Polyvinyl alcohol, and preparation method and application thereof

A polyvinyl alcohol and vinyl technology, which is applied in the field of organic polymer compounds, can solve the problems of affecting the COD value of waste water discharged from PVC factories, the absorption capacity of plasticizers cannot reach the ideal, and the effect of auxiliary dispersants cannot be fully exerted. The effect of plasticizing time, convenient industrial production and excellent processing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

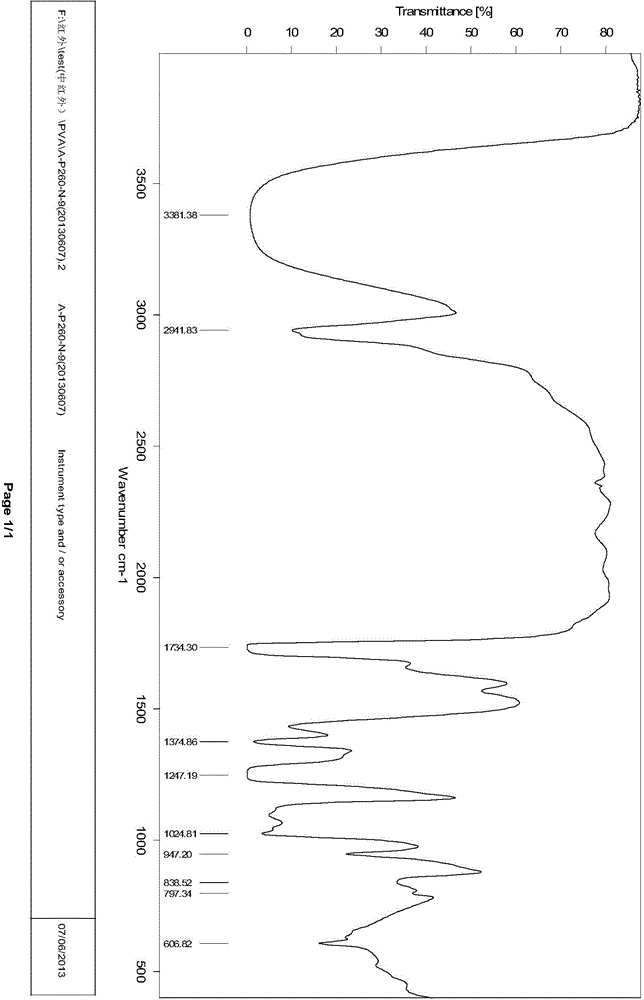

[0031] In the presence of 2.0 parts of AIBN, 100 parts of vinyl acetate are solution polymerized in a mixed solvent of 100 parts of methanol and 40 parts of acetone. The polymerization temperature is 60 ° C. When the polymerization reaction is over, switch to blow out the residual sheet to obtain polyvinyl acetate Resin, take a part of polyvinyl acetate resin and adjust it into a methanol solution with a concentration of 46wt%, and then carry out alcoholysis with a methanol solution with a concentration of 40g / L sodium hydroxide. Mole of glacial acetic acid terminates the reaction, obtains polyvinyl alcohol with low degree of polymerization and low degree of alcoholysis of the present invention, and its degree of polymerization is 218, and degree of alcoholysis is 58.4 (mol / mol)%, and its concentration is that the cloud point of the aqueous solution of 4wt% is At 12.5°C, the viscosity of the aqueous solution with a concentration of 40wt% at 25°C is 1100mPa.s, and the viscosity ...

Embodiment 2

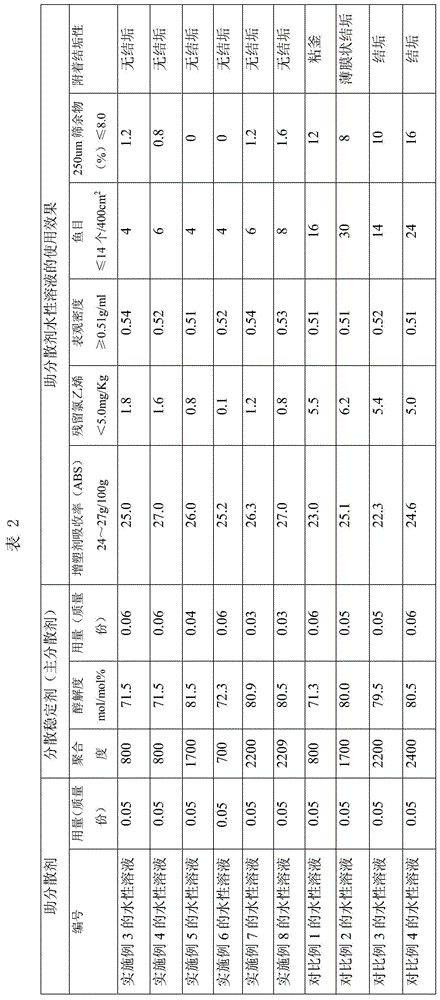

[0044] The aqueous solutions made of the polyvinyl alcohol with low degree of polymerization and low degree of alcoholysis obtained in Example 1 are used as auxiliary dispersants for suspension polymerization of vinyl polymers; for suspension polymerization of vinyl chloride: in an autoclave Add 180 parts of soft water, add 0.05 parts of the above-mentioned auxiliary dispersant while stirring at 400 rpm, 0.06 parts of polyvinyl alcohol with an alcoholysis degree of 70mol% and a polymerization degree of 800, 0.2 parts of lauryl peroxide, and then add 150 parts of vinyl chloride mono Body, when the temperature is raised to 60 ° C for suspension polymerization, the polyvinyl chloride resin is obtained. Adopt the resin obtained in embodiment A1, its apparent density is respectively 0.54g / ml, 0.51g / ml, and the number of fish eyes is respectively 4 / 400cm 2 , 6pcs / 400cm 2 , plasticizer absorption rate is 25g / 100g, 27g / 100g, 250um sieve residue is less than 2.0, residual vinyl chlori...

Embodiment 3~8

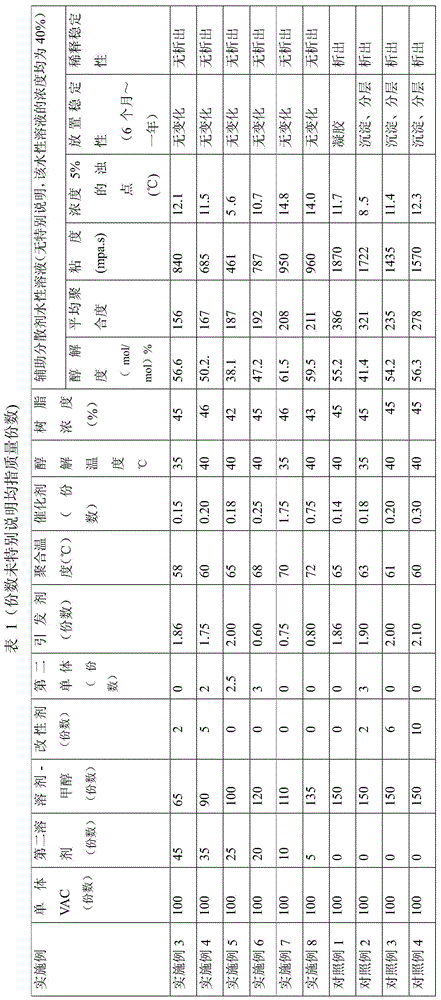

[0059] The second solvent in embodiment 3-4 in table 1 is toluene, the second solvent in embodiment 5-6 is ethanol, the second solvent in embodiment 7-8 is Virahol; In embodiment 5-8 The initiators are respectively Perkadox16, EHP, peroxypivalic acid-pivalic acid ester, dipropyl peroxydicarbonate (the embodiment is 4, and the initiator is 3, not corresponding), other examples, comparative examples The initiator in all is AIBN; The catalyst in the embodiment and the comparative example is sodium hydroxide; The modifying agent in the comparative example 2-4 is respectively acetaldehyde, valeraldehyde and dodecyl mercaptan. The modifiers in Examples 3-4 are acetaldehyde and valeraldehyde respectively; the second monomer in Examples and Comparative Examples is itaconic acid. Using the relevant parameters described in Tables 1 and 2 below, according to the preparation methods of Examples 1 and 2, the aqueous solution of polyvinyl alcohol auxiliary dispersant with low degree of poly...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cloud point | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com