Patents

Literature

482results about How to "Extended temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

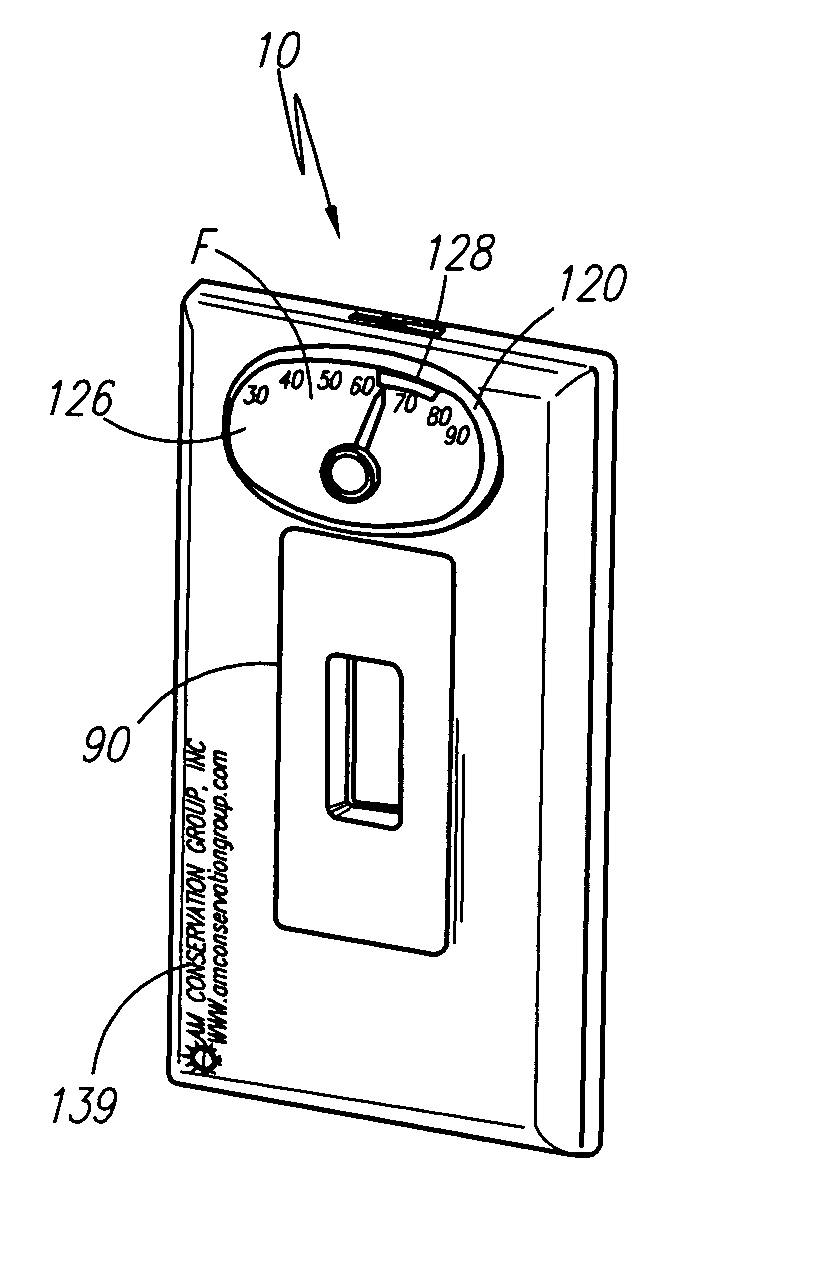

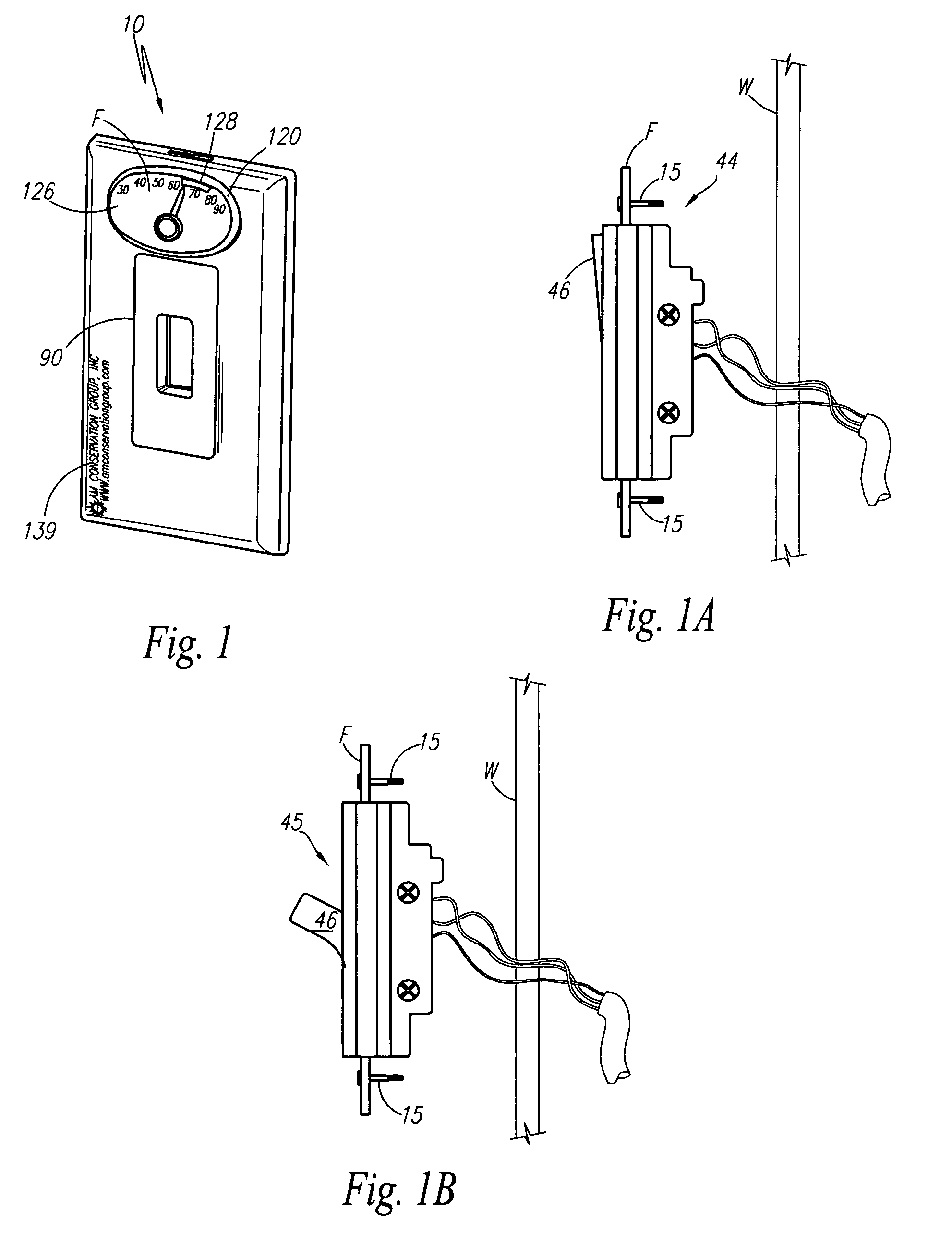

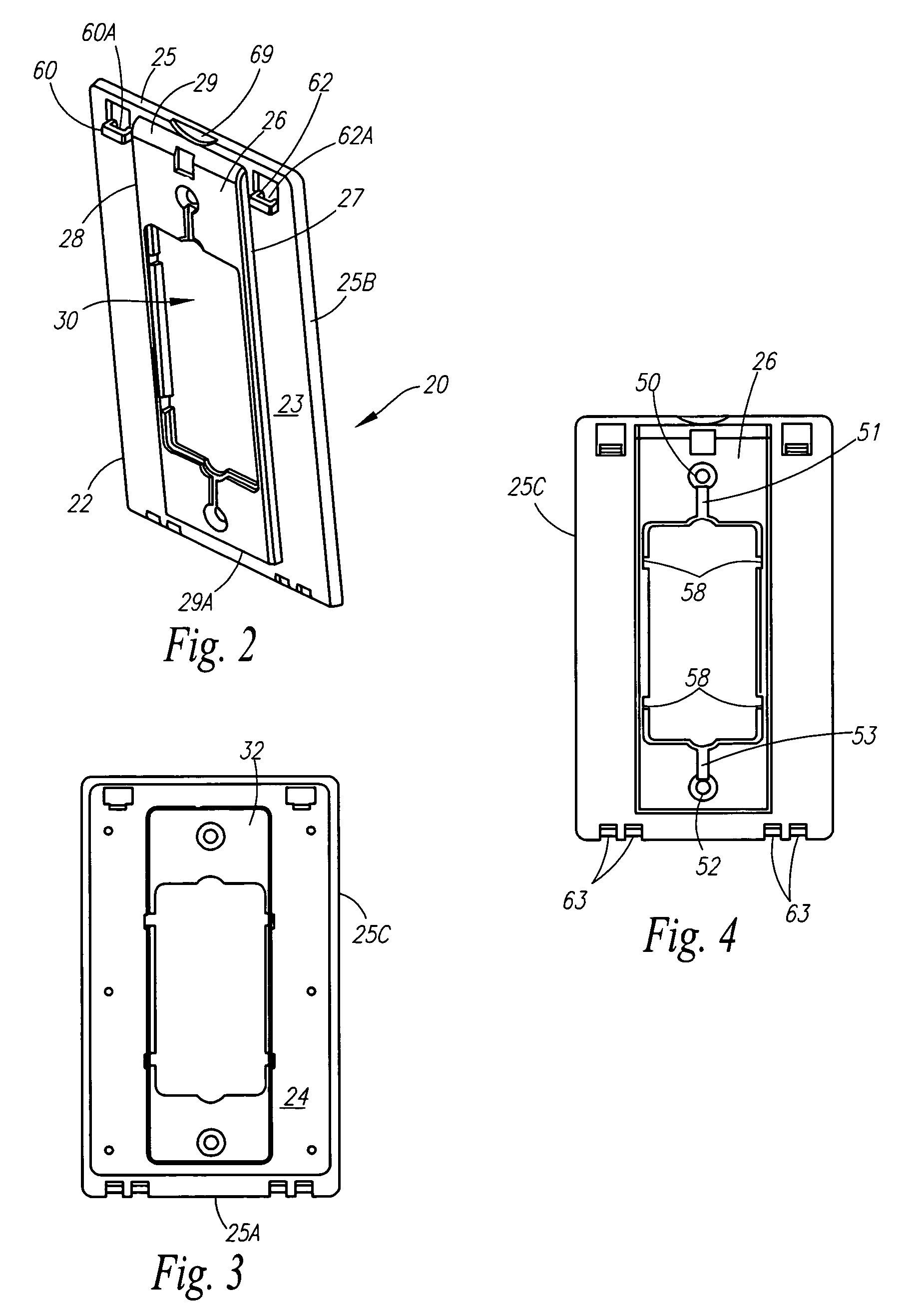

Universal wall plate thermometer

InactiveUS8143520B2Good for conservationGood energyCasings/cabinets/drawers detailsEngineeringLight switch

A light switch cover assembly easily mounted over existing wall type light switches. The cover assembly includes a mounting bracket having an opening provided therethrough which is shapely designed and sizably configured for snug attachment of a bracket plate therein. The bracket plate includes an opening to allow the protruding rocker portion of a light switch to pass therethrough. The bracket plate further includes a plurality of apertures defined therethrough for receipt of mounting screws. A face plate is adapted for removable attachment to the mounting bracket in a snap-fit manner. The face plate includes an opening shapely designed and sizably configured to snugly accommodate a rocker plate therein. The face plate further includes an oblong opening providing a thermometer support enclosure within which a thermometer is swivelably secured.

Owner:FIFTH THIRD BANK

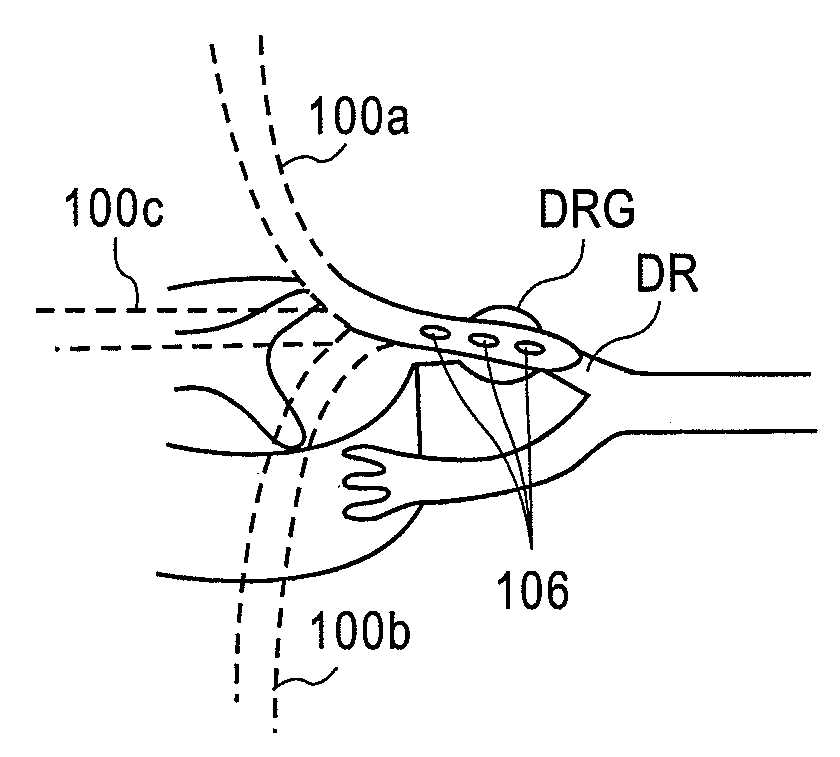

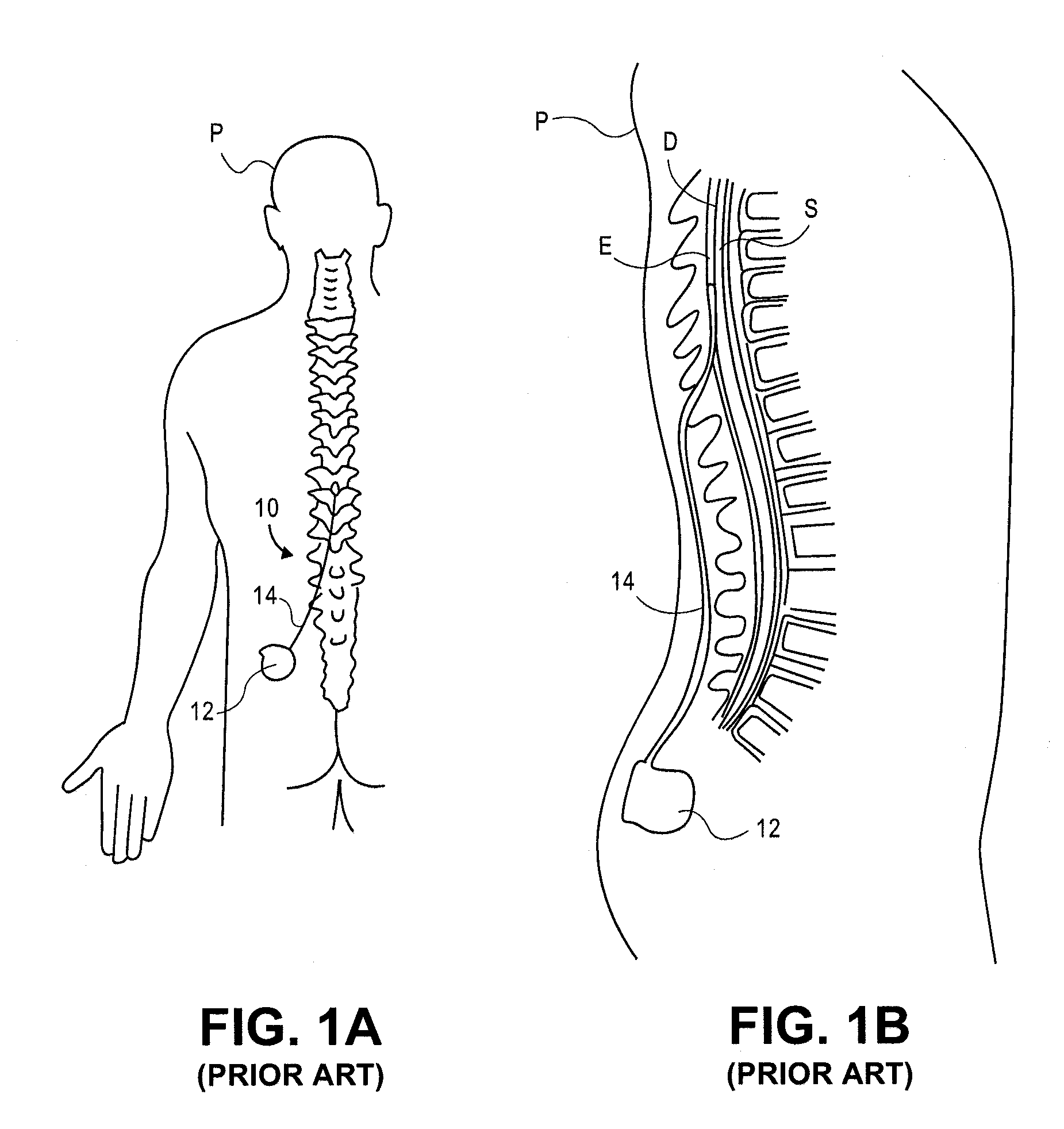

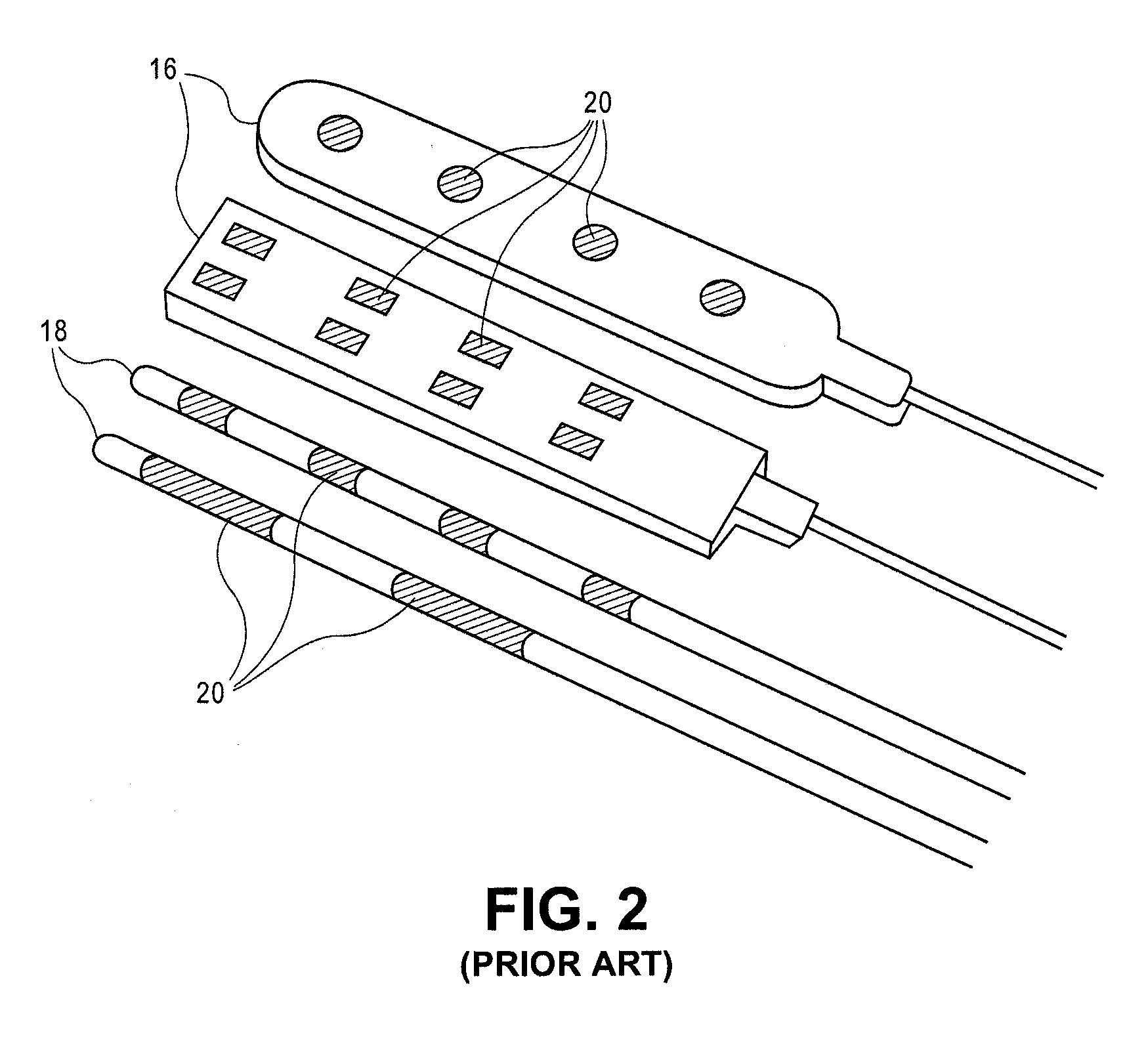

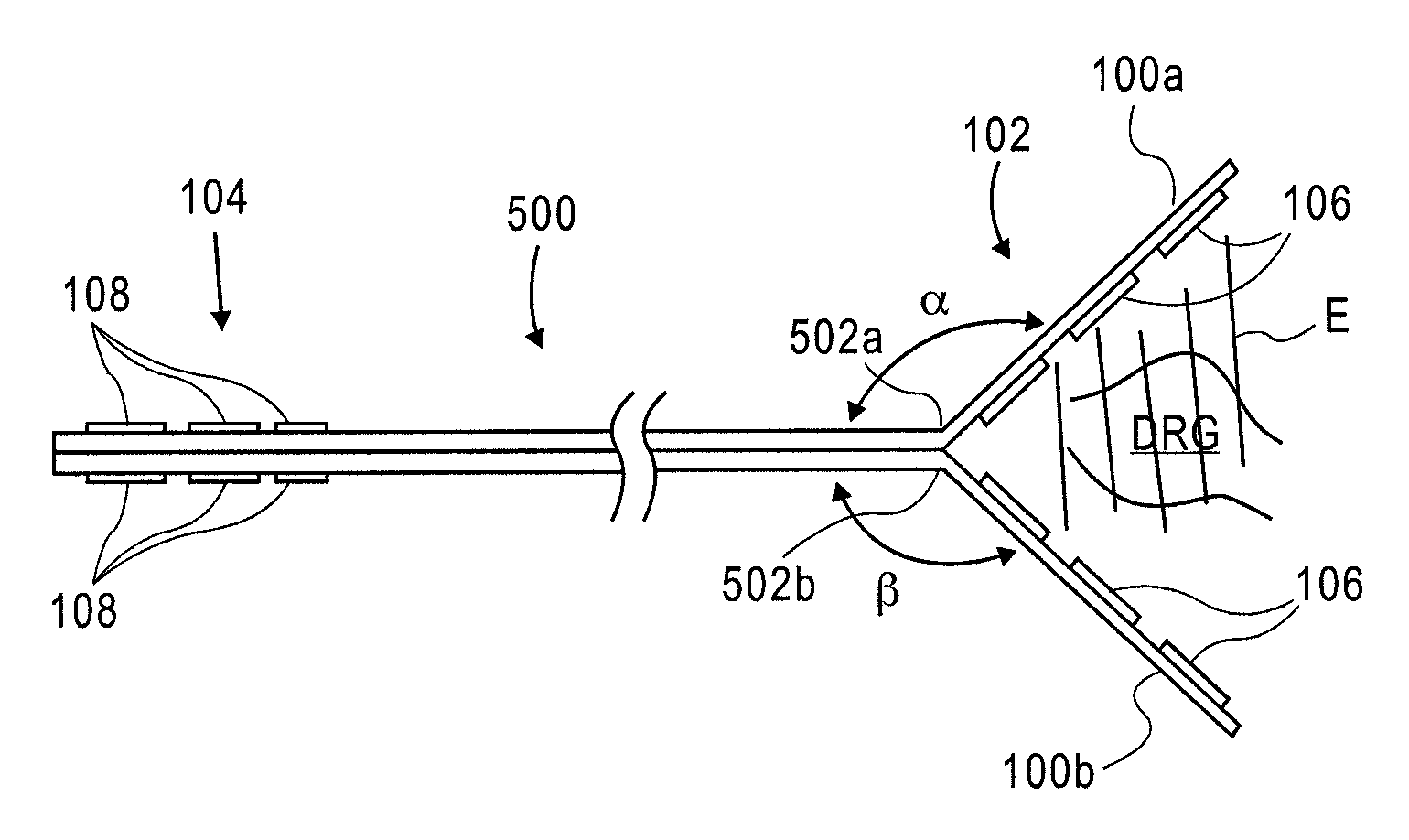

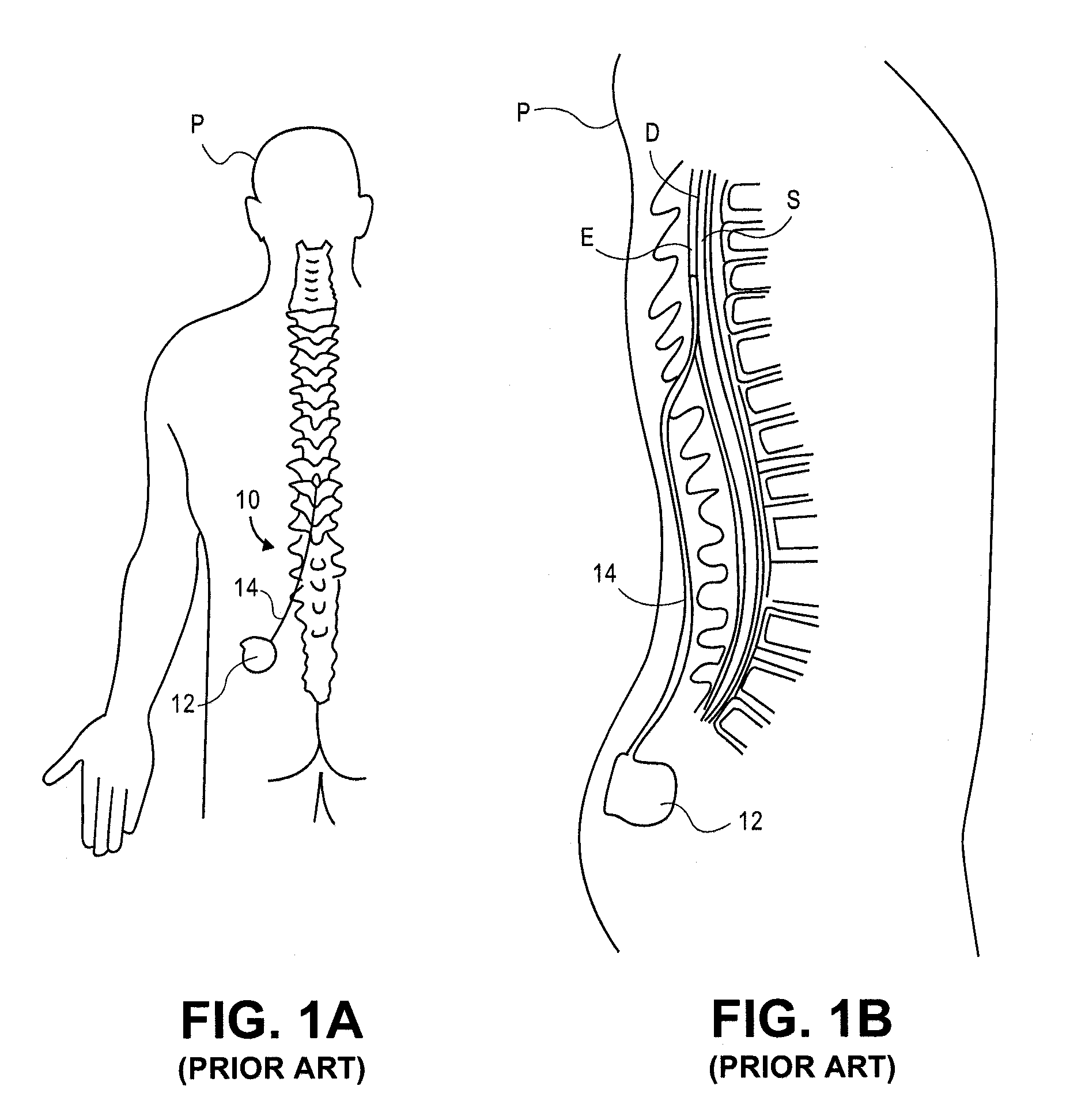

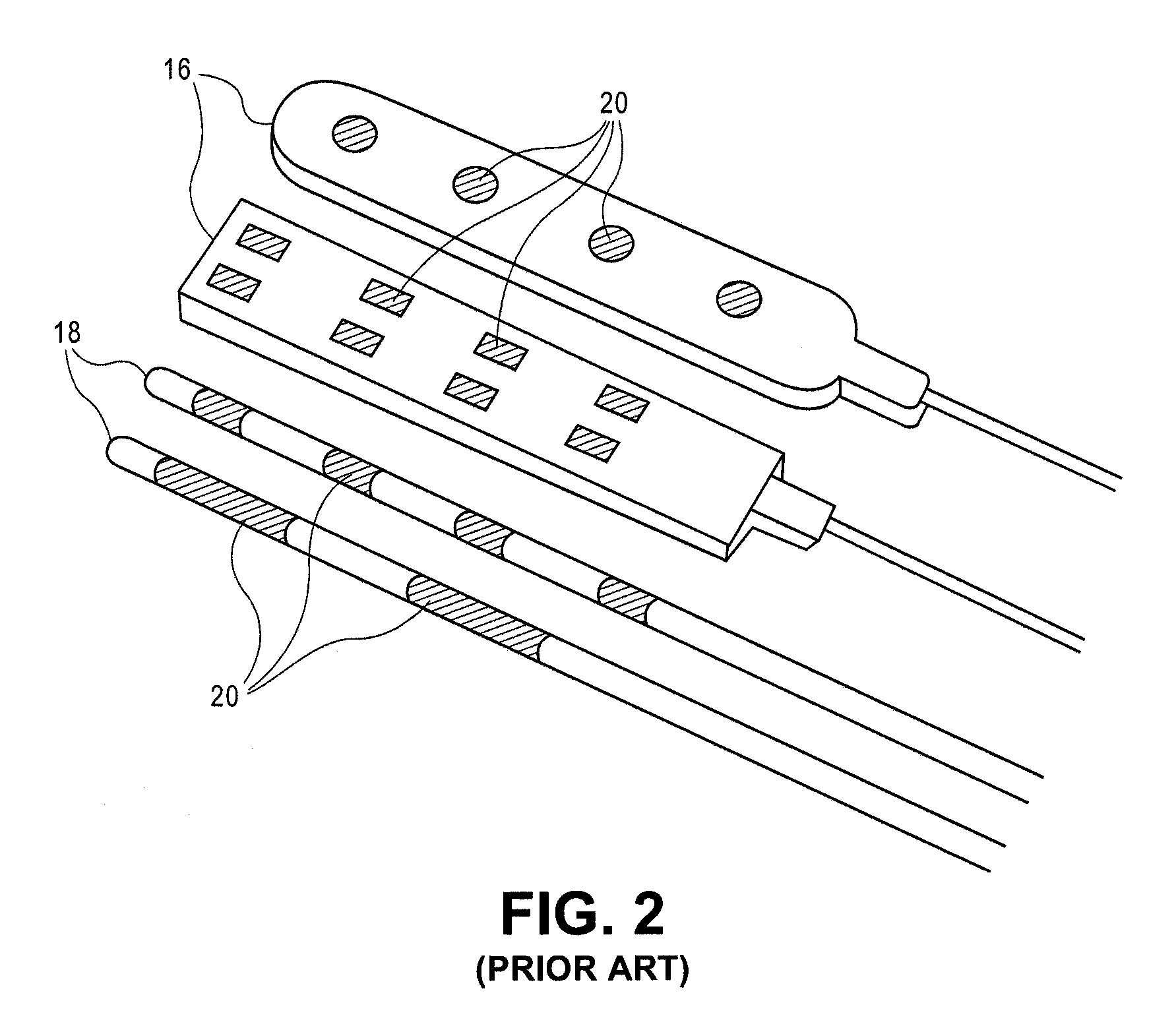

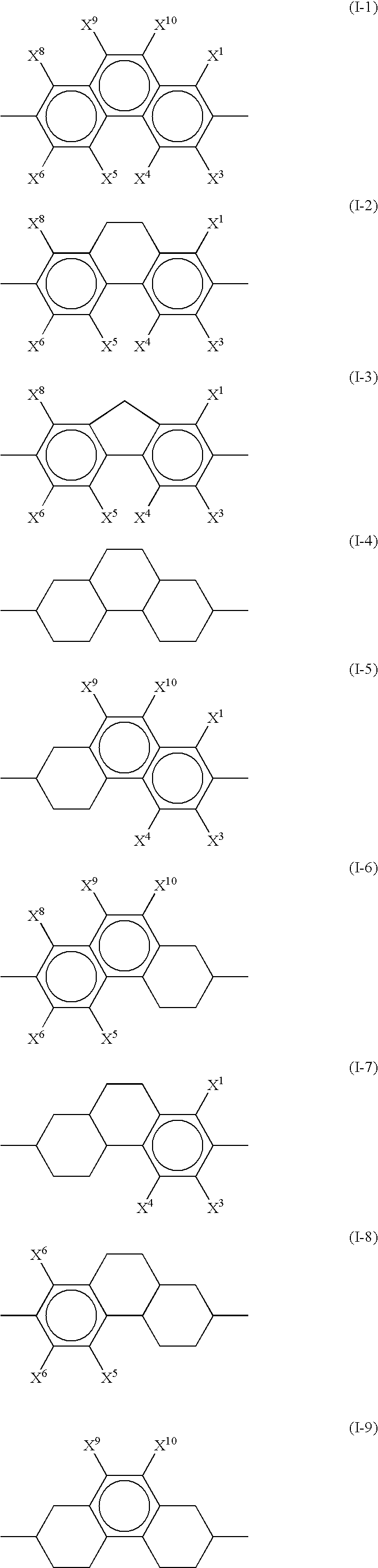

Implantable flexible circuit leads and methods of use

InactiveUS20080140152A1Easy to manufactureStrong specificitySpinal electrodesExternal electrodesDielectricFlexible circuits

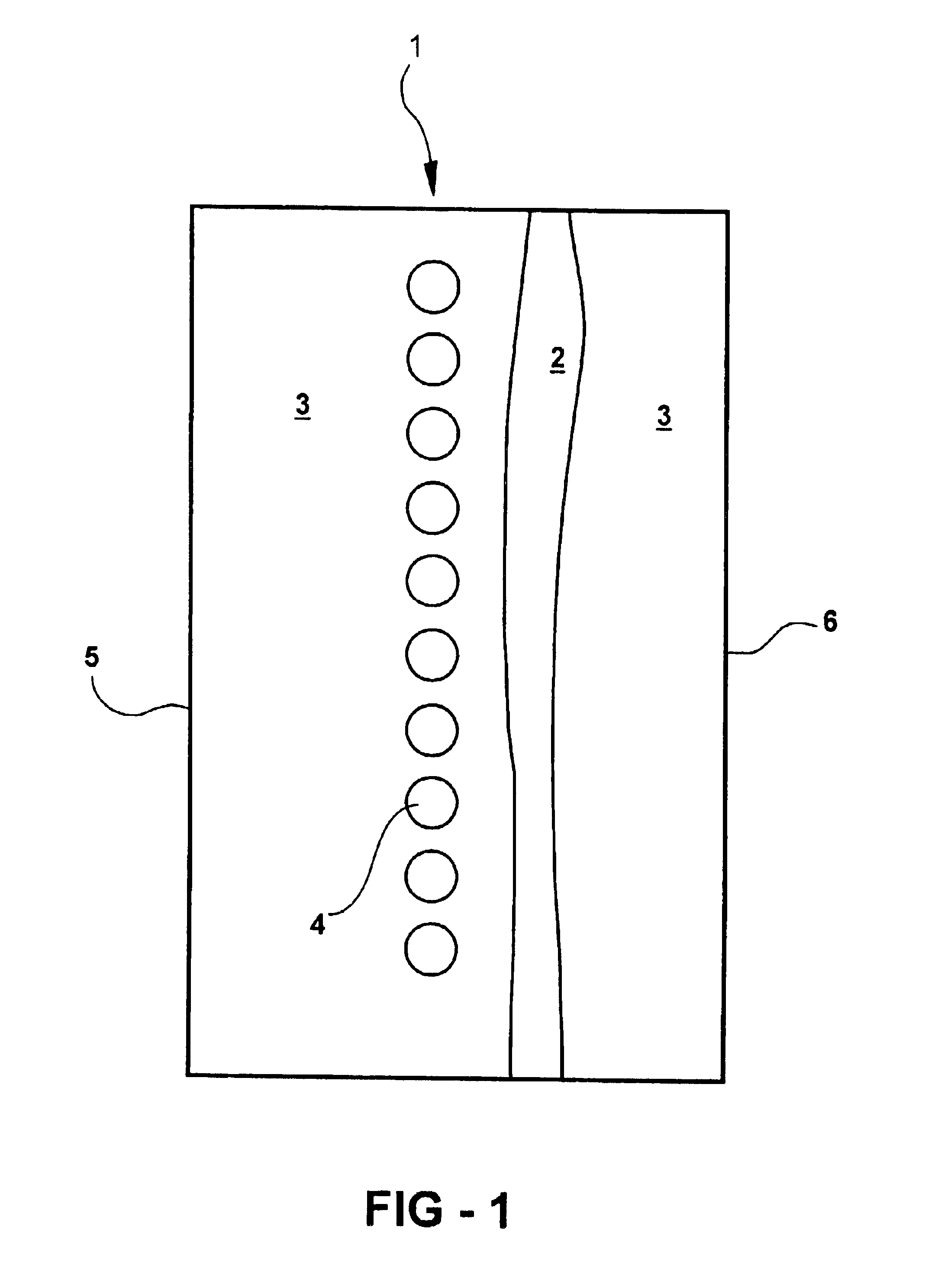

Devices, systems and methods are provided for stimulation of tissues and structures within a body of a patient. In particular, implantable leads are provided which are comprised of a flexible circuit. Typically, the flexible circuit includes an array of conductors bonded to a thin dielectric film. Example dielectric films include polyimide, polyvinylidene fluoride (PVDF) or other biocompatible materials to name a few. Such leads are particularly suitable for stimulation of the spinal anatomy, more particularly suitable for stimulation of specific nerve anatomies, such as the dorsal root (optionally including the dorsal root ganglion).

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

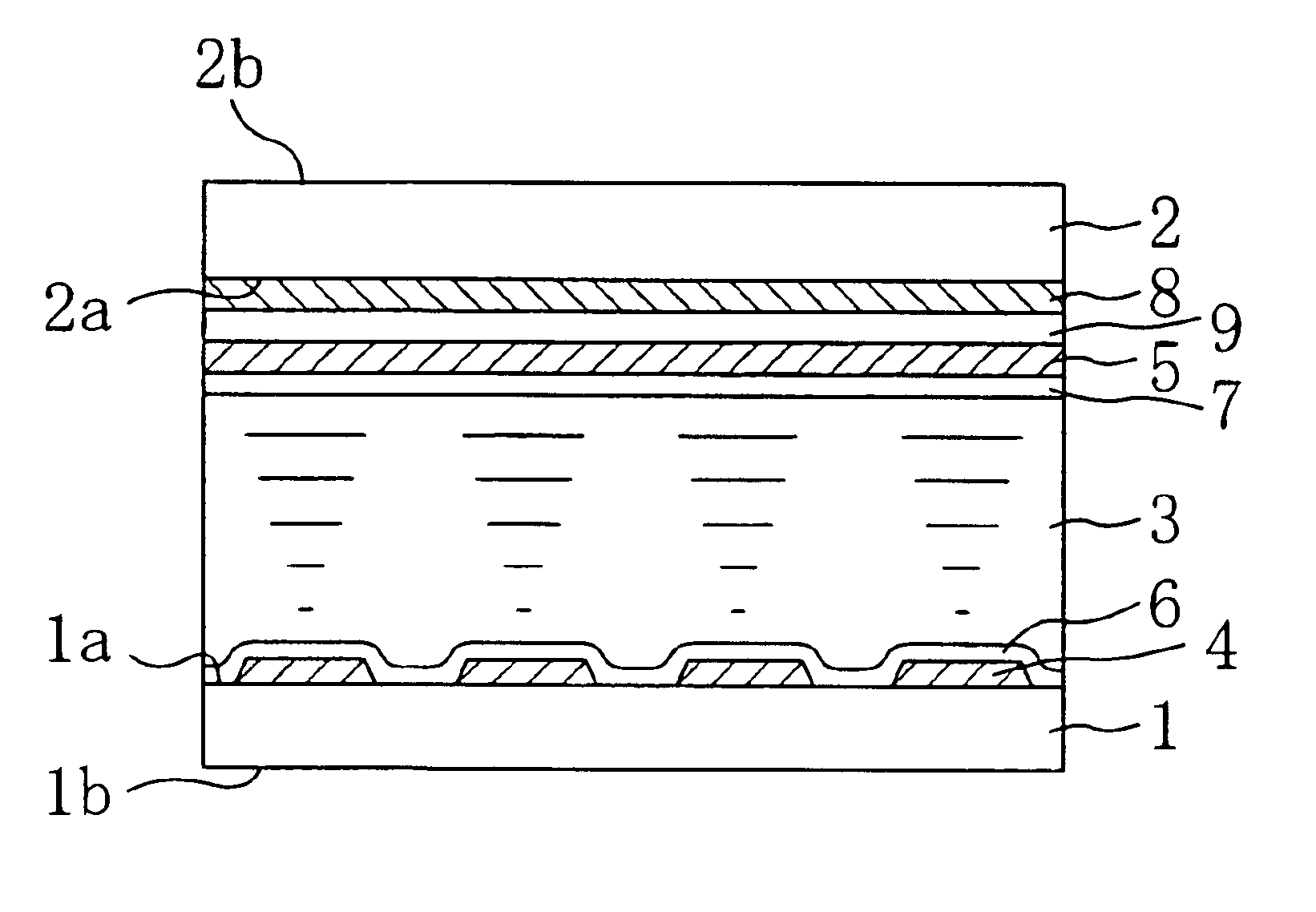

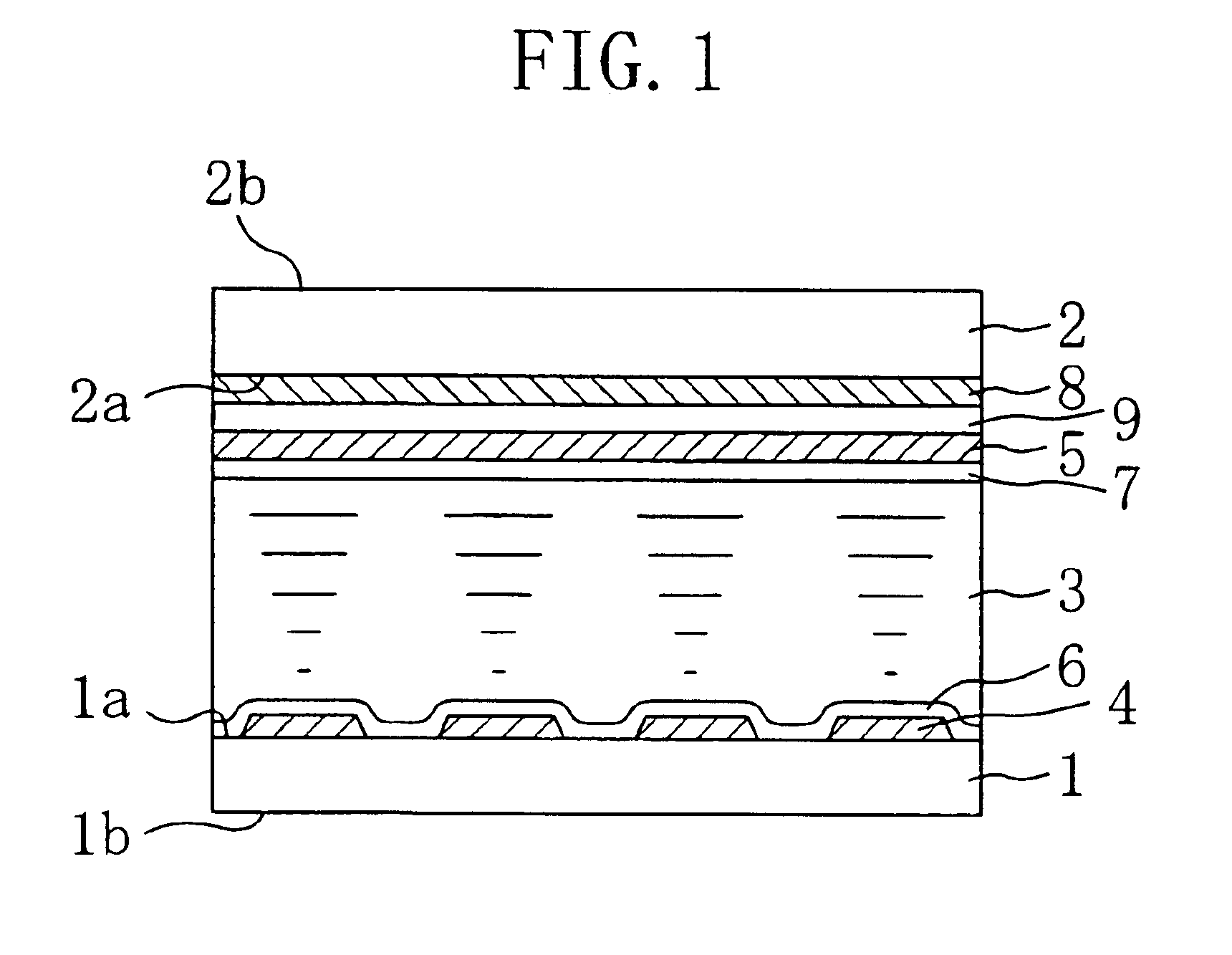

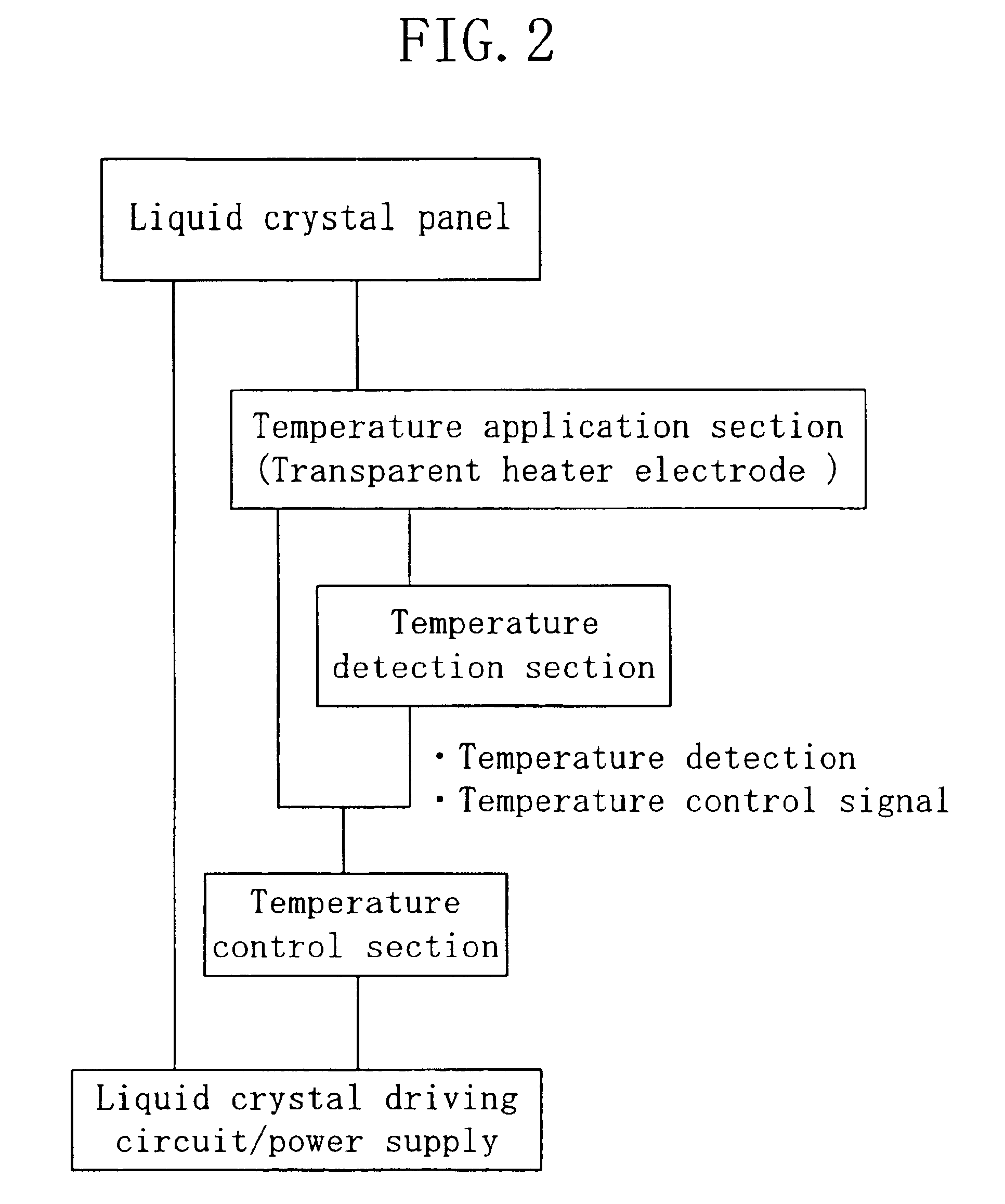

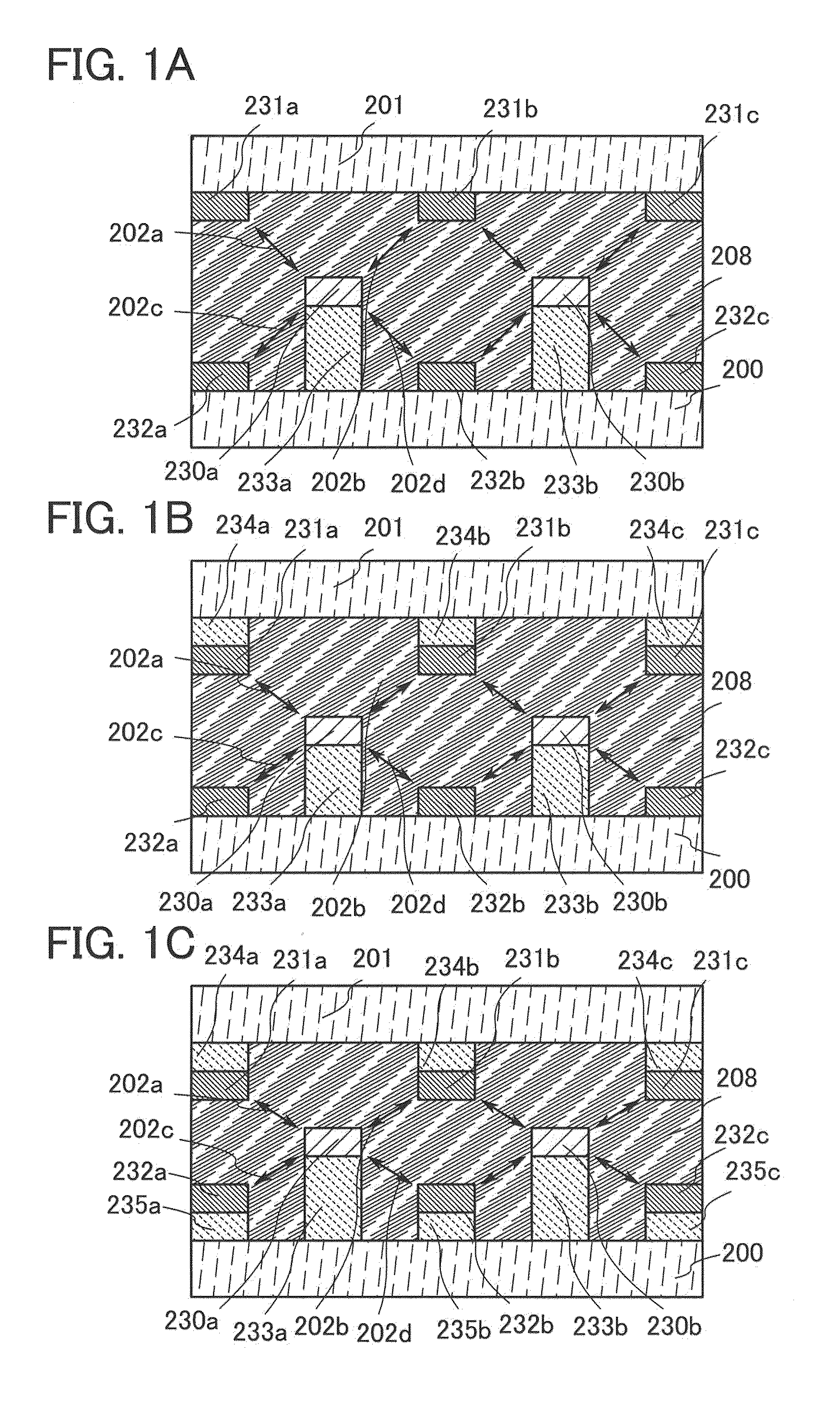

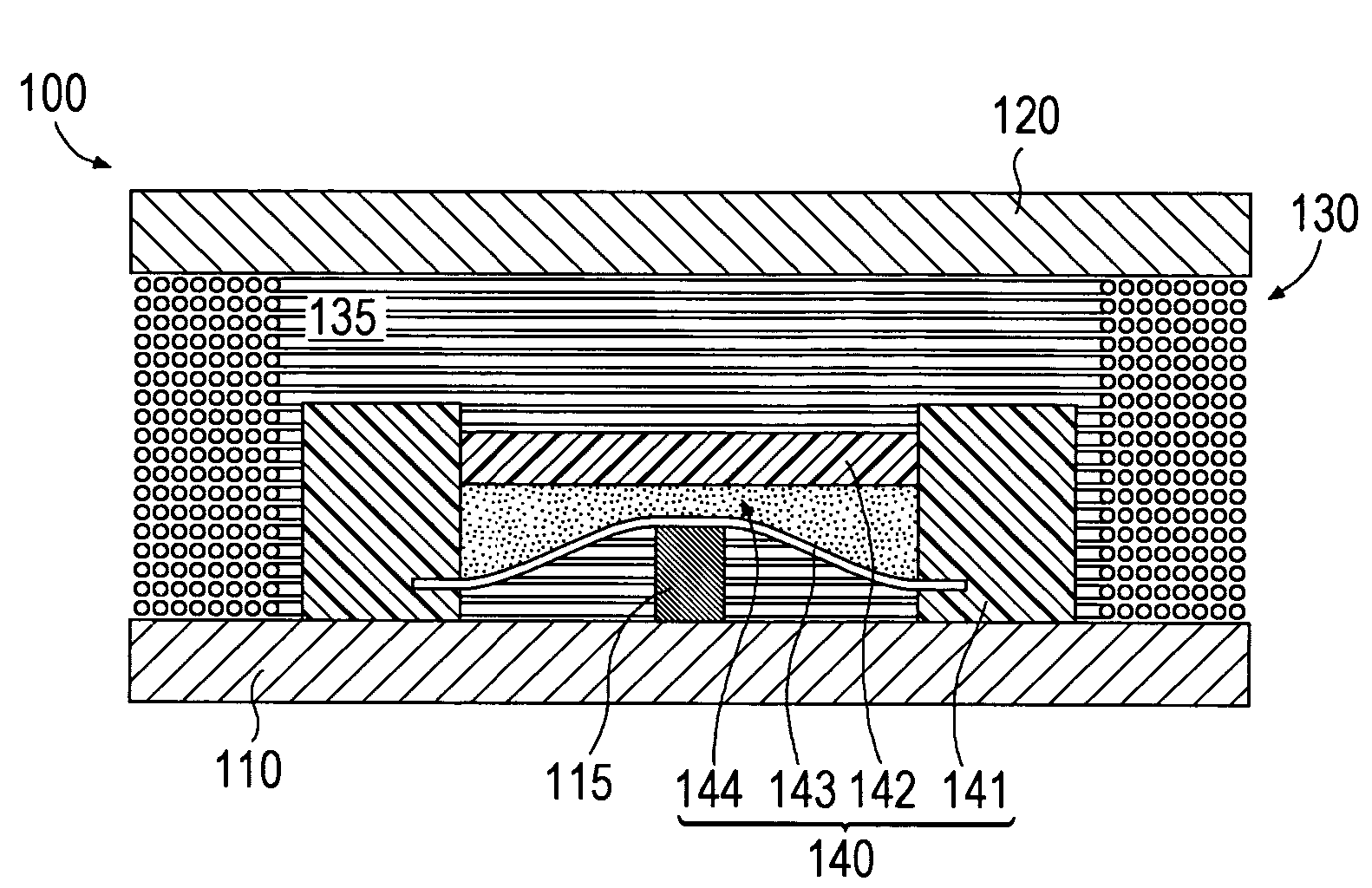

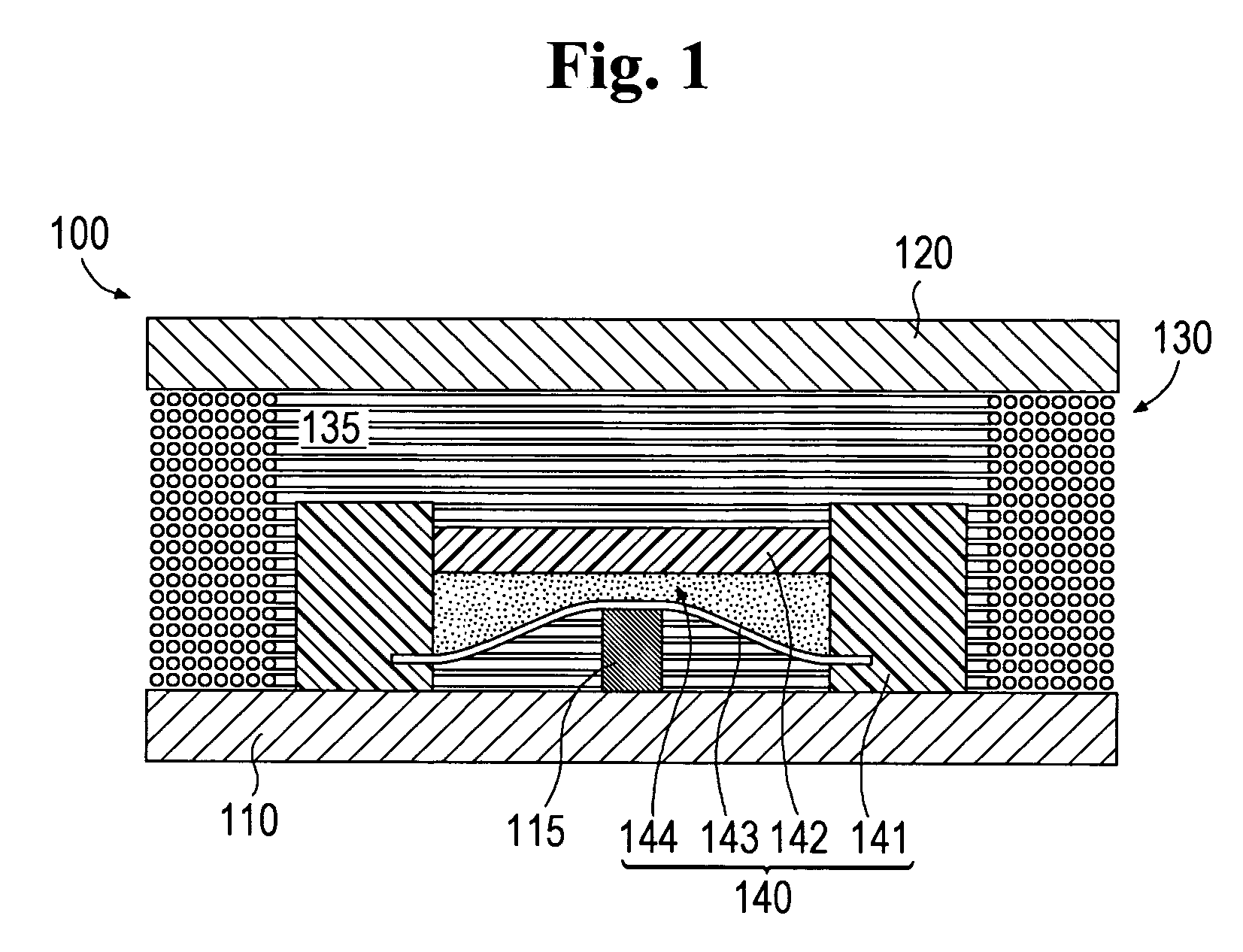

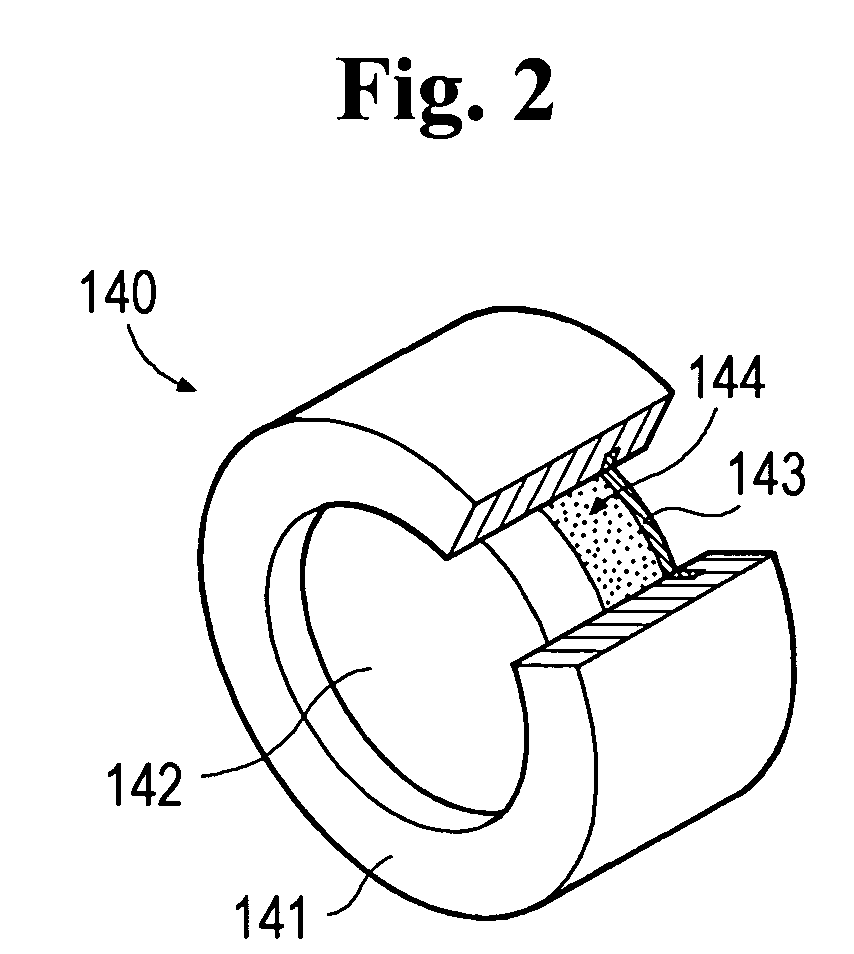

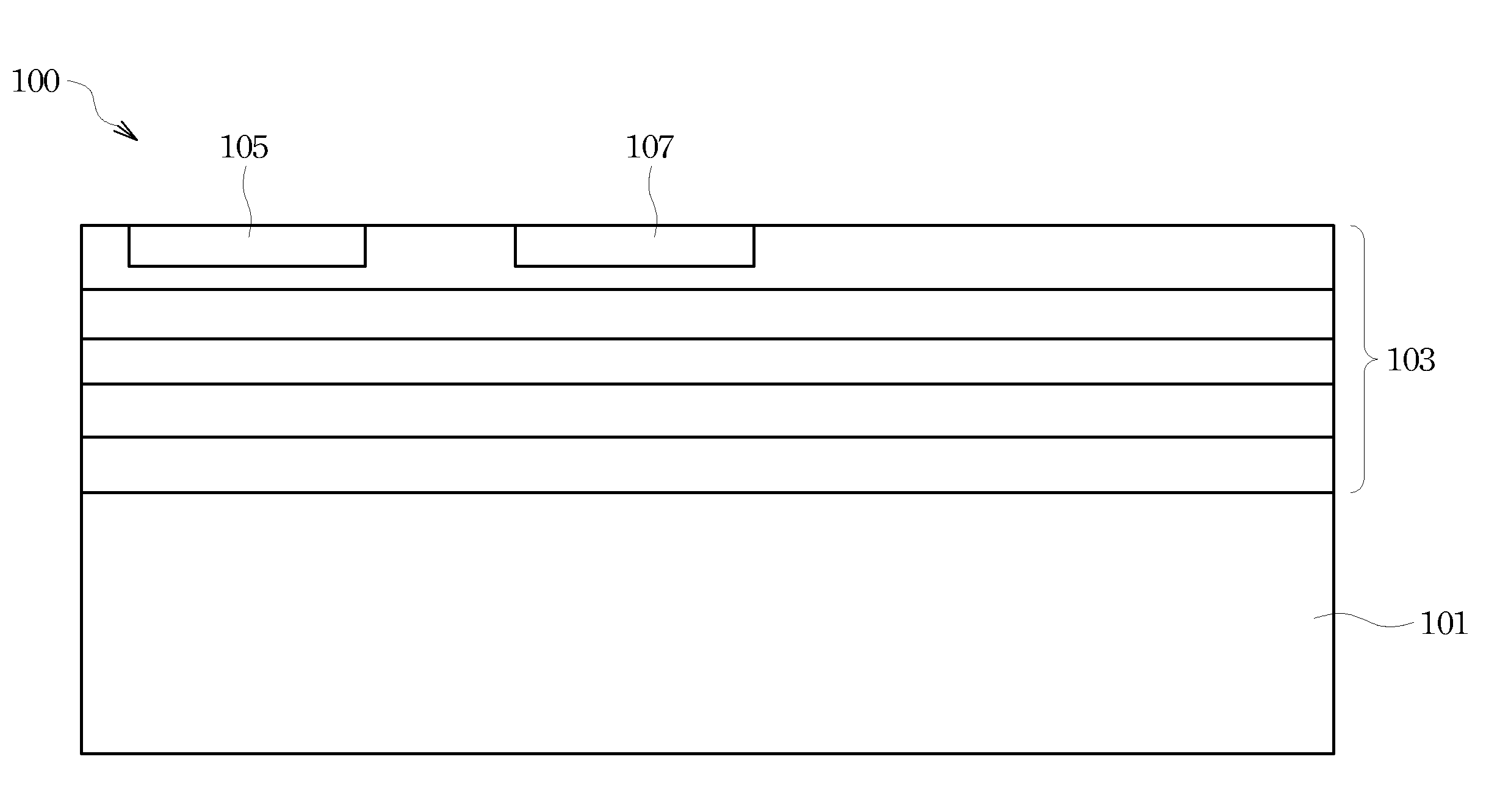

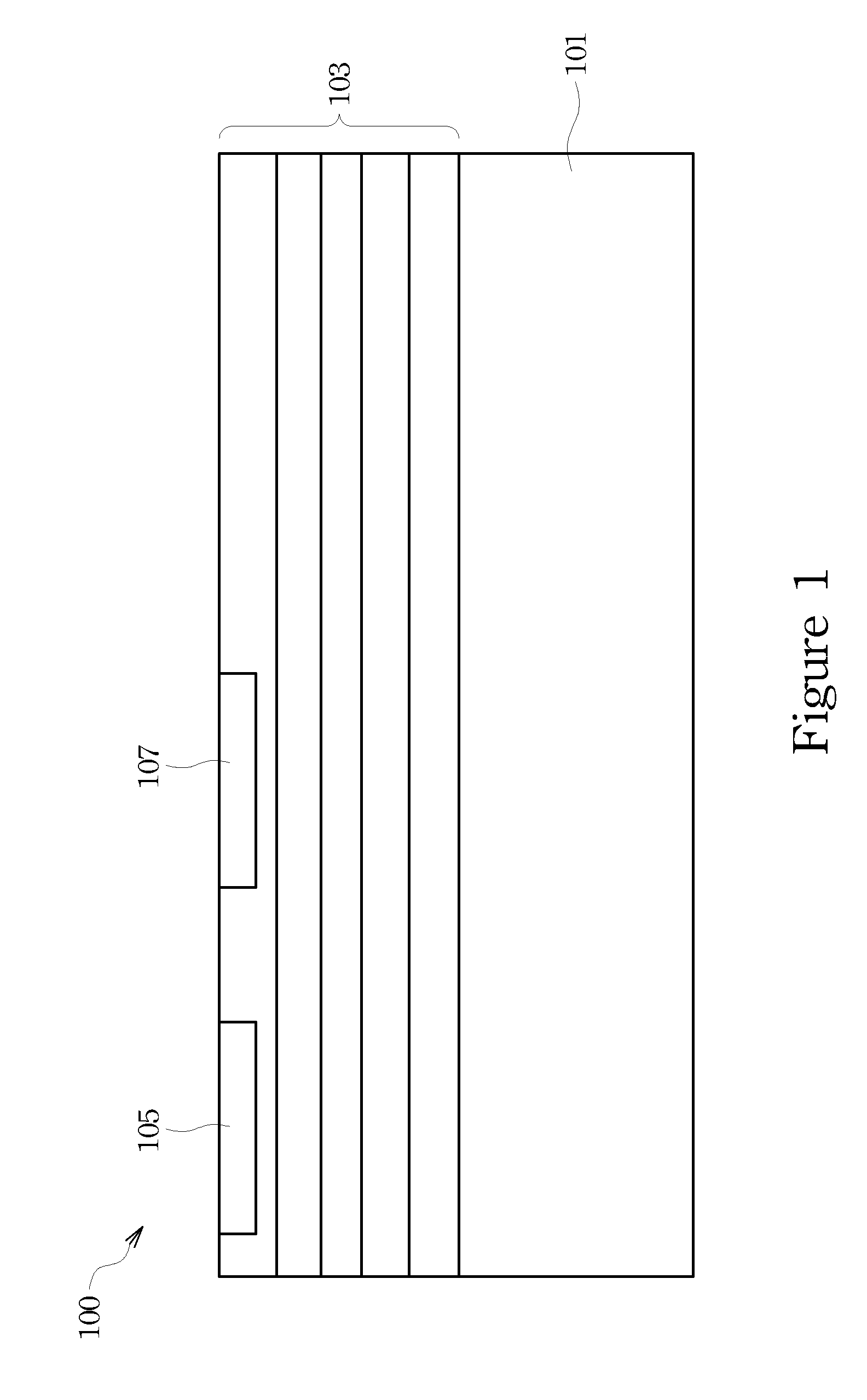

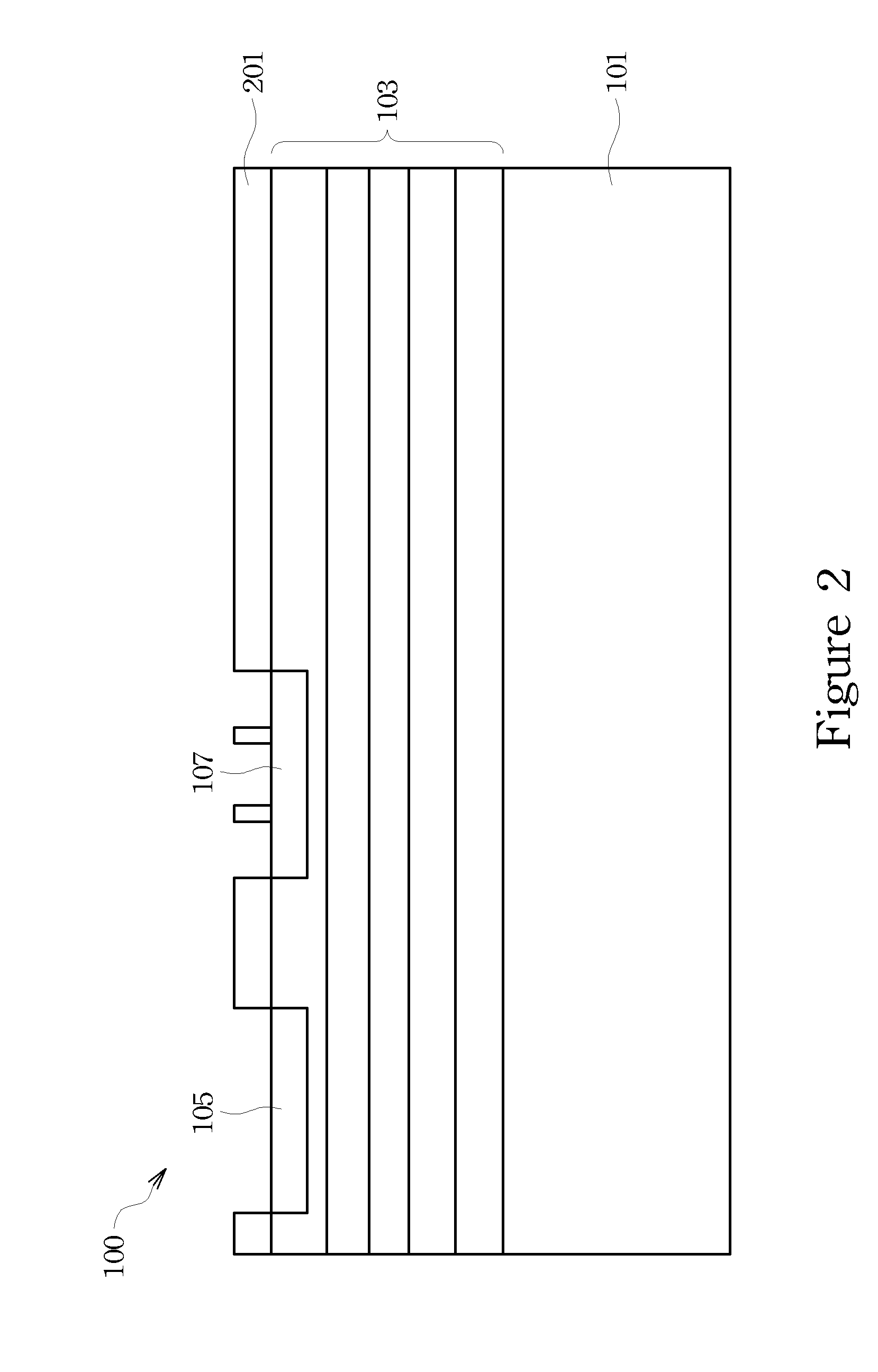

Liquid crystal display device, image shifting device, and image display apparatus

ActiveUS6885412B2Quality improvementQuick responseLiquid crystal compositionsTelevision system detailsLiquid-crystal displayEngineering

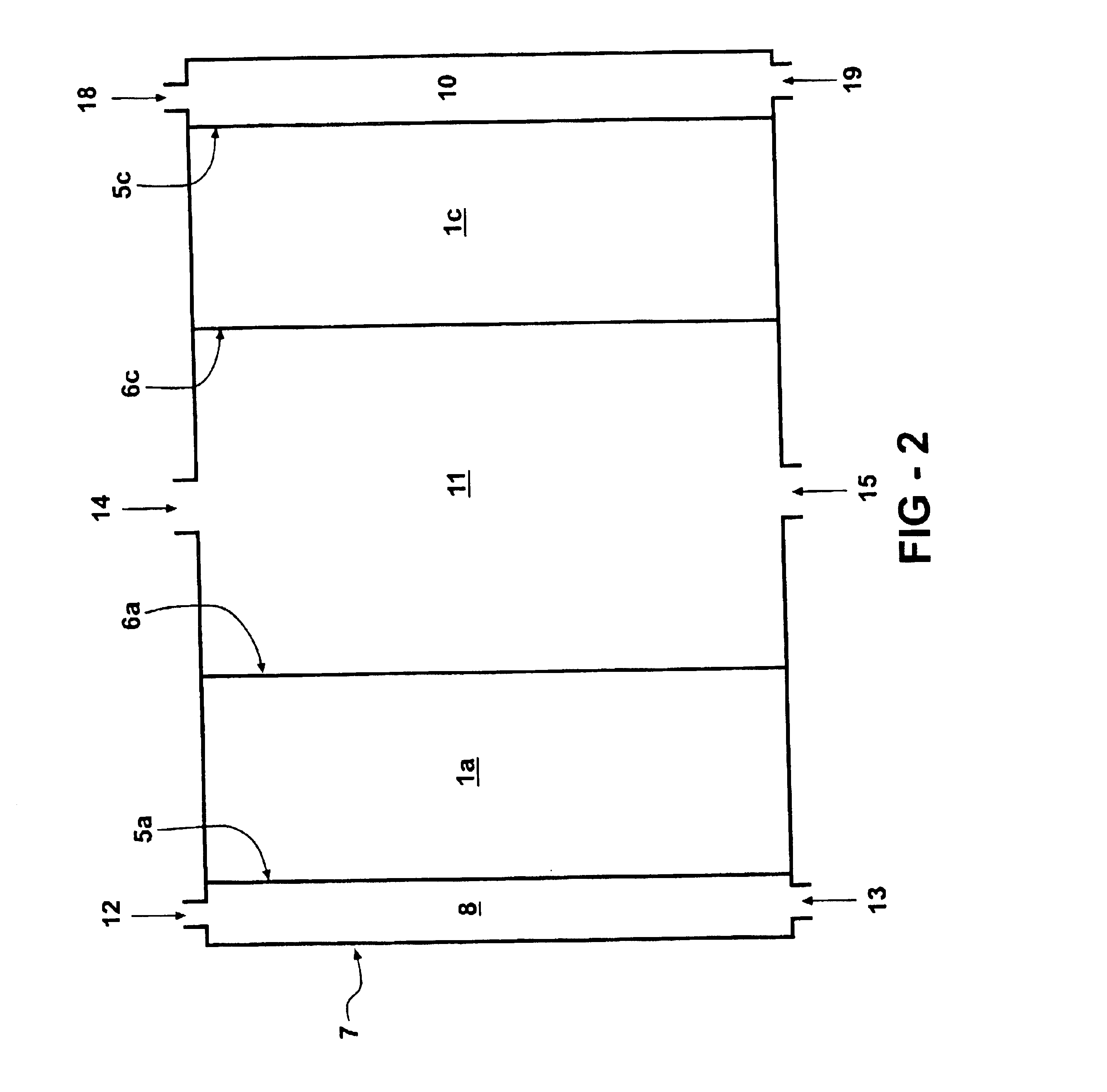

A liquid crystal display device includes a first substrate, a second substrate opposing the first substrate, a liquid crystal layer provided in a gap between the first substrate and the second substrate, and a temperature adjustment member formed on the first substrate and / or the second substrate. The panel temperature T (° C.) of the liquid crystal display device is controlled to be equal to or greater than TNI-65 and less than or equal to TNI-15, where TNI (° C.) is the nematic-isotropic phase transition temperature of the liquid crystal composition of the liquid crystal layer.

Owner:SHARP KK

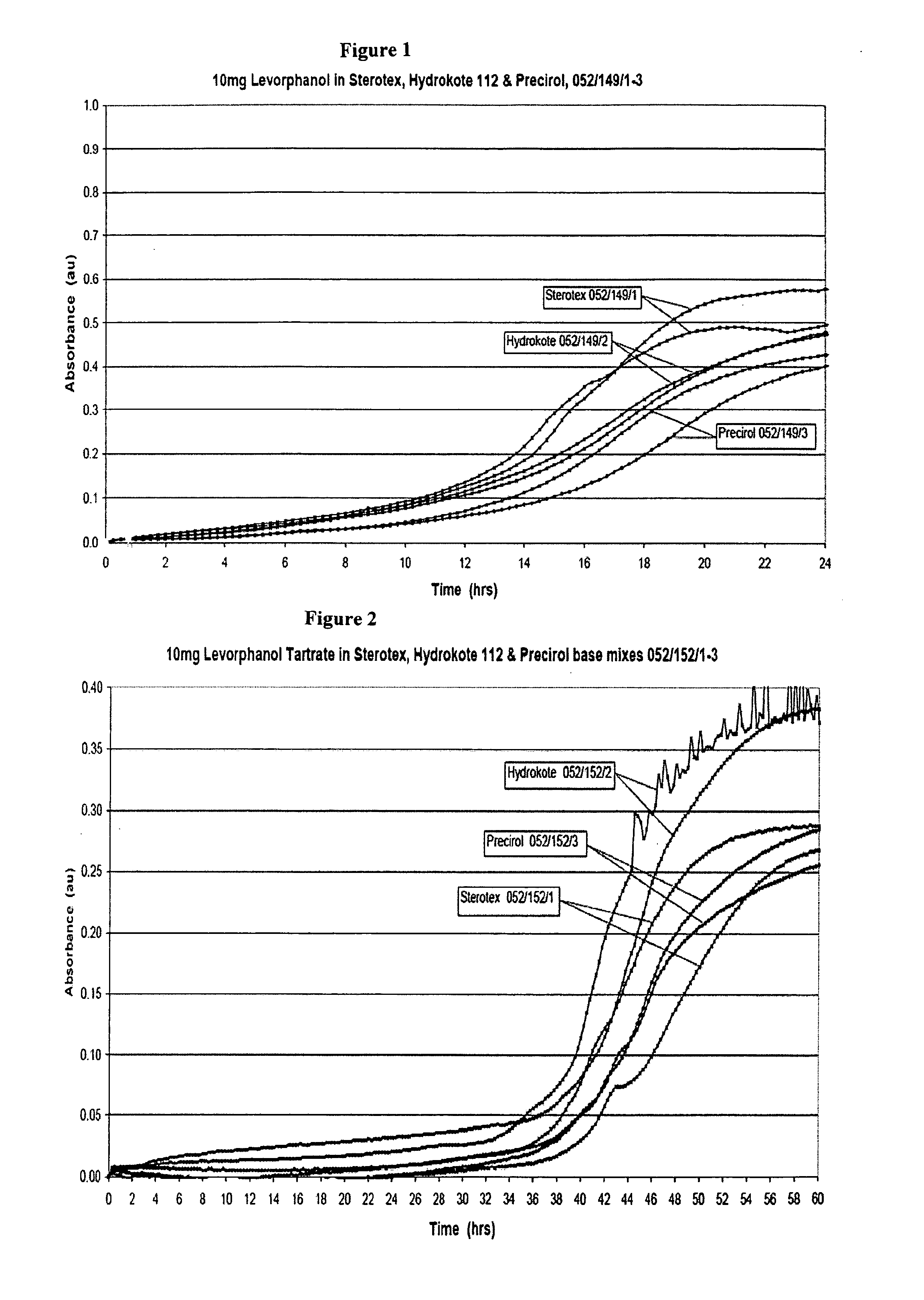

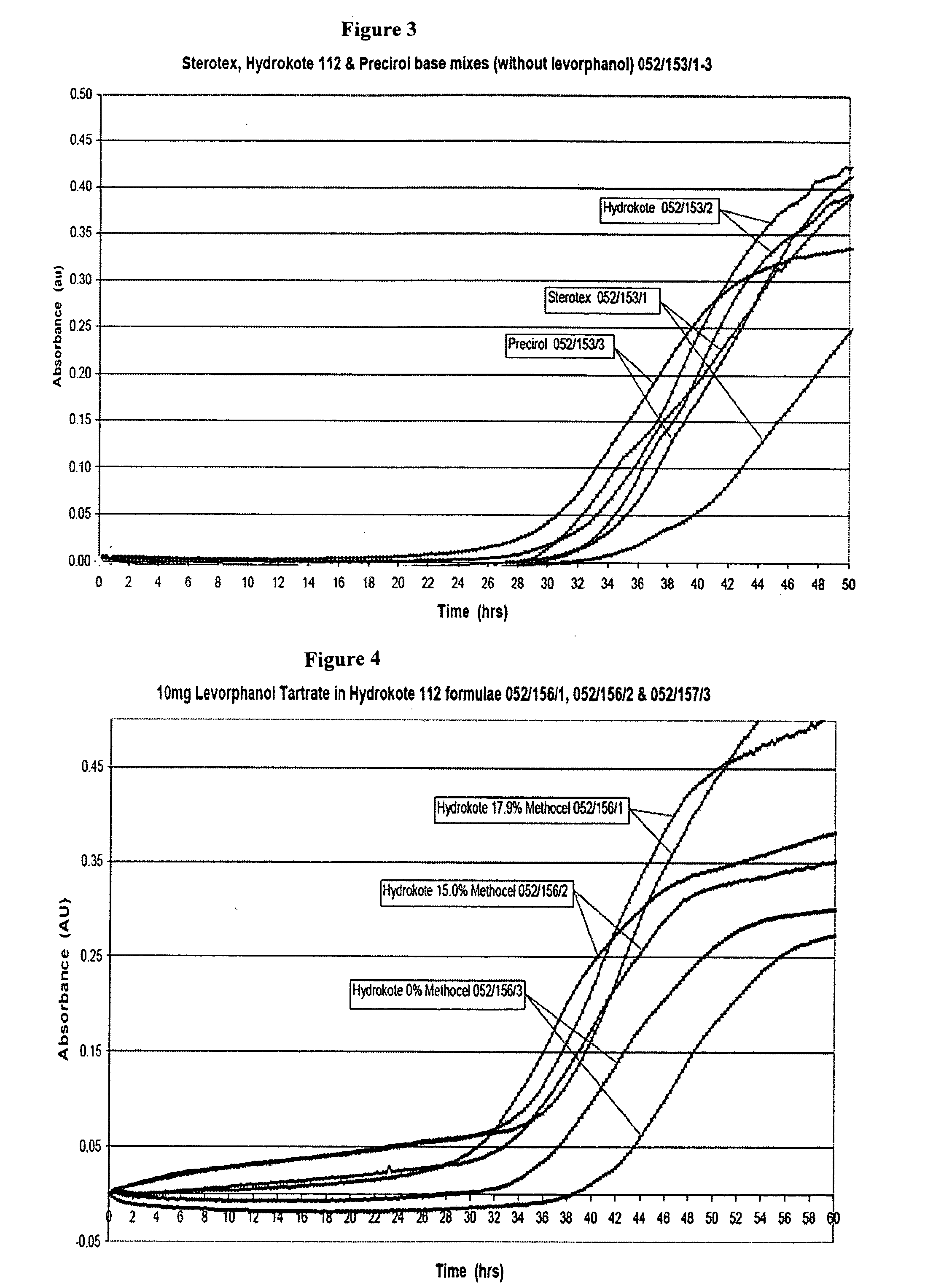

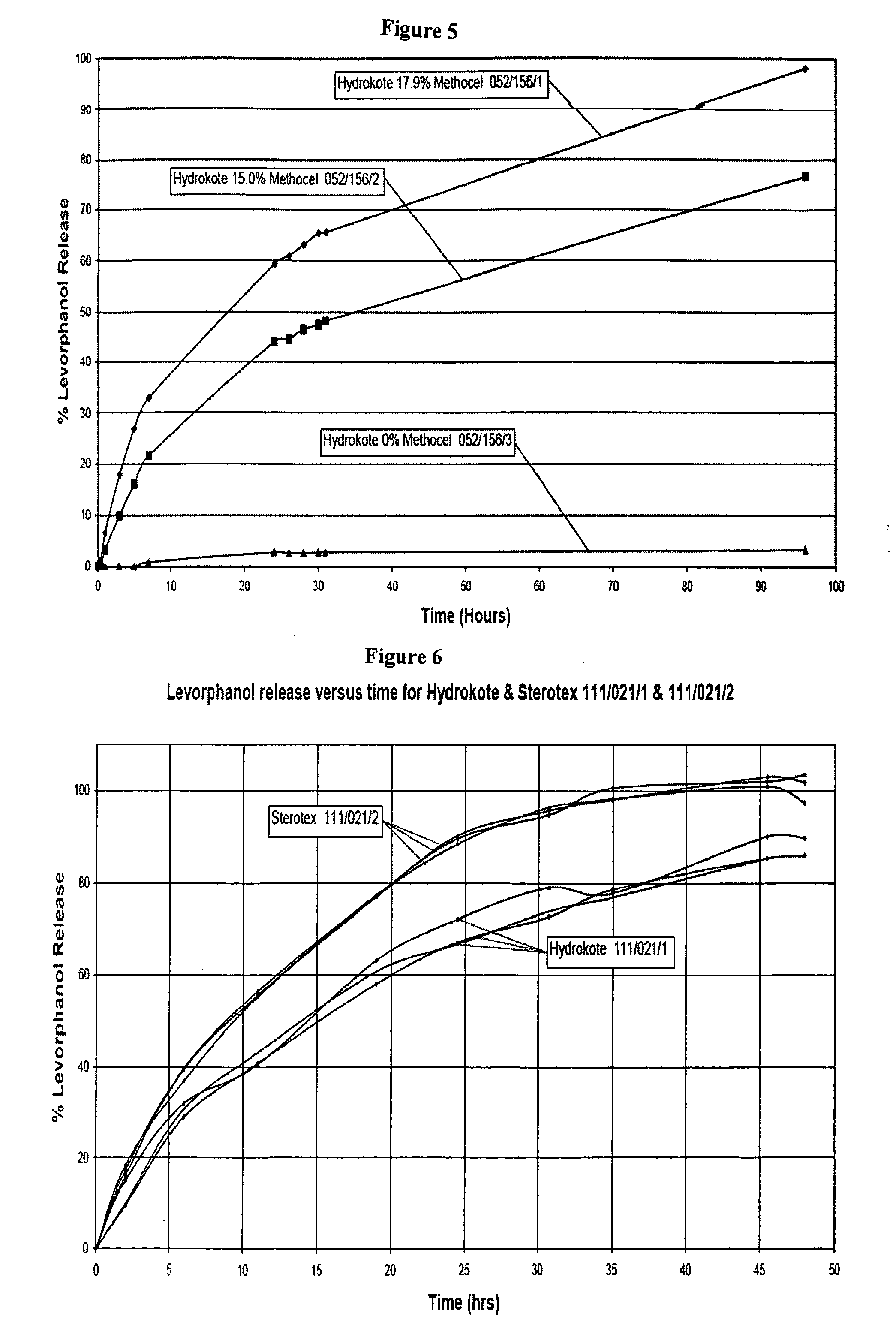

Extended Release Oral Pharmaceutical Compositions of 3-Hydroxy-N-Methylmorphinan and Method of Use

InactiveUS20120065221A1Increased CmaxSufficient bioavailabilityBiocideNervous disorder3-Hydroxy-N-methylmorphinanExtended Release Dosage Form

The present invention is directed to oral, therapeutically effective extended release pharmaceutical compositions of 3-hydroxy-N-methylmorphinan, including delayed onset, extended release dosage forms and the use thereof.

Owner:RELMADA THERAPEUTICS

Implantable flexible circuit leads and methods of use

InactiveUS9314618B2Easy to manufactureStrong specificitySpinal electrodesDiagnostic recording/measuringDielectricAnatomical structures

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG SMI S A R L SJM LUX SMI

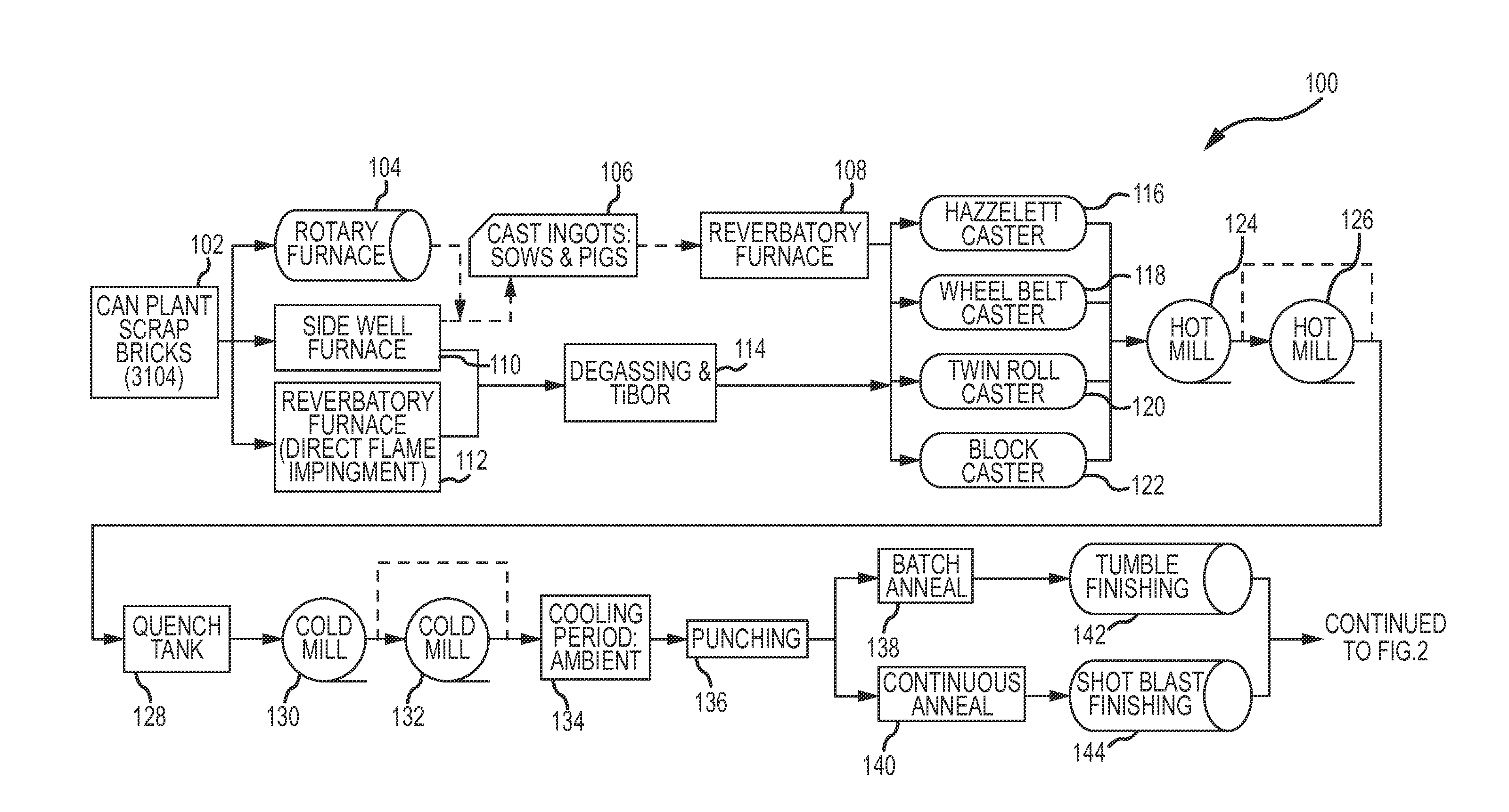

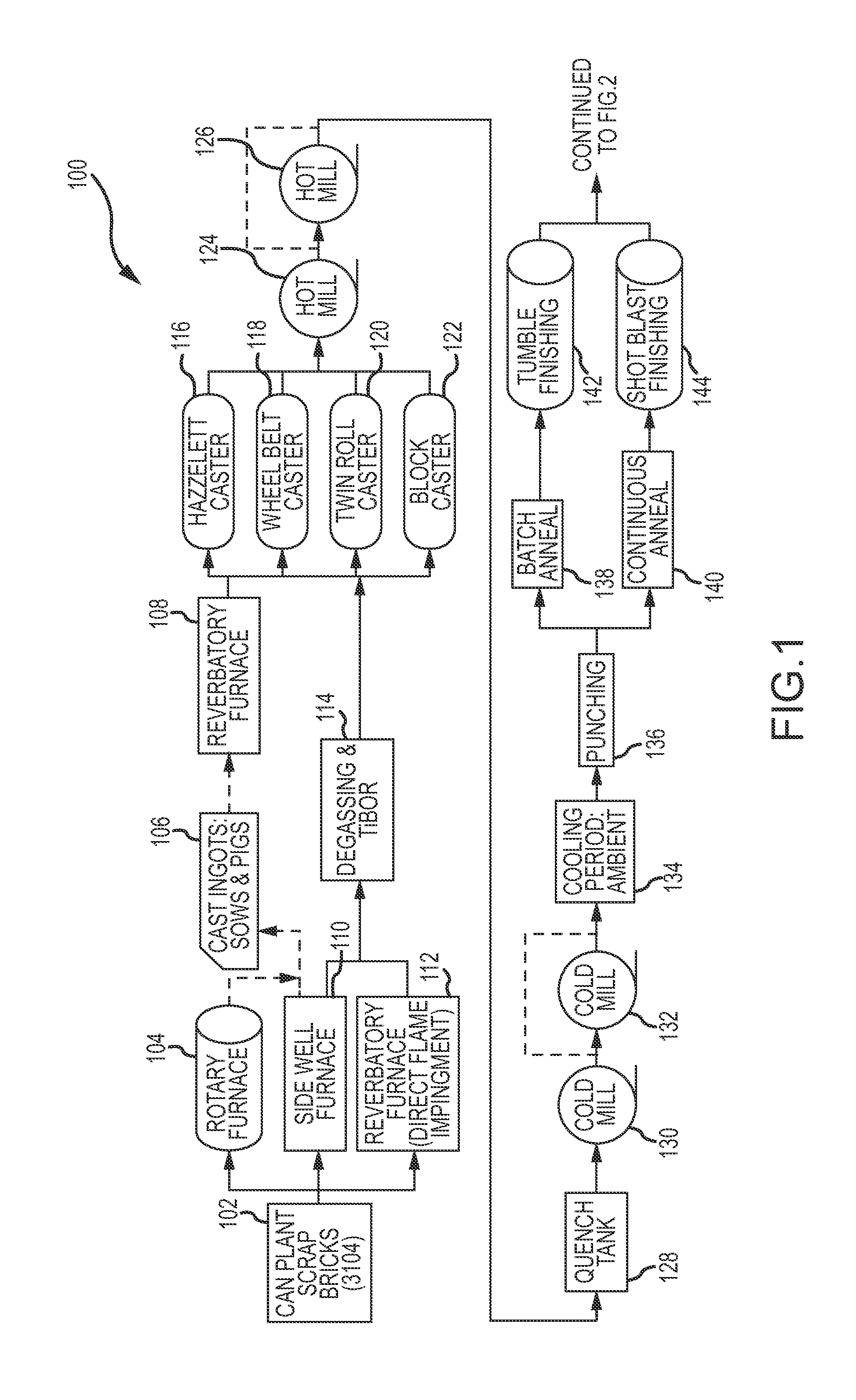

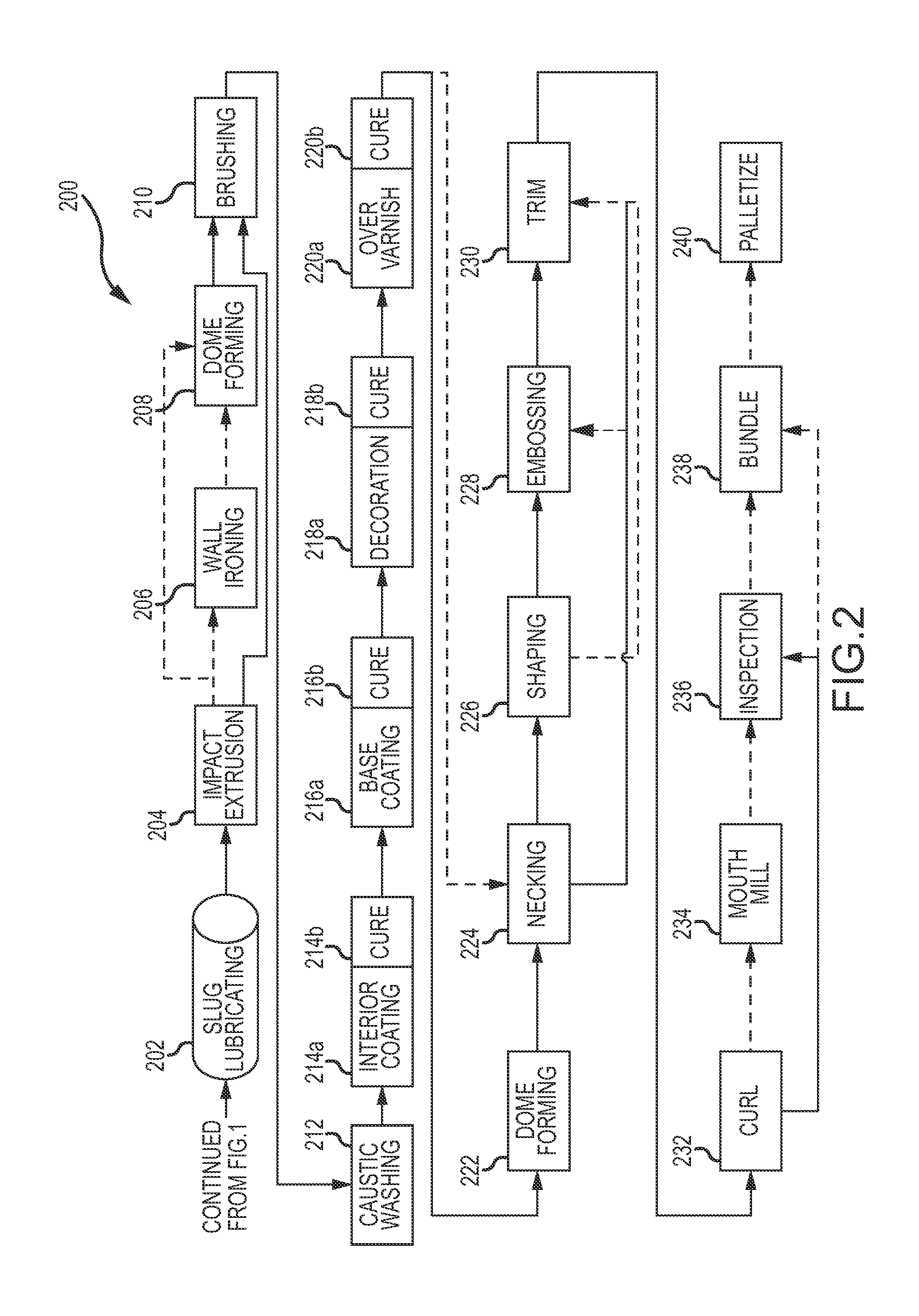

Impact extruded containers from recycled aluminum scrap

ActiveUS20130068352A1Increase resistanceReduction in weight and metal contentLiquid dispensingScrapEnvironmentally friendly

Novel aluminum alloys are provided for use in an impact extrusion manufacturing process to create shaped containers and other articles of manufacture. In one embodiment blends of recycled scrap aluminum are used in conjunction with relatively pure aluminum to create novel compositions which may be formed and shaped in an environmentally friendly process. Other embodiments include methods for manufacturing a slug material comprising recycled aluminum for use in the impact extraction process.

Owner:BALL CORP

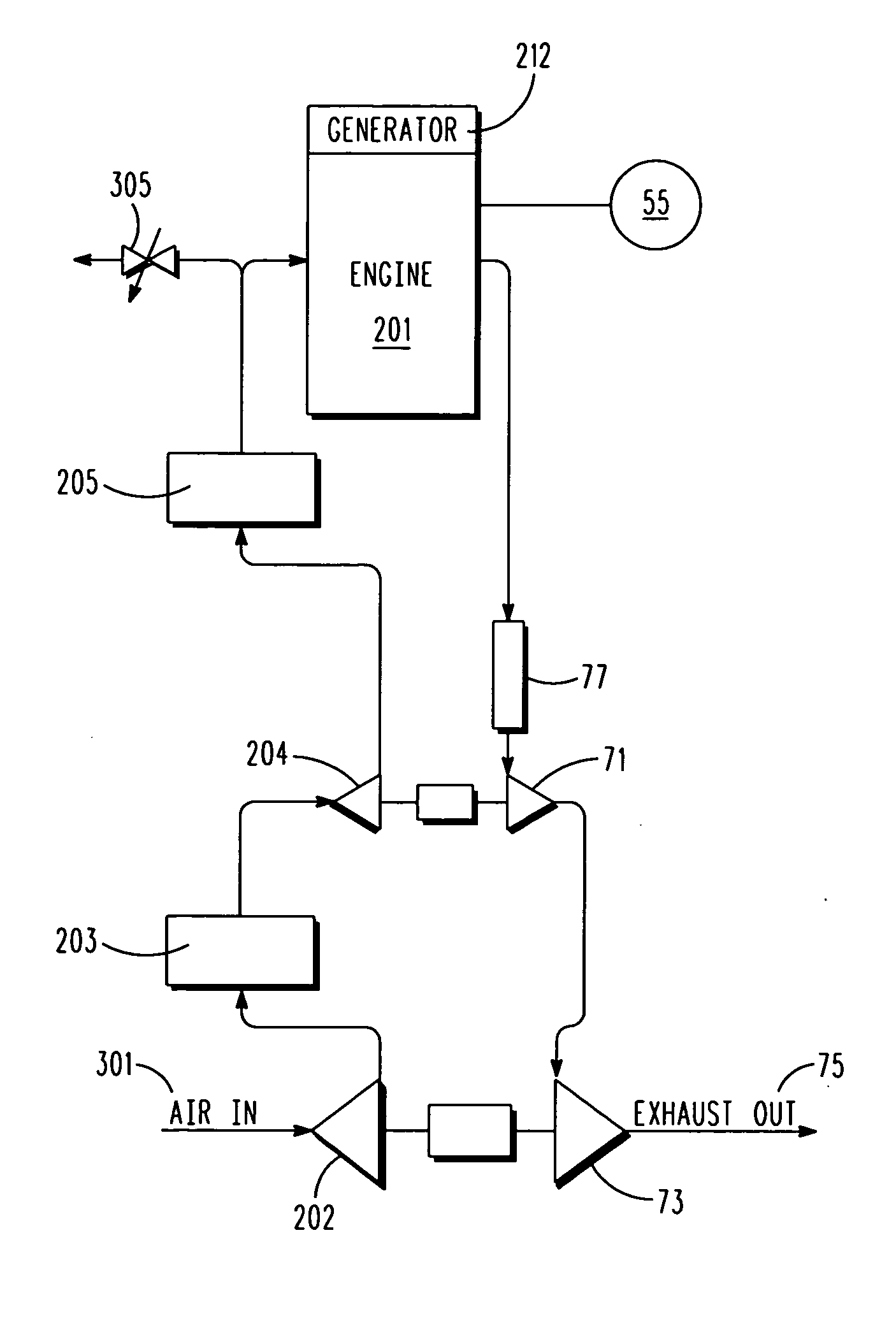

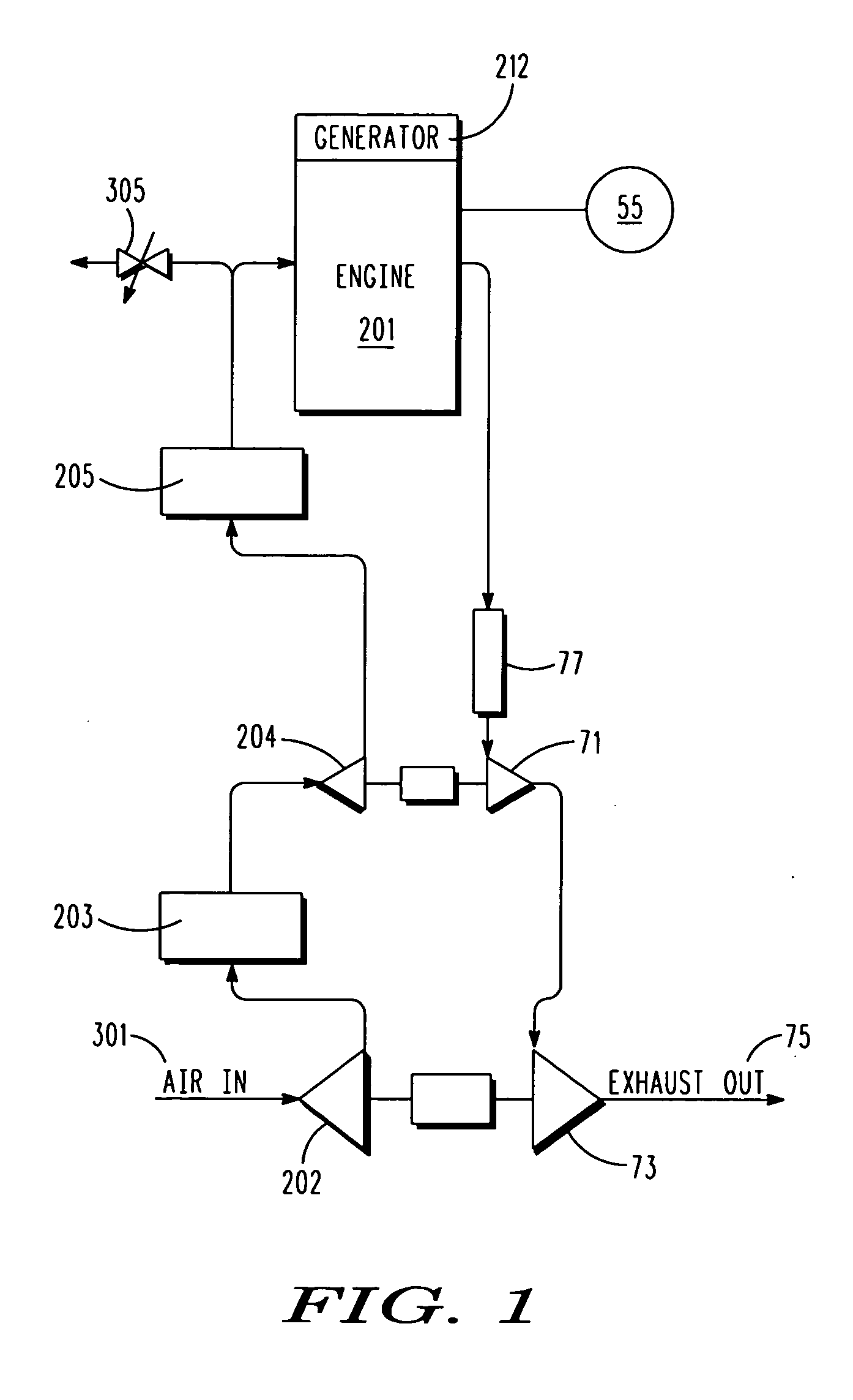

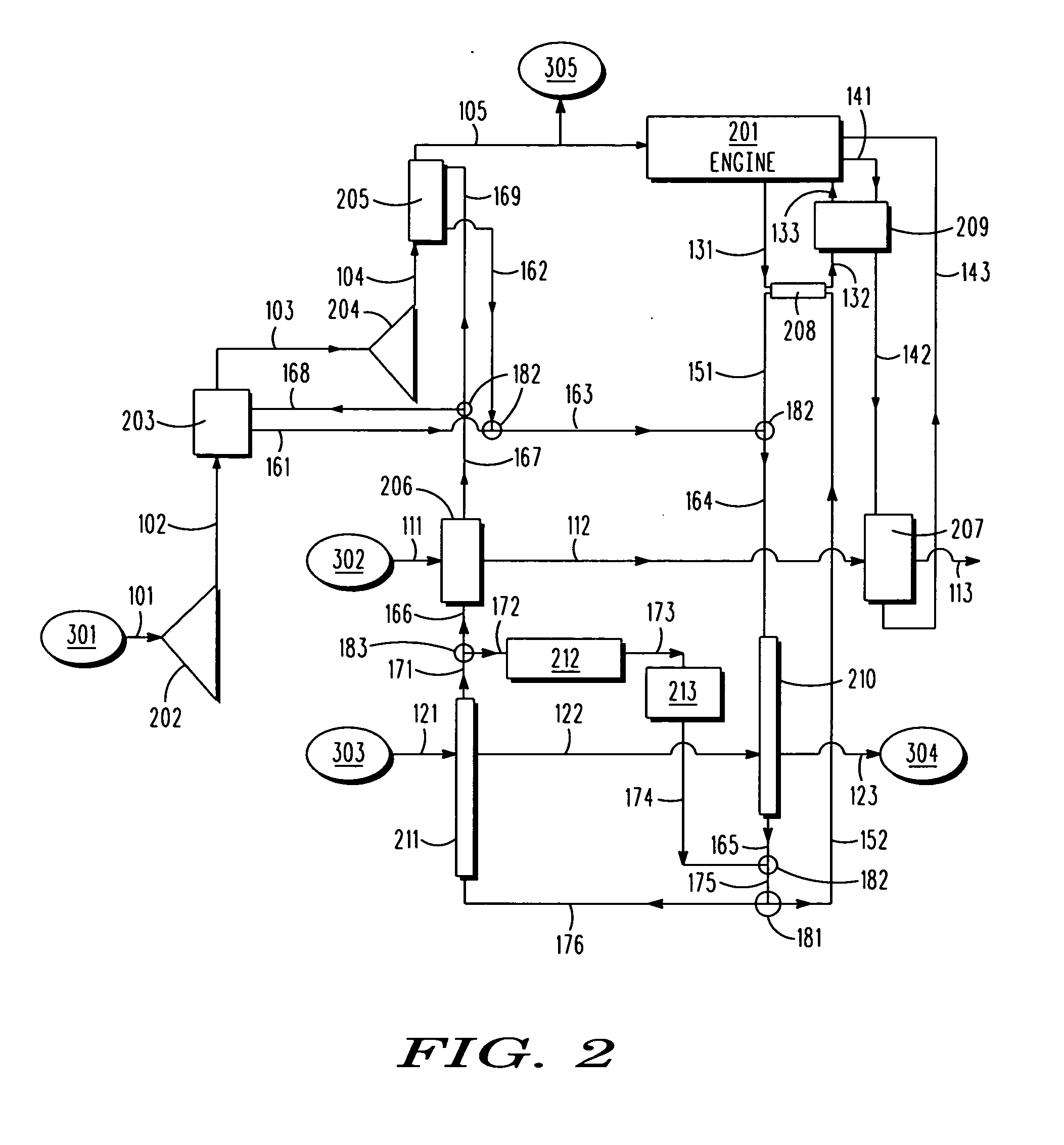

Cold fuel cooling of intercooler and aftercooler

ActiveUS20130074812A1Reduce power consumptionNone have achieved superiorInternal combustion piston enginesPower plant arrangements/mountingTurbochargerNuclear engineering

Owner:AEROVIRONMENT INC

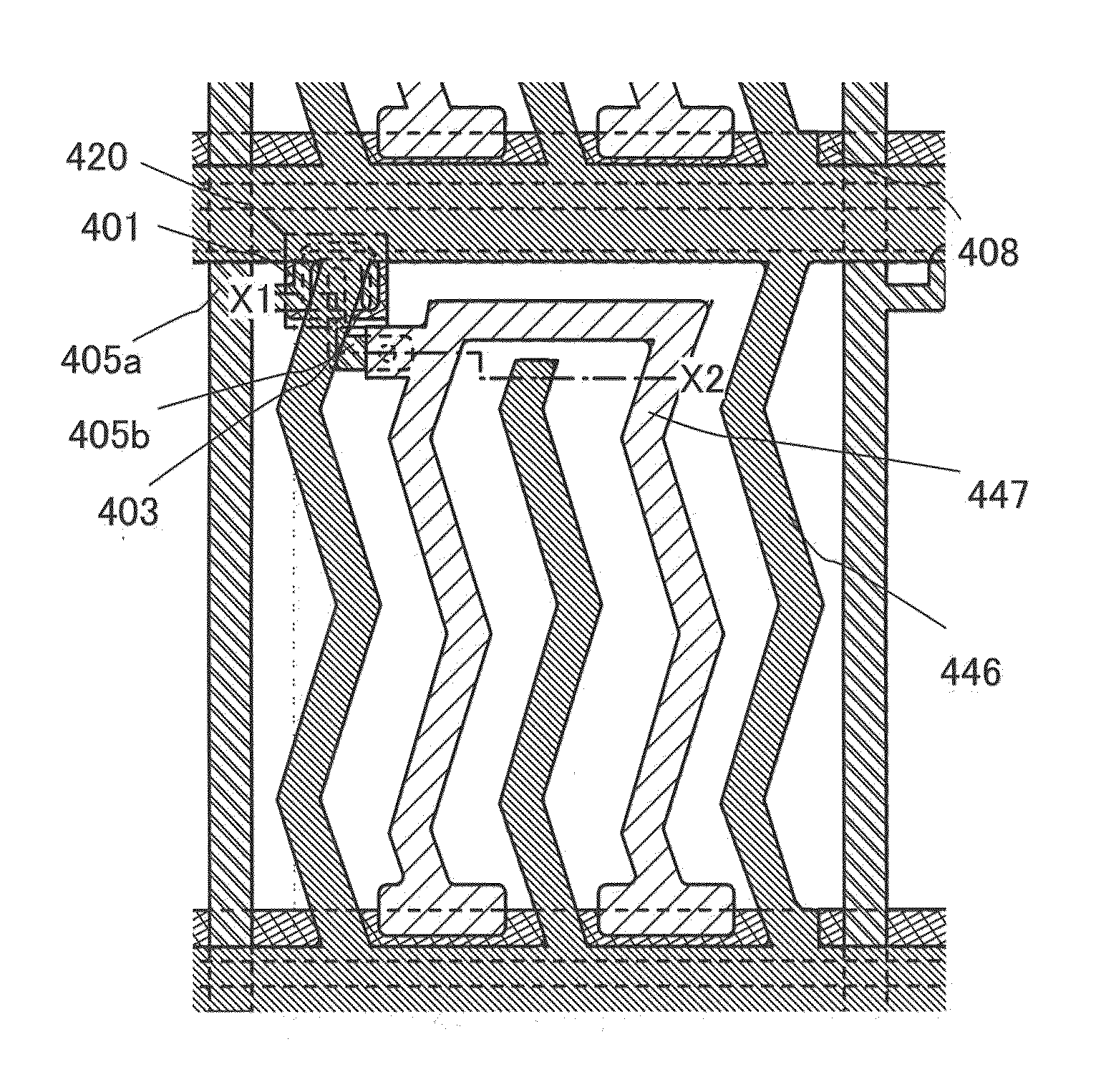

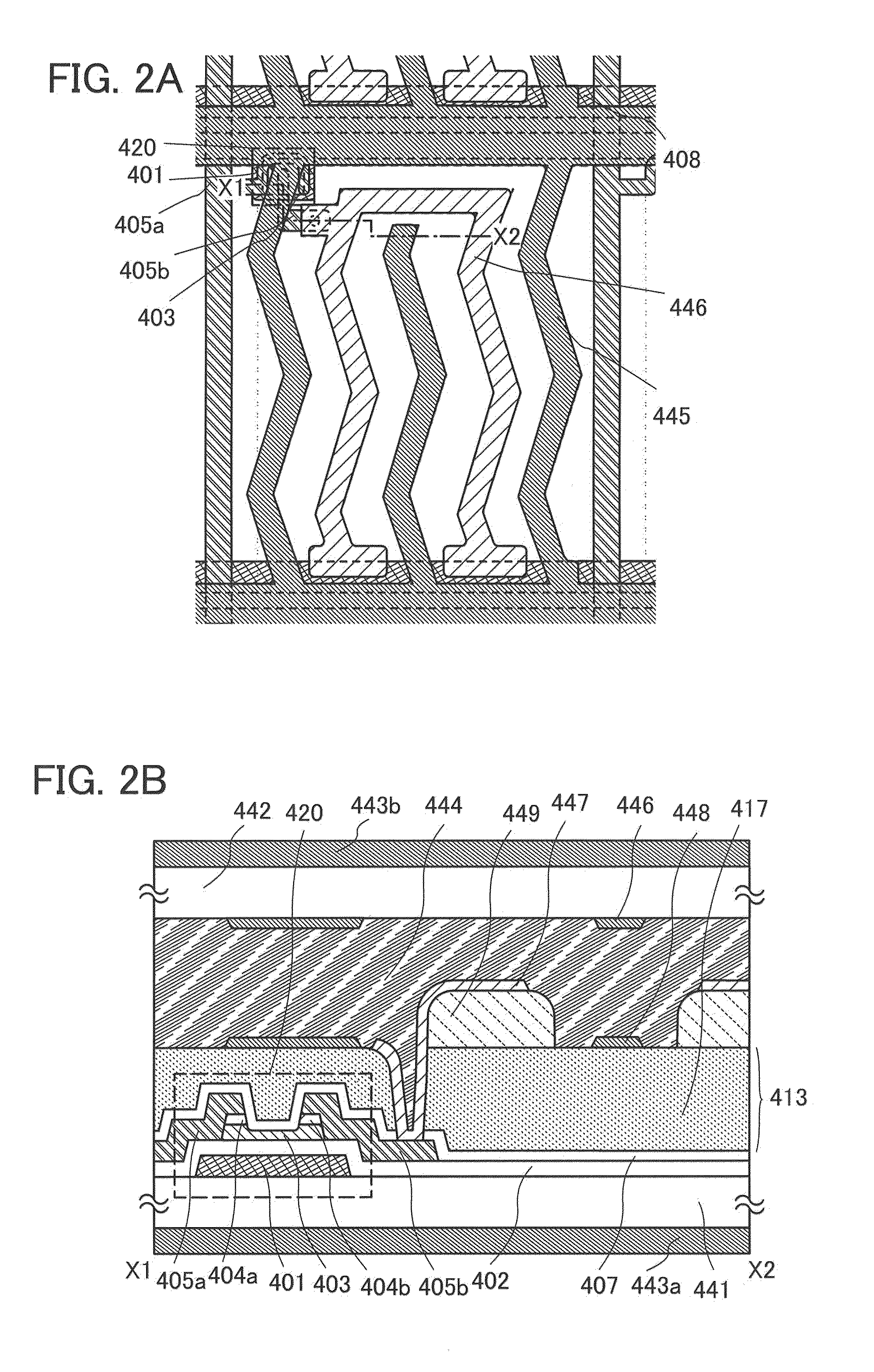

Liquid crystal display device

ActiveUS20100195028A1Improve transmittanceIncrease contrastNon-linear opticsLiquid crystal moleculeBlue phase liquid crystal

In a liquid crystal display device including a blue phase liquid crystal layer, first and second common electrode layers, which are positioned to face each other, sandwich the blue phase liquid crystal layer therebetween and have opening patterns (slits), and a pixel electrode layer has an opening pattern. The pixel electrode layer is formed over a structure body which projects into the liquid crystal layer from a surface of a first substrate on a liquid crystal layer side, and the pixel electrode layer is positioned between the first and second common electrode layers in the liquid crystal layer. Electric fields are applied between the pixel electrode layer and the first and second common electrode layers, so that the electric fields are formed in the entire liquid crystal layer and liquid crystal molecules can be controlled by using the electric fields.

Owner:SEMICON ENERGY LAB CO LTD

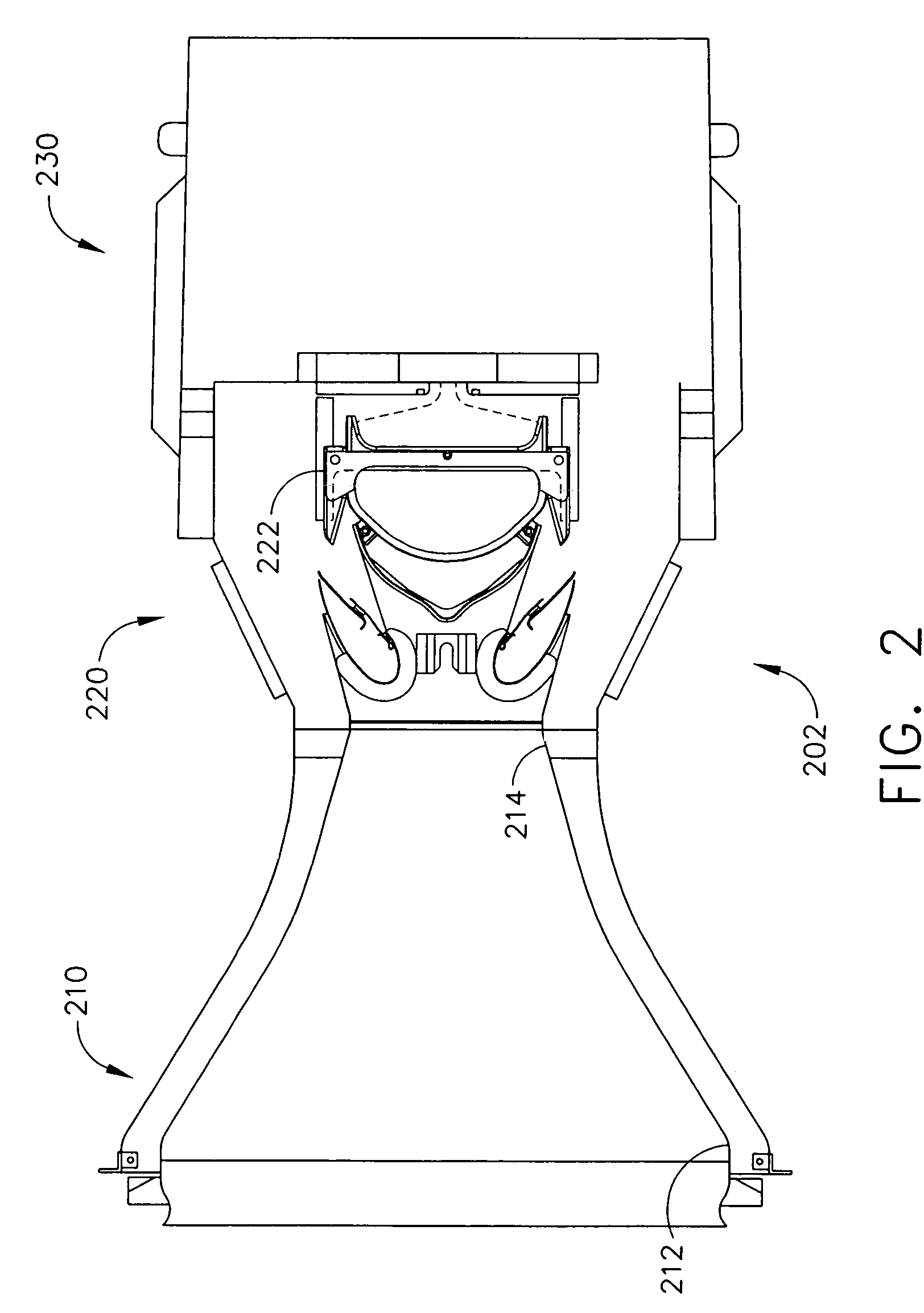

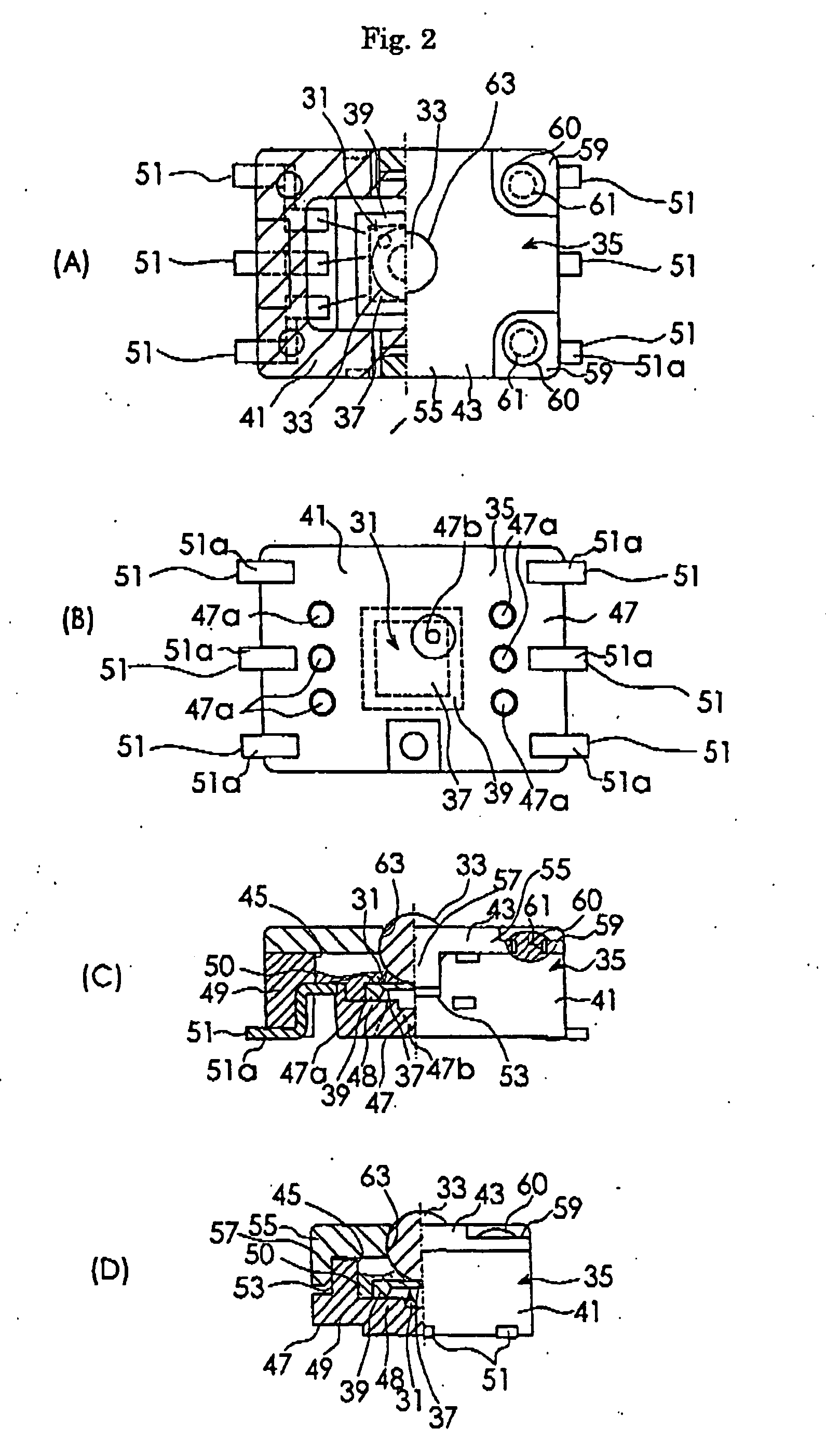

Micro power generator and apparatus for producing reciprocating movement

InactiveUS7329959B2Improve output and efficiencyExtended temperature rangeSteam useGas turbine plantsReciprocating motionEngineering

There is provided a micro power generator enhanced in efficiency and power generation output, and having an increased temperature range for operation. The micro power generator comprises: a high-temperature heat source; a low-temperature heat source; an enclosed body containing a working substance therein, the enclosed body being deformable by means of a phase change of the working substance between a first shape wherein heat can be transferred from the high-temperature heat source and a second shape wherein heat can be transferred to the low-temperature heat source; a permanent magnet constituting the enclosed body, the permanent magnet being maintained in a first position when the enclosed body has the first shape and in a second position when the enclosed body has the second shape; and a wire in which an electric current is induced by a movement of the permanent magnet. Further, the present invention provides an apparatus for producing a reciprocating movement between two heat sources having a temperature difference therebetween.

Owner:KOREA INST OF SCI & TECH

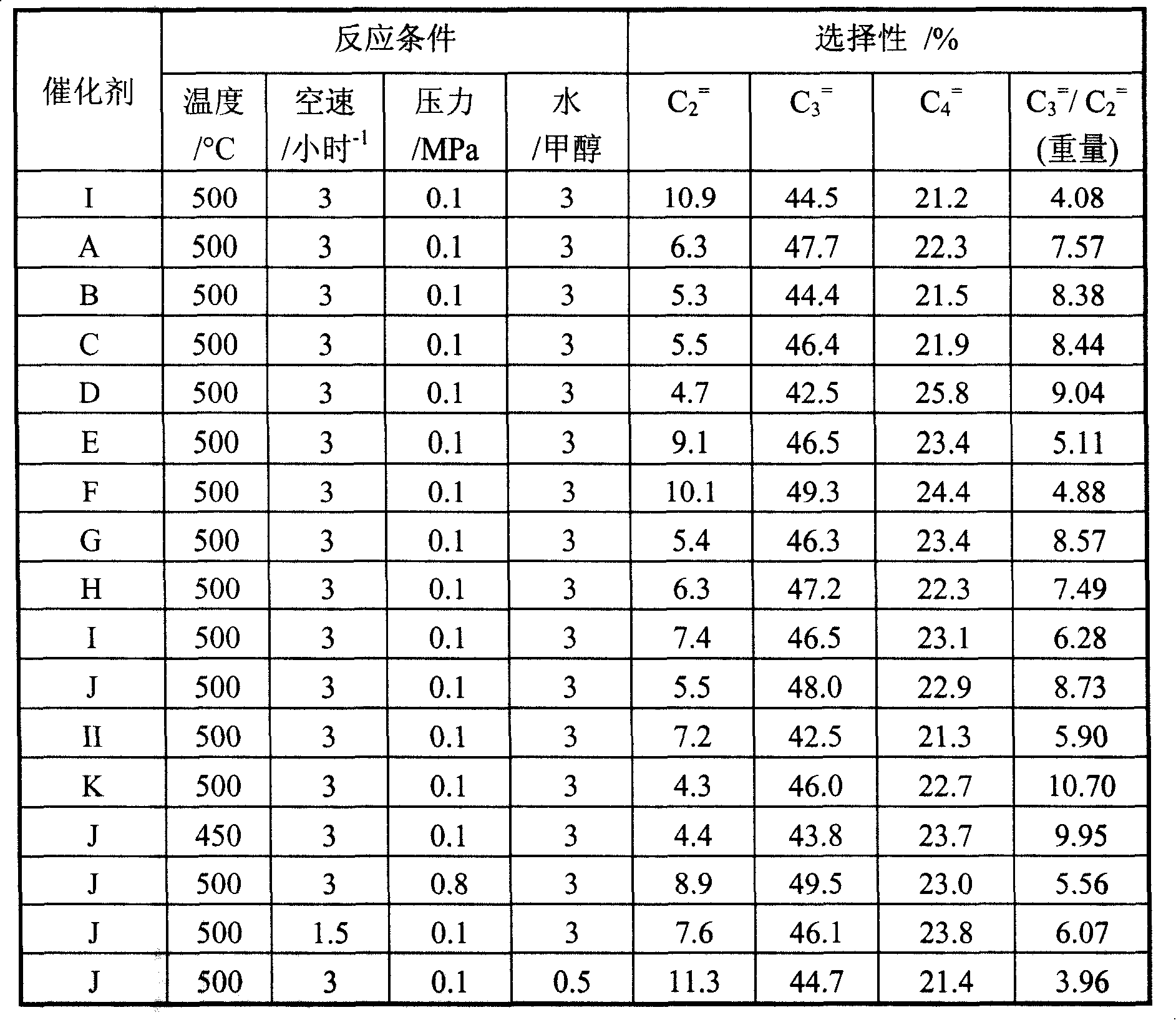

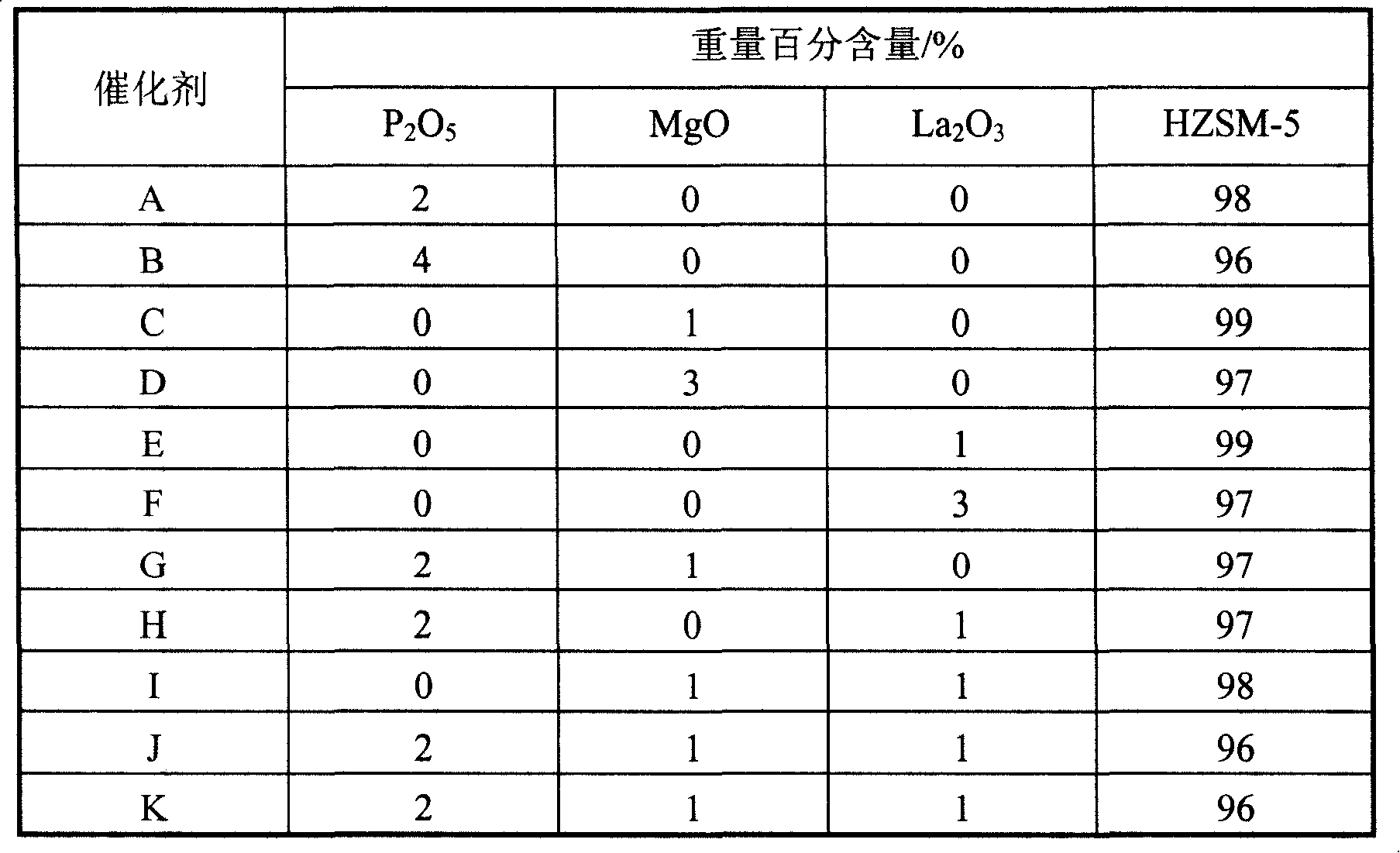

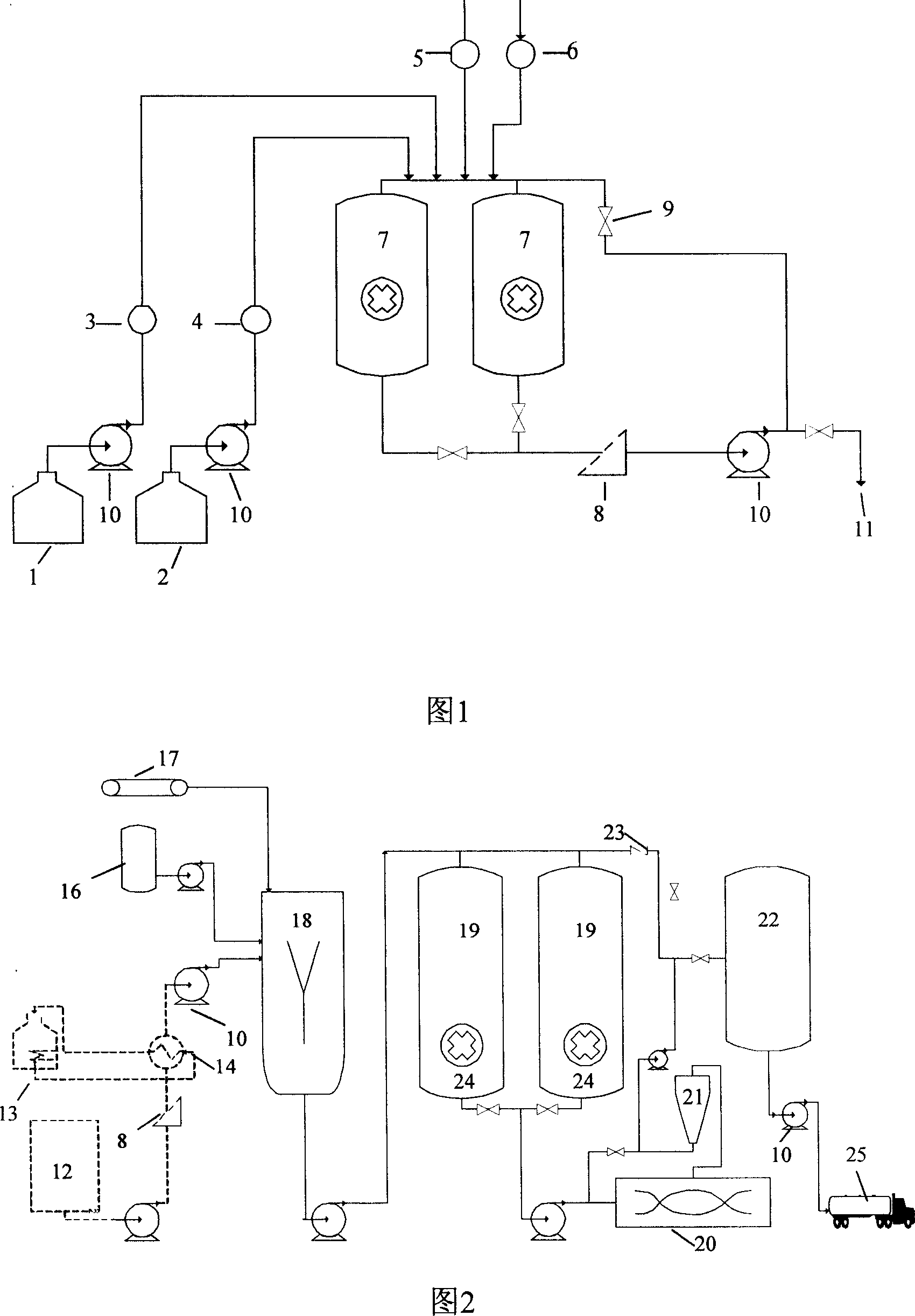

Method for preparing propylene from methanol

ActiveCN101239875AHigh selectivityHigh weight ratioMolecular sieve catalystsHydrocarbon from oxygen organic compoundsSpace velocityZSM-5

The invention relates to a method for preparing propylene from methanol, which mainly solves problems of the prior art, such as low weight ratio of propylene / ethylene and low propylene selectivity. The invention solves the problems by using the methanol / water mixing liquid as material, contacting the material with a catalyst under conditions of 400-550 DEG C, 0.1-1Mpa, 1-5 hour<-1> of methanol weight hourly space velocity and 0.2-5:1 of water / methanol weight ratio, reacting and generating an effluent containing propylene, wherein the catalyst contains following componets by weight percent: a) 0-10% P of P2O5; b) 0-10% Mg of MgO; c) 0-10% La of La2O3; d) and the rest ZSM-5 molecular sieve, wherein the dosage of a, b, and c can not be zero at the same time. Thereby, the invention is useful in industrial production of propylene from methanol.

Owner:CHINA PETROLEUM & CHEM CORP +1

Waste rubber tyre powder modified asphalt and its prepn process

InactiveCN101089049AInhibition of segregationAvoid elastic recoveryBuilding insulationsPolymer scienceWaste rubber

The present invention relates to one kind of waste rubber tyre powder modified asphalt and its preparation process. The waste rubber tyre powder modified asphalt consists of asphalt matrix 100 weight portions, waste rubber tyre powder 10-30 weight portions, compatilizer 1-10 weight portions, dissolution promoter 0.5-30 weight portions, activating modifier 1-40 weight portions and emulsifier 0-5 weight portions. It is prepared through a chemical and physical process including the steps of degrading and activating the waste rubber tyre powder, vulcanizing and cross-linking, stirring and shearing. It is suitable for paving and repairing highway.

Owner:SHANGHAI MIRONGKE ELECTRICAL DIGITAL INTEGRATION

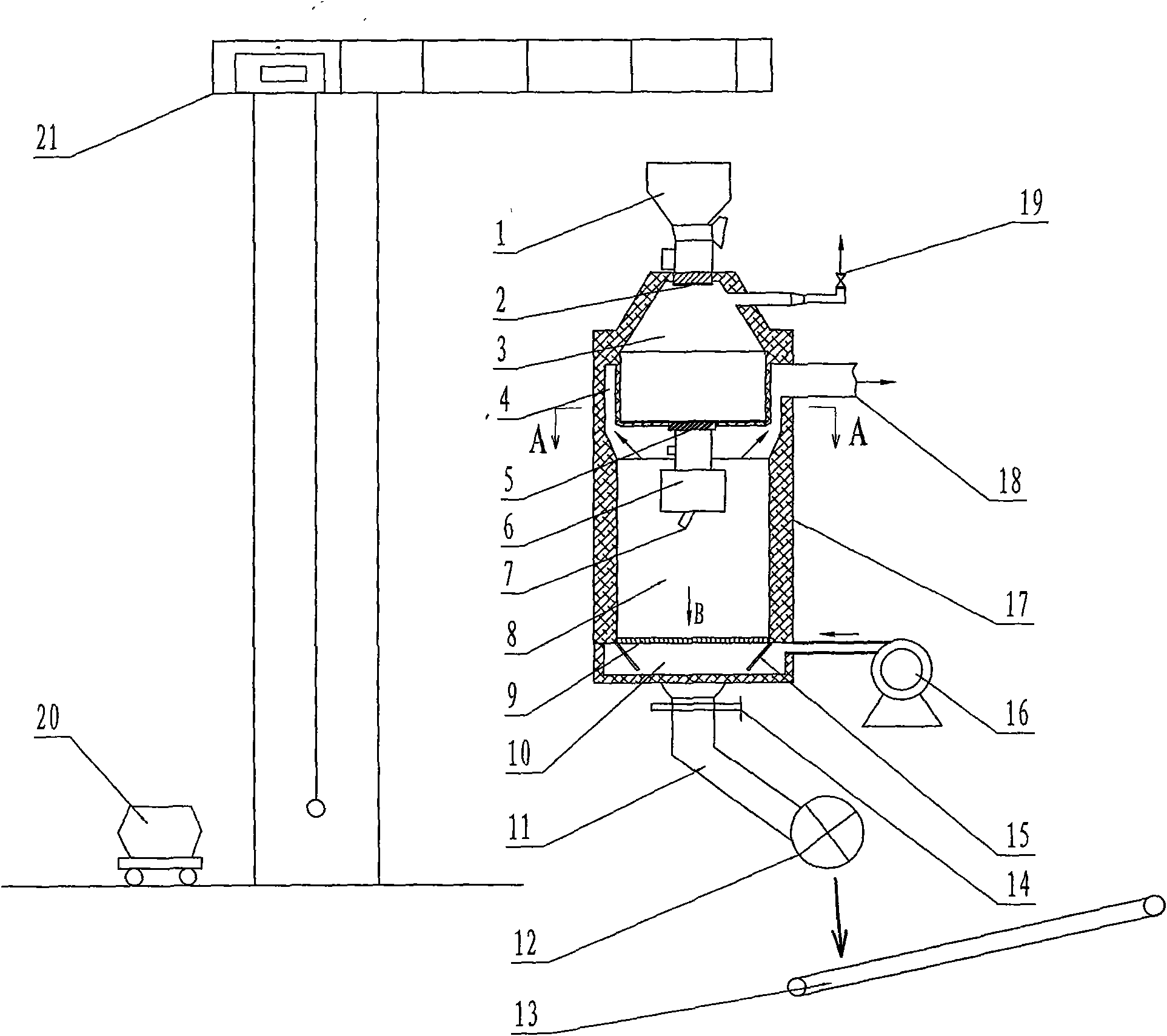

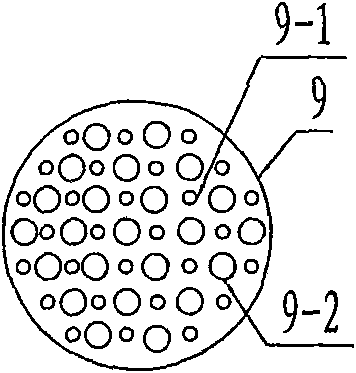

Vertical sinter ore cooling machine capable of efficiently recycling sensible heat of sinter ores

InactiveCN101576351AReduce heat transfer temperature differenceRaise the gradeIncreasing energy efficiencyHandling discharged materialGas solidMaterials science

The invention discloses a vertical sinter ore cooling machine capable of efficiently recycling the sensible heat of sinter ores, which pertains to the technical field of sintering equipment and is used for preventing air leak in the cooling course of sinter ores and effectively recycling the sensible heat of the sinter ores. The technical proposal of the invention is that: the cooling machine consists of a feeding part, a cooling part and a conveying part; the cooling part comprises a vertical closed body, a hot wind pipeline, a blower, as well as a hopper, an upper sealing valve, a pre-storing chamber, a lower sealing valve, a heat exchanging chamber, a wind distributing board, an isopiestic wind chamber and a discharging channel which are in sequence arranged on the body from top to bottom; an annular wind chamber is arranged between the pre-storing chamber and the heat exchanging chamber; the annular wind chamber is communicated with the hot wind pipeline; the isopiestic wind chamber is communicated with the blower; and wind shields and ore falling openings are distributed evenly on the wind distributing board . The vertical sinter ore cooling machine has the following advantages of: 1. an air leak rate near to 0; 2. improved gas-solid heat exchange efficiency of the cooling machine; 3. raised quality of the recycled hot air; and 4. being beneficial to increasing the utilization rate of exhaust-heat boilers. Based on the advantages, the vertical sinter ore cooling machine is expected to be used commonly as an upgraded replacement of the existing sinter cooling machine.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY +1

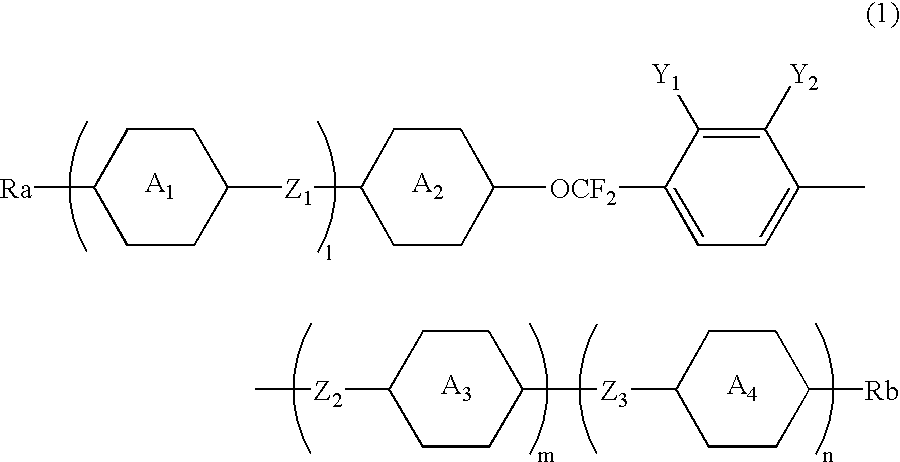

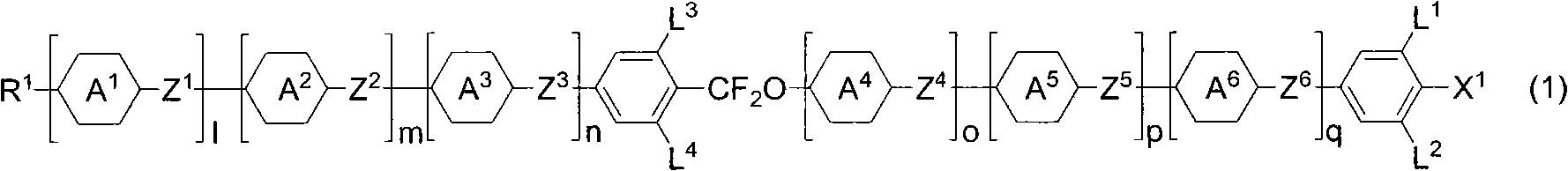

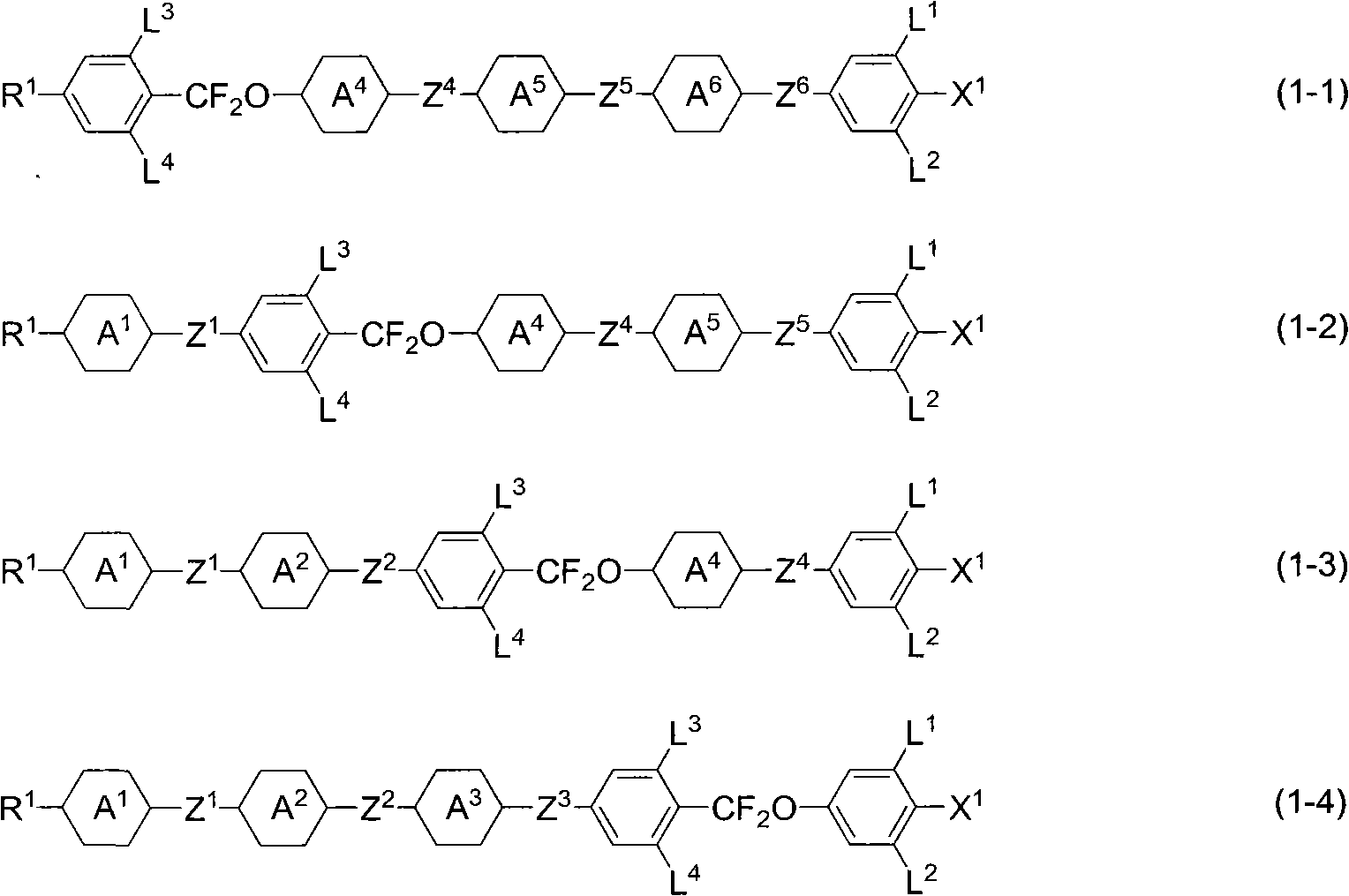

2,3-difluorophenyl derivative having negative dielectric anisotropy, liquid crystal composition, and liquid crystal display device

InactiveUS6548126B1Good compatibilityIncrease resistanceLiquid crystal compositionsOrganic chemistryLiquid crystallineCrystallography

The invention is to provide liquid crystalline compounds having a negative and extremely large dielectric anisotropy value and a small optical anisotropy value at the same time; liquid crystal compositions comprising the compound; and liquid crystal display devices fabricated by using the liquid crystal composition; the liquid crystalline compounds have 2,3-dihalogenophenylene moiety and are expressed by formula (1)wherein Ra and Rb each independently represents a linear or branched alkyl having 1 to 10 carbon, any methylene in the alkyl may be replaced by -O-, -S-, -CH=CH-, or -C=C-, but -O- is not successive, and any hydrogen in the alkyl may be replaced by halogen; rings A1 to A4 each independently represents trans-1,4-cyclohexylene, cyclohexene-1,4-diyl, pyridine-1,4-diyl, pyrimidine-2,5-diyl, or 1,4-phenylene, wherein at least one hydrogen in these rings may be replaced by halogen, and any nonadjacent methylene in cyclohexane ring may be replaced by -O-; Y1 and Y2 each independently represents F or Cl; Z1, Z2 and Z3 each independently represents a single bond, -CH2CH2-, -(CH2)4-, -COO-, -OCO-, -CH2O-, -OCH2-, -CF2O-, or -OCF2-; and l, m and n each independently is 0, 1 or 2, and the sum of l+m+n is 3 and less.

Owner:CHISSO CORP

Asphalt compositions and methods of preparation thereof

InactiveUS6228909B1Reduce the amount requiredExtended temperature rangeBuilding insulationsPolymer modifiedPolymer science

Systems and methods for combining a mineral acid and a polymer additive in an asphalt composition are described. Methods of preparing a polymer modified asphalt include providing a source of a neat asphalt; heating the neat asphalt; providing a source of a polymer; adding the polymer to the neat asphalt to form a blend; providing a source of a dilution asphalt; and adding the blend to the dilution asphalt to form a diluted product. The systems and methods provide advantages in that the addition of the mineral acid widens the temperature range in which satisfactory performance from a given polymer asphalt composition can be achieved or, as a corollary, reduces the amount of polymer additive that would otherwise be needed to achieve satisfactory performance within a given temperature range.

Owner:ERGON INC

Catalytic hydrogen storage composite material and fuel cell employing same

InactiveUS6875536B2High catalytic activityImprove corrosion resistanceWater management in fuel cellsElectrode carriers/collectorsFuel cellsPhysical chemistry

A composite hydrogen storage material including 1) an active material having hydrogen storage capacity; and 2) a catalytic material having greater catalytic activity toward the dissociation of molecular hydrogen and / or oxidation of hydrogen than that of said active material having hydrogen storage capacity. Also, a fuel cell employing anodes formed from the composite hydrogen storage material. The fuel cell has the ability to start up instantly and can accept recaptured energy such as that of regenerative braking by operating in reverse as an electrolyzer.

Owner:TACTICAL FUEL CELLS

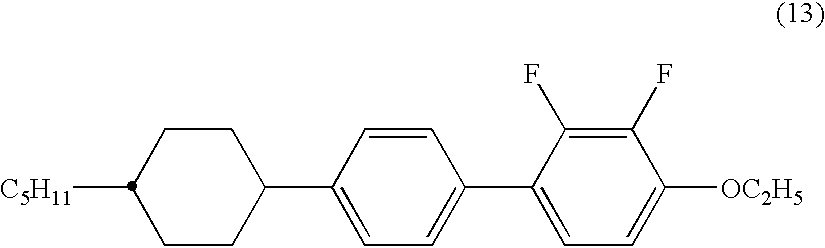

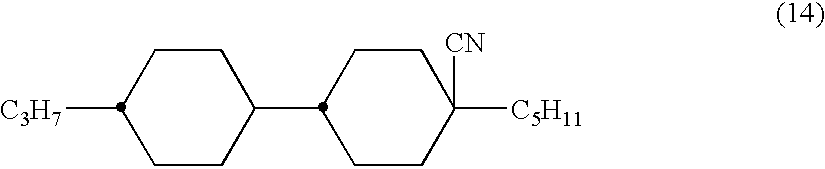

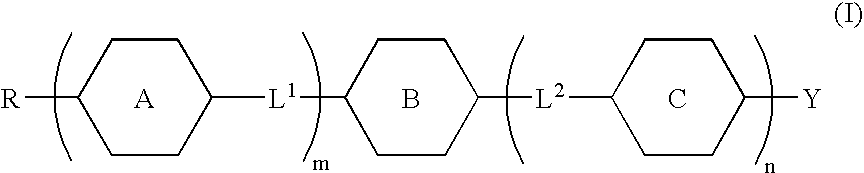

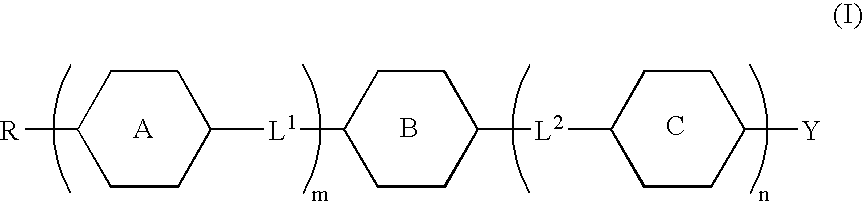

Pentacyclic liquid crystal compound having CF2O bonding group, liquid crystal composition and liquid crystal display

ActiveCN101631759AWide temperature rangeExtended temperature rangeLiquid crystal compositionsOrganic chemistryDielectric anisotropyRefractive index

Disclosed is a novel compound, namely a pentacyclic liquid crystal compound having a CF2O bonding group, which has general physical properties necessary for a compound, stability against heat and light, a wide temperature range of a liquid crystal phase, a high clearing point, good compatibility with other compounds, and large dielectric anisotropy and large refractive anisotropy. This pentacyclic liquid crystal compound has a particularly high clearing point and particularly large refractive anisotropy. Also disclosed are a liquid crystal composition and a liquid crystal display.

Owner:JNC CORP +1

Asphalt compositions and methods of preparation thereof

InactiveUS6031029AExtended temperature rangeReduce amountIn situ pavingsBuilding insulationsPolymer modifiedMineral acid

Systems and methods for combining a mineral acid and a polymer additive in an asphalt composition are described. Methods of preparing a polymer modified asphalt include providing a source of a neat asphalt; heating the neat asphalt; providing a source of a polymer; adding the polymer to the neat asphalt to form a blend; providing a source of a dilution asphalt; and adding the blend to the dilution asphalt to form a diluted product. The systems and methods provide advantages in that the addition of the mineral acid widens the temperature range in which satisfactory performance from a given polymer asphalt composition can be achieved or, as a corollary, reduces the amount of polymer additive that would otherwise be needed to achieve satisfactory performance within a given temperature range.

Owner:ERGON INC

Liquid crystal composition, liquid crystal device, driving method thereof and liquid crystal apparatus

InactiveUS6417828B1Reduce ion contentGood uniform alignment characteristicLiquid crystal compositionsStatic indicating devicesVoltageLiquid crystal devices

An active matrix-type liquid crystal device is constituted by a pair of substrates, a chiral smectic liquid crystal composition disposed between the pair of substrates so as to form a plurality of pixels, and a plurality of active elements provided to the pixels, respectively, for driving the liquid crystal device in a matrix driving scheme. The chiral smectic liquid crystal composition may preferably comprise at least two specific fluorine-containing mesomorphic compounds and assume two stable states between which a threshold voltage for switching from one of the two stable states to the other stable state is different from a threshold voltage for switching from the other stable state to said one of the two stable states and liquid crystal molecules of the liquid crystal composition change their alignment states so as to provide a halftone state depending on a voltage applied to the chiral smectic liquid crystal.

Owner:CANON KK

Novel process and catalyst system for improving dewaxing catalyst stability and lubricant oil yield.

ActiveUS20110079540A1High product yieldExtended temperature rangeTreatment with plural serial cracking stages onlyMolecular sieve catalystsWaxOxide

The invention provides for a process for dewaxing a waxy hydrocarbon feedstock to form a lubricant oil. The invention is also directed to a catalyst system comprising a hydrotreating catalyst upstream of a dewaxing catalyst, used in the dewaxing of a waxy hydrocarbon feedstock to form a lubricant oil. In particular, the invention is directed to a process and catalyst system designed to maintain yield of lubricant oil product. Specifically, the yield of lubricant oil does not decrease more than 2%, at a target pour point, over a dewaxing temperature range. The hydrotreating catalyst helps prevent aging of the dewaxing catalyst and maintains lubricant oil product yield at a target pour point over a wide temperature range. The hydrotreating catalyst comprises platinum, palladium, or combinations thereof on a low acidity inorganic oxide support where acidity is measured by a decalin conversion of less than 10% at 700° F.

Owner:CHEVROU USA INC

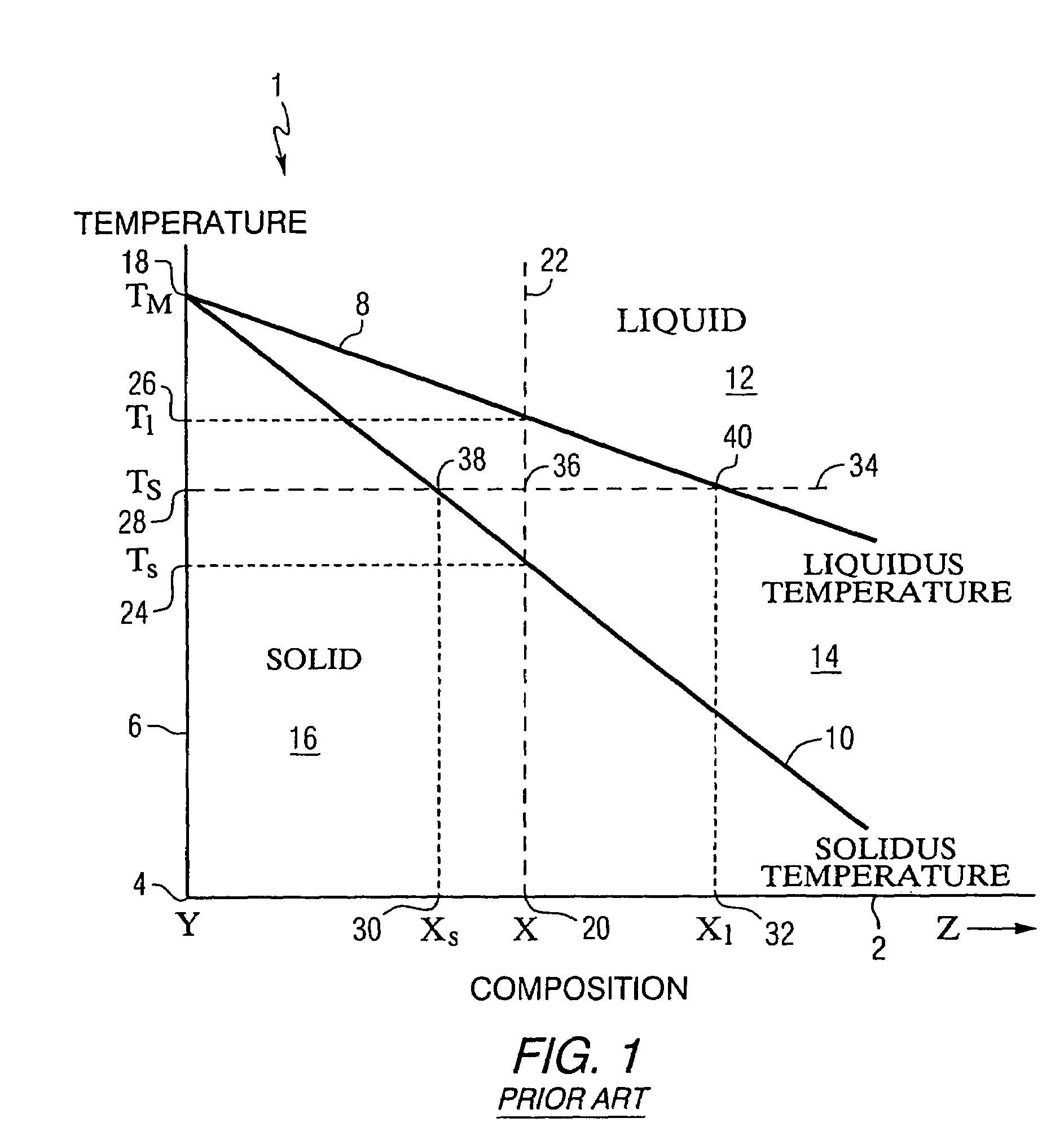

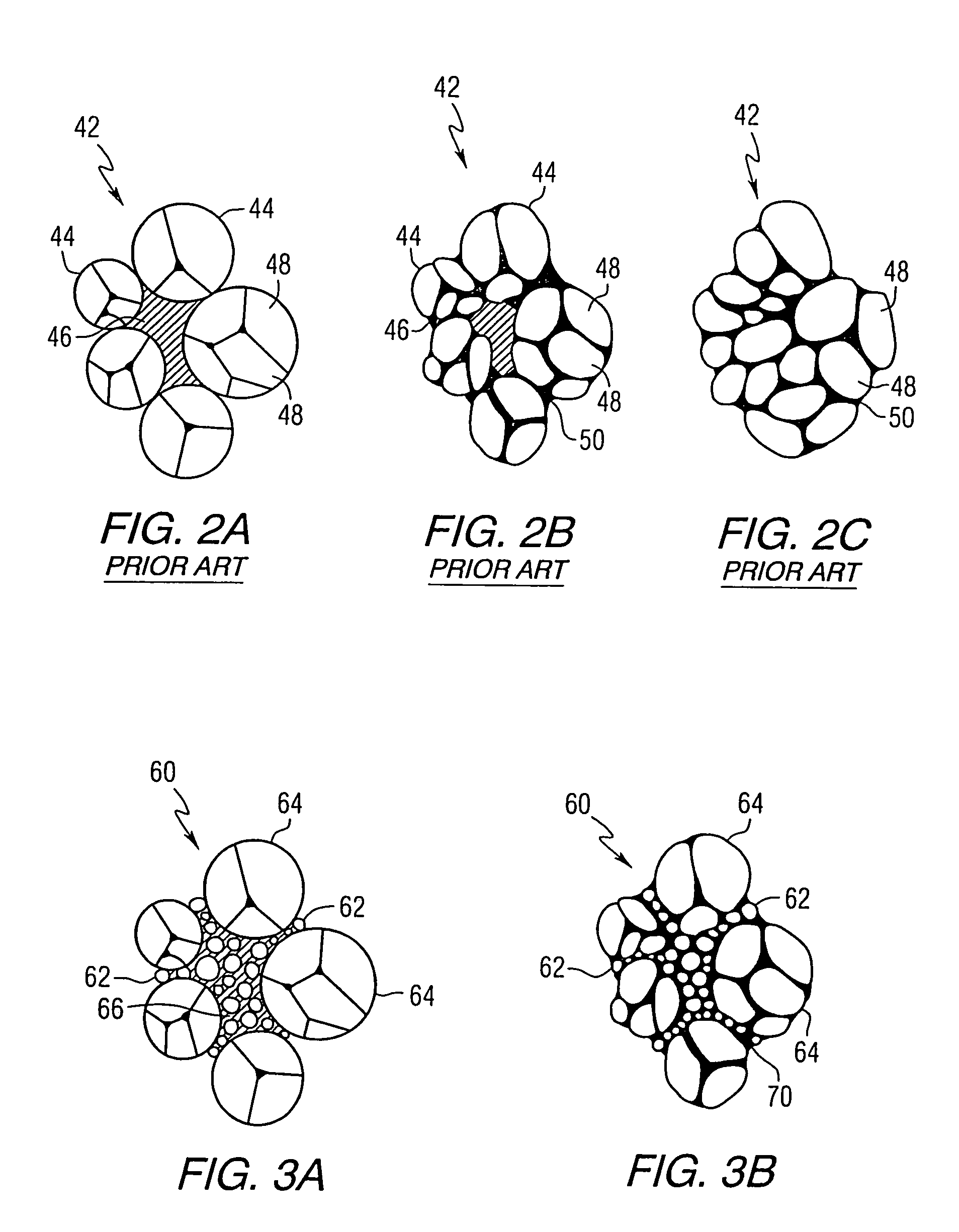

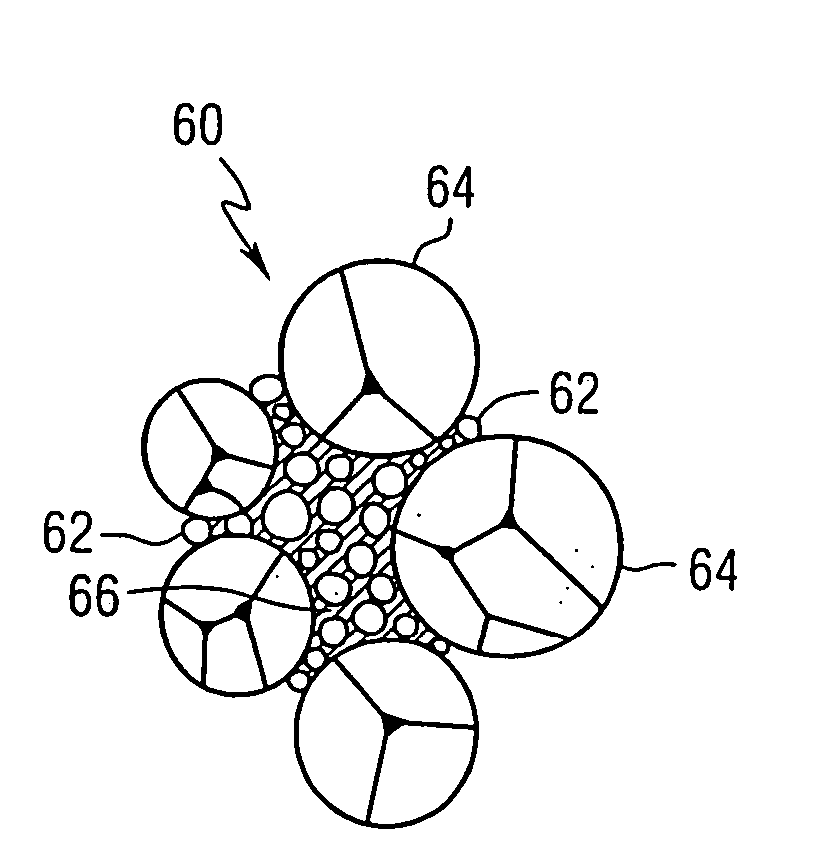

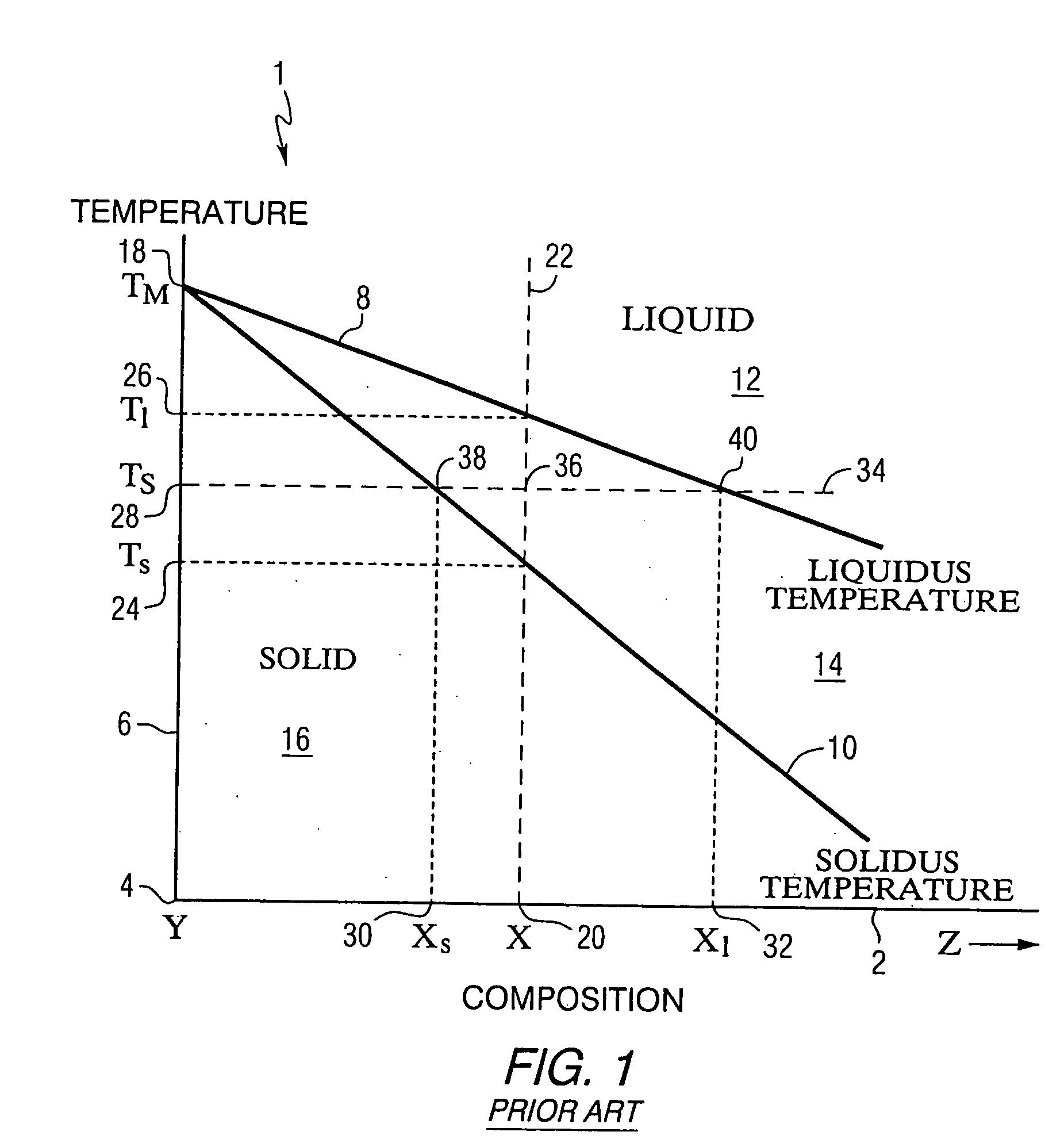

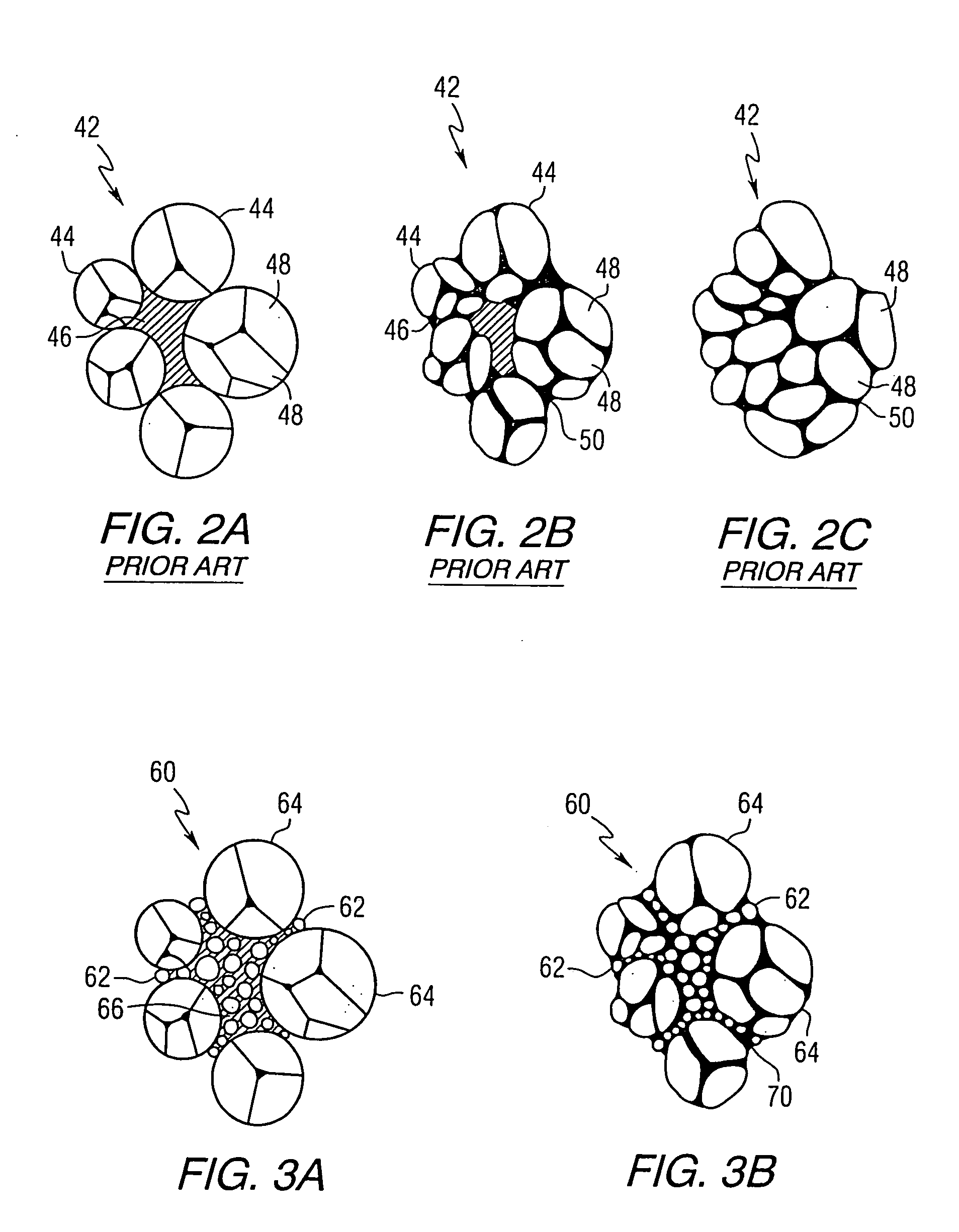

Blended powder solid-supersolidus liquid phase sintering

InactiveUS7070734B2Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

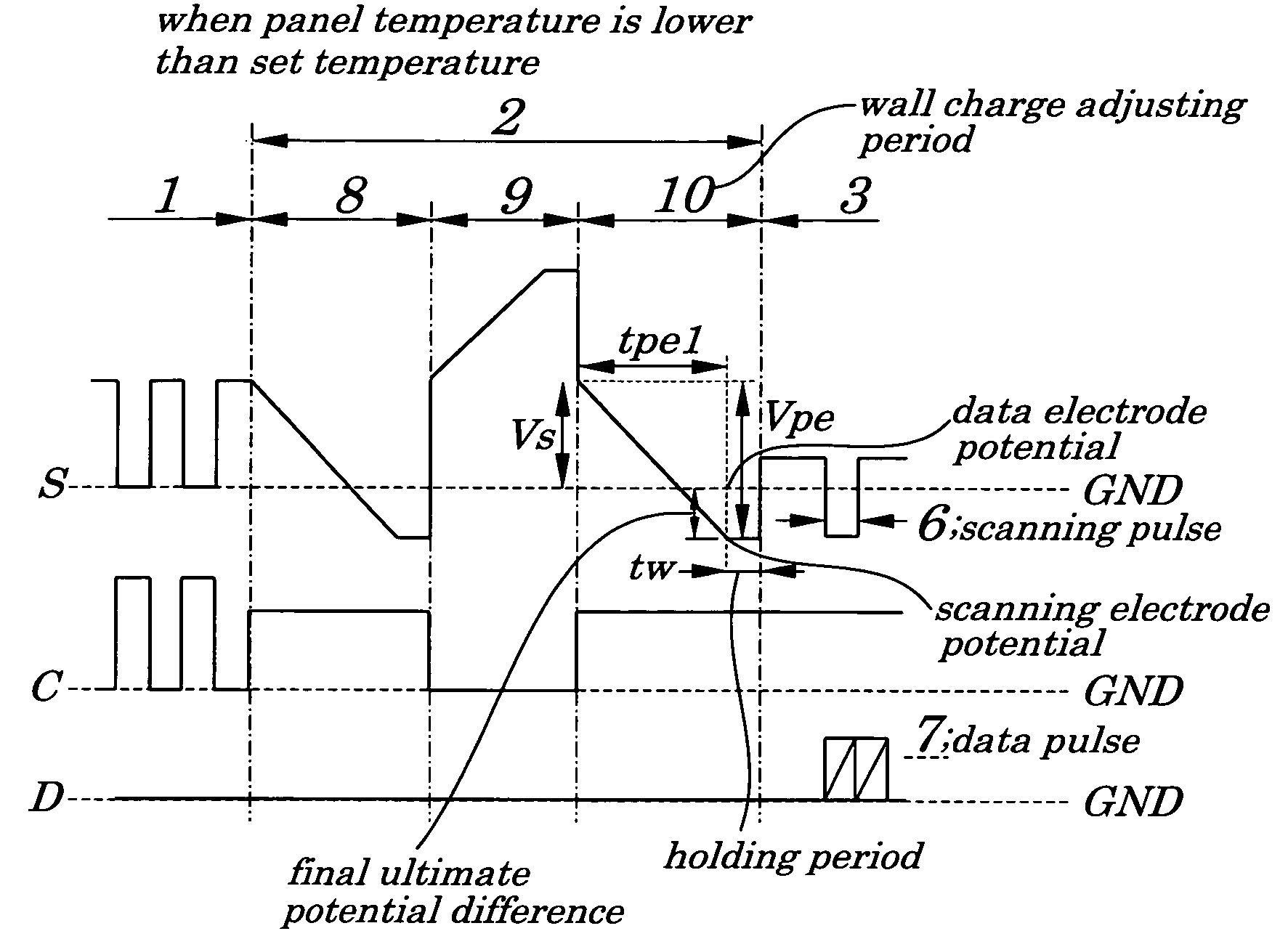

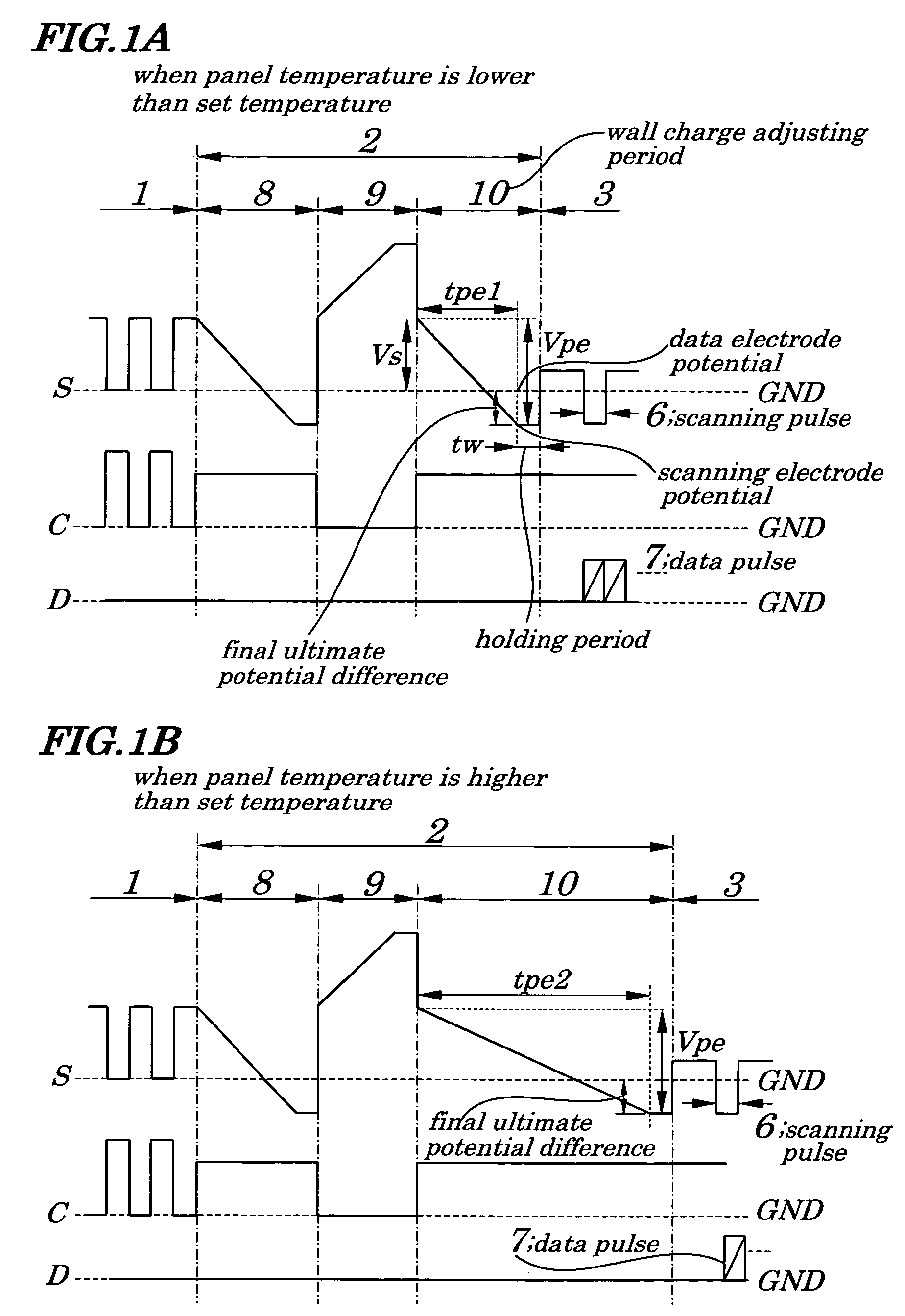

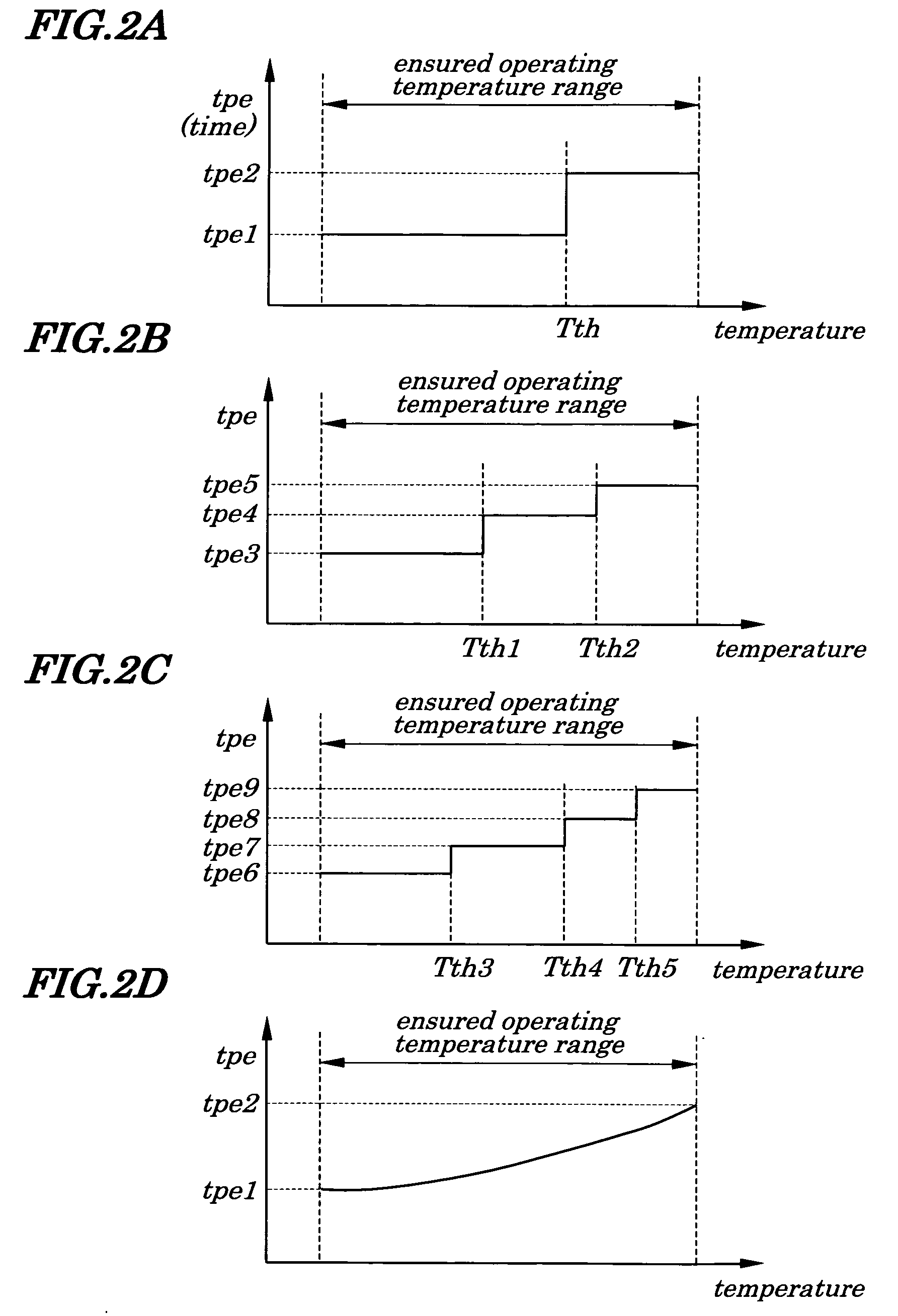

Plasma display device and method for driving the same

InactiveUS20050068262A1Avoid misuseGuaranteed uptimeStatic indicating devicesPotential differenceEngineering

A plasma display device is provided which is capable of expanding an ensured operating temperature range or operating life time even at time of changes of a driving margin induced by a panel temperature or cumulative operating time of the panel. Display is controlled in a scanning period during which writing discharge is made to occur in a cell, in a sustaining period during which a cell having undergone writing discharge is turned ON for displaying, and in an initializing period during which wall charges in a cell and space charges accumulated before the scanning period starts are initialized. A wall charge adjusting period during which a potential difference between scanning electrodes and data electrodes varies gradually is set and a change rate of a potential between scanning electrodes and data electrodes during the wall charge adjusting period is changed according to the panel temperature and / or cumulative operating time of the panel.

Owner:PANASONIC CORP

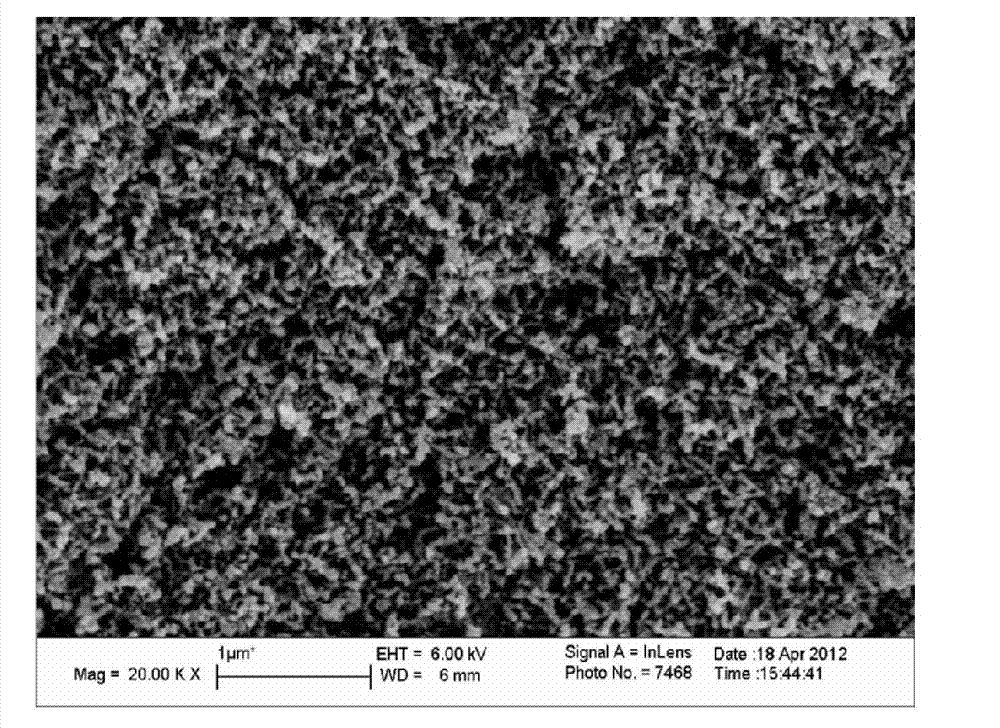

Preparation method of blocky SiO2-Y2O3 compound aerogel

The invention relates to a preparation method of a blocky SiO2-Y2O3 compound aerogel. The preparation method comprises the steps of: uniformly mixing tetraethyl orthosilicate, an acid catalyst, deionized water, absolute ethyl alcohol, yttrium chloride hexahydrate, ammonia water and the like to obtain a colorless clear SiO2-Y2O3 compound sol solution, drying to obtain a compound wet gel, carrying out solvent replacement on the compound wet gel and then drying to obtain the blocky SiO2-Y2O3 compound aerogel. The high-temperature thermal stability performance of a SiO2 aerogel material is improved by adopting a rare earth element doping mode so that the prepared SiO2-Y2O3 compound aerogel has all excellent characteristics of the original SiO2 aerogel, and has the advantages of higher temperature use range, complex structure, high specific area, low heat conductivity, low density and the like. The preparation method is simple and easy to operate, has the profound significance for improving the high-temperature thermal stability of the widely applied SiO2 aerogel material, and provides a new idea for improving the performance of the aerogel material.

Owner:江苏安珈新材料科技有限公司

Preparation technology of carbon/carbon composite material crucible for monocrystalline silicon furnace

InactiveCN102660768AExtended temperature rangeHigh densityBy pulling from meltCarbon compositesDifferential pressure

The invention discloses a preparation technology of a carbon / carbon composite material crucible for a monocrystalline silicon furnace, and the preparation technology comprises the following steps of: adopting a polyacrylonitrile nitrile base carbon fiber-woven performing body, taking mixed gas of natural gas, propylene, liquefied petroleum as a carbon source and nitrogen or argon as carrier gas, in a uniform temperature thermal field formed by a vertical pot type deposition furnace, timely switching the upper gas charging and lower gas charging of a pipeline, due to the pressure difference of the gas inside and outside the crucible, and in combination with a uniform temperature method, a differential-pressure method and a compulsive gas current method, realizing the quick densifying of the whole crucible blank body, wherein after 300-350 hours, the intensity of the crucible can reach to more than 1.6g / cm<3>, compared with the conventional free deposition technology, the preparation technology can be used for greatly shortening the deposition time, and reduces the production cost. After being mechanically machined, the crucible is used for a thermal field of the monocrystalline silicon furnace, compared with the hot isostatic pressure graphite crucible, the carbon / carbon composite material crucible has the advantages that the service life is prolonged by 3-5 times, the cost performance is obviously better than that of the graphite crucible, and the production cost and labor intensity of the monocrystalline silicon are greatly reduced.

Owner:保定顺天新材料股份有限公司

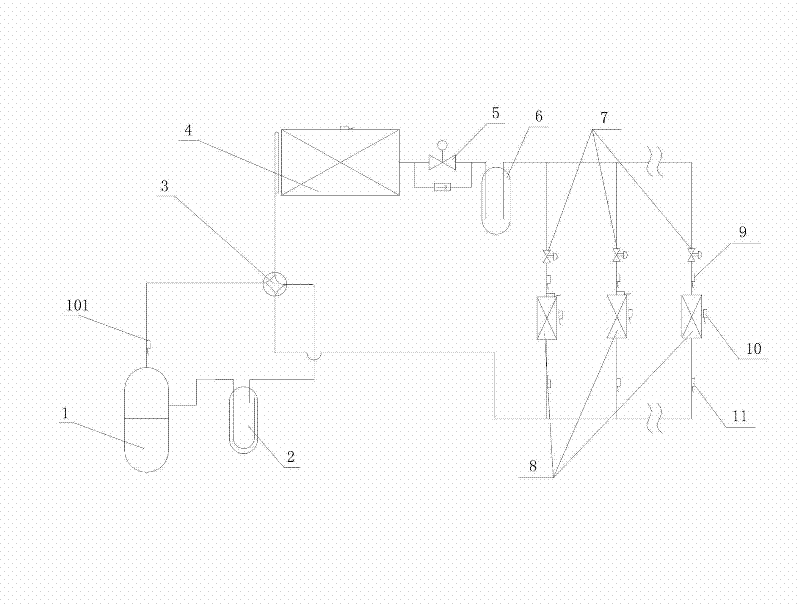

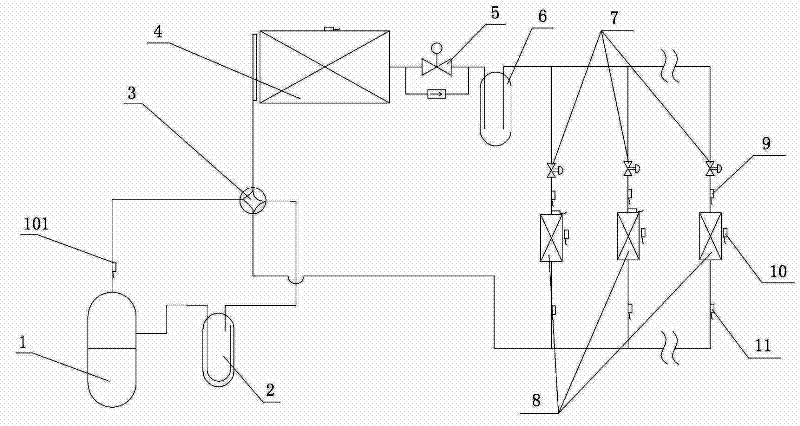

Control method of electronic expansion valve of indoor machine during refrigerating of convertible frequency air conditioner

ActiveCN102368009AEvaporating temperature fluctuations are reducedPrevent the opening from being too smallRefrigeration safety arrangementEngineeringElectronic expansion valve

The invention discloses a control method of an electronic expansion valve of an indoor machine during refrigerating of a convertible frequency air conditioner. The control method comprises the following steps of: 1, judging whether a microprocessor of the indoor machine (8) is in a heating standby state; 2, regulating the openness of the corresponding indoor electronic expansion valve (7) to reach 30-50 paces by the microprocessor; and 3, keeping the openness of the indoor electronic expansion valve (7) in the step 2 for 2-6min, regulating the openness of the corresponding indoor electronic expansion valve (7) by the microprocessor according to temperatures transmitted by a liquid pipe temperature sensor (9) and an indoor heat exchanger coil temperature sensor (11) every 15-35S in accordance with the following rules: the openness of the regulated indoor electronic expansion valve (7) is equal to the sum of the openness of the indoor electronic expansion valve (7) before the regulation and the openness of the regulation of the indoor electronic expansion valve (7), and the openness of the regulation of the indoor electronic expansion valve (7) is equal to (T3-Tmin-A)*E+delta(T3-Tmin)*F. Compared with the prior art, the control method disclosed by the invention has the characteristics of being suitable for a one-more air conditioner, being capable of effectively ensuring stable operation of the system and improving heating efficiency of the system, being low in energy consumption, and ensuring that the temperature change range of an indoor environment is smaller and the comfort degree of the indoor environment is higher.

Owner:NINGBO AUX ELECTRIC

Blended powder solid-supersolidus liquid phase sintering

InactiveUS20060083652A1Deleterious effectHigh densityAdditive manufacturing apparatusTransportation and packagingPowder mixtureAlloy

A green article comprising an A-B powder mixture and methods of manufacturing such green articles and corresponding sintered articles are disclosed. The A-B powder mixture consists of a minor volume fraction of a relatively fine powder A and a complementary major volume fraction of a relatively coarse prealloyed powder B wherein the A-B powder mean particle size ratio is at least about 1:5. Metal powder A consists of one or more elemental metals or alloys which has a melting or solidus temperature above the highest sintering temperature at which the A-B powder mixture may be sintered without slumping. Prealloyed metal powder B consists of one or more alloys which are amenable to supersolidus liquid phase sintering. Green articles made from the A-B powder have a wider sintering temperature window than do articles made from prealloyed metal powder B alone.

Owner:THE EX ONE

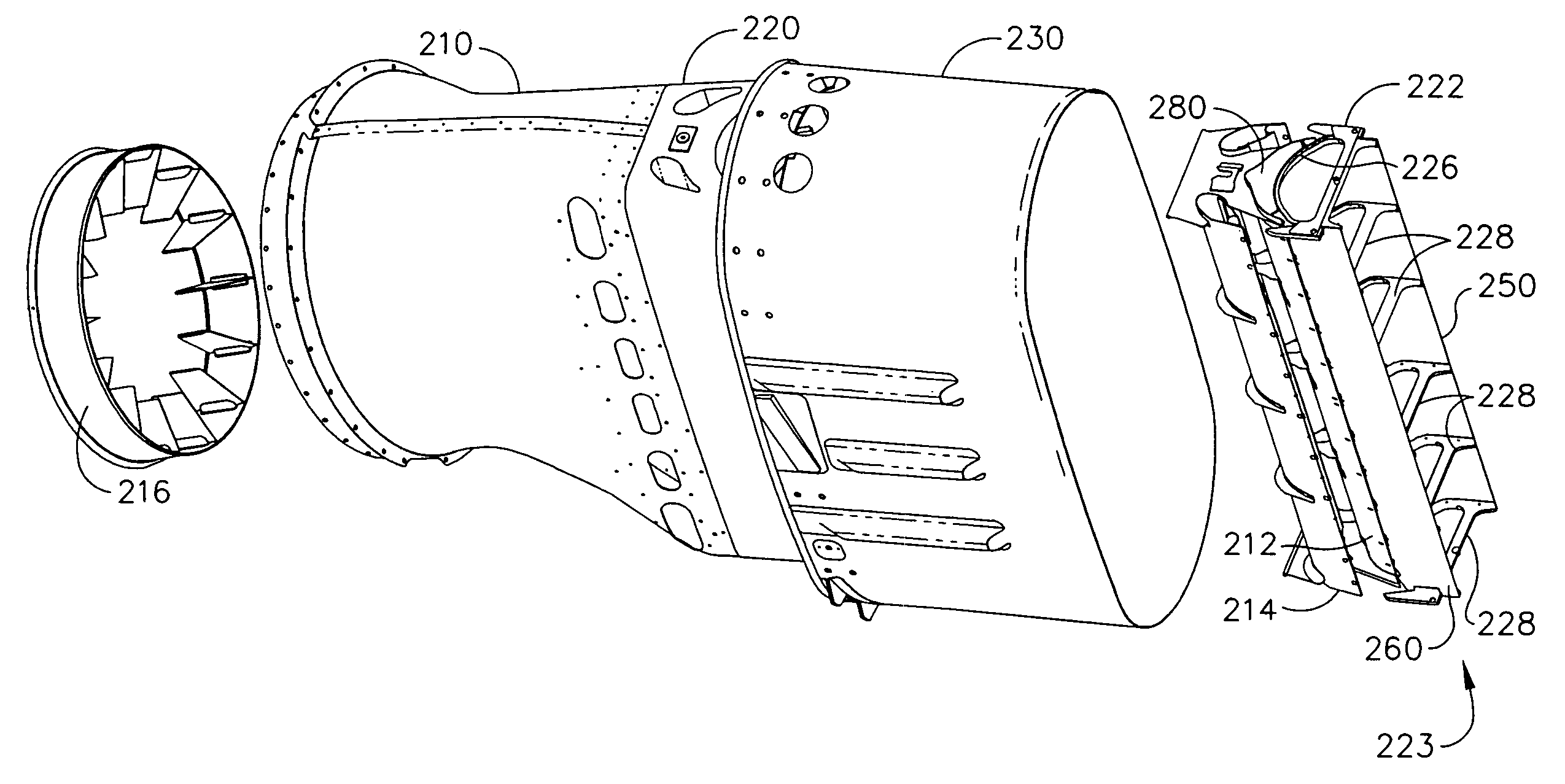

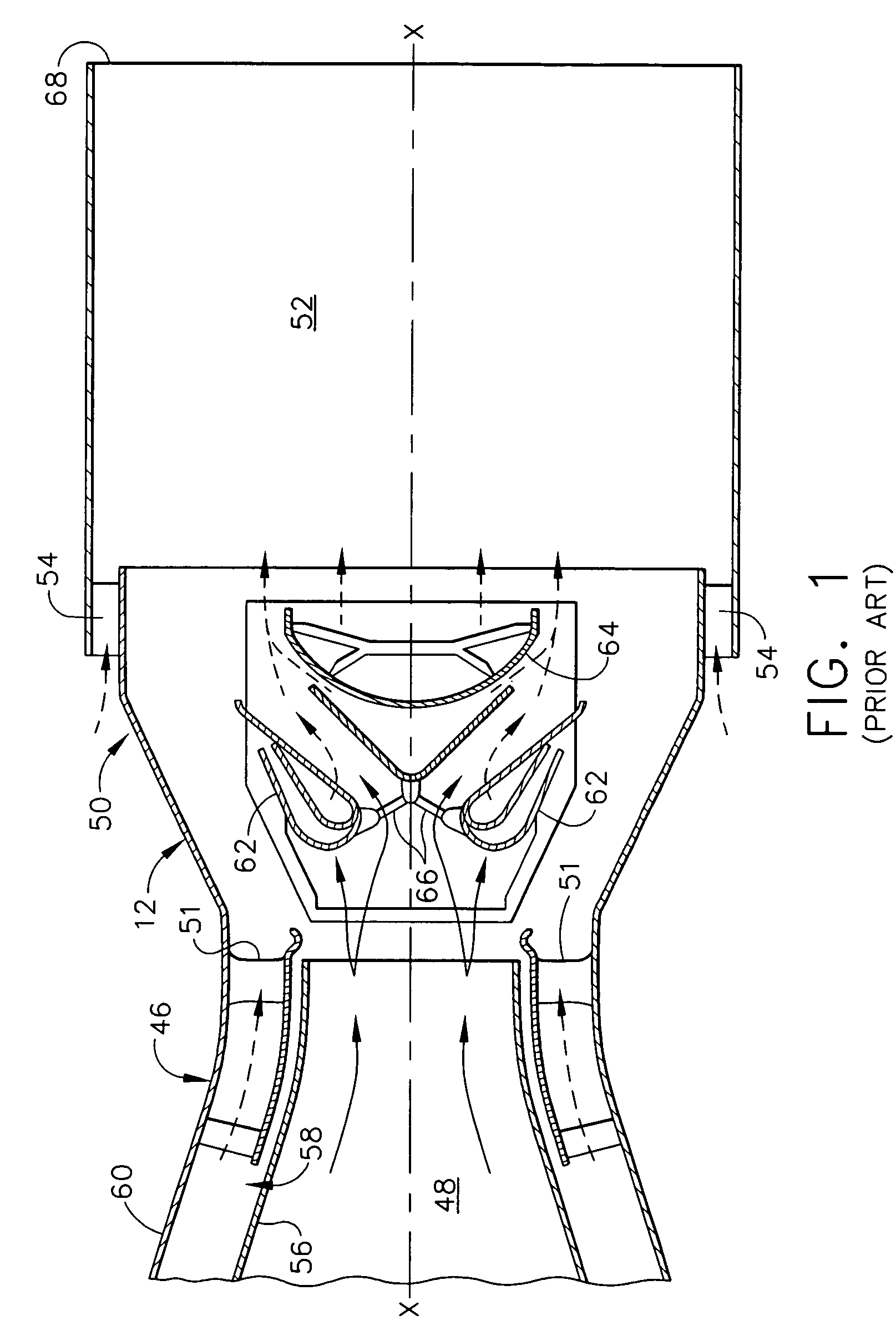

High-emissivity infrared coating applications for use in HIRSS applications

ActiveUS7313909B2Improve IR performance of materialReducing and eliminating likelihoodMolten spray coatingBlade accessoriesSurface finishEmissivity

Owner:GENERAL ELECTRIC CO

Zigzag Pattern for TSV Copper Adhesion

ActiveUS20100084747A1Improve adhesionMore process flexibilitySemiconductor/solid-state device detailsSolid-state devicesContact padGrid pattern

A system and method for forming a TSV contact is presented. A preferred embodiment includes a TSV in contact with a portion of the uppermost metal layer of a semiconductor die. The interface between the TSV conductor and the contact pad is preferably characterized by a non-planar zigzag pattern that forms a grid pattern of contacts. Alternatively, the contacts may form a plurality of metal lines that make contact with the contact pad.

Owner:TAIWAN SEMICON MFG CO LTD

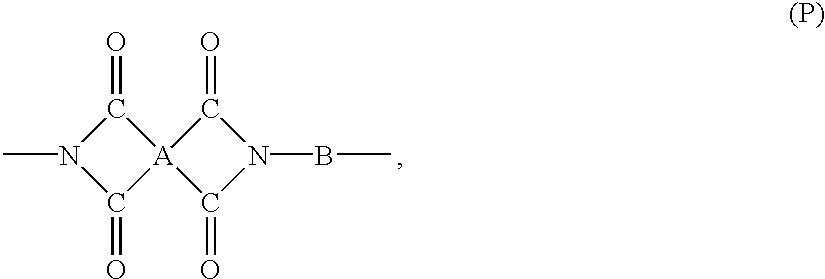

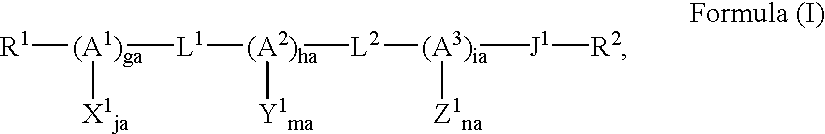

Fused ring compound

InactiveUS7067179B1Extended temperature rangeLiquid crystal compositionsHalogenated hydrocarbon preparationCompound aGeneral purpose

A novel compound represented by the general formula (I), and a nematic liquid crystal composition incorporating the same.A compound represented by the general formula (I) can be produced industrially extremely easily, as shown in the examples, displays superior compatibility with current general purpose host liquid crystals as a nematic phase, and also shows little crystal precipitation at low temperatures. Moreover, by addition of a small amount of such a compound to a host liquid crystal, the liquid crystal temperature range at low temperatures can be effectively widened without any significant worsening of the various characteristics of the liquid crystal material. Consequently, a compound of the present invention is an extremely useful liquid crystal material which is suitable for various liquid crystal display elements which require a broad operating temperature range.

Owner:DAINIPPON INK & CHEM INC

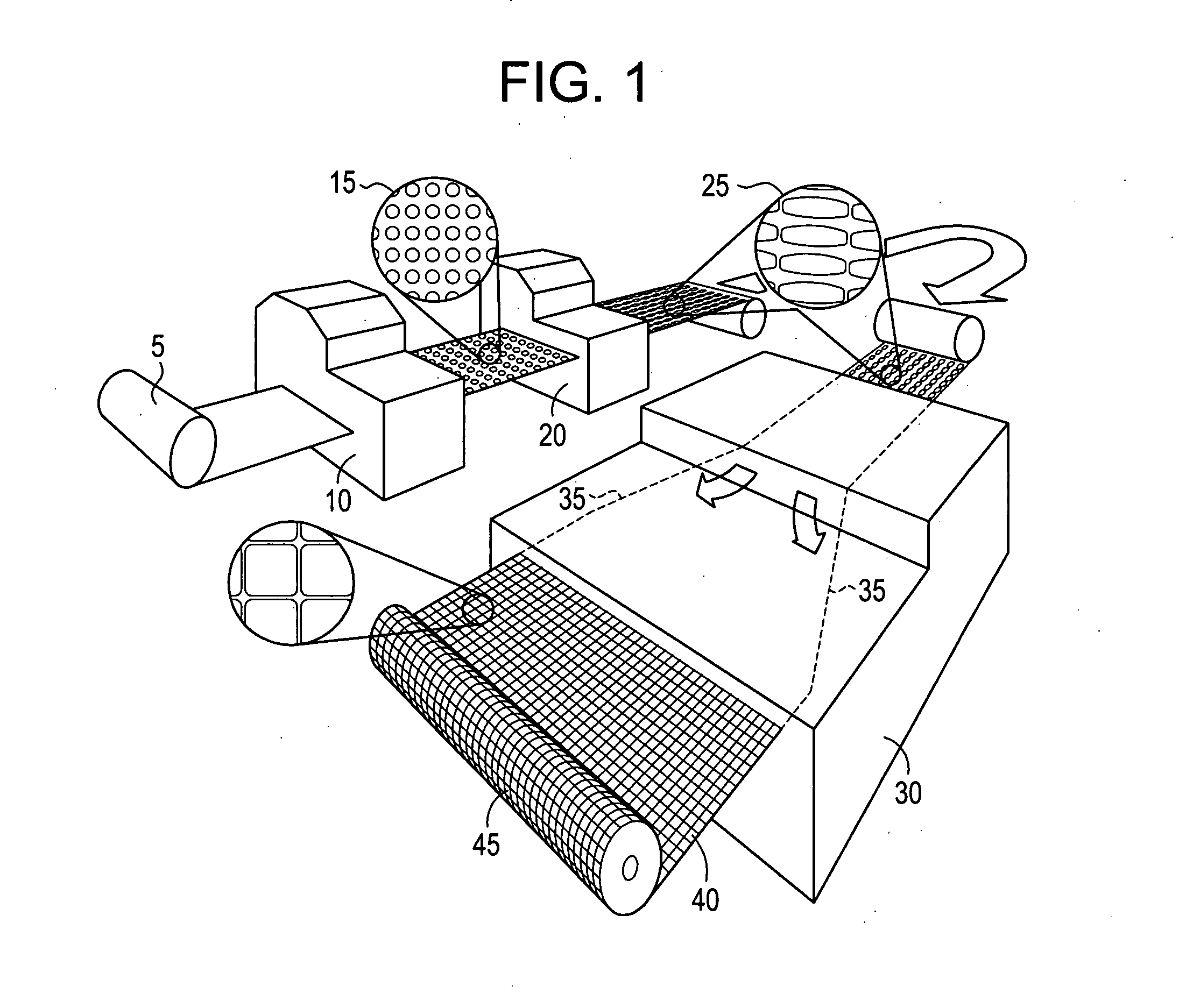

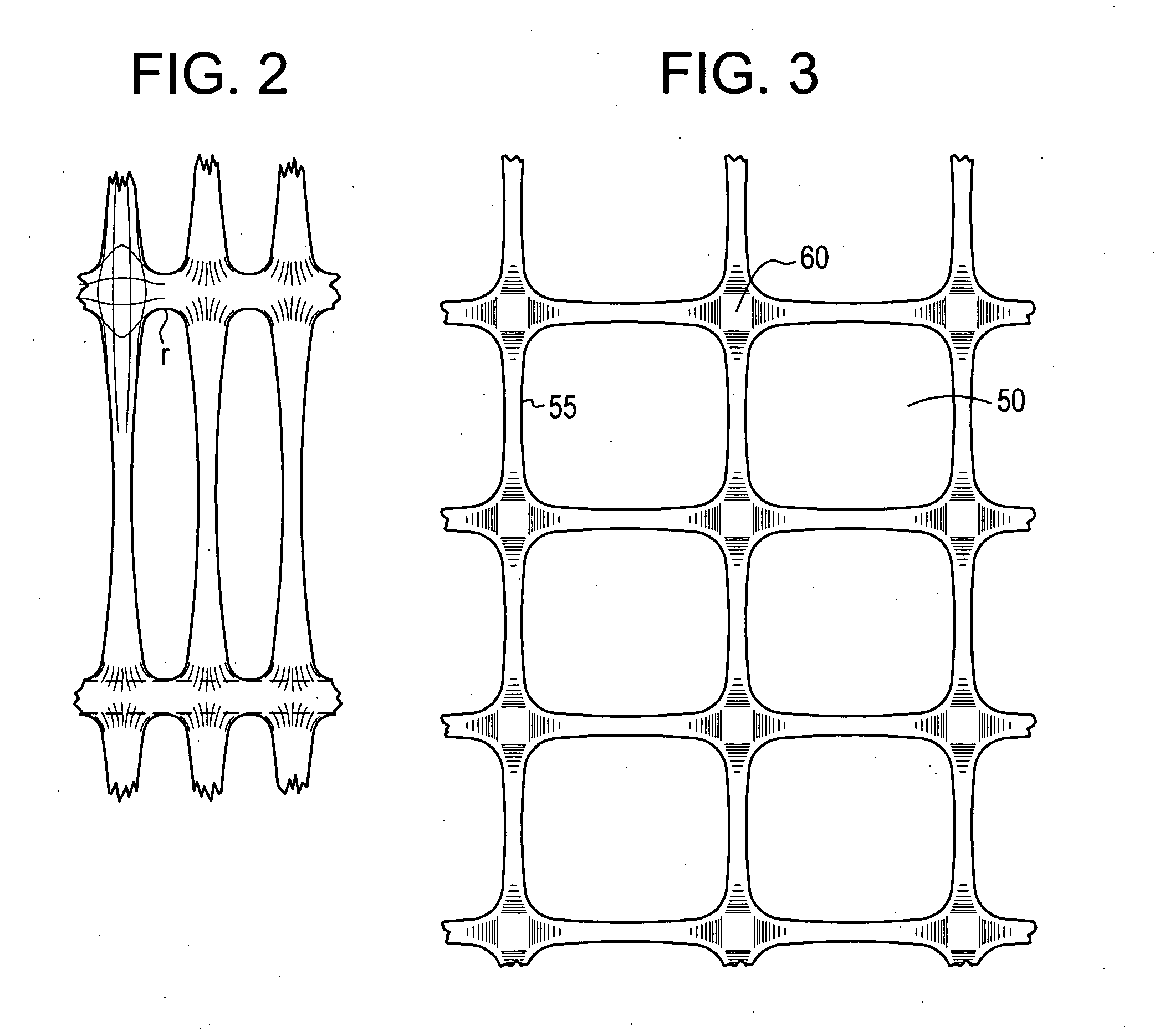

Extruded polypropylene sheets containing beta spherulites

ActiveUS20050003151A1Improve the level ofLow densityLayered productsFlat articlesPolymer sciencePolypropylene mesh

An improved extruded polypropylene sheet that contains a high level of beta crystallinity and a process for making such sheets are disclosed herein. The polypropylene sheet contains at least one layer of a resinous polymer of propylene and an effective amount of beta spherulites. The beta spherulites in the sheet are produced by the incorporation of a beta nucleating agent in the polymer. The presence of the beta spherulites in the sheet facilitates the process of post-stretching the perforated sheet to produce a uniaxially or biaxially oriented mesh structure, and also broadens the temperature range over which this stretching can be performed. The final mesh has a lower density than a polypropylene mesh without beta spherulites. The perforated beta nucleated sheet also exhibits different stretching characteristics during the orientation steps such that more resinous polymer is drawn out of the node junction region between the machine direction and transverse direction oriented strands and a greater percentage of the web area has a solid polymer structure. This altered stretching behavior results in an oriented web that has higher strength and torsional rigidity characteristics. Thus lighter weight mesh structures which meet all of the physical property requirements for end-use applications, such as reinforcing grids to stabilize concrete and soil in civil engineering and landfill applications, are produced. The lighter weight extruded beta nucleated sheet can also be stretched at higher line speeds, thereby reducing the manufacturing costs.

Owner:MAYZO

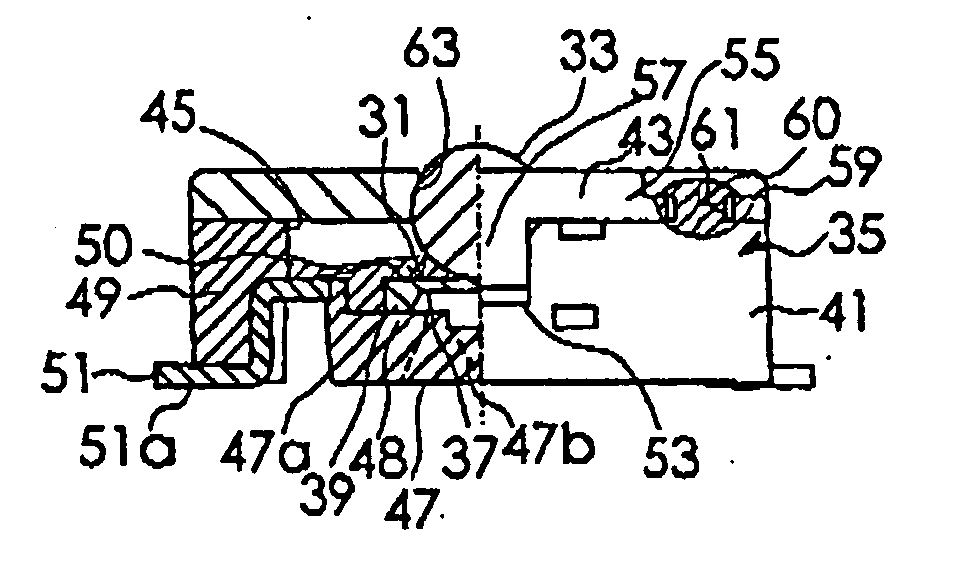

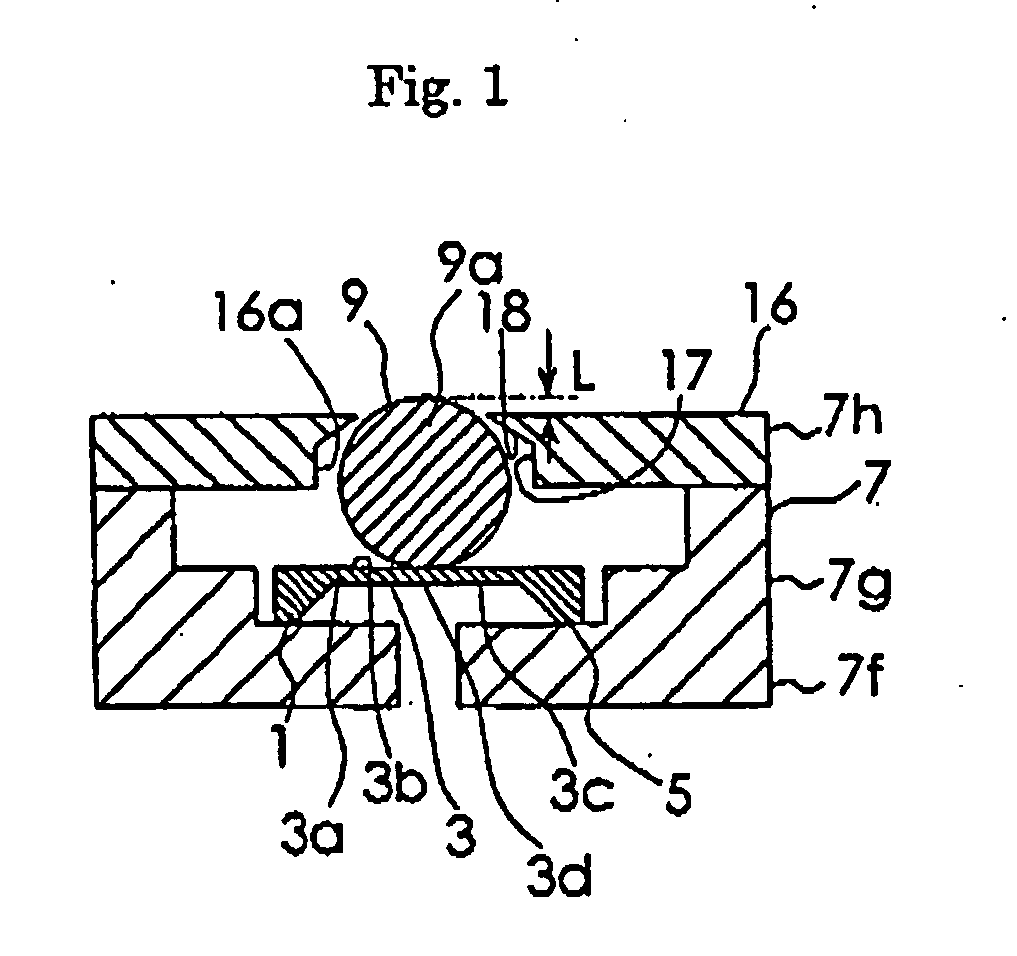

Semiconductor force sensor

ActiveUS20050217386A1Precise positioningWell formedTesting/calibration apparatusUsing electrical meansEngineeringForce sensor

A semiconductor force sensor capable of preventing a diaphragm part (37) from being broken and accurately measuring a force applied thereto in a direction orthogonal to the diaphragm part (37), wherein a force transmitting means for applying a measured force to the diaphragm part (37) of a semiconductor force sensor element (31) is formed of a sphere (33) having a rigidity, and a through hole (63) passing through an opposed wall part (55) toward the diaphragm (37) is formed in the opposed wall parts (55) at a position opposed to the center part of the diaphragm part (37) so that a part of the sphere (33) can face the outside of the opposed wall part (55) and stores a part of the remaining part of the sphere (33) to allow the sphere (33) to be moved only in a direction orthogonal to the diaphragm part (37) and rotated on the center part of the diaphragm part (37).

Owner:HOKURIKU ELECTRIC INDS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com