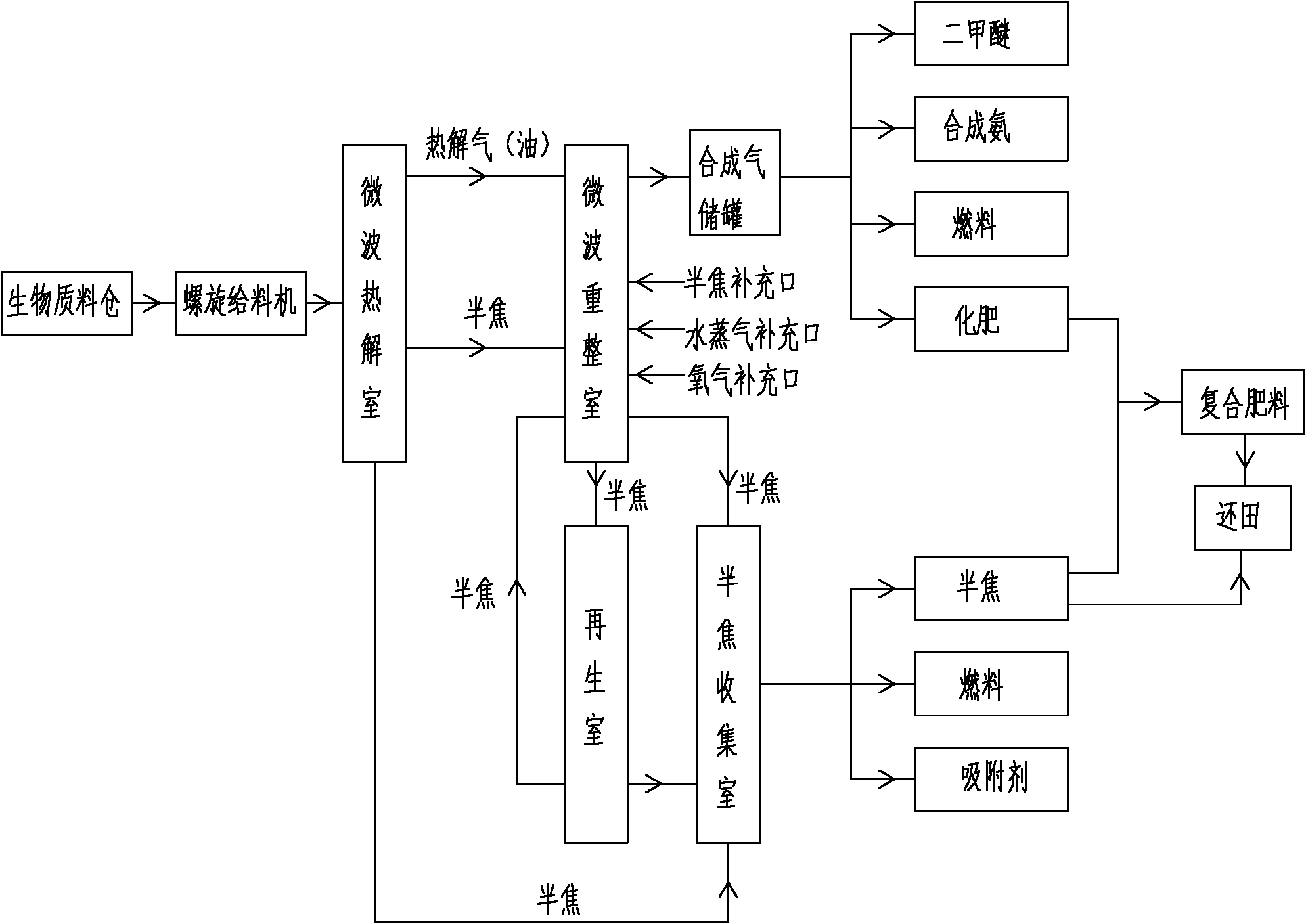

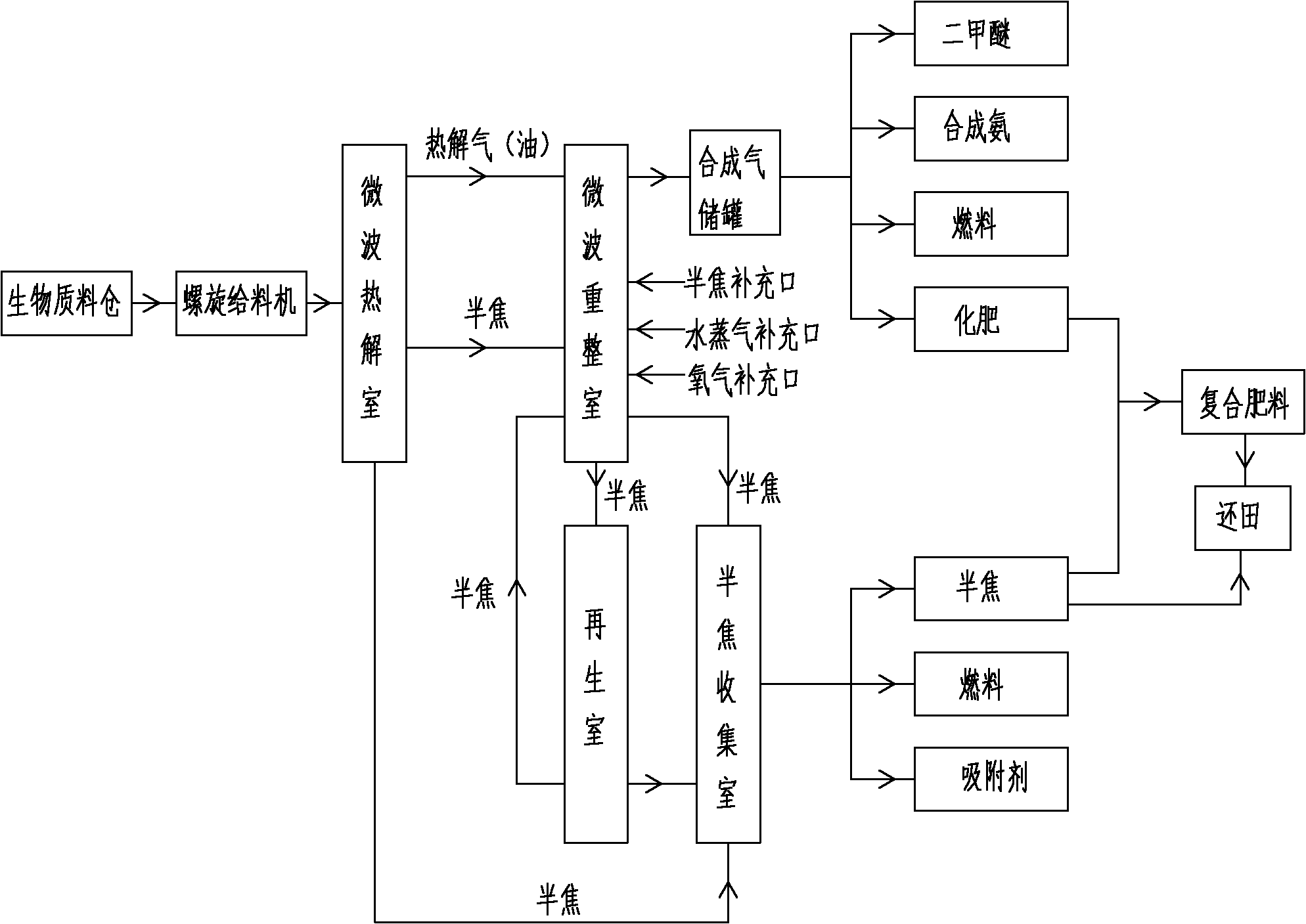

Biomass poly-generation comprehensive utilization method and device

A poly-generation and biomass technology, applied in the fields of biofuels, fertilization devices, bulk chemical production, etc., can solve the problems of incomplete utilization of semi-coke, improve the utilization efficiency and process economy, and save the preparation cost. , the effect of improving the conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

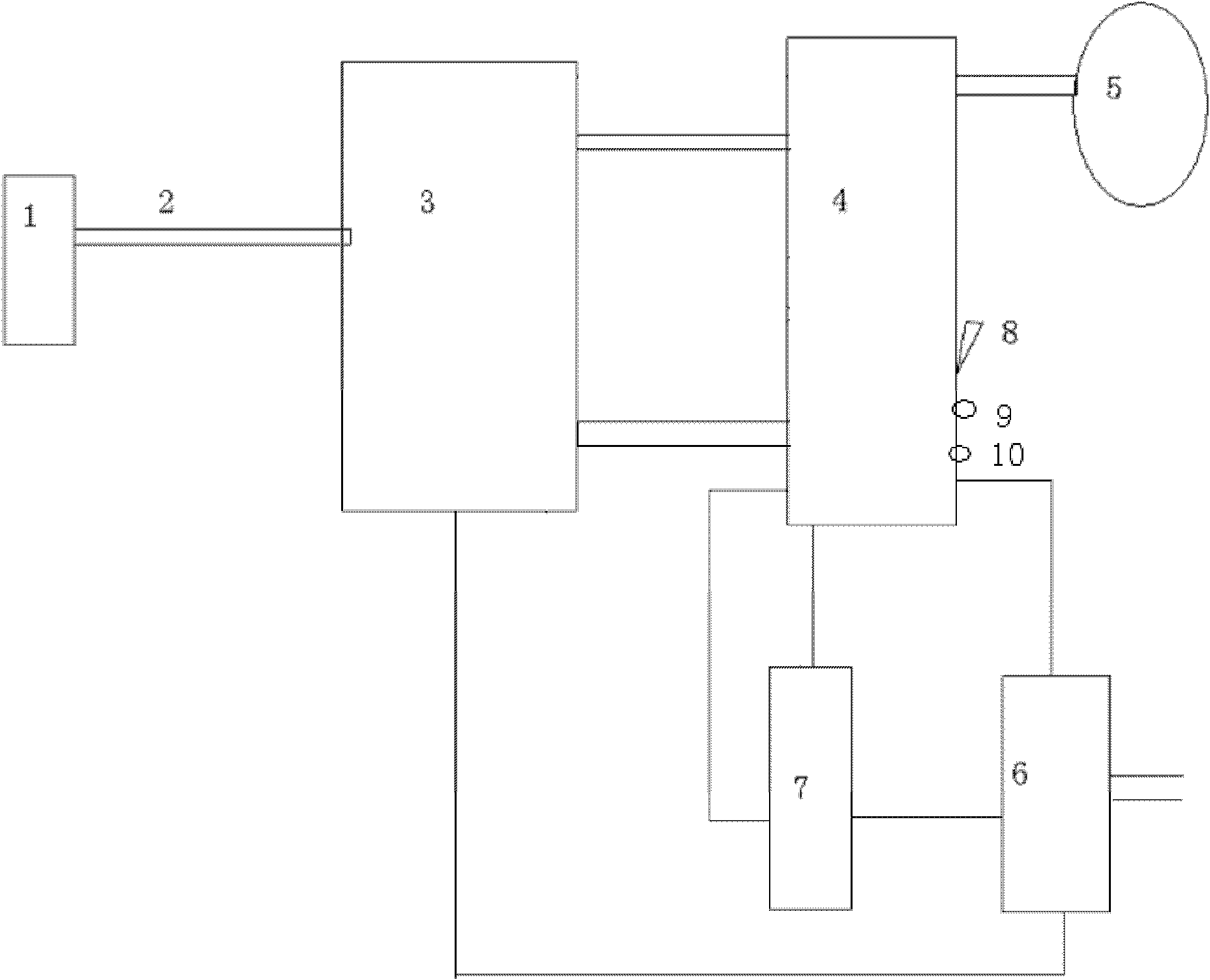

[0030] The steps of the polygeneration comprehensive utilization method of biomass are as follows:

[0031] (1) Biomass raw materials are first naturally dried and coarsely crushed (the average particle size is about 1-10cm), and then transported to the microwave pyrolysis chamber through a screw feeding device. The microwave generator is evenly arranged around the microwave pyrolysis chamber, the excitation gun is embedded in the wall of the pyrolysis chamber, and the inner wall is made of non-absorbing material. Before the microwave generator is started, a certain amount of nitrogen is introduced to replace the air in the microwave pyrolysis chamber.

[0032] (2) After the microwave is started, the pyrolysis reaction of biomass begins, and the generated pyrolysis gas (including tar) is directly introduced into the microwave reforming chamber from the tail of the microwave pyrolysis chamber, and the produced semi-coke is directly sent into the microwave reforming chamber . ...

Embodiment 2

[0037] The steps of the polygeneration comprehensive utilization method of biomass are as follows:

[0038] (1) Biomass raw materials are first naturally dried and coarsely crushed (the average particle size is about 1-10cm), and then transported to the microwave pyrolysis chamber through a screw feeding device. The microwave generator is evenly arranged around the microwave pyrolysis chamber, the excitation gun is embedded in the wall of the pyrolysis chamber, and the inner wall is made of non-absorbing material. Before the microwave generator is started, a certain amount of nitrogen is introduced to replace the air in the microwave pyrolysis chamber.

[0039](2) After the microwave is started, the pyrolysis reaction of biomass begins, and the generated pyrolysis gas (including tar) is directly introduced into the microwave reforming chamber from the tail of the microwave pyrolysis chamber, and the produced semi-coke is directly sent into the microwave reforming chamber . U...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com