Energy-saving recycling system for low-grade heat energy in smoke pollutant treatment of thermal power plant

A technology for pollutant treatment and heat energy recovery, which is applied in the directions of preheating, greenhouse gas reduction, and climate sustainability. , to achieve the effect of reducing energy consumption and operating costs, reducing coal consumption for power generation, and reducing the amount of low-pressure extraction steam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] In this embodiment, the structure of the present invention is described in detail with reference to the drawings.

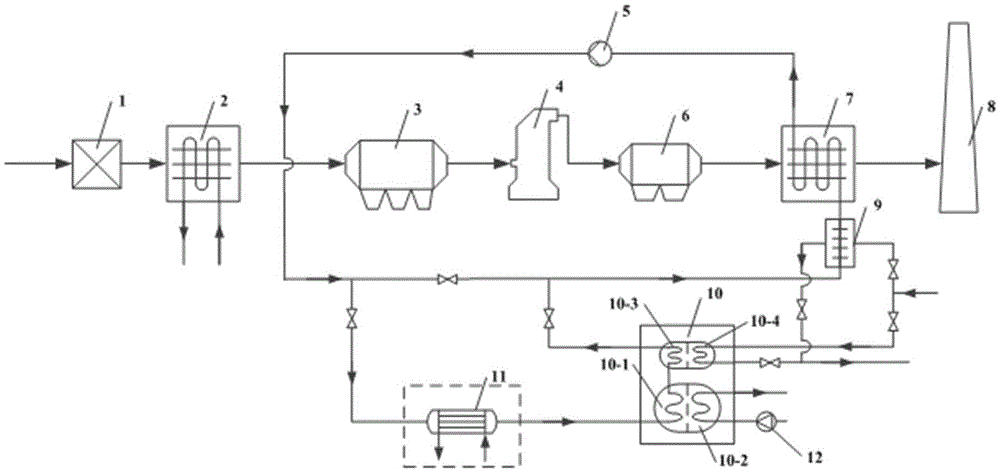

[0031] Please refer to the attached drawing, a low-grade heat energy recovery and energy-saving system in the treatment of flue gas pollutants in thermal power plants. The system includes air preheater 1, flue gas cooler 2, electrostatic precipitator 3, desulfurization tower 4, wet type Electrostatic precipitator 6, flue gas reheater 7, chimney 8. The flue gas cooler 2 and the flue gas reheater 7 operate independently, and the outlet of the flue gas reheater 7 is also equipped with an energy-saving branch for recovering low-grade heat energy of the thermal power plant. 7 inlet is also equipped with flue gas auxiliary heater 9, the function of flue gas auxiliary heater 9 is when the water temperature at the outlet of the heat pump heating system cannot meet the water temperature demand of the flue gas reheater 7 inlet or when the heat pump energy-saving bra...

Embodiment 2

[0051] In the energy-saving branch circuit working mode, after the flue gas is discharged from the boiler, it passes through 1, the flue gas cooler 2, the electrostatic precipitator 3, the FGD desulfurization tower 4, the wet electrostatic precipitator 6 (may or may not be installed), the flue gas The reheater 7 is finally discharged through the chimney 8.

[0052] When the boiler is running normally, the flue gas cooler absorbs the heat in the flue gas to heat the condensate water of the boiler to reduce the coal consumption of power generation, and at the same time reduce the temperature of the flue gas entering the electrostatic precipitator to improve the dust removal efficiency. The first type of absorption heat pump 10 is in operation, the bypass channel valve is closed, and the water diversion pump 12 and the booster pump 5 are in operation. Automatically adjust the steam flow rate and The open-loop cooling water or closed-loop cooling water flow into the evaporator 10...

Embodiment 3

[0057] In the energy-saving branch fault working mode, combined with Embodiment 1, when the first type of absorption heat pump 10 fails or is overhauled, the valve entering and exiting the heat pump 10 is closed, the bypass valve is opened, and the medium water is only heated by the flue gas auxiliary heater 12 to The required inlet temperature of the flue gas reheater.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com