Patents

Literature

919 results about "Soft water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Soft water is surface water that contains low concentrations of ions and in particular is low in ions of calcium and magnesium. Soft water naturally occurs where rainfall and the drainage basin of rivers are formed of hard, impervious and calcium-poor rocks. Examples in the UK (United Kingdom) include Snowdonia in Wales and the Western Highlands in Scotland.

Aqueous and elastic thermal-insulation energy-conservation paint and preparation thereof

InactiveCN101343453AShielding from heatImprove temperature resistanceFireproof paintsWater basedNoise control

The invention discloses water-based elastic heat proofing, heat insulation and energy-saving coating. The coating comprises elastic emulsion, hollow micro-beads powder, far-infrared ray reflecting powder, titanium dioxide, filler, cellulose, anti-foaming agent, dispersing agent, pH conditioning agent, rheologic thickening agent and soft water. The invention also discloses a preparation method of the water-based elastic heat proofing, heat insulation and energy-saving coating. The water-based elastic heat proofing, heat insulation and energy-saving coating has the advantages that the coating can be coated on a variety of backing materials, and of heat insulation and heat preservation, fire prevention, water resistance, anti cracking and noise control, and the like. The coating is suitable for the coating of the exterior wall, the roof and the interior wall and the like, and is also suitable for decreasing the temperature and reducing the tricking water of the metal surface such as the petrochemical industrial storage tank pipeline and the like.

Owner:WUXI HUHUANG PAINT

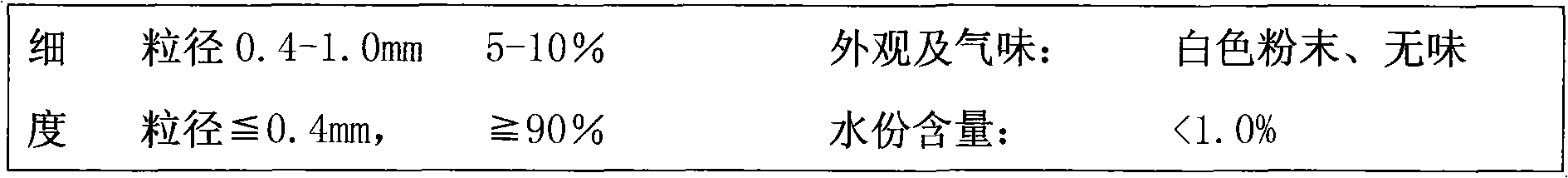

Non-polymeric organic particles for chemical mechanical planarization

InactiveUS20050005525A1Reduce defectsHigh selectivityPigmenting treatmentOther chemical processesSoft waterSURFACTANT BLEND

An abrasive composition comprising non-polymeric organic particles that is useful for chemical mechanical planarization (CMP), and which can widely be used in the semiconductor industry. The inventive compositions preferably comprise soft water in combination with 0.001-20 w / w % of non-polymeric organic particles, 0.1-10 w / w % of an oxidizing agent, 0.05-10 w / w % of a chelating agent, 0.01-10 w / w % of a surfactant, and 0-10 w / w % of a passivation agent at a pH in the range of 2-12, wherein said percentages are w / w (weight / weight) percentages, based on the total weight of said compositions. The abrasive compositions provide an efficient polishing rate, excellent selectivity and good surface quality when utilized as a new abrasive composition in CMP applications.

Owner:DYNEA AUSTRIA

Method for synthesizing carboxyl butadiene-styrene latex used for cement group water-proofing material

ActiveCN101139413AAvoid pollutionReduce energy consumptionAntifouling/underwater paintsPaints with biocidesSodium bicarbonateEthylenediamine

This invention relates to a synthesis method for carboxylated styrene-butadiene latex used in the cement-based waterproof coating. The preparation method involves 30 to 50 shares of butadiene or isoprene isoprene, 30 to 55 shares of styrene, 0.1 to 5 shares of methyl acrylate , 1 to 5 shares of itaconic acid, 1 to 8 shares of n-butyl acrylate butyl acrylate, 1.2 to 2.8 hares of emulsifier, 0.3 to 1.2 hares of initiator potassium supersulphate, 0.2 to 0.8 shares of molecular weight regulator, 0.01 to 0.5 shares of pH buffer sodium bicarbonate, 0.01 to 5 shares of electrolyte, 0.01 or 5 shares of chelating agent ethylenediamine tetraacetic acid or endrate disodium and 100 to 150 shares of soft water for polymerization. The electrolyte is the combination of potassium phosphate and disodium hydrogen phosphate, with the ratio of 3 to 2: 1; in the polymerization reaction, monomer and a variety of agents are added with intermission. And reaction temperature control adopts the two-step laddered control. When the conversion rate reaches 99.0 percent, the mixture experiences the vacuum degassing treatment. The latex produced by the present invention is of good compatibility with the additives as the paint during the paint preparation. The prepared paint is of excellent fluidity, water retention and machinery stability under the high-cut condition. The improved mortar has the advantages of good permeability, high bond strength and so on.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

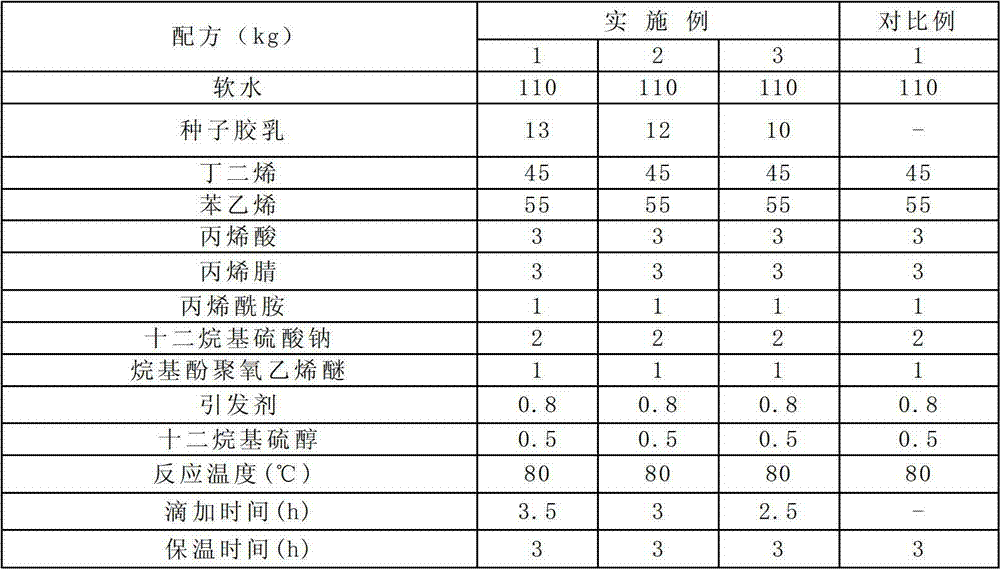

Small-particle-size carboxylic styrene-butadiene latex and its preparation method

ActiveCN102786620AAdjustable particle sizeSimple processPaper coatingCoatingsPolymer scienceFunctional monomer

The invention belongs to the technical field of seed emulsion polymerization, relates to a preparation of a high polymer material, and especially relates to a small-particle-size carboxylic styrene-butadiene latex and its preparation method. Technical problems comprising unadjustable particle size, bad mechanical stability, bad chemical stability and the like of latexes in the prior art are solved in the invention. The preparation method which adopts a seed emulsion polymerization technology and adopts butadiene and styrene as monomers comprises the following steps: adding soft water, a seed latex, an electrolyte, a chelating agent and a pH buffering agent; heating; adding functional monomers, unsaturated carboxylic acid, a molecular weight adjustment agent, a composite emulsifier and an initiator; degassing when the conversion rate reaches above 98%; cooling; and synthesizing the carboxylic styrene-butadiene latex. Compared with the prior art, the preparation method of the small-particle-size carboxylic styrene-butadiene latex has the advantages of realization of the adjustment of the particle size of the latex, and simple operation; and compared with present carboxylic styrene-butadiene latexes, the carboxylic styrene-butadiene latex prepared in the invention has the advantages of narrow monodispersion, good fluidity, excellent mechanical stability and excellent chemical stability.

Owner:WEIFANG LANLI NEW MATERIAL CO LTD

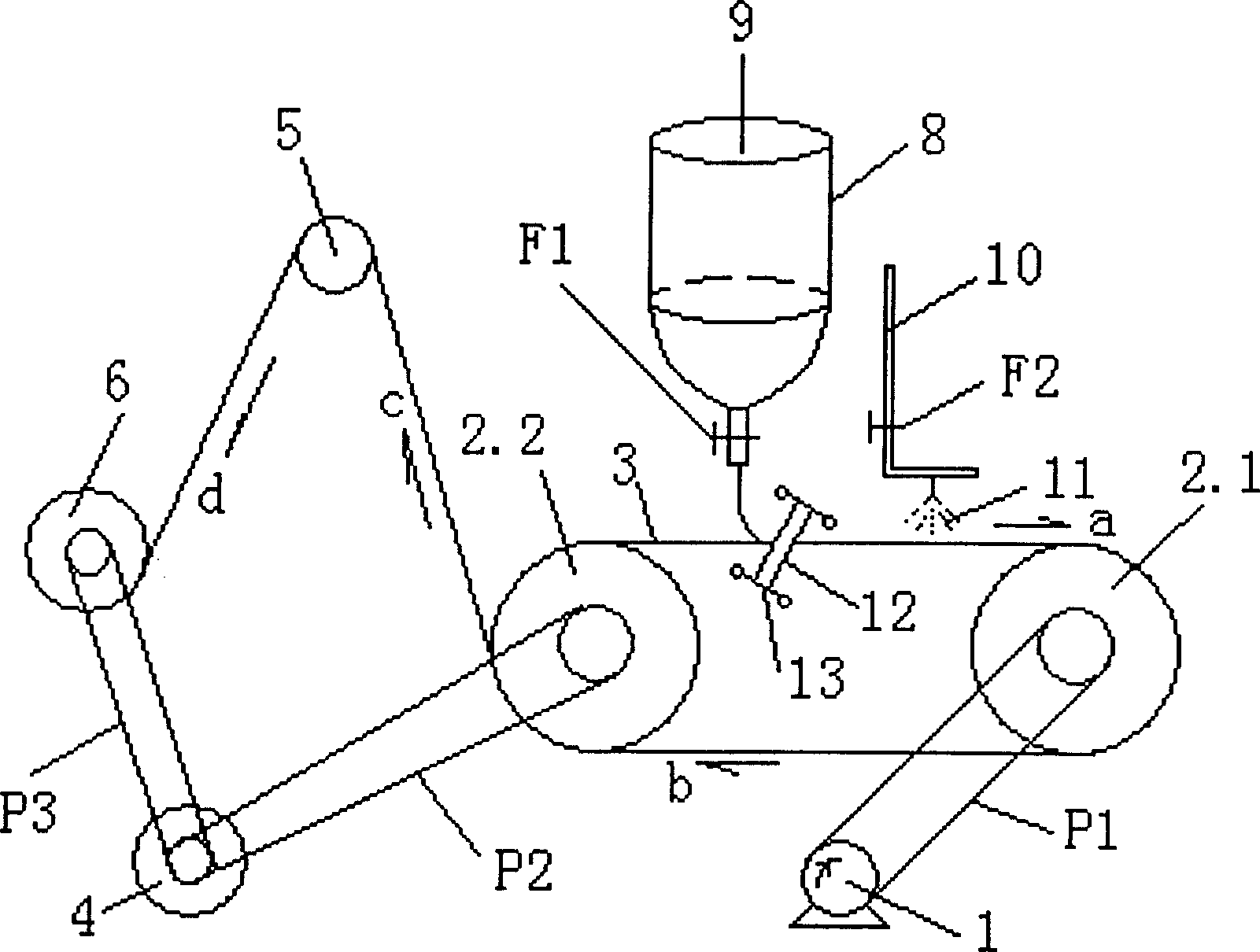

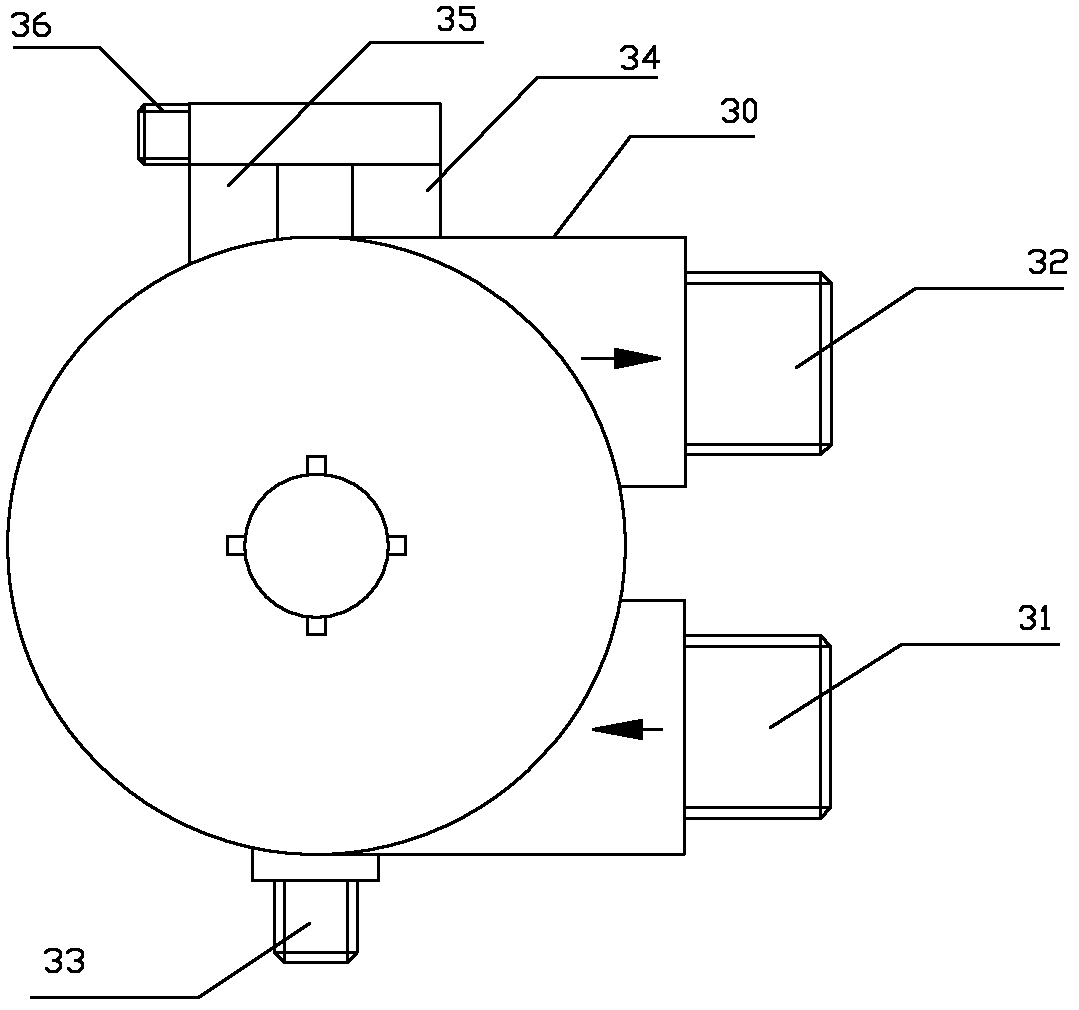

Soft-membrane paper soap, preparing method and apparatus thereof

InactiveCN1583991AHas advantagesHave a positive effectAmpholytes/electroneutral surface-active compoundsDetergent materialsMetal stripsFree cooling

The invention publishes a kind of paper-soft fancy soap and its producing method and equipment, which relates to washing things. Its prescription is made of component sof membrane, wash, bacterium-resistance and antisepsis, and pigment, essence. The producing method is: first, put the membrane components into kettle according to prescription and then unfreeze it to starchiness by soft water; secondly, when the temperature reaches 60-80 deg.C, mix components around for 90 minutes by 70-75 per minutes until is presents even-density white transparent liquid; thirdly, mix around the rest of components evenly and cool naturally, then get a kind of even-density glassy soap plasm after filter the output-material; finally, make soap plasm to paper-soft fancy soap by professional producing equipment. The equipment is made from engine and shifting machine, platen, transmitted metal strip, ..., and valve. The invention is schlepped expediently and healthful because of one-off use. Moreover, it has the function of protect skin and take good are of the health to consumers.

Owner:HUAZHONG NORMAL UNIV

Preparation method of acidic water and alkaline water

The invention discloses a preparation method of acidic water and alkaline water, which includes the steps of: 1) preparation of soft water: preparing soft water through a water softening machine; 2) preparation of a NaCl solution: adding NaCl to the soft water to prepare the NaCl solution; 3) electrolysis: electrolyzing the NaCl solution, wherein the acidic water and alkaline water are formed respectively on a positive pole and a negative pole. In the method, through the electrolysis, H<+> and chlorine gas, which has strong activity, are formed on the positive pole, wherein the chlorine gas can be dissolved in water to form the strong acidic water, which is a colorless and transparent liquid, has a slight chlorine smell, is free of irritation on skin and mucosas and can kill various bacterial vegetative forms. The acidic water can be gradually reduced into common water during contact with air, light and organic substance, so that the acidic water is an excellent green disinfectant.

Owner:康亦健(集团)有限公司

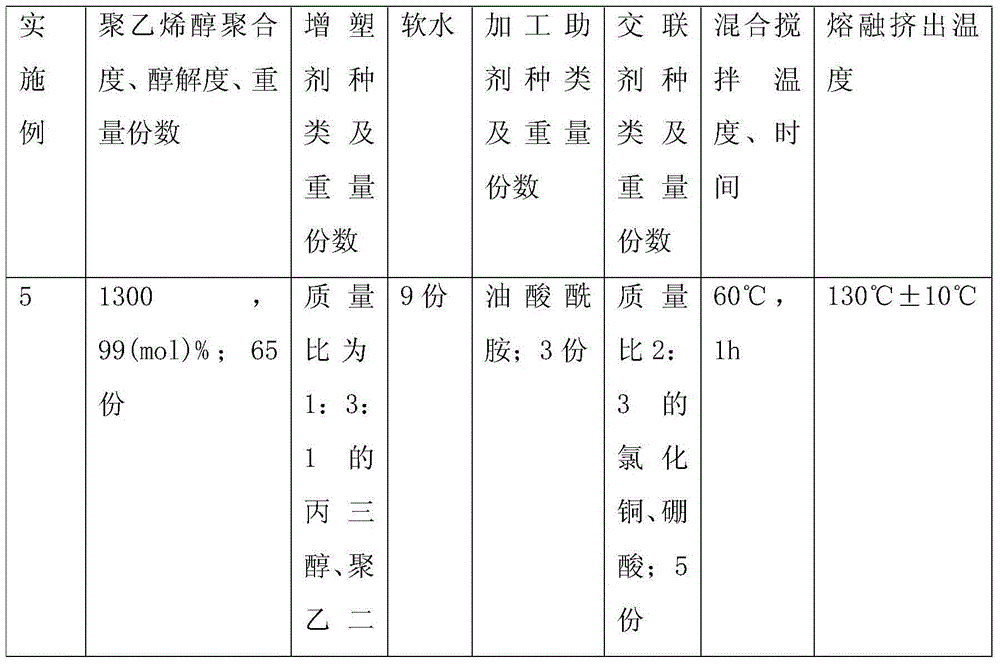

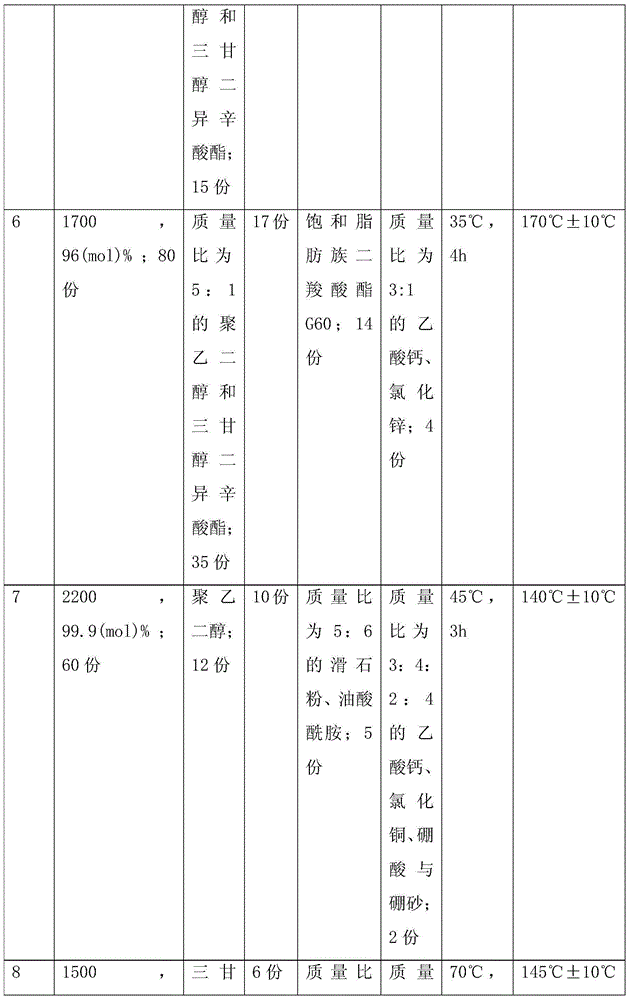

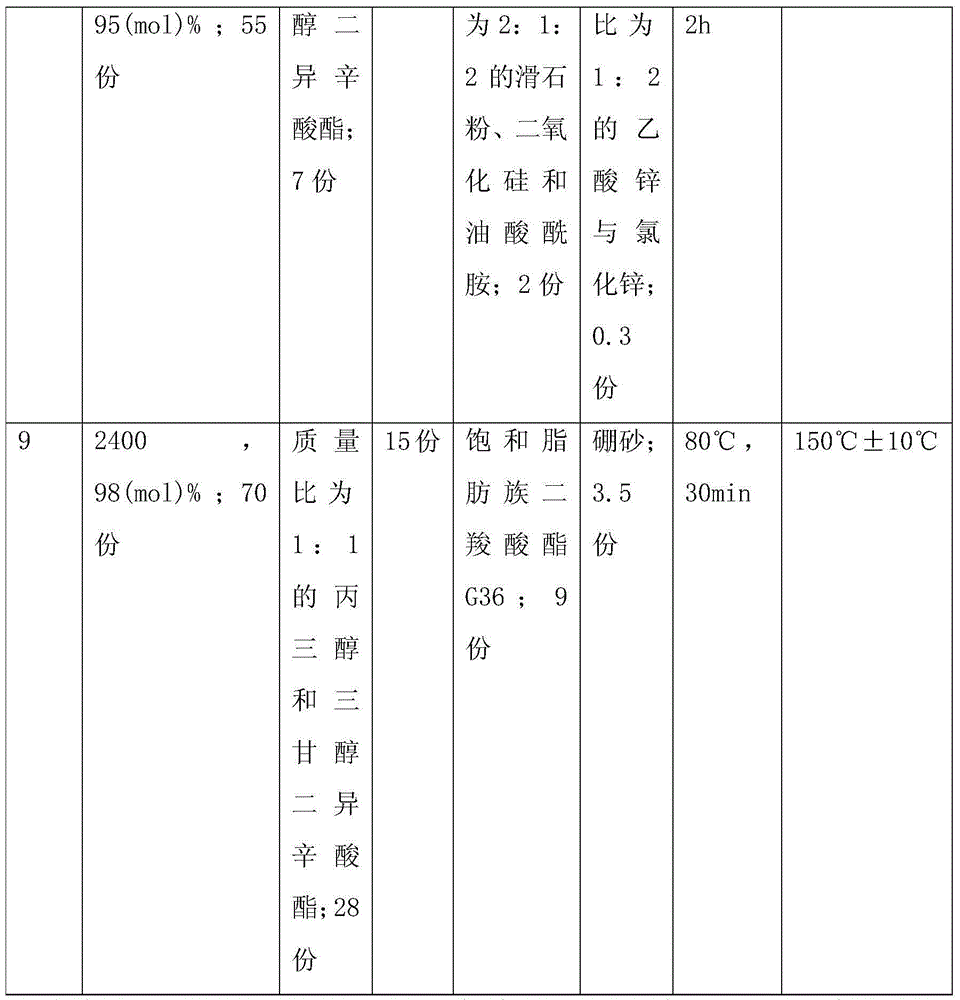

Biaxial orienting drawing formed polyvinyl alcohol membrane and production method thereof

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through melt extrusion-biaxial orientating drawing formation of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 40 MPa, the polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 95 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The polyvinyl alcohol membrane has the advantages of simple technology, less device investment and less occupied area. The polyvinyl alcohol membrane can be used in the field of high-end packaging, such as packaging of high-end clothes and packaging of foods and oil products, and can prolong the shelf life of the foods.

Owner:CHINA PETROCHEMICAL CORP +2

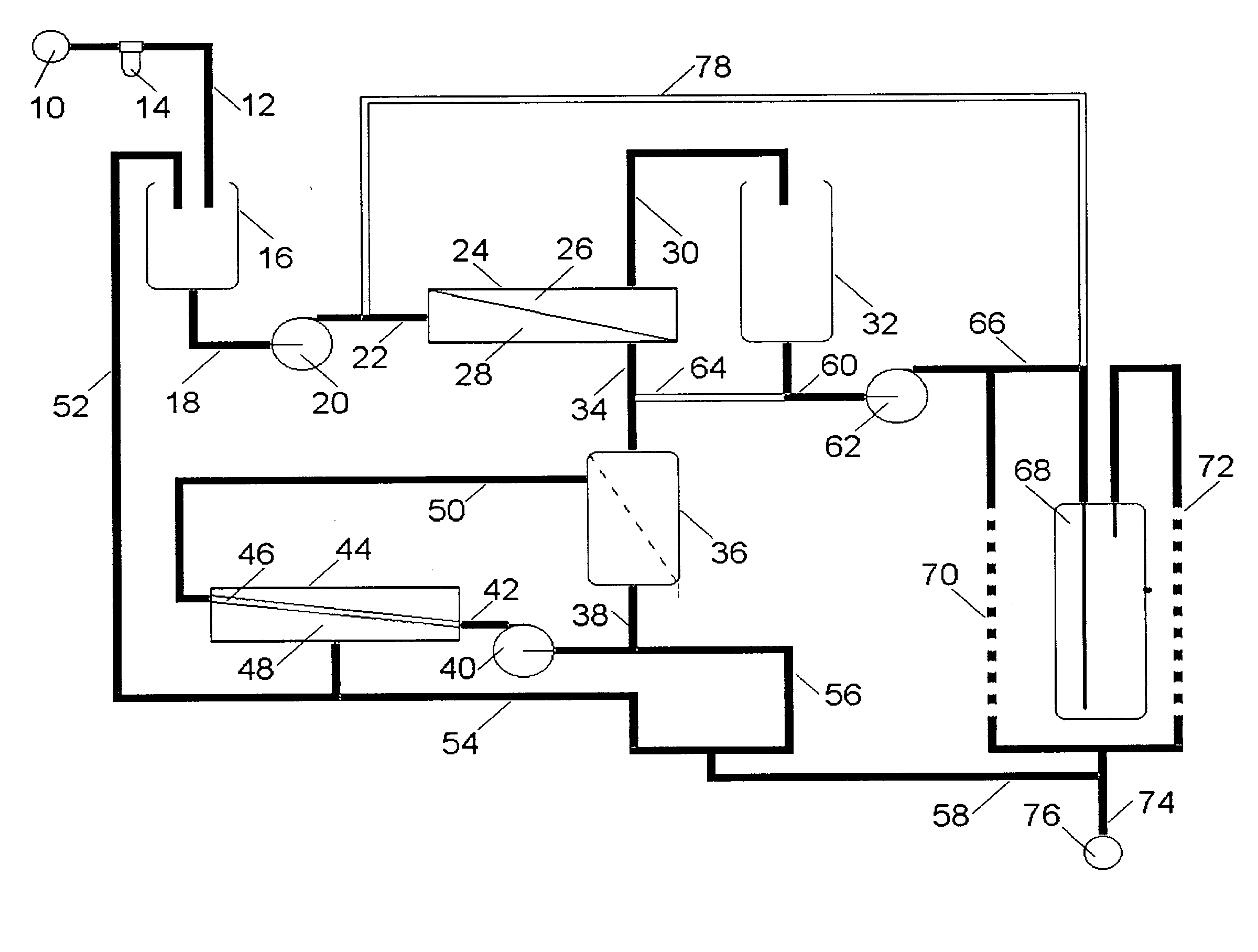

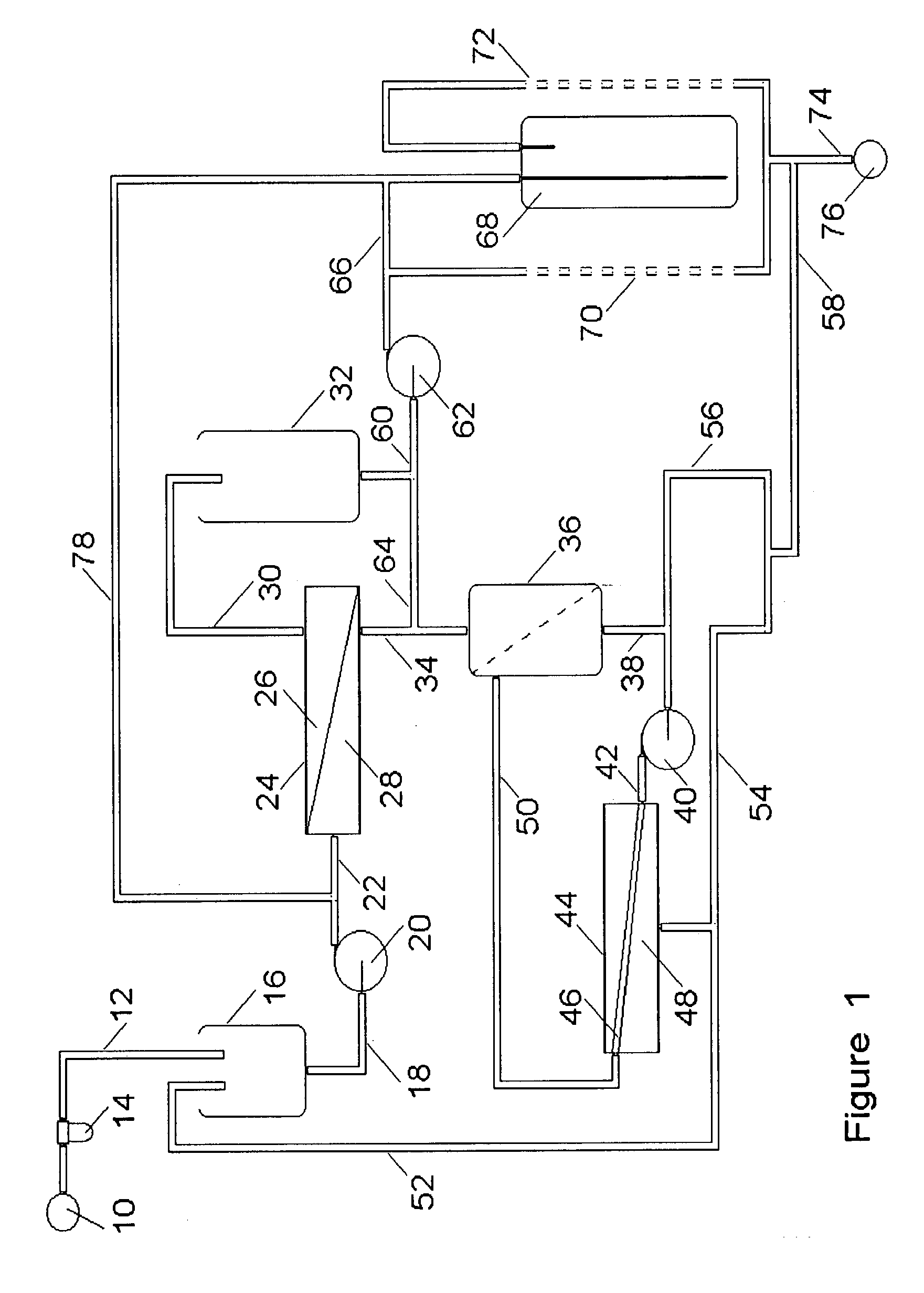

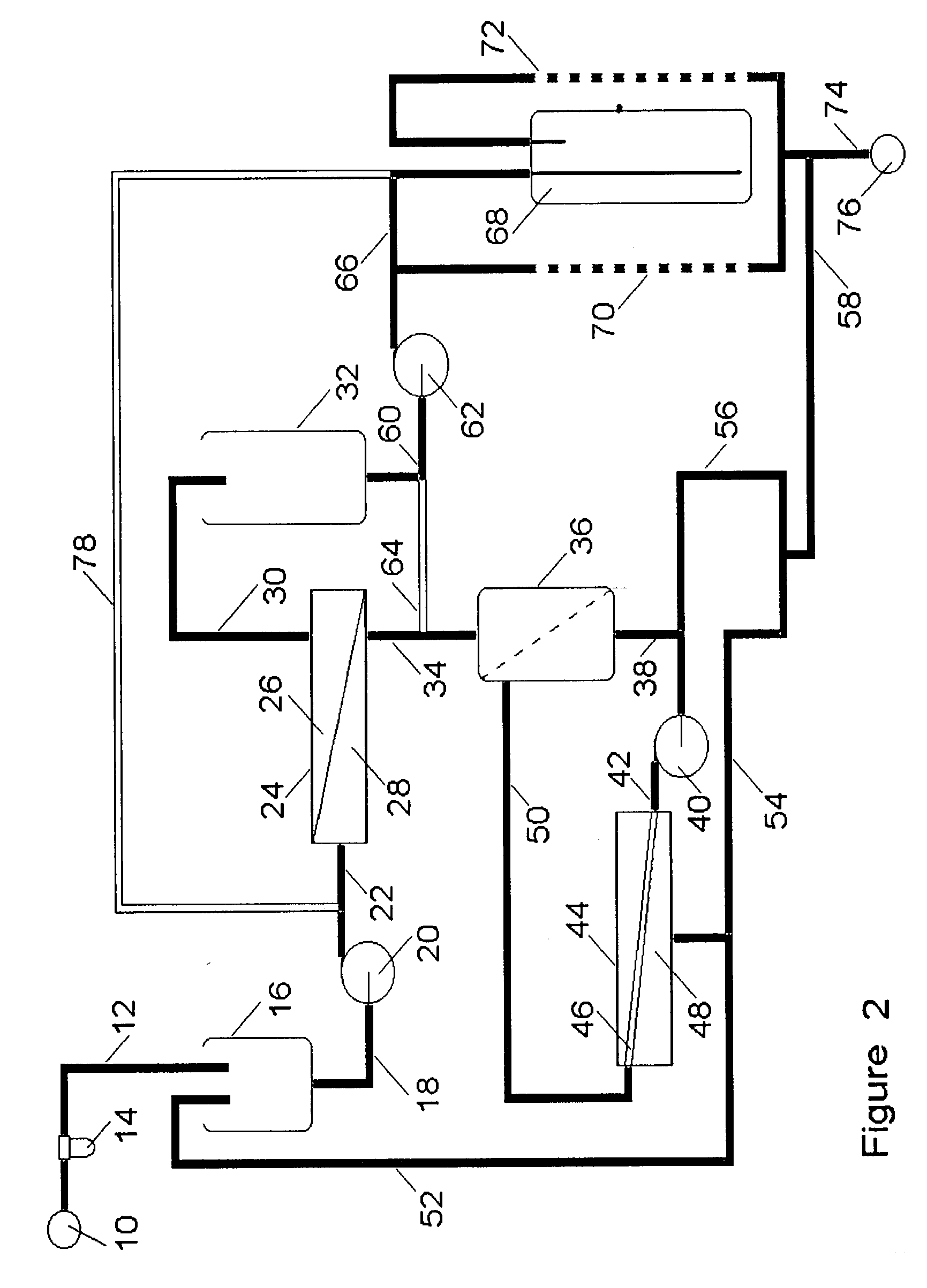

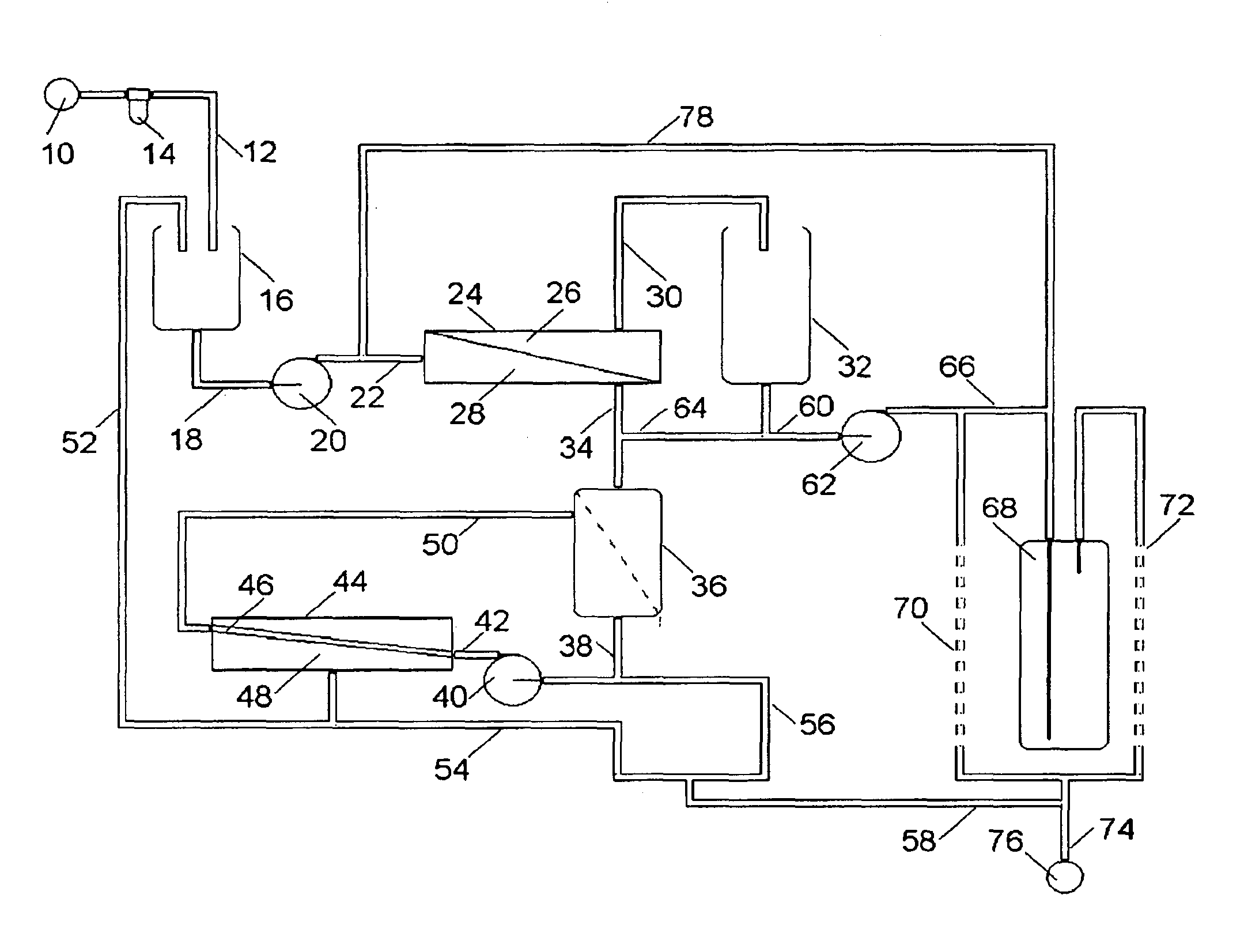

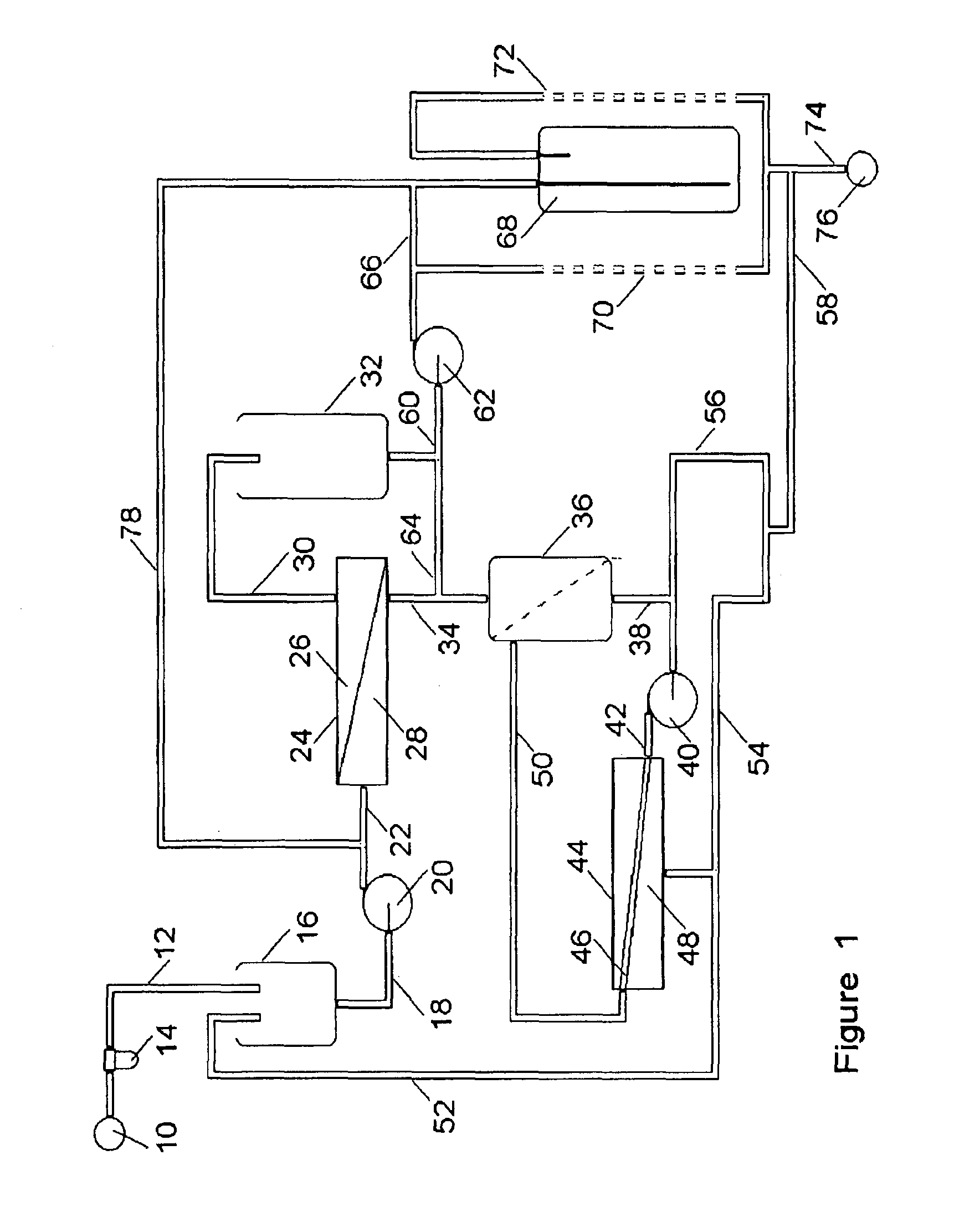

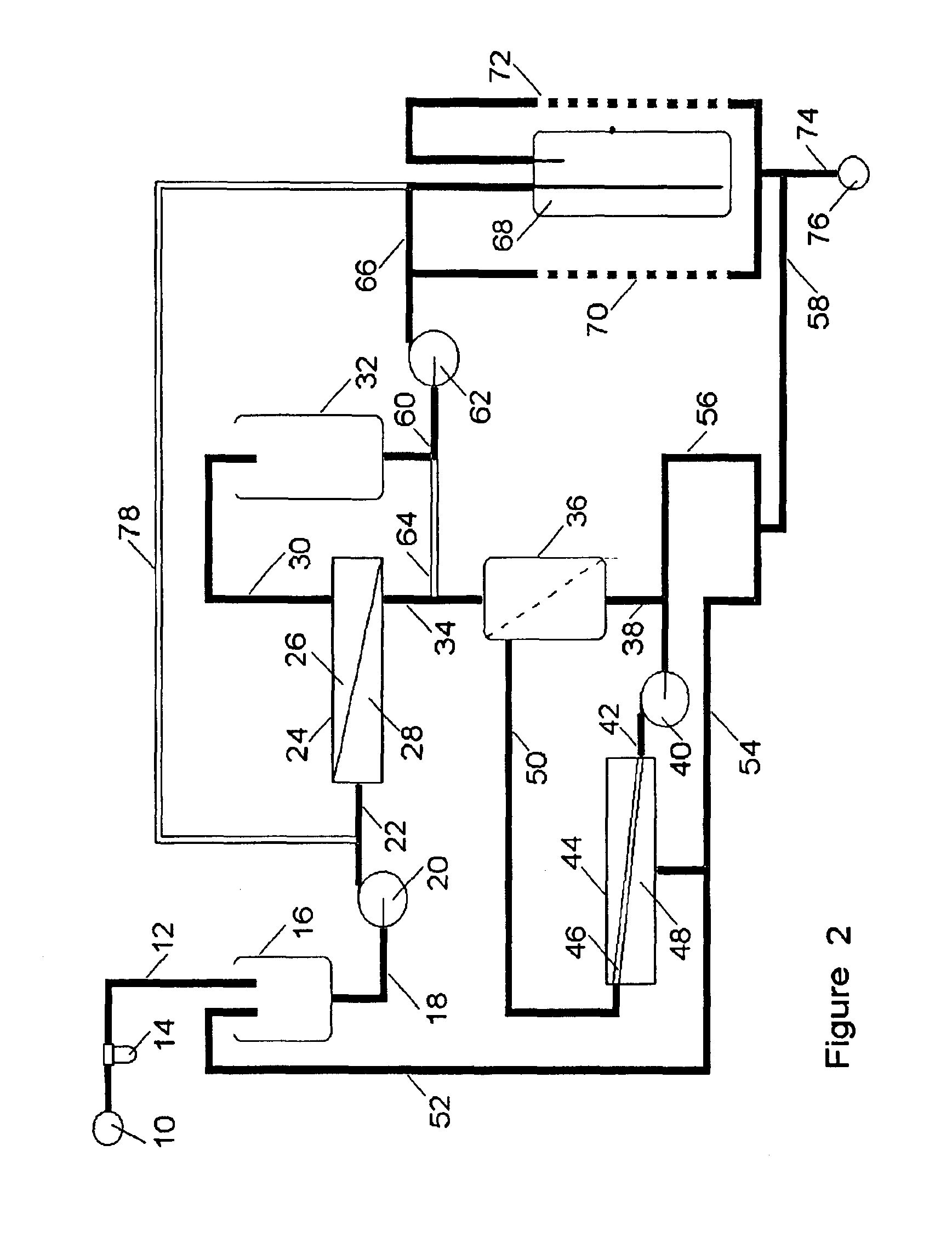

Method and apparatus for parallel desalting

InactiveUS20040245177A1Reduce water hardnessPercent reusableLiquid separation auxillary apparatusGeneral water supply conservationPotable waterDesalination

Parallel desalting (PDS) includes a hybrid membrane softening (MS) system for de-mineralizing water for residential and commercial use. Parallel desalting produces "soft" water without the use of salt, or any other liquid chemical reagent normally used to carry out pH adjustment in industrial membrane and precipitation processes. The PDS process balances the operation of a RO (potable water) membrane unit with the operation of a tubular MF (wastewater) membrane unit, thereby providing a highly efficient and regenerative water treatment technology: (1) The optimum operation for the PDS system transforms roughly 90 percent of a potable, slightly brackish water supply into <50 mg / L TDS water with <1-grain (10-15 mg / L as calcium carbonate)-water hardness; and (2) The operation of the PDS system produces, in salinity terms, in a 100 percent reusable effluent for downstream recycling. Virtual prototype results suggest that with Colorado River Aqueduct source water (570-620 mg / L TDS and 16-grain water hardness), parallel desalting can produce an effluent with a TDS 40-70 mg / L lower than the originating supply (excluding TDS contributed directly by the particular type of use of the soft water).

Owner:PERRION

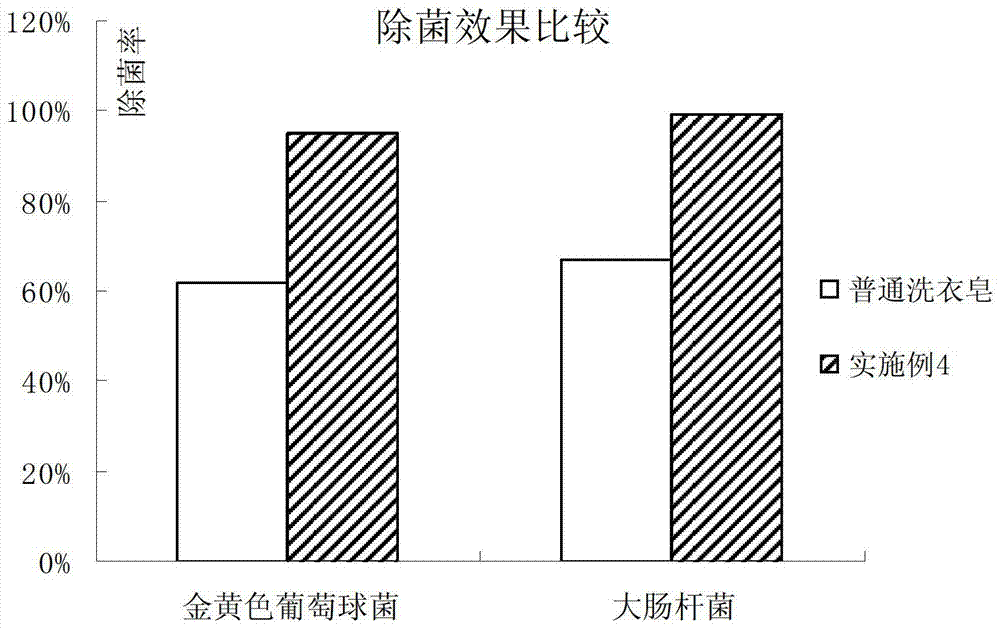

Washing soap with functional colored granules and production method thereof

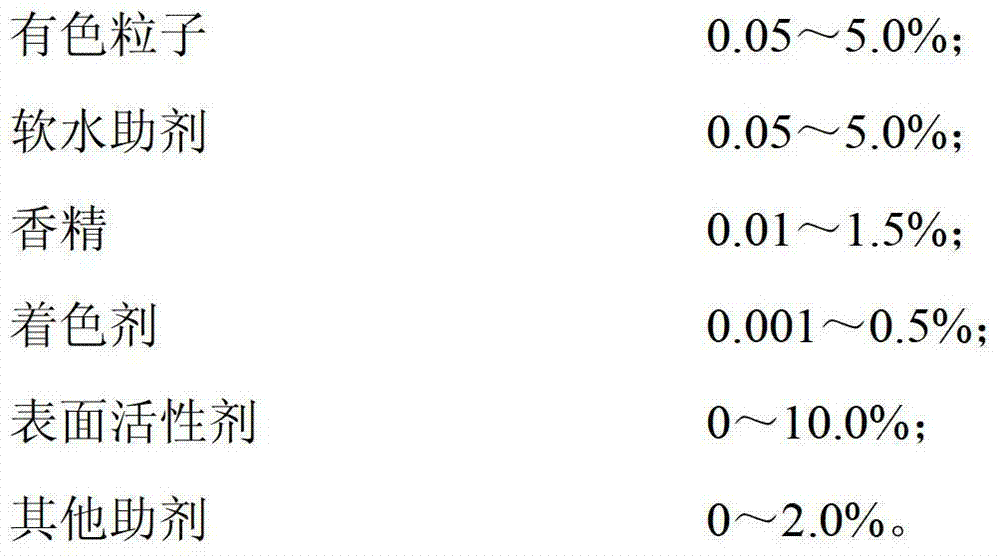

ActiveCN103242992AGive full play to special effectsEfficient combinationSoap detergent compositionsSoft waterSURFACTANT BLEND

The invention discloses a washing soap with functional colored granules and a production method thereof. The washing soap is formed by mixing the following components by weight percent: 60.0-99.0% of soap granules, 0.05-5.0% of colored granules, 0-10% of a surfactant, 0.05-5.0% of a soft water additive, 0.01-1.5% of essence, 0.001-0.5% of a colorant and 0-2.0% of other additive. Due to the adoption of the washing soap, the appearance acceptance and the visual beauty of a washing soap product can be improved; and due to the addition and application of the functional colored granules, the washing functionality of the washing soap can be improved, the washing effect of the washing soap can be enhanced, and the integrated effect of the washing performance of the washing soap product can be achieved.

Owner:GUANGZHOU LIBY

Blow molded polyvinyl alcohol membrane and production method thereof

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through blow molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 20 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 99.9 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. The method has the advantages of simple process, less device investment, small occupied area, and realization of blow molding of normal-temperature, medium-temperature and high-temperature water soluble membranes. The method is mainly used for producing double-layer membranes, and the membranes can be directly processed to produce various water-soluble bags, and the water-soluble bags are used in the field of medium and low end packaging application, and can be used as a pesticide and chemical engineering product inner packaging liner bag, a hospital washing packaging bag and a refuse bag.

Owner:CHINA PETROCHEMICAL CORP +2

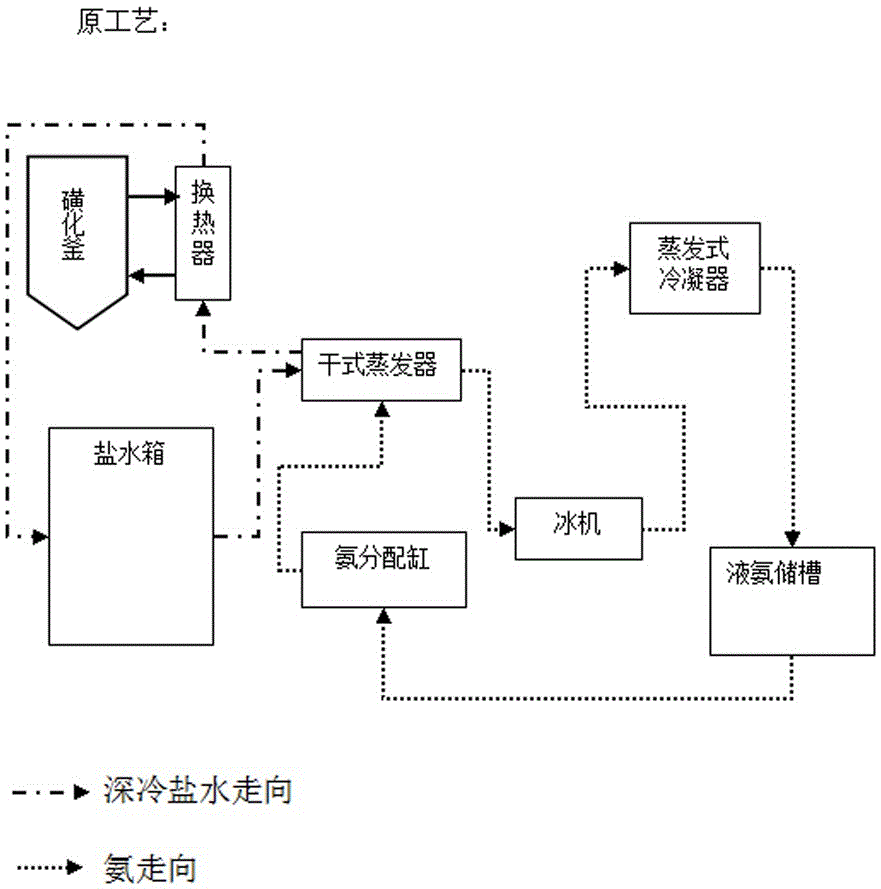

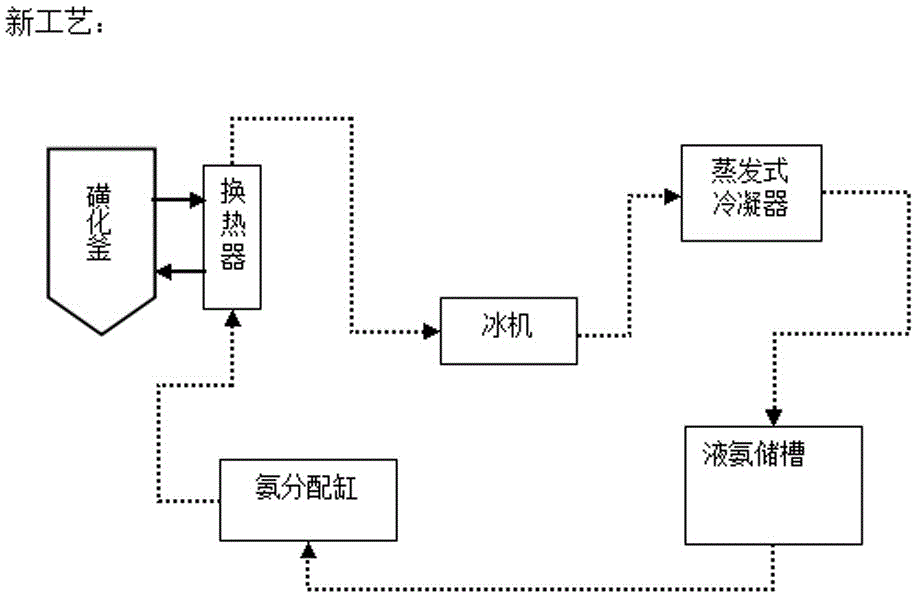

Sulfonation reaction cooling method in acesulfame synthesis technology

InactiveCN105111166ARemove constraintsEliminate useOrganic chemistryChemical industryBoiling pointSoft water

The invention discloses a sulfonation reaction cooling method in an acesulfame synthesis technology. The method is characterized in that liquid ammonia is adopted to replace copious cooling brine and enters a heat exchanger as a cooling agent to directly cool a sulfonation kettle, and the temperature in the sulfonation kettle is controlled by regulating the flow of the liquid ammonia so as to meet the temperature requirement of sulfonation reaction. The method has the advantages that based on the characteristics of low specific gravity and low boiling point of the liquid ammonia, heat generated in sulfonation reaction is taken away through sublimation of the liquid ammonia so as to achieve cooling. Compared with an existing cooling method, restrictions on production from brine pumps are eliminated, the usage quantity of brine pumps is reduced, and a large amount of electric energy is saved; the purchase and installation cost and the repair and maintenance cost of brine tanks and dry evaporative cooling equipment are lowered, annual calcium chloride consumption and soft water consumption are reduced, and influences on the environment in the overhaul process are eliminated.

Owner:ANHUI JINGHE IND

Melt extrusion-casting/calendering molded polyvinyl alcohol membrane and production method thereof

InactiveCN106189008ALower melt processing temperatureReduce processing temperatureFlat articlesProcedure AgentsPolyethylene glycol

The invention provides a polyvinyl alcohol membrane. The polyvinyl alcohol membrane is produced through casting or calendering molding of melt-processible polyvinyl alcohol resin, the tensile strength of the polyvinyl alcohol membrane is not lower than 25 MPa, the melt-processible polyvinyl alcohol resin comprises effective amounts of polyvinyl alcohol, a plasticizer, soft water and a processing assistant, the degree of polymerization (DP) of the polyvinyl alcohol is 1000-3500, the degree of hydrolysis (DH) of the polyvinyl alcohol is greater than 72 (mol)% and is smaller than 95 (mol)%, the plasticizer is at least one of glycerol, polyethylene glycol and triethylene glycol di-2-ethylhexoate, and the processing assistant is at least one of talcum powder, silica, oleamide and saturated aliphatic dicarboxylate. A production method of the polyvinyl alcohol membrane has the advantages of simple process, less device investment, small occupied area, and formation of normal-temperature and medium-temperature water-soluble membranes through melt extrusion casting / calendering. The method is mainly used for producing single-layer membranes which are applied to the fields of hydrographics transfer printing base membranes, printing paper hot melt adhesive membranes, agricultural membranes and other medium-and-high end products.

Owner:CHINA PETROCHEMICAL CORP +2

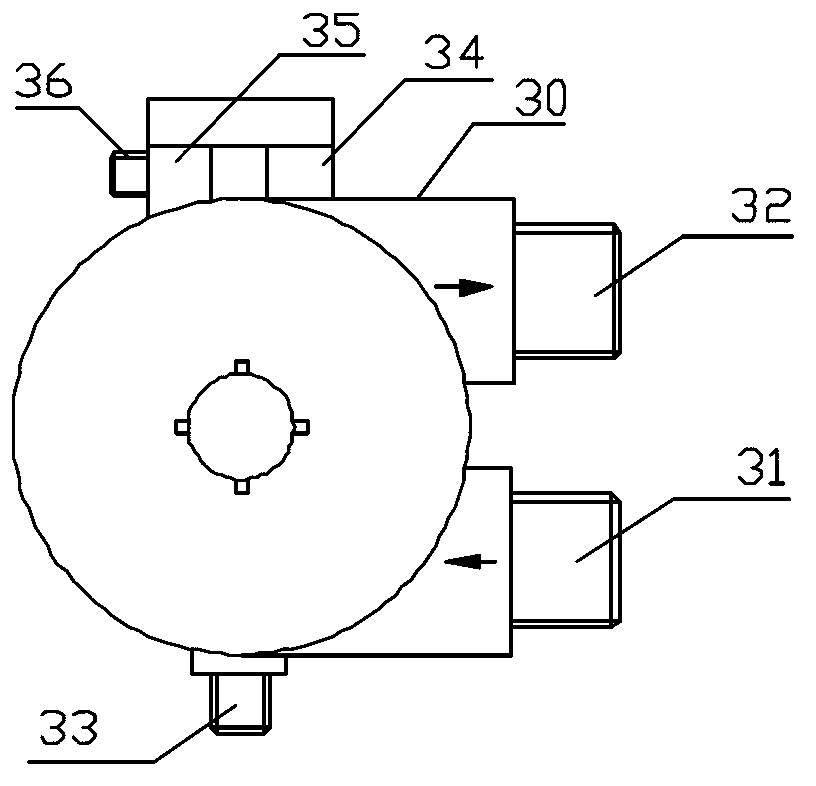

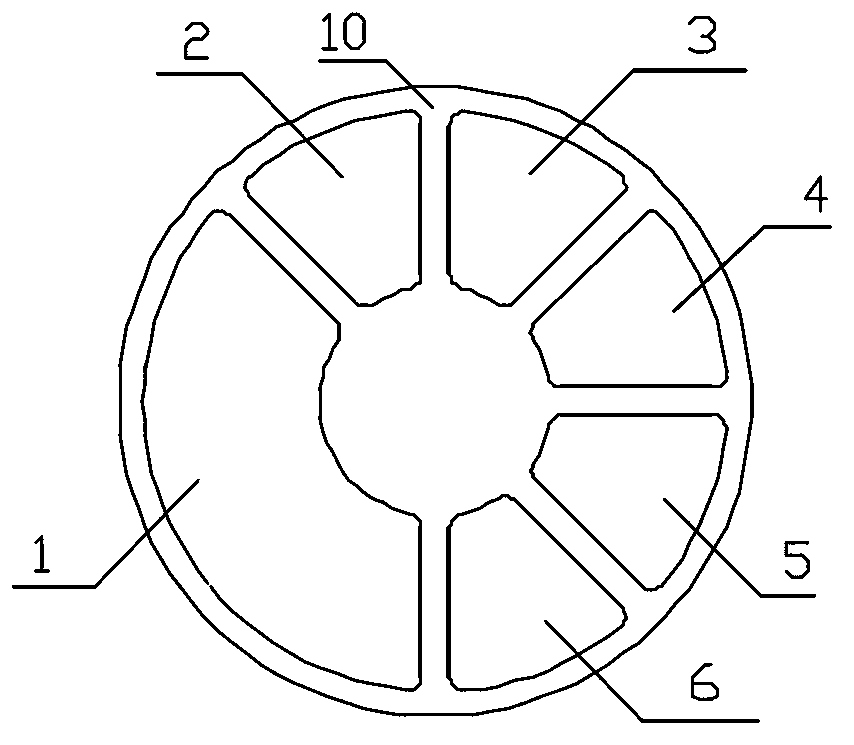

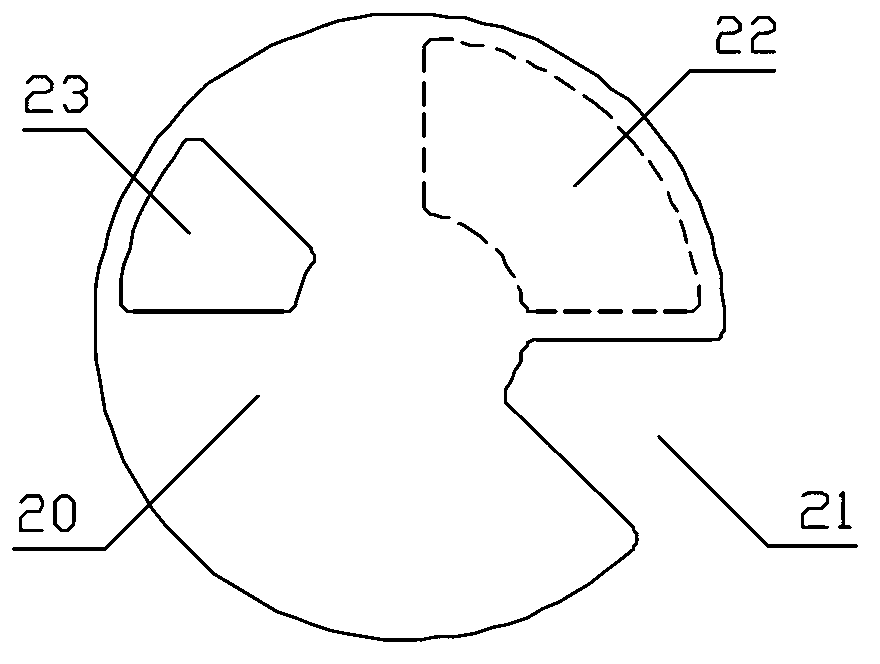

Multifunctional soft water valve for soft water supplement

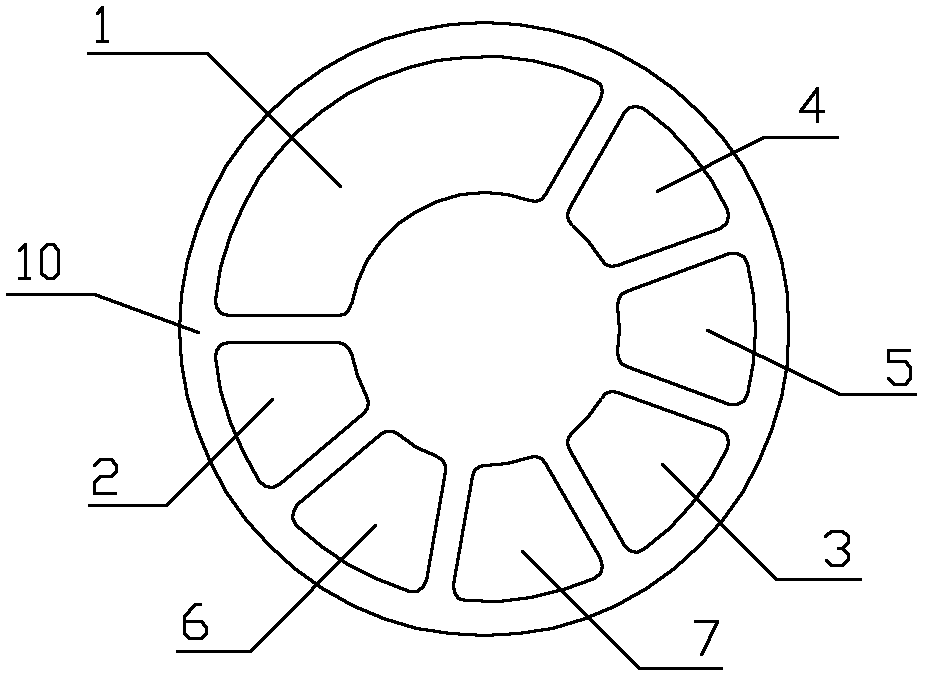

ActiveCN102635706AHigh trafficConserve waterWater/sewage treatment by ion-exchangeMultiple way valvesWater savingInlet channel

The invention discloses a multifunctional soft water valve for soft water supplement, which comprises a valve body, a bonnet, an ejector, a fixed valve slice and a movable valve slice. The movable valve slice is connected with a valve rod. A water inlet, a water outlet, a sewage discharge outlet, an outer joint of a filter element, an inner joint of the filter element and a salt-absorbing inlet are arranged on the soft water valve. Flow channels for an ejector inlet and an ejector outlet are arranged inside the soft water valve. The multifunctional soft water valve for soft water supplement is characterized in that seven through holes including a first through hole, a second through hole, a third through hole, a fourth through hole, a fifth through hole, a sixth through hole and a seventh through hole are arranged on the fixed valve slice. Each through hole is respectively communicated with one of the water outlet, the ejector outlet, the ejector inlet, the outer joint of the filter element and the inner joint of the filter element. A water inlet channel, a conducting blind hole and a sewage discharge channel are arranged on the movable valve slice, the water inlet channel is communicated with the water inlet, and the sewage discharge channel is communicated with the sewage discharge outlet. The multifunctional soft water valve for soft water supplement has the advantages of capability of supplementing soft water to brine box, high flow rate, water and salt economization and environmental protection.

Owner:YUYAO YADONG PLASTIC

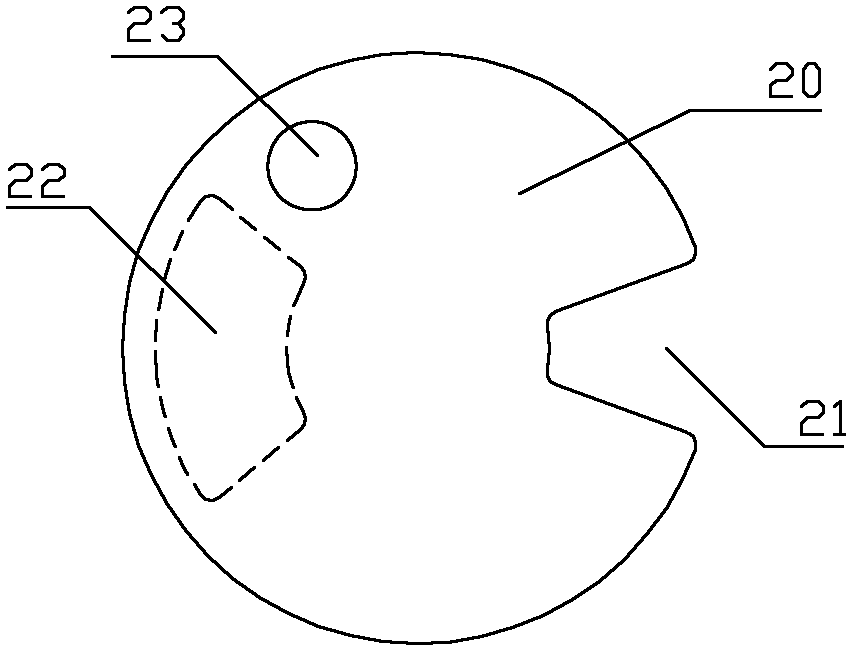

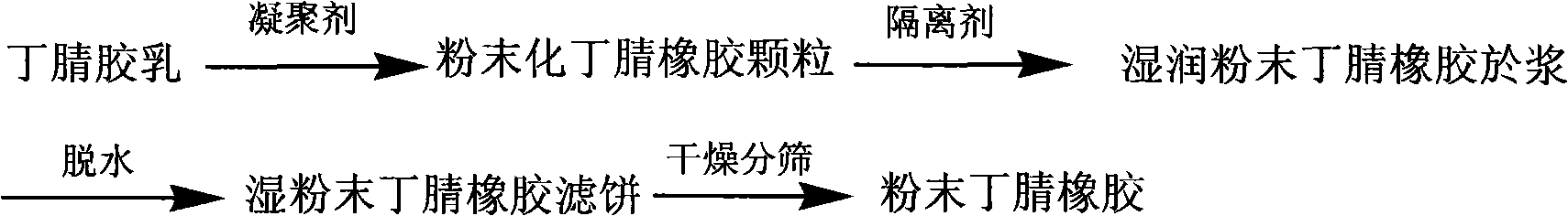

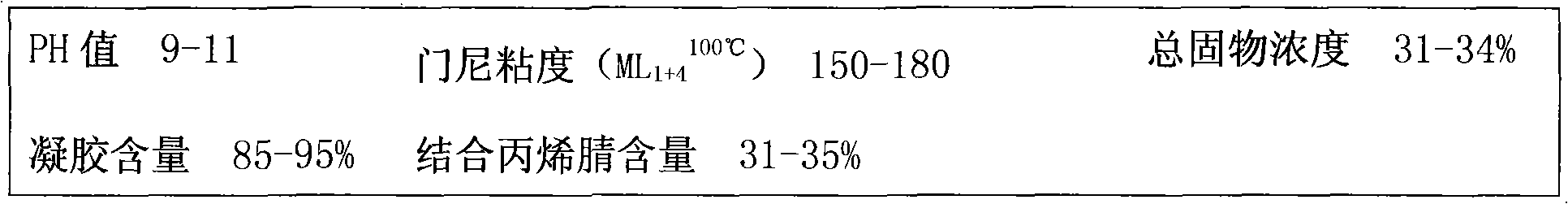

Method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content

The invention relates to a method for producing cross-linking powder nitrile-butadiene rubber with medium and high nitrile content; the method comprises the steps of synthesizing nitrile-butadiene rubber slurry, then flocculating the nitrile-butadiene rubber slurry followed by separating and powdering, and dehydrating and drying. In the stage of polymerization reaction, potassium carbonate is added to be a buffering agent of the reaction, and the mixed liquor of diethylhydroxylamine, hydroxylamine sulphate, potassium hydroxide and soft water is used as a composite terminator; in the stage of separating and powdering, WSL and DLTP are added to be an antiager, and univalent sodium salt and bivalent magnesium salt or univalent sodium salt or bivalent calcium salt are taken as a flocculant forcarrying out flocculating, separating and powdering on the nitrile-butadiene rubber slurry at 30-75 DEG C. The invention is simple in production technique, easy for operation, low in production cost,less in energy consumption and high in conversion rate which can be more than 95%; a novel composite terminator is adopted, so that mooney is stable and termination effect is good; the rubber powderis finer, and dispersity during processing is improved; and the heat-resistant quality of the product is very good, the wear resistance is good, and the invention can satisfy the requirement on application in high friction composite brake shoes of trains.

Owner:HUANGSHAN HUALAN TECH

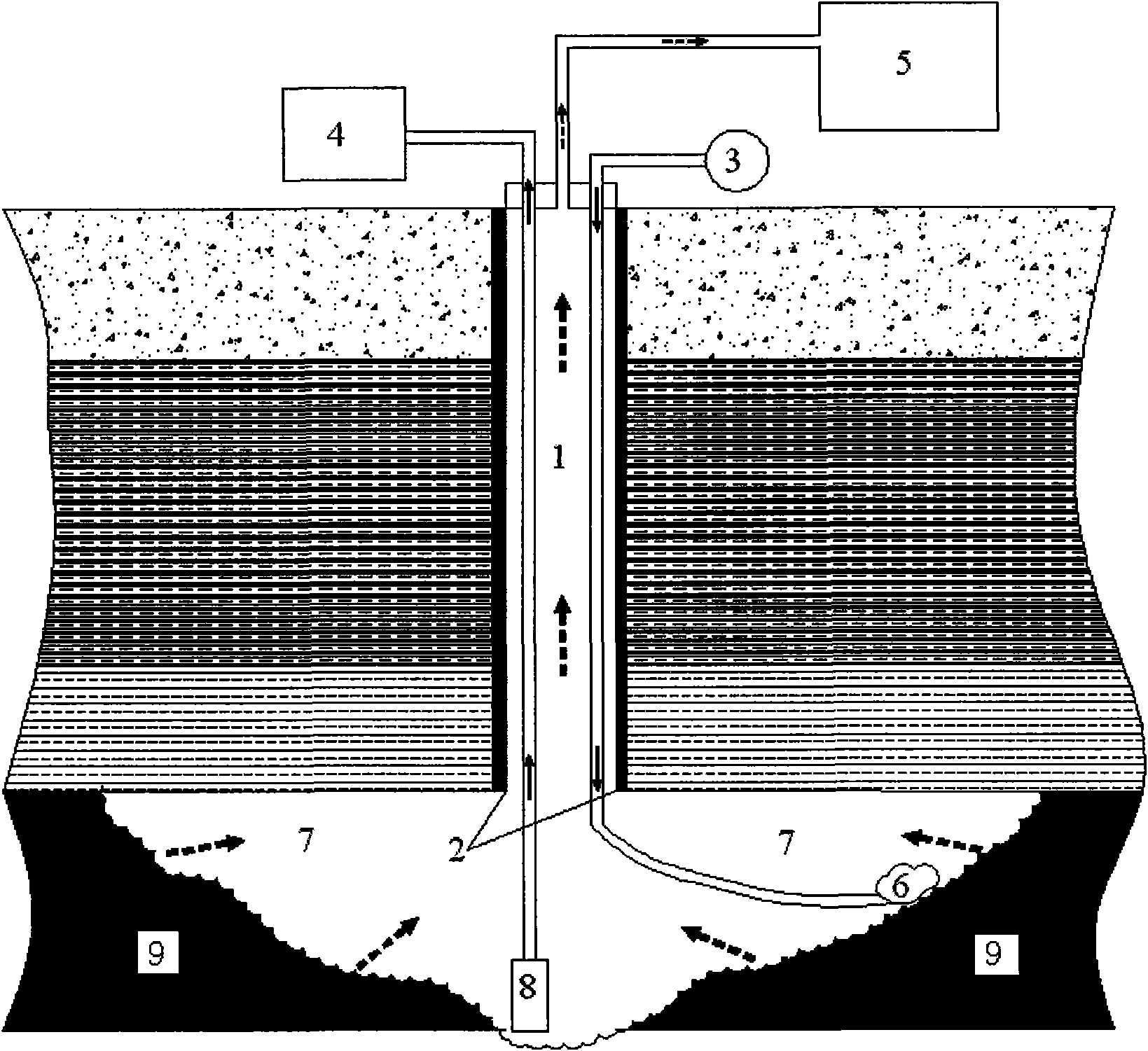

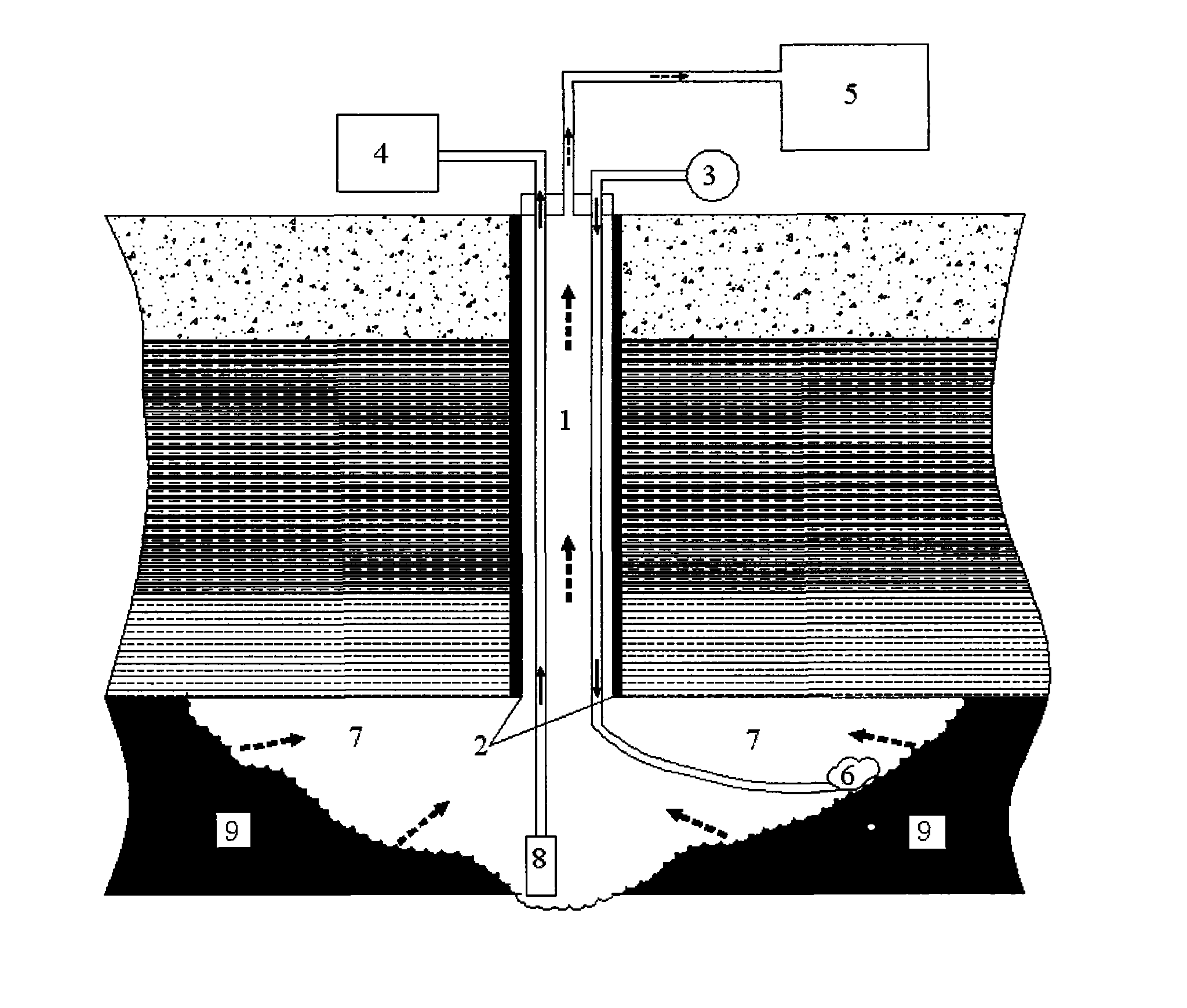

Method for exploiting coal bed gas by hydraulic drilling and pressure relieving

The invention discloses a method for exploiting coal bed gas by hydraulic drilling and pressure relieving. The method comprises the following steps of: drilling a large-caliber well to the coal bed(9), building a coal bed gas exploitation well(1) capable of adding water, discharging water and discharging gas, making a sleeve pipe(2) arranged on the drilling well, and performing mechanical drilling at the bottom of the well; making a well-sealing device arranged on an opening of the coal bed gas exploitation well(1), and making a ground water pump(3), a coal-water separating device(4) and a gas storage device(5) arranged; distributing water-discharging devices(8) and flushing robots(6) on both sides in the coal bed gas exploitation well(1), wherein the flushing robots(6) are connected with the ground water pump(3) by soft water pipes and can continuously flush the coal down in caves at the bottom of the well to form a pressure relieving space(7); discharging the coal-water mixture to the coal-water separating device(4) by the water-discharging devices(8); and discharging the coal bed gas continuously generated by the coal bed(9) after pressure relieving to the gas storage device(5) by the coal bed gas exploitation well(1). The method has the advantages of easily solving the problem of early exploiting the coal bed gas in the coal mass with looseness, extremely low permeability and high bursting, eliminating bursting risk and lowering a gas content of the coal mass.

Owner:ZHENGZHOU UNIV +2

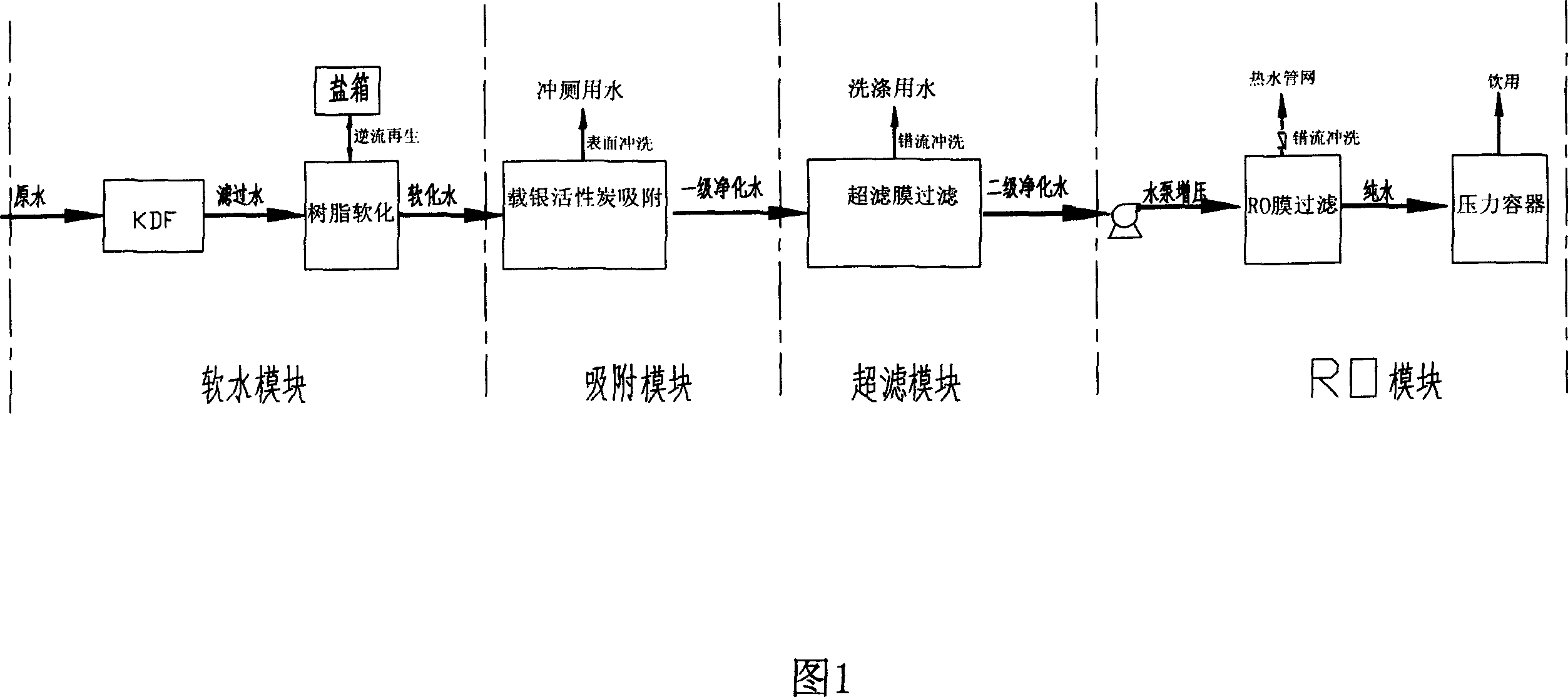

Household different water supply system

ActiveCN1944816AEliminate Concentration PolarizationExtend your lifeGeneral water supply conservationMultistage water/sewage treatmentWater softeningActivated carbon

The dual water supply system for household includes a soft water module with KDF filter connected to the raw water pipeline, a water softening resin device with salt box and resin jar, an adsorbing module with active carbon with water outlet connected to toilet water pipeline, an ultrafilter module, an RO module with pressurizing water pump, a bath water inlet pipeline, and a pressure container connected to the pure water outlet of the RO module. The dual water supply system makes the drinking water and the living use water flow separately, and has reverse resin regeneration, active carbon surface flushing and ultrafiltering membrane cross flow filtering to complete the timely system washing for eliminating pollutant and prolonging service life.

Owner:ZHEJIANG QINYUAN WATER TREATMENT S T

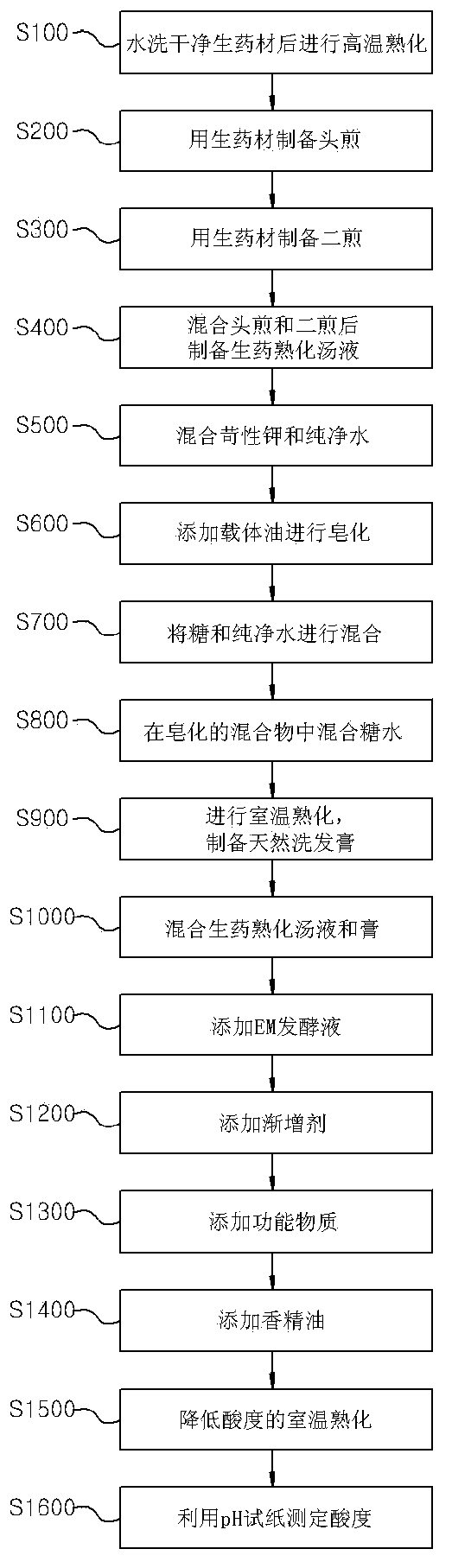

Natural shampoo using herbal medicine mature decoction, and method of preparing the same

InactiveCN103505388AReduces pungent odorsReduced characteristicsCosmetic preparationsHair cosmeticsSoft waterAngelica gigas

A natural shampoo is provided. The natural shampoo is made using a herbal medicine mature decoction which is obtained by putting herbs including lotus roots, lotus leaves, red ginseng, Hippophae rhamnoides leaves and trunk, persimmon leaves, thuja orientalis, ginger, rosemary, black beans, black sesame, aloe, mulberry leaves, Orostachys japonicus, Angelica gigas, green tea, pine needles, mint, pleuropterus multflorus, blueberry, Acorus gramineus, and garlic in a maturing device, maturing the herbs in temperatures of 65 to 95° C. depending on the herb for 3 to 21 days, then pouring distilled water or soft water, and decocting the matured herbs mixed with the water.

Owner:高银珠

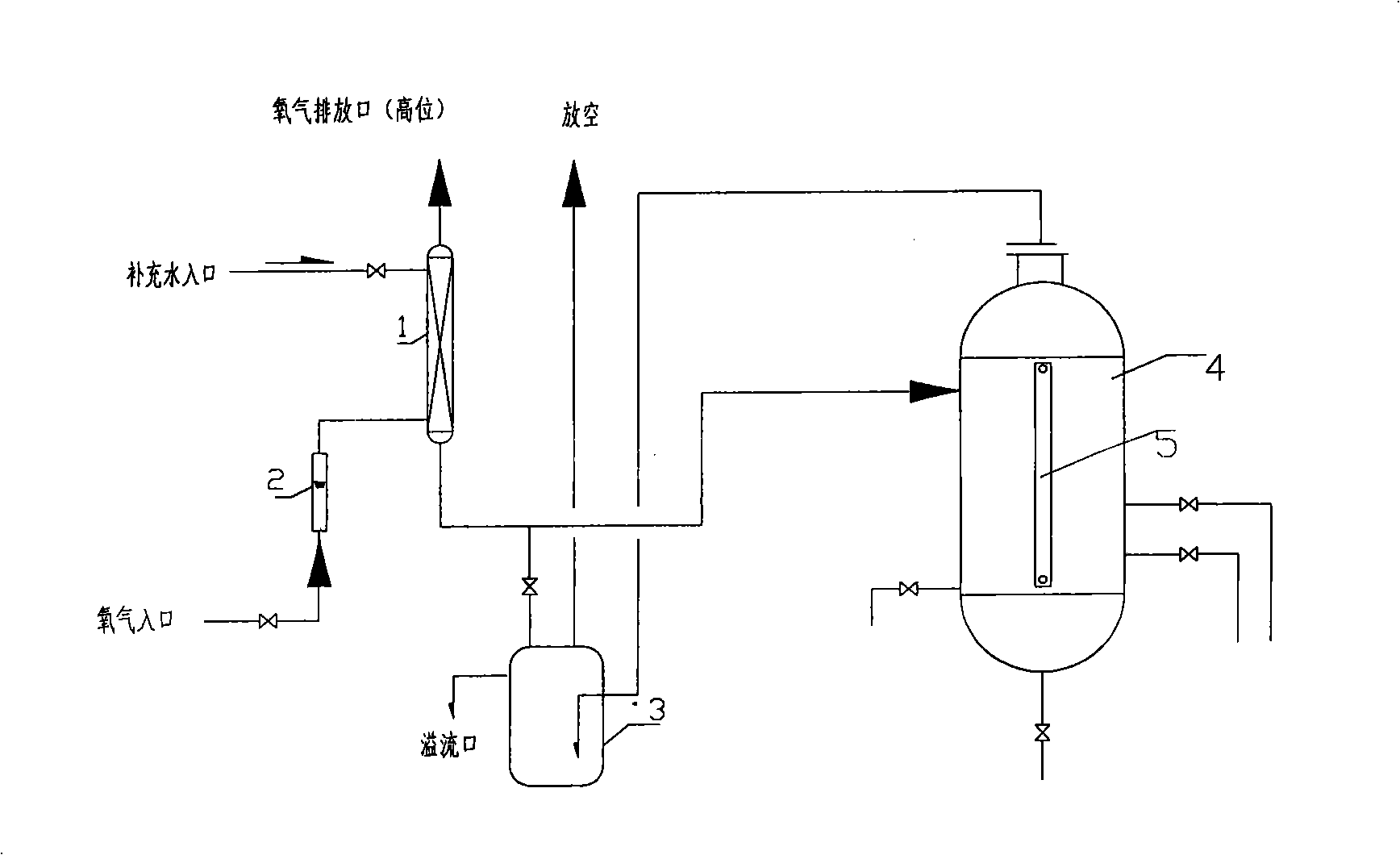

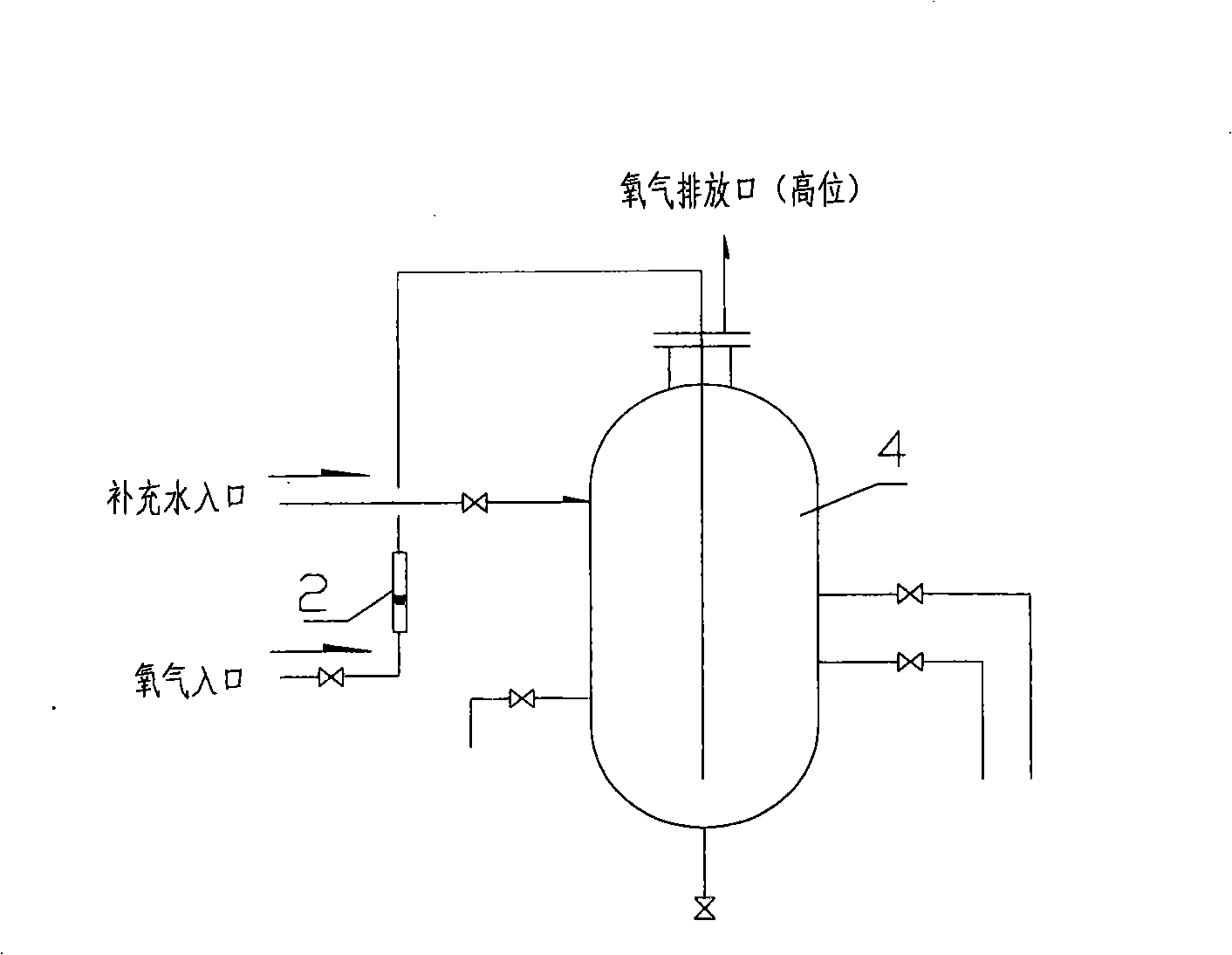

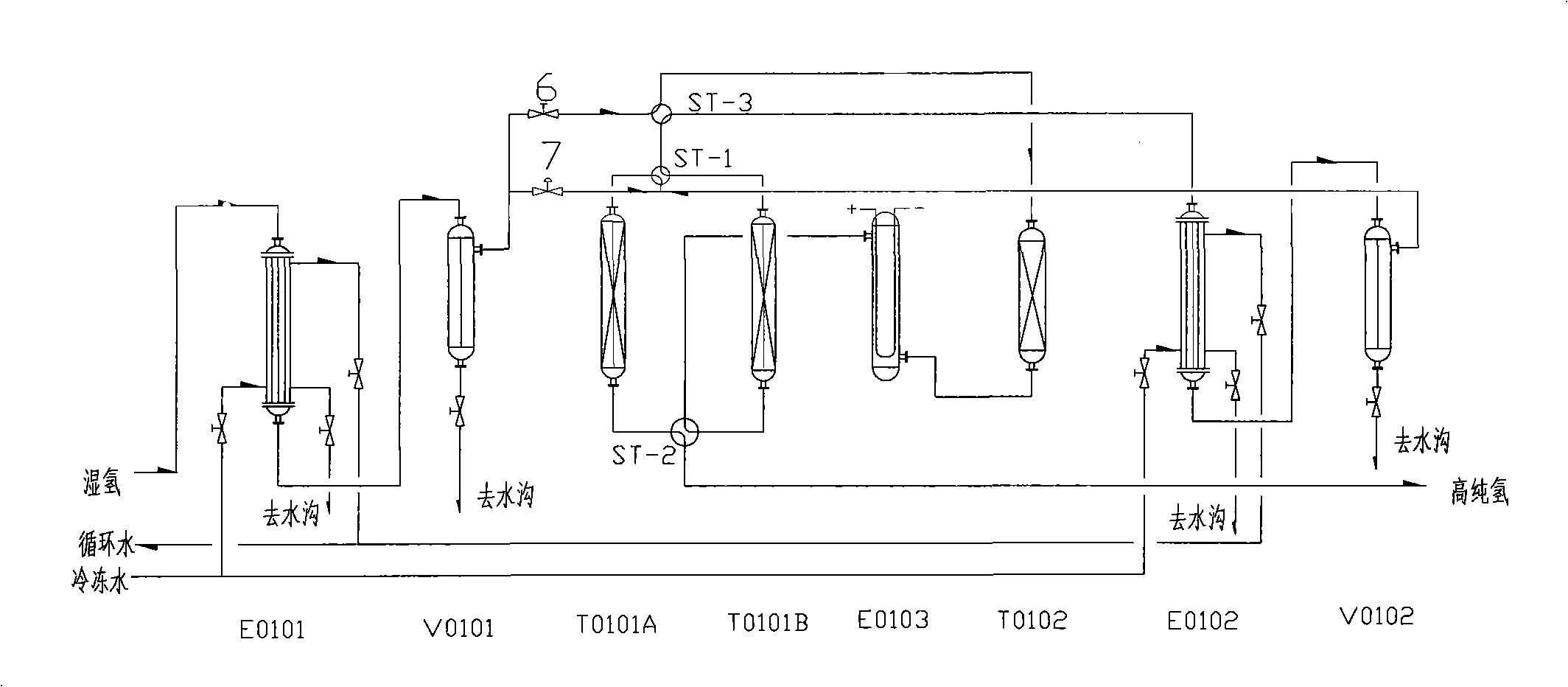

Technique for continuously producing high purity hydrogen by water electrolysis

The invention discloses a technology for continuously producing high-purity hydrogen by water electrolysis, which utilizes soft water deprived of dissolved air as a raw material and finally obtains a high-purity hydrogen product conforming to the national standard GB / T 7445 by electrolysis, catalytic deoxidization and adsorption dewatering. The main steps are as follows: (1) the deprivation of the dissolved air in water: a small amount of oxygen is adopted to carry out counter-current bubbling back blowing to the raw material water so as to deprive nitrogen and other dissolved gases in the water; (2) water electrolysis: an industrial electrolysis unit is used for electrolyzing the nitrogen-deprived soft water, and industrial electrolysis hydrogen is obtained from the cathode of an electrobath; (3) catalytic deoxidization: Pd or Pt is taken as a catalyst, and the H and O in hydrogen are electrolyzed to react and generate water; and (4) dewatering and drying: the molecular sieve constant pressure temperature swing adsorption technology is adopted to deprive the water in the hydrogen so as to obtain the high-purity hydrogen. The technology is the improvement of the existing industrial hydrogen producing technology by electrolysis, and can continuously produce high-purity hydrogen, with the advantages of low investment, no environment pollution and high hydrogen recovery rate.

Owner:SOUTHWEST RES & DESIGN INST OF CHEM IND

Water soluble adhesive and preparation method thereof

ActiveCN101486882APrevent agingMaintain performanceNatural rubber adhesivesFootwearNon toxicityPolymer science

The invention provides a water-soluble adhesive and a preparation method thereof. The water-soluble adhesive is prepared mainly by natural latex, soft water, a vulcanizing agent, a vulcanization accelerator, a vulcanizing activator, a dispersant, anhydride casein, borax, a stabilizer, a wetting agent, ammonia and potassium hydroxide. In order to improve the performance of the water-soluble adhesive, carboxymethyl cellulose sodium, the wetting agent, an age inhibitor, an antifoaming agent and a mildew inhibitor also can be added; the obtained water-soluble adhesive is an environment-friendly material which is used for shoes, has the processing advantages of low energy consumption, non-toxicity, good processing property, simple operation and the like in the preparation process, strengthens self deterioration resistance, greatly prolongs the storage stabilization period of slurry, improves the intrinsic performance of the adhesive, and fundamentally realizes the demand of high adhesive strength on rubber shoes.

Owner:际华制鞋工业有限公司

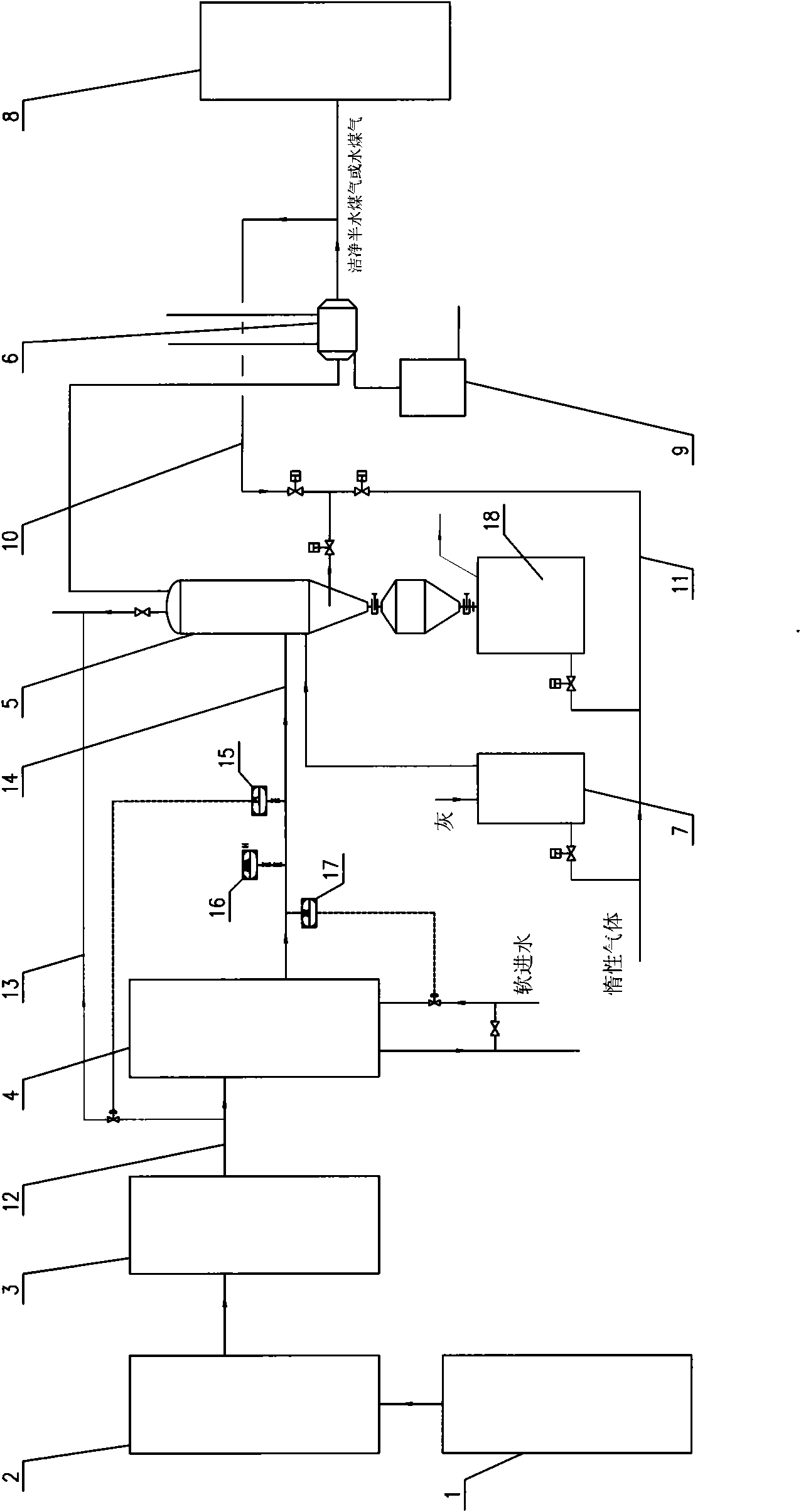

Gasification dry dedusting technology

ActiveCN101550362AAvoid direct contactSolve secondary pollutionCombined combustion mitigationGas dust removalPositive pressureSoft water

The invention discloses gasification dry dedusting technology which comprises the following technological steps: 1) the semi-water gas or the water gas from a normal-pressure or micro-positive pressure gasification furnace with gasification pressure of smaller than or equal to 0.1 MPa of smaller (gauge pressure) is dedusted by a cyclone dust collector to remove most of the dust, and then the gas enters a combined waste pot to exchange heat with soft water and saturated vapor to reduce temperature; 2) after temperature reduction, the semi-water gas or the water gas enters a soft water heater, the flow of the soft water is adjusted to reduce the temperature of the semi-water gas or the water gas going through the soft water heater once again; 3) after further temperature reduction, the semi-water gas or the water gas enters a bag-type dust collector to be dedusted and purified, wherein the air in the bag-type dust remover is replaced by inert gases; and 4) after fine dedusting, the semi-water gas or the water gas enters a spacing exchanger to reduce the temperature to 35-45 DEG C by a coolant and is prepared for producing or synthesizing ammonia or methanol. The technology has the advantages of avoiding the direct contact of the semi-water gas or the water gas with water, reducing the water consumption, enhancing the dedusting efficiency, protecting the environment, saving investment and operating expenses, and having great significance in environmental protection and large economic benefit.

Owner:CHINA NAT OFFSHORE OIL CORP +2

Multifunctional soft water valve

ActiveCN102840362AGuaranteed lifeImprove regeneration efficiencyScale removal and water softeningMultiple way valvesInlet channelSoft water

The invention discloses a multifunctional soft water valve, which comprises a valve body, a cover, an ejector, a fixed valve plate and a movable valve plate, wherein the soft water valve is provided with a water inlet, a water outlet, a drain outlet, a first filter core interface, a second filter core interface and a salt absorbing port; an ejector outlet and an ejector inlet are formed in the soft water valve; the fixed valve plate is provided with a first through hole, a second through hole, a third through hole, a fourth through hole, a fifth through hole and a sixth through hole; the first through hole is communicated with the first filter core interface; the second through hole is communicated with the fifth through hole, and is communicated with the second filter core interface; the third through hole is communicated with the ejector inlet; the fourth through hole is communicated with the ejector outlet; the sixth through hole is communicated with the water outlet; the first through hole is adjacent to the second through hole; the second through hole is adjacent to the third through hole; the third through hole is adjacent to the fourth through hole; and the movable valve plate is provided with a water inlet channel, a conduction blind hole and a pollution discharge channel. The multifunctional soft water valve has the beneficial effects of practicability, large flow, saving in salt, environment friendliness and prolonging of the service life of the valve body.

Owner:YUYAO YADONG PLASTIC

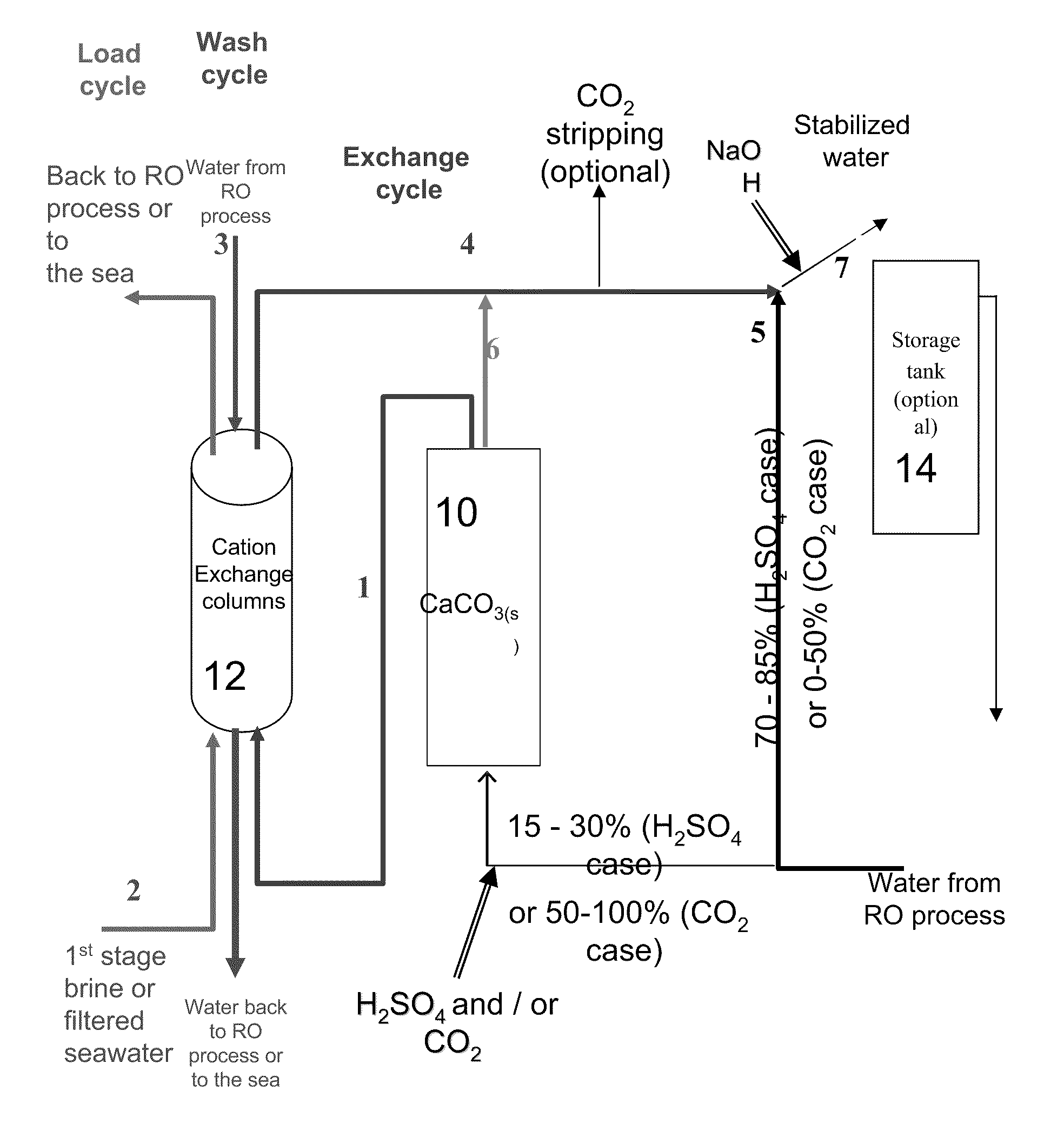

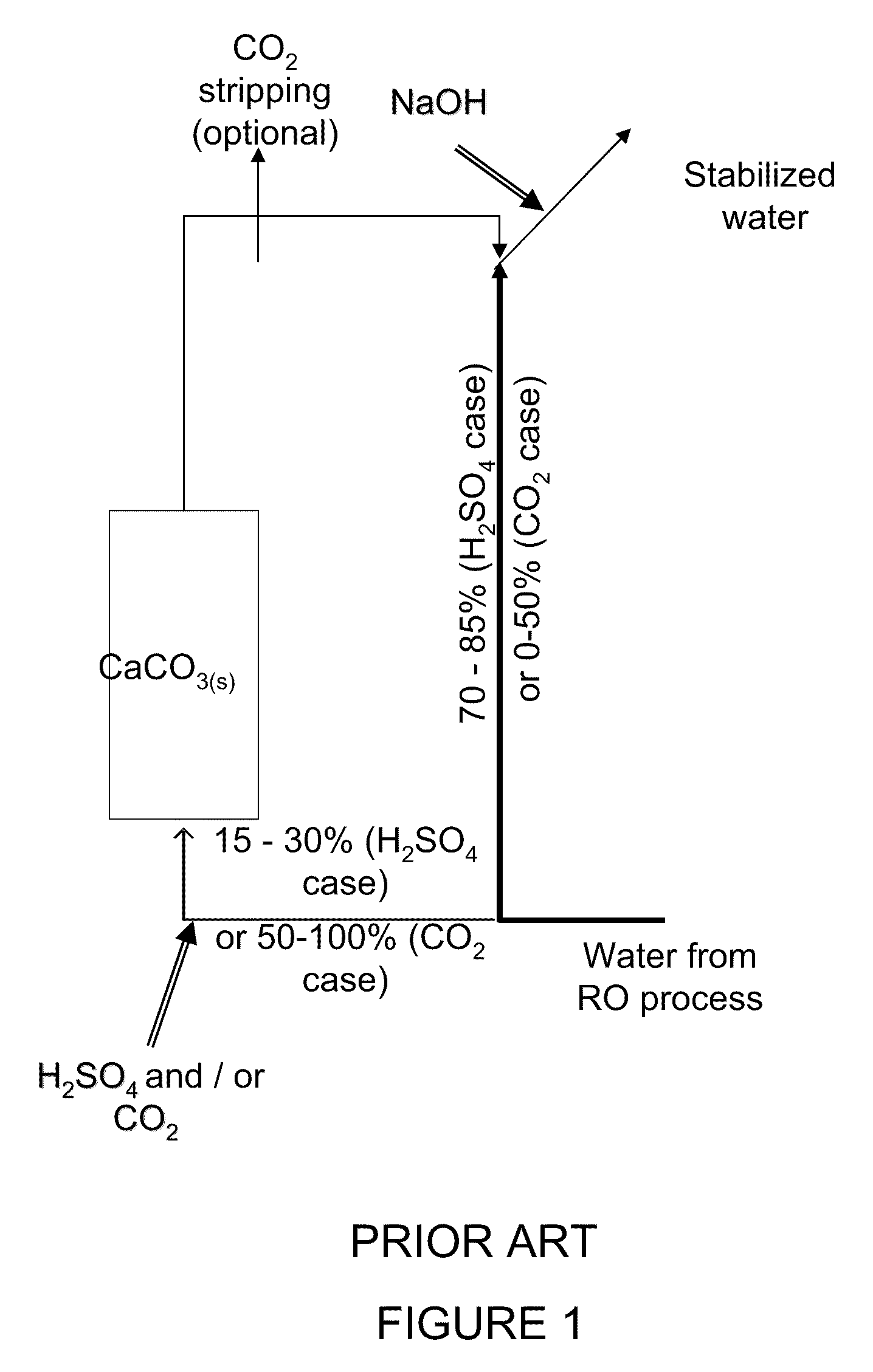

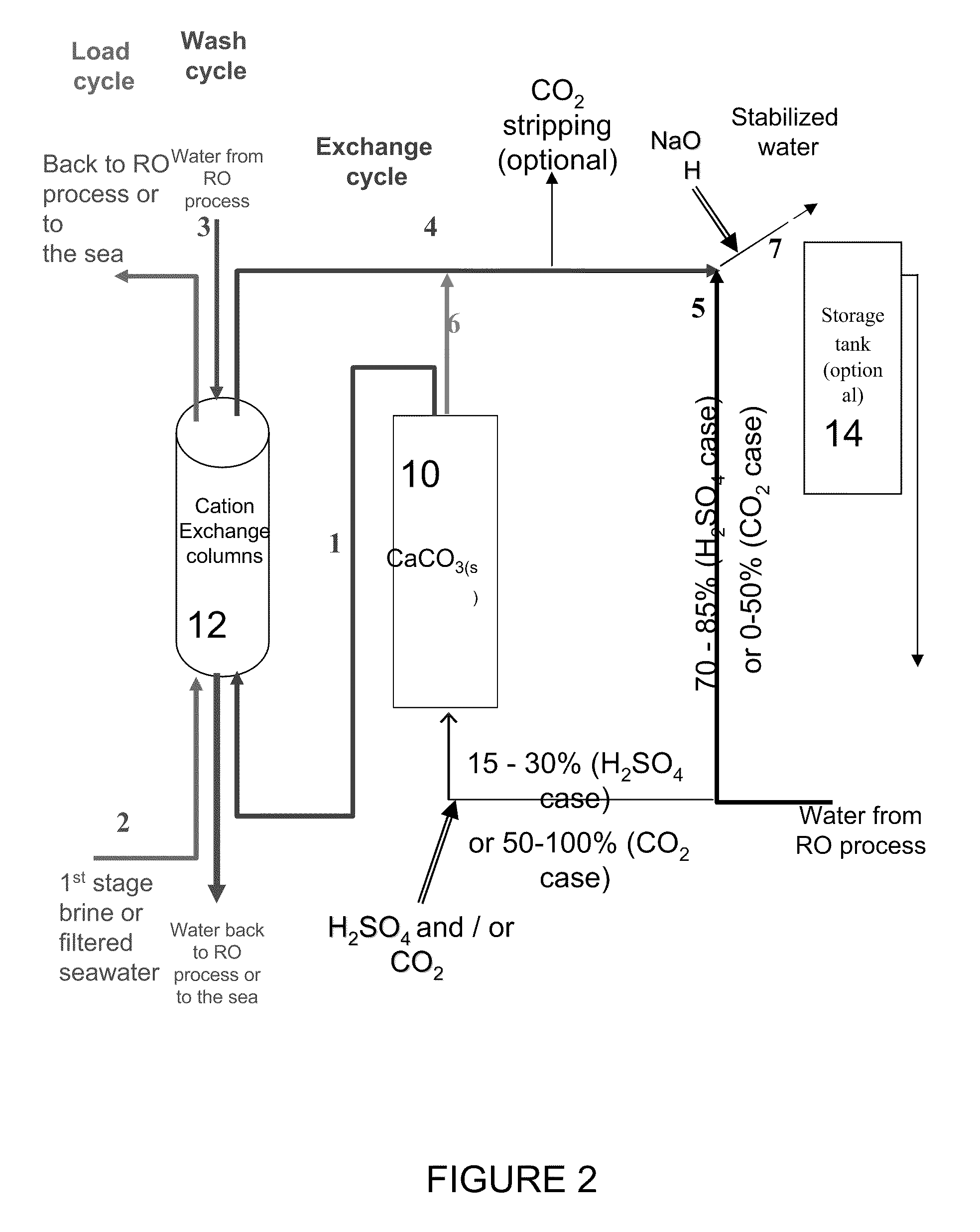

Post treatment of desalinated and soft water for balanced water composition supply

A calcite dissolution post-treatment process and apparatii for desalinated water are provided. The process comprises separating cations from seawater or brackish / seawater desalination brines by ion exchange resin(s) onto which the ions are loaded, contacting the ion exchange resin(s) loaded with the cations with an effluent of a calcite dissolution reactor wherein the cations are exchanged with Ca2+ from this effluent. The Ca2+ concentration of the resulting desalinated water decreases while the cations concentration increases to comply with required quality criteria. Batch type and continuous apparatii by which the process can be carried out are described.

Owner:TECHNION RES & DEV FOUND LTD

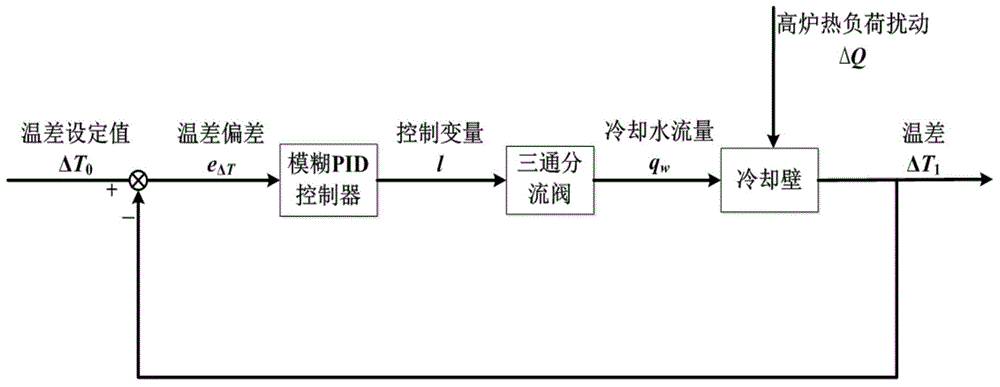

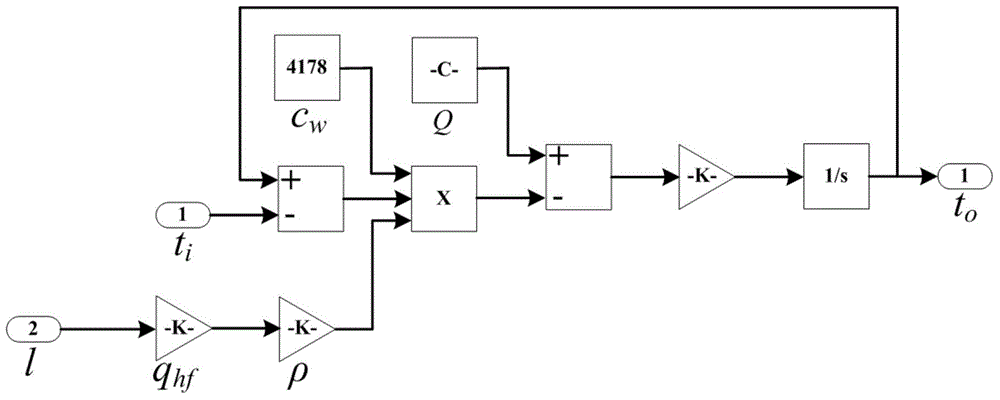

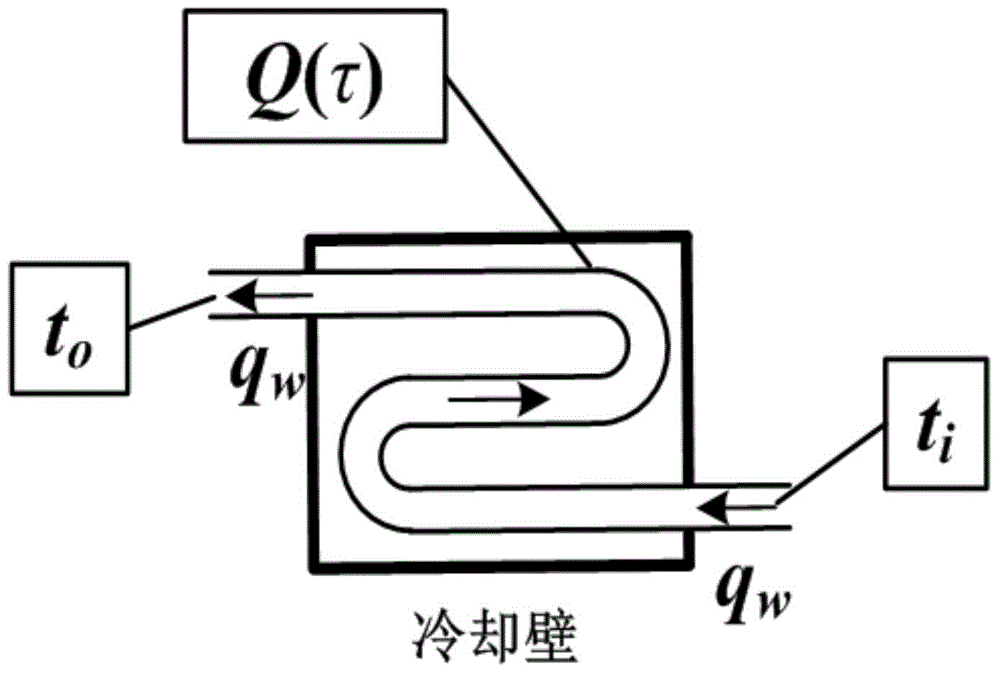

Furnace cooling intensity control method based on vague PID control

ActiveCN104898433ARealize automatic controlReduce volatilityCooling devicesAdaptive controlClosed loopSoft water

The present invention discloses a furnace cooling intensity control method based on vague PID control, and belongs to the technical field of furnace cooling control. The control method is based on the heat transfer theory and the engineering thermodynamics. A novel furnace water supply cooling method is provided; a diverging three-way valve serves as an executing mechanism; advantages of conventional PID control and vague control are combined; according to nonlinearity, obsoleteness and possible uncertain factors of a furnace cooling intensity control method and operating characteristics of a furnace closed-loop soft water circulating cooling system, PID parameter self-tuning inference rules are established, and opening of the diverging three-way valve is adjusted, thereby controlling cooling wall cooling intensity; in comparison with those in the prior art, real-time control of the cooling intensity is realized, control accuracy and stability are also raised, and manpower consumption is reduced.

Owner:马鞍山市安工大智能装备技术研究院有限公司

Method and apparatus for parallel desalting

Owner:PERRION

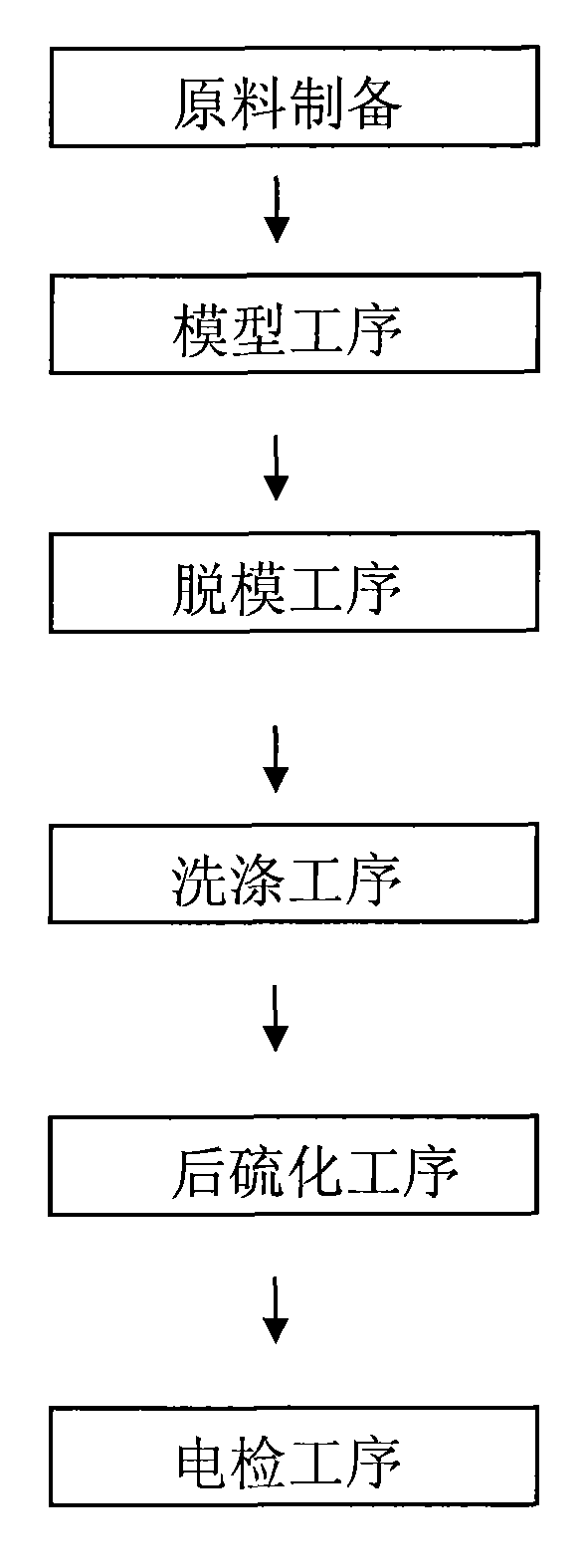

Method for preparing latex condoms

InactiveCN101628996ARemove or reduce residualEdge curling is normalMale contraceptivesCoatingsCelluloseCapillary gas chromatography

The invention relates to a method for preparing condoms, in particular to a method for preparing latex condoms. The method for preparing latex condoms comprises preparation of raw materials, a modeling process, a demolding process, a washing process, a post-curing process and an electrical inspection process, wherein the cleaning solution in the washing process comprises the following components in percentage by mass: 0.5 to 5 percent of borax, 1 to 8 percent of fruit acid, 2 to 9 percent of vitamin C, 1 to 8 percent of cellulose, 1 to 3 percent of silicon dioxide, 0.2 to 3 percent of alkylbenzene sulfonic acid, 0.1 to 3 percent of guar gum, 0.2 to 2 percent of sodium metasilicate pentahydrate, and the balance of soft water up to 100%. Detection through high-performance liquid chromatography and capillary gas chromatography-mass spectrometry proves that the latex condoms prepared according to the method is less than 0.01 mg / kg in remaining N-nitrosamines of nitrosamines, thereby having use safety and reliability and greatly reducing carcinogenic risk.

Owner:LVSHEN BEIJING LATEX

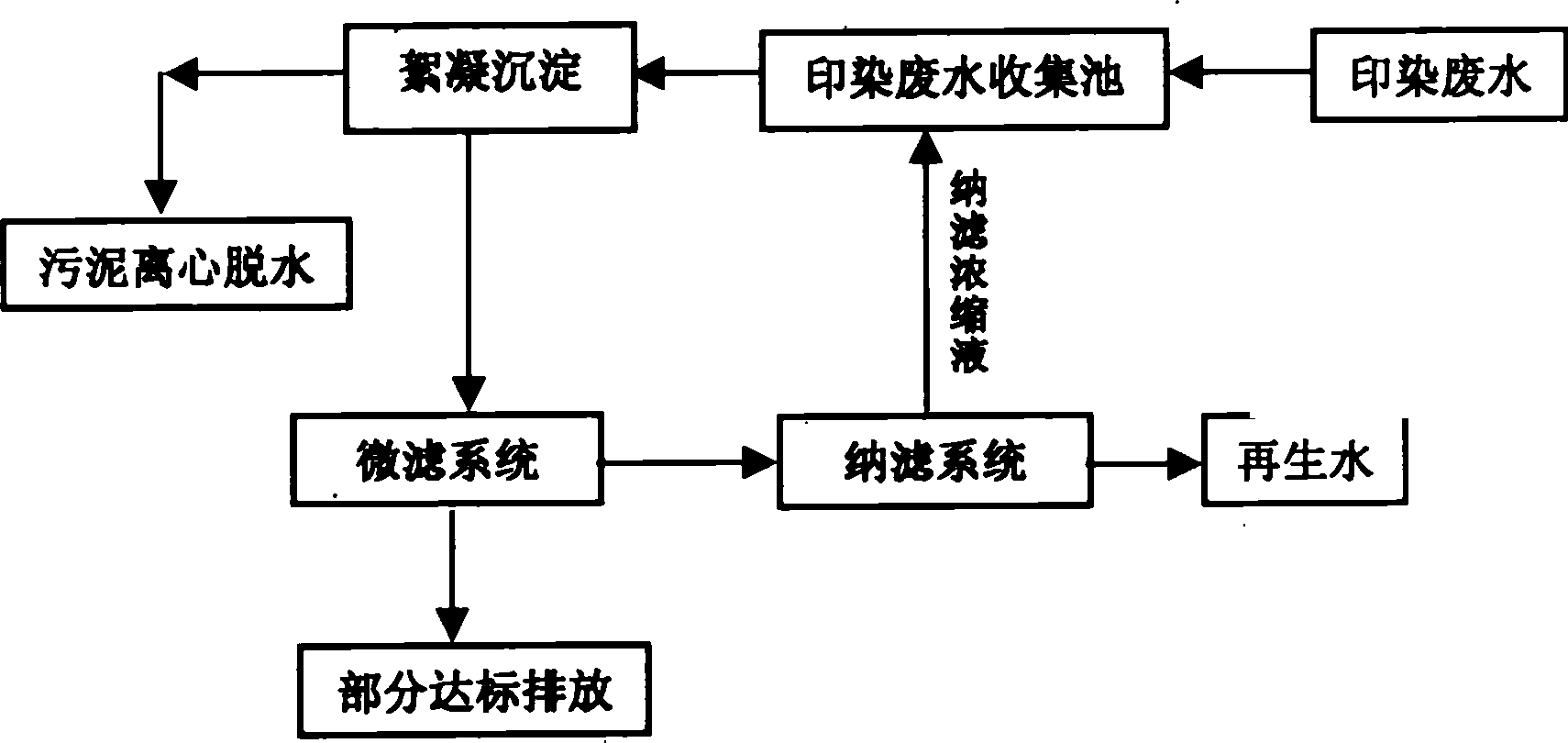

Method for realizing closed cycle of dyeing waste water

InactiveCN1884146AEasy to close loopEasy to achieve closed loop industrializationMultistage water/sewage treatmentWater/sewage treatment by flocculation/precipitationWater sourceWastewater

The invention discloses a disposing method of loop circulating printing and dyeing wastewater, which is characterized by the following: regenerating printing and dyeing wastewater; removing most of COD and colority in the printing and dyeing wastewater through flocculating and sedimenting; proceeding further disposal in the micro-filter; obtaining the disposed water with less than 10mg / L COD and 300 mus / ms conductivity without turbidity, SS and colority; utilizing soft water in the printing and dyeing technology as washing water to realize loop circulation.

Owner:王克佳

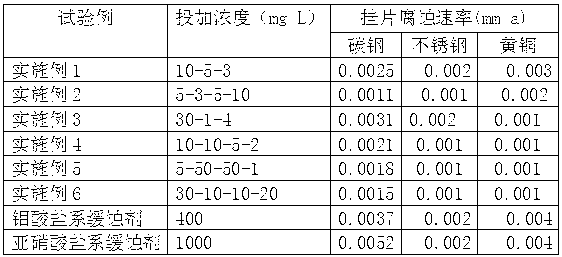

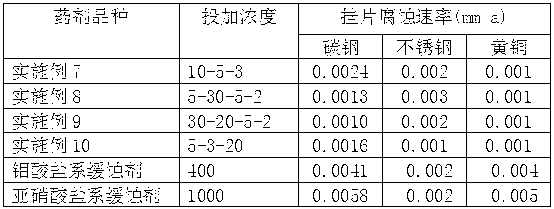

Corrosion and scale inhibition method for soft water closed circulation system

InactiveCN103130359ANo pollutionLow costMultistage water/sewage treatmentEnvironmental resistanceSoft water

The invention discloses a corrosion and scale inhibition method for a soft water closed circulation system, and relates to the technical field of water treatment. The method comprises the following steps: A, regulating the pH value of a soft water closed circulation system to 8.5-10; B, adding deoxidizer into the soft water closed circulation system of which the pH value is regulated in the step A, wherein the addition concentration of the deoxidizer is 5-30 mg / L; and C, adding scale inhibitor and corrosion inhibitor into the soft water closed circulation system subjected to deoxidation treatment in the step B, wherein the addition concentration of the scale inhibitor is 1-100 mg / L, and the addition concentration of the corrosion inhibitor is 1-20 mg / L. According to the invention, soft water is deoxidized, and a tiny amount of scale inhibition component is added on the basis of deoxidation according to the mass of the soft water; the method is non-toxic and environment-friendly, and discharged water can not cause pollution to the environment even if the system leaks; the method is applicable to a high-temperature soft water system such as a blast furnace soft water system and the like; the method is low in cost; and the corrosion inhibition property is obviously enhanced to ensure that the method is superior to a molybdenum-phosphorus system formula commonly used at present.

Owner:LIUZHOU SHENGPENGYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

Production method of vehicle top using wet treatment

ActiveCN101332791AReduce weightMeet the requirements of lightweight designSuperstructure subunitsEnvironmental resistanceHeat resistance

The invention relates to a production method for vehicle top wet processing, in particular to a vehicle top which is mounted at the top part of the vehicle, plays the roles of heat isolation, sound isolation and beautification as well as belongs to the technical field of the interior decorating piece of the vehicle. The invention is characterized by selecting a PU material as the base material of the top, heating, rolling glues on the front surface and the back surface as well as spraying soft water on the PU material; laying a combination layer and cutting a roll type material; then pressing and forming, cooling and shaping, cutting by a water cutter and packaging into a box and warehousing after inspection. The production method of the invention realizes the performance indexes of the sound suction, heat resistance, light weight and high intensity of a top assembly, reaches the international top level of Grade three, greatly reduces the weight of the top, meets the requirements of the light weight design of the whole vehicle; during the working procedure of rolling glues, the PU material is adopted to carry out flow operation of glue rolling on the front surface and back surface, heating and shaping; the technique is stable; the rigidness of a product is high; besides, the product can not be broken or droop; no semi-finished products are accumulated during the process, thus saving the manufacturing cost; the whole production process of the product does not generate harmful matters; besides, the product belongs to environment-friendly product.

Owner:广州吉兴汽车内饰件有限公司

Cardanol epoxy resin

The invention relates to a cardanol epoxy resin, belonging to epoxy resin materials. The process comprises the following steps of: 1, adding bisphenol A, cardanol and epichlorohydrin in proportion into a reaction kettle; 2, heating and adding solid sodium hydroxide; 3, dropwise adding a sodium hydroxide solution, discharging water generated by reaction and the epichlorohydrin out of the reaction kettle by azeotropy, and returning the epichlorohydrin into the reaction kettle after condensing and decomposing for continuing the reaction; 4, after the reaction, distilling off water and most of the epichlorohydrin from the material in the reaction kettle, and removing the residual epichlorohydrin by a film evaporator to obtain crude resin; 5, adding an organic solvent and soft water into a refining kettle, dropwise adding the residual sodium hydroxide solution, wherein the organic solvent is toluene or methyl isobutyl ketone; and 6, removing the organic solvent from the refined resin solution by a film evaporator to obtain the product. The used cardanol is environment-friendly, energy-saving and pollution-free, and the cardanol epoxy resin obviously improves the brittleness, toughness and weatherability of the cured resin.

Owner:徐州中研科技工业有限公司

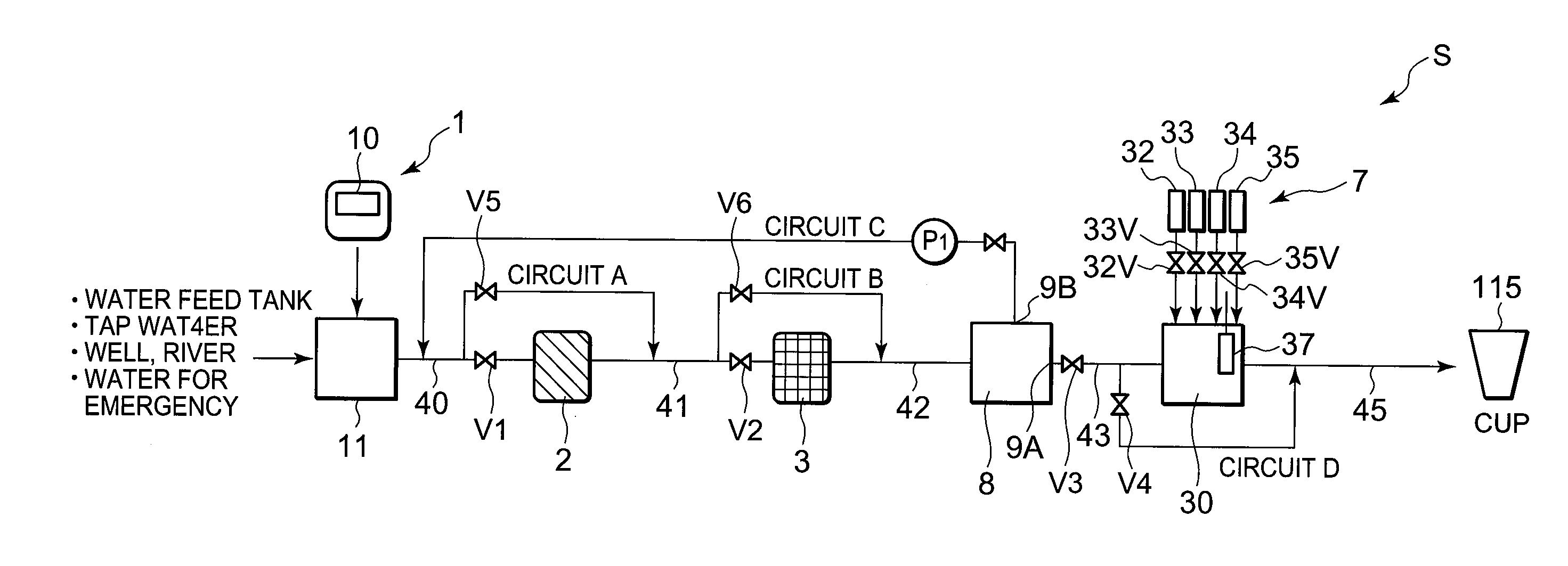

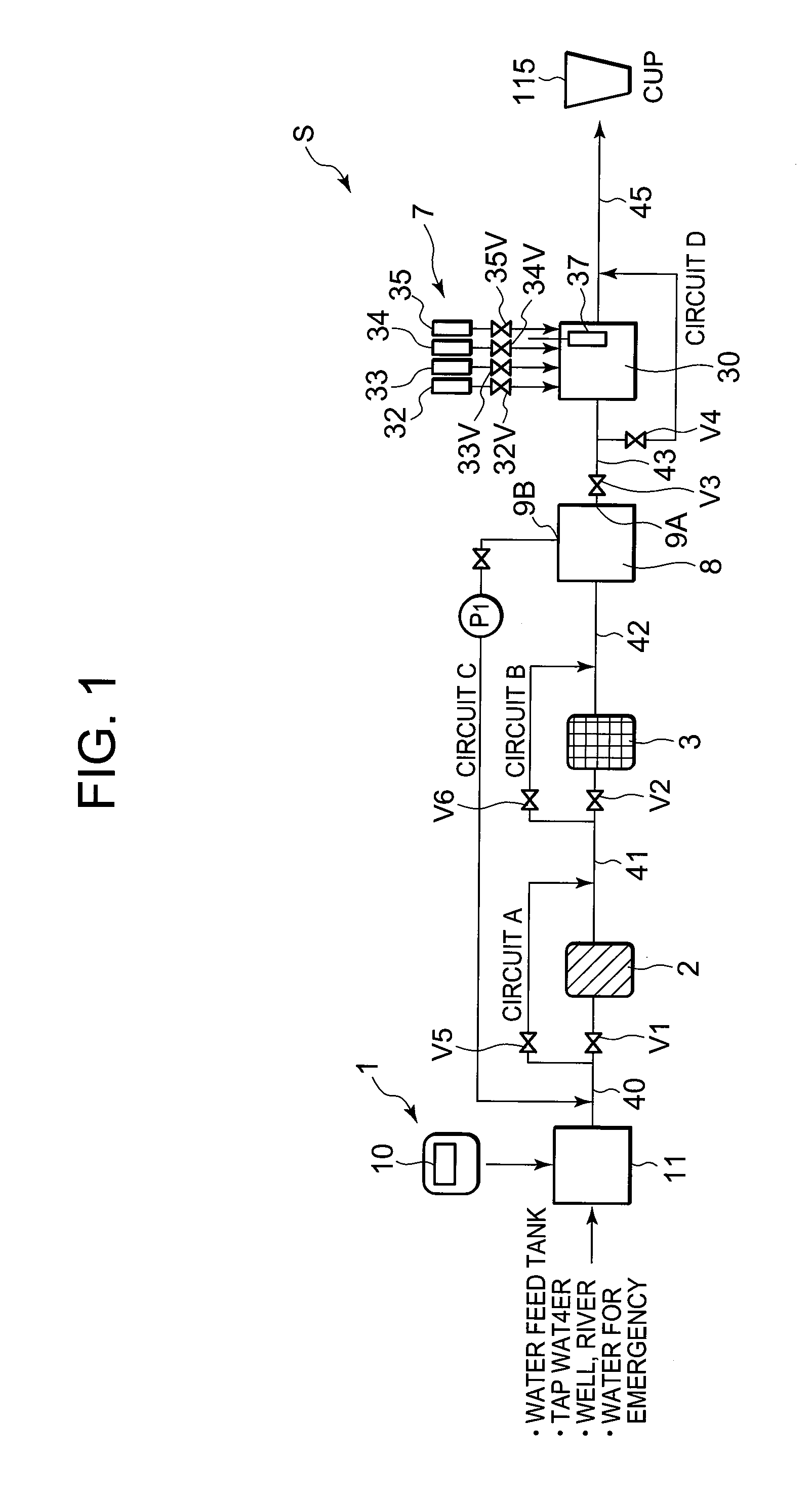

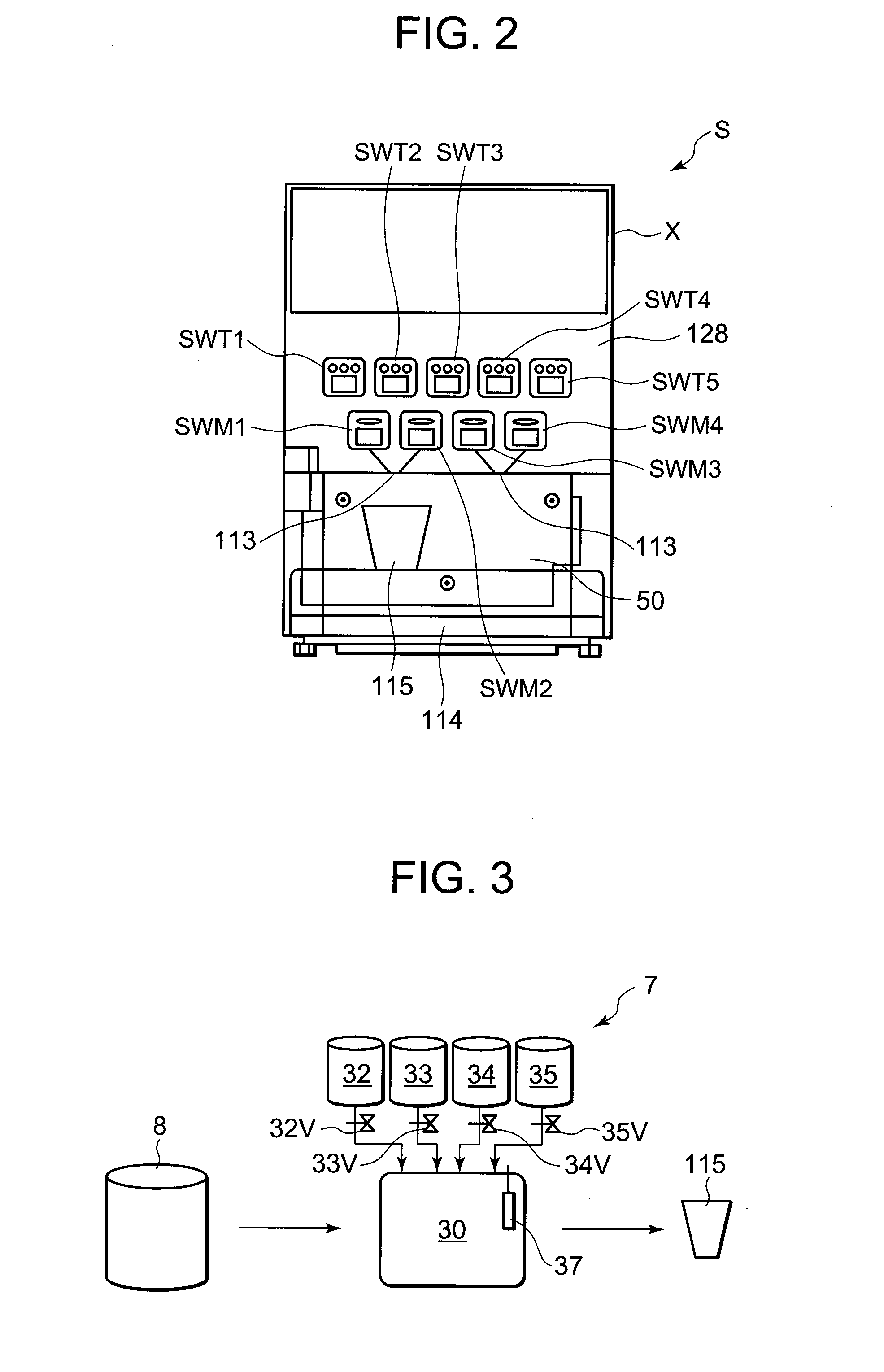

Water feed device

InactiveUS20090283464A1Easy to manageStable removalSemi-permeable membranesOther chemical processesSoft waterEngineering

There is disclosed a water feed device capable of adding mineral components to for-treatment water in accordance with user's request to feed a variety of water including the mineral components from soft water to hard water. Furthermore, there is disclosed a water feed device capable of selecting a treatment function to be performed with respect to the for-treatment water in accordance with the type of water for use as the for-treatment water, a use situation and a purpose, to perform an optimum treatment. A water feed device S of the present invention includes a mineral addition treatment unit which has one or more mineral components and which adds the mineral components to the for-treatment water; and a control unit which has data concerning the one or more mineral components of mineral water and which controls the addition of the mineral components by the mineral addition treatment unit in accordance with the selected mineral water.

Owner:SANYO ELECTRIC CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com