Gasification dry dedusting technology

A technology of dry dust removal and coal gasification, which is applied in the field of resources and environment, can solve problems such as not solving problems from the source, and achieve the effects of saving investment and operating costs, improving dust removal efficiency, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

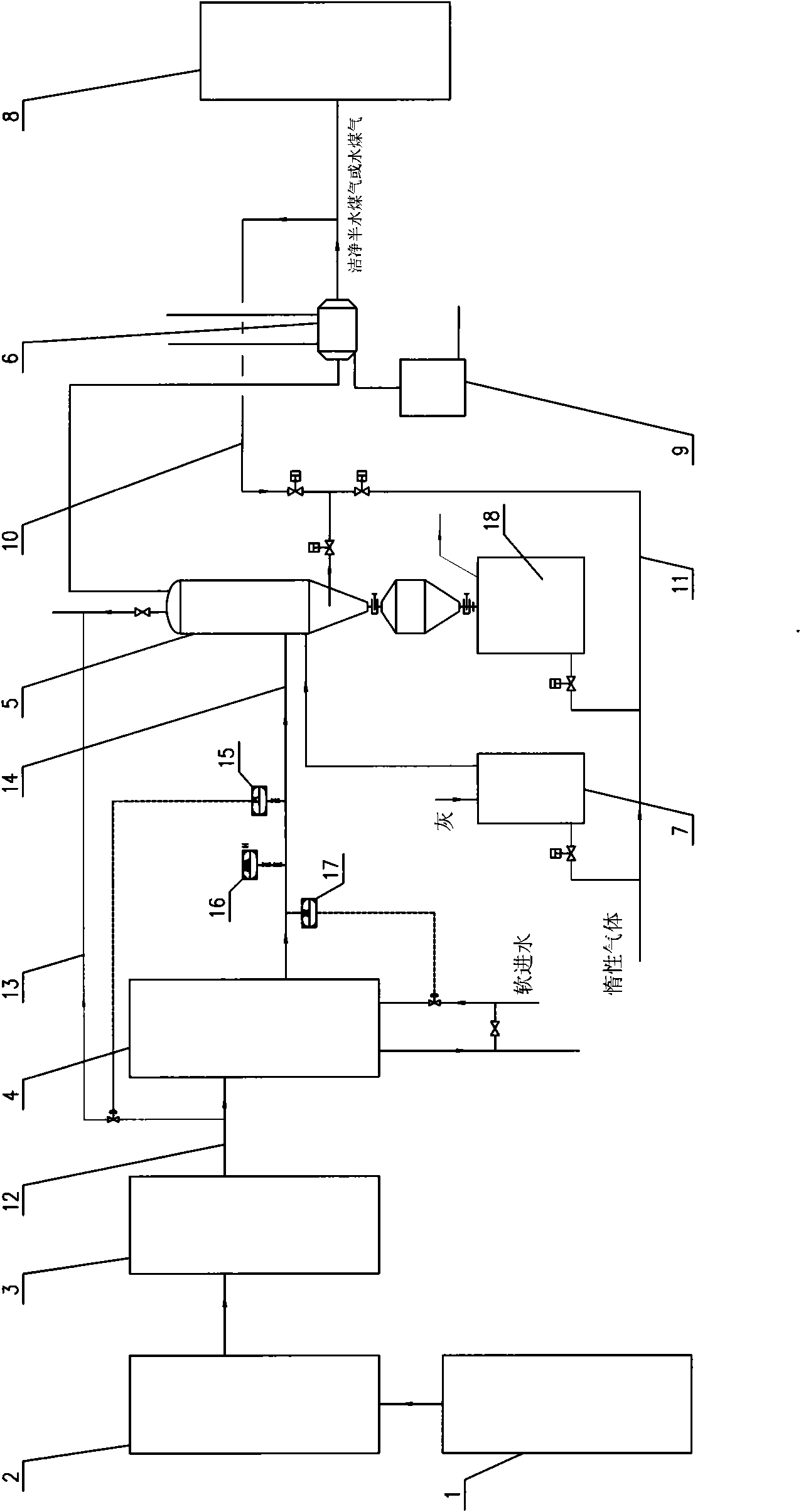

[0019] The semi-water gas or water gas from the normal pressure or micro-positive pressure coal gasifier 1 (gasification pressure ≤ 0.1MPa (gauge pressure)) is about 350-600°C, and the dust volume percentage is about 40-80g / m 3 , the oxygen volume percentage content is about 0.2% to 0.5%, and the dust is removed by the cyclone dust collector 2, and the dust volume percentage content is reduced to 10 ~ 20g / m 3 After entering the combined waste pot 3 and exchanging heat with soft water and saturated steam, the temperature drops to about 160-290°C; after entering the soft water heater 4 and exchanging heat with soft water, the temperature further drops to between 150-200°C, and then enters the bag filter 5 The remaining fine ash is removed, and the ash blown back with nitrogen or clean semi-water gas or water gas enters the ash hopper 18, and the accumulated ash in the ash hopper 18 is pneumatically transported to the ash store with nitrogen or carbon dioxide gas; the purified sem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com