Patents

Literature

111results about "Catalytic liquid-gas reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

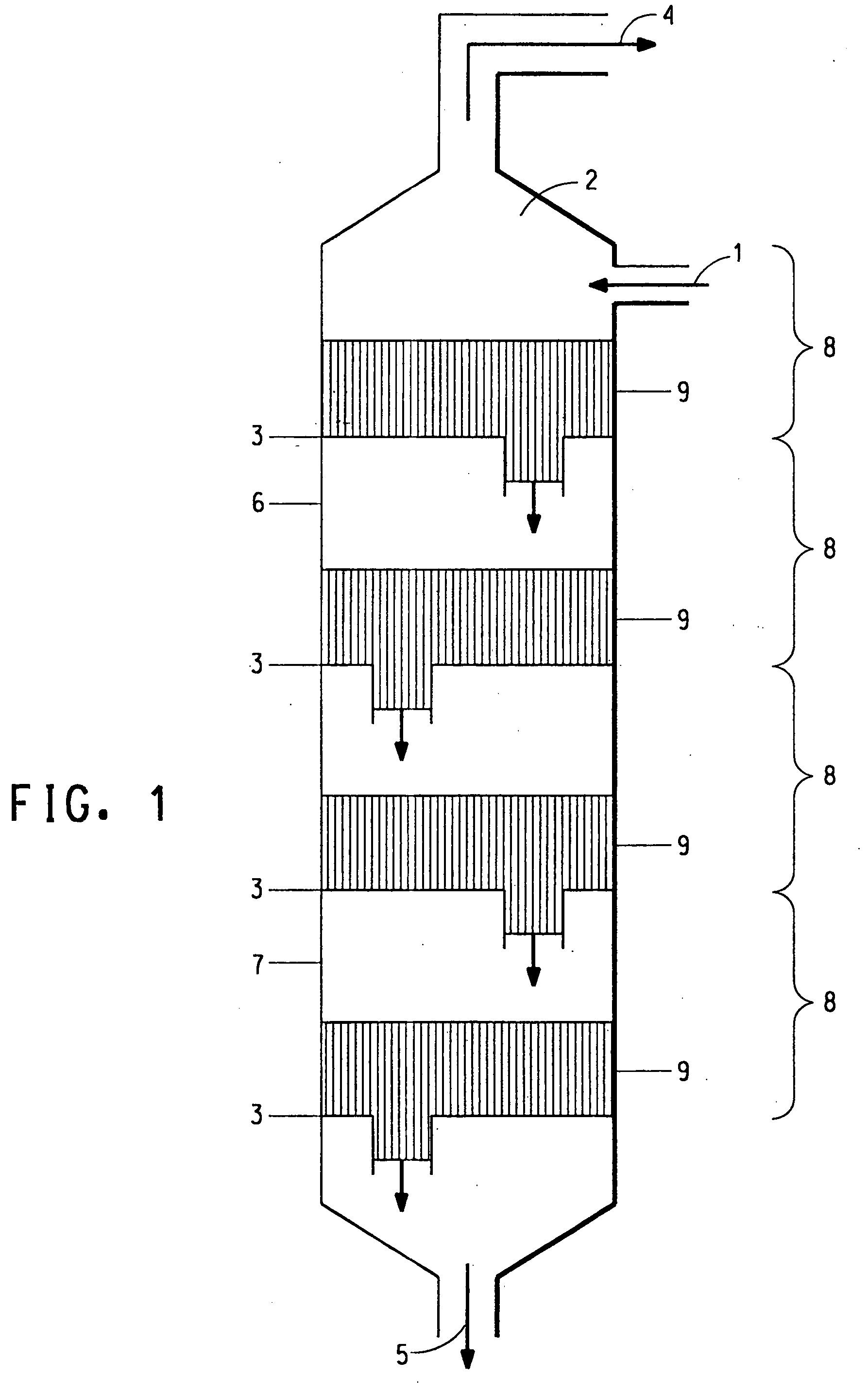

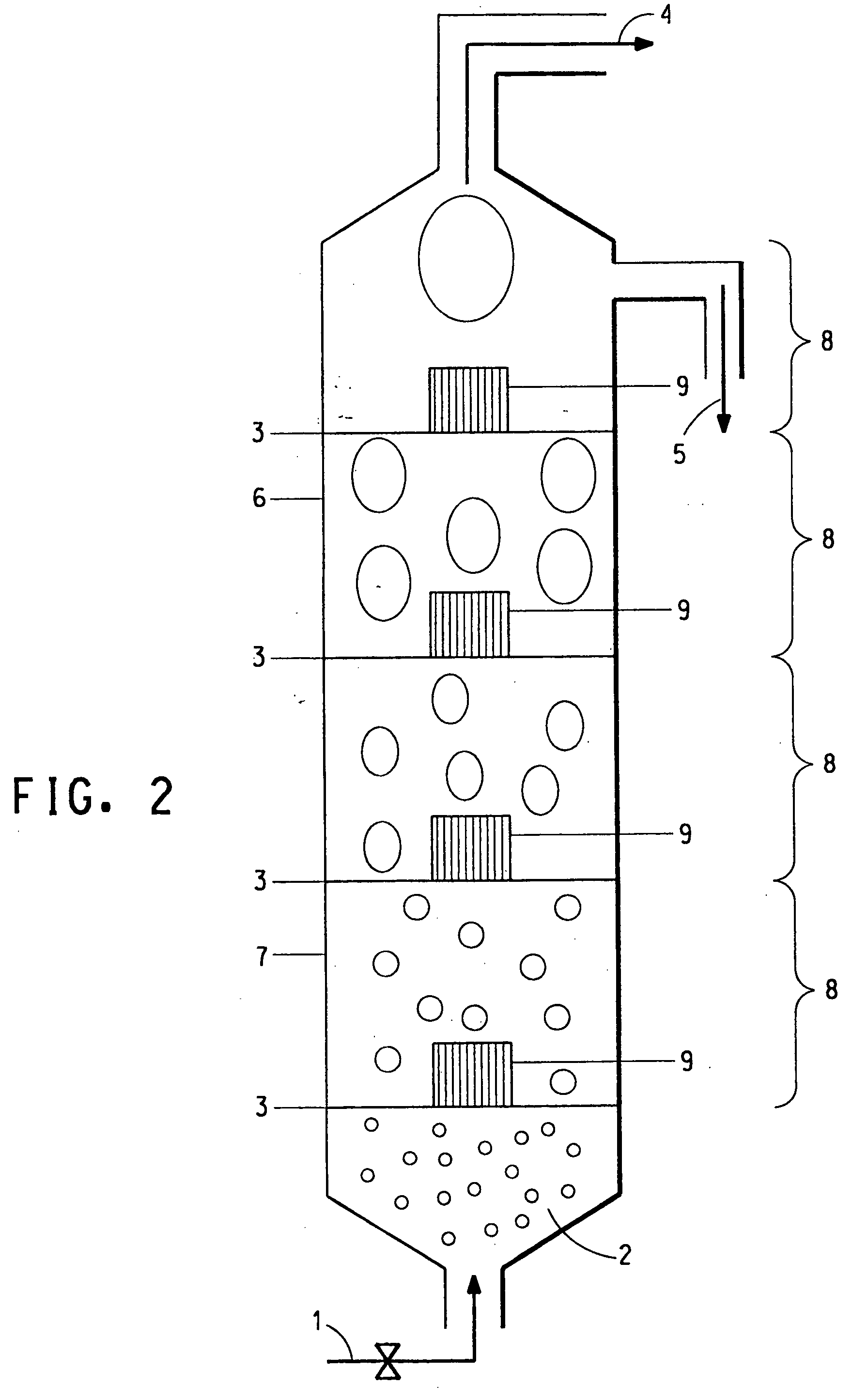

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS6720459B2Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

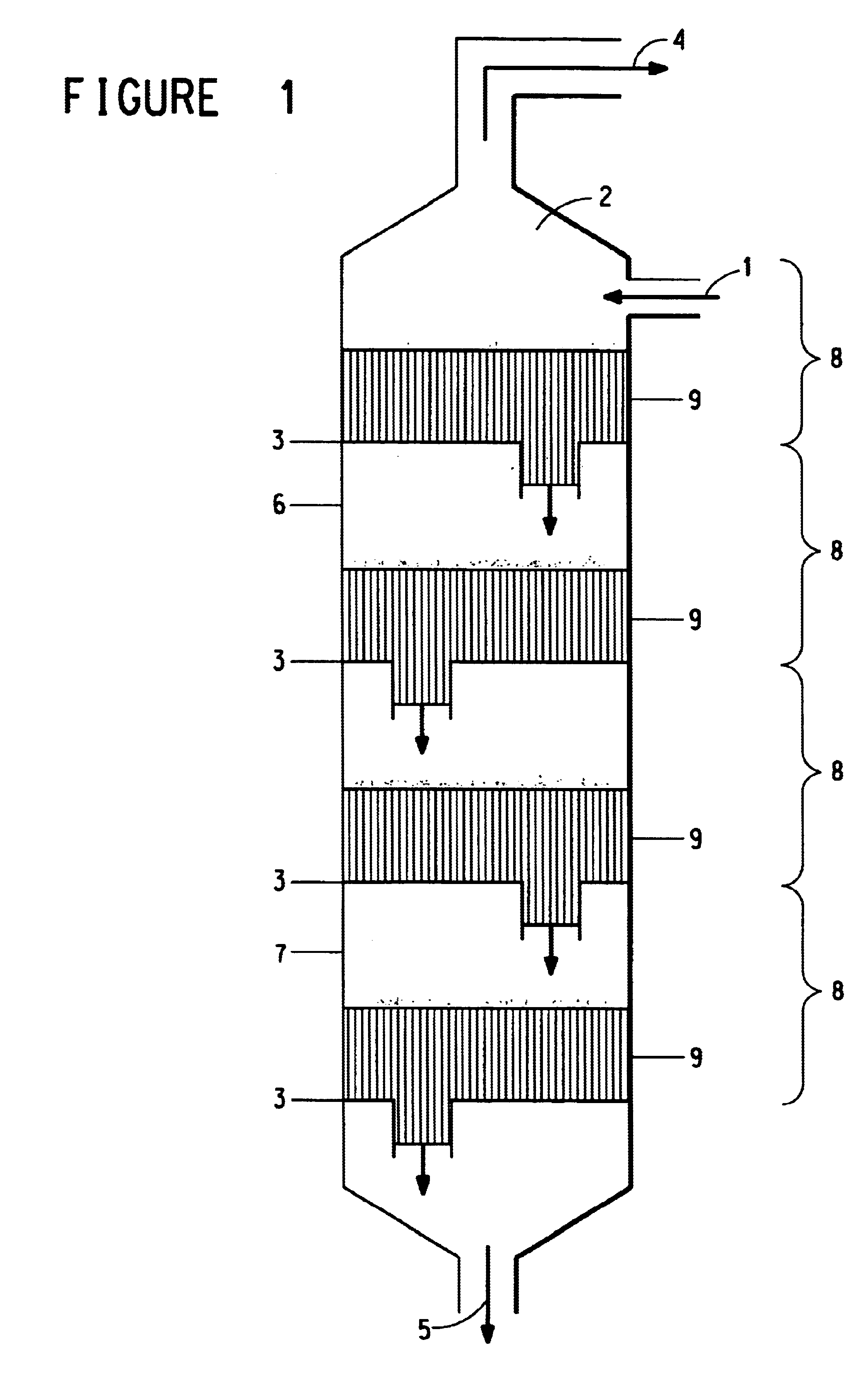

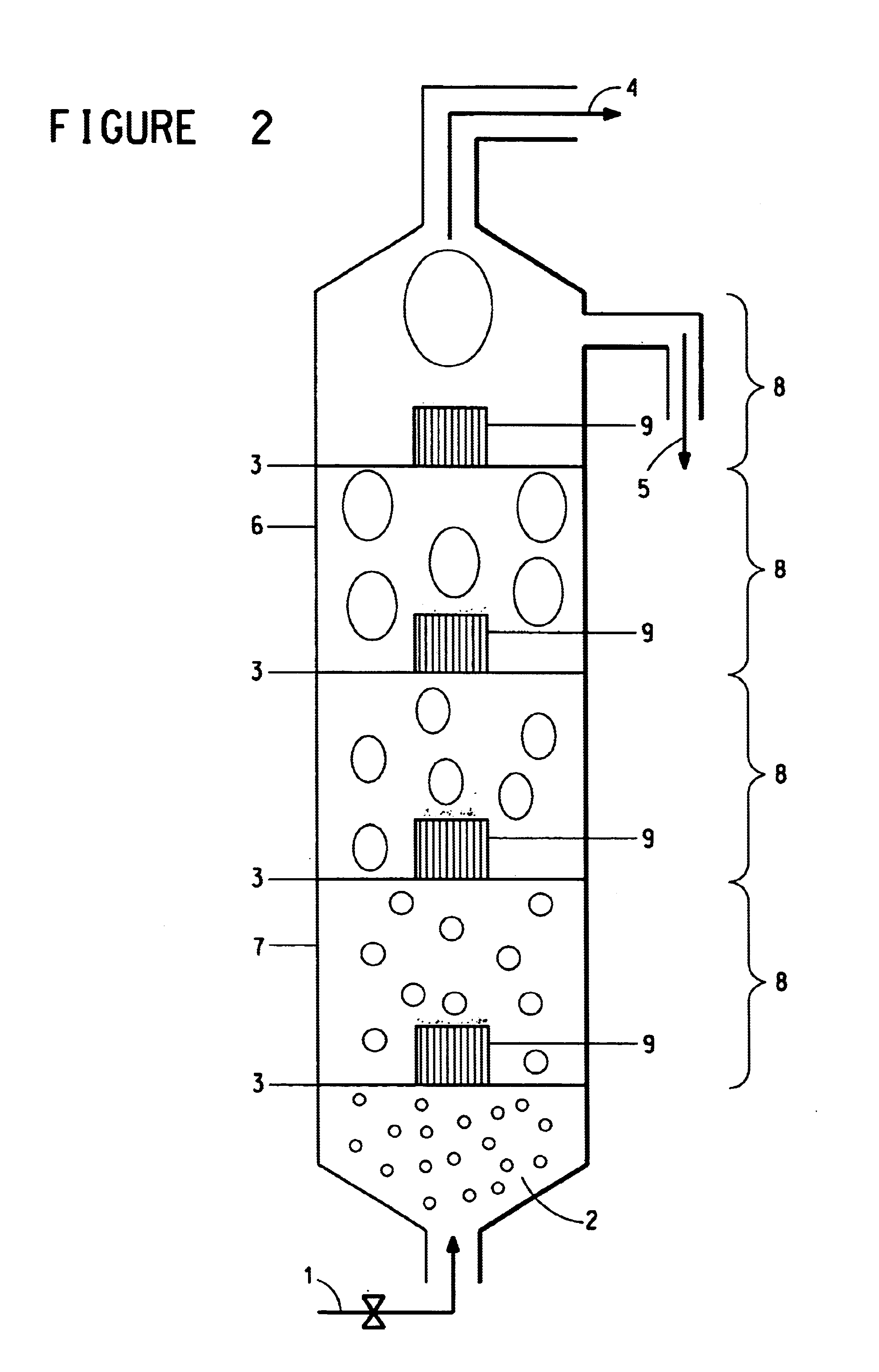

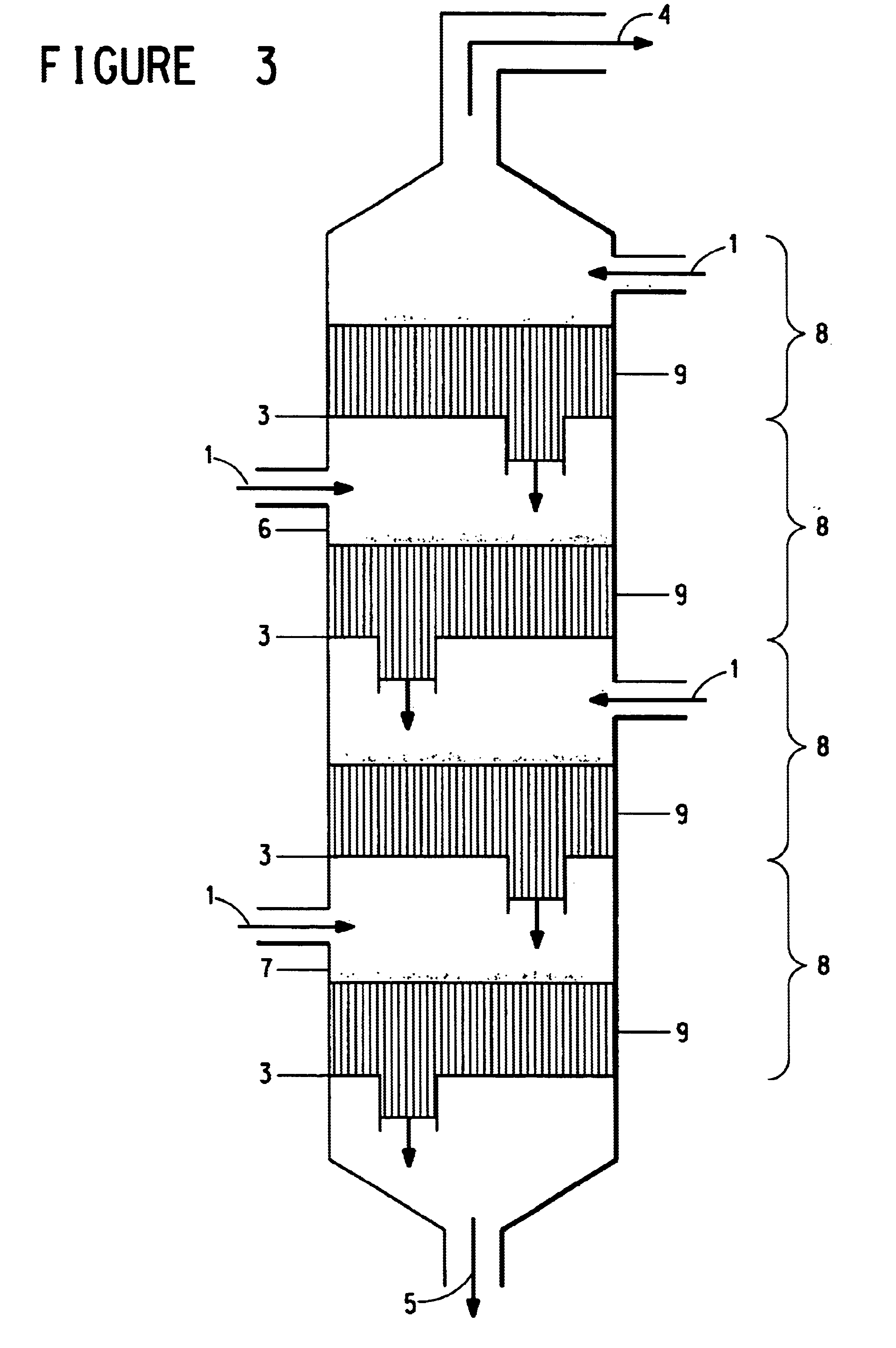

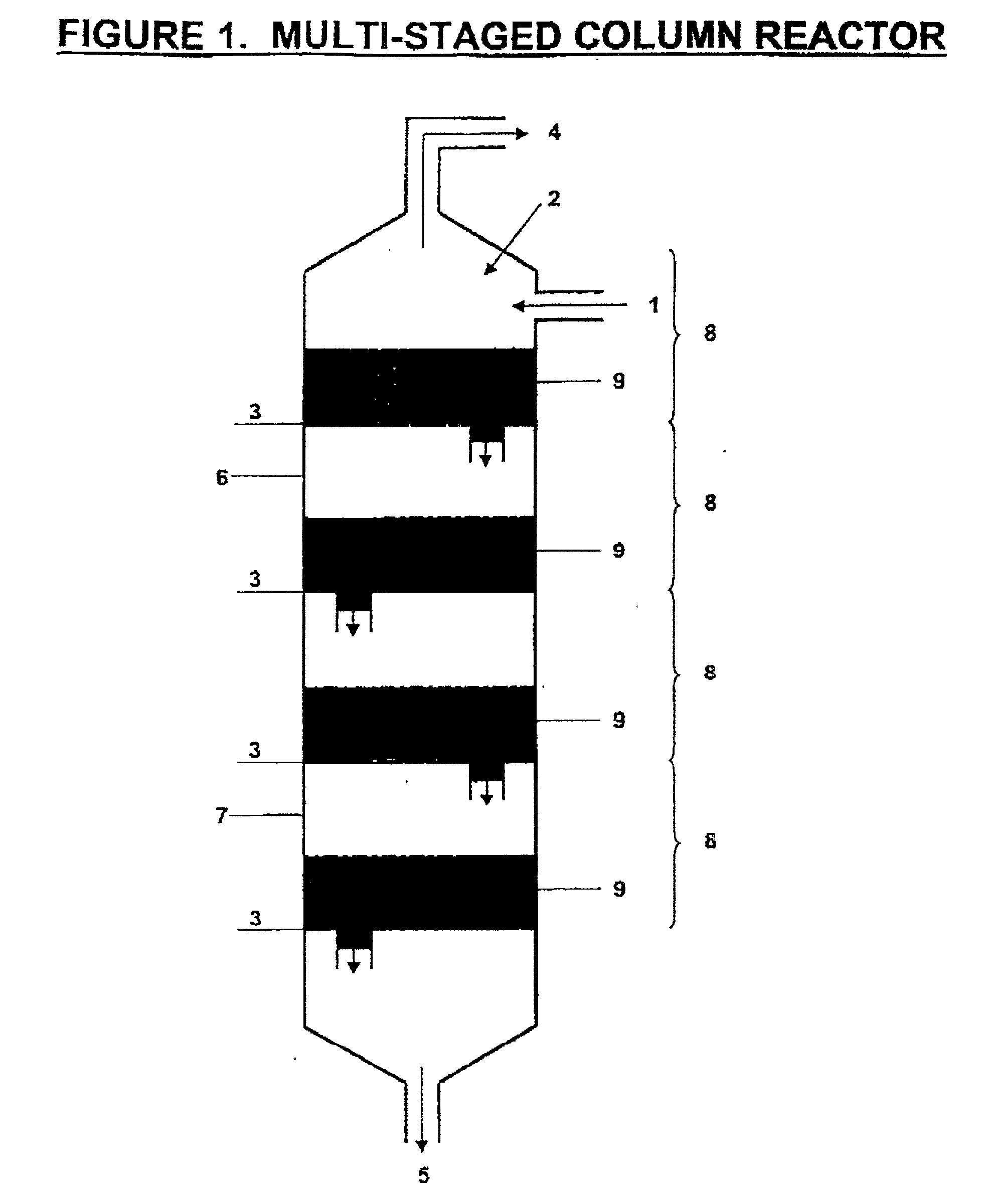

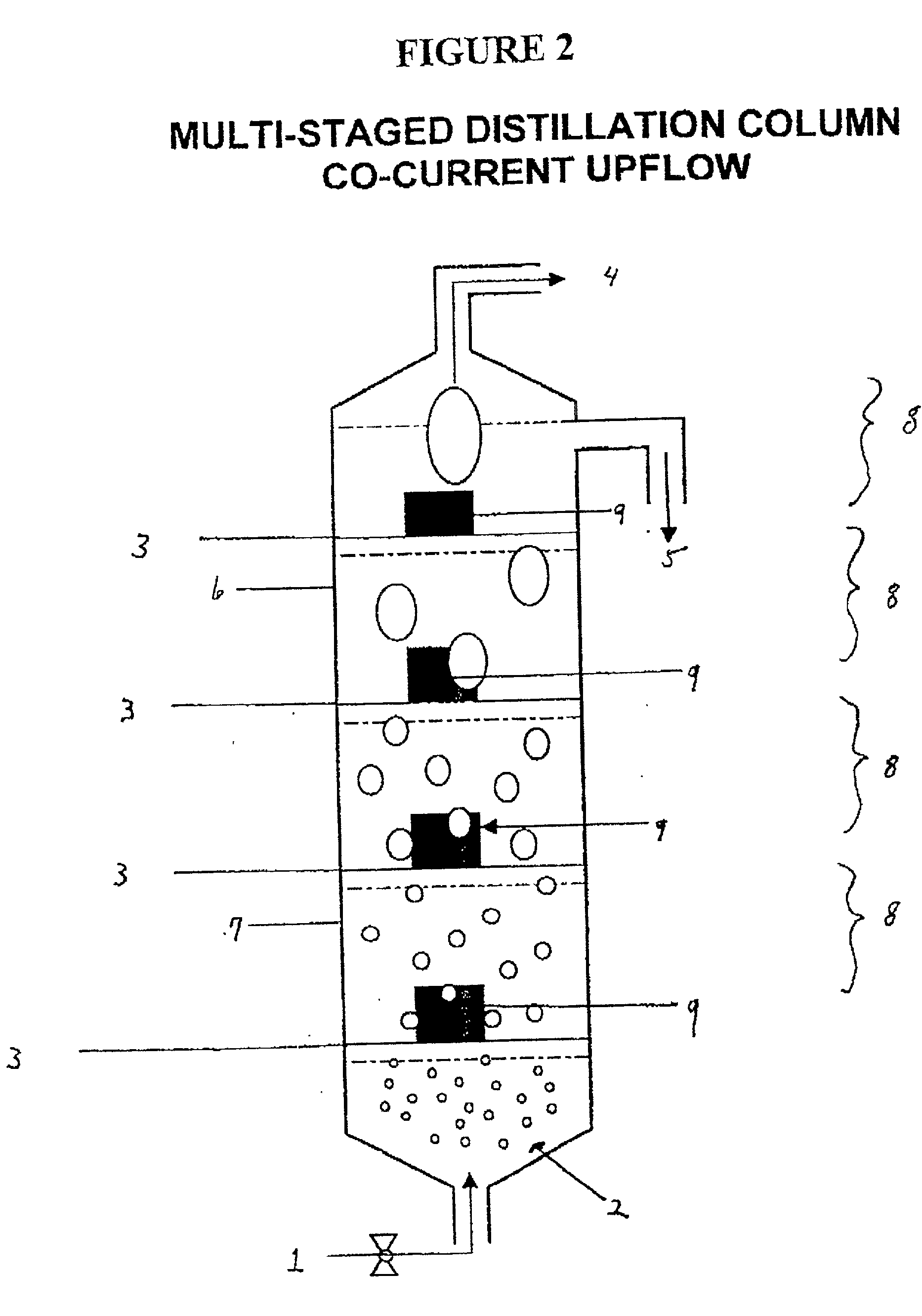

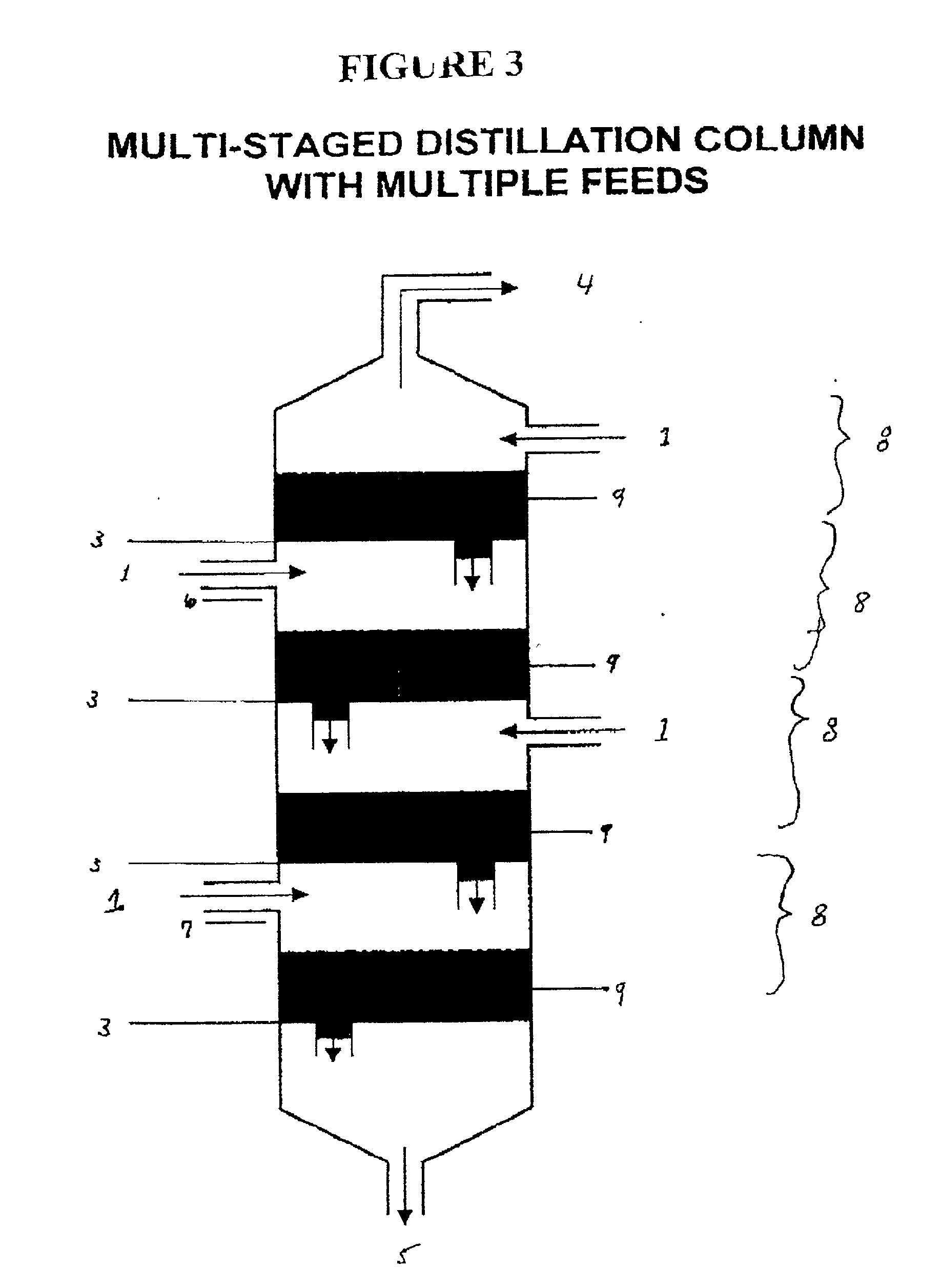

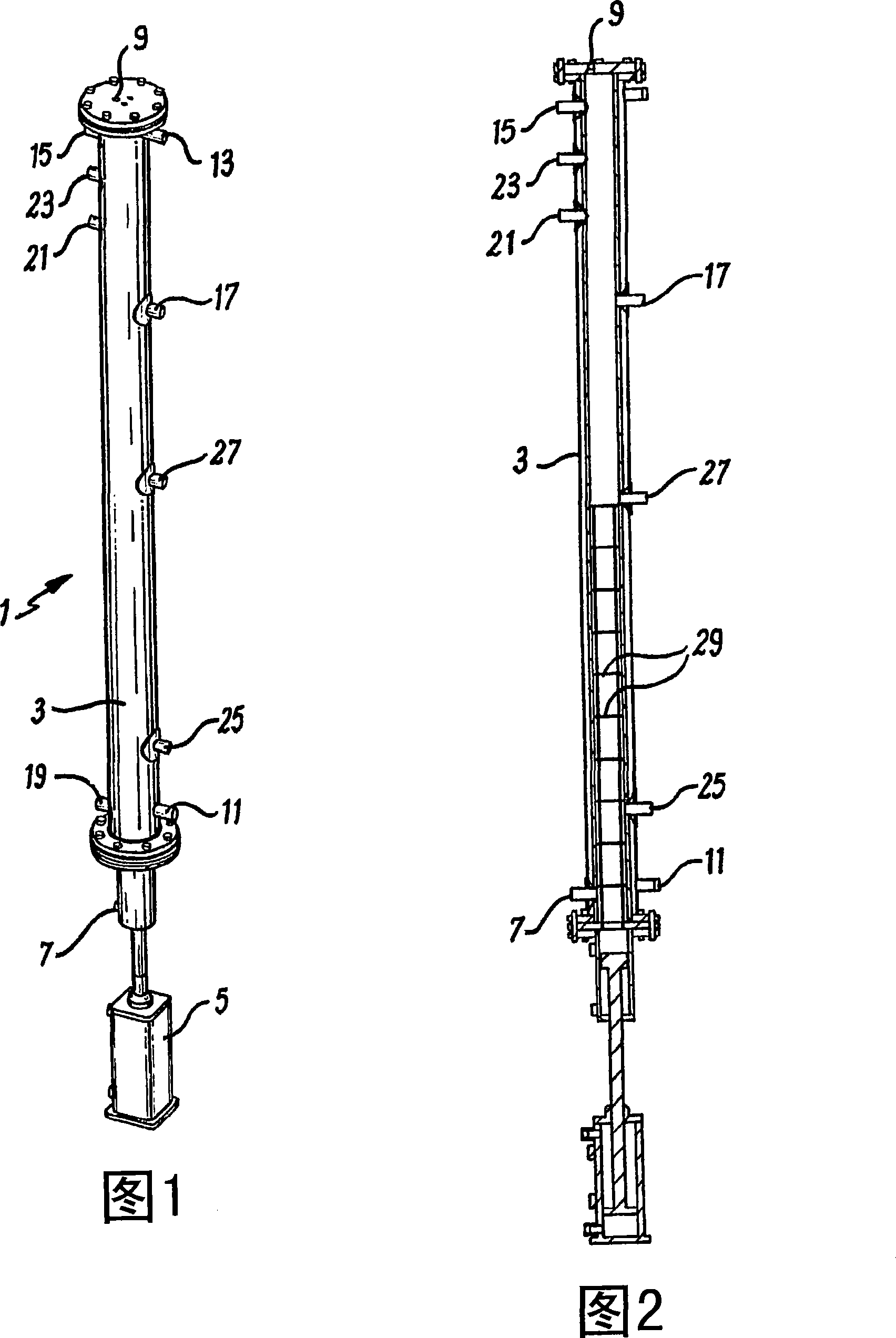

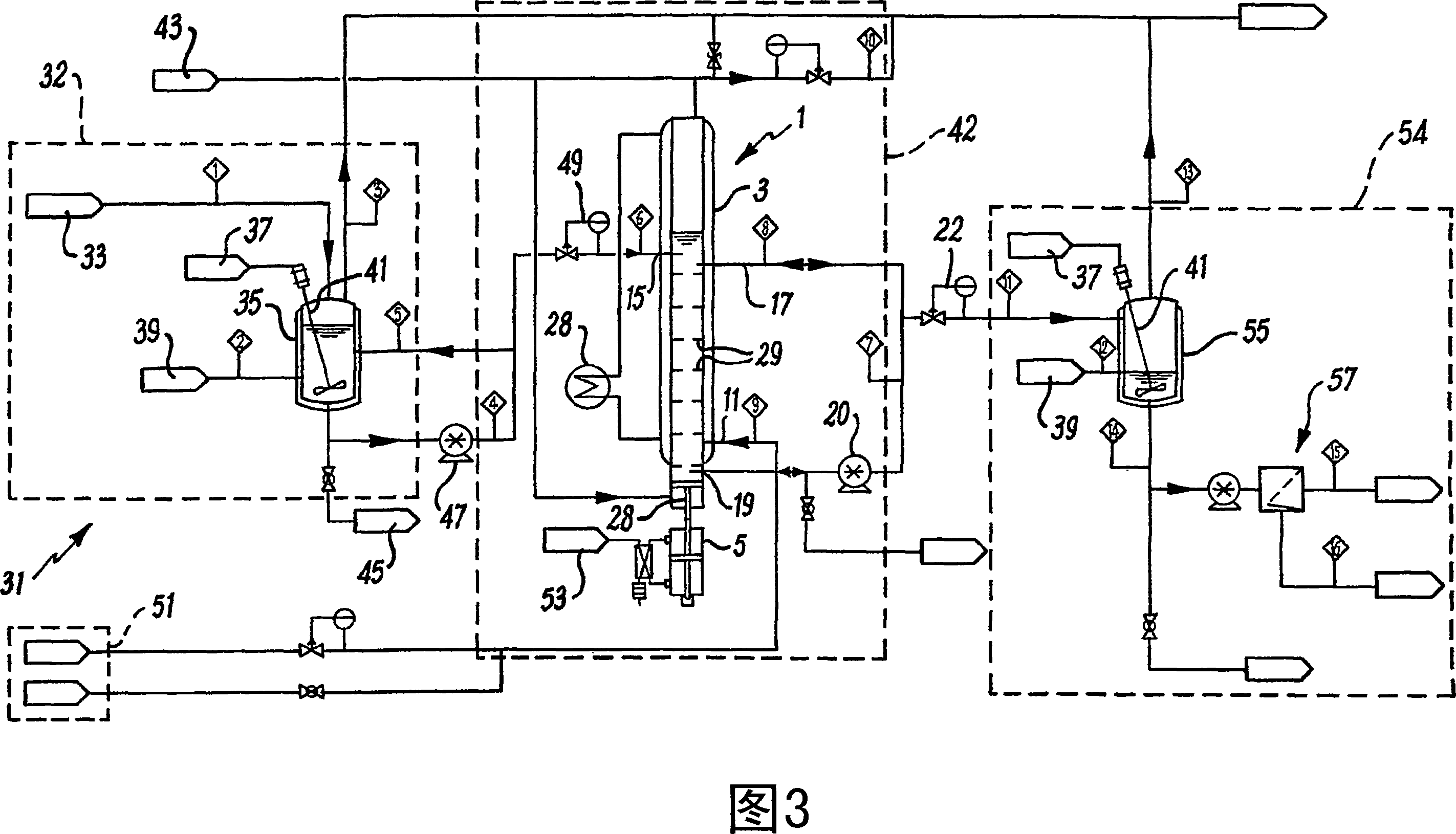

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

Continuous process for the preparation of polytrimethylene ether glycol

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an up-flow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT CA +1

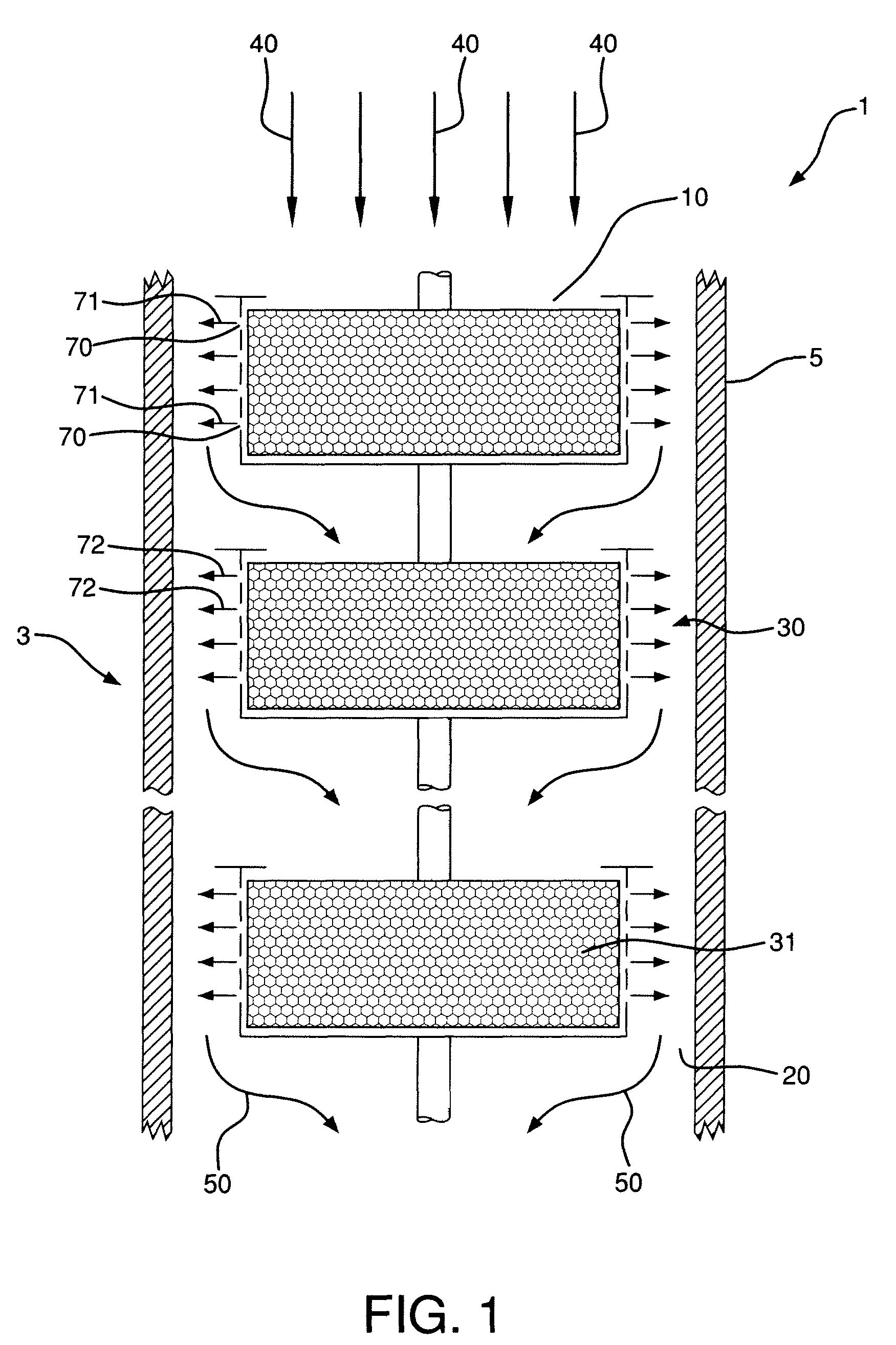

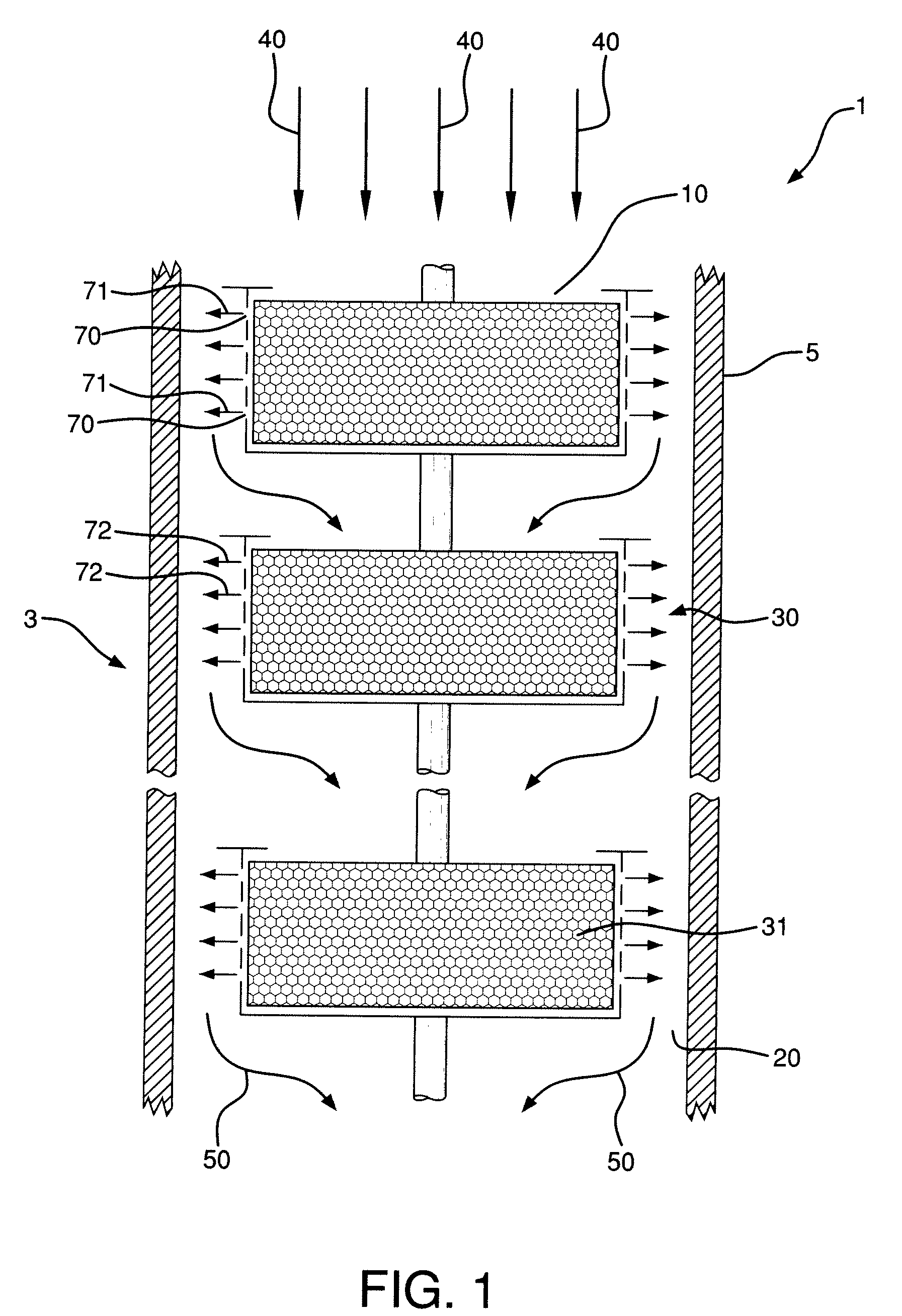

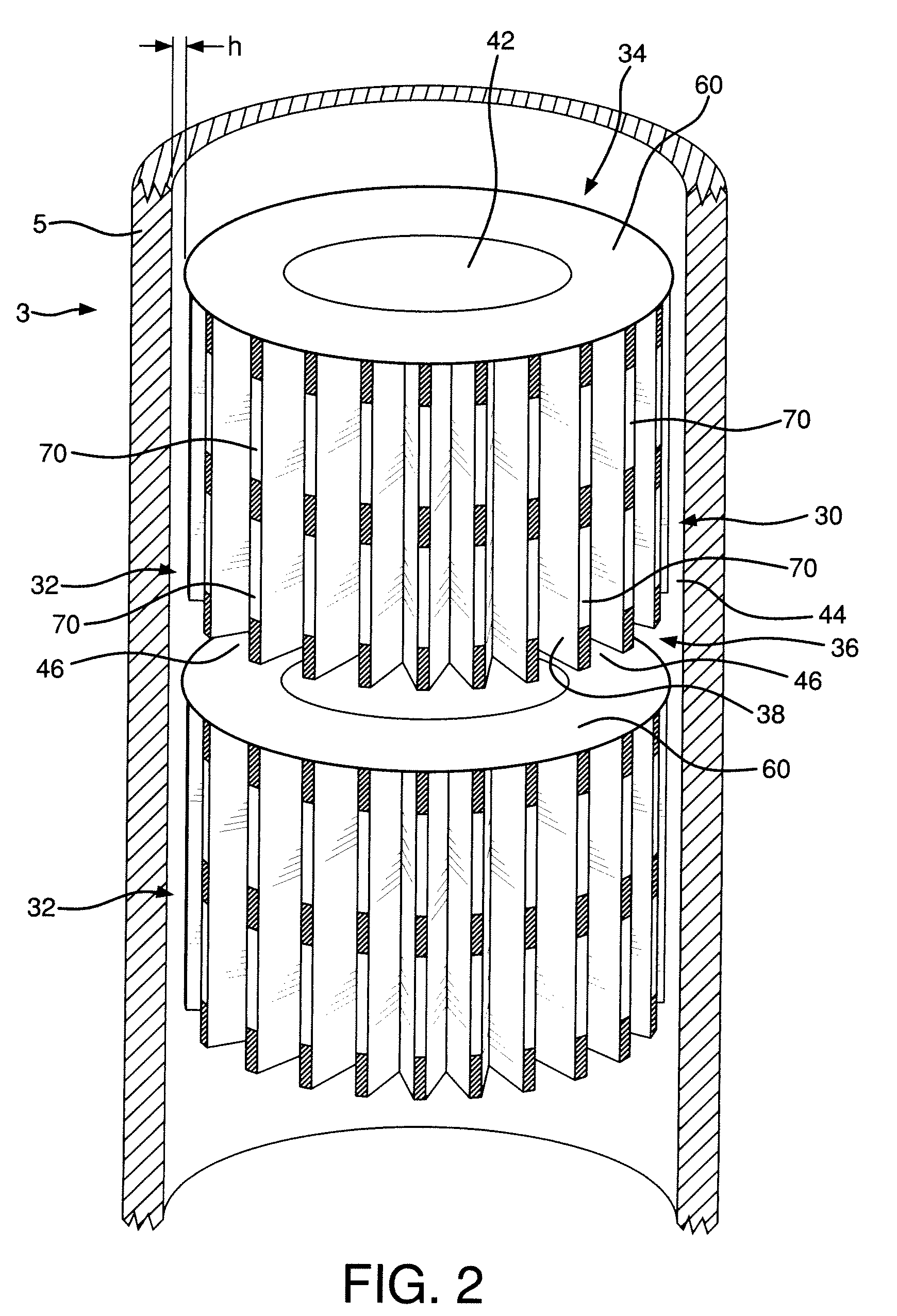

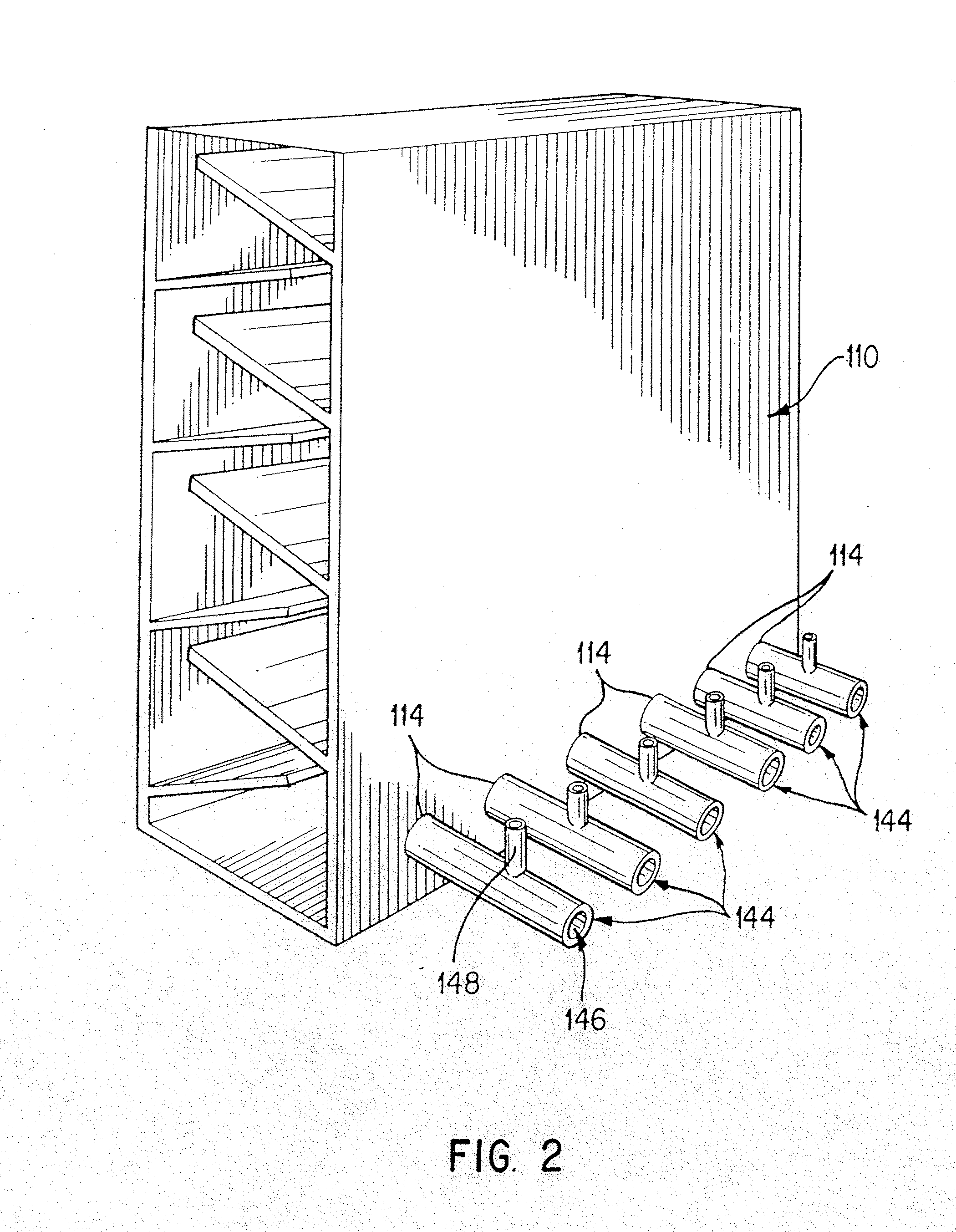

Stackable structural reactor

Owner:JOHNSON MATTHEY PLC

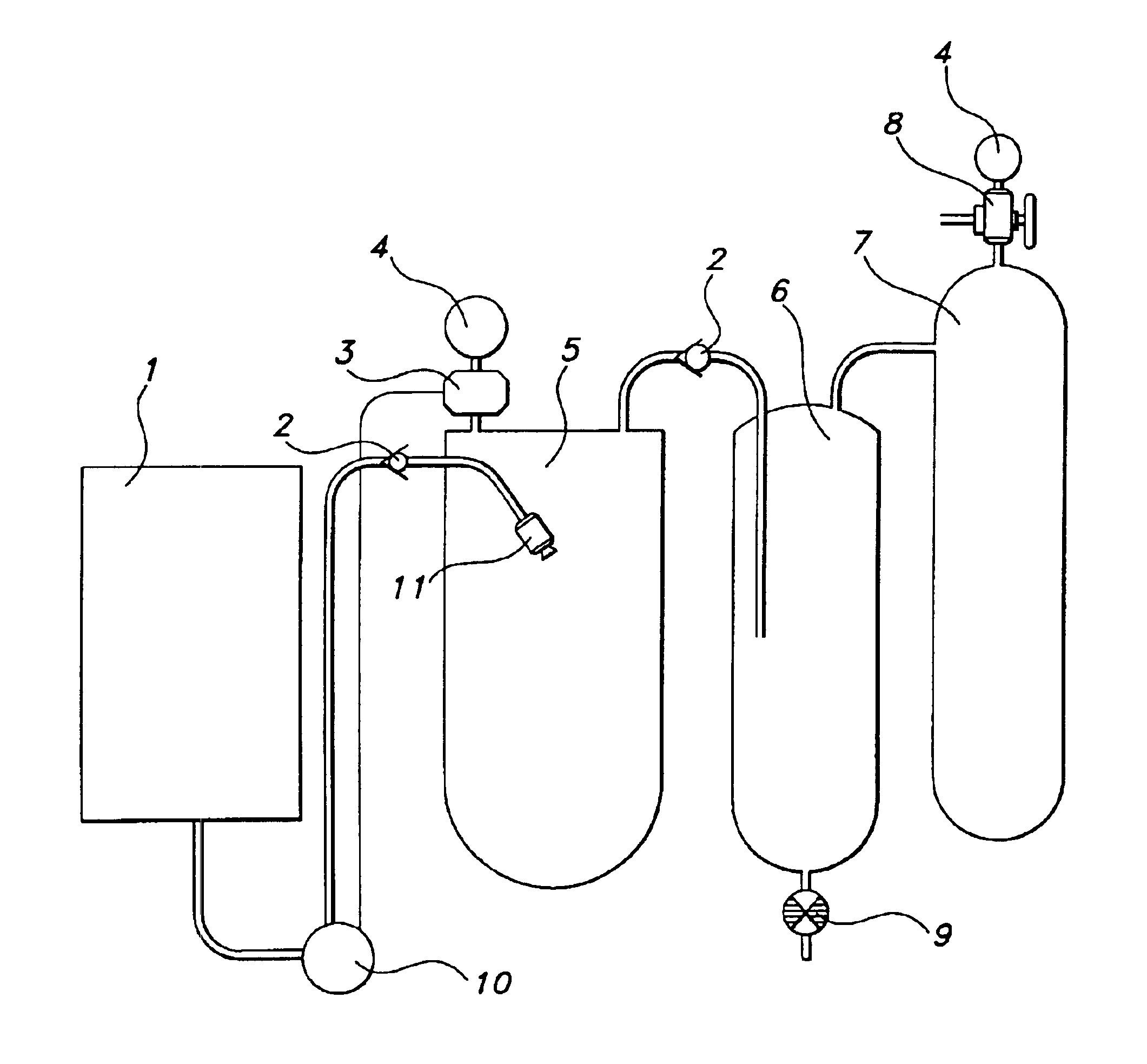

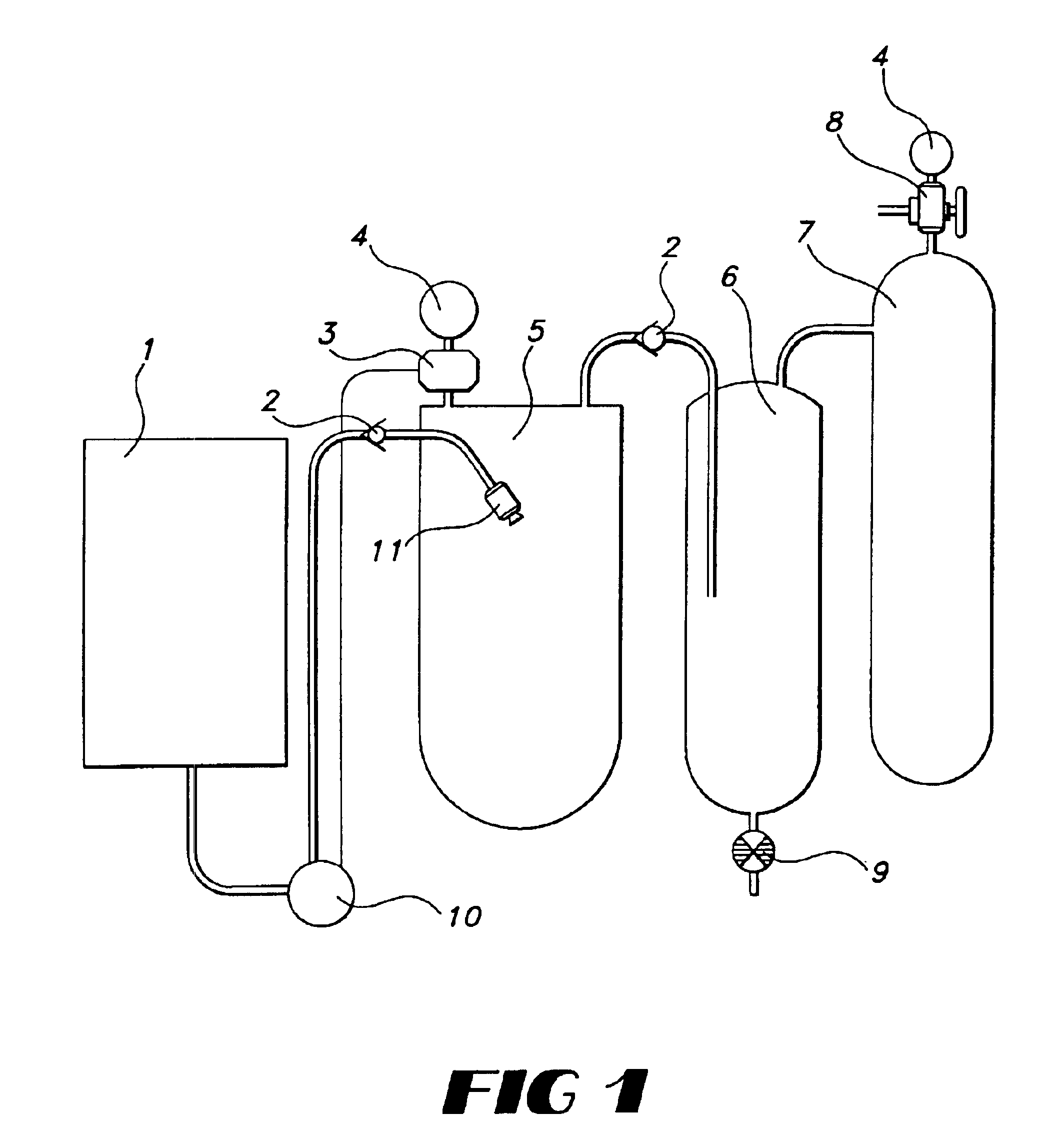

Method for controlled generation of hydrogen by dissociation of water

The invention relates to a method and apparatus for controlling the dissociation of water into hydrogen and oxygen, the method including contacting a quantity of aqueous liquid with a quantity of dissociation initiating material in a reaction vessel; monitoring the temperature and / or pressure in the reaction vessel; monitoring the surface area of dissociation initiating material in contact with the aqueous liquid; and controlling the surface area of dissociation initiating material in contact with the aqueous liquid in response to the temperature, pressure, or both, or changes therein, or both, in the reaction vessel.

Owner:HYDROGEN ENERGY AMERICA

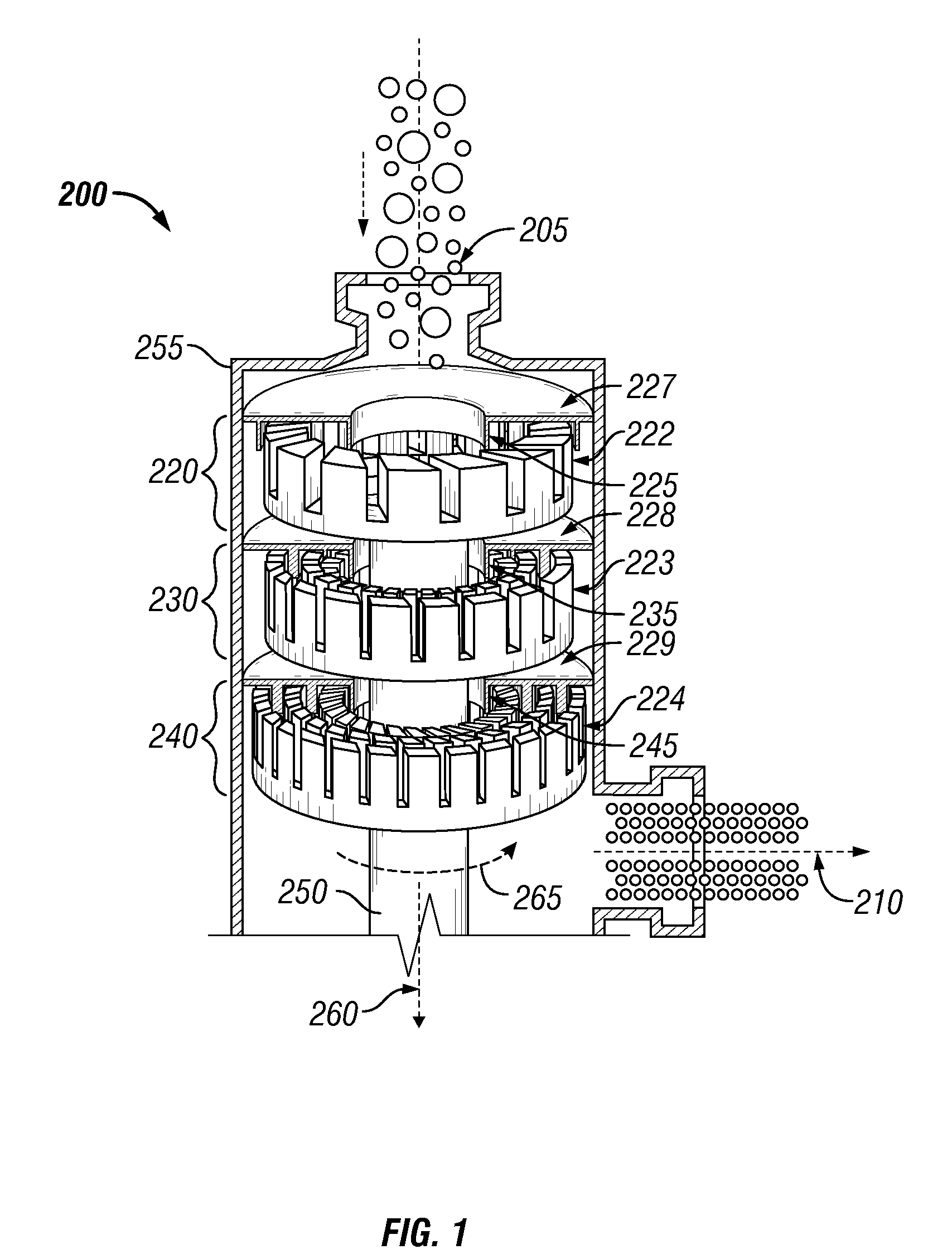

High shear rotary fixed bed reactor

InactiveUS20100004419A1Low costReduce usageTransportation and packagingRotary stirring mixersFixed bedHomogeneous catalysis

A reactor comprising at least one contact surface made from, coated with, or impregnated by a catalyst, wherein the contact surface comprises a sintered metal or a ceramic, and wherein the reactor is configured to subject a reactant stream to shear. A system for carrying out a heterogeneously catalyzed reaction, the system comprising a reactor as described above and a pump configured for delivering reactants to the at least one reactor. A method for carrying out a heterogeneously-catalyzed reaction by introducing reactants into a reactor comprising at least one contact surface made from, coated with, or impregnated by a catalyst under conditions which promote production of a desired product, wherein the contact surface comprises a sintered metal or a ceramic, and forming a dispersion of reactants within the reactor, wherein the dispersion comprises droplets or gas bubbles of reactant with an average diameter of less than about 5 μm.

Owner:HRD CORP

Stackable structural reactor

Owner:JOHNSON MATTHEY PLC

Continuous process for the preparation of polytrimethylene ether glycol

InactiveUS20040152925A1Liquid-gas reaction as foam/aerosol/bubblesOrganic compound preparationGas phaseEther

The invention is a continuous process for the preparation of polytrimethylene ether glycol from 1,3-propanediol reactant. In addition, the invention is directed to a continuous multi-stage process comprising reacting at least one reactant in a liquid phase in an upflow column reactor, and forming a gas or vapor phase by-product wherein the gas or vapor phase by-product is continuously removed at the top and at least one intermediate stage.

Owner:DUPONT IND BIOSCIENCES USA LLC

Process for mixing and reacting two or more fluids

InactiveUS7195747B2Increase pressure dropInsufficient diffusionHydrogen peroxideProcess control/regulationCycloneMixing chamber

A novel process for continuously mixing and reacting at least two fluids are disclosed. Excellent mixing and superior pressure drop characteristics are achieved using cyclone mixing where at least two supply channels feed a mixing chamber to create a vortex of the fluids to be mixed. The alignment of the supply channels is such that fluids are introduced into the chamber at both tangential and radial directions. In the case of gas / liquid mixing, particularly advantageous is the injection of the liquid stream tangentially and the gas stream radially. Reaction of the fluids can take place within the mixing chamber or in a separate reactor in fluid communication with the mixing chamber outlet. The process is especially useful for reacting potentially explosive mixtures of reactants where a homogeneous reactor feed mixture is critical to maintaining a non-explosive environment.

Owner:UOP LLC

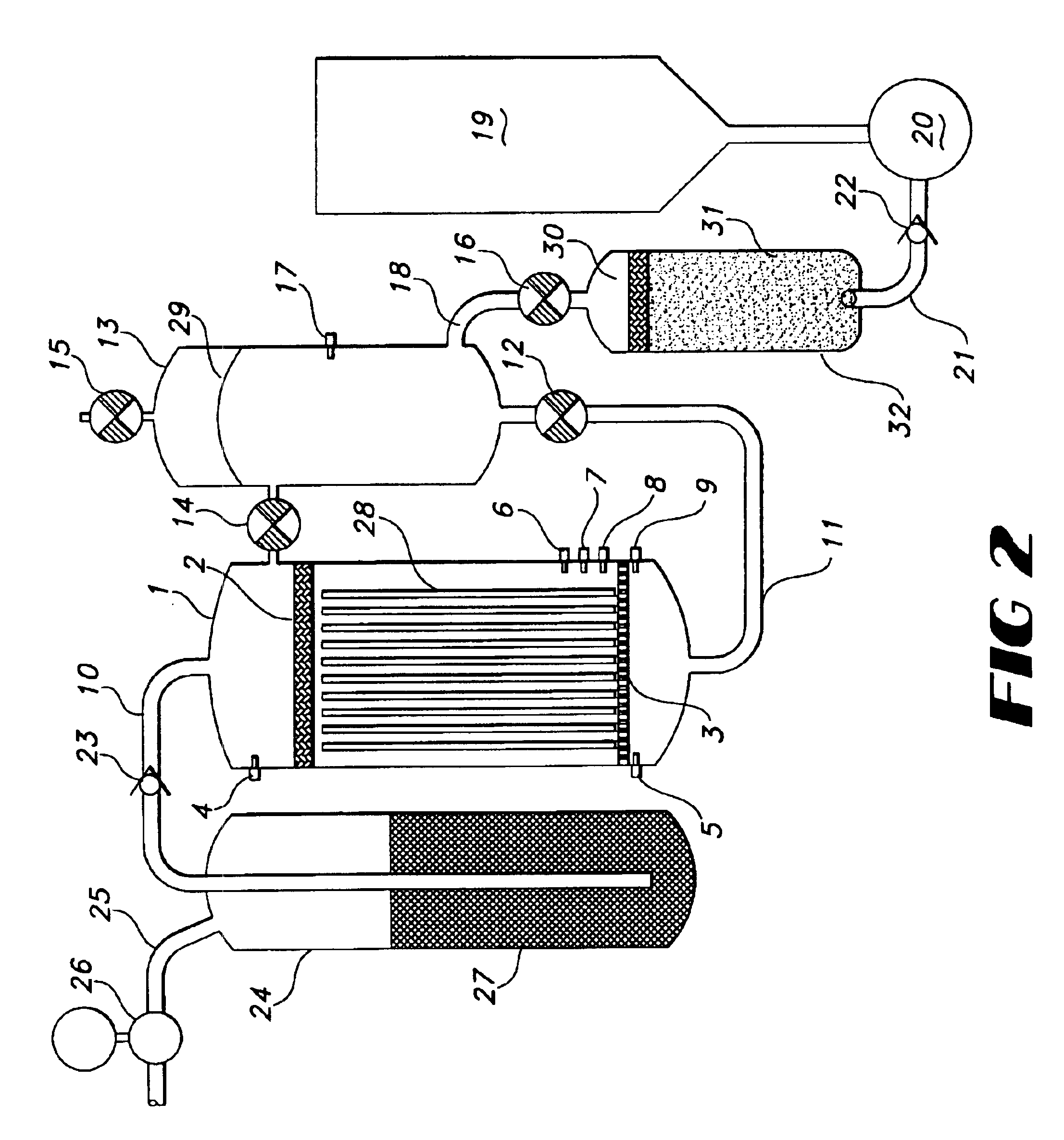

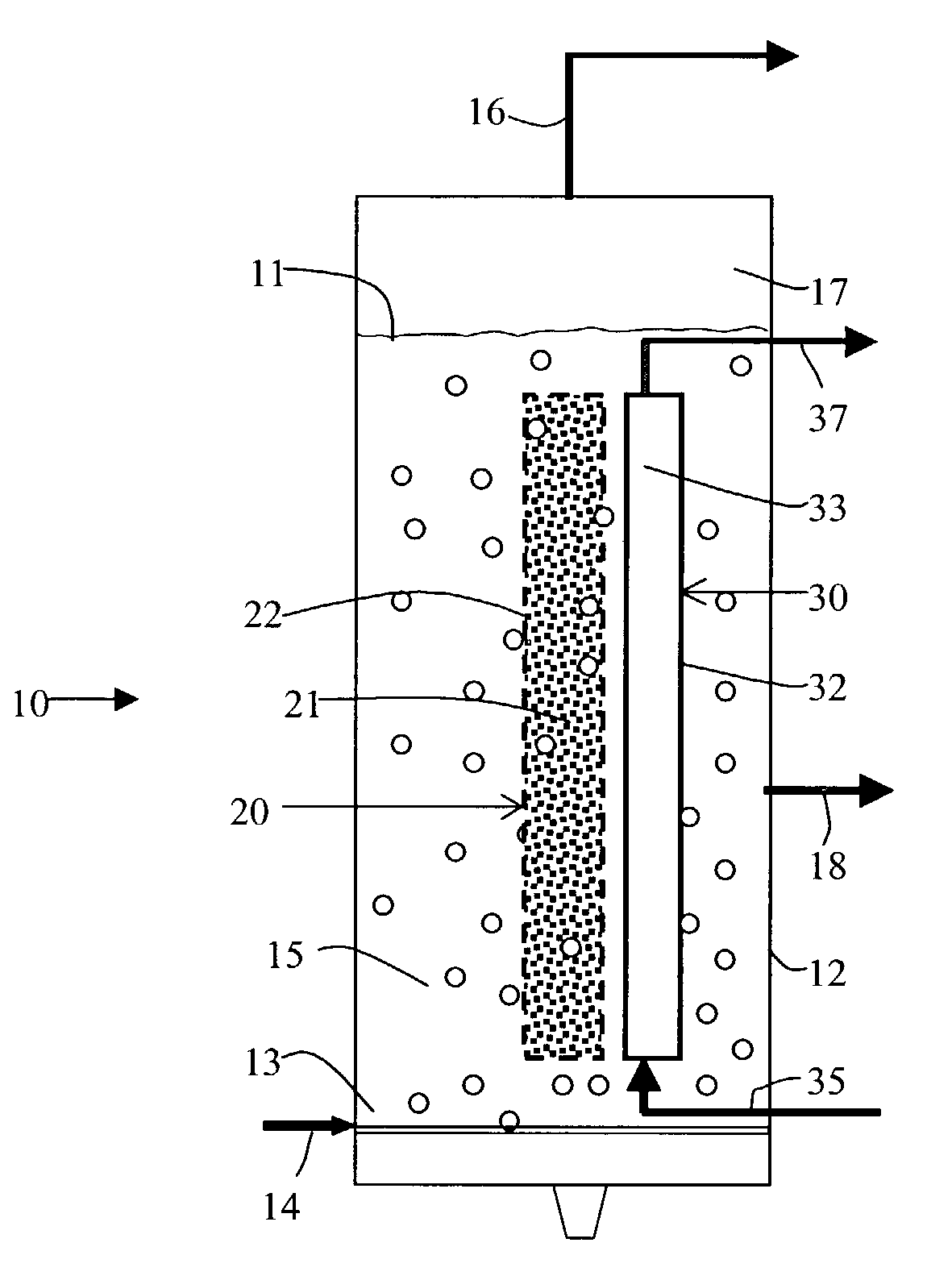

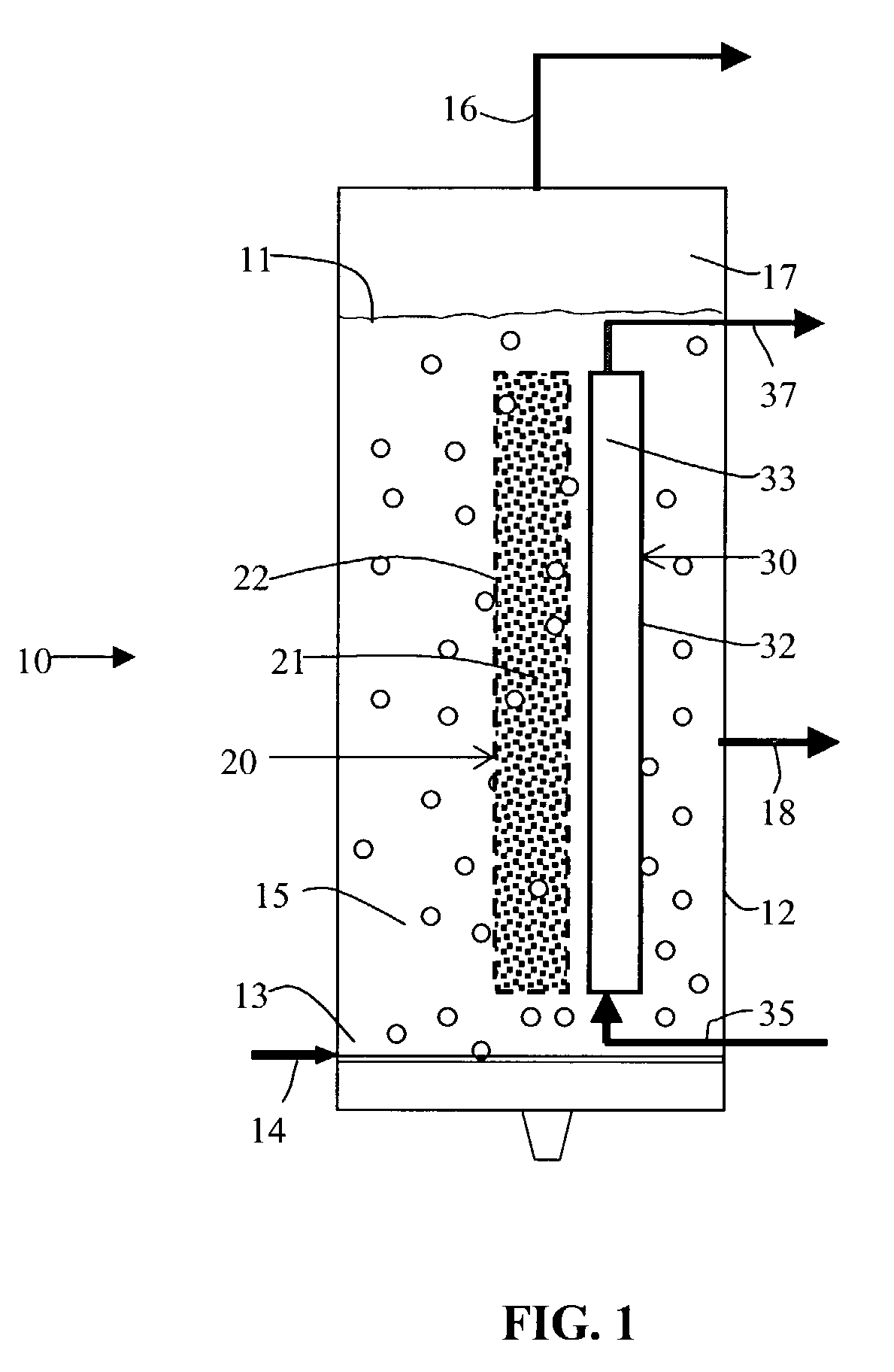

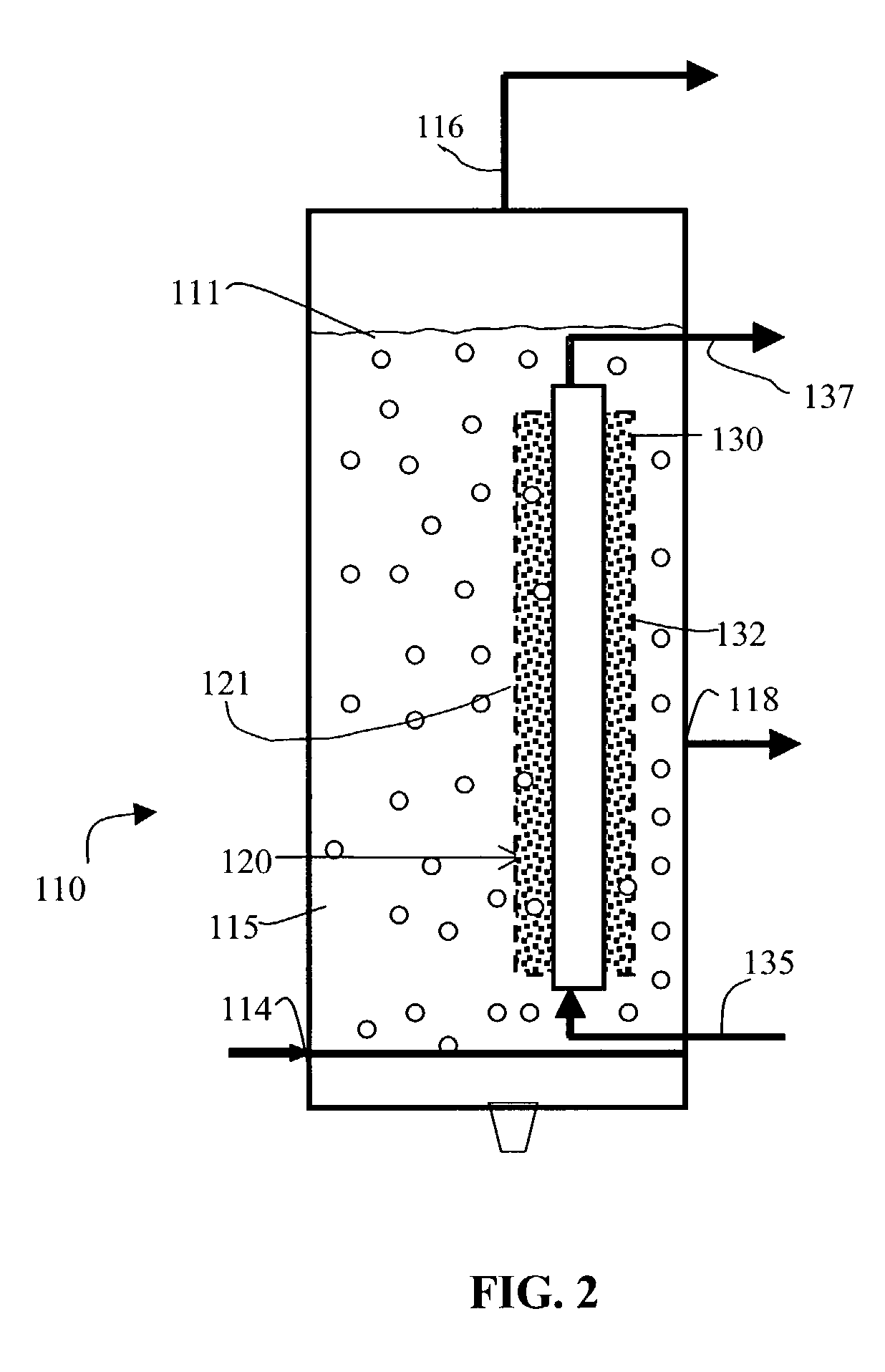

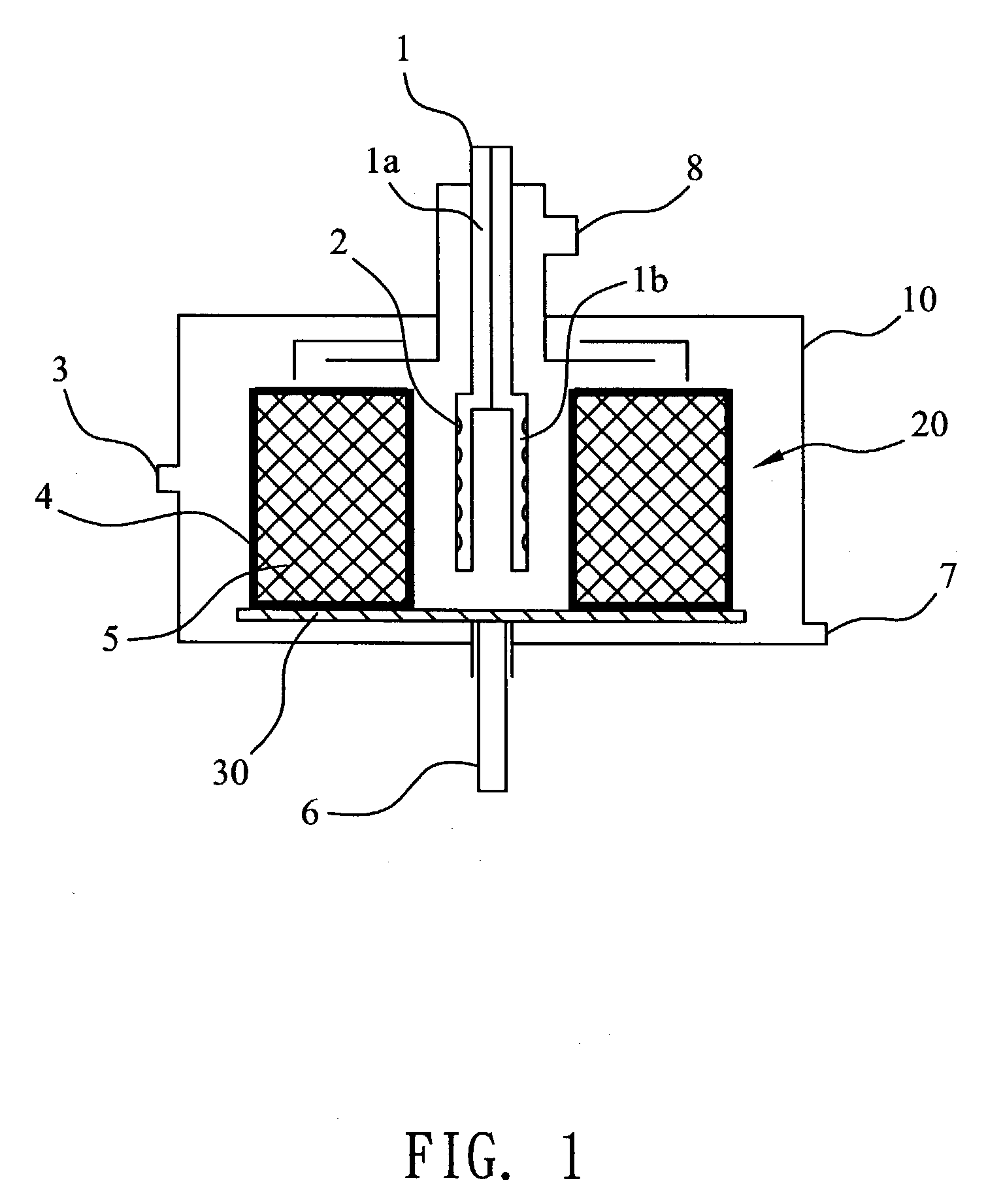

Gas agitated multiphase reactor with stationary catalyst solid phase

ActiveUS7232848B2Improve heat transfer performanceMinimizing catalyst attritionCombination devicesExhaust apparatusLiquid productThermal contact

An apparatus for converting a gaseous and / or liquid feed fluid to gaseous and / or liquid products using a solid catalyst comprises a reactor, a liquid phase disposed within the reactor volume, a fixed catalyst at least partially disposed in the liquid phase, a cooling system having a cooling element in thermal contact with the liquid phase, a feed inlet positioned to feed the feed fluid into the reactor volume, and a fluid outlet in fluid communication with the liquid phase. The catalyst is contained in a catalyst container and the container may be adjacent to said cooling element, extend through said cooling element, or may surround the catalyst container. The catalyst may be a Fischer-Tropsch catalyst.

Owner:PHILLIPS 66 CO

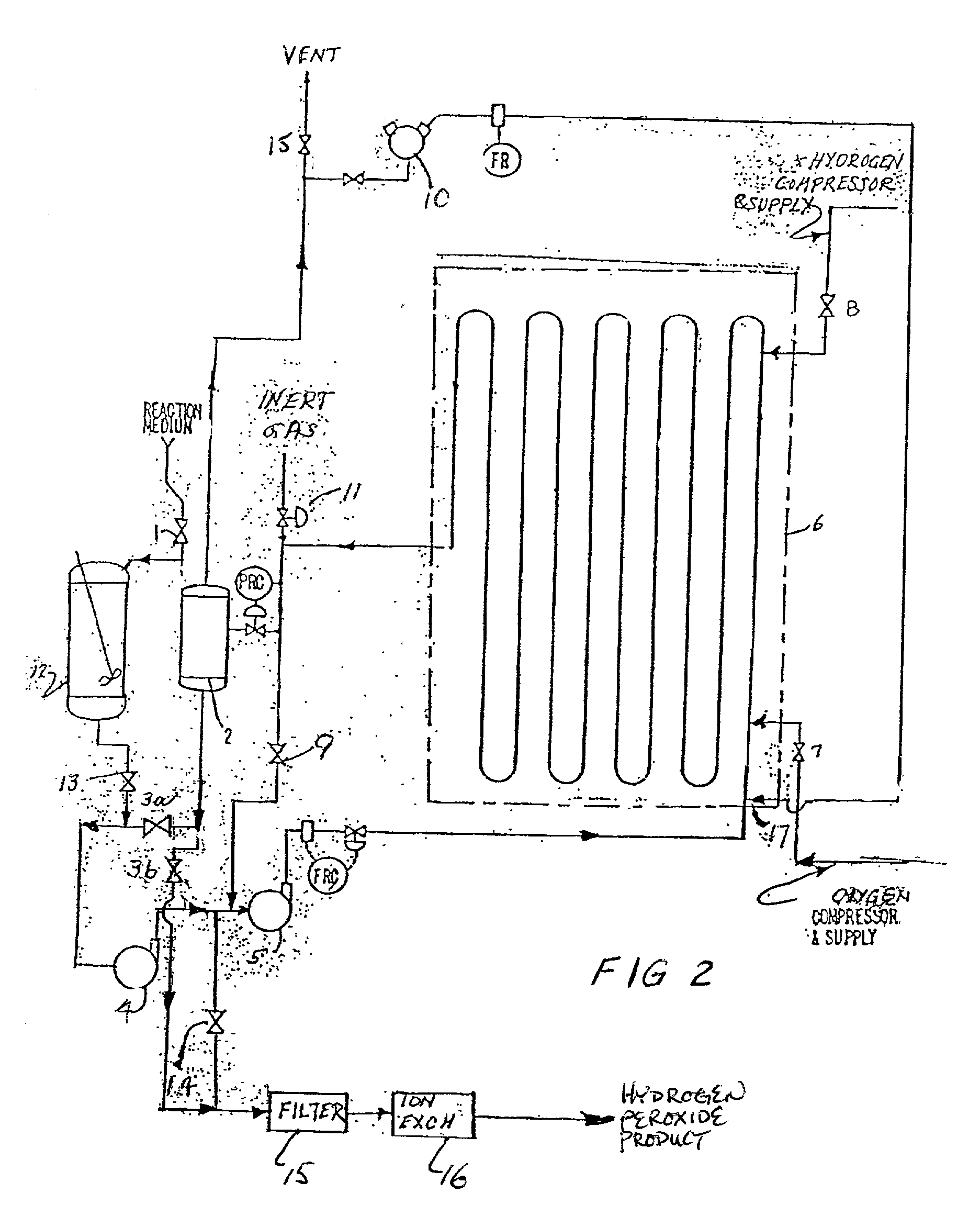

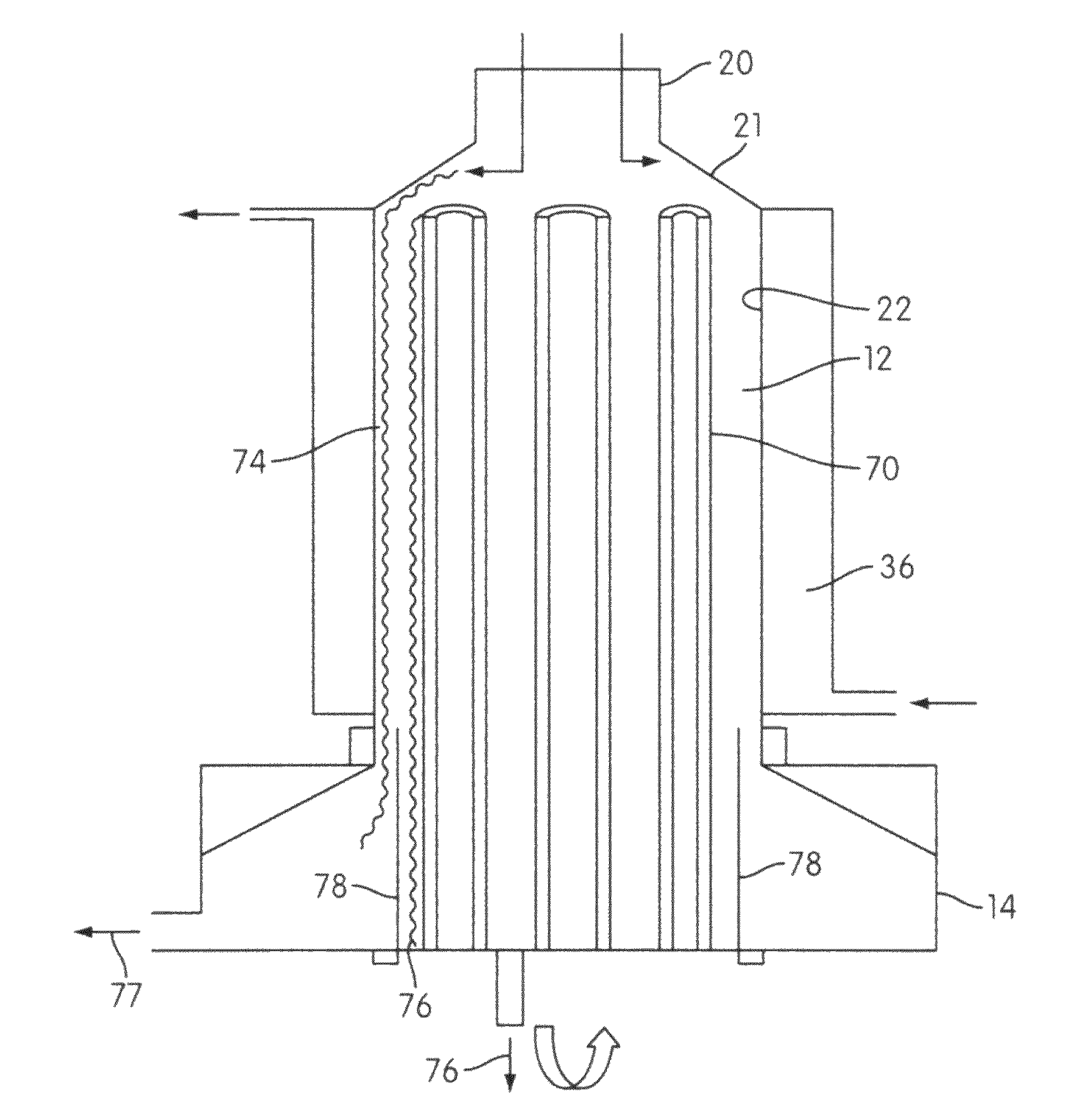

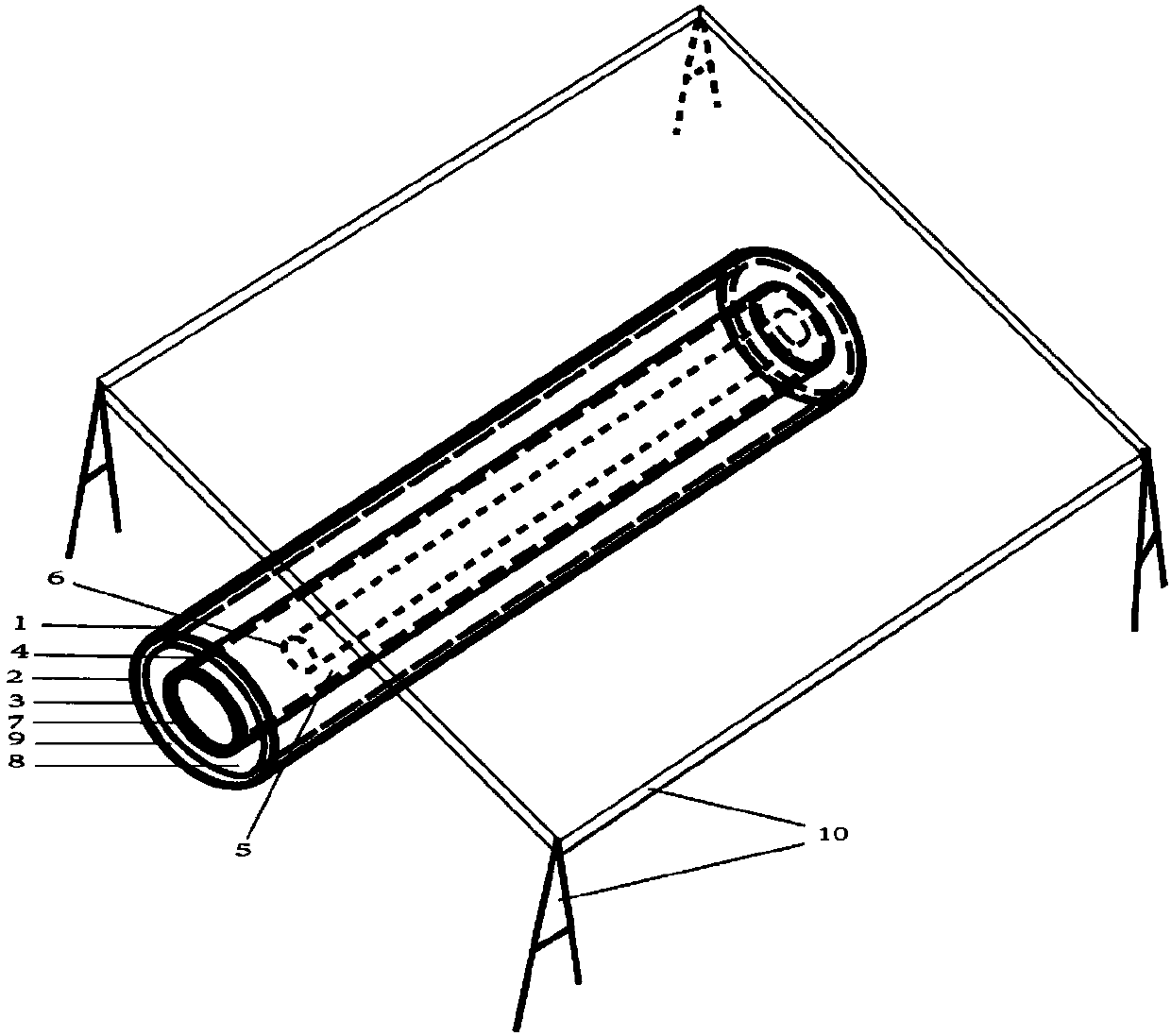

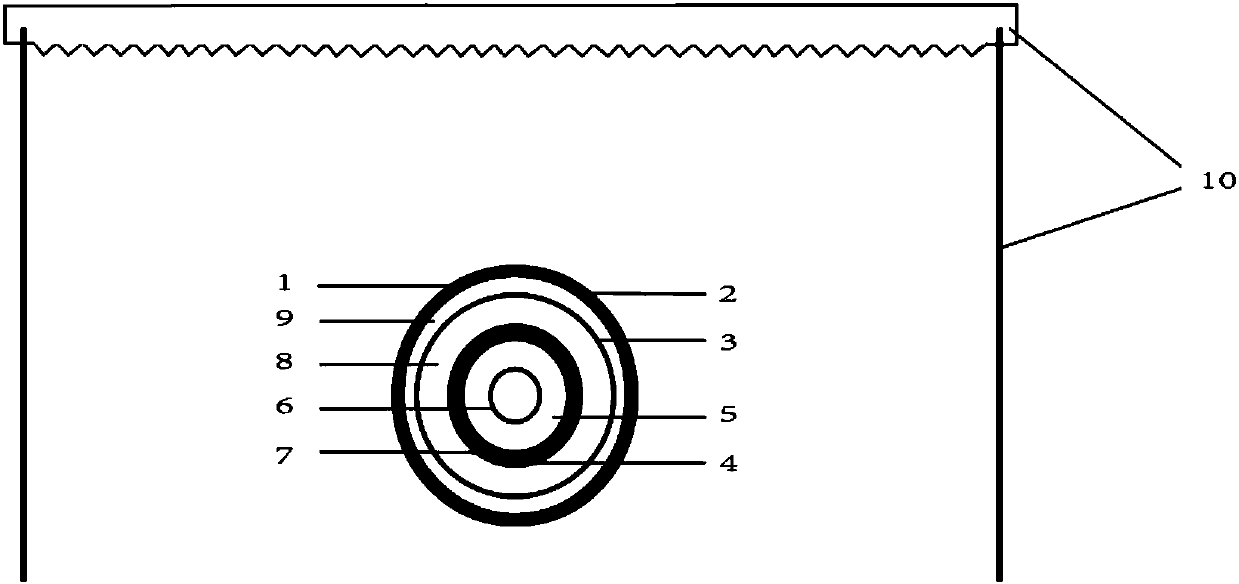

Tubular reactor with jet impingement heat transfer

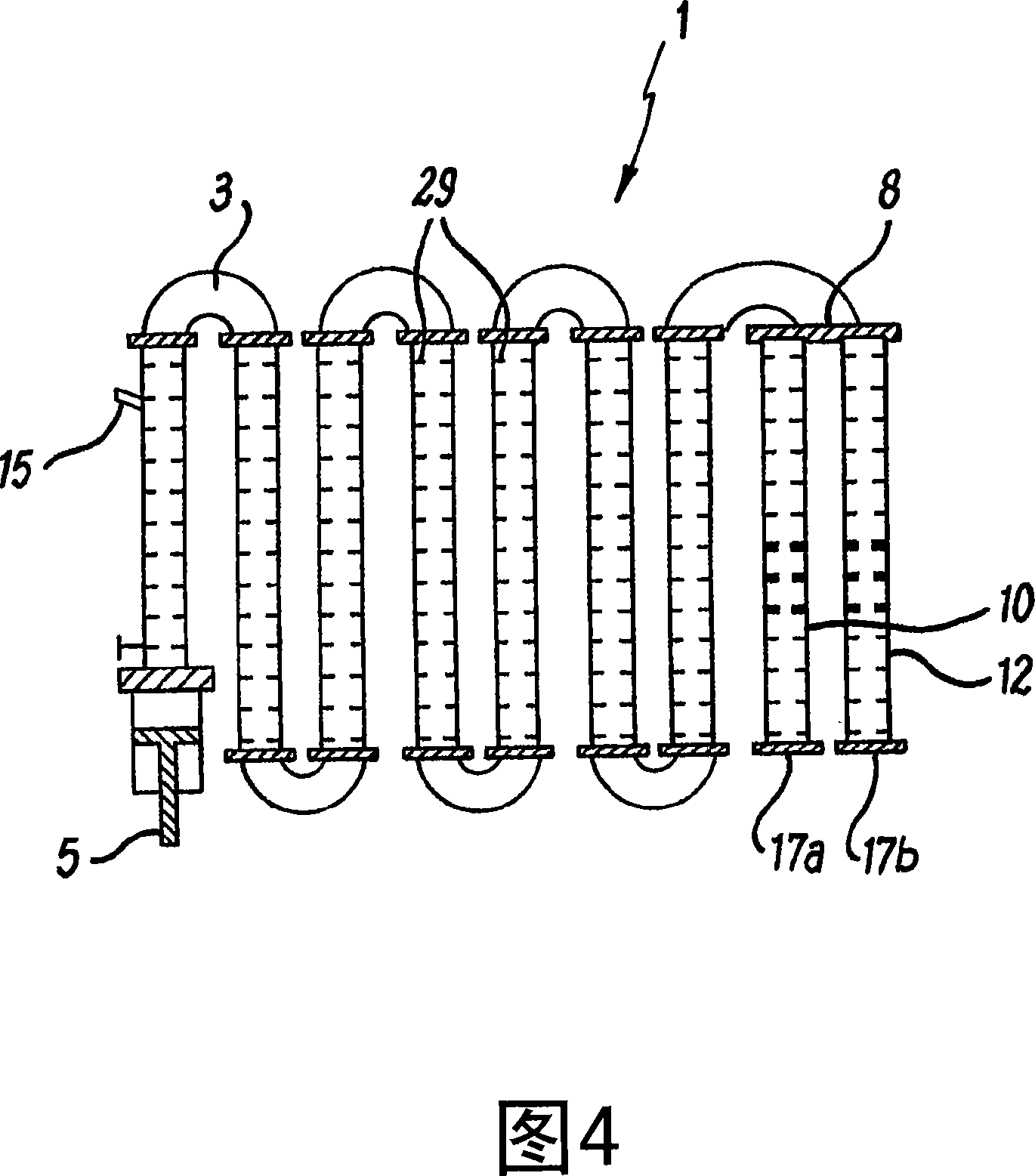

InactiveUS8178075B2Reduce flow rateReduce heat transferHydrogenCatalytic liquid-gas reactionMethanationProcess engineering

A tubular reactor and method for producing a product mixture in a tubular reactor where the tubular reactor comprises an internal catalytic insert having orifices for forming fluid jets for impinging the fluid on the tube wall. Jet impingement is used to improve heat transfer between the fluid in the tube and the tube wall in a non-adiabatic reactor. The tubular reactor and method may be used for endothermic reactions such as steam methane reforming and for exothermic reactions such as methanation.

Owner:AIR PROD & CHEM INC

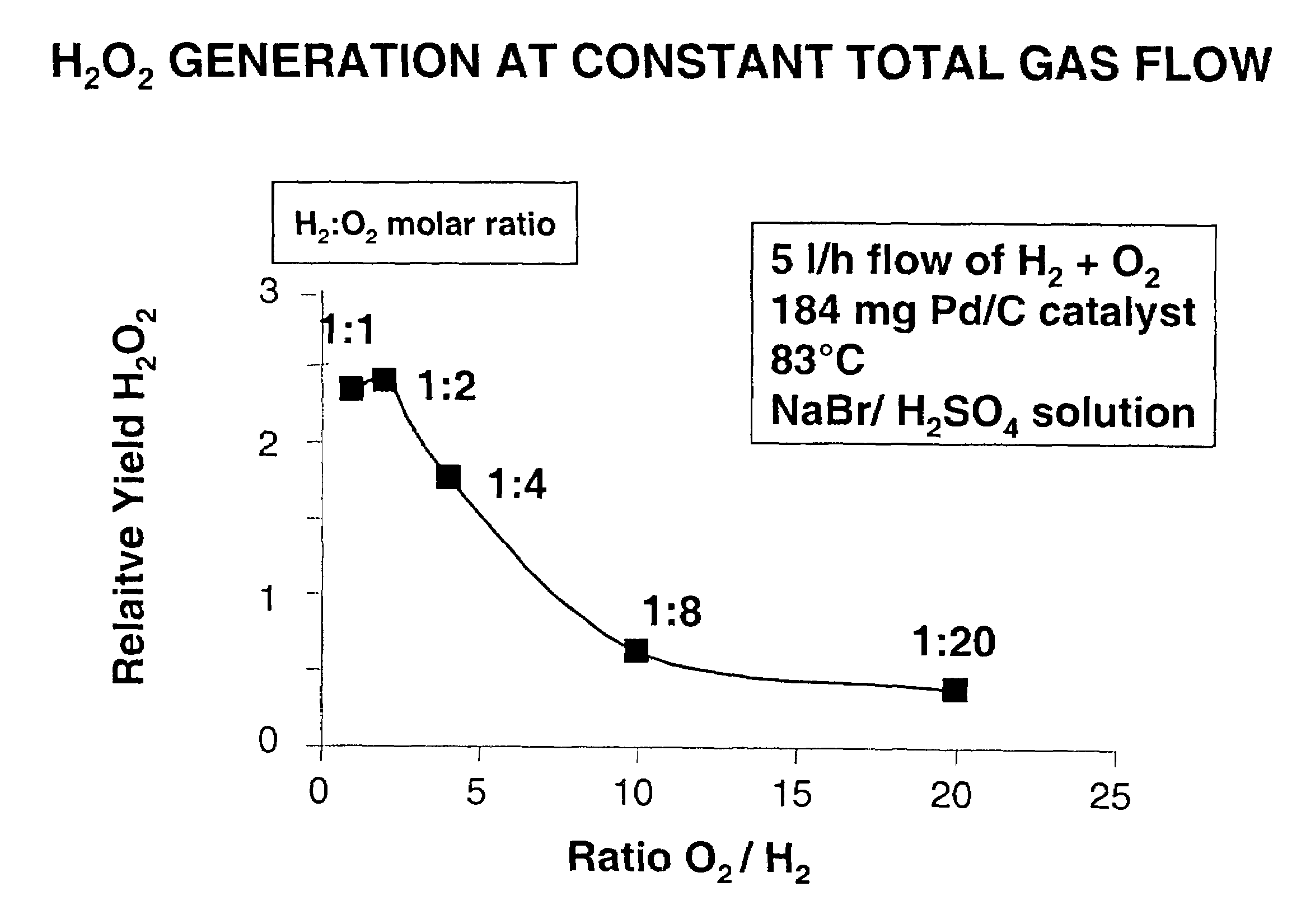

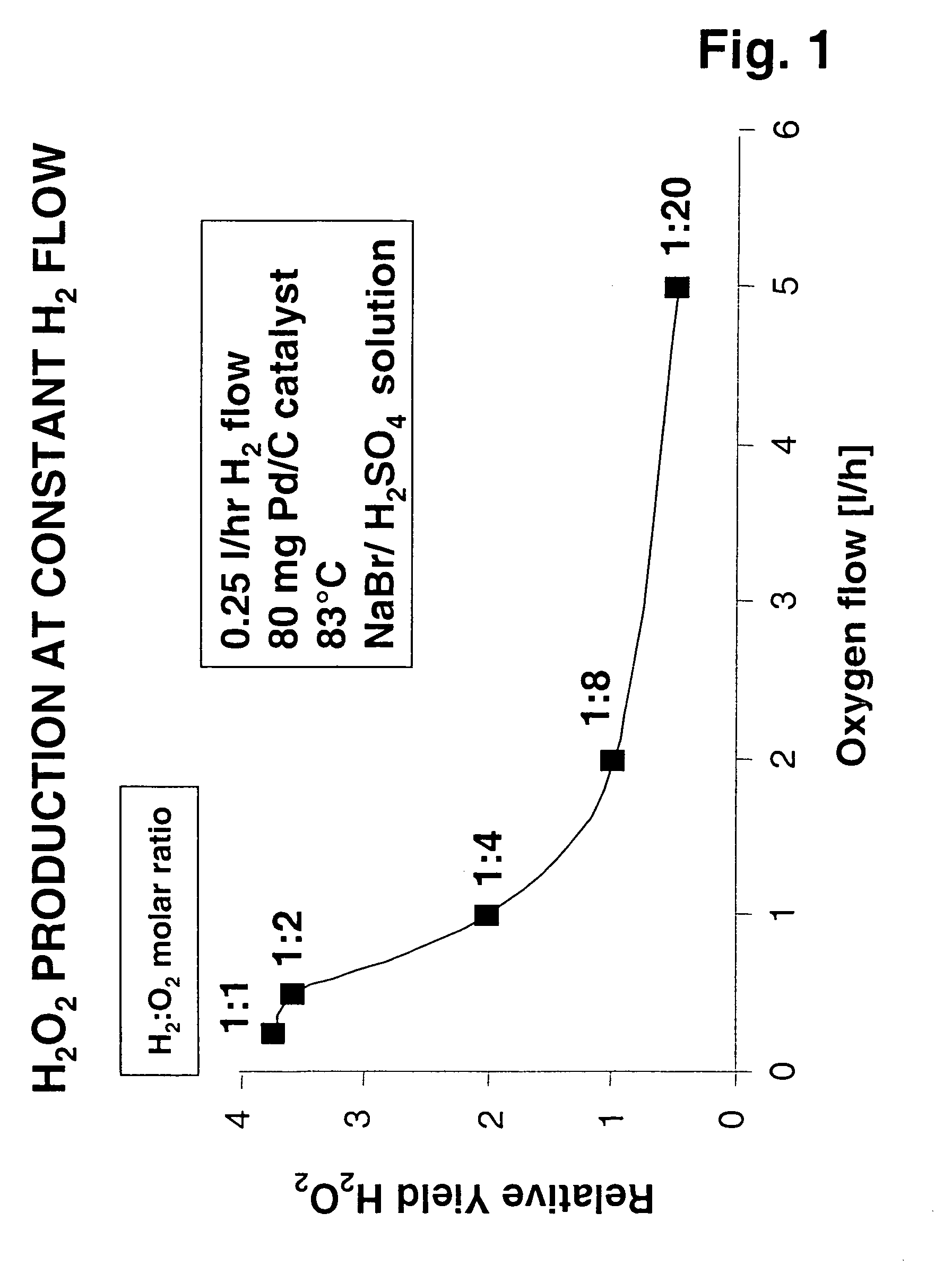

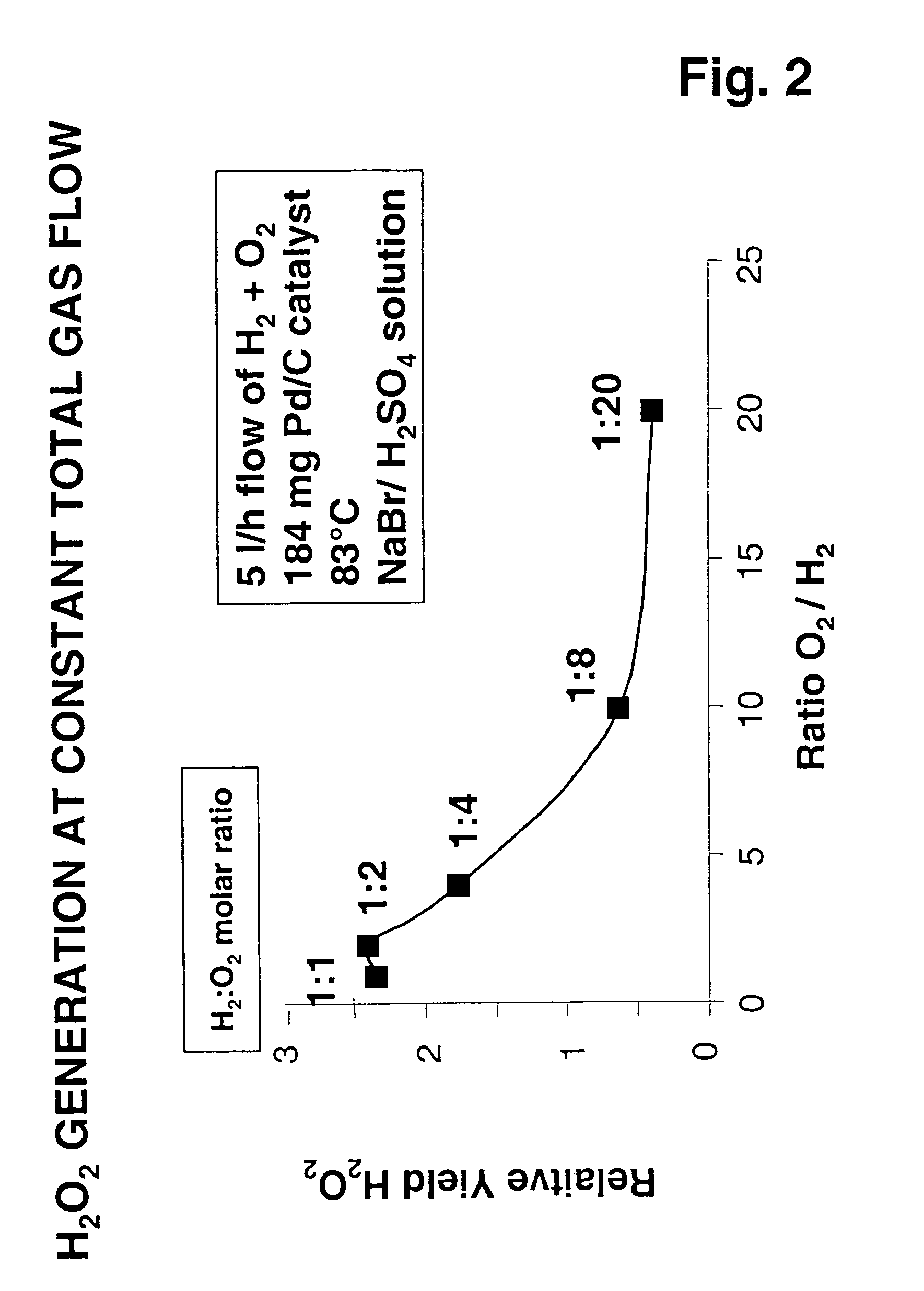

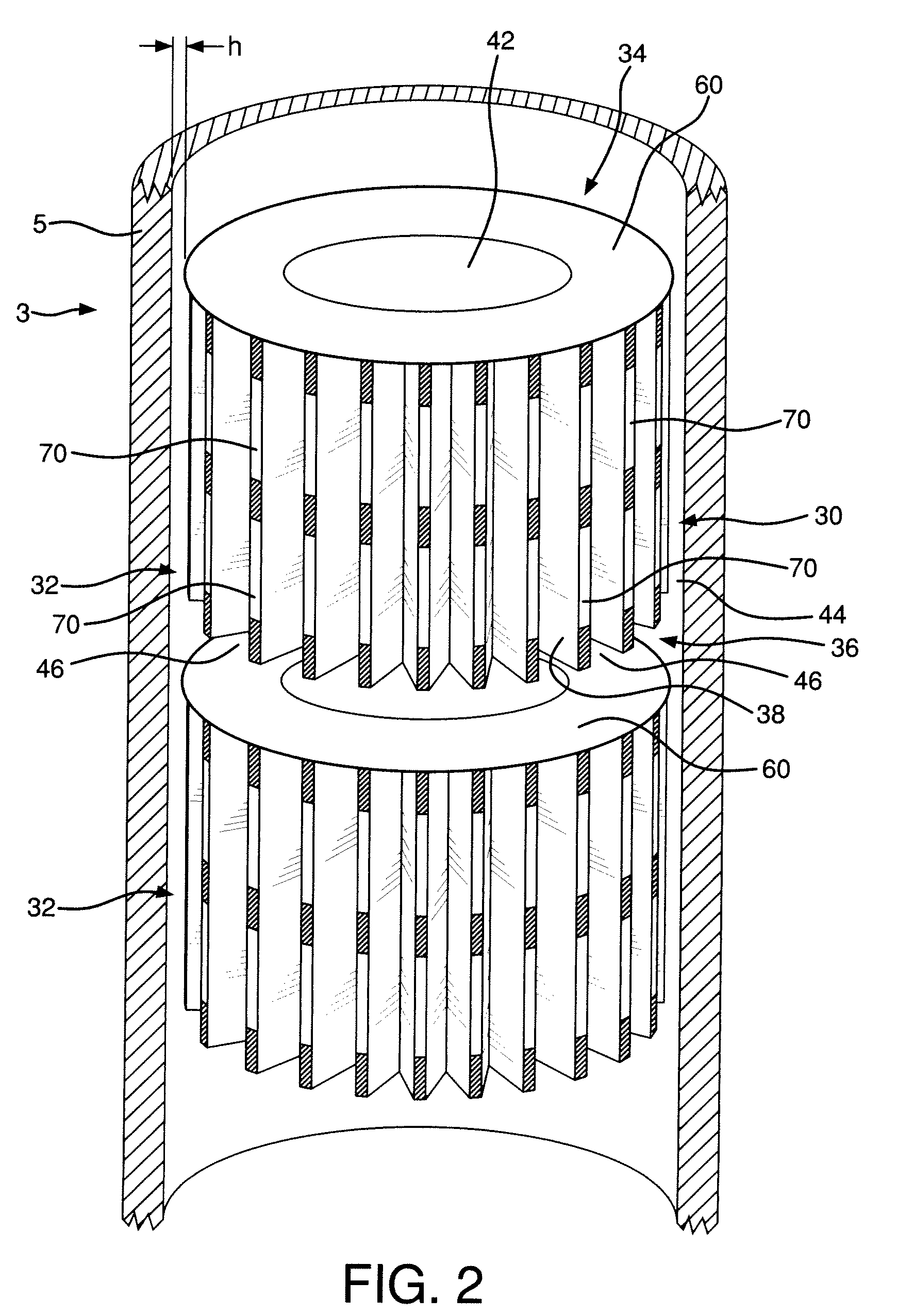

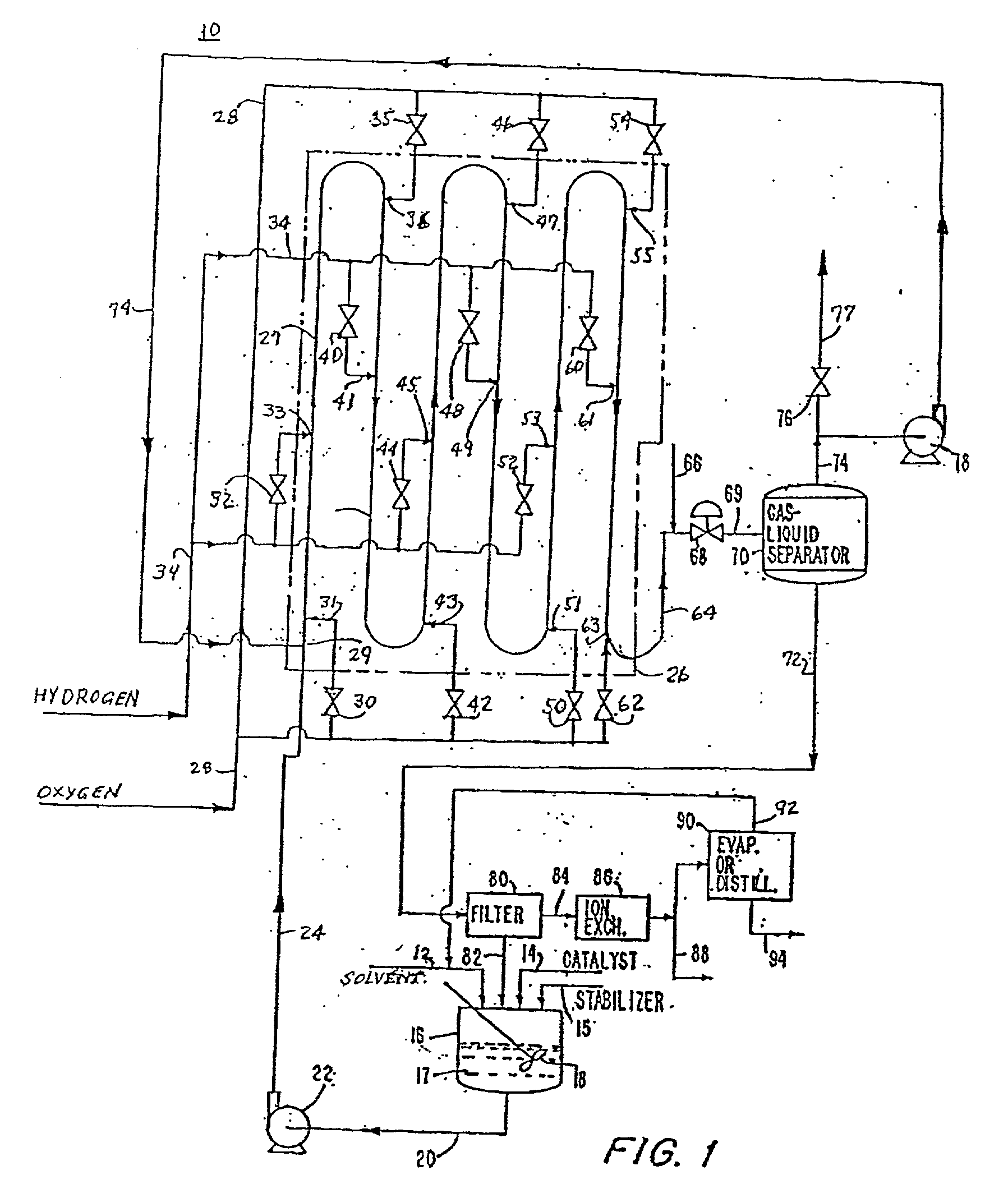

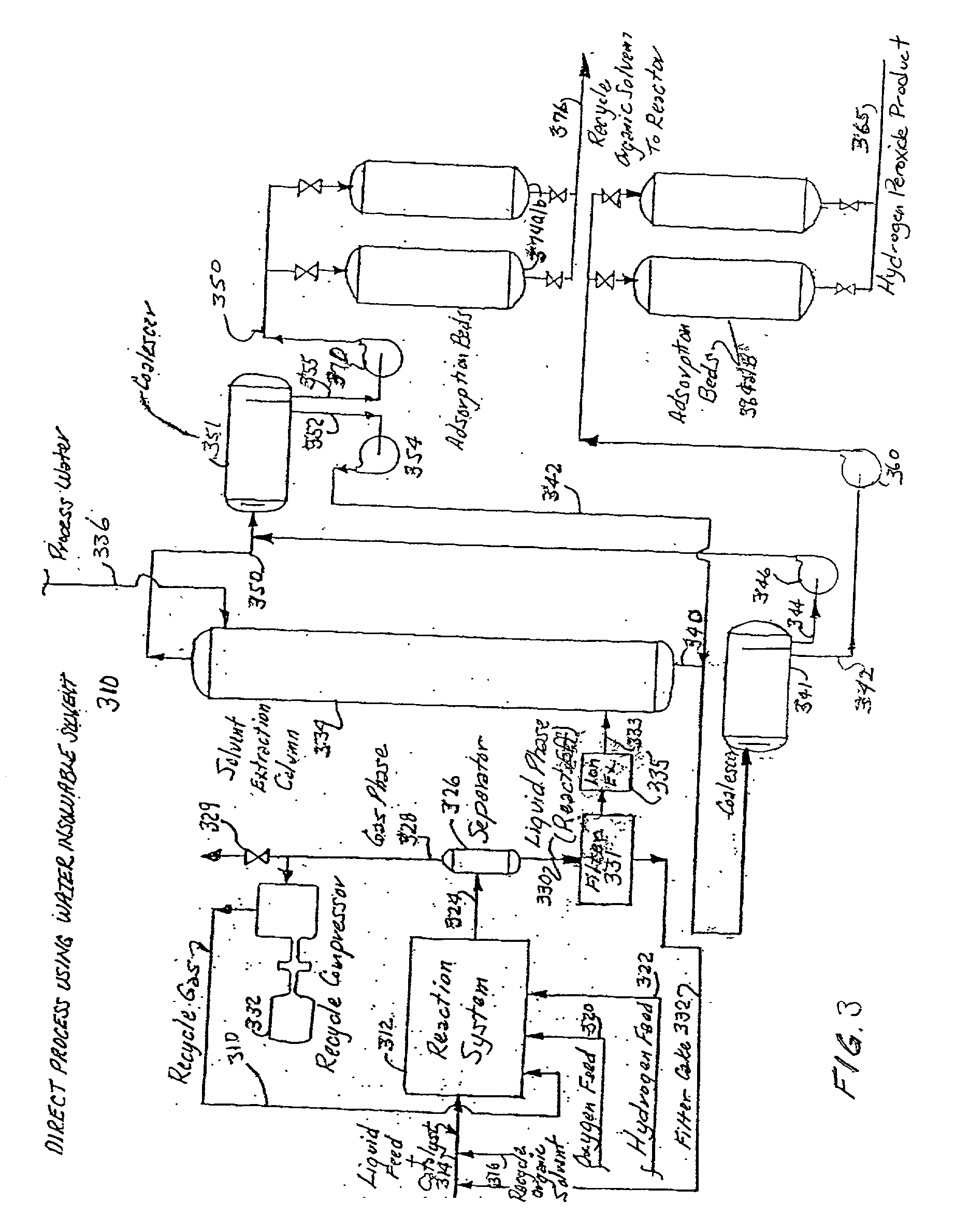

Method for producing hydrogen peroxide from hydrogen and oxygen

InactiveUS20030180212A1SolubilityLess-expensive reaction systemHydrogen peroxideCatalytic liquid-gas reactionLiquid mediumHydrogen

The invention relates to a method and apparatus for safely producing hydrogen peroxide by injecting dispersed minute bubbles of hydrogen and oxygen into a rapidly flowing liquid medium. The liquid medium can contain either a water-soluble organic compound, a water-insoluble organic compound, a combination of a water-insoluble organic compound with water, liquid carbon dioxide or supercritical carbon dioxide. The minute bubbles are surrounded by the liquid medium of sufficient volume for quench cooling any explosive reaction between the hydrogen and oxygen. The present invention also relates to reactors with internal catalyst structures and reactors that have a circular path, both of which may be used to produced hydrogen peroxide.

Owner:HUCKINS HAROLD A

High shear process for the production of acetaldehyde

InactiveUS20090005605A1Improve productivityReduced mass transfer limitationsOrganic compound preparationTransportation and packagingEmulsionAcetaldehyde

A method of use for a high shear device incorporated into a process or system for the production of acetaldehyde from ethylene as a reactor device is shown to be capable of decreasing mass transfer limitations, by forming a feed stream emulsion, and thereby enhancing the acetaldehyde production process in the system.

Owner:HRD CORP

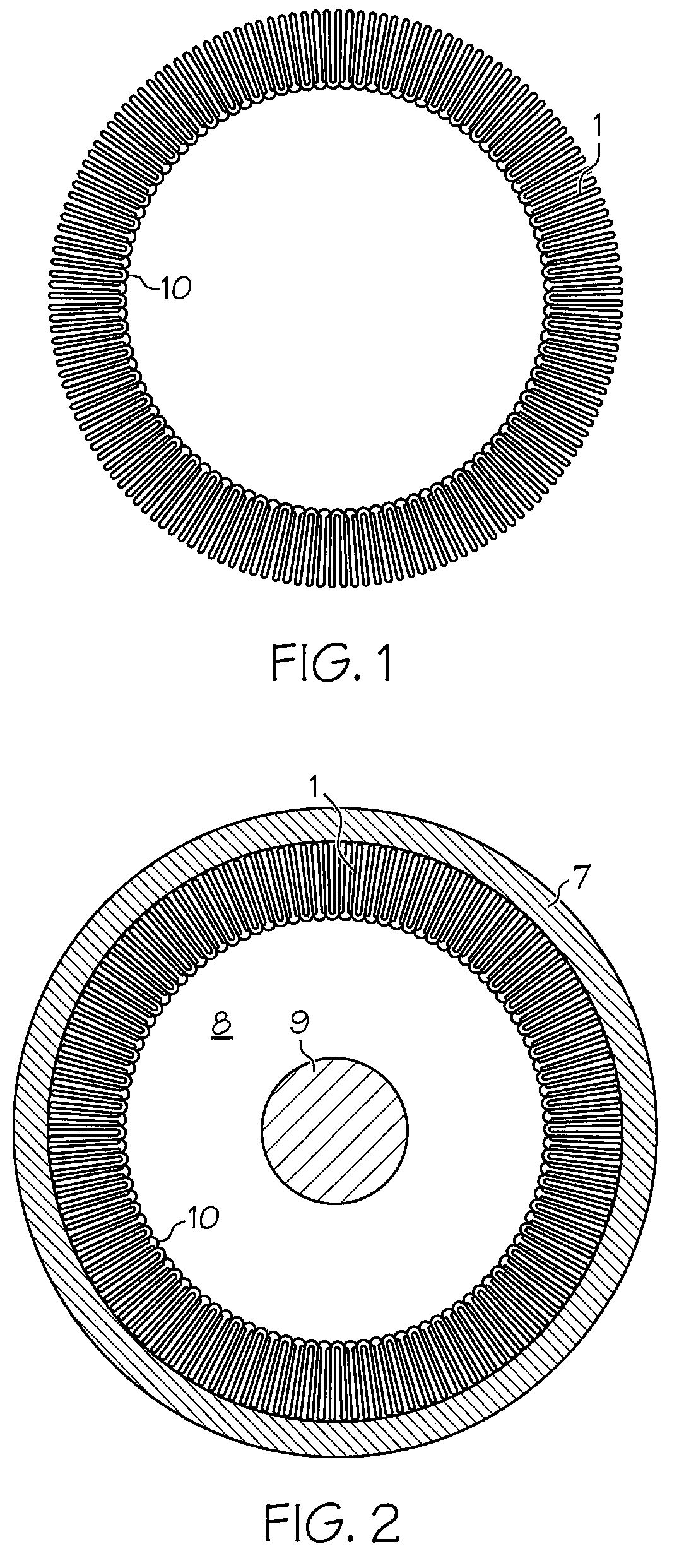

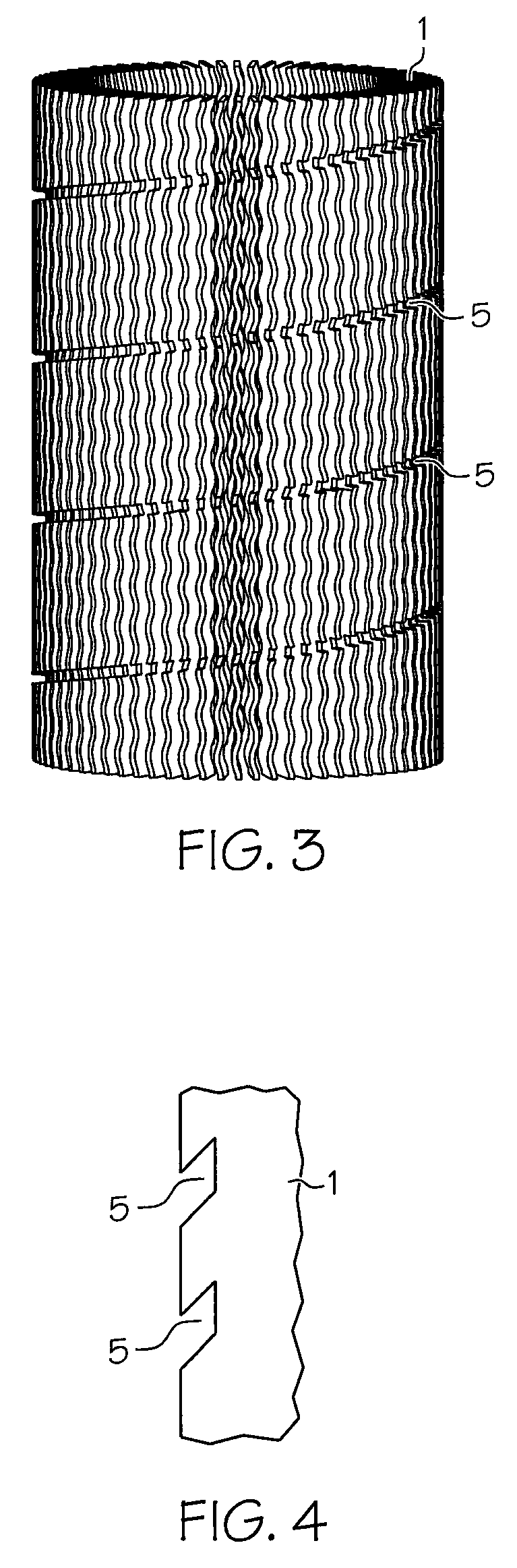

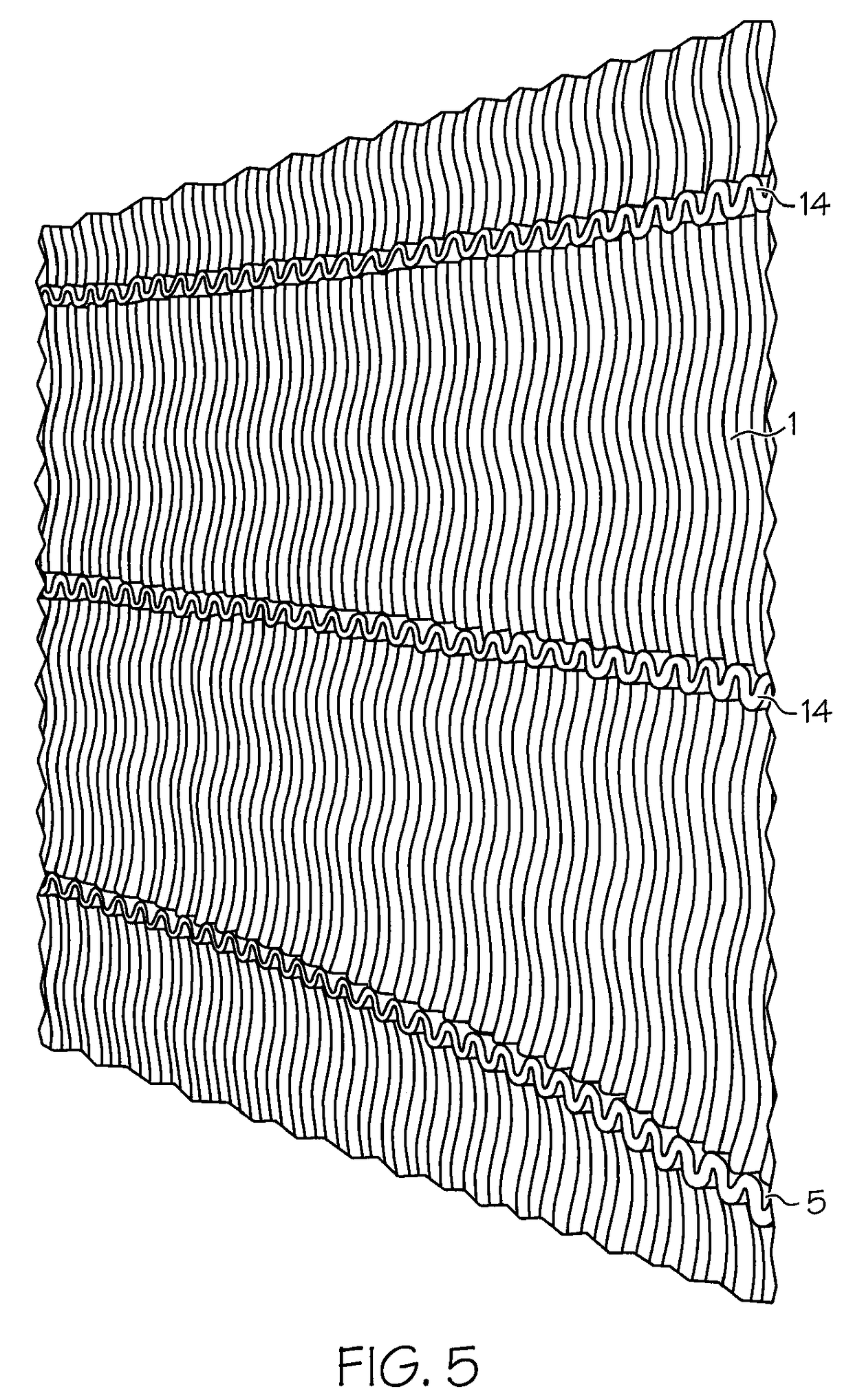

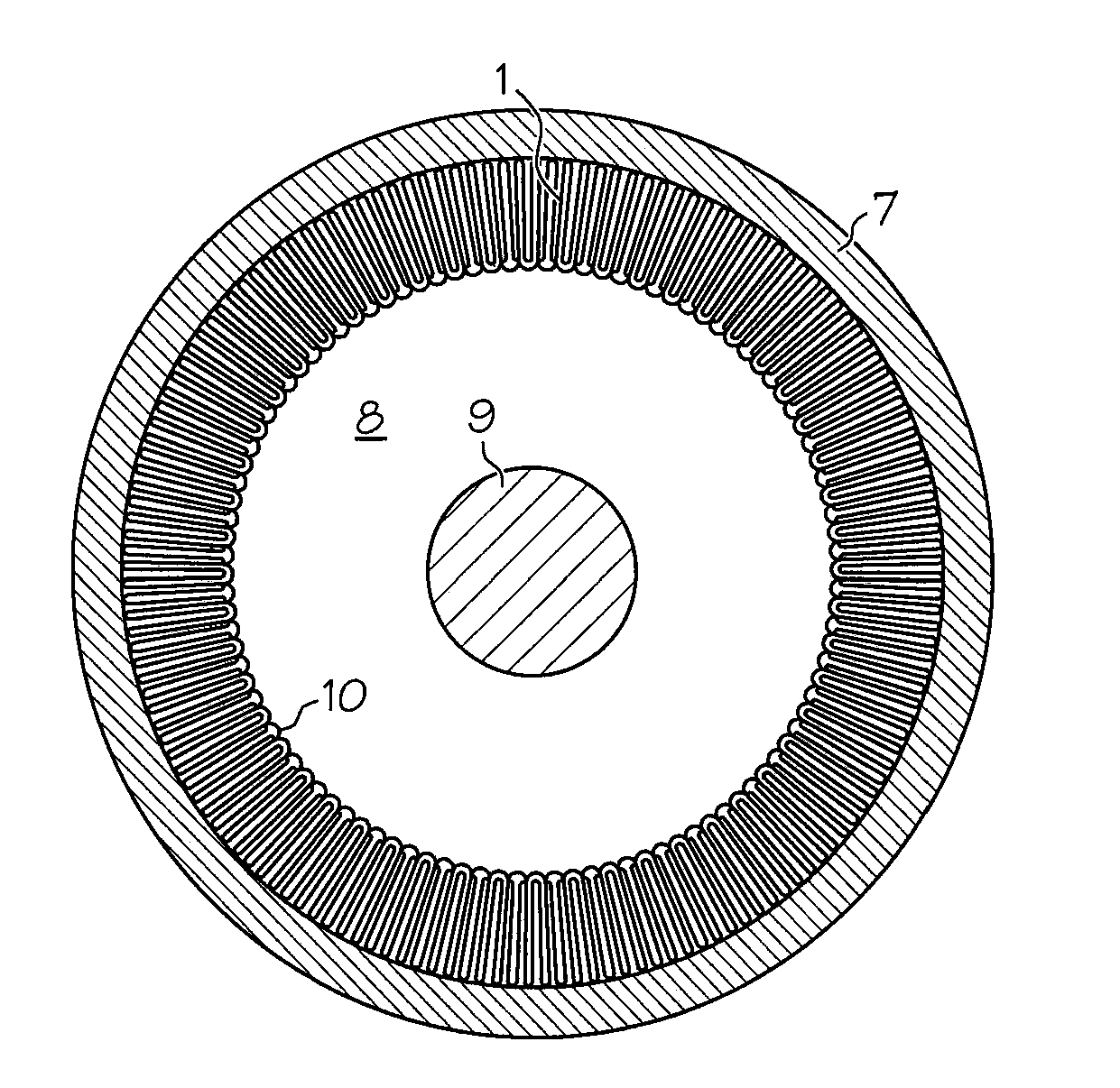

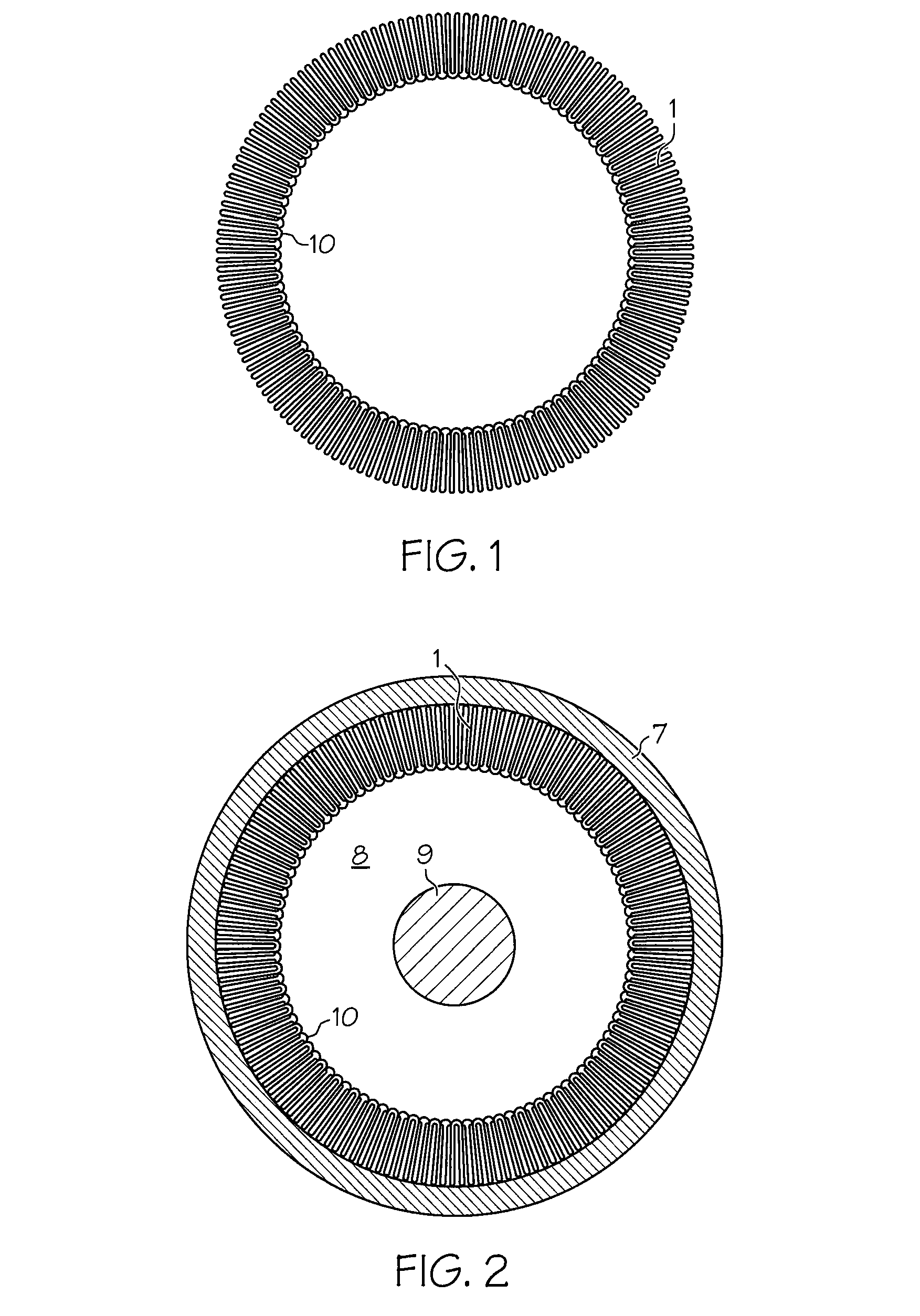

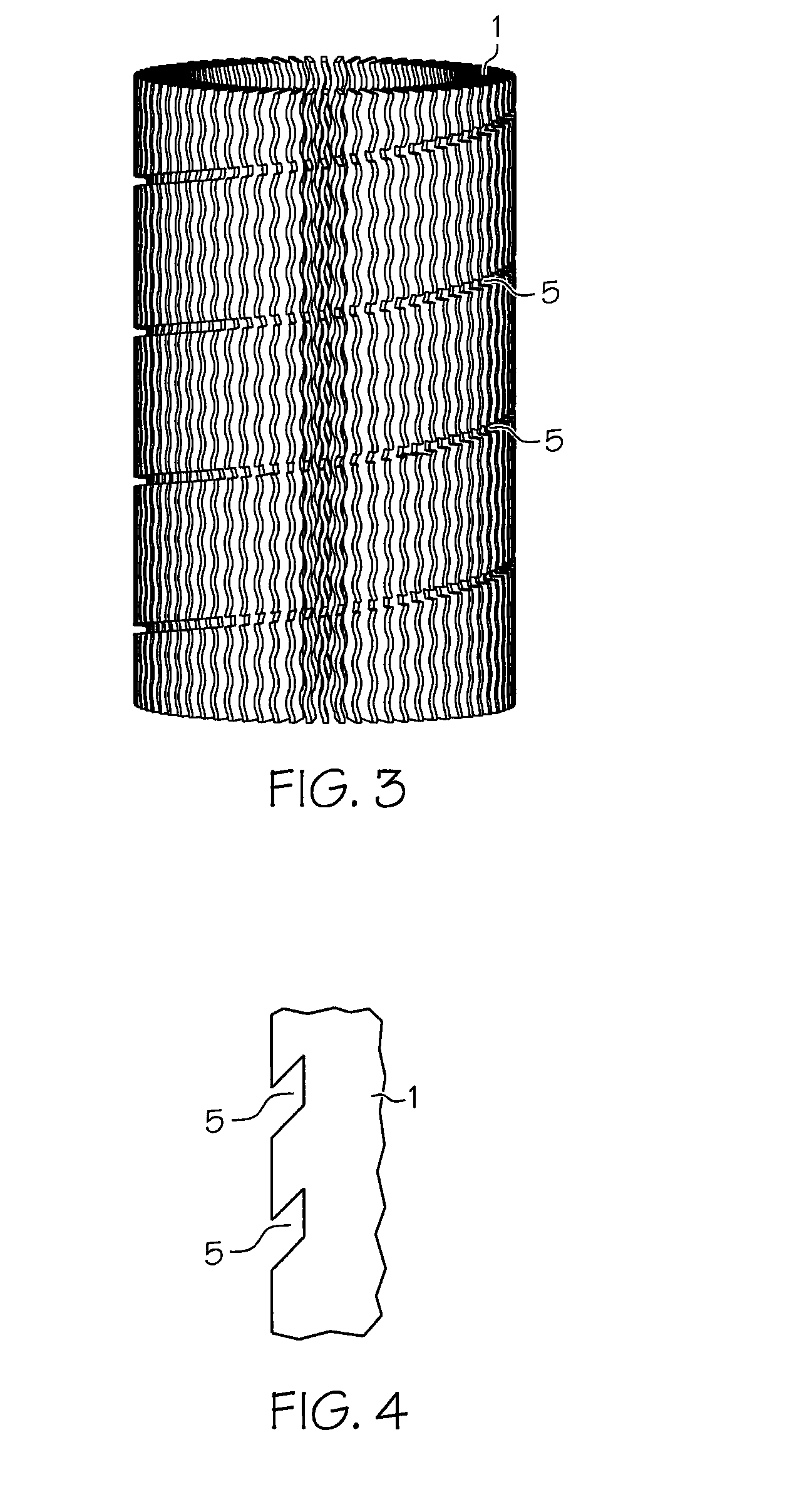

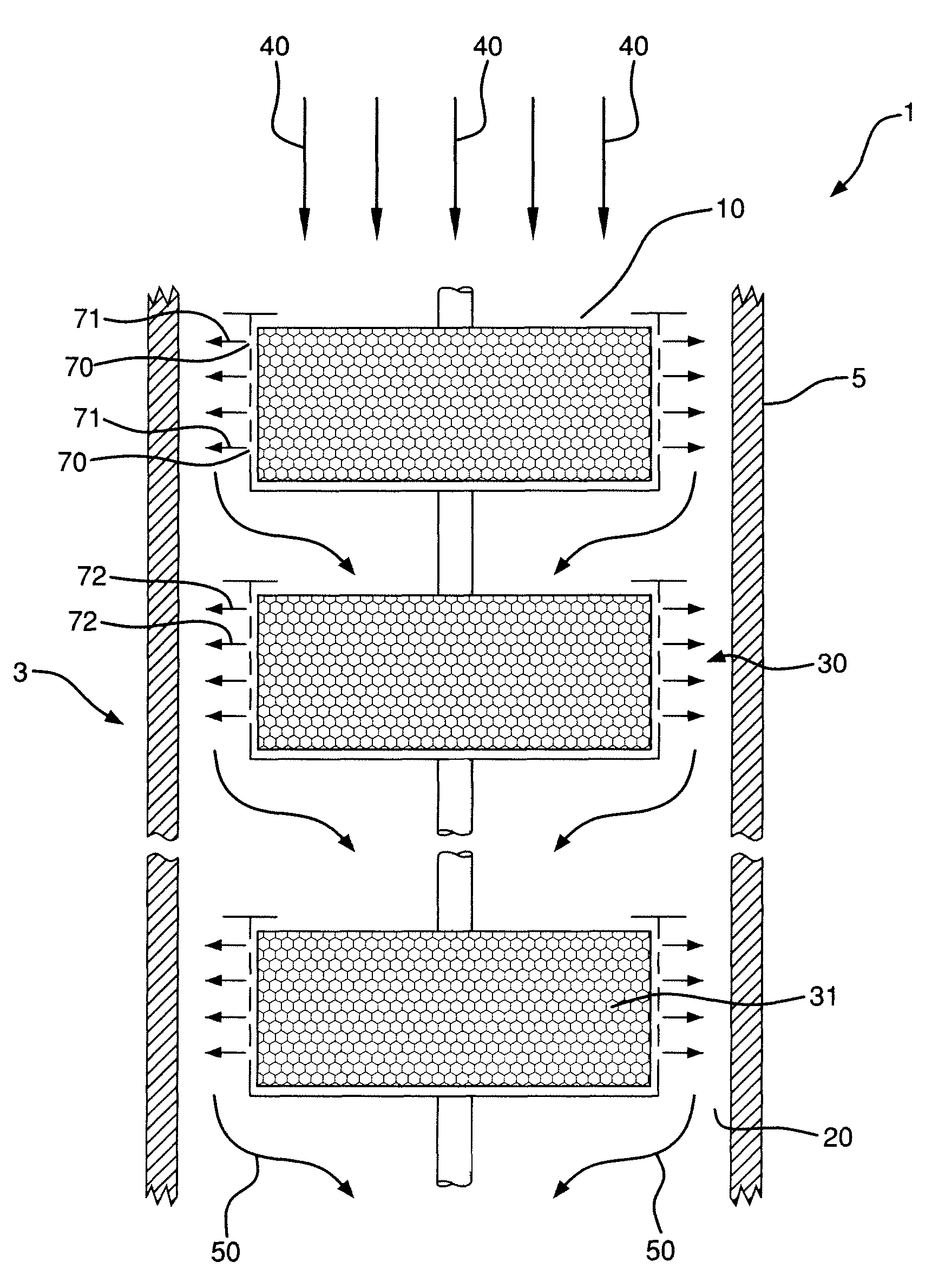

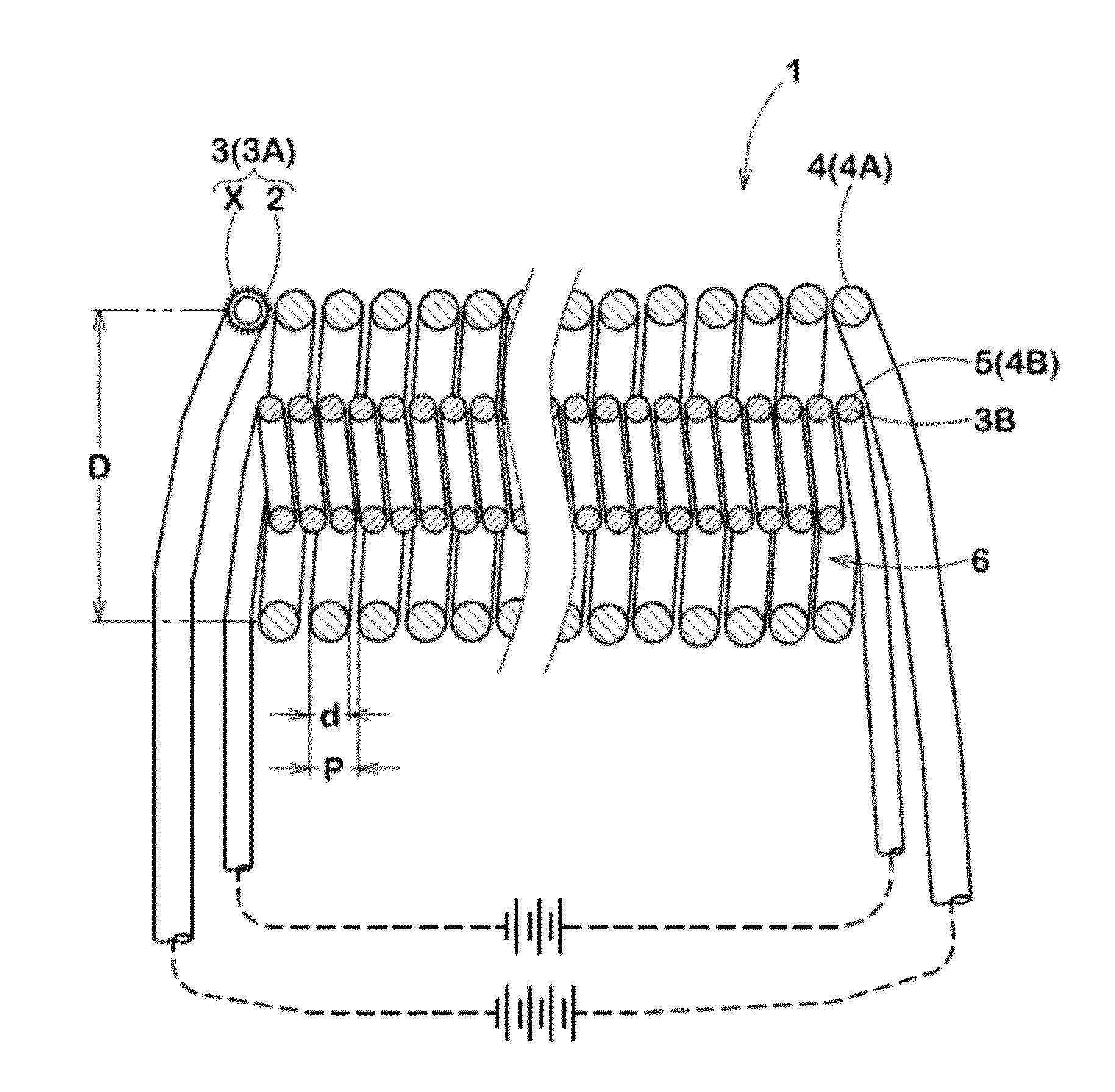

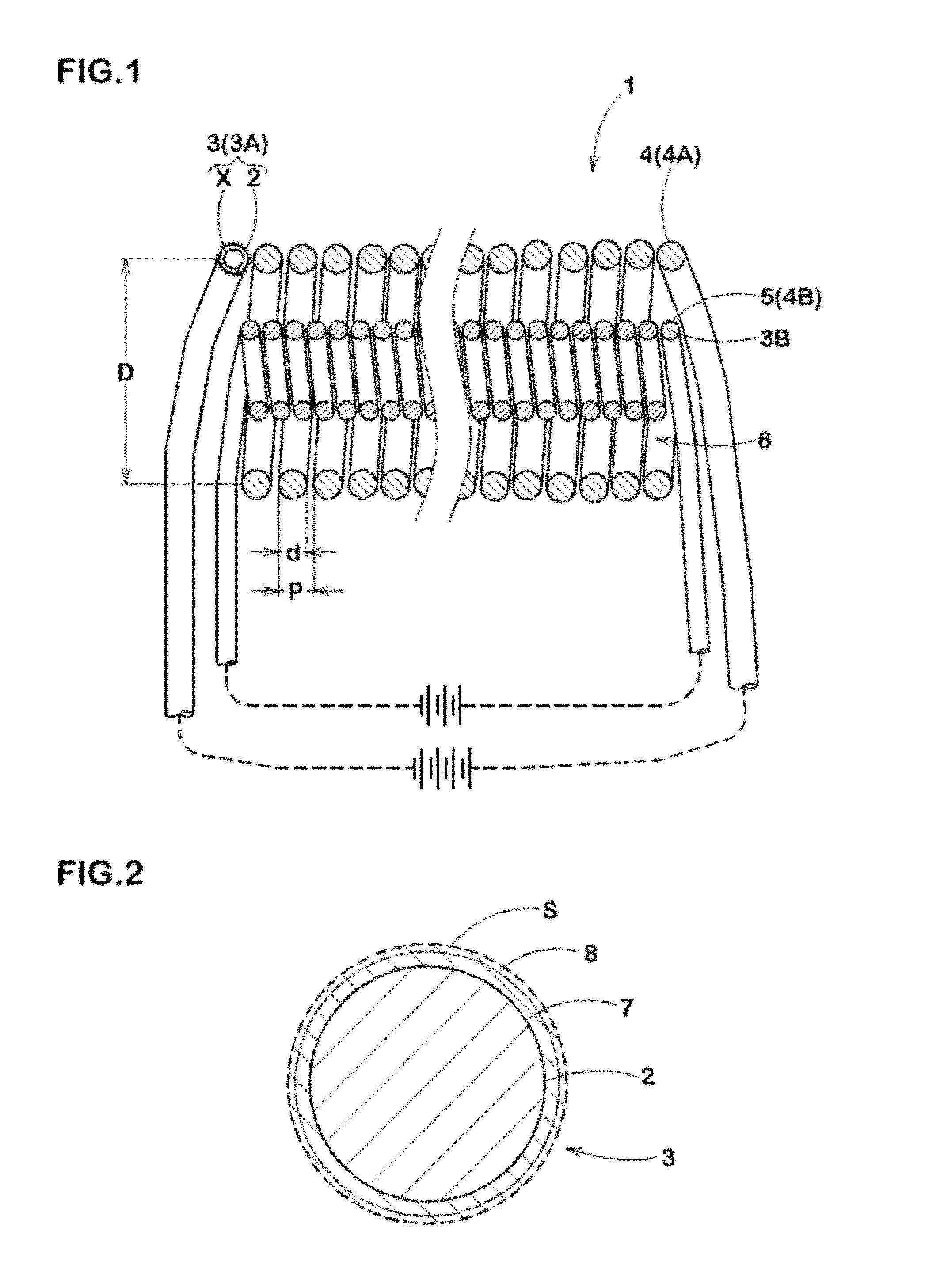

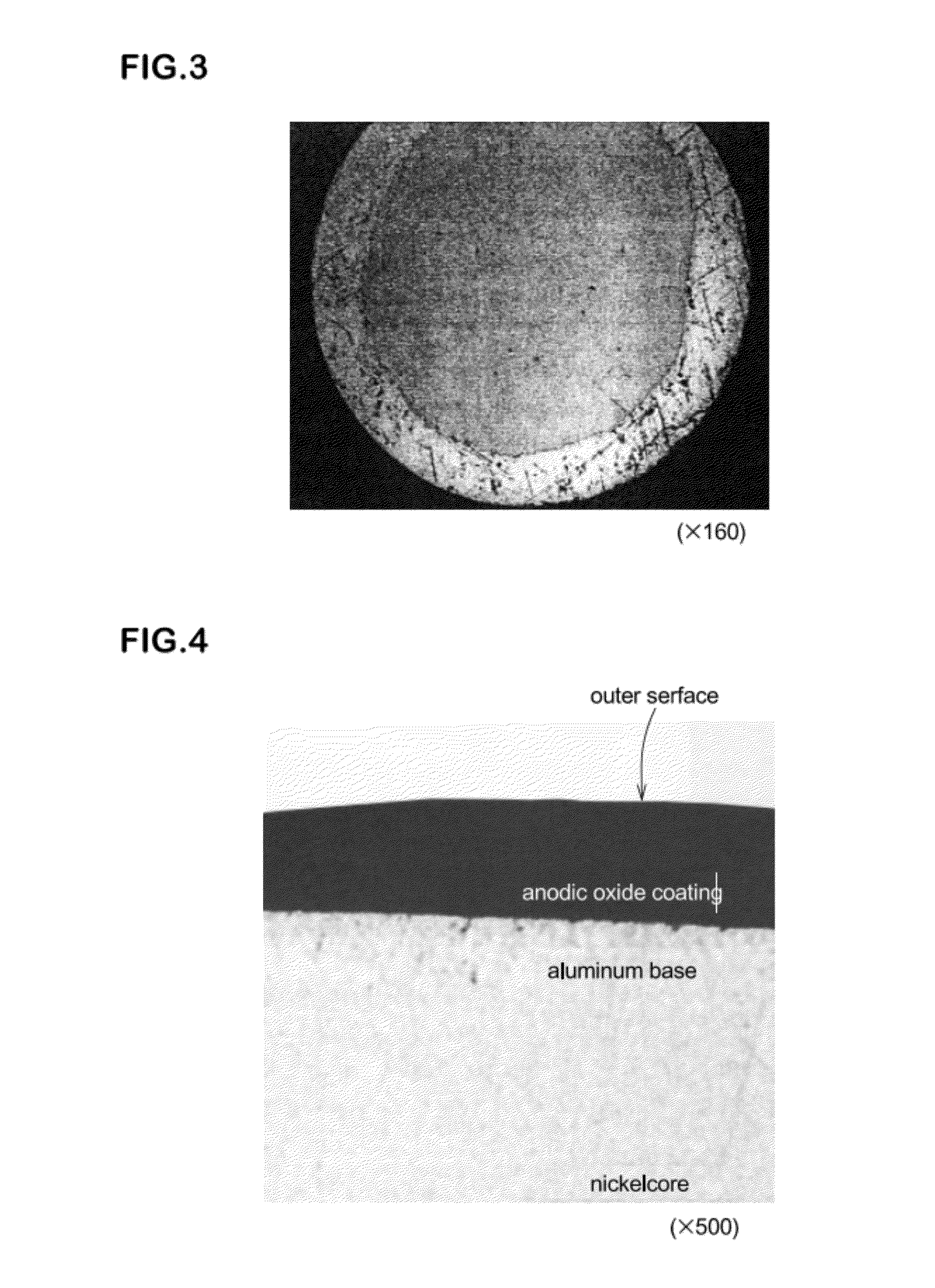

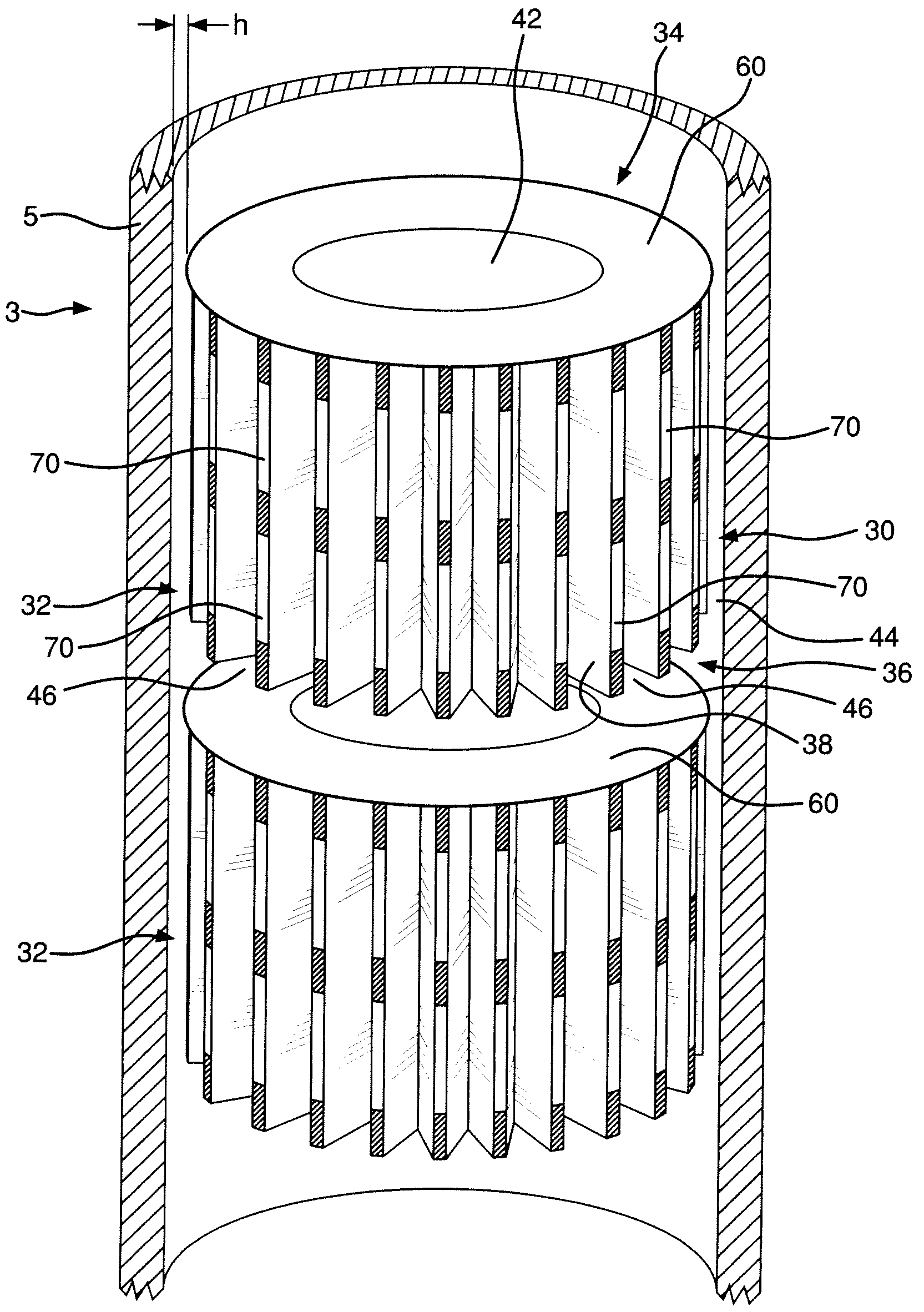

Catalyst structure and hydrogenation/dehydrogenation reaction module using the same catalyst structure

A catalyst structure 1 used for hydrogenation reaction or dehydrogenation reaction is characterized by the inclusion ofa first coiled catalytic wire body 4 formed by coiling a catalytic wire in which a catalytic material is supported on the surface of a metallic core material, anda second catalytic member 5 disposed on the inner surface side and / or outer surface side of the coiled catalytic wire body 4.

Owner:NIPPON SEISEN CO LTD +1

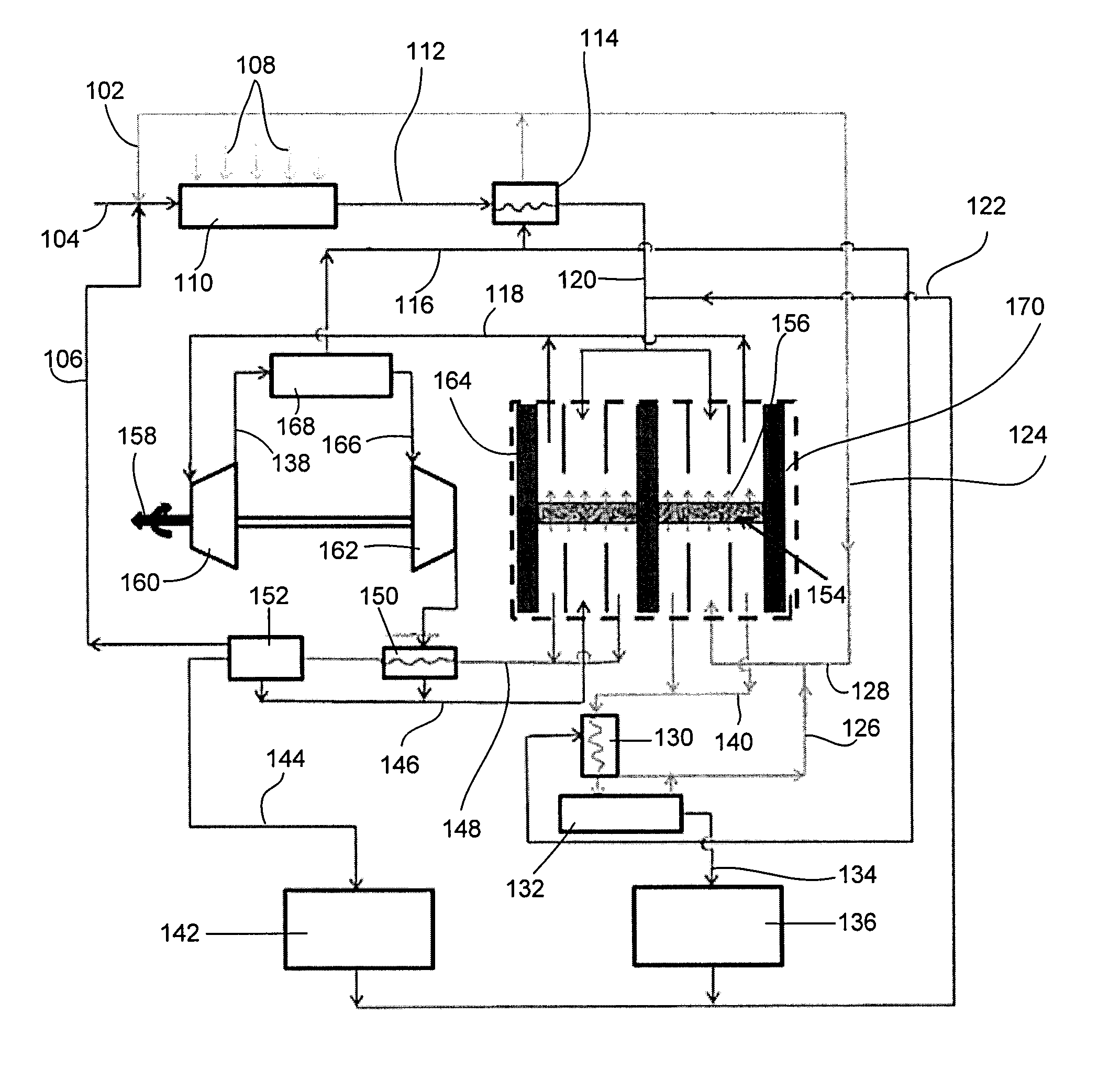

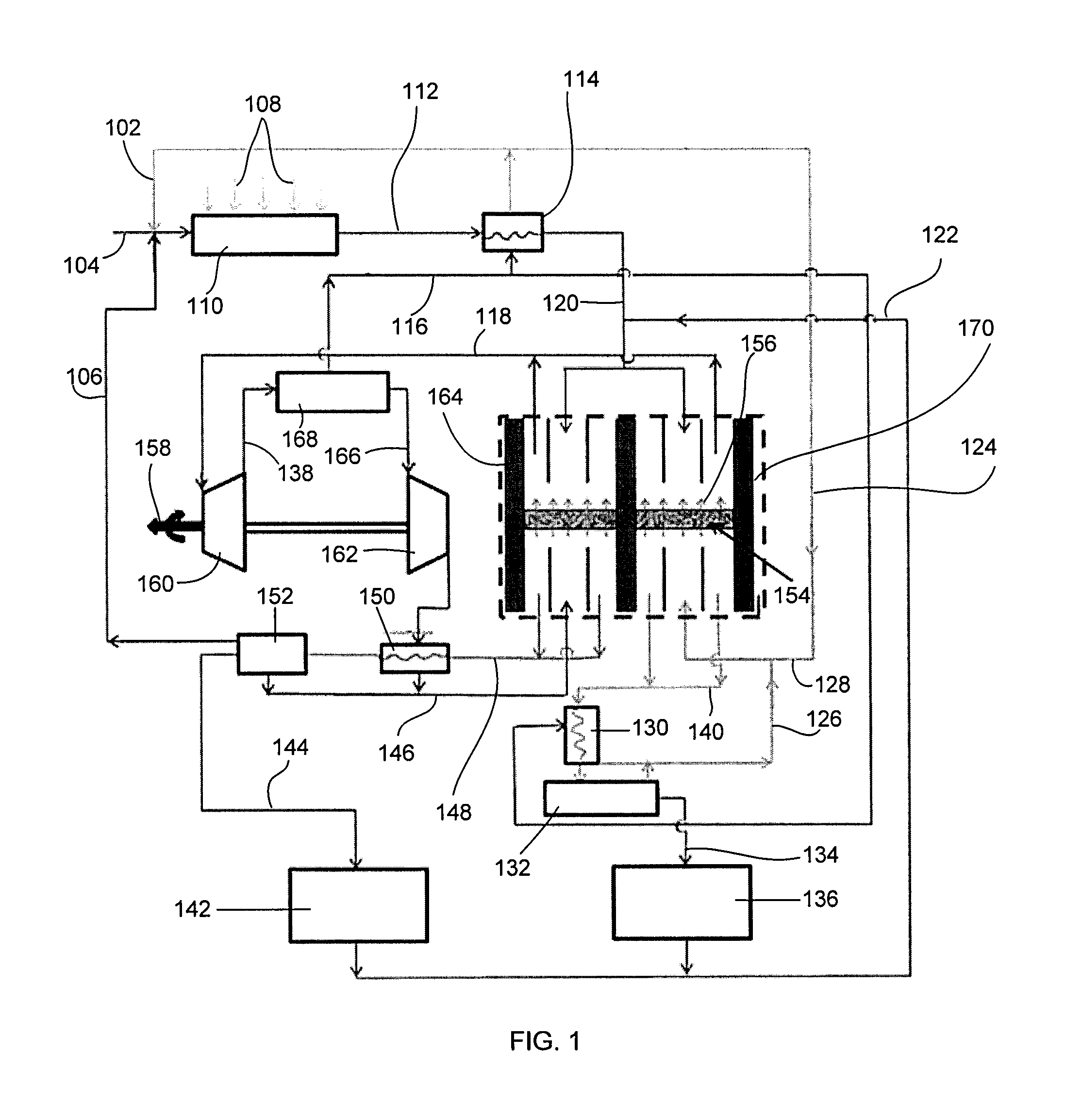

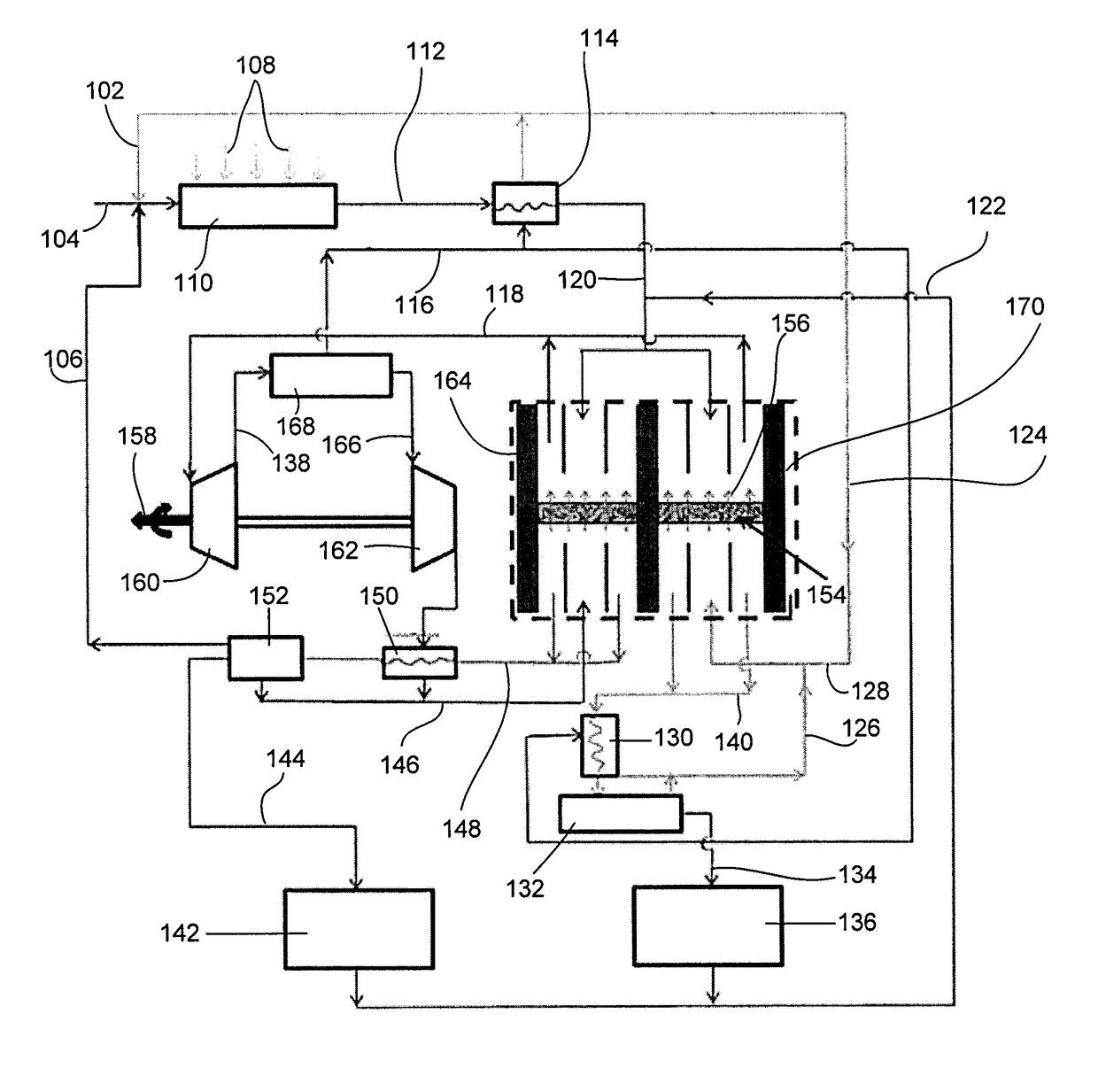

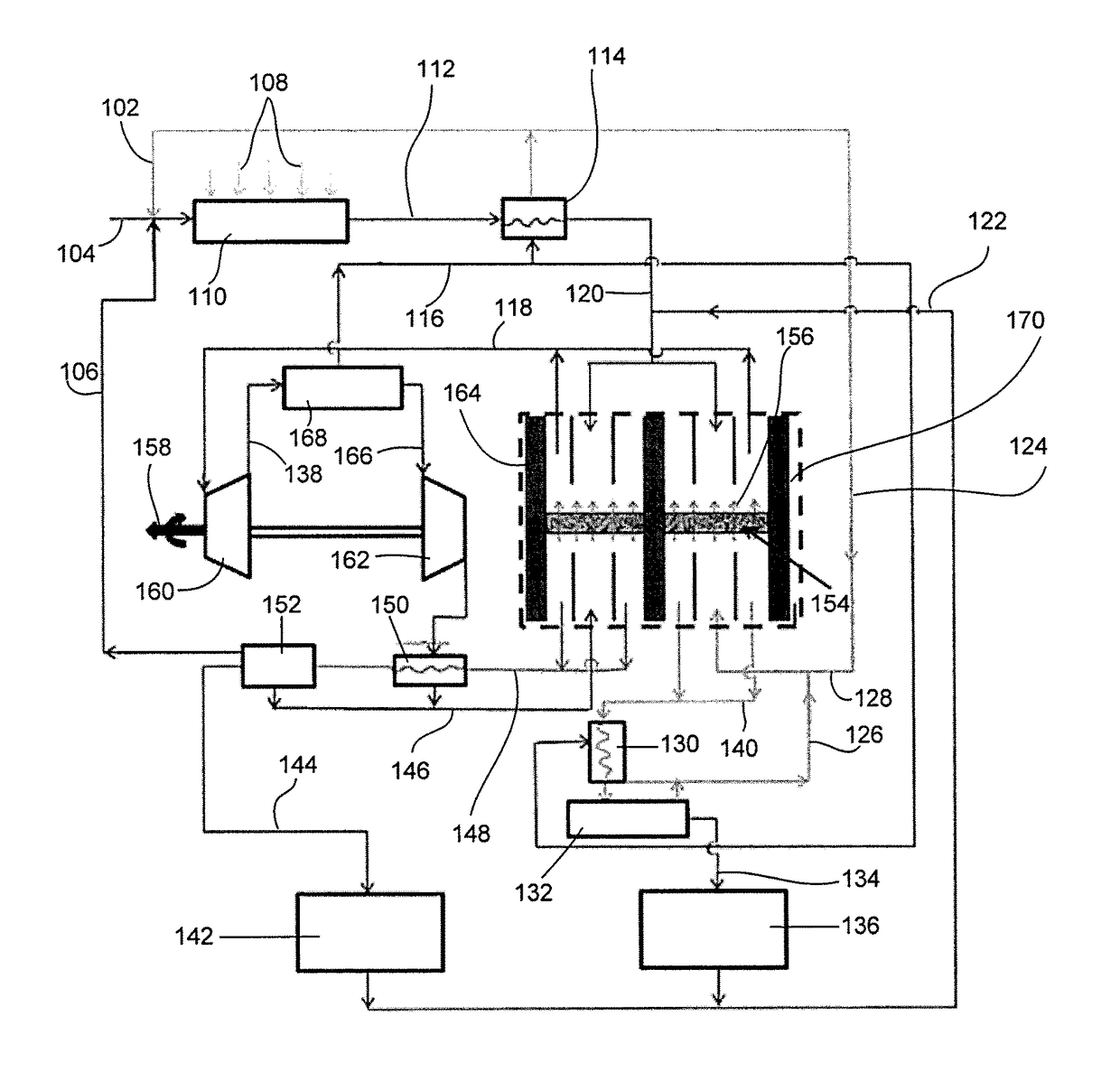

Zero-emission, closed-loop hybrid solar-syngas otr power cycle

A zero-emission, closed-loop and hybrid solar-produced syngas power cycle is introduced utilizing an oxygen transport reactor (OTR). The fuel is syngas produced within the cycle. The separated oxygen inside the OTR through the ion transport membrane (ITM) is used in the syngas-oxygen combustion process in the permeate side of the OTR. The combustion products in the permeate side of the OTR are CO2 and H2O. The combustion gases are used in a turbine for power production and energy utilization then a condenser is used to separate H2O from CO2. CO2 is compressed to the feed side of the OTR. H2O is evaporated after separation from CO2 and fed to the feed side of the OTR.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

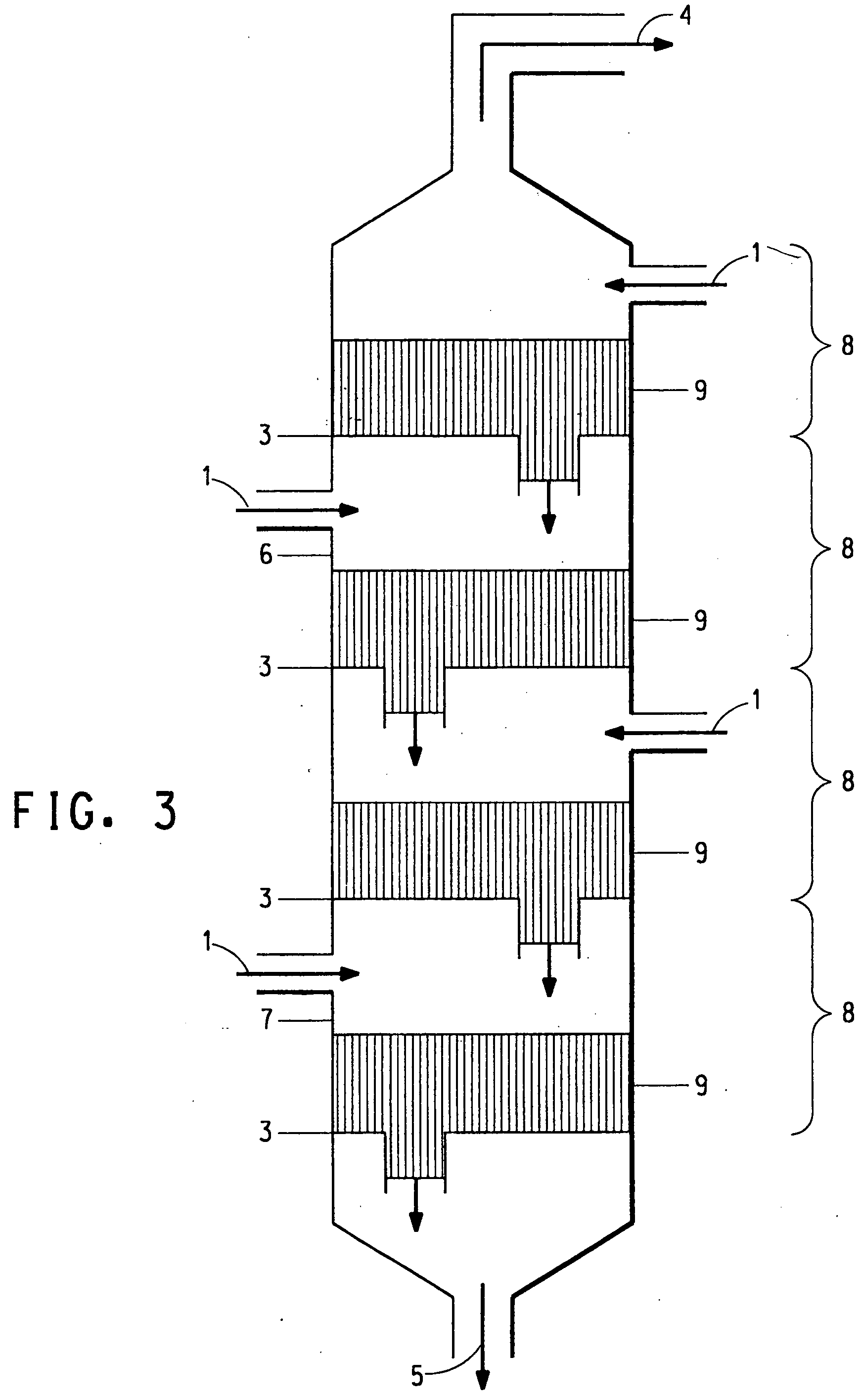

Apparatus and process for the synthesis of hydrogen peroxide directly from hydrogen and oxygen

InactiveUS7115192B1Raise the ratioIncrease concentrationProcess control/regulationHydrogen peroxideHydrogenElectrolysis of water

Owner:UOP LLC

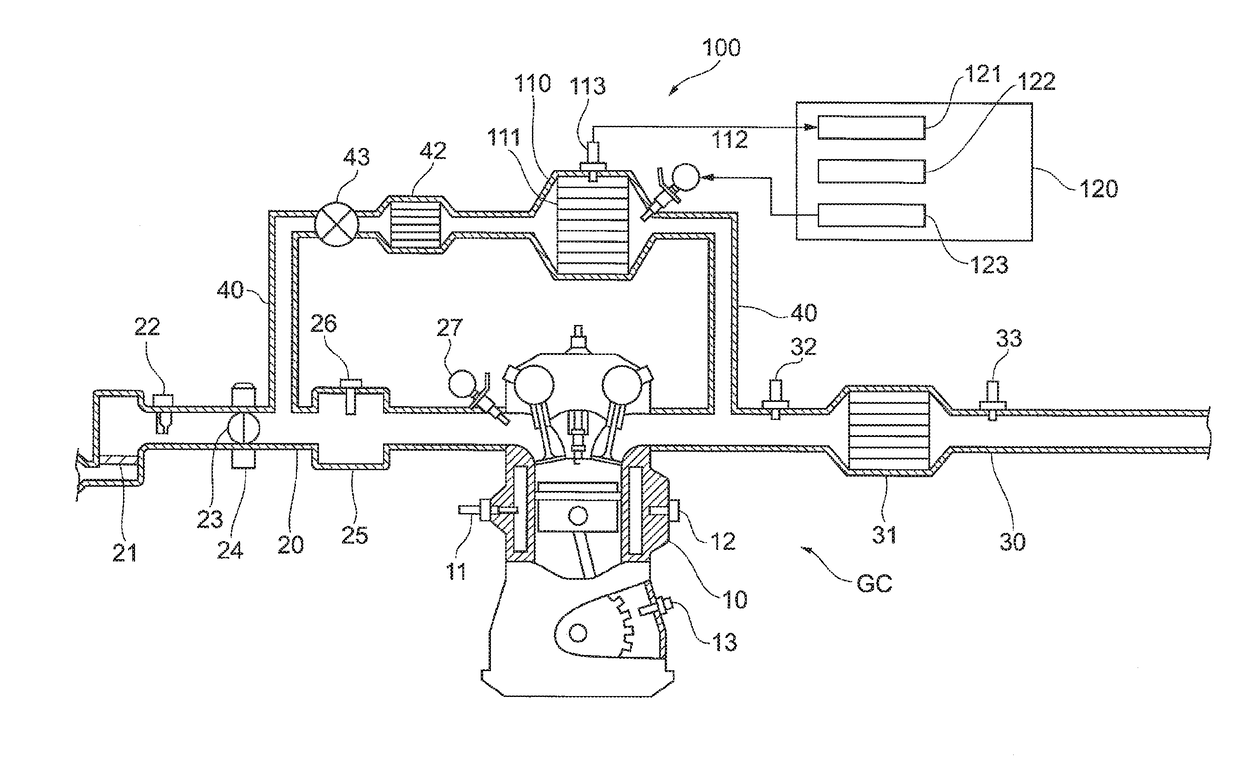

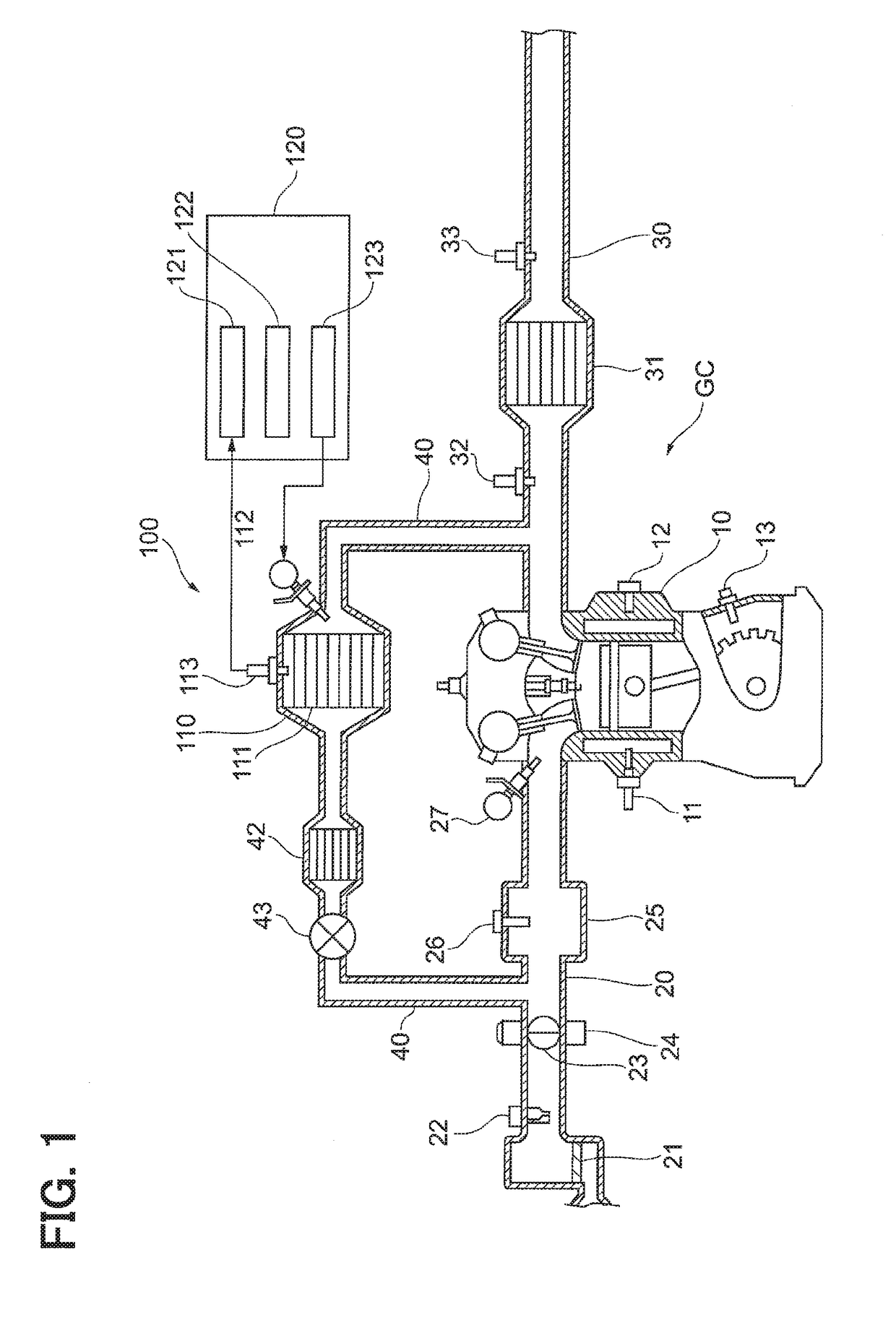

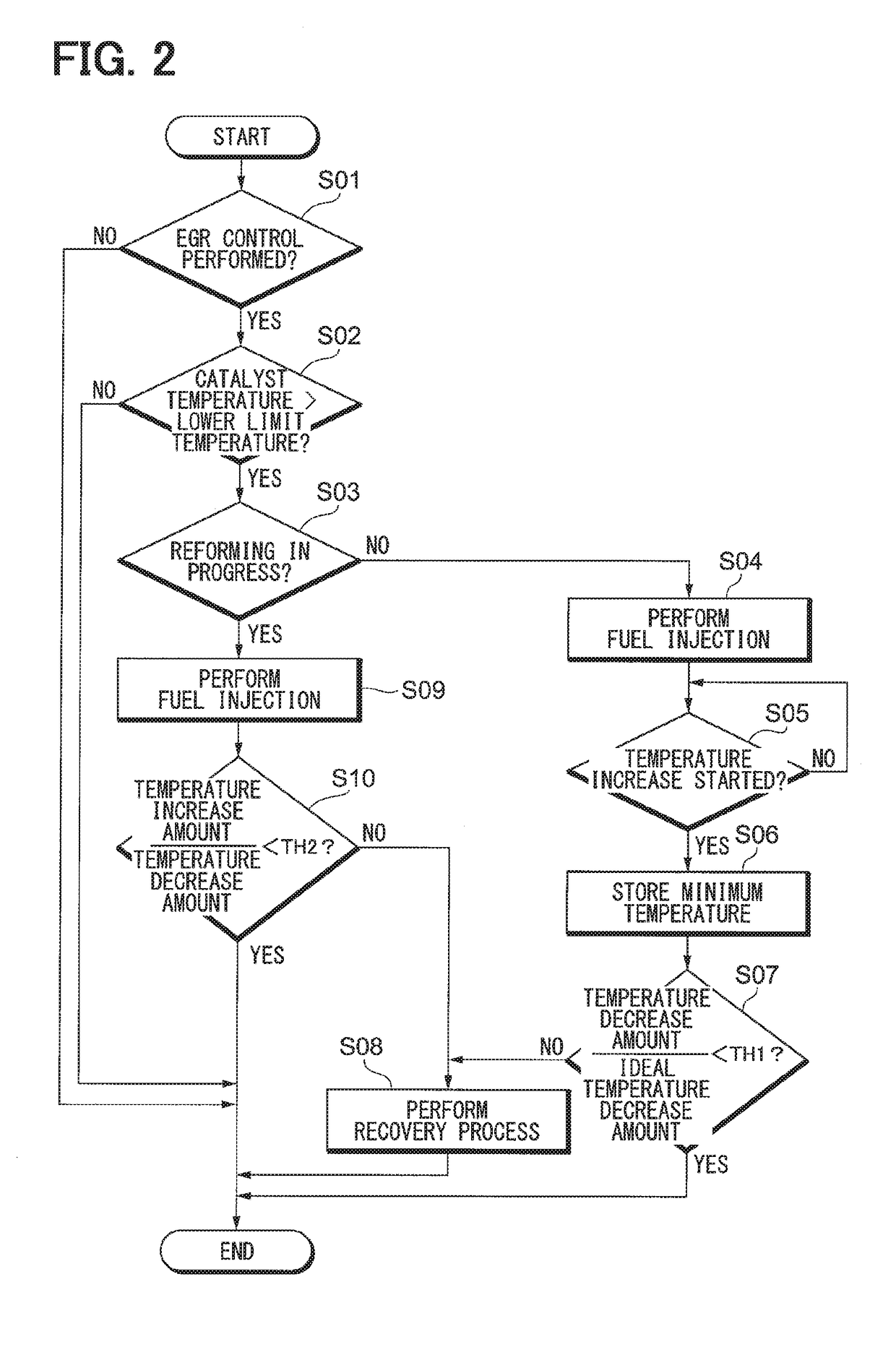

Fuel reformer

A fuel reformer for producing a steam reforming reaction between fuel and water on a reforming catalyst includes a fuel injection part that injects and supplies fuel into the reforming catalyst, a temperature measurement part that measures a temperature of the reforming catalyst, and a determination part that determines whether a process for recovering the reforming catalyst is necessary. The determination by the determination part is made based on a temperature change of the reforming catalyst when the steam reforming reaction is produced.

Owner:DENSO CORP

Tubular Reactor With Jet Impingement Heat Transfer

InactiveUS20100038593A1Reduce flow rateReduce heat transferHydrogenHydrocarbon from carbon oxidesMethanationEngineering

A tubular reactor and method for producing a product mixture in a tubular reactor where the tubular reactor comprises an internal catalytic insert having orifices for forming fluid jets for impinging the fluid on the tube wall. Jet impingement is used to improve heat transfer between the fluid in the tube and the tube wall in a non-adiabatic reactor. The tubular reactor and method may be used for endothermic reactions such as steam methane reforming and for exothermic reactions such as methanation.

Owner:AIR PROD & CHEM INC

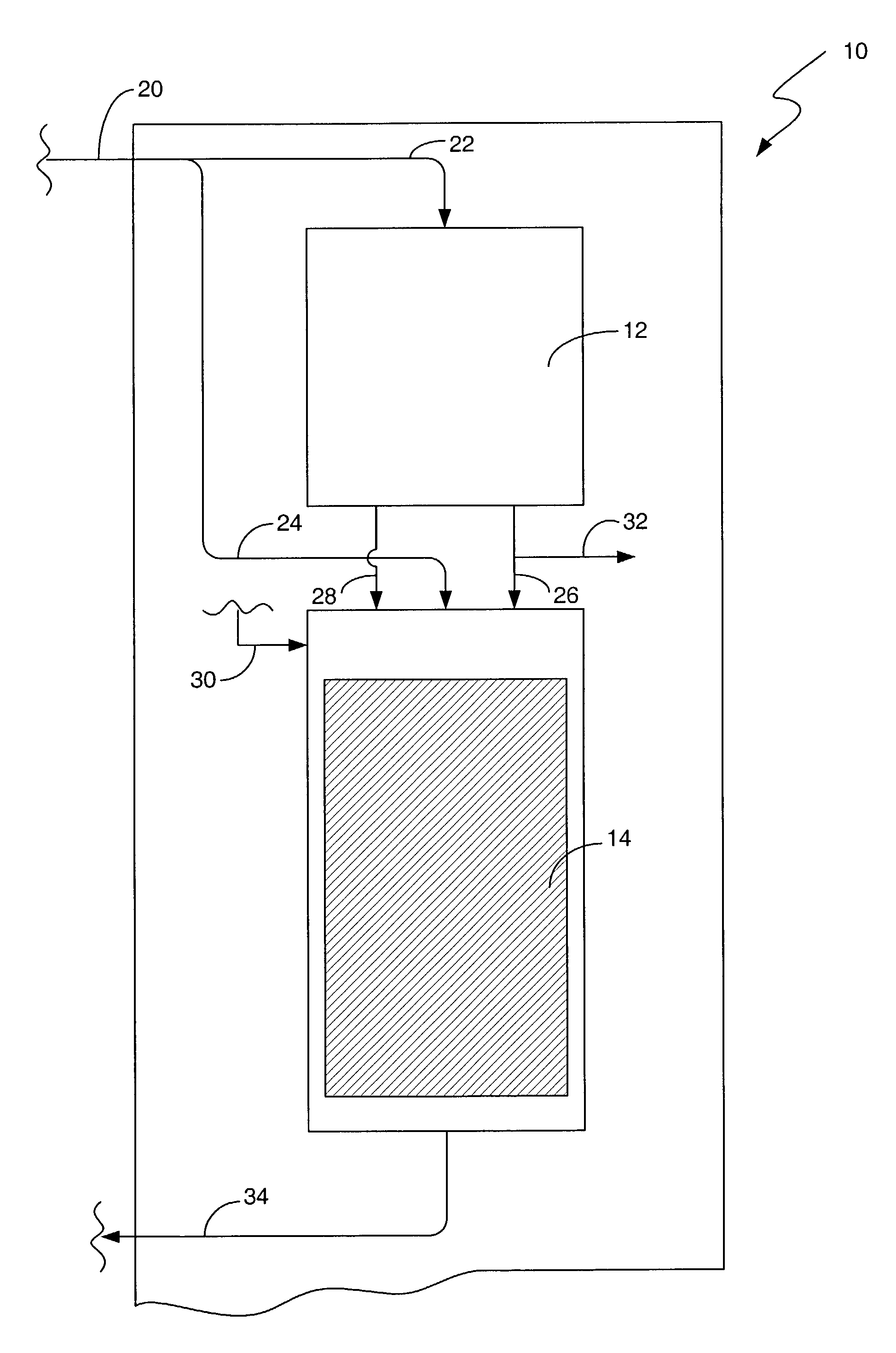

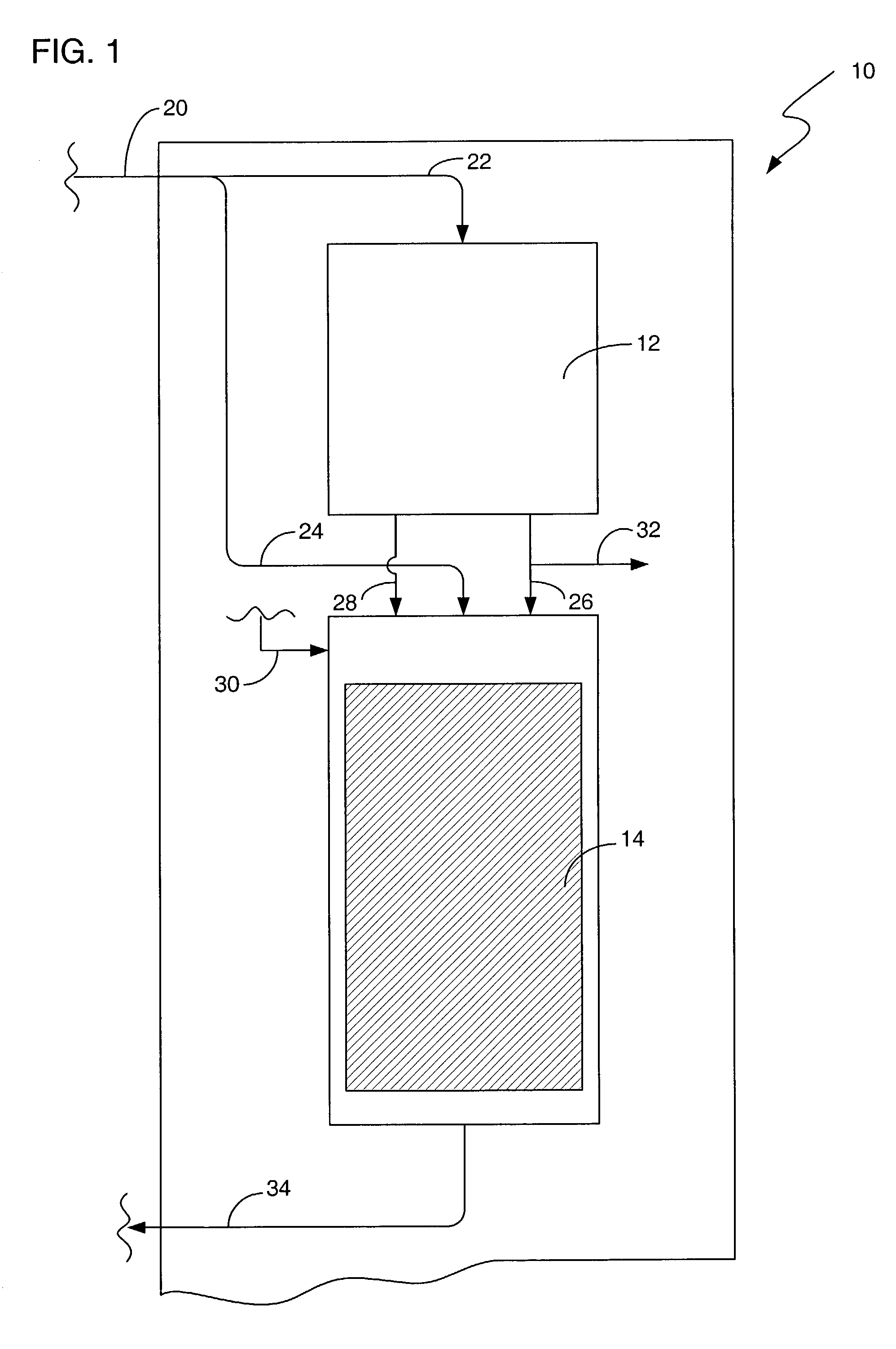

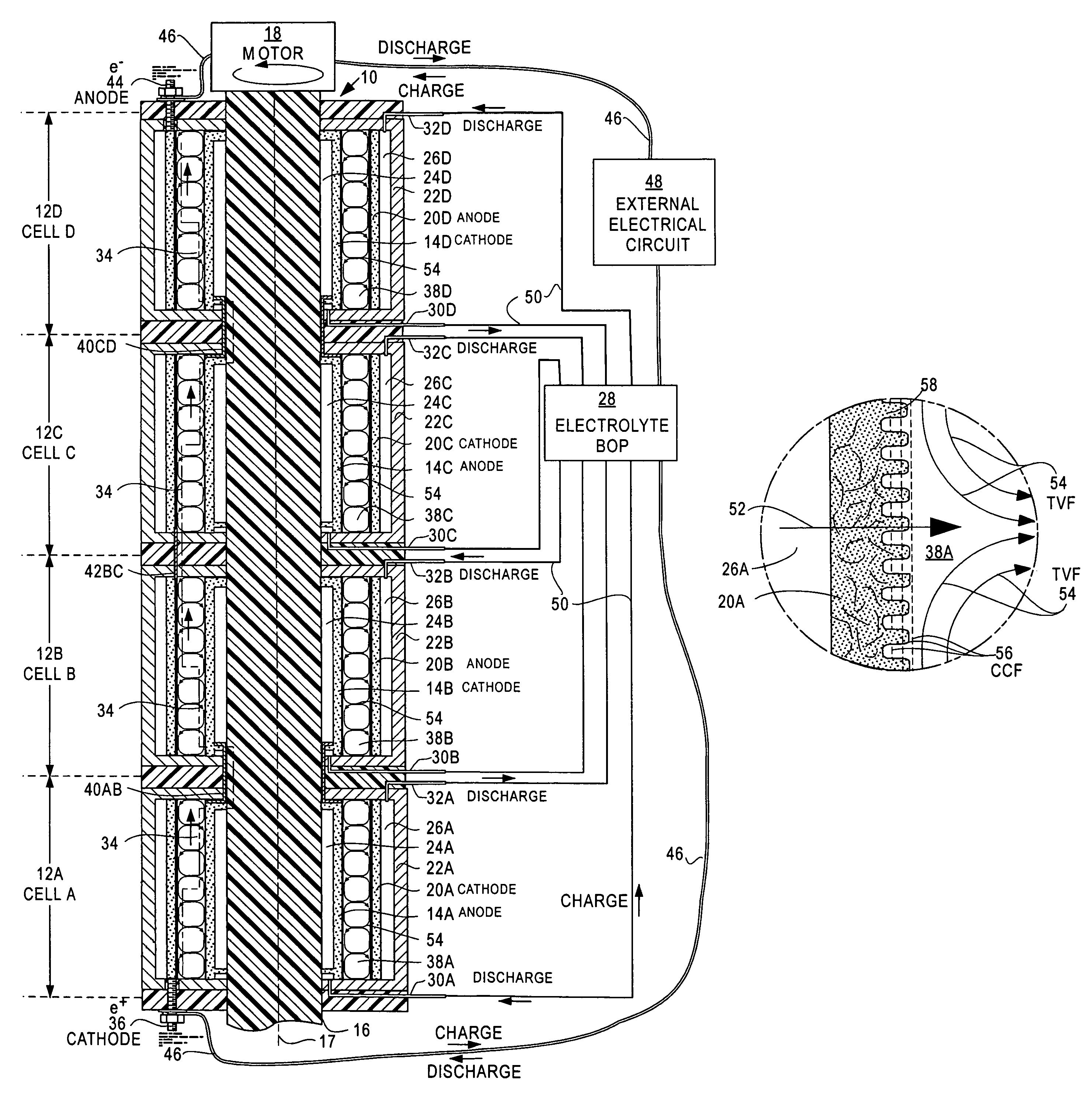

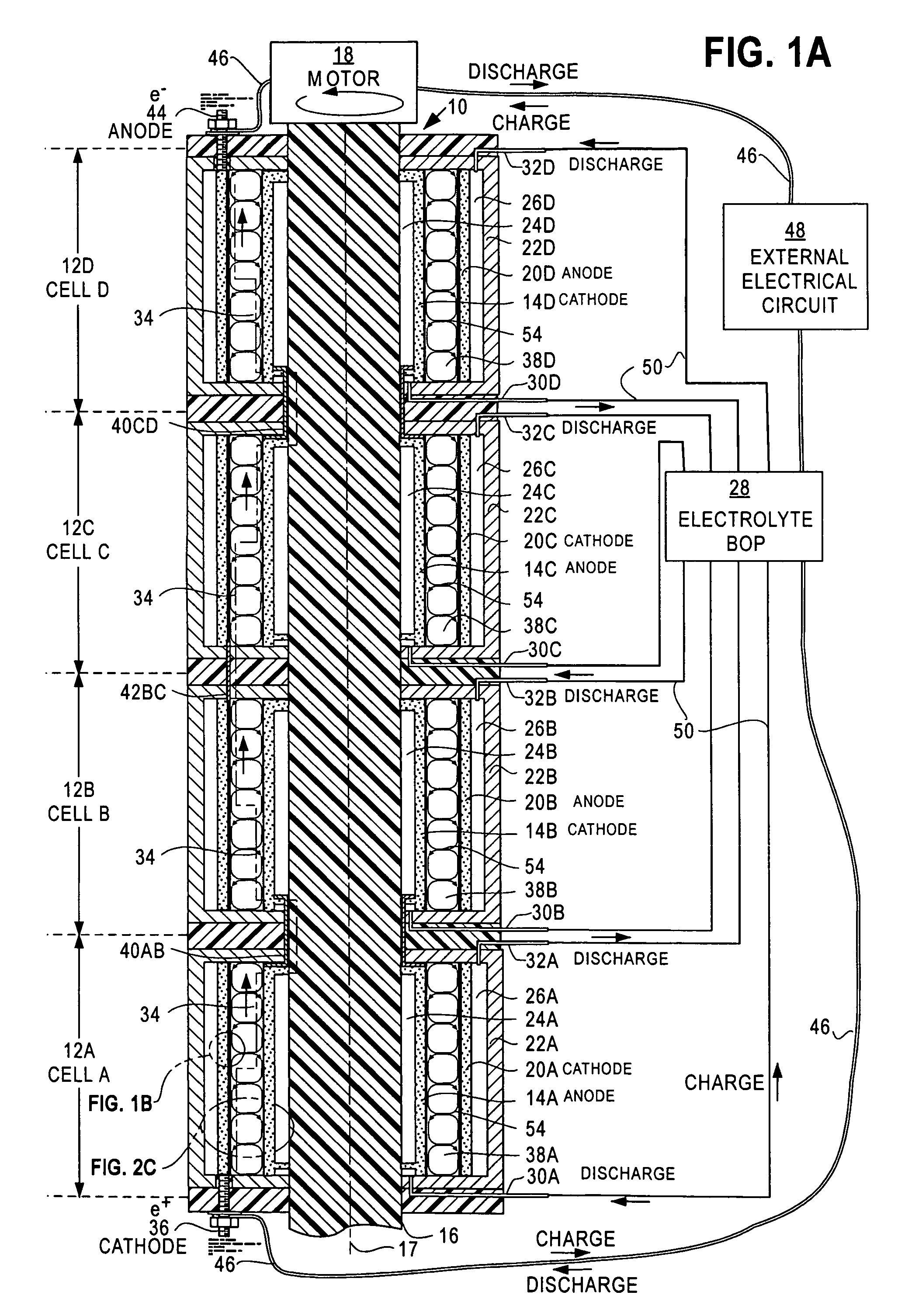

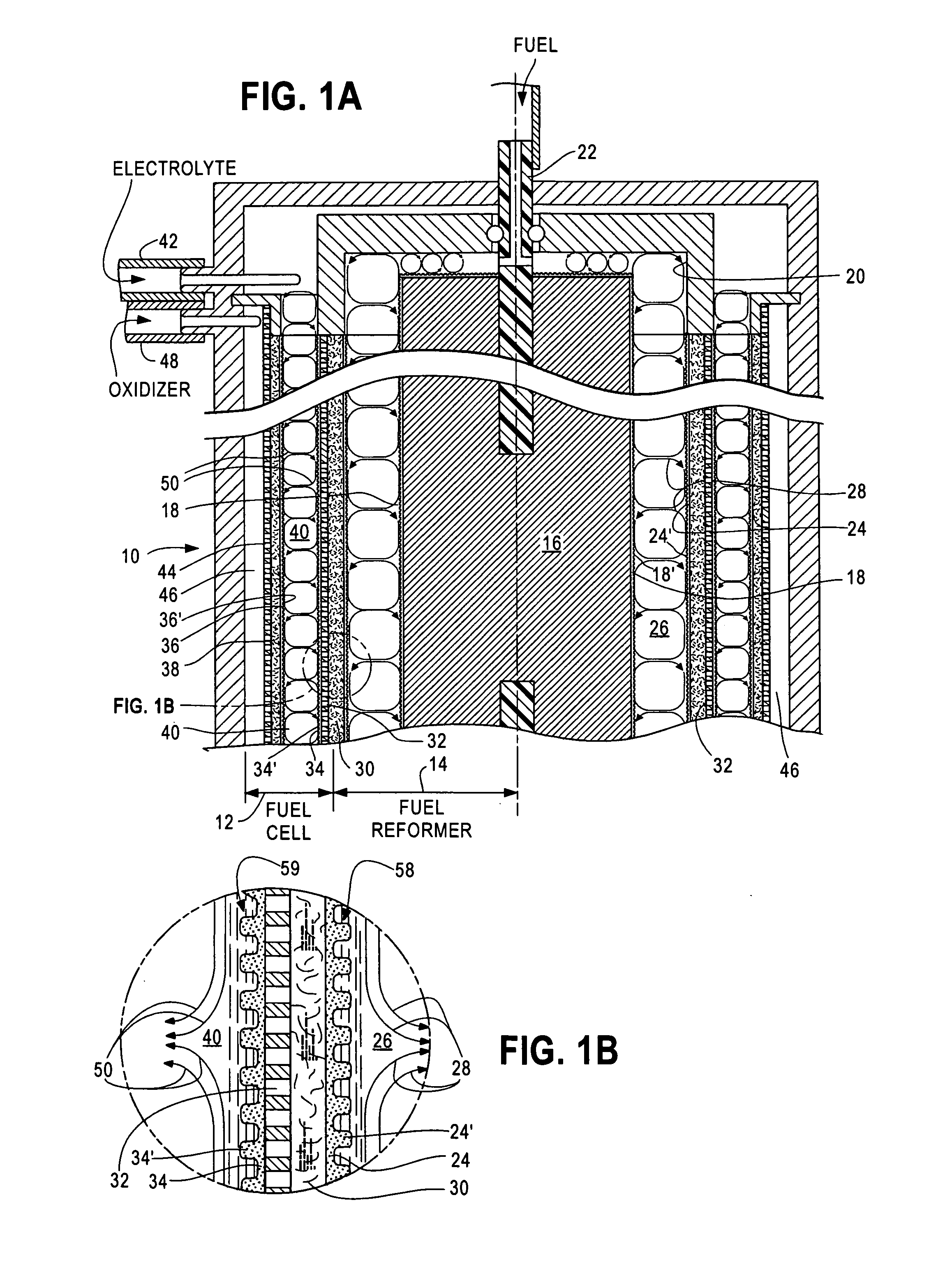

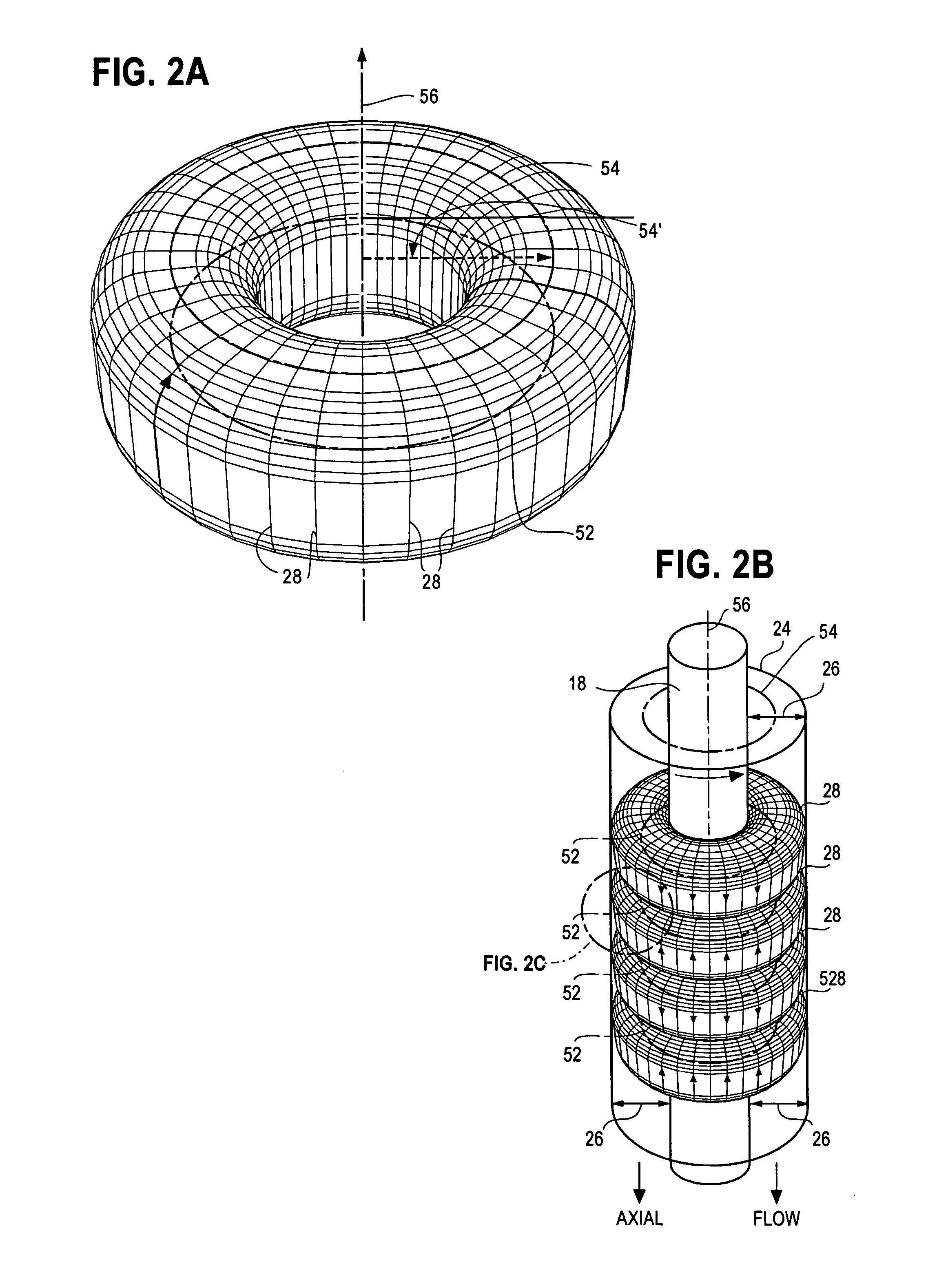

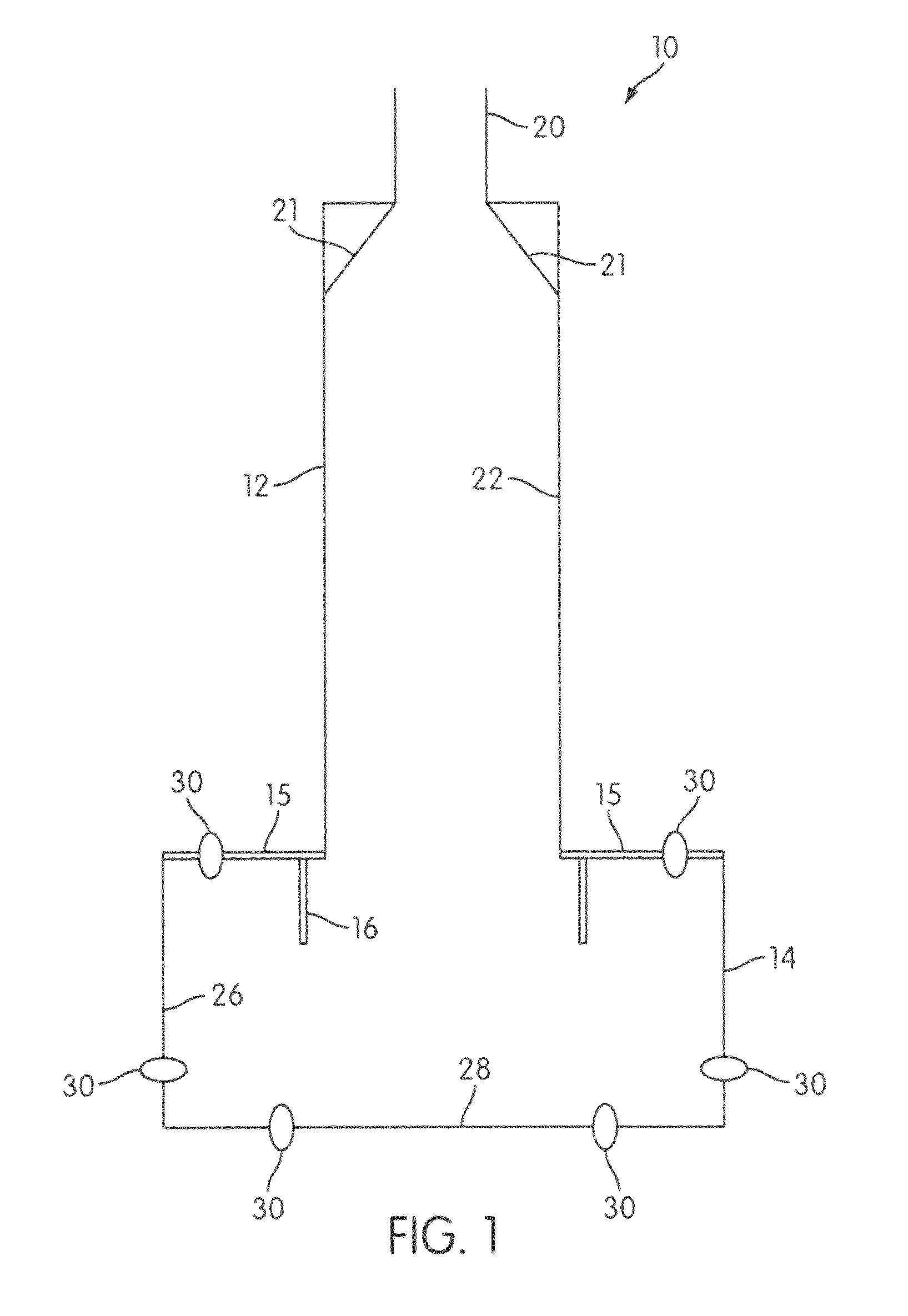

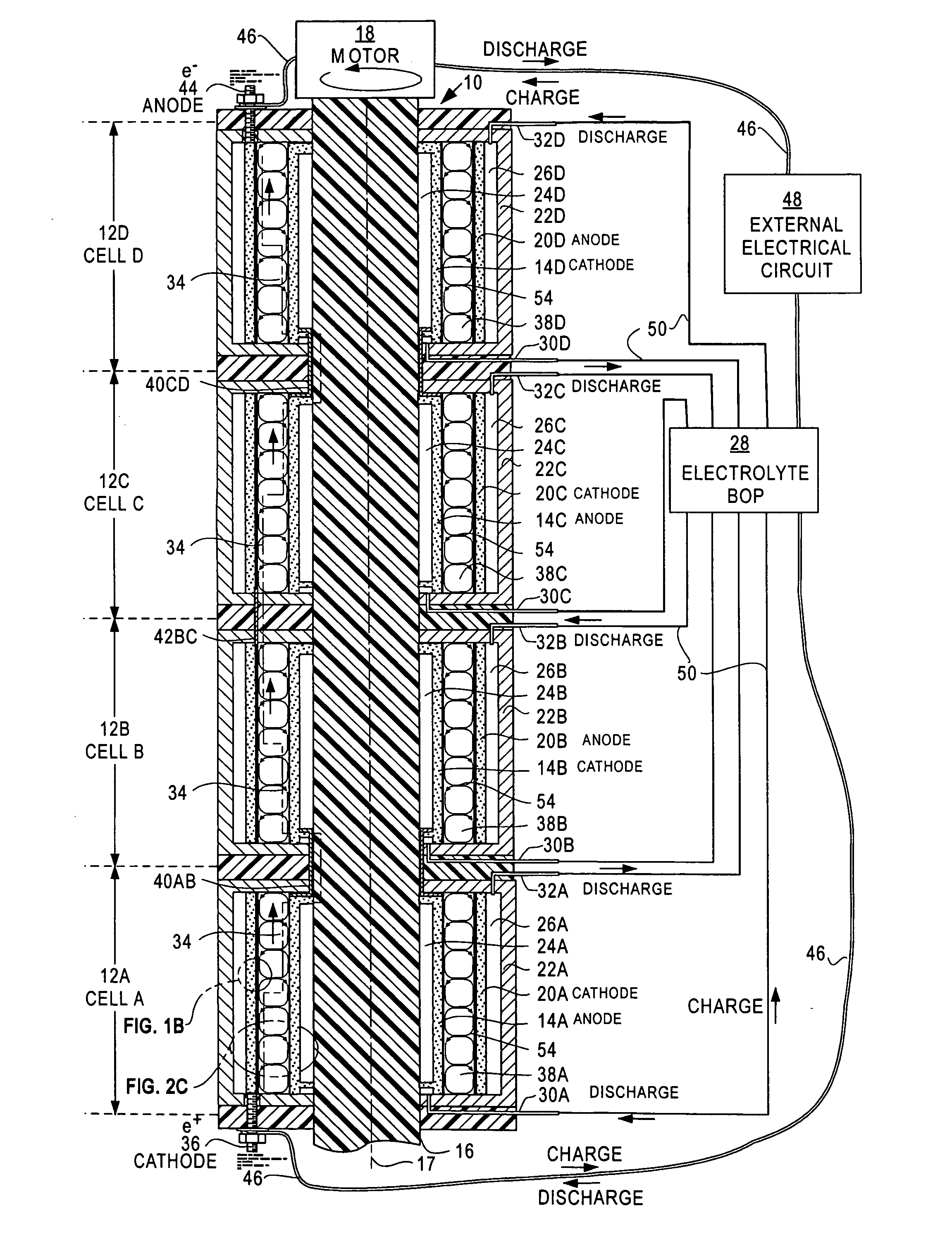

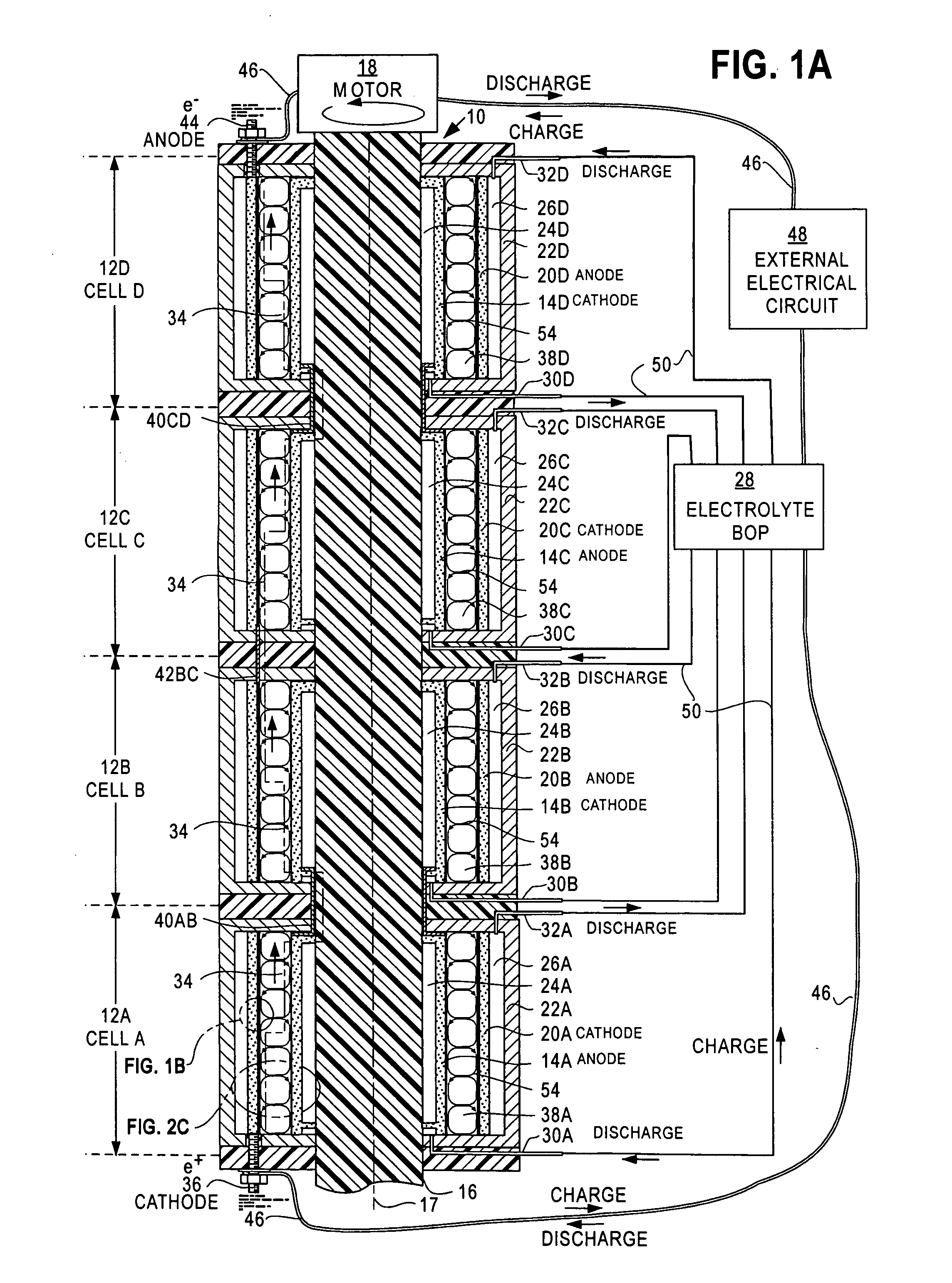

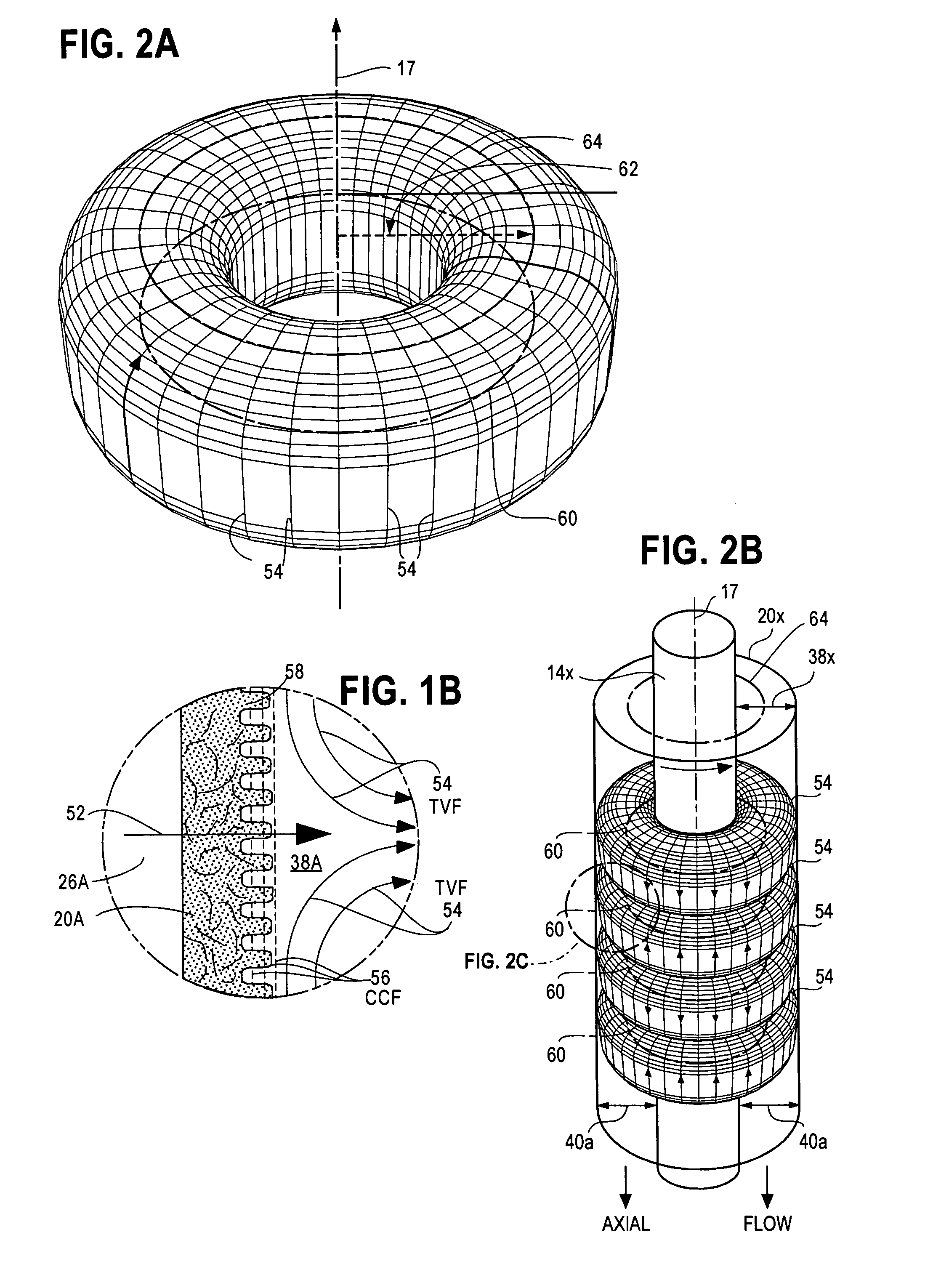

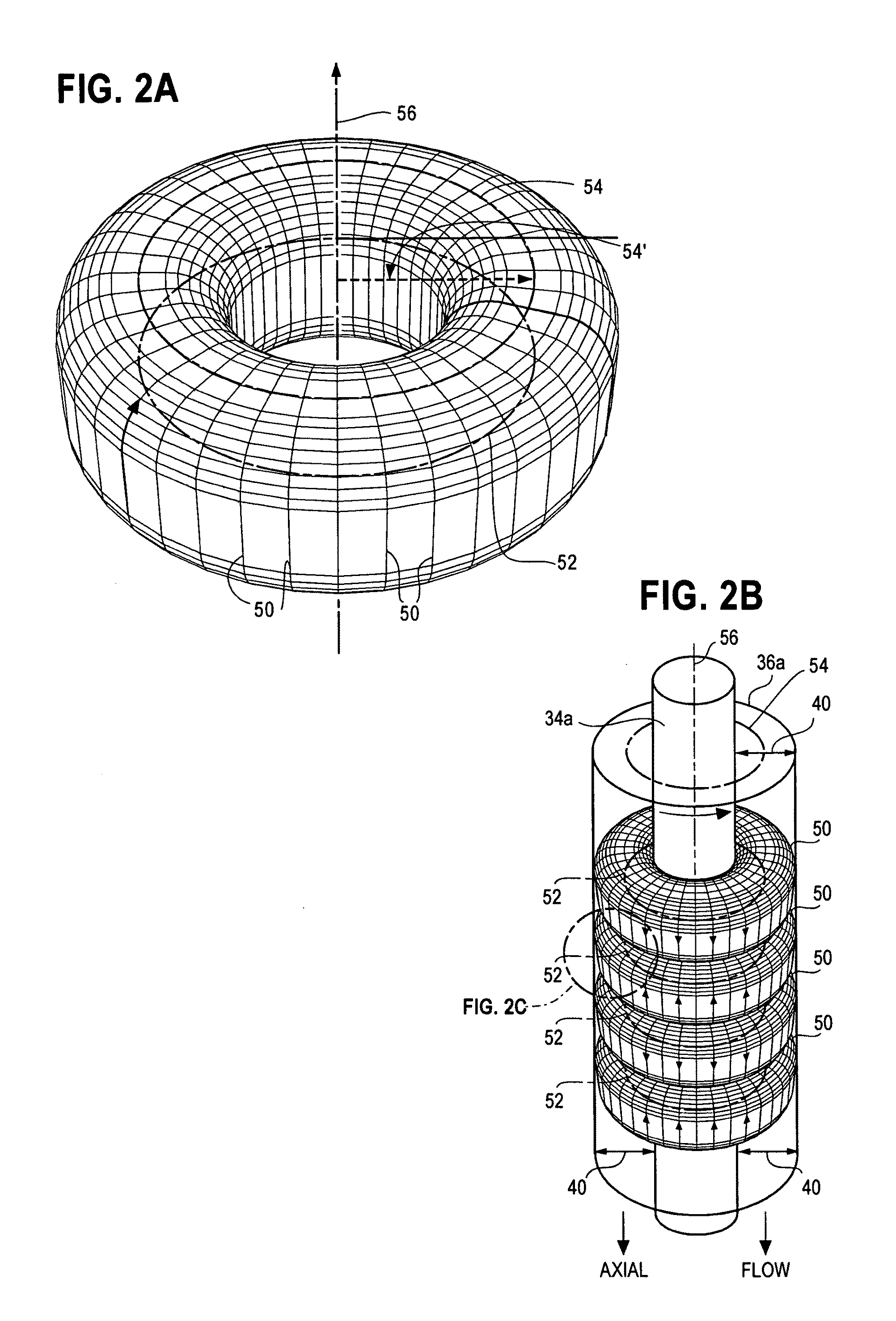

Dynamic accelerated reaction batteries utilizing Taylor Vortex Flows

InactiveUS7964301B2Improve reaction speedExtended temperature rangeTransportation and packagingCell electrodesFuel cellsEngineering

Dynamic accelerated reaction batteries (10, 100, 200) with rotating electrodes (14x, 20x, 104x, 106x,) or rotating membranes (208) or fuel cells (412C, 412D) that generate Taylor Vortex Flows (54, 122, 228, 454) and Circular Couette Flows (56, 124, 230) in electrolyte chambers (38x, 126x, 206, 438x) are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

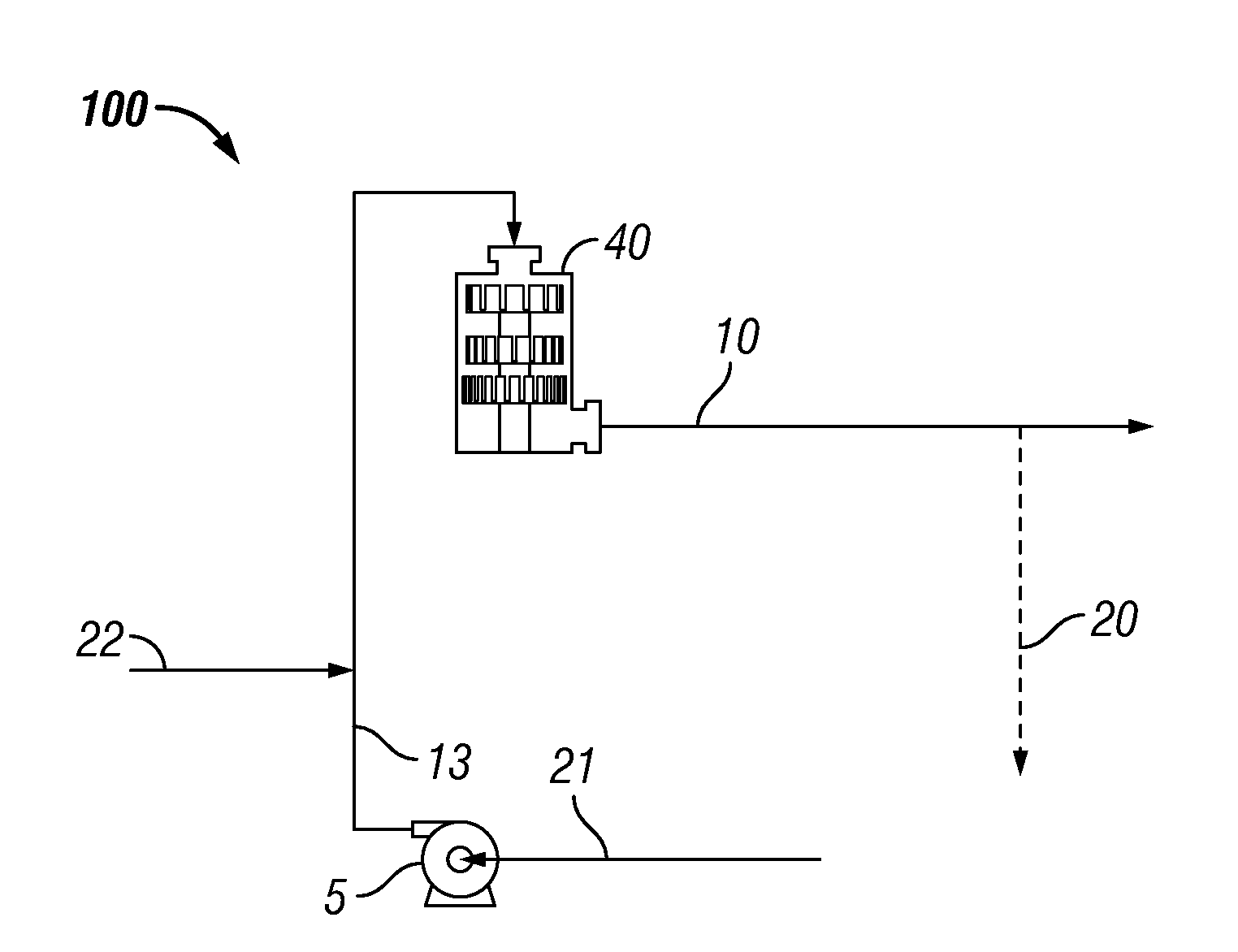

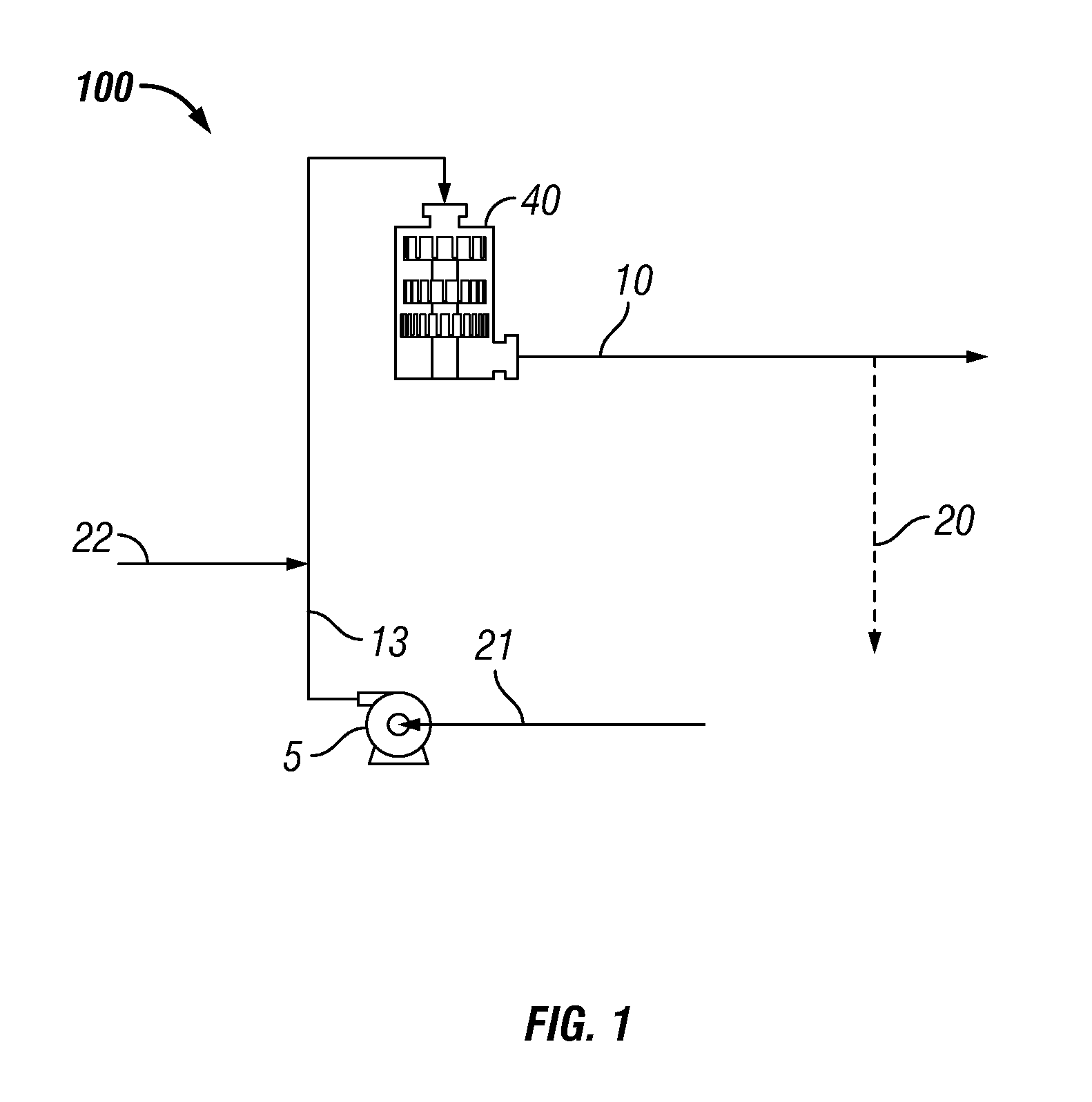

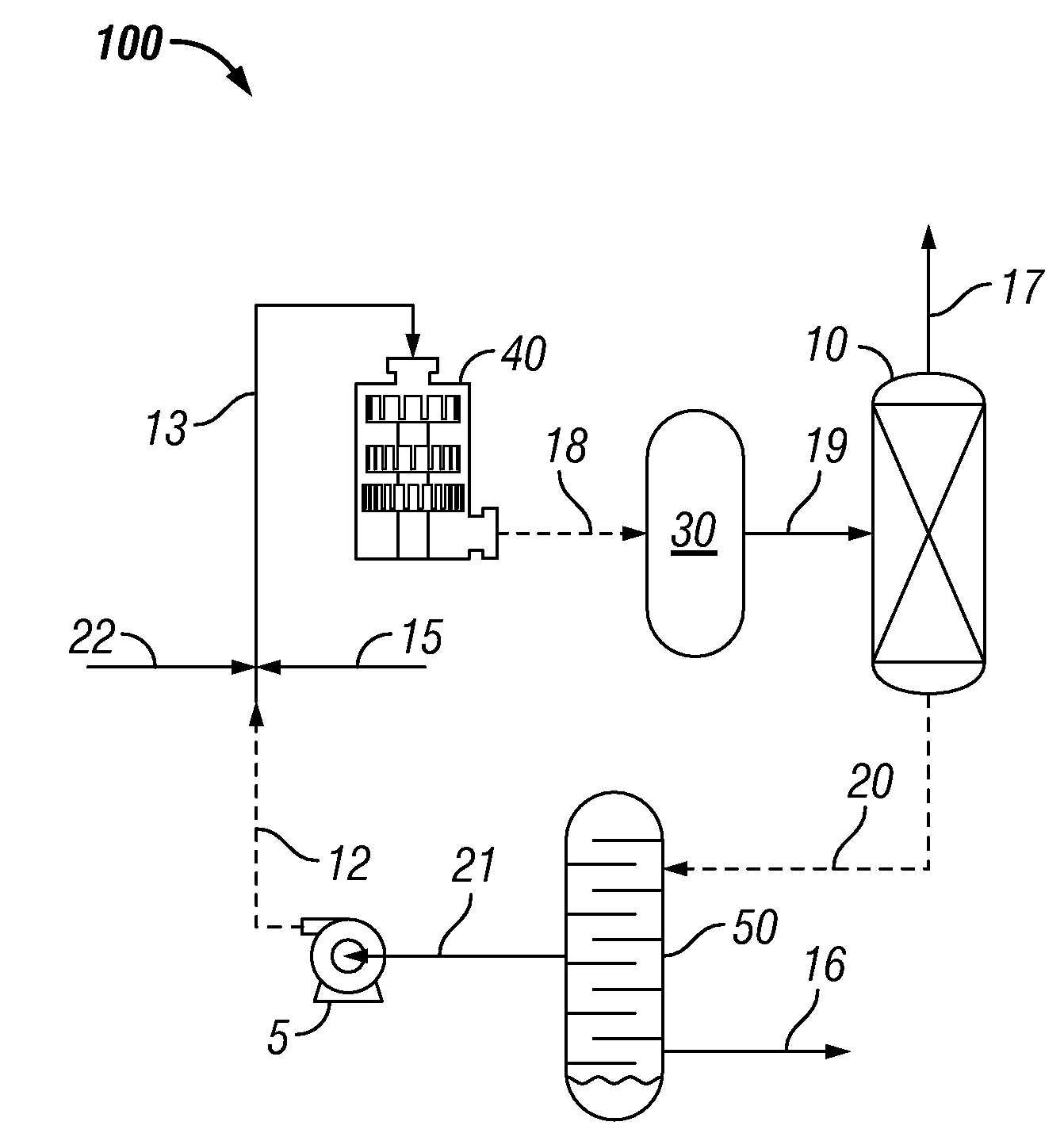

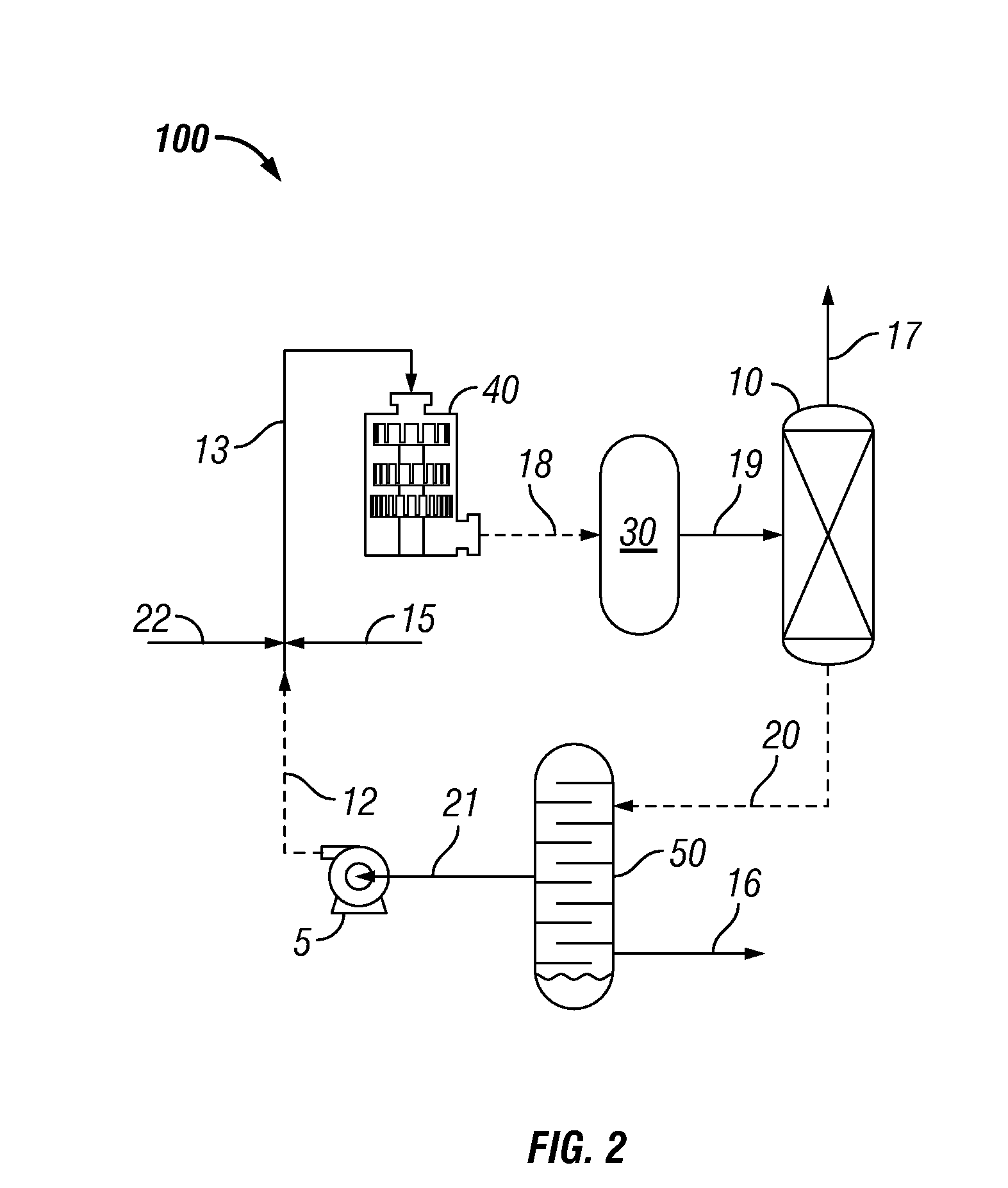

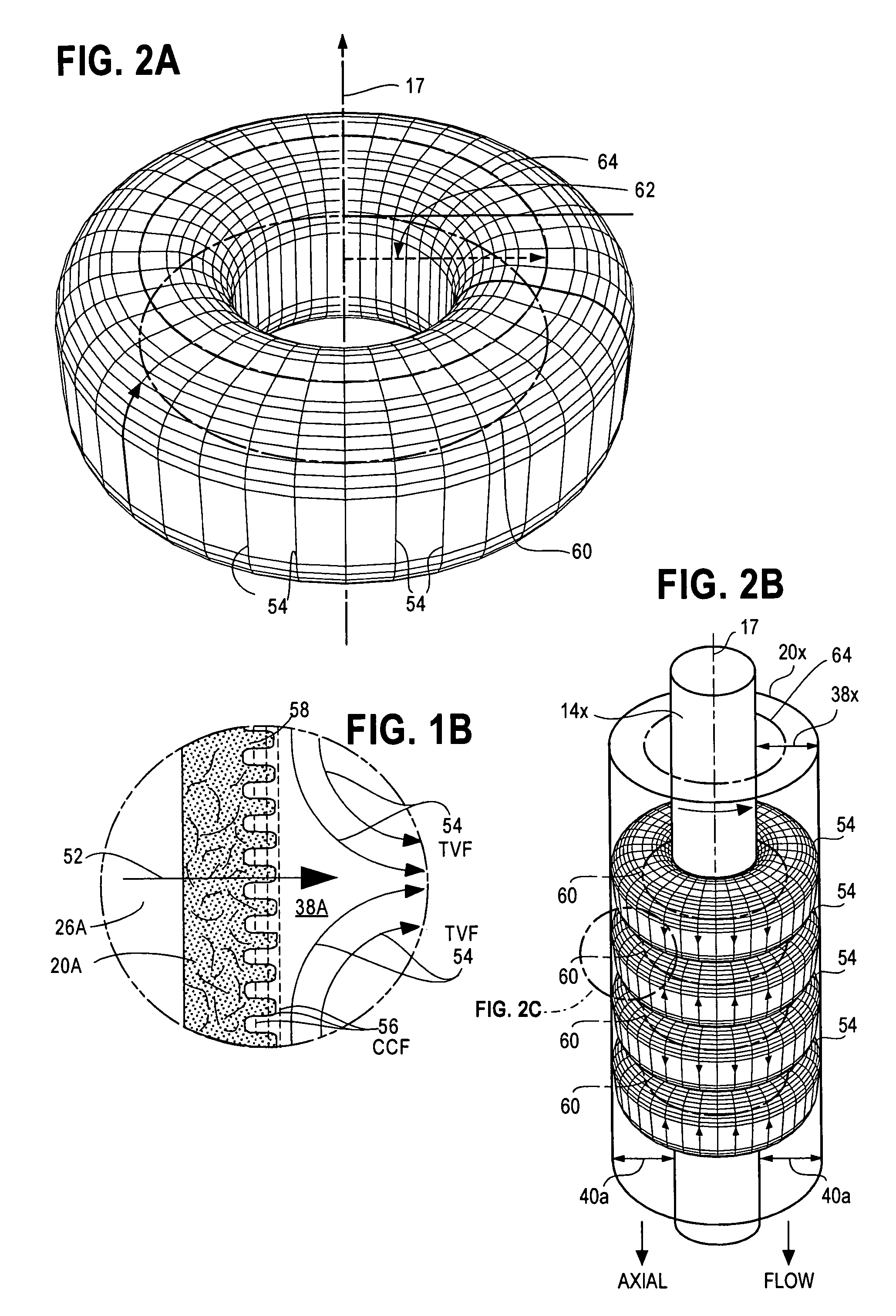

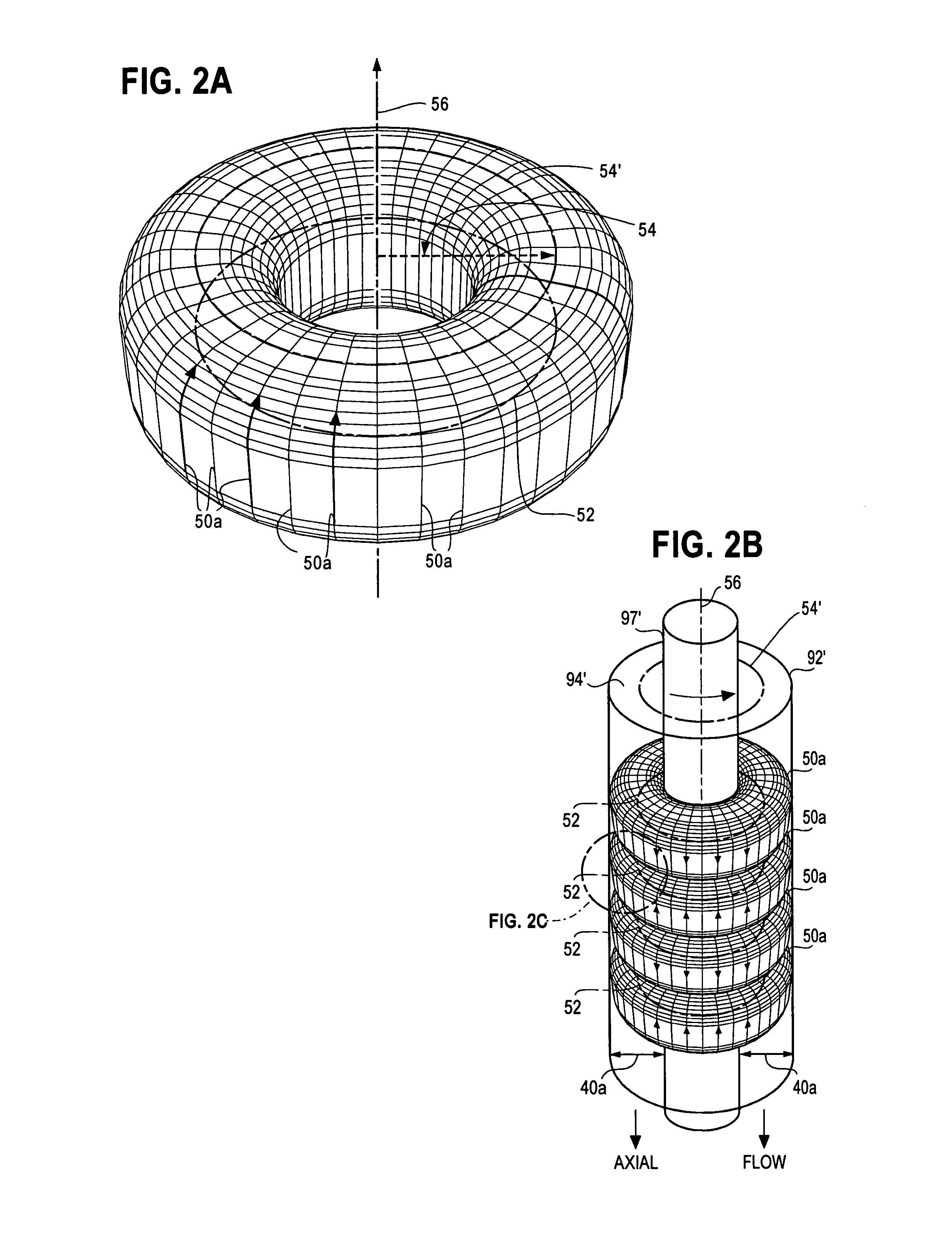

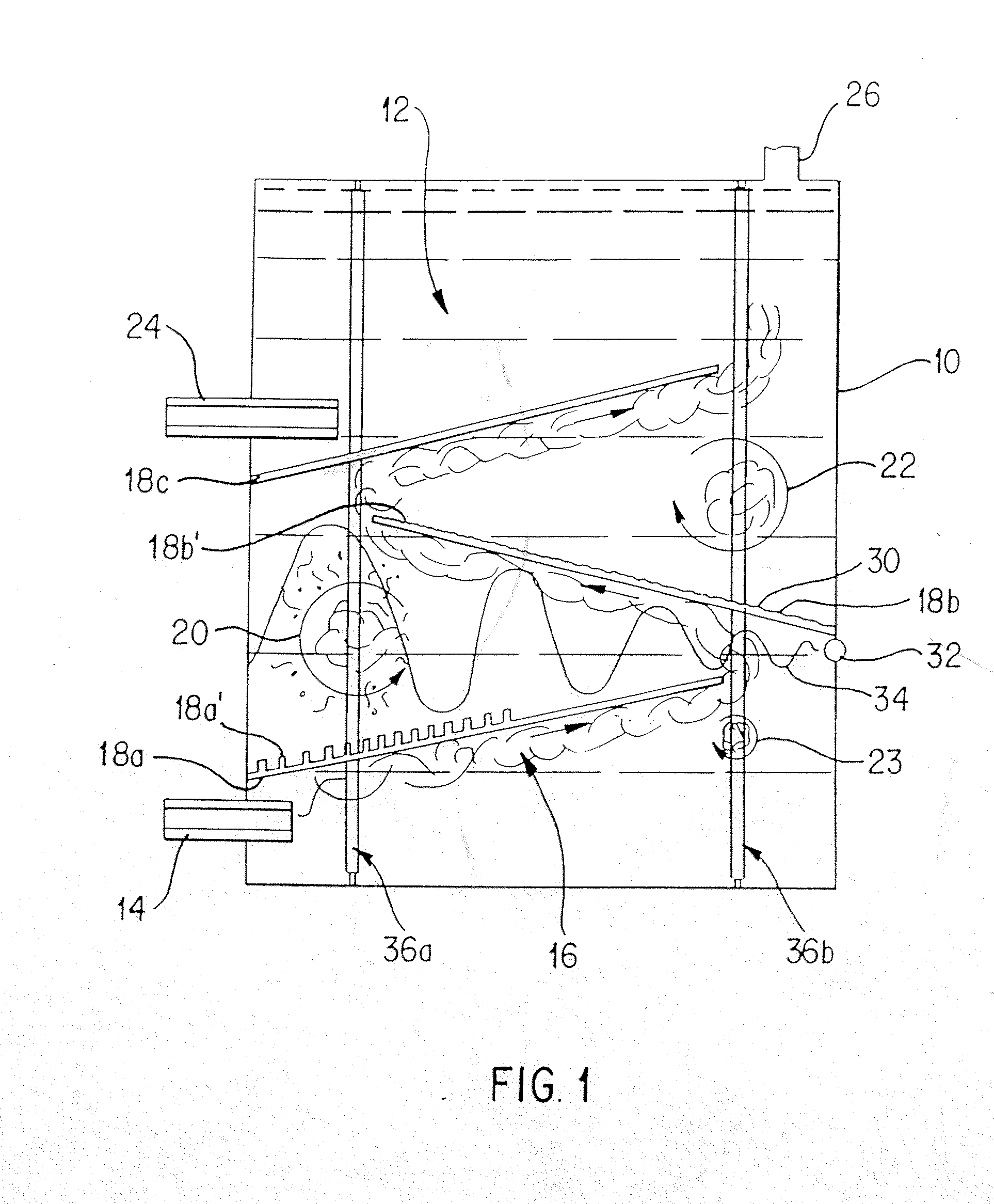

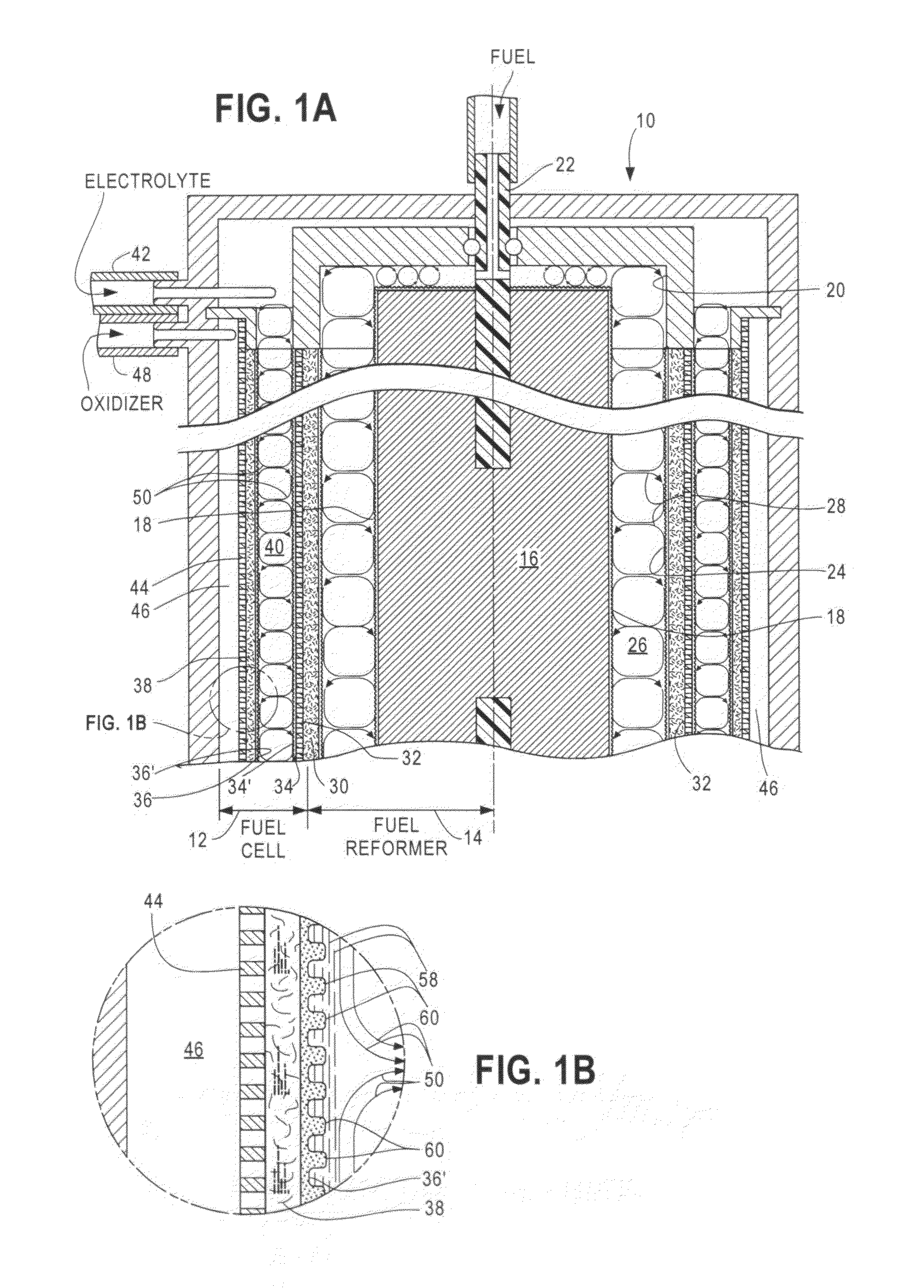

Chemical process accelerator systems utilizing taylor vortex flows

ActiveUS20100329947A1Facilitates removal of contaminantReducing surface-limitingCell electrodesRotary stirring mixersFuel cellsChemical reactor

Chemical process accelerator systems comprising viscid fluid Taylor Vortex Flows (98, 50a) with high-shear-rate laminar Circular Couette Flows (58) in contact with catalysts (92, 92′, 30, 32, 32f, 32g, 36, 40, 44, 45, 46, 47, 48), catalytic compositions and structures in chemical reactors and electrochemical cells (e.g. fuel cells, fuel reformers) are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

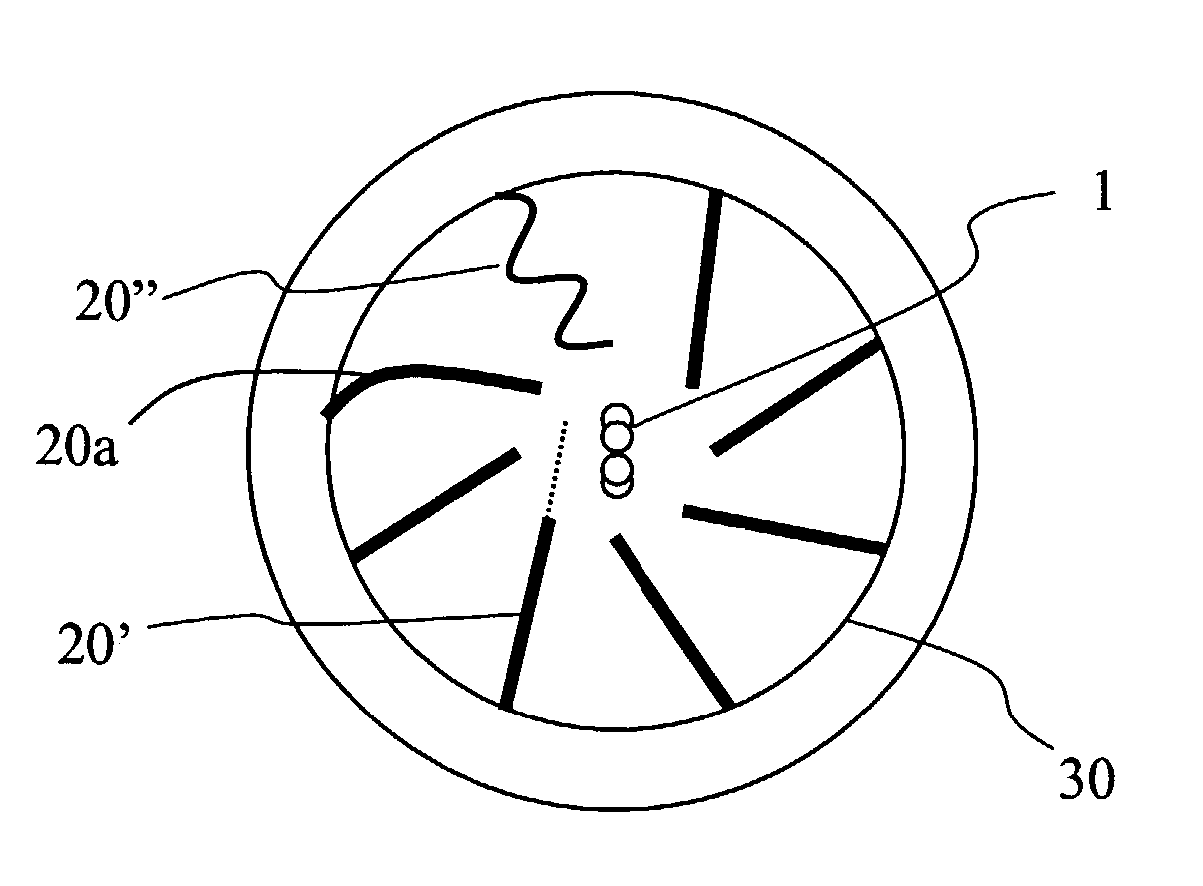

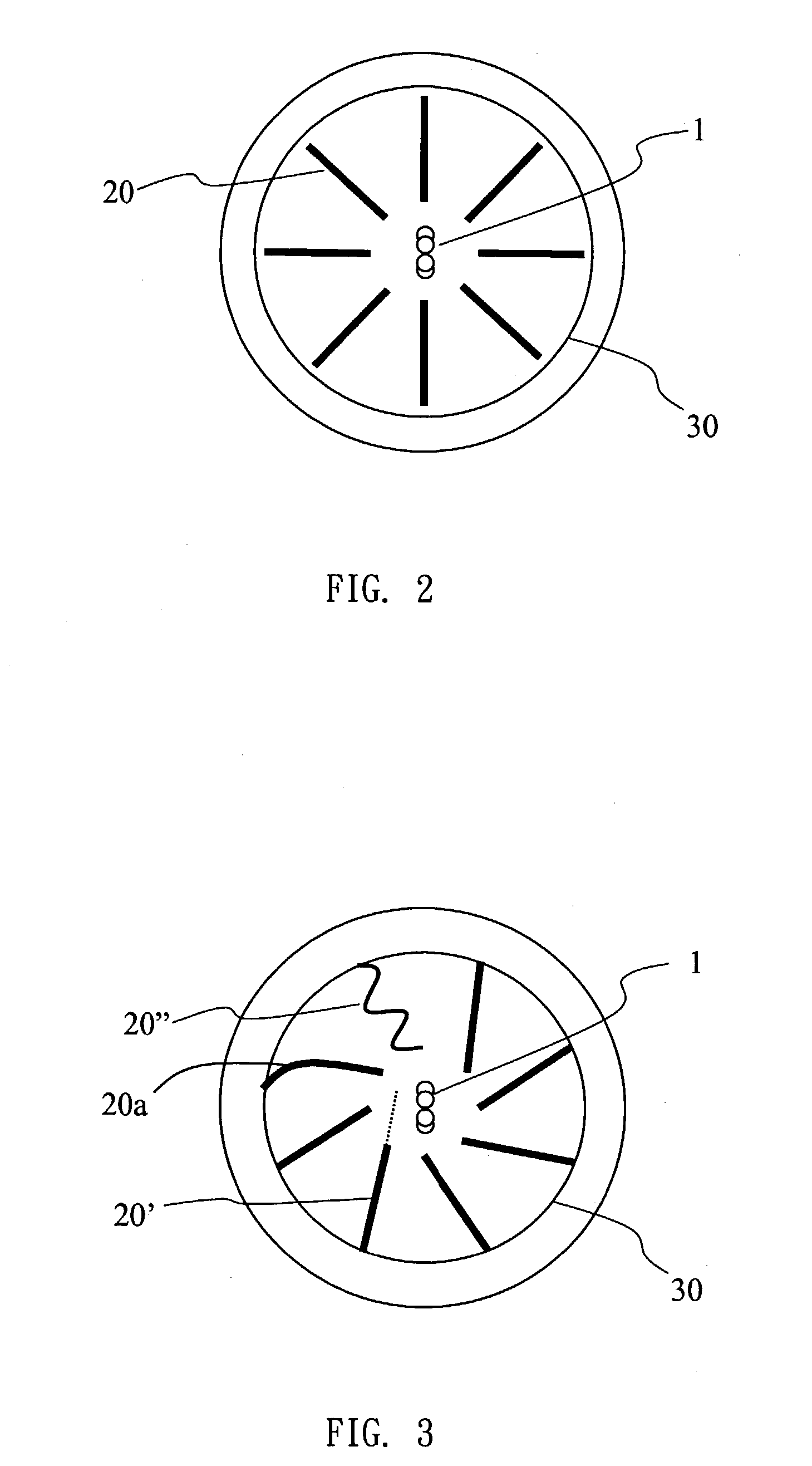

Reactor for producing ultra fine particles

InactiveUS7166260B2Fast nucleationMore reactantTransportation and packagingRotary stirring mixersUltra fineReagent

A reactor containing a plurality of porous rotors is disclosed. A liquid sprayed in a direction from a rotating axis to the rotors is hit by the porous rotors, creating fine liquid particles, so that a mass transfer takes place between the surfaces of the liquid particles and a gas injected into the reactor, and thus a crystallization reaction is initiated. The crystallization reaction is confined by the amounts of the reactants contained in the liquid particles, and will stop as soon as one of the reactants is consumed, so that the resulting crystals can be controlled in nanometer level. The reactor of the present invention is also suitable for use in a liquid-liquid reaction, wherein two different liquids are separately sprayed in a direction from the rotating axis and hit by the porous rotors, and the resulting fine liquid particles of the two different liquids contact and react with each other, so that ultra fine particles are formed.

Owner:IND TECH RES INST

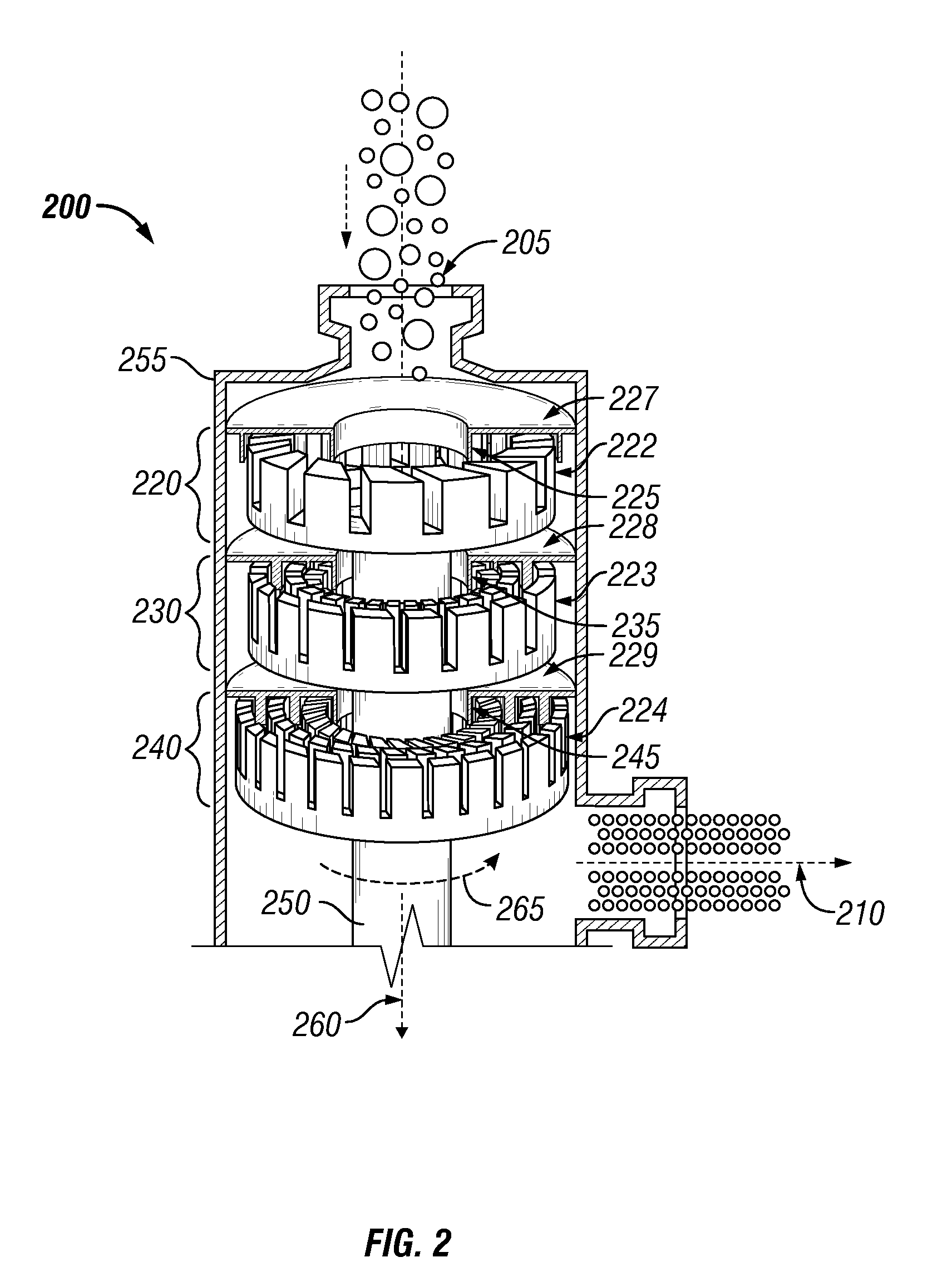

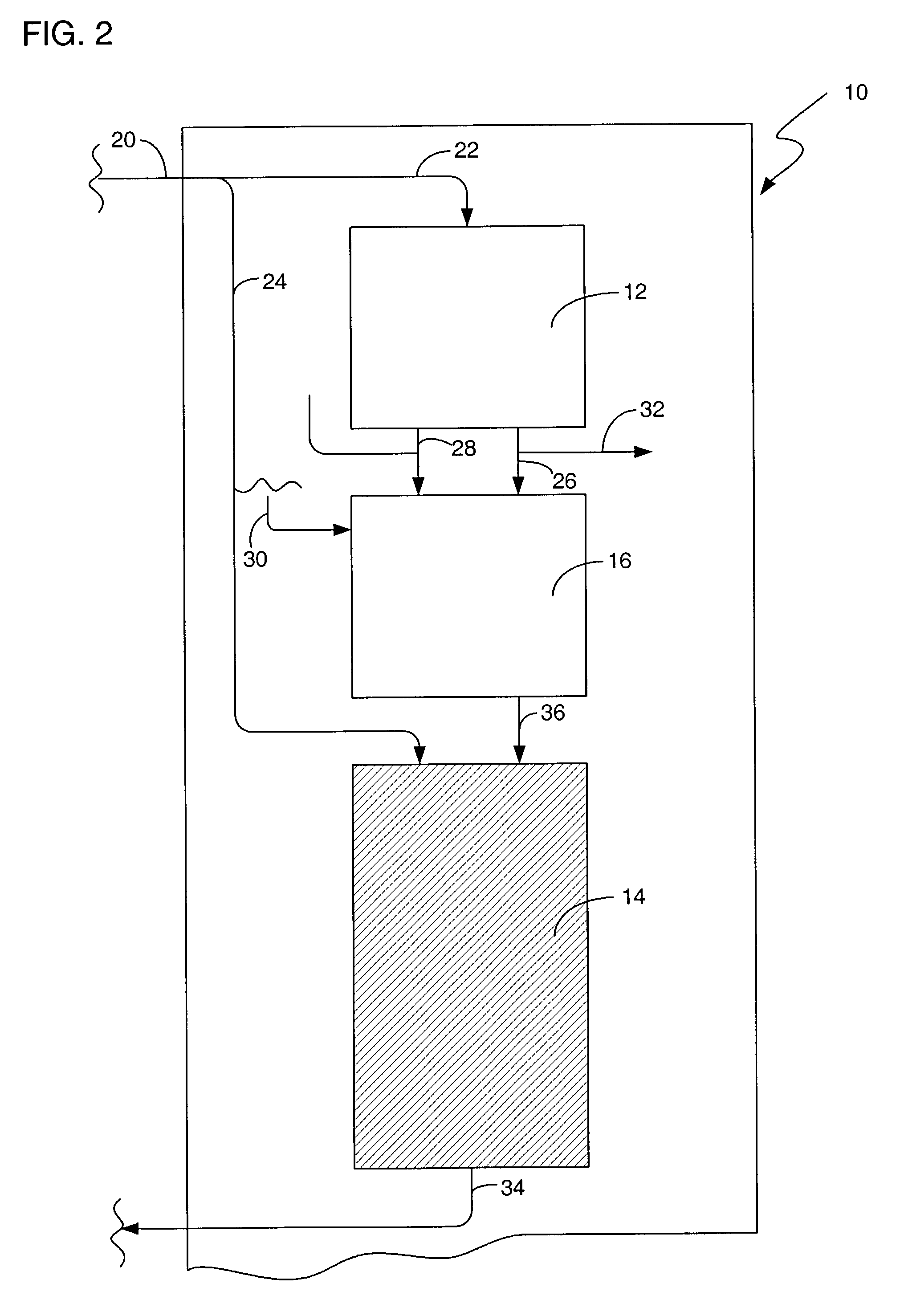

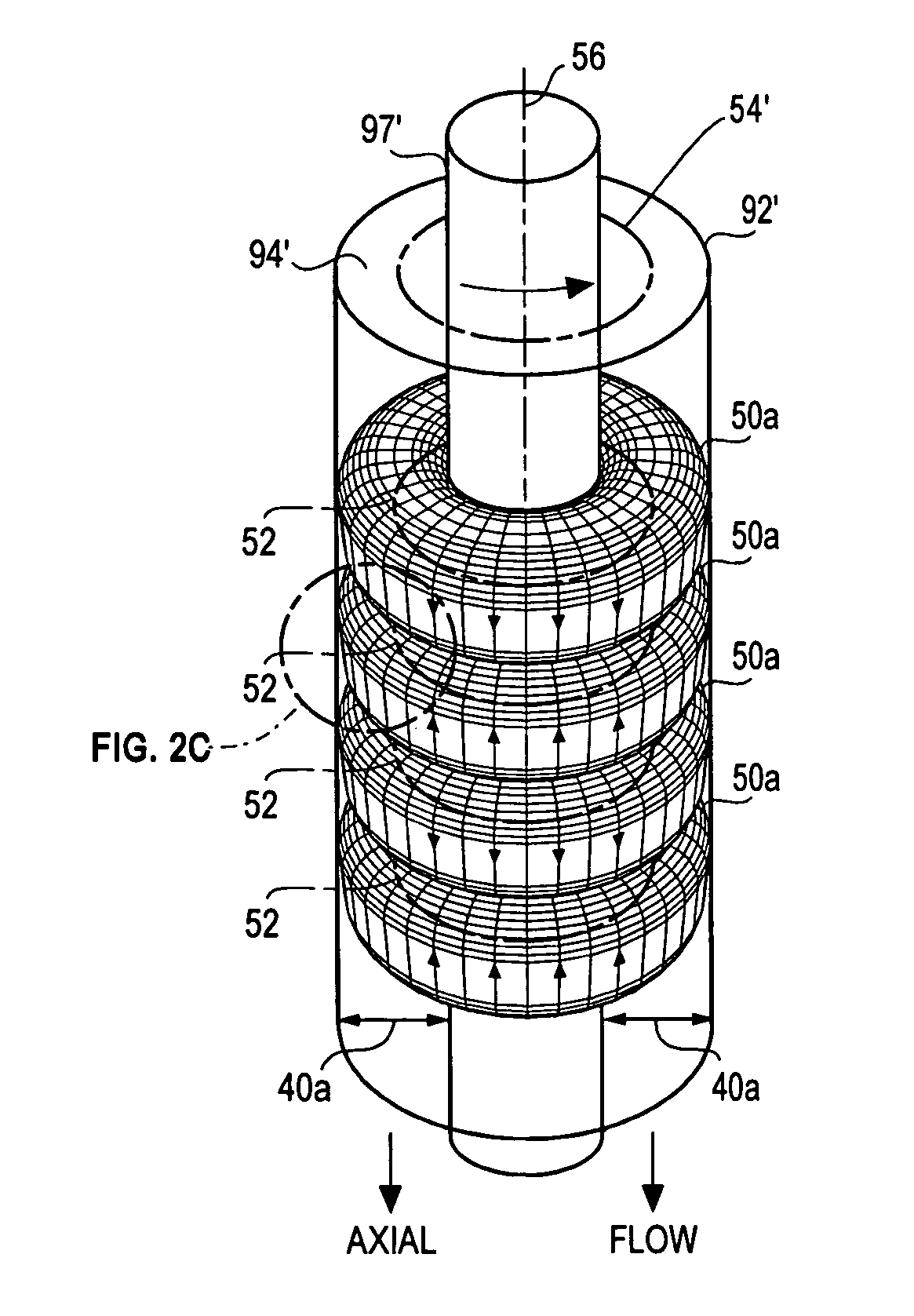

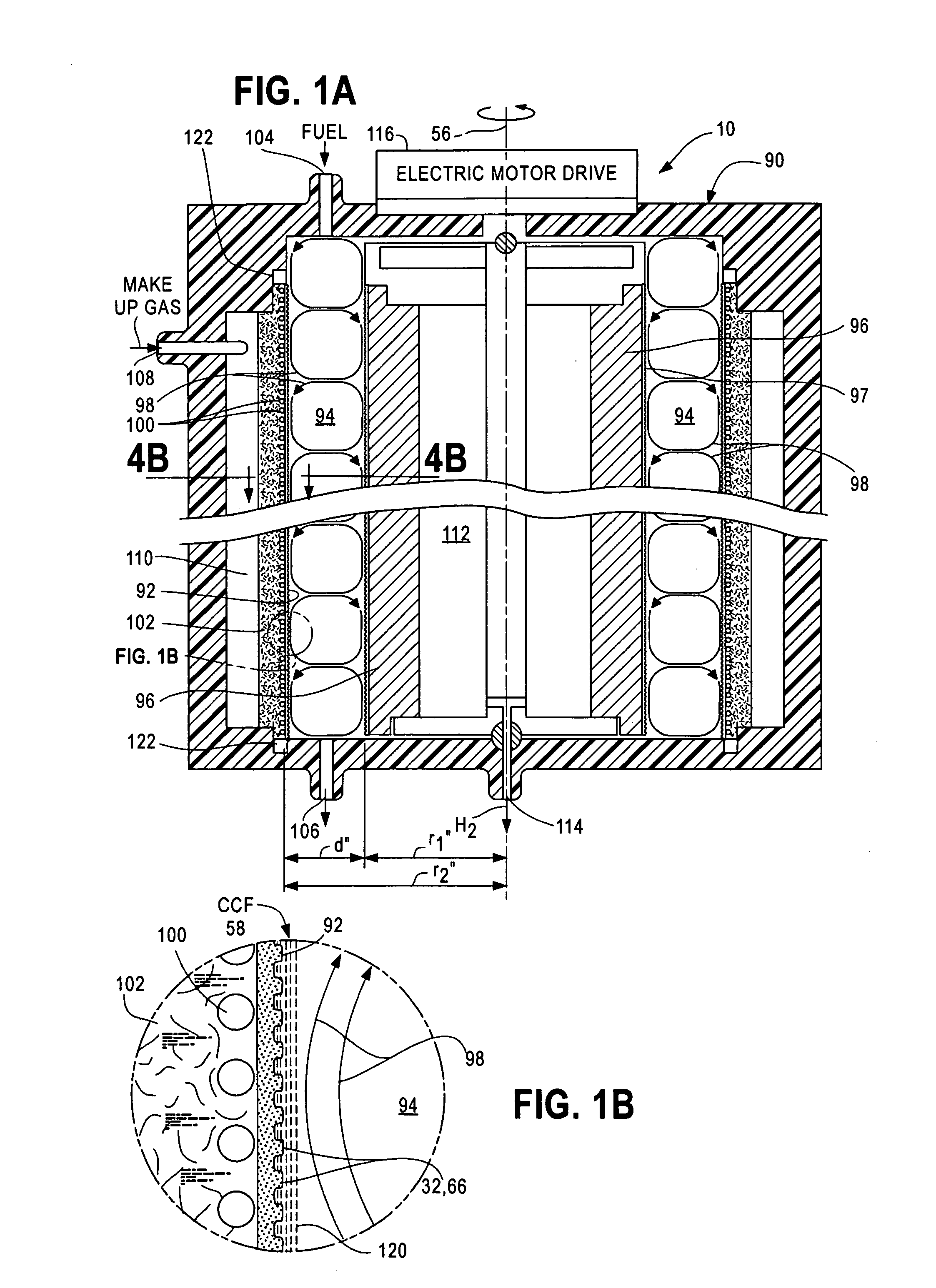

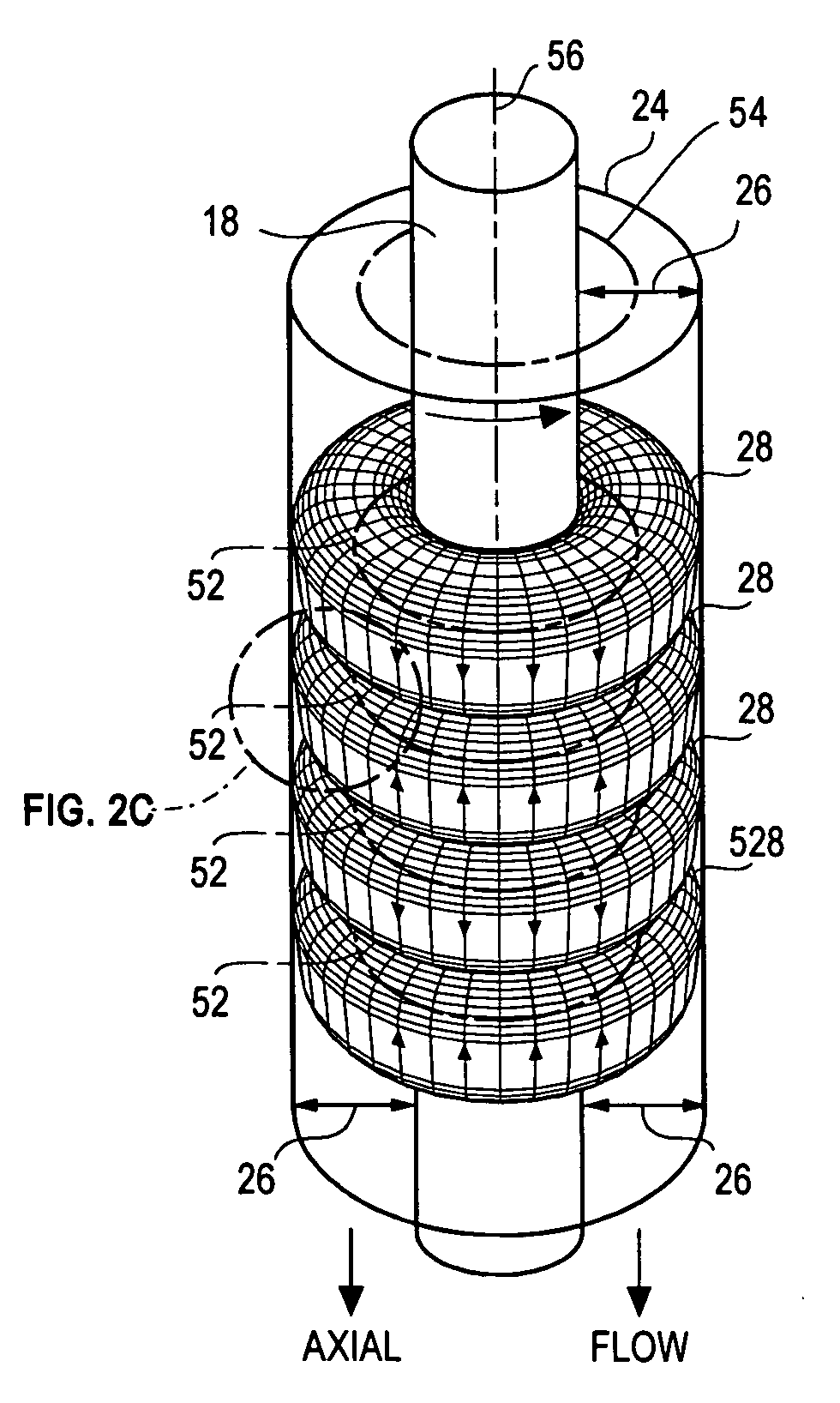

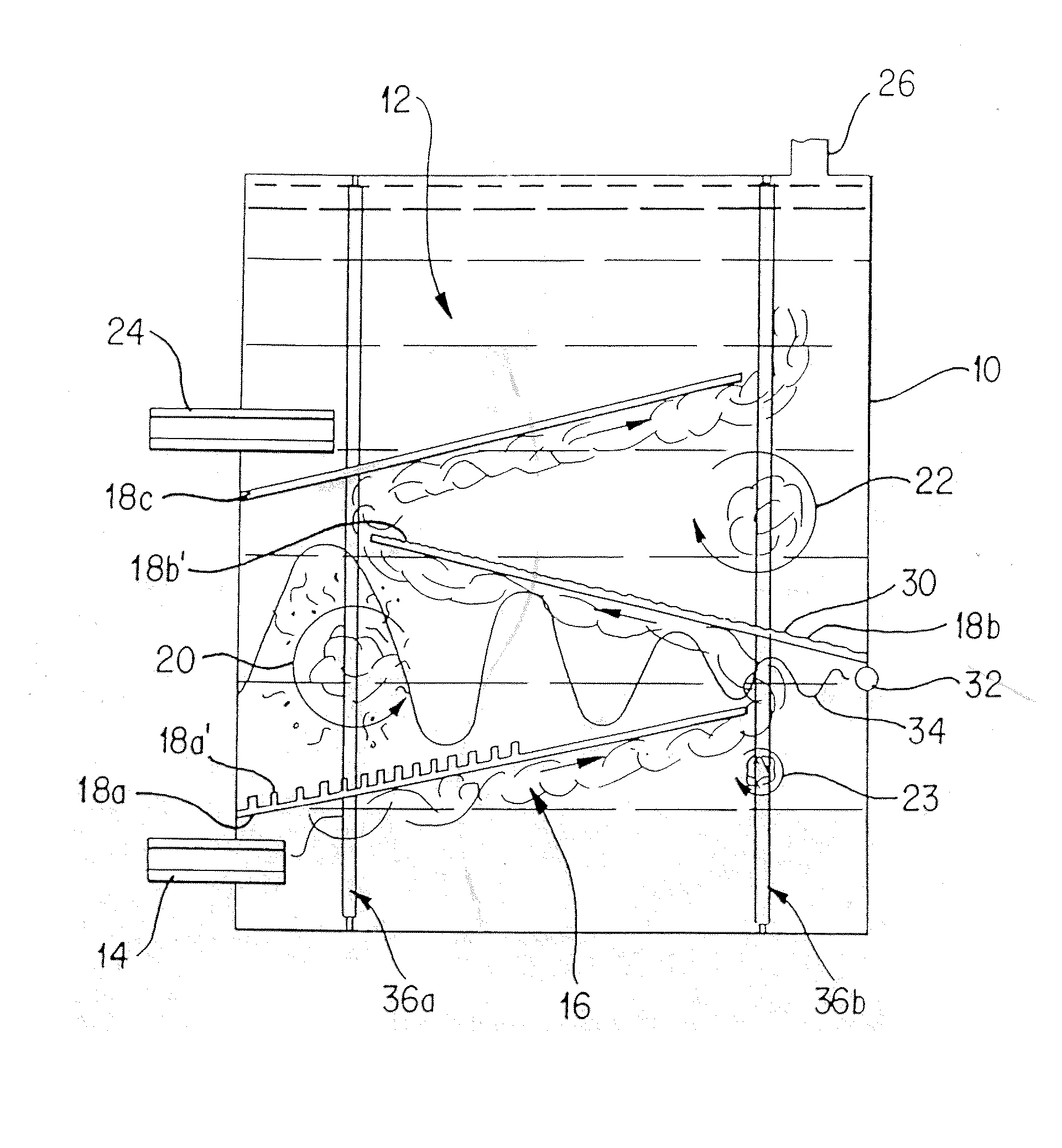

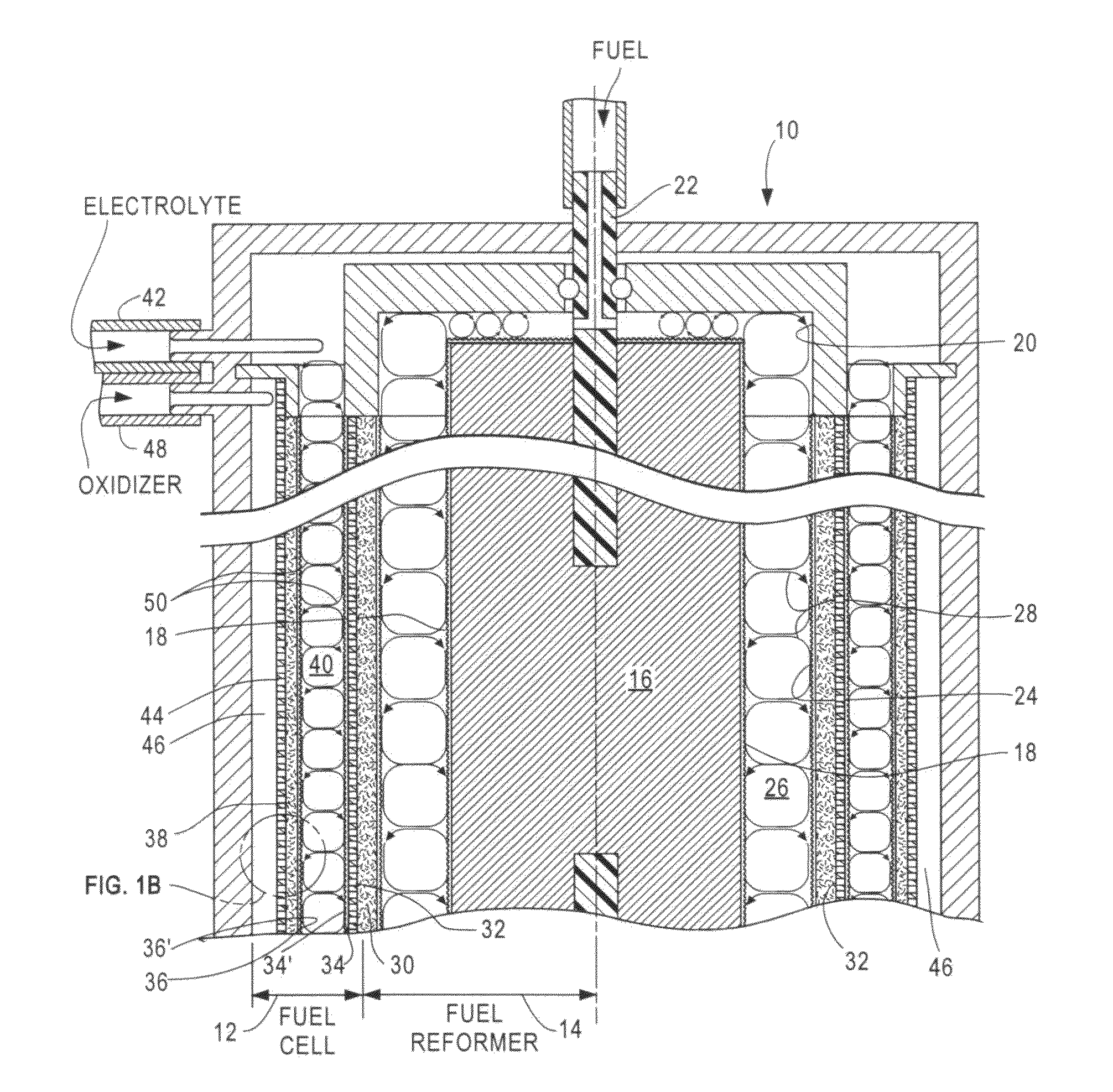

Fuel reformers utilizing taylor vortex flows

ActiveUS20100330445A1Easy to disassemblePromote increased reformer reaction rateRotary stirring mixersTransportation and packagingPartial oxidationHydrogen

Steam, partial oxidation and pyrolytic fuel reformers (14 or 90) with rotating cylindrical surfaces (18, 24 or 92, 96) that generate Taylor Vortex Flows (28 or 98) and Circular Couette Flows (58, 99) for extracting hydrogen from hydrocarbon fuels such as methane (CH4), methanol (CH3OH), ethanol (C2H5OH), propane (C3H8), butane (C4H10), octane (C8H18), kerosene (C12H26) and gasoline and hydrogen-containing fuels such as ammonia (NH3) and sodium borohydride (NaBH4) are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

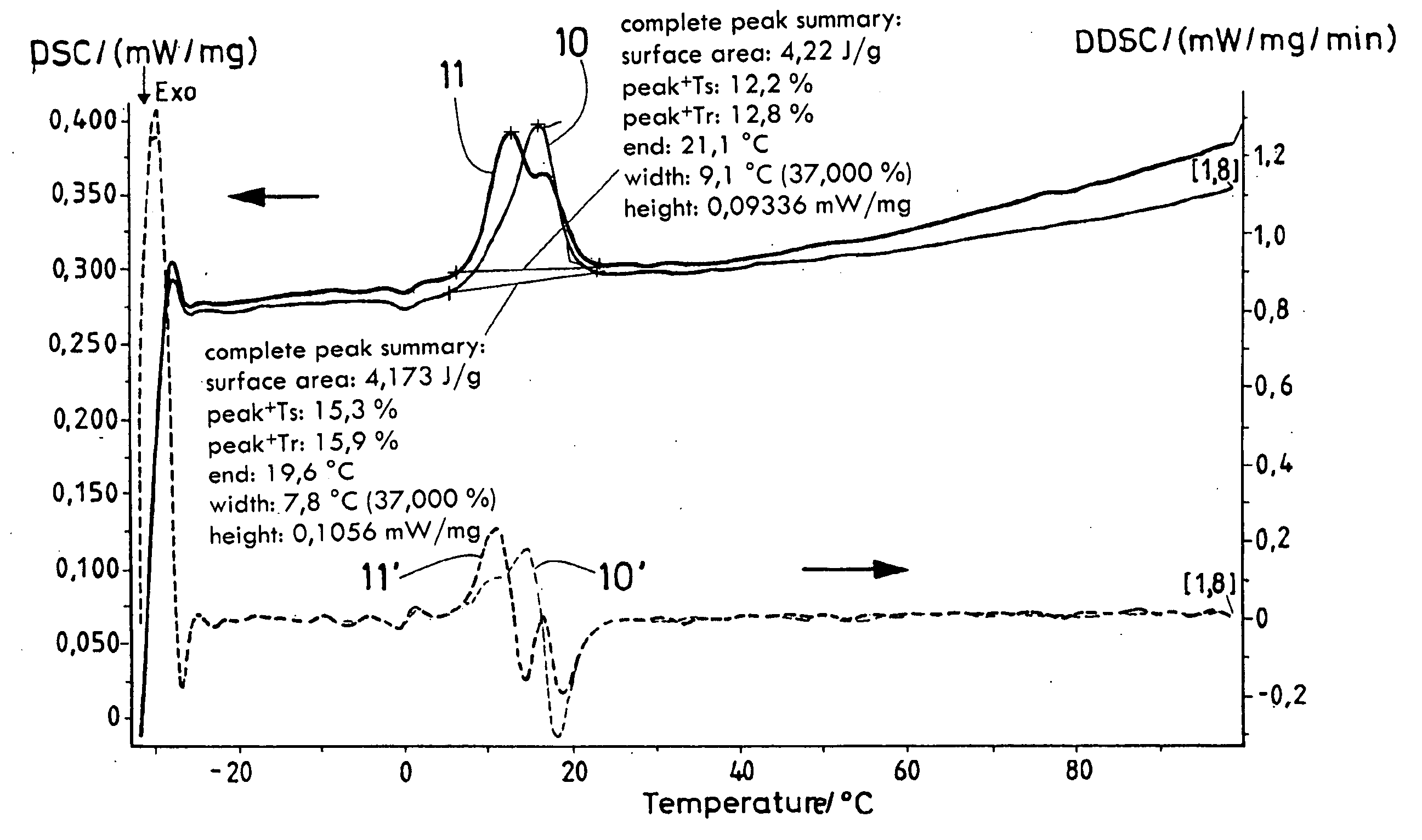

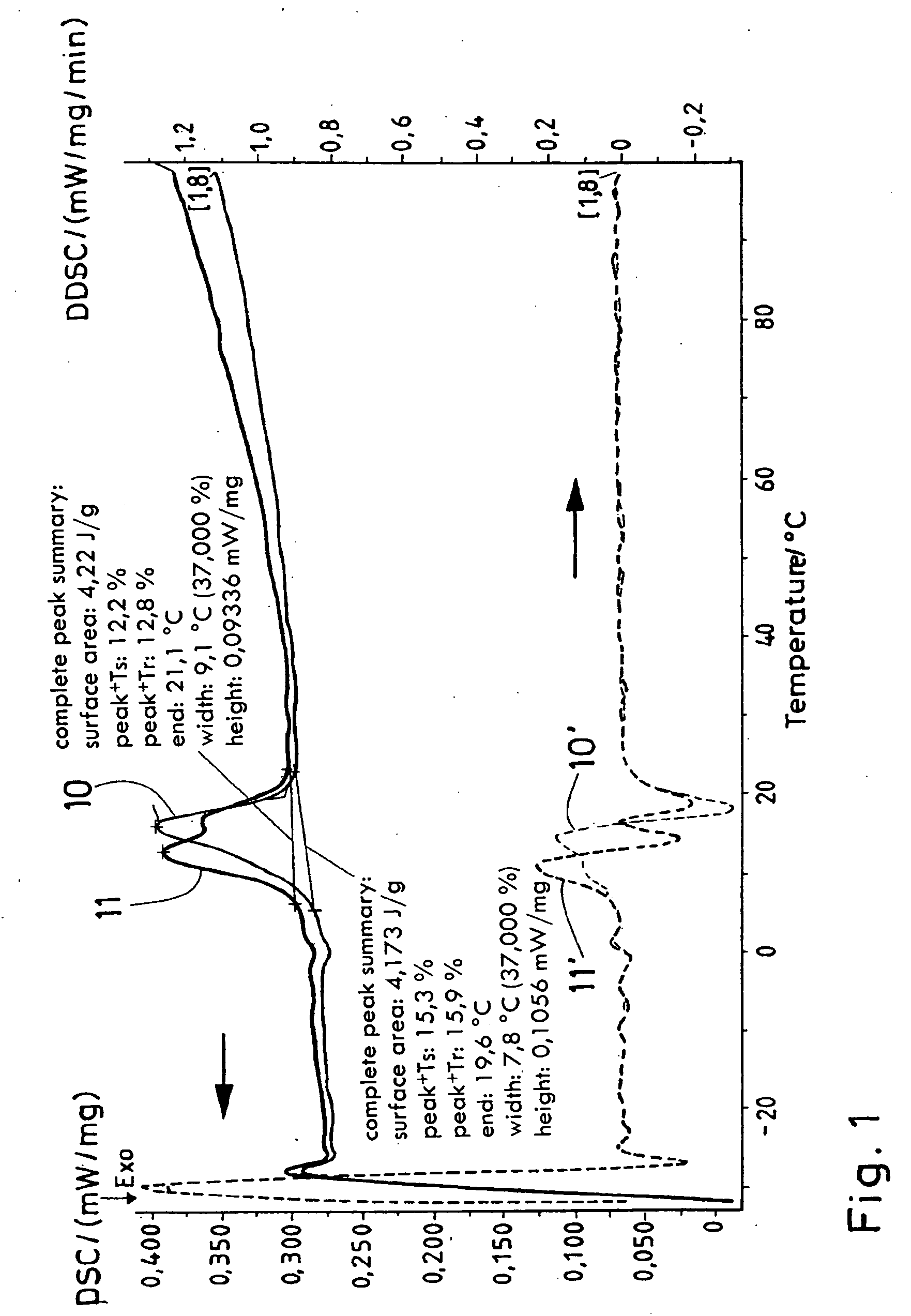

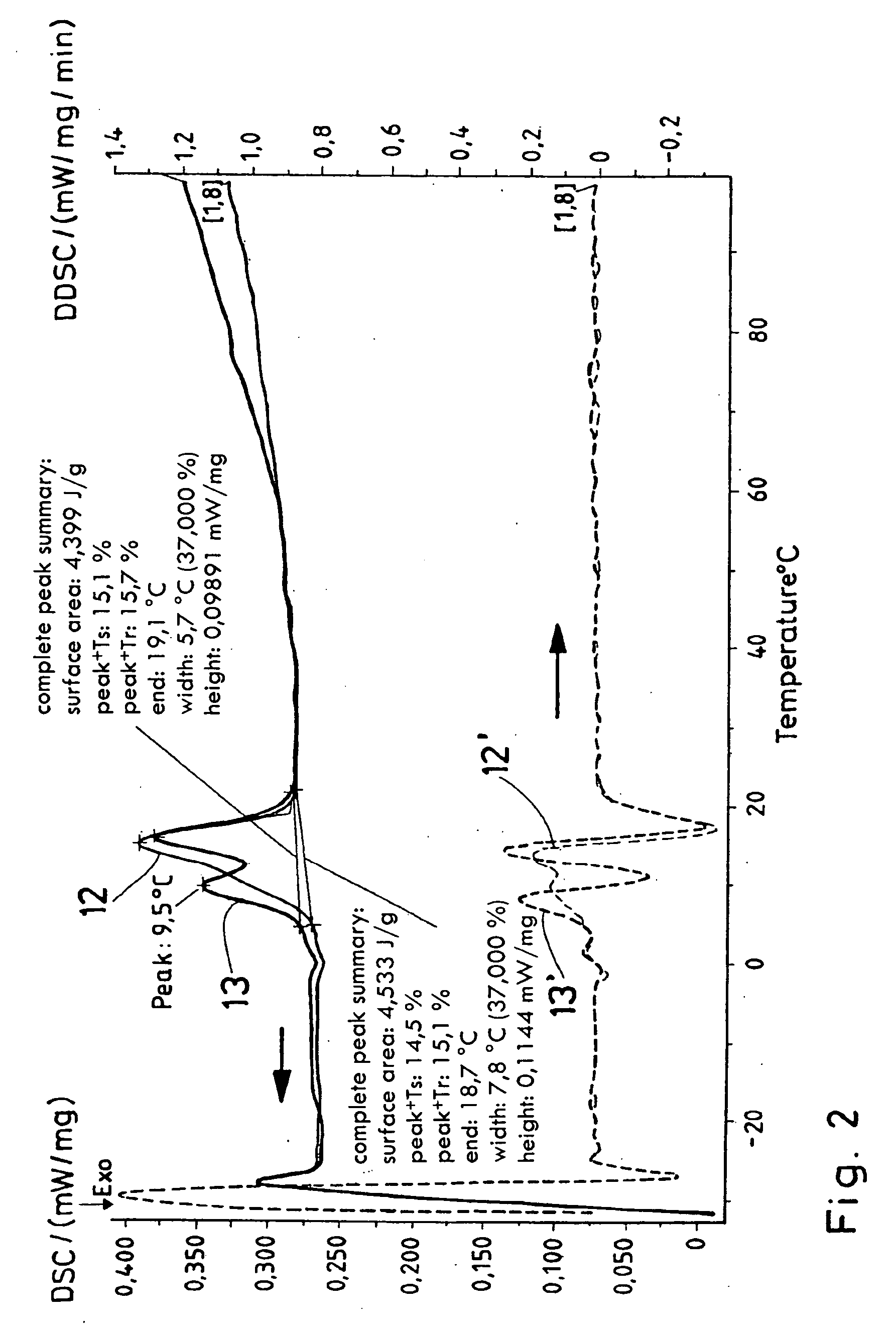

Process for producing a polymer membrane, and polymer membrane

InactiveUS20080004457A1Increase oil flowLarge and well distributed poreFatty acid chemical modificationIsotope separationPolymer scienceOligomer

The invention relates to a process for producing a polymer membrane, the polymer membrane being produced from a solution, in particular a casting solution, comprising at least one first polymer. The invention further relates to a polymer membrane. The process of the invention is distinguished by the fact that a water-soluble second polymer and / or oligomer that forms phases in the solution is part of the solution. The polymer membrane of the invention, preferably produced by the process of the invention, has an oil flow rate, in particular of a refined edible oil, of greater than 200 l / m2 h bar at 60° c.

Owner:HELMHOLTZ ZENT GEESTHACHT ZENT FUER MATERIAL UND KUESTENFORSCHUNG

Zero-emission, closed-loop hybrid solar-syngas OTR power cycle

InactiveUS9664115B2Catalytic gas-gas reactionTurbine/propulsion fuel supply systemsSyngasPower cycle

A zero-emission, closed-loop and hybrid solar-produced syngas power cycle is introduced utilizing an oxygen transport reactor (OTR). The fuel is syngas produced within the cycle. The separated oxygen inside the OTR through the ion transport membrane (ITM) is used in the syngas-oxygen combustion process in the permeate side of the OTR. The combustion products in the permeate side of the OTR are CO2 and H2O. The combustion gases are used in a turbine for power production and energy utilization then a condenser is used to separate H2O from CO2. CO2 is compressed to the feed side of the OTR. H2O is evaporated after separation from CO2 and fed to the feed side of the OTR.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS

Fluid contact chamber

InactiveUS20080035226A1Good contact timeWell mixedFlow mixersCircuit elementsEngineeringChemical Modifier

A fluid contactor is taught for mixing and reacting of fluids. Mixing is enhanced by providing a suitable residence time and suitable surface area contact by forming eddy flow within the fluid and thereby the formation of vortexes. Such a contactor does not require the use of mechanical mixers. The contact chamber of the present invention can enhance chemical modification by use of chemical modifiers such as ultraviolet lamps, by allowing the positioning of such modifiers adjacent the vortexes.

Owner:CONRAD WAYNE E +3

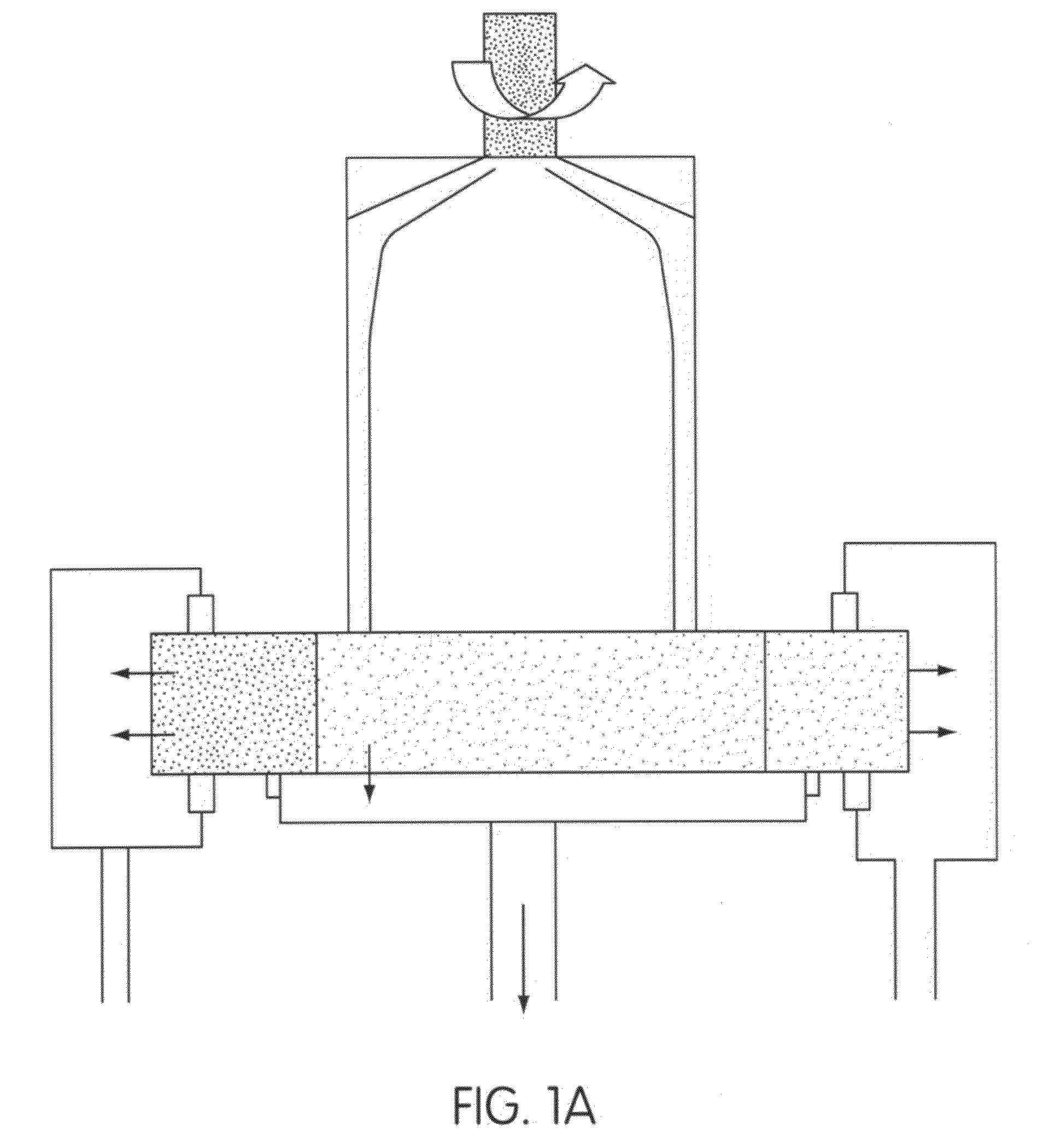

Thin film tube reactor with rotating reservoir

InactiveUS7875248B1Minimize turbulenceSemi-permeable membranesGaseous chemical processesEngineeringVolumetric Mass Density

A tube reactor having a substantially tubular body portion including a conical section, an entry port, an opposing exit port, and an axis extending between the ports through the body portion. The tubular body portion being rotatable about the axis. At least one reactant can be fed into the tubular body portion and directed toward the conical section. An inner surface of the tubular body portion receives the reactants from the conical section, and processes the reactants. An insert may be positioned within the tubular body portion to further process the reactants along the inner surface. A rotating reservoir having a damper can be coupled to the rotating tubular body portion. The damper receives the processed reactants from the inner surface of the tubular body portion, and guides the processed reactants into the rotating reservoir to minimize turbulence. The rotating reservoir then separates the processed reactants by density.

Owner:CLARKSON UNIVERSITY

Dynamic accelerated reaction batteries utilizing taylor vortex flows

ActiveUS20100330460A1Easy to transportIncreased mass transportTransportation and packagingCell electrodesFuel cellsEngineering

Dynamic accelerated reaction batteries (10, 100, 200) with rotating electrodes (14x, 20x, 104x, 106x,) or rotating membranes (208) or fuel cells (412C, 412D) that generate Taylor Vortex Flows (54, 122, 228, 454) and Circular Couette Flows (56, 124, 230) in electrolyte chambers (38x,126x, 206, 438x) are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

Method and apparatus for fluid-liquid reactions

A method and apparatus for fluid-liquid reactions including gas-liquid and liquid-liquid reactions. The method and apparatus is suitable for mixing a fluid phase species and a liquid phase species to facilitate chemical reaction between said phases. The apparatus comprises a reactor vessel with a plurality of orificed plates and flow control means which initiates and maintains uniform mixing and efficient dispersion of a fluid-liquid mixture within the reactor vessel.

Owner:NITECH SOLUTIONS LTD

Electrochemical cells utilizing Taylor Vortex Flows

ActiveUS20100330439A1Reduce mass-transportReduce reaction-rate limitationRotary stirring mixersTransportation and packagingFuel cellsEngineering

Electrochemical cells (10), such as fuel cells (12) and fuel reformers (14), with rotating elements or electrodes (34, 24) that generate Taylor Vortex Flows (28, 50) and Circular Couette Flows (58) in fluids such as electrolytes and fuels are disclosed.

Owner:GLOBAL ENERGY SCI CALIFORNIA

Solar hydrogen permeation membrane reaction device and use method thereof

InactiveCN107930552ARealize integrationSimplify the process stepsHydrogenLiquid-gas reaction of thin-film typeChemical reactionHigh energy

The invention discloses a solar hydrogen permeation membrane reaction device. The device comprises a solar heat collection device and a thermal chemical reactor; the solar heat collecting device comprises a solar concentrating device and a solar heat collecting tube arranged below the solar concentrating device; the solar heat collecting tube sequentially comprises an antireflection film, a light-transmitting glass tube and a metal heat absorption inner tube; the outer surface of the light-transmitting glass tube is coated with the antireflection film; a sealed vacuum interlayer is formed between the light-transmitting glass tube and the metal heat absorption inner tube; the thermal chemical reactor is arranged in the metal heat absorption inner pipe; the thermal chemical reactor comprisesa porous ceramic substrate tube; the outer surface of the porous ceramic substrate tube is coated with a selective hydrogen permeation membrane; a hot chemical reaction channel is formed between theporous ceramic substrate pipe and the metal heat absorption inner pipe; and a hydrogen separation channel is formed in the porous ceramic substrate pipe. According to the solar hydrogen permeation membrane reaction device provided by the invention, solar energy is used as reaction energy, so that the device can save energy and protect the environment, and has higher energy utilization efficiency.Meanwhile, the generation and separation of hydrogen are integrated, the flow is simplified, and the reaction conversion rate is improved.

Owner:WUHAN UNIV

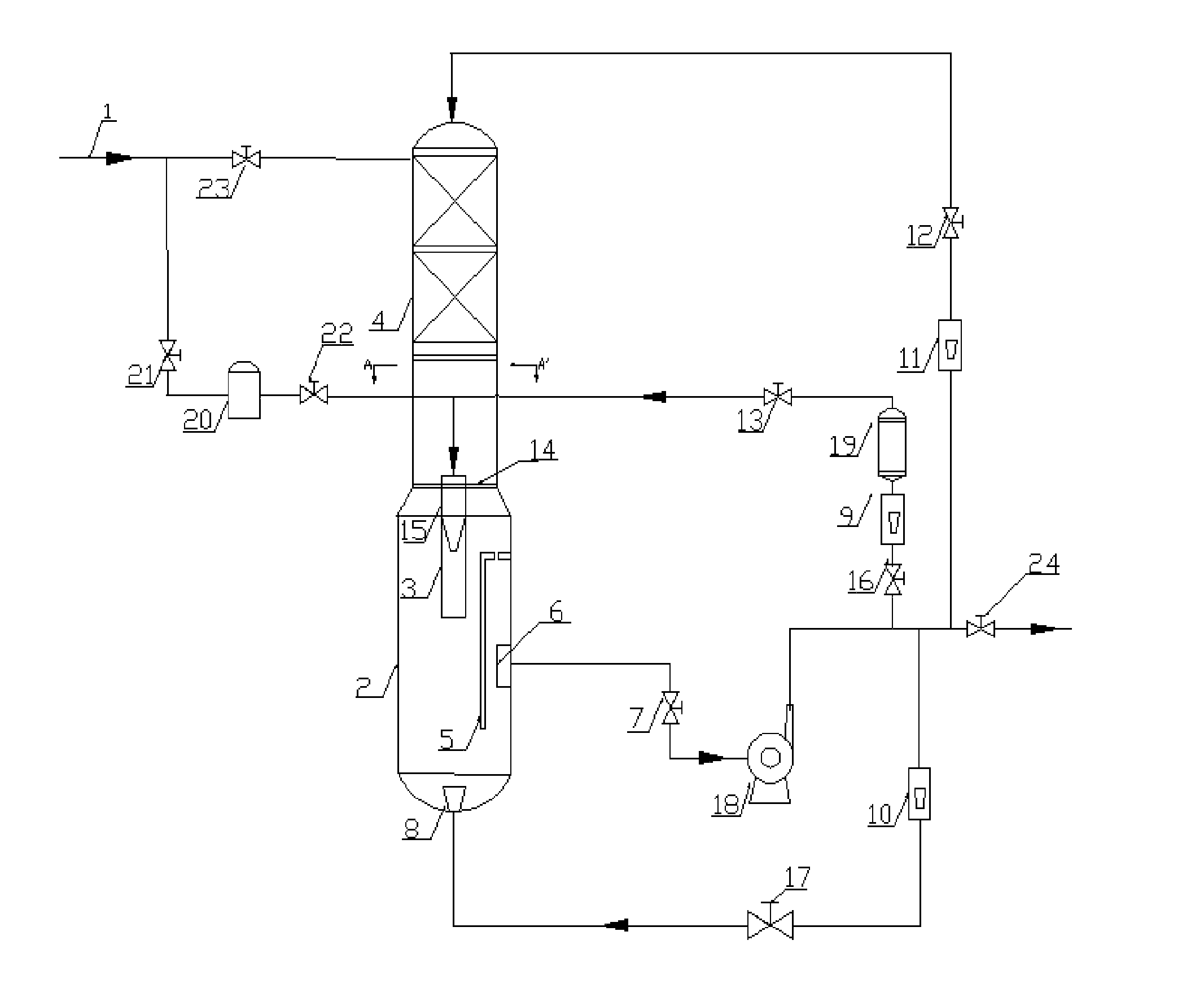

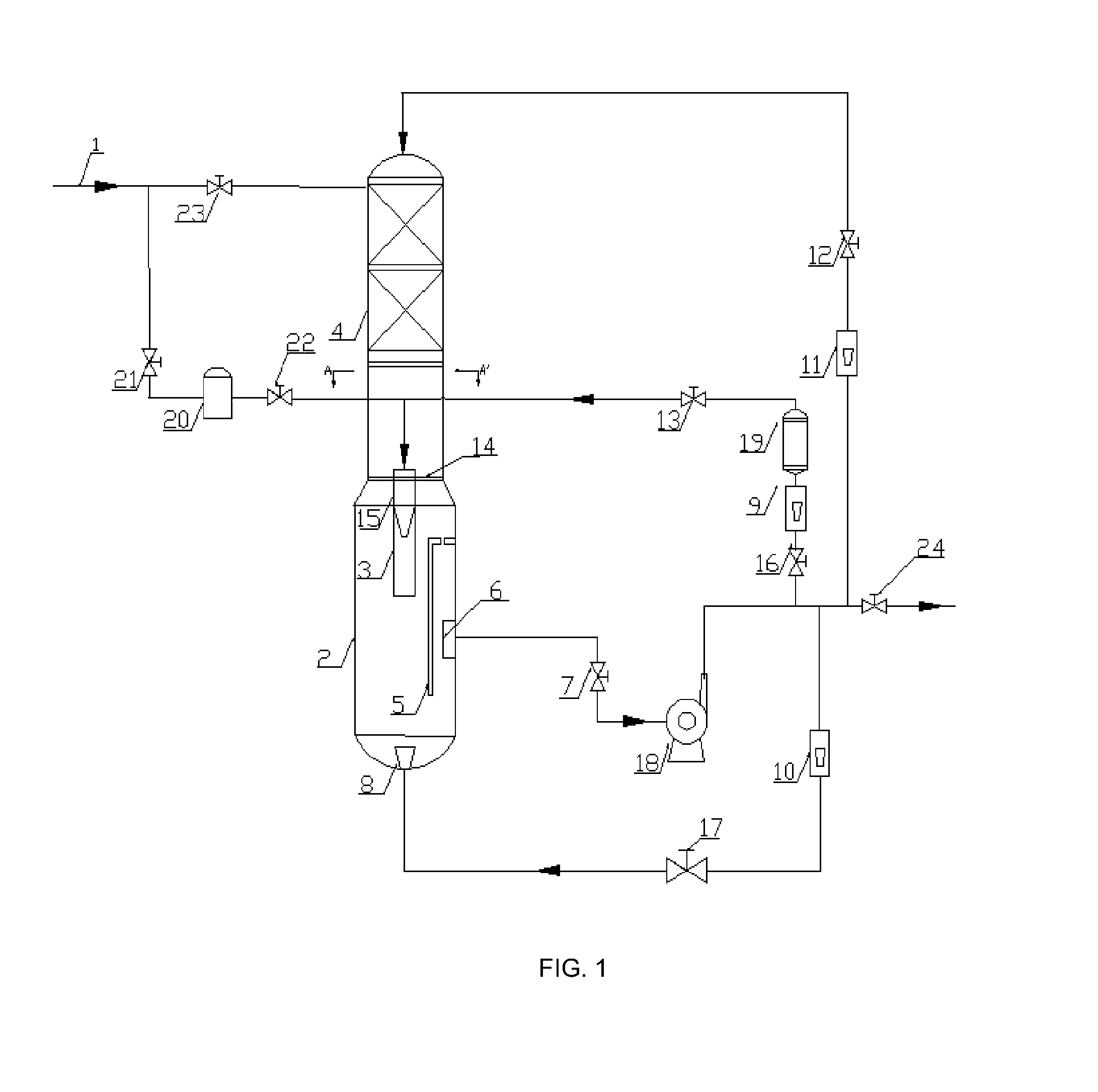

Multiphase catalytic tower-type impinging-stream reactor

ActiveUS20130129576A1Smooth connectionEqually distributedCatalytic liquid-gas reactionChemical/physical/physico-chemical stationary reactorsTowerInjector

A multiphase catalytic tower-shaped impinging-stream reactor in the form of a tower, the upper part of which is a plate or packed tower 4 and the lower part of which is a multiphase catalytic impinging-stream reaction kettle 2; the upper part and the lower part are separated by a flow channel plate 14 which has a plurality of round holes serving as flow channels 62; at the top of the reaction kettle 2 exists an upper ejector 3 and at the bottom of the reaction kettle 2 exists a lower ejector 8; near to the side wall of the reaction kettle 2 stands a baffle plate 5, which separates a static liquid zone within the reaction kettle 2 is disclosed.

Owner:NANJING UNIV

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com