Patents

Literature

203results about How to "Multiple functions" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

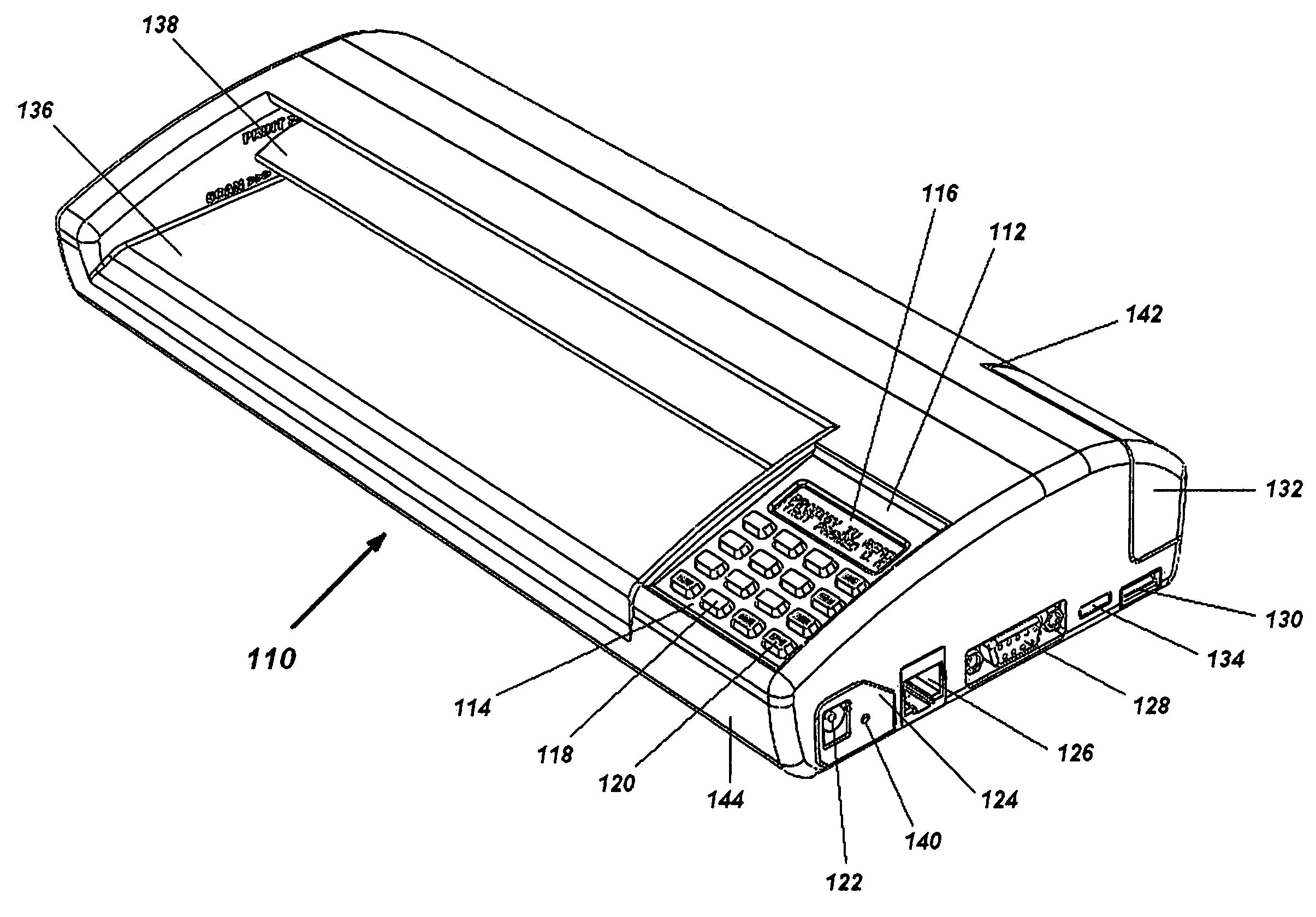

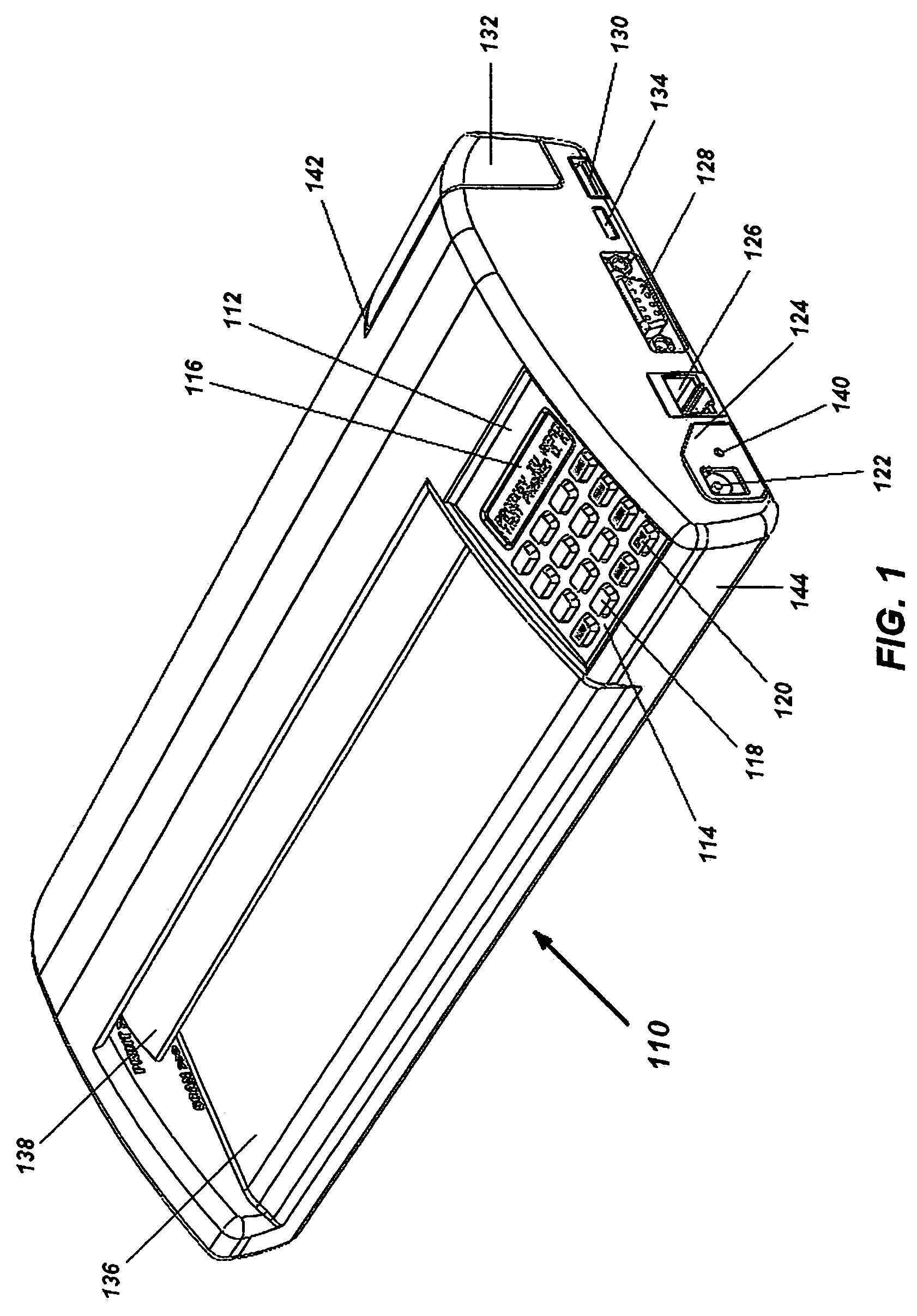

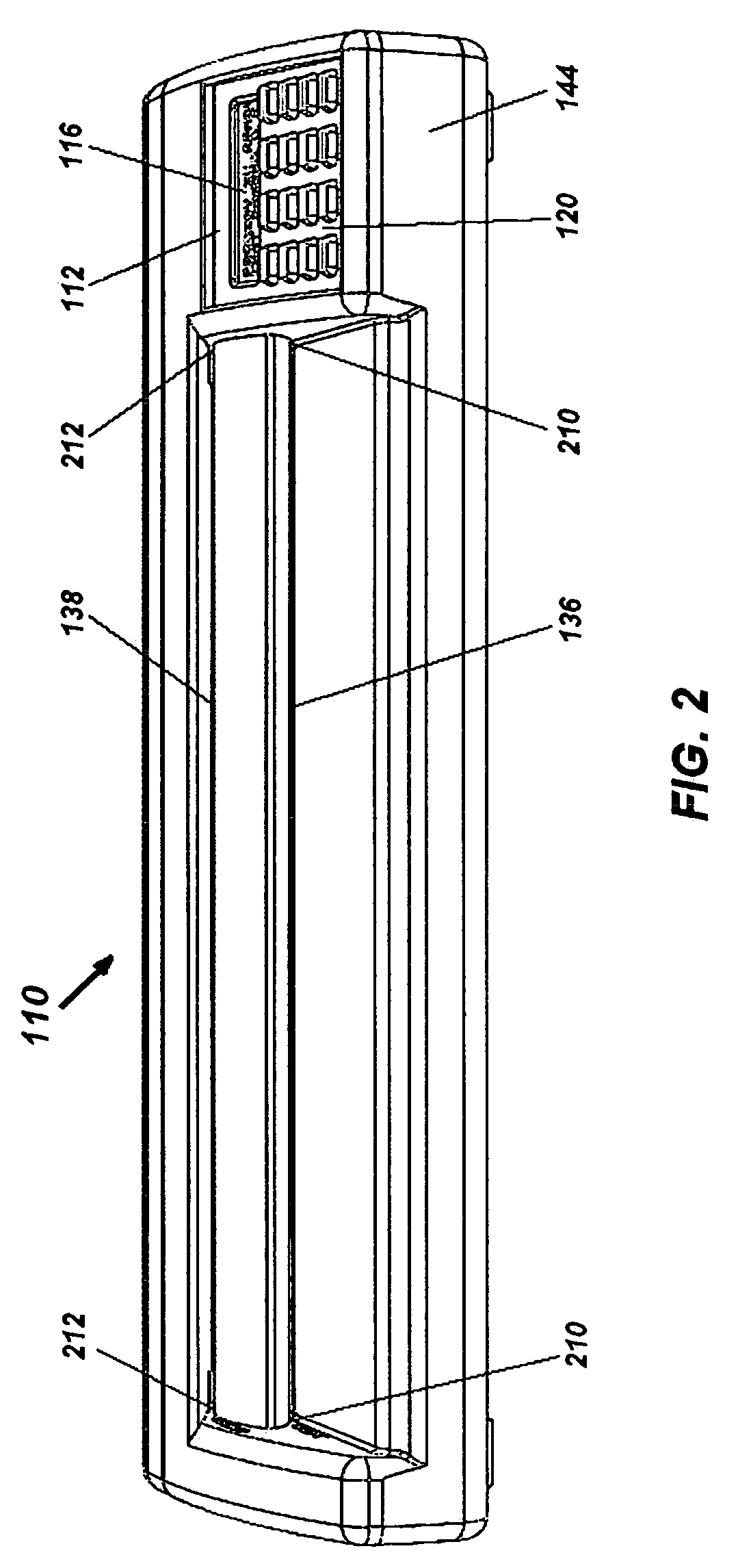

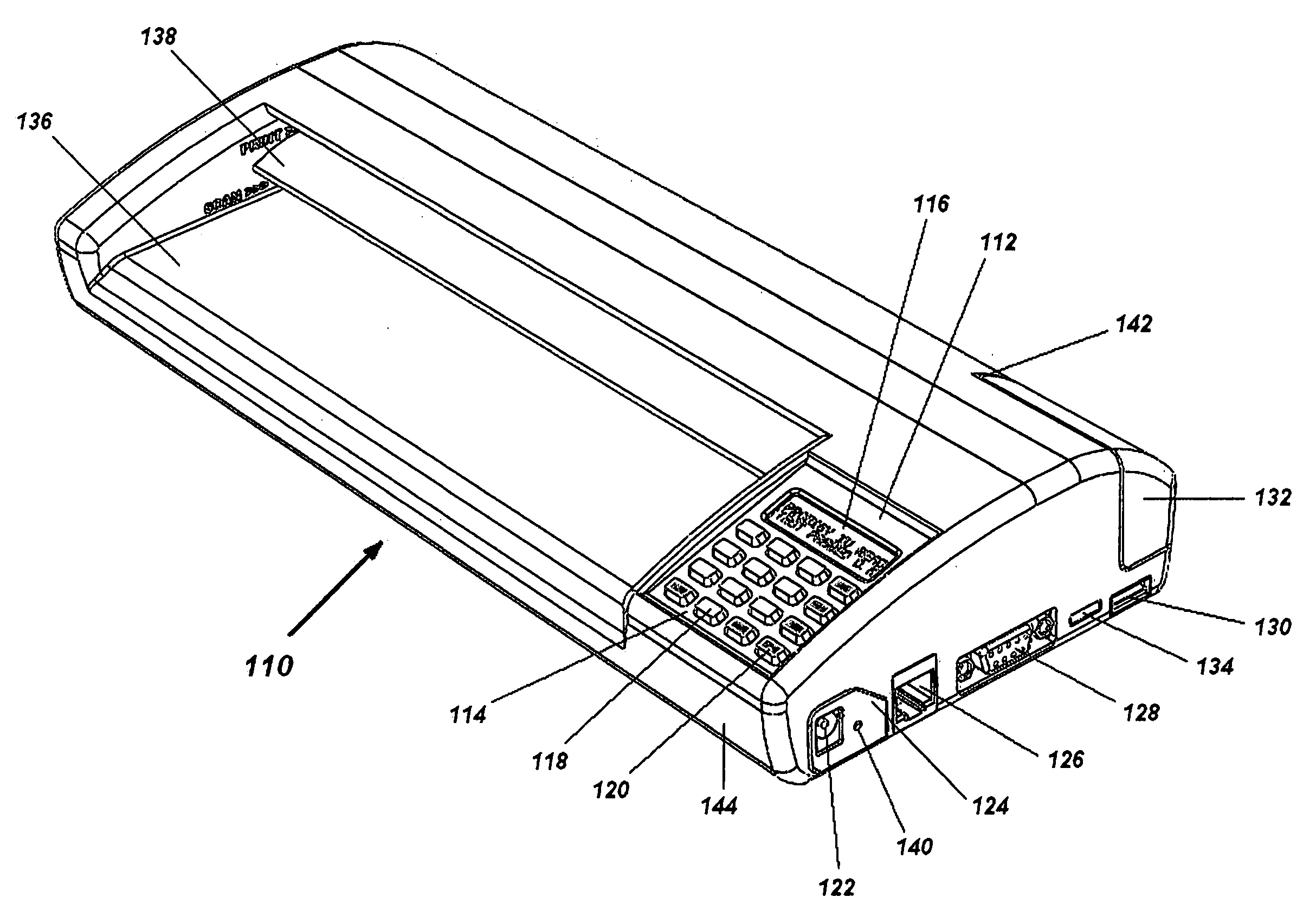

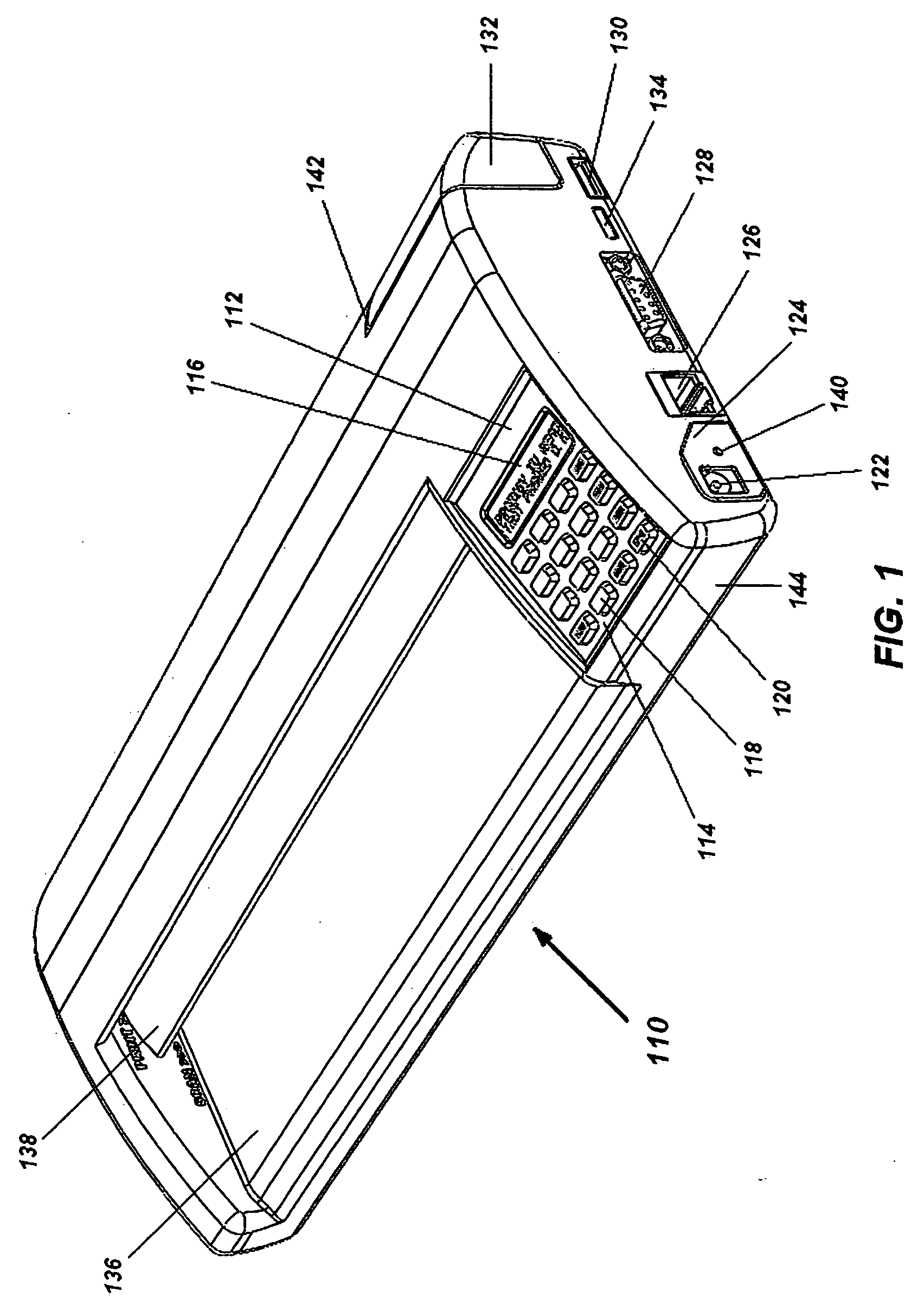

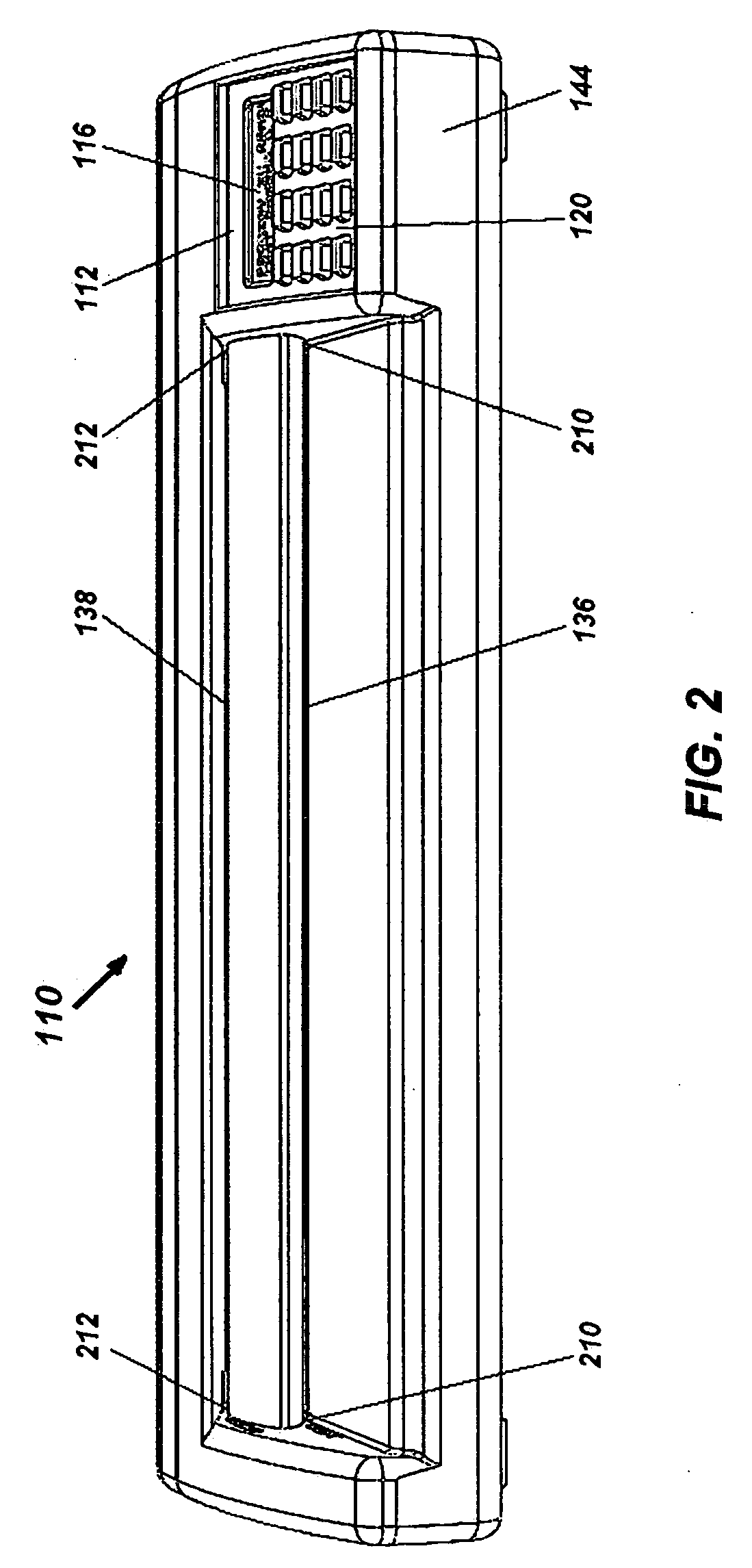

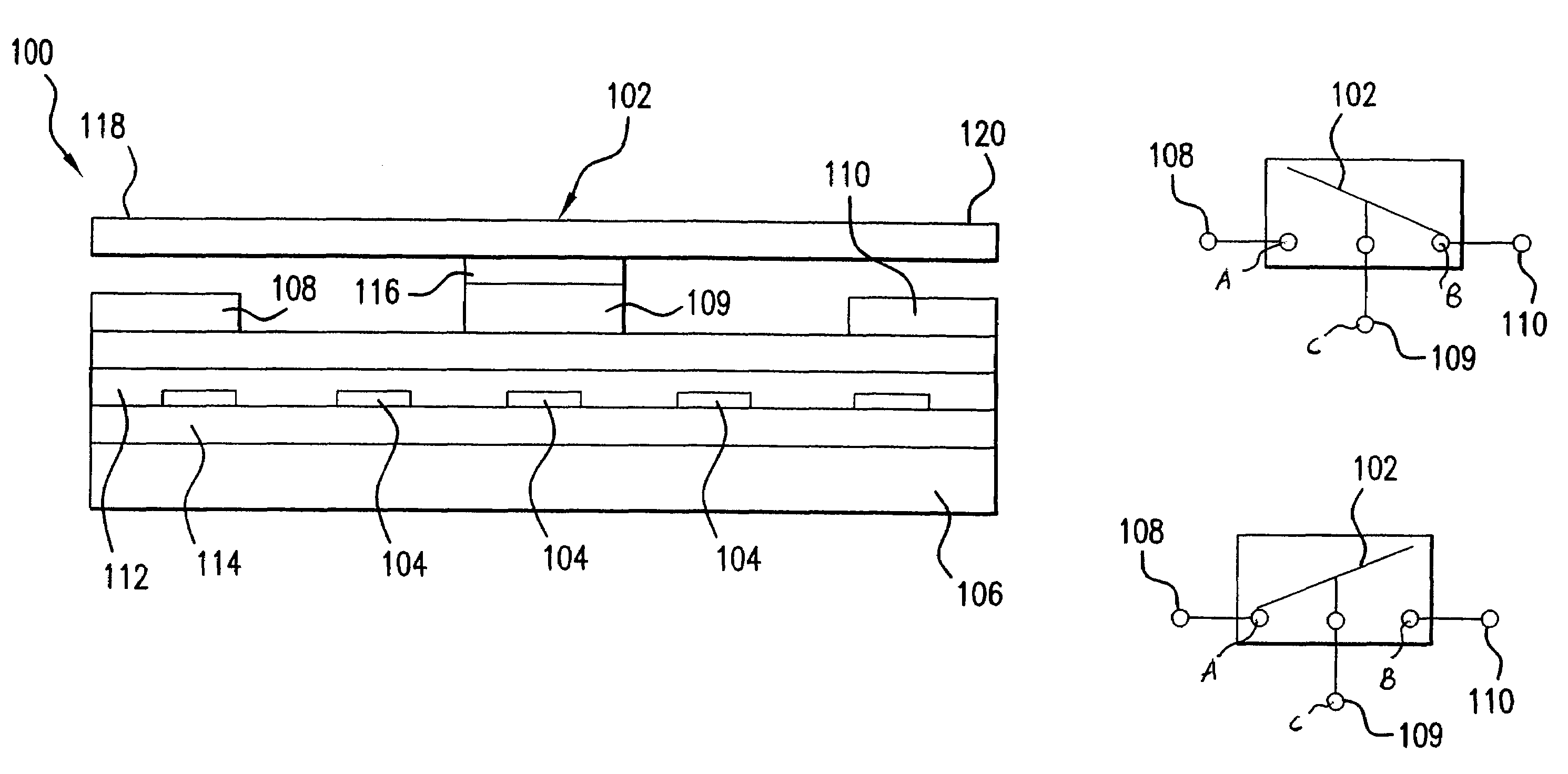

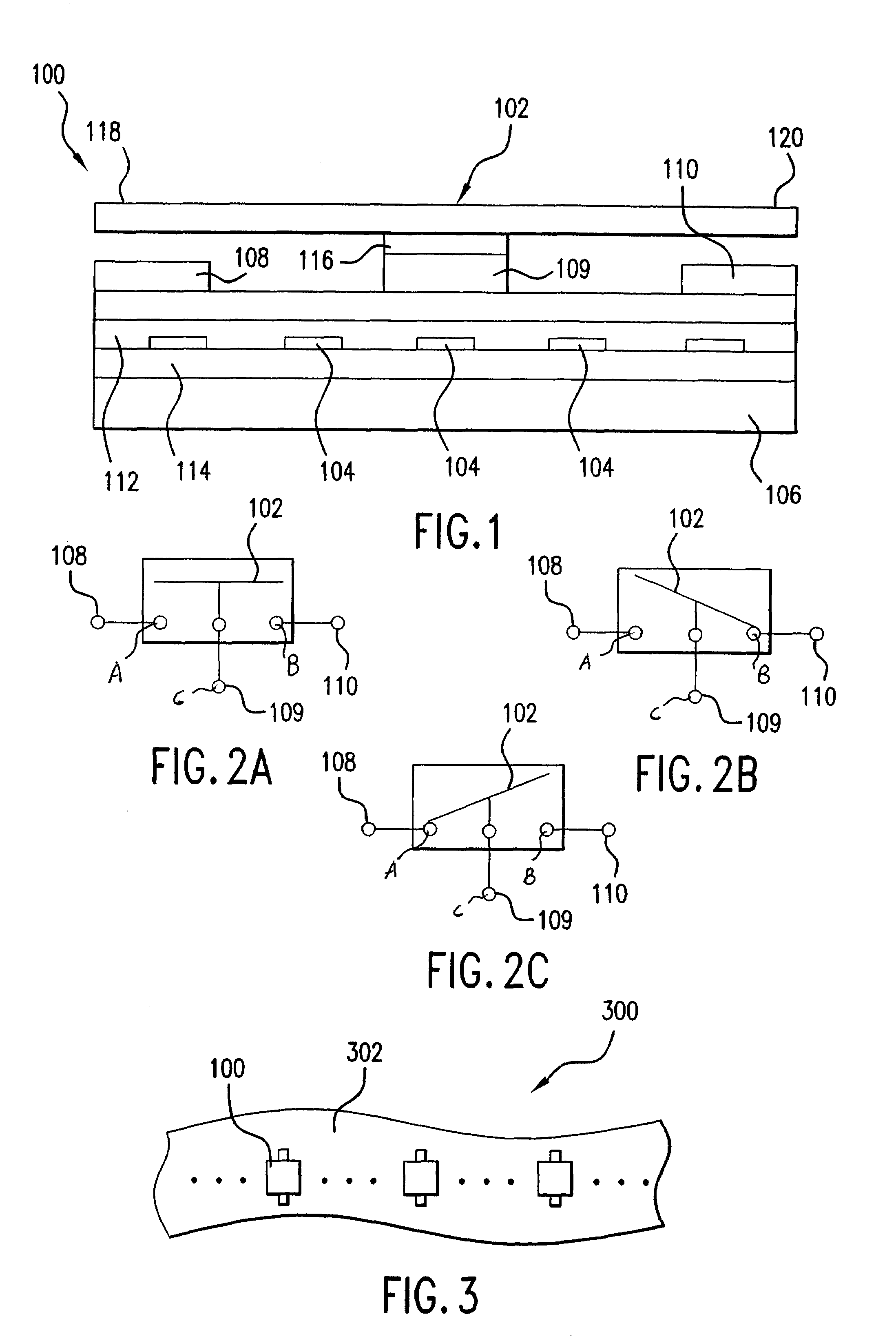

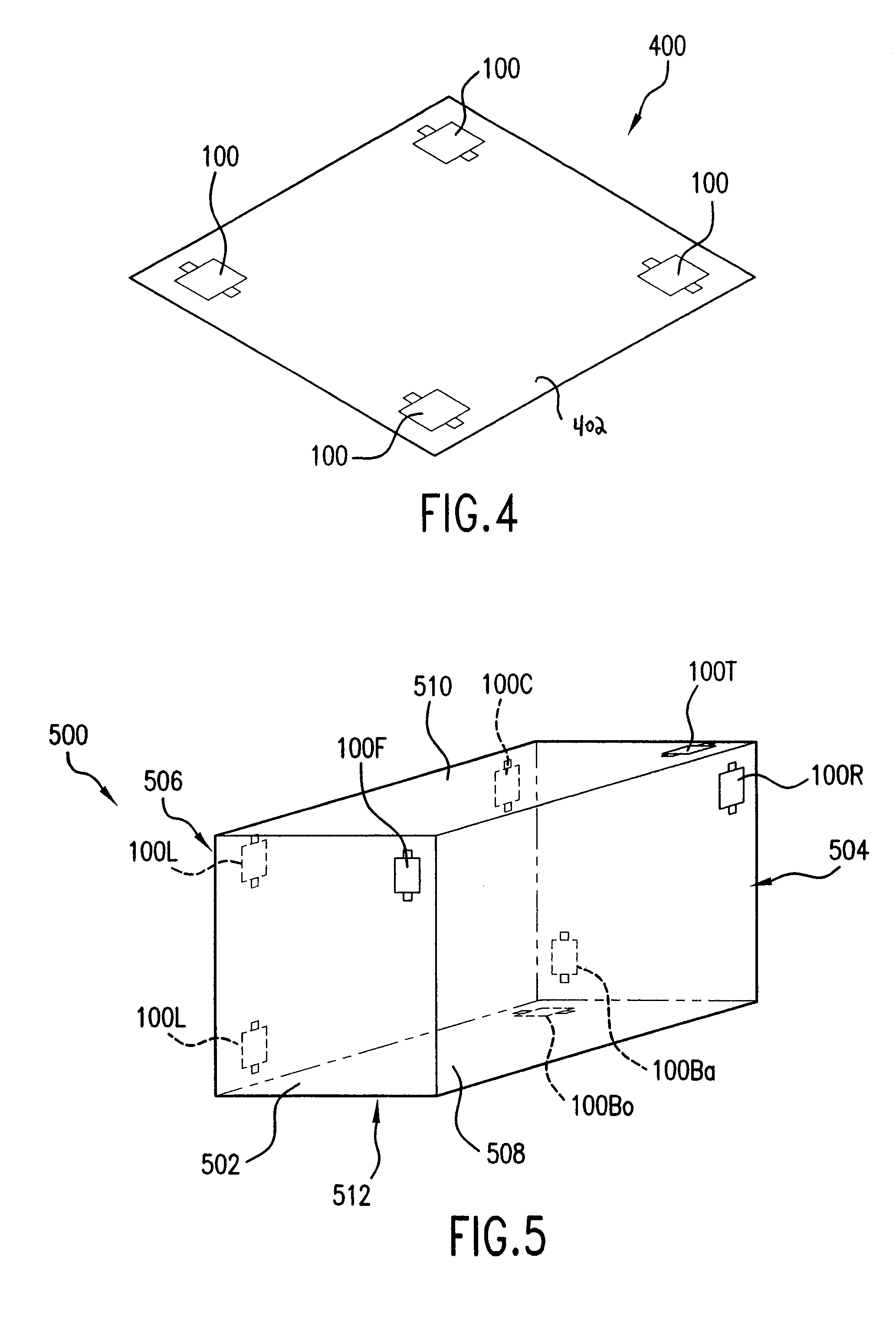

Portable electronic faxing, scanning, copying, and printing device

A lightweight, battery operated, portable, personal electronic device capable of faxing, scanning, printing and copying media as a standalone device or in cooperation with other electronic devices including PCs, mobile telephones, PDAs, etc. is provided. The device automatically detects the presence of fax-capable devices and reconfigures the software for compatibility with the fax-capable device eliminating the need for user programming. The device's ergonomic design, intrinsic physical stability, and same side paper feeds and user interface provide use in work areas having limited space. The device includes unidirectional, independent pathways for original and recording media such that paper jams are minimized. Portability is maximized through innovative power management software and hardware.

Owner:SCI FORGE

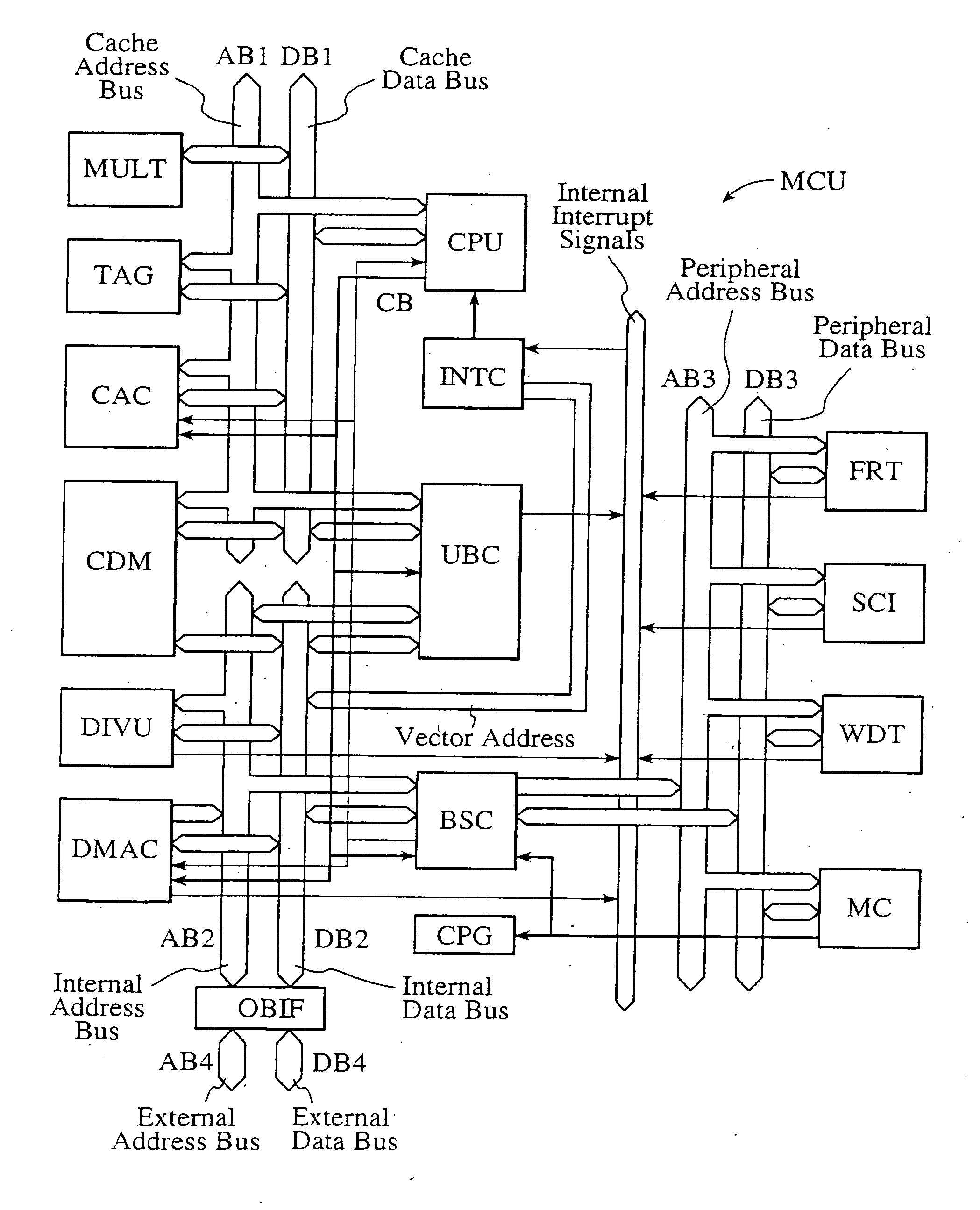

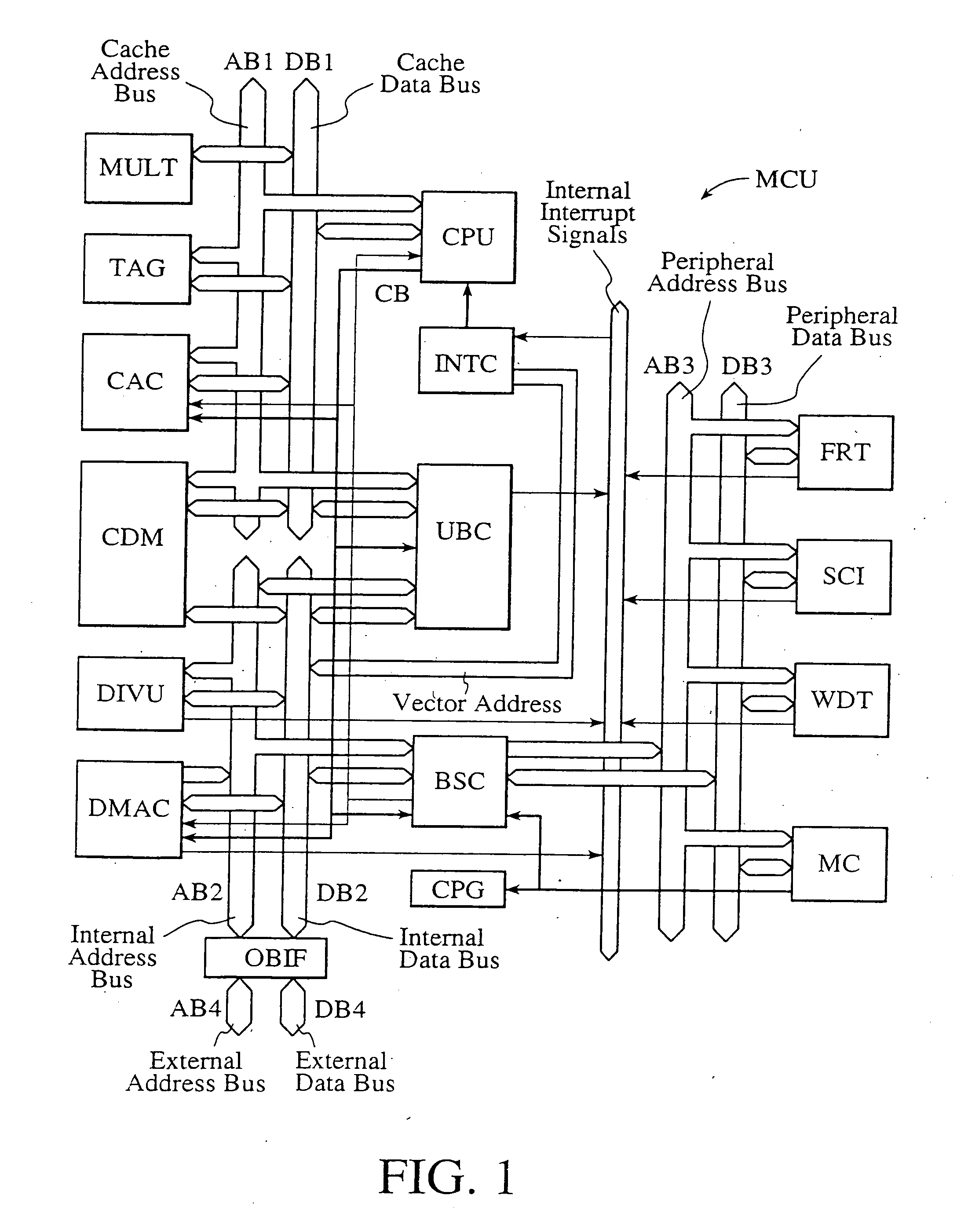

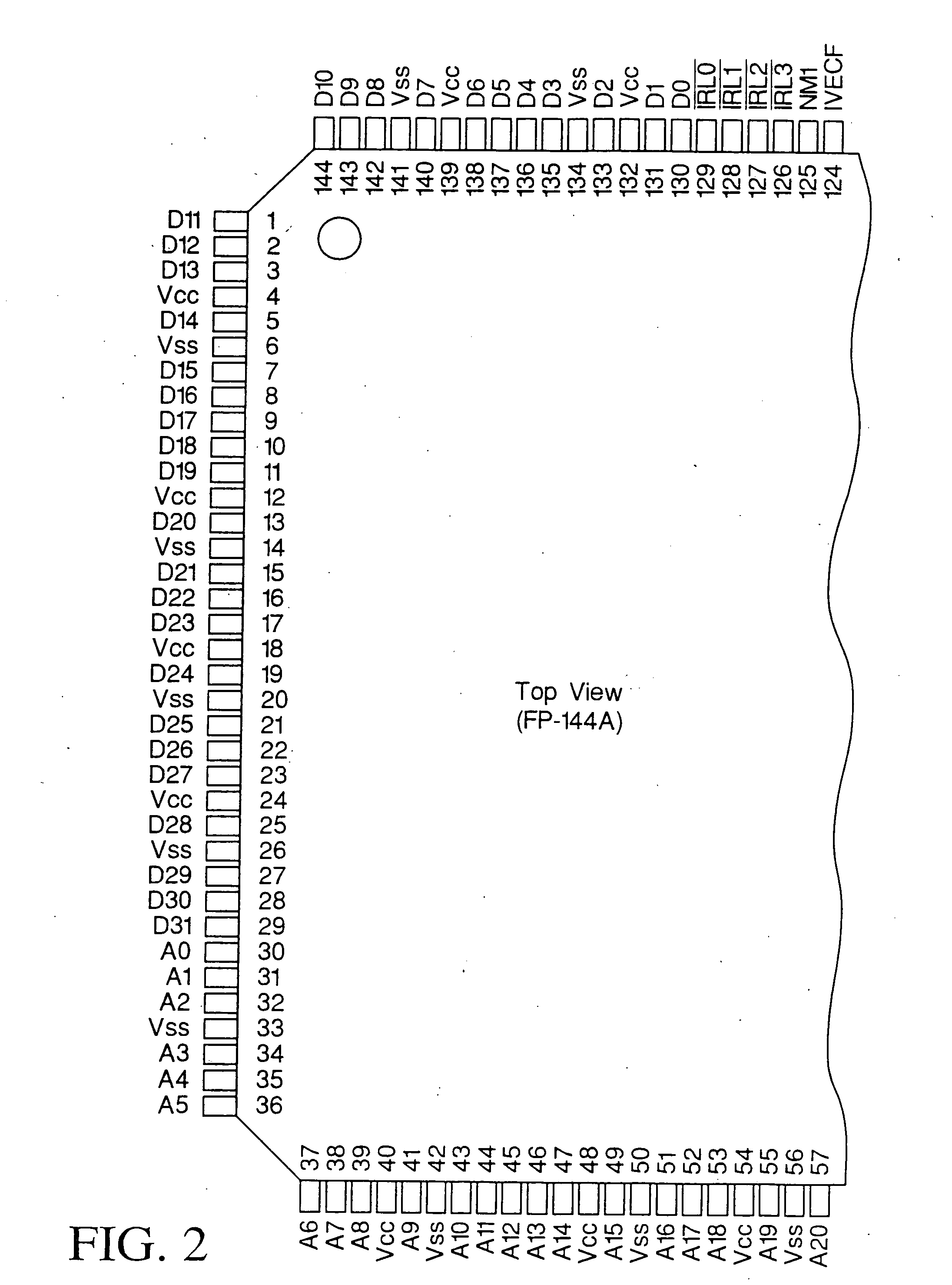

Single-chip microcomputer

InactiveUS20120023281A1Multiple functionsPerformance multiplePower managementEnergy efficient ICTMicrocontrollerMicrocomputer

A single-chip microcomputer comprising: a first bus having a central processing unit and a cache memory connected therewith; a second bus having a dynamic memory access control circuit and an external bus interface connected therewith; a break controller for connecting the first bus and the second bus selectively; a third bus having a peripheral module connected therewith and having a lower-speed bus cycle than the bus cycles of the first and second buses; and a bus state controller for effecting a data transfer and a synchronization between the second bus and the third bus. The single-chip microcomputer has the three divided internal buses to reduce the load capacity upon the signal transmission paths so that the signal transmission can be accomplished at a high speed. Moreover, the peripheral module required to have no operation speed is isolated so that the power dissipation can be reduced.

Owner:KAWASAKI SHUMPEI +8

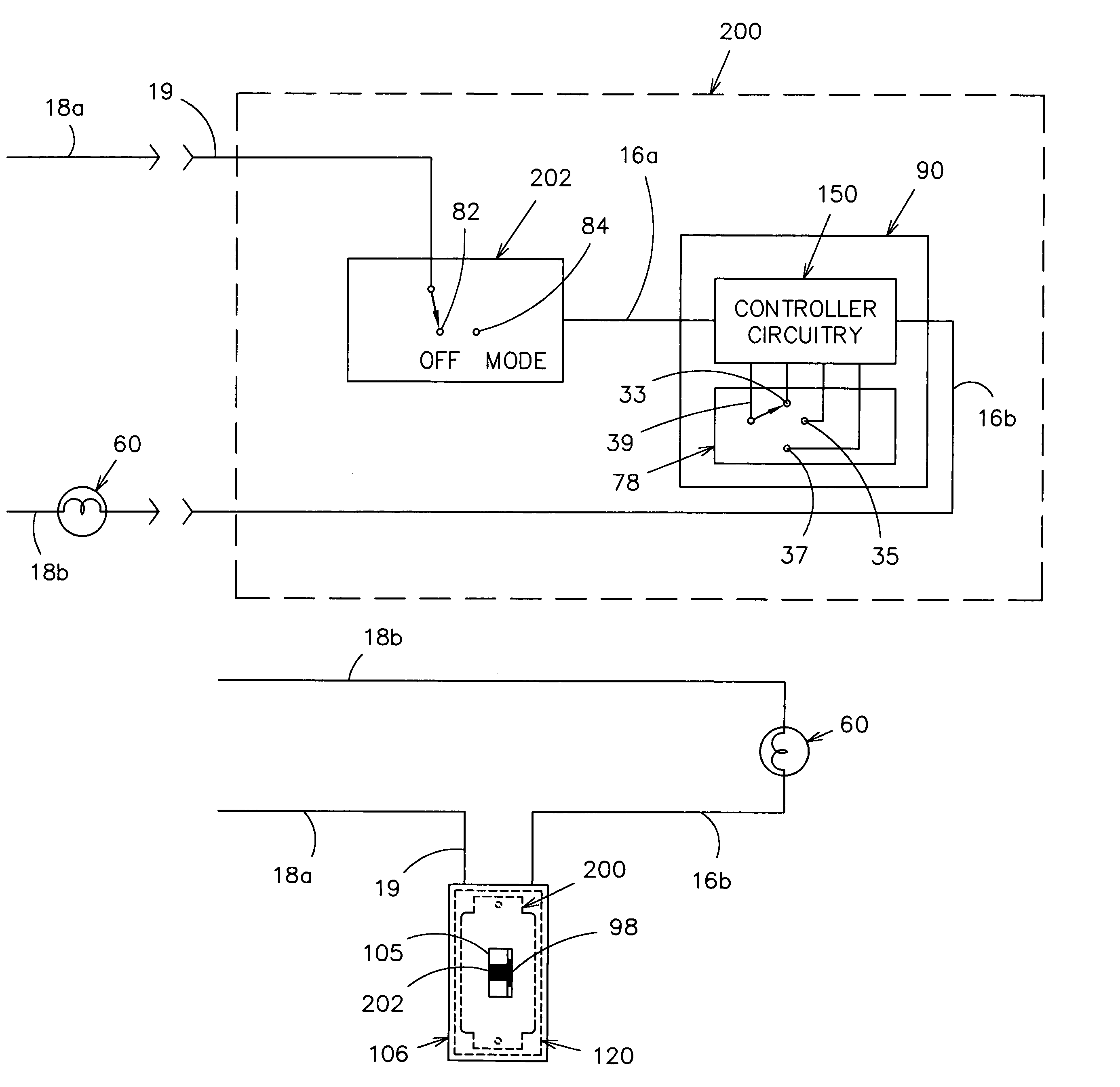

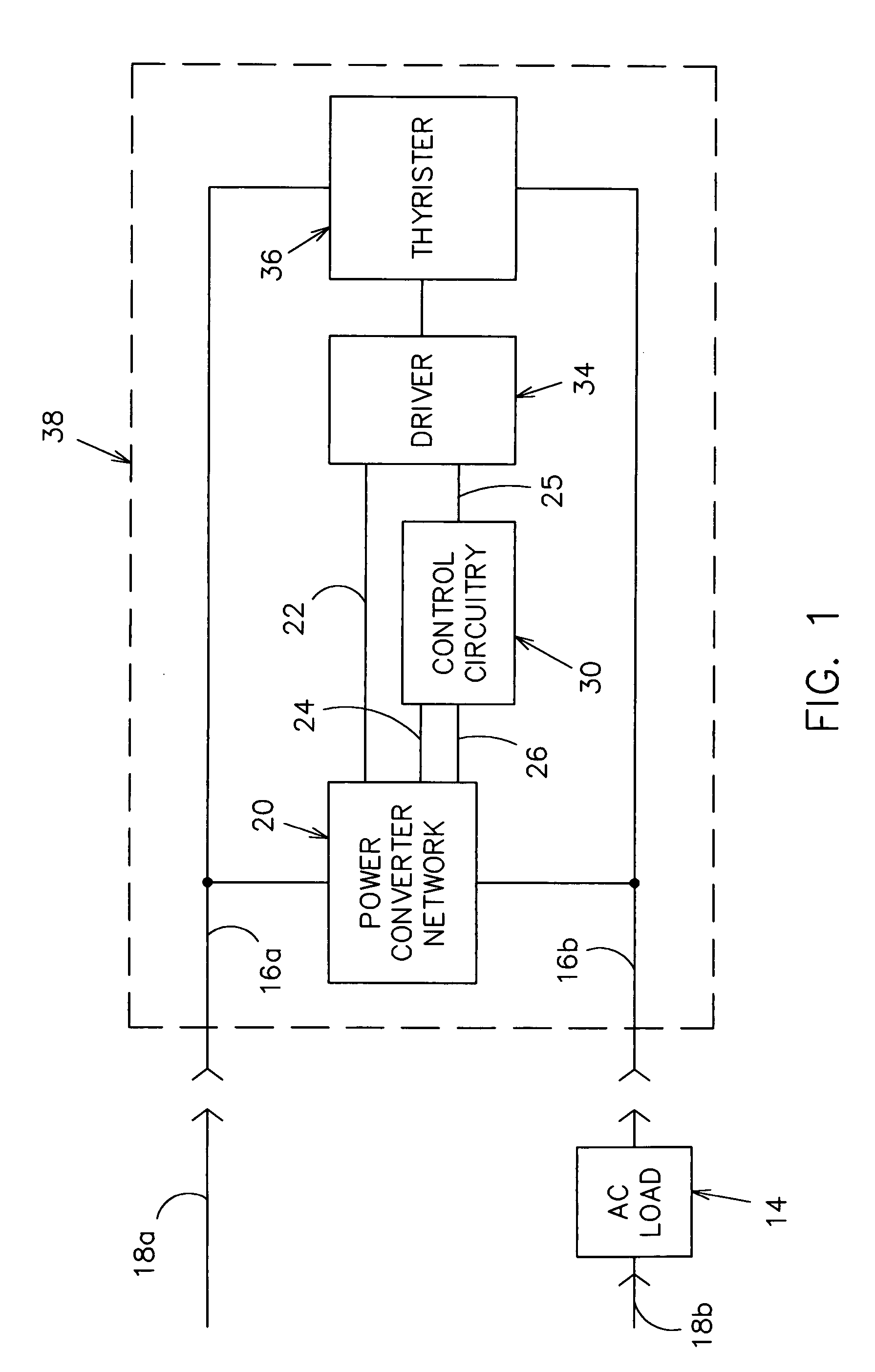

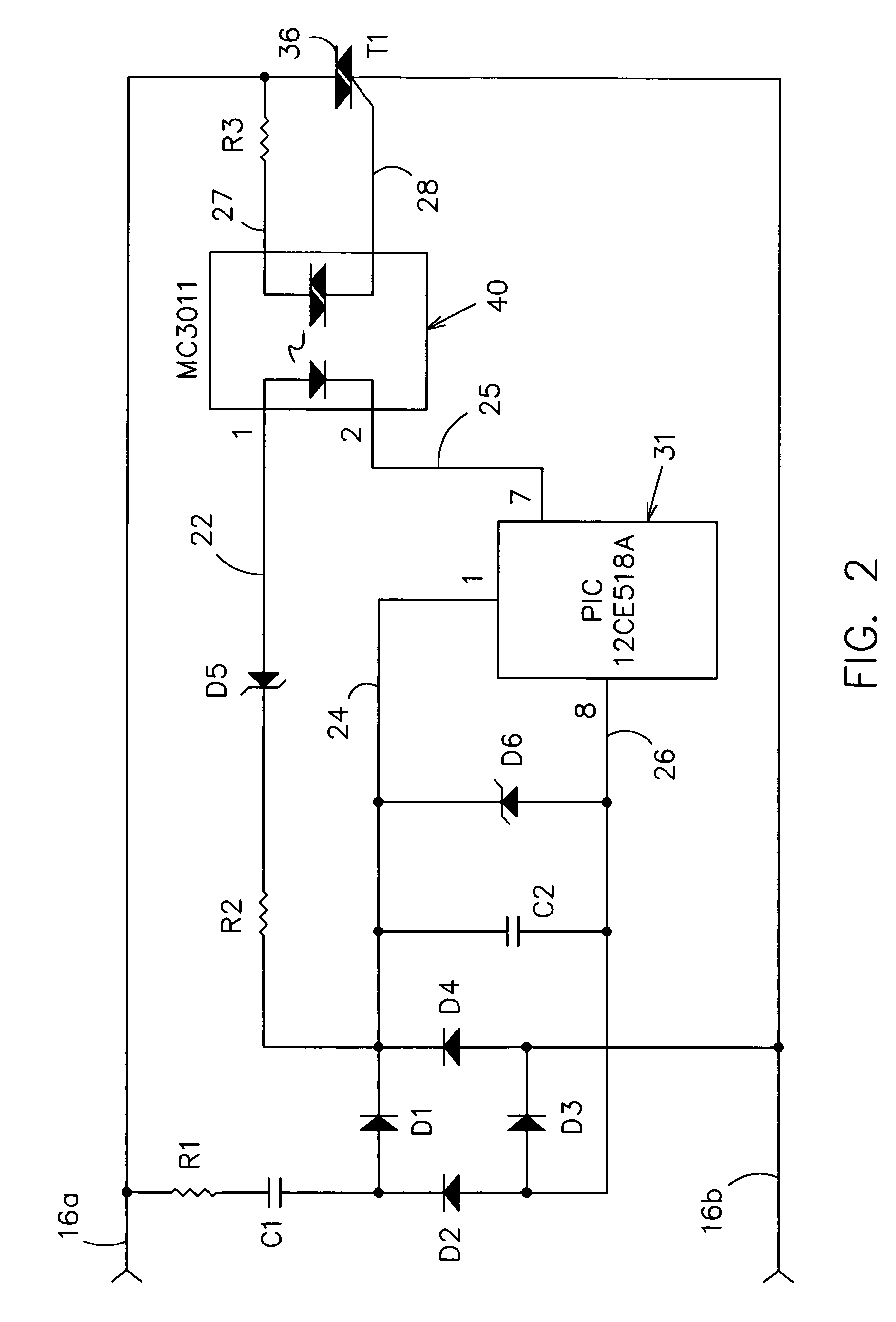

Programmable AC power switch

InactiveUS6933686B1Low costInexpensive and effectiveTime indicationBoards/switchyards circuit arrangementsMicrocontrollerTime delays

An AC controller provides programmable switching of AC power flow, together with producing a source of DC power for the AC controller. The AC controller is connected in series with only one side of the AC power source and the AC load, and uses a microcontroller or a Programmable Logic Device (PLD) for the programmable capability. The AC controller can be programmed to provide a light flasher function, a time delay off function, an automatic fade function, a dimming function, a burglar deterrent function, and a time delay dim function. With a multiple-position switch replacing a current wall switch, the operator can easily select many pre-programmed functions.

Owner:BISHEL RICHARD A

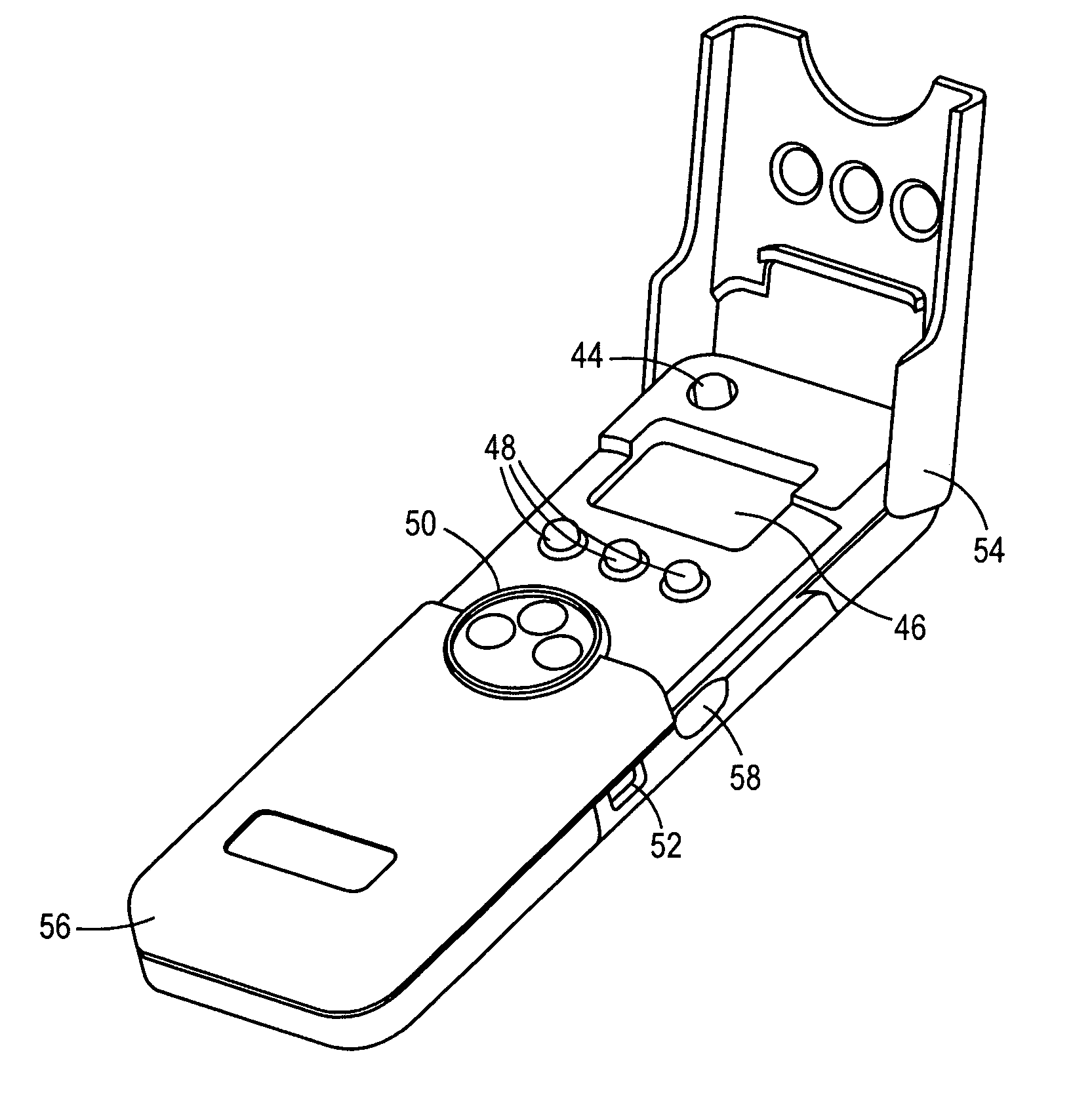

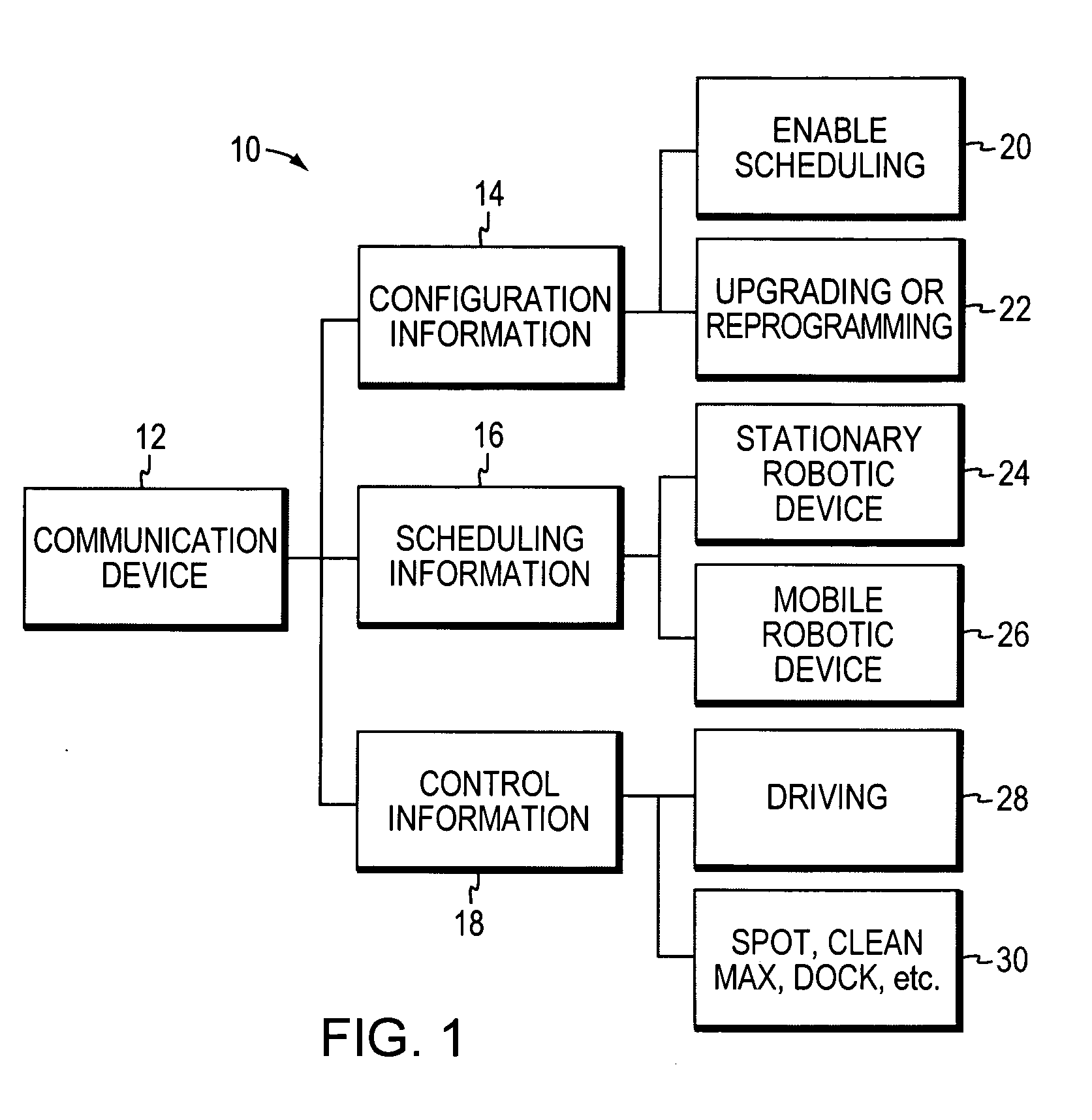

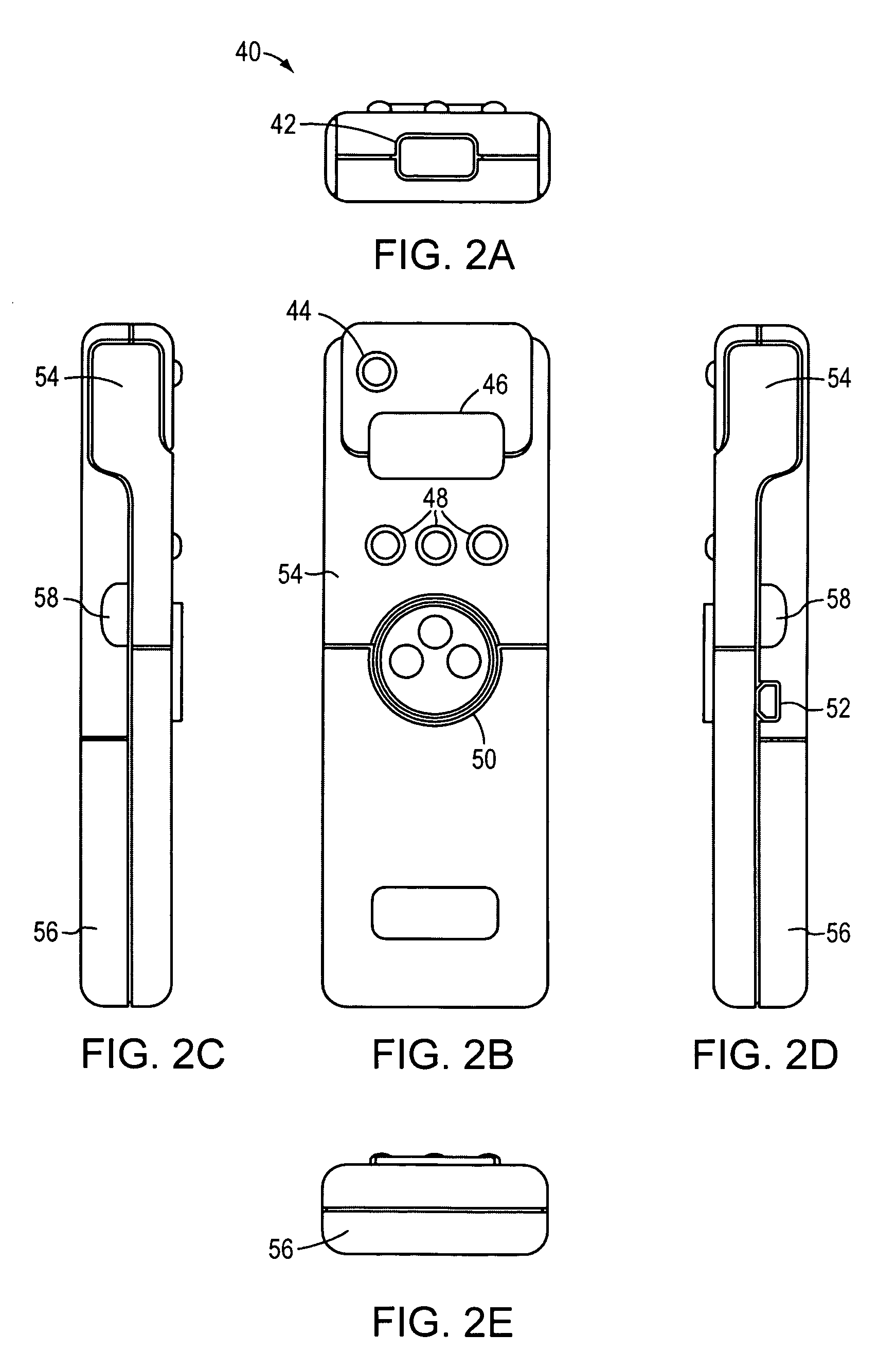

Remote control scheduler and method for autonomous robotic device

ActiveUS20050287038A1Multiple functionsProgramme-controlled manipulatorAutonomous decision making processRemote controlHand held

A method of scheduling a robotic device enables the device to run autonomously based on previously loaded scheduling information. The method consists of a communication device, such as a hand-held remote device, that can directly control the robotic device, or load scheduling information into the robotic device such that it will carry out a defined task at the desired time without the need for further external control. The communication device can also be configured to load a scheduling application program into an existing robotic device, such that the robotic device can receive and implement scheduling information from a user.

Owner:IROBOT CORP

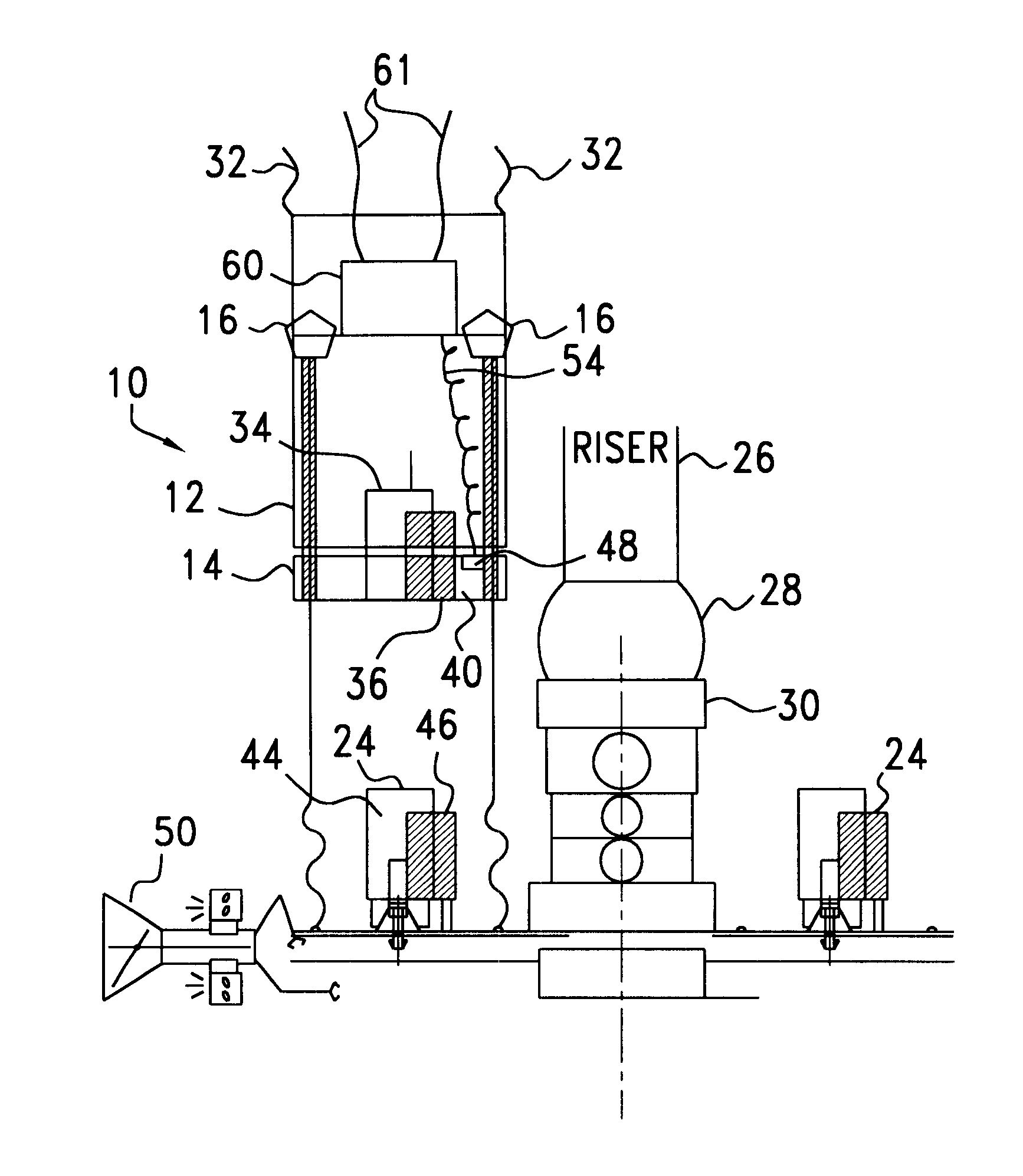

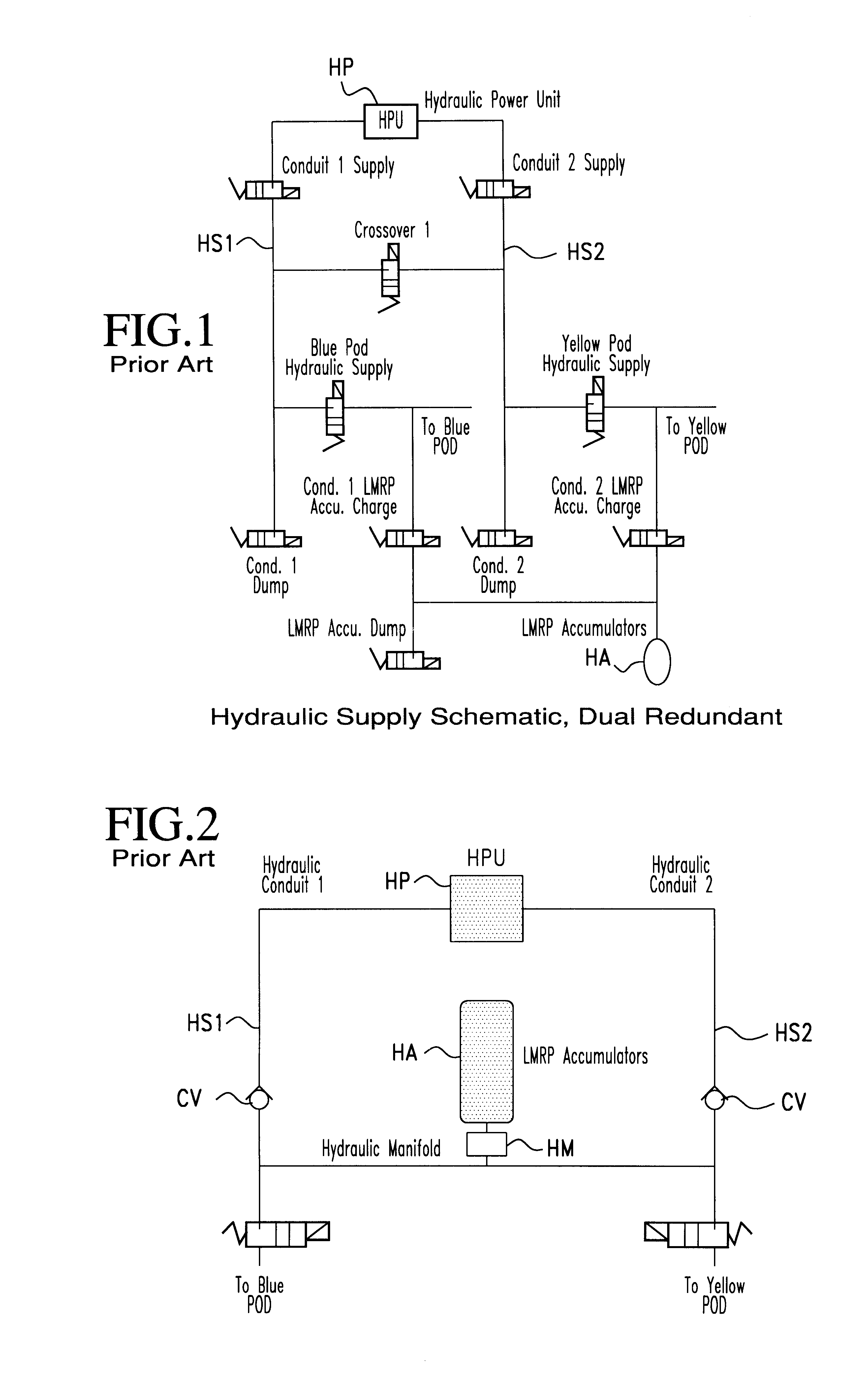

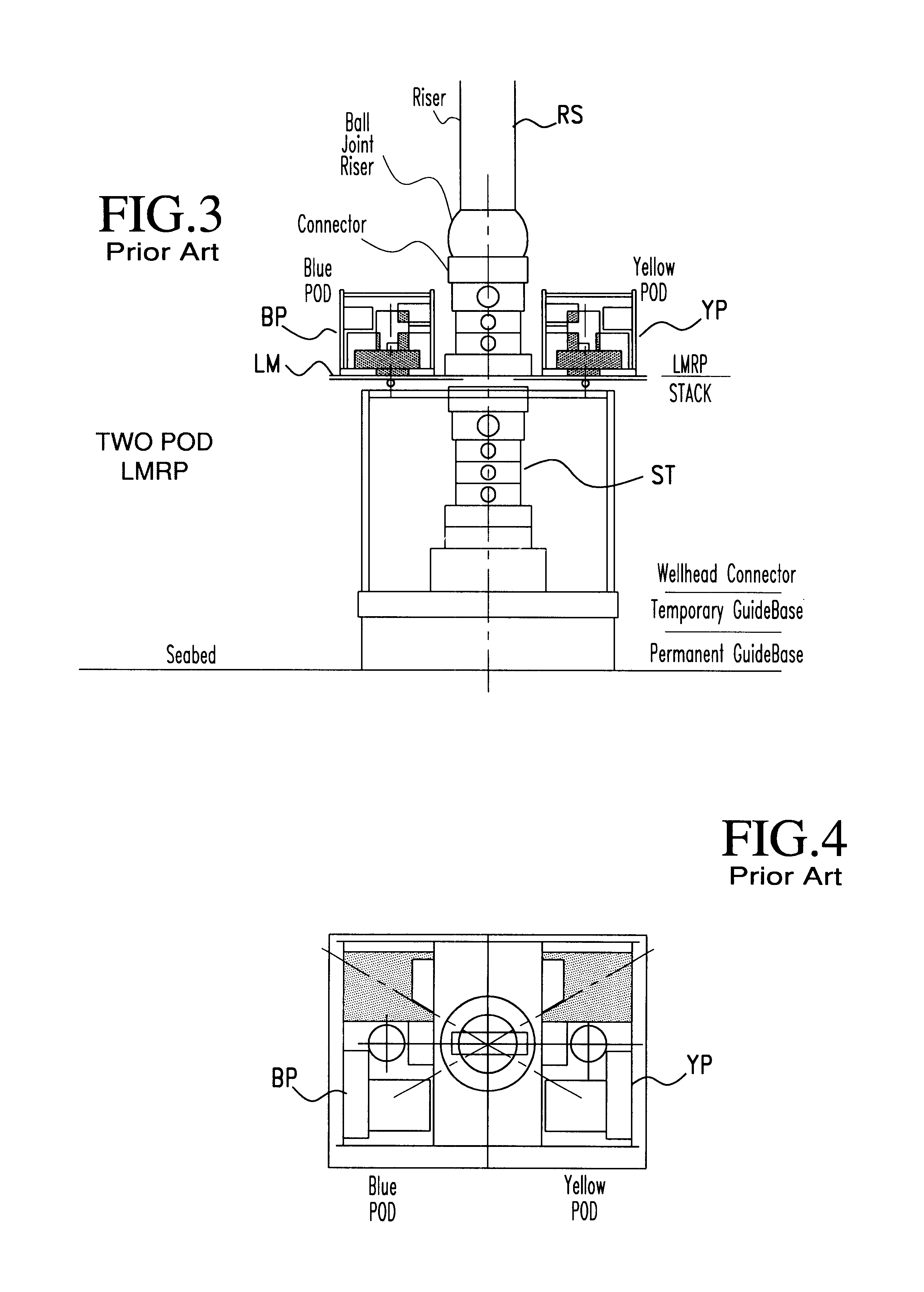

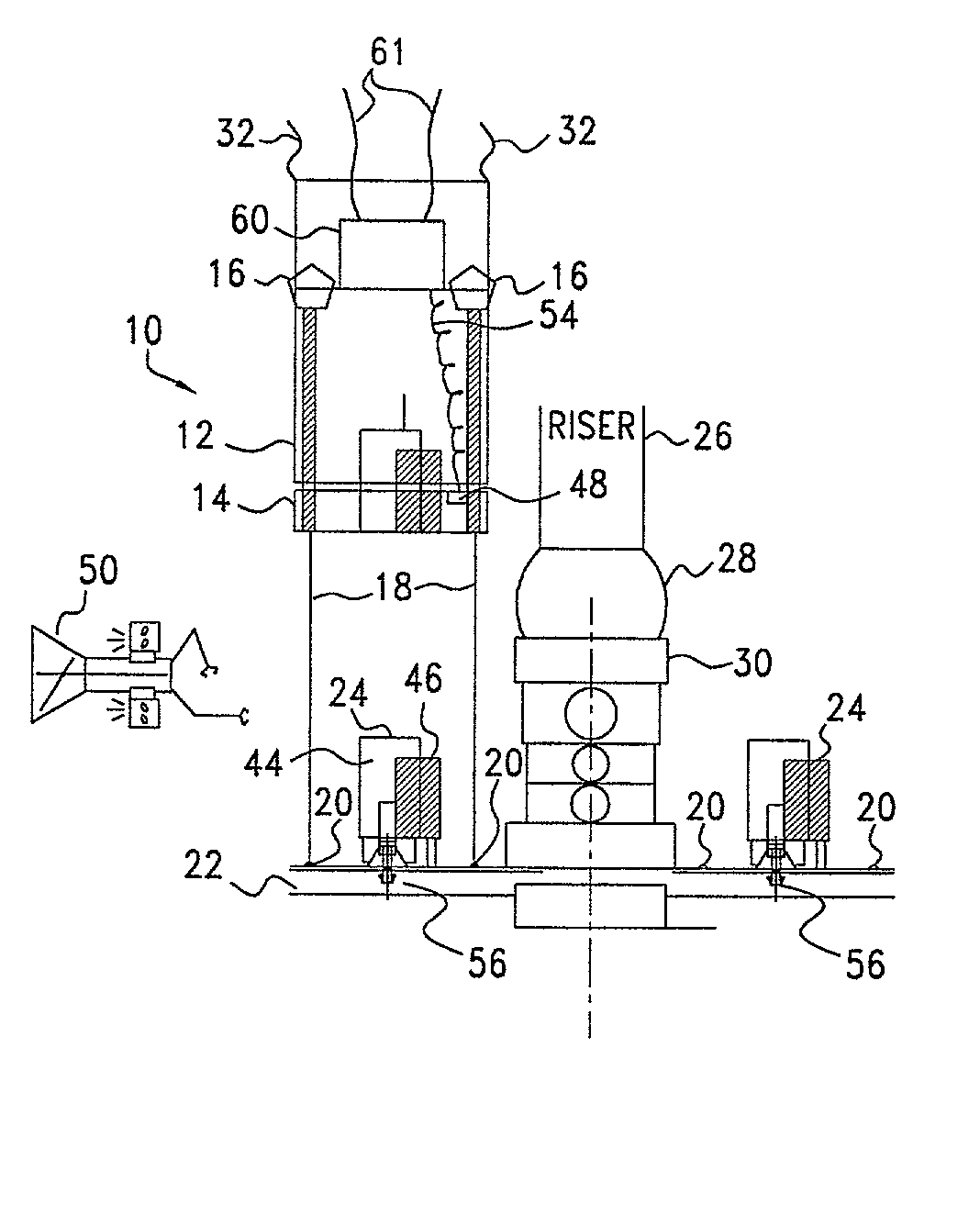

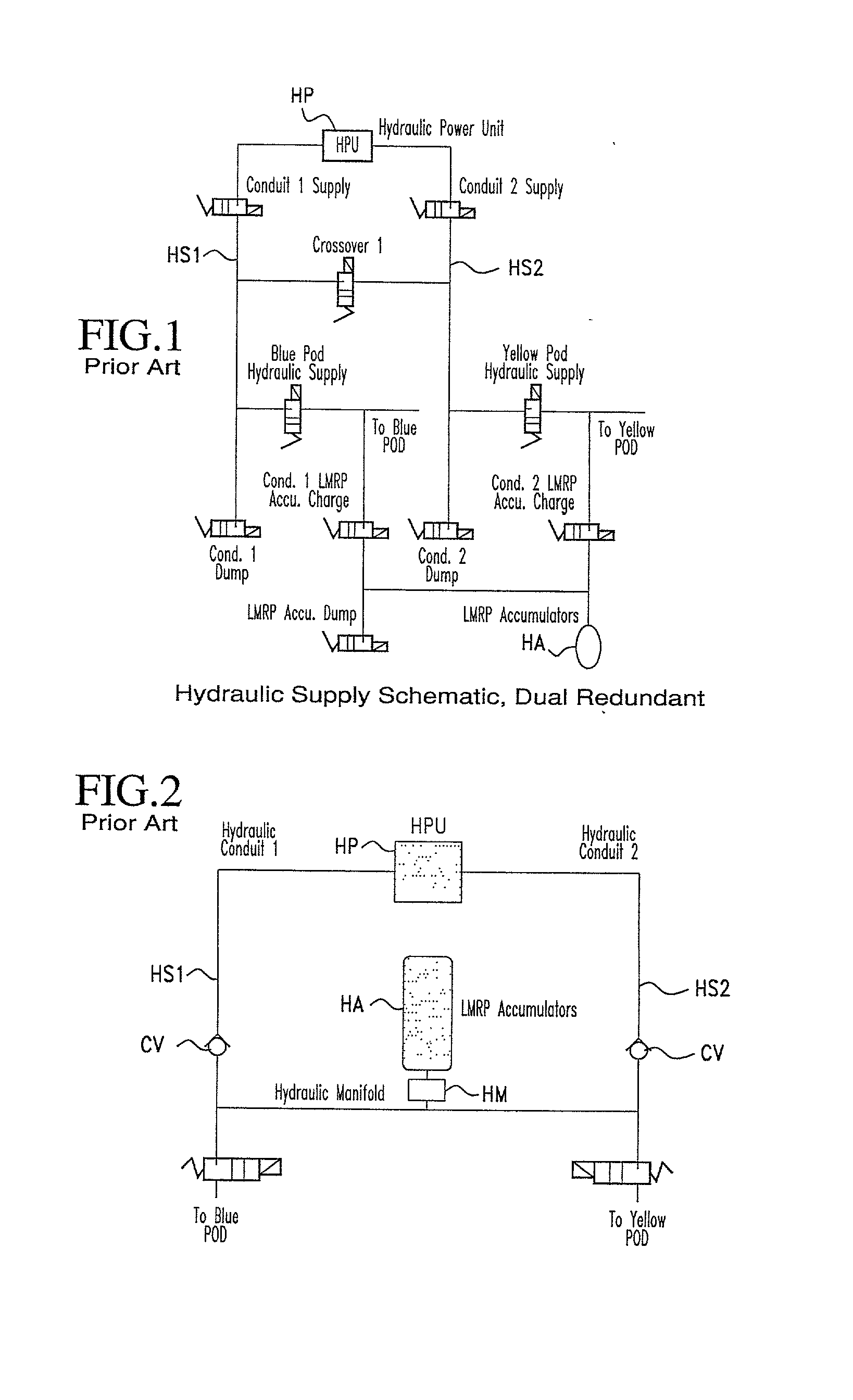

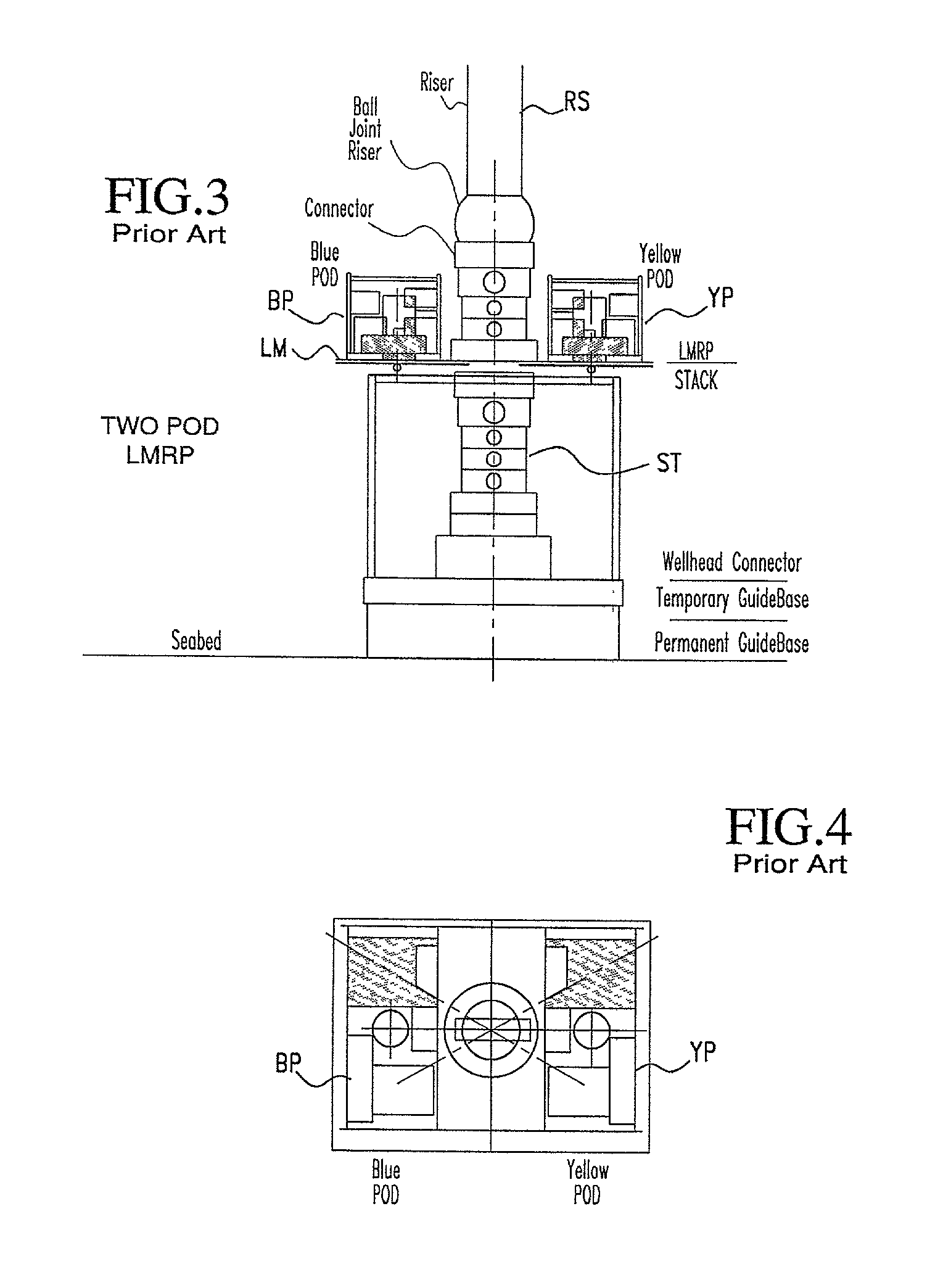

Subsea drilling operations

InactiveUS6422315B1Multiple redundancyLower Drilling CostsDerricks/mastsFluid removalSea bottomControl system

A method for retrieving a subsea pod from a lower marine riser package platform by connecting a buoyant pod retriever to the subsea pod and raising the subsea pod to the surface. In certain aspects, such a method is accomplished without an interruption of associated subsea drilling operations and / or without disconnecting the lower marine riser package from an associated subsea stack. Such a method, in certain aspects, includes: positioning a retrieval module above the pod container, the retrieval module having a pod holder releasably connected thereto; disconnecting the pod holder from the retrieval module; lowering the pod holder to the pod container and releasably connecting the pod holder to the pod container; releasing the pod container from the subsea lower marine riser platform; raising the pod holder to the retrieval module and releasably connecting the pod holder with the pod container to the retrieval module; and raising the retrieval module with the pod container to a location at the surface. Such pod containers are, in certain aspects, part of a multiply redundant control system.

Owner:DEAN QUENTON WAYNE

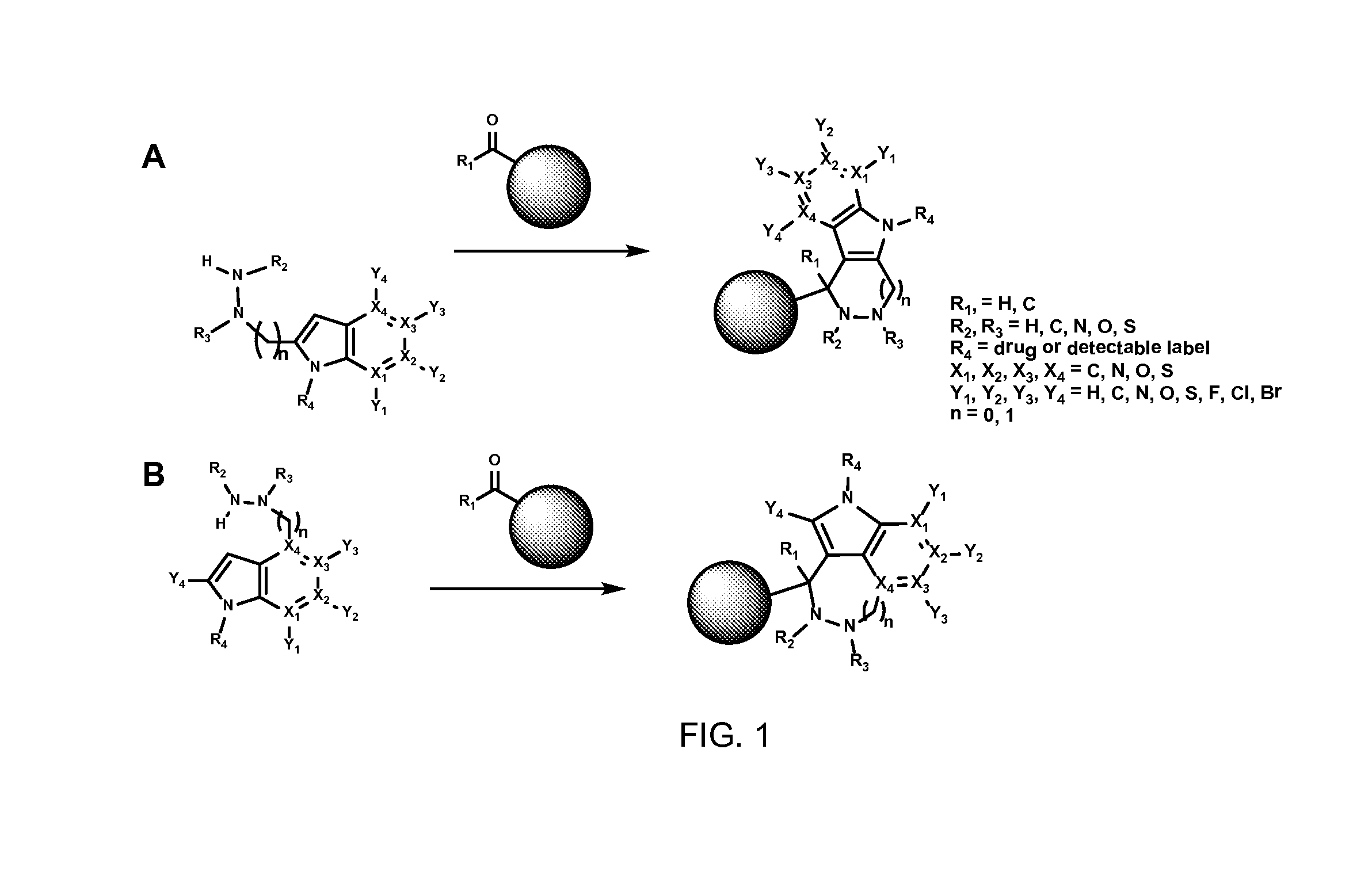

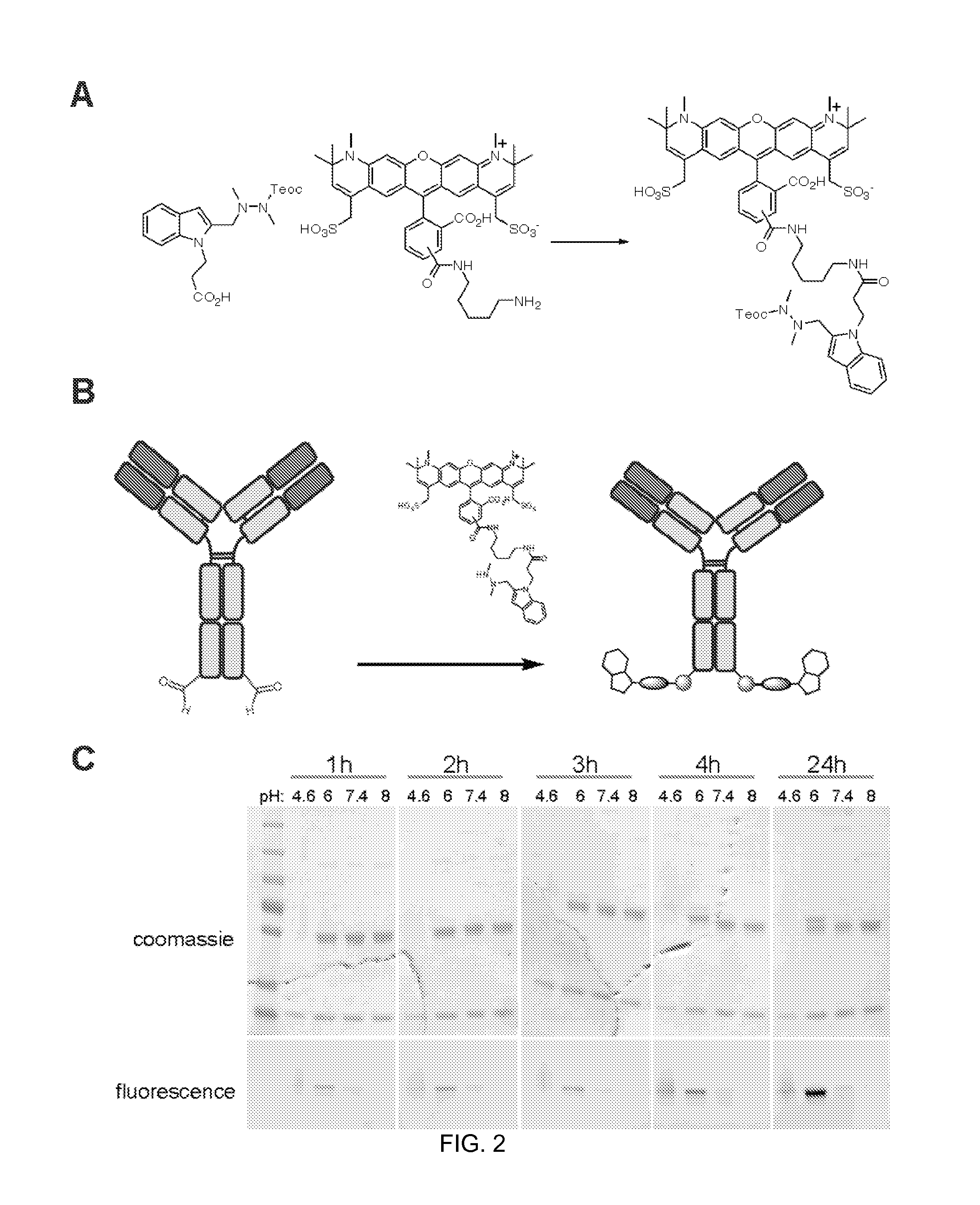

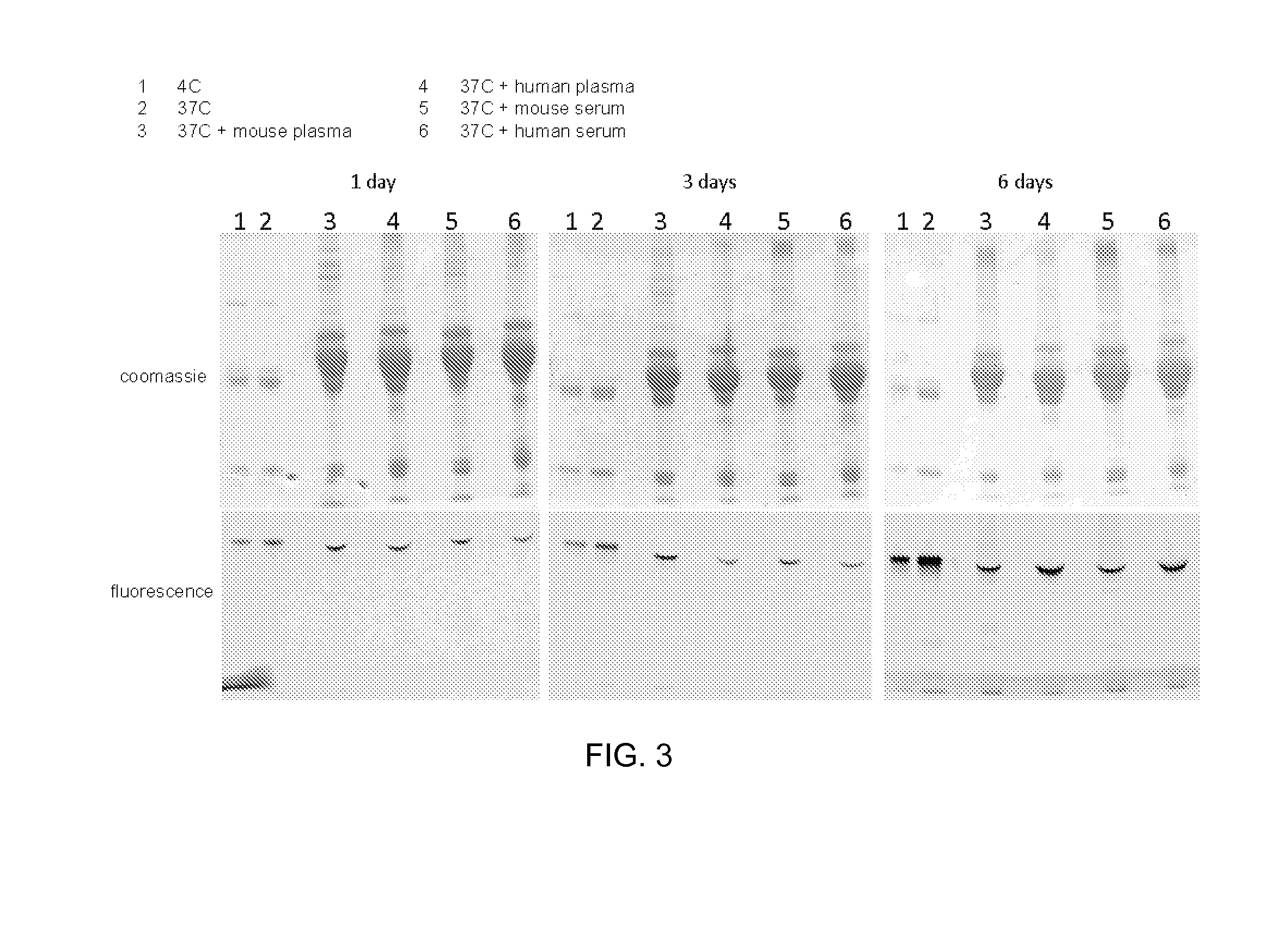

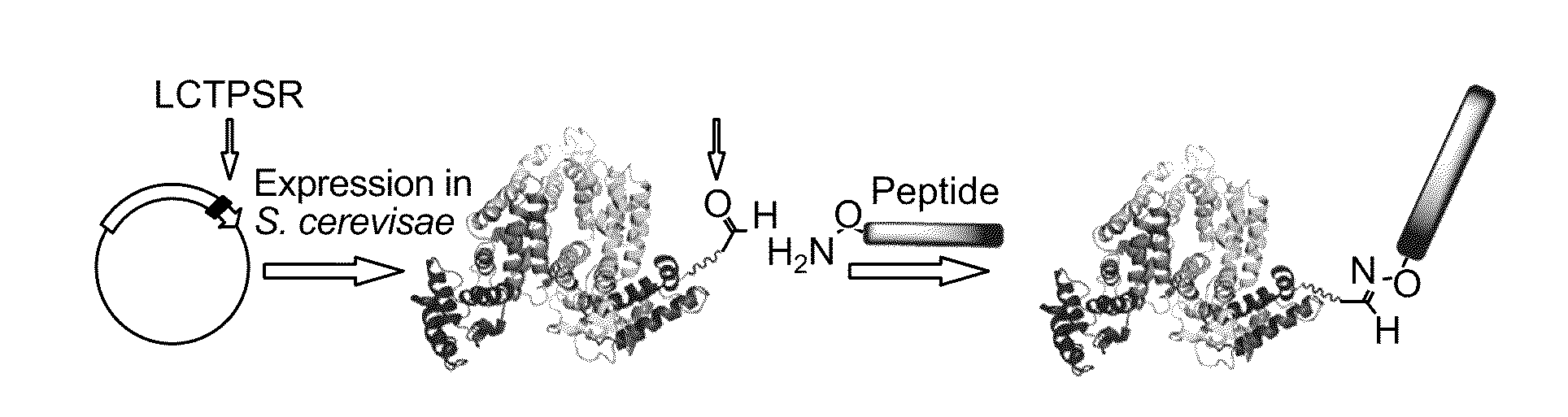

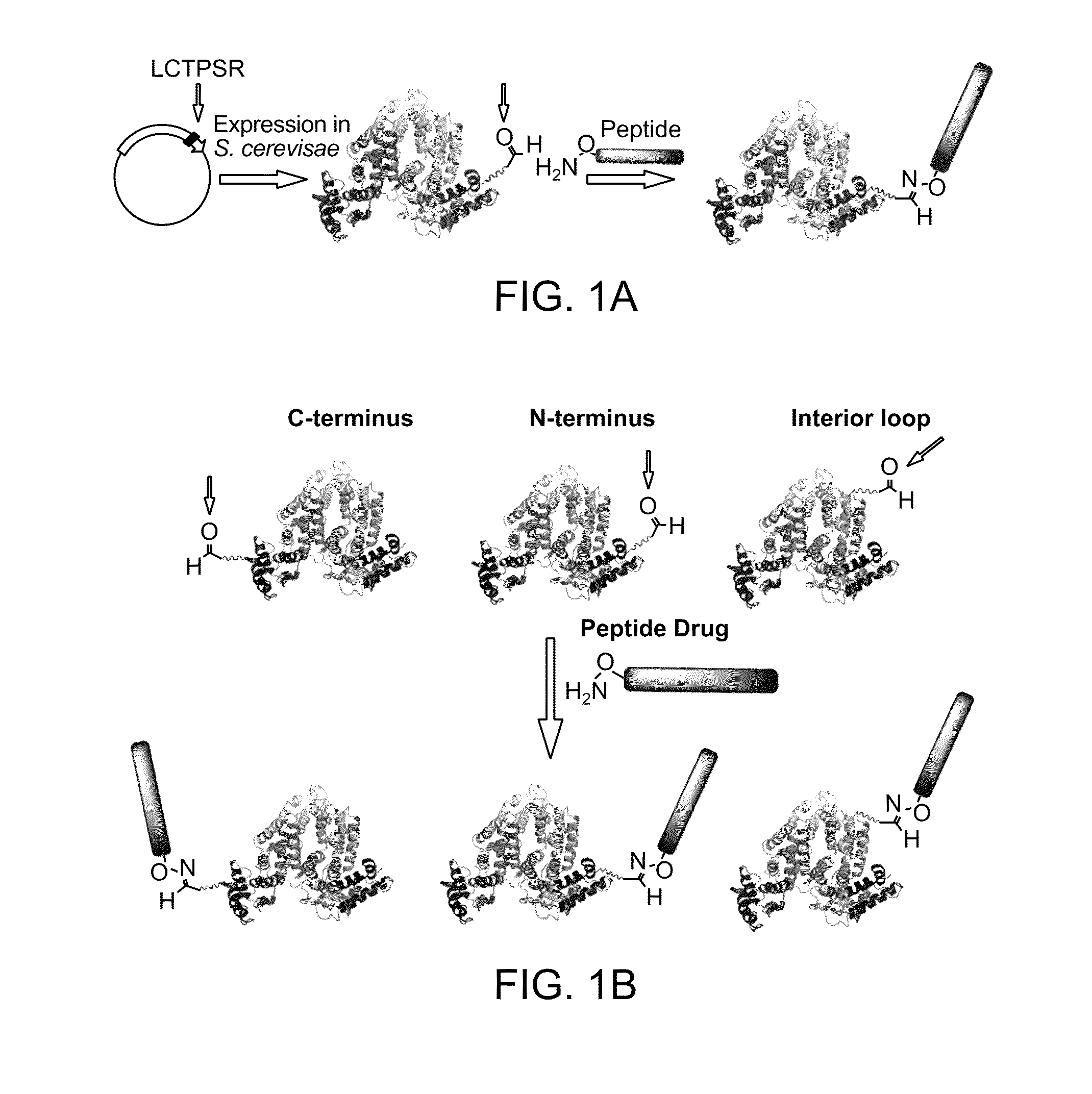

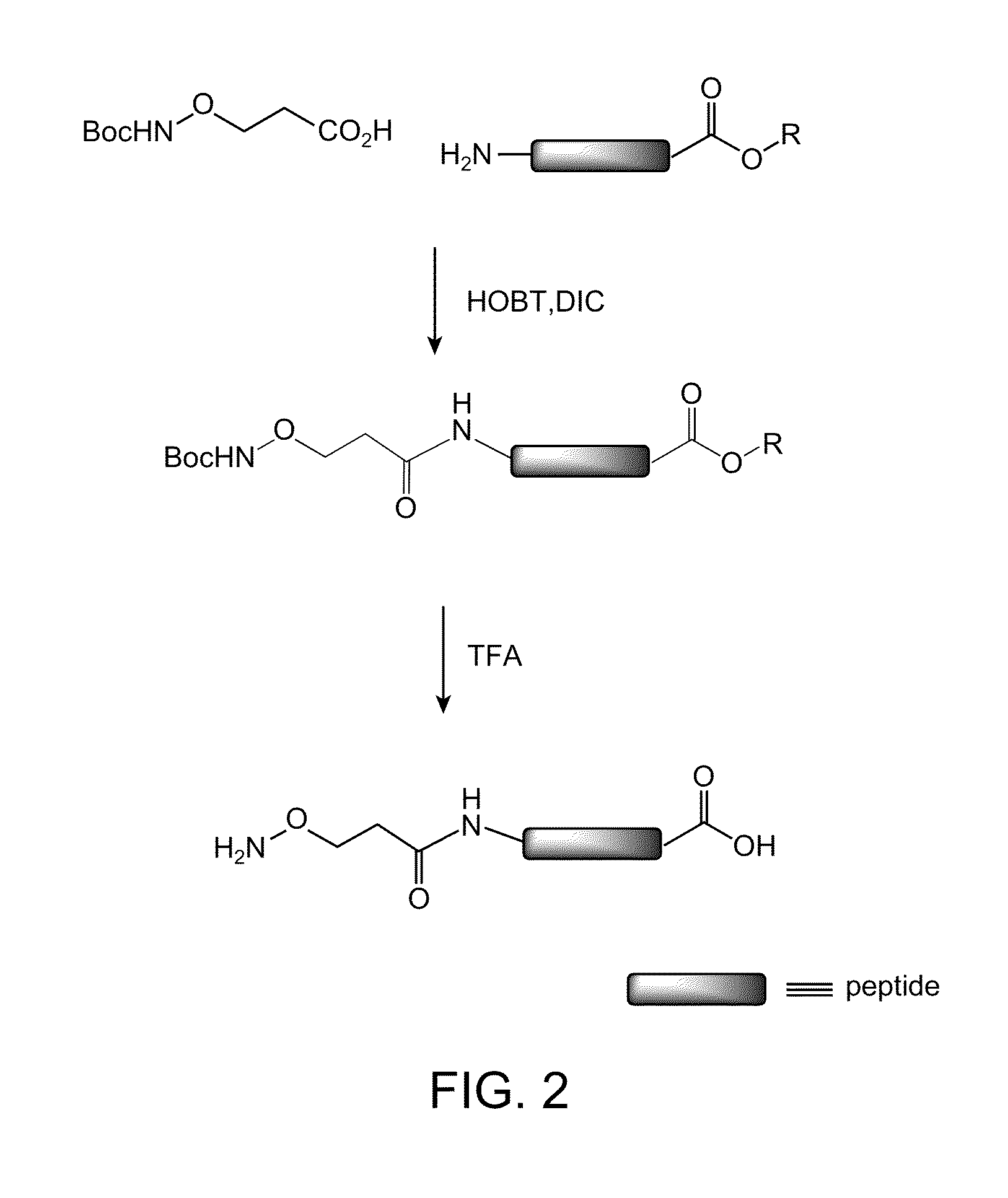

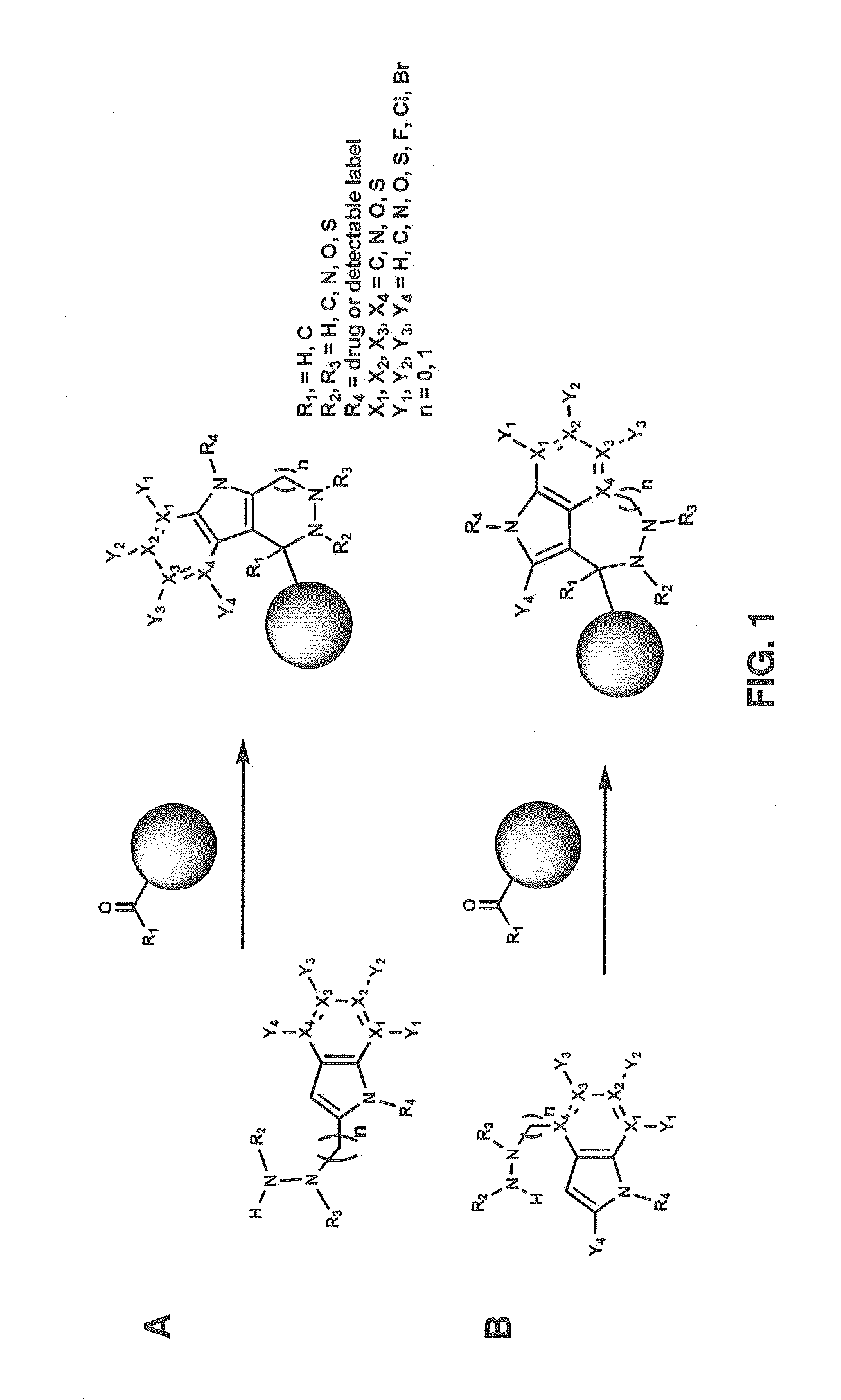

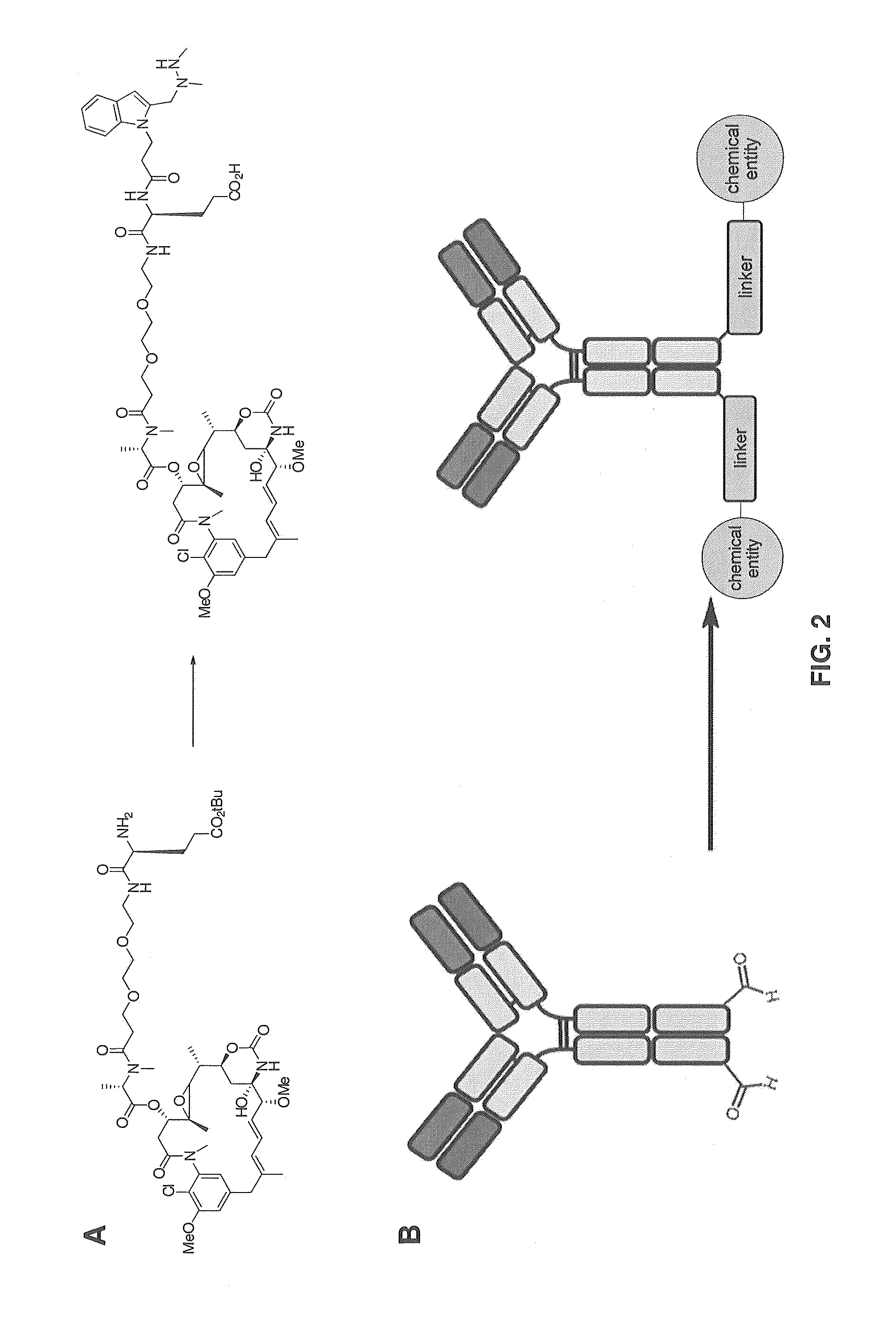

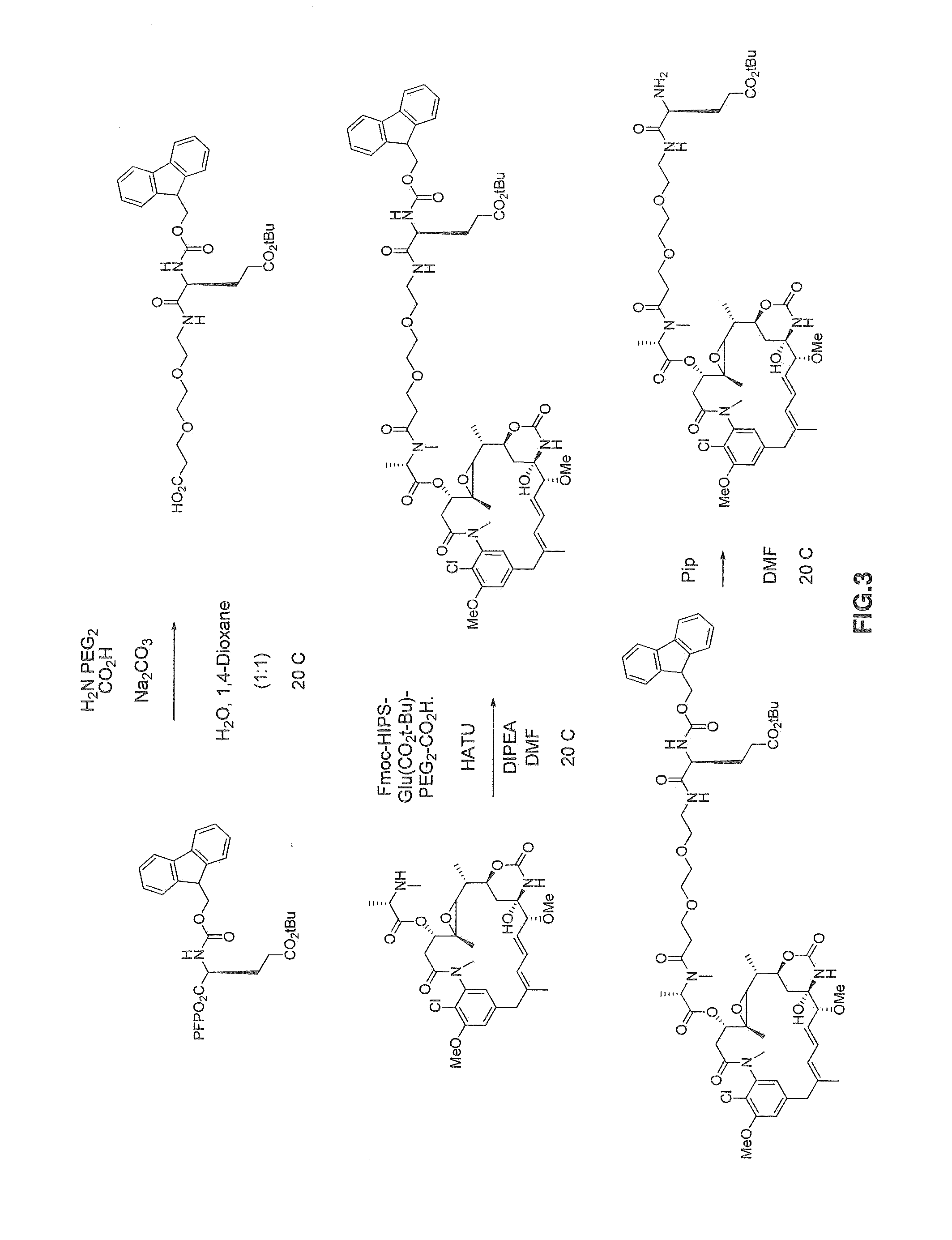

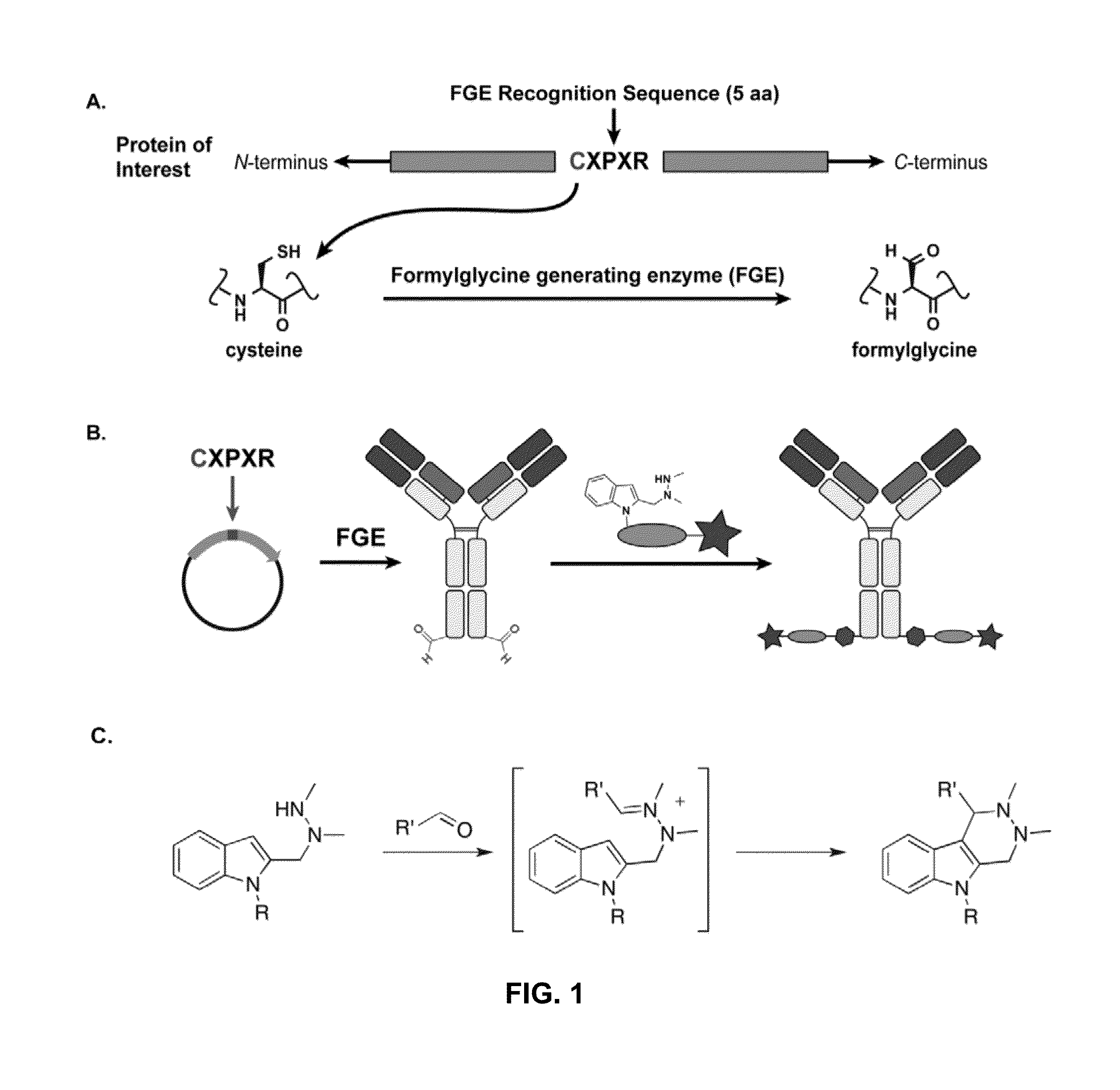

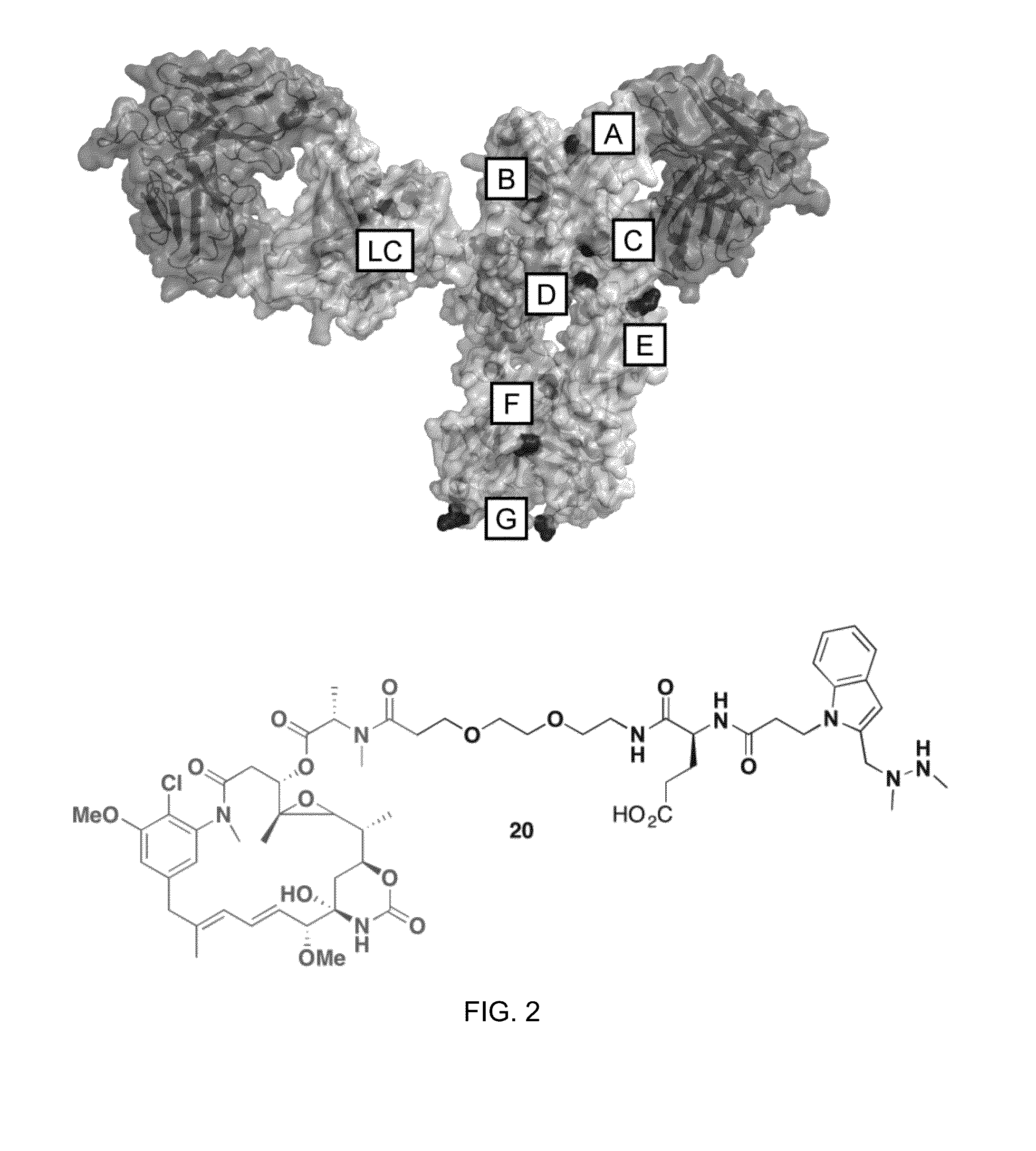

Hydrazinyl-indole compounds and methods for producing a conjugate

ActiveUS20140141025A1Effective treatmentMultiple functionsPeptide/protein ingredientsPeptide preparation methodsMethods of productionStereochemistry

The present disclosure provides conjugate structures (e.g., polypeptide conjugates) and hydrazinyl-indole compounds used to produce these conjugates. The disclosure also provides methods of production of such conjugates, as well as methods of using the same.

Owner:REDWOOD BIOSCI

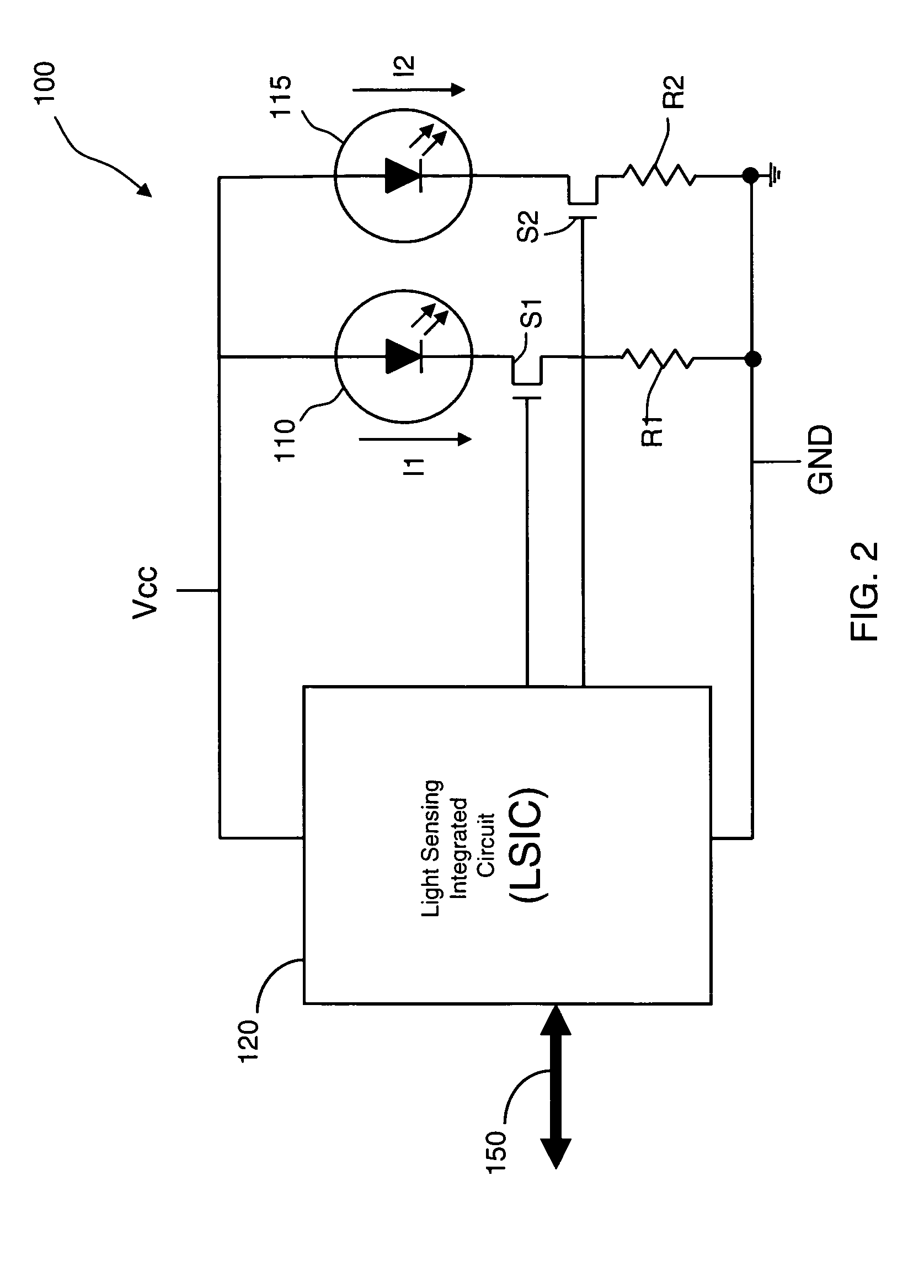

Integrated ambient light sensor and distance sensor

ActiveUS20090027652A1Multiple functionsOptical rangefindersScattering properties measurementsLight sensingDistance sensors

An integrated proximity and light sensor includes an indicating light-emitting device (“ILD”), a projecting light-emitting device (“PLD”), and a light sensing integrated circuit (“LSIC”) configured as a single package. The LSIC controls each of the ILD and the PLD to emit light therefrom and the LSIC is configured to detect an ambient light level and also to detect a reflection of the light projected by the PLD from a surface for proximity detection.

Owner:EMINENT ELECTRONICS TECH

Aldehyde-Tagged Protein-Based Drug Carriers and Methods of Use

ActiveUS20100210543A1Readily apparentExquisite specificityPeptide librariesSugar derivativesMedicineDrug carrier

Owner:REDWOOD BIOSCI

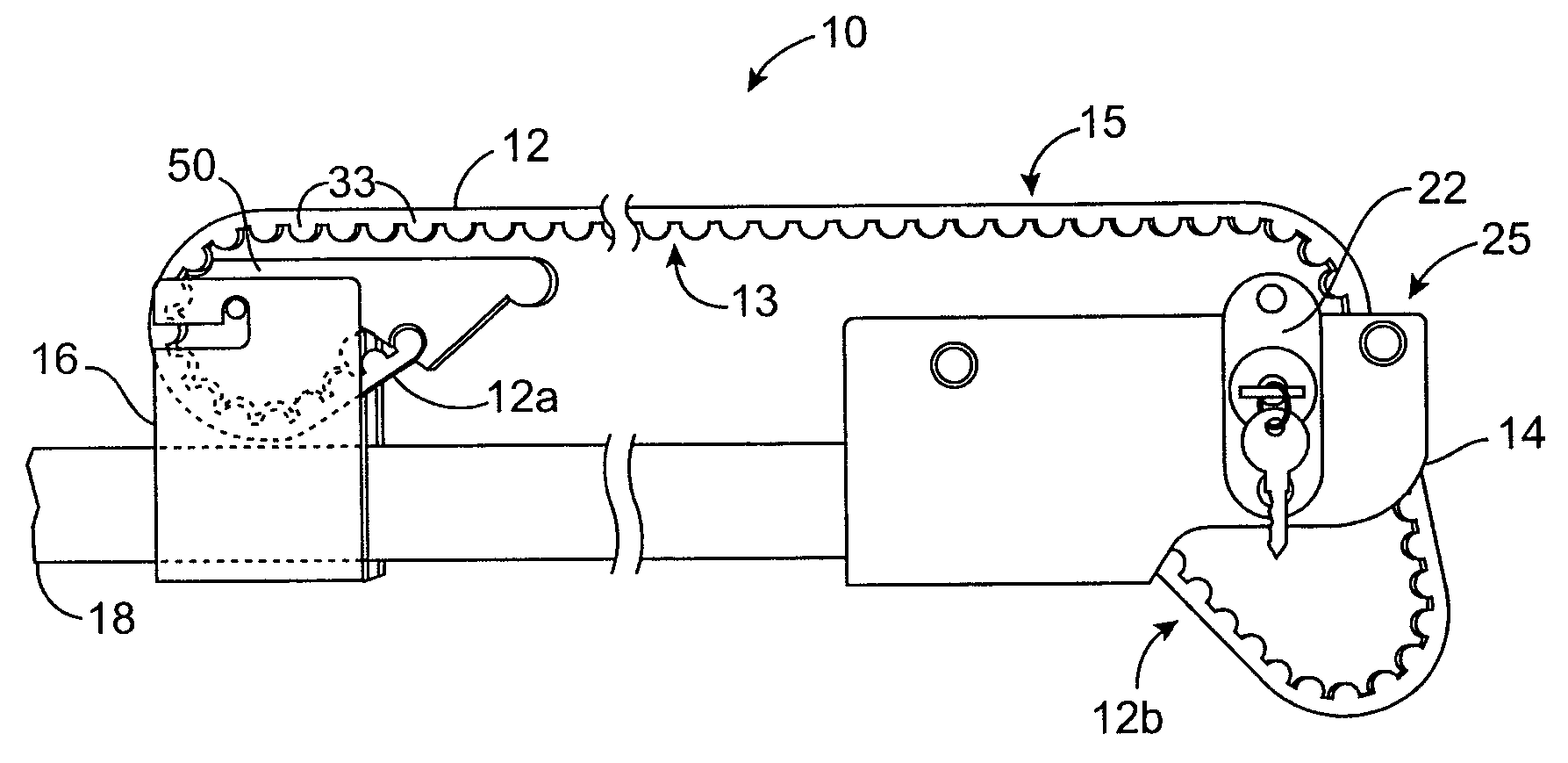

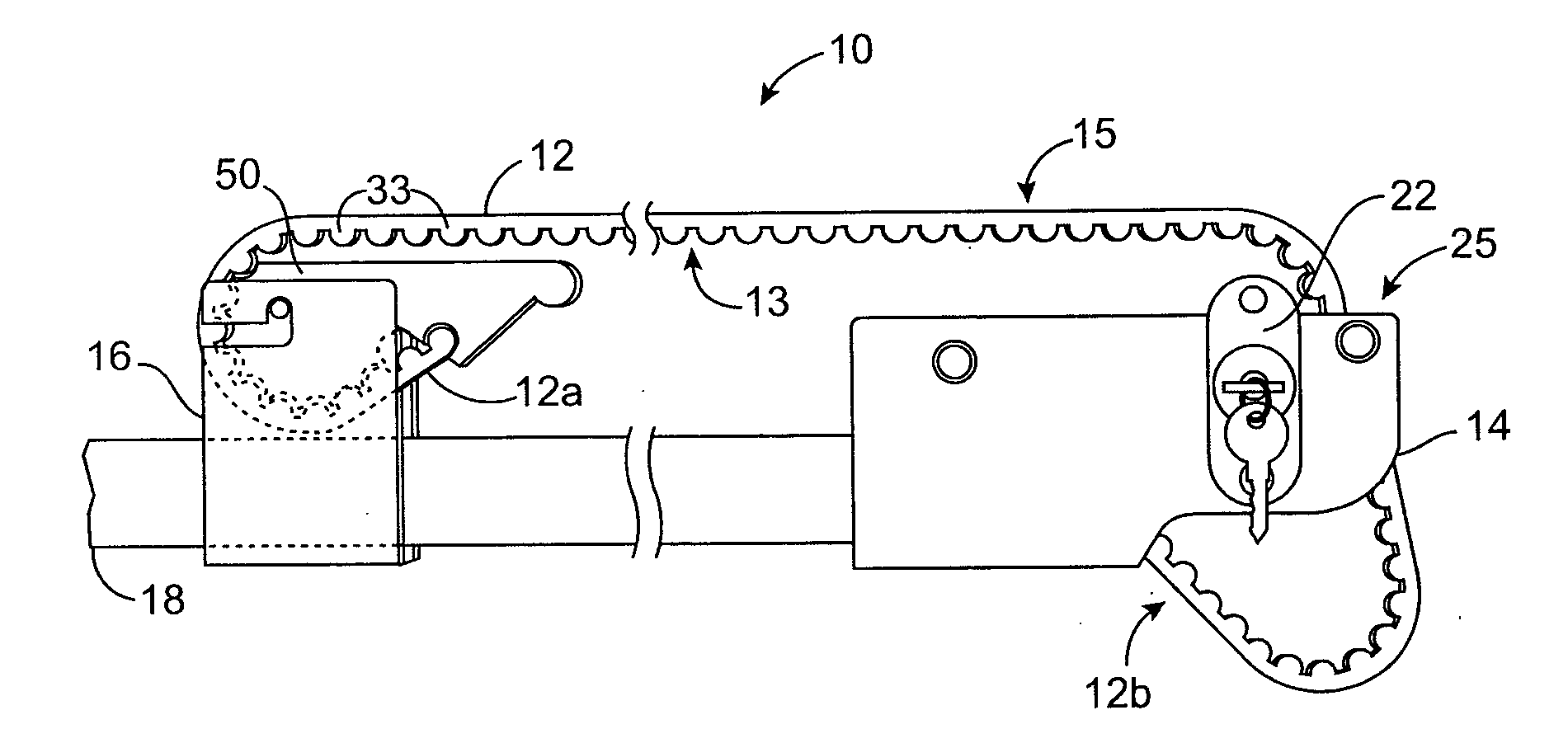

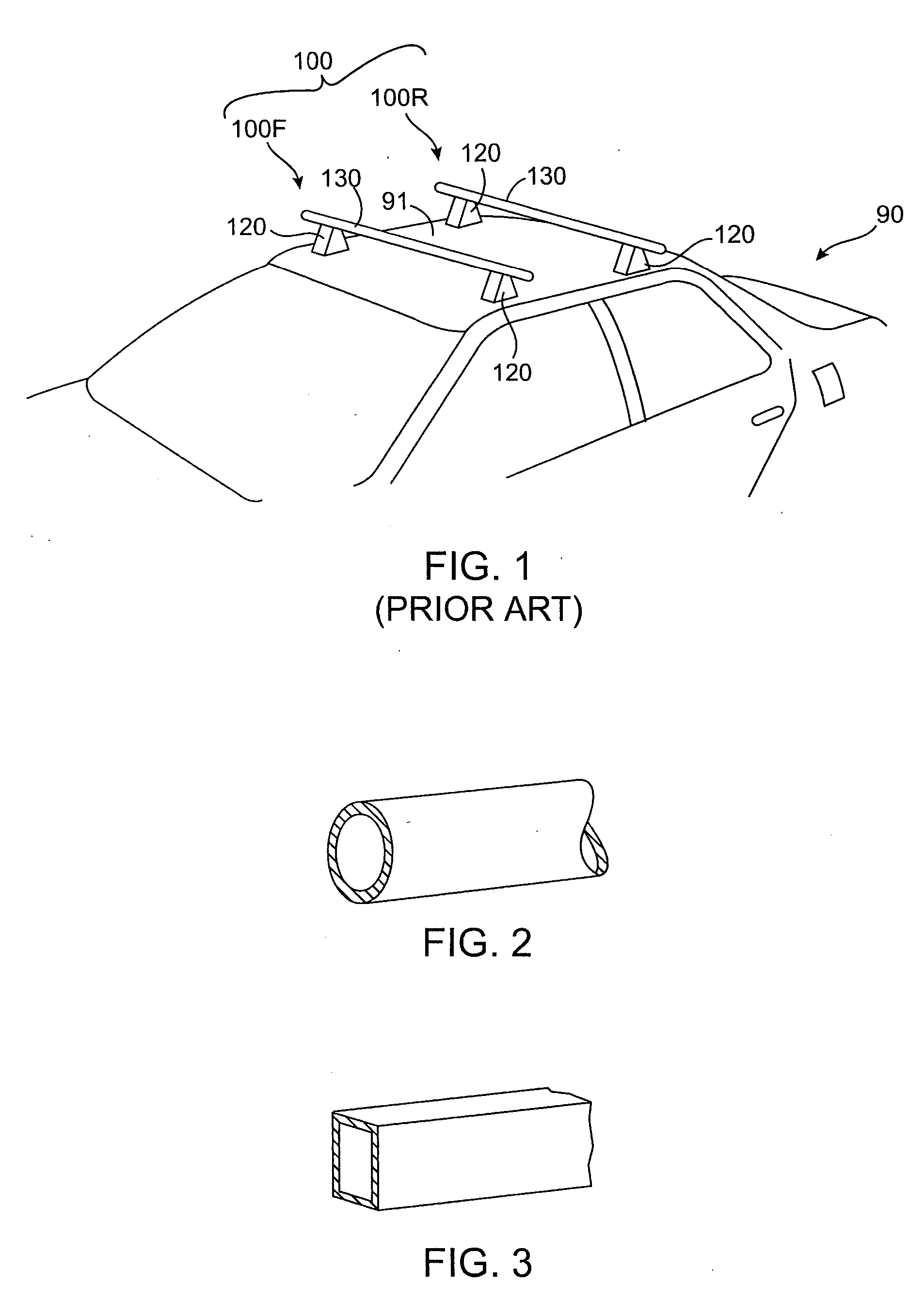

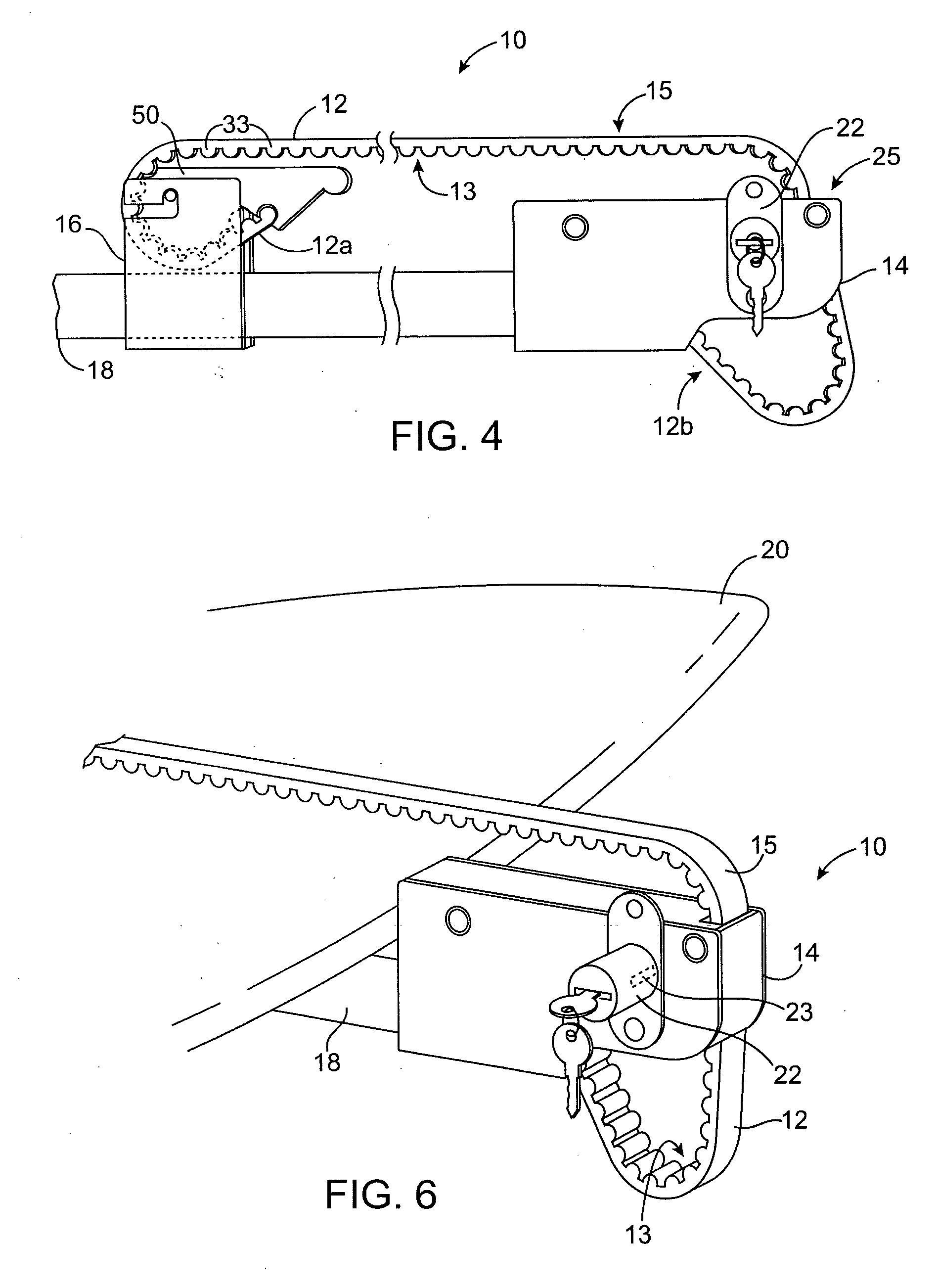

Ratcheting strap-down system

InactiveUS8020737B2Simple and efficient to useAdjustable and versatileSupplementary fittingsStowing appliancesLocking mechanismEngineering

A ratcheting strap-down system for use with a crossbar to securely transport any variety of objects. The ratcheting strap-down assembly includes a ratcheting receiver and a cam clamp receiver. The ratcheting receiver includes a ratcheting assembly and a locking mechanism and is adapted to engage a second end of a flexible strap. The flexible strap is preferably made from reinforced steel cog belt, making the system and the objects it's securing less susceptible to theft. The ratcheting strap-down system is particularly useful for securing one or more surfboards to the crossbars of an after-market roof rack assembly.

Owner:SWEENEY MICHAEL T

Ratcheting strap-down system

InactiveUS20060213941A1Simple and efficient to usePrevent theftSupplementary fittingsStowing appliancesLocking mechanismGear wheel

A ratcheting strap-down system for use with a crossbar to securely transport any variety of objects. The ratcheting strap-down assembly includes a ratcheting receiver and a cam clamp receiver. The ratcheting receiver includes a ratcheting assembly and a locking mechanism and is adapted to engage a second end of a flexible strap. The flexible strap is preferably made from reinforced steel cog belt, making the system and the objects it's securing less susceptible to theft. The ratcheting strap-down system is particularly useful for securing one or more surfboards to the crossbars of an after-market roof rack assembly.

Owner:SWEENEY MICHAEL T

Method for subsea pod retrieval

InactiveUS20030006070A1Lower Drilling CostsMultiple functionsDrilling rodsDerricks/mastsOcean bottomControl system

A method for controlling subsea drilling operations which, in at least certain aspects, includes controlling the subsea drilling operations with a control system having three subsea pod containers of a control system, each with apparatus for controlling the subsea drilling operations, the system also having activation apparatus for activating a chosen one of the subsea pod containers and maintenance apparatus for maintaining the two subsea pod containers other than the chosen one in a standby mode so that triple redundancy of control of the subsea drilling operations is provided, so that the subsea drilling operations are not interrupted during retrieval of a pod whose apparatus for controlling the subsea drilling operations has failed; and methods with such a system for retrieving a subsea pod from a lower marine riser package platform.

Owner:DEAN QUENTON WAYNE

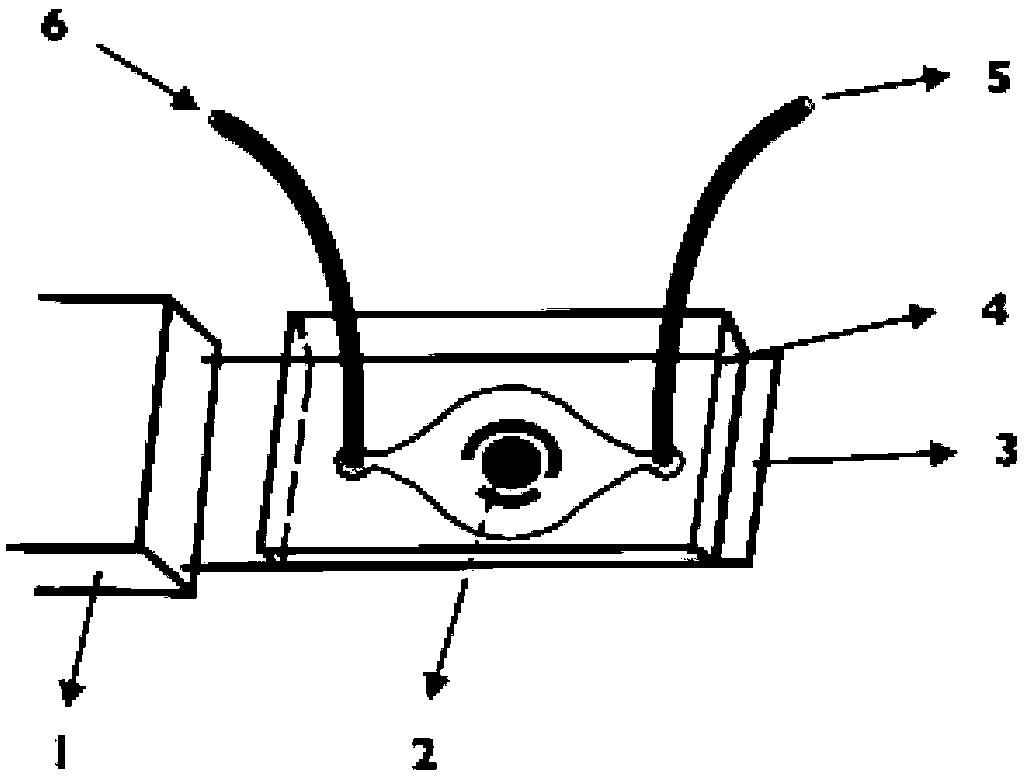

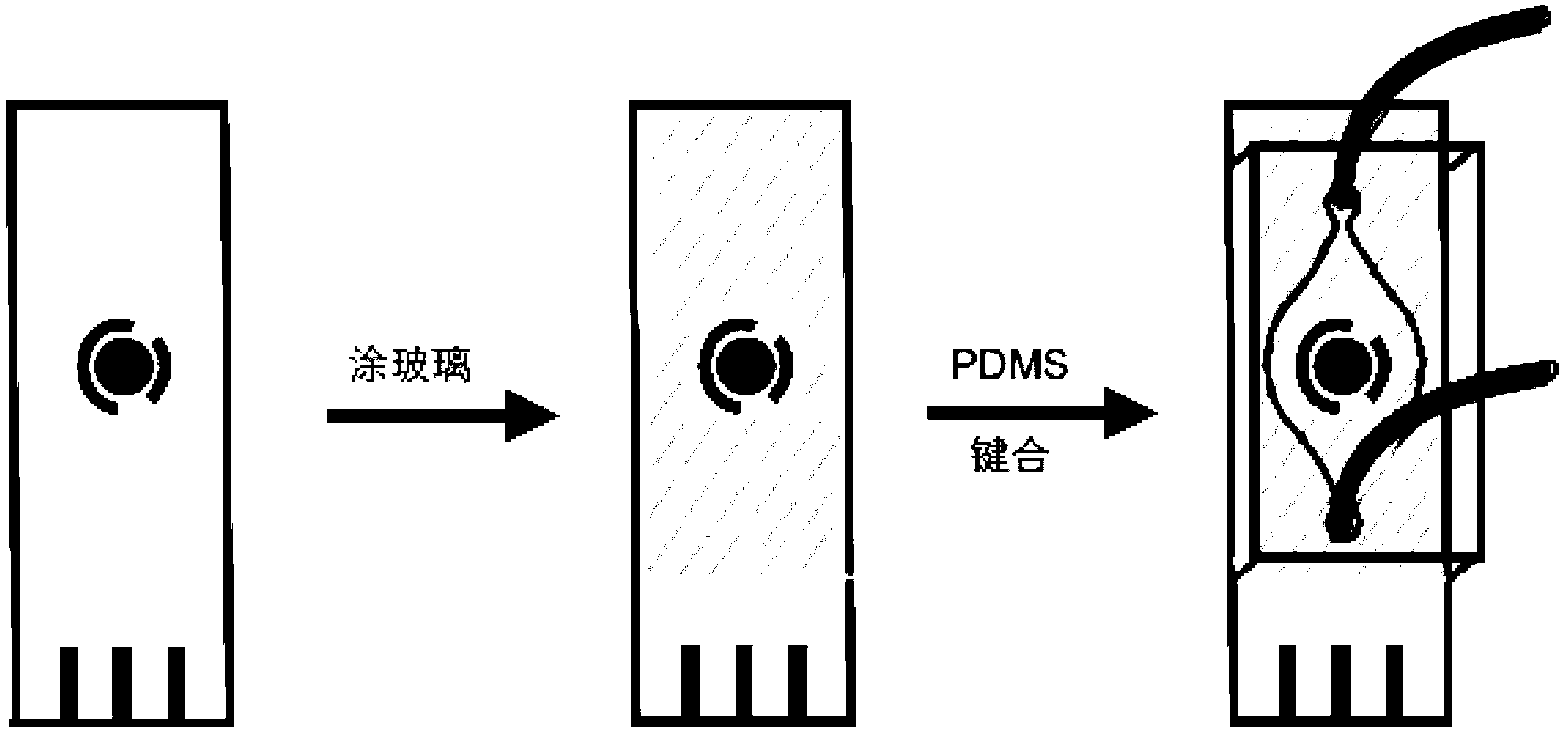

Preparation method and application of electrochemical micro-fluidic sensing chip

ActiveCN103182334AEasy to manufactureReduce weightMaterial analysis by electric/magnetic meansLaboratory glasswaresElectrochemical detectorStandardization

The invention provides a preparation method and the application of an electrochemical micro-fluidic sensing chip. The preparation method comprises the following steps: directly coating an improved glass solution on a commercial standard printed electrode; and performing vacuum plasma treatment on a PDMS (Polydimethylsiloxane) chip with pre-designed pipelines and the printed electrode coated with the glass solution together, and directly bonding the PDMS chip on the commercial standard printed electrode to form a novel electrochemical microfluidic sensing platform. A sensor provided by the invention can perform ultrasensitive detection on various sample analytes in a biological fluid sample, taking the detection of a prostate cancer marker PSA (Prostate-specific Antigen) in human serum as an example, a coulomb amperometry is used for detection, and a result shows that the detection sensitivity can reach 0.84 pg / mL which is improved by two magnitudes than the standardized clinical testing requirement of 0.1 ng / mL, so that the sensor has superhigh detection sensitivity and accuracy, which are higher than those of other electrochemical detection devices, is convenient in operation, and can integrates sample processing, separation and the like on one micro electrochemical microfluidic sensing chip.

Owner:SHANGHAI JIAO TONG UNIV

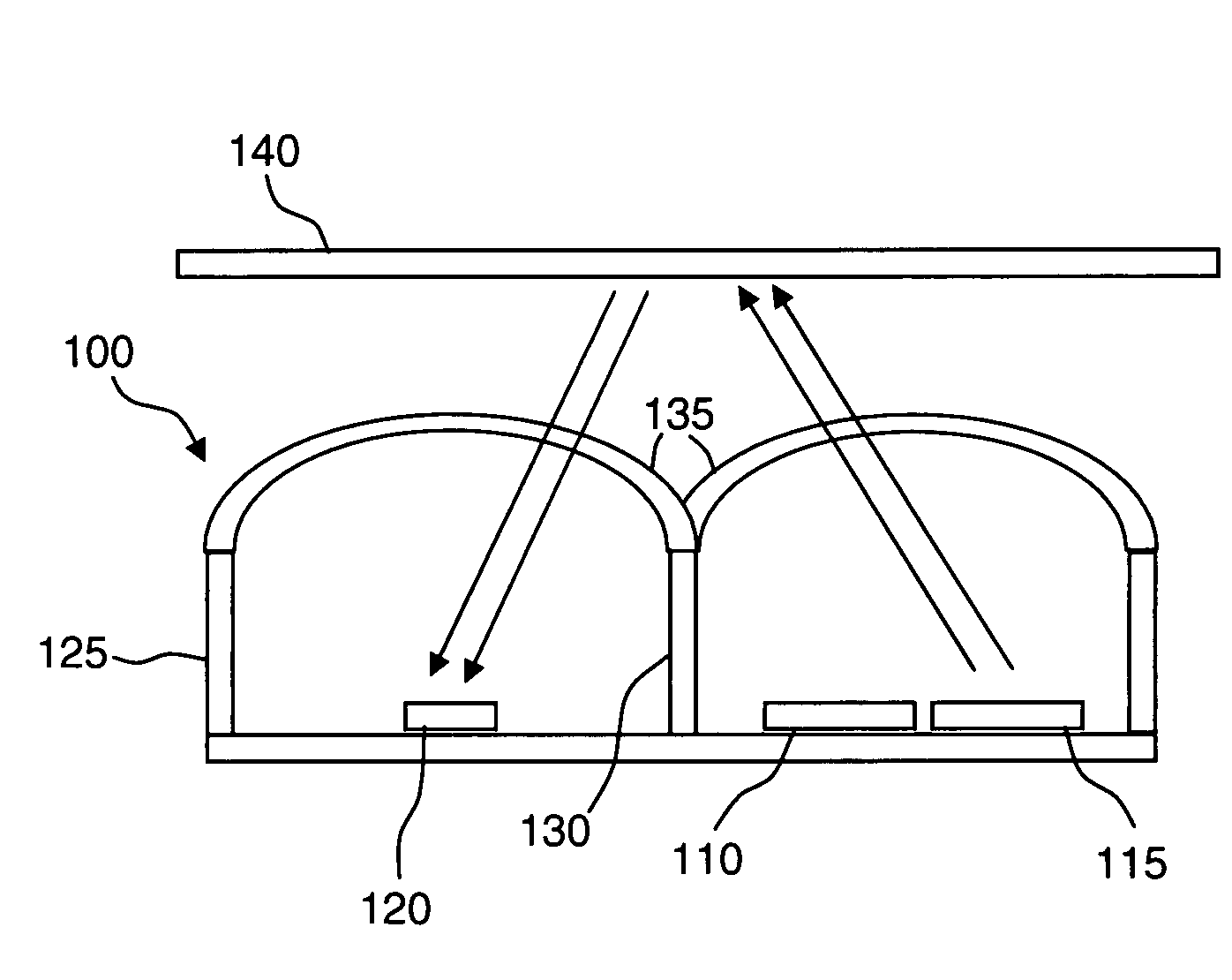

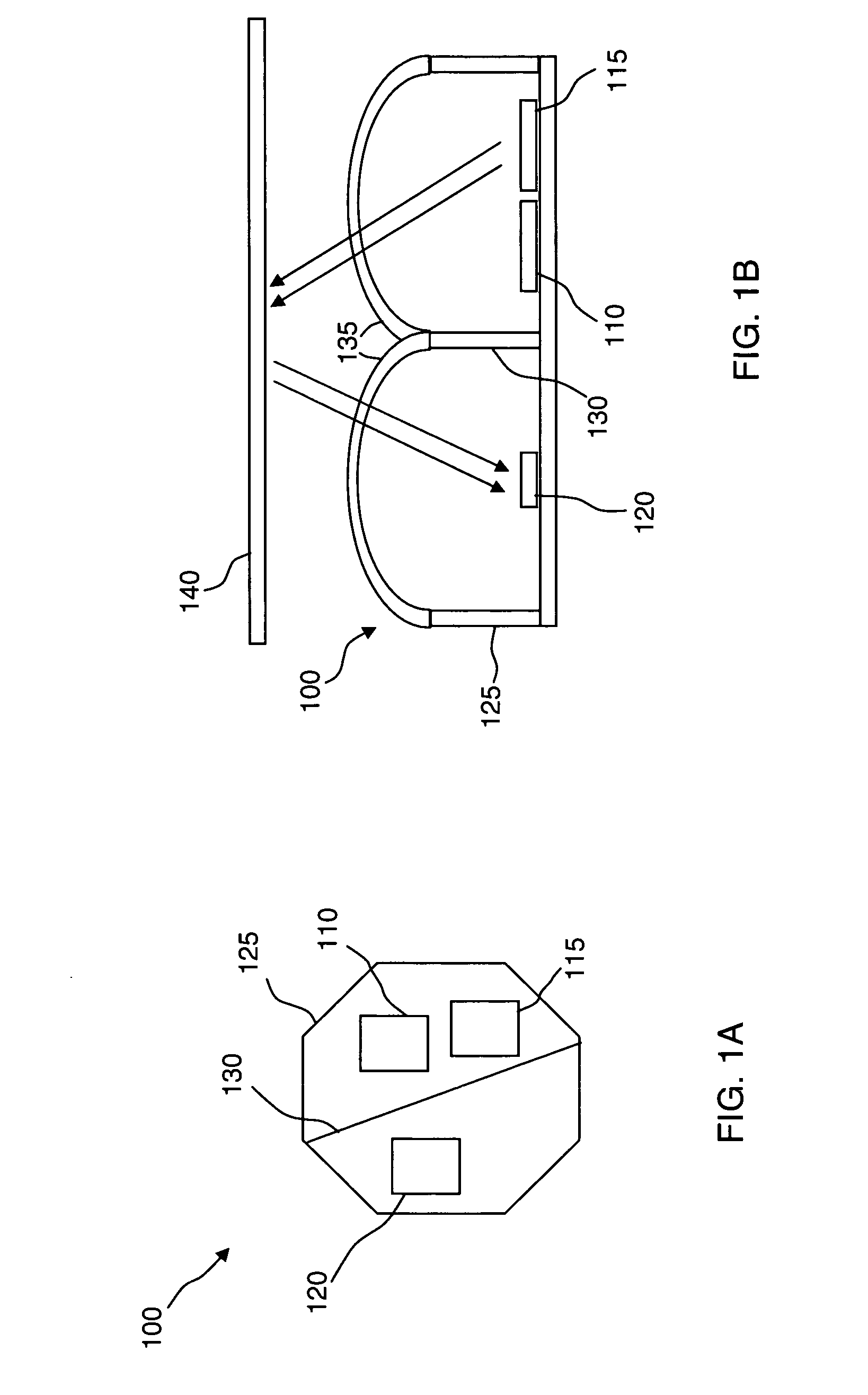

Portable electronic device

InactiveUS20060001920A1Lower levelMultiple functionsPictoral communicationEngineeringPhysical stability

A lightweight, battery operated, portable, personal electronic device capable of faxing, scanning, printing and copying media as a standalone device or in cooperation with other electronic devices including PCs, mobile telephones, PDAs, etc. is provided. The device automatically detects the presence of fax-capable devices and reconfigures the software for compatibility with the fax-capable device eliminating the need for user programming. The device's ergonomic design, intrinsic physical stability, and same side paper feeds and user interface provide use in work areas having limited space. The device includes unidirectional, independent pathways for original and recording media such that paper jams are minimized. Portability is maximized through innovative power management software and hardware.

Owner:SCI FORGE

Hydrazinyl-pyrrolo compounds and methods for producing a conjugate

ActiveUS20150157736A1Effective treatmentMultiple functionsOrganic active ingredientsSugar derivativesCompound structureCombinatorial chemistry

The present disclosure provides conjugate structures and hydrazinyl-pyrrolo compound structures used to produce these conjugates. The disclosure also encompasses methods of production of such conjugates, as well as methods of using the same.

Owner:REDWOOD BIOSCI

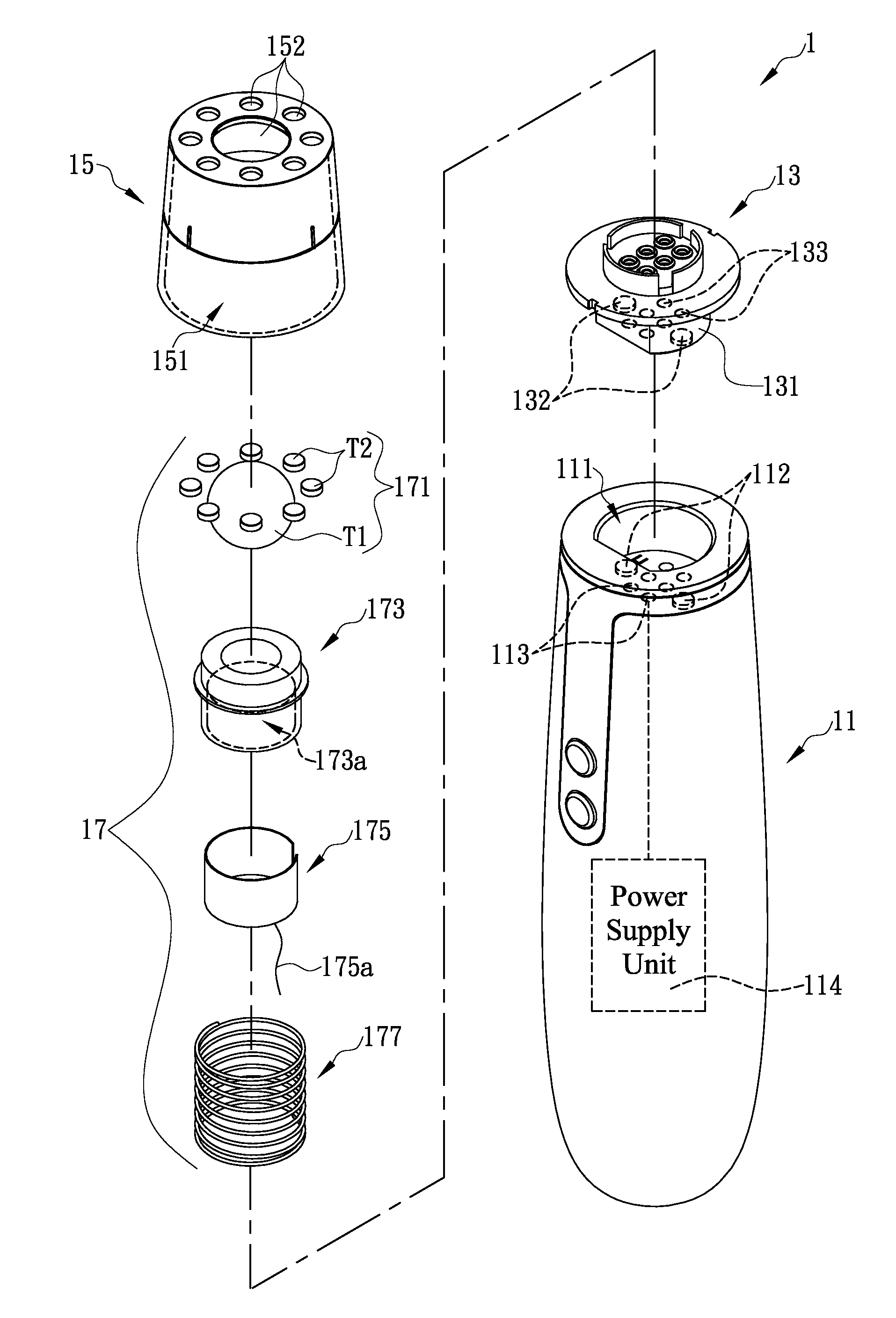

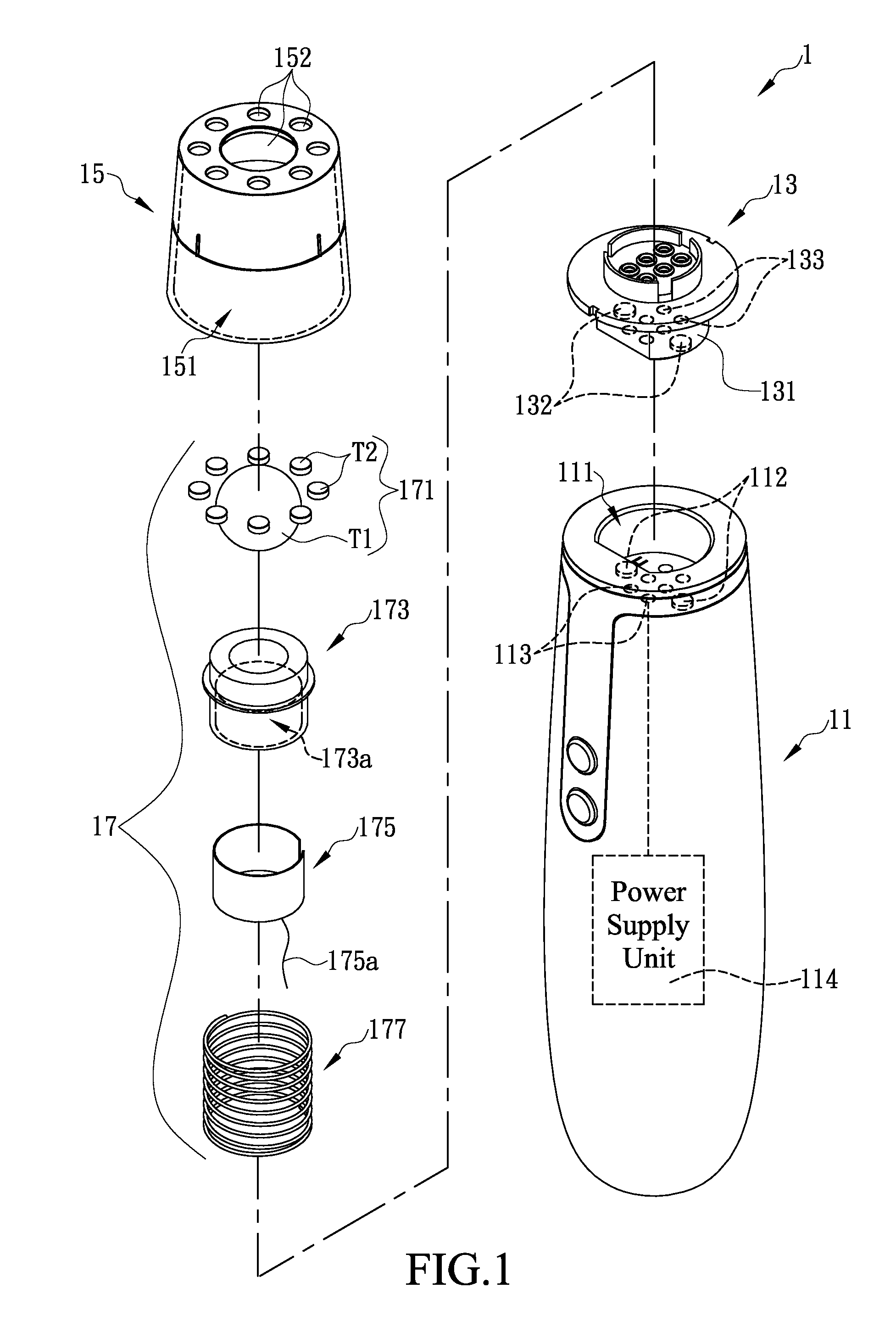

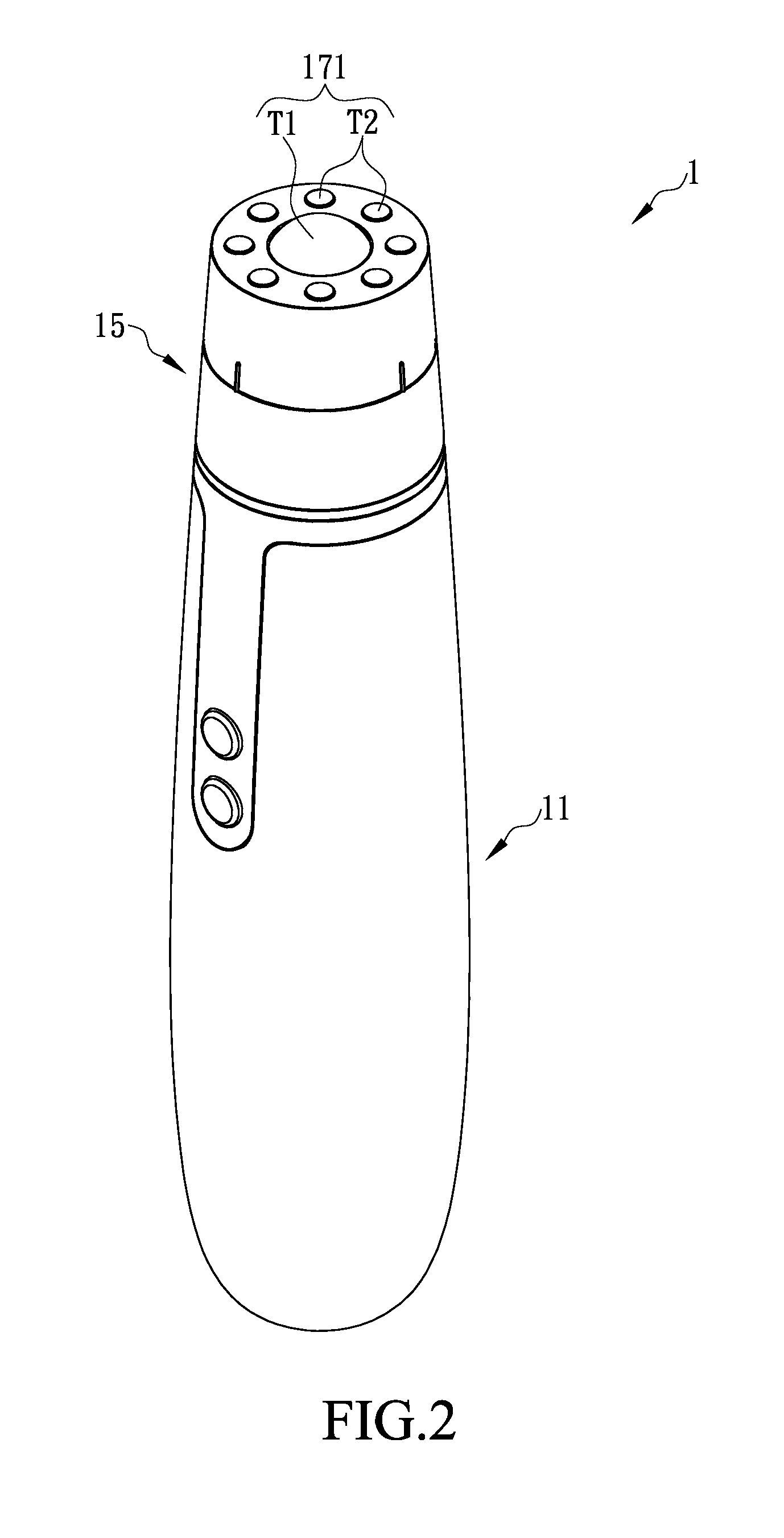

Cosmetic device disposed with magnetic attraction structure and replaceable cosmetic assembly

InactiveUS20150045702A1Low costNot convenient can be usedChiropractic devicesEye exercisersElectricityEngineering

A cosmetic device disposed with a magnetic attraction structure and a replaceable cosmetic assembly is disclosed. The cosmetic device includes a holding unit, a connection part, a cover body, and the cosmetic assembly. The holding unit has a power supply unit and a notch disposed with a first magnetic attraction component and several first connection terminals. The power supply unit electrically connects with the first connection terminals for transmitting electric power. The connection part includes a fixing block disposed with a second magnetic attraction component and several second connection terminals. The second magnetic attraction component and the first magnetic attraction component may attract each other for binding the connection part with the holding unit. The second connection terminals are electrically connected with the first connection terminals. The cosmetic assembly assembled with the cover body, and the cosmetic assembly is electrically connected with the second connection terminals for performing cosmetic functionalities.

Owner:MEI CHI HSINYEN

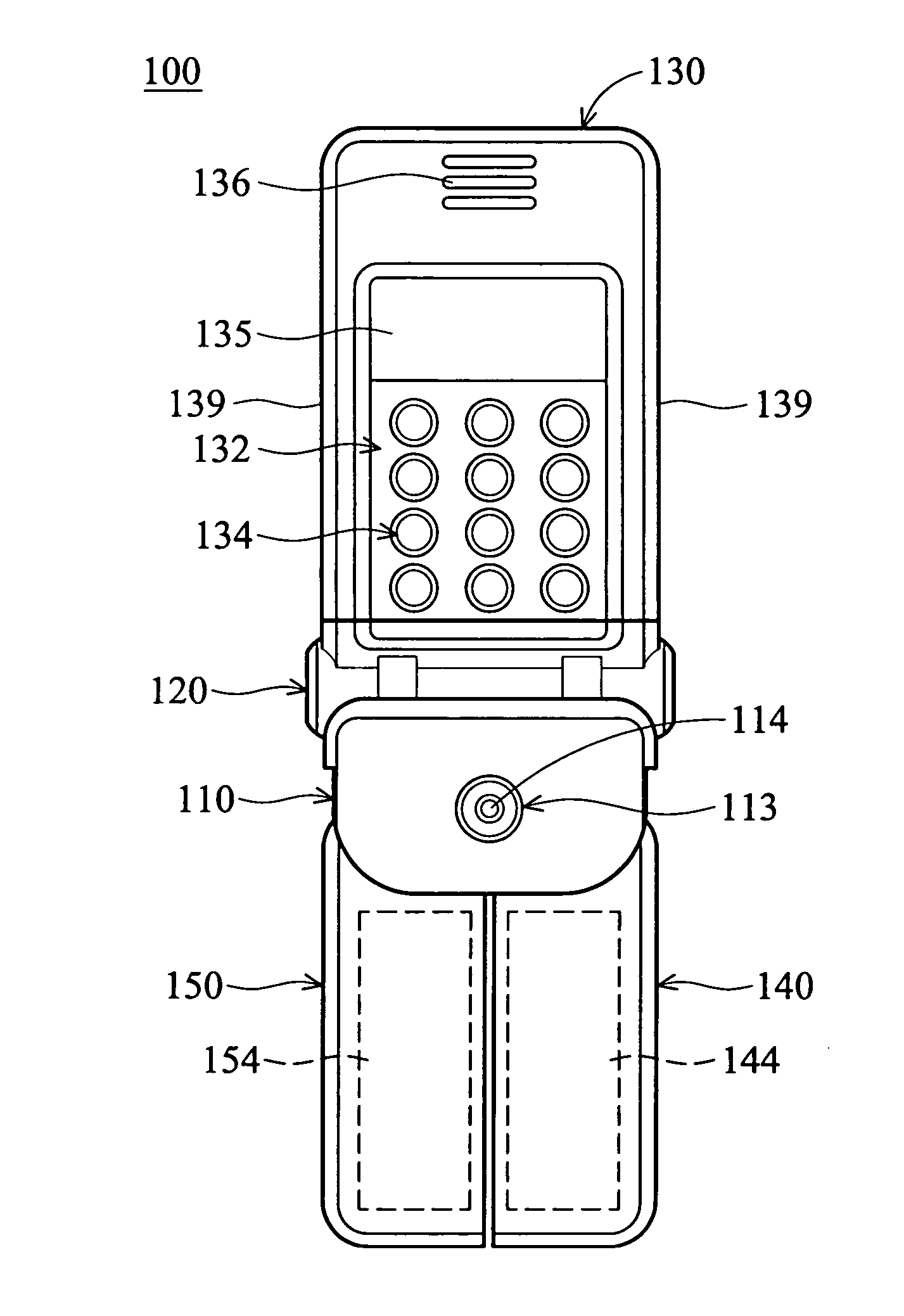

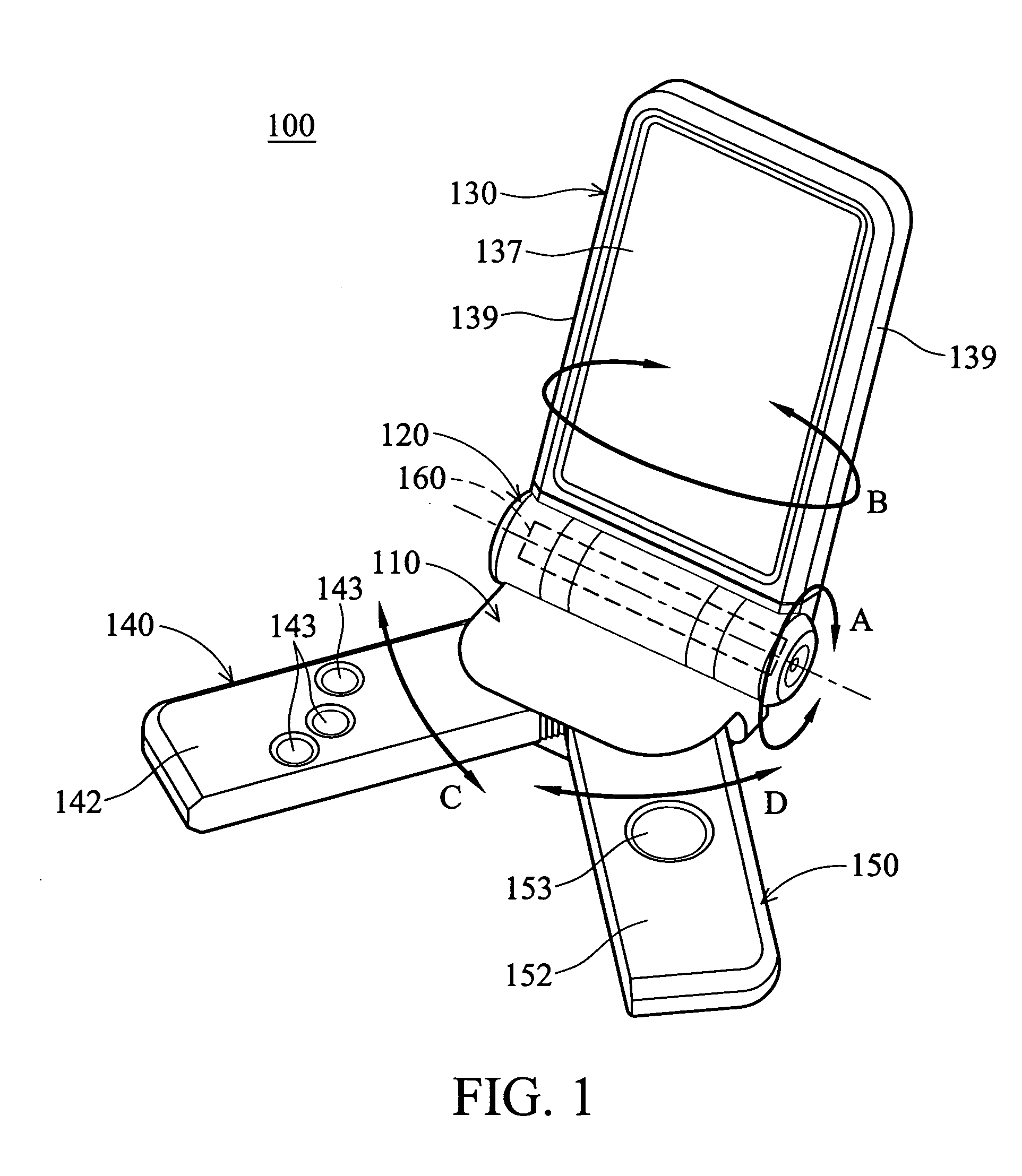

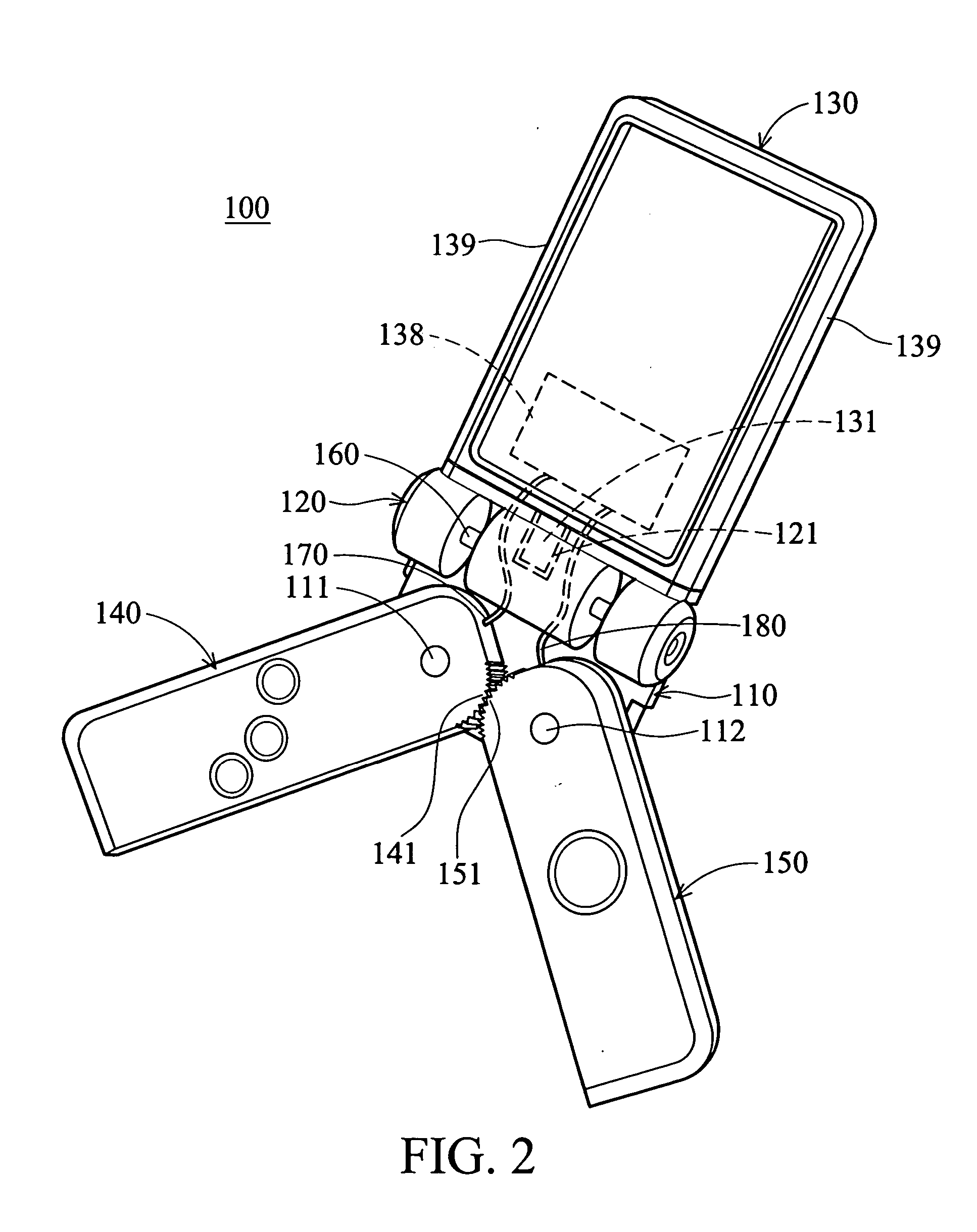

Handheld electronic apparatus

InactiveUS20050070328A1Reduce shapingReduce weightDetails for portable computersTelevision systemsEngineeringElectrical and Electronics engineering

A handheld electronic apparatus. The handheld electronic apparatus includes a first connecting member, a second connecting member, an operating member, a first holding member and a second holding member. The second connecting member is rotatably connected to the first connecting member. The operating member is rotatably connected to the second connecting member. The first holding member is rotatably connected to the first connecting member. The second holding member is rotatably connected to the first connecting member. The first and second holding members relatively rotate between a closed position and an open position. The invention thereby provides convenient use of communication, digital photography, PDA, and video game functions in a single device.

Owner:QUISDA CORP

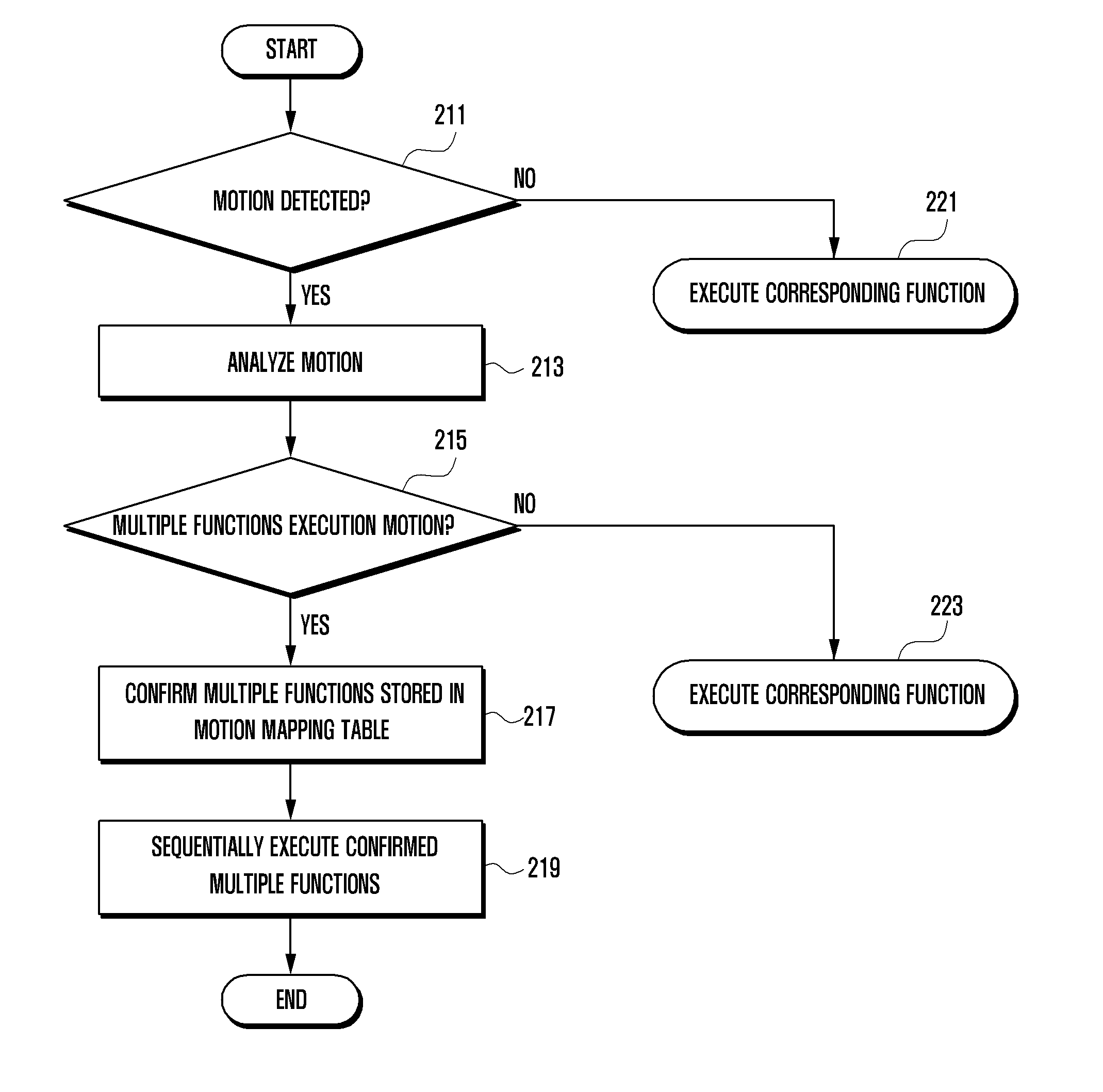

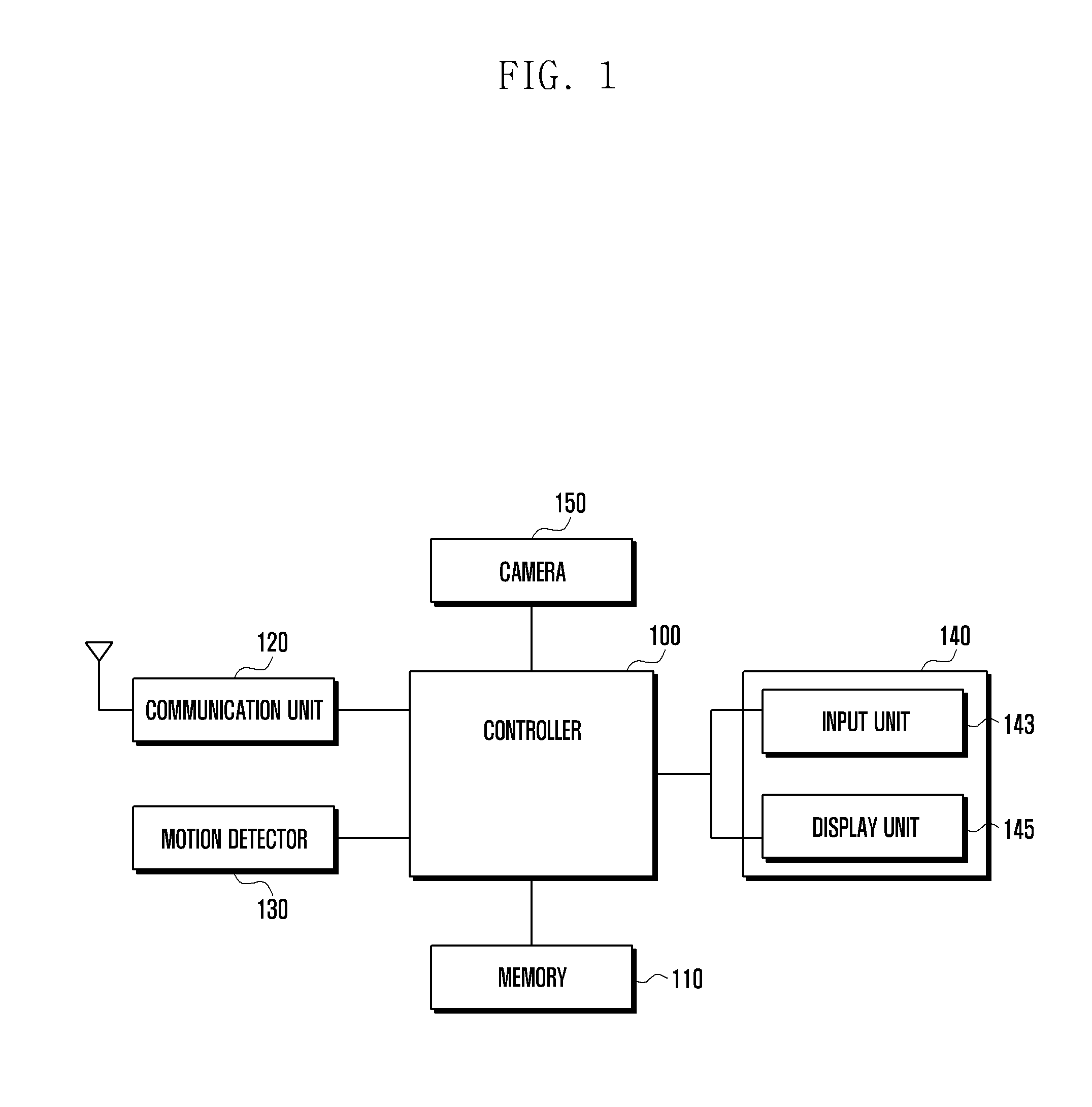

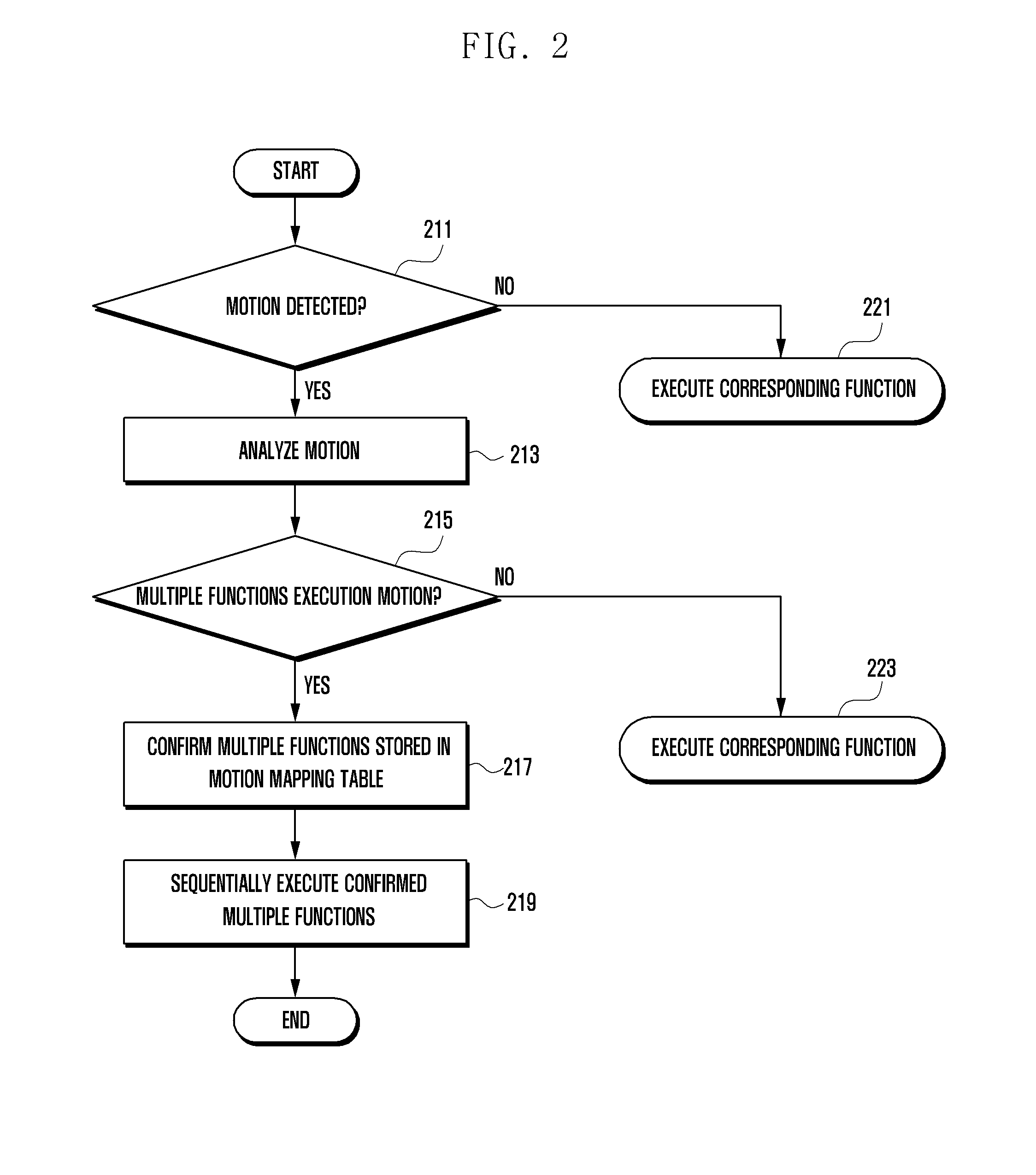

Device and method for executing function of portable terminal

InactiveUS20130154926A1Multiple functionsInput/output for user-computer interactionDigital data processing detailsMotion detectorComputer terminal

A method for executing a plurality of functions in a portable terminal, includes: confirming a type of a motion experienced by the portable terminal when the motion experienced by the portable terminal is detected by a motion detector; confirming at least two functions preset to correspond to the confirmed type of the motion by referencing a motion mapping table that stores both the at least two functions and the type of motion corresponding to the at least two functions such that the at least two functions are continuously executed in response to a one motion experienced by the portable terminal; and sequentially executing the confirmed at least two functions.

Owner:SAMSUNG ELECTRONICS CO LTD

Micro magnetic proximity sensor system

InactiveUS7301334B2Easy to fabricateEasy to usePermanent magnet reed switchesUsing electrical meansProximity sensorEngineering

A system that senses proximity includes a magnet producing a magnetic field and a sensor having a switch. The switch includes a cantilever supported by a supporting structure. The cantilever has a magnetic material and a longitudinal axis. The magnetic material makes the cantilever sensitive to the magnetic field, such that the cantilever is configured to move between first and second states. The switch also includes contacts supported by the support structure. The switch can be configured as a reed switch. When the magnet moves relative to the sensor, the cantilever interacts with a respective one of the contacts based on the position of the magnet during movement.

Owner:SCHNEIDER ELECTRIC IND SAS

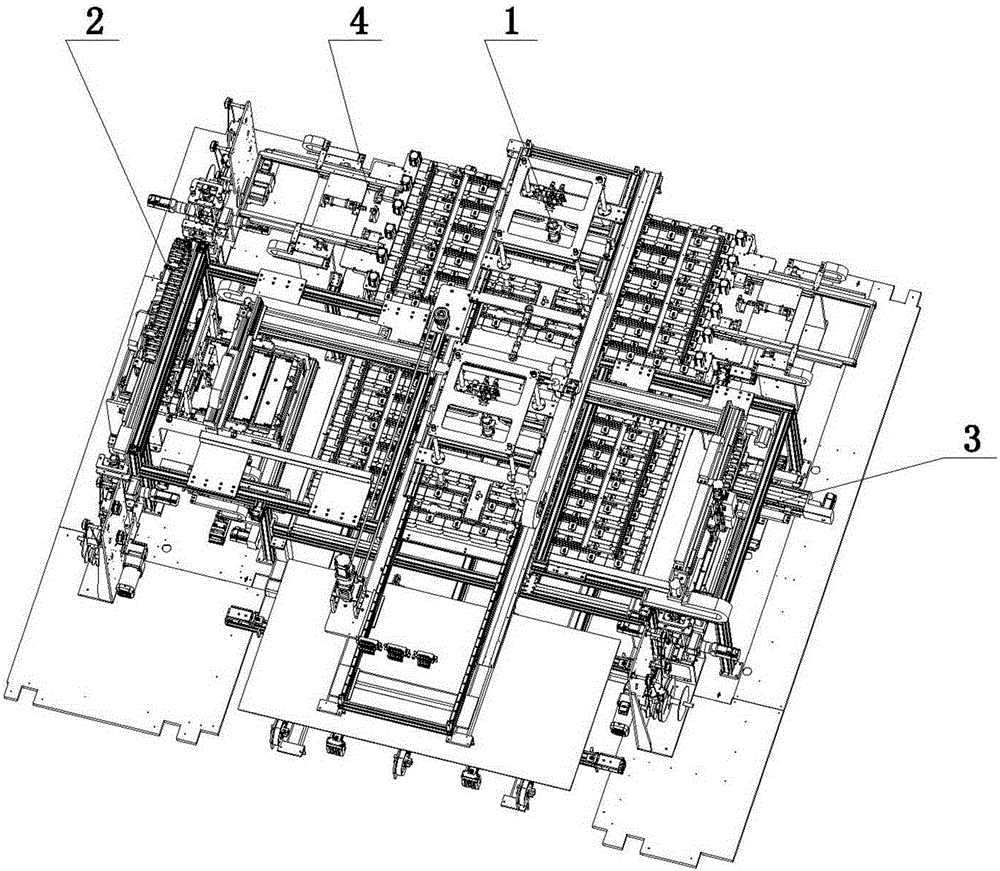

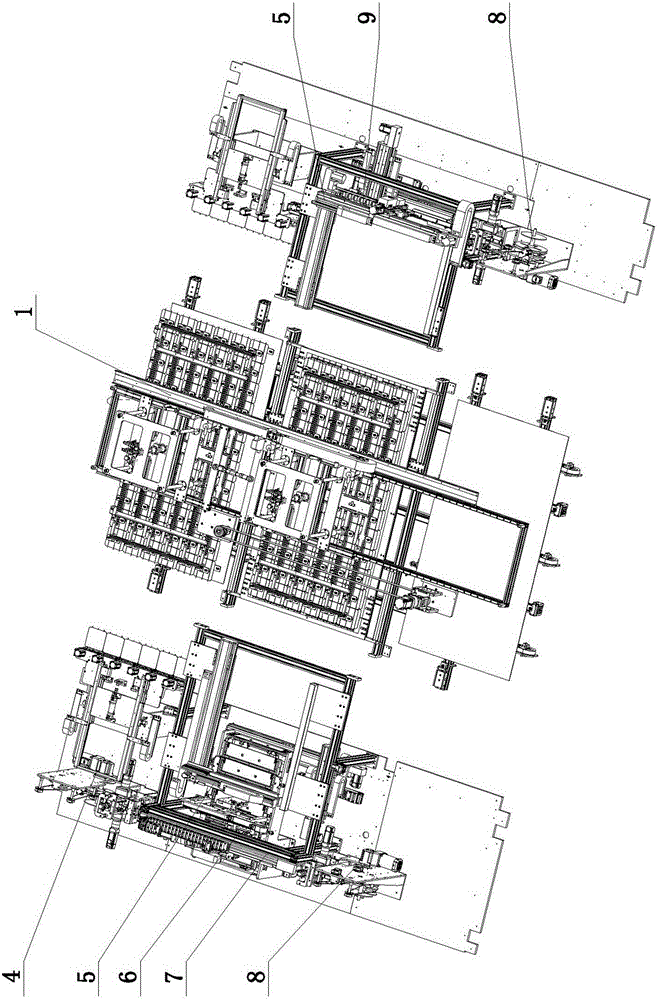

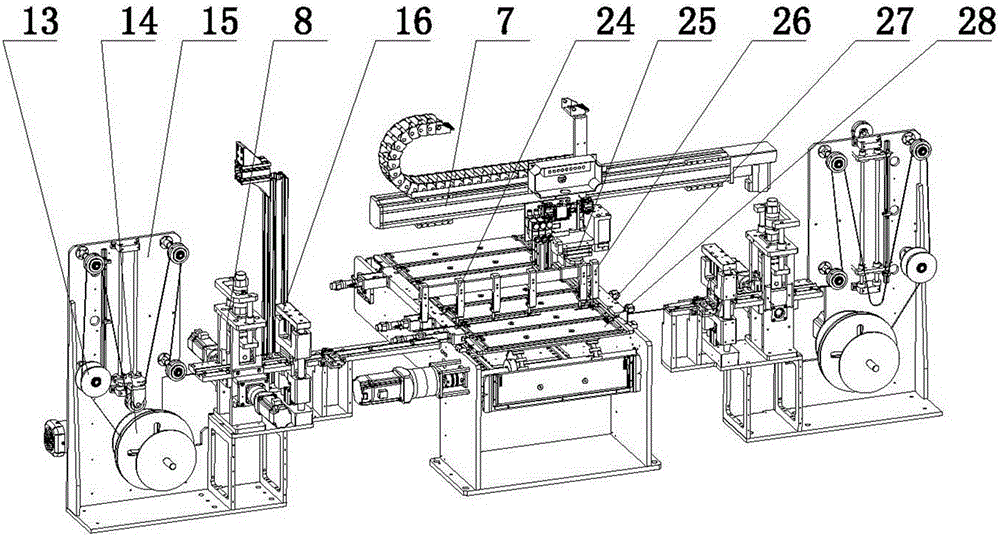

Automatic battery string bus bar welding machine

ActiveCN105108366ARealize automated production and processingIncrease productivityWelding/cutting auxillary devicesAuxillary welding devicesElectrical batteryEngineering

The invention belongs to the technical field of automatic solar battery pack production devices, and particularly relates to an automatic battery string bus bar welding machine. The automatic battery string bus bar welding machine is compact in structure, capable of saving occupied space and high in automation degree. The automatic battery string bus bar welding machine comprises a welding platform transmission line, and is characterized in that an L-shaped bus bar welding module is arranged on one side of the welding platform transmission line, and a linear bus bar welding module is arranged on the other side of the welding platform transmission line.

Owner:YINGKOU JINCHEN MACHINERY

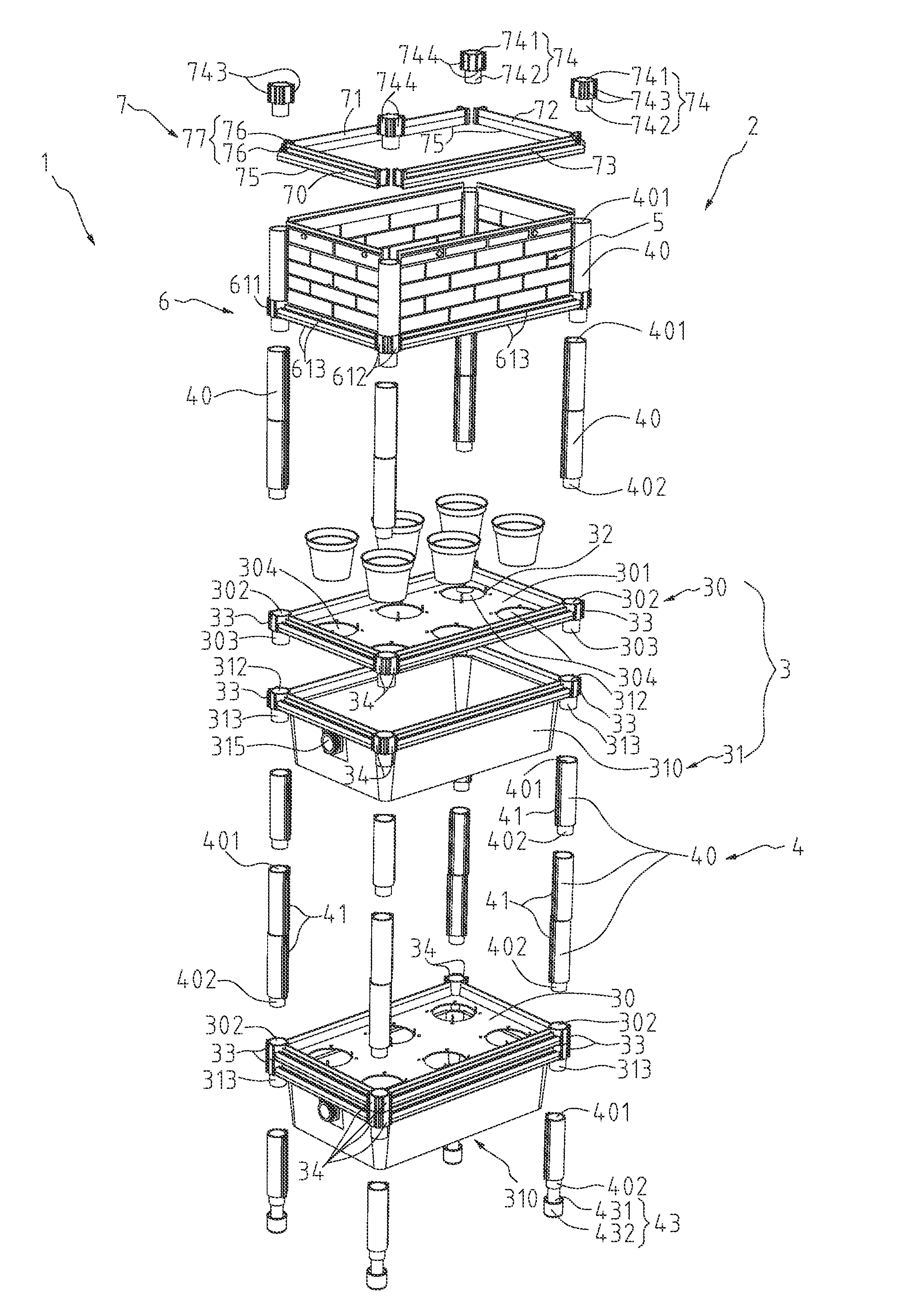

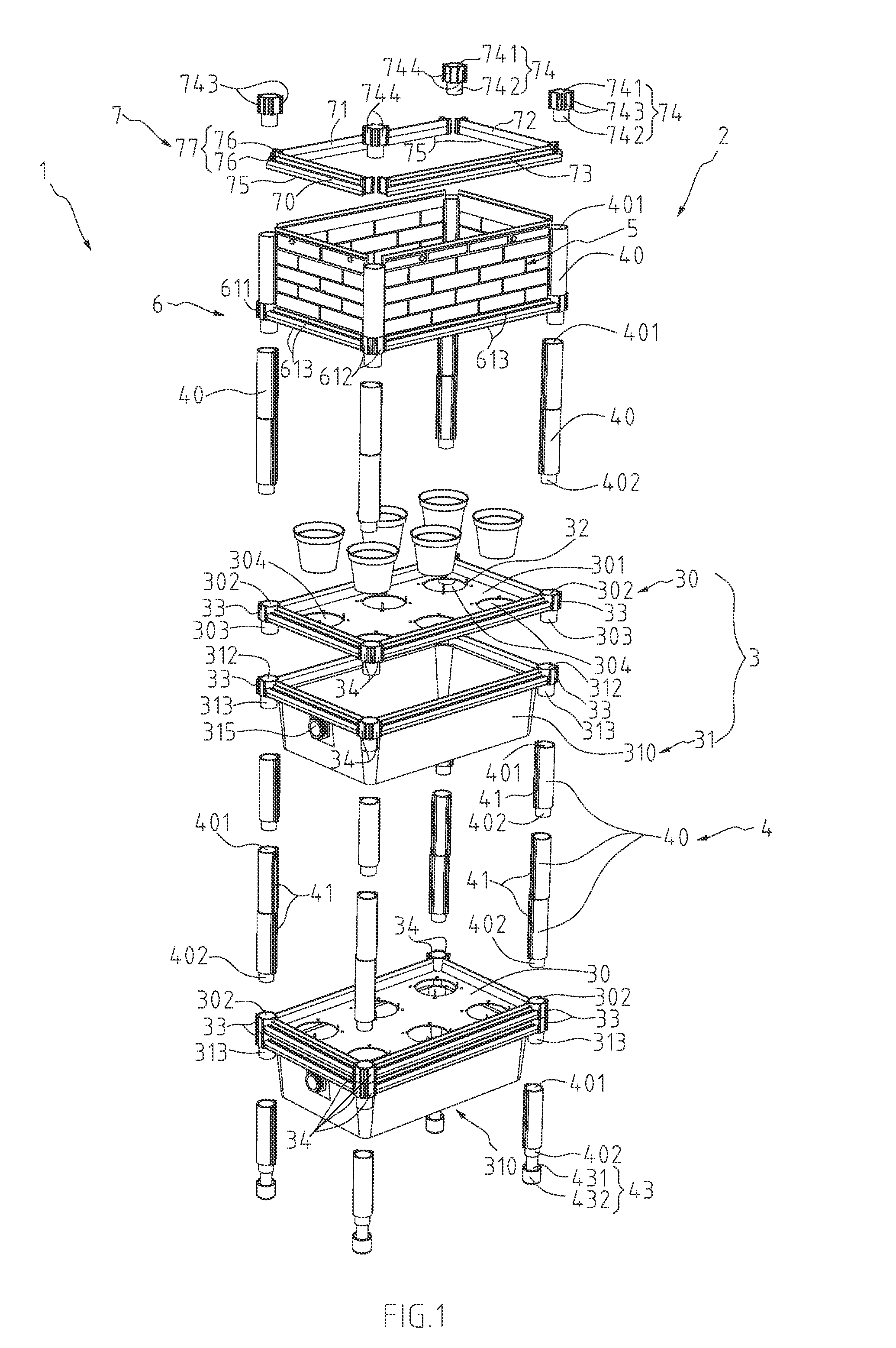

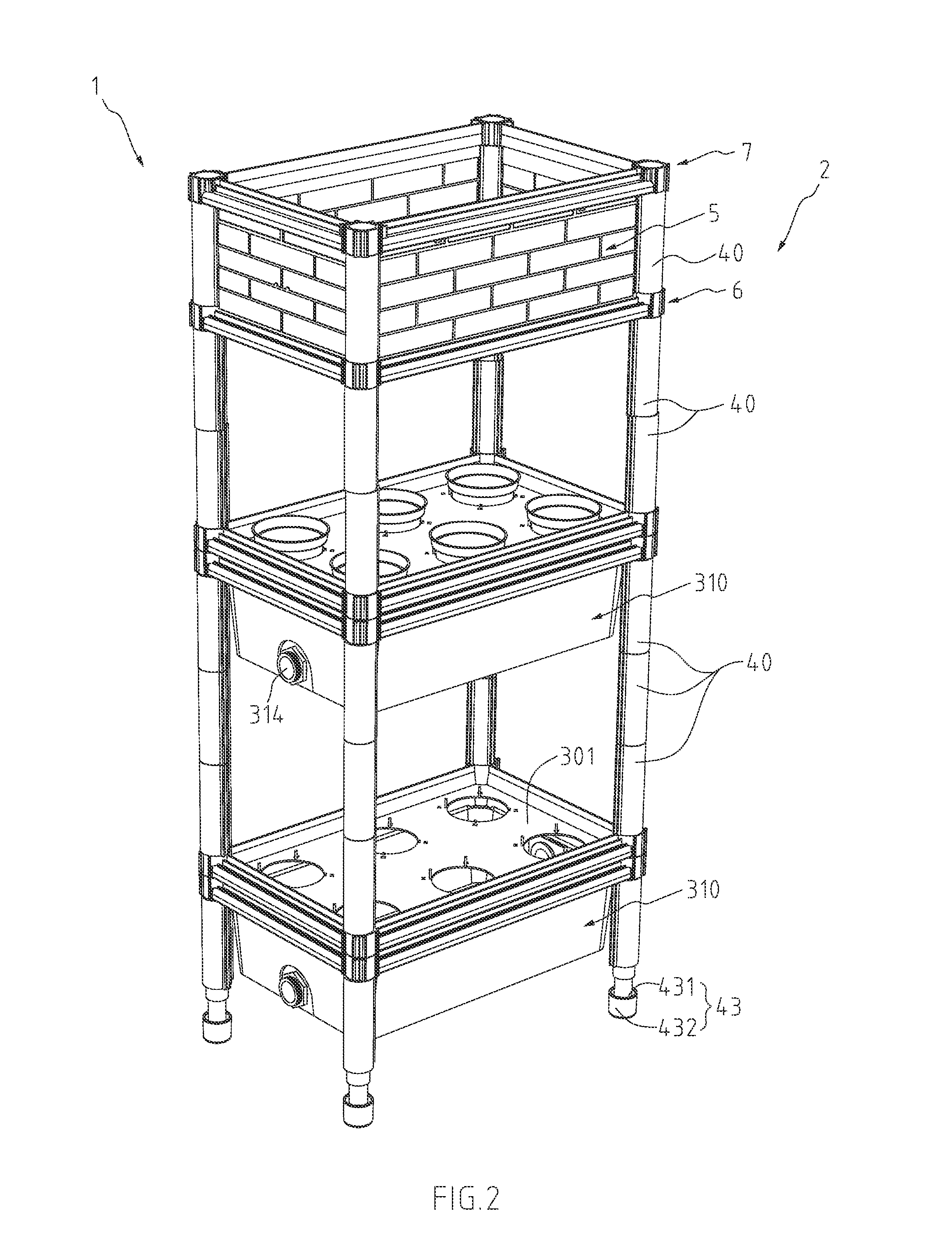

Planting box device

ActiveUS20150201563A1Simple structureReasonable designFlower tablesCultivating equipmentsModularityEngineering

The present invention provides a planting box device composed of at least a modular frame, which further comprises a frame set, a connecting rod group, wherein the frame set includes a first frame and a second frame; the first frame has a bearing plate, four corners of which are positioned by first openings and first posts and which also forms a plurality of positioning openings; the second frame having a sink forms second openings and second posts on its four corners, wherein the second posts are accommodated with the first openings in size and the sink has an inlet and an outlet; the connecting rod group comprises a plurality of connecting rods, each of which has rod openings and rod posts, so that the composition of the planting box device described above has function of structural expansion in horizontal and vertical direction and thus provides convenience in assembly and disassembly.

Owner:CHIANG YI CHENG +1

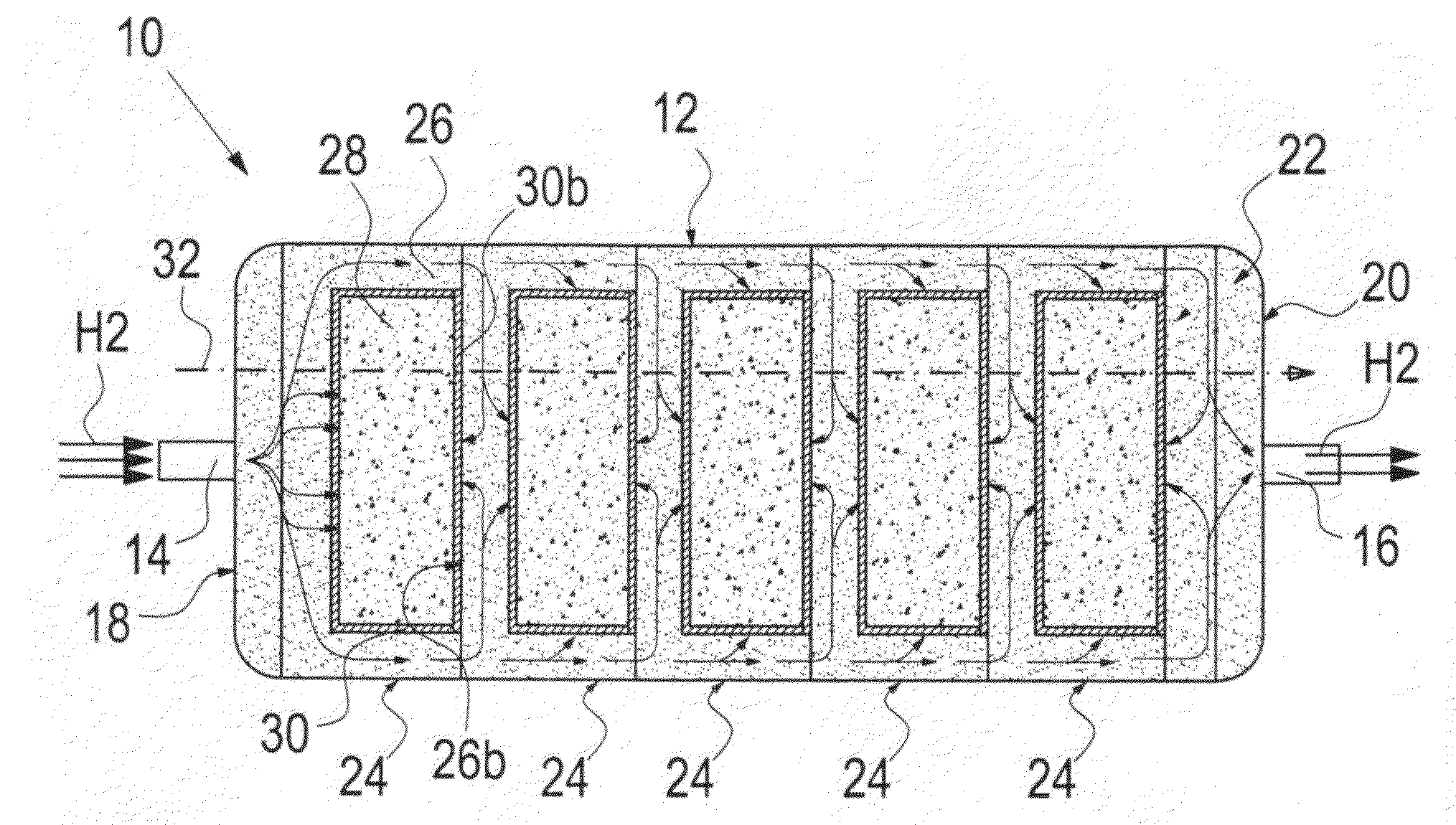

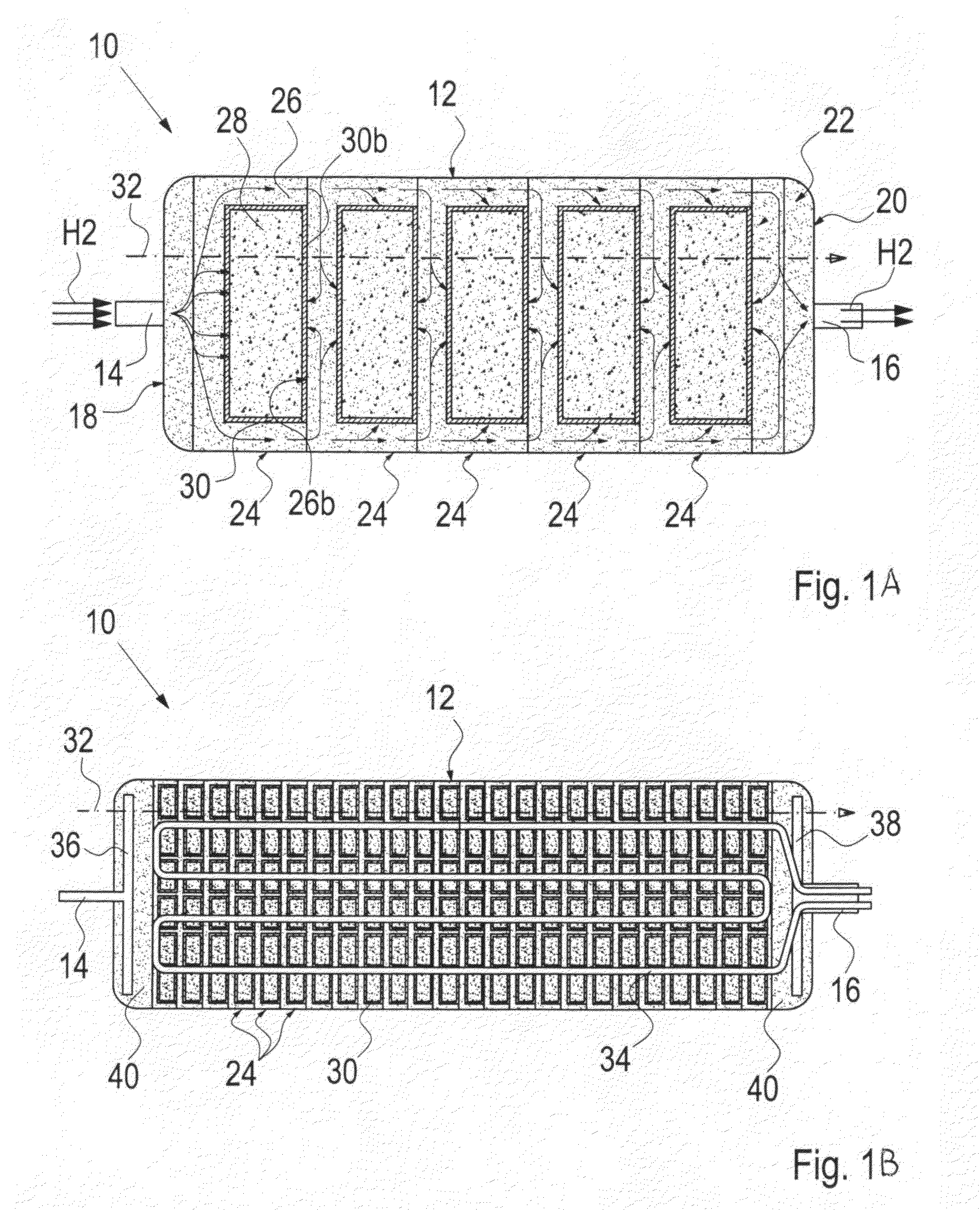

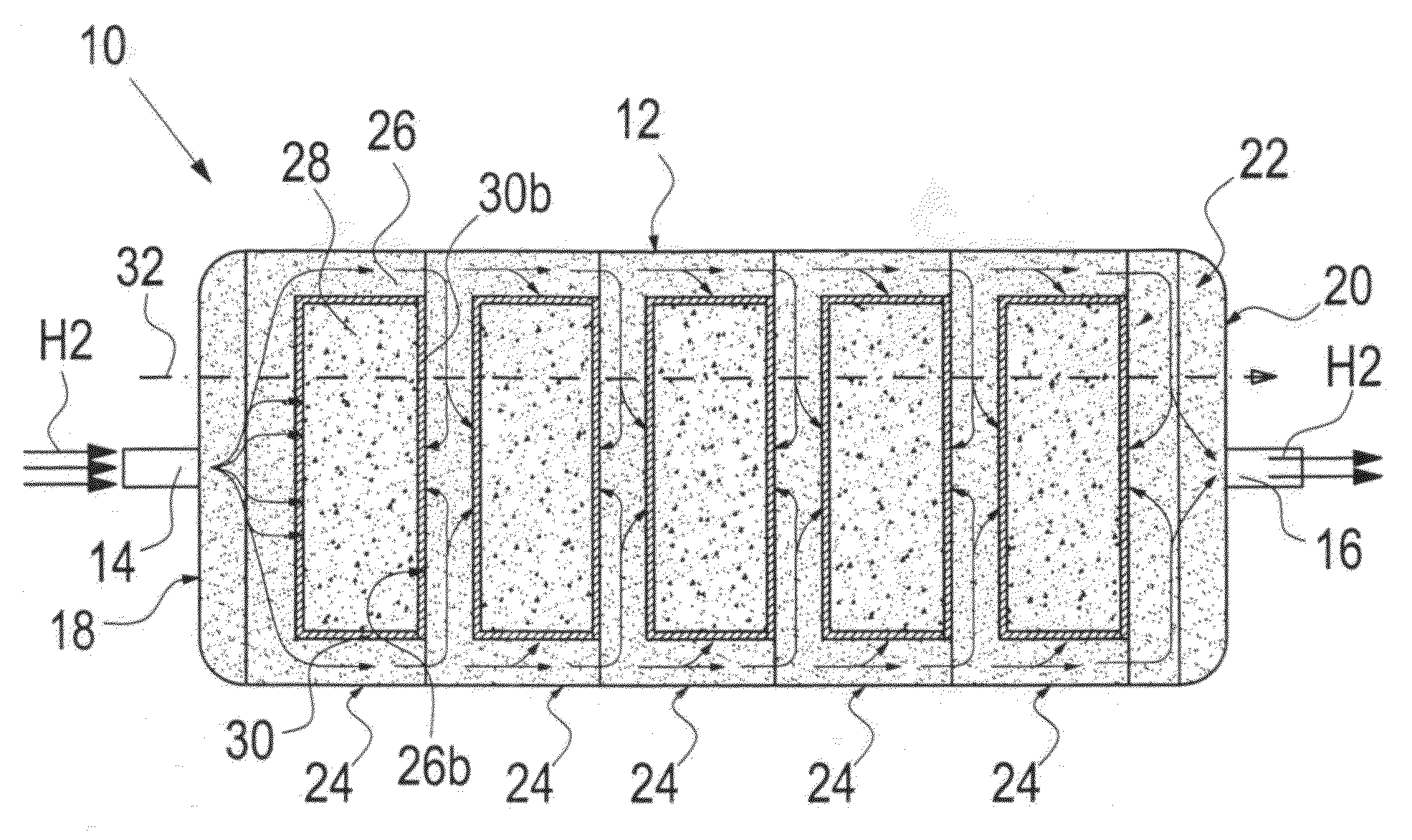

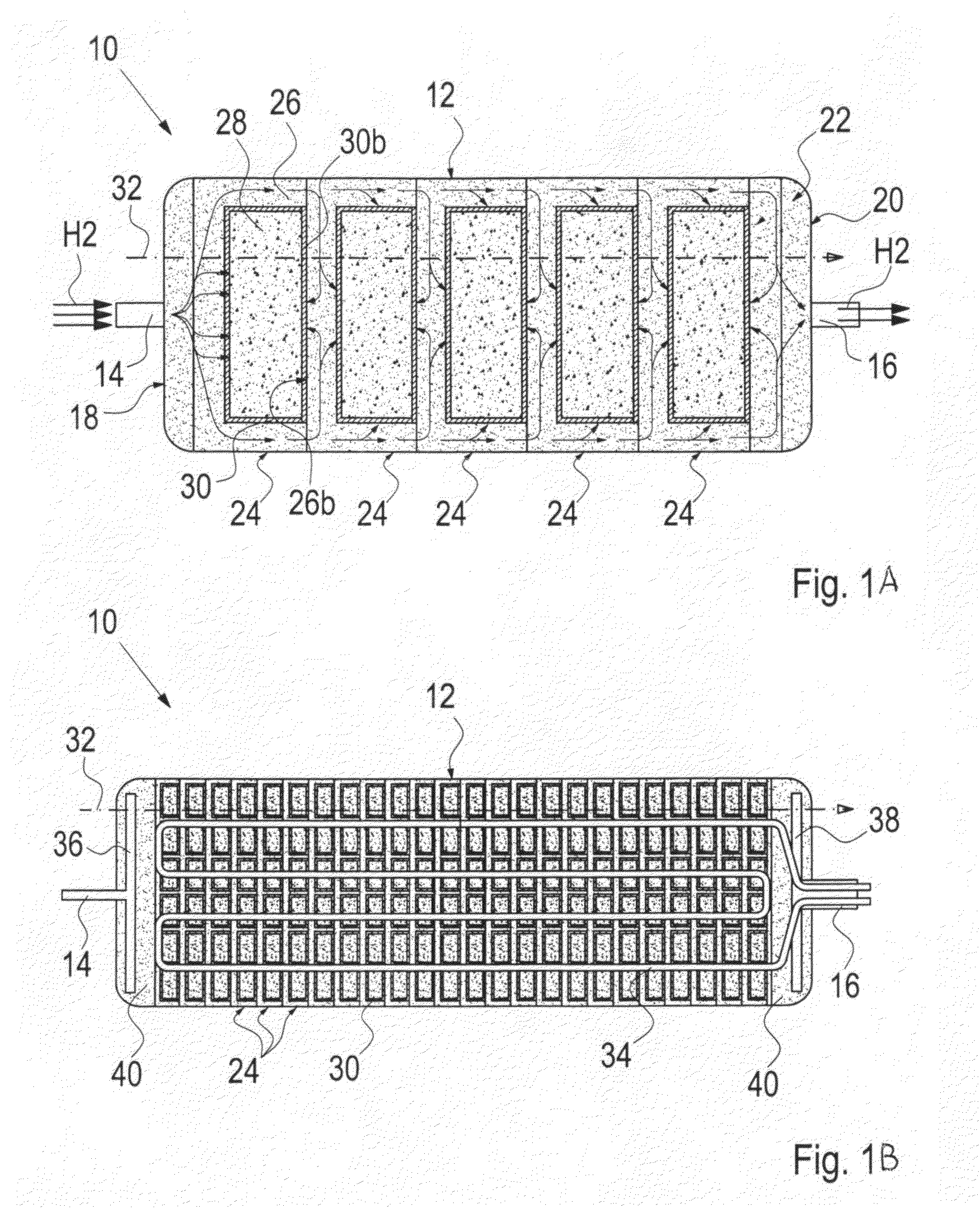

Hydrogen reservoir and process for filling a hydrogen reservoir

InactiveUS20090127137A1Increase profitImprove reaction kineticsReversible hydrogen uptakeContainer filling methodsProcess engineeringHydrogen storage

In a hydrogen reservoir having a housing with a hydrogen storage material arranged in the housing for absorbing and releasing hydrogen as needed, the hydrogen reservoir includes at least one unit having a porous body surrounding a container in which the hydrogen storage material is contained and a method is provided for charging the hydrogen reservoir with hydrogen from a hydrogen filling stations.

Owner:DAIMLER AG

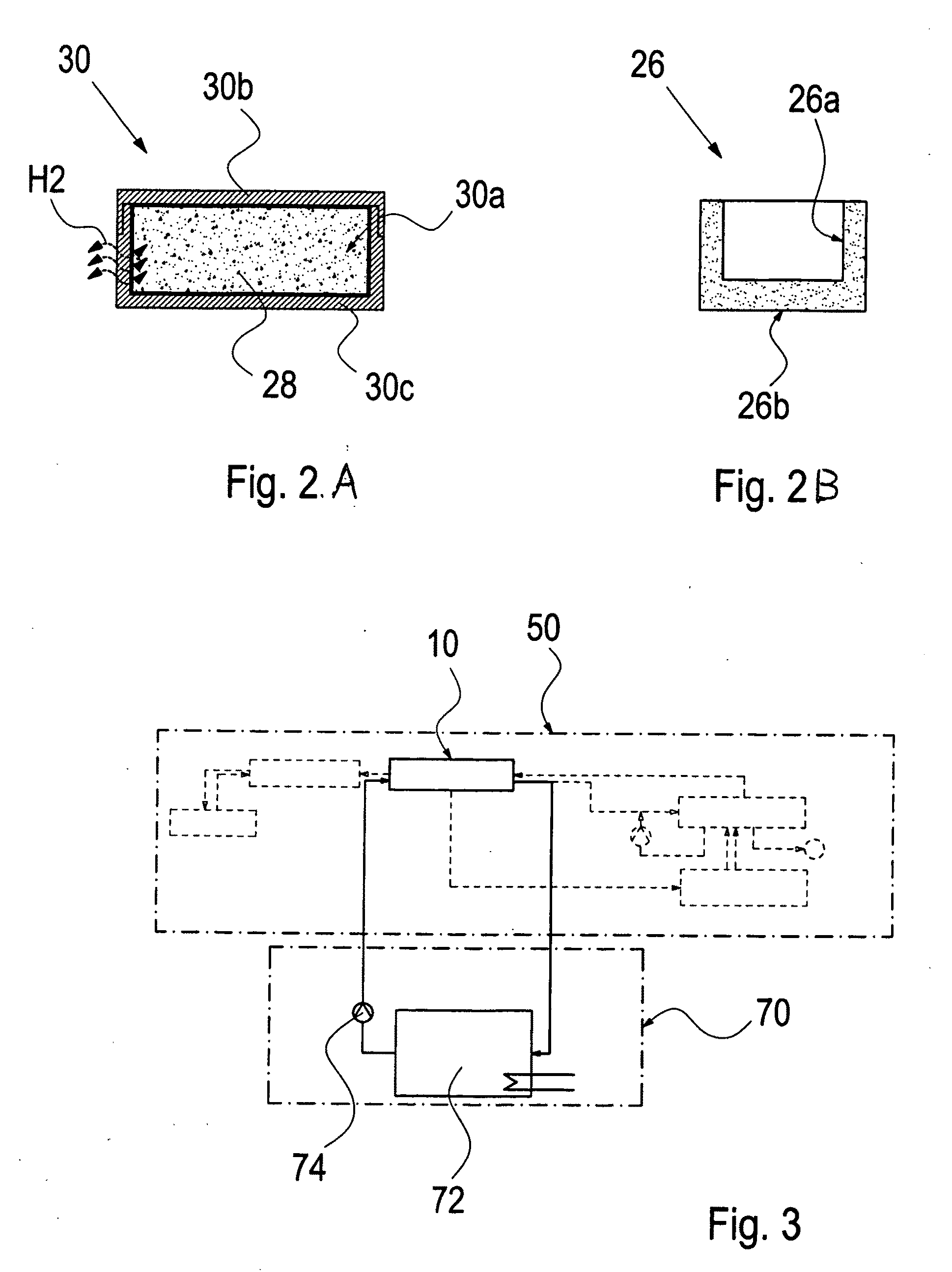

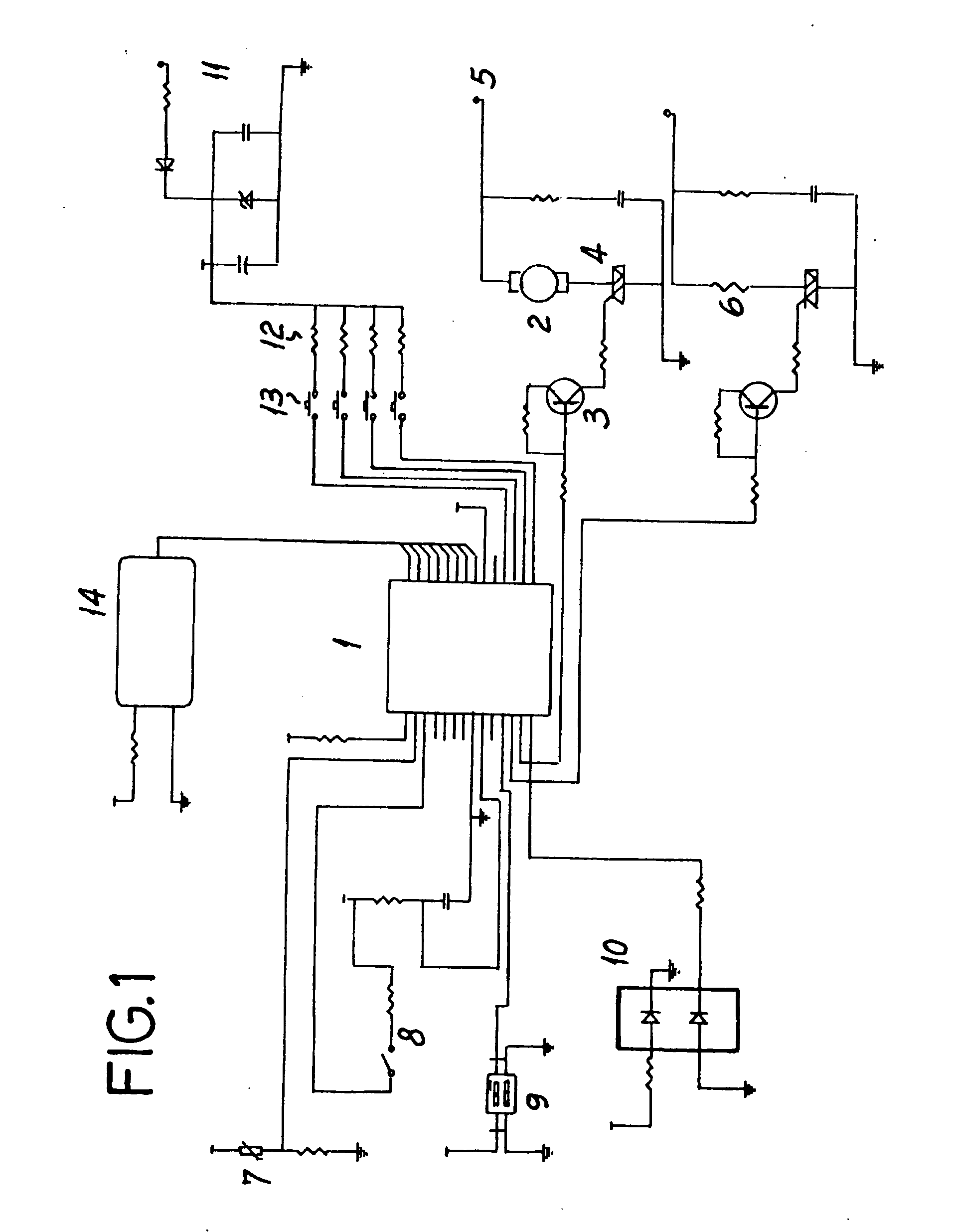

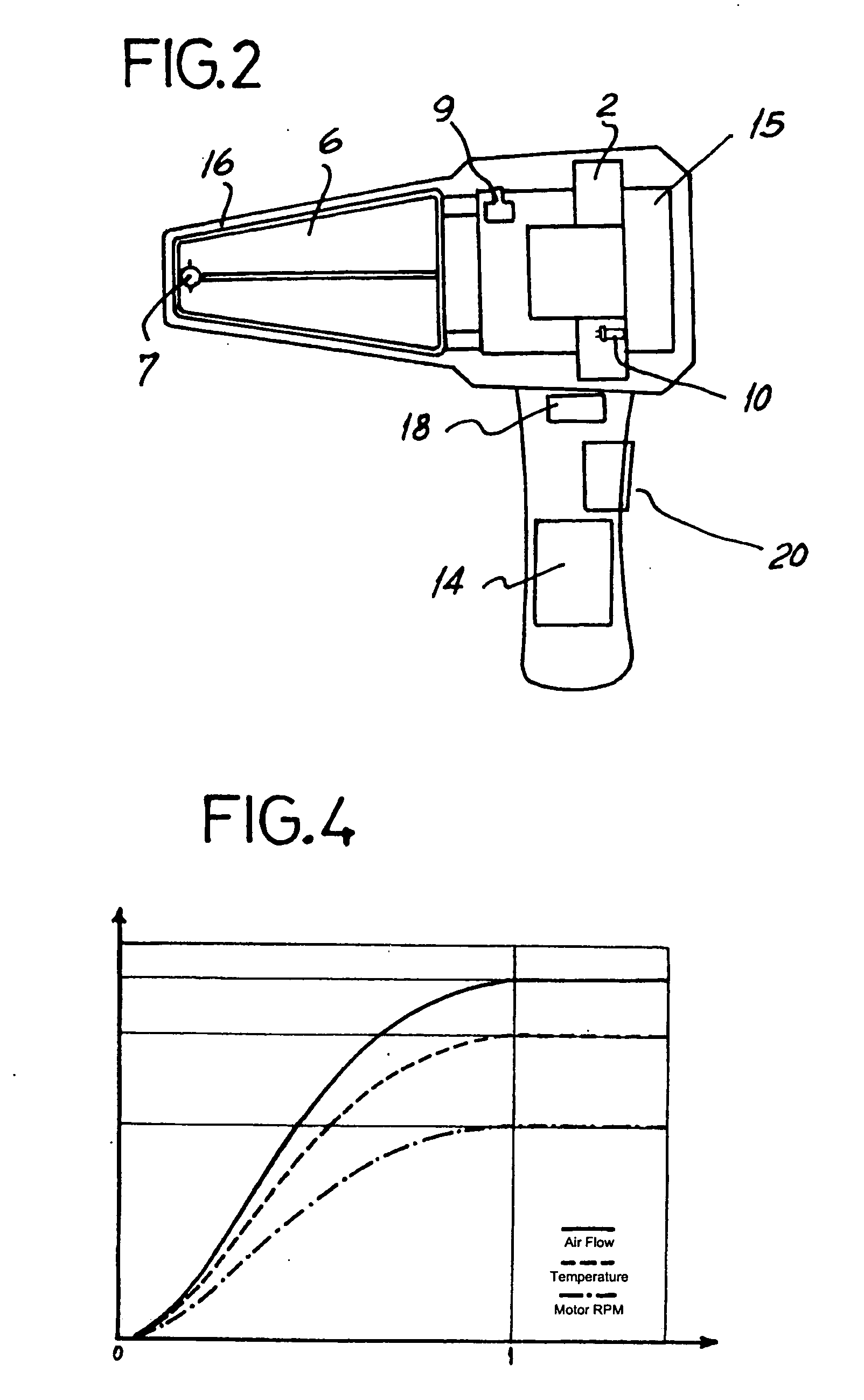

Programmable manual hair dryer with multiple functions

InactiveUS20060098962A1Simple and economical arrangementMultiple functionsDrying solid materials with heatDrying gas arrangementsMotor speedDisplay device

The dryer includes in its programmable control circuit a microprocessor to which are connected at least a temperature sensor, a static pressure sensor, a motor revolution sensor, a ion generator, a resistor battery with its selector switches in series, and the respective power circuits of the motor and the air heater aforesaid, in which, in order to optimize the processing route, said microprocessor, after the dryer is turned on and the operating values of parameters, establishes the initial operating configuration at 50% of the value thereof, and then defines continuously, in terms of the ordinary data base, the constant functional conditions, and responds to electric, thermal and mechanical discrepancies being involved with its corrective stabilization, recording, signaling and information by means of a display. The stabilization of the ordinary operation conditions, both of the motor and of the heating resistor is achieved by means of the corresponding sensor, the information from which is channeled towards and from the respective speed and temperature control while the signaling and the information are carried out by connecting the respective control in turn to the corresponding VU meter and the equipment display. The recording of events receives directly the information from sensors and from speed and temperature controls, while from the aforesaid speed and temperature controls the information is sent back to the parameter status verification point.

Owner:DUNA ENTERPRISES SA

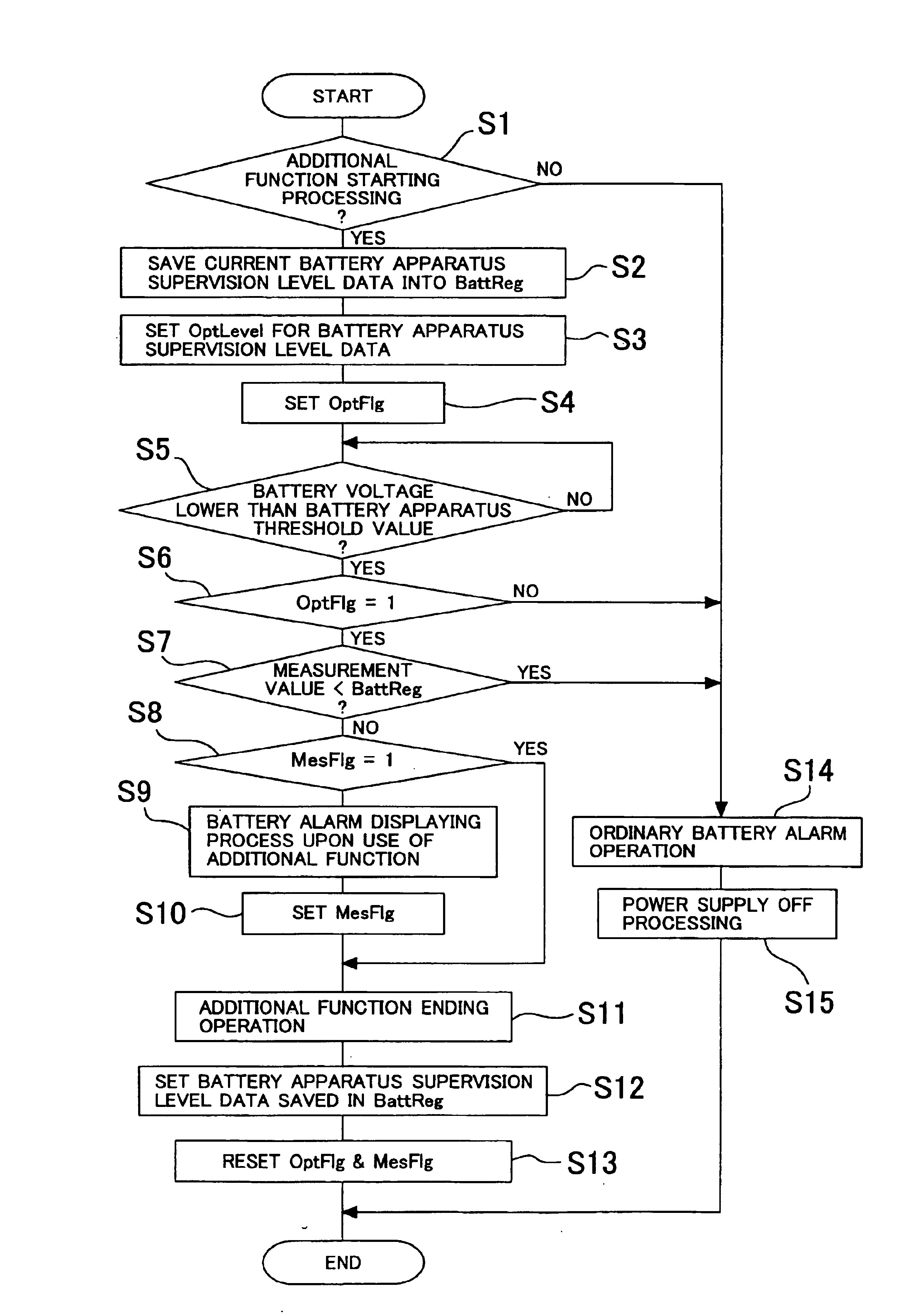

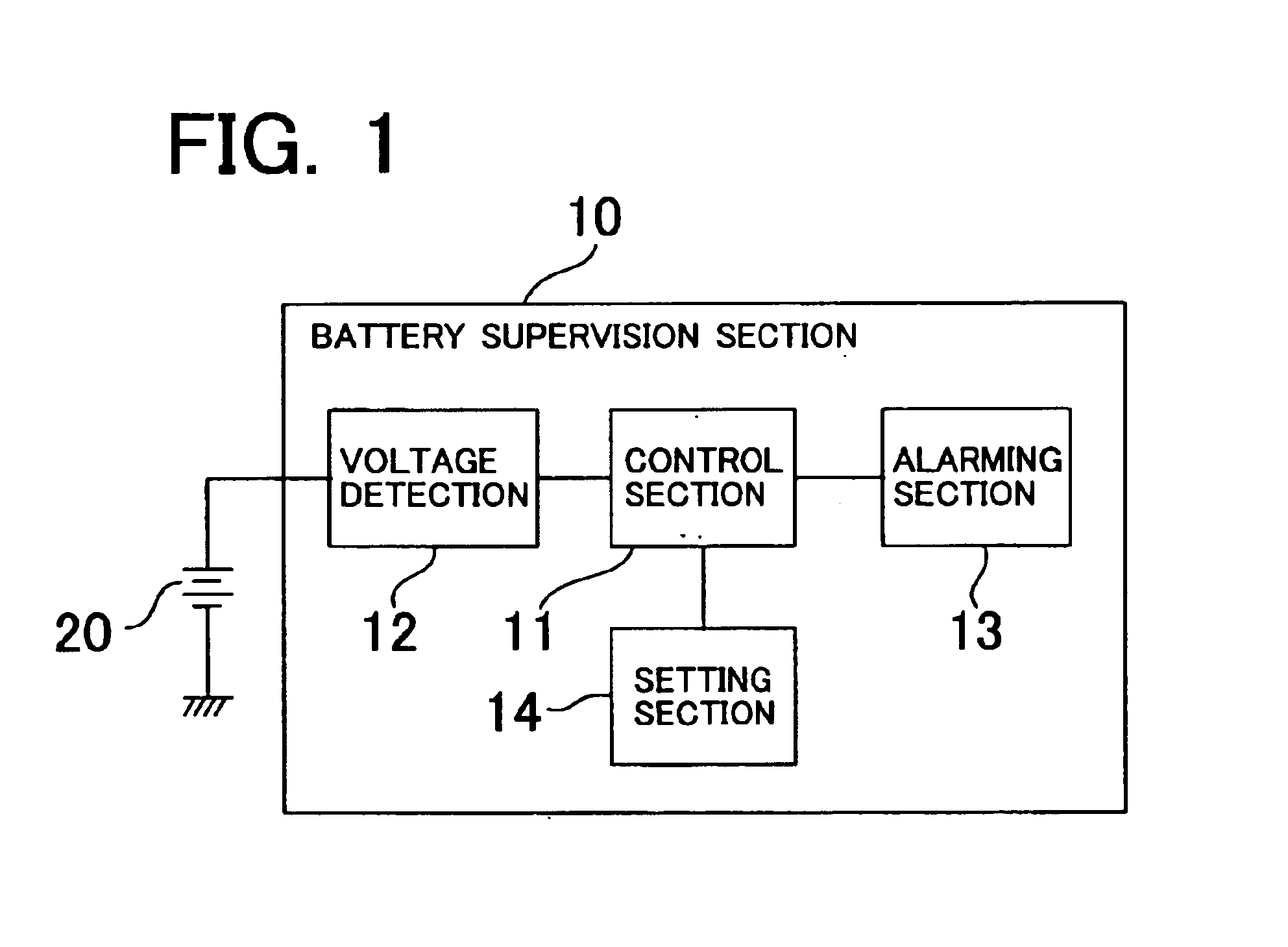

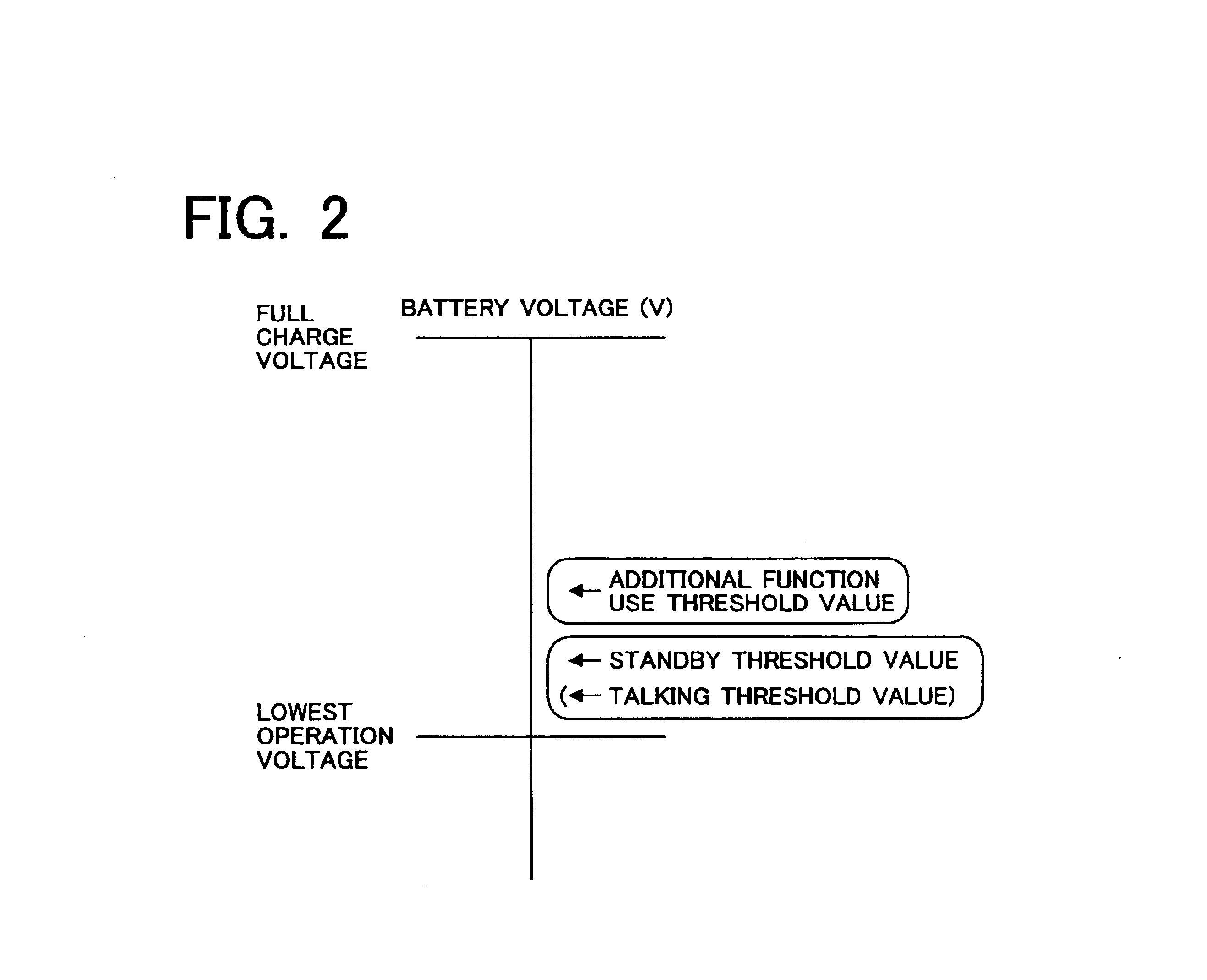

Portable telephone with a battery alarm function indicating lowest level for communication

InactiveUS6898446B2Low working voltageMultiple functionsCordless telephonesPower managementRechargeable cellVoltage drop

A portable telephone apparatus including a battery alarm function wherein consumption of a battery apparatus through use of an additional function other than a talking function can be prevented to assure a lowest operation voltage for the talking function. The portable telephone apparatus includes a rechargeable battery, and a battery supervision section. The battery supervision section includes a voltage detection section for supervising and detecting a voltage of the battery controlled by a control section, and an alarming section for issuing a lowest operation voltage level alarm under the control of the control section when the detected voltage drops to a lowest operation voltage level that a talking function of the portable telephone apparatus can operate. The alarming section issues a supervision voltage level alarm when the detected voltage of the battery drops to a supervision voltage level different from the lowest operation voltage level.

Owner:LENOVO INNOVATIONS LTD HONG KONG

Hydrogen reservoir and process for filling a hydrogen reservoir

InactiveUS7947119B2Inexpensive and safe constructionSimple to fillReversible hydrogen uptakeEnergy inputProcess engineeringHydrogen storage

In a hydrogen reservoir having a housing with a hydrogen storage material arranged in the housing for absorbing and releasing hydrogen as needed, the hydrogen reservoir includes at least one unit having a porous body surrounding a container in which the hydrogen storage material is contained and a method is provided for charging the hydrogen reservoir with hydrogen from a hydrogen filling stations.

Owner:DAIMLER AG

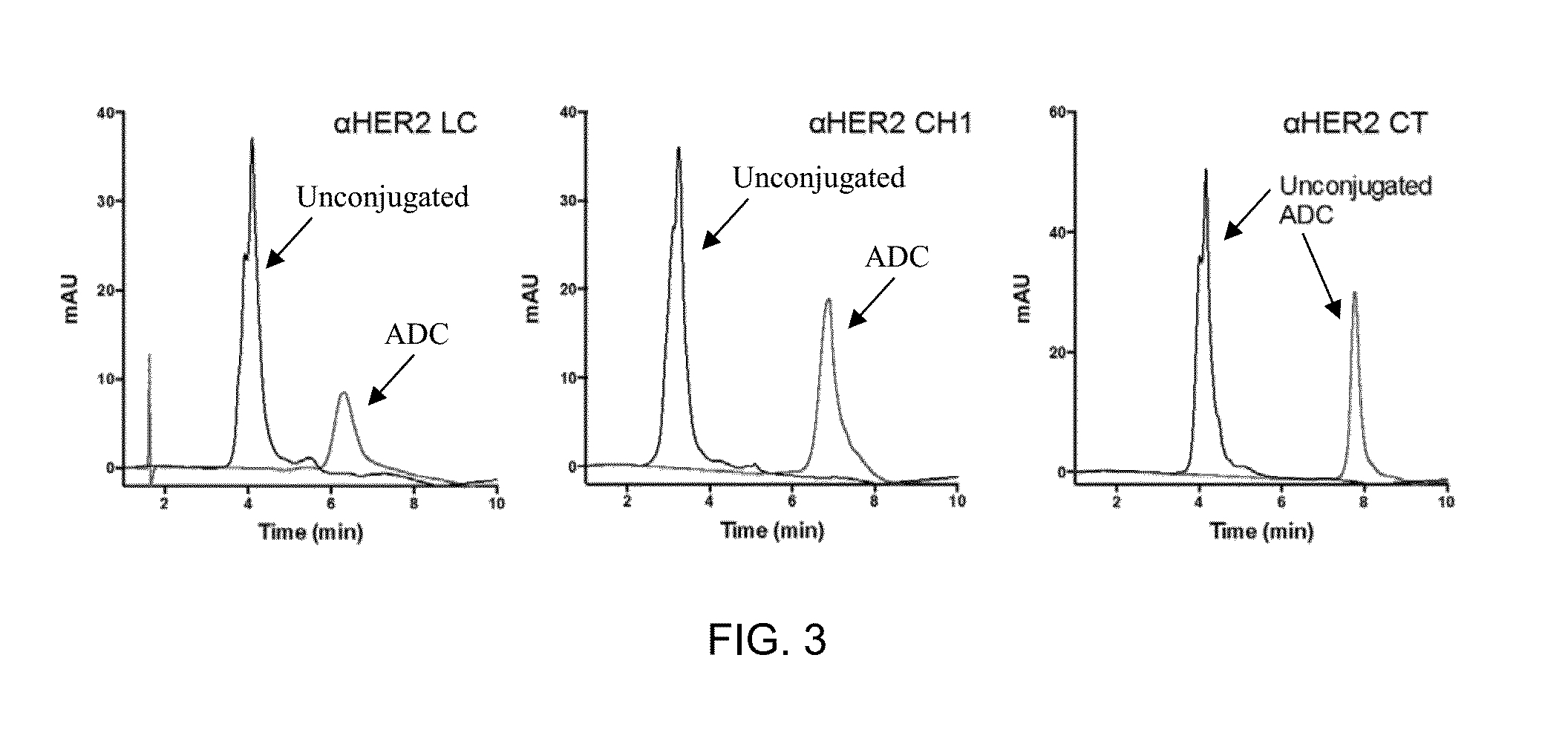

Anti-Her2 Antibody-Maytansine Conjugates and Methods of Use Thereof

ActiveUS20150352225A1Efficient managementEfficient releaseOrganic active ingredientsPharmaceutical non-active ingredientsMethods of productionStereochemistry

The present disclosure provides anti-HER2 antibody-maytansine conjugate structures. The disclosure also encompasses methods of production of such conjugates, as well as methods of using the same.

Owner:REDWOOD BIOSCI

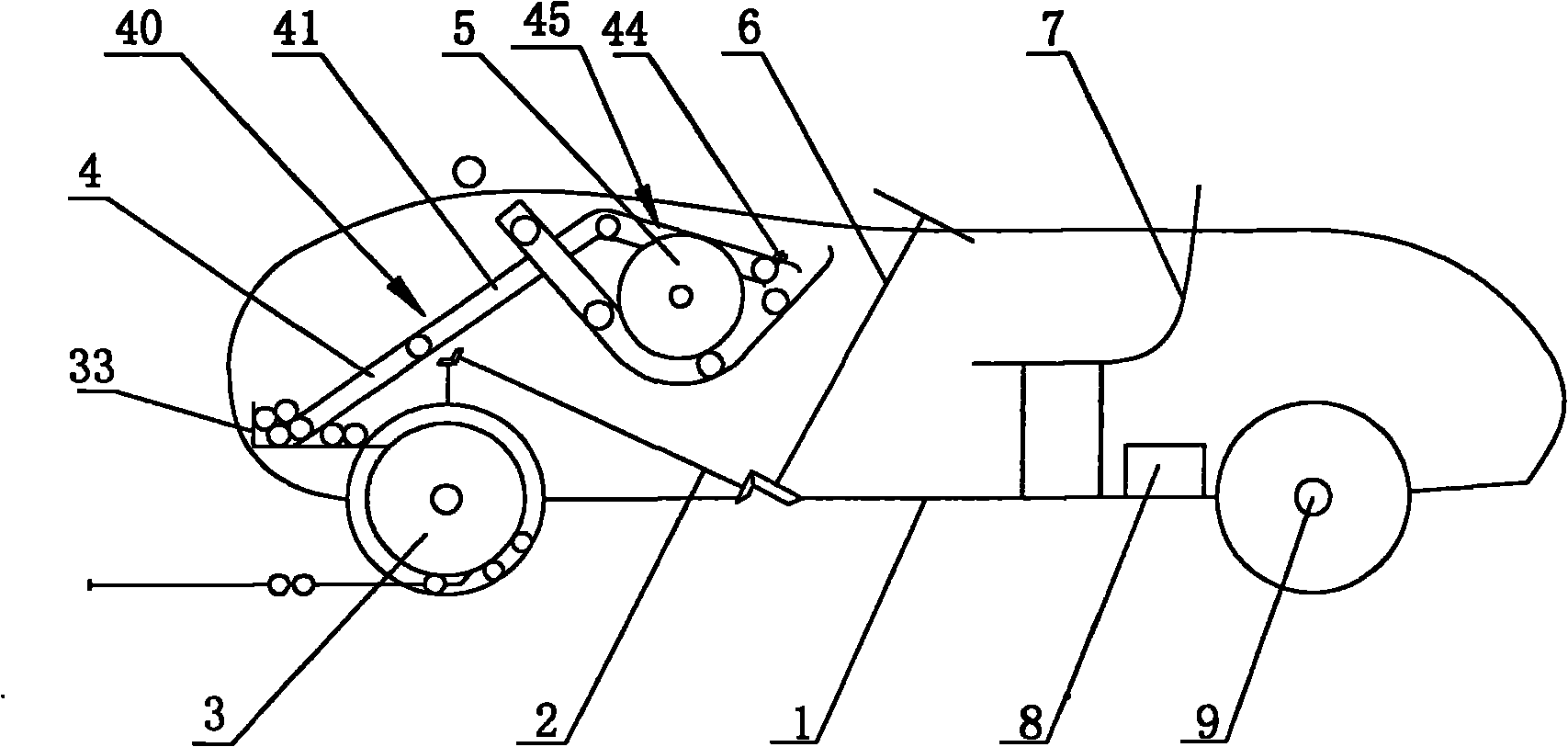

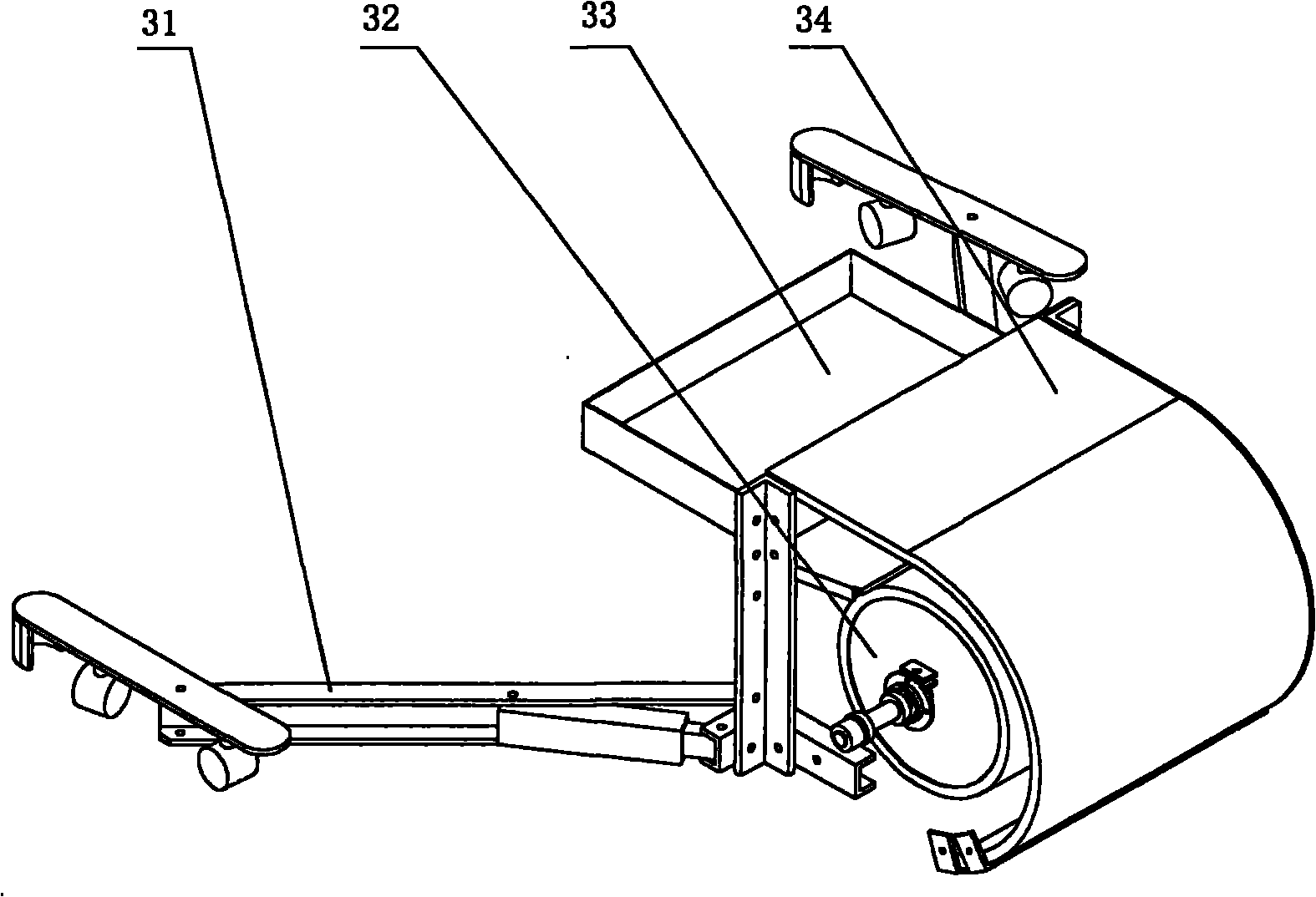

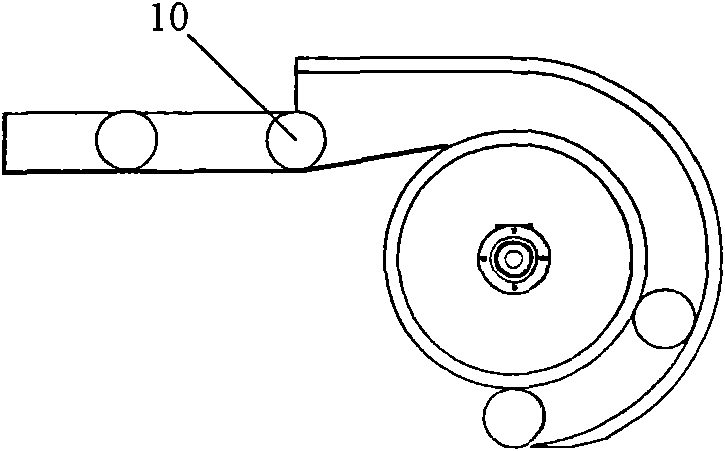

Intelligent tennis ball vehicle

The invention discloses an intelligent tennis ball vehicle. The intelligent tennis ball vehicle is characterized by comprising a vehicle body (1), a ball pickup mechanism (3), a ball service mechanism (5) and a delivery mechanism (4), wherein the ball pickup mechanism (3) is fixed at the front part of the vehicle body (1); a round pickup roller (32) in the ball pickup mechanism (3) is coaxially connected with a front-row wheel (9); and the ball service mechanism (5) is positioned at the upper part of the ball pickup mechanism (3) and connected with a ball storage box (33) in the ball pickup mechanism (3) by the delivery mechanism (4). The intelligent tennis ball vehicle is compact and rational in structure design, convenient to move, simple and convenient to operate and economical and practical.

Owner:SOUTHEAST UNIV +1

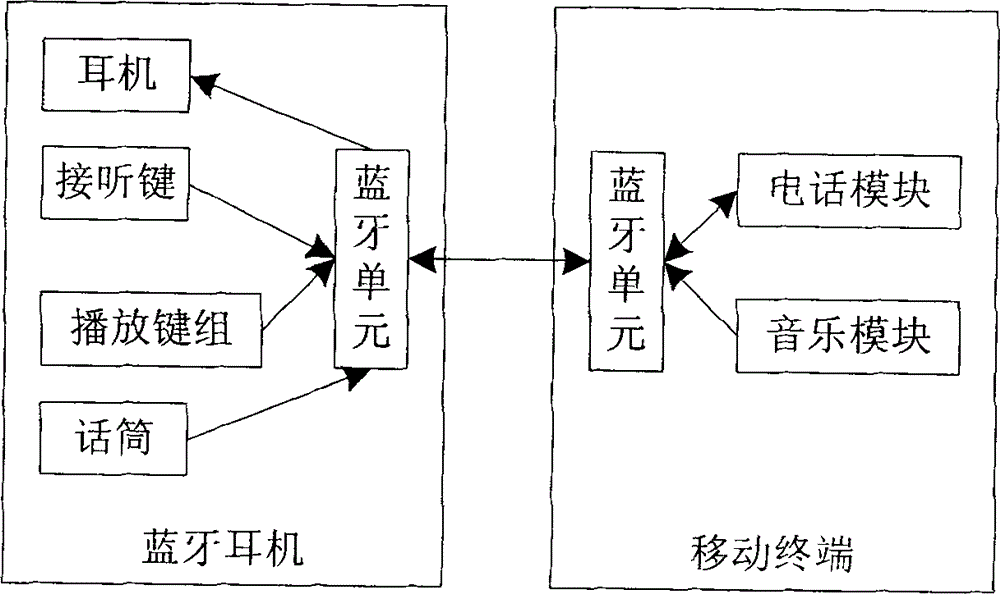

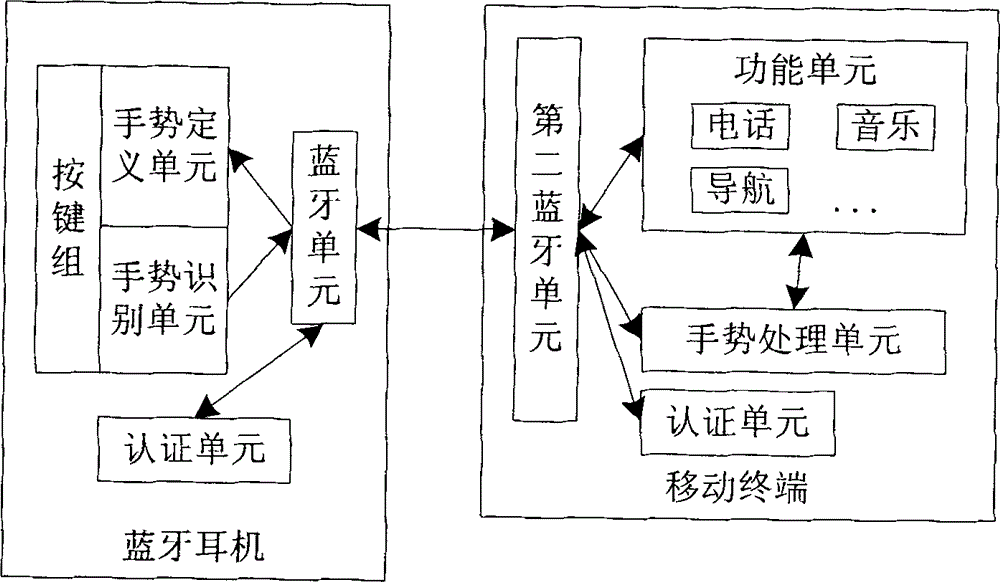

Interactive Bluetooth headset and mobile terminal

InactiveCN104135559AMultiple functionsFlexible handlingInput/output for user-computer interactionNear-field transmissionComputer terminalHeadphones

The present invention relates to the technical field of Bluetooth communications, and discloses an interactive Bluetooth headset and mobile terminal. The Bluetooth headset includes: a key group, a gesture defining unit, a gesture identify unit, and a Bluetooth unit, wherein the key group includes a plurality of keys; the gesture defining unit is coupled to each key in the key group, records each key gesture generated in the key group in the defining mode, and records the key gesture after associated with a key function; the gesture identify unit is coupled to each key in the key group and the gesture defining unit, identifies each key gesture generated in the key group in the functional mode, and generates a corresponding functional signal after obtaining the key function associated with the key gesture from the gesture defining unit; and the Bluetooth unit is coupled to the gesture identify unit, and is further wirelessly coupled to the mobile terminal via a Bluetooth link to send the functional signal to the mobile terminal via the Bluetooth link. The present invention improves the interaction capabilityof the Bluetooth headset through a custom key function and makes full use of the Bluetooth.

Owner:深圳市乐驰互联技术有限公司

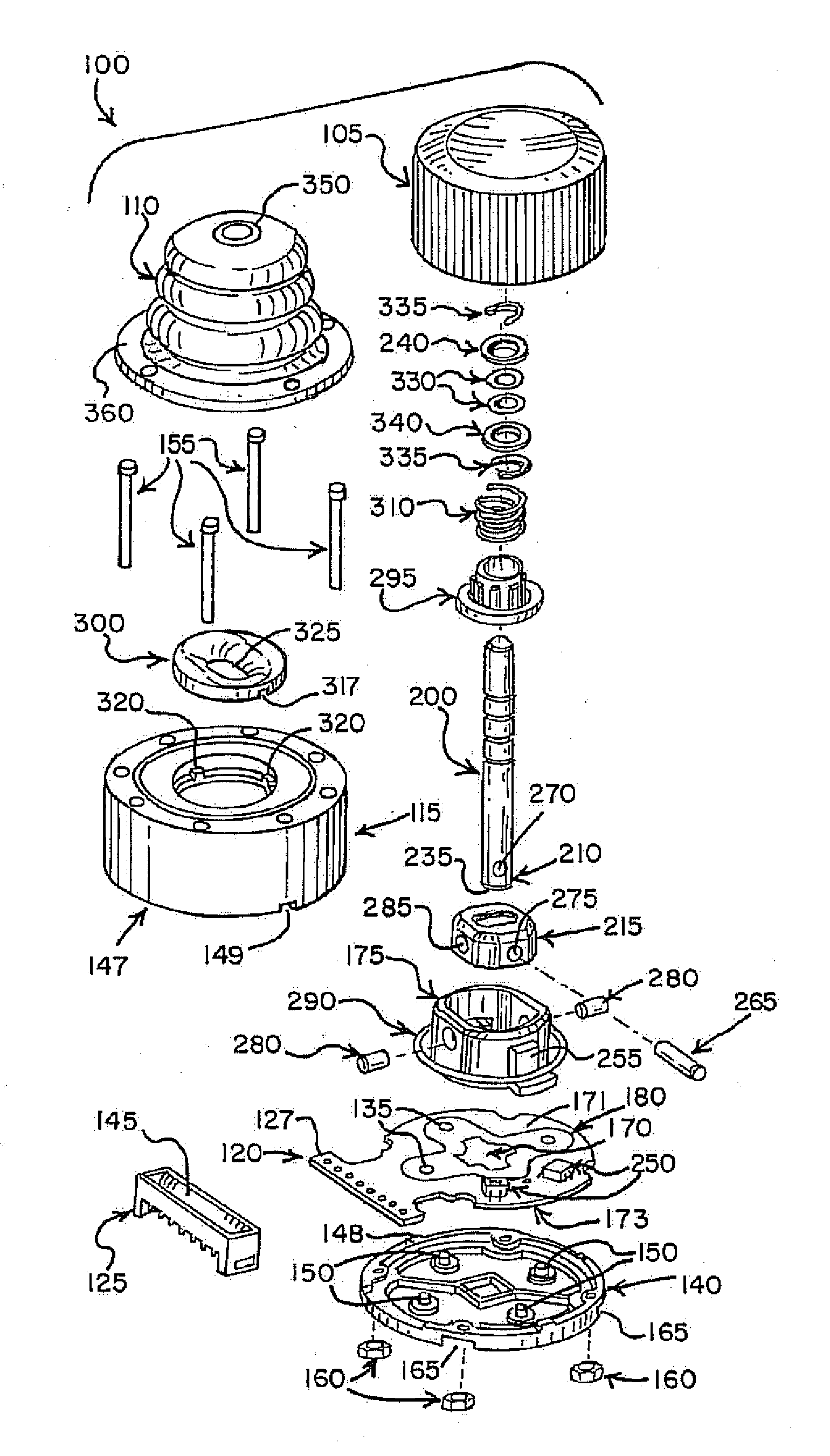

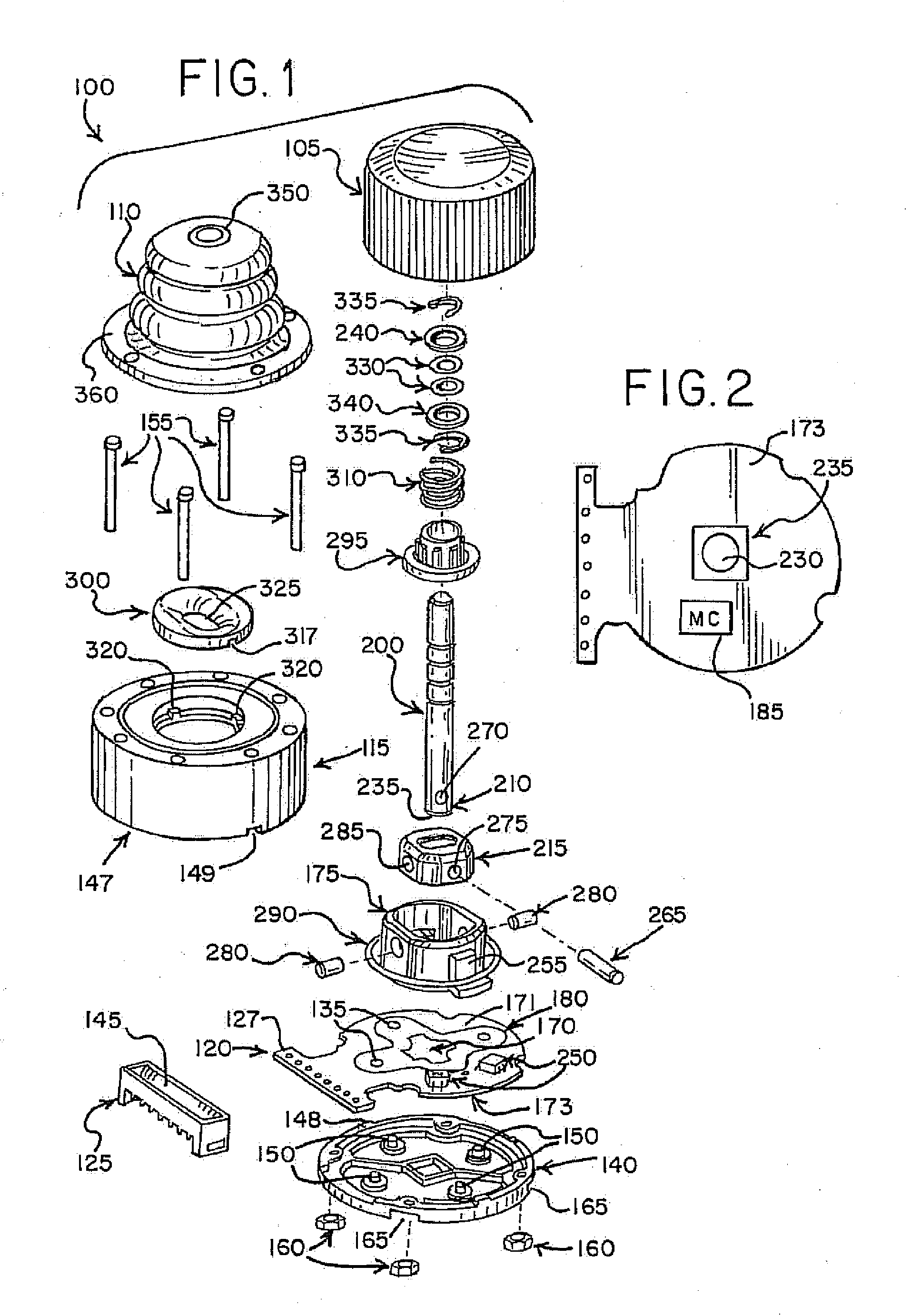

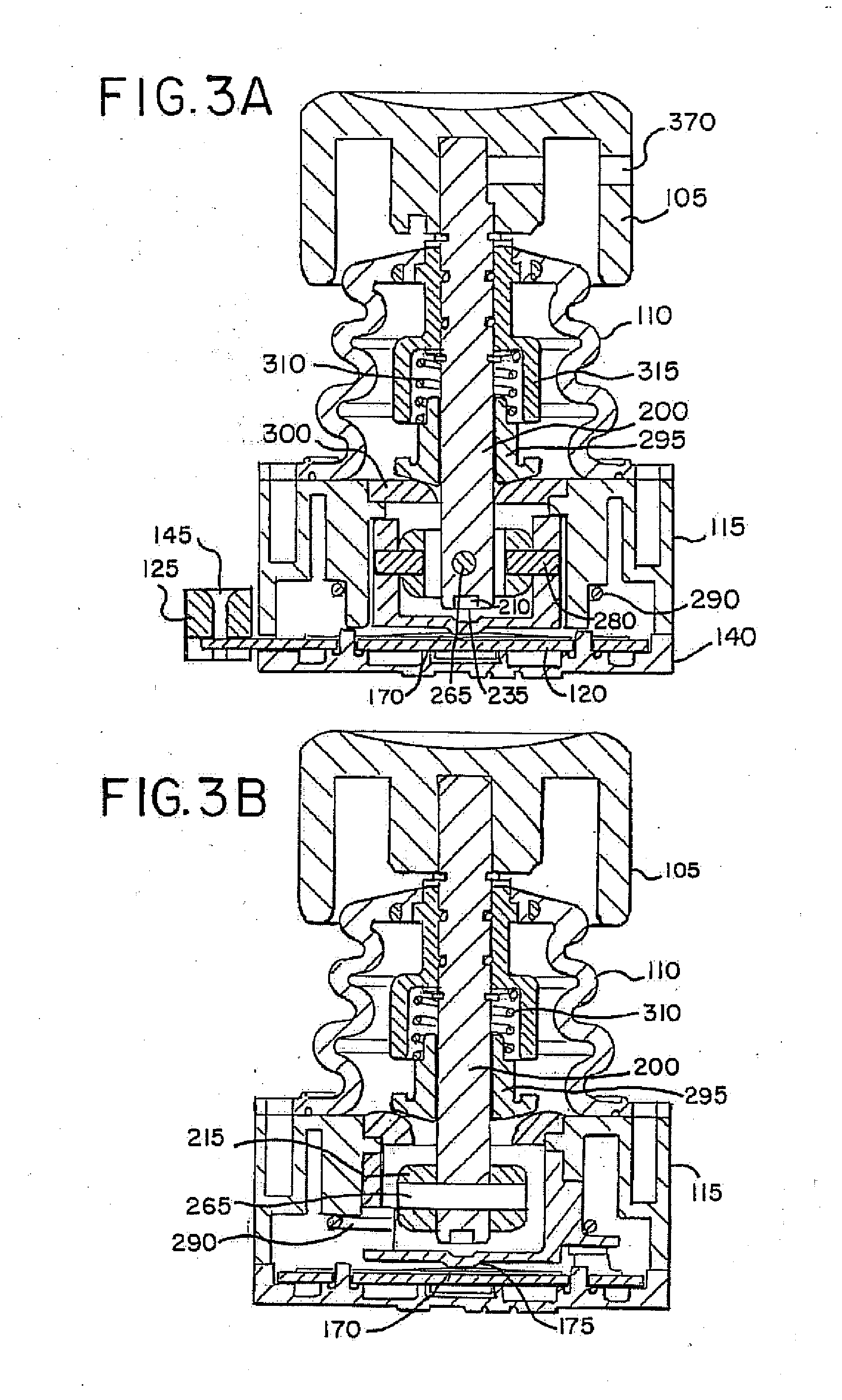

Multifunction joystick apparatus and a method for using same

ActiveUS20160077543A1Low powerMultiple functionsManual control with multiple controlled membersManual control with single controlling memberDiagnostic Radiology ModalityJoystick

A joystick apparatus has a housing and a printed circuit board in the housing. A shaft is pivotably connected to a U-joint assembly to allow movement of the shaft relative to the center position within a circle. A concentric reduced power zone circle is associated with the circle. Operation of the joystick within the reduced power zone circle uses less power than operation outside of the reduced power zone. A knob and a magnet are located on the shaft. A Hall effect integrated circuit detects movement of the magnet in response to corresponding movement of the shaft by a user and generates a corresponding proportional joystick output signal indicative of a direction and an extent of rotation of the shaft. A multifunction joystick control system has a joystick configured to provide multiple operational modalities on a joystick. An electrical interface connects the joystick apparatus and the host central processing unit.

Owner:GRAYHILL

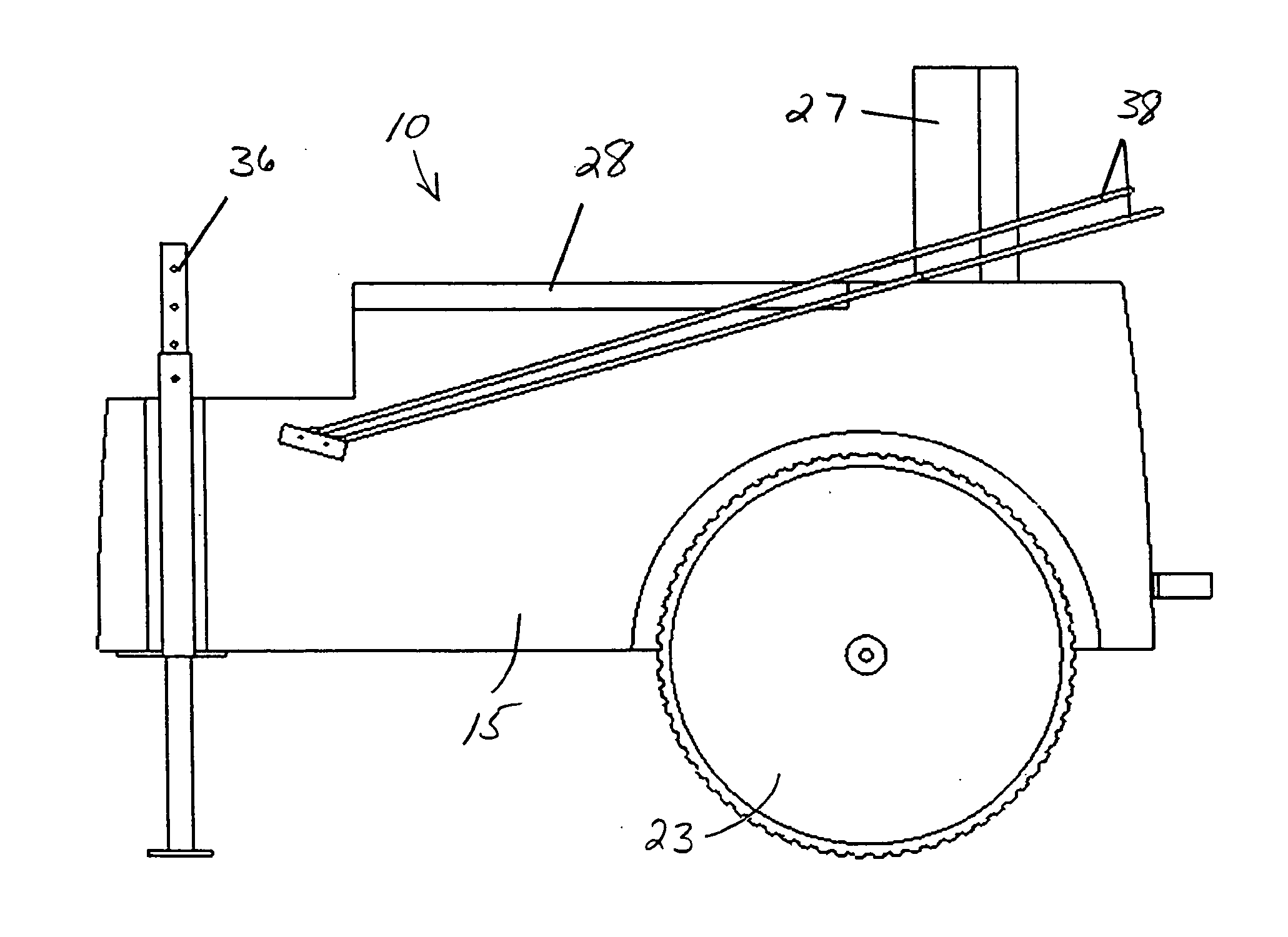

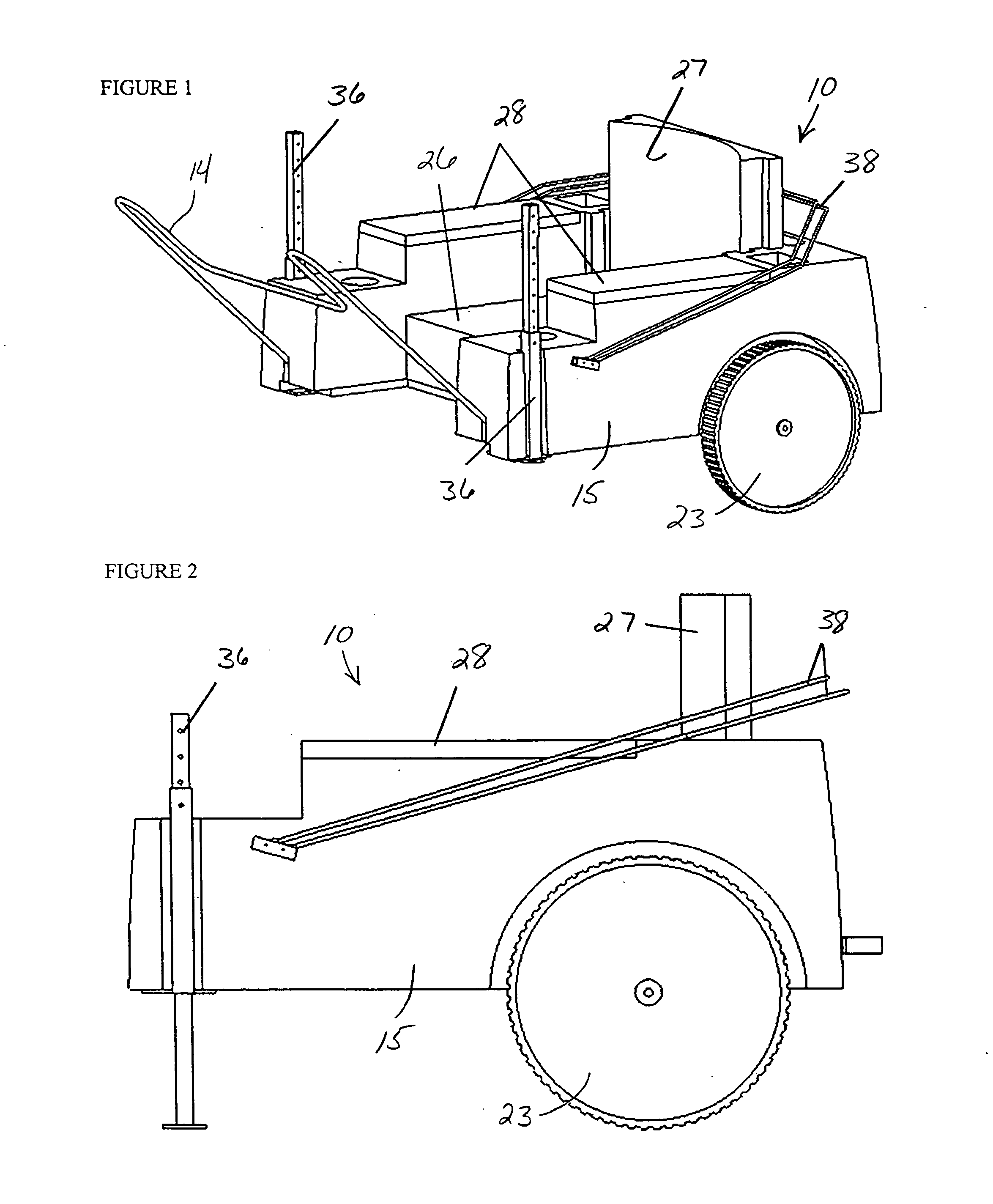

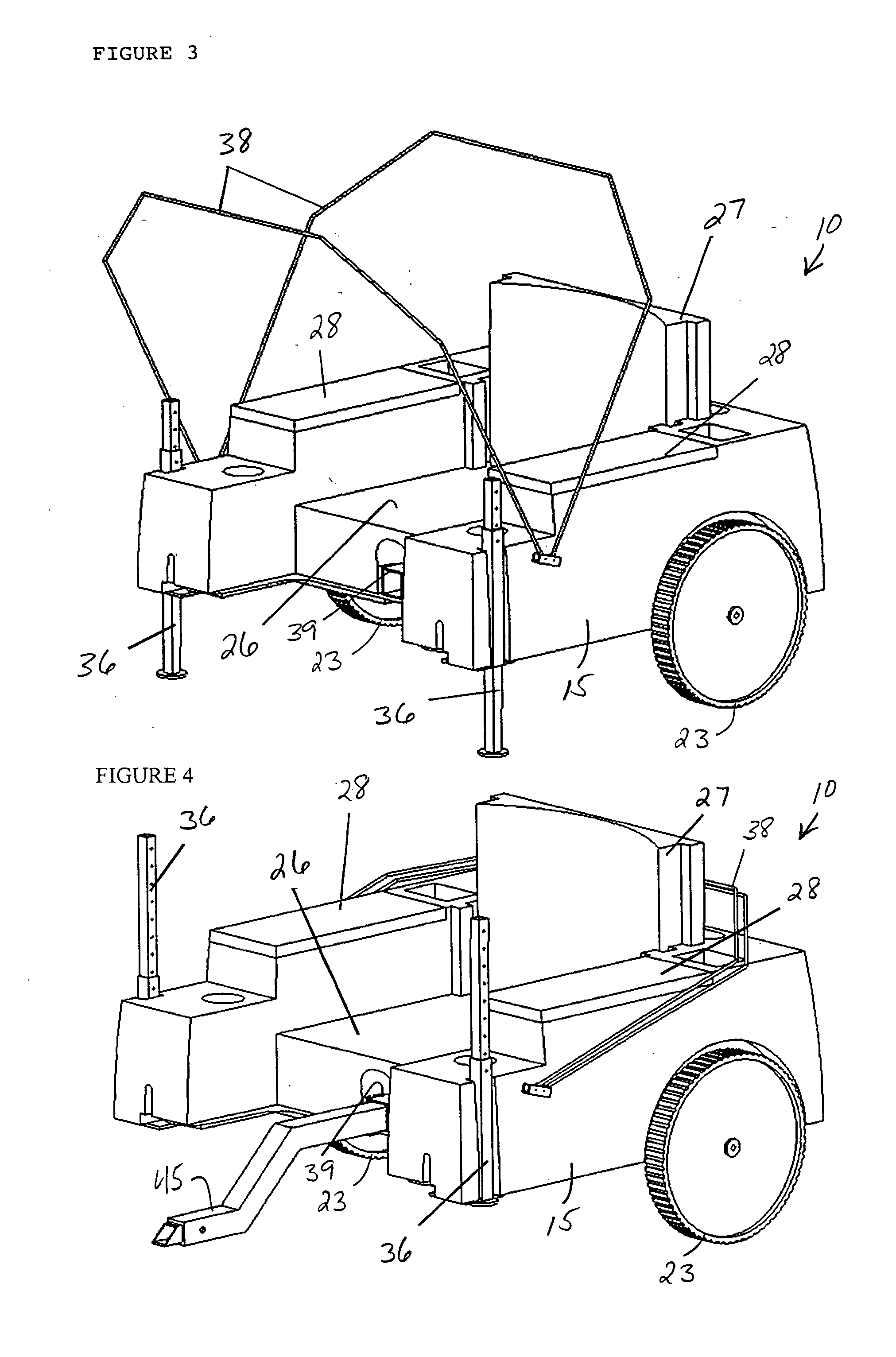

Amphibious utility cart and transport system incorporating same

InactiveUS20080048417A1Easy to transportEffectively conceals the outdoorsmanAmphibious vehiclesCarriage/perambulator accessoriesCartEngineering

An amphibious utility cart aids an outdoorsman in transporting equipment from home to a hunting site, and may further provide seating. The apparatus comprises framing to which a molded plastic platform is attached. The entire unit is designed to be rolled on land with wheels and to float on water with the buoyant seat platform. The platform, in a lounge chair design, is used as an equipment tote platform while going to a destination, and then as a chair for an outdoorsman or his dog when at the destination. The chair is designed for maximum floatation for water crossings and shallow-water seating. The two wheels provide the rear seating base and two retractable poles extend downward to provide frontal leg braces for a stable seating base. A handle is extended for the cart for either land or water transportation, and slides into the metal frame while in the chair mode.

Owner:SCHROEDER JEFFREY M

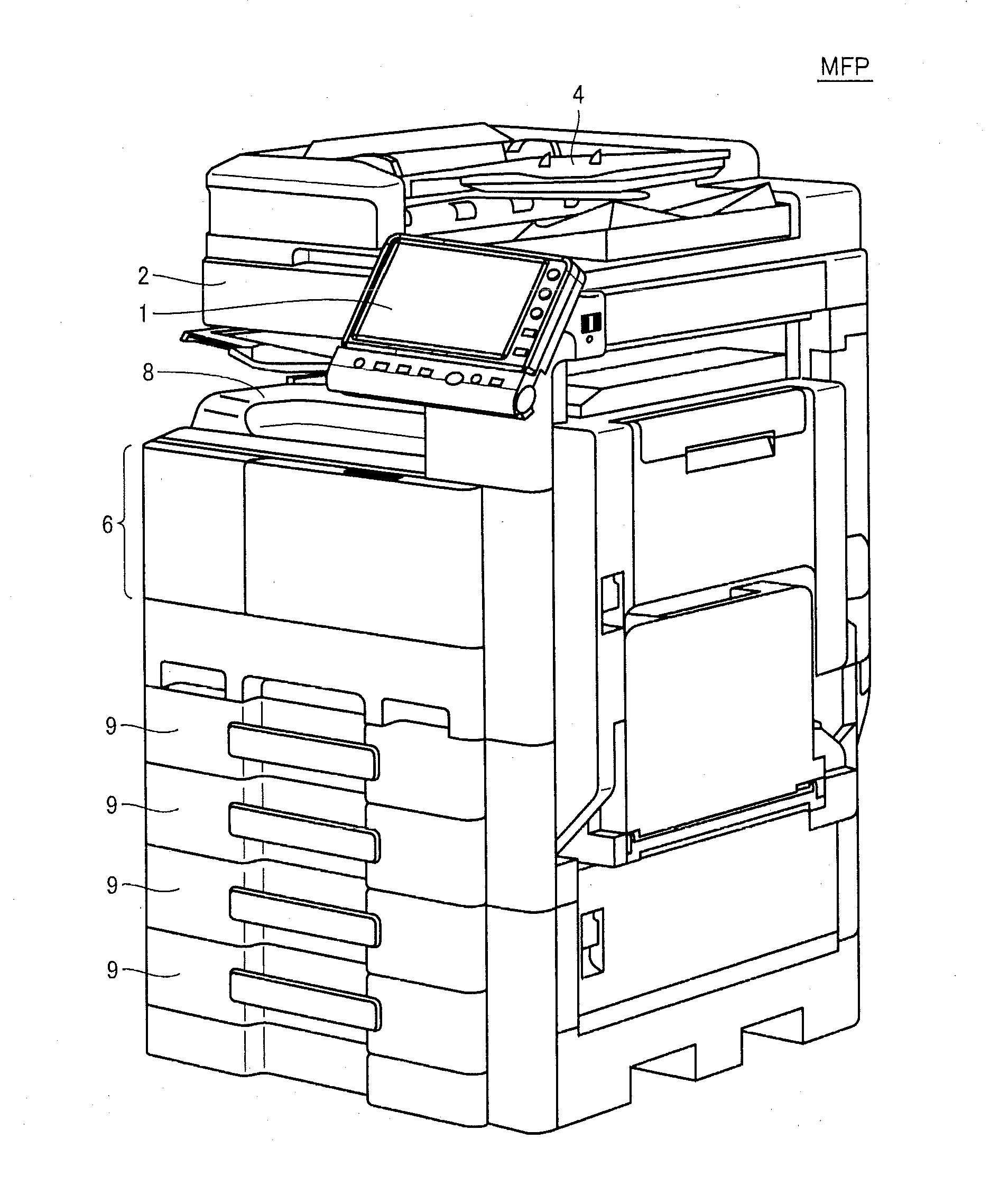

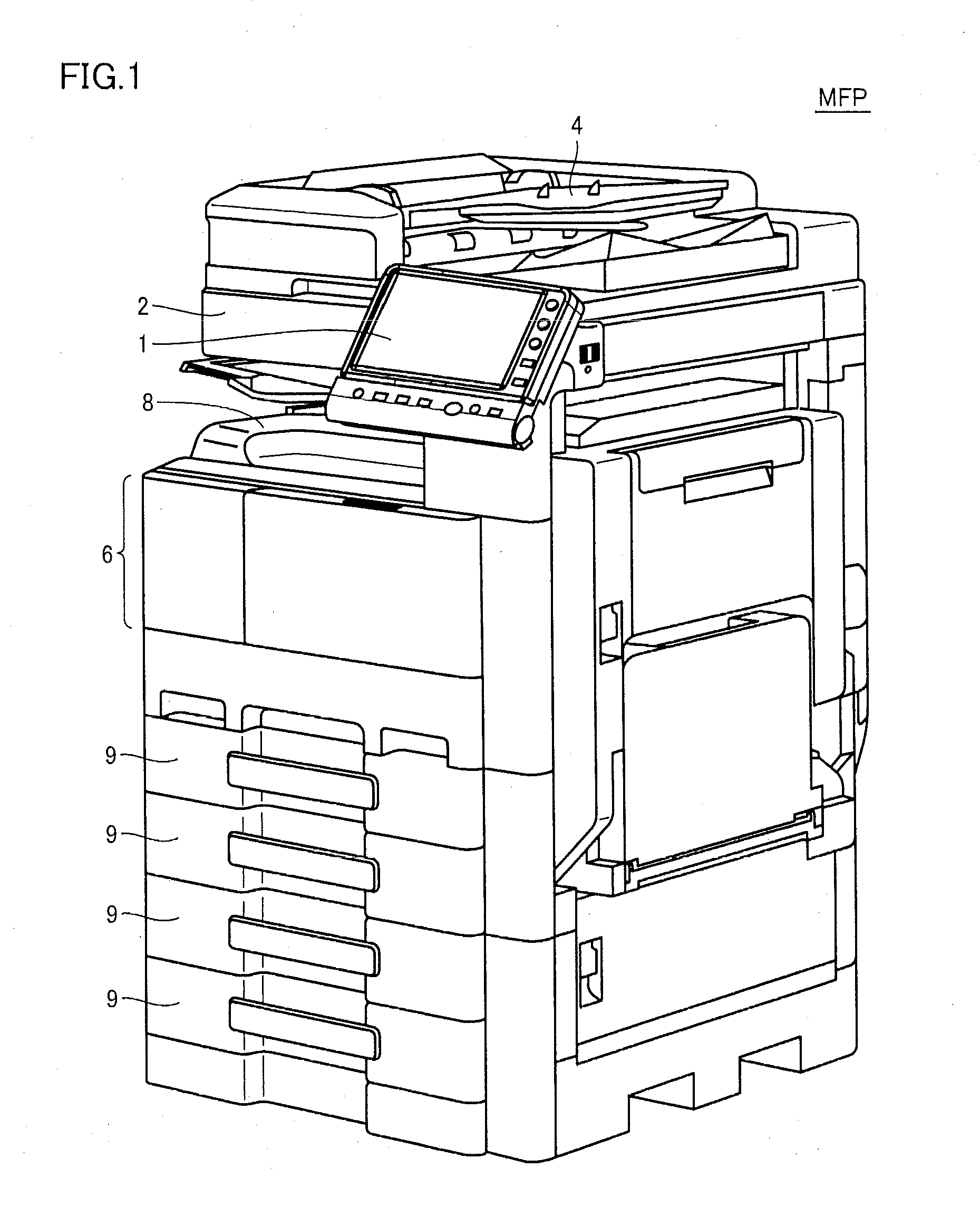

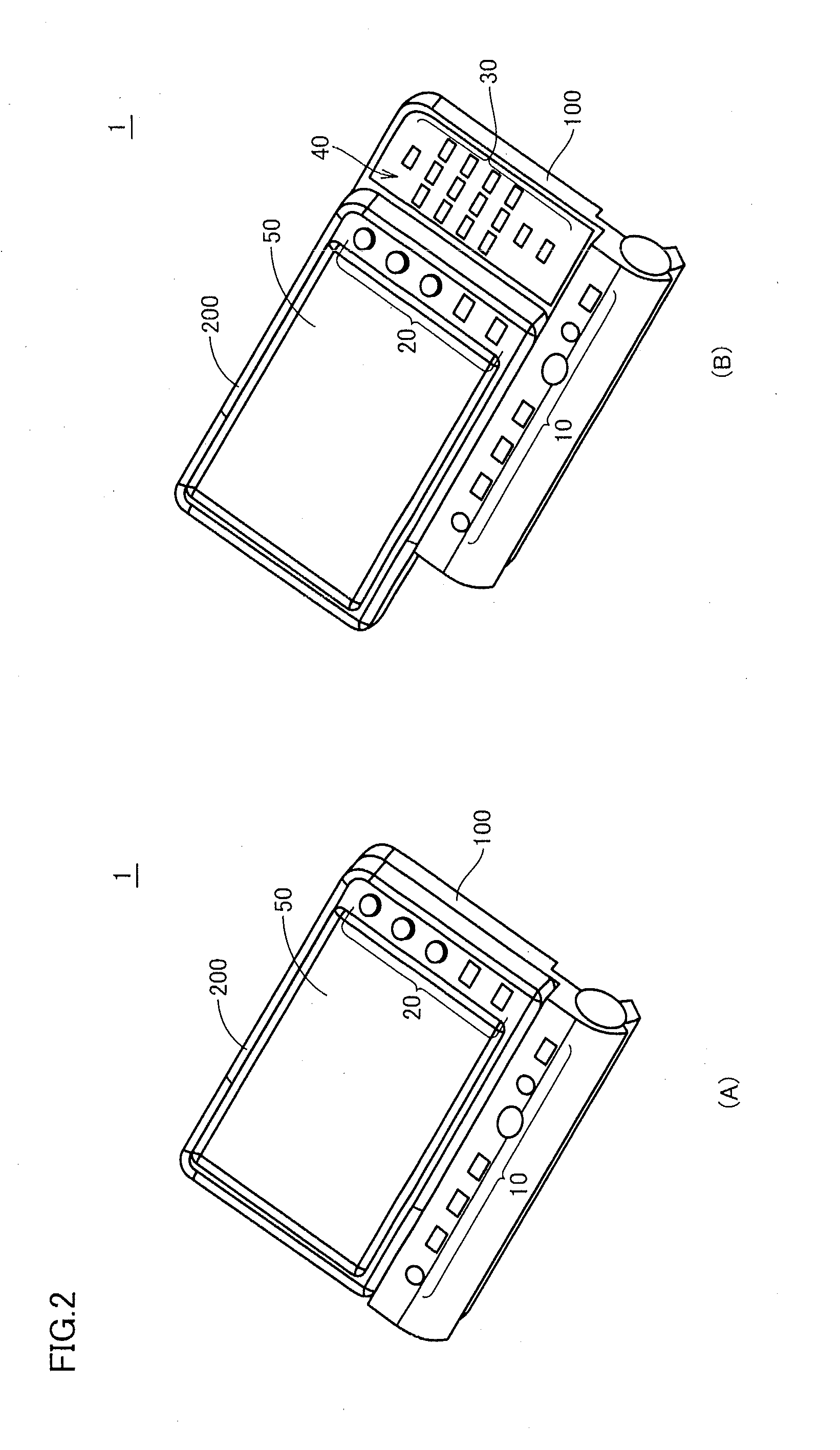

Operation panel device and image forming apparatus provided therewith

InactiveUS20120243042A1Improve visibilityIncrease awarenessDigital data processing detailsElectrographic process apparatusProjected areaImage formation

An operation panel device with a display surface is provided with mounted on an image forming apparatus. The operation panel device includes first and second panels that are relatively movable along a plane parallel to the display surface. The first panel is fixed to the image forming apparatus. The second panel is disposed opposite to the image forming apparatus with respect to the first panel. A projection area of the second panel to the plane parallel to the display surface is smaller than a projection area of the first panel. Each of the first and second panels includes a first group of keys disposed in a region that is exposed independent from relative positions of the first and second panels. The first panel includes a second group of keys disposed in a region that is exposed only when the first panel and second panels do not overlap each other.

Owner:KONICA MINOLTA BUSINESS TECH INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com