Patents

Literature

1343results about How to "Flexible handling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

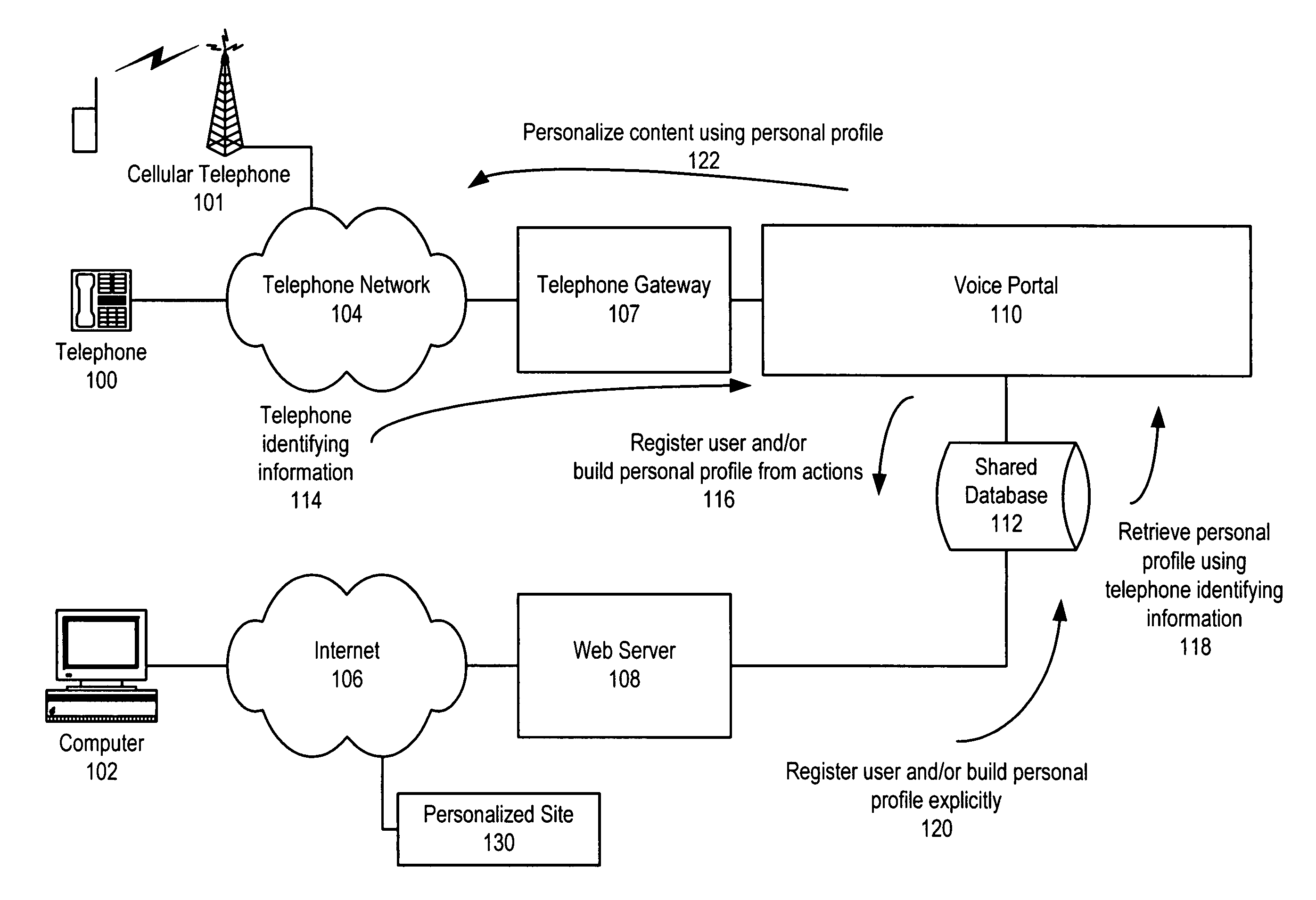

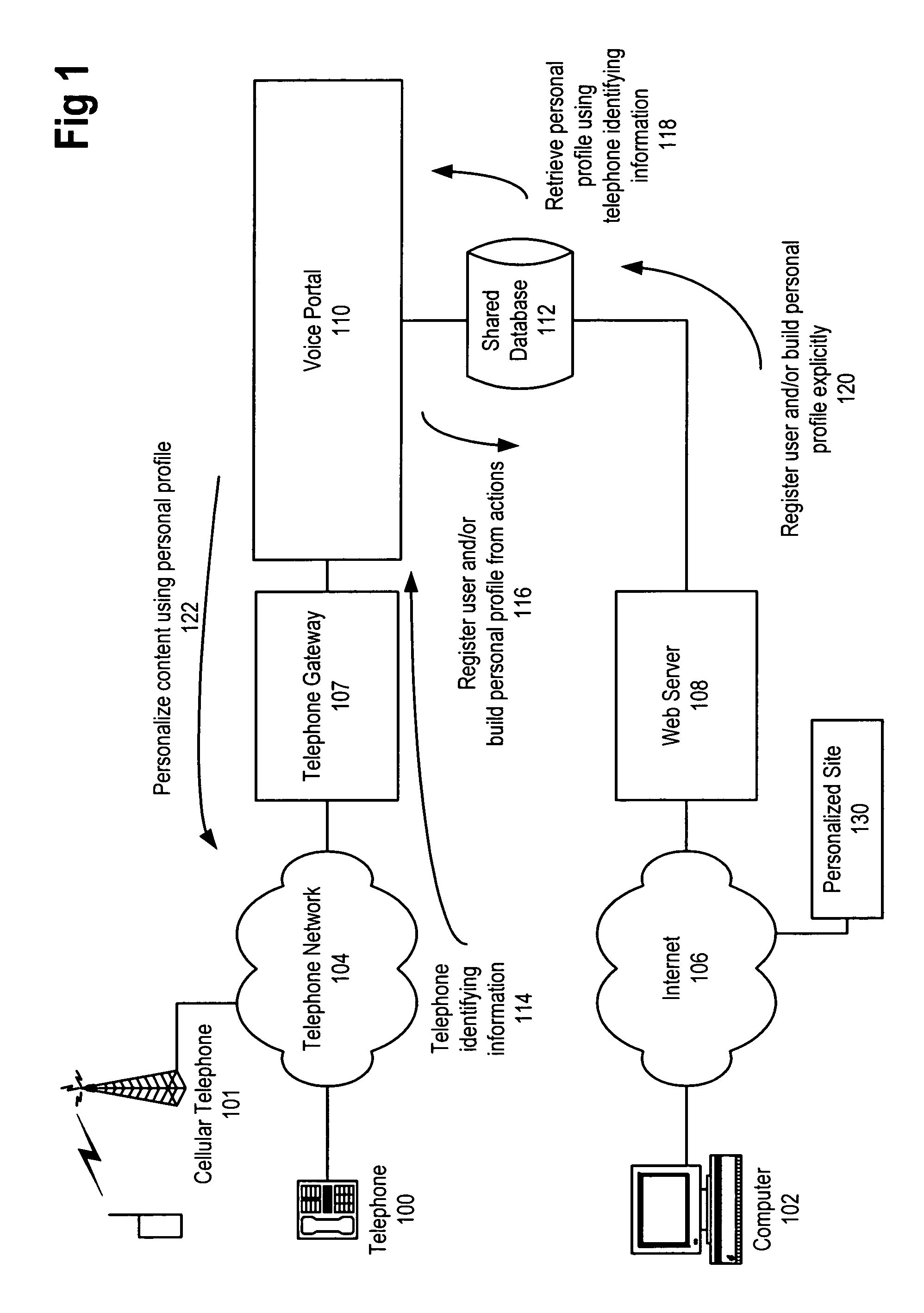

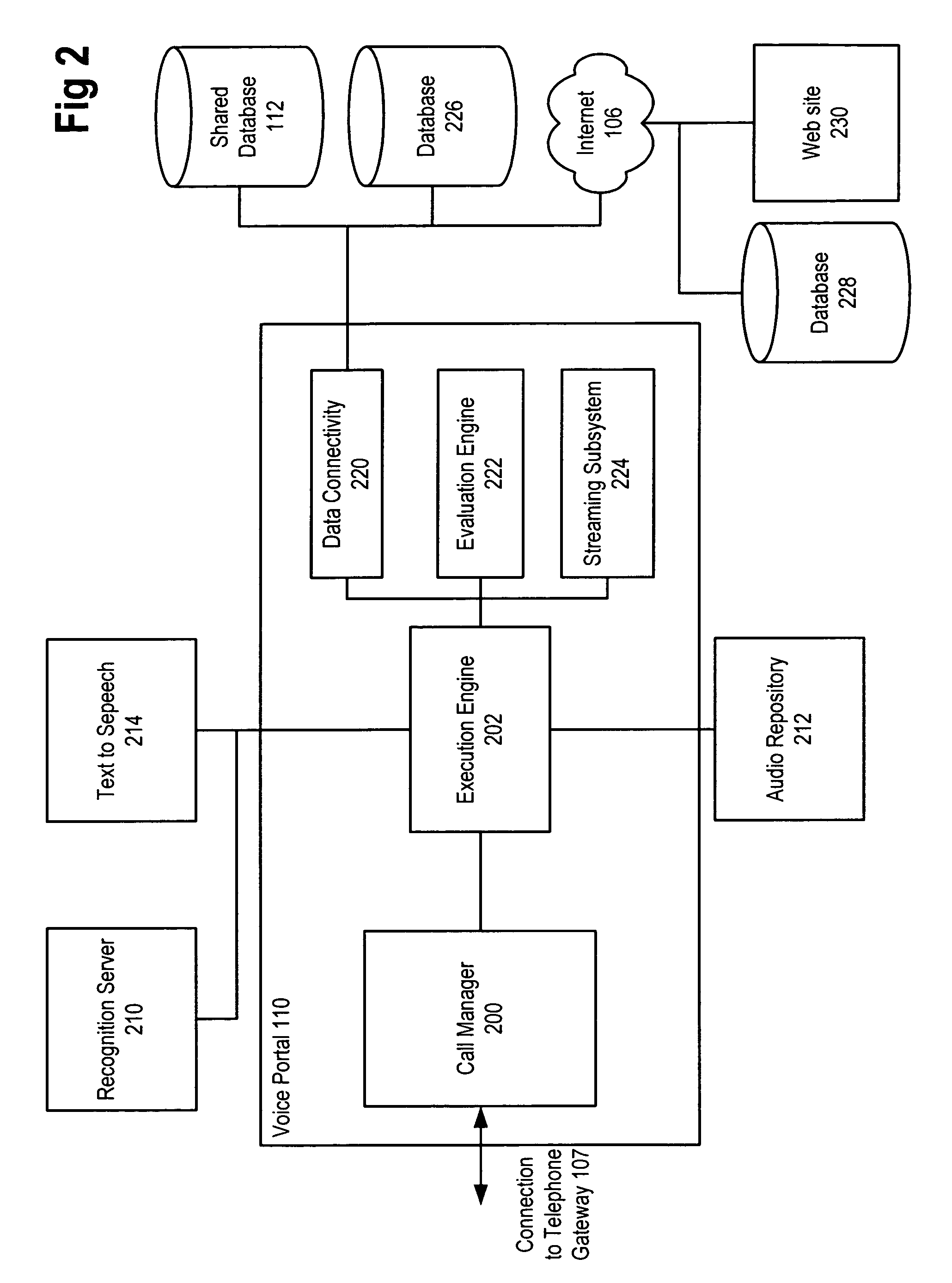

Phone application state management mechanism

InactiveUS7376740B1Lowered byMore flexiblyData switching by path configurationMultiple digital computer combinationsApplication procedureState management

Owner:MICROSOFT TECH LICENSING LLC

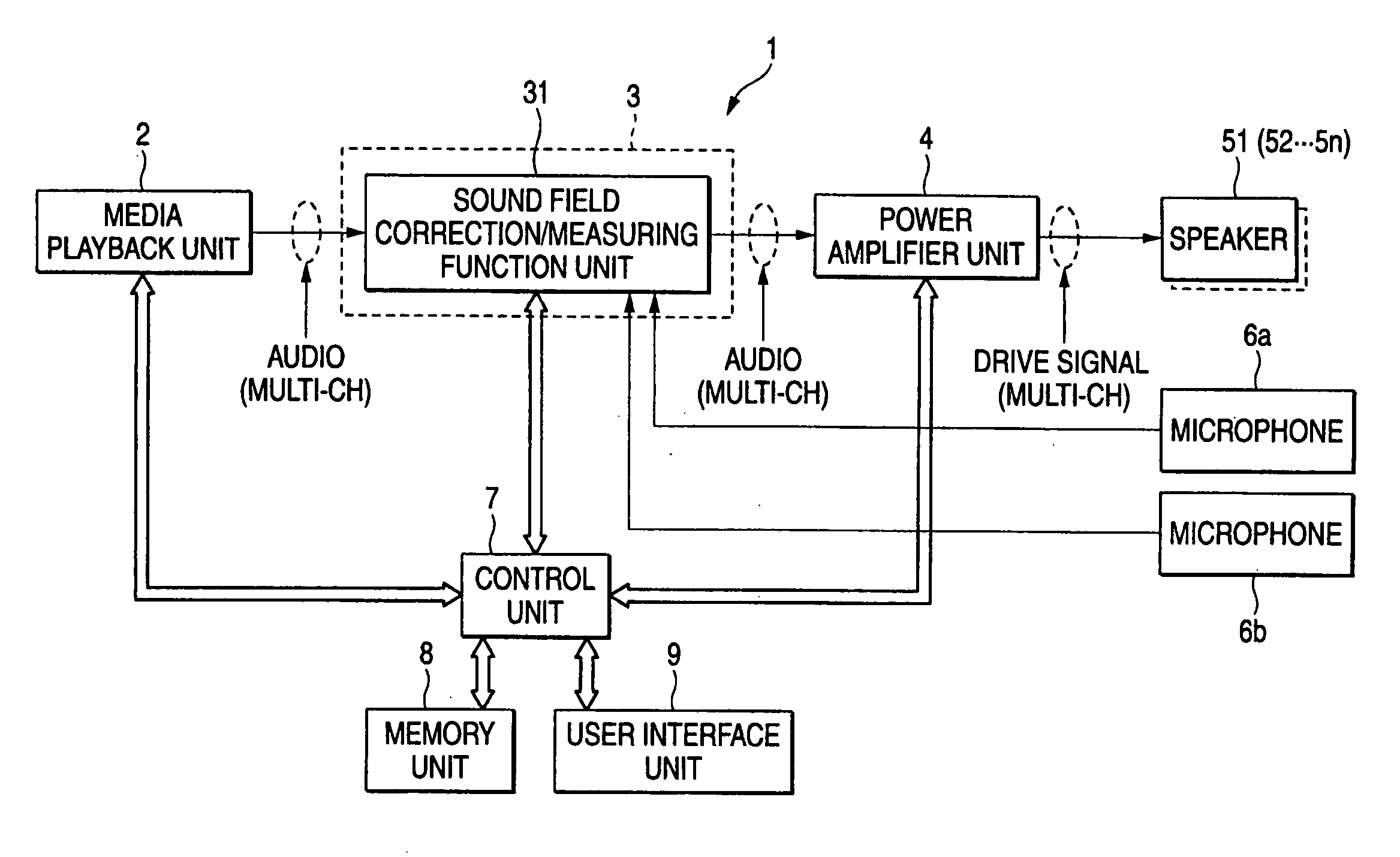

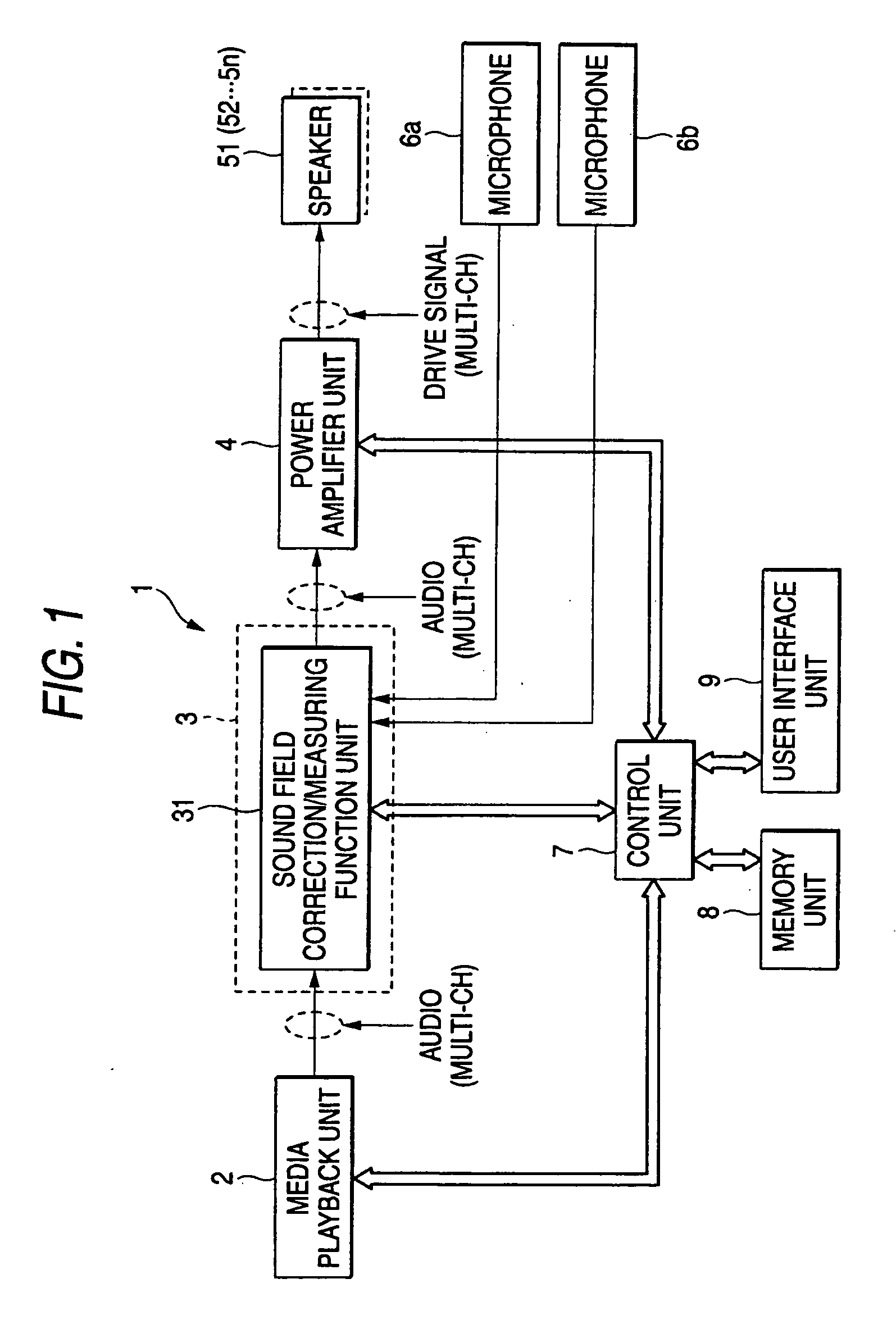

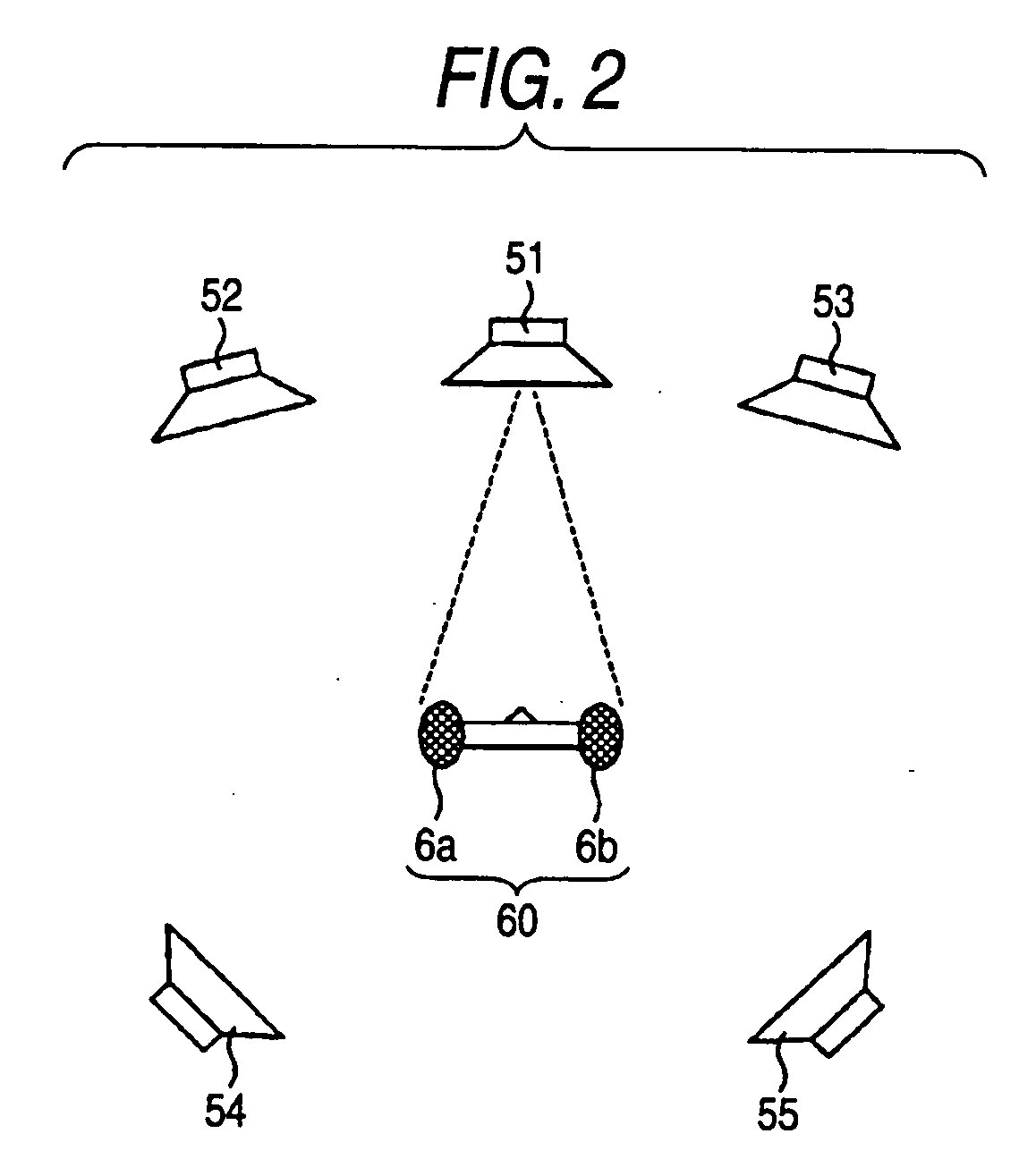

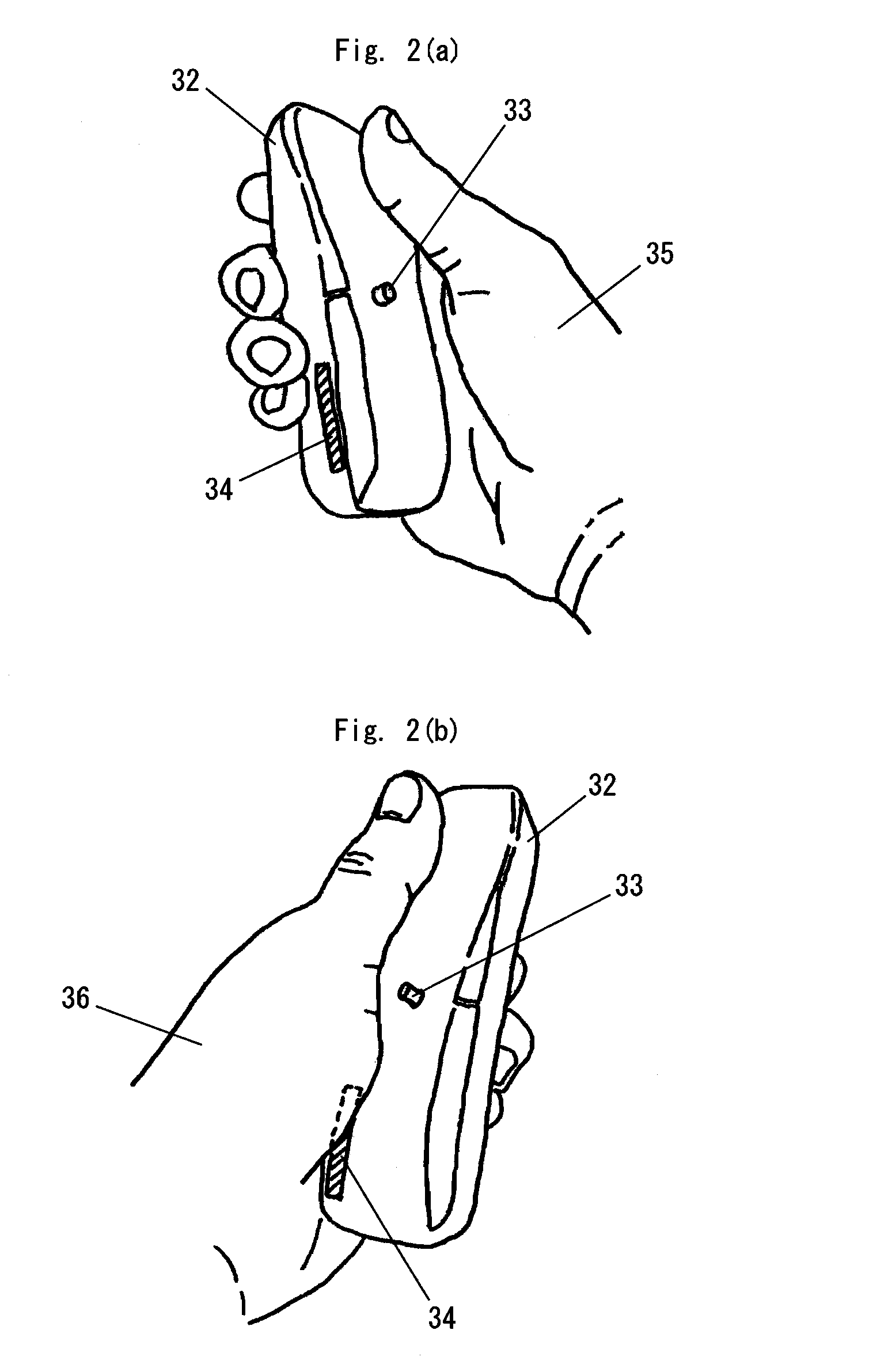

Sound field measuring apparatus and sound field measuring method

InactiveUS20070019815A1Flexible handlingLoudspeaker enclosure positioningLoudspeaker spatial/constructional arrangementsLoudspeakerAudio frequency

A sound field measuring apparatus includes a microphone set having a first and second microphones arranged at a prescribed interval, which collects audio signals outputted from a first and second speakers, a measuring unit measuring distances between the first and second speakers, and the first and second microphones based on audio signals collected by the first and second microphones, and a position calculating unit calculating a position of the first and second microphones and a position of the second speaker when the first speaker is taken as a standard position based on the respective measured distances.

Owner:SONY CORP

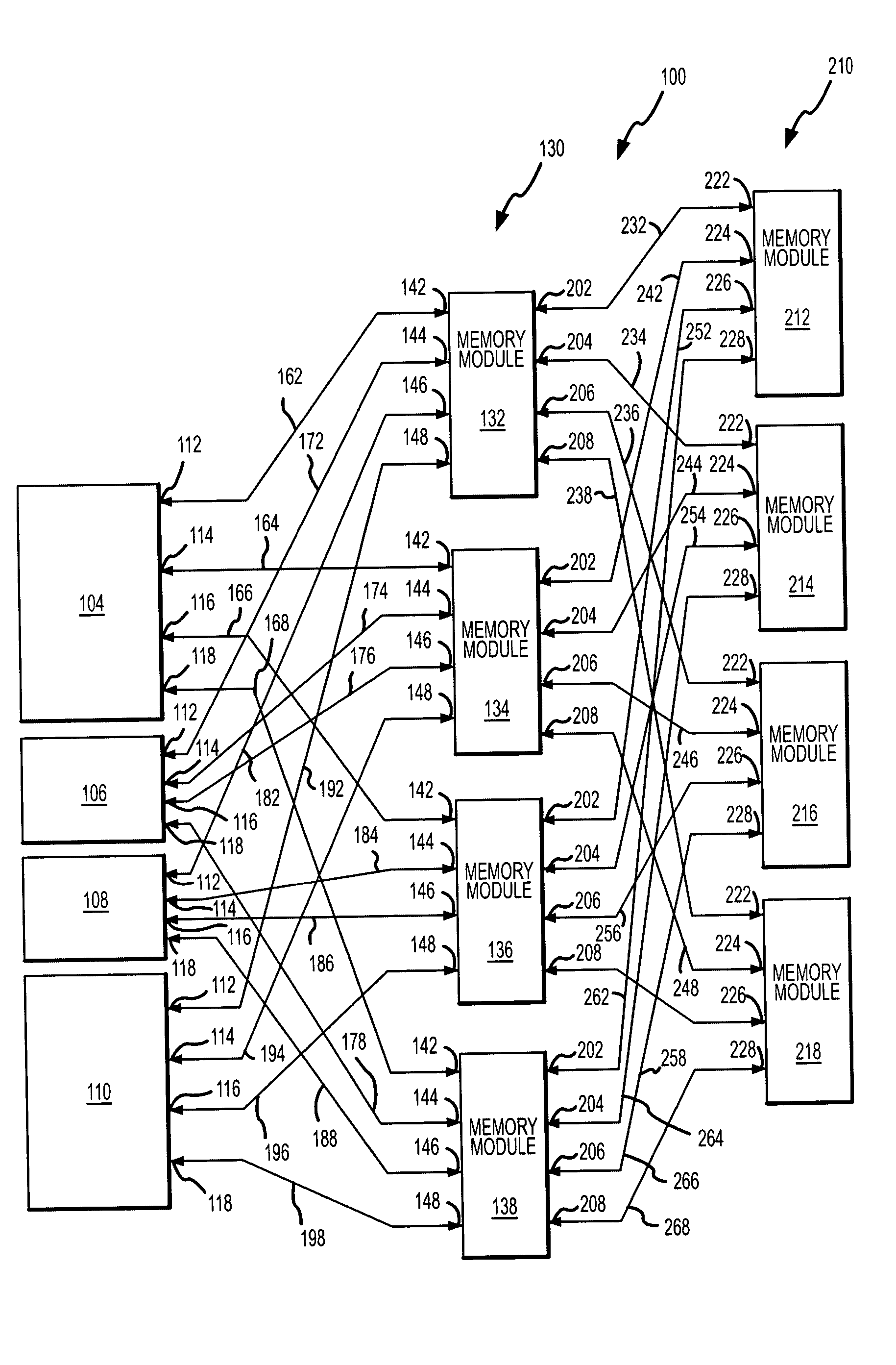

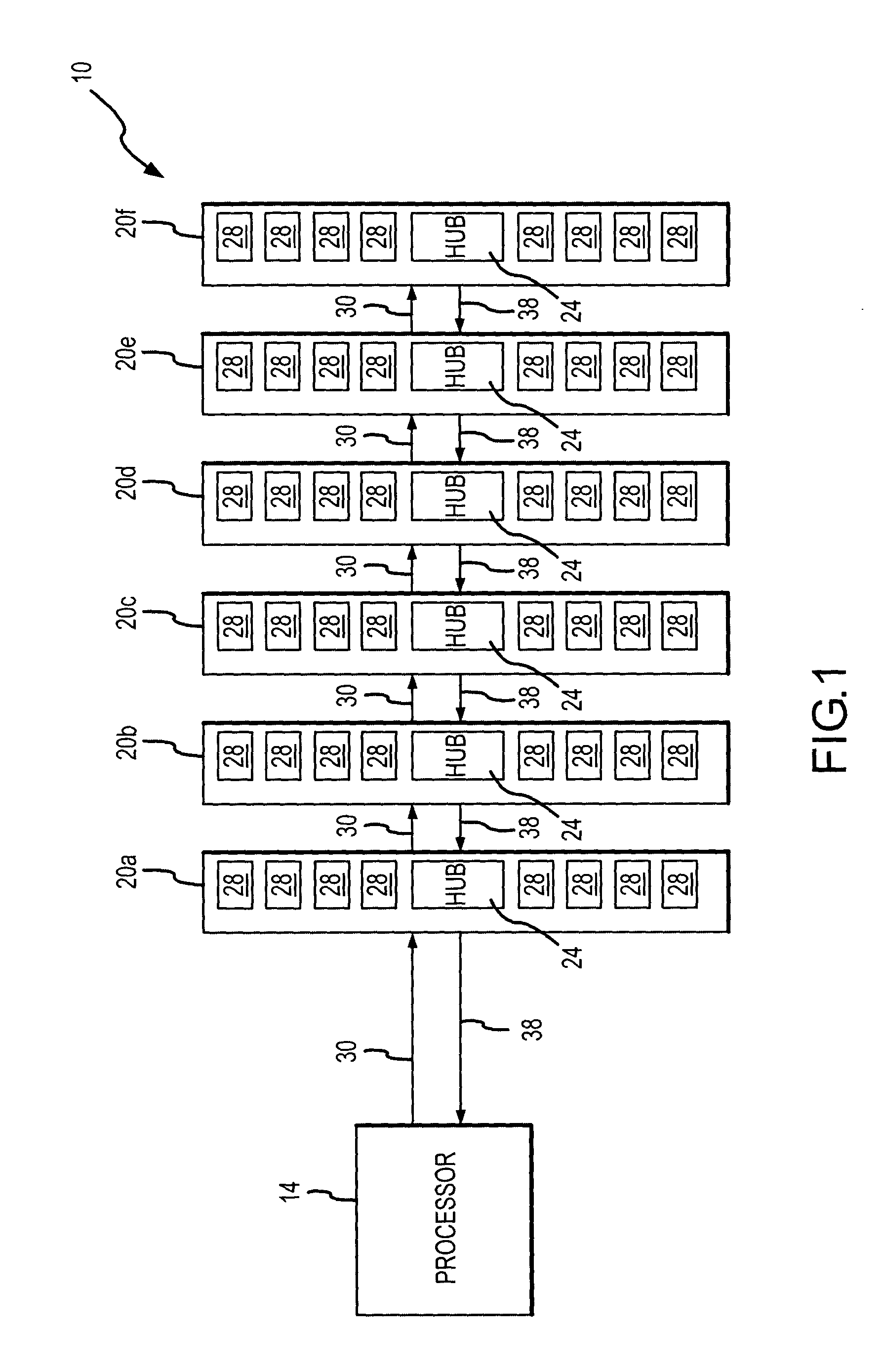

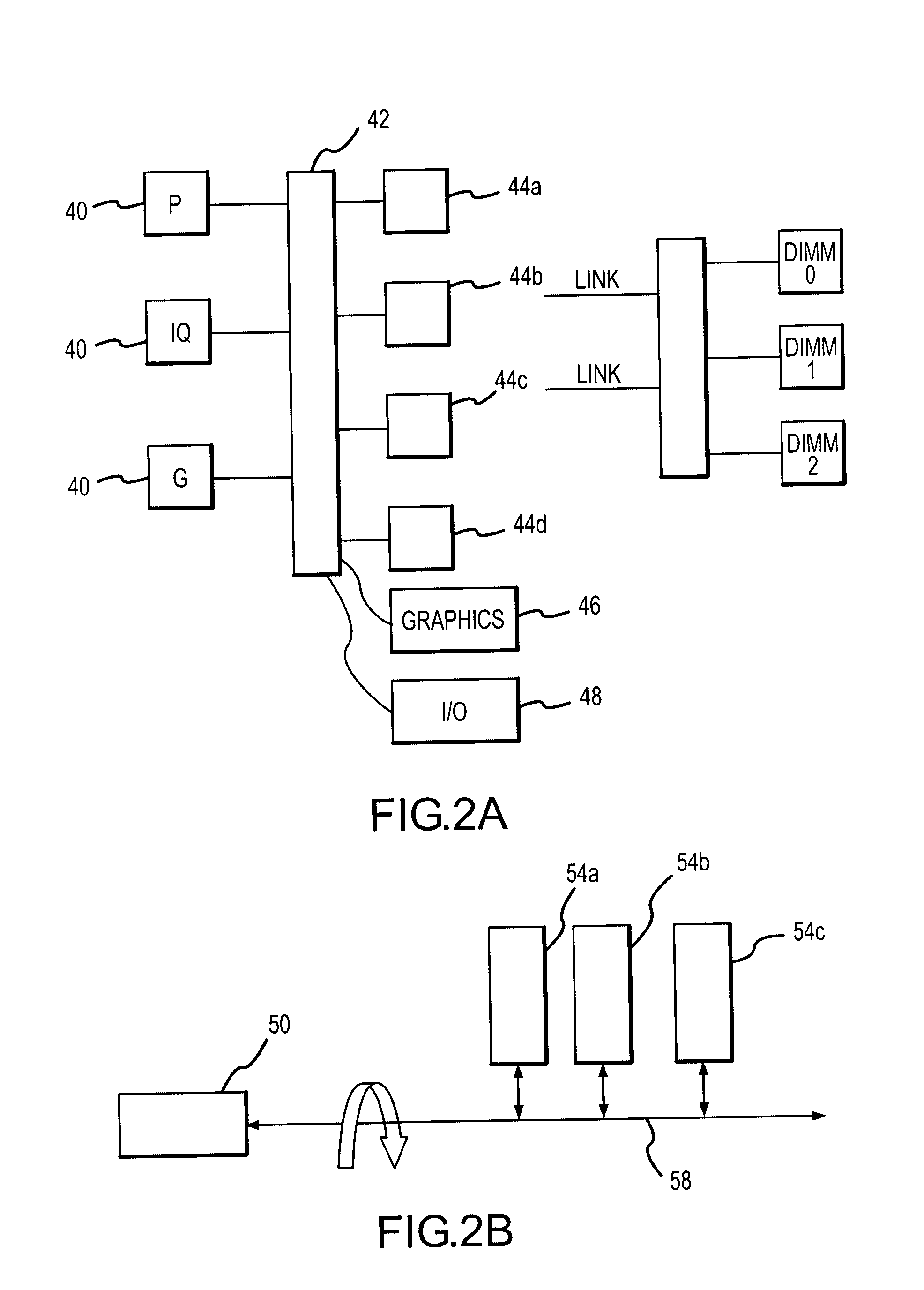

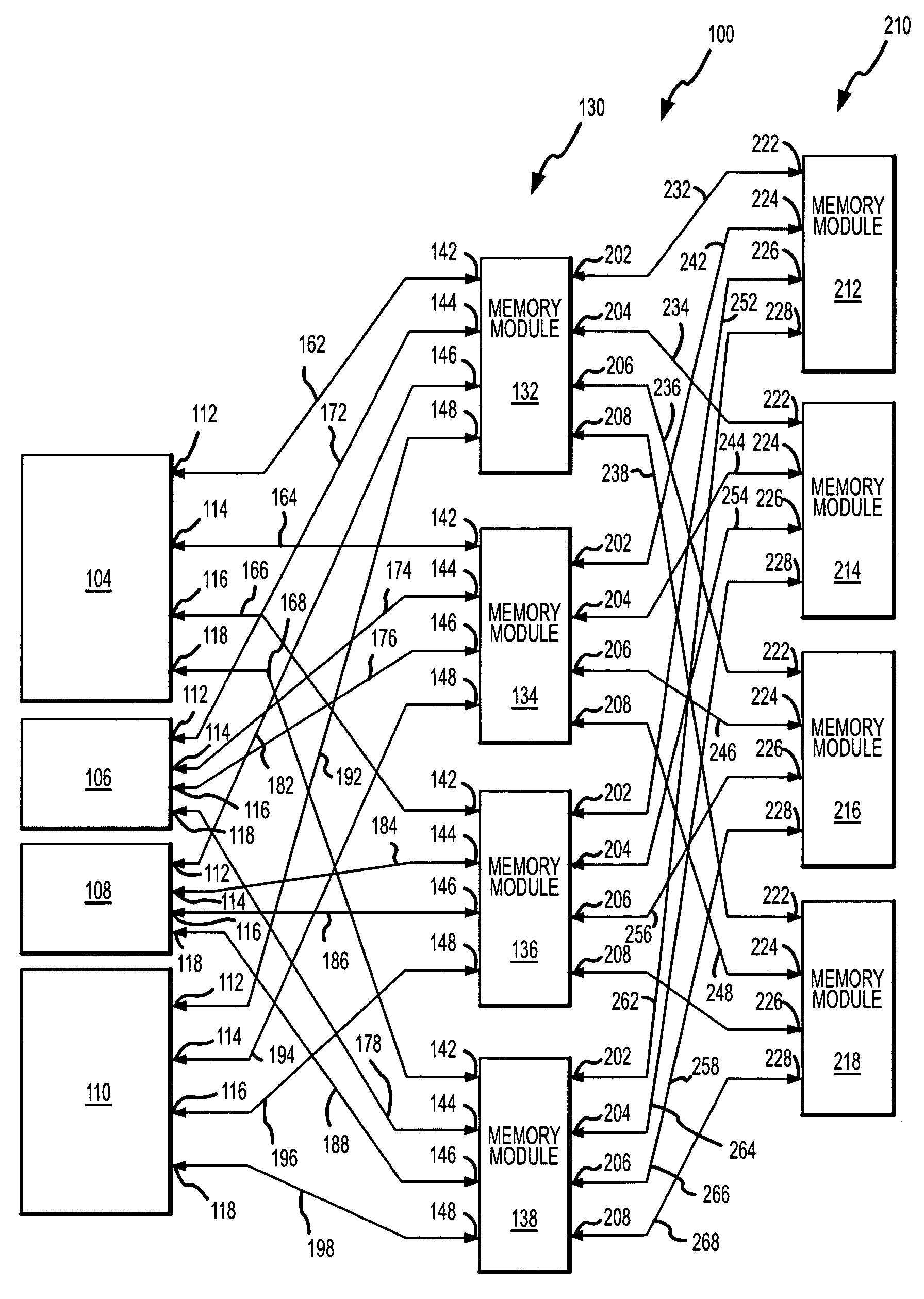

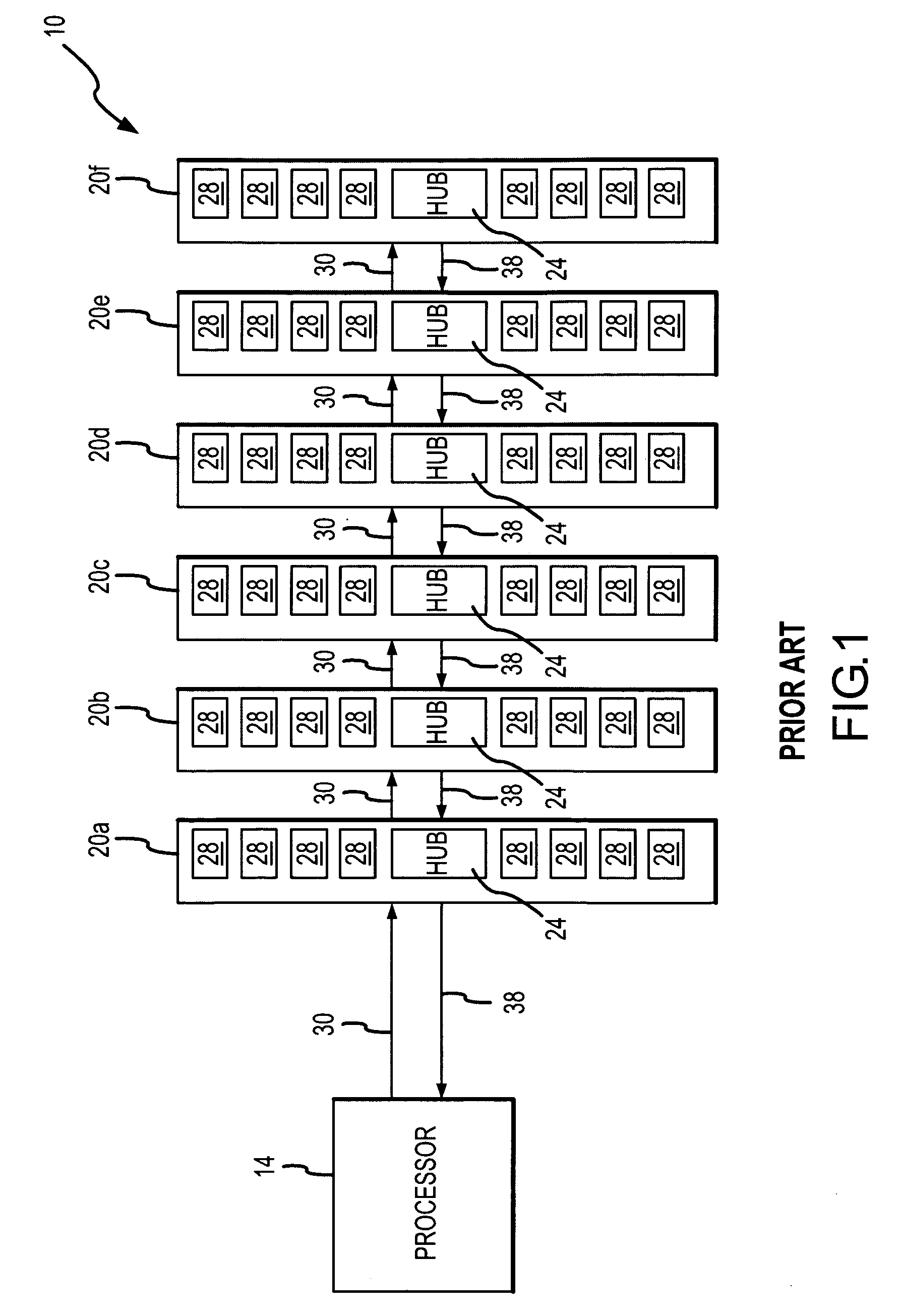

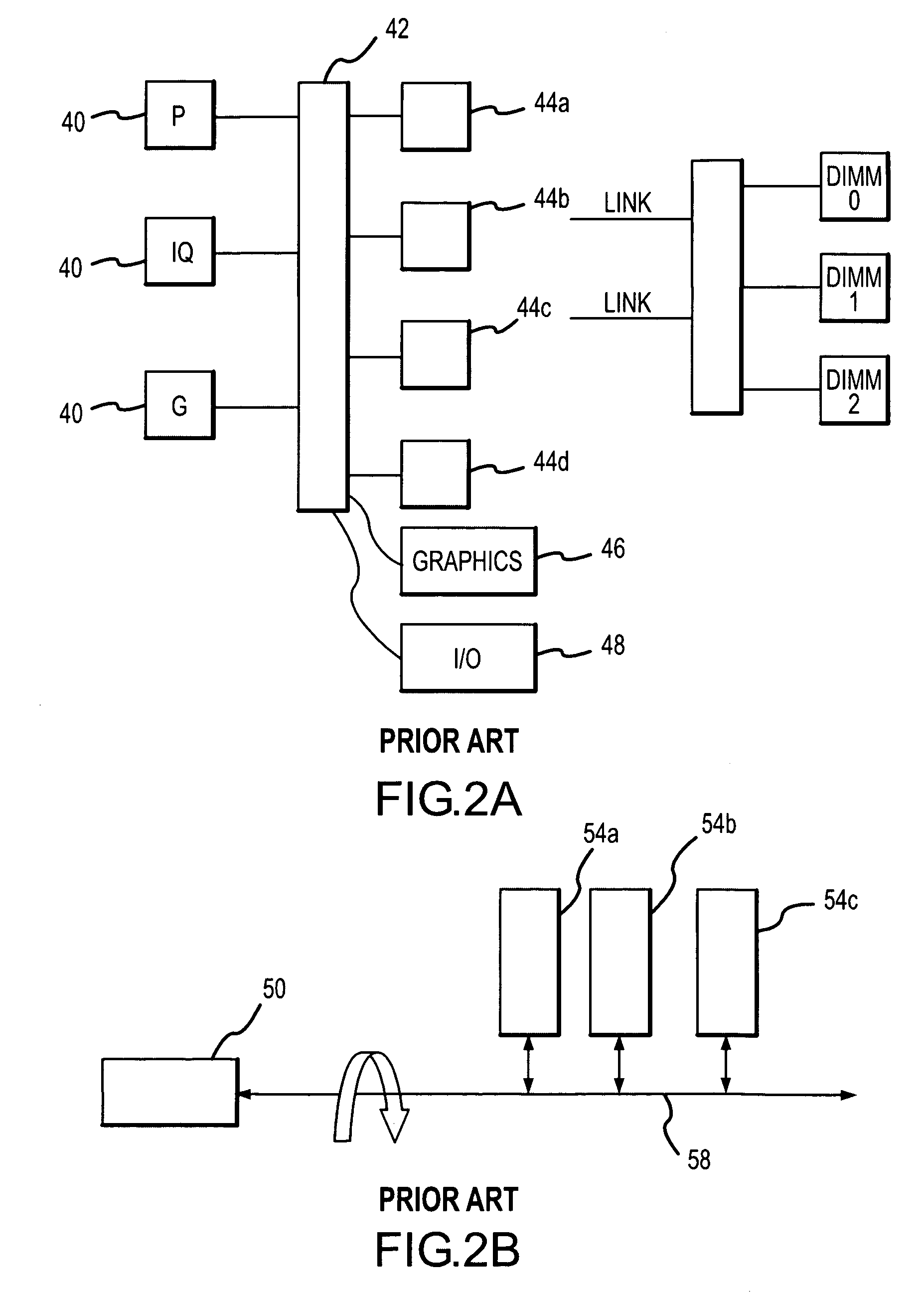

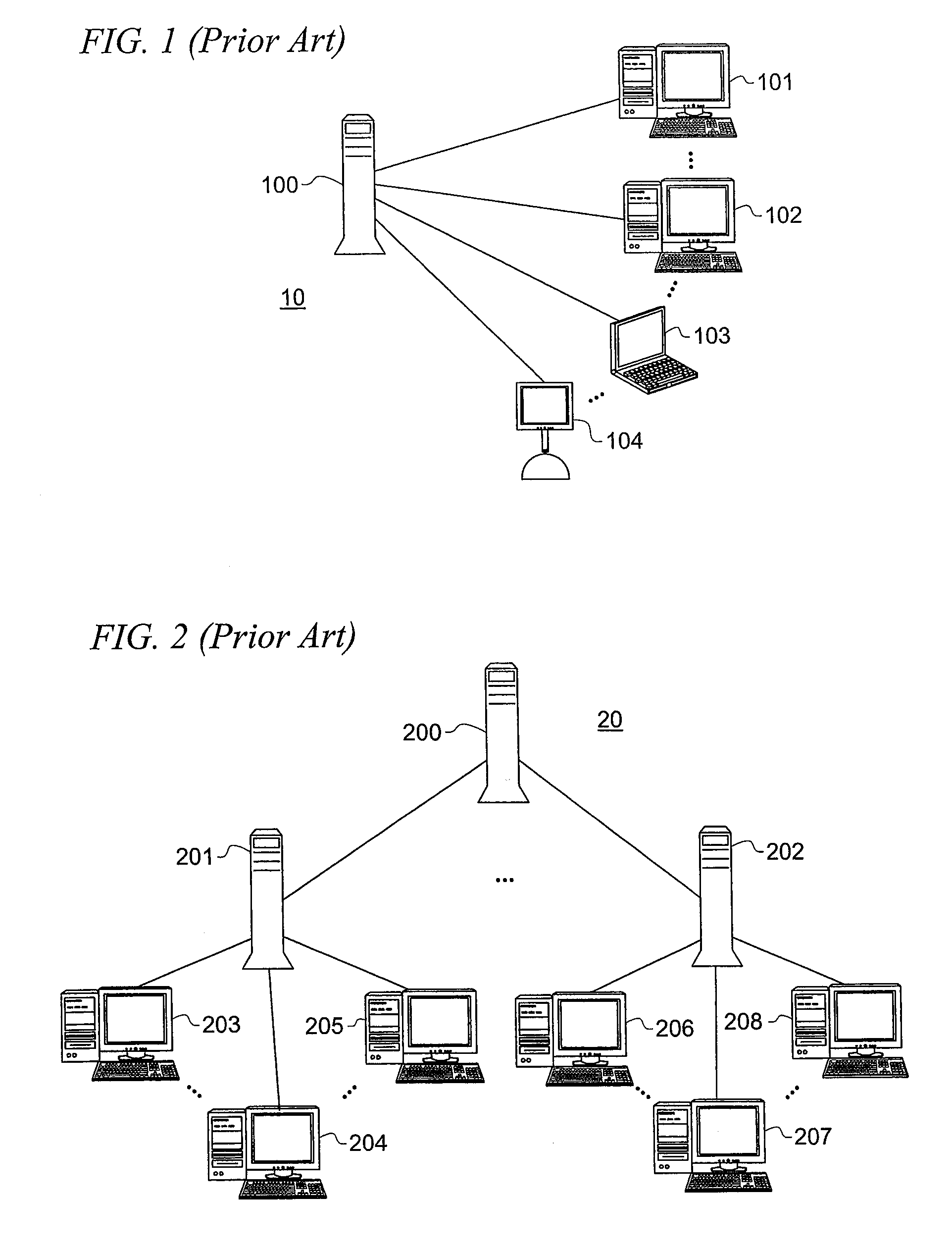

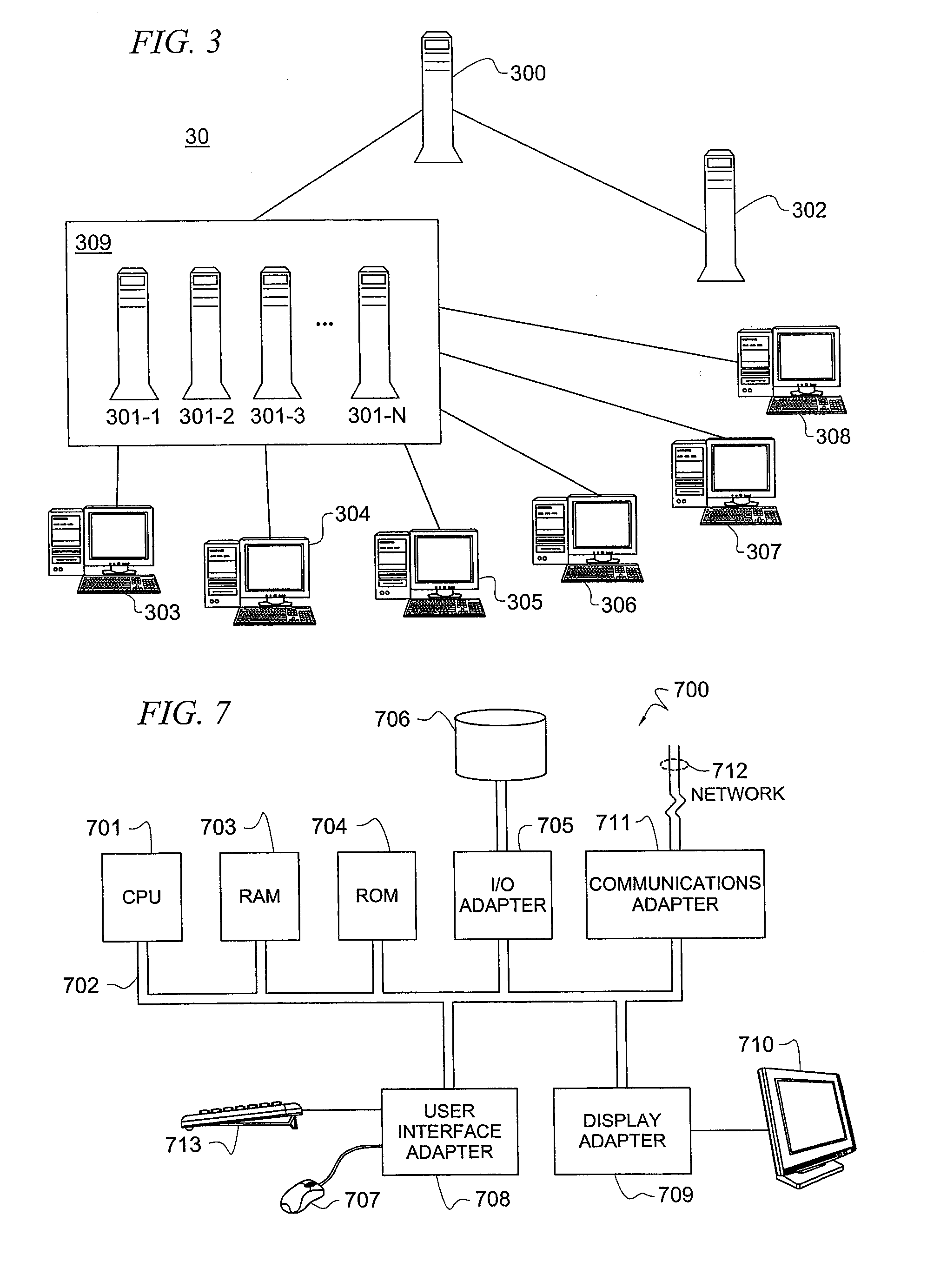

Multiple processor system and method including multiple memory hub modules

InactiveUS20050050255A1Low latency memory accessFlexible handlingStatic storageMemory systemsMemory controllerCrossover switch

A processor-based electronic system includes several memory modules arranged in first and second ranks. The memory modules in the first rank are directly accessed by any of several processors, and the memory modules in the second rank are accessed by the processors through the memory modules in the first rank. The data bandwidth between the processors and the memory modules in the second rank is varied by varying the number of memory modules in the first rank that are used to access the memory module in the second set. Each of the memory modules includes several memory devices coupled to a memory hub. The memory hub includes a memory controller coupled to each memory device, a link interface coupled to a respective processor or memory module, and a cross bar switch coupling any of the memory controllers to any of the link interfaces.

Owner:ROUND ROCK RES LLC

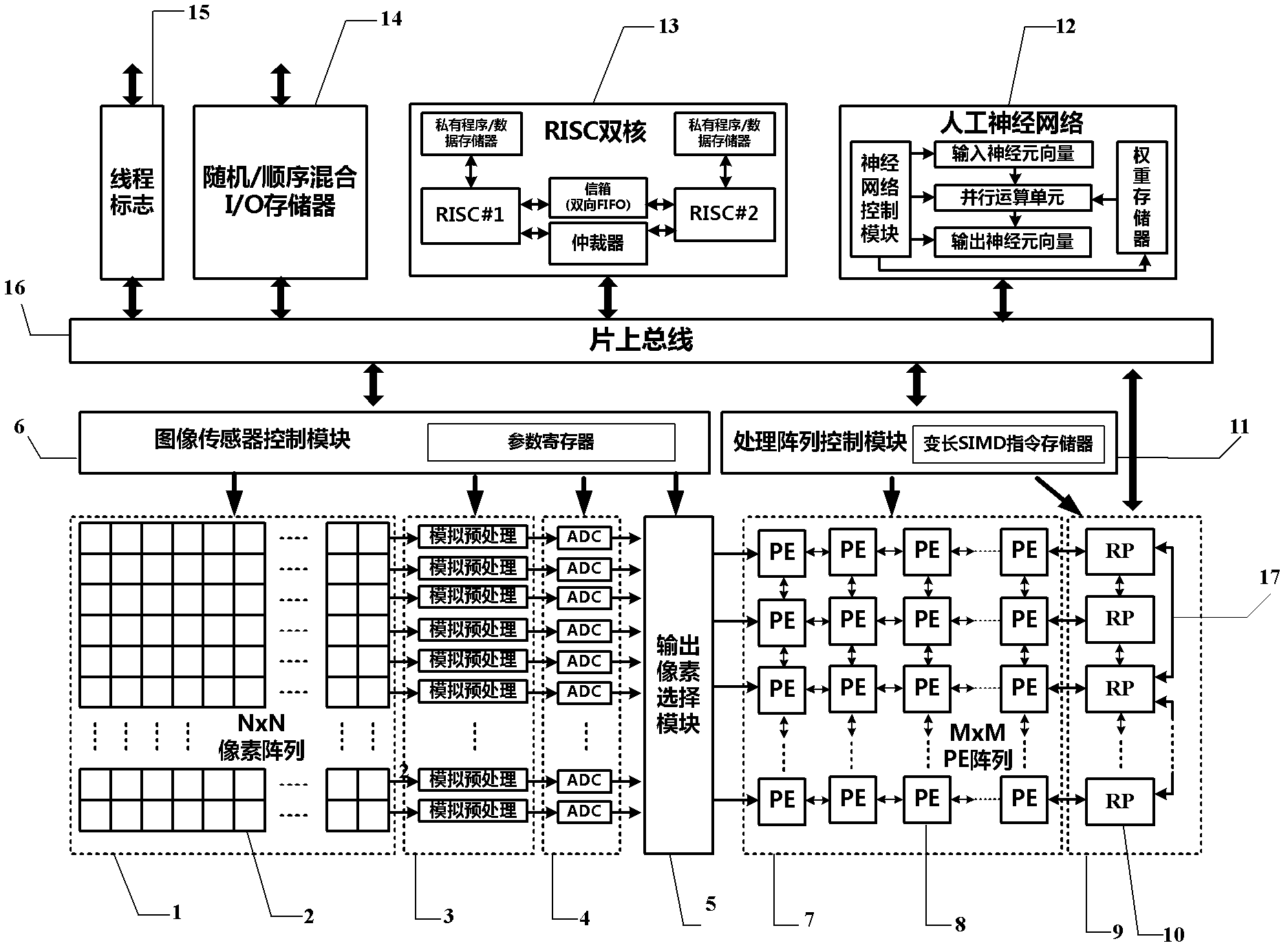

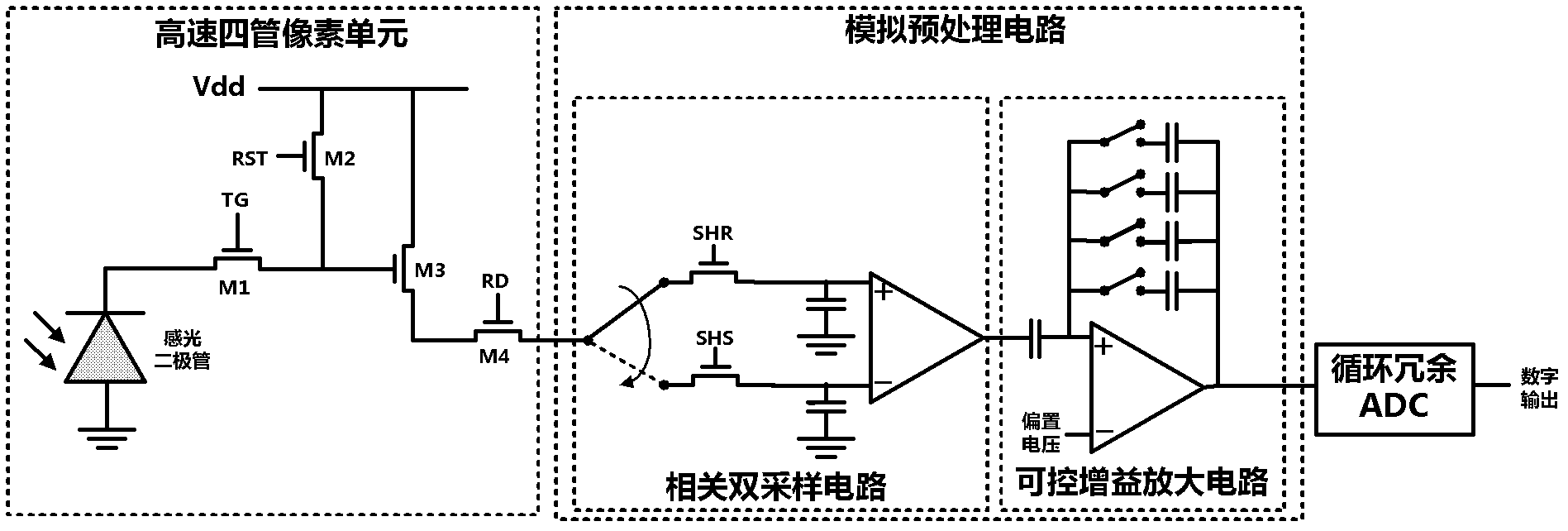

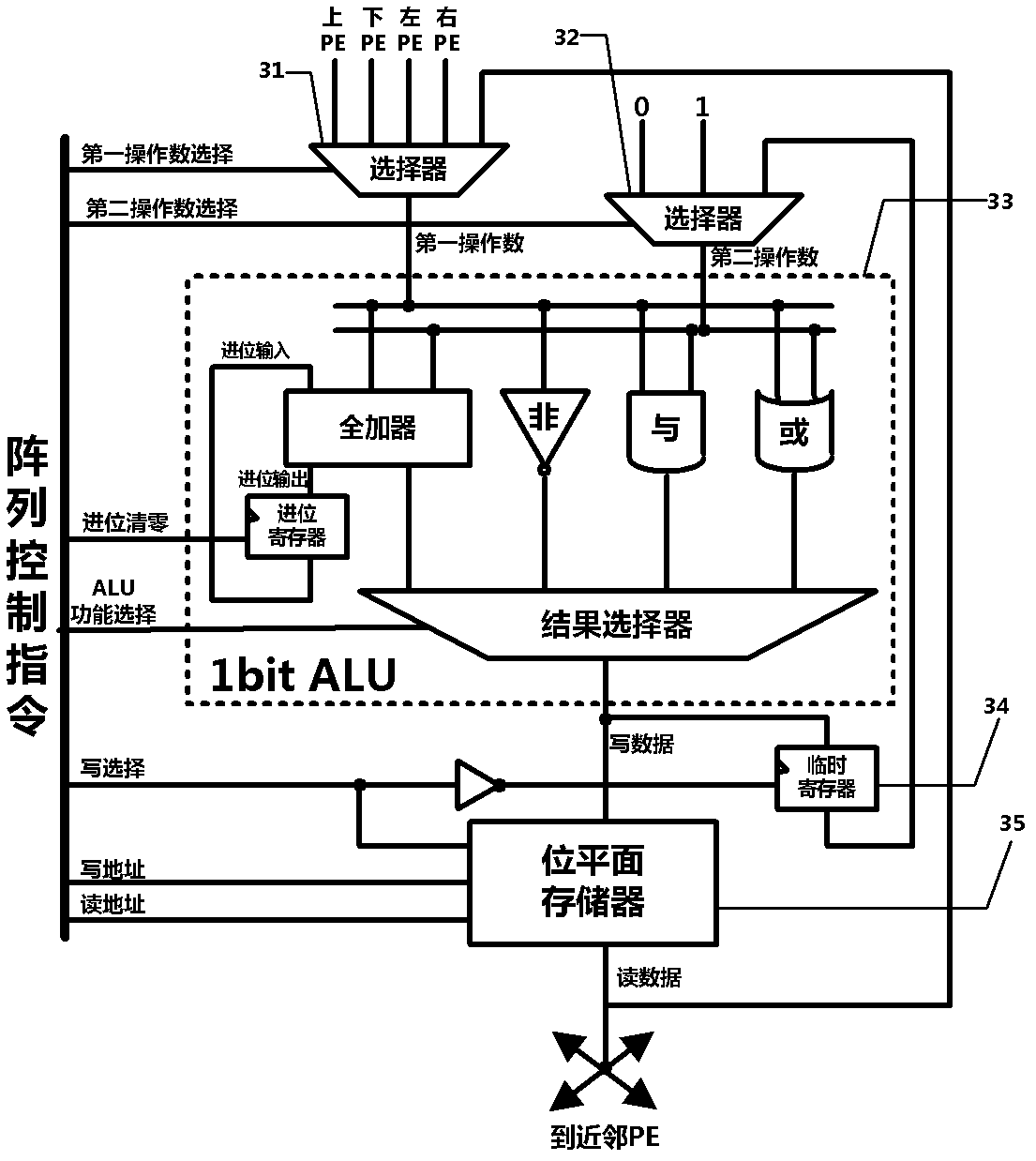

Programmable visual chip-based visual image processing system

ActiveCN102665049AFlexible handlingFlexible multi-resolution processingTelevision system detailsColor television detailsFace detectionDual core

Disclosed in the invention is a programmable visual chip-based visual image processing system, comprising an image sensor and a multilevel parallel digital processing circuit. The image sensor mainly includes a pixel array, an analog preprocessing circuit array and an analog-to-digital conversion circuit array; and the digital processing circuit consists of a parallel processing unit array with an M*M pixel level, a parallel processing unit array with M*1 rows, an on-chip artificial neural network and a reduced instruction processor dual-core subsystem. According to the provided system, high quality image collection with high speed and multilevel parallel image processing are realized and several high-speed intelligent visual application can be realized by programming; and compared with a traditional image system, the provided system has advantages of high speed, high integration, low power consumption and low cost. Moreover, the invention brings forward an embodiment for realizing the above-mentioned system as well as several high-speed intelligent visual image processing algorithms based on the embodiment. High-speed motion detection, high-speed gesture identification and rapid face detection are included; and the processing speed can reach 1000 frames per second. Therefore, a requirement of high-speed real-time processing can be met.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

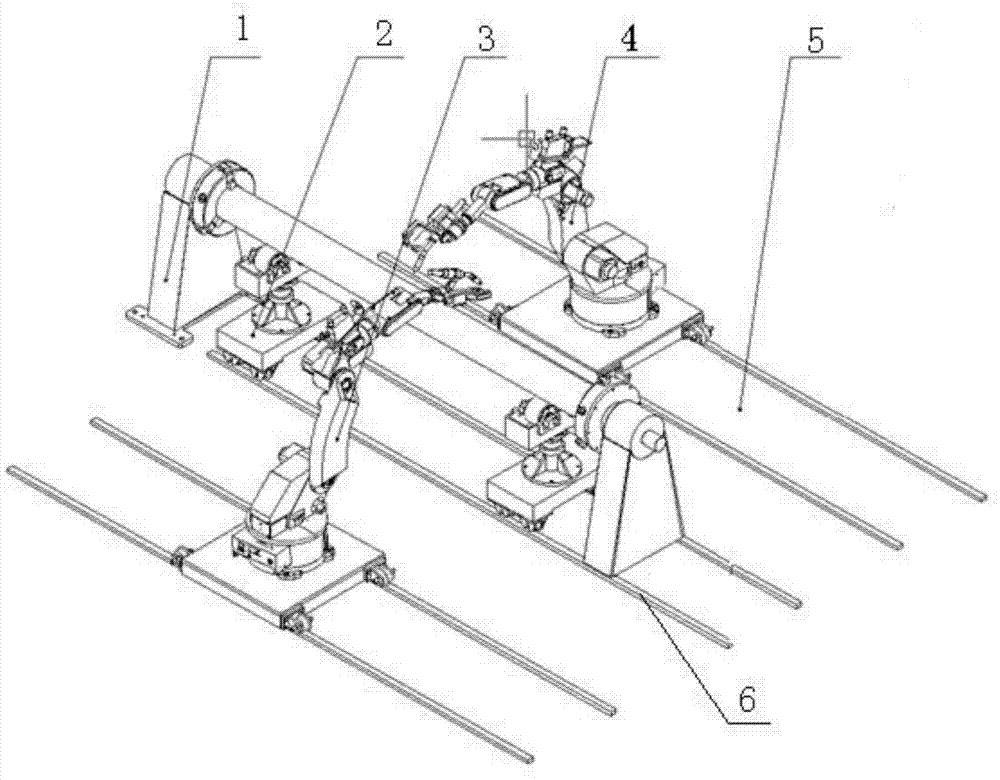

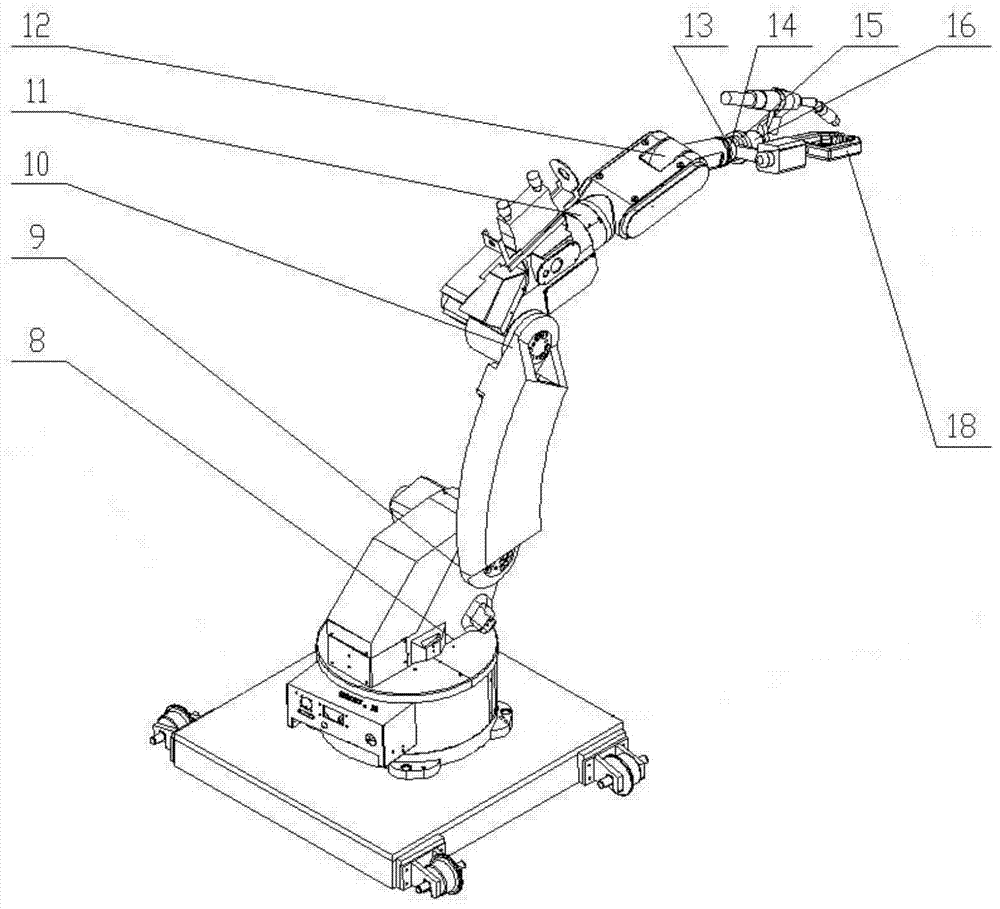

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

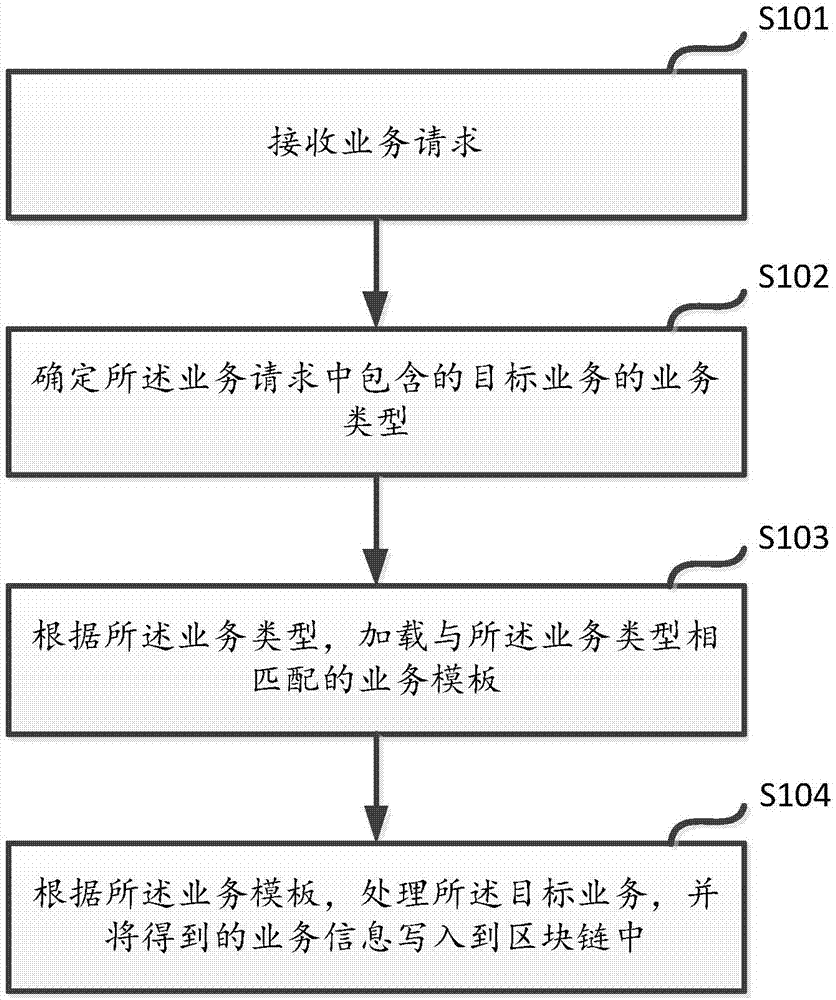

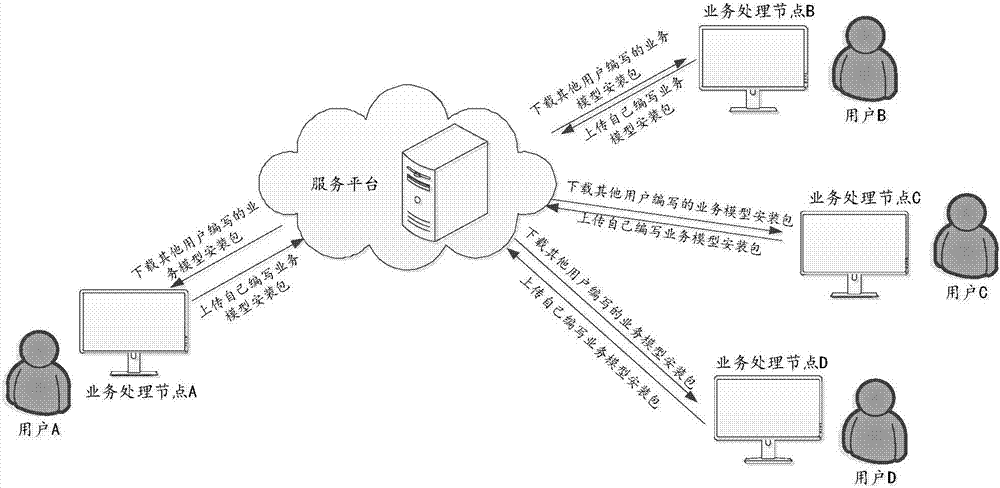

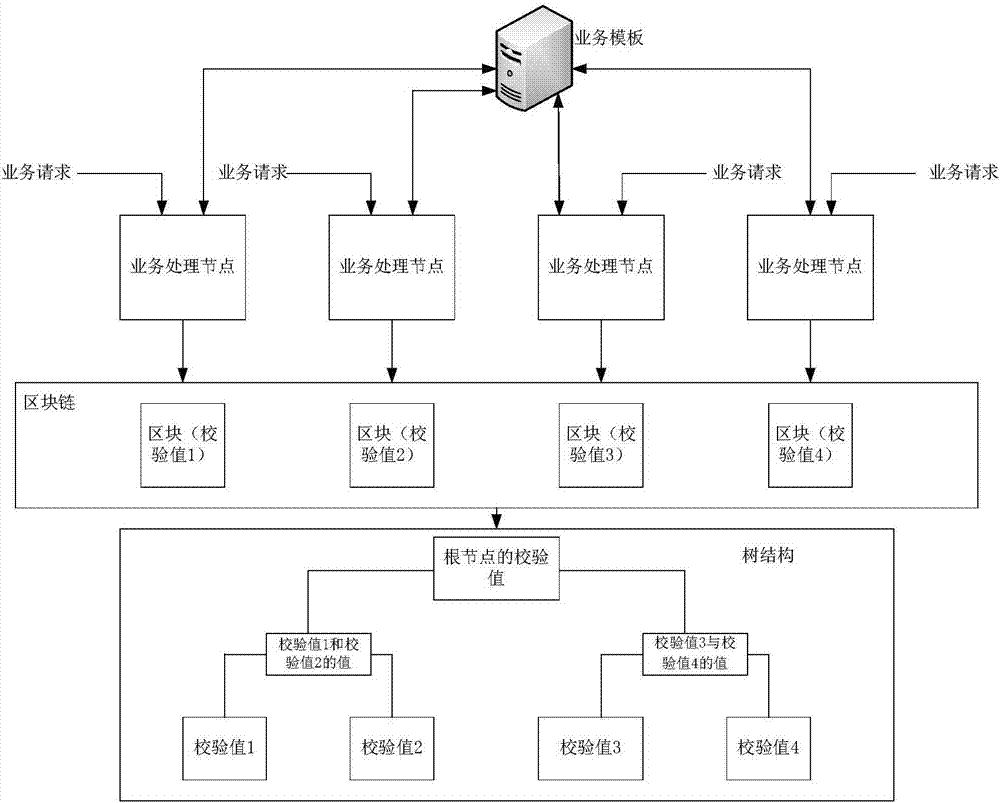

Method and device for service processing

ActiveCN107025559AFlexible handlingEasy to handleFinanceElectronic credentialsTemplate matchingComputer network

The invention discloses a method and a device for service processing. In the method, after receiving a service request sent by a user, a service processing node can load a service template matching a service type of a target service contained in the service request according to the service type, and process the target service through the service template. In the process of service processing, the service processing node can load a service template capable of processing a target service contained in a service request sent by a user according to the service request. Therefore, fixed and non-expandable service processing based on a block chain in the prior art is broken, and convenience is brought to users in service processing based on a block chain.

Owner:ADVANCED NEW TECH CO LTD

Multiple processor system and method including multiple memory hub modules

InactiveUS7136958B2Low latency memory accessFlexible handlingMemory adressing/allocation/relocationStatic storageElectronic systemsMulti processor

A processor-based electronic system includes several memory modules arranged in first and second ranks. The memory modules in the first rank are directly accessed by any of several processors, and the memory modules in the second rank are accessed by the processors through the memory modules in the first rank. The data bandwidth between the processors and the memory modules in the second rank is varied by varying the number of memory modules in the first rank that are used to access the memory module in the second set. Each of the memory modules includes several memory devices coupled to a memory hub. The memory hub includes a memory controller coupled to each memory device, a link interface coupled to a respective processor or memory module, and a cross bar switch coupling any of the memory controllers to any of the link interfaces.

Owner:ROUND ROCK RES LLC

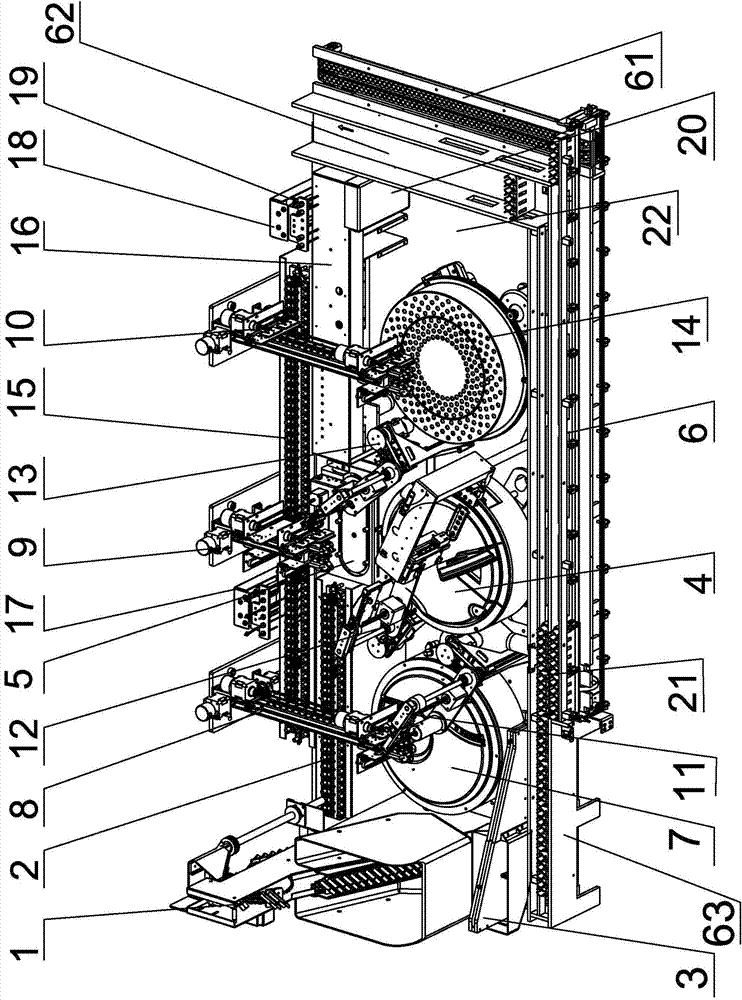

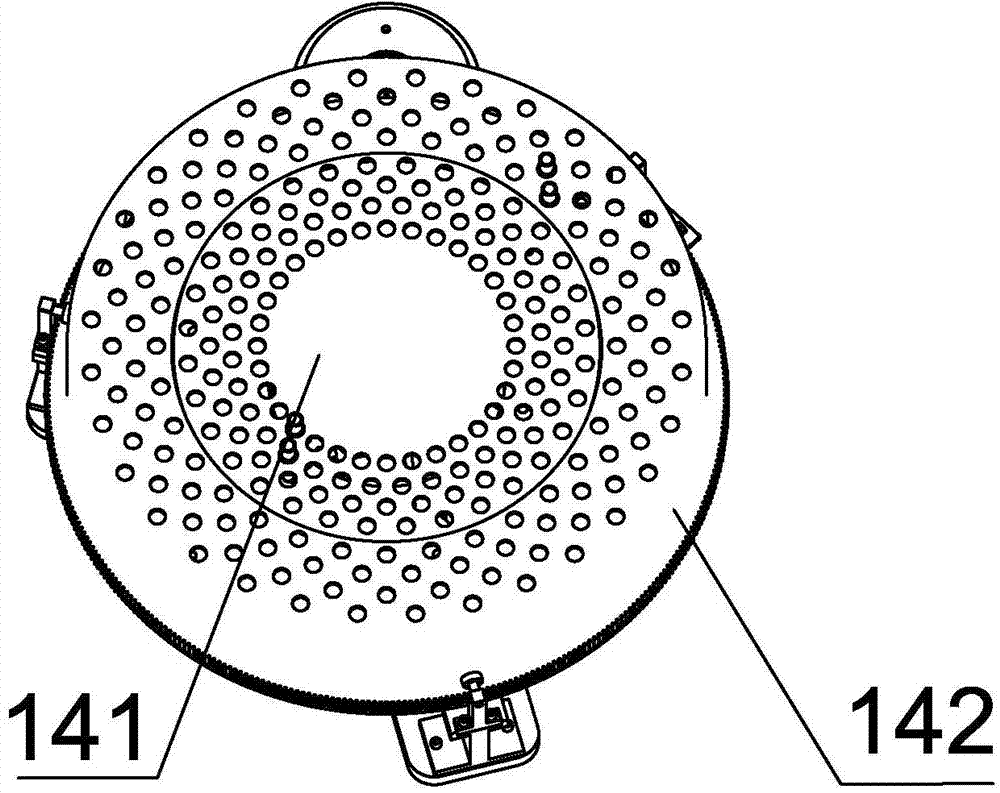

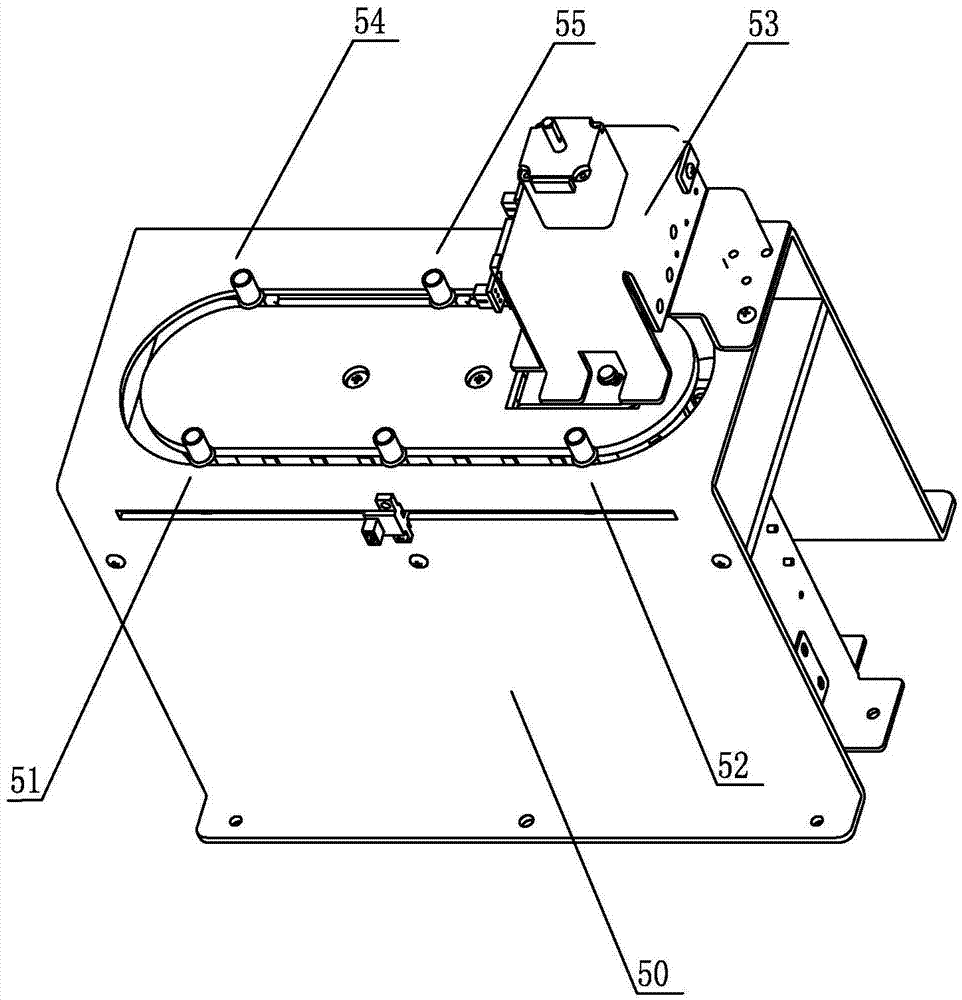

Full-automatic chemiluminescence immune analyzer and use method thereof

ActiveCN104714042AHigh degree of automationSimple controlMaterial analysisEngineeringChemiluminescence

The invention provides a full-automatic chemiluminescence immune analyzer comprising a rack, and a sample introduction device, a reaction control device and an optical detection assembly which are arranged on the rack, wherein the sample introduction device comprises a reaction cup array mechanism, a reaction cup delivery rail, a sample adding gun head array mechanism, a reagent storage disc, a reagent filling rail, a sample conveying device, a sample storage disc, a first mechanical arm, a second mechanical arm, a third mechanical arm, a sample filling needle, a first reagent filling needle and a second reagent filling needle; the reaction control device comprises a reaction cup incubating disc, a primary magnetic separation rail, a secondary magnetic separation rail, a first cleaning and magnetic separation mechanism, a second cleaning and magnetic separation mechanism and a substrate filling mechanism; the optical detection assembly comprises a photomultiplier and a control circuit. The full-automatic chemiluminescence immune analyzer can automatically perform operations such as sample adding, reaction, data reading and the like in the chemiluminescence immune testing flow.

Owner:SHENZHEN YHLO BIOTECH

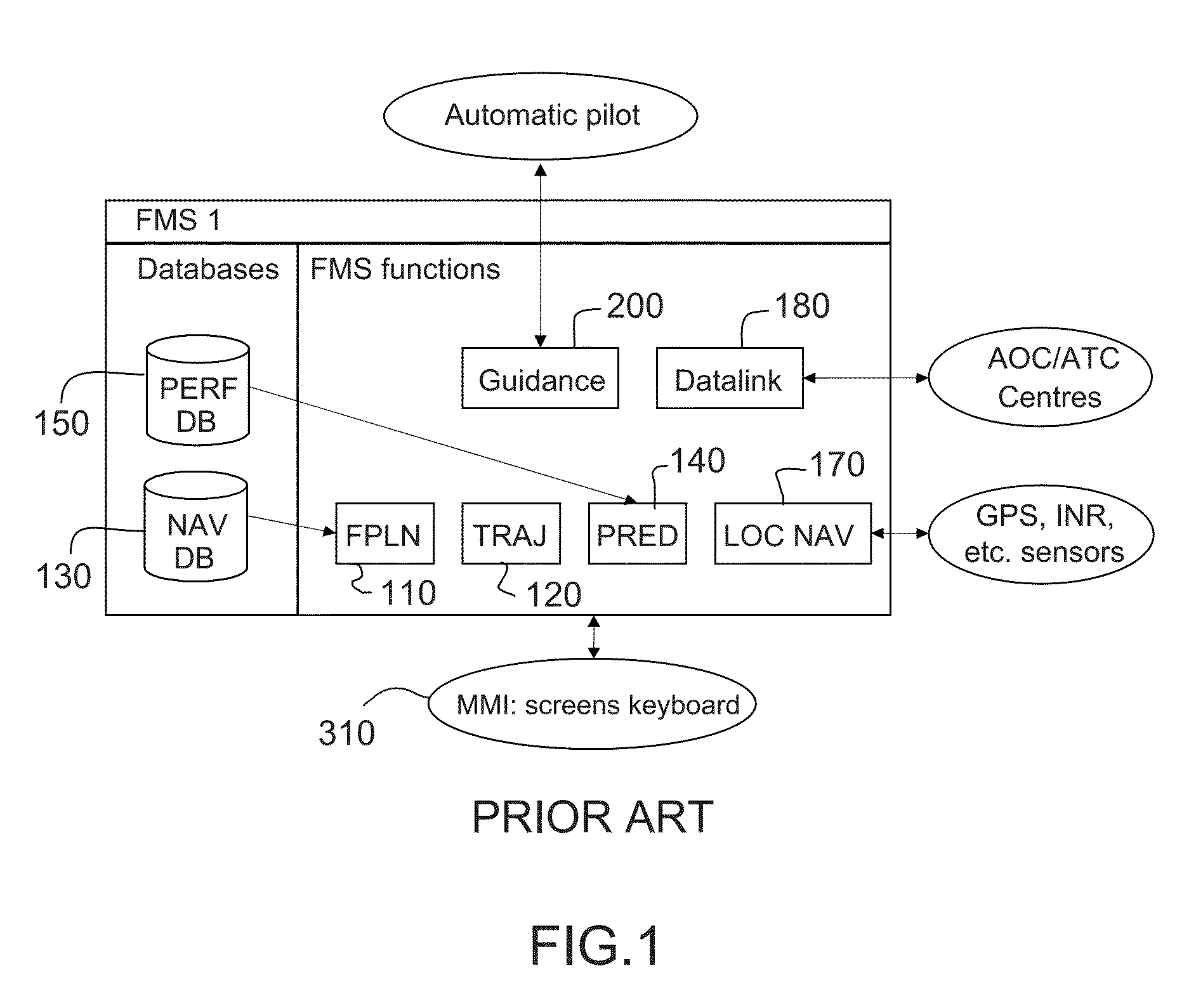

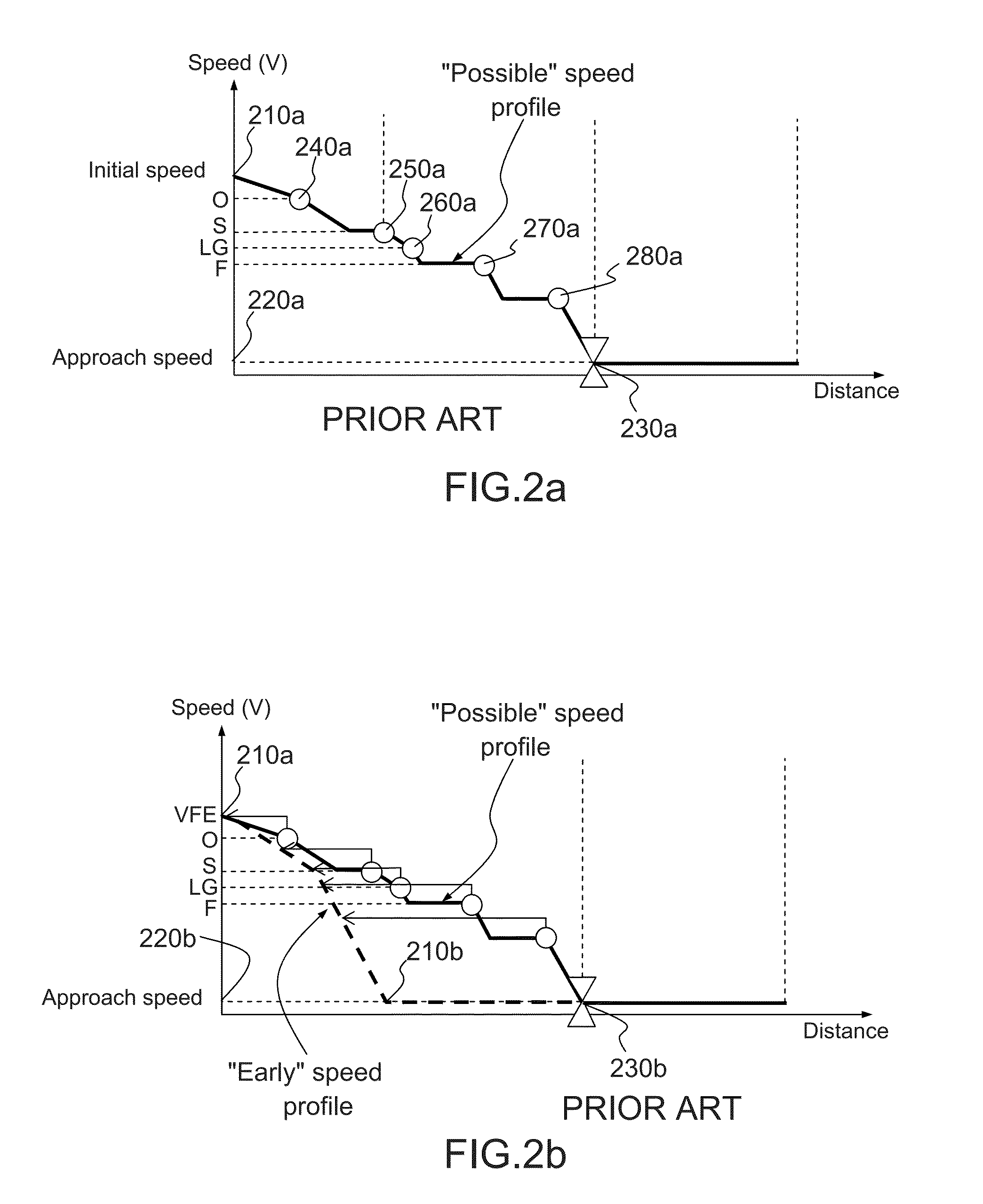

Method of adapting a segment of an aircraft trajectory with constant ground gradient segment according to at least one performance criterion

ActiveUS20160085239A1Optimization pathEasy to useEnergy efficient operational measuresDigital data processing detailsState variableEngineering

A method for adapting an aircraft constant-gradient descent segment comprises: an acquisition step in which state variables characterizing the aircraft, environment variables characterizing the environment thereof and path variables characterizing the predicted path thereof at one of the initial and final points of the segment are acquired; a calculation step whereby a limit ground gradient for at least one performance criterion is calculated from the state variables, environment variables and path variables; a validity verification step checking the validity of the path initially predicted against the most restrictive limit ground gradient; and when the path initially predicted is not valid: a feasibility verification step checking the feasibility of a command to modify at least one state variable; if feasibility is verified, a prediction of executing the command; otherwise, a prediction of modifying one of the initial and final points of the segment with respect to constraints of the flight plan.

Owner:THALES SA

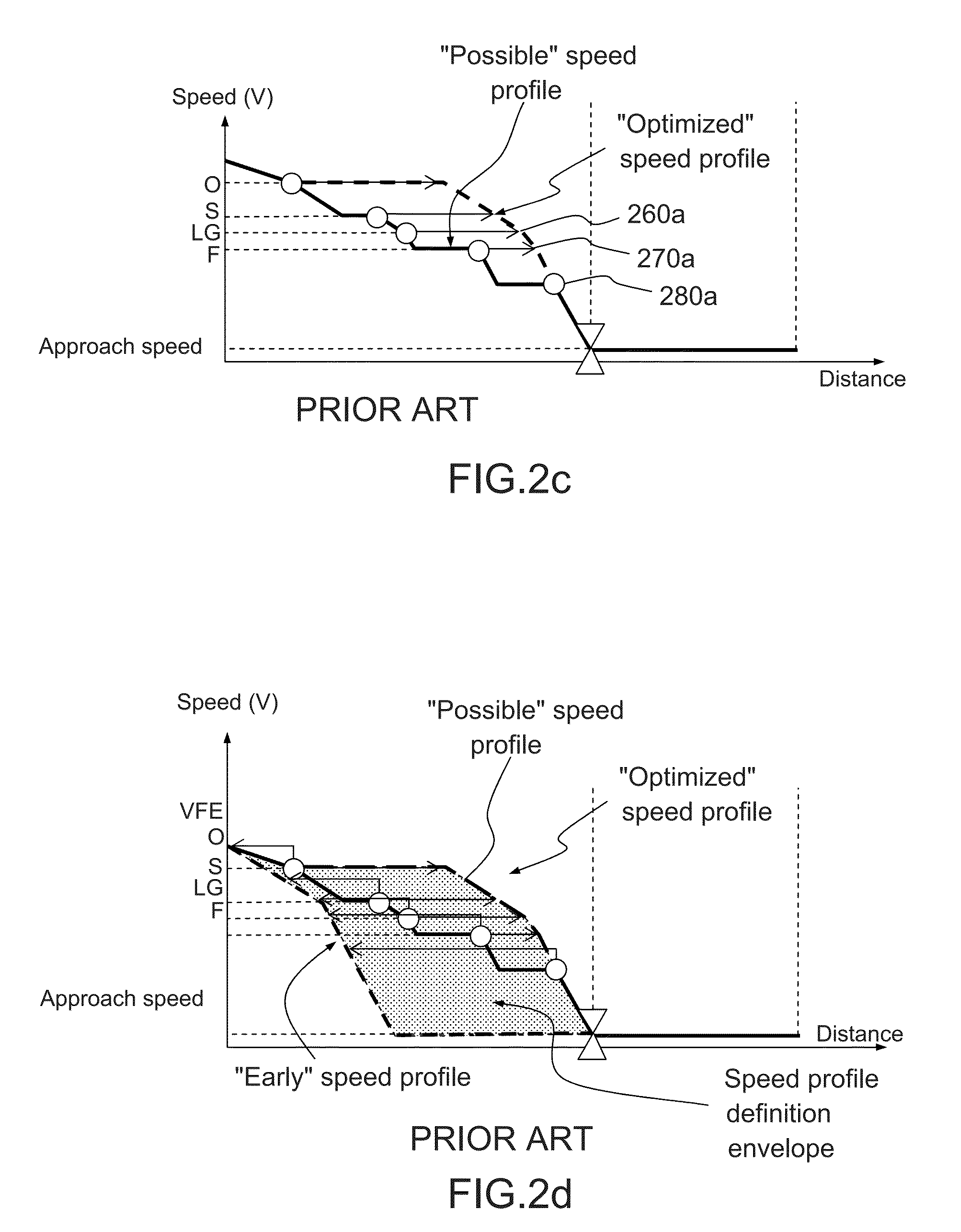

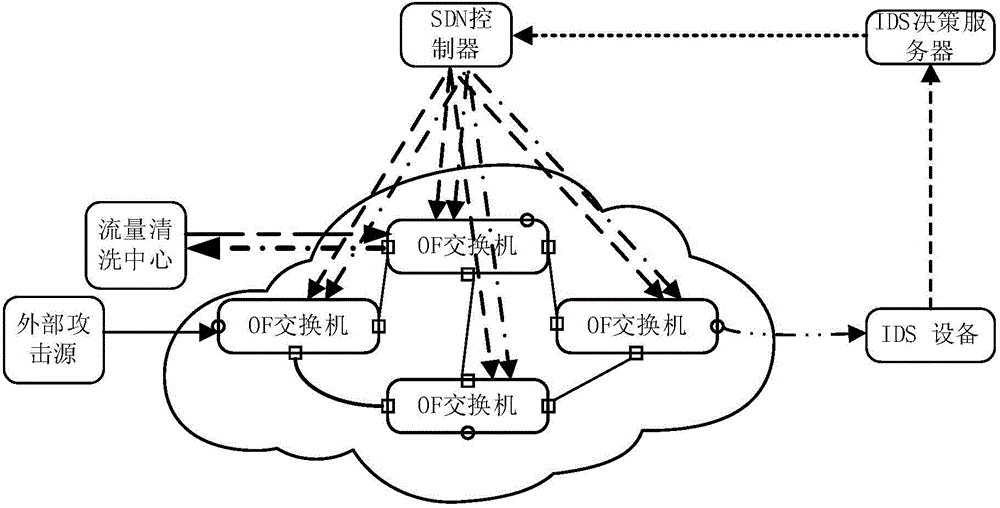

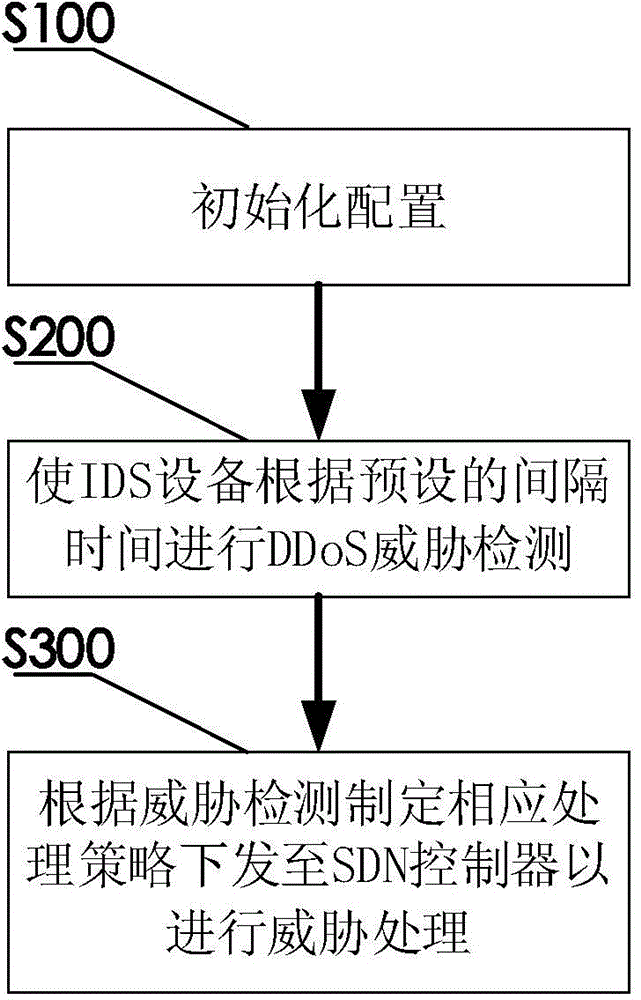

Network security defense system based on software-defined network and working method of network security defense system

The invention discloses a network security defense system based on a software-defined network and a working method of the network security defense system. The network security defense system comprises an SDN controller, an IDS decision making server and an IDS device. The IDS device is suitable for spot-checking messages, and in other words, when the IDS device detects the messages with the DDoS attack characteristics, the messages are reported to the IDS decision making server; the IDS decision making server formulates a processing strategy corresponding to the messages with the DDoS attack characteristics according to reported information, and the processing strategy is issued to the SDN controller for threat processing. The messages are detected in a spot-checking mode, the burden on the SDN controller is greatly reduced, the burden on the server is further reduced in the mode that detection and decision making are separated, and the system is more suitable for network transmission of high-flow data.

Owner:常州麦拉风网络科技有限公司

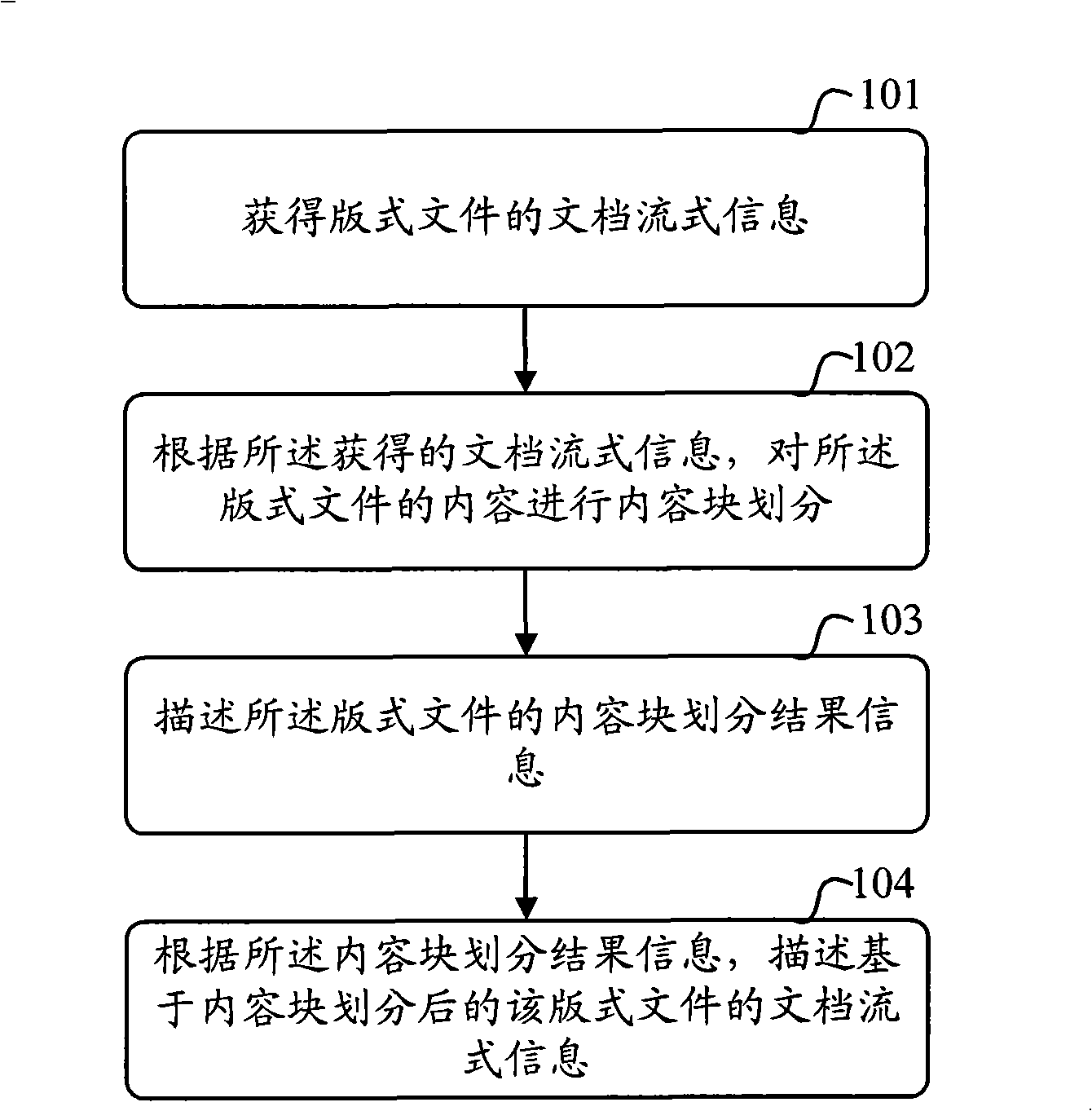

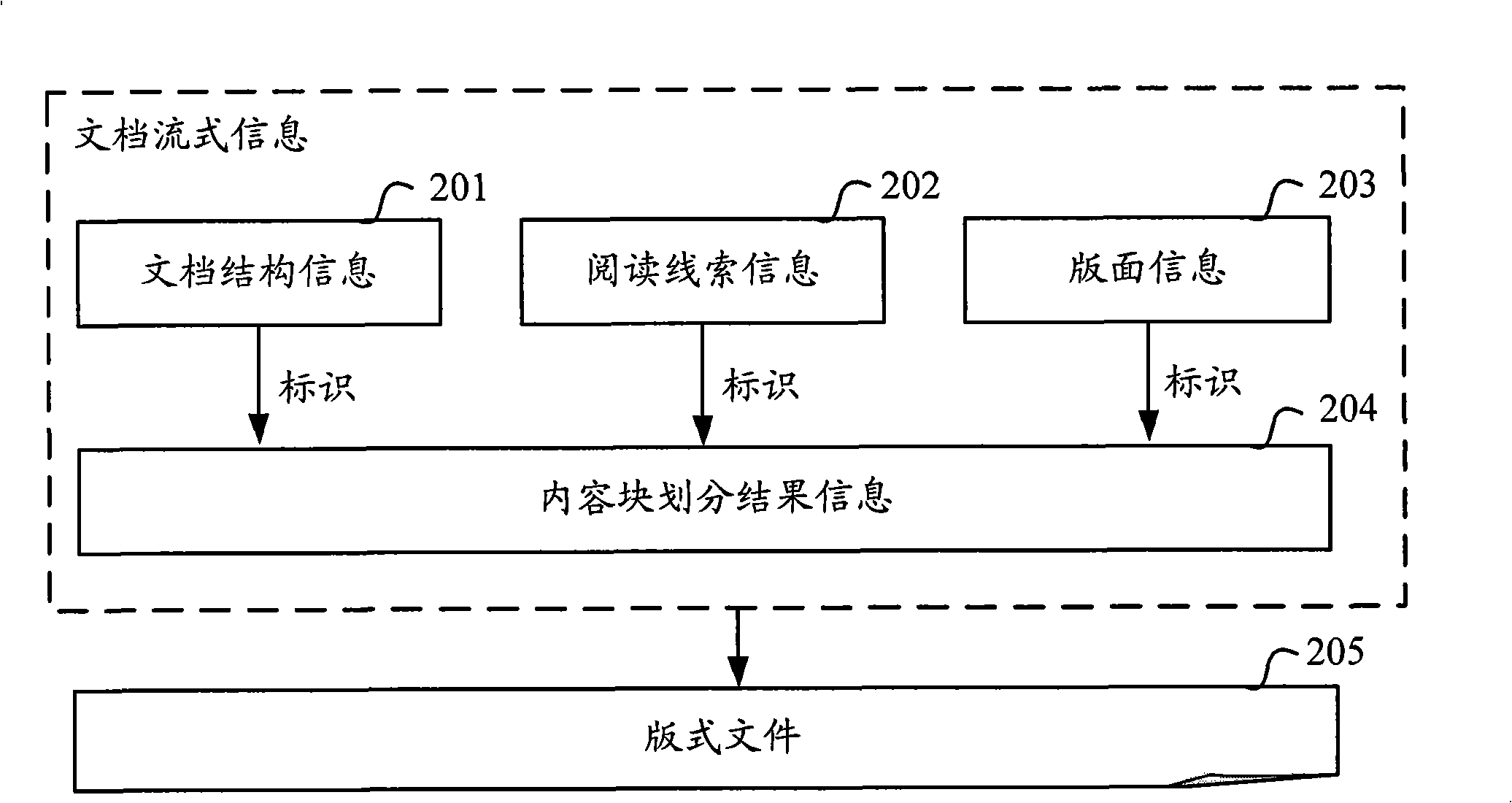

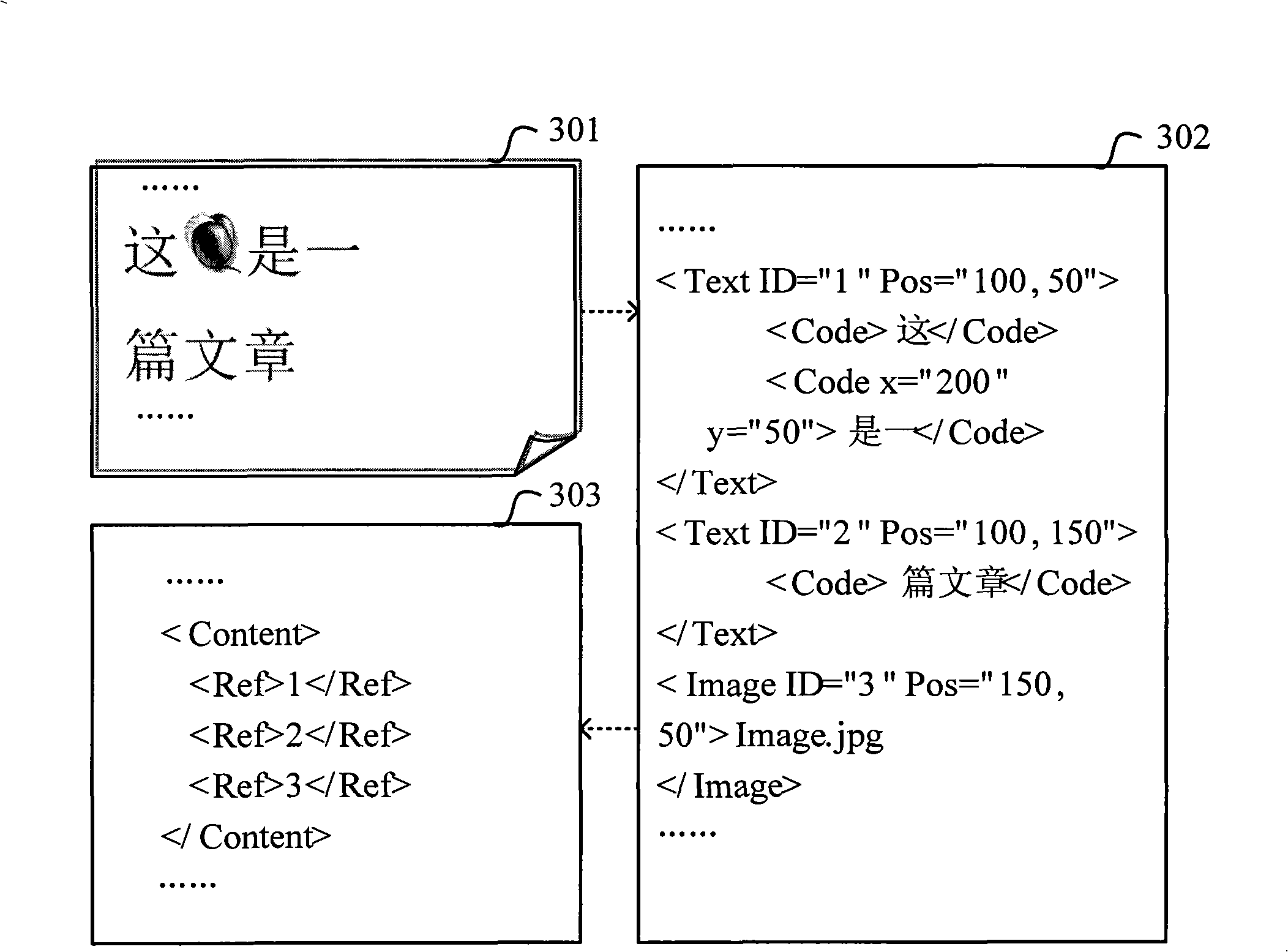

Document stream type information processing method based on format document and device therefor

ActiveCN101308488AAccurate descriptionFlexible handlingNatural language data processingSpecial data processing applicationsArbitrary contentDocument preparation

The invention discloses a document flow information processing method and a device based on a format file and particularly discloses the following technical proposal: the file flow information of the format file is acquired, which is the file content structure information in the format file and / or the file layout self-adaptive presentation information in the format file; the file content of the format file is divided into content blocks according to the acquired file flow information; the content block division result information of the format file is described; the file flow information based on the format file after content block division is described, according to the content block division result information. Therefore, the file flow information for describing the format file is more practical and applicable, and any content of the format file can be flexibly described in file flow information, with more accurate description scope; besides, the file flow information processing is more flexible and simplified.

Owner:PEKING UNIV +2

Method of recovery copper, nickel and noble metal in waste water and slag by combined technology of wet method and fire method

A process for recovering the copper, Ni and noble metals from the sewage and dregs by the combination of wet method and fire method includes the wet process including extracting, Cu-Ni separation, removing Fe, extracting, and refining nickel carbonate, and the fire process including sintering and smelting to produce nickel matte and black copper. Its advantages are high recovery rate of Ni, Cu, Au, Ag and Pd, and no secondary pollution.

Owner:孙涛 +1

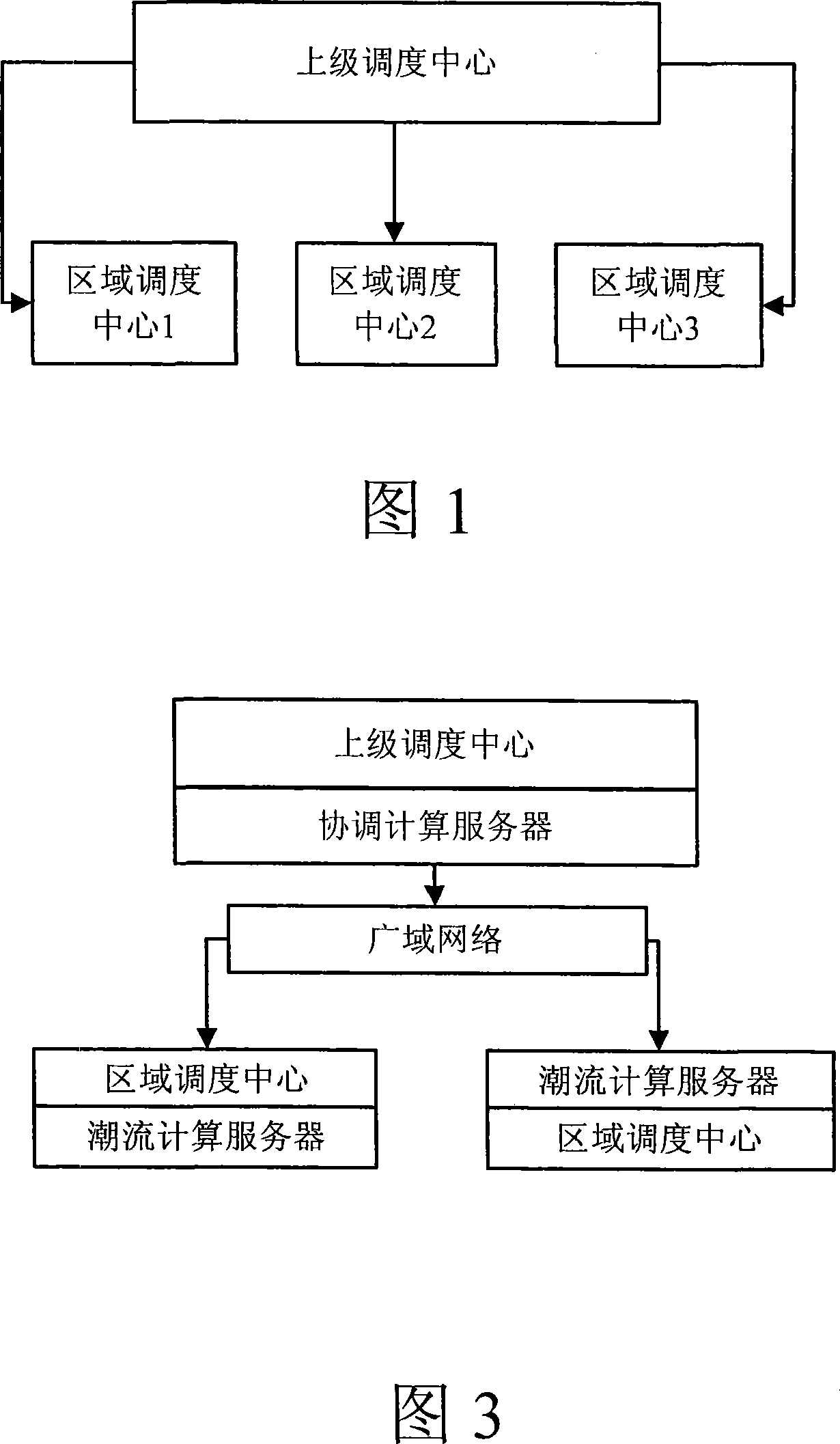

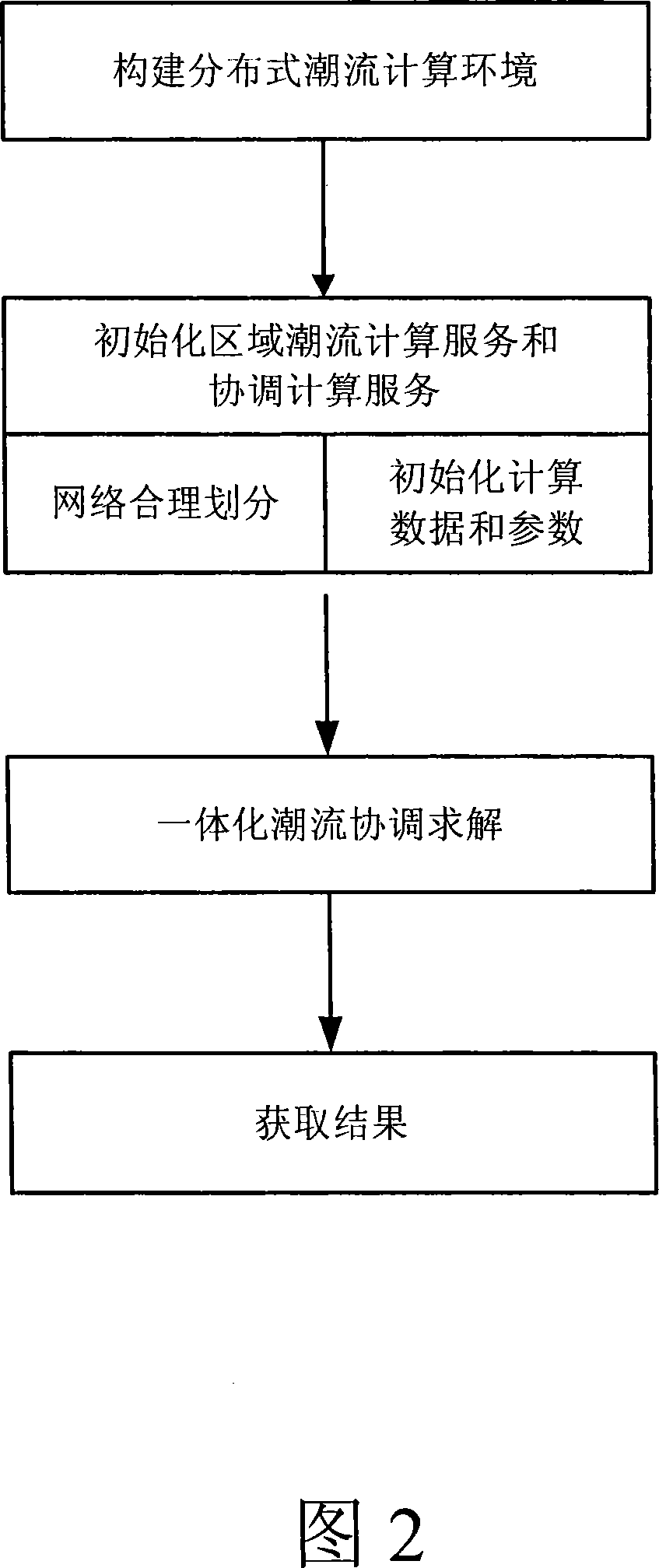

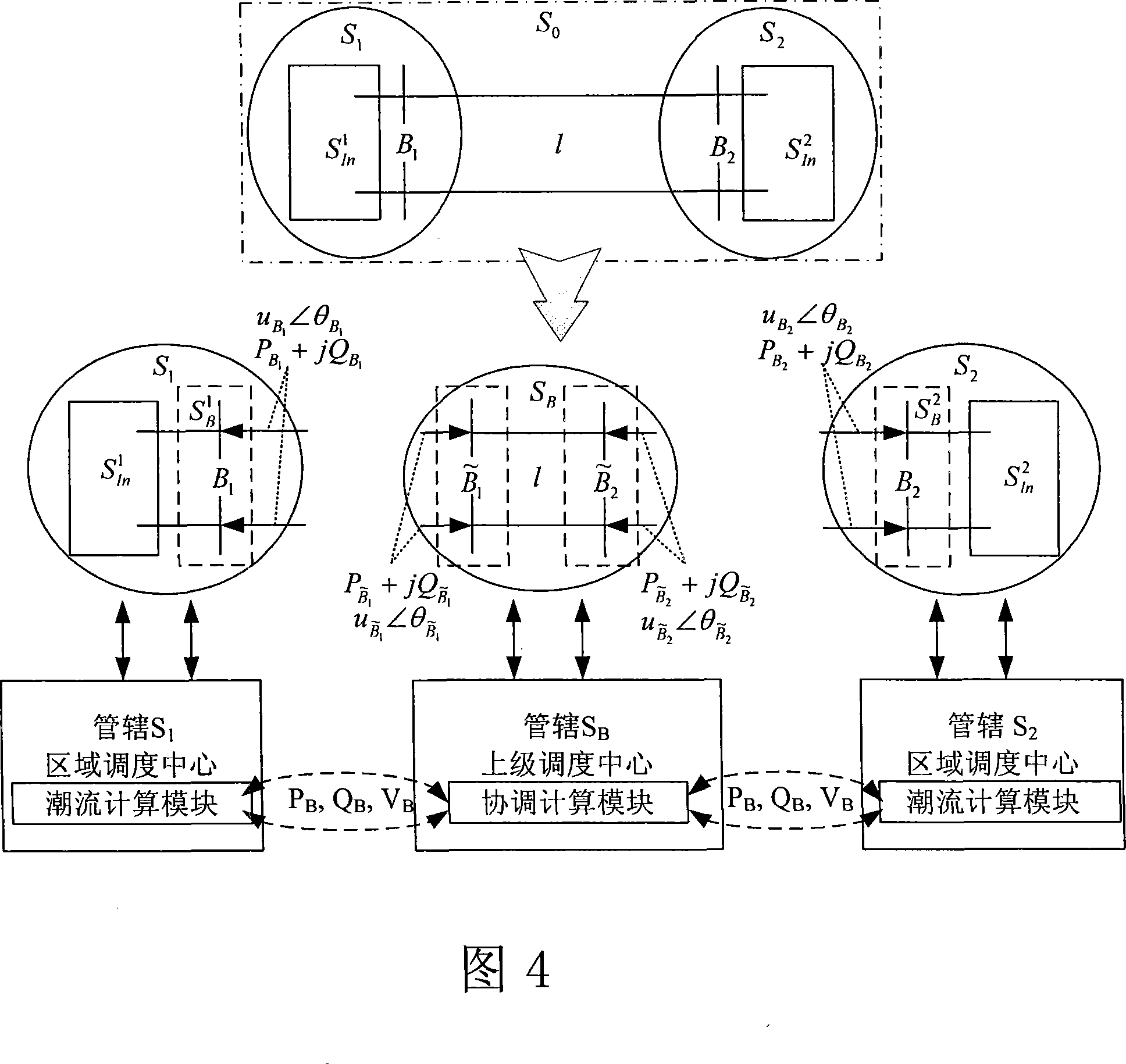

Method for distributed tidal current analyzing by exchange boundary node state and net damage information

ActiveCN101141064AFlexible handlingThe problem of flexible unbalanced power distributionData processing applicationsSpecial data processing applicationsDecompositionData source

The invention discloses a method of completing the distributed tide analysis by exchanging the border node state and the network damage information, which comprises: establishing a distributed tide analyzing system according to the actual scheduling management manner of the electric power system; based on the topology connection relations of the electric power system and the operation situations of the practical system, dividing the interconnected electric network by the dividing method with border area, and clarifying the counting objects and the data sources of the counting server and the coordinating counting server; a domain tide counting server and the superior coordinating counting server are initialized by counting data and parameters, while the coordinating counting server calls the domain tide counting server to together complete the network integrative tide decomposition coordinating solve; besides, the servers call the processes, the domain tide counting server feeds back the result to the coordinating counting server so as to make the coordinating counting server obtain the convergent network integrative tide result.

Owner:TSINGHUA UNIV

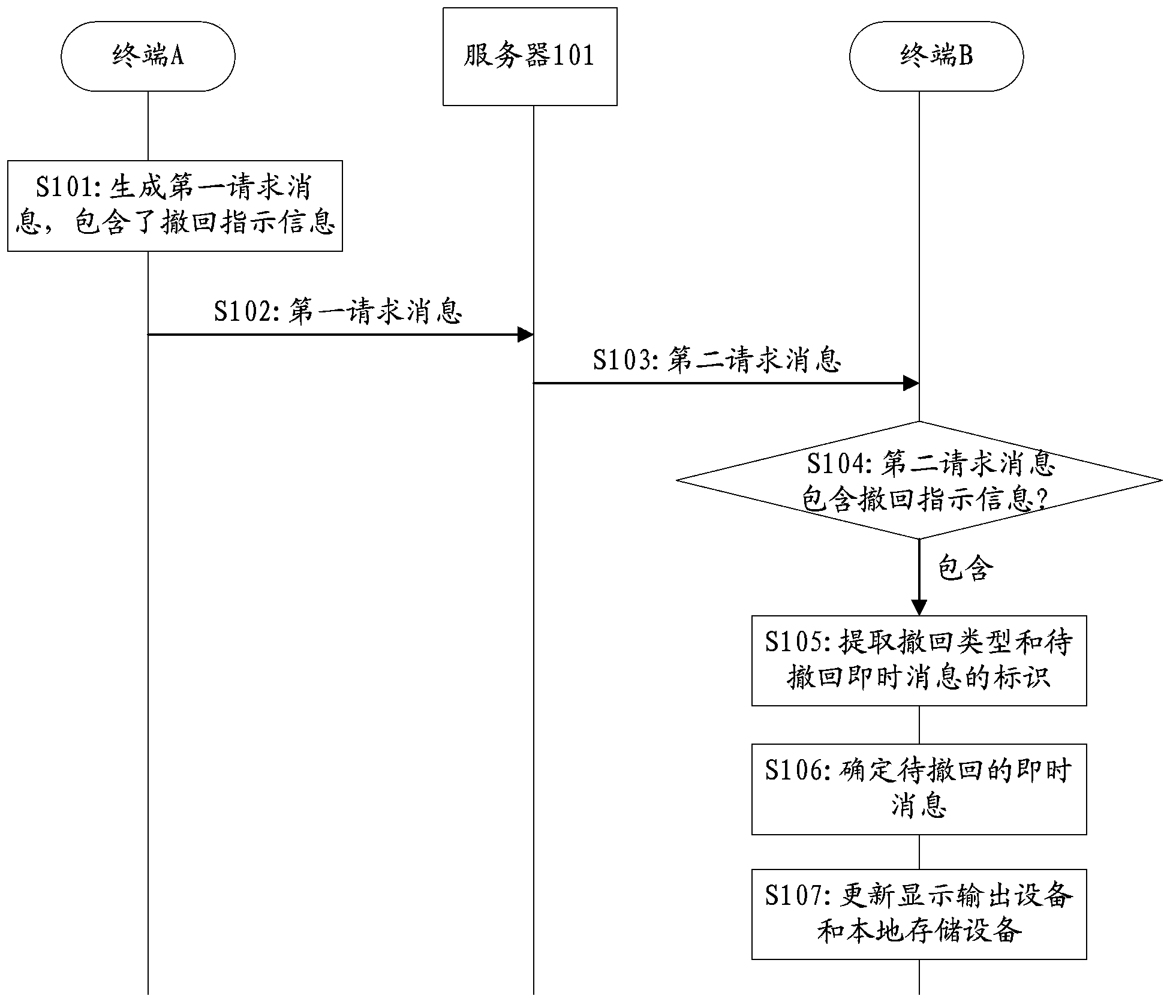

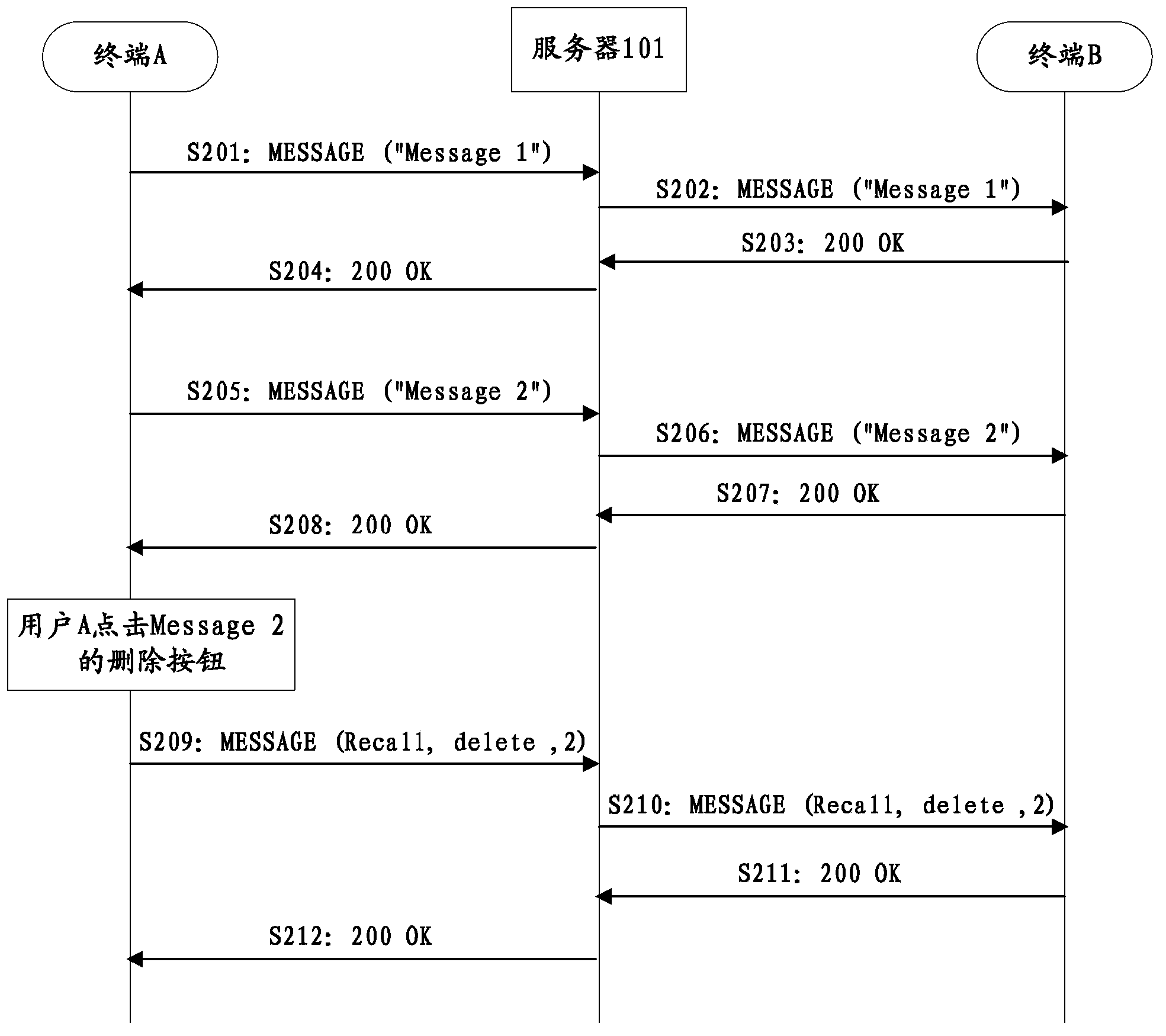

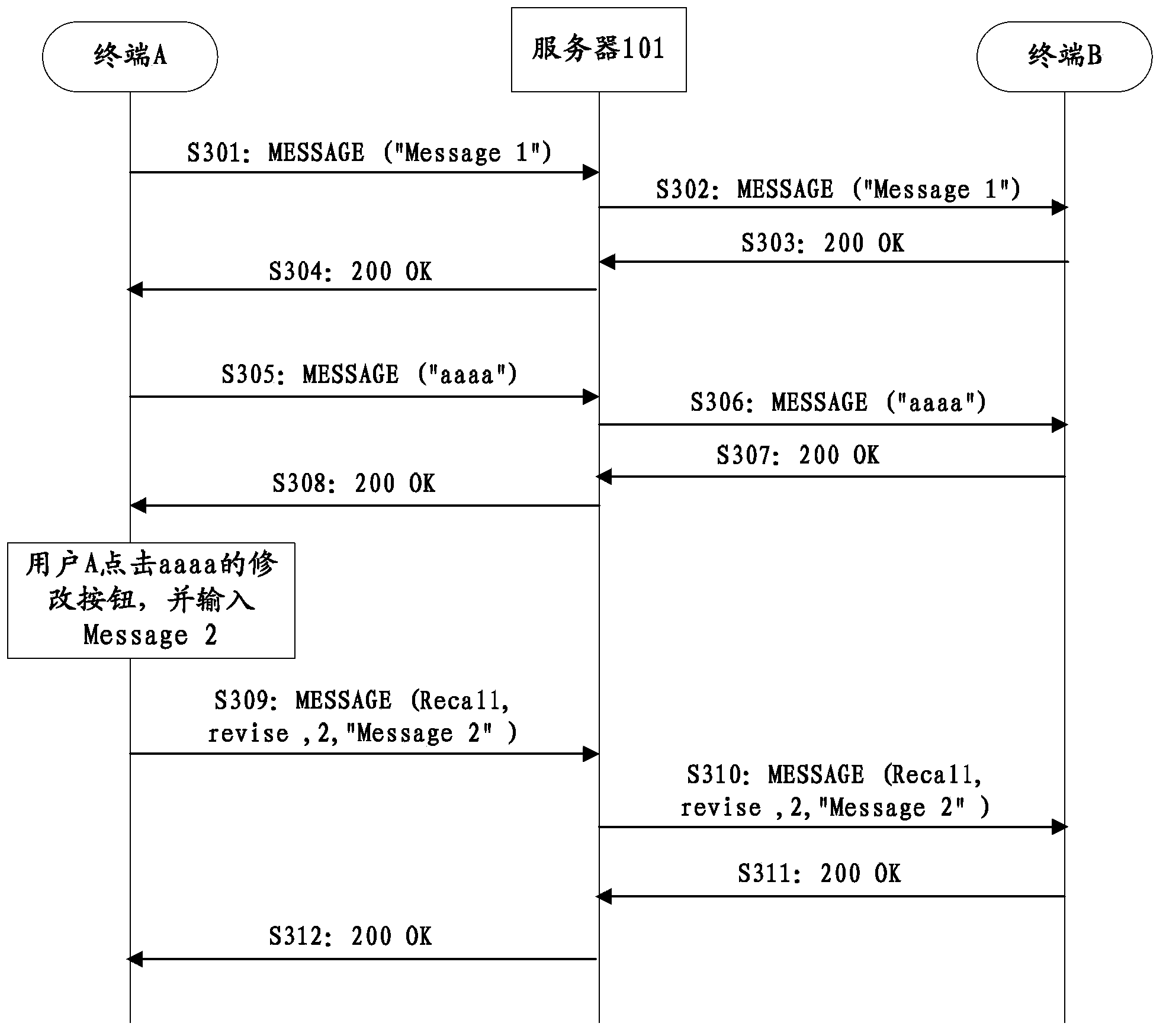

Method for processing instant message and device thereof

The present invention provides a method for processing an instant message and a device thereof. A terminal A responds to input of a user and generates a first request message, wherein the first request message comprises indicating information for withdrawing the instant message, withdrawing type and mark of the instant message to be withdrawn, and the instant message to be withdrawn is the instant message which is already transmitted by the terminal. The instant message arrives a terminal B through a server 101. The terminal B updates the instant message to be withdrawn according to the withdrawing type. Through the method of the invention, the user can withdrawn the transmitted instant message. Higher convenience and higher flexibility are obtained for the user.

Owner:ALCATEL LUCENT SAS

Scratch masking coating for glass containers

InactiveUS20090208657A1Flexible handlingMinimizes problemPretreated surfacesCoatingsBottleScratch marks

The present invention provides a scratch masking coating system for glass containers such as bottles that is adaptable to a variety of bottle surface and application conditions. The scratch masking coating is applied as an oil in water emulsion which provides flexibility in handling and application techniques while minimizing handling problems. In the present invention, the oil in water emulsion is treated with an emulsion breaker or destabilizer so that the emulsion is destabilized or broken after application to the surface to be treated. The destabilization or breaking is instigated by the addition of an emulsion breaker or heat to the emulsion in sufficient quantity to provide the desired break time.

Owner:ARKEMA INC

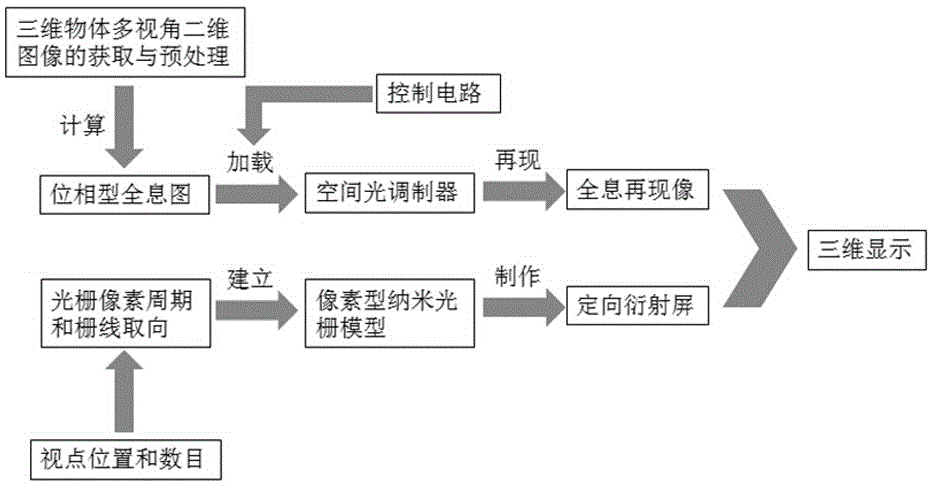

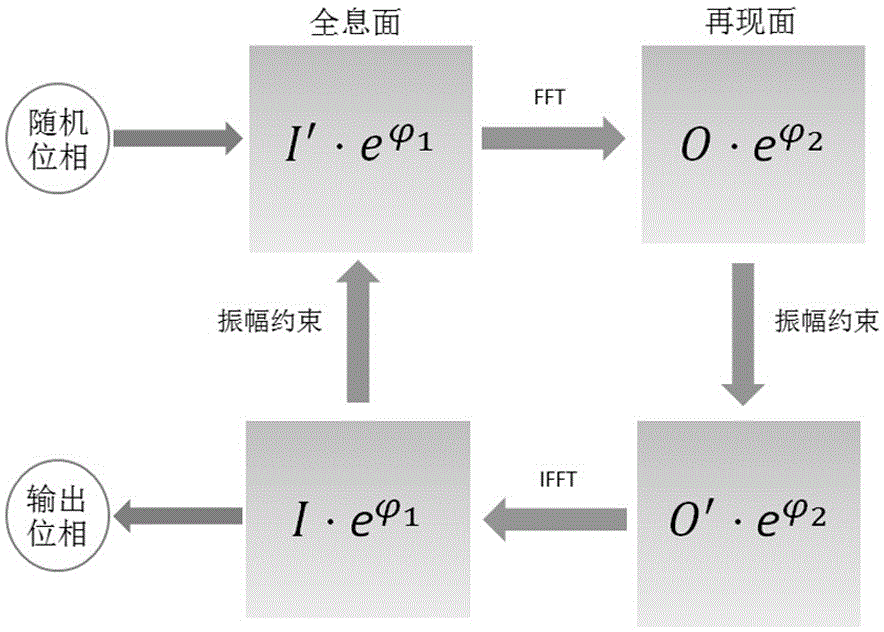

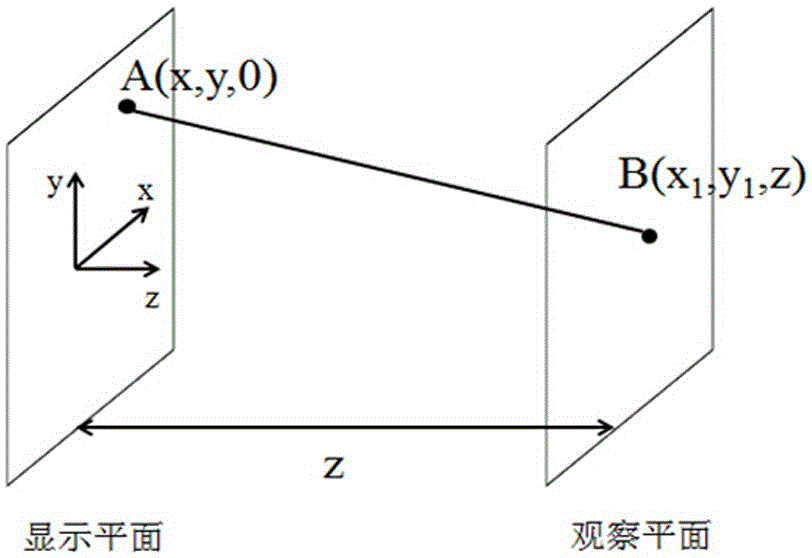

Holographic three-dimensional display method and device based on spatial light modulator

ActiveCN105700320AIn line with observation habitsRealize multi-view full parallax dynamic holographic three-dimensional displayOptical elementsSpatial light modulatorBeam splitter

The invention discloses a holographic three-dimensional display method and a holographic three-dimensional display device based on a spatial light modulator; the display device is composed of a laser light source, a polarization modulation component, a beam splitter prism, a spatial light modulator, a computer, a lens, and a pixel-type nano grating based directional diffraction screen; and the display method comprises the following steps: obtaining a multi-view two-dimensional image of a target object and undergoing preprocessing conversion process to generate a group of image arrays used for phase type hologram calculation; calculating corresponding phase type holograms with an iterative Fourier transform algorithm, loading the holograms to the spatial light modulator, and irradiating the holograms with the laser light source to obtain holographic reproductive images; and designing and manufacturing the pixel-type nano grating based directional diffraction screen, and directionally diffracting corresponding reproductive image pixels to fixed positions to form different viewpoints. The method and the device disclosed by the invention, by combing with fast refreshing and loading of the spatial light modulator for the holograms, realize multi-view full-parallax dynamic holographic three-dimensional reproduction of the target object, and provide a feasible scheme for application of a naked-eye three-dimensional display technology.

Owner:SUZHOU UNIV

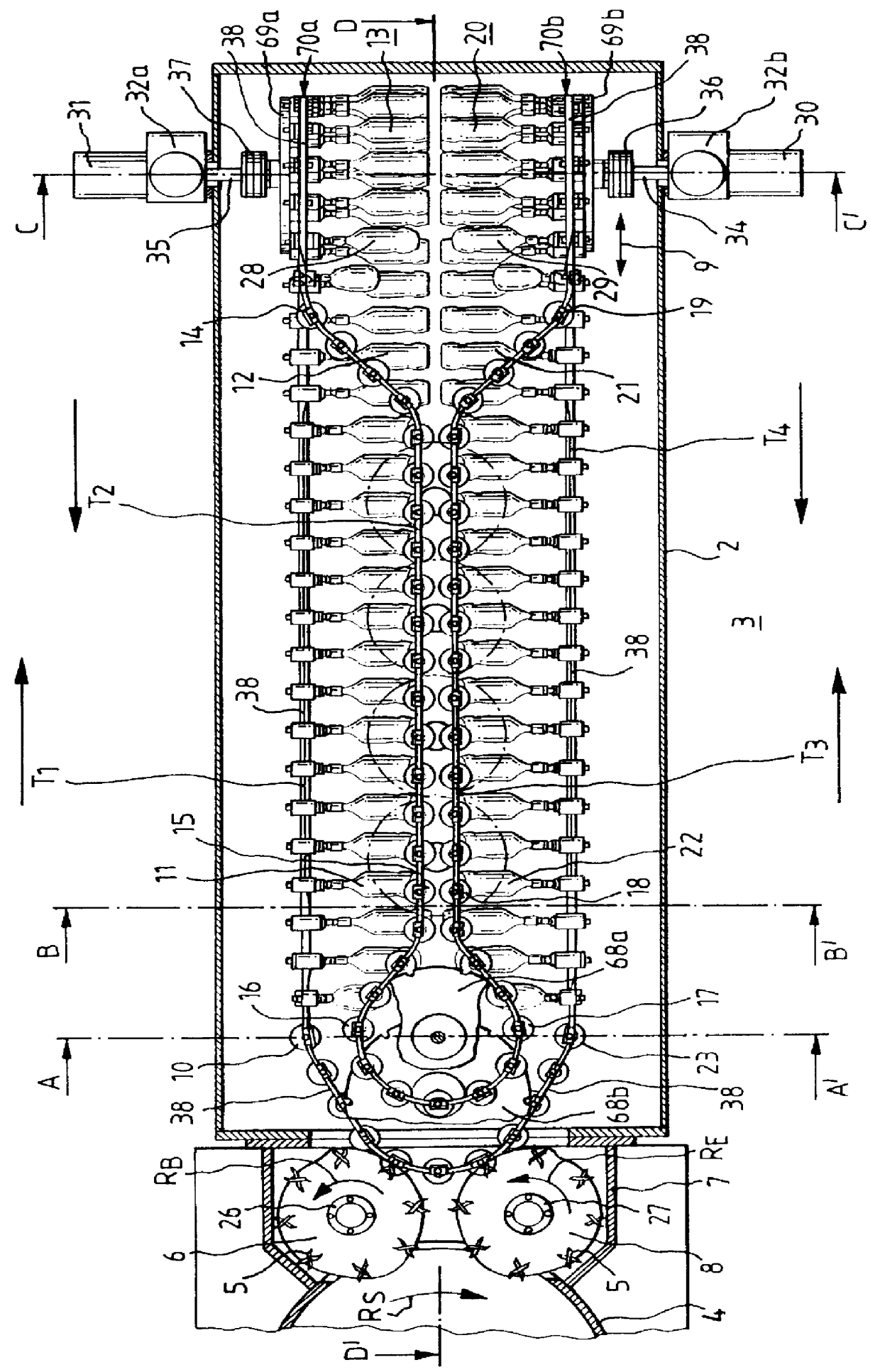

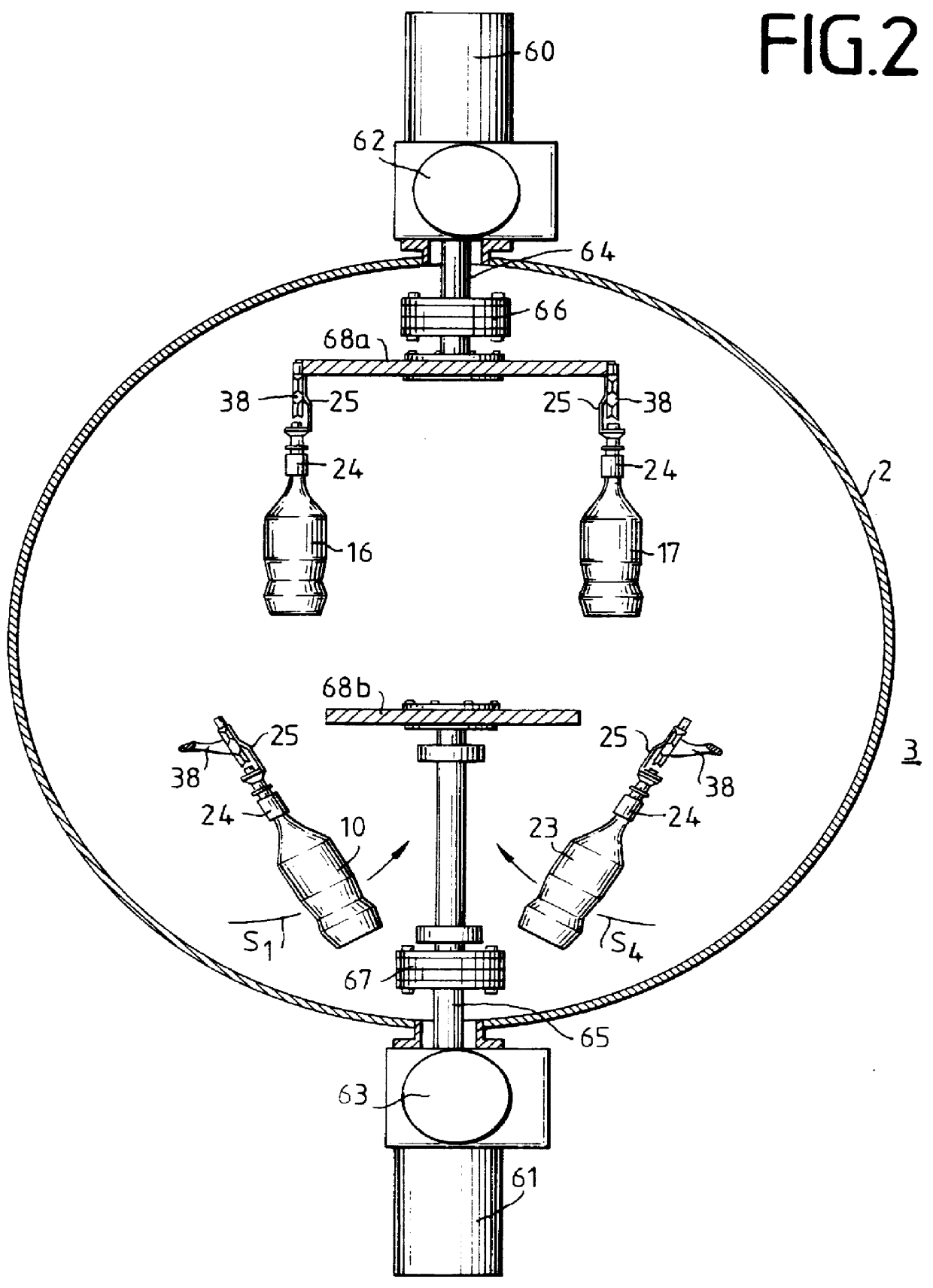

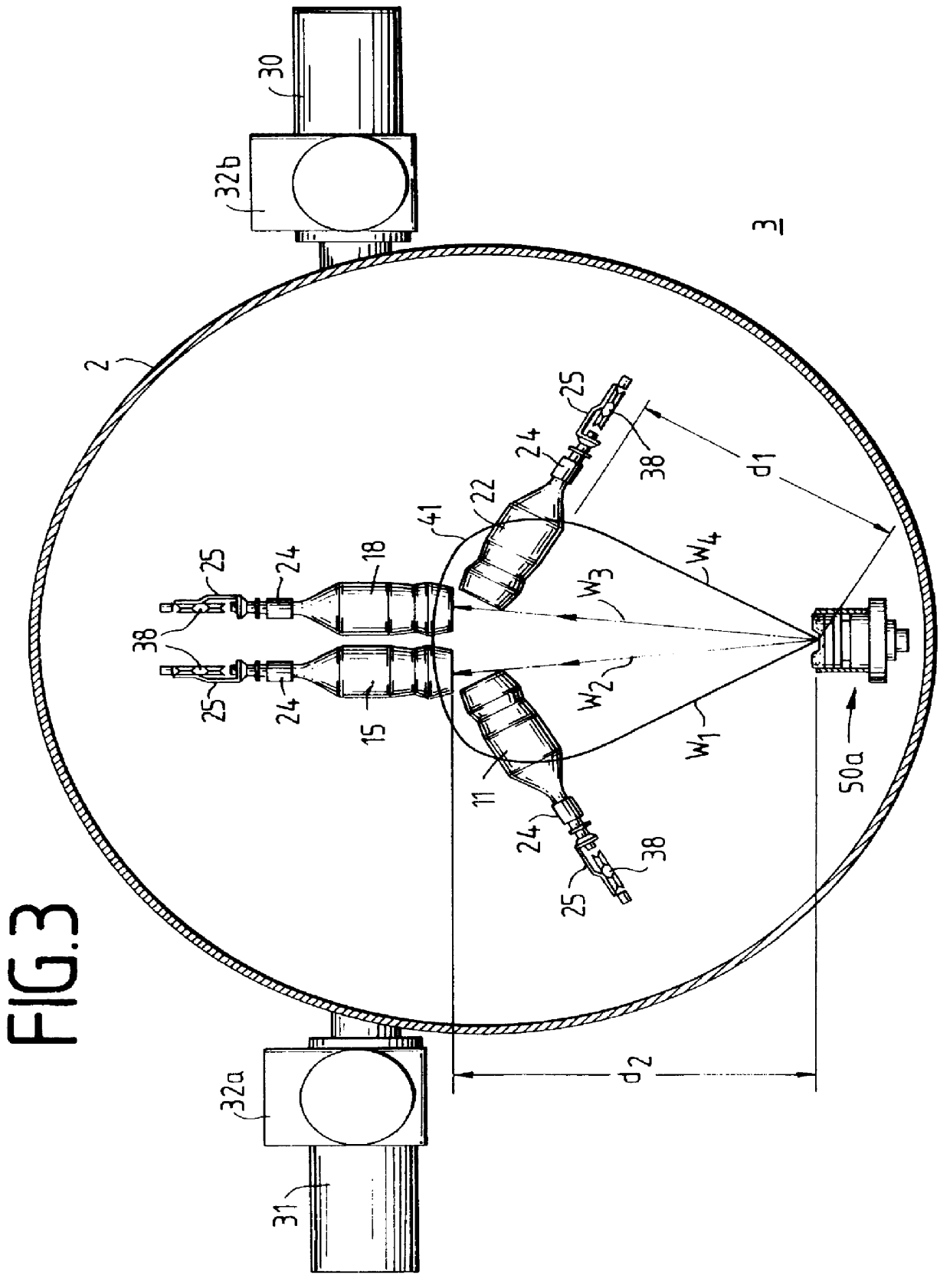

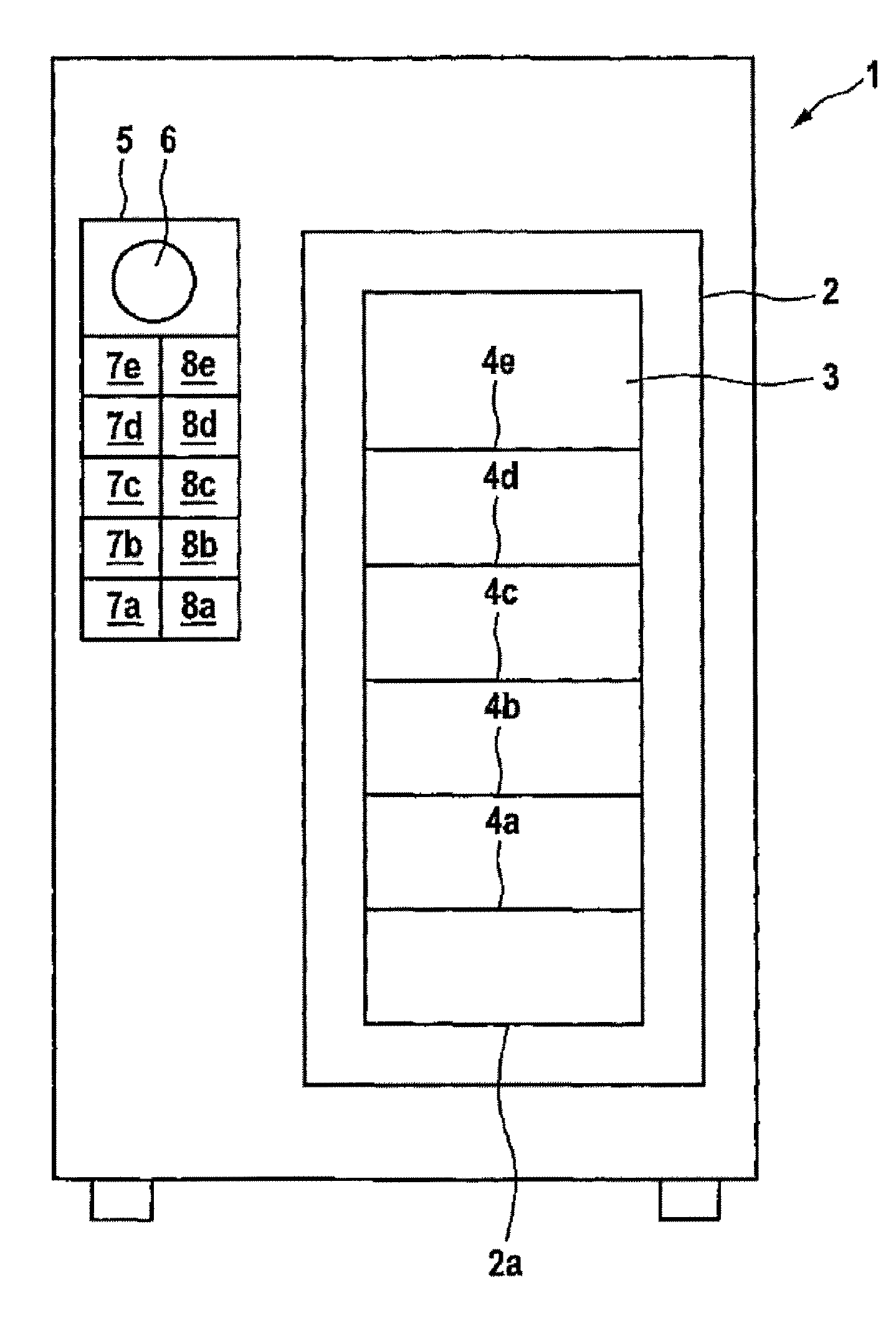

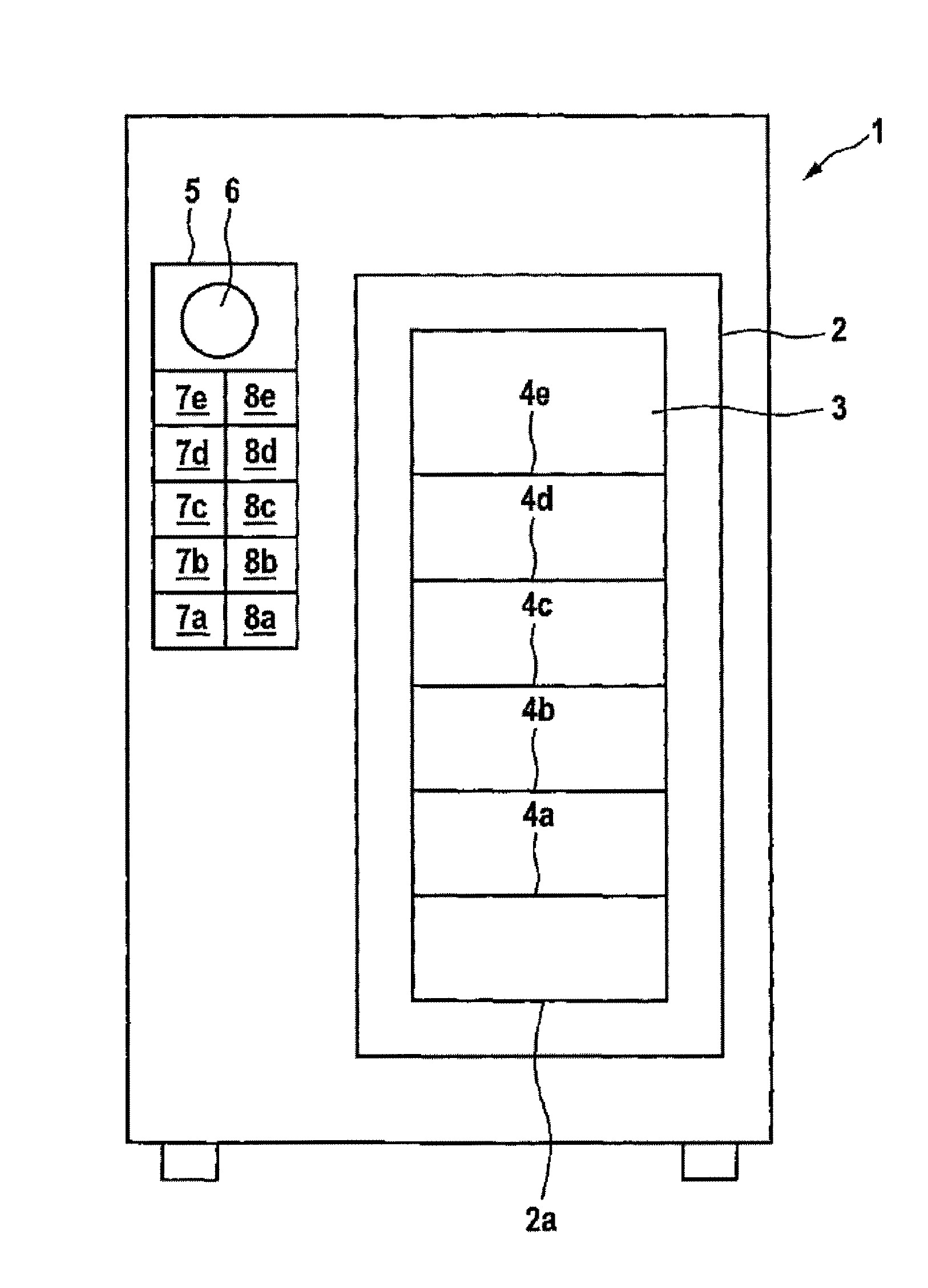

Method and device for transporting cylindrical substrates to be coated

InactiveUS6132562AProcess economyFlexible handlingCellsLiquid surface applicatorsEngineeringPlastic bottle

For coating substrates (17,18,20,21,22) in a vacuum-coating chamber (2) the substrates are introduced by an air lock into the coating chamber (2) and moved along a transport path in front of the coating sources (50a,b,c,d) producing a coating cloud. To this end, the substrates (17,18,20,21,22) are led past the coating sources (50a,b,c,d) by means of holding devices (24) arranged movably on a transport belt (9) during at least two successive coating phases. During the one coating phase, the substrates (17,18,20,21,22) are oriented along one transport direction T3 oriented towards the coating sources (50a,b,c,d) such that essentially the substrate bottom of the cylindrical substrate is coated. During the subsequent second coating phase, the substrates are oriented in front of the coating sources (50a,b,c,d) in a direction T4 opposite the transport direction T3, wherein the substrates (17,18,20,21,22) are oriented such that essentially the cylindrical side surface is coated. By this method, the substrates (17,18,20,21,22) are coated successively in an identical manner and independently of possible substrate positions with relation to the coating sources (50a,b,c,d) during the coating process. Bottle-shaped containers, in particular, plastic bottles are vapor-coated with a gas- or fluid-barrier layer using the method. The coating sources (50a,b,c,d) include thermal vaporizers and / or plasma cathode sputter sources.

Owner:LEYBOLD SYST

Dispatching method and server

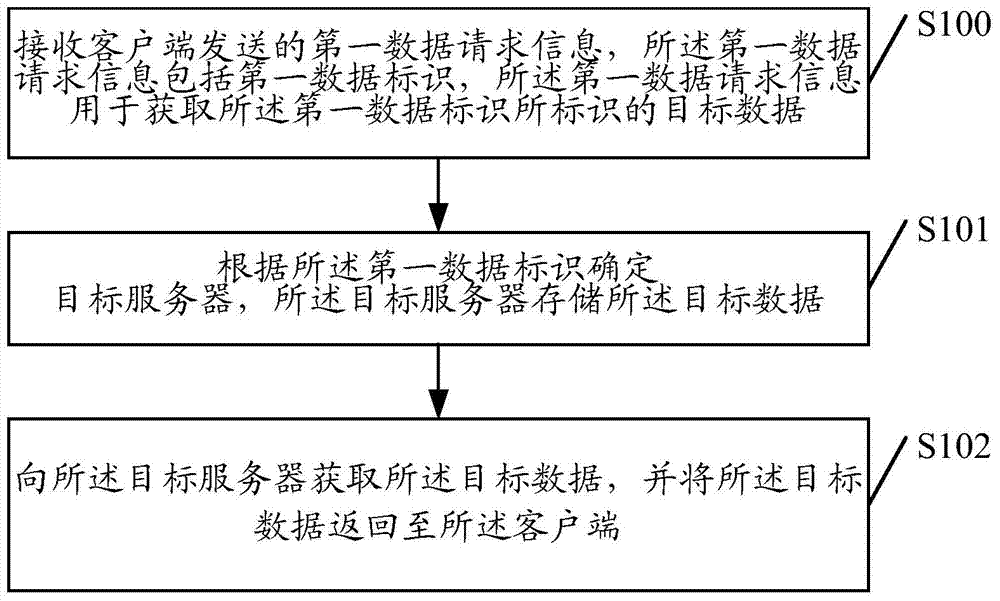

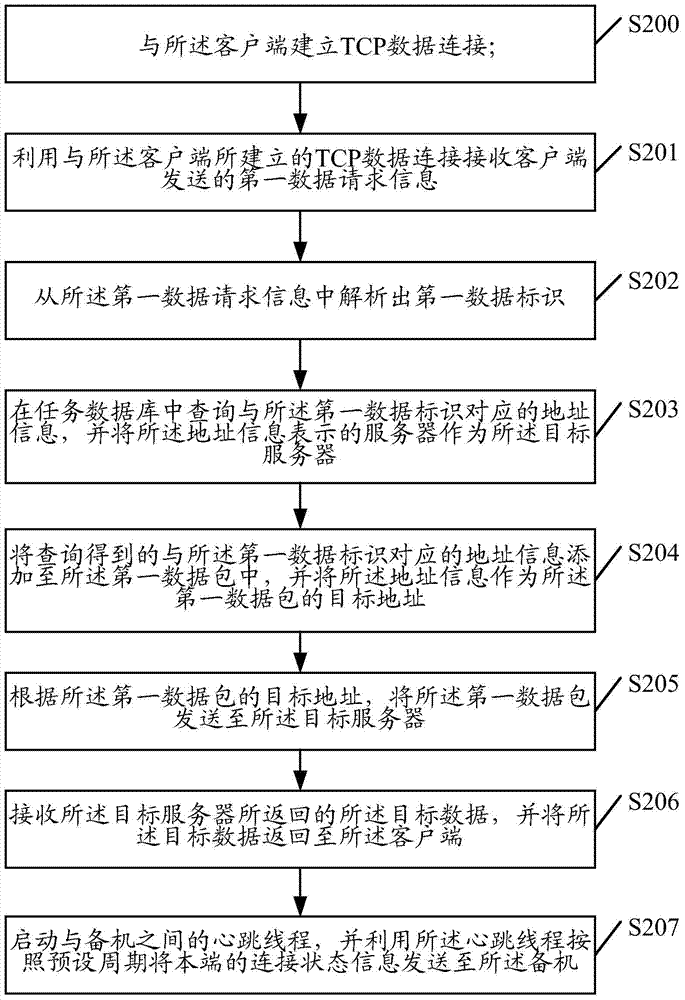

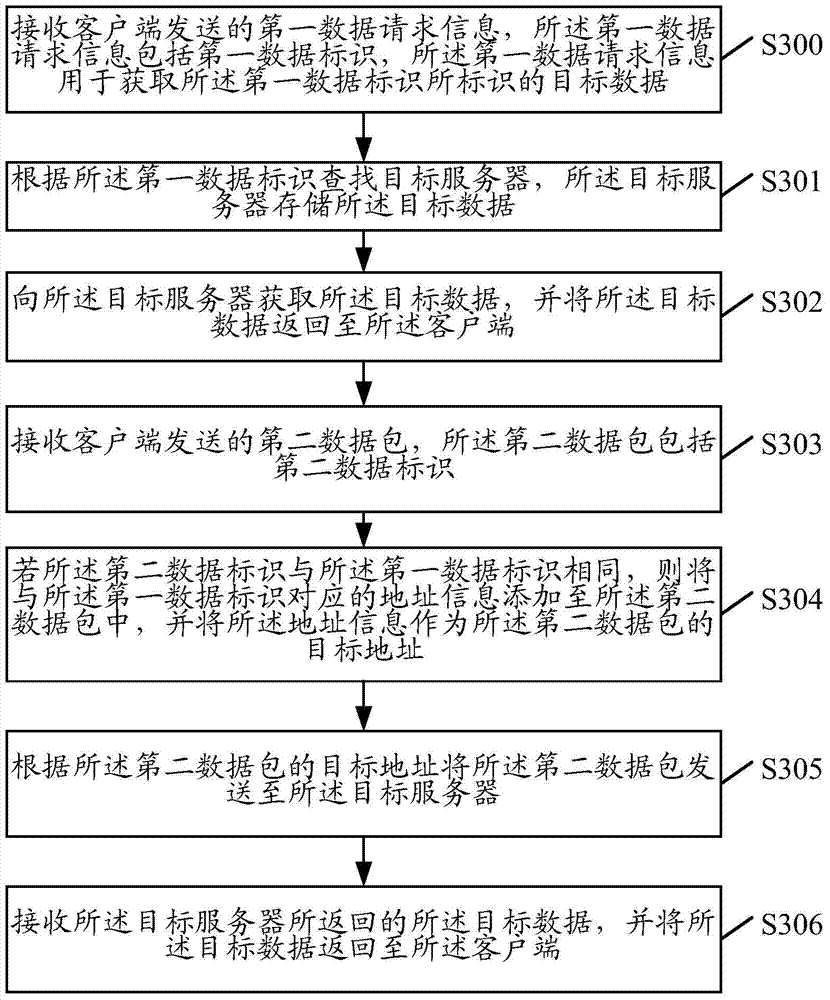

The embodiment of the invention discloses a dispatching method and a server. The dispatching method comprises the steps of receiving a first data request message sent by a client side, wherein the first data request message comprises a first data mark and used for obtaining target data marked by the first data mark; determining a target server according to the first data mark, wherein the target server is used for storing the target data; obtaining the target data from the target server and feeding the target data back to the client side. By means of the dispatching method and the server, the target server storing the target data can be found according to the data mark in the first data request message, and the searching method is simple and high in efficiency.

Owner:SHENZHEN COSHIP ELECTRONICS CO LTD

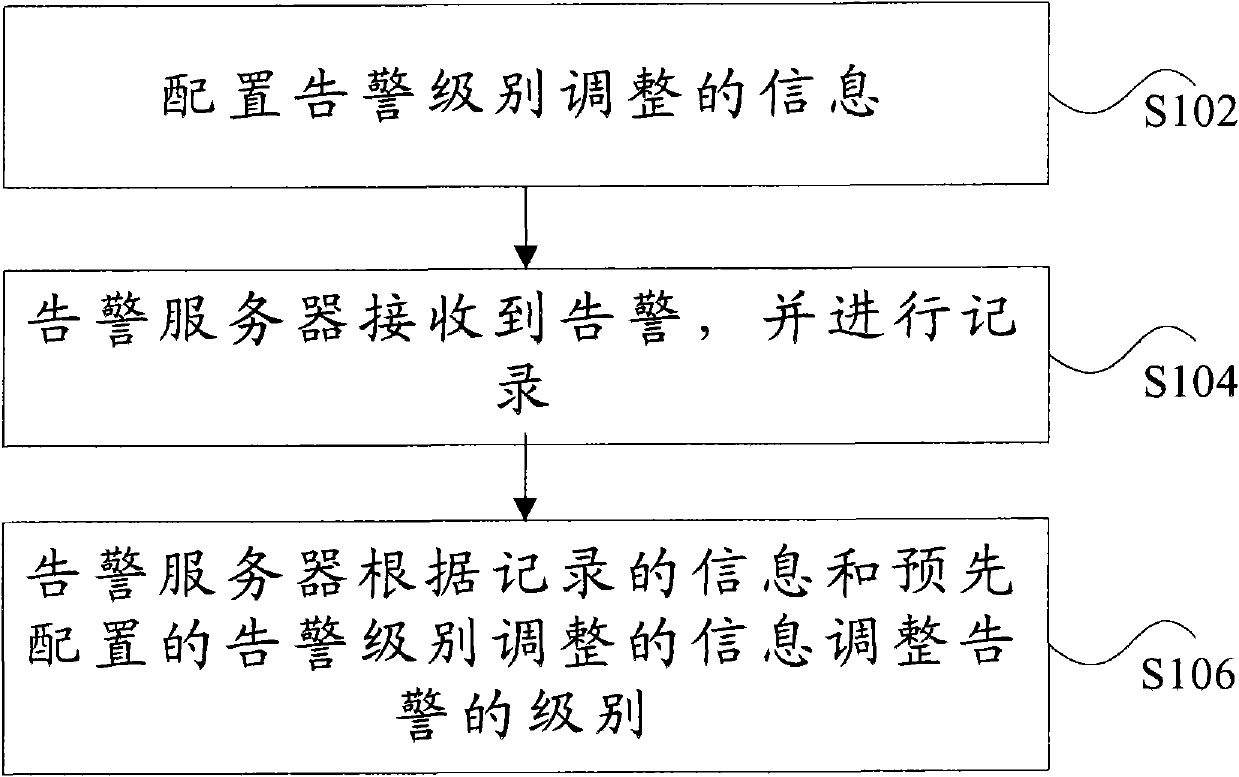

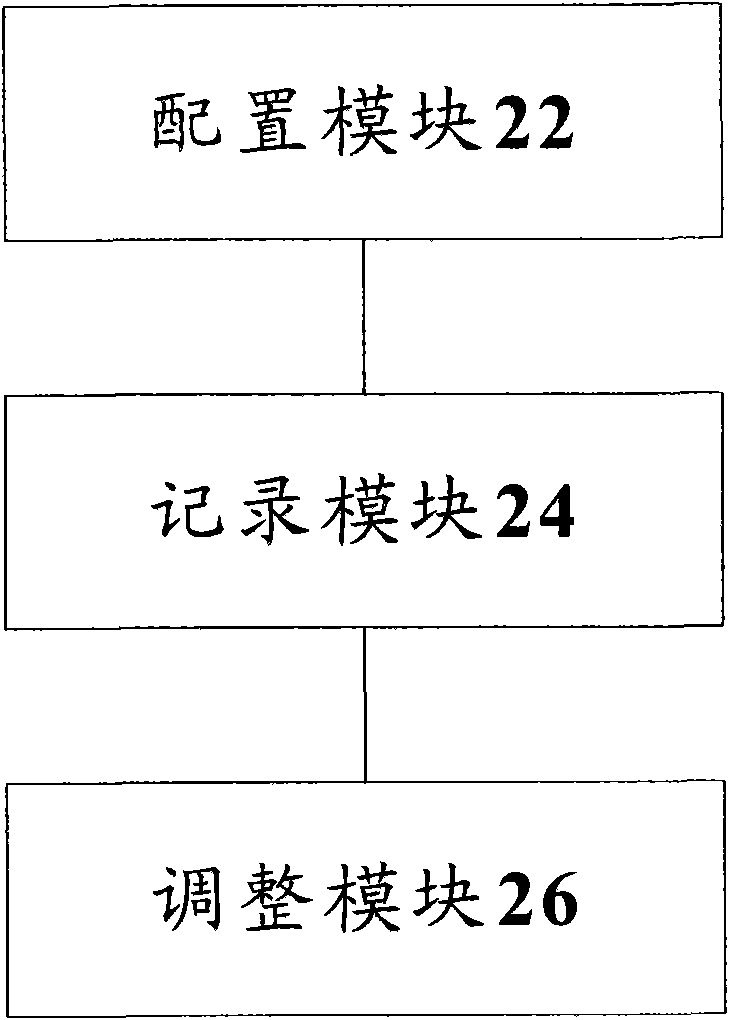

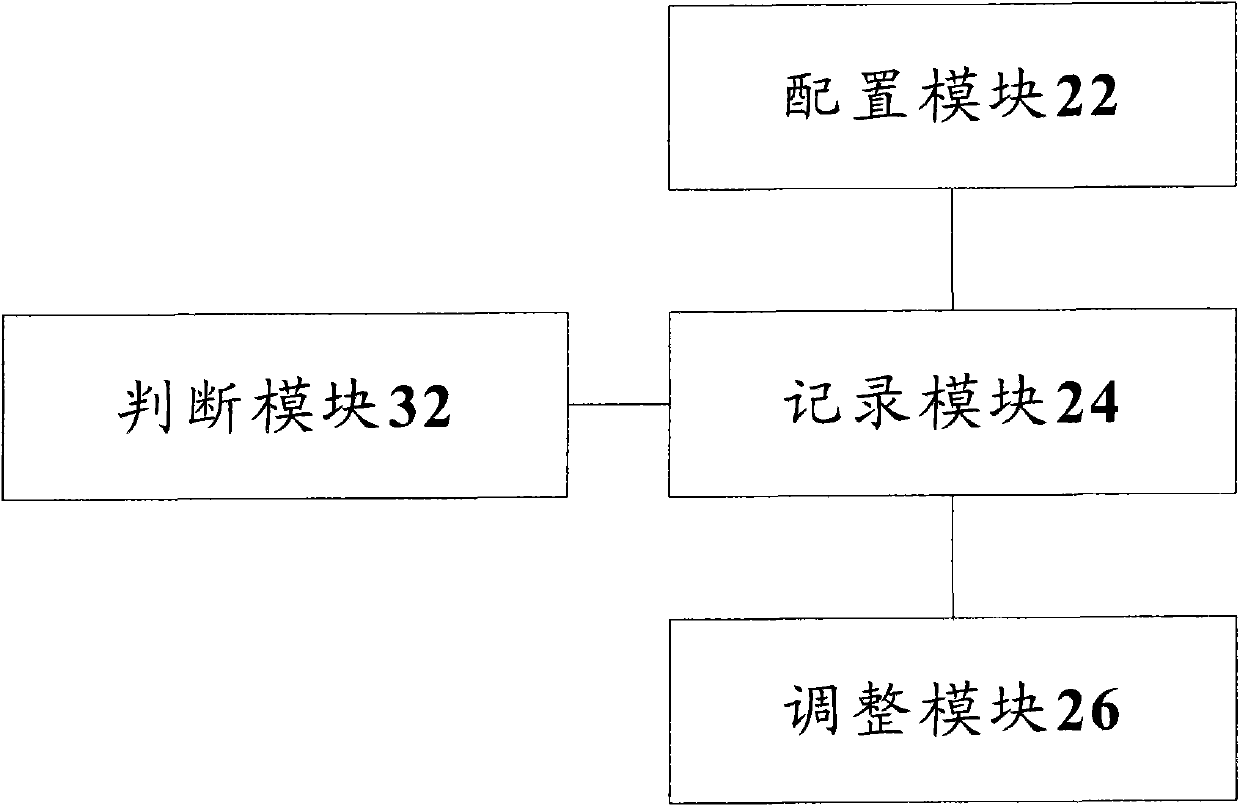

Alarm level processing method and alarm server

InactiveCN102201928AFlexible handlingSolve potential safety hazardsData switching networksSystem safetyReal-time computing

The invention discloses an alarm level processing method and an alarm server. The method comprises the following steps of: pre-configuring information of alarm level adjustment; receiving an alarm and making a record by using the alarm server; and adjusting the level of the alarm according to recorded information and the pre-configured information of the alarm level adjustment by using the alarm server. By adopting the alarm level processing method and the alarm server, the system security is enhanced.

Owner:ZTE CORP

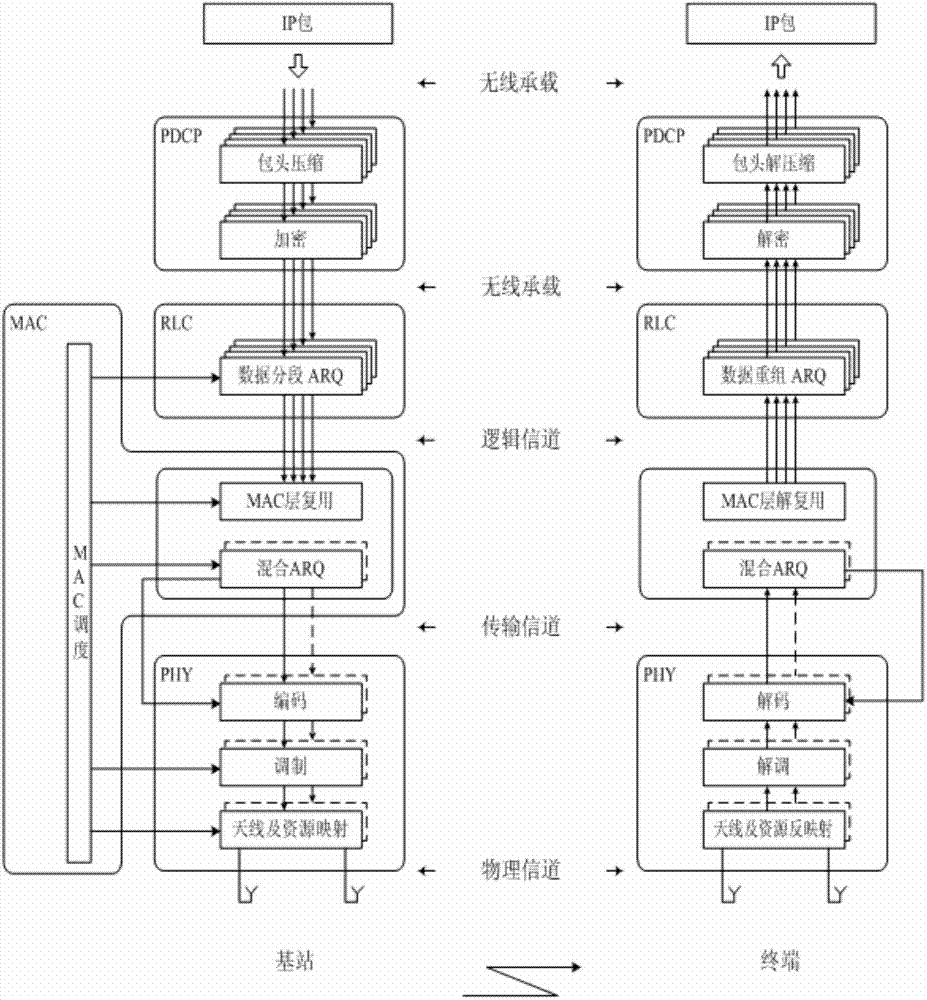

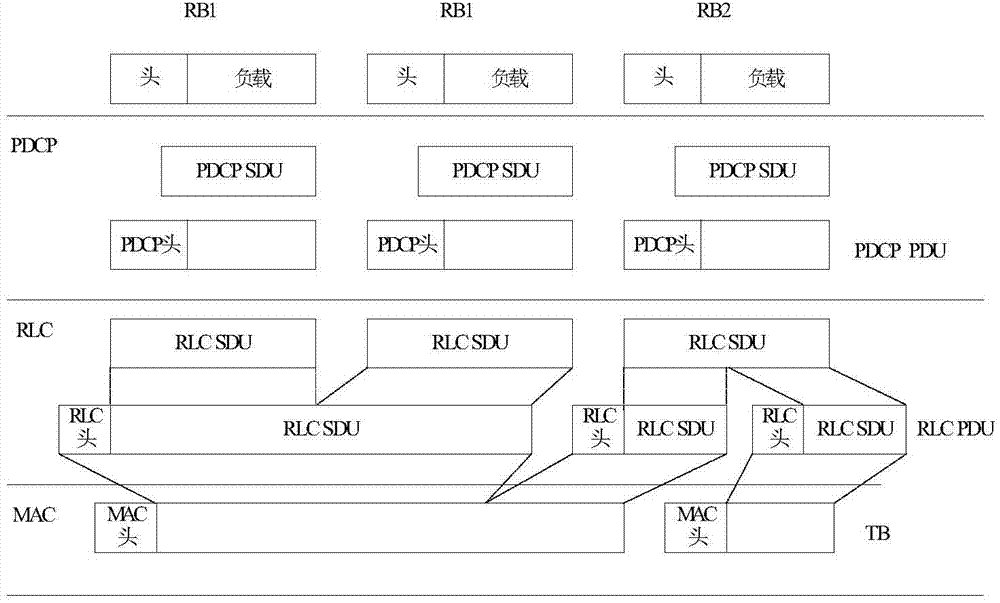

Data processing device and method

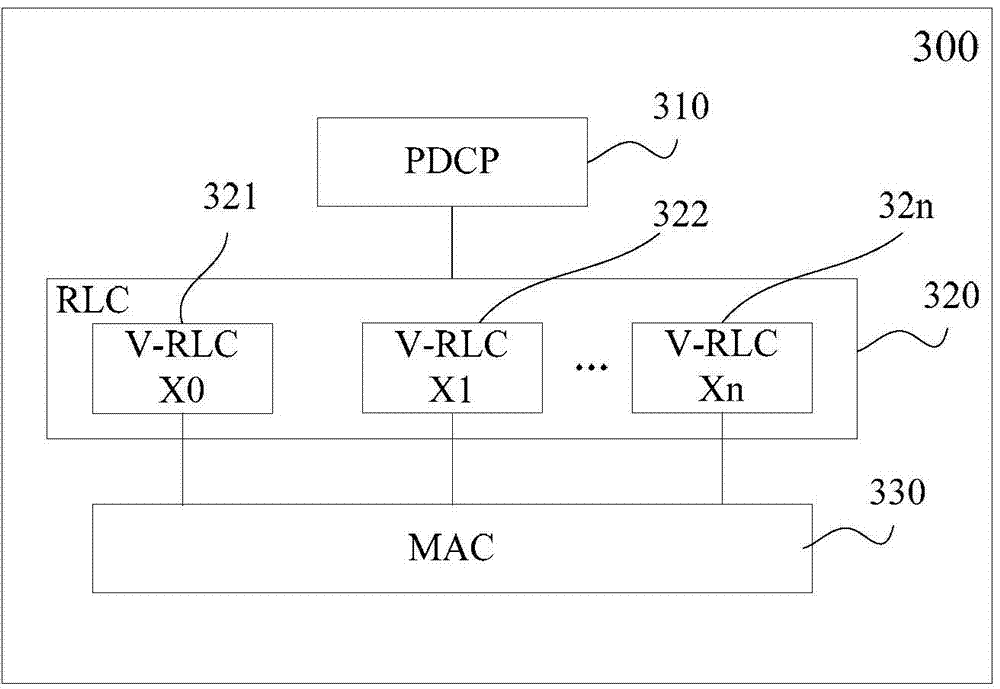

ActiveCN103782569AFlexible handlingWireless network protocolsTransmissionComputer scienceData processing

An embodiment of the invention provides a data processing device and method. A plurality of RLC sub-units are configured for a logical channel, and then a plurality of independent RLC processing is performed on data on a same RB, thereby equaling that one RB is detached into a plurality of virtual RBs, so that processing of an L2 protocol upon the data is more flexible.

Owner:HUAWEI TECH CO LTD

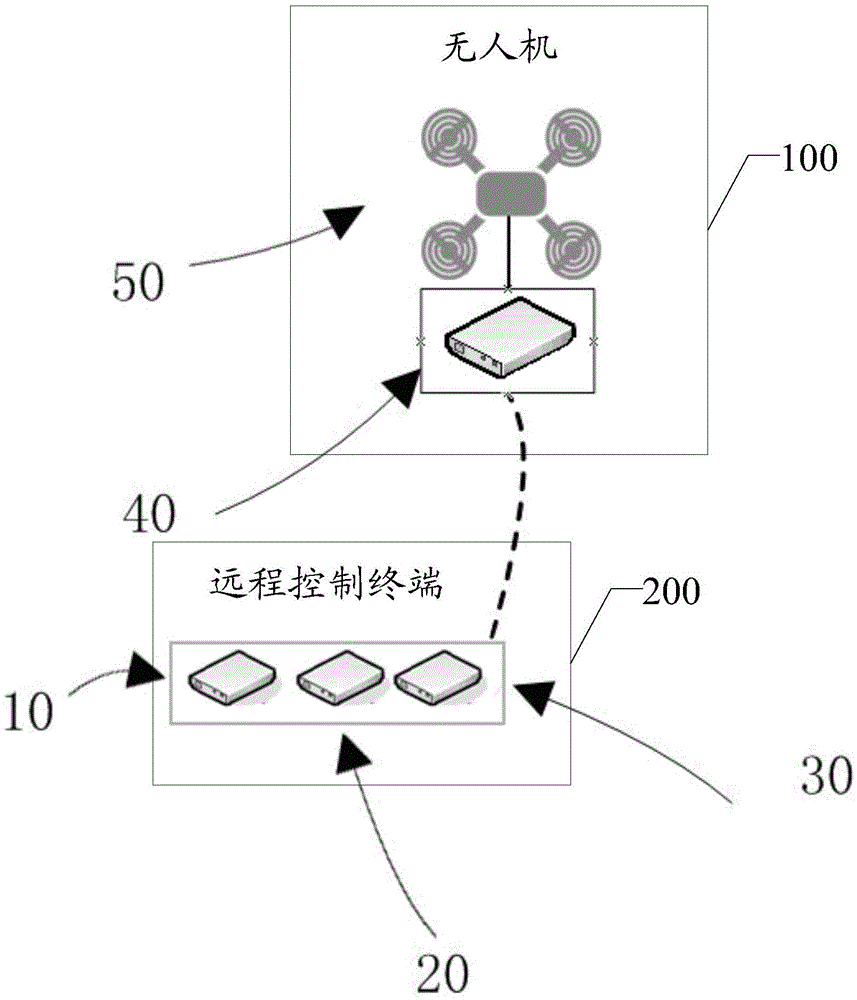

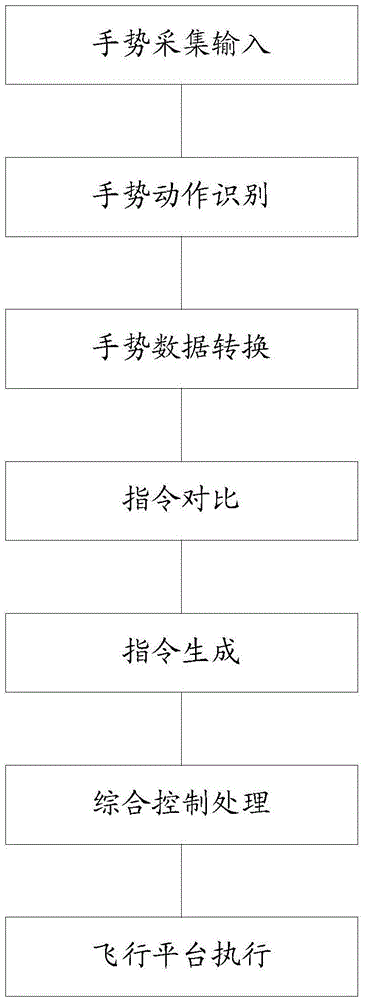

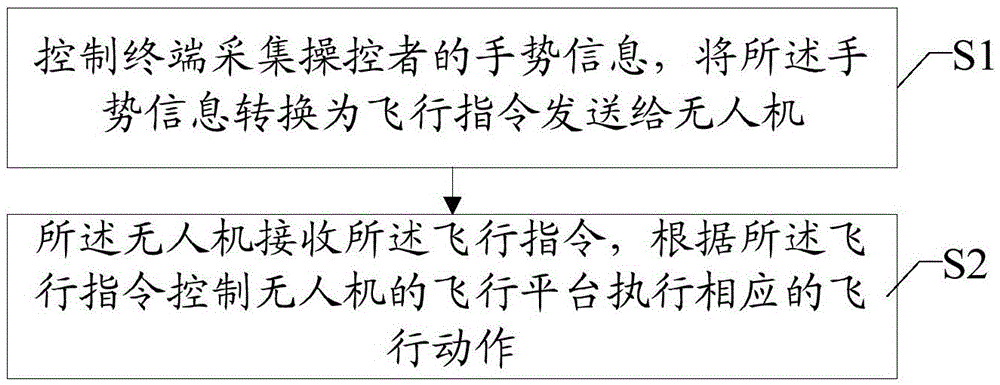

Gesture identification based unmanned aerial vehicle control method and system as well as unmanned aerial vehicle

InactiveCN105677300AEasy to operateFlexible controlCharacter and pattern recognitionPosition/course control in three dimensionsUser controlRemote control

The invention discloses a gesture identification based unmanned aerial vehicle control method and system as well as an unmanned aerial vehicle. The system comprises the unmanned aerial vehicle and a remote control terminal wirelessly communicating with the unmanned aerial vehicle, wherein the remote control terminal is used for acquiring gesture information of a controller, converting the gesture information into a flight instruction and sending the flight instruction to the unmanned aerial vehicle; and the unmanned aerial vehicle is used for receiving the flight instruction and controlling a flight platform of the unmanned aerial vehicle to execute a corresponding flight action according to the flight instruction. According to the method and system as well as the unmanned aerial vehicle, a user controls the unmanned aerial vehicle to fly in a somatosensory manner through gesture identification; and the unmanned aerial vehicle is simple to operate and flexible to control, so that the interestingness and convenience of unmanned aerial vehicle control are enhanced.

Owner:PRODRONE TECH (SHENZHEN) CO LTD

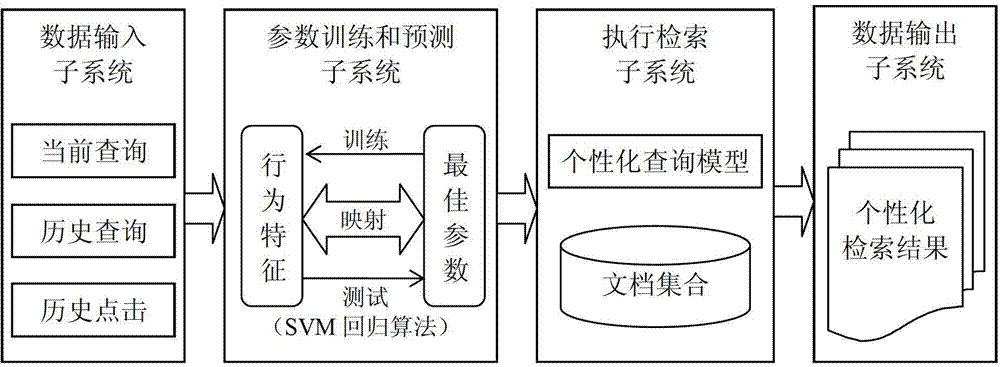

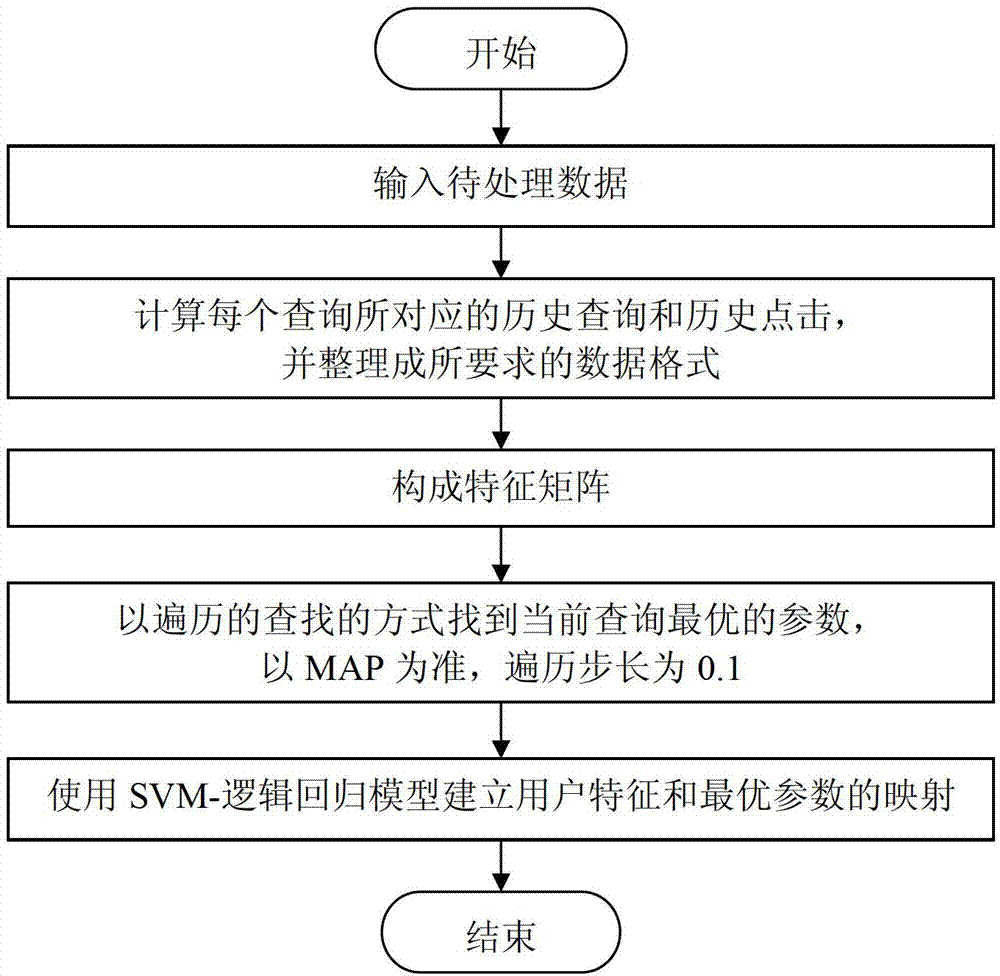

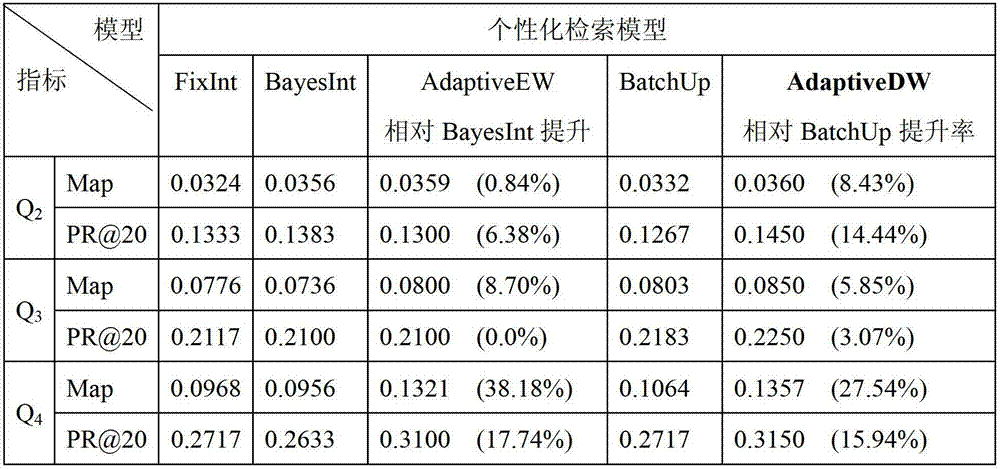

Self-adaptive personalized information retrieval system and method

ActiveCN102779193AFlexible handlingIncrease flexibilitySpecial data processing applicationsPersonalizationSelf adaptive

The invention discloses a self-adaptive personalized information retrieval system and method. For timely catching irregularly distributed dynamic retrieval requirements of a user, a retrieval module is timely updated through interaction of the user and a search engine. The system comprises a data input sub system, a parameter training and predicating sub system, a retrieval performing sub system and a data output sub system, wherein the data input sub system is used for combining historical inquiry information and historical click information to form a characteristic matrix according to the current inquiry information, and acquiring a training parameter predicating module according to the characteristic matrix; the parameter training and predicating sub system is used for training and applying the parameter predicating module to acquire the predicated parameters according to the characteristic matrix; the retrieval performing sub system is used for predicating the parameters to organize the current inquiry and the historical inquiry, and combining the user module and the inquiry module to form a personalized inquiry module; and the data output sub system is used for searching a document matched with the personalized inquiry from the document to be retrieved as a primary retrieved result, and sequencing the primary retrieved result according to the correlation to obtain the final retrieved result for outputting.

Owner:哈尔滨工业大学高新技术开发总公司

Method for the intelligent continuous filling of a cooking device and cooking device therefor

ActiveUS8147888B2Standardized cooking resultsQuality improvementDomestic stoves or rangesBoiling over preventionThermodynamicsEngineering

A method for managing cooking programs first comprises selecting, at a point in time (t0), a type of item to be cooked (i), items (j) of the type of item to be cooked (i), and various treatment planes (k) of a cooking compartment that are to be filled at a point in time (t2) with the items (j). Then, each treatment plane (k) is filled at point in time (t2) with the items (j). Then, in dependence on at least the filling of the cooking compartment with items to be cooked at point in time (t2), a first cooking temperature is set at a point in time (t3). Then, a signal for removing the cooked items (j) from the cooking compartment is emitted at a point in time (t4ki) for each treatment plane (k).

Owner:RATIONAL AG

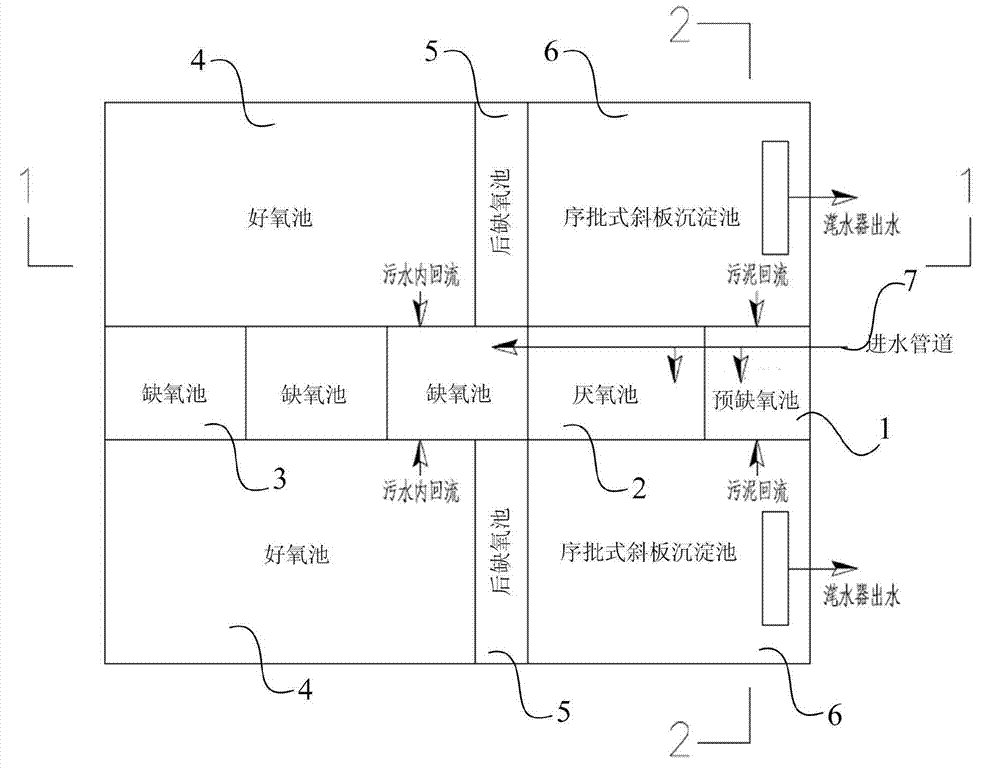

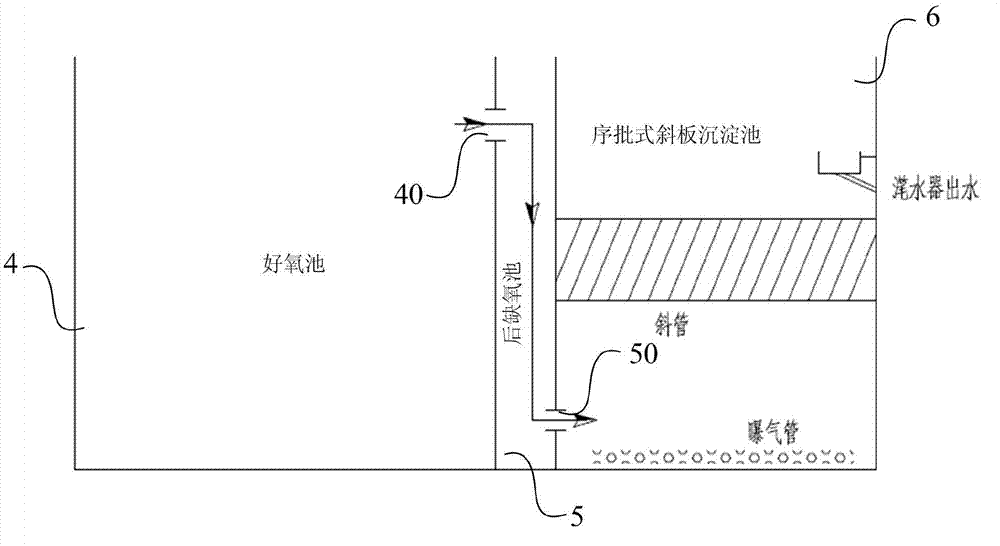

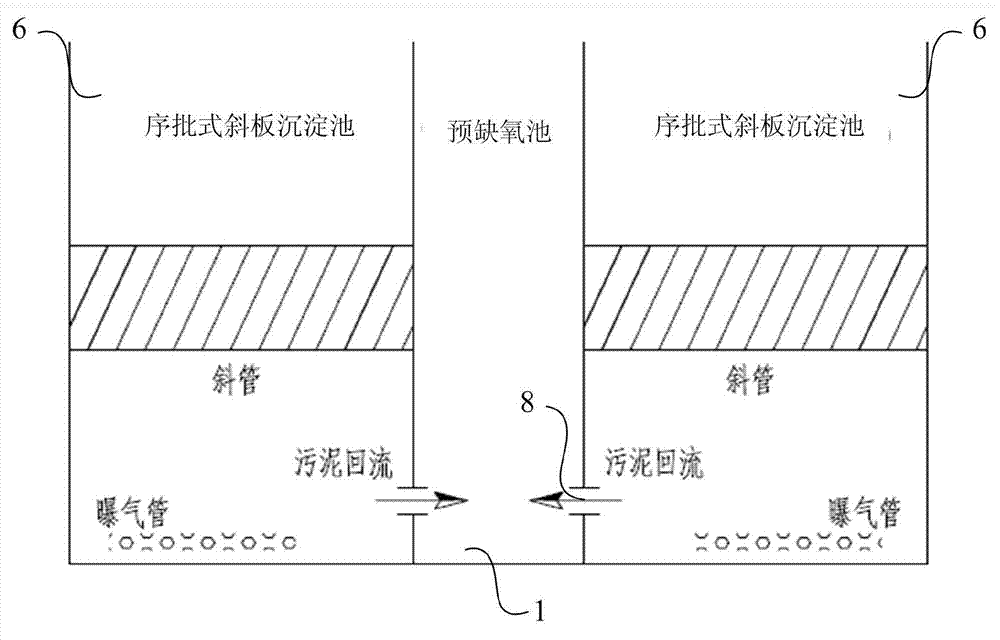

Sewage treatment system

InactiveCN104761100AComprehensivenessAdvantages FlexibilityMultistage water/sewage treatmentNitrogen removalWater quality

The invention relates to a sewage treatment system comprising: a pre-anoxic tank which is connected to a sewage inlet pipeline and is used for an anoxic denitrification reaction of returned sludge and the sewage; an anaerobic tank which is connected to the sewage inlet pipeline and communicated with the pre-anoxic tank and is used for anaerobic phosphorus releasing during biochemical dephosphorization; an anoxic tank which is connected to the sewage inlet pipeline and communicated with the anaerobic tank and is used for nitrogen removal by denitrification; an aerobic tank which is communicated with the anoxic tank and is used for degrading organic substances, nitrating organic nitrogen and ammonic nitrogen and absorbing phosphorus; a post-anoxia tank which is communicated with the aerobic tank and is used for performing nitration and denitrification at the same time; and a sequencing batch sloping plate sedimentation tank which is communicated with the post-anoxia tank and is used for separating muddy water and concentrating the returned sludge, herein the returned sludge is flown back to the pre-anoxic tank. The sewage treatment system is excellent in comprehensiveness and flexibility and can flexibly fit various water quality and treatment requirements generally.

Owner:DONGGUAN ZHIHUI WATER TECH

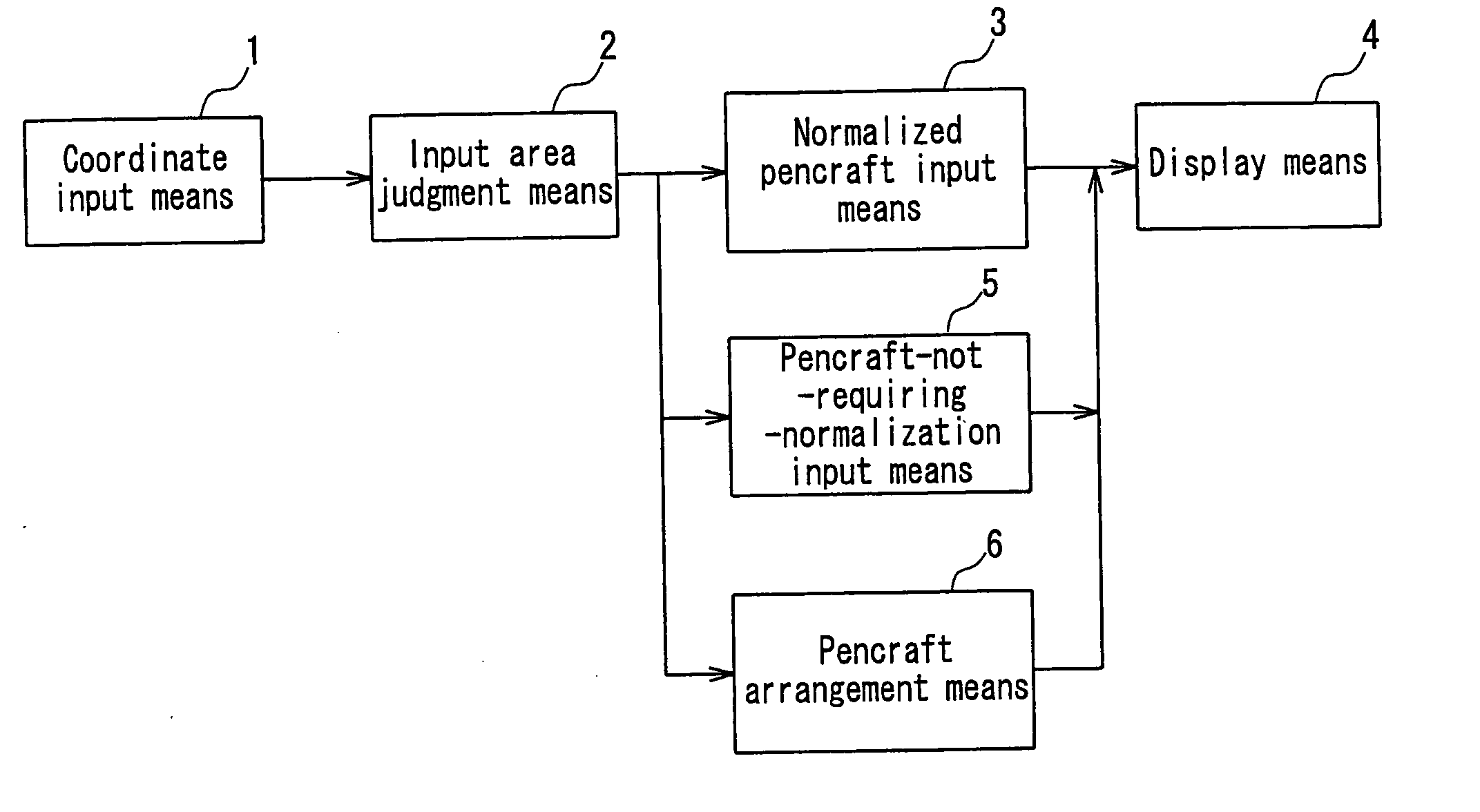

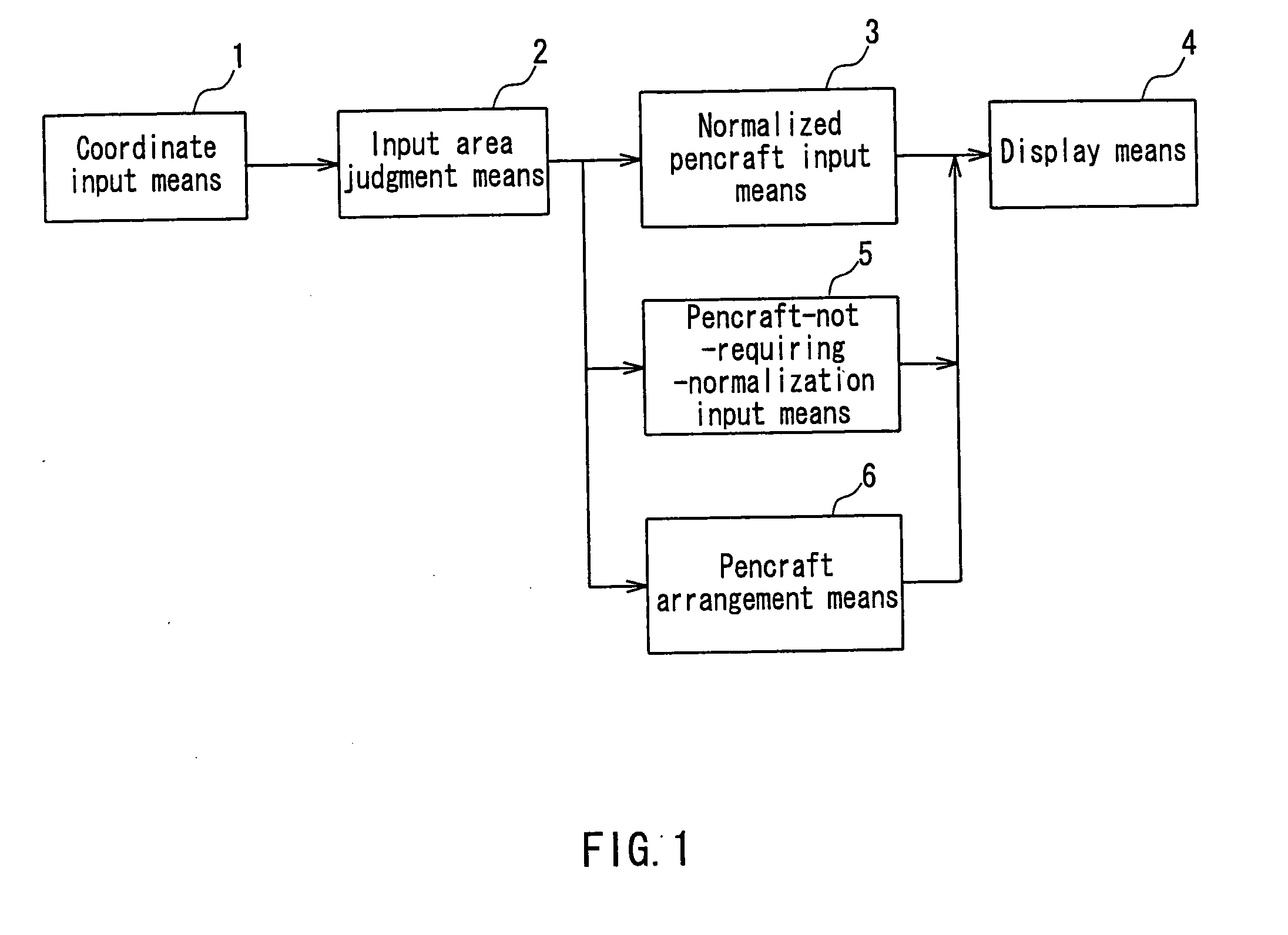

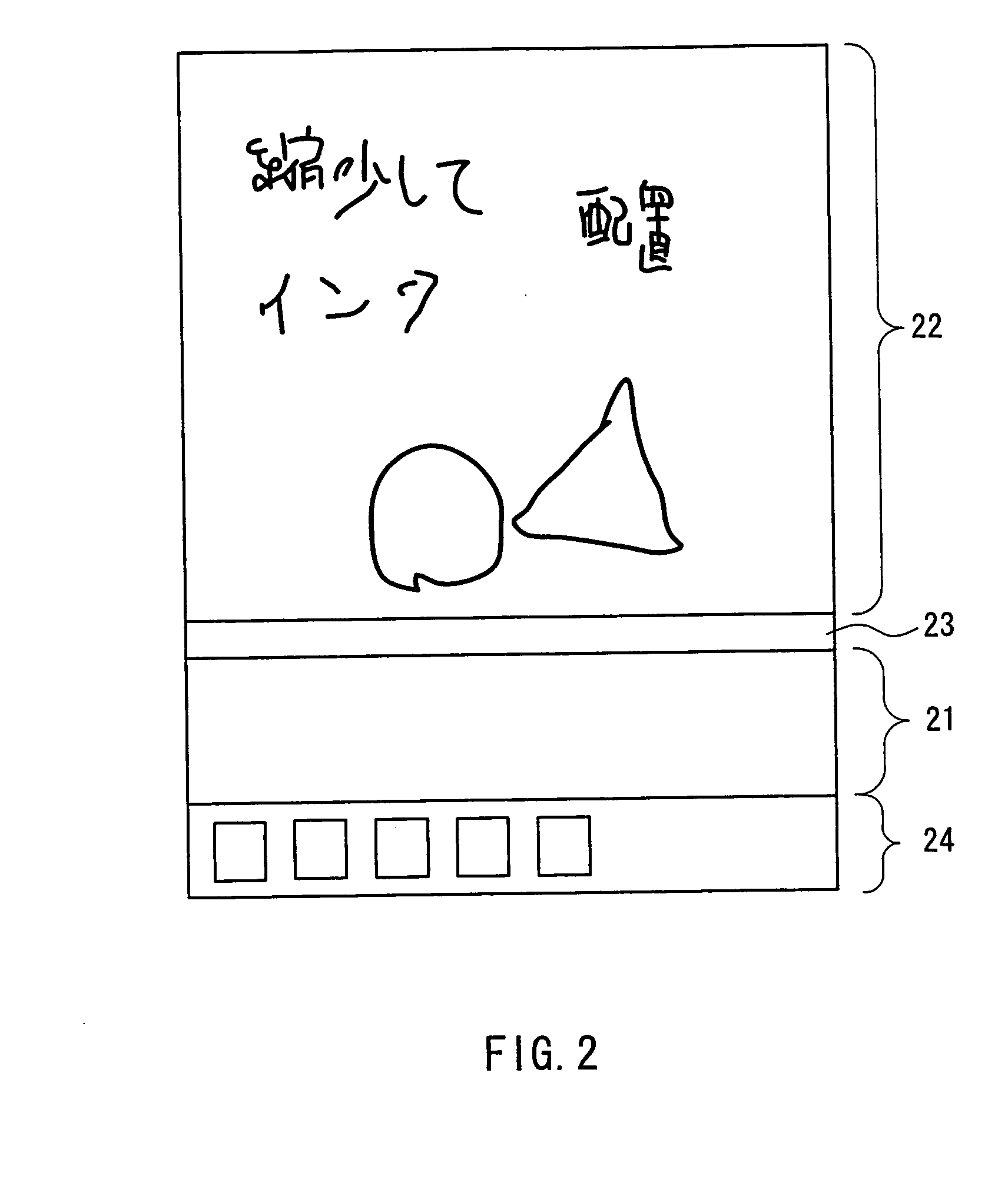

Handwriting-input device and method

InactiveUS20050237311A1Without feelingEnlarging and reducing sizeInput/output for user-computer interactionCathode-ray tube indicatorsHandwritingGraphics

A handwriting-input device and method capable of inputting a mixture of a character and a graphic without feeling discomfort even when an input area is physically limited. A handwriting-input device including, on a display screen, a normalized pencraft input area for inputting a pencraft desired to be normalized to be input and a pencraft arrangement area for inputting a pencraft that is not normalized and normalizing the pencraft to display it, at least includes: coordinate input means to obtain coordinate position information input by an input medium; and input area judgment means to judge which of the normalized pencraft input area and the pencraft arrangement area the pencraft is input in, based on the coordinate position information, wherein the pencraft can be input based on a judgment result in the input area judgment means.

Owner:FUJITSU LTD

Load balancing of server clusters

ActiveUS20090187662A1Flexible handlingEffective balanceMultiple digital computer combinationsTransmissionClient-sideApplication software

A load balancing scheme is described for a server cluster. An application identifier is received by the cluster from a client desiring to connect to the application. Each one of the servers in the cluster independently hashes the application identifier into a unique number. This unique number is used to determine a preferred one of the servers for the connection. The servers then each calculate a priority code using the unique number, a load level for each server, and / or a node identifier assigned to the servers in the cluster. If the preferred cluster server is available, it transmits its priority code to the client before the other servers transmit their priority codes. Otherwise, each of the available cluster servers transmits their priority codes to the client. The client selects the cluster server with the most favorable priority for making the connection.

Owner:ADOBE SYST INC

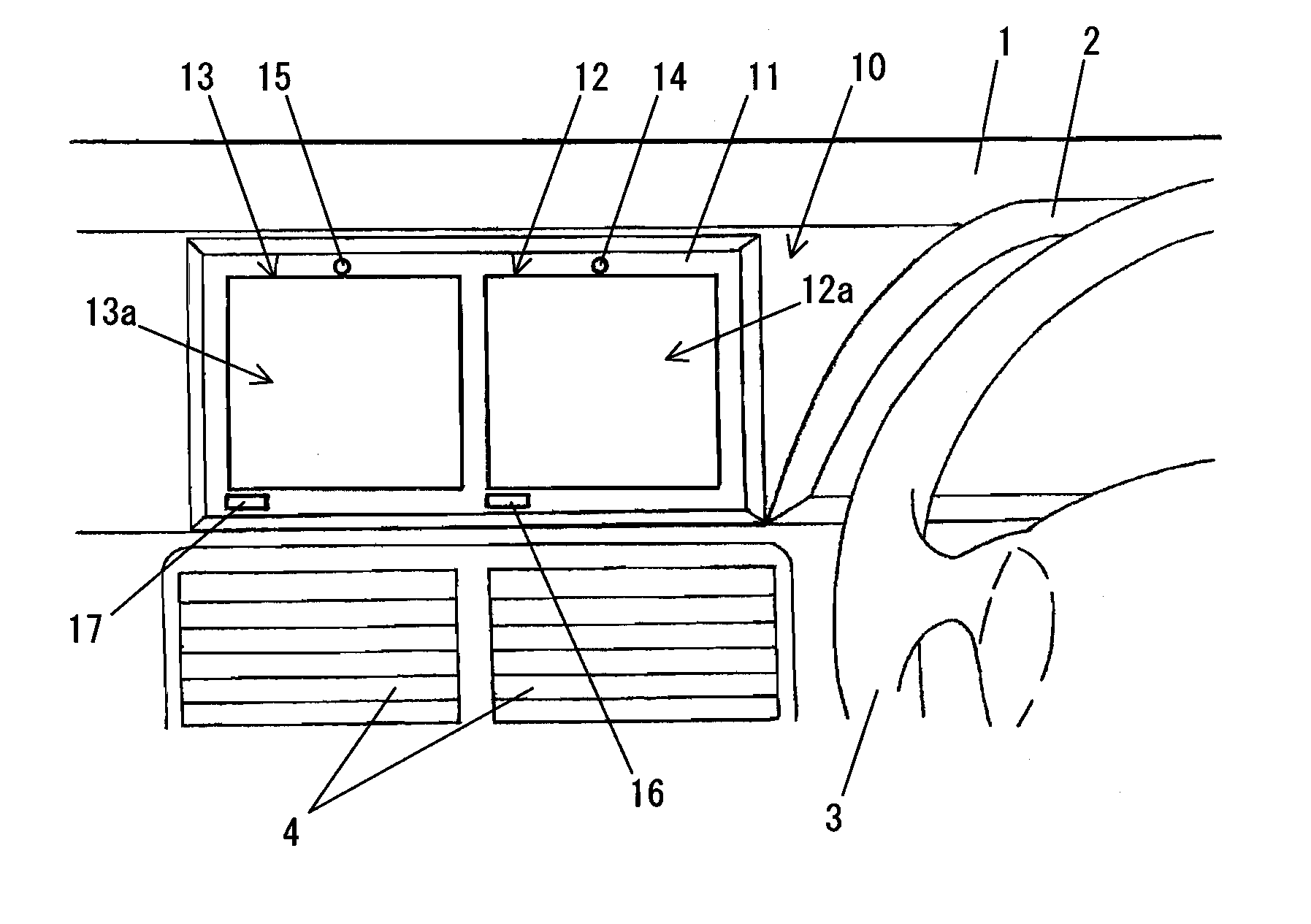

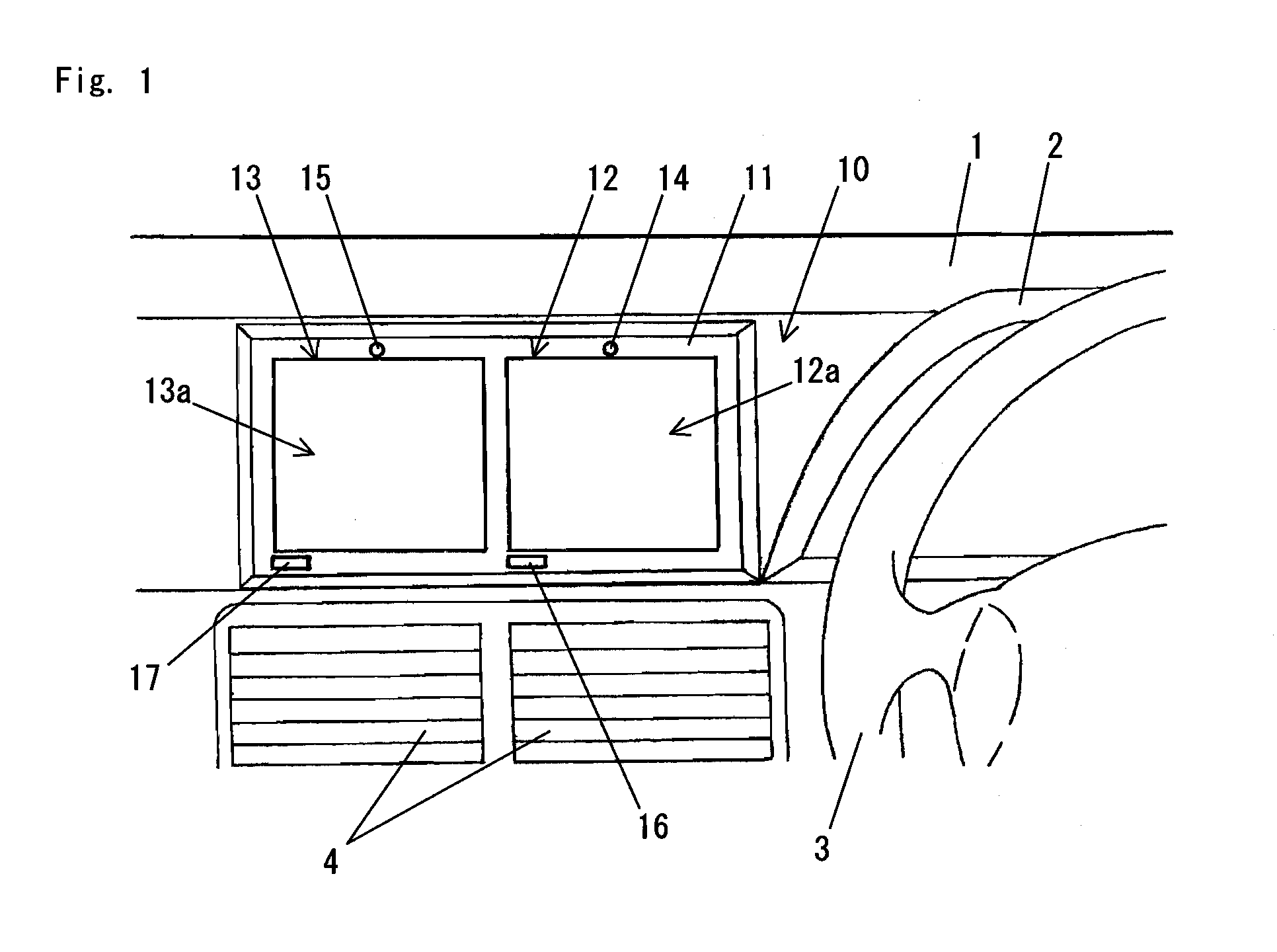

Display apparatus and navigation device

InactiveUS20090284474A1Handle imageFlexible handlingRoad vehicles traffic controlInstrument arrangements/adaptationsRemote controlDisplay device

A display apparatus operable to flexibly perform display control to a plurality of images is provided, when the plurality of images are displayed on the display apparatus, and each image is selected either as a touch operation target or as a remote control target alternatively. The display apparatus comprises: a first display device 12 and a second display device 13 operable to display a first image and a second image simultaneously; a CPU 51 operable to decide either the first image or the second image to be displayed as a remote control target and the other one as a touch operation target; a remote controller 32 operable to accept a control operation input regarding an image to be a remote control target between the first image and the second image; a first touch panel 12a and a second touch panel 13a operable to accept a touch operation input regarding an image to be a touch operation target between the first image and the second image; and a first LED 14 and a second LED 15 operable to indicate that the first image and the second image are either a remote control target or a touch operation target.

Owner:PANASONIC CORP

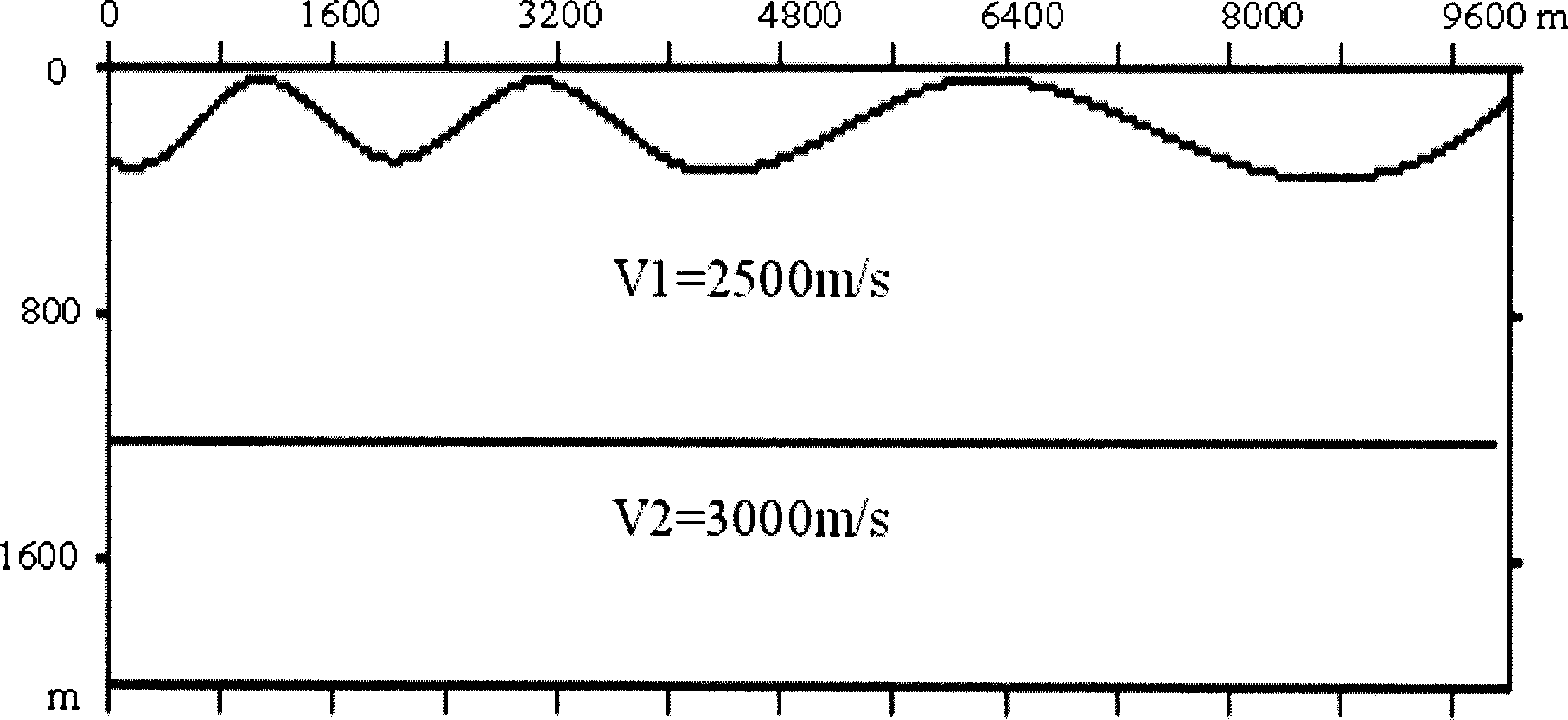

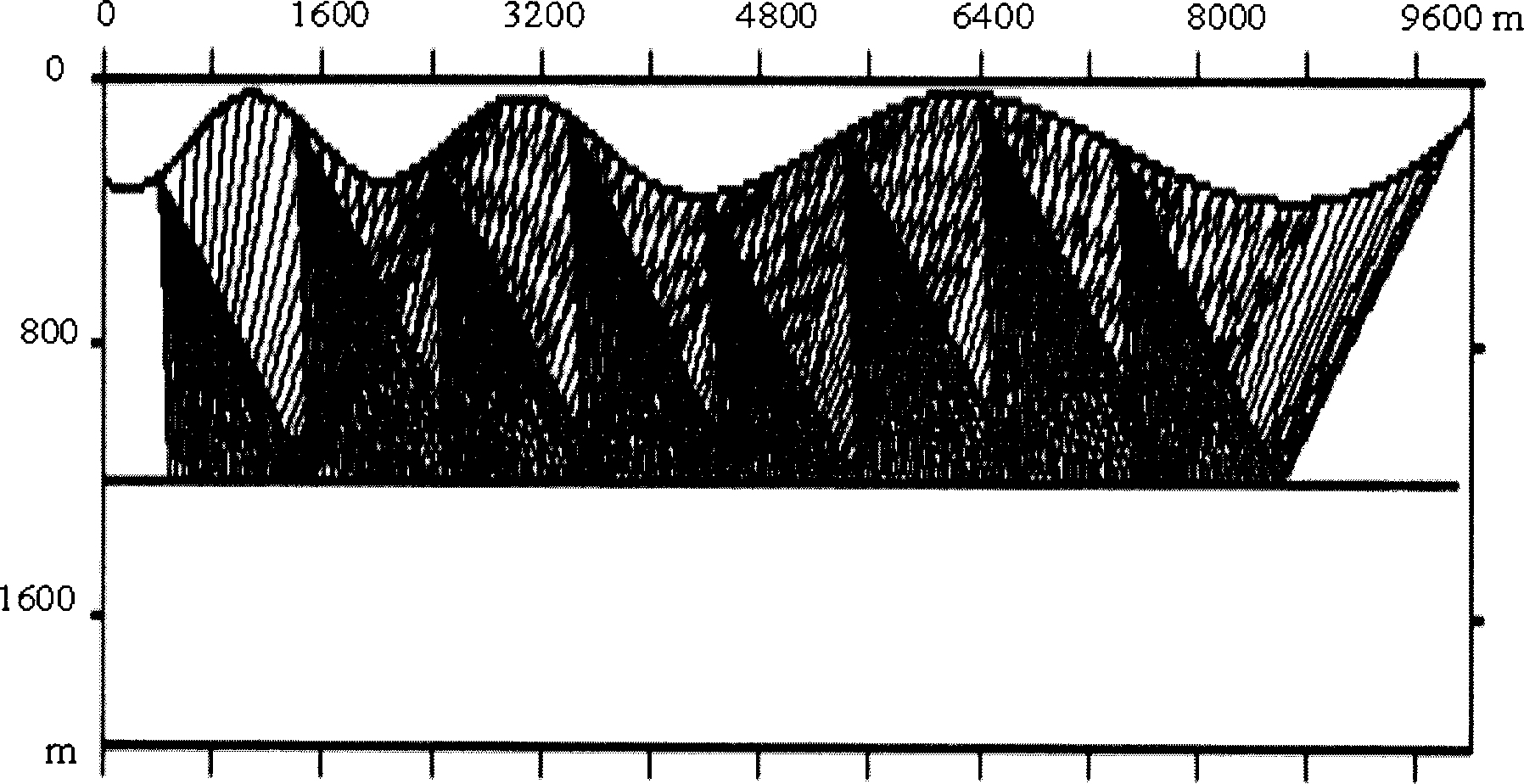

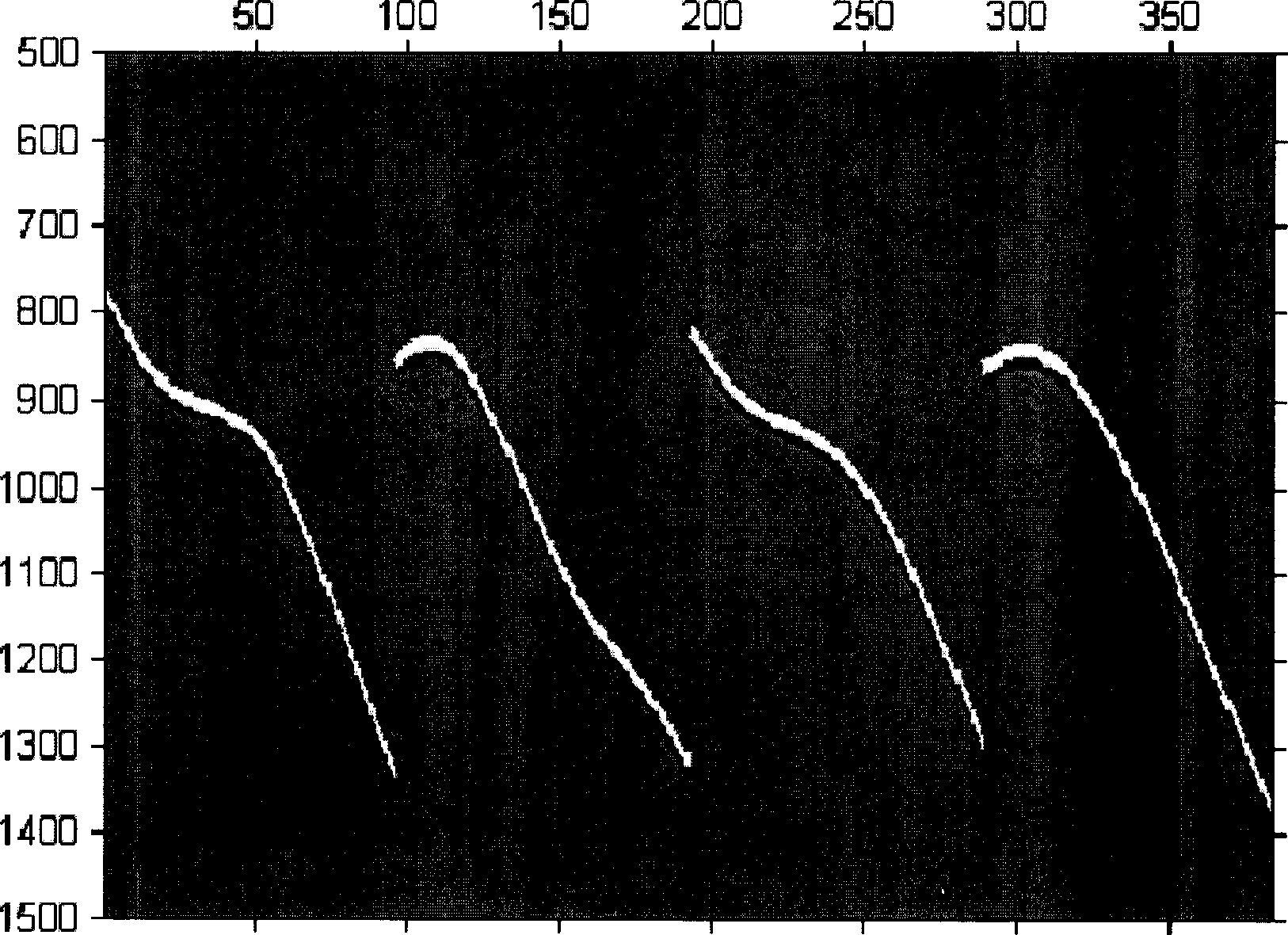

Method for shifting depth before superposition in seismic data process of undulating the earth's surface

ActiveCN1797038AFlexible handlingImproving Imaging AccuracySeismic signal processingImaging conditionWave equation

The invention is a prestack depth migration method for seismic data processing of a relief land surface, determining an imaging reference plane according to the highest point of a collection region, and projecting the relief land surface to a regular grid to fill a constant speed approaching to the near land surface in the relief land surface; using Fourier finite extrapolation operators of one-way wave equation to make wave field extrapolation on shot seismic source wave fields and detector received wave fields along the depth axis, and keeping the wave field between input and output datum equal to zero; imaging the extrapolated shot and detector wave field record by conjugate related imaging conditions, and stacking the related results of each frequency and processing the imaging result into a section image by routine display software, and the invention has an obvious imaging effect of complex construction on the condition of relief land surface.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

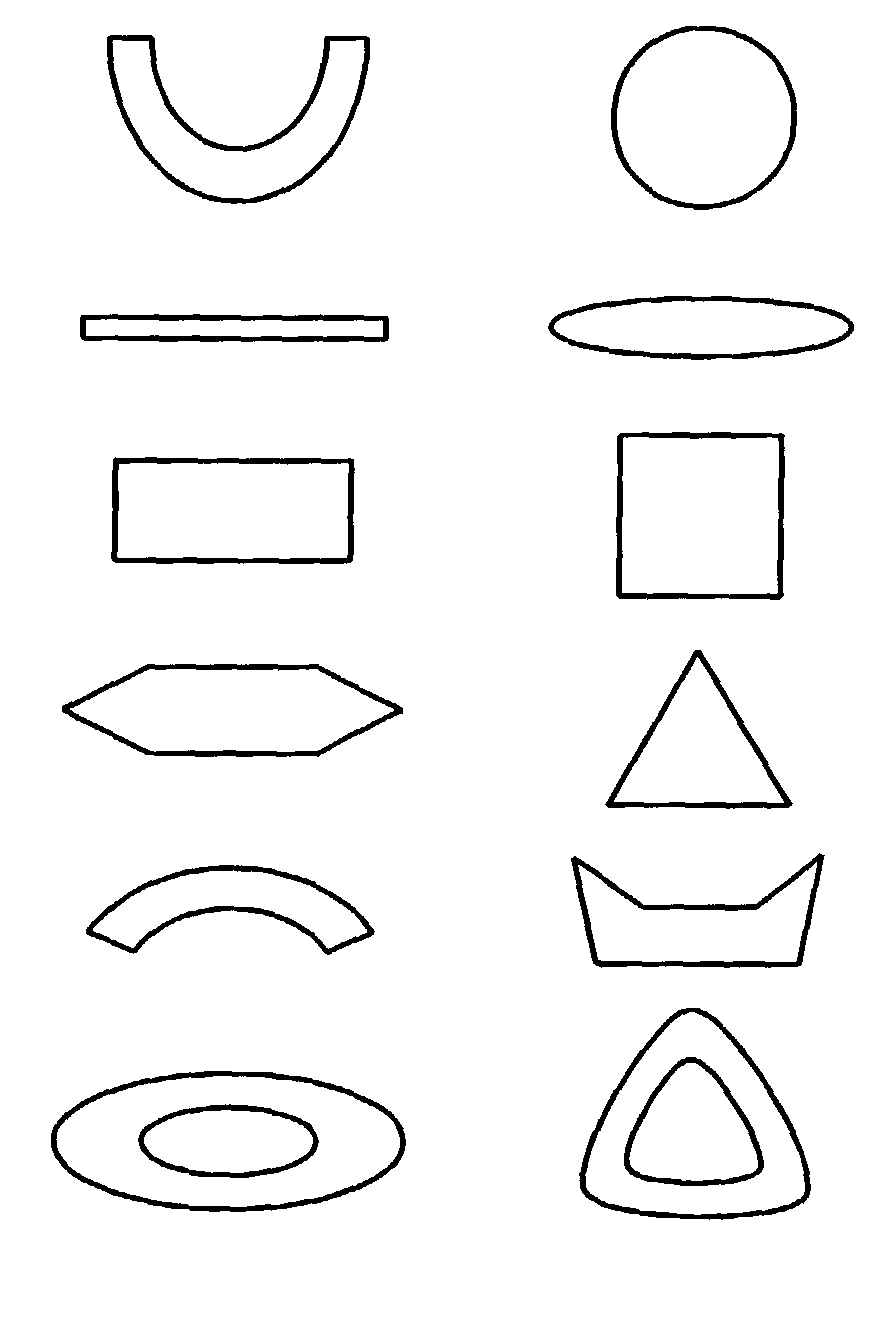

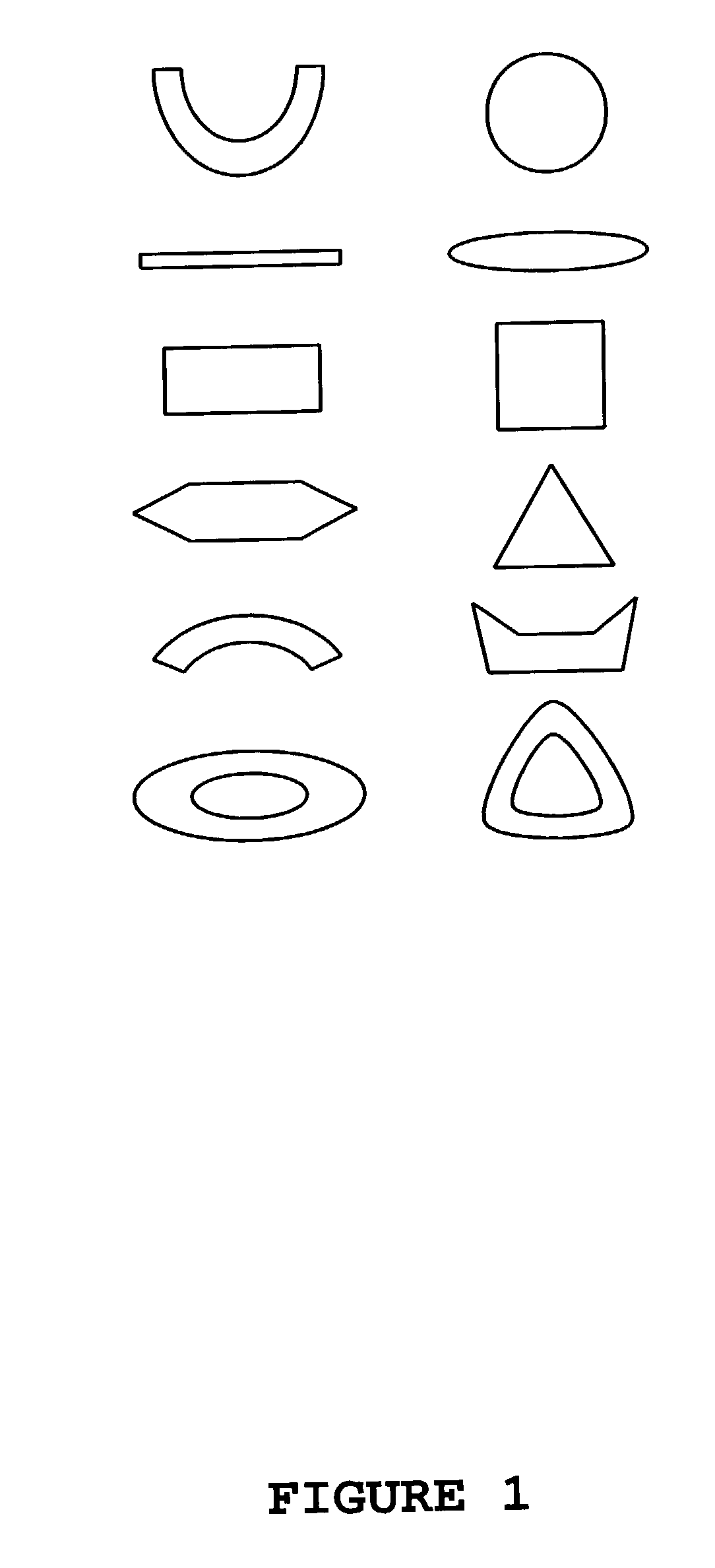

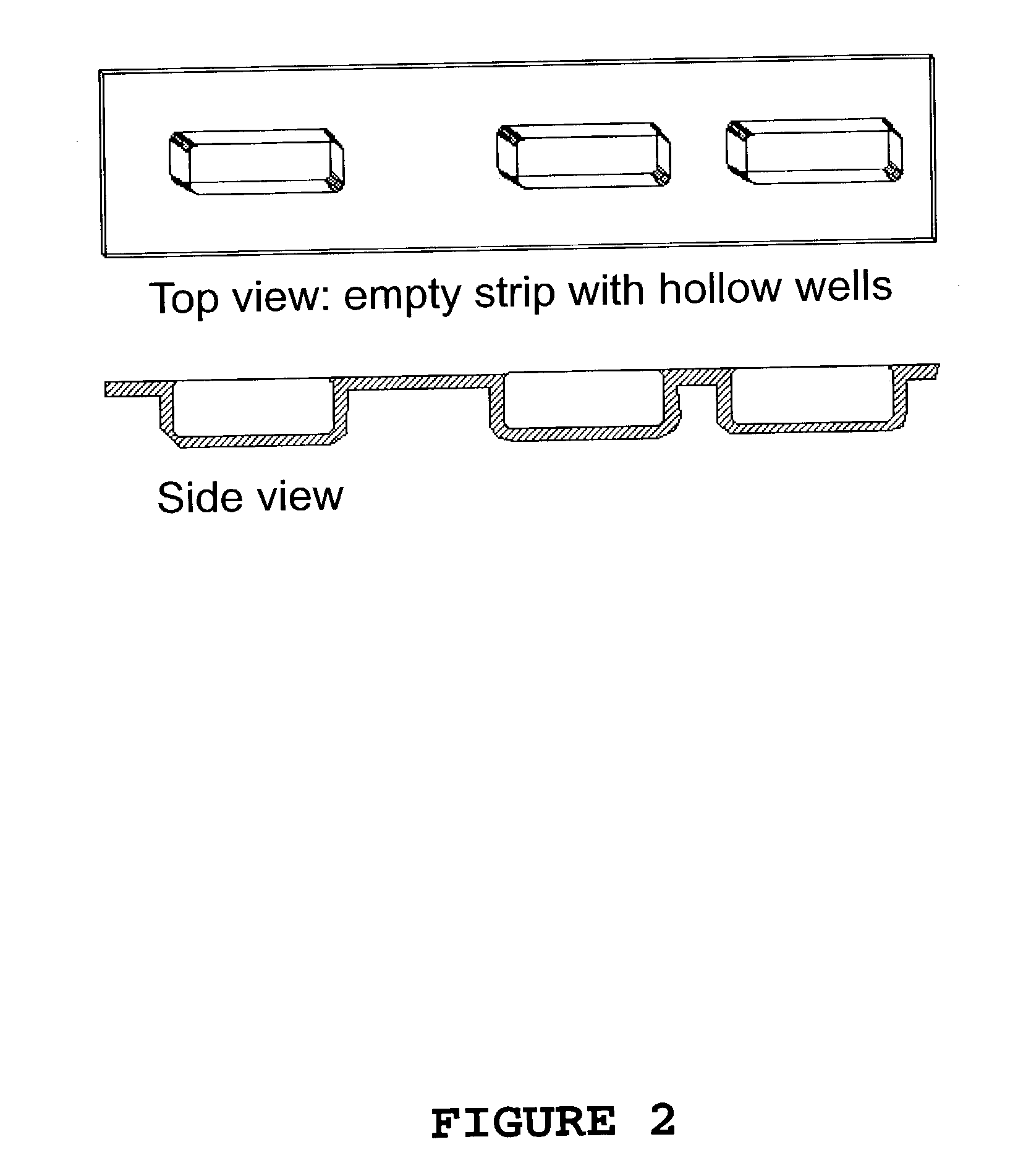

Drug dose-form and method of manufacture

ActiveUS7993674B2Slow and little dissolutionFlexible handlingPill deliveryFlat articlesDrug dosesBiomedical engineering

Disclosed is a novel solid dosage unit, preferably in the form of a film or thin troche, containing at least one pharmaceutical agent, and its method of manufacture, which involves introduction of a fluid containing at least one non-volatile material, such as a polymeric film forming substance, a volatile carrier and at least one pharmaceutical agent into a depression or cavity comprising the major element of the packaging film for the finished dosage unit (s), and removing the volatile carrier from the cavity by exposure to radiant energy, whereby the remaining non-volatile residue comprises the desired dosage unit. The packaging film can be subsequently lidded by conventional sealing methods to produce packaged dosage units which are suitable for sublingual and other oral applications.

Owner:WEIBEL MICHAEL K

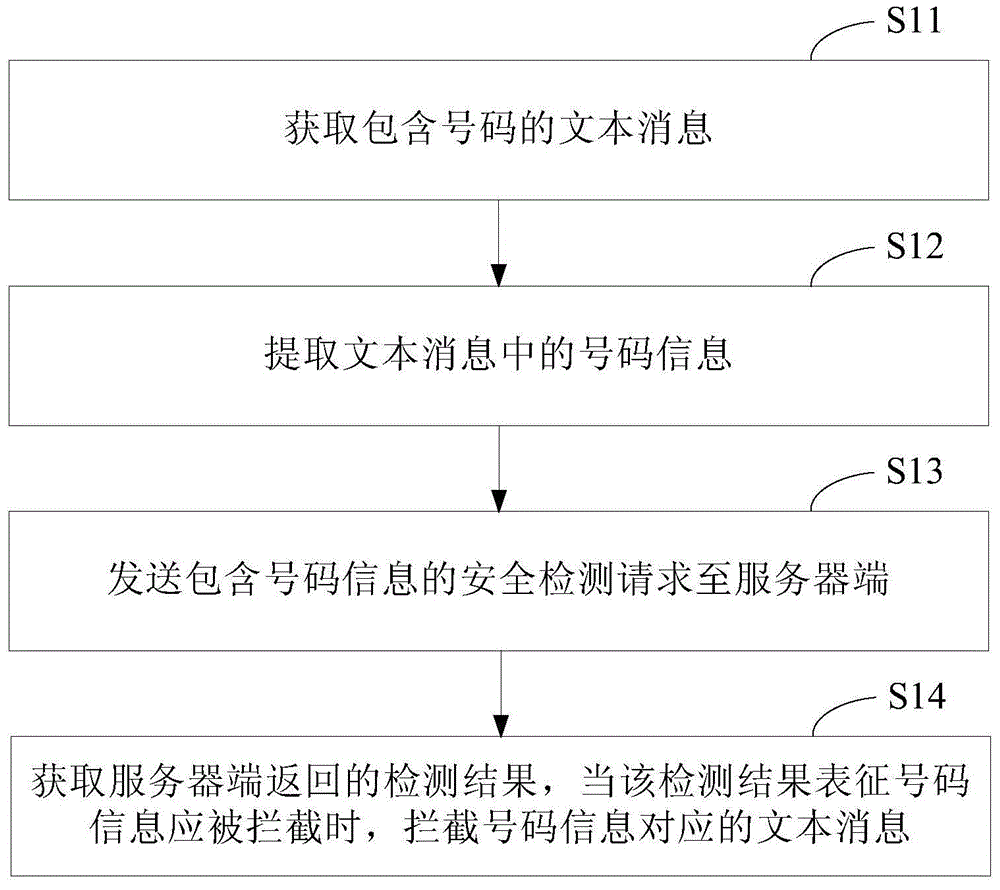

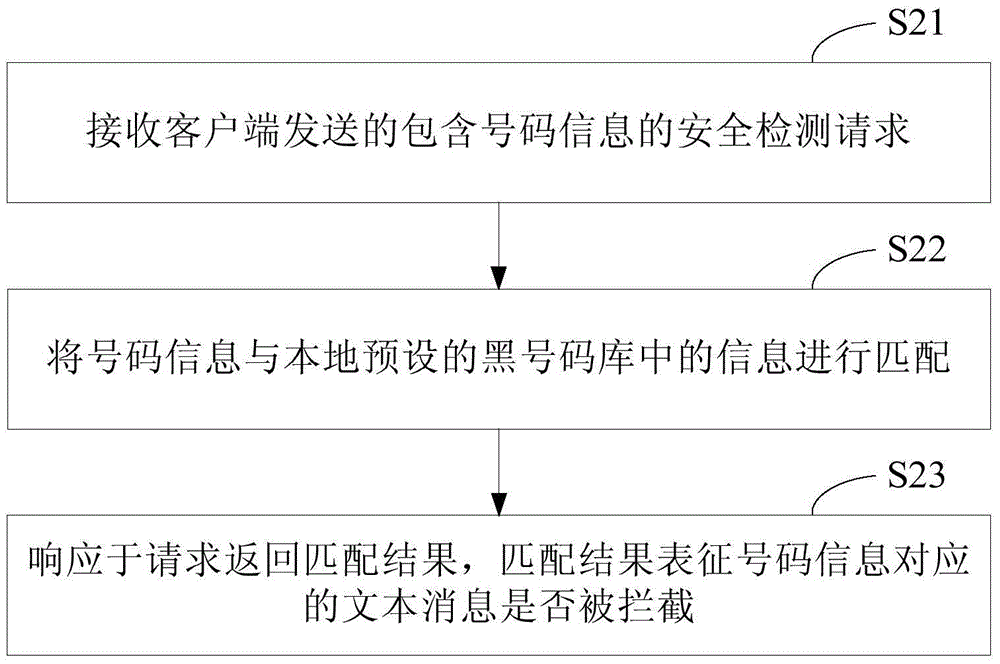

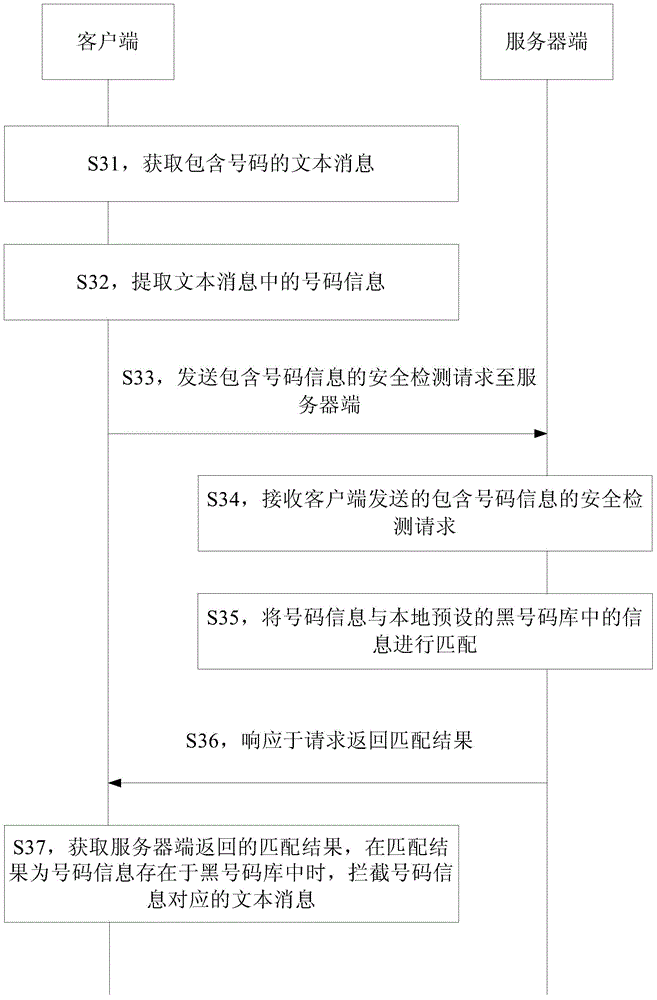

Safety monitoring method and device for number information in text

ActiveCN104539624AEasy to identifyImprove accuracySubstation equipmentTransmissionData miningSafety monitoring

The invention provides a safety monitoring method for number information in a text. The safety monitoring method includes the following steps that text information containing numbers is obtained; the number information in the text information is extracted; a safety detection request containing the number information is transmitted to a server side; a detection result returned by the server side is obtained, and when the number information represented by the detection result is intercepted, the text information corresponding to the number information is intercepted. The invention further provides a safety monitoring device for the number information in the text. By means of the mode, the number information in the text information is matched with information in a black number library, junk information can be recognized accurately, and user loss is reduced.

Owner:BEIJING QIHOO TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com