Patents

Literature

40results about "Coke ovens heating" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

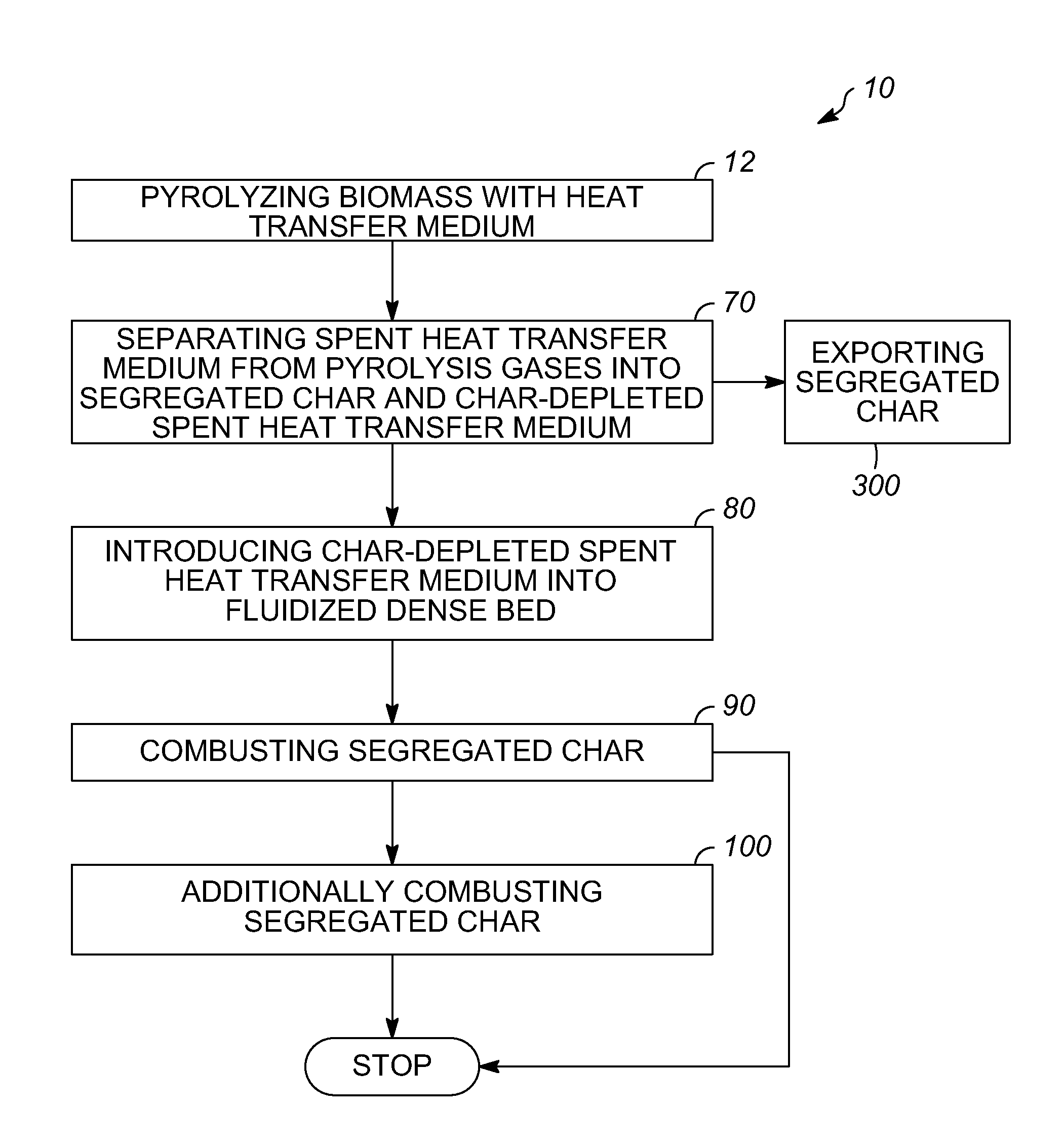

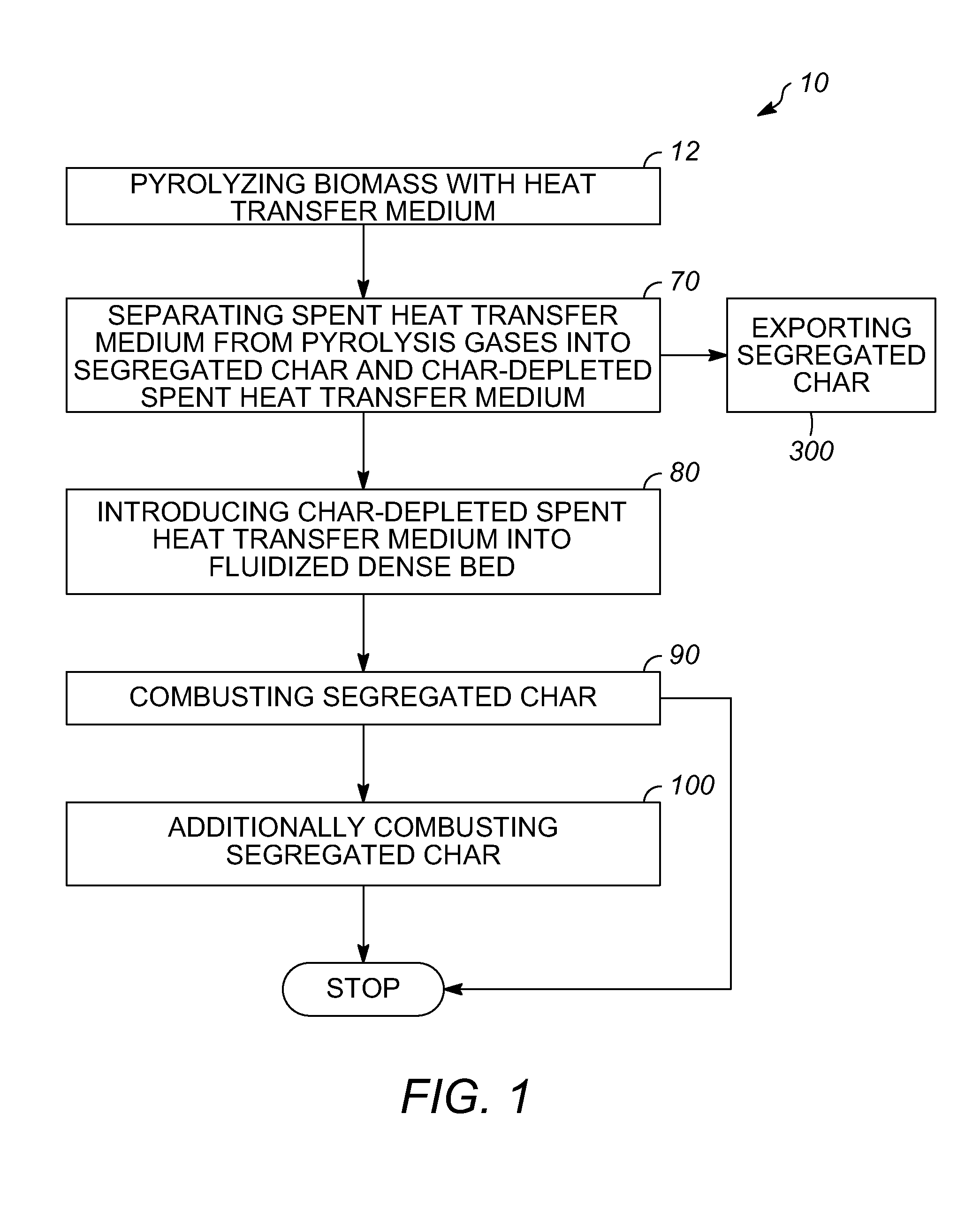

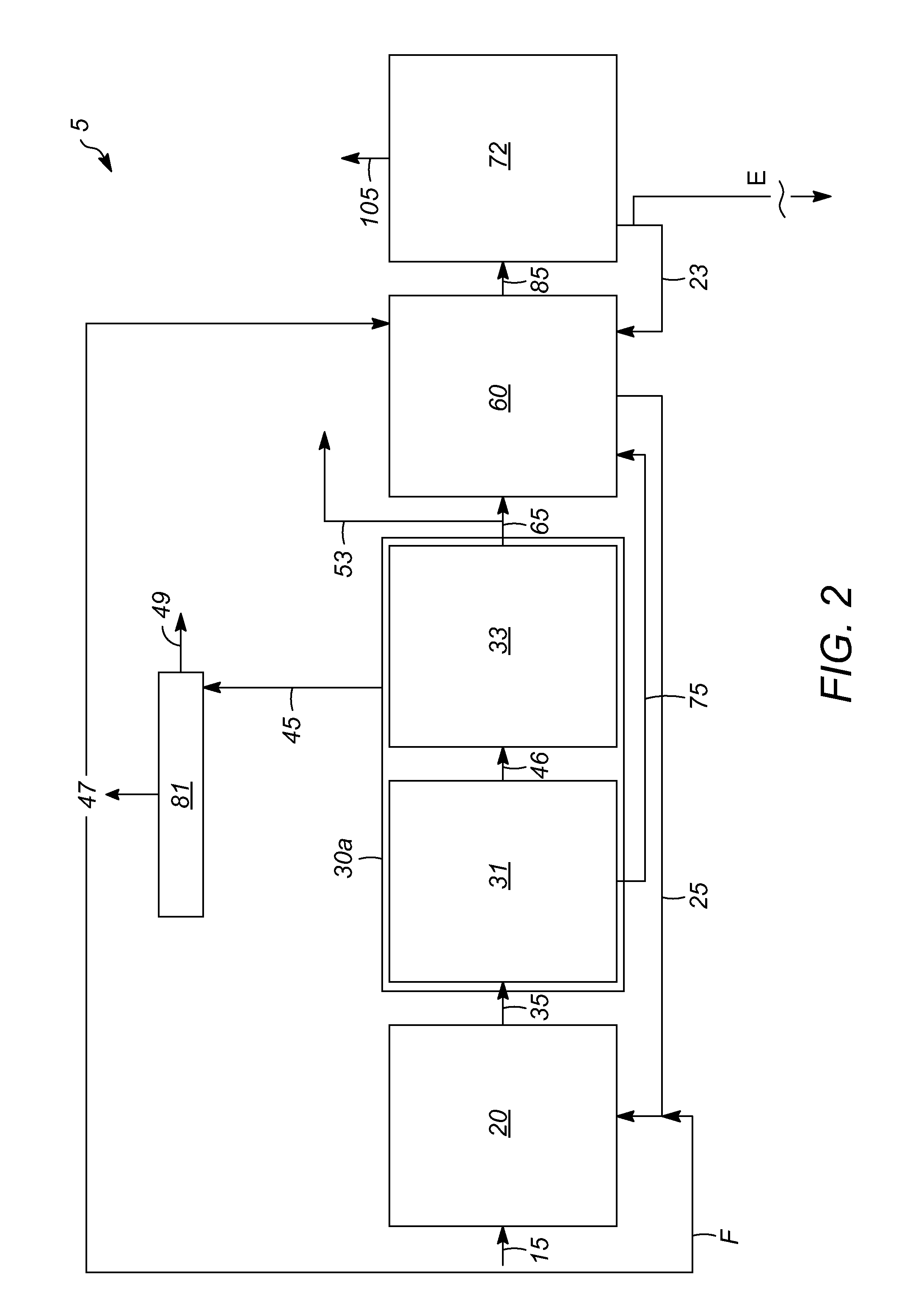

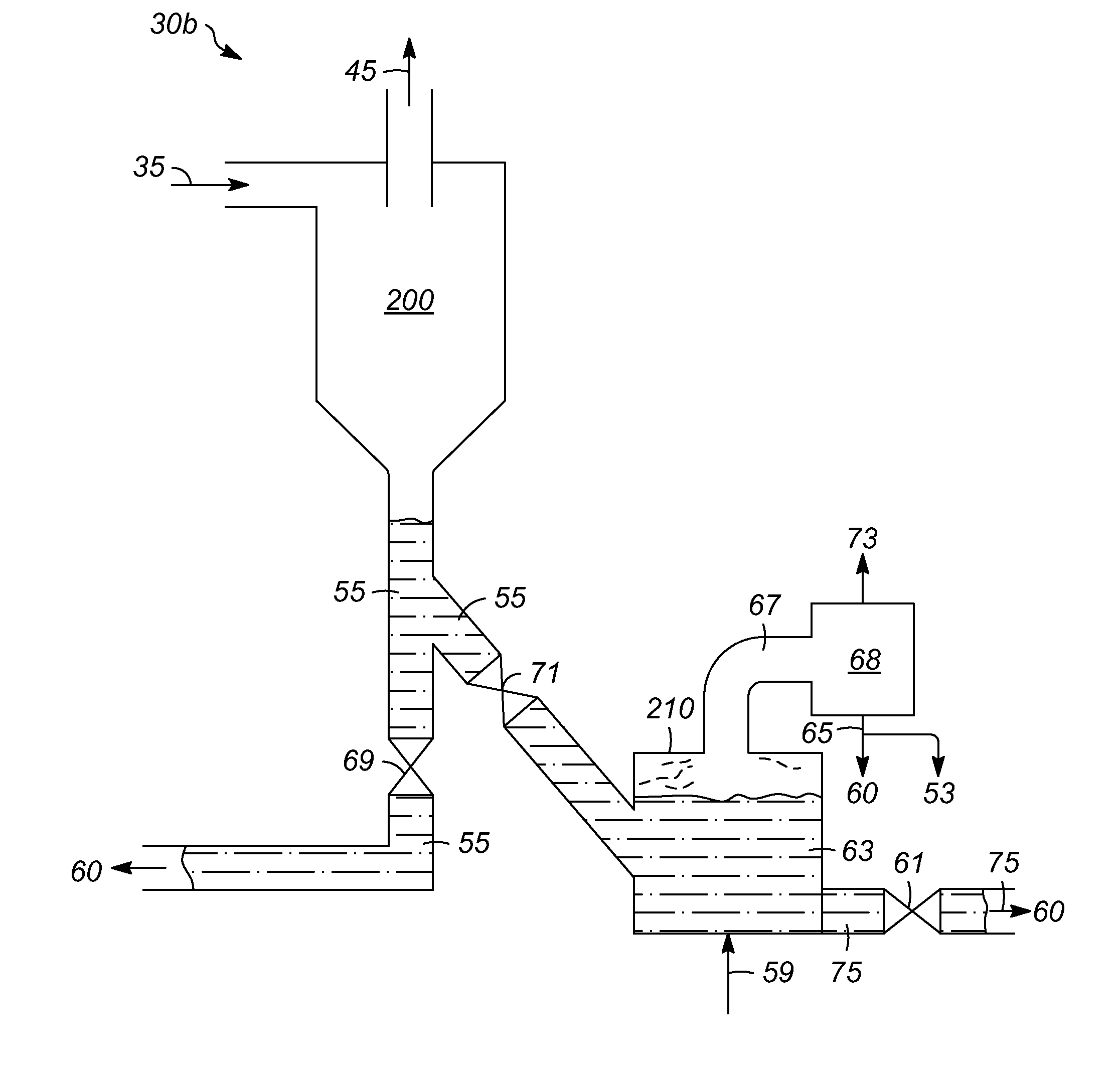

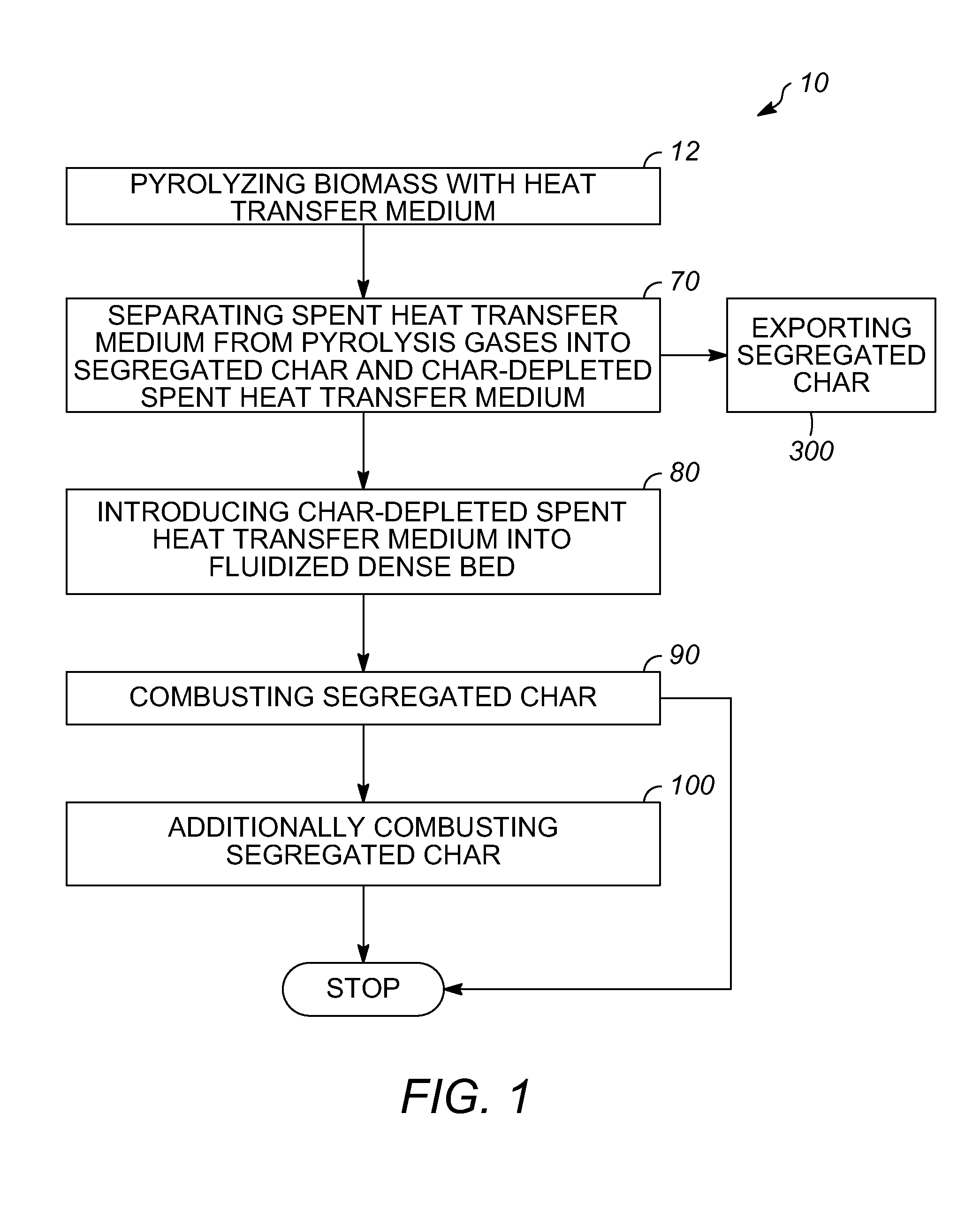

Char-handling processes in a pyrolysis system

Owner:ENSYN RENEWABLES

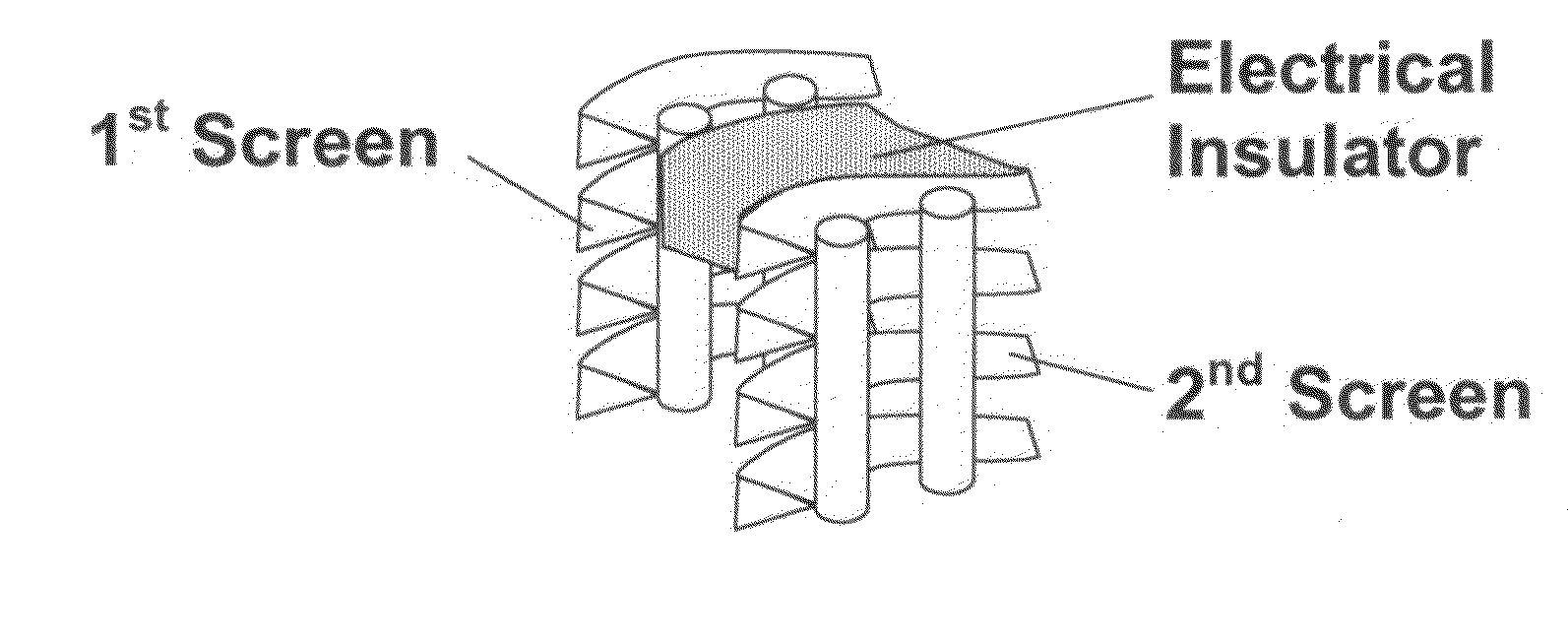

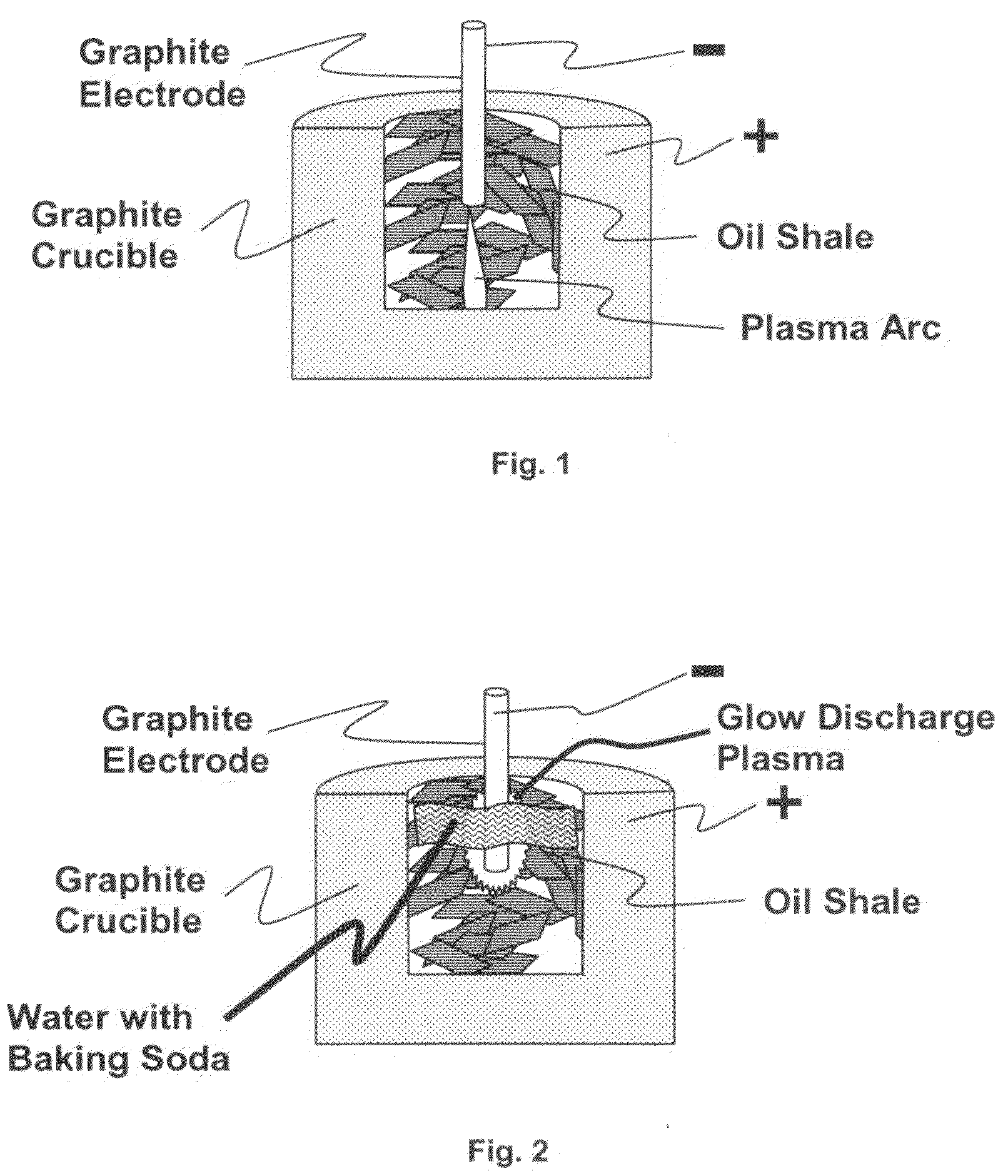

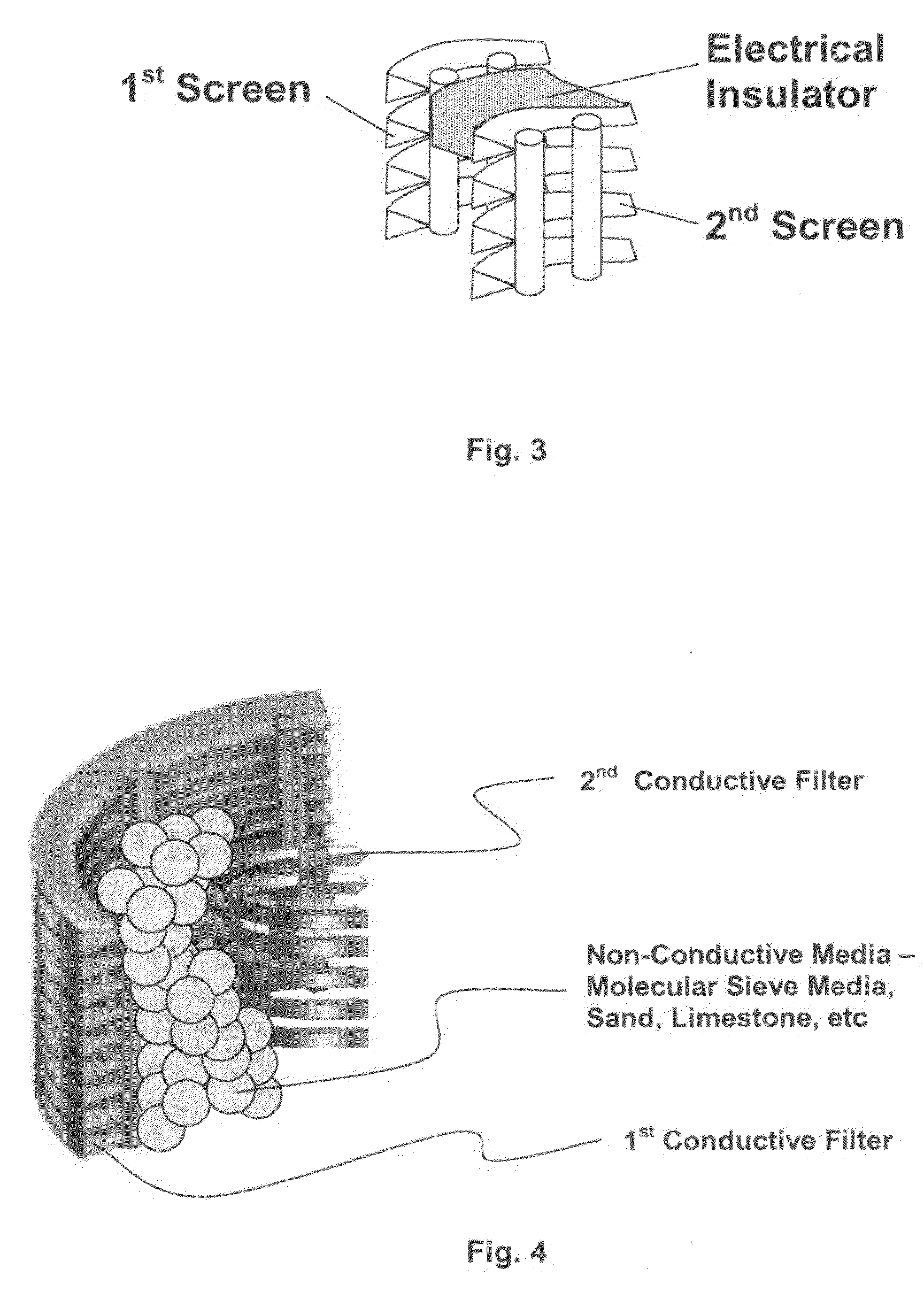

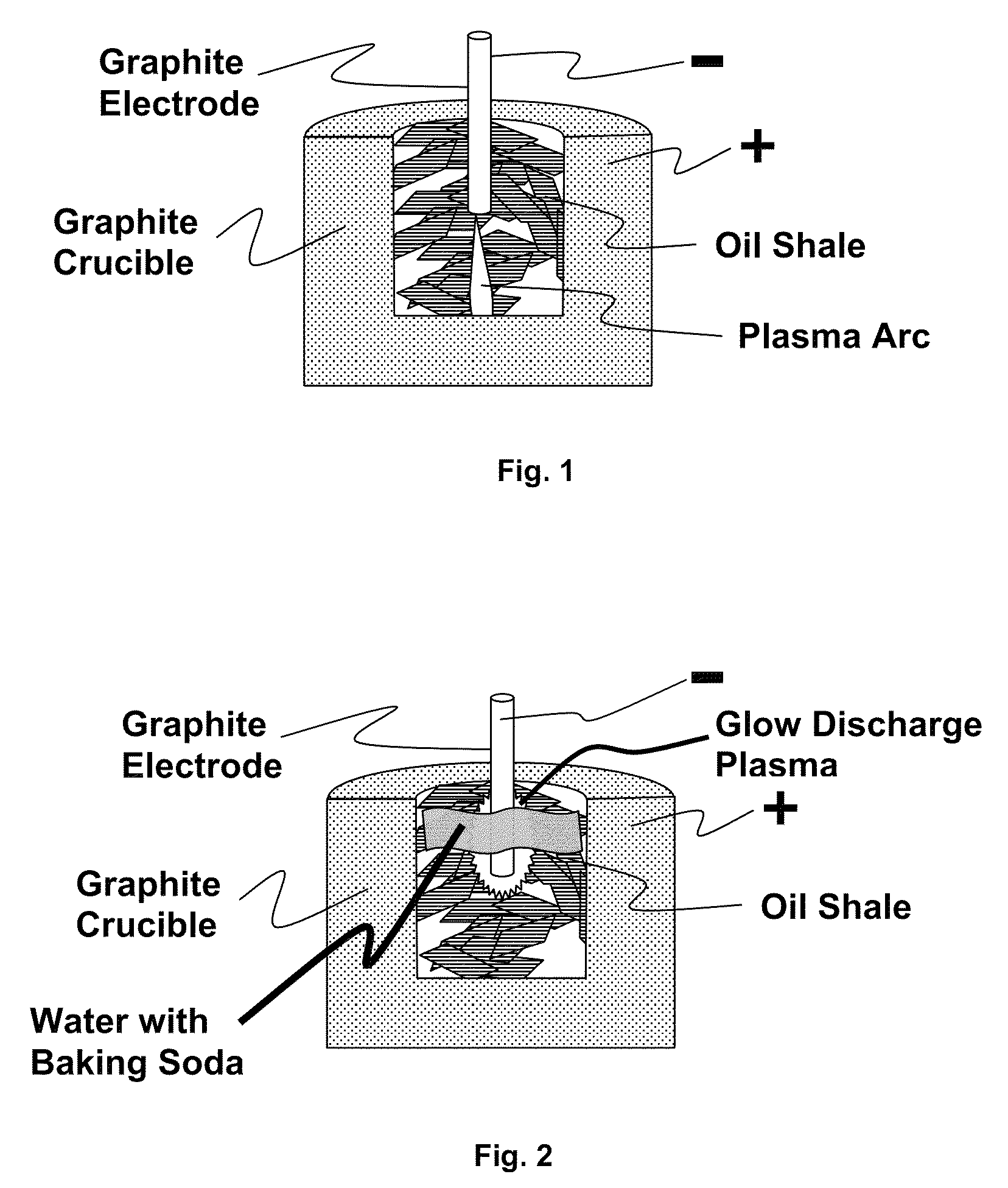

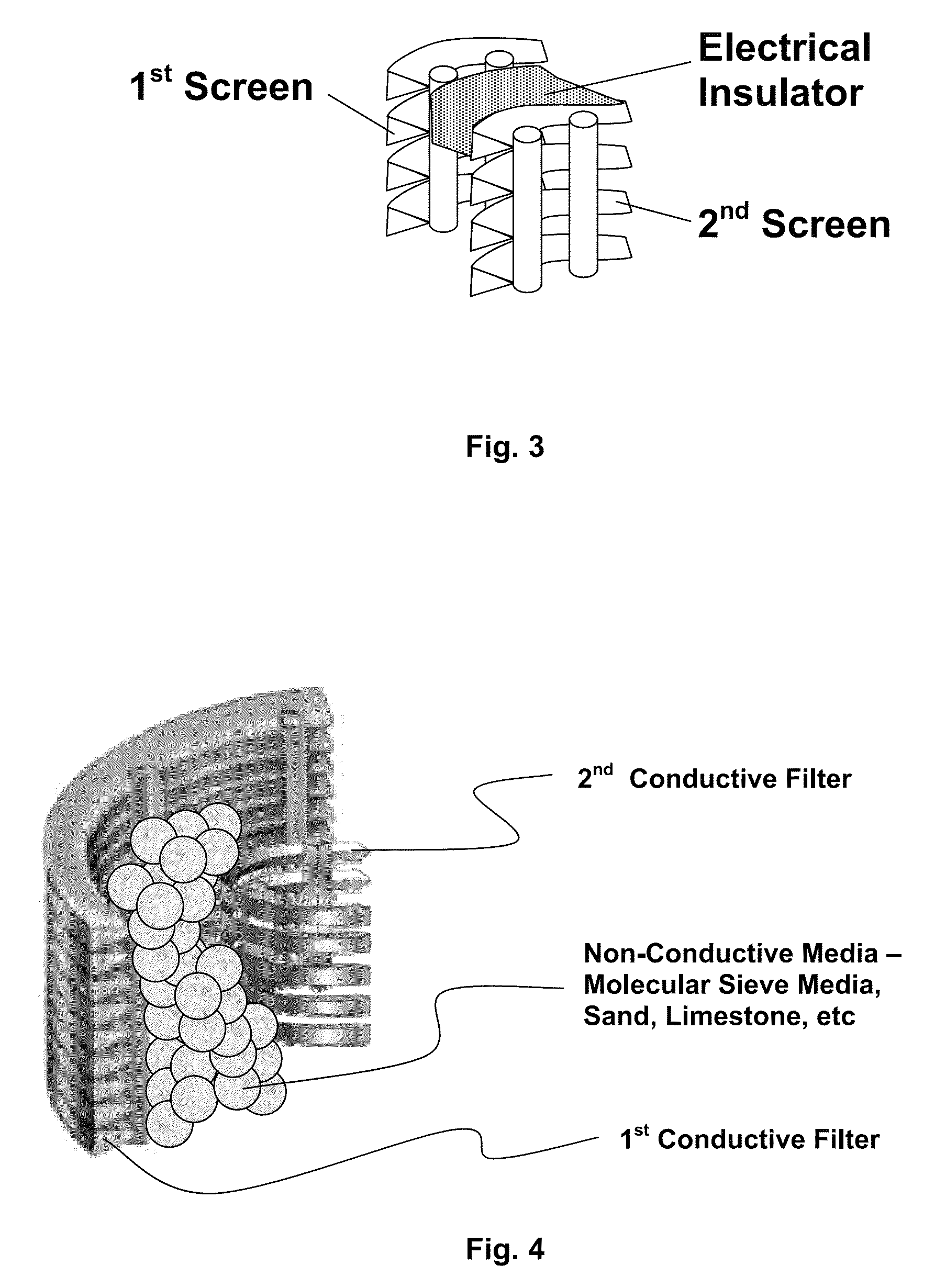

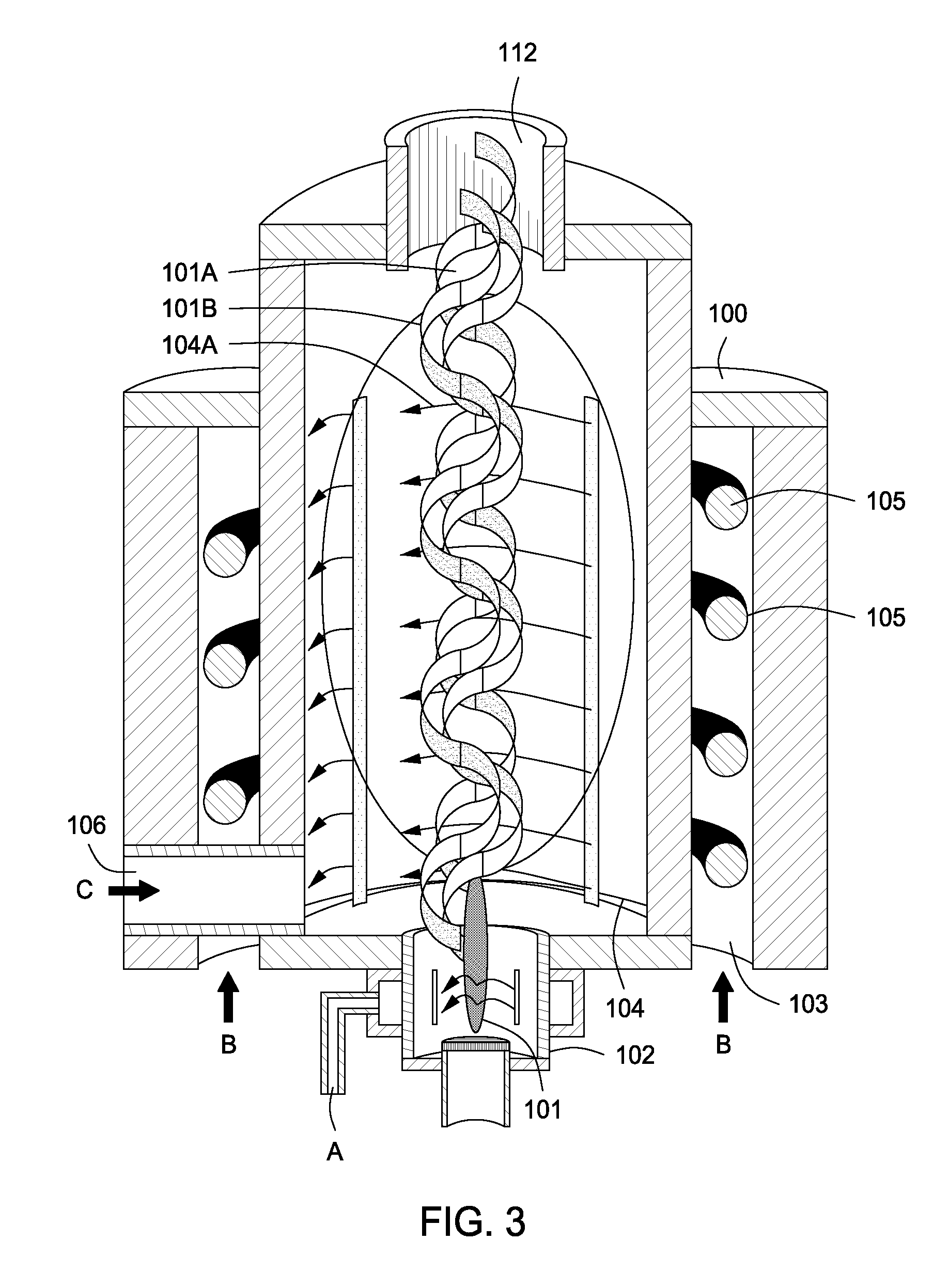

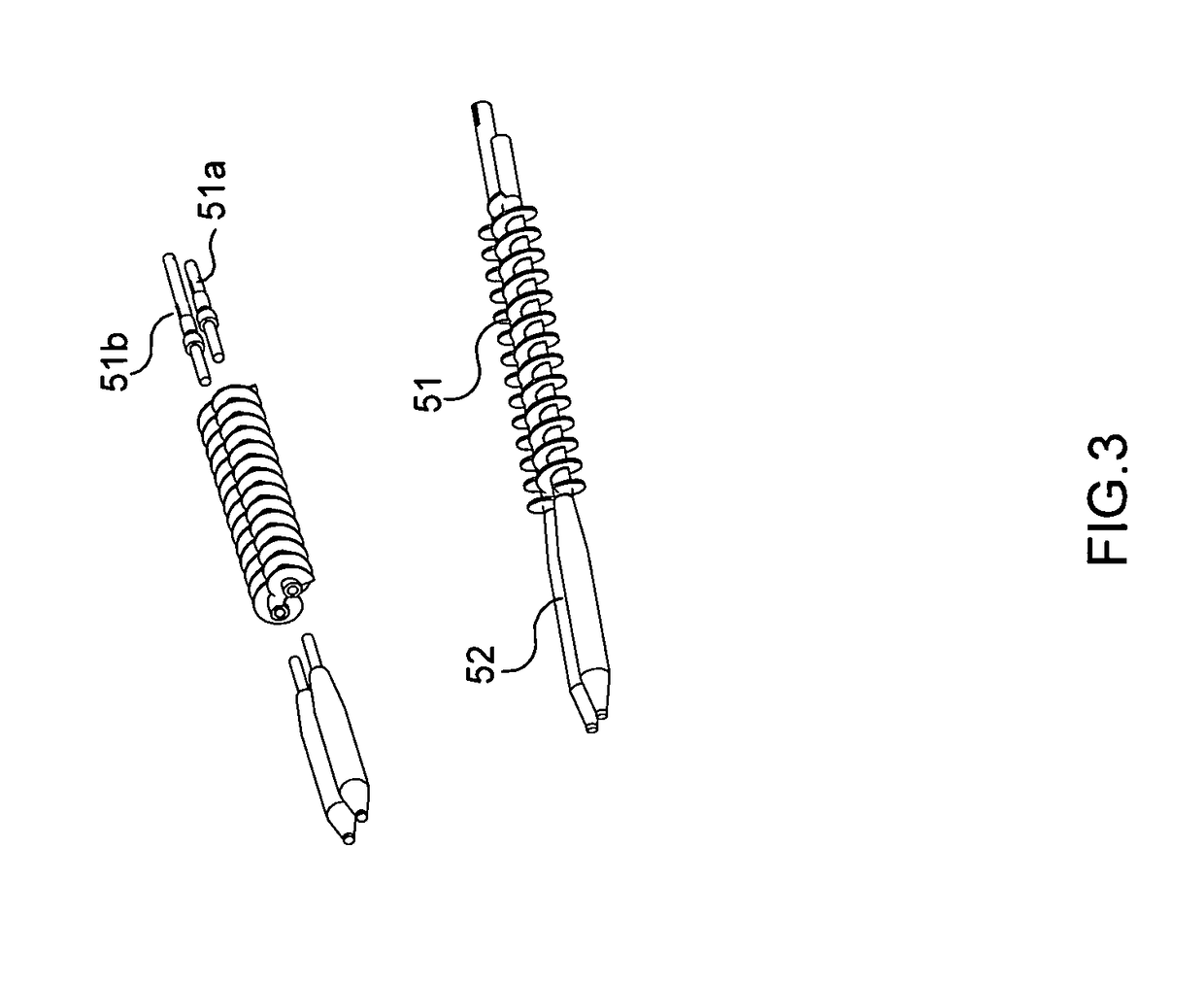

System, method and apparatus for creating an electrical glow discharge

The present invention provides system, method and apparatus for creating an electric glow discharge that includes a first and second electrically conductive screens having substantially equidistant a gap between them, one or more insulators attached to the electrically conductive screens, and a non-conductive granular material disposed within the gap. The electric glow discharge is created whenever: (a) the first electrically conductive screen is connected to an electrical power source such that it is a cathode, the second electrically conductive screen is connected to the electrical power supply such that it is an anode, and the electrically conductive fluid is introduced into the gap, or (b) both electrically conductive screens are connected to the electrical power supply such they are the cathode, and the electrically conductive fluid is introduced between both electrically conductive screens and an external anode connected to the electrical power supply.

Owner:FORET PLASMA LABS

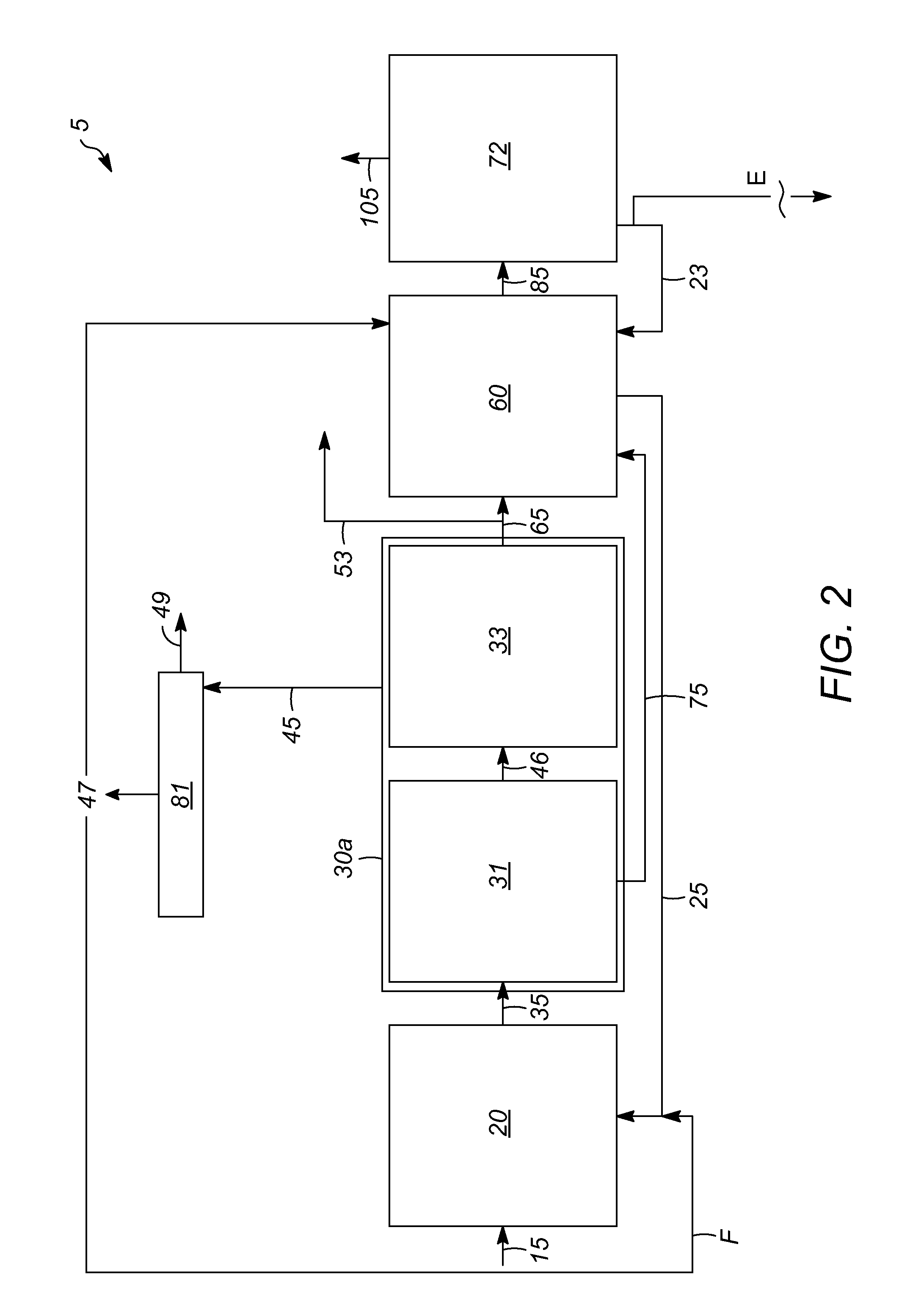

Char-handling processes in a pyrolysis system

Char-handling processes for controlling overall heat balance, ash accumulation, and afterburn in a reheater are provided. Carbonaceous biomass feedstock is pyrolyzed using a heat transfer medium forming pyrolysis products and a spent heat transfer medium. The spent heat transfer medium is separated into segregated char and char-depleted spent heat transfer medium. The char-depleted spent heat transfer medium is introduced into a dense bed of heat transfer medium fluidized by a stream of oxygen-containing regeneration gas. All or a portion of the segregated char is combusted in the dense bed using the stream of oxygen-containing regeneration gas. A portion of the segregated char may be exported out of the pyrolysis system to control the overall heat balance and ash accumulation.

Owner:ENSYN RENEWABLES

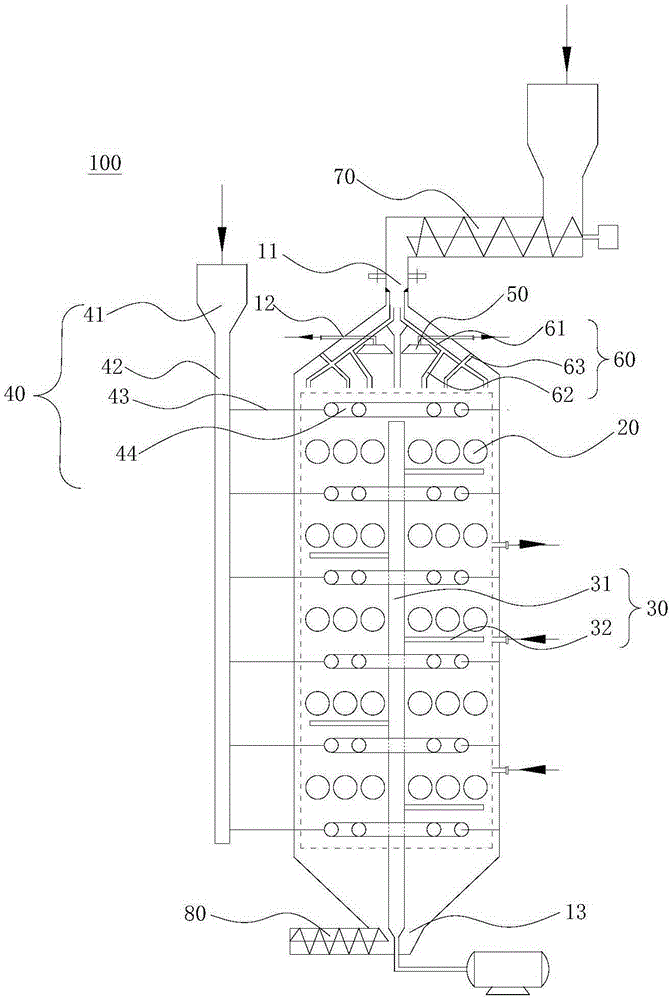

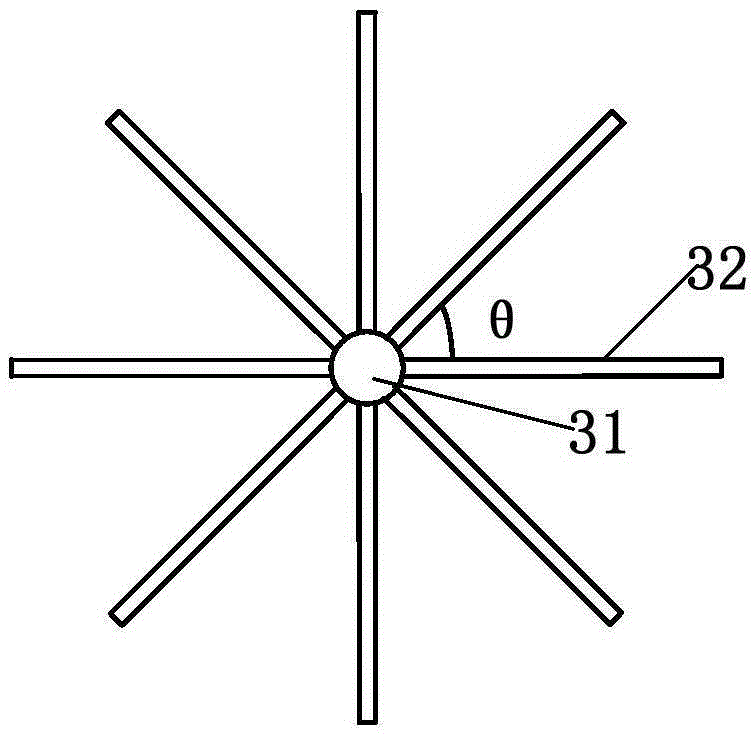

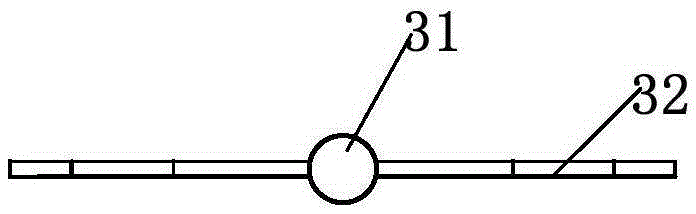

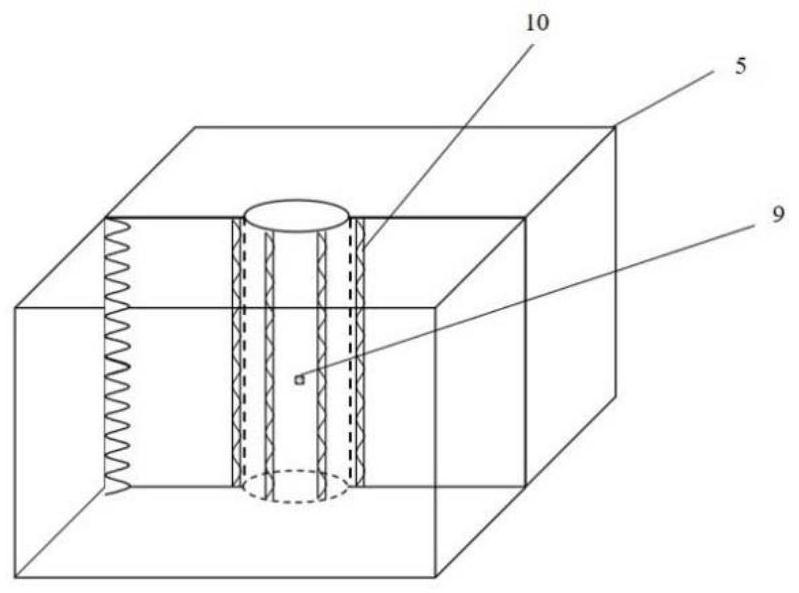

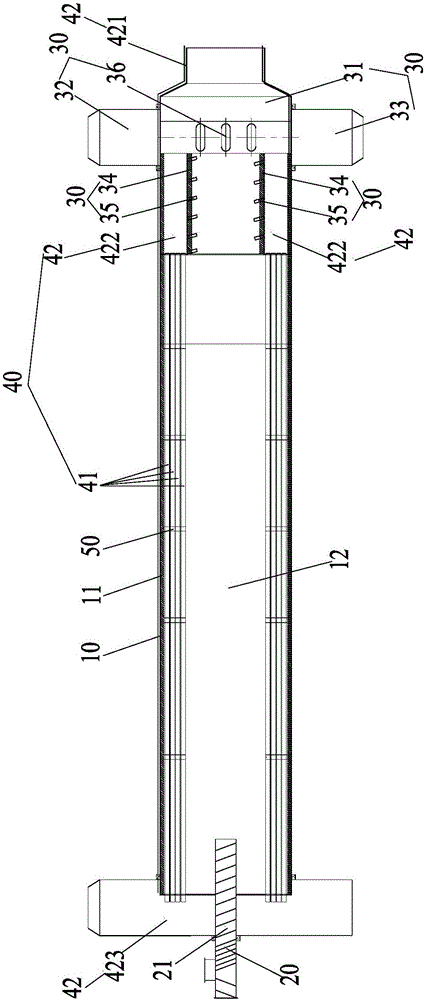

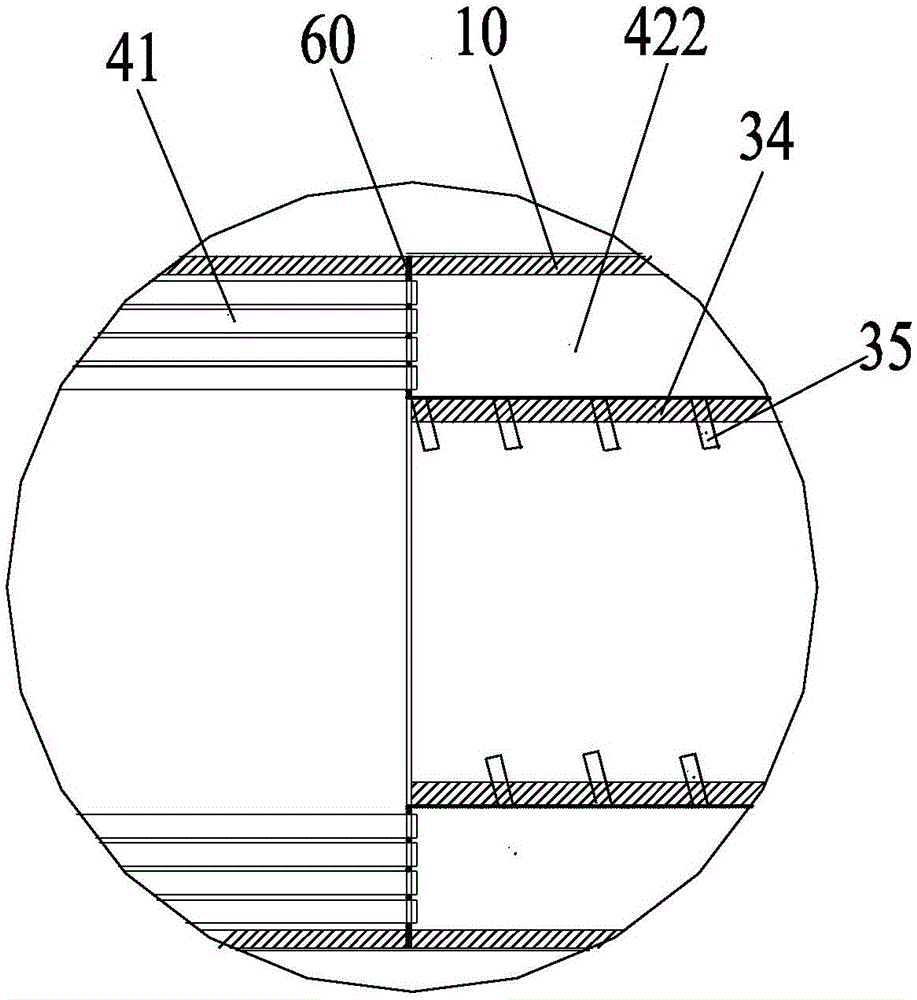

Pyrolysis reactor

PendingCN105400527AImprove pyrolysis efficiencyReduce energy consumptionIndirect heating destructive distillationCoke ovens heatingSlagEngineering

The invention provides a pyrolysis reactor, which includes: regenerative type radiant tubes, a stirring device, a catalyst adding component, an air pumping umbrella and a distributor. The regenerative type radiant tubes are arranged in multiple layers along the height direction of the pyrolysis reactor, and a plurality of regenerative type radiant tubes parallel to each other are disposed in each layer in the horizontal direction; the stirring device consists of a stirring shaft and a plurality of stirring rods connected to the stirring shaft, and the stirring shaft rotatably extends from a slag discharge port into the pyrolysis reactor; the catalyst adding component includes a catalyst main tube; a plurality of catalyst branch tubes, one or more catalyst jet members and a carrier gas delivery member; the air pumping umbrella is disposed on the top wall of the pyrolysis reactor and is connected to oil gas outlets; and the distributor is arranged on the top wall of the pyrolysis reactor and is connected to a feed port through a flange. The pyrolysis reactor provided by the invention can significantly improve the pyrolysis efficiency.

Owner:SHENWU TECH GRP CO LTD

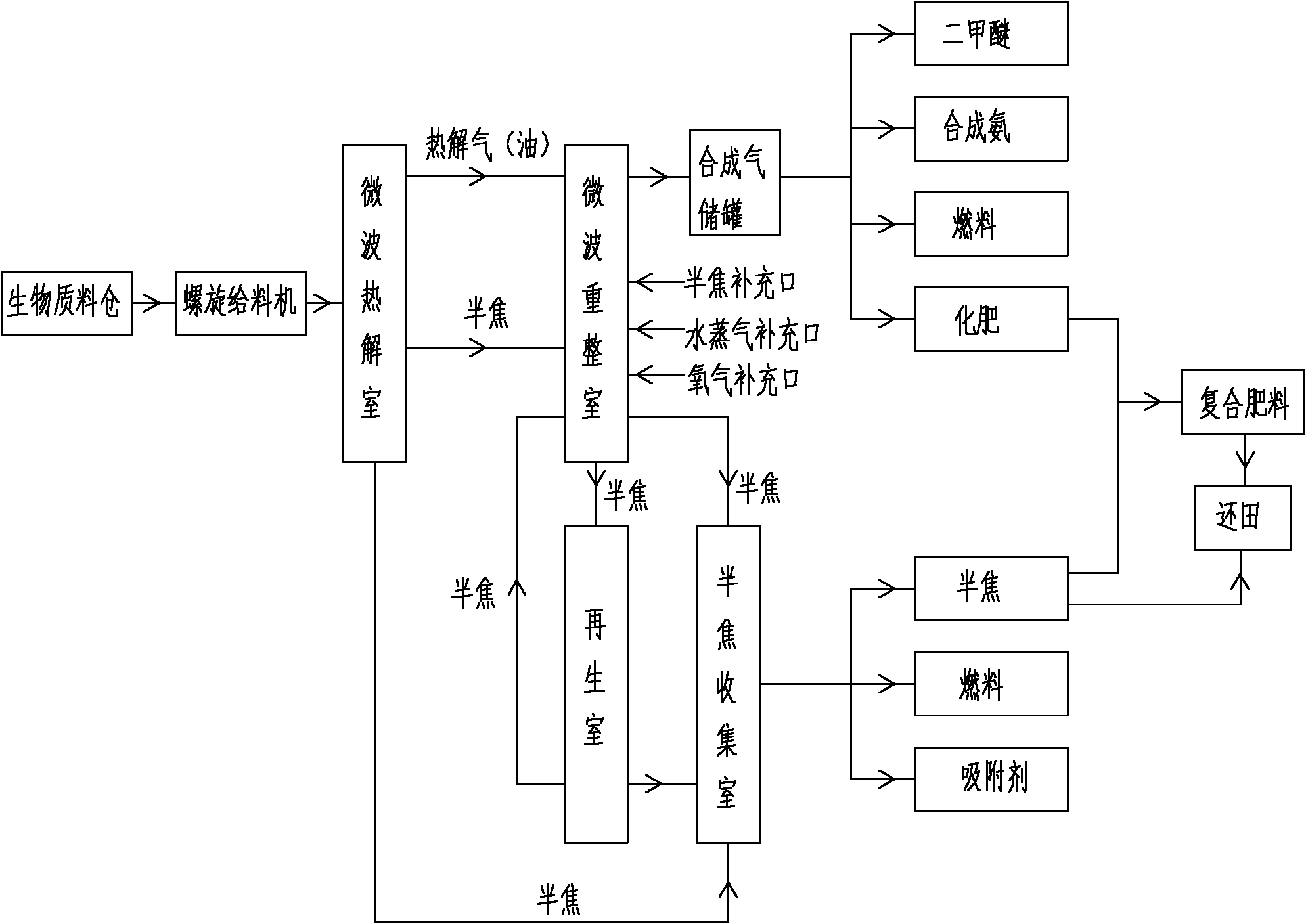

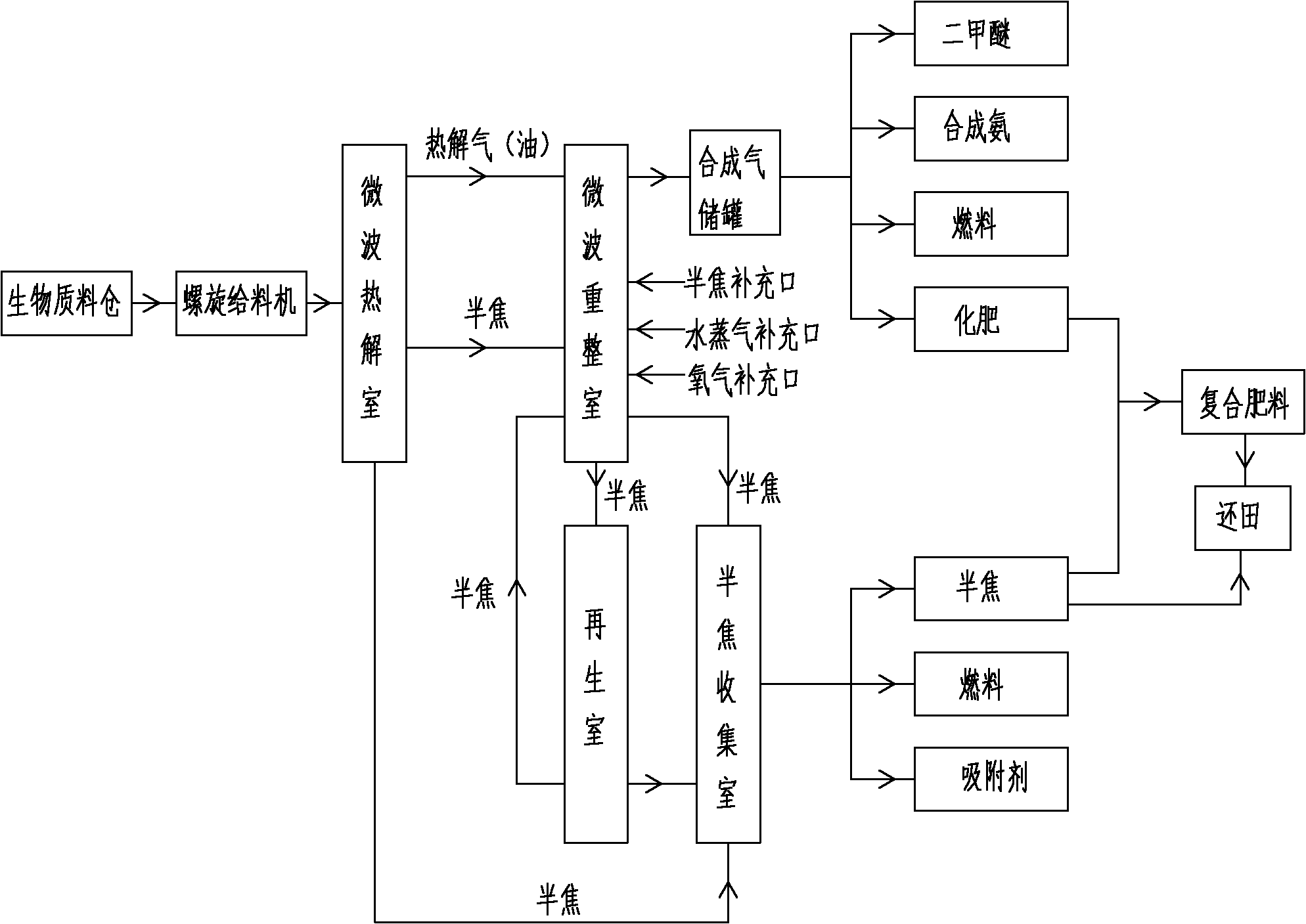

Biomass poly-generation comprehensive utilization method and device

InactiveCN102206515AReduce manufacturing costImprove carbon sinkOther chemical processesBiofuelsMicrowave irradiationDimethyl ether

The invention relates to a biomass poly-generation comprehensive utilization method and device. The method comprises the steps of: naturally drying and roughly crushing biomass materials, then carrying out microwave heating and cracking in a microwave pyrolysis chamber, introducing thermal gas (tar) and solid semicoke which are generated by microwave heating and cracking into a microwave reforming chamber, and further carrying out microwave heating and reforming on the thermal gas (tar) to convert the thermal gas (tar) into synthesis gas under the catalytic reaction of the semicoke; activating and regenerating the semicoke after catalysis and reforming, and then sending to the microwave reforming chamber for continuous catalytic reaction. In the invention, directional conversion from biomass to synthesis gas is realized by means of microwave radiation, the semicoke generated by pyrolysis is used as a reforming catalyst, two technologies of microwave pyrolysis and microwave reforming are integrated, and the semicoke can be activated and regenerated for recycling under microwave radiation. The semicoke that is not suitable for recycling can also be returned to field directly or in the form of a compound fertilizer after being mixed with fertilizer to improve soil carbon sink and enhance soil fertility. Compared with other processes, the method has the advantage of high synthesis gas conversion rate improved by about 10%; the prepared synthesis gas has wide applications and can be used for synthesizing chemical products such as ammonia, dimethyl ether, fertilizer and the like. The method can realize the resource poly-generation comprehensive utilization of biomass.

Owner:SHANDONG UNIV

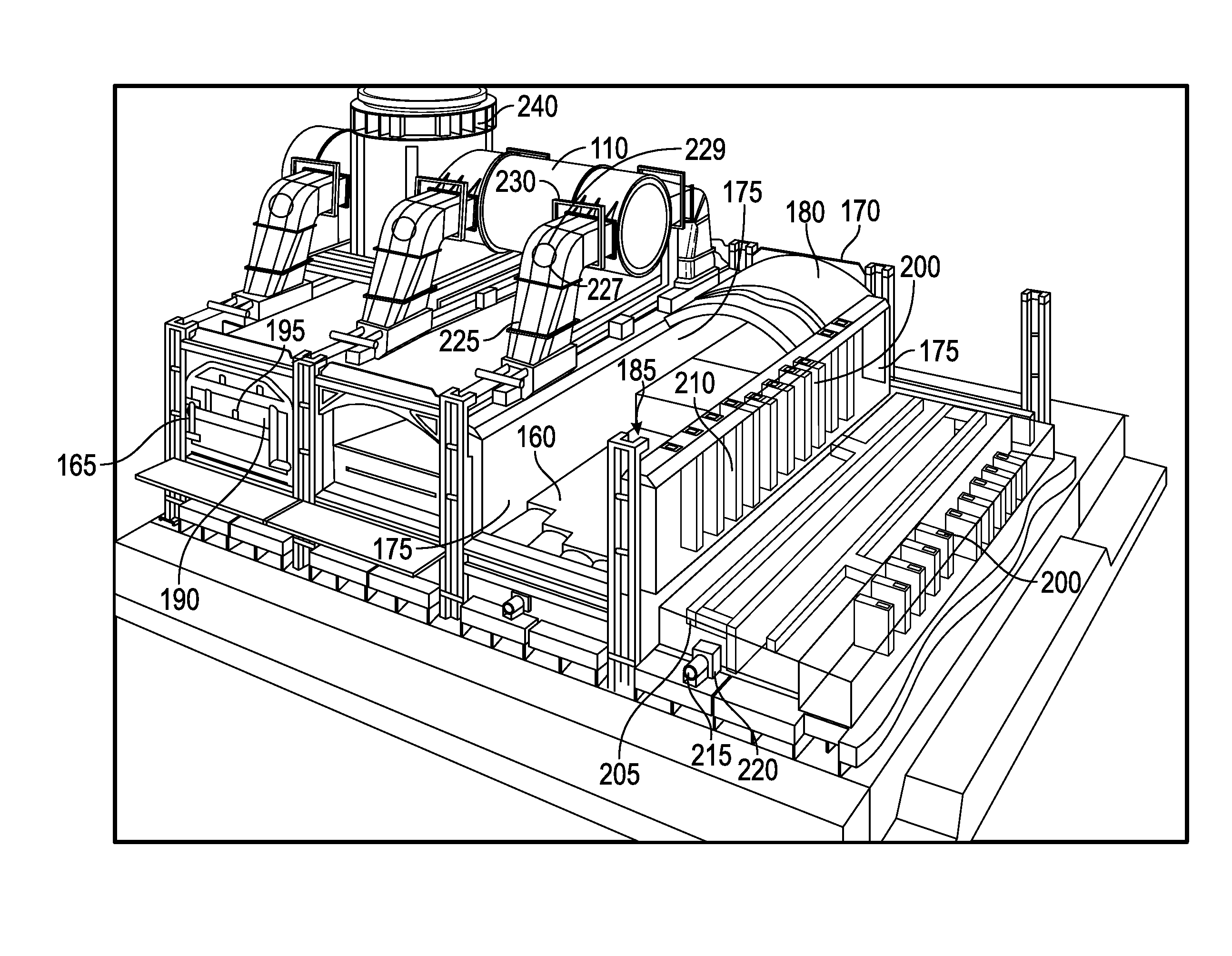

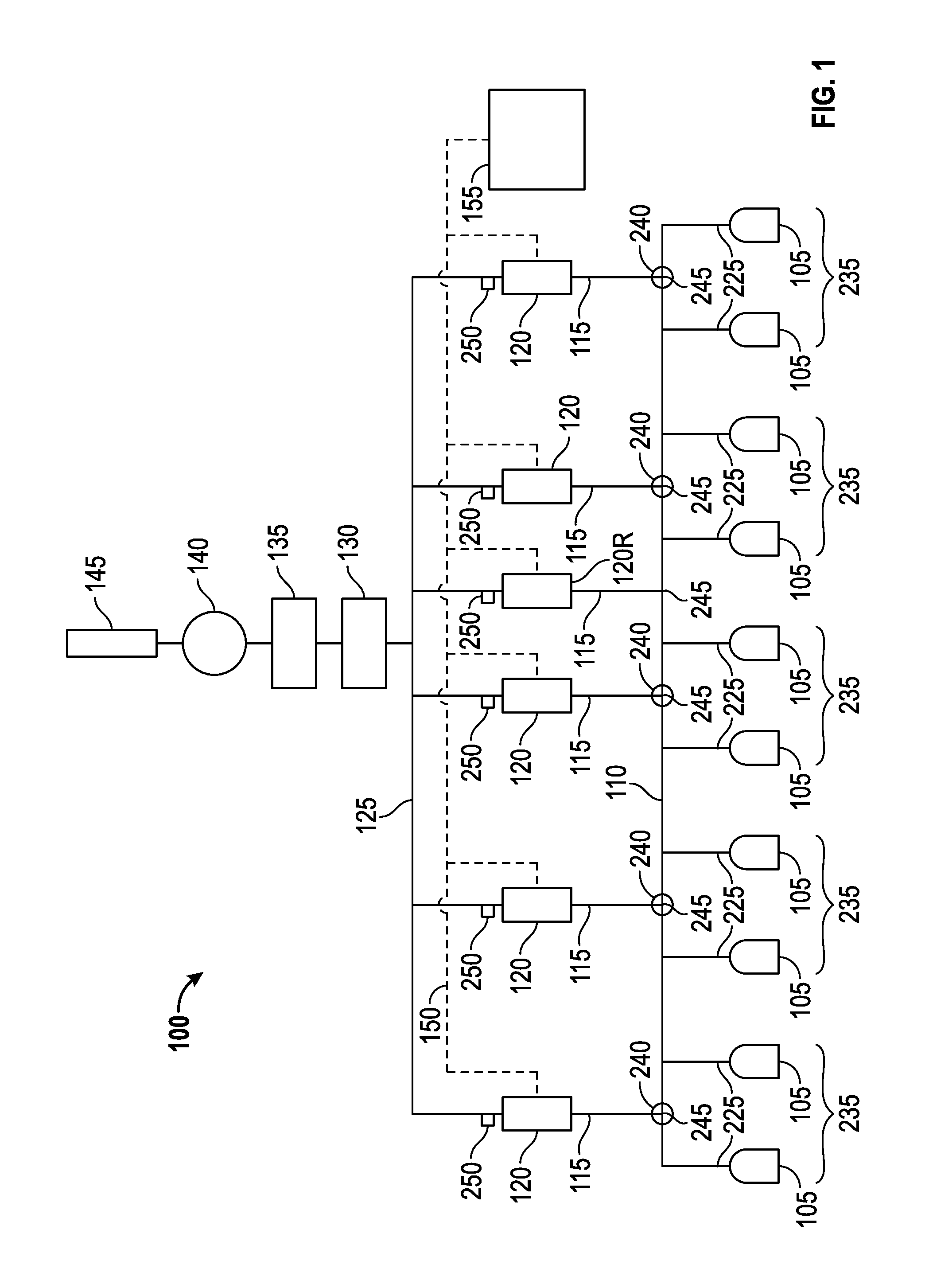

Coke plant including exhaust gas sharing

ActiveUS20140048405A1Mechanical conveying coke ovensCoke oven safety devicesCoke ovenProcess engineering

A coke plant includes multiple coke ovens where each coke oven is adapted to produce exhaust gases, a common tunnel fluidly connected to the plurality of coke ovens and configured to receive the exhaust gases from each of the coke ovens, multiple standard heat recovery steam generators fluidly connected to the common tunnel where the ratio of coke ovens to standard heat recovery steam generators is at least 20:1, and a redundant heat recovery steam generator fluidly connected to the common tunnel where any one of the plurality of standard heat recovery steam generators and the redundant heat recovery steam generator is adapted to receive the exhaust gases from the plurality of ovens and extract heat from the exhaust gases and where the standard heat recovery steam generators and the redundant heat recovery steam generator are all connected in parallel with each other.

Owner:SUNCOKE TECH & DEV LLC

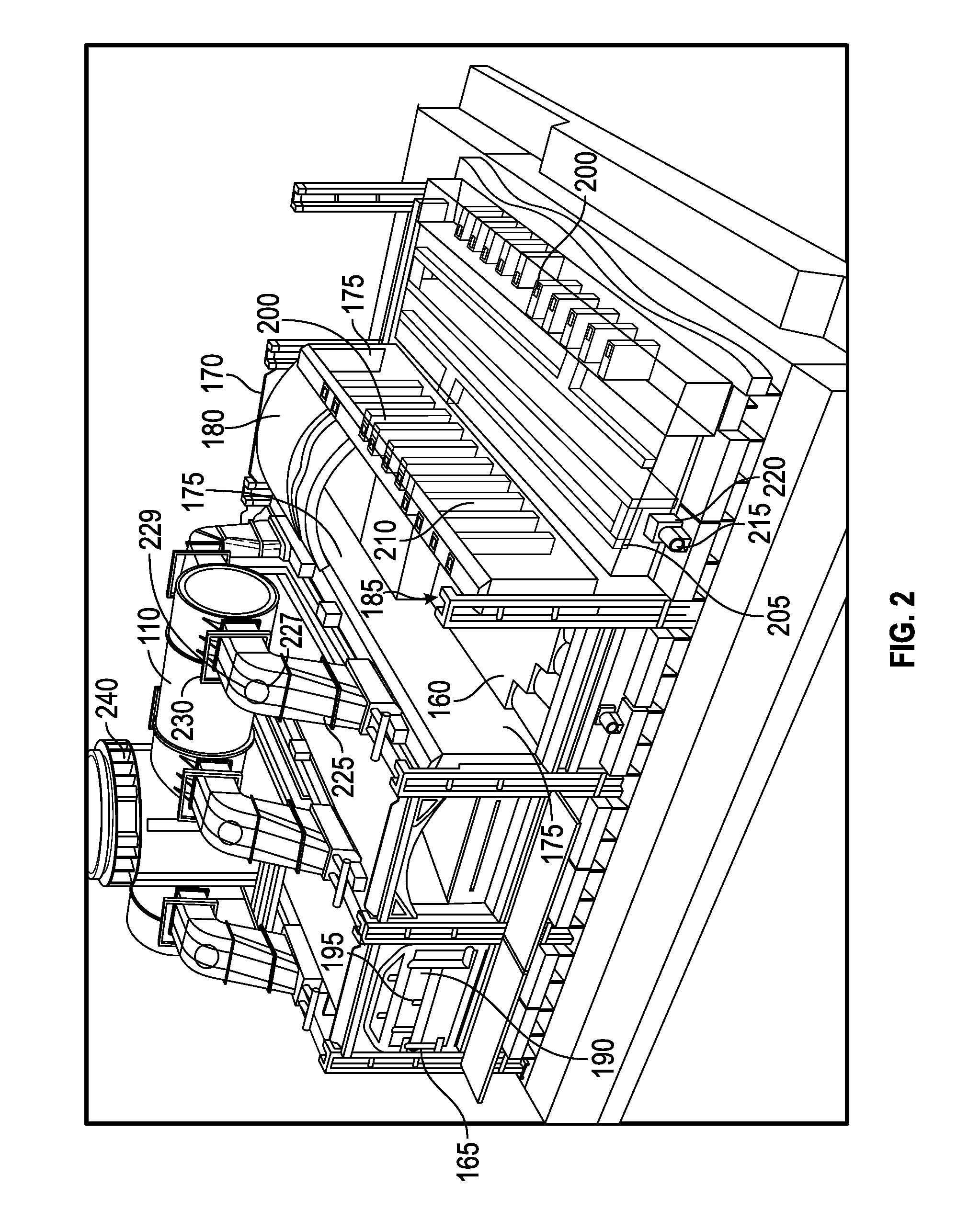

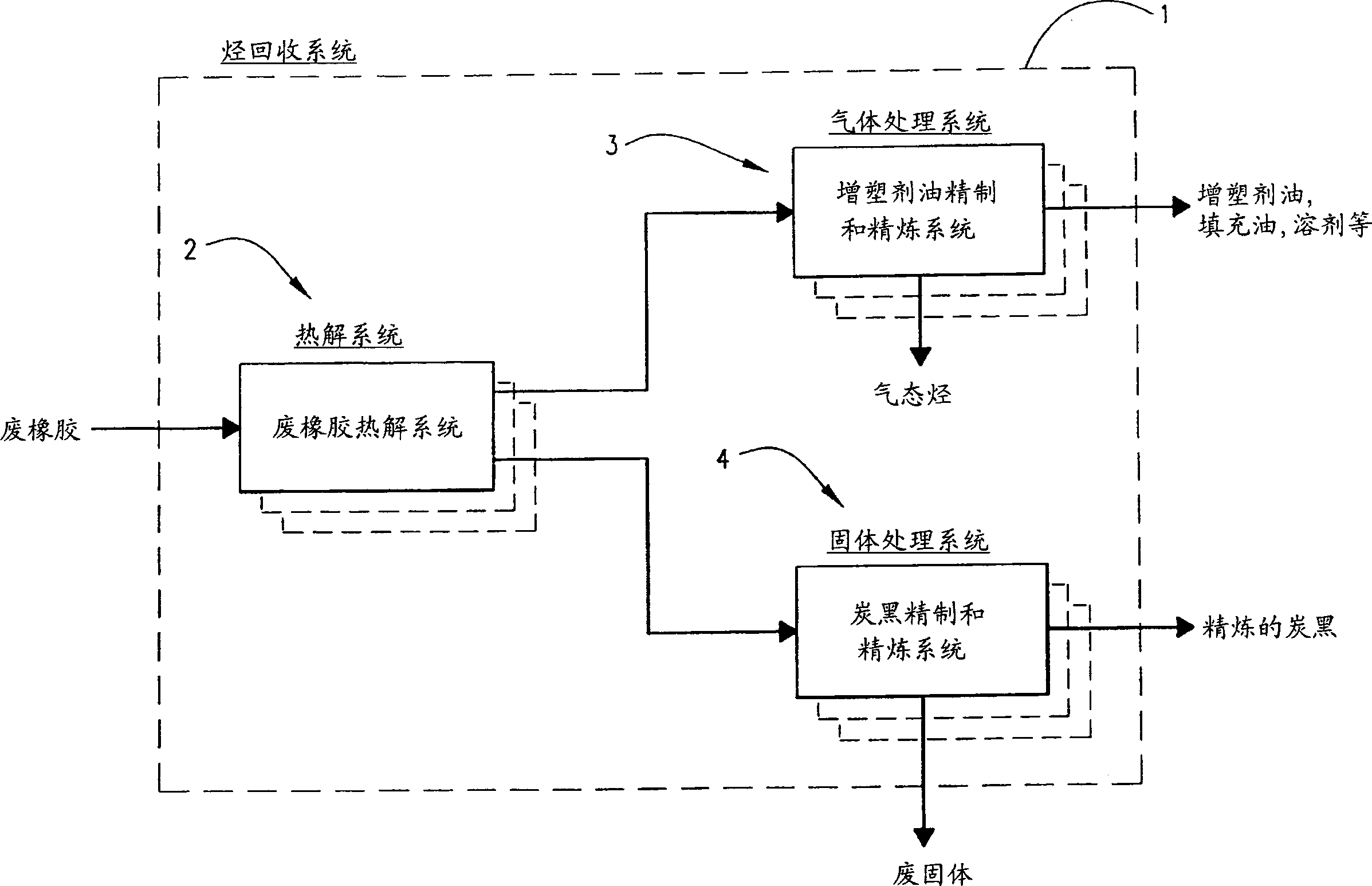

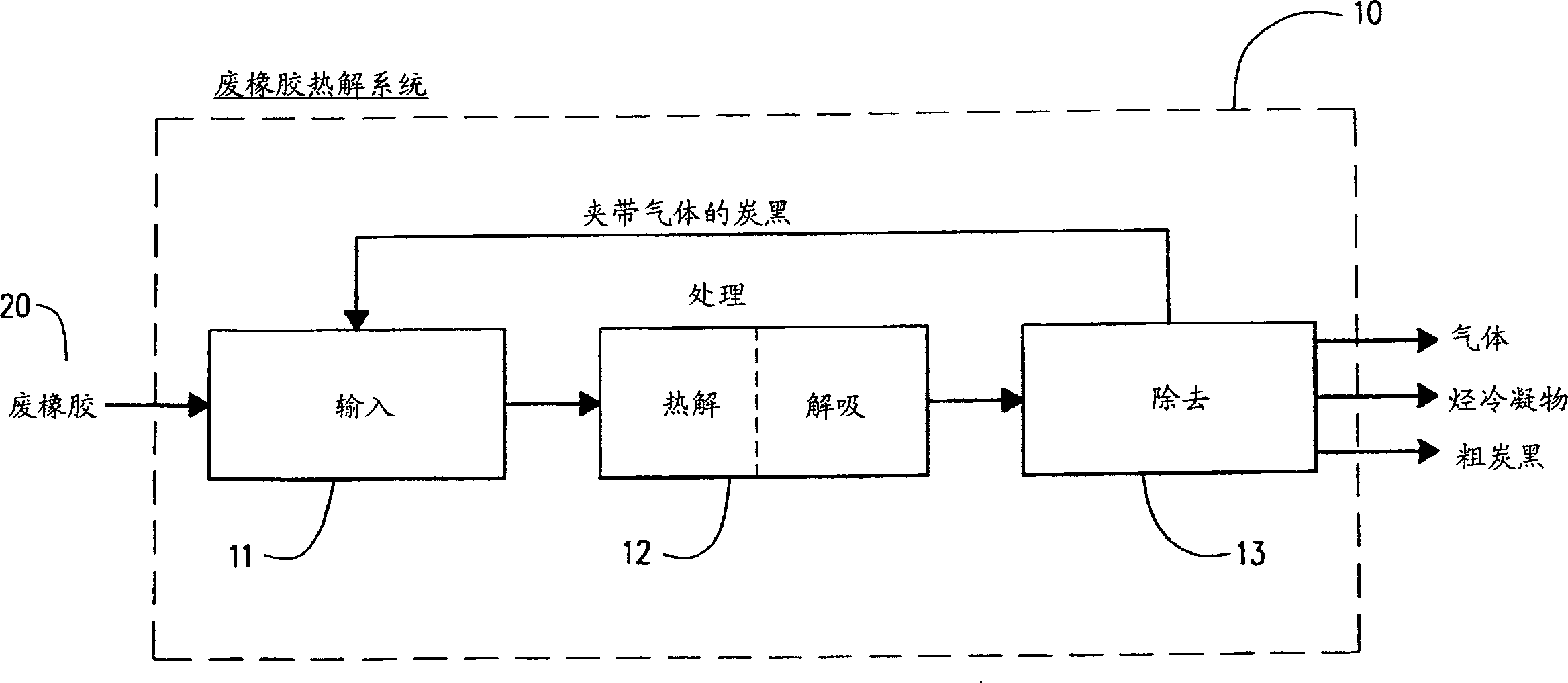

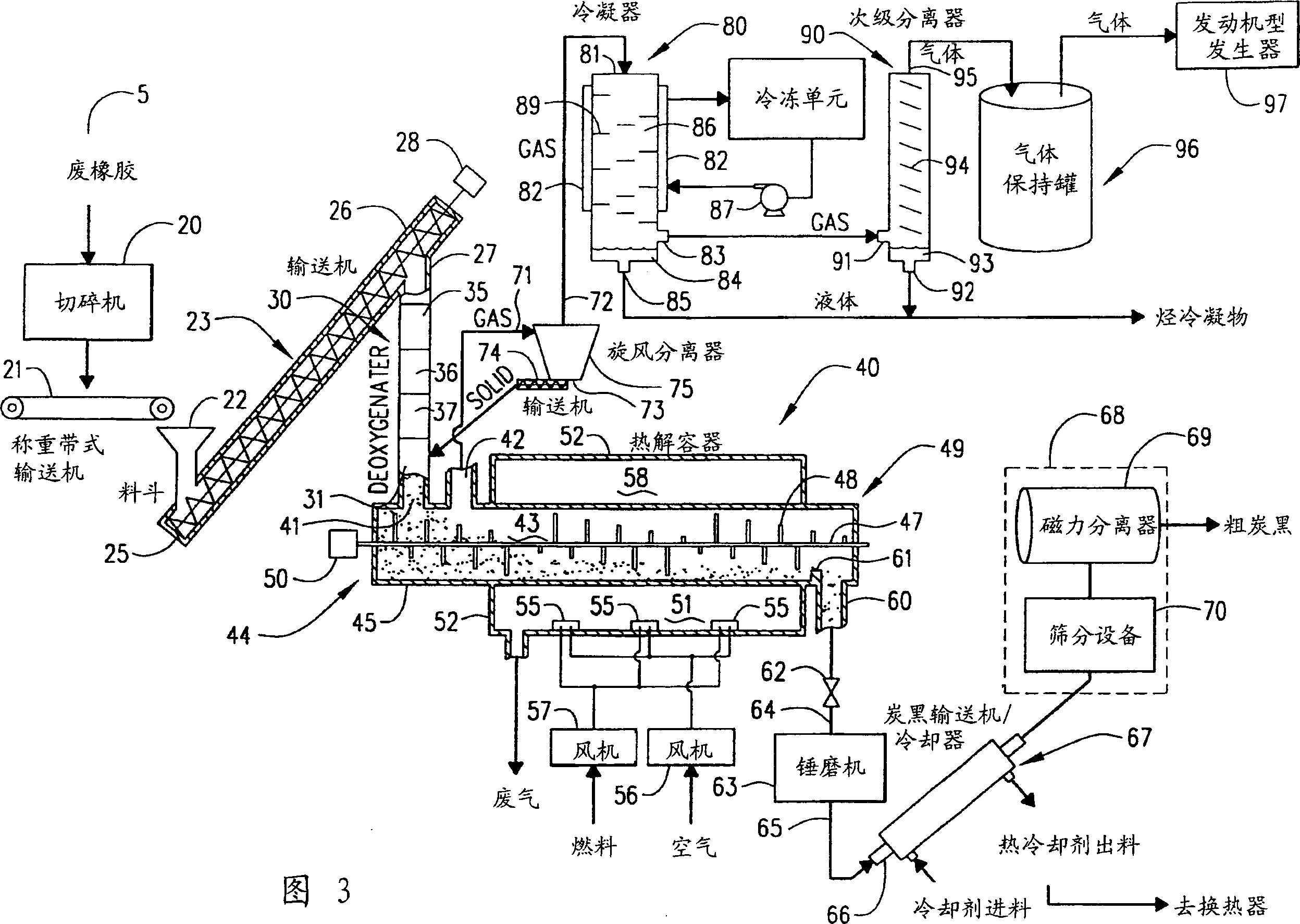

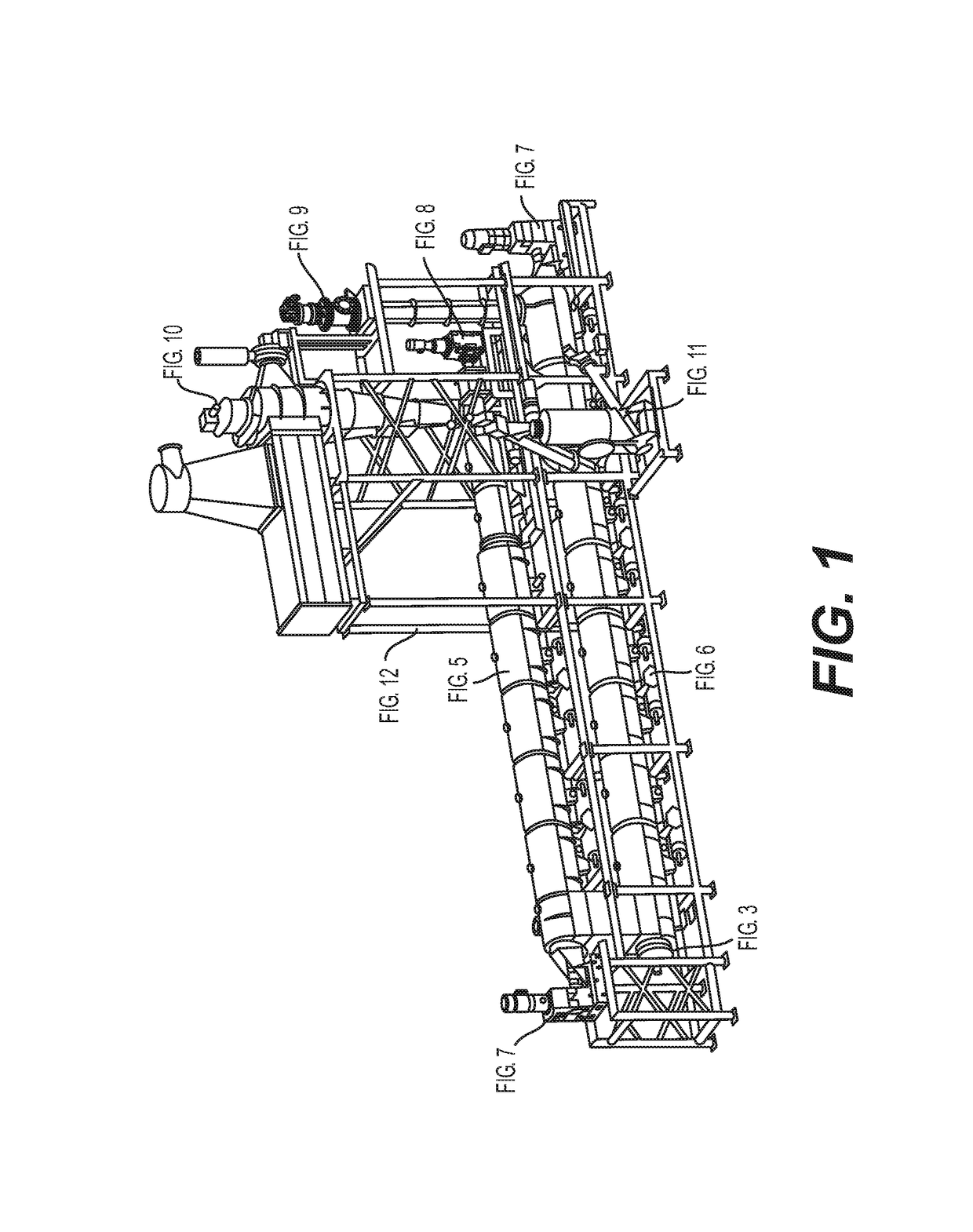

Apparatus and method for recovering marketable products from scrap rubber

Tire pyrolysis systems and processes are provided which include feeding tire shreds to a pyrolysis vessel (40) and pyrolyzing the shreds in a pyrolysis vessel (40) to produce a pyrolysis gas and carbon black mixture. The pyrolysis gas processed by centrifugally separating entrained particles therefrom, separating the pyrolysis gas into a hydrocarbon condensate and a light vapor, removing entrained hydrocarbon condensate from the light vapor, and purifying and refining the hydrocarbon condensate. The carbon black mixture is processed by pulverizing the mixture to break up all strands and clumps of inorganic solids, cooling the carbon black mixture, separating the gross contaminants from the carbon mixture, and purifying and refining the carbon black. The hydrocarbon condensate is purified and refined by removing all remaining contaminants, removing any polycyclic aromatics to produce a clear, colorless plasticizer oil. The carbon black is purified and refined by pulverizing it into a powder, removing all remaining particulate contaminants, optionally pelletizing the carbon black, and bagging or packaging it for shipping.

Owner:FEDERAL RECYCLING TECH +1

System, method and apparatus for creating an electrical glow discharge

Owner:FORET PLASMA LABS

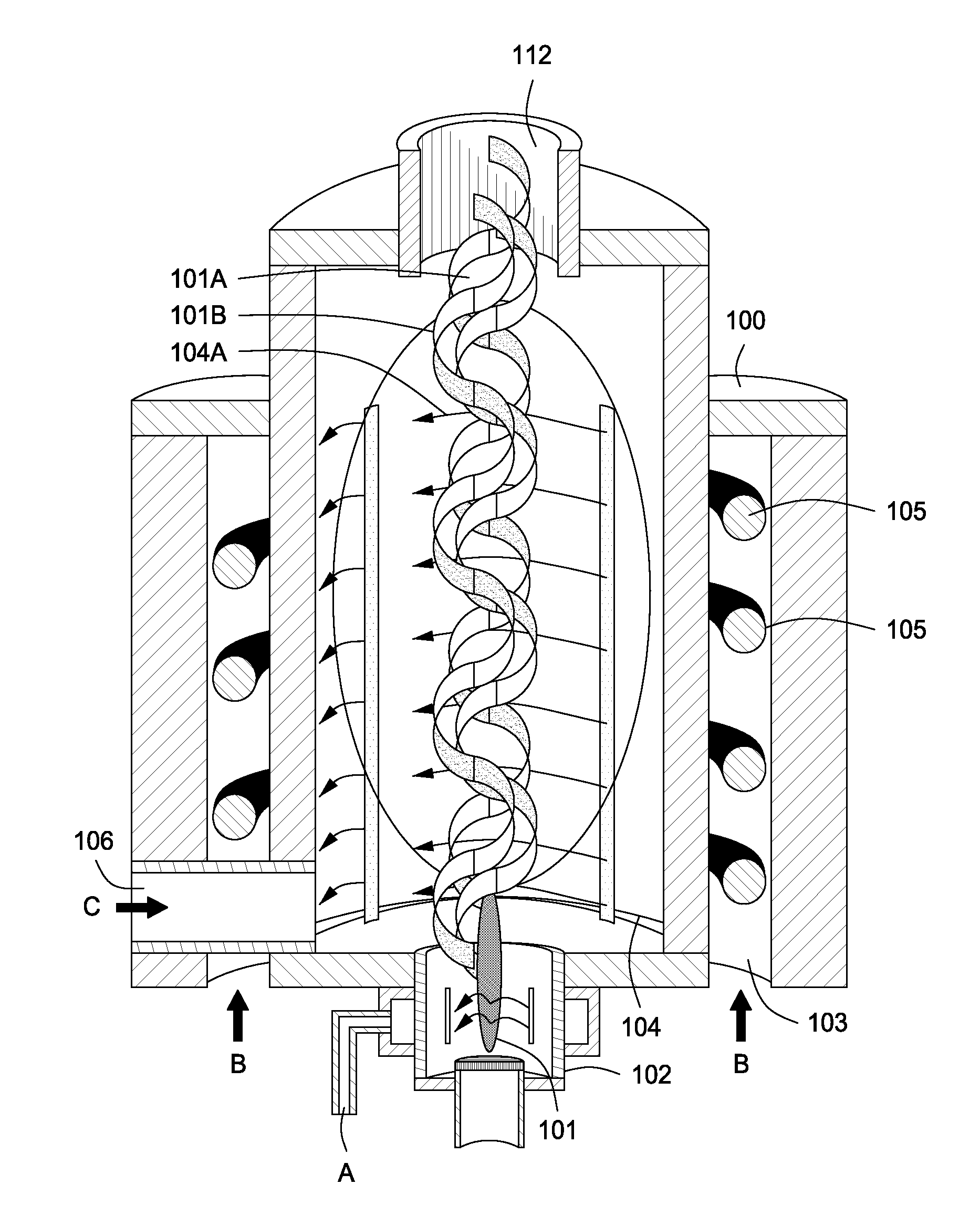

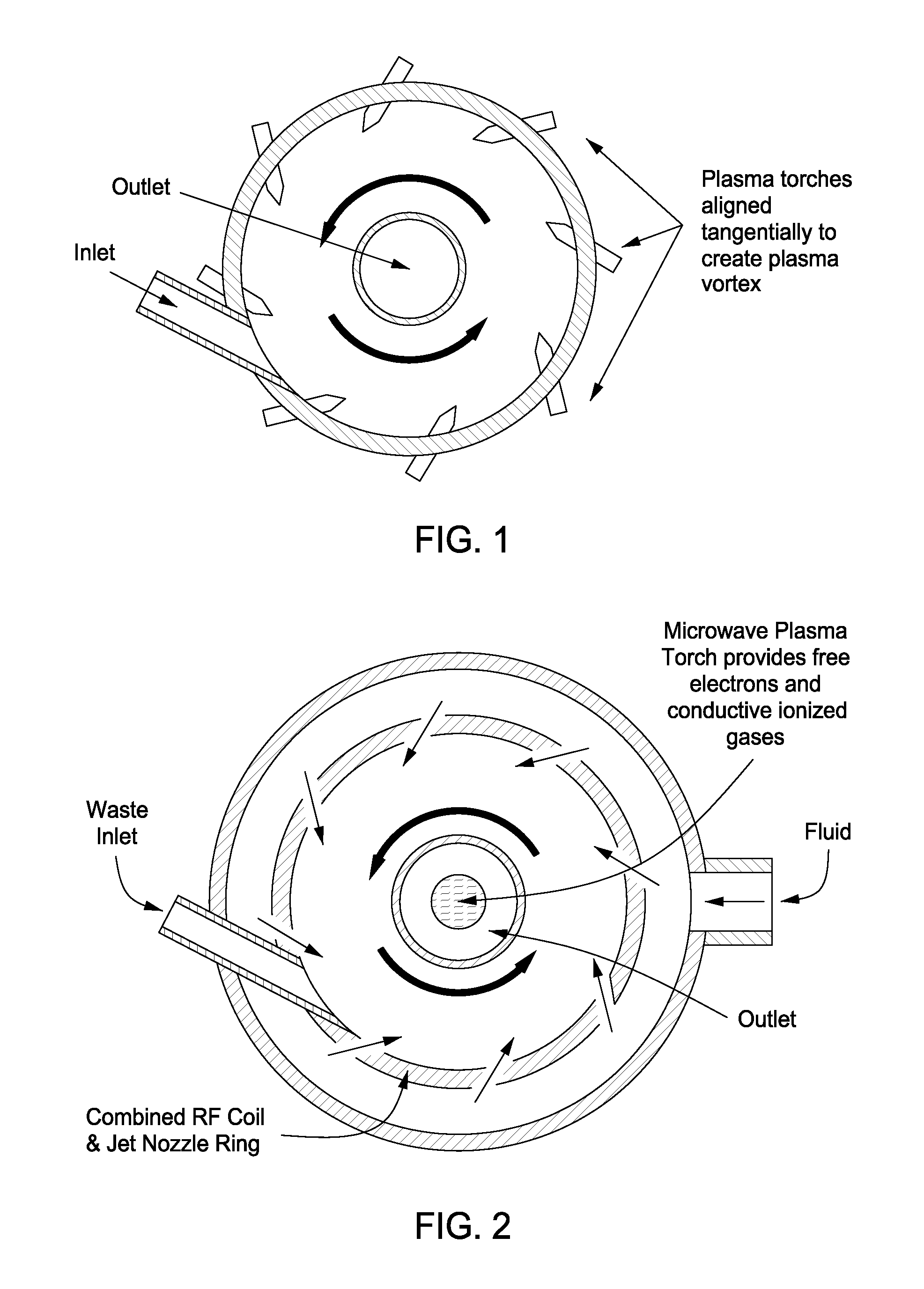

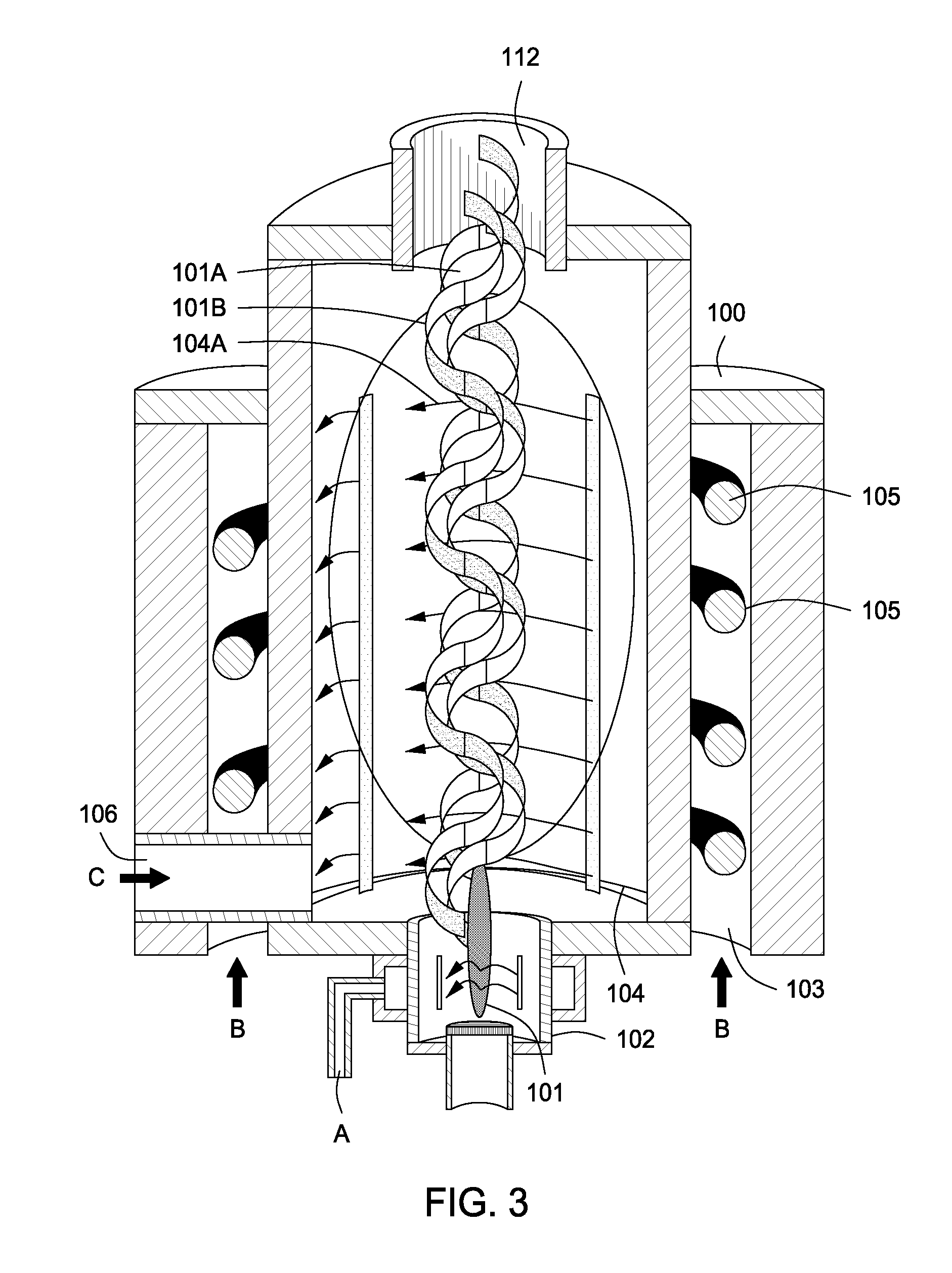

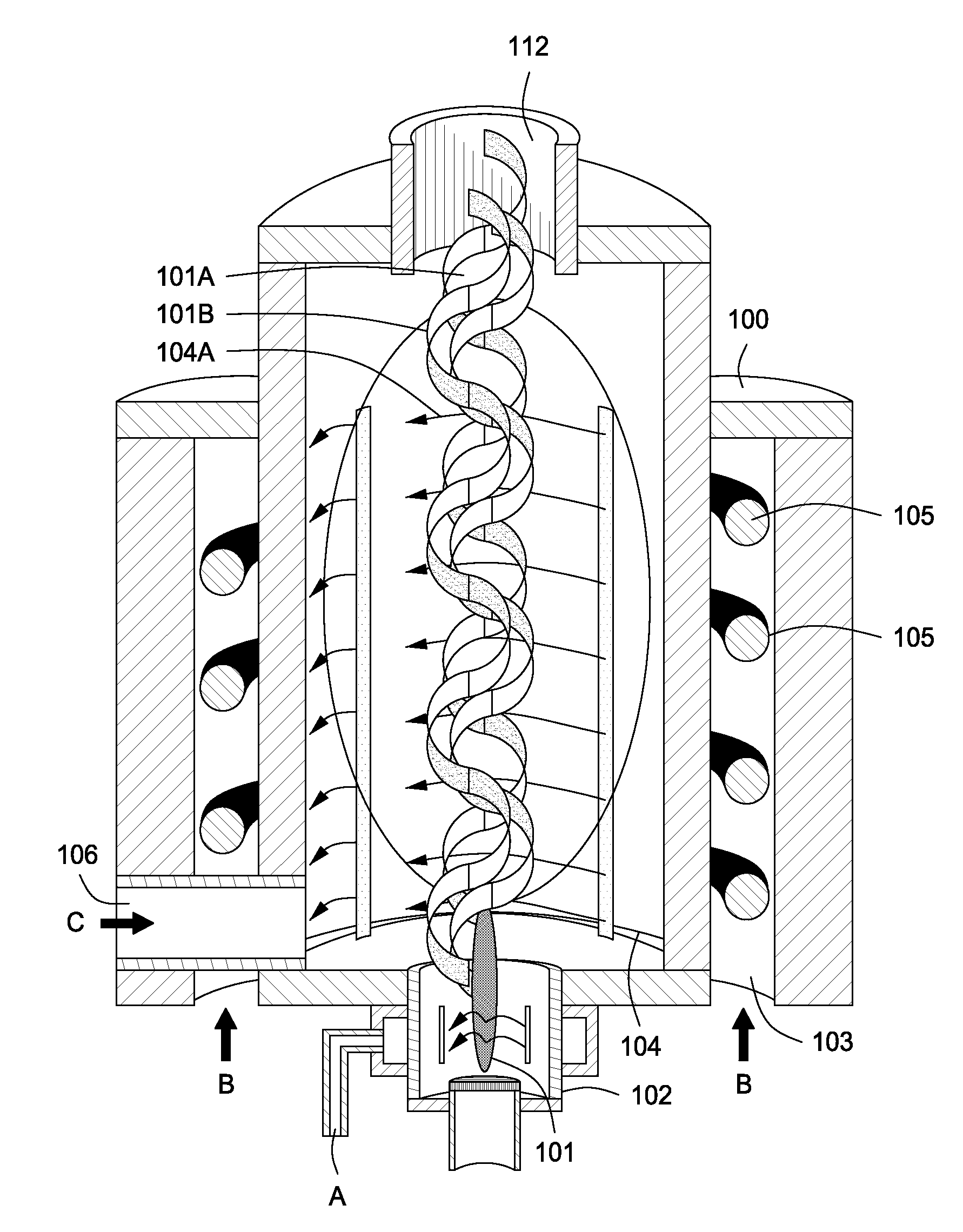

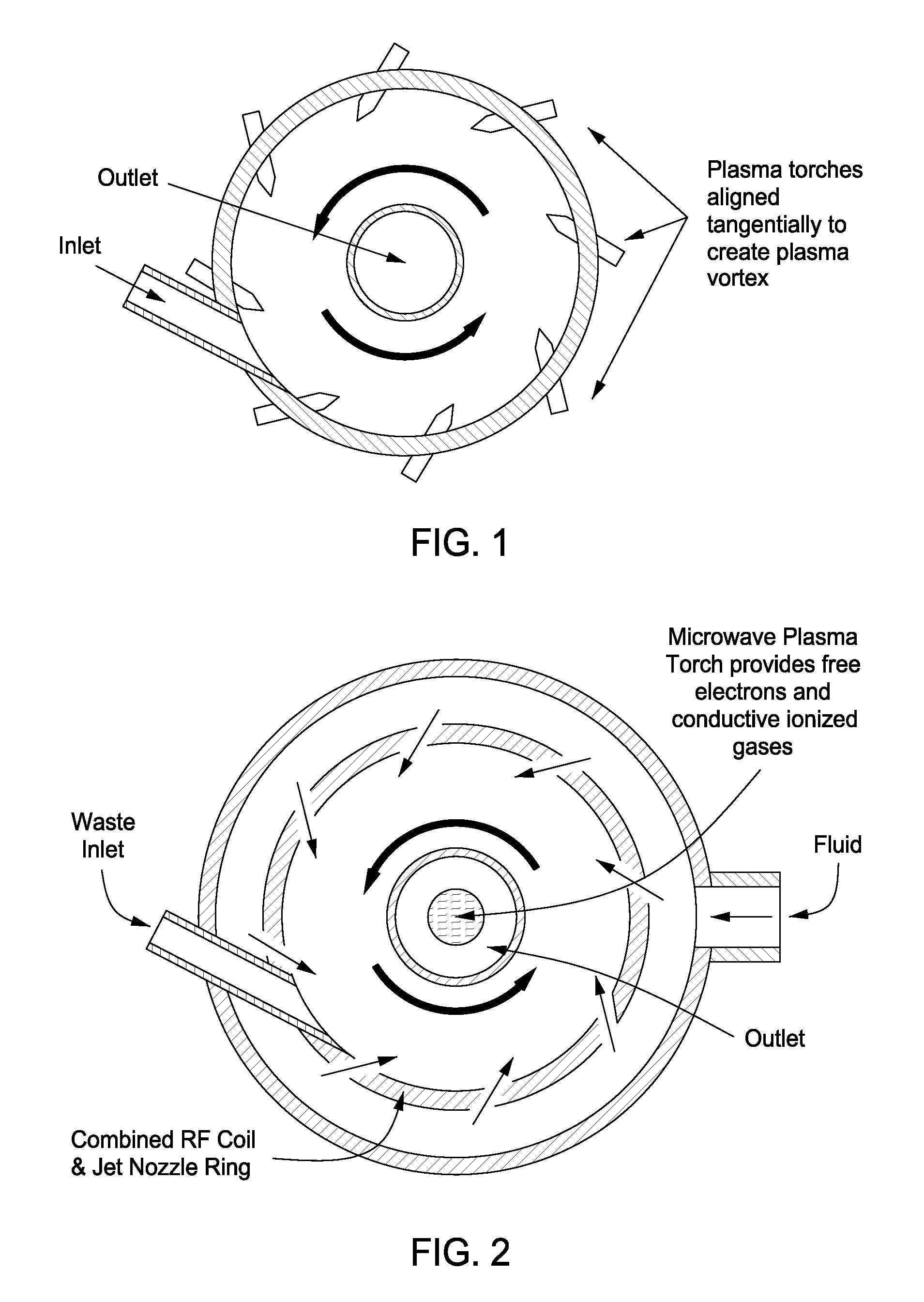

Plasma whirl reactor apparatus and methods of use

InactiveUS20100044483A1Calcium/strontium/barium carbonatesAluminium compoundsSingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

Plasma whirl reactor apparatus and methods of use

InactiveUS20100044477A1Calcium/strontium/barium carbonatesAluminium compoundsSingle processAngular momentum

An apparatus for synergistically combining a plasma with a comminution means such as a fluid kinetic energy mill (jet mill), preferably in a single reactor and / or in a single process step is provided by the present invention. Within the apparatus of the invention potential energy is converted into kinetic energy and subsequently into angular momentum by means of wave energy, for comminuting, reacting and separation of feed materials. Methods of use of the apparatus in the practice of various processes are also provided by the present invention.

Owner:FORET PLASMA LABS

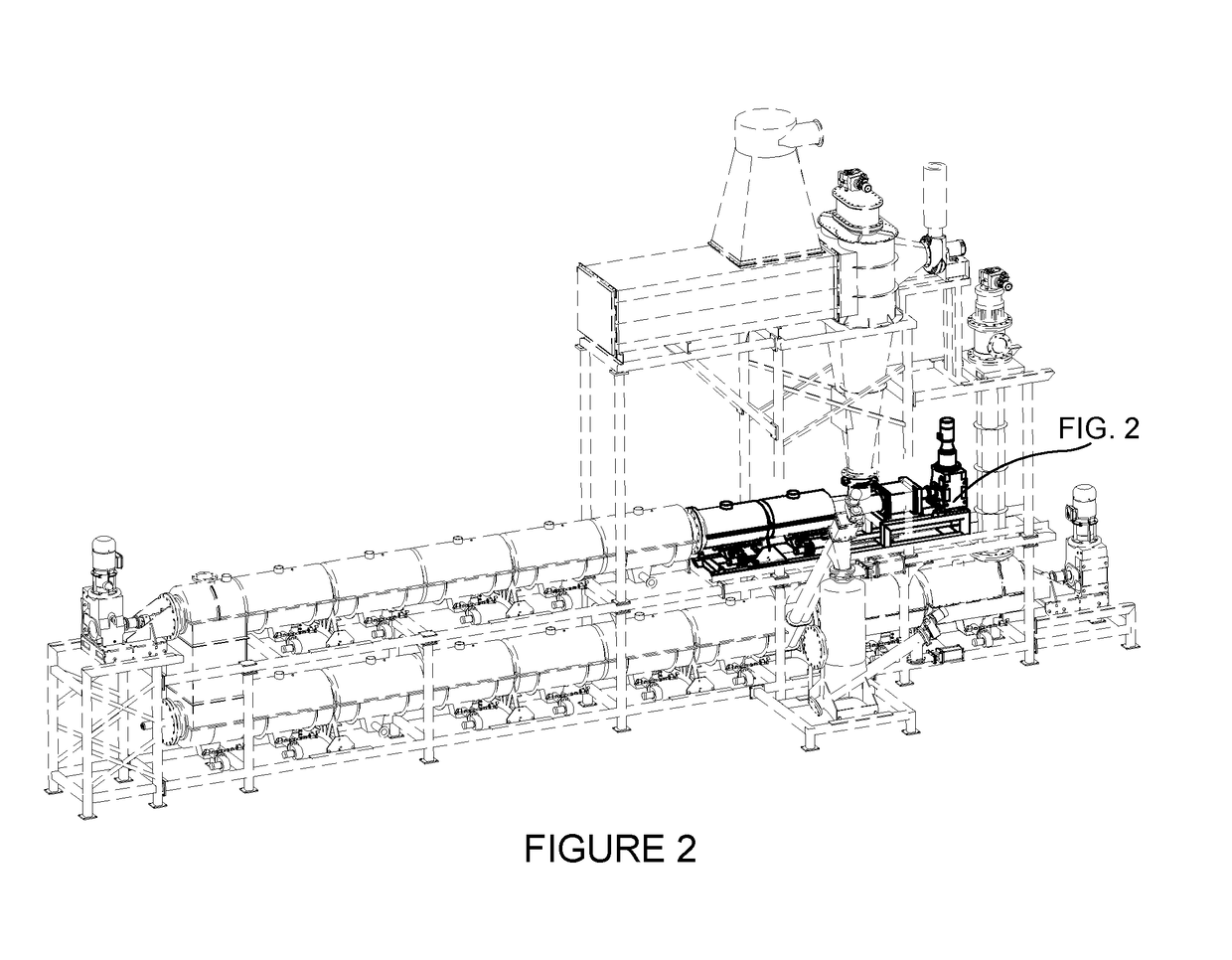

Heated airlock feeder unit

A Heated Airlock Feeder is disclosed. The Heated Airlock Feeder allows for the continuous feeding of solid, shredded plastic into a reactor tube surrounded by clamshell burner boxes. Inside of the reactor tube, two augers, one with right hand flights and one with left hand flights are welded to smooth augers to create two continuous augers that push solid plastic material, liquid plastic material and molten plastic material through two small holes. As the plastic is in its molten state while being forced through the two small holes, an airlock is formed preventing air form entering the system. As the solid, shredded plastic is fed into the system, an airlock is formed allowing for the continuous feeding of the system. The clamshell burner boxes allow for convection and radiant heat allowing for even, continuous heat.

Owner:GOLDEN RENEWABLE ENERGY LLC

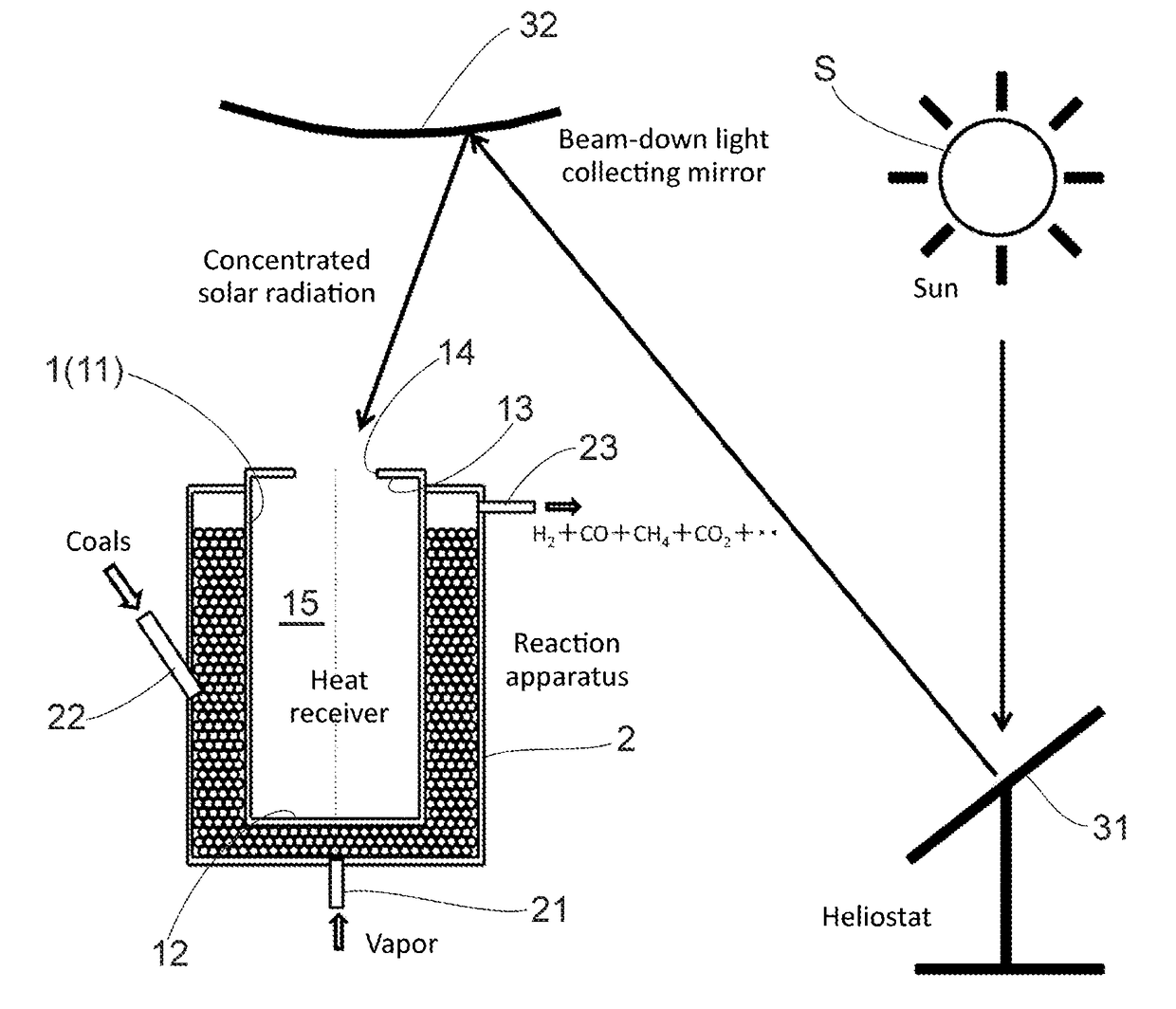

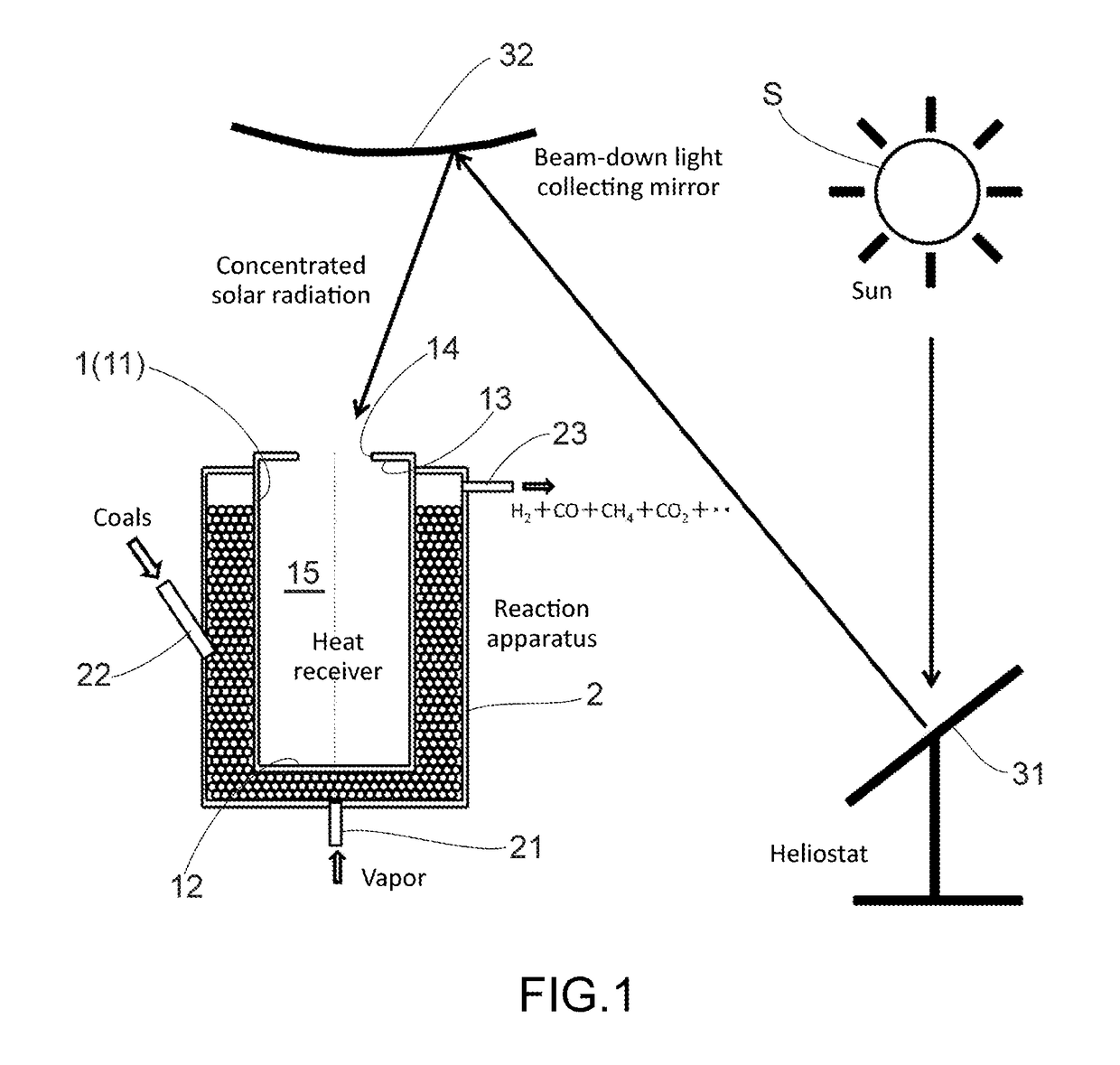

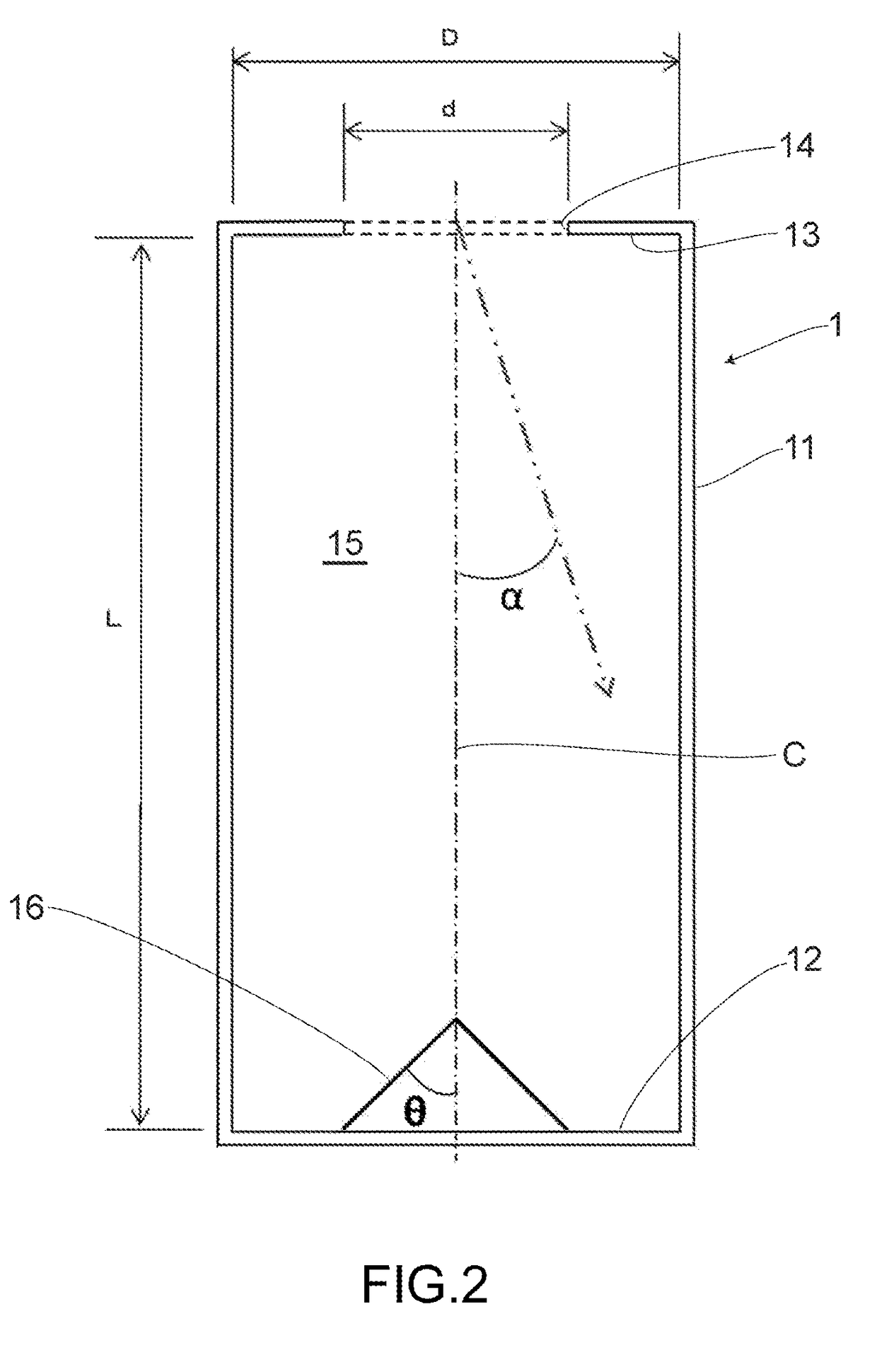

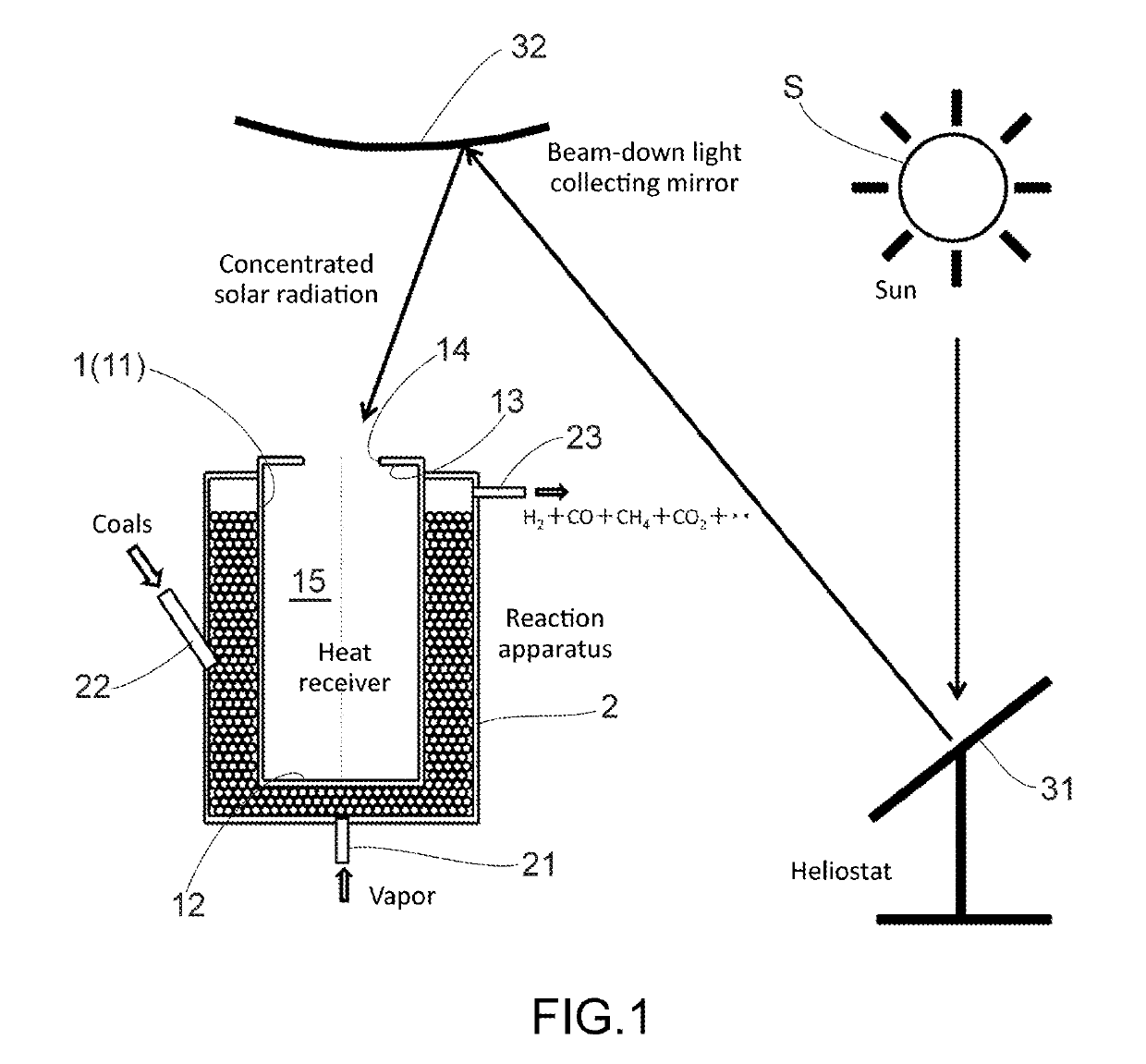

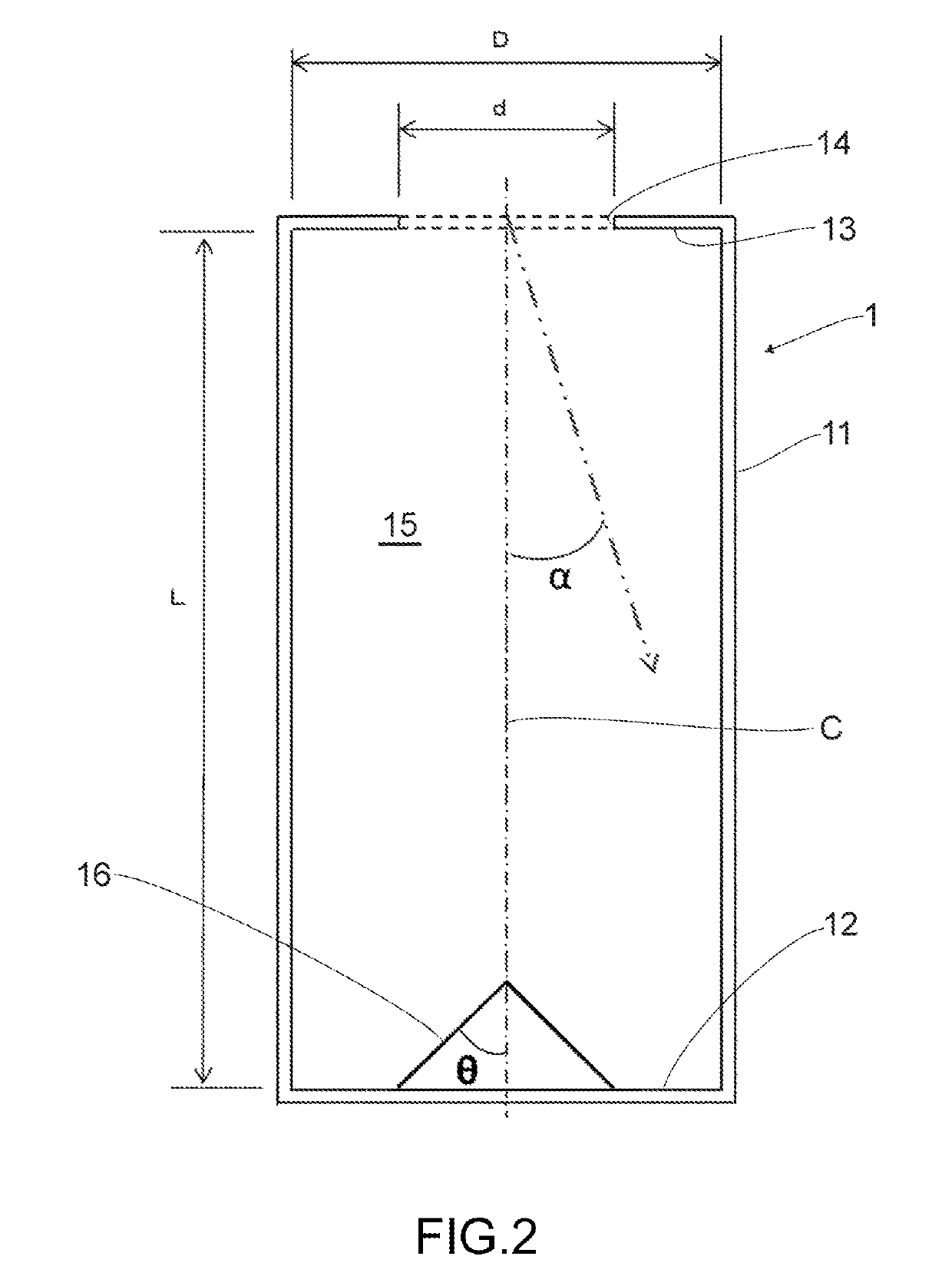

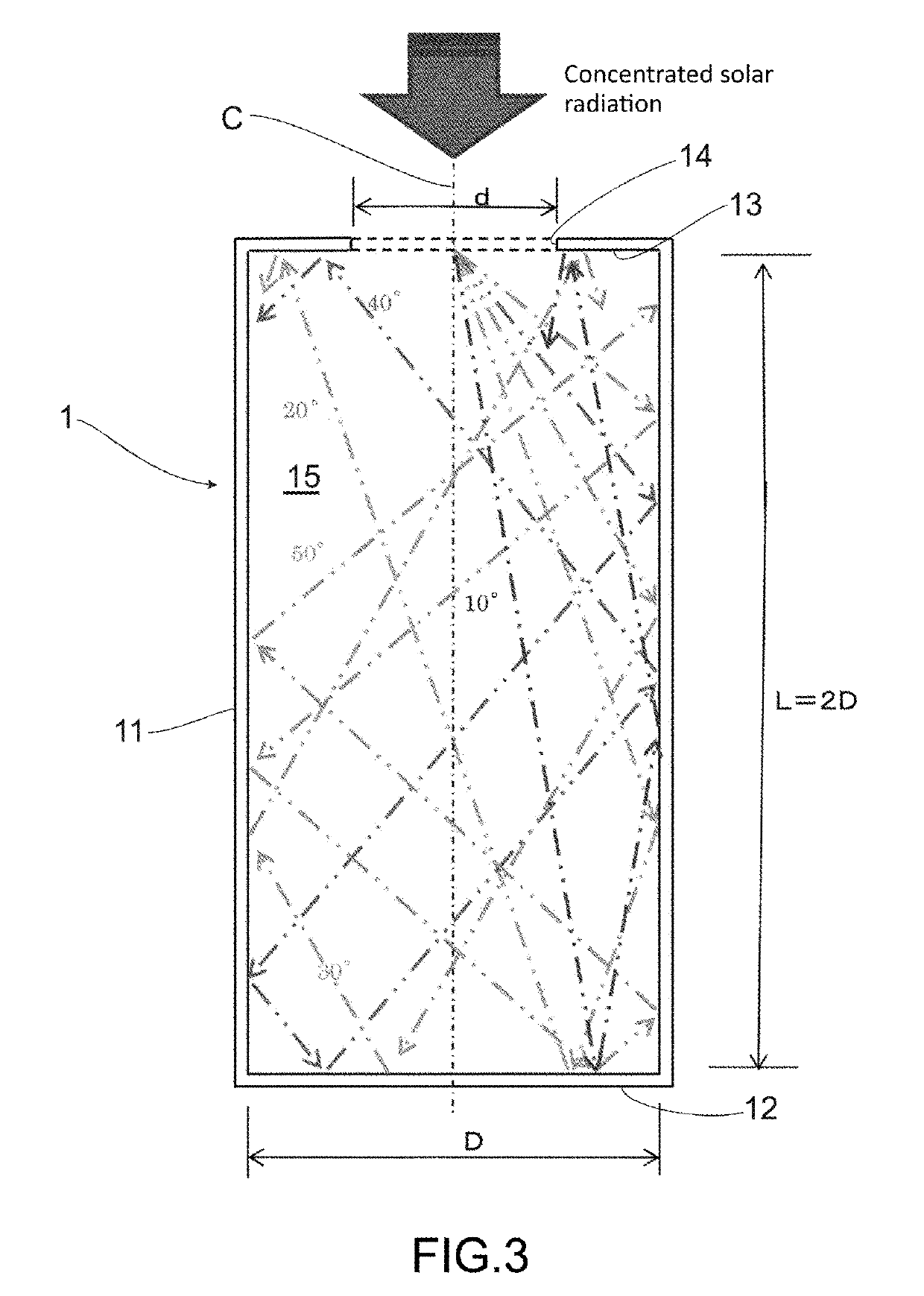

Concentrated solar heat receiver, reactor, and heater

ActiveUS20170145324A1Easy to useSolar heating energyHeat transfer optimizationSolar lightChemical reaction

A heat receiver, a reactor, and a heater utilize the heat of concentrated solar light for thermal decomposition and / or chemical reaction of coals, etc. The heat receiver includes: a side portion forming a substantially cylindrical side surface; a substantially circular bottom portion connected to the lower edge of the side portion; and a ceiling connected to the upper edge of the side portion. A substantially circular aperture is formed in the center of the ceiling. The heat receiver has a substantially cylindrical cavity and the opening portion is open. When the cavity has a diameter of D and a length of L, and the aperture has a diameter of d, d=D / 2 or less and L=2D or more. Concentrated solar light entering the heat receiver is to be contained in the heat receiver to effectively utilize the solar light.

Owner:NIIGATA UNIVERSITY

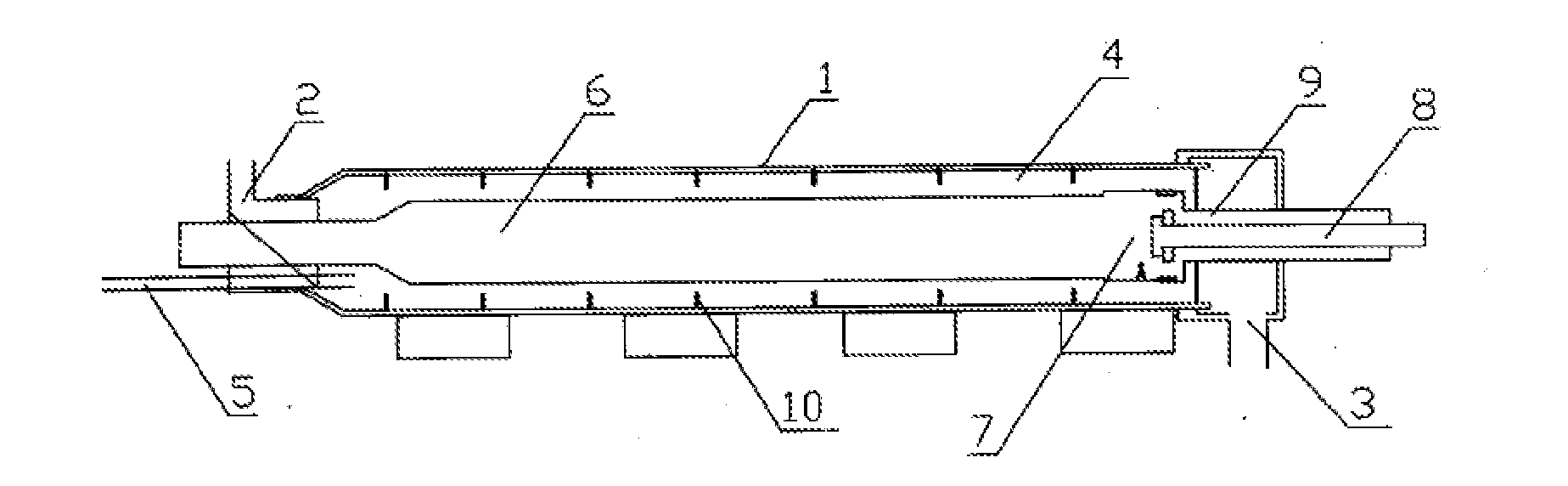

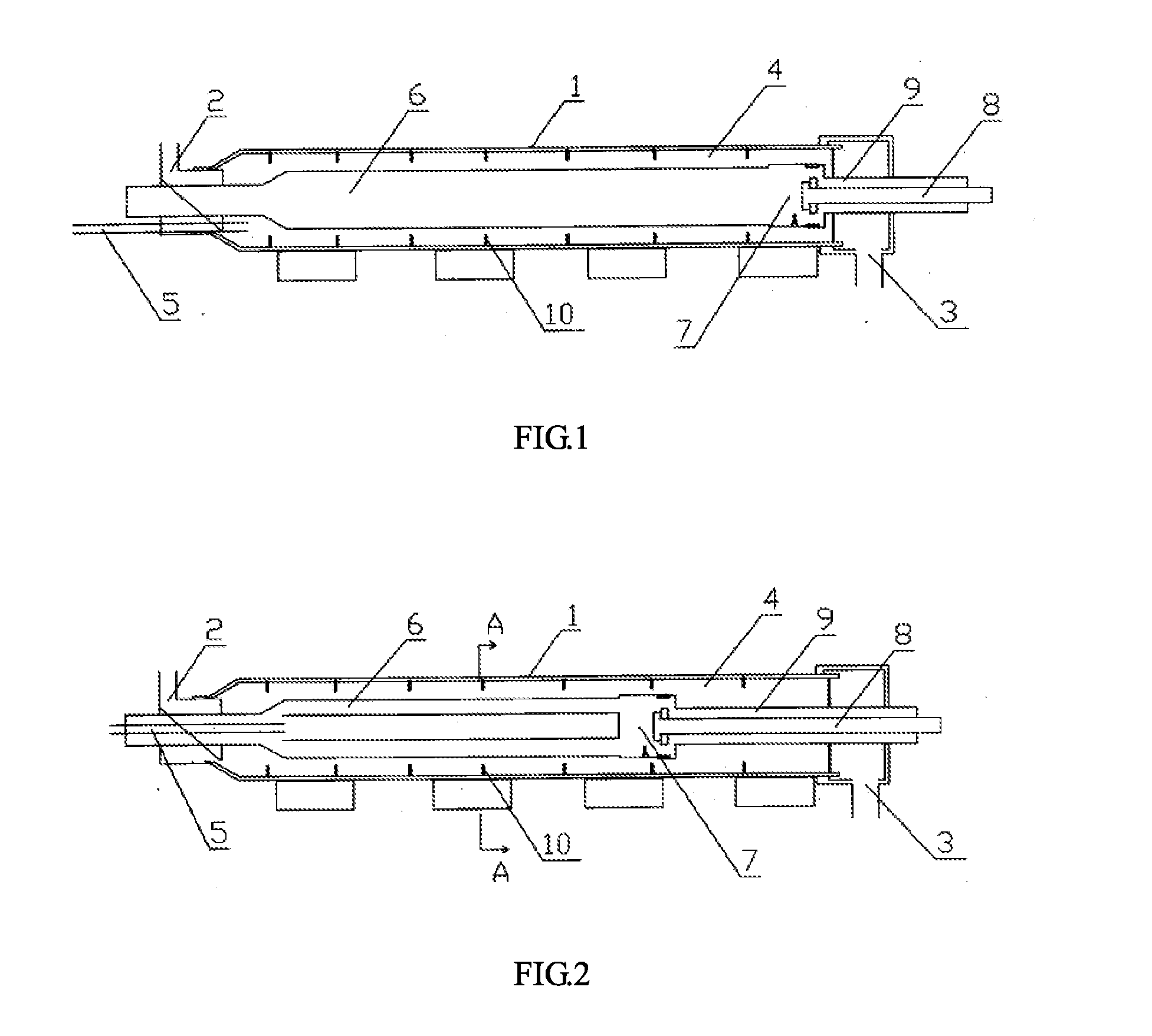

Coal decomposition equipment

InactiveUS20120308951A1Increase valueSave energyMechanical conveying coke ovensMuffle furnacesGas collecting tubeDecomposition

The invention discloses a coal decomposition equipment including an airtight kiln body with an inlet and an outlet, wherein a flame gas pipeline heating facility is set in the kiln body and a channel for impelling and decomposing coal is formed between the flame gas pipeline heating facility and an inner wall of the kiln body; and a coal decomposition gas collecting pipe is provided on the kiln body to communicate with the channel. Since the present invention makes the vast thermal conduction produced by the flame gas pipeline heating facility and radiate to the coal power in the coal substance impel decomposition channel. The pulverized coal fully absorbs the heat so as to be heated and decomposed to the gas, coal tar gas and coal with a higher heat-value in the channel.

Owner:ZHU SHUCHENG +4

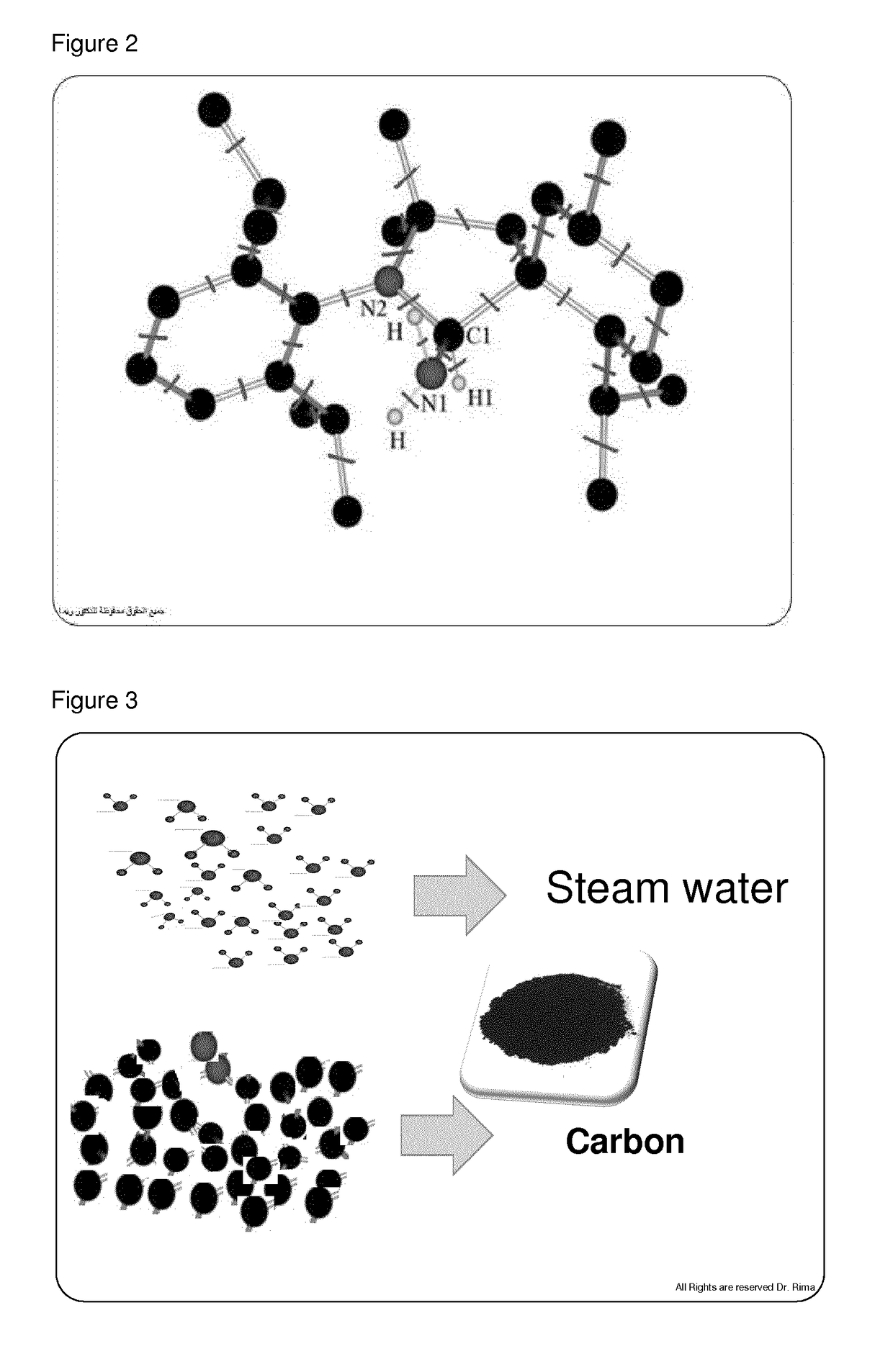

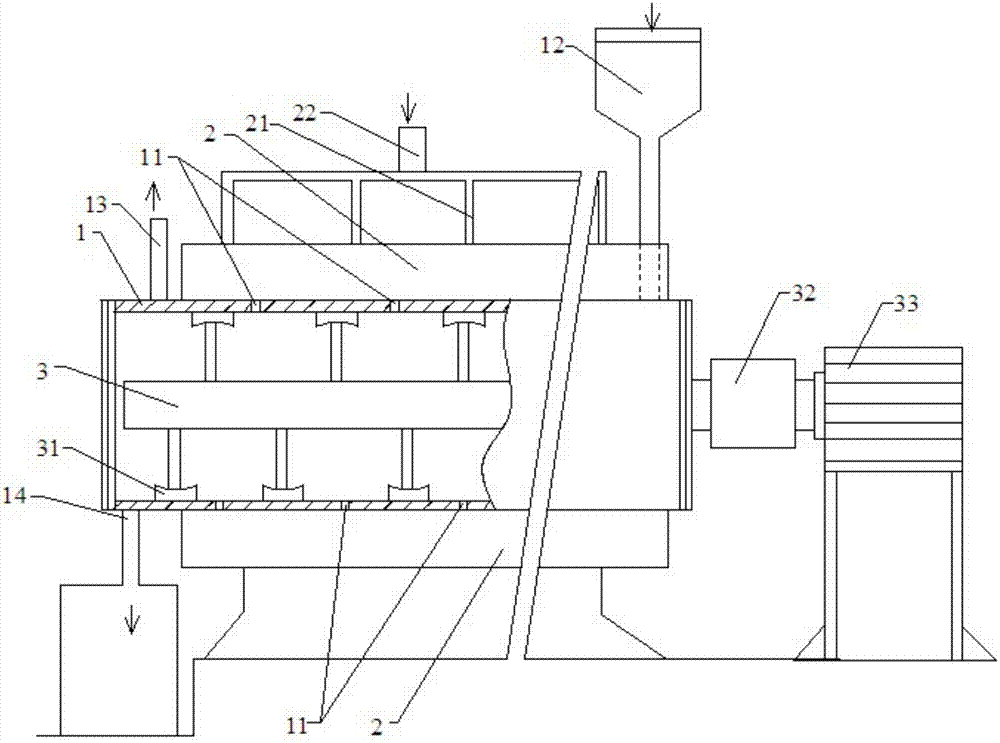

Method and apparatus for rapid dry carbonization of organic waste, apparatus and catalytic system associated to the method

InactiveUS20170313945A1Cheap methodEffective and fast transferMaterial nanotechnologyTransportation and packagingWater vaporCarbonization

A method for transforming waste into carbon in a reactor, said method comprising: a) drying the waste by submitting said waste to a pressure of at least 3 bar, and a temperature of at least 250° C.; b) releasing the water vapor out of the reactor, and; c) carbonizing at least partially the waste by maintaining said waste during a period of time of at least 5 minutes to a pressure of at least 3 bar, and a temperature of at least 250° C., thereby obtaining carbon; and d) optionally separating non-organic material from the obtained carbon.

Owner:RIMA IND S A L HLDG CO

Pyrolysis device for tar residue

InactiveCN107502381AReasonable structural designFast heat conductionIndirect heating destructive distillationCoking carbonaceous materialsFlue gasTar

The invention relates to the technical field of structure design of a pyrolysis device and specifically relates to a pyrolysis device for tar residue. The device comprises a horizontal drum, a flue gas sleeve and a rotating shaft, wherein the flue gas sleeve is arranged on the exterior of the horizontal drum; the rotating shaft is arranged in the horizontal drum along the axial direction of the horizontal drum; interconnecting holes which are communicated with the flue gas sleeve are equidistantly formed in the horizontal drum; scraper blades are equidistantly connected with the rotating shaft; the surfaces of the end parts of the scraper blades are matched with arc-shaped walls in the horizontal drum; the interconnecting holes are equidistantly formed between the adjacent scraper blades. The structure design of the pyrolysis device for tar residue, provided by the invention, is reasonable; the thermal conductivity is higher; the production efficiency is effectively increased; the arrangement of the parallel tubes and equidistant interconnecting holes is beneficial to the uniform mass transfer of the exhaust gas; the arrangement of the scraper blades is beneficial to the prevention for the bonding of the tar residue in the drum; the pyrolysis device is convenient, practical and suitable for further popularization and application.

Owner:邓玉平

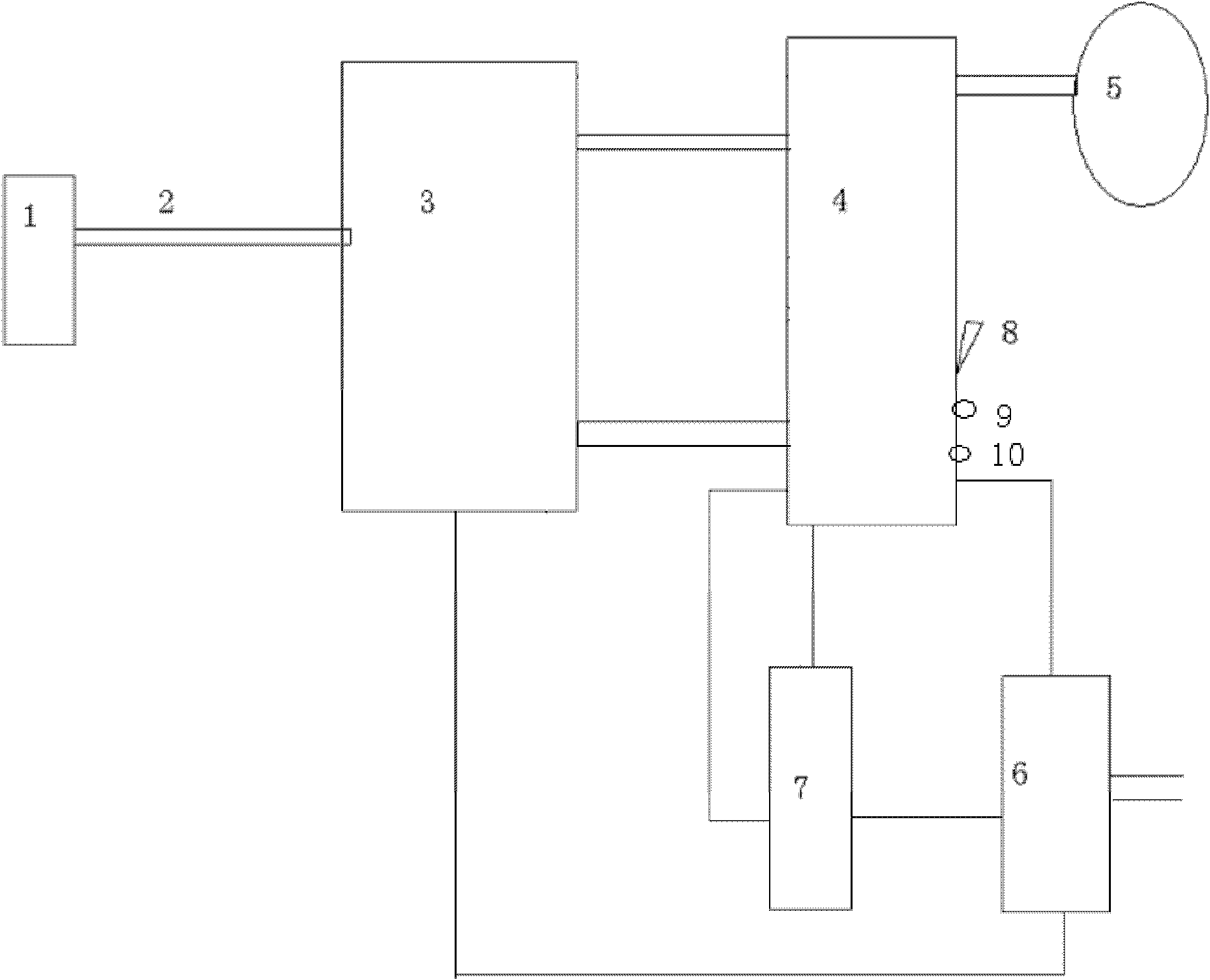

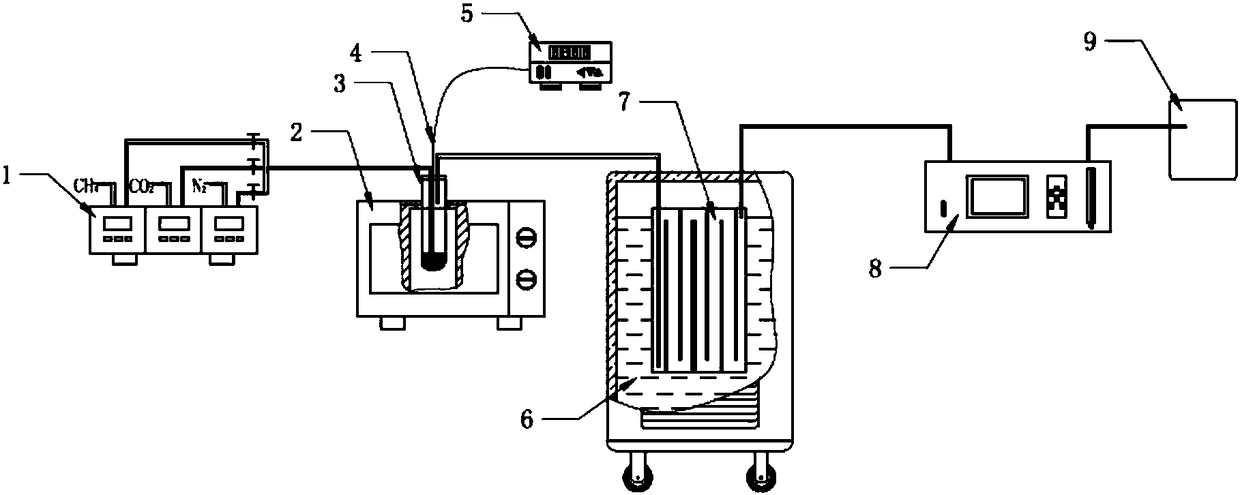

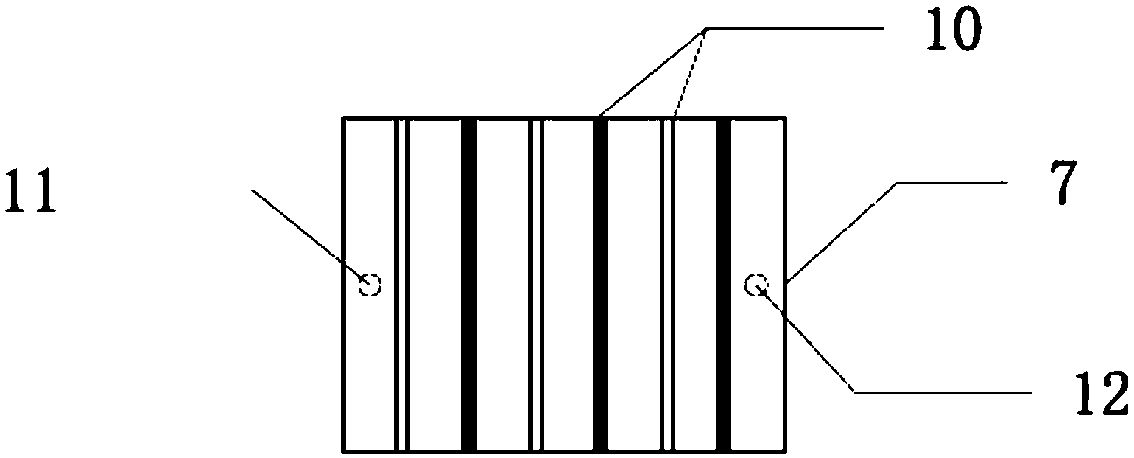

Device and method for lignite and biomass microwave co-pyrolysis reaction

InactiveCN108485689ALow costEasy to replaceBiofuelsLiquid hydrocarbon mixture productionTemperature controlMicrowave oven

The invention belongs to the technical field of energy sources, and discloses a device and method for lignite and biomass microwave co-pyrolysis reaction. The device comprises a microwave furnace, a quartz reactor, a thermocouple, a temperature control instrument, a tar collector and a circulation cooling device. The method comprises the following steps of putting a mixed test sample for preparingthe lignite and biomass into the quartz reactor; putting the quartz reactor into a furnace cavity of the microwave furnace; inserting the thermocouple into the quartz reactor; connecting the thermocouple with the quartz reactor; starting the microwave furnace for co-pyrolysis reaction; guiding generated gas into the circulation cooling device; flowing tar products into the tar collector for storage; guiding co-pyrolysis gas into a gas collecting bag to be stored. Rest solid in the quartz reactor is semi-coke products. The problem of insufficient lignite and biomass combination utilization inthe prior art is solved. The device and the method provided by the invention have the advantages that the lignite and biomass can be cleanly and efficiently combined; mass industrial production is easily realized.

Owner:WUHAN UNIV OF SCI & TECH

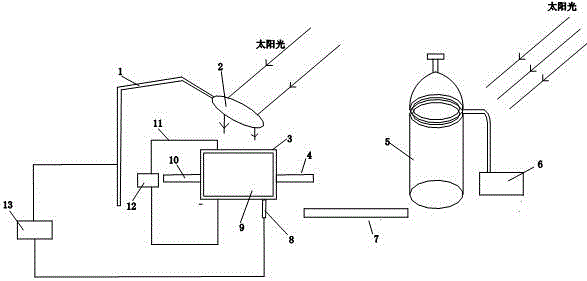

Apparatus and method for pyrolyzing sludge by utilizing solar energy

PendingCN106587562AIncrease profitReduce dissipationSolar heating energySludge treatment by de-watering/drying/thickeningSludgeProcess engineering

The invention discloses an apparatus for pyrolyzing sludge by utilizing solar energy. The apparatus comprises an illumination type sludge drying apparatus, an automatic light focusing system, a rotary reaction apparatus provided with a gas inlet end and a gas outlet end, and a tail gas utilization apparatus, wherein the automatic light focusing system enables sludge in the rotary reaction apparatus to generate a pyrolytic reaction by a high temperature formed after sunlight is focused; the tail gas utilization apparatus is arranged between the gas outlet end of the rotary reaction apparatus and the illumination type sludge drying apparatus; and residual heat of pyrolytic reaction generated gas discharged by the rotary reaction apparatus is used for heating the sludge in the sludge drying apparatus in a heat conduction way. The invention furthermore discloses a method for pyrolyzing the sludge by utilizing the solar energy. The method and the apparatus have the advantages that the use is safe and reliable and the resources are fully utilized, can be used for treating the sludge, and achieve effective utilization of the sludge.

Owner:SOUTH CHINA UNIV OF TECH

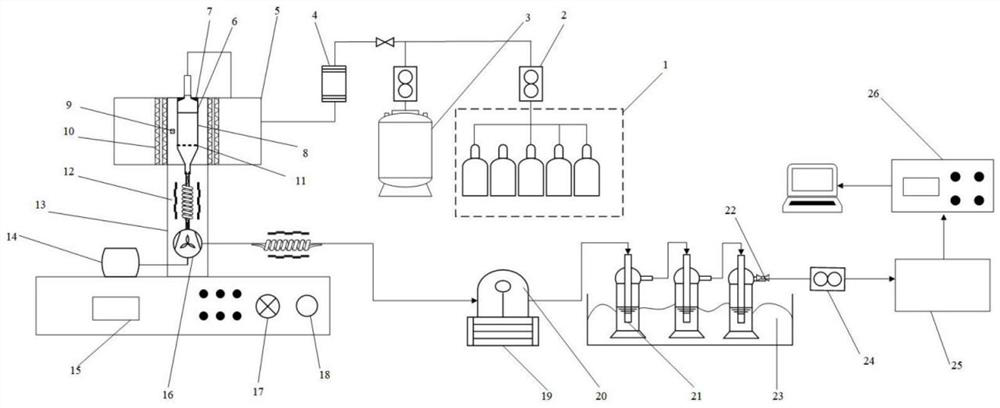

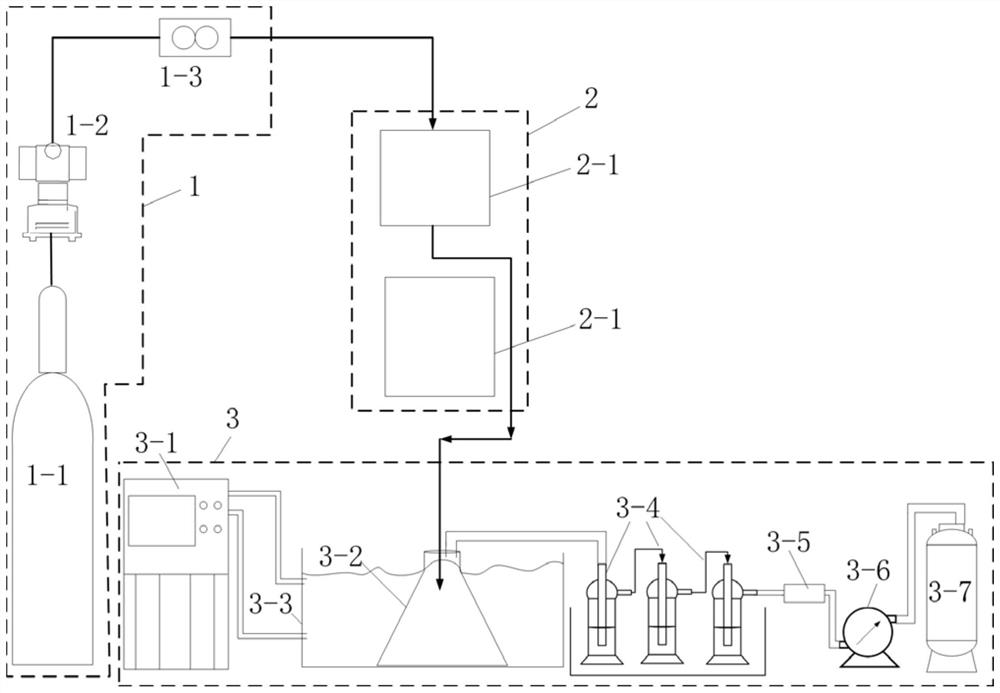

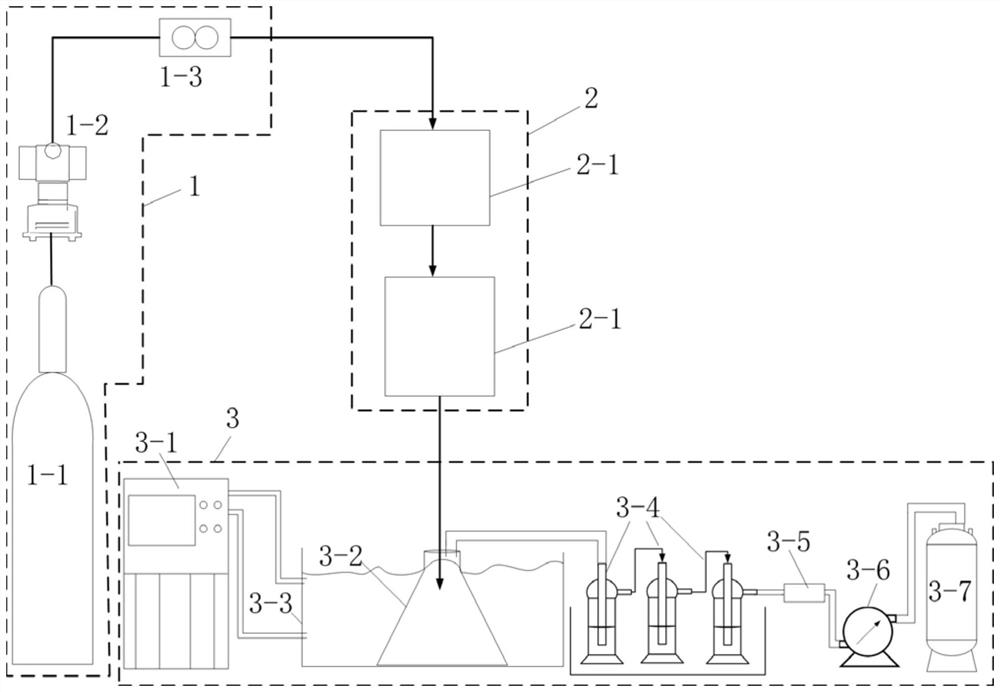

Pyrolysis device and pyrolysis method for infrared pyrolysis of red mud catalyzed biomass

InactiveCN113046104ACatalytic pyrolysisRealize harmless treatmentBiofuelsSpecial form destructive distillationCatalytic pyrolysisGas cylinder

The invention relates to a pyrolysis device and a pyrolysis method for infrared pyrolysis of red mud catalyzed biomass. The pyrolysis device comprises a gas supply system, a pyrolysis reaction system and a product detection and recovery system. A gas cylinder, a gas mass flowmeter, a mixed gas preheater and a steam generator of the gas supply system are connected through a gas guide pipe. Tubular infrared heating elements of an infrared heating device are arranged around a pyrolysis reactor of the pyrolysis reaction system, a quartz plate with holes is mounted in the center of the pyrolysis reactor, and the product detection and recovery system is used for analyzing gas components on line. With the adoption of the device and the method, rapid temperature rise in the biomass pyrolysis process can be realized, the biomass and the red mud are subjected to innocent treatment through the device and the pyrolysis method based on the device, and high-quality tar and pyrolysis gas are obtained under the action of catalytic pyrolysis.

Owner:CHONGQING UNIV

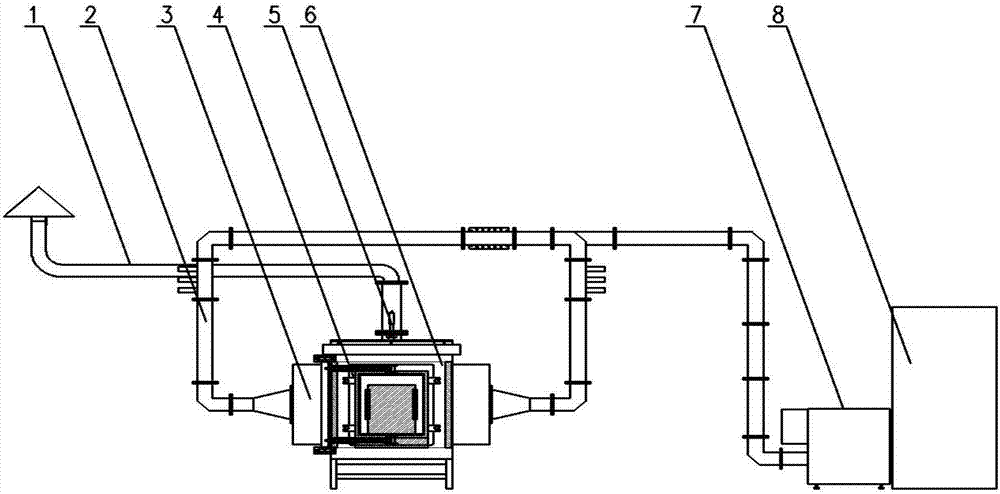

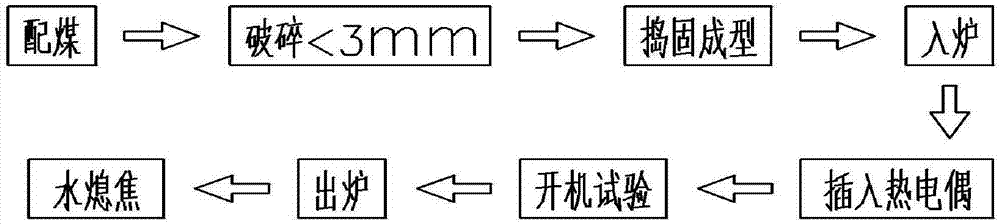

60kg microwave coking trial furnace and coking method

PendingCN107312553AIncrease productionQuality improvementSpecial form destructive distillationCoke ovens heatingThermodynamicsMicrowave

Owner:NANJING SANLE MICROWAVE TECH DEV +1

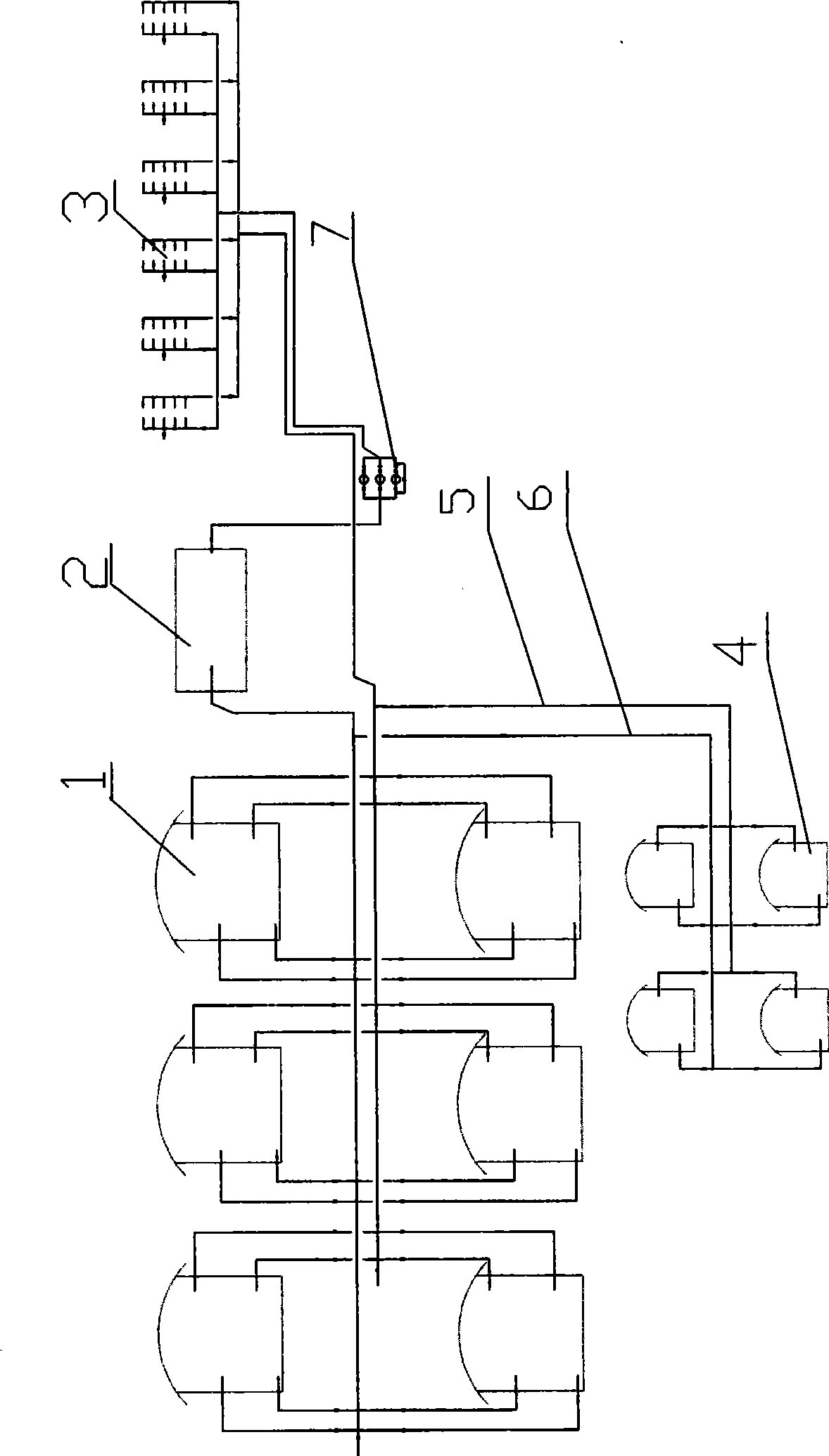

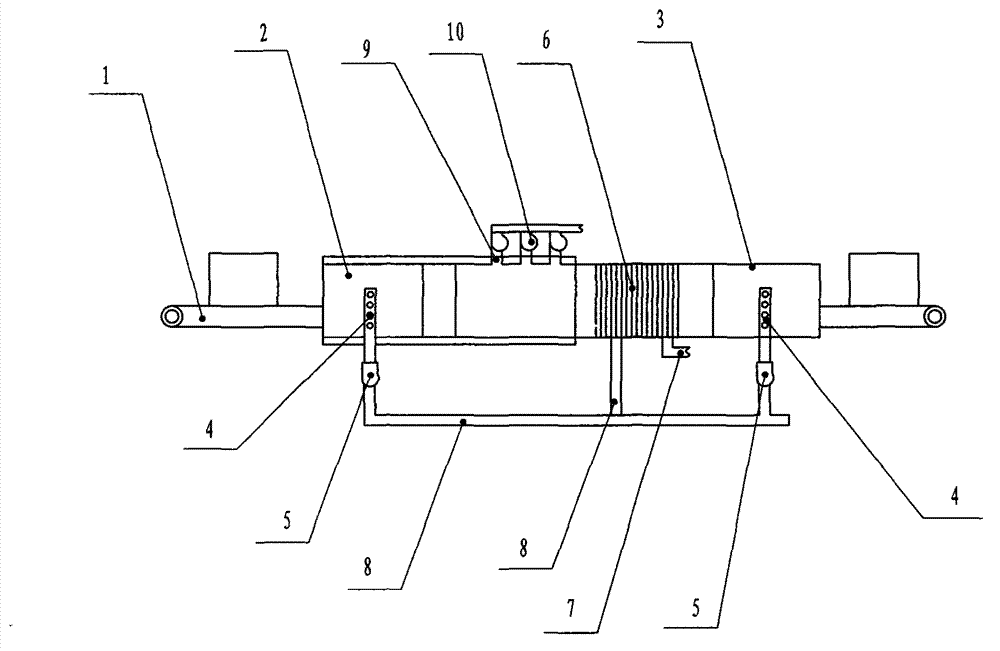

Low temperature dry distillation coke oven hot-water circulation utilizing system

The invention discloses a low-temperature carbonization coke oven hot-water circulation use system. A cooling water jacket is connected below the coke oven for the heat exchange with a fervent semicoke. The system is characterized in that the hot water discharged from a cooling jacket (3) is delivered to a dehydrating tank (4) and a tar tank (1) for heating via a water delivery pipe (5), and is then delivered to a circulation water tank (2) via a water returning pipe (6) to be discharged back to the cooling jacket for recycling. A circulation waster pump (7) is mounted on the water returning pipe between the cooling jacket and the circulation water tank. The system sufficiently utilizes the heat of the discharged semicoke for the heat exchange with the circulation water within the cooling jacket so that the heated circulation water is directly delivered to heating pipelines of the dehydrating tank and the tar tank to play a role of heating. The system does not need a cooling tower and a steam boiler, only uses extremely little power as well as has simple equipments, low running costs, no waste exhaust and the heat energy that can be recycled.

Owner:SHAANXI SHENMU SAN JIANG COAL CHEM

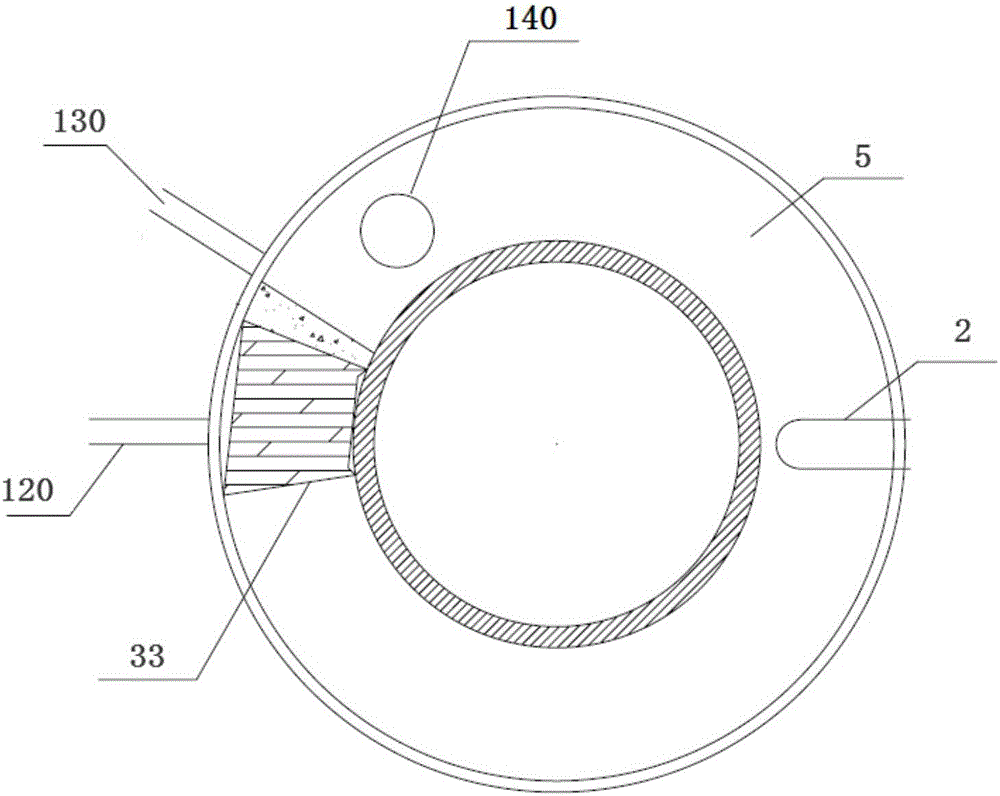

Pyrolysis device and method

ActiveCN105802643AImprove pyrolysis effectGuaranteed uptimeSpecial form destructive distillationCoke ovens heatingMechanical engineeringPyrolysis

The invention discloses a pyrolysis device and method. The pyrolysis device comprises a furnace, a heating device and a transfer device. The furnace comprises a hollow annular cavity, an annular laying plate capable of horizontally rotating is arranged on the bottom face of the cavity, a feeding port and a discharging port are formed in the side wall of the cavity, and the arrangement height of the discharging port is larger than that of the feeding port. The heating device is used for providing a heat source for pyrolysis. The transfer device is arranged in the cavity and comprises a first roller, a second roller and a lifting belt. In the operating direction of the laying plate, the first roller is arranged on the downstream side of the feeding port, and the second roller is arranged on the downstream side of the discharging port. In the vertical direction, the first roller is located above the feeding port and is adjacent to the feeding port, the second roller is located below the discharging port and is adjacent to the discharging port, and the lifting belt is arranged on the first roller and the second roller in a sleeving mode to cyclically roll. According to the pyrolysis device, the pyrolysis effect is good.

Owner:SHENWU TECH GRP CO LTD

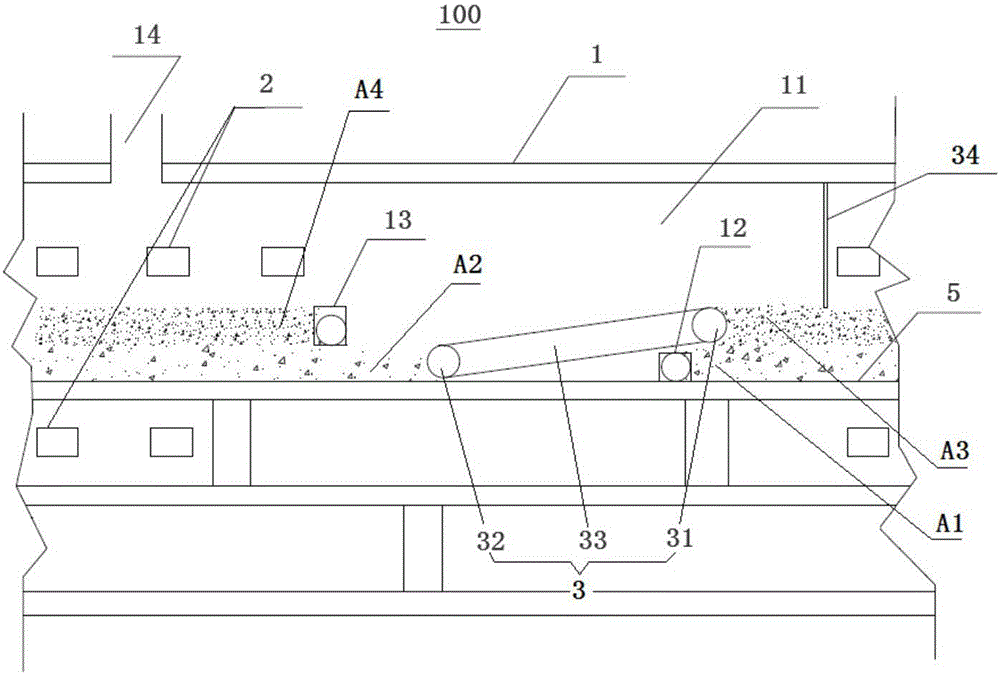

Continuous production line device for microwave dry-distilling and cracking biomass

InactiveCN102776008AImprove yieldUniform penetrationBiofuelsEnergy based chemical/physical/physico-chemical processesCooling chamberRecuperator

The invention discloses a continuous production line device for microwave dry-distilling and cracking biomass. The continuous production line device comprises a carbonization furnace housing and a transportation and transmission belt, wherein the transportation and transmission belt is arranged in the carbonization furnace housing; the carbonization furnace housing is divided into a microwave dry-distilling and cracking chamber and a cooling chamber; microwave threads are arranged in the housing of the microwave dry-distilling and cracking chamber; air ducts are respectively arranged above a preheating region and a drying region; the ends of the air ducts are connected with voltage-controlled frequency conversion air blowers; a nitrogen gas cooling heat exchanger is arranged inside the cooling region; an air inlet tube is designed on one end of the nitrogen gas cooling heat exchanger; an air outlet tube is designed on the other end of the nitrogen gas cooling heat exchanger; the air outlet tube is respectively connected with the voltage-controlled frequency conversion air blowers of the preheating region and the drying region; an air outlet is arranged in a micro positive-pressure high-temperature dry-distillation region; and the air outlet is connected with the frequency conversion air blowers. The continuous production line has the advantages of improving the yield of the wood charcoal and saving the heat energy.

Owner:枣庄新中兴实业有限责任公司

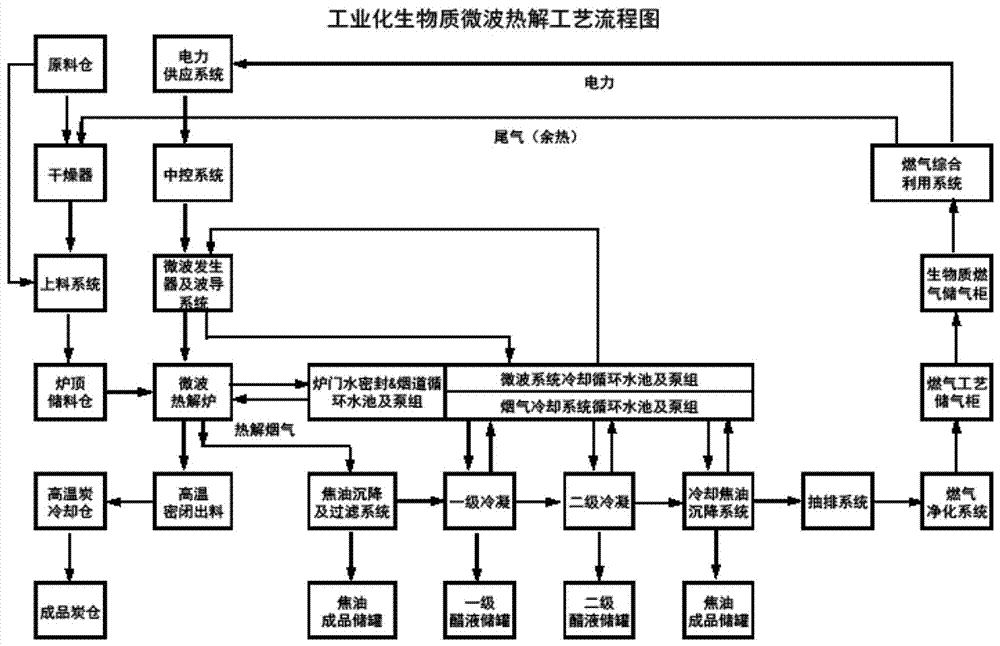

Production process and technology for high-power microwave pyrolysis of biomass

InactiveCN107987858AImprove utilization efficiencyShorten the timeBiofuelsWorking-up tarSolid carbonMicrowave pyrolysis

The invention discloses a production process and technology for high-power microwave pyrolysis of biomass. The production process comprises the following steps: feeding a solid biomass material not required to be crushed into a closed and shielded microwave pyrolysis furnace chamber, adjusting the temperature in the microwave pyrolysis furnace chamber to be uniformly risen to enable the biomass material to be pyrolyzed and flue gas to be produced by controlling the feed-in power of microwave and the feed-in time of the microwave, monitoring the pressure in the pyrolysis furnace chamber to control a flue gas extracting system, performing pyrolysis to obtain solid carbon, condensing pyrolyzed flue gas to produce biomass pyrolysis liquid, and purifying the residual combustible gas into cleanbiomass energy. The process and the technology have the advantages that the whole pyrolysis process is performed in a closed system, pyrolysis products are completely recycled and completely utilized,no waste is discharged, cleaning production is realized, large-scale, high-efficiency and continuous industrial production is realized, automation control is adopted for the whole process, a reliableproduction process and technology is provided with the comprehensive industrial application of biomass and can be widely applied to industrial closed heating, pyrolysis and denaturation treatment ofother similar materials.

Owner:DEHONG SENLANG PYROLYSIS TECH EQUIP

Concentrated solar heat receiver, reactor, and heater

A heat receiver, a reactor, and a heater utilize the heat of concentrated solar light for thermal decomposition and / or chemical reaction of coals, etc. The heat receiver includes: a side portion forming a substantially cylindrical side surface; a substantially circular bottom portion connected to the lower edge of the side portion; and a ceiling connected to the upper edge of the side portion. A substantially circular aperture is formed in the center of the ceiling. The heat receiver has a substantially cylindrical cavity and the opening portion is open. When the cavity has a diameter of D and a length of L, and the aperture has a diameter of d, d=D / 2 or less and L=2D or more. Concentrated solar light entering the heat receiver is to be contained in the heat receiver to effectively utilize the solar light.

Owner:NIIGATA UNIVERSITY

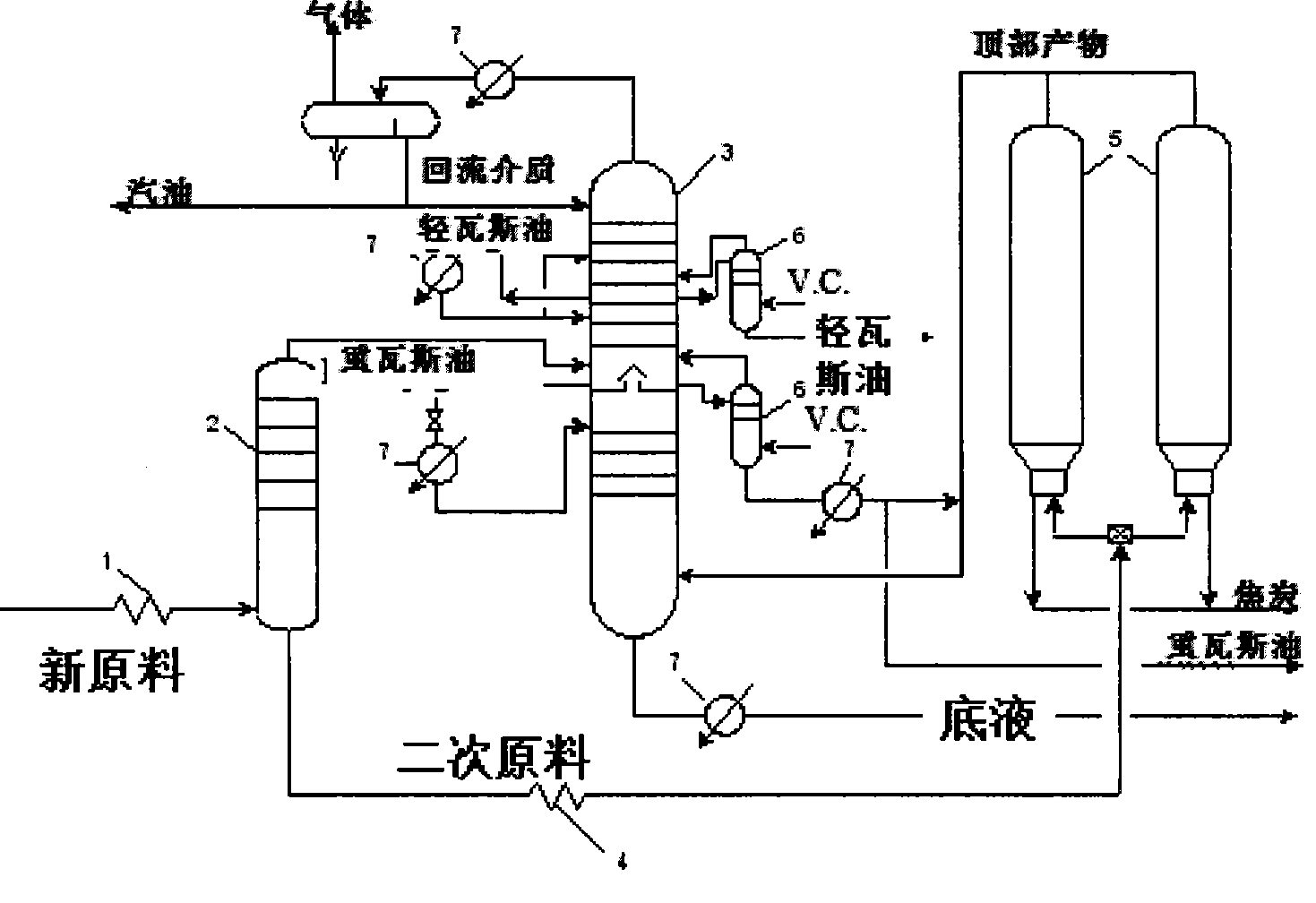

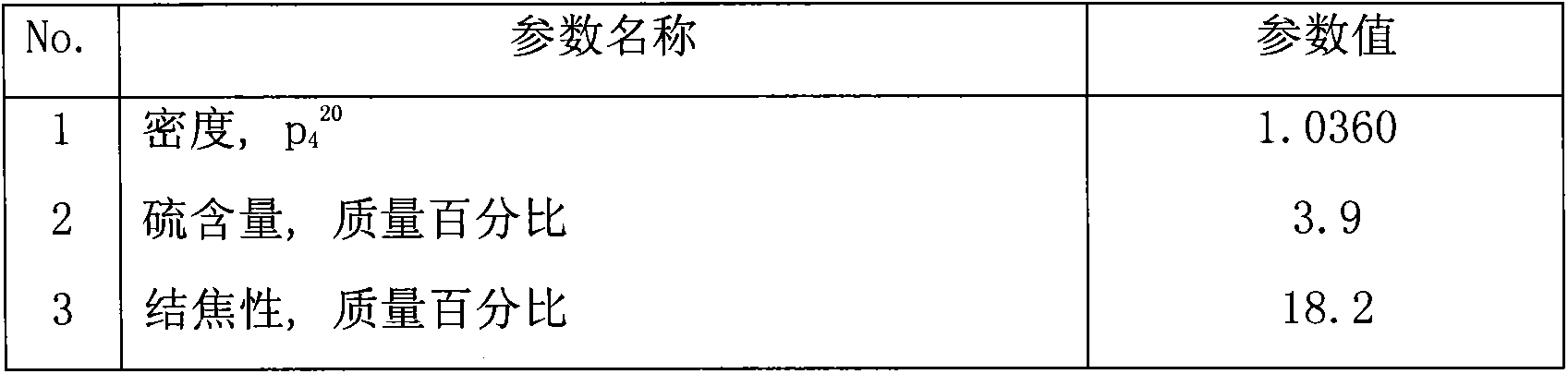

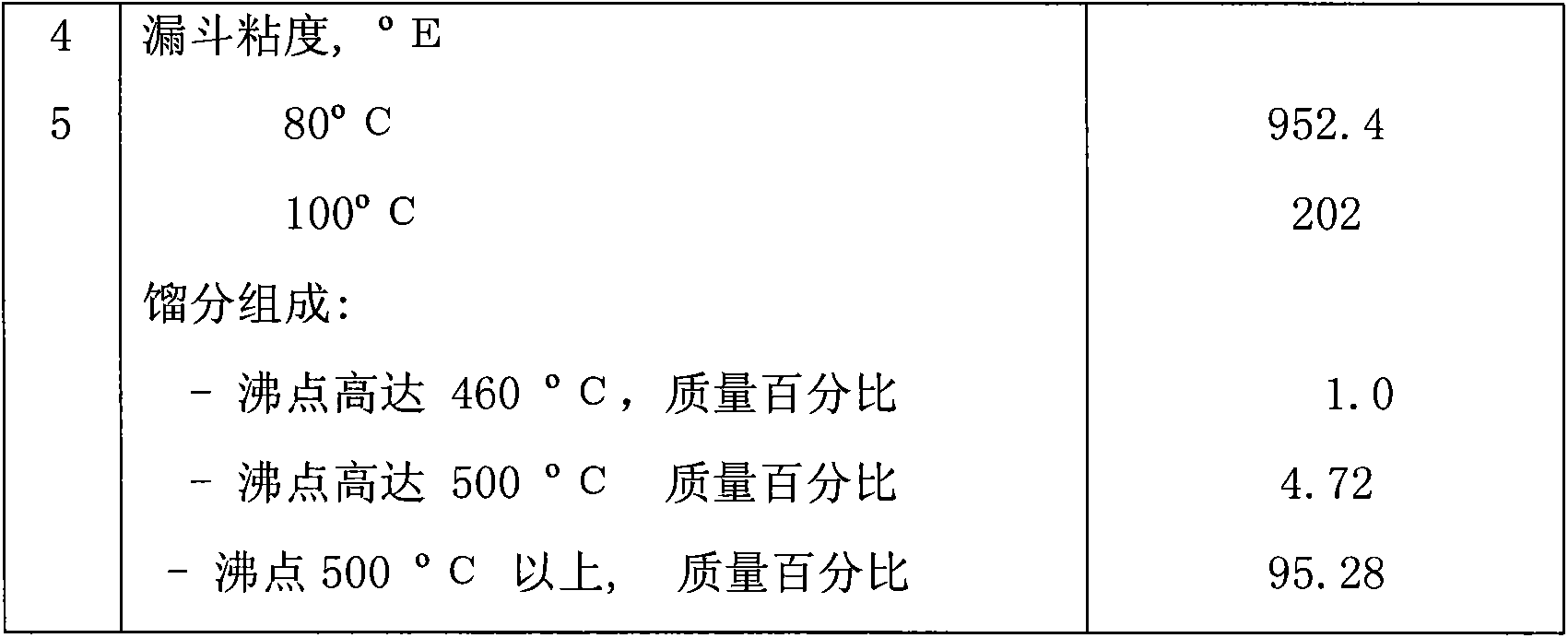

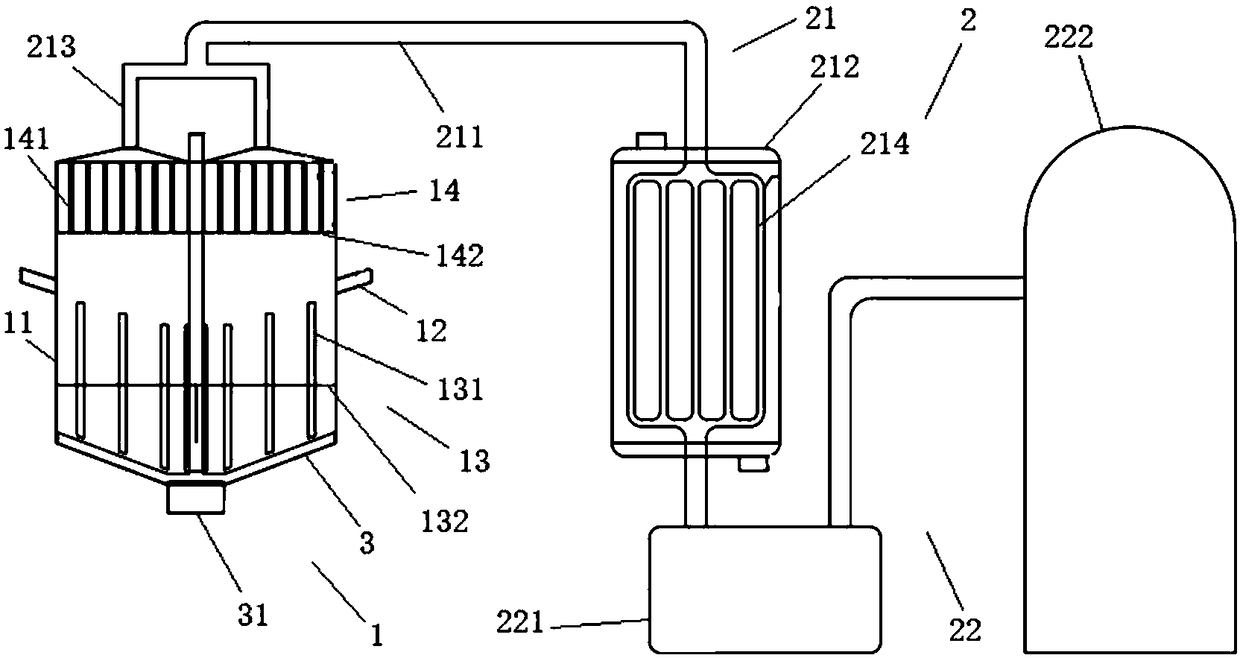

Method for the retarded coking of petroleum residues

The invention relates to the oil-refining industry, in particular to the process of delayed coking with the purpose of obtaining oil coke and gas oil fractions. The exploitation of many delayed coking installations, particularly in the reprocessing of oil residues, from which coke with high sulfur content is obtained in the process of coking, is oriented to obtaining the maximum possible quantity of distillated fractions: gasoline, light and heavy coking gas oil. Further on, high quality motor fuels are produced from the obtained distillates by using hydro-catalytic processes - hydraulic cleaning, catalytic cracking, and hydrocracking.

Owner:普诺米泰克股份有限公司

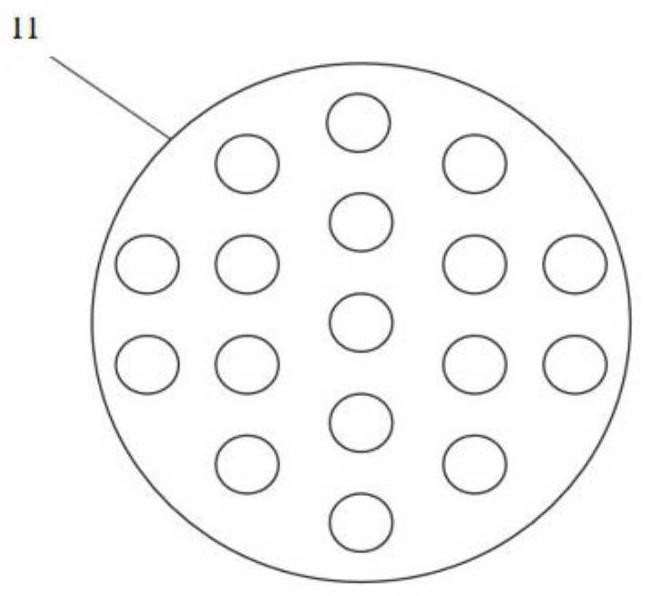

Reaction apparatus of microwave pyrolysis biomass

PendingCN108587653AIncrease the proportion of pyrolysis gasImprove economyGasification catalystsChemical industryMicrowave pyrolysisGas phase

The invention discloses a reaction apparatus of a microwave pyrolysis biomass. The reaction apparatus comprises a microwave pyrolysis unit, the microwave pyrolysis unit comprises a microwave thermal decomposition furnace, and at least a feed inlet arranged outside the microwave thermal decomposition furnace, the microwave thermal decomposition furnace comprises a solid-phase pyrolysis part and a gas-phase pyrolysis part connected in order from down to up, the solid-phase pyrolysis part comprises a solid-phase hollow circular column composed of metal mesh, and the solid-phase hollow circular column is filled with a solid-phase microwave absorbent and a catalyst. The reaction apparatus increases the pyrolysis heating rate, reduces the generation amount of solid carbon residue, increases theproportion of pyrolysis gas in products, and optimizes the pyrolysis reaction process, has the advantages of simple equipment, less land occupation, and convenient operation, can complete operation ofcontinuous feeding and deslagging, and is convenient for operation and management.

Owner:司宸

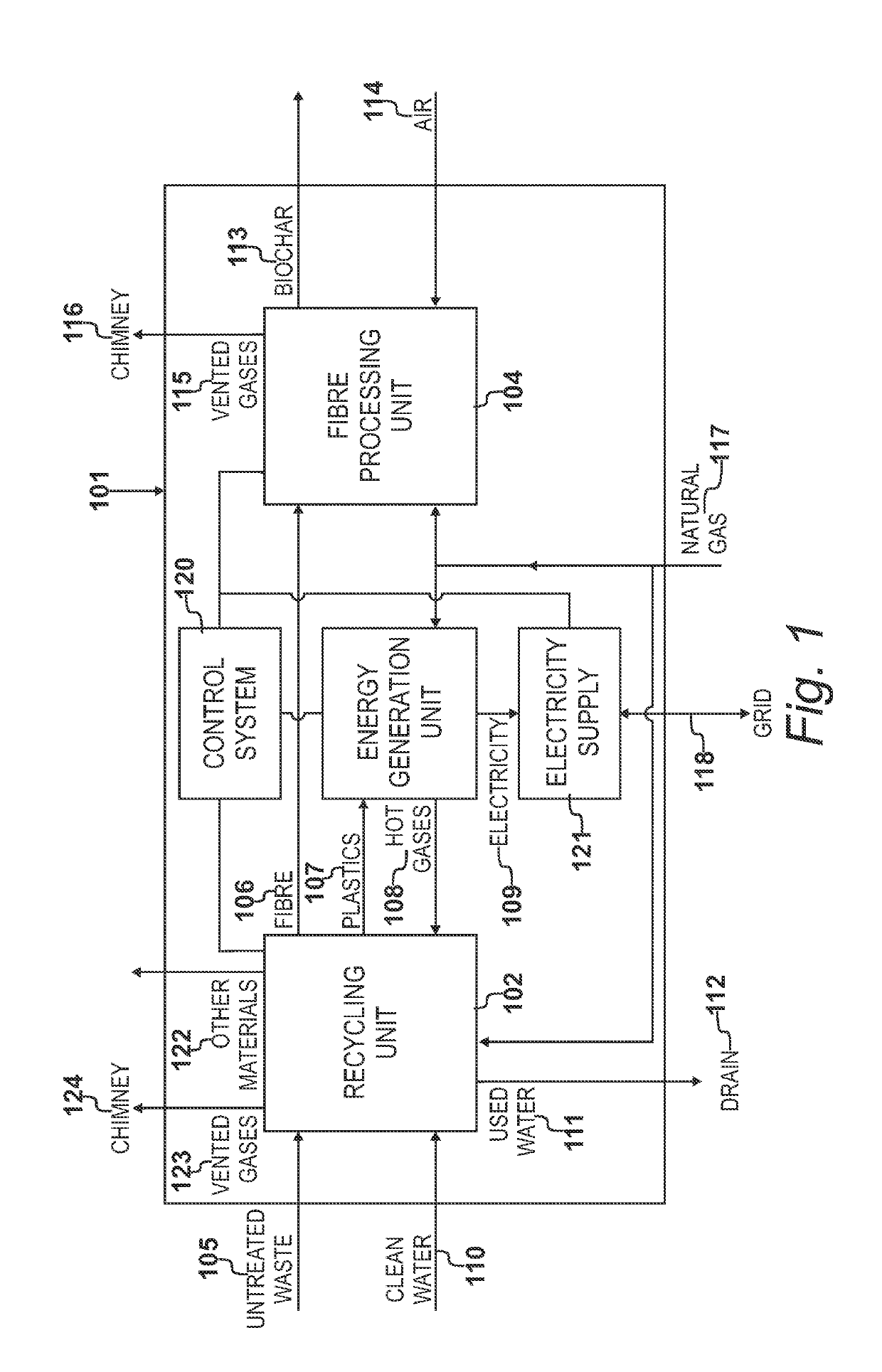

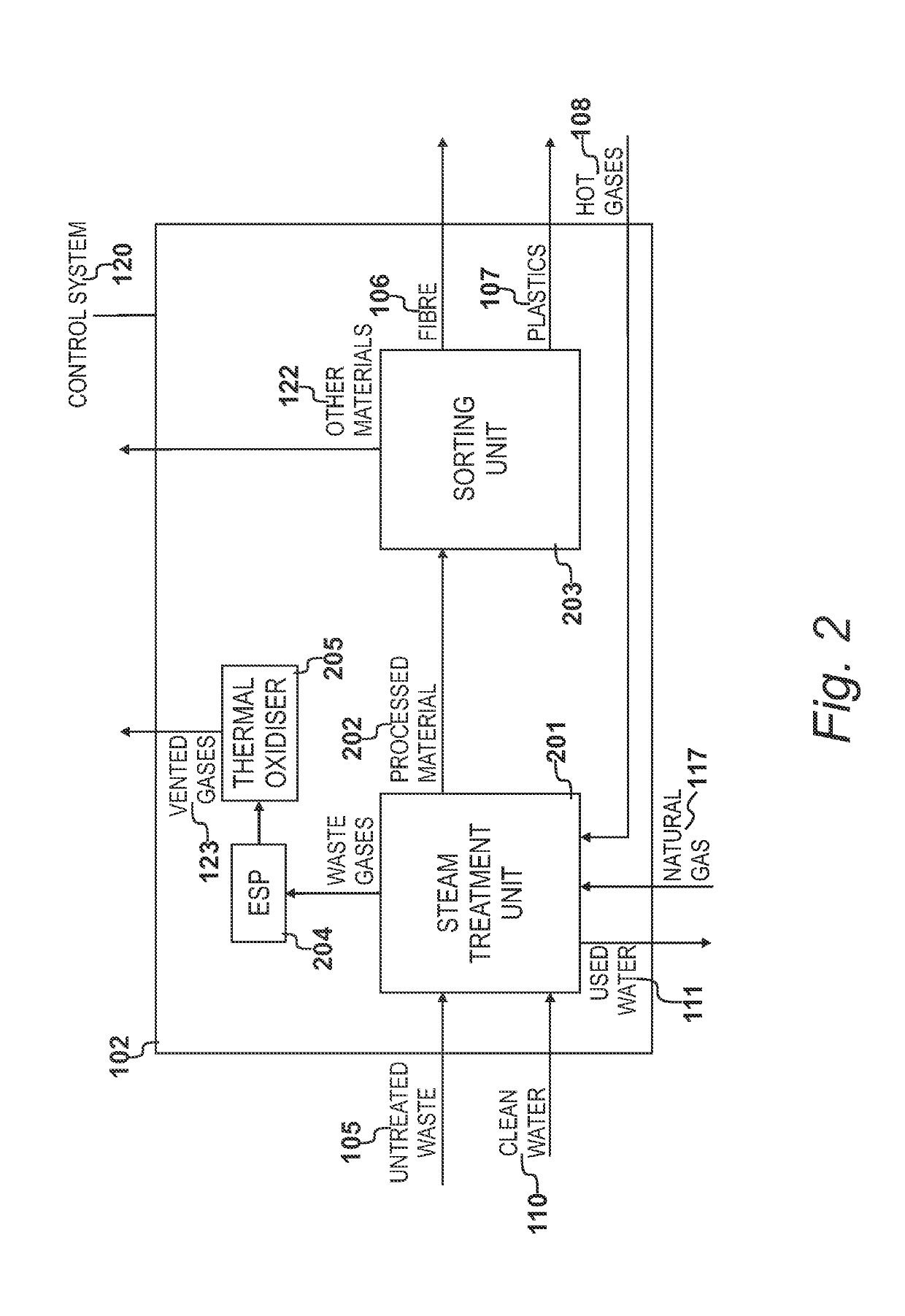

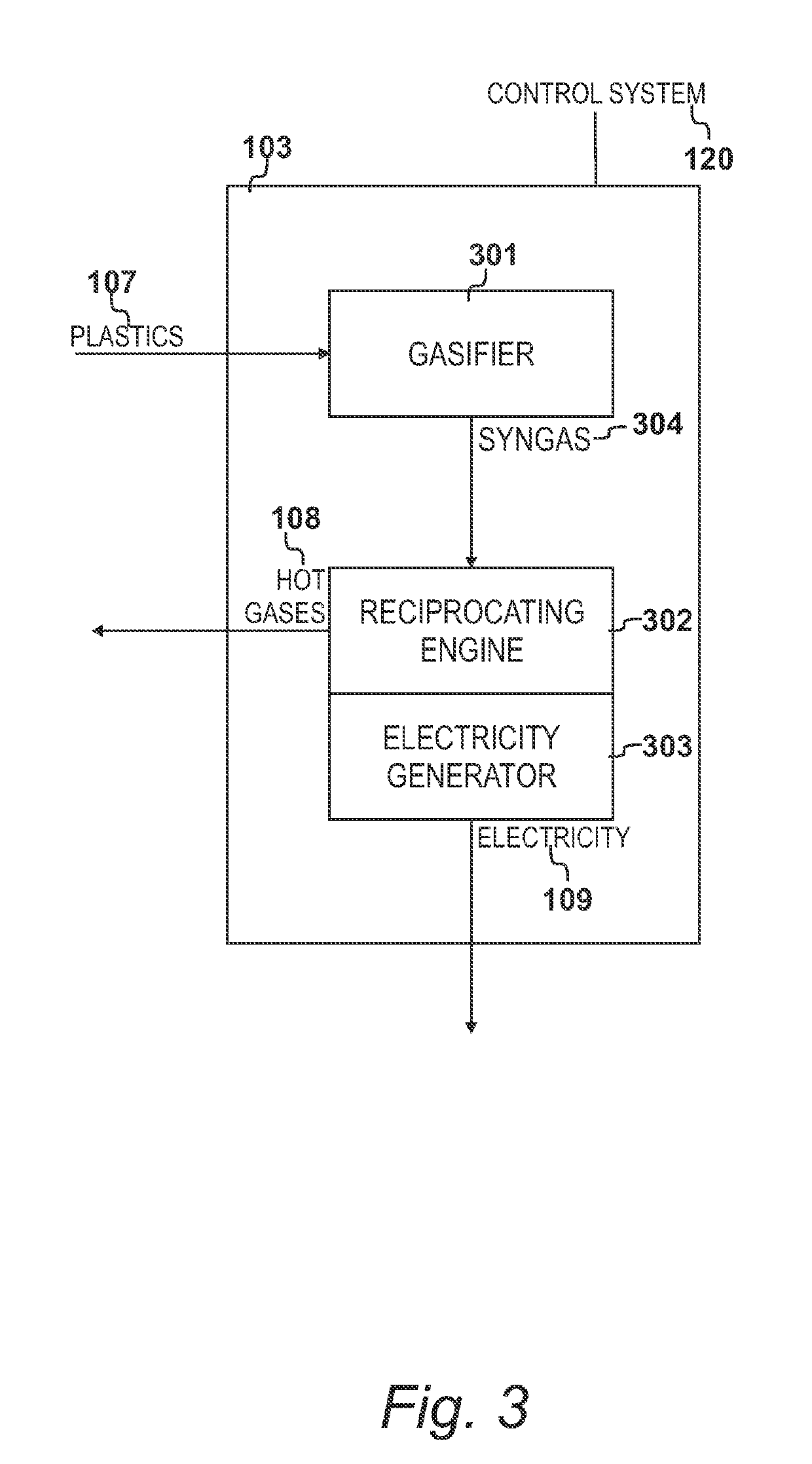

Processing waste into carbon char

InactiveUS20190284477A1Transportation and packagingSolid waste disposalCellulose fiberProcess engineering

Apparatus for processing waste-derived cellulose fibre into carbon char comprises an autoclave for treating waste with steam to produce processed material. The processed material includes cellulose fibre and plastics. The apparatus also includes a drying system for drying the cellulose fibre, and a torrefying unit for torrefying the dried cellulose fibre to produce carbon char. Thermal conversion means for thermally converting either said plastics or said VOCs provides heat for at least one of the autoclave, the drying system and the torrefying unit.

Owner:WILSON BIO CHEM LTD

Rotary radiation bed

PendingCN106281382AImprove retort efficiencySolve low work efficiencySpecial form destructive distillationCoke ovens heatingSlagEngineering

The invention provides a rotary radiation bed. The rotary radiation bed comprises a radiation bed cylinder and a heating device, wherein the radiation bed cylinder is arranged rotationally around the axis of the radiation bed, a feeding device is arranged at one end of the radiation bed cylinder, and a discharging device is arranged at the other end of the radiation bed cylinder; at least part of the heating device is arranged in the radiation bed cylinder and used for heating a raw material entering the radiation bed cylinder. With the adoption of the rotary radiation bed of the technical scheme, continuous feeding into the radiation bed cylinder can be performed through the feeding device, slack coal is evenly heated and dry-distilled by the heating device in the radiation bed cylinder, dry-distilled gas and coal slag are discharged continuously by the discharging device, and accordingly, the dry distilling efficiency of the slack coal is effectively improved, and the problem of lower work efficiency of raw coal dry distilling equipment in the prior art is solved.

Owner:新疆广汇煤炭清洁炼化有限责任公司

Pyrolysis and catalytic pyrolysis method for infrared rapid heating of waste plastics

PendingCN113322089AAchieve reductionRealize resourcesSpecial form destructive distillationCoke ovens heatingCatalytic pyrolysisPtru catalyst

The invention discloses a pyrolysis and catalytic pyrolysis method for infrared rapid heating of waste plastics. The method utilizes infrared heating to realize rapid heating, and pyrolyzes the waste plastics into gas, liquid and solid three-phase products at high temperature. When the waste plastics are subjected to catalytic pyrolysis, the waste plastics are firstly decomposed into long-chain hydrocarbon macromolecular compounds in the pyrolysis reactor, then the substances are subjected to fracture, aromatization and other reactions in the catalytic pyrolysis reactor under the action of a catalyst, and high-quality pyrolysis products are selectively prepared. According to the method, independent rapid pyrolysis and catalytic rapid pyrolysis of the waste plastic are achieved, the pyrolysis reaction and the catalytic reaction are separated, the catalytic temperature can be flexibly controlled, and the catalyst is not prone to inactivation due to the fact that the catalyst is separated from the plastic.

Owner:CHONGQING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com