Patents

Literature

512results about How to "Uniform porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

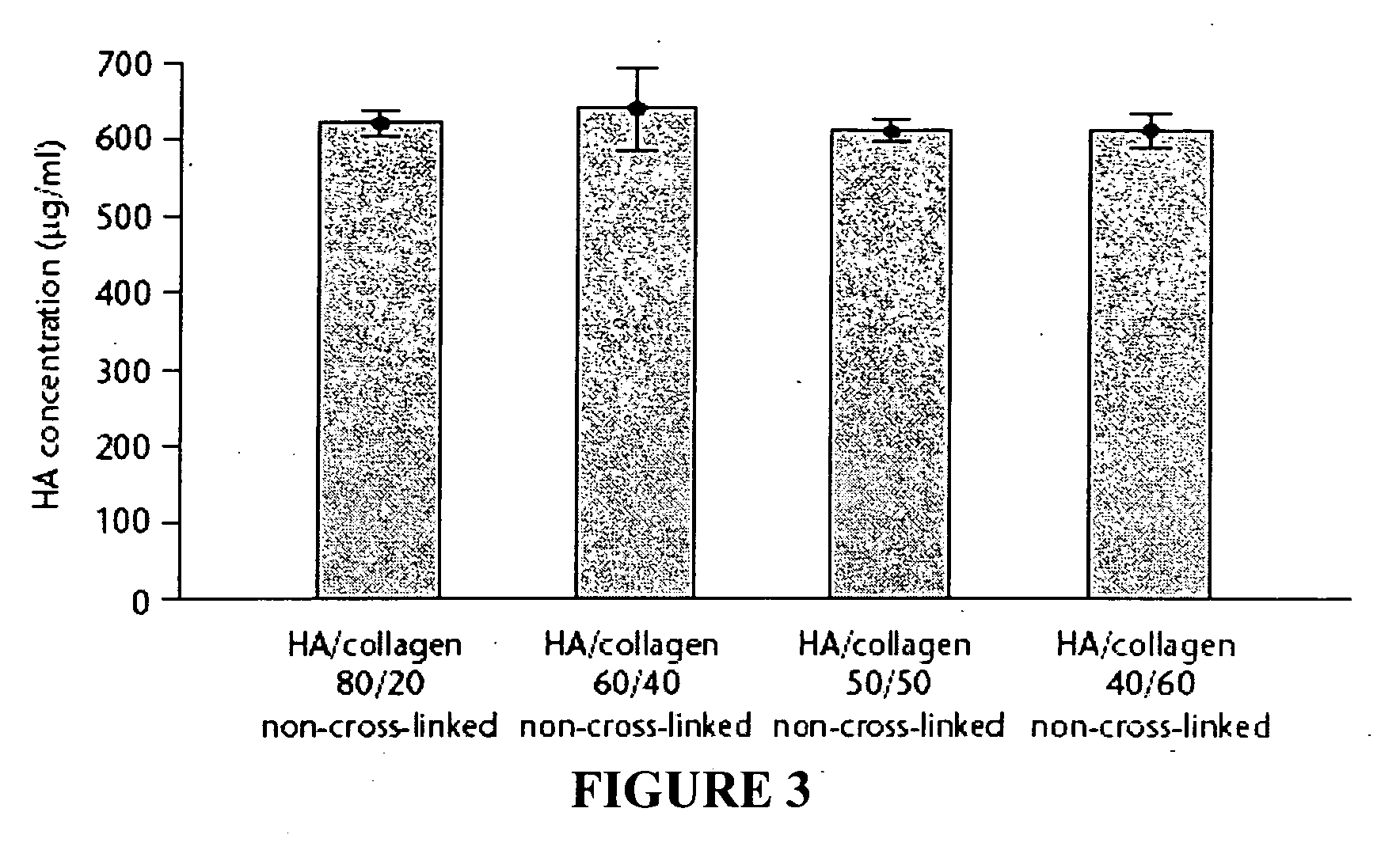

Method for producing cross-linked hyaluronic acid-protein bio-composites

InactiveUS20060189516A1Uniform densityUniform porosityPeptide/protein ingredientsSkeletal disorderCross-linkFiber

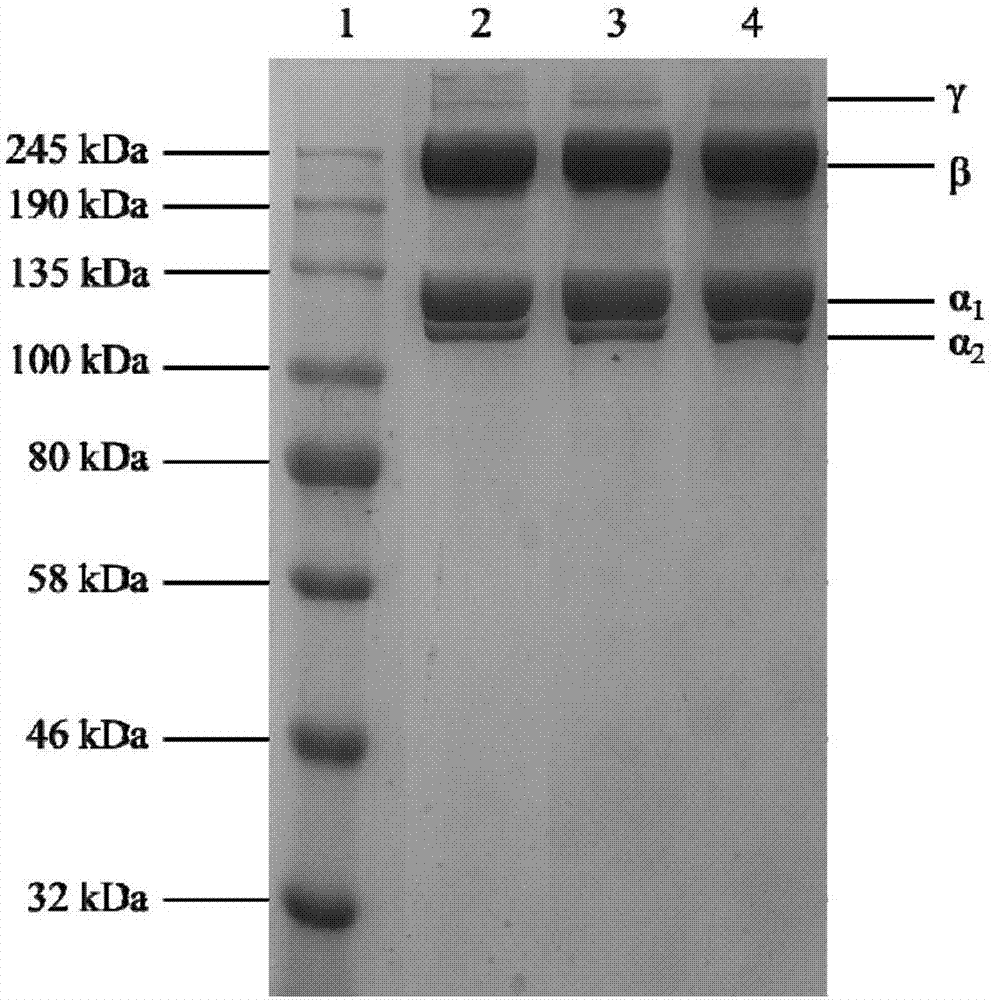

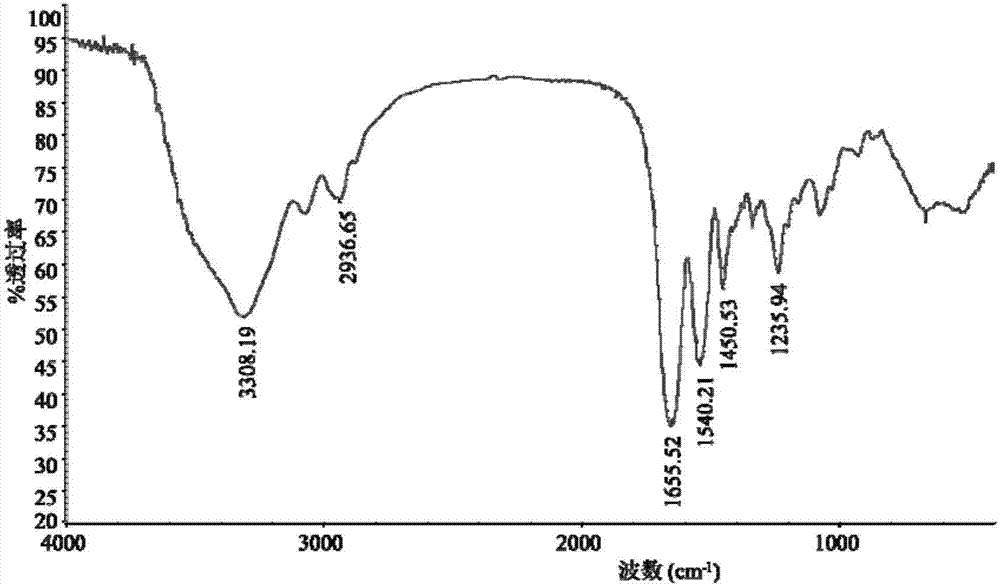

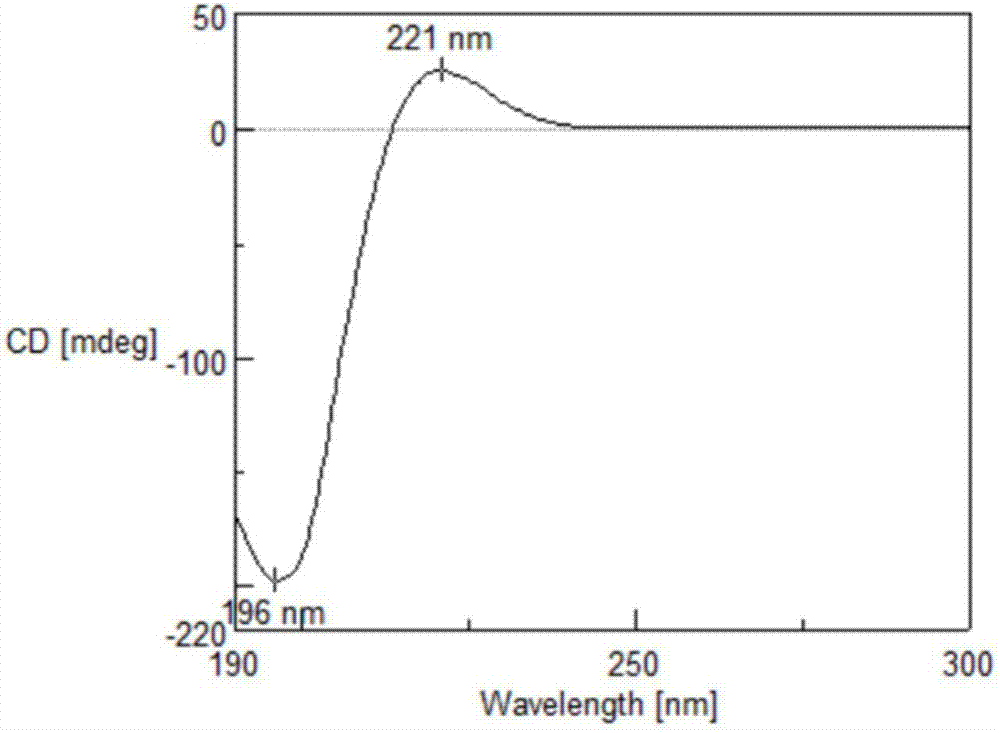

This invention is concerned with a new method for producing cross-linked hyaluronic acid—protein bio-composites in various shapes. In the present process, a polysaccharide solution and a protein solution are mixed under moderate pH values in presence of salts to form a homogenous solution, which can be processed into various shapes, such as membrane, sponge, fiber, tube or micro-granular and so on. After then, the homogenous solution is subjected to a cross-linking reaction in organic solvent containing weak acid to produce an implantable bio composite material having excellent bio-compatibility, biodegradability, prolonged enzymatic degradation time, and good physical properties.

Owner:IND TECH RES INST

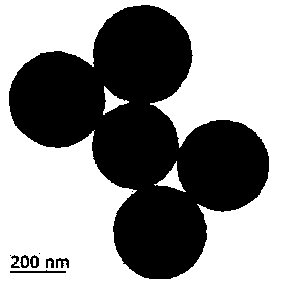

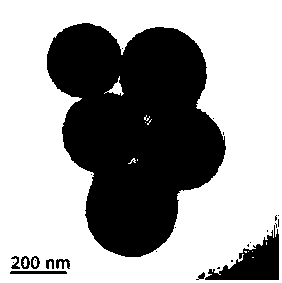

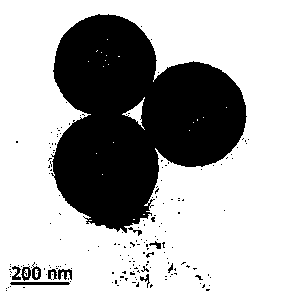

Tantalum powder for capacitors

InactiveUS6689187B2Suitable cohesive strengthUniform porosityElectrolytic capacitorsTransportation and packagingPorosityCapacitance

The tantalum powder for capacitors of the present invention has a specific surface area SB as determined by the BET method of 1.3 m<2> / g or more, and an SB / SF ratio between the specific surface area SB as determined by the BET method and the specific surface area SF determined by the FSS method of 4 to 10. This tantalum powder not only has a large specific surface area SB, but also has suitable cohesive strength and uniform porosity.Consequently, a solid state electrolytic capacitor having high capacitance and low ESR can be obtained by providing with a capacitor anode formed from a sintered body of this tantalum powder. In addition, whether or not this tantalum powder is suitable for the production of a tantalum capacitor having high capacitance and low ESR can be determined easily and reliably by evaluating the tantalum powder using the specific surface area SB as determined by the BET method and the SB / SF ratio between SB and the specific surface area SF determined by the FSS method.

Owner:GLOBAL ADVANCED METALS JAPAN

Tantalum powder for capacitors

InactiveUS20020050185A1Suitable cohesive strengthUniform porosityElectrolytic capacitorsTransportation and packagingPorosityCapacitance

The tantalum powder for capacitors of the present invention has a specific surface area SB as determined by the BET method of 1.3 m2 / g or more, and an SB / SF ratio between the specific surface area SB as determined by the BET method and the specific surface area SF determined by the FSS method of 4 to 10. This tantalum powder not only has a large specific surface area SB, but also has suitable cohesive strength and uniform porosity. Consequently, a solid state electrolytic capacitor having high capacitance and low ESR can be obtained by providing with a capacitor anode formed from a sintered body of this tantalum powder. In addition, whether or not this tantalum powder is suitable for the production of a tantalum capacitor having high capacitance and low ESR can be determined easily and reliably by evaluating the tantalum powder using the specific surface area SB as determined by the BET method and the SB / SF ratio between SB and the specific surface area SF determined by the FSS method.

Owner:GLOBAL ADVANCED METALS JAPAN

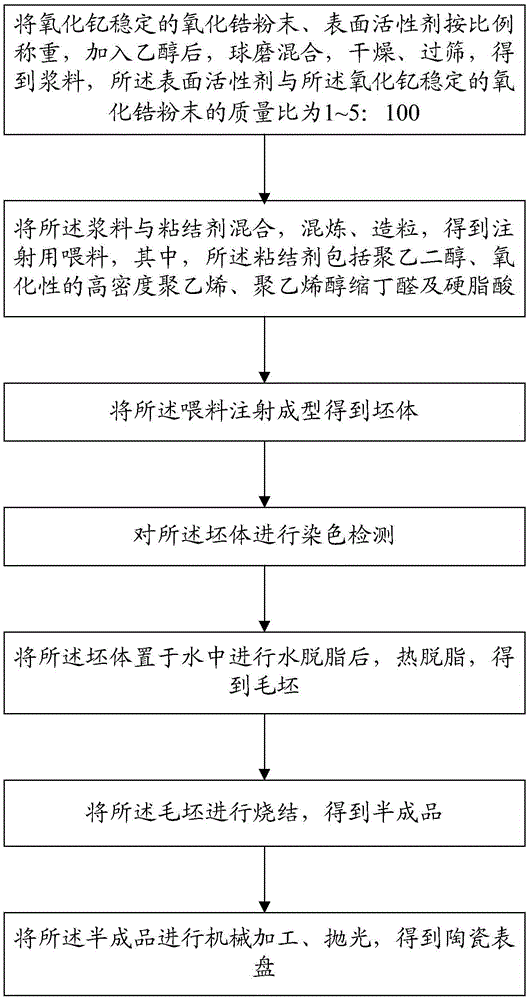

Preparation method of mobile telephone shell

ActiveCN105541324AHigh strengthAvoid breakingTelephone set constructionsLow-density polyethylenePolyethylene glycol

The invention discloses a preparation method of a mobile telephone shell. The preparation method comprises weighing yttrium oxide-stabilized zirconia powder and a surfactant according to a mass ratio of the surfactant to yttrium oxide-stabilized zirconia powder of 1-5: 100, adding ethanol into the weighed materials, carrying out ball milling mixing, carrying out drying and sieving to obtain slurry, mixing the slurry and a binder, carrying out mixing and granulation to obtain feed for injection, wherein the binder comprises polyethylene glycol, oxidizing high density polyethylene, polyvinyl butyral and stearic acid, carrying out injection molding on the feed to obtain a green body, carrying out staining detection on the green body, putting the green body into water, carrying out water debinding, carrying out thermal debinding to obtain a blank, sintering the blank to obtain a semifinished product, and carrying out machining and polishing on the semifinished product to obtain the mobile telephone shell. The mobile telephone shell has high strength, is not easily broken and has high density and uniform apertures. The preparation method has simple processes, operation easiness and high production efficiency.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

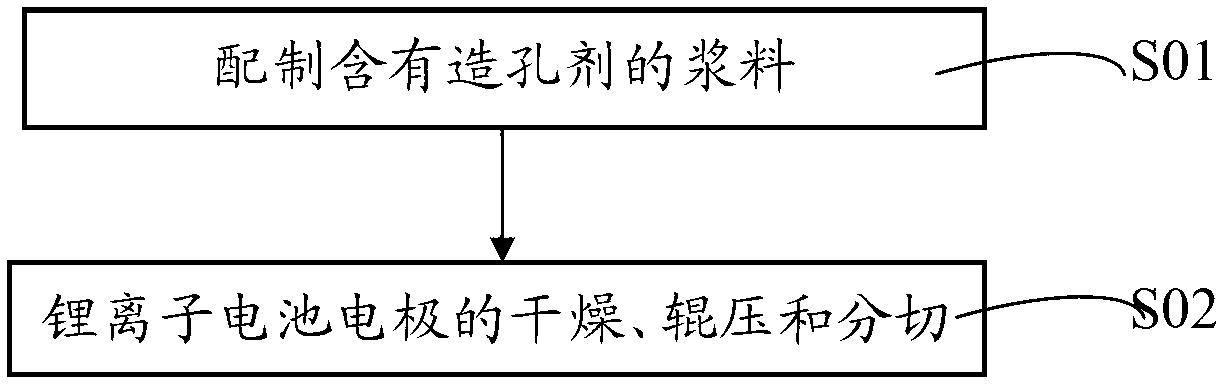

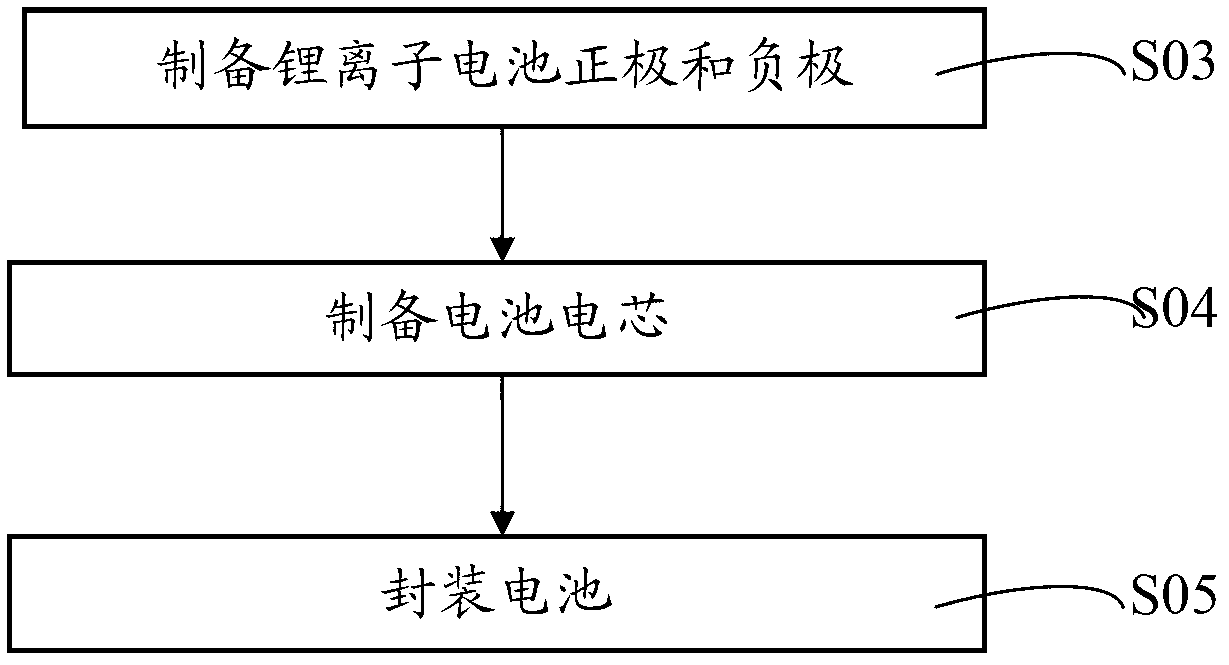

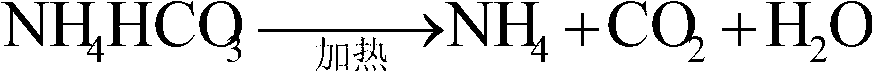

Lithium ion battery electrode, preparation method thereof and lithium ion battery

ActiveCN102931378AUniform porositySimple processSecondary cellsNon-aqueous electrolyte accumulator electrodesVoid ratioInternal resistance

The invention discloses a lithium ion battery electrode, a preparation method thereof, a lithium ion battery, and a preparation method and application of the lithium ion battery. The preparation method for the electrode of the lithium ion battery comprises a step of preparing slurry containing a pore forming agent and a step of drying, rolling and slitting the electrode of the lithium ion battery. The lithium ion battery comprises the lithium ion battery electrode prepared by the preparation method for the lithium ion battery electrode. The preparation method for the lithium ion battery electrode is simple, high in efficiency and suitable for industrial production, and conditions are easy to control. Voids in the prepared lithium ion battery electrode are uniformly distributed, and a void ratio is higher than that of an ordinary electrode. The lithium ion battery has low internal resistance, high cycle performance and high energy density, so that the application range of the lithium ion battery is widened.

Owner:DONGGUAN CHUANGMING BATTERY TECH

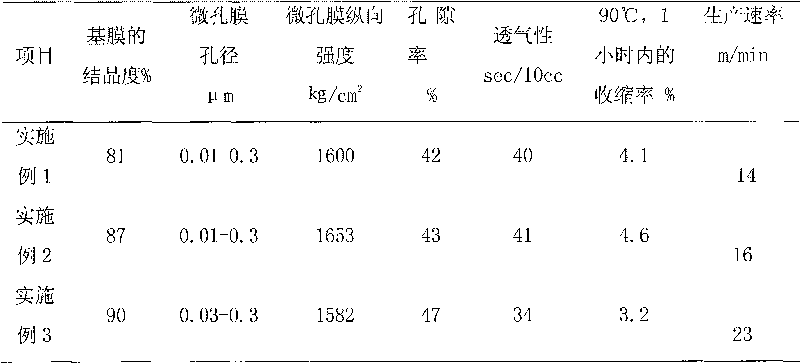

Preparation method of polyolefin microporous film

The invention relates to a preparation method of a polyolefin microporous film, aiming to solve the problems that the traditional preparation method of the polyolefin microporous film has complicated process, low production speed and poorer uniformity of microporous space. A polyolefin microporous film product is prepared by the following steps: a. base film preparation by casting; b. multi-stage annealing processing; c. hole forming by multipoint stretching; and d. heat setting processing. The method does not need solvent, has no pollution to the environment, low equipment investment, high production speed and uniform microporous space, and is suitable for preparing various polyolefin microporous films used for poromeric materials, ultra filtration, film filtration, super capacitors, battery diaphragm materials and the like.

Owner:CANGZHOU MINGZHU SEPARATOR TECH CO LTD

Lamellar corneal stroma bracket as well as preparation method and application thereof

The invention discloses a lamellar corneal stroma bracket as well as a preparation method and application thereof. The method comprises the following steps: carrying out low-permeability swelling, repetitive freeze-thawing, enzyme digesting, drying and sterilizing treatment on a corneal stroma sheet of a fresh animal eyeball cut down under a sterile condition, wherein the enzyme digesting adopts buffer liquor containing DNA (deoxyribonucleic acid) enzyme and RNA (ribonucleic acid) enzyme to treat, ultrasonic treatment is carried out after the enzyme digestion treatment, and then drying and sterilizing treatment is carried out. The invention further provides application of the lamellar corneal stroma bracket as a corneal stroma substrate. The method disclosed by the invention can be used for reducing damages on a corneal stroma collagen structure to the greatest extent; collagenous fiber arrangement is orderly, holes are uniform and regular, cell residues are avoided, the lamellar structure is kept complete, and the biocompatibility of the bracket material is improved.

Owner:QINGDAO CHUNGHAO TISSUE ENG

Preparation method of blocky SiO2-Y2O3 compound aerogel

The invention relates to a preparation method of a blocky SiO2-Y2O3 compound aerogel. The preparation method comprises the steps of: uniformly mixing tetraethyl orthosilicate, an acid catalyst, deionized water, absolute ethyl alcohol, yttrium chloride hexahydrate, ammonia water and the like to obtain a colorless clear SiO2-Y2O3 compound sol solution, drying to obtain a compound wet gel, carrying out solvent replacement on the compound wet gel and then drying to obtain the blocky SiO2-Y2O3 compound aerogel. The high-temperature thermal stability performance of a SiO2 aerogel material is improved by adopting a rare earth element doping mode so that the prepared SiO2-Y2O3 compound aerogel has all excellent characteristics of the original SiO2 aerogel, and has the advantages of higher temperature use range, complex structure, high specific area, low heat conductivity, low density and the like. The preparation method is simple and easy to operate, has the profound significance for improving the high-temperature thermal stability of the widely applied SiO2 aerogel material, and provides a new idea for improving the performance of the aerogel material.

Owner:江苏安珈新材料科技有限公司

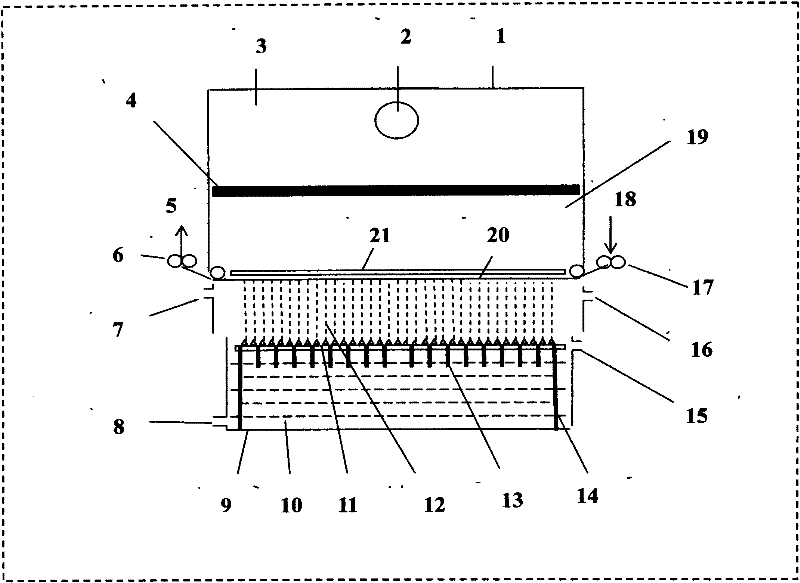

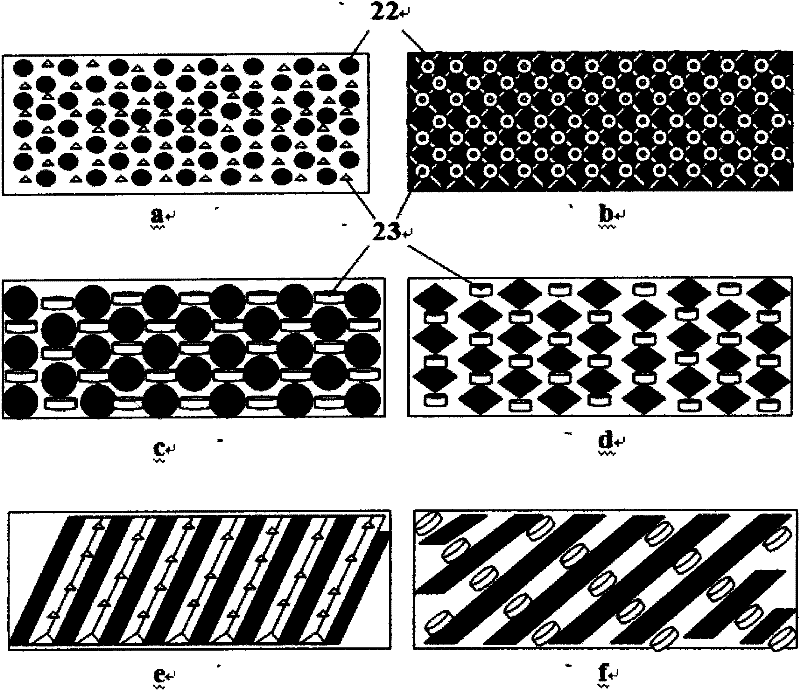

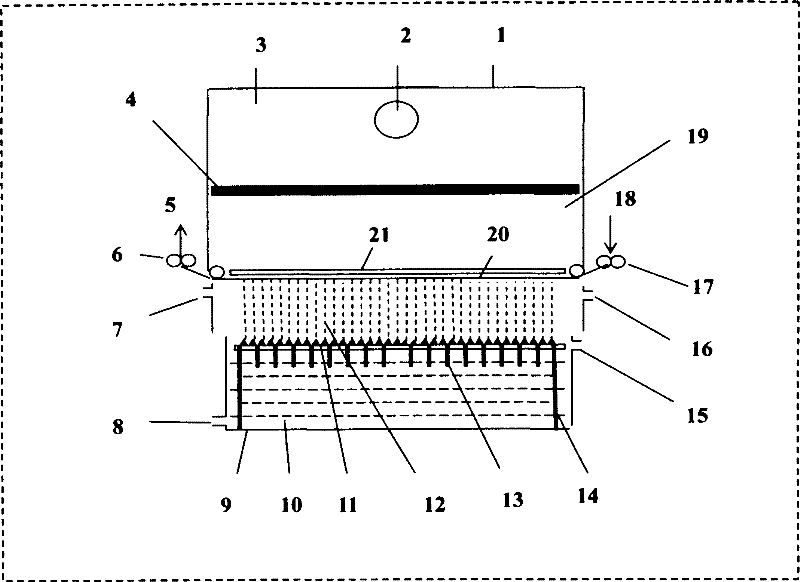

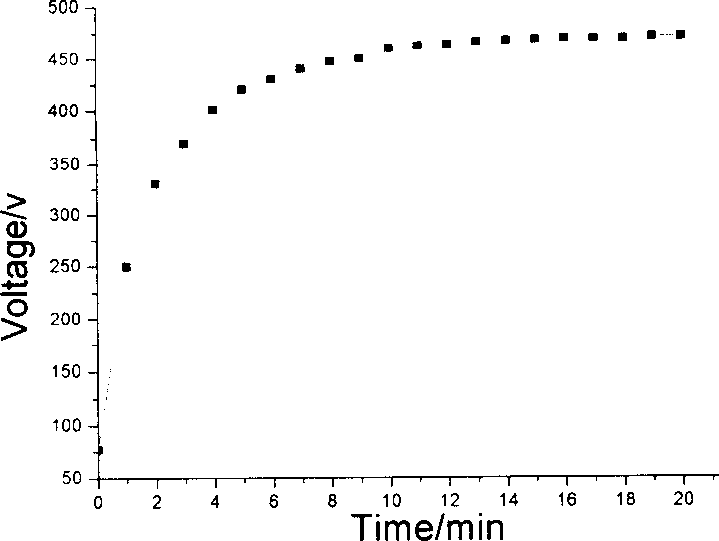

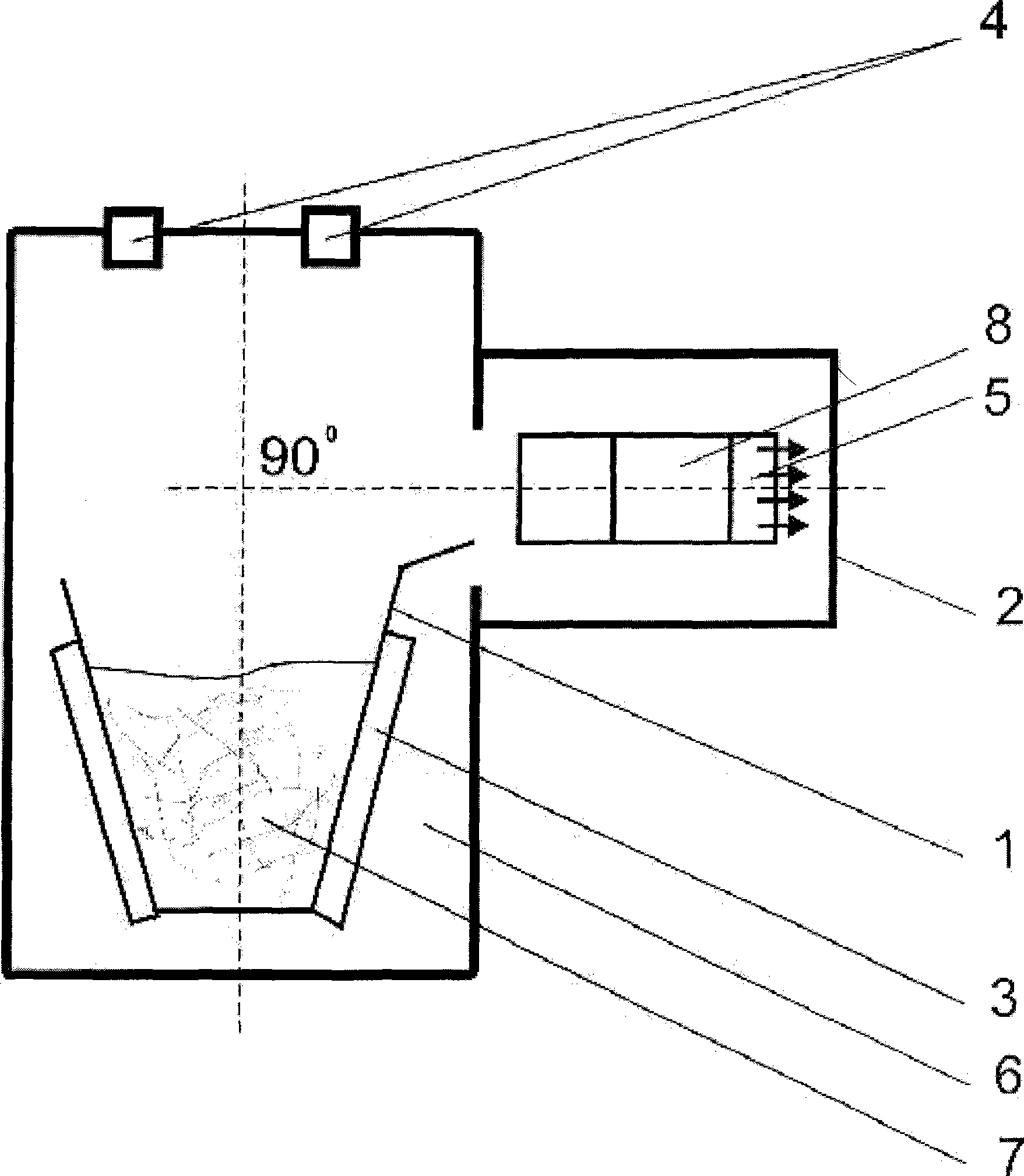

Continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes

InactiveCN102650095AImprove driftOvercoming electrostatic repulsionFilament/thread formingNon-woven fabricsElectrospun nanofiberNanofiber

The invention relates to a continuous mass production method and continuous mass production equipment for electrospun nanofiber membranes. The method comprises the following steps: (1), electrified electrodes are kept in a vibrating state to drive polymer liquor to a plurality of protrusions on the upper surfaces of the electrified electrodes, so as to form a Taylor cone, and ensure that the whole upper surfaces become spinning surfaces, which obtains high spinning production capacity; (2), air in the space between two electrodes is sucked to the back side of a counter electrode to generate an air flow, so that stressed drift of nanofiber is accelerated, and the nanofiber is sucked to be laid on a continuous receiving screen to form a membrane; and (3) the air flow is heated dry hot air. The equipment comprises a polymer container, the vibrating electrified electrodes, the continuous receiving screen, the counter electrode and a negative pressure chamber, wherein the upper surfaces of the vibrating electrified electrodes are approximately in accordance with the liquid level; the counter electrode is made of a metal mesh or a porous metal plate; the negative pressure chamber comprises a hood, a rear air chamber, a balancing plate and an air suction pump; each vibrating electrified electrode is a metal mesh-shaped plane or a porous metal flat plate; innumerous holes and innumerous small protrusions are formed on the plane; and the small protrusions are regularly arranged and higher than the plane. The invention facilitates mass production of the electrospun nanofiber membranes.

Owner:谢维

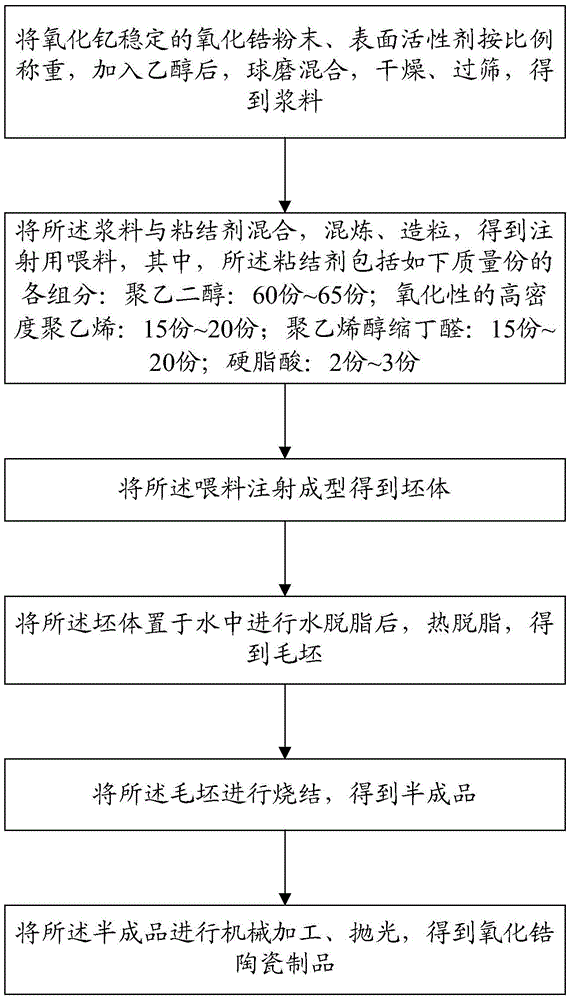

Forming method for zirconia ceramic products

The invention discloses a forming method for zirconia ceramic products. The forming method comprises the following steps: weighing yttria-stabilized zirconia powder and a surfactant in a ratio, adding ethanol, carrying out ball-milling mixing, drying, and sieving to obtain a slurry; mixing the slurry with a binder, mixing, and granulating to obtain a feedstock for injection, wherein the binder comprises the following components in parts by mass: 60-65 parts of polyethylene glycol, 15-20 parts of oxidizing high-density polyethylene, 15-20 parts of polyvinyl butyral, and 2-3 parts of stearic acid; carrying out injection forming on the feedstock to obtain green bodies; placing the green bodies in water and carrying out water debinding, and carrying out thermal debinding to obtain blanks; sintering the blanks to obtain semi-finished products; and machining and polishing the semi-finished products to obtain the zirconia ceramic products. The forming method for the zirconia ceramic products, which is disclosed by the invention, is capable of guaranteeing that the obtained ceramic products are high in strength, not liable to break, high in compactness, and uniform in porosity.

Owner:DONGGUAN XINBO STRUCTURAL CERAMICS CO LTD

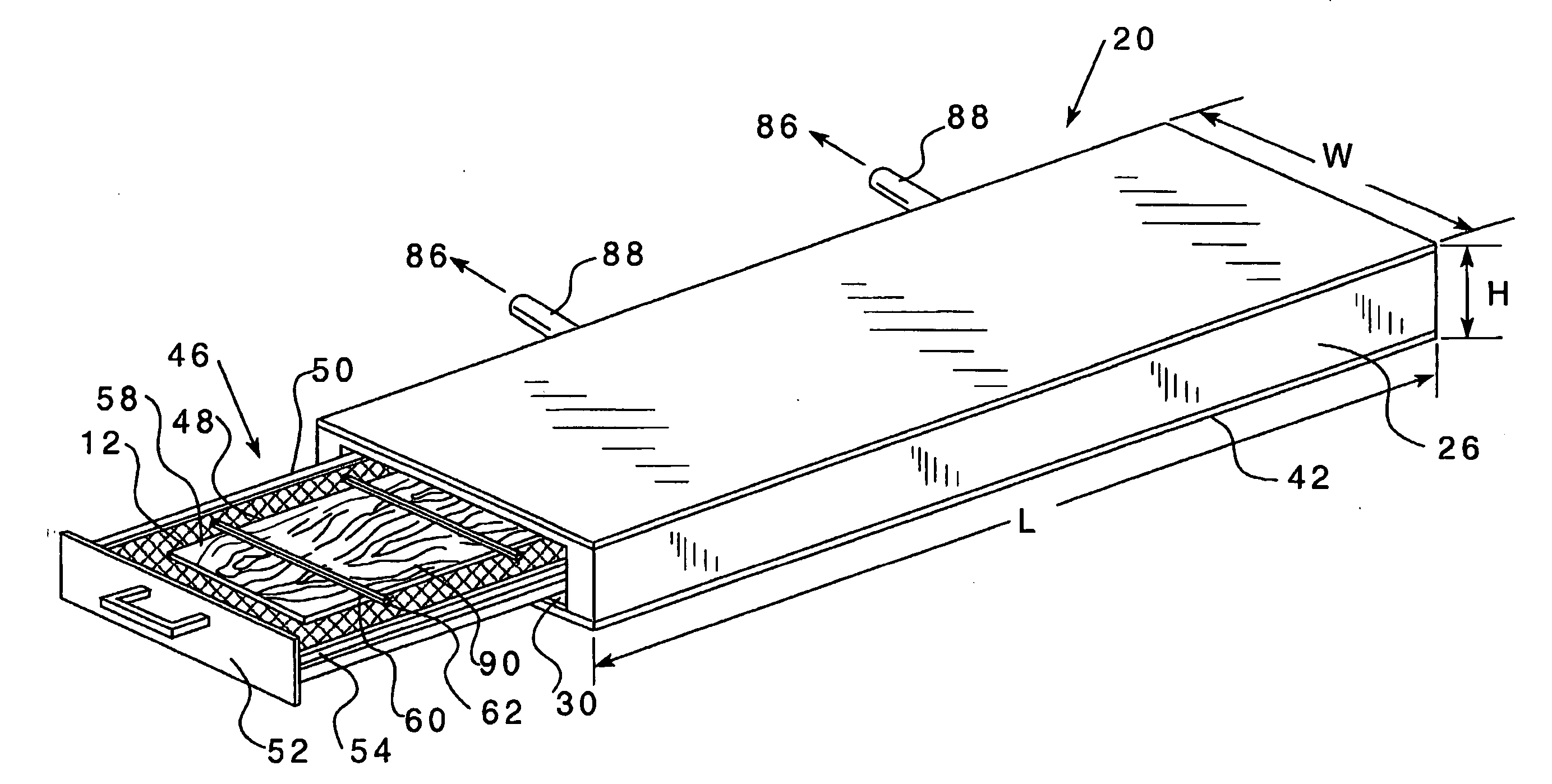

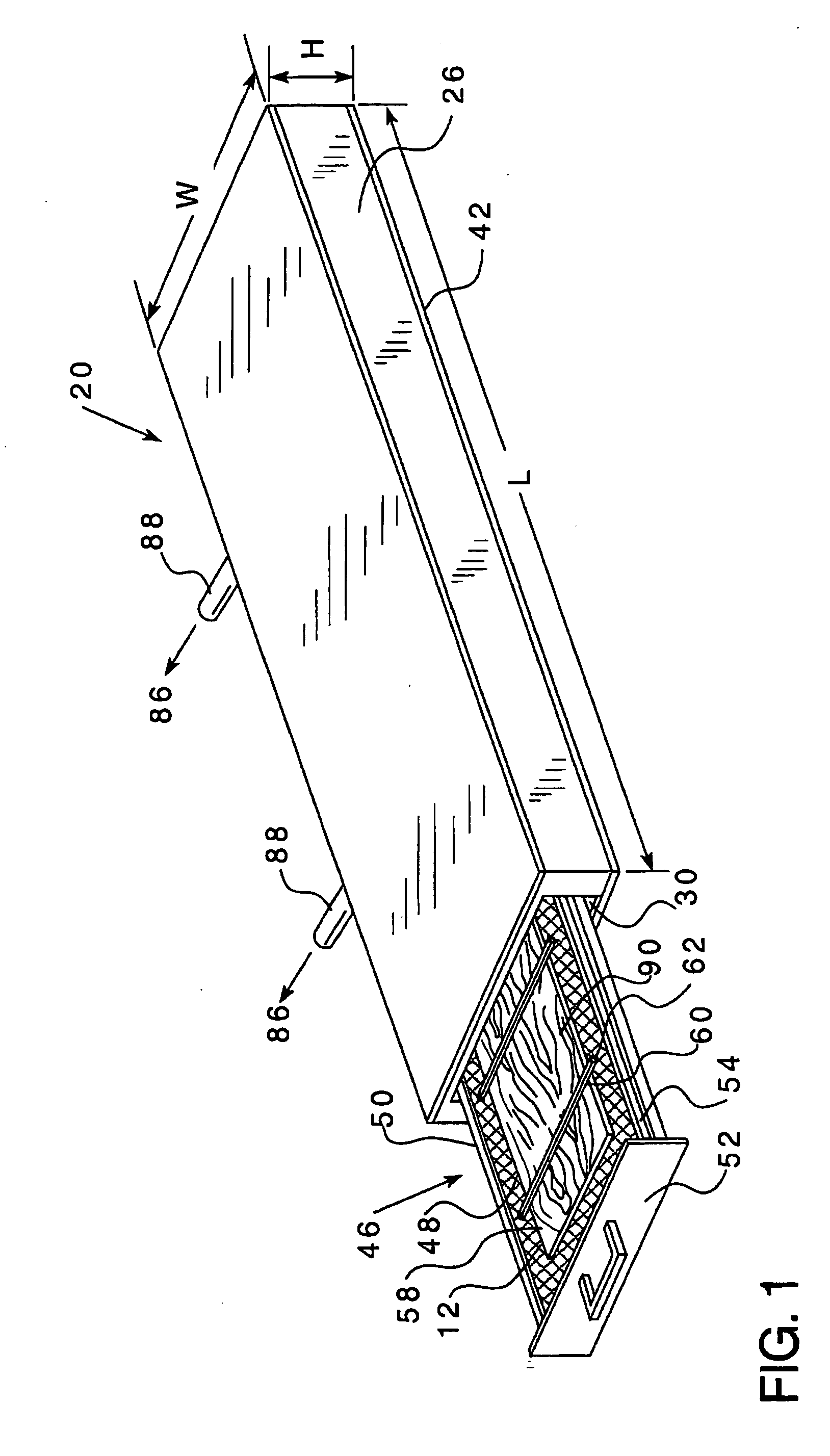

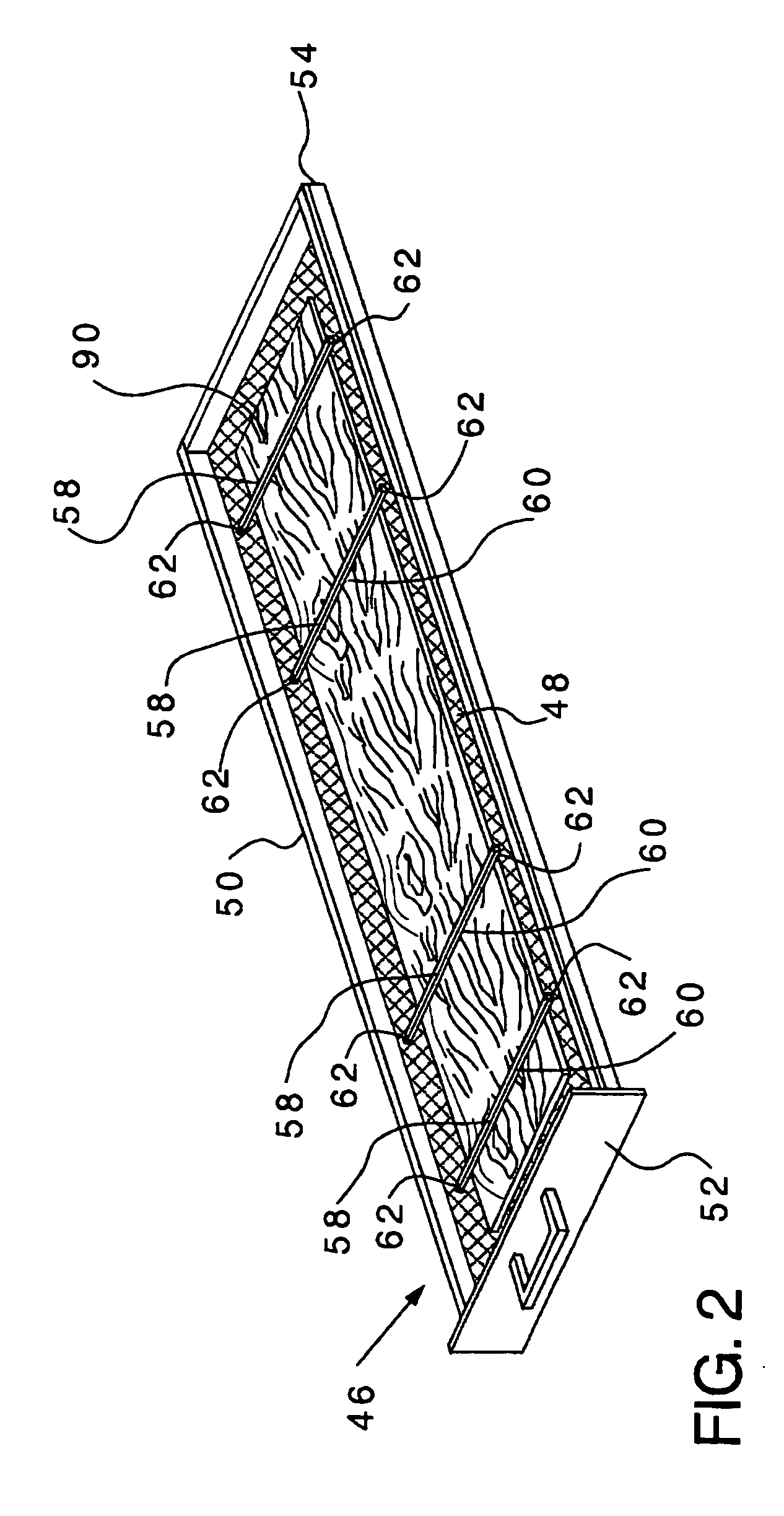

Method and apparatus for drying materials including veneers

InactiveUS20050217136A1Uniform porosityImproved control and monitoringDrying solid materials without heatDrying machines with progressive movementsHermetic sealEngineering

An apparatus and method is provided to dry veneer or other items by vaporization of moisture in the item. Apparatus has an insulated chamber with a frame and a drawer with a door. A mesh surface of the drawer supports item for drying with a heater at sub-atmospheric pressure inside of the chamber. Item is placed on the layer of mesh of the drawer of the apparatus and secured with fasteners such as another layer of mesh. The drawer with fastened item is placed into the chamber of the apparatus. With the drawer fully engaged within the chamber, the drying apparatus is closed with an airtight seal. A pump draws a vacuum in the chamber and heat is directed at the item to raise the temperature of the item to less than 160° F., particularly between 120° F. to 150° F. Apparatus can dry veneer in less than five minutes.

Owner:BASE POINT

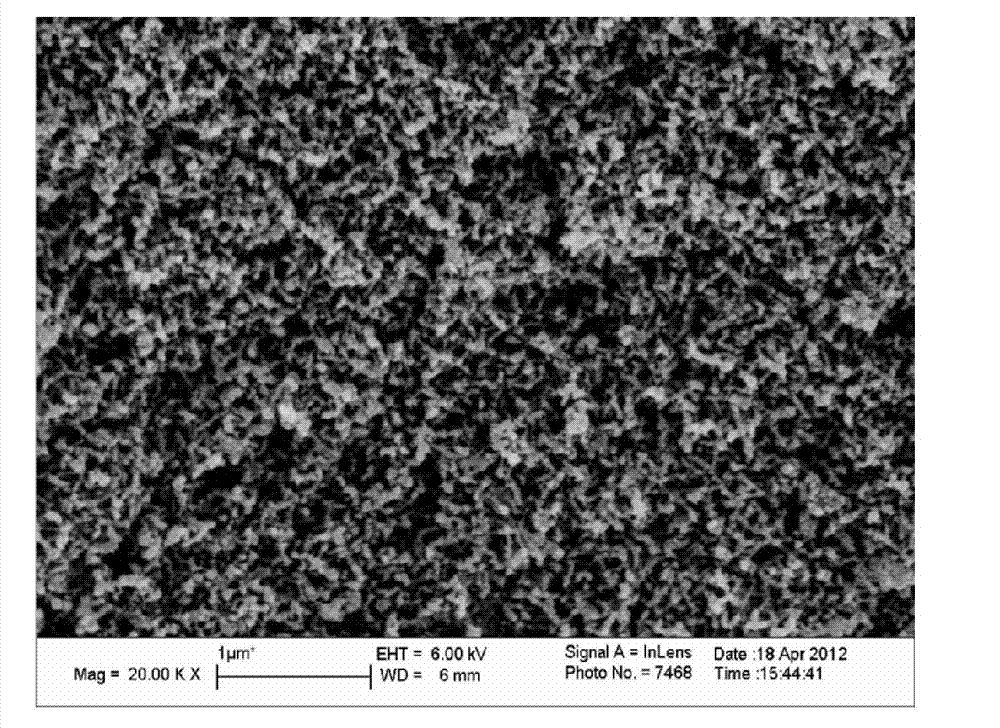

Preparation method for petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth

InactiveCN107591527AUniform particle sizeStable structureMaterial nanotechnologyCell electrodesTetraethyl orthosilicateEnvironmental resistance

The invention relates to a preparation method for a petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth, and belongs to the technical field of nanometer material production. The preparation method comprises the steps of mixing ethanol, deionized water, ammonia water, tetraethyl orthosilicate, resorcinol and formaldehyde for reaction; drying a solid phase and performing calcination in argon; etching the solid phase with a sodium hydroxide solution to obtain the solid phase, and drying the solid phase to obtain the hollow mesoporous carbon nanometer sphere; mixingsodium molybdate dihydrate, thiourea and the hollow mesoporous carbon nanometer sphere for hydrothermal reaction, performing centrifugal washing after hydrothermal reaction, drying the solid phase, and performing high-temperature calcination under protection of argon atmosphere to obtain the petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth. The preparation method has the advantages that the raw material is low in cost, the process is environmental-friendly, high yield is achieved, and the prepared petal-shaped molybdenum disulfide hollow mesoporous carbon sphere by in-situ growth can be used as a lithium ion battery electrode material, a photocatalytic material or an electrocatalytic material.

Owner:YANGZHOU UNIV

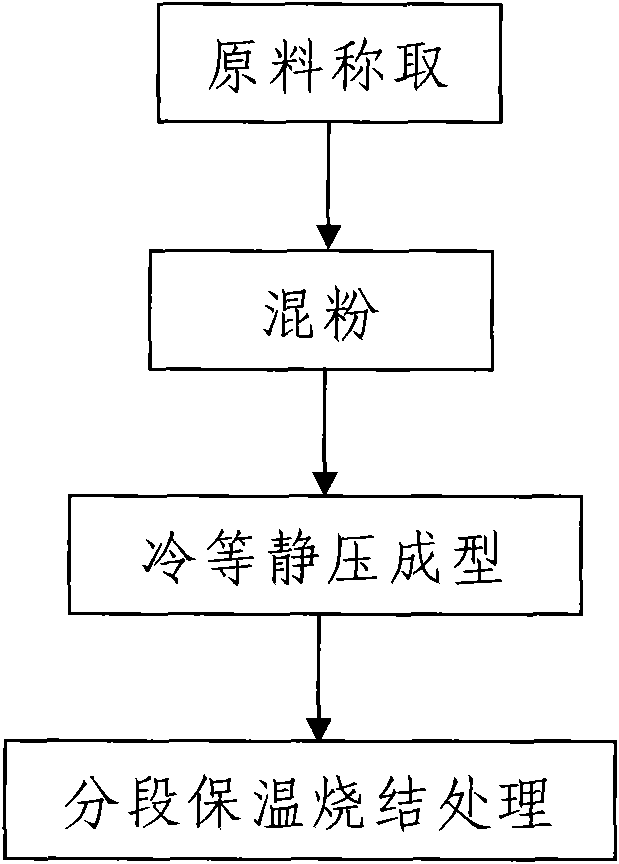

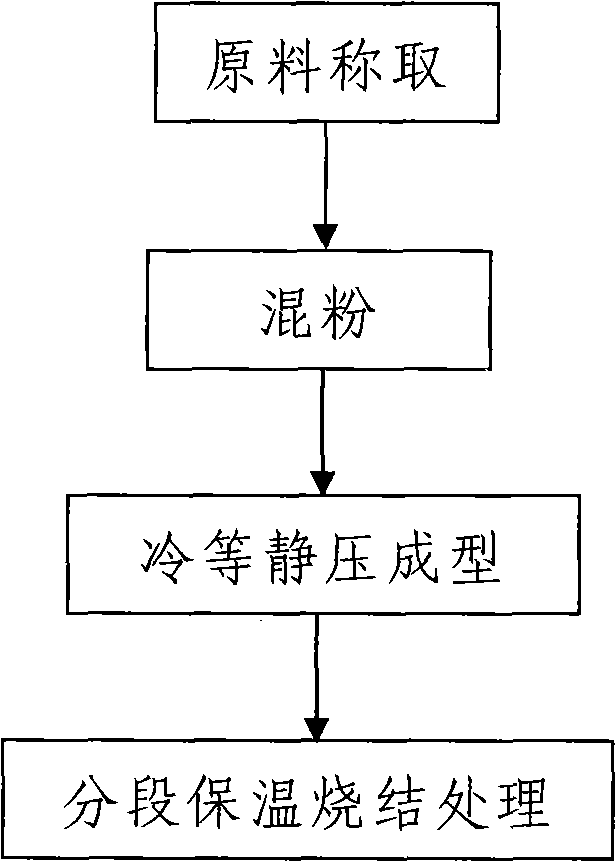

Method for preparing large powder metallurgy TZM blank with uniform carbon and oxygen distribution

The invention discloses a method for preparing a large powder metallurgy TZM blank with uniform carbon and oxygen distribution, which comprises the following steps of: 1, weighing raw materials; 2, mixing powder, namely mixing the weighed four raw materials twice under vacuum or the protection of inert gas, mixing titanium hydride powder, zirconium hydride powder and carbon black powder to prepare mixed powder, adding a volatile organic solvent into the mixed powder, uniformly stirring to prepare suspension, adding the weighed molybdenum powder into the suspension for uniform mixing, and adding residual molybdenum powder for uniform mixing; 3, performing cold isostatic pressing; and 4, sintering by keeping the temperature at stages, namely adopting a vacuum sintering furnace and sintering at three stages, wherein the process comprises the following steps of: raising the temperature at the first stage, raising the temperature at the second stage, and sintering at high temperature. The preparation method has the advantages of reasonable design, simple and convenient operation, and good using effect. The carbon content in the center and on the surface of the prepared larger-size TZM blank can be controlled to be approximately consistent, and the oxygen content in the center and on the surface of the TZM blank also can be reduced to a lower level.

Owner:NORTHWEST INSTITUTE FOR NON-FERROUS METAL RESEARCH

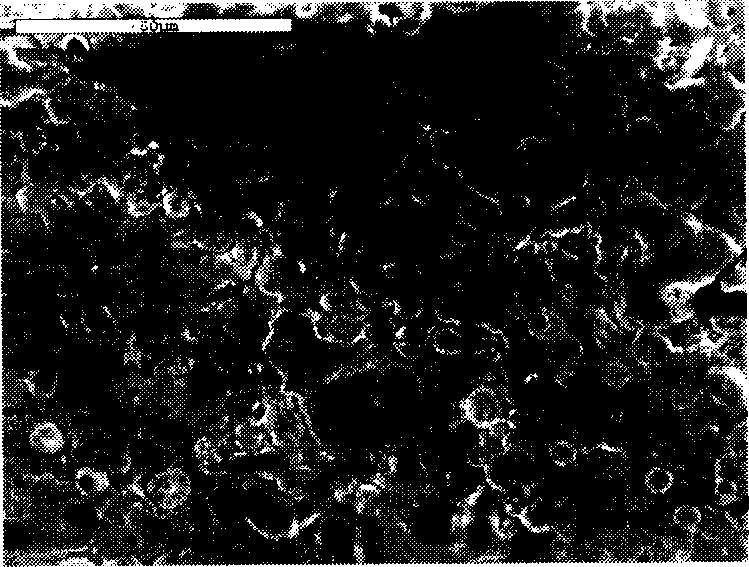

Medical porous tantalum metal material and preparation method thereof

ActiveCN105177523AHigh porosityUniform porosityBone implantTissue regenerationPorous tantalumGas phase

The invention discloses a medical porous tantalum metal material and a preparation method thereof. The medical porous tantalum metal material is prepared through the steps that through a chemical vapor deposition method, tantalum metal compounds are reduced to tantalum metal powder, the tantalum metal powder is evenly deposited on the surface of a porous silicon support to form a tantalum coating, and then the medical porous tantalum metal material is prepared, wherein one of tantalum pentachloride and fluoride tantalum is adopted as the tantalum metal compounds, the porosity of the porous silicon support is larger than 70 percent, the pore diameter of the porous silicon support is 100-600 micrometers, and the thickness of the tantalum coating is 10-50 micrometers. According to the medical porous tantalum metal material and the preparation method thereof, the porous tantalum metal material is of a communicated porous structure, is high in porosity, uniform in pore, few in pore dead space and similar to the cancellous bones of a human body and can promote bone ingrowth and be applied to bone defect repair after bone trauma and osteonecrosis of multiple portions in the human body occur.

Owner:伟坦(大连)生物材料有限公司

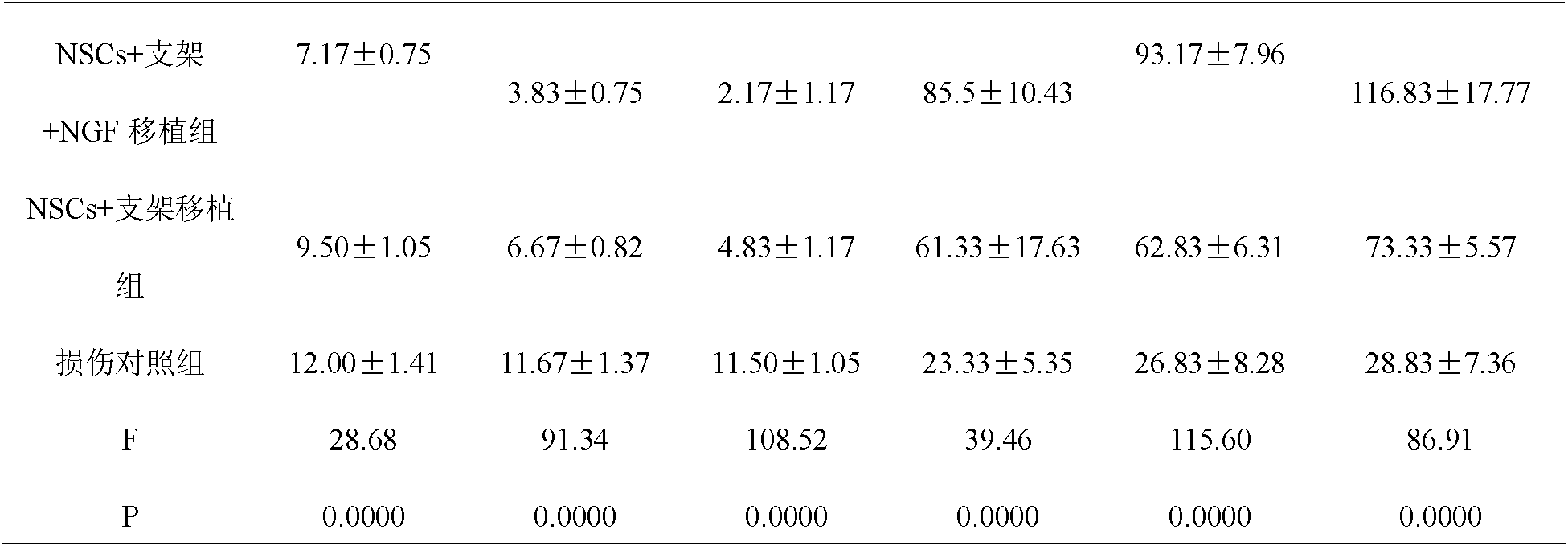

Porous chitosan scaffold, and neural stem cell porous chitosan scaffold and application thereof

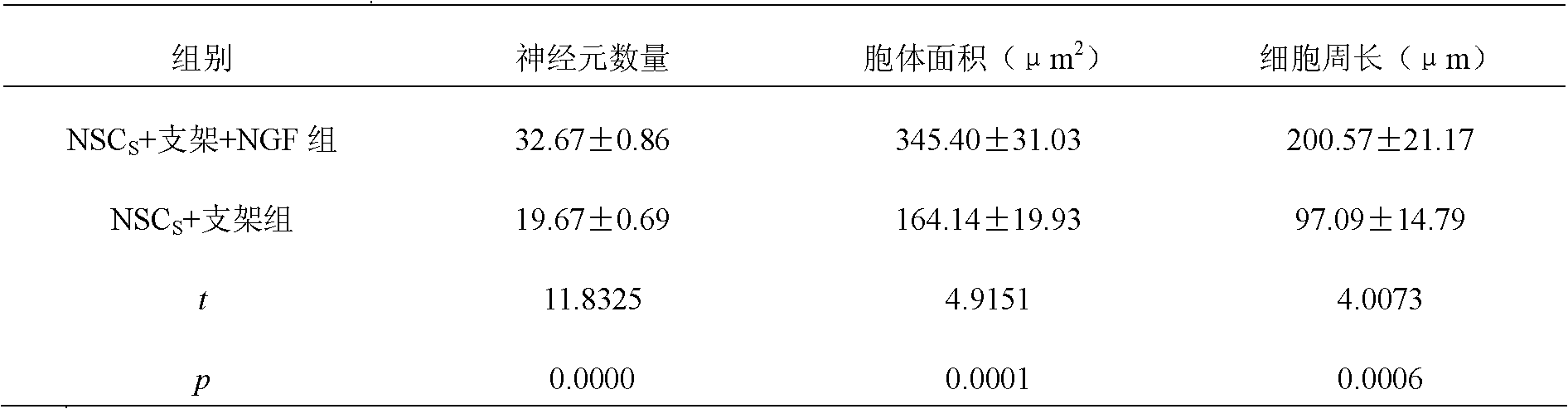

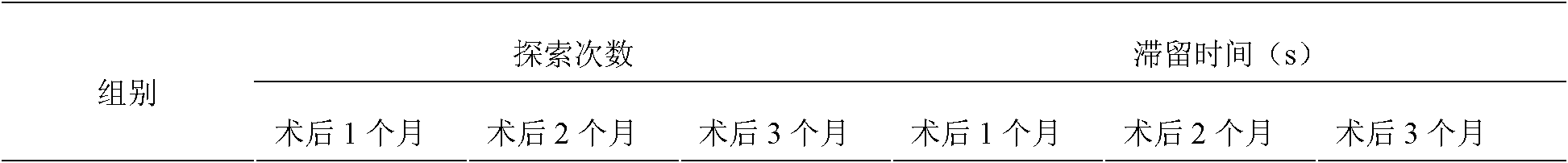

InactiveCN101979104AUniform porosityGood biocompatibilityProsthesisFreeze-dryingBiocompatibility Testing

The invention discloses a porous chitosan scaffold, and a neural stem cell porous chitosan scaffold and application thereof. A method for preparing the porous chitosan scaffold comprises the following steps of: dissolving chitosan in acetic acid to form 2 percent solution, adding the solution into pores of a cell culture plate, freeze-drying, adding NaOH into the pores of the cell culture plate for hydration, and freeze-drying twice at the temperature of -60 DEG C to obtain the porous chitosan scaffold. A method for preparing the neural stem cell porous chitosan scaffold comprises the following steps of: inoculating neural stem cell clone spheres to the sterilized porous chitosan scaffold in the culture spores, and adding a DMEM / F12 serum-free culture medium or an NGF-containing DMEM / F12 serum-free culture medium for culture to obtain the neural stem cell porous chitosan scaffold. The chitosan porous scaffold prepared by a low-temperature freeze-drying method has uniform pores, the porosity of 90 percent, the average pore size of 50 to 350mu m and high biocompatibility with neural stem cells (NSCs). Traumatic brain injury (TBI) is treated by transplanting the NSCs using chitoson as a carrier, and cognitive functions after injury, such as learning, memorizing and the like can be obviously improved.

Owner:NANTONG UNIVERSITY

Electrolytic solution for differential arc oxidization surface treatment of magnesium aluminum alloy in aluminates system

InactiveCN1737210ABroad marketHigh electrochemical impedanceAnodisationElectrolysisPlasma electrolytic oxidation

The invention relates to an electrolytic solution used to oxygenize surface of aluminum-magnesium alloy work-piece by differential arc. Said electrolytic solution comprises 4-40g / L of sodium aluminate, 0-10g / L of caustic soda and other assistants. The invention can generate a ceramic film with smooth surface, strong resistance to soiling, corrosion resistance and great mechanical behavior.

Owner:JILIN UNIV

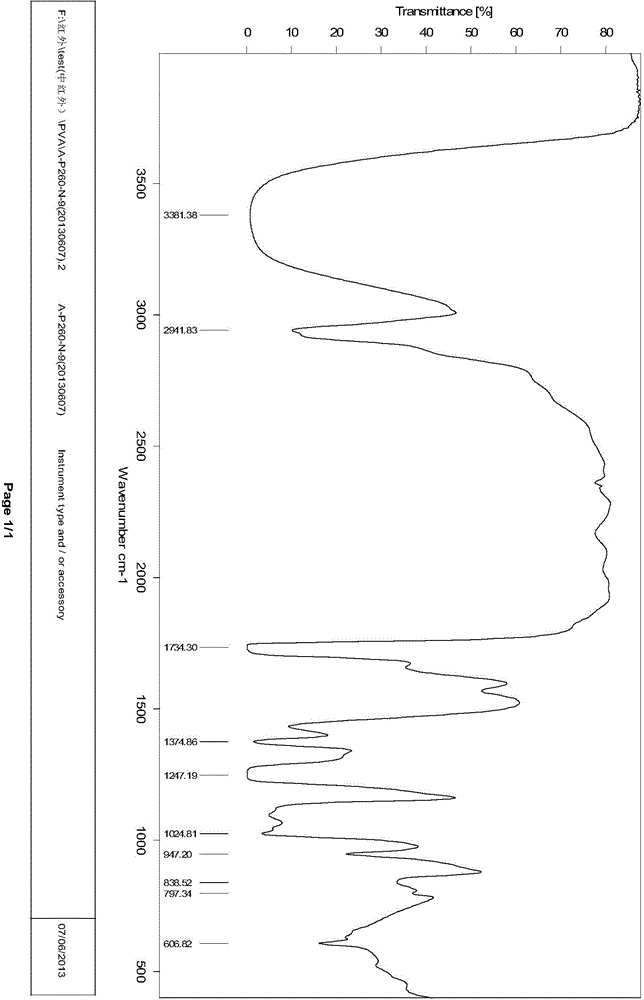

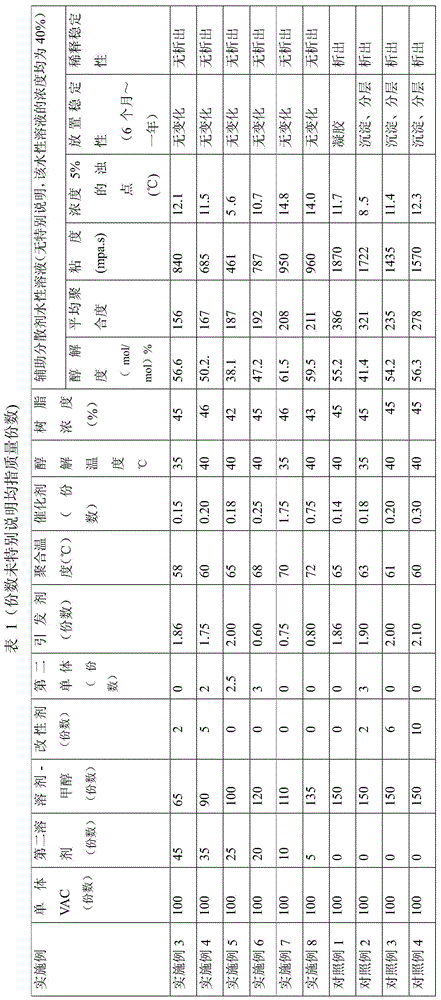

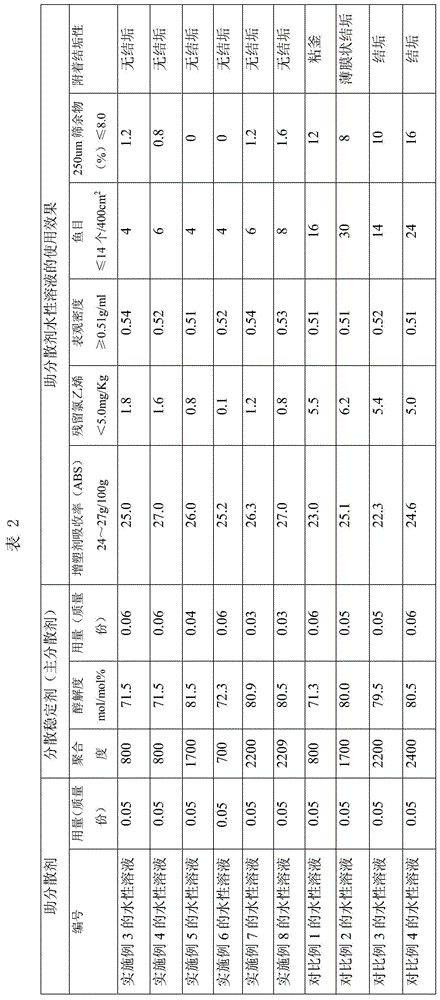

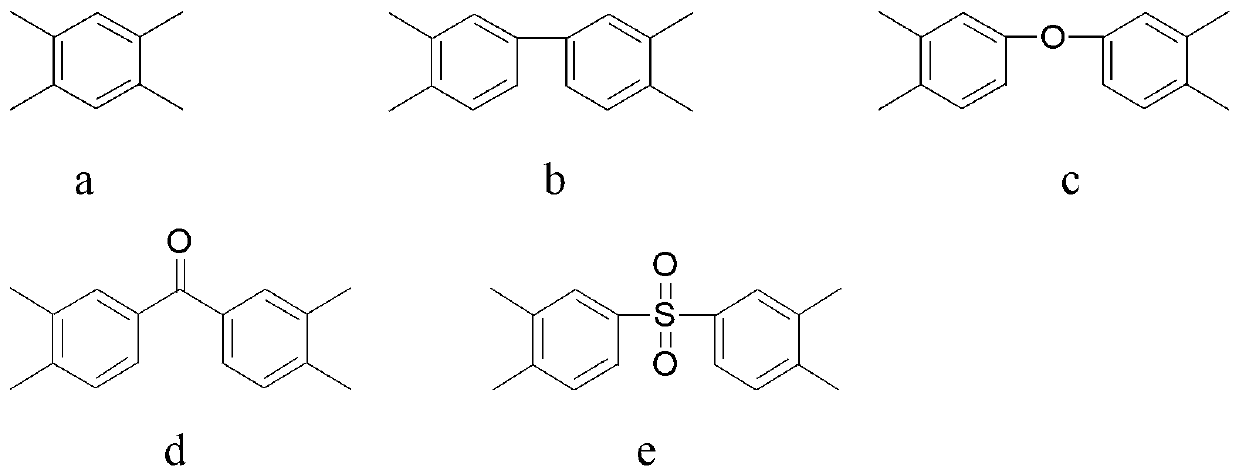

Polyvinyl alcohol, and preparation method and application thereof

The invention provides polyvinyl alcohol, which is characterized by having the average degree of polymerization in a range of 50-500, the alcoholysis degree in a range of 30-65 mol%, and the viscosity no more than 1500 mPa*s. Polyvinyl alcohol is prepared into an aqueous solution, which is taken as an auxiliary dispersant for suspension polymerization of vinyl polymers. The cloud point of an aqueous solution, the concentration of which is 5 wt%, (that is, a polyvinyl alcohol aqueous solution of 5 wt%), is no less than 1 DEG C and less than 15 DEG C. The viscosity measured at 25 DEG C of an aqueous solution, the concentration of which is 40 wt%, is no more than 1500 mpa*s. Gel and layering don't appear in an aqueous solution, the concentration of which is in a range of 30wt%-50wt%, in at least one year, so that the aqueous solution is extremely excellent in stability.

Owner:CHINA PETROCHEMICAL CORP +1

Nanofiber non-woven cloth and manufacture method and application thereof

ActiveCN103132240AHigh porosityUniform porosityFilament/thread formingMonocomponent synthetic polymer artificial filamentElectrospinningSizing

The invention relates to the field of non-woven cloth and discloses nanofiber non-woven cloth and a manufacture method and application thereof. The nanofiber non-woven cloth comprises polyimide nanofiber with the diameter of 50-1500nm and nanometer kaolin, wherein the proportion of the polyimide to the nanometer kaolin by weight is 55:45-95:5. The thickness of the nonofiber non-woven cloth is 10-60mu m, the air permeability is 2-200s, the tensile strength is 10-120MPa, and the average porosity is 50-90%. The invention further provides the manufacture method of the nanofiber non-woven cloth. The method includes: preparing spinning solution, performing spinning through electrostatic spinning, and preparing the nanofiber non-woven cloth through hot imine treatment and hot-pressing sizing. The invention further discloses the application of the nanofiber non-woven cloth. The nanofiber non-woven cloth has the advantages of being high in porosity, small in aperture, even in pore space, good in thermal stability and good in mechanical performance.

Owner:SHENZHEN ZHONGXING NEW MATERIAL TECH CO LTD

Manufacturing method of macrofiber porous metal material

The invention discloses a manufacturing method of a macrofiber porous metal material. The method comprises the following steps: firstly, metal macrofiber filaments are woven into a weaving body, the minimal feature size of the shape of the weaving body is 5 times larger than the maximum feature size of the cross sections of the metal macrofiber filaments, and when the cross sections of the metal macrofiber filaments are round, the minimal feature size of the shape of the weaving body is larger than 5 times of filament diameter; secondly, a metallurgical bonding process is performed on the weaving body, so as to enable the contact parts of the filaments to achieve metallurgical bonding and the non-contact parts of the wires to form pores, and the pores are distributed in the filament track direction; finally, the required macrofiber porous metal material can be manufactured and obtained. The macrofiber porous metal material manufactured by adopting the manufacturing method provided by the invention has continuous macrofiber, high wire mechanical property, high fatigue strength and anti-impact property, has the rigidity which is the same as that of a conventional volume material, and can be machined, as a common metal material, to be mechanical parts with bearing force and in constitutive structure shapes.

Owner:SOUTH CHINA UNIV OF TECH

Compound multilayer medical dressing of aquatic biological source crosslinking collagen

ActiveCN107233613AWide variety of sourcesIncrease profitConnective tissue peptidesSurgical adhesivesFreeze-dryingCollagen sponge

The invention discloses an aquatic biological source medical collagen with high purity and activity, and is capable of solving the problems of a natural collagen dressing that the mechanical strength is bad, the degradation resistance ability is weak and the wound is easily infected by microorganisms. An acid extraction method and a method of removing telopeptide by pepsase are used for extracting the collagen, the extraction ratio is improved by the ultrahigh pressure treatment and a tissue mashing method, and through a series of purification operations, such as decellularization, protein elimination, degreasing, repeated salting out, dialysis, degerming, decoloration and heat source removal, the medical collagen with the high purity and activity is prepared. A netlike collagen sponge with uniform pores is prepared by a vacuum freeze-drying technology, and the collagen sponge is modified by a physical crosslinking and chemical crosslinking mode so as to prepare the inner layer, and is compounded with a chitosan outer layer film and a medical non-woven fabric base cloth layer, finally a compound multilayer medical dressing finished product is obtained by Co-60 sterilization.

Owner:OCEAN UNIV OF CHINA

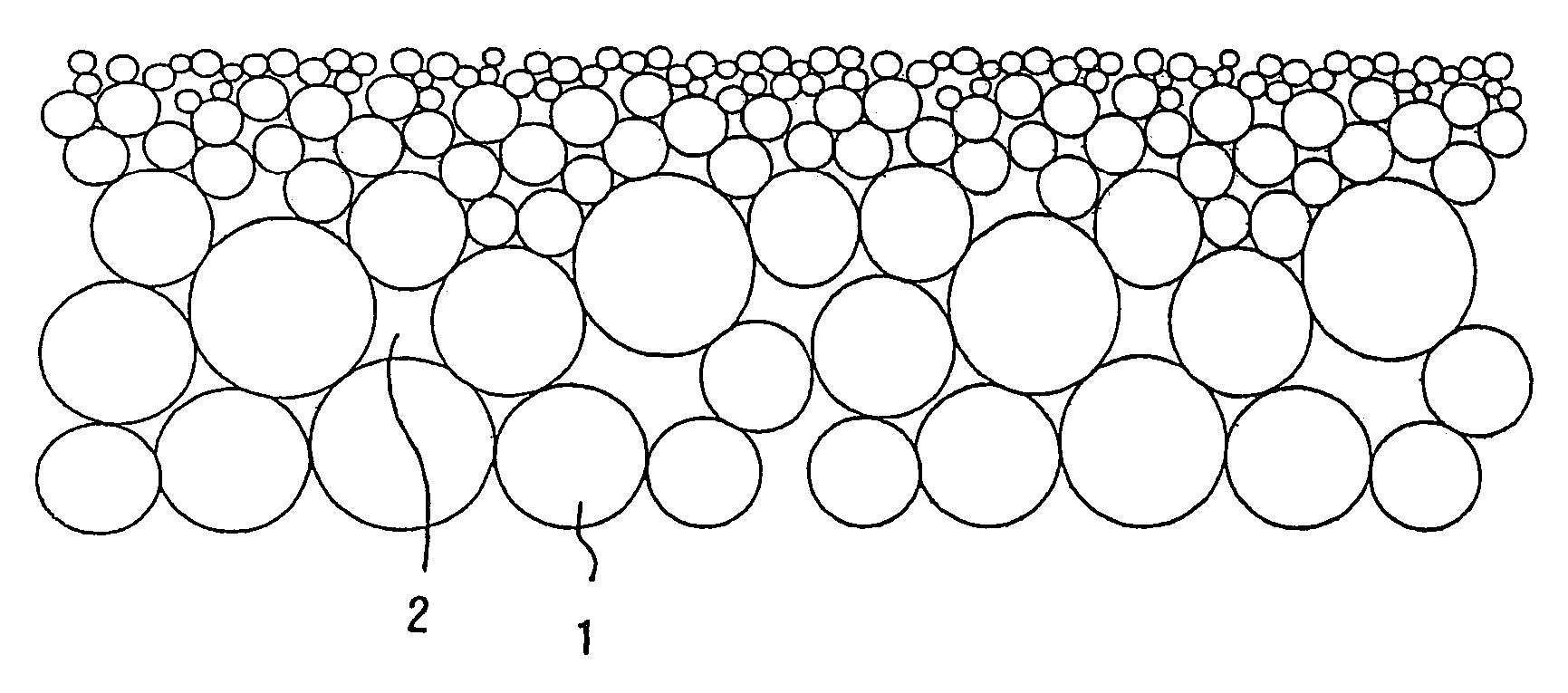

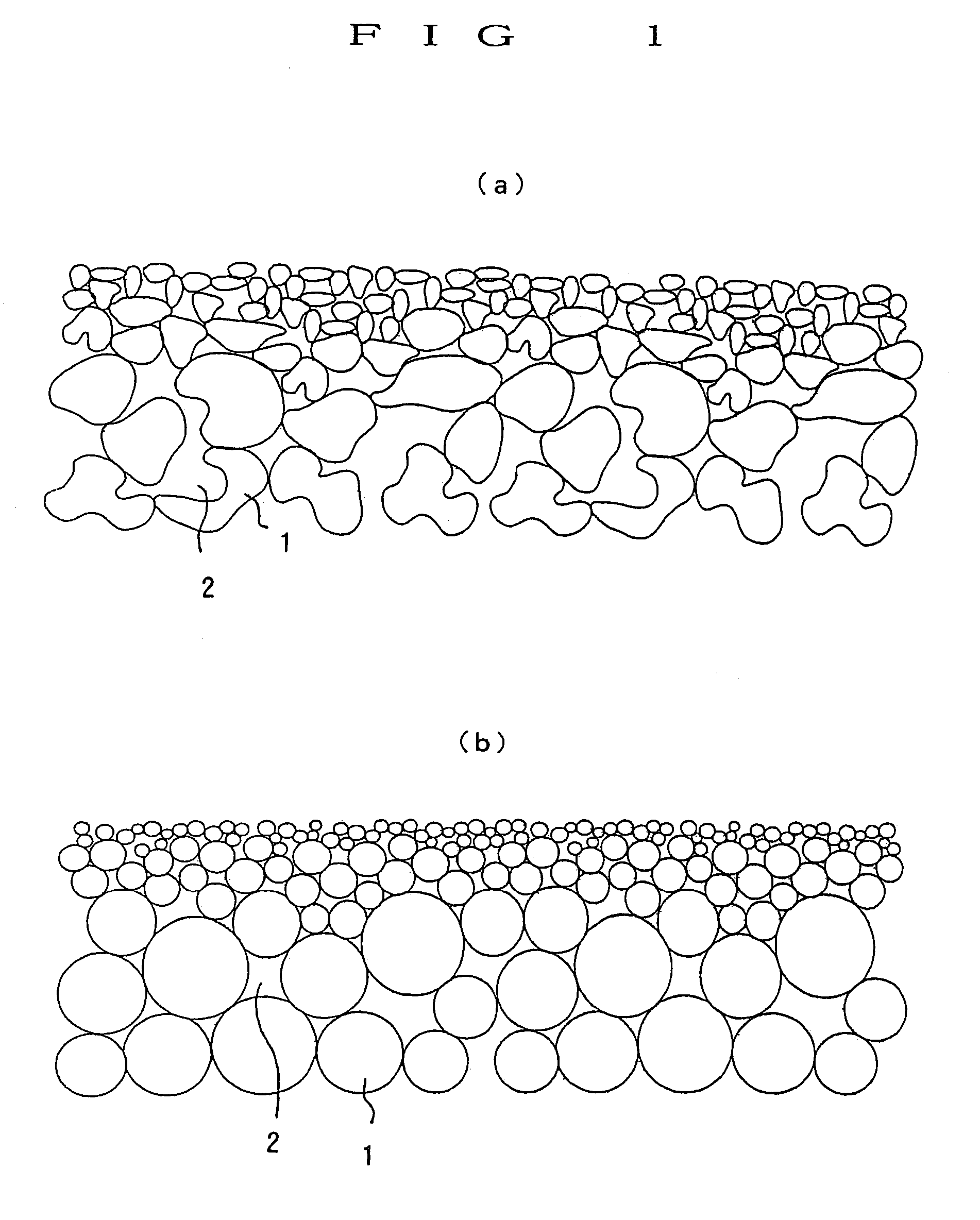

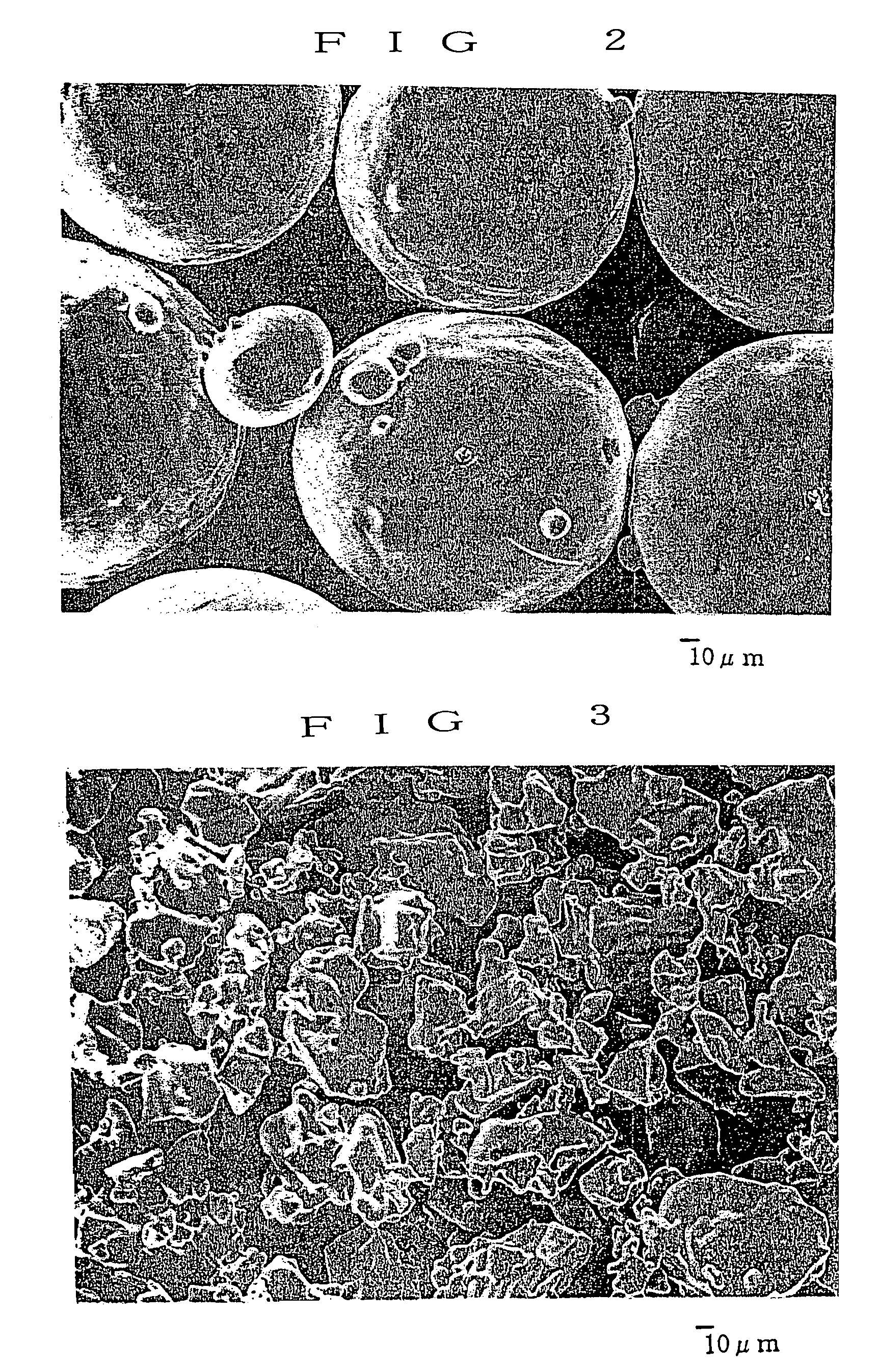

Titanium powder sintered compact

InactiveUS7297271B2Easy to classifyReduce manufacturing costElectrode carriers/collectorsMetal-working apparatusPolymer electrolytesFuel cells

Provided are a porous sintered compact suitable for a filter, a power feeder in a polymer electrolyte membrane type water electrolyzer, a current collector in a solid polymer fuel cell and in addition a liquid dispersion plate, especially an ink dispersion plate for an ink jet printer ink and the like. A titanium powder sintered compact made of a plate-like porous compact is obtained by sintering spherical powder made of titanium or a titanium alloy produced by means of a gas atomization method. A void ratio in the range of from 35 to 55% is realized by filling without applying a pressure and sintering without applying a pressure.

Owner:OSAKA TITANIUM TECHNOLOGIES

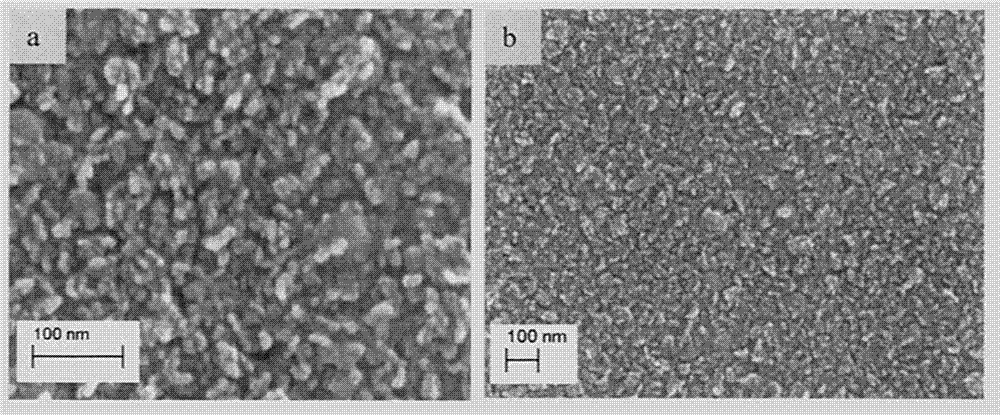

Surface decorated lithium ion cell positive electrode material and its preparing method

InactiveCN1617371AFully contactedFully coveredElectrode manufacturing processesActive material electrodesLithiumPorosity

This invention relates to a material for decorating surface of the positive of Li ionic battery and its preparation method, first of all, putting a positive powder material Li-M1M2-O(M1M2=Co Mn Ni Cr into a solution with organic substance in the concentration of 0.05-2.00mol / 1 then to put the mixed substance into a heat water reactor with mixing for 0.1-4h under 150-200deg. to spray and dry the reacted solution, then a positive material is got covered uniform carbon microspheres having the advantage of high specific capacity, fine circulation performance, uniform porosity and no impurities.

Owner:QINGHAI INST OF SALT LAKES OF CHINESE ACAD OF SCI

Fiber-reinforced silicon dioxide heat-insulating ceramic material and preparation method and application thereof

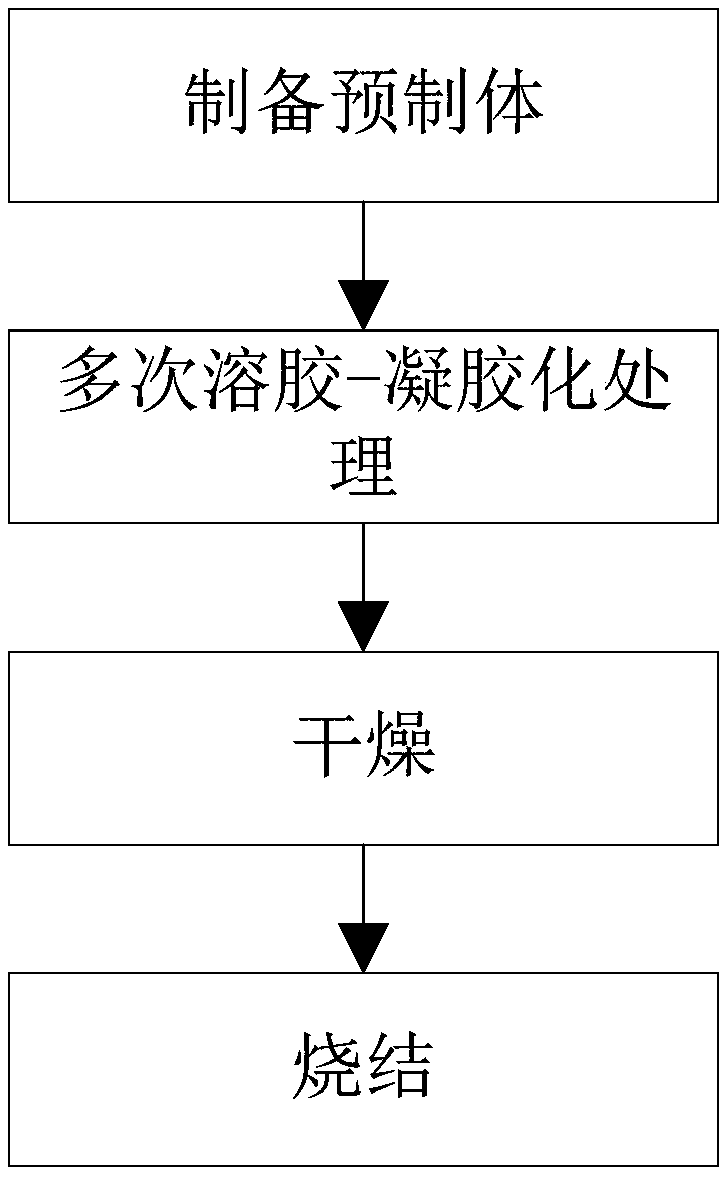

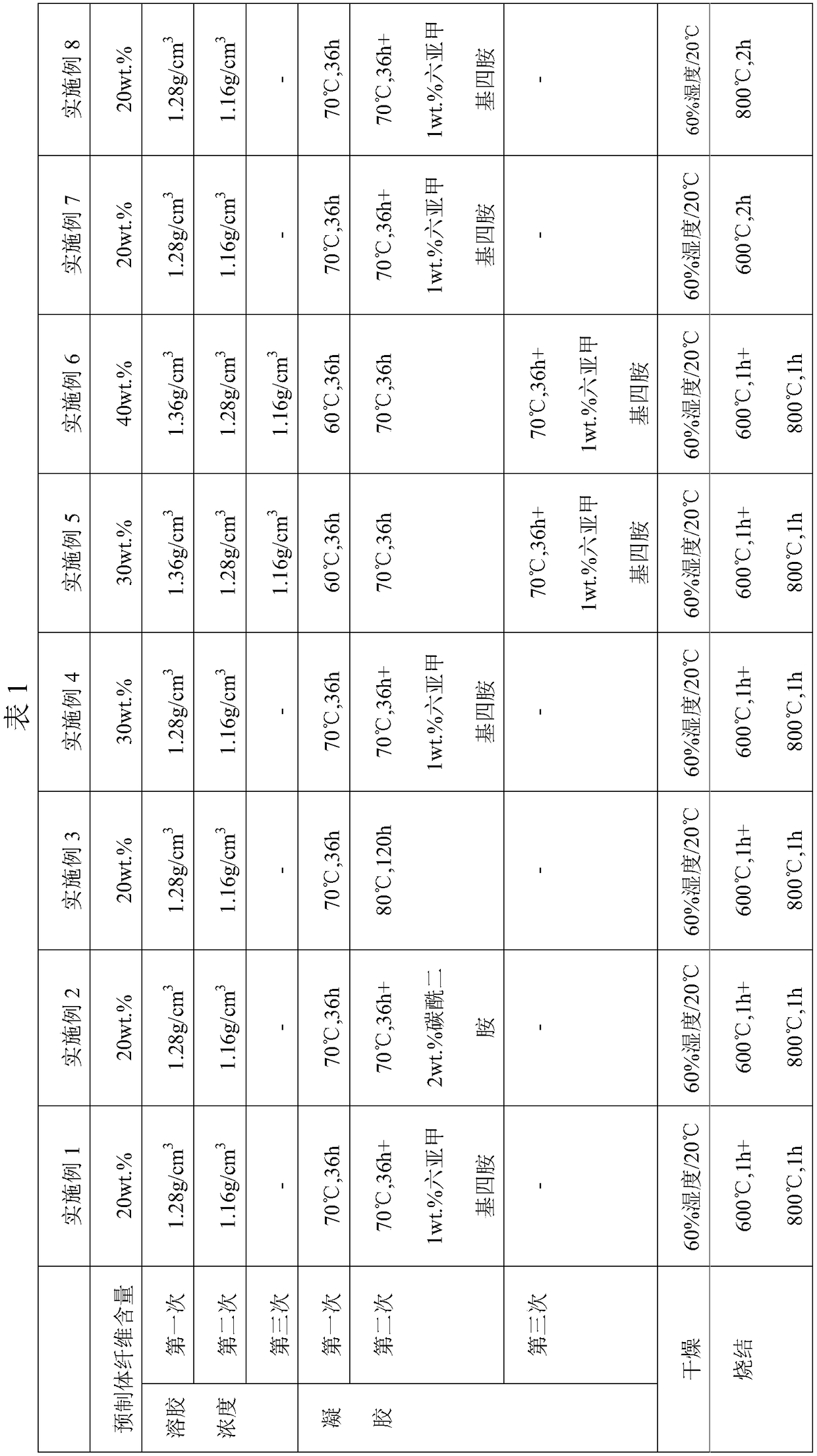

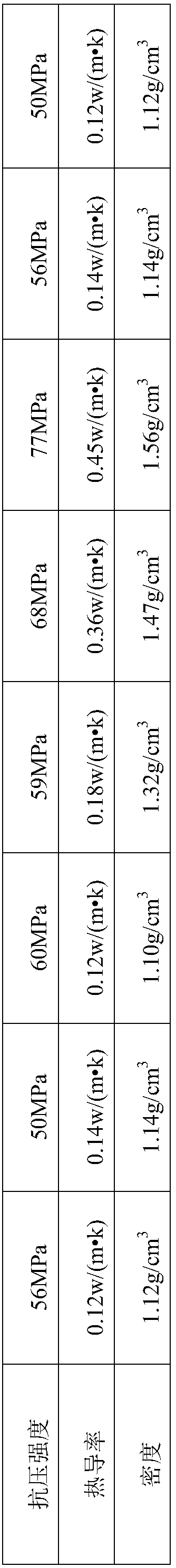

The invention relates to a fiber-reinforced silicon dioxide heat-insulating ceramic material and a preparation method and application thereof. The preparation method comprises the following steps: (1), preparing a preform; (2), performing multiple sol-gelation treatment: impregnating the preform with silica sol, then gelating to complete once sol-gelation treatment, repeating the sol-gelation treatment for multiple times, and sequentially reducing the density of the silica sol for impregnation to form gradient impregnation; (3), drying a material treated in the step (2) to obtain a blank; (4),sintering the blank to obtain the fiber-reinforced silicon dioxide heat-insulating ceramic material. By the preparation method, the heat-insulating ceramic material with high compressive strength andlow heat conductivity can be prepared; the heat-insulating ceramic material can be applied to an aircraft heat insulating system.

Owner:AEROSPACE INST OF ADVANCED MATERIALS & PROCESSING TECH

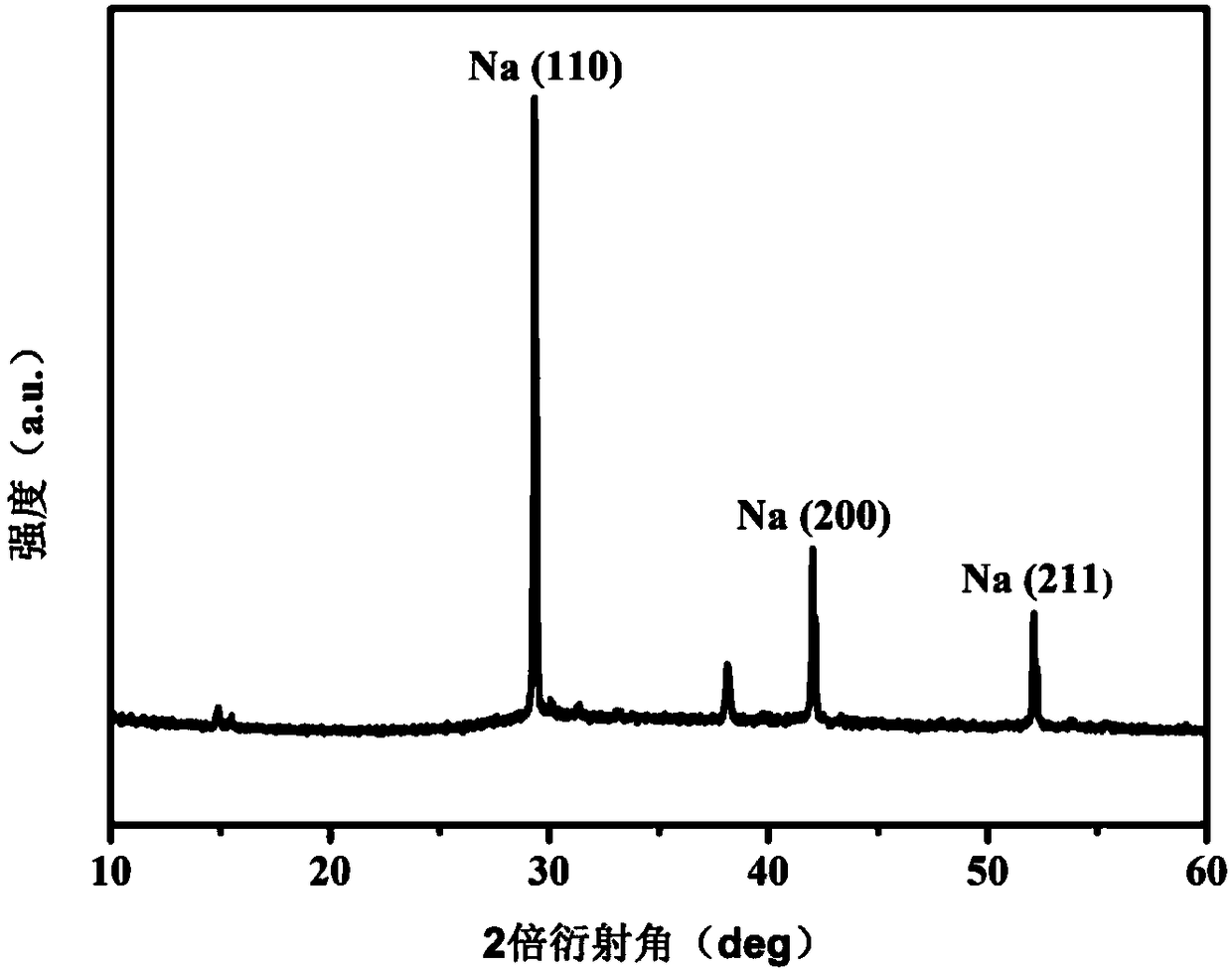

Negative electrode material of flexible sodium metal battery and preparation method thereof

InactiveCN108461732APrecise size controlIncrease profitCell electrodesSecondary cellsPorosityCyclic process

The invention relates to a negative electrode material of a flexible sodium metal battery and a preparation method thereof and belongs to the technical field of sodium metal batteries. The negative electrode material is characterized in that graphene aerogel is adopted as a skeleton, and sodium metal is distributed in a skeleton structure; the hole diameter range of the skeleton is 20-200mu m, andthe mass percentage of the sodium metal in the negative electrode material is 90-98%. The preparation method of the negative electrode material comprises the following steps of: adding a conducting material into water, then adding a reducing agent, and reacting for 6-24 hours at the temperature of 50-200 DEG C to obtain an intermediate product; washing with water, freezing drying under 5-10 MPa to form the graphene aerogel; then adopting the graphene aerogel as a skeleton, and compounding with liquid metal sodium to obtain the negative electrode material. The negative electrode material has good flexibility, uniform porosity and large specific surface area; as a negative electrode of the sodium metal battery, uniform nucleation of sodium ions is ensured, the volume expansion in the circulating process is relieved, and due to higher conductivity, the overpotential is effectively reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

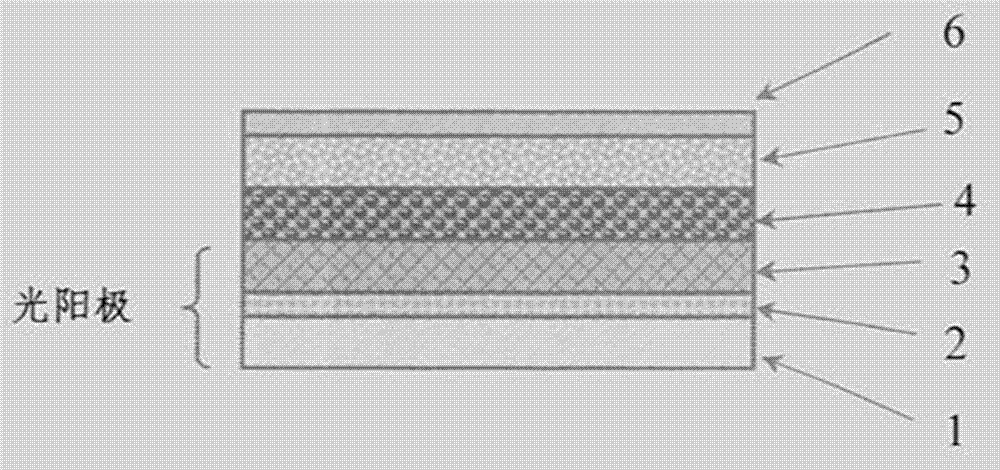

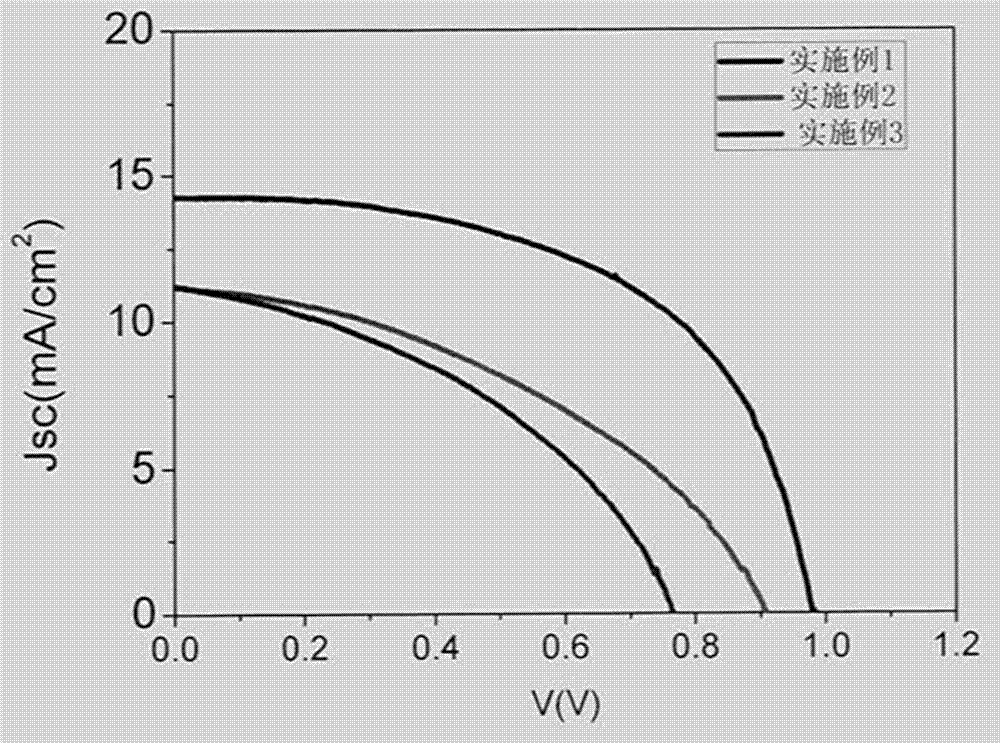

Interruptible perovskite type organic halide thin-film solar cell photo-anode preparing method

ActiveCN104282847ALow costLow preparation temperatureSolid-state devicesSemiconductor/solid-state device manufacturingChemistryElectrochemistry

The invention discloses an interruptible perovskite type organic halide thin-film solar cell photo-anode preparing method and belongs to the field of preparation of semiconductor photoelectric materials and nano-films. According to the method, a dense zinc oxide thin film electron transfer layer is prepared on a flexible transparent conductive substrate with the rotary film coating method, a hierarchical pore zinc oxide thin film electron transfer layer is prepared on the dense zinc oxide thin film with the electrochemical deposition method, and finally a conductive substrate layer / dense semiconductor / hierarchical pore semiconductor laminated thin film, namely an interruptible perovskite type organic halide thin-film solar cell photo-anode is obtained. According to the method, the structure and morphology of the zinc oxide hierarchical pore layer are controlled by controlling the voltage, deposition time, temperature, concentration of deposit liquid and the like during electrochemical deposition. The method has the advantages that the preparation technology is simple, cost is low, resultant temperature is low, controllability is high, and the obtained hierarchical pore zinc oxide film is uniform and stable and suitable for serving as an interruptible perovskite type thin-film solar cell photo-anode material.

Owner:SHIJIAZHUANG TIEDAO UNIV

Pressure difference-based method and device for improving properties of carbon paper of quick CVI coating

InactiveCN101734940AQuick Surface Coating TreatmentUniform distribution of poresSynthetic cellulose/non-cellulose material pulp/paperFiberPorosity

The invention discloses a pressure difference-based method and a pressure difference-based device for improving properties of carbon paper of a quick CVI coating. The method comprises the following steps of: 1) preparation of a carbon fiber blank: using PAN-based carbon fiber serving as reinforcing materials and phenolic aldehyde or epoxy resin serving as a bonding agent to form the carbon fiber to prepare the carbon fiber blank by a the method papermaking method; and 2) deposition process: stacking the products, obtained by the step 1, placing the products in a reaction furnace for chemical vapor deposition. The device is a box-type reaction furnace in which two flat plate heating bodies are arranged, a deposition tank is placed between the two flat plate heating bodies which are parallel to each other, and the carbon paper or carbon paper blank is placed in the deposition tank; and one end and the other end of the reaction furnace are provided with an inlet and an outlet, which are used for flowing of the mixed gas of a carbon source and diluent gas, respectively. The method has the advantages that: the deposition is quick and the structure, density, porosity and the like are controllable; and the deposited carbon is evenly distributed on the surface of the carbon surface, and the prepared carbon paper material is low in resistivity, high in strength and good in isotropic degree.

Owner:CENT SOUTH UNIV

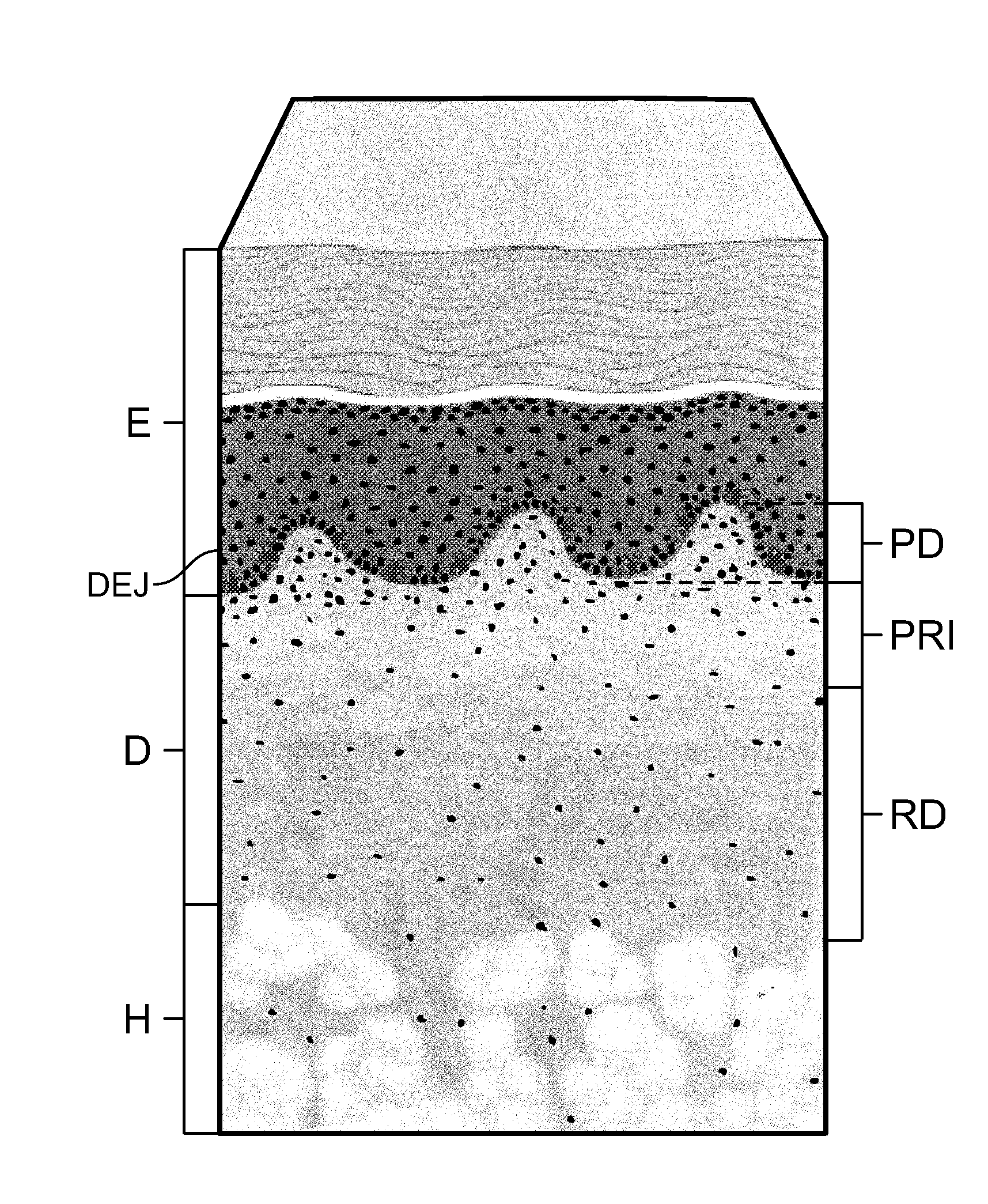

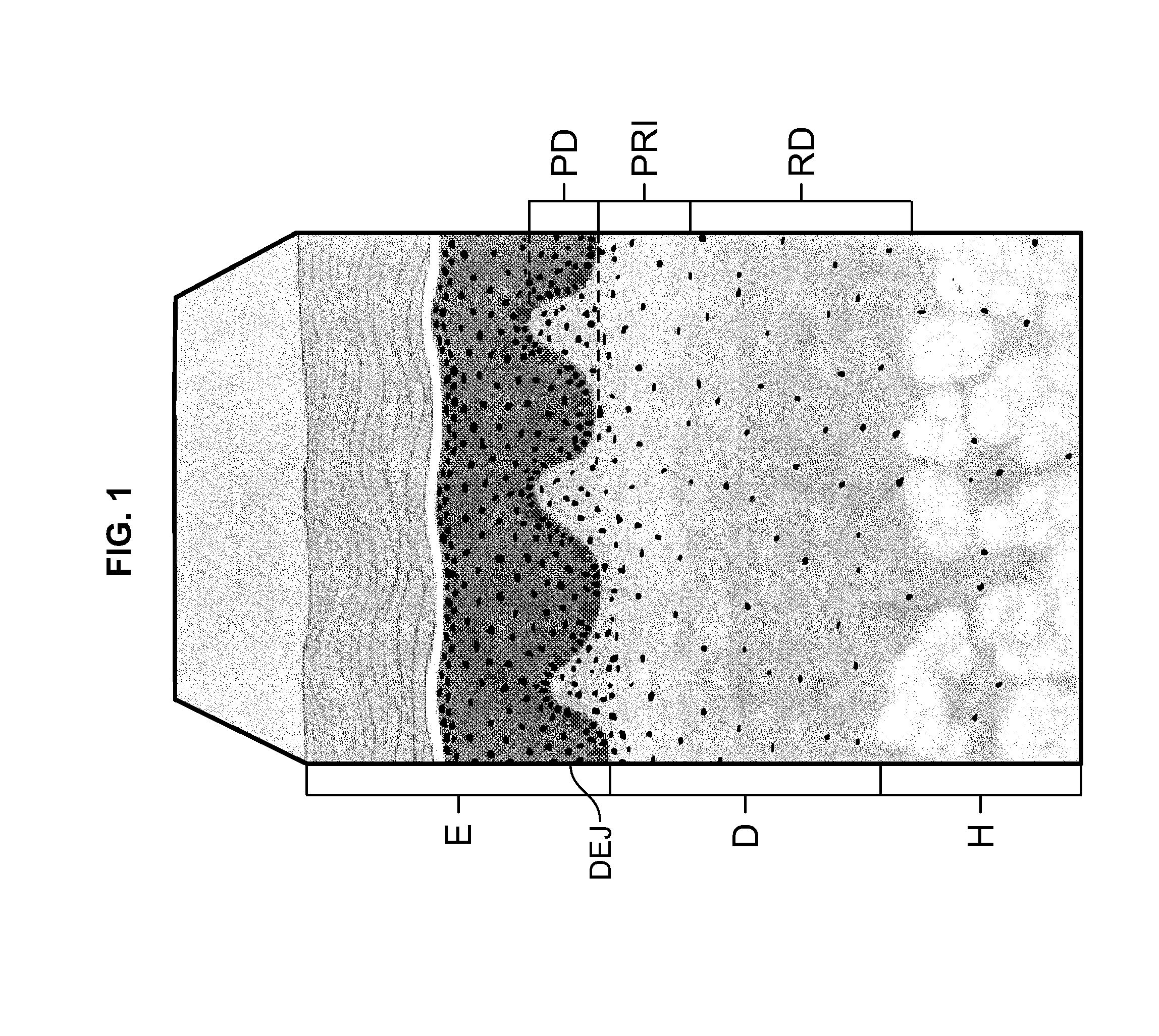

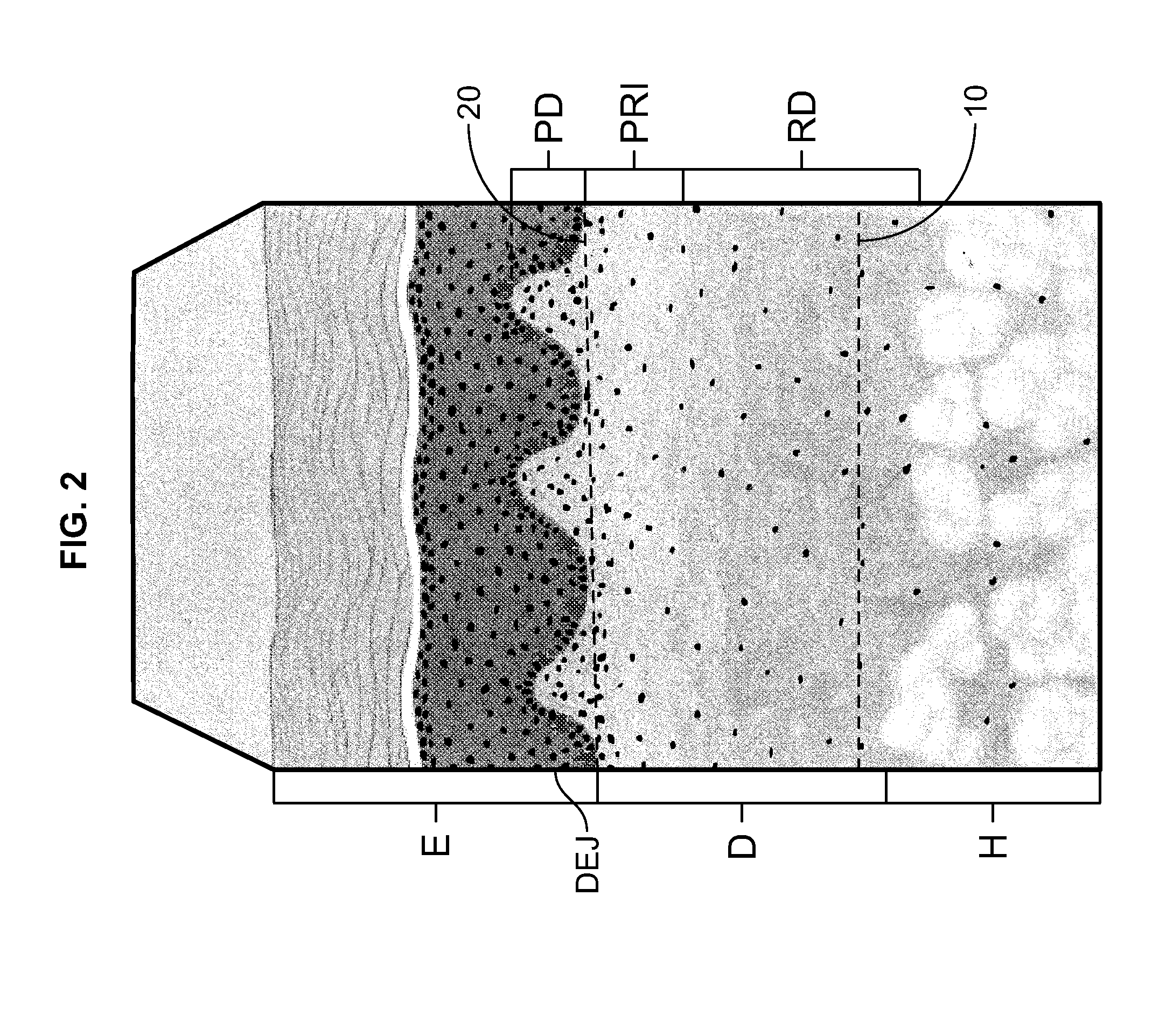

Soft tissue repair allografts and methods for preparing same

InactiveUS20140276957A1Uniform porosityUse of procedureSkin implantsSurgeryPorosityCollagen matrices

Allografts for soft tissue repair, including breast reconstruction and other plastic surgery procedures, are disclosed. One allograft is made from decellularized dermal tissue and constitutes a collagen matrix having substantially uniform density and porosity. Another allograft is a hybrid bilayer tissue form that is made from decellularized dermal and adipose tissues. Methods for making both allografts are also disclosed.

Owner:MUSCULOSKELETAL TRANSPLANT FOUND INC

Decellularized porcine cornea tissue and preparation method and application thereof

The invention relates to the field of corneal stroma substitutions, and discloses a decellularized porcine cornea tissue and a preparation method thereof. The method comprises the steps: performing low-permeability swelling, repeated freeze thawing, enzymic digestion, ultrasonic treatment, sterilization and wet-state sealed storage in sequence on a corneal stroma sheet, which is cut under a germfree condition, of a fresh animal eyeball, wherein the enzymic digestion is implemented by a buffering solution containing DNA enzyme and RNA enzyme. The invention further provides the application of the decellularized porcine cornea tissue in serving as the corneal stroma substitution. According to the method, damage to the collagen structure of the corneal stroma is reduced to the maximum extent; collagen fibers are tidily arrayed, and the porosity is uniform and regular; no cell is retained; the lamellar structure is kept intact; the biocompatibility of a bracket material is improved; furthermore, on the premise that the corneal stroma is not modified, the decellularized porcine cornea tissue can be stored in a wet state for a long time.

Owner:QINGDAO CHUNGHAO TISSUE ENG

Method for producing polyporous material based on solid/gas eutectic directional solidification

ActiveCN101173332AHigh work pressureUniform porosityCasting plantsDirectional solidificationEnergy source

The invention relates to a method for preparing porosint by solid / gas directional eutectic freezing. The equipment and craft adopted the invention can increase the speed of melting by two to ten times as rapid as the speed of the prior art and monitor the total processes of metal melting and casting by increasing the working pressure, accelerating and control the cooling speed and reducing the nonmetal impurity content. The made porosint has an advantages of even pore space (both radial direction and axial direction of the casting piece). The pore space inside the material can be equal or unequal in size, and also can be subuliform pore space with changeable section. The invention can be used in fluid permeation, filter control, efficient combustion, intensification of mass transfer heat transfer, inflaming and explosion prevention, artificial skeleton, absorption of radiation and noisedamping control in industrial processes such as metallurgical machinery, petrochemical industry, energy source and environmental protection, national defense and war industry, nuclear technology and biopharmaceutical industry, and is the critical technology for breaking through various technology.

Owner:大连华乌科技转化有限公司

Production of foamed aluminium alloy deformed piece by secondary foam

The invention carried out a process to produce foamed aluminium alloy with the secondary foaming. The process is: first to melt the aluminium alloy and add the Ca into the molten, then adding into the titanium hydride to get the first foamed aluminium alloy, next to heat the first alloy and make it preformed unit, last to foam the preformed unit and cool to get the secondary foamed aluminium alloy.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com