Patents

Literature

80results about How to "Uniform mass transfer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Activated carbon coating/foam silicon carbide structural catalyst and preparation method thereof

ActiveCN102814188AUniform temperature distributionSufficiently chemically inertCatalyst activation/preparationChemical reactionHeat inactivation

The invention relates to the field of structural catalysts, in particular to an activated carbon coating / foam silicon carbide catalyst with a three-dimensional communicated structure and a preparation method for the catalyst. The invention aims to solve the problems that hole opening is discontinuous, the catalyst and reaction products are separated, a heat transfer and mass transfer effect is poor and the like in the prior art. By taking foam silicon carbide as a catalyst carrier, an activated carbon coating covers on the surface of the foam silicon carbide, wherein the activated carbon coating is between 0.1 micron and 500 microns thick, and a metal catalysis active component is loaded on the activated carbon coating. The activated carbon coating is prepared on the surface of the foam silicon carbide with the three-dimensional communicated structure, then, the metal catalysis active component is loaded, and activating treatment is performed on the metal catalysis active component to obtain the catalyst. According to the activated carbon coating / foam silicon carbide catalyst, holes in the catalyst carrier are totally communicated, thus, an enclosure space does not exist, and a heat transfer and mass transfer process of the chemical reaction can be strengthened. The activated carbon coating / foam silicon carbide catalyst has the characteristics that the temperature field distribution of the catalytic reaction is uniform, the heat inactivation rate is low, the pressure drop is low and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

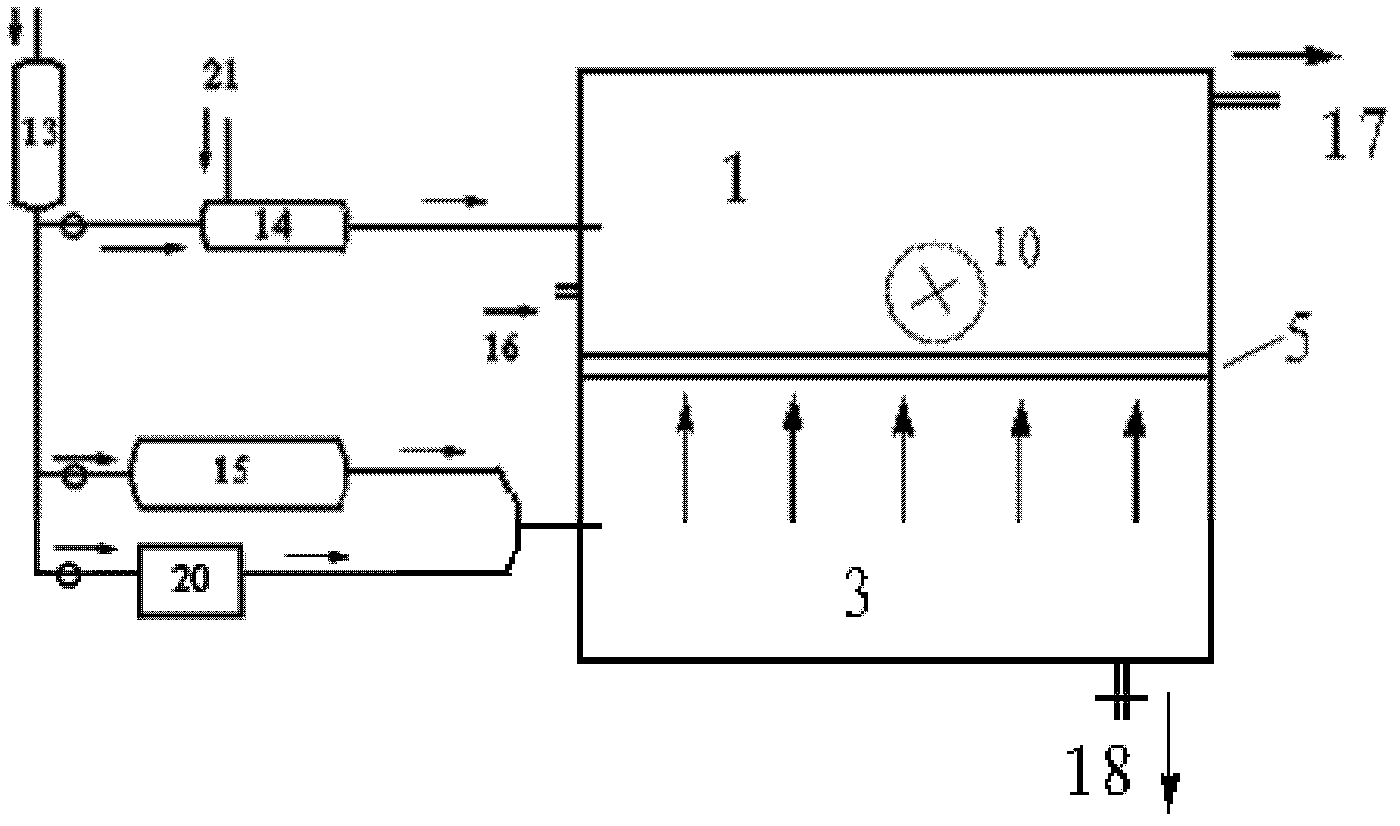

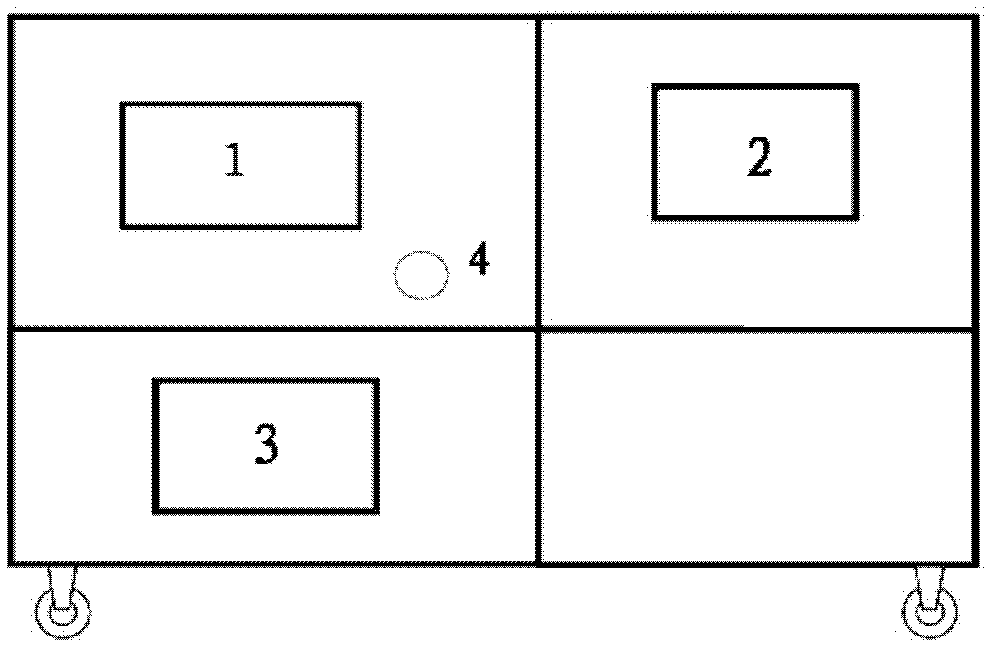

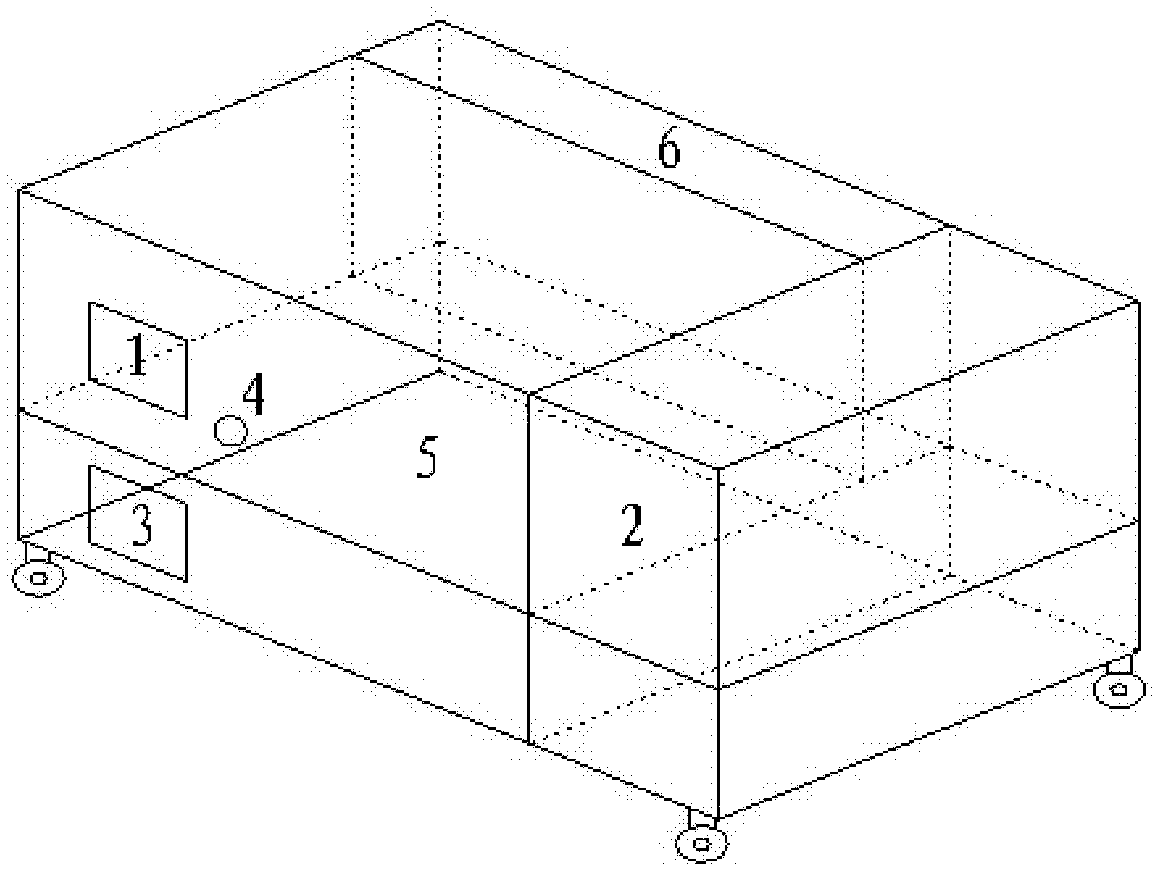

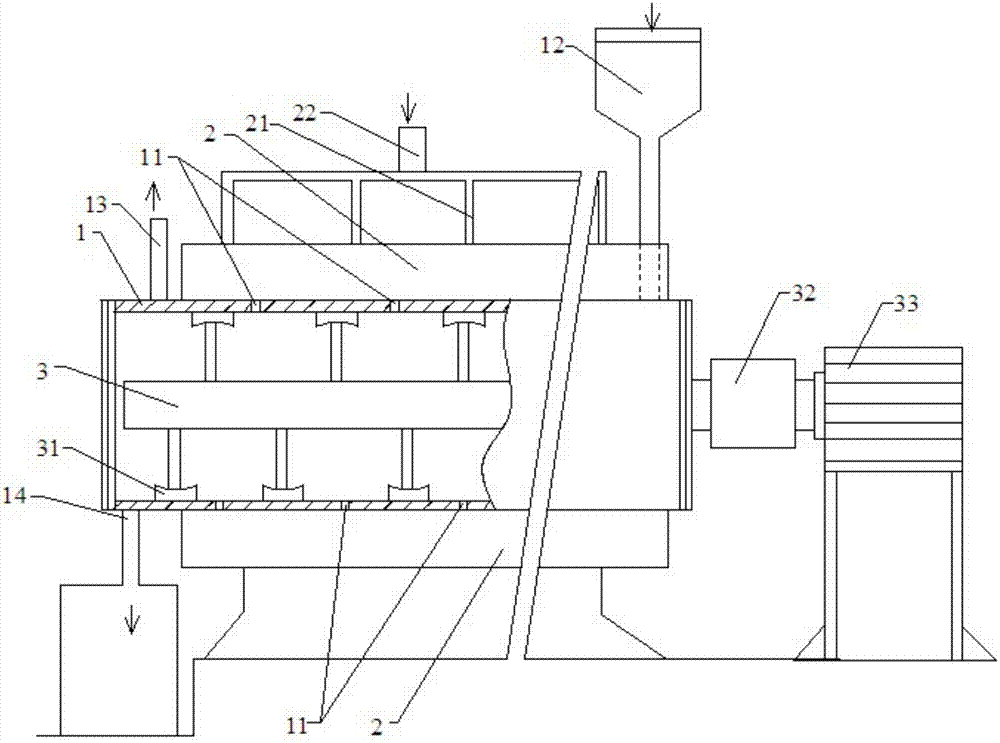

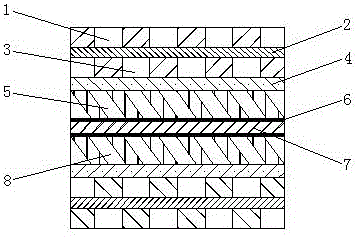

Solid fermentation bioreactor

InactiveCN102443535AAffect growthWell mixedBioreactor/fermenter combinationsBiological substance pretreatmentsBioreactorControl unit

The invention relates to a solid fermentation bioreactor. The reactor comprises a reaction casing , and a porous material layer separator plate (5) is arranged in the reaction casing to divide the reaction casing into an upper fermentation chamber (1) and a lower layer air chamber (3); the reactor also comprises a fermentation control system for controlling a stirring unit, a temperature control unit, a humidity control unit, an air feed control unit and a fermentation tail gas detection and processing unit, so as to realize real time monitoring and control on temperature, humidity, ventilation, stirring and tail gas. The invention realizes totally enclosing on-line fermentation and prevents extraneous pollutants from entering; the tail gas detection system carries out real time on-line monitoring on fermentation gas, and tail gas is treated by tail gas recovery equipment to protect the environment, thereby realizing coupling operation of temperature, humidity, ventilation, stirring and tail gas control system and ensuring necessary essential factors for microbe growth.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

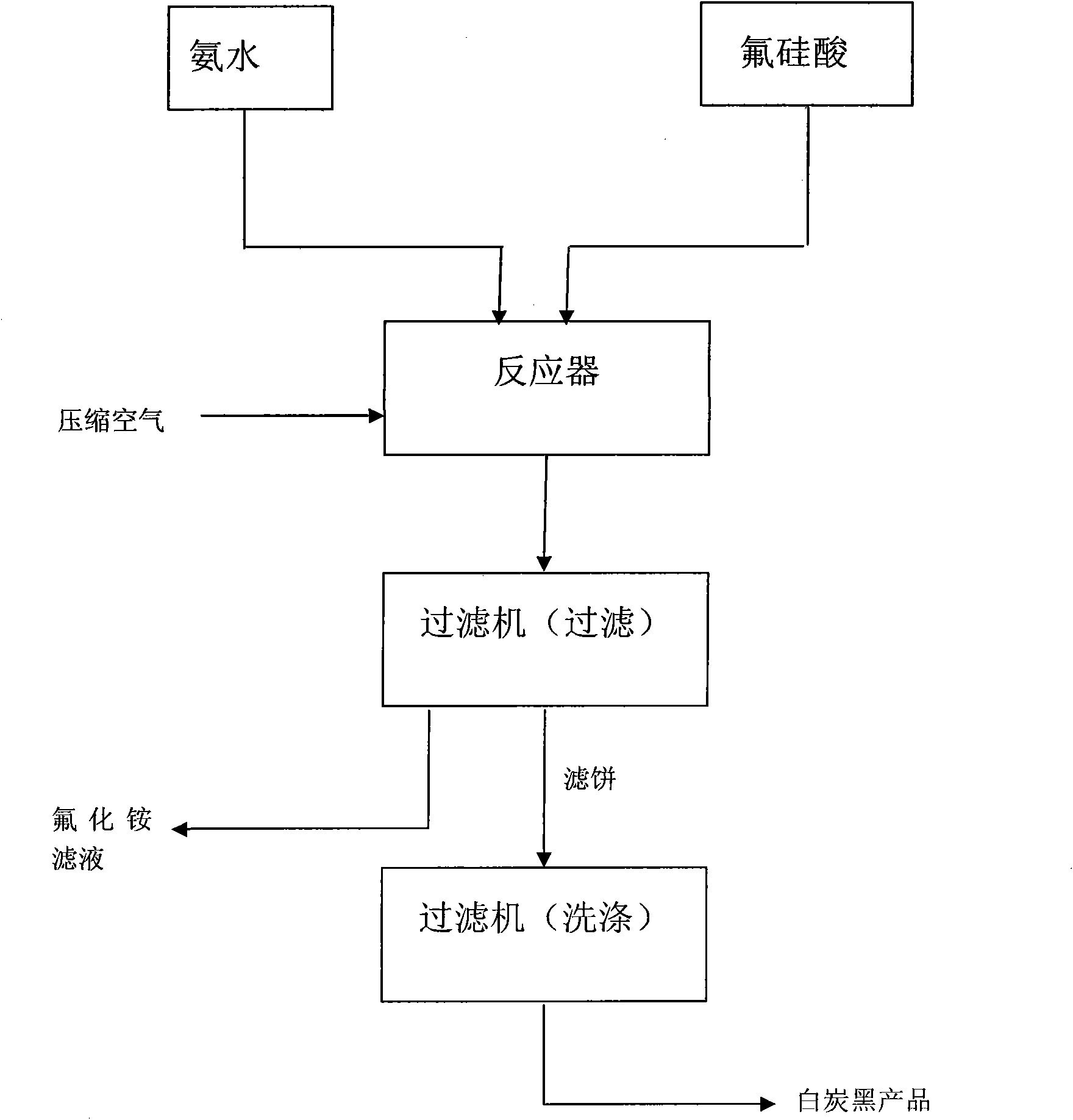

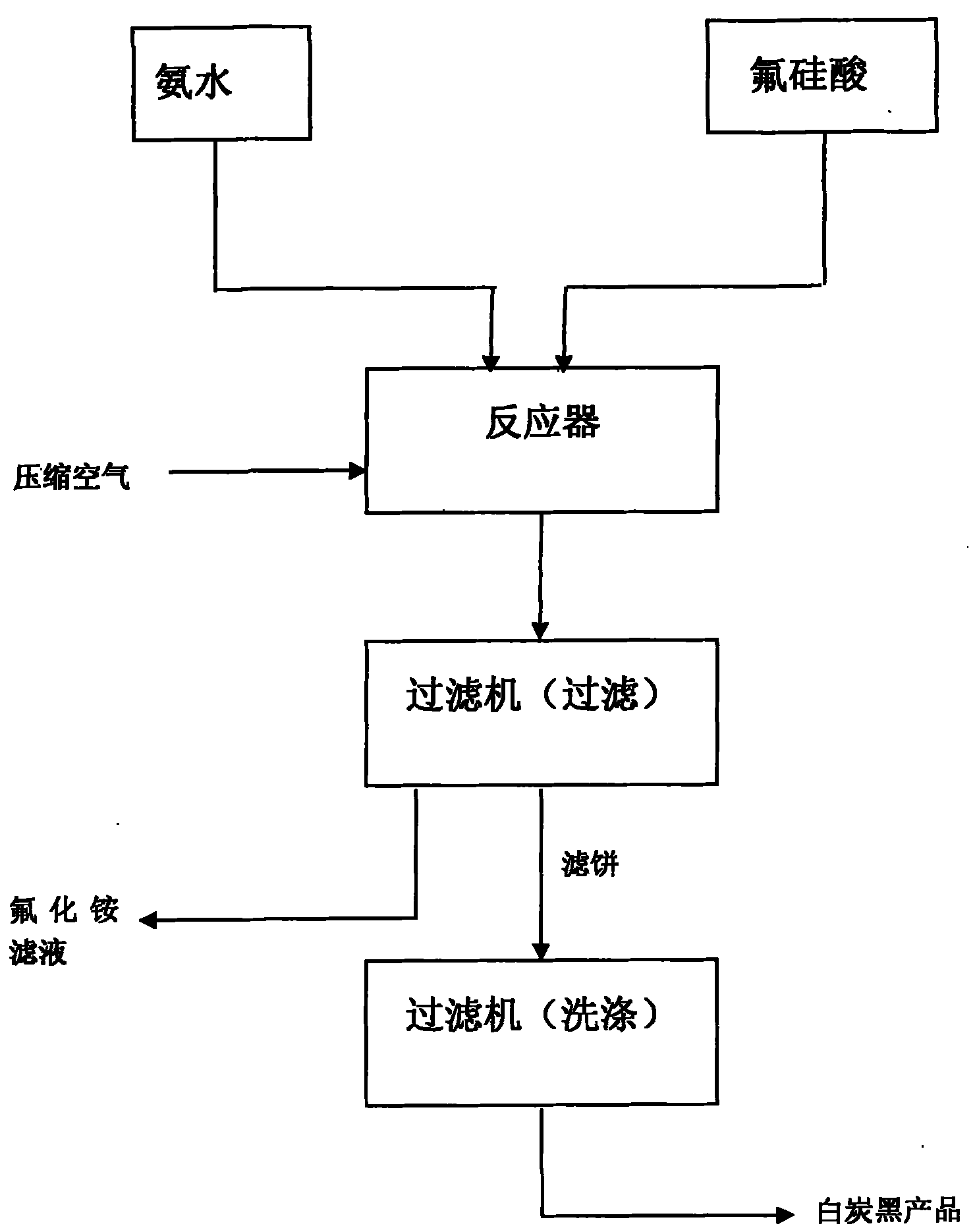

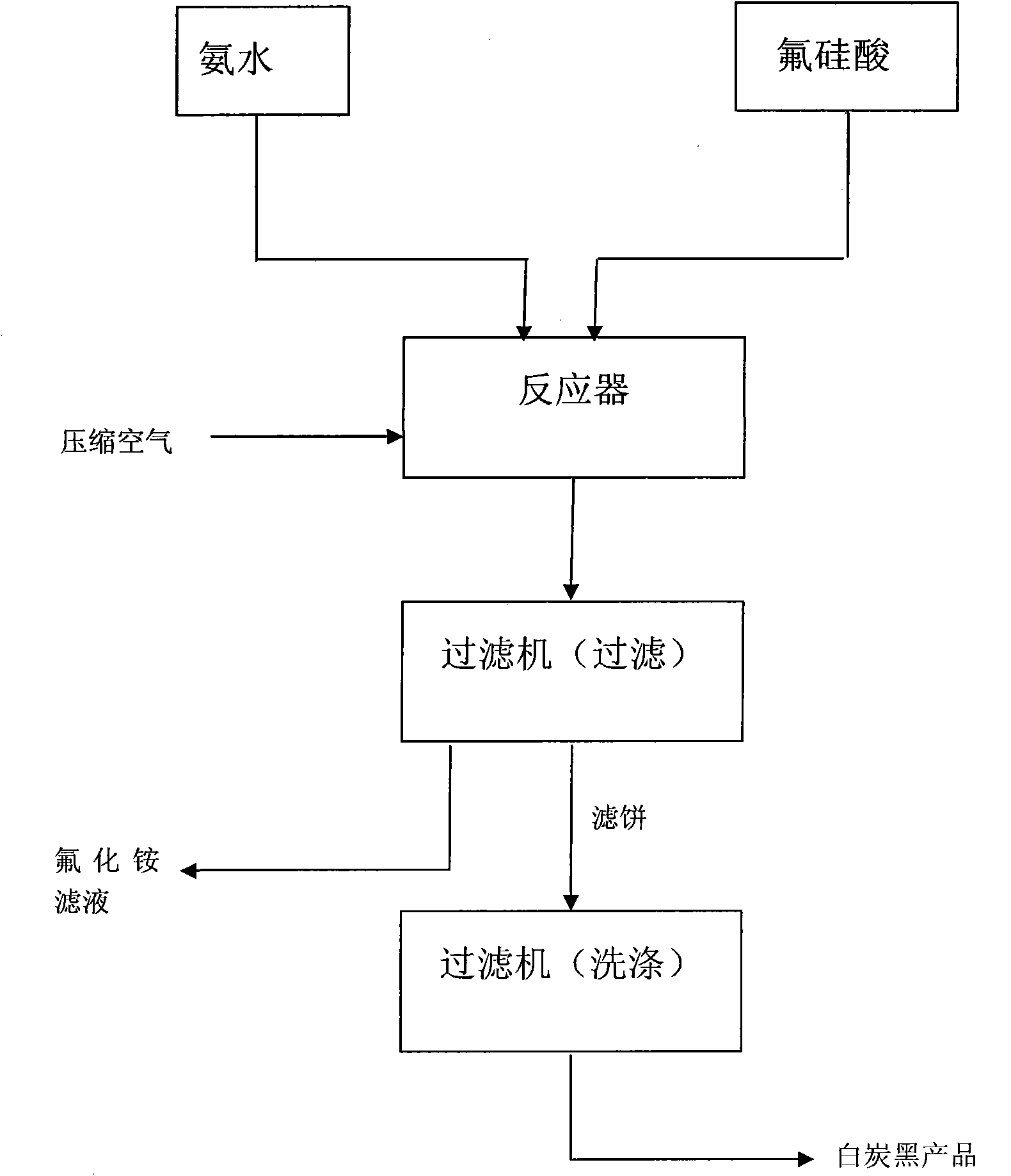

Method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation

ActiveCN101863482AContinuous processProcess stabilitySilicaAmmonium halidesSal ammoniacHexafluorosilicic acid

The invention discloses a method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation, which relates to a chemical production method, in particular to a method for preparing the white carbon black and the ammonium fluoride. The method comprises the following steps: (a) at a temperature between minus 5 and 30 DEG C, starting a stirrer and an air compressor, blowing compressed air into an outlet pipe of a reactor by the air compressor and adding fluosilicic acid and ammonia into the reactor simultaneously; (b) when the fluosilicic acid and the ammonia are added to the position of an overflow pipe in the reactor, opening an emptying valve to continuously feed and discharge materials and controlling a PH value of the reaction, wherein the period of the continuous reaction is 24 hours; (c) in the reaction process, filtering the materials discharged by the step (b) to obtain a white carbon black filter cake and filtrate of ammonium fluoride, and washing and drying the white carbon black filter cake to obtain a white carbon black finished product, wherein the filtrate is ammonium fluoride solution; and (d) after performing a reaction for 24 hours in the reactor, emptying the materials, cleaning the reactor to be used next time and producing the white carbon black finished product by using the materials according to the step (c), wherein the ammoniation yield of the process can reach 99.99 percent. The method of the invention effectively overcomes the defects of the existing intermittent technology and has the advantages of continuous, stable and simple process and long operation period.

Owner:YUNNAN YUNTIANHUA +1

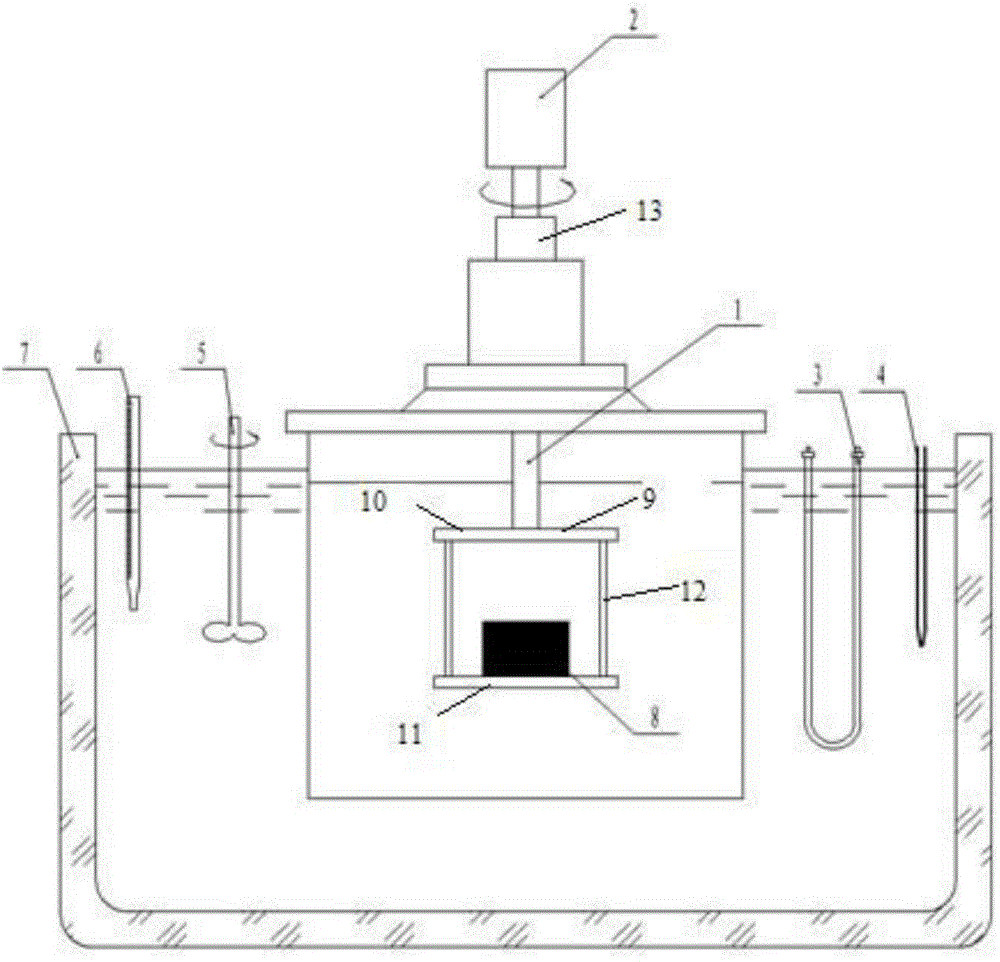

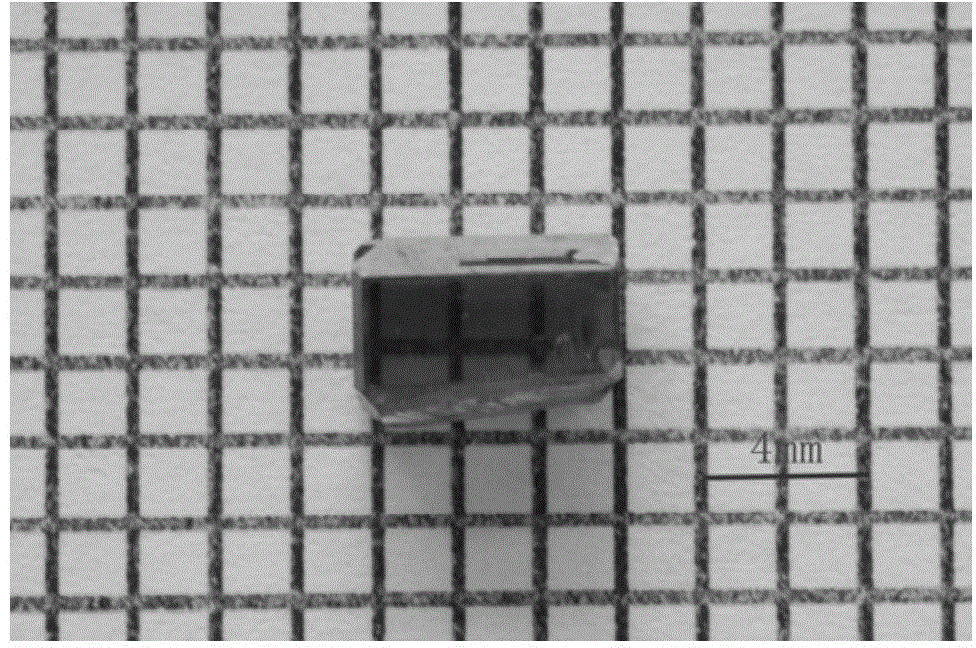

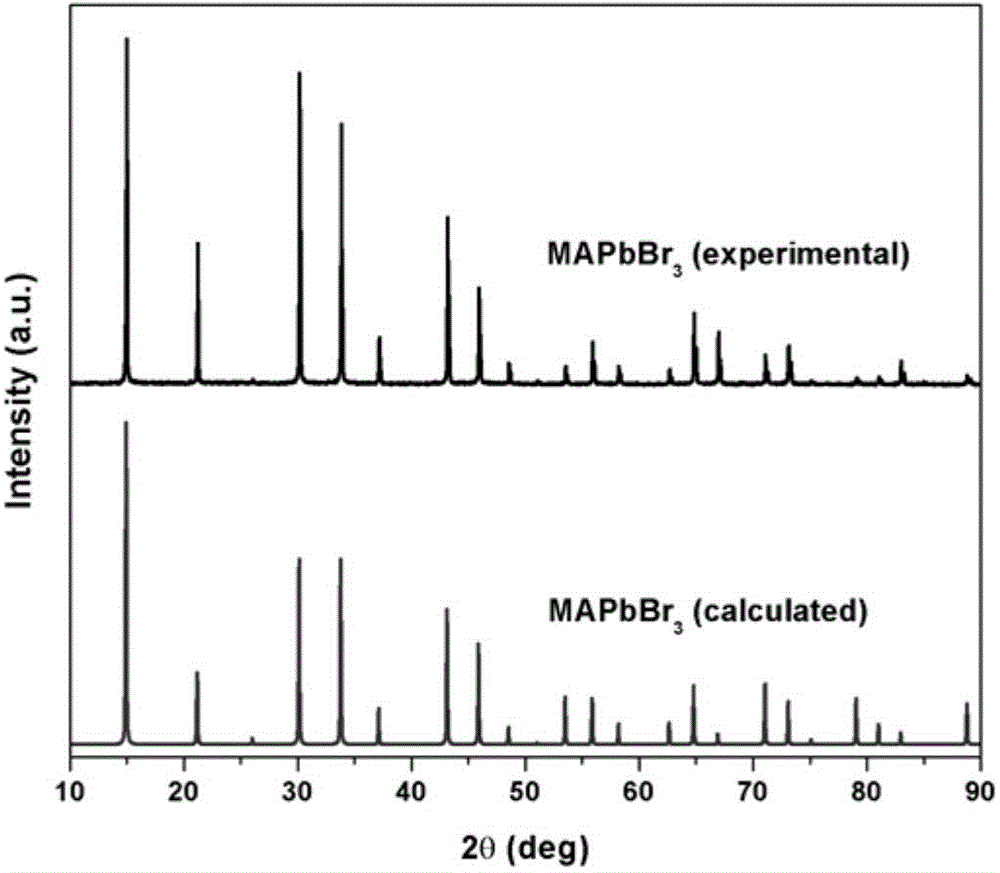

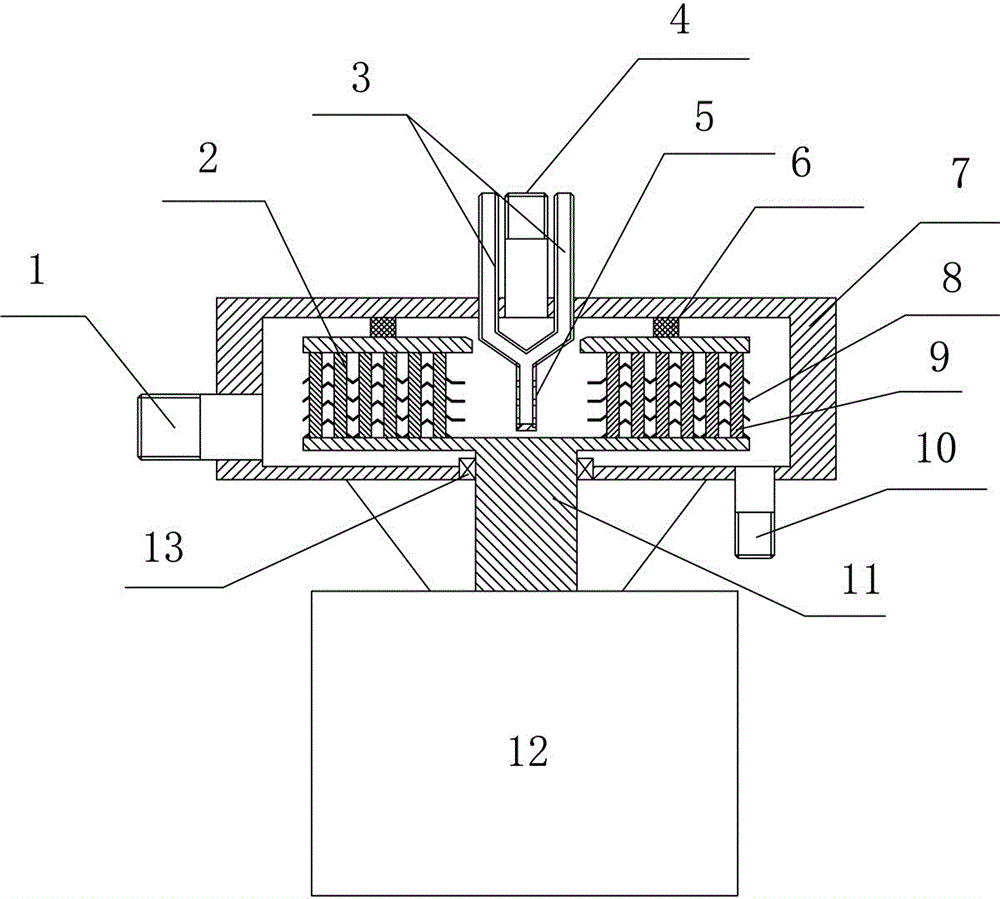

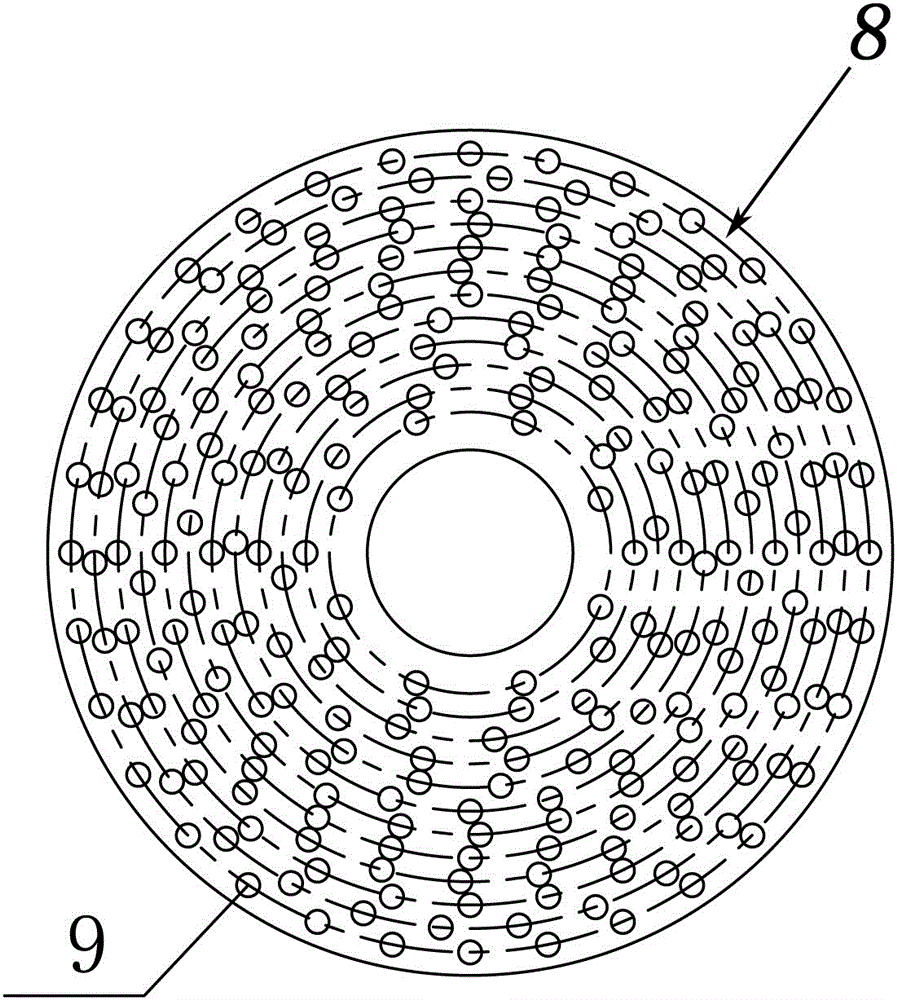

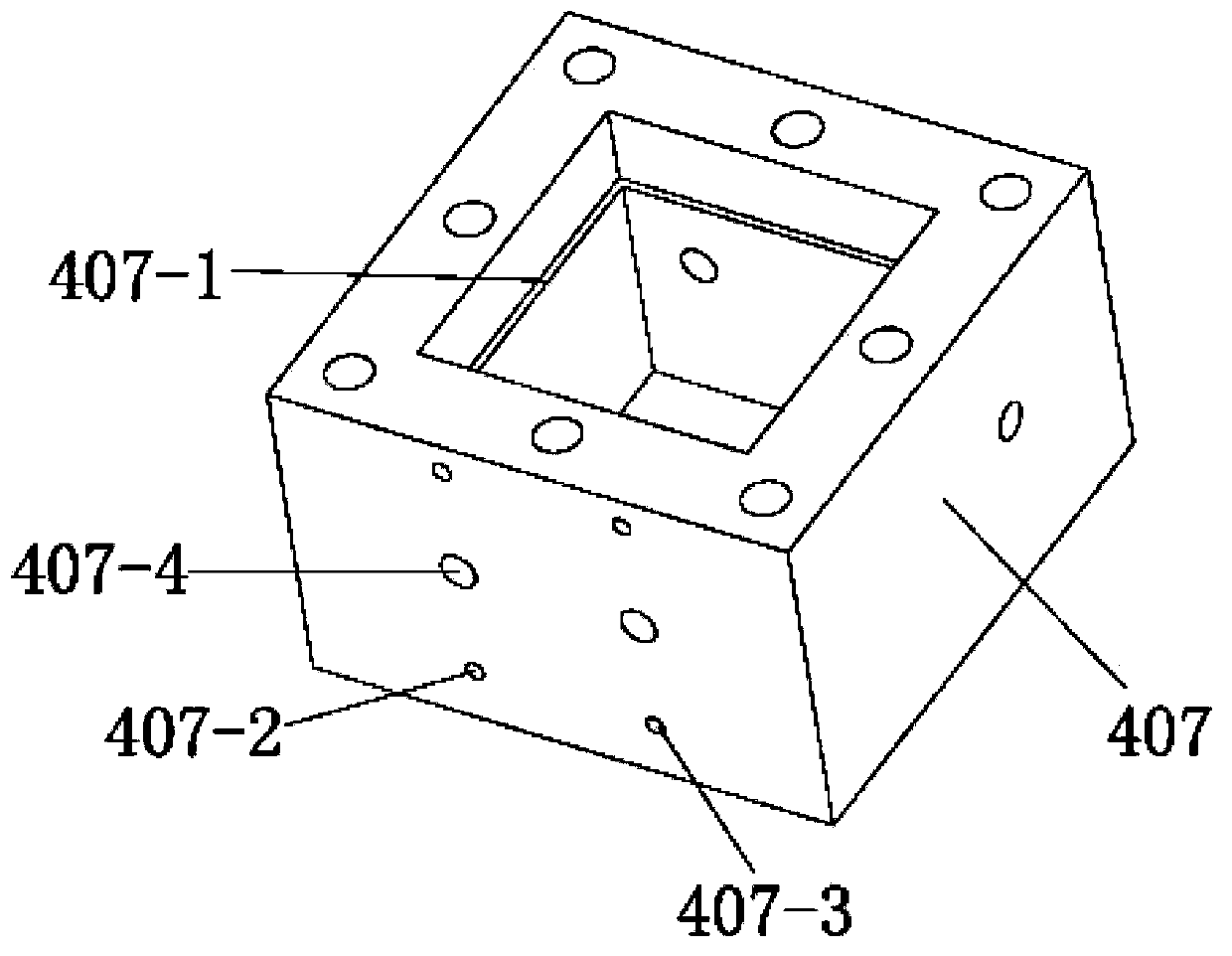

Methylamine halogenated plumbate compound large-size crystal growth method and device

ActiveCN104372412AUniform mass transferAvoid formingPolycrystalline material growthFrom normal temperature solutionsElectrical batteryPhysical chemistry

The invention relates to a methylamine halogenated plumbate compound large-size crystal growth method and device. The crystal growth method is a bottom seed crystal solution cooling process and comprises the following steps: sequentially adding raw materials CH3NH2 and Pb(CH3COOH)2.3H2O into an HX (X is halogen) solution according to the stoichiometric proportion to obtain a precipitate, continuously stirring, heating to completely dissolve the precipitate so as to obtain a clear solution, cooling to the saturation point of the solution, adding the seed crystal, and slowly cooling to perform crystal growth for about 1 month. The invention also relates to a large-size crystal growth device. The prepared CH3NH3PbX3 crystal has favorable light absorption range in the ultraviolet-visible light region, has the advantages of no deliquescence and favorable stability, and is applicable to the fields of solar cells, photoelectricity and the like. Compared with the high-temperature solution volatilization process, the method provided by the invention can obtain the large-size high-quality crystal more easily, and has the advantages of accessible raw materials and low cost.

Owner:SHANDONG UNIV

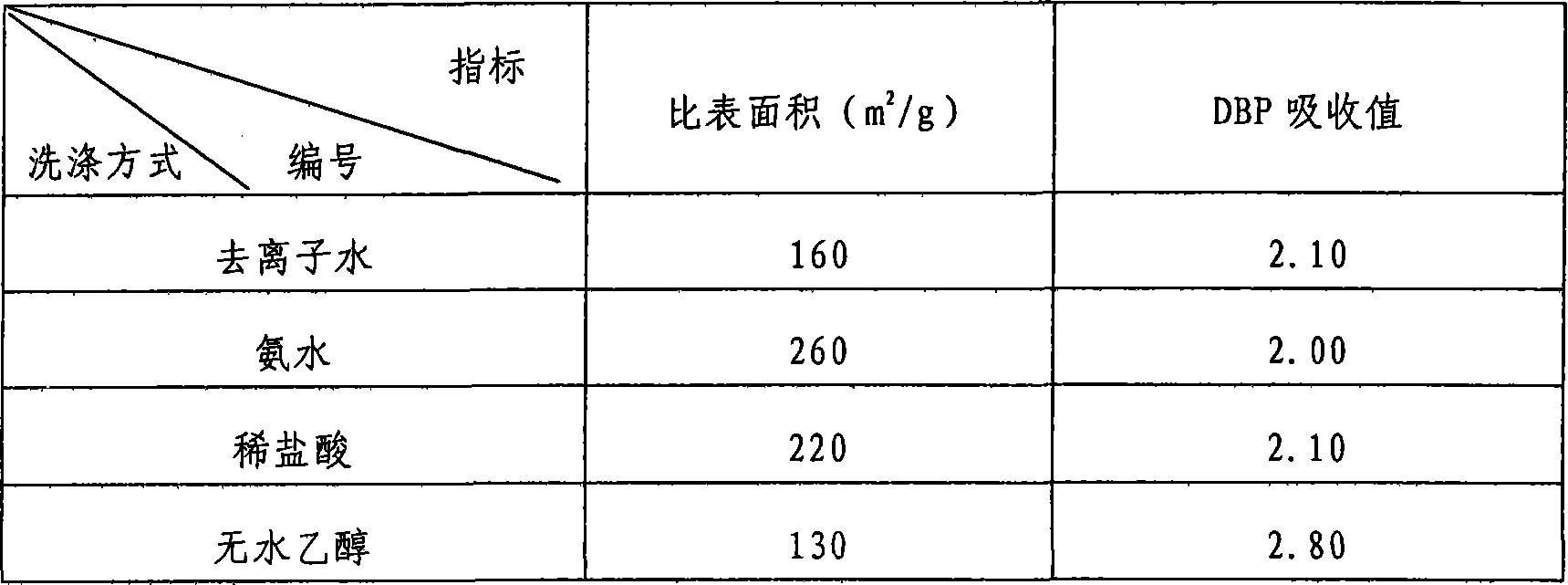

Integrated utilization method for phosphorus chemical industry byproduct fluorosilicic acid

The invention discloses a comprehensive utilization method of hydrofluosilicic acid which is by-product of phosphorus chemical engineering. The method is that hydrofluosilicic acid solution with concentration of 18%-35% is added to a container with intense agitation and rapid heat withdrawing under -5 DEG C to 30 DEG C, the agitation is started with an agitation speed of 500rmp-10000rmp, simultaneously ammonia with concentration of 13%-37% is added, or ammonia gas is added. Silica gel is obtained by filtration, after the silica gel is washed and dried, finished product of white carbon black with surface area of 160-350m2 / g is obtained. The filtering liquid is ammonium fluoride solution with concentration larger than 20%, and the ammonification recovery ratio can reach more than 98%. The invention is simple in technique, the hydrofluosilicic acid is made good use of, and the produced white carbon black has good quality.

Owner:YUNNAN CHEM RES INST

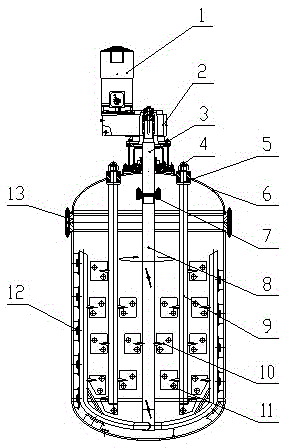

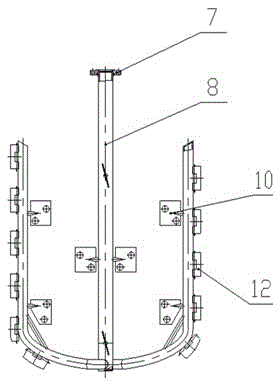

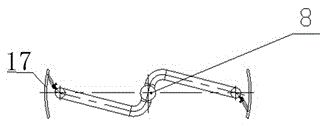

Hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer

InactiveCN105561841ALarge mixing rangeStir wellTransportation and packagingRotary stirring mixersElectric machineryReducer

The invention relates to a hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer comprises a motor, a speed reducer, a transmission shaft, cover-type nuts, fixing bases, end sockets, a coupler, a rotating-anchor-type stirrer body, fixing-type stirrer bodies, rotating stirrer blades, fixing stirrer blades, scratch boards, device flanges and a tank. The fixing-type stirrer bodies are installed at the top ends of the end sockets on the two sides of a stirring shaft of the rotating-anchor-type stirrer body, the scratch boards are installed on the outer sides of supports on the two sides of the rotating-anchor-type stirrer body, and the rotating stirrer blades and the fixing stirrer blades are correspondingly and alternately installed on the stirring shaft and fixing shafts. The hygiene-grade rotating-anchor-type and fixing-type combined blade stirrer has the advantages that the angle positions of all the blades can be installed according to the requirement of technology operation to meet the requirements of the different working conditions; the stirring range of the stirrer is wide and almost free of dead corners, and full stirring can be guaranteed; when materials with different production technologies are stirred, the device is flexible in assembling, reliable in fixing and quite convenient to disassemble, assemble, replace, wash and maintain.

Owner:SHANGHAI SANQIANG VESSEL NANTONG CO LTD

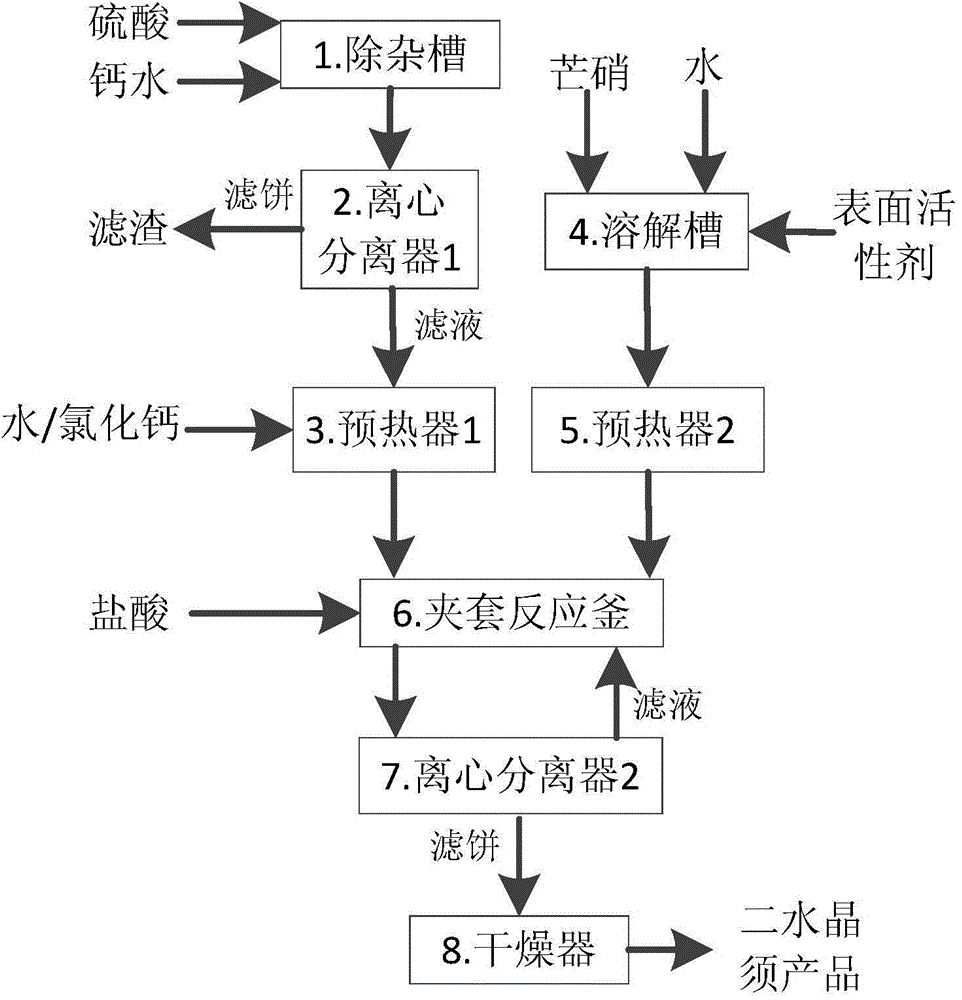

Method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water

ActiveCN104894650AUniform length and diameterUniform aspect ratioPolycrystalline material growthFrom normal temperature solutionsChemical industrySocial benefits

The invention discloses a method for preparing calcium sulfate dihydrate whisker from mirabilite and calcium water. The normal-pressure acidification process, which is utilized to produce the dihydrate gypsum whisker from industrial calcium water and mirabilite, can effectively utilize industrial wastewater (calcium water and mirabilite), solves the problem of discharge of the industrial wastewater, achieves the goal of green chemical industry, and completely conforms to the national industrial policy. The gypsum whisker belongs to a high-tech environment-friendly product, has the advantages of wide market demand prospects and obvious economic benefits, and has sufficient and cheap raw material resources in the local region after being put into production. The method is simple and easy to implement, and can easily implement industrialization. Therefore, the project can obtain huge economic benefit and social benefit if being researched and finally constructed in the local region. The finally obtained calcium sulfate dihydrate whisker has the advantages of uniform shape, proper length-diameter ratio (50 above), high yield (up to 84%) and high whiteness (at least 96%).

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING

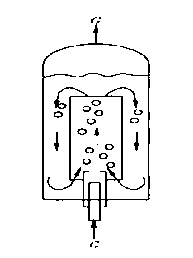

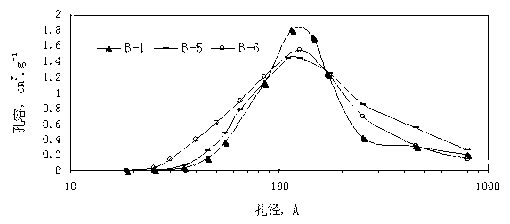

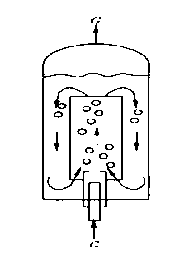

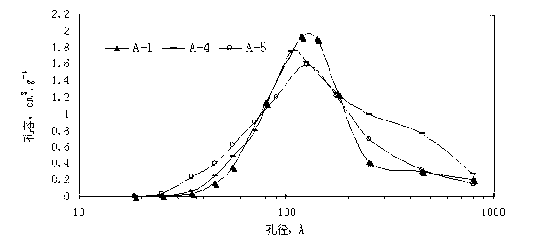

Alumina carrier and its preparation method

ActiveCN103100428ALarge hole volumeLarge specific surface areaCatalyst carriersCarbonizationFuel oil

The invention discloses an alumina carrier and its preparation method. The alumina carrier is prepared in a loop reactor by a carbonization method. The preparation method comprises: placing a reaction material in the loop reactor, then jetting a mixed gas of air and / or an inert gas and CO2 into the reactor, and making use of the directional and regular circular flow of the fluid inside the loop reactor to make the fluid fully mixed, thus achieving gelatinizing at one time. The obtained alumina carrier has the characteristics of large pore volume, large pore diameter, and concentrated pore size distribution, thus being especially suitable to serving as a heavy oil or residual oil hydrodemetallization catalyst carrier.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for degrading cellulose by synergic action of mechanical activation and metal salt

The invention discloses a method for degrading cellulose by synergic action of mechanical activation and a metal salt, belonging to the field of biomass energy and fiber chemicals. The method comprises the following steps: (1) crushing cellulose which serves as a raw material, and screening with a screen of 10-200mesh; (2) mixing the crushed and screened cellulose with a metal salt at a weight ratio of 1:(0.001-0.1) uniformly; and (3) adding the materials mixed uniformly into a mechanical activation reactor, adjusting the mechanical activation temperature to 30-90 DEG C, activating the materials mechanically for 10-180 minutes, and taking the obtained cellulose degradation product out of the mechanical activation reactor. Because the cellulose is degraded by synergic action of mechanical activation and the metal salt, the degree of polymerization of the cellulose can be reduced greatly in a mild condition, the accessibility and the reaction activity of the cellulose degradation product can be improved greatly, and hydrolysis and modification reaction of cellulose can be realized. Little energy is consumed in the whole reaction process, the process for degrading cellulose is simple, the production cycle is short, the cellulose is degraded only under the mechanical force of a ball mill, and the requirement for production equipment is low.

Owner:GUANGXI UNIV

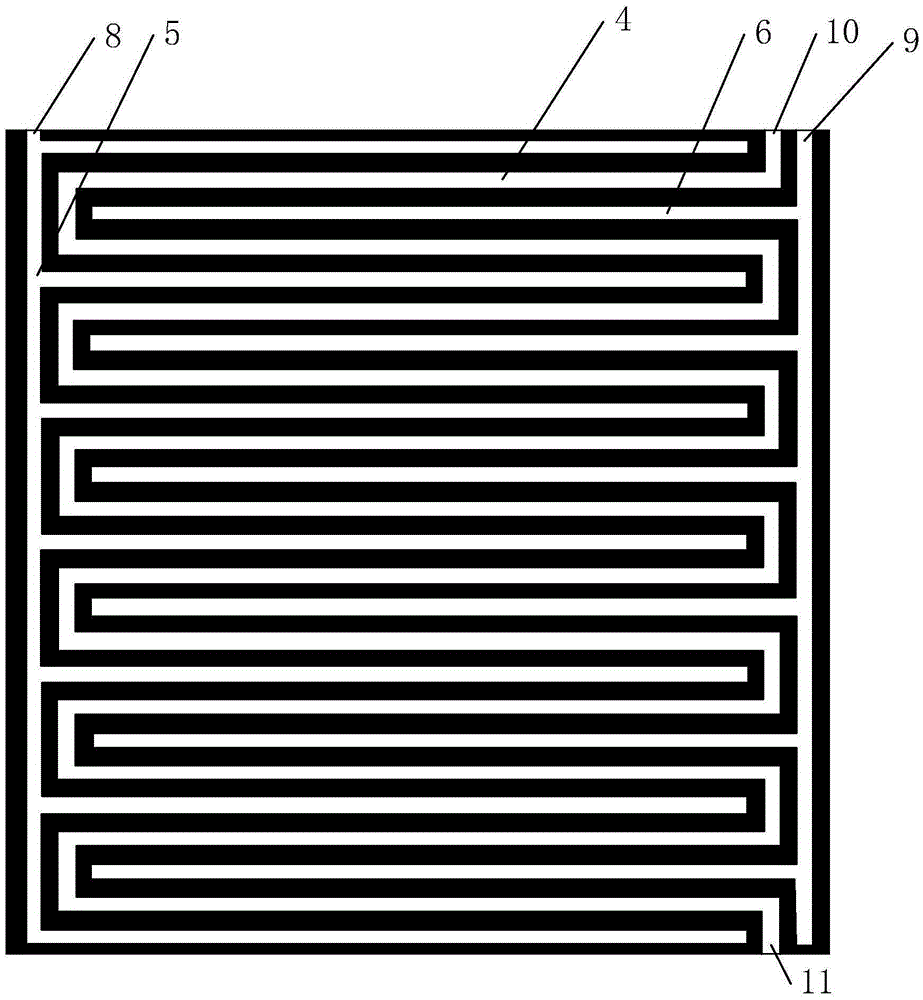

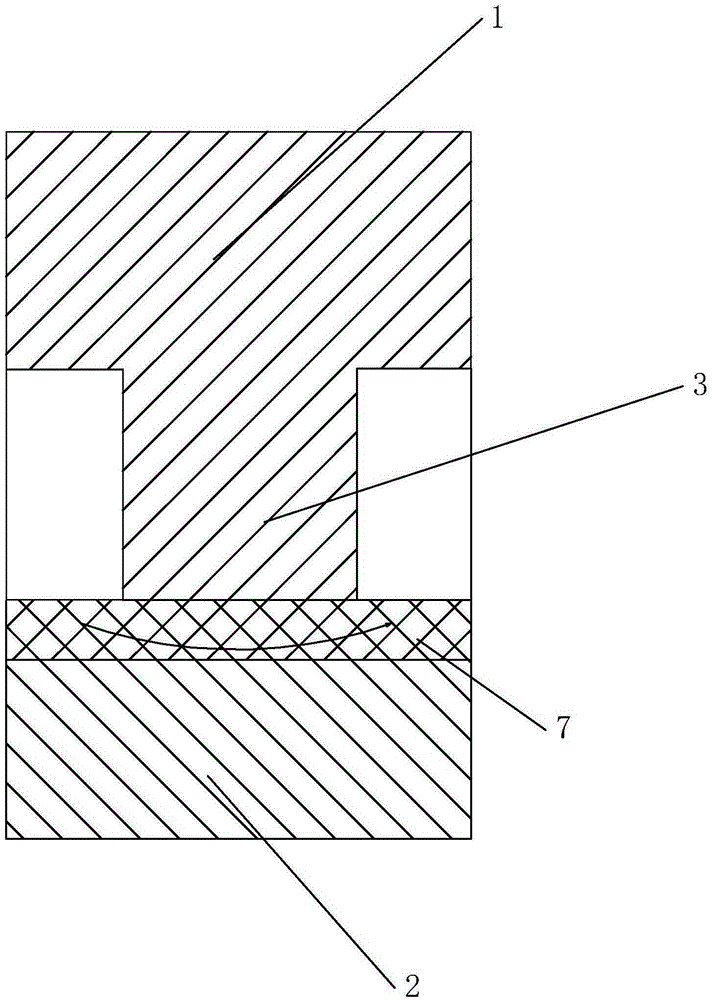

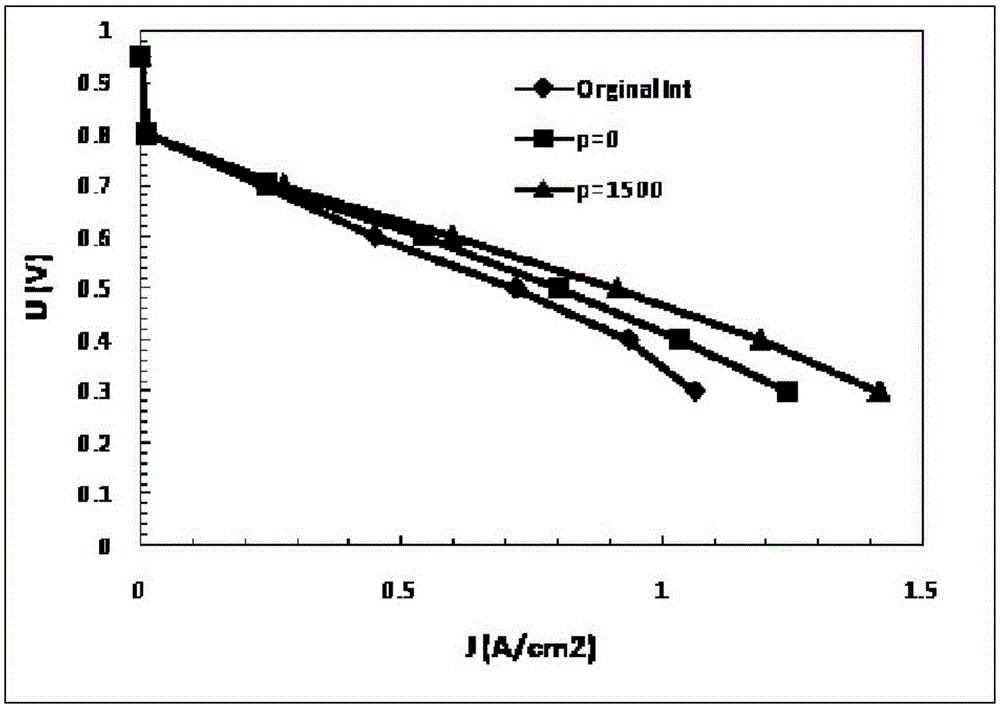

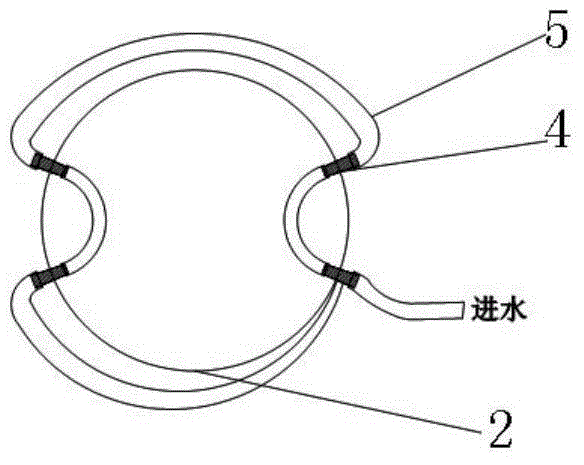

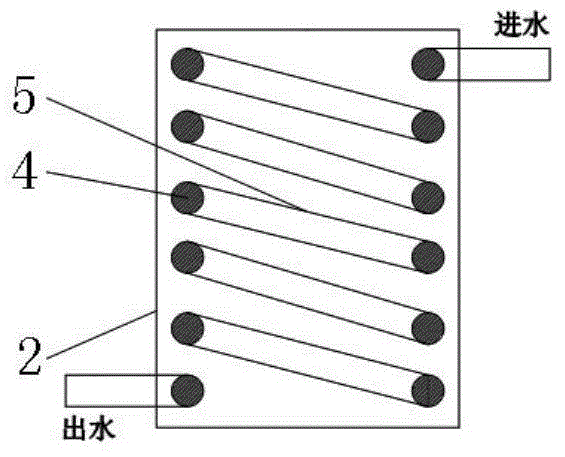

Active drainage flow field for bipolar plate of proton exchange membrane fuel cell

ActiveCN105244517AReduces uneven pressure distributionUniform mass transferCell electrodesCollectors/separatorsDrainage flowEngineering

The invention relates to an active drainage flow field for a bipolar plate of a proton exchange membrane fuel cell. The flow field is in a form of a rectangle, a first air inlet runner and a second air inlet runner are of interdigitated structures and arranged at the two sides, and a drainage runner is of a snakelike structure, is arranged between the first air inlet runner and the second air inlet runner, serves a reaction gas outlet runner and also serves as an active drainage runner. With the design of the active drainage runner, the defect of easiness in water logging of the traditional interdigitated structure can be overcome, thus, the effective reaction area is increased, and the performance and the stability of the cell are improved.

Owner:ZHEJIANG UNIV OF TECH

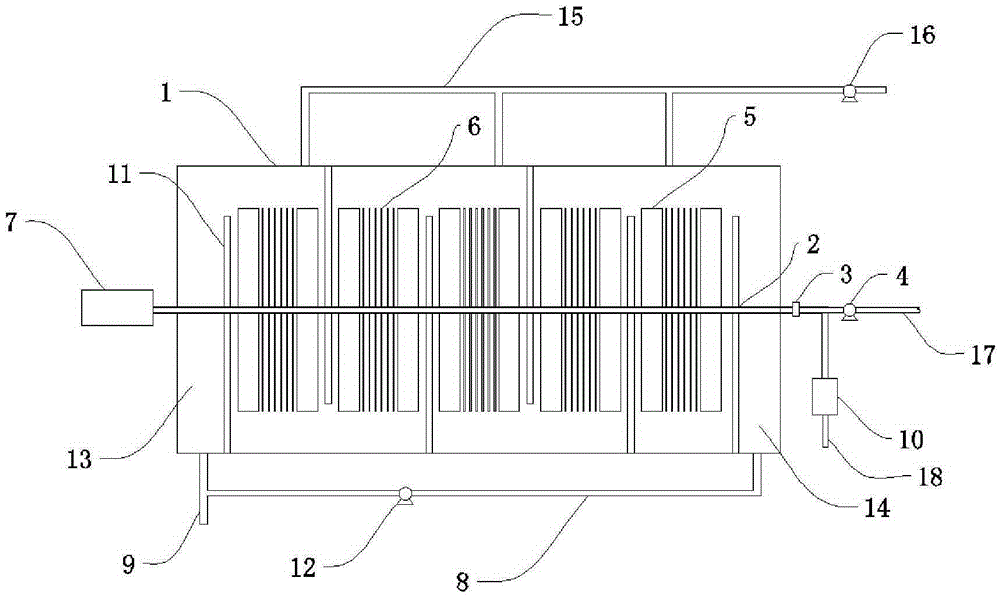

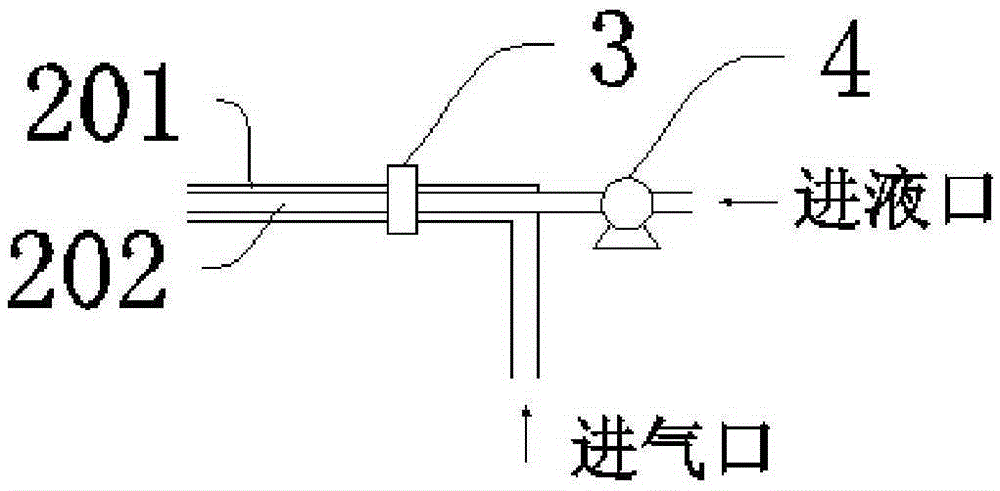

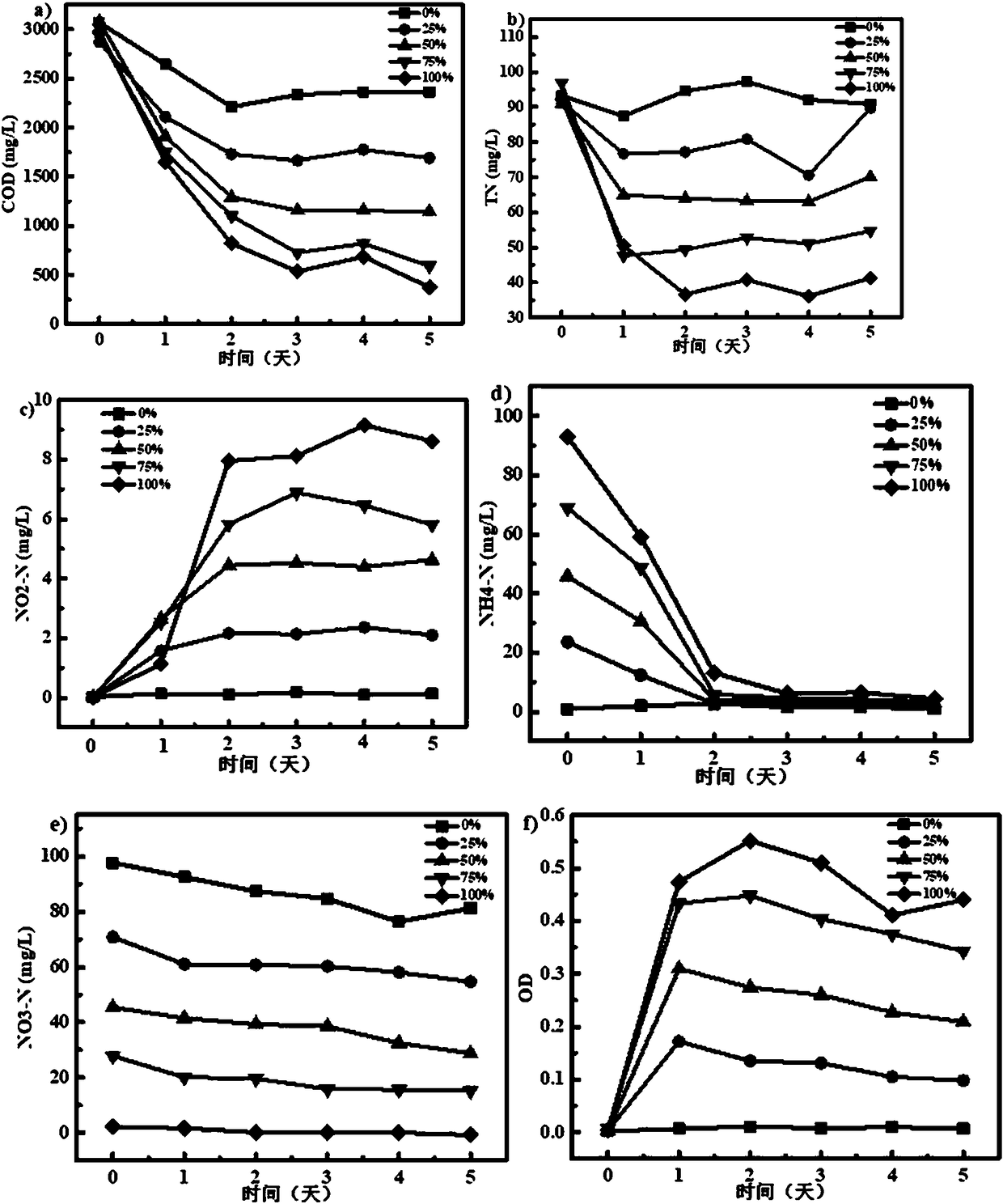

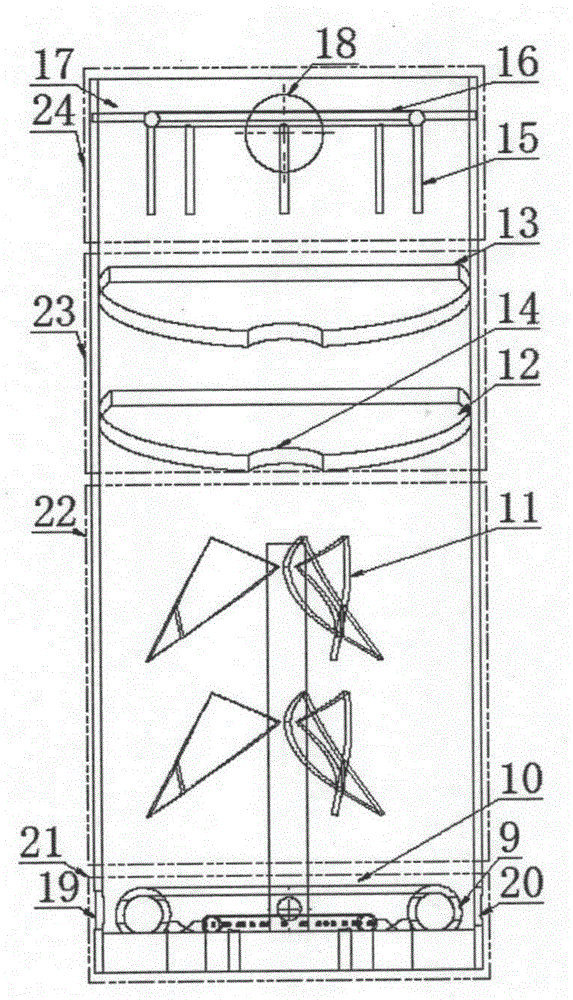

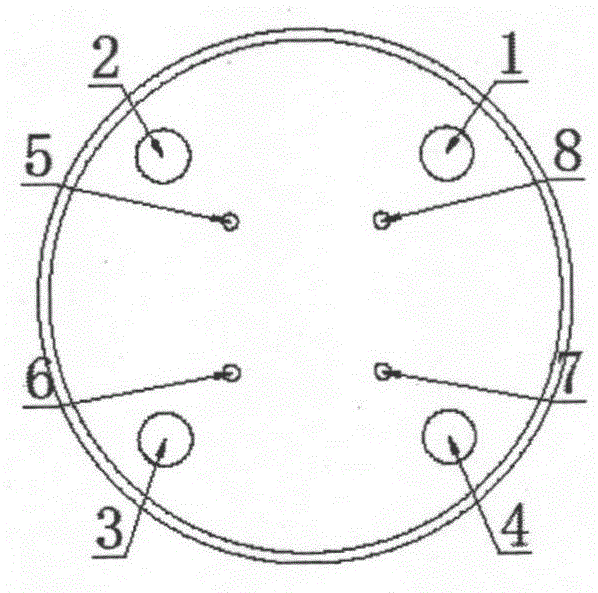

Integrated reactor based on electrode-supergravity biological rotating discs and treatment method therefor

ActiveCN105347464APromote denitrificationDissolve fastGas treatmentTreatment by combined electrochemical biological processesHigh concentrationWastewater

The invention discloses an integrated reactor based on electrode-supergravity biological rotating discs and a treatment method therefor. A center shaft is arranged inside the reactor, the shaft body structure of the center shaft is a coaxial double-layer sleeve, two parts namely an air passage and a liquid passage are formed, and a through hole is formed in the outer wall of the air passage. The interior of a shell is partitioned into a plurality of communicated cavities by partition boards, each cavity is internally provided with two biological rotating discs which are fixed on the center shaft and are connected to a cathode and an anode of a power supply respectively, and the biological rotating discs serve as pairing electrodes while being taken as biofilm formation carriers. A plurality of hollow fibrous membranes are densely arranged in the middle of each disc body. According to the reactor disclosed by the invention, three technologies of electrodes, supergravity and biological rotating discs are organically combined into one reactor, so that the reactor can utilize the supergravity to carry out high efficiency mass transfer on nitrogen-containing waste gas; the nitrogen-containing waste gas is quickly dissolved in waste water; and then the biological rotating discs serve as the electrodes, so that the denitrification of microorganisms is promoted. The reactor is suitable for synchronously removing the nitrogen-containing waste gas and waste water with high concentration, and the treatment effect is greatly superior to that of an ordinary reactor.

Owner:浙江省环境监测中心

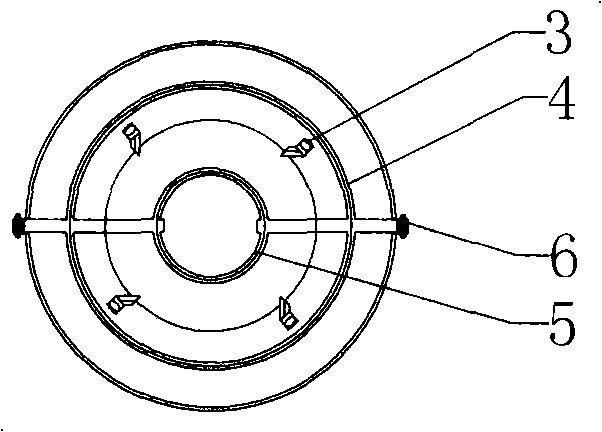

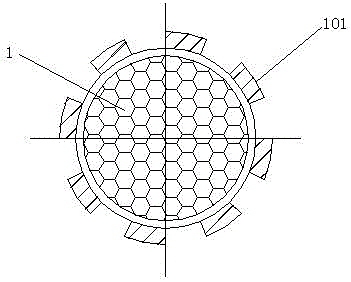

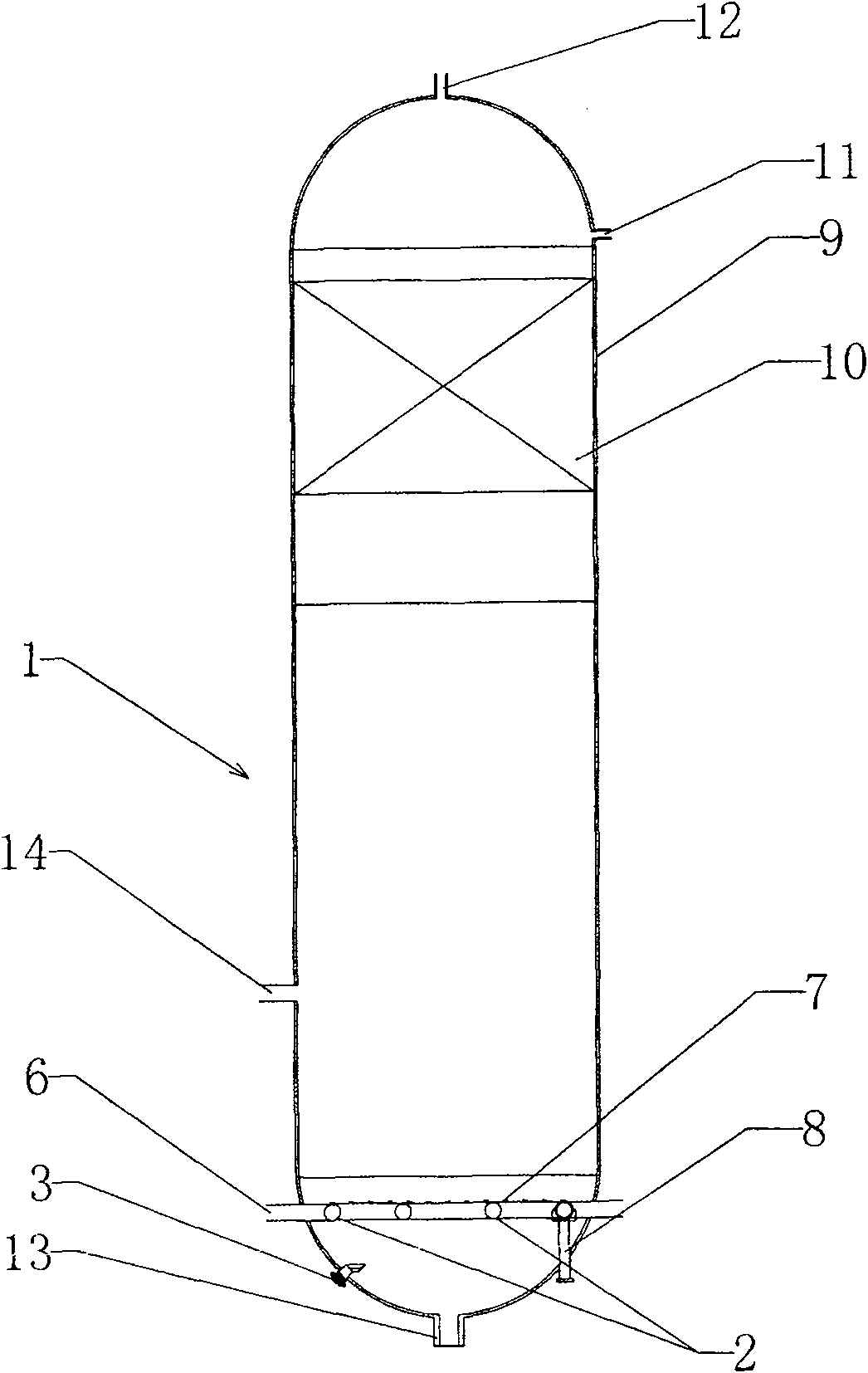

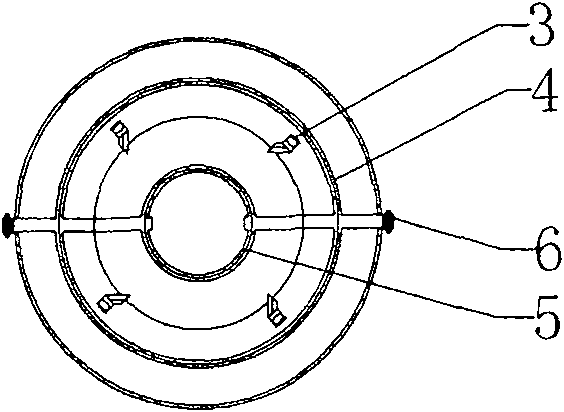

PX oxidation reactor for producing terephthalic acid

ActiveCN101513601AAvoid destructionMeet the need for suspensionOrganic compound preparationCarboxylic compound preparationNuclear engineeringHigh-temperature corrosion

A PX oxidation reactor for producing terephthalic acid comprises a reactor housing; the reactor housing is can-shaped, the ratio of height to diameter is 2.8 to 5, and the bottom of the reactor housing is provided with a distributed inlet duct and a spiral-flow type inlet duct; the distributed inlet duct comprises an upper air flow distribution tube and a middle air flow distribution tube, and the air flow distribution tubes are in the shape of circular rings; the number of spiral-flow inlet tubes is multiple, and the tubes are uniformly arranged surrounding the reactor wall. A combined air inlet gyration device used in the invention pushes the fluid at the bottom of the reactor by proper amount of air so that the reactor conducts rotary motion; the air has good dispersion and uniform distribution, and the material remains in normal suspended state; and the ratio of height to diameter between a high temperature reactor and a low temperature reactor is used, thereby avoiding non-uniform distribution existing in the low temperature reactor with big ratio of height to diameter and also being better than the high temperature reactor in the aspect of low power consumption.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

High-shear baffled reactor

InactiveCN106732210AEvenly distributedWell mixedCatalytic liquid-gas reactionRotational axisChemical industry

The invention relates to the field of chemical industry, and particularly relates to a high-shear baffled reactor. The reactor can be used for the reaction, the separation or the mixing of multiphase systems such as liquid-liquid, gas-liquid, gas-liquid-solid, liquid-solid, gas-solid and the like, and comprises a rotating body, a shell and a liquid distributor, wherein the rotating body comprises a rotating shaft, an upper end cover, a lower end cover and multiple layers of baffle plates which are arranged between the upper end cover and the lower end cover; the rotating shaft stretches into the shell to be connected with the lower end cover; the lower end cover is connected with the upper end cover through a plurality of pins which are arranged on the lower end cover in an annular shape; the upper end cover is in a circular-ring shape; the upper end cover is connected with the shell through an annular sealing device. The high-shear baffled reactor is simple in structure; the rotation of the rotating body is utilized; the baffle plates are rotated along with the rotating body; the high-speed shear and disturbance on gas-phase fluid and liquid-phase fluid and the like and the uniform distribution of the fluid in the rotating body are realized; thus, the multiphase systems are enabled to quickly achieve the uniform mixing of a molecular scale and quick mass transfer; the reaction rate, the mass transfer rate and the product yield are improved.

Owner:西安强华环保科技有限公司

Production of uniform polyphenylene terephthalamide fibre

ActiveCN101220530AStrong anti-aliasingImprove self-cleaning effectWet spinning methodsMonocomponent polyamides artificial filamentFiberPolymer science

The invention relates to a manufacturing method of homogeneous polyphenylene terephthalamide fibers. The polyphenylene terephthalamide fibers with high homogeneity can be produced by thoroughly mixing PPTA resin with 98 to 100 percent of concentrated sulfuric acid in an anisotropic twin-screw extruder, putting the mixture of the PPTA resin and 98 to 100 percent of the concentrated sulfuric acid into a homotropic twin-screw extruder to be dissolved, and leading the mixture through a filter equipment, a continuous film deaeration device and rectangular spinneret holes to carry out dry-jet and wet spinning. By adopting the anisotropic twin-screw extruder to mix materials, the manufacturing method has the advantages of easy feeding, strong mixing effect and weak shearing effect; the continuous film deaeration device can realize uniform and fast deaeration of high viscous PPTA / H2SO4 liquid crystal slurry; the spinneret holes which are arranged in a rectangle shape can ensure a larger contact area between injection tows and solidification liquid, and more even mass transfer and heat transfer between fibers and solidification liquid, thus facilitating the spinning of polyphenylene terephthalamide fibers with high homogeneity.

Owner:SINOCHEM HIGH PERFORMANCE FIBER MATERIALS CO LTD

Aluminum hydroxide and preparation method thereof

The invention discloses an aluminum hydroxide method and a preparation method thereof. The aluminum hydroxide is prepared by a carbonation method in a loop reactor. The method specifically comprises steps of: adding a small amount of an organic pore-expanding agent and a defoaming agent into a sodium metaaluminate solution; placing the solution in the loop reactor; and then injecting a mixed gas of air and / or inert gas and CO2; thoroughly mixing the fluid by using directed regulatory circulation flow of the fluid in the loop reactor, so as to gelatinize at one time and generate pseudo-boehmite with uniform grains; and roasting the pseudo-boehmite to obtain alumina with large pore volume, large pore diameter and concentrated pore distribution. The aluminum hydroxide can be used as a carrier component of an adsorbent or a catalyst, and preferably as a carrier component for a heavy oil hydrogenation demetalation catalyst.

Owner:CHINA PETROLEUM & CHEM CORP +1

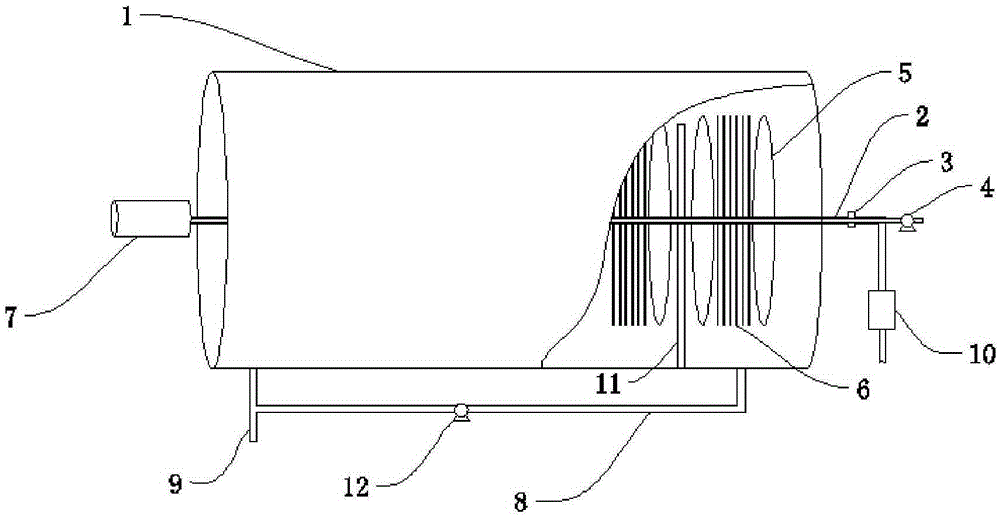

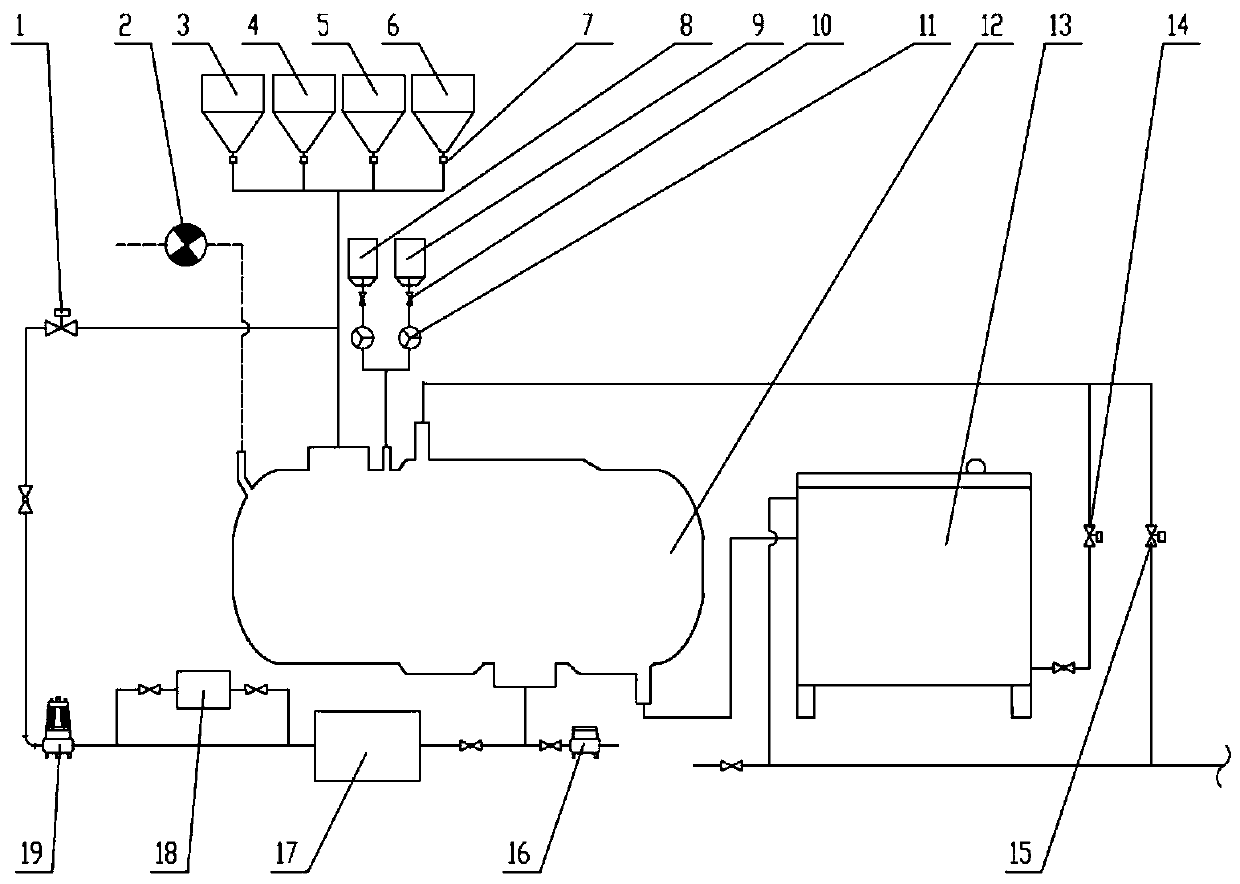

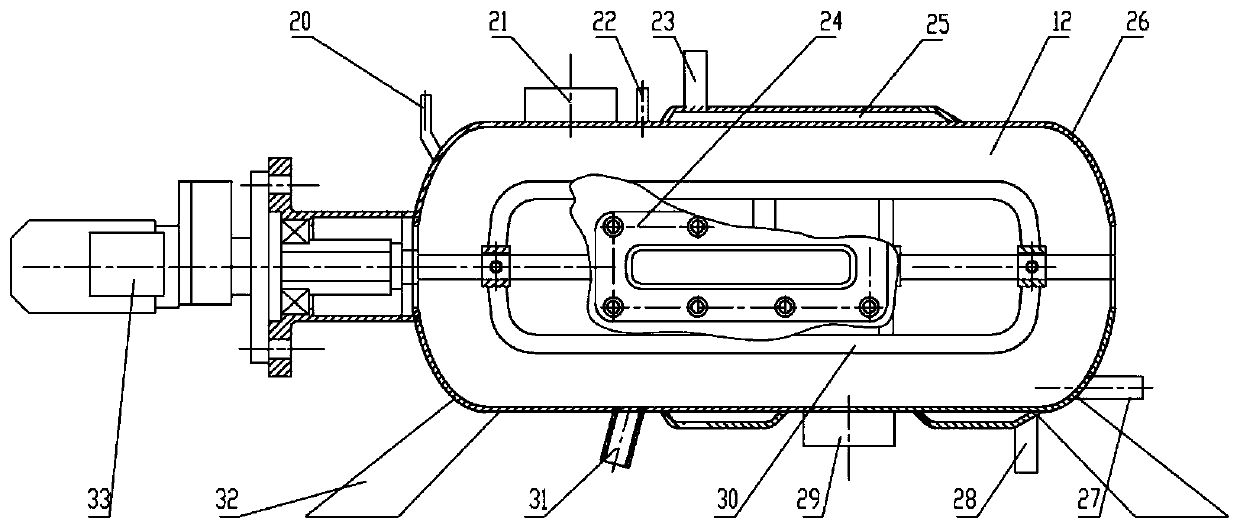

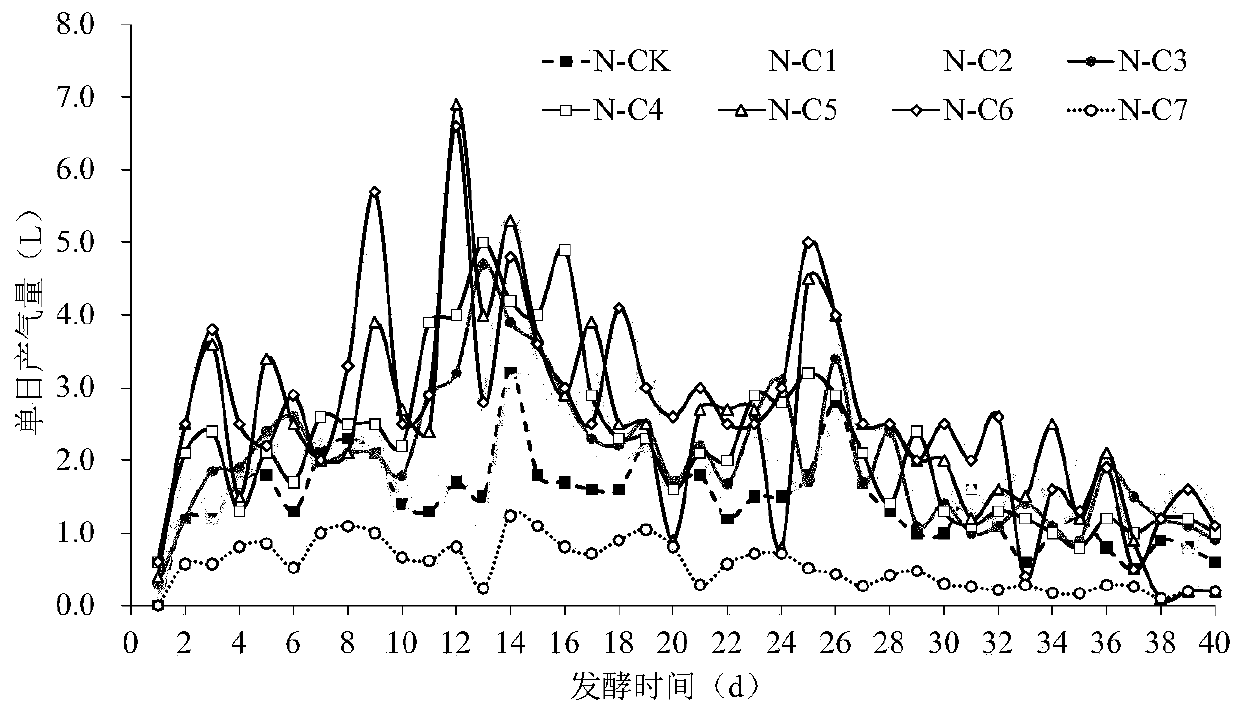

Agricultural waste dry-process anaerobic-fermentation automatic control device and automatic control operation method

PendingCN110055172AUniform mass transferStable responseBioreactor/fermenter combinationsBiological substance pretreatmentsWater bathsAutomatic control

The invention provides an agricultural waste dry-process anaerobic-fermentation automatic control device and an automatic control operation method. The device comprises a horizontal closed fermentation tank, wherein the top of the tank body is provided with a feeding port, and the bottom of the tank body is provided with a discharging port; the fermentation tank is provided with a mechanical stirring system, a water bath circulating heating system, a temperature on-line monitoring system, a pH on-line monitoring system, a gas flow monitoring system and a PLC control system. The method comprises the steps of automatically controlling dry material wet material feeding, inoculum and N source addition through the PLC control system, automatically controlling the temperature and pH value of anaerobic fermentation in running anaerobic fermentation, automatically controlling biogas slurry to flow back to a feeding end, and adjusting and controlling the solid content rate of a reaction material to be 15-20%; automatically stirring turning the materials in time. The device can monitor the biogas production characteristics and potential of different material ratios and especially aims at solving the problem that the types and proportions of agricultural wastes in different regions are different, and the optimal operation parameter testing device is provided for improving the combined dry-process anaerobic treatment efficiency of various agricultural wastes.

Owner:SHANGHAI ACADEMY OF ENVIRONMENTAL SCIENCES

Device and method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction

InactiveCN105013210AReduce concentrationImprove absorption efficiencyAmino compound purification/separationLiquid solutions solvent extractionWastewaterOrtho-Toluidine

The invention relates to a device and a method for recovering and concentrating ortho-toluidine in ortho-toluidine wastewater by membrane extraction. The method comprises: conveying wastewater containing ortho-toluidine to a silicon rubber extraction membrane tube, wherein the silicon rubber extraction membrane tube is put in an acidic extraction solution, ortho-toluidine in the wastewater can penetrate through the tube wall of the silicon rubber extraction membrane tube, enter into the extraction solution and react to generate ortho-toluidine ions, and the rest of the wastewater is discharged from the outlet of the silicon rubber extraction membrane tube with standard level or post-treatment; and taking out the extraction solution when the concentration of the ortho-toluidine ions in the extraction solution exceeds a predetermined value, and adding alkali liquor into the extraction solution to obtain recovered and concentrated ortho-toluidine. According to the device and method provided by the invention, the extraction solution is acidic and is reacted with alkalescent ortho-toluidine to generate the ortho-toluidine ions which cannot penetrate through the silicon rubber extraction membrane tube so as to prevent the ortho-toluidine from returning to the wastewater again. A lot of ortho-toluidine can be separated and concentrated, the mass transfer velocity is relatively rapid, industrial treatment and concentration and recovery of the ortho-toluidine are facilitated, and the use level of the extraction solution is extremely little.

Owner:SHAANXI UNIV OF SCI & TECH

Texture forming method of air-dried beef and mutton

ActiveCN103719887AAchieve non-cryogenic constitutionReduce manufacturing costFood thermal treatmentFood mechanical treatmentFlavorCombined method

The invention relates to a texture forming method of air-dried beef and mutton. The method provided by the invention is a combined method of vacuum stirring and salting and gradient temperature air drying. The method specifically comprises the following steps: adding additives in minced raw material beef and mutton according to a proportion, and carrying out vacuum stirring to uniformly mix the raw material and form gel; putting the stirred meat stuffing in a stainless steel tray, leveling and compacting the meat stuffing, and statically salting the meat stuffing in a salting room; reversely pouring the salted raw material meat on a wire mesh screen, and pushing the wire mesh screen into an air drying room to air-dry the salted raw material meat to 60% of the original weight at a gradient temperature; and cutting the air-dried large meat pie to different specifications to finish the texture formation, and processing the meat according to different ripening processes. By adopting the texture forming method provided by the invention, non-refrigeration texture forming of minced raw material meat is achieved, the cost is low, the raw material source is wide, the yield of the air-dried beef and mutton is increased by 3-5%, the uniform transfer of the additives is guaranteed, and a technological base is laid for the development of air-dried beef and mutton products with a variety of flavors and appearances.

Owner:INST OF AGRO FOOD SCI & TECH CHINESE ACADEMY OF AGRI SCI

Pyrolysis device for tar residue

InactiveCN107502381AReasonable structural designFast heat conductionIndirect heating destructive distillationCoking carbonaceous materialsFlue gasTar

The invention relates to the technical field of structure design of a pyrolysis device and specifically relates to a pyrolysis device for tar residue. The device comprises a horizontal drum, a flue gas sleeve and a rotating shaft, wherein the flue gas sleeve is arranged on the exterior of the horizontal drum; the rotating shaft is arranged in the horizontal drum along the axial direction of the horizontal drum; interconnecting holes which are communicated with the flue gas sleeve are equidistantly formed in the horizontal drum; scraper blades are equidistantly connected with the rotating shaft; the surfaces of the end parts of the scraper blades are matched with arc-shaped walls in the horizontal drum; the interconnecting holes are equidistantly formed between the adjacent scraper blades. The structure design of the pyrolysis device for tar residue, provided by the invention, is reasonable; the thermal conductivity is higher; the production efficiency is effectively increased; the arrangement of the parallel tubes and equidistant interconnecting holes is beneficial to the uniform mass transfer of the exhaust gas; the arrangement of the scraper blades is beneficial to the prevention for the bonding of the tar residue in the drum; the pyrolysis device is convenient, practical and suitable for further popularization and application.

Owner:邓玉平

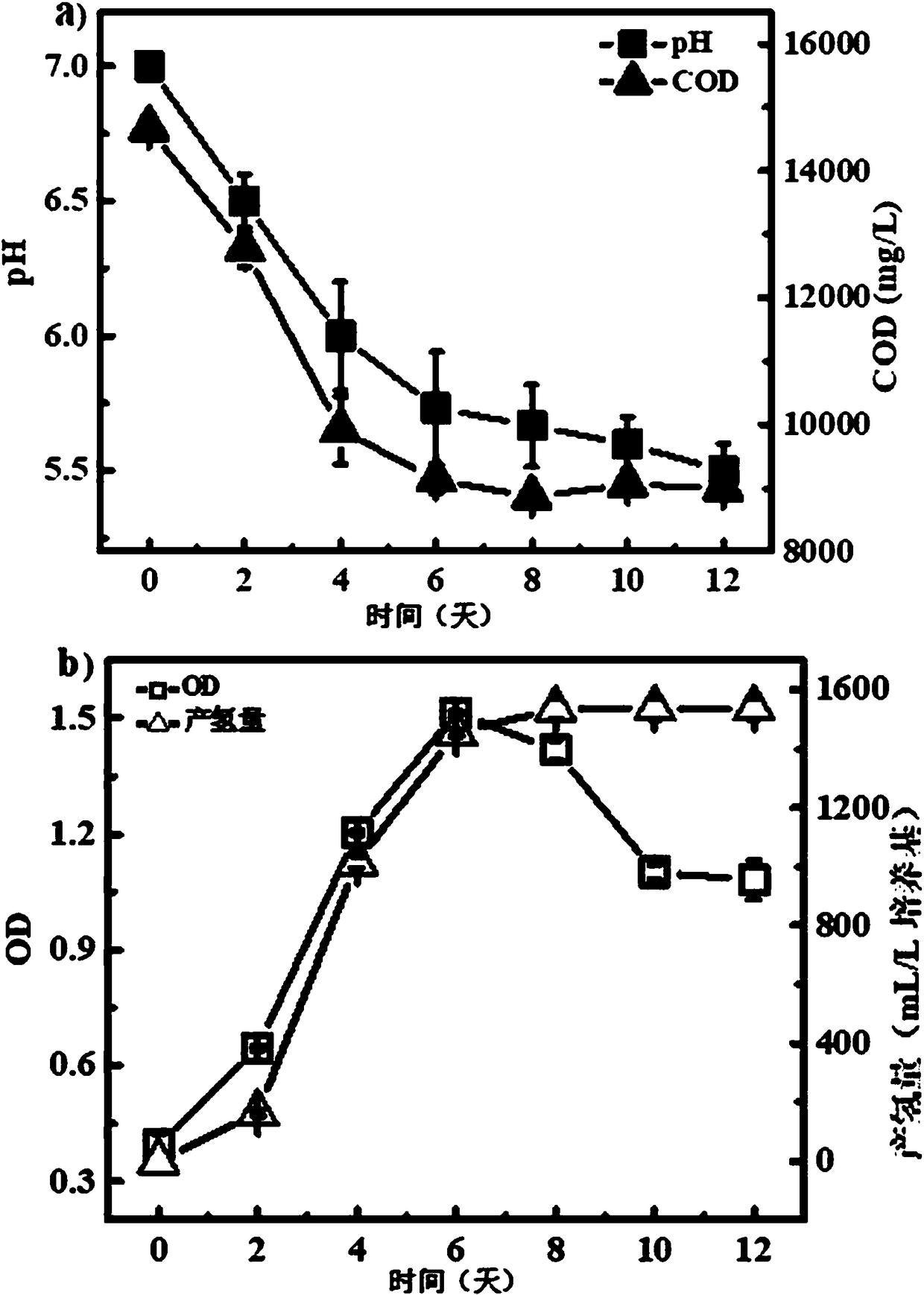

Photo microbial fuel cell can be used for simultaneous processing of high concentration starch waste water and carbon source-free nitrate-containing waste water, and applications thereof

ActiveCN109250805AGood power generation performanceFast degradationTreatment by combined electrochemical biological processesWater contaminantsHigh concentrationCarbon felt

The invention belongs to the technical field of waste water processing with microbiological fuel cells, and discloses a photo microbial fuel cell can be used for simultaneous processing of high concentration starch waste water and carbon source-free nitrate-containing waste water, and applications thereof. The photo microbial fuel cell can be used for simultaneous processing of high concentrationstarch waste water and carbon source-free nitrate-containing waste water is capable of solving problems in the prior art that in processing of low carbon source nitrogen-containing waste water with conventional biological method, extra carbon sources are needed, cost is increased, energy recycling is impossible to realize, and efficiency of single processing of high concentration starch waste water is low. According to the photo microbial fuel cell, a cathode chamber is fixedly arranged on the internal wall of an anode chamber, a cathode water inlet and a water outlet are arranged on two circular organic parts respectively, and are communicated with the outside part of the anode chamber through pipelines; an anode water inlet and the cathode water inlet, an anode water outlet and the cathode water outlet are arranged in the same directions; an anode carbon felt loaded with photosynthetic bacteria is arranged in the anode chamber, a cathode carbon brush loaded with nitrifying bacteria is arranged in the cathode chamber; a complete circuit is formed through connection of the anode and the cathode with an external resistor. Starch waste water COD removing rate ranges from 80 to 90%, nitrate nitrogen removing rate is higher than 95%, and simultaneous processing of high concentration starch waste water and carbon source-free nitrate-containing waste water is realized.

Owner:TAIYUAN UNIV OF TECH

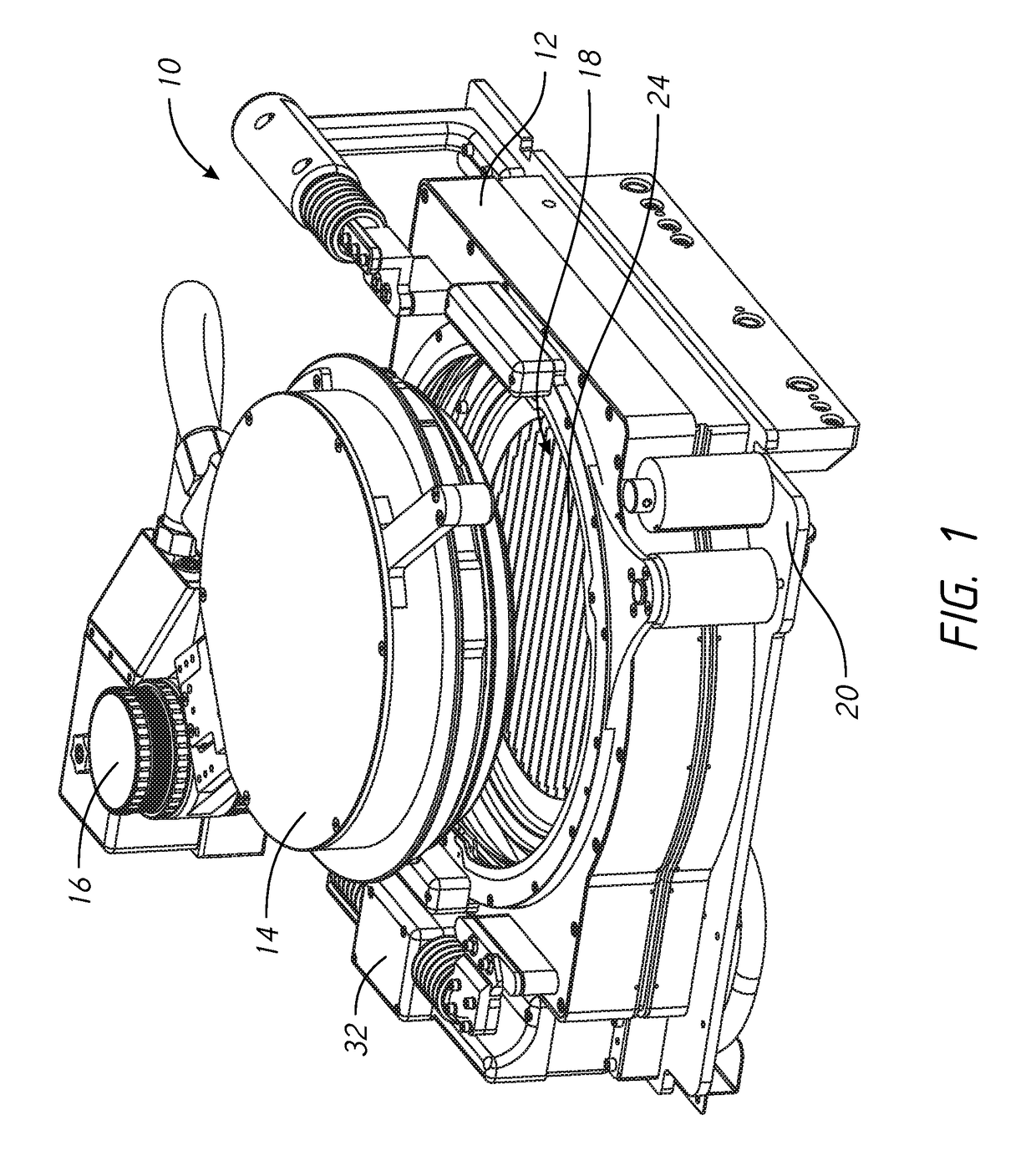

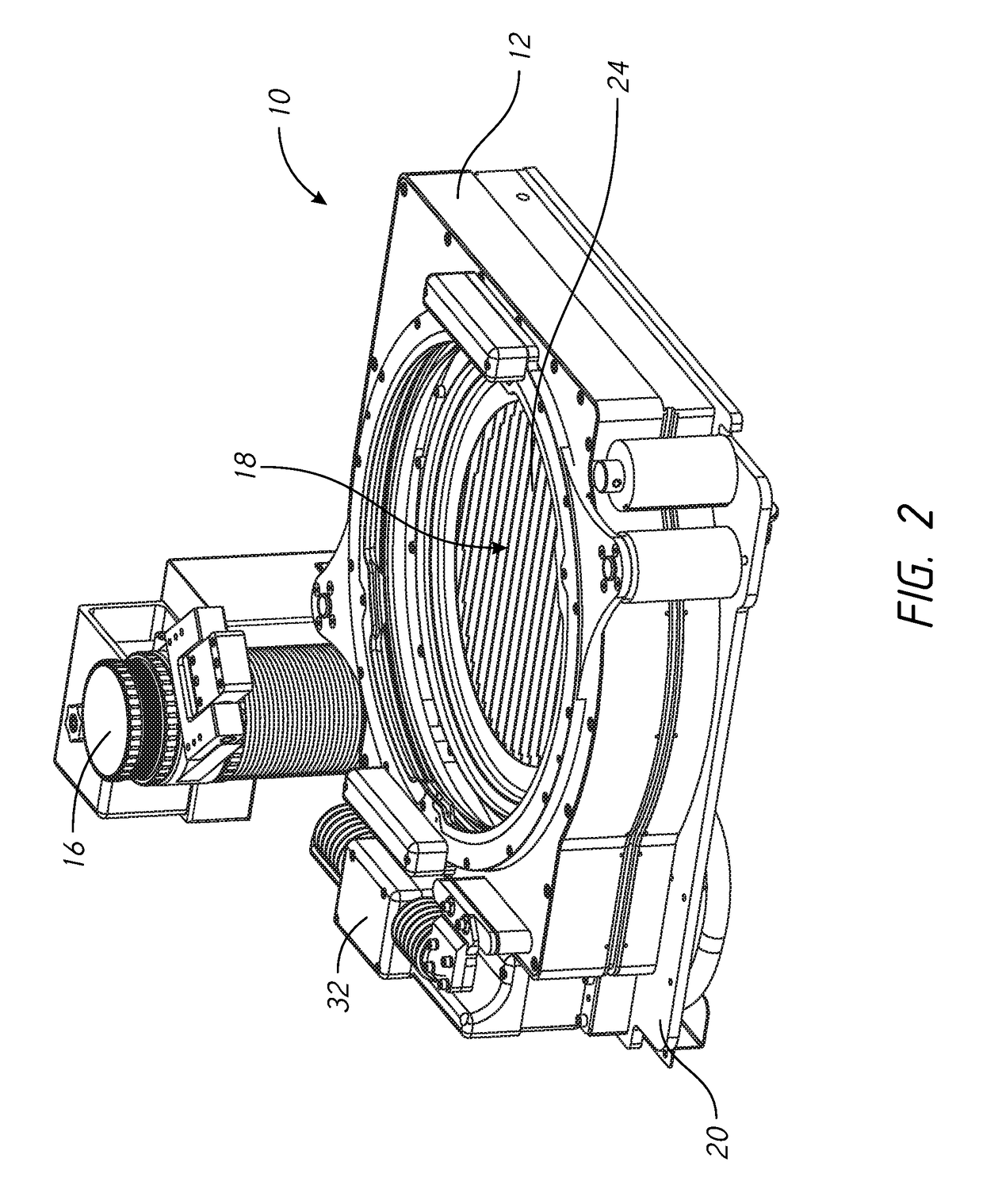

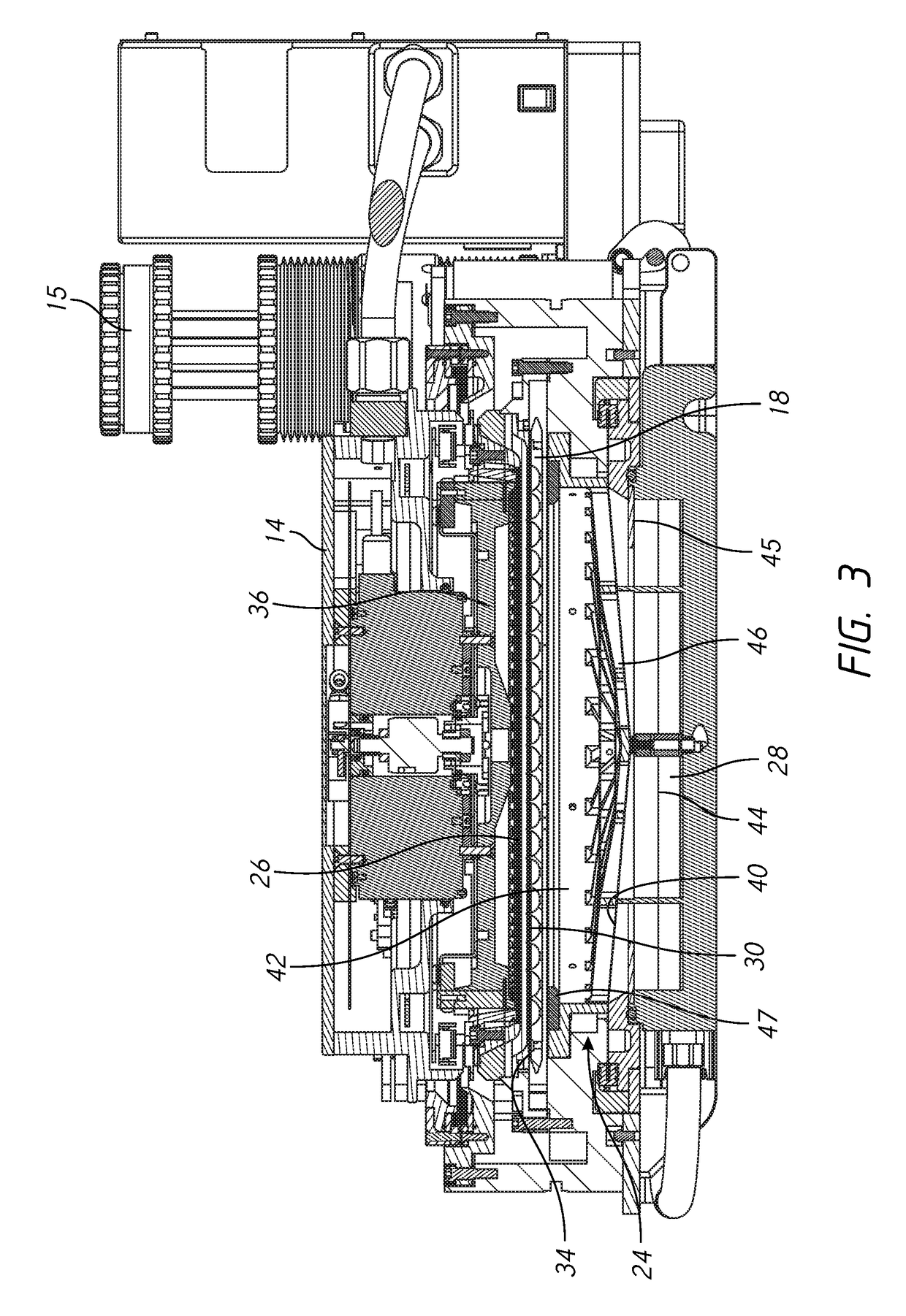

Electroplating apparatus with electrolyte agitation

Electroplating apparatus agitates electrolyte to provide high velocity fluid flows at the surface of a wafer. The apparatus includes a paddle which provides uniform high mass transfer over the entire wafer, even with a relatively large gap between the paddle and the wafer. Consequently, the processor may have an electric field shield positioned between the paddle and the wafer for effective shielding at the edges of the wafer. The influence of the paddle on the electric field across the wafer is reduced as the paddle is spaced relatively farther from the wafer.

Owner:APPLIED MATERIALS INC

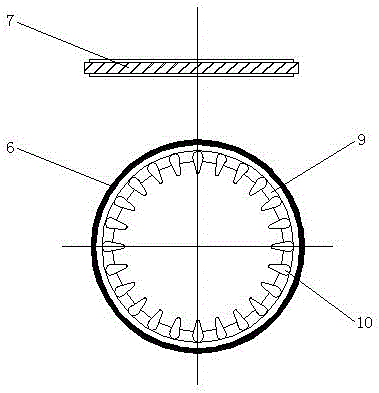

Novel structured corrugated packing without wall flow

PendingCN106732321AImprove separation efficiencyUniform mass transferChemical/physical/physico-chemical processesEngineeringMass transfer

The invention discloses novel structured corrugated packing without wall flow. The novel structured corrugated packing comprises first-layer corrugated packing nets, a third-layer corrugated packing net, a middle fixing hoop ring and a flow guide plate. The first-layer corrugated packing nets are connected with second-layer corrugated packing nets by first fixing hoop rings, the third-layer corrugated packing net is connected with the corresponding second-layer corrugated packing net by a second fixing hoop ring, a first pattern drainage wall is fixed to the outer side of the third-layer corrugated packing net, the middle fixing hoop ring is positioned between the third-layer corrugated packing net and a fourth-layer corrugated packing net, and the flow guide plate is positioned on the inner side of the middle fixing hoop ring. The novel structured corrugated packing without the wall flow has the advantages that mass transfer can be uniformly carried out on liquid, the liquid on inner walls can be preliminarily blocked and can be prevented from downwardly flowing from the inner walls, liquid which is permeated into the inner walls can be guided and can flow onto the flow guide plate, the liquid on the inner walls can be guided to the inner sides of the packing nets, uniform mass transfer can be carried out again, accordingly, wall flow effects can be effectively prevented, and the separation efficiency of the packing can be improved.

Owner:NANTONG SUTONG SEPARATION ENG & TECH

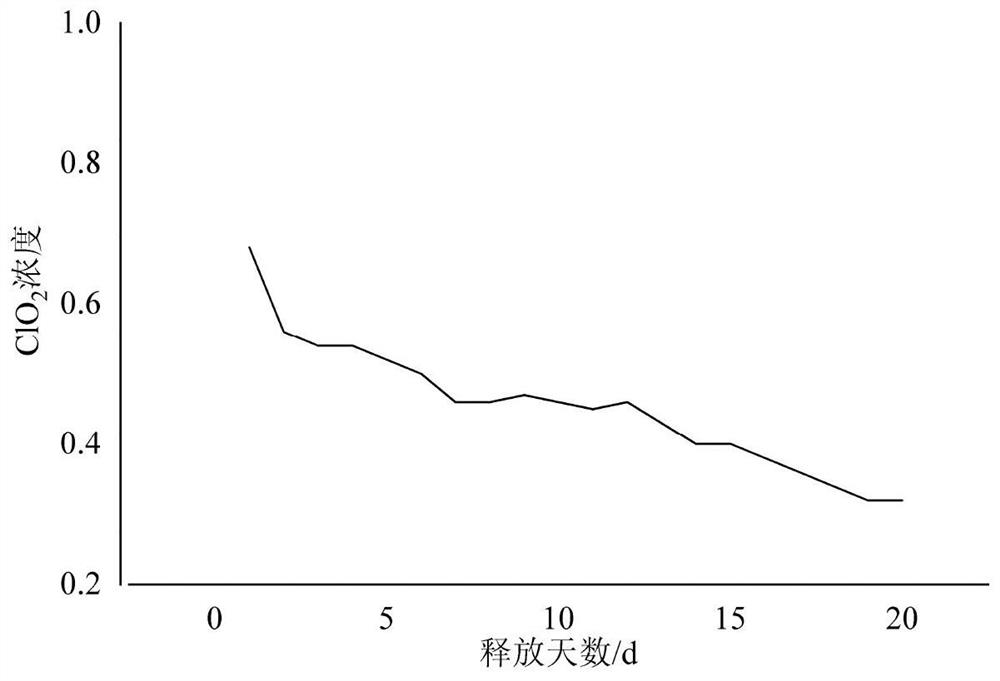

Chlorine dioxide purification gel powder and preparation method thereof

The invention discloses chlorine dioxide purification gel powder and a preparation method thereof. The chlorine dioxide purification gel powder comprises a starch polymerization resin activator and chlorite, wherein the mass of the starch polymerization resin activator is 1 to 10 times that of the chlorite, the chlorine dioxide purification gel powder also comprises a stabilizer, a regulator and acatalyst, and the five components are uniformly mixed and are powdery. The product is safer and more stable, so that the product is more stable before being activated, and the storage life can be prolonged to 2-3 years; the product is released more uniformly; after water is added for activation, mass transfer is uniform in the reaction process, chlorine dioxide is released more stably, and the phenomenon that the content is rapidly reduced due to explosion release as soon as the chlorine dioxide is activated is avoided, and the effect is more rapid; meanwhile, due to the fact that protons andwater-absorbing resin are completely fused into a whole, under the action of a catalyst, a rapid reaction can be achieved after water is added, the effect can be achieved within 30 s, and chlorine dioxide is released; in addition, the gel powder is safe and environment-friendly, and is prepared from degradable and inorganic components; and after use, the residues are green and safe and can be treated as common garbage.

Owner:江苏时光之箭健康科技有限公司

Industrial preparation method of iron oxide-loaded cation resin base composite adsorbent

ActiveCN107537449AStrong loadPromote dissolutionOther chemical processesWater contaminantsSorbentResin-Based Composite

The invention discloses an industrial preparation method of an iron oxide-loaded cation resin base composite adsorbent, and belongs to the industrial production field of composite resin adsorbents forwaste water treatment. The preparation comprises the following steps: (A) acidic cation resin is added into a ferric salt solution in batch with stirring; (B) filtering is carried out, and filtrate is recycled and reused in the step (A); (C) vacuum hot air and drying are carried out for a Fe3+ composite intermediate loaded cation resin base; (D) the material obtained in the step (C) is added intoa sodium hydroxide solution in batch for carrying out a reaction, and filtering is carried out; (E) hydrochloric acid is added into the solid obtained in the step (D) for adjusting the pH value, andfiltering is carried out; (F) filtered solids obtained in the step (E) are washed with water, and water is filtered and dried. In the industrial preparation method of the iron oxide-loaded cation resin base composite adsorbent, ferric salt solution, alkali solution, acid solution and other materials can be recycled and reused, production cost and environment pollution can be greatly reduced, the method accords with national energy saving and emission reduction industrial policy at present, and the method is suitable for industrial promotion.

Owner:NANJING UNIV +1

Micro-electrolysis catalysis strengthening hydrolytic acidification reactor

InactiveCN105036323AGood water distribution effectWell mixedTreatment with anaerobic digestion processesElectrolysisLoad resistance

The invention provides a micro-electrolysis catalysis strengthening hydrolytic acidification reactor. The micro-electrolysis catalysis strengthening hydrolytic acidification reactor is characterized by comprising a water distribution and gas distribution area, a hydrolytic acidification area, a two-phase separation area and a catalysis strengthening micro-electrolysis area from the bottom up. The reactor provided by the invention is uniform in water distribution, uniform and controllable in gas distribution, unlikely to blockage and high in liquid and solid separation effect and shock load resistance, effectively improves the biodegradability of wastewater, and is suitable for treatment of recalcitrant sewage; trials show that the water inflow COD can be up to 50,000 mg / l, and the COD removal rate can reach 41%.

Owner:DONGHUA UNIV

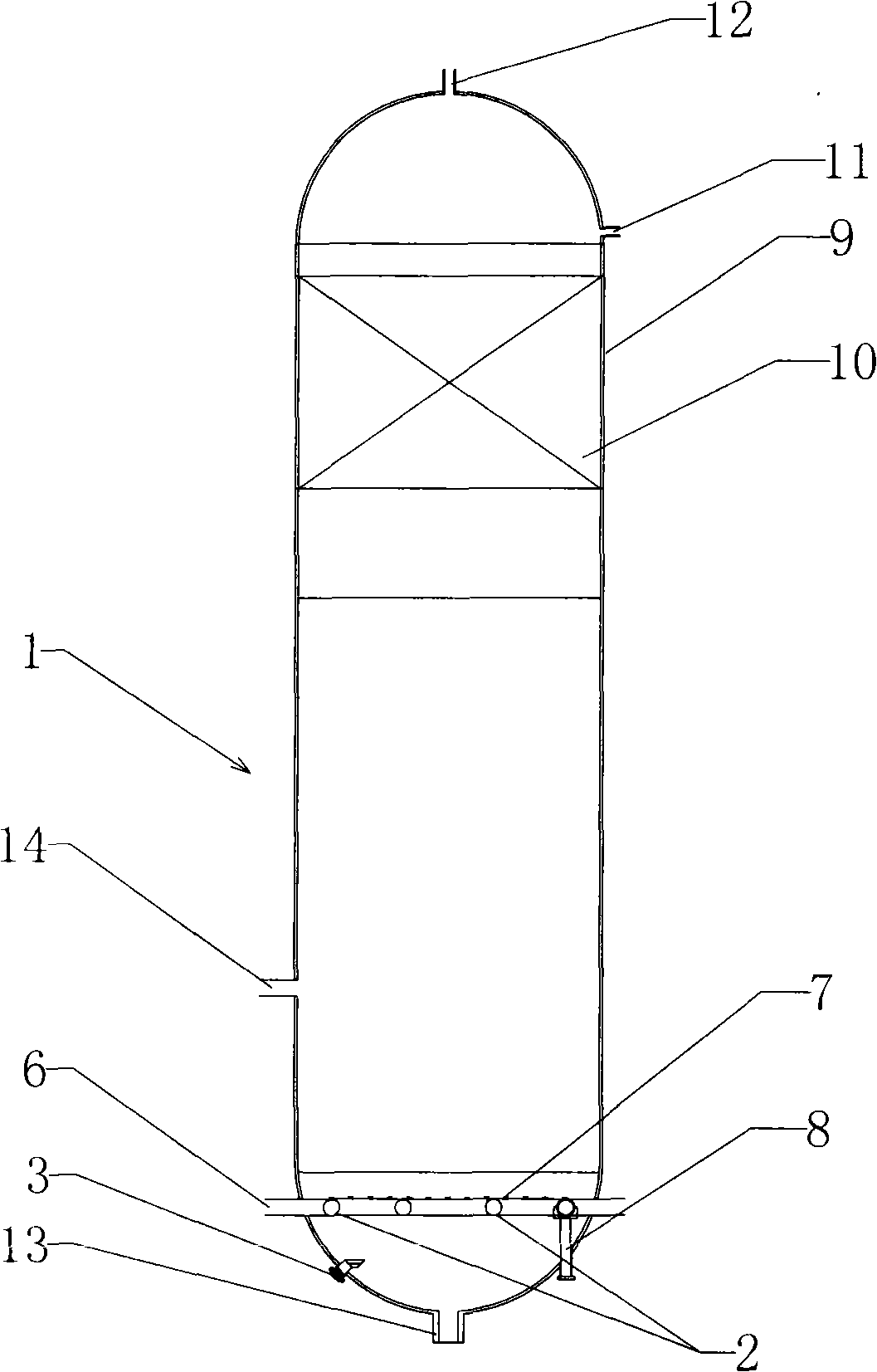

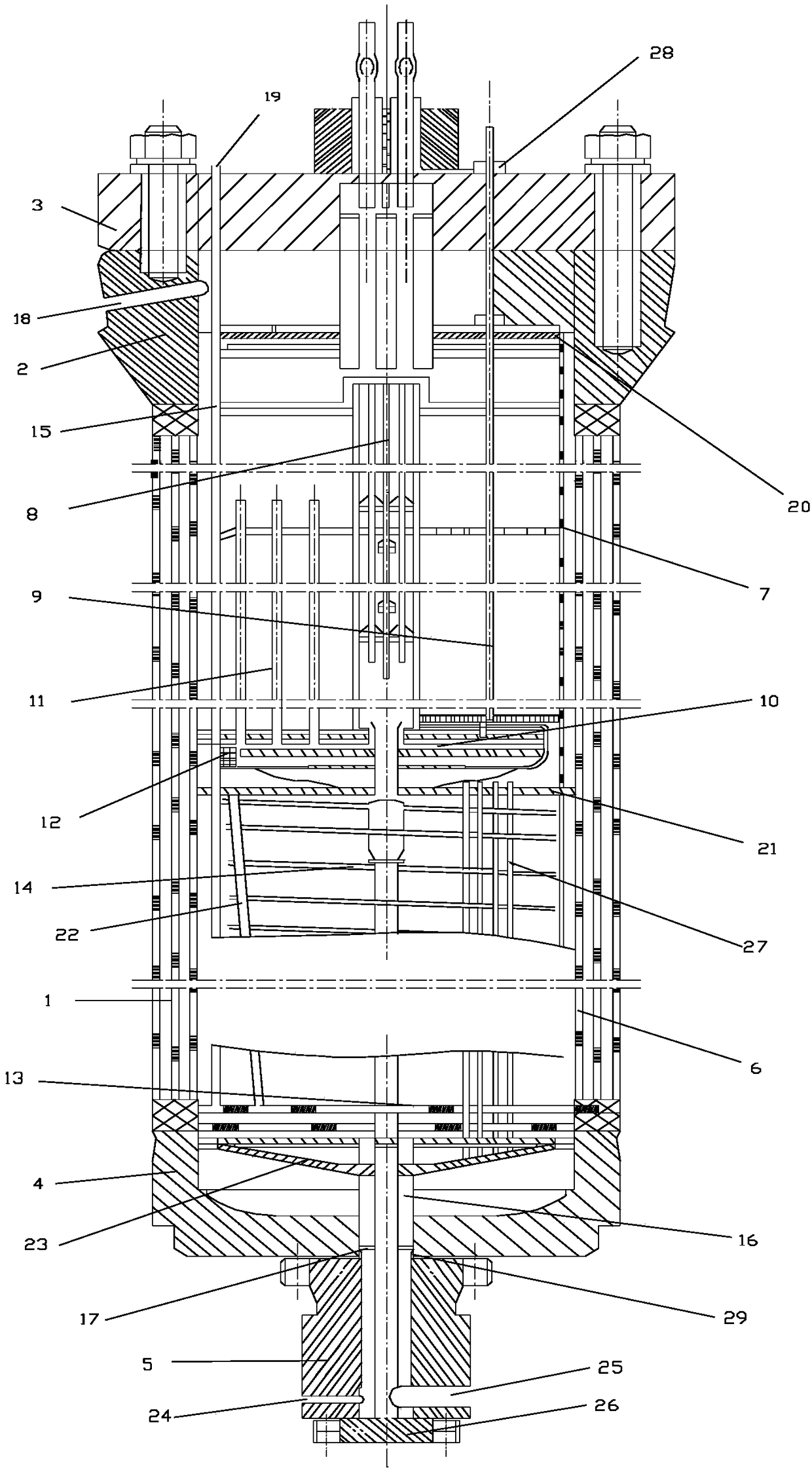

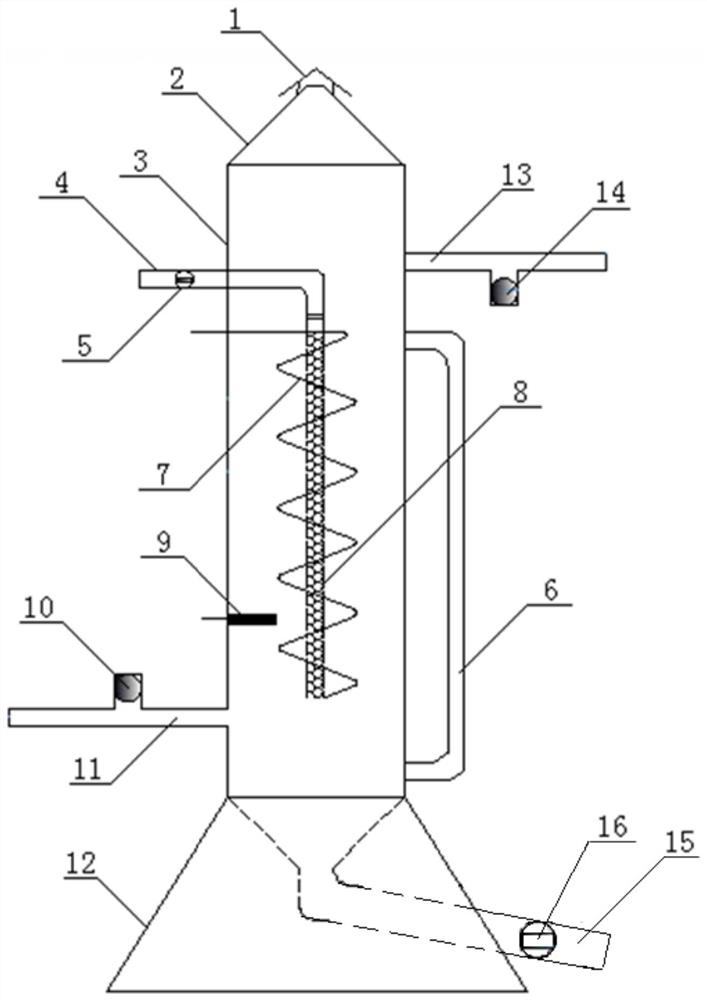

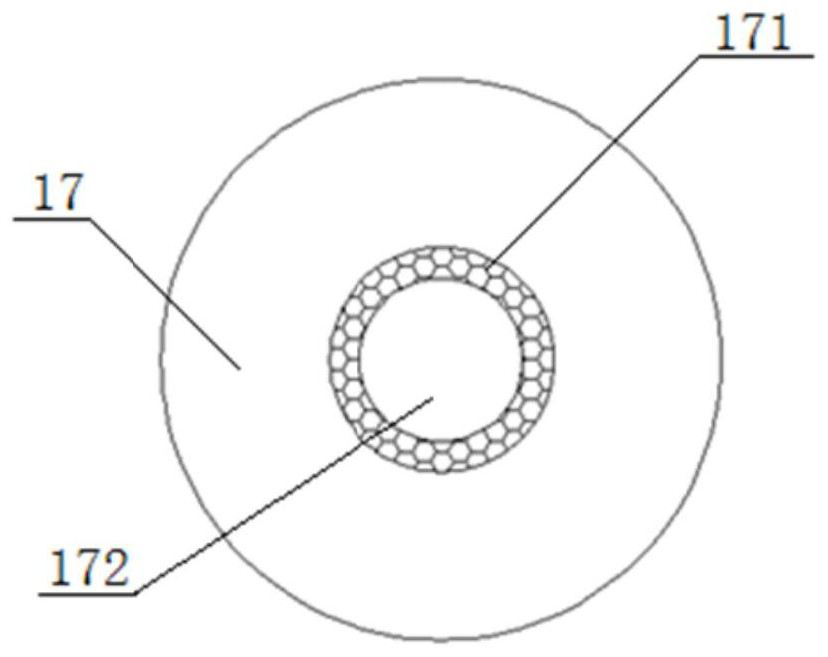

Reaction tower for ammonia synthesis

InactiveCN108910915AUniform mass transferReduce mass transfer resistanceBulk chemical productionAmmonia preparation/separationSmall footprintEngineering

The invention relates to a reaction tower for ammonia synthesis. Main components comprise an outer cylinder, a top cover, a tower top flange, a bottom cover, a tower bottom assembly, an inner cylinder, a catalyst basket, a casing pipe mechanism, a heat exchanger, heat exchange pipes, a circulation pipe, a product output pipe and a filter membrane. The upper end of the outer cylinder is connected to the top cover. The upper end of the top cover is connected to the tower top flange. The top cover is provided with a raw material inlet. The lower end of the outer cylinder is connected to the bottom cover. The lower end of the bottom cover is connected to the tower bottom assembly. The outer cylinder wraps the inner cylinder. The upper part of the inner cylinder is provided with the catalyst basket. The casing pipe mechanism is arranged at the lower end of the catalyst basket. The heat exchanger is arranged at the lower end of the inner cylinder. The heat exchanger is provided with the heatexchange pipes spirally and inclinedly distributed, the heat exchanger is provided with a circulation pipe, a product output pipe is arranged at the lower end of the heat exchanger and the filter membrane is arranged in the product output pipe. The reaction tower has the advantages of high ammonia synthesis conversion rate, compact structure, small floor space, neat internal structure, convenientmaintenance, energy saving, high ammonia separation efficiency and high ammonia quality.

Owner:张波

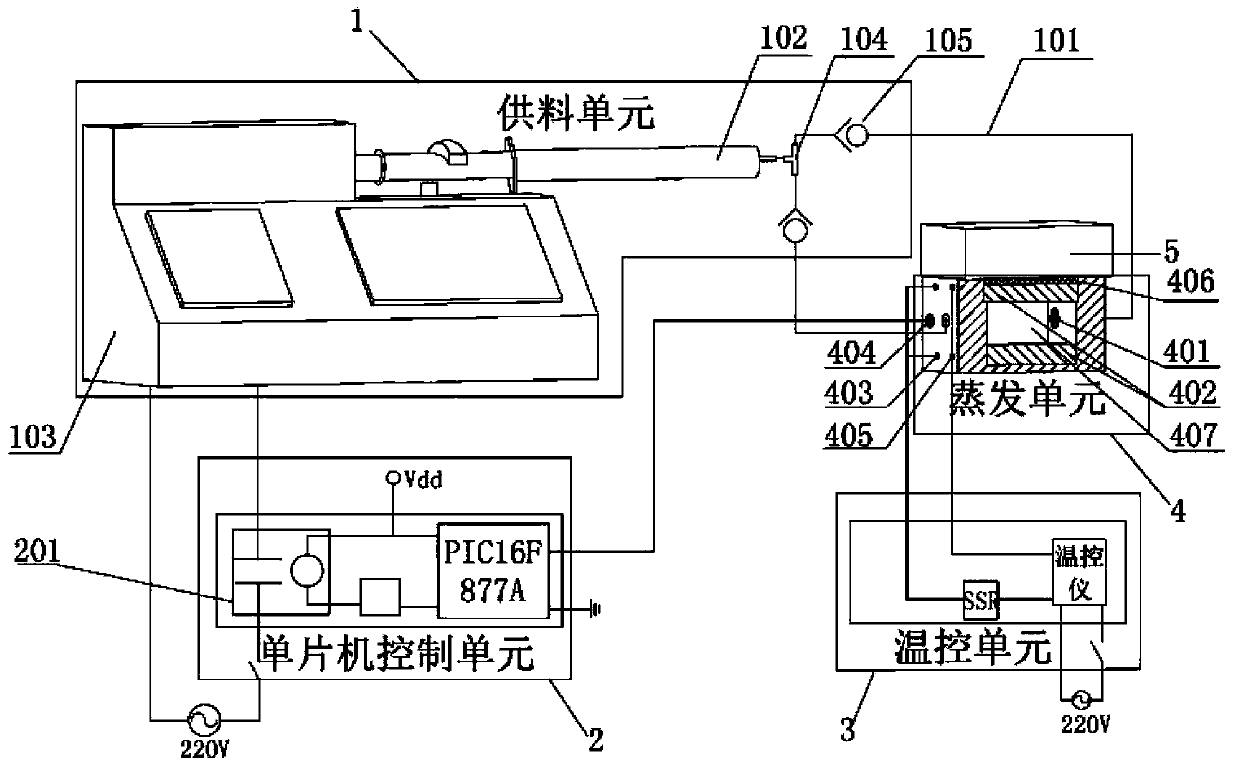

Intelligent feeding system used for passive direct methanol fuel cell

ActiveCN103427100APromotes boilingImprove responsivenessFuel cell auxillariesHeater RodDirect methanol fuel cell

The invention discloses an intelligent feeding system used for a passive direct methanol fuel cell. The intelligent feeding system comprises a feeding unit, a singlechip control unit, a temperature control unit and an evaporation unit; the feeding unit is connected with a spraying nozzle of the evaporation unit through an infusion pipe; the evaporation unit is provided with a boiling strengthening plate which is heated by a heating rod of the evaporation unit; the singlechip control unit is connected with a pressure sensor of the evaporation unit and the feeding unit; the pressure sensor detects the internal pressure of the evaporation unit, and generated electrical signals are fed back to the singlechip control unit; the temperature control unit is connected with the heating rod of the evaporation unit and a thermocouple; the thermocouple detects the temperature of the evaporation unit, and generated electrical signals are fed back to the temperature control unit; the temperature control unit regulates the heating temperature of the heating rod according to the fed electrical signals. The intelligent feeding system can supply material for the passive direct methanol fuel cell according to actual requirements, flexibly controls the running time of the cell and improves the fast reaction capacity of the cell.

Owner:SOUTH CHINA UNIV OF TECH +1

Method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation

ActiveCN101863482BSpeed up the flowShort staySilicaAmmonium halidesHexafluorosilicic acidAir compressor

The invention discloses a method for continuously preparing white carbon black and ammonium fluoride by carrying out fluosilicic acid ammoniation, which relates to a chemical production method, in particular to a method for preparing the white carbon black and the ammonium fluoride. The method comprises the following steps: (a) at a temperature between minus 5 and 30 DEG C, starting a stirrer and an air compressor, blowing compressed air into an outlet pipe of a reactor by the air compressor and adding fluosilicic acid and ammonia into the reactor simultaneously; (b) when the fluosilicic acid and the ammonia are added to the position of an overflow pipe in the reactor, opening an emptying valve to continuously feed and discharge materials and controlling a PH value of the reaction, wherein the period of the continuous reaction is 24 hours; (c) in the reaction process, filtering the materials discharged by the step (b) to obtain a white carbon black filter cake and filtrate of ammonium fluoride, and washing and drying the white carbon black filter cake to obtain a white carbon black finished product, wherein the filtrate is ammonium fluoride solution; and (d) after performing a reaction for 24 hours in the reactor, emptying the materials, cleaning the reactor to be used next time and producing the white carbon black finished product by using the materials according to the step (c), wherein the ammoniation yield of the process can reach 99.99 percent. The method of the invention effectively overcomes the defects of the existing intermittent technology and has the advantages of continuous, stable and simple process and long operation period.

Owner:YUNNAN YUNTIANHUA +1

PX oxidizing reactor for producing terephthalic acid

ActiveCN100594972CAvoid destructionMeet the need for suspensionOrganic compound preparationCarboxylic compound preparationNuclear engineeringSpiral flow

A PX oxidation reactor for producing terephthalic acid comprises a reactor housing; the reactor housing is can-shaped, the ratio of height to diameter is 2.8 to 5, and the bottom of the reactor housing is provided with a distributed inlet duct and a spiral-flow type inlet duct; the distributed inlet duct comprises an upper air flow distribution tube and a middle air flow distribution tube, and theair flow distribution tubes are in the shape of circular rings; the number of spiral-flow inlet tubes is multiple, and the tubes are uniformly arranged surrounding the reactor wall. A combined air inlet gyration device used in the invention pushes the fluid at the bottom of the reactor by proper amount of air so that the reactor conducts rotary motion; the air has good dispersion and uniform distribution, and the material remains in normal suspended state; and the ratio of height to diameter between a high temperature reactor and a low temperature reactor is used, thereby avoiding non-uniformdistribution existing in the low temperature reactor with big ratio of height to diameter and also being better than the high temperature reactor in the aspect of low power consumption.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

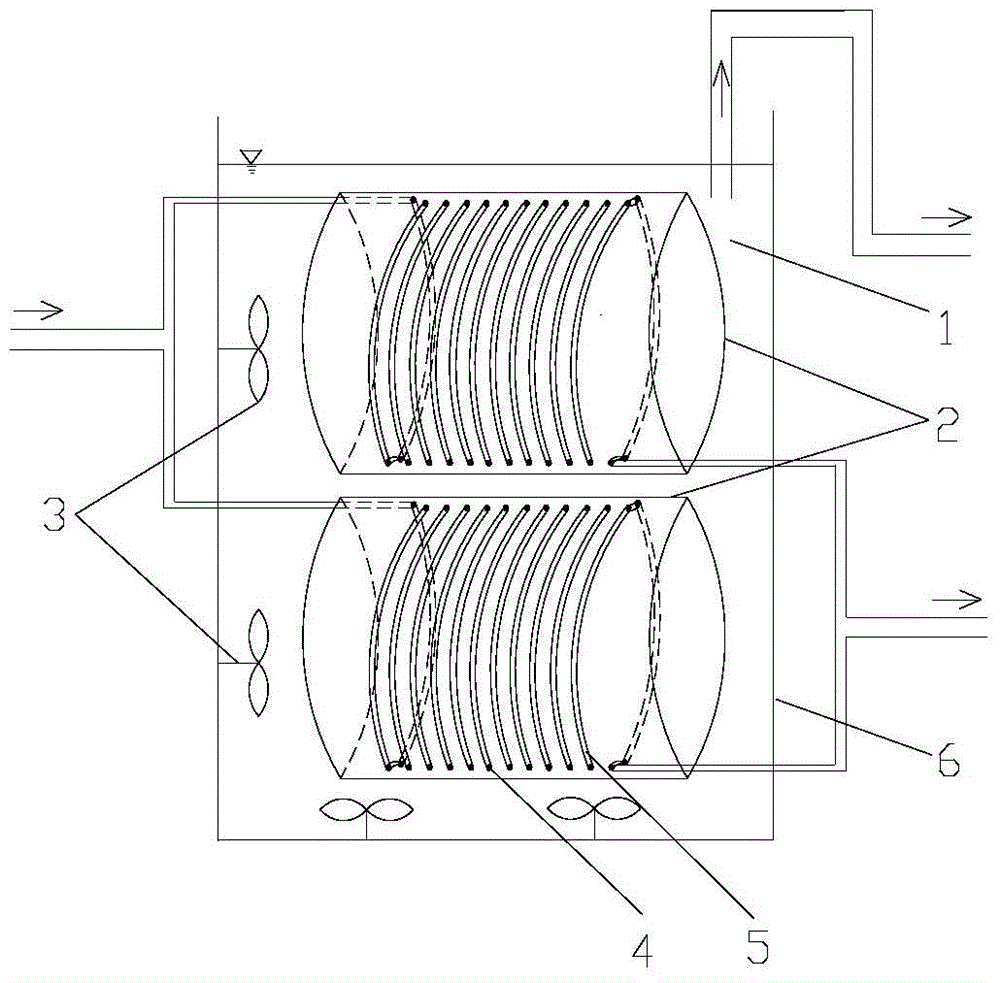

Microorganism continuous culture device

ActiveCN112226347AUniform heat transferExtended service lifeBioreactor/fermenter combinationsBiological substance pretreatmentsBiotechnologyMicroorganism

The invention belongs to the field of microorganism culture devices, and particularly relates to a microorganism continuous culture device. The device comprises a culture tank and an aeration pipe arranged in the culture tank, and further comprises a heating pipe which surrounds the periphery of the aeration pipe and is used for heating a culture solution in the culture tank. A plurality of baffles distributed in the axial direction of the aeration pipe are further fixed to the aeration pipe, the baffles are annular, the centers of the baffles are sunken downwards, and leaking holes are formedin the positions close to the aeration pipe, of the baffles. The heating pipe spirally surrounds the periphery of the aeration pipe, and the spiral diameter is larger than that of each baffle. The microorganism continuous culture device is simple in structure, convenient to operate and low in manufacturing cost, iron and vanadium attached and deposited on the heating pipe and the culture tank canbe greatly reduced while ore leaching microorganisms are continuously cultured, so that the purpose of continuously obtaining the microorganisms for a long time is achieved, and the service life of the heating device is greatly prolonged.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com