Patents

Literature

1728 results about "Gas solid" patented technology

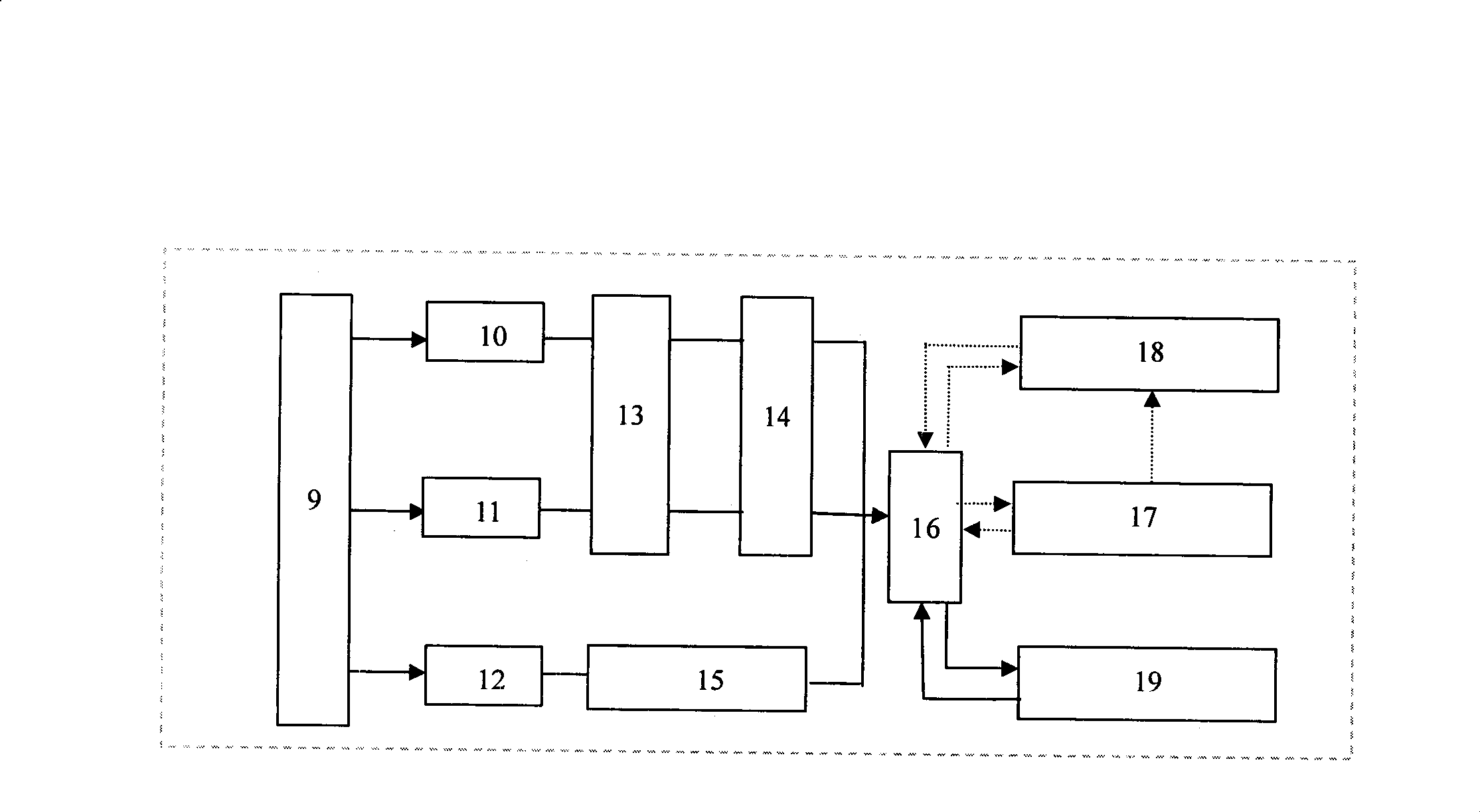

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Examples of Gas to Solid: 1. Making dry ice or solid carbon dioxide involves the removal of gaseous carbon dioxide from air and using cold temperatures and higher pressure causes the gas particles to skip the liquid phase and deposit into a solid to form a chunk of dry ice.

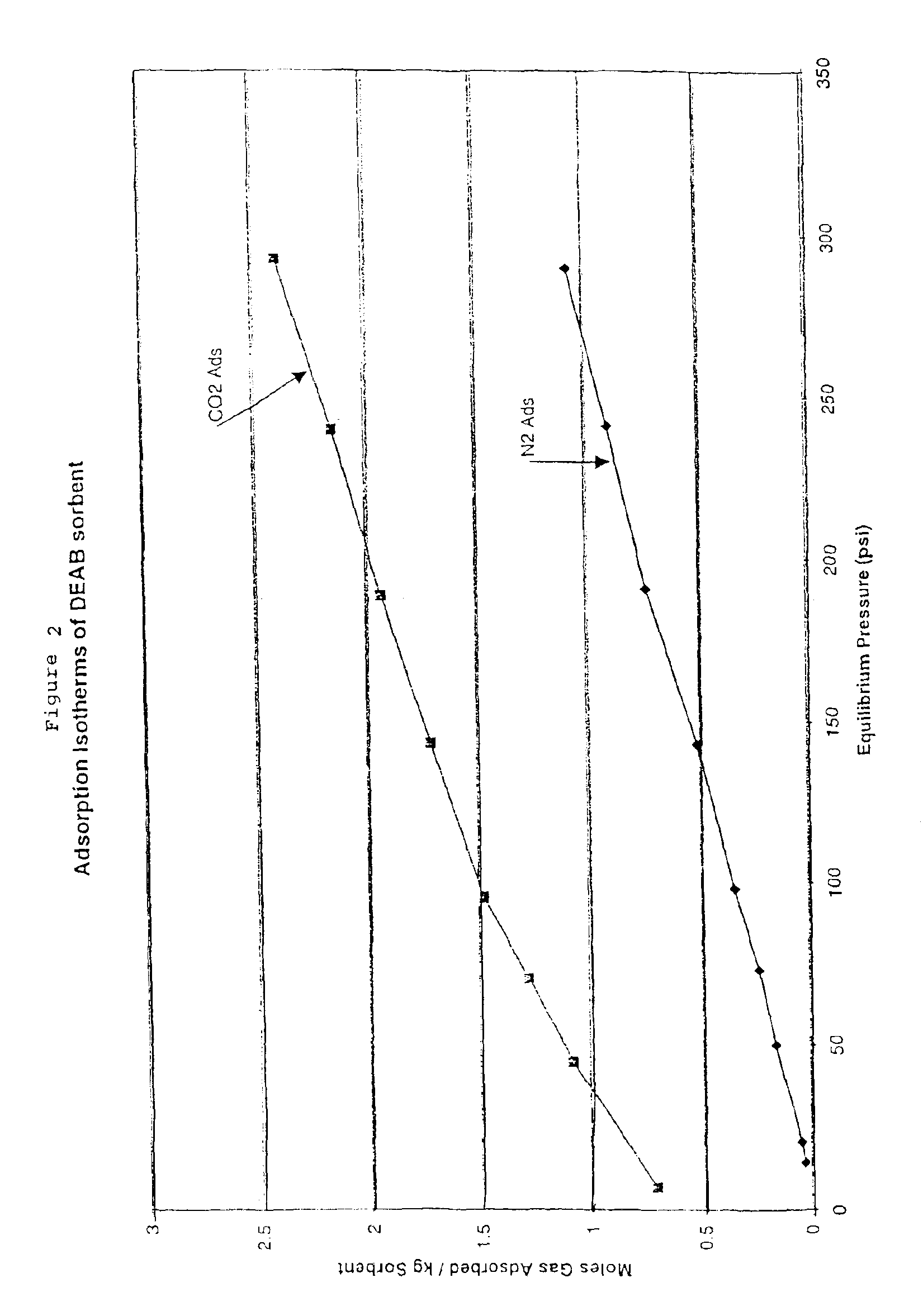

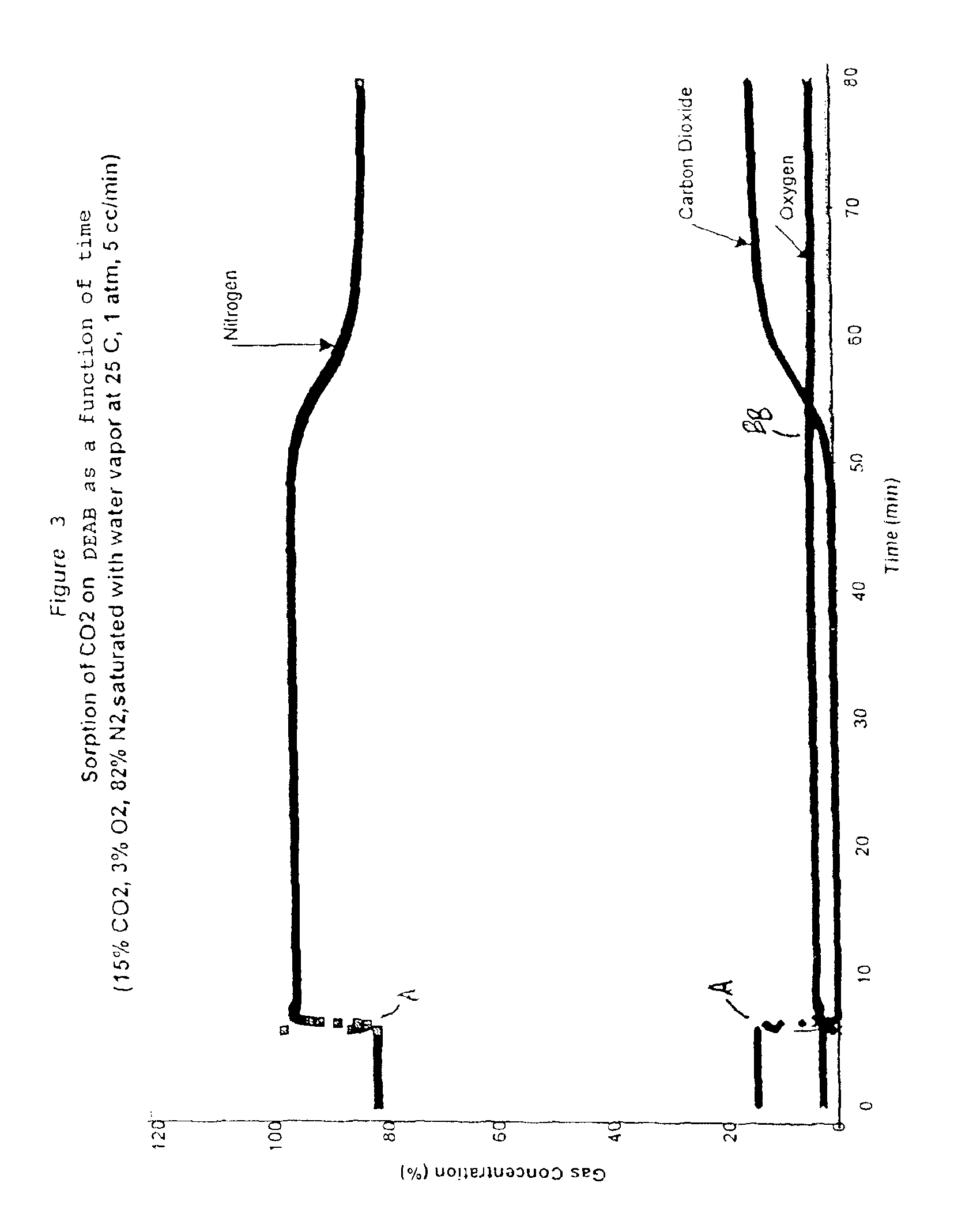

Solid sorbents for removal of carbon dioxide from gas streams at low temperatures

InactiveUS6908497B1Promote regenerationRegeneration process is inexpensiveGas treatmentOther chemical processesGas solidSorbent

New low-cost CO2 sorbents are provided that can be used in large-scale gas-solid processes. A new method is provided for making these sorbents that involves treating substrates with an amine and / or an ether so that the amine and / or ether comprise at least 50 wt. percent of the sorbent. The sorbent acts by capturing compounds contained in gaseous fluids via chemisorption and / or physisorption between the unit layers of the substrate's lattice where the polar amine liquids and solids and / or polar ether liquids and solids are located. The method eliminates the need for high surface area supports and polymeric materials for the preparation of CO2 capture systems, and provides sorbents with absorption capabilities that are independent of the sorbents' surface areas. The sorbents can be regenerated by heating at temperatures in excess of 35° C.

Owner:ENERGY U S DEPARMENT OF

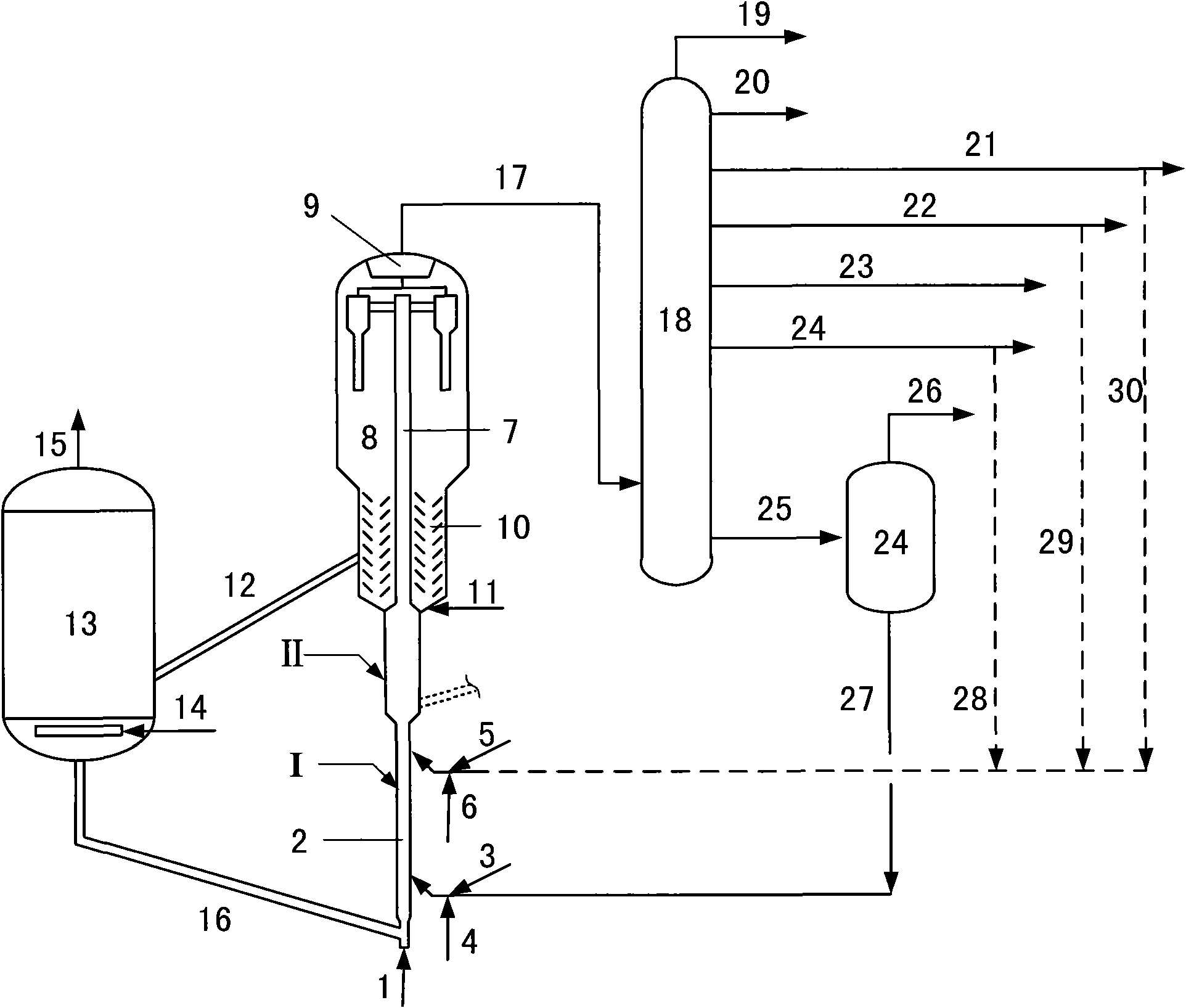

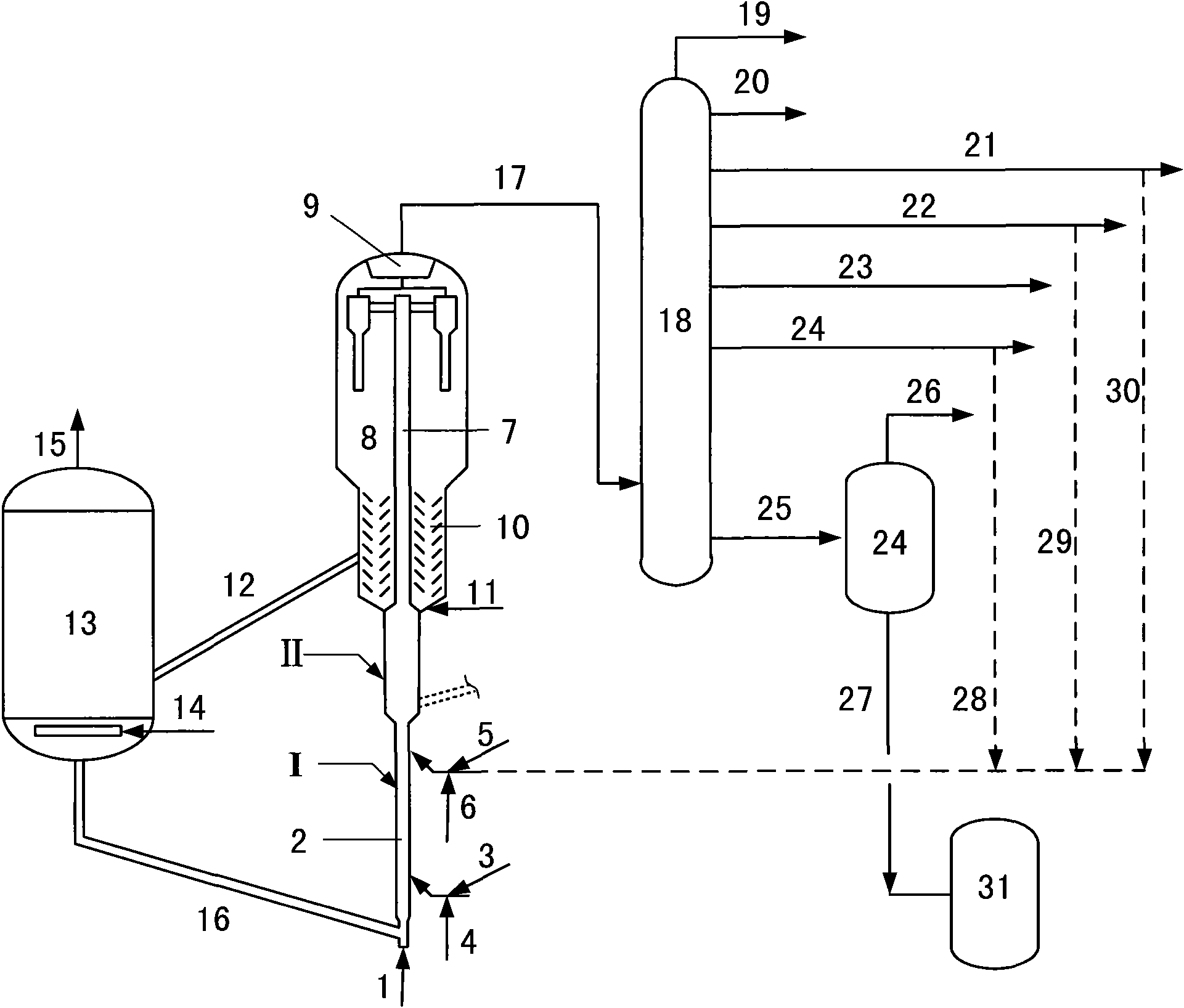

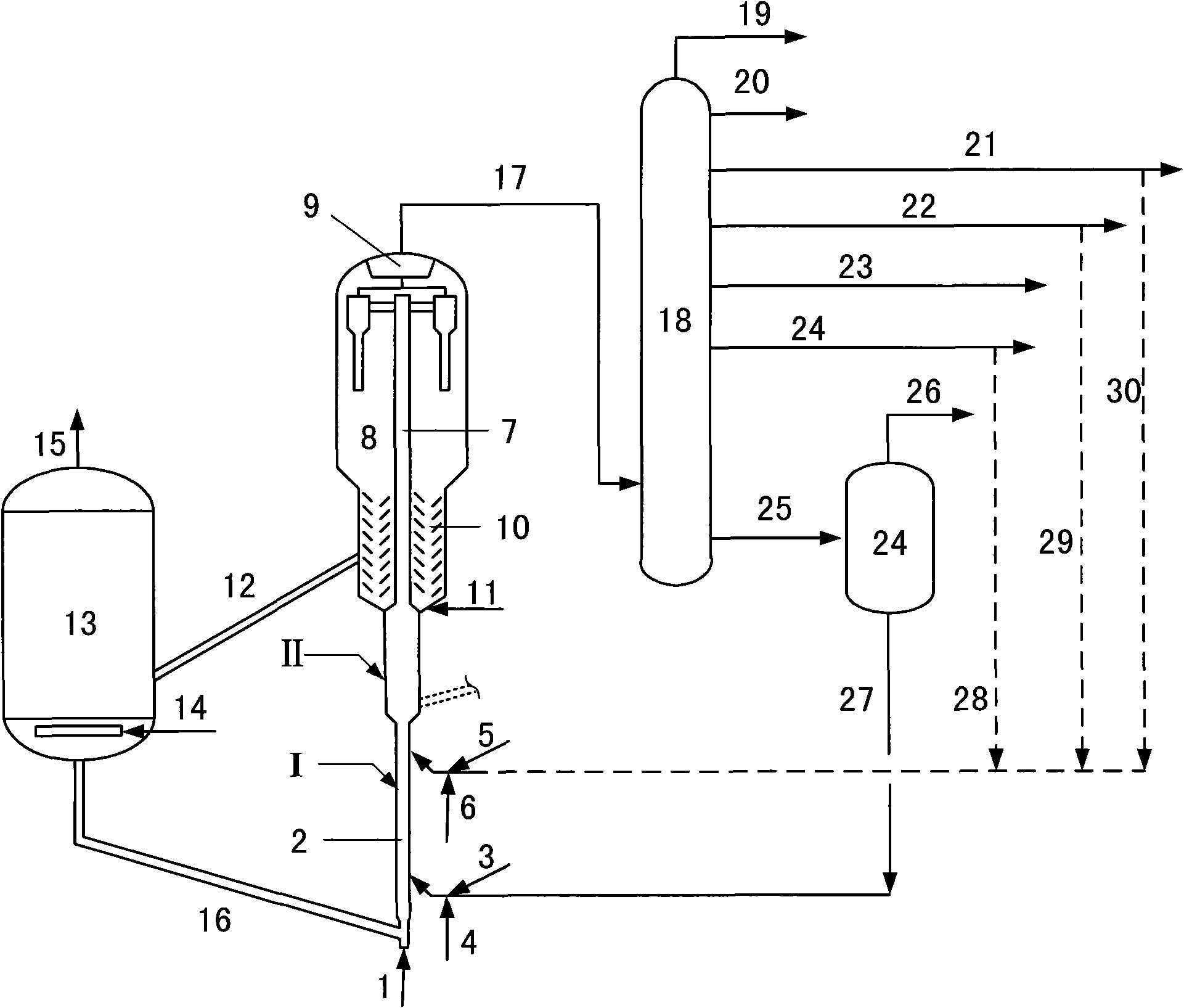

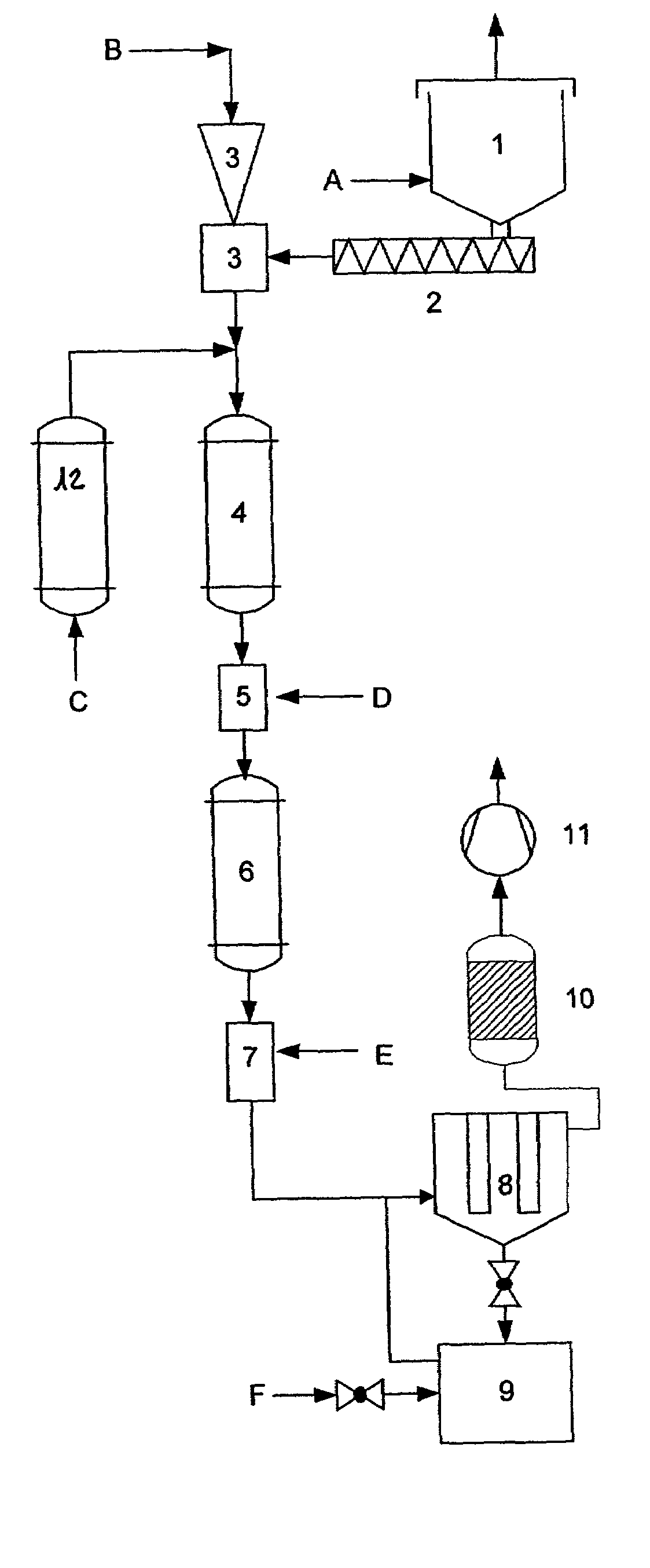

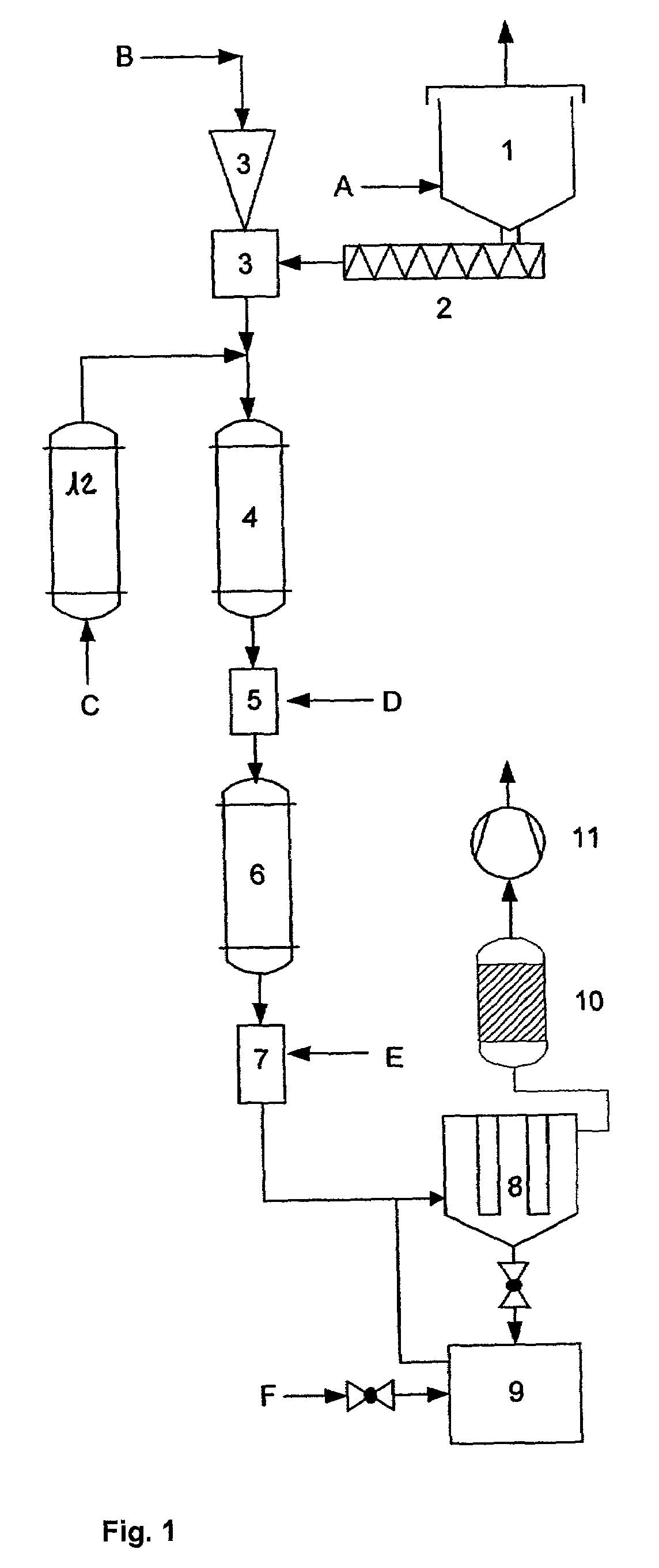

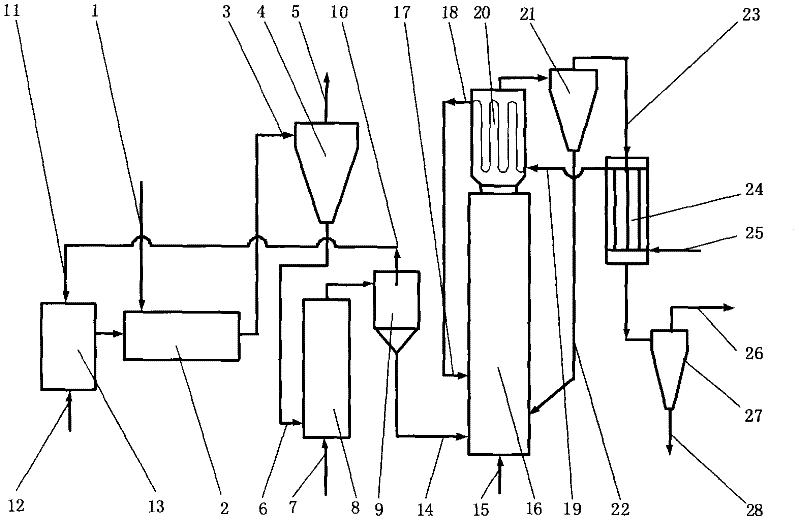

Process and system for preparing low-carbon olefin from methanol or dimethylether

InactiveCN1356299AReduce wearReduce aggregationHydrocarbon from oxygen organic compoundsChemical recyclingAlkaneGas solid

A process for preparing low-carbon olefin from methanol or dimethyl ether includes loading its raw material and silicon aluminium phosphate (SAPO34) molecular sieve as catalyst into gas-solid parallel down-flowing fluidized bed reactor, super-short contact, reaction, fast gas-solid separation to separating resultant from catalyst to prevent secondary reaction, and regerating catalyst for cyclic use. Its advantages include high output rate (93%), high conversion rate of raw material, and less by-product.

Owner:TSINGHUA UNIV

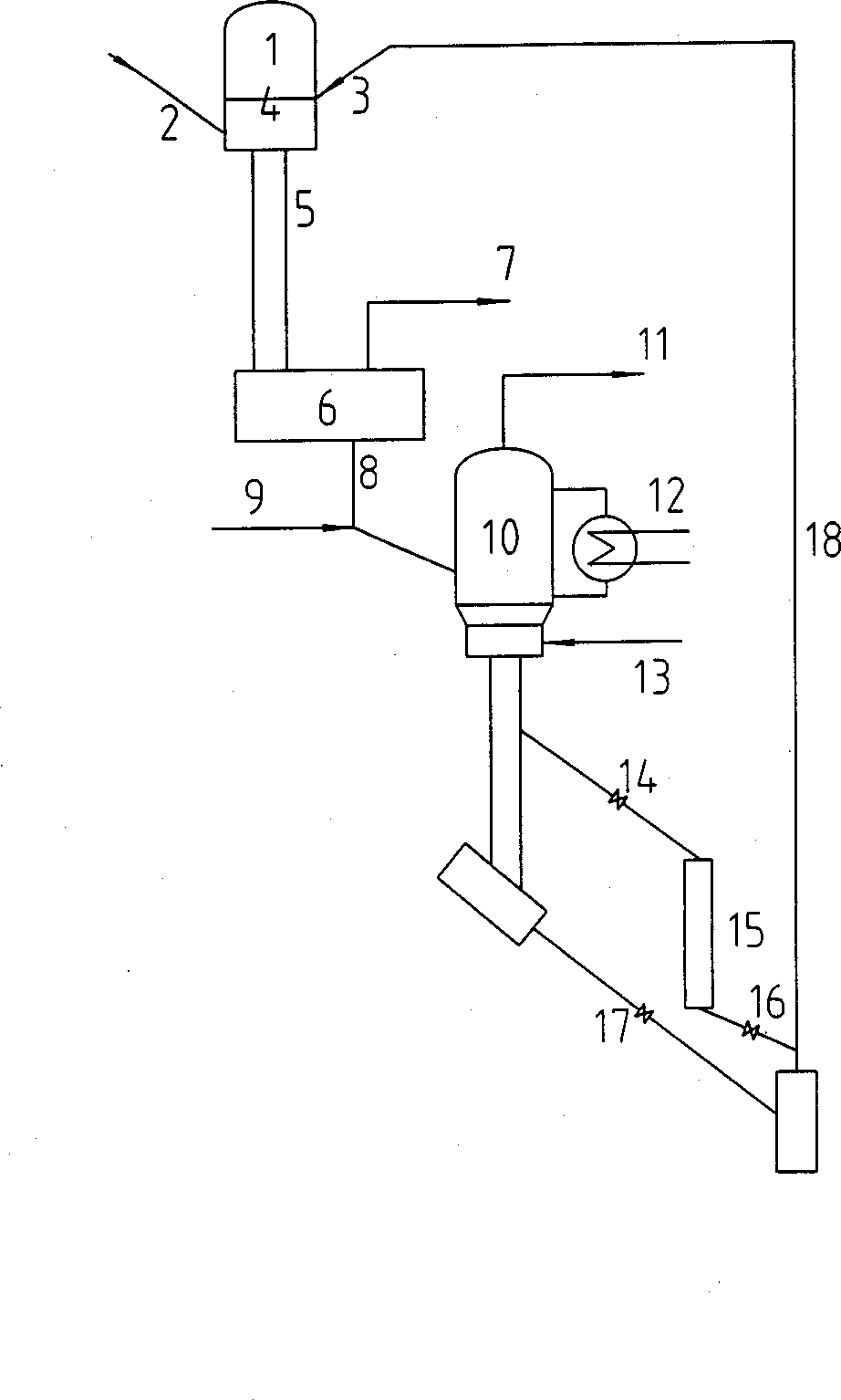

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

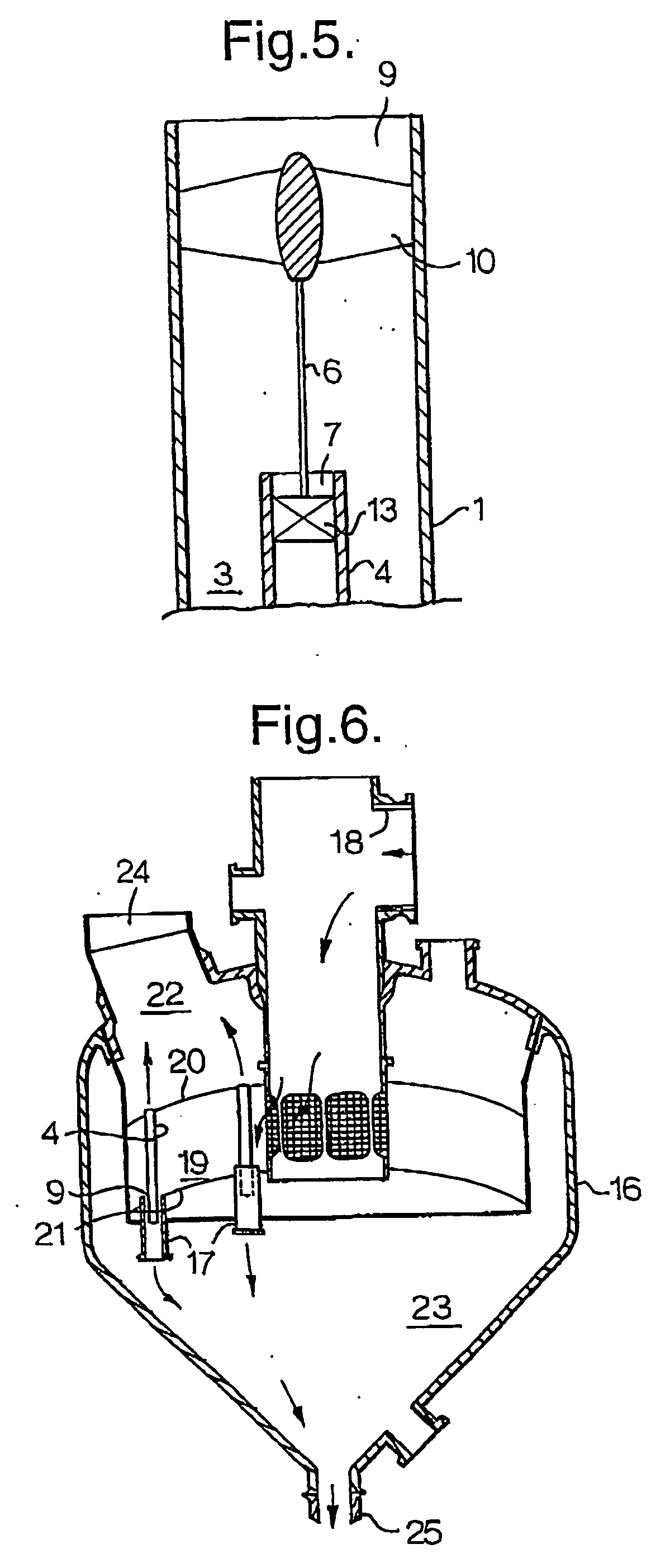

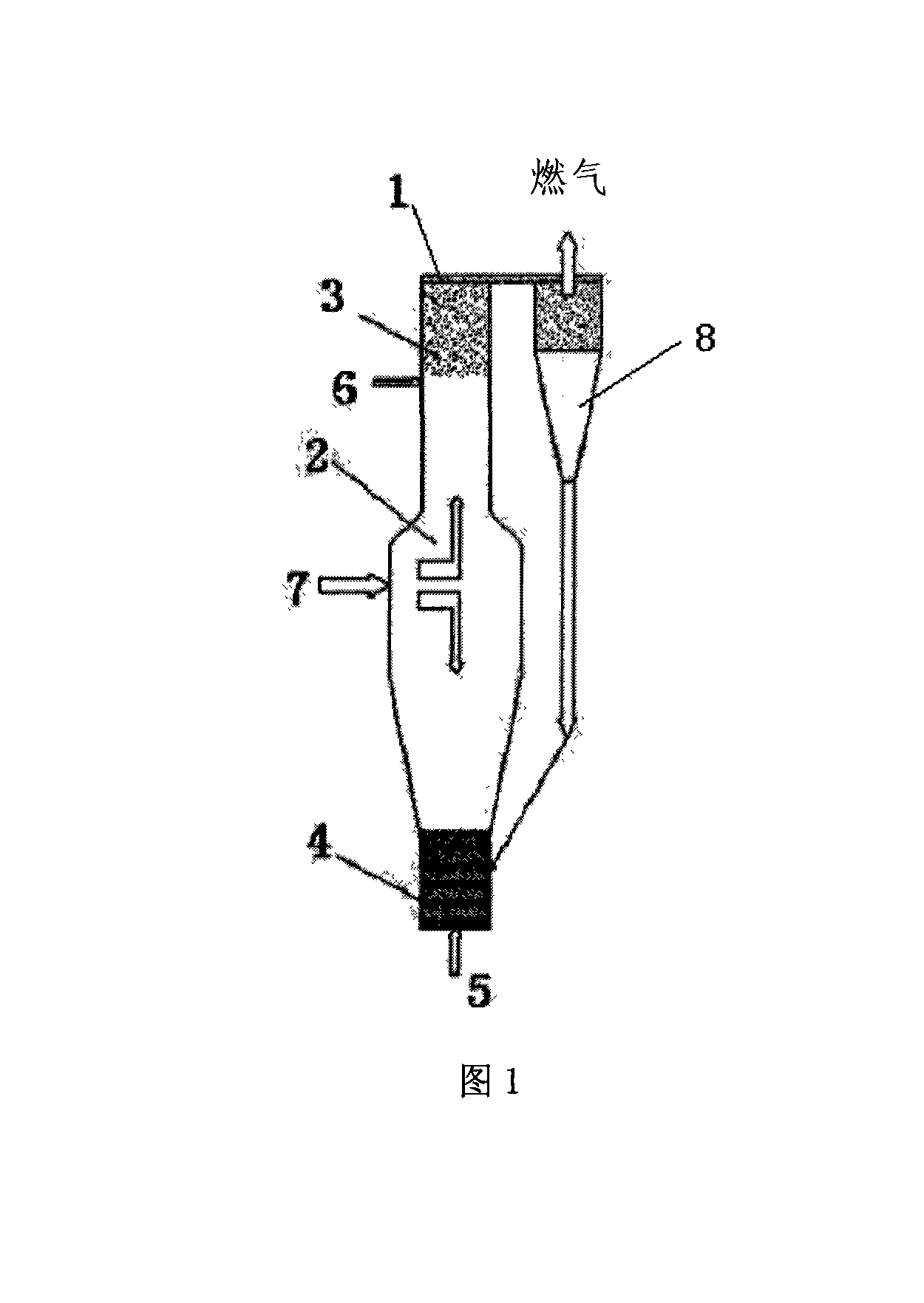

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

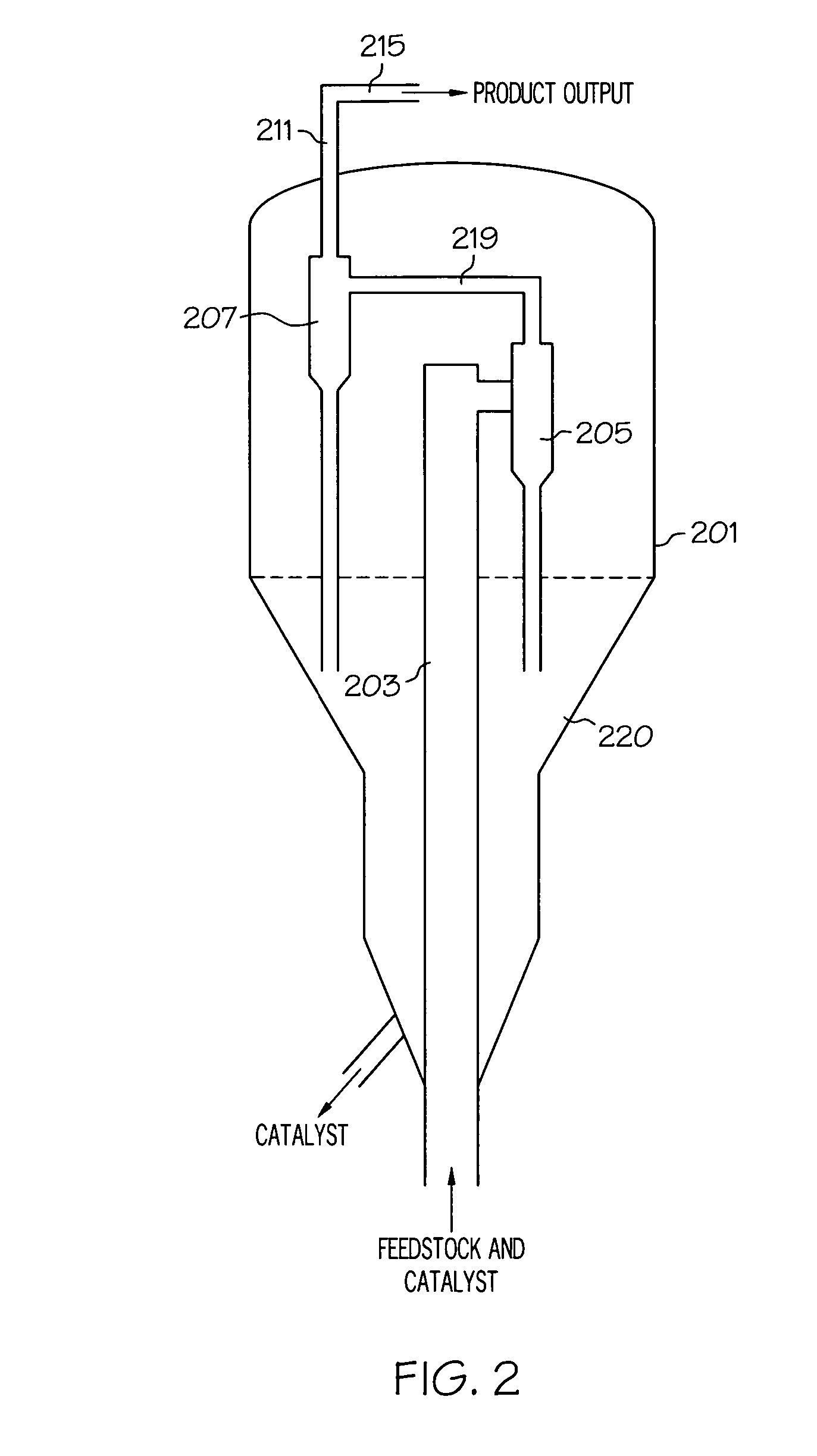

Process for removing solid particles from a gas-solids flow

Catalyst losses are prevented in riser reactor systems by using a low inlet velocity for the first cyclone separator in each multi-stage cyclone separator in the reactor. Catalyst particles not separated from the product output flow in an oxygenate-to-olefin reactor are also recaptured by cooling the product output flow and passing the flow through an electrostatic precipitator.

Owner:EXXONMOBIL CHEM PAT INC

Method for preparing light fuel oil and propylene from inferior raw material oil

ActiveCN101942340AImproved raw material propertiesExtended operating cycleTreatment with plural serial stages onlyTreatment with hydrotreatment processesGas solidWax

The invention discloses a method for preparing light fuel oil and propylene from inferior raw material oil. The inferior raw material oil enters a first reaction area and a second reaction area of a catalytic conversion reactor in turn to contact a catalytic conversion catalyst with coarse particle size distribution so as to perform primary reaction and secondary reaction respectively; after the reaction product and the spent catalyst undergo gas-solid separation, the spent catalyst is subjected to steam stripping and charring in turn and then returned to the reactor for recycling; and the reaction product is separated to obtain propylene, gasoline, catalytic wax oil and other products, wherein the catalytic wax oil enters at least one of hydrotreatment device, an arene extraction device and a hydrocracking device so as to obtain hydrogenated catalytic wax oil, raffinate oil and hydrocracking tail oil. The method improves the yield of the light oil, reduces the yield of oil slurry, realizes efficient utilization of petroleum resources, reduces the consumption of the catalyst, and reduces the catalyst content of the catalytic wax oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

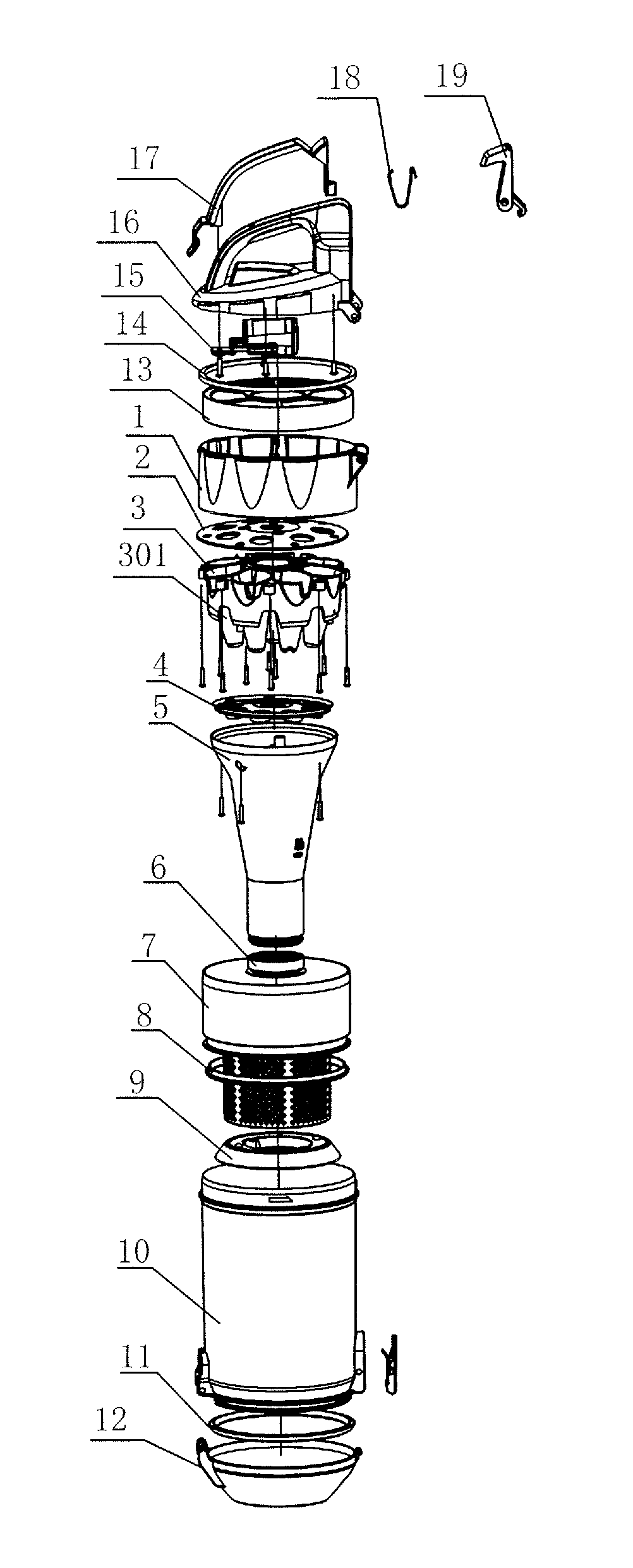

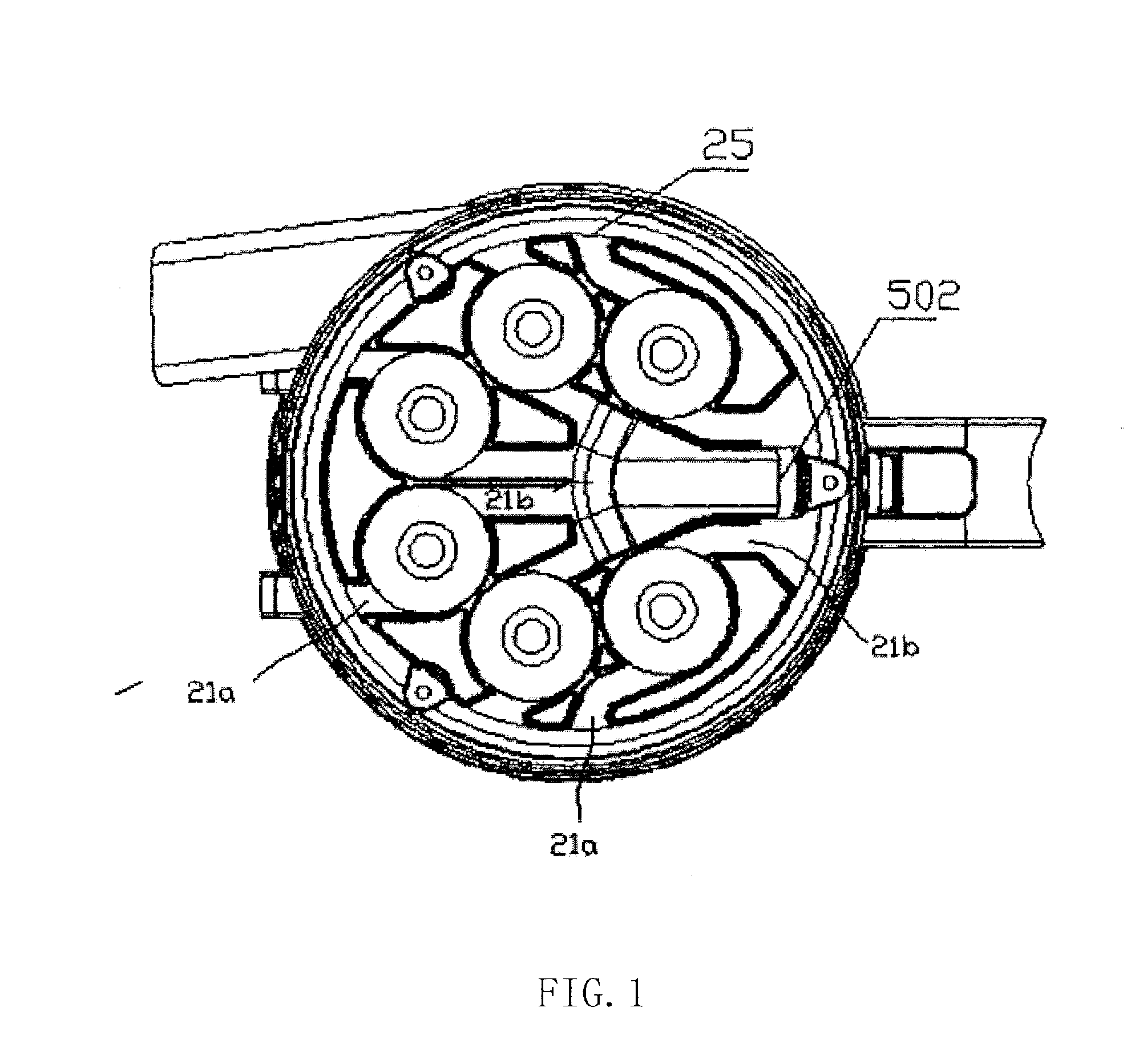

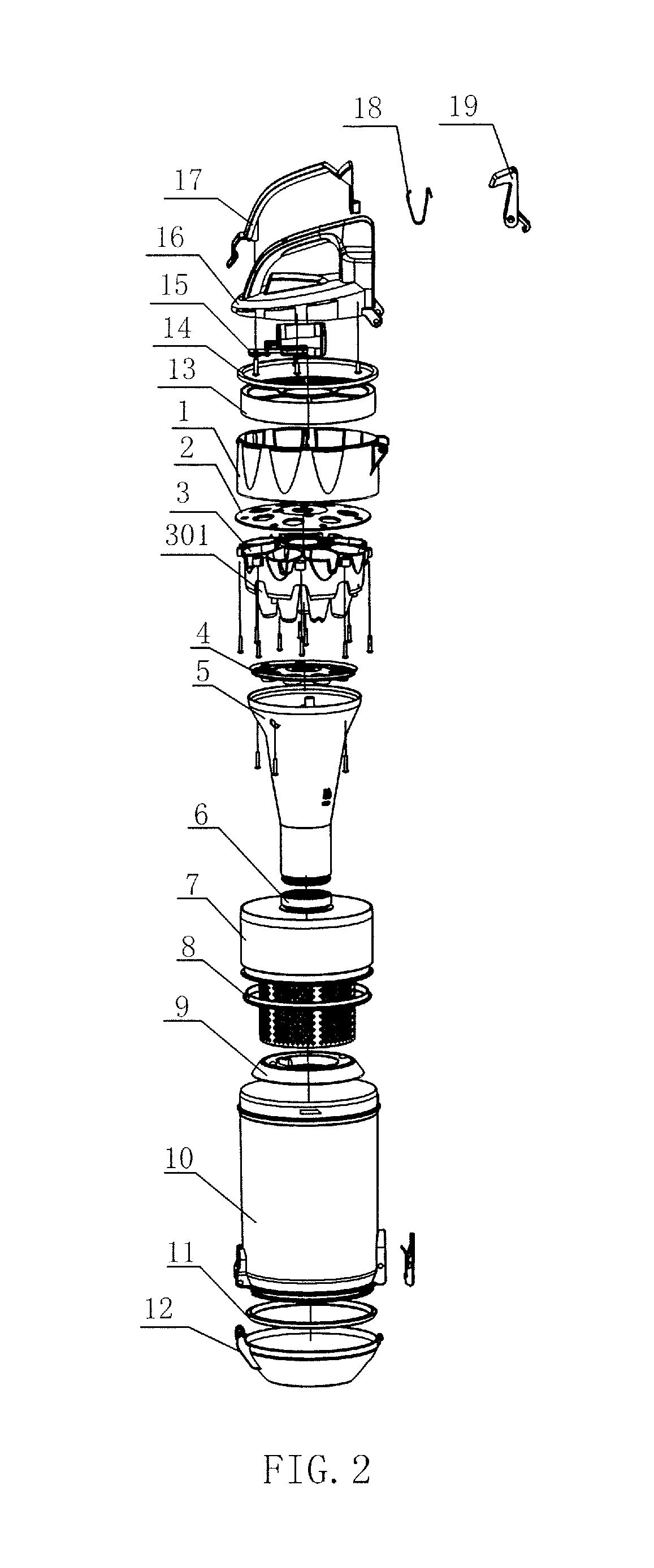

Cyclone separation device and cyclone vacuum cleaner mounted with same

ActiveUS20130291334A1Simple structureImprove vacuum efficiencyCleaning filter meansCombination devicesCycloneGas solid

A cyclone separation device (102, 202) and a cyclone vacuum cleaner (100, 200) mounted with the device. A first cyclone separation unit in the cyclone separation device (102, 202) comprises a dust bucket (10) and a mesh filter (7) with air holes (7a). Airflow enters the first cyclone separation unit to undergo first gas-solid separation. The airflow after the separation enters a second cyclone separation unit through the air holes (7a) of the mesh filter (7). A filter in the second cyclone separation unit comprises a plurality of cyclone barrels (31). An upper end and a lower end of the cyclone barrel (31) are open. A first air inlet (31a) and a second air inlet (31b) are disposed on a side wall of the cyclone barrel (31). The airflow (41a, 41b) after the gas-solid separation enters the first air inlet (31a) and the second air inlet (31b) through a first airflow passage and a second airflow passage respectively, is mixed in the cyclone barrel (31), and then undergoes second gas-solid separation. The airflow after the gas-solid separation is discharged from an opening at the upper end of the cyclone barrel (31). In the cyclone separation device (102, 202), the direction of travel of the airflow and the cross-sectional area of the air inlet are changed, thereby improving a separation effect. The cyclone vacuum cleaner (100, 200) mounted with the cyclone separation device (102, 202) increases separation efficiency and improves an air purification effect.

Owner:ECOVACS ROBOTICS (SUZHOU ) CO LTD

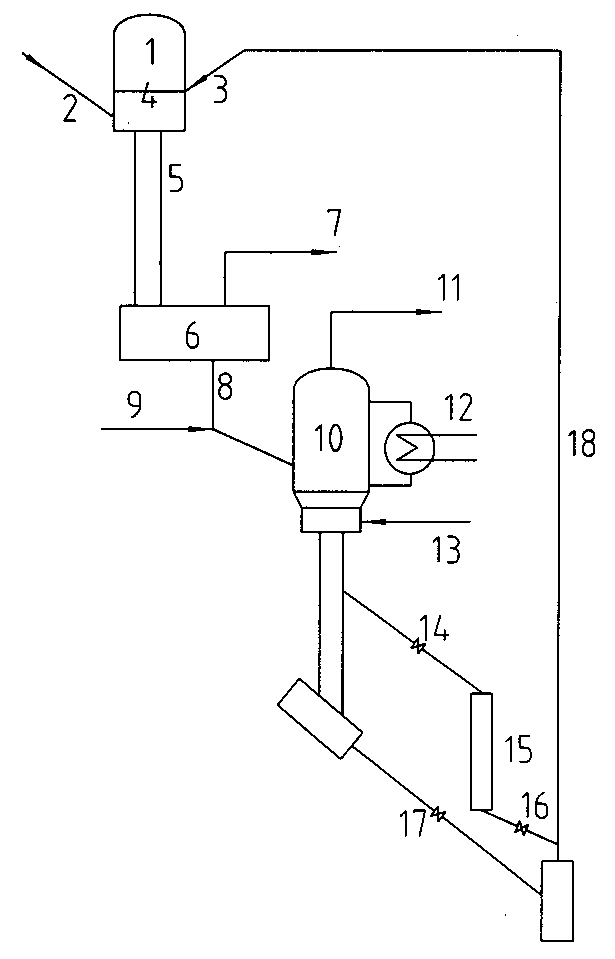

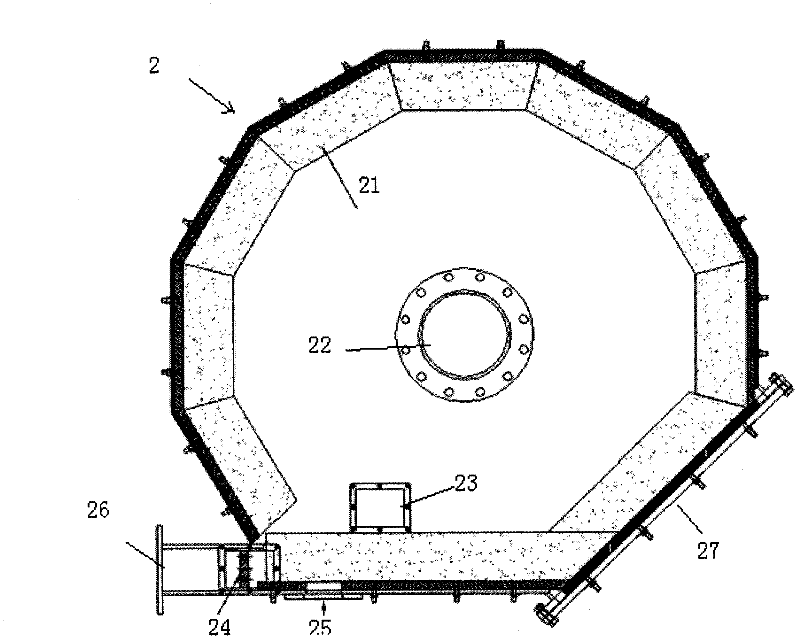

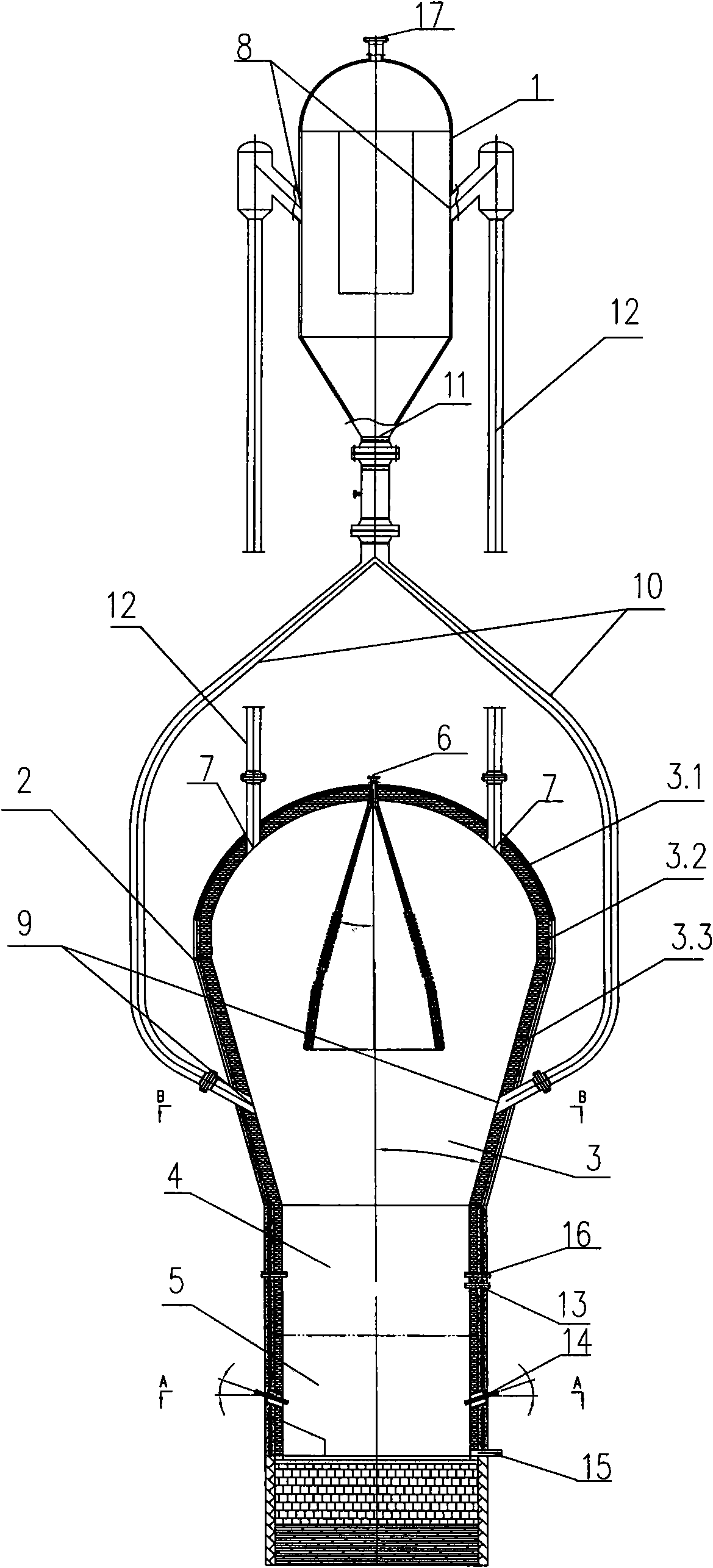

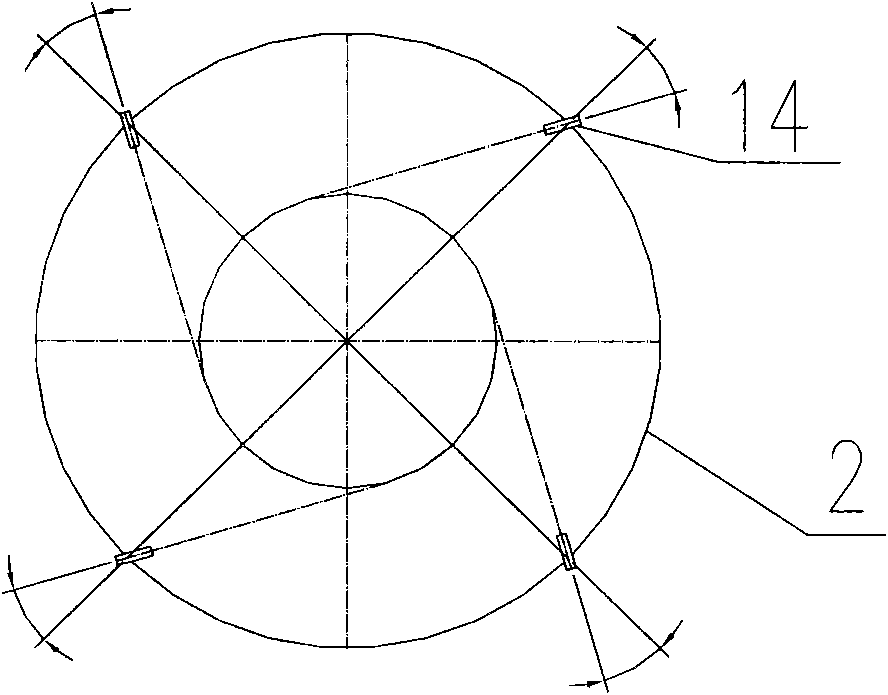

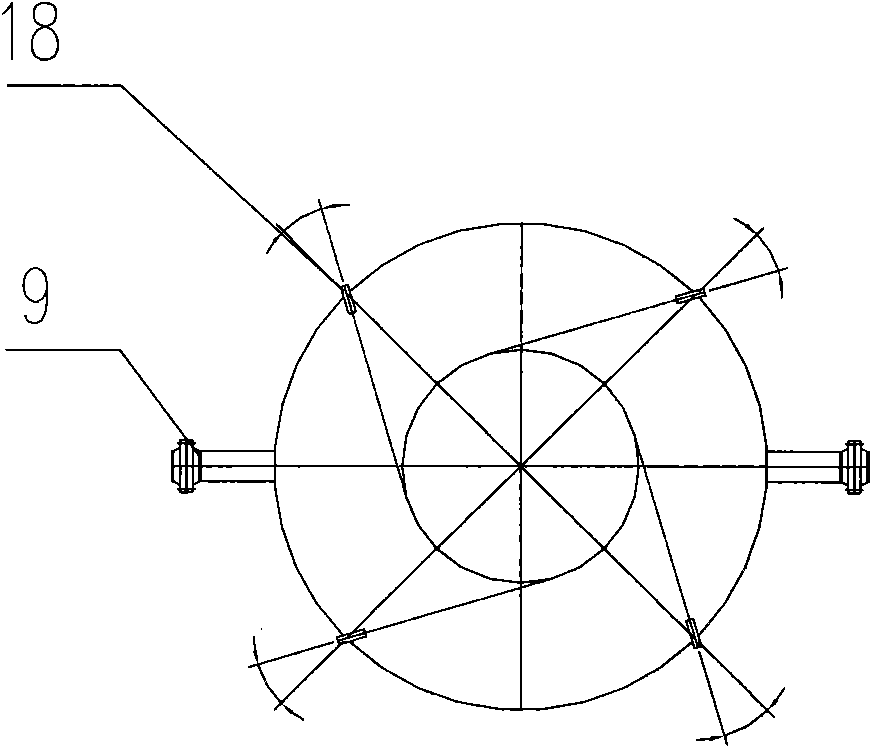

Combustible material plasma high-temperature gasification technique and equipment thereof

ActiveCN101671578AImprove gasification efficiencyImprove carbon conversionCombined combustion mitigationFixed-bed gasificationSyngasSlag

The invention relates to a combustible material plasma high-temperature gasification technique and equipment thereof. The technique comprises the following steps: firstly, laying a coke bed layer at the bottom part of a gasification furnace; secondly, putting the combustible material, a fluxing agent and an extra coke on the coke bed layer continuously to form a fuel bed layer; then injecting a primary oxidizing agent, starting a first-stage plasma torch to generate high temperature and high heat, forming a fusing zone at the joint of the coke bed layer and the fuel bed layer, forming a gasifying zone above the fusion zone, gasifying the combustible material to generate crude synthesis gas, and discharging the generated fused slag from the bottom part of the gasification furnace; then introducing the crude synthesis gas into a gas-solid separator for removing impurities to obtain purified synthesis gas; and finally introducing the purified synthesis gas into a detarrer, injecting a secondary oxidizing agent, starting a second-stage plasma torch to generate high temperature and high heat, cracking residual tar therein to obtain fined synthesis gas. The equipment mainly comprises three parts, namely the gasification furnace, the gas-solid separator and the detarrer. The fuel has good adaptability, high gasification efficiency, few tar content in the synthesis gas and high activeingredient.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

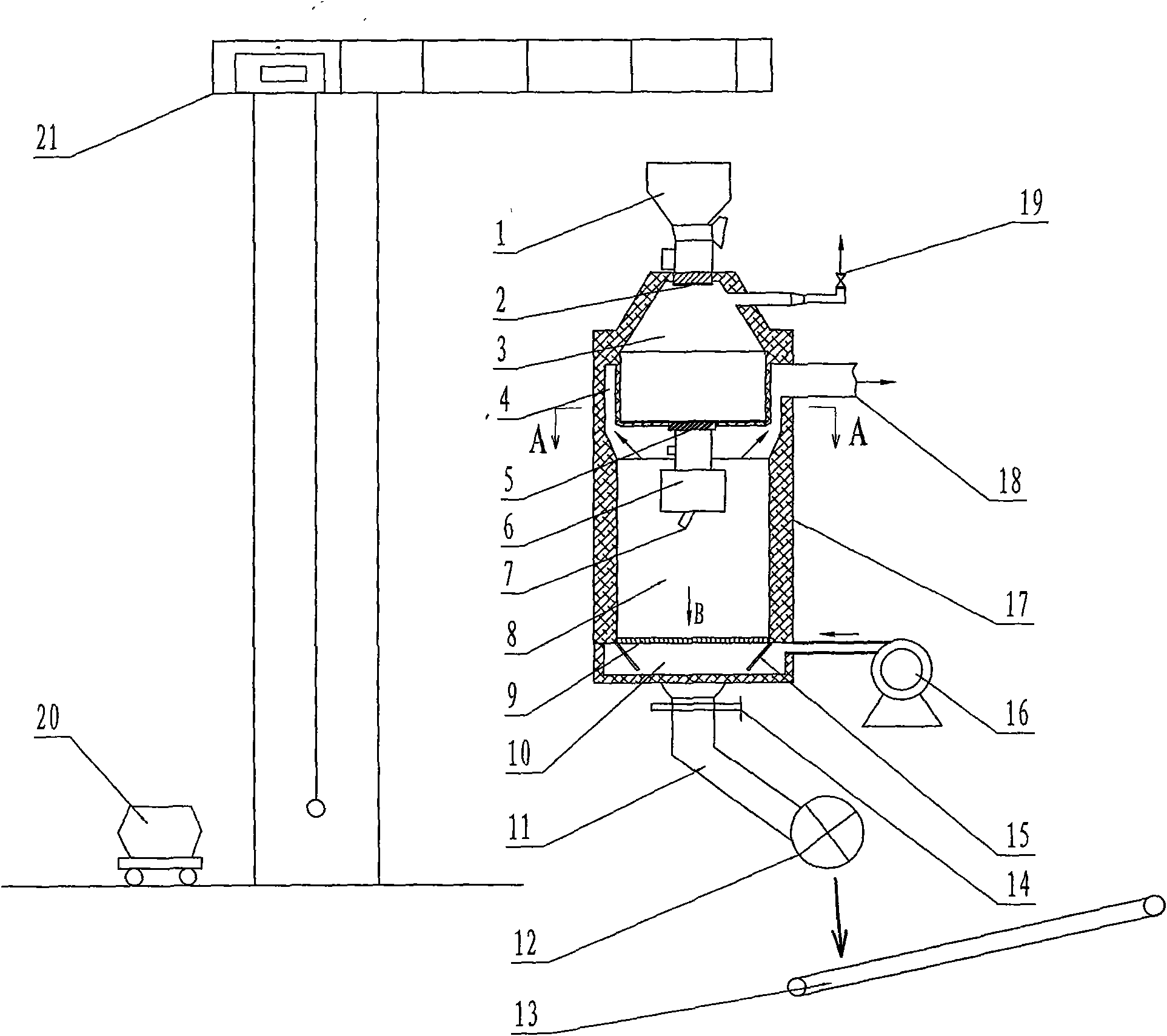

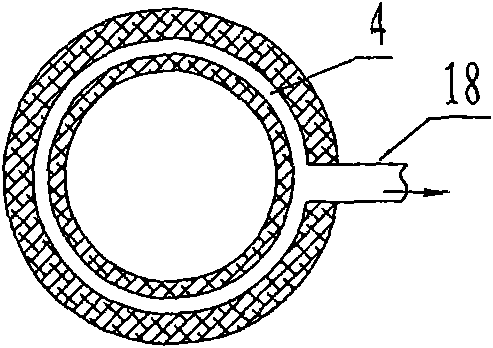

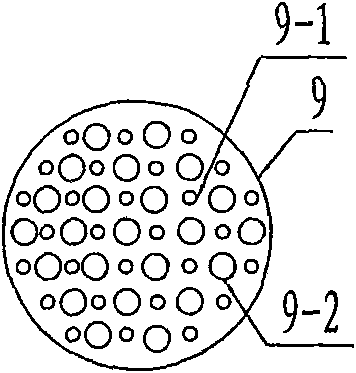

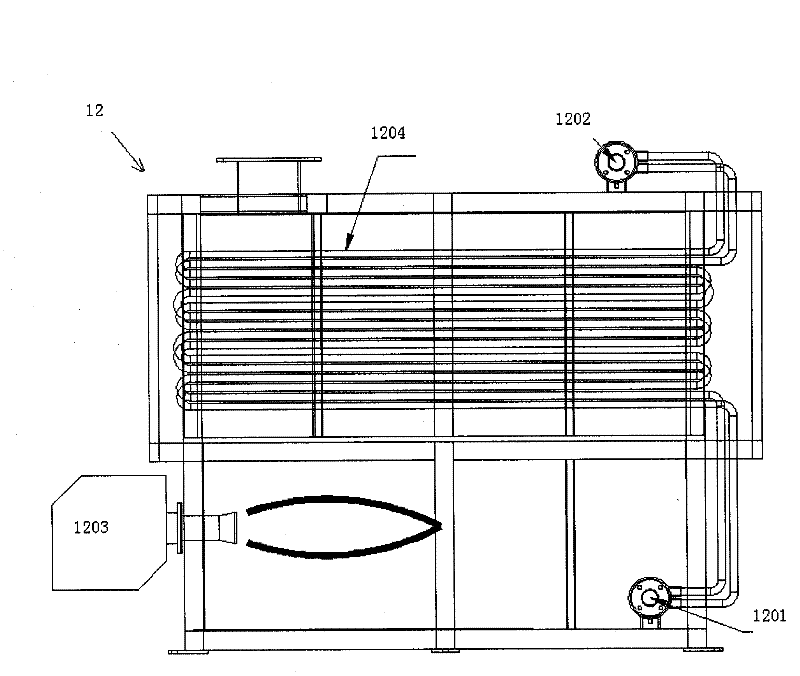

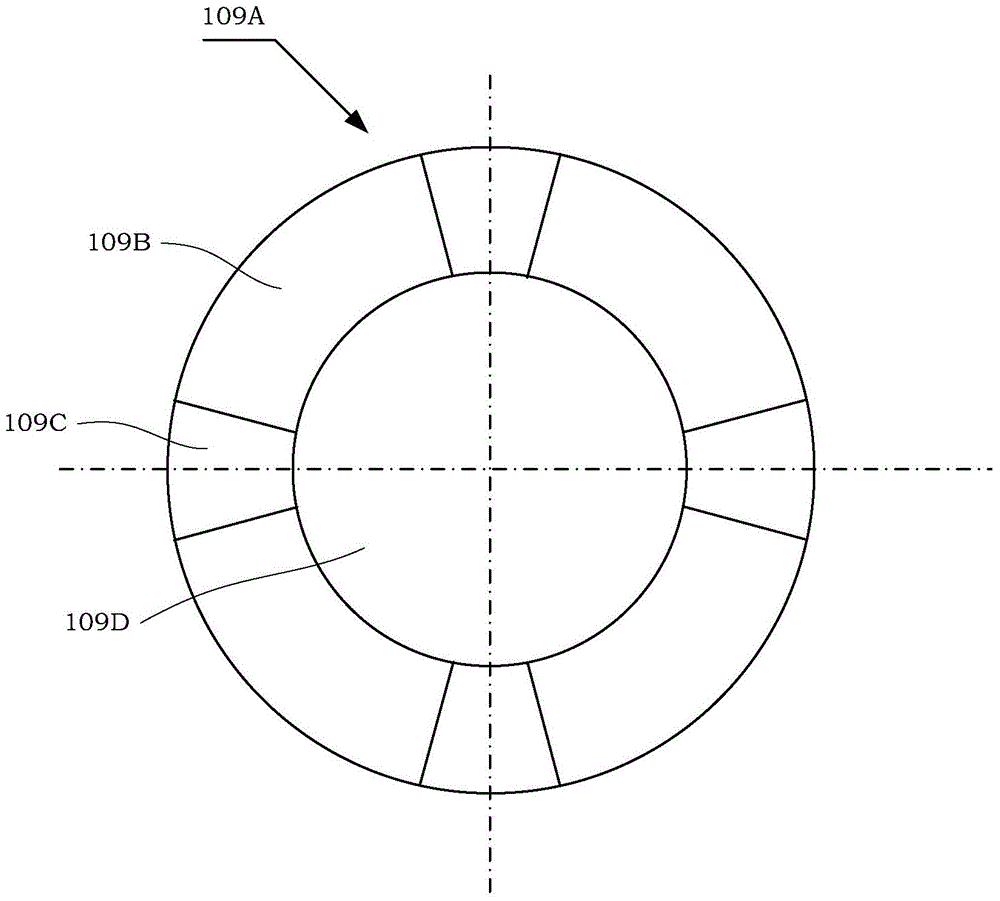

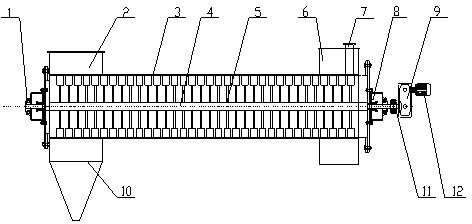

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

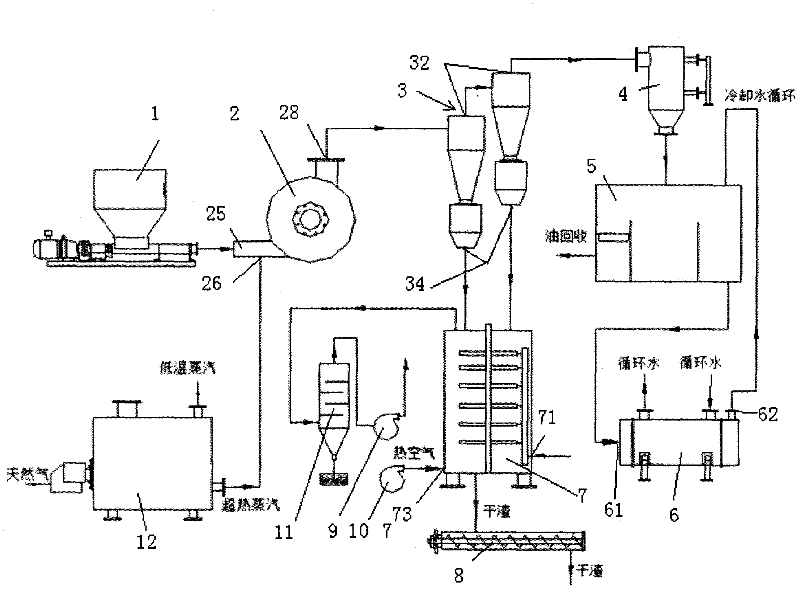

Treatment method and treatment apparatus of oily sludge

InactiveCN102503055AHigh recovery rateReduce moisture contentSludge treatment by thermal conditioningSludgeLiquid state

The invention provides a treatment method of oily sludge, which comprises the steps of: introducing overheated vapor into a high temperature treatment groove to roast the oily sludge so as to evaporate the liquid containing oil and water in the oily sludge to gas; separating the solid granules from the oily sludge and contained in the gas in a gas-solid separator, and conveying the solid granules to a drying machine to be dried and burnt so as to be discharged; condensing the gas separated from the gas-solid separator to liquid state oil and water, separating the liquid state oil and water in an oil-water separator to be respectively recycled, wherein the oily sludge is introduced into the high temperature treatment groove in a pumping manner, the overheated vapor is introduced into the high temperature treatment groove by supersonic jet flow and is vertically collided with the oily sludge. The invention further provides a treatment apparatus of oily sludge for executing the method; the treatment method and treatment apparatus provided by the invention have the advantages of guaranteeing high crude oil recovery, and small water content and oil content of finally generated dry residues.

Owner:河北海清大地环保科技有限公司

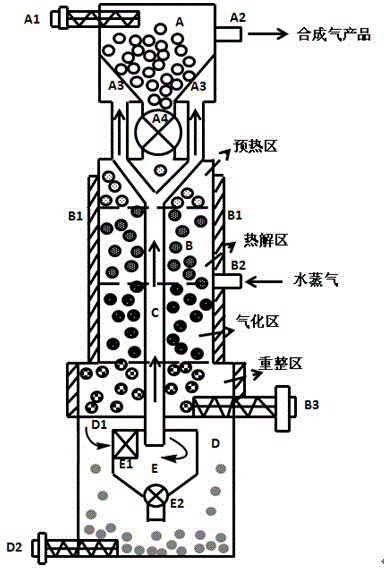

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

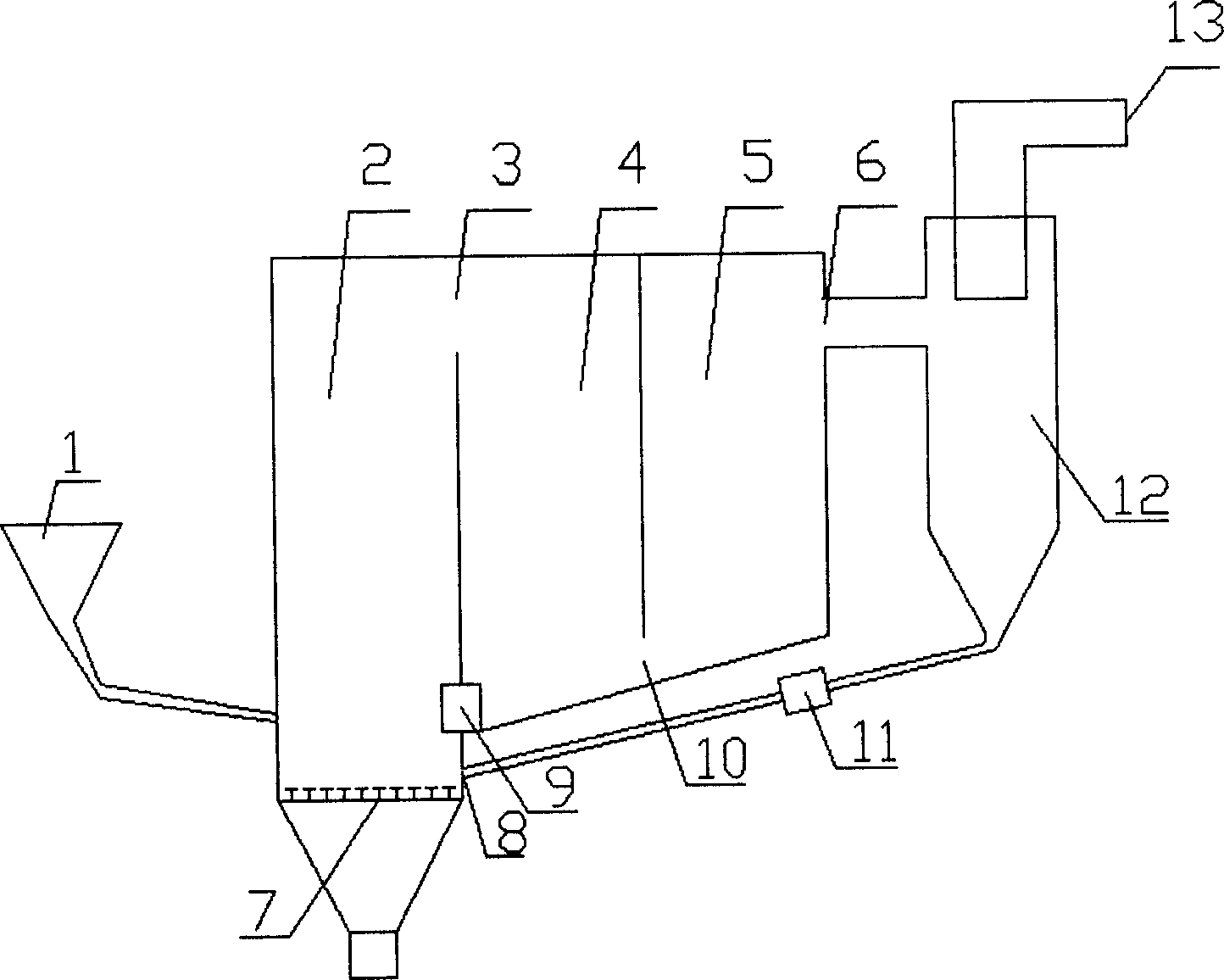

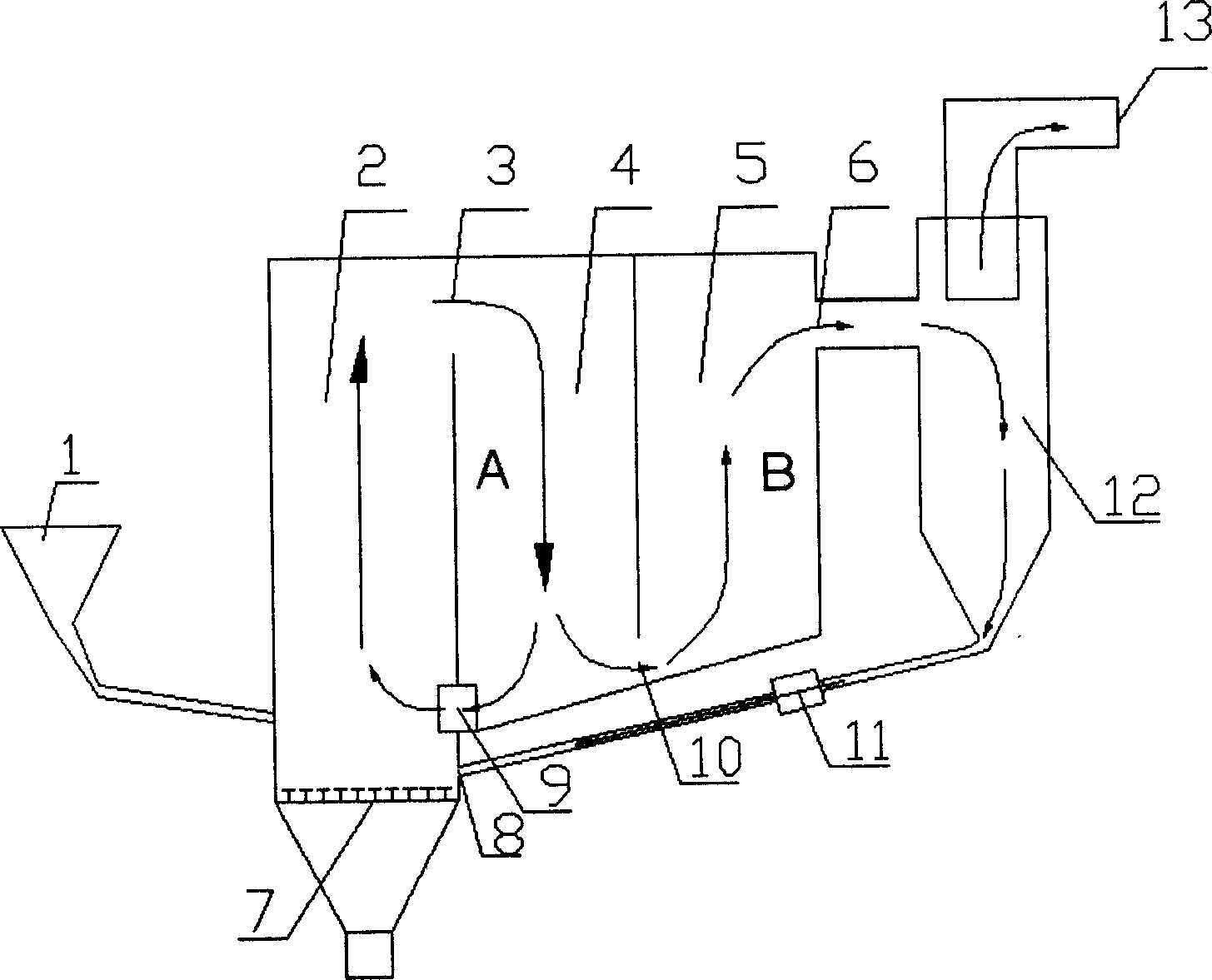

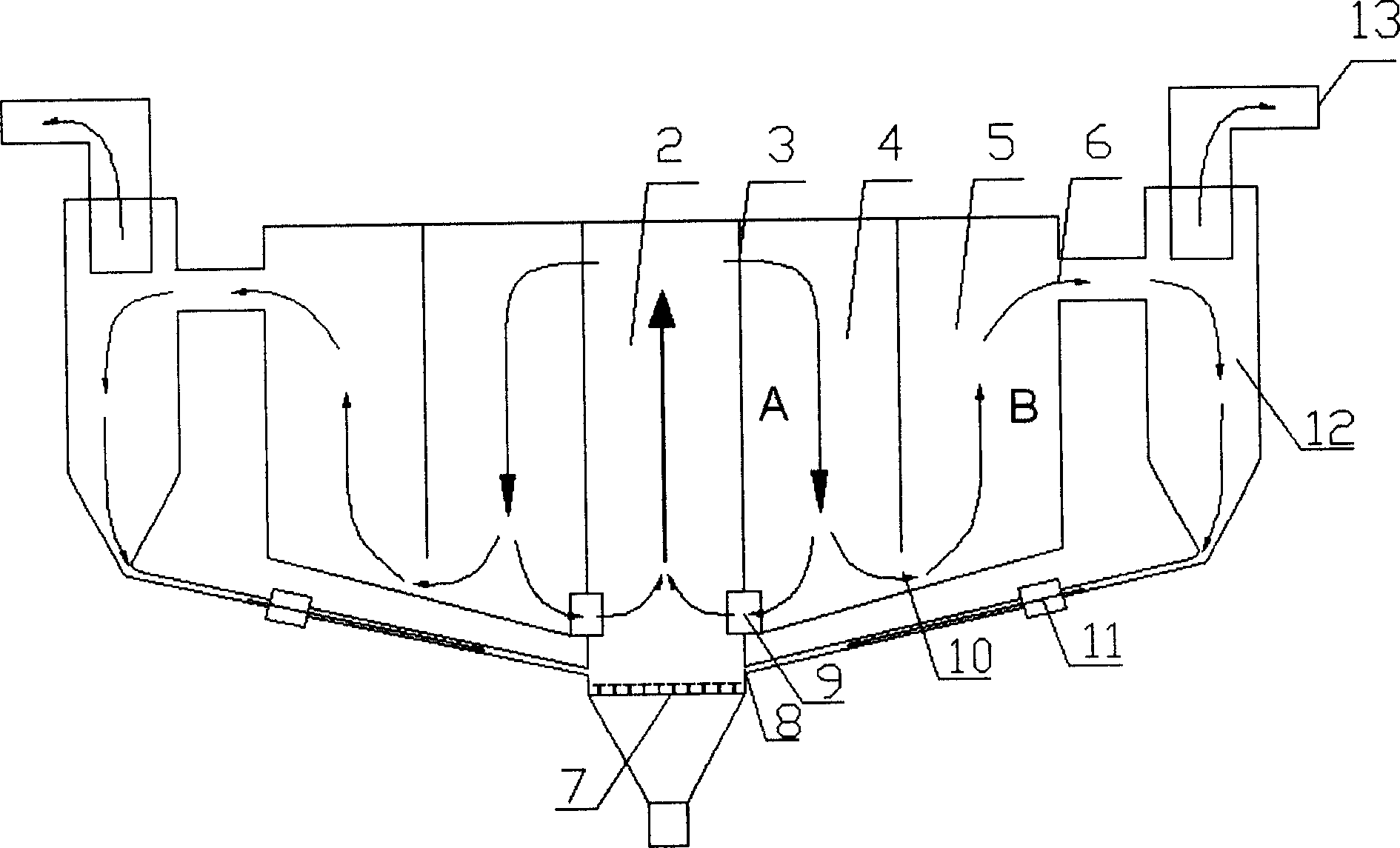

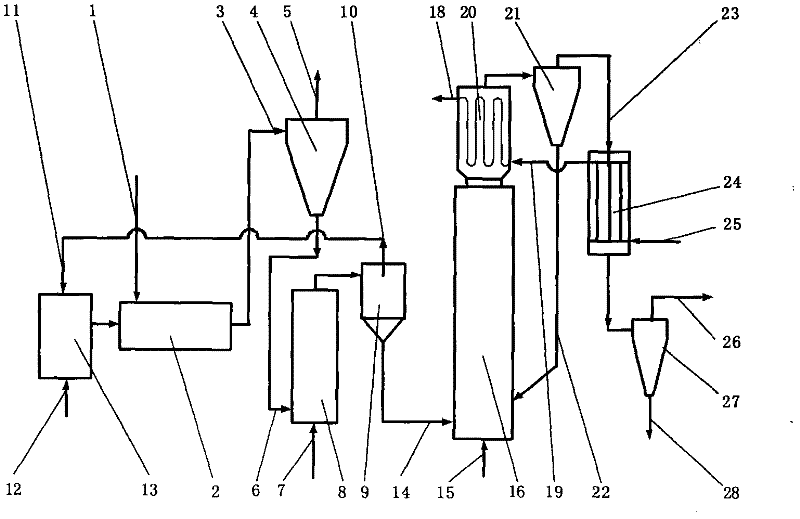

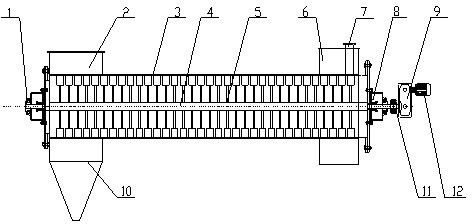

Horizontal circulating fluidized bed burning equipment and its circulating burning method

ActiveCN1786565ALow costReduce construction costsFluidized bed combustionIncinerator apparatusGas solidSingle stage

The invention relates to horizontal type circulating fluid bed combustion equipment and its circulating combustion method. It belongs to inferior fuel combustion equipment and combustion method. It is made up of main combustion chamber, multistage subsidiary combustion chamber, and gas solid separator. It can change the national single stage vertical type circulating structure of the circulating fluid bed, effectively reduce boiler height, and reduce the cost. In the combustion equipment, the material is formed two stages or more material circulating. So the combustion efficiency is high. The combustion equipment has the all advantages of the circulating fluid bed. And it can use inferior fuel such as inferior coal, solid waste, and so on. So its fuel adaptability is wide. It is the high efficiency combustion equipment with cleaning combustion, compact structure, and long using life.

Owner:TSINGHUA UNIV

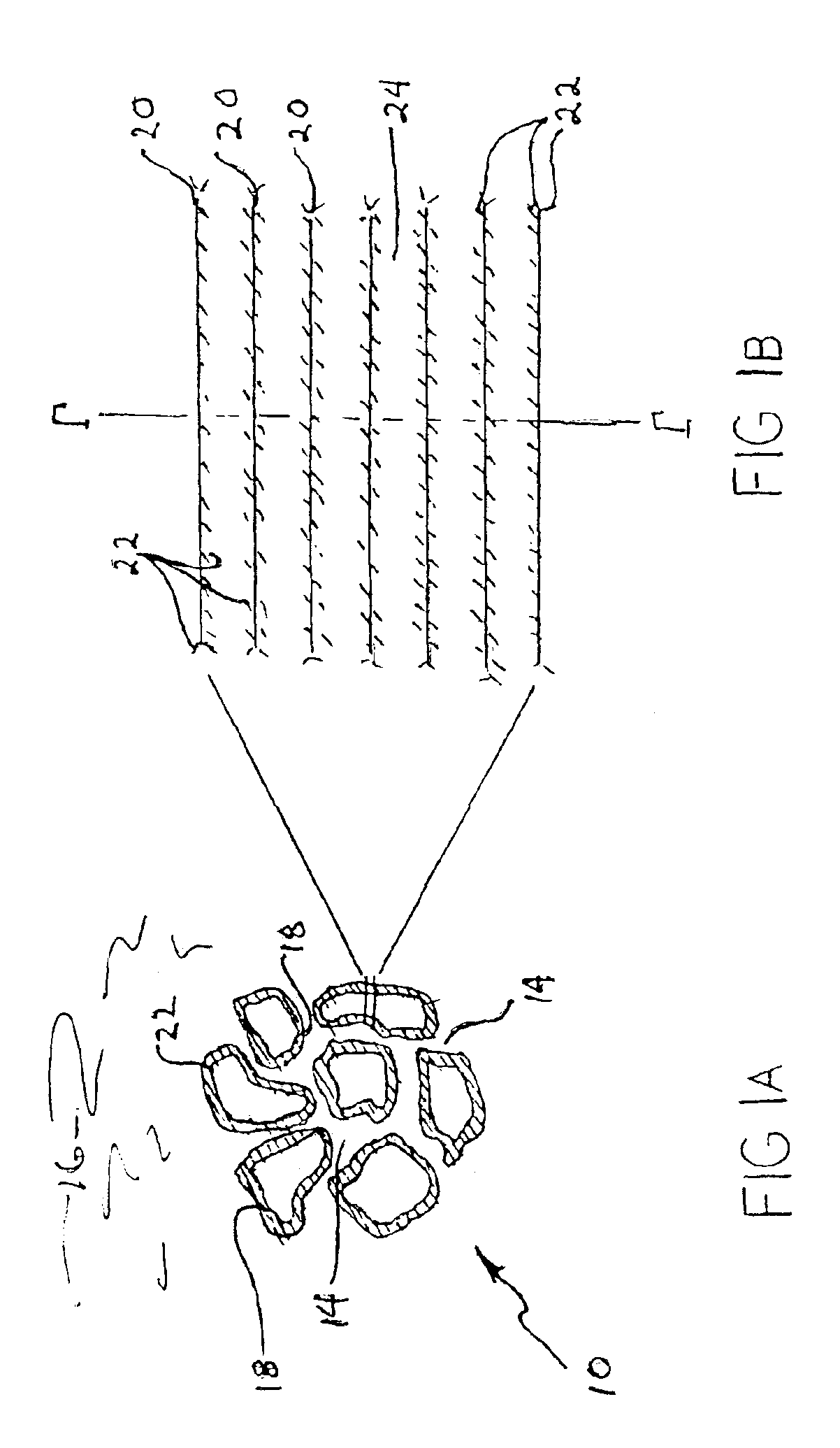

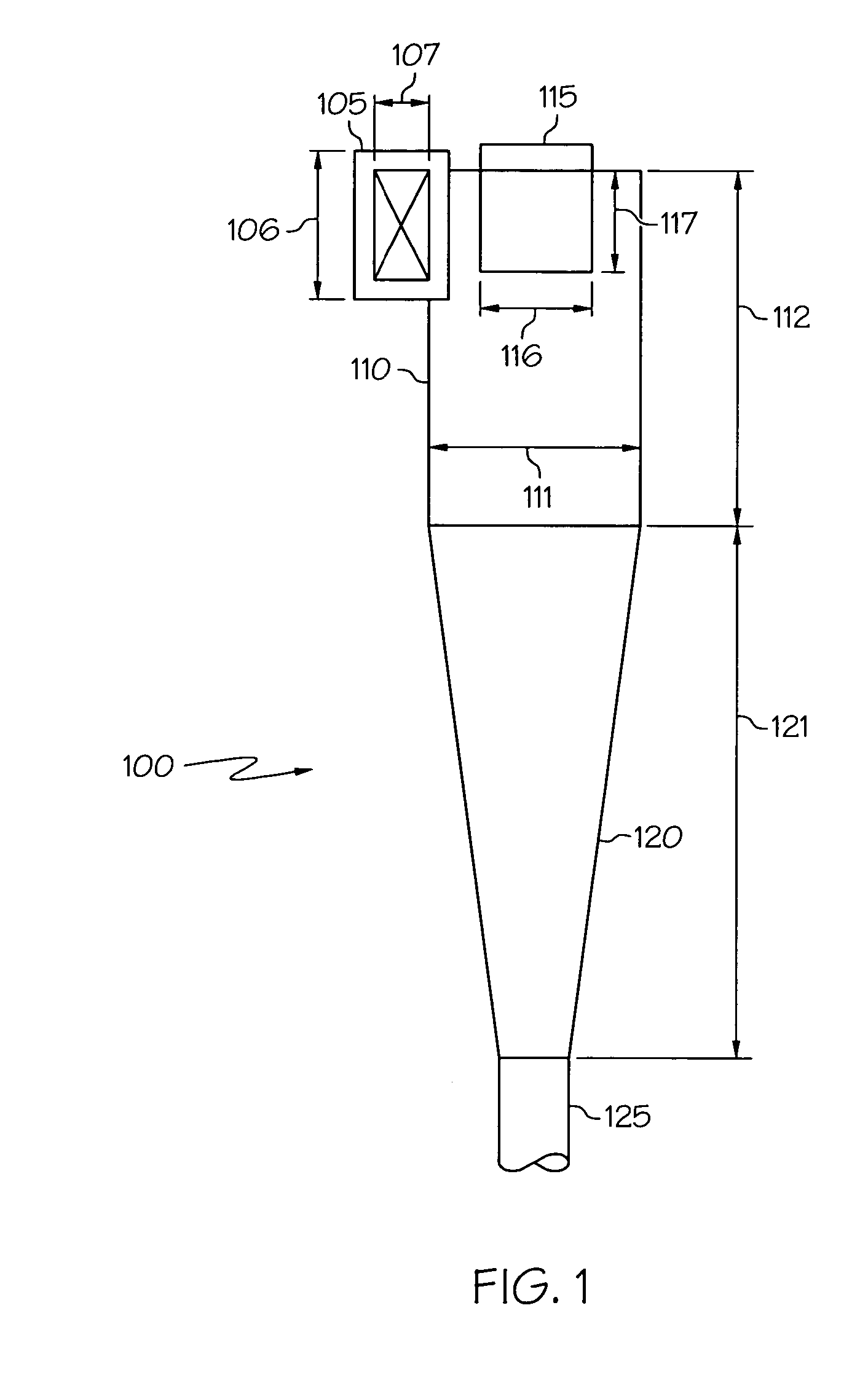

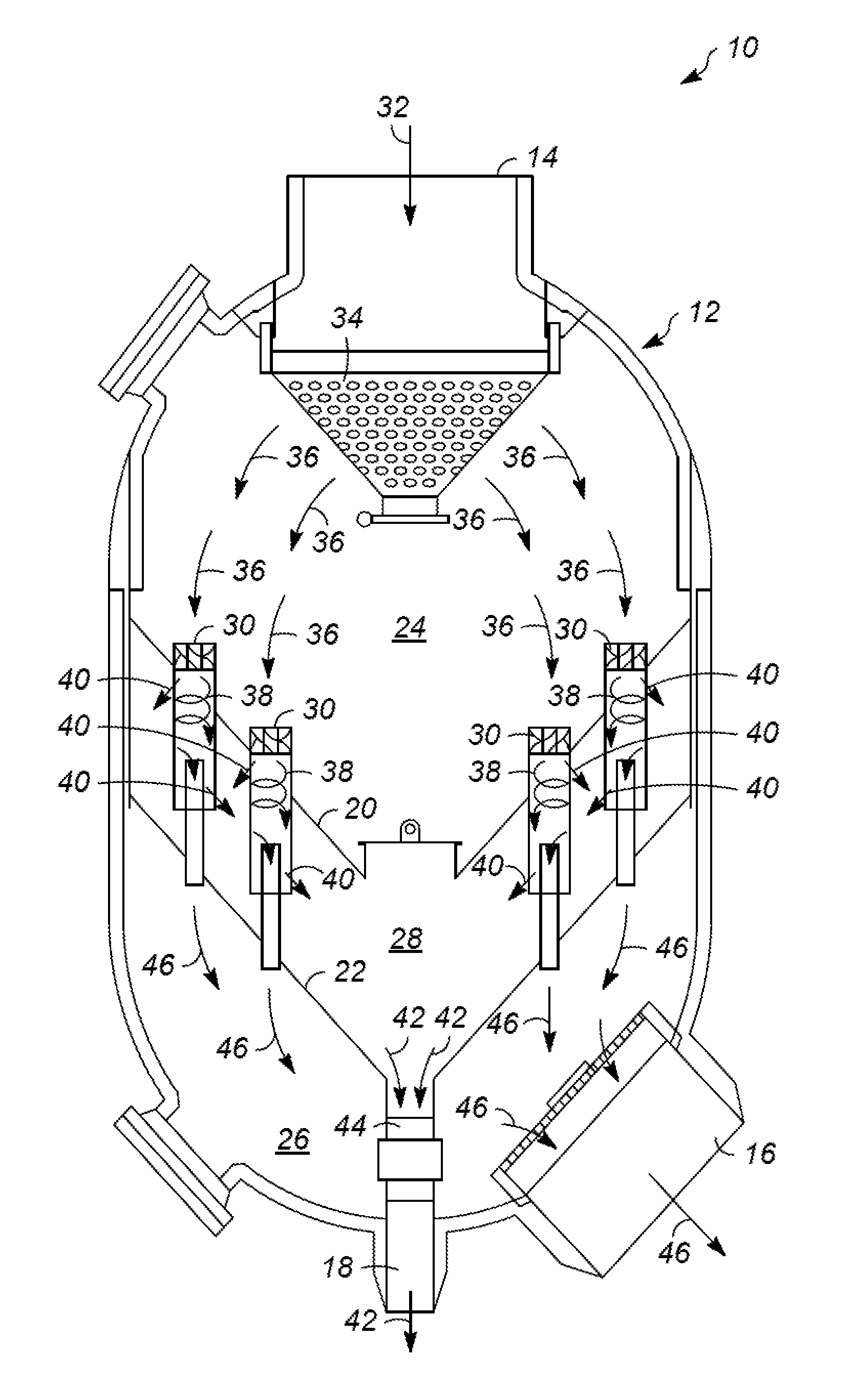

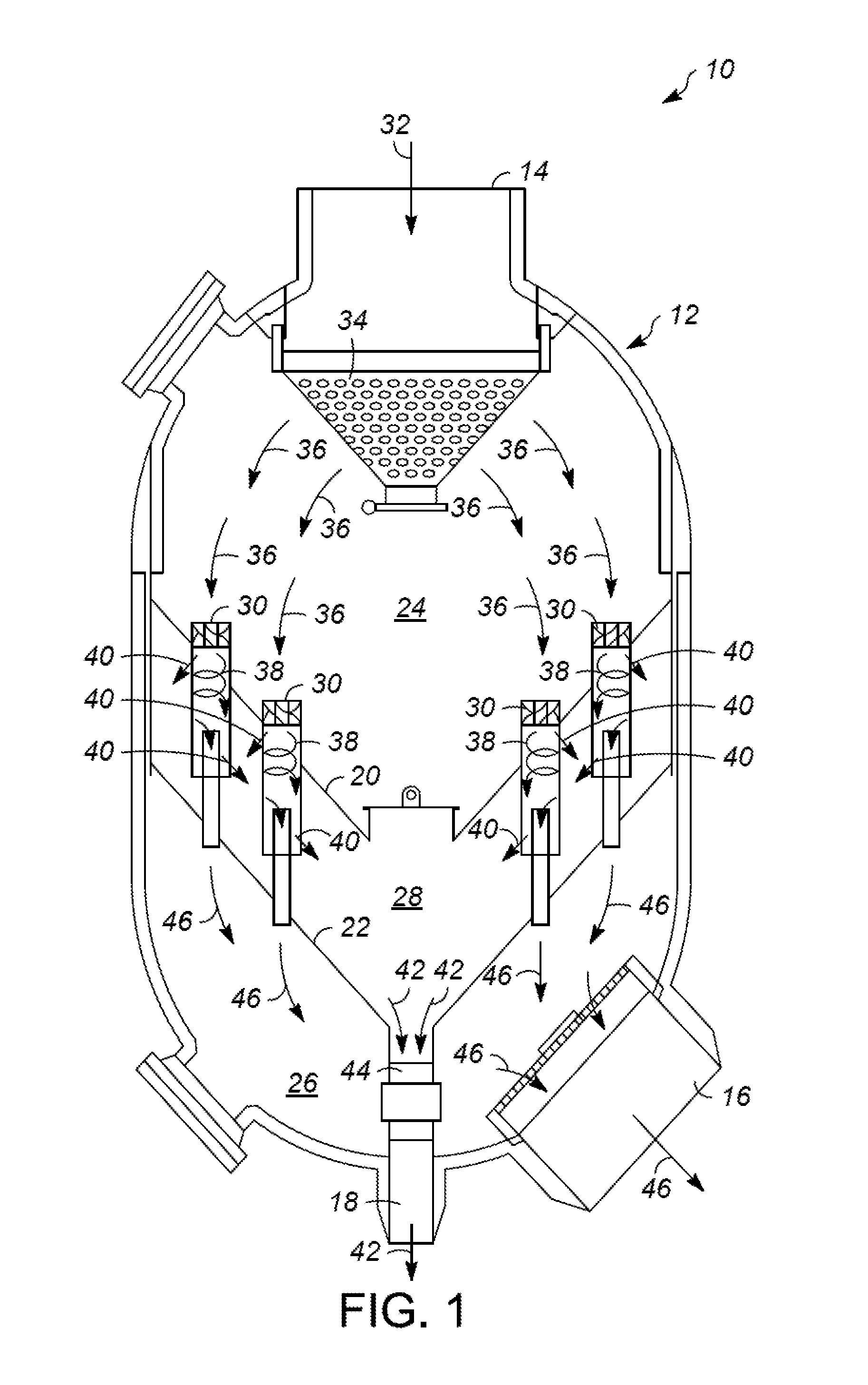

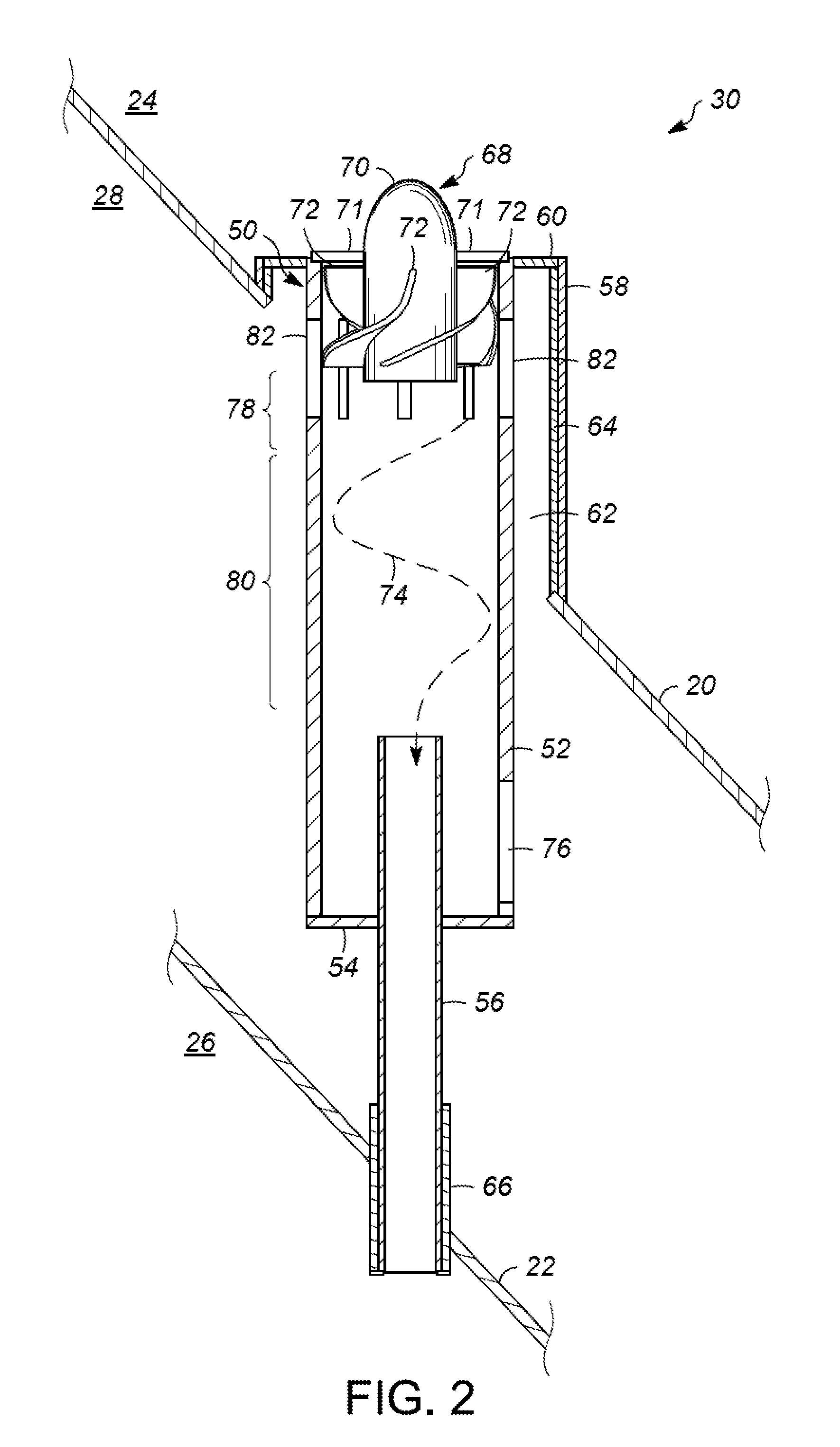

Gas-solids separation units and methods for the manufacture thereof

Embodiments of a gas-solids separation unit and embodiments of a method for manufacturing a separation unit are provided. In one embodiment, the separation unit includes a cyclonic separator and a vessel having a flue gas chamber, a clean gas chamber, and an entrained solids chamber between the flue gas chamber and the clean gas chamber. The cyclonic separator includes, in turn, a cyclone barrel extending from the flue gas chamber toward the clean gas chamber, a swirl vane positioned across the cyclone barrel, a gas outlet tube fluidly coupling the cyclone barrel to the clean gas chamber, and a first check valve opening formed through the barrel sidewall upstream of the gas outlet tube.The check valve opening fluidly couples the cyclone barrel to the entrained solids chamber to permit the centrifugal separation of the particulate matter from the gas stream during operation of the gas-solids separation unit.

Owner:UOP LLC

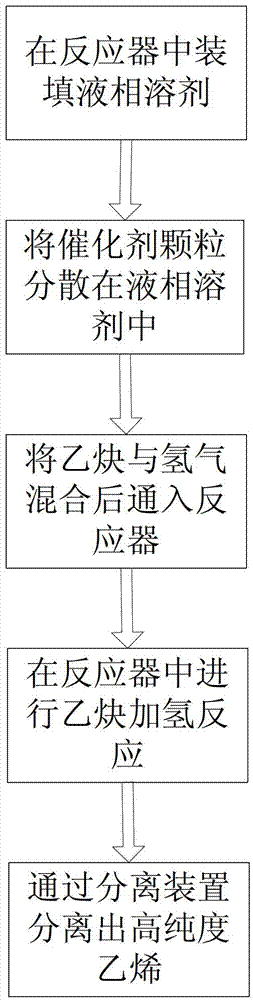

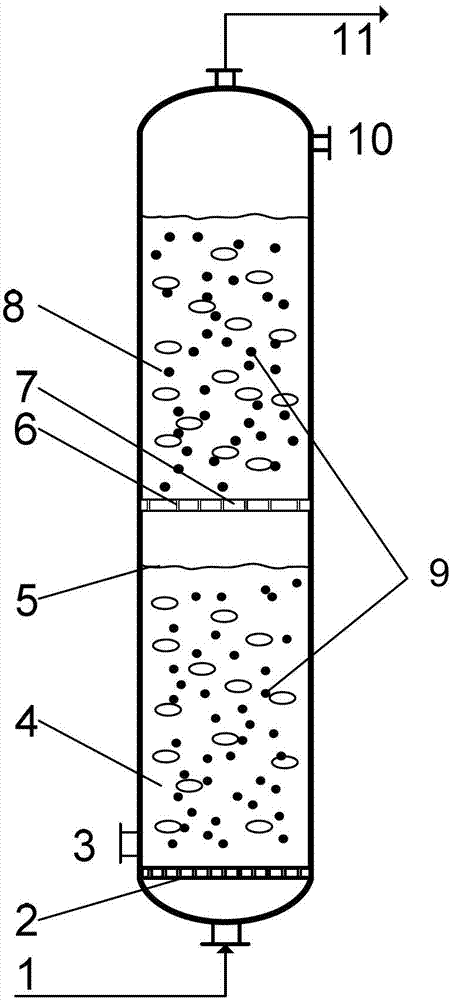

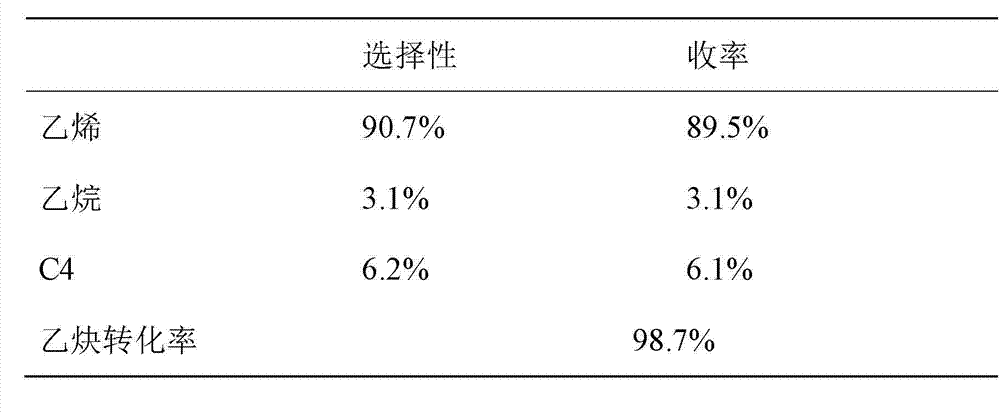

Method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in slurry reactor

InactiveCN103044179AImprove conversion rateHigh yieldHydrocarbon by hydrogenationBulk chemical productionSolubilitySlurry reactor

The invention belongs to the technical field of chemical material preparing methods, and particularly relates to a method for preparing ethylene through liquid-phase selective hydrogenation of acetylene in a slurry reactor. A liquid-phase solvent with high selective solubility for acetylene and low selective solubility for ethylene is introduced into a gas-solid catalytic system, and the relative solubility coefficient of the solvent is larger than 8; a catalyst is dispersed evenly in the liquid-phase solvent, and process coupling is achieved through the high selective solubility of the liquid-phase solvent for acetylene, so that the selectivity of ethylene is improved; and ethylene is prepared and separated through an hydrogenation reaction of acetylene. According to the method, the concentration of ethylene on the surface of the catalyst is reduced through the process coupling, therefore a path of ethane generation through deep hydrogenation is blocked to a certain extent, and the selectivity of ethylene can be improved remarkably. Simultaneously, the liquid-phase dilution thermal effect can accelerate heat transfer in the slurry reactor, and temperature runaway is avoided. The method is not only used for preparing ethylene from acetylene obtained from natural gas pyrolysis, but also is an efficient method in a process for removing acetylene in ethylene.

Owner:TSINGHUA UNIV

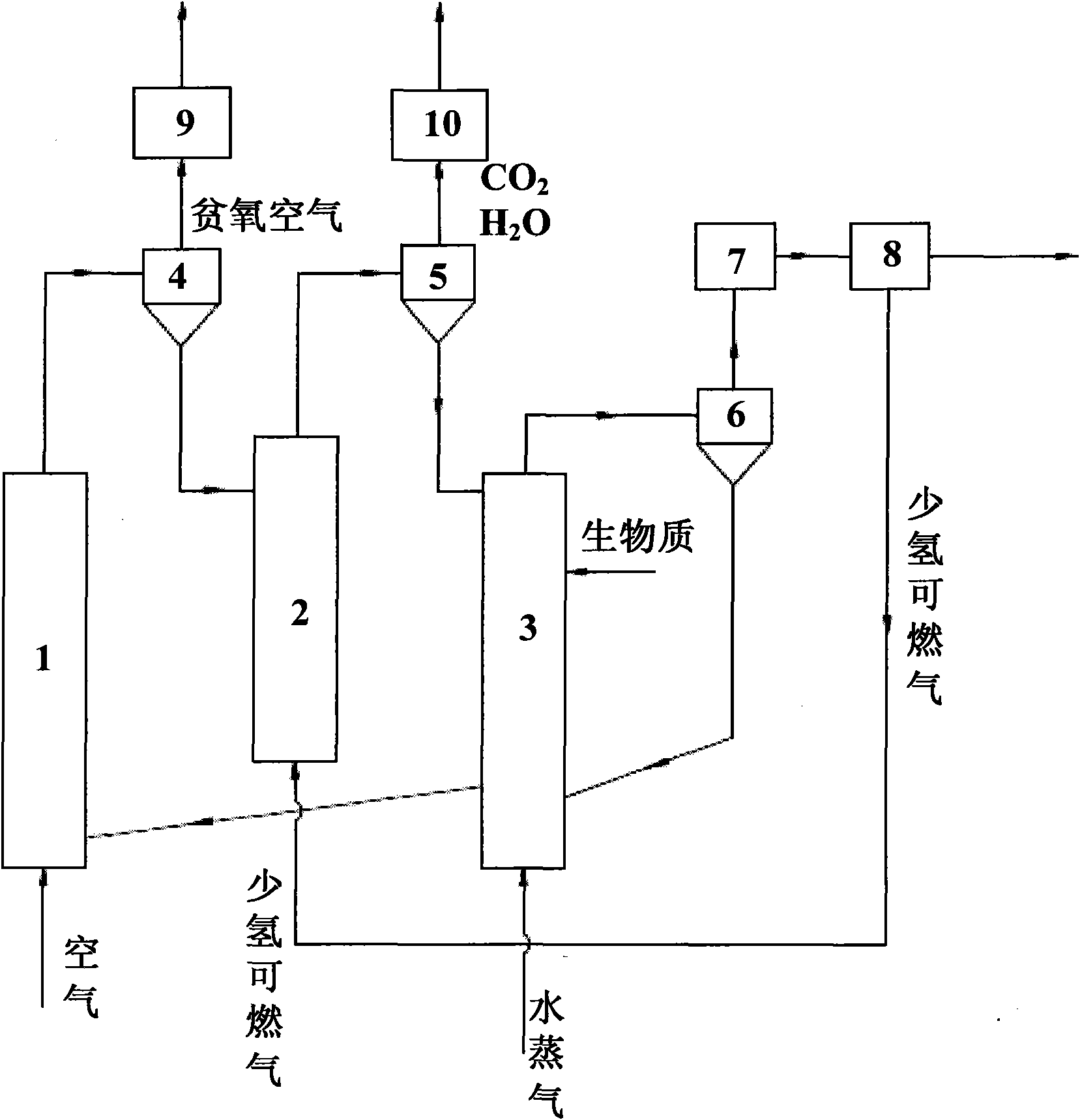

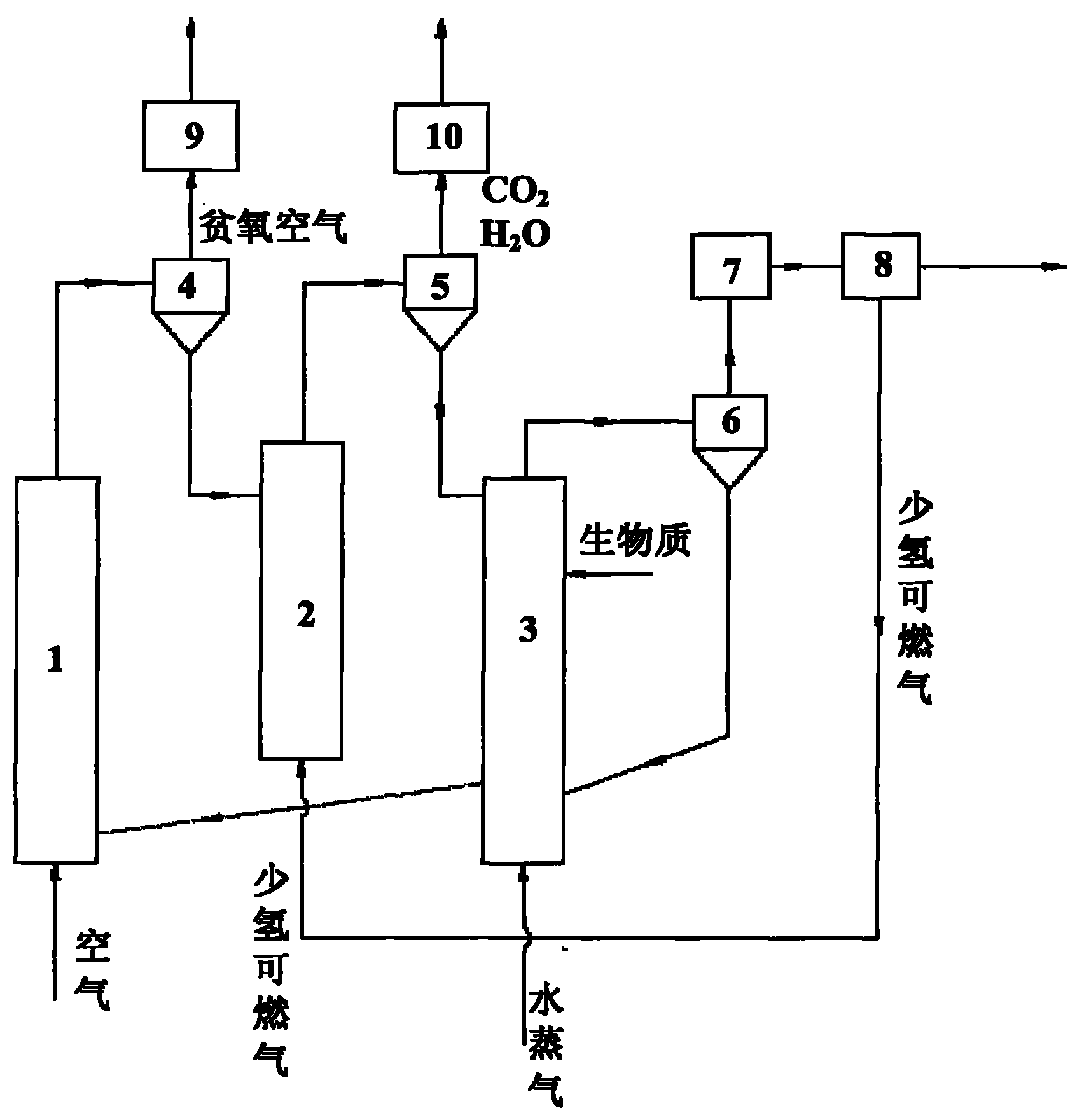

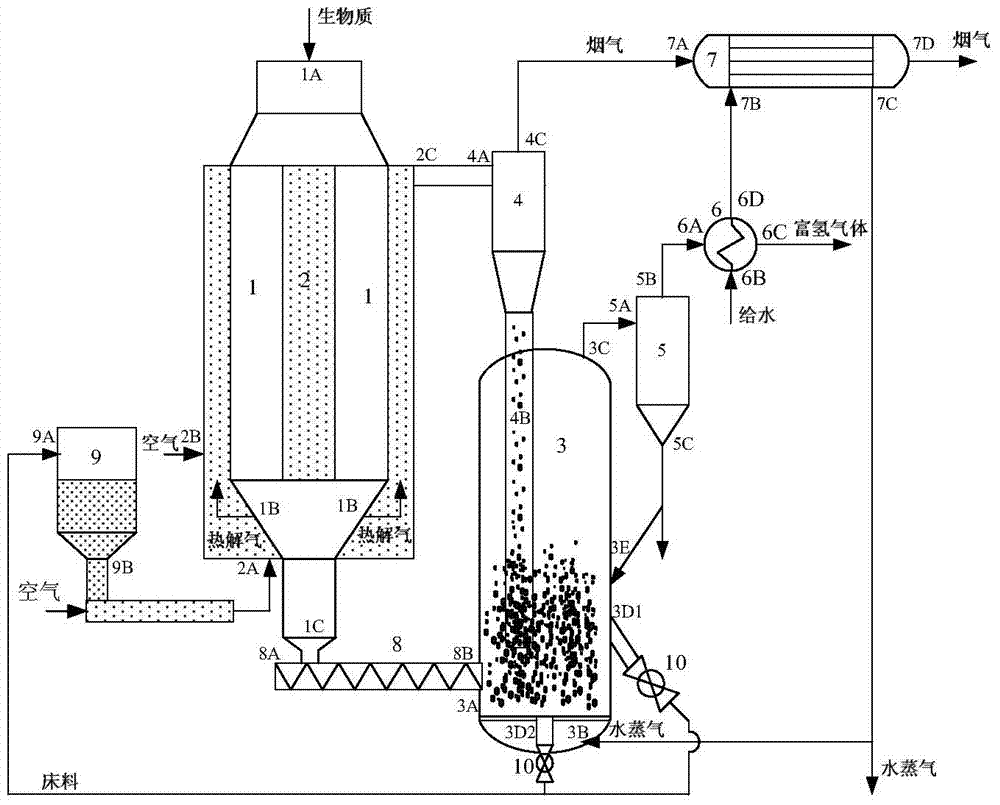

Biomass gasification hydrogen-producing system and method

InactiveCN101774542AReduce utilizationTo achieve hierarchical utilizationHydrogen productionGas solidHeat carrier

The invention discloses a biomass gasification hydrogen-producing system and a method, which belongs to the technical field of hydrogen production. Biomass gasification hydrogen production and chemical-looping combustion are combined to realize low-cost separation of carbon dioxide; and the fractional utilization of matter and energy is realized via the circulation among three beds with metal oxide as a heat carrier and an oxygen carrier. The system mainly comprises an air reactor, a fuel reactor, a moving bed gasifier, a gas-solid separation device, a gas purification device, a hydrogen separation device and a follow-up hydrogen-producing device. The system not only can realize hydrogen production, but also can realize hydrogen production with near zero emission of CO2, thereby realizing efficient cleaning and utilization of biomass.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

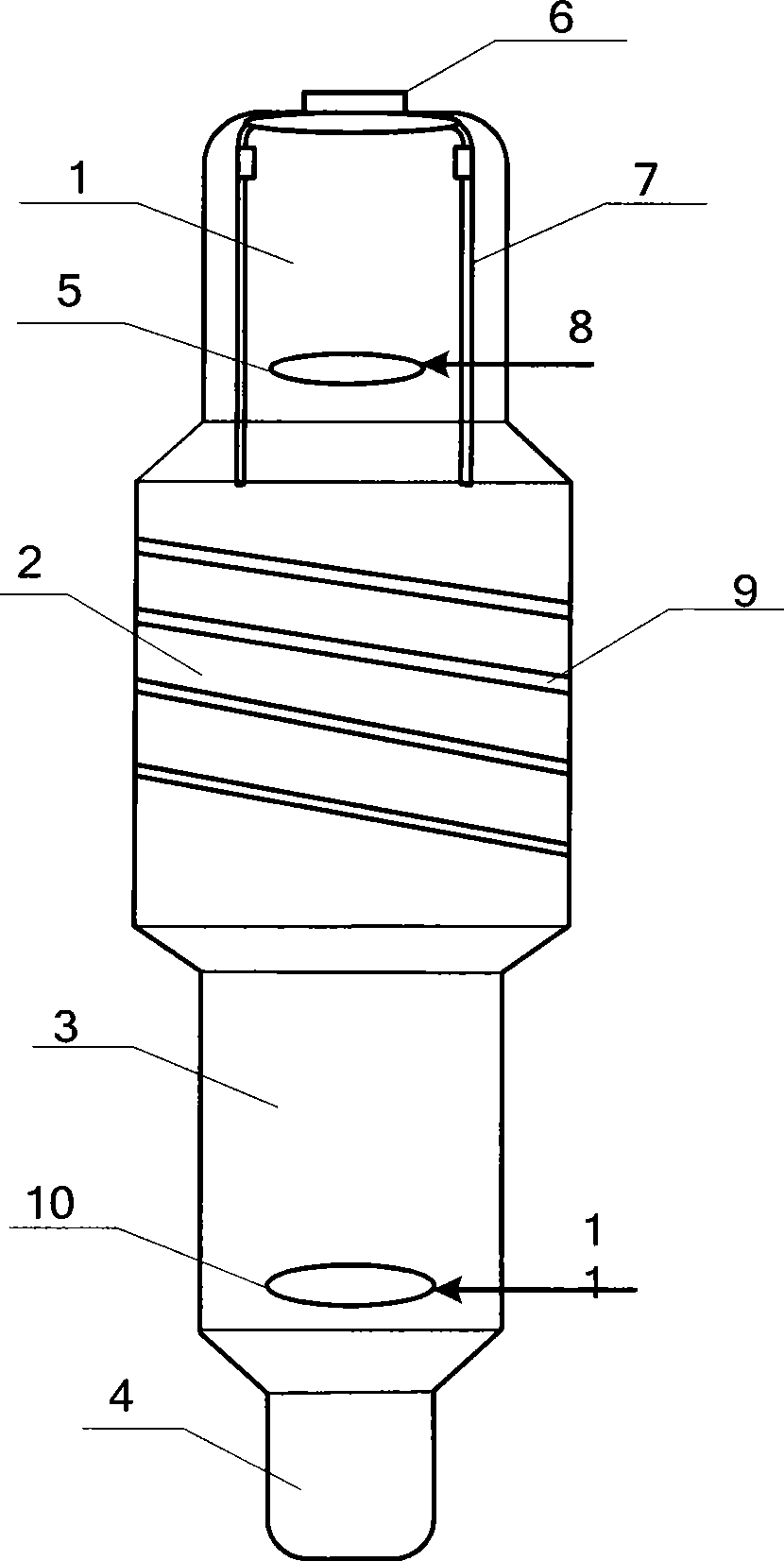

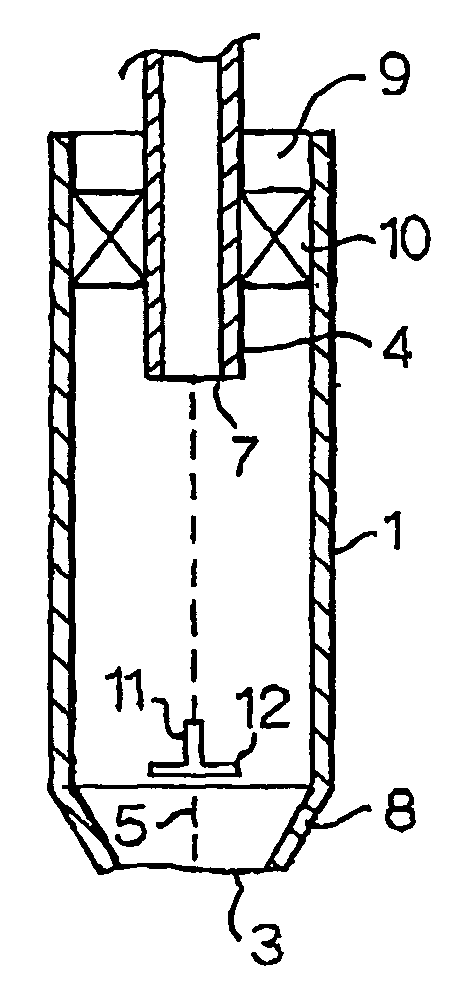

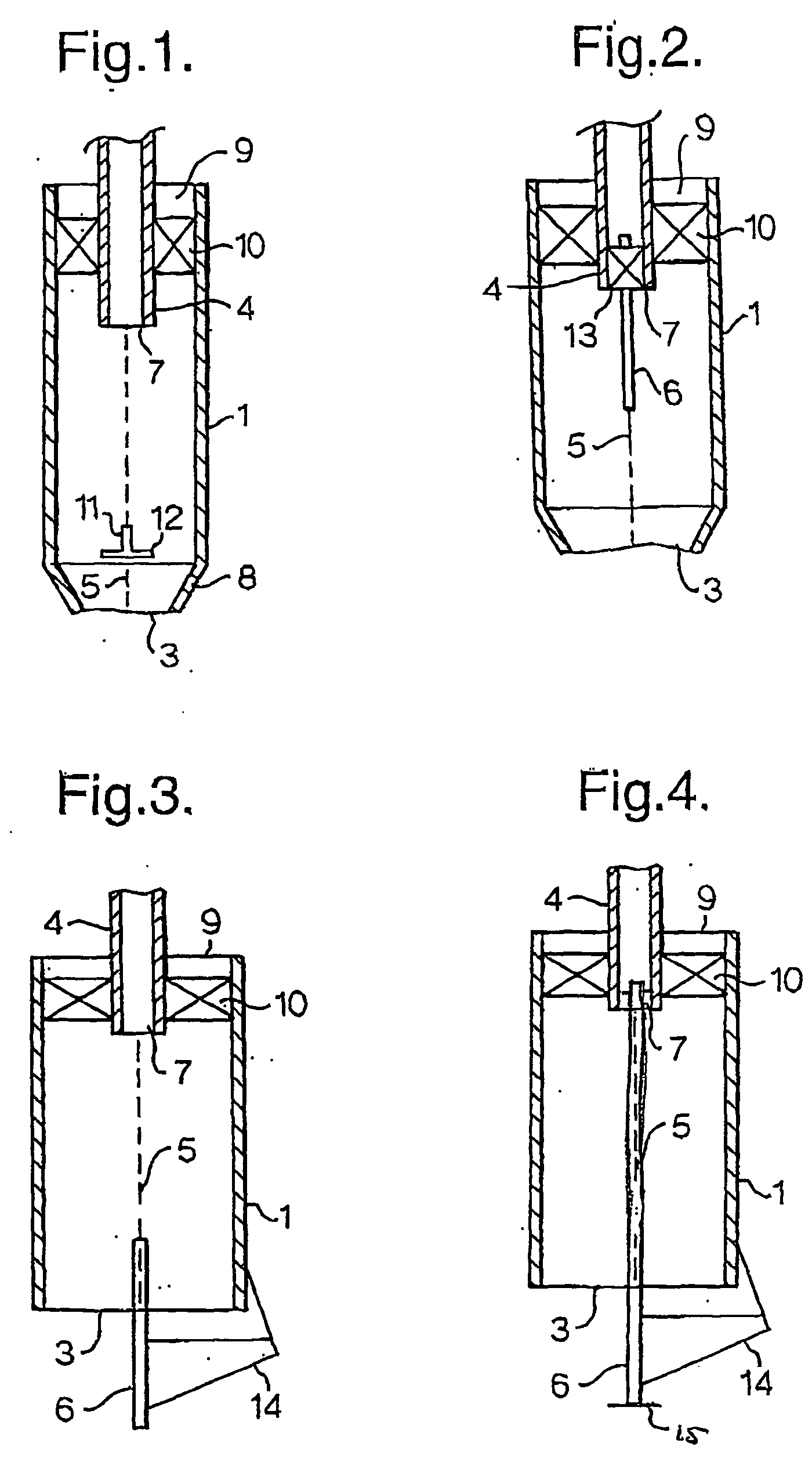

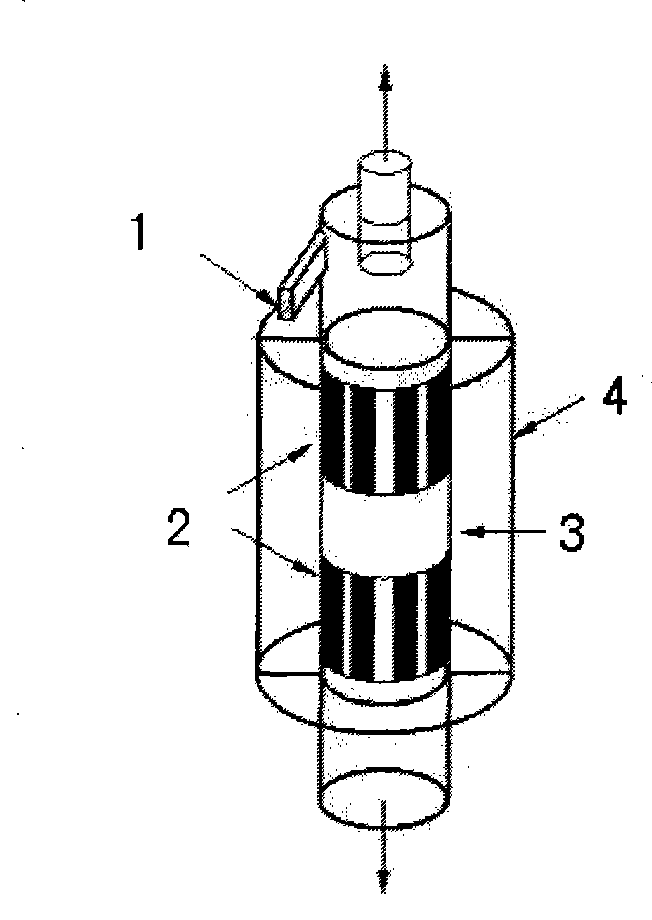

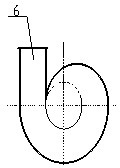

Swirl tube separator

InactiveUS20060070362A1Easy to separateGuaranteed uptimeCombination devicesLiquid degasificationEngineeringGas solid

Swirl tube separator for separating solids from a gas-solid containing feed comprising a tubular housing, an inlet for introducing a gas-solids mixture at one end of said housing, a solids outlet opening at the opposite end of said housing, and a co-axial positioned tubular gas outlet conduit placed at an end of said housing, wherein along the axis of the tubular housing a vortex extender pin is present.

Owner:SHELL OIL CO

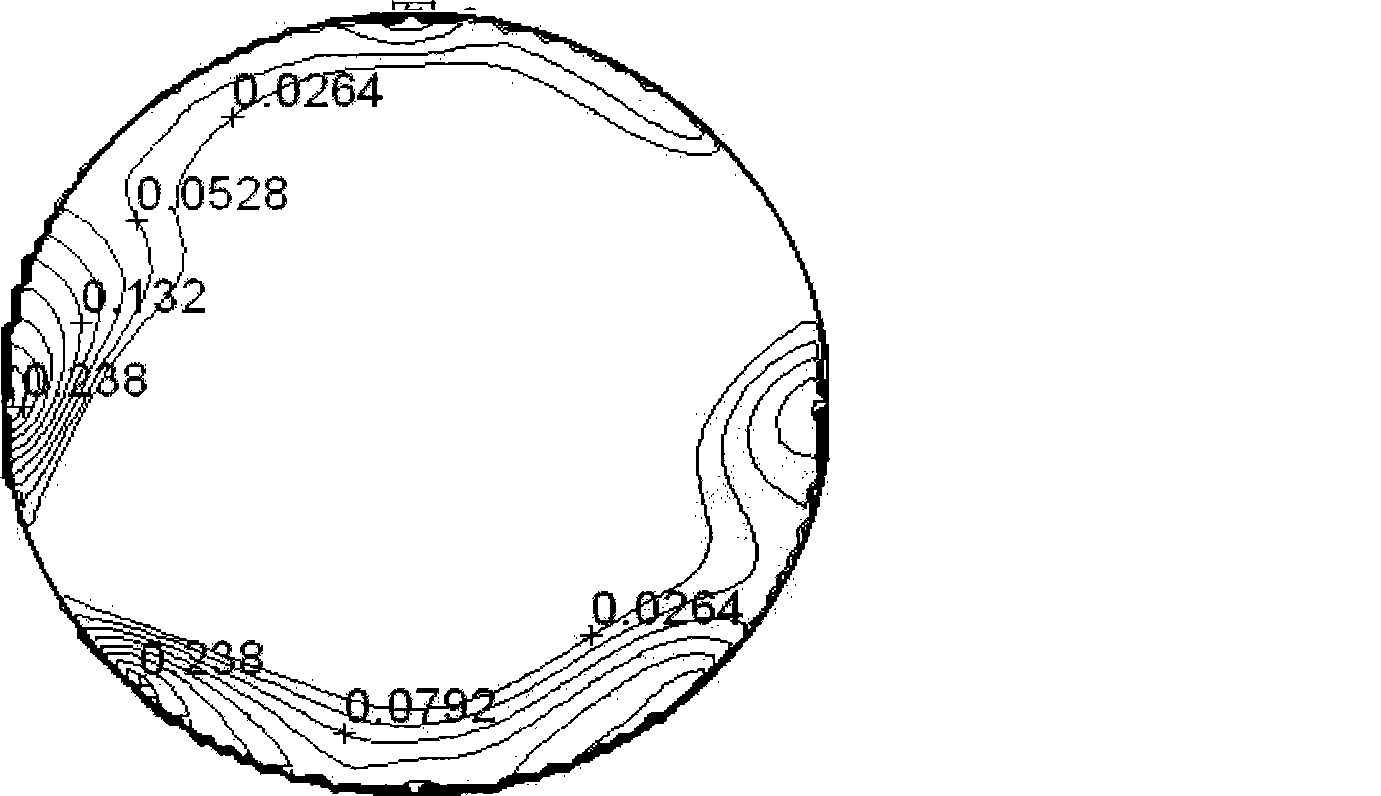

On-line measurement method for particle size distribution and shape distribution of granules in airflow conveying pipe

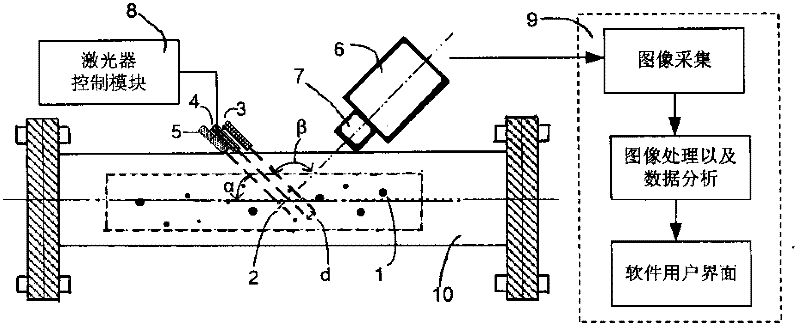

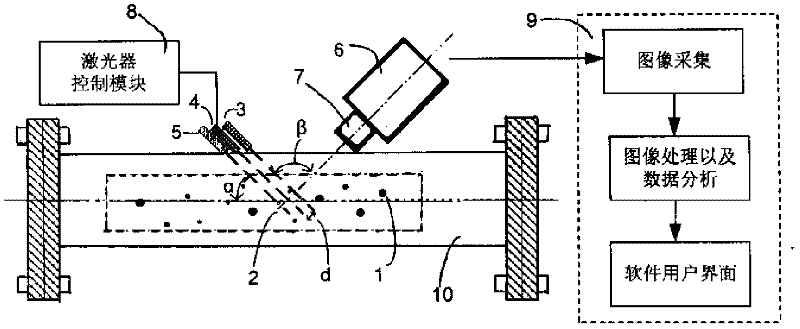

InactiveCN102410974ALower requirementLow costParticle size analysisUsing optical meansMeasurement deviceRgb image

The invention discloses an on-line measurement method for particle size distribution and shape distribution of granules in an airflow conveying pipe, and belongs to the technical field of on-line measurement of gas-solid phase flow. The on-line measurement method comprises the following steps: in the gas-solid phase fluid pipe, irradiating three sections in a granular flow field at the same time by three pulse laser sheet sources with different spectrums, and capturing RGB (red, green and blue) images of the flowing granules on the three illuminated sections of the flow field at the same time by adopting an RGB digital camera; and decomposing the RGB image of each frame and respectively processing three sub-images by an image processing method so as to obtain particle size distribution and shape distribution of the measured granules. The on-line measurement method has the beneficial effects that the images of the granules on three different sections of the flow field can be acquired at the same time by adopting three lasers with different spectrums, the RGB camera and a telecentric lens; imaging on a plurality of focusing surfaces can be realized simultaneously; and the exposure time of the camera can be controlled by means of pulse feedback of the lasers so as to realize imaging of the flowing granules, thus greatly lowering the complexity of a measuring device and improving the measurement efficiency.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

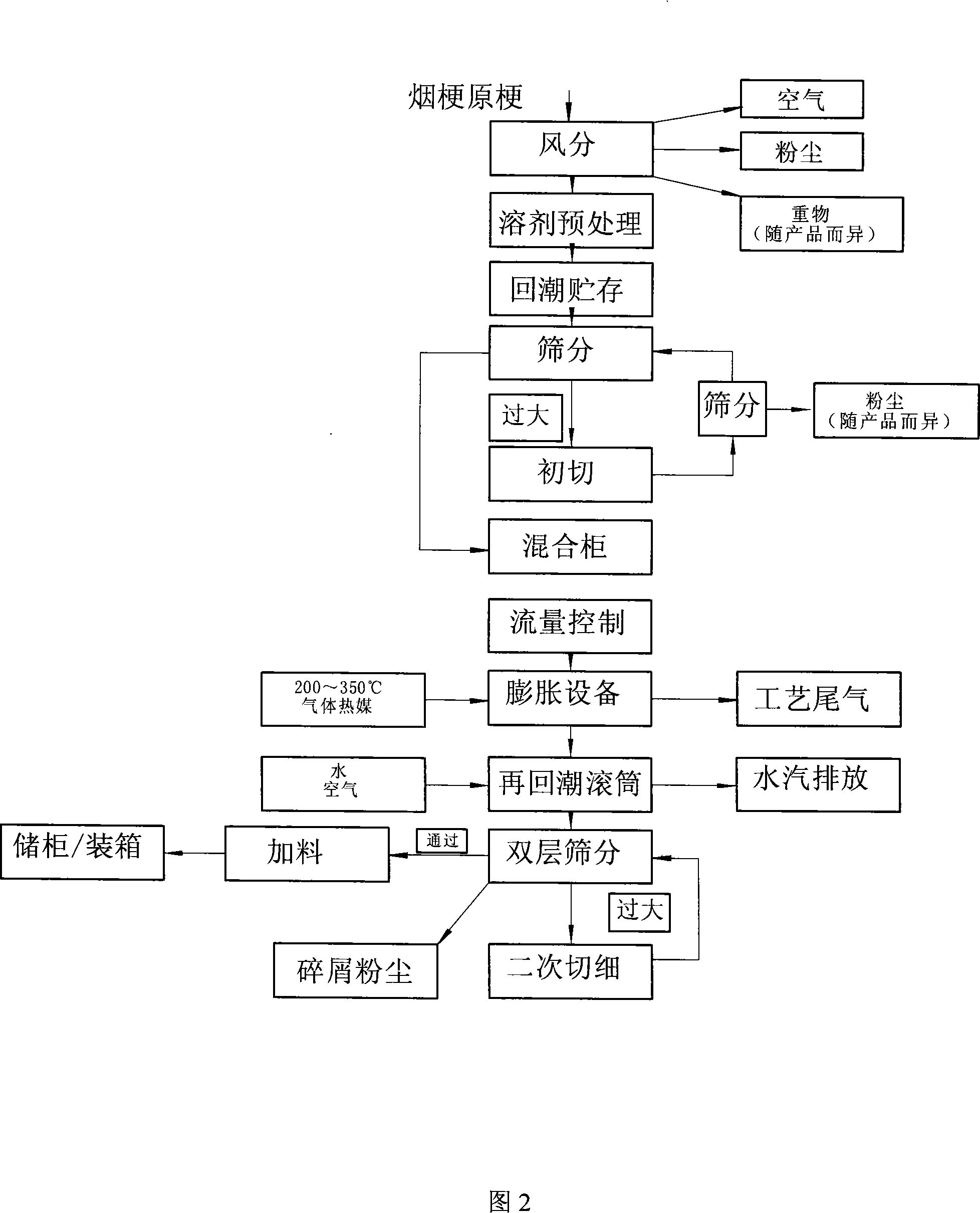

Method and equipment for pretreatment cabo

ActiveCN101214086AImprove uniformityHigh expansion rateTobacco preparationTobacco treatmentGas solidPretreatment method

The invention relates to a pretreatment method of tobacco stem which is preheated through gas heat medium and is treated with microwaves in the gas heat medium environment and equipment which adopts the method. The tobacco stem which is required to be processed is treated: preheating the raw materials to be 100-170 DEG C; heating the gas heat medium to be 150-350 DEG C; mixing the tobacco stem and the gas heat medium and implementing the gas-solid separation after the microwave field action to obtain solid expanded tobacco stem which is treated completely. Then,granular expanded tobacco stem is obtained after the moisture regaining, the screening, the fine shearing, etc. The equipment includes a gas heat medium preheating mechanism, a microwave complex expansion treatment mechanism, etc. With the process and the equipment of the invention, the breakage during the expansion process is small; the pressure used by the process is close to the normal pressure; the pressure resistance requirement for the equipment is not high; the production process is simple and easy; the most fundament lies in that through the gas heat medium with low oxygen content used for preheating the tobacco stem, the evenness and the expansion ration of the tobacco stem and the aspiration quality of the tobacco stem materials are obviously improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Device and method for preparing hydrogen-rich gas by gasifying biomass

ActiveCN103923705AAvoid mixingEfficient use ofEnergy inputGasification with fuel pre-distillationWater vaporGas cooler

The invention discloses device and method for preparing hydrogen-rich gas by gasifying biomass. The device mainly comprises a pyrolysis reactor, a combustion reactor, a gasification reactor, a gas-solid separator, a gas cooler and an exhaust heat boiler, wherein the pyrolysis reactor is arranged in the combustion reactor. In a process course, the biomass is firstly pyrolyzed in the pyrolysis reactor to generate pyrolysis gas and coke, the pyrolysis gas is directly combusted to provide heat for biomass pyrolysis and gasification, and the coke is subjected to gasification reaction with water vapor to obtain the hydrogen-rich gas. The device and method disclosed by the invention realize the separation of the pyrolysis process and coke gasification process of the biomass and can be used for displacing the hydrogen contained in the water vapor by sufficiently utilizing fixed carbon contained in the biomass. According to the device and method, the obtained hydrogen-rich gas mainly contains H2, CO2 and a small amount of CO, so that the conventionally gasified hydrogen-rich gas product is prevented from being mixed with low-carbon hydrocarbon gas and tar, and the subsequent decontamination and purification utilization are simple, convenient and economic.

Owner:SOUTHEAST UNIV

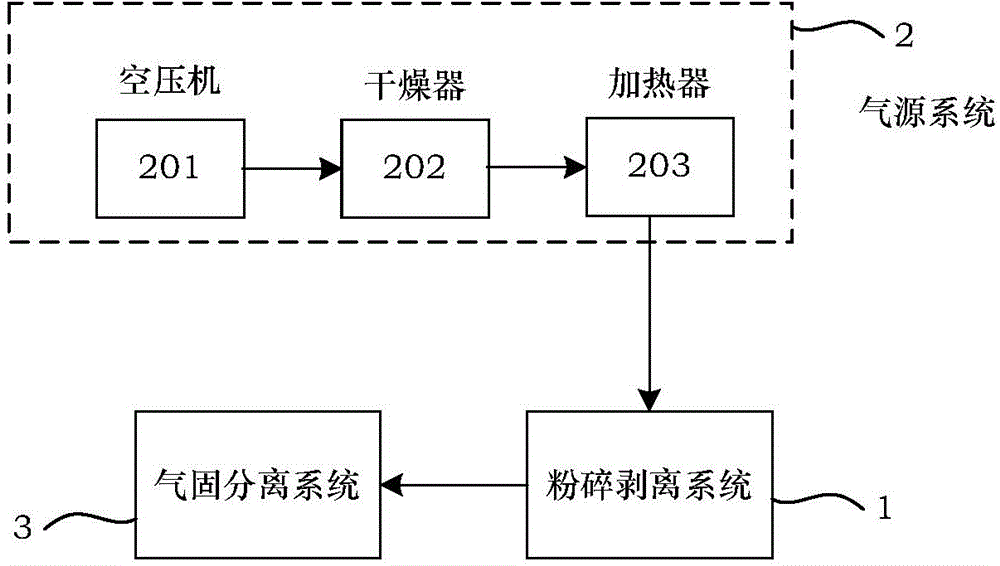

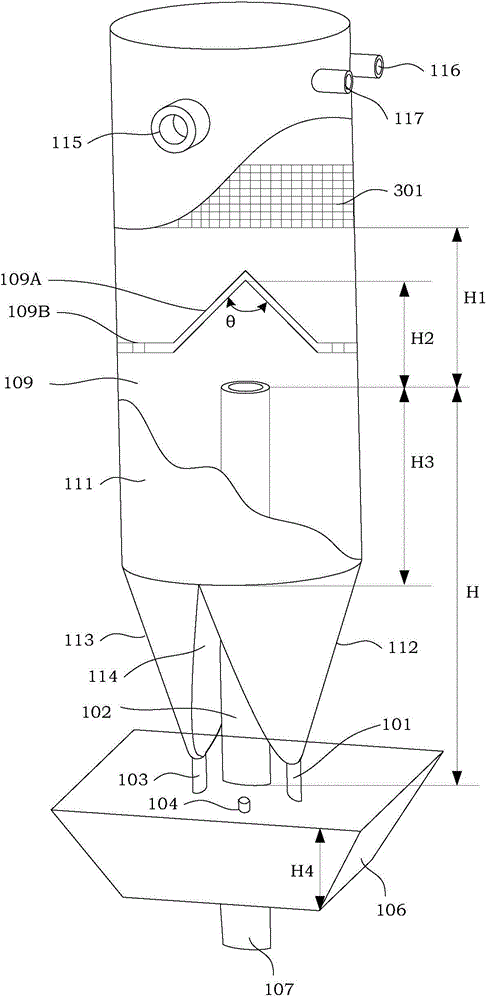

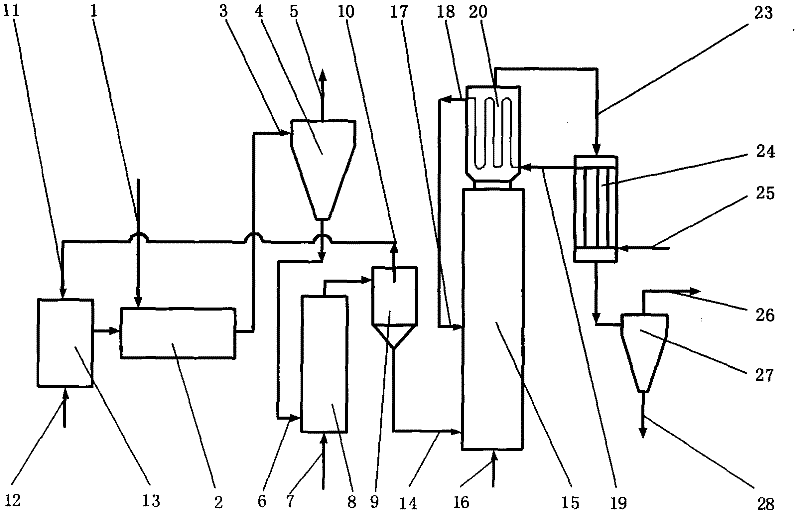

Process and device for preparing graphene precursor two-dimension nanoscale graphite powder by adopting airflow crushing and peeling method

The invention discloses a method and a device for preparing graphene precursor two-dimension nanoscale graphite powder by adopting an airflow crushing and peeling method. The device comprises an air source system, a crushing and peeling system and a gas-solid separation system; in the crushing and peeling system, an A return pipe, a B return pipe and a riser pipe form a material circulation loop of an airflow crushing and peeling process; an A gas guide pipe, a B gas guide pipe and a C gas guide pipe form an airflow crushing passage of the airflow crushing and peeling process. The graphene precursor two-dimension nanoscale graphite powder is prepared by adopting three supersonic speed jet flows to carry graphite particles together; through collision and friction of strip jet flows, high-purity crushing and peeling of the graphite particles are realized; through circulated and continuous crushing and peeling of the graphite particles, the two-dimension nanoscale graphite powder is obtained. The process is adopted for crushing and peeling the graphite powder, the crushing and peeling of the graphite powder are realized by utilizing mutual collision and friction among the graphite powder, friction of other media does not exist, and thus the two-dimension nanoscale graphite powder with high purity can be obtained.

Owner:BEIHANG UNIV

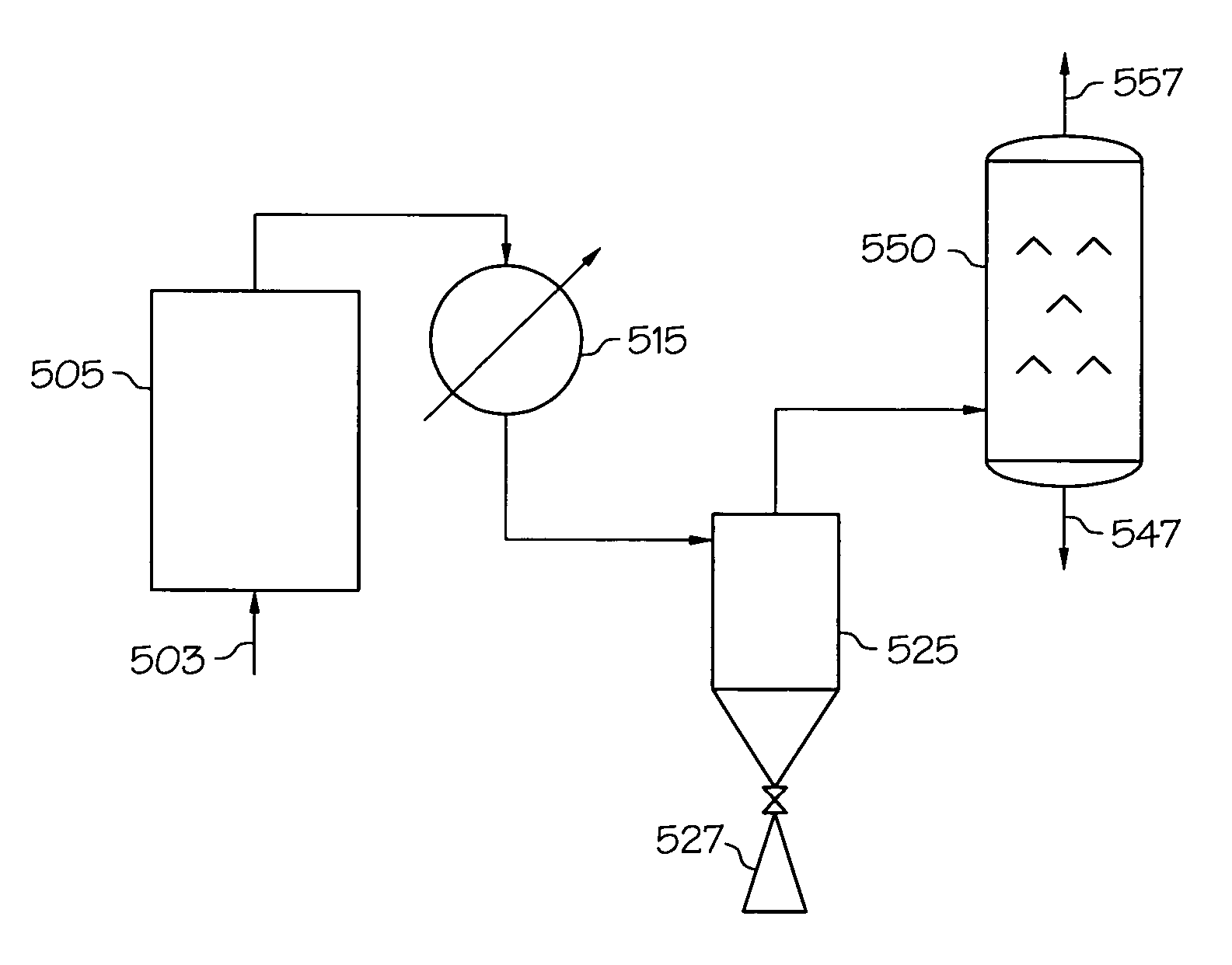

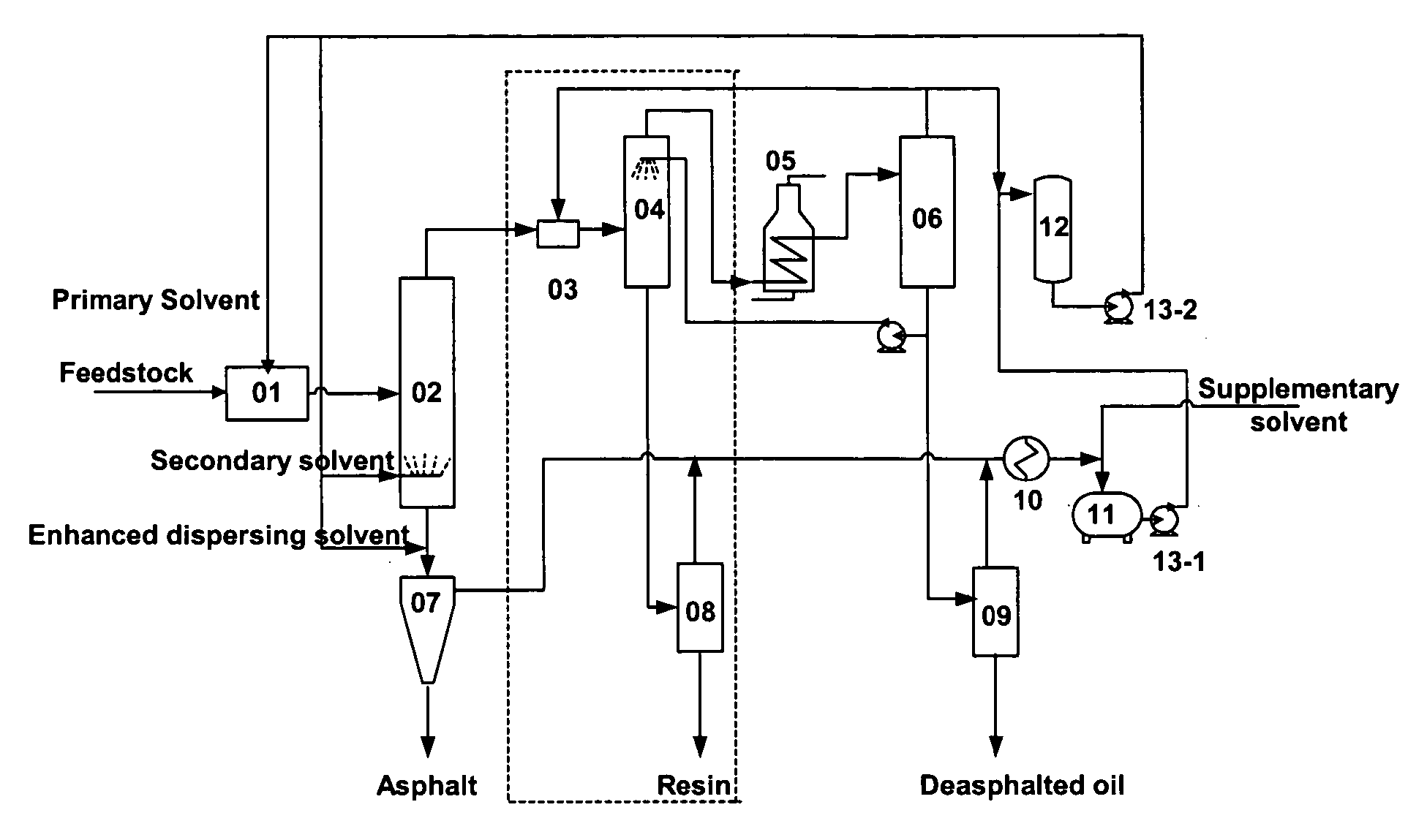

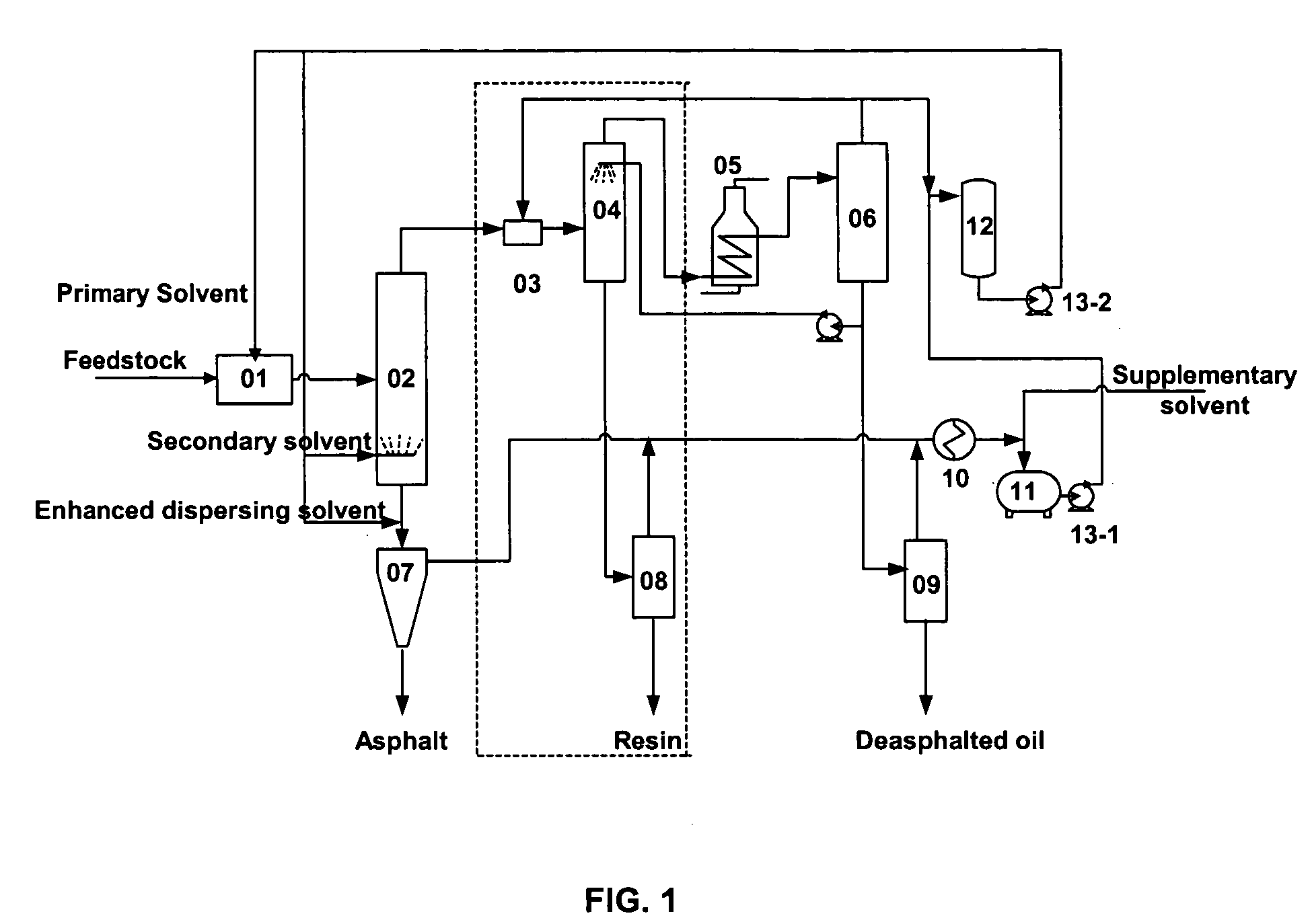

Deep separation method and processing system for the separation of heavy oil through granulation of coupled post-extraction asphalt residue

ActiveUS20070007168A1High yieldSimple processWorking-up pitch/asphalt/bitumen by selective extractionWorking-up pitch/asphalt/bitumen by solidifying/disintegratingSolid particleOil phase

The present invention is a separation method and system in which granulation of coupled post-extraction asphalt residue is used to achieve deep separation of heavy oil. A dispersion solvent is introduced into the asphalt phase after separation by solvent extraction and the asphalt phase undergoes rapid phase change in a gas-solid separator and is dispersed into solid particles while the solvent vaporizes, resulting in low temperature separation of asphalt and solvent with adjustable size of the asphalt particles. The separation method of this invention also includes a three-stage separation of heavy oil feedstock, in which the deasphalted oil phase separated from heavy oil is treated with supercritical solvent and results in the further separation of the resin portion of the deasphalted oil, maximizing the yield and quality of the deasphalted oil. The processes and systems in this invention use atmospheric pressure and a low temperature gas-solid separator instead of a high temperature and high pressure furnace and do not require the feed pre-heating or heat exchange equipment at the inlet of resin separator column, resulting in a simplified process flow and reduced investment.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

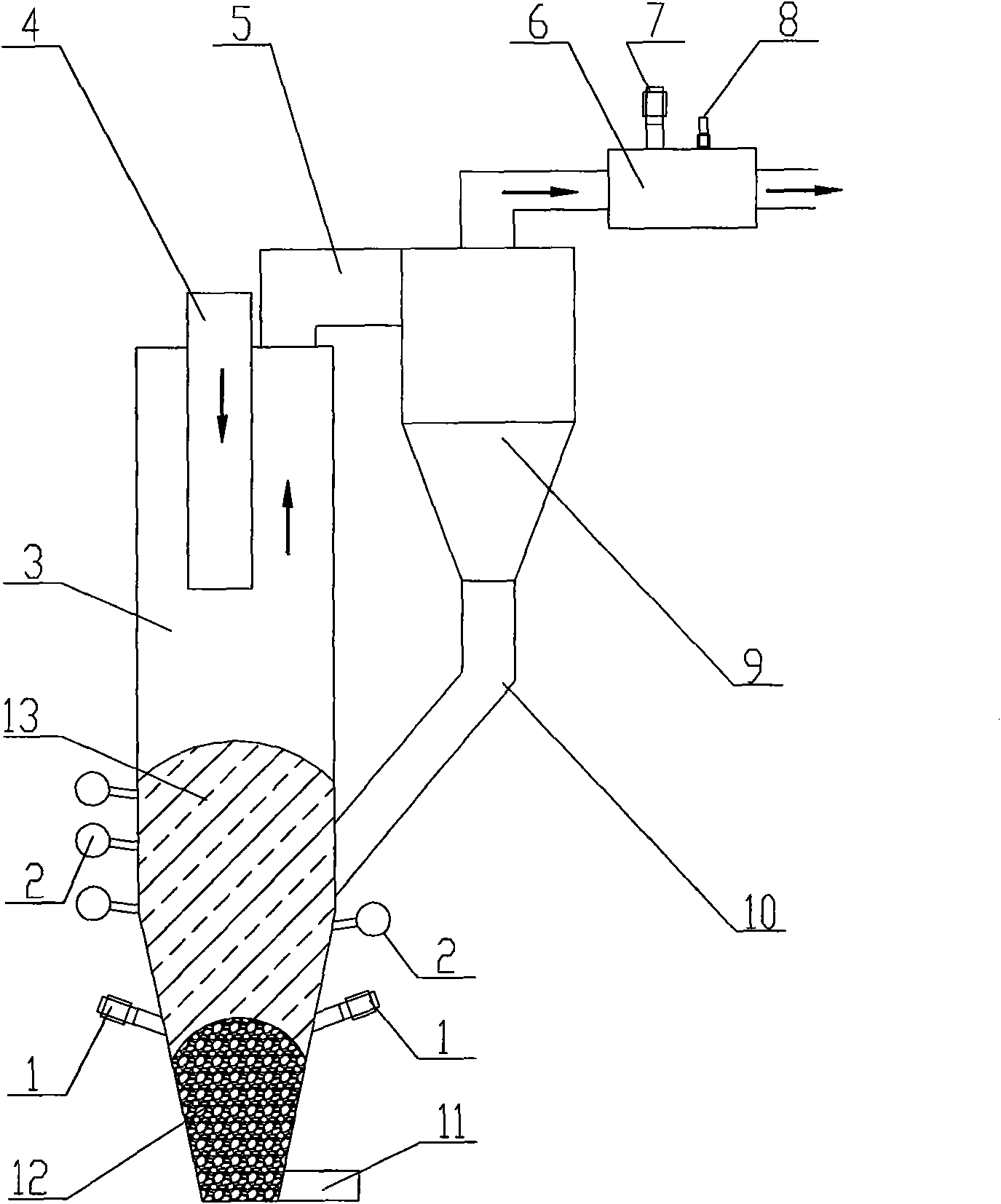

Method and device for biomass compound gasification

InactiveCN101225315AImprove gasification efficiencyReduce tar contentBiofuelsSpecial form destructive distillationTarBiomass

The invention discloses a biomass complex gasification method and a device of the gasification. The thermal decomposition, the gasification, part of the oxidation process are combined in one reactor by the integrating the fluidized bed and the airflow bed. Firstly, the biomass is decomposed at 500 to 600 degrees C and generates hard coke; secondly, the hard coke with large grain sizes are partly oxidized and gasified in the hard coke gasifying section, which provides heat and generates combustible gas for the thermal decomposition section; thirdly, the reaction gases with small hard coke grains discharged from the thermal decomposition section and the catalyst fast flows upwards through the macromolecular gasifying section, and the reaction gas are partly oxidized because of the function of the secondary gasifying agent, the heavy tar component is forced simultaneously through thermal cracking reaction and catalytic cracking reaction with the catalyst at the temperature over 1000 degrees C and transformed to lightweight combustible gas; at last, the unreacted hard coke is sent back to the furnace through the gas-solid separation device and the solid recycling device. The biomass complex gasification method has the advantages of high gasification efficiency, low tar content, high control ability of the gas component, stable operation and easy enlargement.

Owner:江苏中科龙城能源系统有限公司

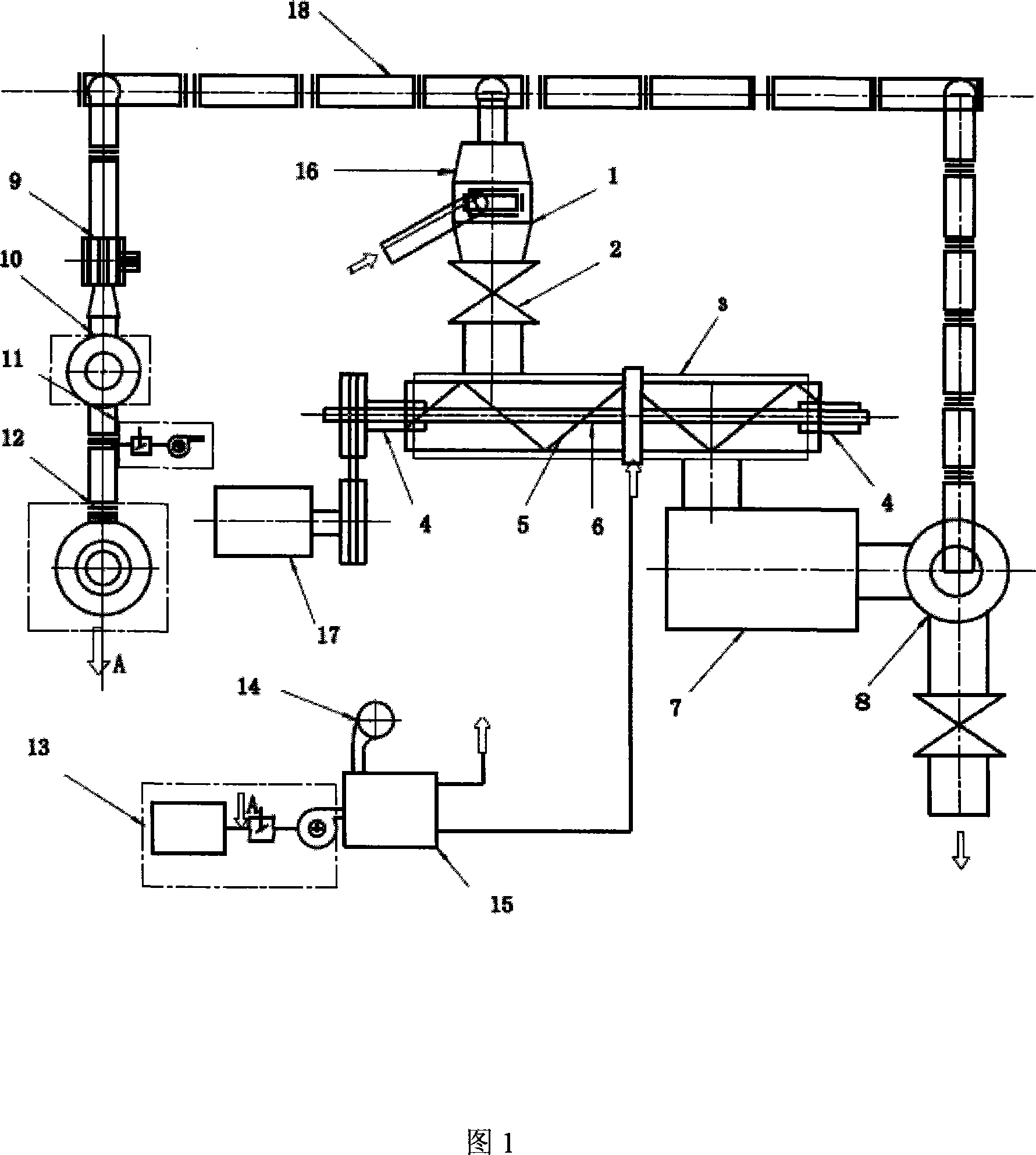

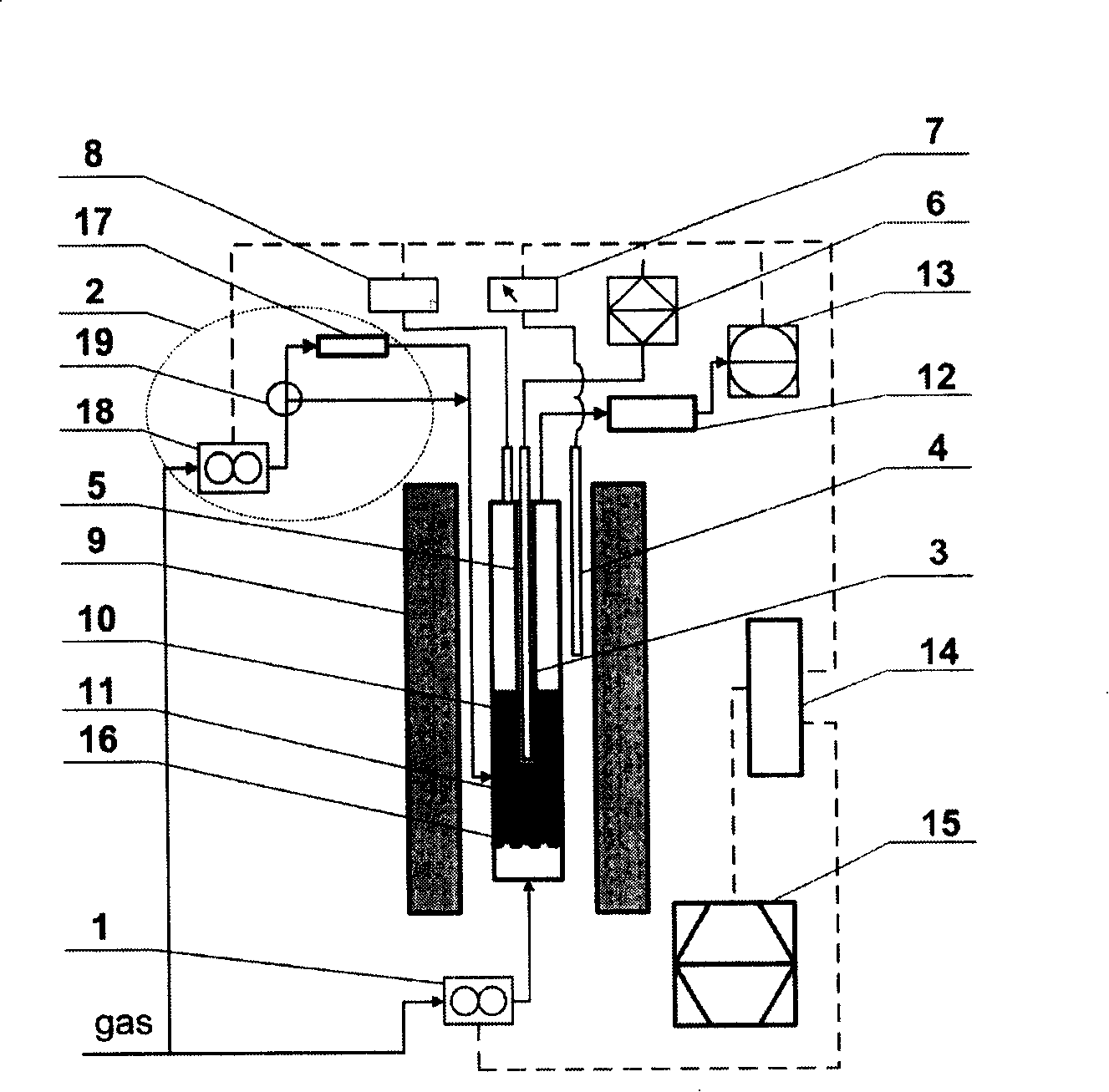

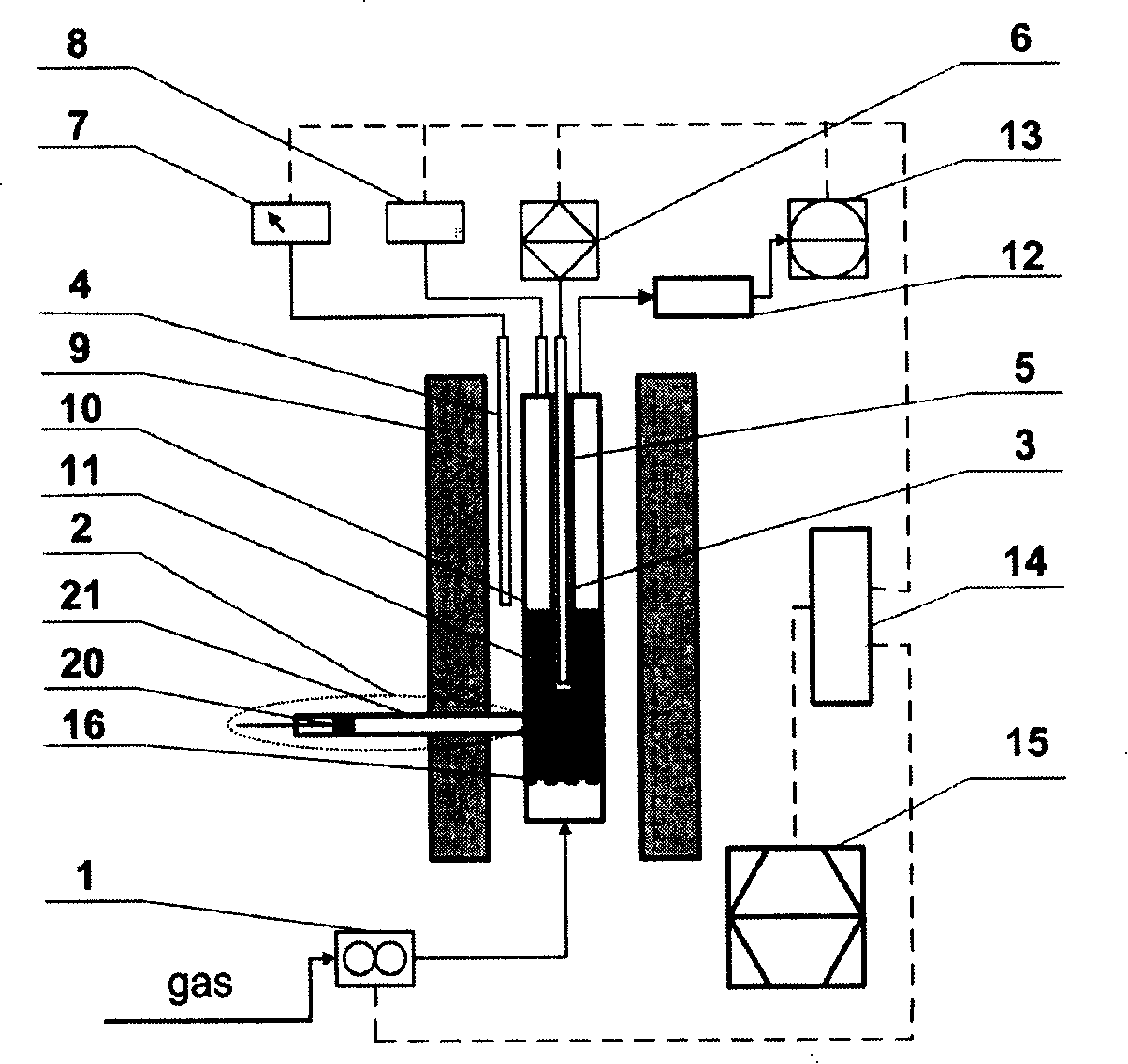

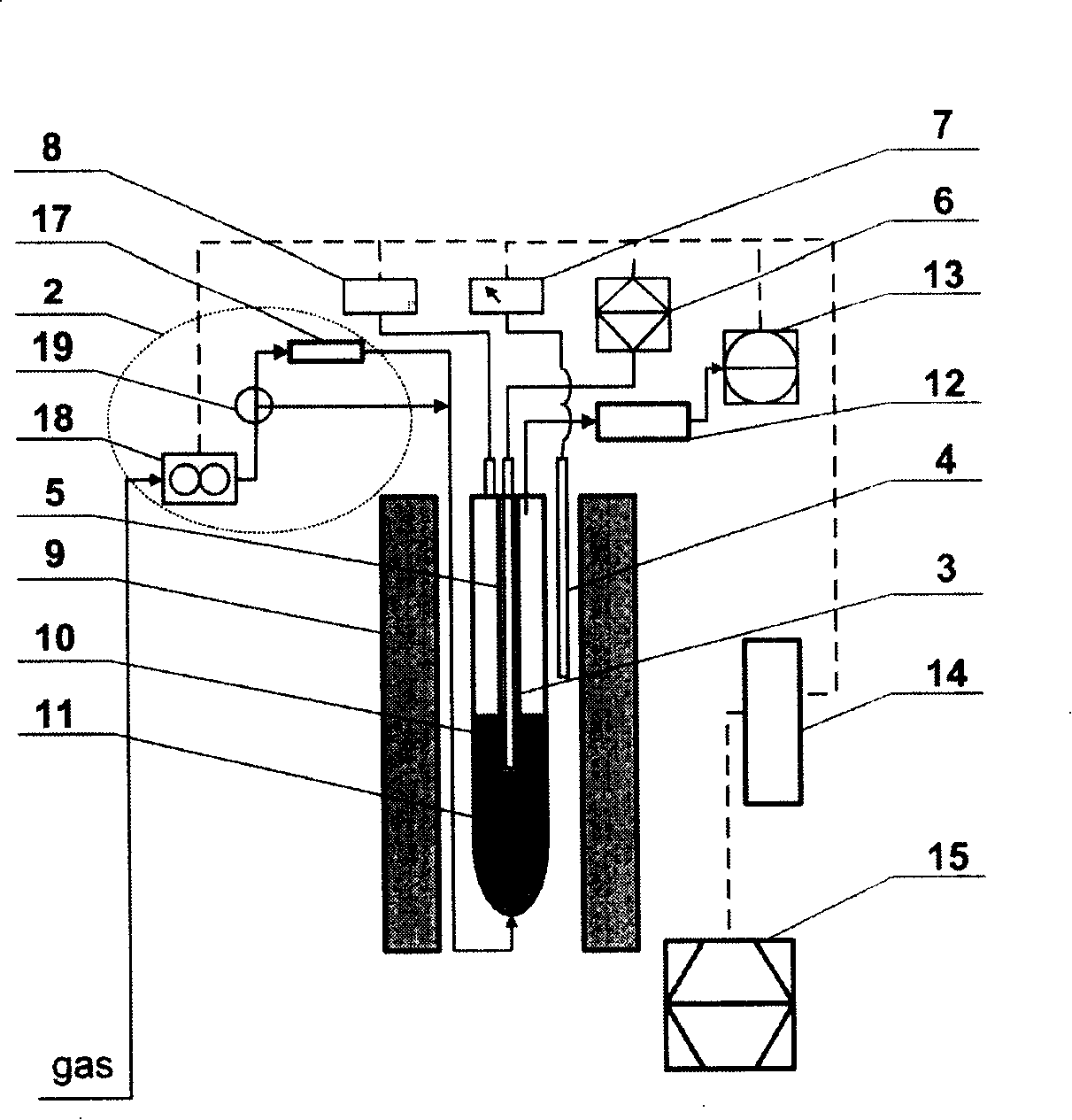

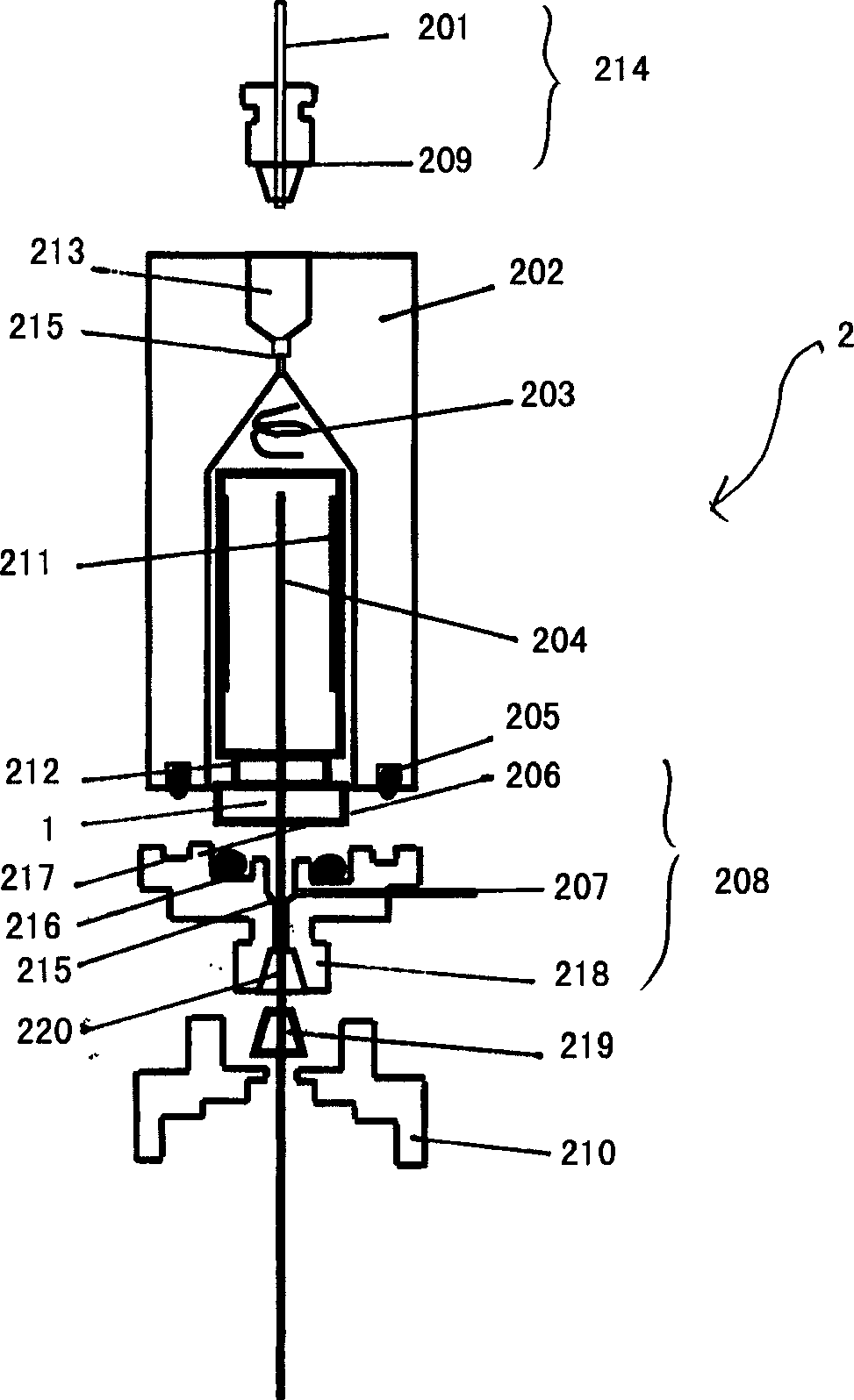

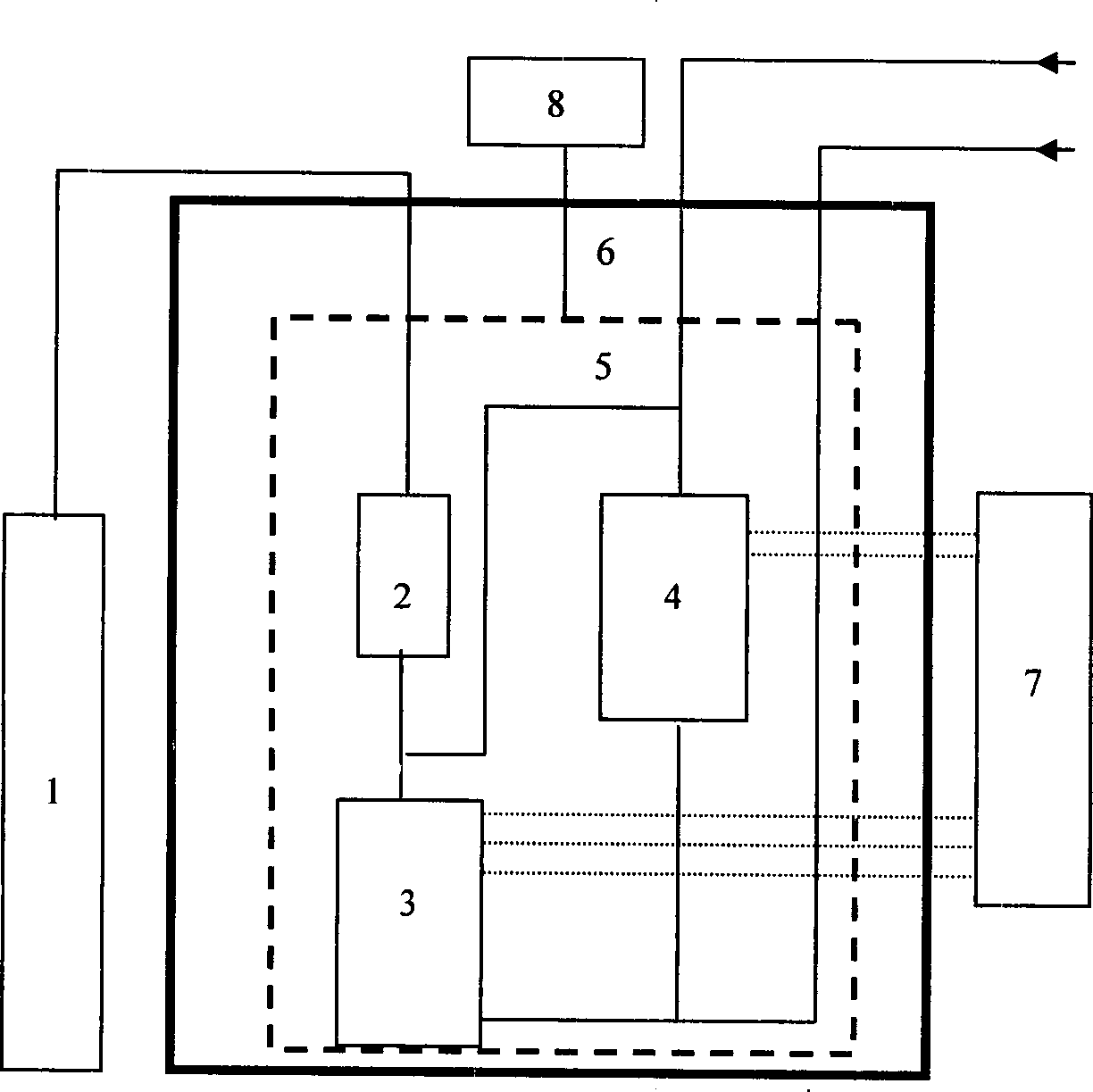

Gas-solid reaction kinetic parameter analyzer

A kinetic parameter analyzer for gas / solid reaction comprises an electric furnace arranged with a thermocouple; a micro-reactor loaded with flowing medium particles and positioned in the electric furnace; a pressure sensor and a temperature control device for controlling the temperature of the flowing medium particles, which are arranged in the reactor; a reactant supplier for supplying solid-state reactant to the flowing medium particles; a gas supply device arranged on the bottom of the reactor for providing gas into the reactor; a gas purifier and a detector sequentially communicated with the upper gas outlets of the reactor; a data collector with the input terminals thereof respectively connected with the output terminals of the pressure sensor, the temperature control device, a temperature display meter and the detector; and a computer for controlling the opening / closing of the reactant supplier and analyzing the data inputted by the data collector. The analyzer adopts a micro-fluidized bed or a micro-spouted bed as the reactor, which facilitates the online addition of the solid-state reactant, so that the reaction environment is more approximate to the actual environment and to the actual reaction conditions and that the measured kinetic parameters are more close to intrinsic reaction kinetics.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

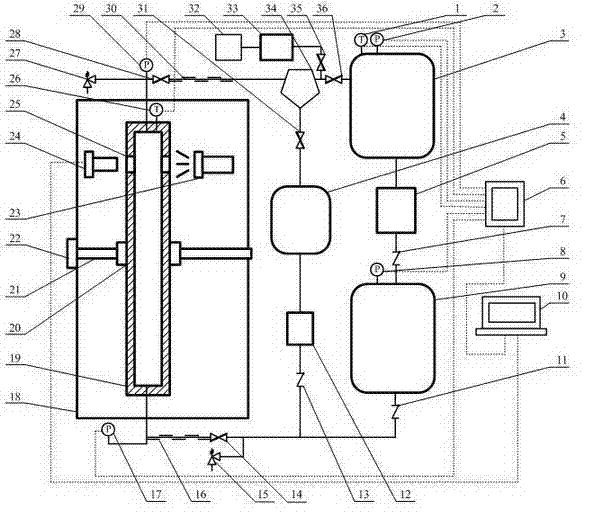

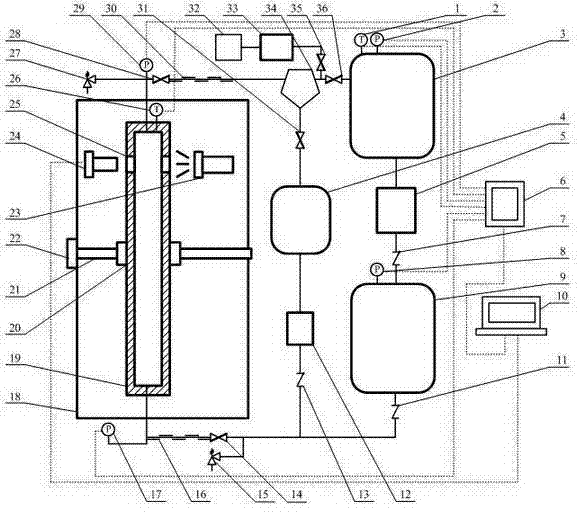

Visual dynamic simulating device for deposition in gas hydrate pipeline

InactiveCN102507871AAchieve recyclingReduce experiment costMaterial analysisLiquid storage tankData acquisition

The invention relates to a visual dynamic simulating device for deposition in a gas hydrate pipeline, which is used for simulating the generation, the transportation and the deposition of gas hydrate in high-pressure high-speed air flow and can be used for summarizing the high-speed motion characteristic, the transportation mechanism and the deposition rule of a pipeline gas-solid phase. The invention has the technical schemes that: the top end of a low-pressure gas storage tank is provided with a temperature sensor and a pressure sensor, the outlet end of the low-pressure gas storage tank is connected with a high-pressure gas pump and then is connected with a high-pressure gas storage tank, and the top end of the high-pressure gas storage tank is provided with a pressure sensor; the outlet end of a liquid storage tank is connected with a metering pump, and the upper end of a gas-liquid separator is connected with a vacuum pump and a tail gas treating device; the top end of a high-pressure reaction tube is connected with an outlet electrical heating insulation pipeline, and the bottom end of the high-pressure reaction tube is provided with a pressure sensor and an inlet electrical heating insulation pipeline; and a data acquisition system is formed by a data acquisition card, a computer, a cold light source and a high-speed camera, and a pipeline temperature attitude control system is additionally arranged. According to the visual dynamic simulating device disclosed by the invention, the generation process, the transportation process and the deposition process of the gas hydrate in the high-pressure high-speed air flow can be really simulated, and the visual dynamic simulating device is used for evaluating a gas hydrate inhibitor.

Owner:SOUTHWEST PETROLEUM UNIV

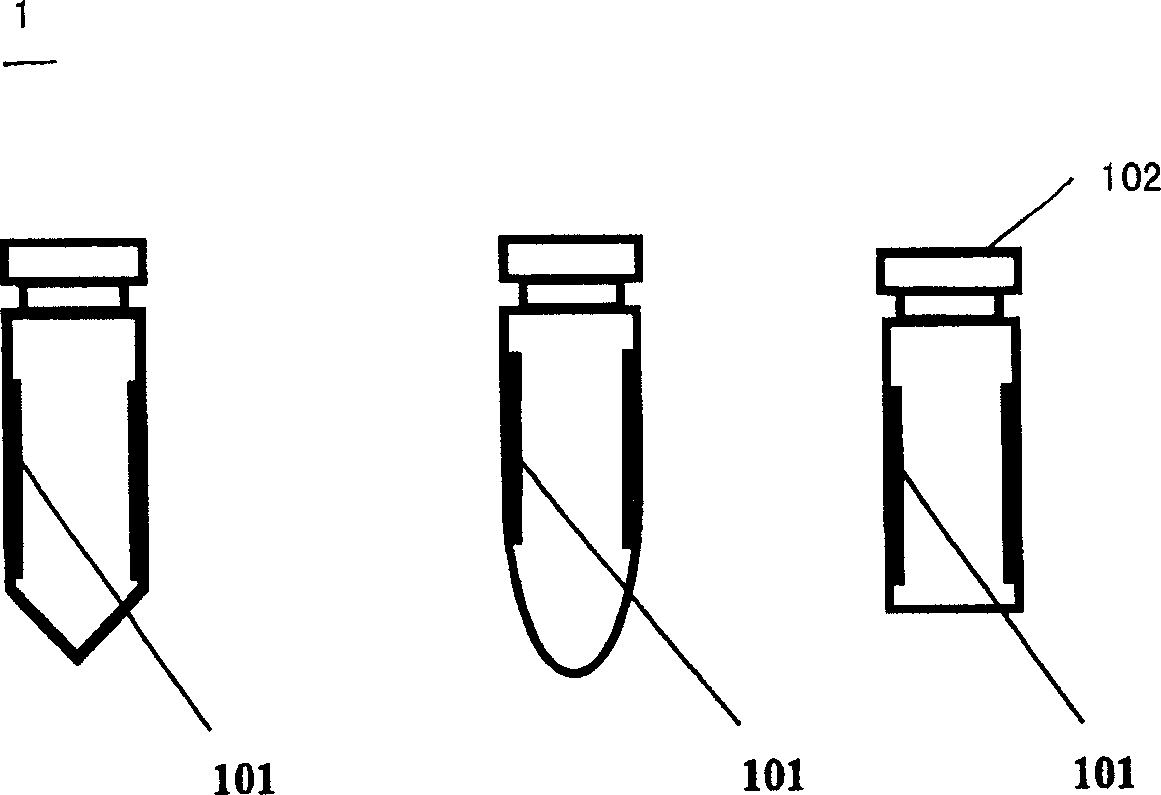

Solid phase extraction sample bottle and thermal analysis apparatus

ActiveCN1721850AImprove preprocessing efficiencyGood data repeatabilityComponent separationSample MeasureBottle

The invention relates to a solid phase extract sampling bottle and heat analysis device in the field of sample measuring technology. It is a liquid-solid extraction and gas-solid absorption technology, which is used to pre-treat gas sample, liquid sample and isotropy sample and to extract and collect the objecting component, especially in color analysis and instrumental analysis. The solid phase extract sampling bottle and heat analysis device comprises an extract sampling bottle which is like a cylinder with one open end and one sealed end as bottom, and a casing and one layer extracting fixed phase on the middle part of the cylinder's inner wall, a heat analysis device and an extract sampling bottle cleaning device.

Owner:QINGDAO SHENGHAN CHROMATOGRAPH TECH CO LTD

Method for preparing calcium carbide and synthesis gas through thermal oxidation reaction and calcium carbide reactor

ActiveCN102153085ACompact structureLess investmentCalcium carbideGranular/pulverulent flues gasificationGas solidCalcium carbide

The invention discloses a method for preparing calcium carbide and a synthesis gas through a thermal oxidation reaction and a calcium carbide reactor, which solve the problems of great raw material consumption, more equipment, large investment, complex process, less CO byproduct quantity and difficult industrial application of the traditional calcium carbide preparation method. The calcium carbide reactor comprises a gas-solid separator, a closed reacting furnace is arranged below the gas-solid separator, and the closed reacting furnace comprises an upper preheating chamber, a middle vaporizing chamber and a lower reaction chamber. In the method provided by the invention, a special calcium carbide reactor is adopted; when calcium carbide is synthesized, a large amount of produced CO can be industrially applied; and thus, the method has low production and operation costs, low energy consumption, great by-product gas quantity and a broad market prospect.

Owner:WUHUAN ENG +1

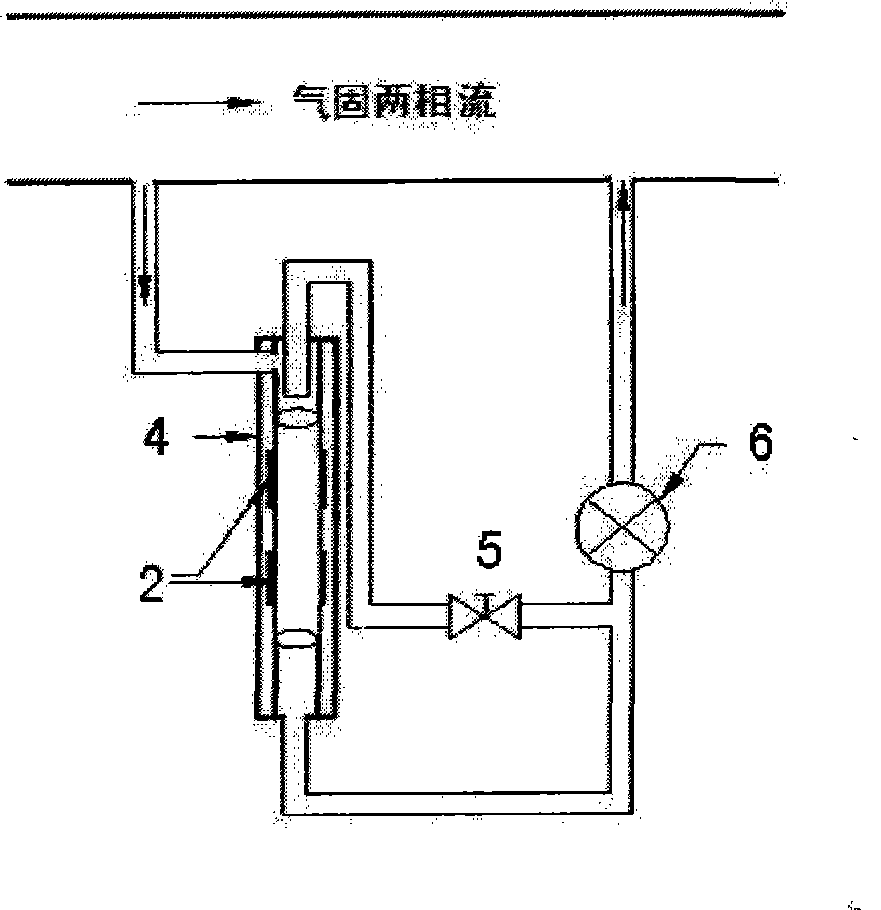

Measuring method and device of eddy flow enriched sparseness gas and solid two-phase flow capacitance chromatography imaging

InactiveCN101441099AHigh measurement accuracyImprove spatial resolutionVolume flow measuring devicesIndirect mass flowmetersGas solidAir pump

The invention discloses an eddy flow concentration sparse gas-solid two-phase flow capacitance chromatography imaging measurement method and device which belong to gas-solid two-phase flow measurement technology. The device includes an eddy flow concentration apparatus connected with a sparse gas-solid two-phase flow channel, the eddy flow concentration apparatus is connected with a control valve and an air pump, an outlet of the air pump is connected to the sparse gas-solid two-phase flow channel. The method includes that after eddy flow concentration of the sparse gas-solid two-phase flow, solid particle is concentrated at wall surface, solid particle concentration is measured by single-layer capacitance sensor, speed is measured by double-layer capacitance sensor, and mass flow of the solid particle can be calculated by combining the solid particle concentration and the speed. Capacitance chromatography imaging technology is used to measure improved measurement precision. The measurement method and sensor provided by the present invention integrate concentration, speed and mass flow measurement, have advantages of simple structure and convenient calibration, solve problem of measuring the sparse gas-solid two-phase flow in large-diameter pipeline by using the capacitance chromatography imaging technology, and have wide application field.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Coalbed gas high pressure desorption instrument

The invention relates to a coal bed gas high pressure desorption meter, while the prior coal bed gas high pressure constant temperature adsorption instruments utilizes coal powder samples to test coal bed gas constant temperature adsorption parameters, and the coal bed gas desorption test generally utilizes normal-pressure desorption instruments, to test the parameters of drilling well coal core, such as coal bed gas content and adsorption time and the like. The coal bed gas high pressure desorption meter comprises an automatic temperature control water bath apparatus, a stainless steel mechanical device, and an image and pressure data acquisition system, wherein the stainless steel mechanical device comprises a gas collection cylinder, a sample cylinder, a gas regulation cylinder, a frame, a high pressure pipeline and a valve, the cylinder is fixed on the frame, the frame and the cylinder are arranged in the automatic temperature control water bath device, and the frame is connected with a lifting machine. The invention can effectively simulate reservoir bed conditions and discharge-mining working systems, realize the switch between gas-solid two-phase system and gas-liquid-solid three-phase system under high pressure condition, the desorption, gas collection and measurement processes under high pressure water injection conditions, effectively observe the desorption of coal bed gas, and test the parameters such as desorption pressure, desorption quantity and lost gas quantity and the like.

Owner:XIAN RES INST OF CHINA COAL TECH& ENG GROUP CORP

Process and apparatus for the thermal treatment of pulverulent substances

InactiveUS7288501B2Safe handlingMaterial nanotechnologyCatalyst activation/preparationGas solidThermal treatment

Process and apparatus for the thermal treatment of pulverulent substances, in which the pulverulent substance is dispersed in a carrier gas and is passed in a continuous manner through a heated reactor where it is thermally treated and is then quenched by a cooling medium and is collected in a gas-solids separating unit.

Owner:UMICORE AG & CO KG

Processing method of cellulose industrial biomass waste and process device thereof

ActiveCN102311742AWide adaptabilityOvercome the disadvantages of difficult continuous processingWaste processingCarbon compoundsCellulosePorous carbon

The invention discloses a processing method and a process device of cellulose industrial biomass wastes, and the method comprises the following steps: feeding raw materials into a drying system continuously, supplying heat by high-temperature flue gas from the combustion of volatile matter precipitated in pyrolysis and carbonization so as to dry the raw materials; allowing the dried raw materials to enter a carbonization reactor for pyrolysis and carbonization, delivering the intermediate products of pyrolysis and carbonization to a riser reactor, preparing porous carbon-based adsorption functional material (namely active carbon), syngas (or called biomass gas), or steam under the action of an oxidative medium and an activator, or an oxidative medium and an gasifying agent, or an oxidative medium. The steam required by the system is prepared by the activated or gasified high-temperature gas-solid products through heat exchange, which can increase the energy recovery efficiency of the process; the process adopts a continuous running mode with complete self-heating, and realizes the high-value conversion of cellulose industrial biomass wastes.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Sludge harrow type drying method and device

InactiveCN102674655AIncrease production capacityImprove work efficiencySludge treatment by de-watering/drying/thickeningGas solidSludge

The invention relates to a method for drying sludge and a drying device. A heat medium ( generally hot gas fume or hot air) for drying the sludge enters a sludge harrow type dryer from the tangential direction; wet sludge is added from one end of the harrow type dryer and is directly contacted with the heat medium in the drier to realize the drying process; the harrow type device can crush the block-shaped sludge and push the sludge from an inlet to an outlet; dry sludge is moved to the other end of the harrow type drier under the functions of the drying medium and the harrow type device and is separated from the drying medium through a function of an internal gas-solid separator and discharged out of the drier. The method has the characteristics that the drier can be securely and continuously operated, so that the obvious effects of high heat efficiency, low energy consumption and high yield are achieved.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com