Patents

Literature

72results about How to "Flexible welding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

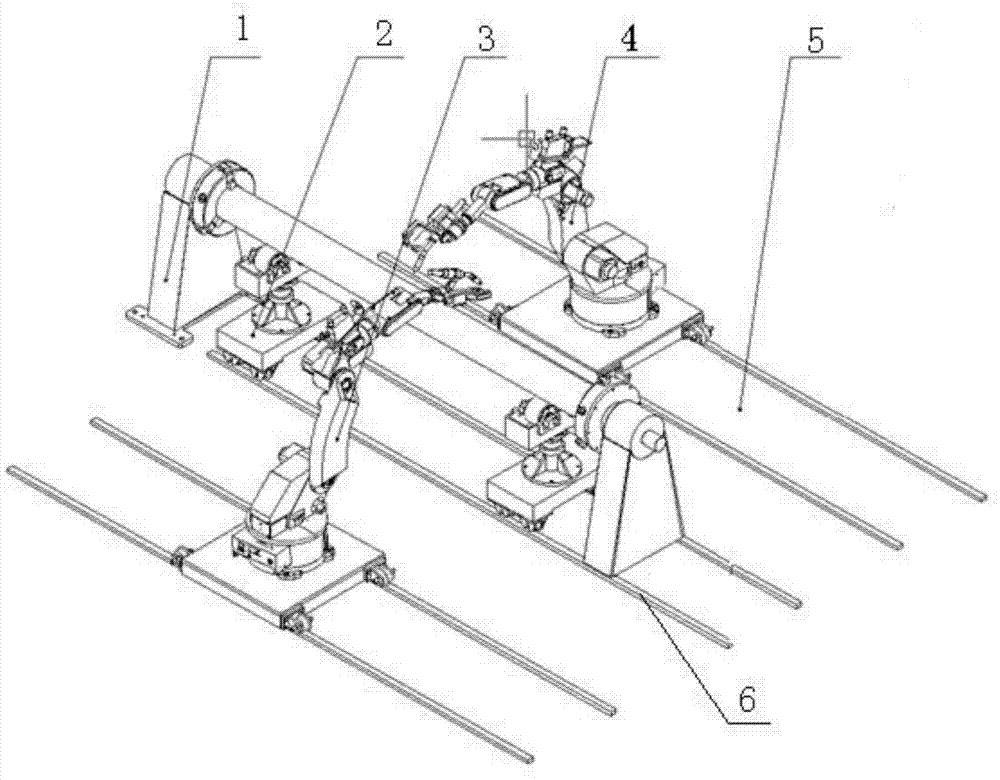

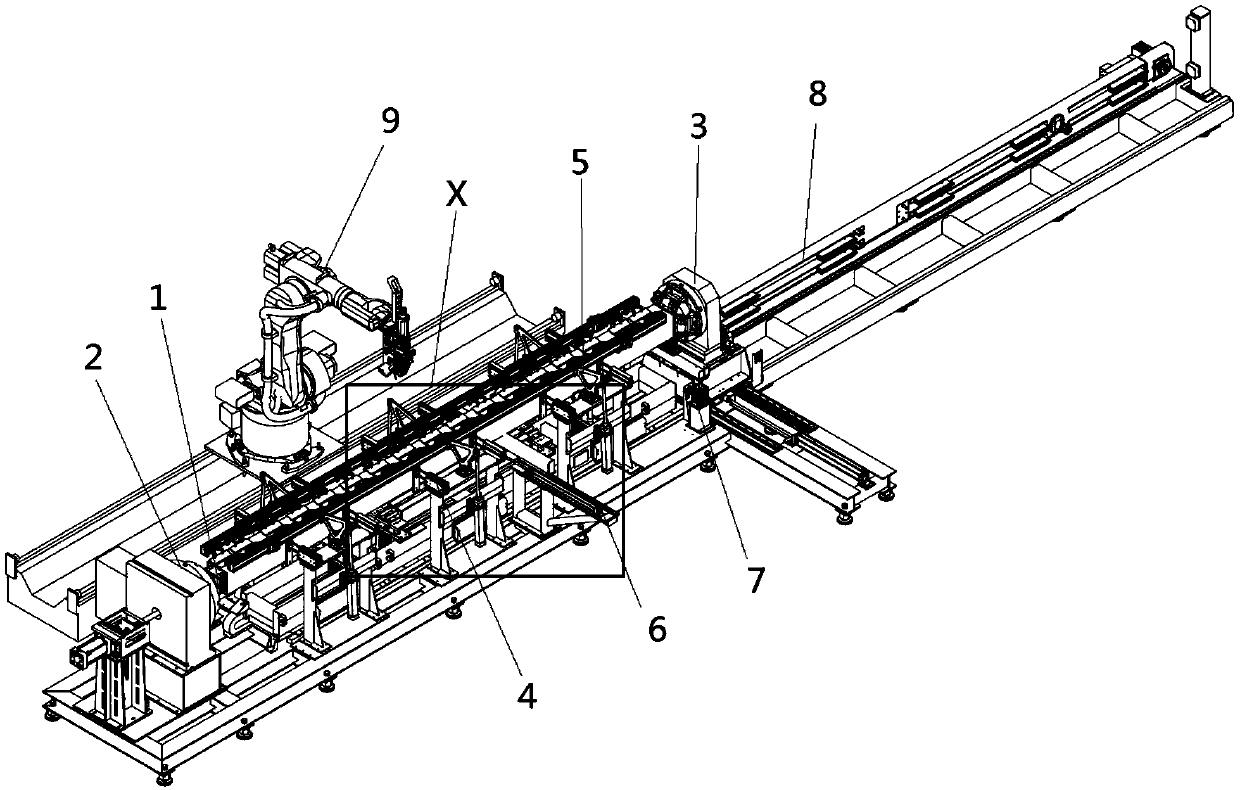

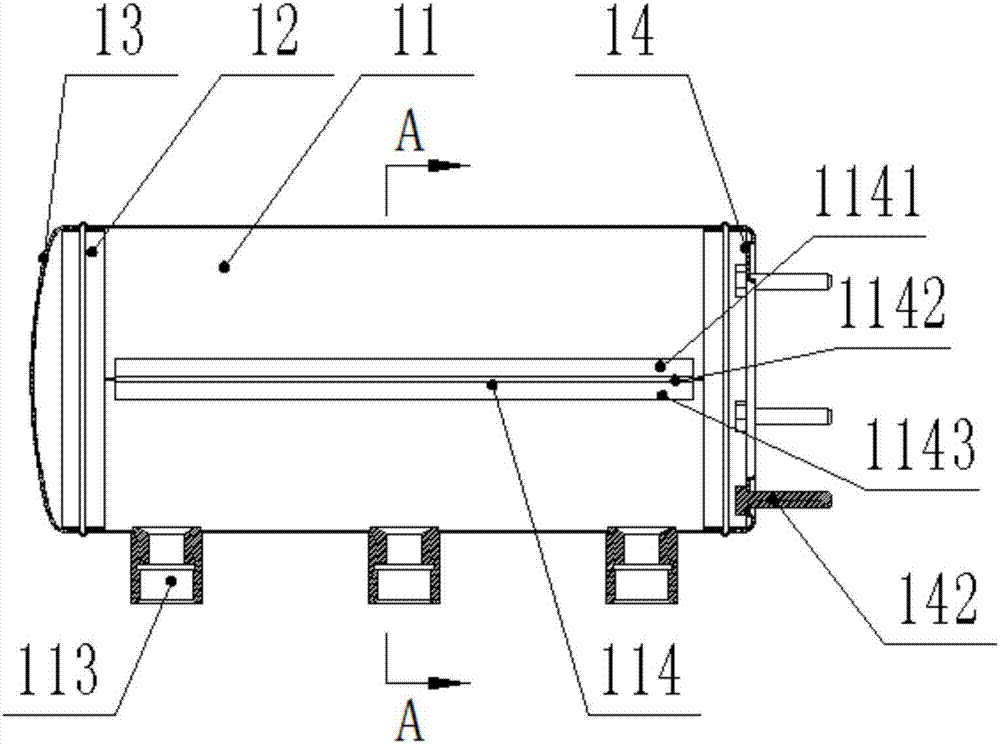

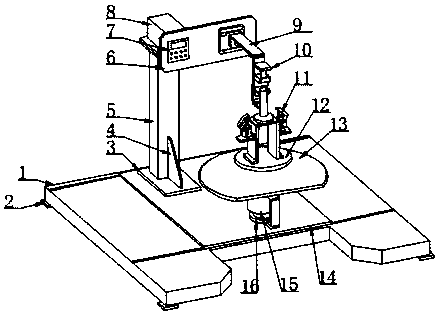

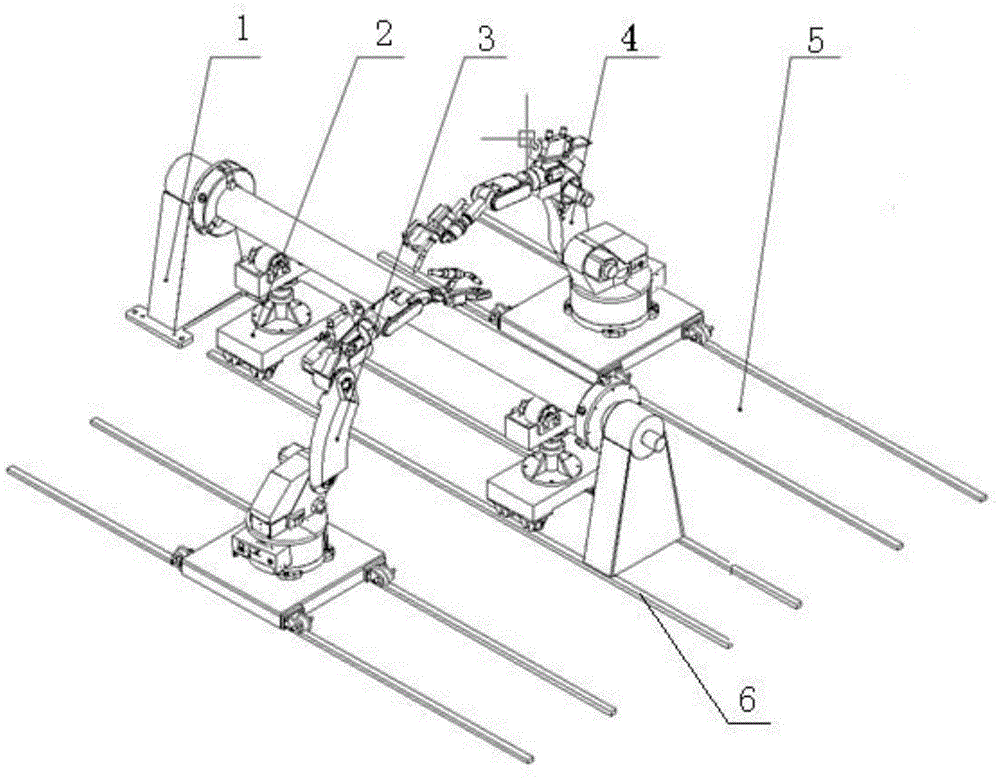

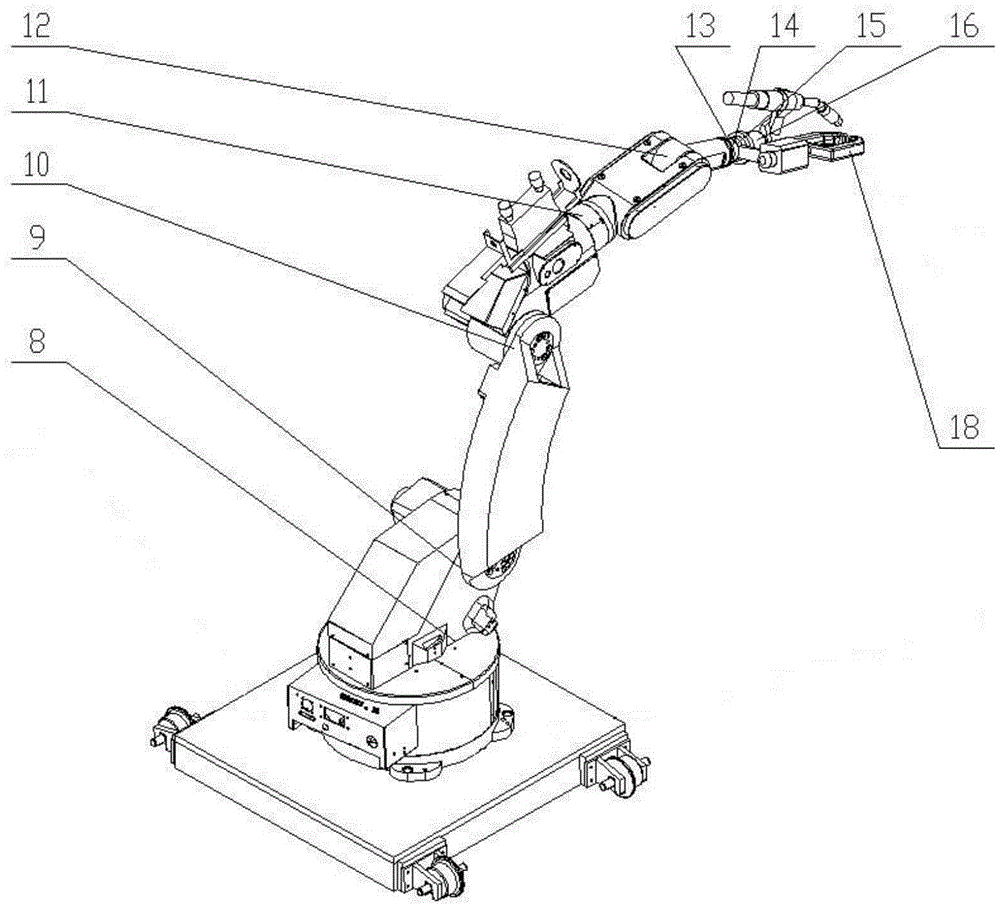

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677AImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSmall footprint

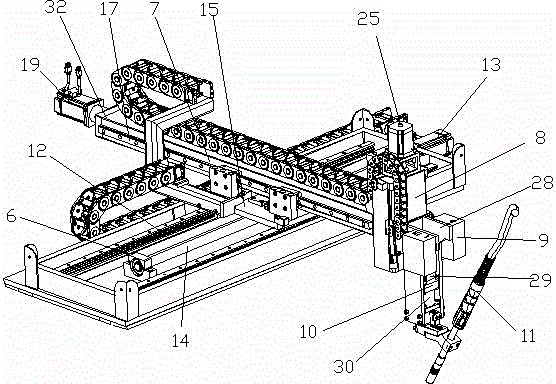

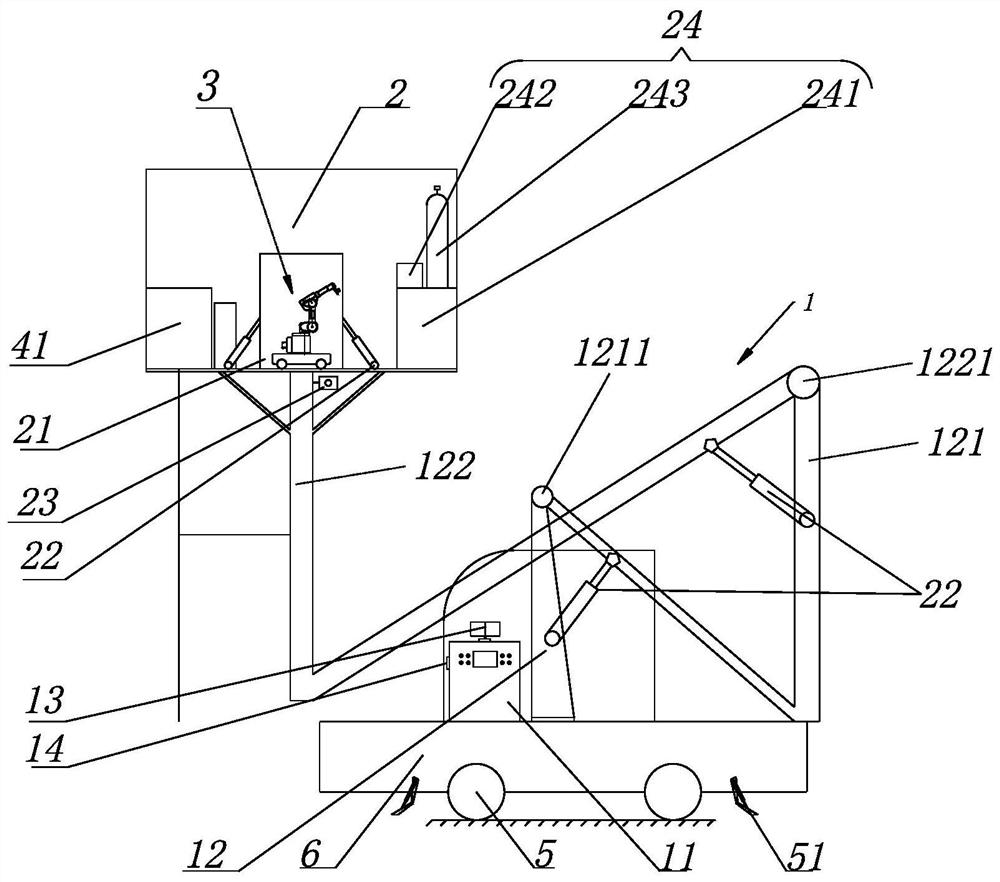

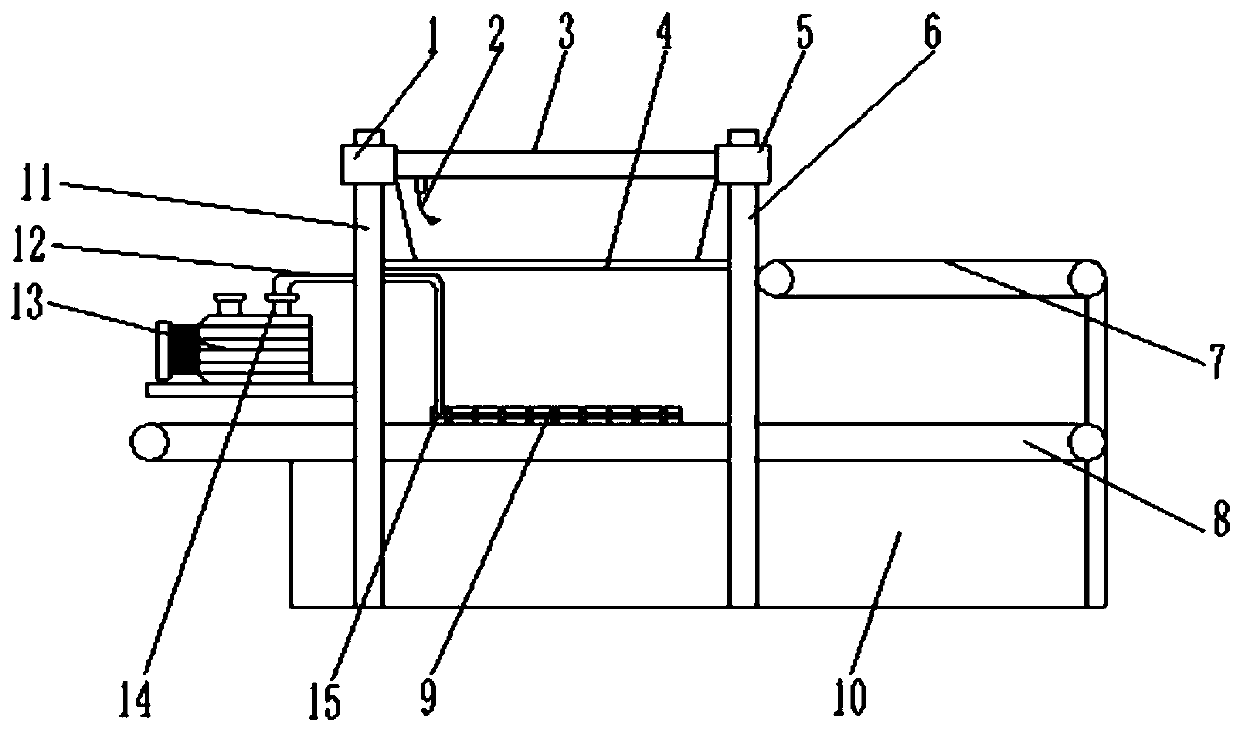

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

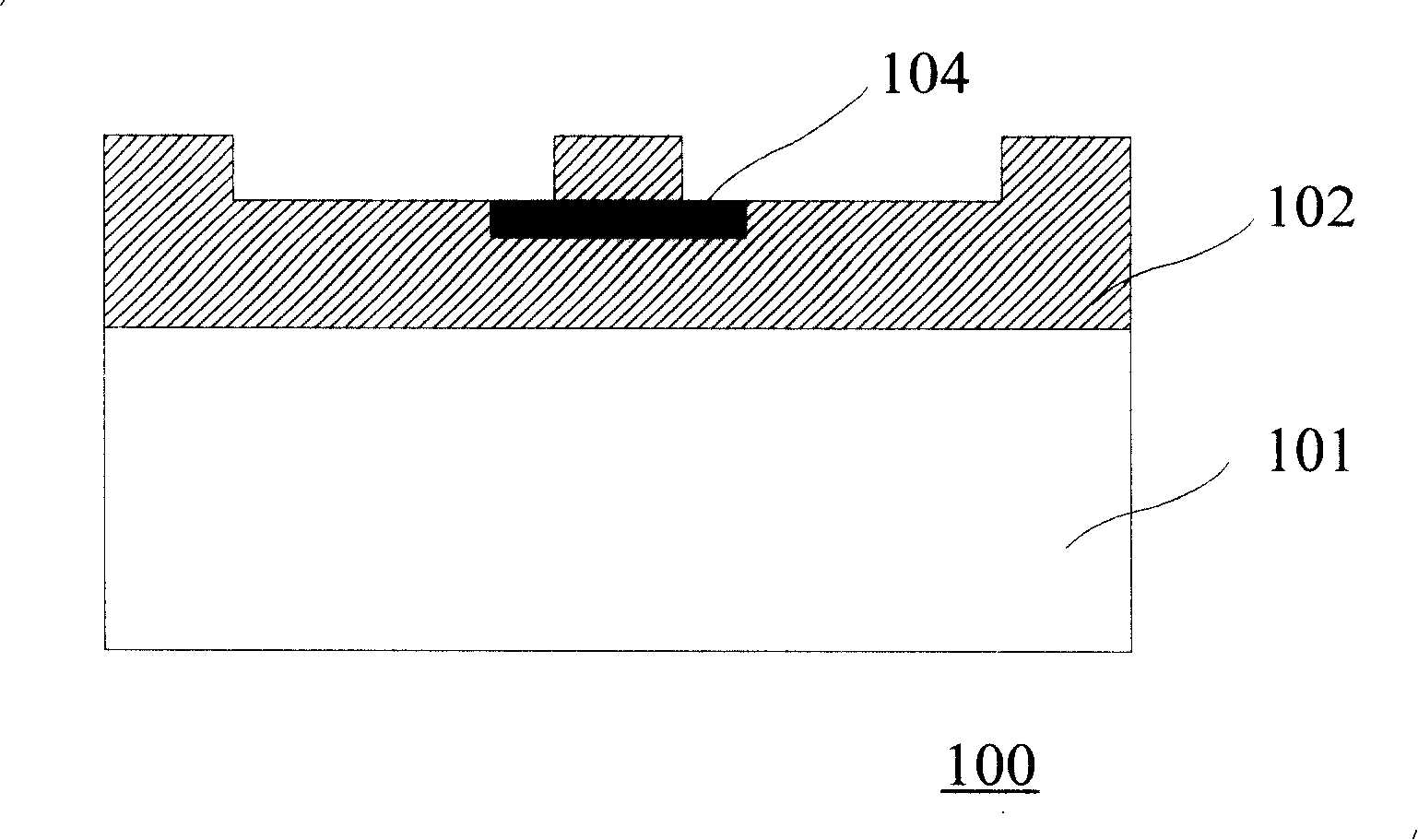

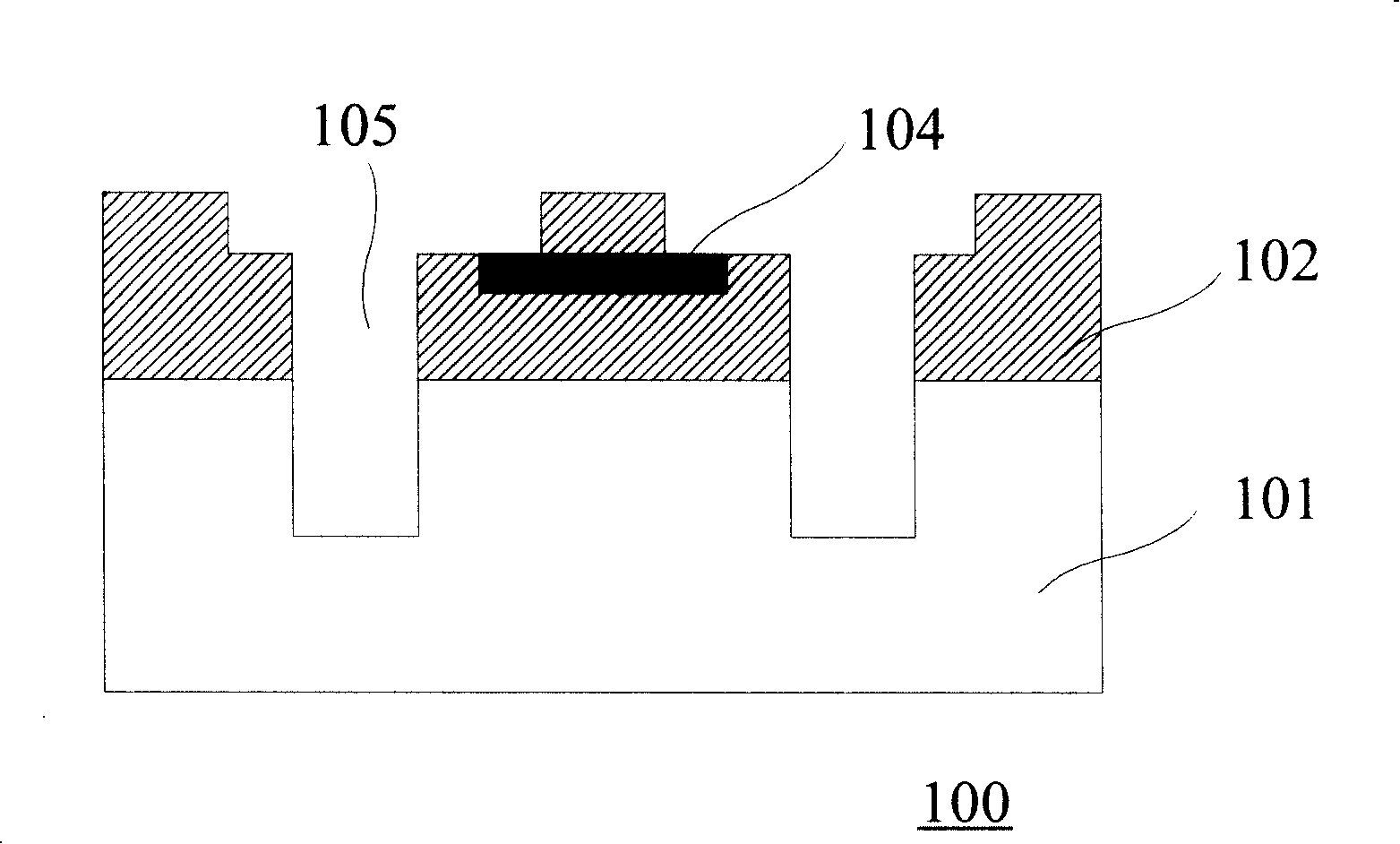

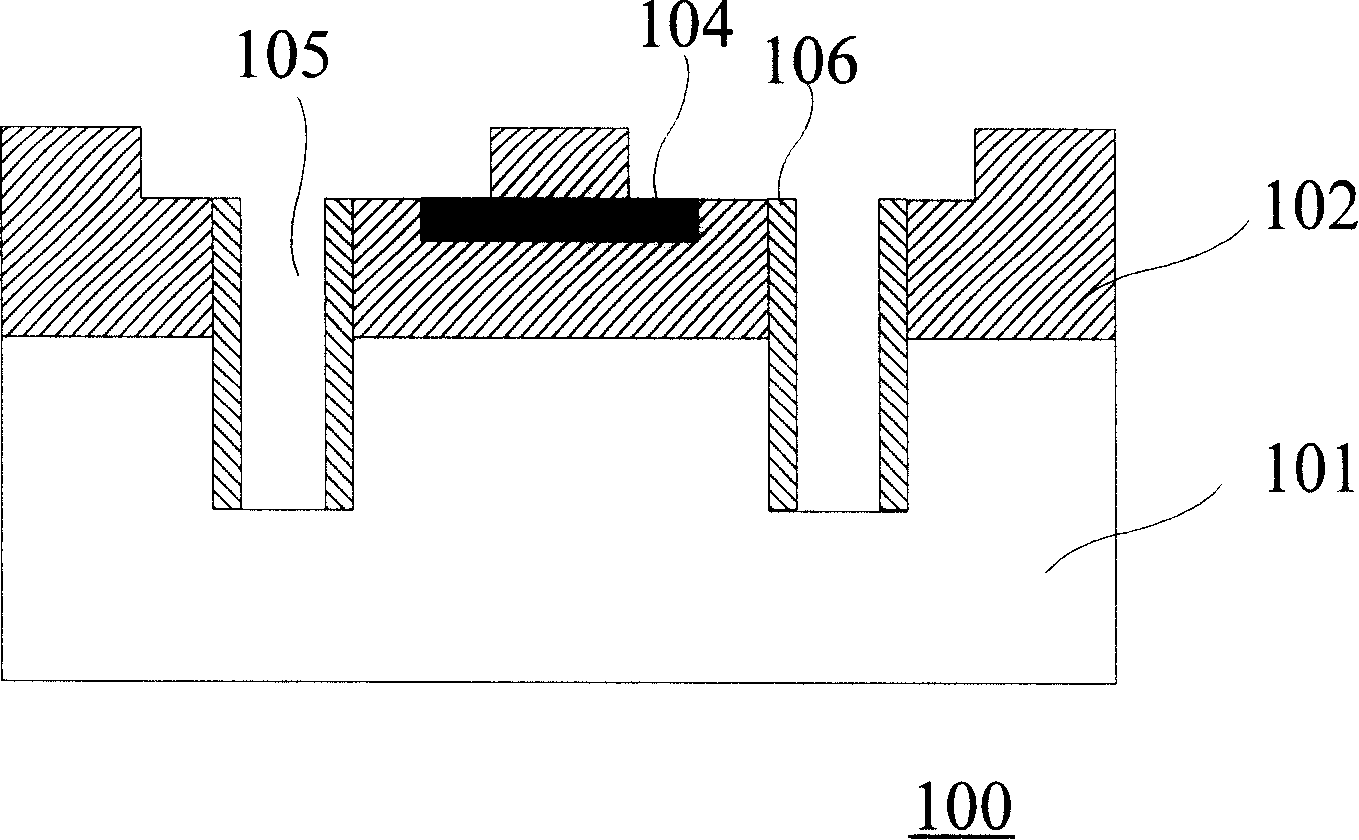

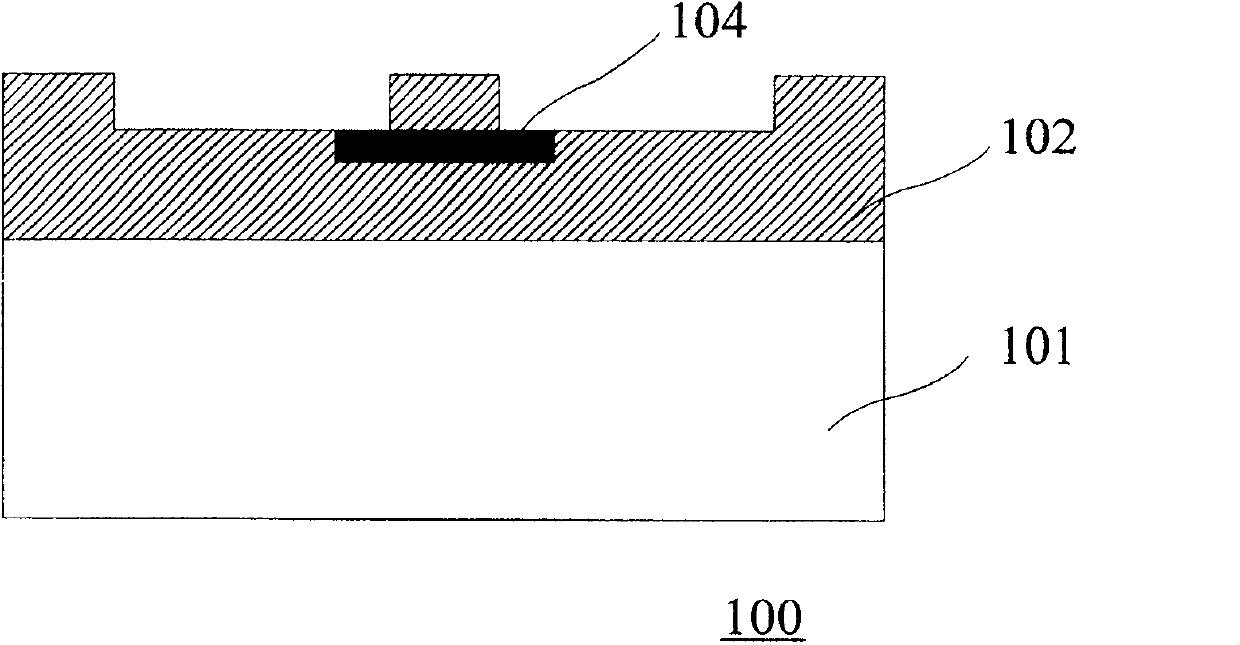

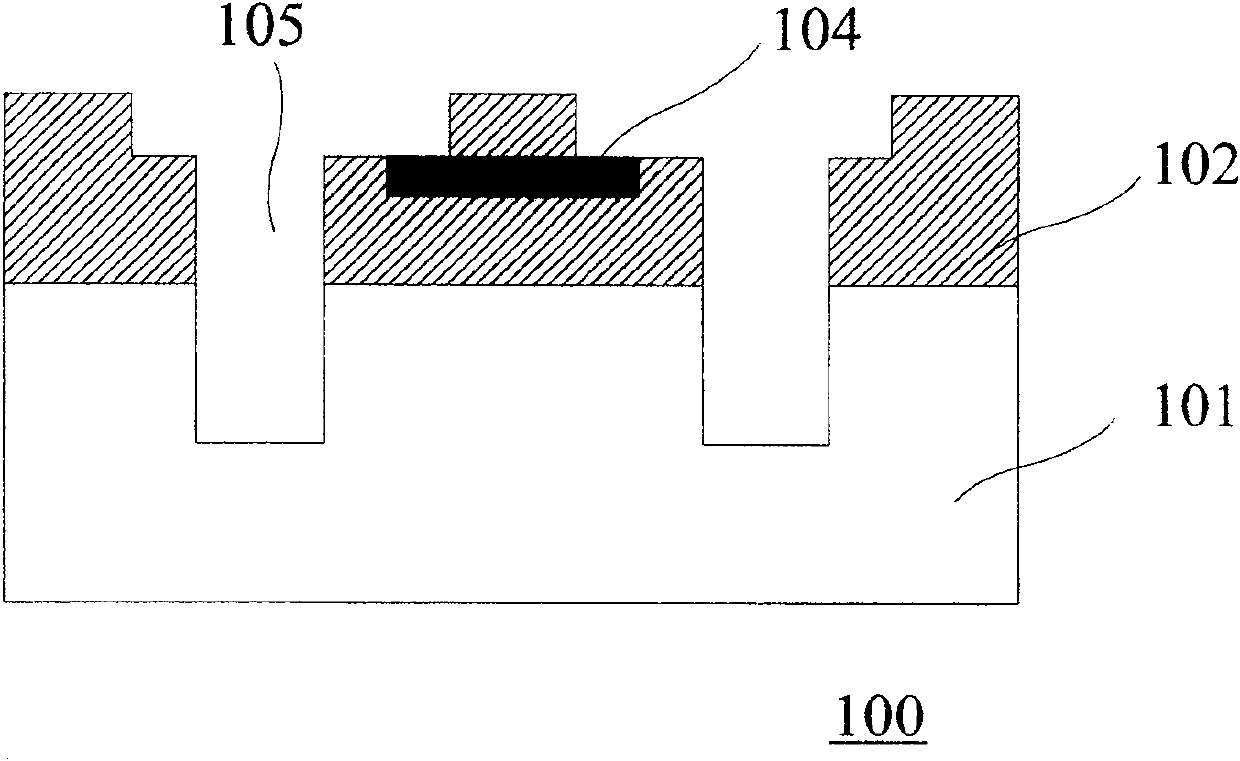

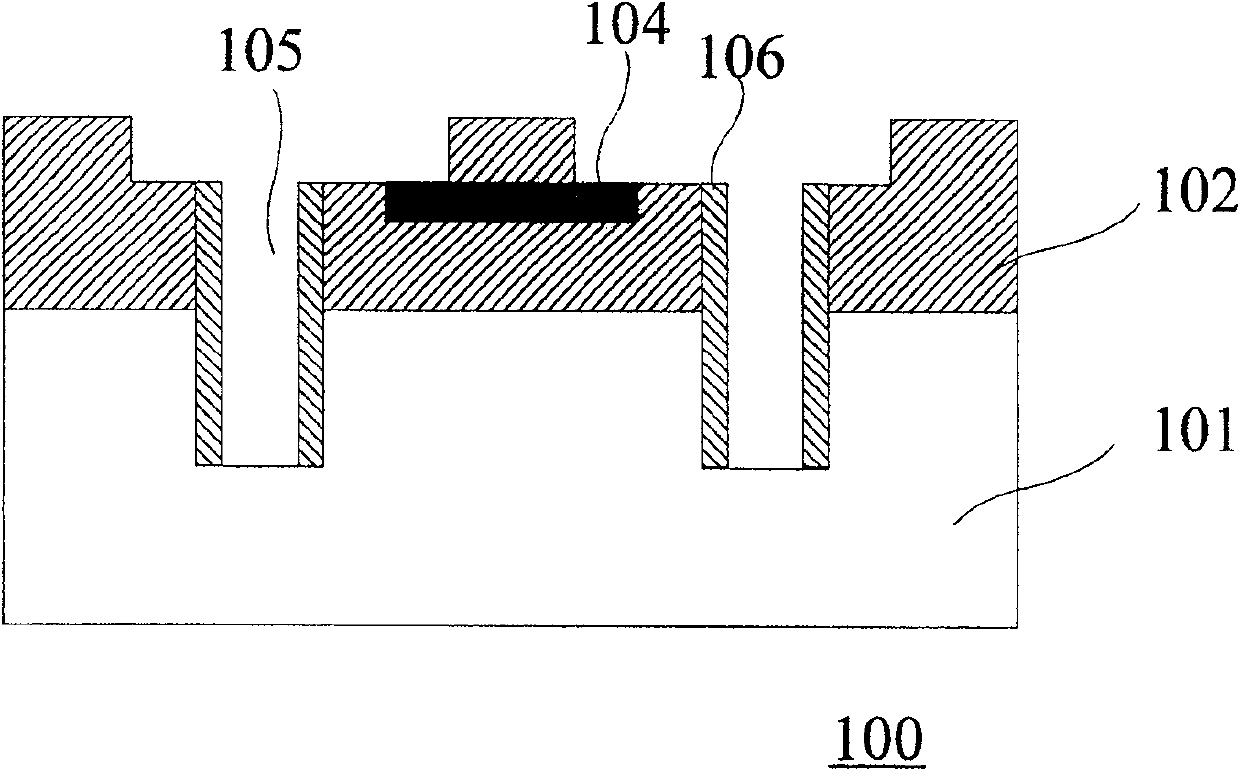

Wafer press welding and bonding method and structure thereof

ActiveCN101197297AWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

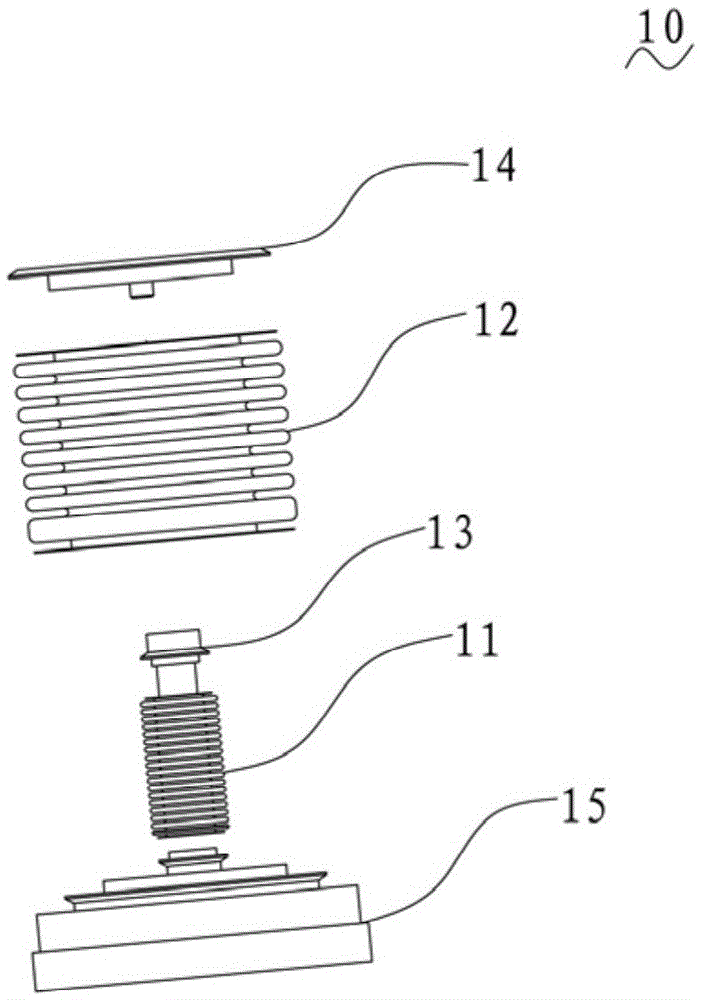

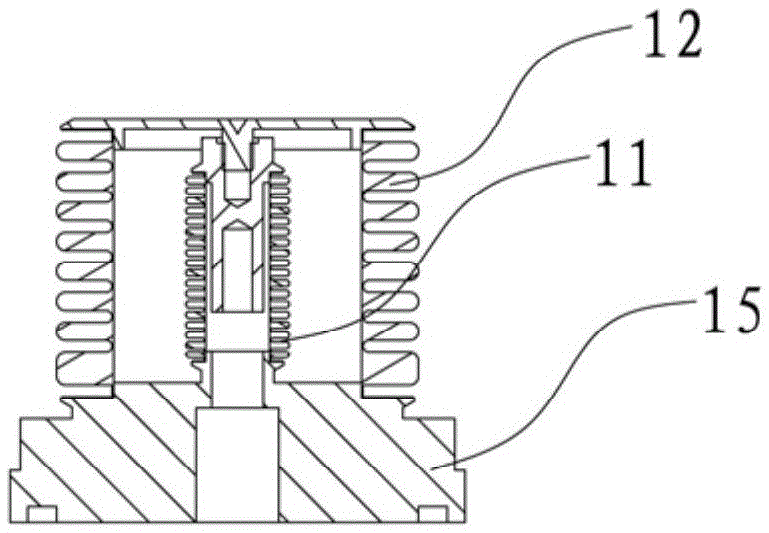

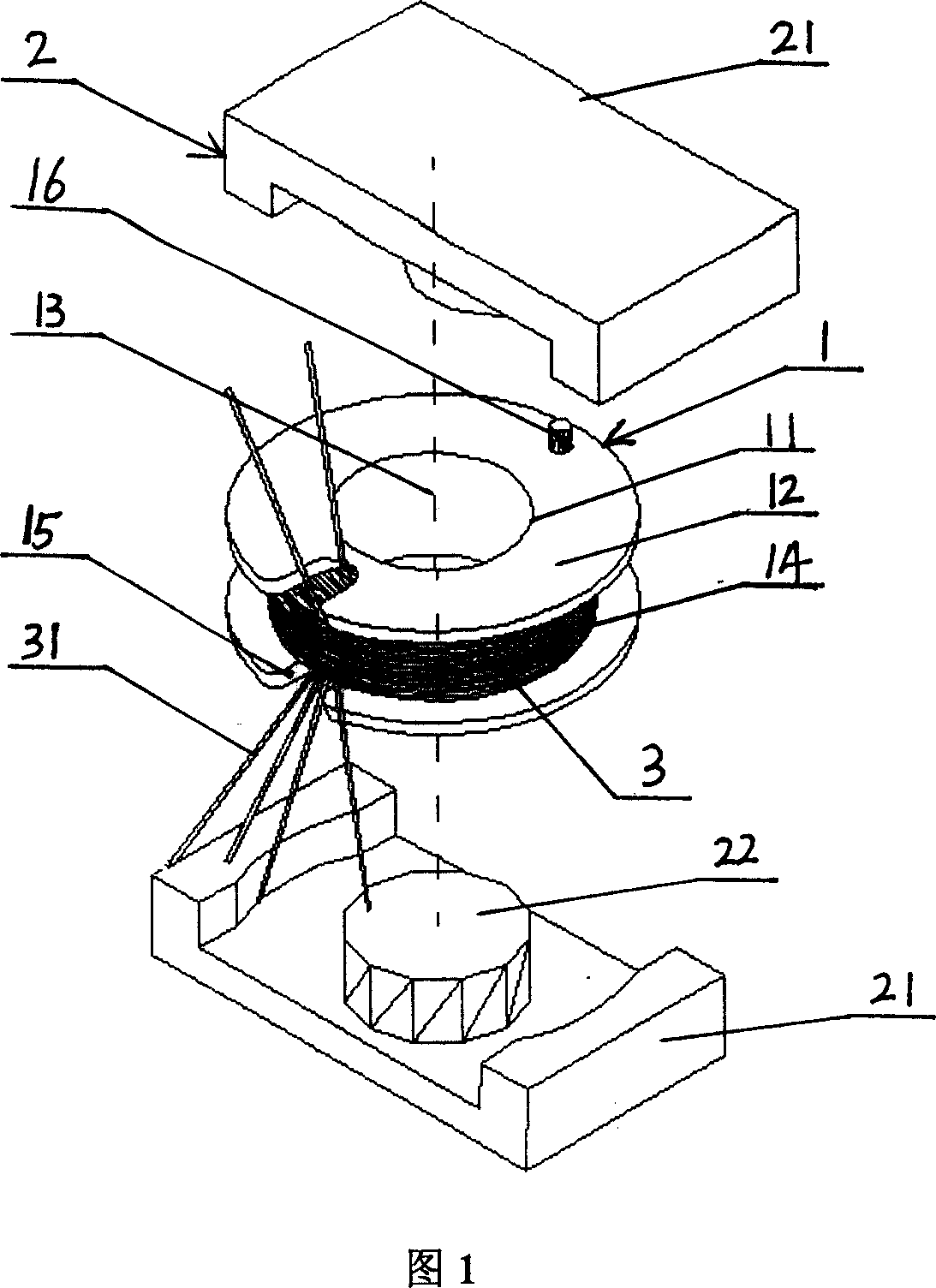

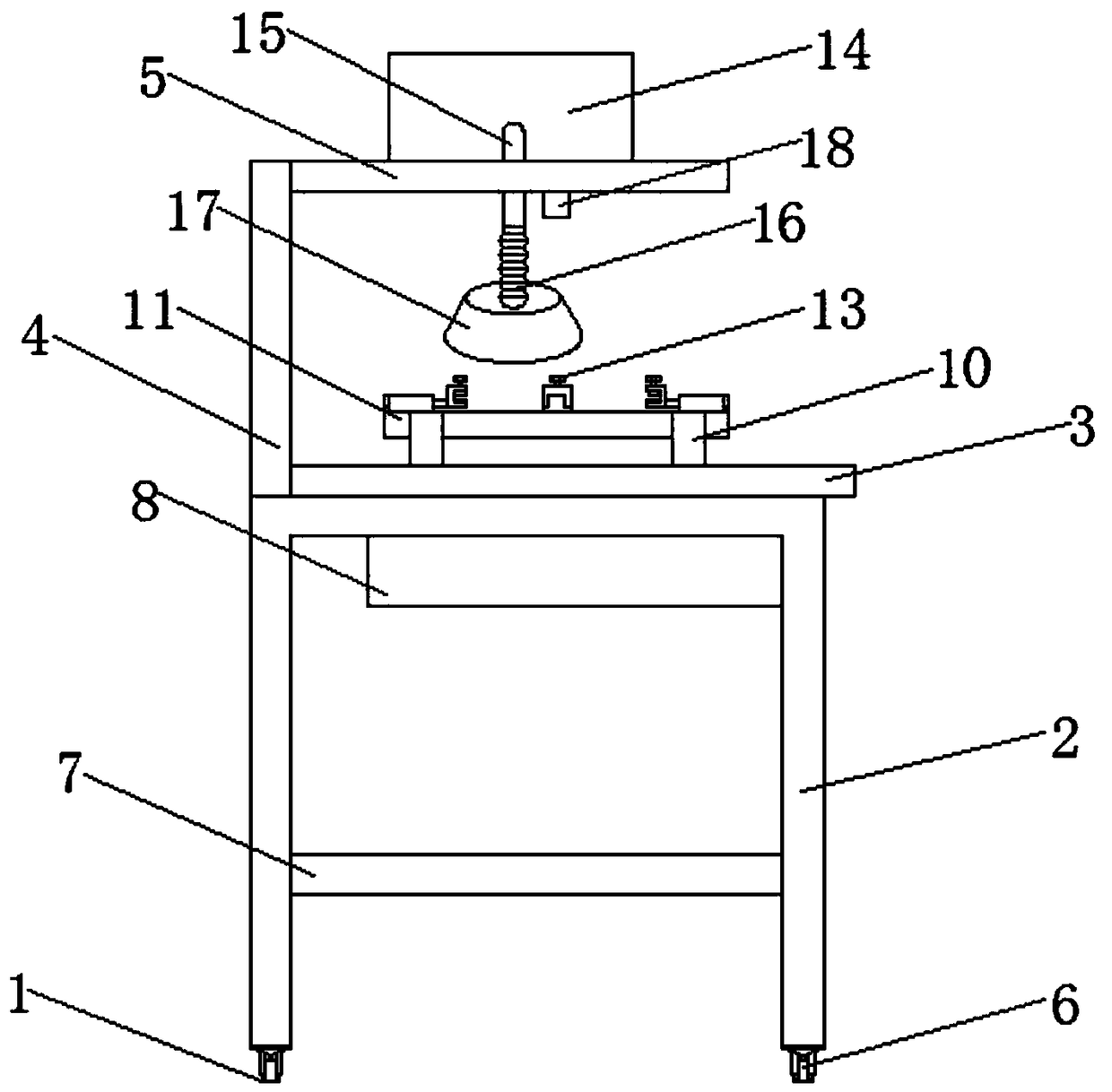

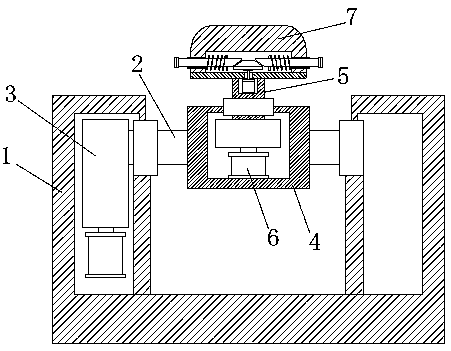

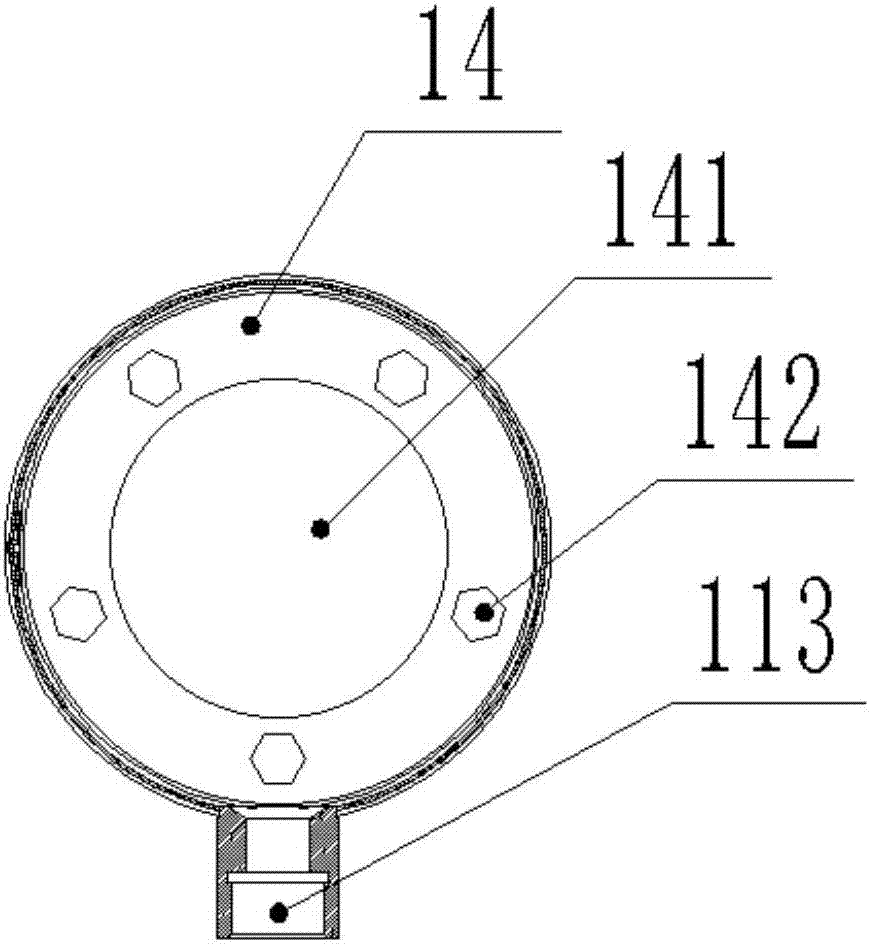

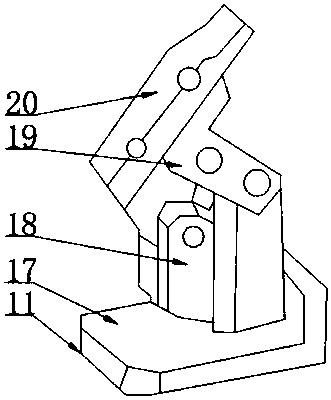

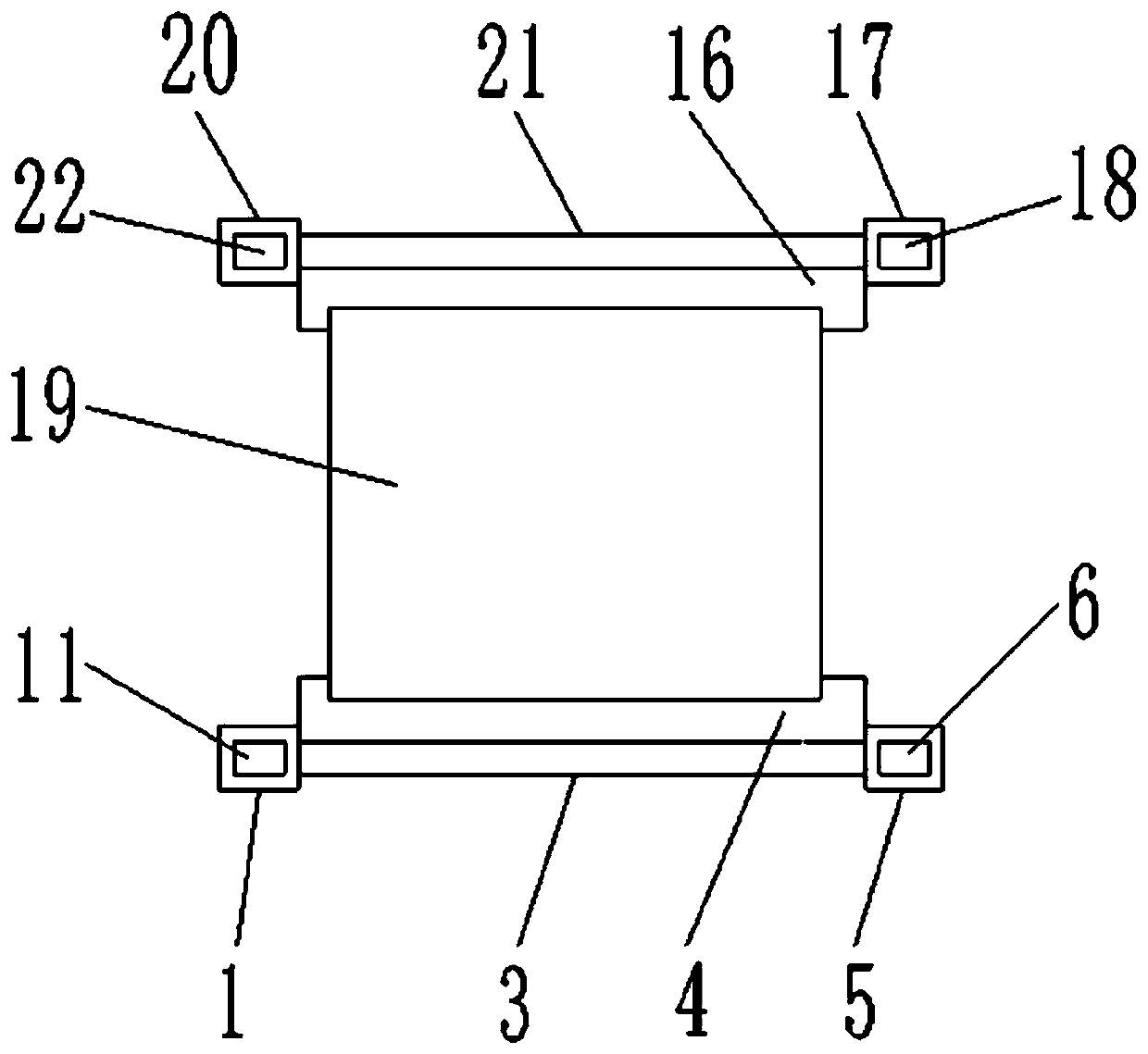

Rotating fixture and rotating welding device

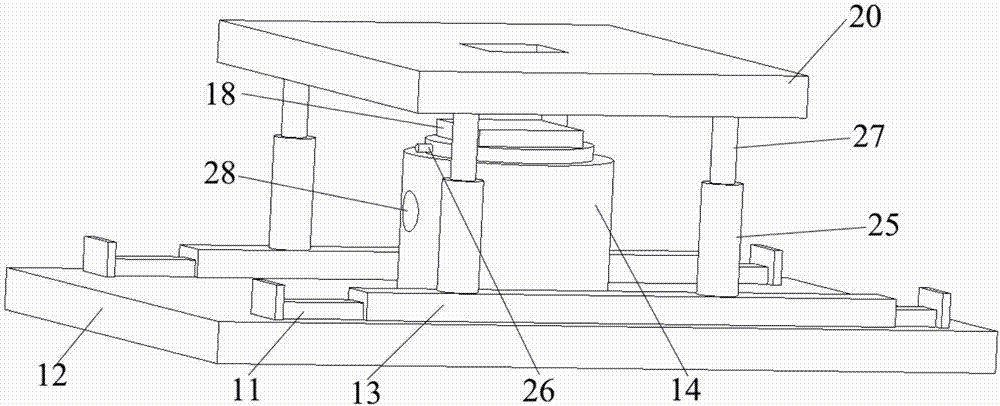

ActiveCN105666023AReduce complexityReduce welding roughnessWelding/cutting auxillary devicesAuxillary welding devicesEngineeringLaser beams

The invention is suitable for the field of laser machining, and provides a rotating fixture. The rotating fixture comprises a base, a rotating driving device, a positioning device and a pressing device, wherein the base is used as a substrate; the rotating driving device is positioned on the base; the positioning device is used for positioning a product to be welded; the pressing device is matched with the positioning device to press the product to be welded; a rotatable pressing head is arranged on the pressing device; the positioning device is fixed at a rotating end of the rotating driving device; and the rotating driving device drives the positioning device, the product to be welded and the pressing head to rotate integrally. According to an embodiment, the product to be welded rotates but a welding head is fixed, so that complexity of the mechanism is reduced, shaking during rotating of the fixture, and unsmooth welding, product air leakage and the like which are caused by shaking are reduced to a maximum extent; the rotating fixture is prevented from interfering with a laser beam and the welding head; and by pneumatic clamping and discharging of a cylinder, efficient and automatic welding is realized. The embodiment of the invention further provides a rotating welding device.

Owner:HANS LASER TECH IND GRP CO LTD

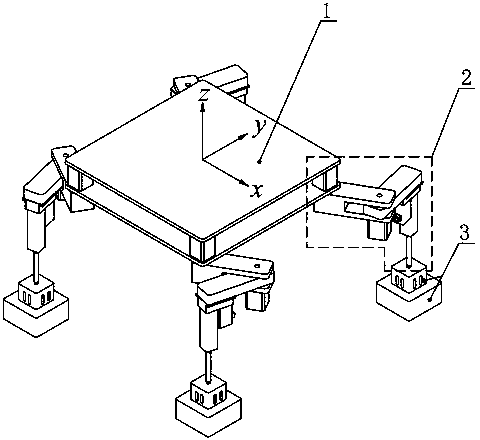

A foot-type magnetic adsorption wall climbing robot

The invention belongs to the field of wall-climbing robots, in particular to a foot-type magnetic adsorption wall-climbing robot, which is composed of a carrying platform, a walking leg and an adsorption foot. Various actuators can be mounted on the carrier platform to perform various operations on the iron-based wall surface. Each walking leg comprises a two-degree-of-freedom series mechanism, aservo-electric cylinder and a ball hinge, wherein the end of each walking leg is connected and absorbed sufficiently. The suction foot adopts a screw nut mechanism to adjust the height of the permanent magnet and the wall surface so that the suction force can be adjusted. Robots can be thought of as combinations of 4-RRR Planar mechanisms and elevating mehcanisms. the movement of the two mechanisms is controlled to realize the omni-directional movement of the platform in the space. Robot can move straight, turn and adjust posture flexibly on the different curvature of the wall. The invention solves the shortcomings of unreliable adsorption and inflexible steering of the conventional magnetic adsorption wall climbing robot, and has the advantages of simple structure, strong load capacity, good obstacle-crossing ability, flexible movement and reliable adsorption.

Owner:SOUTHWEST PETROLEUM UNIV

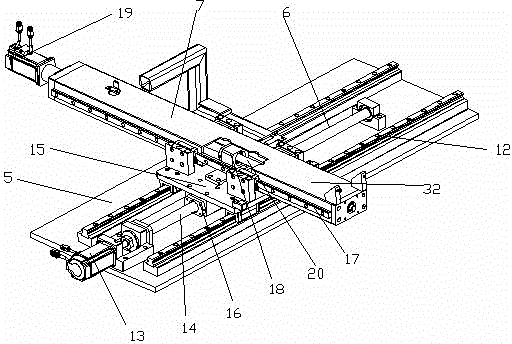

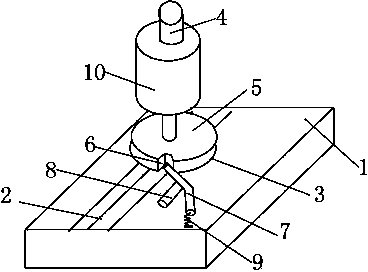

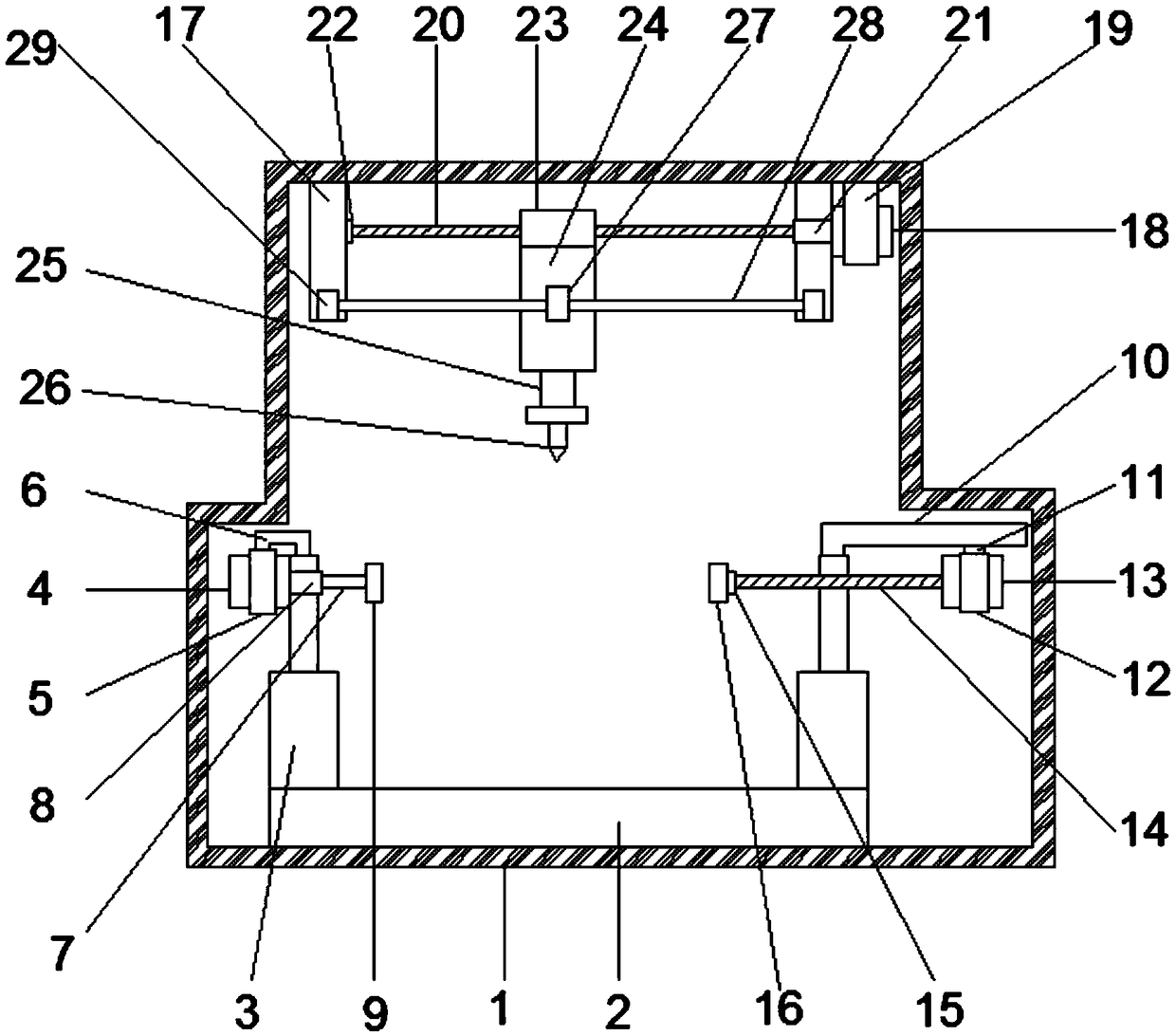

Container top reinforced plate automatic welding device with three dimensional weld recognition

ActiveCN104858575AAccurate detectionQuick checkWelding/cutting auxillary devicesAuxillary welding devicesEngineeringContainer tops

The invention discloses a container top reinforced plate automatic welding device with three dimensional weld recognition, which comprises an installation chassis, wherein an operation box and an X shaft walking mechanism are respectively mounted on the installation chassis; a Y shaft walking mechanism is mounted on the X shaft walking mechanism; a Z shaft walking mechanism is mounted on the Y shaft walking mechanism; an R shaft rotation mechanism and a laser displacement sensor are mounted on the Z shaft walking mechanism; a straight shank welding gun is mounted on the R shaft rotation mechanism; and the operation box is respectively connected to the X shaft walking mechanism, the Y shaft walking mechanism, the Z shaft walking mechanism, the R shaft rotation mechanism and the laser displacement sensor through wires, so that the welding trace is detected more accurately and faster.

Owner:绍兴汉立工业自动化科技有限公司

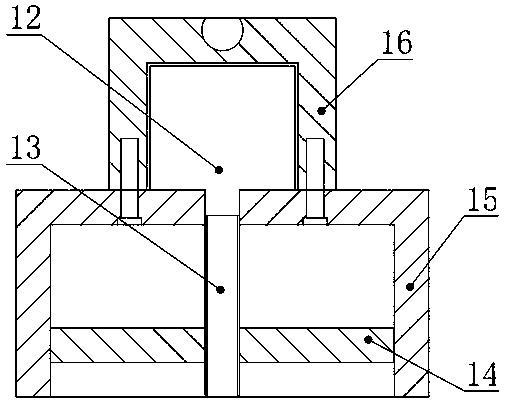

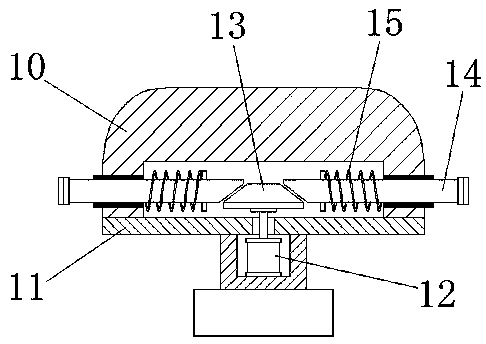

Device and method of laser impact welding in warm state

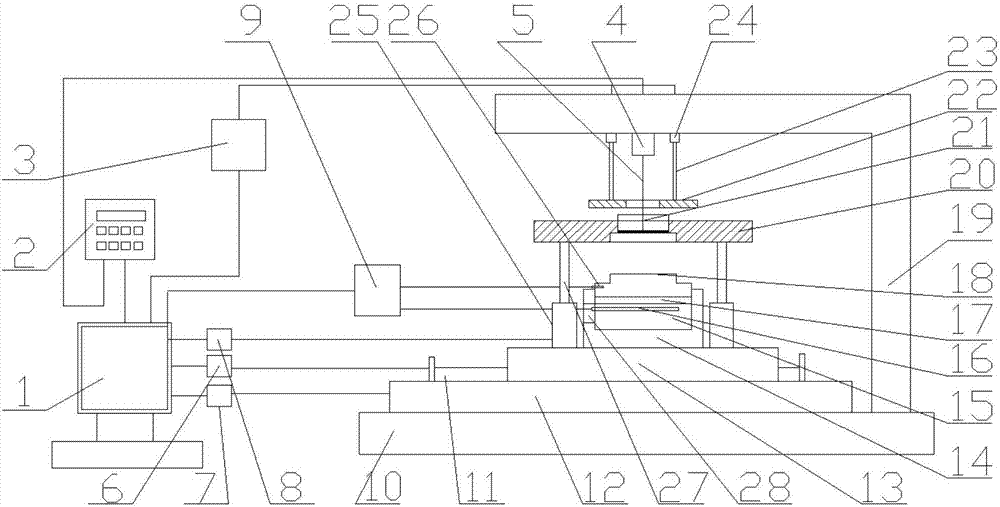

InactiveCN107252975AFor precise clampingGuarantee welding qualityWelding/cutting auxillary devicesAuxillary welding devicesControl systemEngineering

The invention discloses a device and method of laser impact welding in a warm state. The device comprises a laser emitting system, a control system and a workpiece warm welding operation system. The workpiece warm welding operation system comprises a workpiece warm device, a base plate pressing device and a workpiece pressing device. Before-welding preheating of a workpiece is achieved through the workpiece warm device, the plasticity of the to-be-welded workpiece is improved, and the welding performance of the workpiece is improved; by means of the base plate pressing device and the workpiece pressing device, the precise clamping of the workpiece in the warm state is achieved. The device is high in precision and automation degree and wire in application range, and warm welding of various different materials can be conducted.

Owner:JIANGSU UNIV

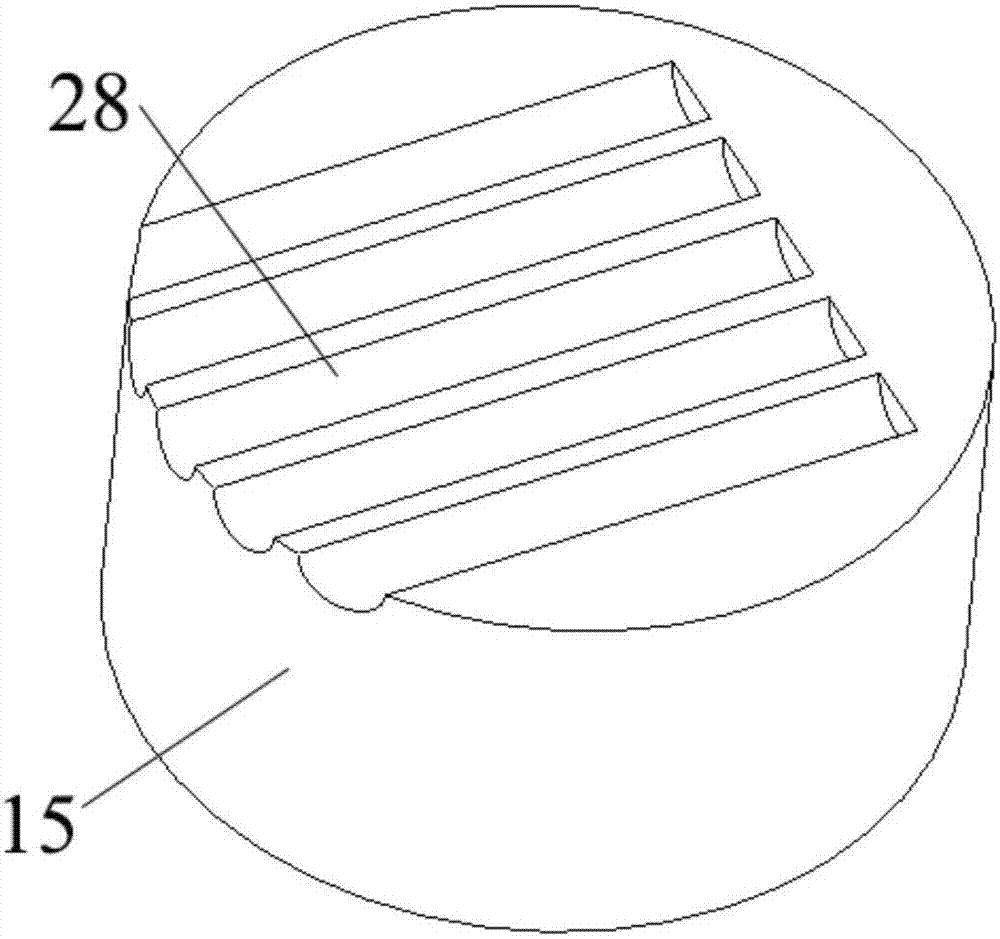

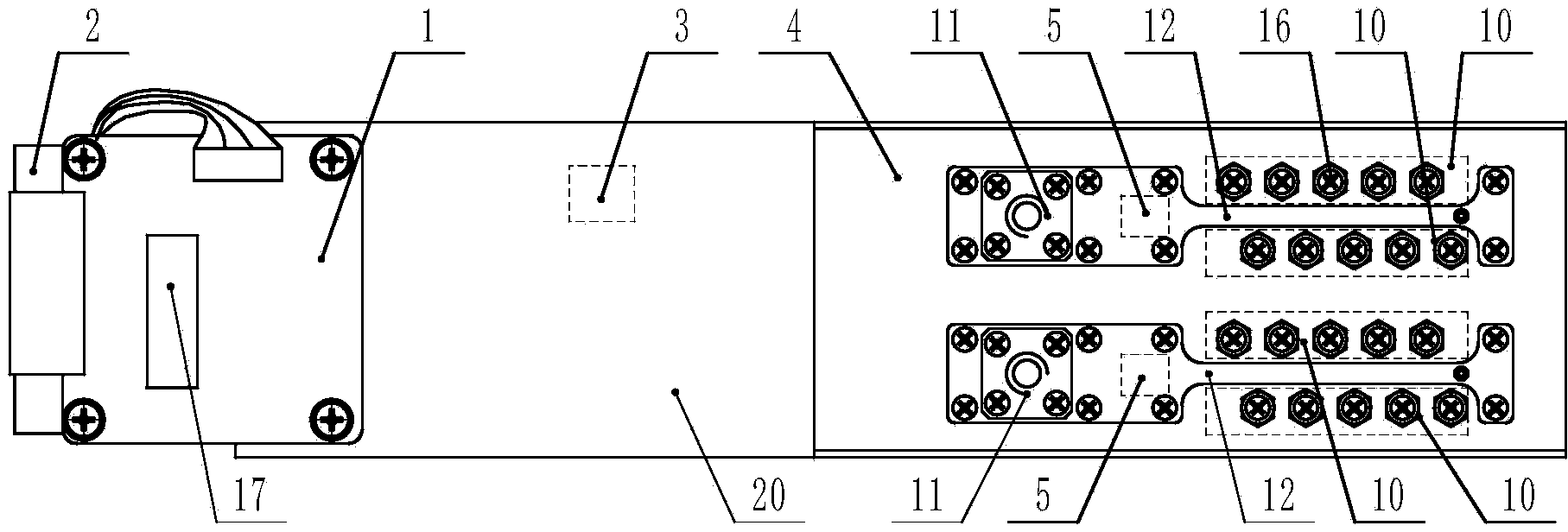

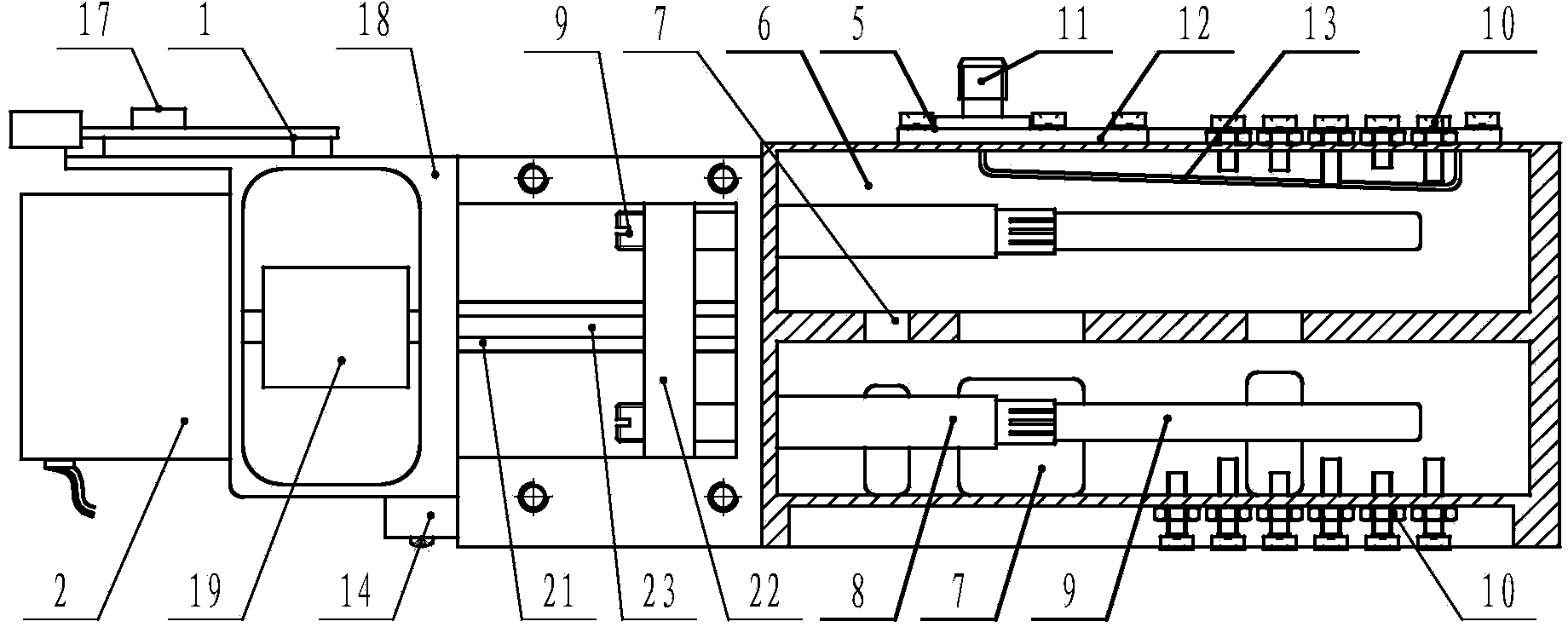

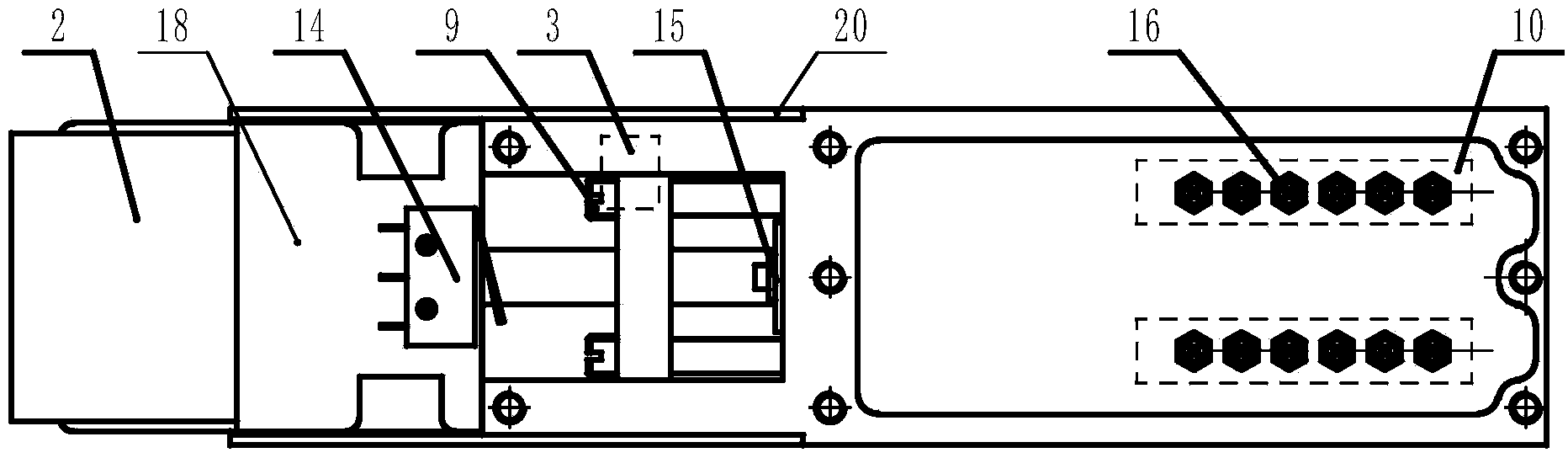

Broad tuning coaxial electrically tunable filter and debugging method thereof

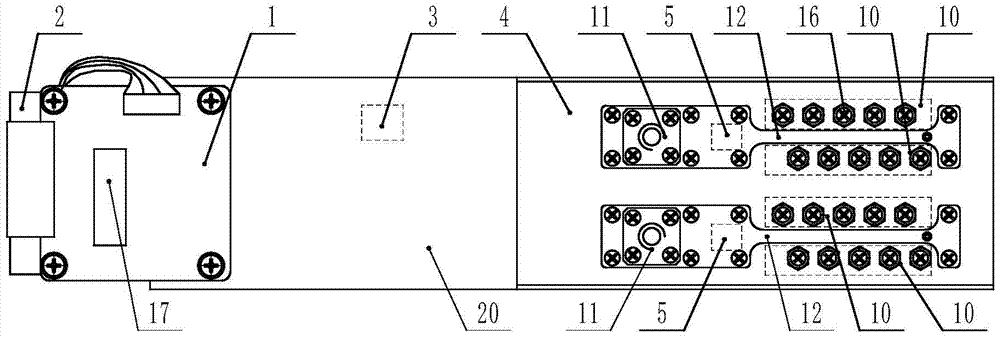

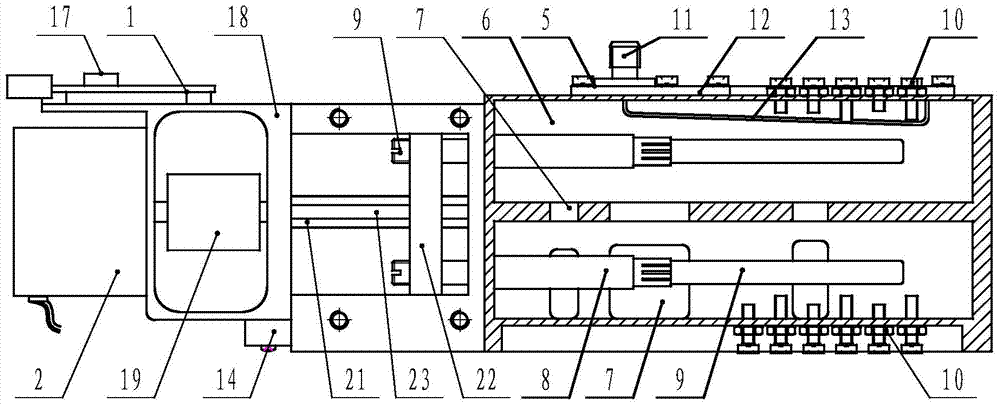

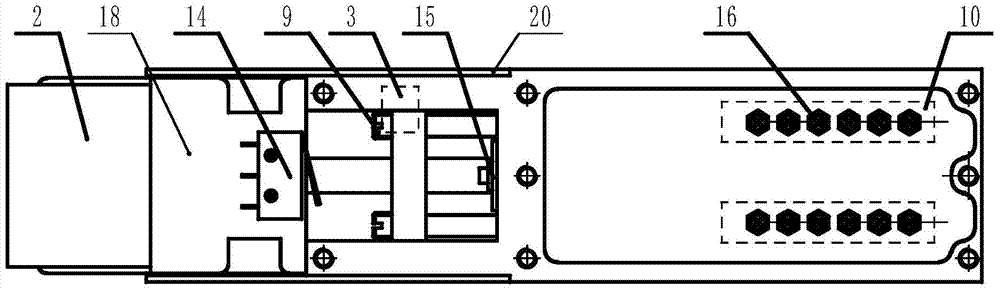

ActiveCN104393383AHigh frequencyConstant bandwidthWaveguide type devicesResonant cavityFrequency compensation

The invention discloses a broad tuning coaxial electrically tunable filter and a debugging method thereof, and relates to the technical field of microwave communication. The electrically tunable filter comprises a driving circuit, a stepping motor, a transmission mechanism and a filter part, wherein the filter part is provided with two coupling seats, a plurality of resonant cavities and a plurality of intercavity coupling structures; the coupling seats are fixedly equipped with trapezoidal coupling loops; adjustable frequency compensation devices are arranged on outer conductors of the resonant cavities; the intercavity coupling structures are metal plates with two or more circular holes or polygonal holes. The debugging method can allow the electrically tunable filter to reach a tuning range above an octave and have constant band width, stable amplitude frequency and echoing characteristics, improves product debugging efficiency and lowers manufacture and debugging costs.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

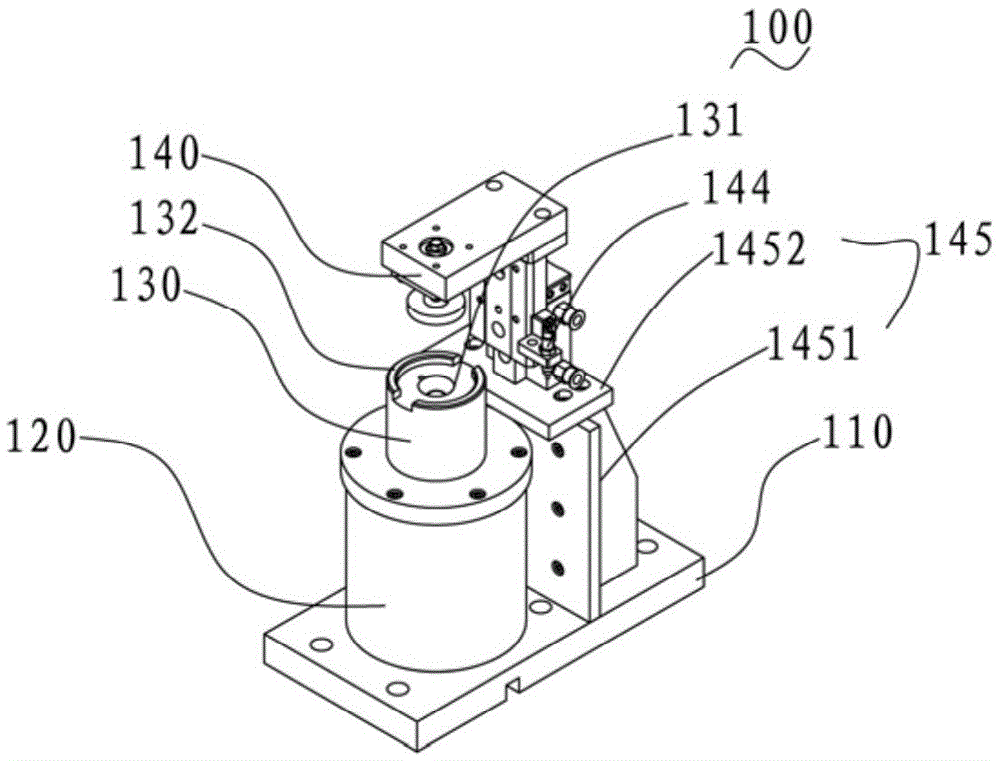

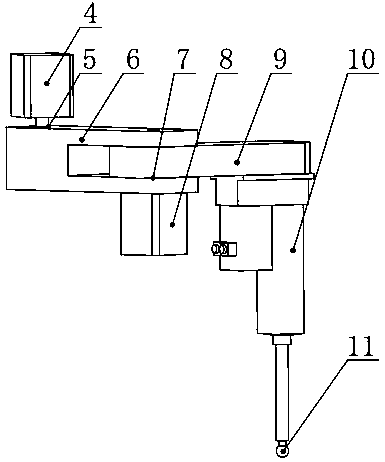

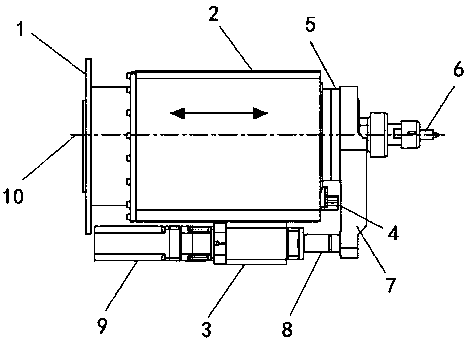

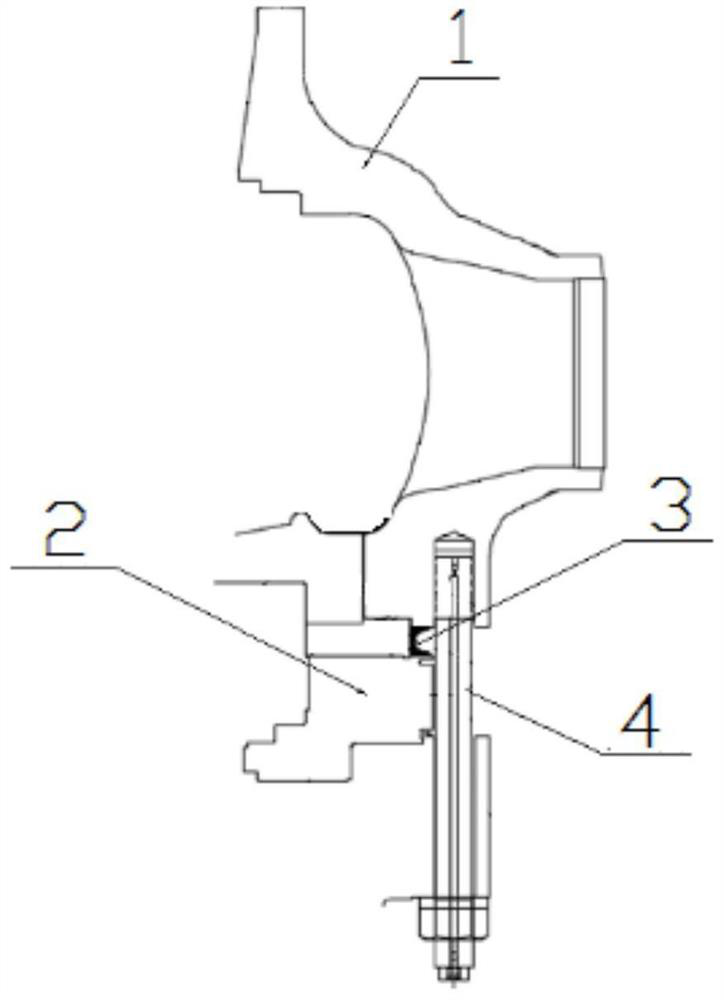

Friction-stir welding device

InactiveCN108526679AFlexible weldingRealize Displacement Compensation ControlNon-electric welding apparatusElectricityThird party

The invention provides a friction-stir welding device. The friction-stir welding device comprises a flange base, a main machine box, a ball screw pair, a guide rail sliding block, an electric spindle,a stirring tool, a limiting plate, a constant pressure sensor and an A-axis driving servo motor. The flange base is used for connecting third-party equipment. The main machine box and the ball screwpair are connected with the flange base. The guide rail sliding block and the electric spindle are arranged on the main machine box. The stirring tool is connected to the electric spindle in a boltingmanner. The limiting plate and the constant pressure sensor keep the static state relative to the electric spindle. The A-axis driving servo motor is connected with the ball screw pair. The guide rail sliding block serves as a sliding support for the electric spindle along the A axis. The constant pressure sensor is used for acquiring the real-time pressure feedback numerical value when a shaft shoulder end face of the stirring tool makes contact with the surface of a part to be welded. The A-axis driving servo motor receives the real-time pressure feedback numerical value and controls the A-axis press-in regulating quantity of the stirring tool according to the real-time pressure feedback numerical value. The friction-stir welding device is easy and convenient to operate, can achieve welding of more types of light alloy more flexibly in a wider range, and is stable in operation and convenient to move.

Owner:JIANGSU ASWEMET PRECISION TECH CO LTD

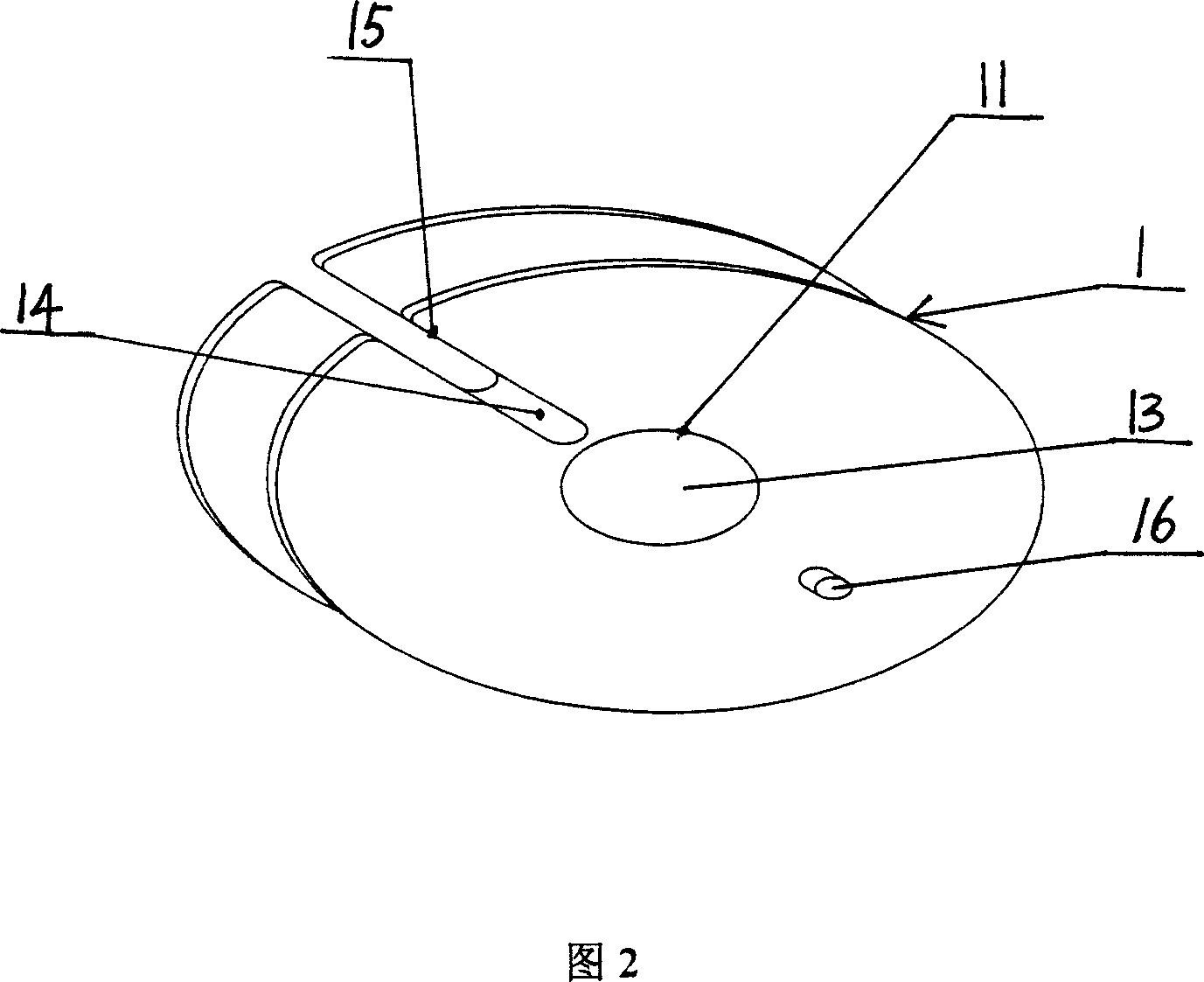

Small non-pin transformer structure

InactiveCN1933052ASave effective spaceSimplifies wiring requirementsTransformers/inductances coils/windings/connectionsTransformers/inductances magnetic coresBobbinTransformer

A small non-pin transformer structure, includes the magnetic core, the skeleton, the winding wire material, the skeleton consists of the bobbin and two ring-type end-face, the axis hole sets in the bobbin, the two ring-type end-face set on both side of the bobbin and form the bobbin slot; the magnetic core sets in the axis hole, and the wire material rolls in the bobbin slot, each end head of the rolling group wire material educes directly to be the connecting pin. The invention can not only be serried lay with other former piece when using to the module power weld, but also use the longer pin to process jump, save the efficient space, predigests the request of making line.

Owner:MORNSUN GUANGZHOU SCI & TECH

Welding positioning clamp

ActiveCN105945490AFlexible moving processFlexible weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSupport plane

The invention discloses a welding positioning clamp, and relates to the technical field of welding tools. The welding positioning clamp comprises a pair of first supporting frames which are fixedly arranged on the ground, and a fixing clamp body which is arranged between the first supporting frames. The first supporting frames are provided with motors used for driving the fixing clamp body to rotate. The fixing clamp body comprises baffles installed on the first supporting frames. A base is installed between the baffles, and the base is provided with a plurality of longitudinal guide grooves capable of sliding. A plurality of pressing devices used for clamping workpieces are installed in the longitudinal guide grooves. The welding positioning clamp can move flexibly according to the size and structure of each workpiece, so that fixing and clamping work of each workpiece is completed. In addition, due to the fact that the supporting frames of the clamp are provided with the rotating motors, the fixing clamp body can be driven to turn over so that multi-angle welding can be achieved. The welding positioning clamp is simple in structure, flexible in fixation, high in applicability, and capable of improving work efficiency and lowering the defective rate in actual welding.

Owner:GUANGZHOU YUANSHENG AUTOMATION TECH CO LTD

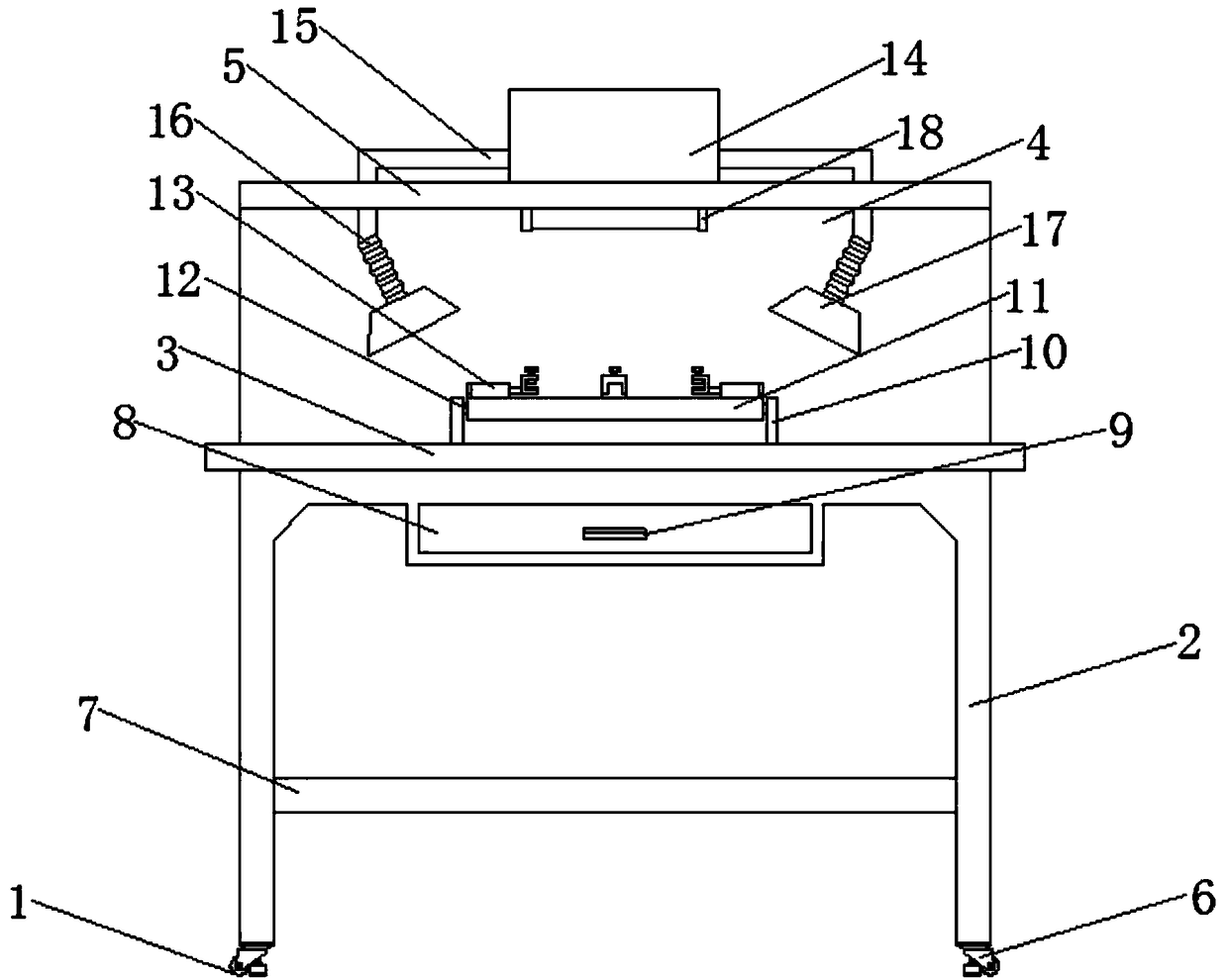

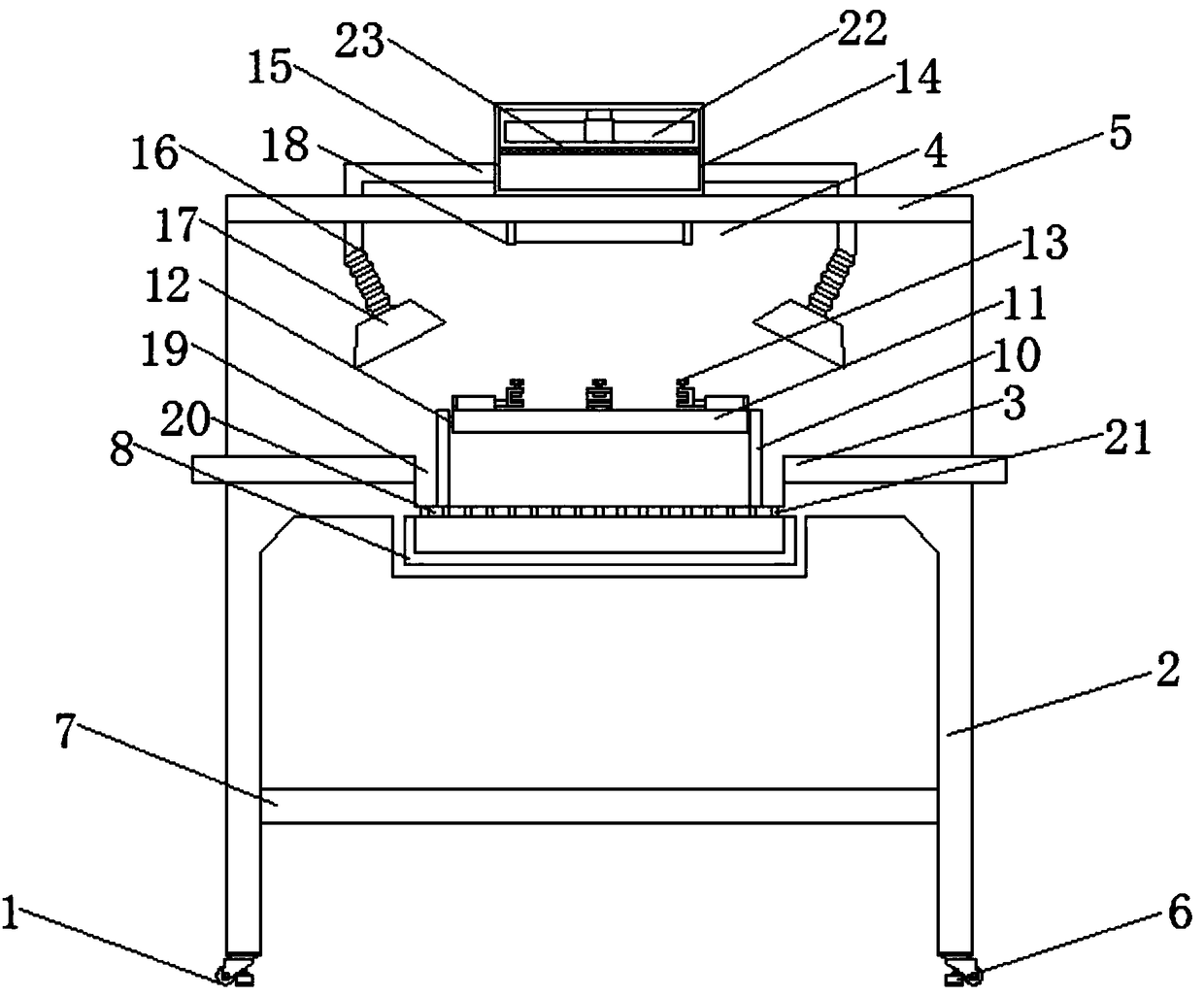

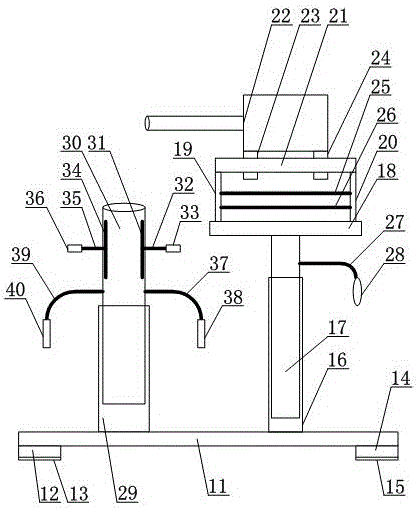

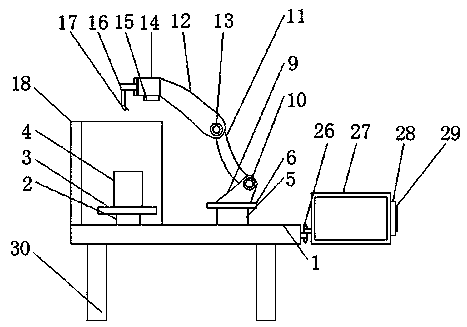

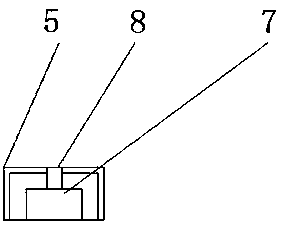

Welding workbench for electronic product machining

InactiveCN108608087AHigh strengthImprove practicalityDirt cleaningSoldering auxillary devicesEngineeringWorkbench

The invention discloses a welding workbench for electronic product machining. A table frame is arranged at the bottom of a workbench body; a table surface is installed at the top of the table frame; agroove is formed in the middle part of the table surface; a bottom plate is arranged at the bottom end of the groove; support plates are installed at the two ends of each of the two sides of the topof the bottom plate; a rotary shaft is installed at the top end of each support plate; a welding plate is installed at one end of each rotary shaft; a fixer is installed around the top of each weldingplate; a tin collection drawer is installed at the bottom of the bottom plate; a vertical plate is installed on the back surface of the table surface; a top plate is installed at the top of the vertical plate; a smoke extraction box is installed at the top of the top plate; a smoke extraction machine is installed at the top end in the smoke extraction box; smoke extraction pipes are installed atthe bottom ends of the two sides of the smoke extraction box; a universal telescopic pipe is fixedly connected to the bottom end of each smoke extraction pipe; a smoke absorption cover is installed atthe bottom of each universal telescopic pipe; an illumination lamp is installed on the bottom surface of the top plate; and castors are installed at the bottom of the table frame. According to the welding workbench for electronic product machining, a filter screen is installed at the bottom of the smoke extraction machine, so that filtering for the smoke generated due to welding is facilitated; and the welding workbench for electronic product machining is simple and practical, and secondary pollution is avoided.

Owner:芜湖通全电子电器科技创业有限公司

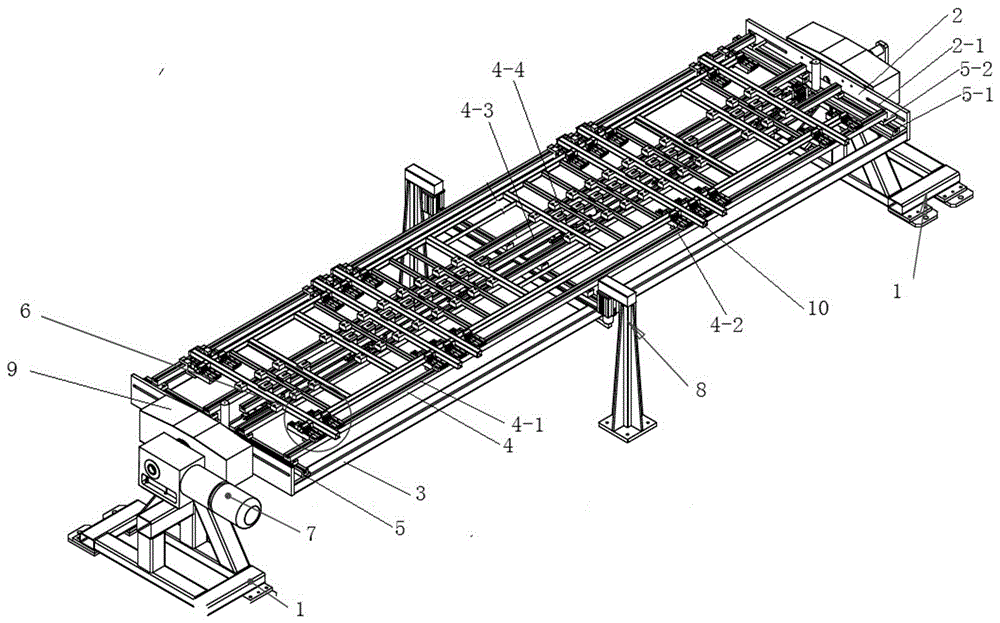

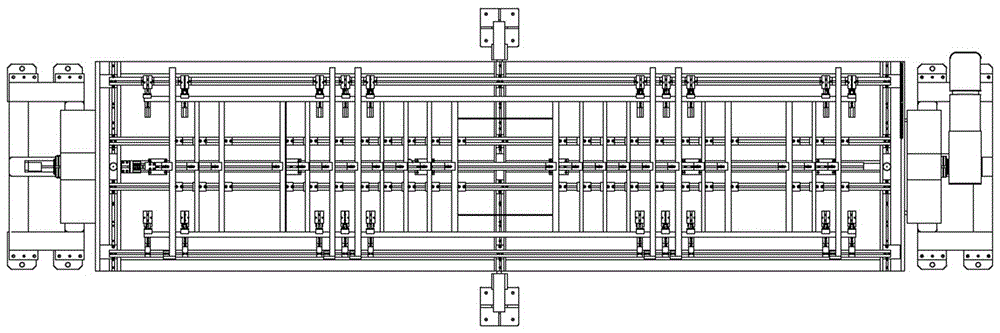

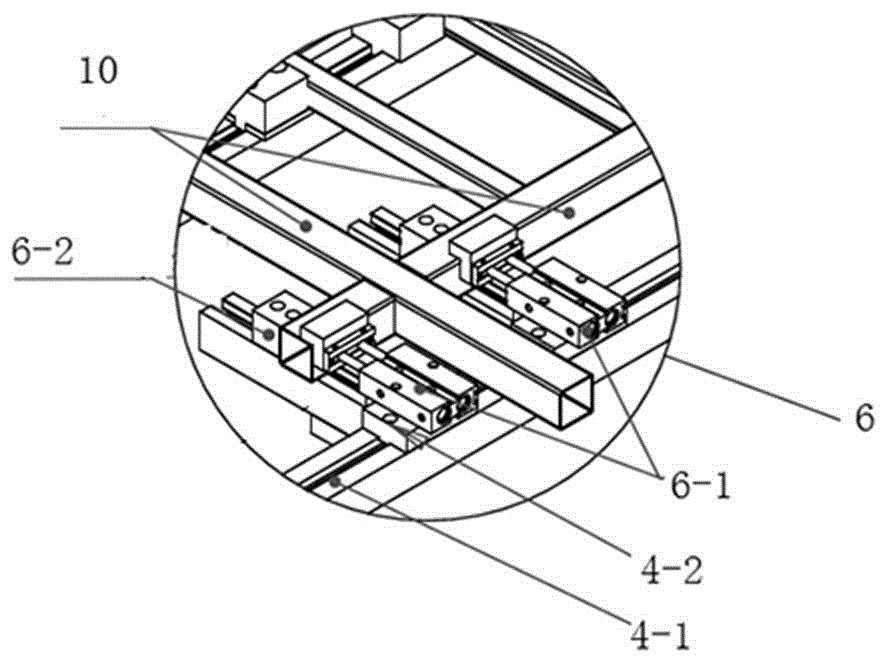

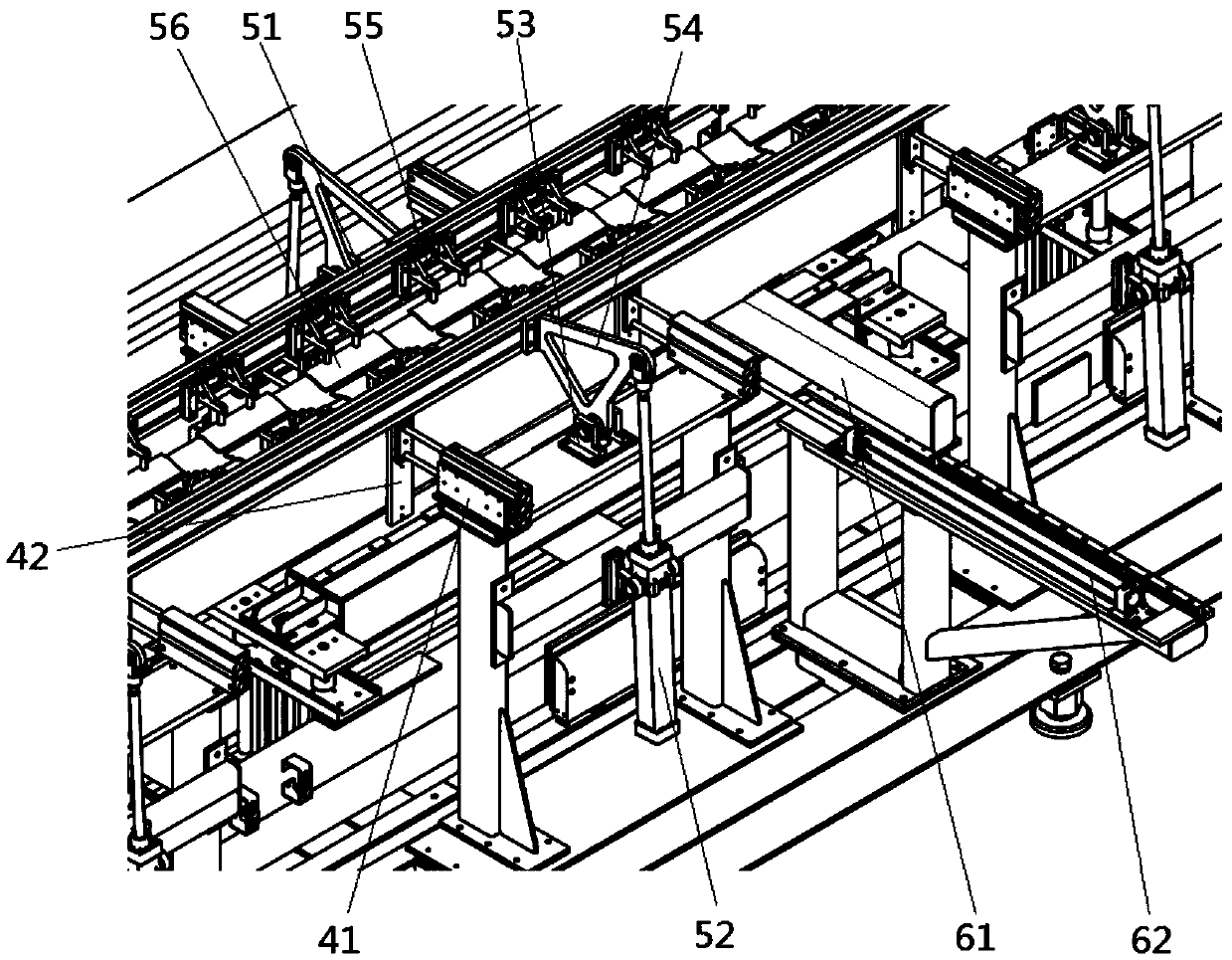

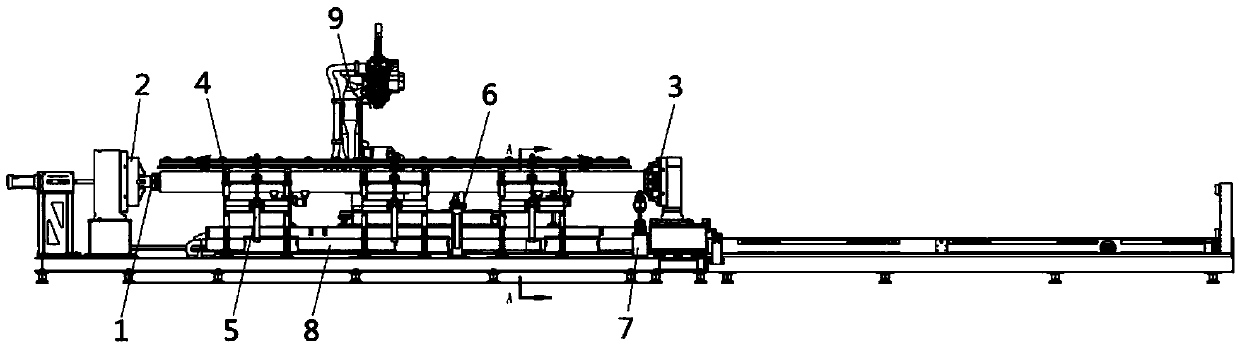

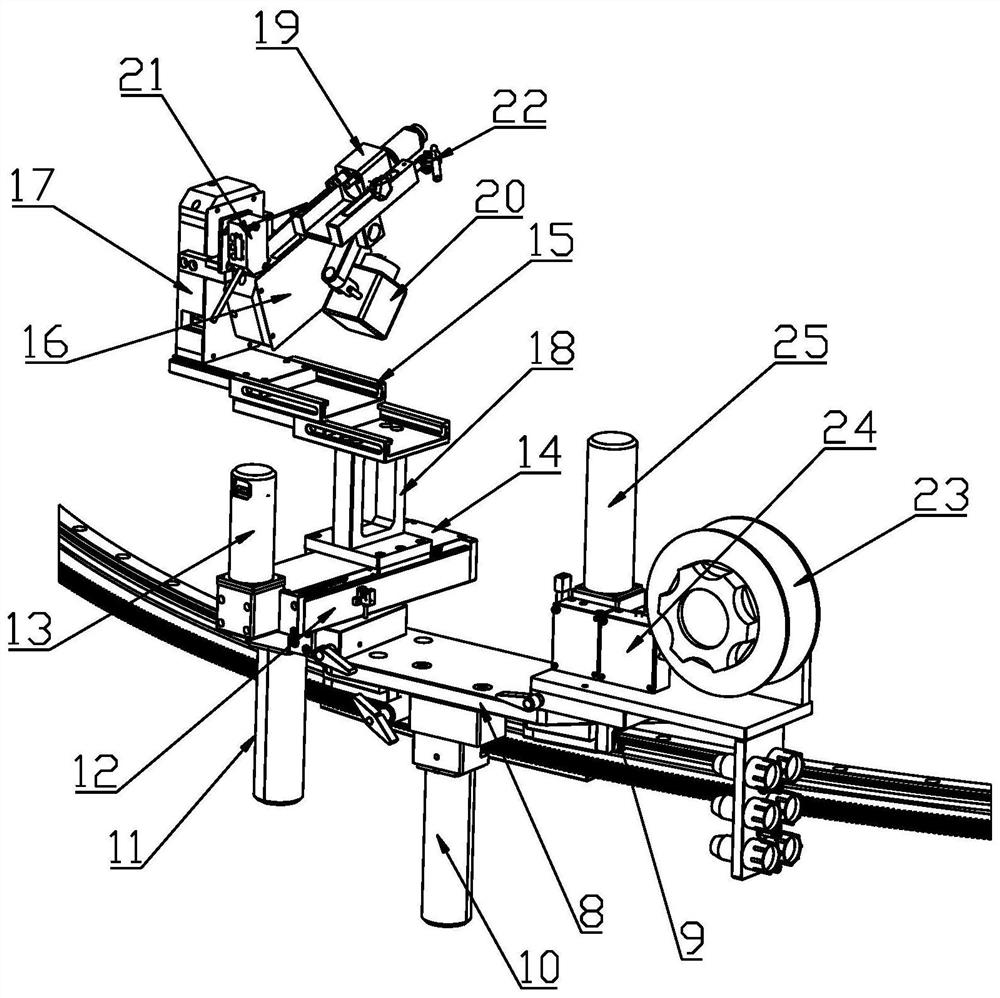

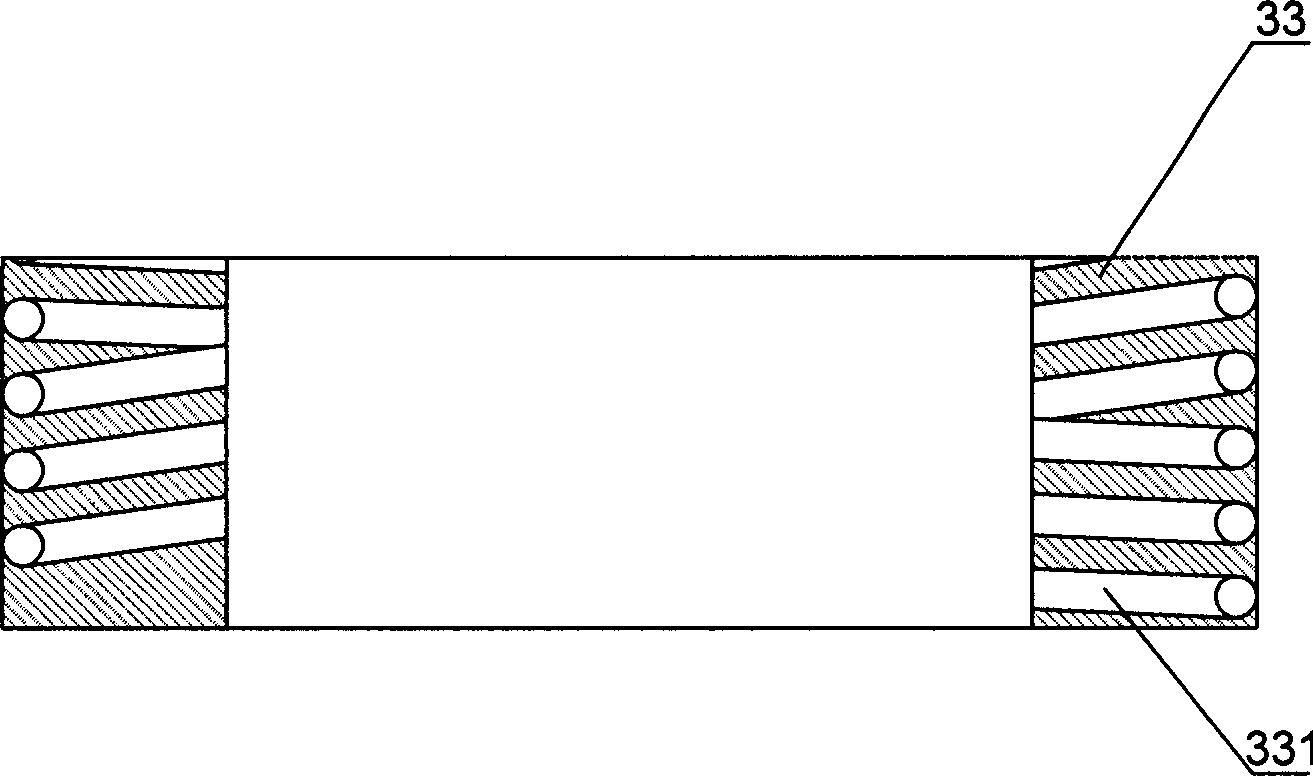

Welding equipment for single-end-face square pipe

InactiveCN109676249AImprove welding qualityFlexible weldingLaser beam welding apparatusEngineeringMechanical engineering

The invention discloses welding equipment for a single-end-face square pipe. The welding equipment for the single-end-face square pipe comprises a welding robot, a fixed clamping disk mechanism, a movable clamping disk mechanism, a transverse pressing mechanism, a vertical pressing mechanism, a supporting transverse beam mechanism, a vertical supporting mechanism, an internal-supporting fixture and a workpiece moving mechanism. The workpiece moving mechanism is divided into two segments of a welding segment and a feeding-and-blanking segment. The welding robot is arranged in a manner that thewelding robot is close to the welding segment. The fixed clamping disk mechanism is fixed to one end of the workpiece moving mechanism. The movable clamping disk mechanism is arranged in a middle position of the workpiece moving mechanism. The transverse pressing mechanism and the vertical pressing mechanism are arranged on the two sides of the workpiece moving mechanism. The internal-supporting fixture is arranged between the fixed clamping disk mechanism and the movable clamping disk mechanism. The supporting transverse beam mechanism is arranged in a manner that the supporting transverse beam mechanism is corresponding to a middle position of the internal-supporting fixture. The vertical supporting mechanism is arranged in a position close to the movable clamping disk mechanism. Throughthe above-mentioned arrangement, square pipes with longer length can be welded by the welding equipment for the single-end-face square pipe, deficiencies of staggered edges and lack of weld do not occur in the welding process, and the welding quality is high.

Owner:SHANGHAI PURUIMA INTELLIGENT TECH CO LTD

Welding device for bent part of street lamp post head

InactiveCN105921902AStable supportConvenient horizontal rotation adjustmentWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention discloses a welding device for a bent part of a street lamp post head. The welding device comprises a bottom plate provided with a first guiding pipe. A first cyclophon is sleeved with the first guiding pipe. A fixing plate is arranged at the end portion of the first cyclophon. Side plates are arranged on the fixing plate. A guiding pipe is arranged between the end portions of the side plates and provided with a welding machine. The bottom plate is provided with a second guiding pipe. A second cyclophon is sleeved with the second guiding pipe. A lock piece is arranged on the inner side of the end portion of the second cyclophon. A lock rod is connected the end portion of the second cyclophon in an inserted manner and is in threaded connection with the second cyclophon. The outer end of the lock rod is a free end, and the inner end of the lock rod is connected with the lock piece. By means of the welding device, a street lamp post can be conveniently subjected to horizontal rotation and flexible adjustment, and the street lamp post head can be conveniently welded through the welding machine.

Owner:SUZHOU HONGYE LAMP EQUIP CO LTD

Core clamping device

ActiveCN109365755ALow costHigh versatilityFoundry mouldsFoundry coresEngineeringBiomedical engineering

Owner:KOCEL EQUIP

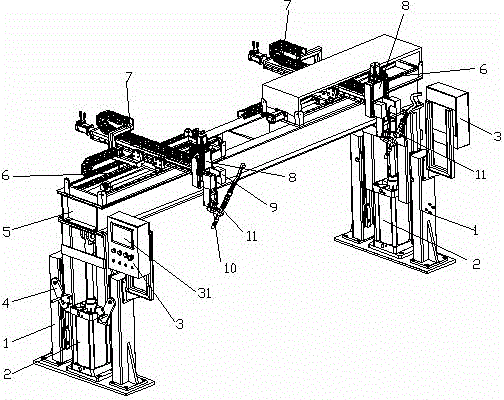

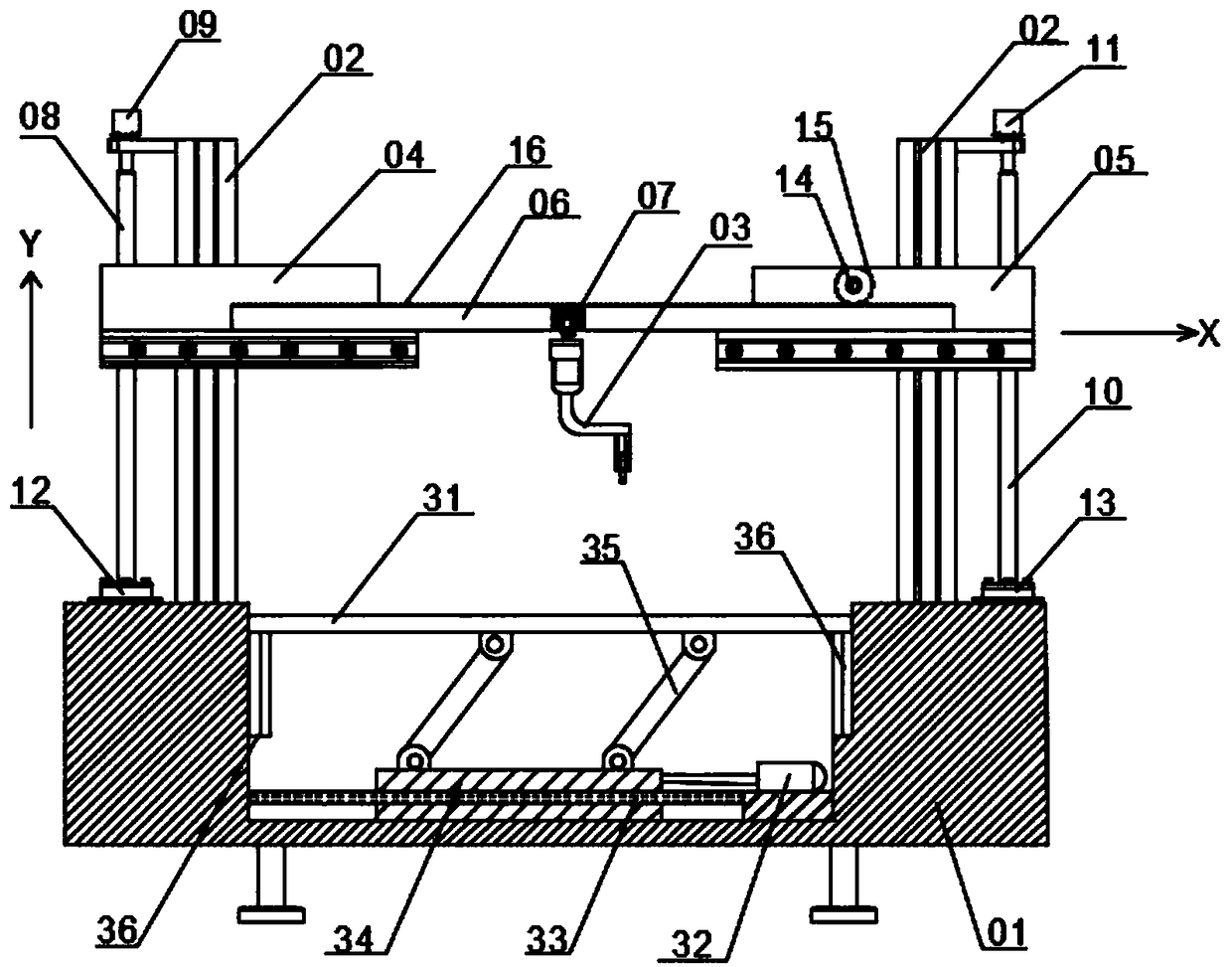

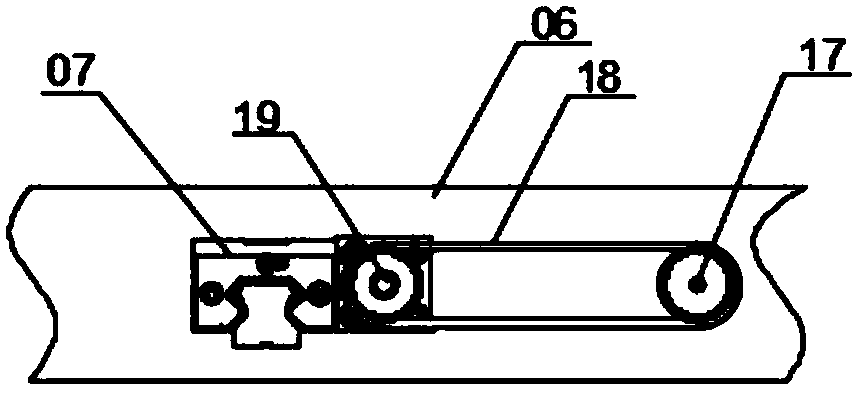

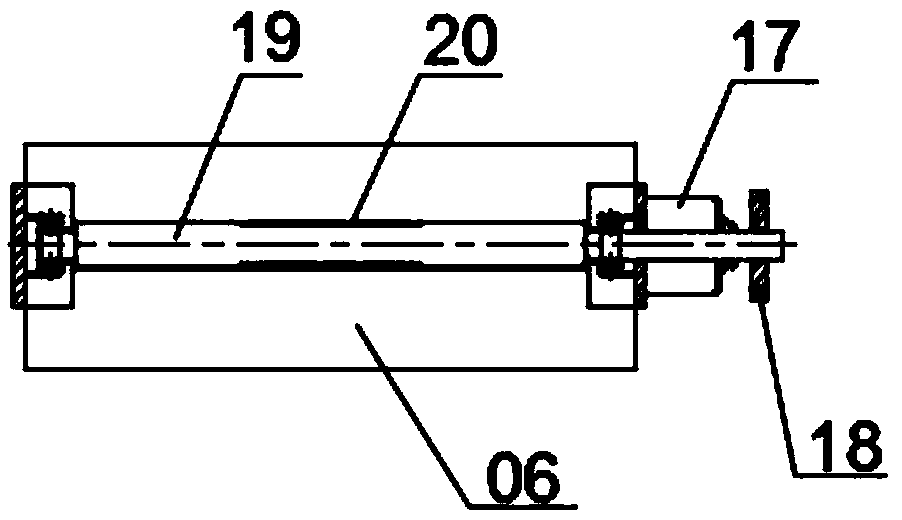

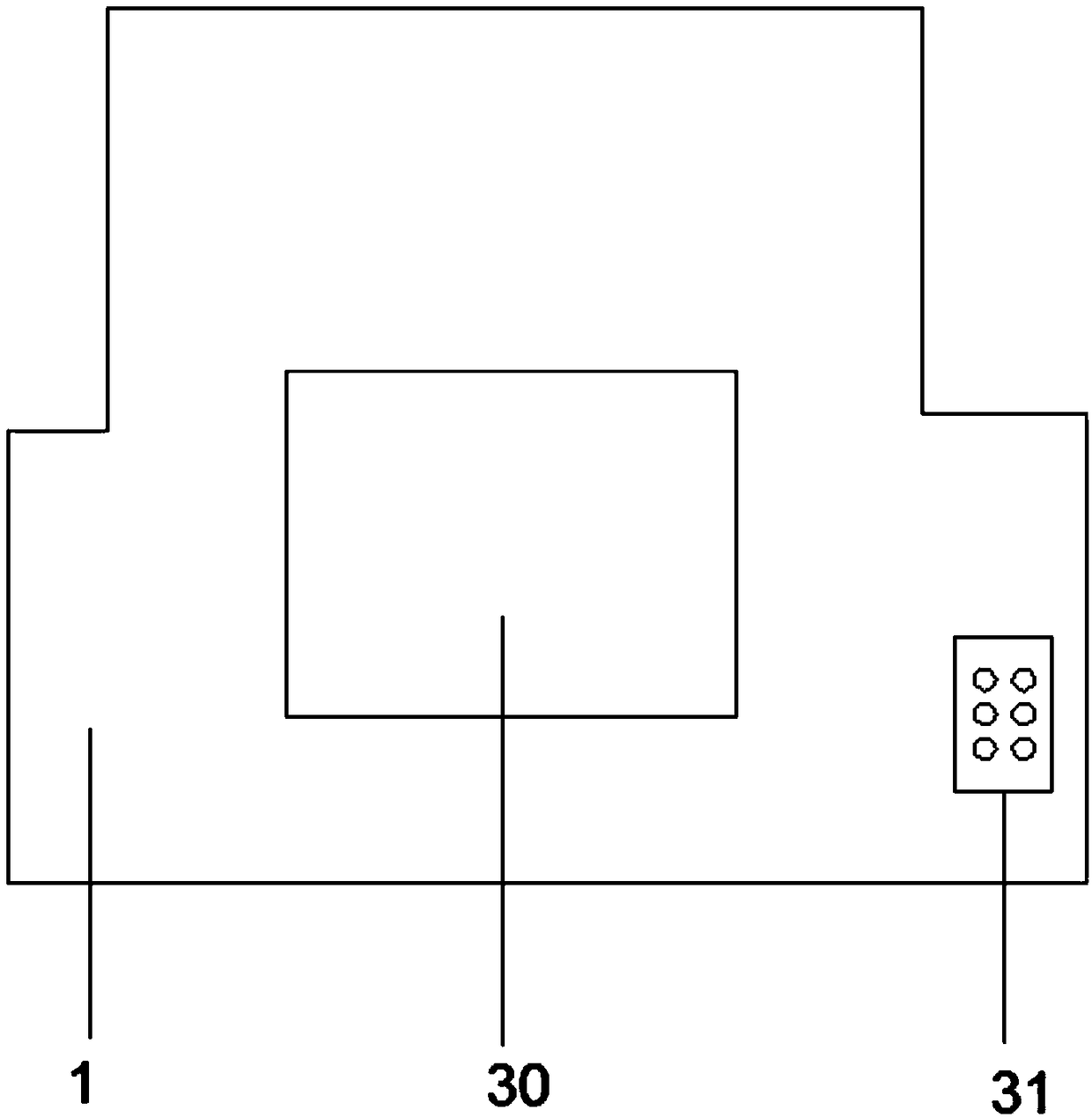

Automatic welding equipment capable of improving welding precision

InactiveCN108480870AHigh flexibilityFlexible continuous and repeated weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAutomation

The invention discloses automatic welding equipment capable of improving welding precision, and relates to the field of welding automation. The automatic welding equipment capable of improving the welding precision solves the defects that in the prior art, the welding precision requirements of sheet metal in precision devices cannot be ensured. The automatic welding equipment comprises a base, a gantry mechanism disposed on the base and a welding mechanism disposed on the gantry mechanism. The welding mechanism is separately driven by an X-axis traveling assembly, a Y-axis traveling assembly and a Z-axis traveling assembly which move in the X-axis direction, the Y-axis direction, and the Z-axis direction. The welding mechanism comprises a welding gun, an X-axis rotating assembly for driving the welding gun to rotate along the X-axis and a Y-axis rotating assembly for driving the welding gun to rotate along the Y-axis separately. The welding gun is provided with a laser tracking systemand a spectral confocal sensor, and the laser tracking system comprises a laser device and a monitoring lens. By implementing the technical scheme, different sheet metal can be flexibly welded, and the sheet metal in the precision device processing and production process can be accurately welded to ensure the welding precision requirements of the sheet metal in the precision devices.

Owner:CHENGDU RONGCHUANG ZHIGU SCI & TECH

Fixing mechanism for fan blade welding device

InactiveCN103846607AAccurate welding positionFlexible weldingWelding/cutting auxillary devicesAuxillary welding devicesWelding

The invention belongs to the technical field of fan appliances and particularly relates to a fixing mechanism for a fan blade welding device. The fixing mechanism comprises a pedestal, wherein a chute is formed in the middle of the pedestal, a platform is arranged on the pedestal, and a spring is connected to the other end of a clamping strip and is fixed on the platform; a fan positioning seat is arranged in the middle of an upright post and is fixed with a disc. According to the fixed mechanism, a fan engine can be well fixed and positioned, so that the welding position between the fan engine and blades is accurate, and a fan can be flexibly welded.

Owner:DEQING ZHENDA ELECTRIC

Welding and fixing device for fixing seat of axial flow fan

PendingCN111438468AReduce difficultyFlexible weldingWelding/cutting auxillary devicesAuxillary welding devicesClassical mechanicsStructural engineering

The invention discloses a welding and fixing device for a fixing seat of an axial flow fan. The welding and fixing device comprises a base, transverse rotating shafts, a swing driving mechanism, a rotating seat, a vertical rotating shaft, a rotary driving mechanism and a fixed head, the base is U-shaped and fixedly connected with the ground, two transverse rotating shafts are symmetrically arranged on the two sides of the upper end of the base through a bearing seat, the swing driving mechanism is arranged in the base, the output end of the swing driving mechanism is fixedly connected with oneof the transverse rotating shafts, the two ends of the rotating seat are correspondingly and fixedly connected with the inner ends of the transverse rotating shafts, the vertical rotating shaft is arranged at the top end of the rotating seat through the bearing seat, the rotary driving mechanism is arranged in the rotating seat, the output end of the rotary driving mechanism is fixedly connectedwith the vertical rotating shaft, the fixed head is used for fixing a fan blade fixing seat, and the fixed head is fixedly connected to the top end of the vertical rotating shaft. The welding and fixing device has the advantages of simple structure, wide applicability, good use effect and the like.

Owner:HUNAN XINHONGYUAN HI-TECH CO LTD

Electricity auxiliary heater and production method thereof

ActiveCN107249225AFlexible weldingImprove welding efficiencyImmersion heating arrangementsHeating element shapesWater storageLap joint

The invention provides an electricity auxiliary heater and a production method thereof. The electricity auxiliary heater comprises a water cavity for storing water and heat tubes which stretch into the water cavity and are used for heating water in the water cavity. The water cavity comprises a water cavity straight barrel, two water cavity transition connection rings and two water cavity seal heads. Two ends of the water cavity straight barrel are connected with the corresponding water cavity seal heads through the water cavity transition connection rings. The water cavity straight barrel is a cylindrical barrel body with a hollow cavity. The water cavity transition connection rings are equipped with first annular lug bosses. Two sides of the first annular lug bosses are equipped with first water cavity lap joint rings and second water cavity lap joint rings. The water cavity transition connection rings, the water cavity straight barrel and the water cavity seal heads are concentric. The electricity auxiliary heater and the production method have the beneficial effects that the seal heads and the straight barrel are concentric; a yield is high; and parts or components are mutually independent and do not restrict each other in a production process.

Owner:威海市远大电器制造有限公司

Flange positioning welding tool

InactiveCN109967957APrevent slidingFlexible weldingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringFlange

The invention discloses a flange positioning welding tool. The flange positioning welding tool comprises a tool body, gaskets, a stabilizing piece, a reinforcing rib, a supporting column, a telescopictable, a control plate, a telescopic air cylinder, a bearing table, a connecting pipe pressure head, a flange pressing claw, a rotary table, a flange circular truncated cone, a workbench, a rotary motor and a buffer pad, wherein the gaskets are arranged at the four corners of the bottom of the tool body, the top of the tool body is provided with the workbench, the top of the workbench is providedwith the stabilizing piece, the top of the stabilizing piece is provided with the supporting column, the top of the supporting column is provided with the telescopic air cylinder, one side of the telescopic air cylinder is provided with the telescopic table, one side of the telescopic table is provided with the control plate, the other side of the telescopic table is provided with the bearing table, the connecting pipe pressure head is arranged on one side of the bearing table, and the flange pressing claw is arranged at the lower part of the connecting pipe pressing head. The tool has the functions of fast positioning, flexible clamping and convenient regulation, thus improving the convenience of use.

Owner:QINGDAO BAIJIANCHENG ENVIRONMENTAL PROTECTION TECH CO LTD

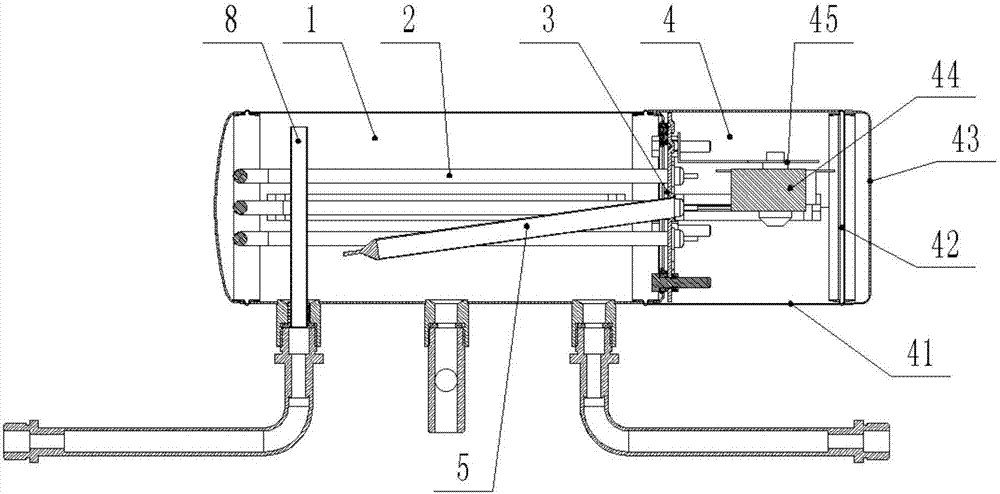

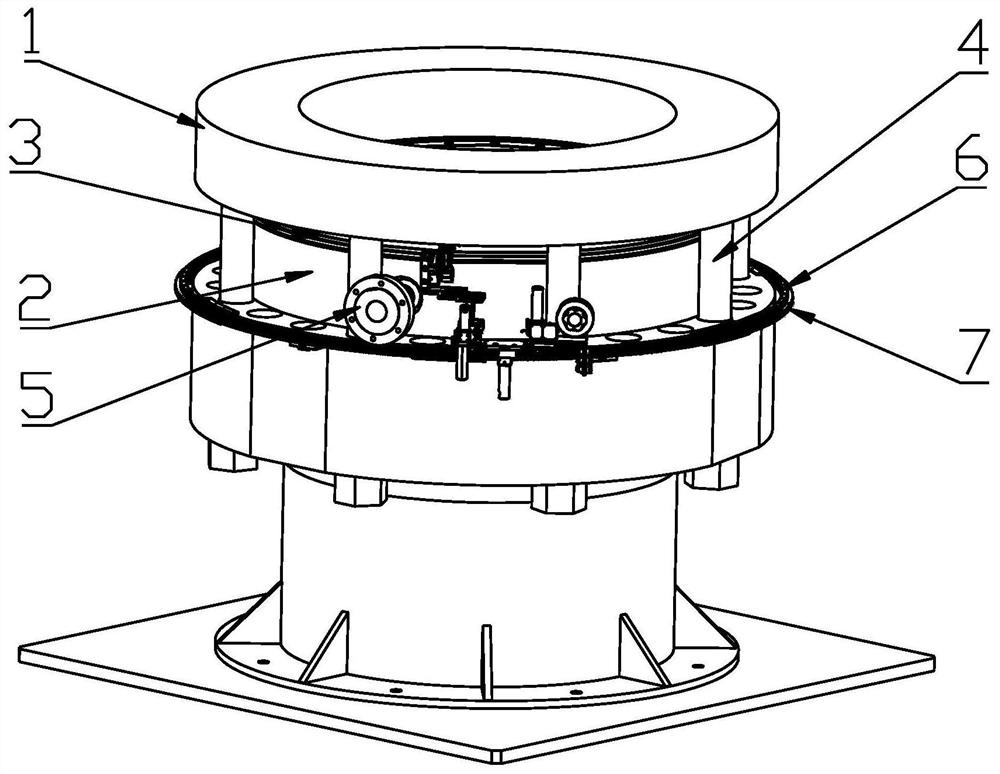

Automatic welding equipment and method for Canopy sealing ring of nuclear power shielding main pump

ActiveCN114101868AFlexible weldingReduce manual operationsNuclear energy generationElectrode supporting devicesControl systemEngineering

The invention relates to an automatic welding device and method for a nuclear power shielding main pump Canopy sealing ring, the automatic welding device comprises an annular guide rail, a movable seat plate, a welding device, a welding wire supply device, a walking driving mechanism and a control system, the annular guide rail is located below the Canopy sealing ring and is coaxial with the Canopy sealing ring, the movable seat plate is installed on the annular guide rail, and the movable seat plate is installed on the annular guide rail. The walking driving mechanism drives the movable seat plate to move along the annular guide rail, and the welding device and the welding wire supply device are installed on the movable seat plate. The welding device comprises a welding gun, a radial feeding mechanism for driving the welding gun to move in the radial direction of the annular guide rail, an angle adjusting mechanism for adjusting the elevation angle of the welding gun and a linear feeding mechanism for driving the welding gun to linearly move in the elevation angle direction of the welding gun. The welding wire supply device supplies welding wires to the welding gun. The control system controls actions of the walking driving mechanism, the radial feeding mechanism, the angle adjusting mechanism, the linear feeding mechanism and the welding wire supply device.

Owner:STATE NUCLEAR POWER PLANT SERVICE

Integrated workstation based on robot cutting, welding and carrying in pipe processing

ActiveCN103567677BImprove processing qualityImprove machining accuracyWelding/cutting auxillary devicesAuxillary welding devicesSmall footprintWorkstation

The invention discloses an integrated workstation based on robot cutting, welding and carrying in pipe processing. The integrated workstation comprises a headstock and tailstock position changer, a movable support, a welding robot, a cutting robot, a middle sliding rail and two side sliding rails, wherein the headstock and tailstock position changer comprises a headstock base and a tailstock base; a pipe workpiece is clamped between clamping and fixing devices on the headstock base and the tailstock base; a lifting driving device is installed on a sliding base of the movable support; a roller is installed on the lifting driving device and is tangent with the pipe workpiece; the welding robot and the cutting robot are slidably installed on the two side sliding rails on the two sides of the pipe workpiec respectively to finish carrying, cutting and welding operation and the like. The integrated workstation based on the robot cutting, welding and carrying in pipe processing is an integrated working system, can ensure good consistency in pipe processing, improves the processing quality and the processing precision of the whole pipe workpiece, and is simple in structure, less in equipment and small in occupied area.

Owner:NANJING PANDA ELECTRONICS +1

Wafer press welding and bonding method and structure thereof

ActiveCN100517623CWon't breakIncreasing the thicknessSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorBonding process

A three-dimensional interconnection method between wafers comprises the following steps that: firstly, two semiconductor wafers are bonded face to face, secondly the back of one of two semiconductor wafers is thinned to complete the three-dimensional interconnection between the wafers, thirdly the backs of the semiconductor wafers which complete interconnection are bonded spoon-fashion, thinned, and interconnected and the bonding spoon-fashion-thinning-interconnecting technique is repeated; the surfaces of a plurality of semiconductor wafers are overlaid in order. The invention also provides a three-dimensional interconnection structure between the wafers; the surfaces of two semiconductors are bonded face to face; a second connecting welding block is formed on a back underlay of one of the semiconductor wafers; a plurality of semiconductor wafers in order are overlaid on the semiconductor wafer underlay with the second connecting welding block. The method of the invention can not cause the damage to the wafer in a bonding process; a formed semiconductor wafer bonding structure can save the chip area of the semiconductor wafer.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Metal door welding device

InactiveCN108620732AFlexible weldingFlexible moving processLaser beam welding apparatusControl engineeringLaser

The invention discloses a metal door welding device. The metal door welding device comprises a base. A lifter is arranged on the right side of the upper end of the base. A connecting platform is fixedly connected with the top of the lifter. A fixed platform is connected with the upper end of the connecting platform through a bearing. Stationary fixtures are fixedly connected with the front side and the rear side of the fixed platform respectively. The stationary fixtures are in thread connection with screws. A control cabinet is arranged on the left side of the upper end of the base. A motor is fixedly connected with the upper end of the control cabinet. An output shaft of the motor is fixedly connected with a rotary plate. A mechanical arm is fixedly connected with the upper end of the rotary plate. A laser welding head is arranged at the tail end of the mechanical arm. The height of the fixed platform is controlled by the lifter, and when the height of the fixed platform is lowered to the maximum extent, more labor is saved in the process of placing a door body to be processed in. The door body is tightly clamped by the structures between the stationary fixtures and the screws. The metal door welding device is reasonable in design, and applicable to promotion and production for application.

Owner:天津市龙甲门业有限公司

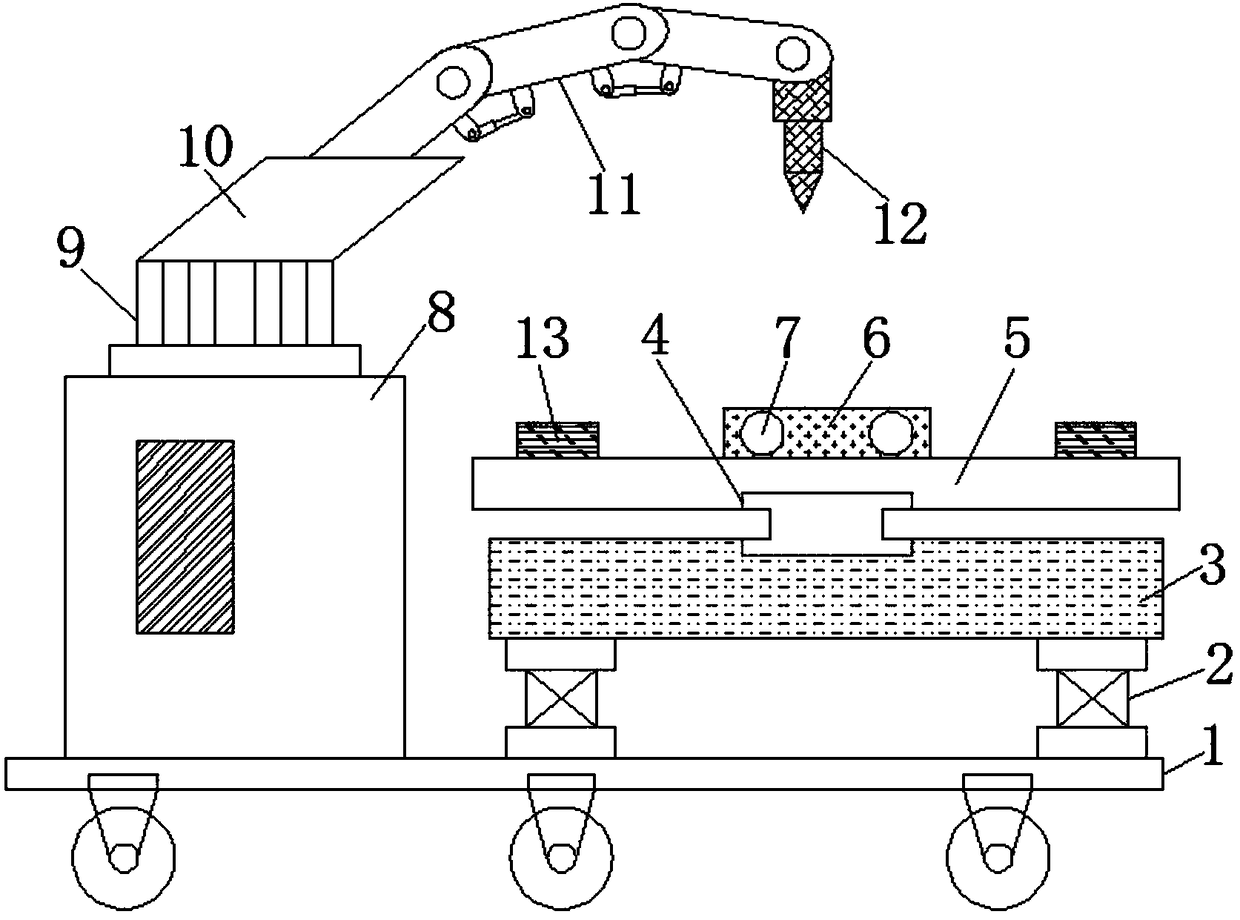

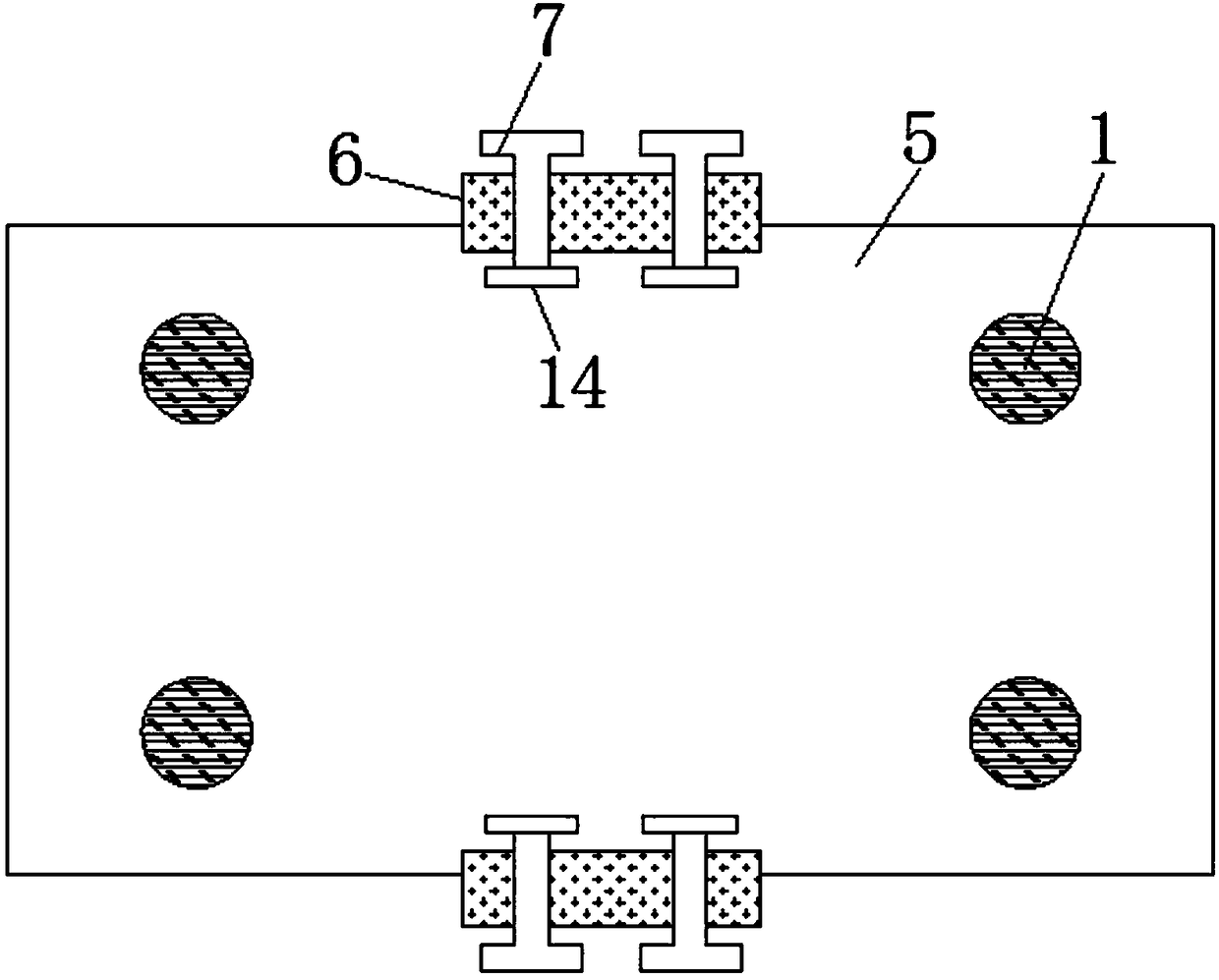

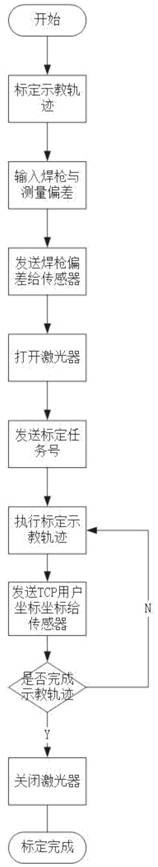

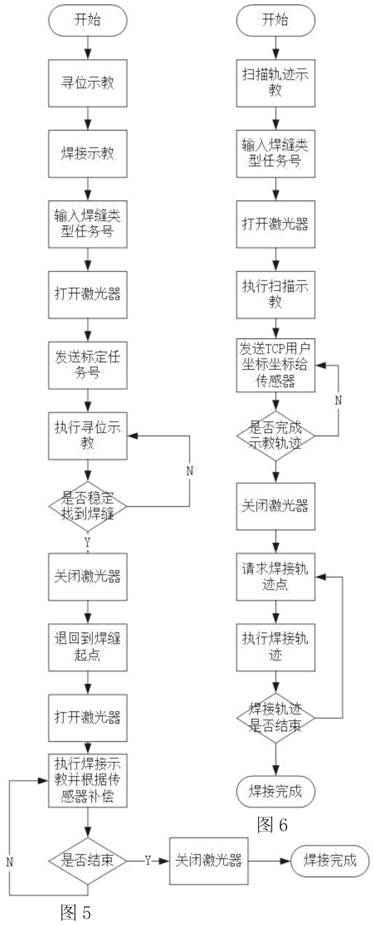

Auxiliary welding device of crawling welding robot, control method and welding method of auxiliary welding device

ActiveCN113199175ASolve the load problemSolve the problem of not being able to carry peripheral devicesProgramme-controlled manipulatorWelding/cutting auxillary devicesCrankEngineering

The invention relates to an auxiliary welding device of a crawling welding robot, a control method and a welding method of the auxiliary welding device. The welding device comprises a crank arm type lifting mechanism assembly for controlling an operation room to flexibly move to the surface and the periphery of any operation position of a large component, the crawling welding robot is arranged in the operation room, and whole machine electric control equipment and peripheral equipment are arranged in the operation room; and the crank arm type lifting mechanism assembly comprises a combined general control operation table and a crank arm lifting mechanism which are arranged on a carrying tool. The crank arm lifting mechanism is rigidly connected with the tail end operation room by adopting a three-section hydraulic folding type working arm; the crank arm lifting mechanism comprises a welding operation arm pivoted to the combined general control operation table through a first pivot and a first crank arm pivoted to the end of one end of the welding operation arm through a second pivot; and each crank arm is driven by a cylinder.

Owner:SHENZHEN CIMC SECURITY & SMART TECH

A wide-tuning coaxial electric tuning filter and its debugging method

ActiveCN104393383BHigh frequencyConstant bandwidthWaveguide type devicesResonant cavityFilter tuning

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

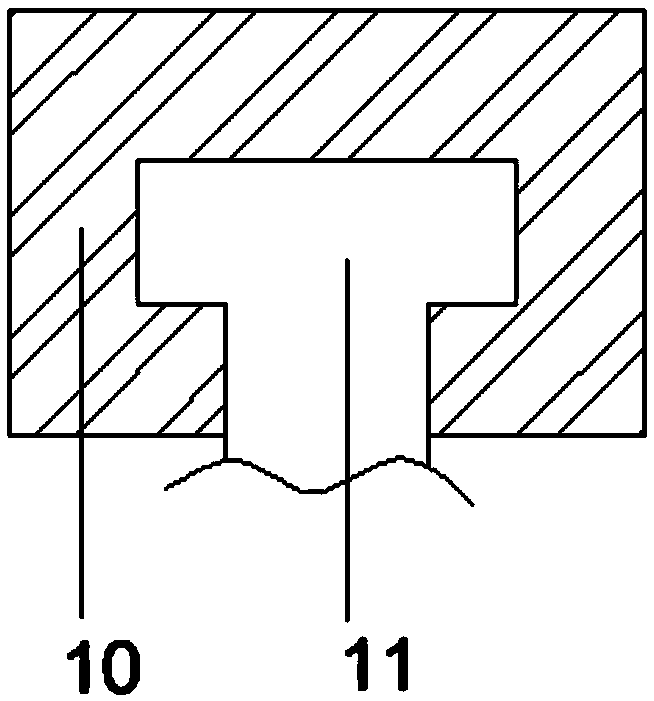

Power distribution cabinet body welding equipment

InactiveCN109014679AAchieve fixationReduce manual laborWelding/cutting auxillary devicesAuxillary welding devicesArchitectural engineeringWelding

The invention discloses power distribution cabinet body welding equipment which comprises a shell, hydraulic telescopic assemblies, a first fixed part, a second lead screw and a welding gun. A base isarranged at the bottom end in the shell, and the hydraulic telescopic assemblies are symmetrically arranged on the left side and the right side of the upper end of the base. A first motor is arrangedat the upper end of the left side of the hydraulic telescopic assembly on the left side, and a rotary shaft is arranged in the middle of the right side of the first motor. The right end of the rotaryshaft penetrates the hydraulic telescopic assemblies, and the first fixed part is arranged at the right end of the rotary shaft. According to the power distribution cabinet body welding equipment, asecond motor can drive the first lead screw to rotate, the rotating first lead screw controls a second fixed part to move left and right in cooperation with a threaded hole, a T-shaped sliding grooveand a T-shaped sliding block, and therefore power distribution cabinets of various sizes are fixed. The first motor can drive the rotary shaft to rotate, and therefore the first fixed part is driven to rotate, and the power distribution cabinets are turned over in cooperation with a first sleeve. Then manual labor is saved, and the work efficiency is improved.

Owner:ANHUI JINMA ELECTRIC TECH CO LTD

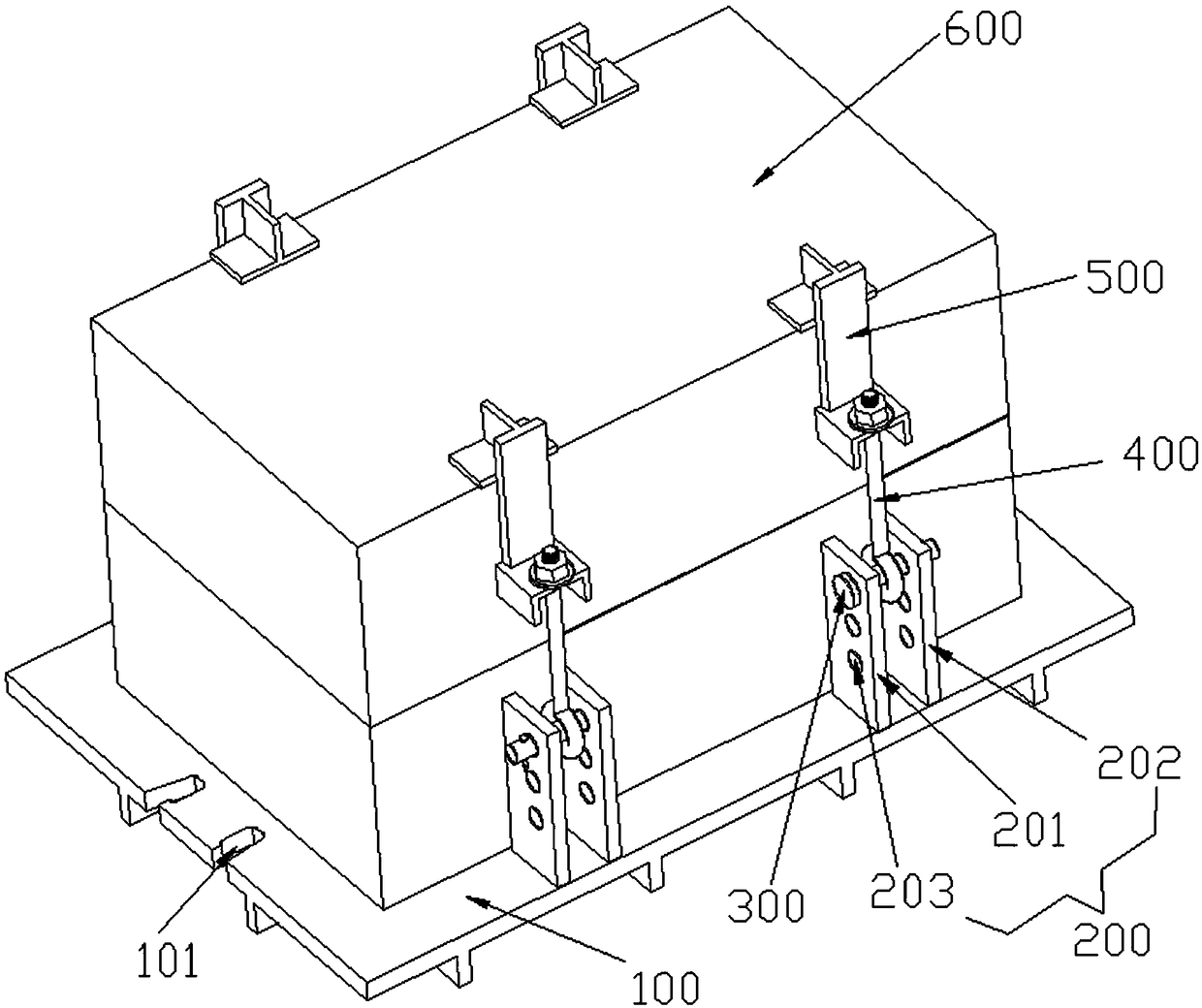

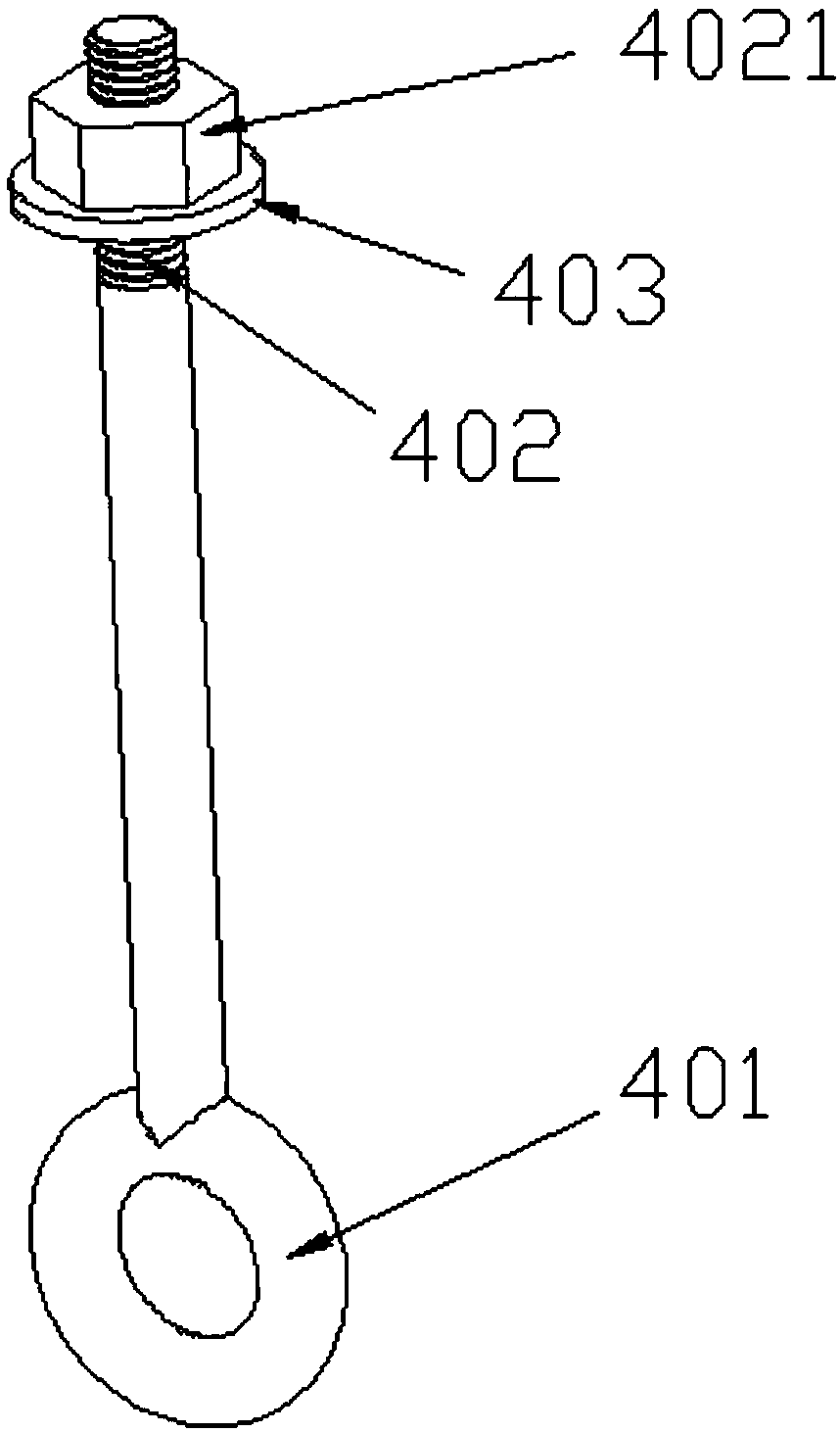

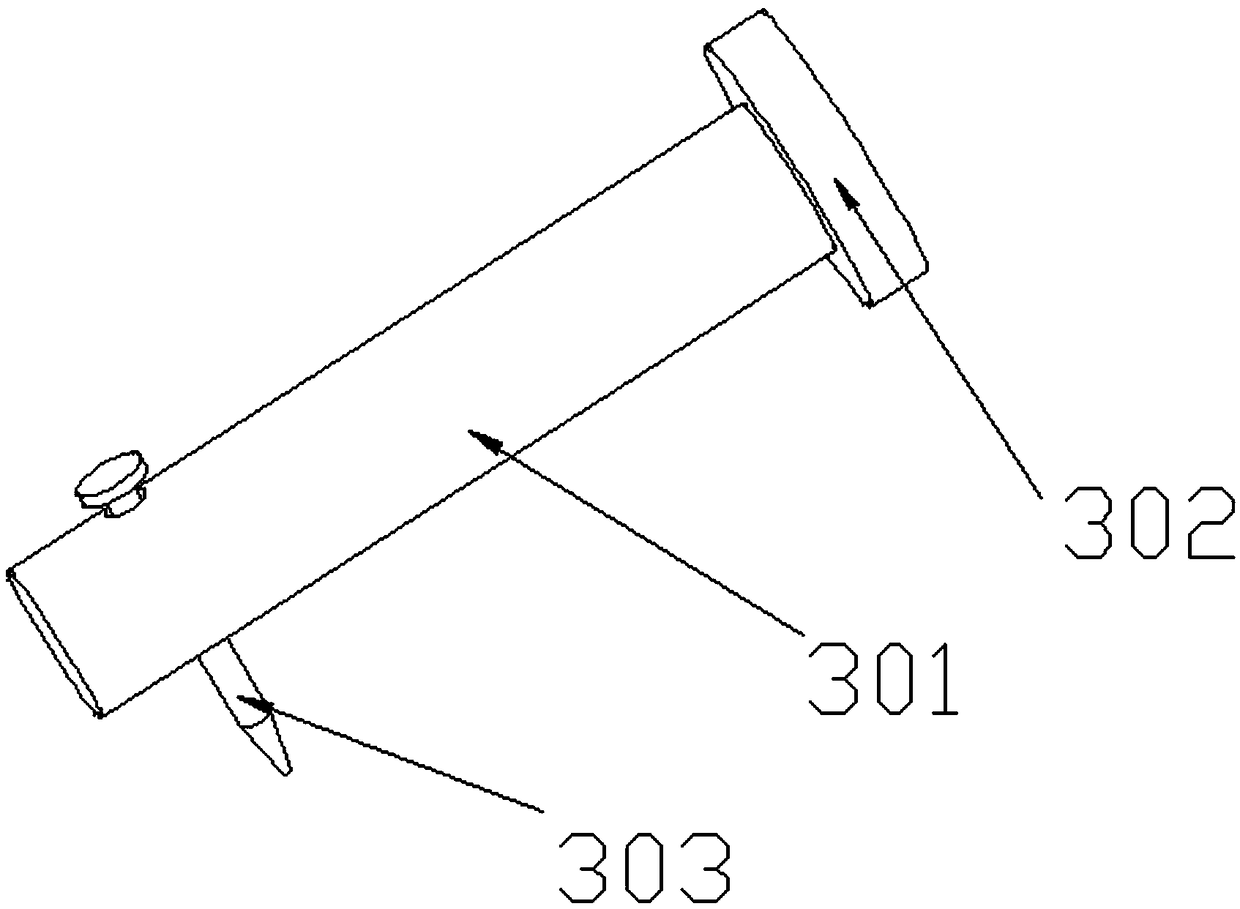

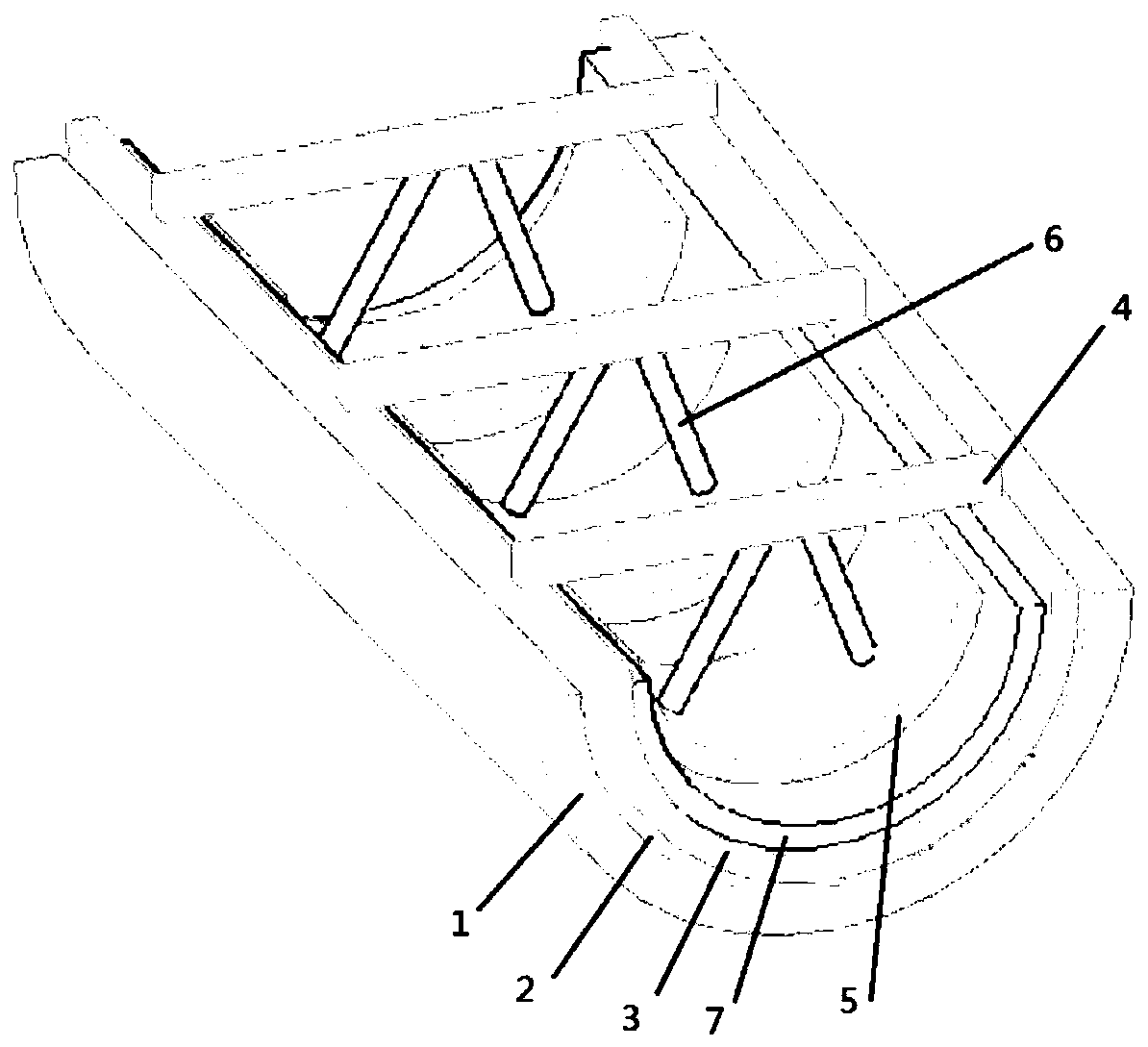

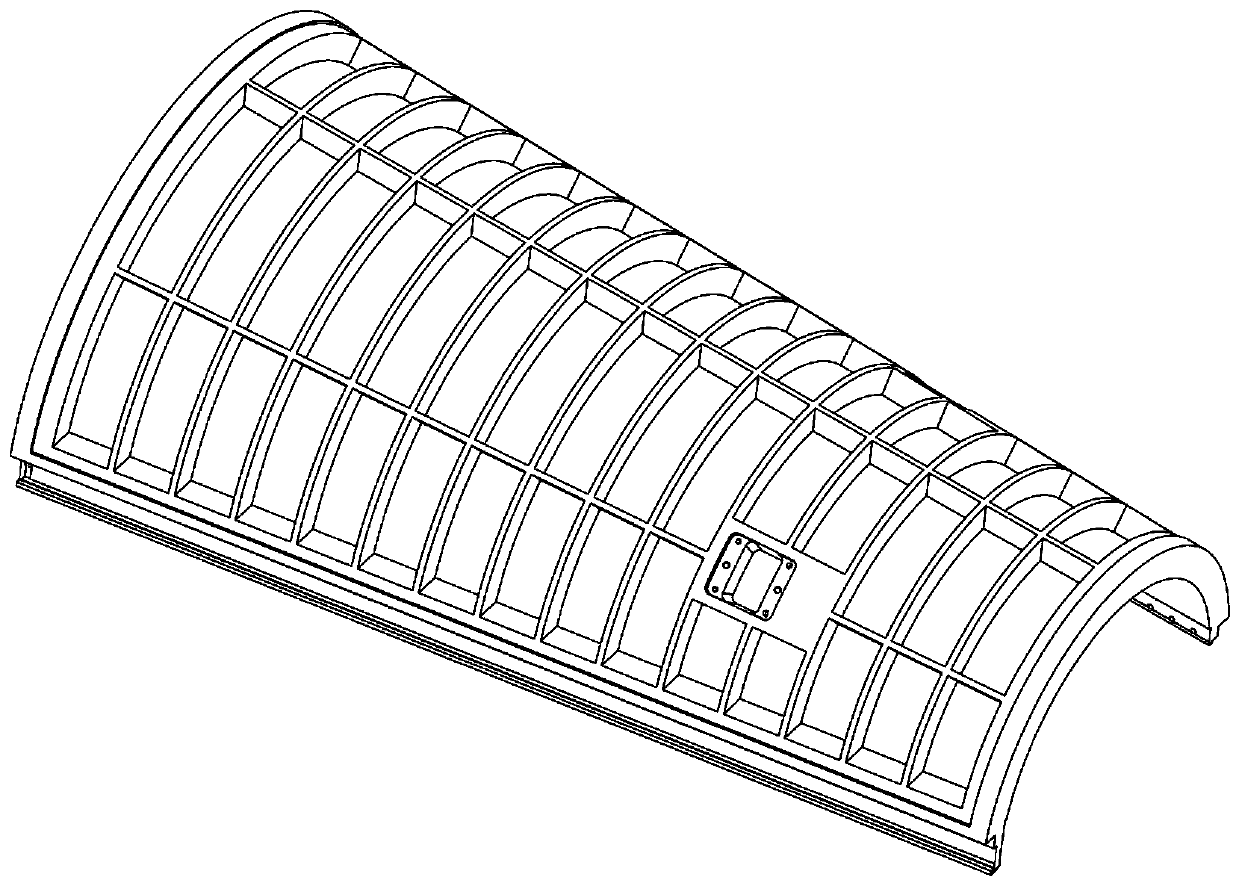

Welding fixture and method of brazing large-scale aluminum alloy curved skin and ribbed skeleton structure

ActiveCN110899896ASmall sizeThe shape is not limitedWelding/cutting auxillary devicesAuxillary welding devicesFiller metalHeat treating

The invention relates to a welding fixture and a method for brazing a large-size aluminum alloy curved skin and a ribbed skeleton structure. The purpose of the welding fixture and the method is to solve the problem that the existing brazing method is not suitable for the brazing of the large-size aluminum alloy curved skin and the ribbed skeleton structure or the deformation of a component is occurred after brazing. The welding fixture comprises a heat preservation layer, a heating blanket, a limiting mold, a mold pull rod, a pressurizing gasket and a pressurizing screw rod; and the method comprises the following steps that heat treatment before welding, polishing and cleaning, brazing filler metal coating are carried out for the aluminum alloy curved skin and the ribbed skeleton structure, then brazing is carried out through using the welding fixture. According to the welding fixture and the method for brazing the large-size aluminum alloy curved skin and the ribbed skeleton structure, the size of the weldable component is large, the deformation amount in the process of workpiece welding is reduced, the welding precision is high, and the welding fixture and the method is applied to the field of aluminum alloy brazing.

Owner:HARBIN INST OF TECH +1

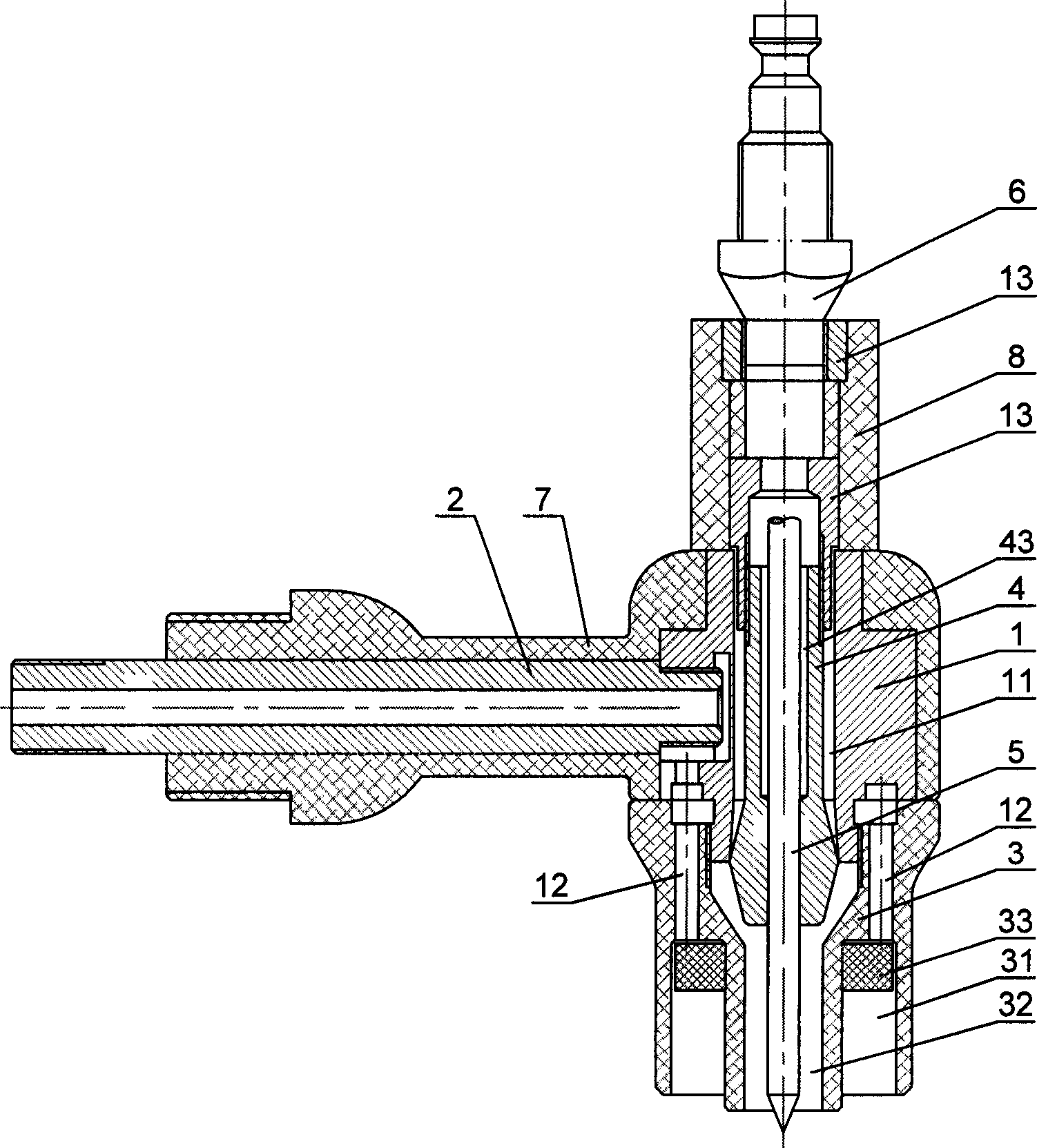

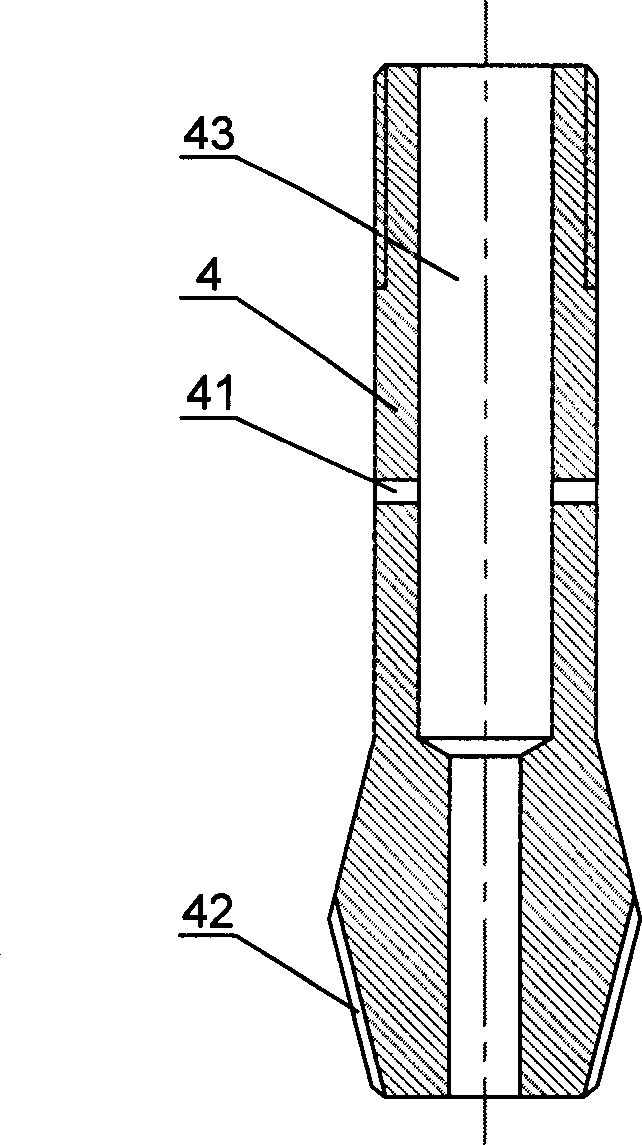

High pressure cyclone double layer gas protective welding gun

The high pressure cyiclonic double layer gas protected welding gun includes one gun body with central tungsten electrode clamp holding cavity; one outer gas inlet pipe connected to the side wall of the gun body; one double layer nozzle connected to the lower part of the gun body and including one outer pipe, one outer pipe and one cyclone inside the outer pipe; one outer gas path connecting the outer gas inlet pipe and the outer pipe; one tungsten electrode clamp; one tungsten electrode with head extending beyond the double layer nozzle; one inner gas inlet pipe connected to the upper part of the gun body and communicated to the inner cavity of the tungsten electrode clamp. The present invention has weld protecting gases introduced through two different inlet passages to realize layered flow of the inner gas layer and the outer gas layer by means of the double layer nozzle.

Owner:CHINA NAT OFFSHORE OIL CORP +2

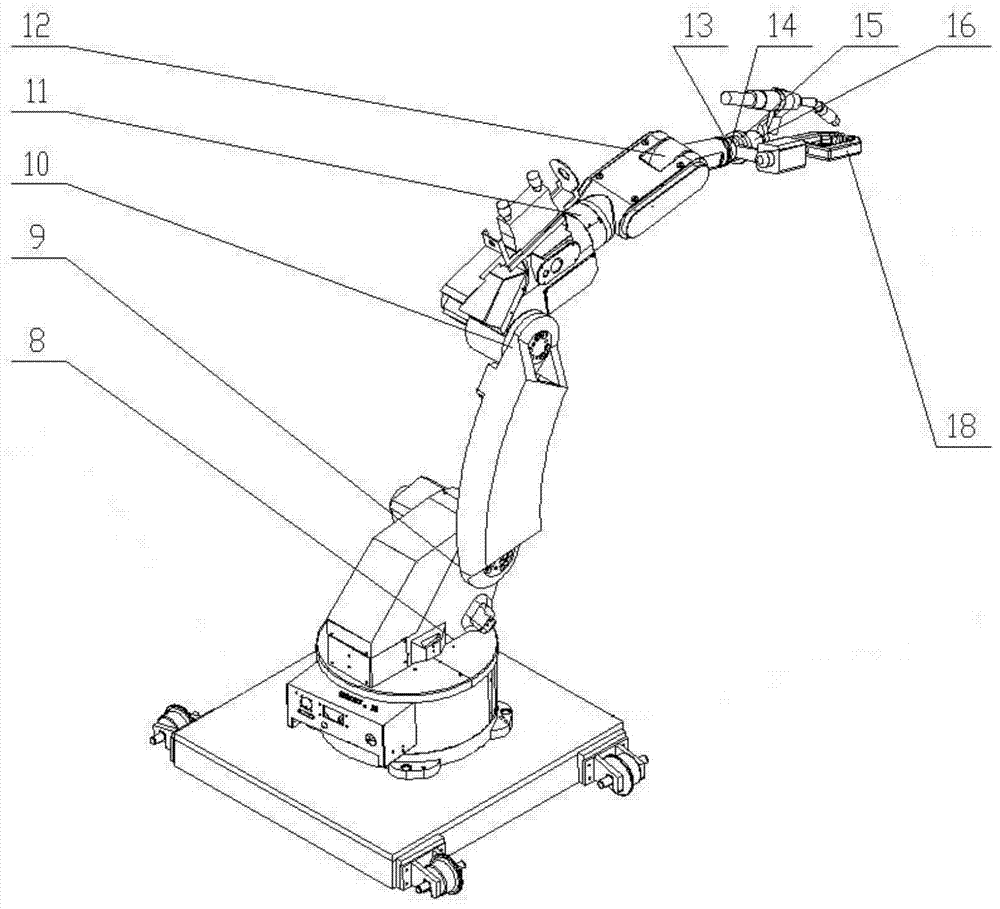

Welding robot with vision positioning function

InactiveCN108705234AIncrease flexibilityArticulation works wellWelding/cutting auxillary devicesAuxillary welding devicesEngineeringDisplay device

The invention provides a welding robot with a vision positioning function, and relates to the field of robots. The welding robot with the vision positioning function comprises a base. A supporting block is fixedly arranged on the left side of the top of the base. An installing table is fixedly arranged on the top of the supporting block. An installing base is fixedly arranged on the right side ofthe top of the base. A rotation base is movably arranged on the top of the installing base. A rotation motor is fixedly arranged at the bottom of the inner side of the installing base. According to the welding robot with the vision positioning function, through an expansion arm and an installing support arm, under the action of a first motor and a second motor, a component on a clamping head can be flexibly welded, and flexibility of the robot is improved; through a welding camera, the implementation situation can be transmitted to a display, and the welding development situation can be seen;and through the rotation base, the robot can flexibly rotate, and the better hinge work can be conducted on the component.

Owner:扬州市诚智自动化装备有限公司

Vacuum glass laser welding table

A vacuum glass laser welding table belongs to the technical field of vacuum glass and is structurally formed by connecting a workbench, an upper-layer conveying belt, a lower-layer conveying belt, a vacuum pump, a sliding rail, a sliding block, a laser welding head, a discharging support and a supporting plate. Vacuum plate glass coated with welding flux is conveyed to a working area through the lower-layer conveying belt; the upper-layer conveying belt is used for conveying another piece of vacuum plate glass coated with the welding flux to the supporting plate; when the discharging support drives the supporting plate to descend together and reach a designated position, the supporting plate is pulled out, the upper-layer plate glass covers the lower-layer plate glass, the vacuum pump pumps out air between the two pieces of plate glass through an air pumping copper pipe, the laser welding head conducts edge sealing on the periphery of the vacuum glass, meanwhile, the air pumping copperpipe is broken through welding to seal an air pumping hole, and the whole welding work is completed. The vacuum glass laser welding table overcomes the defects of high welding temperature, complex technological process, harsh welding conditions and the like in the traditional method. The rotary laser head can flexibly weld, so that the welding quality is improved.

Owner:CHANGSHU JIANGWEI VACUUM GLASS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com