlet portion (6) for receiving exhaust gas emissions from the internal combustion engine and with an outlet portion (7) for discharging said exhaust gas emissions after catalytic conversion thereof in said volume. The device (1) comprises a pipe member (8) within said tubular member (3) of the catalytic converter (2), which pipe member connects the inlet portion (6) with the volume (4) in said tubular member (3) and guides the exhaust gas emissions from said inlet portion in a first direction of flow (A), and said pipe member (8) opens downstream into a deflector means (9) which deflects the exhaust gas emissions into the volume (4) of the tubular member (3) of the catalytic converter (2) in a second direction of flow (B) other than said first direction of flow (A) ( Fig. 1 ).

Owner:VOLVO CAR CORP

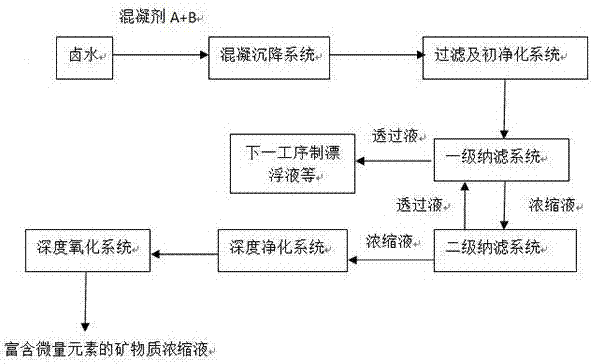

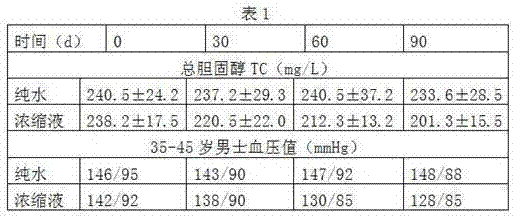

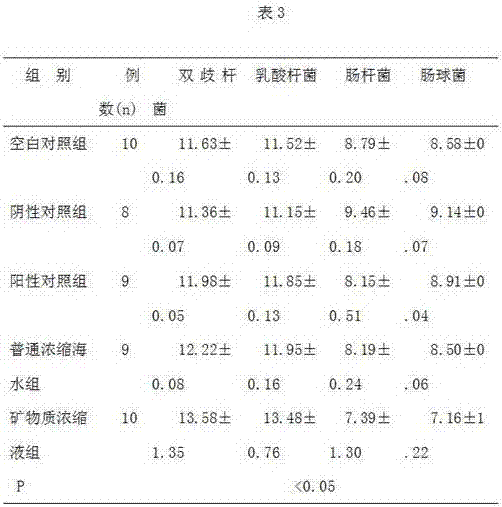

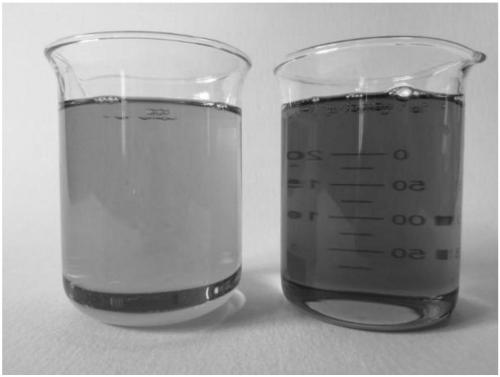

Mineral matter concentrate rich in trace elements, and preparation method and application thereof

InactiveCN107032519AEasy to processSimple preparation processSeawater treatmentTreatment involving filtrationSolubilityFiltration

The invention provides a mineral matter concentrate rich in trace elements, and a preparation method and an application thereof. The concentrate is prepared from brine obtained after concentrating seawater, the total content of soluble solids in the concentrate is 200,000-230,000 mg / L, the concentration of Ca<2+> in the concentrate is 100-200 mg / L, the concentration of Mg<2+> in the concentrate is 28000-35000 mg / L, the concentration of K<+> in the concentrate is 2500-3500 mg / L, and the concentration of Cl<-> in the concentrate is 8000-15000 mg / L. Coagulation sedimentation, filtration and pre-purification, nanofiltration and deep purification processes are carried out to remove a large number of monovalent salts in the seawater and heavy metals harmful to human bodies and obtain the mineral matter concentrate reserving beneficial minerals and trace elements needed by human bodies; and the concentrate has the advantages of supplementation of trace elements missing in the human bodies, deep removal of wastes and toxins from the human bodies, purification of blood, and stimulation of the regeneration and self-repairing ability of cells, and has the efficacy of promoting human body metabolism, enhancing the systemic immunity and restoring youthfulness.

Owner:张轶男

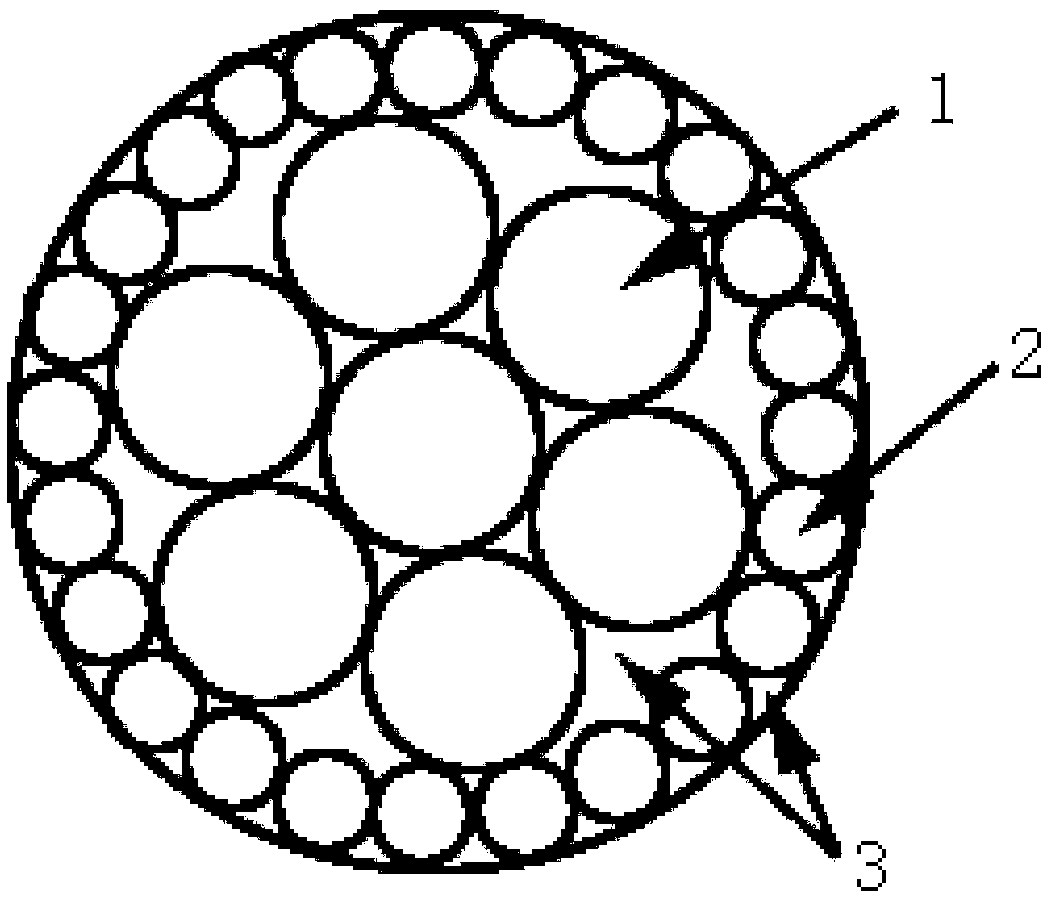

Carbon fiber compound core of power transmission circuit

InactiveCN103426558ACorrosion resistantExtended service lifeInsulated cablesPower cablesEpoxyCarbon fibers

A carbon fiber compound core of a power transmission circuit comprises an inner core body and an outer core body. The outer core body wraps the periphery of the inner core body, wherein the inner core body is carbon fibers prepared by carbonizing polyacrylonitrile fibers, the outer core body is high-strength glass fibers or basalt fibers, the inner core body and the outer core body are fixed and formed by heating cured resin, the cured resin is high-temperature-resistant special pultrusion epoxy resin prepared by adding modified anhydride compounds, the carbon fiber inner core body is of a straight-line type, and the high-strength glass fibers or basaltic fibers are of a twist increasing bundling type. The strength of a compound wire produced by the carbon fiber compound core is twice higher than the strength of an existing wire of the same type, the electric conductivity is higher, magnetic loss and heat loss are not generated, energy can be saved by more than 6%, the sag is lower due to the fact that the weight of the wire is reduced by 10-20%, and the compound core further has the advantages of being wearproof and long in service life.

Owner:SUZHOU SUYUE NEW MATERIAL

Electroslag ignition agent and preparation method thereof

InactiveCN104726721AGood arc starting effectReduce manufacturing costCarrying capacityGraphite electrode

The invention discloses an electroslag ignition agent and a preparation method thereof. The electroslag ignition agent is used for igniting and remelting slag material in an electroslag remelting technology to establish electroslag. The ignition agent comprises the following raw material components in percentage by weight: 25-35% of fluorite powder, 2-12% of silica powder, 30-40% of graphite electrode powder, 1-11% of quicklime powder and 18-28% of water glass. The preparation method comprises the following process steps: preparing mixed dry powder: uniformly mixing the raw materials according to the content in percentage by weight of each raw material and the carrying capacity of a mold to obtain the mixed dry powder; mixing with sludge, loading into the mold, adding the water glass into the mixed dry powder, stirring till no dry powder exists, loading a mixture which is uniformly stirred into the mold, tamping and compacting; blowing gas, demolding, blowing CO2 into the mold, and demolding after stopping gas blowing to obtain an ignition agent block; and drying at low temperature. The ignition agent disclosed by the invention has a good arc starting effect in the using process and can avoid a titanium-increasing effect, and high-temperature smelting is not required in the manufacturing process of the ignition agent.

Owner:SINOSTEEL XINGTAI MACHINERY & MILL ROLL

Transparent reflective heat-insulating window curtain for external window of building

InactiveCN102486082AReduce indoor temperatureReduce energy savingLight protection screensReflecting/signal paintsPolyesterEngineering

The invention discloses a transparent reflective heat-insulating window curtain for an external window of a building. The base film of the window curtain is a nylon film, a terylene film, a polyester film or other similar transparent plastic films with certain rigidity and capable of being curled around a circular shaft. The thickness of the base film is 0.05mm to 1.5mm. The surface of the base film is coated with nanometer transparent heat-insulation coating to form the transparent reflective heat-insulation window curtain. The main function of the window curtain is to reflect infrared heat irradiated by sunlight to a window in summer, but the permeability of visible light is not obviously influenced. The opening / closing type of the window curtain is an around-shaft rotating type. When the infrared heat irradiated by the sunlight to the window is required in winter, the window curtain can be conveniently disassembled.

Owner:ANHUI INST OF BUILDING RES & DESIGN

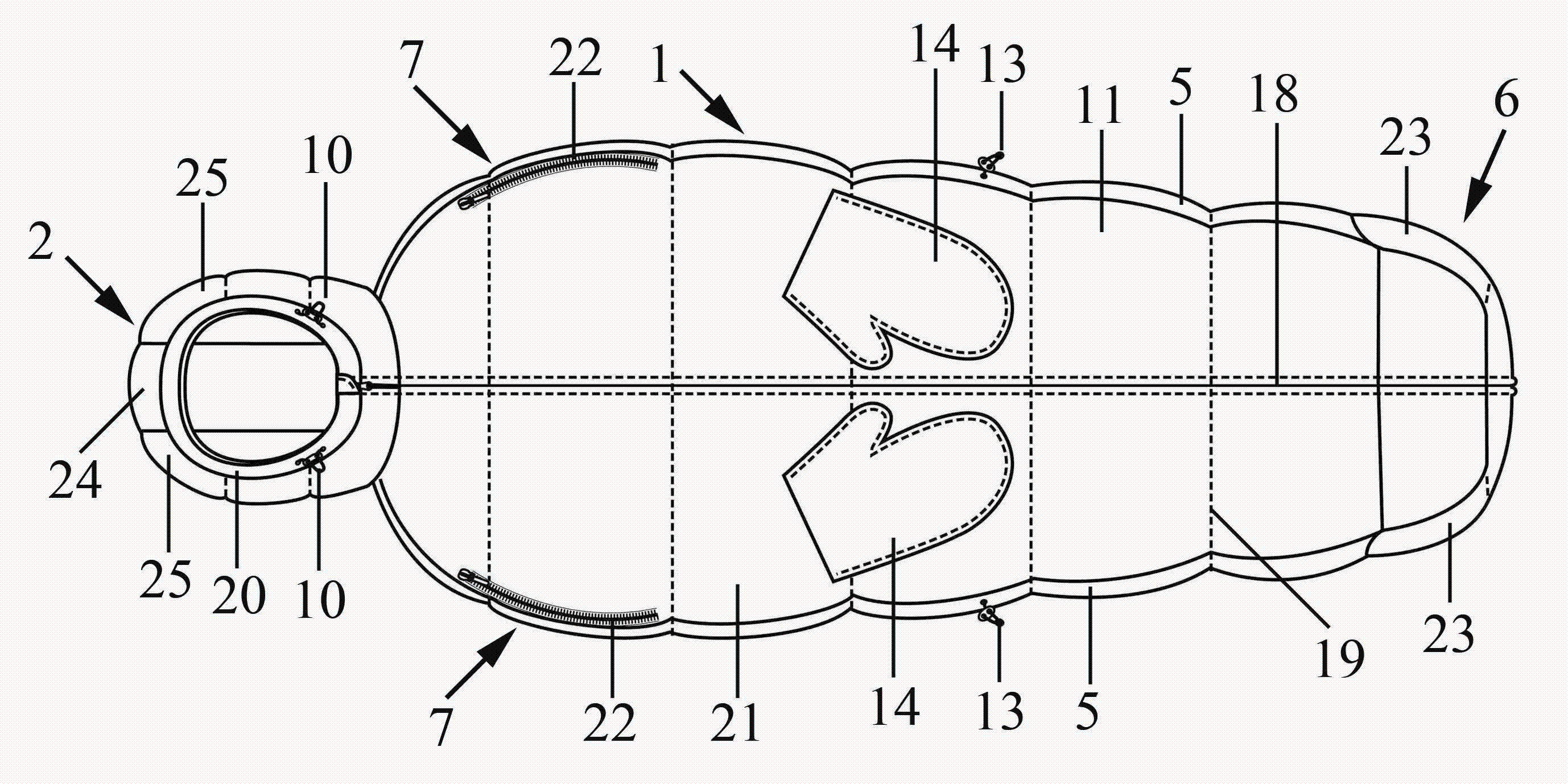

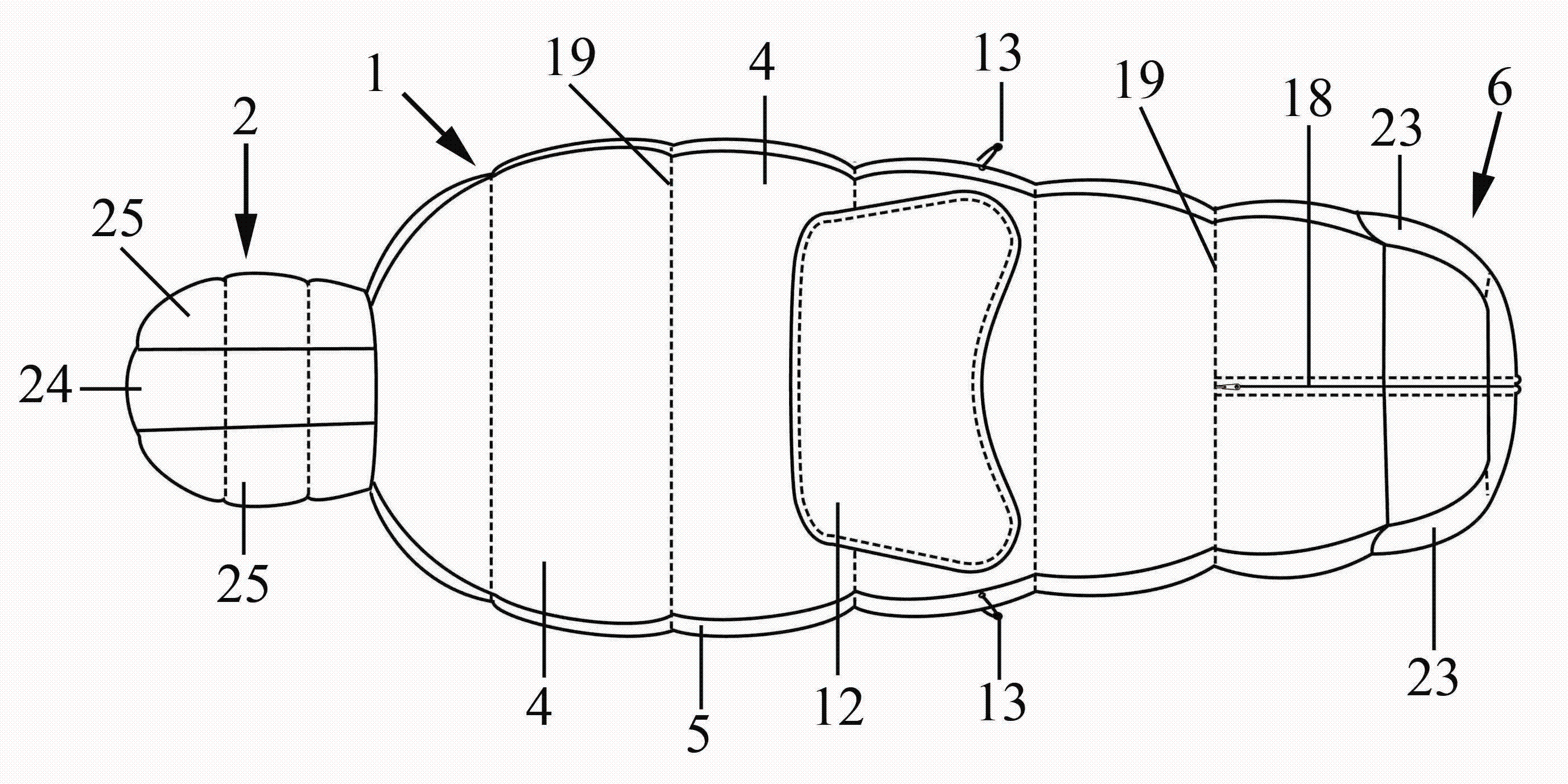

Walk sleeping bag and manufacture method

The invention provides a walk sleeping bag and a manufacture method. The upper part of the bag is a bag cap; the bag body is connected with the bag cap into a whole; the opening of the bag cap is provided with a wind-baffling cap strip along the edge of the opening of the bag cap; the bag body consists of a front piece, a back piece and a side wall; the front piece of the bag body consists of a folio left opening and a folio right opening; the left opening and the right opening are provided with opening zip fasteners; the two sides of the upper part of the front piece of the bag body are provided with hand outlets along the edge of the front piece of the bag body, the middle of the back piece of the bag body is provided with a buttocks protecting pad; the lower part in the bag body is provided with a bag foot windproof piece; and the bag foot windproof piece is wholly in the shape of U. The invention has reasonable design, novel structure, simple manufacture, low cost, beautiful shape, comfortable use and good heat retention. The unique design of the bag foot windproof piece, the hand outlets and hand protecting pockets on the sleeping bag leads the user not only to be capable of sleeping but also to be capable of walking after entering into the sleeping bag to do some exercise, thereby preventing the heat energy from losing and not influencing the exercise. The walk sleeping bag is applied to the use of outdoor camp, tour, business trip and family, and is suitable for different environments and crowds.

Owner:HIGH ROCK RECREATION PROD CO LTD

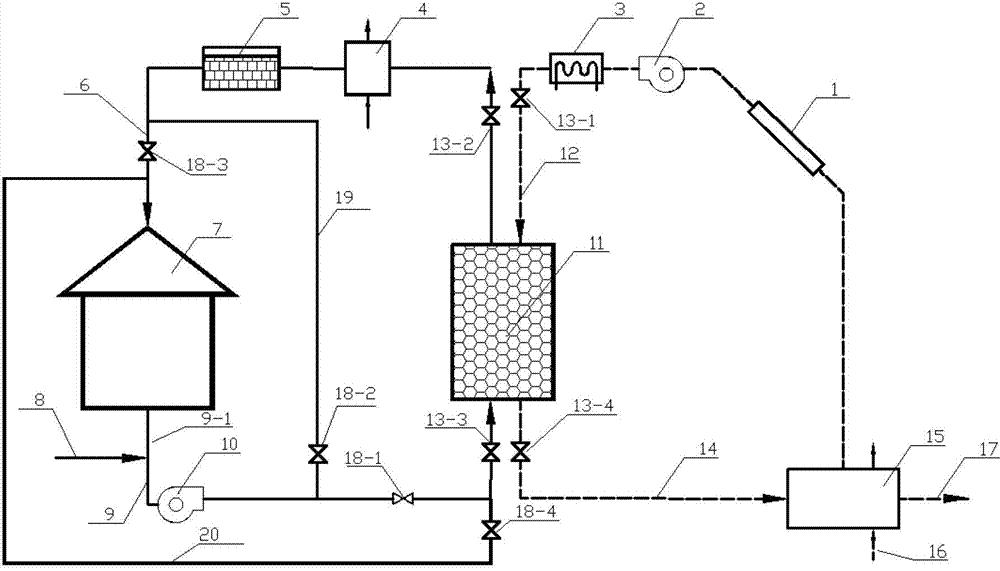

Solar dehumidifying air conditioner system with energy storage effect

ActiveCN102954545AImprove efficiencyReduce usageSpace heating and ventilation safety systemsLighting and heating apparatusTransition seasonMoisture

The invention discloses a solar dehumidifying air conditioner system with an energy storage effect. The solar dehumidifying air conditioner system comprises a treatment air passage system, a regeneration air passage system and a solid dehumidifier energy storage bed, wherein the treatment air passage system and the regeneration air passage system are connected with each other through the solid dehumidifier energy storage bed. The solar dehumidifying air conditioner system has the advantages that the lower humidity and temperature can be realized under standard working conditions in summer, so the comfort requirement of an air conditioner is met; the humidifying and heating requirements can be realized by increasing the moisture content in the air under standard working conditions in winter; the requirements by insufficient radiation in rainy days and at night are met by the excessive energy stored in the solid dehumidifier energy storage bed in transition seasons; and the structure is simple, the easiness in control is realized, and the investment cost of equipment is low.

Owner:SHANGHAI JIAO TONG UNIV

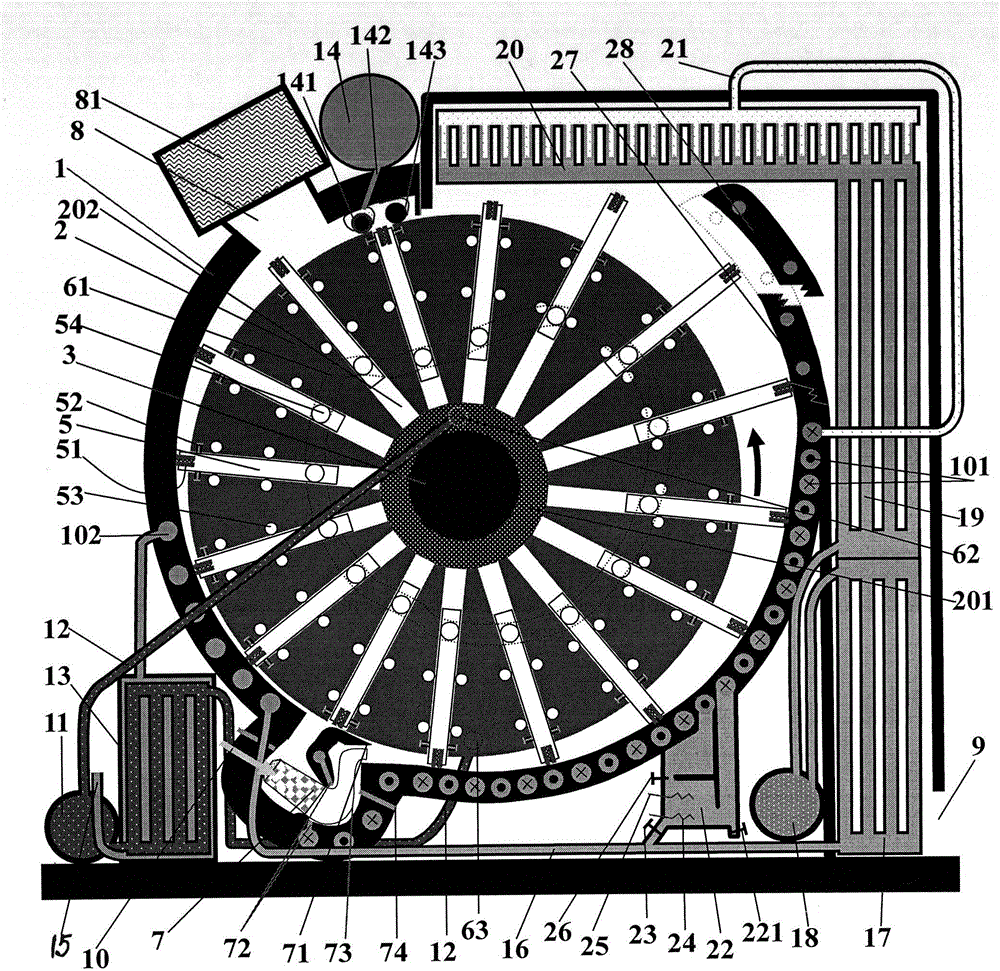

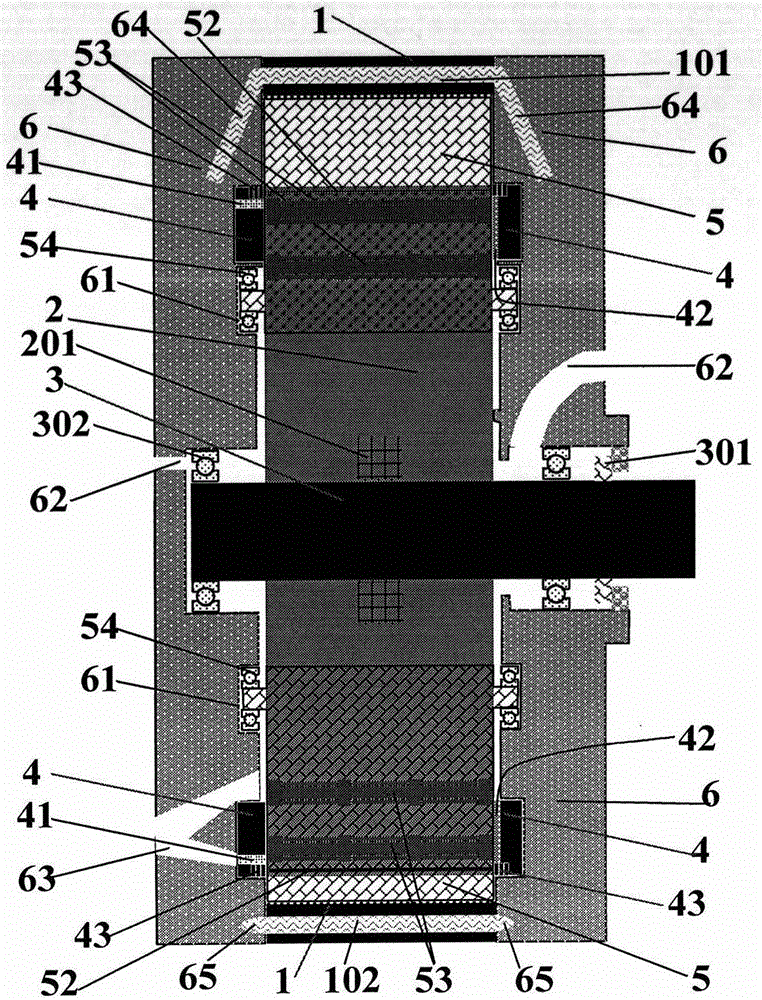

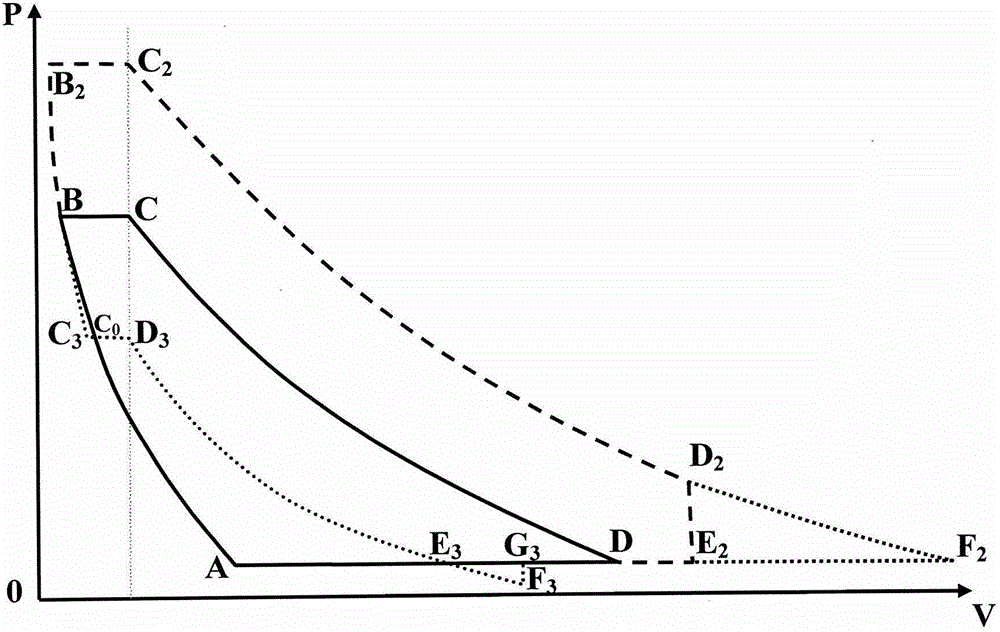

Fuel gas-steam combined cycle equal-pressure variable capacitance slide piece rotor engine

ActiveCN105952526AImprove mechanical efficiencyImprove efficiencyInternal combustion piston enginesGas turbine plantsCapacitanceCombustion chamber

The invention discloses a fuel gas-steam combined cycle equal-pressure variable capacitance slide piece rotor engine, and the engine is similar to an ideal variable high-efficiency combustion gas turbine. A stator shaped like an involute curved surface, a cylindrical rotor, a rotor shaft, a rotor cover, a slide piece assembly, a side cover and a combustor form a basic acting system. The stator, the rotor, the side cover and a slide piece enable the interior to be divided into an air gradual compression chamber (like multistage compression) and a gradual expansion chamber (multistage expansion) which is large in size and acts through fuel gas after combustion. During operation, the rotor rotates to inhale air from an air inlet, carries out gradual compression while the slide piece moves, and enables air to enter the combustor from a compressed air outlet and to be mixed with fuel gas. The gas absorbs heat to expand in an equal pressure manner. Because the compression area of an expansion chamber slide piece is larger than the compression area of a compression chamber slide piece by several times and the pressure intensities are equal, the thrust at the expansion chamber side is greater than the resistance of the compression chamber by several times, an external acting force moment is formed, and an equal-pressure expansion work is done. The expanded gas is divided by the slide piece in the expansion room, and the size of the expanded gas becomes large in operation, and then an adiabatic expansion work is done.

Owner:钱百成

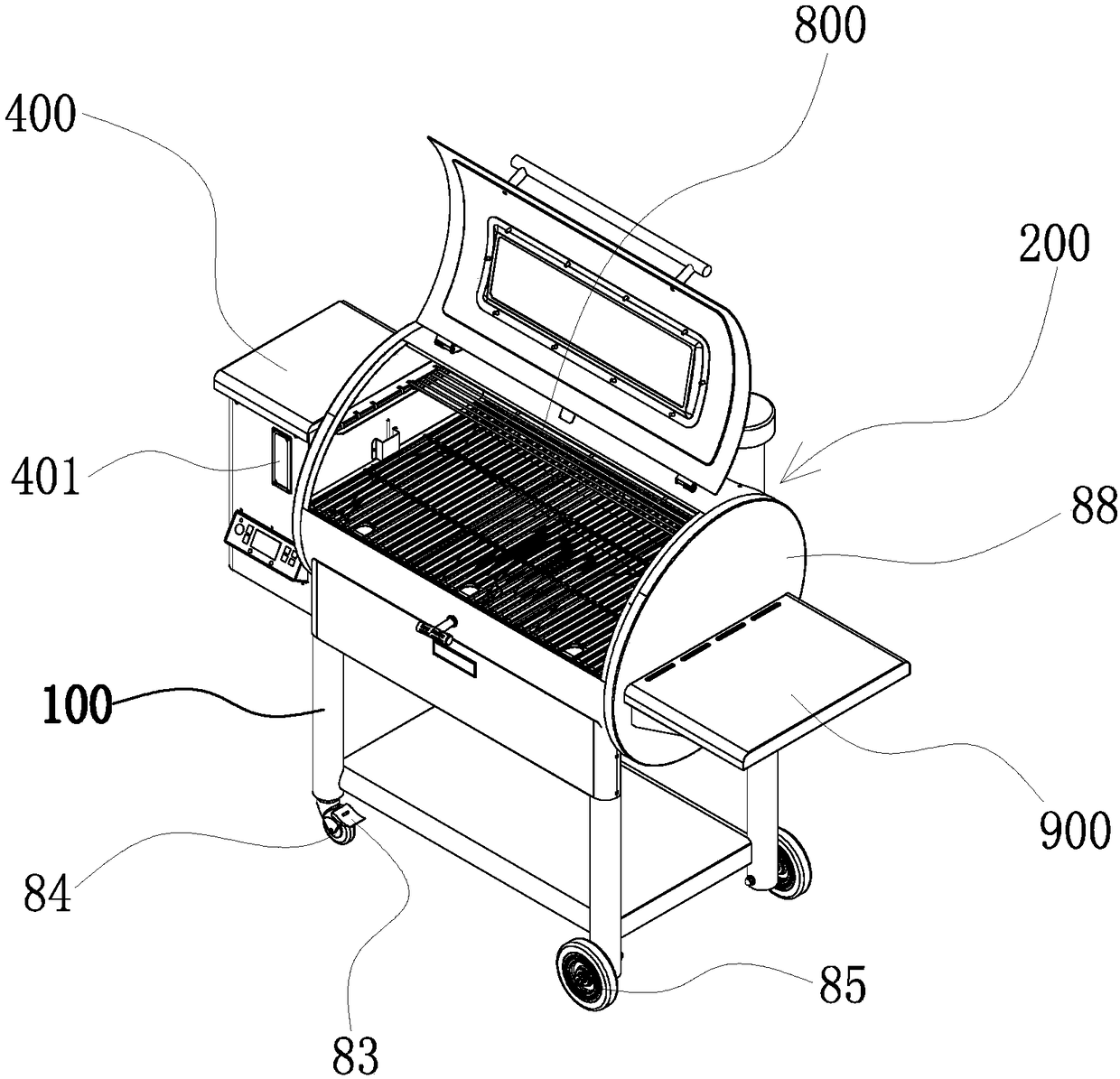

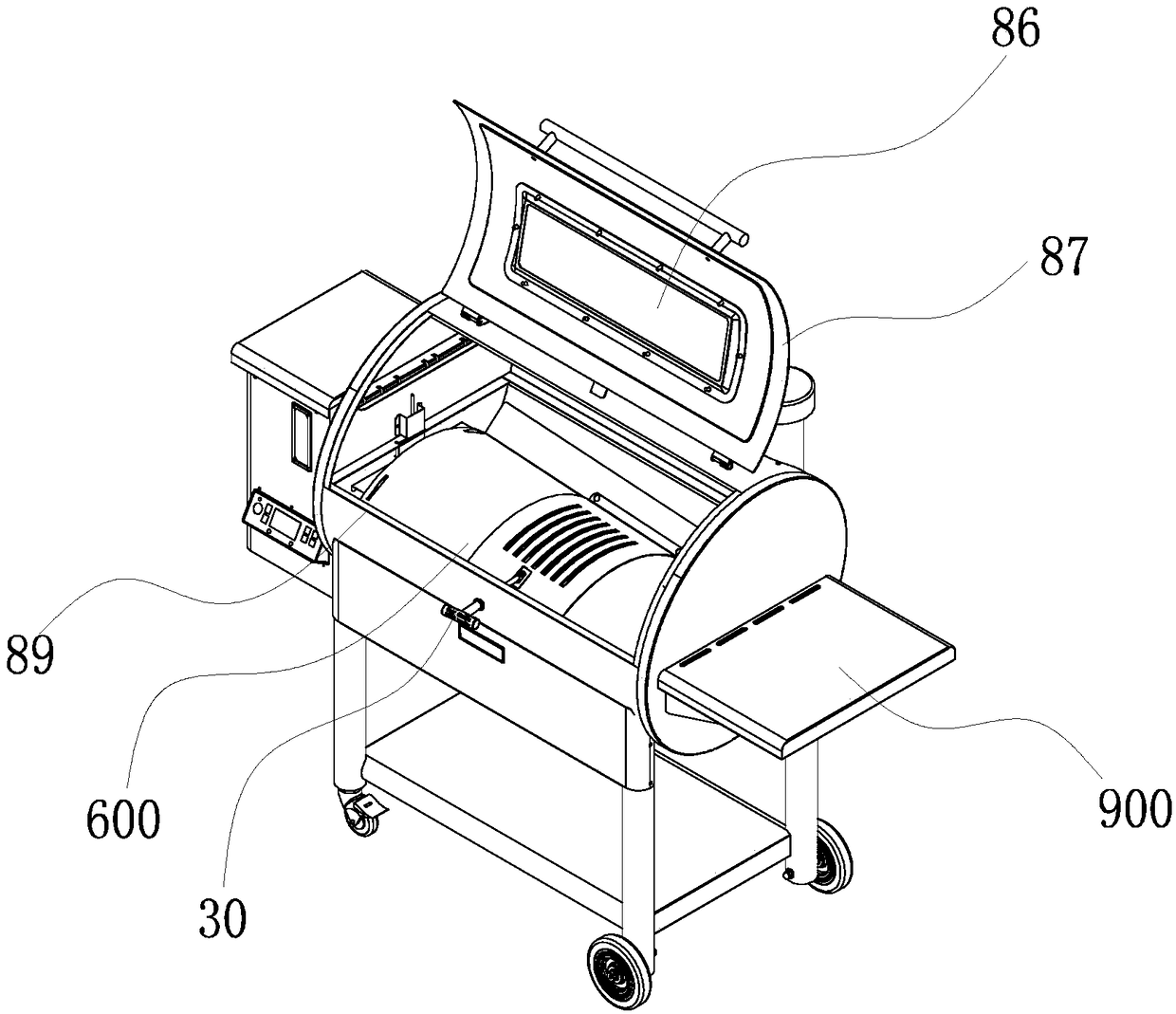

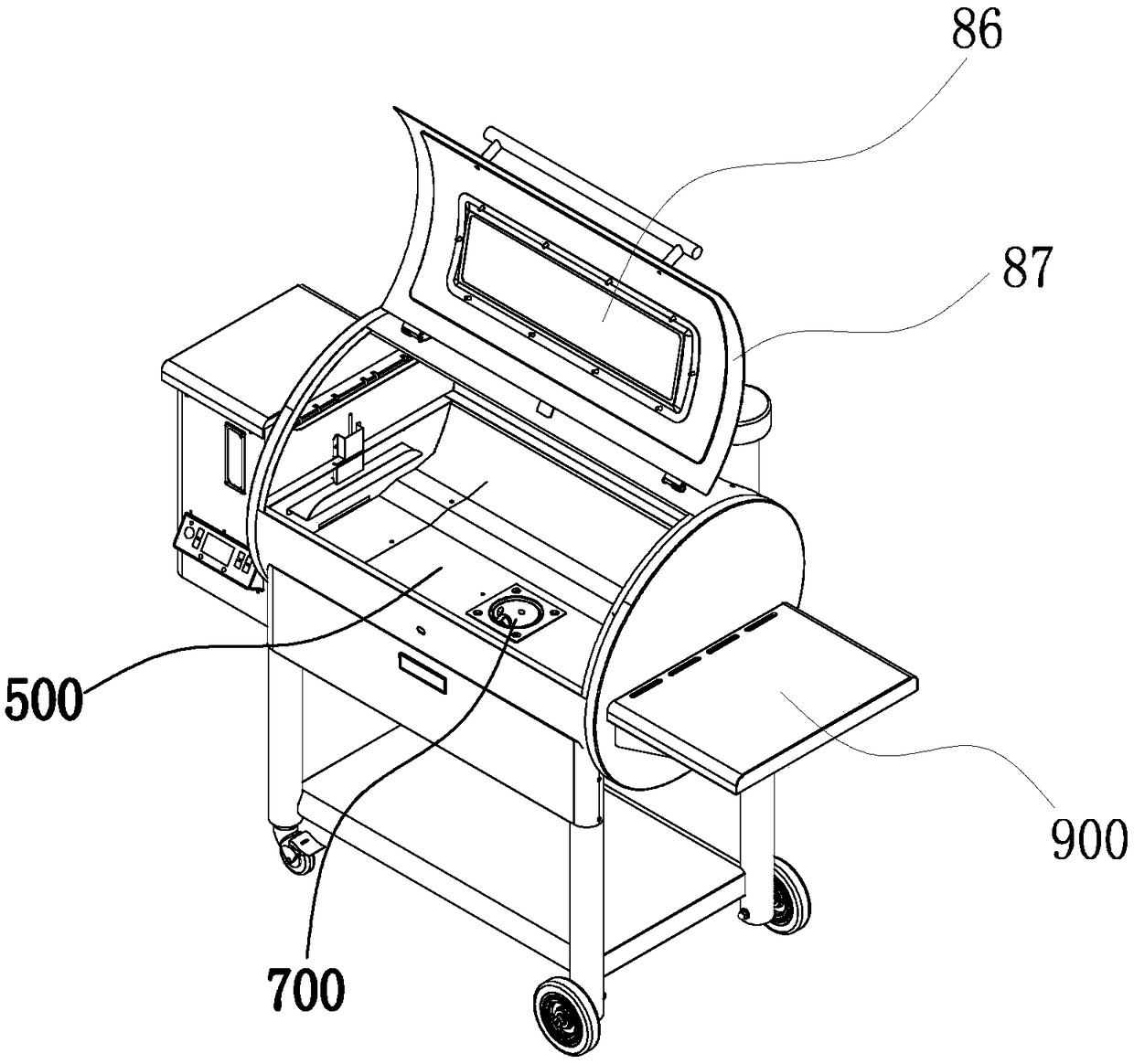

Fuel barbecue grill

PendingCN109363526AIncrease the grilling areaReal-time observation of barbecue statusFood scienceEngineeringFeeding observations

Owner:ZHEJIANG GIANT TECH CO LTD

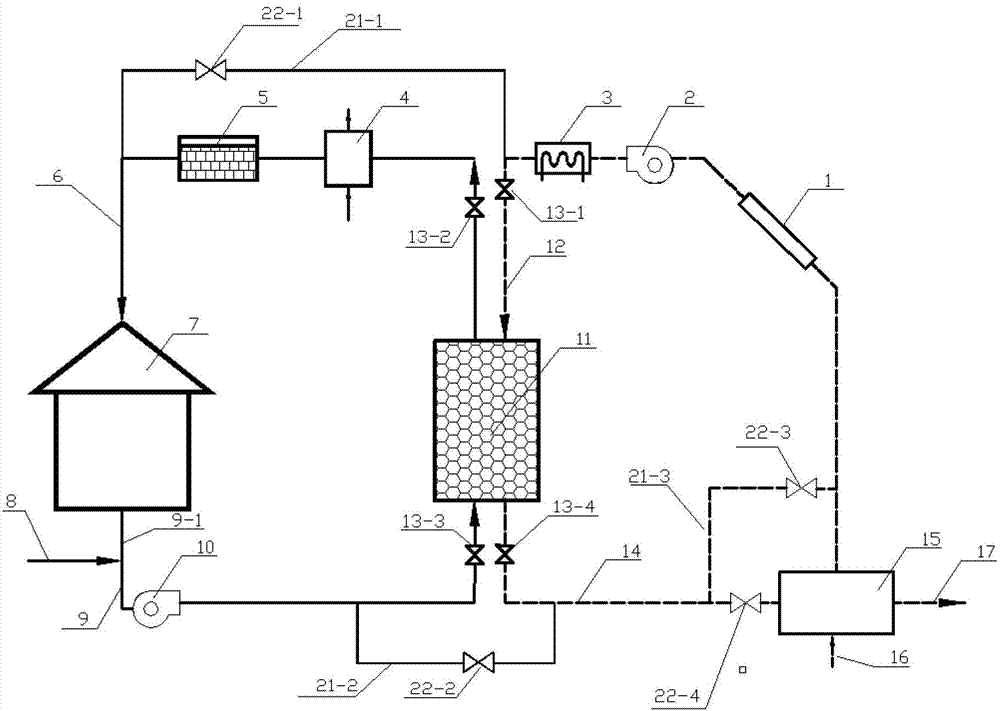

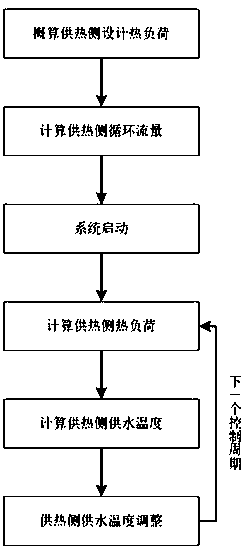

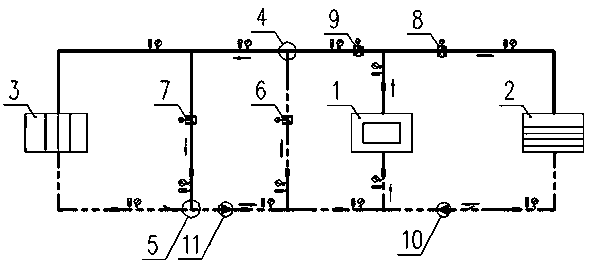

Method for decoupling operation of heat supply and heat storage in same heat source system,

PendingCN109405056ARealize heating on demandGuaranteed uptimeLighting and heating apparatusSpace heating and ventilation detailsProcess engineeringHeating efficiency

The invention discloses a method for decoupling operation of heat supply and heat storage in a same heat source system. The method for decoupling operation of heat supply and heat storage in the sameheat source system comprises the following steps that a design heat load of a heat supply side is estimated, circulating water quantity of the heat supply side is calculated, a system is started, a heat load of the heat supply side is calculated, a water supply temperature of the heat supply side is calculated, and a water supply temperature of a user side is adjusted. The method for decoupling operation of heat supply and heat storage in the same heat source system can effectively separate the influence between the heat supply side and a heat storage side in the same heat source system, on the one hand, the heat supply side realizes on-demand heat supply and stable operation, and on the other hand, the heat storage side can stably store heat at high temperature, so that the process of supplying while storing is simplified and efficient. The temperature adjustment process is a mixed flow process of adjusting the proportion of the heat source outlet water and the heat supply side returnwater, in the whole temperature adjustment process, the heat energy of the whole system is not lost, and the heating efficiency of a heat source is effectively improved. According to the method for decoupling operation of heat supply and heat storage in the same heat source system, a mass regulation mode is adopted in the he heat supply side to realize the balance of heat supply and heat demand.Simple management, convenient operation and stable network hydraulic conditions are achieved.

Owner:HEBEI INSTITUTE OF ARCHITECTURE AND CIVIL ENGINEERING

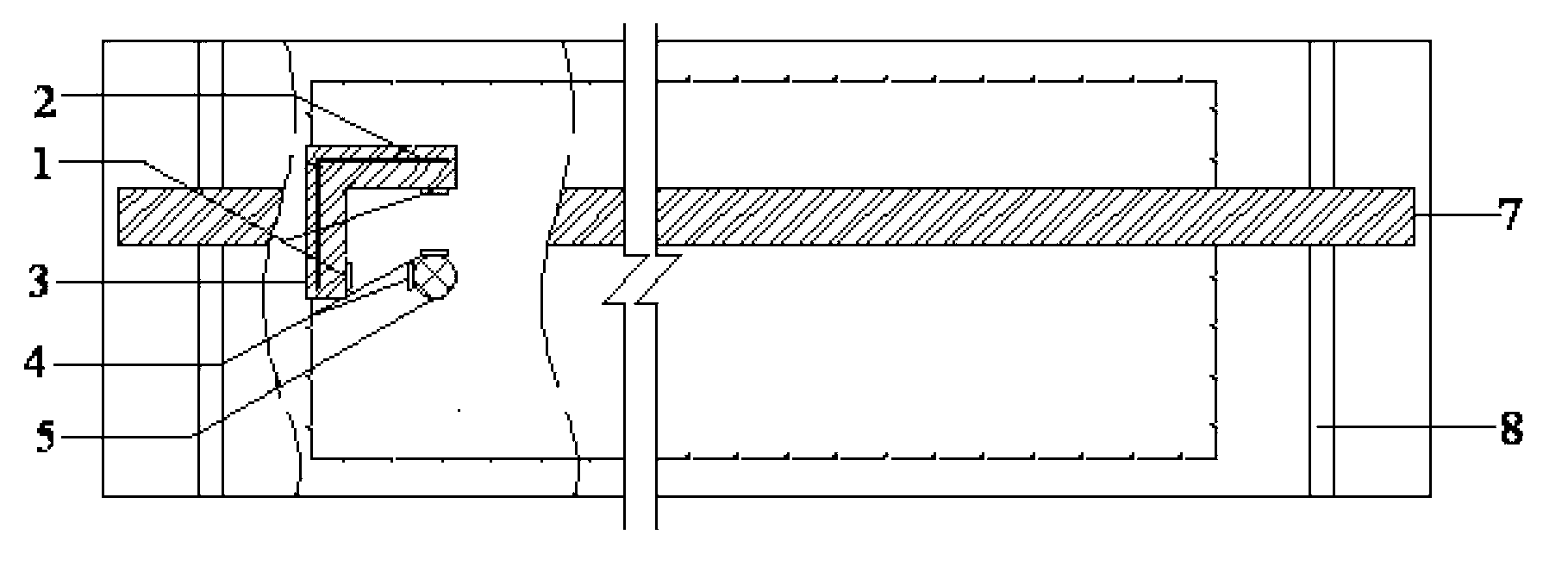

Introduced capacitive device for measuring horizontal ground micro-vibration

ActiveCN103017890AImprove the shortcoming of only testing displacement in one directionNo contact measurement errorSubsonic/sonic/ultrasonic wave measurementUsing electrical meansLow-pass filterEngineering

The invention discloses an introduced capacitive device for measuring horizontal ground micro-vibration. The device comprises a standard signal generator (11), an introduced capacitive sensor (12), a negative feedback operational amplifier (13) and a low-pass filter and display system (14). The introduced capacitive sensor comprises an introduced copper cylinder (5) and a capacitor piece (4), wherein the introduced copper cylinder (5) is arranged on the ground, and the capacitor piece (4) is arranged at the top end of the introduced copper cylinder (5). A vibration isolation ditch (8) is arranged at a 2m<2> position surrounding the periphery of the copper cylinder, a steel cylinder A (6) and a steel cylinder B (10) are arranged on the outer side of the vibration isolation ditch, a steel beam (7) is arranged at the top ends of the two steel cylinders, a measuring electrode (1), a shielding electrode (2) and a shielding electrode shell (3) are arranged below the steel beam, and an excitation source (9) is arranged within an enclosed scope of the vibration isolation ditch (8). The introduced capacitive device is simple in structure and convenient to use, facilitates simultaneous measurement of horizontal vibration in two vertical directions, and can be specially used for precisely measuring horizontal ground micro-vibration.

Owner:TIANJIN UNIV

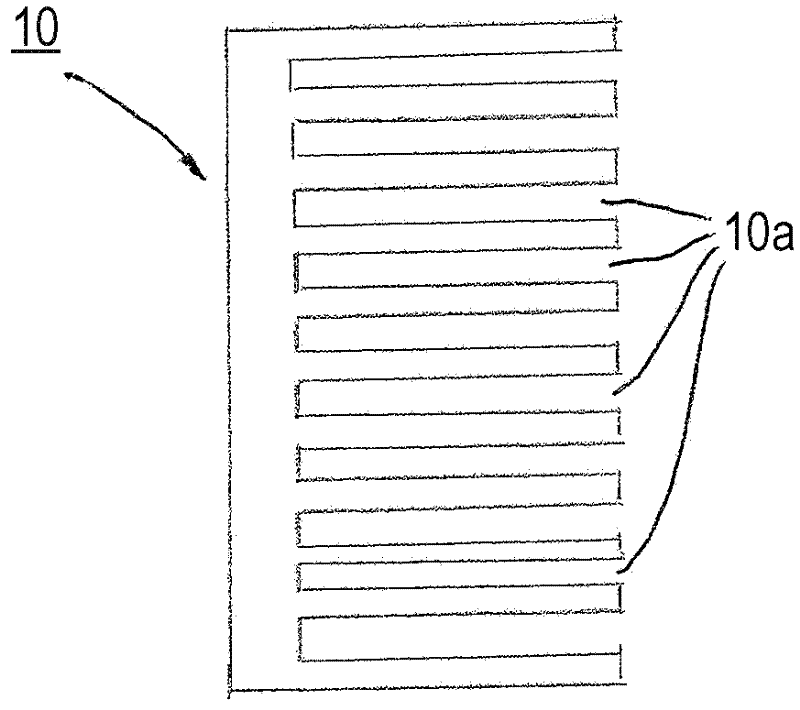

Flat plate type solar heat collector

ActiveCN101726122AEfficient conductionNo heat lossSolar heating energySolar heat devicesThermal energyEngineering

The invention relates to a flat plate type solar heat collector. The flat plate type solar heat collector comprises a shell and a pipeline arranged in the shell, wherein the shell comprises a heat collecting plate, a back cover plate, and a frame in sealed connection with the heat collecting plate and the back cover plate; the heat collecting plate is a whole piece of sheet; the pipeline comprises a plurality of heat collecting pipes and a discharge pipe, the plurality of heat collecting pipes are on the heat collecting plate side by side and connected with the heat collecting plate as a whole, and the discharge pipe is connected with and communicated with the heat collecting pipes; after each heat collecting pipe absorbs heat, water is discharged by the discharge pipe. The flat plate type solar heat collector uses the heat collecting plate made by a whole piece of sheet, and no heat loss is generated; because a plurality of heat collecting pipes are connected with the heat collecting plate into a whole, so that after the sun irradiates the heat collecting plate, the heat energy can be transferred to the pipeline with high efficiency; and because the heat collecting plate is a whole piece of sheet, the splicing procedure is unnecessary, so that the manufacturing cost is saved.

Owner:SHENZHEN TOPRAY SOLAR

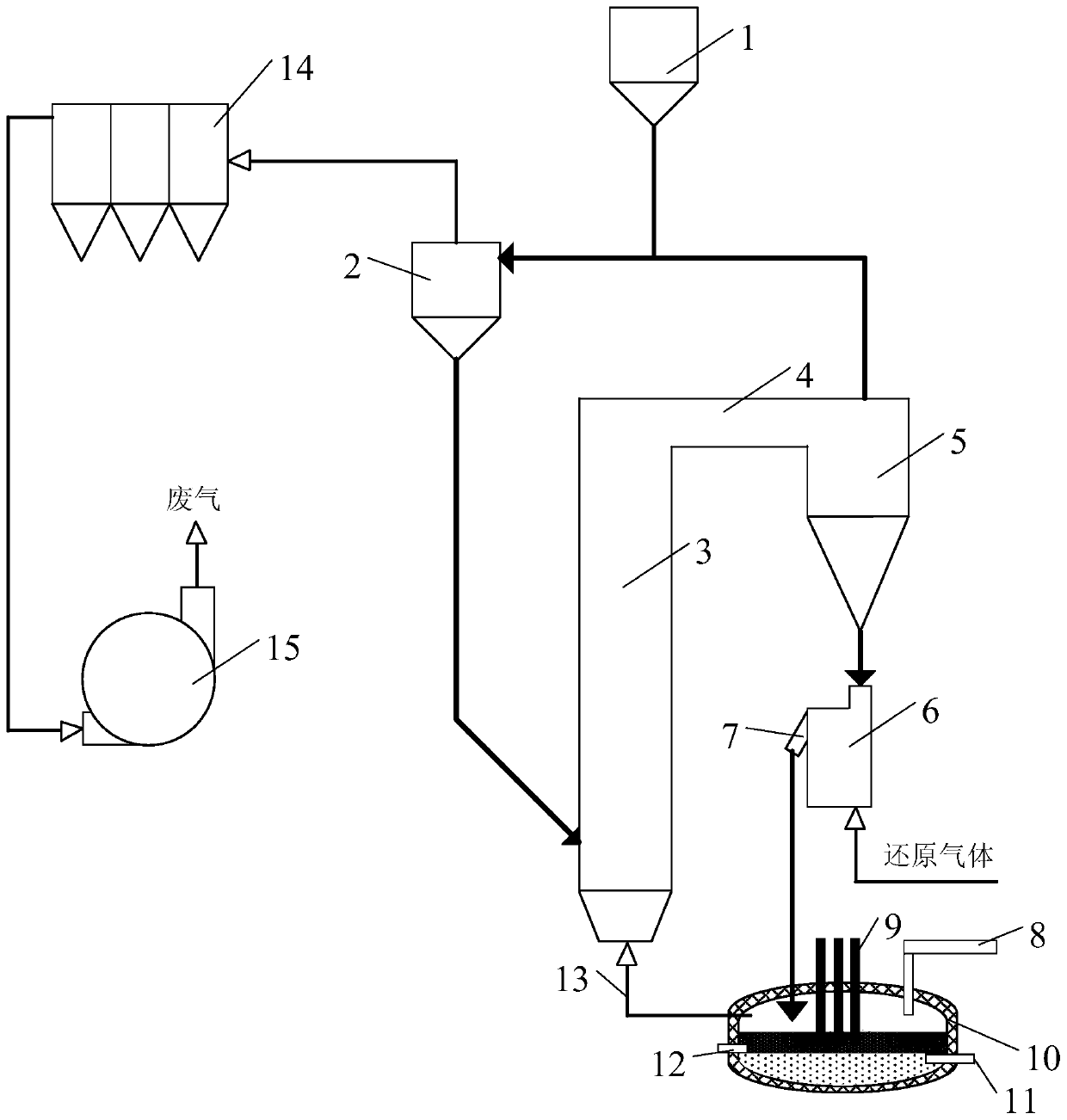

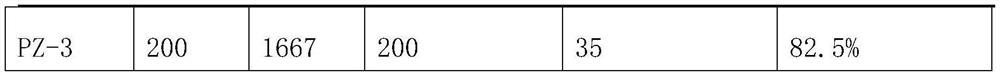

Method for producing molten iron through powdery iron ore suspension state direct reducing-electric arc furnace smelting

ActiveCN109811105ASimplify the restore processSimplify the process of smelting molten ironElectric furnaceCycloneIronstone

A method for producing molten iron through powdery iron ore suspension state direct reducing-electric arc furnace smelting is conducted according to the following steps that firstly, powdery iron oreis arranged in a material bin; secondly, the material bin is used for conveying the powdery iron ore to a first-level cyclone separator, first-level solid materials are separated out and enter the lower portion of a suspension heating furnace, and the bottom of the suspension heating furnace is inflated with high-temperature smoke; thirdly, under the action of the negative pressure, the first-level solid materials enter a second-level cyclone separator, and second-level solid materials are separated out and enter a reducing reactor; fourthly, the interior of the reducing reactor is inflated with reducing gas, the second-level solid materials are subjected to the reducing reaction, and reducing powder is generated; and fourthly, the reducing powder directly enters an electric furnace, electric arc melting is conducted, meanwhile, a fluxing agent is added in the electric furnace, and a liquid slag layer and molten iron are formed through the reducing powder. According to the method, theheat utilization efficiency is high, heat losses are avoided in various procedures, energy is greatly saved, and the processes of iron ore reducing and molten iron smelting are simplified.

Owner:NORTHEASTERN UNIV

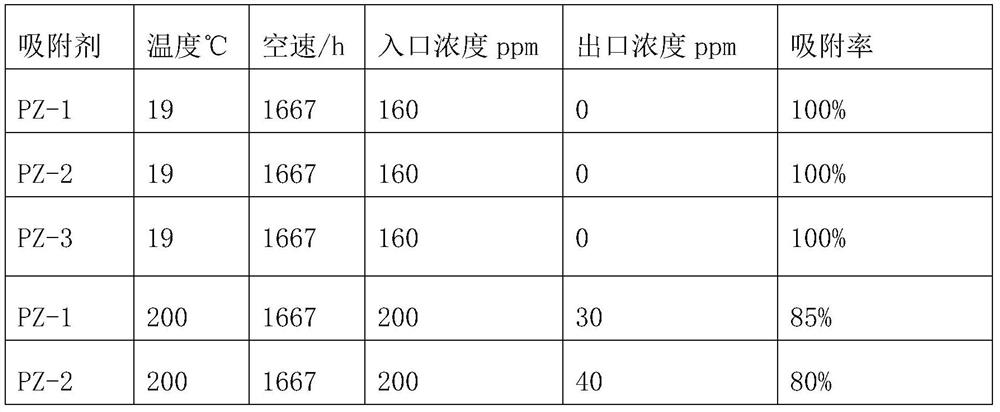

Sulfur-containing malodorous gas adsorbent and preparation method thereof

PendingCN111686683ANo heat lossImprove adsorption capacityGas treatmentOther chemical processesSorbentSulfur containing

The invention belongs to the technical field of tail gas treatment, and particularly relates to a sulfur-containing malodorous gas adsorbent and a preparation method thereof. The preparation method comprises the steps: taking molecular sieve, a binder, an auxiliary agent and deionized water as raw materials; fully mixing and kneading into blocky pug; drying the formed blocky pug at the temperatureof 70-200 DEG C, and curing for 1-3 hours; and extruding the cured blocky pug into strips by using a vacuum extrusion molding machine, and roasting for 1-5 hours at the temperature of 300-700 DEG C to obtain the adsorbent. The sulfur-containing malodorous gas adsorbent provided by the invention does not generate wastewater, does not pollute the environment, is low in cost, few in process, large in particle and high in strength, can be used as a filler to be applied to adsorption of industrial flue gas, is low in cost, and has the advantages of convenience, simplicity and no secondary pollution.

Owner:SHANXI PULI ENVIRONMENT ENG CO LTD

Preparation method of highly flavored edible oil

ActiveCN108998206AIncrease moistureReduce procurement costsFatty-oils/fats refiningFatty-oils/fats productionMicrowaveEdible oil

The invention provides a preparation method of highly flavored edible oil, and belongs to the technical field of food processing. The preparation method of the highly flavored edible oil comprises thefollowing steps: softening raw materials; carrying out microwave drying on the softened materials; squeezing the dried materials; and carrying out oil residue separation to obtain the edible oil. According to the preparation method, through a material softening agent and a microwave drying technology, the pressed highly flavored edible oil conforming to a standard can be produced without the needof blending with light-colored oil, so that the operation is simple and convenient, and cost is saved.

Owner:吴亮鑫

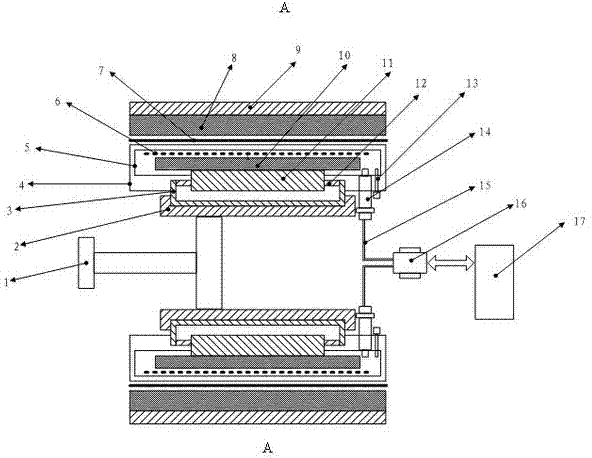

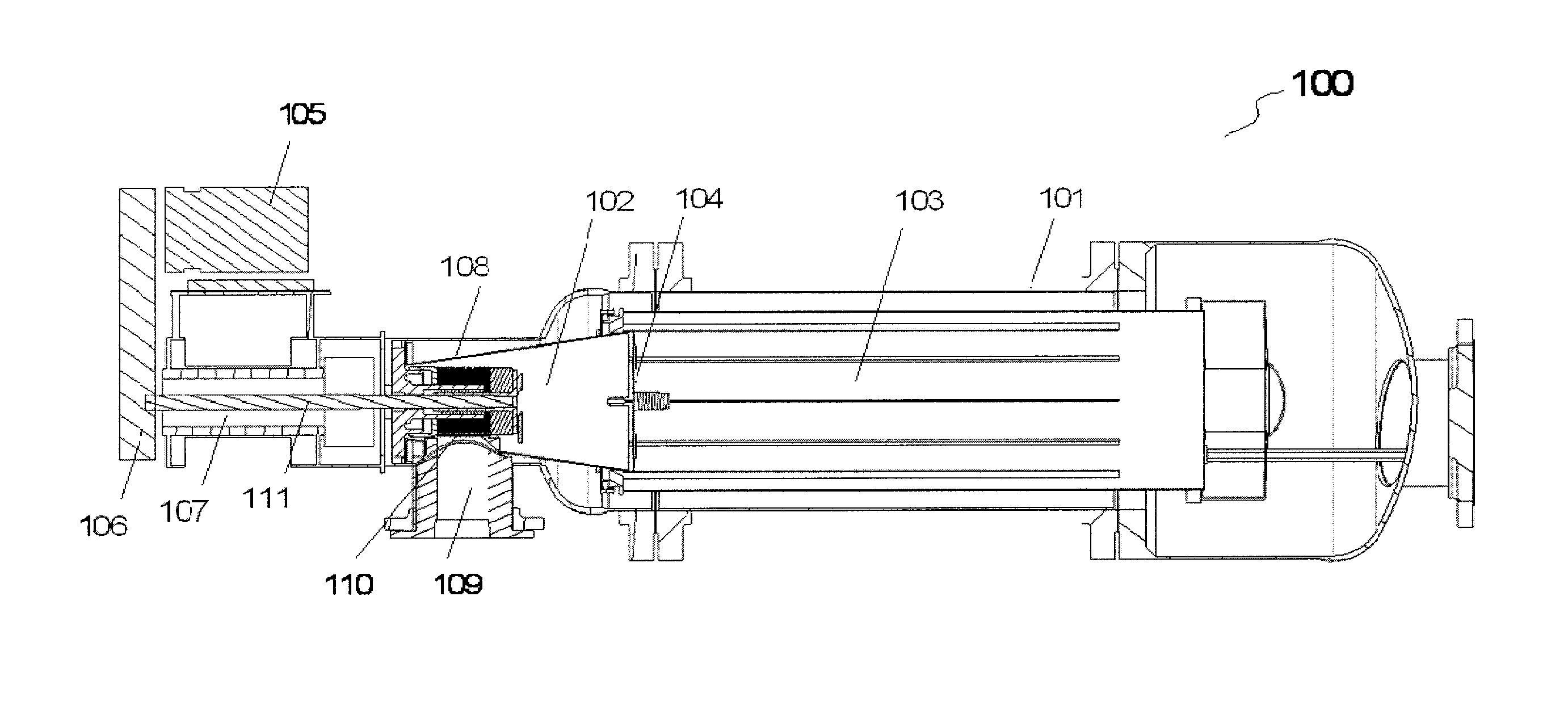

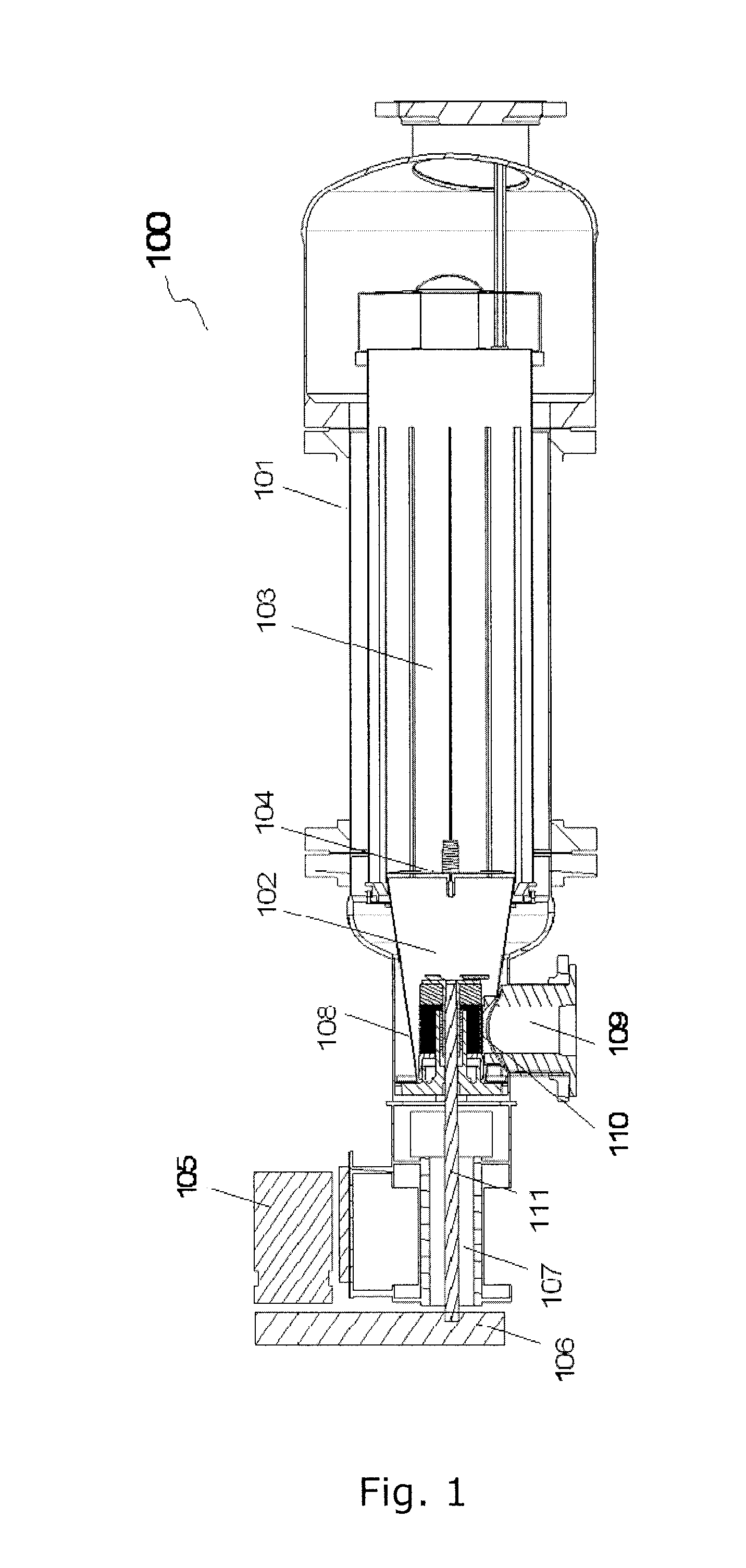

Apparatus for rapid mixing of media and method

ActiveUS8845976B2Avoid energy lossMechanical energyTransportation and packagingRotary stirring mixersLignocellulosic biomassPre treatment

The present invention relates to an apparatus, which can be part of a pre-treatment system in a plant for the production of fuels, e.g. bio-ethanol, derived from plant biomass, e.g. first generation crops, such as grain, sugarcane and corn or second generation crops such as lignocellulosic biomass. The invention relates to an apparatus for processing, such as fluffing and mixing, at least two media, such as a solid, e.g. biomass, and a fluid, e.g. steam, so as to rendering the first medium susceptible to efficient receiving of energy and / or mass which is provided by localized release of the second medium. Although the description of the present invention focuses on biomass, it is envisaged that the invention is generally applicable to control the mixing of at least two media by crossing their stream of while dispersing at least one of them.

Owner:BIO GASOL IPR APS

Multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling temperature

PendingCN114100165AImprove system energy efficiencyReduce processing timeEvaporator accessoriesEvaporation by sprayingWater circulationRefrigerant

The invention belongs to the field of industrial processes, energy and environmental protection, and particularly relates to a multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling temperature. The multi-energy gradient utilization heat pump low-temperature evaporation and concentration system capable of accurately controlling the temperature comprises a heating tank, a steam cooling and condensing system, a heat pump circulating system, a vacuumizing and re-condensing system, a water circulating temperature adjusting system, a heat dissipation system and a material preheating system. According to the system, efficient heat exchange on the refrigerant side can be achieved, the pressure environment of the material heating coil is improved, the adverse problems caused by heating materials through a high-temperature refrigerant are effectively solved, the material treatment quality is improved, meanwhile, the superheat degree of secondary steam can be reduced, and the heat exchange environment on the evaporator side during initial starting is improved. The system can accurately control the boiling evaporation temperature of the materials and efficiently utilize the materials in a gradient manner according to energy grades, so that the purposes of saving energy and reducing carbon are achieved, and the system is very significant.

Owner:李爱松

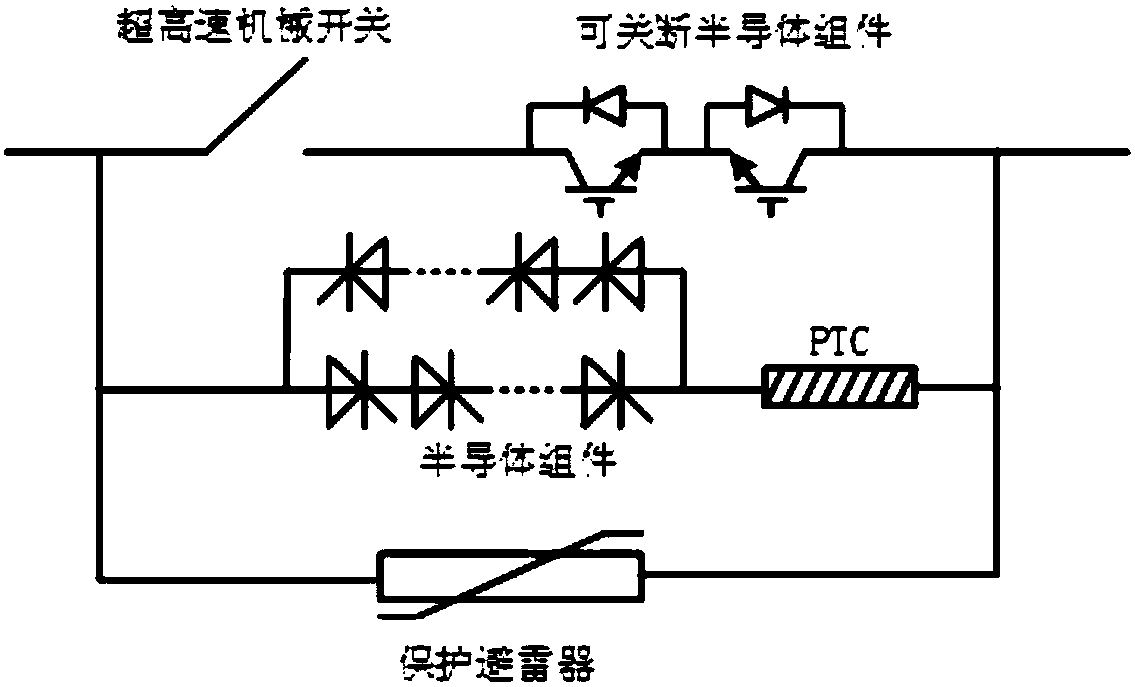

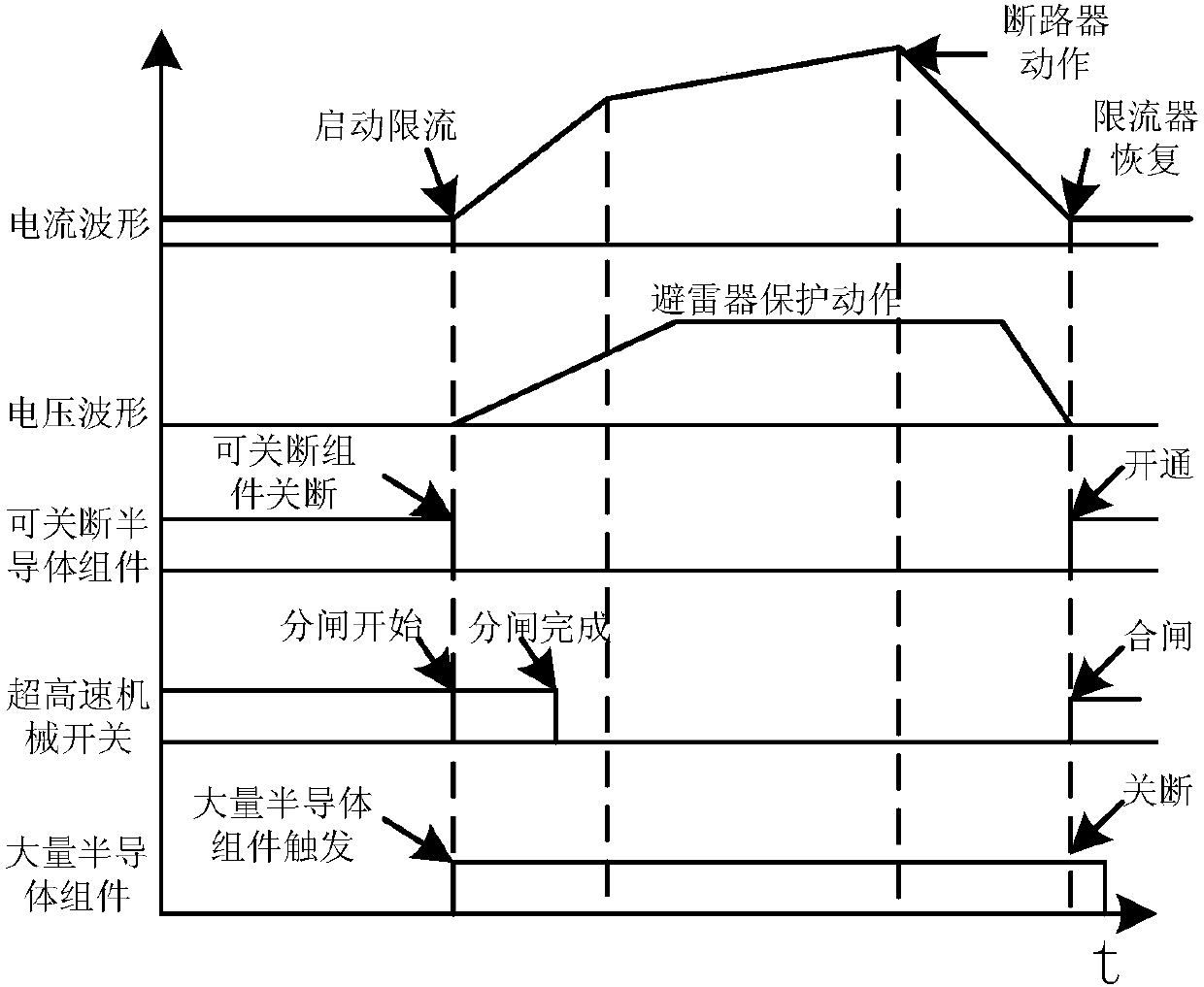

Positive temperature coefficient resistance material-based hybrid current limiter

PendingCN107769178ANo heat lossImprove reliability and longevityEmergency protective arrangements for limiting excess voltage/currentTemperature coefficientPositive temperature

The invention provides a positive temperature coefficient resistance material-based hybrid current limiter. The positive temperature coefficient resistance material-based hybrid current limiter comprises a steady-state current through branch, a current limitation path and a lightning arrester path which are connected in parallel, wherein the steady-state current through branch comprises an ultrahigh-speed mechanical switch and a semiconductor assembly capable of being switched off, which are connected in series, the steady-state current through branch is used for bypassing the current limitation path so as to transmit a load current when a power system normally runs, the current limitation path comprises a positive temperature coefficient (PTC) resistor and a semiconductor assembly which are connected in series, and the current limitation branch is used for suppressing a fault current when a fault occurs in the power system. Compared with the prior art, the PTC resistance material-based hybrid current limiter provided by the invention has the advantages that a limitation threshold of the fault current can be flexibly set, arc-free disconnection of the ultrahigh-speed mechanical switch also can be achieved, and the PTC resistance material-based hybrid current limiter is simple to operate and is reliable and practical.

Owner:GLOBAL ENERGY INTERCONNECTION RES INST CO LTD +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com