Patents

Literature

286results about How to "Improve carbon conversion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

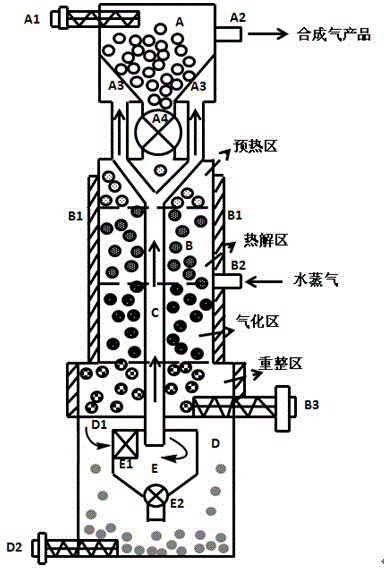

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

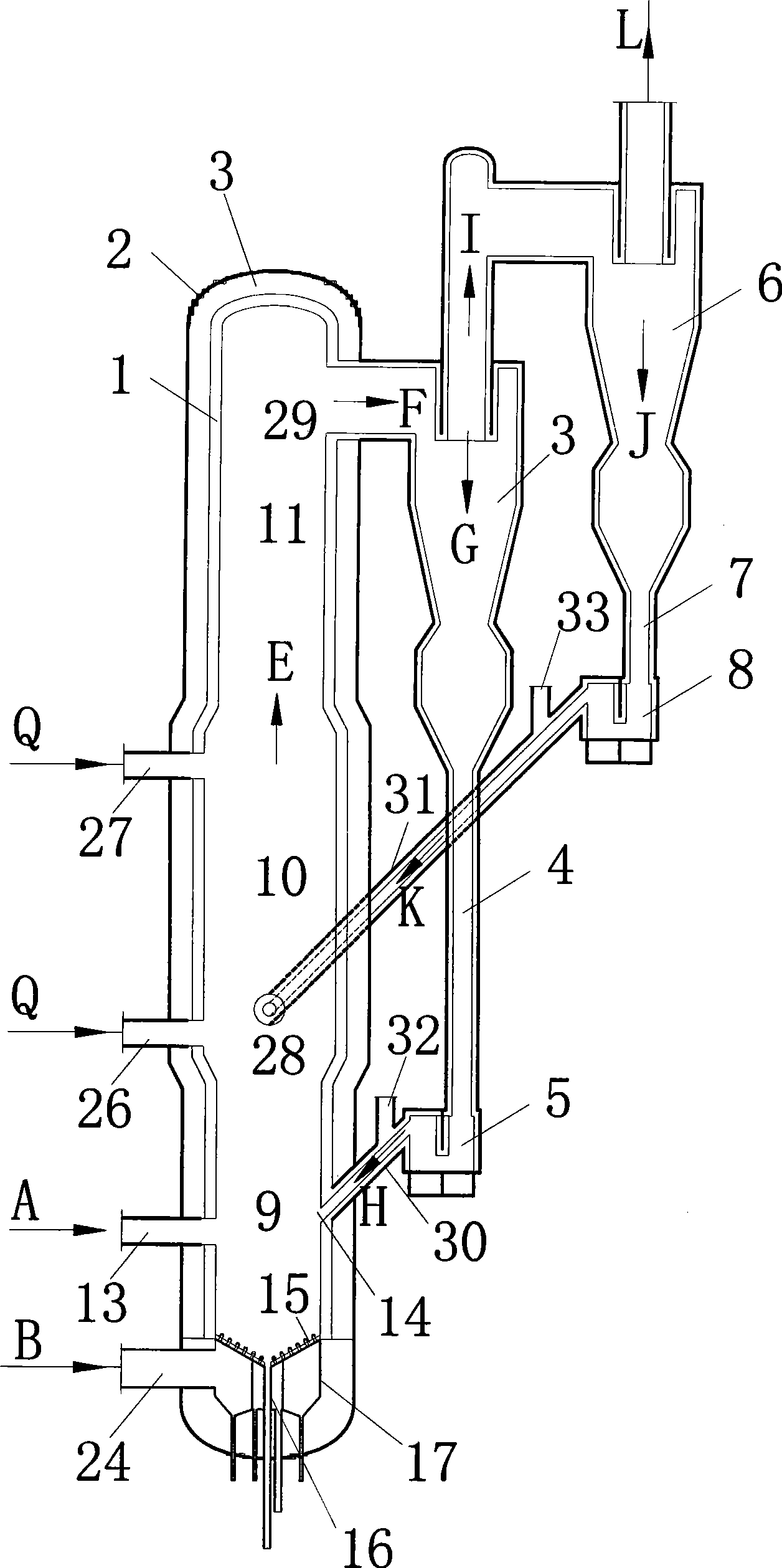

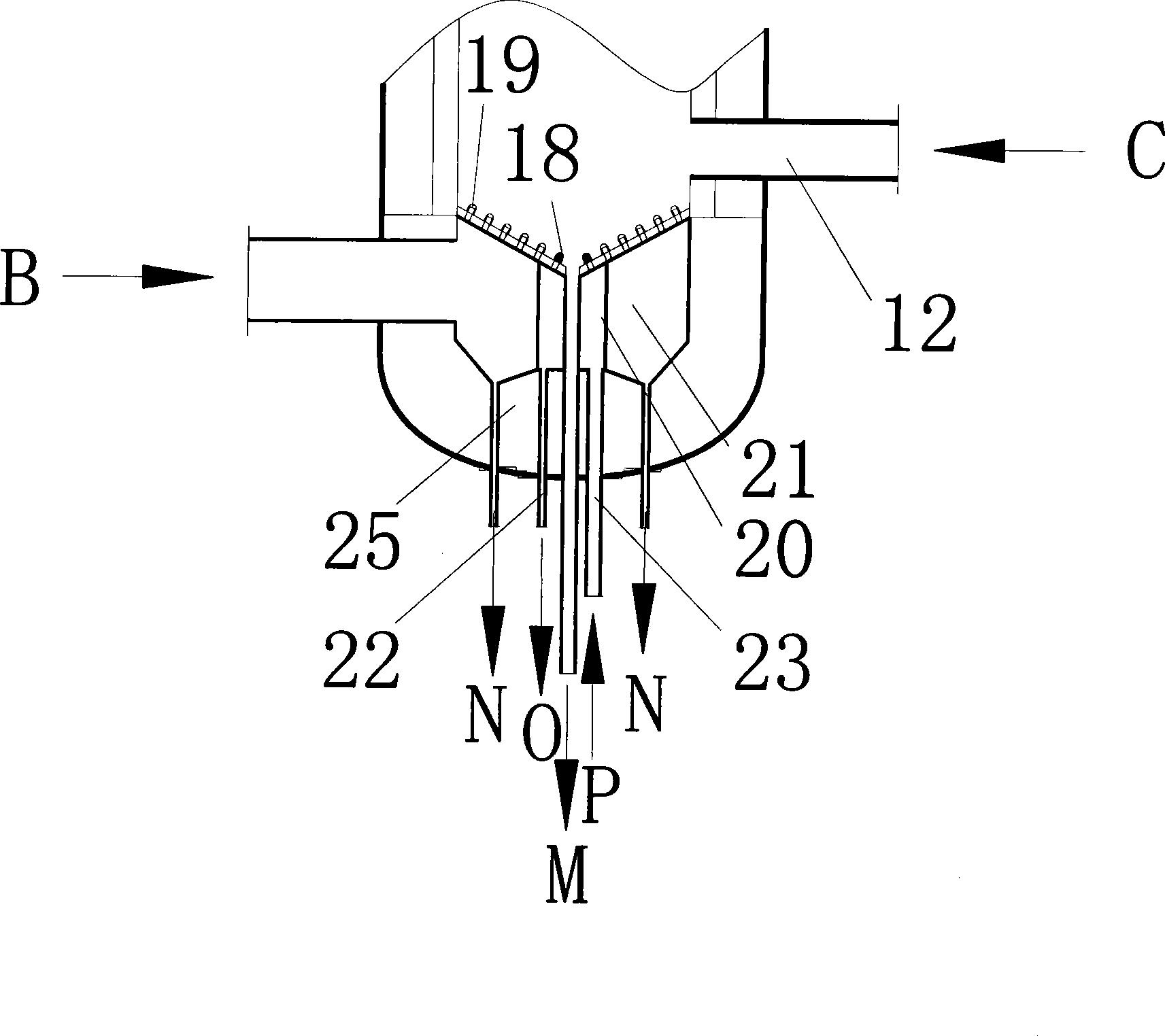

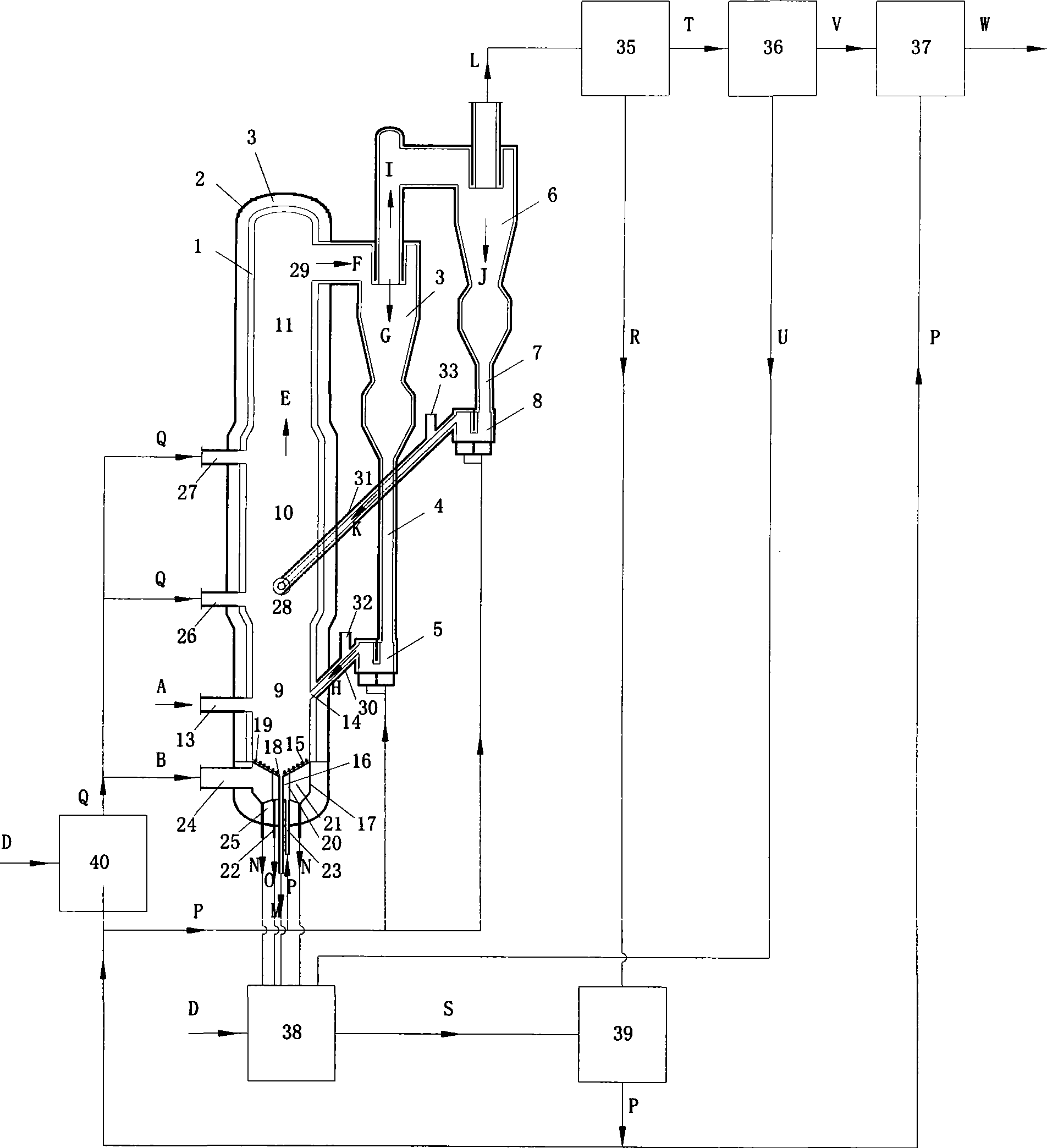

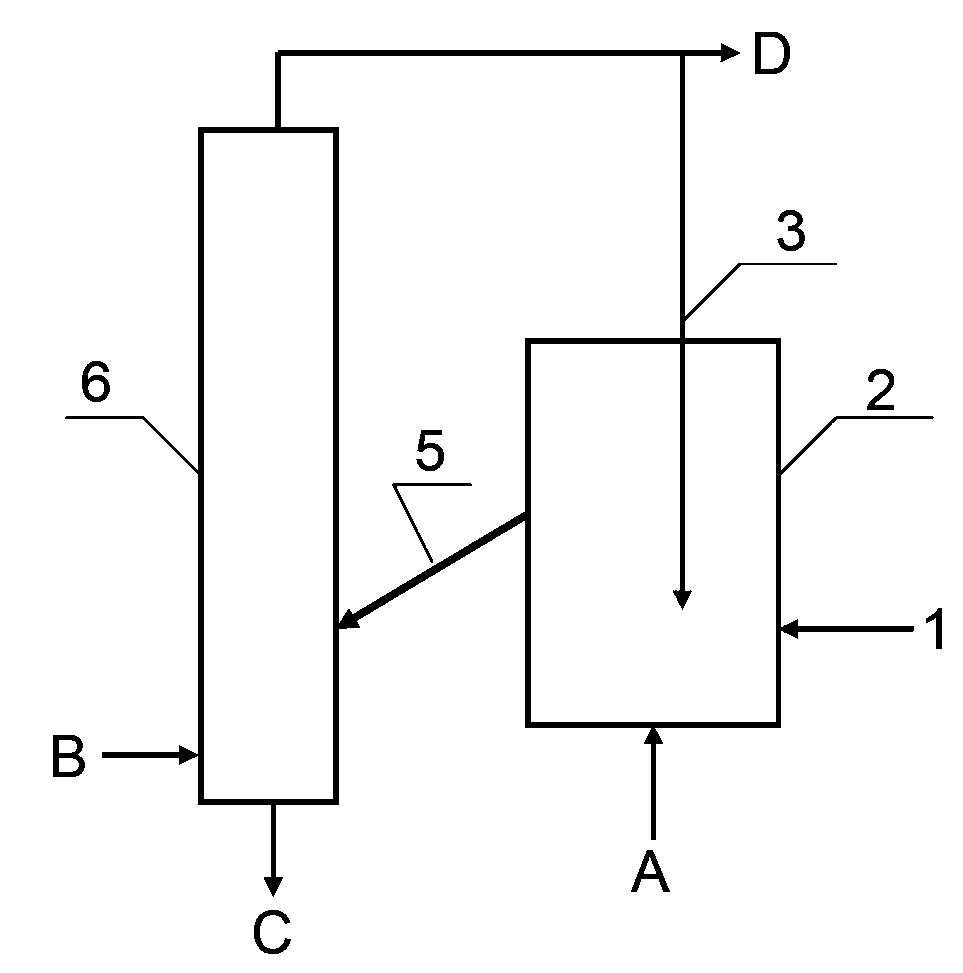

Method and device for coal gasification in combined type fluidized bed

ActiveCN102533345AImprove gasification efficiencyEasy to handleEnergy inputGranular/pulverulent flues gasificationRetention timeSlag

The invention discloses a method for coal gasification in a combined type fluidized bed, which comprises coal preparation, gas supply, gasification, slag discharge, dedusting, waste heat recovery and fine powder conveying. An ash agglomeration fluidized bed realizes gasification of large-particle coal; the non-completely converted carryover fine powder enters an entrained flow bed gasifier in a dense phase pneumatic conveying manner; secondary gasification is carried out by using a short retention time high temperature gasification manner; the produced ash slag is carried into an intersection segment of the fluidized bed and the entrained flow bed with high temperature coal gas, and rapidly mixed with ''low temperature'' large-particle partially carbonized coal in the fluidized bed and the produced ''low temperature'' coal gas; and partial ash slag is selectively discharged out of the gasifier in the form of solid. The method and the device of the invention have the advantage of being suitable for various coal types and high in carbon conversion rate.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

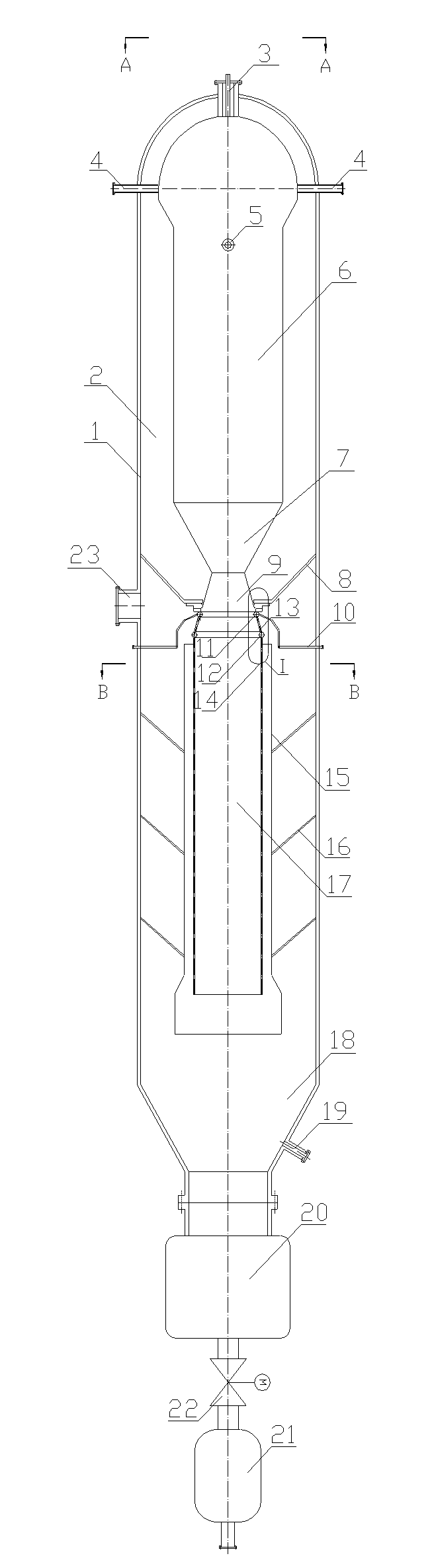

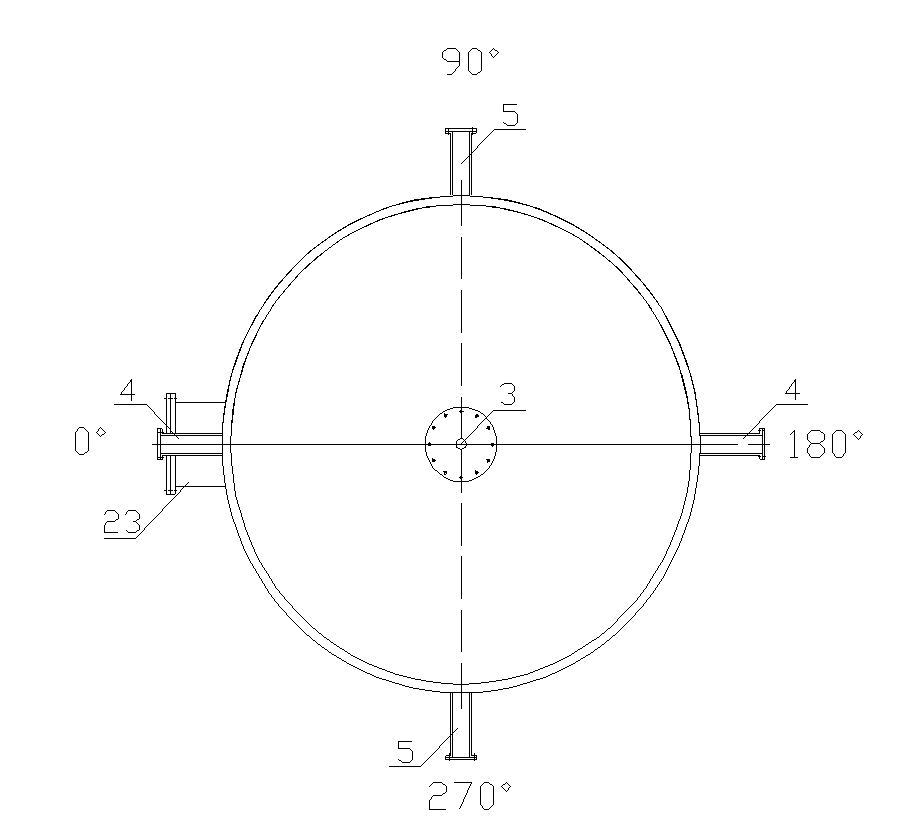

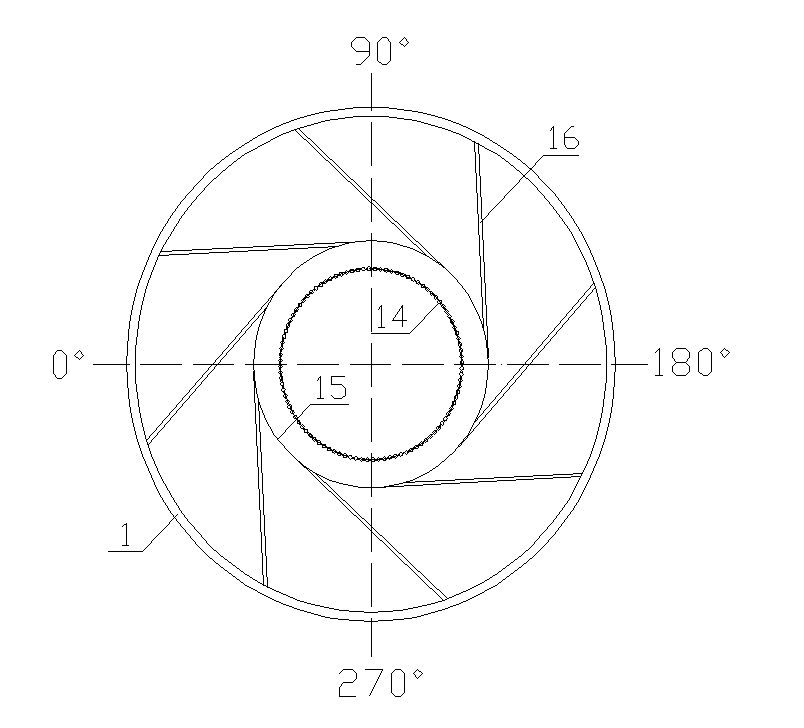

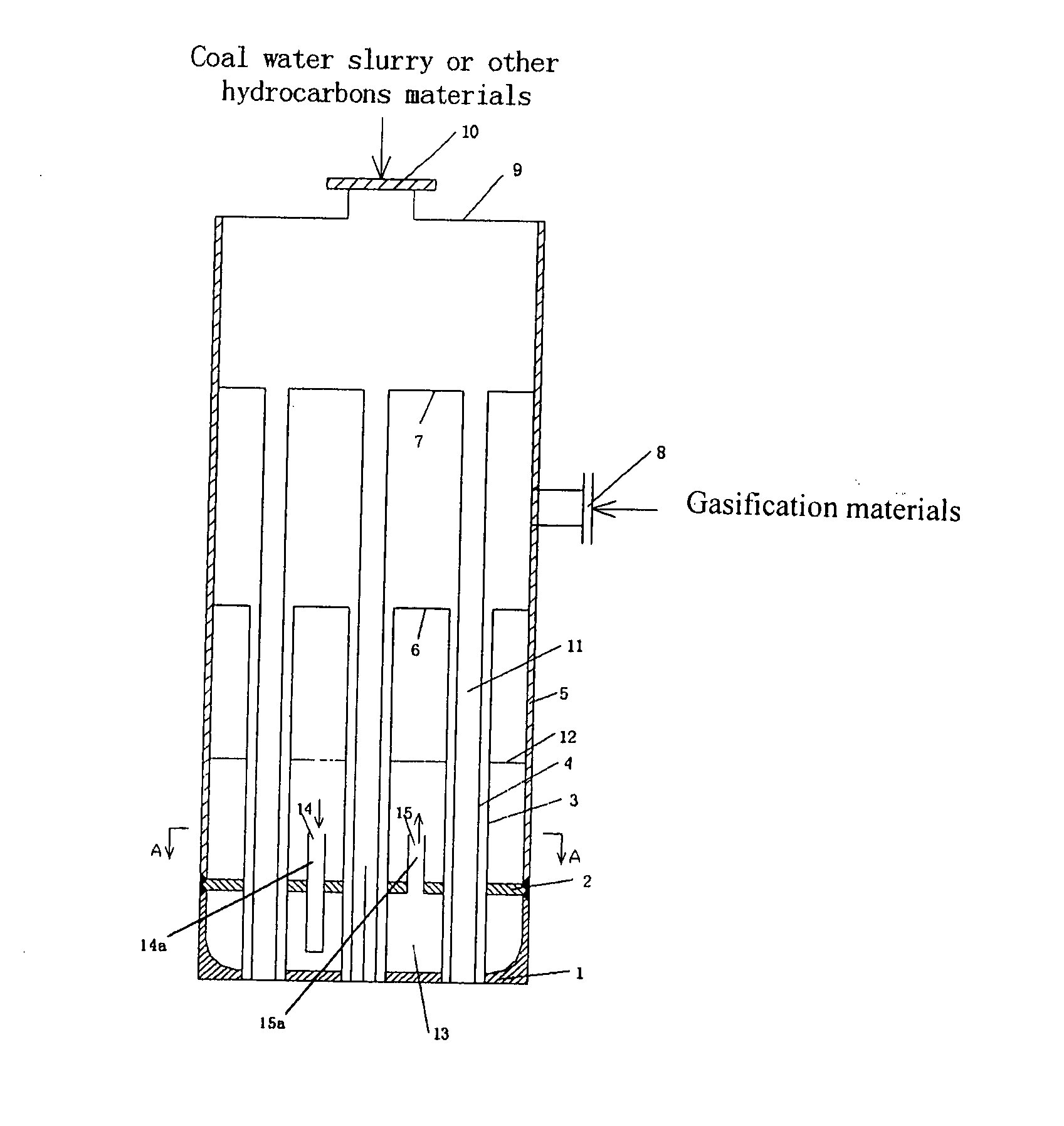

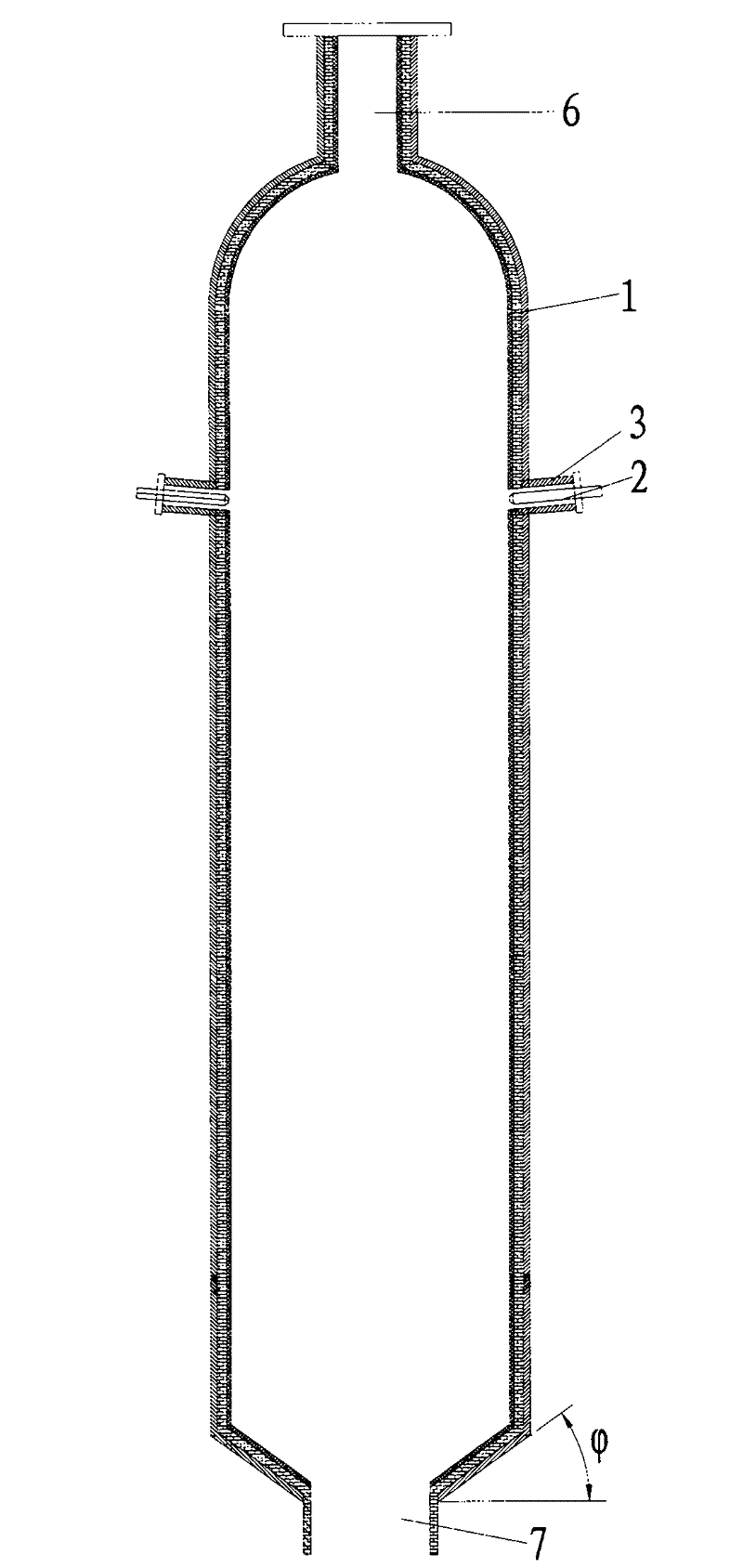

High-density pressurized fluidized bed coal gasification apparatus and method

ActiveCN101372635AGood amplification performance of flow dynamic characteristicsImprove carbon conversionCombined combustion mitigationGranular/pulverulent flues gasificationProcess engineeringTransformation ratio

A high-density pressurized fluid bed coal gasification device and a method relate to a gasification device and a method which are especially suitable for the efficient treatment of the high-sulfur, high-ash and high ash fusion point coal with high reserve volume in China and have the advantages of broad coal type adaptability, high carbon transformation ratio in the gasification process, high heat value of coal gas, low investment and excellent environment-friendly performance. A gasification reactor (1) is arranged in a pressure shell (2) and is divided into a dense-phase turbulent flow fluidizing section (9), a high-density core-annulus flow section (10) and a density rapid flow section (11) from bottom to top, and according to the gasification character of the goal with high sulfur, high ash and high ash fusion point, flow states with different features are adopted for pressurizing and sectionalized gasification from bottom to top and the pressure for gasification is 1.0-2.5MPa.

Owner:SOUTHEAST UNIV

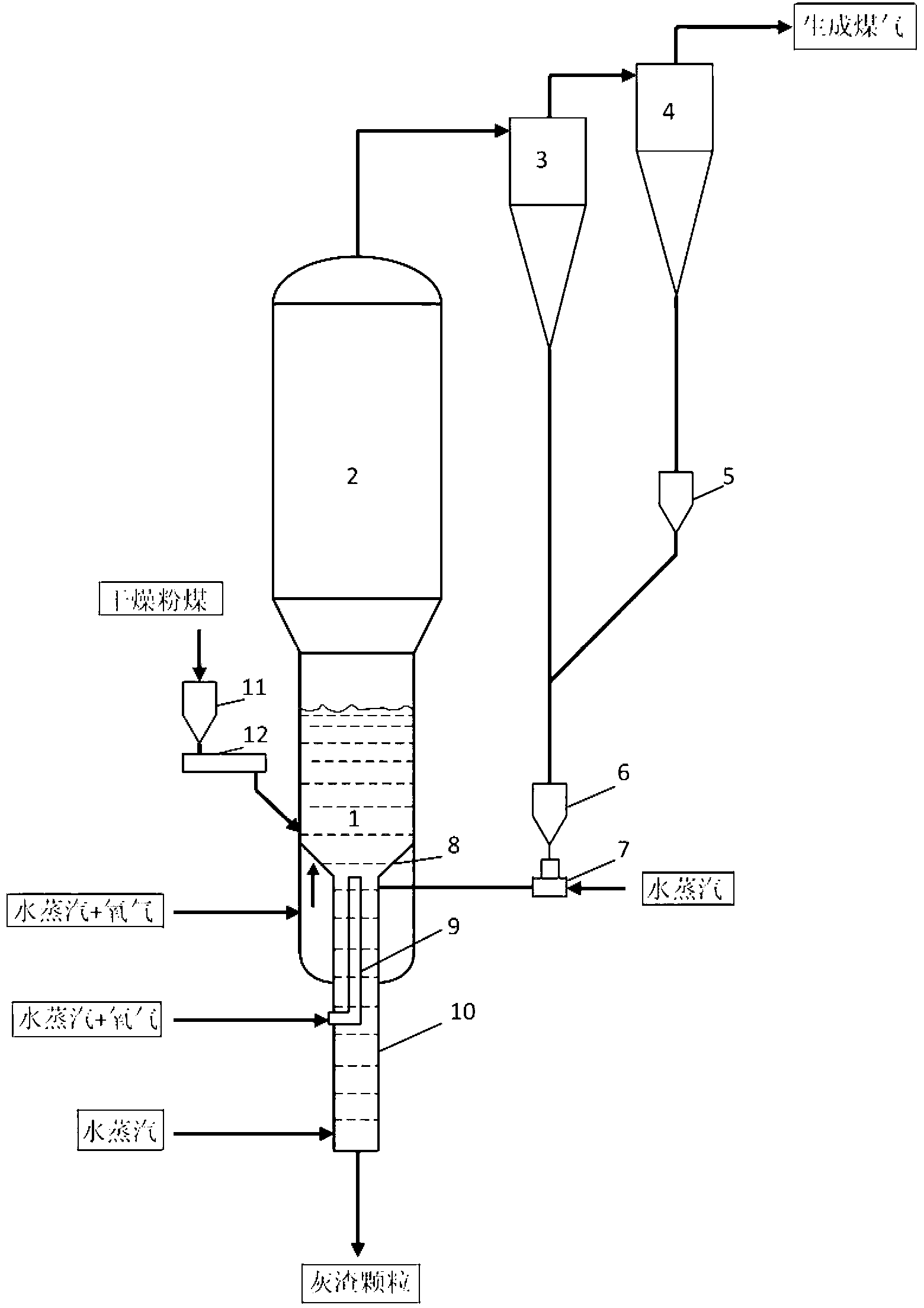

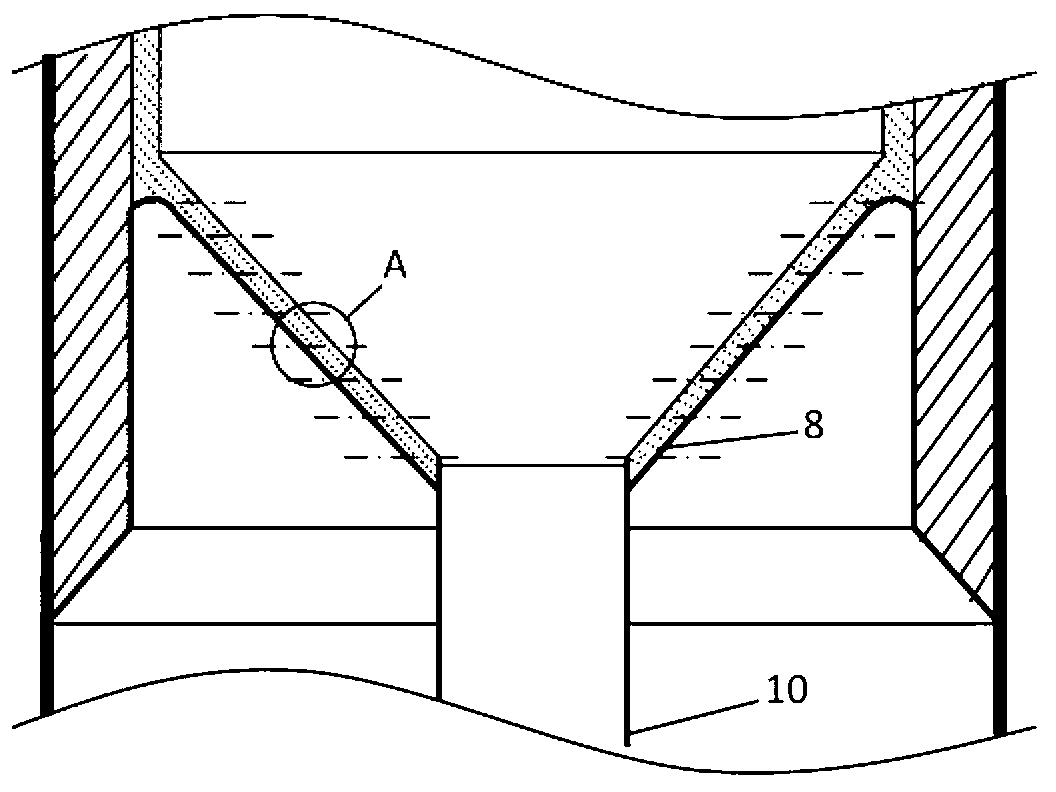

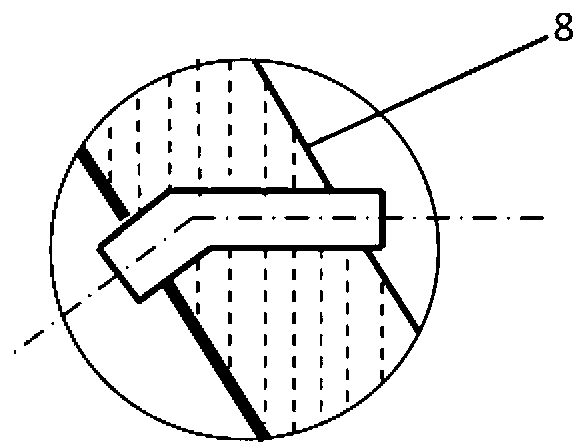

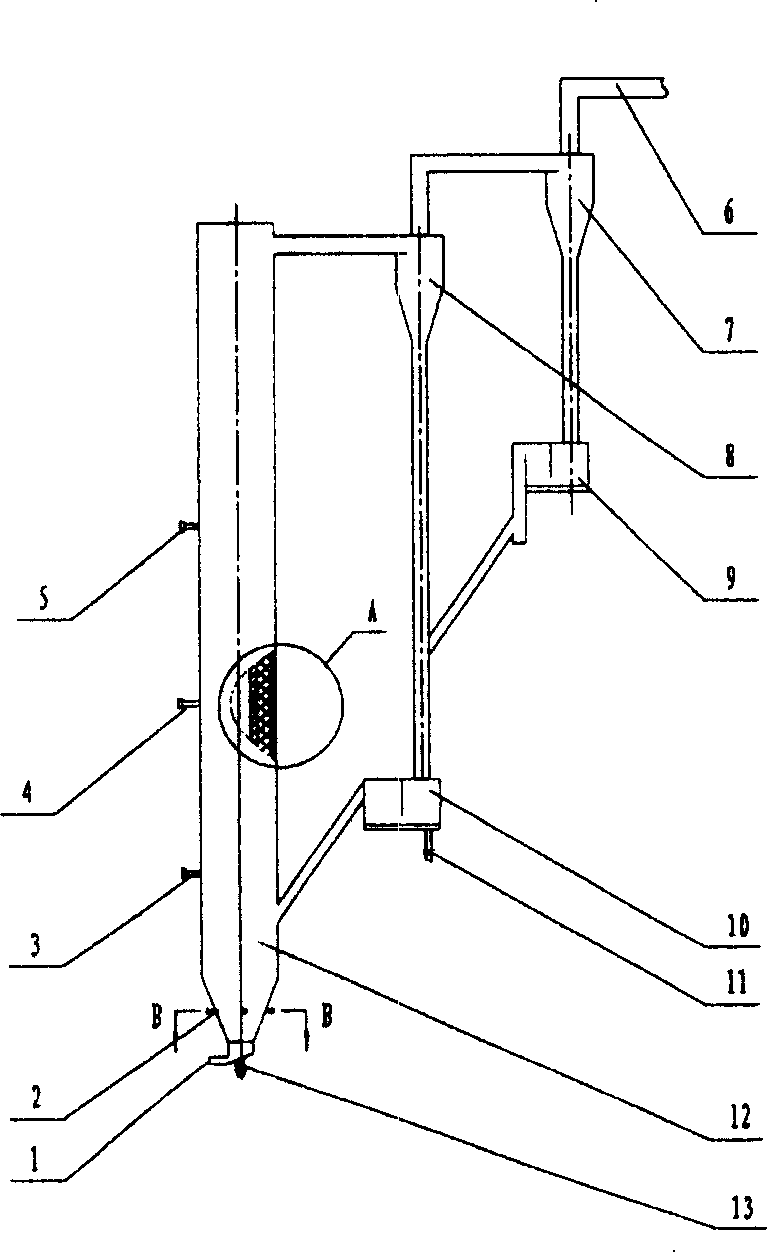

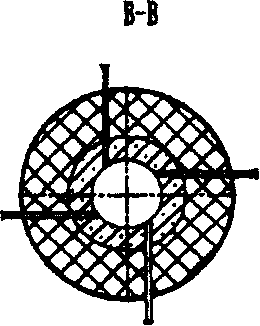

Fine coal gasification method with fly ash compulsory recycling system

InactiveCN103184077AImprove carbon conversionAvoid cloggingGranular/pulverulent flues gasificationPhencycloneFluidized bed

The invention relates to a fine coal gasification method with a fly ash compulsory recycling system, which is characterized in that coal gas produced by the fine coal gasification reaction carries fly ash particles; gas and fly ash particles in the coal gas carrying with the fly ash particles can be separated through a cyclone separator; and the separated fly ash particles enter the lower part of a gas distribution plate (8) of a gasifer to conduct further burning and gasification reaction. According to the method provided by the invention, a gas ejector (7) is mounted between a vertical tremie pipe of a fine coal fluidized bed coke powder circulating system and the gasifer, and the recovered fly ash particles pass the lower part of the gas distribution plate, and then directly enter a high-temperature oxidation zone in the center area of the gasifier by the gas ejector to conduct further burning and gasification reaction, so that the carbon conversion efficiency of the fine coal is improved, and the carbon conversion efficiency of wood coal and bituminous coal can achieve above 98 percent. Even though for the 'three high one low' poor coal, namely the coal with high sulfur, high ashy, high ash fusion temperature and low reactivity, the conversion rate of one way coal can also achieve above 92 percent.

Owner:ZHEJIANG ZHONGGONG PETROCHEMICAL EQUIP CO LTD

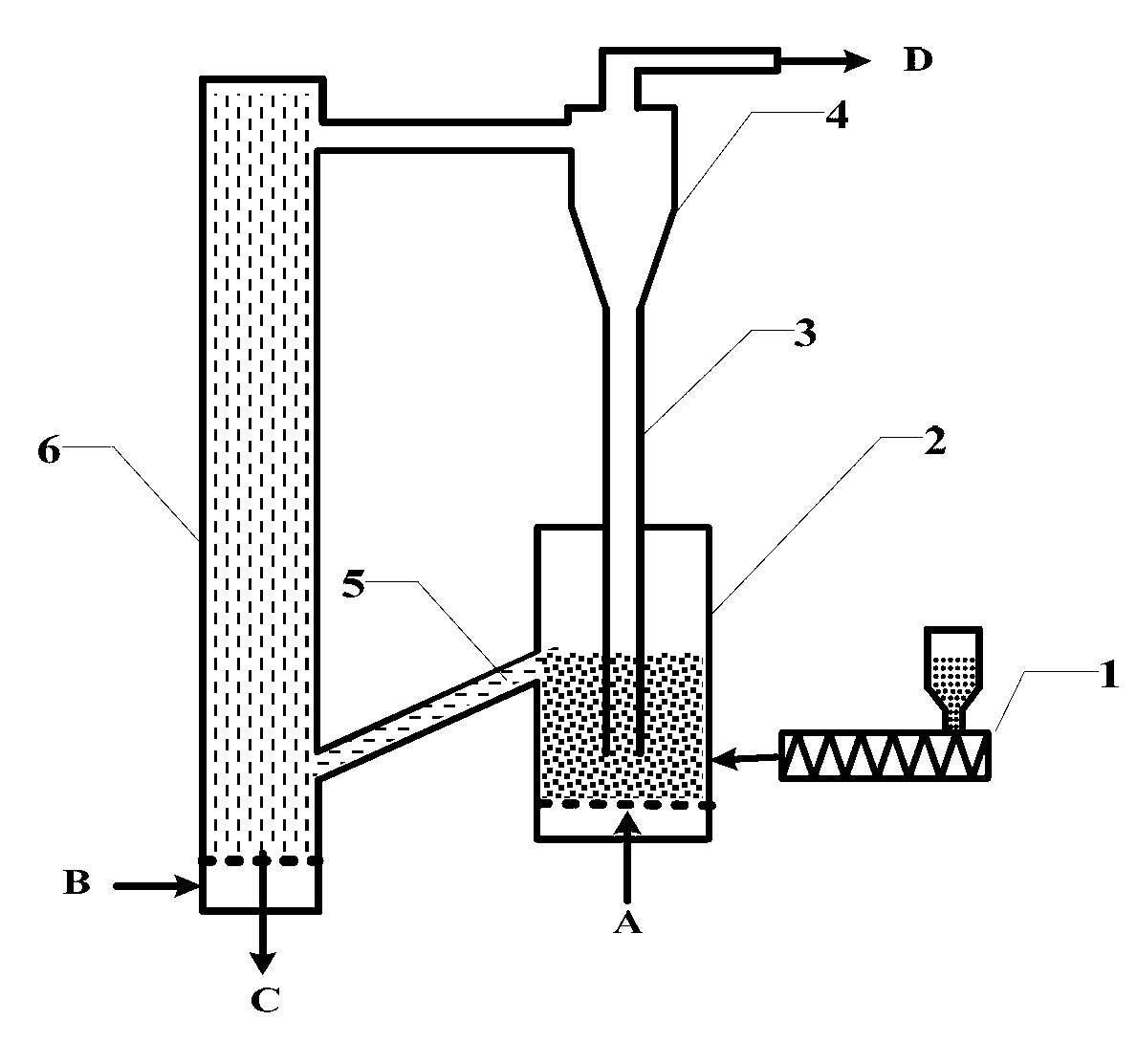

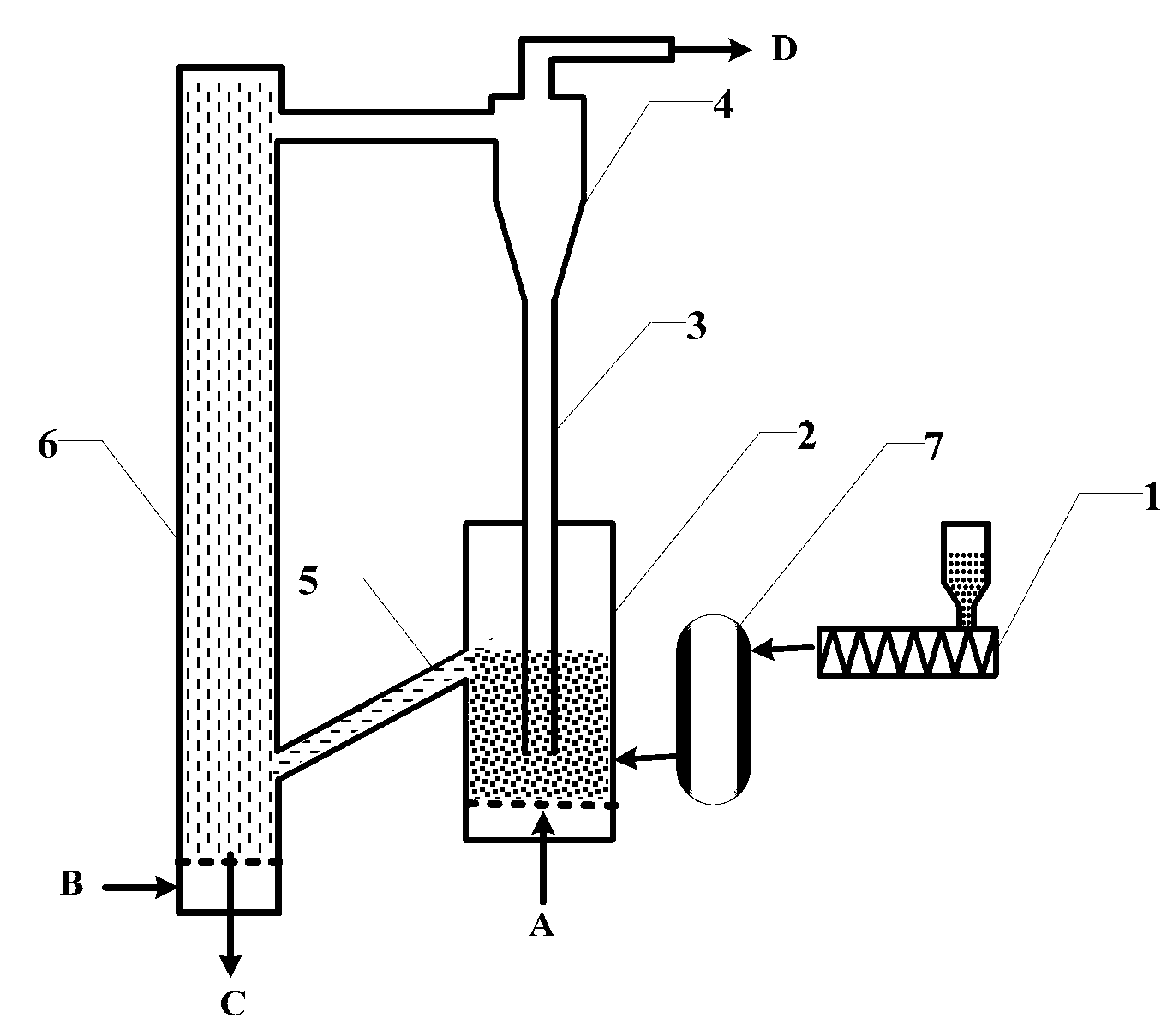

Fine coal pressurization dense phase transporting bed gasification method and device

ActiveCN101240196AIncrease speedGuaranteed to loop multiple timesCombined combustion mitigationGranular/pulverulent flues gasificationHigh rateHigh flux

A pulverized coal pressure dense transport bed gasification method and installation of the invention relates to gasification technology and employs in-furnace desulfurization craft. Pulverized coal and desulfurizer are sent into gasification furnace through the middle and lower part of gasification furnace by a feeder, and then react with a gasifying agent. Reaction mass flow upward from the bottom of the gasification furnace, and enter into a multistage gas-solid separator from an export on the top of the gasification furnace. Most solids are separated in the gas-solid separator and enter into the low part of the gasification furnace by a high flux return feeder to continue to participate in reaction. Gas products with a small amount of solid enter into a gas cooler which can recover gas manifested heat to generate steam. The enter modes of the gasifying agent are bottom once wind and cyclone twice wind, otherwise, the reactor can also be use to burn. Because of the high-rate cycle, high solid content and high gas-solid mixing in the gasification furnace of the invention, the gasification strength and gasification rate of the gasification furnace can be improved and higher gasification efficiency and carbon conversion rate can be obtained.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

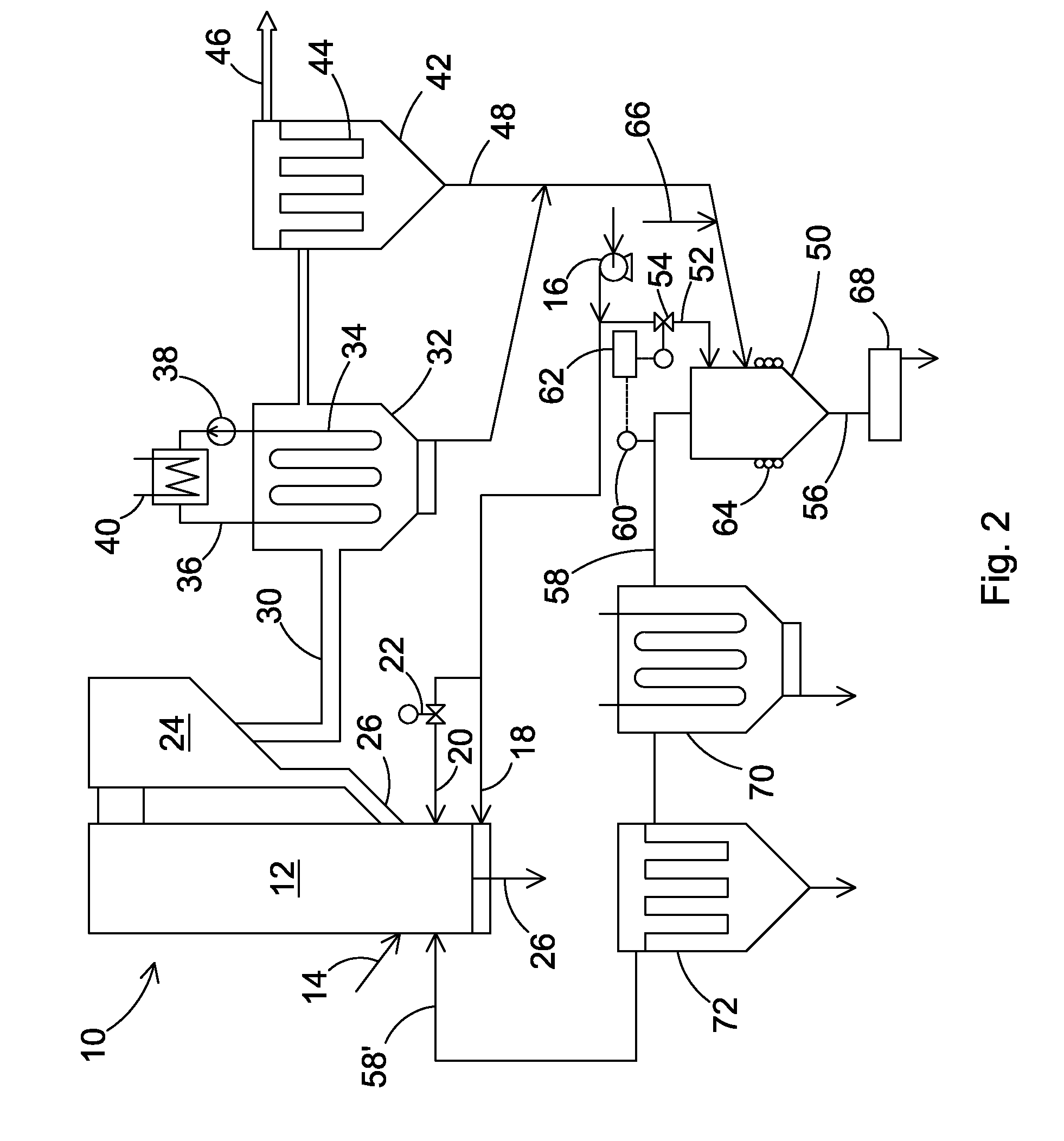

Two-stage gasification method and gasification device for fuels with wide size distribution

ActiveCN102703131AExtensive sources of raw materialsWide particle size distributionCombined combustion mitigationGranular/pulverulent flues gasificationTarProcess engineering

The invention relates to a two-stage gasification method and a gasification device for a fuel with wide size distribution. The two-stage gasification method for the fuel with wide size distribution comprises the steps of 1) adding the fuel to a fluidized bed pyrolyzer by a feeding device; adding a gasifying agent to the fluidized bed pyrolyzer; drying / pyrolyzing or partly gasifying the fuel under semicoking of the pyrolyzer and heating of the gasifying agent; and 2) sending the solid and gas generated in the step 1) to a fluidized bed gasification furnace, adding the gasifying agent to the fluidized bed gasification furnace, finishing complete gasification of semicoke; removing tar by high-temperature pyrolysis, part oxidization and semicoke catalytic reforming in the fluidized bed so as to produce clean gas. With the adoption of the method, the traditional fuel gasification process is divided into a material pyrolysis stage and a semicoke gasification stage, which are performed in an upper fluidized bed pyrolyzer and a lower fluidized bed gasification furnace.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

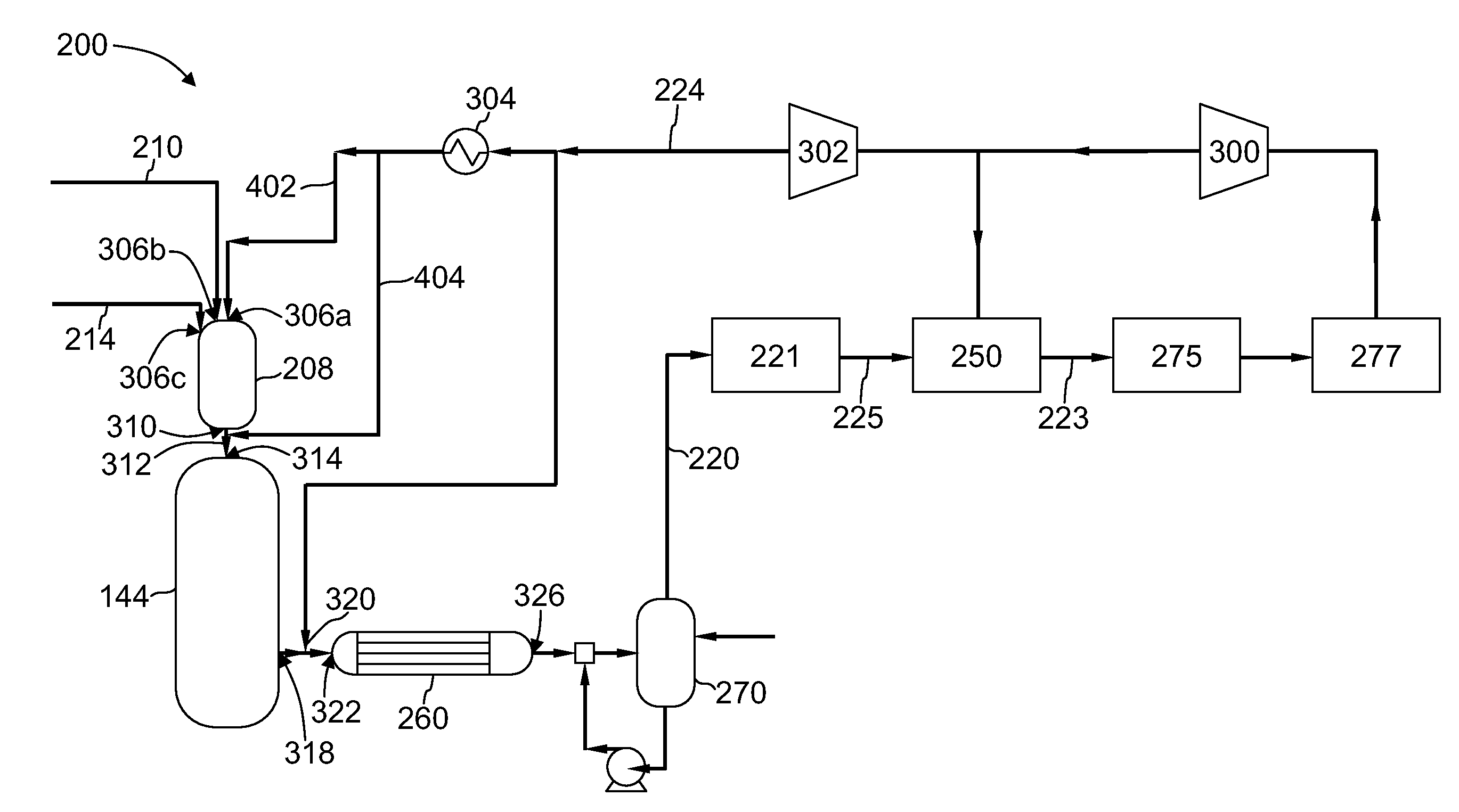

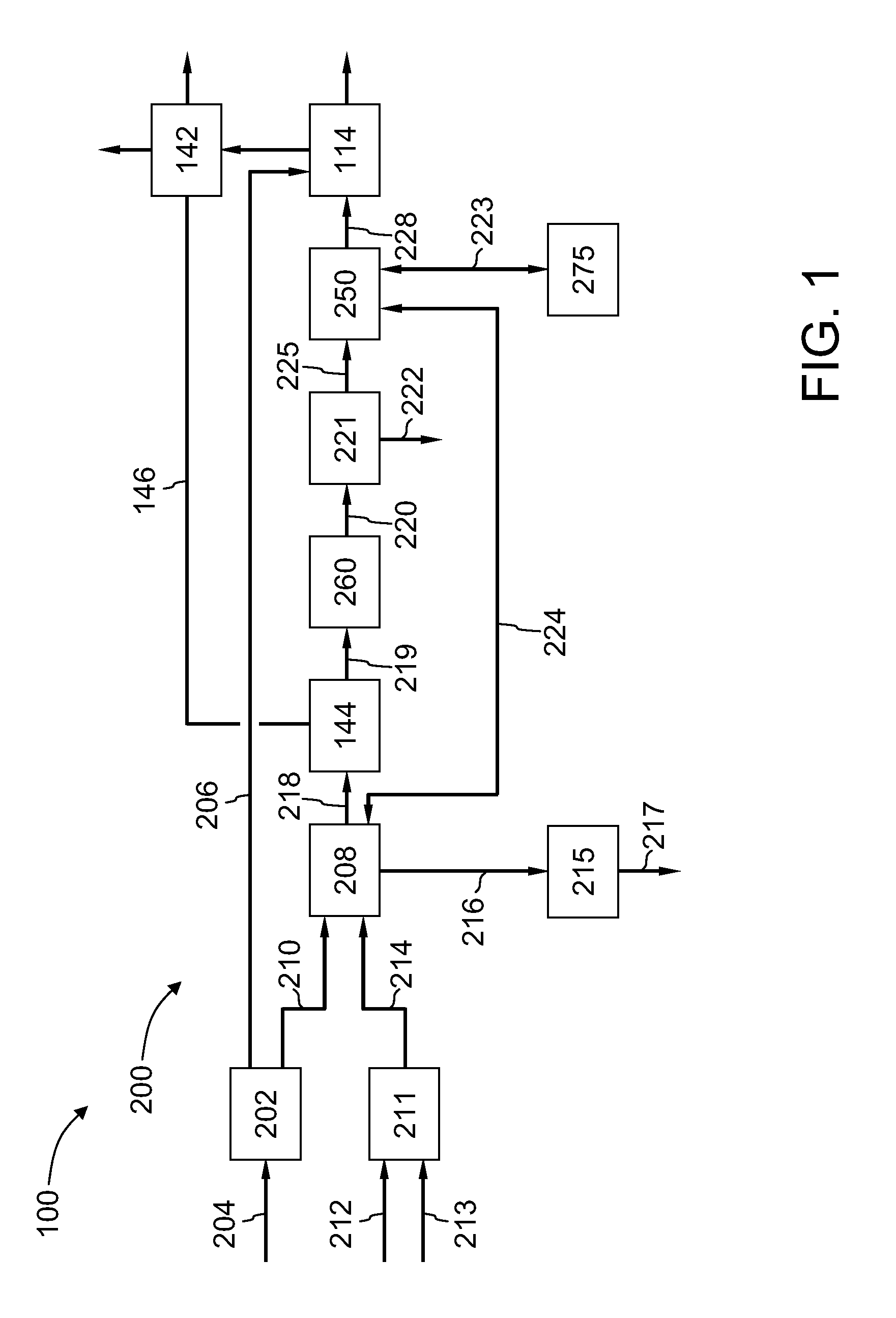

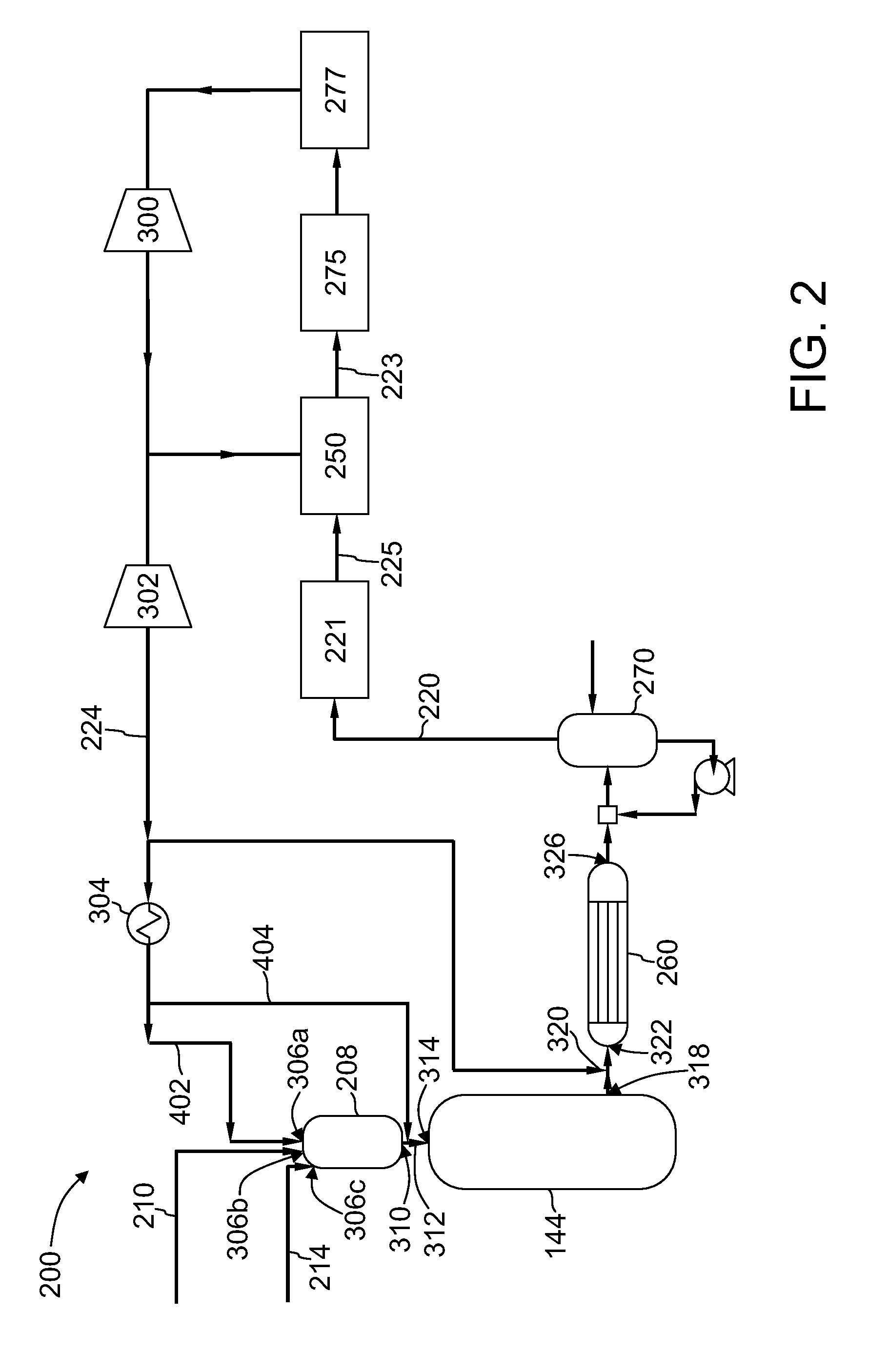

Methods of recycling carbon dioxide to the gasification system

ActiveUS20100324156A1Improve cooling effectEasy to produceUsing liquid separation agentGas modification by gas mixingSyngasChiller

Method of producing syngas in an IGCC system, comprising compressing and heating carbon dioxide-rich gas to produce heated compressed carbon dioxide-rich gas, mixing the heated compressed carbon dioxide-rich gas with oxygen and feedstock to form a feedstock mixture, subjecting the feedstock mixture to gasification to produce syngas, cooling the syngas in a radiant syngas cooler, contacting syngas cooled in the radiant syngas cooler with compressed carbon dioxide-rich gas to further cool the syngas, and removing an amount of carbon dioxide-rich gas from the product mixture and compressing the removed carbon dioxide-rich gas prior to mixing with oxygen and feedstock.

Owner:AIR PROD & CHEM INC

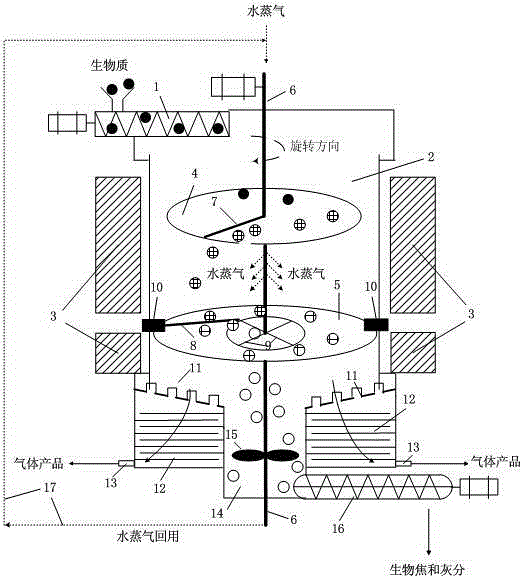

Method for continuous pyrolysis and gasification of material

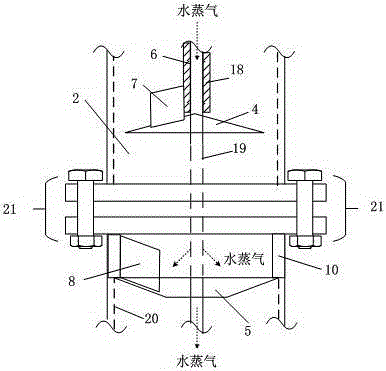

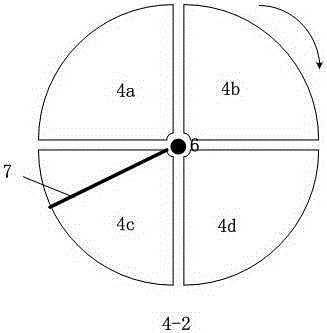

ActiveCN106675661ASmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

The invention discloses a method for continuous pyrolysis and gasification of a material. The method comprises the following steps: 1, a raw material and a catalyst enter a microwave pyrolysis and gasification system, fall to a first-stage rotating disc of a microwave reaction chamber, and sequentially undergo drying, activating and pyrolysis treatment with rotating; 2, a pyrolysis treated material falls to a second-stage rotating disc of the microwave reaction chamber, and the pyrolysis treated material and a pyrolysis volatile compound undergo a gasification and reforming reaction under the action of water vapor; and 3, a solid product obtained in step 2 falls to a residue storage tank below the microwave reaction chamber from middle holes of the second-stage rotating disc through a second-stage pushing baffle plate, and is discharged from a reaction system under stirring and screw dual action, and a gas product enters a settlement chamber from an annular sieve plate at the bottom of the microwave reaction chamber, and undergoes settlement treatment to obtain the gasification product. The method has the advantages of fast cracking speed, high gasification efficiency, high quality of the gas product, meeting of liquid fuel synthesis requirements, and good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

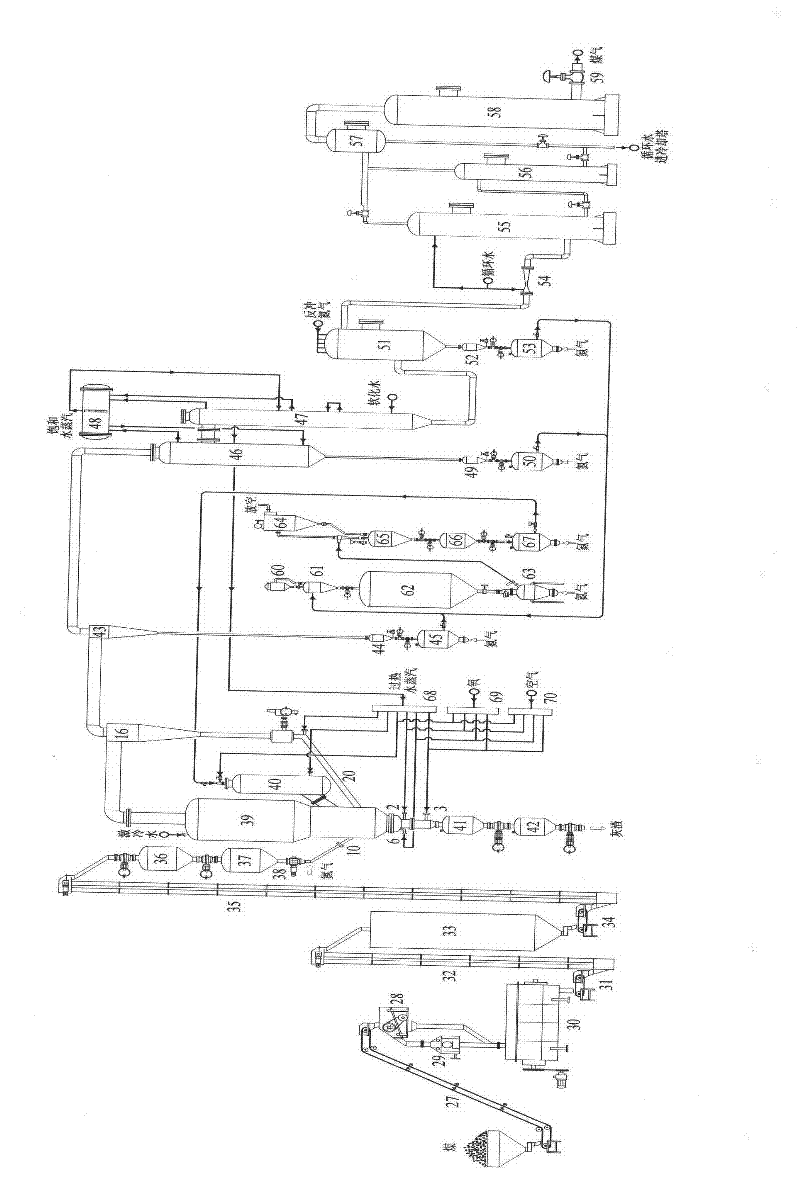

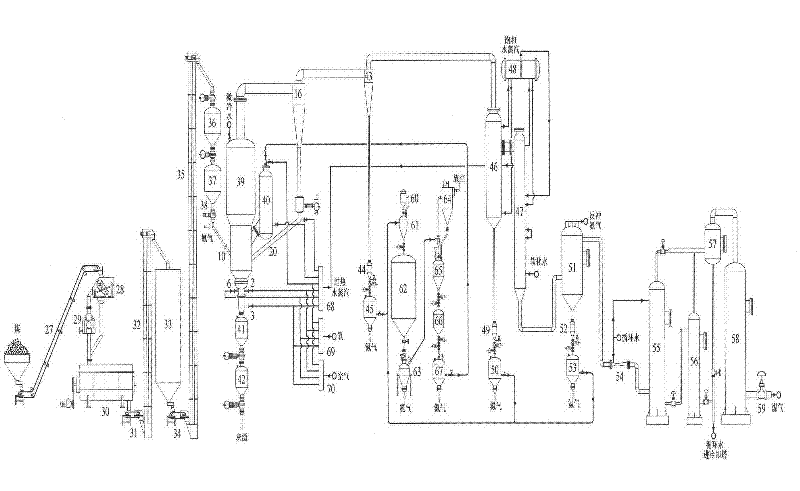

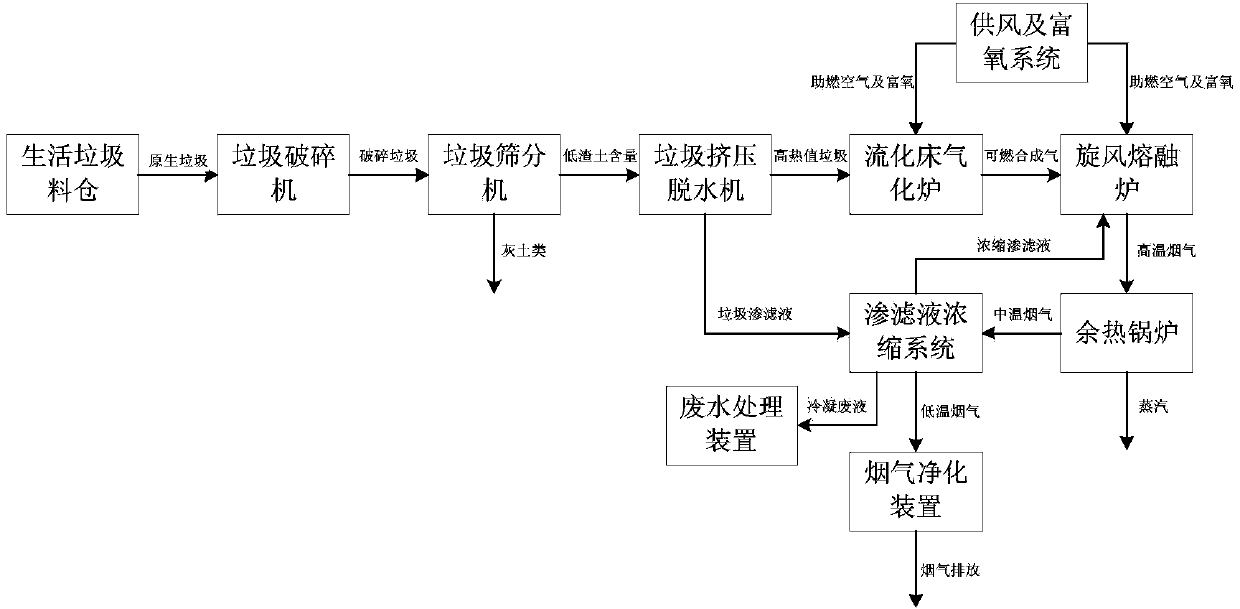

System and method for gasification melting of household refuse and treatment of household refuse leachate

ActiveCN103471105AHigh calorific valueAchieve enrichmentIndirect carbon-dioxide mitigationIncinerator apparatusCrusherTreatment system

The invention provides a system and a method for gasification melting of household refuse and treatment of household refuse leachate. The system comprises a household refuse pretreatment system, a refuse energy recovering system and a refuse leachate concentration and flue gas treatment system, wherein the household refuse pretreatment system comprises a household refuse stock bin, a household refuse crusher, a household refuse sieving machine and a household refuse extrusion dehydrator which are sequentially connected; the refuse energy recovering system comprises a fluidized-bed gasifier, a cyclone melting furnace, a waste heat boiler and an air-supplying and oxygen-enriching system matched with the fluidized-bed gasifier, the cyclone melting furnace and the waste heat boiler; the refuse leachate concentration and flue gas treatment system comprises a leachate concentrating system, a flue gas purifying device and a wastewater treatment device. According to the system, the heat value of the refuge is increased by a pretreatment process; an oxygen-enriching gasifier and a high-temperature cyclone melting furnace technology are used as a recovering system of refuge energy; the refuge leachate is concentrated by using medium-temperature flue gas exhausted by the waste heat boiler; the concentrated leachate is sprayed into the high-temperature cyclone furnace for harmless treatment.

Owner:陕西圣昊朗道科技有限公司

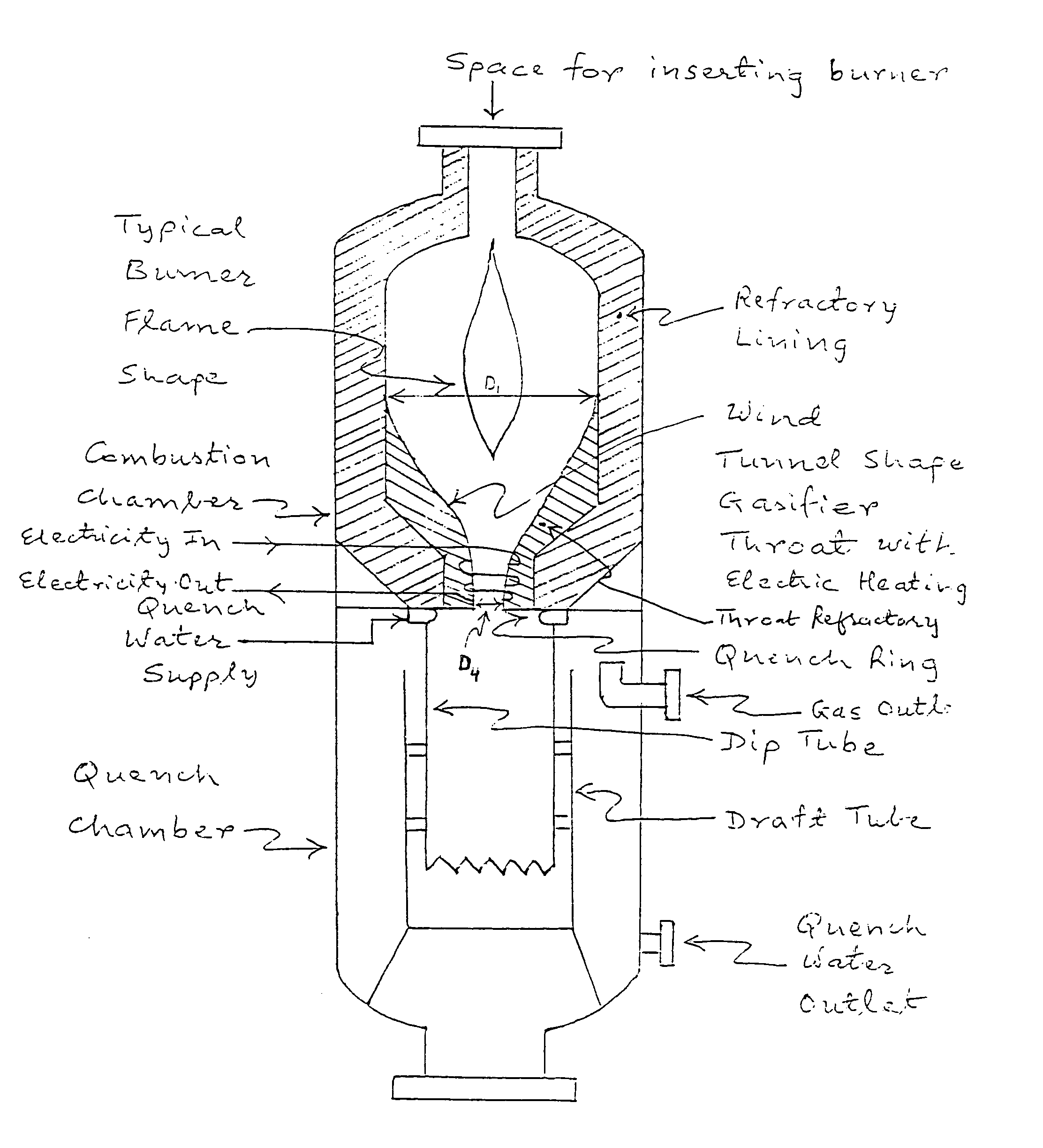

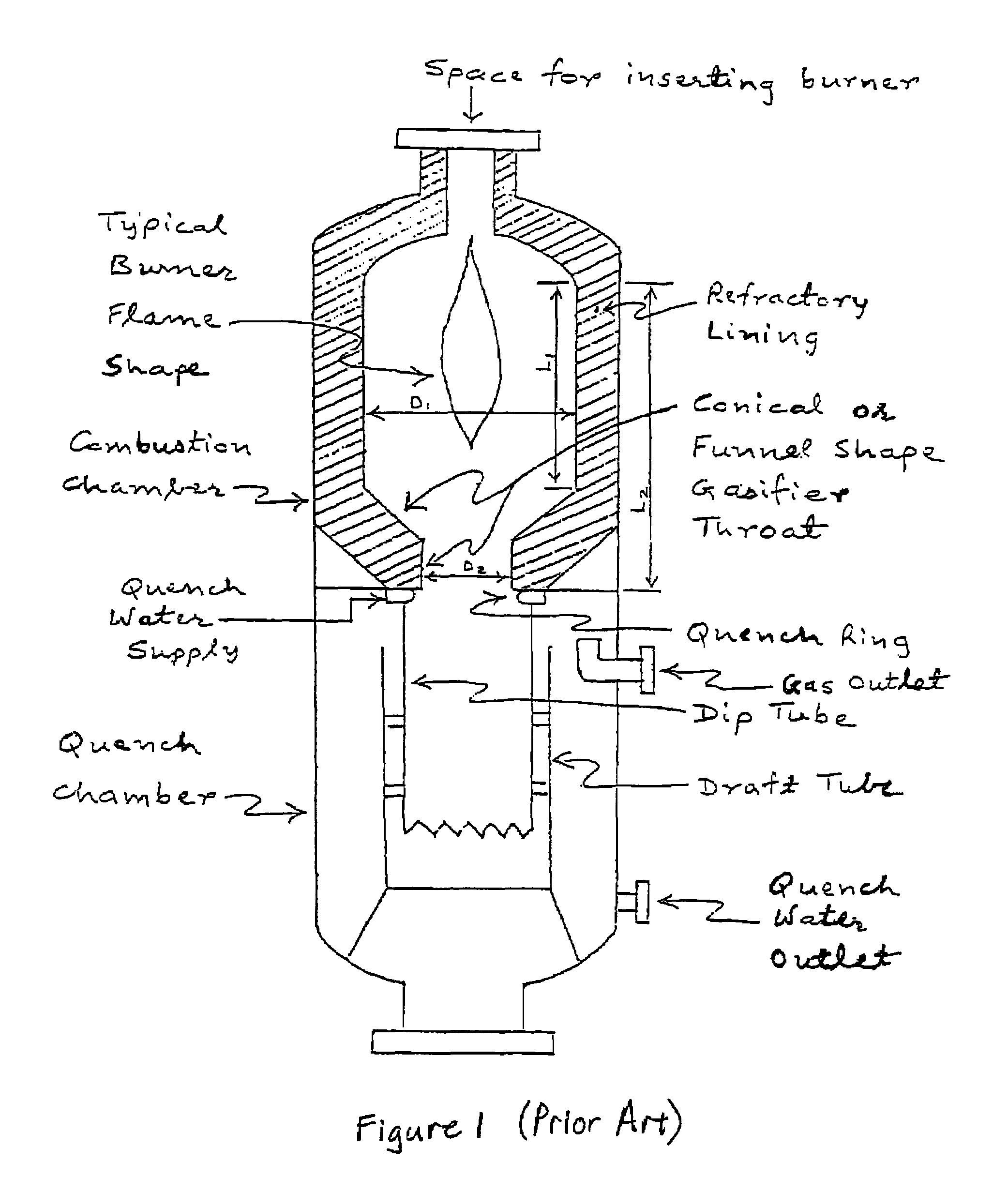

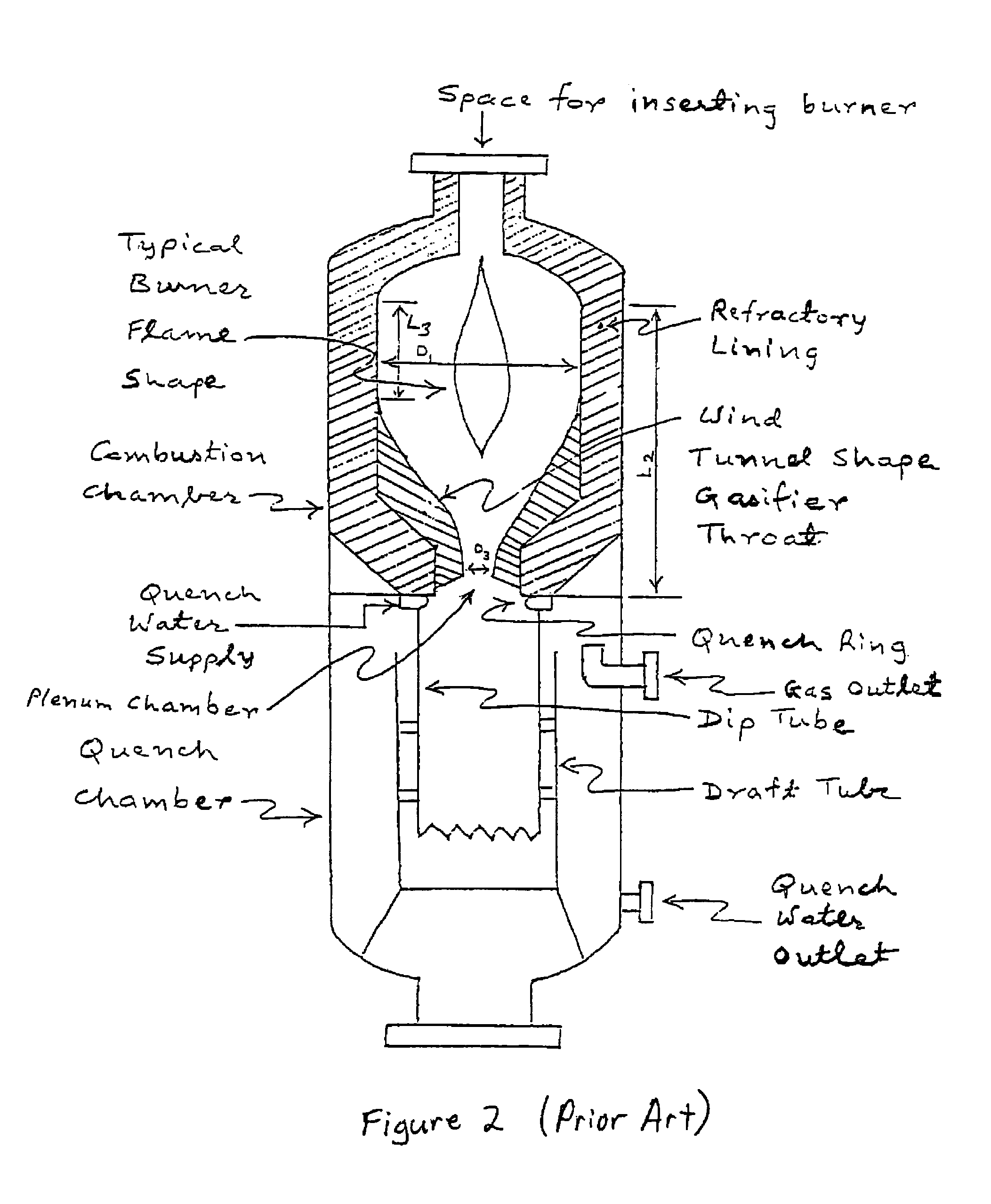

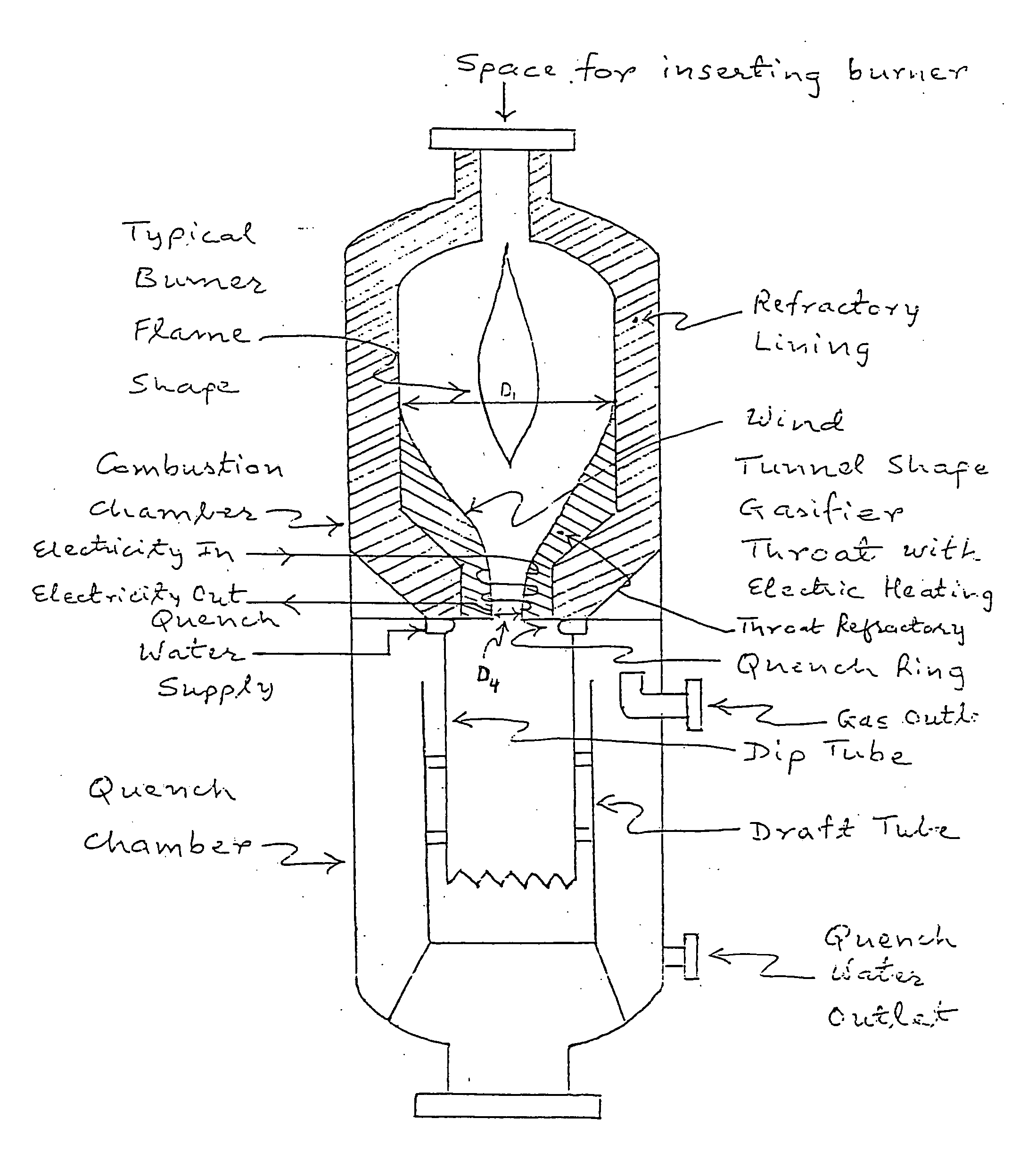

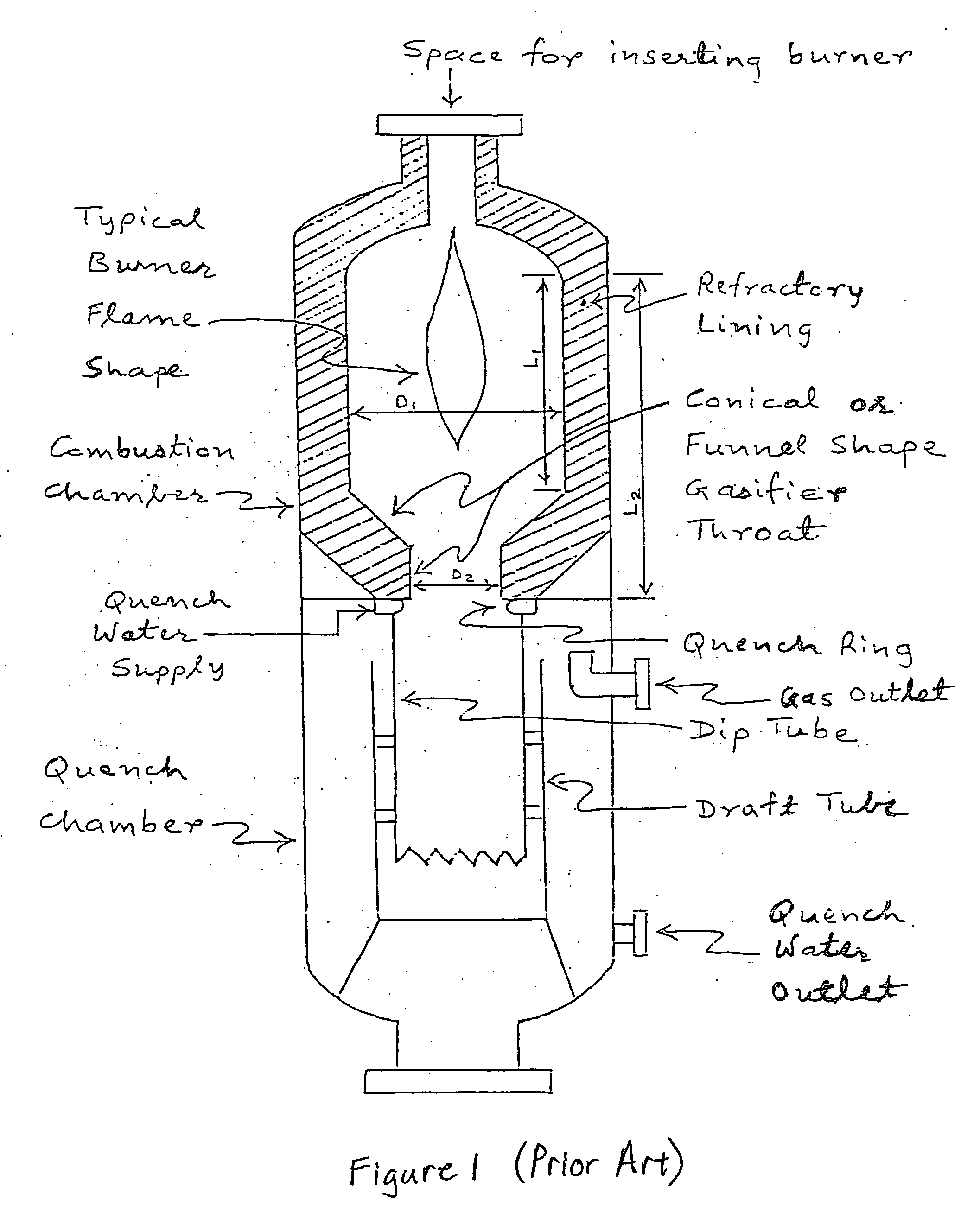

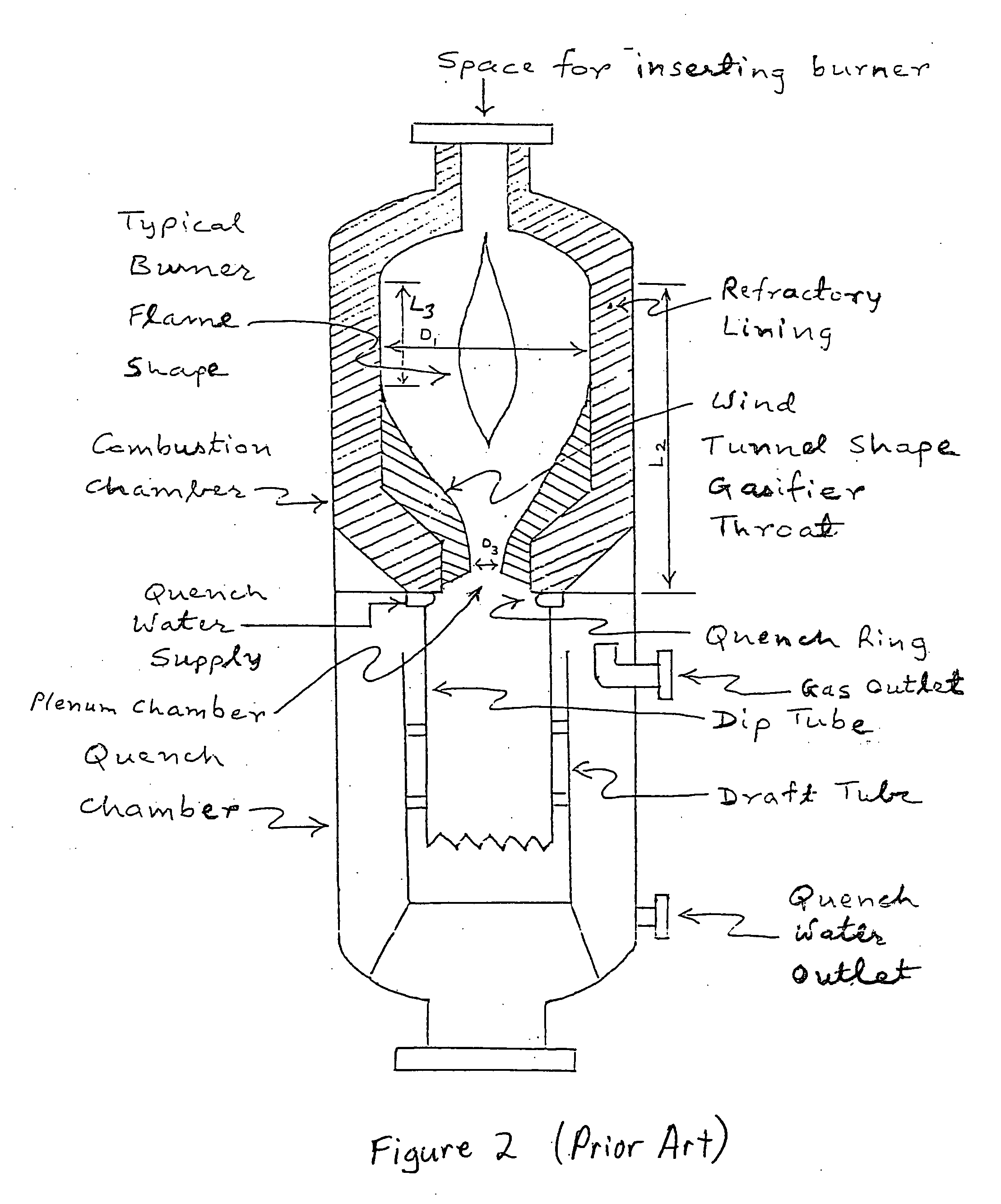

Combustion chamber design for a quench gasifier

InactiveUS7090707B1Increase consumptionIncrease working temperatureGasifier mechanical detailsGas modification by gas mixingThroatElectricity

A new combustion chamber design for a quench gasifier. Electrical heating is used in the throat area of the combustion chamber to achieve temperatures up to 3500° F. to melt ash deposits and to increase carbon conversion (reduce soot production). Silicon carbide and / or silicon nitride refractory materials are used in the hot face of the throat to withstand high temperatures and high temperature shocks. The proposed design reduces the capital cost of a gasification plant by eliminating the need for soot recovery and recycle system. This design also reduces the operating cost of the gasification plant by decreasing the frequent refractory damages that have been experienced in the throat area of the existing quench gasifiers.

Owner:BAROT DEVENDRA T

Two-stage oxygen supply dry slag removal pressurized gas flow bed gasification furnace

InactiveCN101985568APrevent instantaneous high temperatureIncrease injection volumeCombined combustion mitigationGranular/pulverulent flues gasificationTemperature controlAutomatic control

The invention relates to a two-stage oxygen supply dry slag removal pressurized gas flow bed gasification furnace, comprising a cylinder-shaped pressure-bearing case, a gasification chamber arranged in the cylinder-shaped pressure-bearing case, a synthesis gas cooling chamber, a mechanical slag crusher and a slag locking tank; wherein the gasification chamber and the synthesis gas cooling chamberare respectively arranged at the upper part and the lower part in the cylinder-shaped pressure-bearing case, the mechanical slag crusher is arranged below the bottom of the gasification furnace, and the slag locking tank is arranged below the mechanical slag crusher. The invention adopts two-stage oxygen supply temperature control technology and water vapour temperature control technology, and reasonable dry slag removal structure and necessary automatic control means are combined, solid slag removal of China 'double-high' coal large-scale pressurized gas flow bed gasification is realized, and the invention is especially applicable to 'double-high' coals with high ash content (25-27%) and high ash melting point (FT is more than 1400 DEG C), and handing capacity of single day can reach about 2000t / d.

Owner:SHANGHAI JIAO TONG UNIV +2

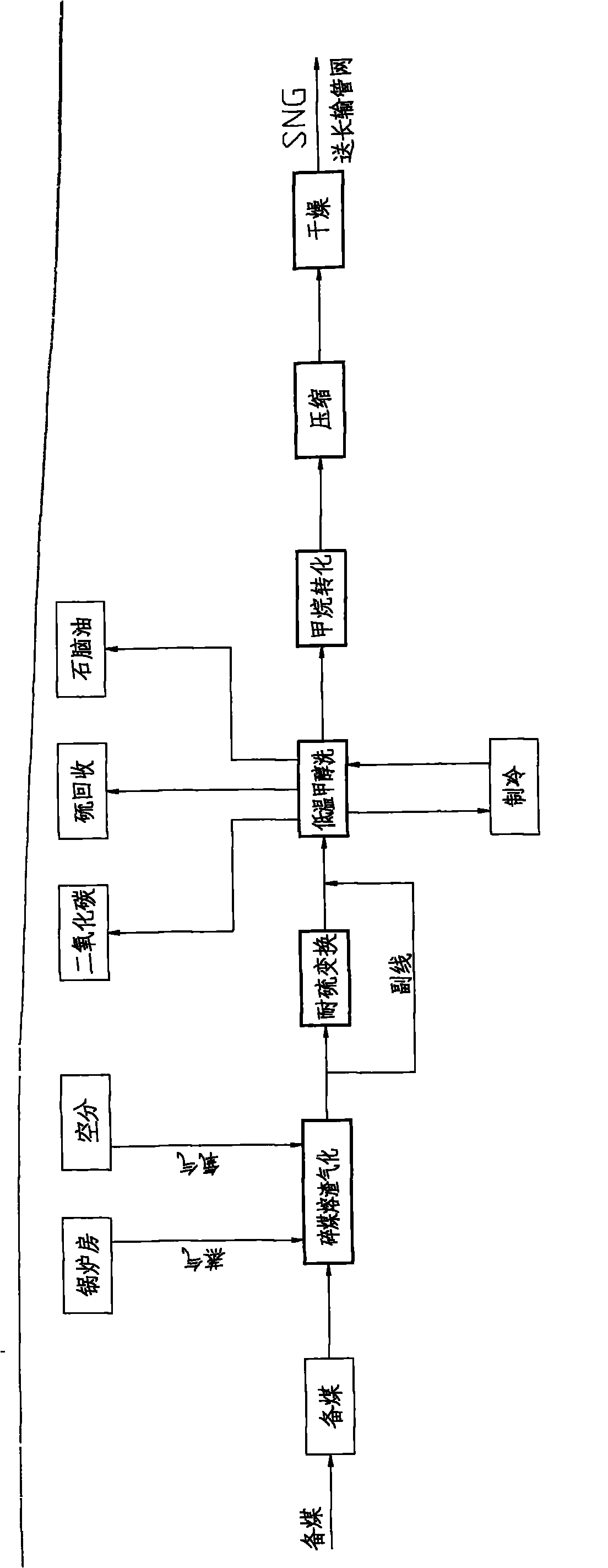

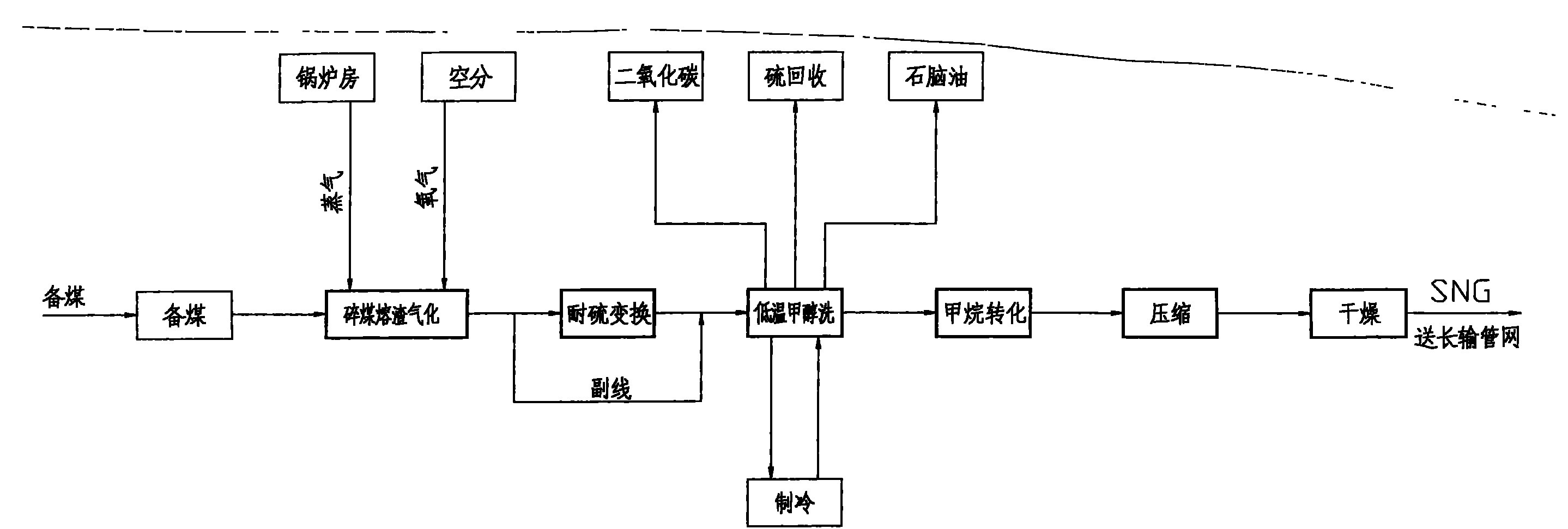

Technique for producing coal natural gas by utilizing crushed coal slag through gasification

ActiveCN101768488AMature and reliable technologyStable operation and maintenanceGaseous fuelsCombustible gas catalytic treatmentNaphthaSulfur

A technique for producing coal natural gas by utilizing crushed coal slag through gasification includes that part of crude coal gas containing CH4 produced by crushed coal slag through gasification receives sulfur tolerant shift, the other part of crude coal gas is conveyed in a sub-line and converges with the gas after sulfur tolerant shift to be cooled, the cooled gas is purified to remove CO2,H2S, naphtha and H2O and other impurities to obtain synthesis gas meeting the methane synthesis H / C ratio, the synthesis gas performs methane synthesis under the effect of methane conversion catalyst, and the methane-synthesis natural gas (SNG) is transmitted in long-distance pipeline network after compression and drying. The invention has the advantages of high gasification rate, high gasification intensity, low consumption and low water content of coal gas.

Owner:SEDIN ENG

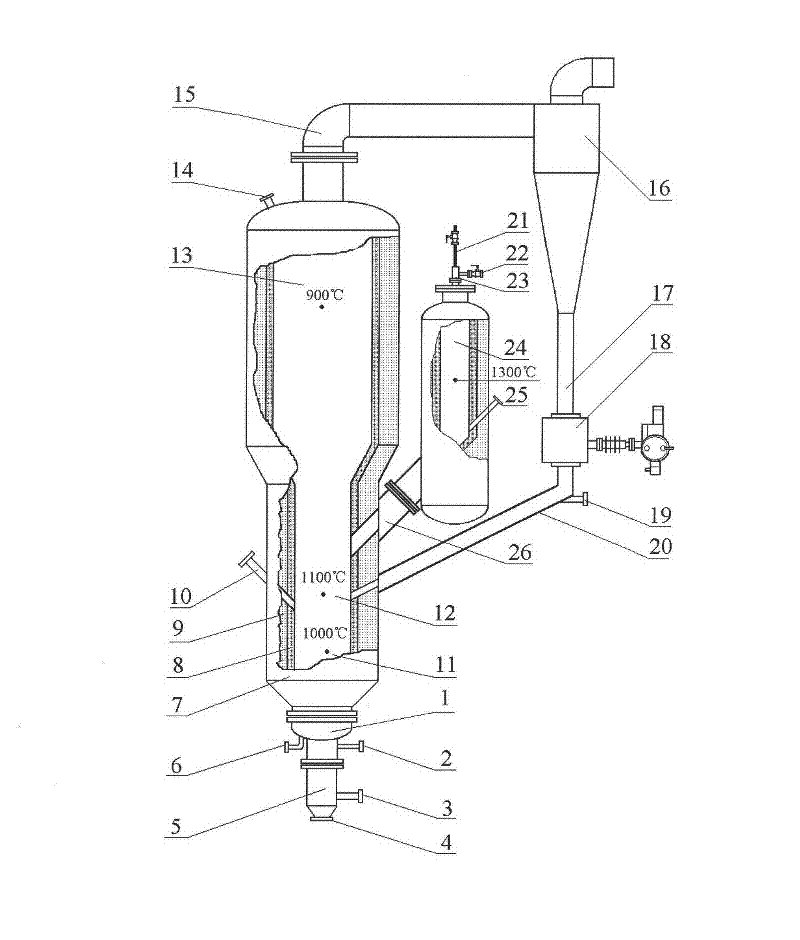

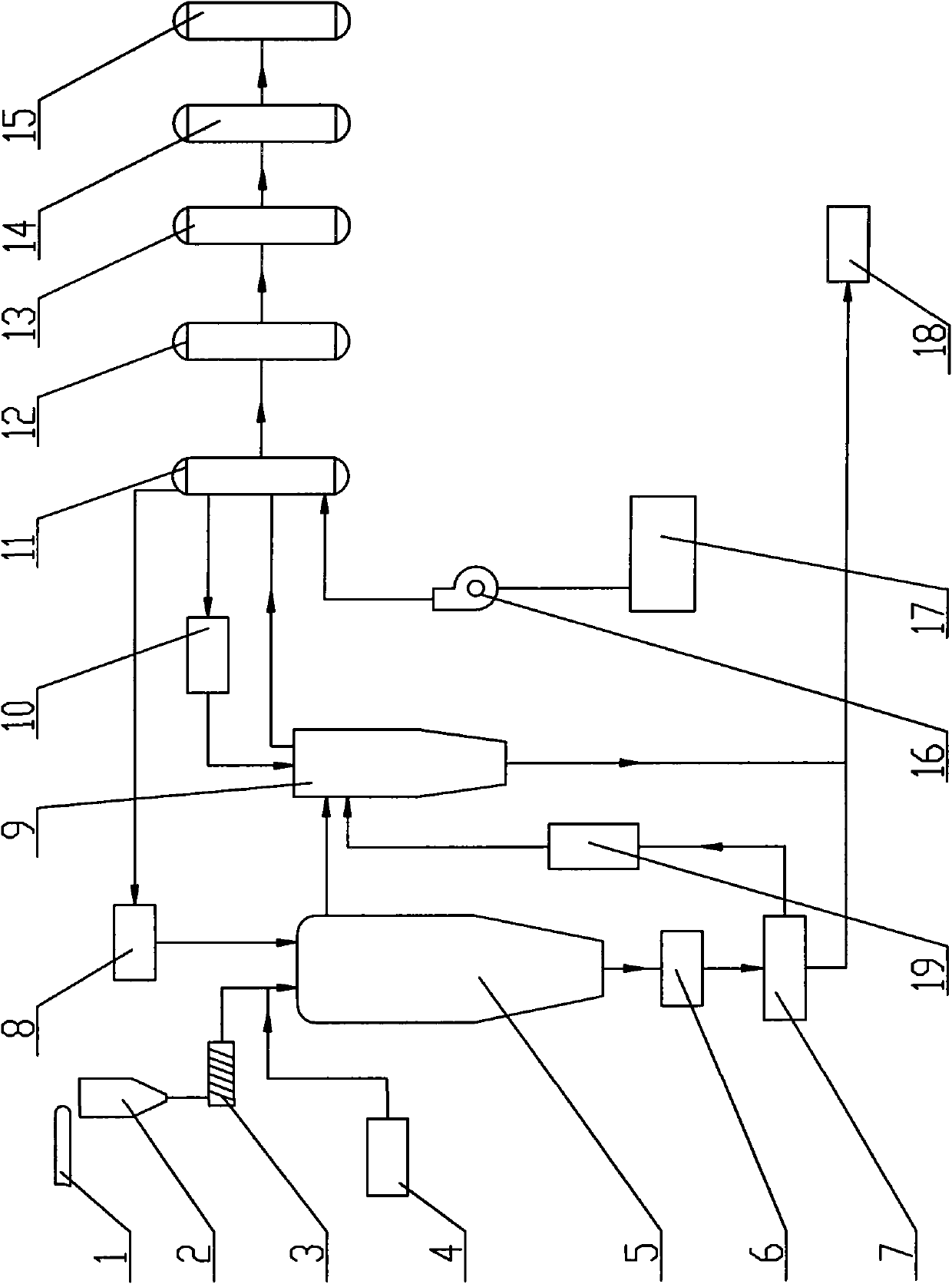

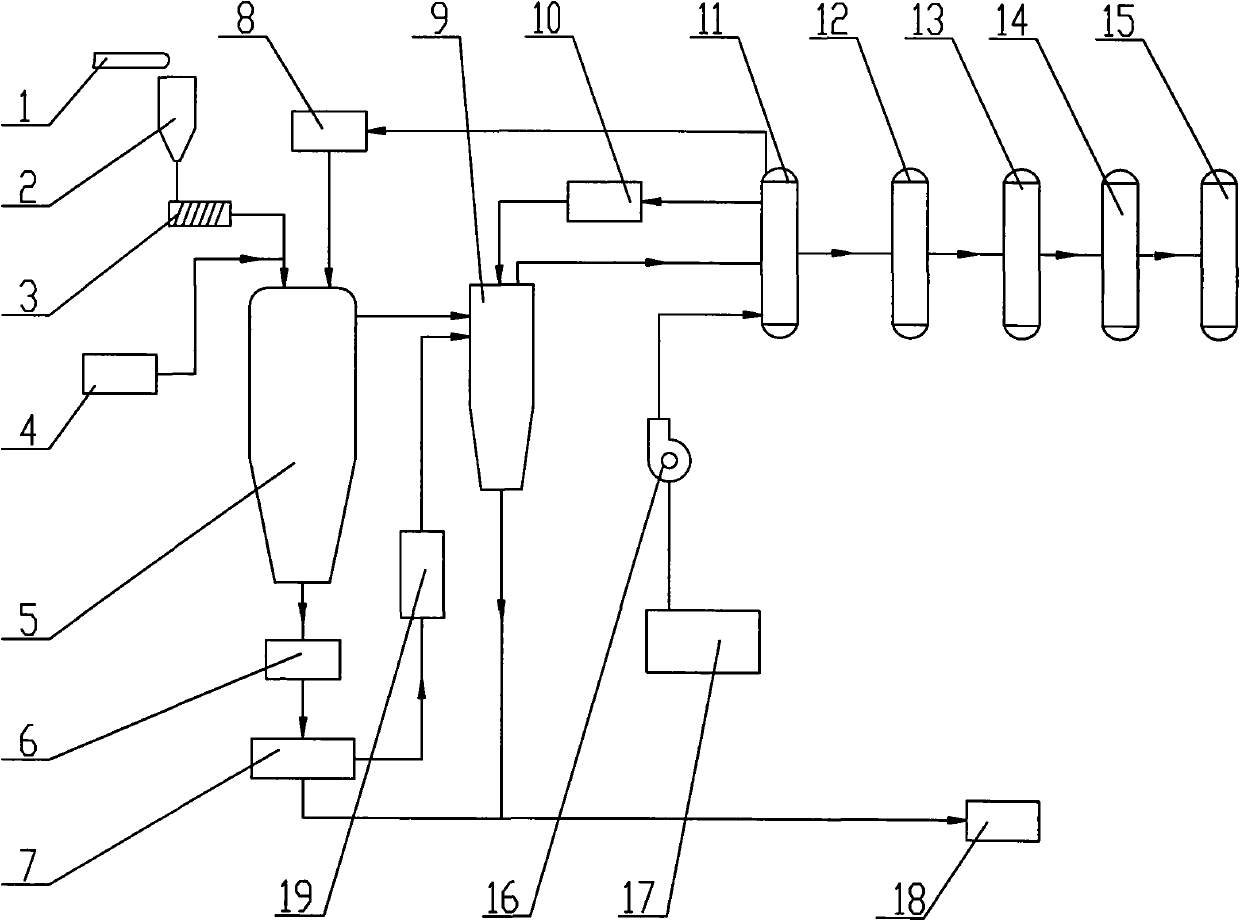

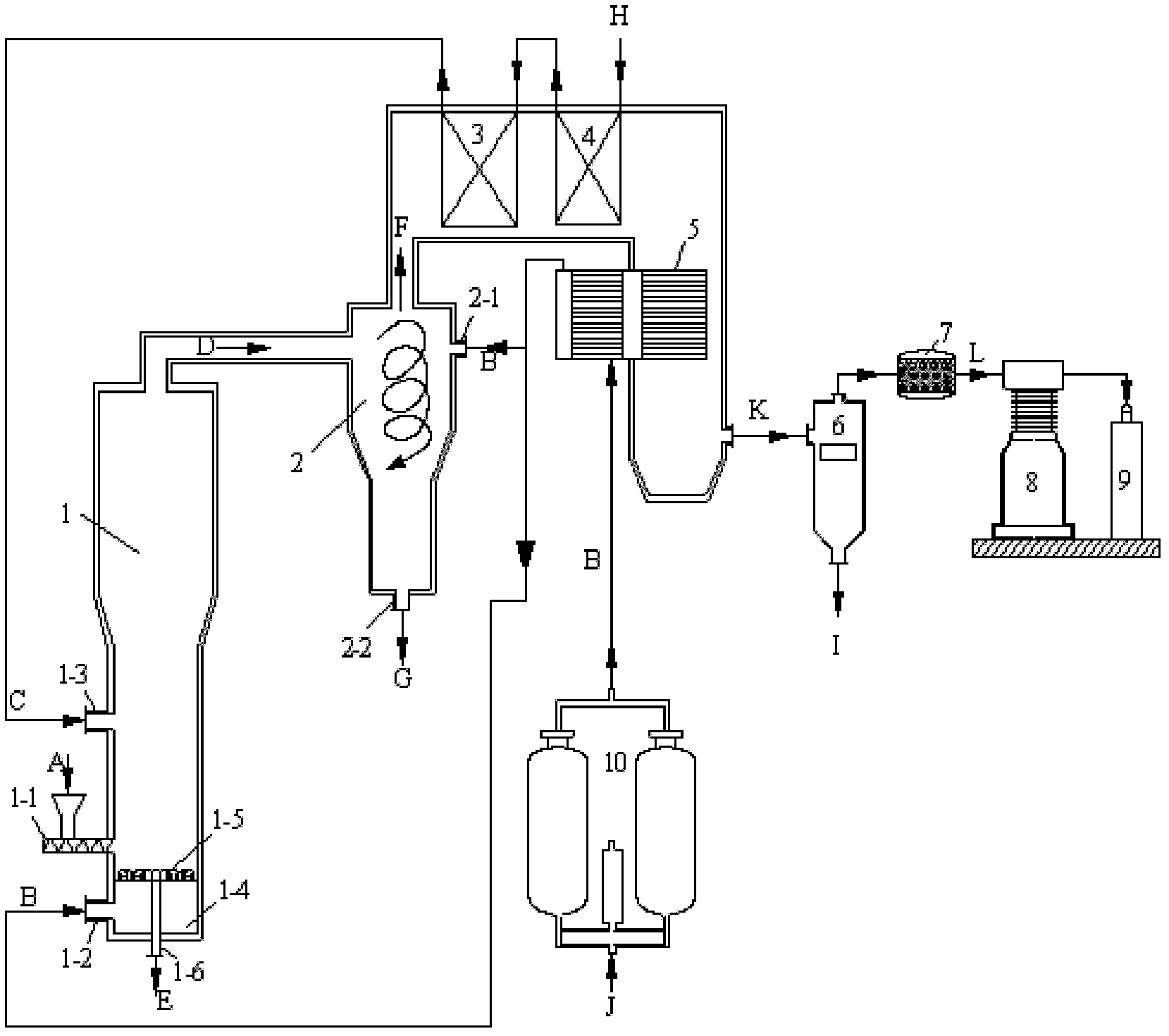

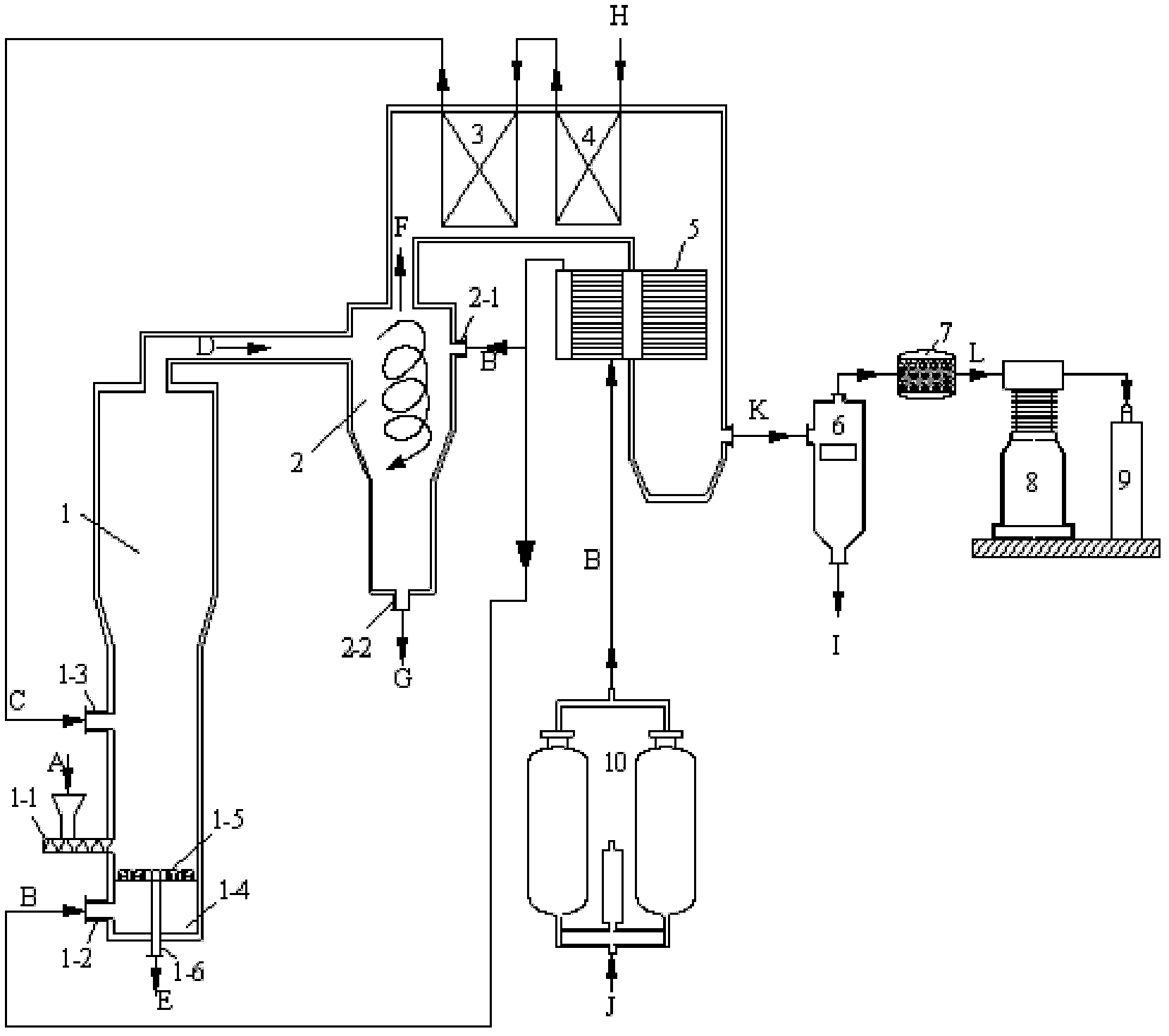

Process and apparatus thereof for low-temperature cracking and high-temperature gasification of biomass

ActiveCN101906325AReduce energy consumptionReduce the total project investmentProductsReagentsAlkali metal oxideWater storage tank

The invention discloses a process and an apparatus thereof for low-temperature cracking and high-temperature gasification of biomass. By adopting superheated vapor steam as oxidizing agent and an energy carrier, the process comprises the following steps of: firstly, carrying out the low-temperature cracking on the biomass fuel in the temperature region of 500-800 DEG C and obtaining the crude synthetic gas and the coke without containing alkali metal oxides; secondly, carrying out the high-temperature gasification on the crude synthetic gas and the coke in the temperature region of 1200-1600 DEG C to obtain the initial synthetic gas without containing tar component; finally, cooling, dust-removing, deacidifying and drying the generated initial synthetic gas, i.e., acquiring the pure synthetic gas of high quality. The apparatus mainly consists of a cracking furnace, a gasifying furnace, a low-temperature plasma torch heater, a high-temperature plasma torch heater, a water storage tank,a water delivery pump and a heat exchanger and the like. The process of the invention has the advantages of easy control, low energy consumption and investment cost and high efficiency of cooled coalgas; the generated synthetic gas has high calorific value and does not contain tar and alkali metal compounds. The invention is suitable for not only biomass gasification combined cyclic power generation, but also preparation of biomass liquid fuel.

Owner:SUNSHINE KAIDI NEW ENERGY GROUP CO LTD

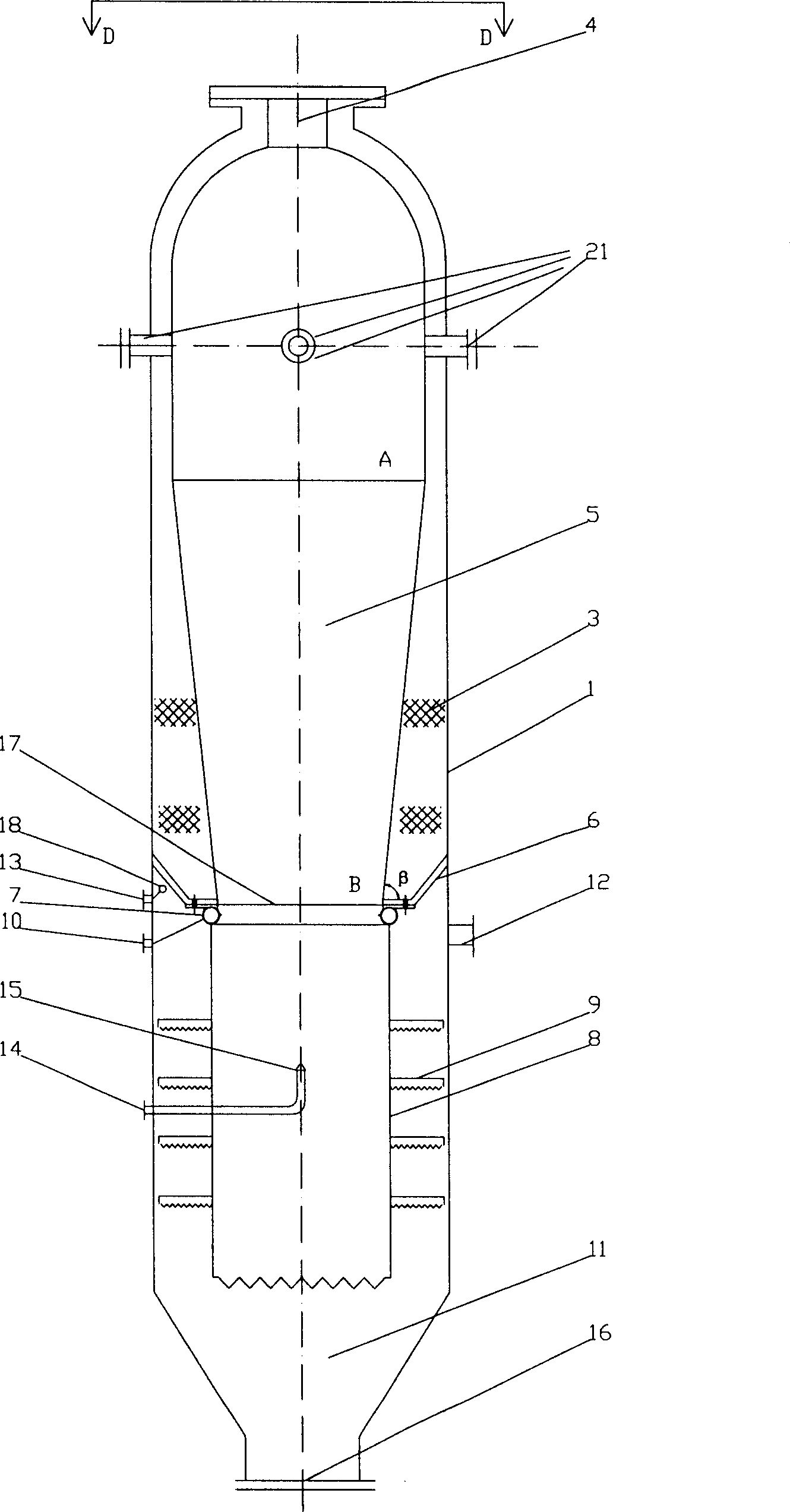

Fluidized bed gasification furnace with solid-state aih discharge and its indnstrial application

ActiveCN1869166AWide applicabilityImprove carbon conversionGasification processes detailsCombustible gas purificationFluidized bedRefractory

The invention relates to a coal gas preparation facilities used carbon and ash containing compound as the material. It discloses entrained flow gasification furnace with solid state ash discharging and its industrial application. The gasification furnace is upright and has many nozzles. Its fireproof lining is conical surface. Its water spraying ring is set softening jam and two rows of holes. It can be applied to treat the coal with high ash fusing point, high ash content, and high sulfur and the big gasifier.

Owner:EAST CHINA UNIV OF SCI & TECH

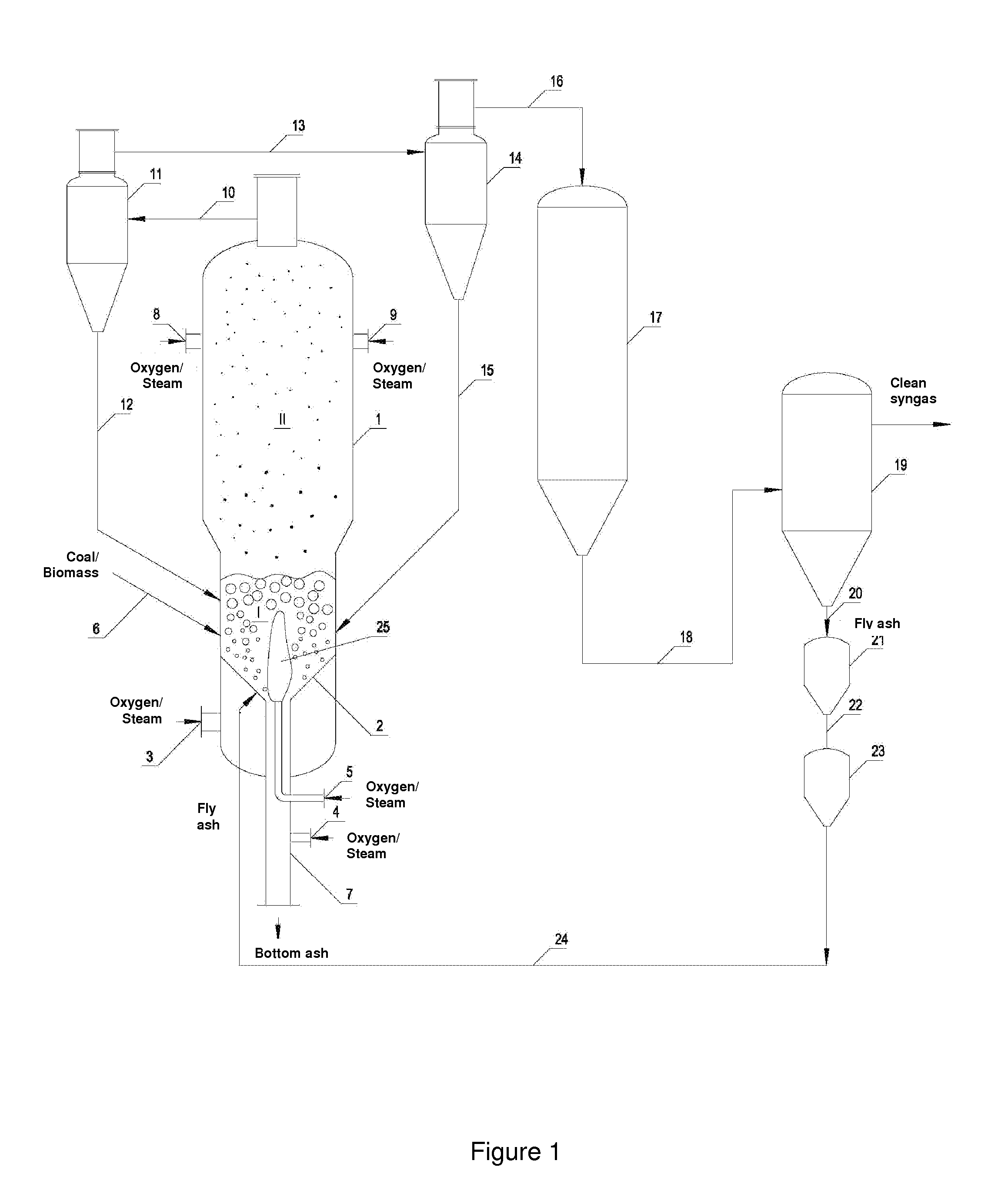

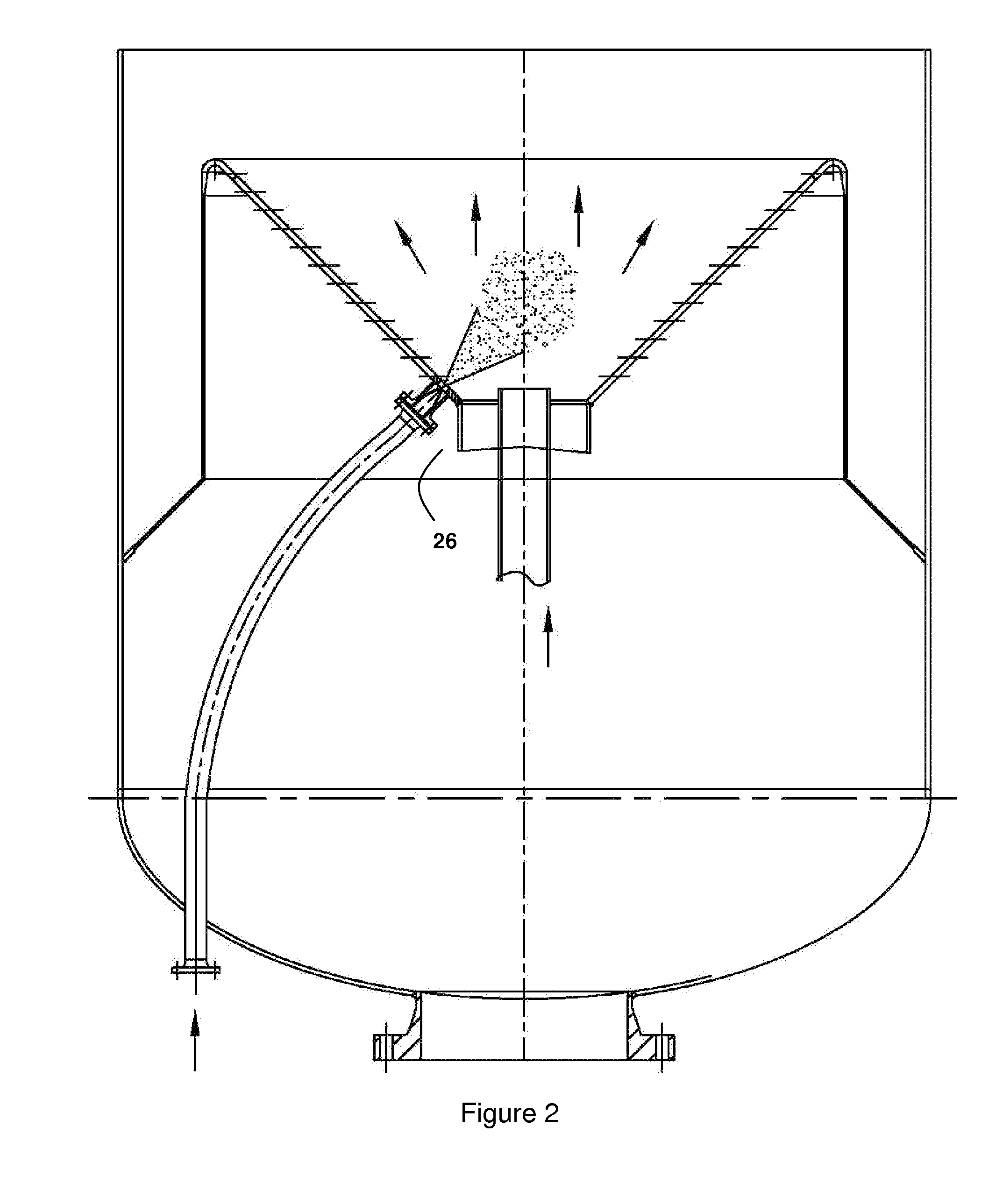

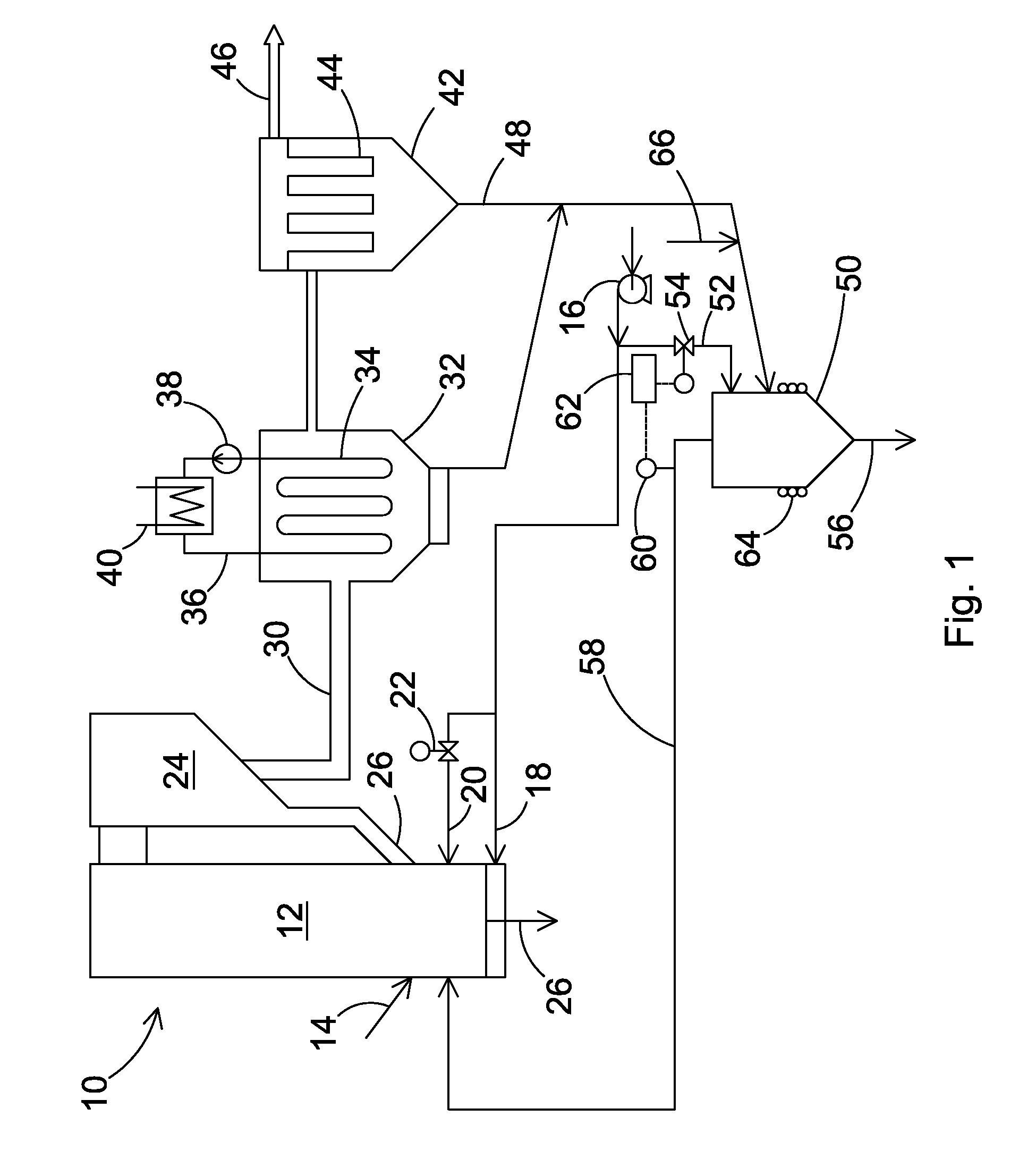

Method and apparatus for particle recycling in multiphase chemical reactors

InactiveUS20130312328A1Reduce ash quantityGasification can be simplifiedCarburetting by solid carbonaceous material pyrolysisGasification processes detailsChemical reactorProduct gas

Method and apparatus for recycling fine ash particles for a multiphase chemical reactor (MCR), wherein coal is partially oxidized in the MCR to produce an exit gas stream in which fine ash particles are entrained, and wherein the MCR comprises a high temperature region with a temperature at or above a fusion temperature of the fine ash particles, wherein substantially all of the fine ash particles from the exit gas stream are returned to the high temperature region, to achieve improved carbon conversion and reduction in fly ash quantity.

Owner:SYNTHESIS ENERGY SYST

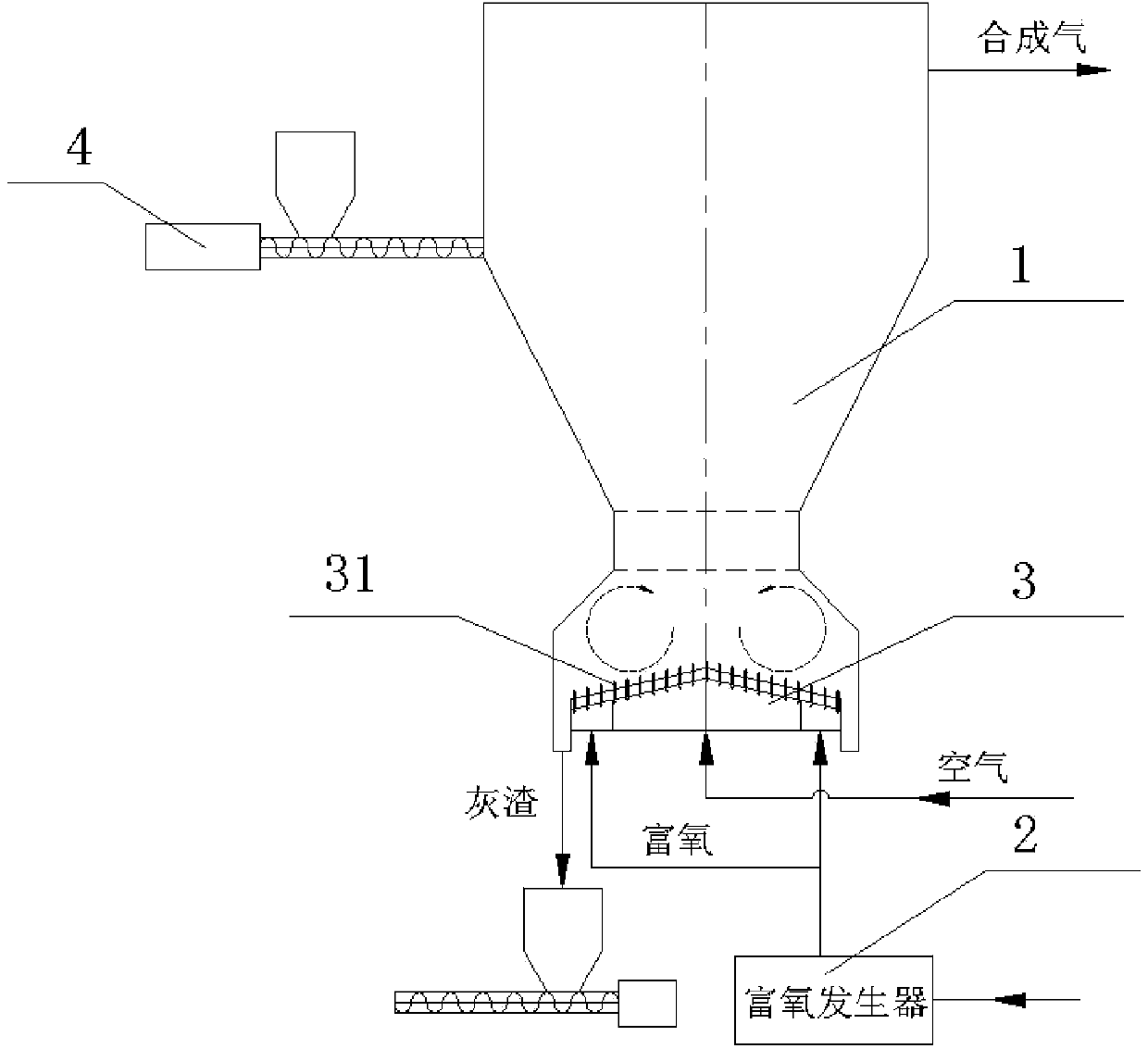

Device and method for preparing high-calorific value combustible gas through biomass gasification and melting

ActiveCN102517089ARelieve pressureReduce nitrogen contentChemical industryGranular/pulverulent flues gasificationCycloneCompression device

The invention discloses a device and a method for preparing high-calorific value combustible gas through biomass gasification and melting. The device and the method provided by the invention are utilized for preparation of high-calorific value clean combustible gas. The device provided by the invention comprises a fluidized bed gasification reactor, a cyclone melting furnace, a superheater, an economizer, a heat pipe exchanger, a cloth bag deduster, a desulfurization tower, a compression device and a gas storage tank. The method provided by the invention is a high-efficiency biomass gasification technology breaking through the prior art, can realize preparation of high-calorific value combustible gas, and can effectively reduce the content of tar, carbon particles and ash of combustible gas. The device provided by the invention has high heat utilization efficiency and is safe and reliable.

Owner:SOUTHEAST UNIV

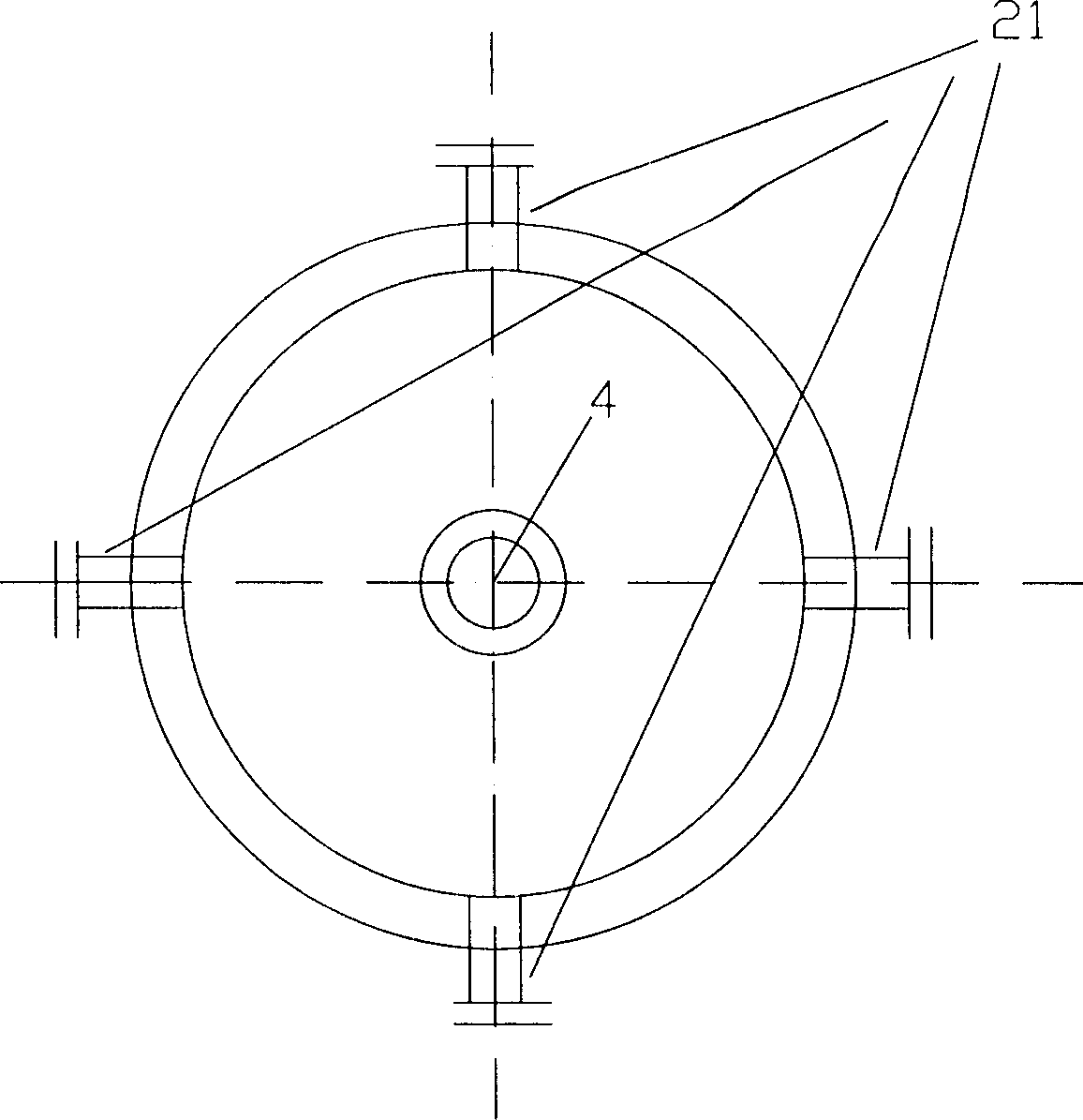

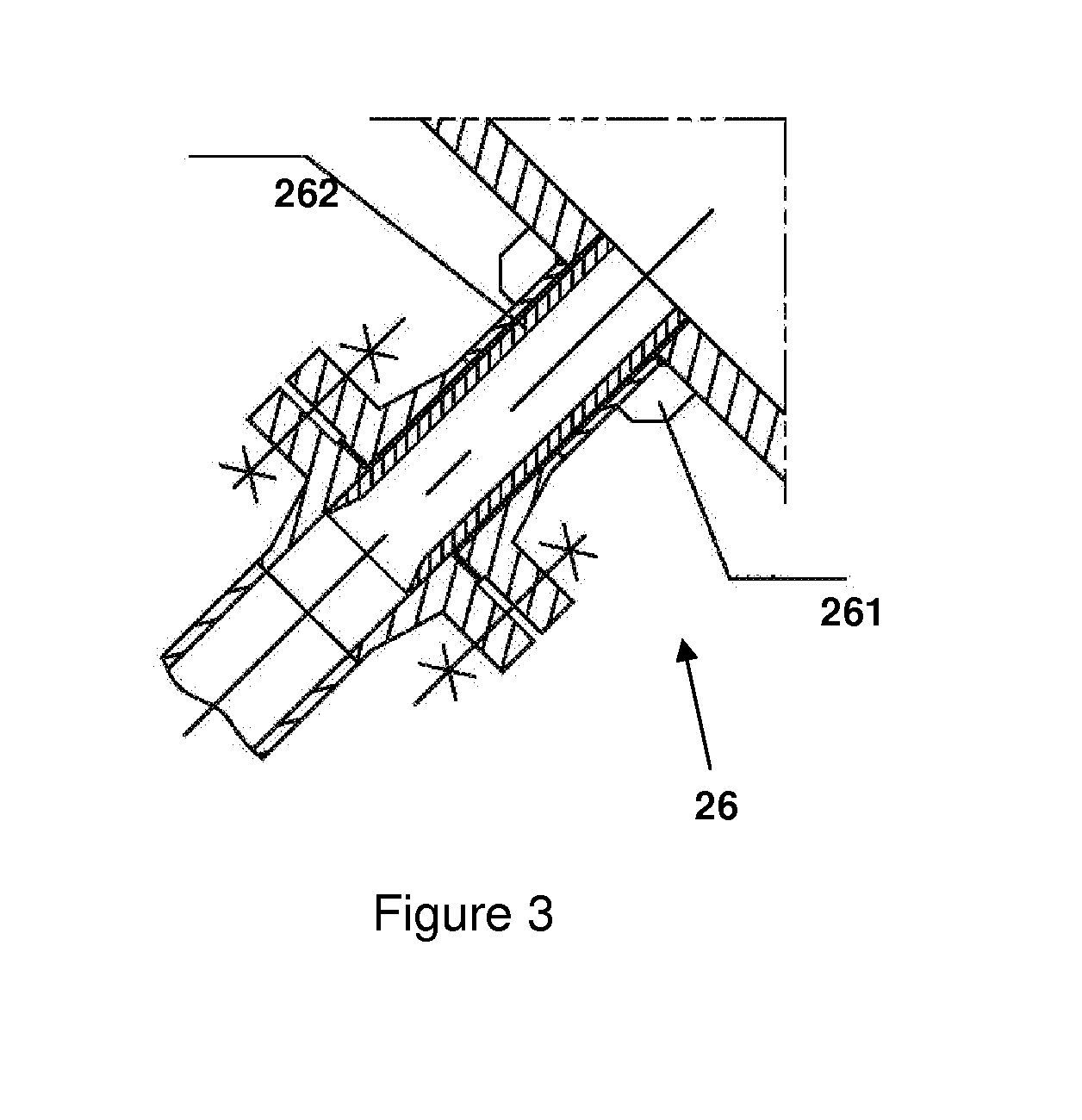

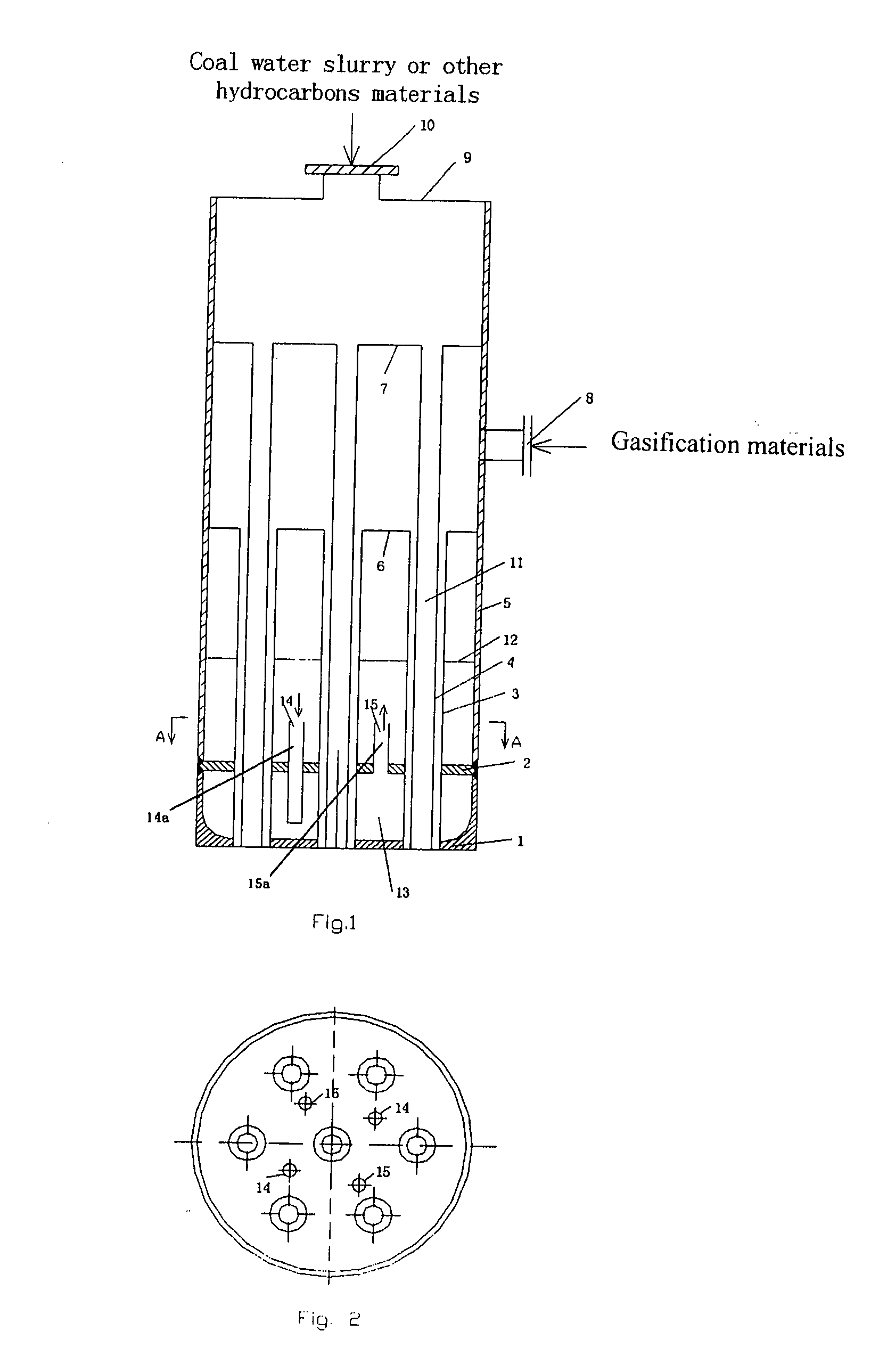

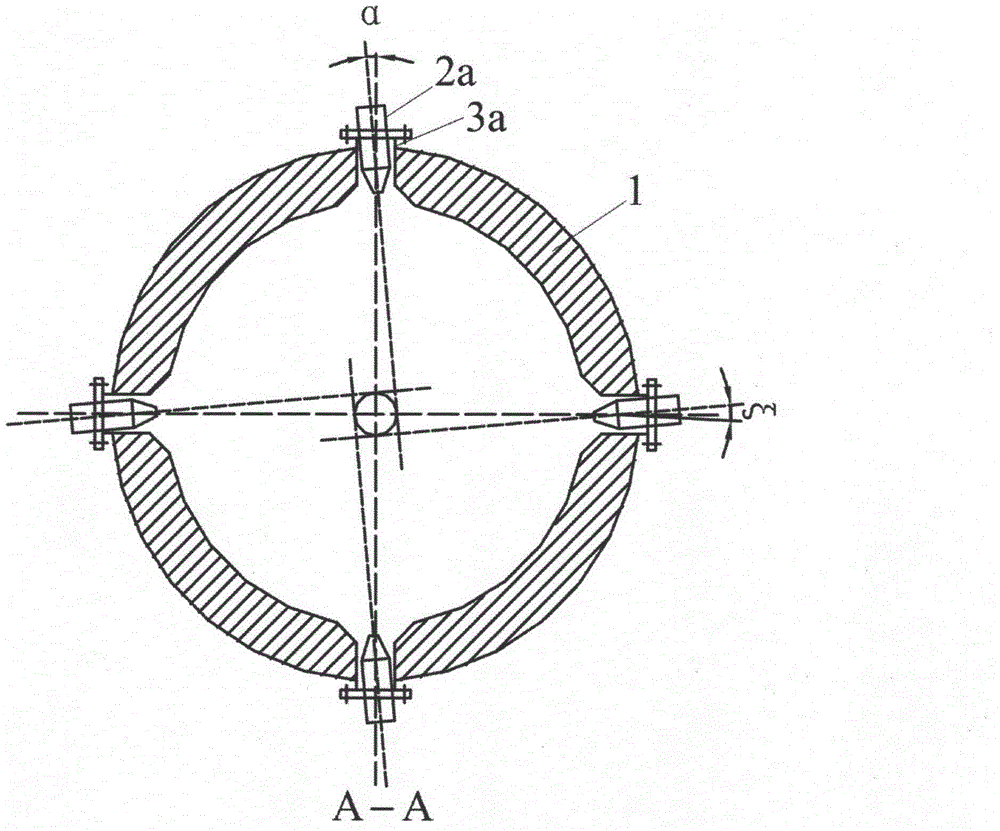

Clustered nozzle for gasification or combustion and its industrial application

InactiveUS20080073445A1Improve carbon conversionShorten the lengthGasifier mechanical detailsGas modification by gas mixingCombustionWorking life

This invention relates to a kind of clustered nozzle for gasification or combustion and its industrial applications. The clustered nozzle comprises a body case (5) and a plurality of nozzles (11) in the body case (5). The nozzle (11) includes an outer cannula (3) and an inner cannula (4) inside the outer cannula (3), a lower tubesheet (6), an upper tubesheet (7) and a cooling chamber (13). Compared with traditional coaxial double-pipe nozzles (e.g., dual-channel nozzles, triple-channel nozzles and multi-channel nozzles), the clustered nozzle for gasification or combustion has the following advantages: the length of combustion flame is shorter and the shape of flame is approximately rectangular, which help to protect the lower firebricks of the gasifier, thus prolonging their working life; the distribution of the residence time is narrower, which helps to increase the conversion rate of carbon; and the nozzle is properly-structured, which helps to prolong its working life.

Owner:EAST CHINA UNIV OF SCI & TECH

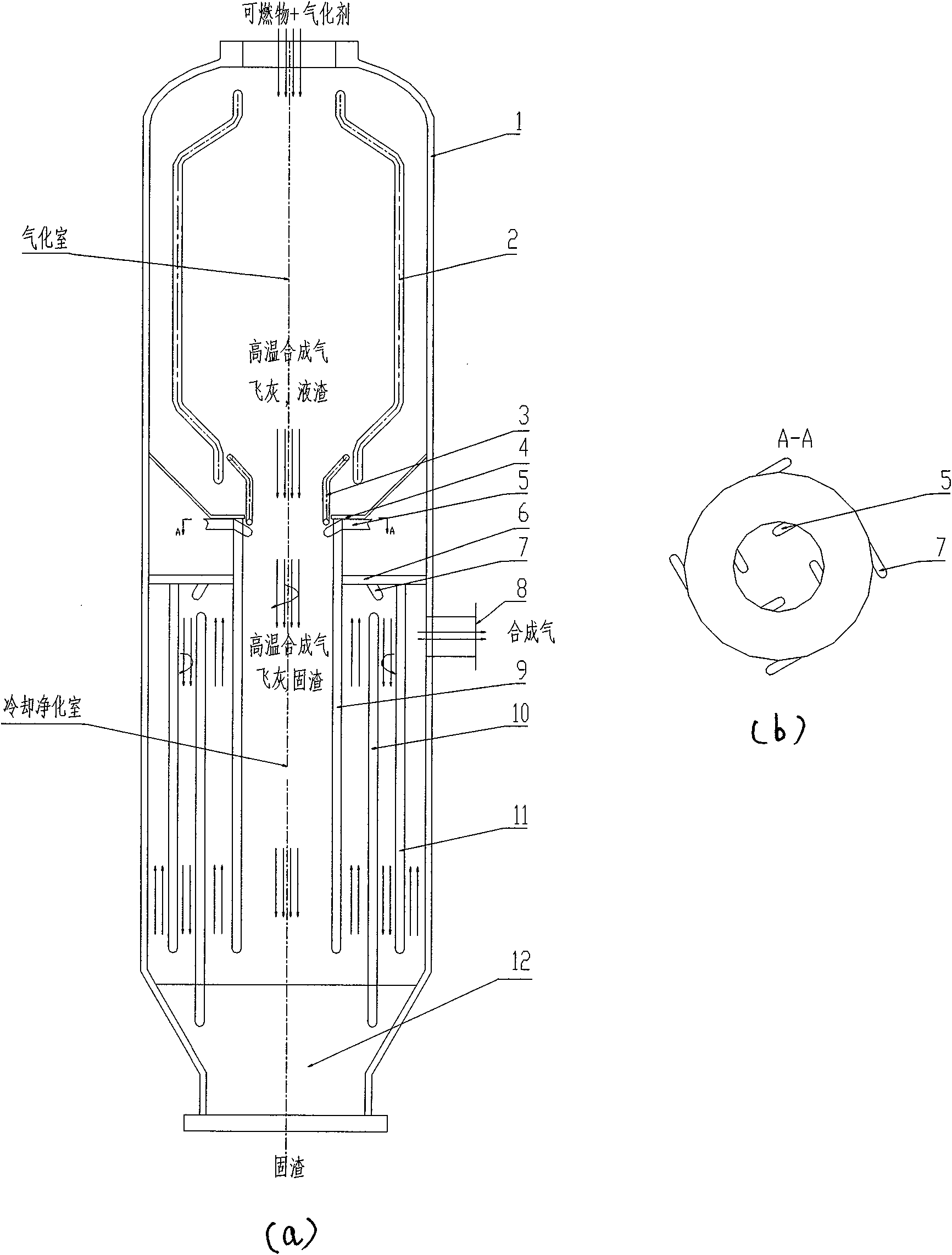

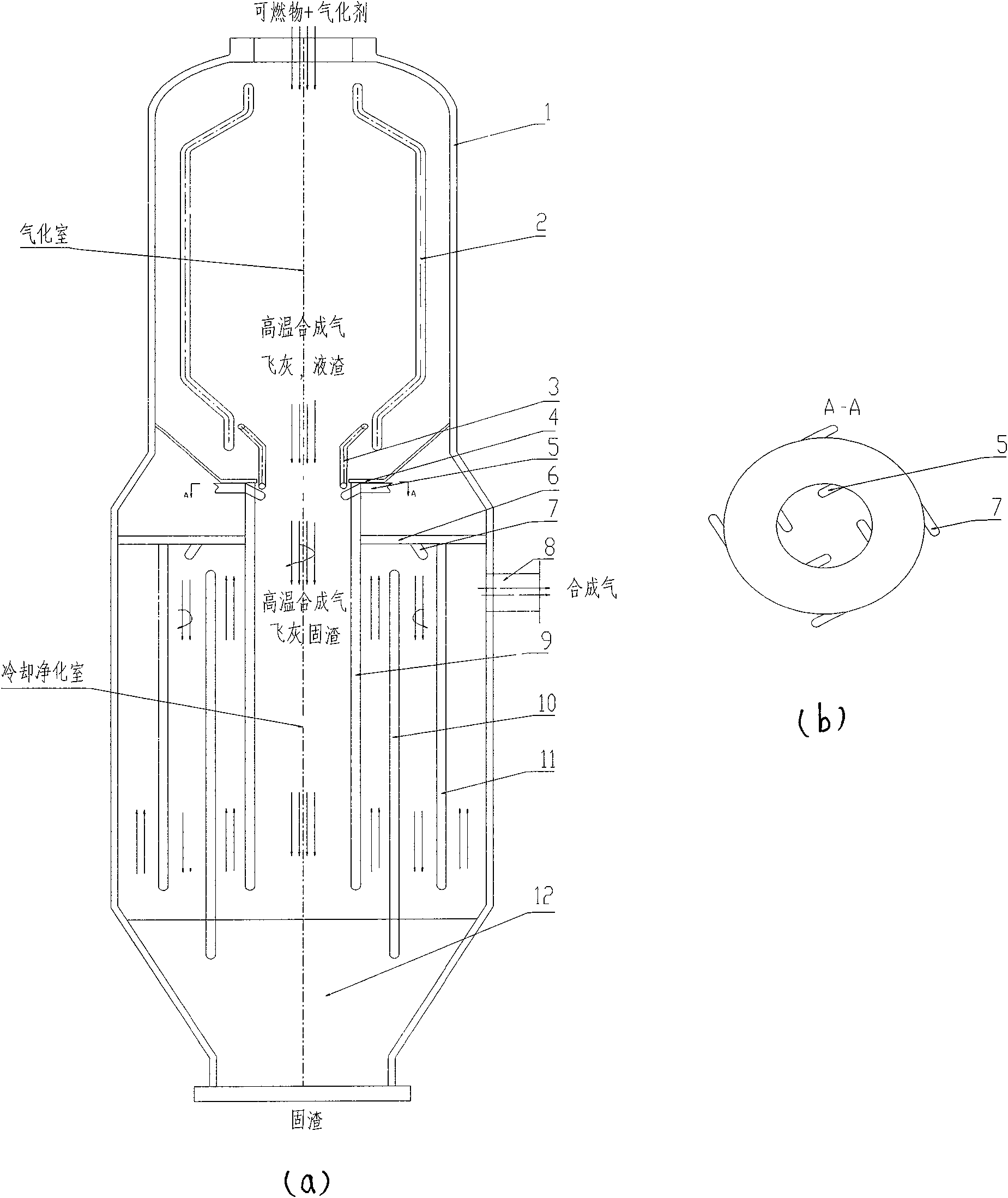

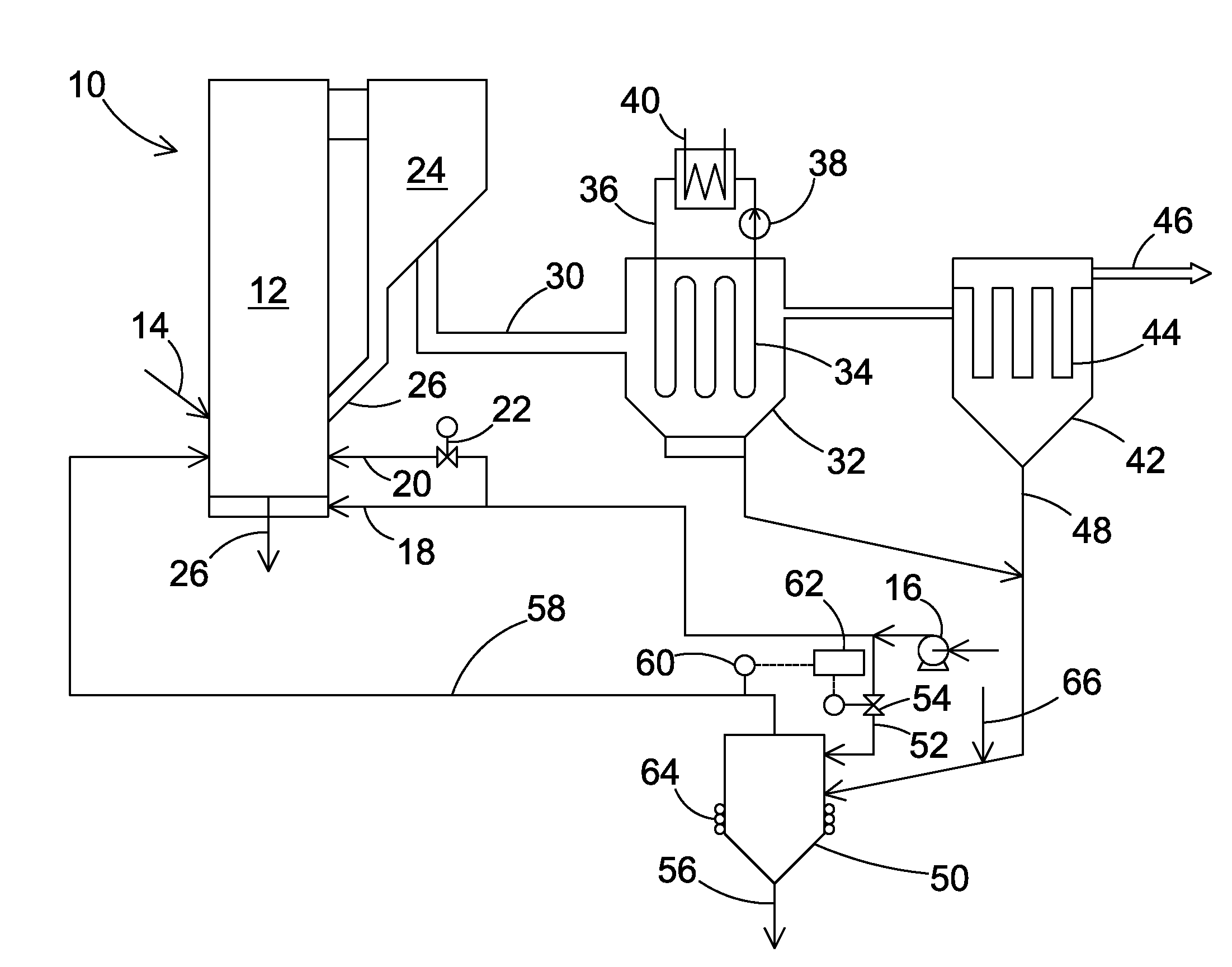

Gasification device for solid fuel and method for producing synthetic gas

ActiveCN101570699AImprove carbon conversionReduce water consumptionEnergy inputCombined combustion mitigationForming gasHigh carbon

The invention provides a gasification device for solid fuel, which comprises a gasification chamber and a cooling purification chamber. A first cooling medium distributor (5) is arranged at an inlet of the cooling purification chamber, and is used for injecting a low-temperature cooling medium into high-temperature synthetic gas from the gasification chamber along the circumferential direction, thereby making the high-temperature synthetic gas cooled and removing solid impurities from the high-temperature synthetic gas. The invention also provides a method for producing synthetic gas, which comprises the steps: ensuring that the quick incomplete reaction of the solid fuel and an oxidizing agent is performed to generate the high-temperature synthetic gas; and injecting the low-temperature cooling medium into the high-temperature synthetic gas along the circumferential direction to purify the high-temperature synthetic gas and make the temperature of the high-temperature synthetic gas reduced. The device and the method improve the purity of the synthetic gas which is finally obtained by temperature reduction, impurity removal and heat recovery for multiple times; and the device has high carbon conversion rate, and also has good complementary energy and waste heat recovery effect, low water consumption and no pollution.

Owner:CHANGZHENG ENG

Combustion chamber design for a quench gasifier

InactiveUS20060260192A1Increase consumptionIncrease working temperatureHydrogenGasifier mechanical detailsThroatElectricity

A new combustion chamber design for a quench gasifier. Electrical heating is used in the throat area of the combustion chamber to achieve temperatures up to 3500° F. to melt ash deposits and to increase carbon conversion (reduce soot production). Silicon carbide and / or silicon nitride refractory materials are used in the hot face of the throat to withstand high temperatures and high temperature shocks. The proposed design reduces the capital cost of a gasification plant by eliminating the need for soot recovery and recycle system. This design also reduces the operating cost of the gasification plant by decreasing the frequent refractory damages that have been experienced in the throat area of the existing quench gasifiers.

Owner:BAROT DEVENDRA T

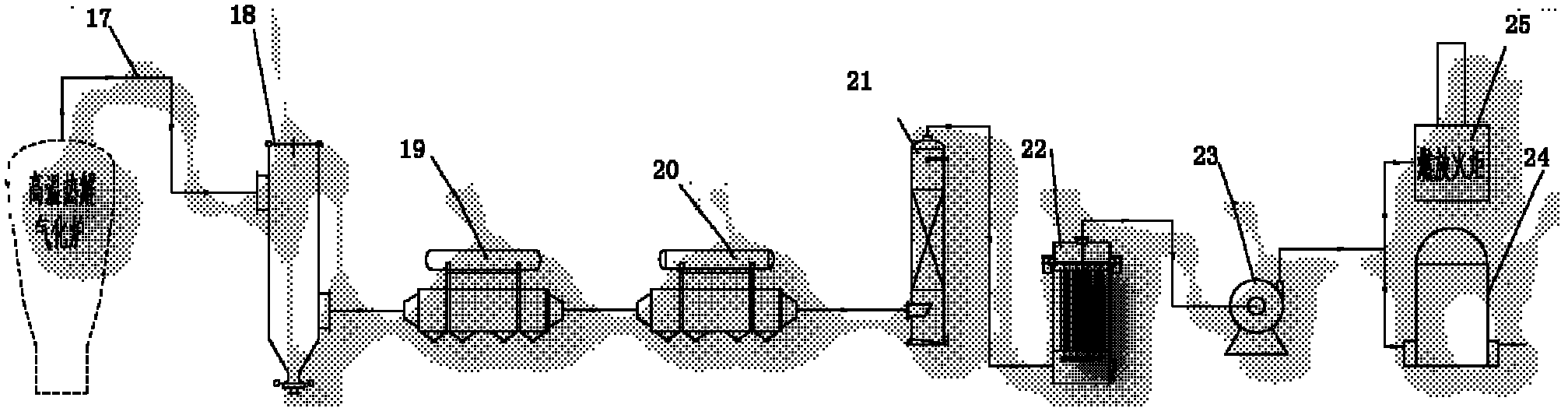

High temperature normal pressure biomass gasification island process

The invention provides a high temperature normal pressure biomass gasification island process. The process comprises the procedures of pretreatment and storage of biomass, gasification by using a biomass gasification furnace, cooling of gasified crude gasification gas, rinsing, dedusting and storage of fresh gasification gas, wherein in gasification by using the biomass gasification furnace, an external heat source is used to supply heat, reaction temperature in the gasification furnace is controlled to be 1300 to 1750 DEG C, liquid state slag removal is adopted by the gasification furnace, cooling of gasified crude gasification gas is realized through recovery of sensible heat by a quenching tower and a two-stage heat boiler, cooled crude gasification gas is subjected to rinsing and electric precipitation, fresh gasification gas is stored in a gas storage cabinet, and whole gasification island equipment operates under a negative pressure or a positive pressure of 0 to 50 KPa. According to the process, the external heat source is utilized for gasification, which enables the quality of crude gasification gas to be improved; a normal pressure fixed bed is employed for gasification, which enables the equipment of gasification furnace body to have the advantages of simpleness, small investment and easy operation; feeding, deslagging and purifying systems are simple; a wide variety of raw materials are applicable, gasification of various biomass, MSW, raw coal, sludge and the like can be realized, and blended gasification of a plurality of fuels can be realized; systems and equipment are mature, and a high localization degree is obtained.

Owner:WUHAN KAIDI ENG TECH RES INST CO LTD

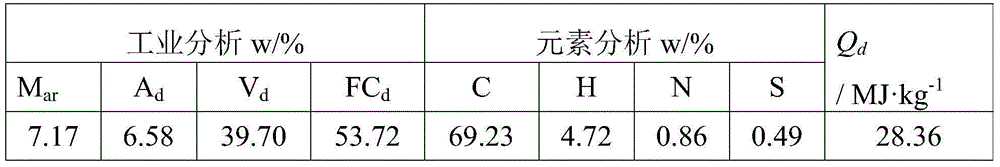

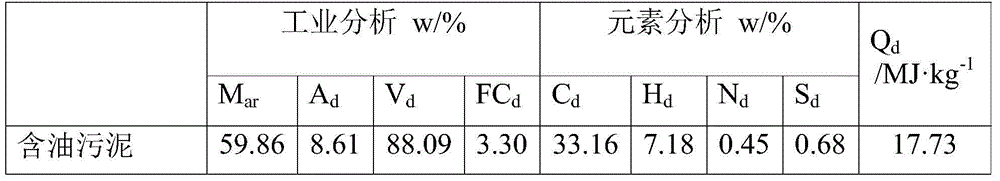

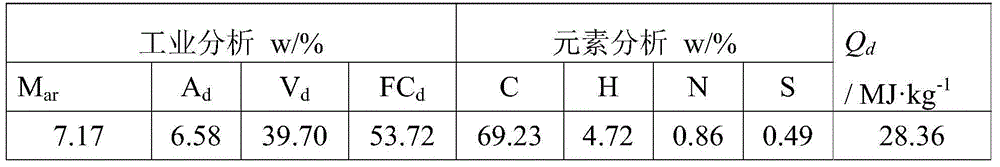

Oil-containing sludge coal slurry and preparation method thereof

ActiveCN103980968AHigh slurry concentrationTake advantage ofLiquid carbonaceous fuelsCombustionSludge

The invention discloses oil-containing sludge coal slurry and a preparation method thereof. The oil-containing sludge coal slurry comprises the following components in percentage by mass: 57-62% of coal powder, 3-14.3% of oil-containing sludge, 0.2-0.7% of a dispersing agent and water, totaling 100%. The method comprises the following steps: uniformly mixing the oil-containing sludge and the coal powder to obtain a mixture A; and uniformly mixing the mixture A, the water and the dispersing agent to obtain the oil-containing sludge coal slurry. The oil-containing sludge coal slurry disclosed by the invention is easily available in raw material, good in fluidity, high in slurry concentration, and quite high in conversion rate when being applied to combustion and gasification.

Owner:EAST CHINA UNIV OF SCI & TECH +1

Method of and an Apparatus For Gasifying Carbonaceous Material

InactiveUS20080250714A1Efficient and reliableSimple methodGaseous fuelsGas modification by gas mixingCombustorResidual carbon

Owner:FOSTER WHEELER ENERGIA OY

Multi-nozzle multi-stage oxygen supplying entrained-flow gasifier and gasification method thereof

ActiveCN102453550ASolution to short lifeSimple processHydrogenGranular/pulverulent flues gasificationSlagFire brick

The present invention discloses a multi-nozzle multi-stage oxygen supplying entrained-flow gasifier. The entrained-flow gasifier comprises a top closed type gasifier body, an ignition nozzle chamber, a gasifier outlet, and at least two process nozzle chambers, wherein process nozzles are arranged inside the process nozzle chambers. The entrained-flow gasifier further comprises at least two secondary oxygen supplying nozzle chambers, wherein secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers, the secondary oxygen supplying nozzle chambers are arranged between the process nozzle chambers and the gasifier outlet, and are symmetrically arranged on the circumference of the gasifier body, and the secondary oxygen supplying nozzles are arranged inside the secondary oxygen supplying nozzle chambers. The present invention further discloses a gasification method of the gasifier. According to the gasification method, an oxidizing agent is introduced to the secondary oxygen supplying nozzle during the reaction process to promote the further gasification reaction. With the present invention, a plurality of the nozzles are adopted to carry out multi-stage oxygen supplying on the gasifier, such that the service life of the fire brick structure on the upper space of the gasifier is substantially prolonged so as to substantially improve the operating rate and the performance of the gasifier. In addition, with the present invention, the liquid slag tapping of the gasifier is ensured, and the phenomenon of slag blocking of the outlet is avoided.

Owner:EAST CHINA UNIV OF SCI & TECH

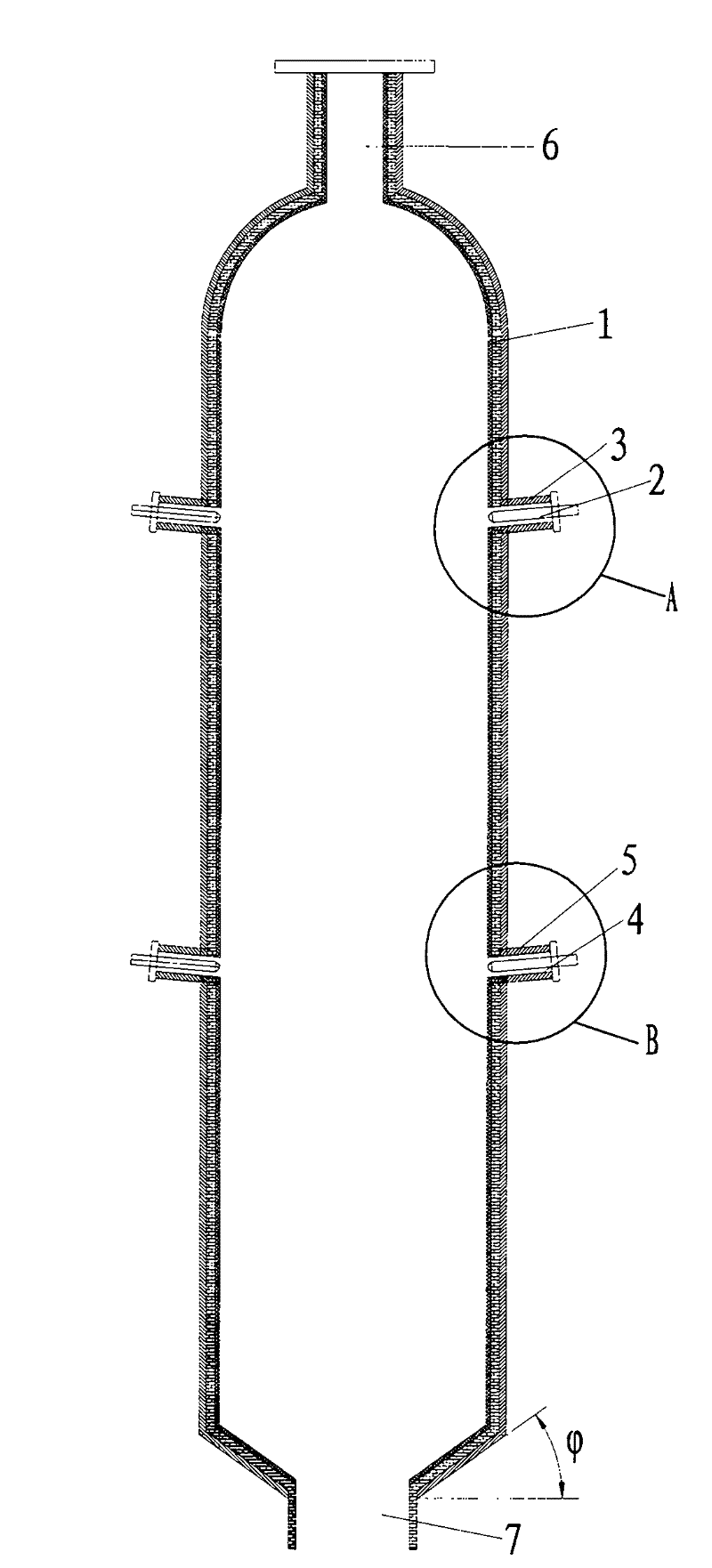

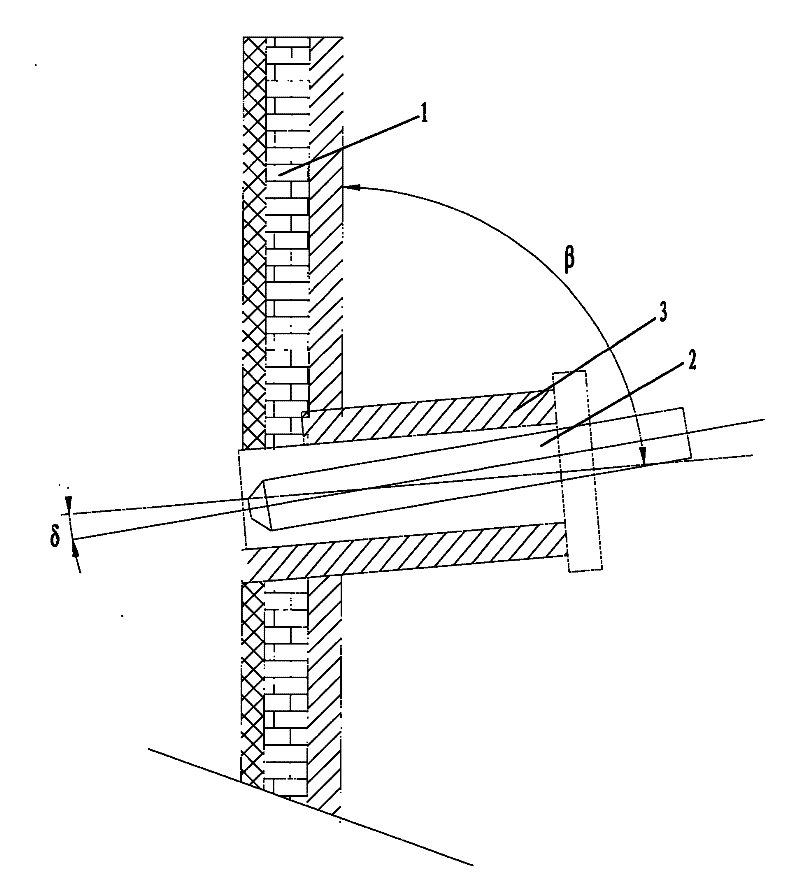

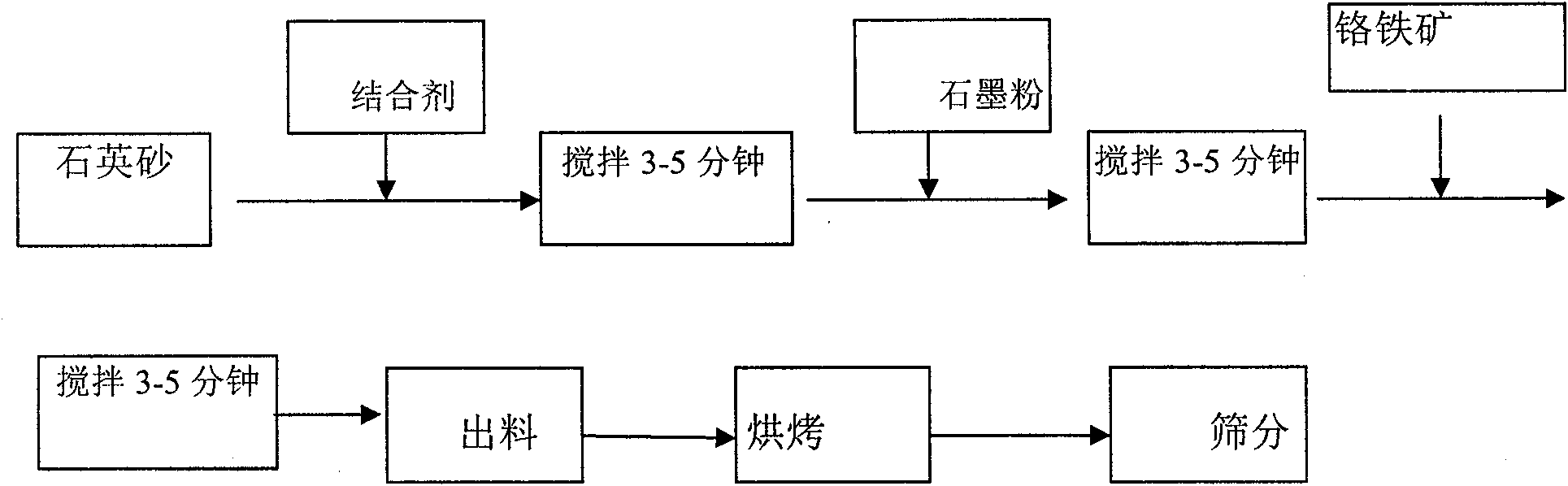

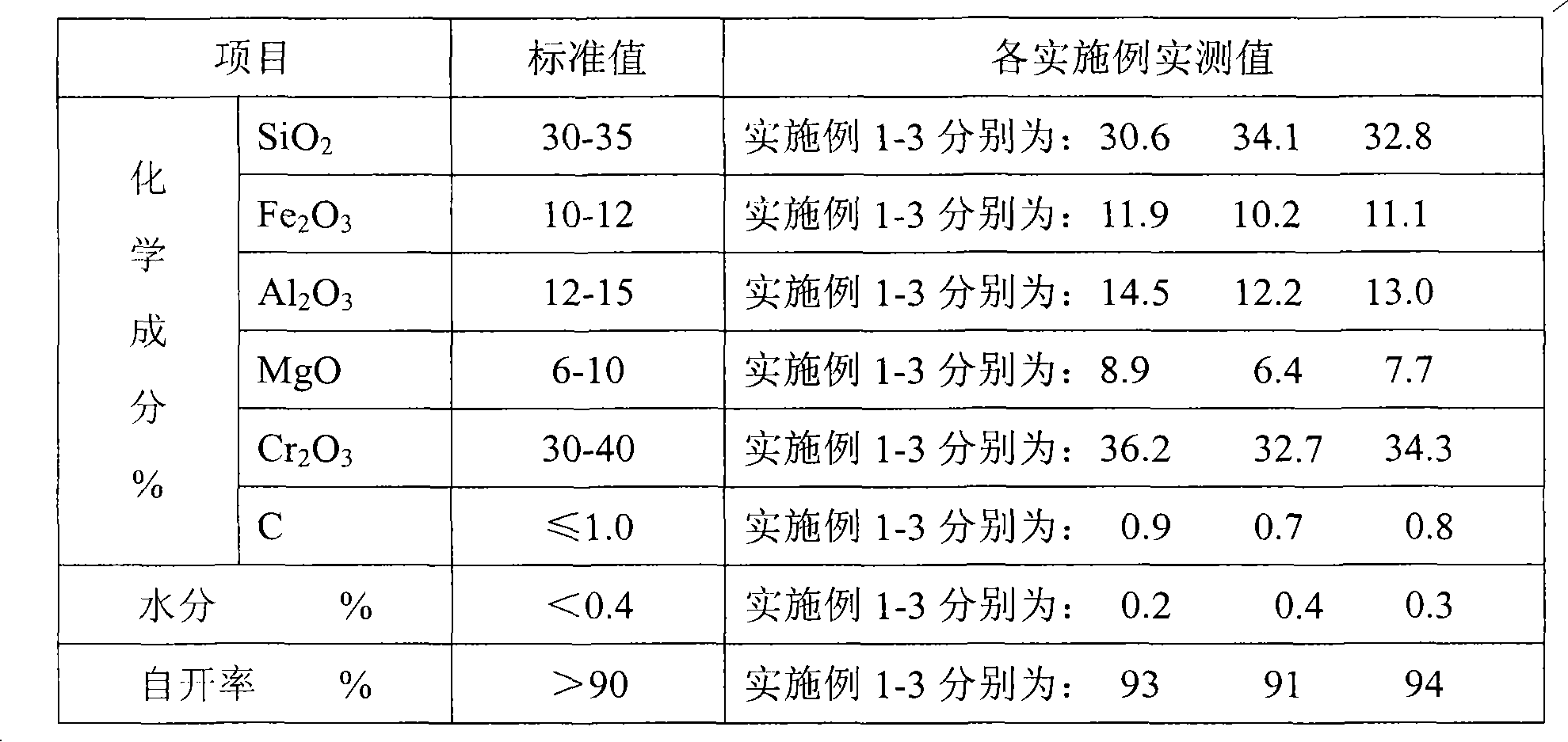

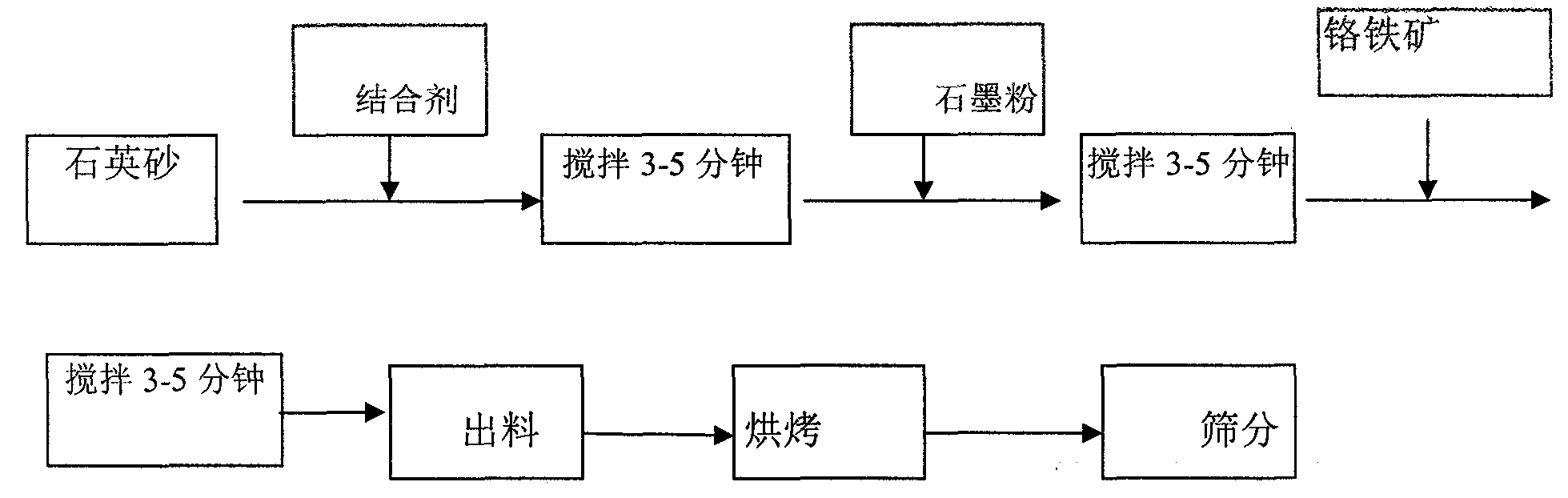

Chrome drainage sand for special steel and preparation technology thereof

InactiveCN101972847AImprove self-opening rateSuitable for sinteringMelt-holding vesselsTO-18Graphite

The invention relates to chrome drainage sand for special steel and a preparation technology thereof, belonging to the technical field of steel smelting. The chrome drainage sand for special steel comprises the following components in percentage by mass: 28-33 % of quartz sand as aggregate, 62-70 % of ferrochrome as a base material, 1-1.5 % of graphite powder as an additive and 0.5-1.5 % of phenolic resin as a bonding agent. The preparation technology comprises: 1) in mixing equipment, adding 28-33 % of quartz sand and 0.5-1.5 % of bonding agent phenolic resin, stirring, and adding 1-1.5 % of graphite powder and stirring after the quartz sand particles are completely wetted; after the graphite powder and the quartz sand particles are evenly mixed, adding 62-70 % of ferrochrome ore, and continuously stirring to obtain an even mixture; 2) adding the well mixed chrome drainage sand into a roasting kiln for roasting, wherein the highest roasting temperature is 200 DEG C, and the total roasting time is equal to 18 hours; and 3) removing fake particles in the chrome drainage sand, and screening the product particles to cause the product particles to have suitable bulk density. Aiming at the requirement of smelting special steel, the invention develops special chrome drainage sand and causes self opening rate of the chrome drainage sand to be above 90%.

Owner:上海盛江特种耐火材料有限公司

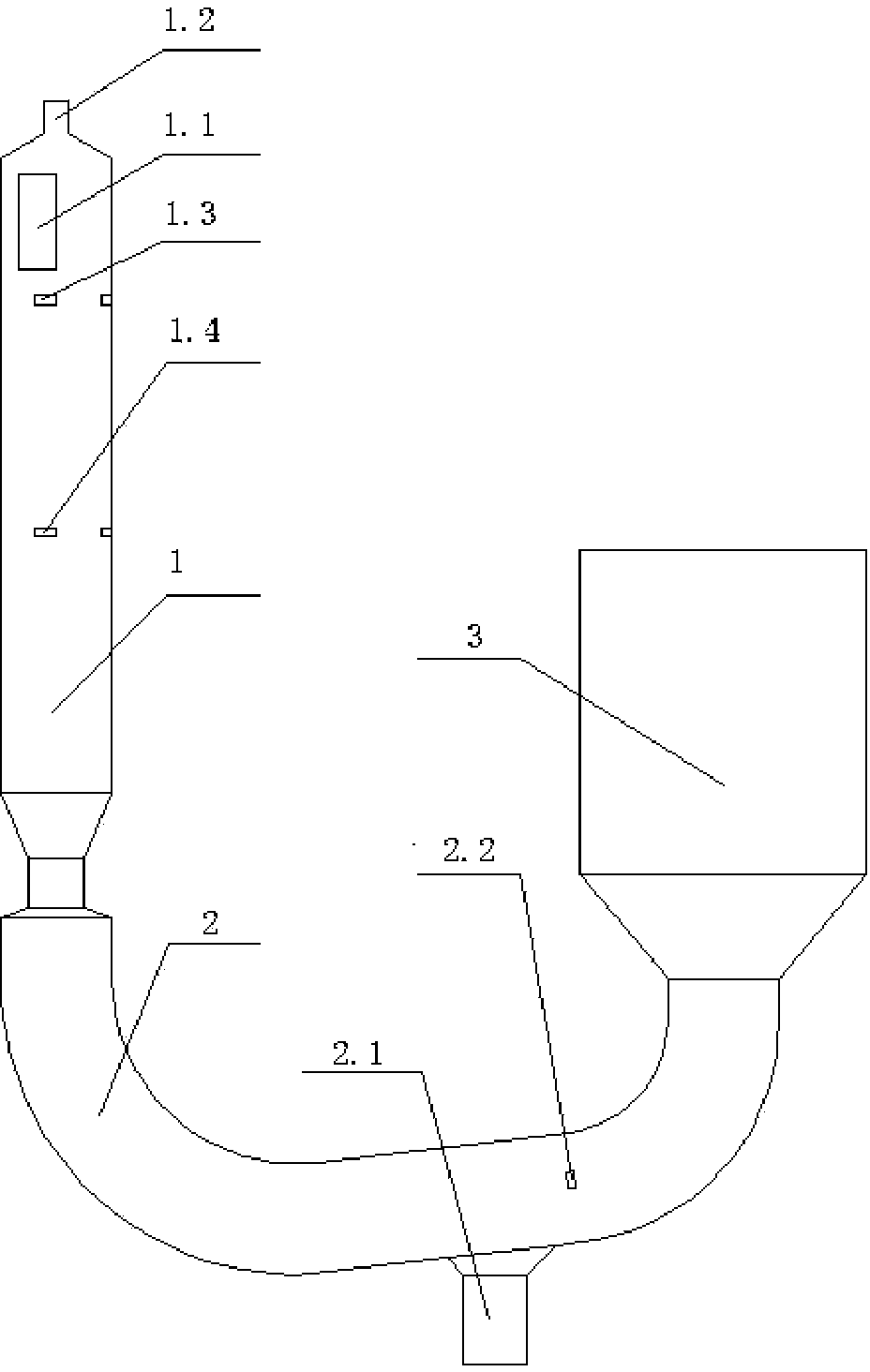

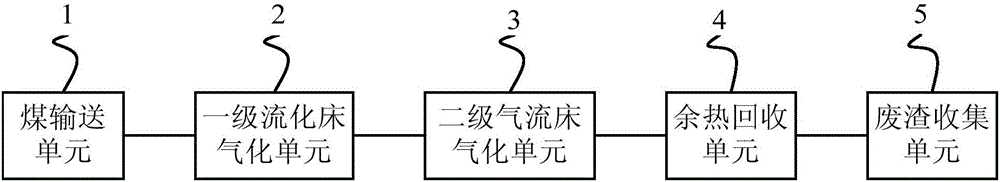

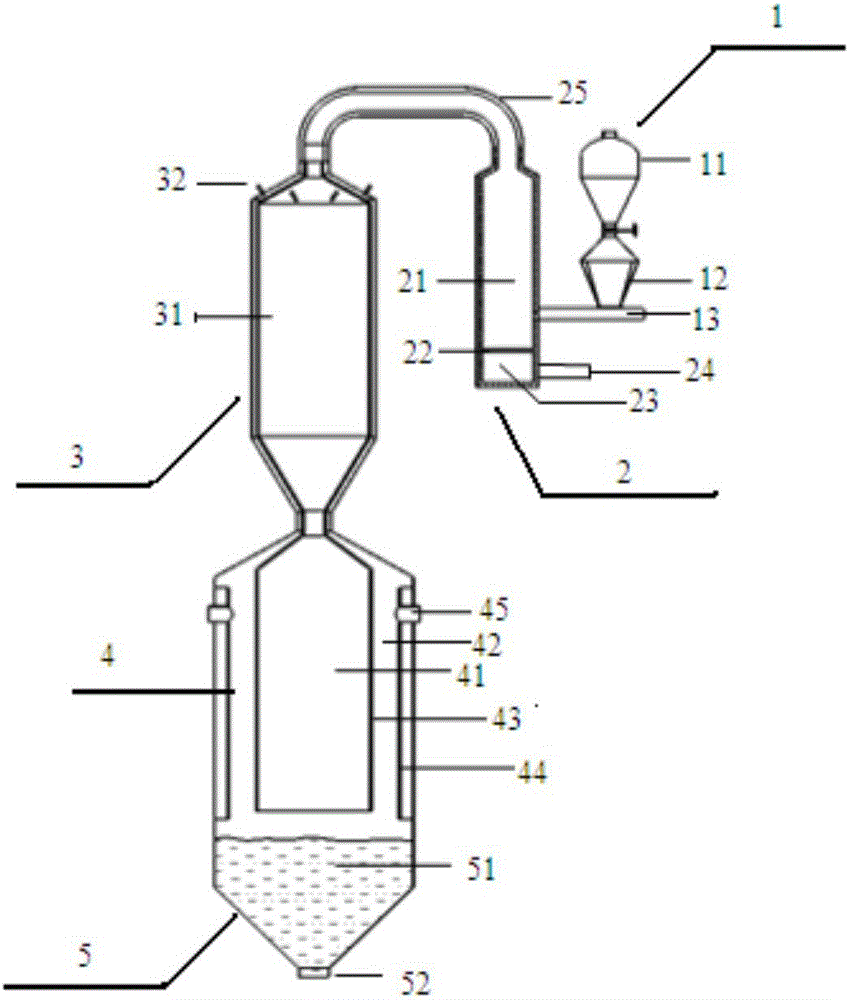

Gradient combined bed gasification system

InactiveCN106118750AReduce investmentImprove carbon conversionEnergy inputGasification processes detailsFluidized bedProcess engineering

The invention provides a gradient combined bed gasification system which comprises a coal conveying unit, a first-stage fluidized bed gasification unit, a second-stage fluidized bed gasification unit, a waste heat recycling unit and a waste residue collecting unit, wherein the coal conveying unit is communicated with the first-stage fluidized bed gasification unit; the first-stage fluidized bed gasification unit is communicated with the second-stage fluidized bed gasification unit; the second-stage fluidized bed gasification unit is communicated with the waste heat recycling unit; the waste heat recycling unit is communicated with the waste residue collecting unit. By adopting the gradient combined bed gasification system provided by the invention, coal powder can be subjected to gradient gasification, so that high-efficiency conversion of coal can be achieved.

Owner:KEDA MAS CLEAN ENERGY

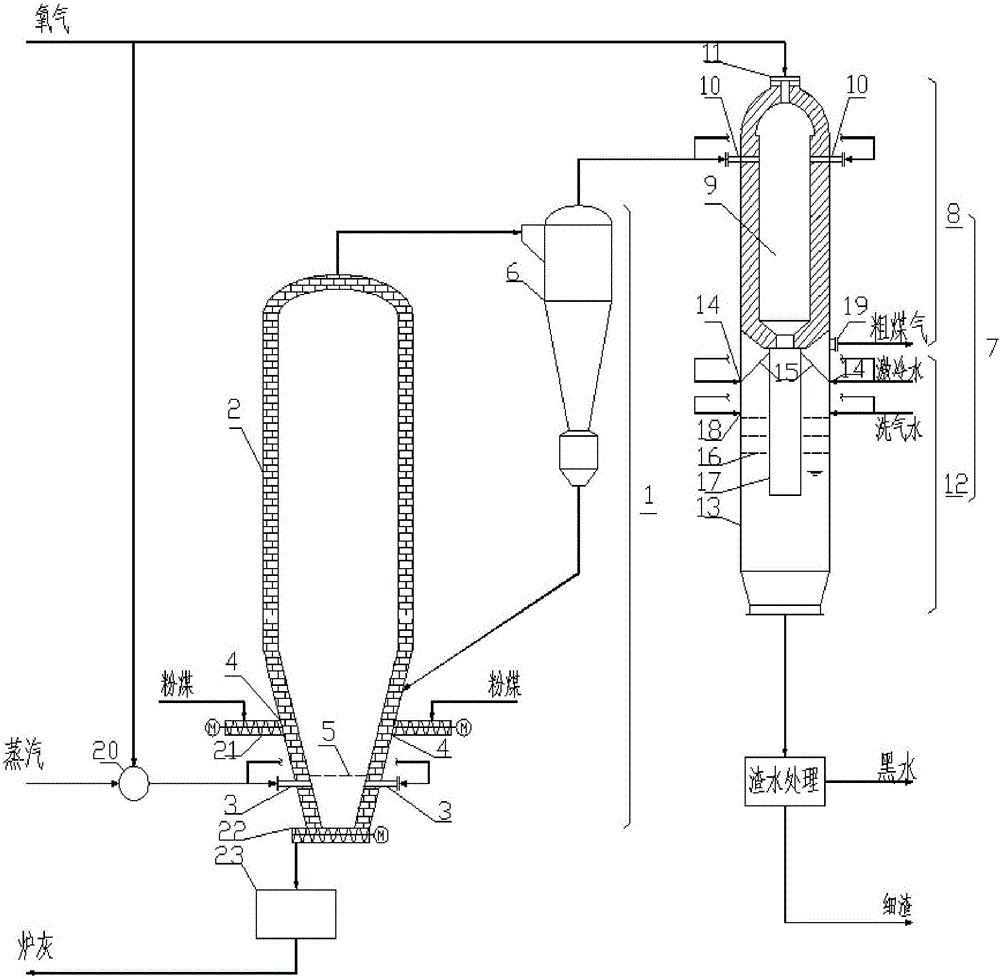

Method for gasifying pulverized coal step by step in double beds connected in series

InactiveCN105838451AImprove applicabilityReduce contentGasification processes detailsCombustible gas productionFluidized bed gasifierFluidized bed

The invention discloses a step-by-step gasification method of pulverized coal with double beds in series, which adopts the form of circulating fluidized bed gasification furnace in series with entrained flow bed gasification furnace. The core of the invention is to use oxygen in the entrained bed to perform secondary gasification on the high-temperature dust-containing gas produced by the gasification of the circulating fluidized bed. The present invention takes circulating fluidized bed gasification as the main body, and coal gasification is mainly completed in the circulating fluidized bed. By virtue of the advantages of circulating fluidized bed gasification, the coal type adaptability of the gasification device is expanded, and the single set of gasification device is improved. production capacity. Supplemented by entrained bed gasification, with the help of its high reaction temperature and the characteristics of crude gas needing to be washed by chilled water, it solves the problems of low carbon conversion rate, low content of effective gas in syngas and coarse gas produced in circulating fluidized bed gasification. There are a series of problems such as high ash content and pyrolysis products.

Owner:HUALU ENG & TECH

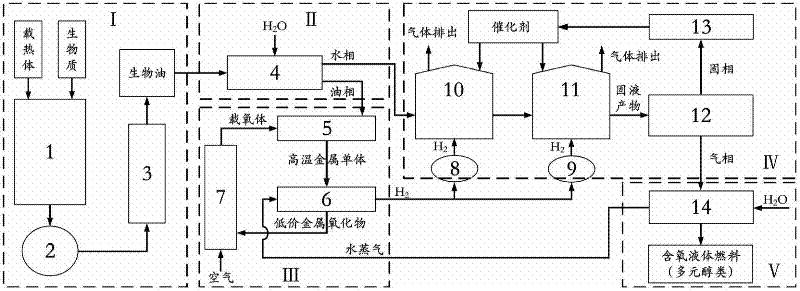

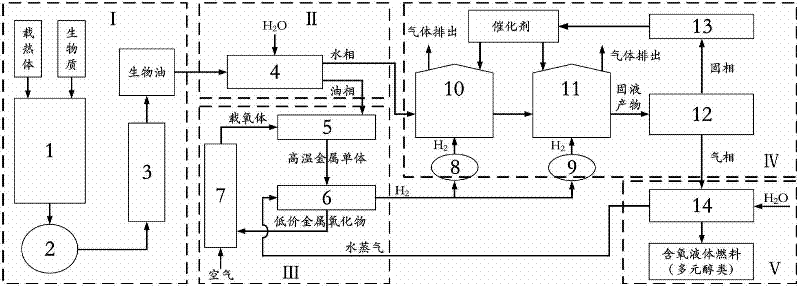

Device and method for preparing oxygen-containing liquid fuel by catalytically converting biological oil

InactiveCN102653691AHigh yieldReduce processing costsDirect heating destructive distillationBiofuelsCatalytic transformationLiquid fuel

The invention provides a device and a method for preparing oxygen-containing liquid fuel by catalytically converting biological oil. The device comprises a biomass rapid thermal cracking oil preparing system (I), a biological oil oil-water phase separation system (II), an oil phase biological oil chemical chain hydrogen production system (III) and a hydrogen output water supply phase biological oil catalytic hydrogenation system (IV), wherein the biomass rapid thermal cracking oil preparing system is used for preparing the biological oil; the biological oil oil-water phase separation system is used for receiving the biological oil and separating the biological oil into oil-phase biological oil and water-phase biological oil to be respectively output to the oil phase biological oil chemical chain hydrogen production system (III) and the hydrogen output water supply phase biological oil catalytic hydrogenation system (IV). The method comprises the following steps of: carrying out heat cracking on a biomass to prepare oil; carrying out water phase and oil phase separation on the obtained biological oil; carrying out chemical chain method on the oil-phase biological oil to produce hydrogen; and providing a'hydrogen source' to the water-phase biological oil to carry out two-step catalytic hydrogenation in a slurry bed; and directly separating and extracting a hydrogenated product to obtain the oxygen-containing liquid fuel. The device and method disclosed by the invention can be used for realizing full-component'graded conversion' of the biological oil.

Owner:SOUTHEAST UNIV

Two-section gasifying device of entrained-flow bed and gasifying method of two-section gasifying device

InactiveCN102911740ARealize gasification partitionReasonable distribution of temperature fieldCombined combustion mitigationGranular/pulverulent flues gasificationEngineeringOxygen

The invention provides a two-section gasifying device of an entrained-flow bed. The two-section gasifying device comprises an upper-section gasifying chamber of a gasification furnace and a lower-section gasifying chamber of the gasification furnace. At least one layer of side technological burner chambers is arranged on the periphery of the upper-section gasifying chamber of the gasification furnace, at least two side technological burners are symmetrically arranged inside each side technological burner chamber, opposite technological burner chambers are coaxially arranged on two sides of the lower-section gasifying chamber of the gasification furnace, and two opposite technological burners are coaxially arranged in each opposite technological burner chamber. The invention further provides a gasifying method of the two-section gasifying device of the entrained-flow bed. The method includes respectively feeding carbonic fuel and gasifying agents together into the two-section gasifying device from the side technological burners and the opposite technological burners. The volume of oxygen in the gasifying agents fed into the two-section gasifying device via the opposite technological burners accounts for 80-100% of the total volume of oxygen in the carbonic fuel and oxygen in the gasifying agents. The device is stable and reliable in running, wide in fuel adaptability, long in service life and suitable for large-scale application, a synthesis gas cooling process is efficient, and the carbon conversion rate is increased.

Owner:SHANGHAI BOILER WORKS

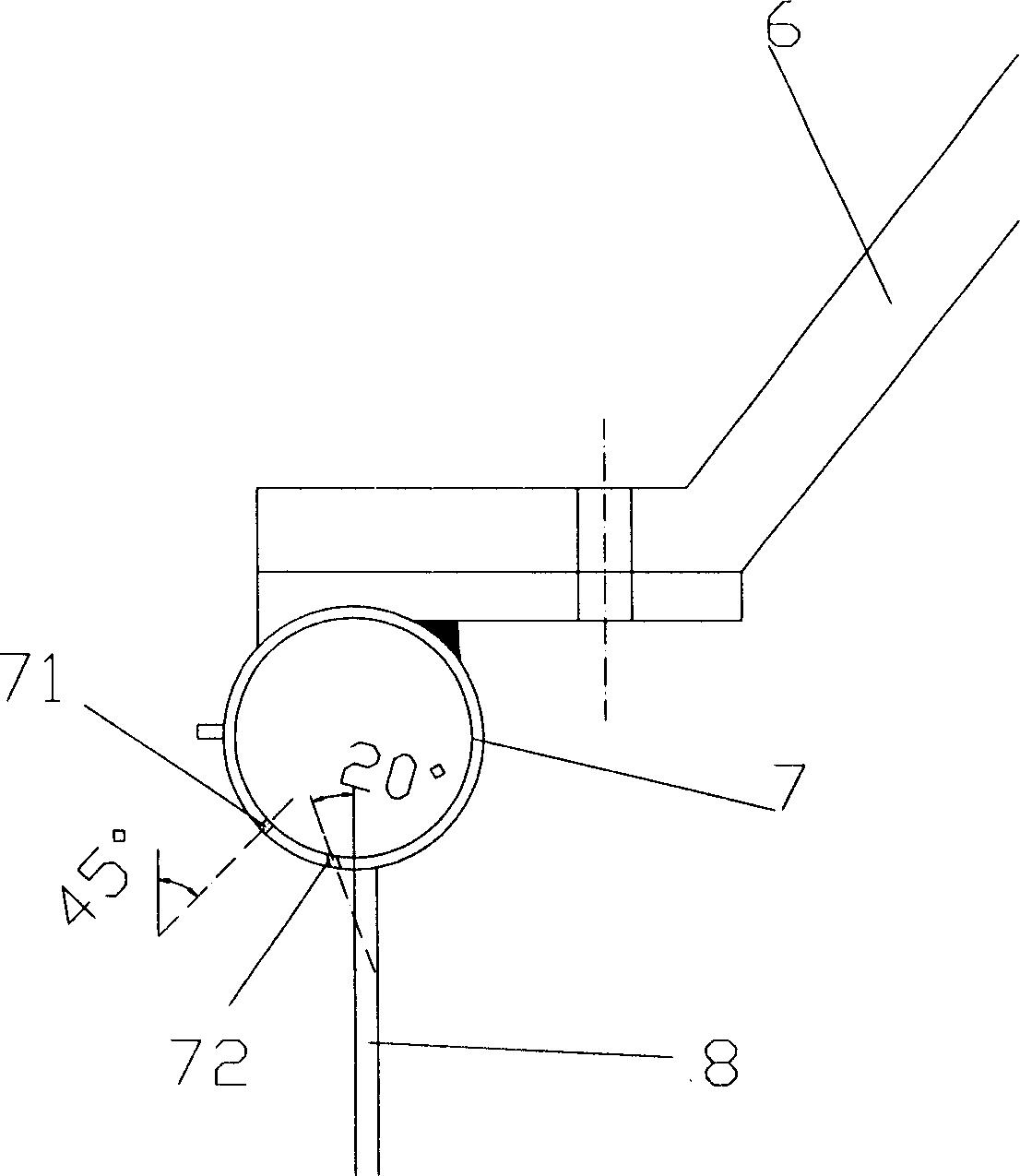

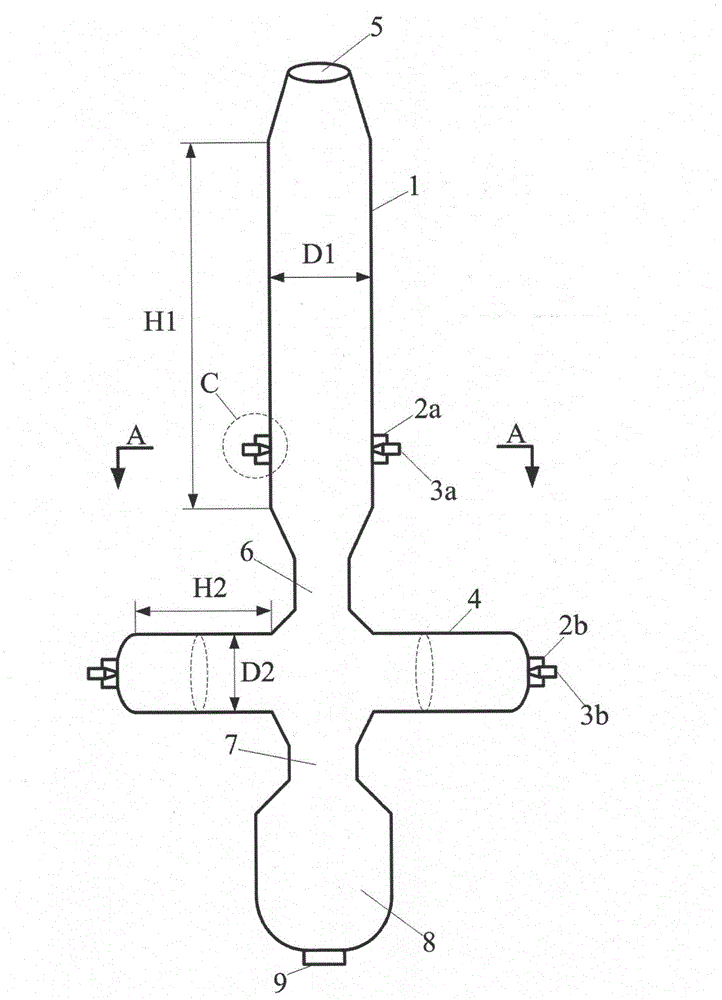

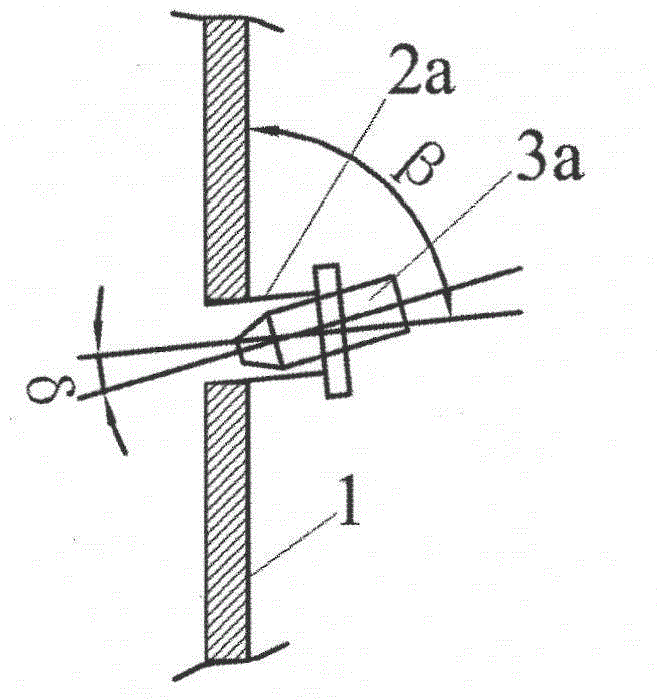

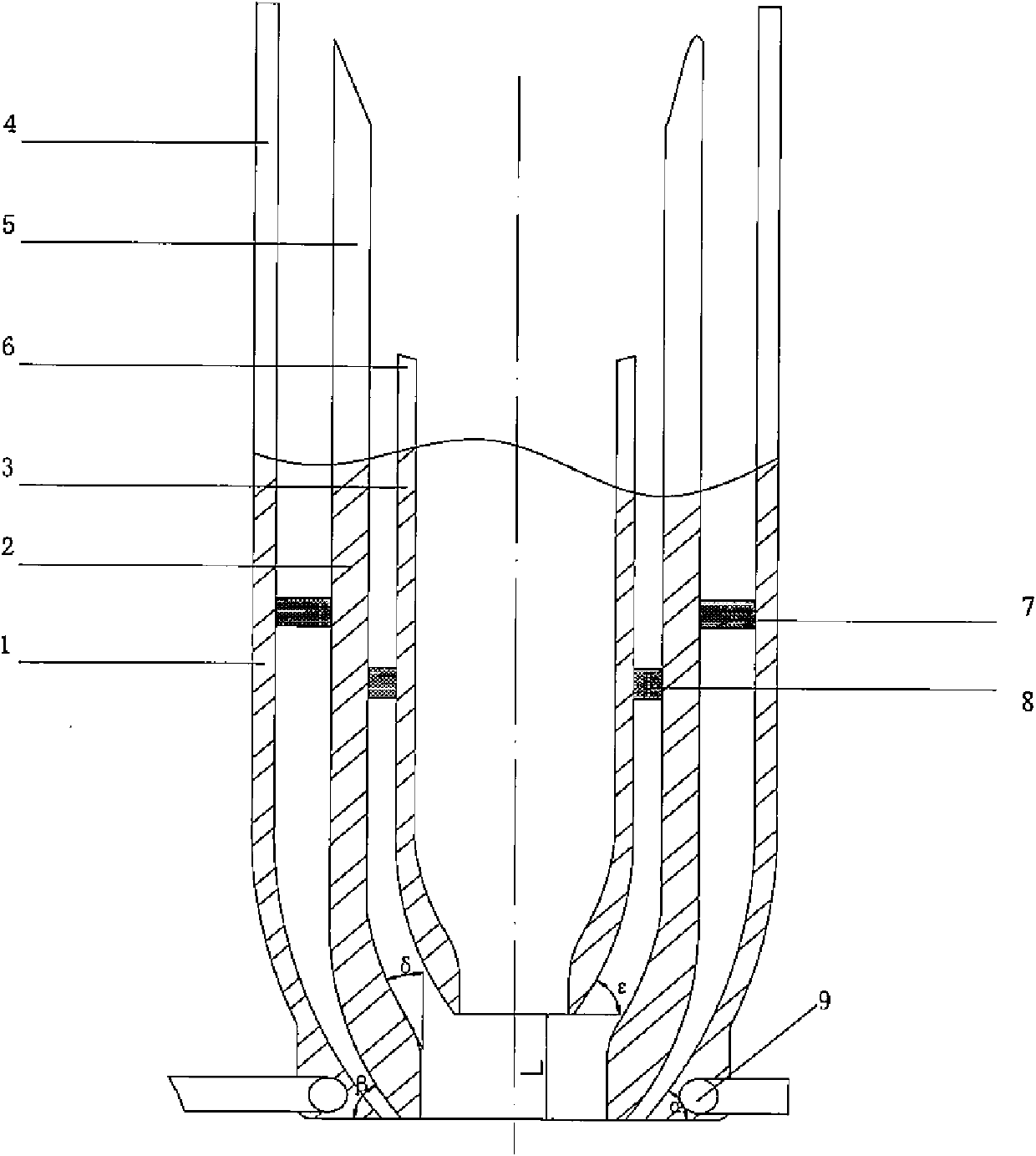

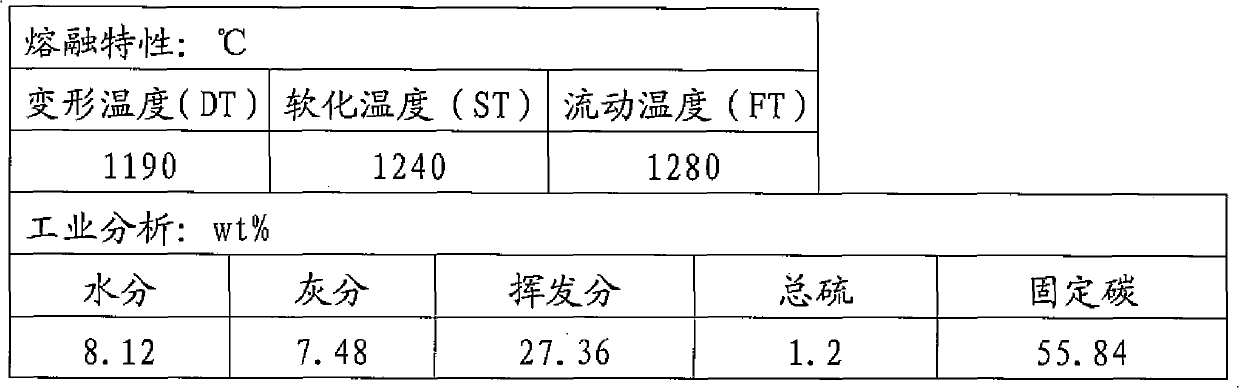

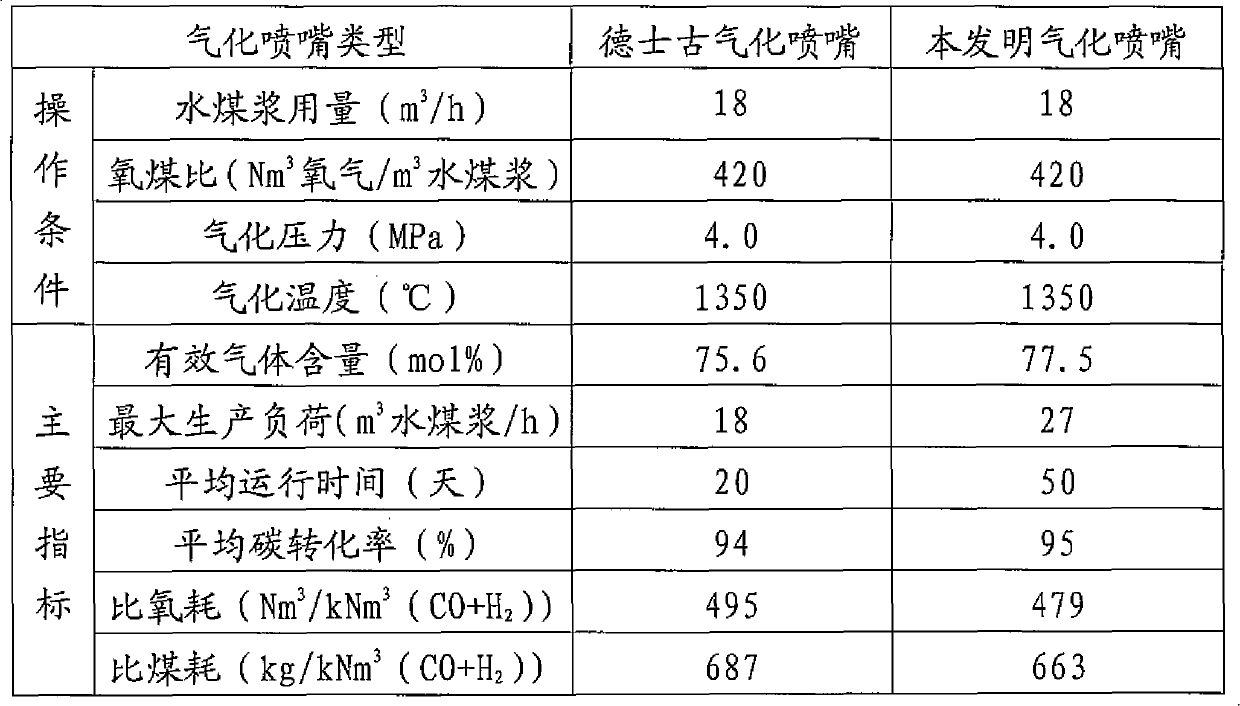

A gasification nozzle

InactiveCN102260533AImprove premix atomization effectWell mixedLiquid spraying apparatusGranular/pulverulent flues gasificationEpoxyCoal water

A gasification nozzle, which comprises a central oxygen nozzle, a coal-water slurry nozzle and an epoxy nozzle that are concentrically arranged from the inside to the outside, wherein the end section of the central oxygen nozzle is relative to the inner diameter of the end section of the coal-water slurry nozzle. The shrinkage is 20mm-100mm; the inclination angle of the epoxy nozzle is 20°-50°; the inclination angle of the outer side of the coal-water slurry nozzle is 30°-70°, and the inclination angle of the inner side is 30°-80°; the center The outside inclination angle of the oxygen nozzle is 30°-70°; a first locator is arranged in the epoxy channel, and a second locator is arranged in the coal-water slurry channel, and the top of the first locator is in the shape of a swirl sheet, so The included angle between the top and the feeding direction of oxygen is 20°-60°. When the gasification nozzle of the invention is used for gasification, the gasification effect of the coal-water slurry is better, the maximum production load of the gasification nozzle is increased, and the service life of the gasification nozzle is longer.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

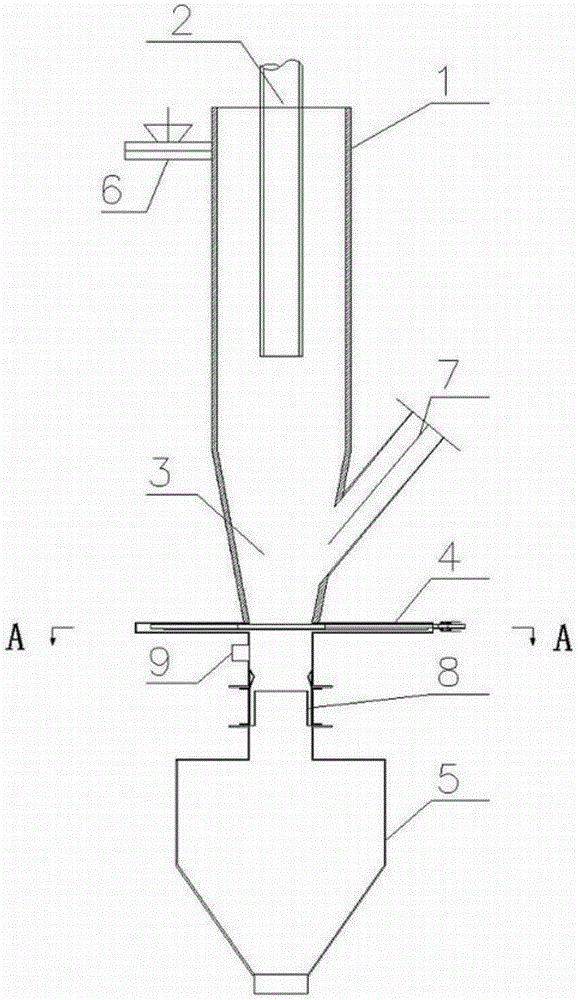

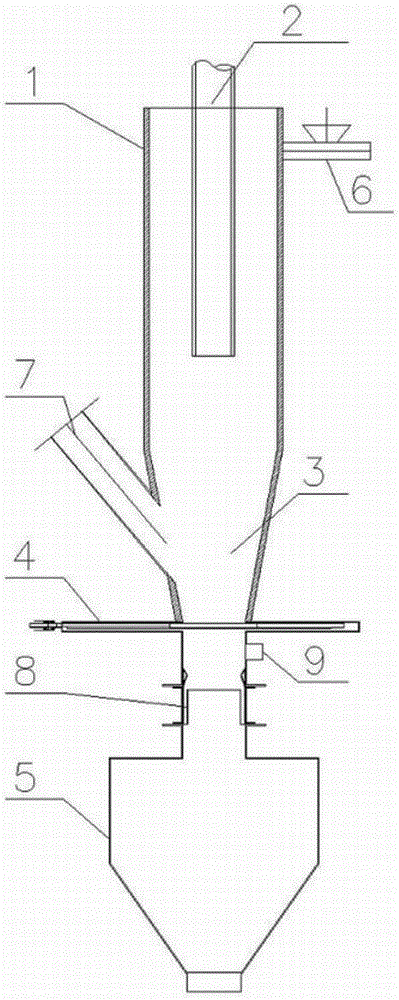

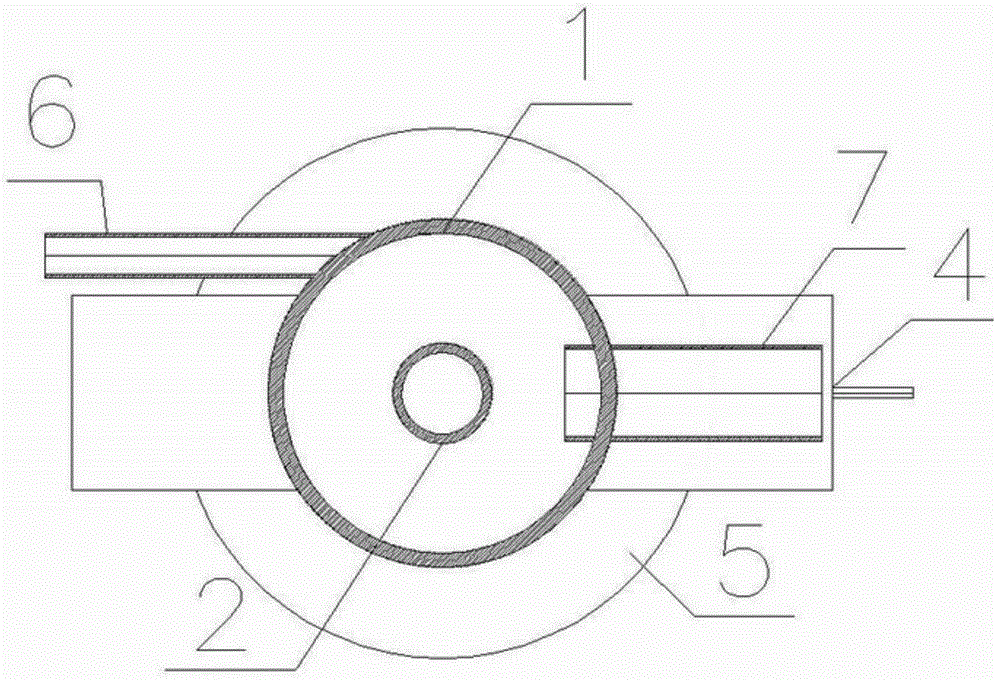

Biomass cyclone pyrolysis-suspension combustion composite gasification device and gasification method thereof

ActiveCN104152184AFacilitate the reduction reactionImprove conversion rateGranular/pulverulent flues gasificationCycloneCombustion chamber

The invention relates to a biomass cyclone pyrolysis-suspension combustion composite gasification device and a gasification method thereof. An existing cyclone gasification furnace has the defects of low biomass fuel conversion rate and low biomass gasification fuel gas heat value. The device provided by the invention has the following components: a central exhaust pipe (2) is concentrically suspended in a cyclone pyrolysis chamber (1); the cyclone pyrolysis chamber (1), a suspension combustion chamber (3), a switch grate (4), an air ring (8) and an ash hopper (5) are connected sequentially; an ignition hole (9) is arranged between the switch grate (4) and the air ring (8). A set of biomass fuel feeding pipes (6) is inserted on a tangential direction on the upper part of the cyclone pyrolysis chamber (1); an ignition fuel feeding pipe (7) is inserted on the lower part of the suspension combustion chamber (3). The gasification method comprises the following steps: a biomass fuel is sprayed into the cyclone pyrolysis chamber (1) along a tangential direction, and rotates downwards, such that a pyrolysis reaction is carried out; biomass coke particles in a pyrolysis reaction product enter the suspension combustion chamber (3), and is subjected to a combustion reaction with a main air flow from the air ring (8); and produced carbon dioxide moves upwards and is subjected to a reduction reaction with the biomass coke particles moving downwards from the suspension combustion chamber (3). The technical scheme provided by the invention is applied to the biomass gasification device and method.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com