Patents

Literature

351 results about "Microwave pyrolysis" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

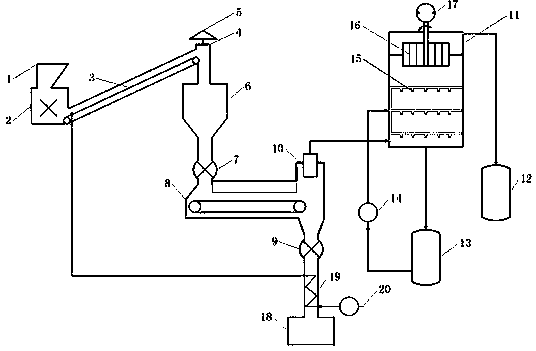

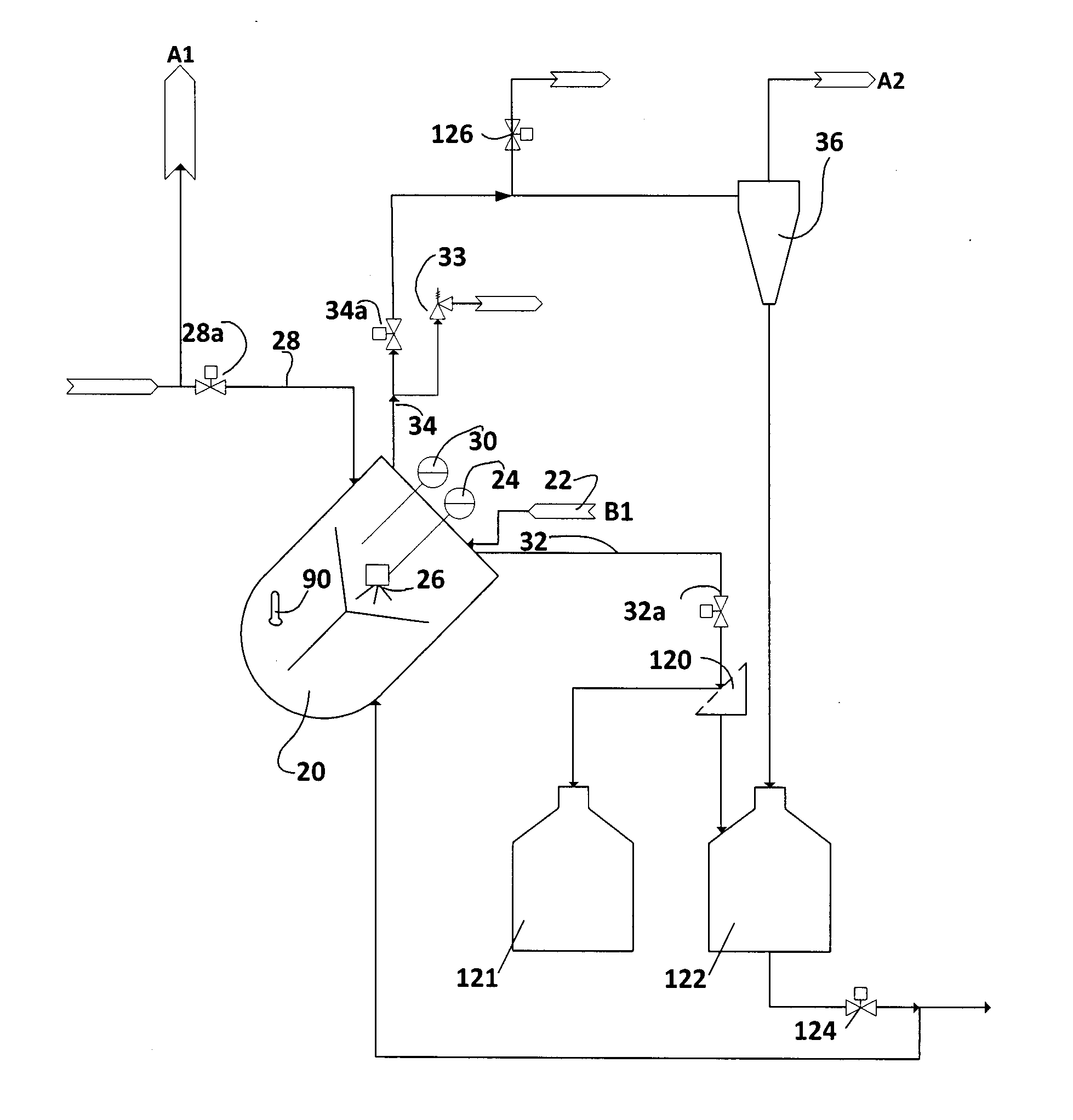

Industrial treatment method and industrial treatment device for oil field waste

ActiveCN103923670ALow boiling pointIncrease gasification rateElectrical coke oven heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisEnvironmental engineering

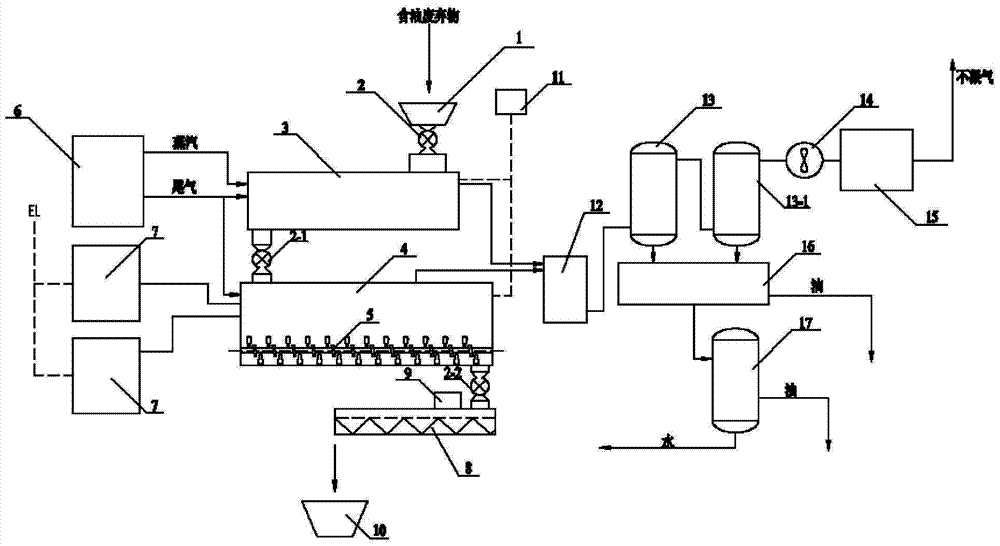

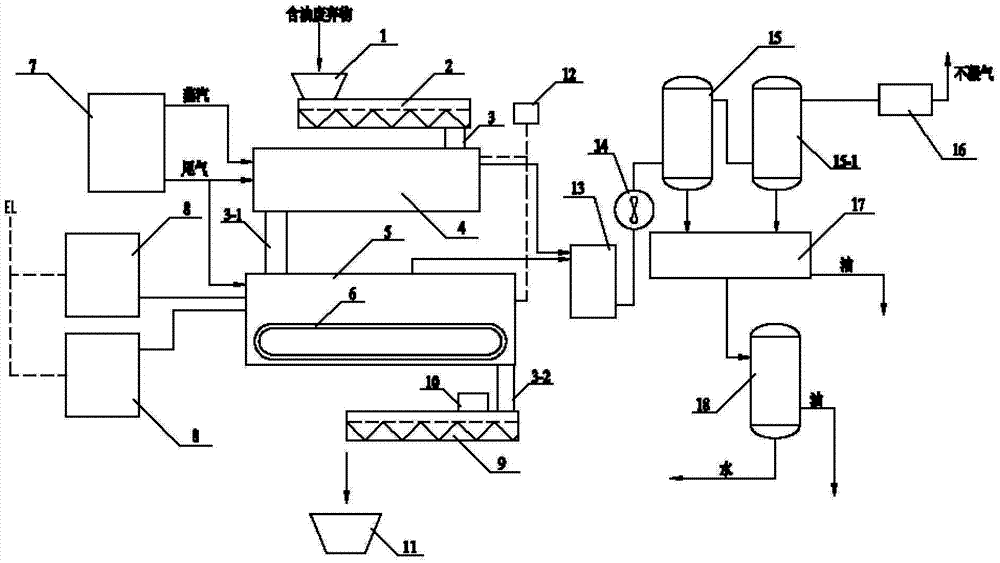

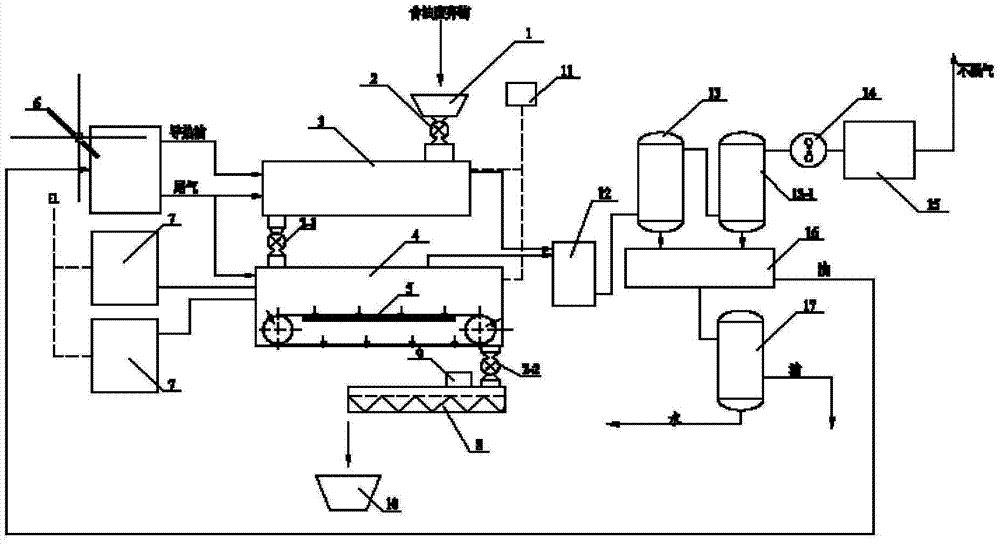

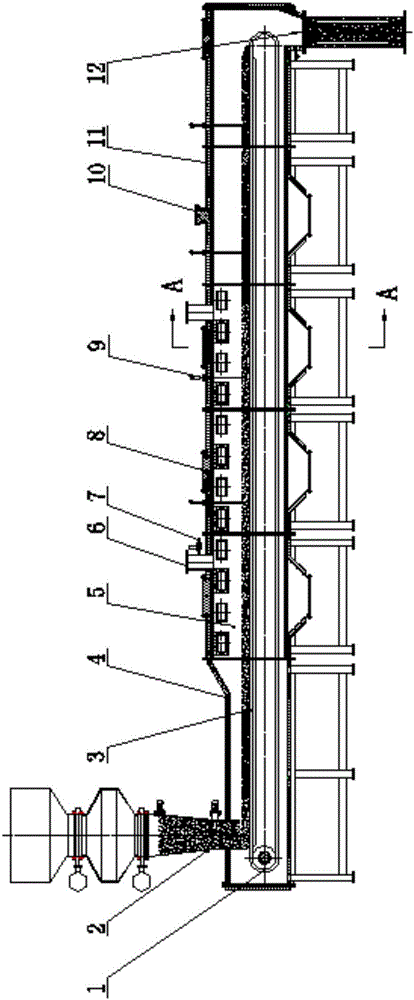

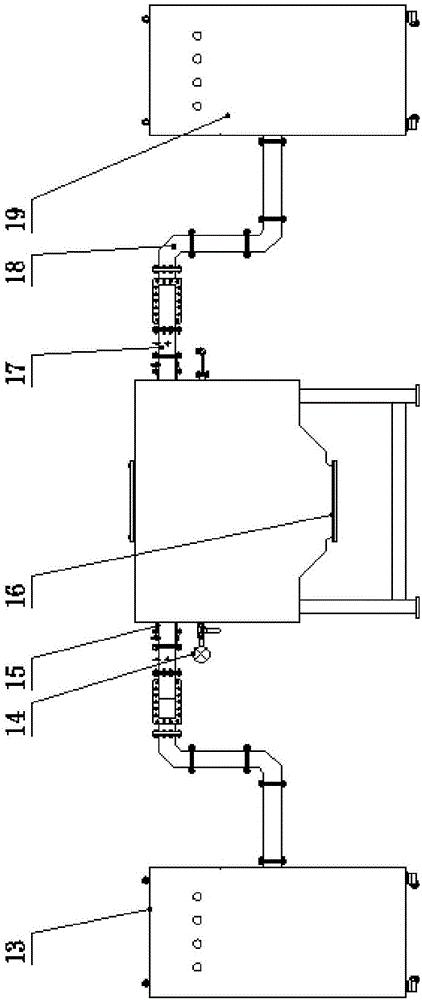

The invention provides an industrial treatment method for oil field waste. The industrial treatment method for oil field waste comprises the following steps: carrying out sampling analysis on the oil field waste, preheating to 80-300 DEG C by using high-temperature steam or conduction oil, then carrying out microwave pyrolysis treatment, controlling pressure at minus 5000 to minus 100 Pa, thus obtaining solid treatment substances and gas, condensing, separating and purifying the gas, and finally recycling so as to obtain water, oil and non-condensable gas. An industrial treatment device for oil field waste comprises a feed hopper, a dryer, a microwave heating cavity, a microwave generator, a heating device and a condensation separation purification device, wherein the feed hopper is connected to the dryer which is connected to the microwave heating cavity, a steam or conduction oil outlet of the heating device is connected to a steam or conduction oil outlet of the dryer; gas outlets of the dryer and the microwave heating cavity are connected to the condensation separation purification device; the microwave generator is connected to the microwave heating cavity. The industrial treatment method and the industrial treatment device have good treatment effects, high utilization rate of energy sources and good economical efficiency.

Owner:RUIJIE ENVIRONMENTAL PROTECTION TECH CO LTD

Method performing microwave pyrolysis on garbage

InactiveCN102585860AGuaranteed uptimeContinuous Industrialization ImplementationSolid waste disposalSpecial form destructive distillationMicrowave pyrolysisResource utilization

The invention discloses a method for performing microwave pyrolysis on garbage. The method comprises the following steps of: 1) pretreating the garbage to obtain structured garbage which is suitable for microwave pyrolysis; 2) performing microwave pyrolysis on the garbage, namely introducing pyrolysis gas out of a pyrolysis gas outlet of a microwave pyrolysis device, continuously outputting pyrolysis solid products from a pyrolysis solid residue discharge port on the microwave pyrolysis device, sealing the rest parts of the microwave pyrolysis device except a garbage inlet, the pyrolysis solid residue discharge port and a pyrolysis gas outlet to prevent the pyrolysis gas from being leaked and preventing external air from entering the microwave pyrolysis device to ensure that the pyrolysis gas is used as protective gas for pyrolysis reaction; and 3) recovering pyrolysis products, namely treating according to the pyrolysis products. The method has the characteristics of rapidness and high efficiency, low energy consumption, low cost, high resource utilization rate, simplicity in operation, high garbage volume reduction rate, capacity of obviously reducing damage of garbage to environment and the like; and by the method, innocent treatment of the garbage can be realized really.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +1

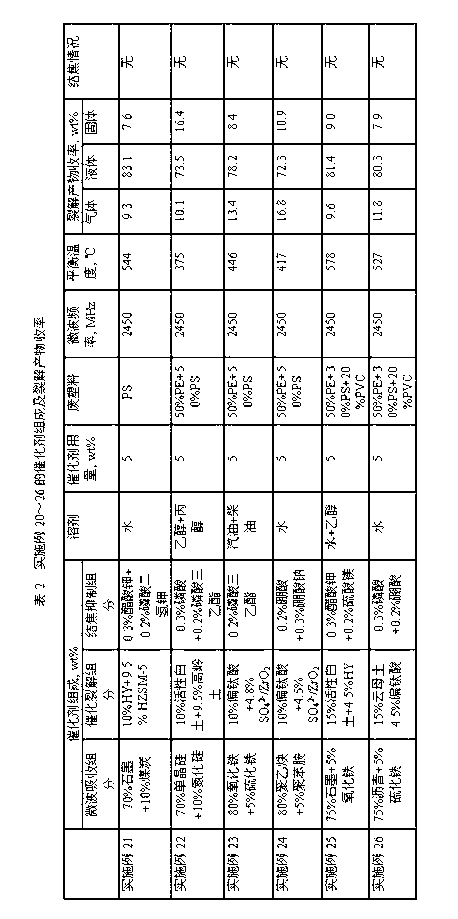

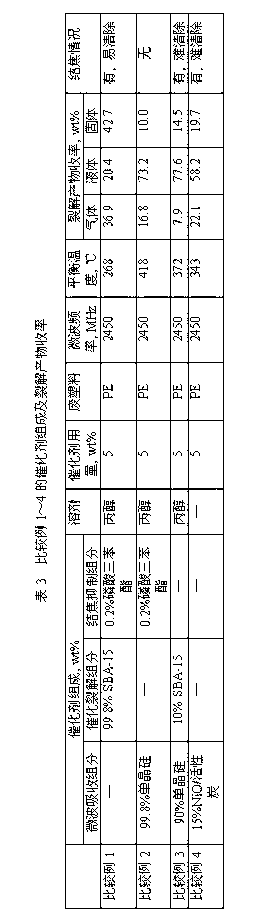

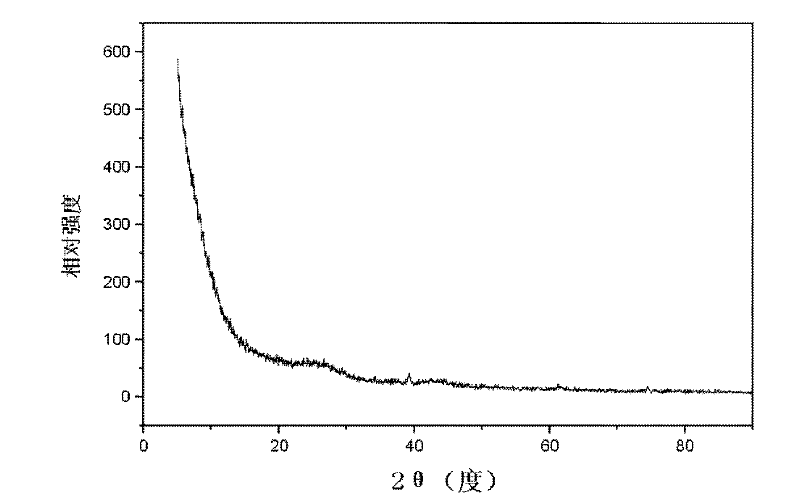

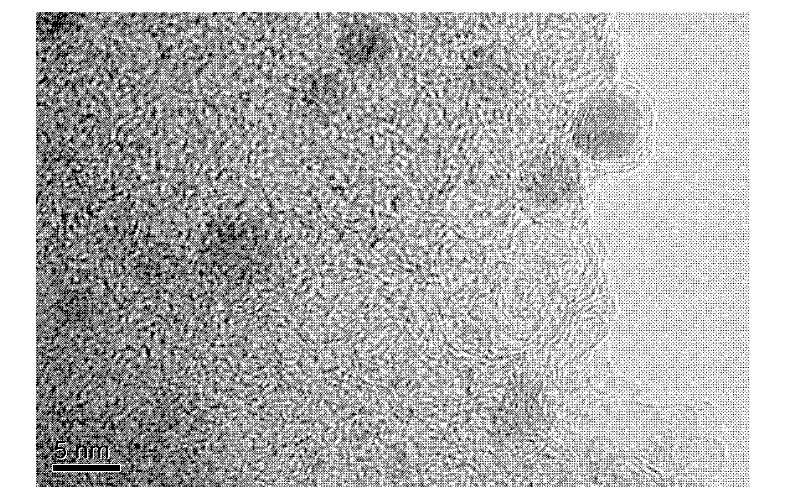

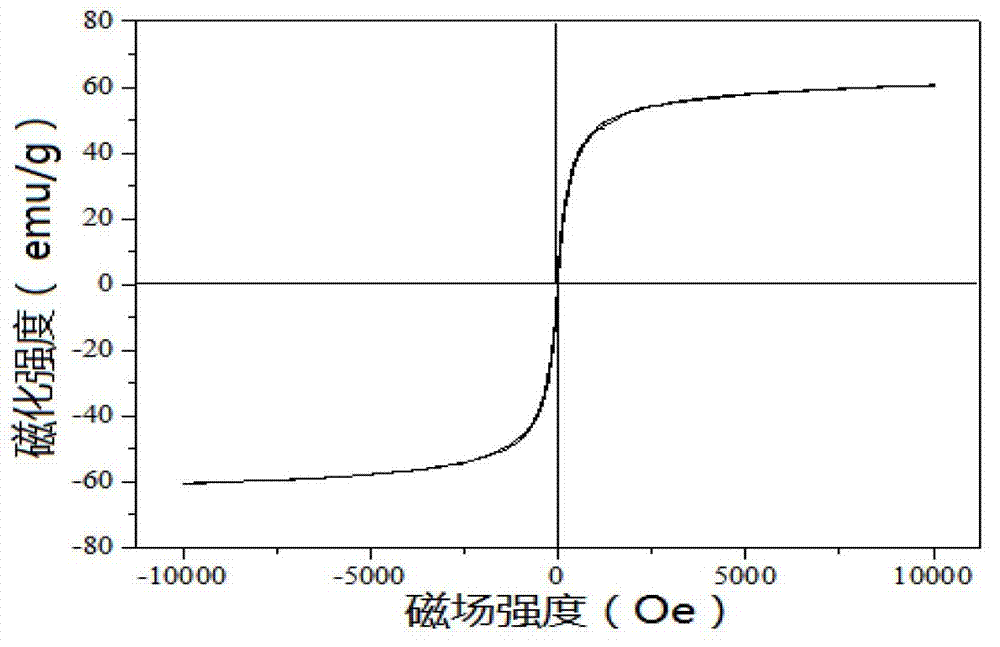

Catalyst for waste plastic microwave pyrolysis and preparation method thereof

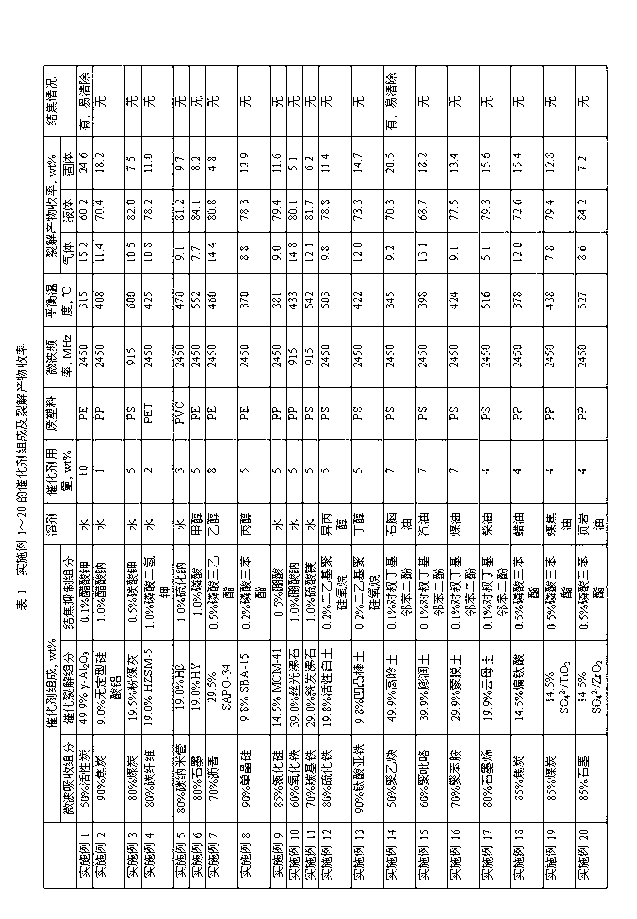

InactiveCN103252226AEasy to prepareHigh yieldMolecular sieve catalystsOrganic-compounds/hydrides/coordination-complexes catalystsMicrowave pyrolysisPtru catalyst

The invention discloses a catalyst for waste plastic microwave pyrolysis and a preparation method thereof. The catalyst comprises the following components by mass percent: 50.0-90.0% of a microwave absorption component, 9.0-49.9% of a catalytic cracking component, and 0.1-1.0% of a coking inhibiting component. The invention also discloses the preparation method of the catalyst. Compared with the prior art, the catalyst has the advantages that firstly, the catalyst has multiple functions, can effectively convert the microwave electromagnetic energy into heat, provides necessary energy for waste plastic pyrolysis and catalytic cracking, and can reach high equilibrium temperature in action; secondly, the yield of liquid pyrolysis oil is high, no coke is generated in the pyrolysis or the coke is loose and is easy to clear away; and thirdly, the preparation method of the catalyst is simple and is applicable to industrial production.

Owner:王文平 +2

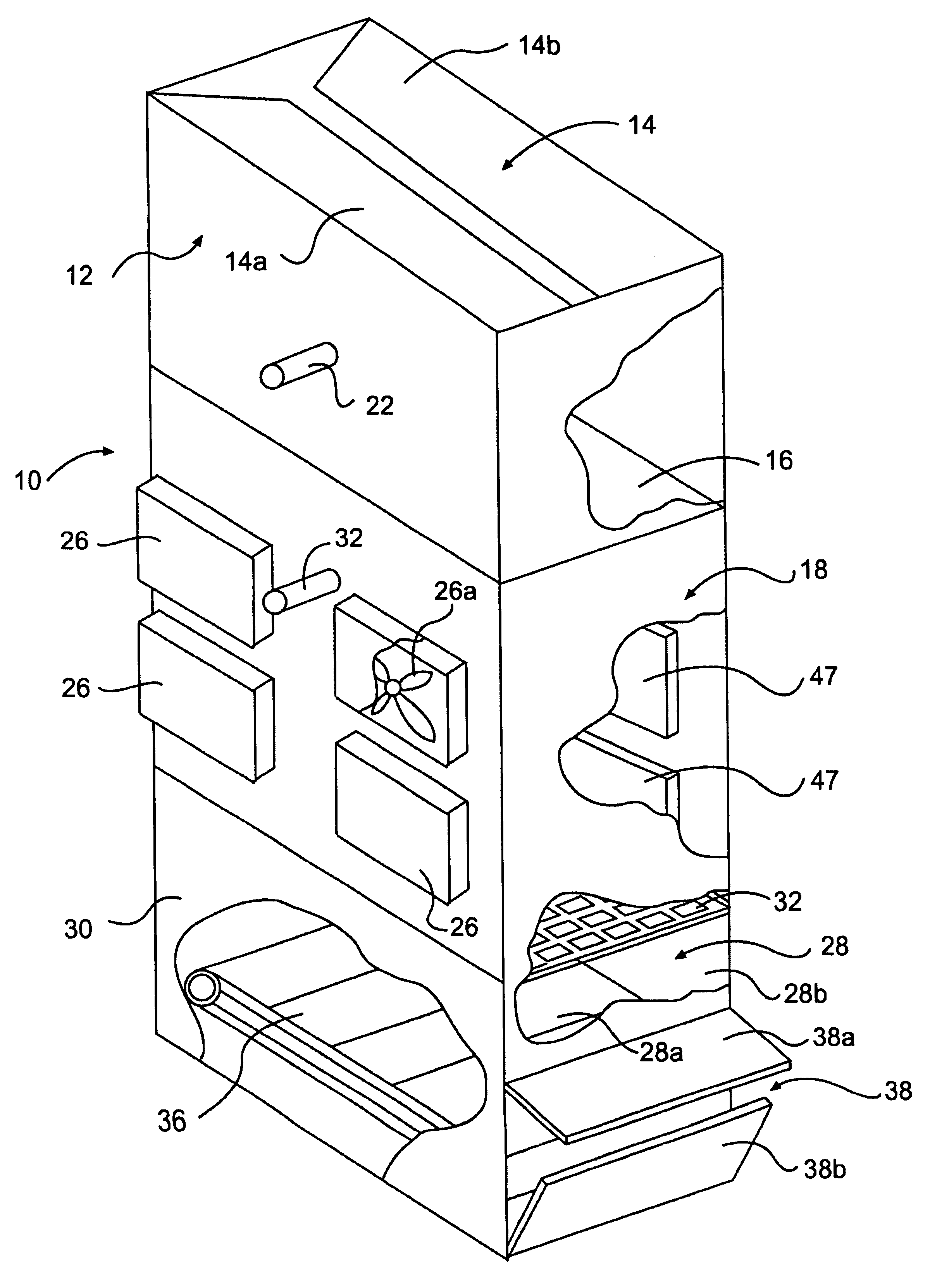

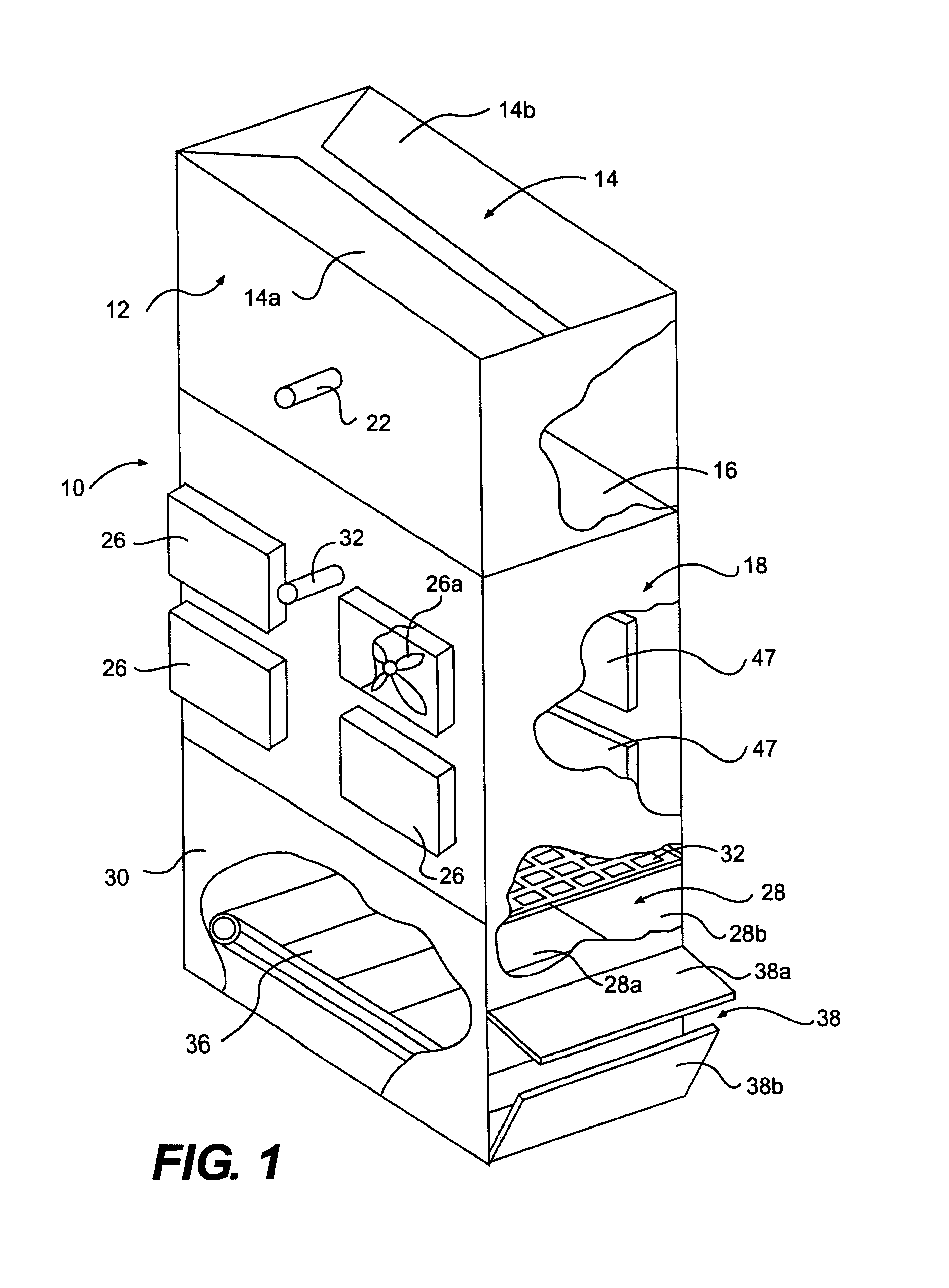

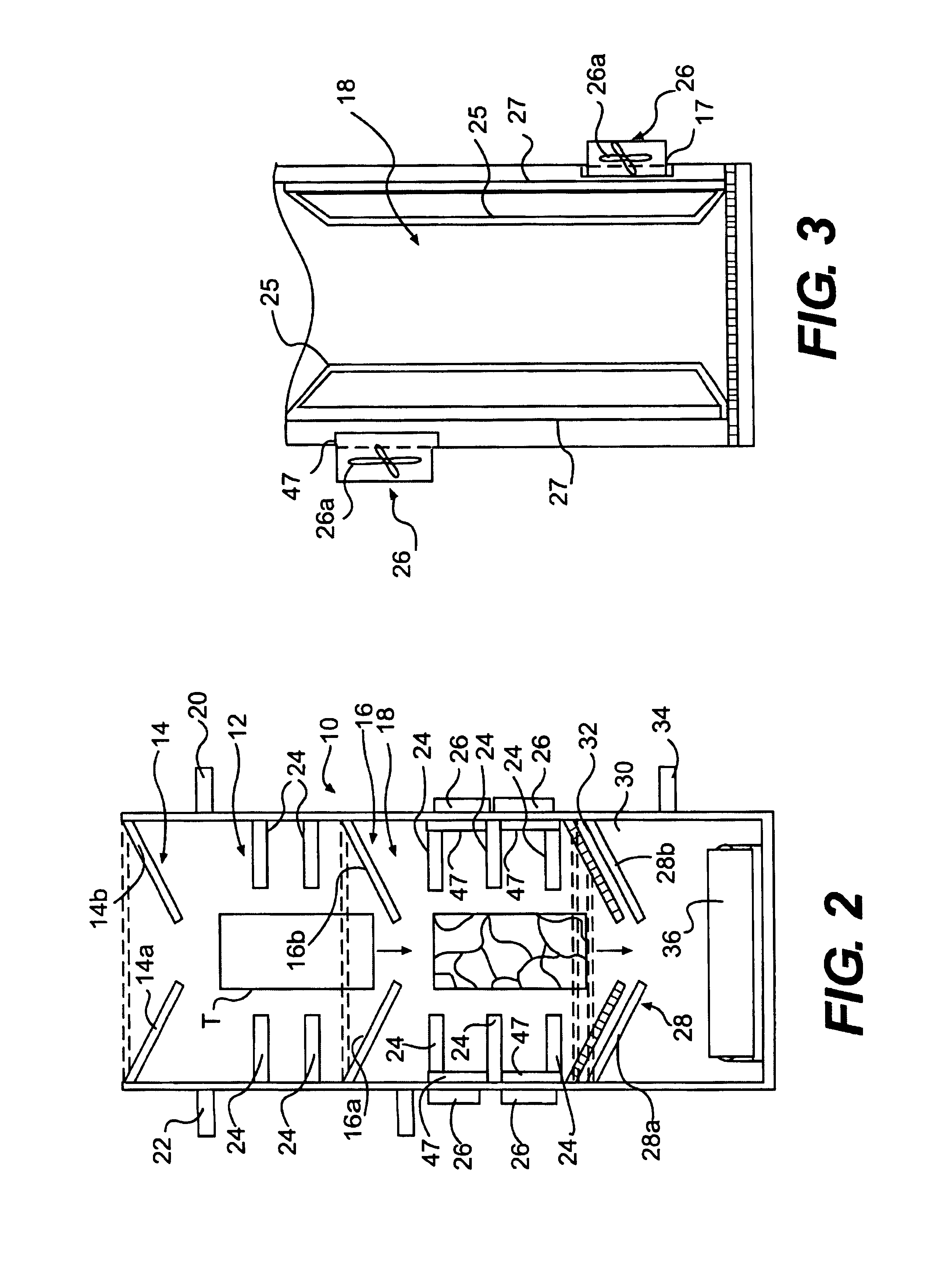

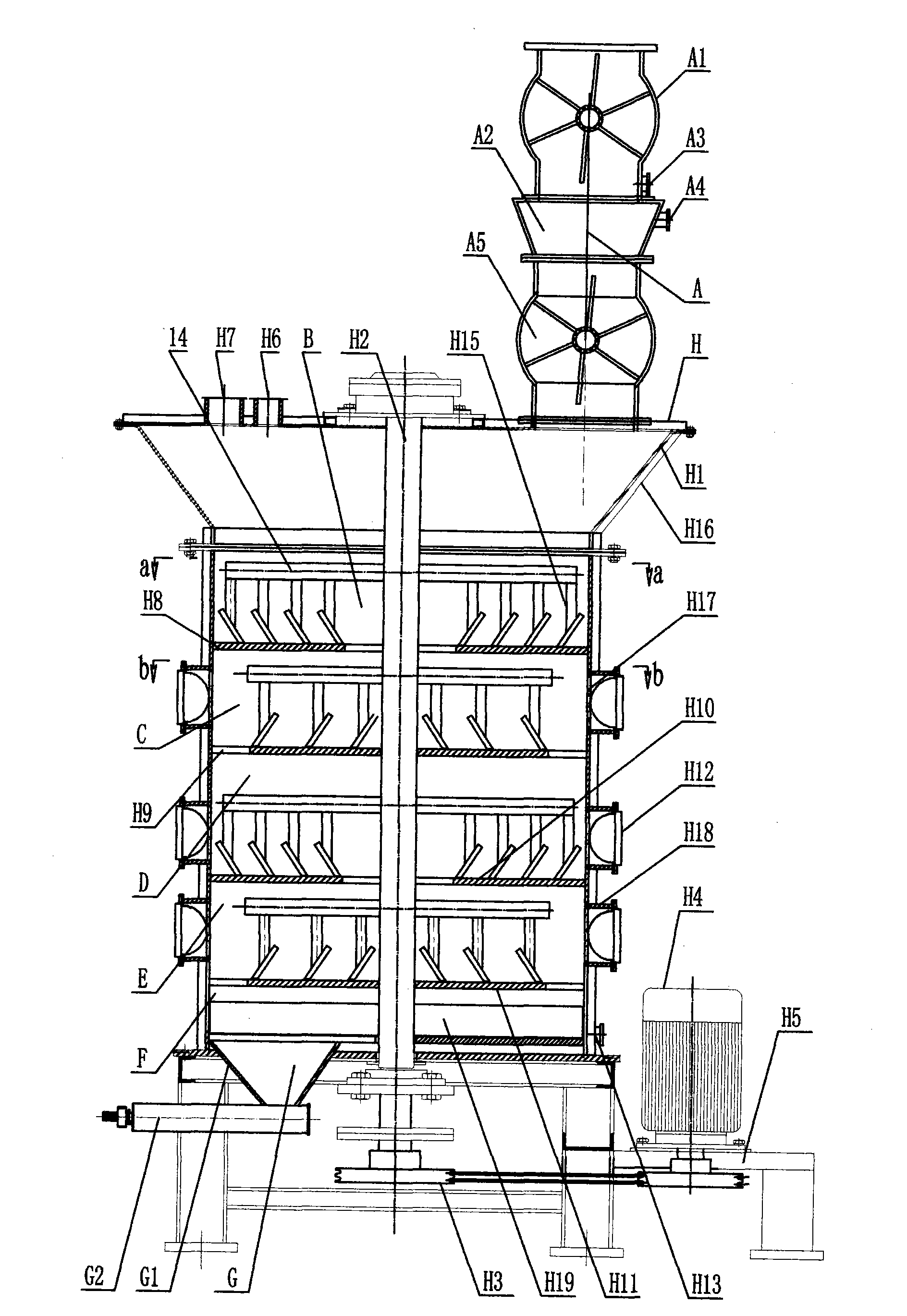

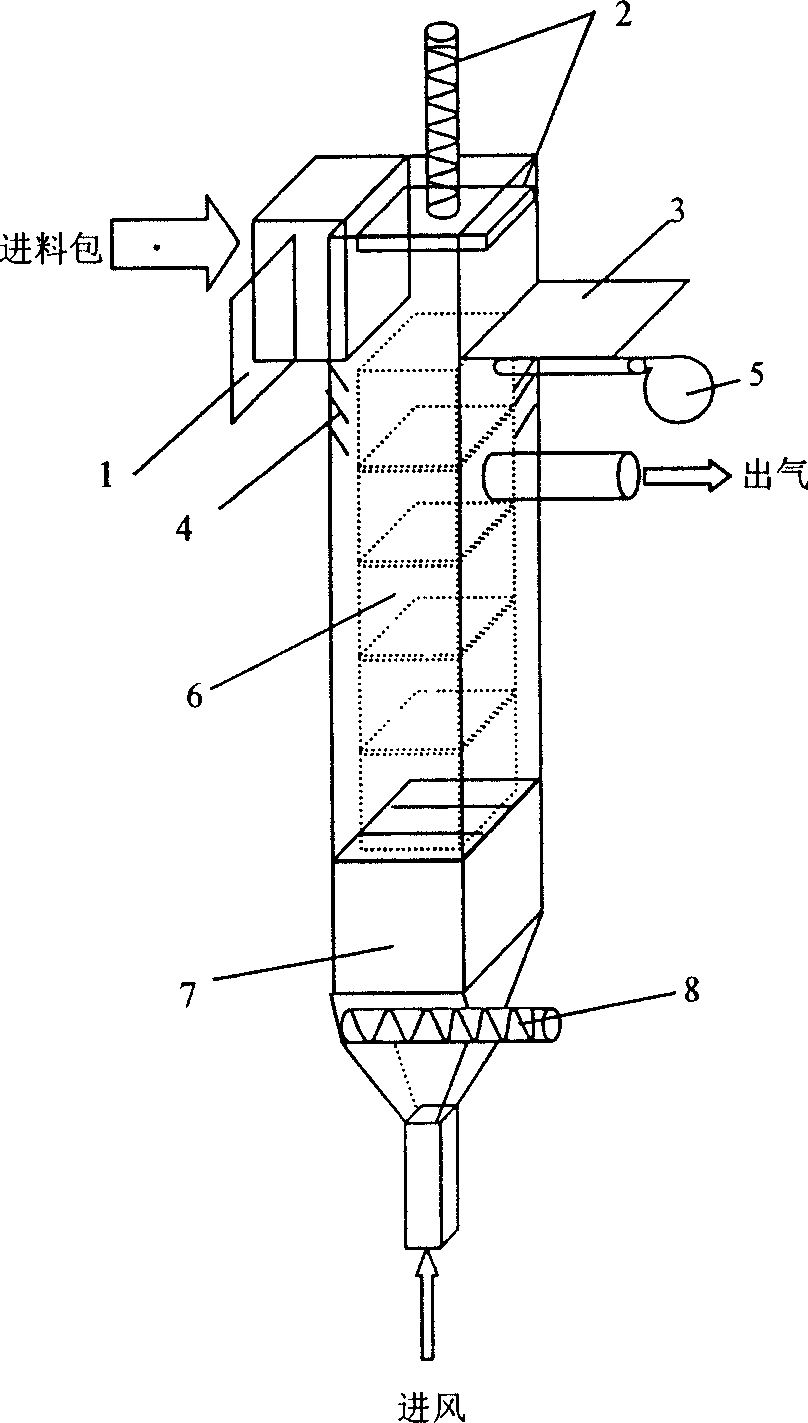

Microwave pyrolysis apparatus for waste tires

InactiveUS7101464B1Electrical coke oven heatingCombustible gas coke oven heatingMicrowave pyrolysisDistillation

A microwave distillation apparatus provides destructive distillation of whole waste tires. The apparatus includes a housing including a plurality of vertically arranged chambers. A preheat chamber provides preheating of a whole waste tire received therein. An irradiation chamber, located below the preheat chamber and thermally coupled to the preheat chamber such that heat generated in the irradiation chamber creates heat convection currents in the preheat chamber, receives a preheated whole waste tire from the preheat chamber. A microwave energy supply supplies microwave energy to the irradiation chamber to provide destructive distillation of a tire received in that chamber. A cooling chamber, located below the irradiation chamber, receives by-products of the destructive distillation therefrom and provides delivery of the by-products from the housing.

Owner:PRINGLE JOE A MR +1

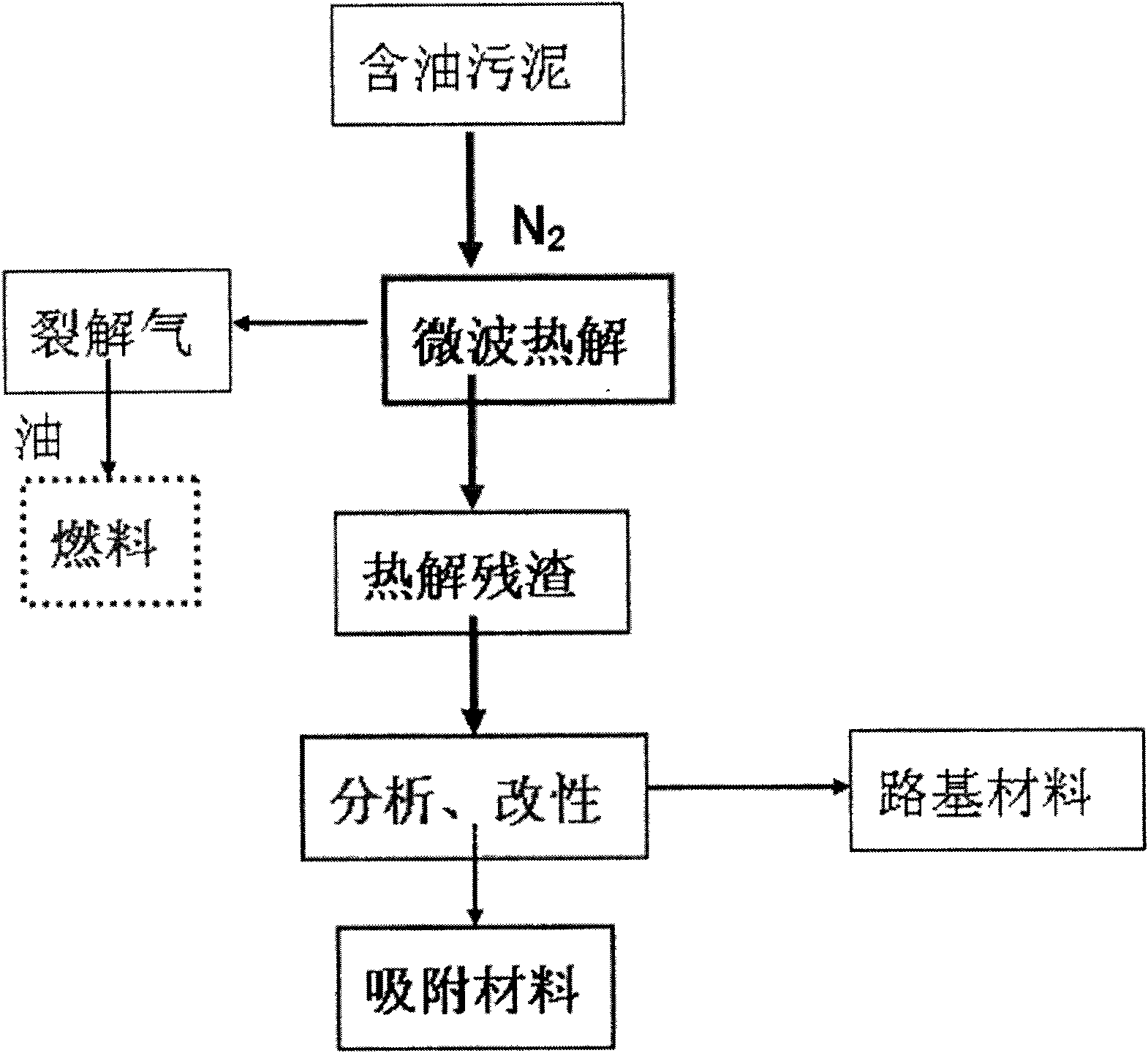

Resourceful treatment method and device for oil-containing sludge in oil fields by microwave pyrolysis

ActiveCN101838094ASolve pollutionAvoid Hazardous Waste Sewage FeesOther chemical processesSludge treatment by pyrolysisMicrowave pyrolysisSludge

The invention discloses a resourceful treatment method and a resourceful treatment device for oil-containing sludge in oil fields by microwave pyrolysis. The oil-containing sludge is conveyed into an enclosed reactor heated by microwaves, and is subjected to pyrolysis treatment at the temperature of between 200 and 900 DEG C; oil, gas and water generated by the pyrolysis treatment are recycled; the residue after the pyrolysis is used as a roadbed material or modified by nitric acid or NaOH alkali; and the modified residue is used as an adsorbing material. After the method and the device are implemented, over 75 percent of crude oil in the oil-containing sludge can be recycled, the pollution fee of 1,000 yuan / t can be saved, the social and economic benefits are obvious, and the method and the device have wide market application prospect.

Owner:CHINA PETROCHEMICAL CORP +2

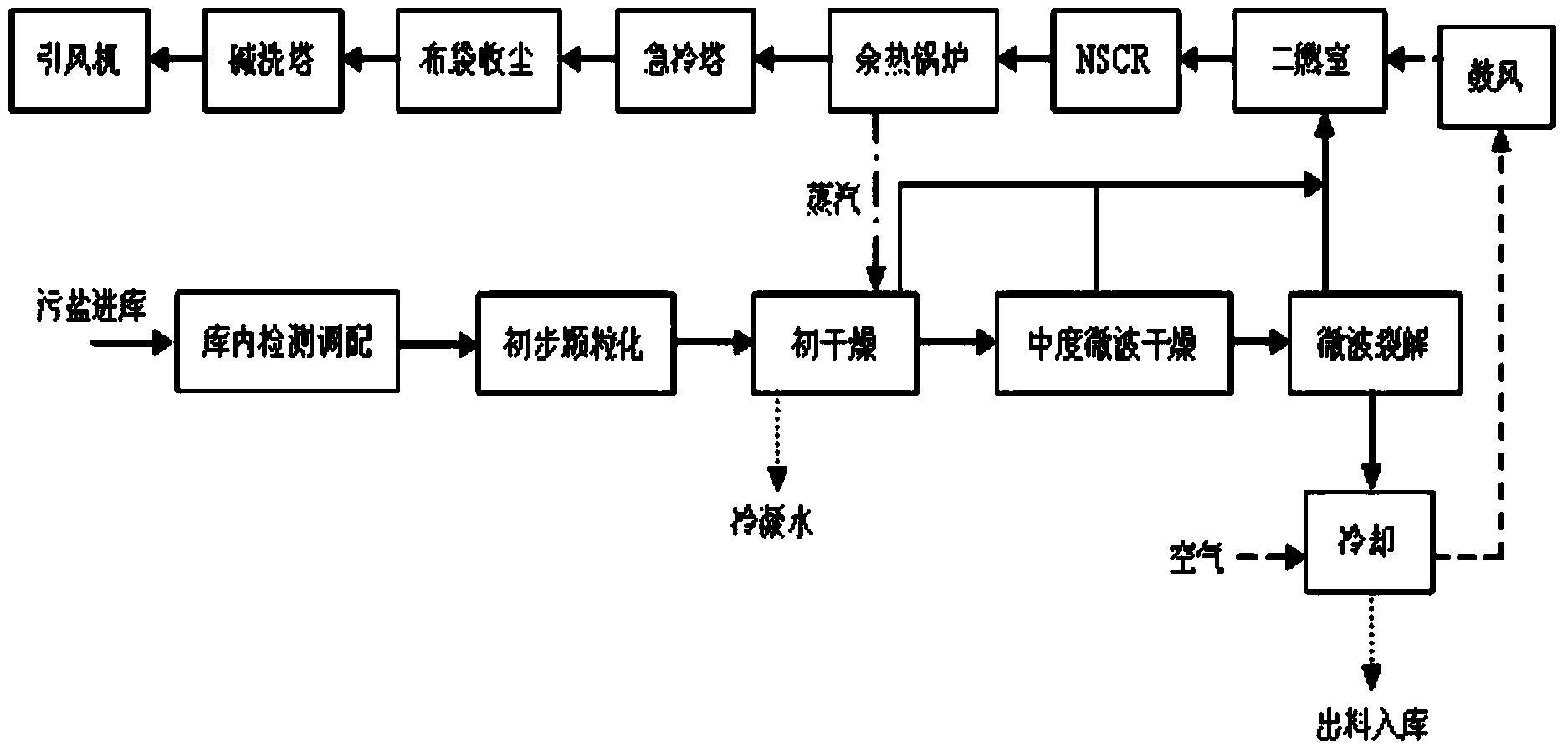

Industrial waste salt slag innocent treatment method

ActiveCN104344407AAlleviate the pressure of solid waste managementPromote sustainable developmentIncinerator apparatusSlagPetrochemical

The invention discloses an industrial waste salt slag innocent treatment method. The industrial waste salt slag innocent treatment method mainly comprises the following steps: a) burdening materials according to types of the industrial waste salt slag, and uniformly mixing the materials; 2) drying the mixture, wherein the drying process at least comprises initial drying and medium microwave drying, the initial drying process can remove the most part of free water, the medium microwave drying can remove the crystal water and gasify a part of organic matters, and the drying temperature is a continuously adjustable stable temperature gradient; c) anaerobic microwave pyrolysis: pyrolyzing the dried mixture at the temperature of 450-500 DEG C and under a nitrogen charged environment for more than 100 minutes, so as to pyrolyze the organic matters to form micromolecules to be gasified, organic salt to be split and gasified and the contained ammonium salt to be decomposed; 3) conducting air cooling to the pyrolyzed waste salt to be put in storage, and then conducting complete innocent treatment to the pyrolyzed waste salt, detecting and then selling the qualified product or reusing the treated waste salt. The industrial waste salt slag innocent treatment method has the characteristics of safety, efficiency, energy conservation and the like, has the obvious advantage in the resource recycling aspect, can greatly slow down the solid waste management stress in the industrial developed area, in particular the chemical engineering petrochemical industry park, is favorable to promote the related sustained development of the park.

Owner:ZHEJIANG DONGTIANHONG ENVIRONMENTAL PROTECTION ENG CO LTD

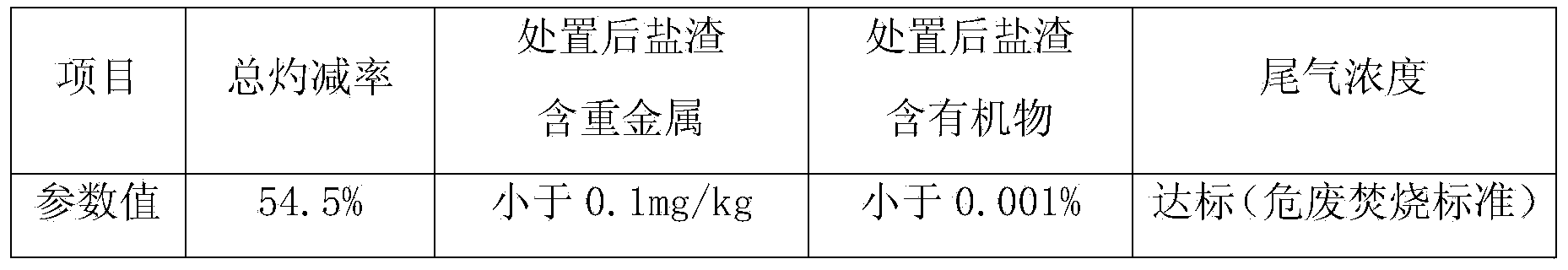

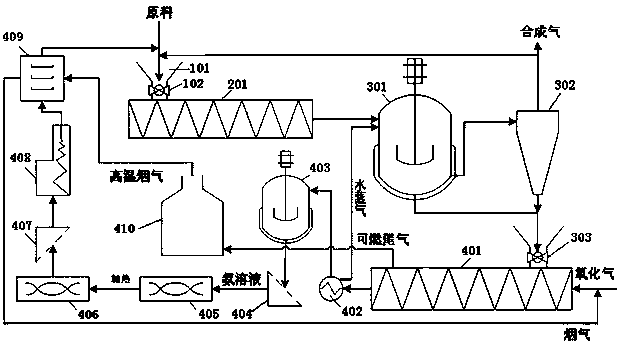

Method for preparing synthetic gas through microwave pyrolysis and gasification of biomass

ActiveCN105524662ARelaxed size requirementsReduce preprocessing power consumptionCombustible gas chemical modificationFixed-bed gasificationHigh carbonLiquid fuel

The invention discloses a method for preparing synthetic gas through microwave pyrolysis and gasification of biomass. The method comprises the following steps: a biomass raw material sent to a bunker and a catalyst are introduced into a microwave pyrolysis reactor, and passes through a preheating zone, a pyrolysis zone, a gasification zone and a reforming zone in order for reactions of dehydration, cracking, gasification and reforming, the reformed product is performed with gas-solid separation, gas and a few of carried tar and coke are subjected to a cracking reaction in a gas lifting pipe again, synthetic gas is released from an outlet, and the coke and ash obtained by gas-solid separation can be discharged from a reactor. The method has the advantages of high biomass gasification rate and high carbon conversion rate, the obtained synthetic gas product has high quality, can satisfy synthesis requirement of a liquid fuel, and has good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

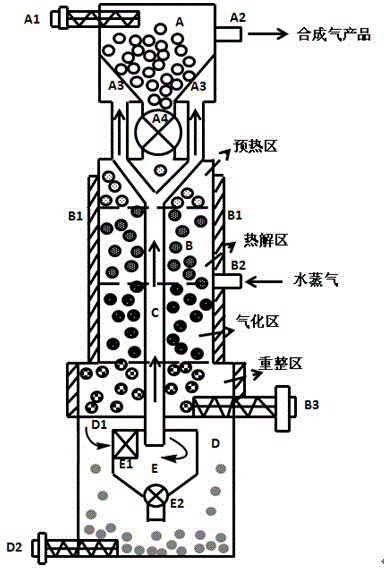

Method for preparing biomass oil in microwave thermal decomposition way

InactiveCN101560404AImprove microwave absorption performanceFast heatingLiquid hydrocarbon mixture productionMicrowave pyrolysisScrew conveyor

The invention discloses a method for preparing biomass oil in a microwave thermal decomposition way, which comprises the following steps: biomass enters a screw conveyer from a storage hopper, the feeding speed of the screw conveyer is 30-60 kilogram / h; the biomass enters a microwave pyrolysis reactor through the screw conveyor, the temperature of the biomass after absorbing microwave rapidly rises to 450-550 DEG C to reach the best temperature 475-500 DEG C of the biomass producing the oil; the biomass is thermally decomposed in the microwave pyrolysis reactor to produce high-temperature organic steam, the organic steam is sent to a cyclone separating device for gas and solid separation to remove carbon grains and sand; the organic steam is discharged through the cyclone separating device, the biomass is sent to a condenser for quenching, a condensable part of the biomass is changed into the biomass oil, and the biomass oil is dropped into an oil tank, thereby the biomass oil is prepared. The invention accords with the best process requirement of the biomass oil extraction without thermal conduction and has low cost, controllable and precise thermal decomposition temperature and no thermal inertia.

Owner:上海鸿泽企业发展有限公司

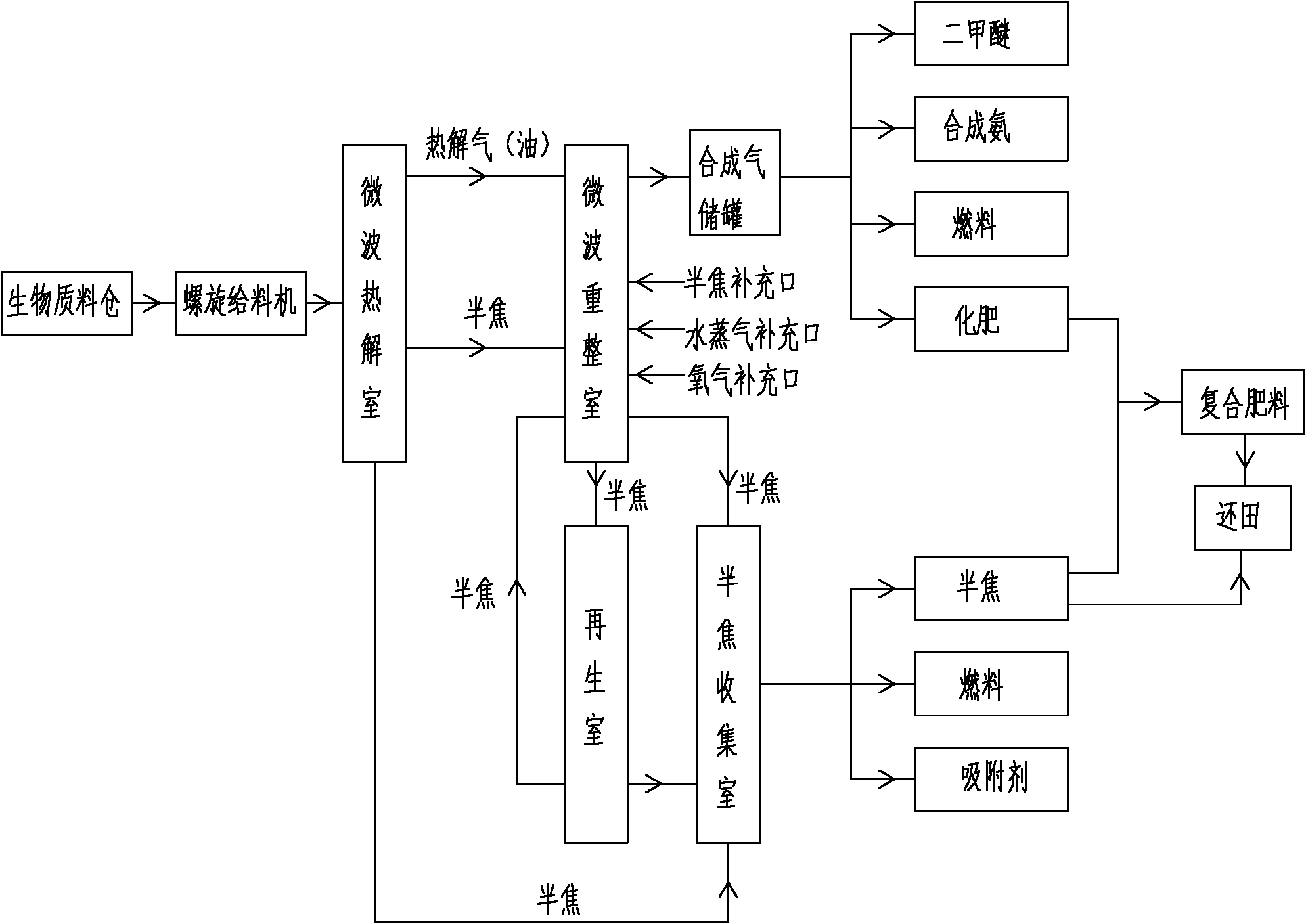

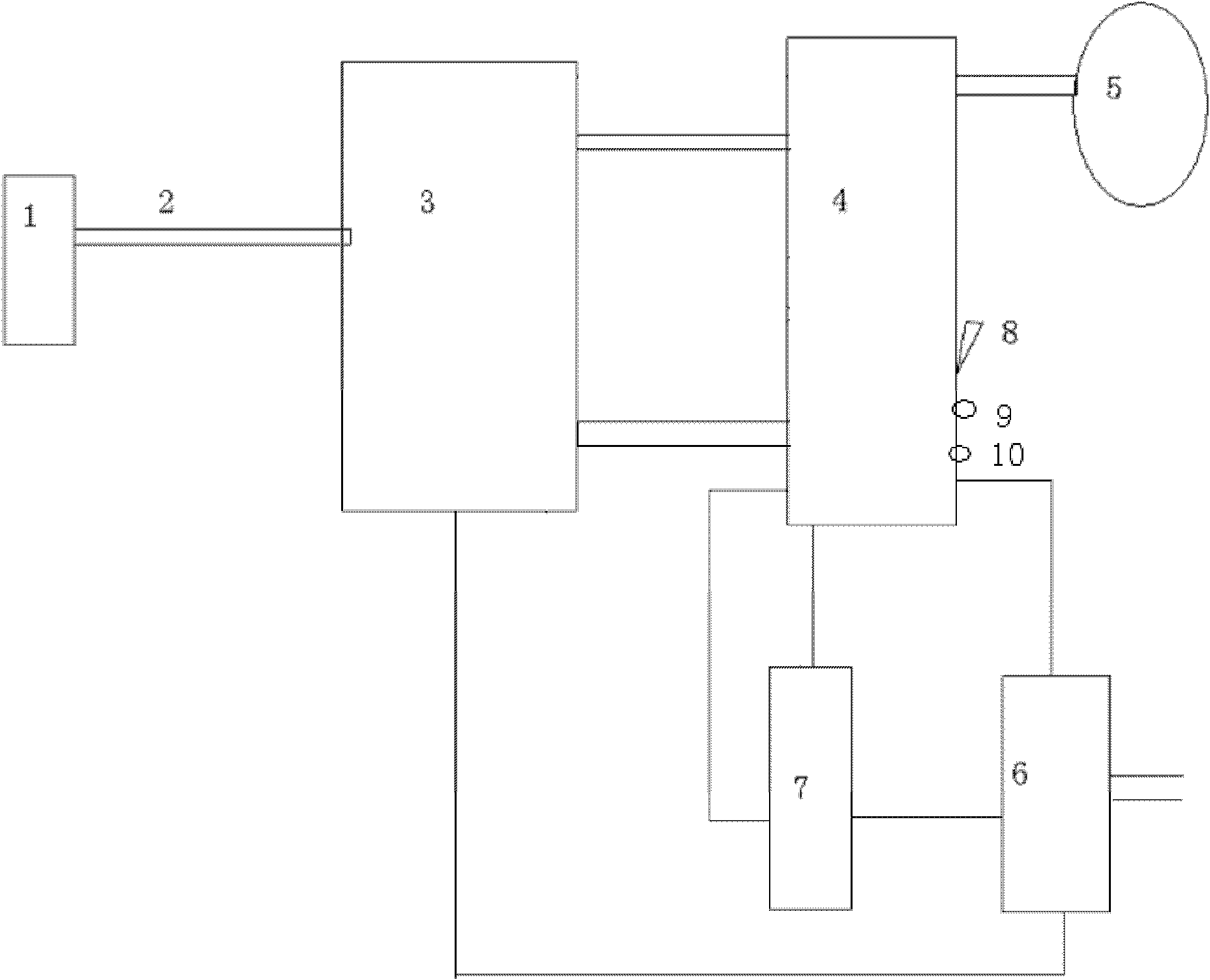

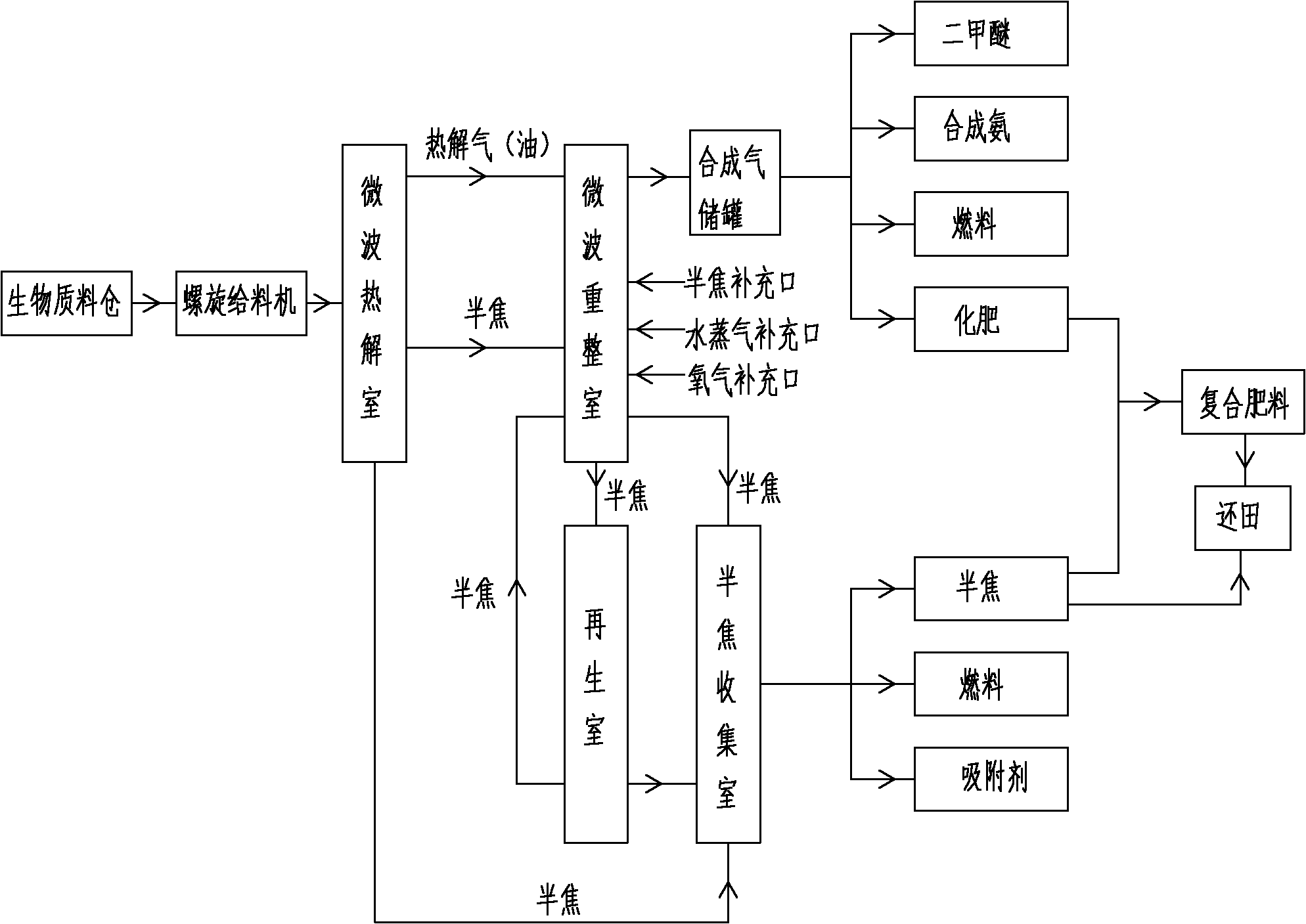

Biomass poly-generation comprehensive utilization method and device

InactiveCN102206515AReduce manufacturing costImprove carbon sinkOther chemical processesBiofuelsMicrowave irradiationDimethyl ether

The invention relates to a biomass poly-generation comprehensive utilization method and device. The method comprises the steps of: naturally drying and roughly crushing biomass materials, then carrying out microwave heating and cracking in a microwave pyrolysis chamber, introducing thermal gas (tar) and solid semicoke which are generated by microwave heating and cracking into a microwave reforming chamber, and further carrying out microwave heating and reforming on the thermal gas (tar) to convert the thermal gas (tar) into synthesis gas under the catalytic reaction of the semicoke; activating and regenerating the semicoke after catalysis and reforming, and then sending to the microwave reforming chamber for continuous catalytic reaction. In the invention, directional conversion from biomass to synthesis gas is realized by means of microwave radiation, the semicoke generated by pyrolysis is used as a reforming catalyst, two technologies of microwave pyrolysis and microwave reforming are integrated, and the semicoke can be activated and regenerated for recycling under microwave radiation. The semicoke that is not suitable for recycling can also be returned to field directly or in the form of a compound fertilizer after being mixed with fertilizer to improve soil carbon sink and enhance soil fertility. Compared with other processes, the method has the advantage of high synthesis gas conversion rate improved by about 10%; the prepared synthesis gas has wide applications and can be used for synthesizing chemical products such as ammonia, dimethyl ether, fertilizer and the like. The method can realize the resource poly-generation comprehensive utilization of biomass.

Owner:SHANDONG UNIV

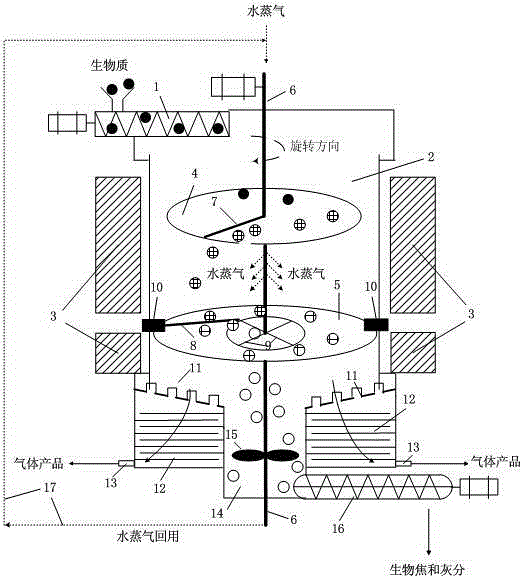

Method for continuous pyrolysis and gasification of material

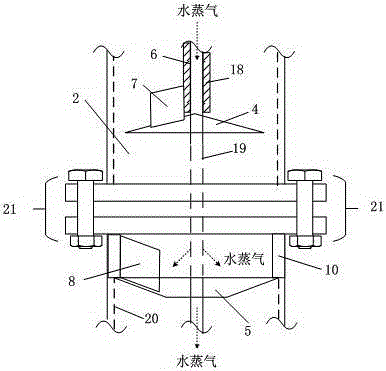

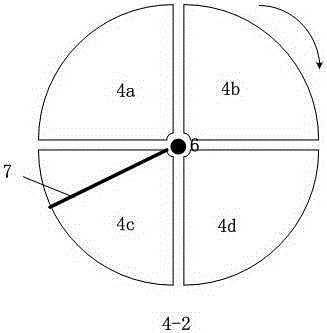

ActiveCN106675661ASmall footprintExtended stayCombustible gas productionMicrowave pyrolysisWater vapor

The invention discloses a method for continuous pyrolysis and gasification of a material. The method comprises the following steps: 1, a raw material and a catalyst enter a microwave pyrolysis and gasification system, fall to a first-stage rotating disc of a microwave reaction chamber, and sequentially undergo drying, activating and pyrolysis treatment with rotating; 2, a pyrolysis treated material falls to a second-stage rotating disc of the microwave reaction chamber, and the pyrolysis treated material and a pyrolysis volatile compound undergo a gasification and reforming reaction under the action of water vapor; and 3, a solid product obtained in step 2 falls to a residue storage tank below the microwave reaction chamber from middle holes of the second-stage rotating disc through a second-stage pushing baffle plate, and is discharged from a reaction system under stirring and screw dual action, and a gas product enters a settlement chamber from an annular sieve plate at the bottom of the microwave reaction chamber, and undergoes settlement treatment to obtain the gasification product. The method has the advantages of fast cracking speed, high gasification efficiency, high quality of the gas product, meeting of liquid fuel synthesis requirements, and good application prospect.

Owner:SINOPEC DALIAN RES INST OF PETROLEUM & PETROCHEMICALS CO LTD +1

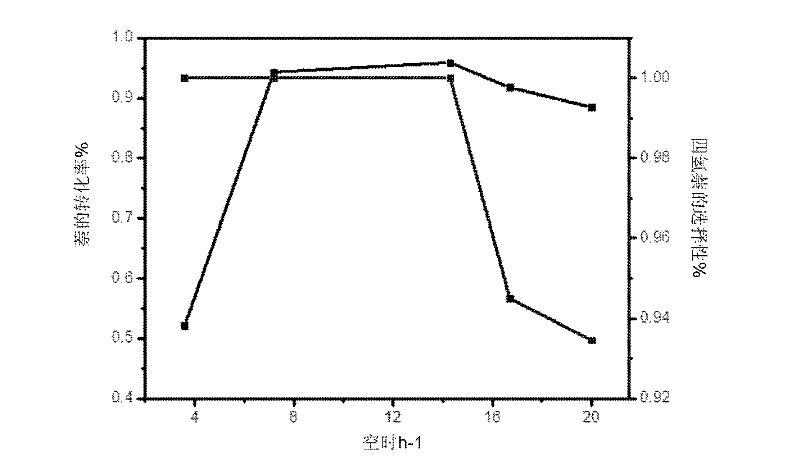

High-selectivity catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and preparation method thereof

InactiveCN102600877AHigh selectivityPrevent polymerization and sinteringMolecular sieve catalystsHydrocarbon by hydrogenationMicrowave pyrolysisHydrogenation reaction

The invention discloses high-selectivity carbide catalyst for naphthalene hydrogenation reaction for preparing tetrahydronaphthalene and a quick microwave preparation method thereof, belonging to the technical field of catalyst material application and preparation. The method comprises the steps of: fully grinding complex compounds containing relevant metals and carriers, or supporting the complex compounds containing the relevant metals onto the surfaces of carriers through a solution impregnation method and conducting microwave pyrolysis in inert gas to form the supported carbide catalyst. The invention provides the high-efficiency carbide catalyst with 100 percent selectivity aiming at the naphthalene hydrogenation reaction for preparing the tetrahydronaphthalene and a simple, convenient, quick, environmental-friendly and energy-saving preparation method thereof. The prepared carbide particles are evenly dispersed on the carriers, so that the situation of surface carbon deposition is avoided. The contradiction between high catalyst selectivity and high cost is successfully avoided, and therefore the high-selectivity carbide catalyst and the preparation method thereof have promising industrial application prospect.

Owner:DALIAN UNIV OF TECH

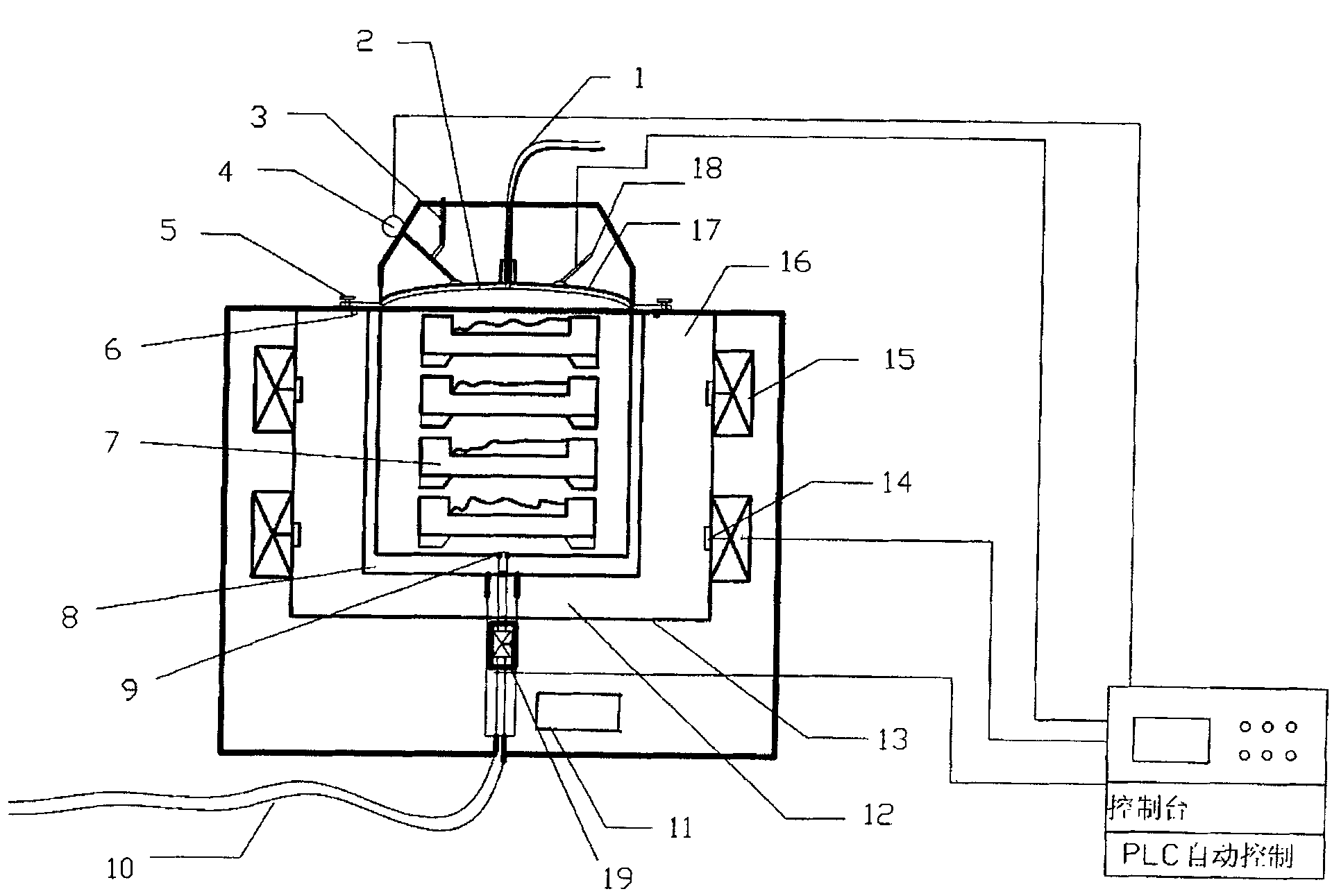

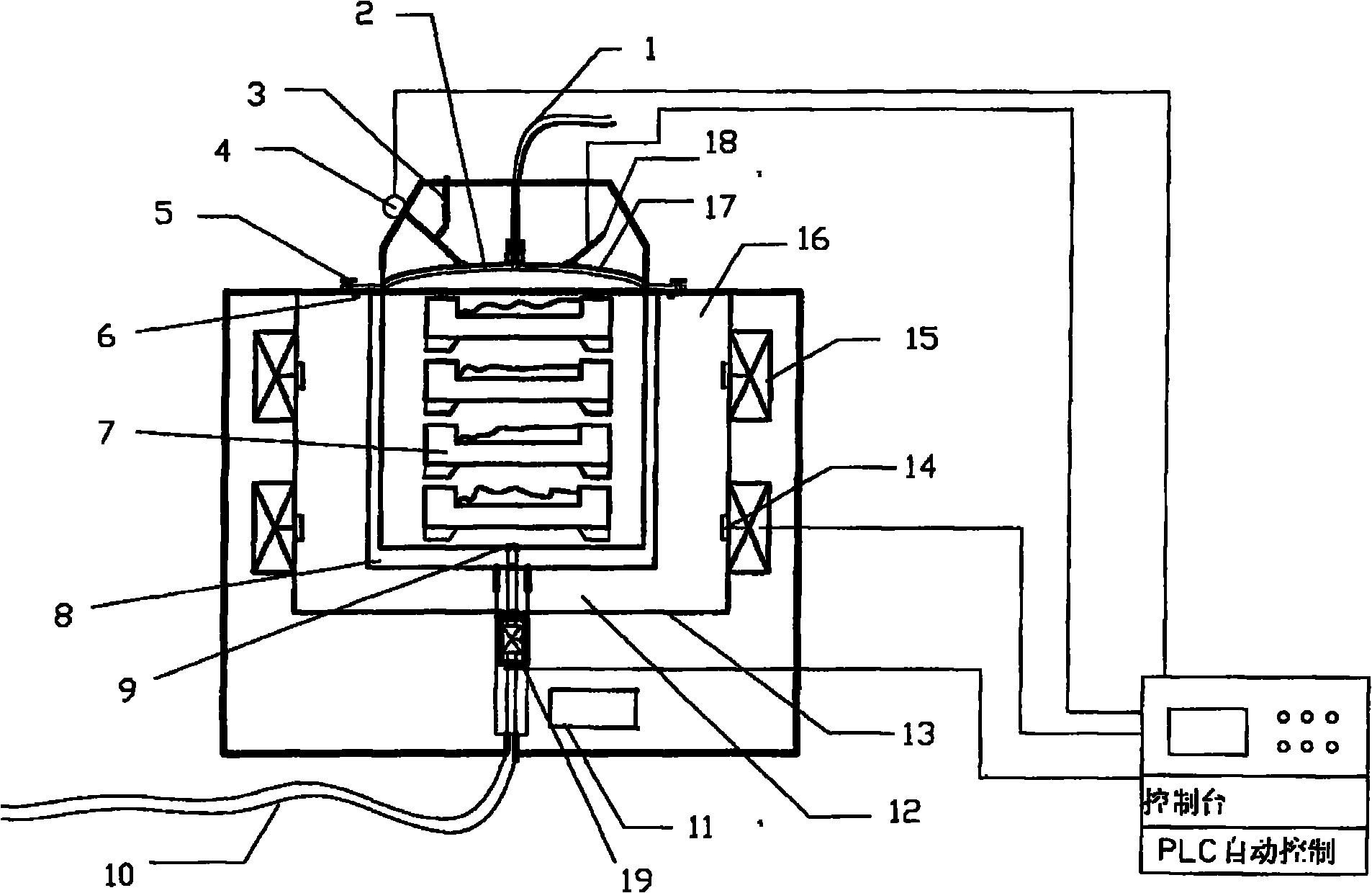

Consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as method thereof

ActiveCN104163555AGood heating selectivityRapid pyrolysisSludge treatment by pyrolysisByproduct vaporizationRadiation lossNitrogen generator

The invention discloses a consecutive reaction apparatus for moisture sludge through anhydration and pyrolysis under microwave irradiation as well as a method thereof. The condensation comprises a sludge warehouse, a stirrer, a hopper feeder, a sludge-shaped controller, a belt sender, a power control microwave irradiation device, a microwave pyrolysis reaction chamber, a pressure sensing controller, a blower fan, a condensation heat exchanger, a scraper plate separator, an oil-water separating device, a liquid dredging groove, a coke storage tank, a product oil tank, a product gas tank, a nitrogen generator, a coke crusher, a sludge water pot and a gas shunting plate. According to the invention, microwave material internal heating characteristic can be fully used for reducing heat radiation loss, moisture sludge is directly performed with anhydration and pyrolysis to obtain the cracking oil, combustible gas and solid coke; heat recovery of the product gas and auxiliary microwave heating characteristic of the products residue are fully used for reducing the operation cost, and sludge pyrolysis efficiency and products quality can be increased. The apparatus has the advantages of simple structure, small volume, reasonable design and convenient market popularization, and is suitable for industrial application of microwave sludge continuous pyrolysis.

Owner:ZHEJIANG UNIV

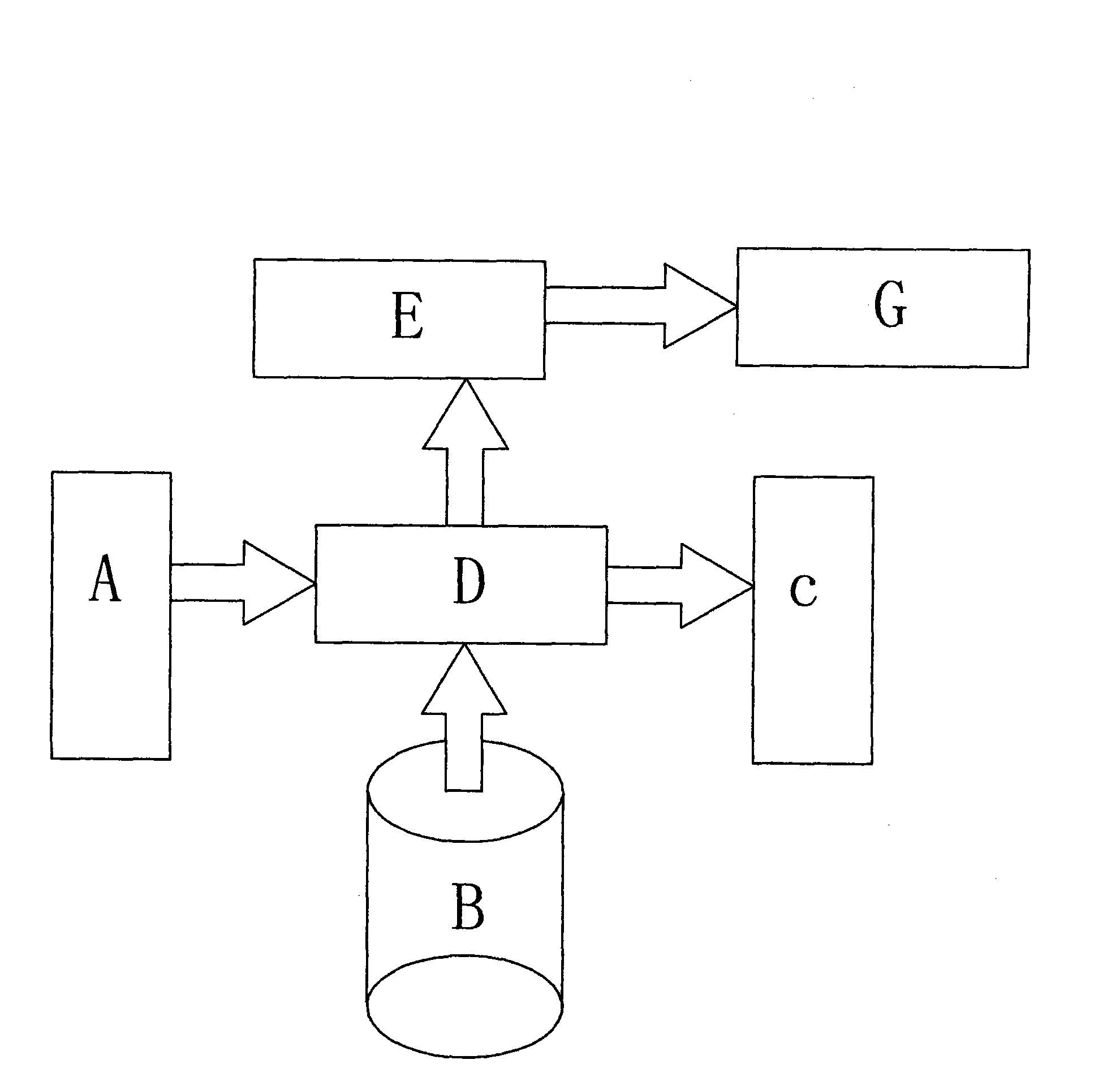

Garbage microwave pyrolysis comprehensive treatment system and method and equipment used by same

InactiveCN101797578AReduce oxygen contentLower operating temperatureSolid waste disposalHydrocarbon distillationLiquid productFuel oil

The invention discloses a garbage microwave pyrolysis comprehensive treatment system and a method and equipment used by the same, aiming to solve the problems of microwave pyrolysis treatment, and the method and equipment used by the system. The comprehensive treatment system comprises a municipal solid waste (MSW) preprocessing system A, a vertical garbage continuous microwave heating low temperature cracking furnace B, a solid product activated carbon production system C, a pyrolysis gas preparation fuel gas system D, a liquid product distilled extraction light oil and fuel oil system F and a matched sewage treatment system G, wherein the MSW preprocessing system A, the solid product activated carbon production system C and the pyrolysis gas preparation fuel gas system D are respectively connected with the vertical garbage continuous microwave heating low temperature cracking furnace B; and the liquid product distilled extraction light oil and fuel oil system F is connected with the oil recovery pipeline of the pyrolysis gas preparation fuel gas system D. The invention has the advantage that: low carbon emission is realized in the treatment process under the reducing atmosphere, fixed carbon in the garbage is emitted without violent toxicity like dioxin and heavy metal solid powder, the treated wastewater can be recycled and max garbage resource recycling is realized.

Owner:深圳市兖能环保科技有限公司

Device and method for preparing biological oil, activated carbon and combustible gas by use of biomass poly-generation

InactiveCN103923673AEvenly heatedFast heating rateBiofuelsLiquid hydrocarbon mixture productionActivated carbonMicrowave pyrolysis

The invention discloses a device and a method for preparing biological oil, activated carbon and combustible gas by use of biomass poly-generation. The method comprises: carrying out microwave pyrolysis on biomass by use of a horizontal rate furnace microwave pyrolysis device, and filtering and condensing the obtained gas phase product to obtain the biological oil and the combustible gas. After being heated by heat exchange with high temperature activated carbon, air is used for drying a raw material. In the device, microwave radiation heating and horizontal rate furnace delivery are adopted, the raw material does not need to be crushed to fine granules, no carrier gas is needed in the pyrolysis process, the yield of the combustible gas can be improved to achieve a poly-generation effect, and biochar granules are avoided of entering the pyrolysis gas, so that the quality of the biological oil is improved.

Owner:SOUTHEAST UNIV

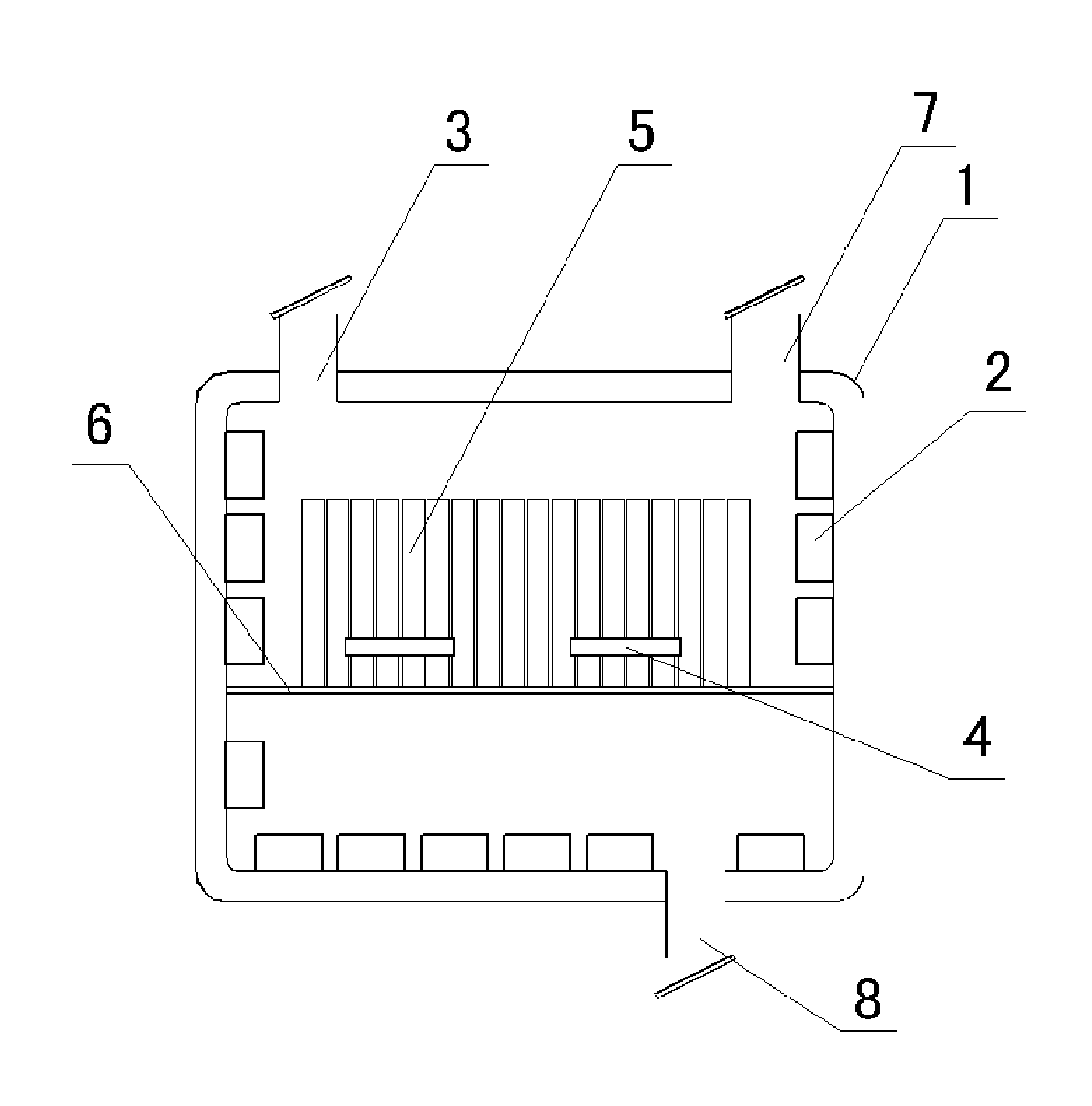

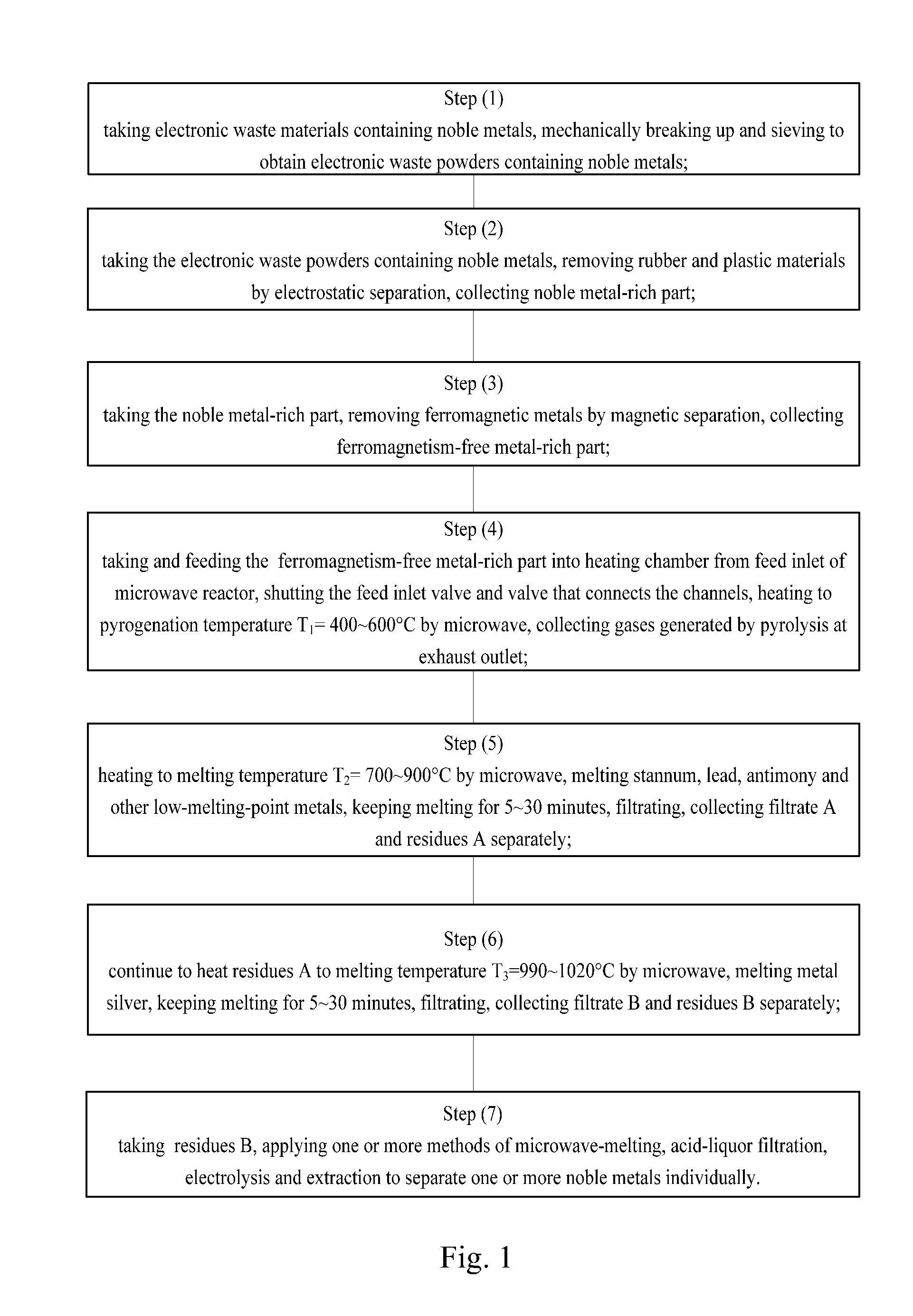

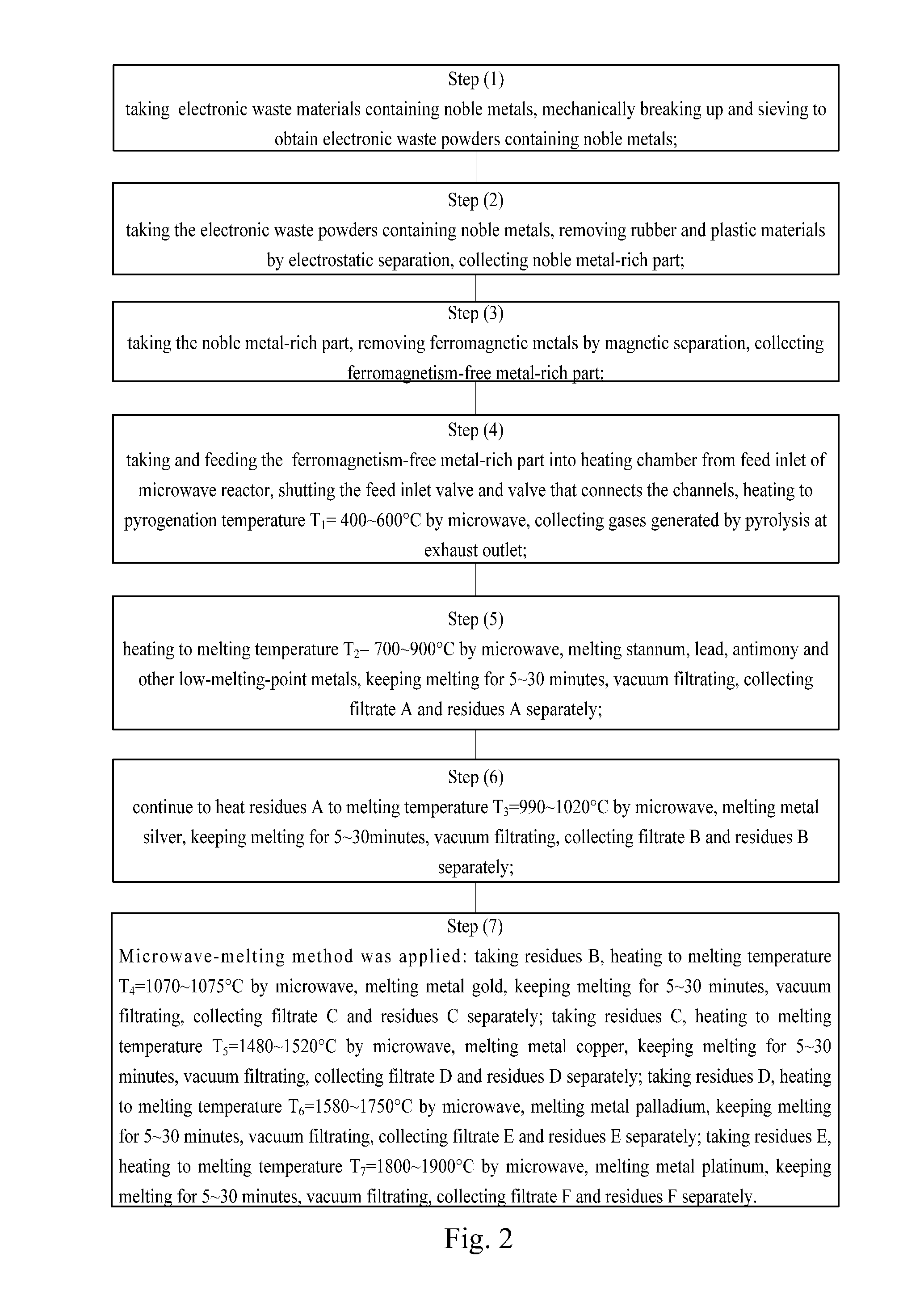

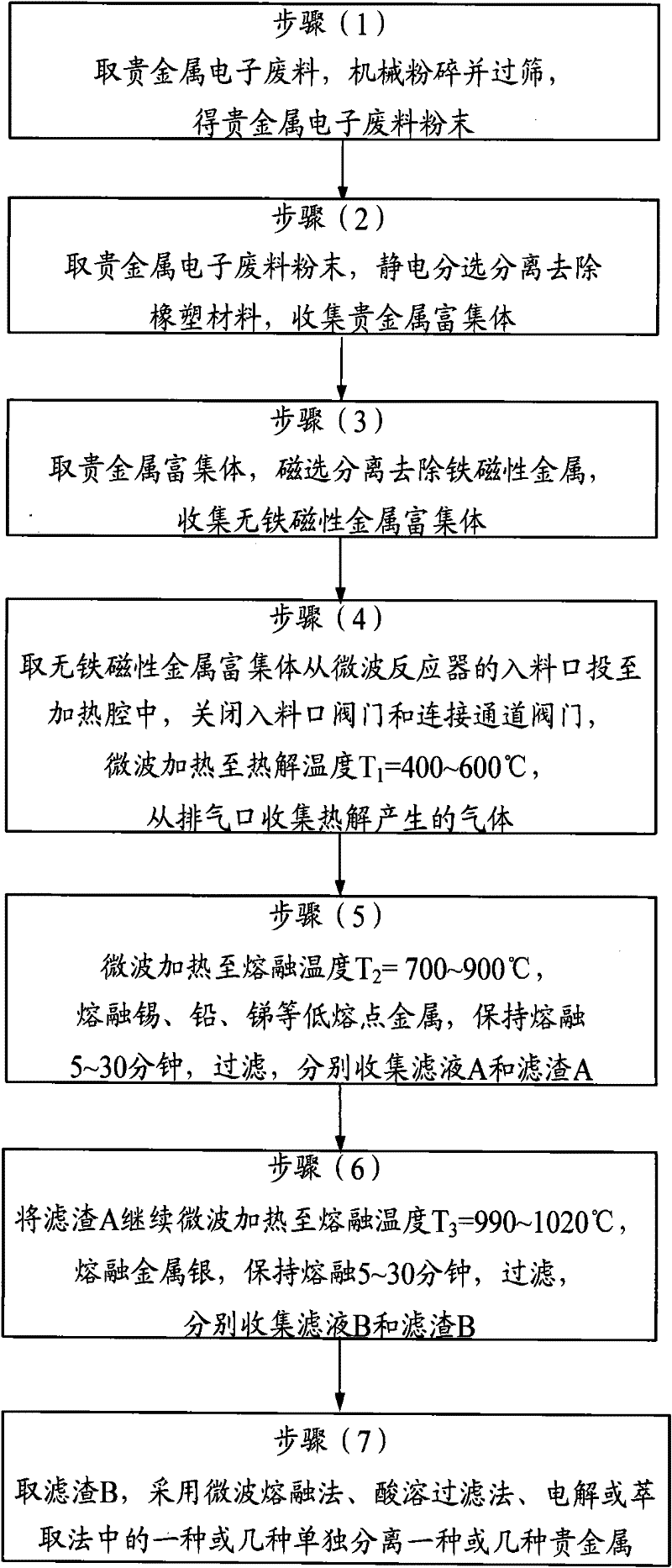

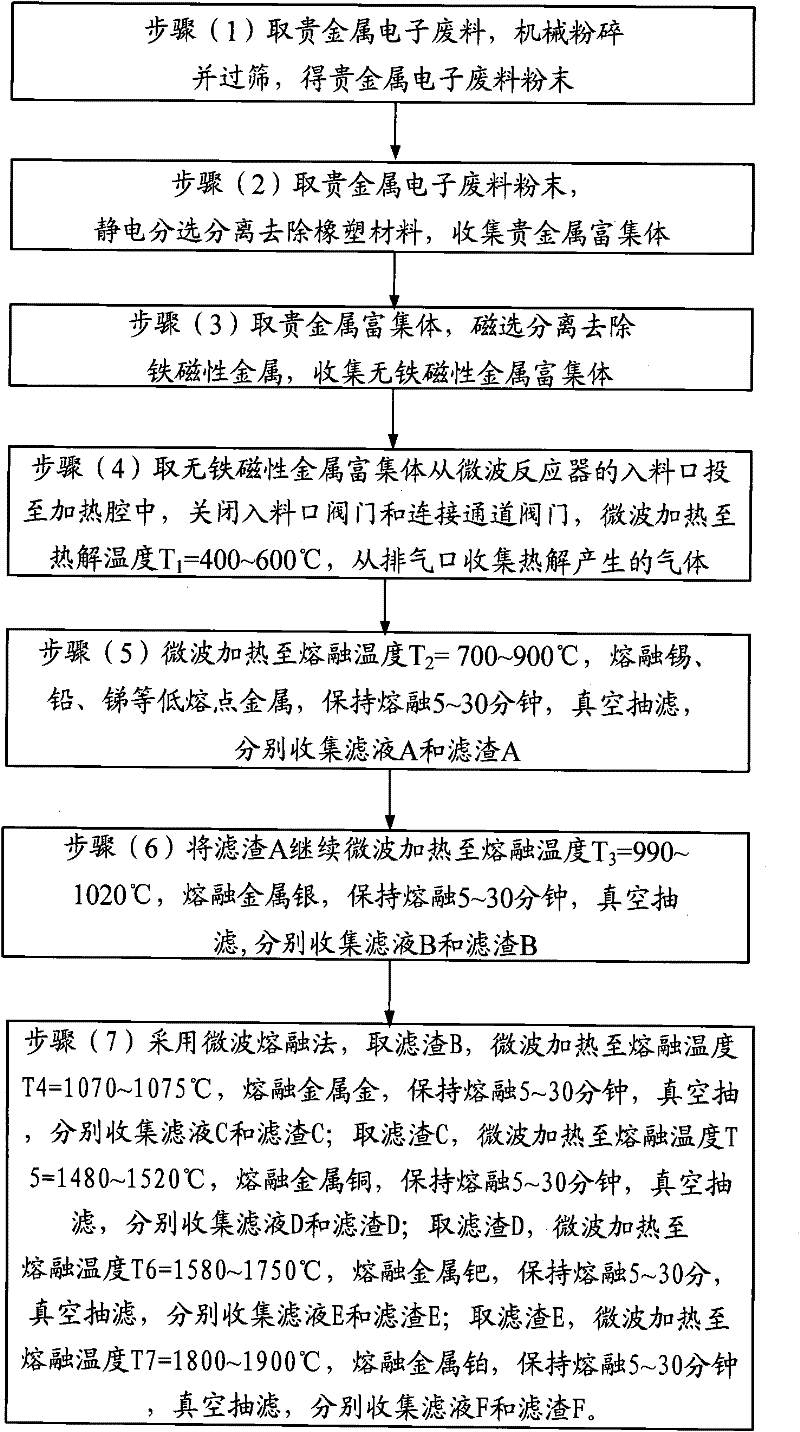

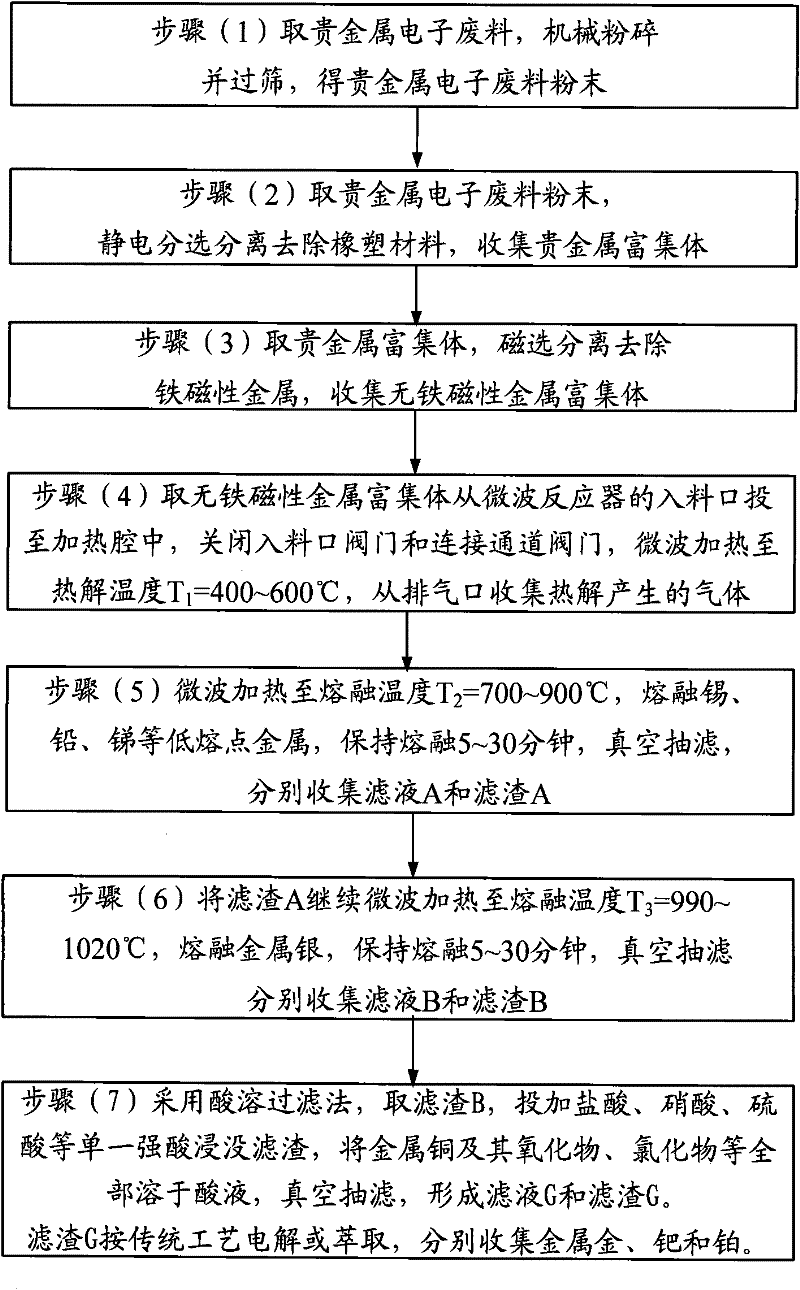

Method for recycling noble metal from electronic waste material and apparatus thereof

ActiveUS20130174694A1Heating up fastEasy to controlFrom normal temperature solutionsLiquid separation by electricityElectrostatic separationMicrowave pyrolysis

A method for recycling noble metals from electronic waste materials and apparatus thereof. The method comprises the following steps: mechanically breaking up the electronic waste materials; removing rubber and plastic materials by electrostatic separation; removing ferromagnetic metals by magnetic separation; removing residual rubber and plastic materials by microwave pyrolysis; removing low-melting-point metals by indirectly heating using microwave; separating the noble metals from one another in turn from low-melting-point metal to high-melting-point metal for recycle. The apparatus includes a microwave housing. A filtering screen is positioned on the inside wall of the housing horizontally, and vertically-arranged and open-ended heating pipes are positioned over the filtering screen. The method and apparatus can adequately recycle resources in the electronic waste materials.

Owner:GEM CO LTD

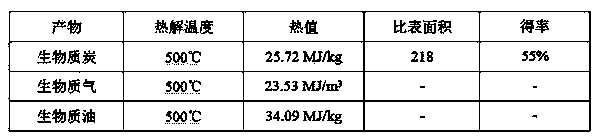

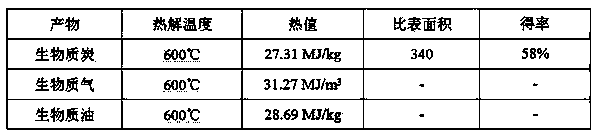

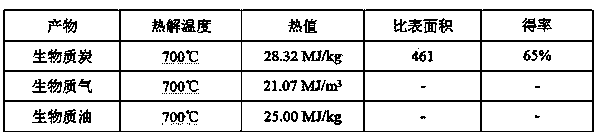

Method for directionally producing biomass charcoal, biomass oil and biomass gas through microwave catalytic pyrolysis of biomass

ActiveCN104357071AIncrease added valueImprove performanceBiofuelsLiquid hydrocarbon mixture productionCatalytic pyrolysisResource utilization

The invention relates to a method for directionally producing biomass charcoal, biomass oil and biomass gas through microwave catalytic pyrolysis of biomass, and belongs to the technical field of biomass energy utilization. According to the method, firstly, the biomass is subjected to impurity removal, crushing and drying, added with a catalyst and uniformly mixed, and a gaseous product and a solid product are obtained through microwave pyrolysis; and the obtained gaseous product is rapidly condensed, a condensable part is directly condensed to form liquid-phase high-quality biomass oil, non-condensable gas is high calorific value gas fuel, the obtained solid product is taken out after cooled to the room temperature with a furnace, and high-yield biomass charcoal is obtained. The high-yield biomass charcoal is taken as a raw material for producing activated carbon or fuel to be directly used. The method is simple, efficient and environment-friendly, and the resource utilization rate is high.

Owner:KUNMING UNIV OF SCI & TECH

Method and device for recovering precious metals from precious metal electronic scraps

ActiveCN102441553AReduce manufacturing costHeating evenlySolid waste disposalPlastic recyclingMicrowave pyrolysisPlastic materials

The invention provides a method for recovering precious metals from precious metal electronic scraps, which includes the following steps: precious metal electronic scraps are mechanically ground, electrostatically separated and magnetically separated in advance, residual rubber and plastic materials are removed by microwave pyrolysis, microwaves are utilized to indirectly heat precious metal electronic scrap powder, so that the precious metal electronic scrap powder is quickly melted, and thereby precious metals can be sequentially separated and recovered from the lowest melting point of precious metal to the highest melting point of precious metal. The method has the advantages of uniform heating, high speed, energy saving, high efficiency, no pollution and low production cost, and is easy to control. The method also can be used for separating and recovering other ordinary metals with highly different melting temperatures, and is not limited by whether heated materials absorb microwaves or not. The invention also provides a corresponding device, the structure design of the device is reasonable, and the device can help to increase the reaction speed and separate solid from melt in the process of melting precious metals, and is convenient to automatically operate. The invention can recover precious metals in precious metal electronic scraps, so that the resources in scraps can be utilized to the max, and therefore the invention can bring great social and economic benefits.

Owner:JIANGXI GREEN ECO MFG RESOURCE CYCLE

Method and device for pyrolysising bio-matter using microwave

Owner:SHANDONG UNIV +1

Catalyst for distributed batch microwave pyrolysis, system and process thereof

ActiveUS20140020286A1Avoid accumulationElectrical coke oven heatingOrganic chemistryChemistryMicrowave pyrolysis

Owner:PYROWAVE

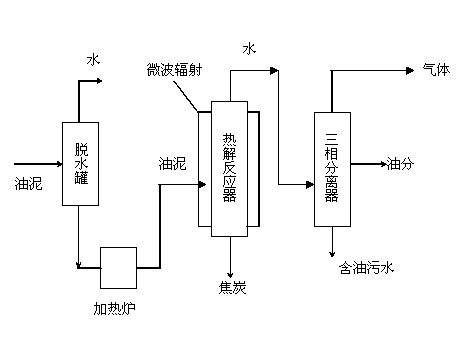

Method for microwave pyrolysis treatment of oil sludge

InactiveCN103739180AHigh degree of processingReduce yieldSludge treatment by pyrolysisByproduct vaporizationGas phaseReaction temperature

The invention discloses a method for microwave pyrolysis treatment of oil sludge. The method adopts microwave pyrolysis to treat the oil sludge and has the characteristics of simple equipment operation and high oil sludge treatment degree. The method comprises the steps of (1) pretreating the oil sludge through dehydration to remove mechanical impurities, preheating, and then delivering the oil sludge into a pyrolysis reactor provided with external microwave radiation; (2) performing thermal conversion on the input material entering the pyrolysis reactor in the reactor, wherein the reaction temperature is controlled to be 400-500 DEG C, the reaction time is controlled to be 10-30min, the microwave radiation frequency is 2450MHz, and the power is 0-750W and is continuously adjustable; and (3) introducing pyrolytic reaction gas into a three-phase separator, recycling the gas phase component at the upper part, discharging the oily sewage at the bottom into a sewage treatment system, recycling oil and delivering the oil into a storage tank for storage. The temperature preheated in a heating furnace is 300-350 DEG C. The method disclosed by the invention is low in coke yield, high in reliability and capable of realizing clean production.

Owner:LIAONING UNIVERSITY OF PETROLEUM AND CHEMICAL TECHNOLOGY

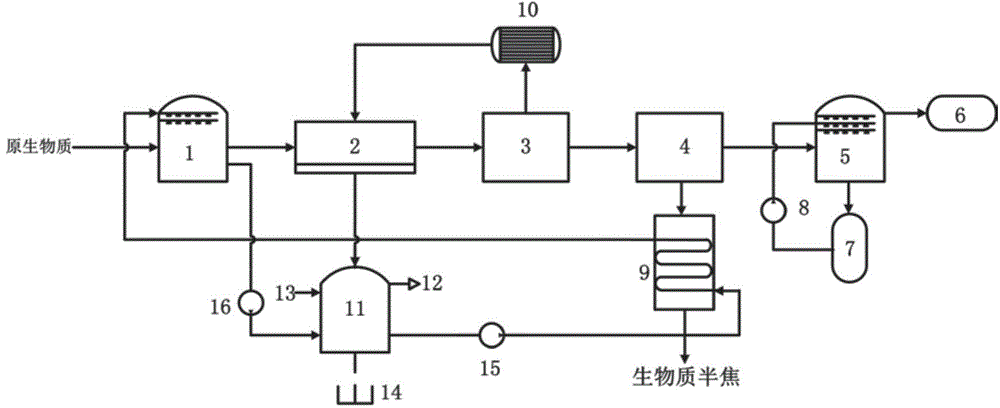

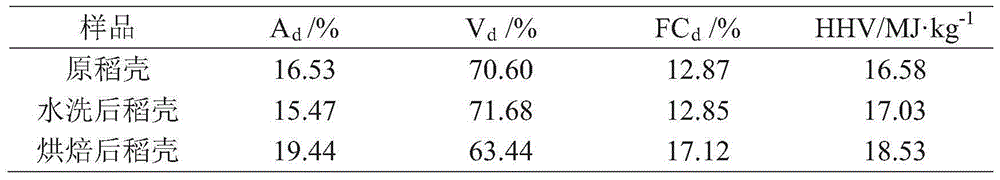

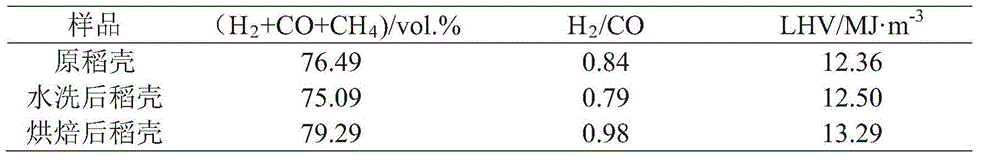

Systematic device and method for biomass microwave pyrolysis poly-generation by adopting combined washing and baking pretreatment

ActiveCN104673340AReduce moistureReduce stabilityBiofuelsSpecial form destructive distillationMoistureOperation safety

The invention discloses a systematic device and a method for biomass microwave pyrolysis poly-generation by adopting combined washing and baking pretreatment. The systematic device comprises a biomass washing-baking-pyrolysis system and a washing liquor circulatory system. According to the method, firstly, biomass raw materials are washed to remove part of alkali metal and impurities and then pre-dried, then large quantities of hemicellulose components are decomposed through baking pretreatment, the physical microstructure of biomass is improved, and the quality of a biomass microwave pyrolysis product after pretreatment is improved; the obtained biomass has high char calorific value and ash fusion point, low bio-oil water content and acidity, stable chemical composition, high syngas calorific value and great follow-up utilization potential. Energy of volatile matters is recovered and taken as a pre-drying heat source; meanwhile, the washing liquor circulatory system recovers sensible heat of pyrolysis char and moisture and latent heat in exhaust gas of flue gas after drying, the energy efficiency of the system is high, exhaust gas is not discharged in an operation process, operating parameters can be adjusted according to the biomass raw materials, the system operation safety is high, and the cost is low.

Owner:SOUTHEAST UNIV

Method for treating waste lithium battery by microwave pyrolysis

InactiveCN103247837AAchieve near-zero emissionsEnergizeWaste accumulators reclaimingBattery recyclingMicrowave pyrolysisMicrowave oven

The invention discloses a method for treating a waste lithium battery by microwave pyrolysis. The method comprises the following steps of: placing a waste lithium battery which is discharged thoroughly in an industrial microwave oven for the pyrolysis, and respectively performing aftertreatment on oil gas and solid generated during the pyrolysis, wherein a shell of the battery is removed, and the pyrolysis temperature is 400-900 DEG C. The method is simple in treatment process, high in energy utilization rate, few in generated wastes, small in occupying area, low in treatment cost, and short in treatment time. In addition, by using the method, the environment friendliness can be realized, three wastes can not be generated, the zero discharging of the wastes can be realized basically, and the energy and resource recycling of the waste lithium battery can be realized, so that the method has a good development prospect.

Owner:STATE GRID CORP OF CHINA +1

Ternary cathode material modified by carbon quantum dots and preparation method thereof

ActiveCN109860534AReduce surface alkali contentImprove conductivityCell electrodesSecondary cellsMicrowave pyrolysisManganese

Owner:LANGFANG GREEN IND TECH CENT +1

Preparation method for light-aromatic-rich bio-oil

ActiveCN104560091AAlleviate the phenomenon of secondary crackingMitigate or even avoid the phenomenon of secondary crackingLiquid hydrocarbon mixture productionMicrowave pyrolysisOil water

The invention discloses a preparation method for light-aromatic-rich bio-oil. The preparation method comprises the following steps: uniformly mixing a biomass raw material and a microwave additive, performing microwave preheating treatment, then performing microwave pyrolysis, condensing generated pyrolyzed volatile components, and performing oil-water separation to obtain the light-aromatic-rich bio-oil. The target product prepared by the preparation method disclosed by the invention is high in yield, high in component content and low in moisture content; furthermore, the process is simple, a catalyst is not required to be added, and the product can be easily separated; the preparation method is suitable for industrial application.

Owner:CHINA PETROLEUM & CHEM CORP +1

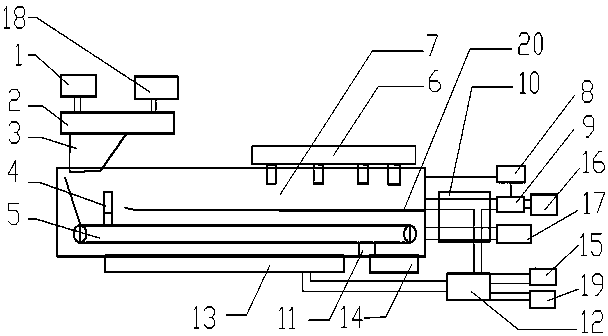

Horizontal microwave cracking furnace for solid organic matter

ActiveCN106147807AEasy to collectImprove qualitySpecial form destructive distillationMicrowave pyrolysisMicrowave oven

The invention discloses a horizontal microwave cracking furnace for solid organic matter. A furnace chamber formed by sequential butt joint of a feeding device (2), a feeding microwave inhibitor (4), a microwave oven (5), a discharging microwave inhibitor (11) and a discharging device (12) is installed on a machine frame (1), a conveyer (3) is installed in the furnace chamber and passes through the microwave oven (5), one end of the conveyer (3) is in butt joint with the feeding device (2), the other end of the conveyer (3) is in butt joint with the discharging device (12), and the center axis of a whole furnace body is placed horizontally. A microwave pyrolysis technique is adopted, and heating speed is high; due to the fact that microwave heating is integral heating, microwaves can directly act on medium molecules for heat energy conversion, the inside and outside of a material can be heated at the same time, and microwaves can penetrate through the material evenly no matter the shape of the material; meanwhile, based on microwave non-thermal catalytic effect, cracking speed is high, cracking is thorough, the quality of obtained products is high, energy can be saved greatly, and control is easy; besides, microwave energy is transmitted in an airtight chamber made of metal and a waveguide tube, so that leakage and emission of harmful gases are avoided, and safety performance is quite high.

Owner:湖南省中晟热能科技有限公司

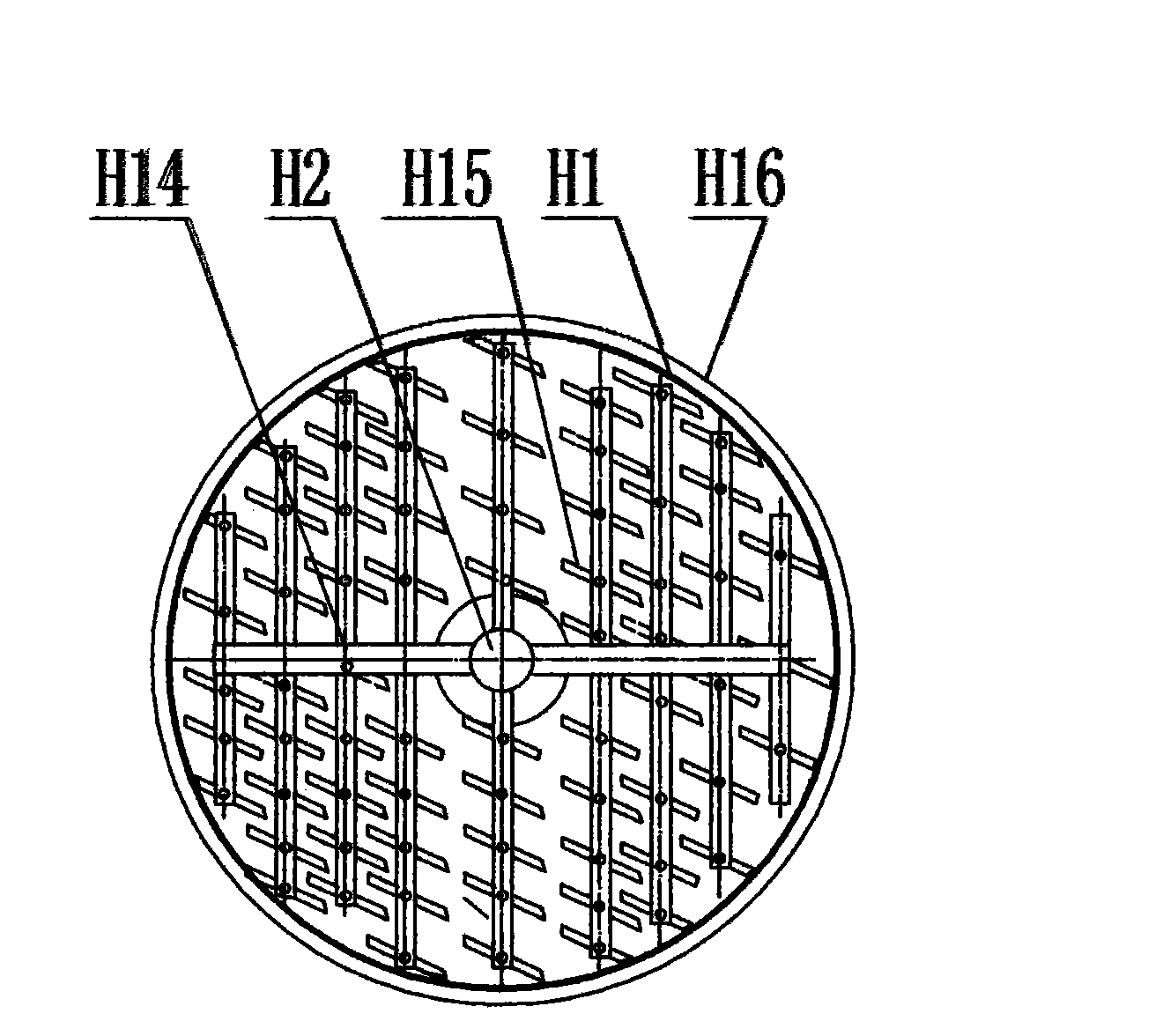

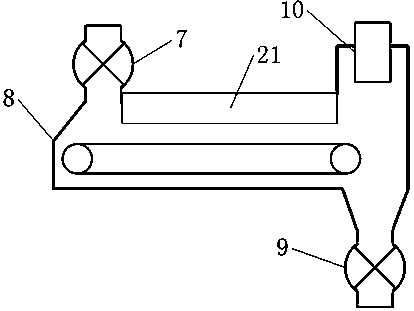

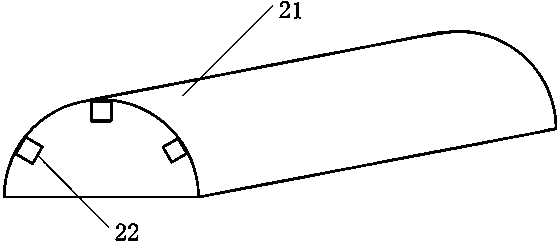

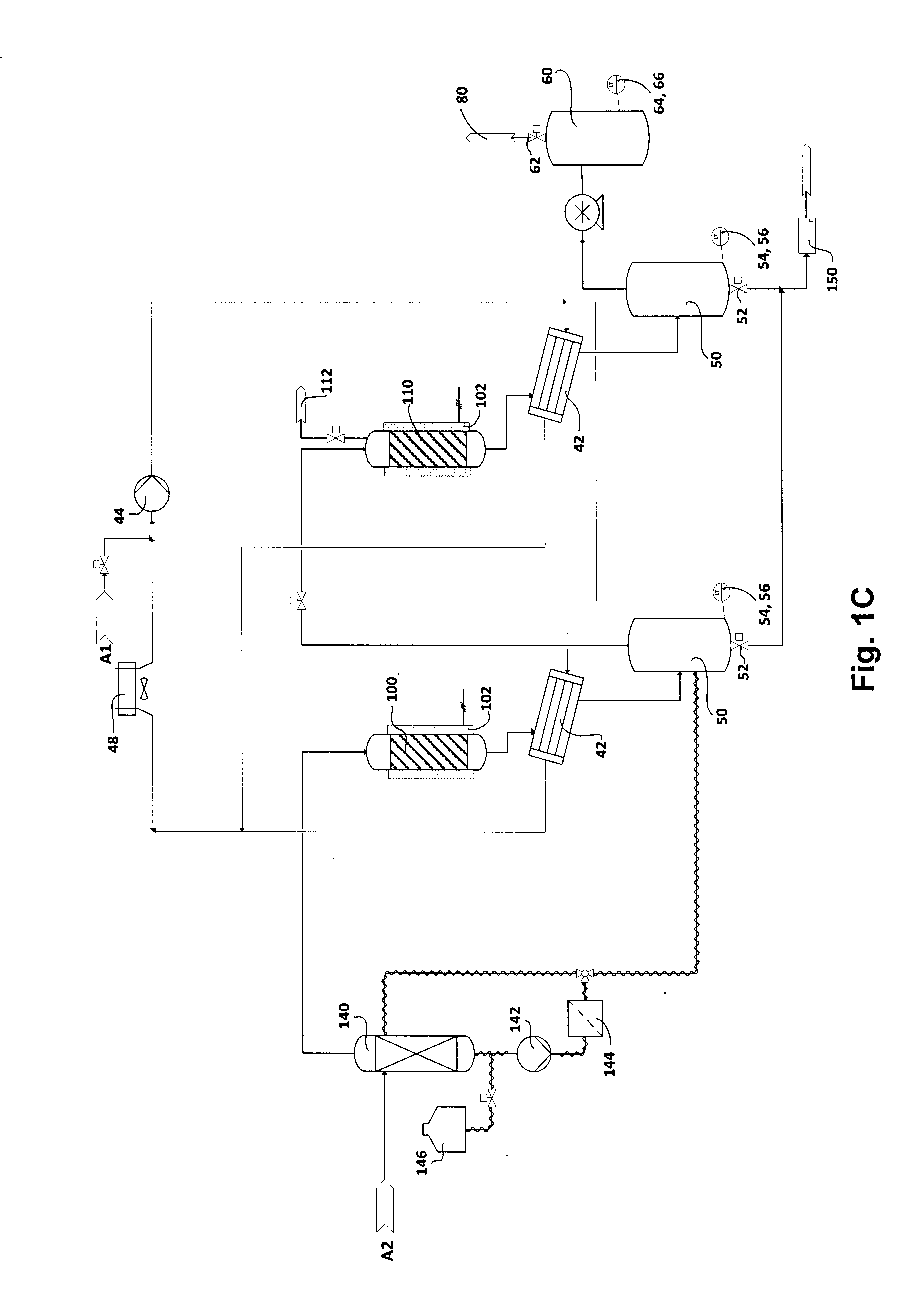

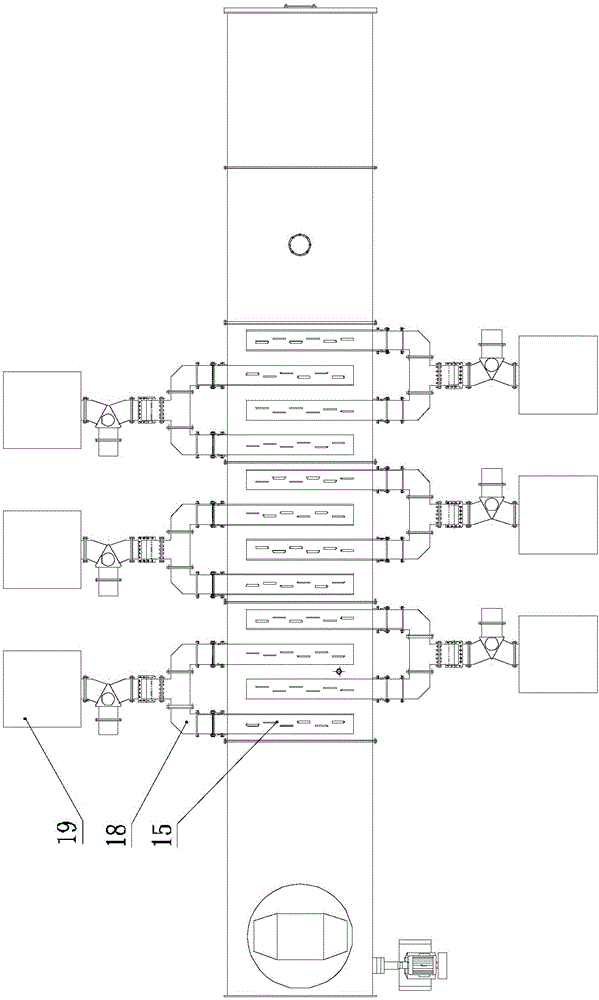

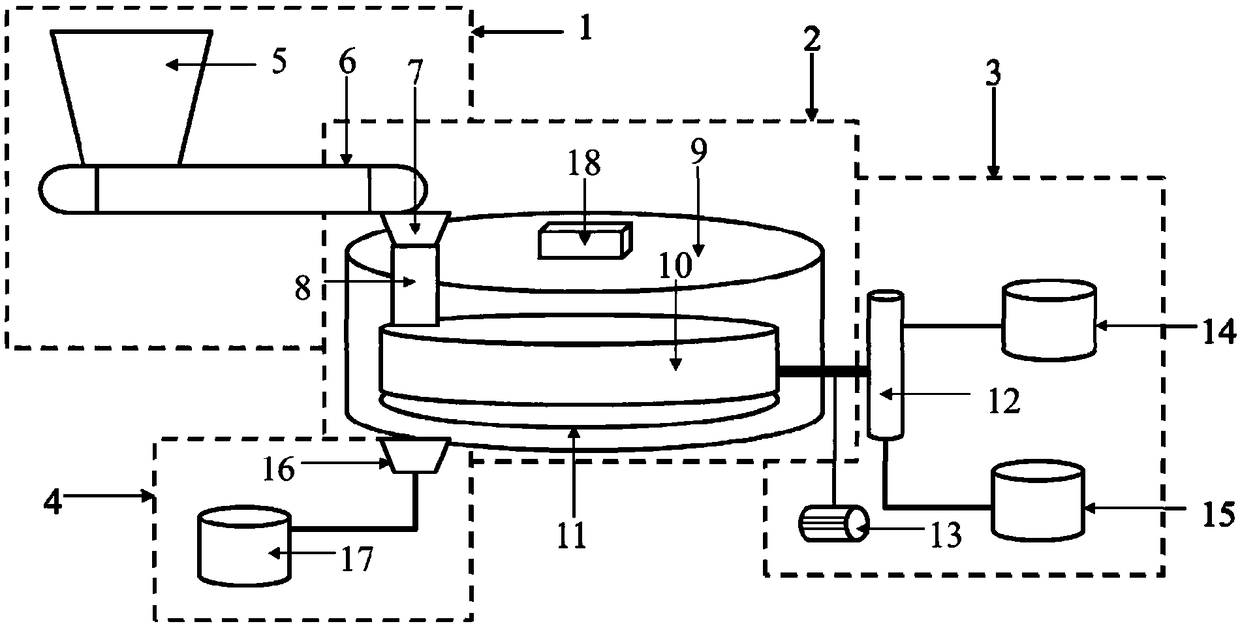

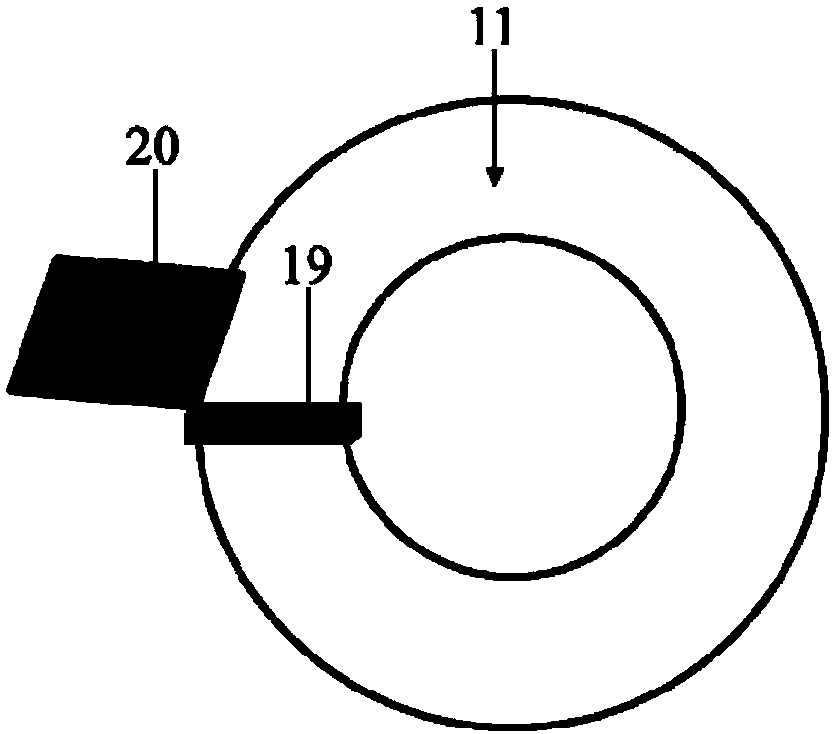

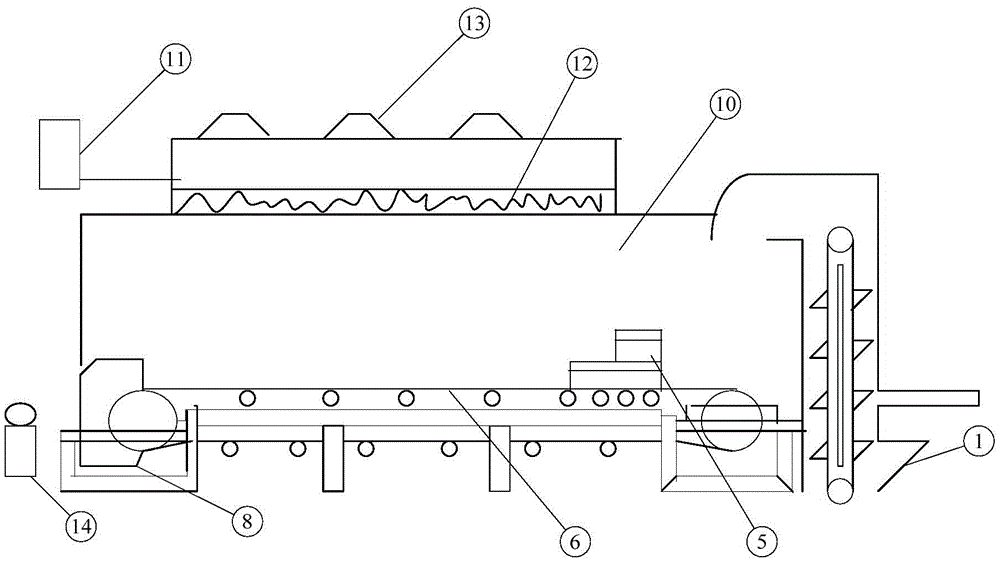

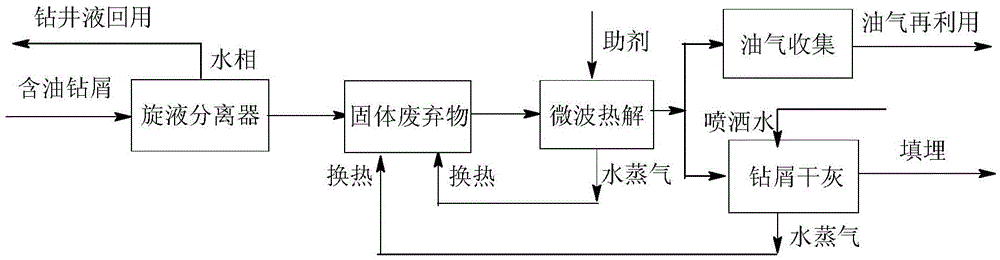

Oil-based drill cutting continuous microwave pyrolysis device and process

ActiveCN108203217APrevent leakageAvoid contactSludge treatment by pyrolysisByproduct vaporizationThermodynamicsMicrowave pyrolysis

The invention discloses an oil-based drill cutting continuous microwave pyrolysis device. The device comprises a feeding device, a microwave reaction device, an oil and gas cooling recovery device anda pyrolysis residue cooling device. The feeding device comprises a feeding bin and a belt conveyor. The microwave reaction device comprises a microwave reaction chamber, a waveguide feed port is arranged at the top end of the microwave reaction chamber, and a quartz chamber is arranged inside the microwave reaction chamber. The quartz chamber is composed of a fixed ring wall and a rotating tray,and the top end of the quartz chamber is open. A feeding buffer bin is disposed below the end of the belt conveyor and communicated with the quartz chamber through a chute. A discharging port is arranged on the fixed ring wall at the position above the corresponding discharge buffer bin. The discharging port is provided with a scraper plate, and the scraper plate is connected to the discharge buffer bin through a chute. The device can achieve continuous uniform feeding and continuous discharging without blockage in the closed environment, prevents leakage of microwaves, and prolongs service life.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

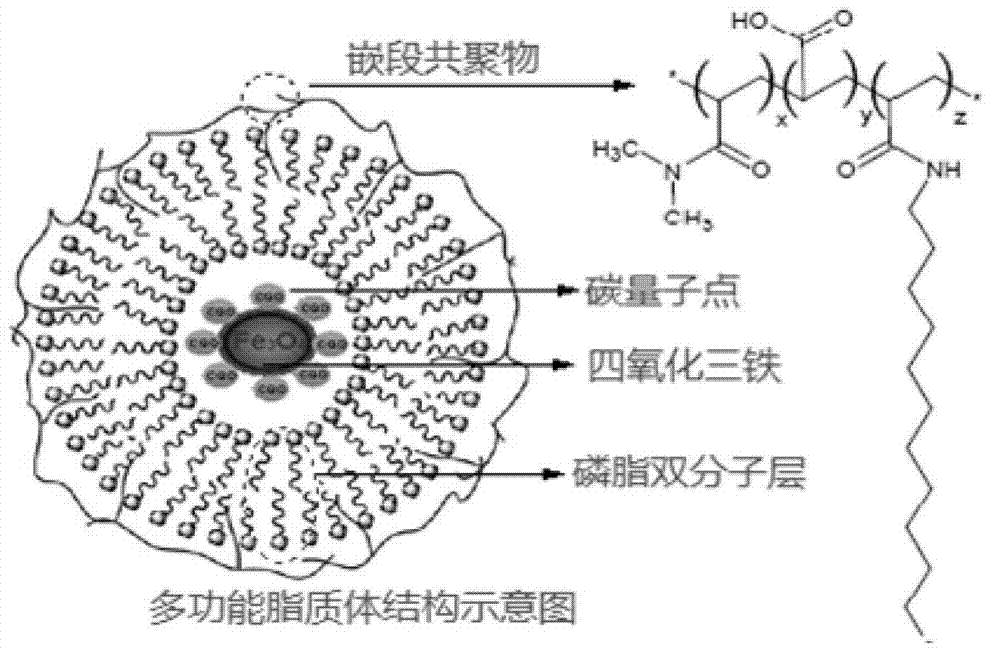

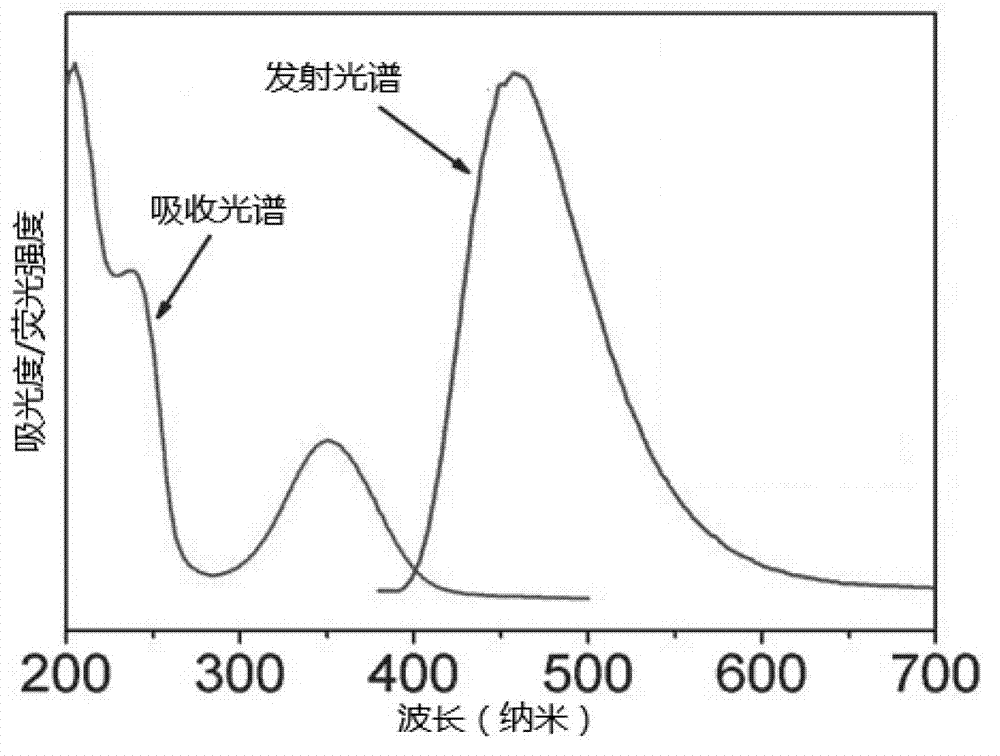

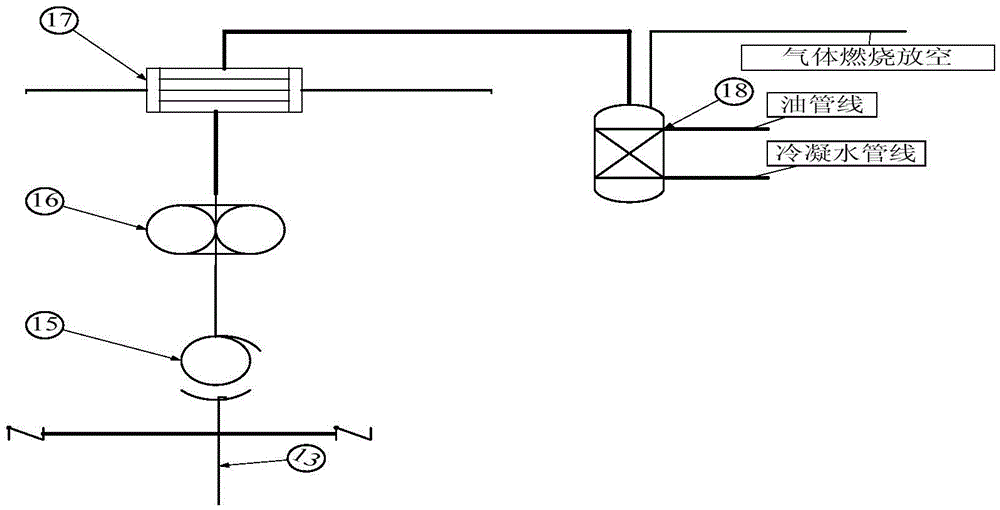

Preparation method of pH and thermal dual-sensitive lipidosome loaded with magnetic carbon quantum dots on internal water phase

InactiveCN103041409ALow costSimple methodPharmaceutical non-active ingredientsEmulsion deliveryPolymer modifiedHigh pressure

The invention relates to a preparation method of pH and thermal dual-sensitive lipidosome loaded with magnetic carbon quantum dots on an internal water phase, which concretely comprises the following steps of: 1) preparing nano ferroferric oxide by a co-precipitation method, carrying out surface modification by polyethyleneimine, preparing carbon quantum dots by a microwave pyrolysis method, and adding the carbon quantum dots into the modified magnetic particle solution to form the magnetic carbon quantum dots; and 2) loading the magnetic carbon quantum dots into the internal water phase of the lipidosome by a low-pressure film formation-high-pressure incubation method, and grafting the pH and heat sensitivity triblock copolymer on the surface of the lipidosome by hydrophobic effect to prepare the lipidosome modified by nano particles and polymer. Compared with the prior art, the preparation method is simple and lower in cost; the prepared product can be developed into a diagnosis therapeutic agent with functions of magnetic targeting, fluorescence imaging or tracing; and the medicine carrying system of pH and thermal controlled-release medicine has important reference value for developing other types of multifunctional medicine carriers.

Owner:SHANGHAI JIAO TONG UNIV

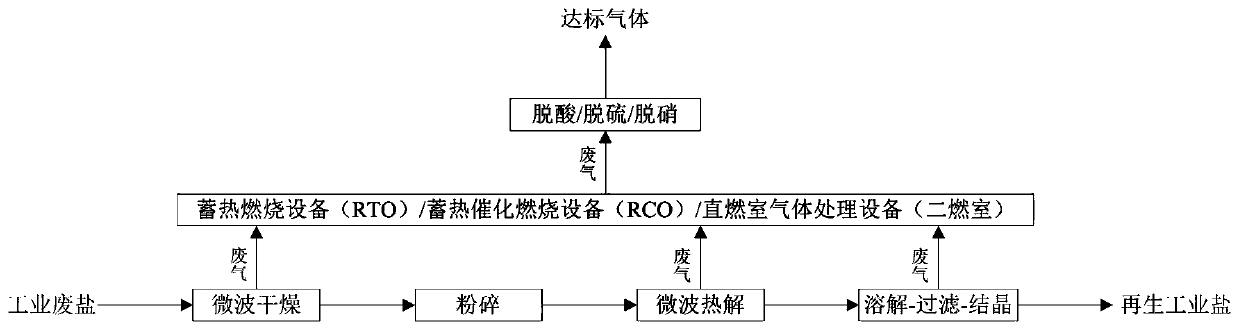

Treatment process of industrial waste salt

InactiveCN110404943ASimple processImprove processing efficiencySolid waste disposalTransportation and packagingMicrowave pyrolysisEnvironmental engineering

The invention belongs to the field of environmental protection, and particularly relates to a treatment process of industrial waste salt. The treatment process of the industrial waste salt comprises the following steps of (a), carrying out microwave drying on the industrial waste salt under a closed condition to obtain dry waste salt; (b) crushing the dry waste salt to obtain waste salt powder; (c) carrying out microwave pyrolysis on the waste salt powder under an aerobic condition to obtain pyrolyzed salt; and (d), sequentially dissolving, filtering and crystallizing the pyrolyzed salt to obtain regenerated industrial salt. According to the treatment process of the industrial waste salt, the industrial waste salt is subjected to microwave drying, crushing, microwave pyrolysis and purification treatment to obtain the high-purity regenerated industrial salt. The treatment process has the advantages of simple process, high treatment efficiency, suitability for large-scale treatment of the industrial waste salt and good industrial popularization prospects.

Owner:北京诺芯环境科技有限公司

Harmless treatment method and harmless treatment device for industrial petroleum wastes

InactiveCN105414155ATake advantage ofReduce consumptionTransportation and packagingSolid waste disposalMicrowave pyrolysisProcess engineering

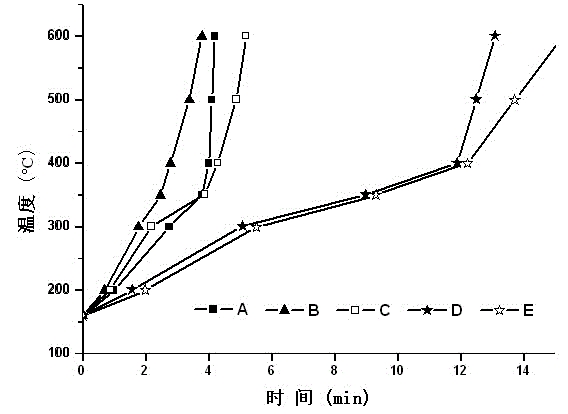

The invention provides a harmless treatment method and a harmless treatment device for industrial petroleum wastes. The method comprises the following steps: performing microwave heating treatment by taking industrial petroleum wastes or pre-treated industrial petroleum wastes as a microwave pyrolytic raw material; heating to a temperature of 500 to 1400 DEG C; controlling the temperature increment speed in a temperature increasing process in which the material is heated to the temperature of 350 to 400 DEG C to be 10 to 50DEG C / min; controlling the microwave treatment time after the material is heated to the temperature of 350 to 400 DEG C to be 5min to 30min; carbonizing and pyrolyzing the raw material into a gas phase part and a solid phase part during the microwave heating process, and respectively recycling the gas phase part and the solid phase part. The invention also provides the harmless treatment device for the industrial petroleum wastes. In the method provided by the invention, heat energy can be fully utilized; energy consumption is relatively low; the method has the advantages of good operability, stable system, low cost, totally-harmless treatment products and the like.

Owner:BEIJING UPC ENERGY TECH SERVICE CO LTD

Biomass microwave pyrolysis oriented gasification method and system

ActiveCN108117891AStrong microwave absorption propertiesAvoid inactivationOrganic-compounds/hydrides/coordination-complexes catalystsGasification processes detailsSyngasMicrowave pyrolysis

The invention discloses a biomass microwave pyrolysis oriented gasification method and system. The method includes a microwave pyrolysis reaction process, a microwave gasification reaction process anda catalyst recycling regeneration process. An employed catalyst is a catalyst including biological semi-coke, biological tar, nickel oxide and a group I metal hydroxide. The system of the present invention includes a feed assembly, a microwave pyrolysis assembly, a microwave gasification assembly and a catalyst regeneration assembly. The catalyst regeneration assembly includes an oxidation processor, a deashing tank, a dispersion processor, a precipitation processor, an extruder, a baking chamber and a necessary solid-liquid separation device. The method and system of the present invention can catalyze oriented conversion of biomass into syngas to achieve a gas yield of 90% or more, a syngas content of 90% or more, and a H2 / CO ratio controlled between 2.0 and 3.0. The system can effectively couple and integrate products and energy during the production process, and achieve a continuous and streamlined process.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com