Pyrolysis device for tar residue

A tar slag and pyrolysis technology, applied in the heating of coke ovens, coke ovens, petroleum industry, etc., can solve the problems of backward production technology, high labor intensity, poor thermal conductivity, etc., achieve reasonable structural design, improve production efficiency, and heat conduction good sex effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

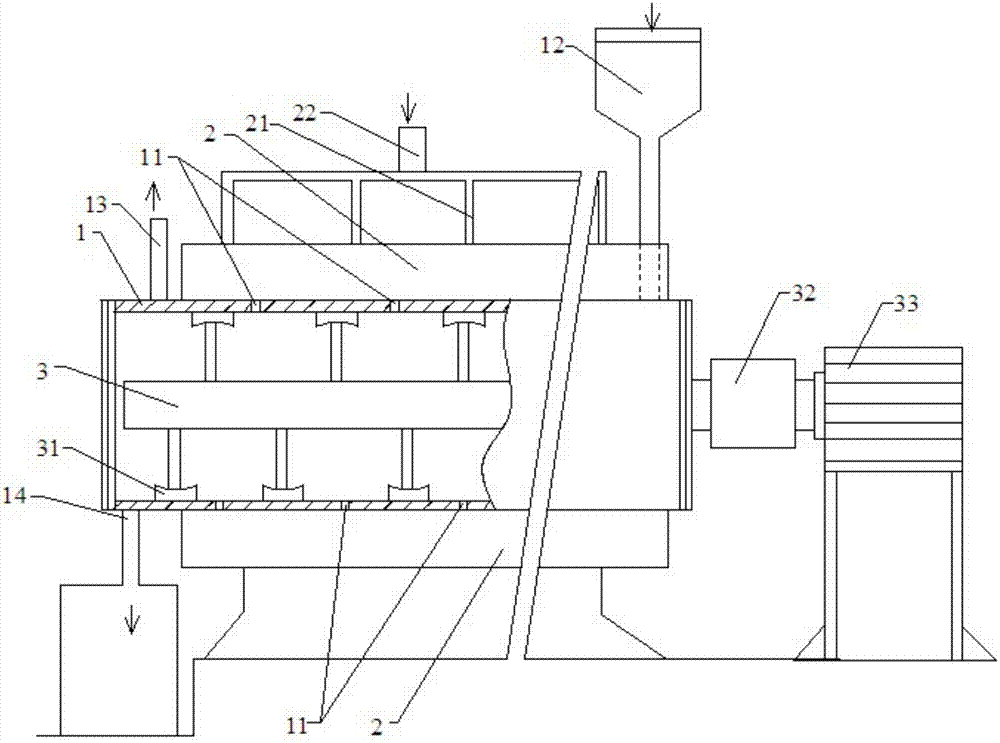

[0014] A pyrolysis device for tar residue as shown in the accompanying drawings, the device includes: a cylinder body 1 placed horizontally, a smoke sleeve 2 arranged outside the cylinder body 1, and a cylinder body 1 arranged axially along the cylinder body 1 Inside the rotating shaft 3, the cylinder body 1 is provided with equidistant communication holes 11 communicating with the flue gas sleeve 2, and the rotating shaft 3 is connected with equidistant scrapers 31, and the end surface of the scraper 31 is in contact with the interior of the cylinder body 1. The arc-shaped walls are matched, and the communication holes 11 at equal intervals are arranged between adjacent scrapers 31 .

[0015] Further, in the above technical solution, the outside of the flue gas jacket 2 communicates with the main flue gas inlet pipe 22 through the parallel tubes 21, and the flue gas jacket 2 is wrapped on the outer surface of the cylinder body 1; the scraper 31 is mounted on a rotating On the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com