Patents

Literature

3322 results about "Electrostatic precipitator" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An electrostatic precipitator (ESP) is a filtration device that removes fine particles, like dust and smoke, from a flowing gas using the force of an induced electrostatic charge minimally impeding the flow of gases through the unit.

Enhanced mercury control in coal-fired power plants

InactiveUS6808692B2Easy to captureEliminate dischargeChloride preparationUsing liquid separation agentPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor, such as calcium hypochlorite, able to decompose to form molecular halogen at flue gas temperature. The molecular halogen converts elemental mercury to mercuric halide, which is adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash, and dry flue gas desulphurization solids, capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), and fabric filters (FFs), with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

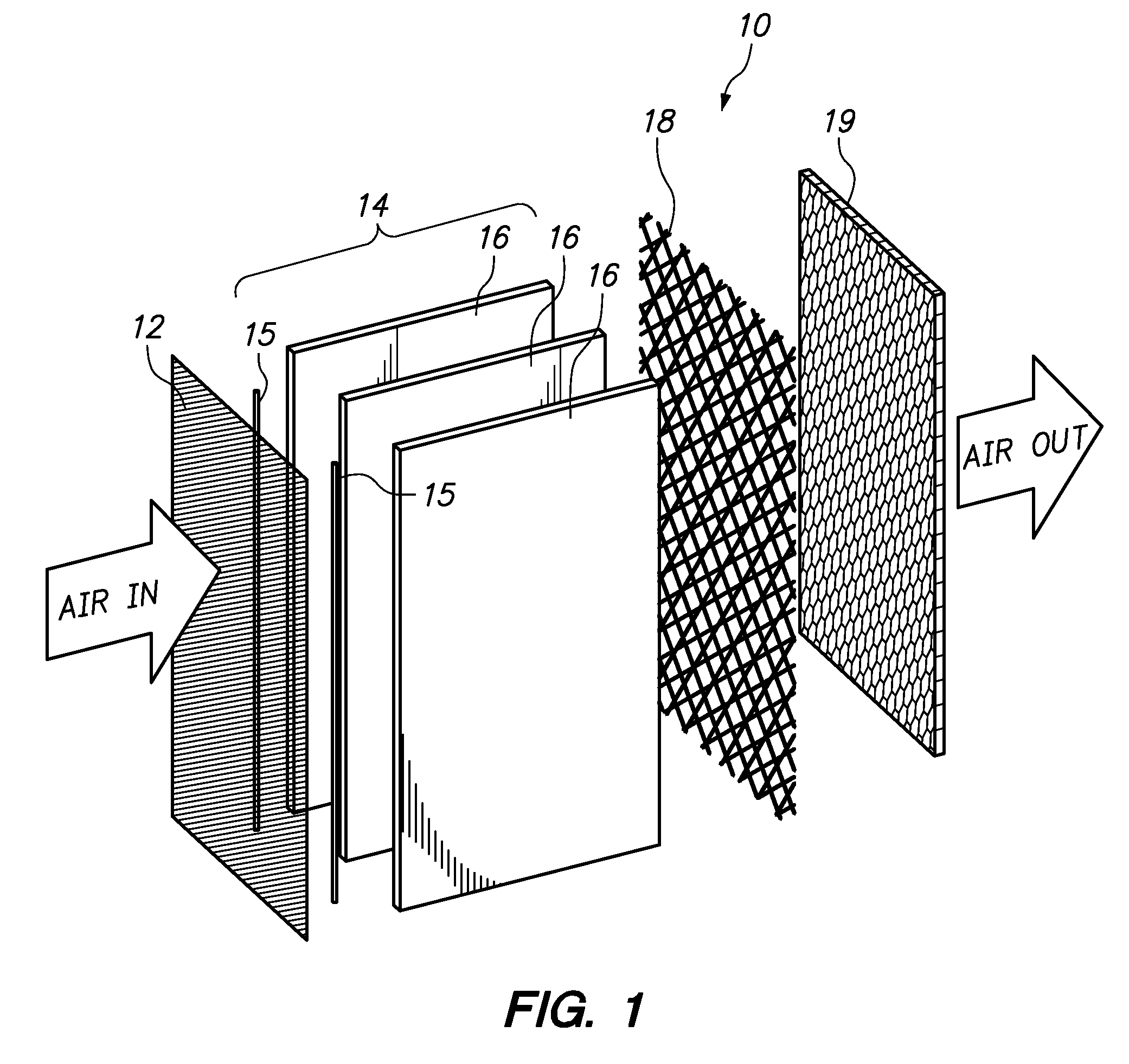

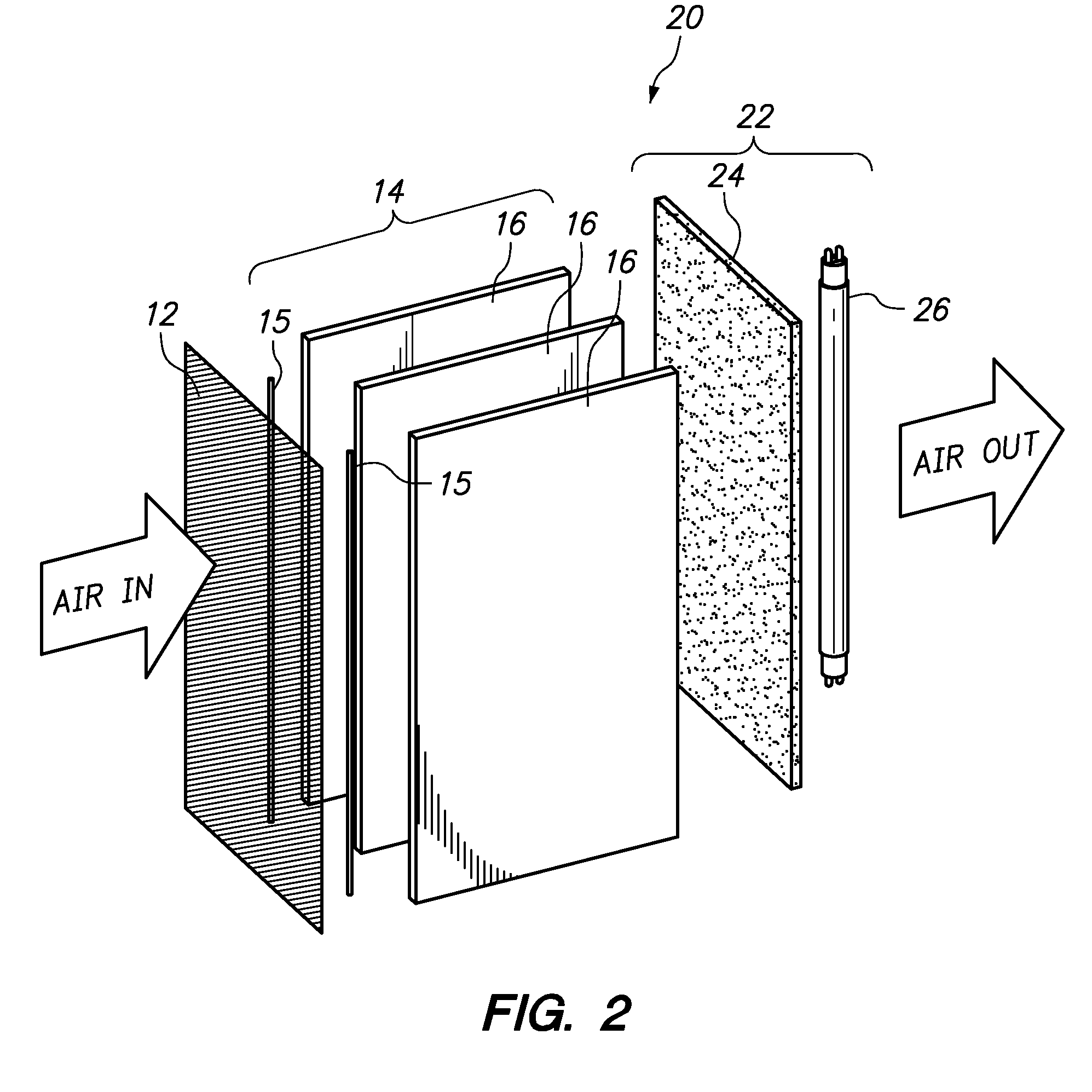

Air cleaner

InactiveUS20090010801A1Consume less spaceIncrease capacityCombination devicesMechanical apparatusPorous substrateParticulates

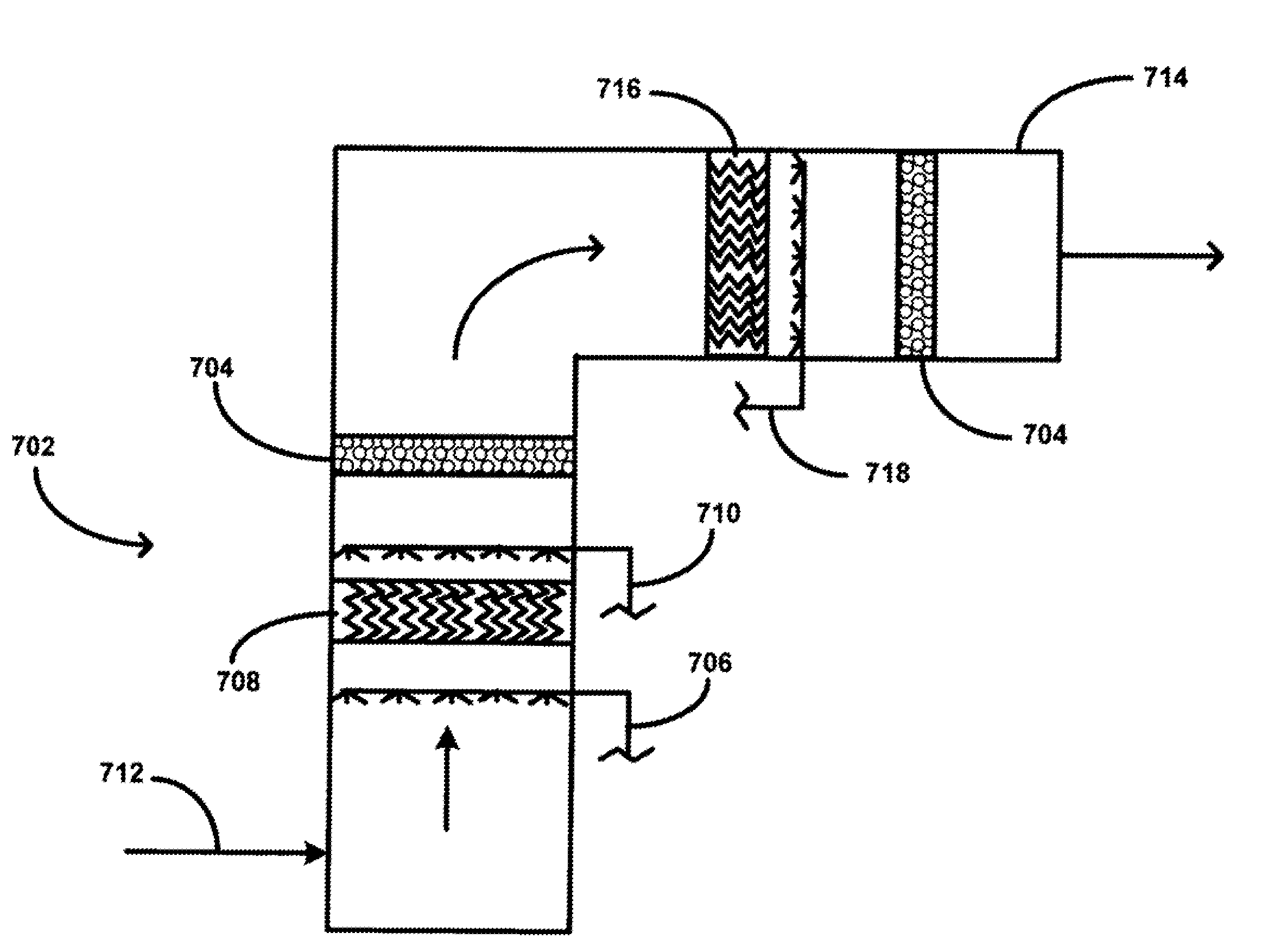

Apparatus and method for cleaning air. An air cleaner includes a housing that defines an airflow pathway and a catalytic reactor having a catalyst secured on a porous substrate that is disposed transverse to the airflow pathway. Preferably, the catalyst includes a light activated oxidizing photocatalyst or a thermally activated oxidizing catalyst. A photocatalytic reactor will include a light source directed at a light activated oxidizing photocatalyst, such as TiO2 particles or a binary oxide particle species, which is disposed on the porous substrate. Most preferably, a metal catalyst is disposed on the photocatalyst particles at a concentration or loading between about 0.01 wt % and about 5 wt %. The air cleaner may further comprise an adsorption matrix upstream of the catalytic reactor, optionally in combination with a heater. A particulate filter and / or an electrostatic precipitator may also be disposed upstream of the adsorption matrix and the catalytic reactor.

Owner:LYNNTECH

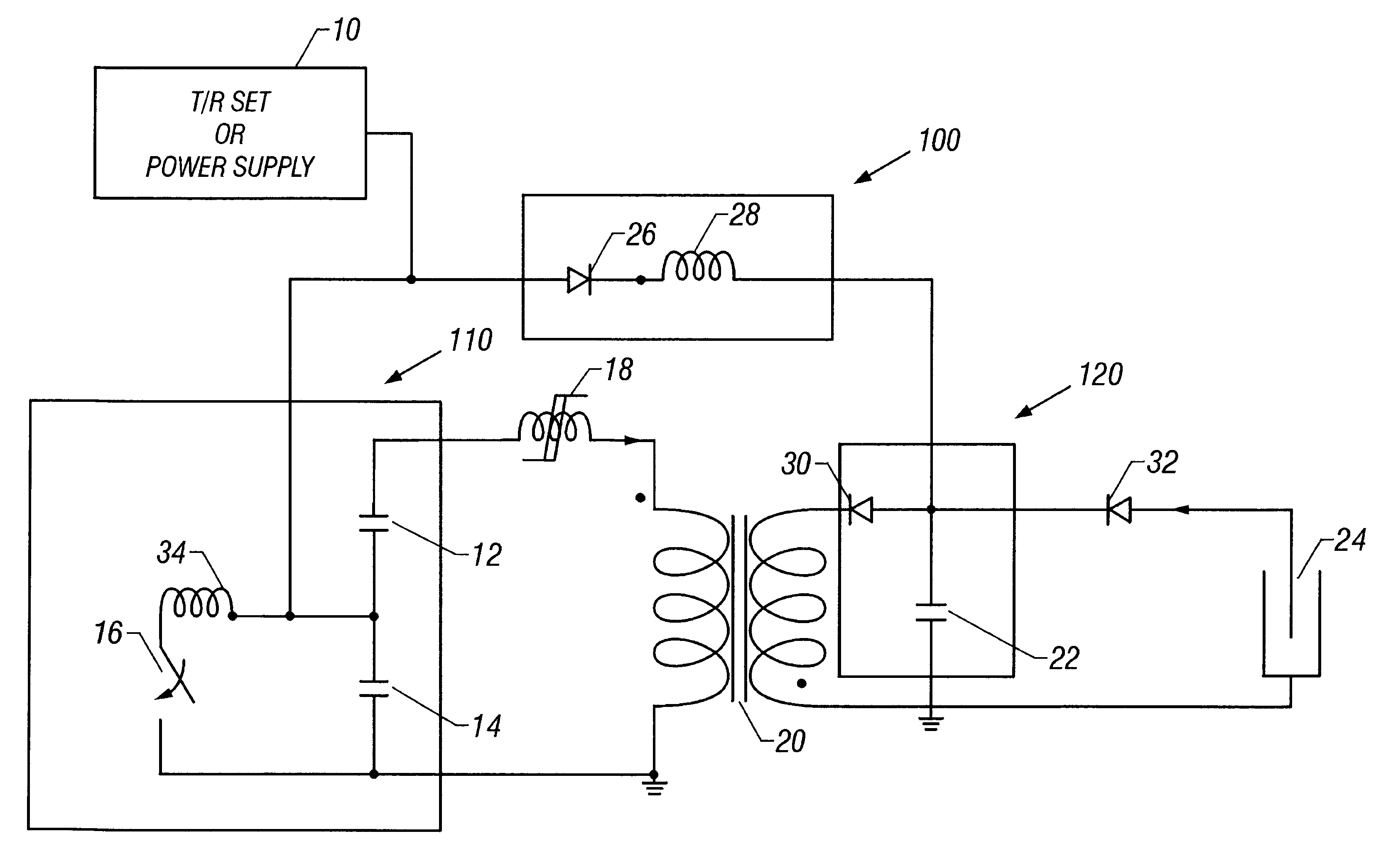

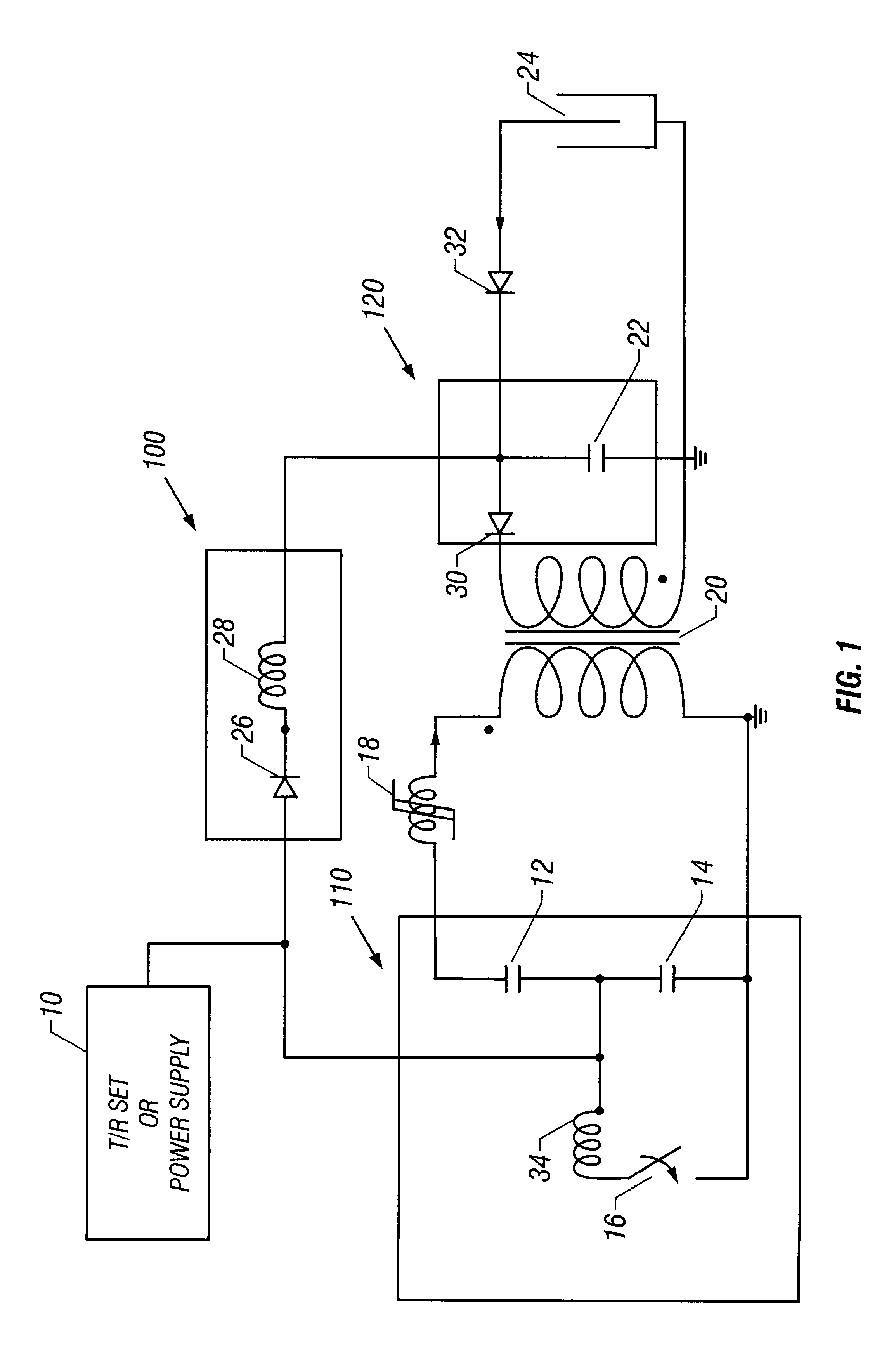

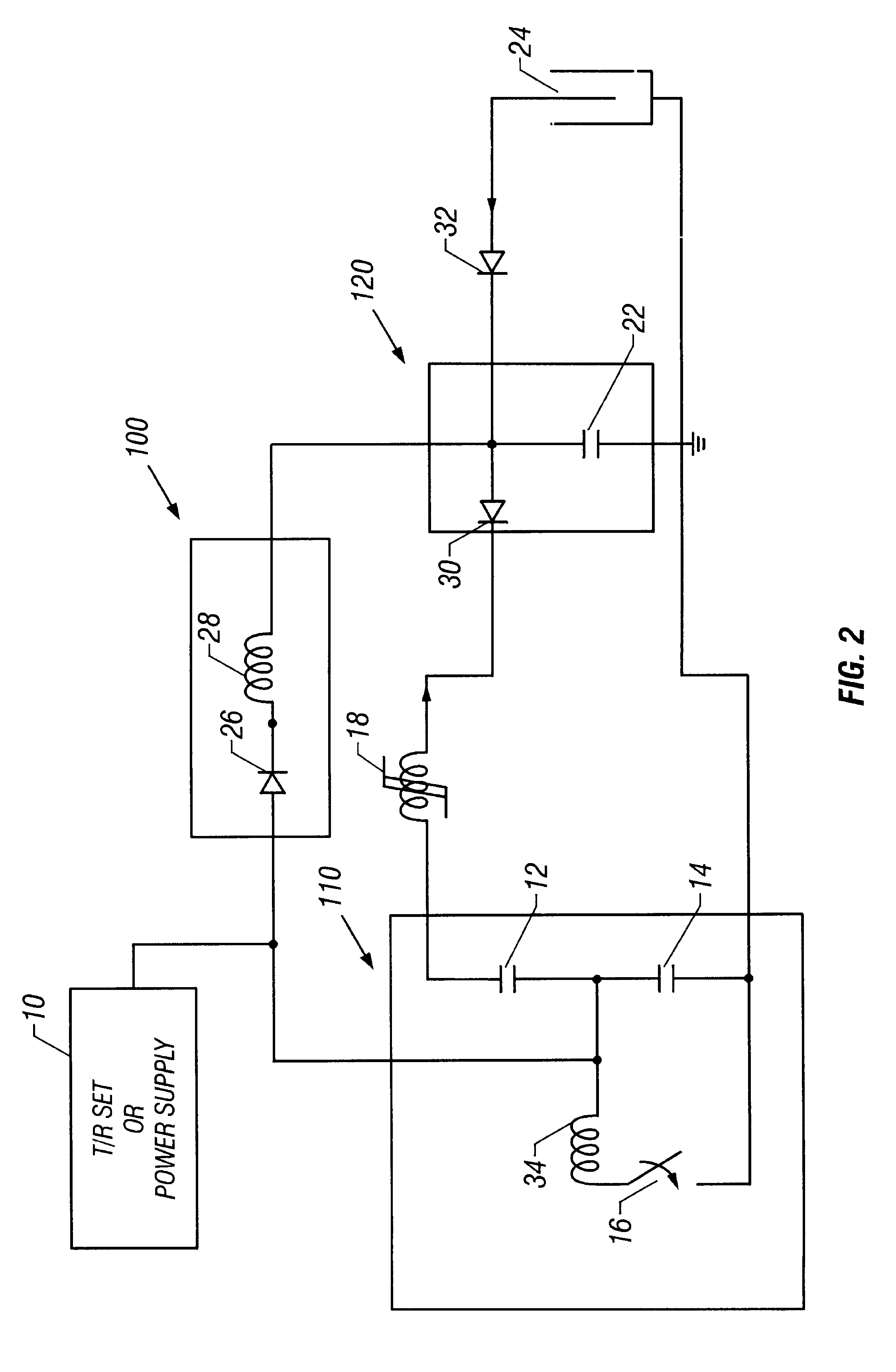

Electrostatic precipitator slow pulse generating circuit

InactiveUS6362604B1Eliminating back-coronaShorten rise timeAc-dc conversionPower supply linesTransformerElectrical impulse

An apparatus and method for generating slow rise-time, high voltage electrical pulses to a load, preferably using an existing transformer / rectifier set or power supply to charge an inversion or high voltage switching circuit to produce the pulsed voltage. An energy recovery circuit (100, 102) is used to return unused energy from the load (24) back to the means for producing pulsed voltage (110, 130). A load matching circuit (120) uses a blocking diode and a capacitor for charging the load. An additional blocking diode (32) inhibits load voltage discharge back through the slow pulse generating circuit. A transformer (20) can be used to step-up voltage from the inversion circuit, or high voltage switching circuit, to the load. One or more magnetic switch stages are used to transfer energy from the inversion circuit, or high voltage switching circuit, to the load matching circuit. A fire-on voltage controller (66) triggers the inversion or high voltage switching circuit.

Owner:ALPHA OMEGA POWER TECH L L C

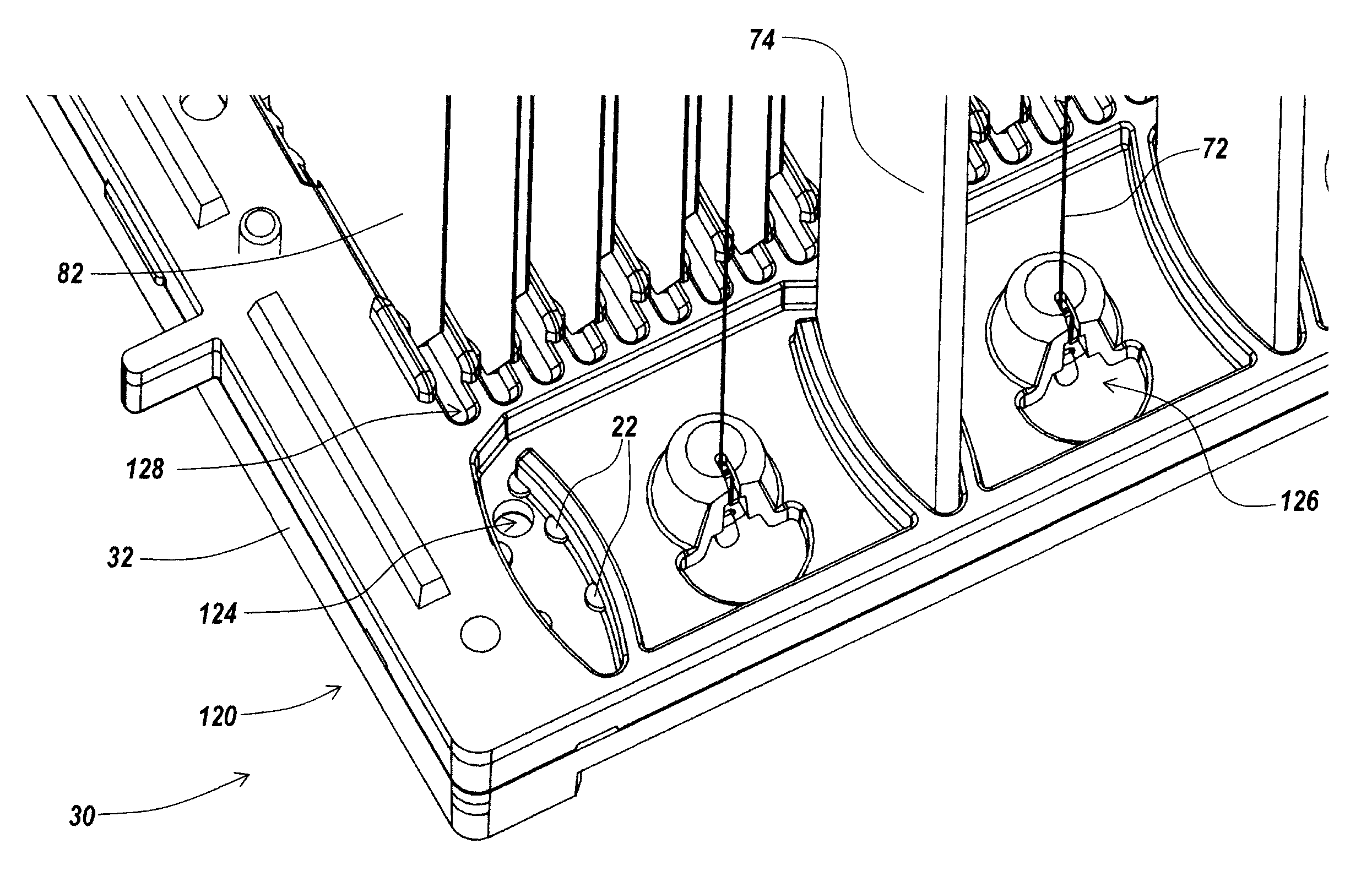

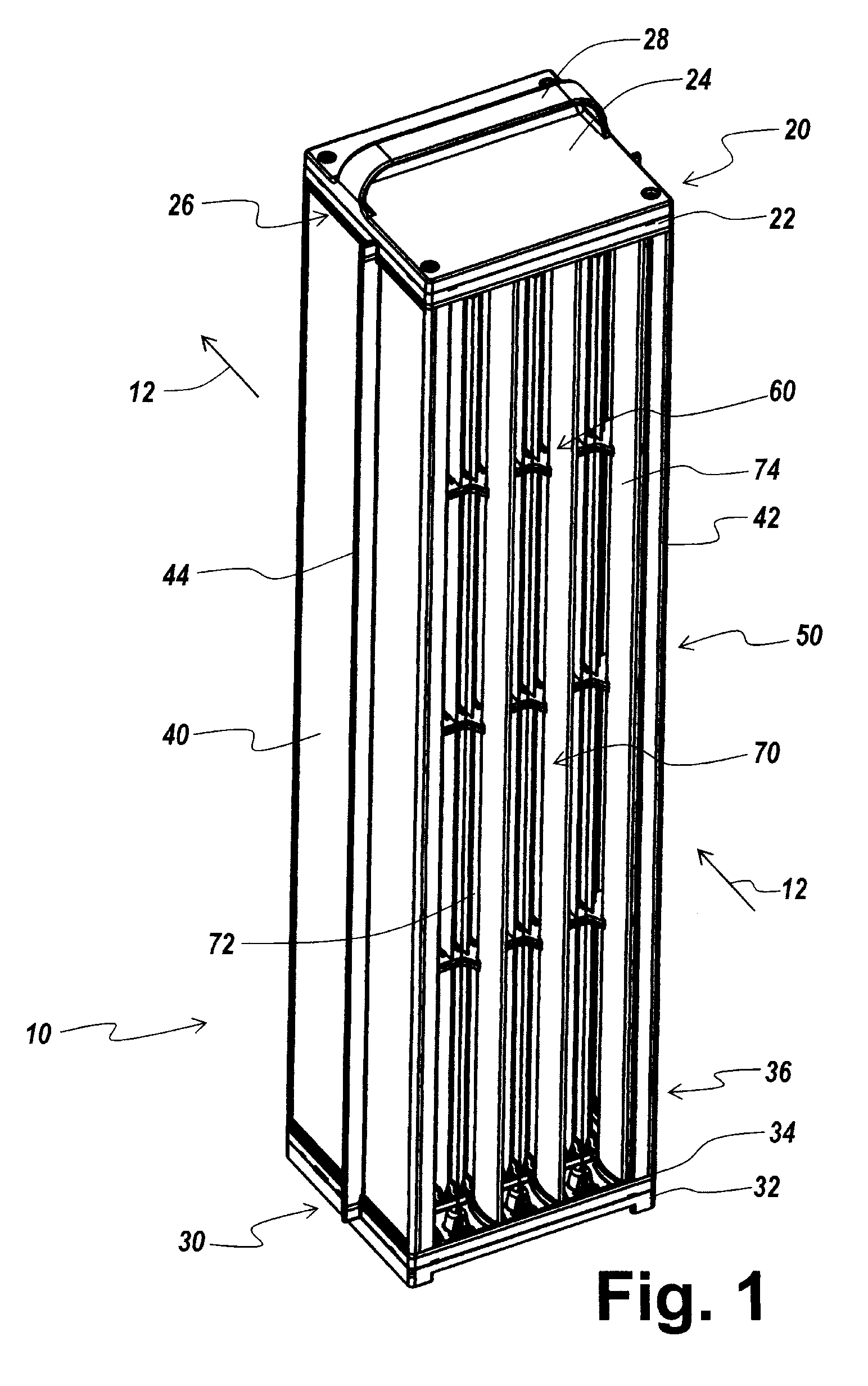

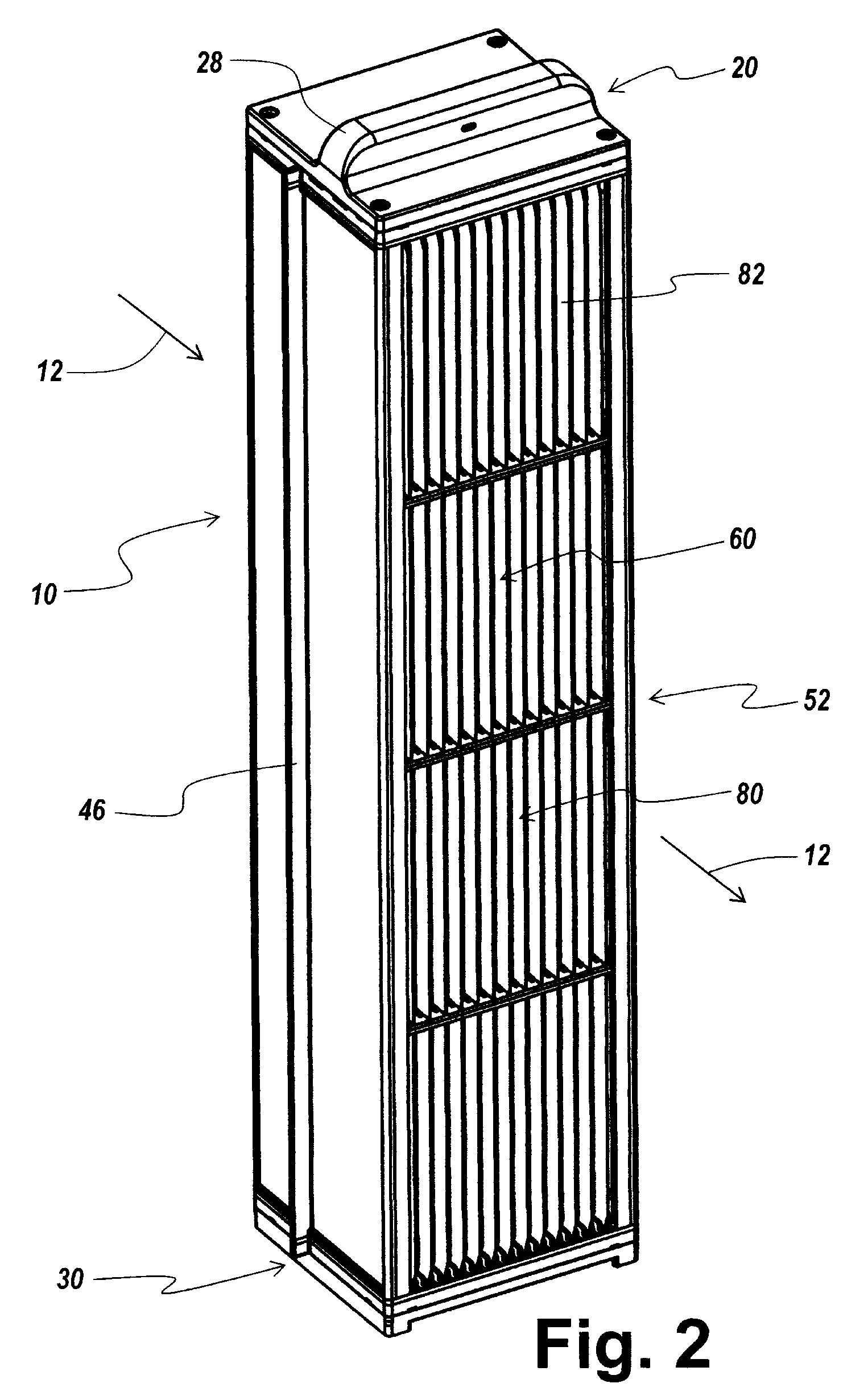

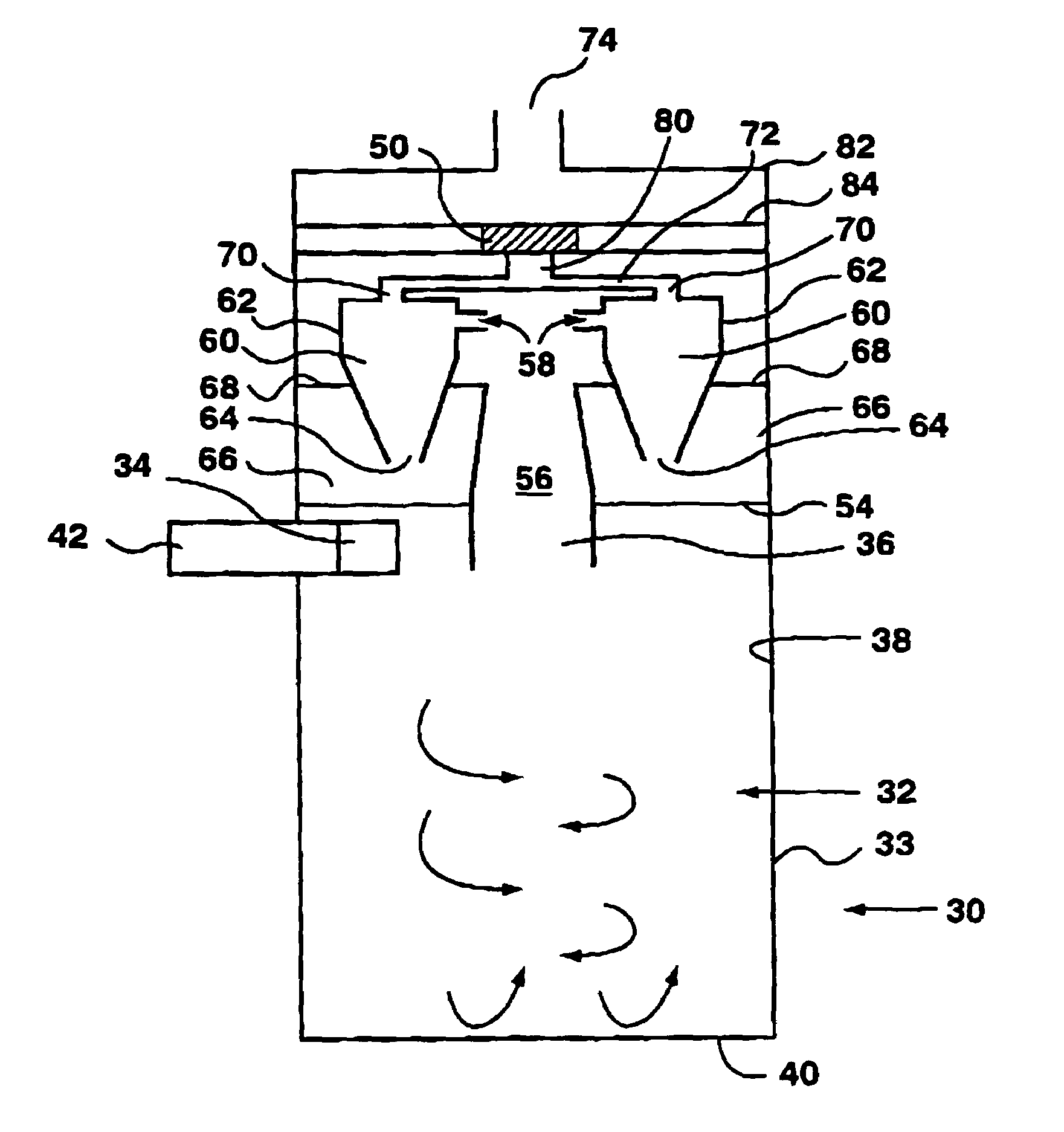

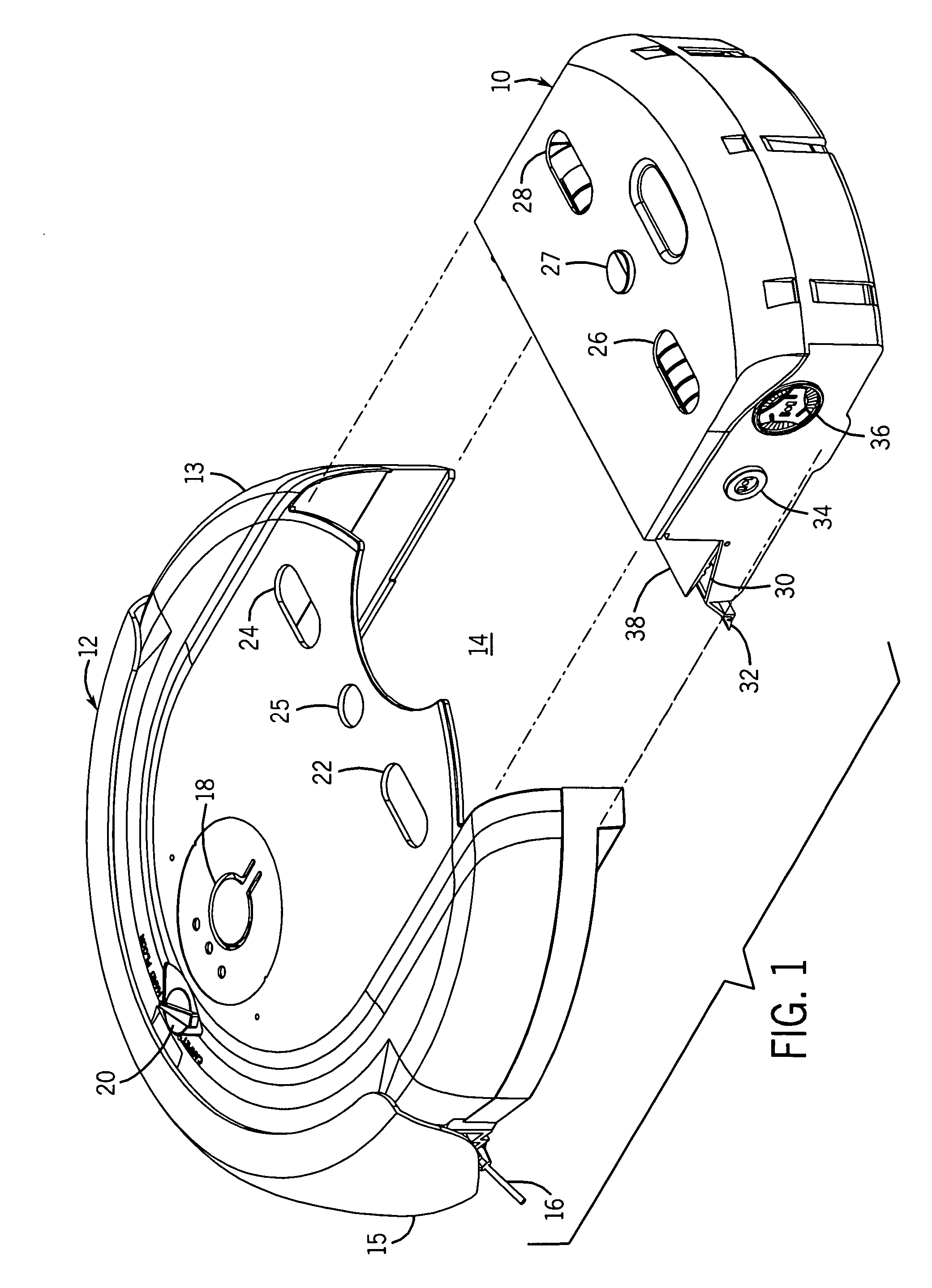

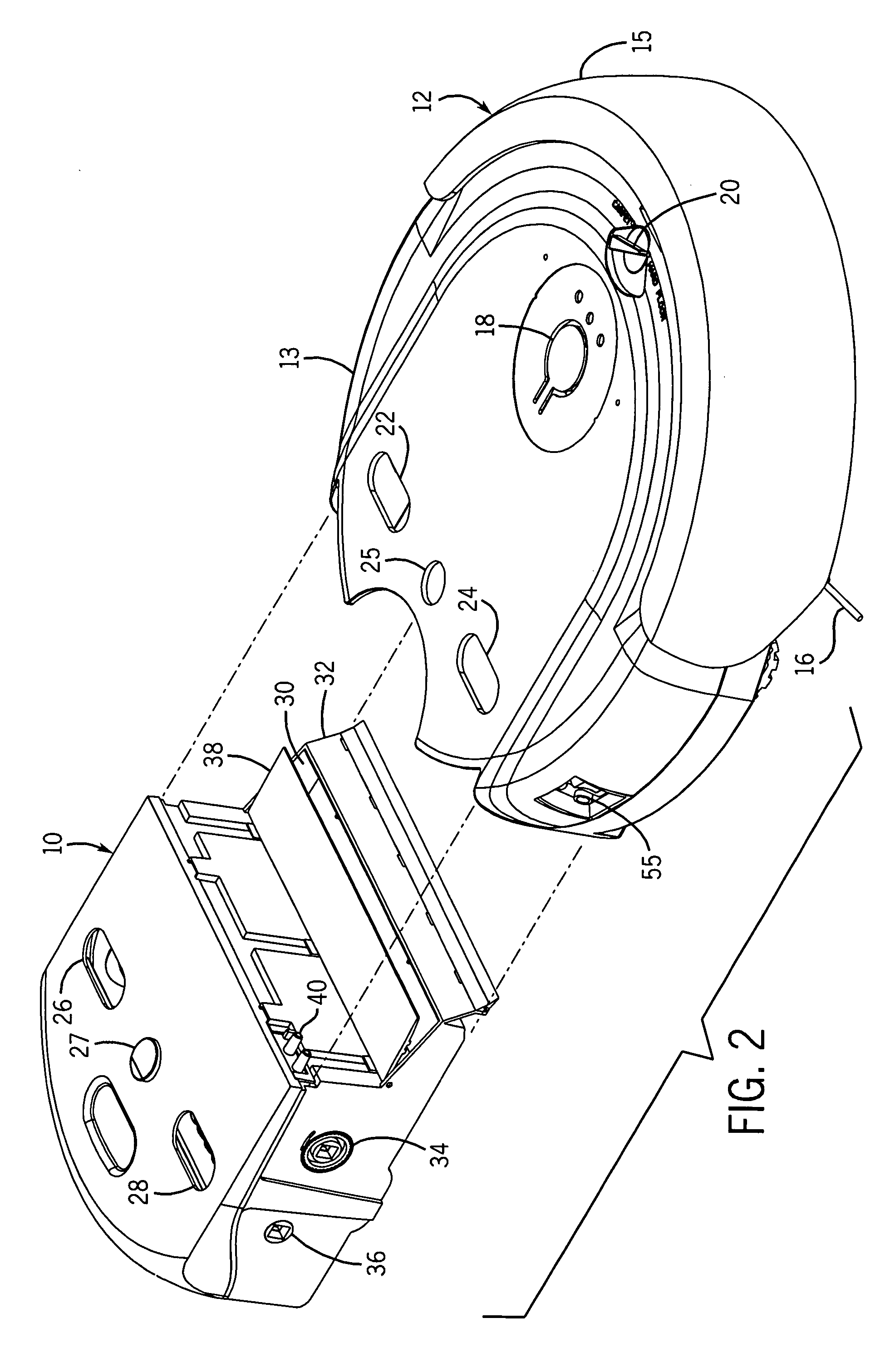

Electrostatic filter cartridge for a tower air cleaner

InactiveUS20080314250A1Improve removal efficiencyImprove drainage capacityHuman health protectionMagnetic separationParticulatesTower

The disclosed electrostatic precipitator cartridge for a tower air cleaner in accord with the present invention is low-cost, because constructed of injected molded plastics material and stamped and extruded metal components. It is easy to clean, not only because it's constitutive metal parts and plastic components are machine washable but also because the cartridge as a whole is machine washable, the pieces and components are designed and arranged to prevent intracartridge fluid buildup or retention after washing, thereby eliminating any electrical shorting or arcing or other undesirable phenomena resulting therefrom that could interfere with the operation of the electrostatic filter cartridge. It is mechanically stable and has high particulate collection efficiency because it's ionizer bars have a predetermined preferably air foil shape that provides improved ionization efficiency and that imparts improved torsion stability rendering it possible to provide taller electrostatic filter cartridges and / or greater cleaning power.

Owner:LASKO OPERATION HLDG LLC

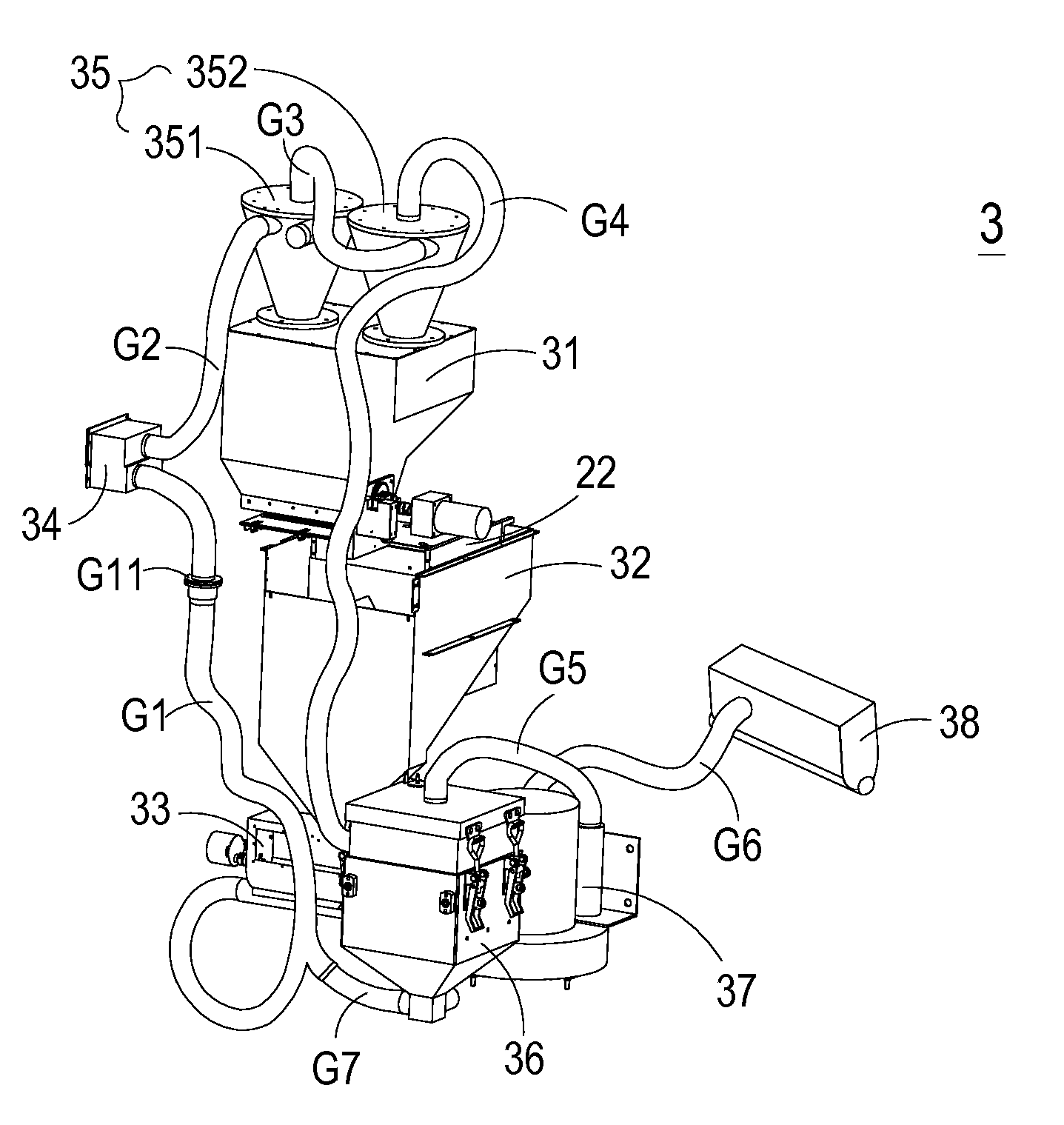

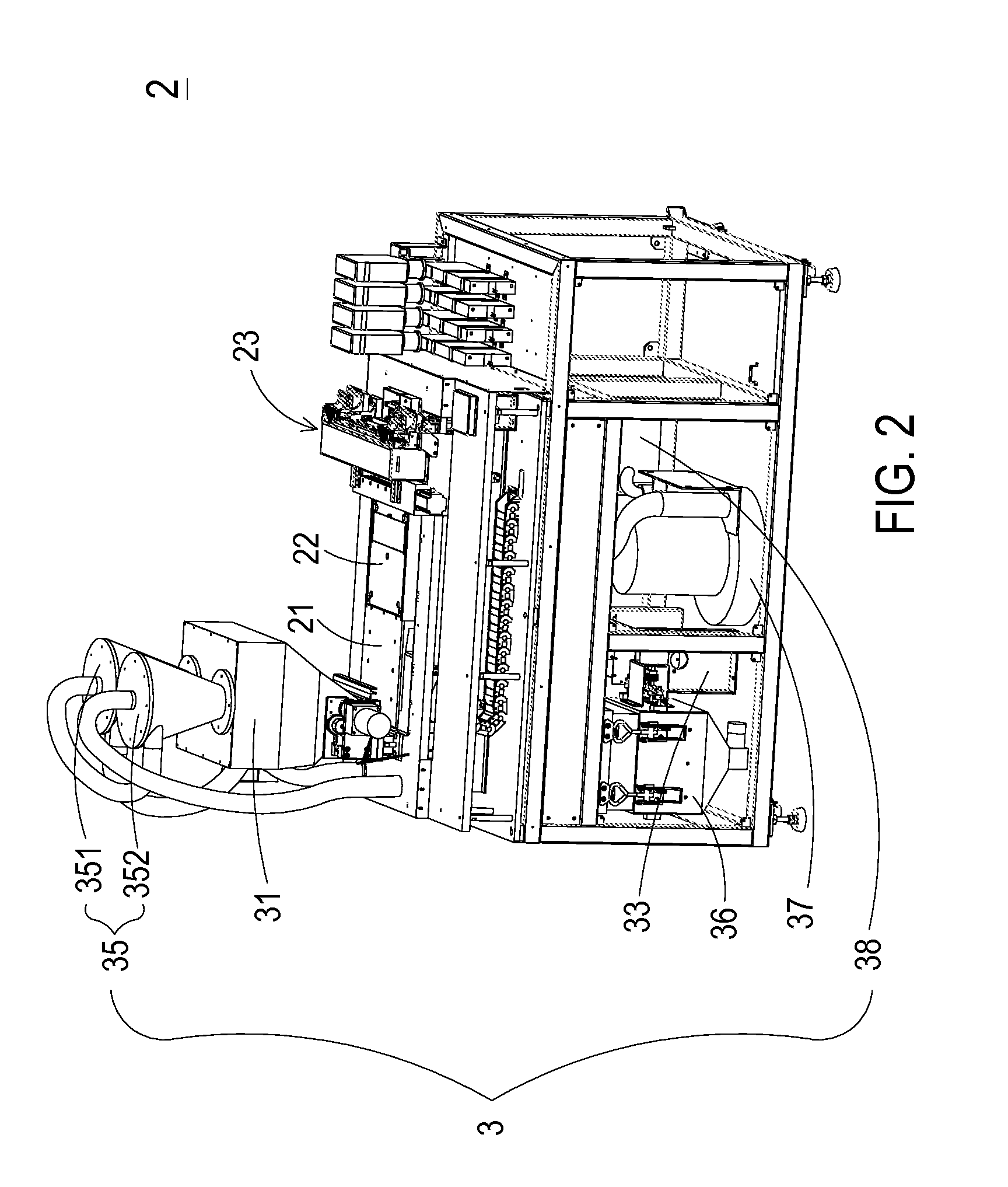

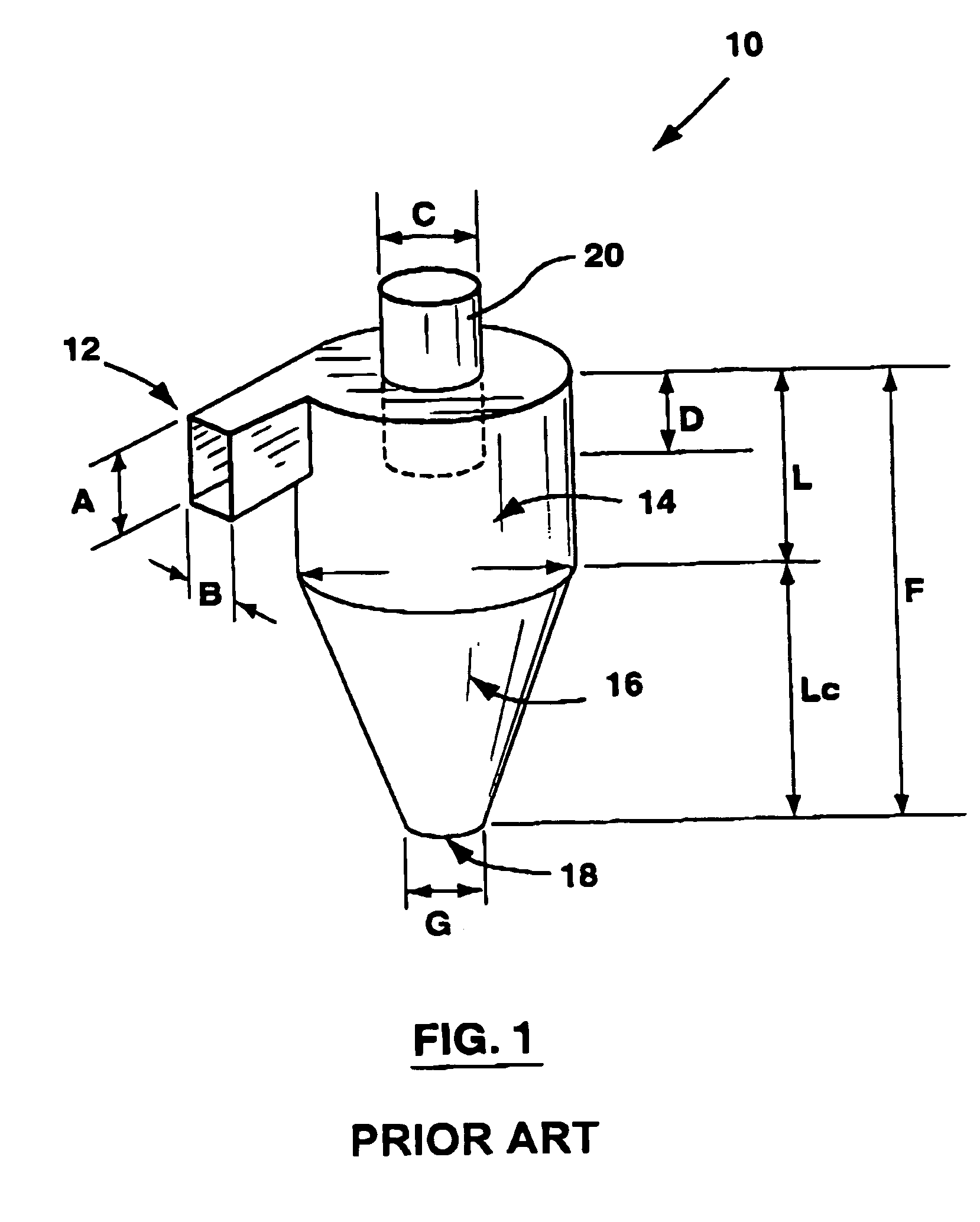

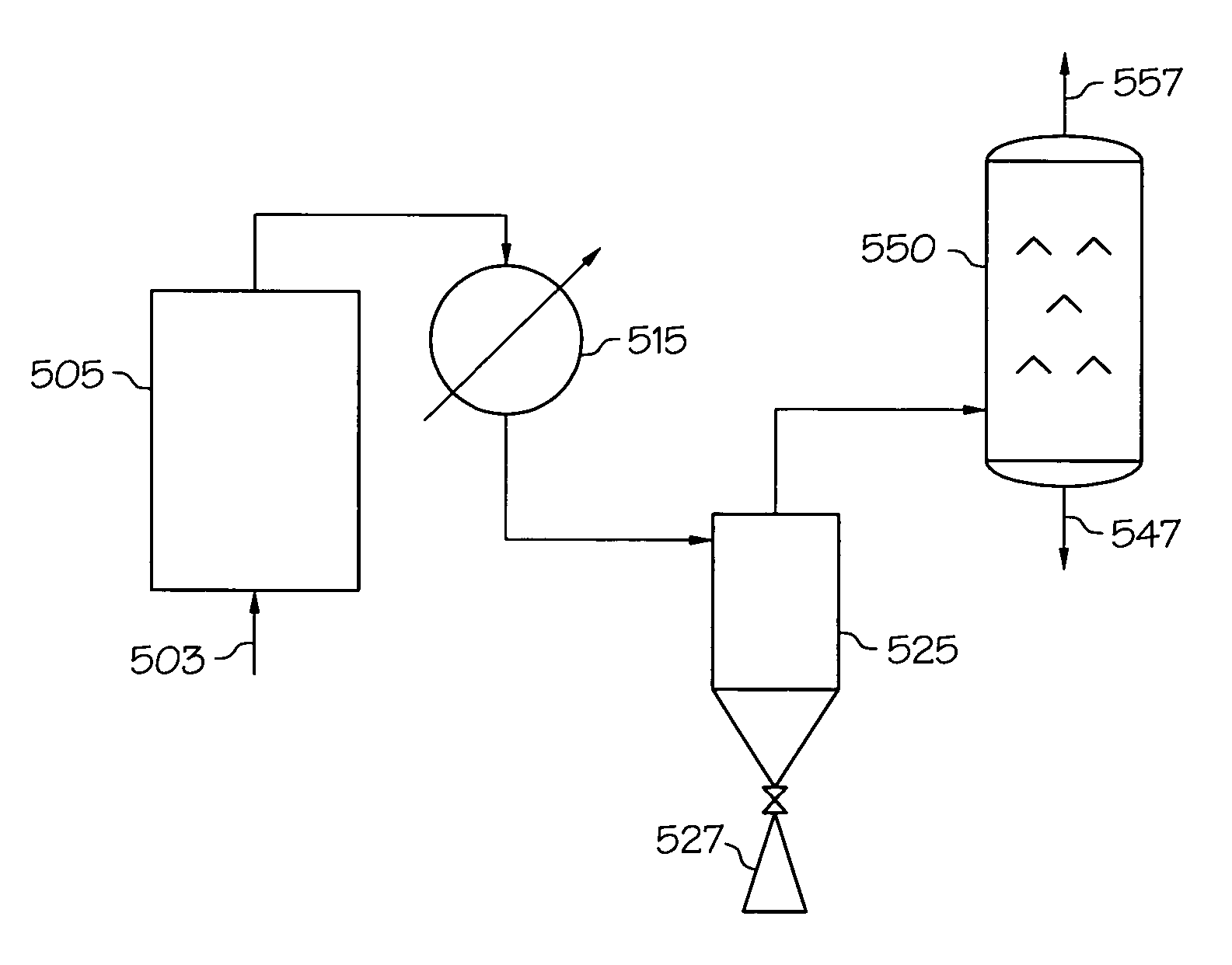

Powder recycling system

ActiveUS20150298397A1More user-friendlyCost-effectiveAdditive manufacturing apparatusGas current separationParticulatesPressure generation

A powder recycling system includes a powder feeder, a remaining powder collector, a bridge breaker, a block powder filter, a cyclone separator, a particulate filter cleaner, an air pressure generation device and an electrostatic precipitator. The powder feeder provides a construction powder to a construction platform. The remaining powder collector for collects the remaining powder. The cyclone separator is used to separate the large-size powdery particles and the small-size powdery particles of the remaining powder from each other through a rotating gaseous stream. The large-size powdery particles fall down to the powder feeder due to gravity, and the small-size powdery particles of the remaining powder is removed from the rotating gaseous stream and transmitted to the particulate filter cleaner. After the small-size powdery particles of the remaining powder are filtered by the particulate filter cleaner, the suspended small-size powdery particles are transmitted to the electrostatic precipitator.

Owner:MICROJET TECH

Enhanced mercury control in coal-fired power plants

InactiveUS20030161771A1Enhanced capture of mercuryEliminating undesirable dischargeUsing liquid separation agentHalide preparation methodsPulverized fuel ashElemental mercury

A method of treating a coal combustion flue gas, which includes injecting a molecular halogen or thermolabile molecular halogen precursor able to decompose to form molecular halogen at flue gas temperature. The molecular halogen coverts elemental mercury to mercuric halide adsorbable by alkaline solids such as subbituminous or lignite coal ash, alkali fused bituminous coal ash capturable in whole or part by electrostatic precipitators (ESPs), baghouses (BHs), fabric filters (FFs), dry flue gas desulphurization solids, with or without subsequent adsorption by a liquid such as a flue gas desulphurization scrubbing liquor.

Owner:HAZELMERE RES

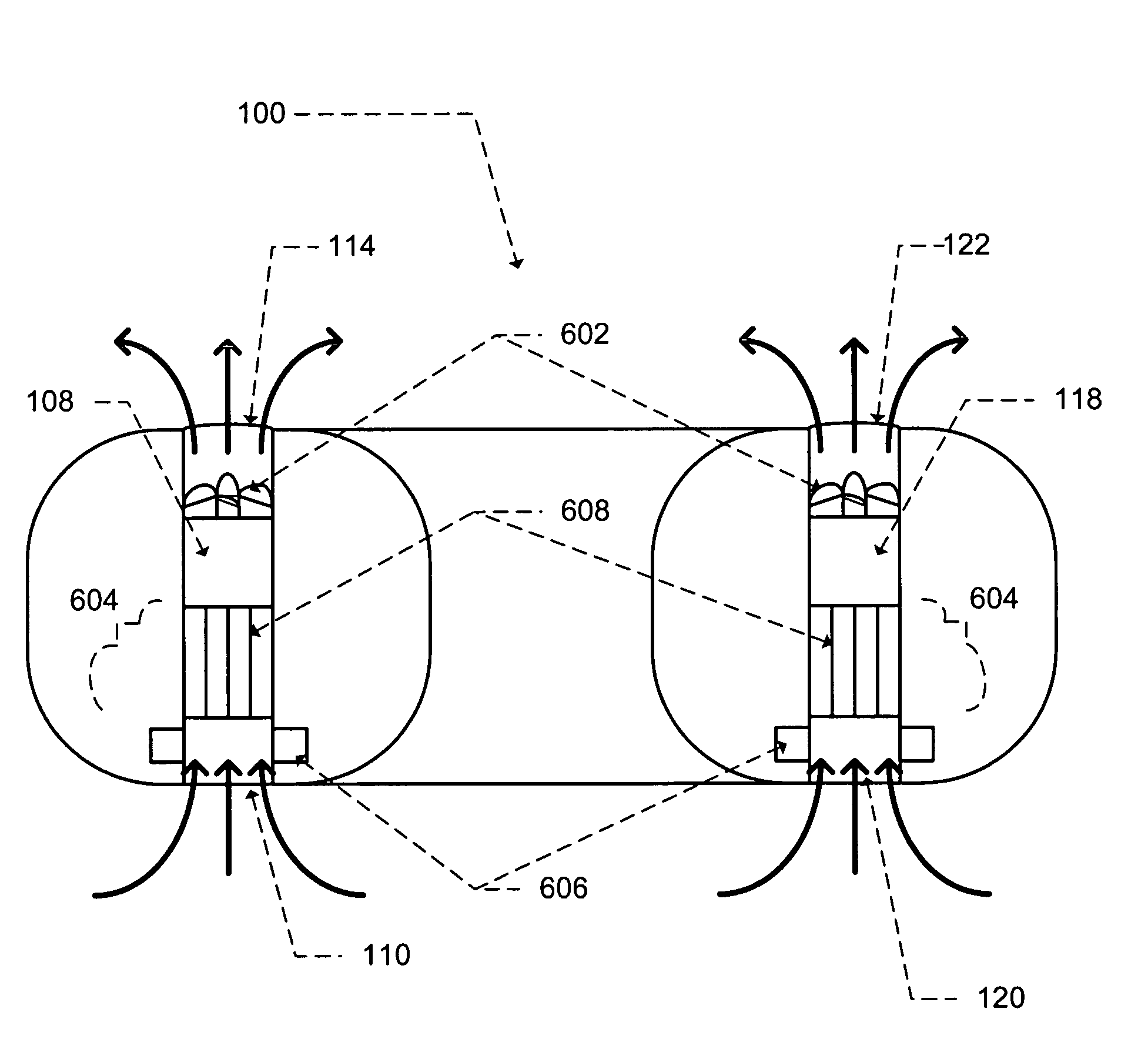

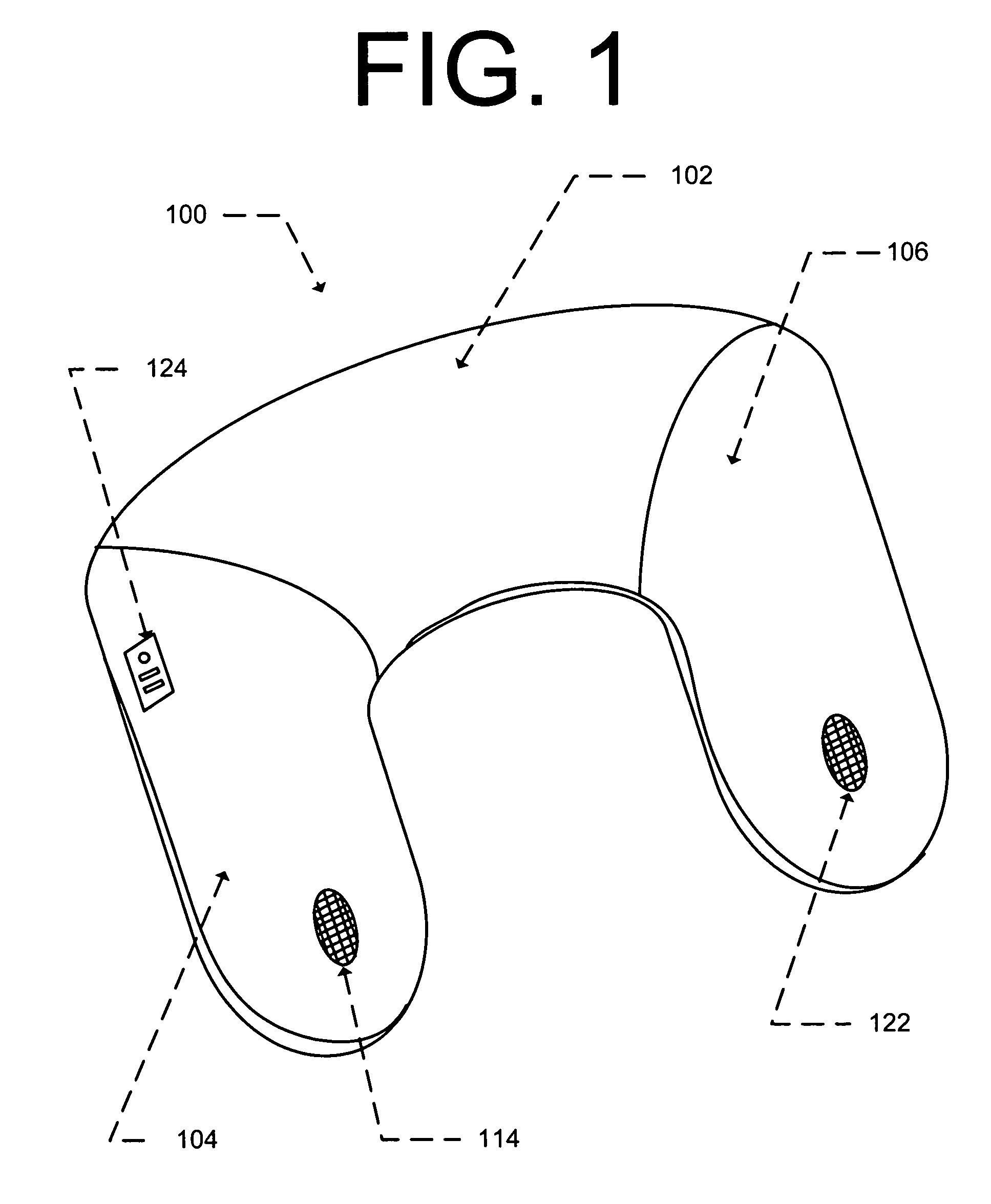

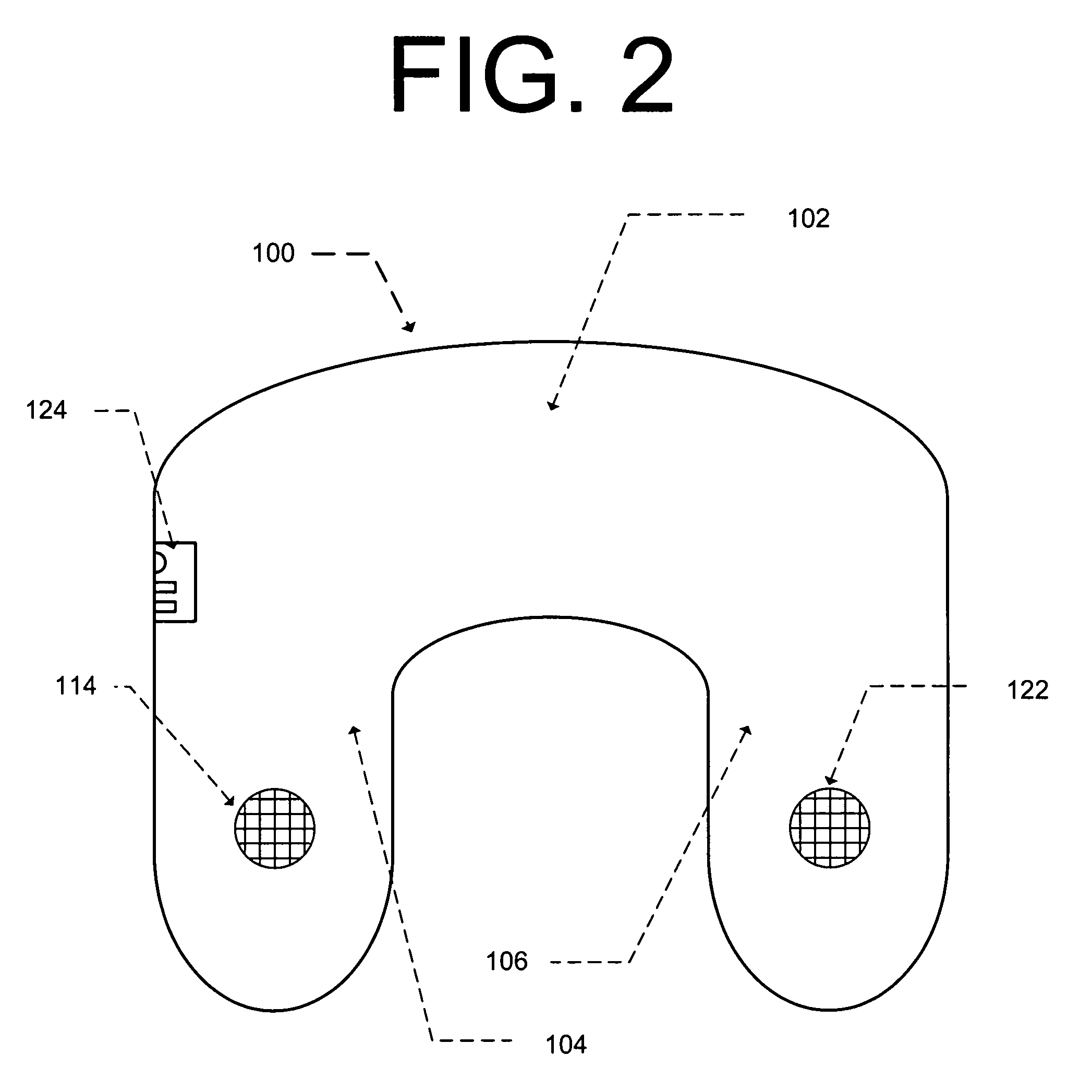

Pillow with air filter

ActiveUS7195660B2Cleanses the air surrounding the user during useCombination devicesLiquid degasificationAir filterEngineering

A travel pillow has one or more air filters and a body with a soft material coupled to the one or more air filters. The air filters can be powered by a power source located within the pillow. The one or more air filters can have an air intake and an air outflow in communication with an exterior surface of the body. The air filters may be an electrostatic precipitator filter or use a filtering material to clean the air.

Owner:BROOKSTONE PURCHASING

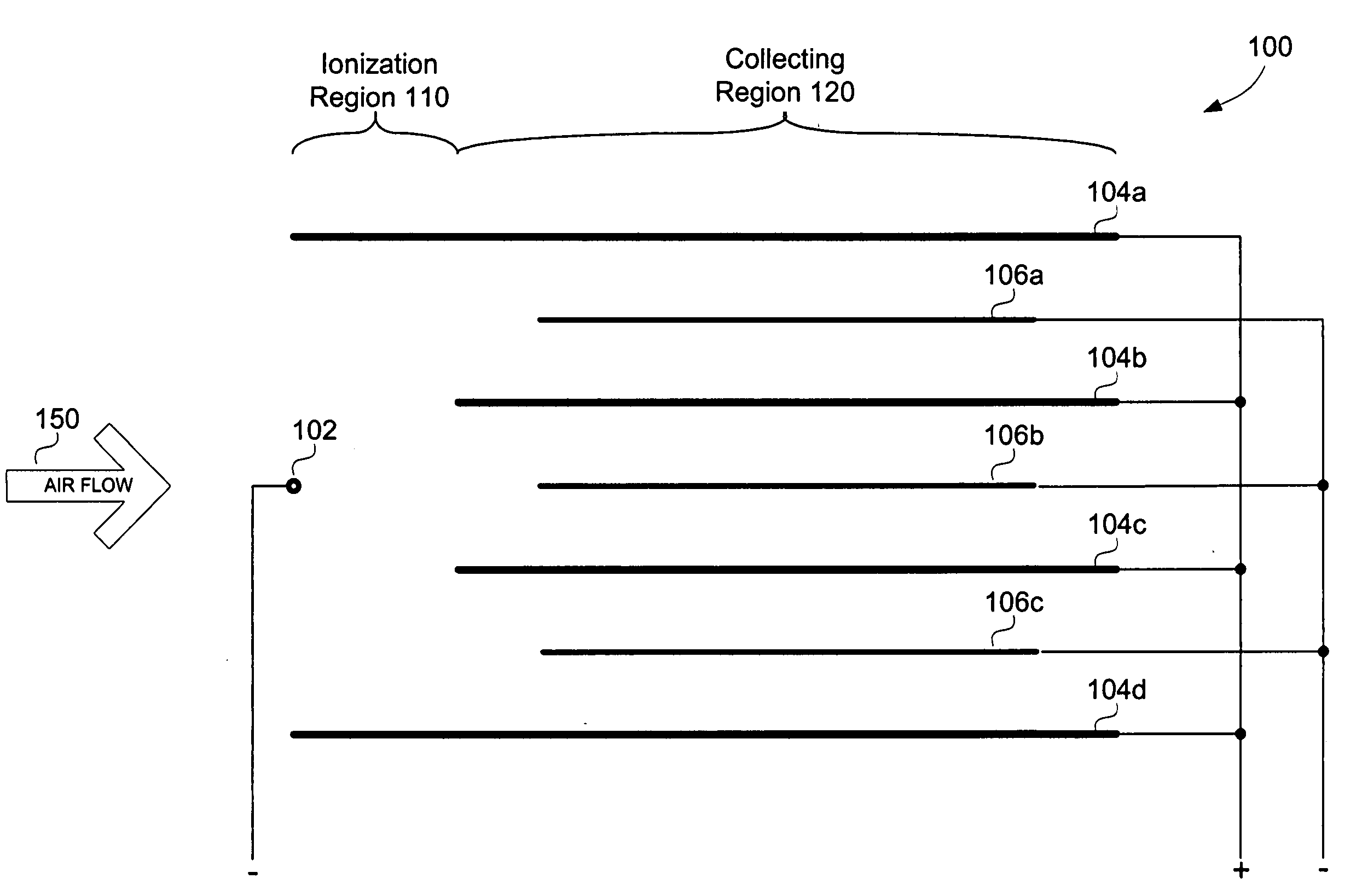

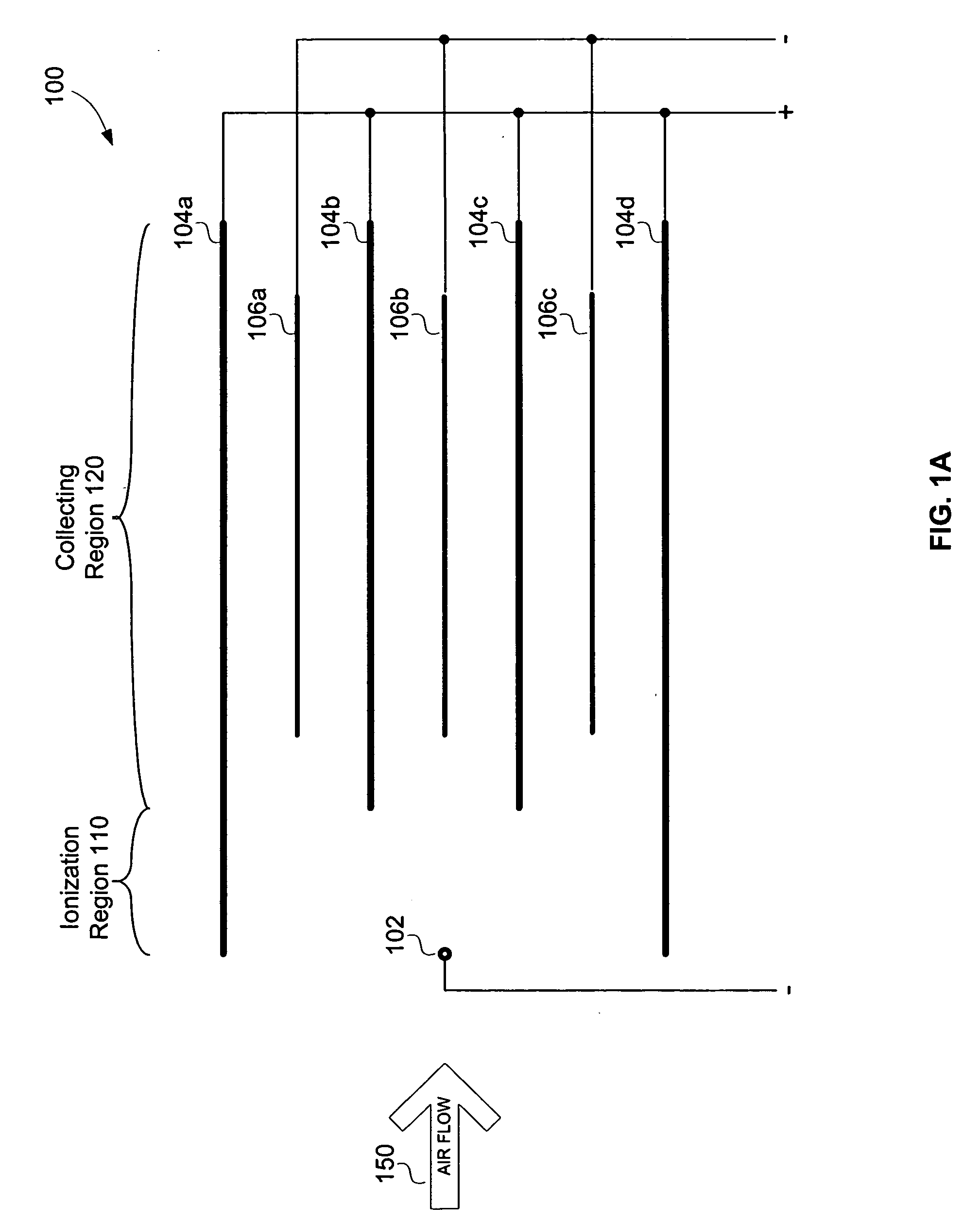

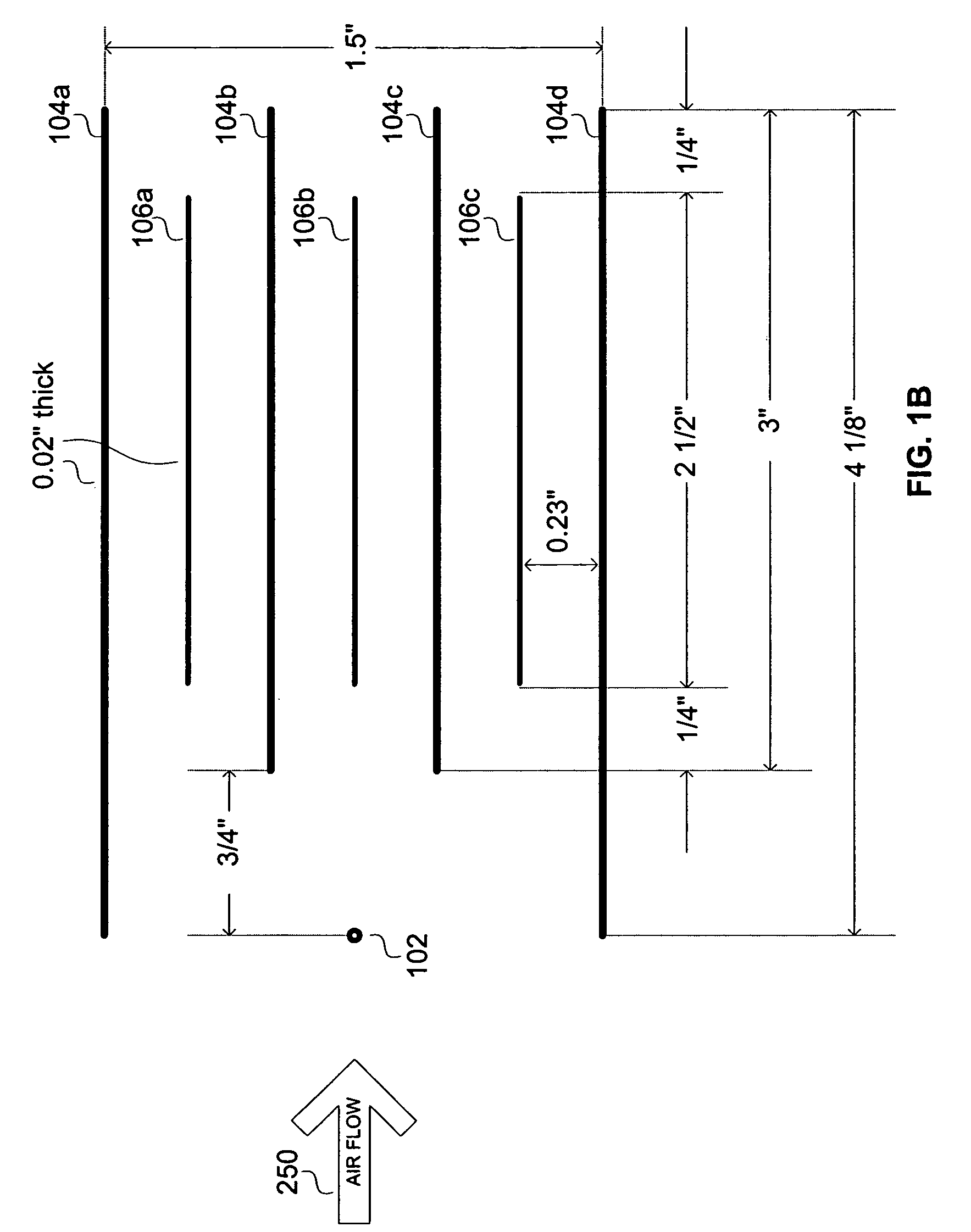

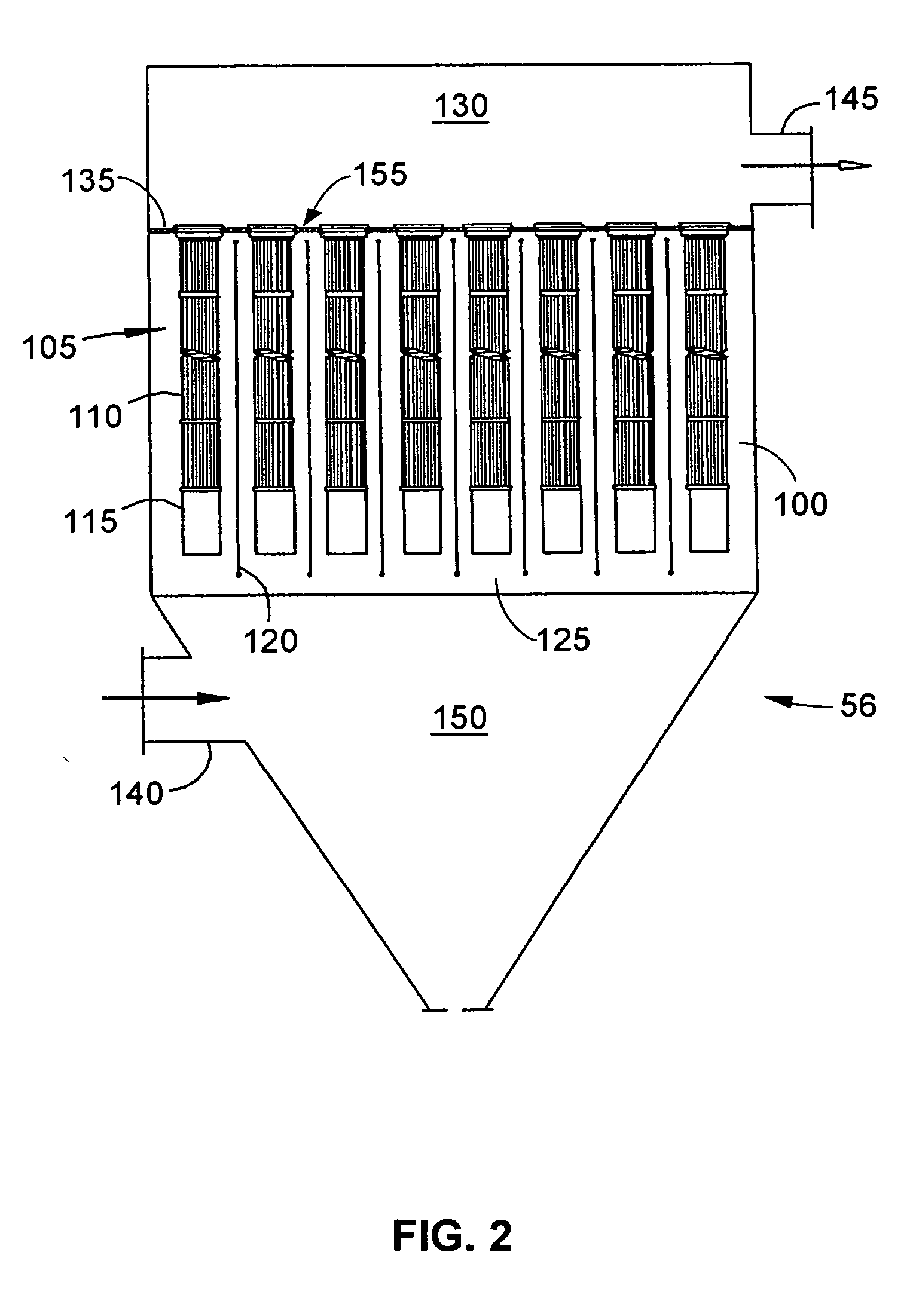

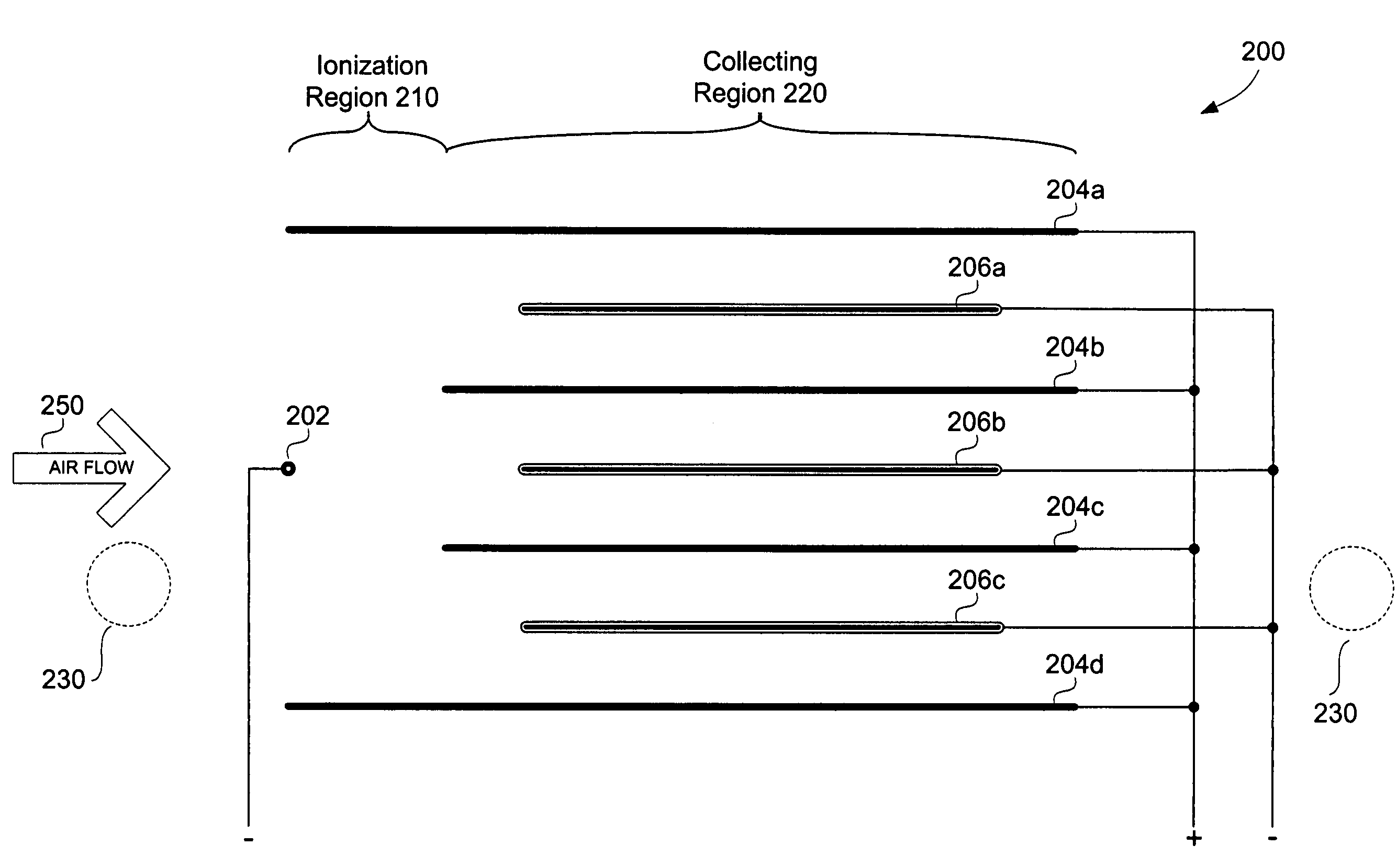

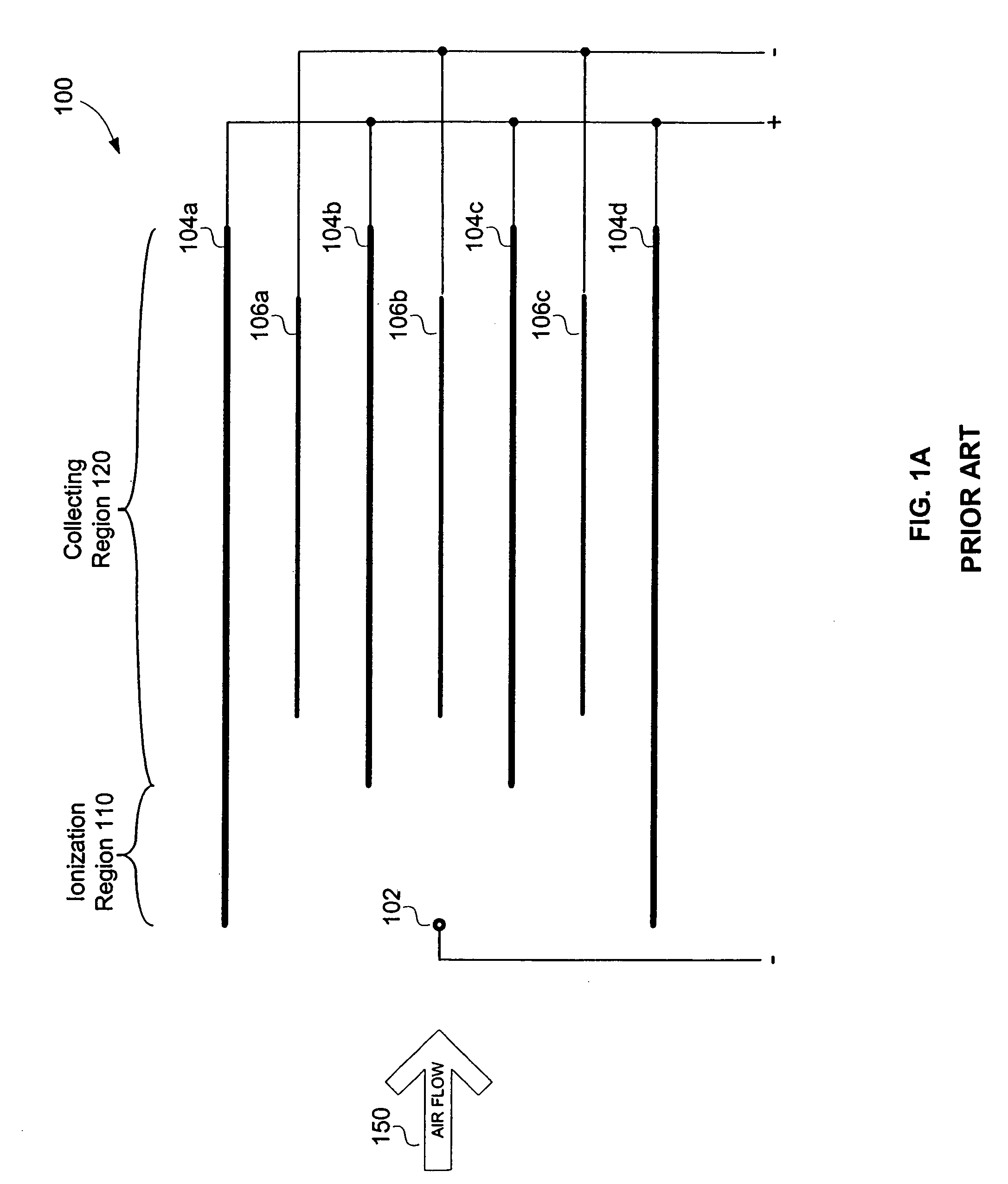

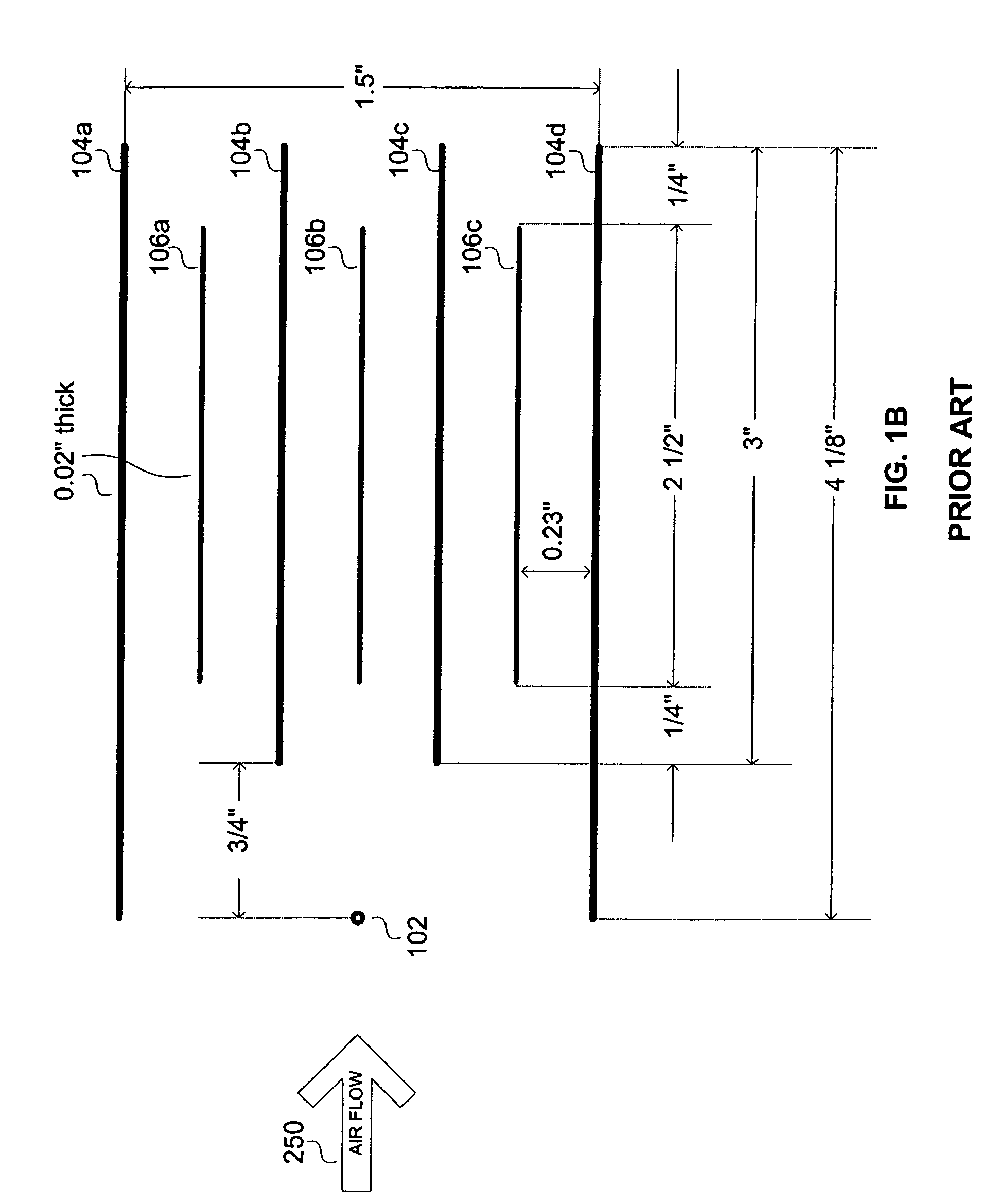

Electrostatic precipitators with insulated driver electrodes

InactiveUS20050051028A1Improve collection efficiencyReduce , and likely prevent , any arcingExternal electric electrostatic seperatorElectrode constructionsElectricityCorona discharge

Electrostatic precipitator (ESP) systems and methods are provided. A system includes at least one corona discharge electrode and at least one collector (and likely, at least a pair of collector electrodes) that extend downstream from the corona discharge electrode. An insulated driver electrode is located adjacent the collector electrode, and where there is at least a pair of collector electrodes, between each pair of collector electrodes. A high voltage source provides a voltage potential to the at least one of the corona discharge electrode and the collector electrode(s), to thereby provide a potential different therebetween. The insulated driver electrode(s) may or may not be at a same voltage potential as the corona discharge electrode, but should be at a different voltage potential than the collector electrode(s).

Owner:THE SHARPER IMAGE

Sorbent Filter for the Removal of Vapor Phase Contaminants

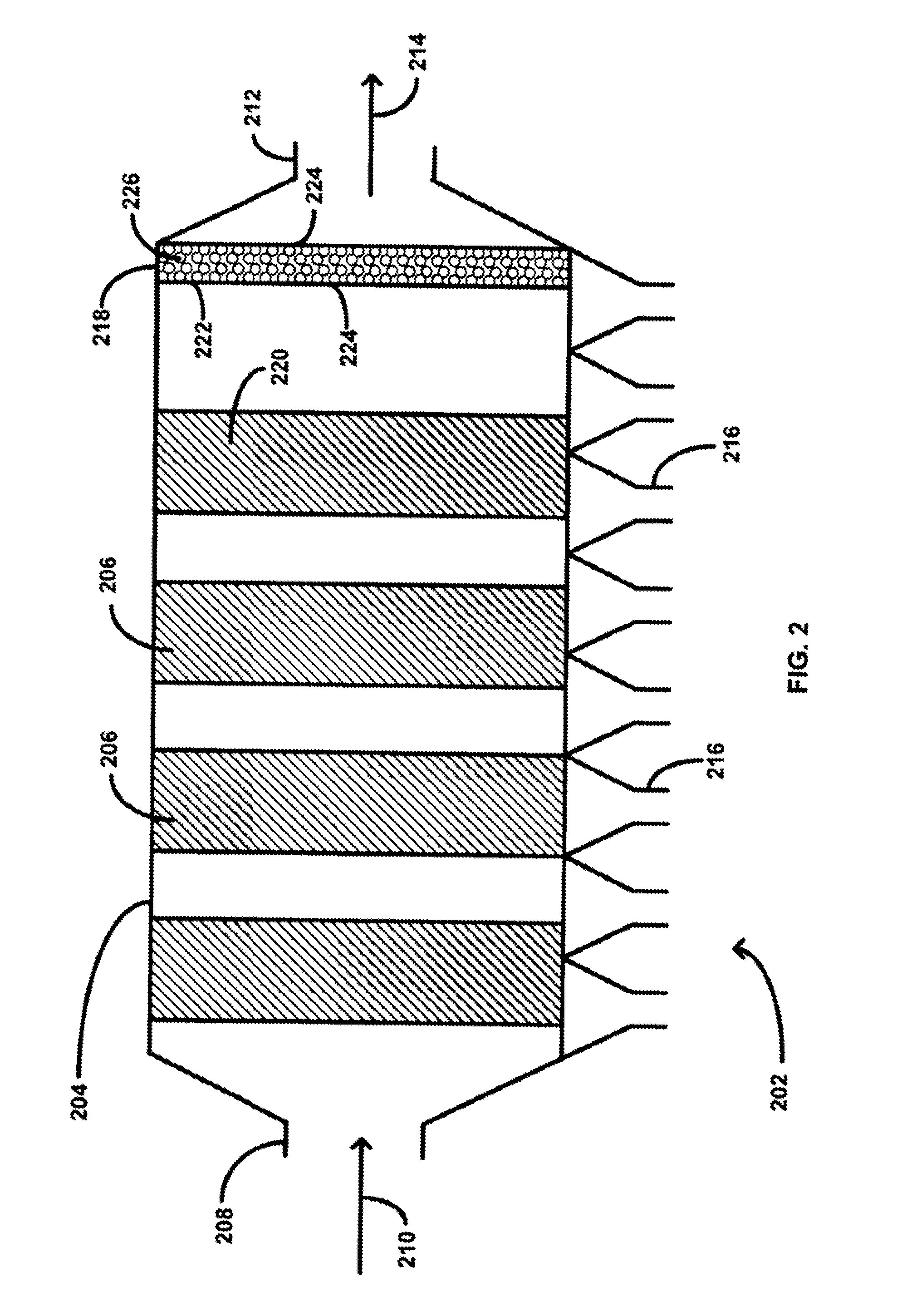

Methods and apparatuses are described for removing a contaminant, such as a vaporous trace metal contaminant like mercury, from a gas stream. In one embodiment, a primary particulate collection device that removes particulate matter is used. In this embodiment, a sorbent filter is placed within the housing of the primary particulate collection device, such as an electrostatic precipitator or a baghouse, to adsorb the contaminant of interest. In another embodiment, a sorbent filter is placed within or after a scrubber, such as a wet scrubber, to adsorb the contaminant of interest. In some embodiments, the invention provides methods and apparatuses that can advantageously be retrofit into existing particulate collection equipment. In some embodiments, the invention provides methods and apparatuses that in addition to removal of a contaminant additionally remove particulate matter from a gas stream.

Owner:ELECTRIC POWER RES INST INC

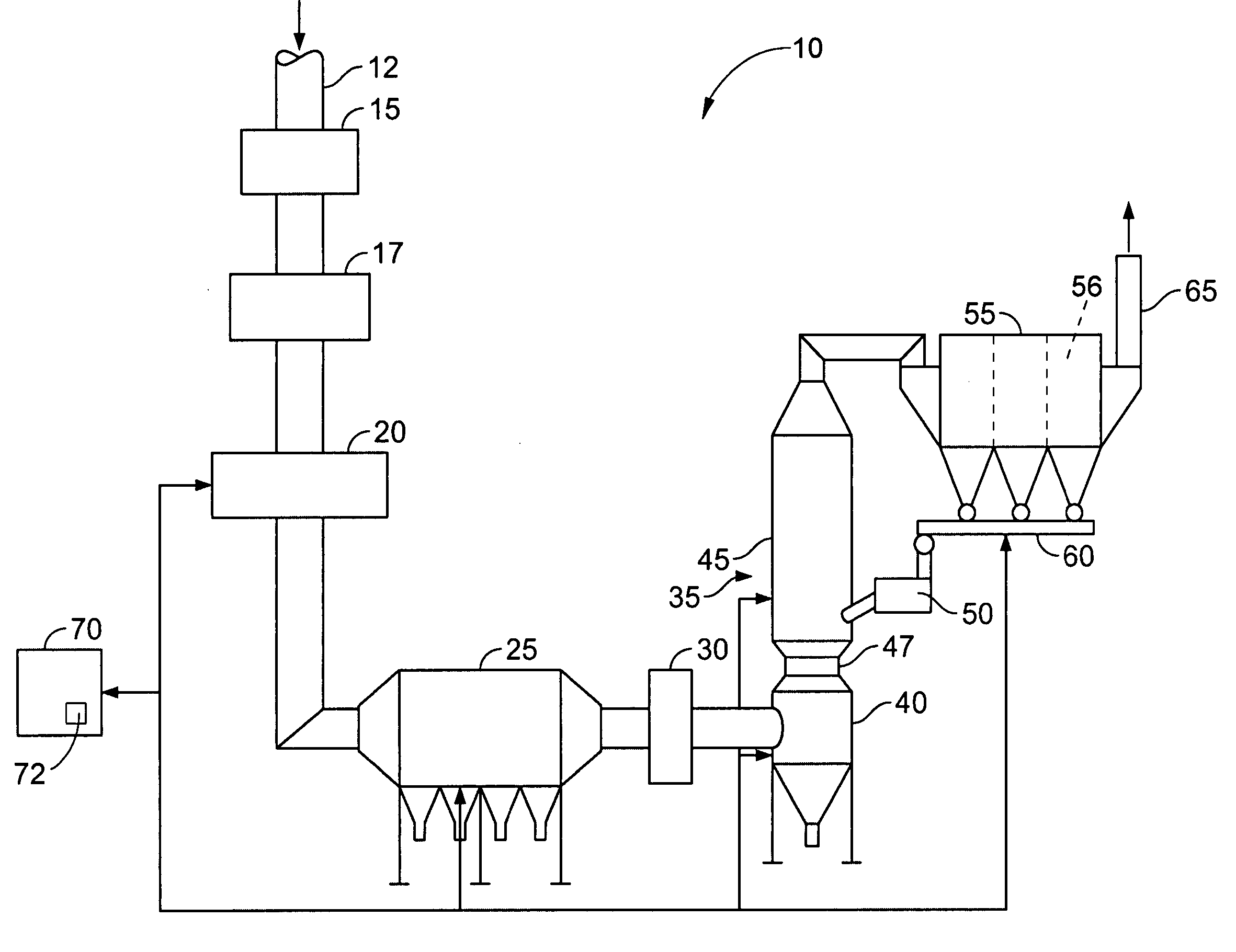

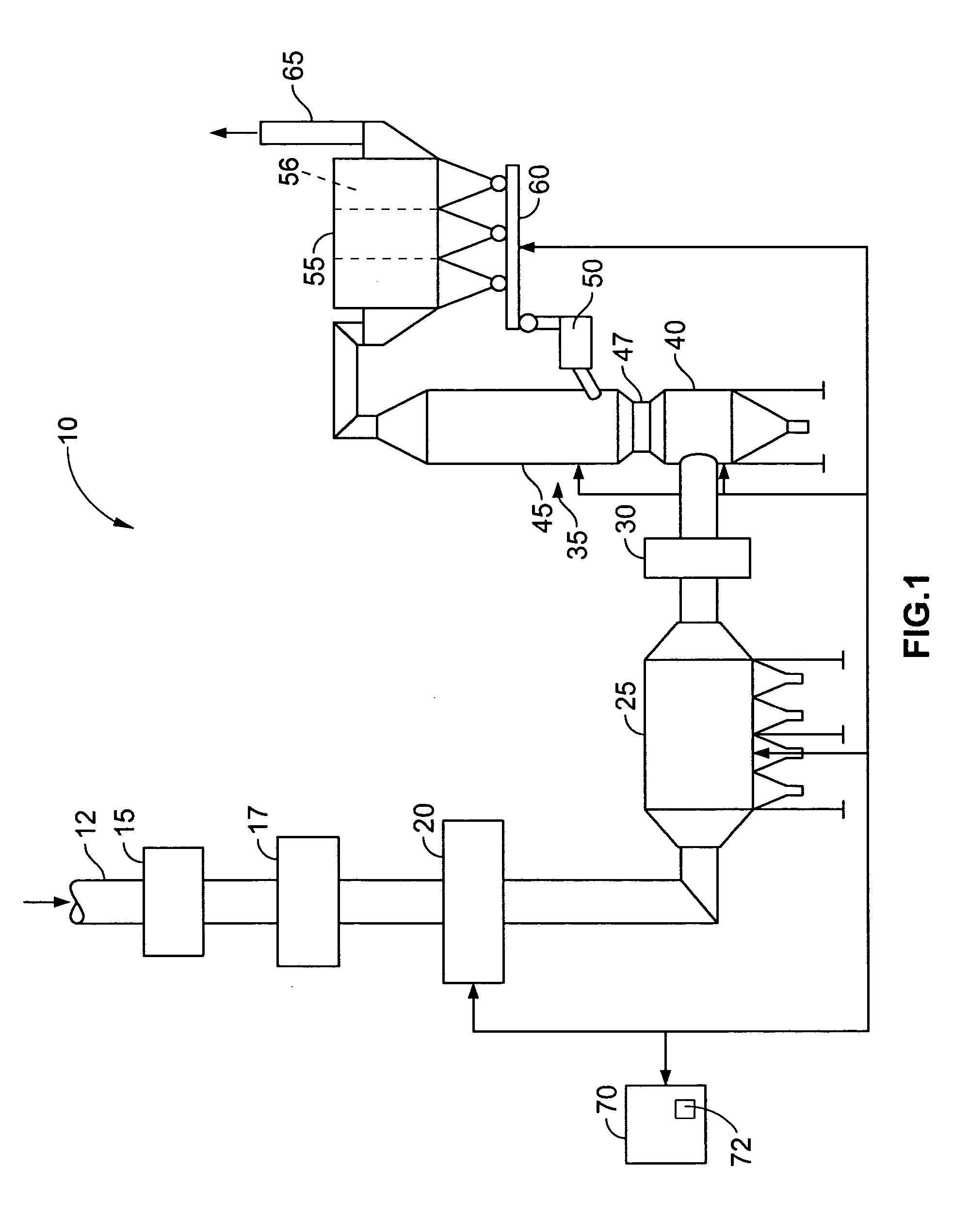

Method and system for removing mercury from combustion gas

A method for continuously removing mercury from a supply of combustion gas is provided. The method includes adjusting a power input to an electrostatic precipitator to control a quantity of fly ash emitted from the electrostatic precipitator. A turbulent flow of combustion gas is produced to suspend particulate matter including the quantity of fly ash contained in the supply of combustion gas. A substantial portion of the mercury is absorbed within the particulate matter including the quantity of fly ash. The supply of combustion gas is filtered to remove the particulate matter from the mercury. A quantity of absorption sites available for absorbing mercury is controlled by monitoring an emission of fly ash from the electrostatic precipitator.

Owner:GENERAL ELECTRIC CO

Electrostatic precipitators with insulated driver electrodes

InactiveUS7077890B2Improve collection efficiencyReduce , and likely prevent , any arcingEnergy based chemical/physical/physico-chemical processesExternal electric electrostatic seperatorElectricityCorona discharge

Electrostatic precipitator (ESP) systems and methods are provided. A system includes at least one corona discharge electrode and at least one collector (and likely, at least a pair of collector electrodes) that extend downstream from the corona discharge electrode. An insulated driver electrode is located adjacent the collector electrode, and where there is at least a pair of collector electrodes, between each pair of collector electrodes. A high voltage source provides a voltage potential to the at least one of the corona discharge electrode and the collector electrode(s), to thereby provide a potential different therebetween. The insulated driver electrode(s) may or may not be at a same voltage potential as the corona discharge electrode, but should be at a different voltage potential than the collector electrode(s).

Owner:THE SHARPER IMAGE

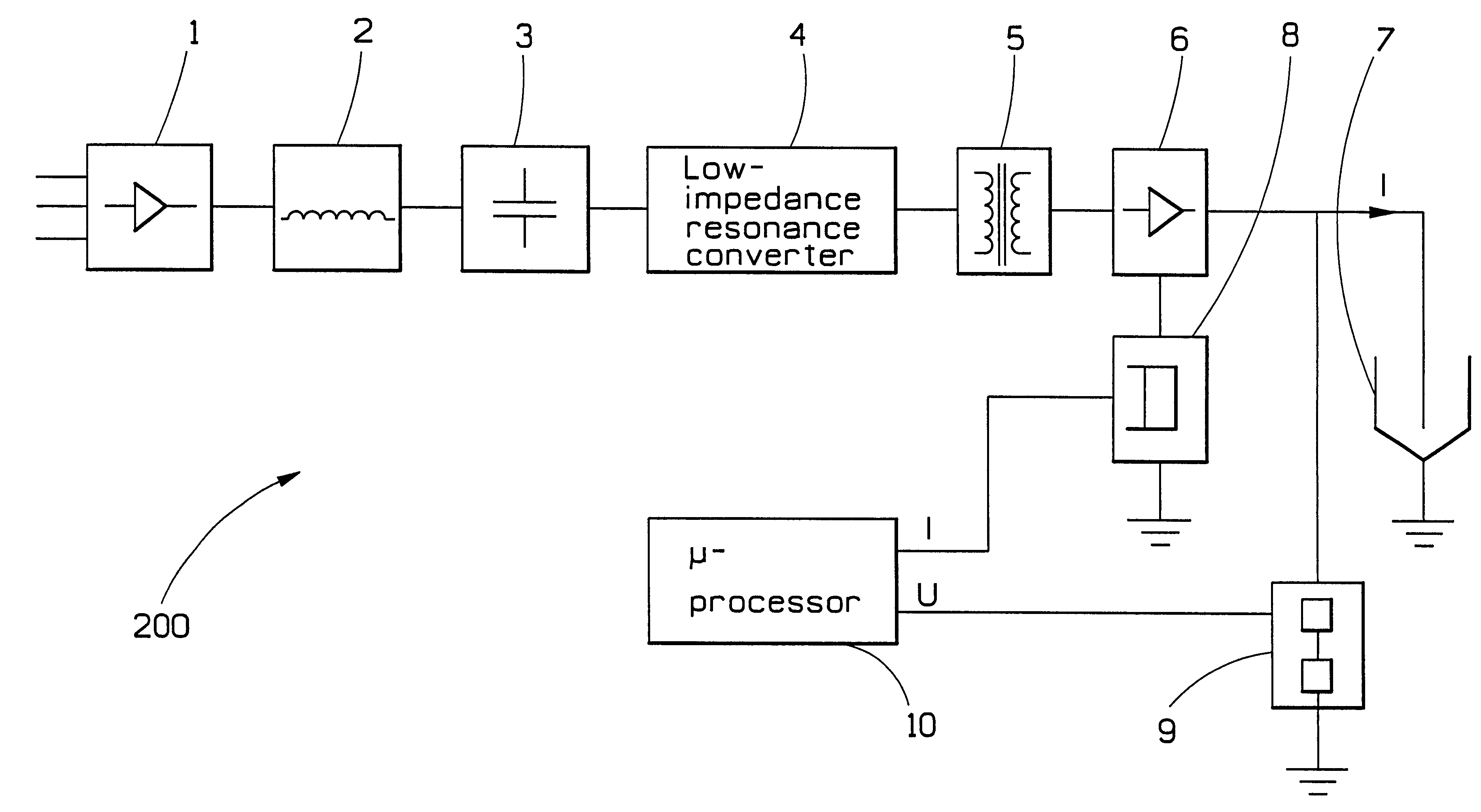

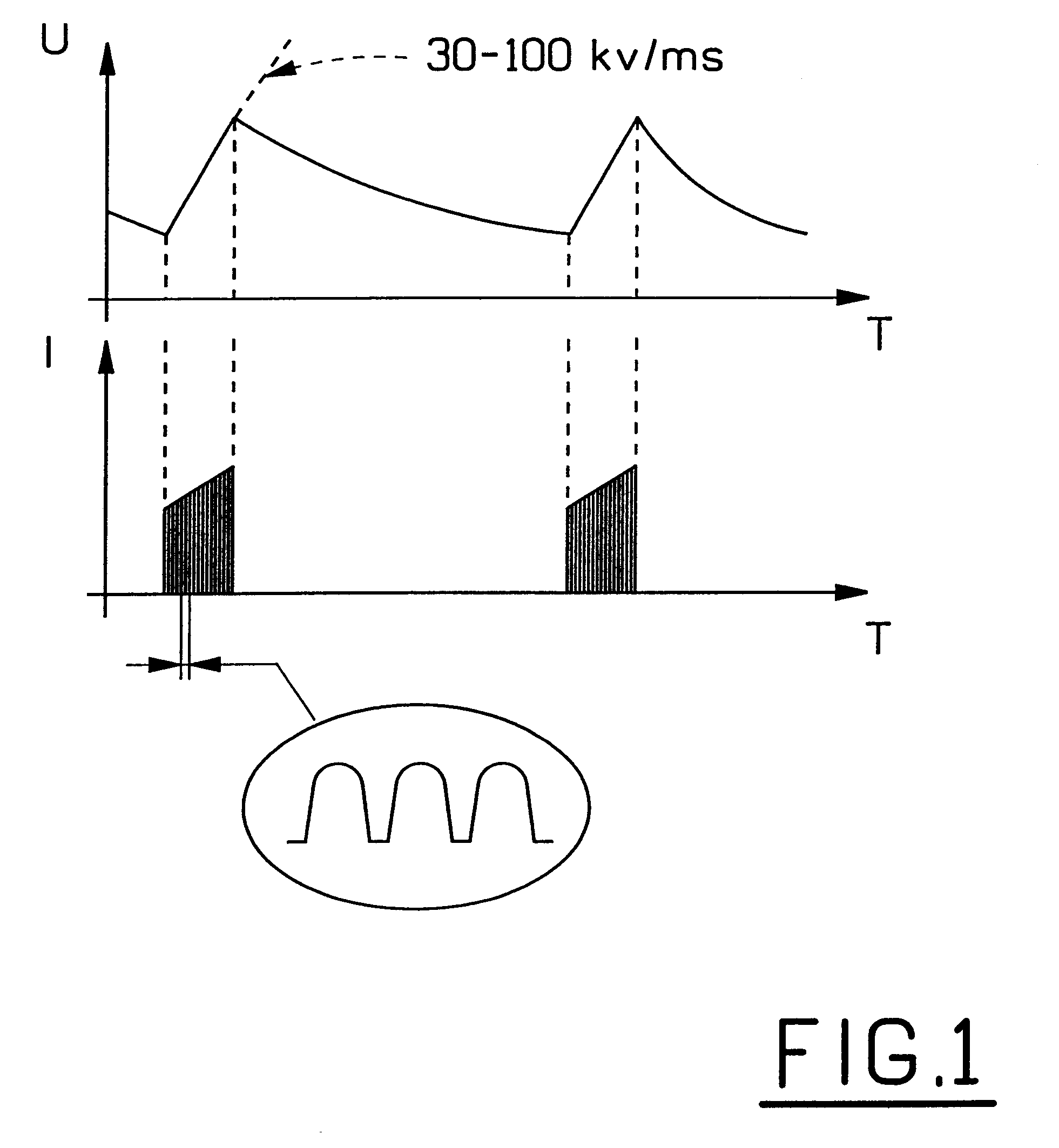

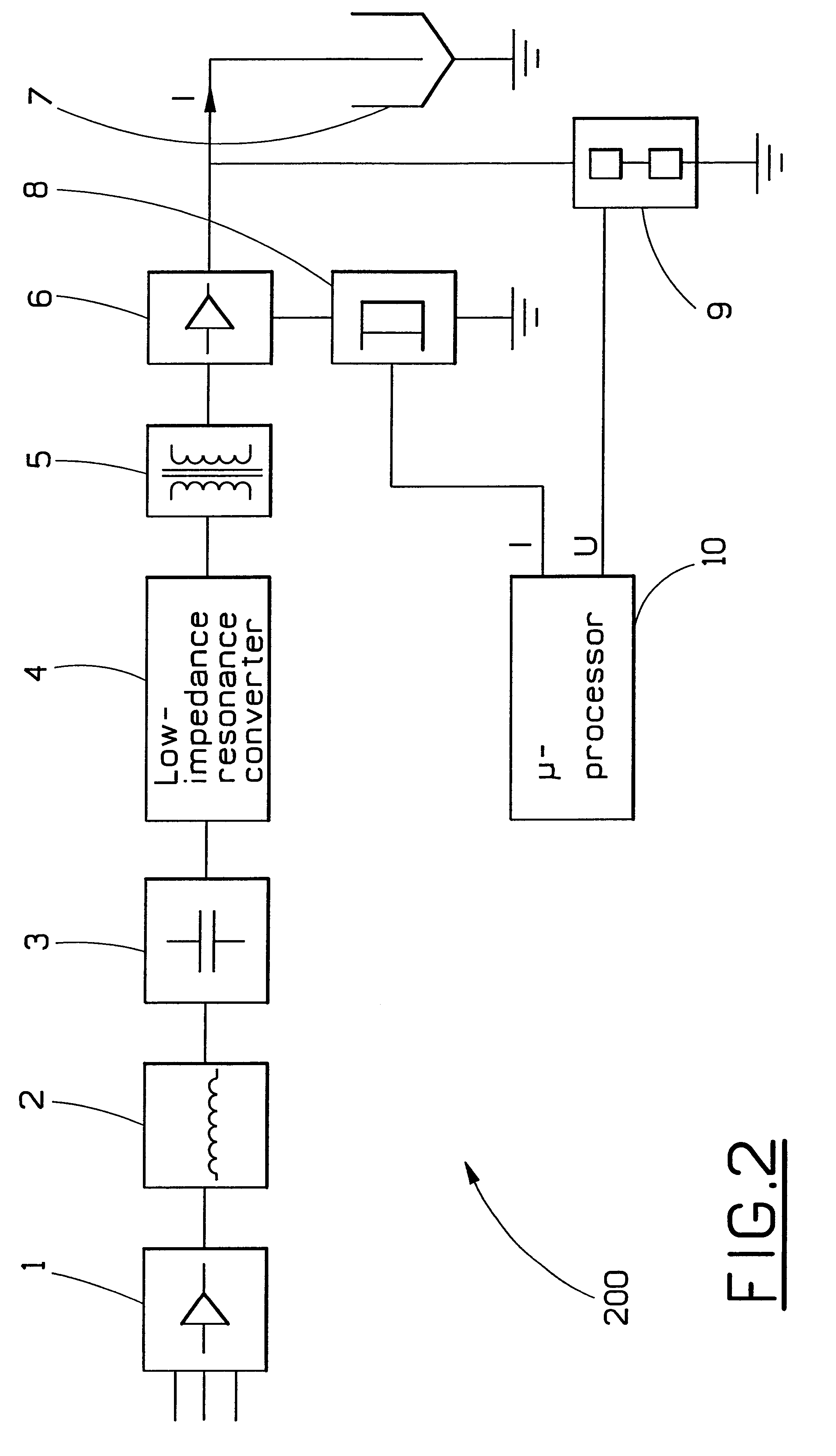

Method and device for generating voltage peaks in an electrostatic precipitator

The method of invention relates to a method and device for generating voltage peaks in an electrostatic precipitator via generation of current pulse, where each voltage peak is generated by a group of current pulses. A device according to the invention comprises a first and a second means for converting alternating current to direct current, and also so first means for converting direct current to alternating current, and the first means for converting direct current to alternating current comprises a resonance converter.

Owner:KRAFTELEKTRONIK

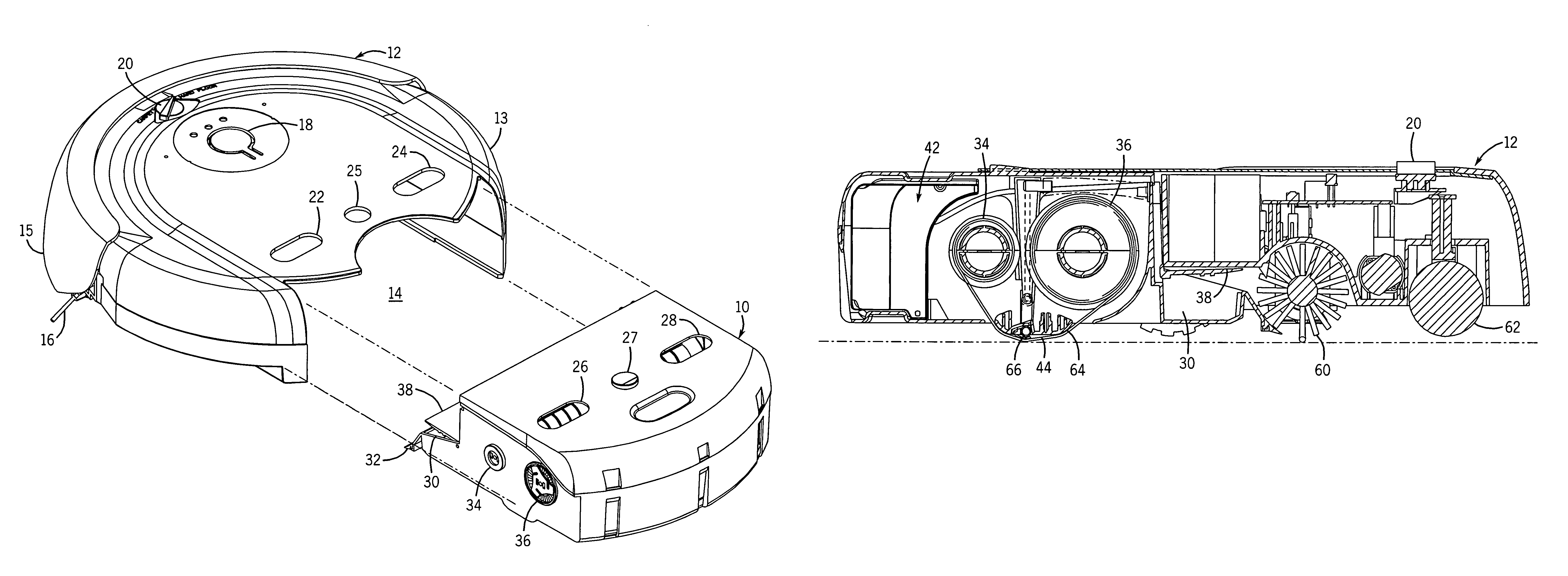

Vacuum cleaner

InactiveUS7179314B2Improve the level ofLarge resistanceCleaning filter meansCombination devicesCyclonic separationFiltration

A method for filtering a dirty air stream in a vacuum cleaner to obtain a clean air stream comprises subjecting the dirty air stream to a first cyclonic separation stage to obtain a partially cleaned air stream and subjecting the partially cleaned air stream to an electronic filtration stage and optionally a second cyclonic separation stage to obtain the clean air stream. The electronic filtration stage is optionally removable with a cyclonic cleaning stage from the vacuum cleaner. The electronic filtration stage is optionally an electrostatic precipitator which utilizes air flow through the vacuum cleaner to generate the voltage used by the electrostatic precipitator.

Owner:POLAR LIGHT

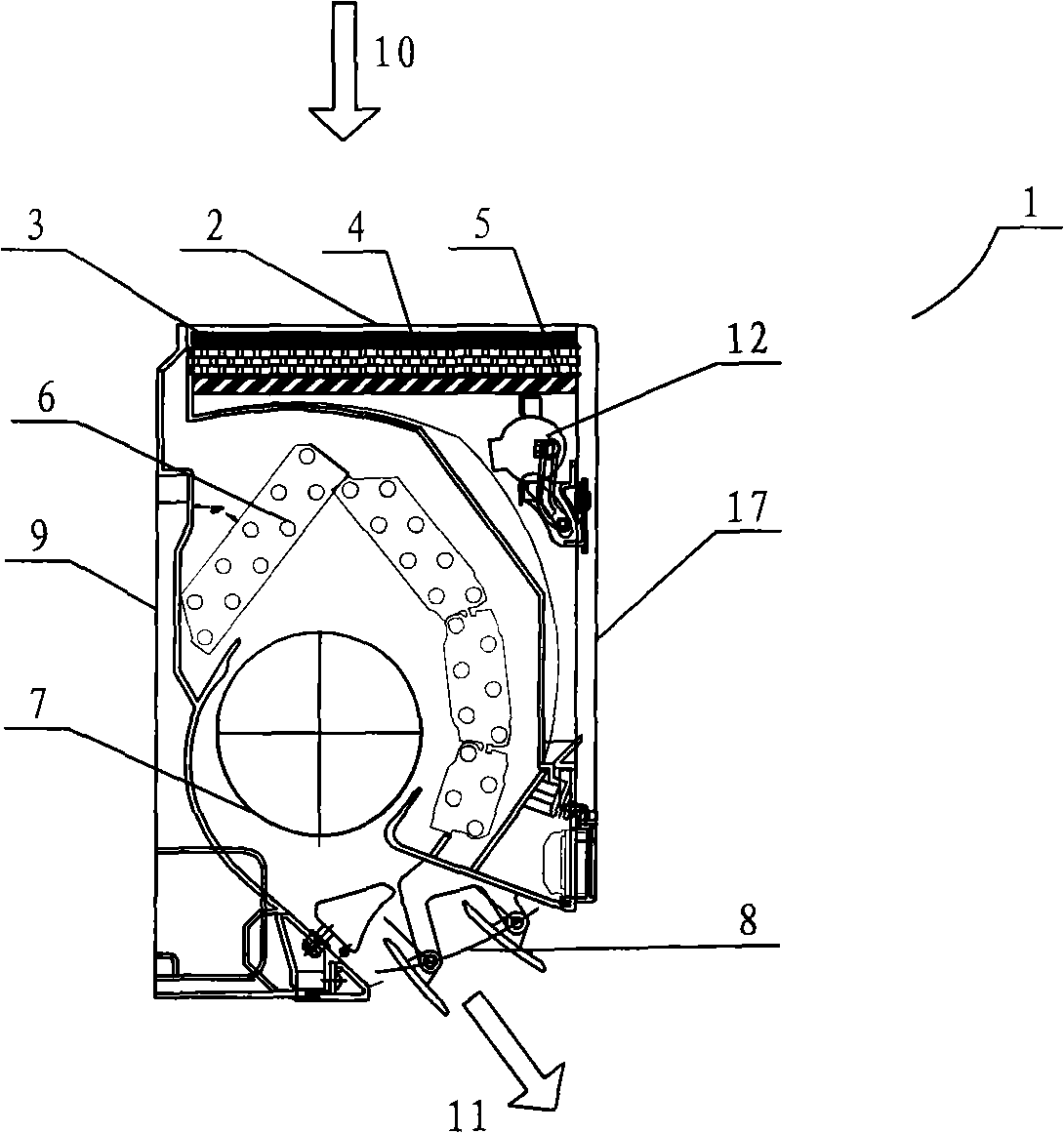

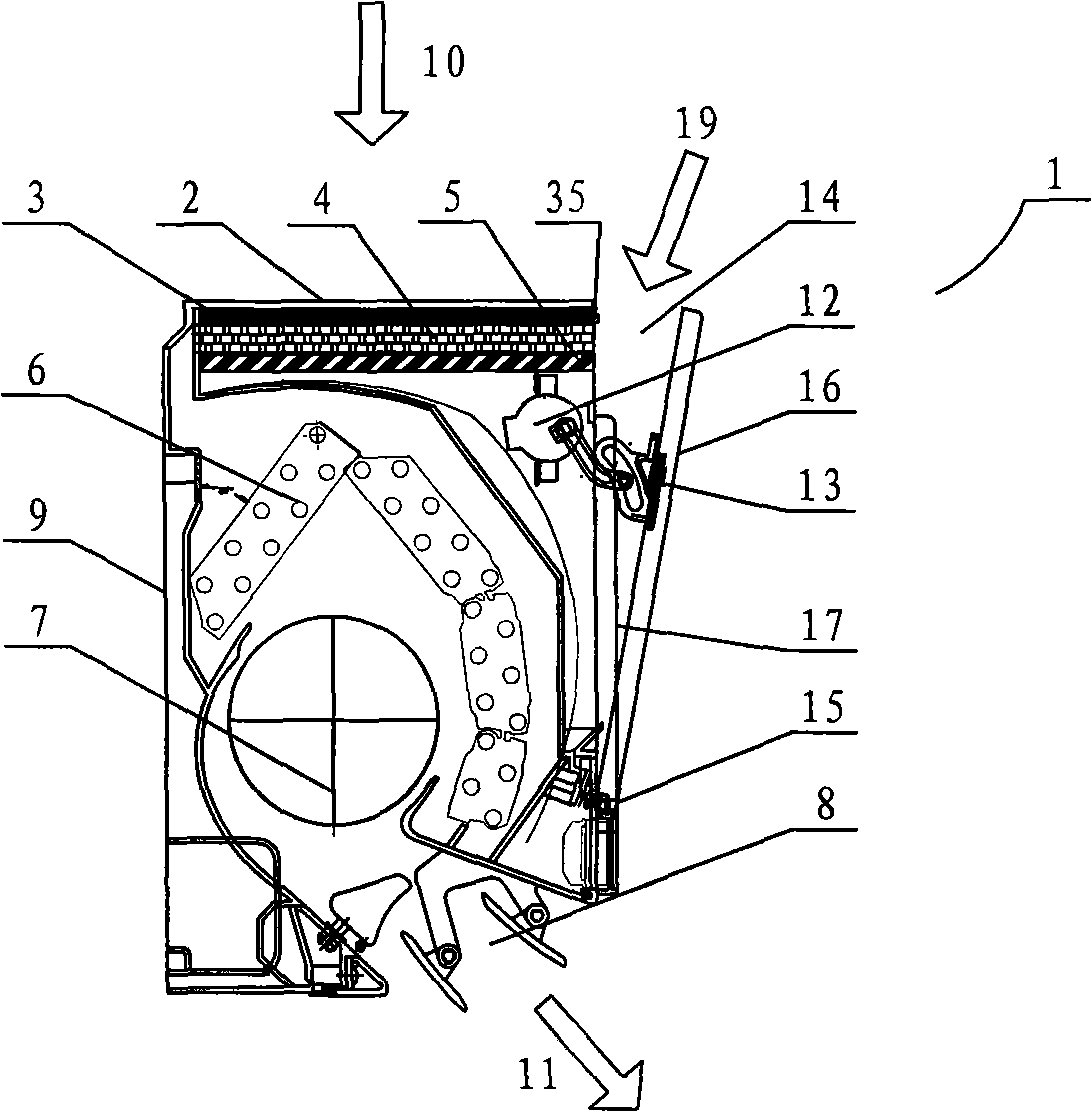

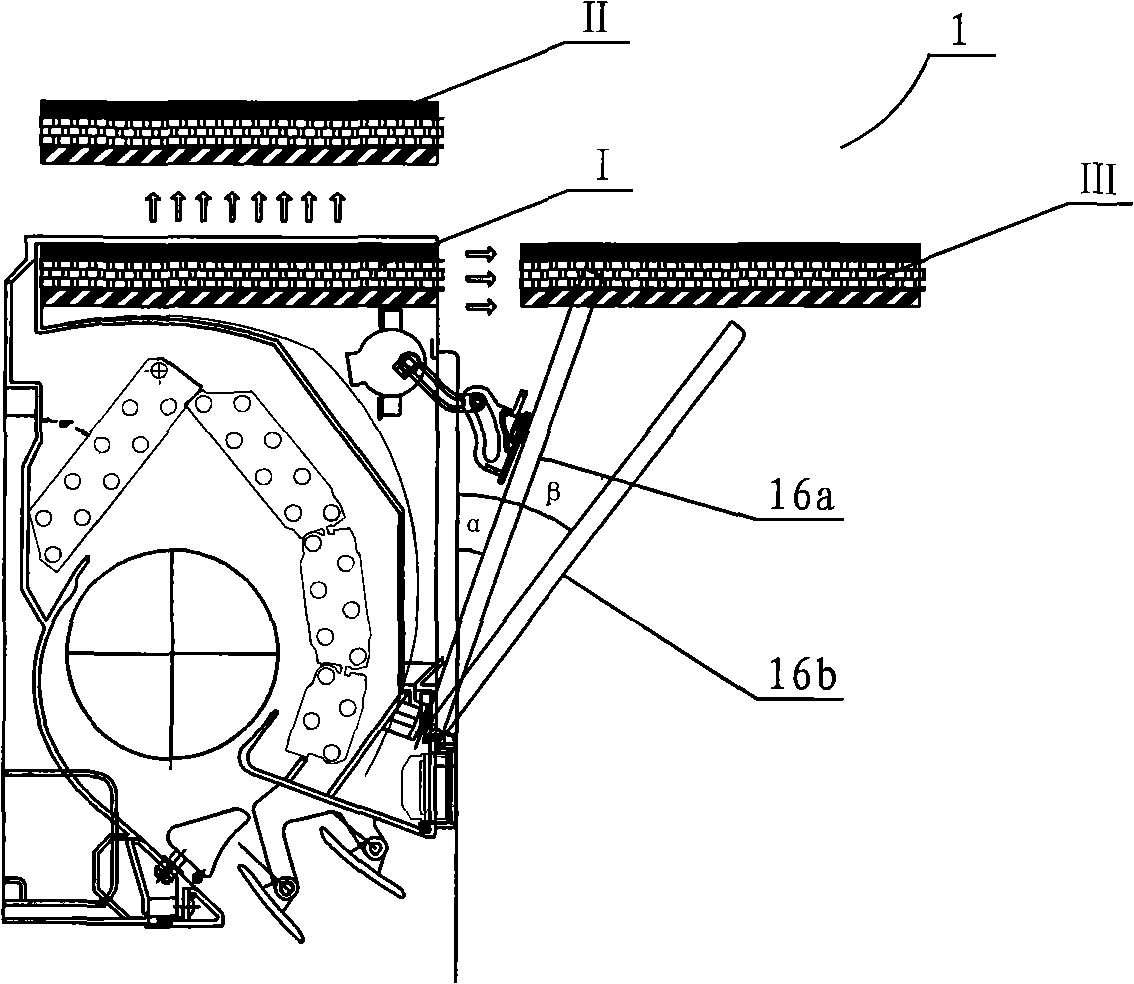

Air conditioner indoor unit and operation mode thereof

InactiveCN101539315ASimple structureVersatileSpace heating and ventilation safety systemsLighting and heating apparatusActivated carbonFixed frame

The invention relates to an air conditioner indoor unit and an operation mode thereof. The air conditioner indoor unit comprises a shell, a blower and a heat exchanger which are both arranged in the shell; the shell is provided with an air outlet and an air inlet which is covered by an air-cleaning device; the shell is also provided with more than one auxiliary air inlet and a movable panel for opening and closing the auxiliary air inlets and provided with a fixed frame which comprises an air inlet grid and a bracket, the air-cleaning device is glidingly sleeved in the bracket, and the air inlet grid is arranged in front of the air-cleaning device; the inner side of the fixed frame is provided with a guide rail, the outer side of the air-cleaning device is provided with a guide plate; the air-cleaning device comprises a filter layer, an electrostatic dust-collecting layer, a composite treatment layer and a main frame, wherein the filter layer, the electrostatic dust-collecting layer and the composite treatment layer are sequentially arranged in the main frame from outside to inside, and the composite treatment layer is any one of an activated carbon layer, a photocatalyst layer, a cold catalyst layer and an anti-mite mesh layer. The invention has the advantage of wide range of application.

Owner:GUANGDONG MIDEA ELECTRIC APPLIANCES CO LTD

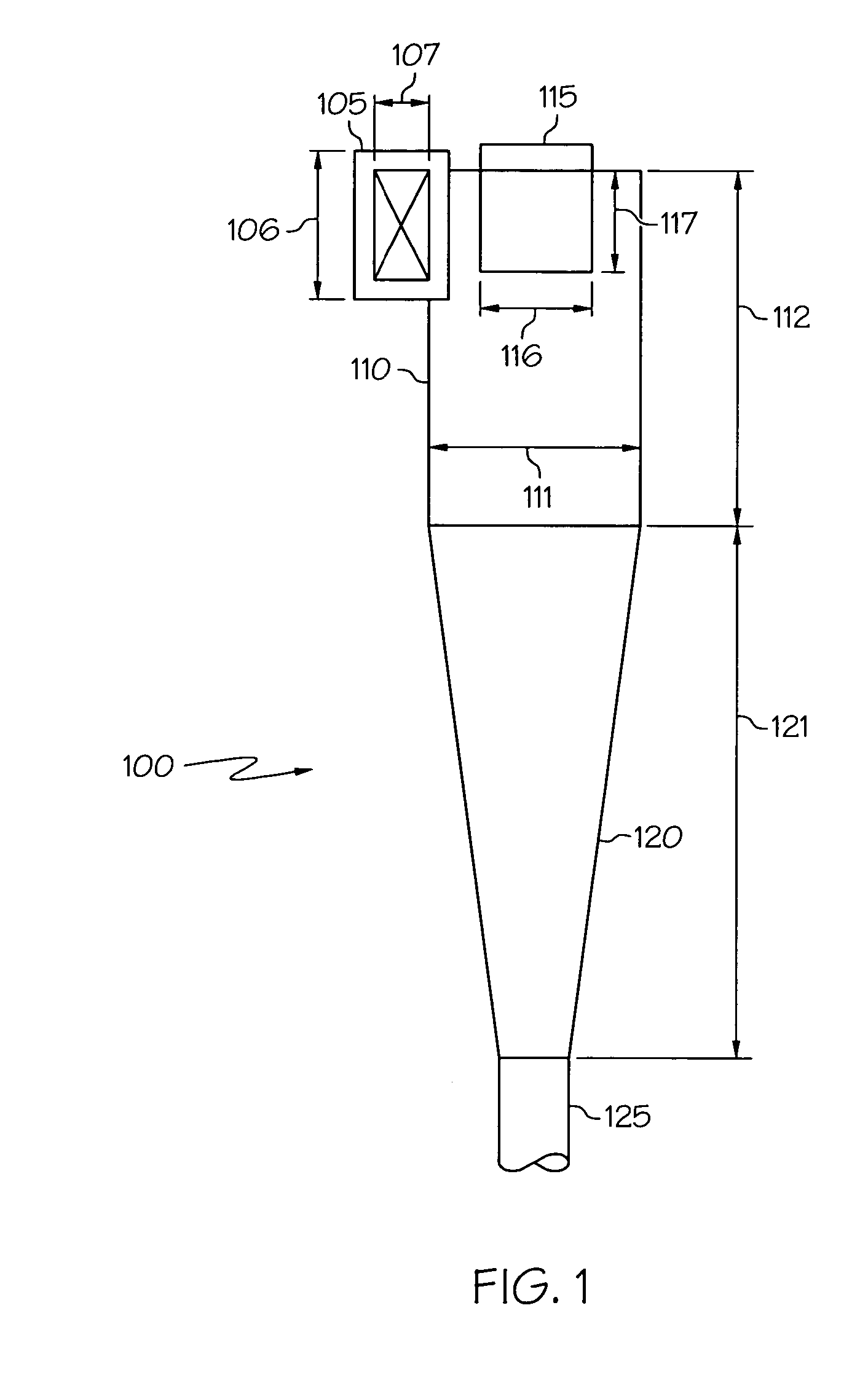

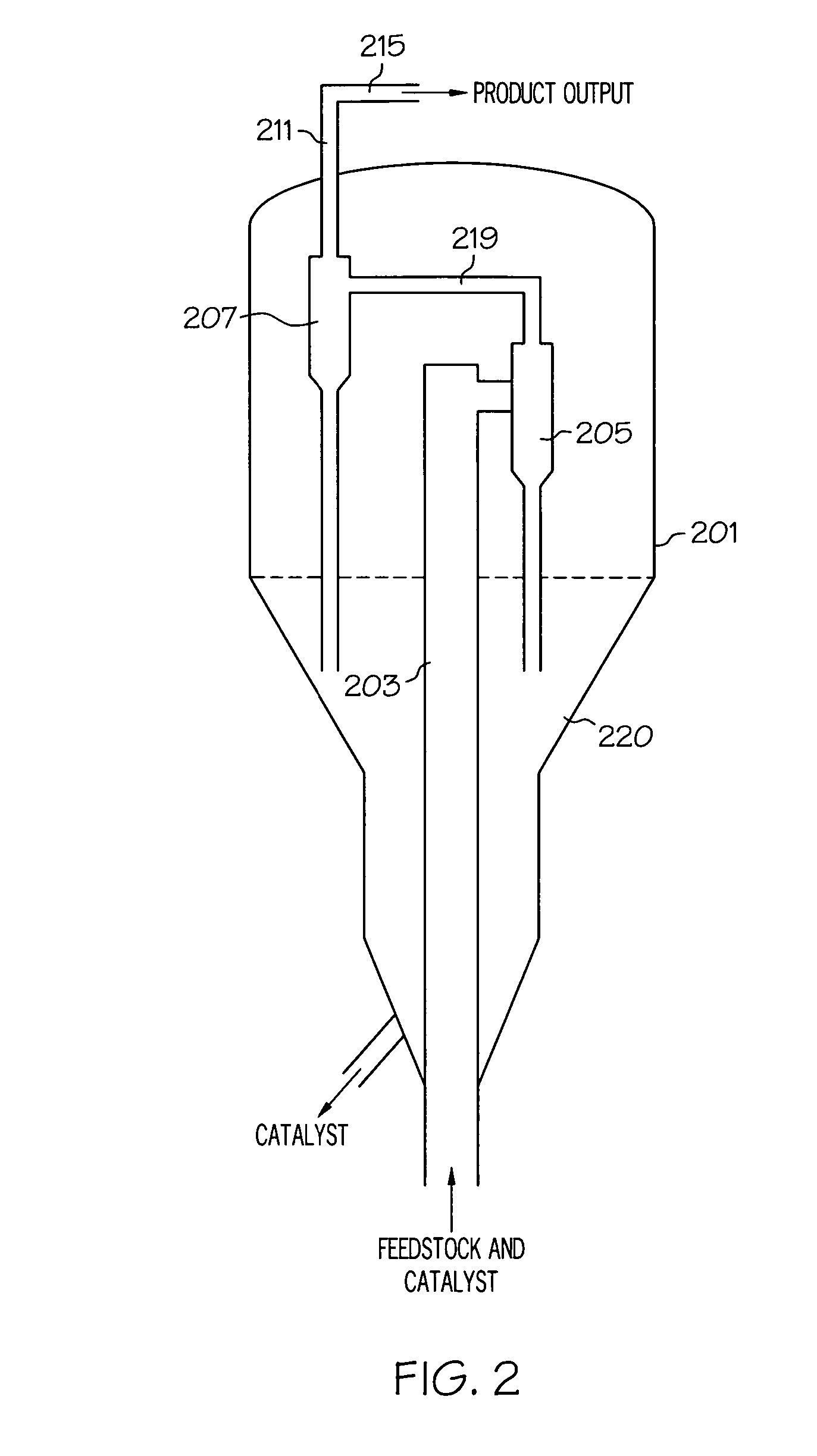

Process for removing solid particles from a gas-solids flow

Catalyst losses are prevented in riser reactor systems by using a low inlet velocity for the first cyclone separator in each multi-stage cyclone separator in the reactor. Catalyst particles not separated from the product output flow in an oxygenate-to-olefin reactor are also recaptured by cooling the product output flow and passing the flow through an electrostatic precipitator.

Owner:EXXONMOBIL CHEM PAT INC

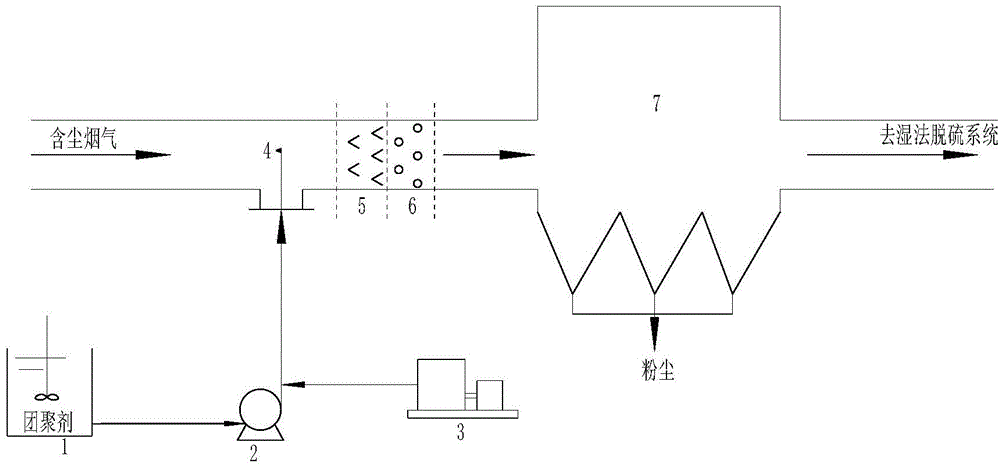

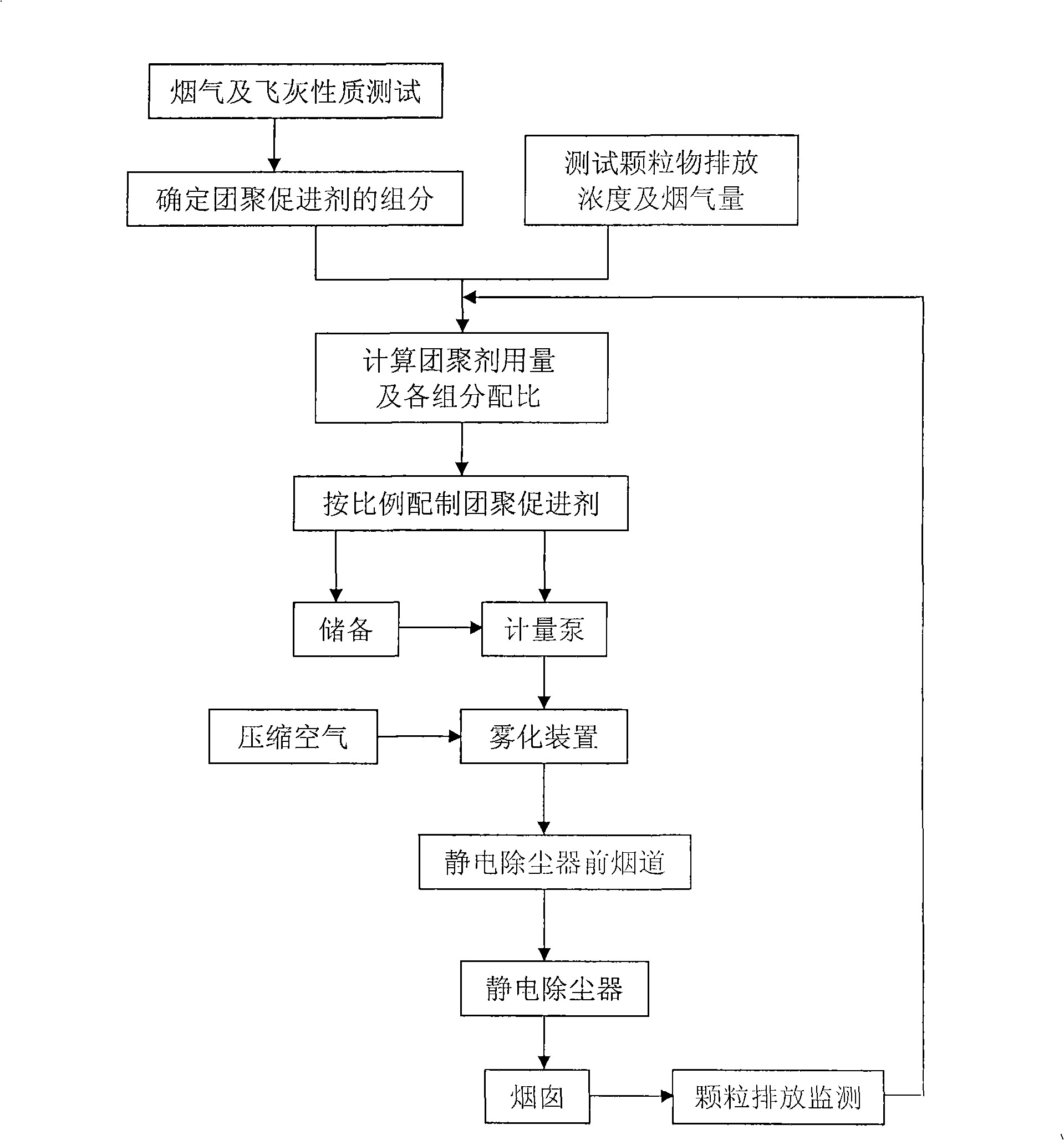

Device and method for increasing grain size of PM2.5 (particulate matter2.5) through turbulent flow and chemical agglomeration coupling

ActiveCN104801420AFacilitate collision contactImprove the growth effectElectrostatic separationParticulatesEvaporation

The invention discloses a device and a method for increasing grain size of PM2.5 through turbulent flow and chemical agglomeration coupling. Dust-containing flue gas sequentially flows through a chemical agglomeration area and a turbulent flow generation area in a flue and finally enters an electrostatic dust collector; when the dust-containing flue gas flows through the chemical agglomeration area, the PM2.5 particles in the flue gas are primarily contacted with agglomeration solution fogdrops sprayed in through a dual-fluid atomizing nozzle, agglomeration solution liquid drops are evaporated, in the evaporation process, the PM2.5 particles are connected through macromolecule chains with polar groups, and the grain size of the PM2.5 is increased; the flue gas flows through the turbulent flow area, the agglomeration solution fogdrops are promoted to collide and contact the PM2.5, the PM2.5 are promoted to collide and contact the crude dust under the turbulent flow disturbance generated by a turbulence bar, the PM2.5 are further aggregated and increased in size, meanwhile, the residence time of the agglomeration solution liquid drops in the flue is prolonged, before entering the electrostatic dust collector, the agglomeration solution liquid drops are completely evaporated, and the particles of which the size is increased through agglomeration are finally moved by the electrostatic dust collector. The agglomeration increasing effect of the PM2.5 is obviously enhanced, and the using amount of an agglomeration solution is reduced.

Owner:SOUTHEAST UNIV

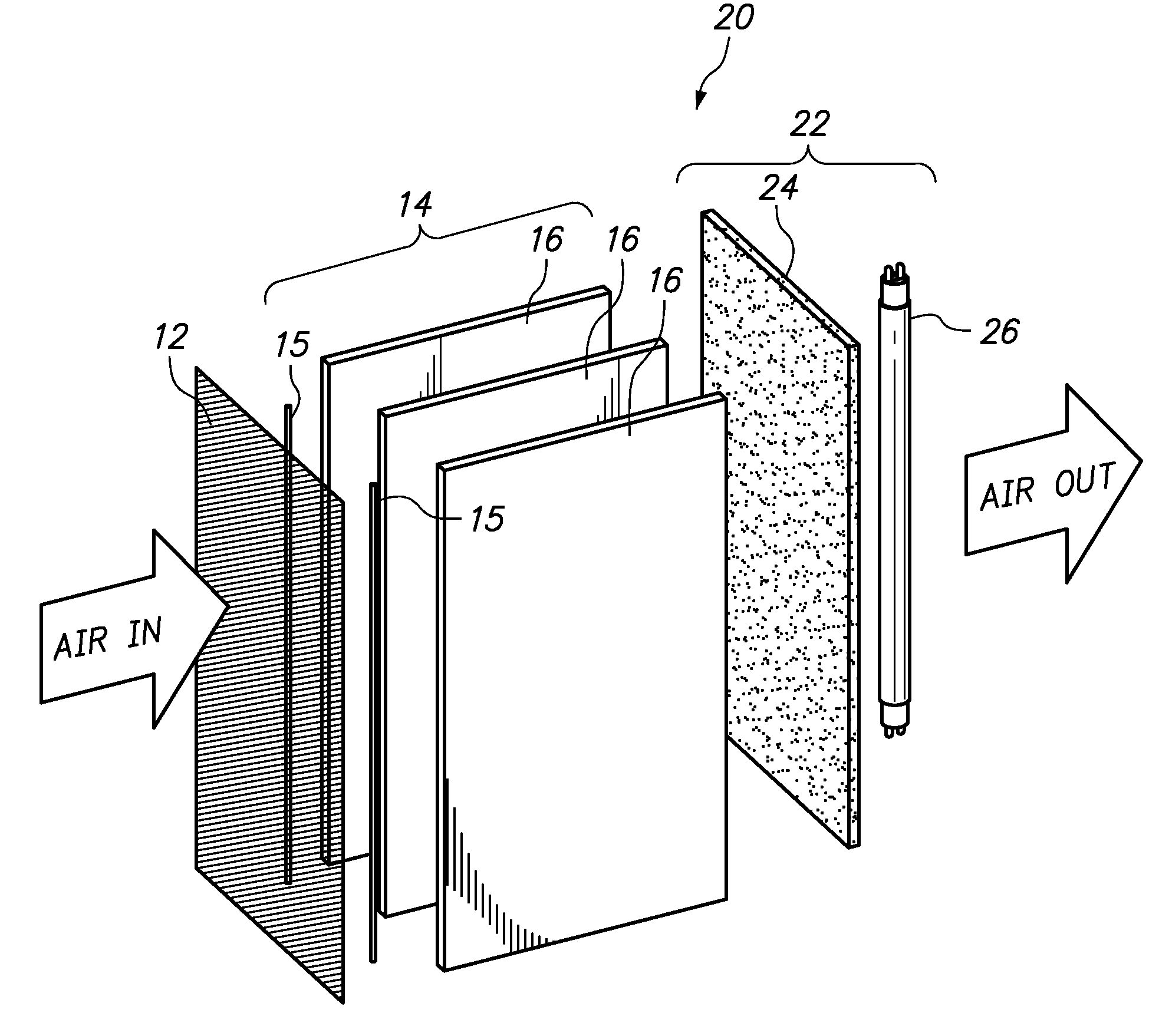

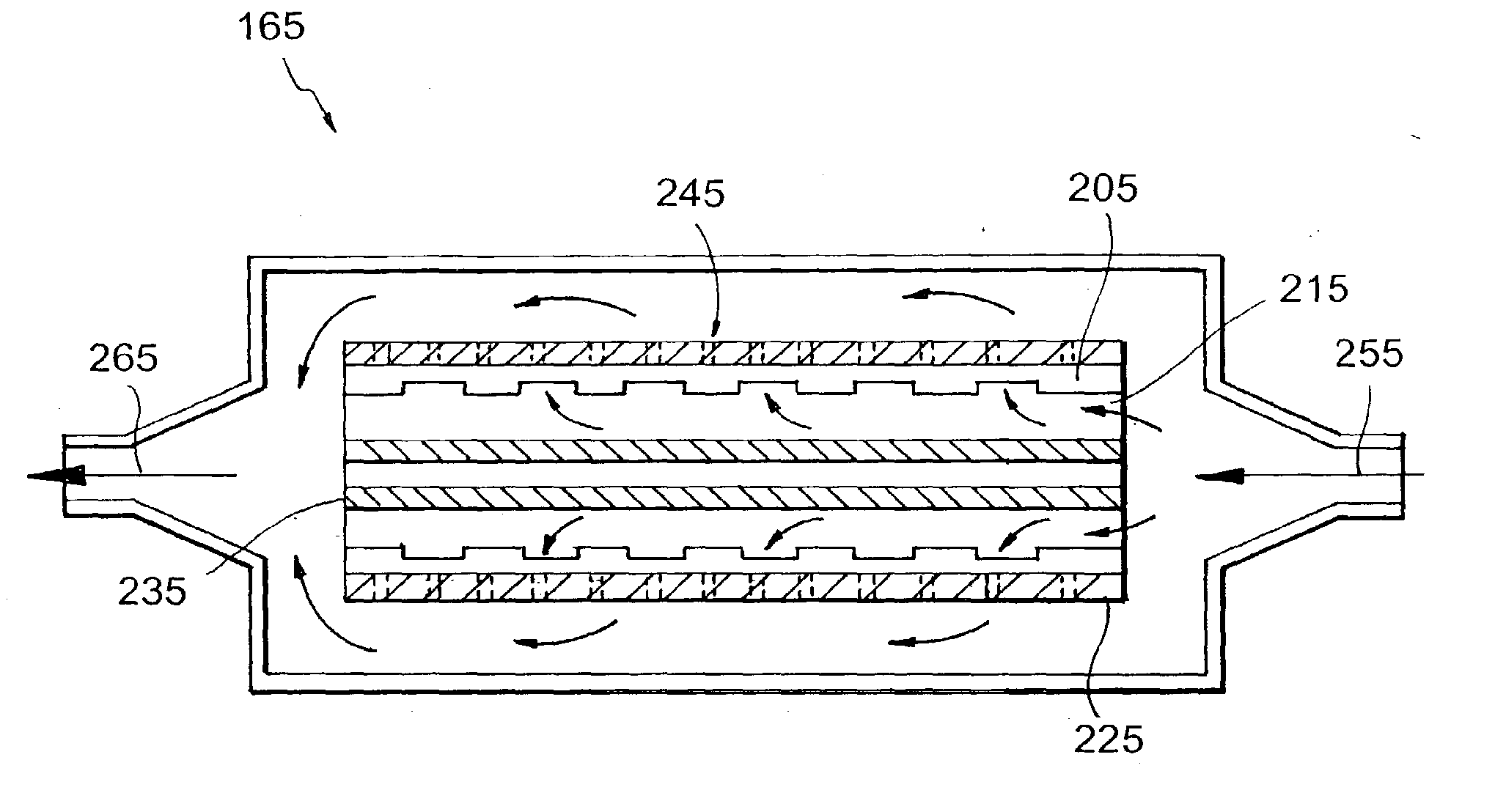

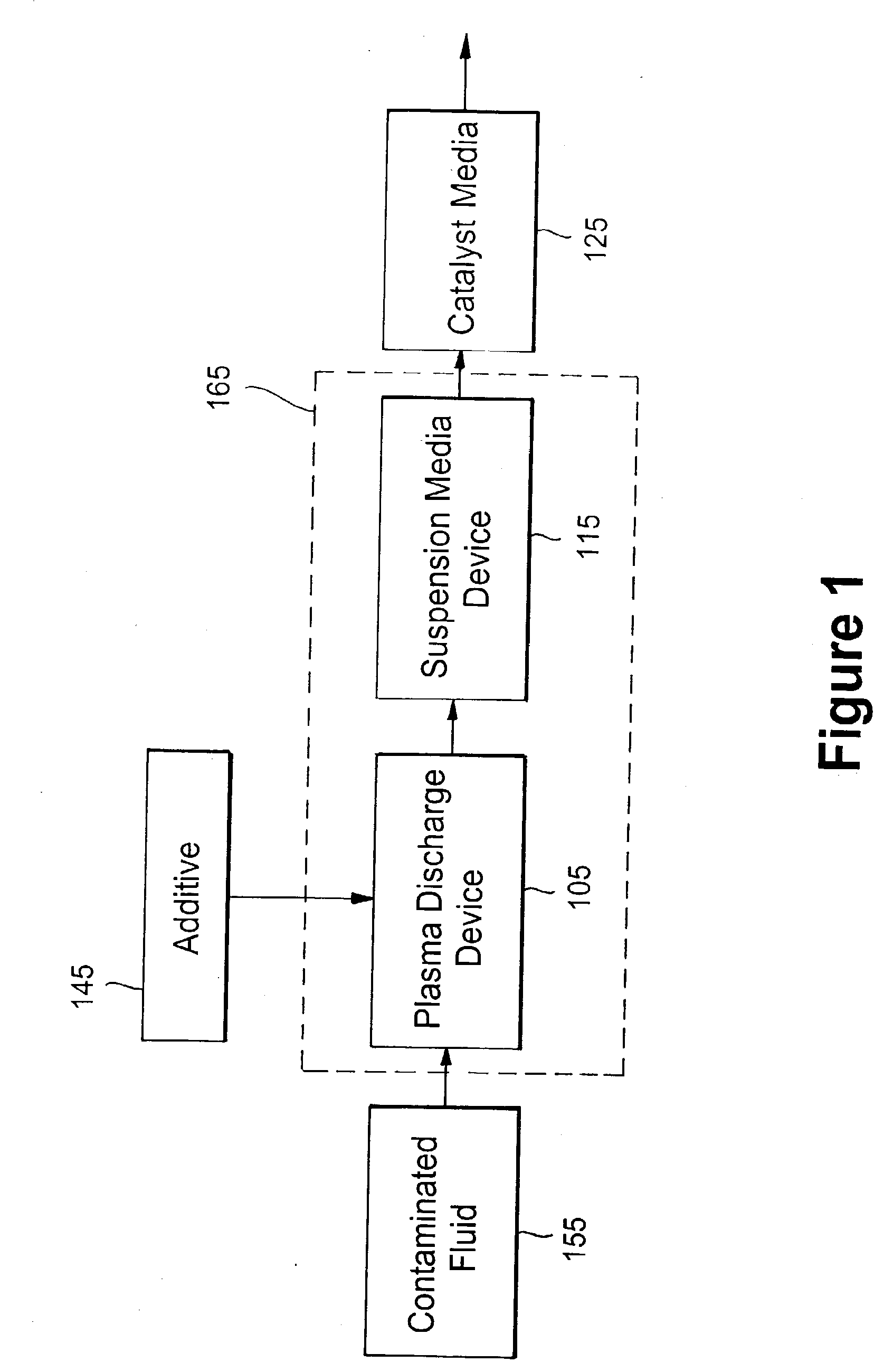

In situ sterilization and decontamination system using a non-thermal plasma discharge

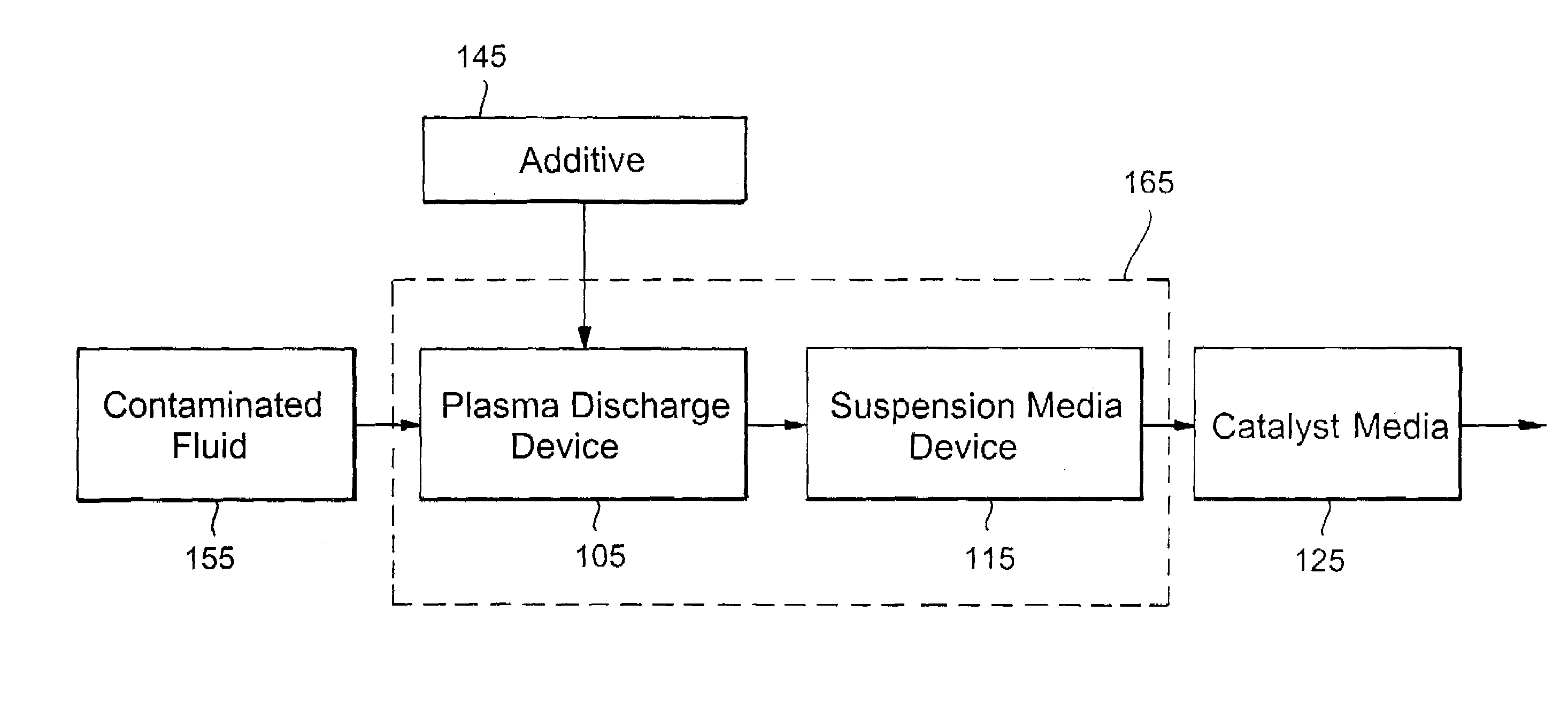

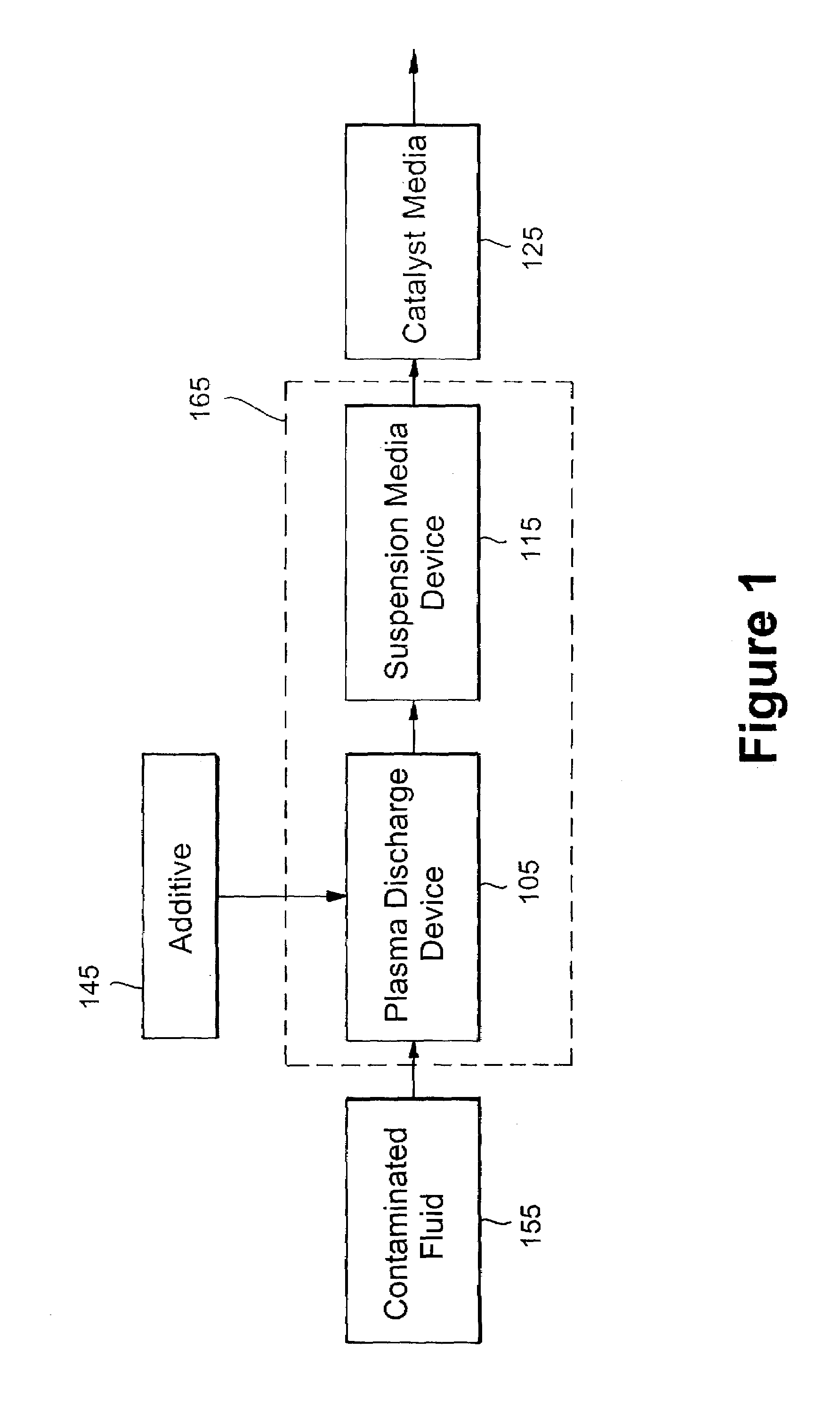

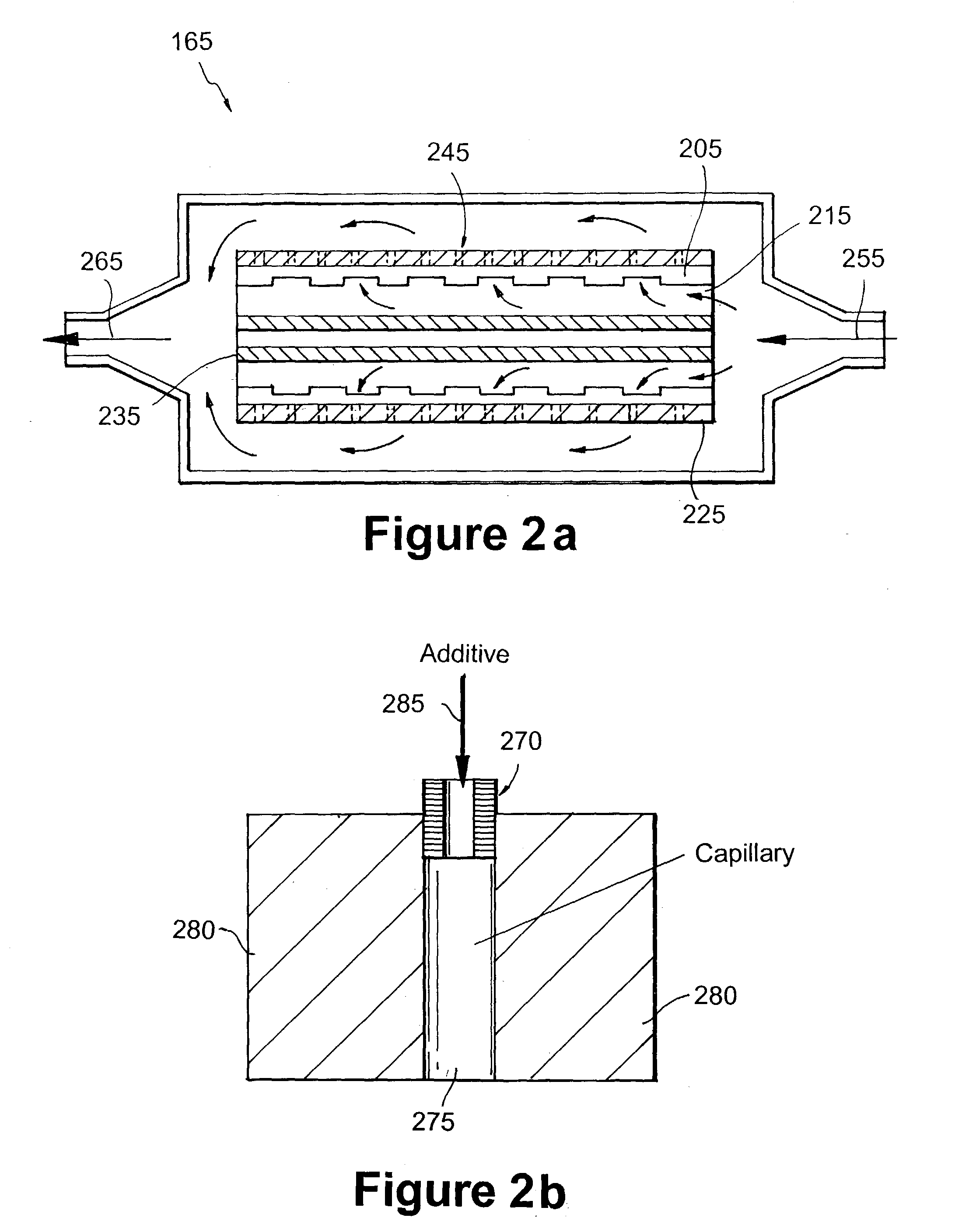

InactiveUS7192553B2Improve sterilization efficiencyReduce healthMechanical apparatusGas treatmentElectricityParticulates

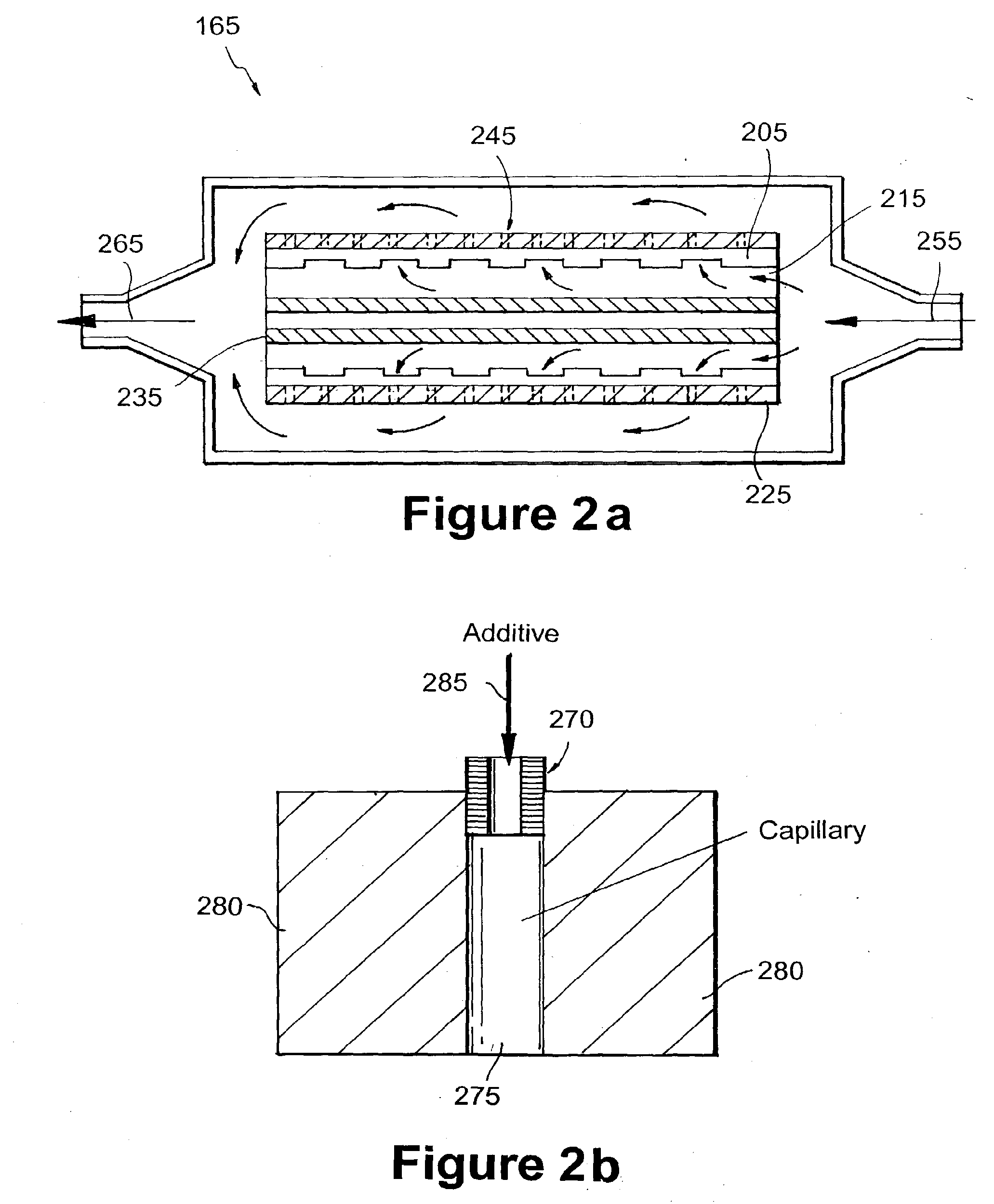

A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e.g., a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e.g., capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and / or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ. To increase the sterilization efficiency an additive, free or carrier gas (e.g., alcohol, water, dry air) may be injected into the apertures defined in the primary dielectric. These additives increase the concentration of plasma generated active sterilizing agents while reducing the byproduct of generated undesirable ozone pollutants. Downstream of the filter the fluid stream may be further treated by being exposed to a catalyst media or additional suspension media to further reduce the amount of undesirable particulate matter.

Owner:PLASMASOL CORP +1

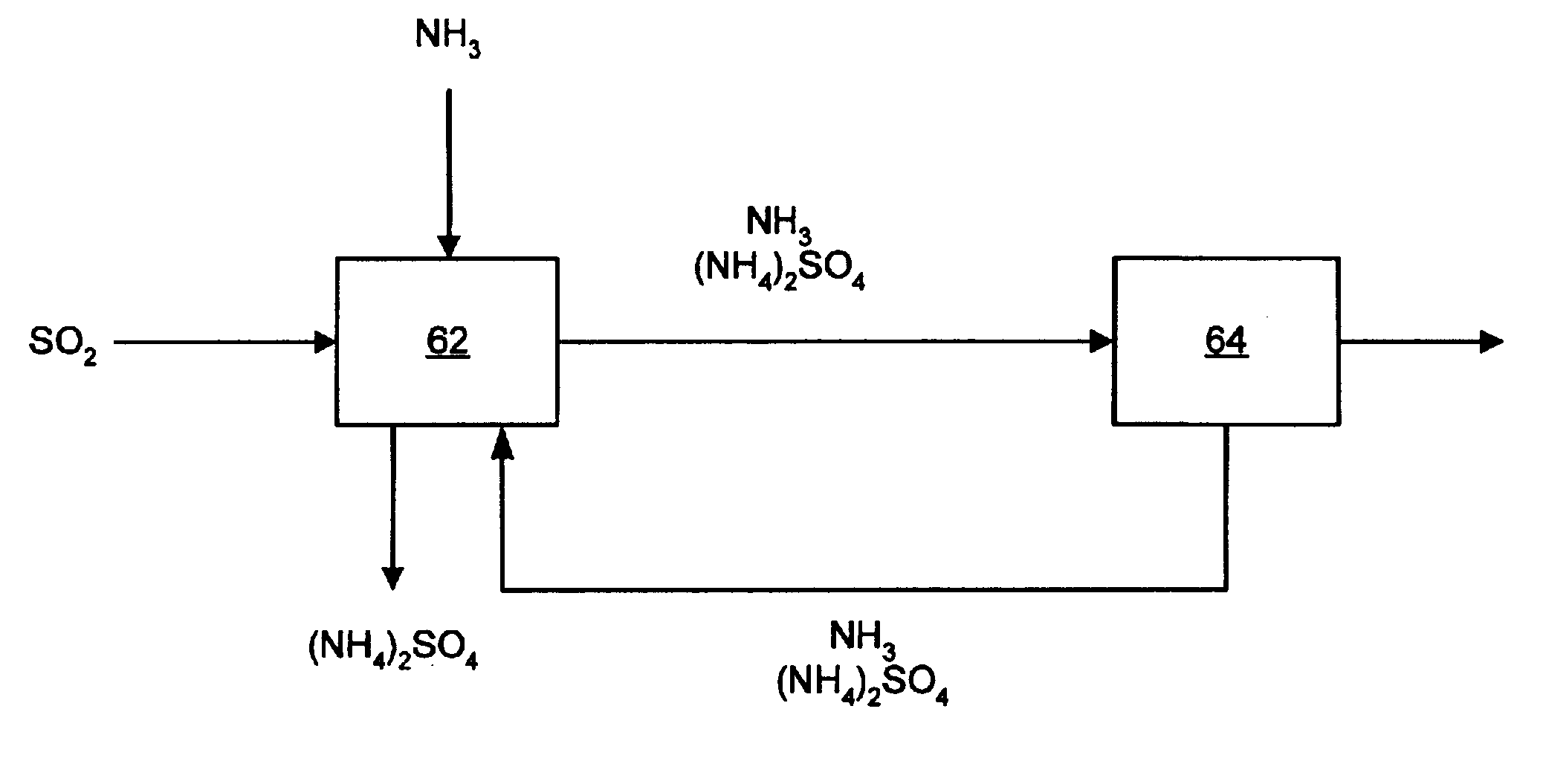

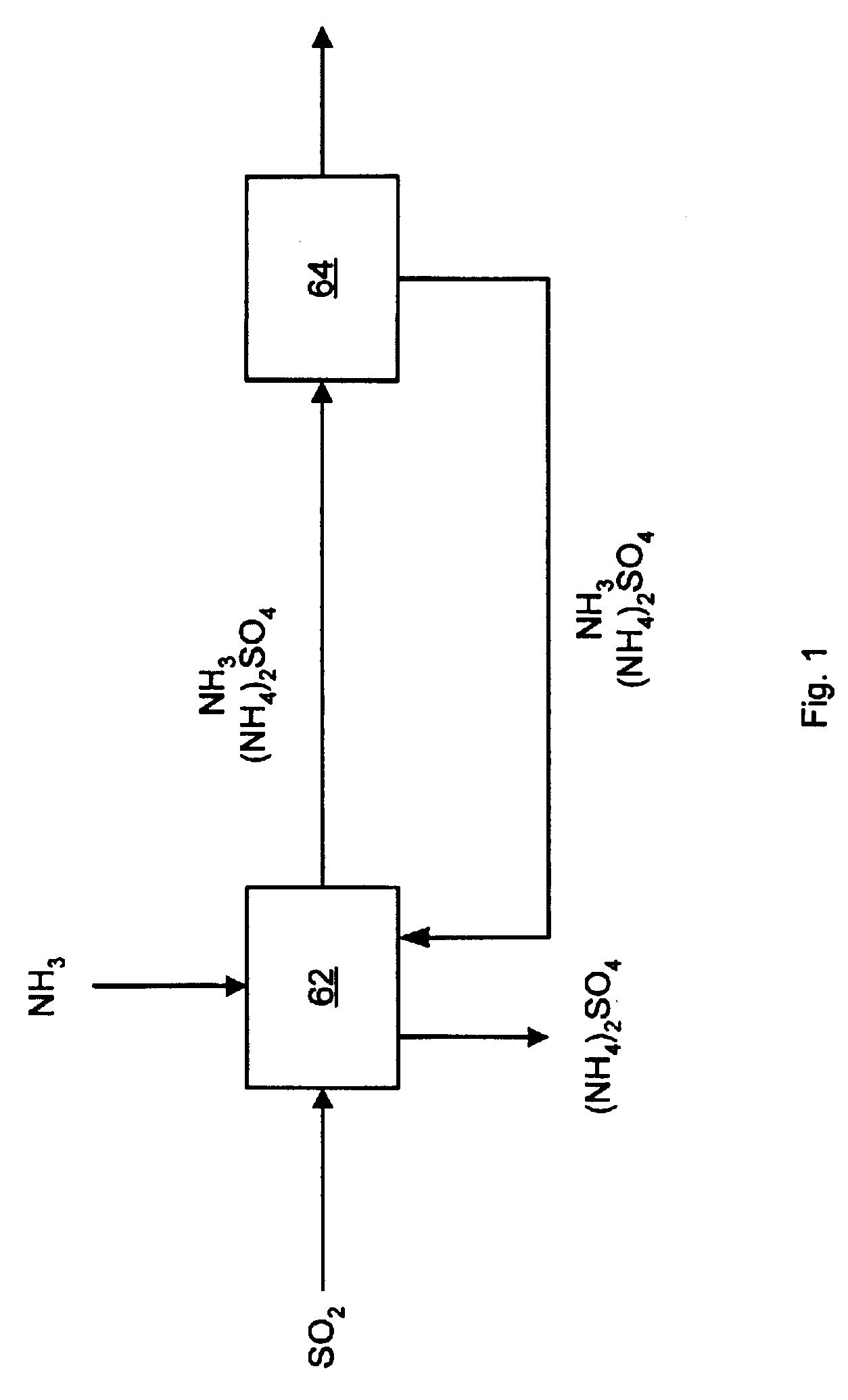

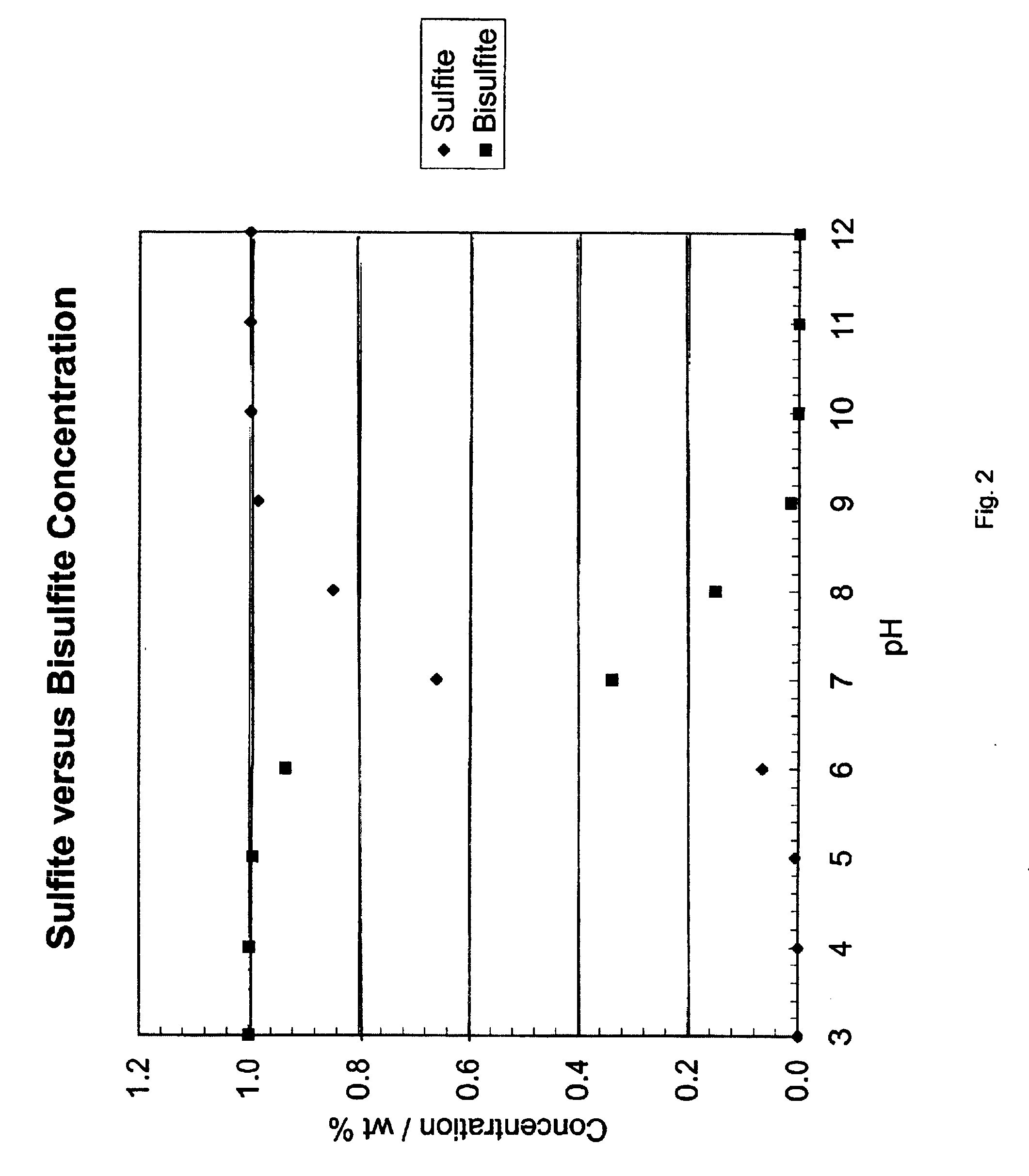

Sulfur dioxide removal using ammonia

InactiveUS6605263B2Small sizeImprove efficiencyCombination devicesAmmonium sulfatesCorrosion resistant alloySulfite

Owner:POWERSPAN CORP

In situ sterilization and decontamination system using a non-thermal plasma discharge

InactiveUS20080063577A1Improve sterilization efficiencyReduce healthMechanical apparatusGas treatmentDielectricParticulates

A sterilization and decontamination system in which a non-thermal plasma discharge device is disposed upstream of a suspension media (e.g., a filter, electrostatic precipitator, carbon bed). The plasma discharge device generates a plasma that is emitted through apertures (e.g., capillaries or slits) in the primary dielectric. Plasma generated active sterilizing species when exposed to contaminants or undesirable particulate matter is able to deactivate or reduce such matter in contaminated fluid stream and / or on objects. Thus, the undesirable contaminants in the fluid to be treated are first reduced during their exposure to the plasma generated active sterilizing species in the plasma region of the discharge device. Furthermore, the plasma generated active sterilizing species are carried downstream to suspension media and upon contact therewith deactivate the contaminants collected on the suspension media itself. Advantageously, the suspension media may be cleansed in situ. To increase the sterilization efficiency an additive, free or carrier gas (e.g., alcohol, water, dry air) may be injected into the apertures defined in the primary dielectric. These additives increase the concentration of plasma generated active sterilizing agents while reducing the byproduct of generated undesirable ozone pollutants. Downstream of the filter the fluid stream may be further treated by being exposed to a catalyst media or additional suspension media to further reduce the amount of undesirable particulate matter.

Owner:STEVENS INSTITUTE OF TECHNOLOGY +1

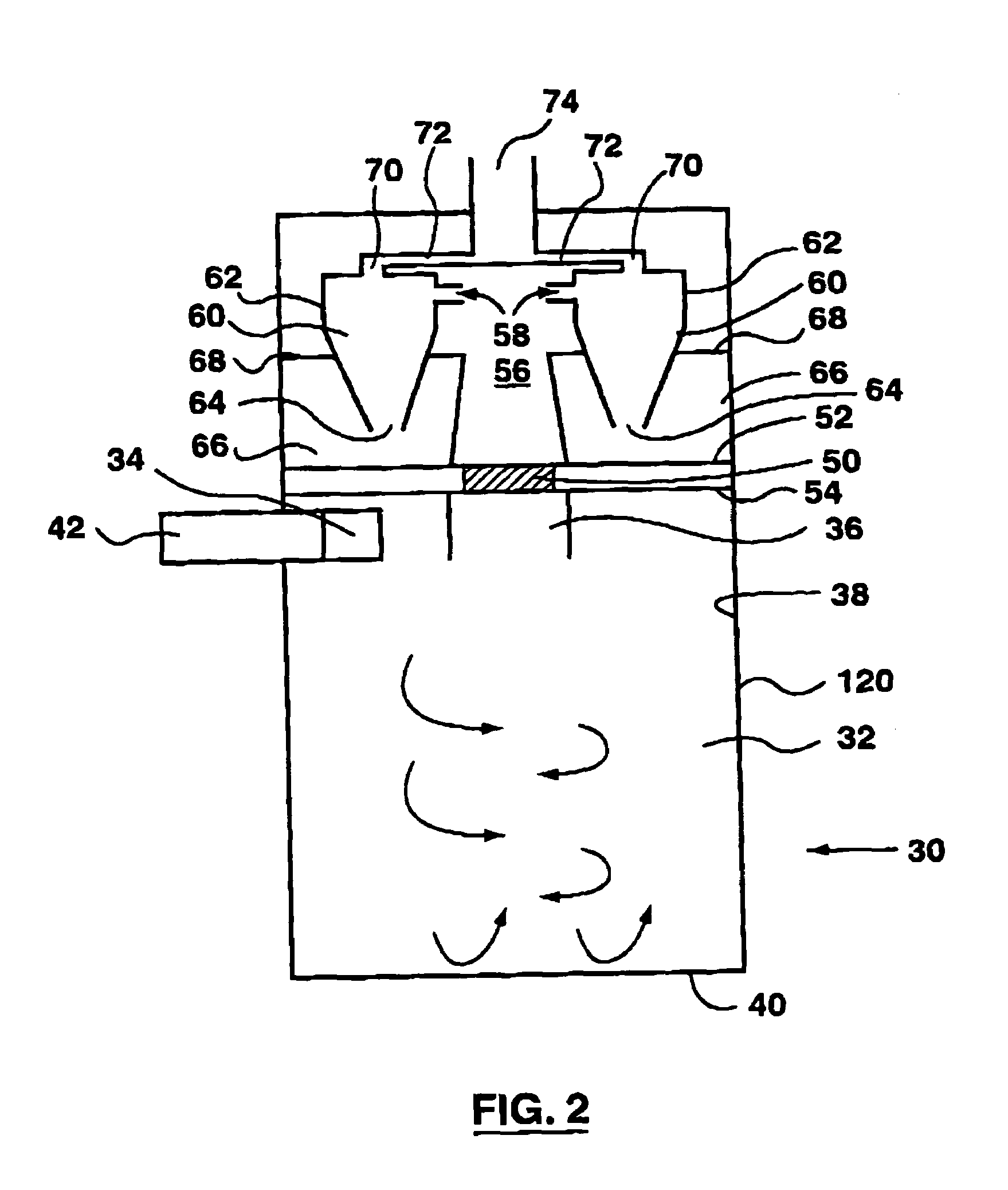

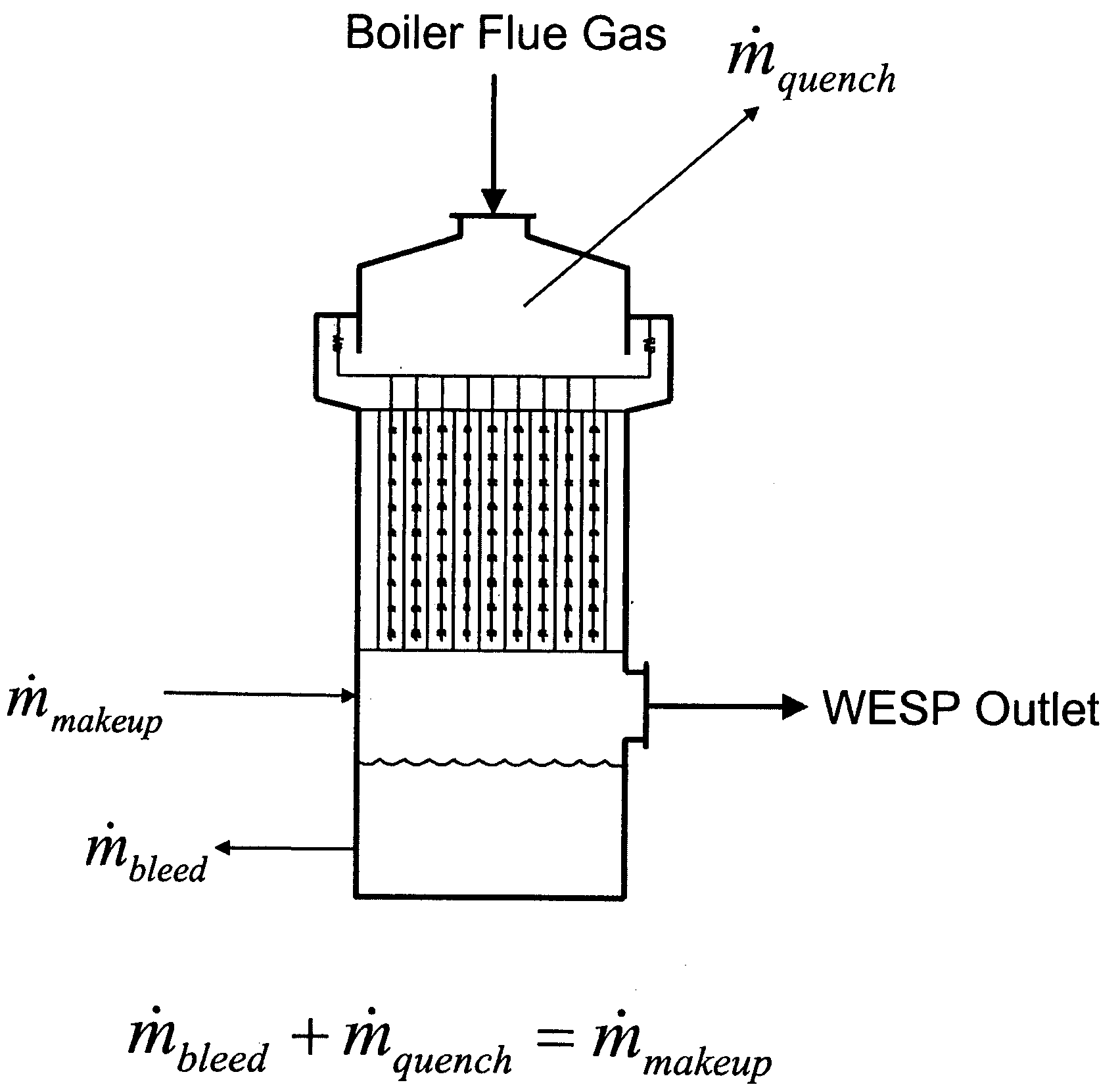

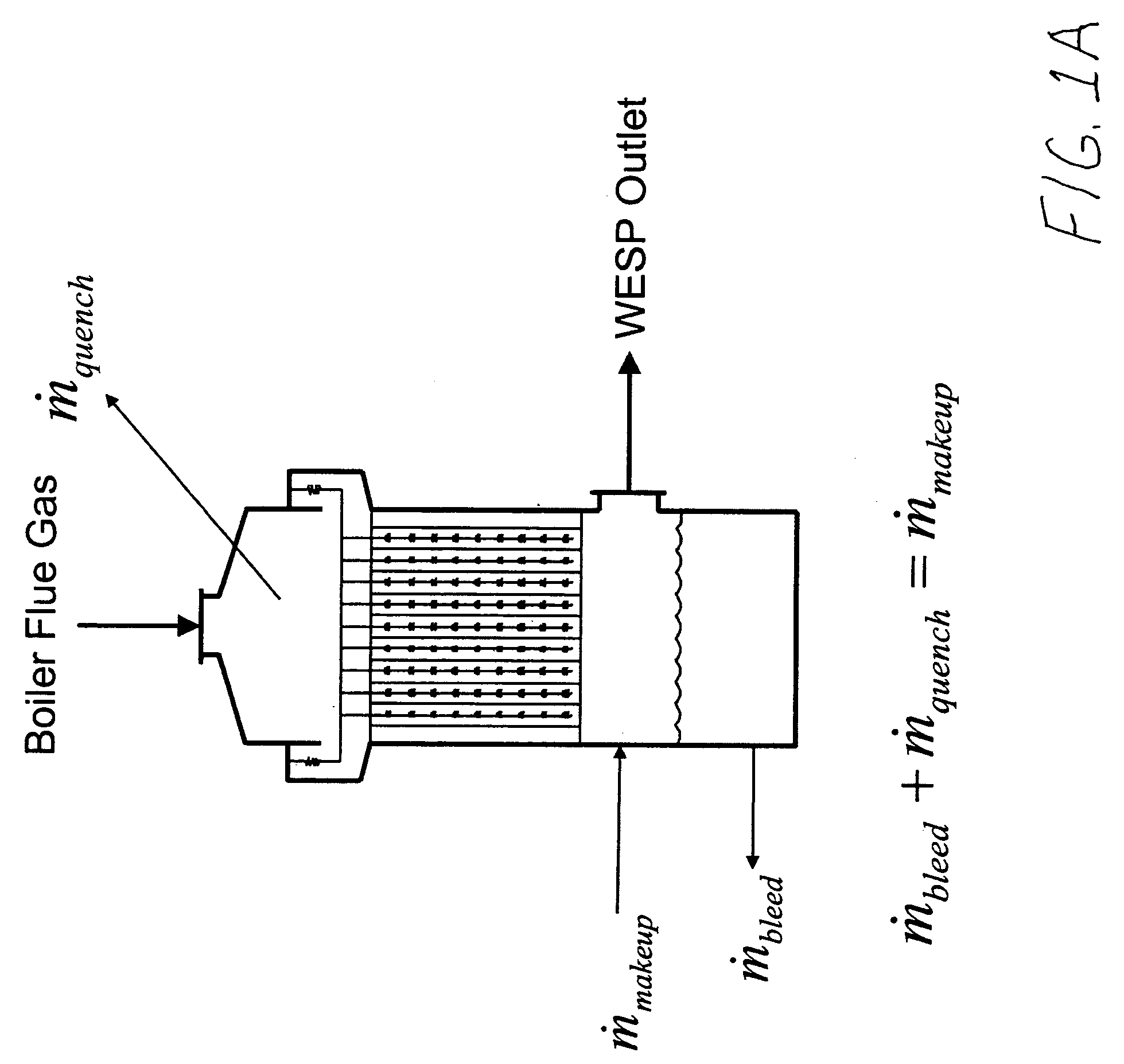

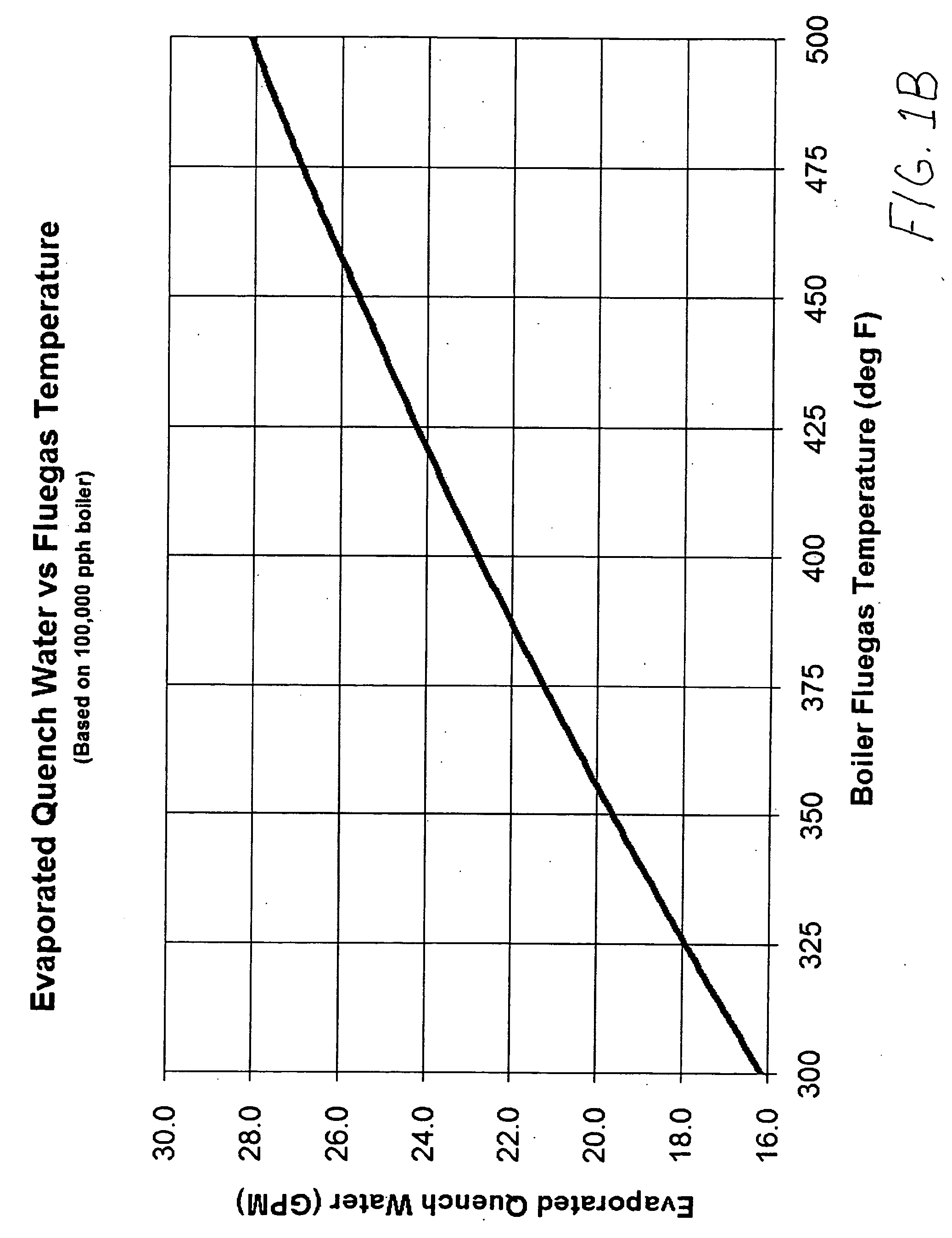

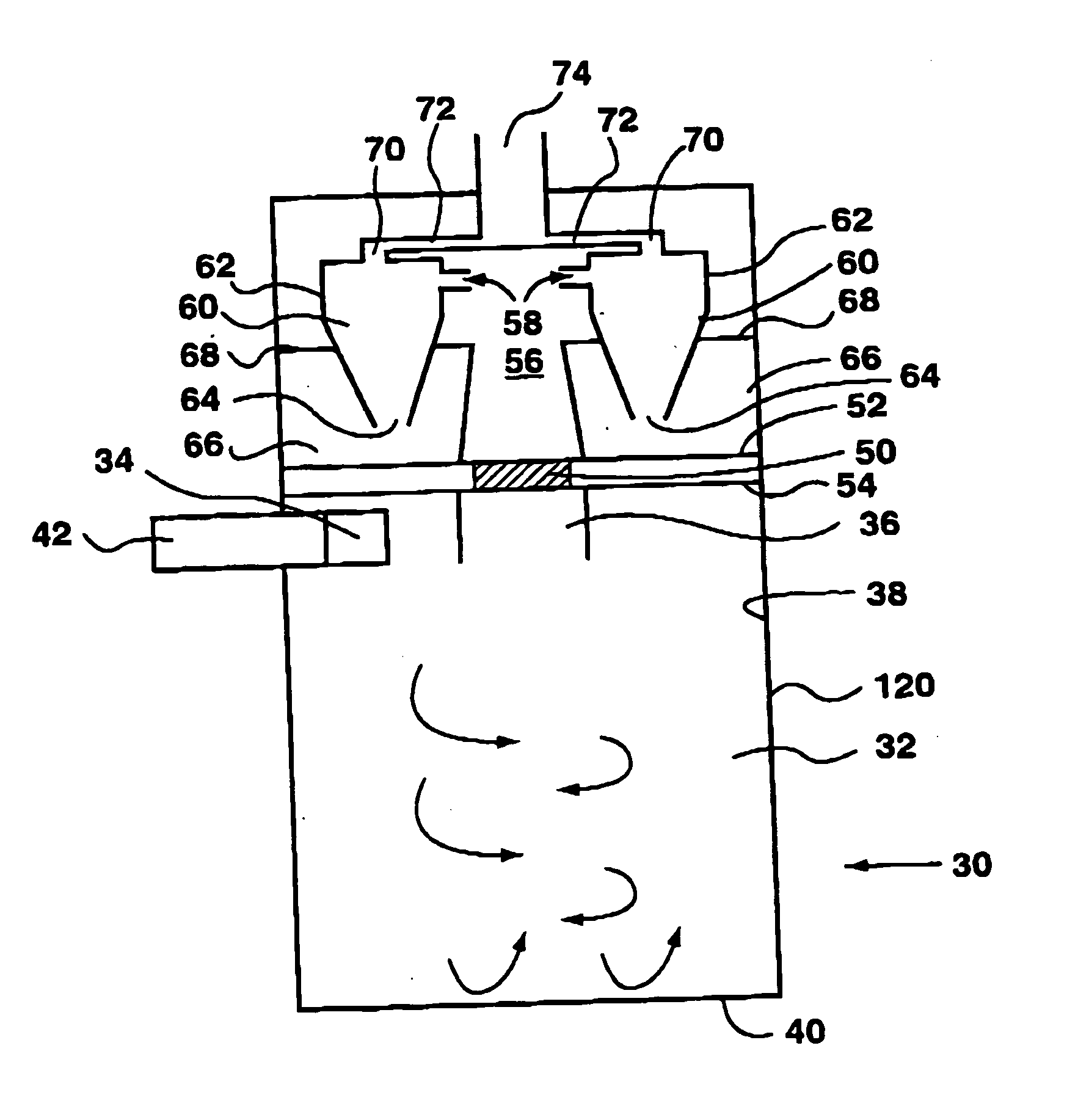

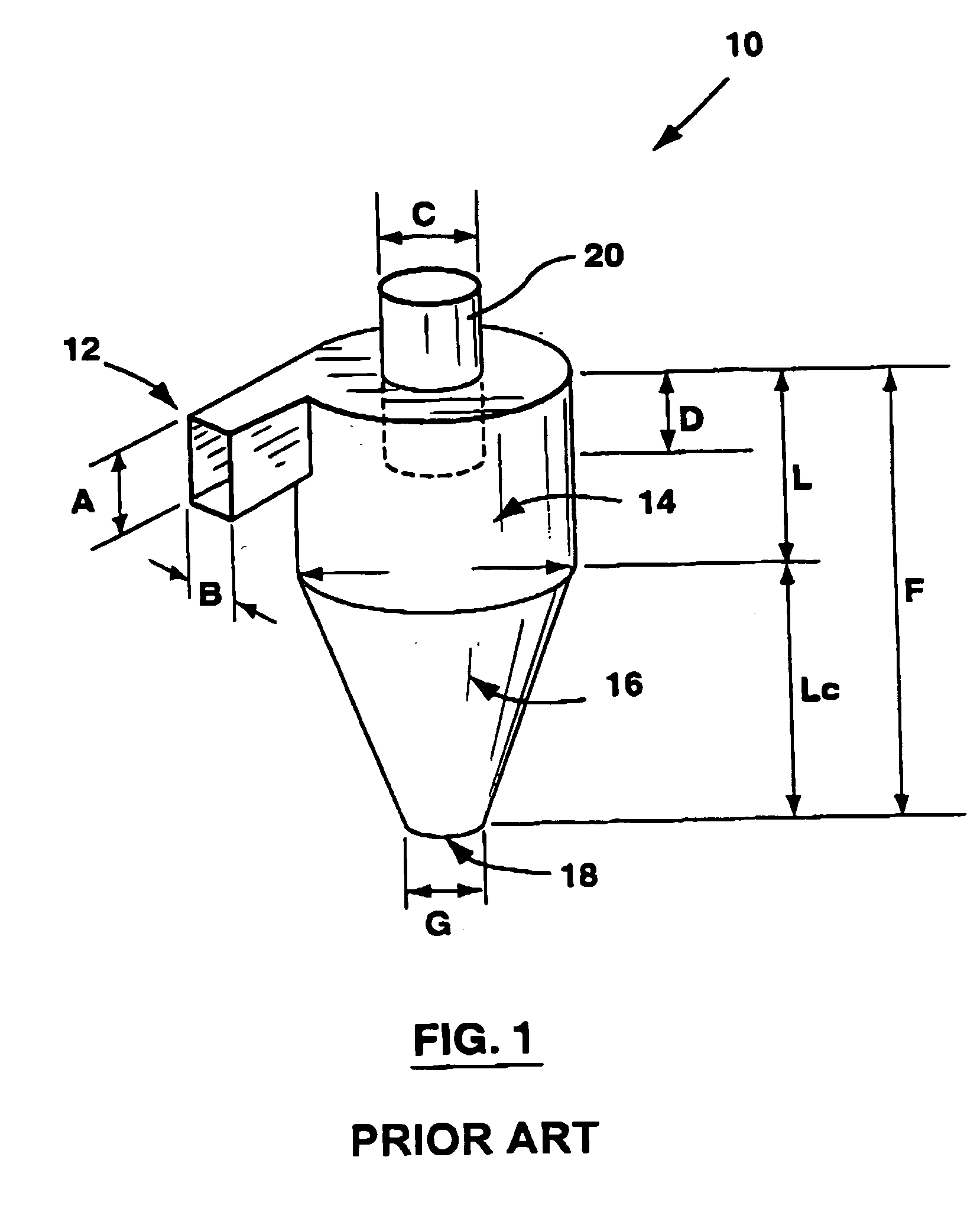

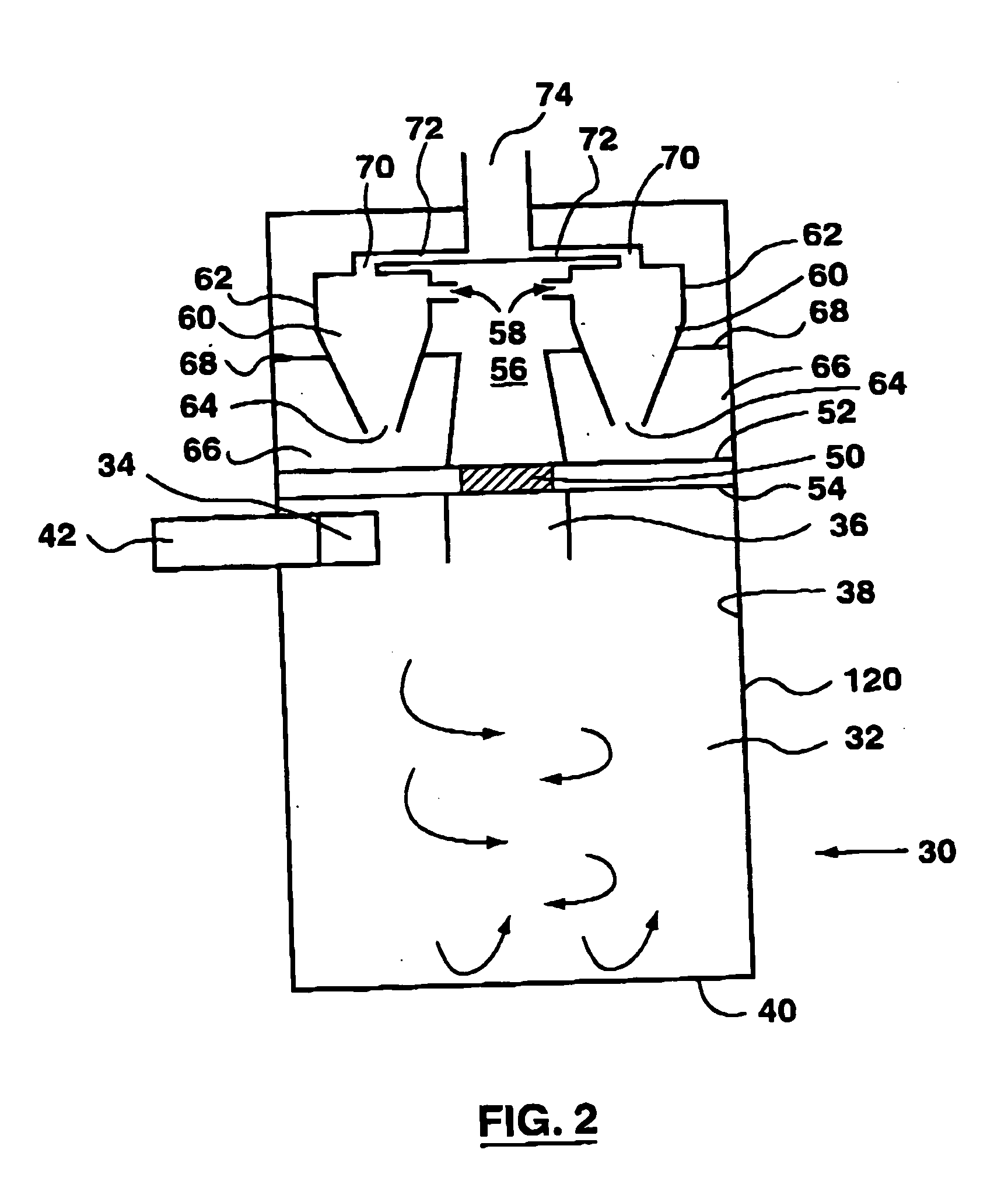

Method and apparatus for eliminating or reducing waste effluent from a wet electrostatic precipitator

ActiveUS20100043634A1Lower requirementReducing bleed water waste effluentExternal electric electrostatic seperatorThin material handlingFlue gasWaste stream

A method and apparatus are provided for reducing significantly or to zero the waste effluent from a system including a boiler and a wet electrostatic precipitator, the waste effluent comprising blow down water discharged by the boiler during a blow down operation and bleed water discharged by the wet electrostatic precipitator. The method comprises collecting the blow down water, providing the collected blow down water to the wet electrostatic precipitator as a makeup water supplement, evaporating a portion the bleed water and leaving residual bleed water, providing the evaporated bleed water to the wet electrostatic precipitator as a further makeup water supplement, and using the residual bleed water to quench ash produced by combustion of solid fuel by the boiler. The apparatus includes an evaporator that provides direct contact between hot boiler flue gas and the bleed water such that a portion of the flue gas is quenched before being provided to the wet electrostatic precipitator.

Owner:ZENVIRO TECH HLDG INC

Vacuum cleaner

InactiveUS20050028675A1Improve the level ofLarge flow resistanceCleaning filter meansCombination devicesCyclonic separationFiltration

A method for filtering a dirty air stream in a vacuum cleaner to obtain a clean air stream comprises subjecting the dirty air stream to a first cyclonic separation stage to obtain a partially cleaned air stream and subjecting the partially cleaned air stream to an electronic filtration stage and optionally a second cyclonic separation stage to obtain the clean air stream. The electronic filtration stage is optionally removable with a cyclonic cleaning stage from the vacuum cleaner. The electronic filtration stage is optionally an electrostatic precipitator which utilizes air flow through the vacuum cleaner to generate the voltage used by the electrostatic precipitator.

Owner:POLAR LIGHT

Surface treating device with cartridge-based cleaning system

Owner:SC JOHNSON & SON INC

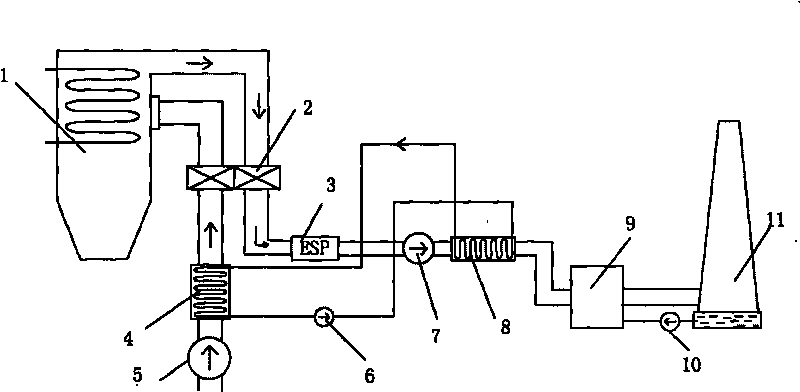

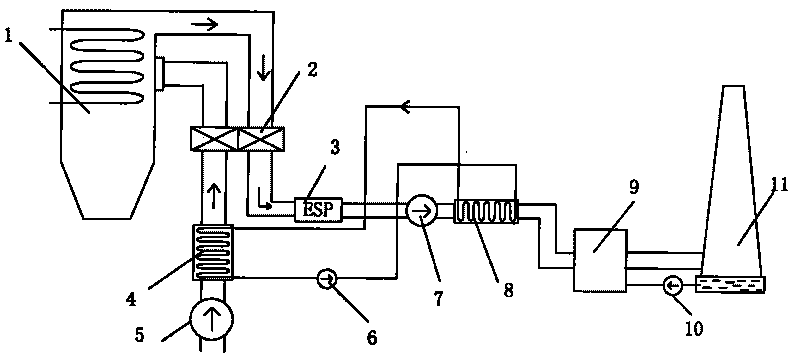

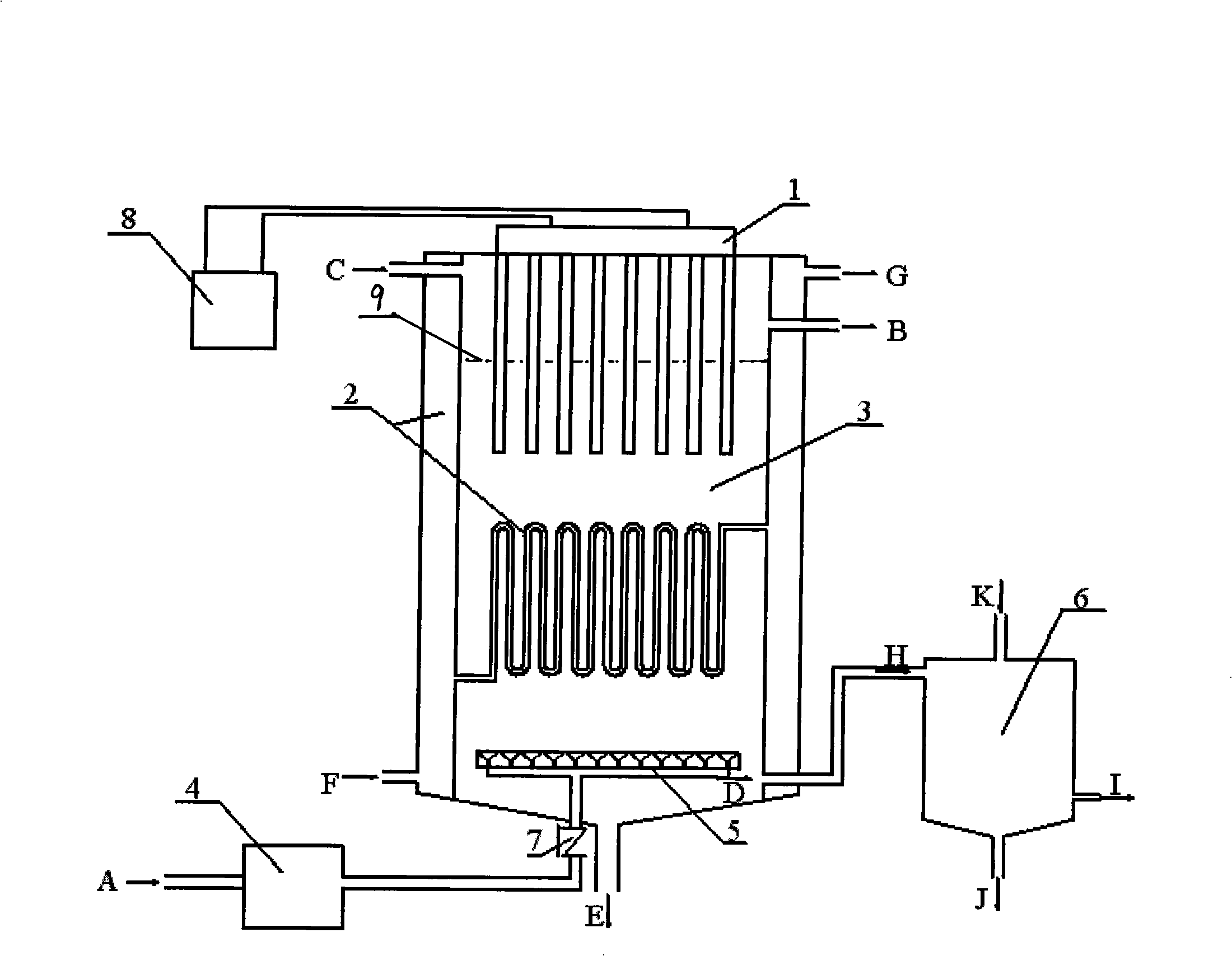

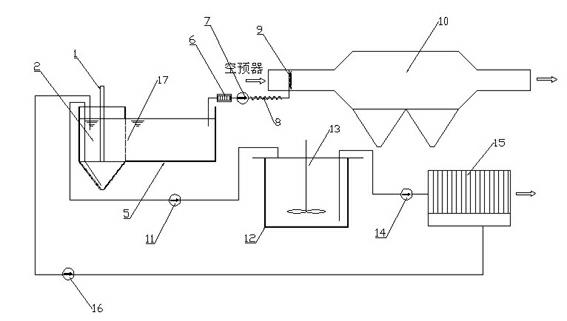

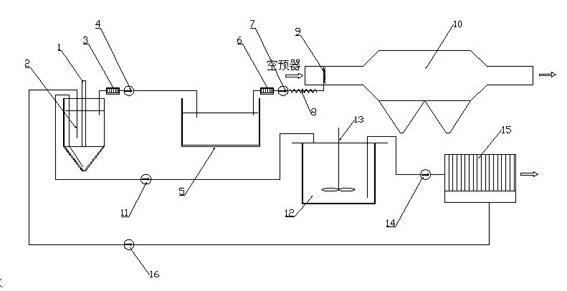

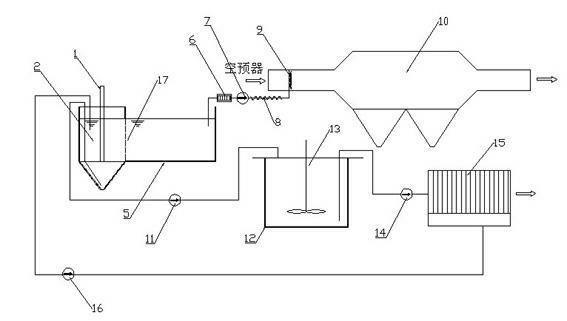

System for deep cooling and waste heat recovery of smoke gas in boiler

ActiveCN101709879AGreat effortDoes not affect normal operationCombustion processIndirect carbon-dioxide mitigationEngineeringWater circulation

The invention relates to a system for deep cooling and waste heat recovery of smoke gas in a boiler with an independent operating system, which comprises a smoke gas deep cooler, an air heater and an independent water circulation system comprising the smoke gas deep cooler and the air heater. The smoke gas of which the dust is removed by an electrostatic dust remover is used for heating the cold water in the smoke gas deep cooler to recover the waste heat of the exhausted smoke, and the hot water at the outlet of the smoke gas deep cooler is transferred to the air heater for preheating the air, thereby increasing the temperature of the combustion-supporting air in the boiler; after the smoke gas passes through the smoke gas deep cooler, the smoke gas is directly introduced into a desulfurizing tower for desulfurization and recovery processing; and finally, the smoke gas is exhausted through a wet chimney. The system of the invention does not need to change the traditional thermodynamic system of the machine unit, and the long-period safe operation of the system can not be influenced in the process of recovering the waste heat of the smoke gas, thereby lowering the temperature of the exhausted smoke, saving the desulfurization water consumption, improving the machine unit efficiency and increasing the machine unit output.

Owner:XI AN JIAOTONG UNIV +1

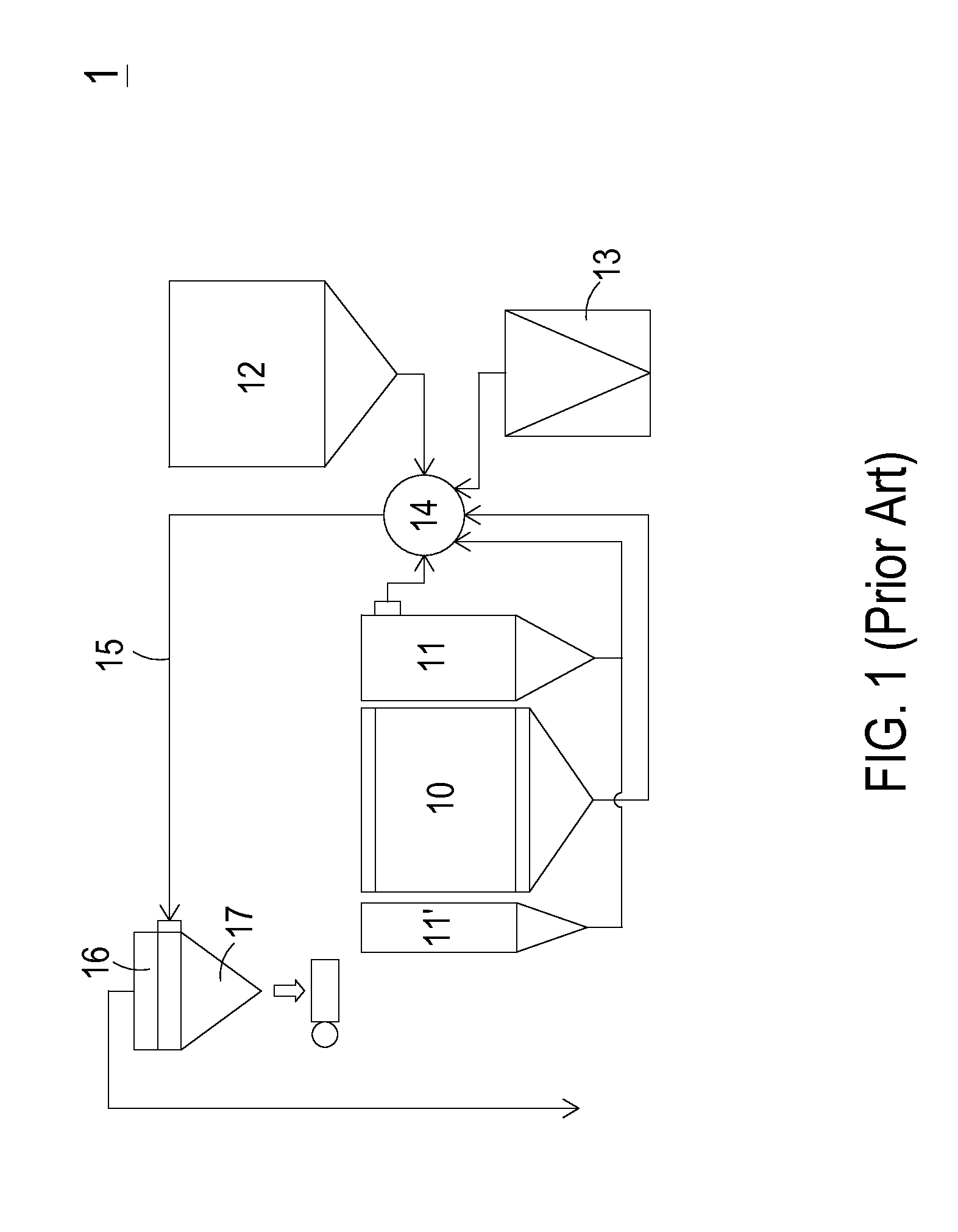

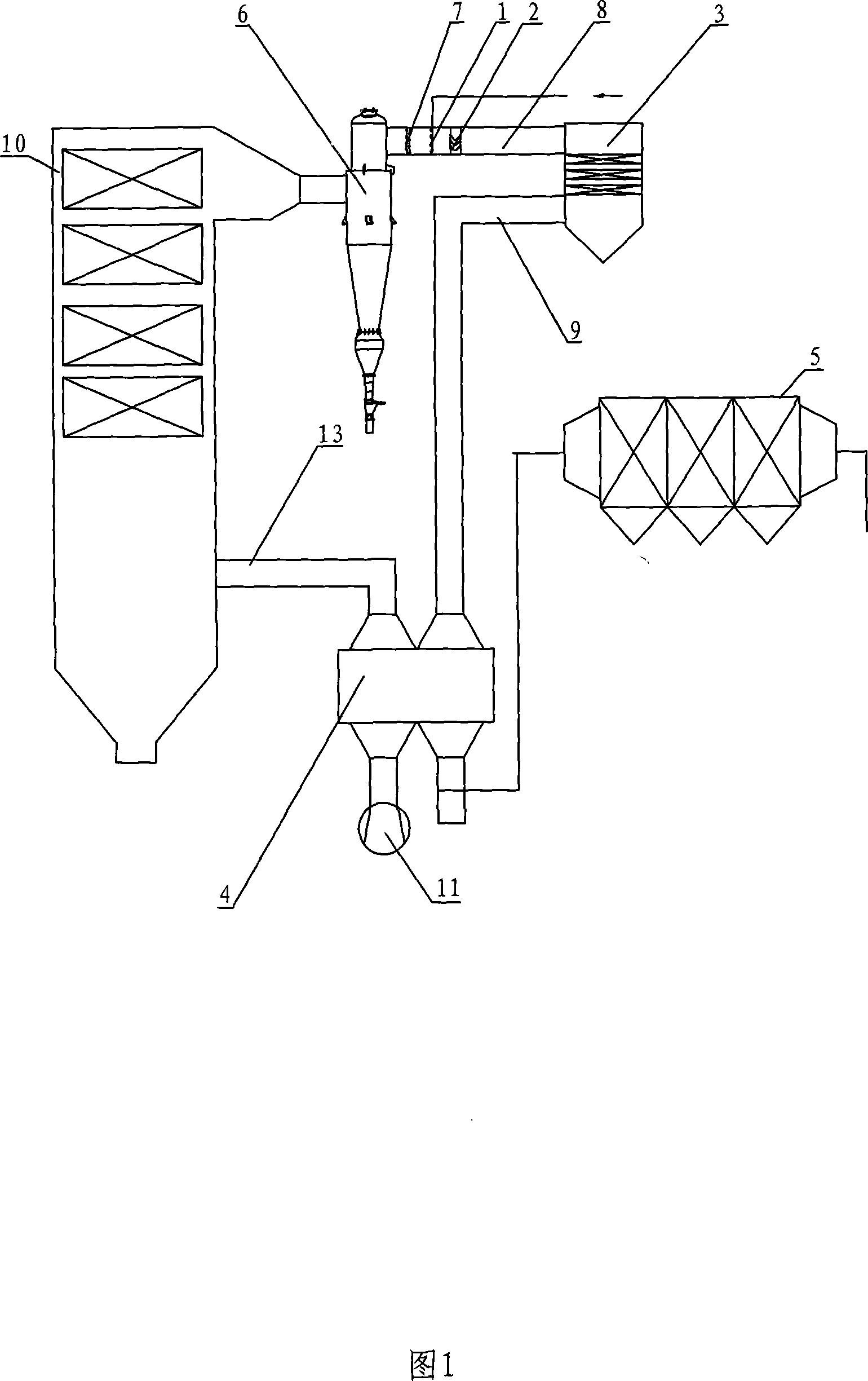

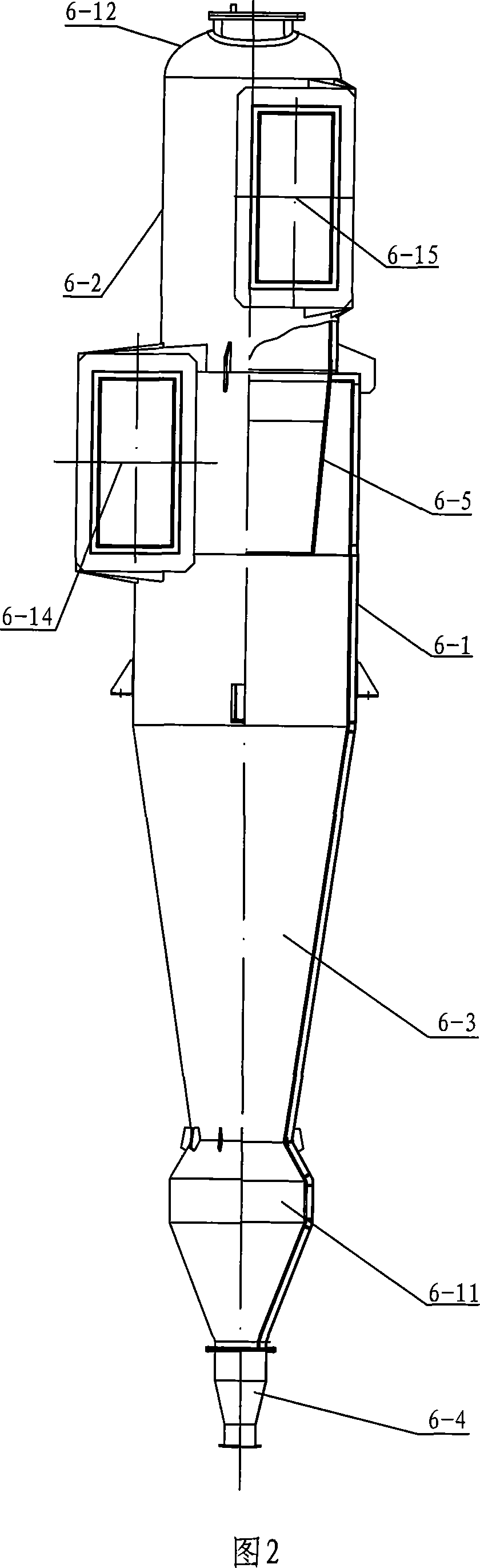

Flue gas denitrating technique with preposed whirlwind beforehand dust removal SCR

The invention discloses a preposing cyclone pre-dedusting SCR flue gas denitration technique. The flue gas extracted from a boiler economizer (12) primarily passes through a high temperature resistant cyclone separator (6), then passes through a flue gas current equalizer (7) and a static mixer (2) to unify the flow direction of the flue gas evenly; meanwhile, the flue gas after being mixed evenly with ammonia is preprocessed before reacting with a catalyst of an SCR reactor (3); finally, the flue gas is output after the temperature is reduced through an air preheater (4) and the flue gas is dedusted through an electrical precipitator (5). The invention reduces the volume of the catalyst and the SCR reactor, reduces the requirements of the support, eliminates an SCR bypass and greatly reduces engineering cost of the SCR; meanwhile, the invention also prolongs the service life of the catalyst and the cleaning period of the air preheater without installing a soot blower or prolonging the period of sootblowing.

Owner:CPI YUANDA ENVIRONMENTAL PROTECTION ENG +1

Ultrasonic integration desulfurization denitration demercuration method and device thereof

InactiveCN101337153ACost savingsSave operation and maintenance costsDispersed particle separationEnergy based chemical/physical/physico-chemical processesCavitationAtmospheric air

The invention provides a method for integrally desulfurizing, denitrating and removing mercury under the ultrasonic action. Hydroxyl free radicals OH* with strong oxidizability are released when a cavitation effect is generated in a reaction solution under the ultrasonic action and subjected to the oxidization removal reaction with sulfur oxides, nitrogen oxides and Hg<0> in fume; the cleaned fume is exhausted to the atmosphere; the separated mixed acid solution is applied for producing fertilizers after being absorbed by ammonia water; and the heavy metal precipitate is extracted for the recovery. An ultrasonic generator, an ultrasonic transmitter, a cooling water system, a bubbling bed reactor, an electrostatic dust collector, a fume diffuser, a separating column and a check valve are provided. The ultrasonic transmitter is disposed in the bubbling bed reactor. The fume is introduced into a pipe, sequentially passes through the electrostatic dust collector and the check valve and is introduced into the fume diffuser from the bottom of the bubbling bed reactor. A fume outlet is positioned at the upper part of the bubbling bed reactor. A residue discharge port is formed at the bottom of the bubbling bed reactor. The inlet of the separating column is connected with the outlet of the reaction products of the bubbling bed reactor. The separating columns are respectively provided with an insoluble substance outlet, a chemical feed port and a soluble substance outlet.

Owner:SOUTHEAST UNIV

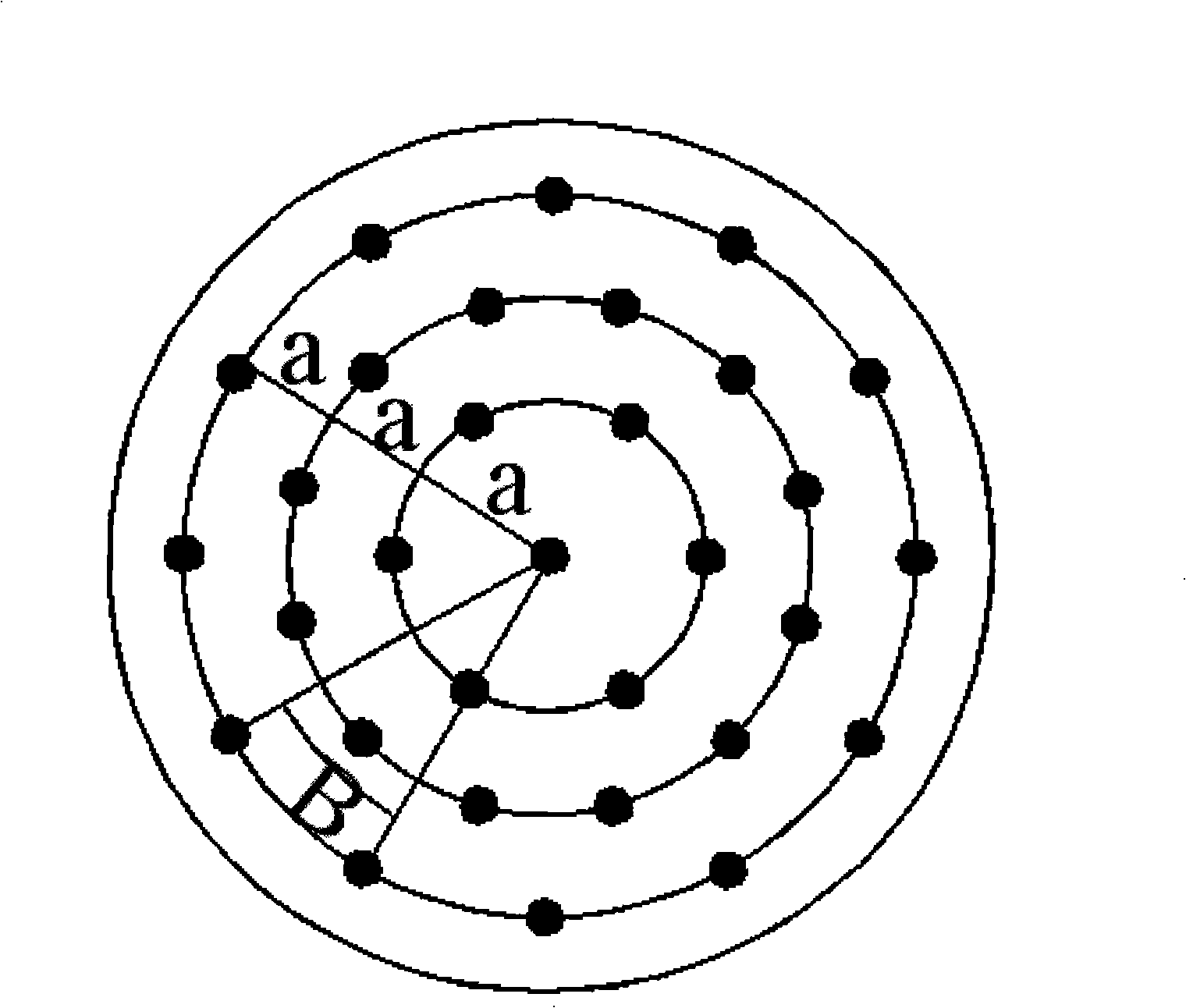

Coal-fired ultrafine grain chemical agglomeration promotor

ActiveCN101513583AWide variety of sourcesEasy to synthesizeAuxillary pretreatmentElectrostatic separationInorganic saltsWater soluble

The invention discloses a coal-fired ultrafine grain chemical agglomeration promotor which comprises the components based on mass percent: 0.001-0.2% of surface active agent, 0.0001-0.01% of water-soluble high molecular compound, 0.001-0.05% of inorganic salt additive and the rest of water. The invention can effectively promote ultrafine grains to agglomerate, improve the removal efficiency of a static precipitator for the ultrafine grains and high specific resistance flying ash, and reduce the soot emission and the charges for disposing pollutant of enterprises. The agglomeration promotor has the components with wide source, economical price, environmental protection, simple synthetic process, easy operation and no environmental pollution.

Owner:武汉天空蓝环保科技有限公司

Method and system for zero emission treatment of desulfured waste water

ActiveCN102180549AConvenient zero-emission disposalSimple processWaste water treatment from gaseous effluentsMultistage water/sewage treatmentSludgeWater filter

The invention discloses a method for zero emission treatment of desulfured waste water. The method comprises the following steps: 1) discharging the desulfured waste water obtained after desulfuration in a desulfuration tower into a preliminary sedimentation tank, carrying out primary separation in the preliminary sedimentation tank, and transporting an upper clear liquid separated out to a buffer pool through a slurry pump; 2) successively passing the desulfured waste water in the buffer pool through an atomization plant and a static dust catcher; 3) transporting the waste water which is from the lower part of the preliminary sedimentation tank and has large solid content to a filter press through an another sludge pump; and 4) feeding the waste water filtered back to the preliminary sedimentation tank through the slurry pump. Simultaneously, the invention also discloses a system for zero emission treatment of desulfured waste water. The zero emission treatment is conveniently carried out on the desulfured waste water through the method, the process is simple and labor is saved; and the system has a compact structure, the method is simple to implement, energy is saved, the quality of smoke at the inlet of the dust catcher is improved, the zero emission of the desulfured waste water can be really achieved, thus the system has the advantage of popularization value.

Owner:CHENGDU SHUKE TECH

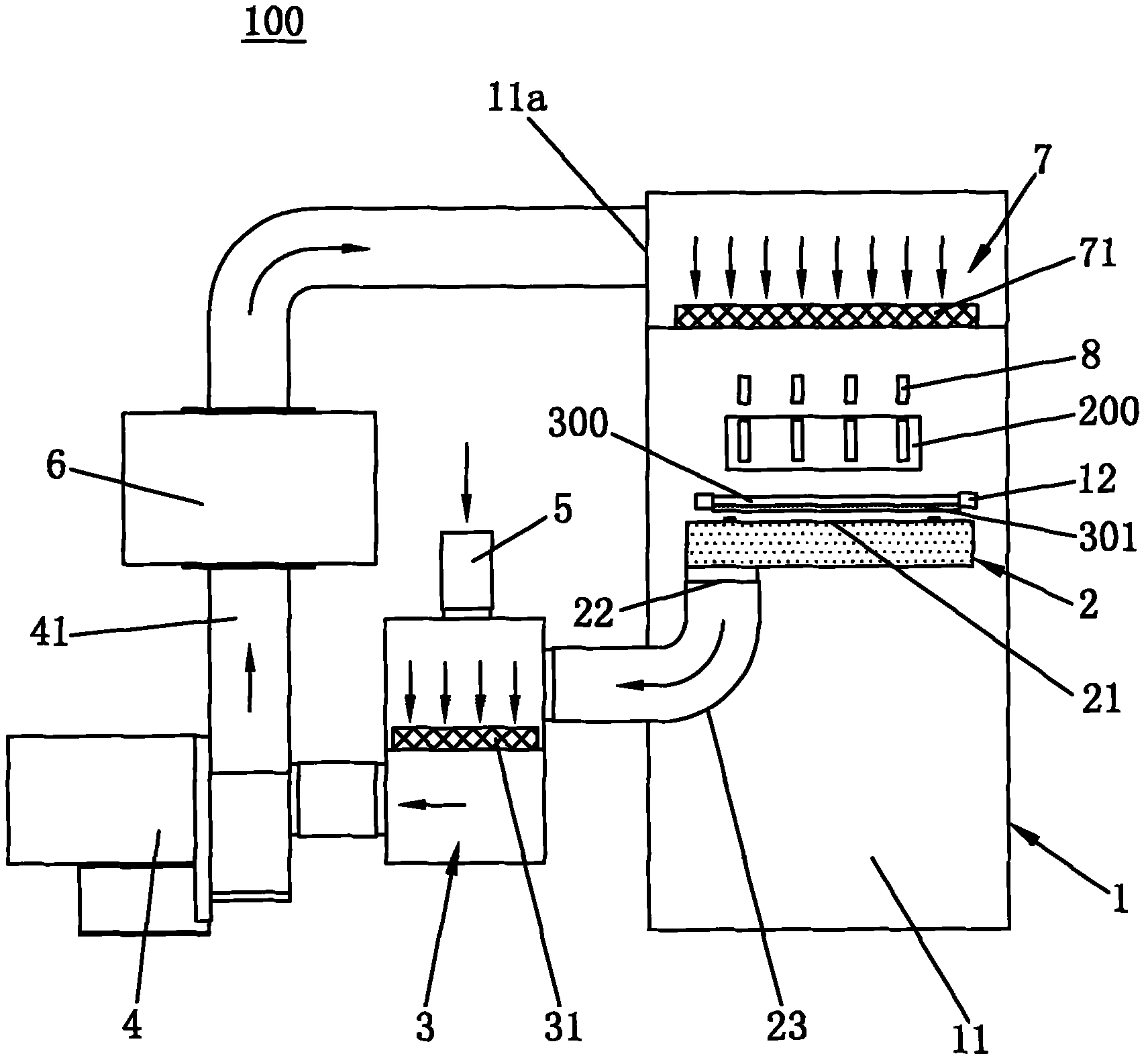

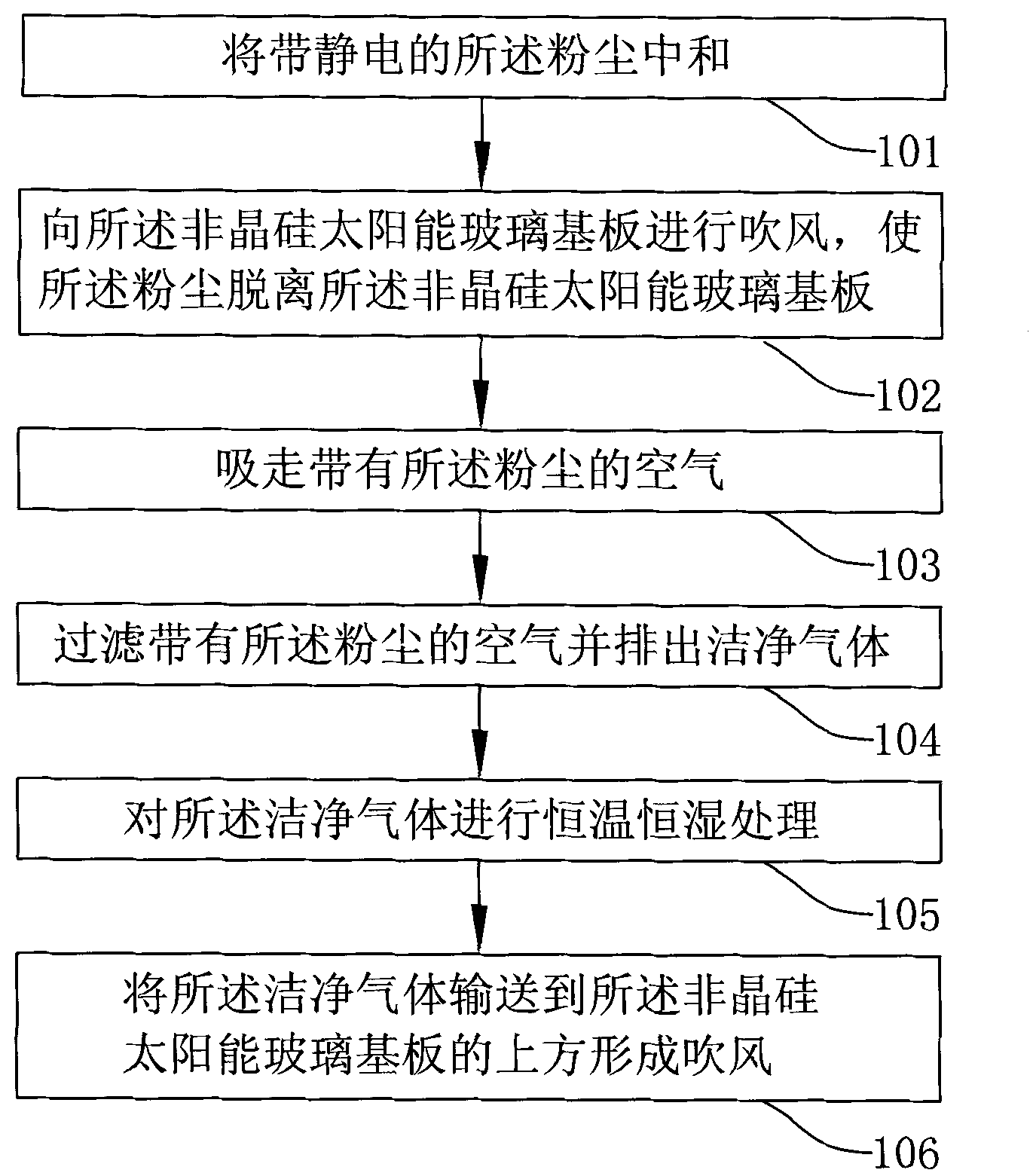

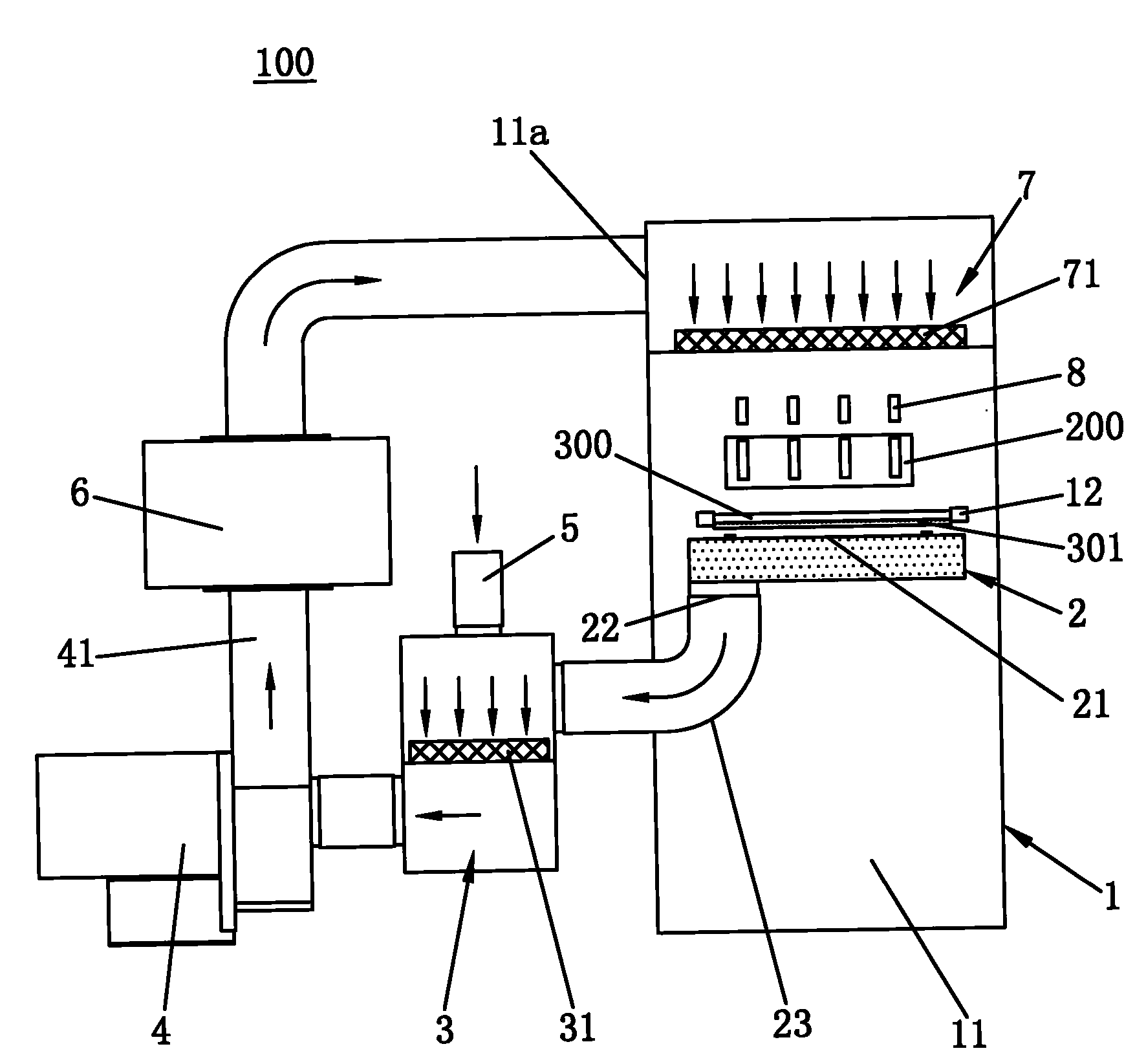

Laser recticle dedusting plant and dedusting method

InactiveCN101829848AEasy to remove dustImprove cleanlinessDirt cleaningAblative recordingLow noiseEngineering

The invention discloses a laser recticle dedusting plant. The laser recticle dedusting plant comprises a processing unit, a dust exhaust apparatus, a first filter unit, a high pressure exhaust fan and a plurality of electrostatic cleaning bars, wherein the processing unit comprises an inner cavity and an operating platform arranged in the inner cavity; the dust exhaust apparatus comprises a dust suction port and a dust-discharging port, the dust suction port is positioned under the operating platform, the dust-discharging port of the dust exhaust apparatus is communicated with the upper end of the first filter unit, the lower end of the first filter unit is communicated with the suction opening of the high pressure exhaust fan, a first filter net core is arranged between the upper end andthe lower end of the first filter unit, the air outlet of the high pressure exhaust fan is communicated with the inner cavity, and the electrostatic cleaning bars are evenly arranged on the laser generator. The laser recticle dedusting plant has high dedusting efficiency, low noise and little energy consumption. The invention also discloses a laser recticle dedusting method.

Owner:东莞晨真光伏有限公司

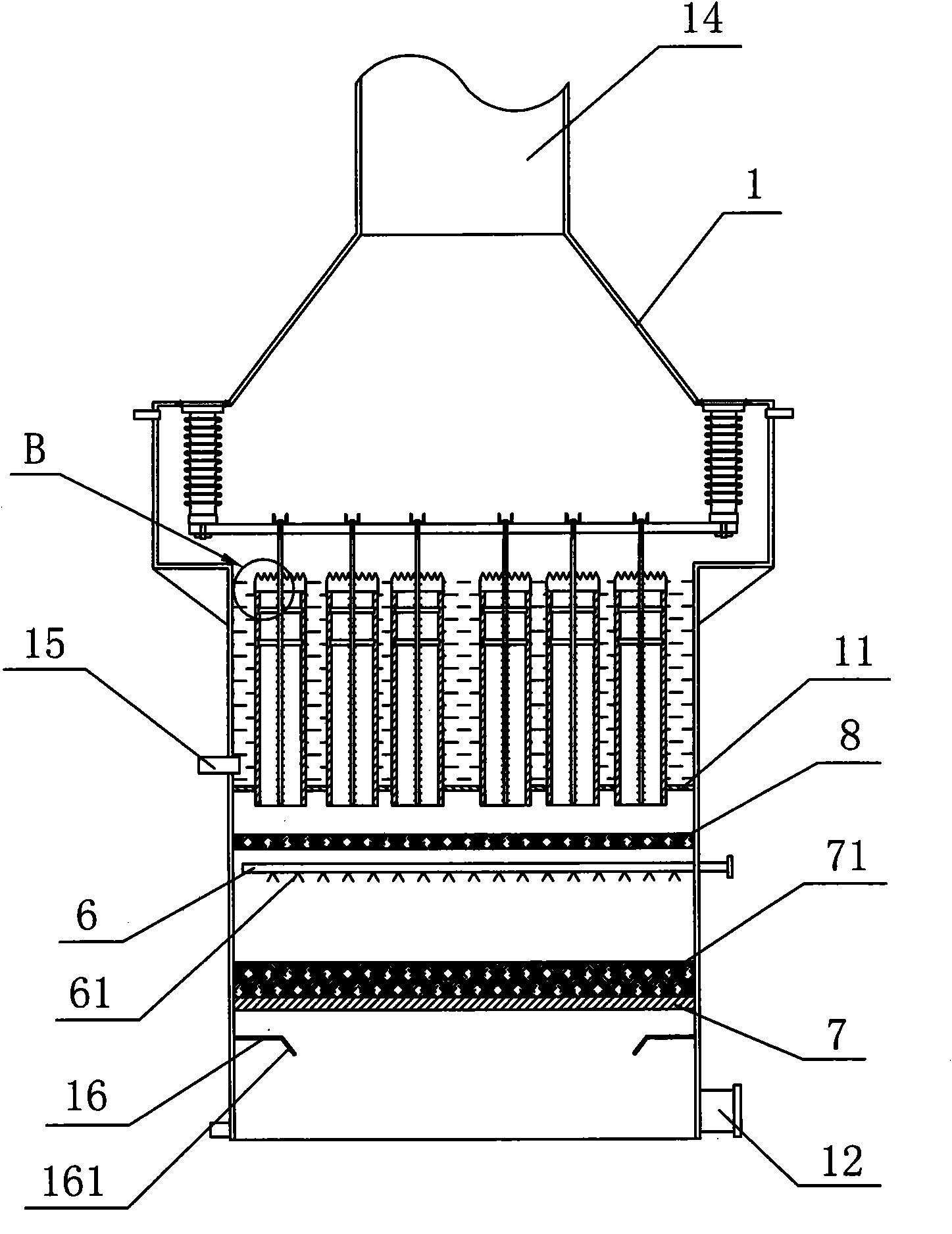

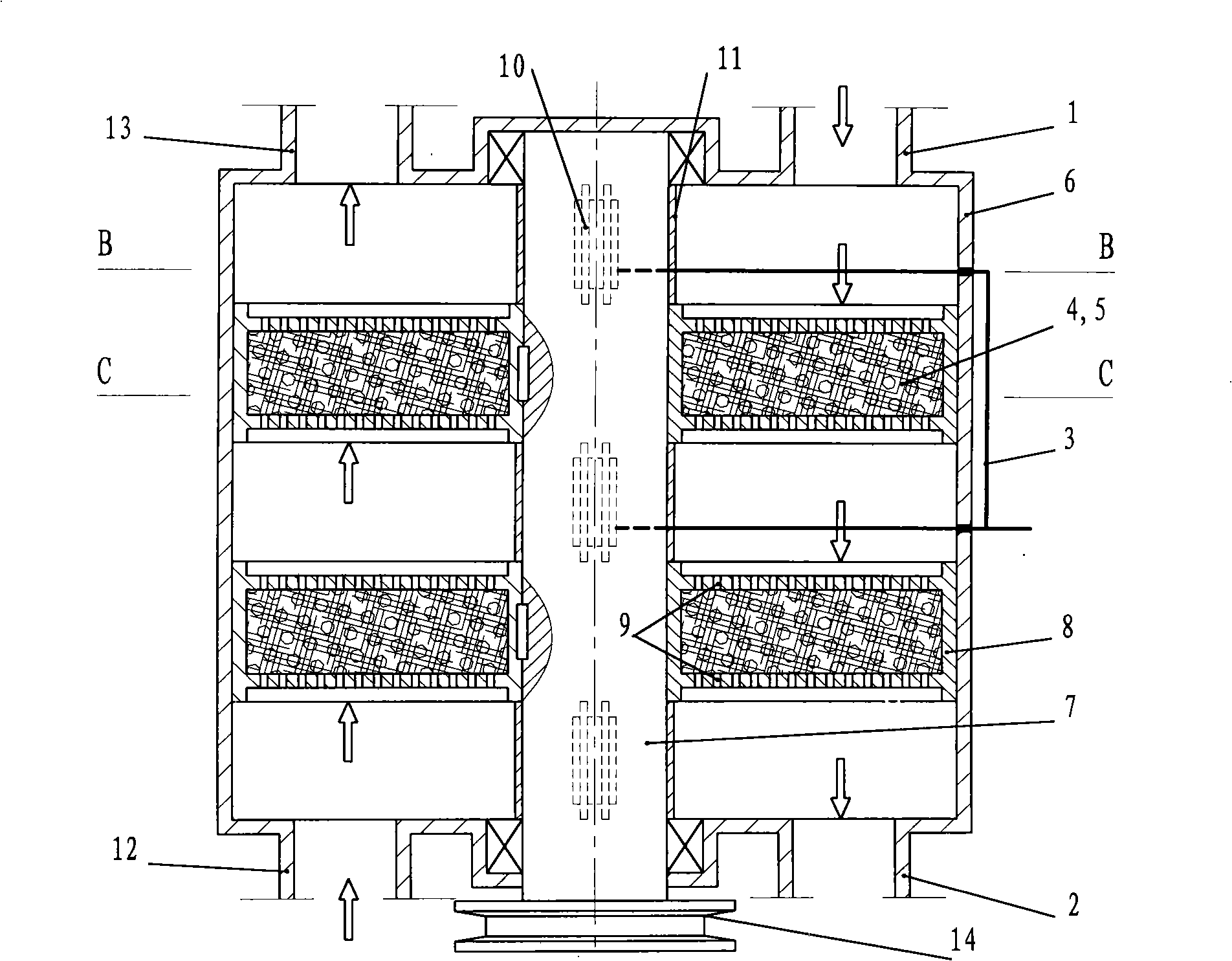

Wet static dedusting device

InactiveCN101780435AAvoid failureExtended service lifeExternal electric electrostatic seperatorHazardous substanceEngineering

The invention discloses a wet static dedusting device which comprises a tower body, an electrode support and an insulated pillar, wherein the electrode support is installed in the tower body. The wet static dedusting device is characterized in that a plurality of suspended electrode rods are fixedly arranged on the electrode support; a hollow condenser tube is sleeved outside the electrode rods; a clapboard is sealed and fixedly arranged in the tower body; the condenser tube is fixedly arranged on the clapboard, with the lower end running out of the clapboard; a water inlet is arranged on the tower body; one end of the insulated pillar is fixedly connected with the electrode support, and the other end of the insulated pillar is fixedly connected with the tower body; a waste gas inlet and a dirt drain port are arranged at the lower end of the tower body; and a gas exhaust port is arranged at the upper end of the tower body. The wet static dedusting device has the advantages that a uniform water film renewed constantly is formed on the inner wall of the condenser tube and serves as a dust collecting electrode when the electrode rods discharge so that a uniform electrostatic field can be formed in the condenser tube; charges of the high voltage electrostatic electrons generated by the electrode rods adhere to the harmful particles in the exhaust gas, and under the action of the high voltage electric field, the harmful particles directionaly migrate to the wall of the condenser tube and then flow down with the water film to be drained; the ozone or plasma free radicals generated when the electrode rods discharge can oxidize and remove the fetid substances in the exhaust gas, so the exhaust gas can get deep purification treatment; and the wet static dedusting device has good dedusting and purifying effects and the whole equipment can operate safely for a long period.

Owner:NINGBO UNIV

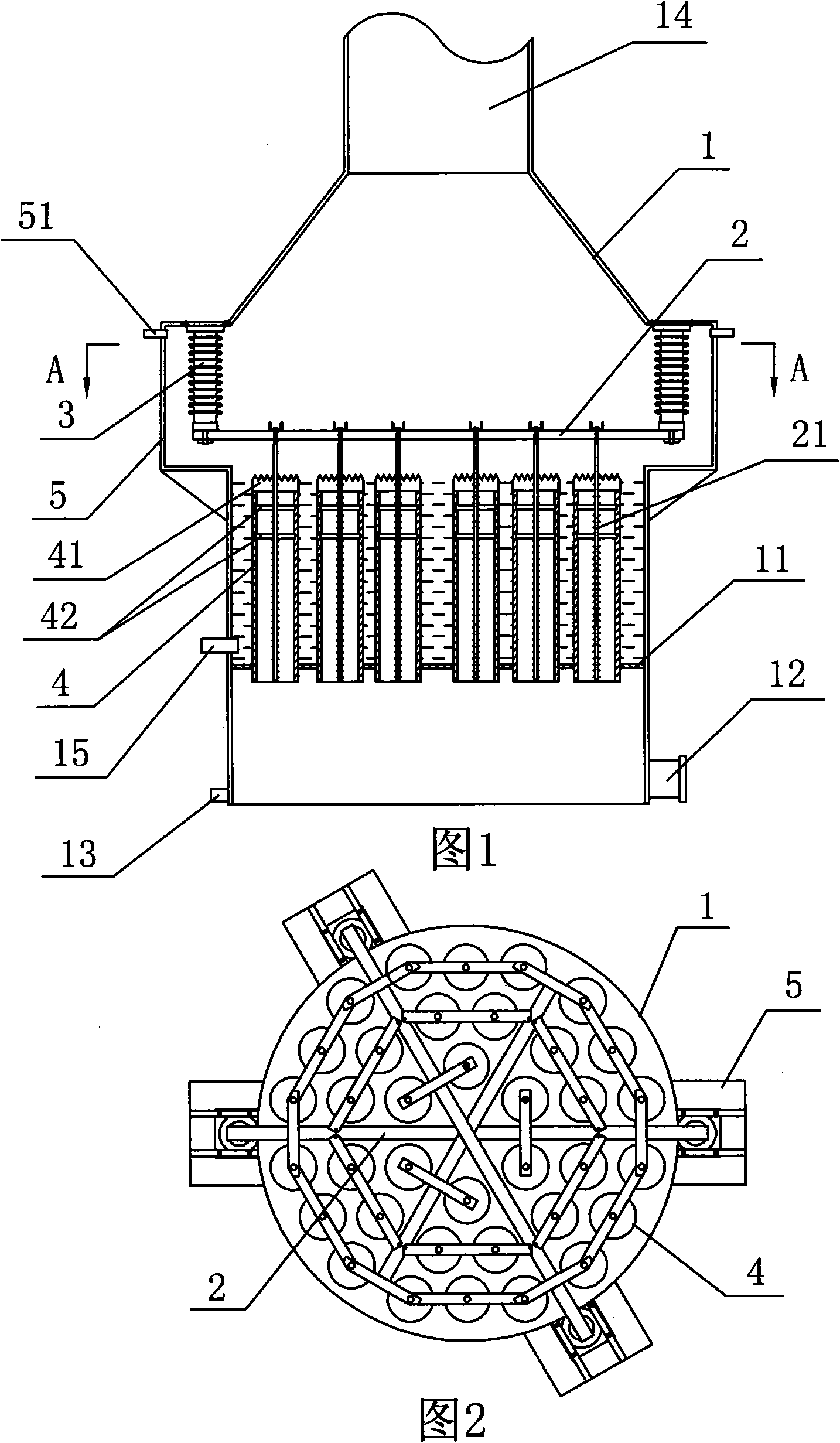

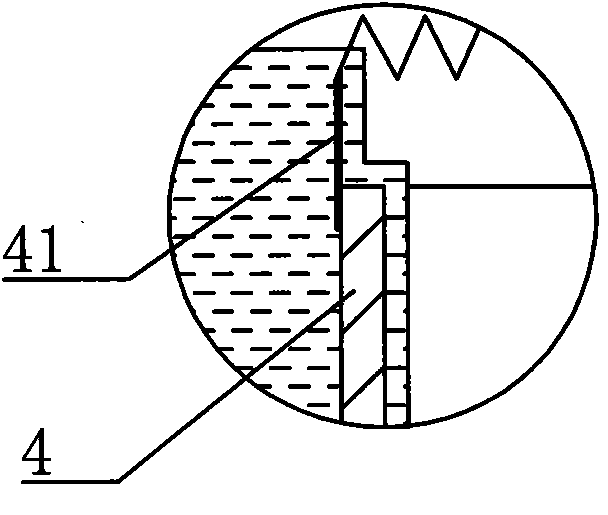

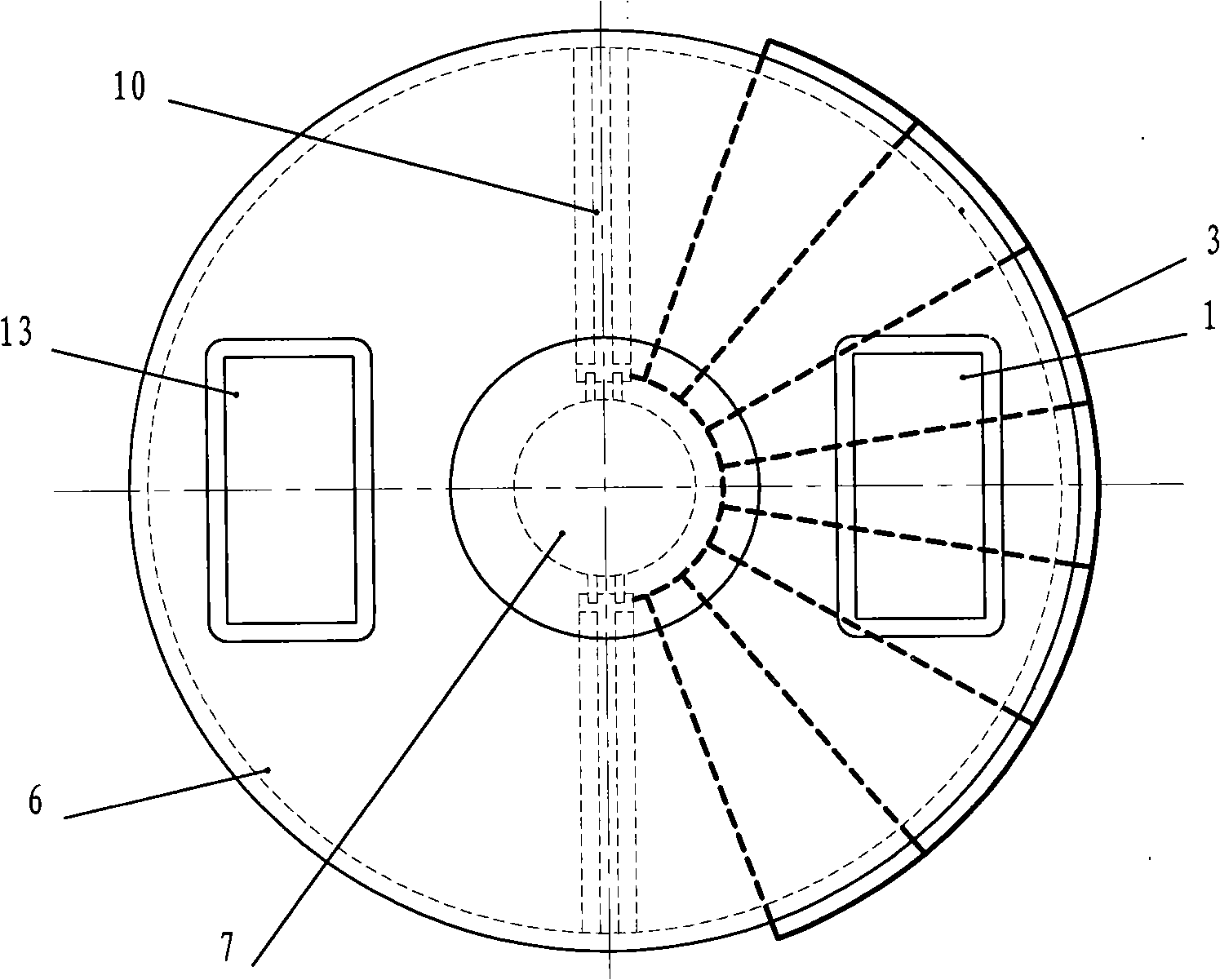

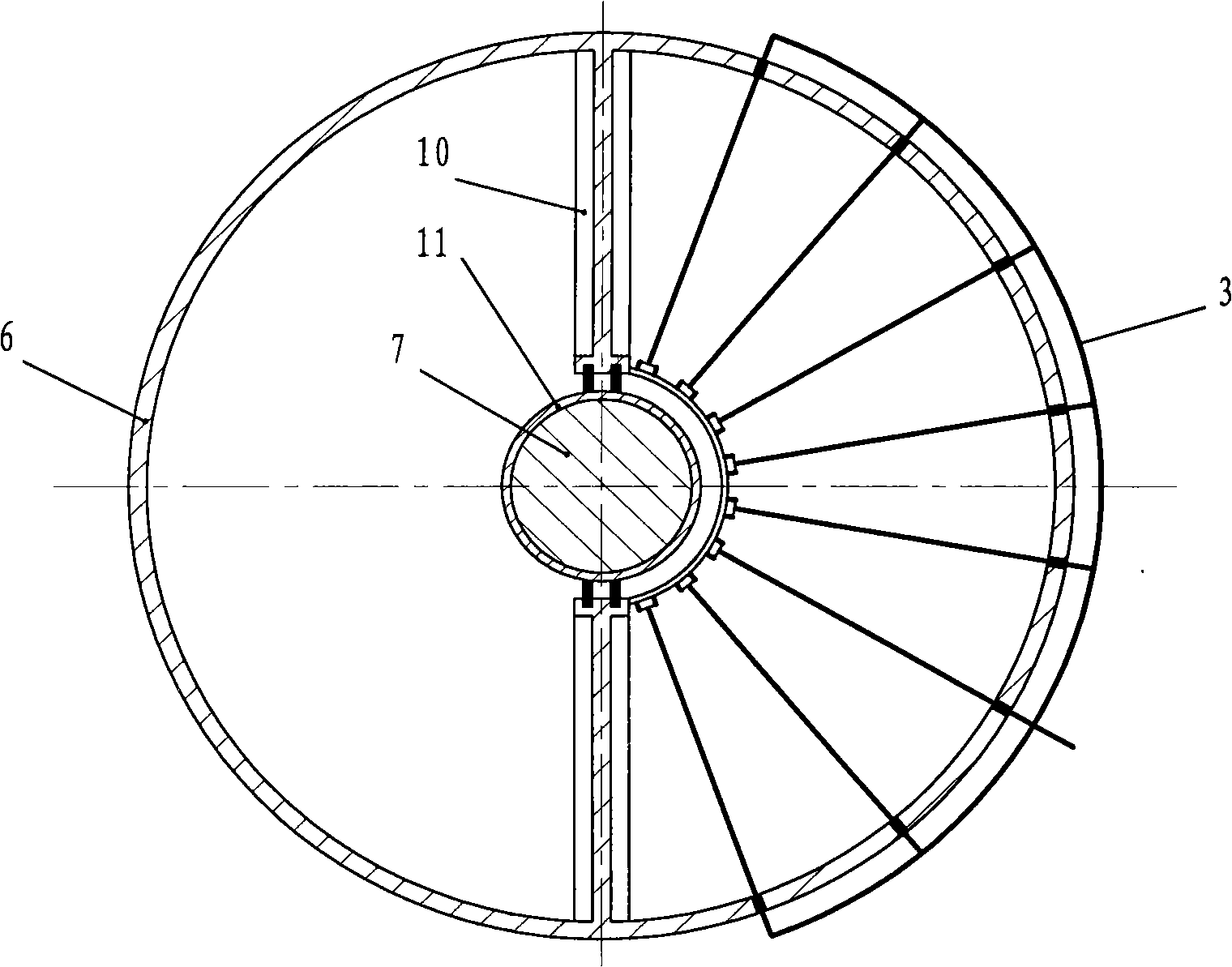

Electrostatic precipitator with high-efficiency dust collecting pole

The invention relates to an electrostatic precipitator of an efficient dust collecting electrode, comprising a shell which is provided with an airflow inlet and an airflow outlet. A discharge electrode and a dust collecting electrode are arranged in the shell. Wherein, the dust collecting electrode comprises a hollowed-out metal shell, and a dust collecting plate or a dust collecting sphere or an alveolar porous plate which is filled in the shell and manufactured by porous metallic foams or porous foam plastics processed via conductive treatment, and the dust collecting plate or the dust collecting sphere moves between an integration chamber and a dust cleaning chamber. The electrostatic precipitator of the efficient dust collecting electrode of the invention selects the porous metallic foams or the porous foam plastics processed conductive treatment, to manufacture a flat type, a granular type or an alveolar porous type to fill in the shell of a metal framework or a reticular formation to manufacture the dust collecting electrode with different structures such as rotary type, flat brattice type, circular flow type and so on, and at the same time separates a dust collecting area and a dust cleaning area to make dust collection efficiency of the electrostatic precipitator reach to more than 99.99%. The dust collecting electrode of the invention is particularly applicable to the last stage of the electrostatic precipitator, wherein, after dust abatement, dust content of the gas per cubic meter is less than or equal to 10mg.

Owner:孟金来

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com