Combustible material plasma high-temperature gasification technique and equipment thereof

A plasma and plasma torch technology, which is applied in the field of plasma high-temperature gasification process and its equipment, can solve the problems of low carbon conversion rate, low proportion of syngas effective components, equipment pollution, etc., and achieve gasification efficiency and carbon conversion rate. Improved, simple fuel pretreatment, low ash content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

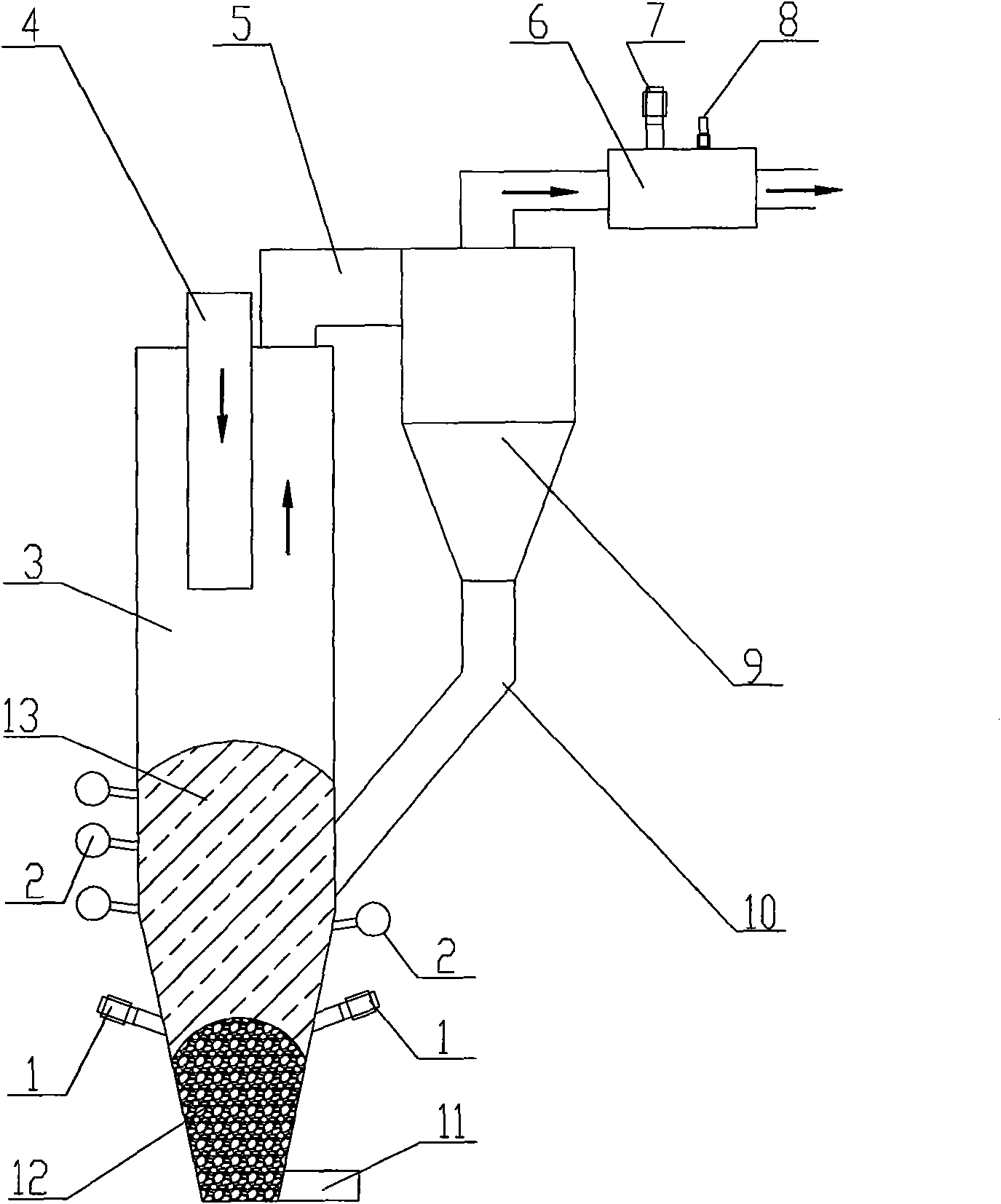

[0038] Below in conjunction with accompanying drawing and specific embodiment, equipment and process of the present invention are described in further detail:

[0039] The combustible material plasma high-temperature gasification equipment shown in the figure is mainly composed of three parts: gasifier, gas-solid separator and tar remover. Wherein, the gasifier has a gasifier shell 3, and the top of the gasifier shell 3 is provided with a feeding device 4, and the length of the feeding device 4 extending into the gasifier can be determined according to the capacity of the actual gasifier. Adjustment. A coke bed 12 can be laid on the bottom of the gasifier shell 3 through the feeding device 4 , and a fuel bed 13 can be laid on the coke bed 12 .

[0040] A primary plasma torch 1 and a primary oxidant nozzle 2 are arranged on the lower side wall of the gasifier shell 3 . In order to ensure a uniform temperature field, there are 2 to 6 primary plasma torches 1, which are evenly ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com