Patents

Literature

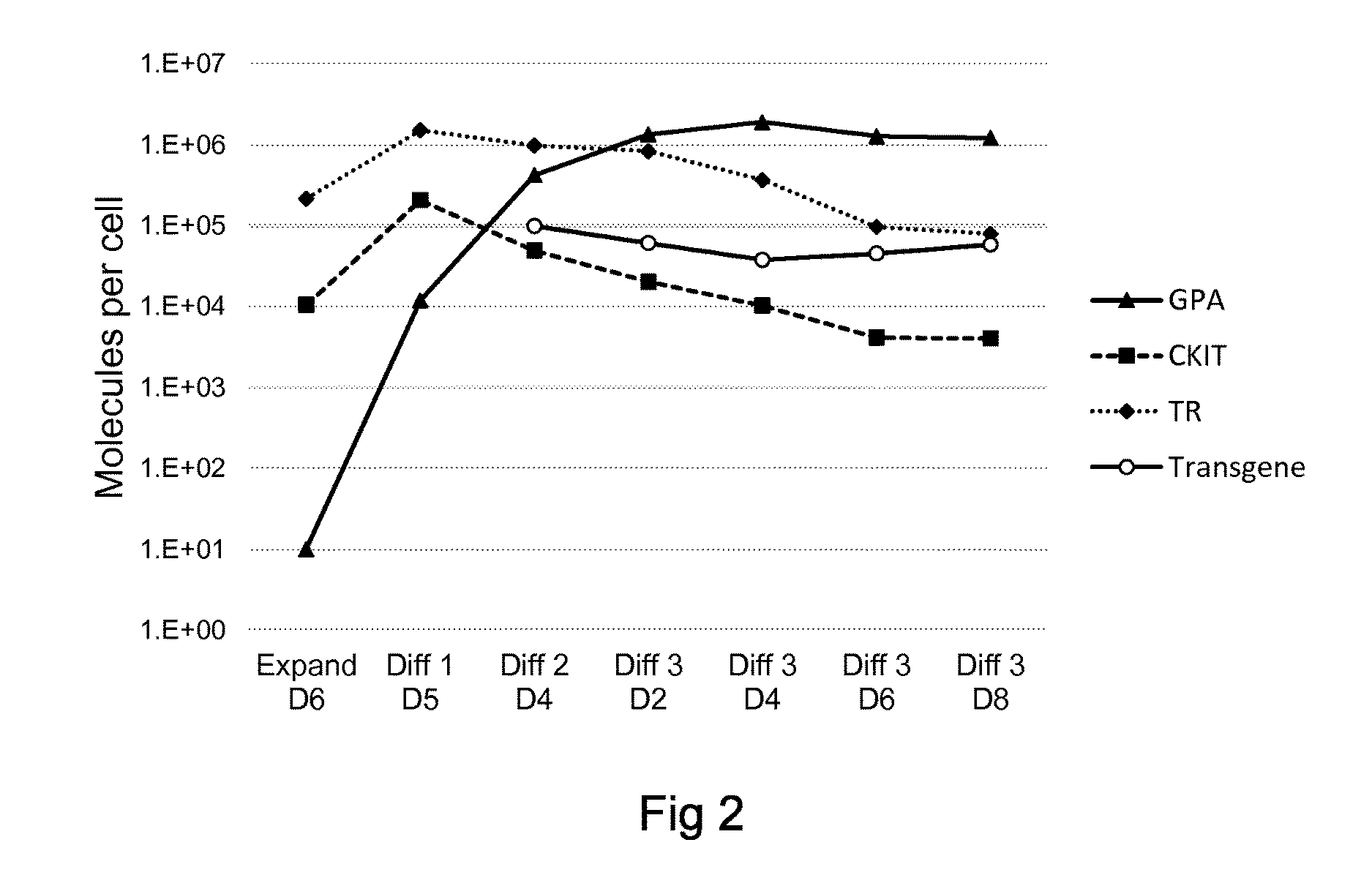

6914results about How to "Less side effects" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

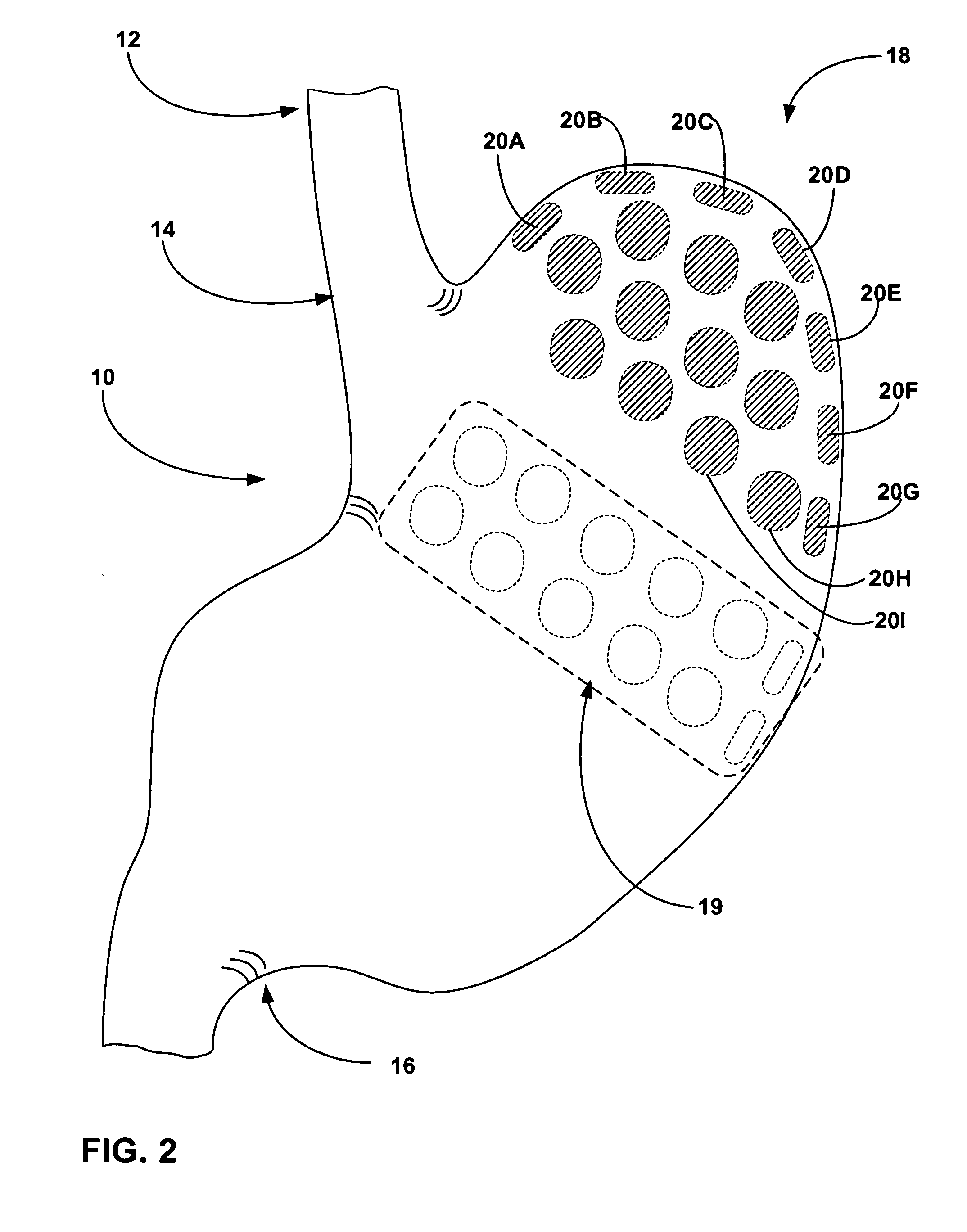

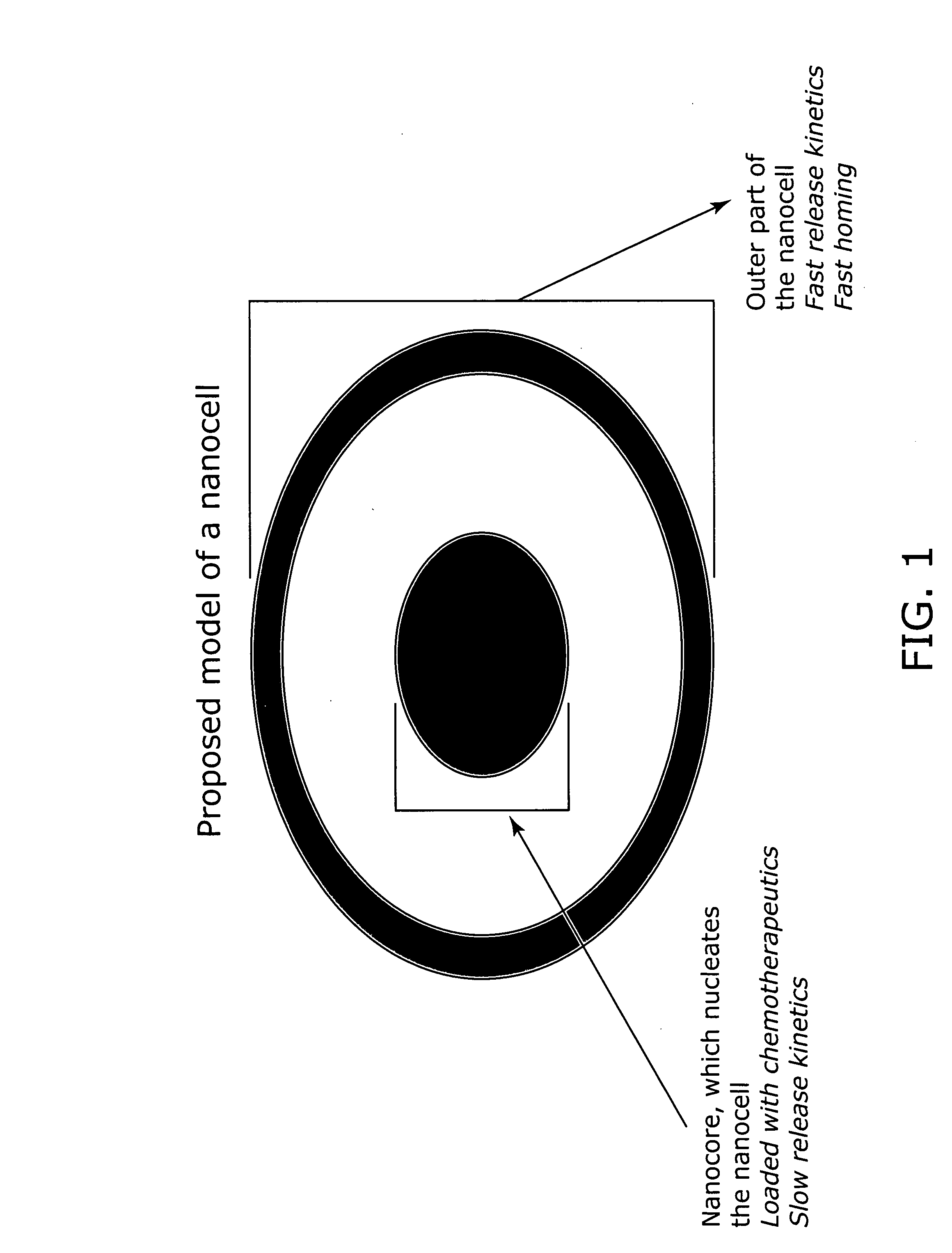

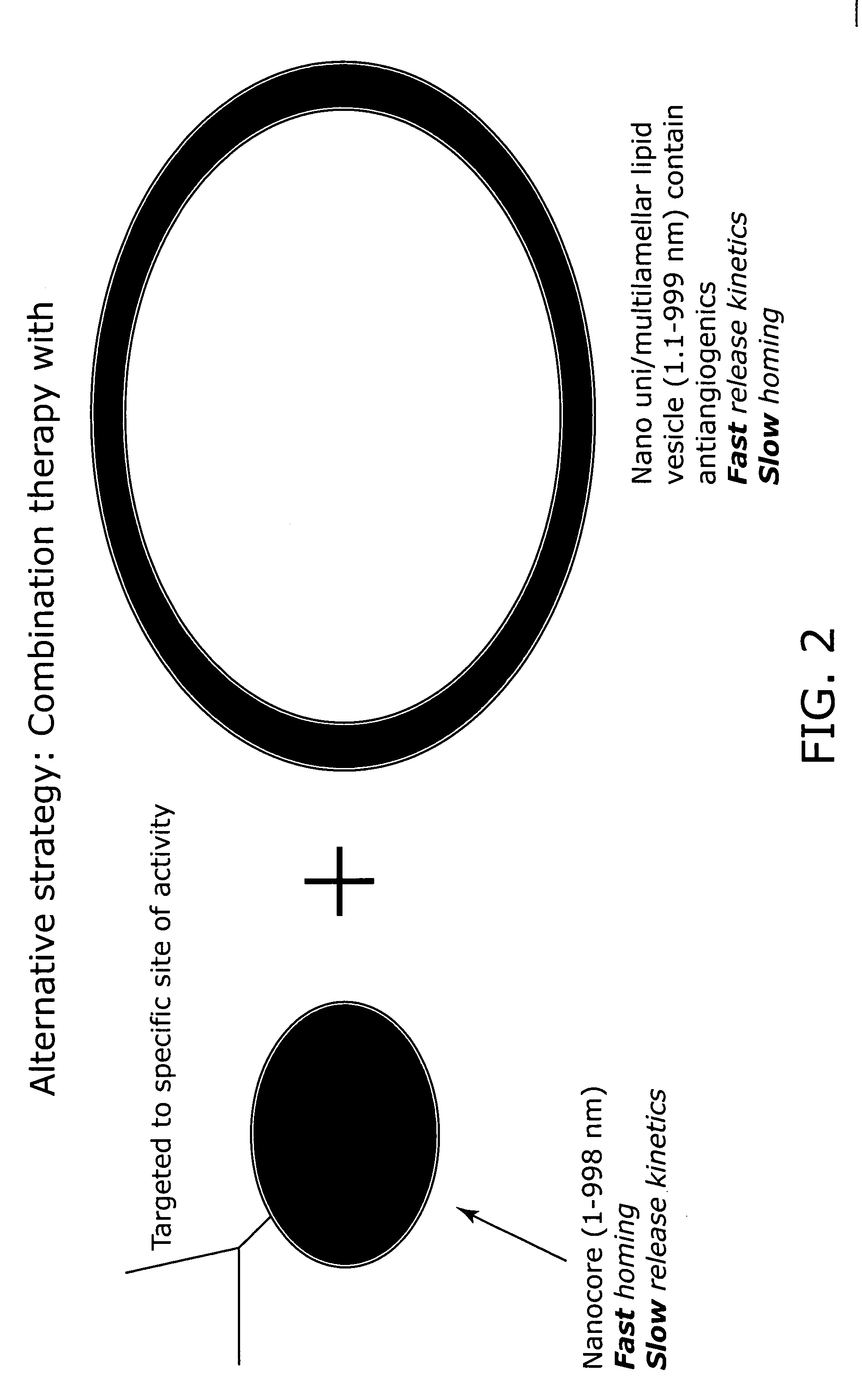

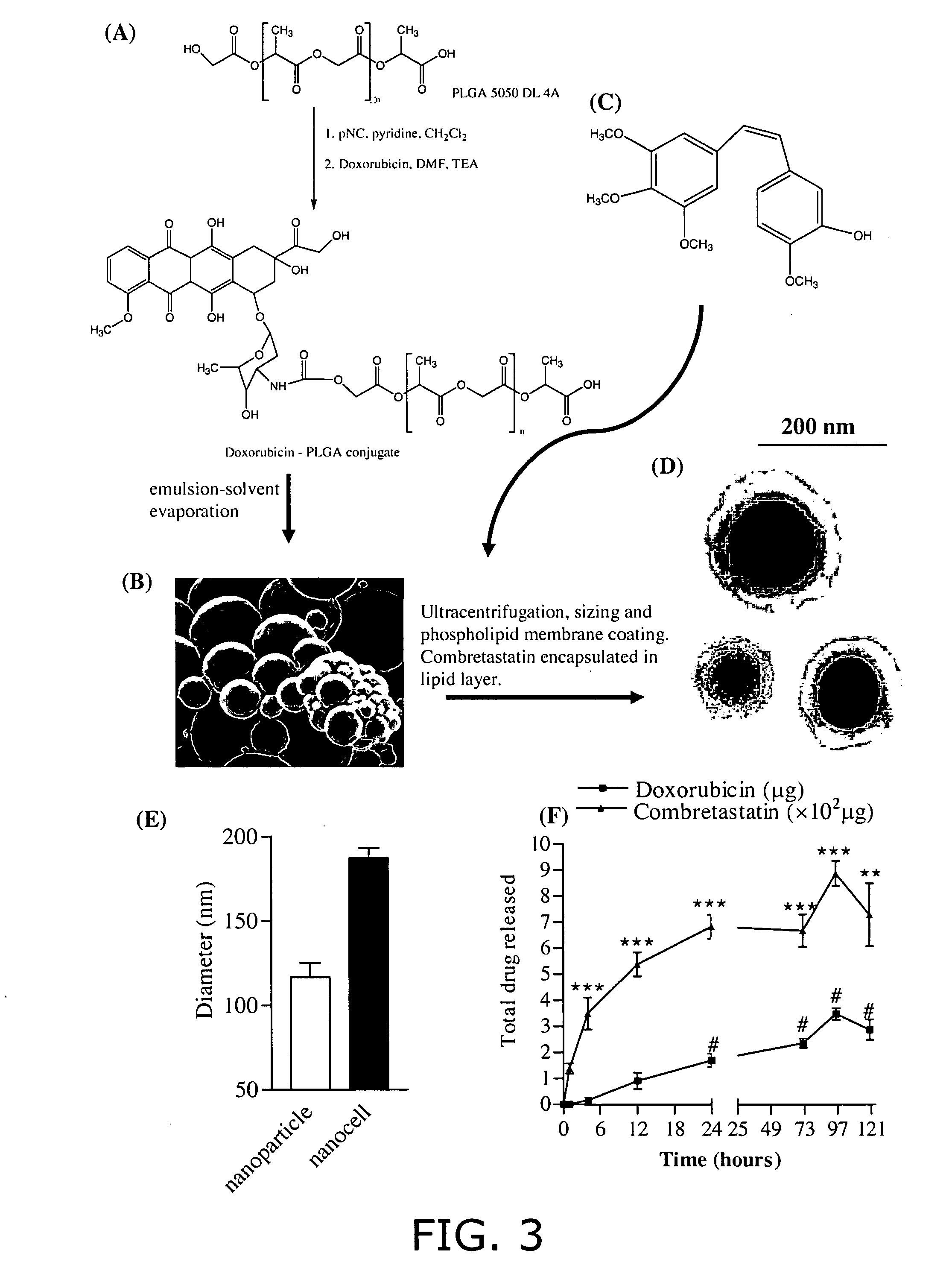

Nanocell drug delivery system

InactiveUS20050266067A1Avoid flowIncreased toxicityAntibacterial agentsOrganic active ingredientsLipid formationAntigen

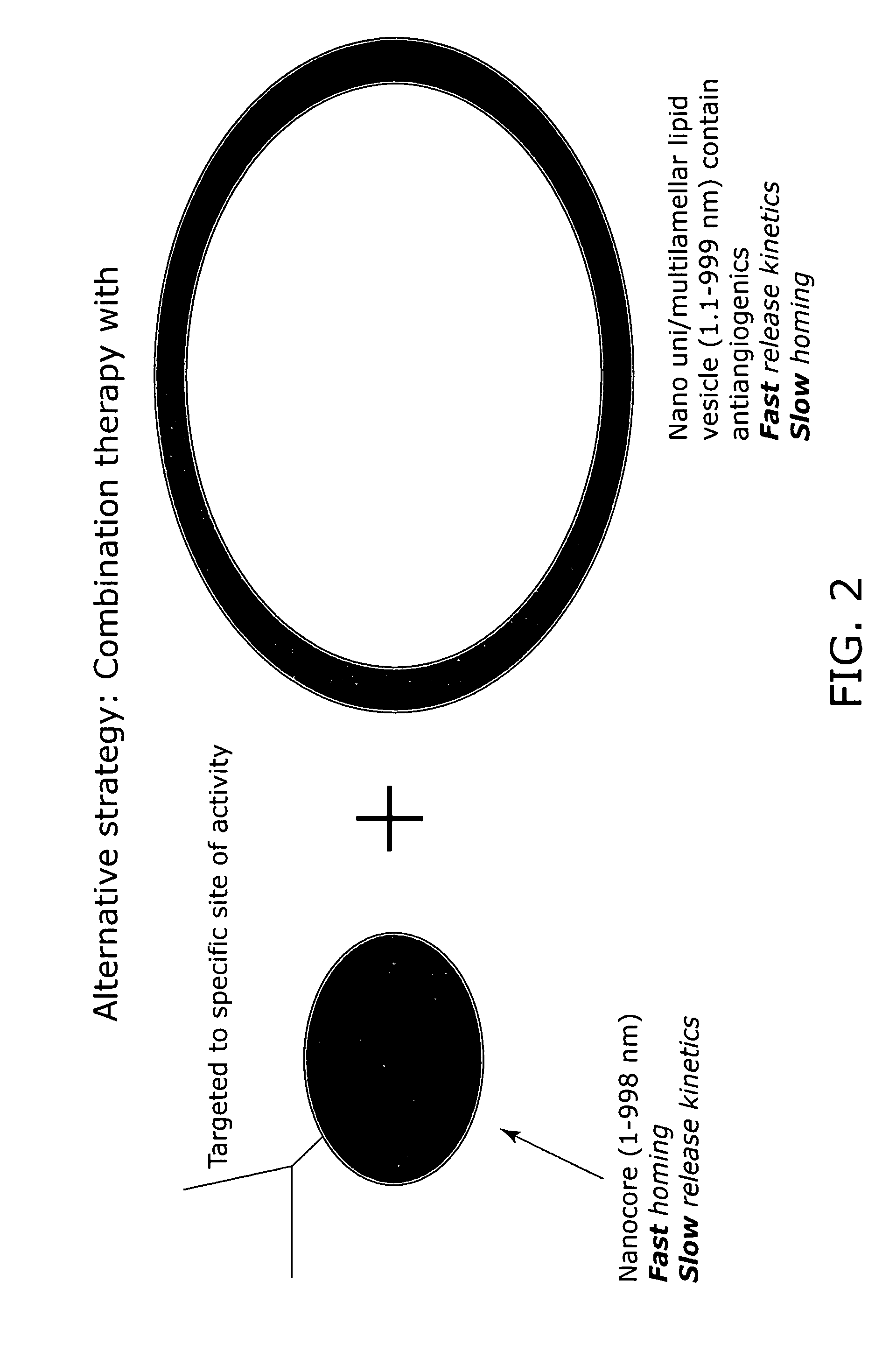

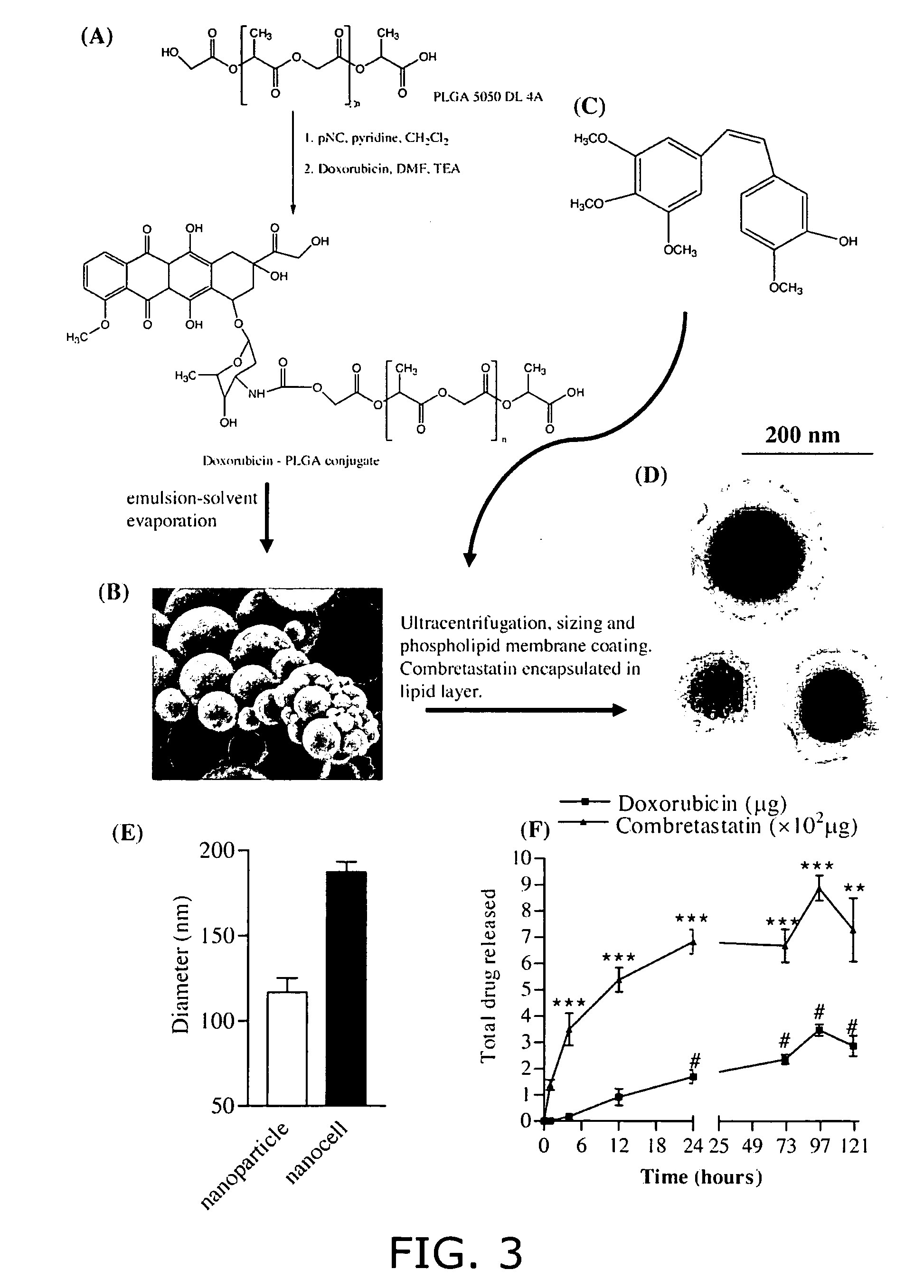

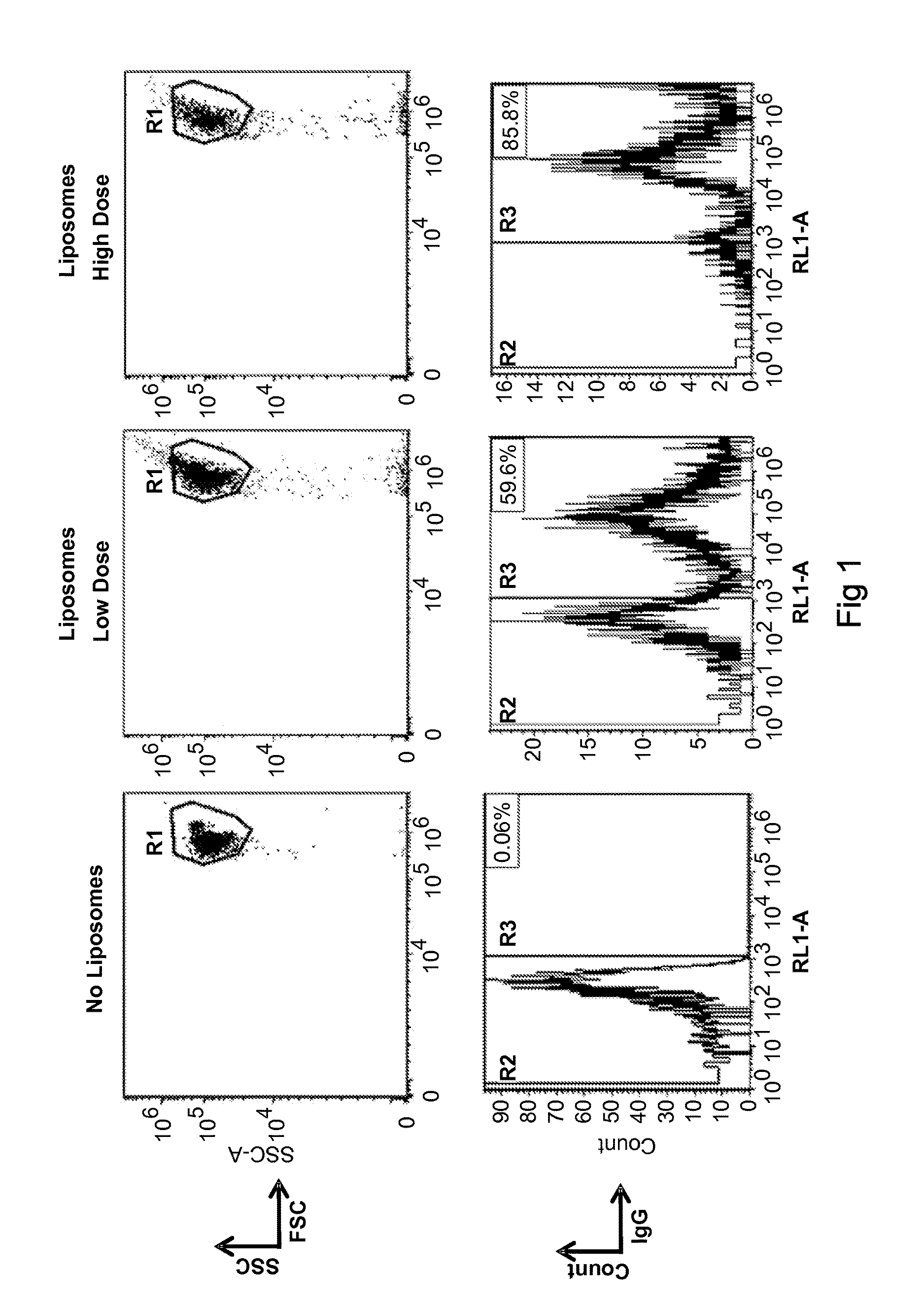

Nanocells allow the sequential delivery of two different therapeutic agents with different modes of action or different pharmacokinetics. A nanocell is formed by encapsulating a nanocore with a first agent inside a lipid vesicle containing a second agent. The agent in the outer lipid compartment is released first and may exert its effect before the agent in the nanocore is released. The nanocell delivery system may be formulated in pharmaceutical composition for delivery to patients suffering from diseases such as cancer, inflammatory diseases such as asthma, autoimmune diseases such as rheumatoid arthritis, infectious diseases, and neurological diseases such as epilepsy. In treating cancer, a traditional antineoplastic agent is contained in the outer lipid vesicle of the nanocell, and an antiangiogenic agent is loaded into the nanocore. This arrangement allows the antineoplastic agent to be released first and delivered to the tumor before the tumor's blood supply is cut off by the antianiogenic agent.

Owner:MASSACHUSETTS INST OF TECH

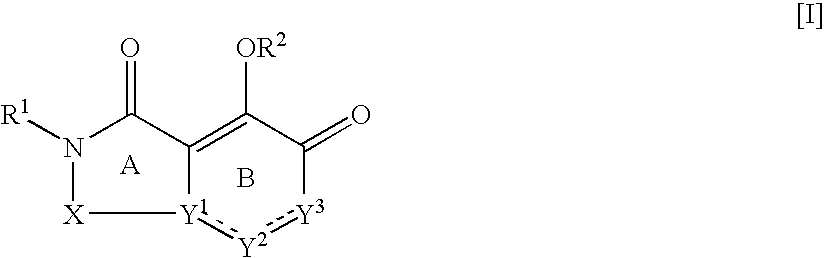

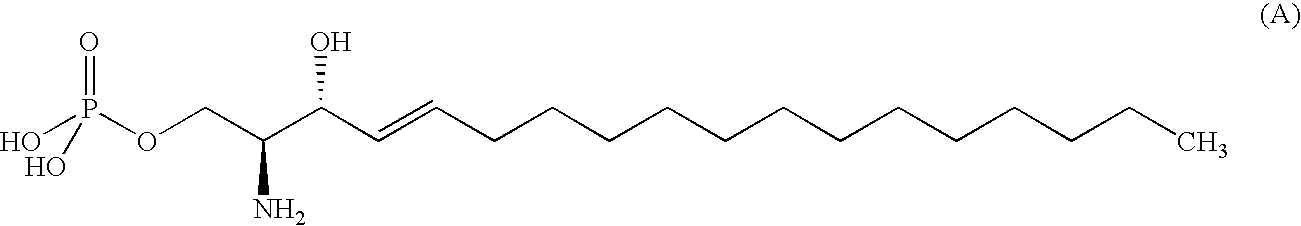

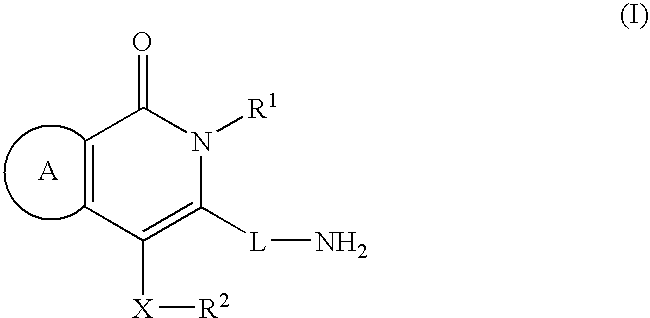

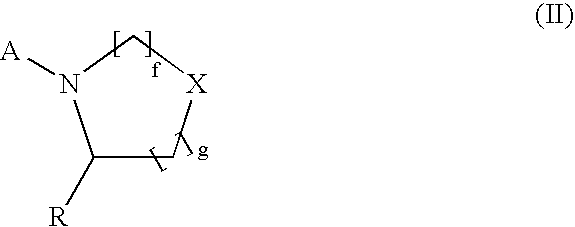

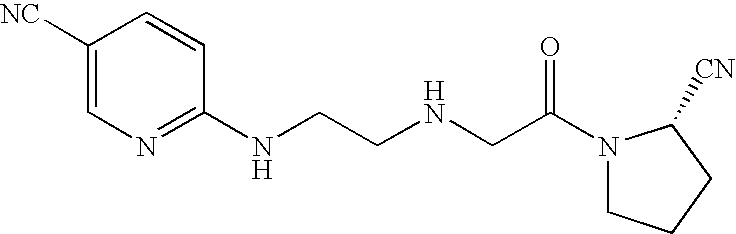

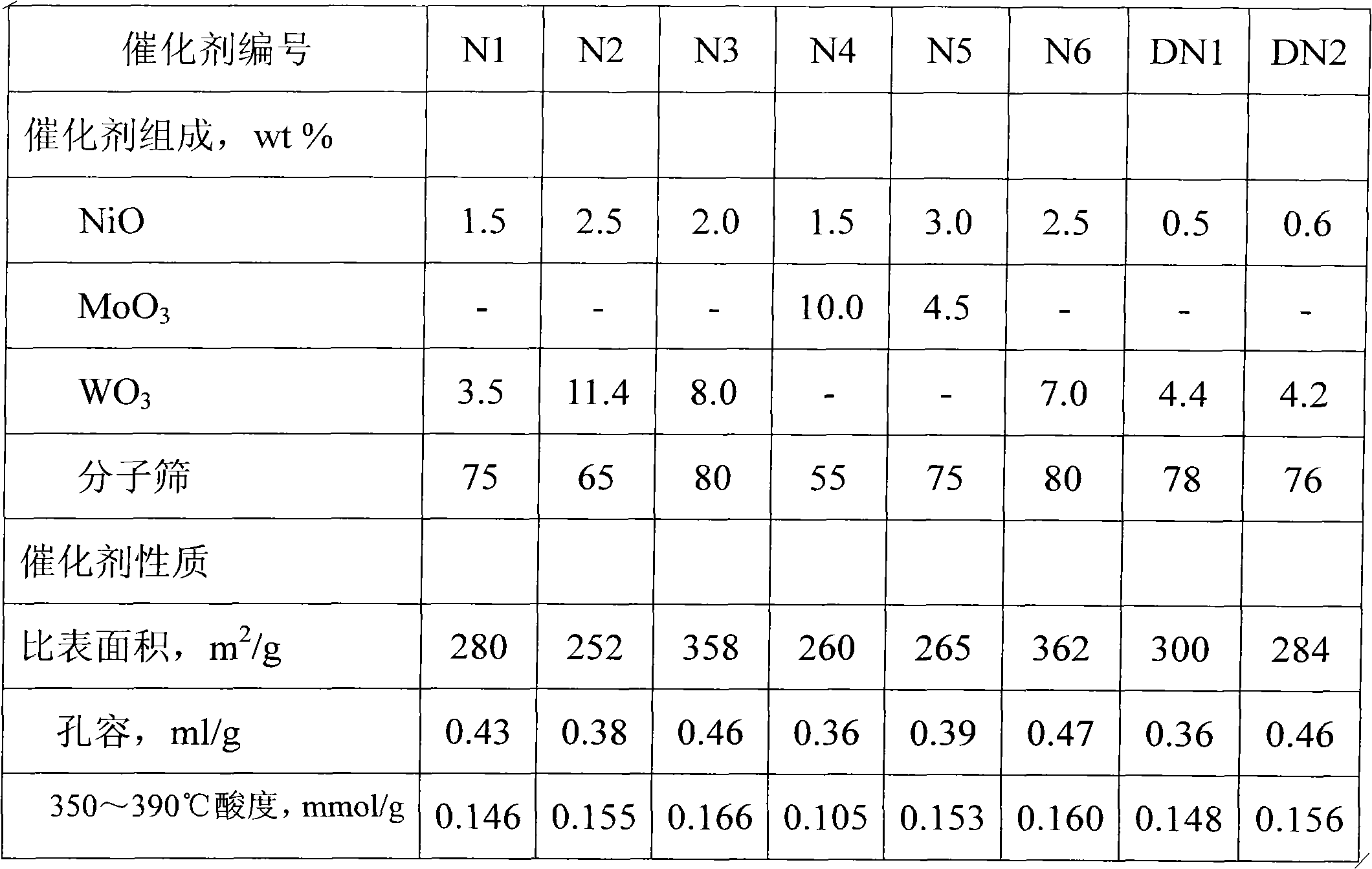

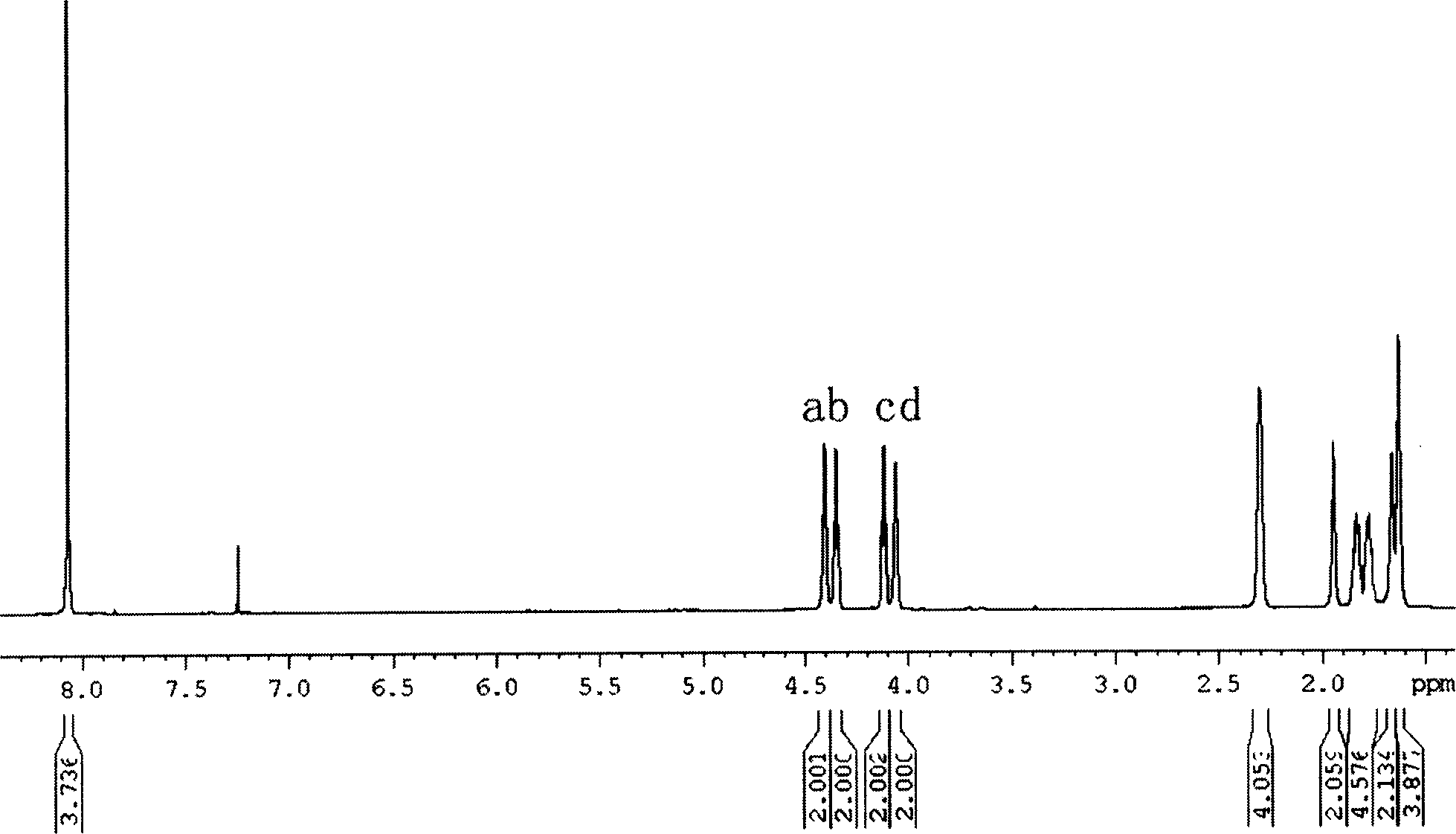

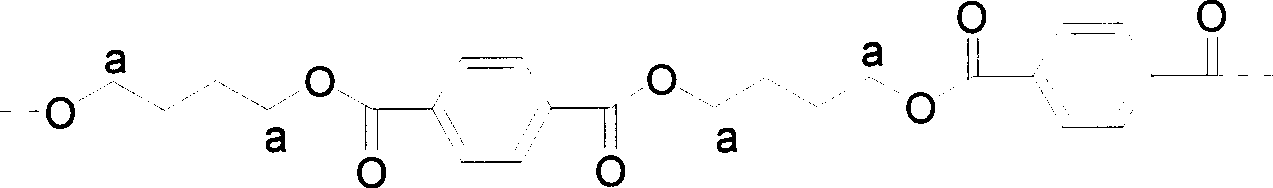

SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR

InactiveUS20140221378A1High inhibitory activityLess side effectsBiocideOrganic chemistryIntegrase inhibitorPharmaceutical medicine

Provided is a substituted spiropyrido[1,2-a]pyrazine derivative or a pharmaceutically acceptable salt thereof, which is useful as an anti-HIV agent. The present invention relates to a compound represented by the following formula [I] or [II] or a pharmaceutically acceptable salt thereof:wherein each symbol is as defined in the specification.

Owner:JAPAN TOBACCO INC

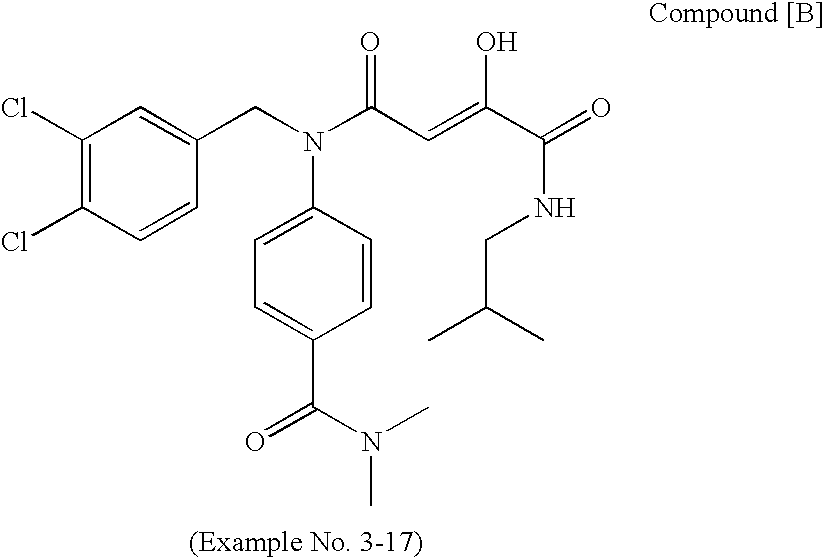

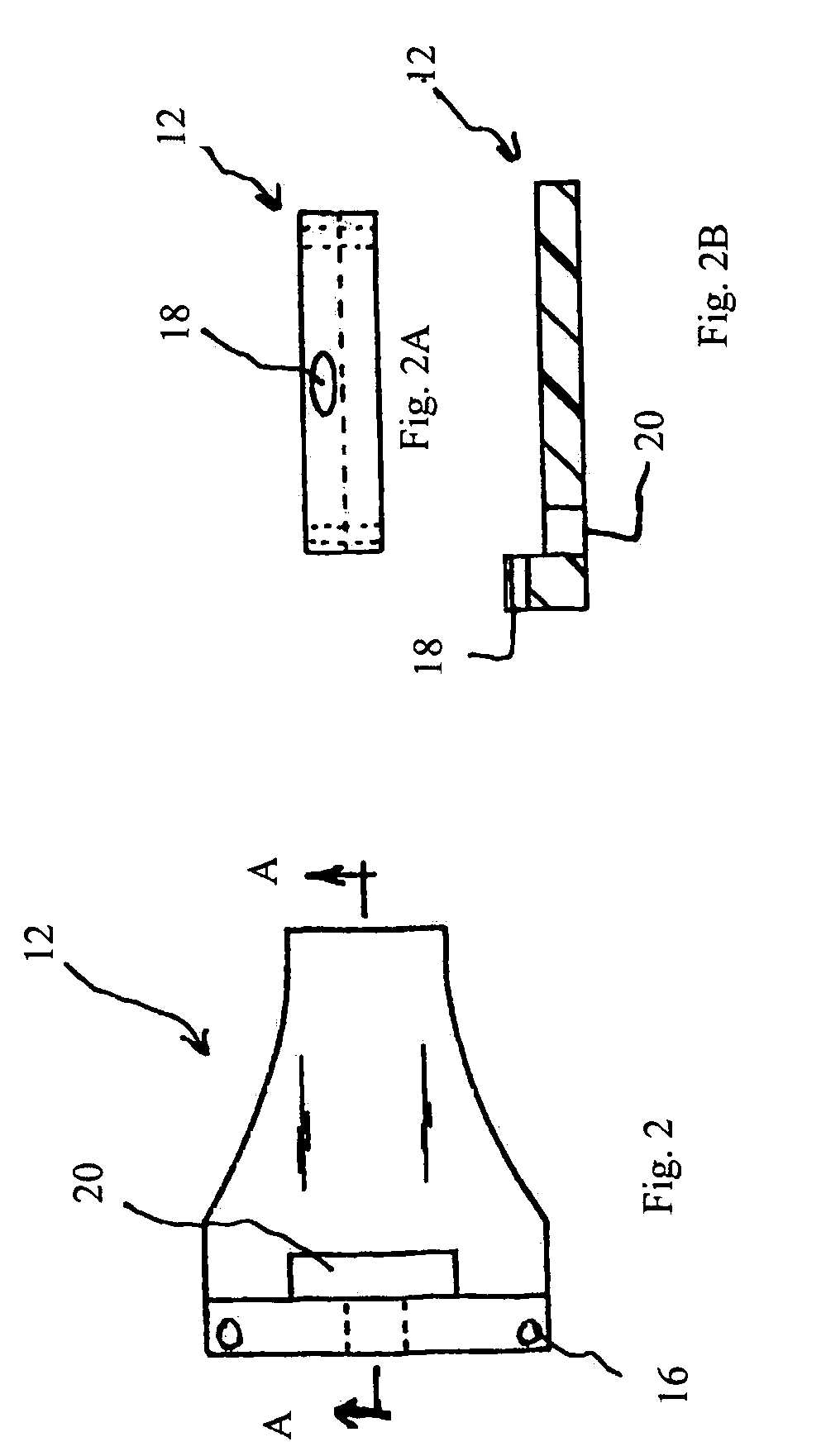

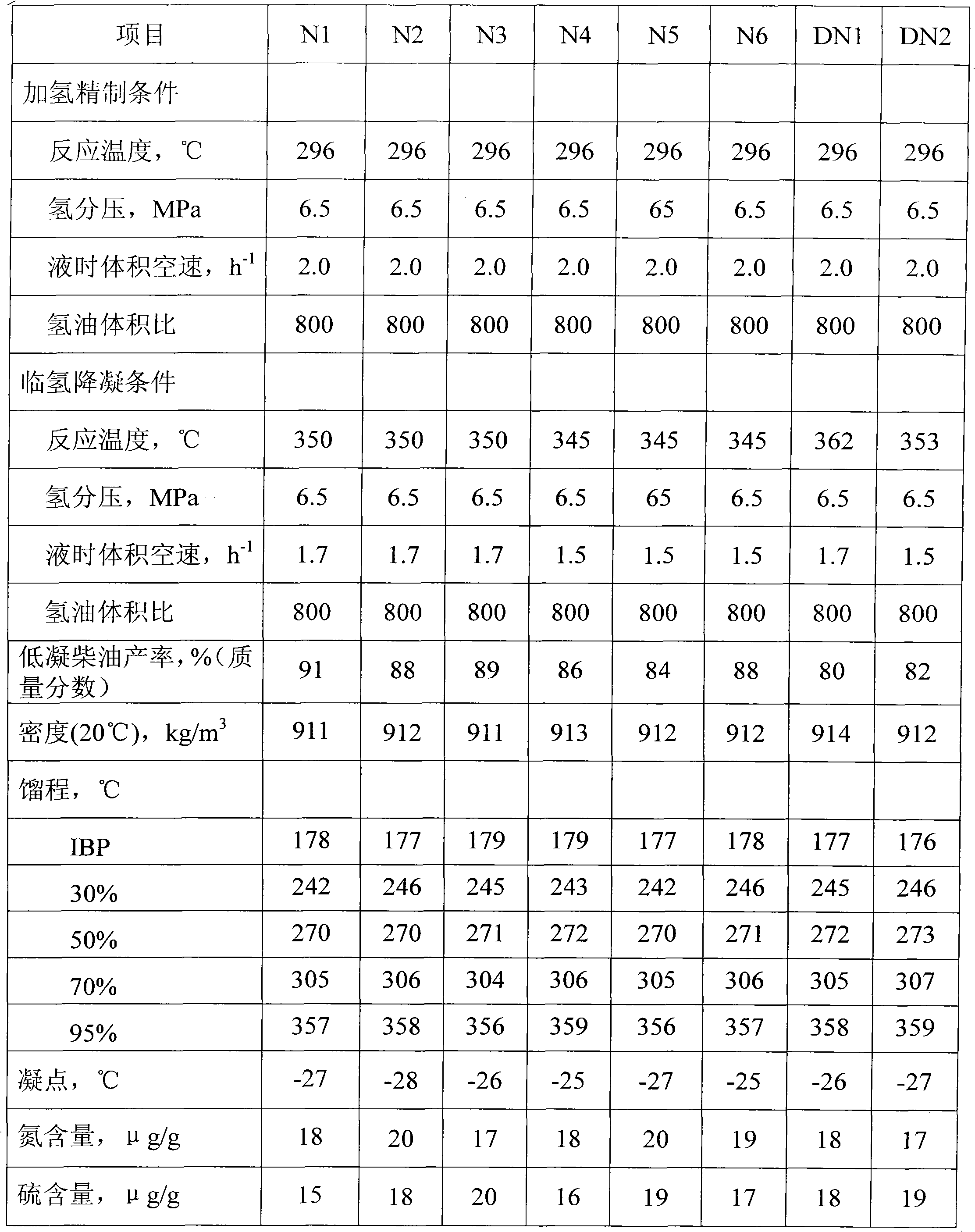

SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR

InactiveUS20140221380A1Strong inhibitory activityLess side effectsBiocideOrganic chemistryPyrazinePharmaceutical drug

[Summary][Problem] Provided is a substituted spiropyrido[1,2-a]pyrazine derivative or a pharmaceutically acceptable salt thereof, which is useful as an anti-HIV agent.[Solving Means] The present invention relates to a compound represented by the following formula [I] or [II] or a pharmaceutically acceptable salt thereof:wherein each symbol is as defined in the specification.

Owner:JAPAN TOBACCO INC

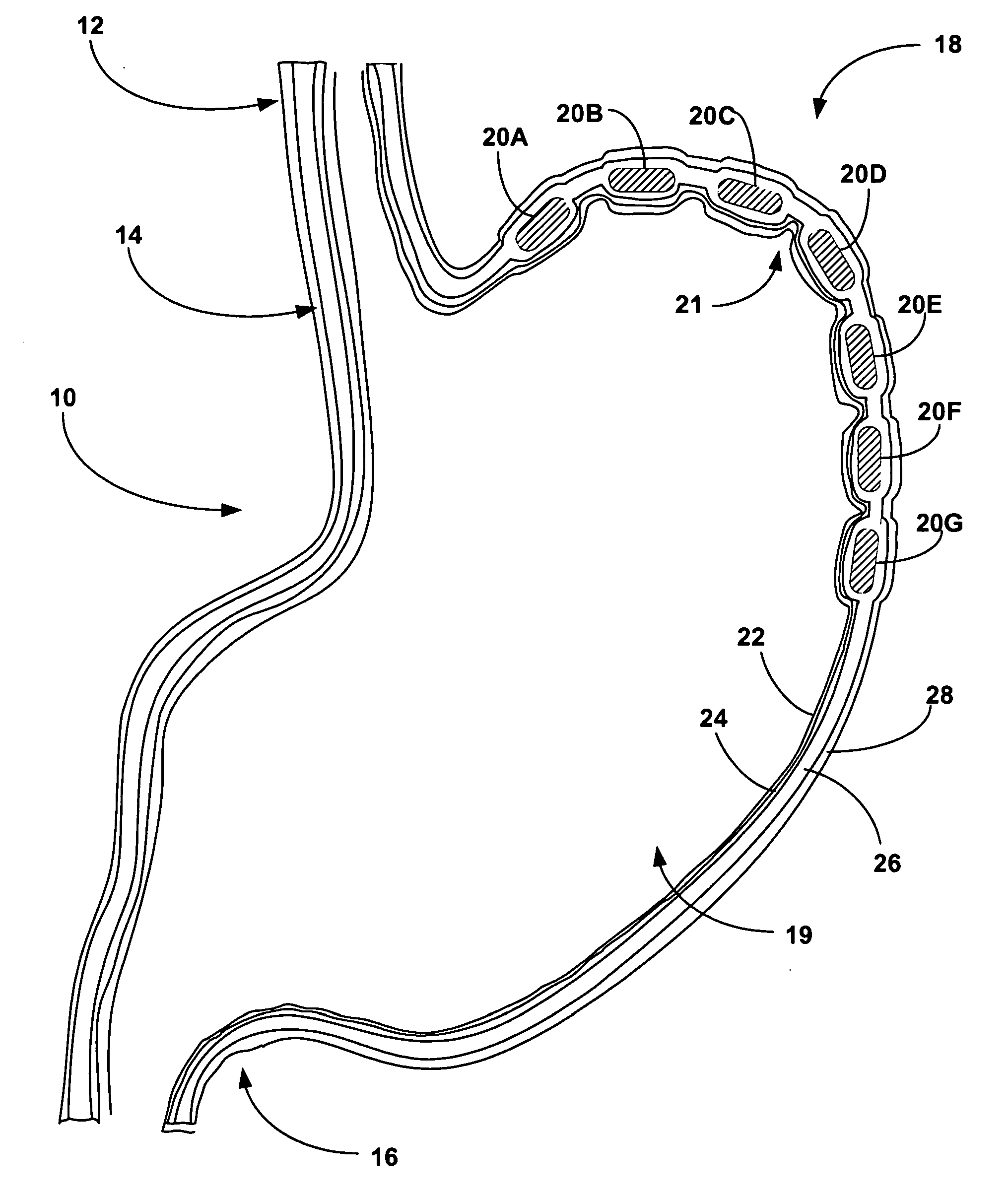

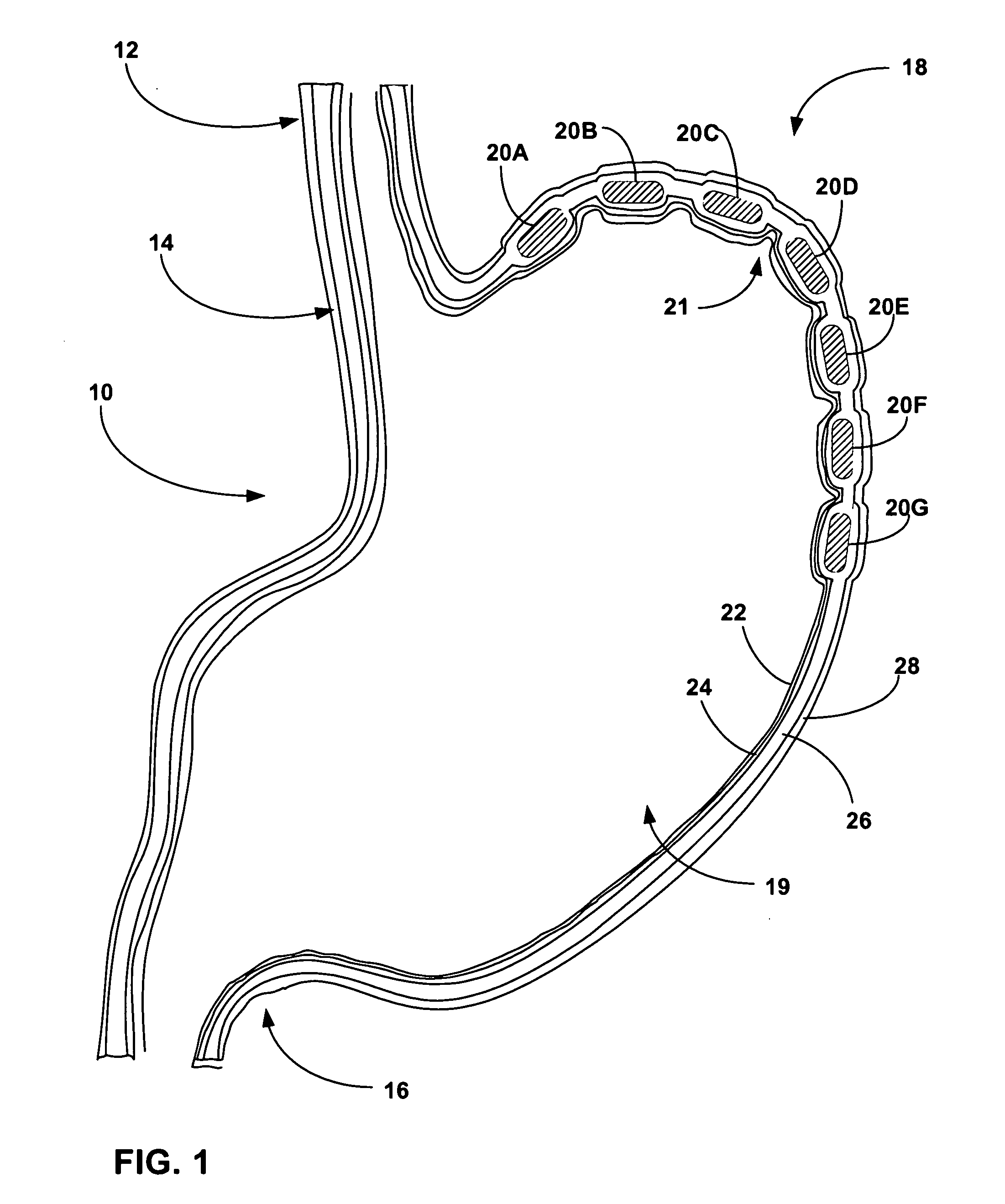

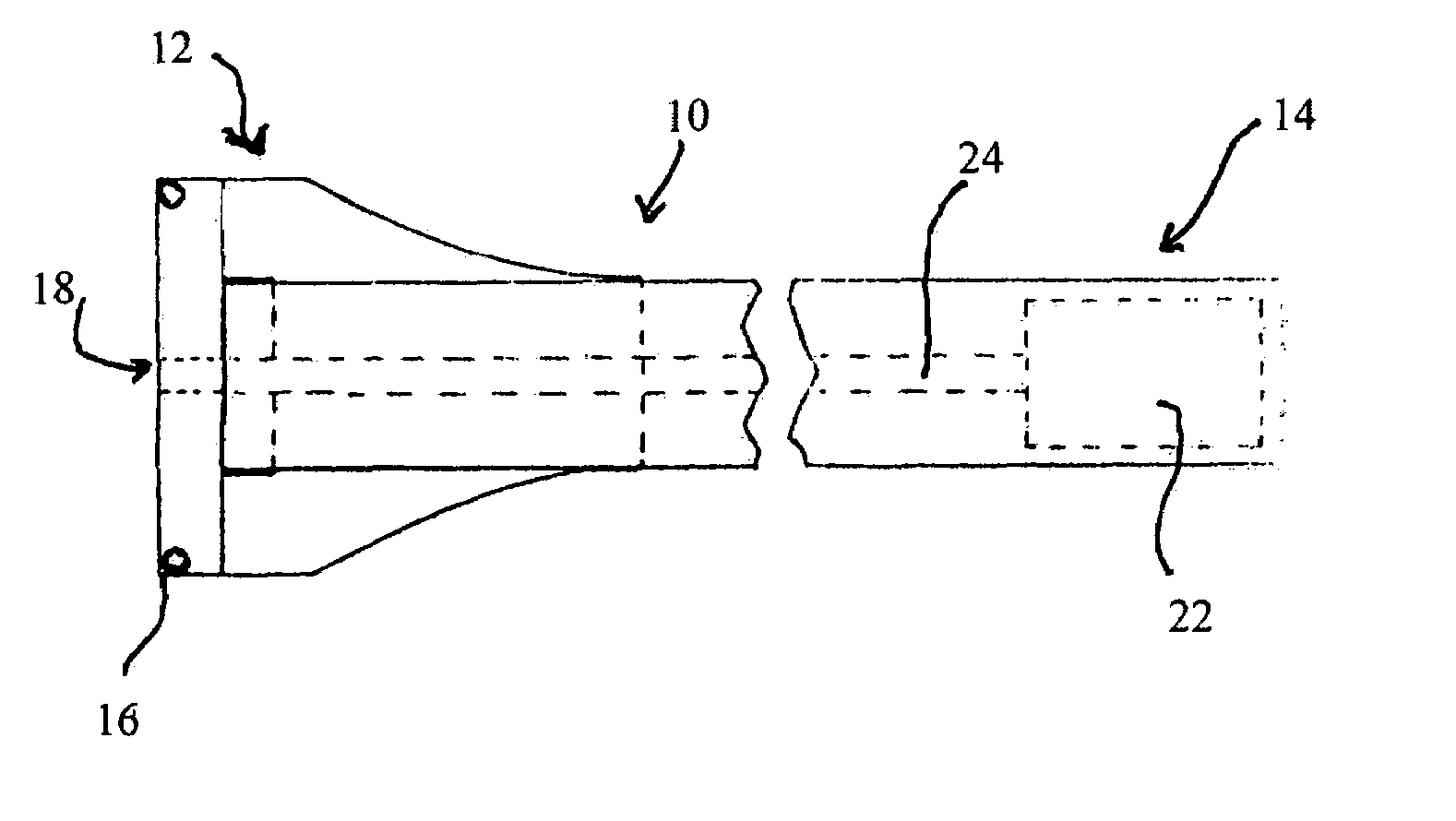

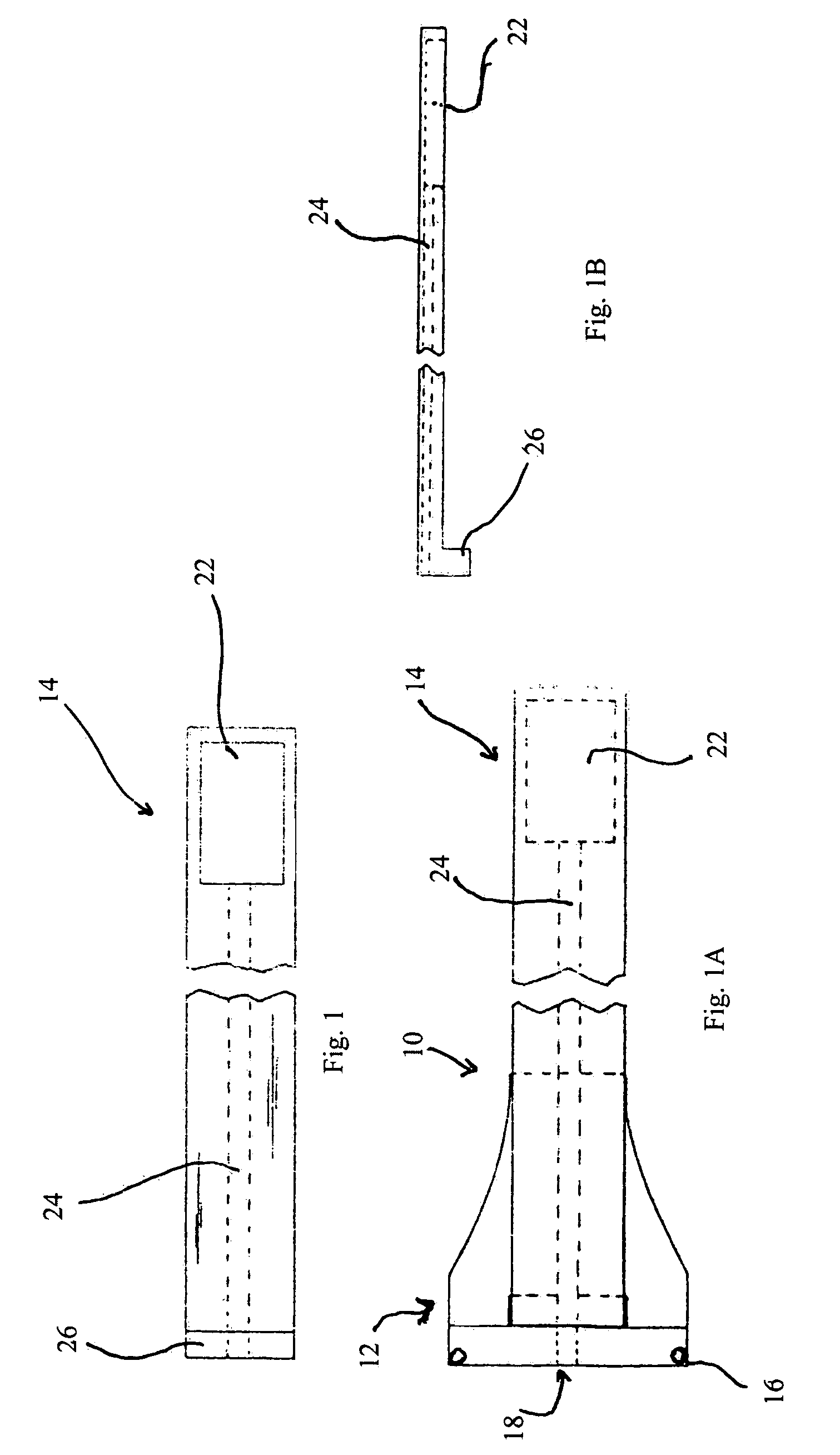

Biasing stretch receptors in stomach wall to treat obesity

Medical devices and methods are designed to bias stretch receptors in the stomach wall of a patient to treat obesity. Biasing of the stretch receptors by pre-stretching induces an early sensation of satiety, causing the patient to consume less food. Biasing of the stretch receptors can be achieved by the placement of bulking devices within the wall of the stomach, e.g., in the mucosa, submucosa or muscle layer. The bulking devices may be expandable and, in some embodiments, may take the form of a hydrogel prosthesis that expands following implantation in a wall of the stomach.

Owner:MEDTRONIC INC

Nanocell drug delivery system

InactiveUS20070053845A1Lose efficacyIncreased toxicityPowder deliveryPeptide/protein ingredientsNervous systemAsthma

Nanocells allow the sequential delivery of two different therapeutic agents with different modes of action or different pharmacokinetics. A nanocell is formed by encapsulating a nanocore with a first agent inside a lipid vesicle containing a second agent. The agent in the outer lipid compartment is released first and may exert its effect before the agent in the nanocore is released. The nanocell delivery system may be formulated in pharmaceutical composition for delivery to patients suffering from diseases such as cancer, inflammatory diseases such as asthma, autoimmune diseases such as rheumatoid arthritis, infectious diseases, and neurological diseases such as epilepsy. In treating cancer, a traditional antineoplastic agent is contained in the outer lipid vesicle of the nanocell, and an antiangiogenic agent is loaded into the nanocore. This arrangement allows the antineoplastic agent to be released first and delivered to the tumor before the tumor's blood supply is cut off by the antianiogenic agent.

Owner:MASSACHUSETTS INST OF TECH

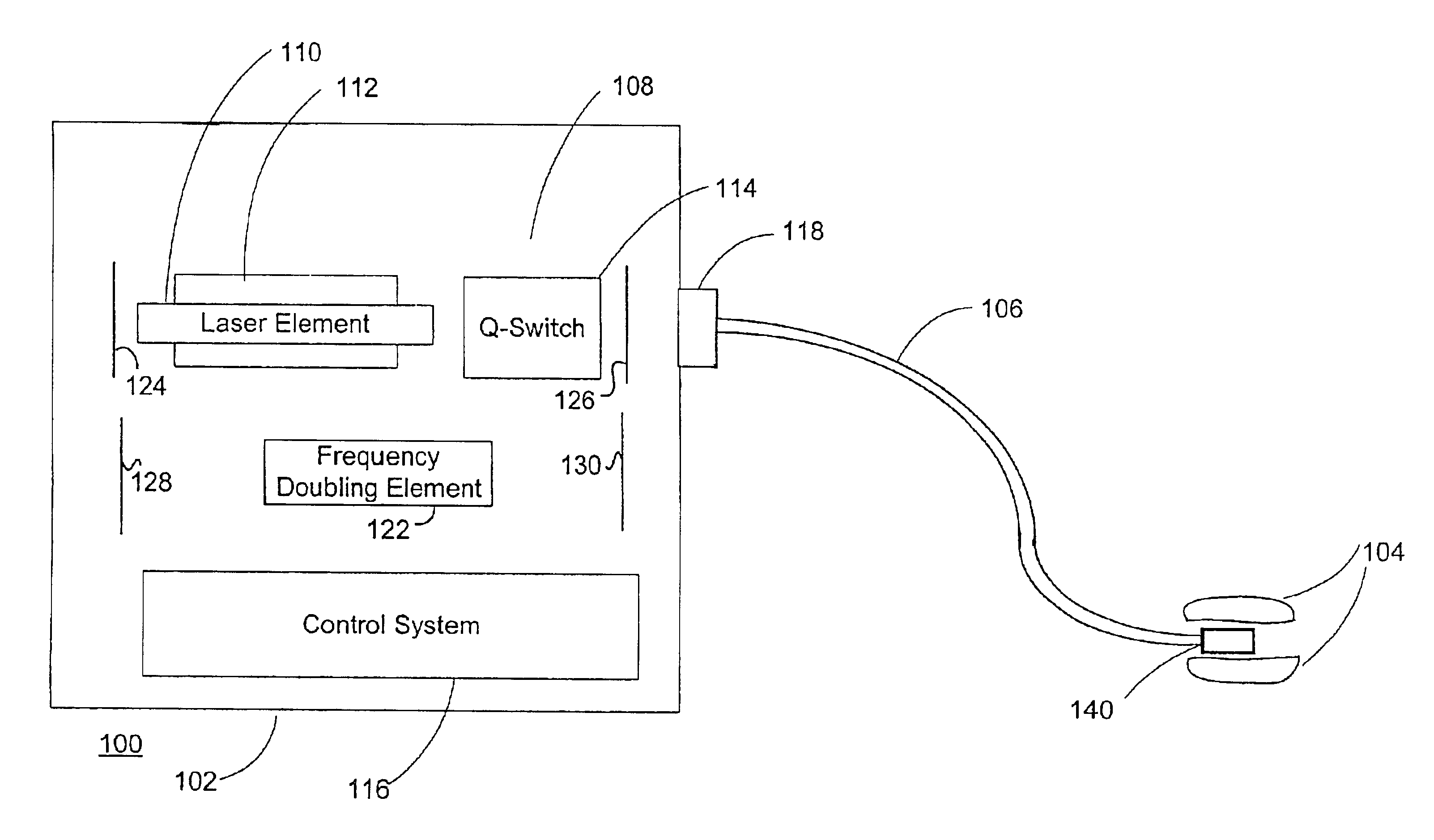

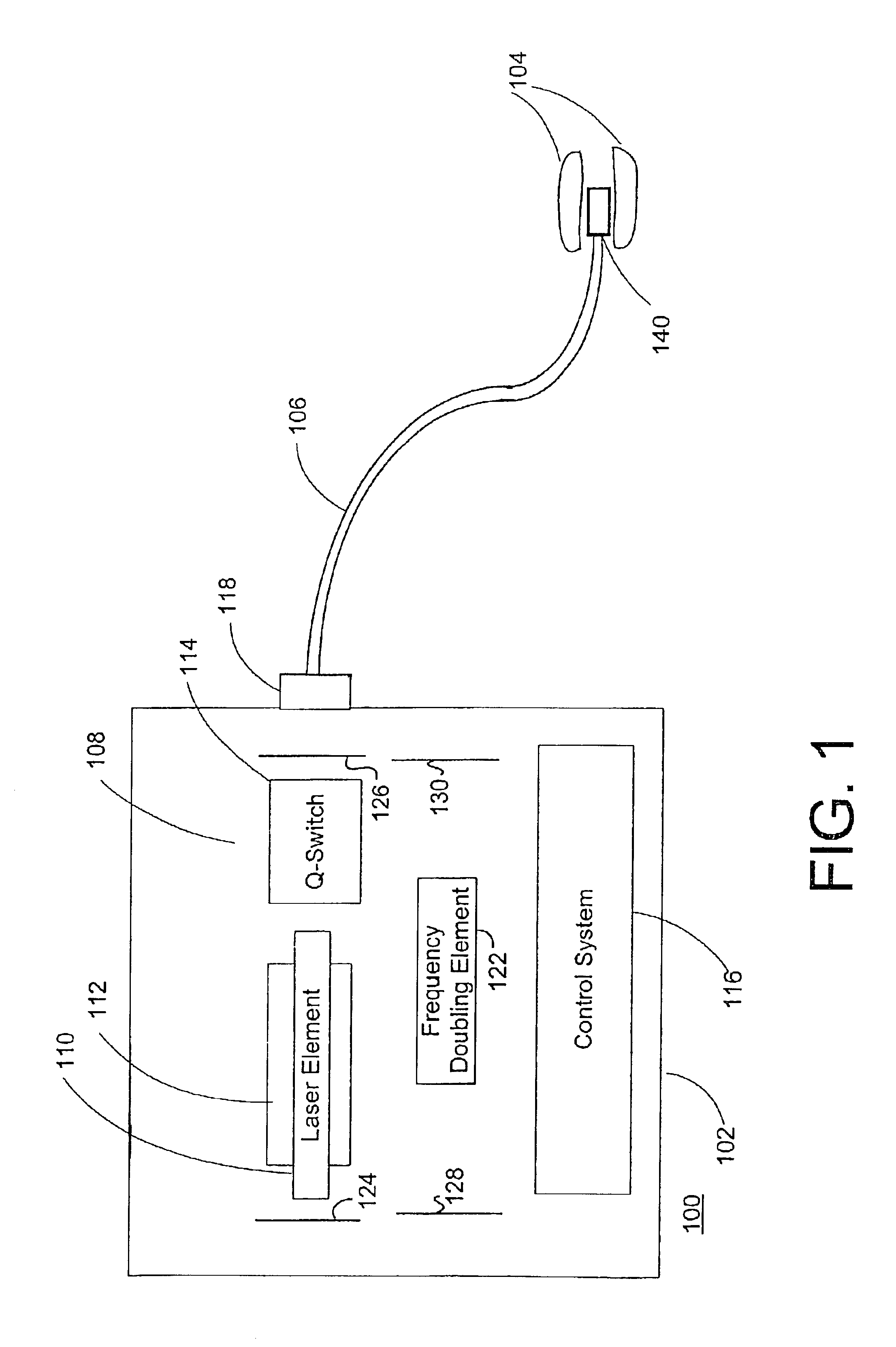

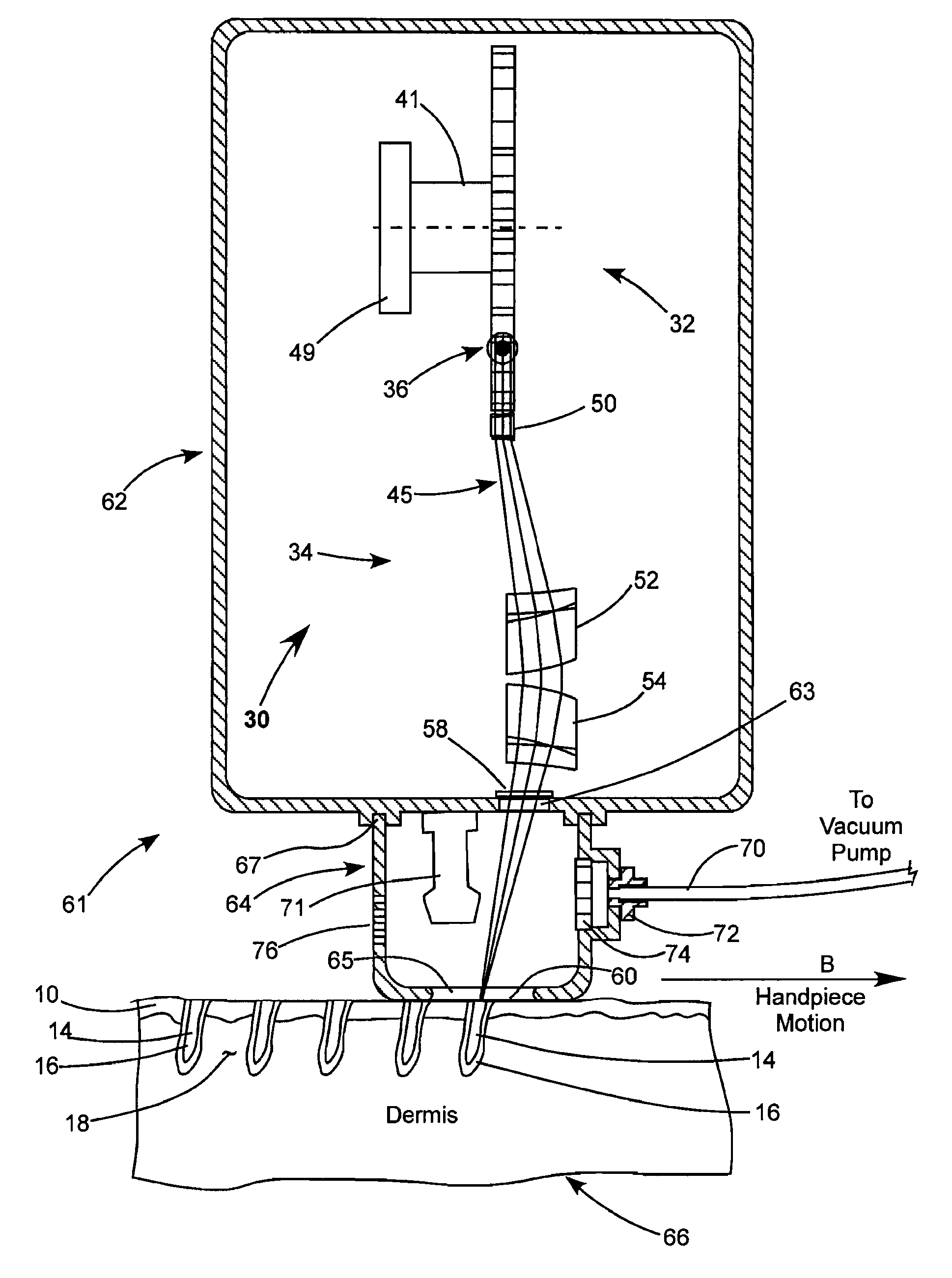

Method and system for photoselective vaporization of the prostate, and other tissue

InactiveUS6986764B2Reduce incidenceLess side effectsEndoscopesSurgical instrument detailsOptical radiationMedicine

A method for photoselective vaporization of prostate tissue includes delivering laser radiation to the treatment area on the tissue, via an optical fiber for example, wherein the laser radiation has a wavelength and irradiance in the treatment area on the surface of the tissue sufficient because vaporization of a substantially greater volume of tissue than a volume of residual coagulated tissue caused by the laser radiation. The laser radiation is generated using a neodymium doped solid-state laser, including optics producing a second or higher harmonic output with greater than 60 watts average output power. The delivered laser radiation has a wavelength for example in a range of about 200 nm to about 650 nm, and has an average irradiance in the treatment area greater than about 10 kilowatts / cm2, in a spot size of at least 0.05 mm2.

Owner:BOSTON SCI SCIMED INC

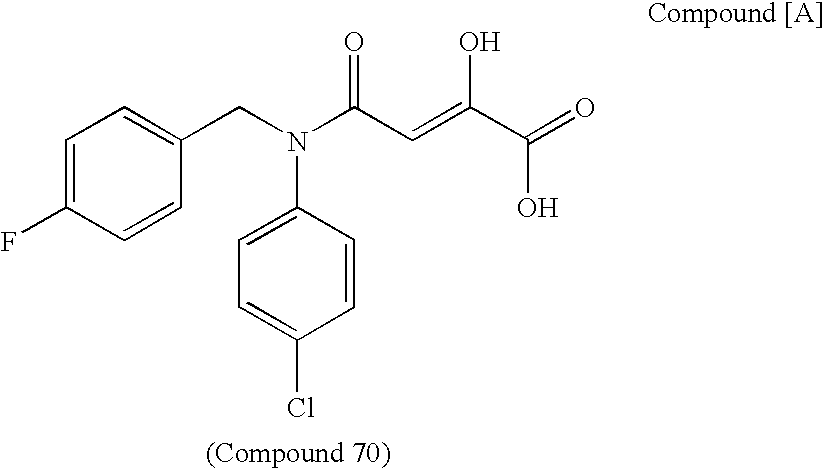

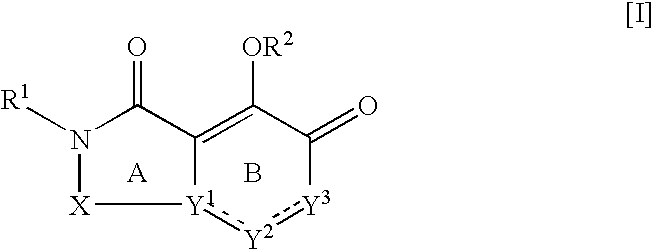

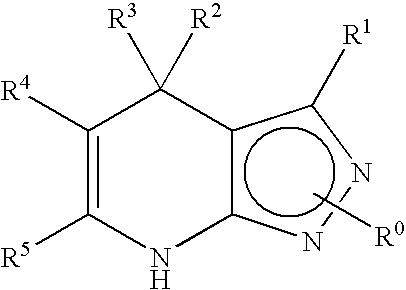

Nitrogen-containing fused ring compound and use thereof as HIV integrase inhibitor

ActiveUS7211572B2Effective anti-HIV agentStrong inhibitory activityBiocideOrganic chemistryAnti-HIV AgentSide effect

The present invention relates to a nitrogen-containing fused ring compound represented by the following formula [I]wherein each symbol is as defined in the specification, or a pharmaceutically acceptable salt thereof, and an anti-HIV agent containing such compound. The compound of the present invention has an HIV integrase inhibitory activity, and is useful as an agent for the prophylaxis or treatment of AIDS, or as an anti-HIV agent. In addition, by the combined use with other anti-HIV agents such as a protease inhibitor, a reverse transcriptase inhibitor and the like, it can be a more effective anti-HIV agent. Because it shows integrase-specific high inhibitory activity, the compound can be a pharmaceutical agent safe on human body, which causes only a fewer side effects.

Owner:JAPAN TOBACCO INC

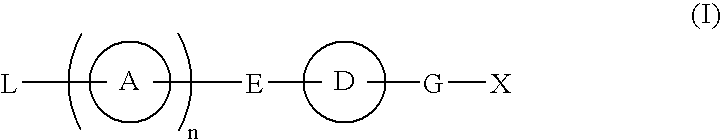

Compound Having S1P Receptor Binding Potency and Use Thereof

InactiveUS20080207584A1Easy to optimizeEasy to separateBiocideNervous disorderAutoimmune conditionS1P Receptor

Provided are: a compound represented by formula (I):(wherein ring A and ring D each represent a cyclic group which may have a substituent(s); E and G each represent a bond or a spacer having 1 to 8 atoms in its main chain; L represents a hydrogen atom or a substituent; X represents amino which may have a substituent(s), or a heterocyclic group which contains at least one nitrogen atom and which may have a substituent(s); n represents 0 to 3, in which when n is 2 or more, a plurality of ring A's may be the same or different from one another); a salt thereof; an N-oxide form thereof; a solvate thereof, a prodrug thereof; and a medicament which includes those. The compound represented by formula (I) is capable of binding S1P receptors (in particular, EDG-1 and / or EDG-6), and useful for preventing and / or treating rejection in transplantation, autoimmune diseases, allergic diseases, etc.

Owner:ONO PHARMA CO LTD

Nitrogen-containing fused ring compound and use thereof as HIV integrase inhibitor

InactiveUS20050054645A1Effective anti-HIV agentStrong inhibitory activityBiocideOrganic chemistryIntegrase inhibitorSide effect

The present invention relates to a nitrogen-containing fused ring compound represented by the following formula [I]wherein each symbol is as defined in the specification, or a pharmaceutically acceptable salt thereof, and an anti-HIV agent containing such compound. The compound of the present invention has an HIV integrase inhibitory activity, and is useful as an agent for the prophylaxis or treatment of AIDS, or as an anti-HIV agent. In addition, by the combined use with other anti-HIV agents such as a protease inhibitor, a reverse transcriptase inhibitor and the like, it can be a more effective anti-HIV agent. Becuae it shows integrase-specific high inhibitory activity, the compound can be a pharmaceutical agent safe on human body, which causes only a fewer side effects.

Owner:JAPAN TOBACCO INC

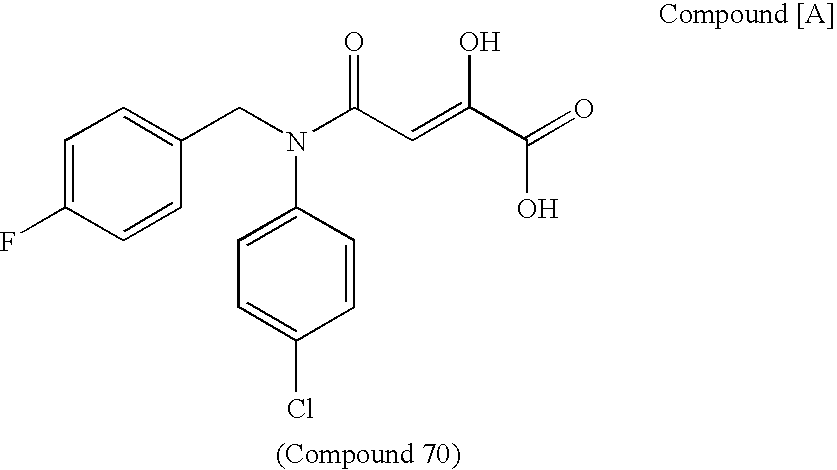

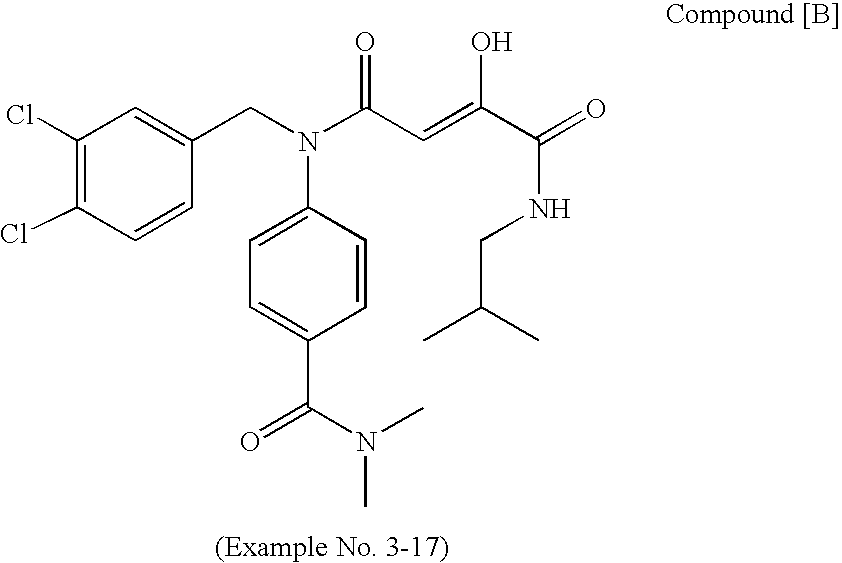

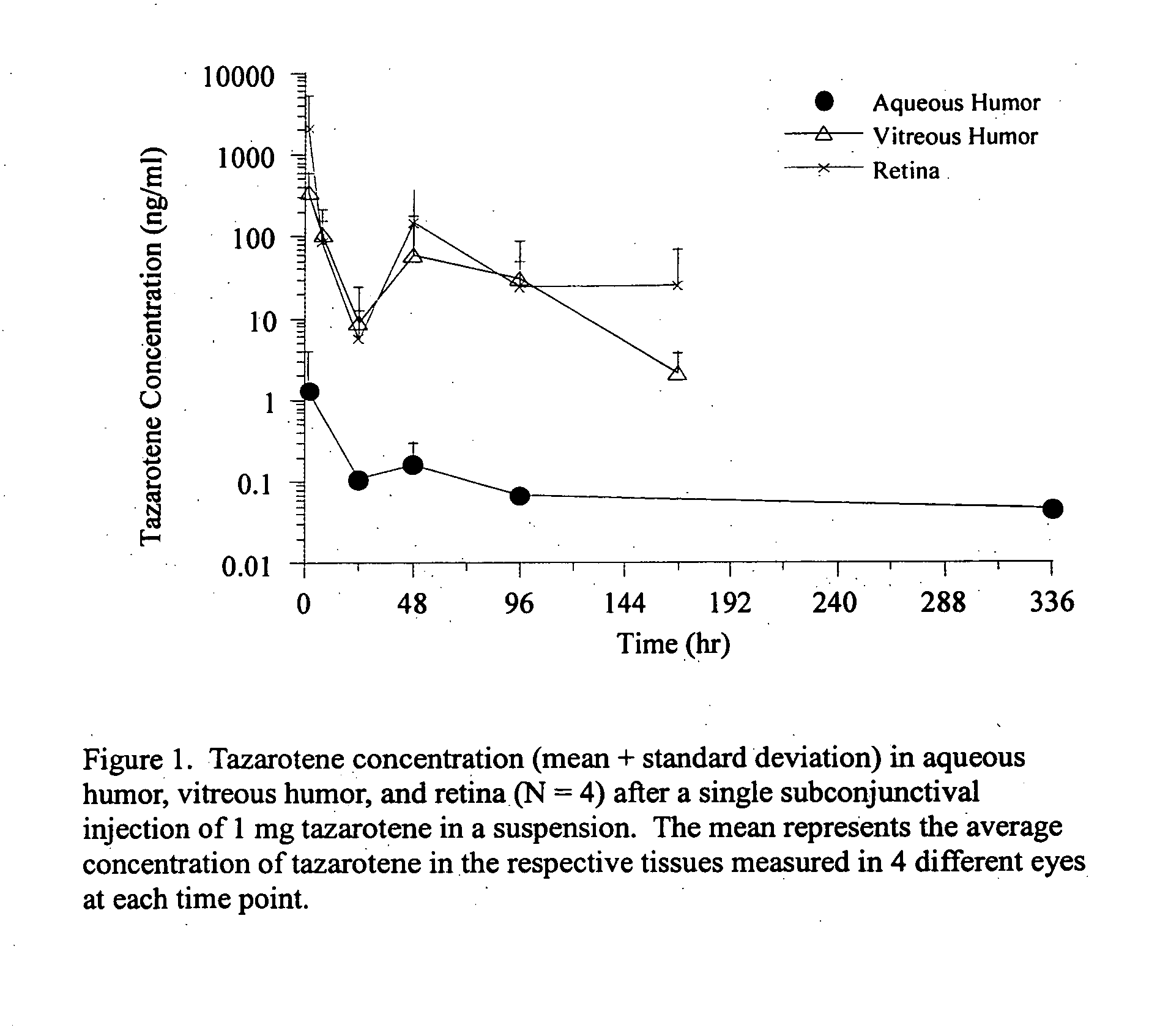

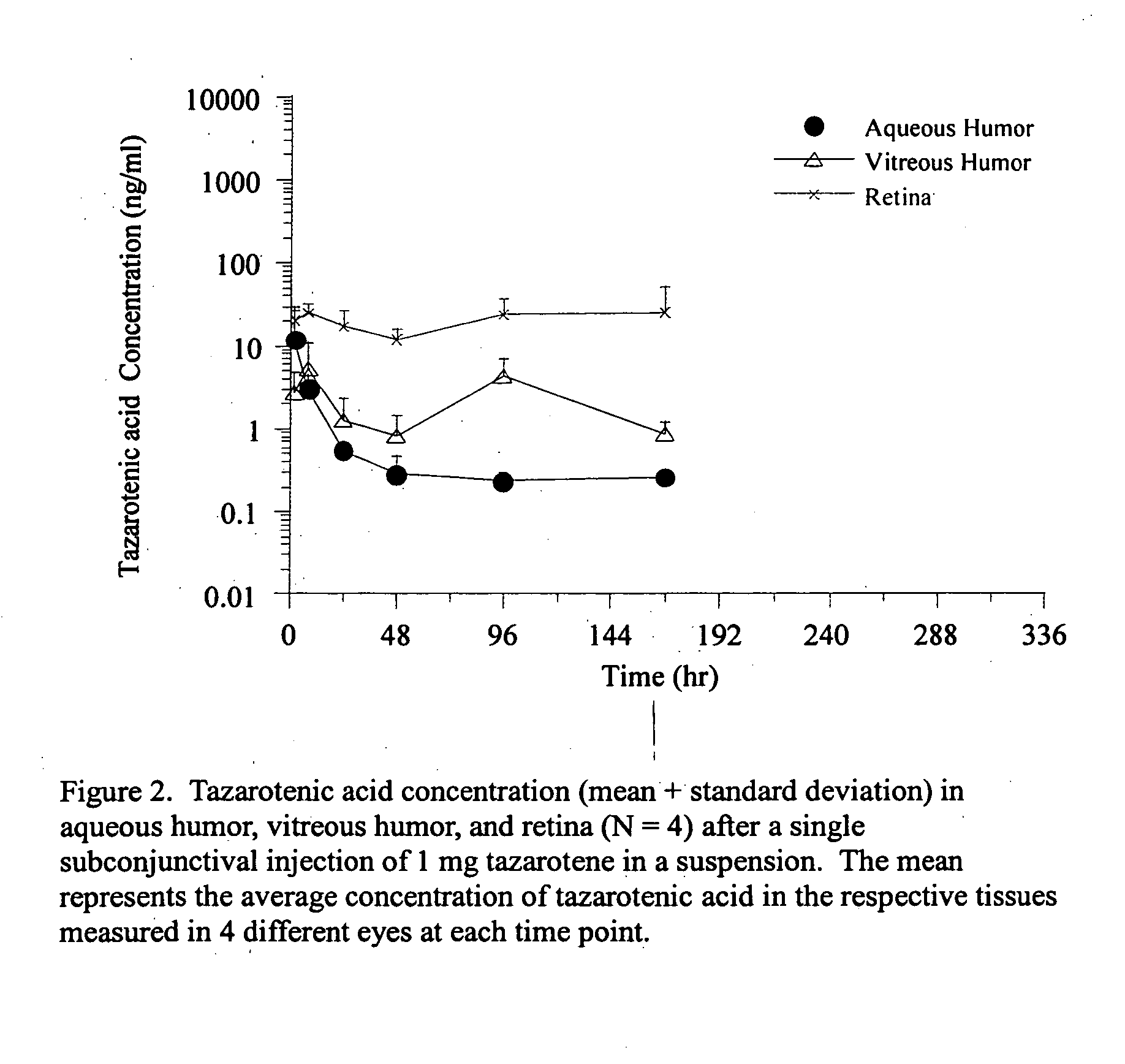

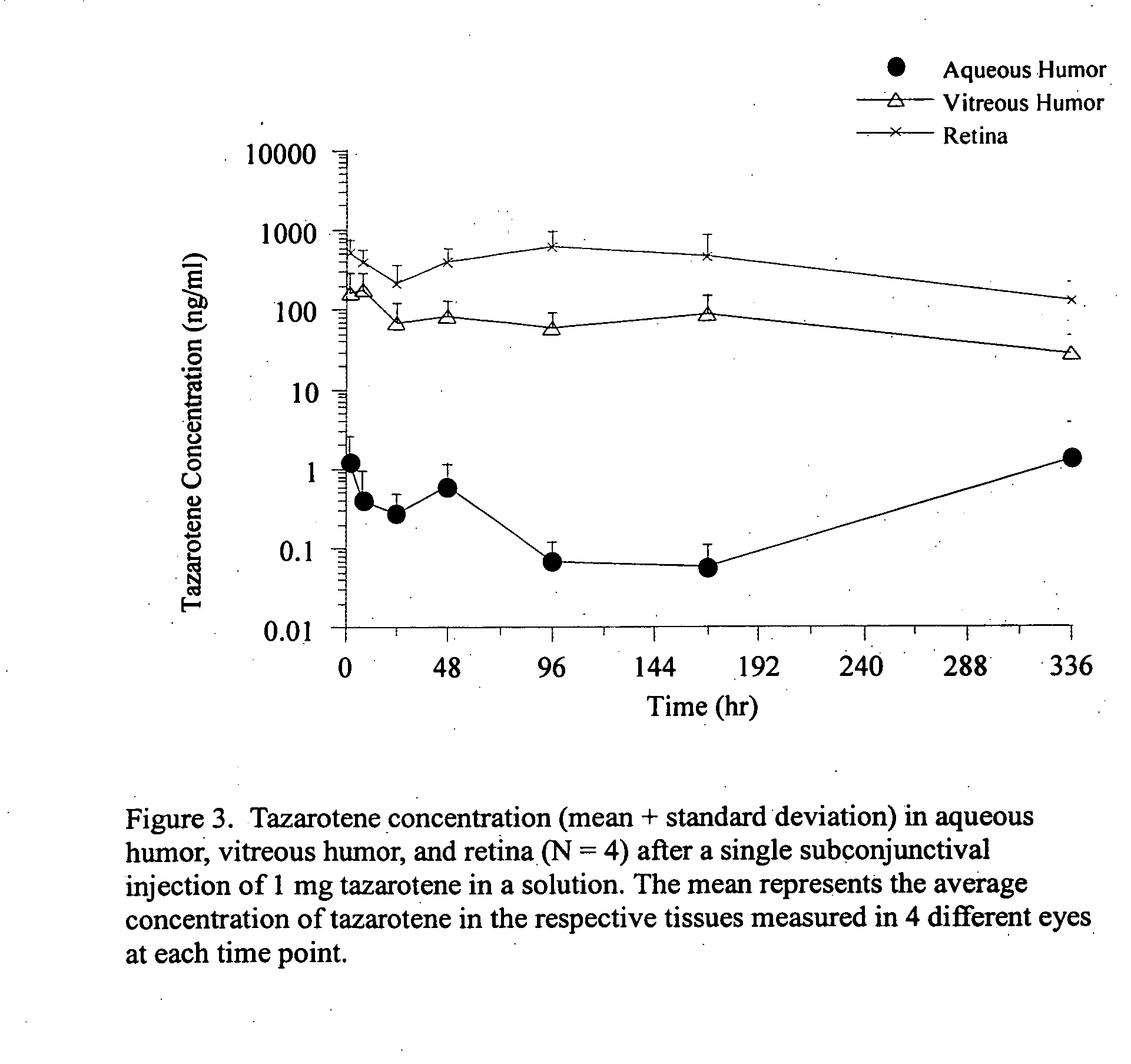

Delivery of an active drug to the posterior part of the eye via subconjunctival or periocular delivery of a prodrug

InactiveUS20050009910A1Prolong the action timeIncrease concentrationBiocideSenses disorderConjunctivaEster prodrug

The present invention relates to method of sustained-delivery of an active drug to a posterior part of an eye of a mammal to treat or prevent a disease or condition affecting said mammal, wherein said disease or condition can be treated or prevented by the action of said active drug upon said posterior part of the eye, comprising administering an effective amount of an ester prodrug of the active drug subconjunctivally or periocularly. Preferably, the active drug is more than about 10 times as active as the prodrug. Other aspects of this invention deal with the treatment of certain diseases by the periocular or subconjunctival delivery of an ester prodrug, and certain pharmaceutical products containing ester prodrugs for periocular or subconjunctival administration.

Owner:ALLERGAN INC

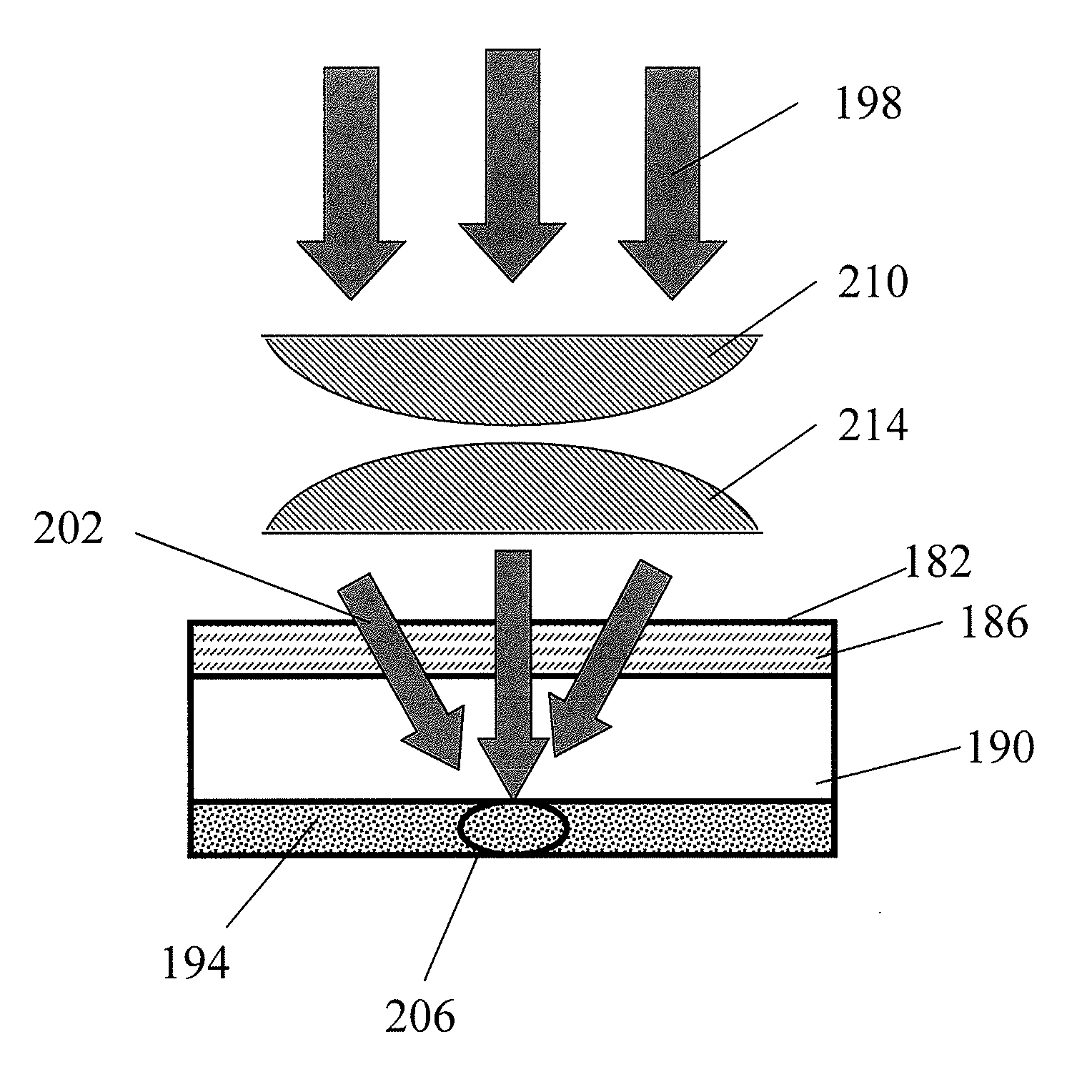

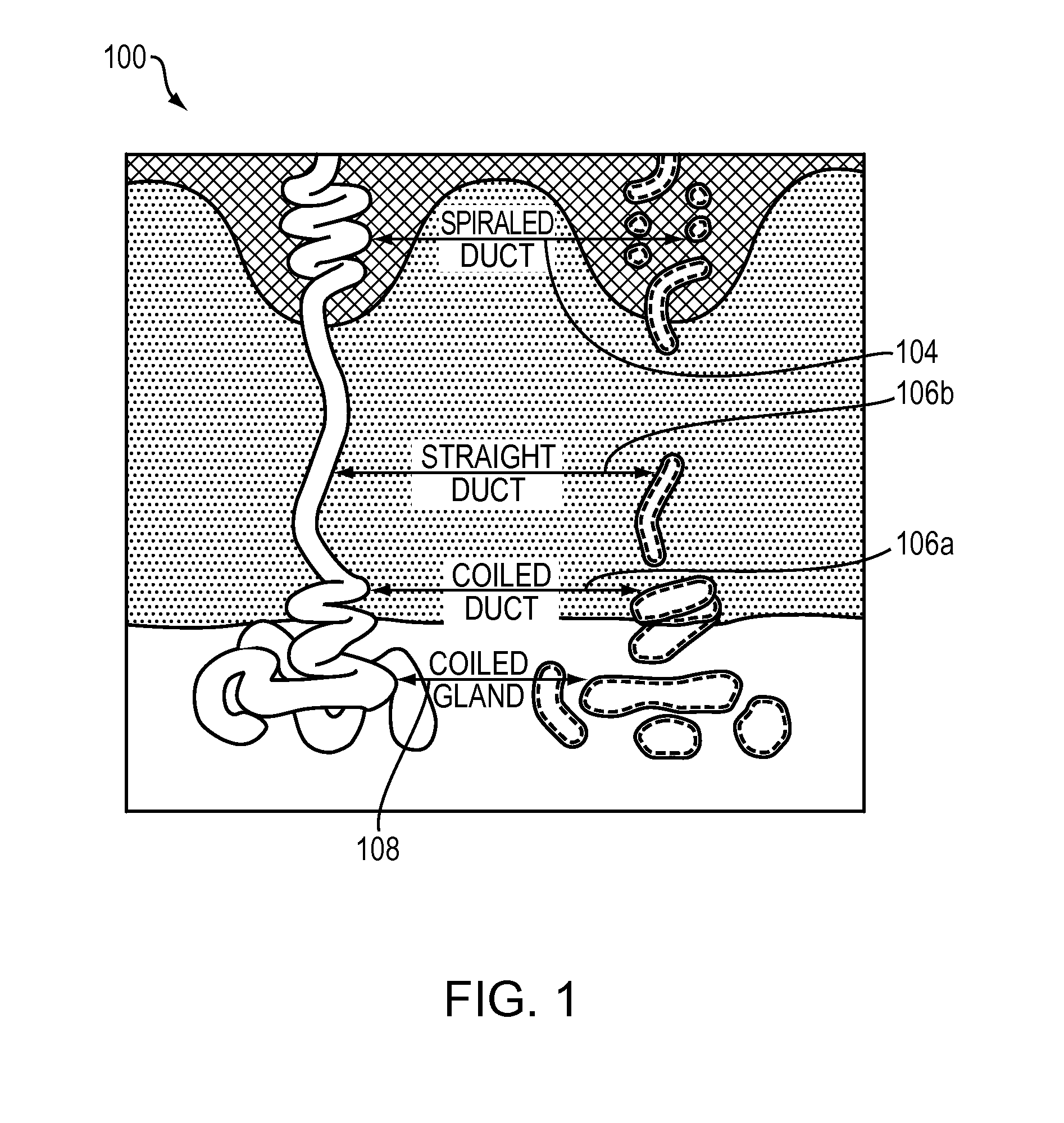

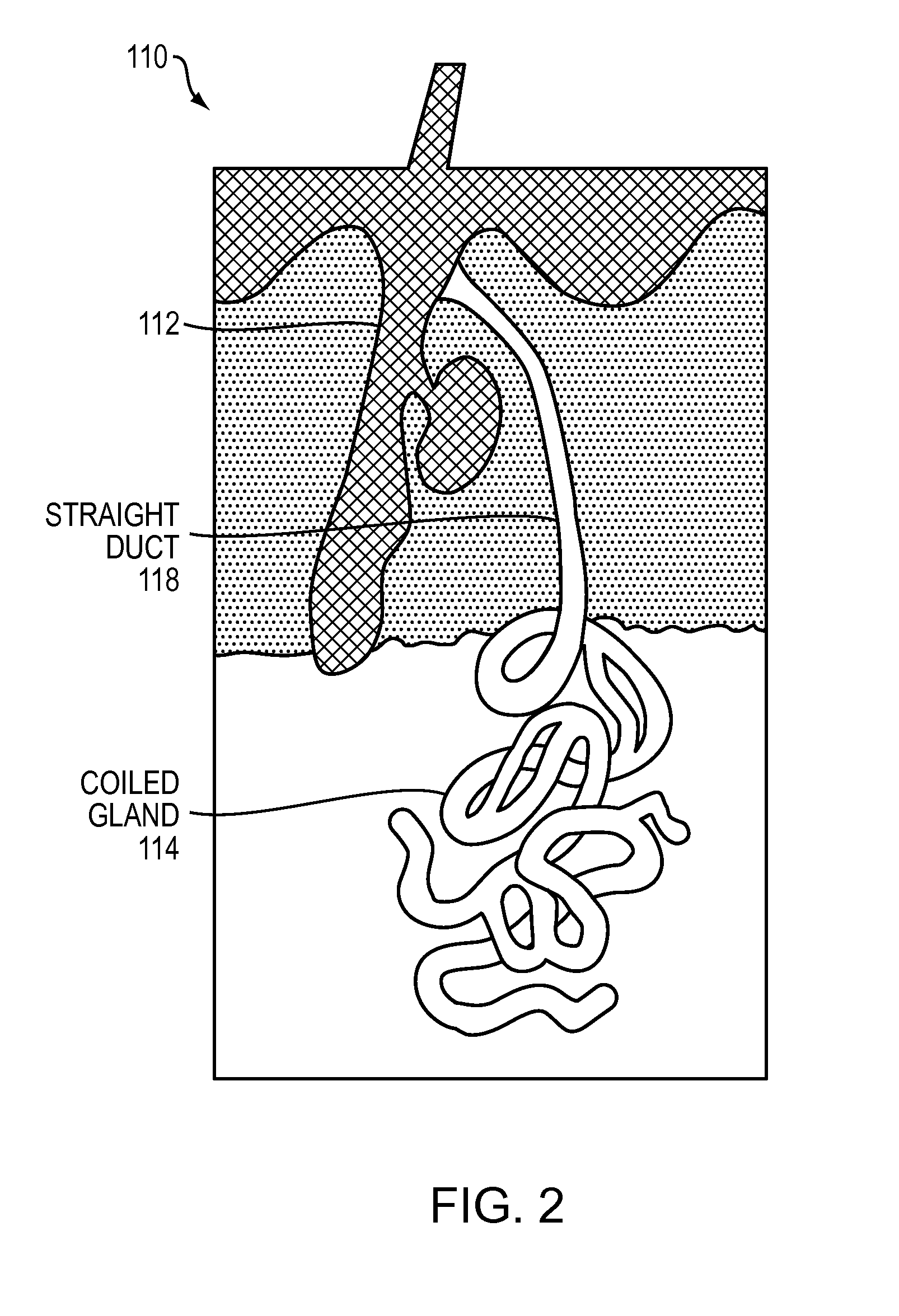

Treatment of sweat glands

InactiveUS20110190745A1Less side effectsLow costSurgical instruments using microwavesRadiation therapyThermal injuryCuticle

A treatment of sweat glands in a target region of skin includes generating electromagnetic radiation having a wavelength of about 1,064 nm to about 1,800 nm. To decrease sweat production in a plurality of sweat glands, the electromagnetic radiation is delivered to a dermal interface defined by a dermal region and a subcutaneous fat region in the target region of skin to cause thermal injury to at least one of the dermal region, the subcutaneous fat region or the dermal interface. An epidermal region of the skin can be cooled at least one of before, during or after delivering the electromagnetic radiation to the dermal interface in the target region of skin.

Owner:CANDELA CORP

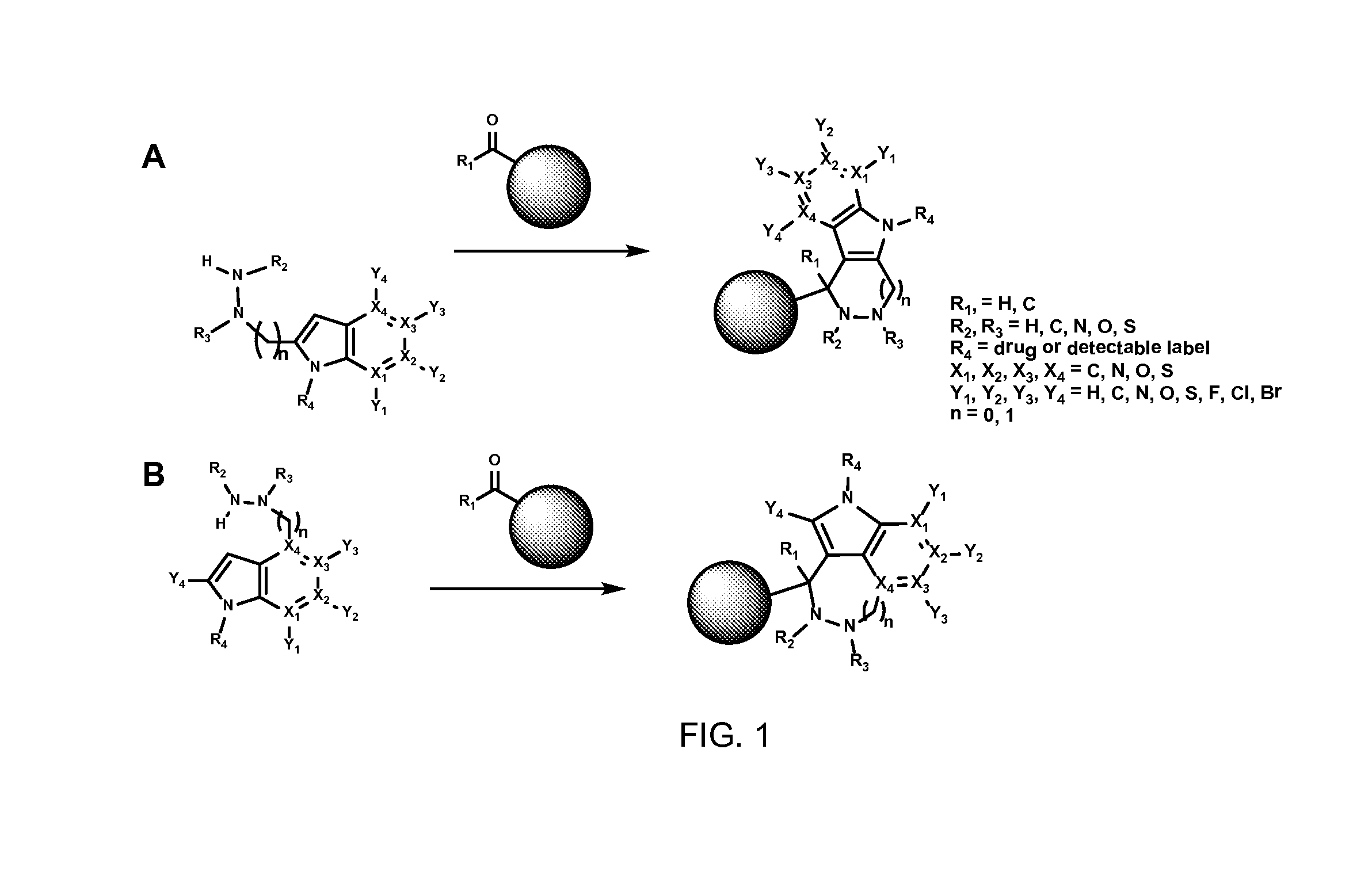

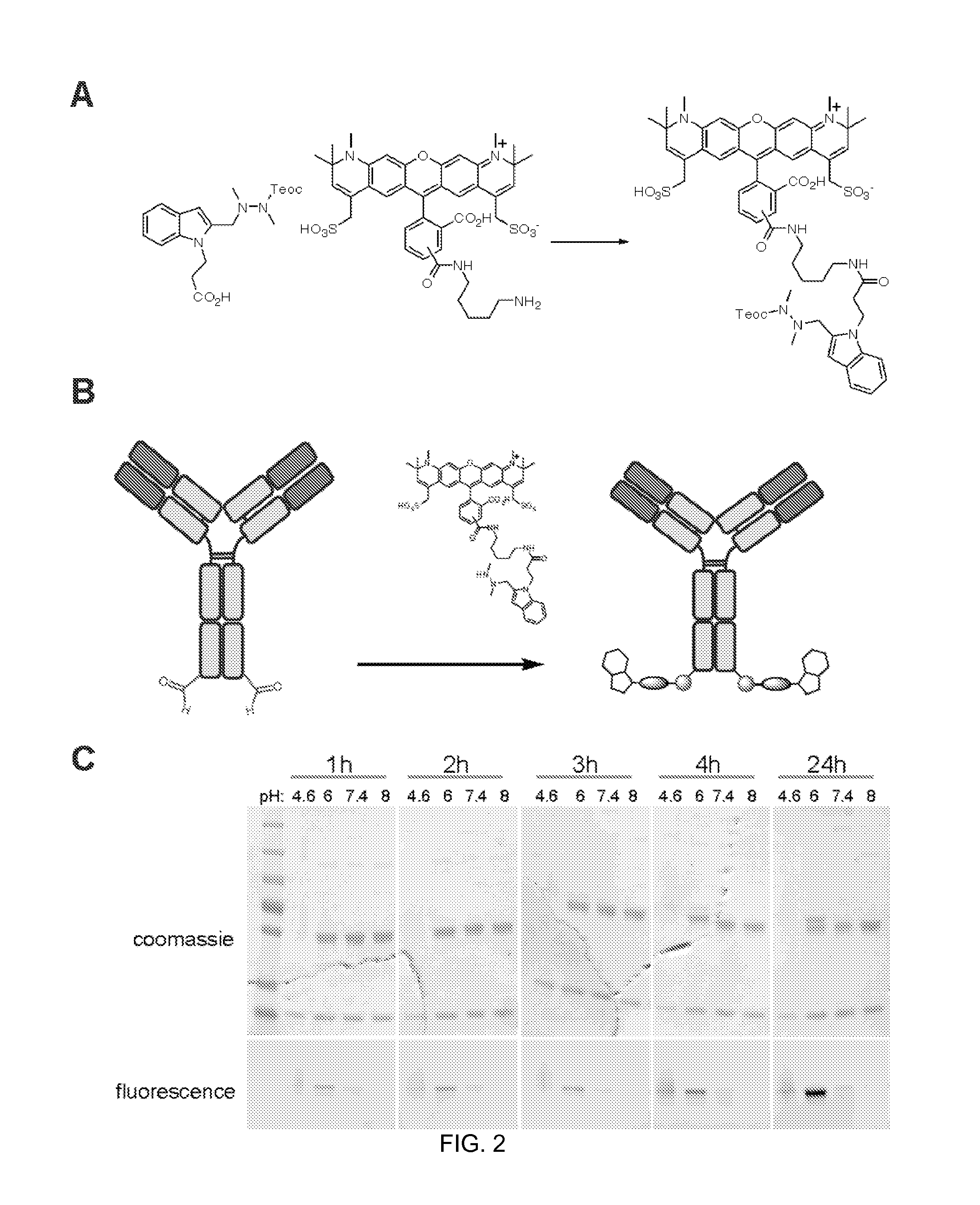

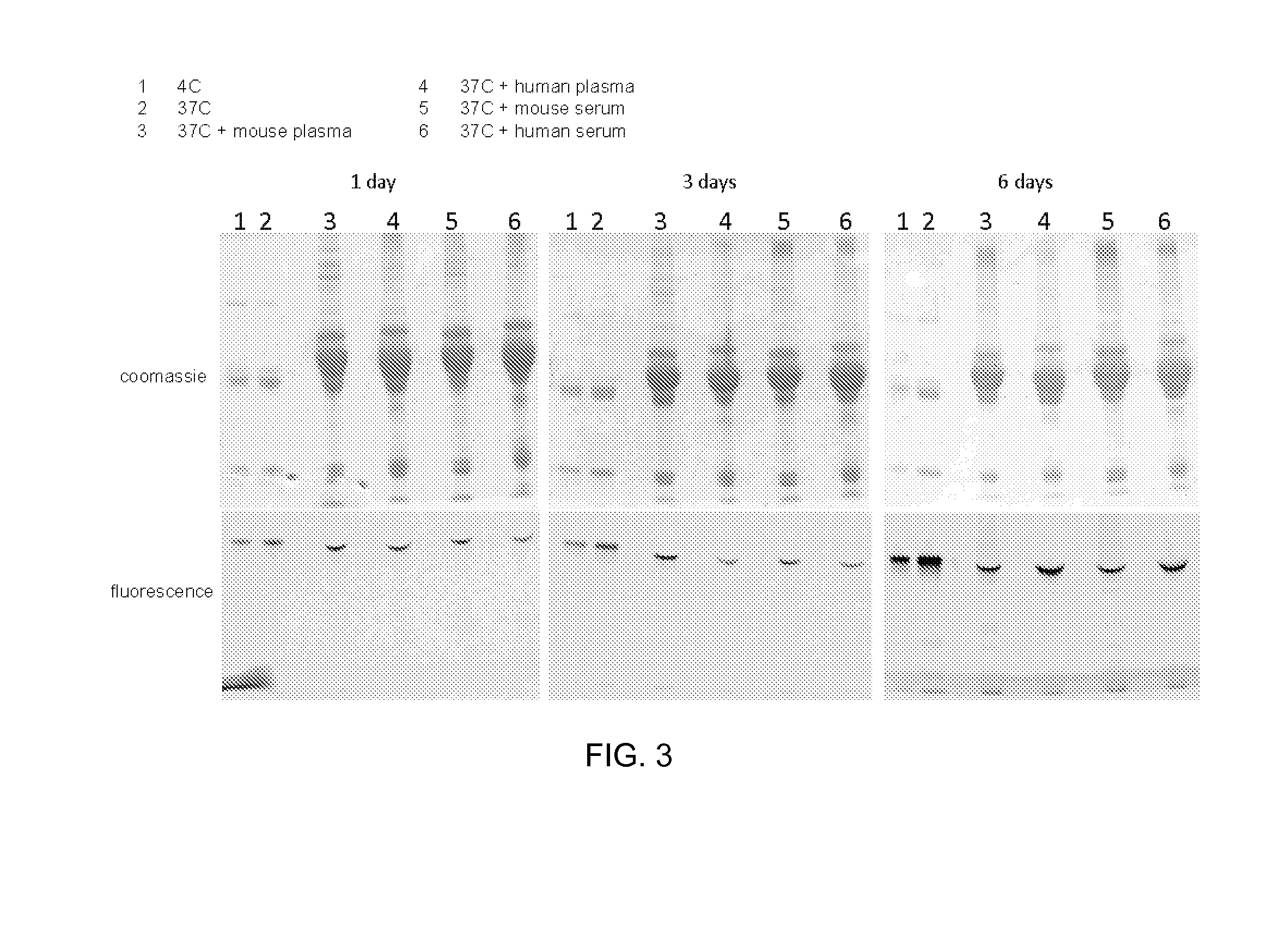

Hydrazinyl-indole compounds and methods for producing a conjugate

ActiveUS20140141025A1Effective treatmentMultiple functionsPeptide/protein ingredientsPeptide preparation methodsMethods of productionStereochemistry

The present disclosure provides conjugate structures (e.g., polypeptide conjugates) and hydrazinyl-indole compounds used to produce these conjugates. The disclosure also provides methods of production of such conjugates, as well as methods of using the same.

Owner:REDWOOD BIOSCI

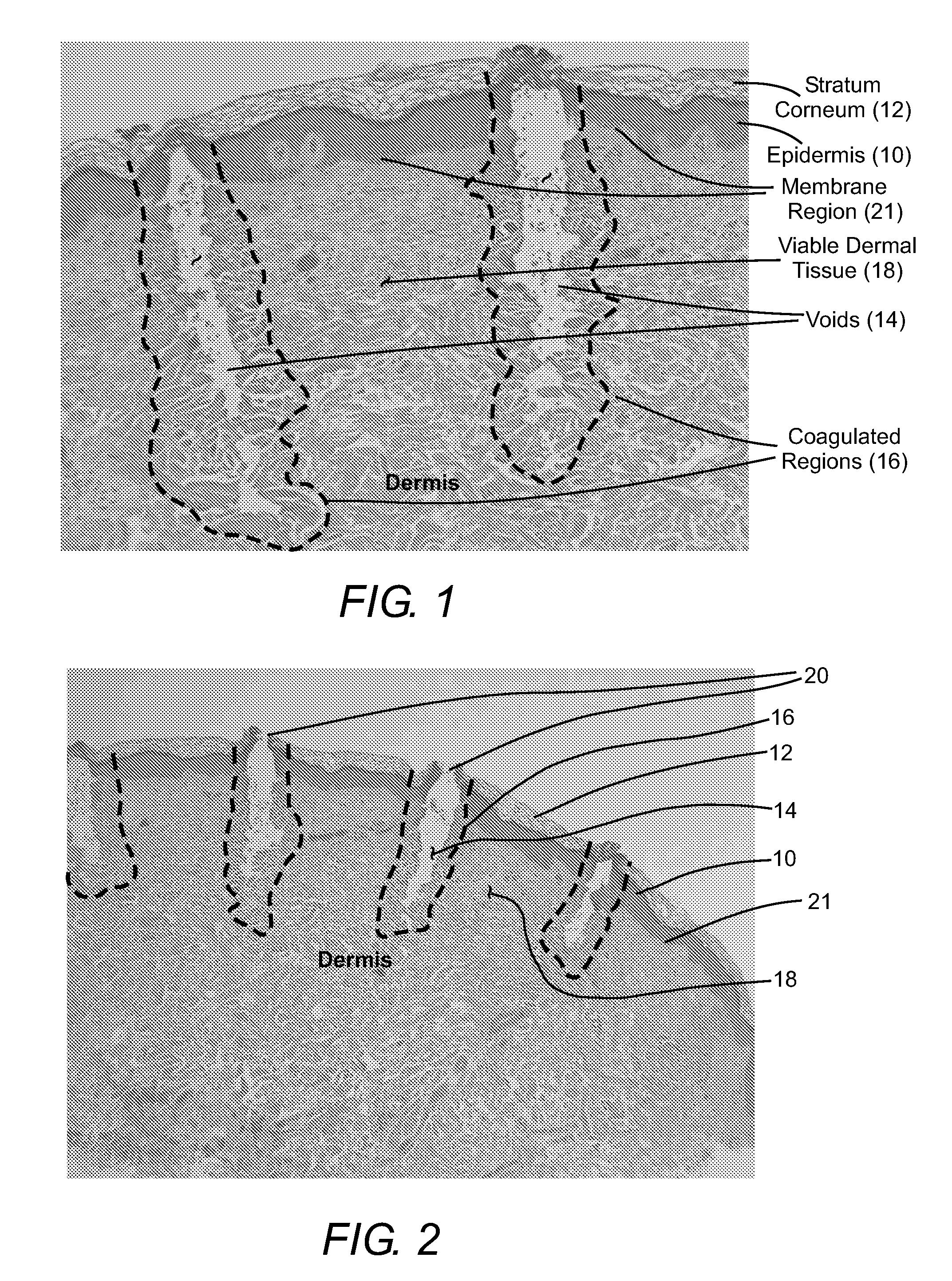

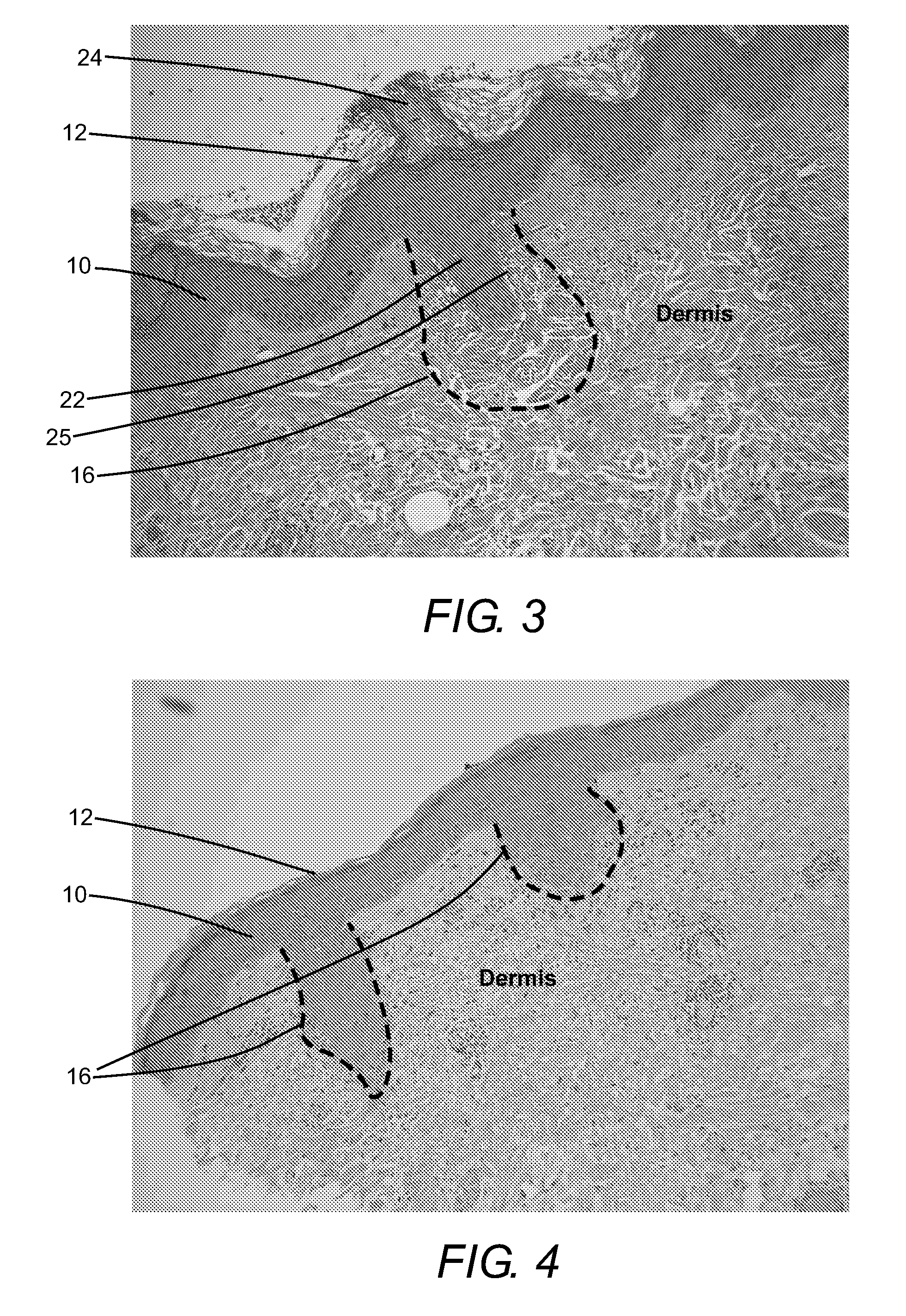

Laser System for Treatment of Skin Laxity

InactiveUS20070179481A1Tighten skinEnhance elasticitySurgical instrument detailsWrinkleBiomedical engineering

A method of reducing wrinkles in skin includes irradiating the skin with laser pulses to ablate an array of spaced apart voids in the skin. A region of coagulated tissue surrounds each of the voids and there viable tissue between the coagulated regions. Tissue in the coagulated regions is in tension due to shrinkage of collagen by the heat generated during the ablation. This tension rapidly closes the voids, tightening the skin and reducing the wrinkles. A healing process replaces the coagulated tissue with new tissue after a period of about one-month. The method is also applicable to lightening abnormally pigmented skin, as the new tissue replacing the coagulated tissue is not abnromally pigmented.

Owner:RELIANT TECH INC

Sustained release preparation

InactiveUS20060039974A1Reduce decreaseReduced activityOrganic active ingredientsMetabolism disorderDipeptidyl peptidaseDipeptidyl-Peptidase IV Inhibitors

The sustained-release preparation of the present invention, which contains a dipeptidyl peptidase IV inhibitor and a hydrophilic polymer, can appropriately inhibit the DPP-IV activity, and is superior in convenience or compliance.

Owner:TAKEDA PHARMA CO LTD

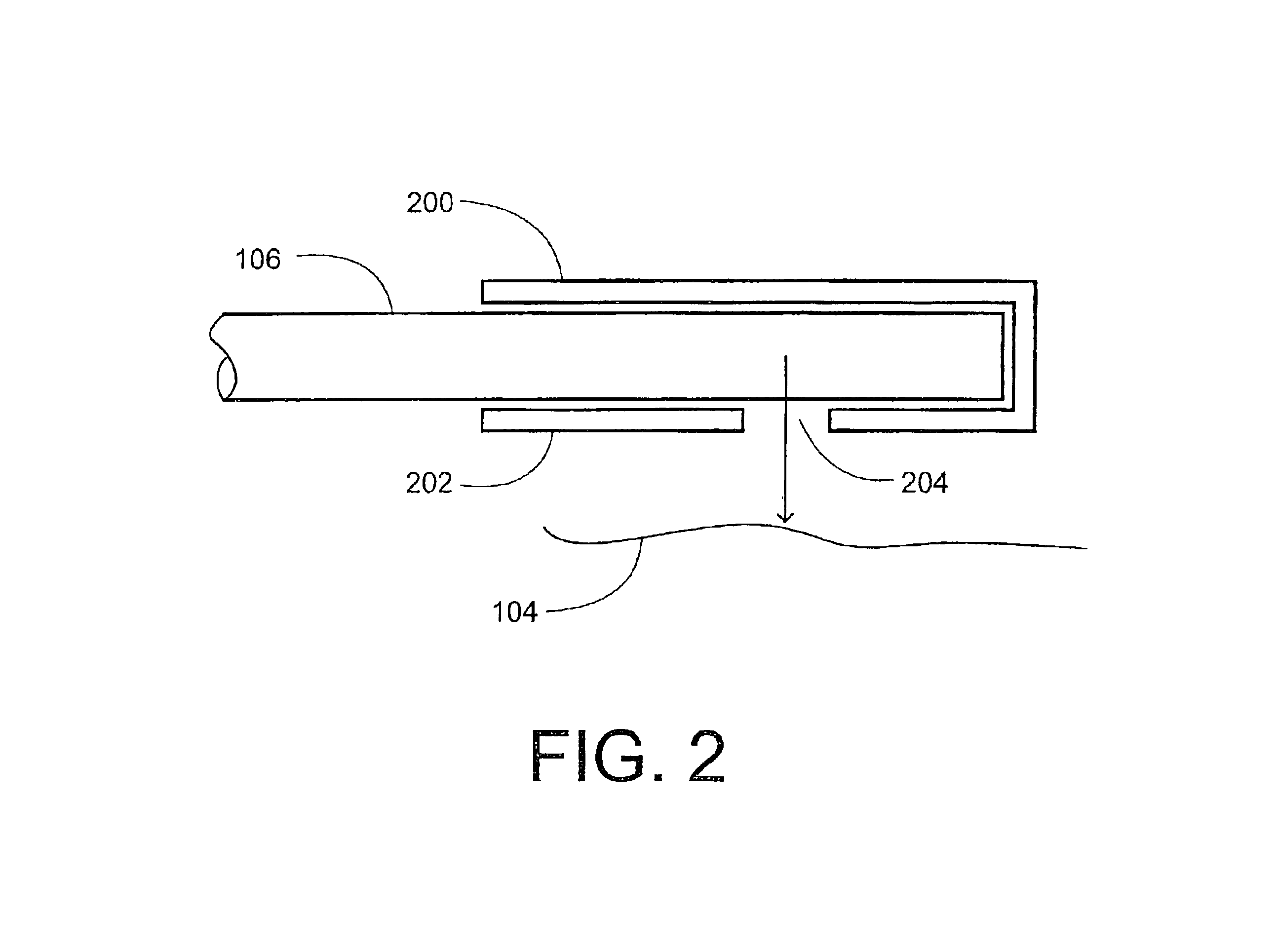

Trans-scleral drug delivery method and apparatus

InactiveUS7276050B2Improved and effectiveImprove acuityOrganic active ingredientsPharmaceutical delivery mechanismDiseaseInjection port

A method of treating ocular disorders involving angiogenesis includes the steps of providing a trans-scleral drug delivery device comprising an insert stabilizer for attachment to a scleral surface and having an interlock opening and a replaceable implant having a reservoir adjacent the scleral surface and an interlock tab, wherein said insert stabilizer and said replaceable implant are removeably connectable by mating said interlock tab and said interlock opening; providing an anti-angiogenic factor; introducing said anti-angiogenic factor into said reservoir; and attaching said insert stabilizer to the scleral surface. The reservoir can be refilled by disengaging the implant from the stabilizer, inserting a new dosage of anti-angiogenic factor, and reconnecting the implant to the stabilizer or injecting a new dosage of anti-angiogenic factor into the reservoir through an injection port in the stabilizer.

Owner:RFE PHARMA LLC

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

Liquid compositions of calcium acetate

ActiveUS20080021104A1Patient compliance is goodLess side effectsBiocideOrganic chemistryAcetic acidAqueous solution

The invention relates to an aqueous liquid composition of calcium acetate, sweetener, and taste masking agent. Also provided is a method for binding phosphorus within the gastrointestinal tract of an individual by administering to the individual an aqueous solution of at least calcium acetate.

Owner:LYNE LAB

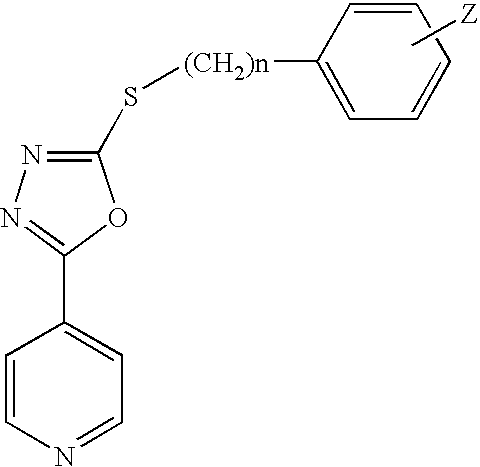

Gsk-3betainhibitor

InactiveUS20100069381A1Superior GSK-3 specific inhibitory activityImprove solubilityAntibacterial agentsBiocideDiseaseDitazole

For the purpose of providing a GSK-3β inhibitor containing an oxadiazole compound or a salt thereof or a prodrug thereof useful as an agent for the prophylaxis or treatment of a GSK-3β-related pathology or disease, the present invention provides a GSK-3β inhibitor containing a compound represented by the formula (I):wherein each symbol is as defined in the specification, or a salt thereof or a prodrug thereof.

Owner:TAKEDA PHARMA CO LTD

Compositions for treating CNS disorders

InactiveUS20110262442A1Improve blood-brain barrier permeabilityGood effectBiocideNervous disorderDiseaseCombination therapy

The present invention provides combination therapies for treating a disease, disorder, or condition, and methods thereof.

Owner:ADENIOS

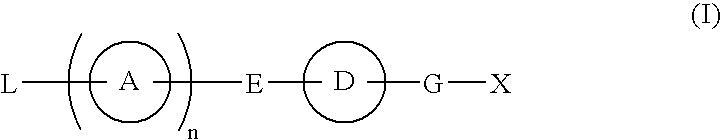

Therapeutic agent for hepatitis C

InactiveUS9006285B2High response rateImprove securityBiocidePeptide/protein ingredientsBULK ACTIVE INGREDIENTActive ingredient

Disclosed is a novel therapeutic means against interferon-resistant hepatitis C. Specifically disclosed are: a pharmaceutical composition for treating interferon-resistant hepatitis C, which is characterized by comprising at least one component selected from the group consisting of an ω-3 polyunsaturated fatty acid, a pharmaceutically acceptable salt of the fatty acid and an ester of the fatty acid as an active ingredient; and a method for utilizing the pharmaceutical composition.

Owner:MOCHIDA PHARM CO LTD

Liquid nutrient composition for improving performance

InactiveUS20080233245A1Reduce mental fatigueRelieve physical fatigueVitamin food ingredientsFood ingredient functionsNervous systemAnti oxidant

Novel, advantageous oral compositions formulated to affect any one or combination of the following: reduce physical and mental fatigue, enhance activity, improve recovery from activity, promote muscle performance, increase energy substrates, contribute to improved antioxidant defenses (i.e., reduce oxidative stress or lipid peroxidation, conserve anti-oxidants in the sera), enhance mood, assist in preventing primary and secondary diseases associated with fatigue and muscle atrophy associated with inactivity, improve nervous system (i.e., neuronal) and musculoskeletal (i.e., increase skeletal muscle protein synthesis, increase satellite cells) health, and contribute to improvements in overall health. The compositions of the subject invention are preferably used as a replacement for a snack or meal in cases of hunger or fatigue for individuals across the broad spectrum of human function from elite athletes to those individuals compromised by aging and certain disease states.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

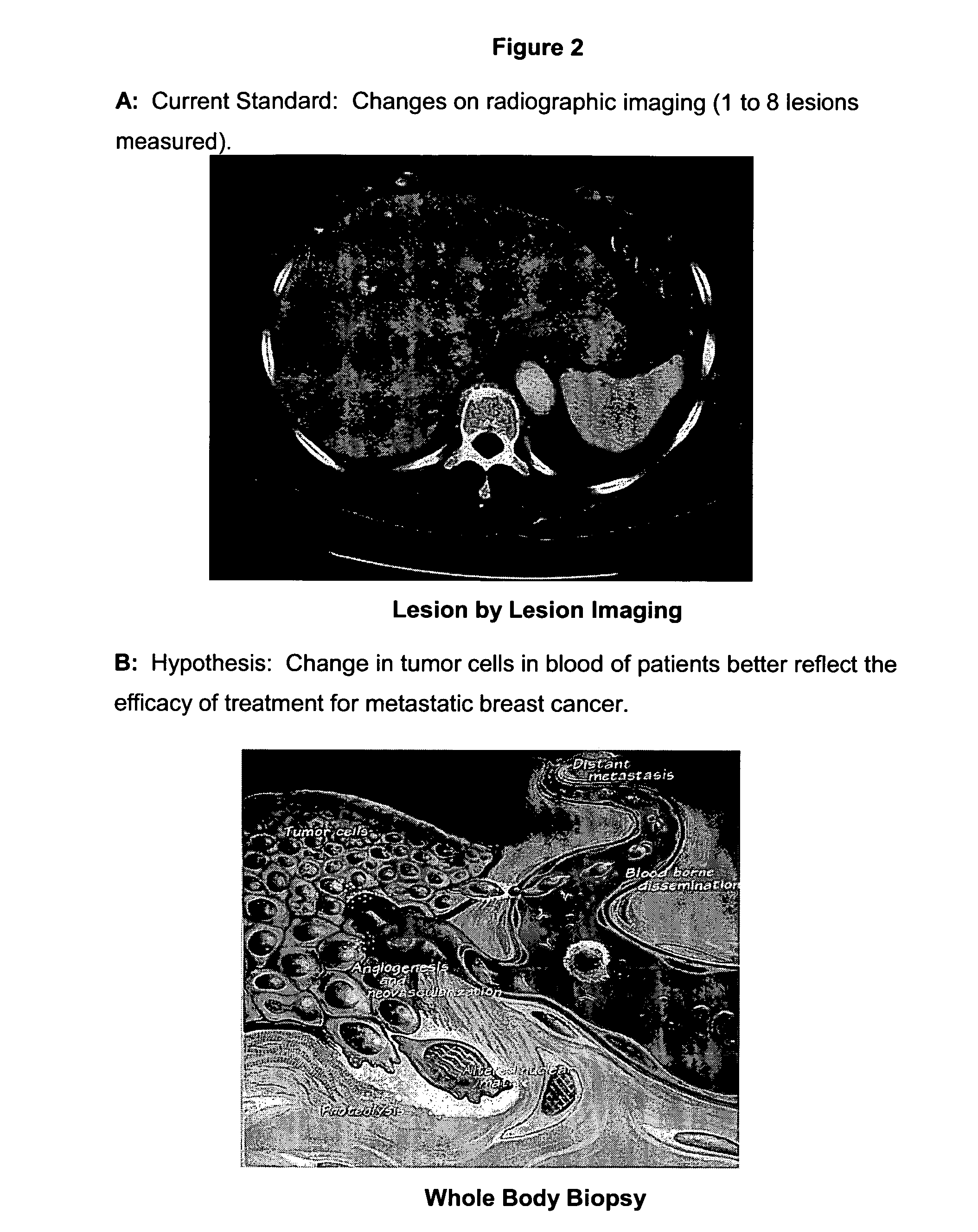

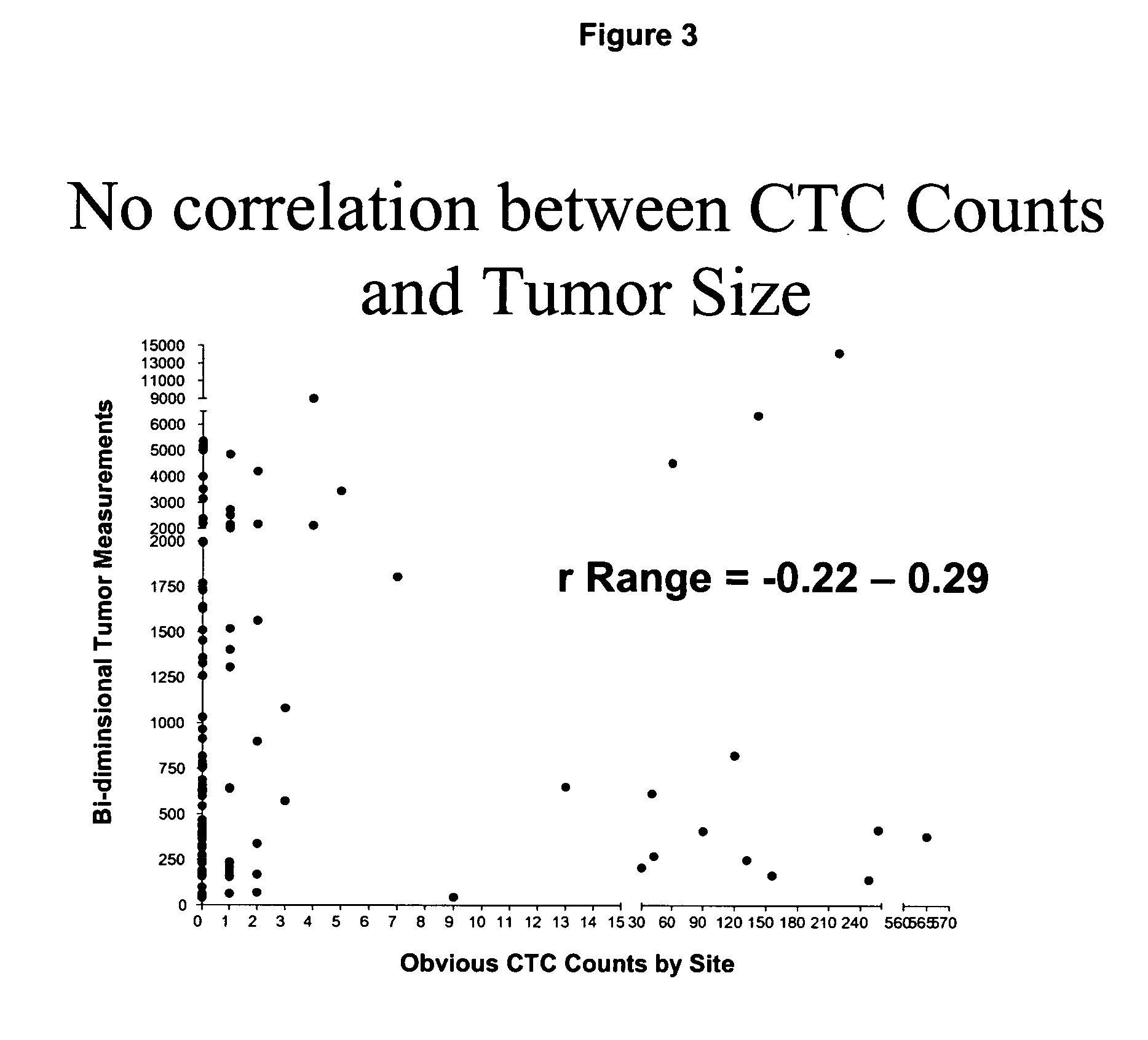

Circulating tumor cells (CTC's): early assessment of time to progression, survival and response to therapy in metastatic cancer patients

InactiveUS20070037173A1Less side effectsImprove the quality of lifeMicrobiological testing/measurementBiological testingClinical trialOncology

A cancer test having prognostic utility in predicting time to disease progression, overall survival, and response to therapy in patients with MBC based upon the presence and number of CTC's. The Cell Spotter® System is used to enumerate CTC's in blood. The system immunomagnetically concentrates epithelial cells, fluorescently labels the cells and identifies and quantifies CTC's. The absolute number of CTC's detected in the peripheral blood tumor load is, in part, a factor in prediction of survival, time to progression, and response to therapy. The mean time to survival of patients depended upon a threshold number of 5 CTC's per 7.5 ml of blood. Detection of CTC's in metastatic cancer represents a novel prognostic factor in patients with metastatic cancers, suggests a biological role for the presence of tumor cells in the blood, and indicates that the detection of CTC's could be considered an appropriate surrogate marker for prospective therapeutic clinical trials.

Owner:JANSSEN DIAGNOSTICS LLC

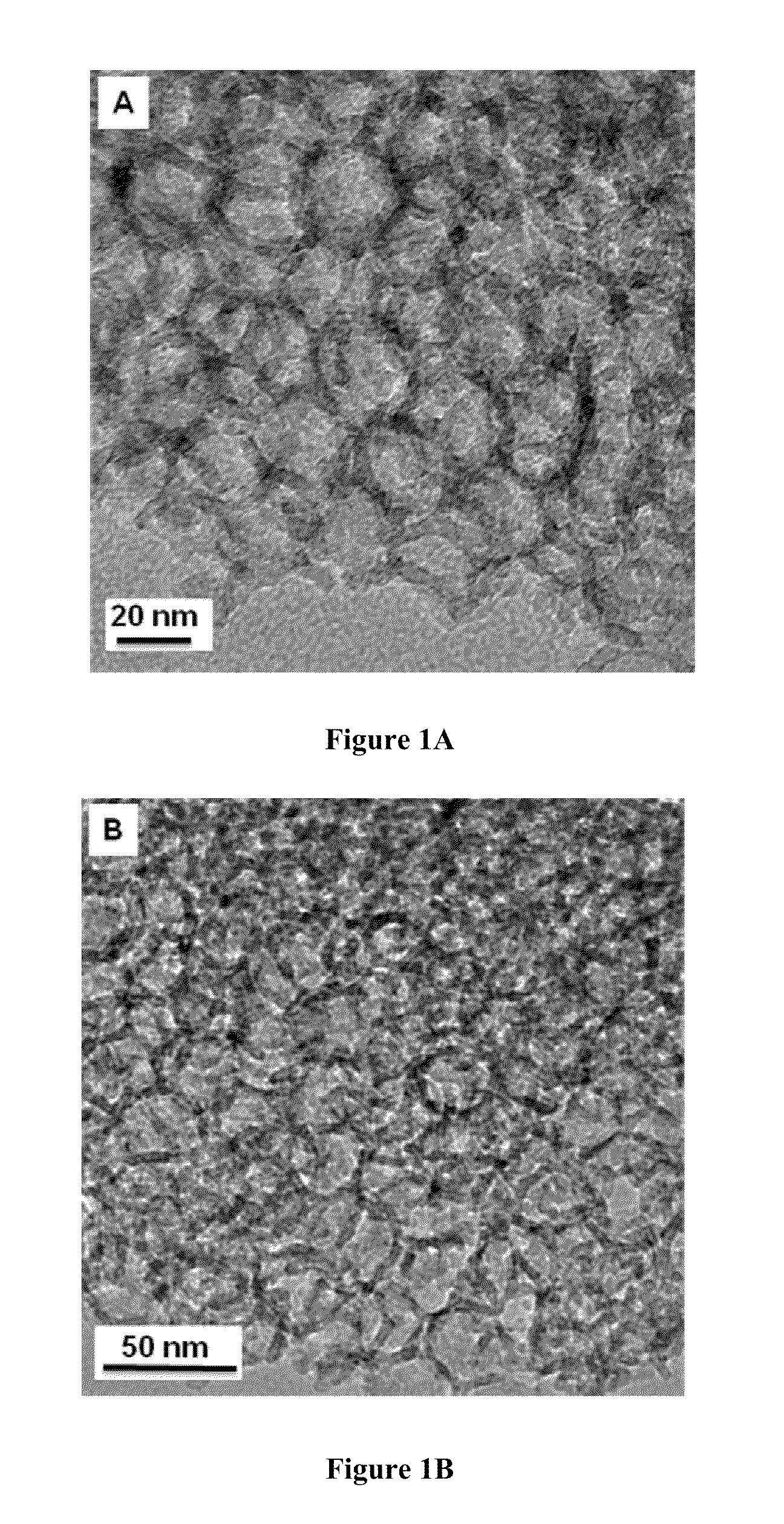

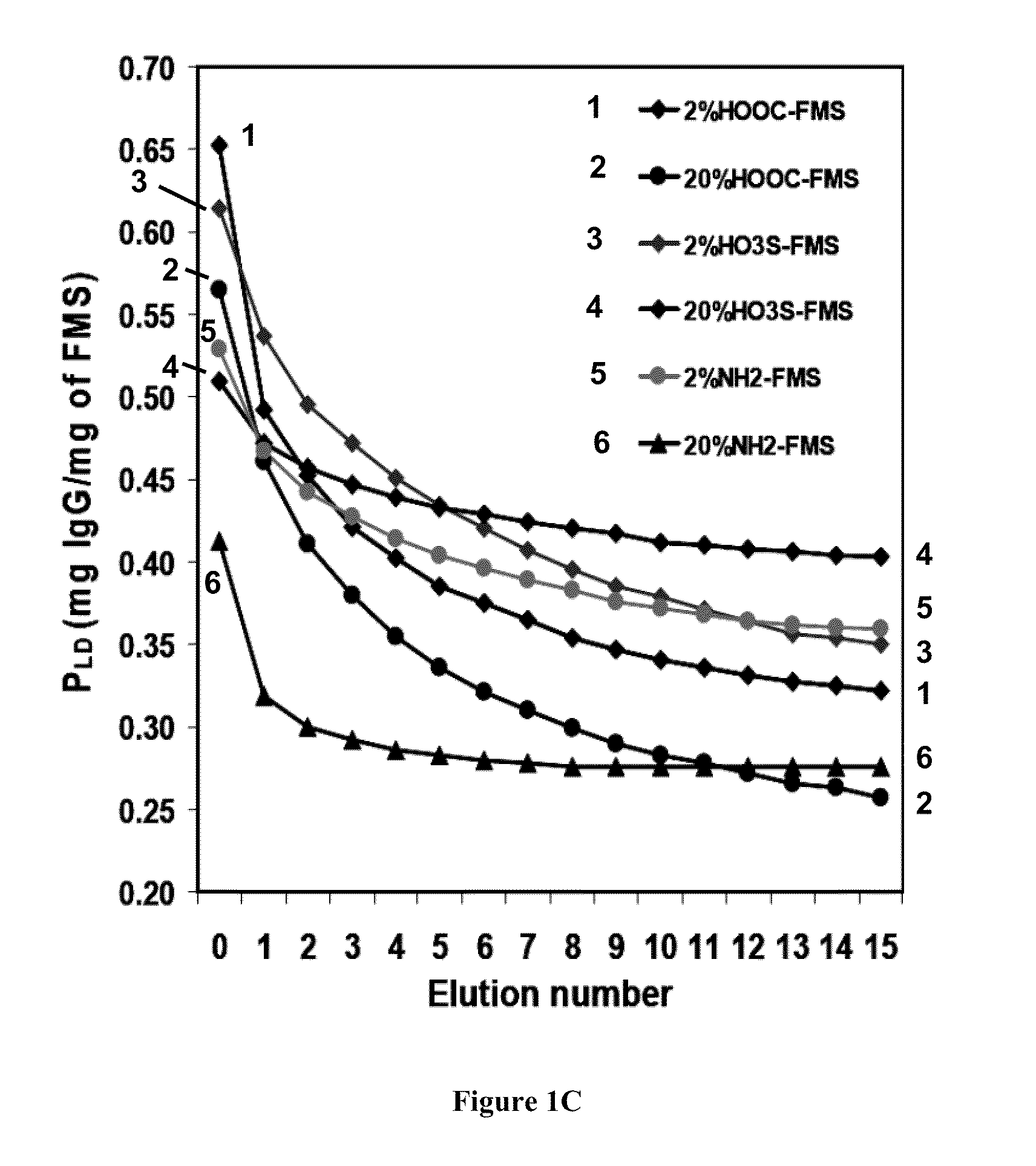

Functionalized Nano- and Micro-materials for Medical Therapies

InactiveUS20110300186A1Effective treatmentEfficient responsePowder deliveryOrganic active ingredientsActive agentDrug biological activity

Compositions containing an optionally surface-functionalized mesoporous support and a biologically active agent, and pharmaceutical compositions of the same, are provided herein. Such compositions can be useful in the treatment of tumors, for example, by injection of the composition at a location near the site of the tumor.

Owner:BATTELLE MEMORIAL INST +1

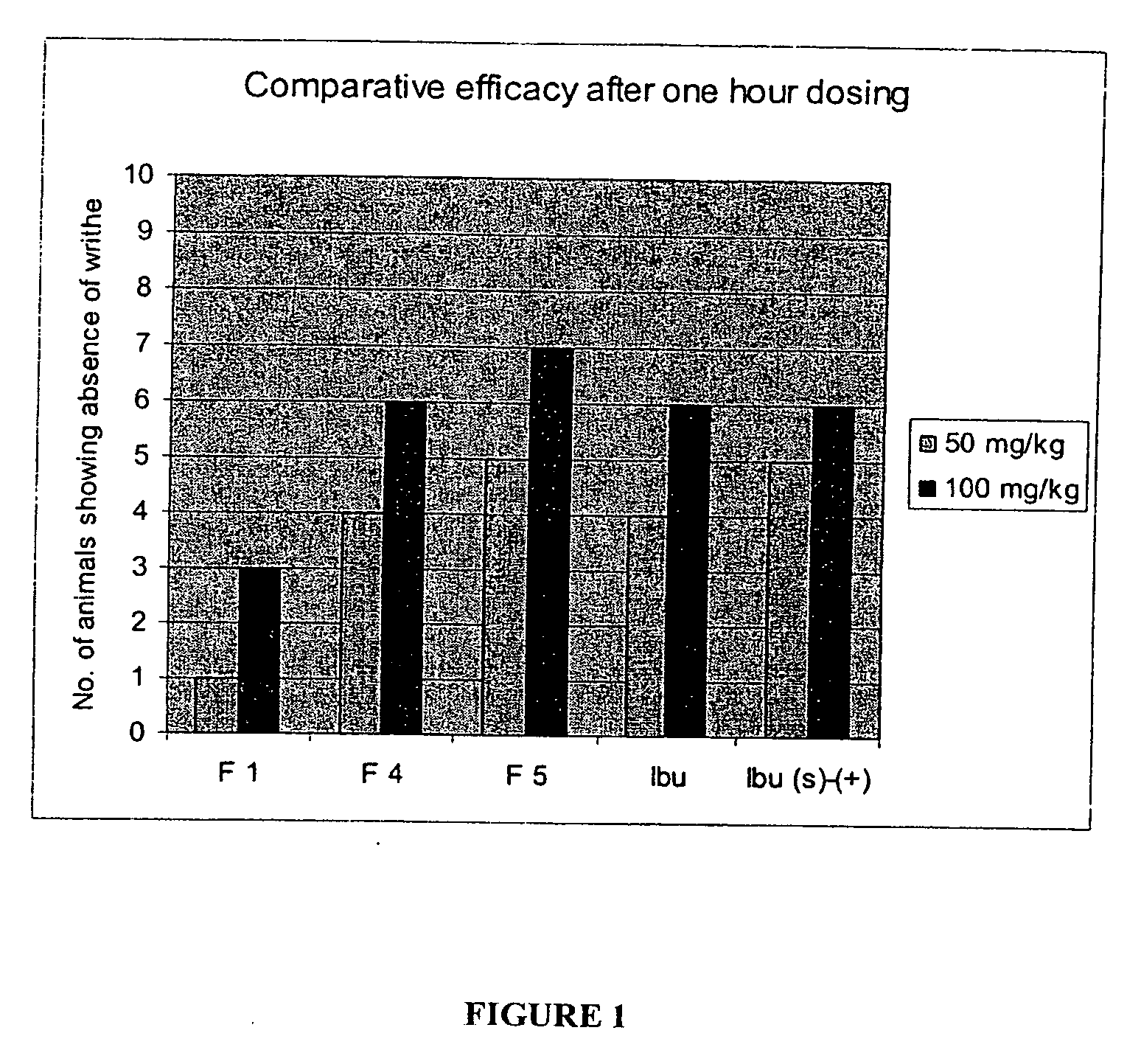

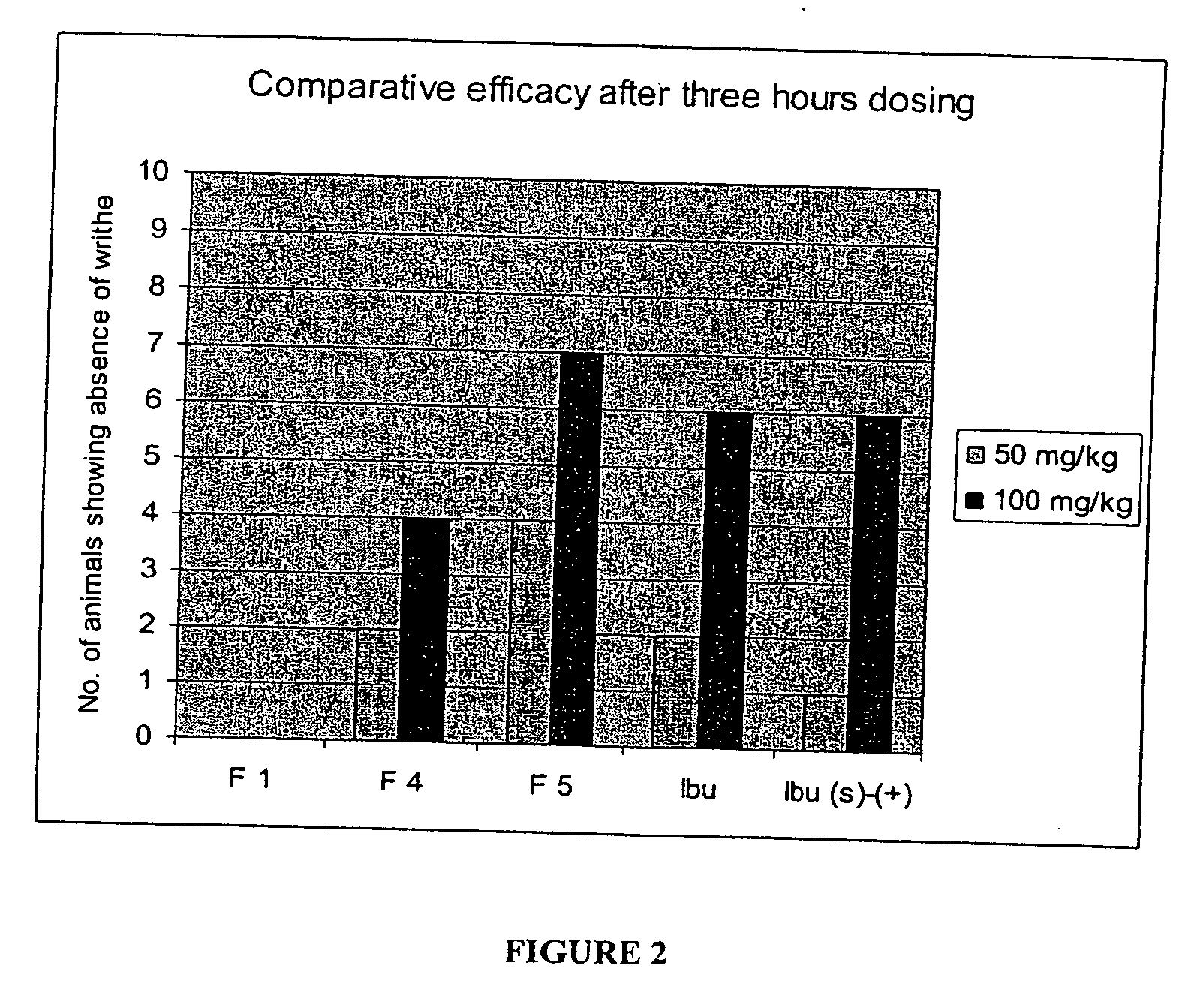

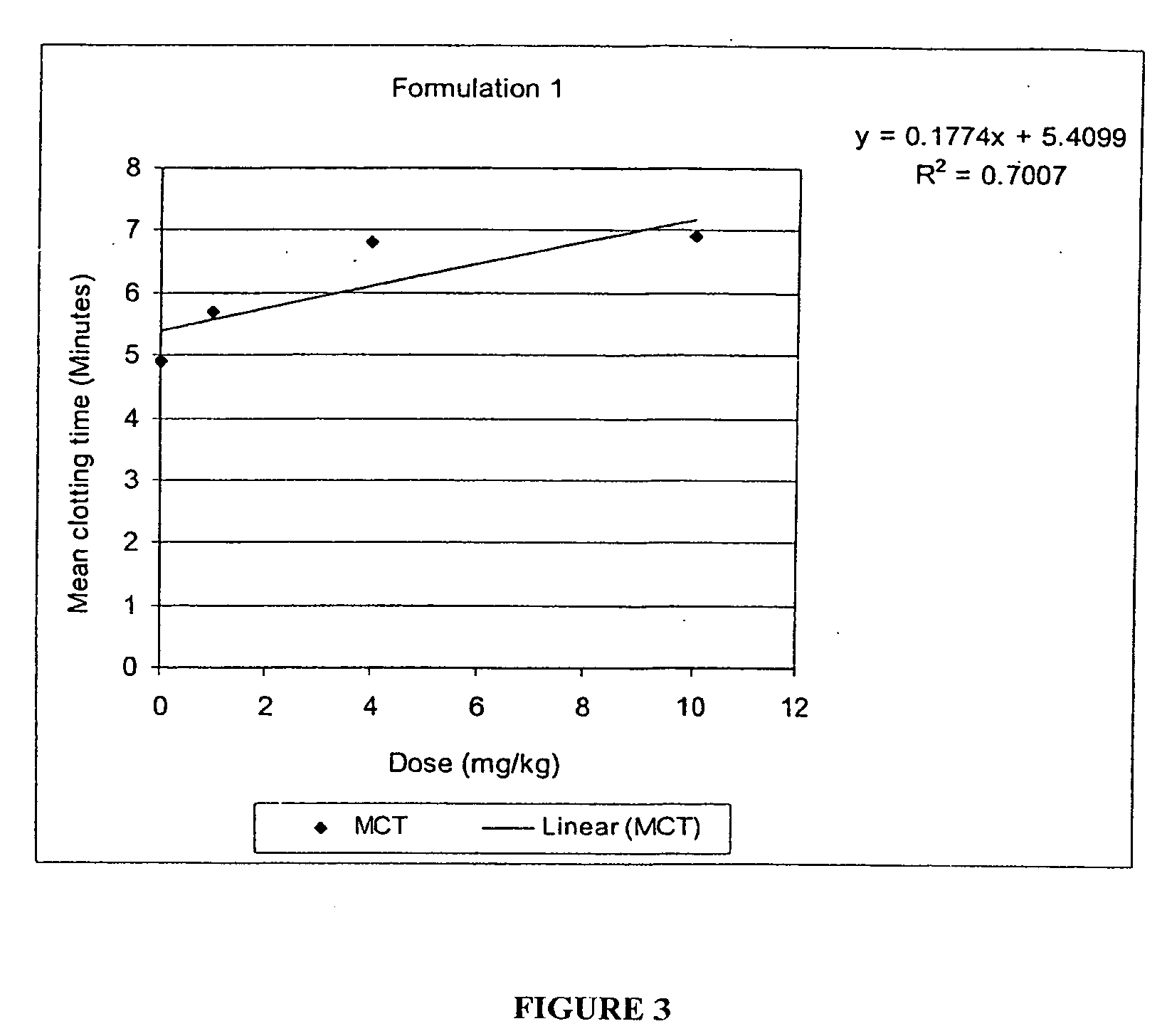

Novel compounds with high therapeutic index

ActiveUS20060241017A1Improve bioavailability and efficacyLess toxicBiocideAntipyreticAmino acid compositionCompound (substance)

The present invention is directed to novel therapeutic compounds comprised of an amino acid bonded to a medicament or drug having a hydroxy, amino, carboxy or acylating derivative thereon. These high therapeutic index derivatives have the same utility as the drug from which they are made, and they have enhanced pharmacological and pharmaceutical properties. In fact, the novel drug derivatives of the present invention enhance at least one therapeutic quality, as defined herein. The present invention is also directed to pharmaceutical compositions containing same.

Owner:SIGNATURE R & D HLDG LLC

Methods and compositions for immunomodulation

ActiveUS20170020926A1Efficient managementLess side effectsNervous disorderAntipyreticImmunomodulationsExogenous antigen

Owner:RUBIUS THERAPEUTICS

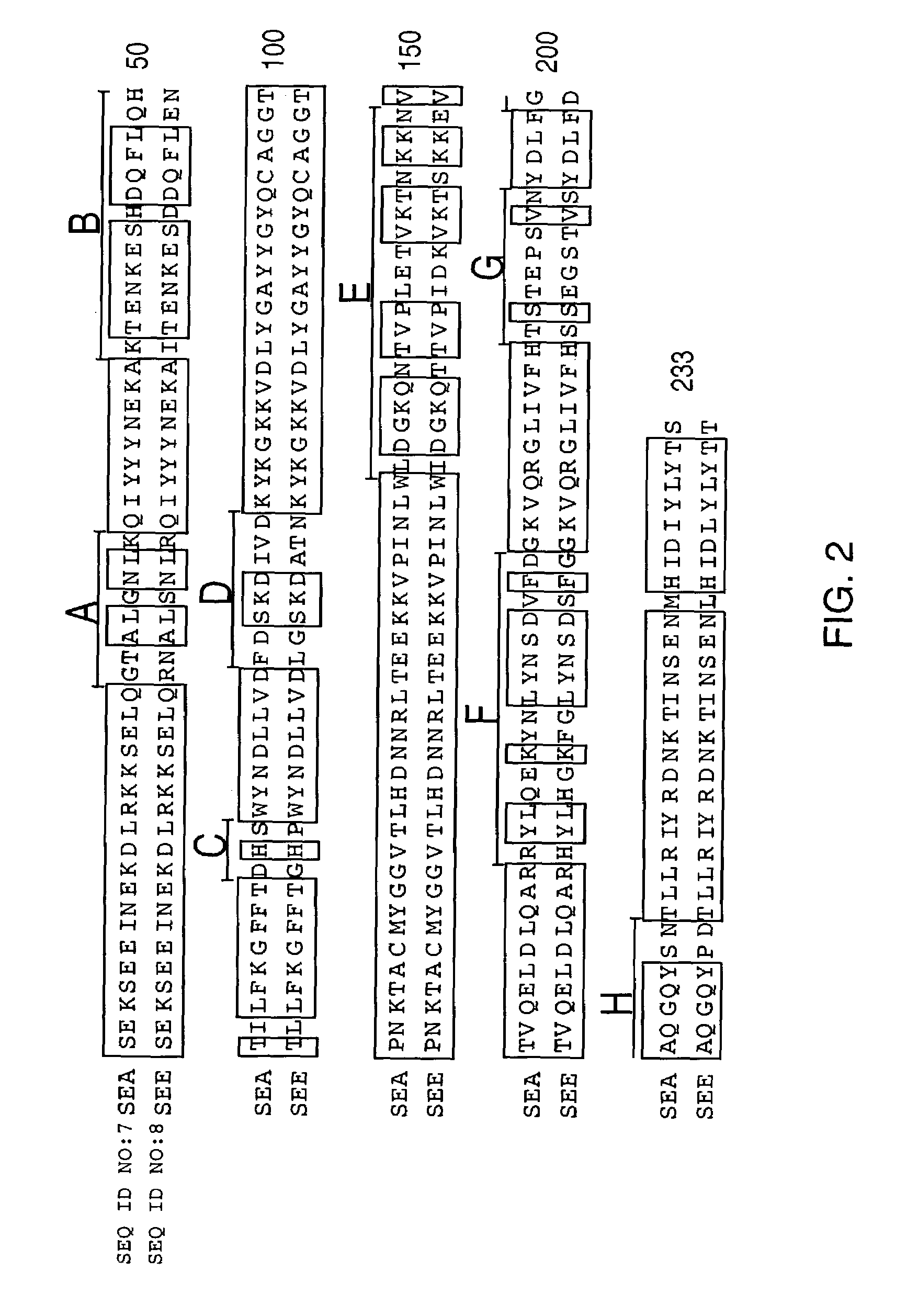

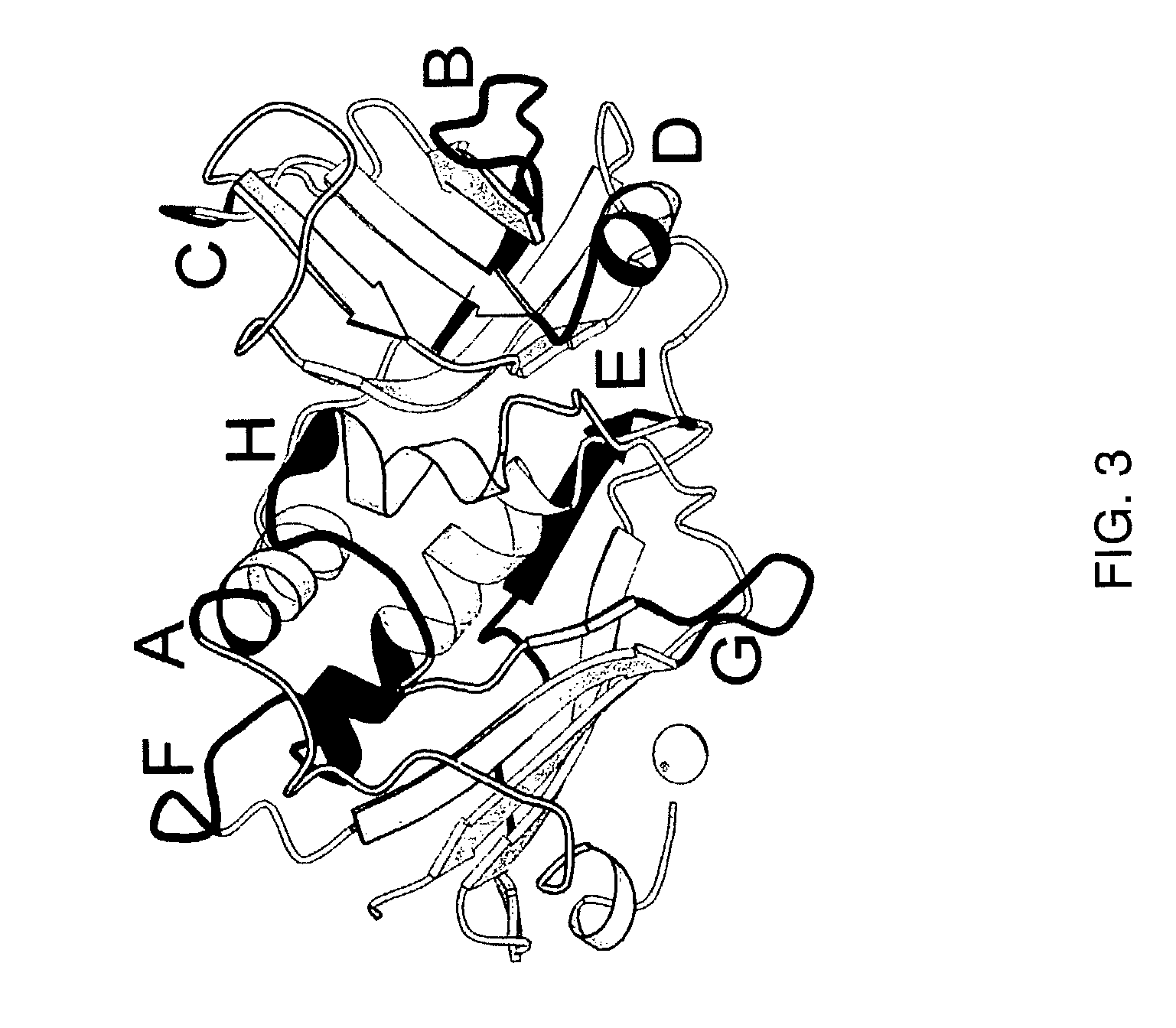

Modified Chimeric superantigens and their use

InactiveUS7226595B2Low immunogenicityReduce reduction reactionPeptide/protein ingredientsAntibody mimetics/scaffoldsAntigenCysteine thiolate

A conjugate between a target-seeking moiety and a modified superantigen, characterized in that the superantigen is a wild-type superantigen (SA I) in which an amino acid residue in a superantigen region (region I) determining binding to TCR, preferably TCRVβ, and T cell activation have been replaced by another amino acid residue while retaining the ability to activate a subset of T cells.In preferred embodiment the modified superantigen is a chimer between at least two wild-type superantigens (SA I, SA II etc) characterized in that one or more amino acid residues in a region determining binding to TCR and T cell activation have been interchanged between various wild-type superantigens.A therapeutic method making use of modified / chimeric superantigens as defined in the preceding paragraphs.An antibody preparation in which the cysteine residues that provide for interchain disulfide bonds have been mutated so as to forbid interchain disulfide bridges, preferably to serine residues, for use as pharmaceutical.

Owner:ACTIVE BIOTECH AB

Joint therapy

InactiveUS20060045904A1Reduce riskPromote resultsOrganic active ingredientsPeptide/protein ingredientsCushioningRegimen

A method for synergistically treating a joint of an animal, including introducing a cushioning agent into a joint; and introducing an enzyme or hormone adapted to stimulate cartilage production into the joint. The joint may be subjected to a compression regimen following injection of the cushioning agent and enzyme / hormone. Alternatively, the invention may include a composition for synergistically treating a joint of an animal, comprising a viscous cushioning material adapted to be introduced within a joint space to provide cushioning for the joint, and hormones dispersed through the cushioning material, the hormones operable to increase cartilage production.

Owner:ARONSON BARRY

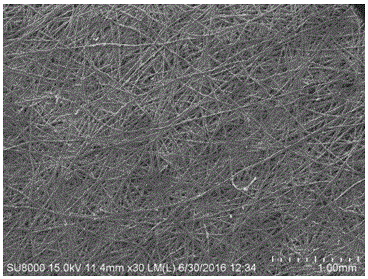

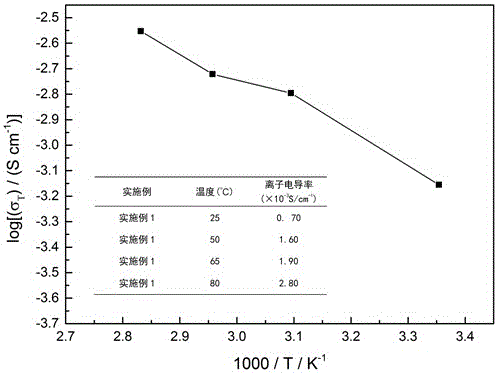

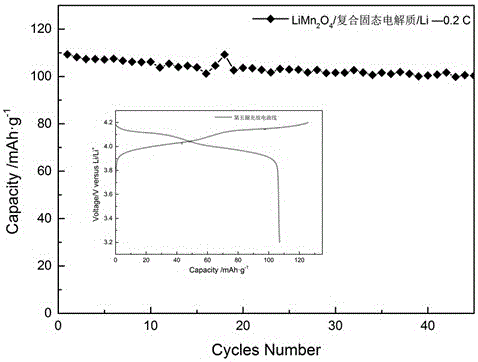

Composite solid polymer electrolyte and preparing method and application thereof

InactiveCN106299471AHigh mechanical strengthImprove thermal stabilitySolid electrolytesSecondary cellsPolymer electrolytesElectrical battery

The invention discloses a composite solid polymer electrolyte and a preparing method and application thereof. The composite solid polymer electrolyte is prepared from a gadoleic acid ester monomer, a porous supporting matrix, lithium salt, an additive and an initiator, wherein the mass ratio of the gadoleic acid ester monomer to the additive is (1-10):1, the lithium salt accounts for 5-30% of the total mass of the gadoleic acid ester monomer and the additive, and the mass ratio of the initiator to the gadoleic acid ester monomer is (1-10):100. The composite solid polymer electrolyte prepared with the method has the advantages of being large in ion conductivity, high in mechanical strength, easy to form, stable in interface contact, high in electrochemical stability and easy to prepare and can be used for forming solid lithium ion secondary batteries, and the prepared solid lithium ion secondary batteries are high in safety, energy density and production efficiency.

Owner:HARBIN INST OF TECH +1

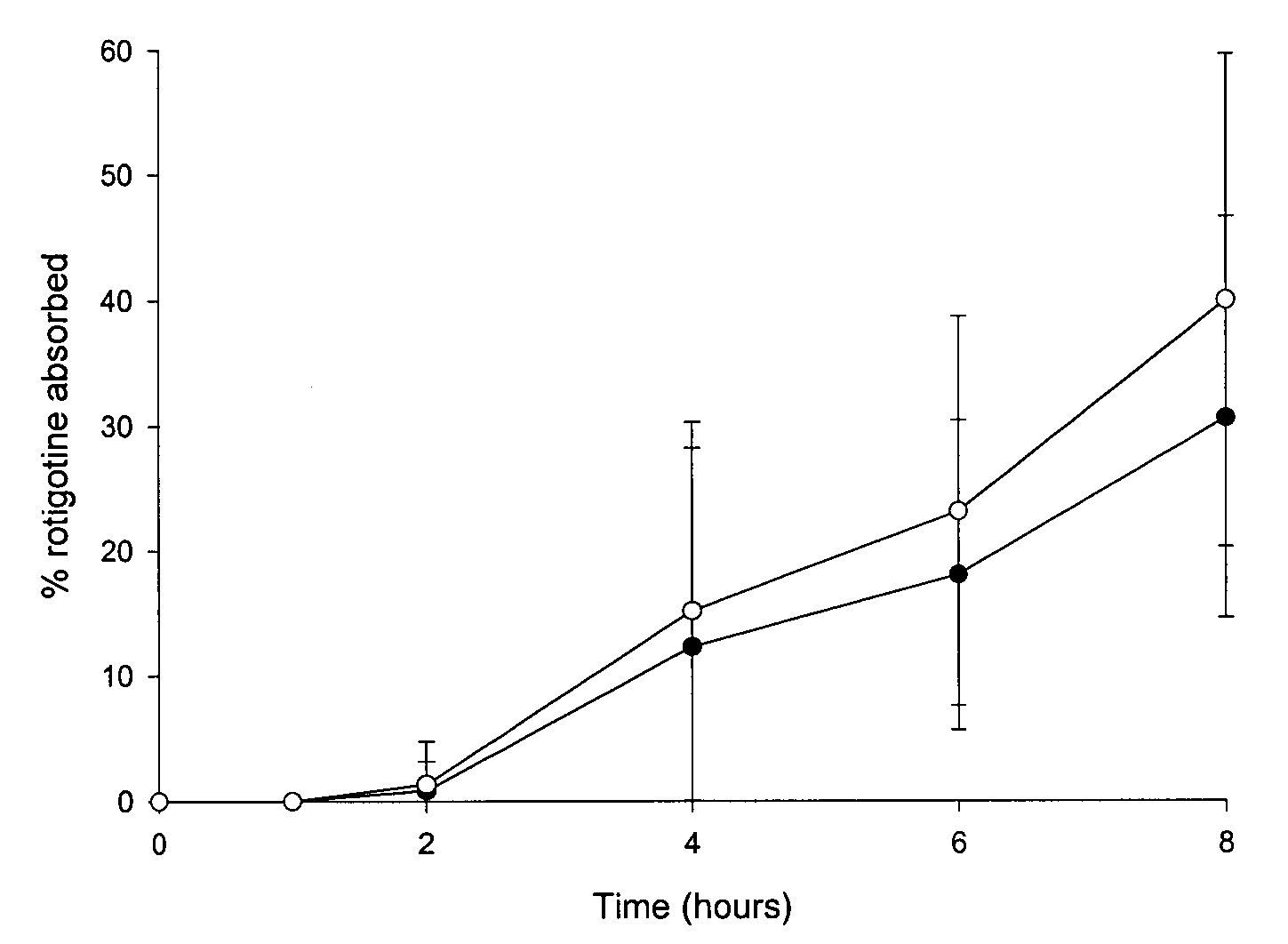

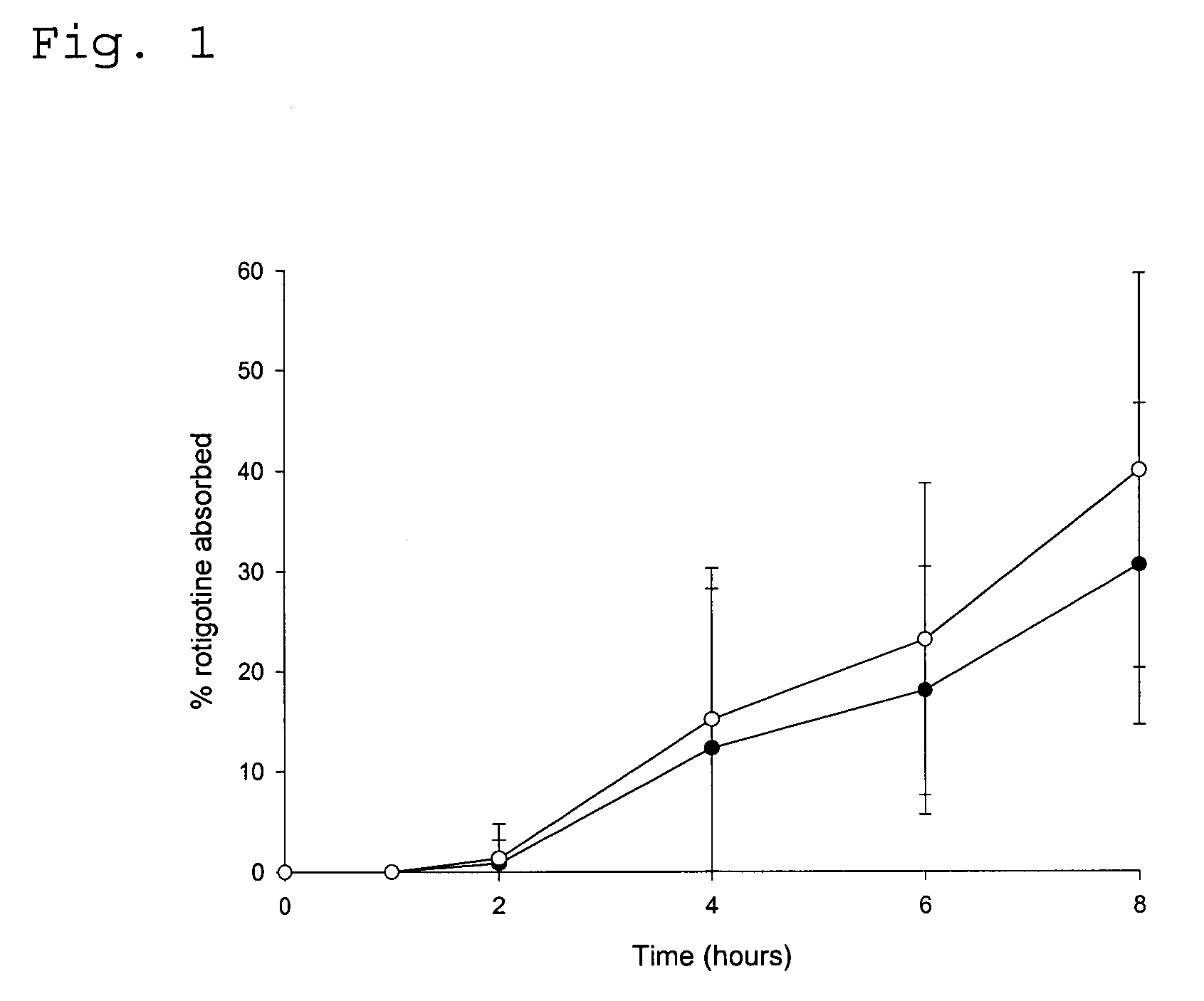

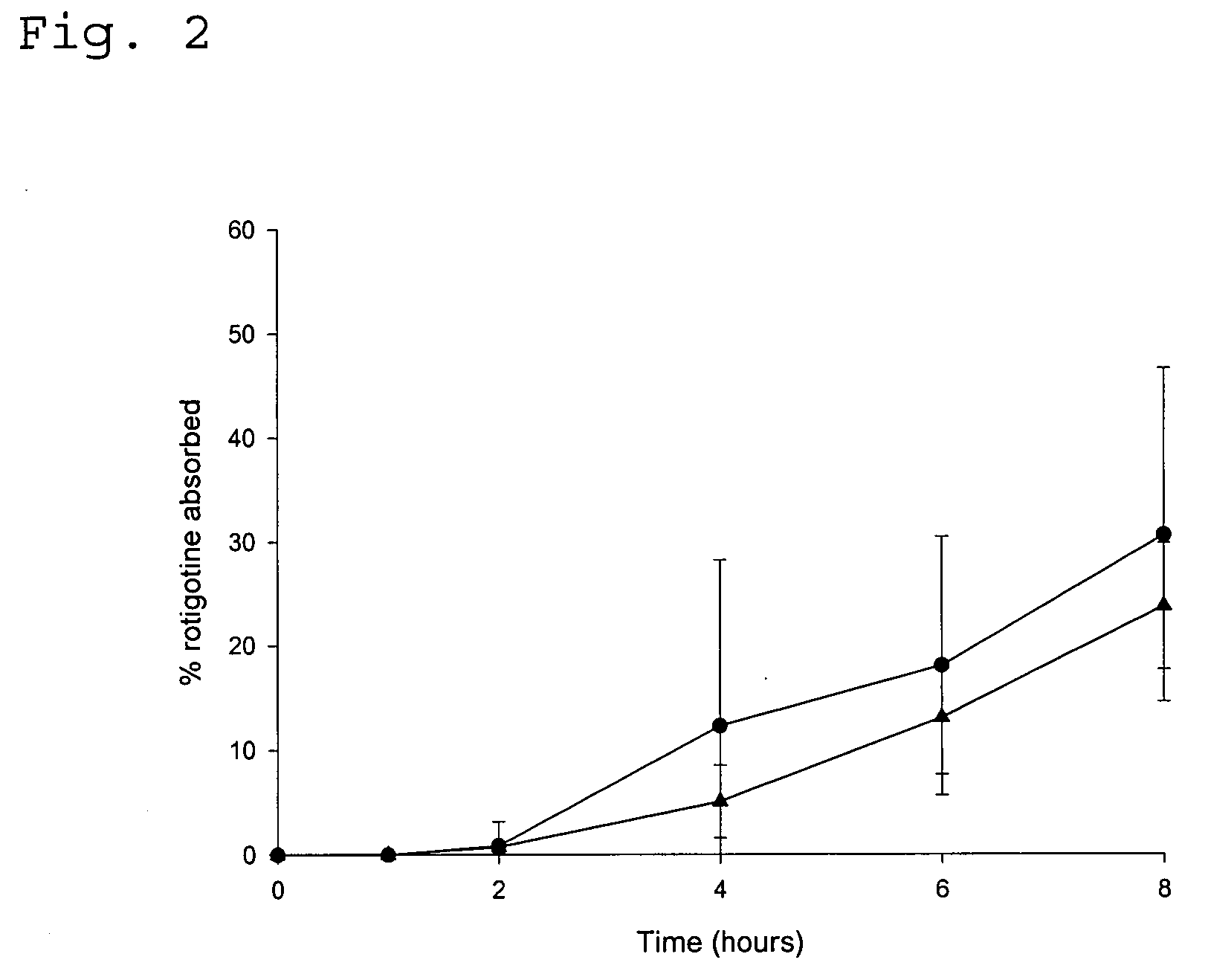

Transdermal delivery system

ActiveUS20040081683A1Facilitated releaseGood release effectPowder deliveryBiocideProtonationMedicine

An improved Transdermal Delivery System (TDS) comprising a backing layer inert to the components of the matrix, a selfadhesive matrix containing an amine-functional drug and a protective foil or sheet to be removed prior to use, characterized in that the self-adhesive matrix consists of a solid or semi-solid semi-permeable polymer (1) wherein an amine functional drug in its free base form has been incorporated, (2) which is saturated with the amine functional drug and contains said drug as a multitude of microreservoirs within the matrix, (3) which is highly permeable for the free base of the amine functional drug, (4) which is impermeable for the protonated form of the amine functional drug, (5) wherein the maximum diameter of the microreservoirs is less than the thickness of the matrix. is provided. Said TDS provides for enhanced flux of the amine functional drug across the TDS / skin interface.

Owner:UCB SA

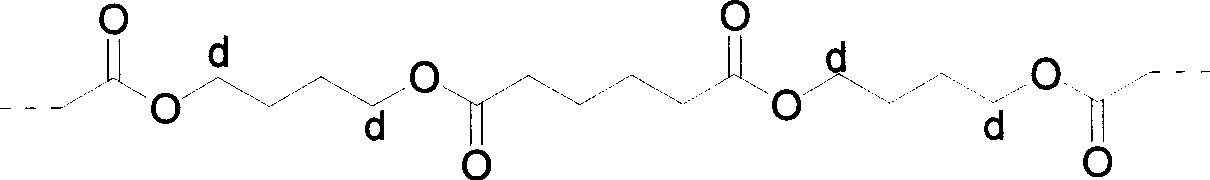

Biodegradable linear random copolyester and its preparation method and uses

ActiveCN1807485AGood colorSimple operation processMonocomponent polyesters artificial filamentPolyester coatingsCopolyesterStructural unit

The invention discloses a biodegradable linear random copolyester, its preparation method and uses, wherein the copolyester has a structural unit of (1), wherein m is an integer of 2-10, n is an integer of 0-8, p is an integer of 2-10, m, n, p are identical or different, x is an integer of 1-10, y is an integer of 1-10, the average molecular weight Mw of the copolyester is 100,000-600,000g / mol, its molecular weight distribution is 1.2-3, which is measured through GPC method. The copolyester can be widely applied into section bar, film, fabric and coating.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/aefc55e0-aaf5-4358-bb44-27968ad47e04/US20140221378A1-20140807-C00001.png)

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/aefc55e0-aaf5-4358-bb44-27968ad47e04/US20140221378A1-20140807-C00002.png)

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/aefc55e0-aaf5-4358-bb44-27968ad47e04/US20140221378A1-20140807-C00003.png)

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/eaca0958-e088-450b-a622-0be890c729fb/US20140221380A1-20140807-C00001.png)

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/eaca0958-e088-450b-a622-0be890c729fb/US20140221380A1-20140807-C00002.png)

![SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR SUBSTITUTED SPIROPYRIDO[1,2-a]PYRAZINE DERIVATIVE AND PHARMACEUTICAL USE OF SAME AS HIV INTEGRASE INHIBITOR](https://images-eureka.patsnap.com/patent_img/eaca0958-e088-450b-a622-0be890c729fb/US20140221380A1-20140807-C00003.png)