Patents

Literature

104results about How to "Reduce steam extraction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

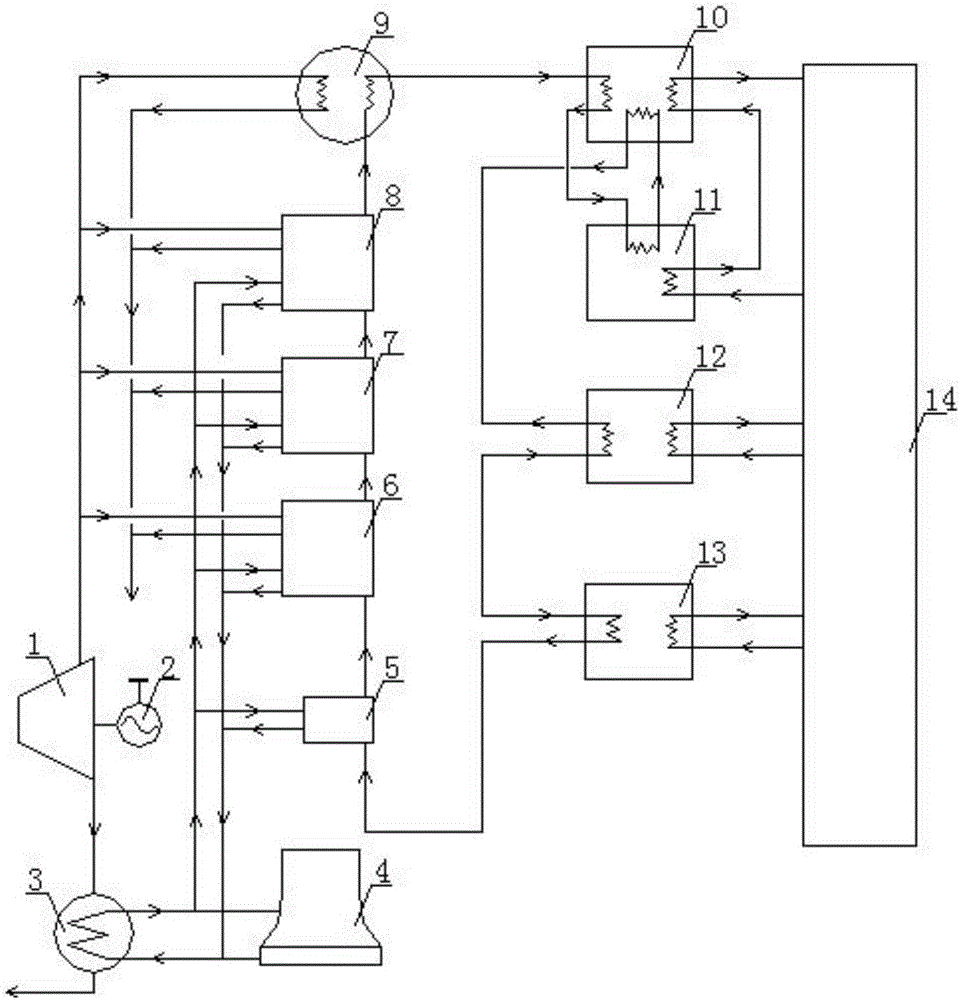

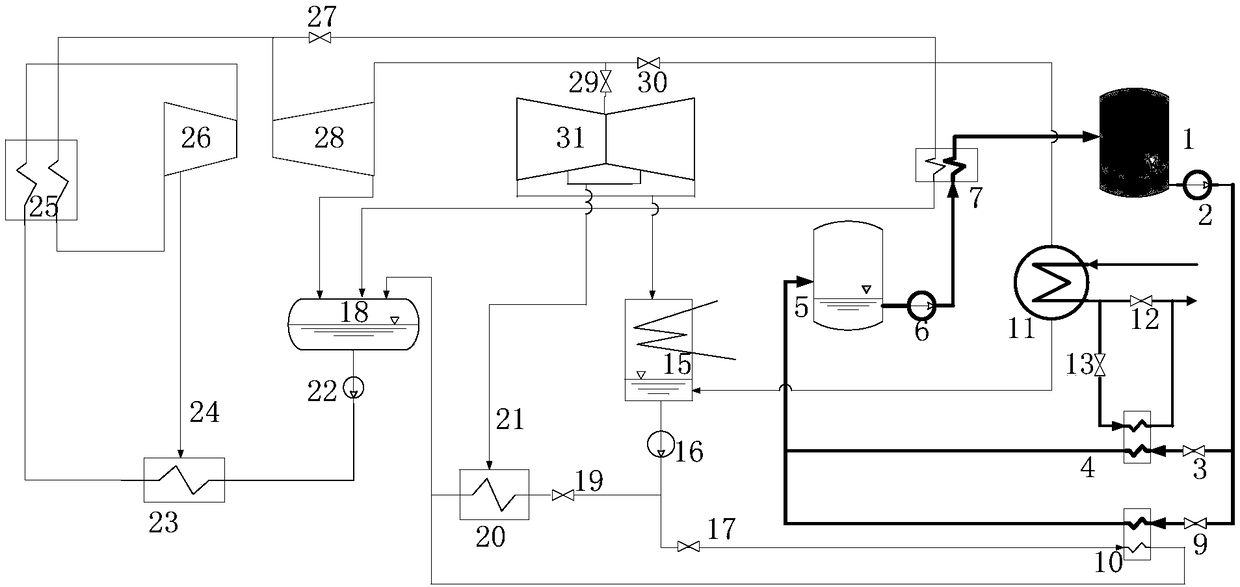

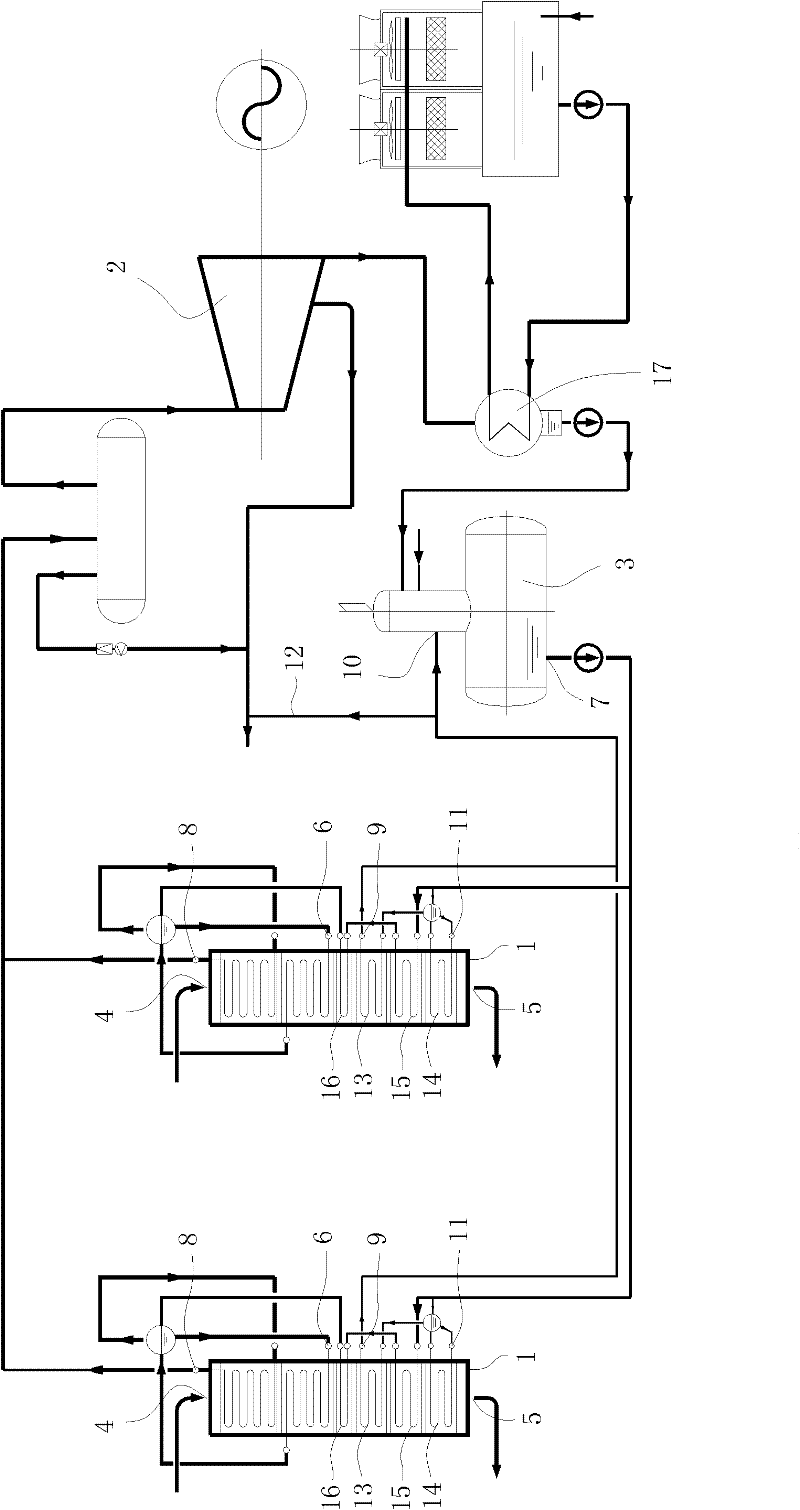

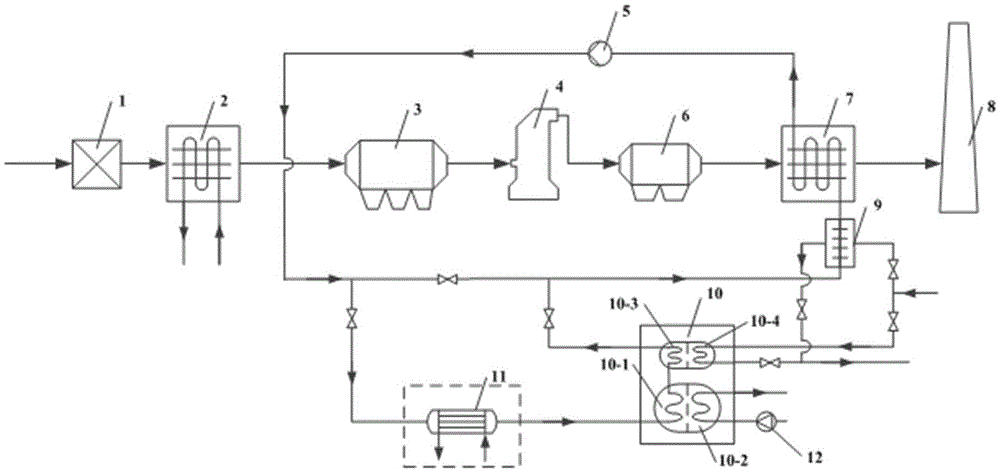

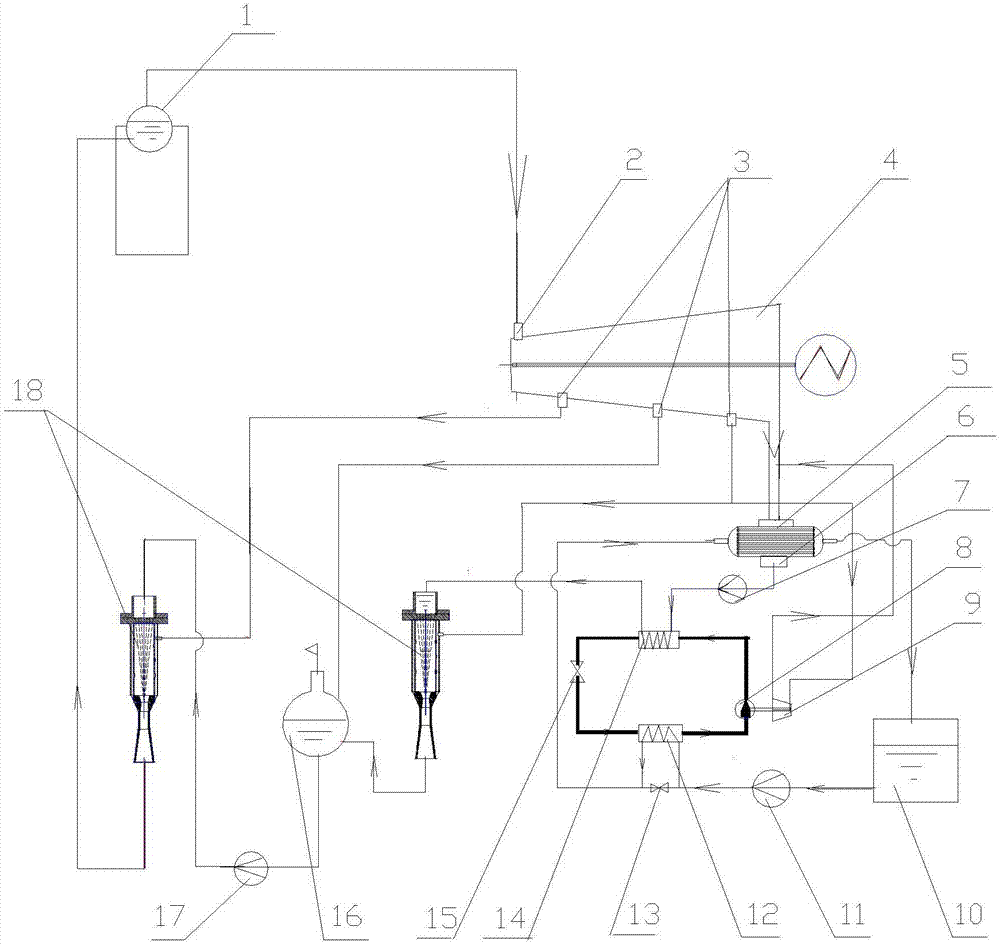

Energy-saving heat supply system with function of reducing temperature of heat supply return water

InactiveCN106705185AIncrease profitReduce circulating water flowLighting and heating apparatusSteam useCooling towerTemperature difference

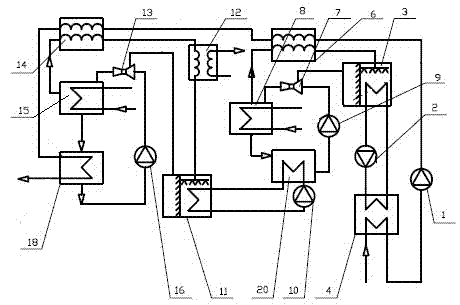

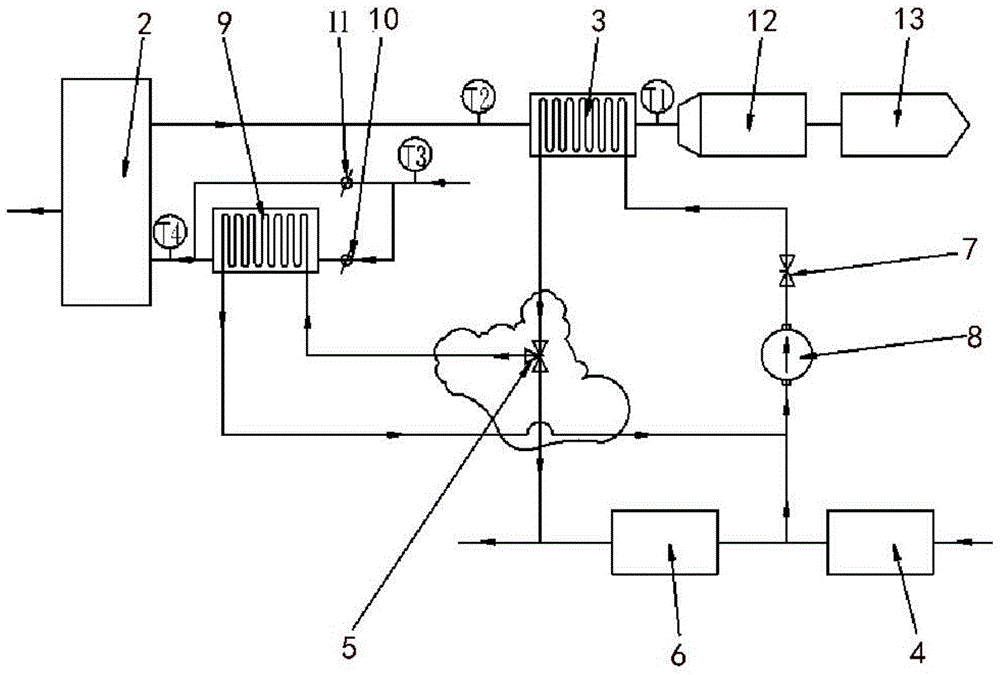

The invention discloses an energy-saving heat supply system with a function of reducing the temperature of heat supply return water, and belongs to the field of improvement of energy utilization efficiency. Heat exchange can be repeatedly carried out on heat sources by multistage heat exchangers, multistage absorption heat exchange units, multistage compression heat pumps and an ice making type refrigerator, accordingly, the heat supply areas can be enlarged, and the energy utilization efficiency can be improved. The energy-saving heat supply system has the advantages that the temperature of the return water of heat supply primary pipe networks can be reduced and reach 0 DEG C, the return water contains 10% of ice particles, accordingly, route heat loss of the return water of the heat supply primary pipe networks can be reduced, the temperature difference of the return water of the heat supply primary pipe networks can be increased and reaches 118 DEG C from the original 60 DEG C, the flow rate of circulating water of the heat supply primary pipe networks can be lowered, energy consumption of circulating pumps can be reduced, heat supply flow rates of a user side can be greatly increased, the delivery efficiency of the pipe networks can be improved, the heat supply scale can be expanded, waste heat of a cooling tower can be recycled, and the like.

Owner:DALIAN BAOGUANG ENERGY SAVING AIR CONDITIONING EQUIP

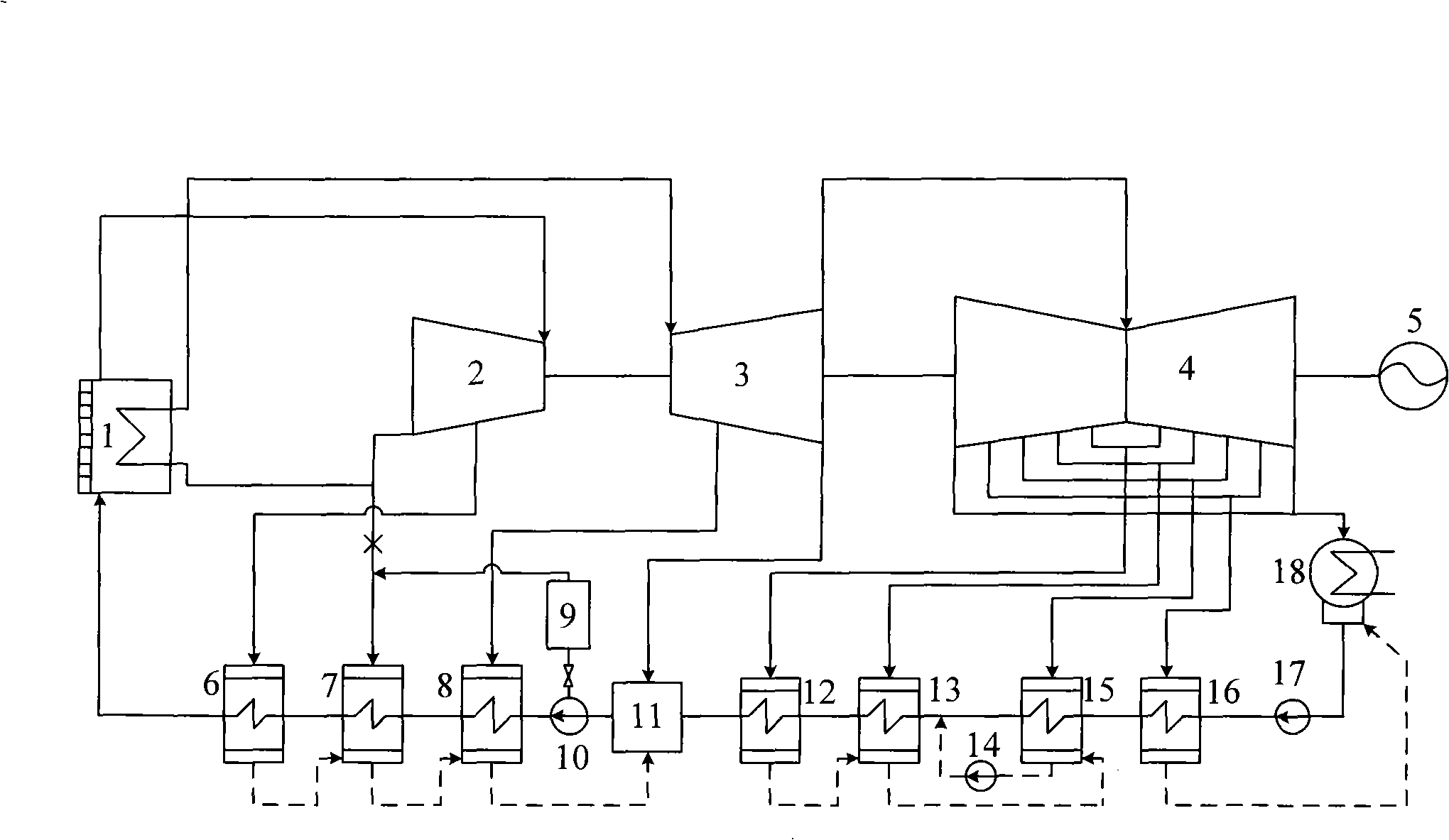

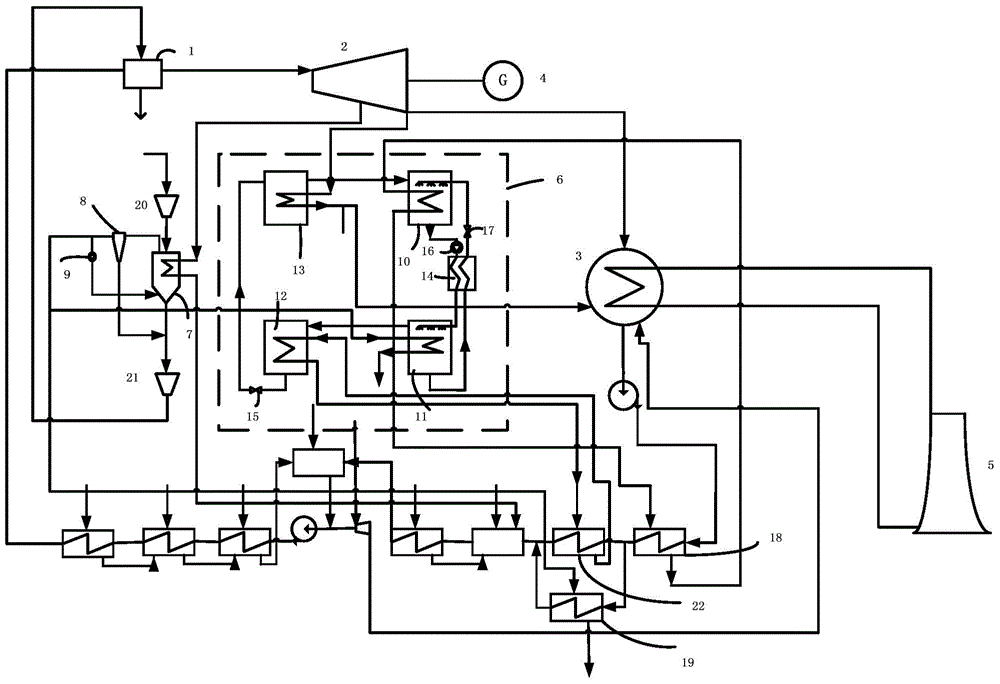

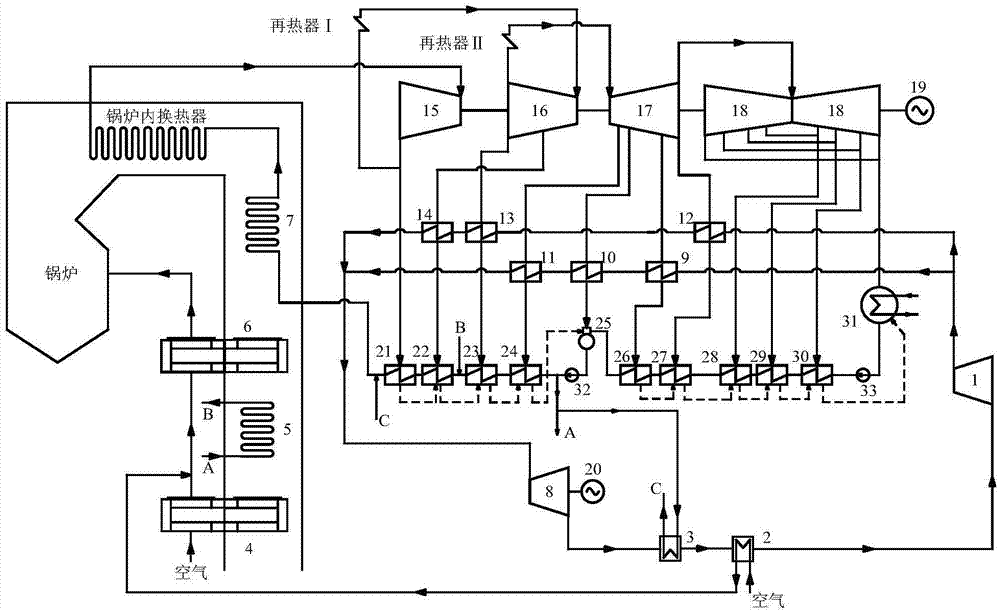

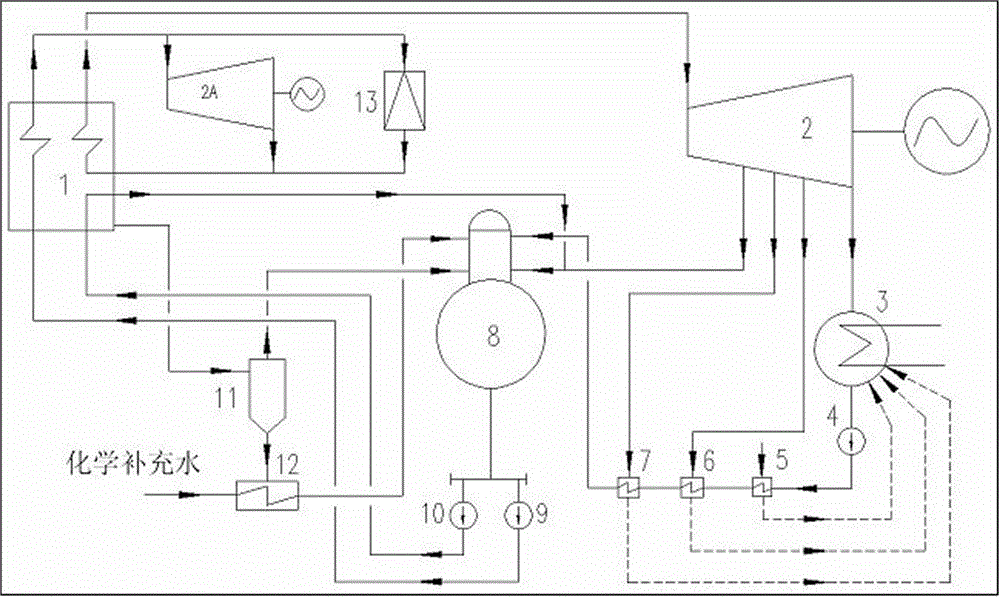

Paraboloid trough type solar heat-collector auxiliary coal-burning boiler mixing heat power generation system

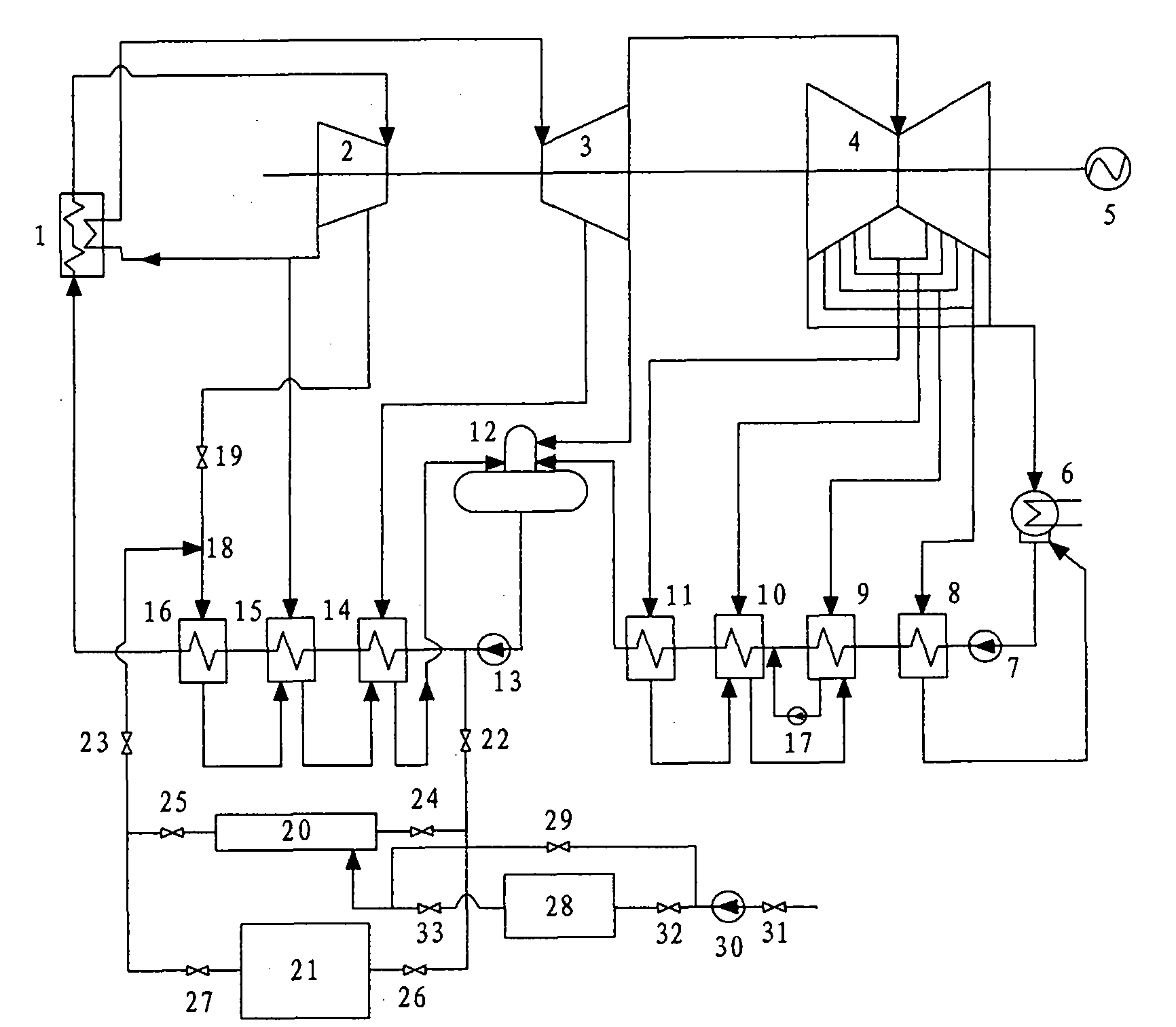

InactiveCN101260815AHigh thermal efficiencyLess coal consumptionSteam engine plantsDeaeratorEngineering

The invention belongs to the generating equipment scope and in particular relates to a mixed heat power generating system with a paraboloid groove type solar heat collector to assist a coal burning boiler. A solar heat collector field is connected with a feed pump and a second or a third high-pressure heater; a condenser, an extraction pump, a low-pressure heater, a deaerator, the feed pump, the high-pressure heater, the coal burning boiler and a steam turbine are connected in series in turn; and the steam turbine drives a dynamo and discharges steam to the condenser. Condensed water flows out from the condenser and is heated up and pressurized up by a the low-pressure heater, deoxidized by the deaerator, fed with water by a leading-out part of the feed pump and enters the solar heat collector field for heat absorption; after reaching a stream drawing parameter of a certain stage high-pressure heater, the condensed water returns and joins the drawing gas of the corresponding stage heater; the other part of feeding water enters the coal burning boiler through the high-pressure heater and becomes steam with high temperature and high pressure; and the steam enters the stream turbine, applies work and flows into the condenser to complete a thermodynamic cycle. The mixed heat power generating system with the paraboloid groove type solar heat collector to assist the coal burning boiler reduces coal consumption of a coal burning unit, improves thermal efficiency of the solar heat power generation and reduces the investment on the simple paraboloid groove type solar heat power generation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

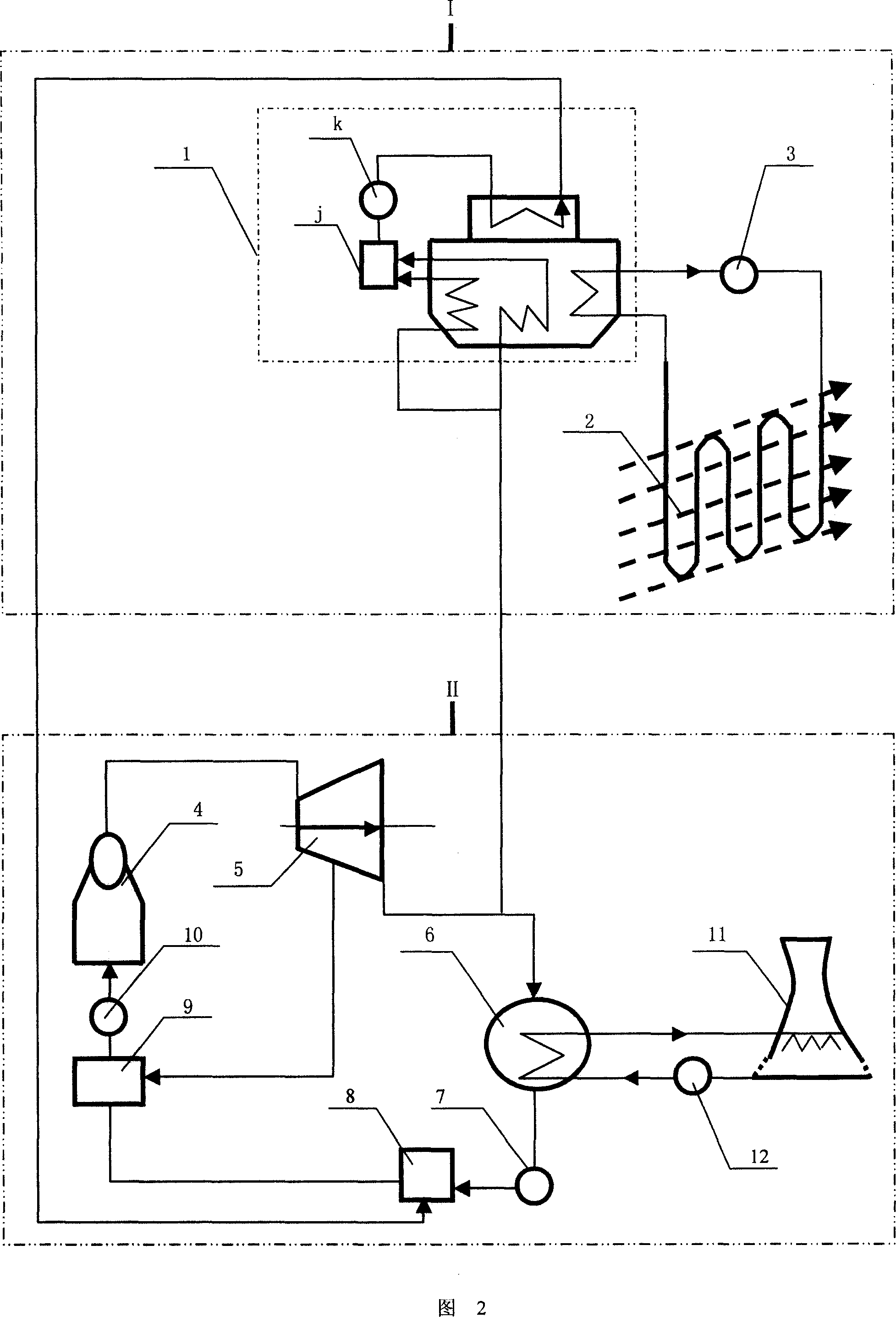

Backheating and heating technology by using residual heat of exhaust steam in steam power cycle

InactiveCN1967055AReduce steam extractionGood energy savingHeat pumpsEnergy efficient heating/coolingSeawaterEvaporator

It relates to a heat supply technique by using left vapor heat in the vapor power circulation. It mainly uses two-level or multi-level secondary absorbing heat pump technique with absorption and evaporator, with the exhaust gas as the heat source, environment as the cooling source. The exhaust heat return technique can improve vapor power circulating heat efficiency, with better energy saving benefit, realizing two times heating for desalinated sea water. It can reduce coolant consumption with less pollution.

Owner:李华玉

Method for recycling flue gas waste heat of thermal power plant boiler

InactiveCN102454980AImprove recycling efficiencyImprove work efficiencyCombustion processFeed water supplyAir preheaterEngineering

The invention discloses a method for recycling flue gas waste heat of a thermal power plant boiler. A first heat exchanger is connected in parallel to an air pre-heater of a boiler exit flue, the heat exchange medium input / output end of the first heat exchanger is connected with a high-pressure condensed water heater through a flow control valve, and the high-pressure condensed water is heated, so that steam extraction of high-quality steam of a steam turbine is reduced. By the method, the recycling efficiency of the exhaust waste heat of the boiler is effectively improved, the work efficiency of the boiler and the steam turbine is improved, the energy consumption of power generation is reduced, and good economic benefits and social benefits are obtained.

Owner:上海成信设施科技有限公司 +1

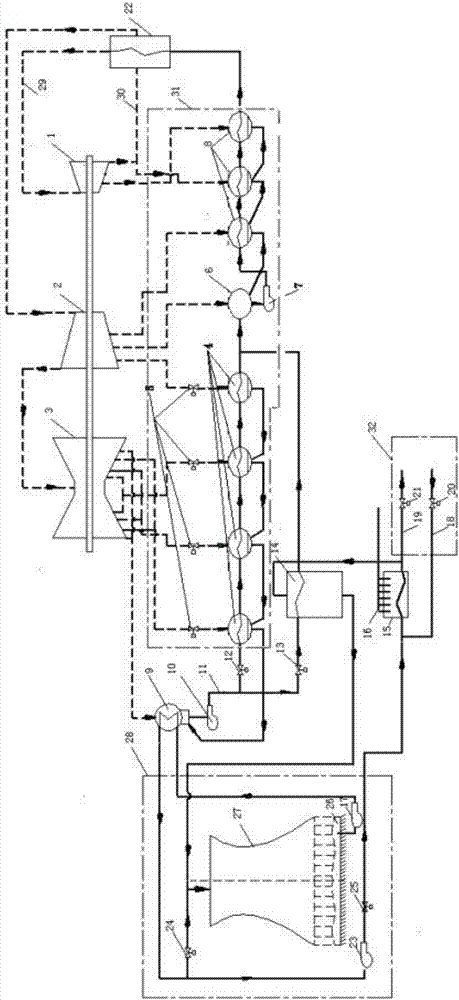

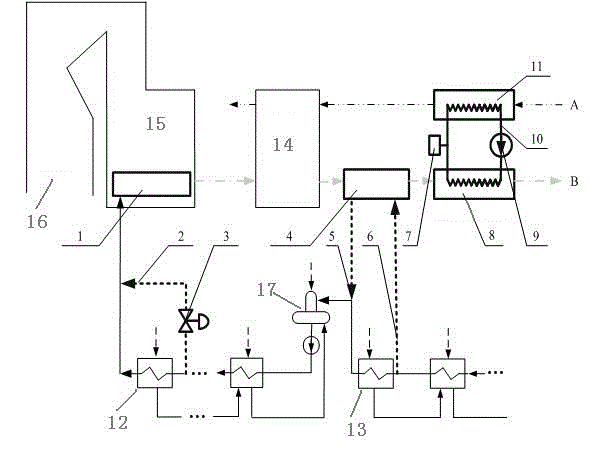

Pre-drying brown coal power generation system integrated with first-class absorption heat pump and pre-drying brown coal power generation method

ActiveCN105179023AReduce steam extractionImprove system efficiencyDrying solid materials with heatSteam useFluidized bed dryingEngineering

The invention discloses a pre-drying brown coal power generation system integrated with a first-class absorption heat pump and a pre-drying brown coal power generation method. The system mainly comprises such apparatuses as a traditional coal-fired power generation system, a steam fluidized-bed dryer with a built-in heater and the first-class absorption heat pump. According to the method, dry tail gas is used as a fluidizing and drying medium in the fluidized-bed dryer. The extracted steam of one stage of a steam turbine low-pressure cylinder flows through the built-in heater of the dryer to provide heat needed by evaporating moisture in brown coal. The dry tail gas serves as a high-temperature heat source for the heat pump, and turbine steam exhaust serves as a low-temperature heat source for the heat pump to generate low-temperature steam at a temperature between the temperatures of the dry tail gas and the turbine steam exhaust for heating the condensed water of the power generation system. The system is capable of reducing the steam extraction amount of a heat regenerative system, reducing the amount of waste heat emitted by the power generation system to the environment, realizing the utilization of the waste heat of the dry tail gas and the turbine steam exhaust and improving the efficiency of the power generation system.

Owner:XI AN JIAOTONG UNIV

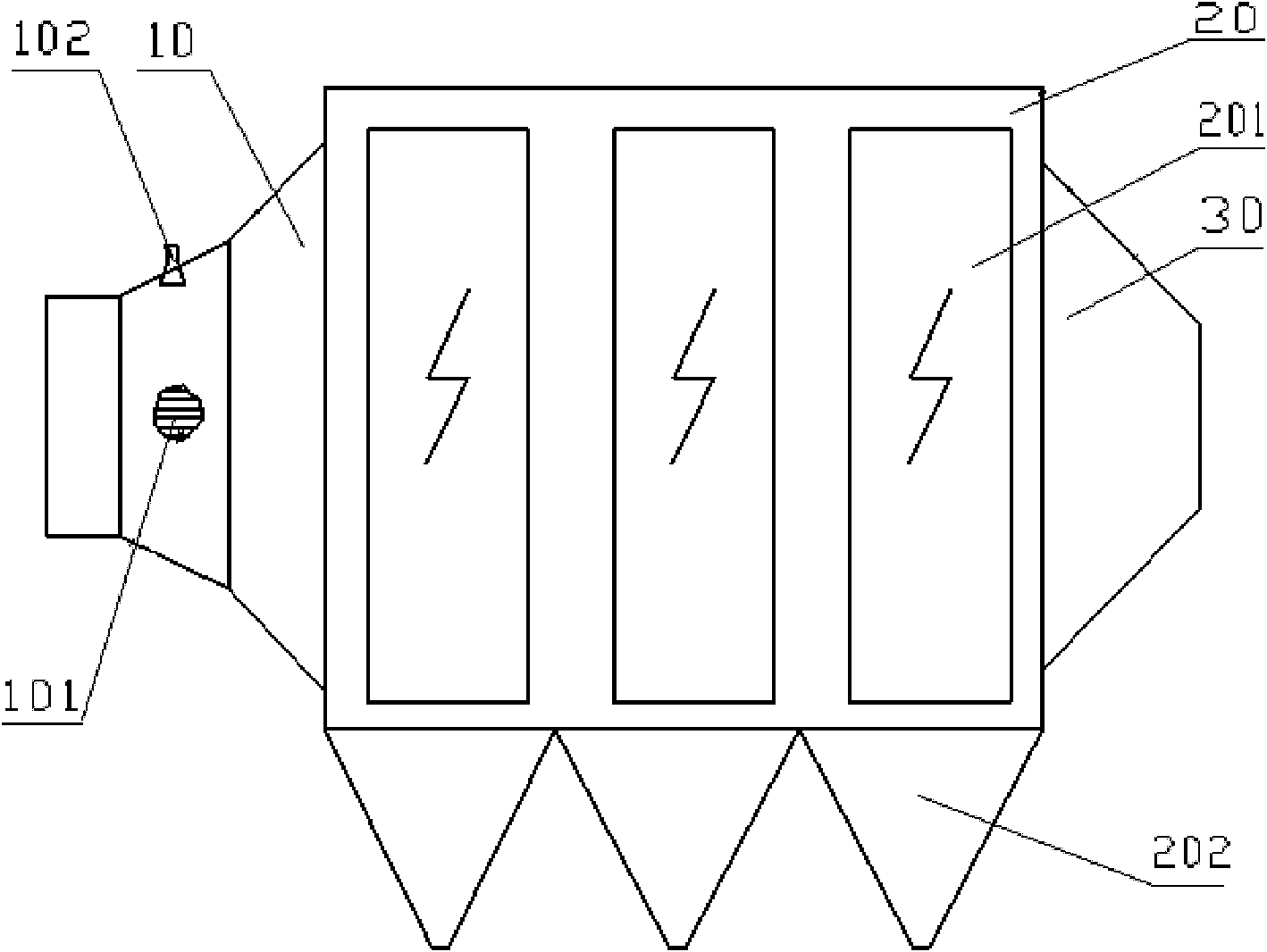

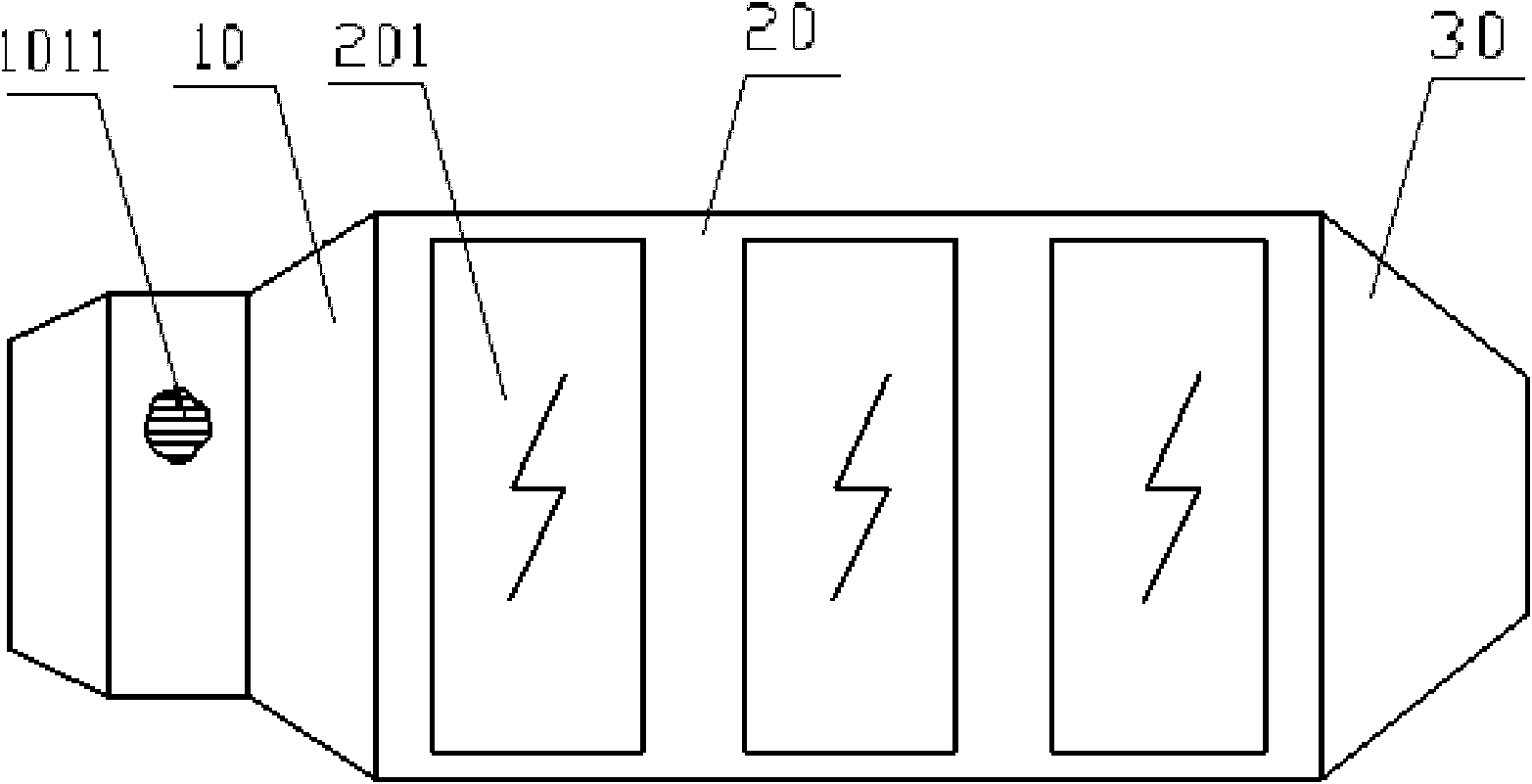

A flue gas dedusting system and its electric precipitator

ActiveCN102284361AImprove dust removal efficiencyCompact structureElectrostatic separationFlue gasProcess engineering

The invention discloses a flue gas electric dust remover. The flue gas electric dust remover comprises an inlet flue gas box, an outlet flue gas box, a high-pressure electrostatic dust collection electric field positioned between the inlet flue gas box and the outlet flue gas box, and a heat exchange device arranged in the inlet flue gas box. The flue gas electric dust remover can reduce the temperature of flue gas before the flue gas enters the high-pressure electrostatic dust collection electric field, so the volume flow rate of the flue gas to be treated which enters the electric field is reduced, and the flow velocity of the flue gas in a flue gas channel of the electric field is correspondingly reduced; meanwhile, the flue gas temperature is reduced, so the dust specific resistance of the flue gas is reduced, and the dust removal efficiency of the electric dust remover is improved; in addition, the heat exchange device is arranged at the inlet flue gas box, so the inner space of the inlet flue gas box on the conventional electric dust remover can be fully utilized, and additional occupied space is not increased while the dust removal efficiency is improved, namely the flue gas electric dust remover has the advantages of compact structure and contribution to system and process arrangement. The invention also discloses a flue gas dust removal system with the flue gas electric dust remover.

Owner:FUJIAN LONGKING

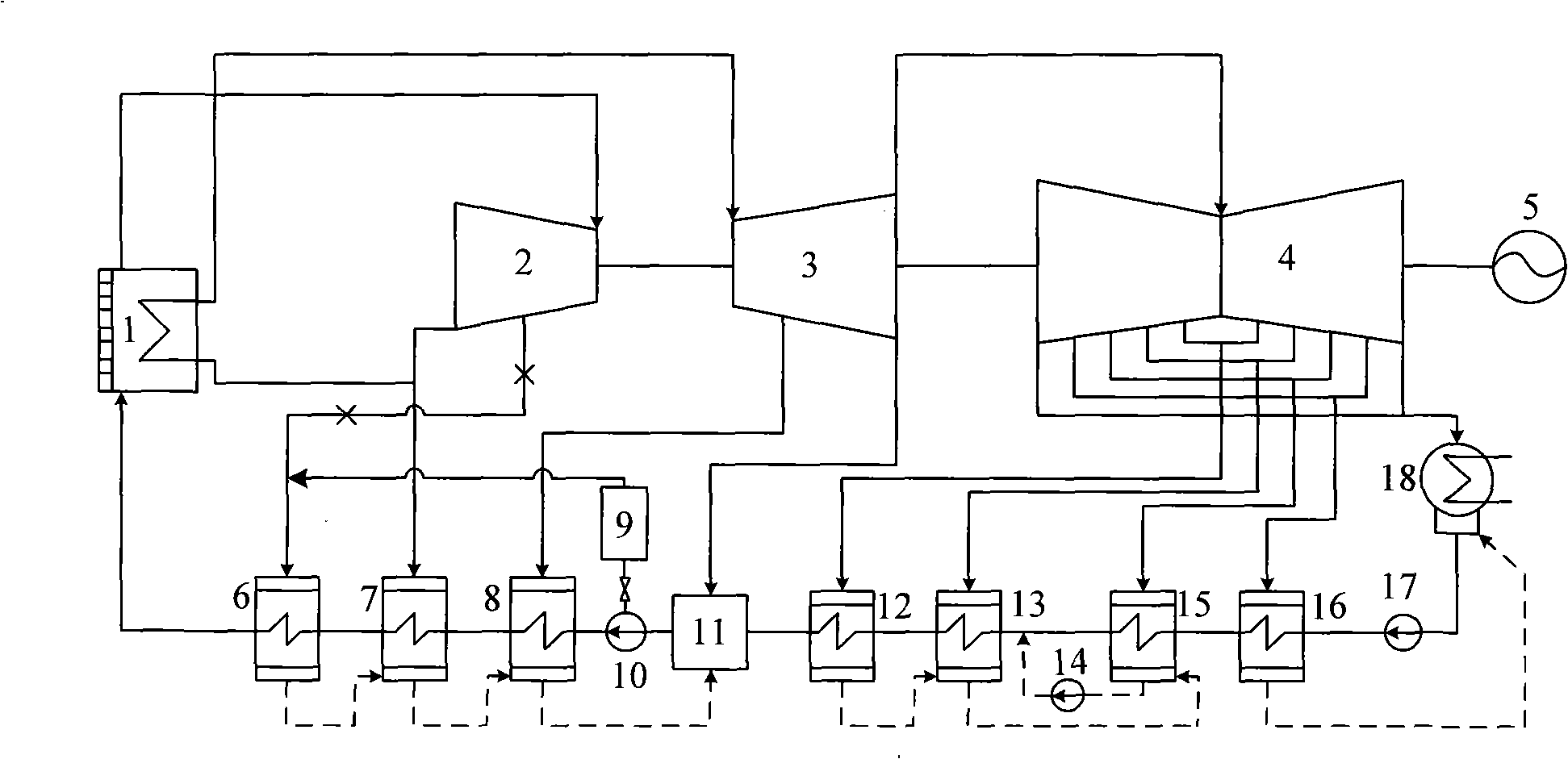

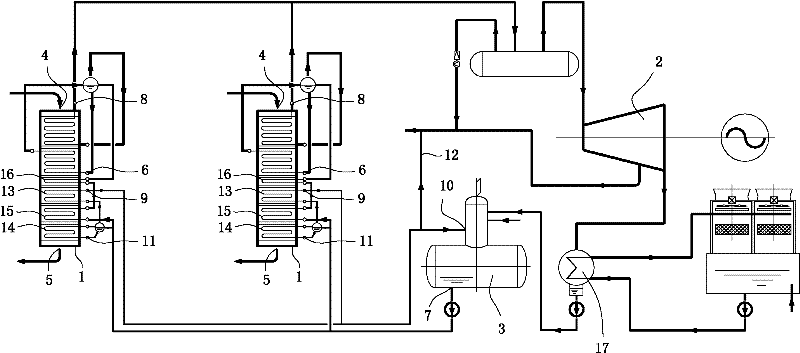

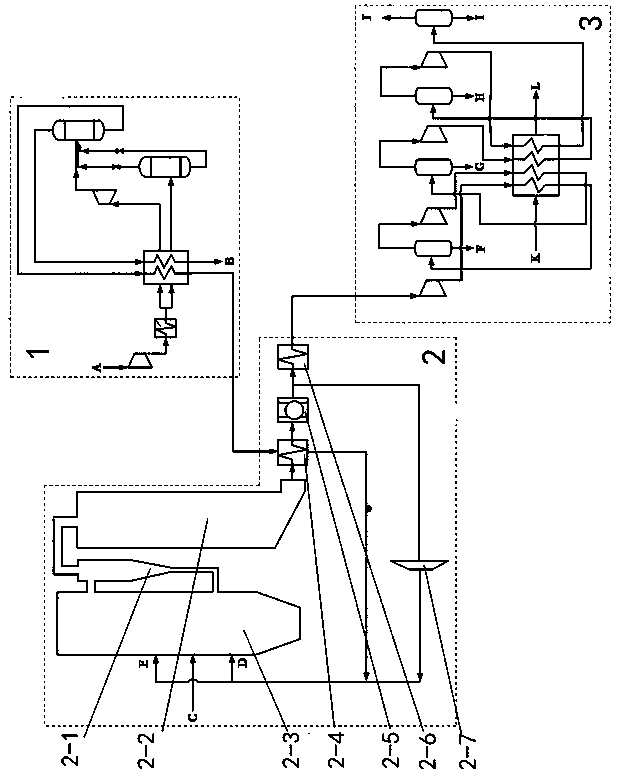

Renewable energy resource assistant coal hybrid power generation system

InactiveCN101892877AReduce coal consumptionReduce steam extractionSteam engine plantsDeaeratorEngineering

The invention discloses a renewable energy resource assistant coal hybrid power generation system. The hybrid power generation system comprises a coal-fired boiler power generation system and a parallel-connection assistant system, wherein the coal-fired boiler power generation system comprises a generator, and a condenser, a condensation water pump, multi-level low pressure heaters, a deaerator, a feed pump, multi-level high pressure heaters, a coal-fired boiler and a steam turbine sequentially connected in series, wherein a steam inlet of the condenser is connected with the steam turbine to exhaust the steam; the multi-level low pressure heaters, the deaerator and the multi-level high pressure heaters are all connected with the steam turbine for steam extraction; the steam turbine drives the generator; and the parallel-connection assistant system consists of a biomass gasifying device and a paraboloid trough type solar heat collector field which are parallelly connected and then connected between an outlet of the feed pump and a steam extraction inlet of one of the multi-level high pressure heaters. The hybrid power generation system reduces coal consumption of the conventional coal-fired power plant, optimizes energy utilization structure, solves a problem of high pollution of the conventional coal-fired power generation system to a great degree and is favorable for ecological protection.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Thermoelectric decoupling system with heat storage function

InactiveCN109139151AIncrease flexibilityImprove energy savingSteam useThermal energyThermoelectric cooling

The invention provides a thermoelectric decoupling system with a heat storage function. The system comprises a fused salt heat storage system arranged on a reheat steam pipeline of a turbine unit, wherein a heat supply network water outlet of the fused salt heat storage system is connected with a heat supply network system through a heat exchange system. Since a reheat steam pipeline of the turbine unit is provided with a branch to be connected with a fused salt heat storage system, and heat produced when a turbine is operated at the high power generation load is stored through fused salt. When the turbine needs to be subjected to low-load peak regulation and the power generation power of the turbine is reduced, fused salt can release heat to supplement heat to the heat supply network so as to achieve thermoelectric decoupling. The problem that an existing thermal power generating unit with a heat supply function cannot meet the adjusting requirements of the generating capacity and theheat supply capacity at the same time is solved, and therefore the system has the important significance in improving flexibility of a heat supply unit, saving energy and reducing emission.

Owner:HUANENG POWER INTERNATIONAL +1

Coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation

ActiveCN107989667ALower extraction temperatureReduce superheatSteam useIndirect carbon-dioxide mitigationAir preheaterEngineering

The invention belongs to the technical field of secondary reheating steam turbine generating and energy saving and discloses a coal-fired secondary reheating steam turbine generator unit integrated with supercritical CO2 circulation. The unit comprises a coal-fired boiler, a secondary reheating steam turbine generator unit and a supercritical CO2 circulating generation system. Six-stage extractionsteam connected with a high pressure cylinder and an intermediate pressure cylinder is connected with steam-CO2 heat exchangers and enters corresponding feed water regenerative heaters after heatingCO2; in the CO2 circulating generation system, CO2 at an outlet of a compressor is divided into two streams, the two streams are heated by three stages of steam-CO2 heat exchangers respectively and are converged to enter a CO2 turbine for working, and CO2 exhaust enters the compressor after passing through a CO2-feed water heater and a CO2-air preheater sequentially; in a flue at the tail of the boiler, air is divided into two streams, and the two streams are preheated by the CO2-air preheater and a low-temperature air preheater respectively and are converged to enter a main air preheater. Bythe aid of the integrated system, the superheat degree of regenerative extraction steam of the secondary reheating unit and the exergy loss of air preheating are substantially reduced, the work of a steam turbine is increased, and the efficiency is improved.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

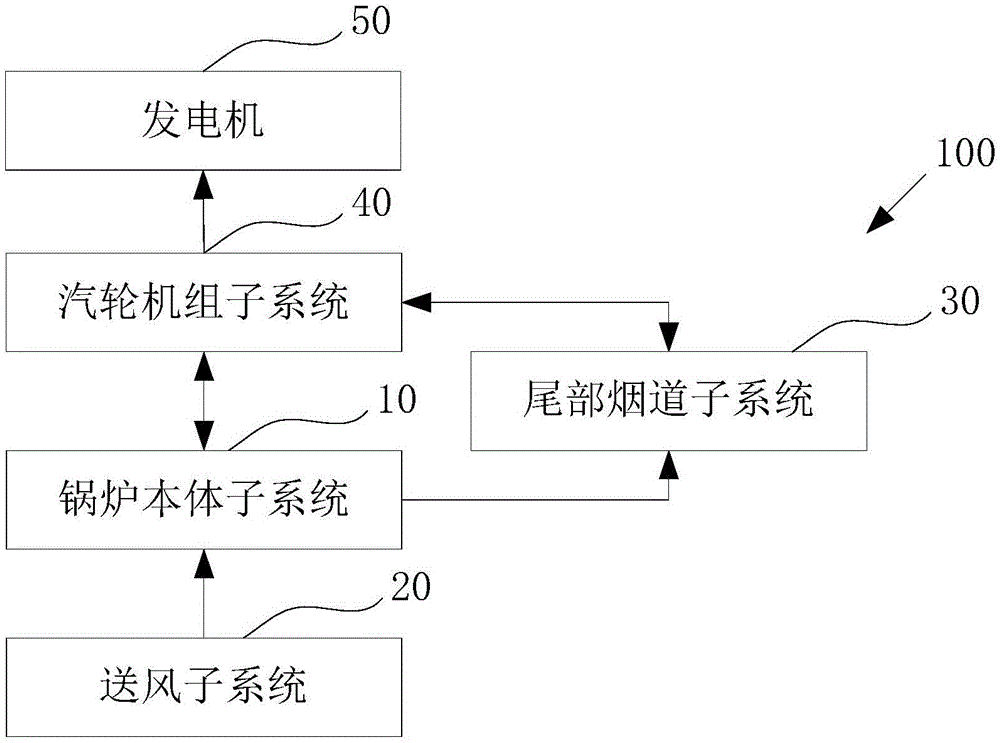

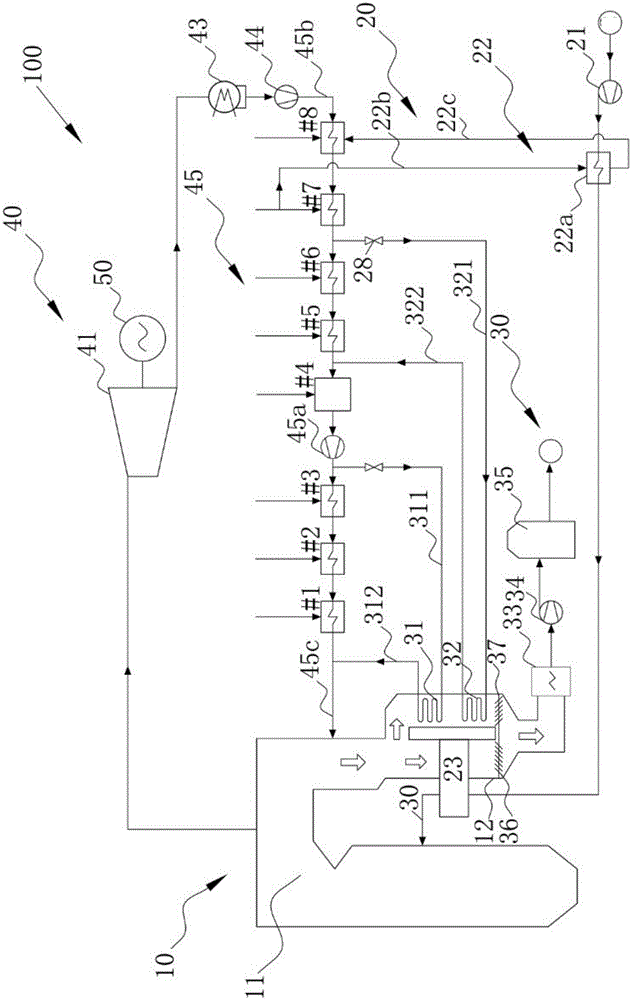

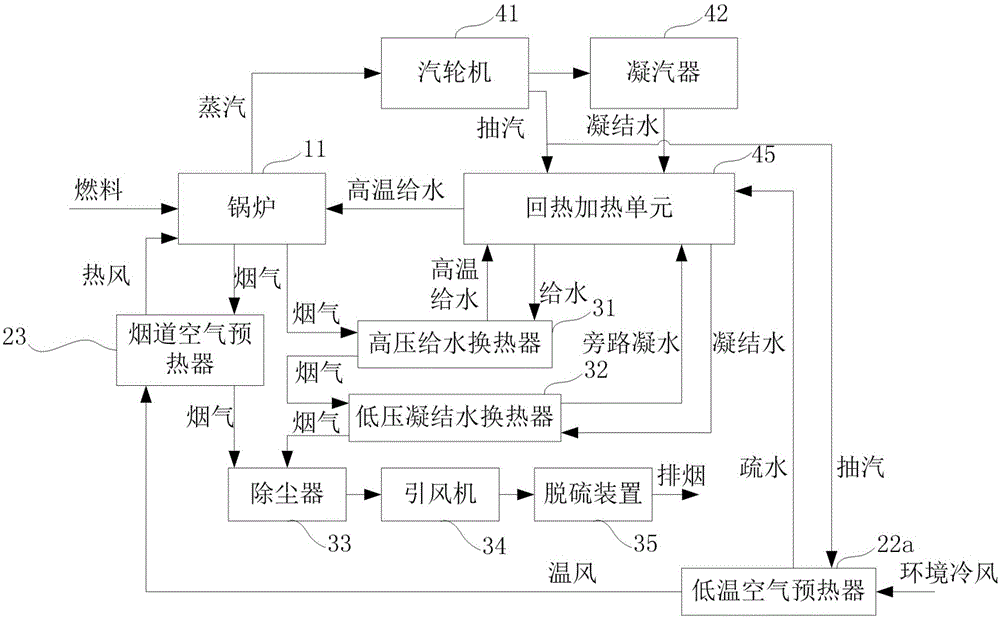

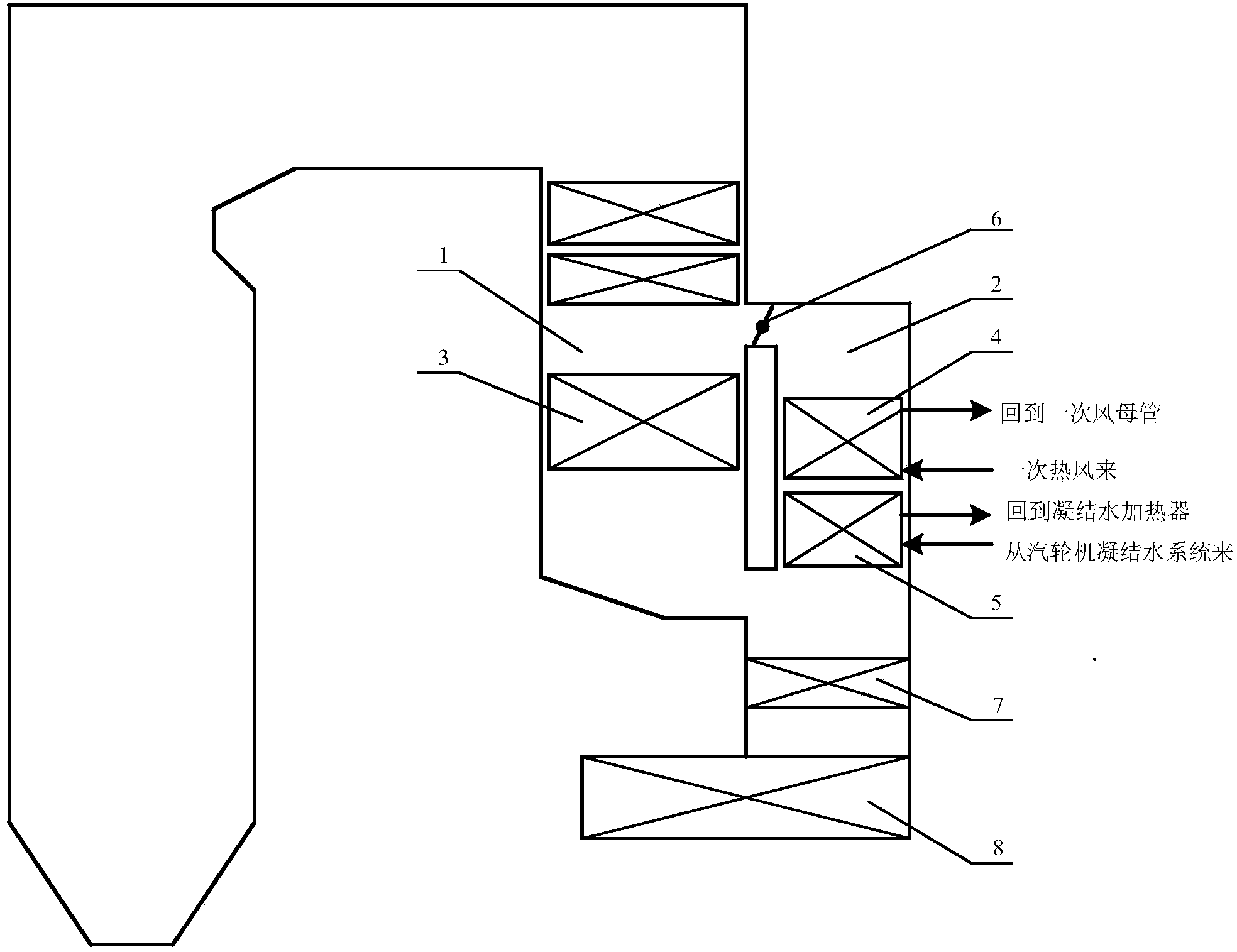

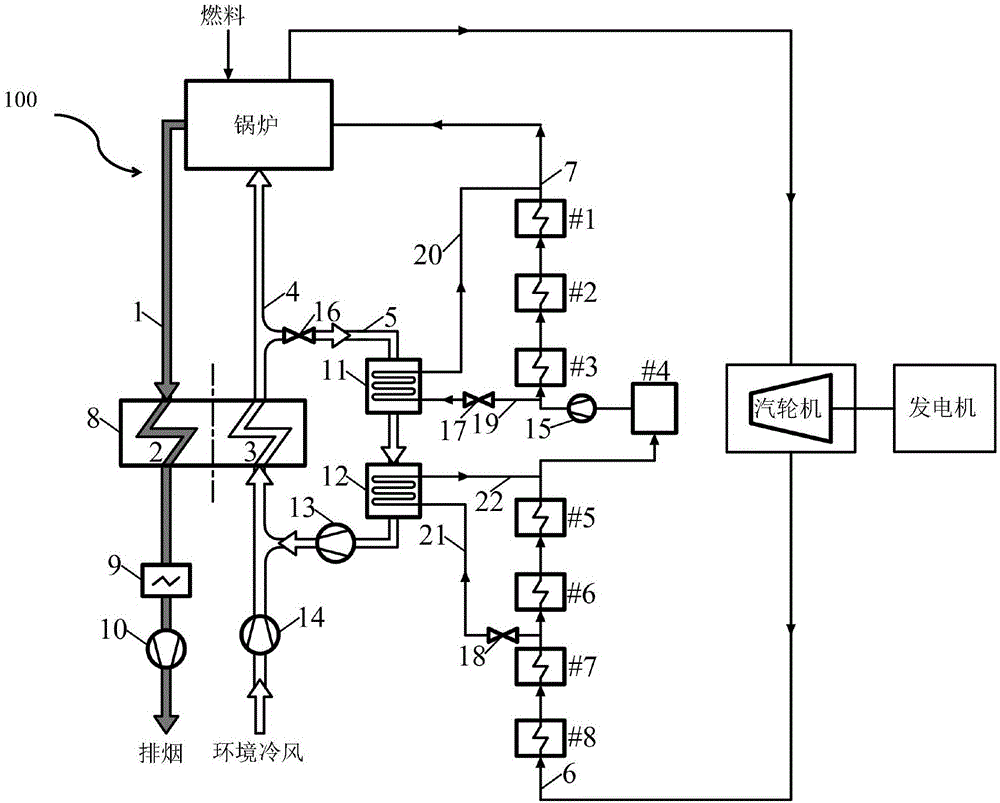

Coal-fired power generation system based on bypass flue at tail part of boiler

InactiveCN105157010ASolve the outstanding problem of severe low temperature corrosion on the heating surfaceImprove power supply efficiencySteam useFeed-water heatersAir preheaterCold air

The invention provides a coal-fired power generation system based on a bypass flue at the tail part of a boiler as well as warm air obtained through steam extraction. The coal-fired power generation system adopts fuel to heat feed water so as to generate power, and is characterized by comprising a boiler body subsystem, an air supply subsystem, a tail flue subsystem, a turboset subsystem and a generator, wherein the boiler body subsystem comprises the boiler and a boiler flue, the boiler is provided with a hearth, and the boiler flue is connected with an outlet of the hearth and divided into a main flue and the bypass flue; the air supply subsystem comprises an air feeder, a front air preheater and a flue air preheater, the air feeder is used for supplying environment cold air, the front air preheater is connected with the air feeder and used for preheating the environment cold air to obtain warm air, and the flue air preheater is arranged in the main flue and used for heating the warm air; the tail flue subsystem comprises a high-pressure feed water heat exchanger and a low-pressure condensed water heat exchanger, the high-pressure feed water heat exchanger is arranged in the bypass flue and close to an inlet of the bypass flue, and the low-pressure condensed water heat exchanger is arranged in the bypass flue and close to an outlet of the bypass flue.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Waste heat utilization system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature

InactiveCN103486566AReduce coal consumptionIncrease workLiquid degasificationFeed-water heatersFlueProcess engineering

The invention discloses a bootstrap system capable of guaranteeing lignite boiler dry output and SCR safe flue gas temperature. The bootstrap system comprises a boiler tail flue and a flue gas denitrification SCR which is arranged at the tail end of the boil tail flue. A bypass flue communicated with the boil tail flue is further parallelly connected between a flue gas inlet of an economizer and a flue gas inlet of the flue gas denitrification SCR. The bypass flue is internally and sequentially provided with a primary-air tubular heater and a low-pressure economizer which are used for lowering temperature of flue gas entering the flue gas denitrification SCR. Due to the arrangement that the bypass flue is additionally arranged on the tail portion of a boiler, and the primary-air heater is arranged on the upper portion of the bypass flue, primary-air temperature is ensured to meet requirements of a coal pulverizing system. The amount of flue gas passing through the economizer can be regulated by the bypass flue, so that flue gas temperature at the exit of the economizer can be regulated. The primary air is heated to the temperature as required by the high-temperature flue gas at the inlet of the economizer, and meanwhile, the flue gas temperature in the bypass flue is lowered through the low-pressure economizer, so that the flue gas temperature at the inlet of the SCR can meet the requirements of catalyst.

Owner:XIAN TPRI BOILER ENVIRONMENTAL PROTECTION ENG CO LTD +1

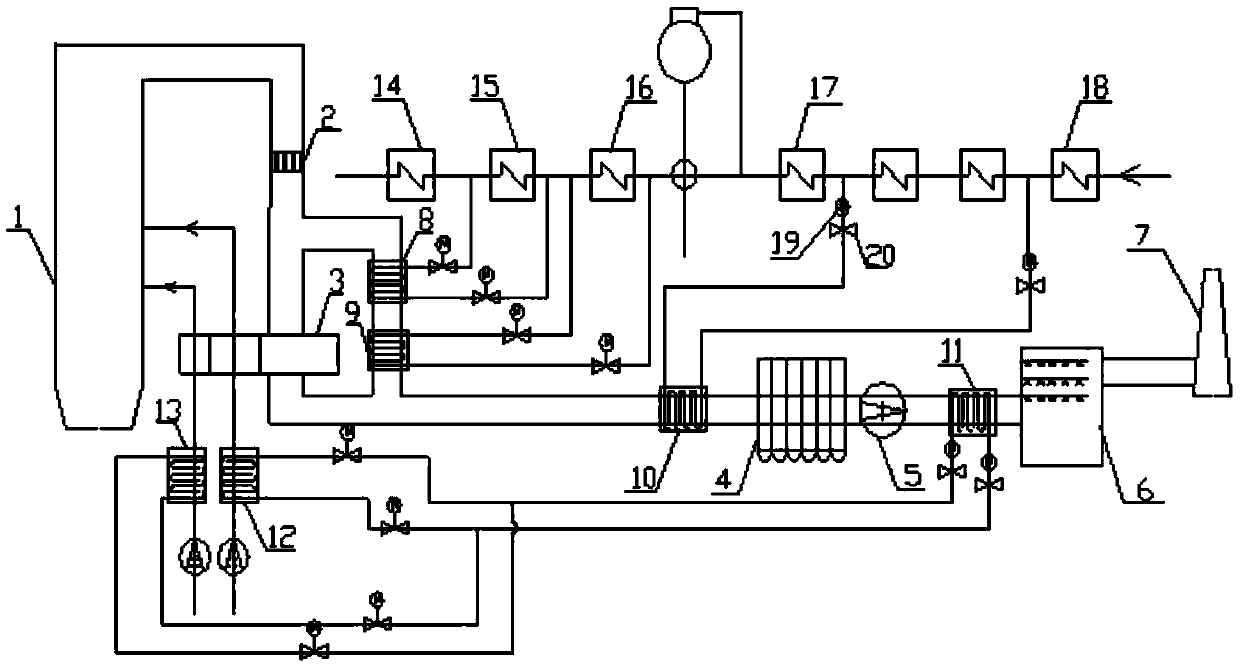

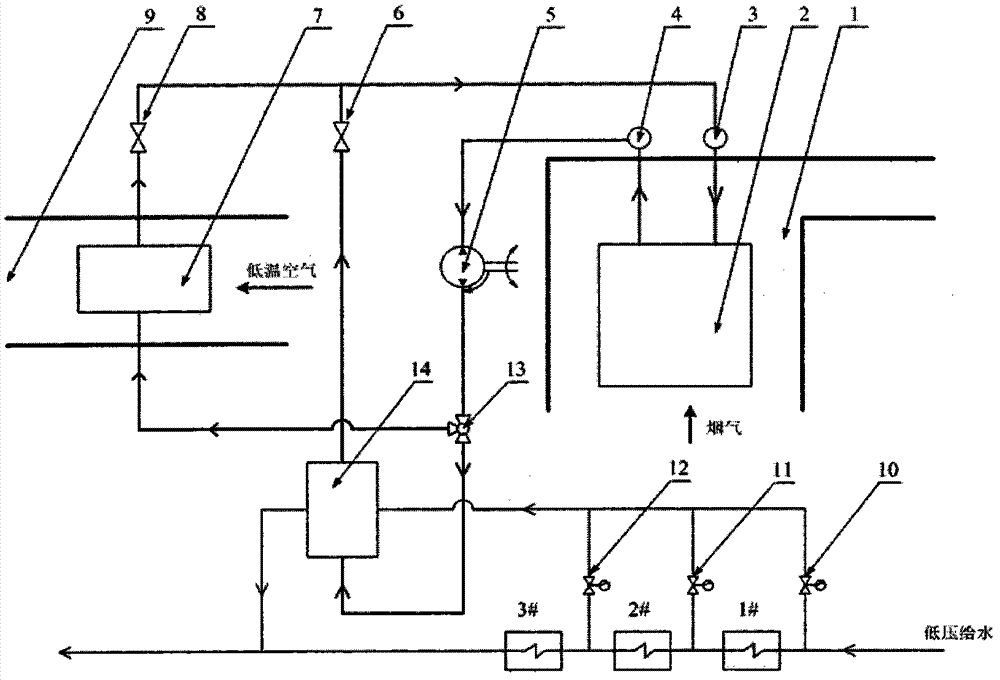

System capable of utilizing smoke waste heat in gradient mode for assisting in removing SO3 and improving dust removing efficiency

InactiveCN105371291AImprove dust removal efficiencyReduce SO3 concentrationLighting and heating apparatusCombustion technology mitigationFlueElectricity

The invention relates to a system capable of utilizing smoke waste heat in a gradient mode for assisting in removing SO3 and improving dust removing efficiency. The system comprises a boiler, a denitration device, an air preheater, an electric dust remover, an induced draft fan, a desulfurizing absorption tower, a chimney, low-pressure heaters, high-pressure heaters, heat exchangers, regulating valves and flow pumps, wherein the denitration device, the air preheater, the electric dust remover, the induced draft fan, the desulfurizing absorption tower and the chimney are connected with a flue at the tail of the boiler in sequence; the low-pressure heaters, the high-pressure heaters and the heat exchangers are arranged on bypasses; the regulating valves and the flow pumps are arranged on pipes and used for controlling flow; the air preheater is connected with the first bypass in parallel, the second bypass is arranged between the air preheater and the electric dust remover, and the third bypass is arranged between the induced draft fan and the desulfurizing absorption tower. The system follows the energy gradient utilization principle, smoke of the boiler is divided to three parts for waste heat utilization, and the smoke waste heat is deeply recycled; besides, the specific resistance of dust in the smoke can be changed, the electric dust removing efficiency can be improved, and the SO3 concentration in the smoke can be reduced.

Owner:HUADIAN ELECTRIC POWER SCI INST CO LTD

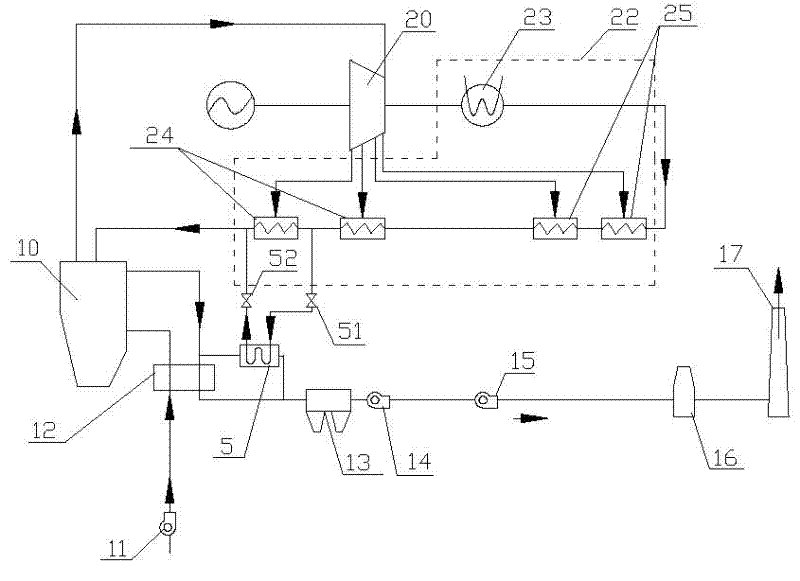

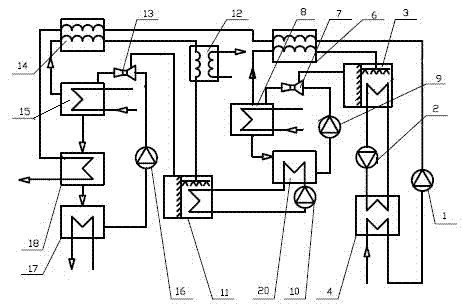

Electric heat storage boiler regeneration system used for regulating peak

ActiveCN107461728AReduce wasteAdaptableLiquid degasificationSteam generation using hot heat carriersCooling towerNetwork connection

The invention discloses an electric heat storage boiler regeneration system used for regulating the peak and belongs to the technical field of power generation equipment. The electric heat storage boiler regeneration system used for regulating the peak comprises a power station boiler, a turbine regenerative extraction system, an electric heat storage boiler, a water-water heat exchanger, a cooling tower circulating water system and a heat supply network connection pipeline. The core of the invention is to provide the electric heat storage boiler regeneration system used for regulating the peak. Surplus generated power in a power plant and abandoned wind power are stored into the electric heat storage boiler in the heating period in winter and are subjected to heat exchange with heat-supply network water to be supplied to a heat user; and when no heat user exists in summer, the deep peak regulation surplus power in the power plant and abandoned wind power in the trough period of a power grid are absorbed. When the power grid is in a peak or normal range, part of cooling tower circulating water is pumped into the electric heat storage boiler to absorb heat, the high-temperature circulating water absorbing heat is subjected to heat exchange with part of condensation water through the water-water heat exchanger, the condensation water is heated to the temperature the same as that of condensation water heated by a lower-pressure heater, stability of the system is ensured, and in this way, the steam extraction capacity of each cylinder is reduced.

Owner:JILIN PROVINCE ELECTRIC POWER RES INST OF JILIN ELECTRIC POWER CO LTD +4

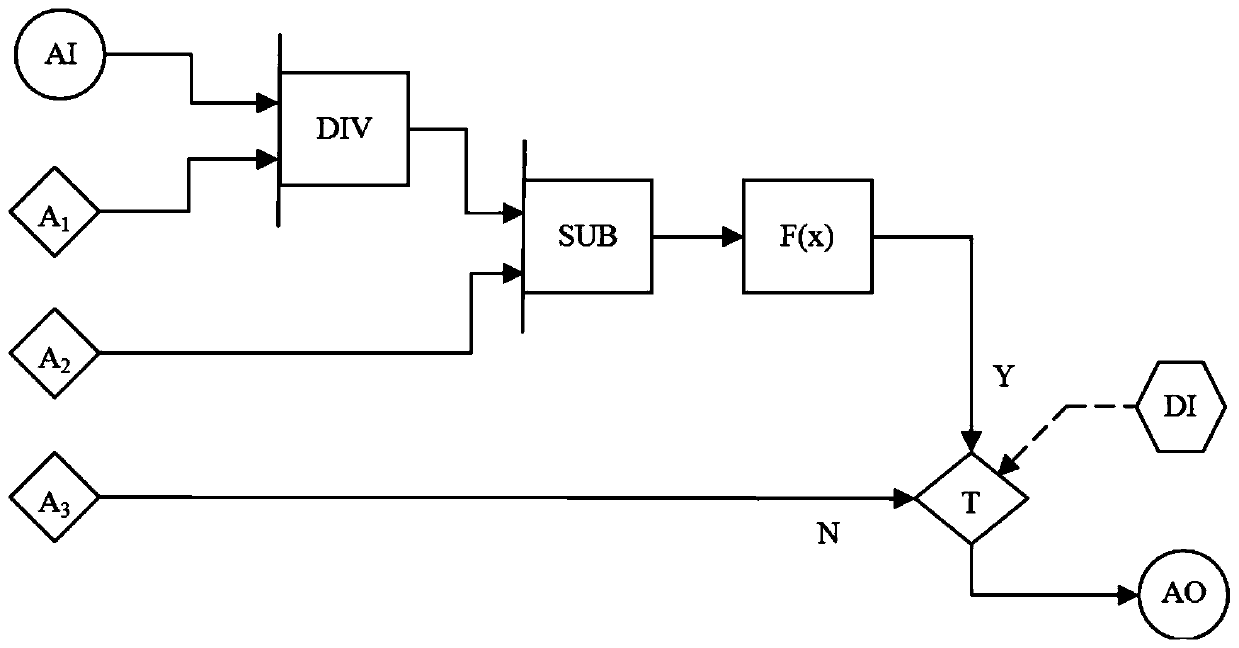

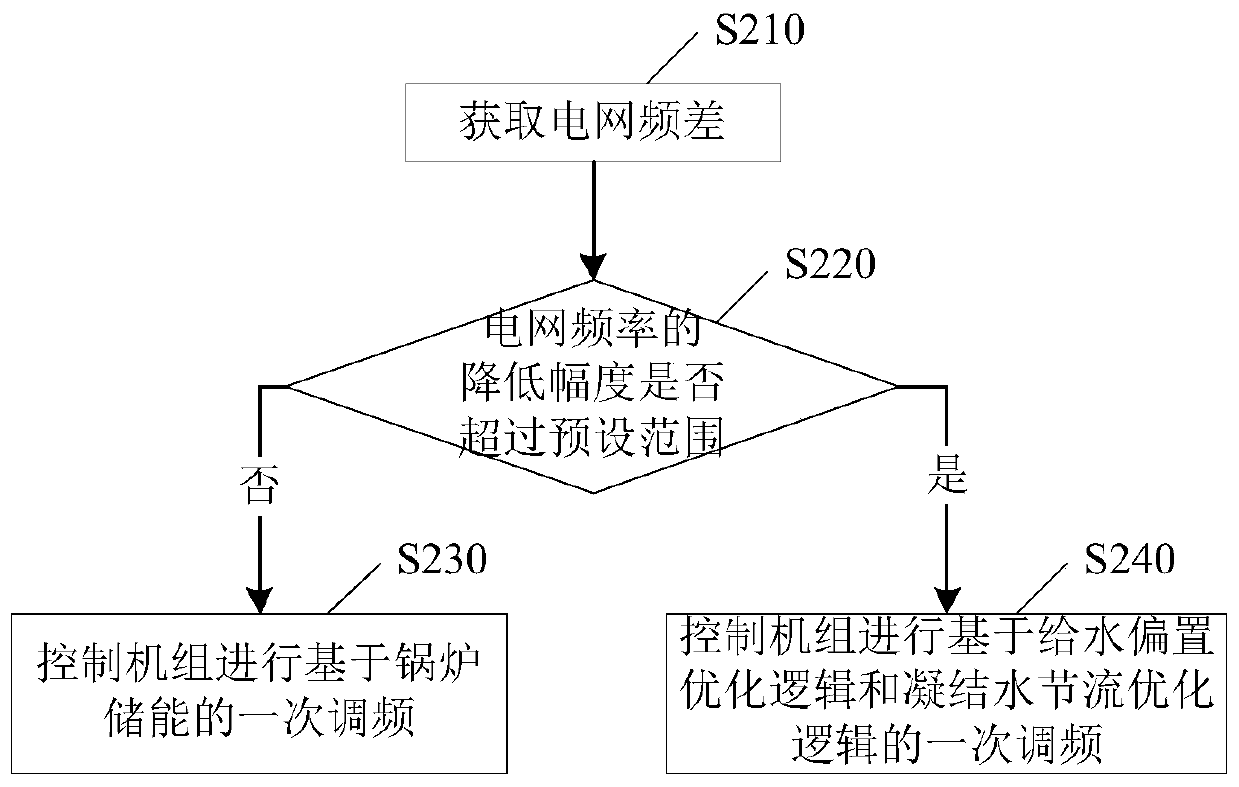

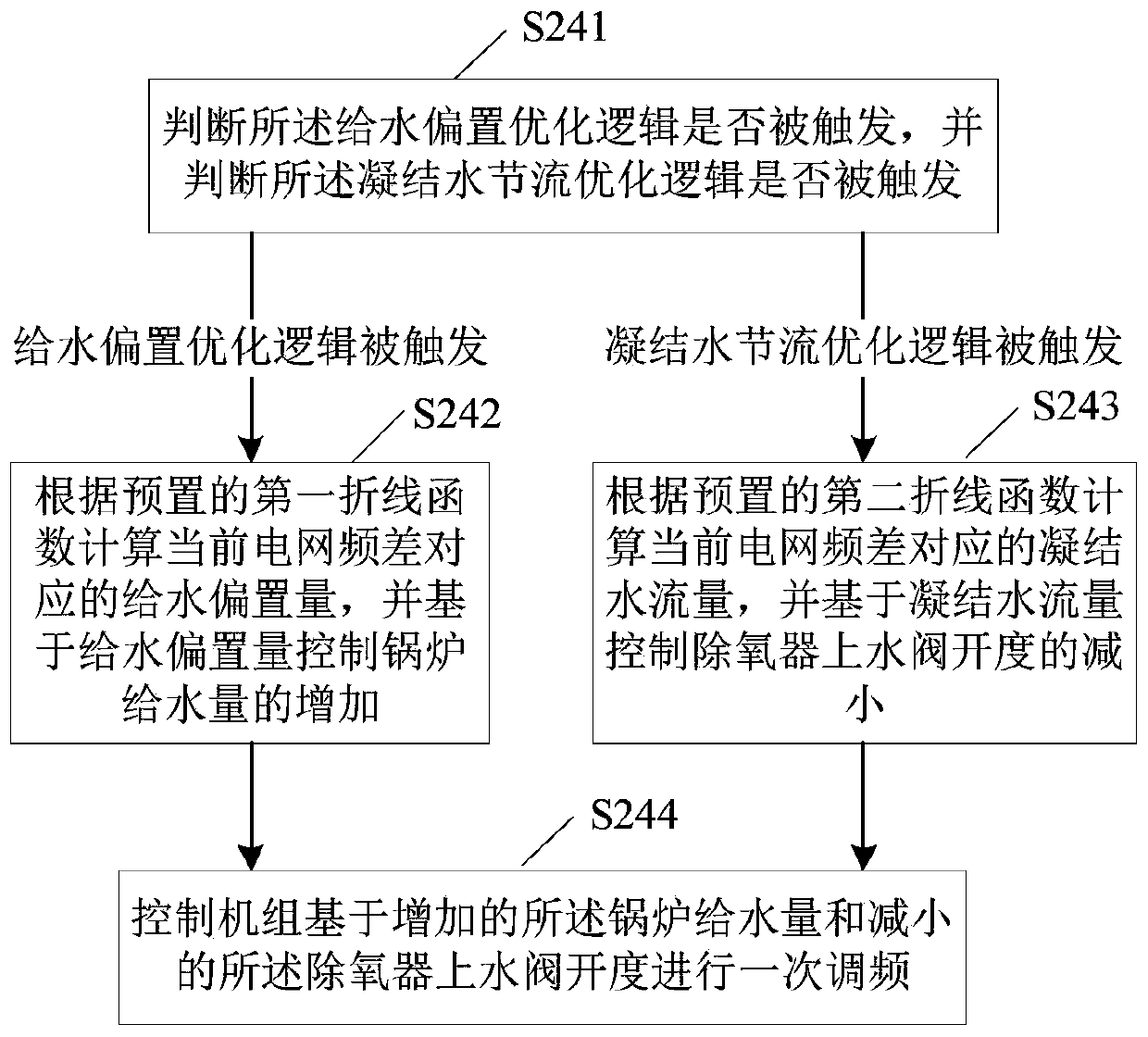

Control method and system for primary frequency modulation of thermal generating units

ActiveCN110212552AIncrease pressureImprove stabilityPower oscillations reduction/preventionSteam pressureEngineering

The embodiment of the invention relates to the technical field of thermal power generation control, and provides a control method and a system for primary frequency modulation of thermal generating units. The control method comprises the following steps: a frequency difference of a power grid is obtained; it is determined whether the reduction amplitude of the power grid frequency exceeds a presetrange according to the frequency difference of the power grid; if not, the primary frequency modulation based on boiler energy storage is performed on the units; and if so, the primary frequency modulation based on a feedwater bias optimization logic and a condensate throttling optimization logic is performed on the units; wherein, the feedwater bias optimization logic is used to increase the feedwater quantity of the boiler; and the condensate throttling optimization logic is used to reduce the opening degree of a water valve on a deaerator. In the embodiment of the invention, when the frequency of the power grid decreases greatly, the main steam pressure and the work capacity of working medium are improved by the two methods of increasing the feedwater quantity through the feedwater bias and reducing the condensate flow through the condensate throttling; steam extraction capacity of a turbine is reduced to improve the work of the working medium; and the frequency modulation accuracyand amplitude of the primary frequency modulation are improved.

Owner:CHINA SHENHUA ENERGY CO LTD +3

Power generation system utilizing waste heat of high-temperature flue gas

ActiveCN106321174AImprove qualityLower exhaust gas temperatureLiquid degasificationEnergy industryFlue gasEngineering

A power generation system utilizing waste heat of high-temperature flue gas comprises a dual-pressure waste heat boiler with a reheater arranged therein, wherein high-pressure steam of the dual-pressure waste heat boiler is pumped into a back-pressure turbo generator set to conduct power generation; steam obtained after power generation of the turbo generator set returns to the dual-pressure waste heat boiler to be heated by the reheater; and the reheated steam passes through a steam pipeline and enters the turbo generator set for power generation. The power generation system is provided with the dual-pressure waste heat boiler, which utilizes waste heat to produce high-temperature high-pressure or ultrahigh-pressure main steam and low-pressure steam and has the reheating function, and the main steam produced by the waste heat boiler is used for power generation through the high-temperature high-pressure or ultrahigh-pressure back-pressure turbo generator set.

Owner:CITIC HEAVY INDUSTRIES CO LTD

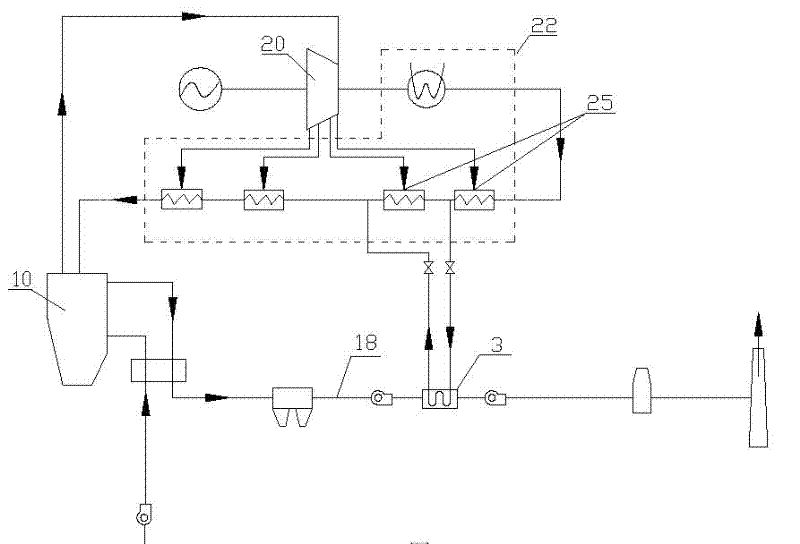

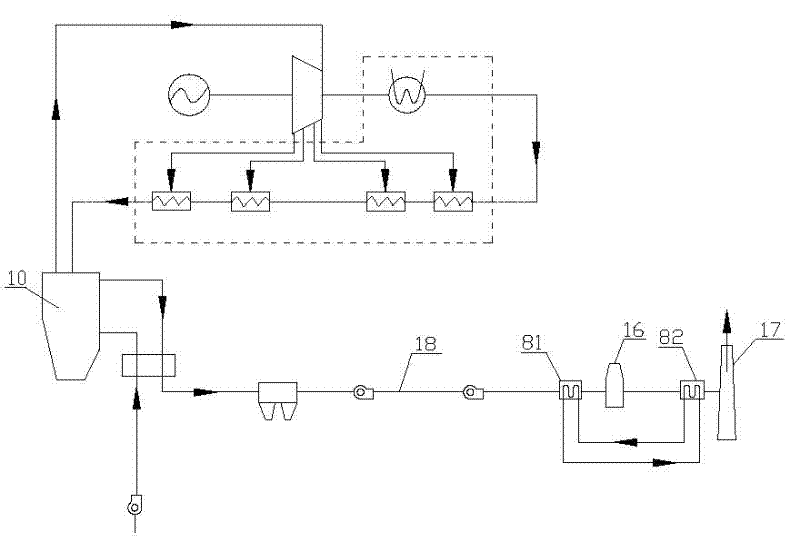

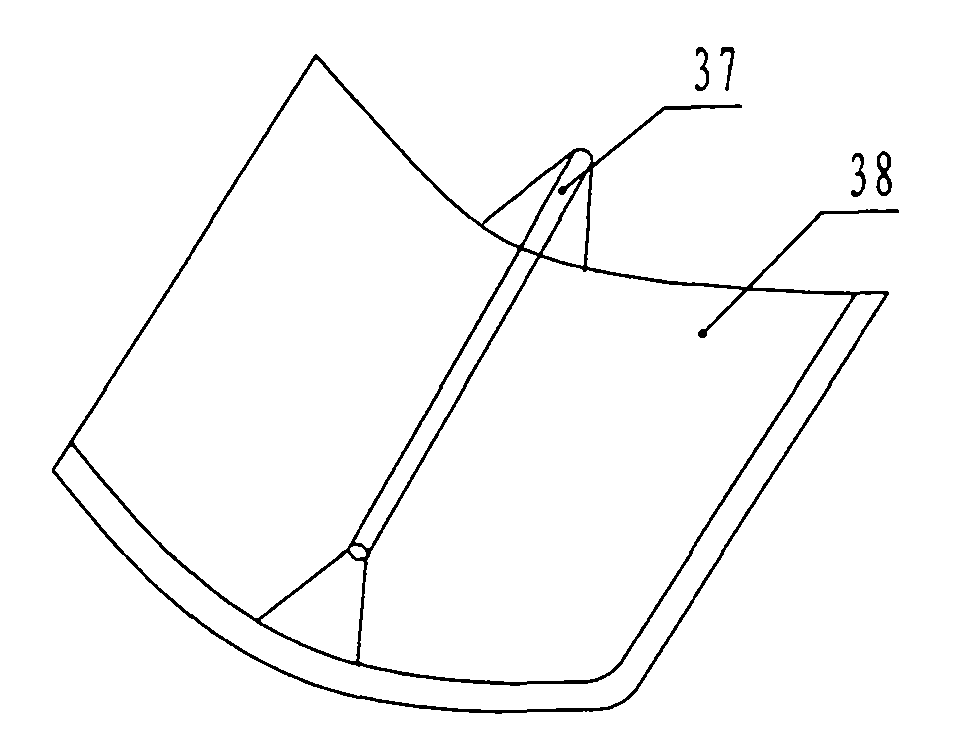

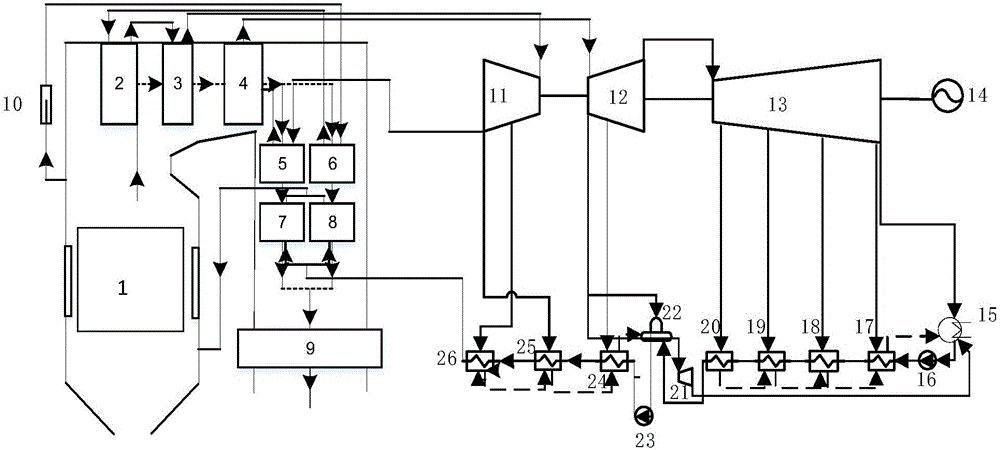

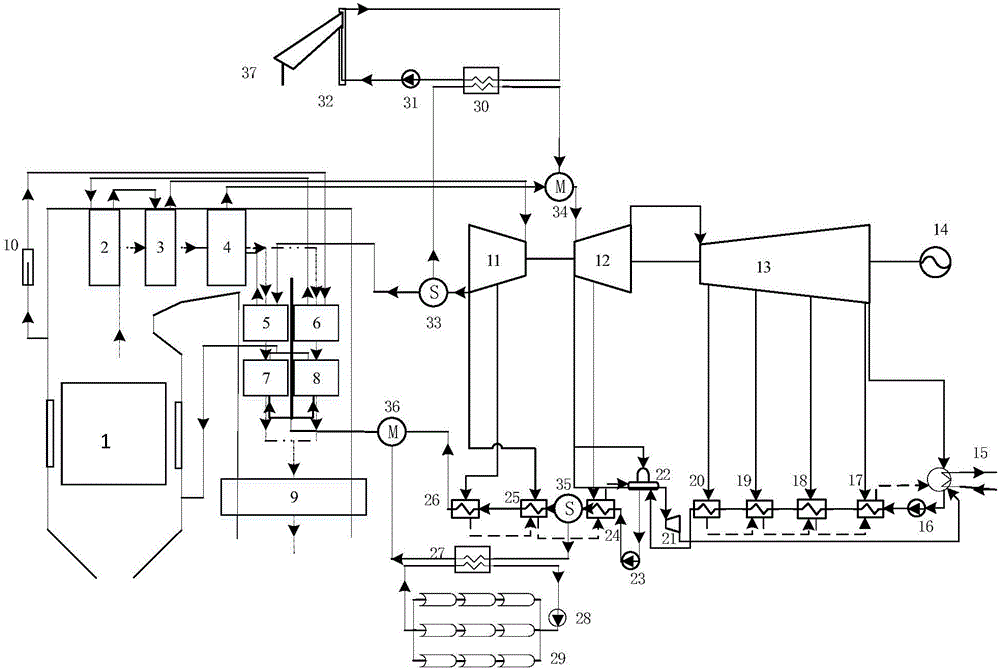

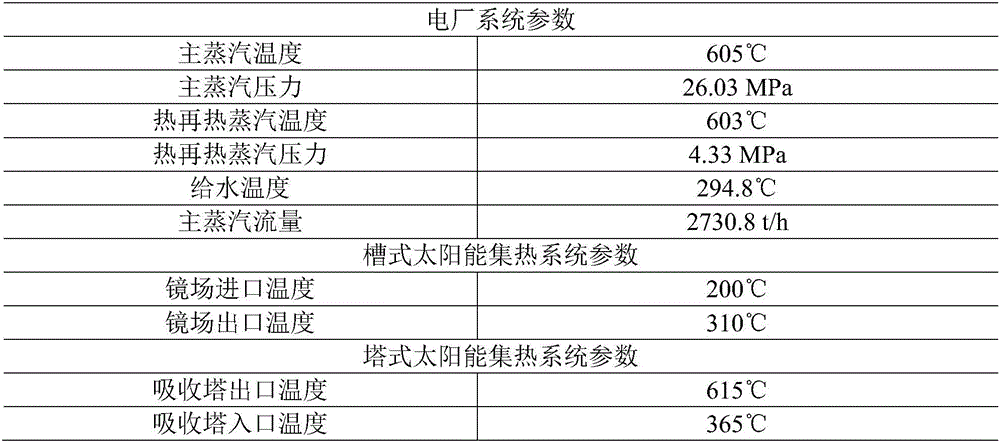

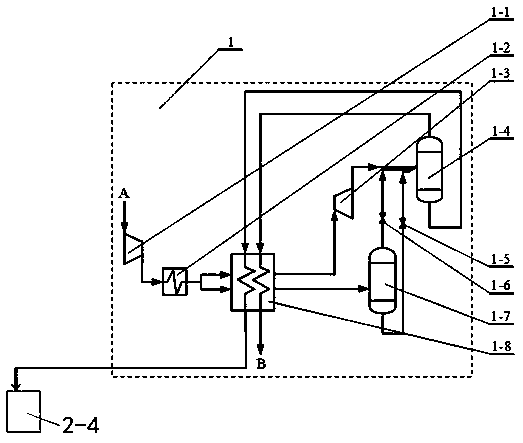

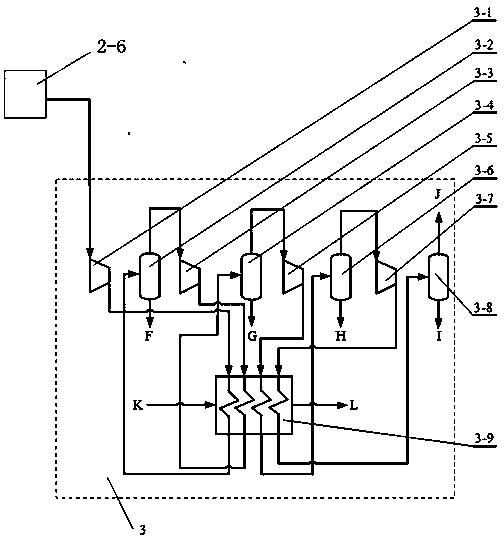

Coal-fired power generation system simultaneously integrating slot type solar heat collecting system and tower type solar heat collecting system

ActiveCN106194293AEffective combinationStable steam intakeSteam useSteam generation using solar heatEngineeringTower

The invention relates to a coal-fired power generation system simultaneously integrating a slot type solar heat collecting system and a tower type solar heat collecting system. The tower type solar heat collecting system is combined with a reheated steam side of the coal-fired power generation system, and the slot type solar heat collecting system is combined with a high-temperature heater side of the coal-fired power generation system. In case of receiving solar radiation, the slot type solar heat collecting system replaces a partial heated surface of a 1# high-temperature heater and a partial heated surface of a 2# high-temperature heater to reduce steam extraction capacity of a high-pressure cylinder of a steam turbine according to the solar radiation condition; and meanwhile, the tower type solar heat collecting system replaces a partial heated surface of the reheated steam side, so that stable and safe operation of a boiler unit is guaranteed. When solar radiation changes, complementary operation of the solar heat collecting systems and a conventional thermal-power coal-fired unit is realized by regulating feedwater flow at a slot type solar heat collecting system side and cold regenerated steam flow at a tower type solar heat collecting system side. The invention discloses a more stable and practical integration idea for energy-saving reconstruction of a conventional coal-fired power plant.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

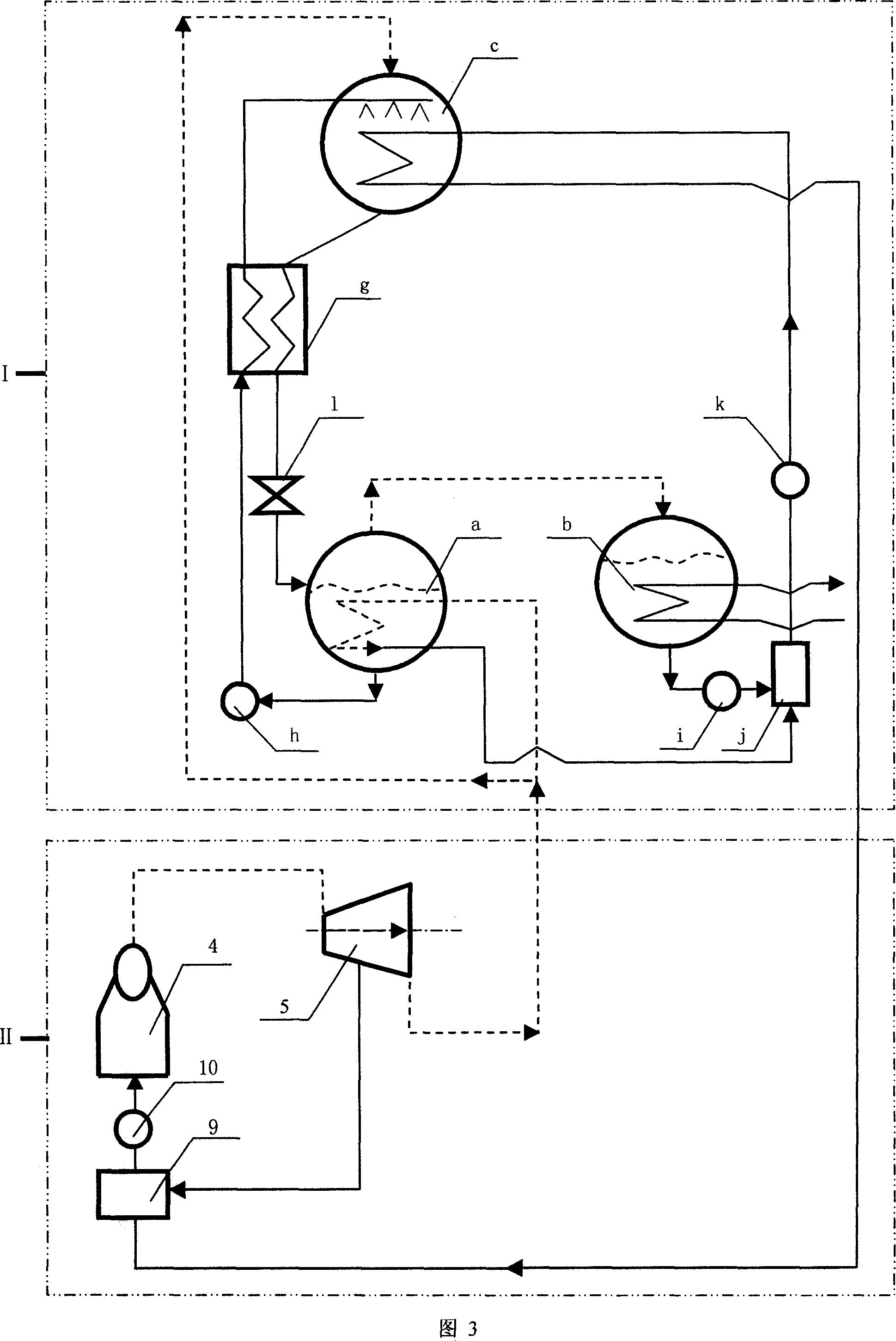

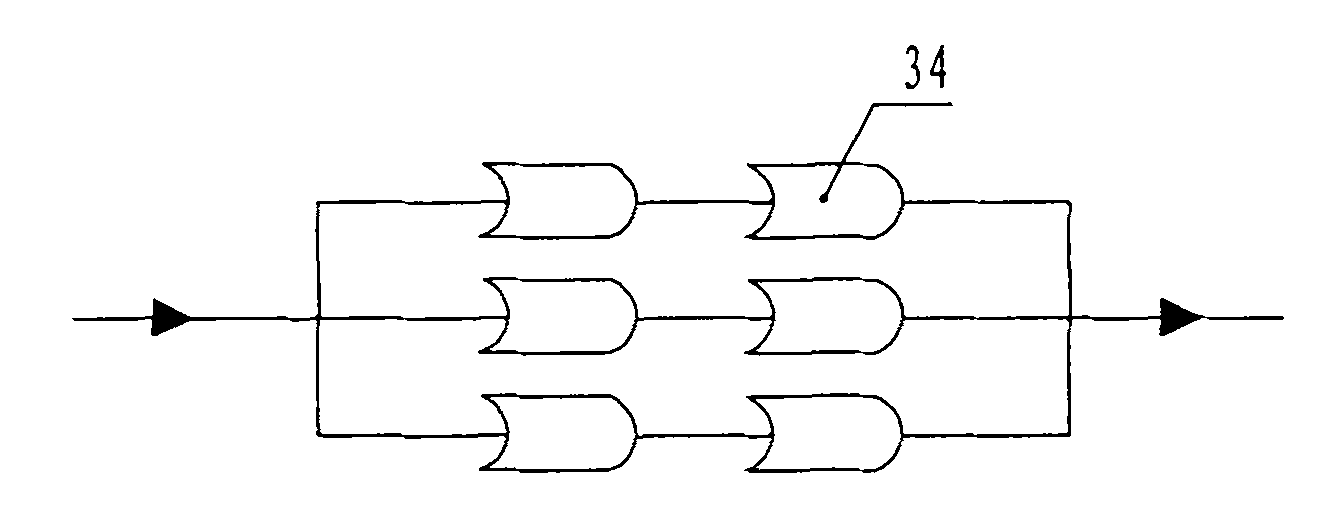

Device and method for using two-stage jet absorption heat pump to improve thermal cycle efficiency

ActiveCN102809144AIncrease temperatureConcentration unchangedHeat pumpsFeed water supplyCirculator pumpAbsorption heat pump

Disclosed are a device and a method for using a two-stage jet absorption heat pump to improve thermal cycle efficiency. The device comprises a steam condenser, a first evaporator, a first condenser, a first jet pump, a first generator, a first absorber, a second evaporator, a second condenser, a second jet pump, a second generator, a second absorber and a second heat exchanger. One side of the second evaporator is connected with the first absorber. The other side of the second evaporator is connected with an injecting end of the second jet pump and the second heat exchanger respectively through a pipeline. One side of the second condenser is connected with the second generator and the second heat exchanger respectively through a pipeline. The other side of the second condenser is connected with the second absorber and the first condenser respectively through a pipeline. The second generator is connected with a jet outlet end of the second jet pump and the second absorber respectively through a pipeline. The second absorber is connected with an inlet end of the second jet pump through a pipeline provided with a second jet absorbing cycle pump. The invention further discloses the method for using the two-stage jet absorption heat pump to improve thermal cycle efficiency. By the device and the method, thermal cycle efficiency can be better improved.

Owner:河北蓝保能源科技集团有限公司

Thermal coupling power generation system of garbage incinerator medium pressure steam and coal-fired unit

ActiveCN107559058AIncrease temperatureIncrease feed water temperatureLiquid degasificationSteam engine plantsEngineeringDeaerator

The invention discloses a thermal coupling power generation system of a garbage incinerator medium pressure steam and coal-fired unit. The thermal coupling power generation system is technically characterized in that a garbage incinerator body and a coal-fired unit are included; a high-pressure heater comprises a first-stage high-pressure heater body and a second-stage high-pressure heater body which communicate with each other; an ultrahigh-pressure cylinder is connected with a high-pressure cylinder; a water feed pump is connected with a low-pressure heater through a pipeline and is connected with a deaerator through a pipeline; the deaerator is connected with the high-pressure heater through a pipeline; the high-pressure heater is connected with the coal-fired unit through a water feedpipeline; the coal-fired unit is connected with a main steam pipeline; the main steam pipeline is connected with the ultrahigh-pressure cylinder; the ultrahigh-pressure cylinder is connected with a third-stage high-pressure heater body through a first-stage steam extraction pipeline; the ultrahigh-pressure cylinder is connected with the second-stage high-pressure heater body through a second-stagesteam extraction pipeline; the coal-fired unit is connected with the high-pressure cylinder through a reheater pipeline; and the high-pressure cylinder is connected with a condenser. According to thethermal coupling power generation system, by means of steam generated by a waste heat boiler for incinerating garbage, the steam is guided into a coal-fired unit thermal system, the efficiency of garbage incineration power generation is improved, and thermal consumption and power generation consumption are reduced.

Owner:HARBIN BOILER

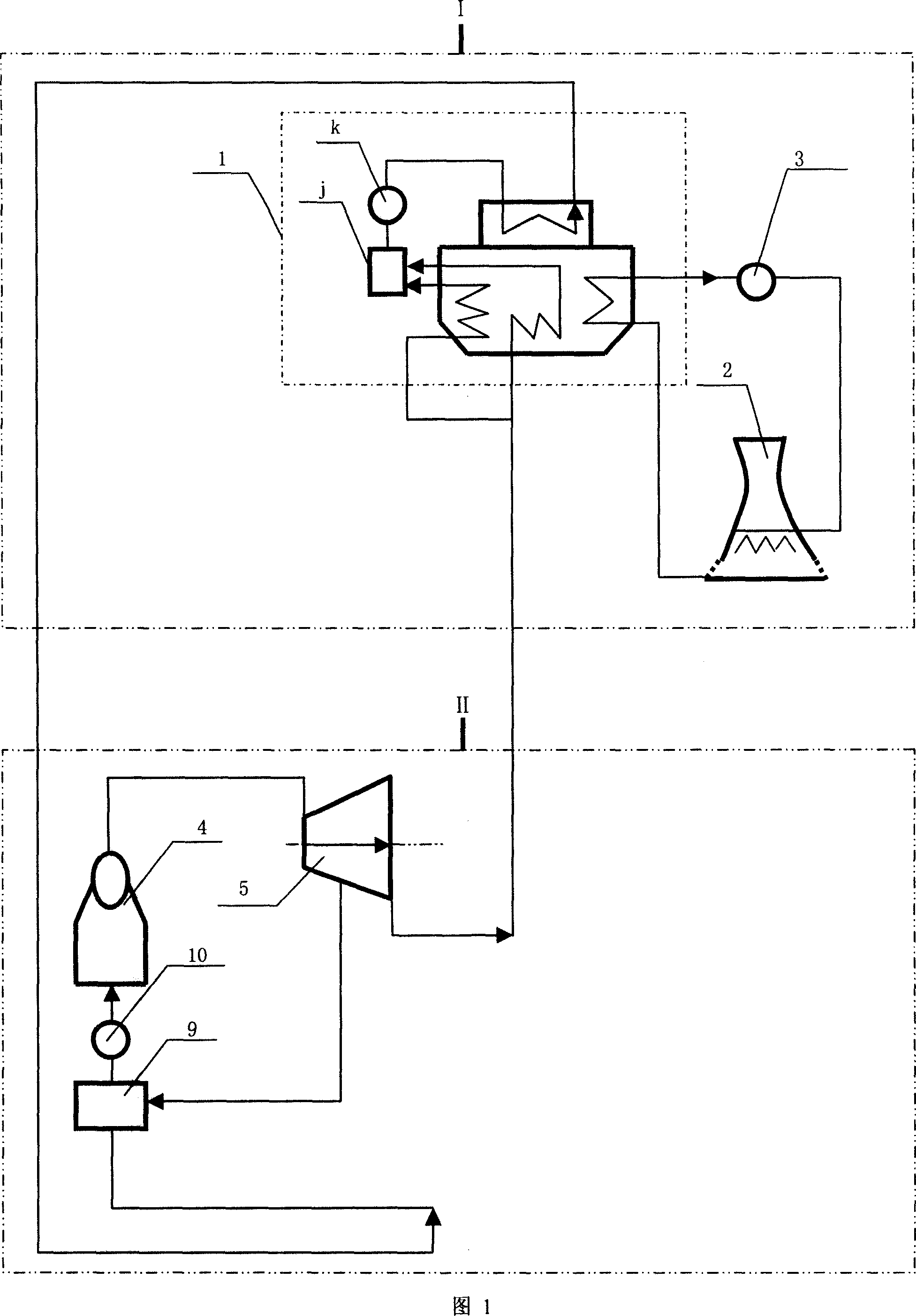

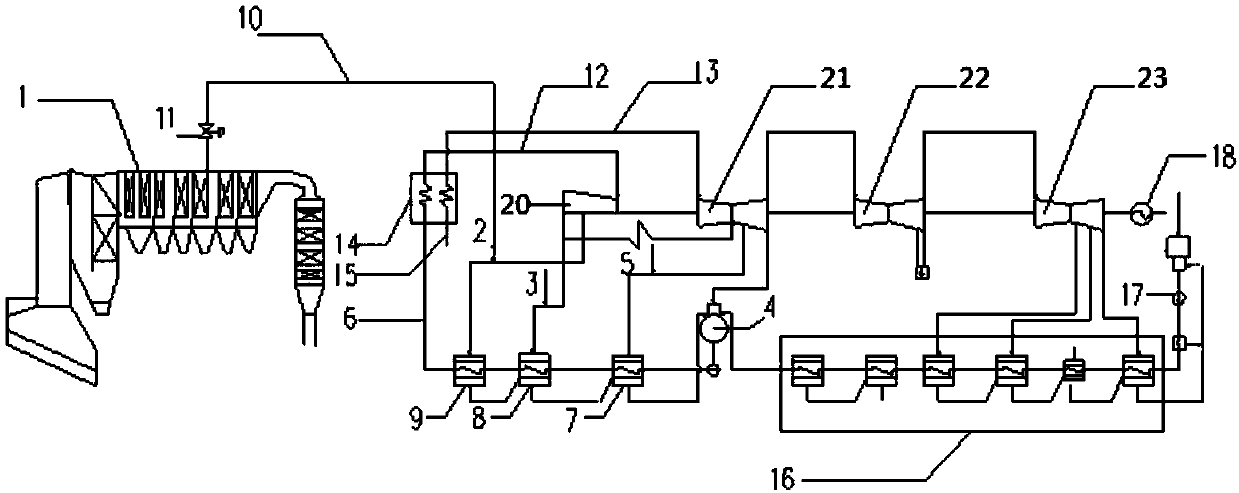

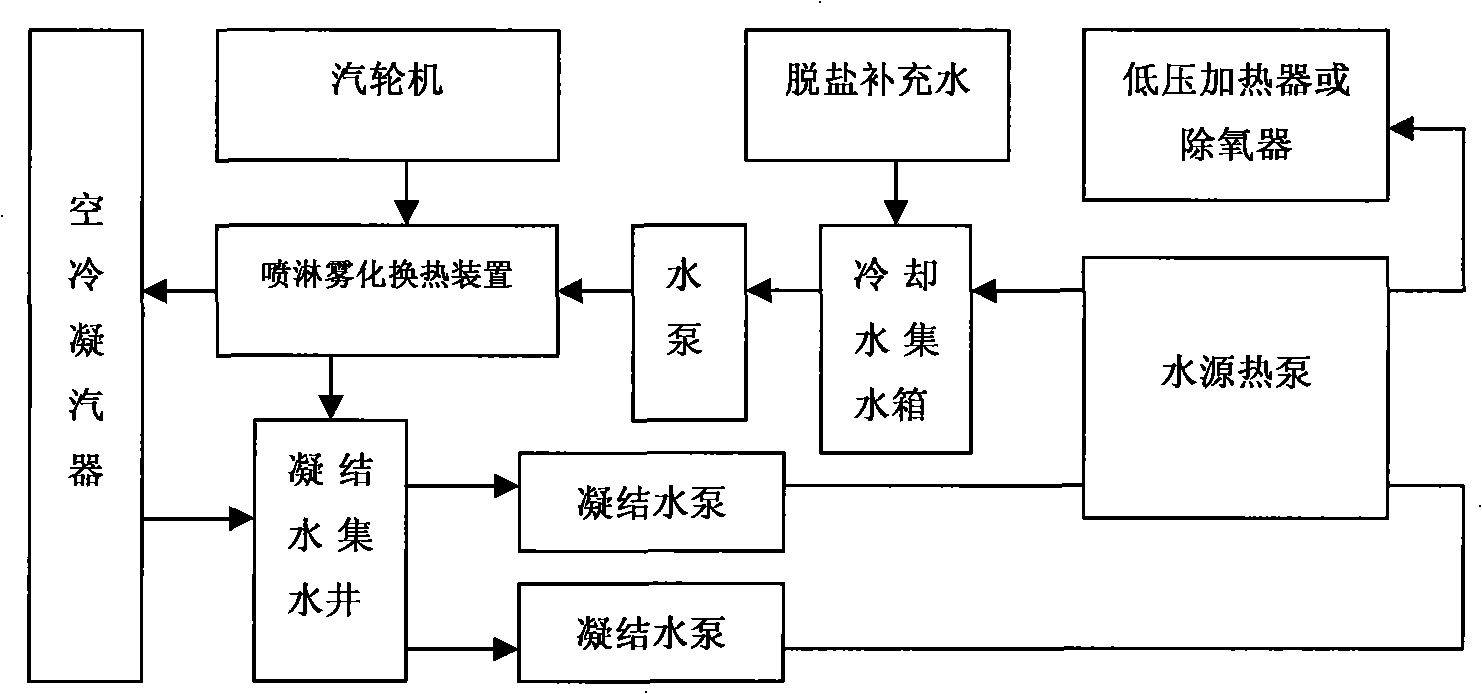

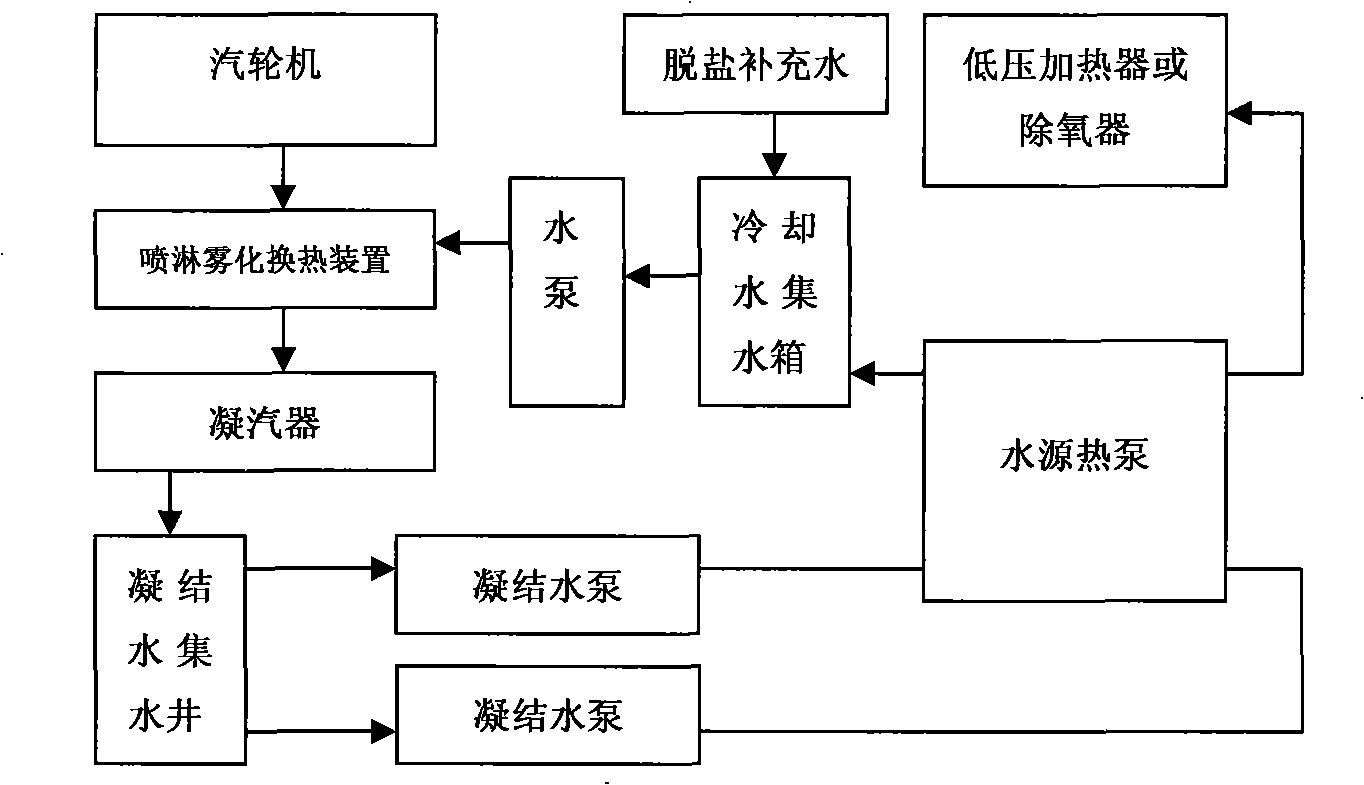

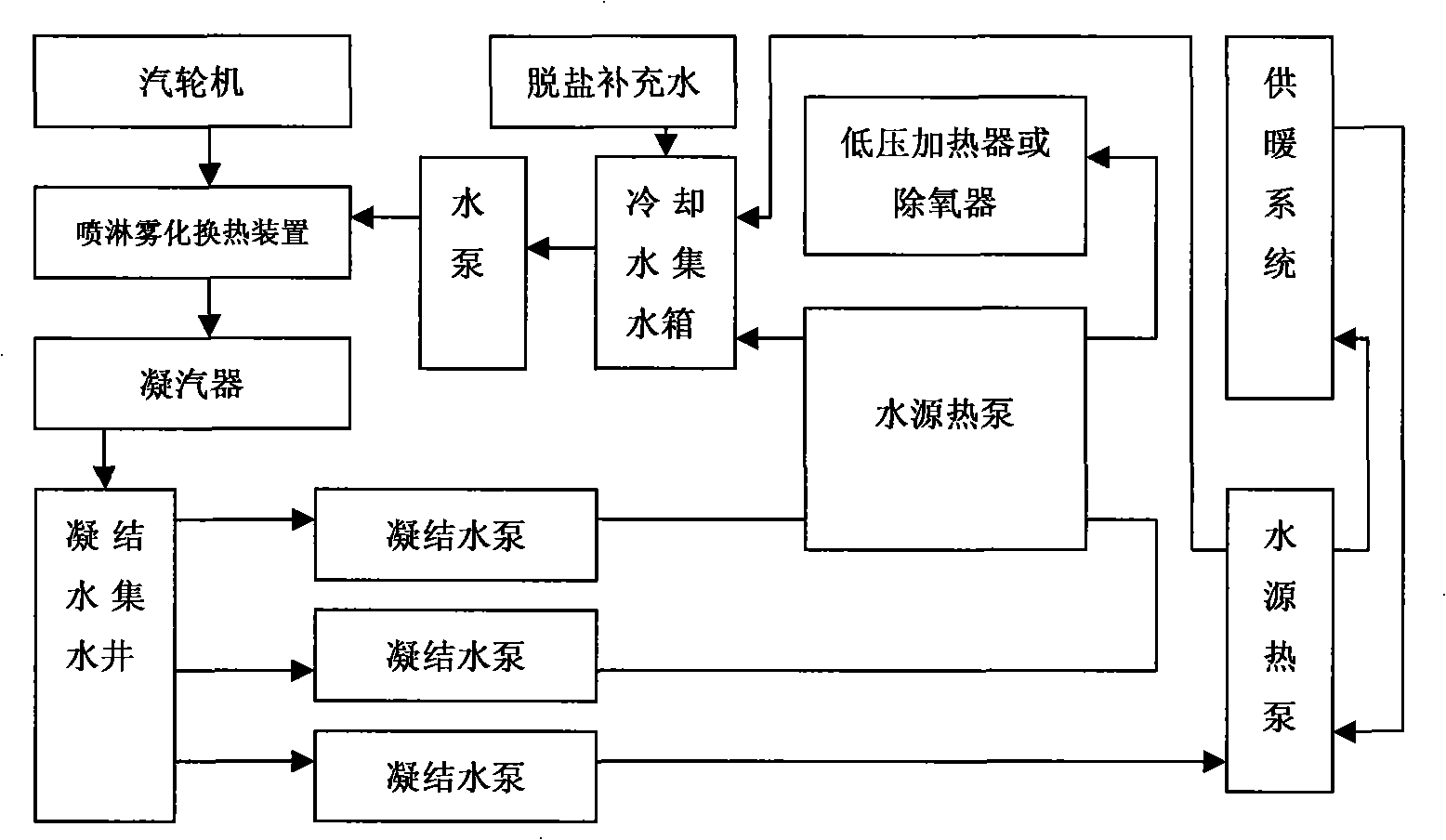

Condensed water circulating cooling energy-conserving and emission-cutting technology

InactiveCN101358547AIncrease vacuumLow running costLiquid degasificationHeat recovery systemsWater sourceWater quality

The invention discloses a condensate water circulation cooling energy-saving emission-reduction technology. Condensate water as well as sprayed and atomized steam water are adopted to be directly mixed with heat exchange condensation at a high temperature end in the exhaust orifice of a steam turbine; the condensate water after heat exchange condensation flows into a condensate water collection well, is pumped into the hot pump of a water source by a condensate water pump, returned to the high temperature end in the exhaust orifice for spraying and atomizing to form cooling circulation after being cooled by the hot pump of the water source; the afterheat is transferred to a boiler simultaneously when being cooled by the hot pump of the water source to form afterheat circulation for the water consumption of water or other different water qualities. The technology has a plurality of functions of energy saving, water saving, environment protection, running cost reducing, efficiency improving, etc. The technology realizes the cooling circulation and afterheat circulation in particular and gains new breakthrough on the aspects of improving the heat exchange effect, increasing the vacuity of a machine set, improving the output, the afterheat recycling and utilizing as well as energy saving and emission reducting; besides, the environment protection and the social benefit are remarkable.

Owner:张贵祥

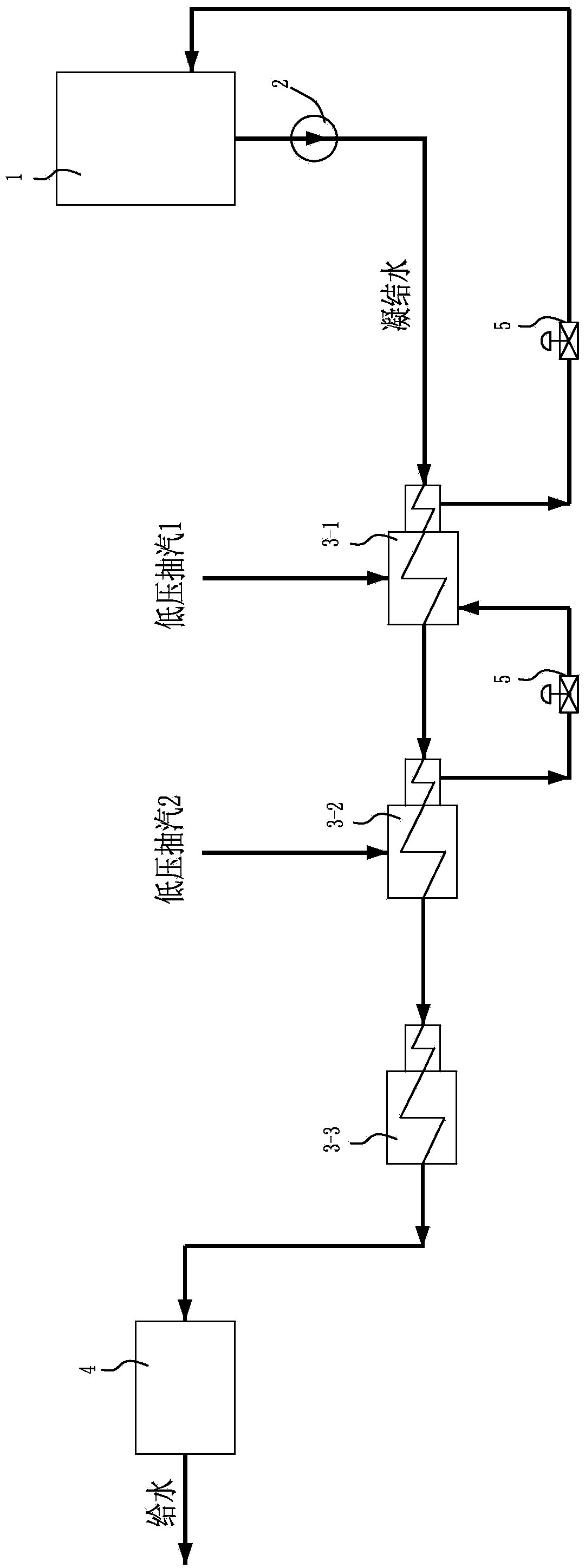

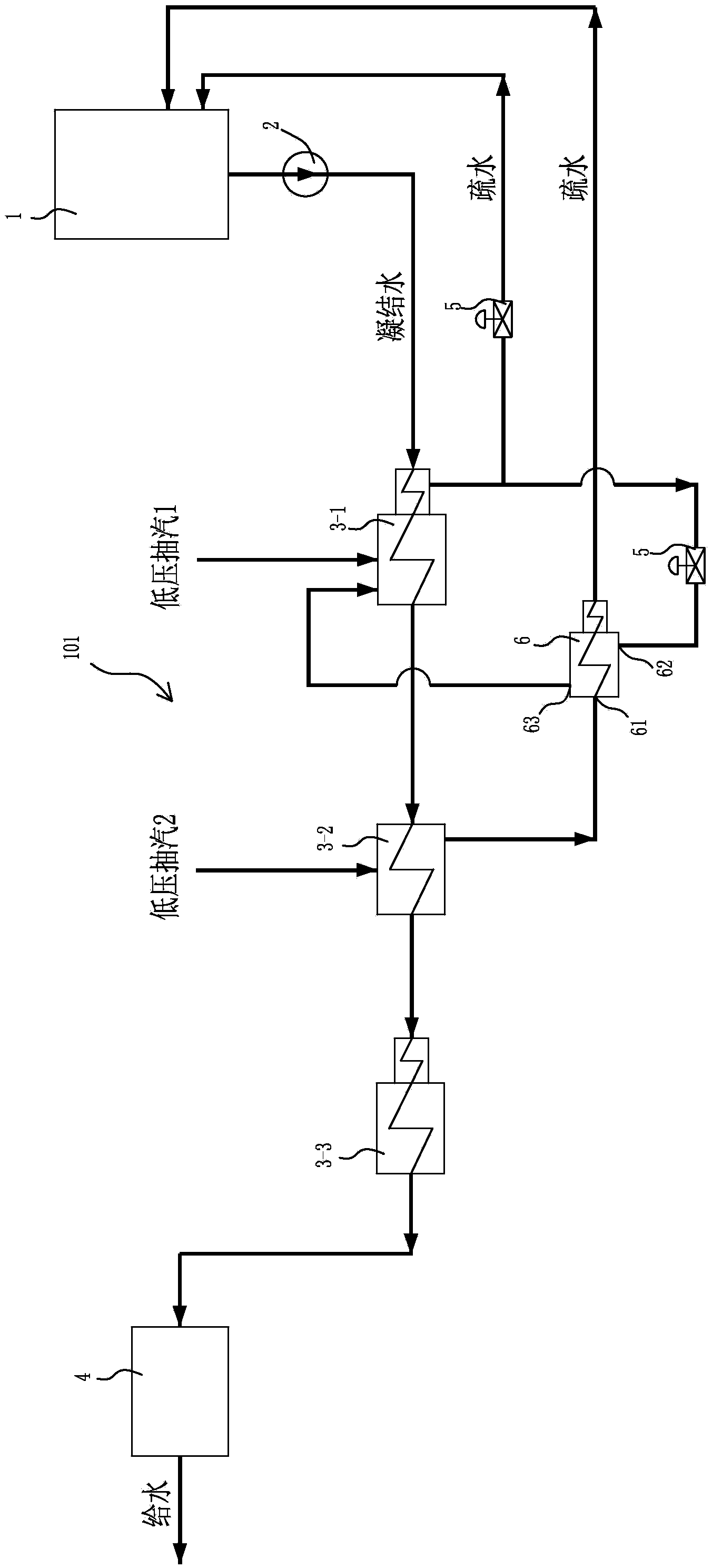

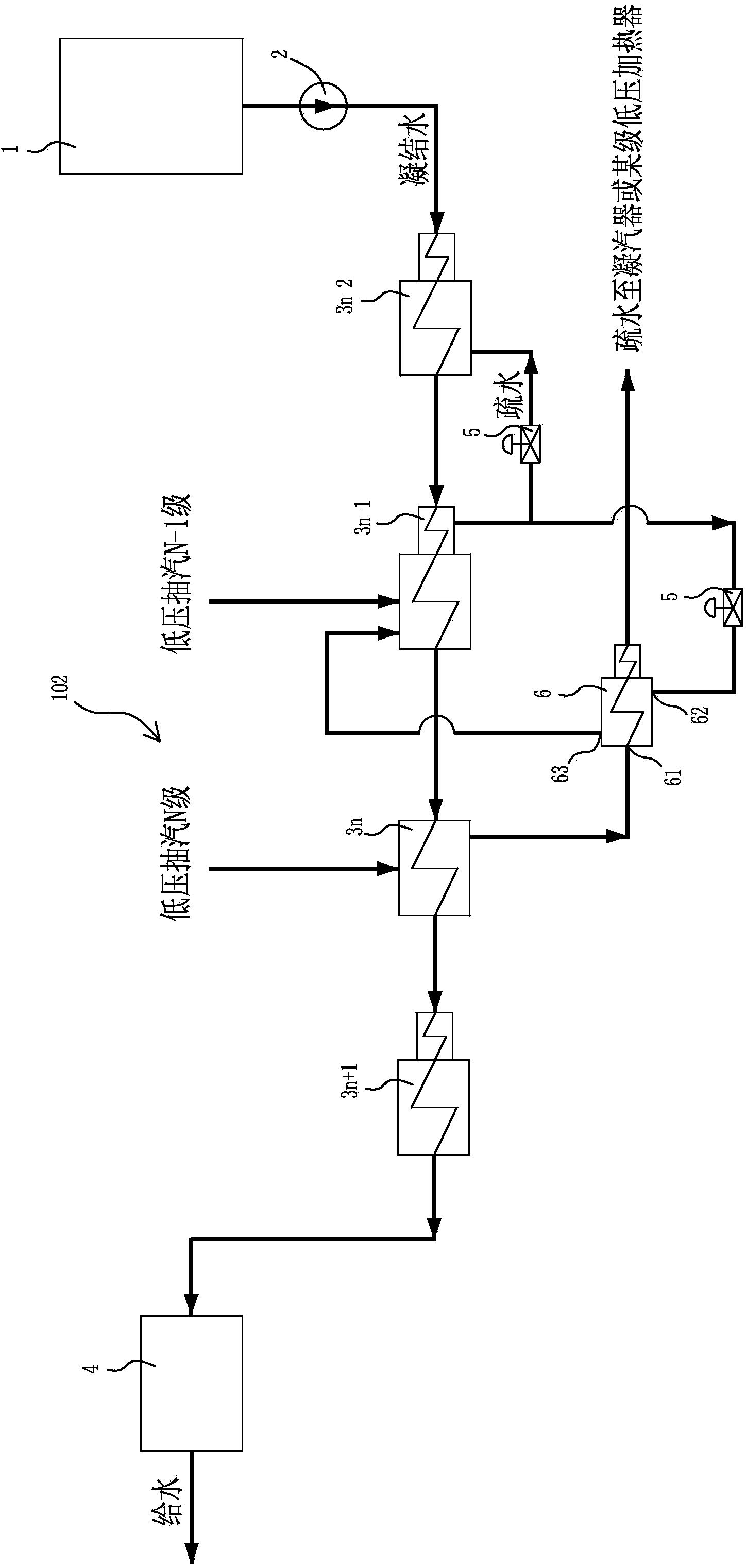

Regenerative system of low-pressure drain water cooler

ActiveCN103836608AImprove economyReduce steam extractionLiquid degasificationFeed-water heatersEnvironmental engineeringRegenerative system

The invention provides a regenerative system of a low-pressure drain water cooler and a generator set. Low-pressure drain water in a low-pressure heater is heated through a low-pressure drain water cooler system by the aid of heat of the drain water in the low-pressure heater, and vapor generated after the drain water is vaporized by heating is guided back to the low-pressure heater. The problem of unsmooth drain water of the low-pressure heater can be solved, and indirect heating of condensation water, reduction of vapor extraction capacity and improvement of unit economy are achieved.

Owner:CHINA POWER ENG CONSULTING GRP CORP EAST CHINA ELECTRIC POWER DESIGN INST

Flue gas waste heat based dual-pressure power generation system

ActiveCN102374514AReduce steam extractionLow costLiquid degasificationSteam engine plantsFlue gasProcess engineering

The invention discloses a flue gas waste heat based dual-pressure power generation system, which is used for power generation by utilizing flue gas waste heat and can be used for further increasing the heat utilization rate of flue gas. The flue gas waste heat based dual-pressure power generation system comprises a power generation system consisting of a waste heat boiler, a steam turbine and a deaerator, wherein a flue gas inlet and a flue gas outlet are arranged on the waste heat boiler; a high-pressure heat exchange device and a low-pressure heat exchange device are sequentially arranged from the flue gas inlet to the flue gas outlet in the waste heat boiler; the high-pressure outlet of the high-pressure heat exchange device is communicated with the steam turbine; the high-pressure inlet of the high-pressure heat exchange device is communicated with a water supply hole of the deareator; the low-pressure outlet of the low-pressure heat exchange device is communicated with the steam inlet of the deaerator; the low-pressure inlet of the low-pressure heat exchange device is communicated with the water supply hole of the deaerator; a steam lead-out pipeline is arranged in the power generation system; and the steam lead-out pipeline is arranged on a pipeline between the low-pressure outlet of the low-pressure heat exchange device and the steam inlet of the deareator. According to the invention, the intensity of the steam turbine can be increased, and the heat of the flue gas can also be effectively utilized.

Owner:CHENGDU HOT NEW ENERGY TECH

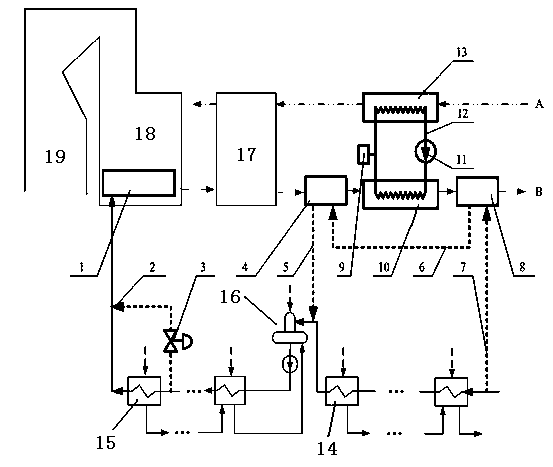

Cascade utilization method and device of waste gas of flue gas of boiler for thermal power unit

ActiveCN103453513ALarge drop in temperatureIncrease temperatureFeed-water heatersAir preheaterDeaerator

The invention discloses a cascade utilization method and device of waste gas of flue gas of a boiler for a thermal power unit. A first low pressure heater heat exchanger is arranged between an air preheater and a flue gas-oil heat exchanger, and a second low pressure heater heat exchanger is arranged at the flue gas outlet side of the flue gas-oil heat exchanger; a diversion pipe is additionally arranged on a low pressure water supply manifold which is arranged at the back of a condenser and in front of a first-stage low pressure heater, and a water inlet pipe is additionally arranged at the water inlet side of a deaerator; the diversion pipe is connected with a water inlet of the second low pressure heater heat exchanger, and the water inlet pipe is connected with a water outlet of the first low pressure heater heat exchanger; and a low pressure water supply pipeline is arranged between the water inlet of the first low pressure heater heat exchanger and the water outlet of the second low pressure heater heat exchanger. Through the arrangement of an additional economizer heating surface, the low pressure heat exchanger, the flue gas-oil heat exchanger and an air-oil heat exchanger, the temperature counterpart and cascade utilization of flue gas waste heat are realized, the boiler efficiency and the unit power generation efficiency are improved, the energy consumption of the thermal power unit is reduced, and meanwhile the carbon dioxide emission is reduced.

Owner:山东英电环保科技有限公司

Comprehensive optimized smoke discharge waste heat deep recycle system of smoke in thermal power plant

InactiveCN102818276AReduce cooling water consumptionReduce the temperatureLiquid degasificationCombustion technology mitigationProcess engineeringTower

The invention relates to a comprehensive optimized smoke discharge waste heat deep recycle system of smoke in a thermal power plant. The system comprises a smoke cooler is arranged at the back of a dust remover and in front of a desulfurizing tower in a smoke channel. A preferable scheme further comprises a smoke discharge waste heat utilizing device used for enabling absorbed heat to heat condensation water or enabling a steam air heater to heat air to improve air supply temperature. Compared with the prior art, the system greatly reduces smoke discharge temperature, simultaneously completely utilizes recycled heat and improves unit efficiency.

Owner:安徽省科捷能源科技有限公司

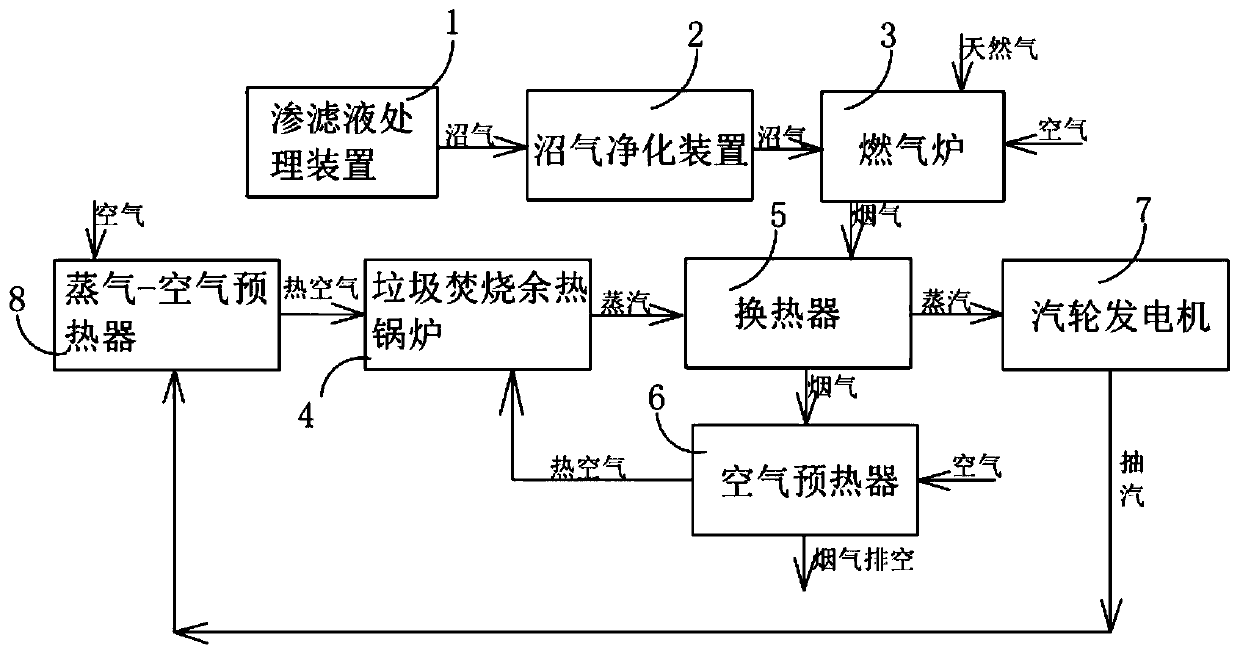

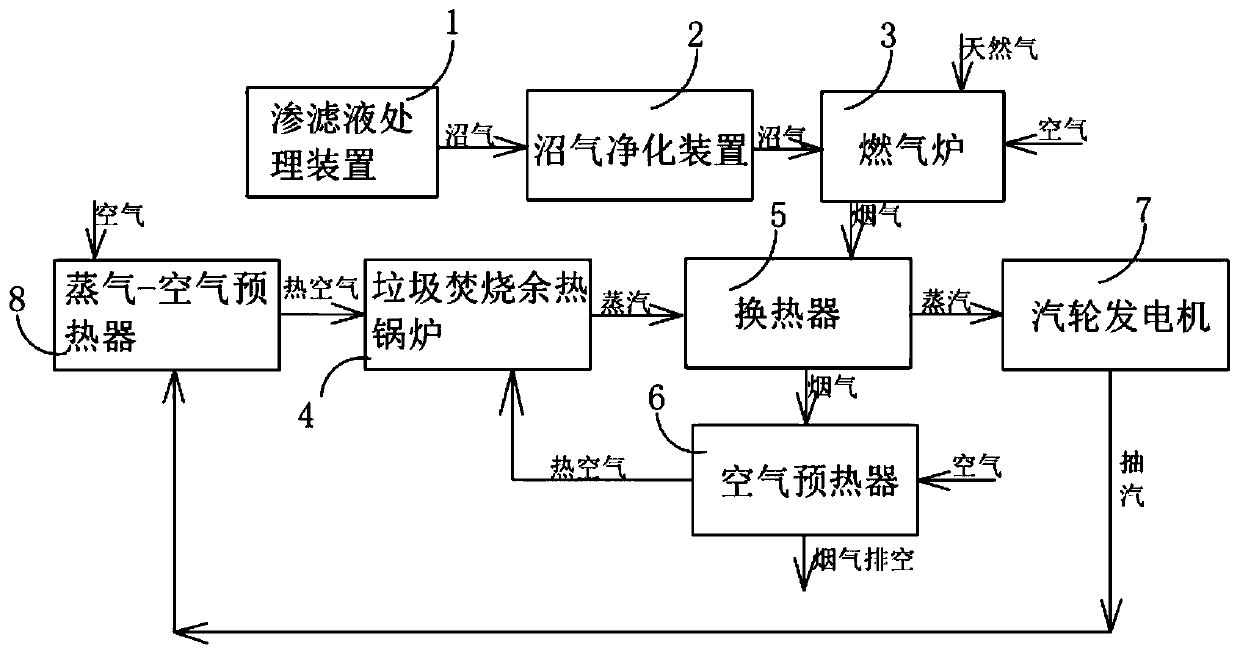

System for increasing garbage incinerator steam temperature through percolate marsh gas

PendingCN109973982AIncrease profitAvoid local high temperatureBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringPower station

The invention provides a system for increasing the garbage incinerator steam temperature through percolate marsh gas. The marsh gas generated by percolate is reasonably utilized, the utilization rateof the marsh gas is increased, the situation that the marsh gas is sprayed into an incinerator to incinerate, and the local high temperature is caused is avoided, and safety influences on boiler equipment due to the flammable and combustible characters of the marsh gas are avoided as well. The high-temperature smoke generated due to marsh gas incineration is used for heating overheat steam of thegarbage incinerator, garbage incineration power plant steam parameters are further improved, and efficient power generation is achieved. Components of smoke generated through marsh gas incineration are simple, the situation of high-temperature corrosion is avoided, and equipment cost and expense increasing caused for improving steam parameters of a conventional garbage incinerator is reduced; andwaste heat of the high-temperature smoke generated due to marsh gas combustion is utilized for heating primary air, the problem about low-temperature corrosion of an air preheater is solved, meanwhile, the steam turbine steam extraction volume, for heating the primary air, of a garbage incineration waste heat boiler is reduced, and the steam volume for power generation is increased.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

Energy-saving recycling system for low-grade heat energy in smoke pollutant treatment of thermal power plant

InactiveCN105546564AReduce energy costsReduce operating costsFeed water supplyCombustion technology mitigationAbsorption heat pumpHeat energy

The invention provides an energy-saving recycling system for low-grade heat energy in smoke pollutant treatment of a thermal power plant. The system comprises a smoke cooler, a smoke reheater and a smoke auxiliary heater; an energy-saving branch for recycling the low-grade heat energy of the thermal power plant is arranged between the smoke cooler and the smoke reheater, and a first absorption heat pump and a water-water heat exchanger are arranged on the energy-saving branch; the first absorption heat pump comprises an absorber, a condenser, an evaporator and a generator; and according to the energy-saving recycling system for the low-grade heat energy in smoke pollutant treatment of the thermal power plant, it is ensured that under the condition that a smoke pollutant treatment system keeps stable running, an original smoke cooler is used for heating boiler condensate water so as to reduce coal consumption, and the water-water heat exchanger is matched with the first absorption heat pump to effectively recycle the low-grade heat energy in circulating water so as to heat medium water drained out of the smoke heater; and water resources are saved, and the comprehensive energy utilization rate of running of the pollutant treatment system is improved.

Owner:ZHEJIANG ZHENENG ENERGY SAVING TECH

Tail flue gas waste heat utilizing system of utility boiler based on hot blast recycling

InactiveCN106402838AReduce the temperatureImprove power generation efficiencyLiquid degasificationCombustion technology mitigationAir preheaterHigh pressure

The invention relates to a tail flue gas waste heat utilizing system of an utility boiler based on hot blast recycling. The tail flue gas waste heat utilizing system comprises a boiler water supply regenerative heating device and a boiler tail flue gas waste heat utilizing device, wherein the boiler water supply regenerative heating device is provided with a low-pressure heating unit, a high-pressure heating unit, a deoxygenizing unit and a water supply pump, which sequentially communicate; low-pressure extraction steam generated after work application of steam generated by the boiler is used by the low-pressure heating unit as a heat exchanging heat source; and high-pressure extraction steam generated after work application of steam is used by the high-pressure heating unit as a heat exchanging heat source. According to the tail flue gas waste heat utilizing system disclosed by the invention, a circulating hot wind is utilized as a heat-transfer medium, so that the temperature level and the heat-into-power conversion efficiency of the flue gas waste heat recycled by the water supply regenerative system are improved, the purpose that the electricity supply efficiency of an electricity generating system is substantially improved is realized, the investment and the operation control difficulty of a waste heat recovery system are reduced, the problems of the corrosion, the ash deposition and the abrasion of the waste heat recovery system are solved, the cold end low temperature corrosion of an air preheater is avoided, besides, newly building a bypass flue is not needed, the system is compact in technological process, and the construction of the engineering is facilitated.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Heat pump circulating water regenerative Rankine cycle system

InactiveCN107060915AReduce steam extractionRaise the condensation water temperatureSteam engine plantsWater sourceDeaerator

Owner:CHONGQING UNIV

Device and method for compressing air and flue gas in oxygen-rich combustion system and recycling residual heat

ActiveCN109107211AGuaranteed stabilityExtended service lifeCombination devicesGas treatmentRecuperatorCoal

The invention discloses a device and a method for compressing air and flue gas in an oxygen-rich combustion system and recycling residual heat. The device comprises an air separation assembly, a circulating fluidized bed boiler assembly and a carbon dioxide compression and purification assembly. According to the device disclosed by the invention, high-purity oxygen and coal are combusted in a hearth of a fluidized bed and part of dust-removed tail gas is circulated into the hearth; the residua flue gas enters a heat exchanger to heat water; the flue gas subjected to heat exchange is subjectedto multi-stage compression, heat exchange and dehydration and is finally stored and transported; the compression heat amount of each stage is recycled and the heat is used for heating the low-temperature water, so that steam extraction of a steam turbine is reduced, the efficiency of a system is improved and the residual heat is recycled.

Owner:SOUTHEAST UNIV

Boiler smoke waste heat use system

ActiveCN104896503AReduce steam extractionReduce power consumptionCombustion processIndirect carbon-dioxide mitigationHeat distributionPower station

The invention relates to the technical field of power station boiler manufacturing and transformation and discloses a boiler smoke waste heat use system. The system comprises a main pipe formed by the successive connection of a boiler body, an air pre-heater, a cryogenic heat exchanger and a water supply tank and further comprises an air pre-heater air inlet branch and a recovery heat distribution system. The cryogenic heat exchanger and a water supply tank outlet tube form a loop. One end of the branch is connected with the air pre-heater and can be selected to heat or not heat inlet air of the air pre-heater. The recovery heat distribution system is communicated with the cryogenic heat exchanger, the air pre-heater air inlet branch and the water supply tank pipe respectively and can be selected to heat inlet air of the air pre-heater or water in the water supply tank. The recovery heat distribution system can adjust the heated condensation water volume of the main pipe and all branches according to actual needs to control the heat use proportion for heating inlet air or the condensation water of the air pre-heater, and accordingly, the system is adapted to various work conditions, and the boiler heat use rate is improved.

Owner:DONGFANG BOILER GROUP OF DONGFANG ELECTRIC CORP

Gradient utilization method and device of boiler flue gas waste heat

InactiveCN104421925ALarge drop in temperatureIncrease temperatureFeed-water heatersAir preheaterExpansion tank

The invention discloses a gradient utilization method and device of boiler flue gas waste heat. An additional heating face is added to an economizer segment of a boiler of a thermal power generating unit; a bypass pipe is provided at a water feed main arranged at an inlet of a steam turbine side high-pressure heater and leads to another water feed main arranged at an outlet of the steam turbine side high-pressure heater; the bypass pipe is provided with a flow regulating valve; a flue gas-oil heat exchanger and an air-oil heat changer are added to the cold end of an air preheater; a circulating pipeline is provided between the flue gas-oil heat exchanger and the air-oil heat changer; the circulating pipeline is filled with heat transfer medium, heat transfer oil; the circulating pipeline is provided with an expansion tank and a circulating pump; a low-pressure heat exchanger is disposed between the air preheater and the flue gas-oil heat exchanger; the inflow side of a low-pressure heater is provided a guide pipe leading to the low-pressure heat exchanger; an inflow pipe from the low-pressure heat exchanger is added to the inflow side of an oxygen extractor. The gradient utilization method and device of boiler flue gas waste heat has the advantages that suited gradient utilization of flue gas waste heat is achieved, boiler efficiency and generating efficiency of the thermal power generating unit are improved, energy consumption of the thermal power generating unit is lowered, and emission of carbon dioxide is reduced.

Owner:JINAN HIPOWER TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com