Lithium ion battery negative electrode comprising diamond-like thin film layer, preparation method for negative electrode, and lithium ion battery

A diamond film, lithium-ion battery technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of low chemical stability, inability to maintain structure, poor mechanical properties, etc., to prevent the formation of unstable SEI layers , good cycle stability, and the effect of being conducive to large-scale production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

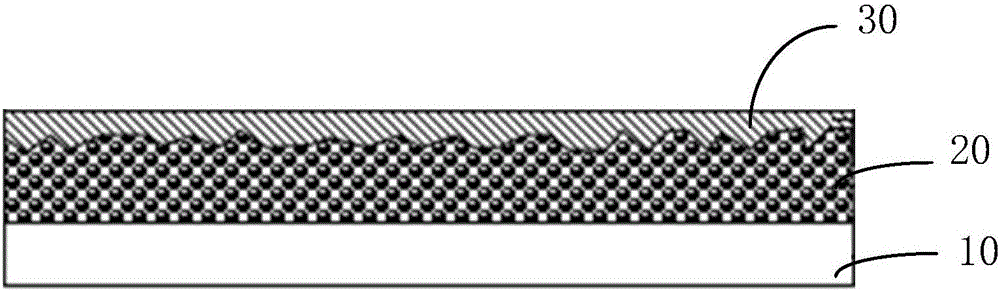

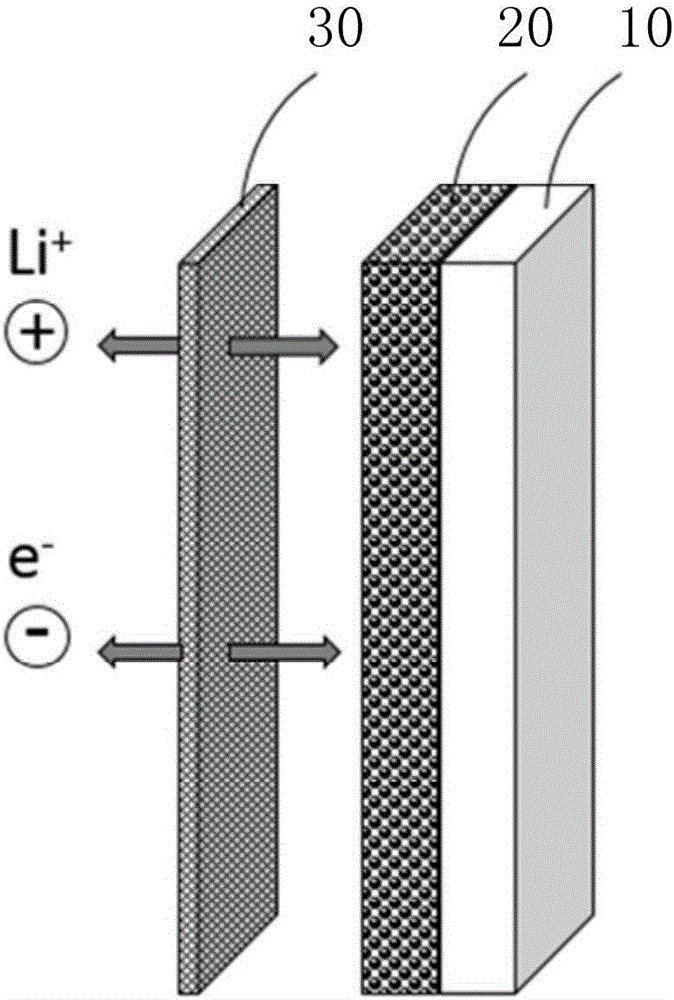

[0036] A preparation method of a lithium-ion battery negative electrode containing a diamond-like film layer, comprising the following steps:

[0037] (1) Take a single crystal silicon wafer, the resistivity is lower than 5mΩ﹒ cm, add a mixed aqueous solution of silver nitrate and hydrofluoric acid (where the concentration of silver nitrate is 0.005M and the concentration of hydrofluoric acid is 4.8M) in a polytetrafluoroethylene container, immerse the silicon chip in the solution for 1 minute, and then The silicon chip is taken out and placed in a mixed solution of hydrofluoric acid and hydrogen peroxide (the concentration of hydrofluoric acid is 4.8M and the concentration of hydrogen peroxide is 0.3M) and kept for 30 minutes. After taking out, the silicon chip is rinsed with water and immersed in a nitric acid solution diluted with water ( 1:1 v / v) to remove the silver catalyst, followed by drying at 60°C. The silicon nanowires are separated from the single crystal silicon ...

Embodiment 2

[0048] A preparation method of a lithium-ion battery negative electrode containing a diamond-like film layer, comprising the following steps:

[0049] (1) According to the ratio of silicon powder: acetylene black: carboxymethylcellulose (CMC) mass ratio of 8:1:1, the three are evenly dispersed in N-methylpyrrolidone (NMP), and evenly mixed in a mortar Mix to form a uniformly dispersed slurry, and evenly coat the resulting slurry on a clean metal copper foil, then dry it in a vacuum oven at 80°C for 24 hours, and then take out the coated copper foil and pass it through a roller press After rolling, press it into a disc with a 12mm tablet press to obtain a copper foil with a negative electrode active material layer;

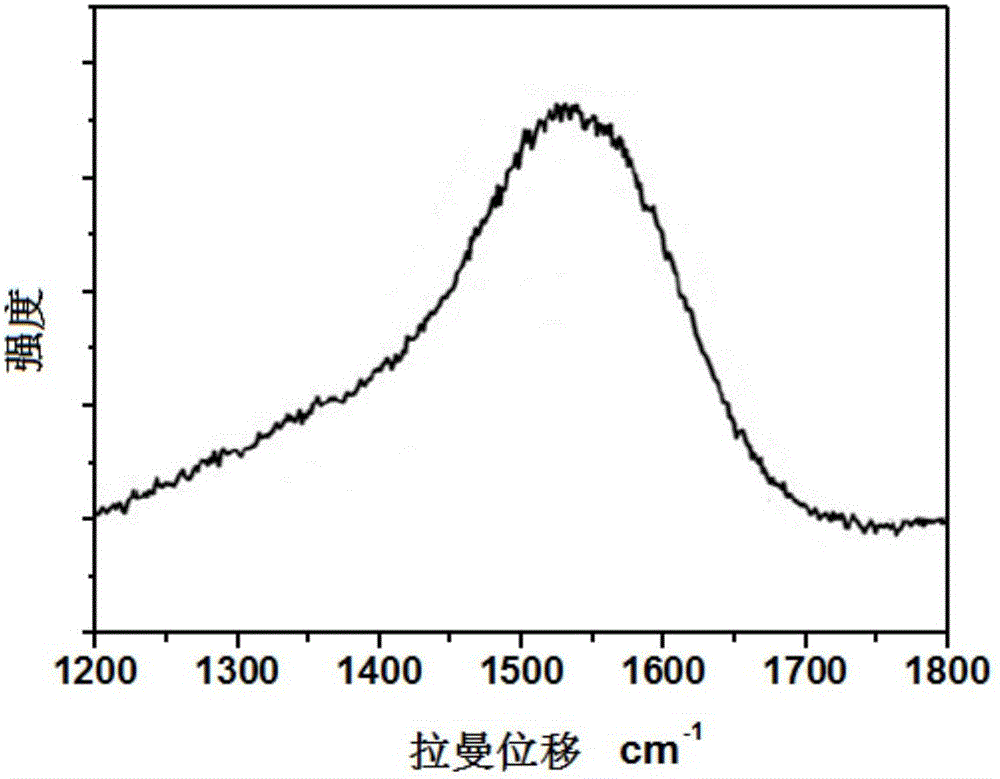

[0050] (2) ECR-MPCVD is used to deposit and prepare a nitrogen-doped n-type conductive diamond-like film layer on the surface of the negative electrode active material layer. During the deposition process, feed methane as a carbon source, nitrogen as a doping gas, ...

Embodiment 3

[0052] A preparation method of a lithium-ion battery negative electrode containing a diamond-like film layer, comprising the following steps:

[0053] (1) According to the ratio of tin-based negative electrode material: acetylene black: carboxymethylcellulose (CMC) mass ratio of 8:1:1, the three are evenly dispersed in NMP, and uniformly mixed in a mortar to form a dispersion Uniform slurry, evenly coat the obtained slurry on a clean metal copper foil, and then dry it in a vacuum oven at 80°C for 24 hours, then take out the coated copper foil and press it with a roller press, Press into a disc with a 12mm tablet press to obtain a copper foil with a negative electrode active material layer;

[0054] (2) Using DC magnetron sputtering to deposit a boron-doped diamond-like carbon film layer on the surface of the negative electrode active material layer, the deposition process is: feed argon into the vacuum chamber and open the composite target, the composite target is carbon Boro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com