Patents

Literature

3379results about How to "Reduce manual labor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vehicle fault solution method and device

InactiveCN104460644AReduce manual laborImprove maintenance efficiencyElectric testing/monitoringUsabilityWorkaround

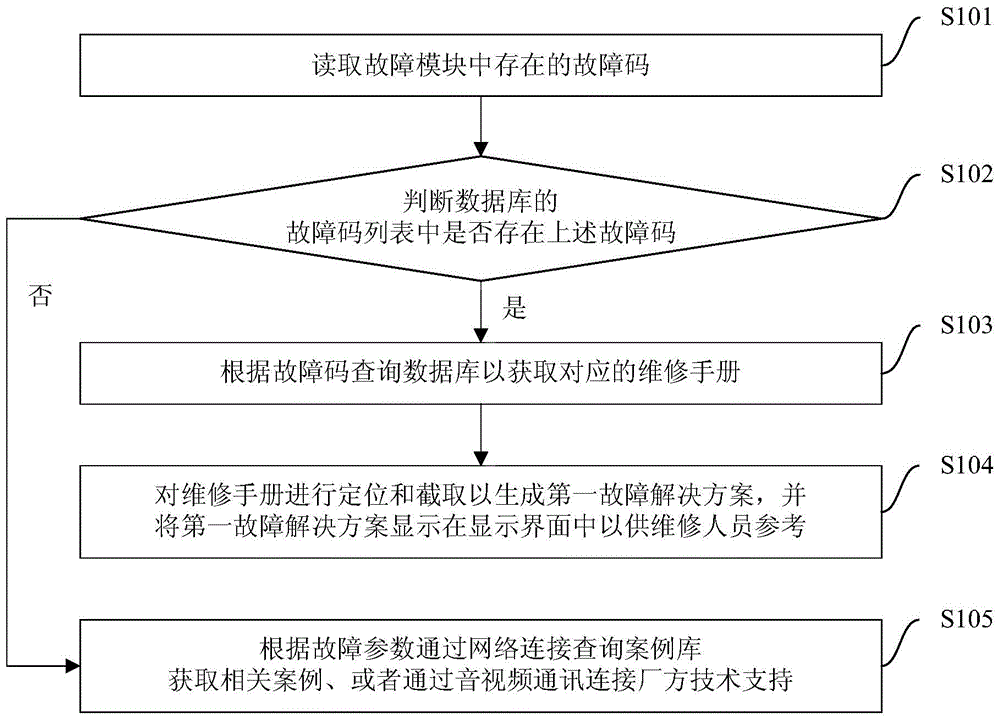

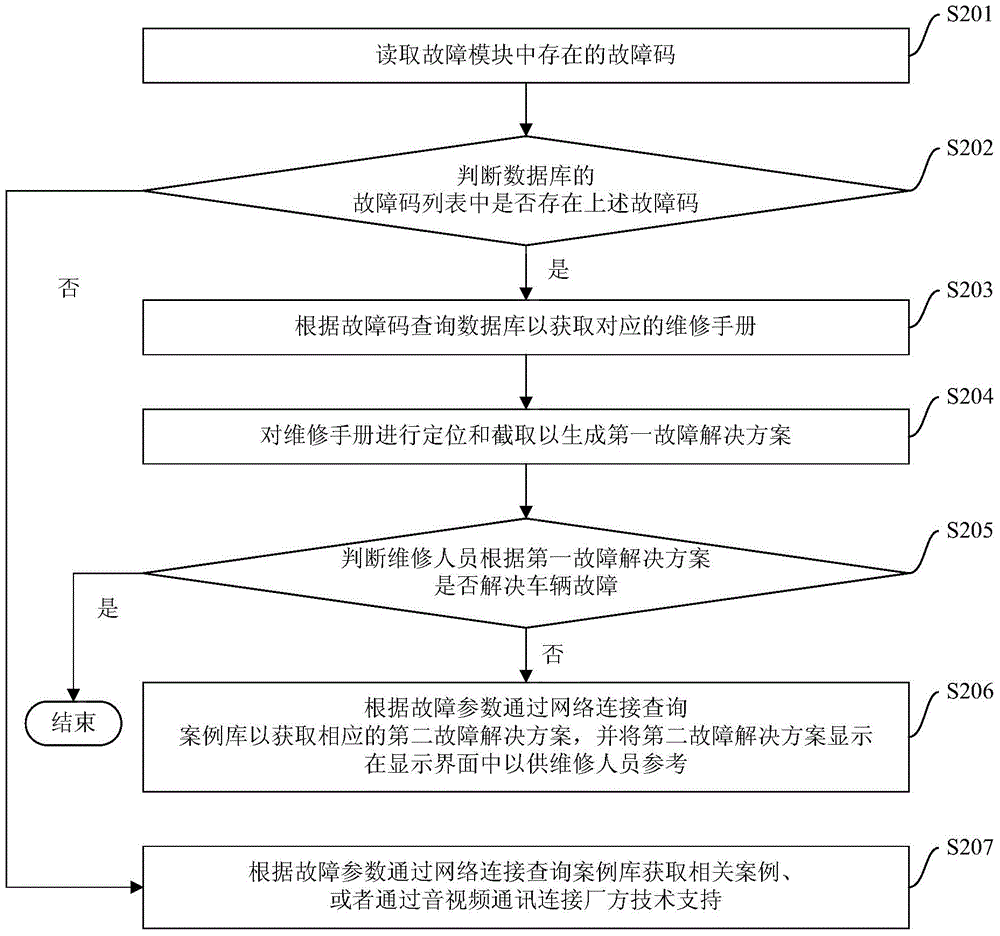

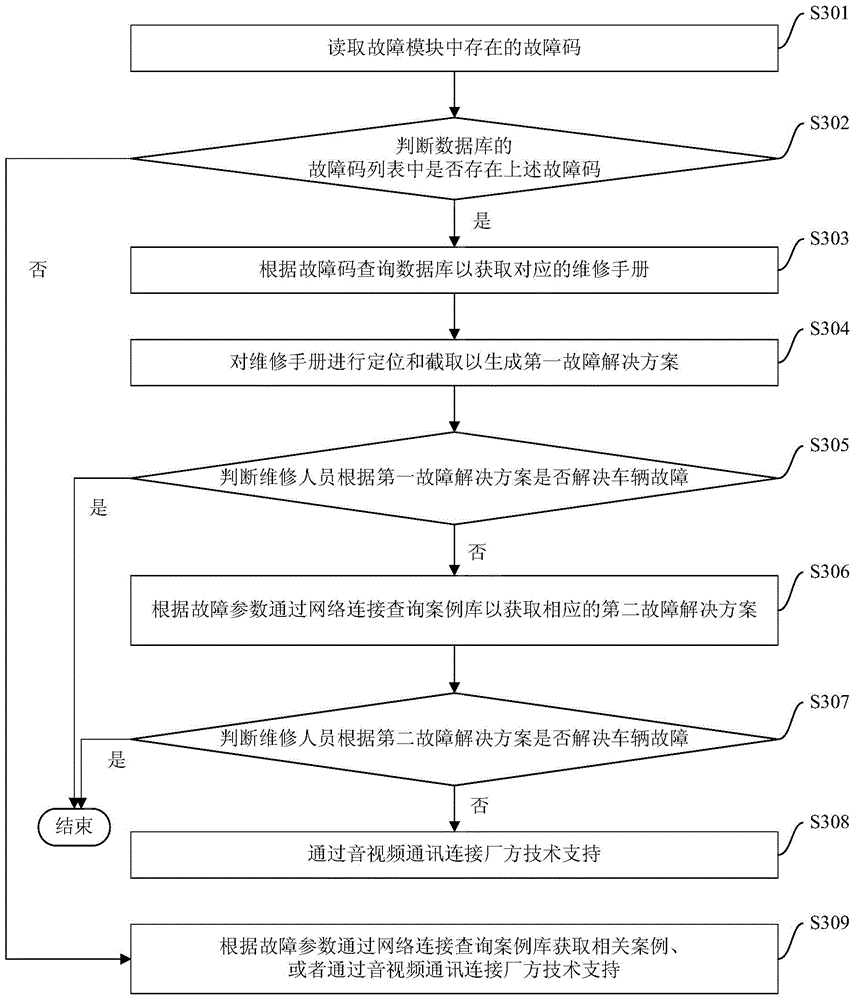

The invention provides a vehicle fault solution method and device. The vehicle fault solution method comprises the steps of reading a fault code existing in a fault module, judging whether the fault code exists in a fault code list of a database or not, querying the fault code in the database to obtain a corresponding service manual if the fault code exists in the fault code list, positioning and intercepting the service manual to generate a first fault solution and displaying the first fault solution on a display interface for reference of a maintainer. According to the vehicle fault solution method, automatic obtaining of the fault solutions is achieved, maintenance efficiency is improved, sharing of the fault solutions is achieved, obtaining approaches of the solutions for difficult faults are increased, and usability is improved.

Owner:BYD CO LTD

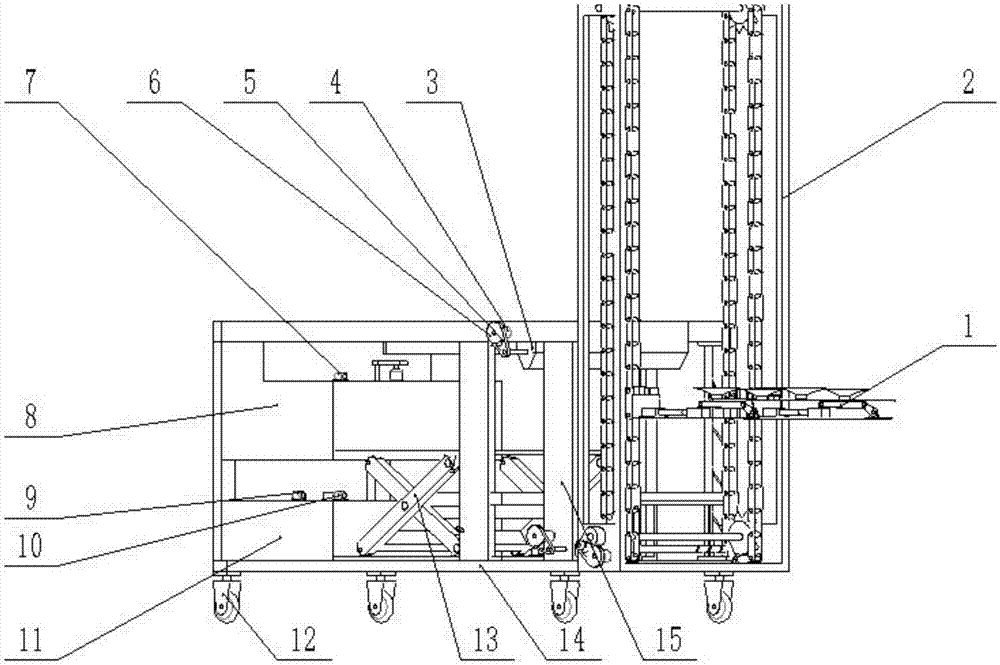

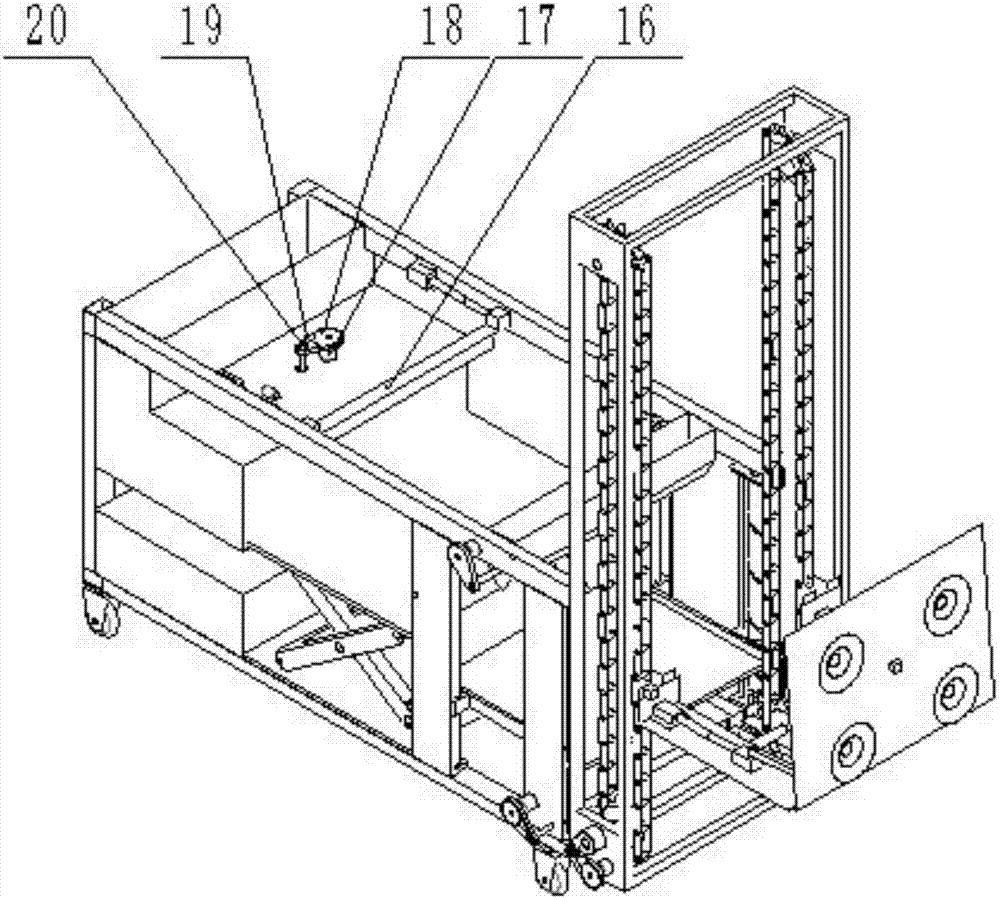

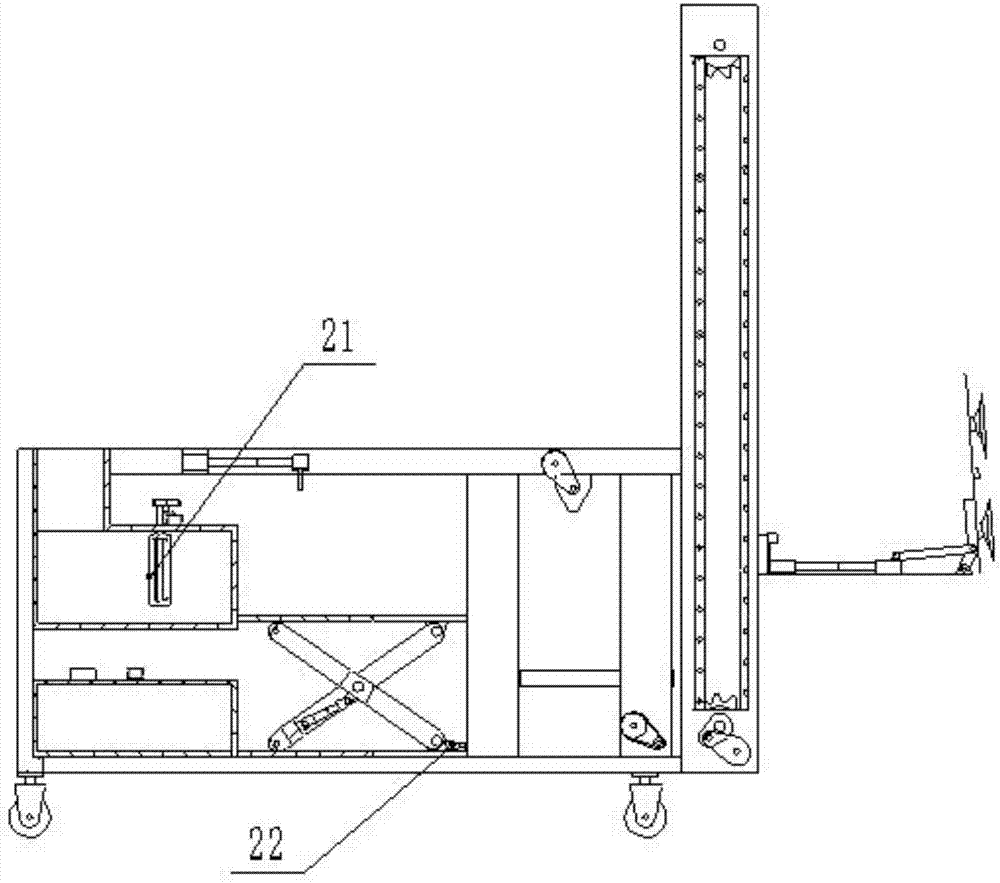

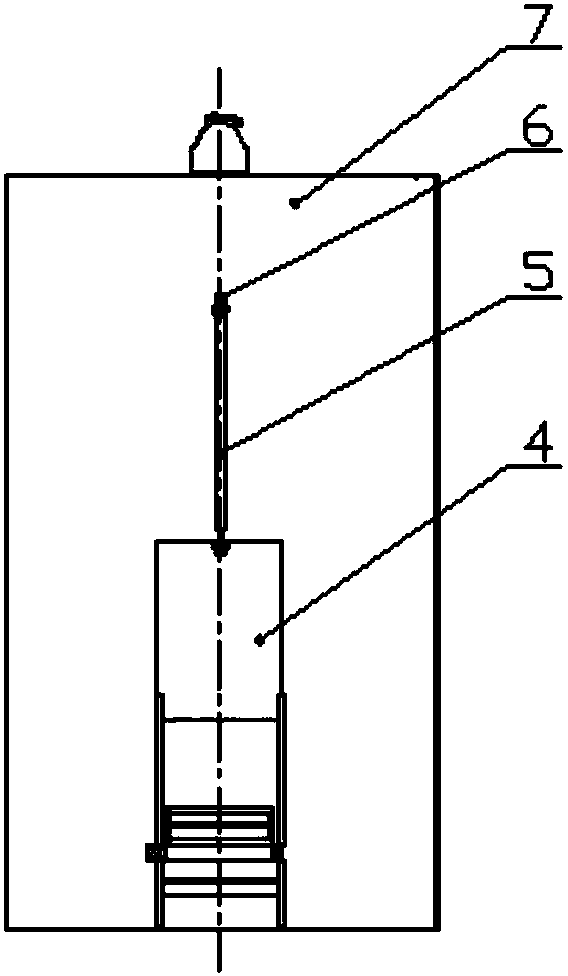

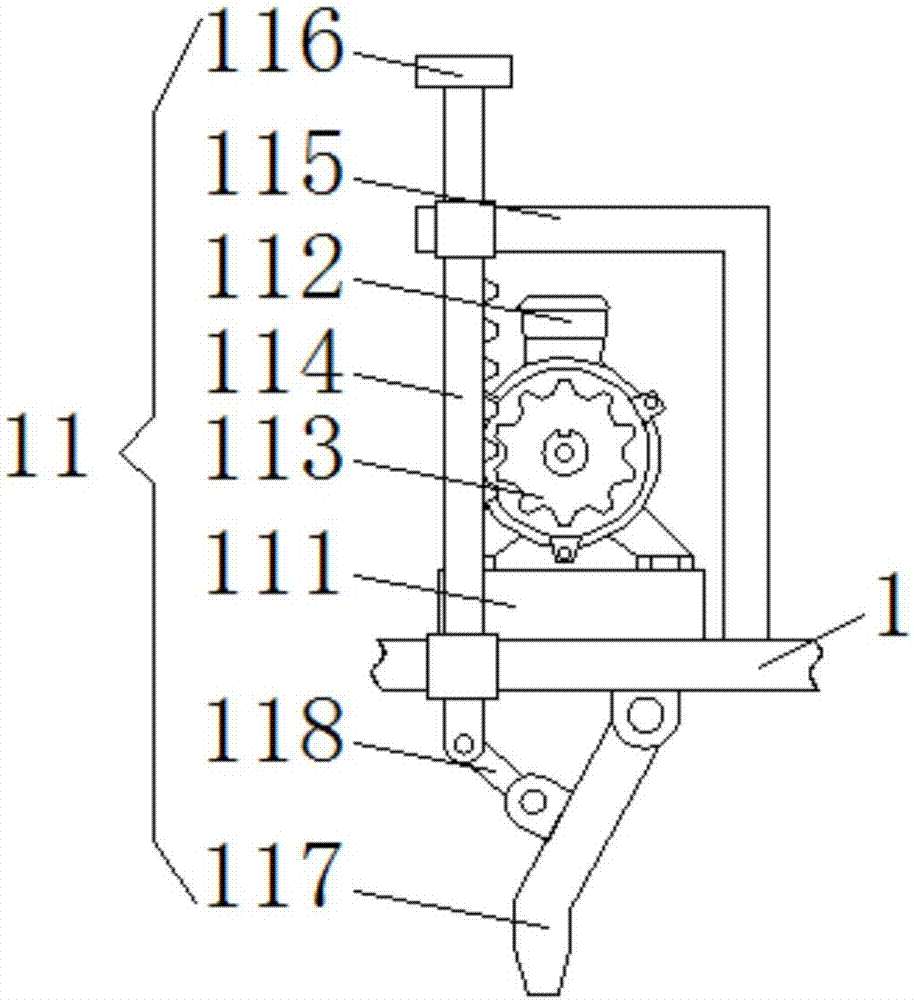

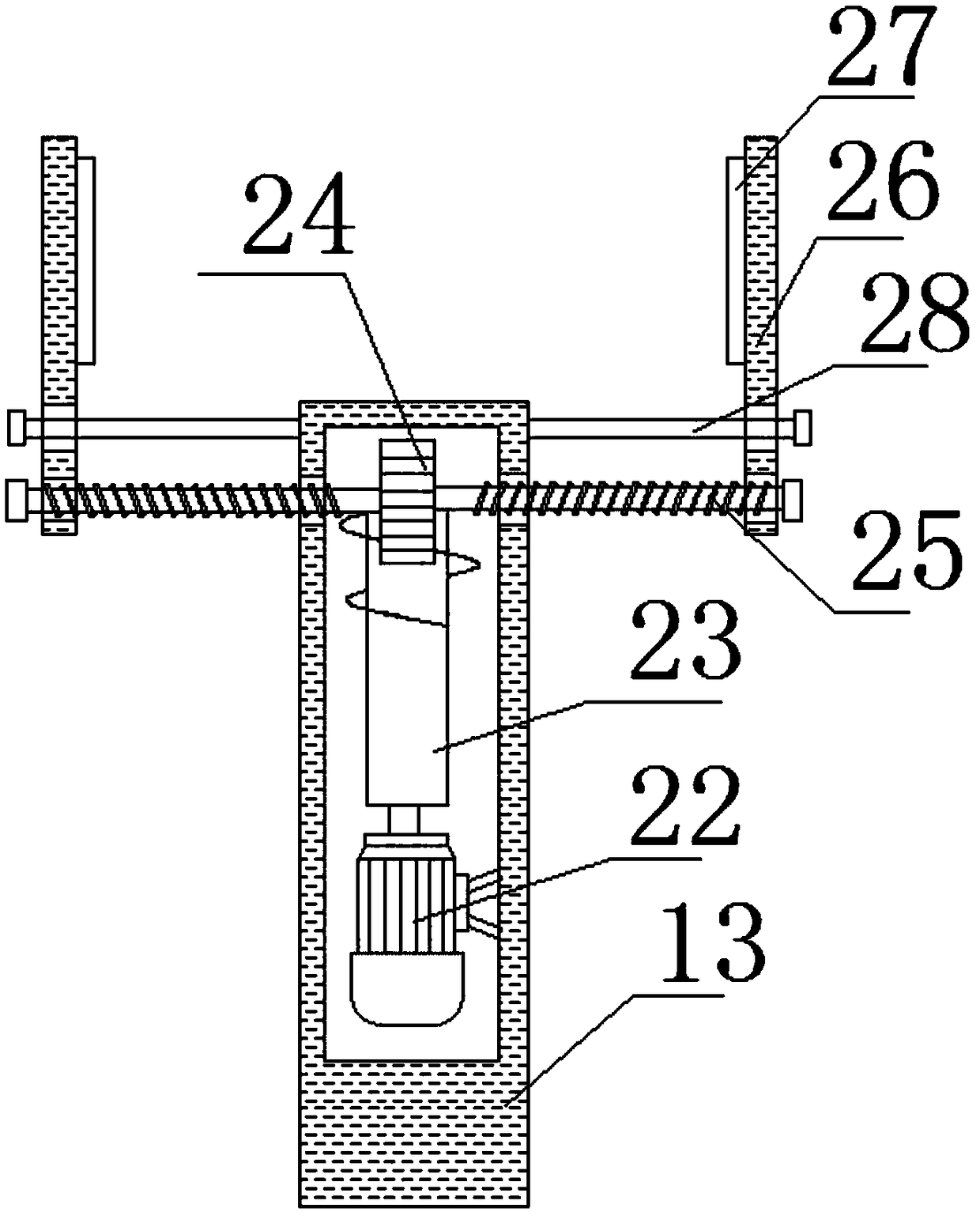

Vertical automatic wall tile sticking device for building construction

ActiveCN107035119ARealize automatic stirringRealize automatic movementBuilding constructionsEngineeringHydraulic cylinder

The invention discloses a vertical automatic wall tile sticking device for building construction and belongs to the field of building construction equipment. A wall tile storeroom lifting device comprises bottom plates, slave arms, a shaft, active arms, wheels, a wall tile lifting device slave hydraulic cylinder and a wall tile lifting device active hydraulic cylinder. The bottom plates are hinged to the slave arms; the slave arms are rotationally connected with the active arms through the shaft; the active arms are hinged to the upper bottom plate; the active arms are hinged to the wall tile lifting device active hydraulic cylinder; the two wheels are mounted at the lower end of the active arms; the slave arms are hinged to the wall tile lifting device slave hydraulic cylinder; and the two wheels are mounted at the upper ends of the slave arms. Concrete is stirred automatically through a concrete stirring case, a wall tile is automatically moved through the wall tile storeroom lifting device and a first tile pushing device, and automatic feeding is achieved through a pump machine, so that labor force is reduced.

Owner:广州市黄埔建筑工程总公司

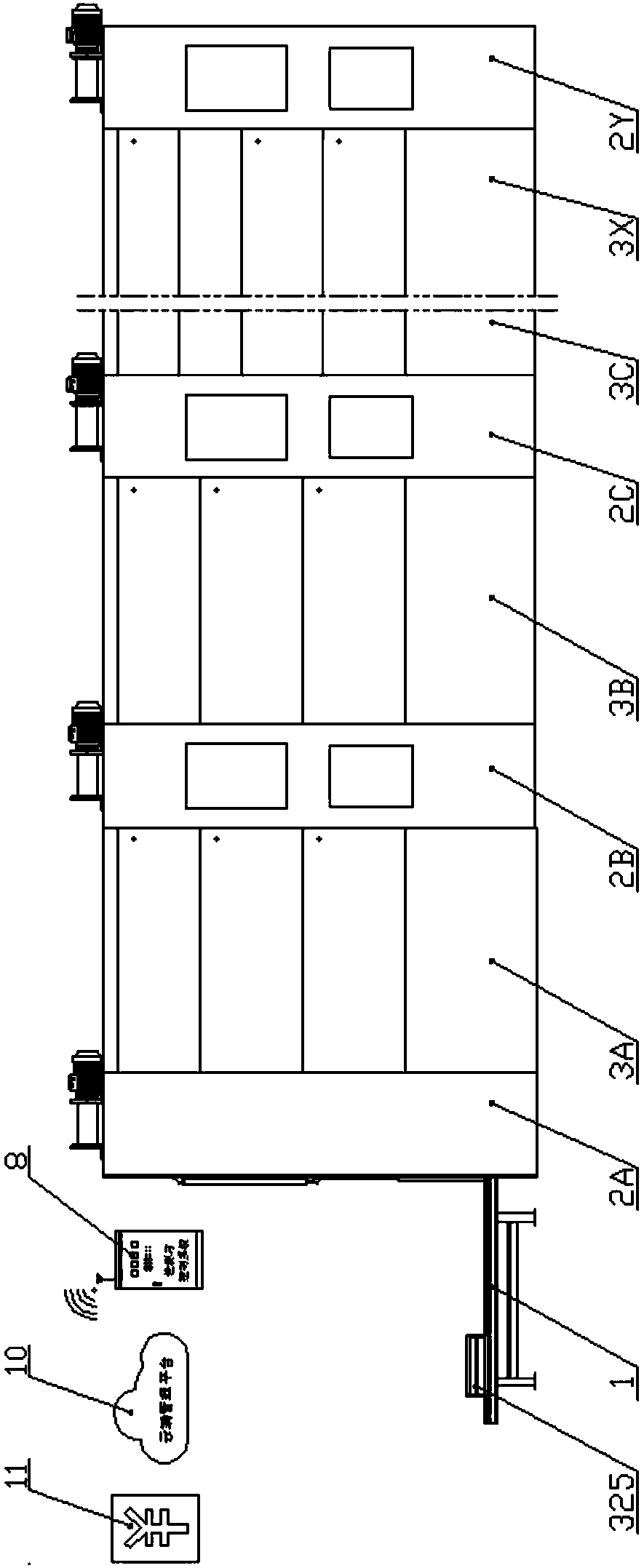

Caterpillar vending machine and automatic vending method

ActiveCN107945378AImprove adaptabilityReduce manual laborAcutation objectsCoin-freed apparatus detailsPayment systemIndustrial engineering

The invention provides a caterpillar vending machine. The caterpillar vending machine comprises a goods replenishing unit, m transshipment units, n container units, a detection control unit, a cloud side management platform and a payment system; the goods replenishing unit, the transshipment units and the container units are connected in sequence, and the integrated caterpillar vending machine isformed, wherein m and n are both natural numbers except 0, when n=1, m=1, and when n>1, m=n+1; regarding the m transshipment units and the n container units, when n>1 and m=n+1, the transshipment units and the container units are connected in an alternated and arranged mode, and the last unit is the transshipment unit; when n=1 and m=1, the transshipment units and the container units are of an integrated structure. The caterpillar vending machine solves the problem of a traditional vending machine that manual work is relied on to replenish goods, goods replenishing is troublesome, time and labor are wasted, and the adaptability of vended commodities are poor.

Owner:HUNAN SCIENTOP AUTOMATIC EQUIP SHARES +1

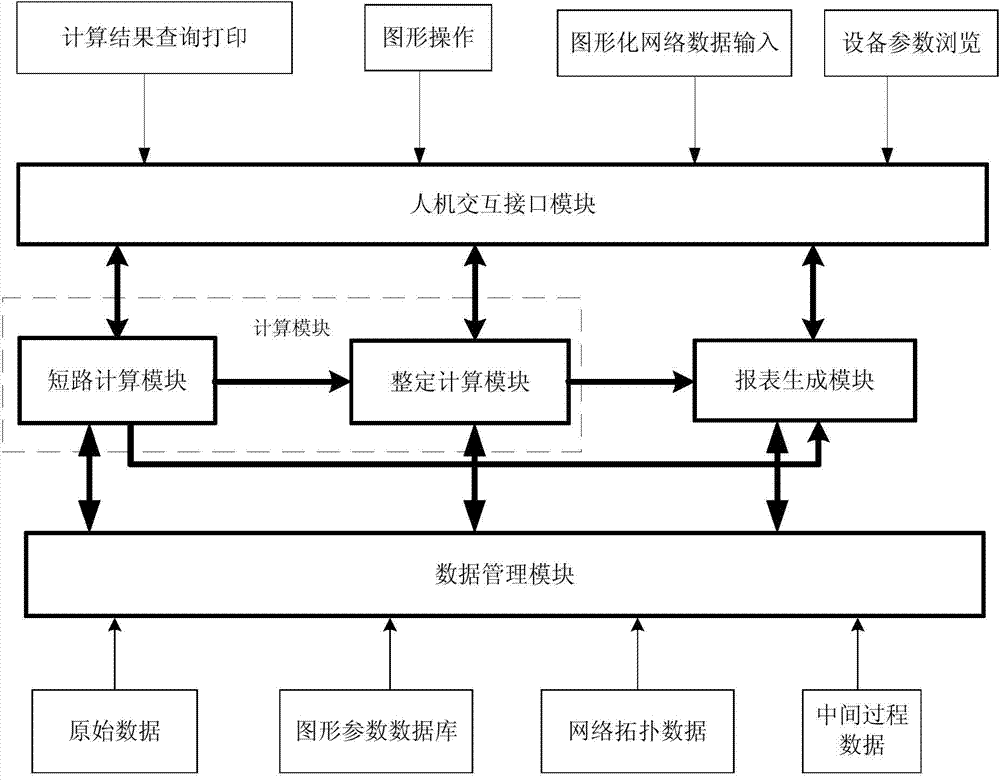

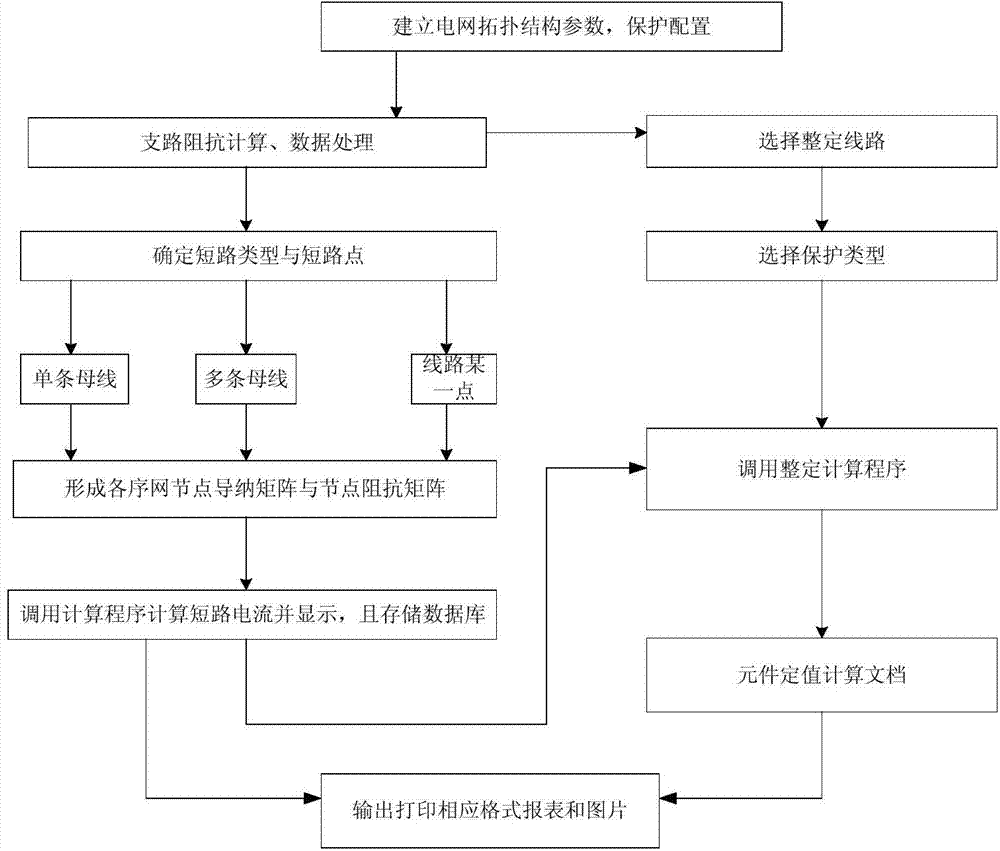

Visual relay protection setting calculation system and method

InactiveCN103500249AReduce tedious manual laborHigh degree of visualizationSpecial data processing applicationsWiring diagramSimulation

The invention provides a visual relay protection setting calculation system and method, and relates to the field of relay protection. According to the using characteristics of power consumers, the visual setting calculation system integrated multiple functions is developed and comprises a man-machine interaction interface module, a calculation module, a data management module and a report generation module. The visual relay protection setting calculation method comprises the steps that drawing of a geographical wiring diagram is finished, a network topology structure is formed by the geographical wiring diagram, node numbering and branch node numbering are automatically finished according to the geographical wiring diagram, and short-circuit calculation is carried out by calling essential data; a setting calculation principle and a formula are stored in the calculation module, stand-by data are formed according to the setting calculation principle, system setting calculation data are formed by the stand-by data and the essential data, and the system gives an alarm when a protection constant value is larger than a set threshold value; finally, a report is generated by calculation results to be output. According to the visual relay protection setting calculation method, short-circuit calculation results are directly called in a setting calculation part, the calculation time can be saved, the report can be singly generated by the calculation data of each module, and subsequent analyzing and processing can be conveniently achieved.

Owner:CHONGQING UNIV +2

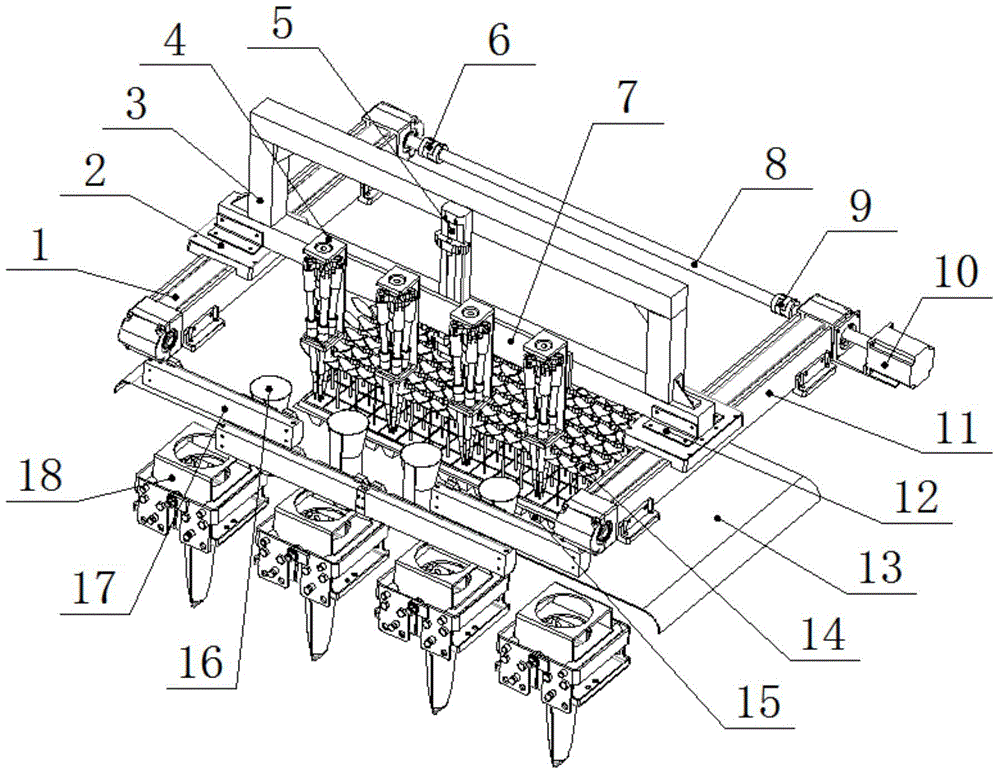

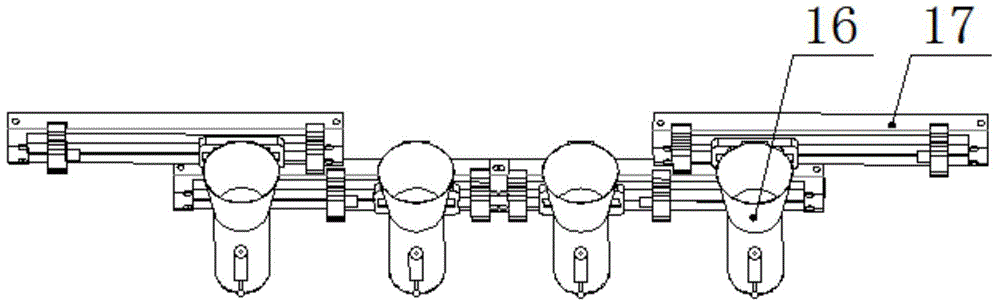

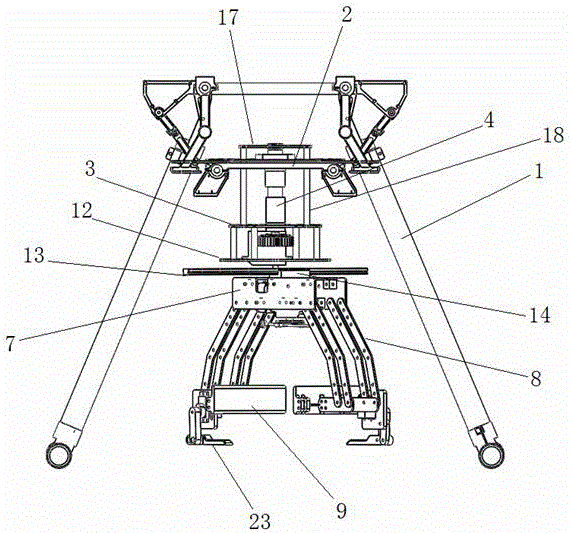

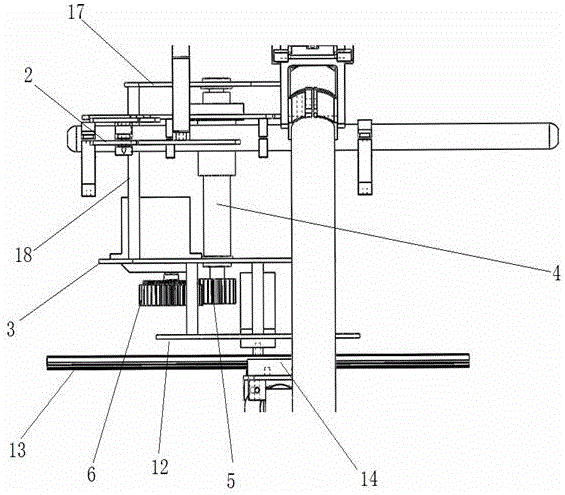

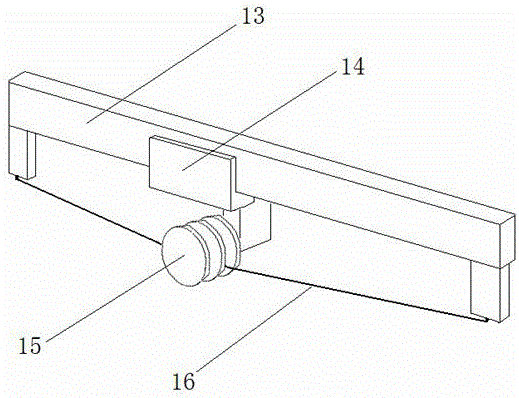

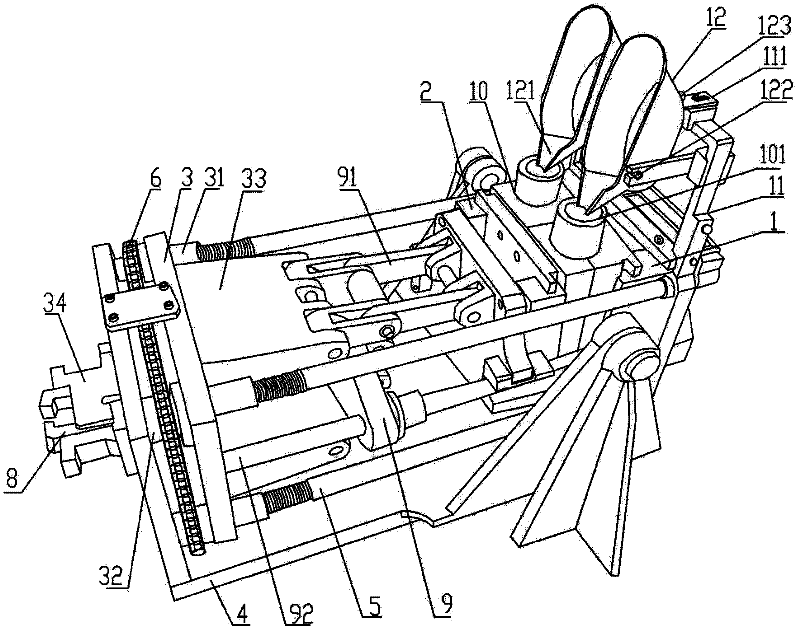

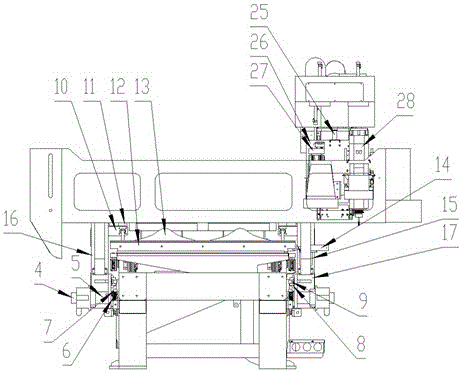

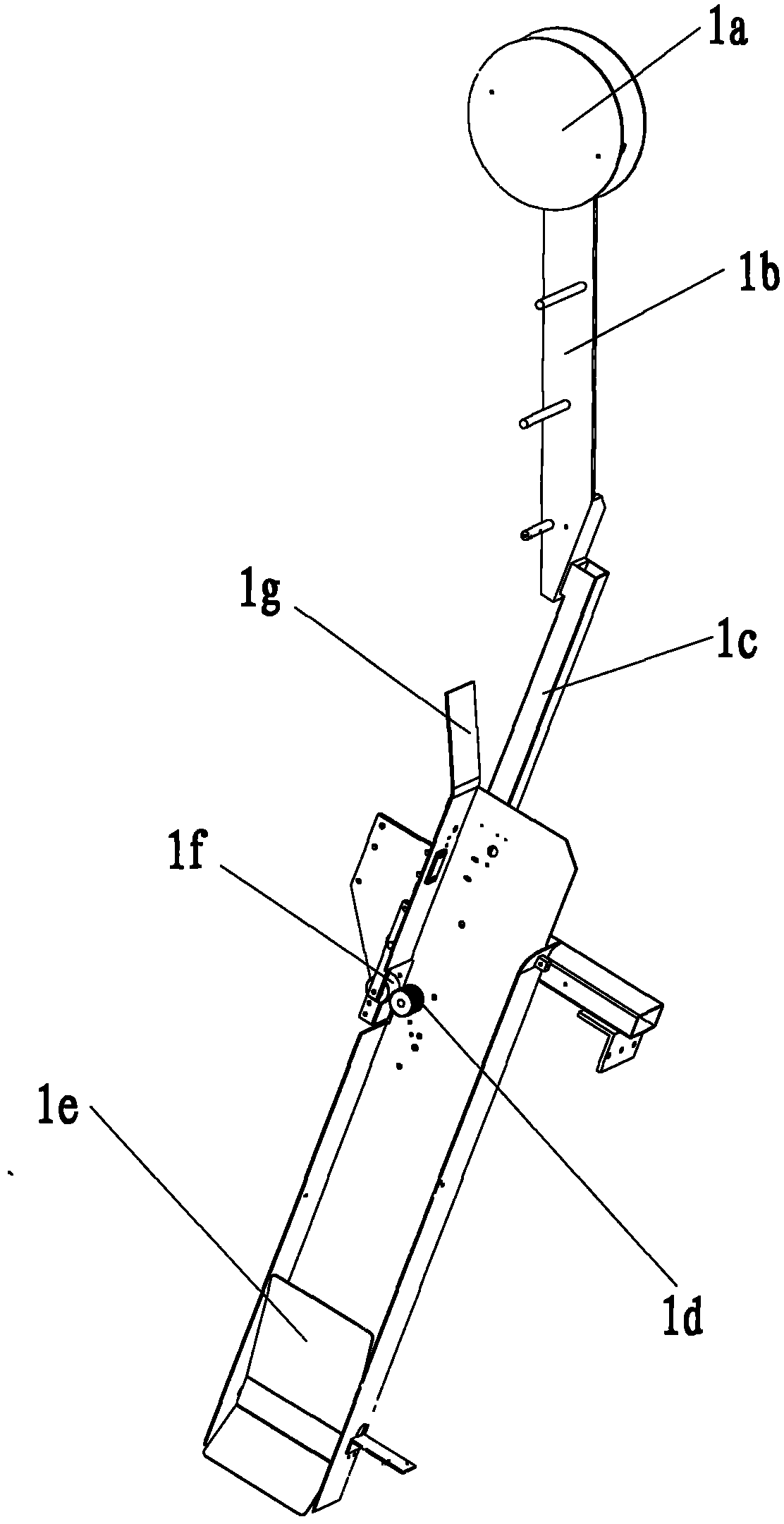

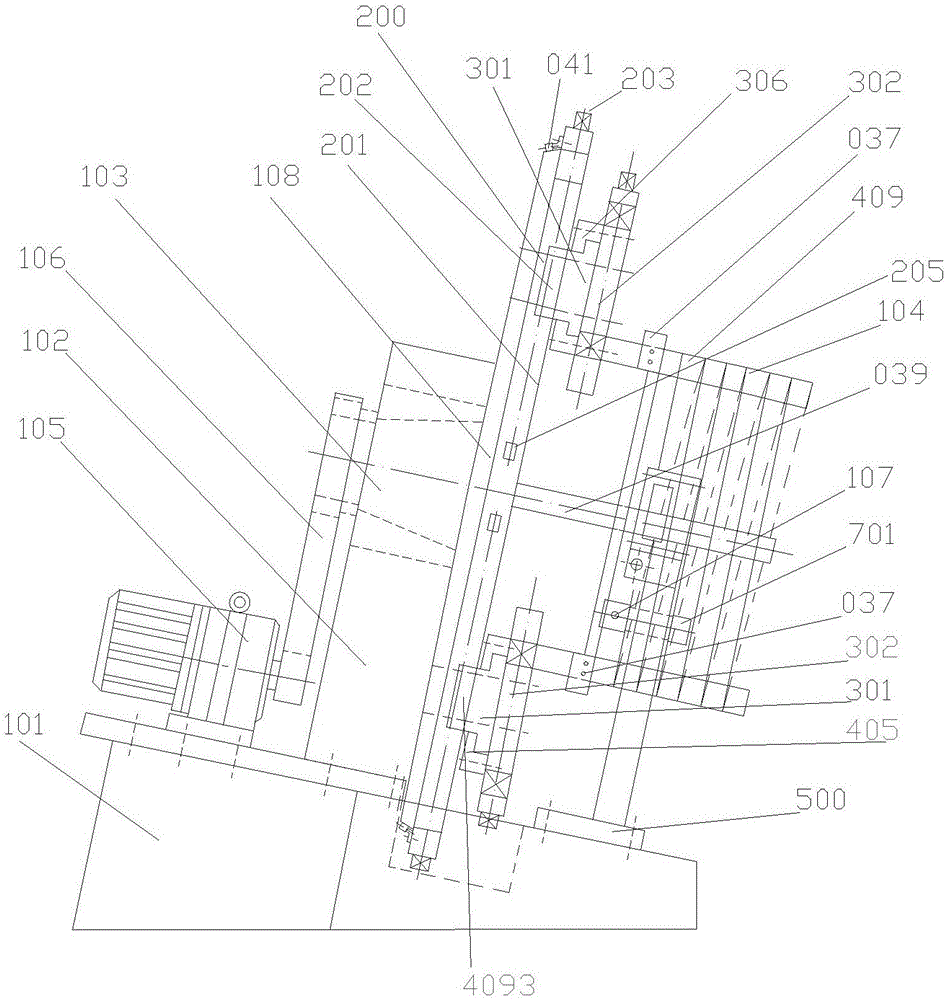

Apparatus and method for automatically picking seedling and separate projection applied to multi-row planting

The present invention provides an apparatus and method for automatically picking seedling and separate projection applied to multi-row planting. The apparatus comprises a shifting disk apparatus, a horizontal delivery apparatus, a vertical lifting apparatus, and a seedling separate projection apparatus. A plurality of seedling claws are mounted on the vertical lifting apparatus to pick a plurality of plug seedlings at one time, the horizontal delivery apparatus delivers the plug seedlings picked by the plurality of seedling claws to put on the corresponding closed seedling separate projection apparatus, the plug seedlings picked by the plurality of seedling claws are put into a corresponding multi-row planting apparatus according to a spreading out effect of the seedling separate projection apparatus, and plug seedlings picked by the plurality of seedling claws are transplanted to a farmland by the multi-row planting apparatus, so as to cooperate a semi-automatic planting apparatus to automatically finish seedling picking, seedling delivery, seedling releasing, seedling separation, and seedling projection, thereby realizing an automatically seedling picking and transplantation operation of the plug seedlings for multiple picking and delivery, scattering, projection and planting. The present invention is simple in structure and reliable for use, and is appliable to an automatical and highly-efficient transplant operation of the plug seedlings.

Owner:JIANGSU UNIV

Flight carrier system of unmanned aerial vehicle

InactiveCN105799935APrecise positioningAvoid labor intensityProgramme-controlled manipulatorRemote controlled aircraftRemote controlFlight vehicle

The invention discloses a flight carrier system of an unmanned aerial vehicle.The flight carrier system comprises a lifting mechanism and a grabbing mechanism.The lifting mechanism comprises a fixing carrier plate, a lifting carrier plate and a lifting lead screw.A driven tooth is arranged at one end of the lifting lead screw.A driving tooth is arranged on the lifting carrier plate.The driving tooth drives the driven tooth to rotate to control the lifting lead screw to be lifted.The lifting lead screw is lifted to drive the lifting carrier plate to move.The grabbing mechanism comprises a base, a movable arm and a traction device controlling the movable arm.The base is provided with a pair of movable arms, a rotating handle and a traction rod.The rotating handle rotates forward and reversely to pull the traction rod to extend and contract to drive the two movable arms.The grabbing mechanism is provided with a bottom carrying mechanism.Compared with the prior art, the flight carrier system of the unmanned aerial vehicle has the advantages that by means of longitudinal moving of the lifting mechanism and clamping of goods through the grabbing mechanism, the unmanned aerial vehicle can transport the goods by means of remote control, labor force is saved, and the working efficiency is improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

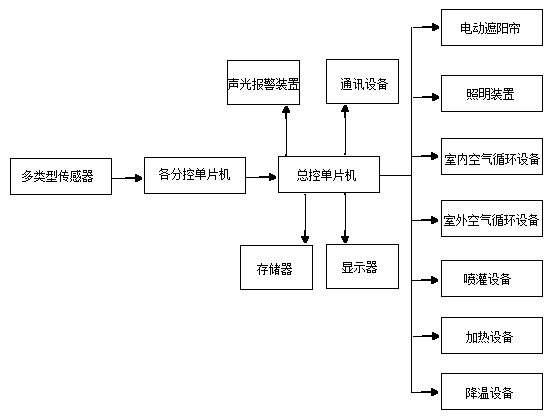

Greenhouse environment intelligent control and management system based on information acquisition

ActiveCN104238602AImprove balanceEasy to adjustSimultaneous control of multiple variablesAir cycleDisplay device

The invention discloses a greenhouse environment intelligent control and management system based on information acquisition. The system comprises various types of sensors arranged in a greenhouse, a memory, a display, a sound and light alarm apparatus and a communication device. The various types of sensors include air temperature sensors, air humidity sensors, illuminance sensors, carbon dioxide sensors, soil moisture sensors and soil temperature sensors, a sub-control single-chip microcomputer is arranged for each type of sensors, all the sub-control single-chip microcomputers are connected with a master control single-chip microcomputer, window shades and / or lighting devices are arranged on the top and the side faces of the greenhouse, an indoor air circulating device, an outdoor air circulating device, a spray irrigation device, a heating device and a cooling device are arranged in the greenhouse, and the window shades are driven by motors. Through the system, various types of environmental data of the greenhouse can be monitored, and environmental parameters of the greenhouse can be automatically adjusted accurately and rapidly according to information acquired by all the sensors.

Owner:JIANGSU YONGLIAN MODERN AGRI DEV

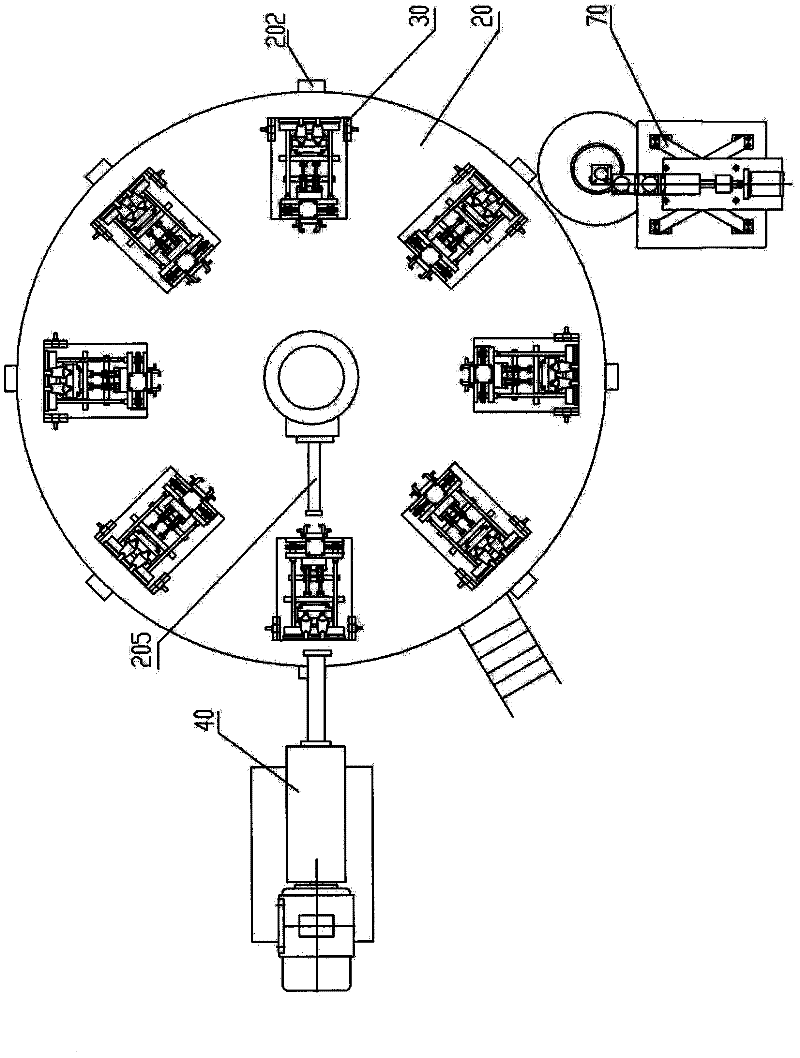

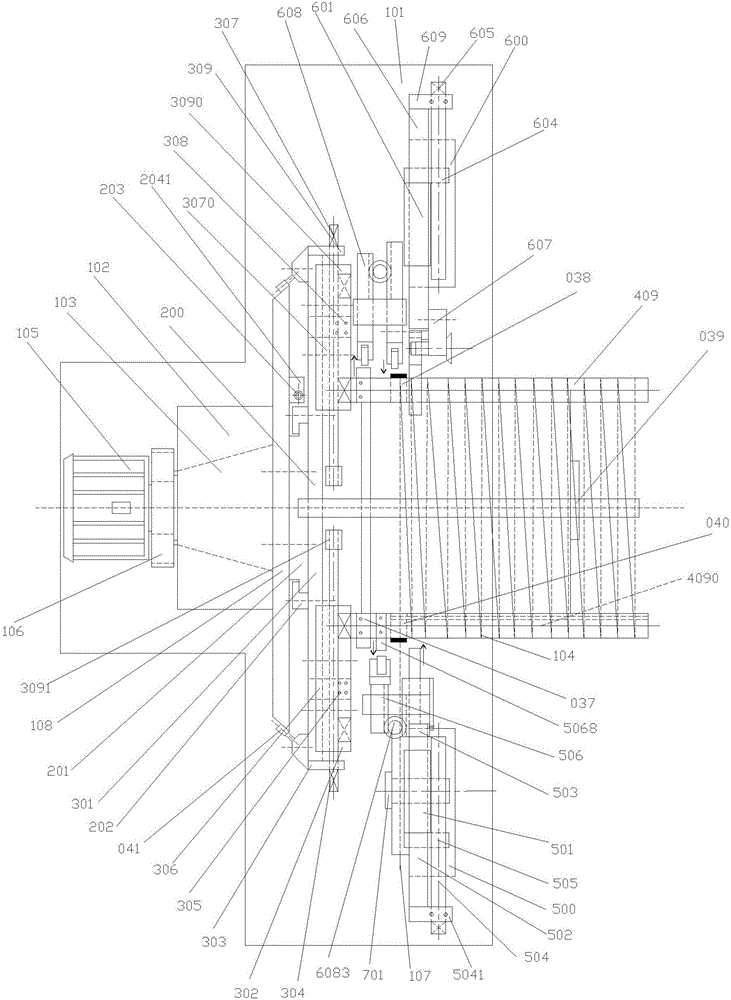

A multi-station automatic pouring machine

ActiveCN102259183AEasy to adjustAccurate adjustmentPig casting plantsMolten metal conveying equipmentsMotor driveGear wheel

The invention discloses a multi-station full-automobile casting machine comprising a casting robot. The casting robot is fixed on one side of a workbench on a mainframe, at least three casting units are annularly distributed on the workbench, and a hydraulic pushrod mechanism is arranged face to face at one casting unit on one side of the workbench; the hydraulic pushrod mechanism supports the casting unit, a bull gear is arranged at the bottom of the workbench, pulley supports are fixed on the edge of the workbench corresponding to the casting units, each pulley support is provided with a pulley, a guide rail table is arranged on the mainframe and is provided with a motor, the motor drives a small pinion to rotate, the small pinion is meshed with the bull gear, and the pulleys acts circular movement along the guide rail table. With the multi-station full-automobile casting machine, a whole lower mould fixture moves to be regulated through the regulation of a guide rod so as to meet the requirement of an upper casting mould and a lower casting mould on compact matching; simultaneously, the casting units rotate through a hydraulic system, thus the manufactured castings have higher degree of crystallization and higher strength.

Owner:浙江文源智能科技有限公司

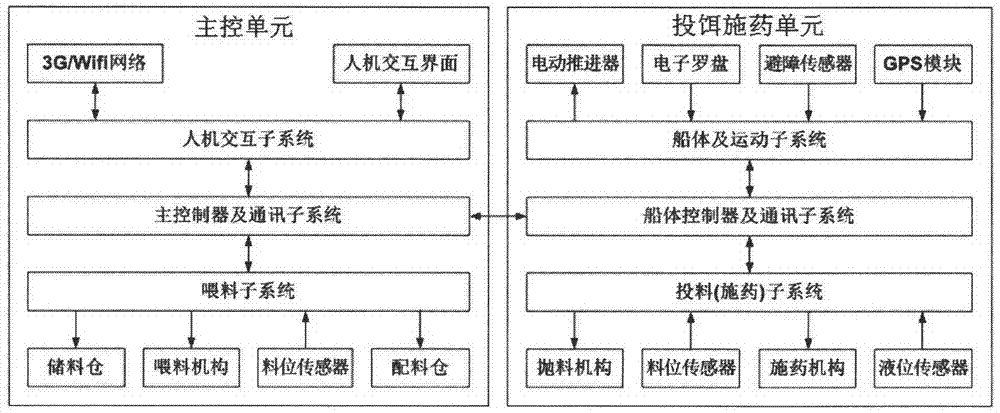

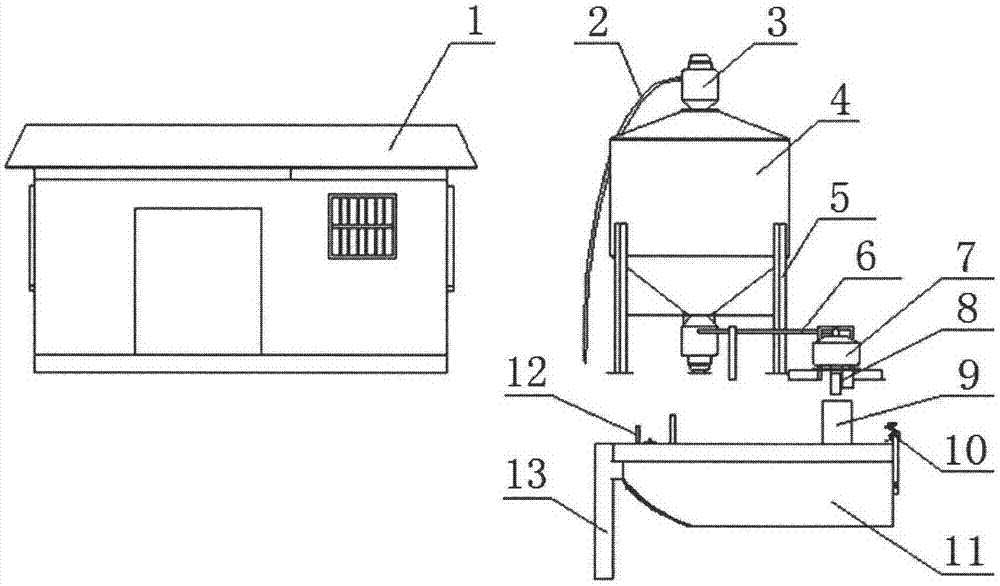

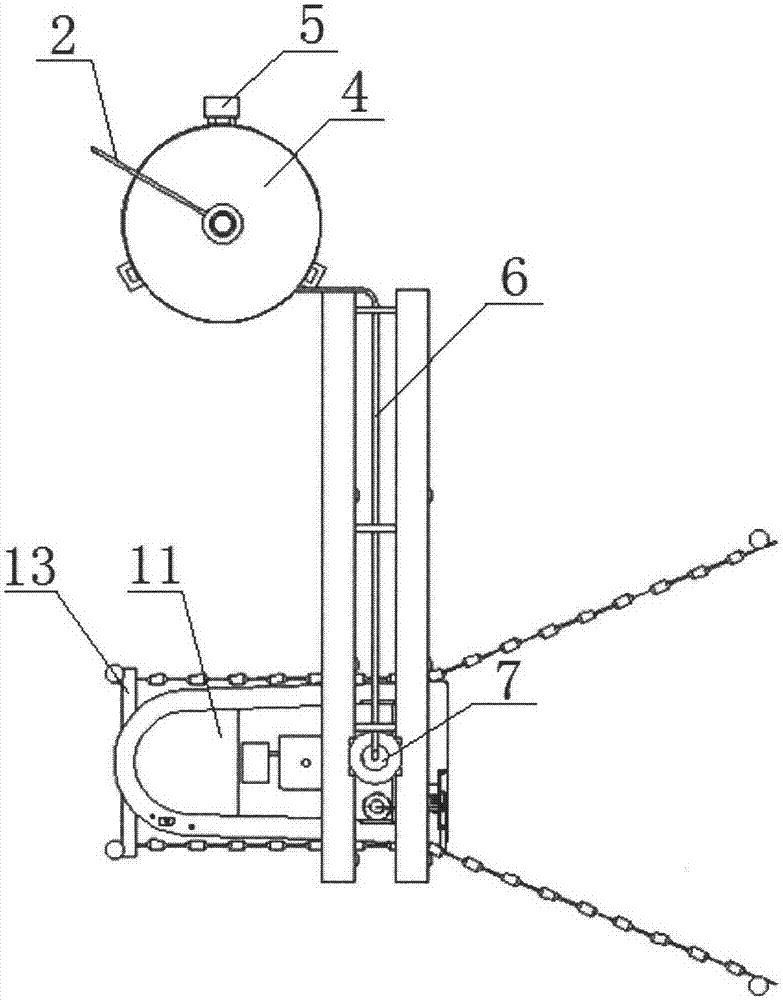

GPS (global positioning system) navigation based intelligent feeding and spraying system and device

InactiveCN103918596AReduce labor intensitySplash evenlyPisciculture and aquariaVeterinary instrumentsShrimpGps navigation

The invention discloses a GPS (global positioning system) navigation based intelligent feeding and spraying system and device, and belongs to the field of aquaculture equipment. A main controller receives a task and an instruction inputted by a man-machine interaction subsystem, and controls a feed subsystem to execute feed action; the feed subsystem feeds back feed information to the main controller, and the feed information is displayed to the man-machine interaction subsystem; a hull controller receives hull movement information inputted by a hull and a movement subsystem and controls the hull to move, and a feeding (spraying) subsystem executes feeding (spraying) action under an instruction of the hull controller; the feeding (spraying) subsystem feeds back feeding (spraying) information to the hall controller; the main controller and the hull controller are wirelessly connected through a communication subsystem. Labor intensity of aquaculture farmers is lowered greatly, accurate feeding of feed and uniform spraying of medicine are realized, use efficiency of the feed and medicine is improved, impact of aquaculture on the environment is reduced, and the system and device is particularly applicable aquaculture of shrimps and crabs.

Owner:常州智能农业装备研究院有限公司

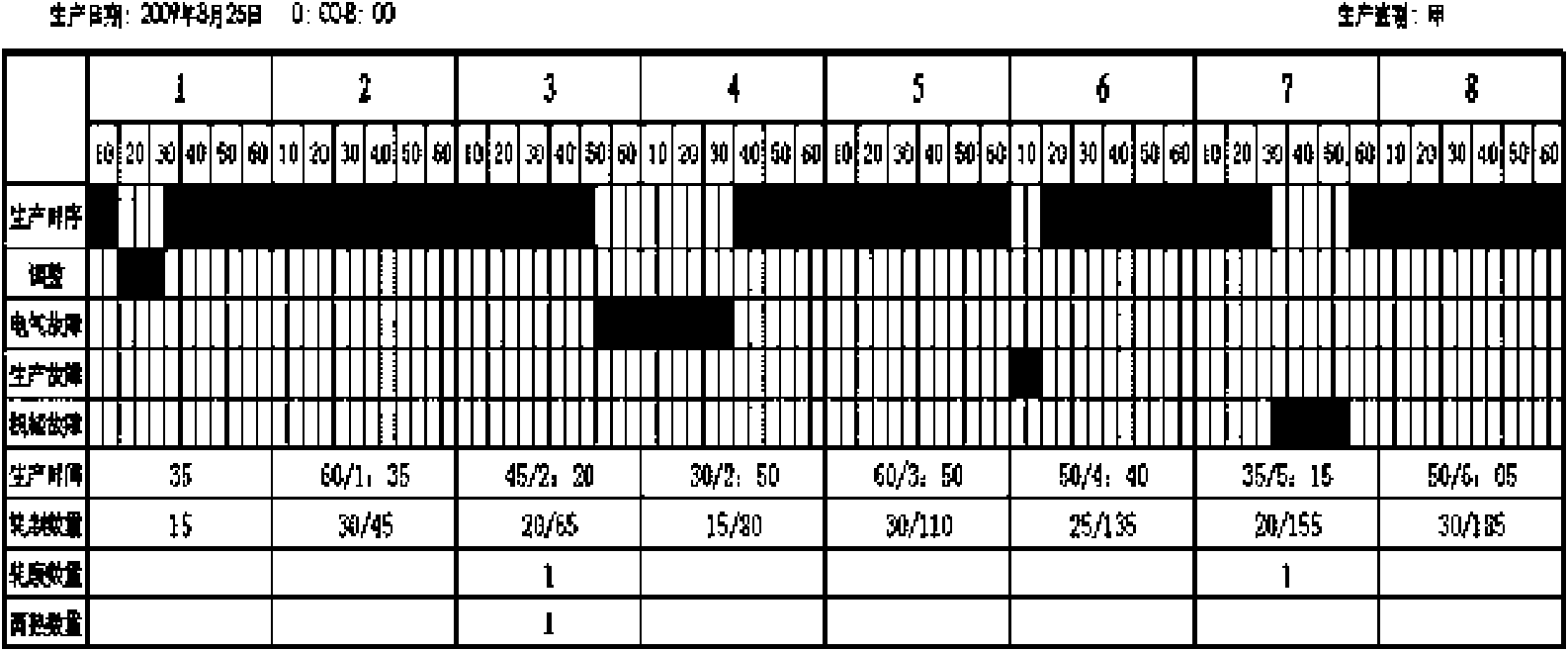

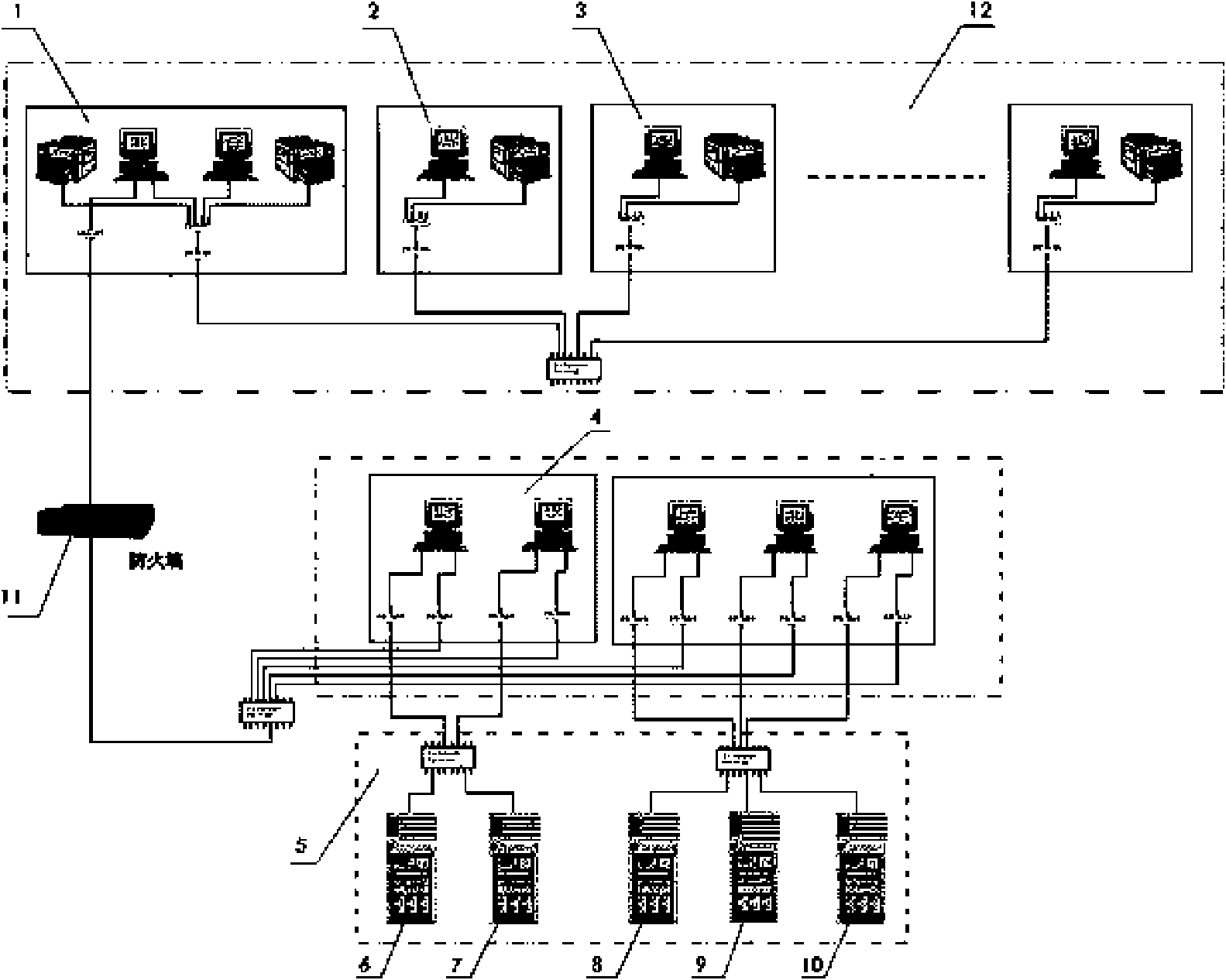

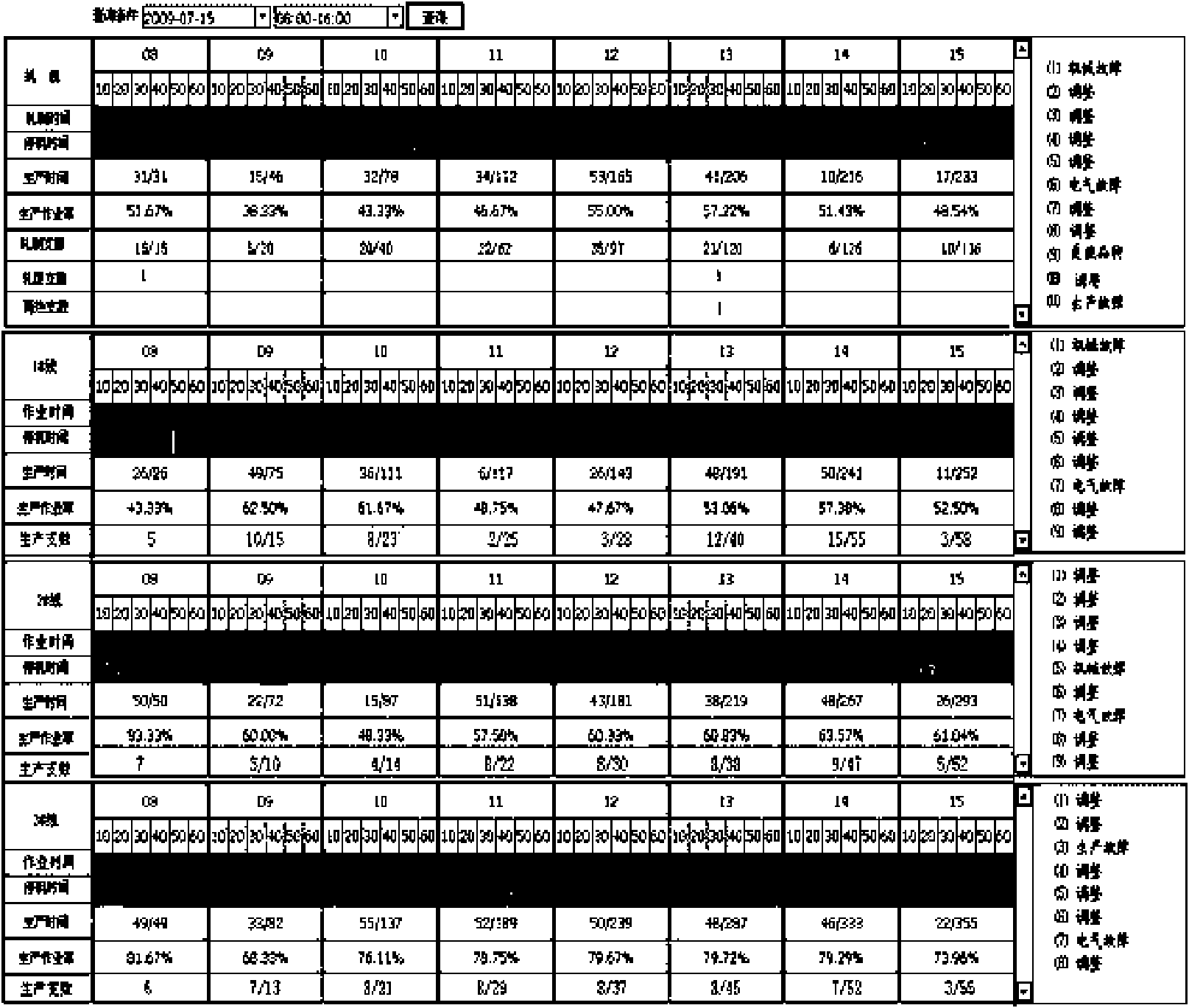

Automatic recording system for running time of production line device

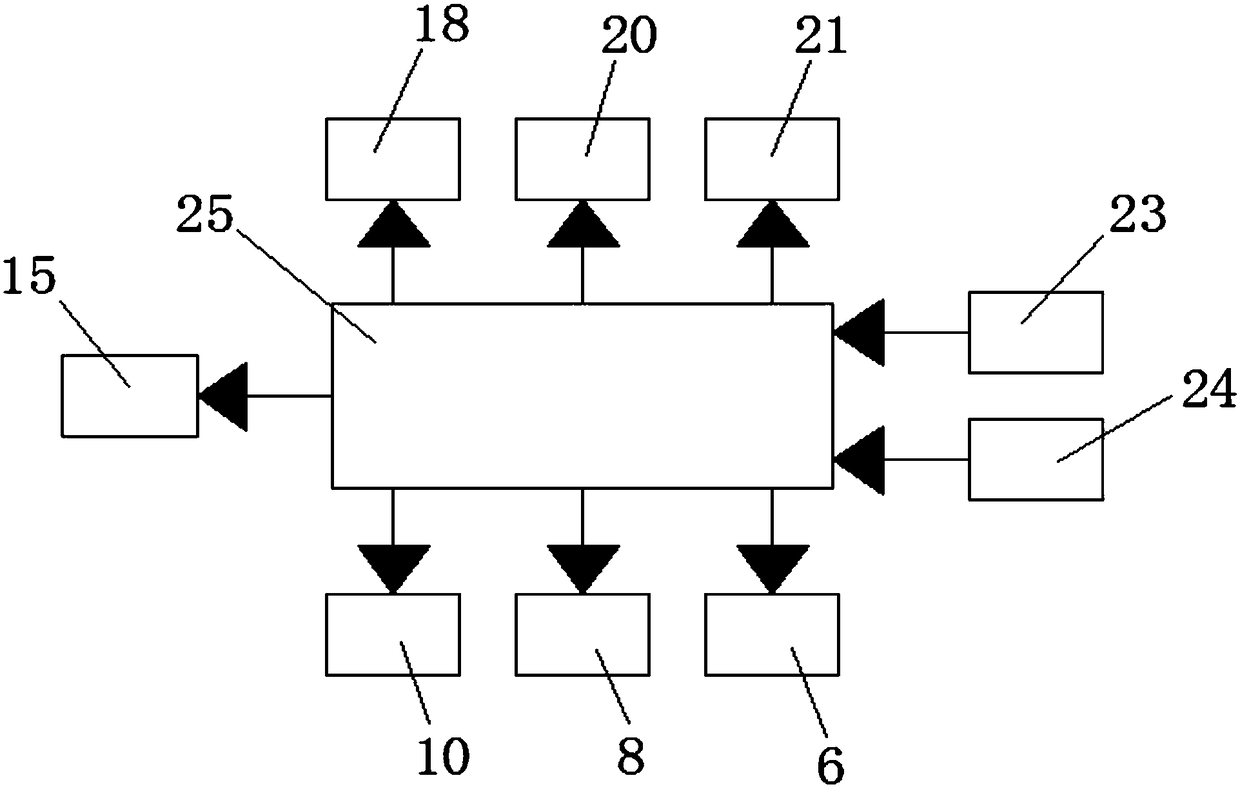

InactiveCN101673421AReduce manual laborImprove real-time performanceRegistering/indicating machine productionRoll mill control devicesProduction lineReal-time data

The invention provides an automatic recording system for running time of a production line device, belonging to the recording field of the running time of the production line device. The automatic recording system for running time of a production line device provided by the invention comprises a real-time data collecting device, a back-stage management device, a display terminal, a production linearea L2 system, a production line area L1 system, a BD1 rolling mill PLC, a TM rolling mill PLC, a 1st processing line PLC, a 2nd processing line PLC, a 3rd processing line PLC, a hardware firewall,and an enterprise local area network. The automatic recording system can reduce manual labor, increases the recording real-time, reality and accuracy of the running time of the production line deviceand the labor production operation performance.

Owner:武钢集团有限公司

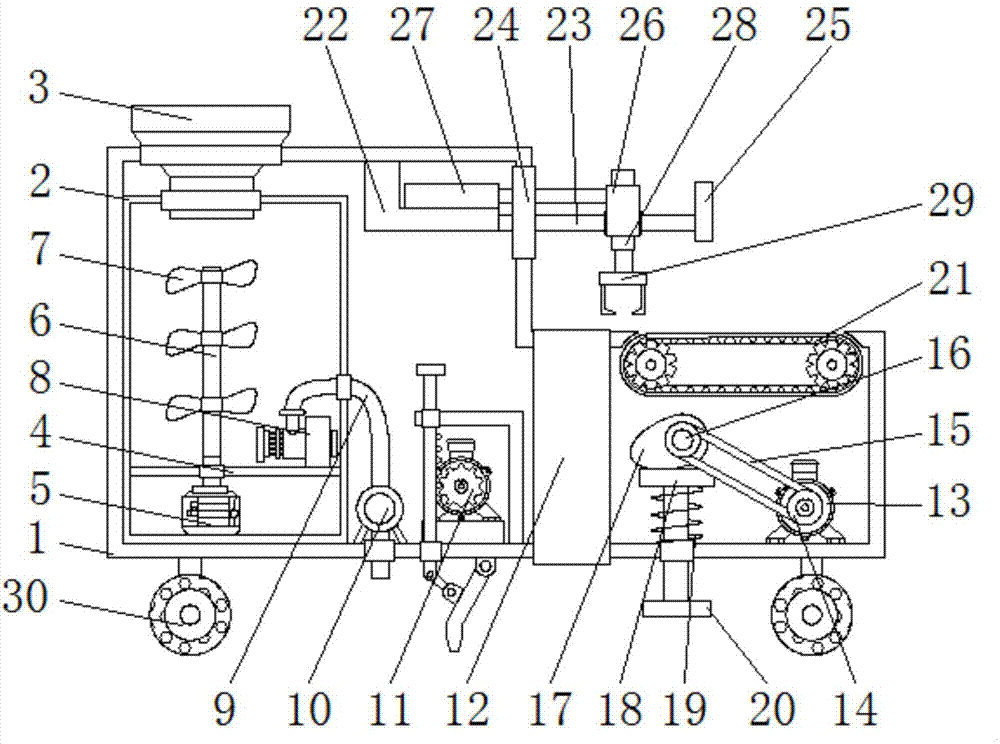

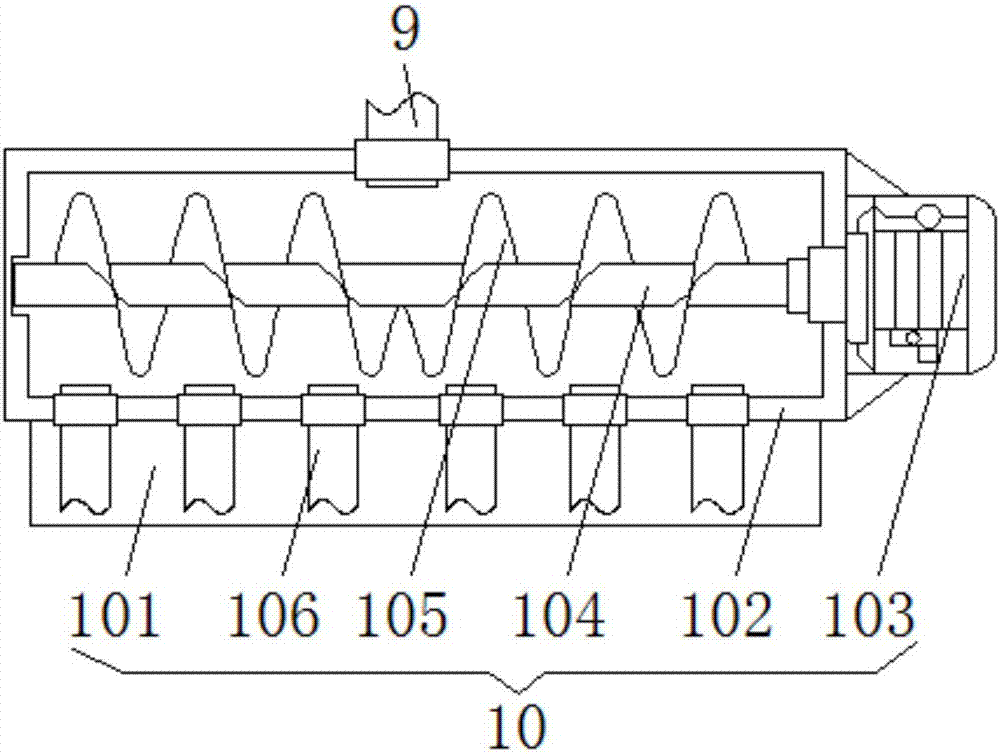

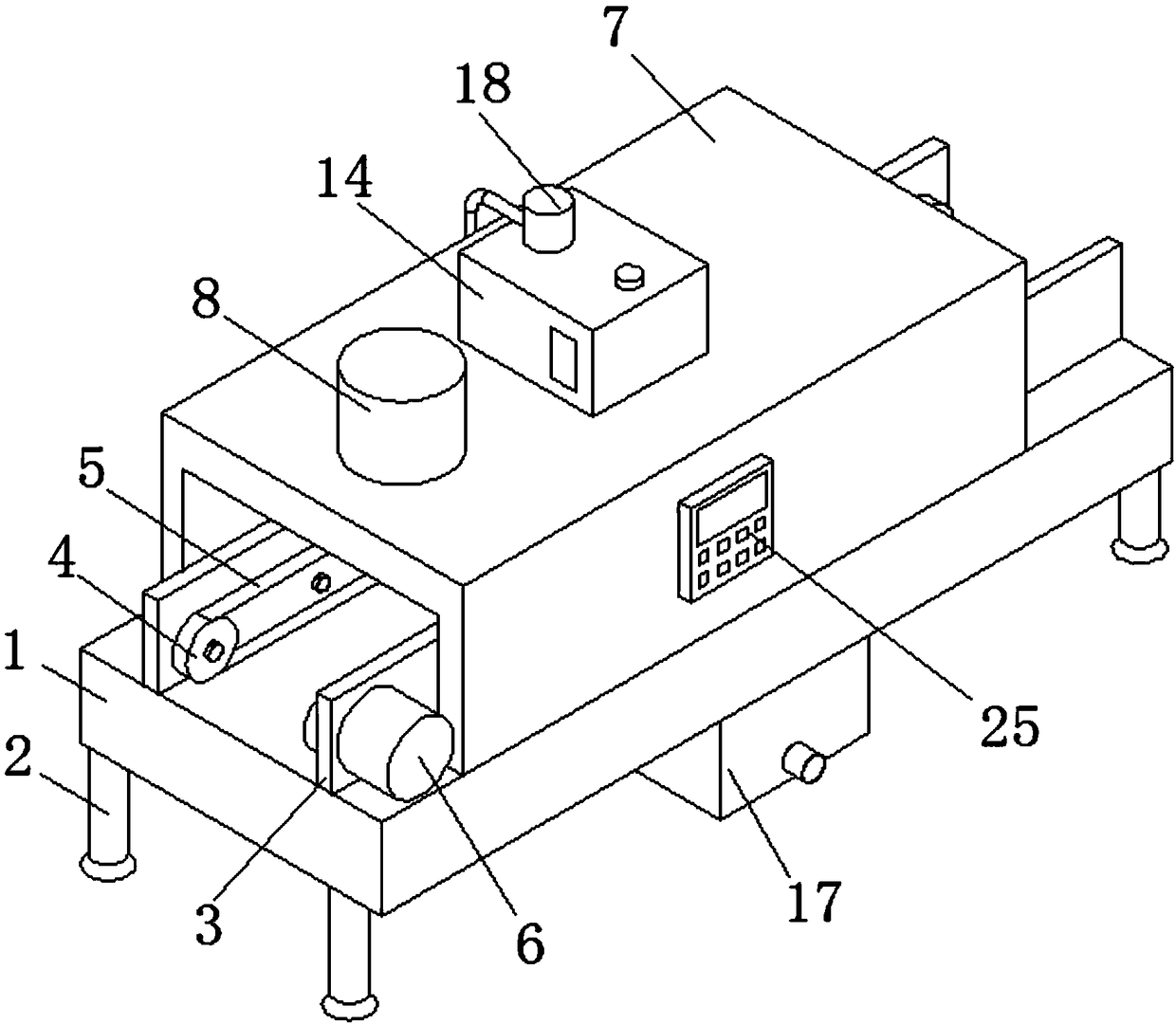

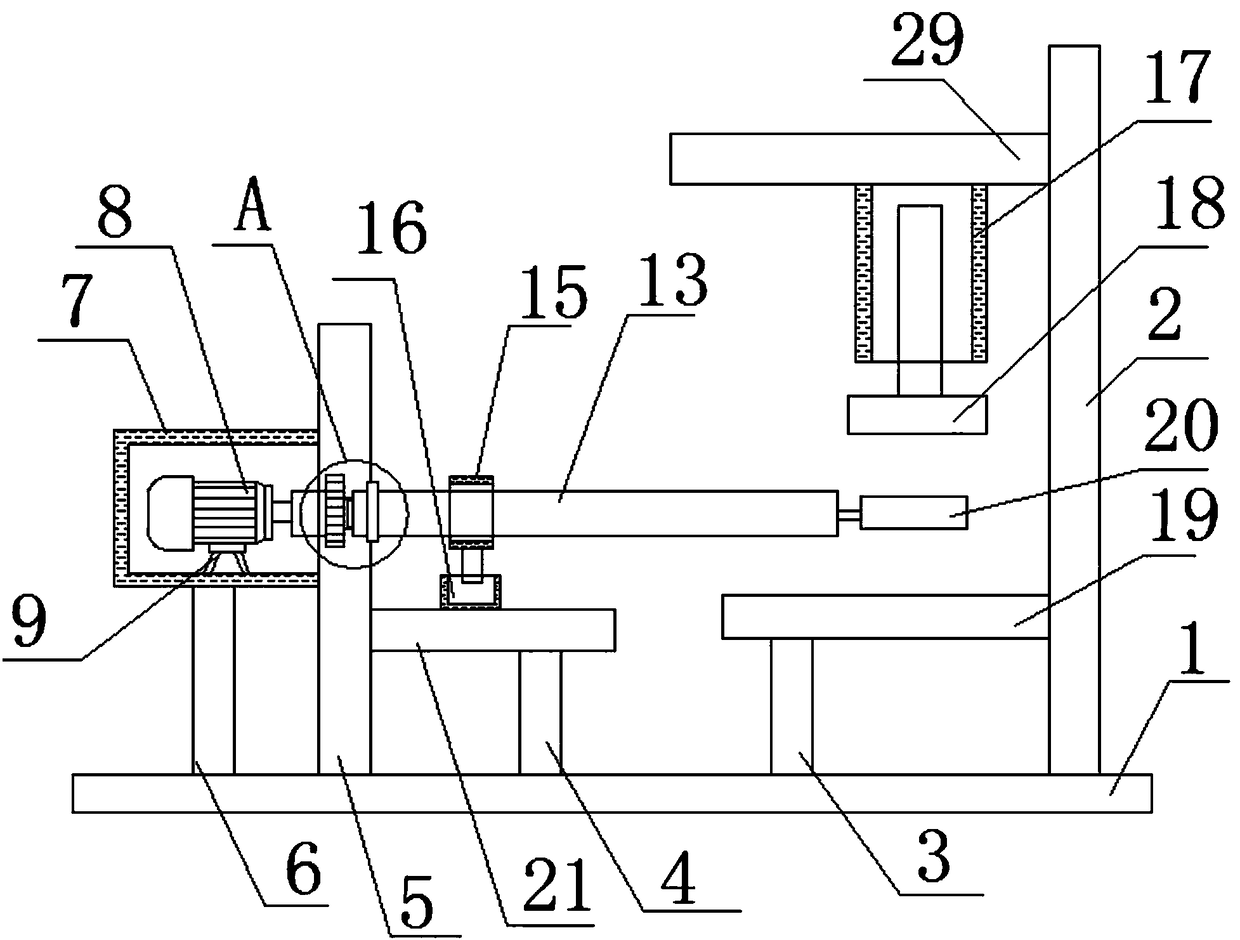

Brick paving device for sidewalks of municipal buildings

InactiveCN107513928ANo manual laying requiredReduce manual laborRoads maintainenceFixed frameArchitectural engineering

The invention discloses a brick paving device for sidewalks of municipal buildings. The brick paving device comprises a tank body, wherein a stirring tank is fixed at one side of the inner wall of the tank body, a partition board is fixed between two sides of the inner wall of the stirring tank, and a material pump is fixed at the top of the partition board; a material falling device is fixed at the bottom of the inner wall of the tank body, and a discharging hole of the material pump is communicated with the material falling device through a flexible pipe; a material smearing device is fixed at the bottom of the inner wall of the tank body, and a brick paving channel is formed in the right side of the material smearing device; a fixing frame is fixed at the top of the inner wall of the tank body, and a brick clamping device is mounted on the fixing frame; and a crawler belt conveying device is fixed on the inner wall of the tank body, and a brick smoothening plate is mounted below the crawler belt conveying device. The invention relates to the technical field of municipal constructions. The brick paving device can be used for uniformly paving cement and brickworks and is integrated with stirring and paving functions, and the manual paving is omitted, so that the use of labor force is saved, and the construction efficiency of a project is greatly improved.

Owner:陈杨平

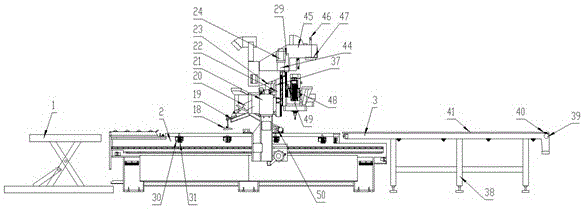

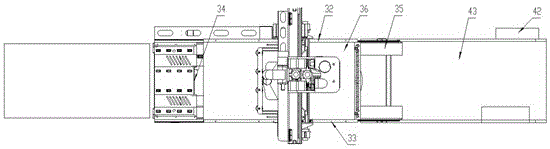

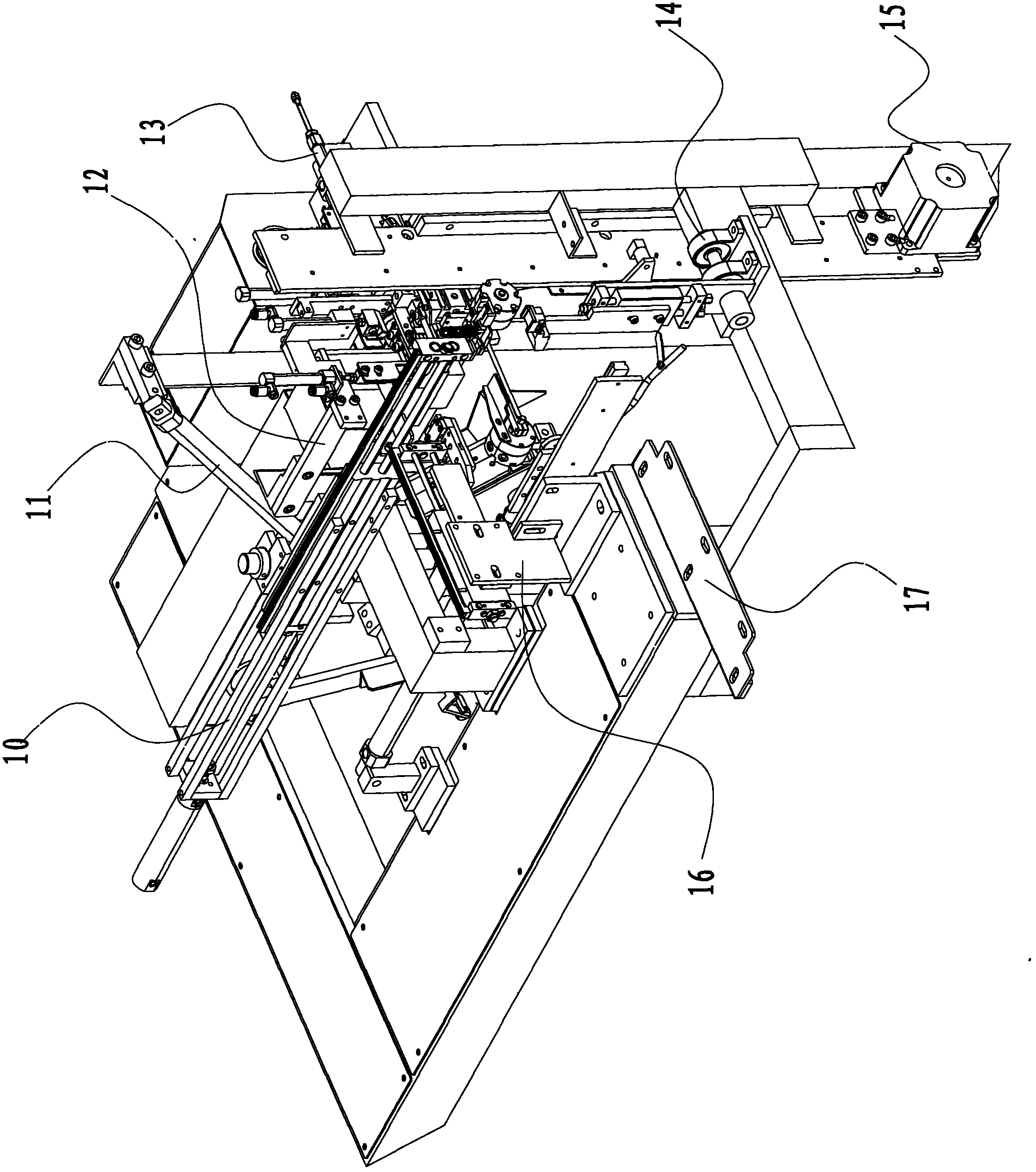

Plate type production line capable of automatically charging and discharging

InactiveCN105058142AHigh positioning accuracyIncrease profitMetal working apparatusMaintainance and safety accessoriesElectricityProduction line

The invention discloses a plate type production line capable of automatically charging and discharging. The plate type production line comprises a charging platform, a machine body and a discharging platform; the charging platform comprises a lifting platform which is arranged on a base, a shear shank is arranged at the lower part of the lifting platform, and one end of a hydraulic cylinder is connected to the base; the discharging platform consists of a motor, a reduction box, a belt, a stopping bakelite plate, a section frame, an optoelectronic switch and a rolling shaft; the machine body consists of a bed body assembly, a gantry assembly, a charging assembly, a rear locator, a lateral locating system, an X sliding plate assembly, a Z shaft assembly, a dust collection system and a pushing system. The plate type production line provided by the invention has the beneficial effects that manual labor can be reduced greatly, the plate locating precision is higher, the use ratio of plates can be improved, and the production cost can be reduced; furthermore, plates can be pushed to the discharging platform timely after the completion of plate processing, so that time that plates occupy the machine main body, after the completion of processing, can be reduced, and the production efficiency can be greatly improved.

Owner:JINAN SINGHUI CNC TECH

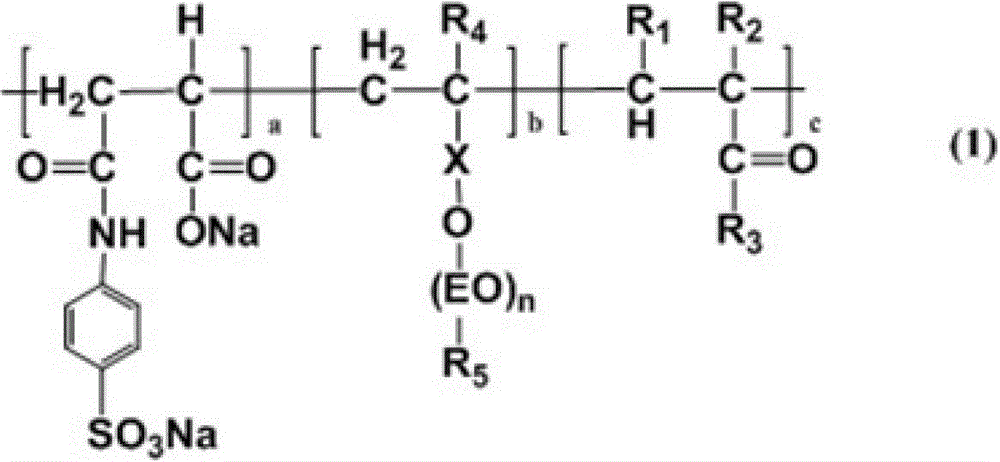

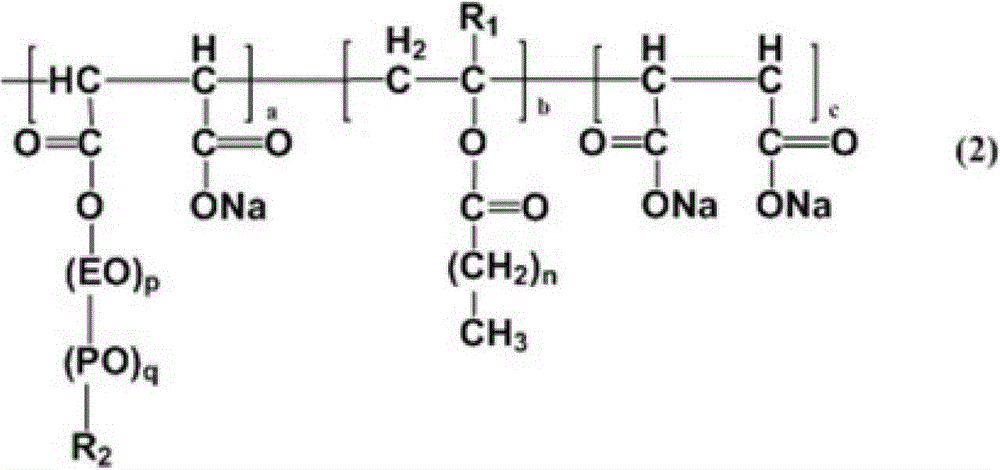

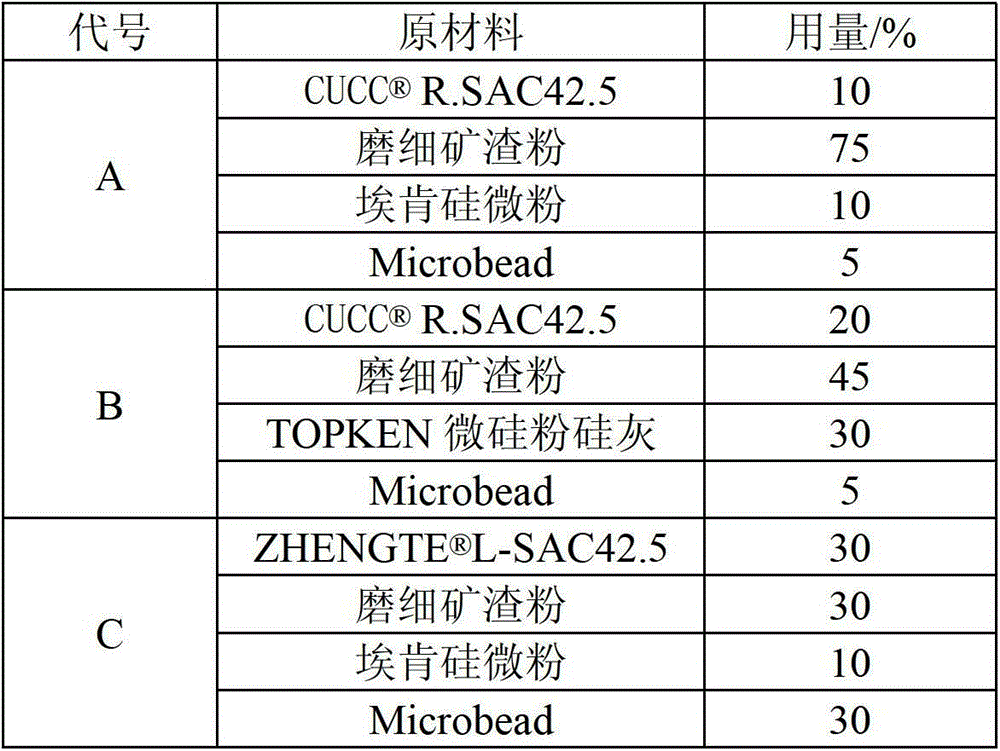

Concrete mixture for PHC (Prestressed High-strength Concrete) pipe pile and PHC pipe pile prepared therefrom

ActiveCN103145390ALow maintenance energy consumptionImprove automationHigh strength concreteCombustion

The invention discloses a concrete mixture for a PHC (Prestressed High-strength Concrete) pipe pile. The concrete mixture comprises the following raw materials: 400-520kg / m<3> of cementing material, 120-145kg / m<3> of water, 675-870kg / m<3> of sand, 1050-1110kg / m<3> of gravel and a polycarboxylate water reducing agent, wherein the usage amount of the polycarboxylate water reducing agent by mass is 1.0-1.5% the mass of the cementing material, and the cementing material is prepared from the following ingredients in percentage by mass: 80-95% of cement and 5-20% of mineral admixture. According to the concrete mixture, after centrifugal molding, the concrete mixture can be over 80MPa only through normal-pressure steam curing and short-time natural curing and can be over 85 MPa through 28-day natural curing, a high-pressure steam curing process is not needed, the production cycle is shortened, and approximately 70% of the consumption of standard combustion coal for the production of every one meter of the pipe pile can be reduced.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

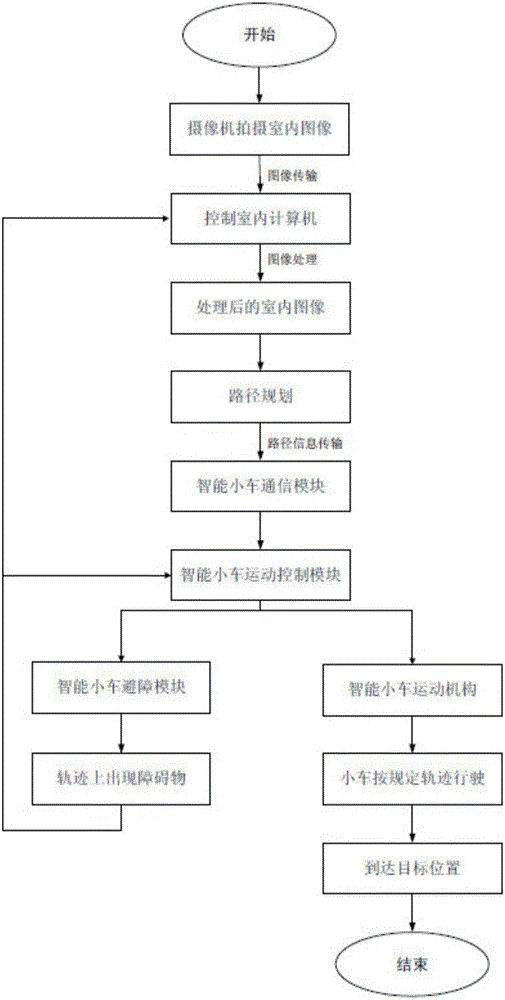

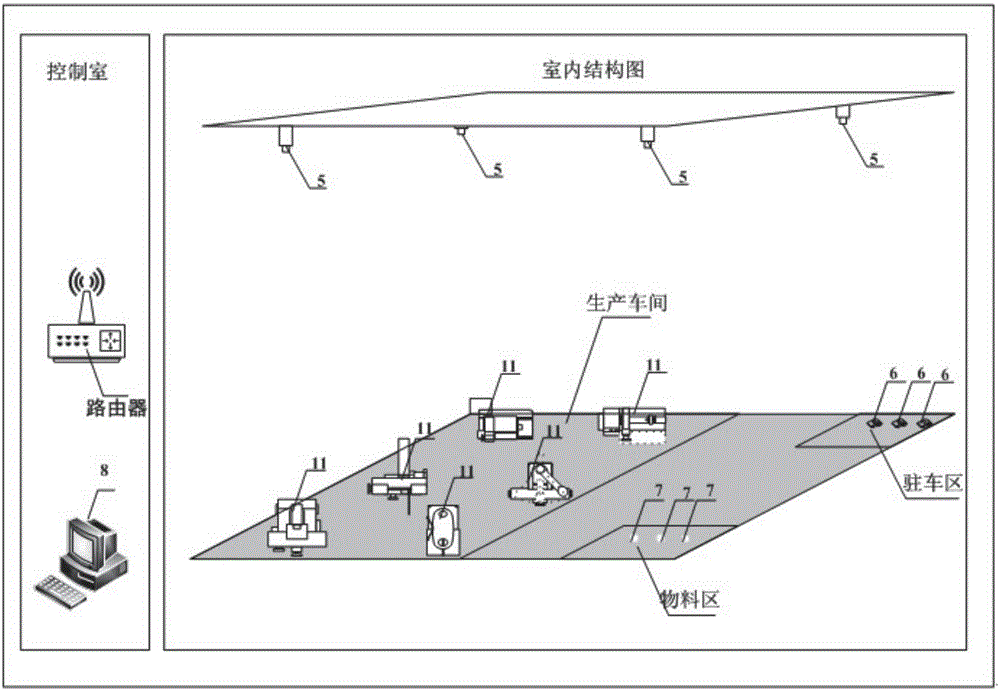

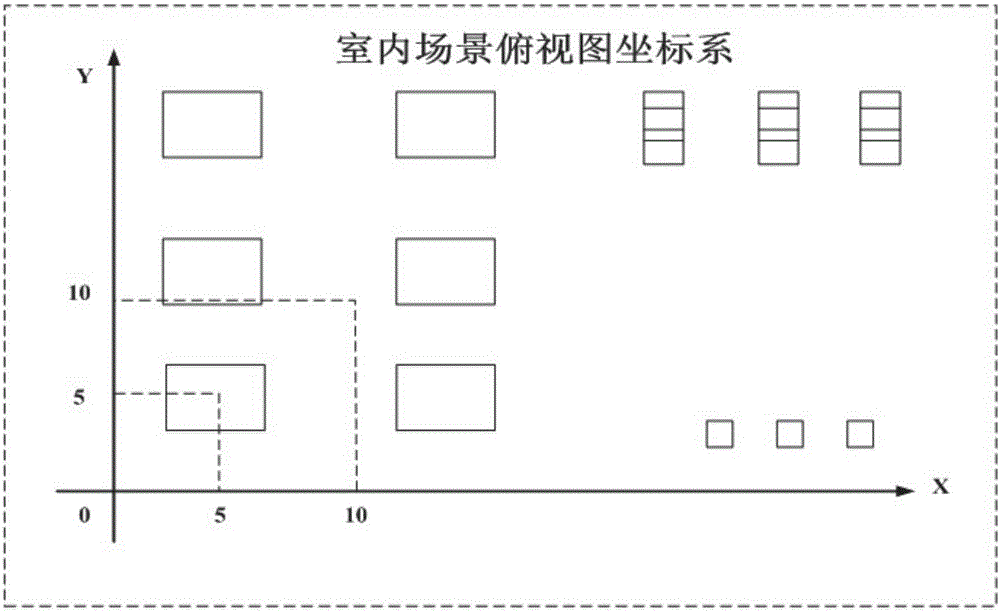

Indoor multi-target track planning system and method

InactiveCN106527426AEasy to operateImprove flexibilityPosition/course control in two dimensionsMultiple targetVideo camera

The invention discloses an indoor multi-target track planning system and method wherein the entire system of the method comprises a plurality of cameras, a computer, a wireless router and smart small vehicles. The plurality of cameras photograph the indoor scenes in real time and the photographed images are transmitted to the computer in the control room through a wireless transmission network. The computer firstly pre-processes the photographed images and then, the photographed images are spliced. The computer plans barrier-free paths from the starting points of the various indoor smart small vehicles to a target point. Through the wireless transmission network, the path information is transmitted to the communication modules of various smart small vehicles. The movement control modules of the smart small vehicles control the movement of the smart small vehicles according to the received instruction information. The barrier avoiding modules of the smart small vehicles cooperate and work with each other in their moving process to assist the smart small vehicles to steer clear of the barriers. The system and the method of the invention increase the flexibility of indoor smart small vehicles in their running, raise the automatic running level of the indoor smart small vehicles and play an important scientific role and have great application value.

Owner:JIANGSU UNIV

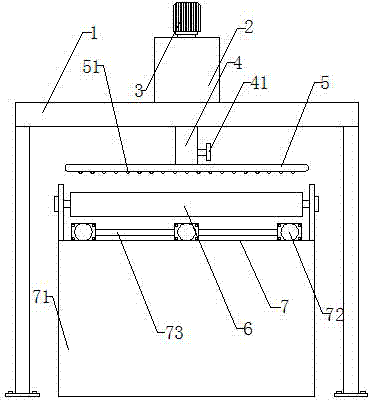

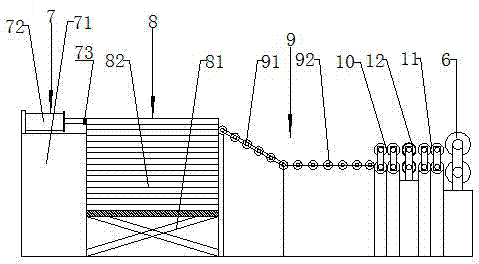

Layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials

ActiveCN104708689AFast processingSpread evenlyOther plywood/veneer working apparatusAdhesive application devicesProduction lineEngineering

The invention discloses layer-by-layer automatic feeding, marking and gluing integrated equipment for sheet materials. The layer-by-layer automatic feeding, marking and gluing integrated equipment for the sheet materials comprises a marking device and a gluing device; the gluing device is arranged on one side of the marking device and a layer-by-layer automatic feeding device is arranged on the other side of the marking device; the layer-by-layer automatic feeding device comprises a pushing mechanism, a hoisting mechanism and a sliding mechanism in sequence; and the gluing device comprises a supporting framework, a stirring mechanism arranged at the upper end of the supporting framework, a material scattering mechanism arranged at the bottom of a transverse beam of the supporting framework, and a compression roller gluing mechanism arranged under the supporting framework. According to the layer-by-layer automatic feeding, marking and gluing integrated equipment, marking and gluing are integrated, transmission and interruption of machines are reduced in the process and the consistency of a production line is improved; and the machining time of the whole sheet material is shortened, materials can be automatically fed layer by layer, the transmission is buffered, the gluing can be automatically realized and the gluing is uniform.

Owner:JIANGSU KENTIER WOOD

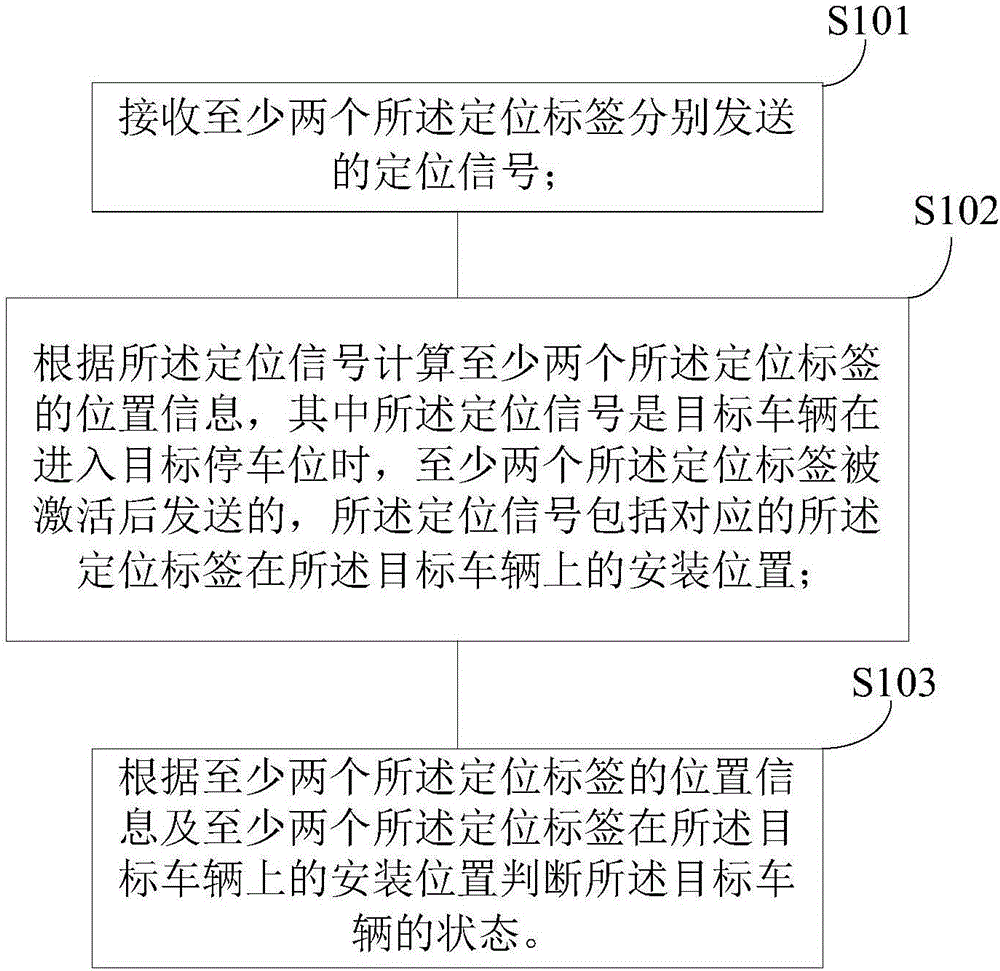

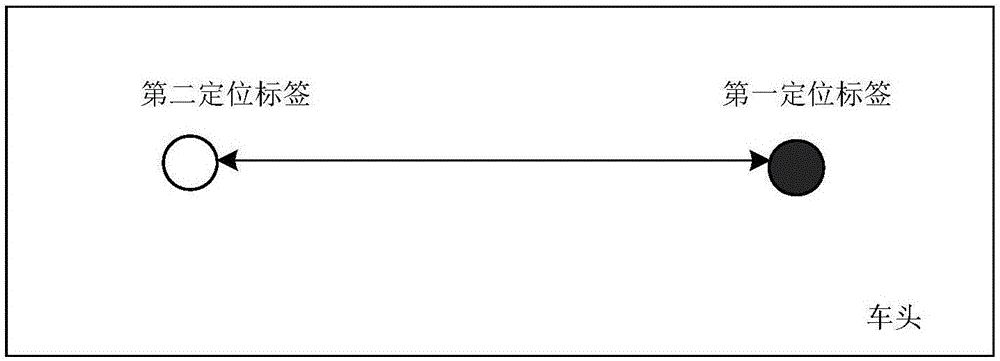

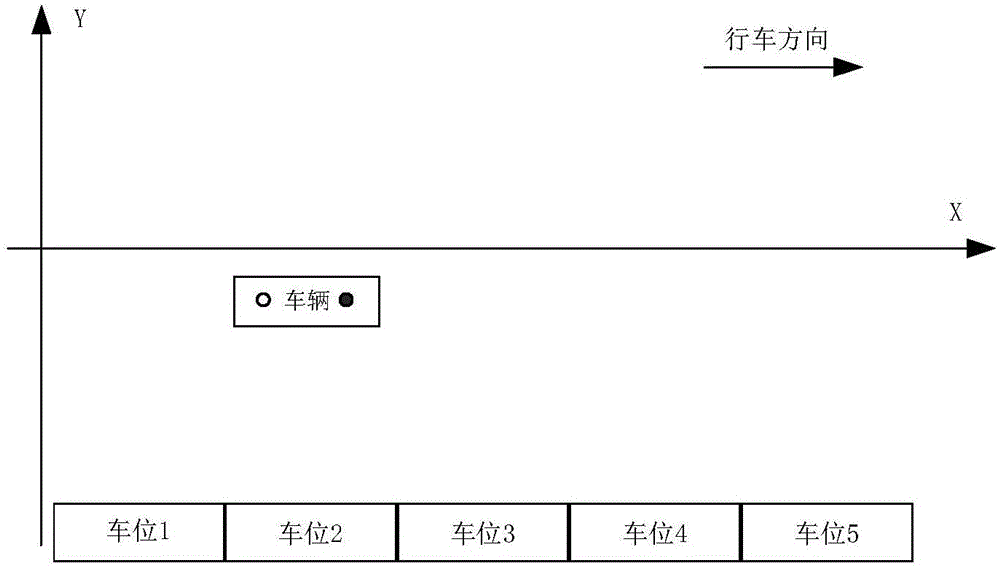

Vehicle parking detection method, terminal, server and system

ActiveCN106297317AImprove accuracyReduce manual laborRoad vehicles traffic controlComputer terminalReal-time computing

The invention provides a vehicle parking detection method, a vehicle parking detection terminal, a vehicle parking detection server and a vehicle parking detection system. The vehicle parking detection method is applied to a target vehicle equipped with a gesture detection terminal; the gesture detection terminal comprises at least two positioning labels arranged at different positions of the target vehicle respectively; the vehicle parking detection method comprises the following steps: receiving positioning signals sent by the at least two positioning labels respectively; calculating position information of the at least two positioning labels, wherein the positioning signals comprise mounting positions of the corresponding positioning labels on the target vehicle; according to the position information of the at least two positioning labels and the mounting positions of the at least two positioning labels on the target vehicle, judging the state of the target vehicle. By the vehicle parking detection method, various illegal parking states of the target vehicle can be determined through a plurality of labels, so that the accuracy of illegal parking detection is improved and the manual labor is reduced.

Owner:SHENZHEN GENVICT TECH

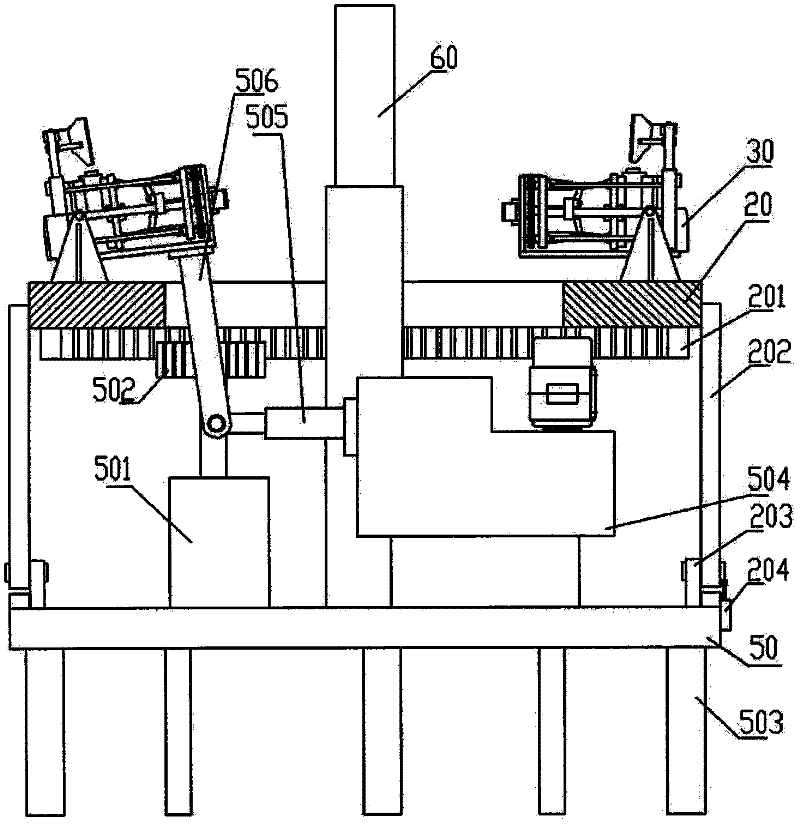

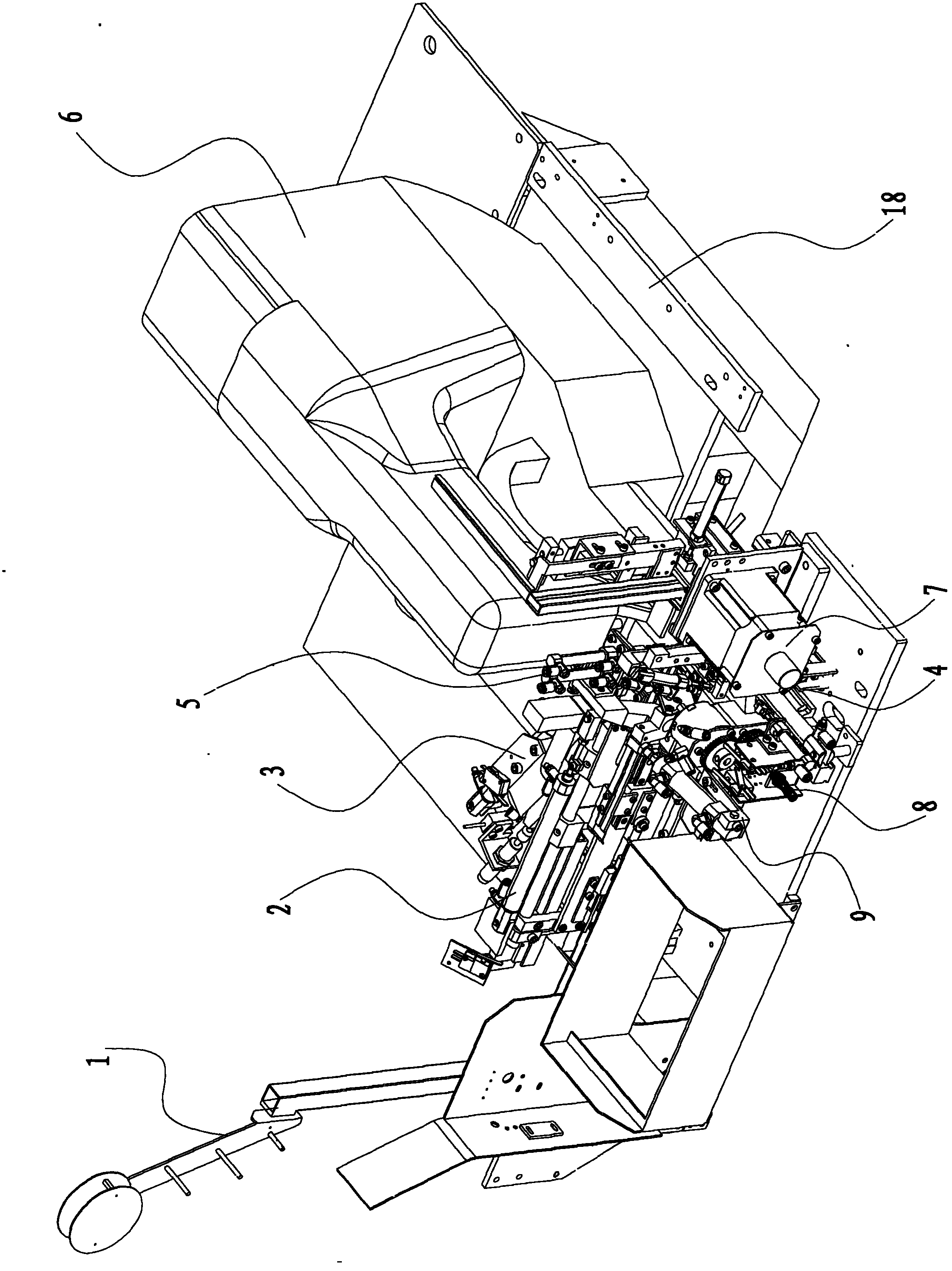

Full-automatic shoulder belt sewing machine

InactiveCN102605562AReasonable structural designEasy to useWorkpiece carriersWork-feeding meansEngineeringSewing machine

The invention relates to a full-automatic shoulder belt sewing machine which consists of a front processing machine and a rear processing machine which are spliced and fastened together by a front processing machine connecting plate and a rear processing machine connecting plate; the front processing machine mainly comprises a belt conveying device, a belt pushing device, a belt cutting device, an eight-button conveying device, a nine-button conveying device or a zero-button conveying device, a belt threading device, a rotary button turning device, a belt drawing device and a sewing device; the belt pushing device is connected with the belt conveying device; the belt threading device is connected with the belt drawing device, the eight-button conveying device, the nine-button conveying device or the zero-button conveying device; and the rear processing machine mainly comprises a belt connecting device, a rear processing belt drawing device, a belt protecting device, a secondary rotarybutton turning device, a belt head clamping device, a tensioning device and a belt connecting button pushing device. By the design of the shoulder belt sewing machine, the automatic button threading of eight buttons and nine buttons on the shoulder belt can be realized; and the front processing machine and the rear processing machine are assembled independently, thereby facilitating the conveyingsafety.

Owner:尤文聘

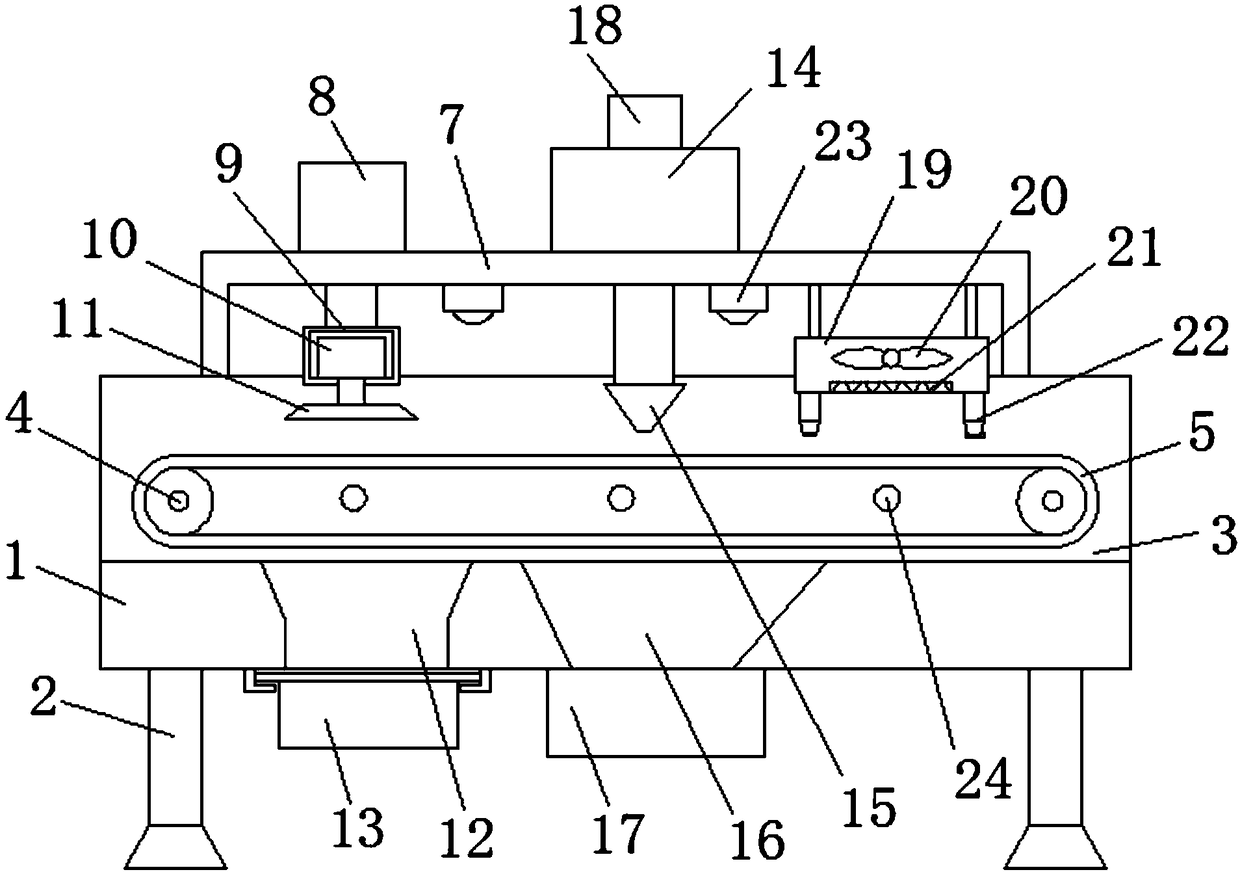

Metal sheet polishing washing device for machining

InactiveCN108296899AQuick clean upSmall footprintCleaning using toolsGrinding feedersSprayerArchitectural engineering

The invention discloses a metal sheet polishing washing device for machining. The metal sheet polishing washing device for machining comprises a base, fixing plates are welded to the front and back ends of the top of the base, rollers are installed on the two ends of the inner sides of the two fixing plates, the surfaces of the rollers are sleeved with a conveying belt body, a shell is welded to the position, located on the outer sides of the fixing plate, of the top of the base, an electric cylinder body is fixedly installed on the left side of the top of the shell, and an output shaft of theelectric cylinder body penetrates the shell to be fixedly connected with an installing frame; and a variable frequency motor is fixedly installed inside the installing frame, an output shaft of the variable frequency motor is fixedly connected with a polishing disc, a water tank is fixedly installed at the middle portion of the top of the shell, and the bottom of the water tank penetrates the shell through a pipe to be fixedly connected with an electric sprayer. The metal sheet polishing washing device is simple and reasonable in structural design, convenient to operate, small in occupied land, low in machining cost, safe, stable, wide in application scope and favorable for generalization and popularization, time and labor are saved, and the working efficiency is improved.

Owner:闻斌壹

Turnable forging device for production of environment-friendly materials

InactiveCN108213309AReduce work accidentsReduce manual laborForging/hammering/pressing machinesMotor driveEngineering

The invention discloses a turnable forging device for production of environment-friendly materials. The turnable forging device comprises a base. A first fixing plate, a first support plate, a secondsupport plate, a second fixing plate and a third support plate are connected to the upper end face of the base sequentially. A mounting box is fixedly connected to the other end of the third support plate. A first motor is arranged in the mounting box. A support frame is connected to the lower end face of the first motor fixedly. A rotating rod is fixedly connected with one end of a rotating shaftof the first motor. The turnable forging device has the advantages that a second motor drives a worm to rotate, a clamping plate moves close to the middle on a screw rod until a workpiece is clamped,the clamping plate completely enters a clamping groove through movement of a first hydraulic elongator, the rotating rod is rotated by 180 degrees through rotation of the first motor to turn over theworkpiece, and the workpiece falls off through retraction of the first hydraulic elongator and reverse rotation of the second motor, so that the workpiece is turned over by 180 degrees mechanically,labor is reduced, working efficiency is improved, and accidents of workers are reduced.

Owner:合肥信比欣新材料有限公司

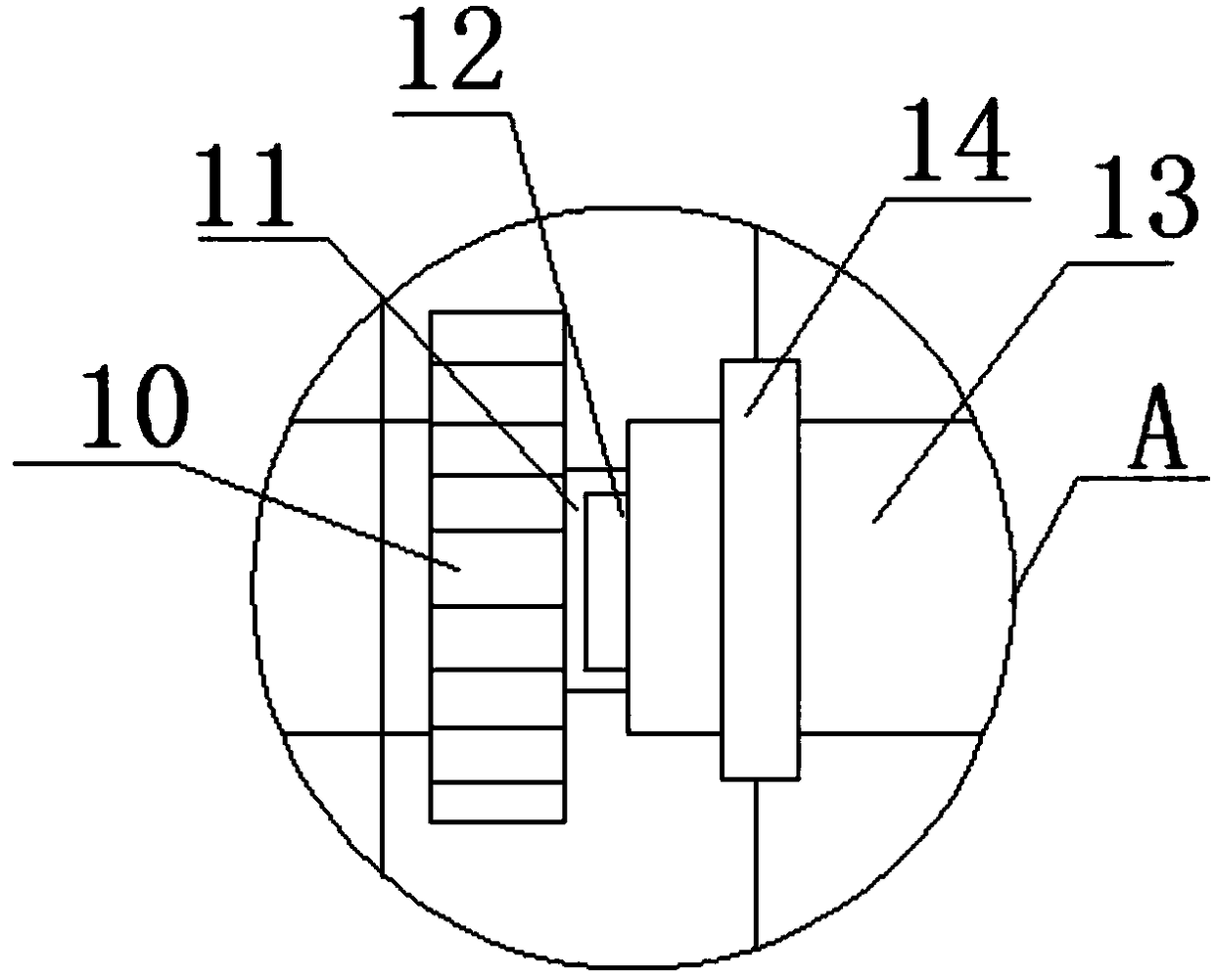

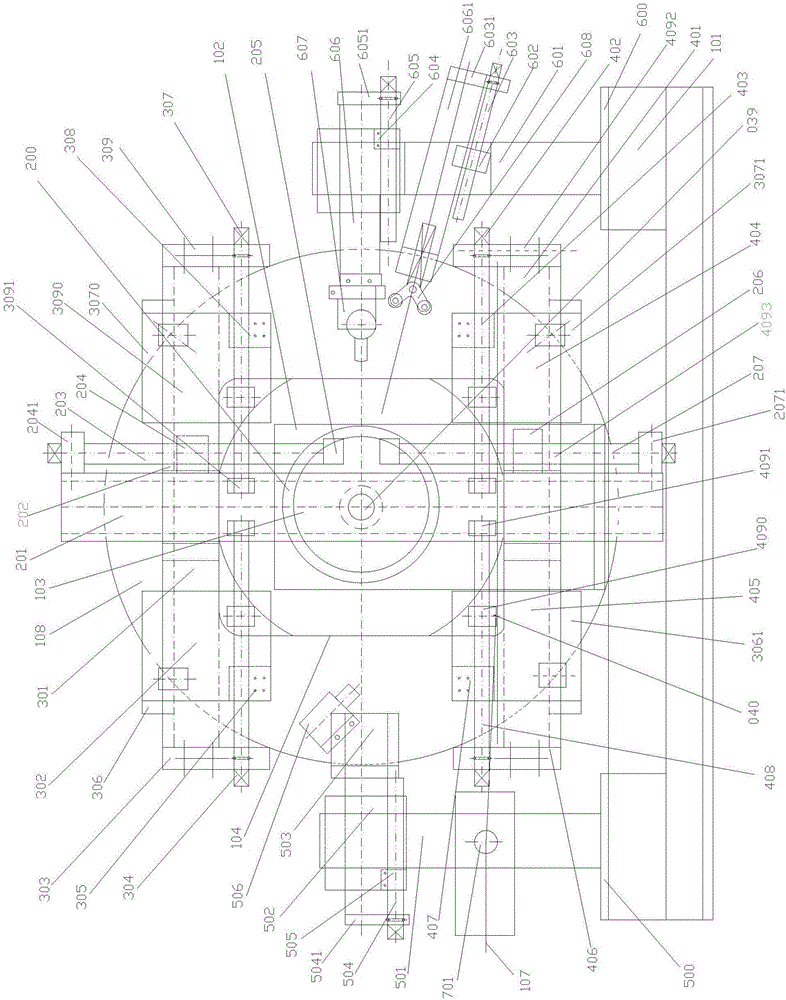

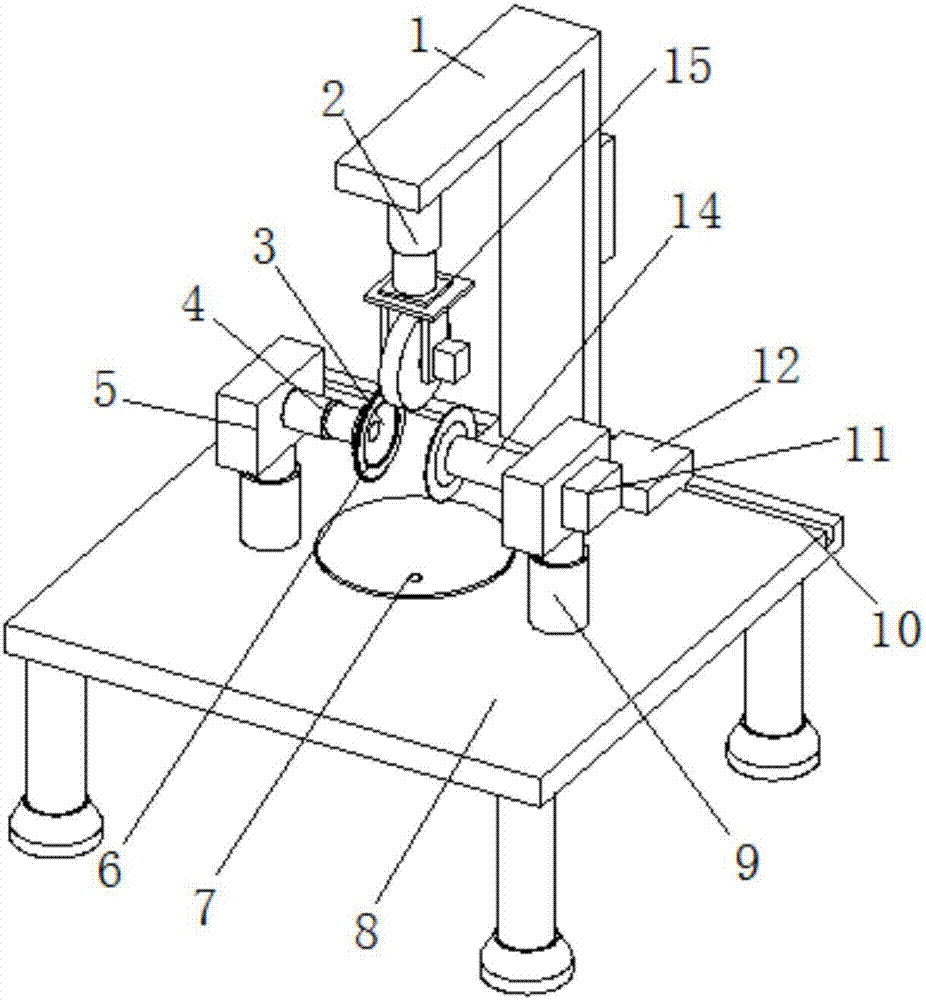

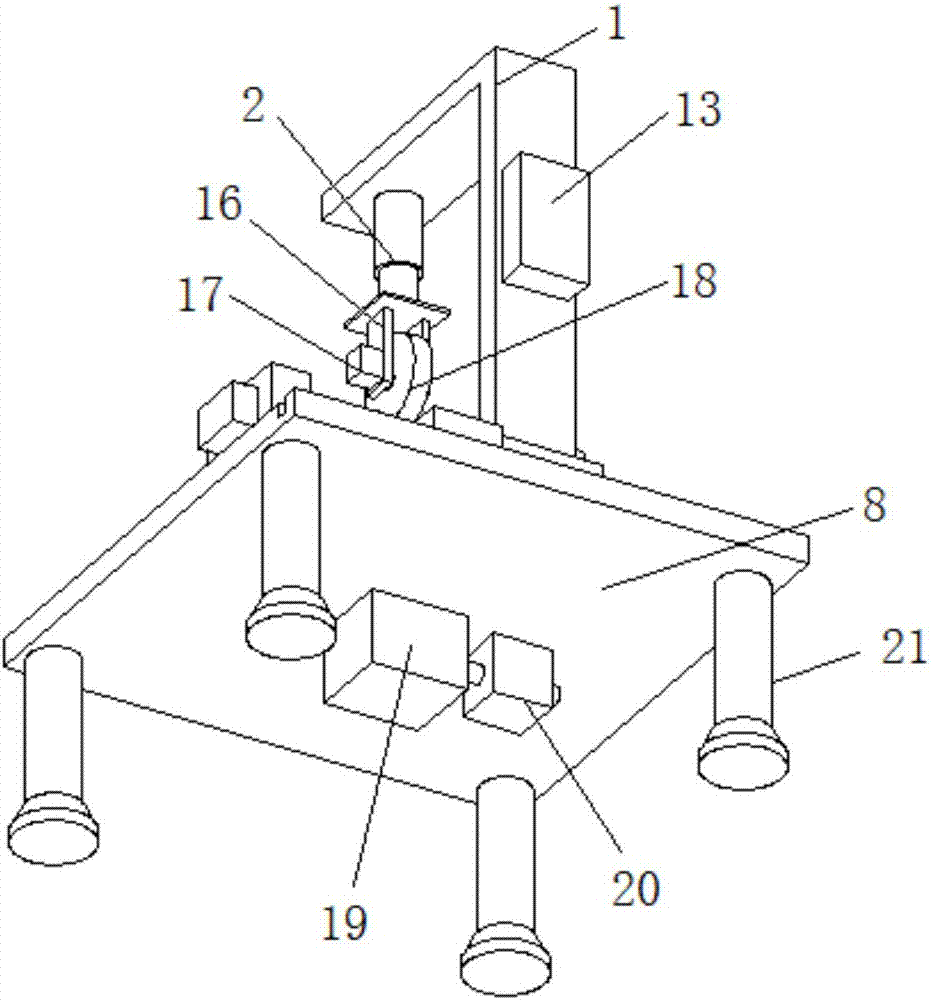

Spiral stirrup continuously and synchronously machining machine and machining method

The invention discloses a spiral stirrup continuously and synchronously machining machine and a machining method. The machining machine comprises a machine body seat, a spiral stirrup machining device and a monitoring device. The spiral stirrup machining device comprises a rotary workbench, a stirrup winding mechanism, a feeding mechanism and a cutting mechanism. The stirrup winding mechanism comprises a stirrup twining frame, a rolling type bending mechanism and a screw pitch axial feed mechanism. The monitoring device comprises a control device, a counting unit and a rotating speed measuring unit. The machining method comprises the first step of determining the number of winding shafts and the installation position, the second step of adjusting the positions of the winding shafts, the third step of feeding and positioning stirrup material, the fourth step of forming spiral stirrups and the fifth step of cutting spiral stirrups. The machining machine is simple in structure, continuous machining of spiral stirrups is achieved, and the production efficiency is high; meanwhile, the concrete constraining force of beam columns of buildings can be improved through the produced spiral stirrups, and therefore the seismic capacity of the buildings is improved. Practicality is high, and the machining machine and the machining method are low in carbon, environmentally friendly and efficient and save energy.

Owner:刘国政 +1

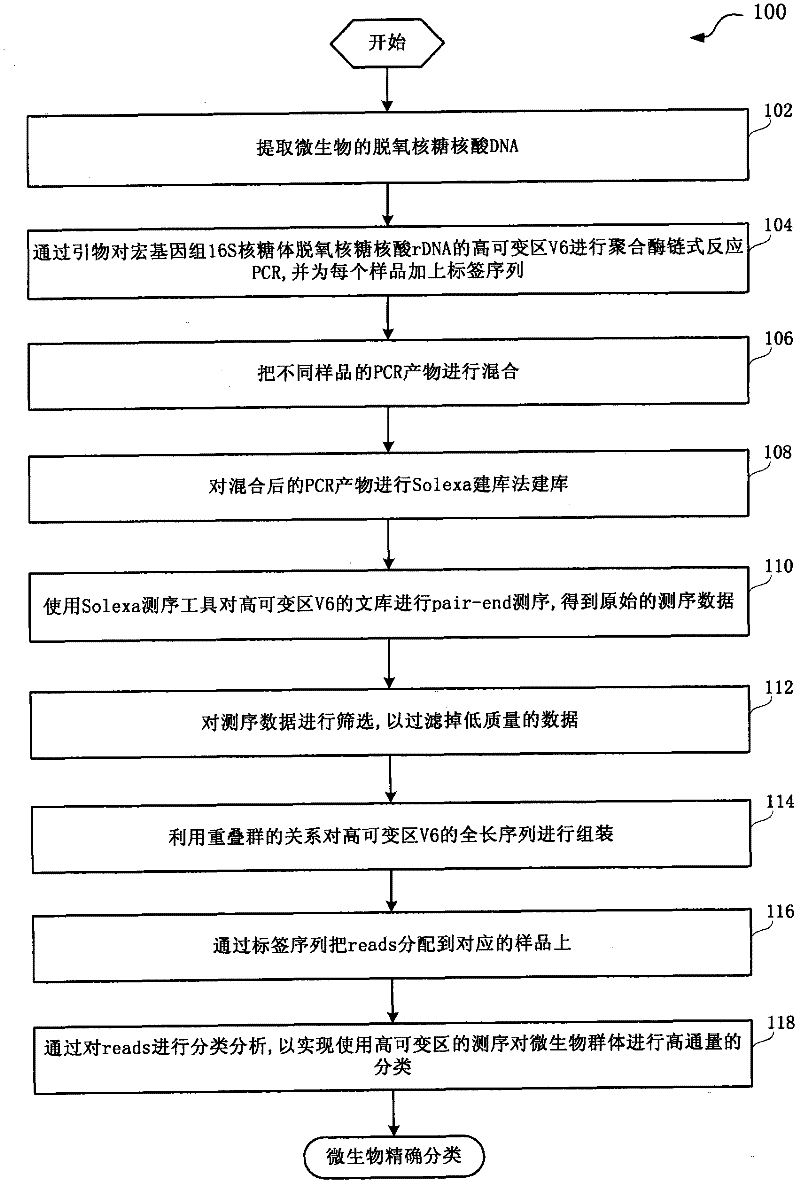

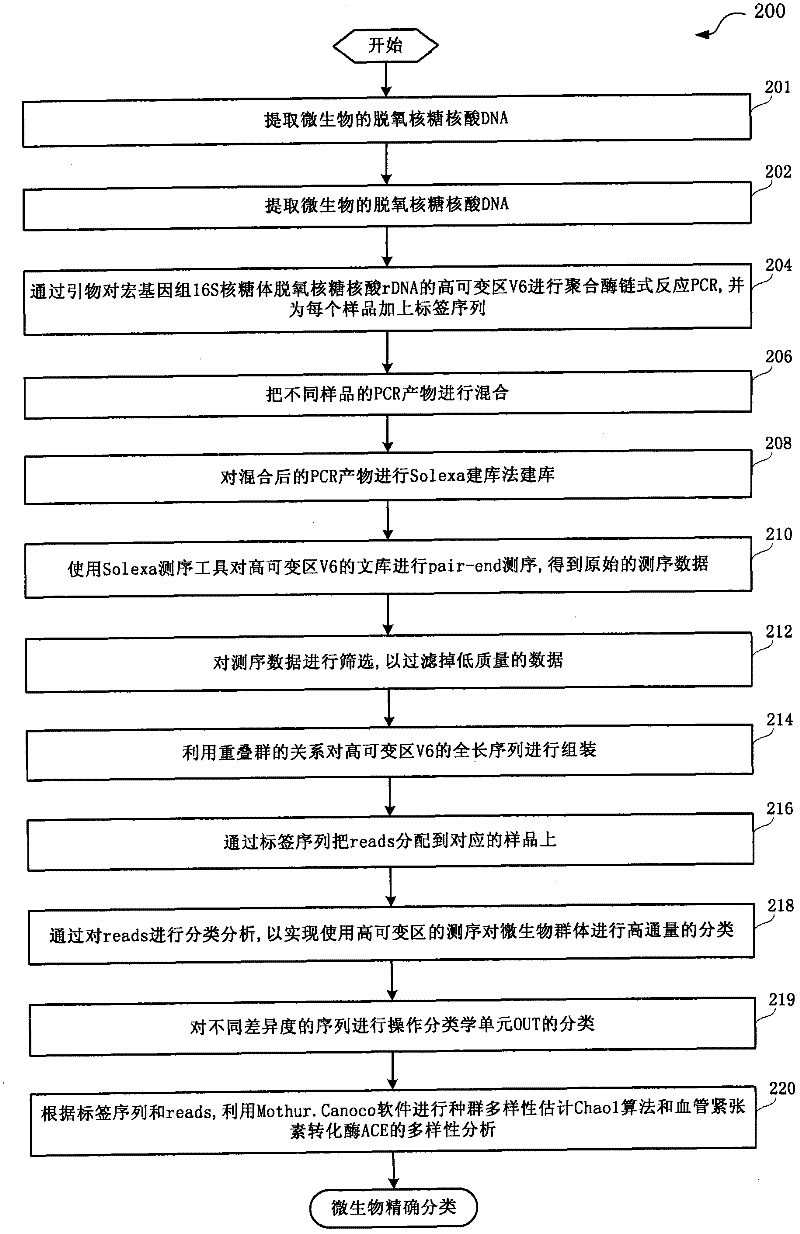

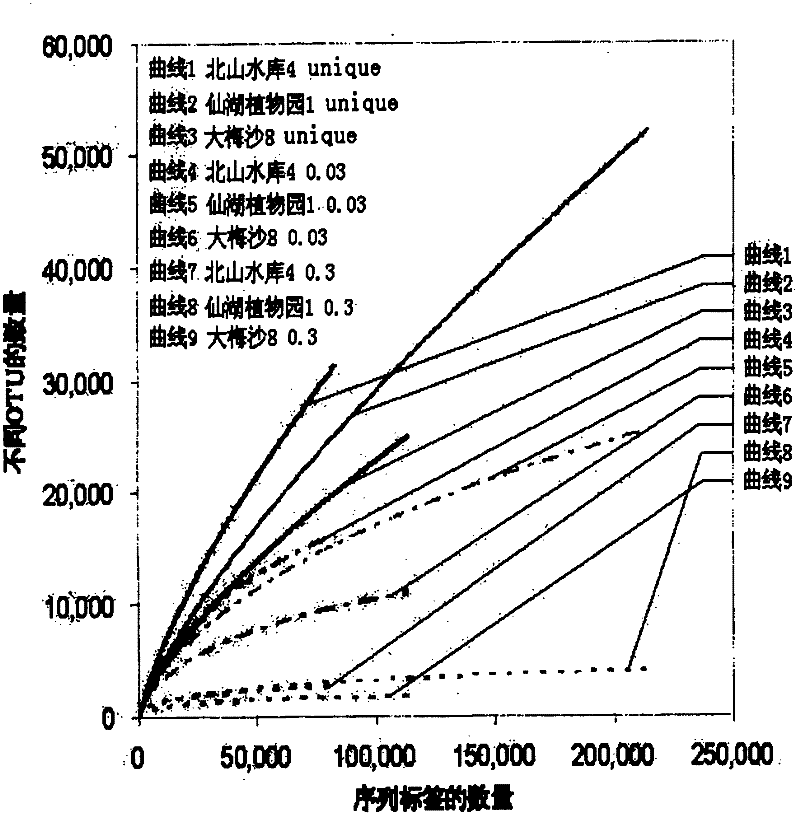

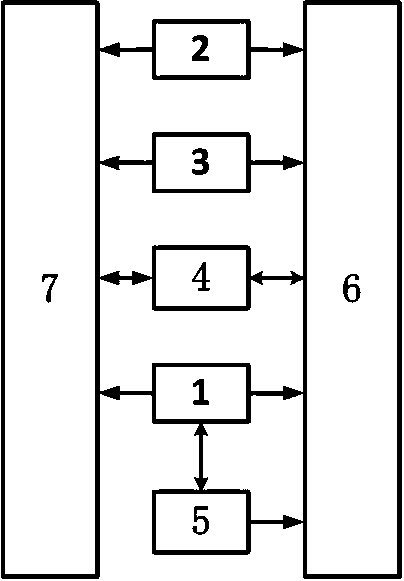

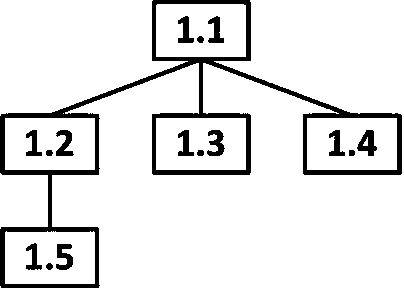

Method for performing sequencing and cluster analysis on V6 hypervariable region of metagenomic 16S rDNA

InactiveCN102477460AReduce manual laborSave moneyMicrobiological testing/measurementPopulationSequencing data

The invention discloses a method for performing sequencing and cluster analysis on V6 hypervariable regions of metagenomic 16S rDNAs. The method comprises the following steps of: extracting DNAs of microbes; performing polymerase chain reaction (PCR) on V6 hypervariable regions of metagenomic 16S rDNAs, and inserting a tag sequence in each sample; hybridizing PCR products of different samples; setting a database of hybrid PCR products by Solexa method; performing pair-end sequencing on the library of V6 hypervariable regions by using Solexa sequencing tools to obtain primary sequencing data; screening the sequencing data to filter low-quality data; assembling full-length sequences of the V6 hypervariable regions by means of contig relationship; distributing reads to the corresponding samples by the tag sequences; and performing classification analysis on the reads to complete high-throughput and accurate classification of microbial populations by sequencing the hypervariable regions.

Owner:BGI SHENZHEN CO LTD +1

Driverless tractor control system and control method

PendingCN110531764AEnsure safetyImprove reliabilityPosition/course control in two dimensionsDecision controlEnvironmental perception

A driverless tractor control system and control method comprises: a satellite positioning module, an environmental perception module, a telecontrol interference module, a cloud platform module, a pathplanning module, a decision-making control module and a security module. The satellite positioning module, the environmental perception module, the telecontrol interference module, the cloud platformmodule and the path planning module are separately connected to the decision-making control module. The satellite positioning module, the environmental perception module, the telecontrol interferencemodule and the cloud platform module are separately connected to the security module. The satellite positioning module is connected to the path planning module. Because a multisensor of a laser radar, a millimeter wave radar and a machine vision camera is used, reliability is high, and a type and a distance of a barrier are identified more accurately and fast. There are the telecontrol interference module and the cloud platform module, so that security and usability of the driverless tractor are significantly improved. Two path planning modes of a nesting mode and a shuttling mode are developed, which are convenient and flexible, so that efficiency is improved, and a requirement of collaborative operation among multiple machines can be met.

Owner:FIRST TRACTOR

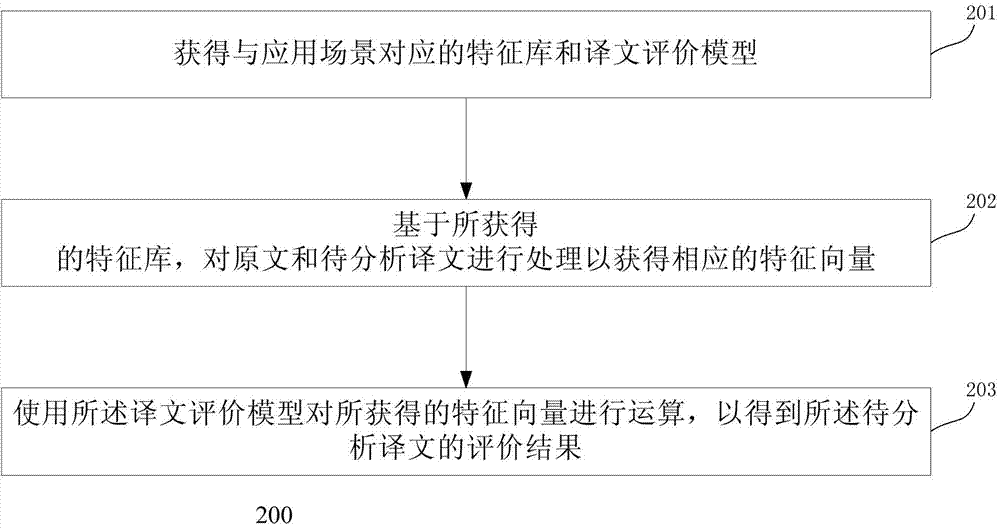

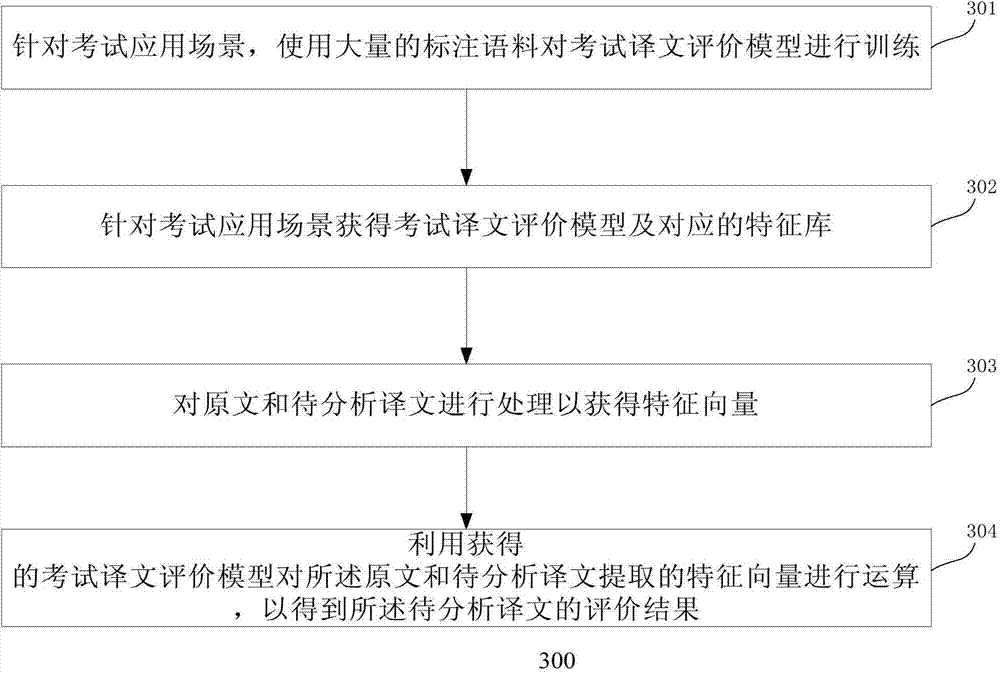

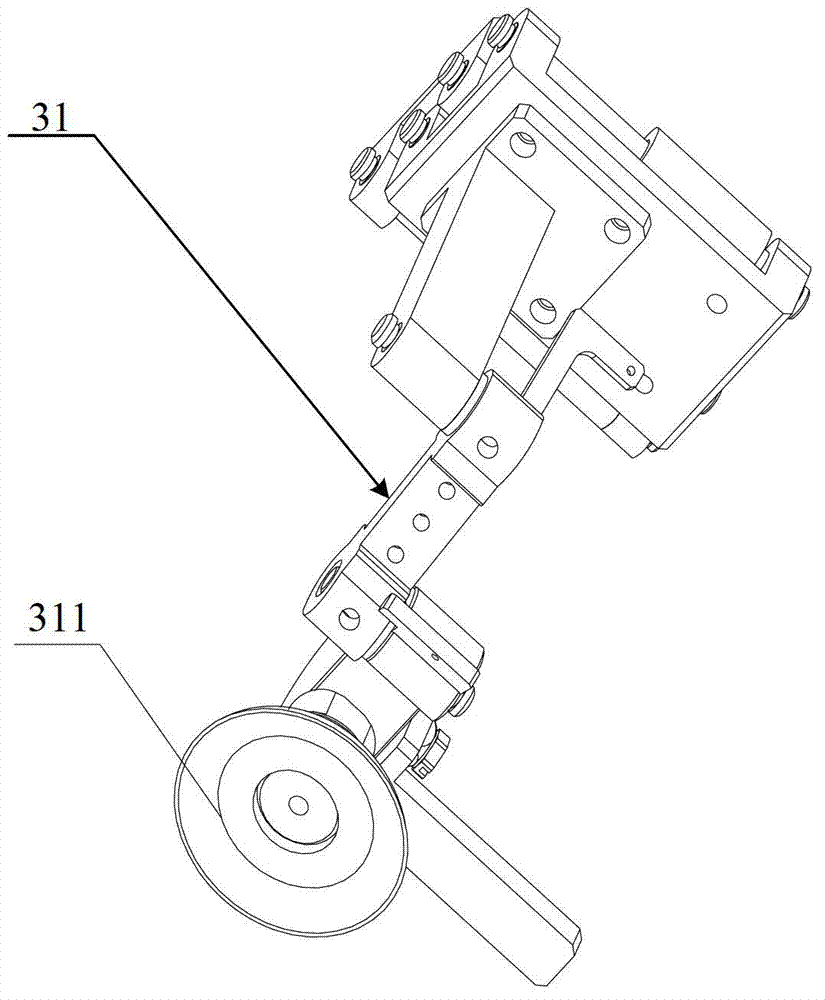

Translation evaluation method and device

ActiveCN104731777ANo language restrictionsThe evaluation result is accurateSpecial data processing applicationsNatural language processingFeature vector

The embodiment of the invention provides a translation evaluation method. The method includes the steps that feature libraries and translation evaluation models corresponding to application scenarios are acquired; an original text and the translation to be analyzed are processed based on the acquired feature libraries so as to acquire corresponding feature vectors; the translation evaluation models are used for calculating the acquired feature vectors, so that the evaluation result of the translation to be analyzed is obtained. According to the method, the adaptive feature libraries and the translation evaluation models can be selected to be used for evaluating the translation to be analyzed according to different application scenarios, so that the evaluation result is more accurate, the manual labor is reduced, the language types of the original text and the translation are not limited, and the method is suitable for various application scenarios. In addition, the embodiment of the invention provides a translation evaluation device.

Owner:网易有道信息技术(北京)有限公司

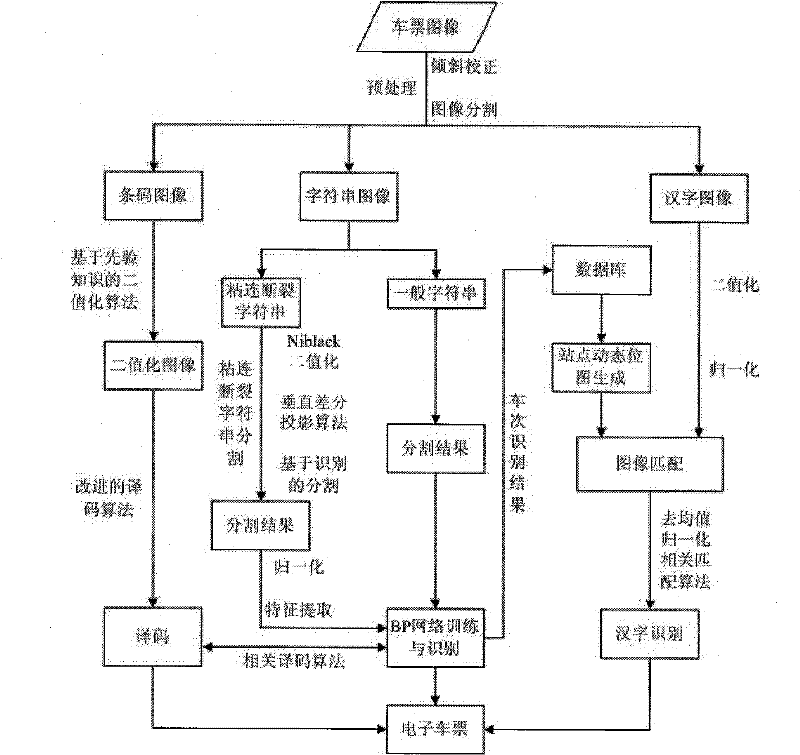

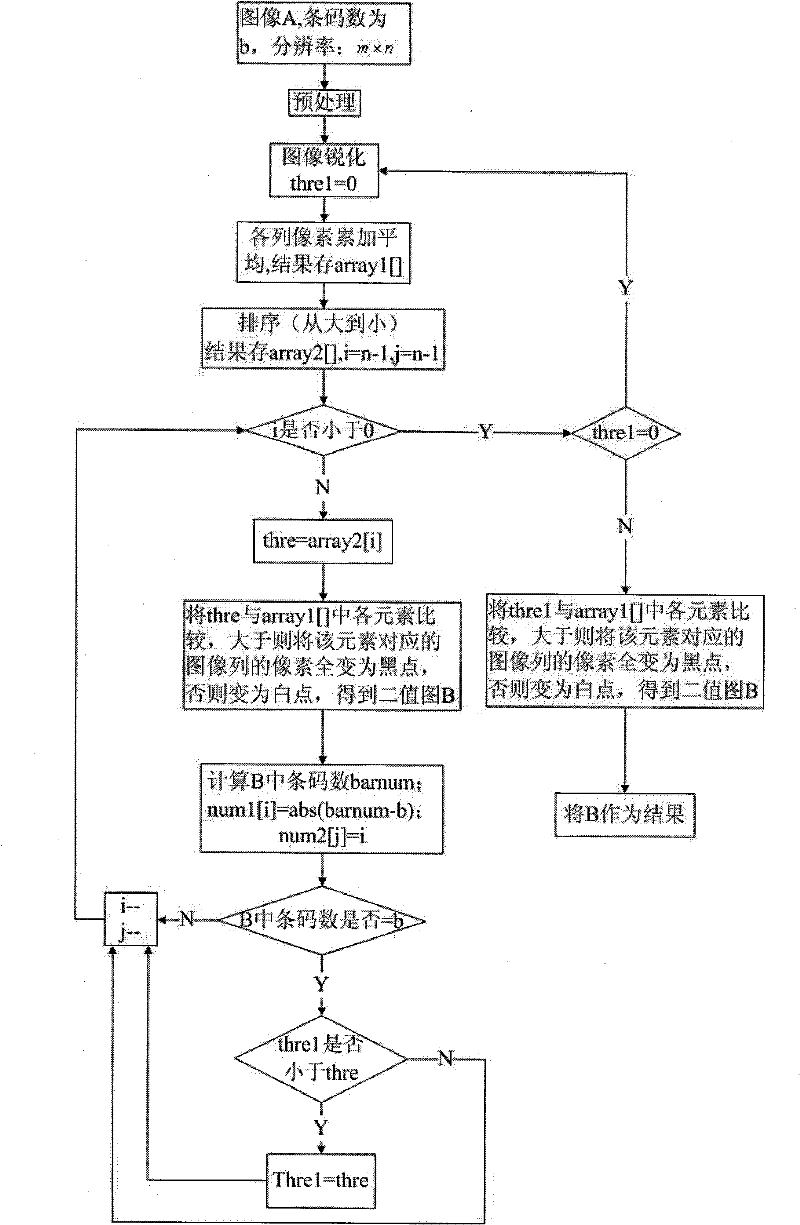

Automatic ticket checking method for train tickets

InactiveCN102194275AAccurate identificationReduce manual laborPaper-money testing devicesCharacter and pattern recognitionImaging processingChinese characters

The invention discloses an automatic ticket checking method for train tickets. The automatic ticket checking method comprises the following steps: segmenting each train ticket image through pretreatment to get three types of main text information (character strings, bar codes and Chinese characters), further realizing text content identification through a mode identification means based on image processing, and realizing automatic ticket checking of the train tickets on the basis of identification. By adopting the method, the identification of the text information of the train tickets can be effectively realized, the identification rate is higher, and the identification speed is fast; and the various text information of the train tickets can be effectively got, the ticket checking of the train tickets can be realized fast, and the accuracy in ticket checking is high.

Owner:党力

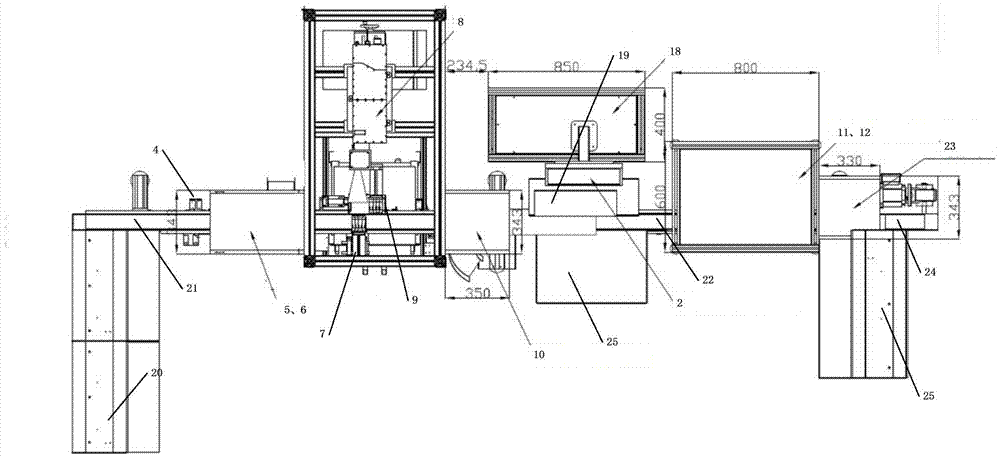

Production line device used for similar multistage assembly product code assigning and tracing

ActiveCN104494985AVersatilityLow costPackaging automatic controlSensing by electromagnetic radiationProduction lineAutomatic control

The invention is suitable for the technical field of automatic control, and provides a production line device used for similar multistage assembly product code assigning and tracing. A first bar code reader 5 is used for reading EAN-13 codes of single stage products after separation, a first rejection device 6 is used for rejecting the single stage products with the reading EAN-13 codes, not involved in current work order information, a first obstruction cylinder 7 is used for obstructing the single stage products under a laser coding machine 8, the laser coding machine 8 is used for printing two-dimensional codes on the upward sides of the single stage products, a first pushing cylinder 9 is used for pushing the obstructed single stage products periodically, an interval separation device 10 is used for separating the single stage products moving again at equal intervals according to a setup parameter, a two-dimensional code collector 11 is used for reading the two-dimensional codes of the single stage products, and a second rejection device 12 is used for rejecting the single stage products with the two-dimensional codes which cannot be read successfully. Through operations of an IPC and a PLC device, the parameter setting is finished, so that the production line device can produce special-type or special-stage finished products as required, and has the universality, and the cost is reduced.

Owner:武汉华工赛百数据系统有限公司

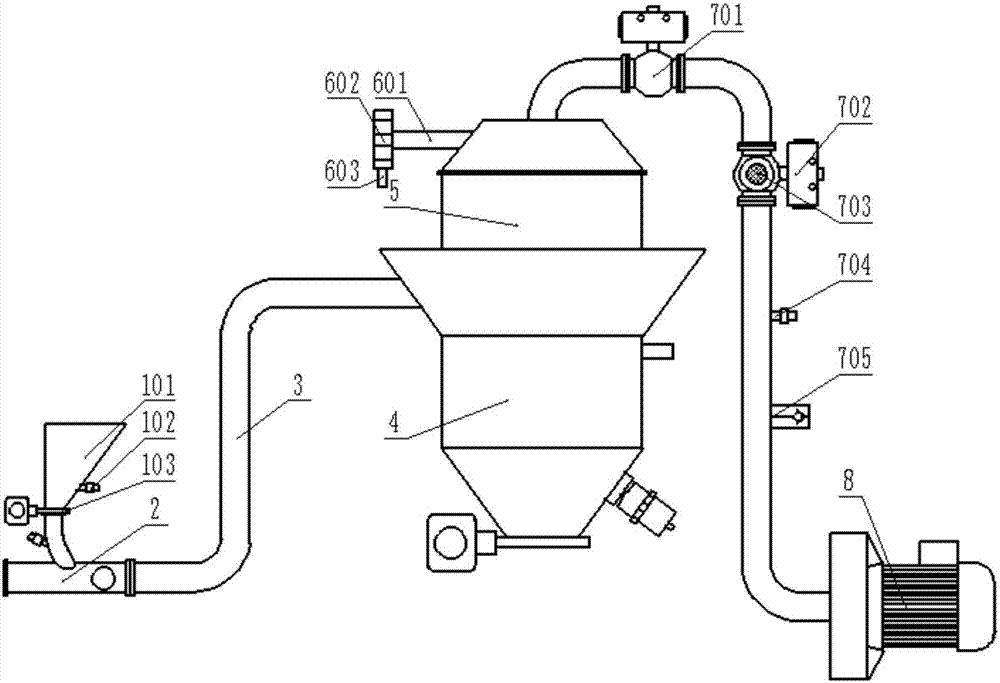

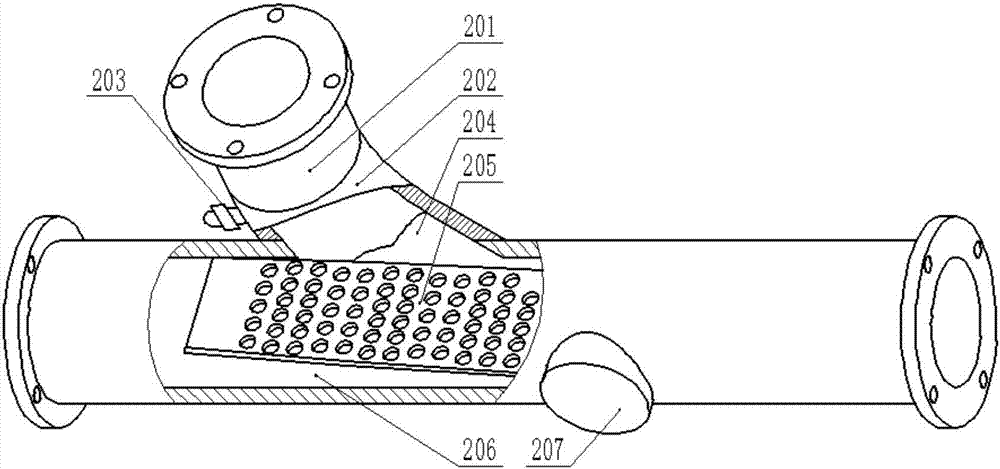

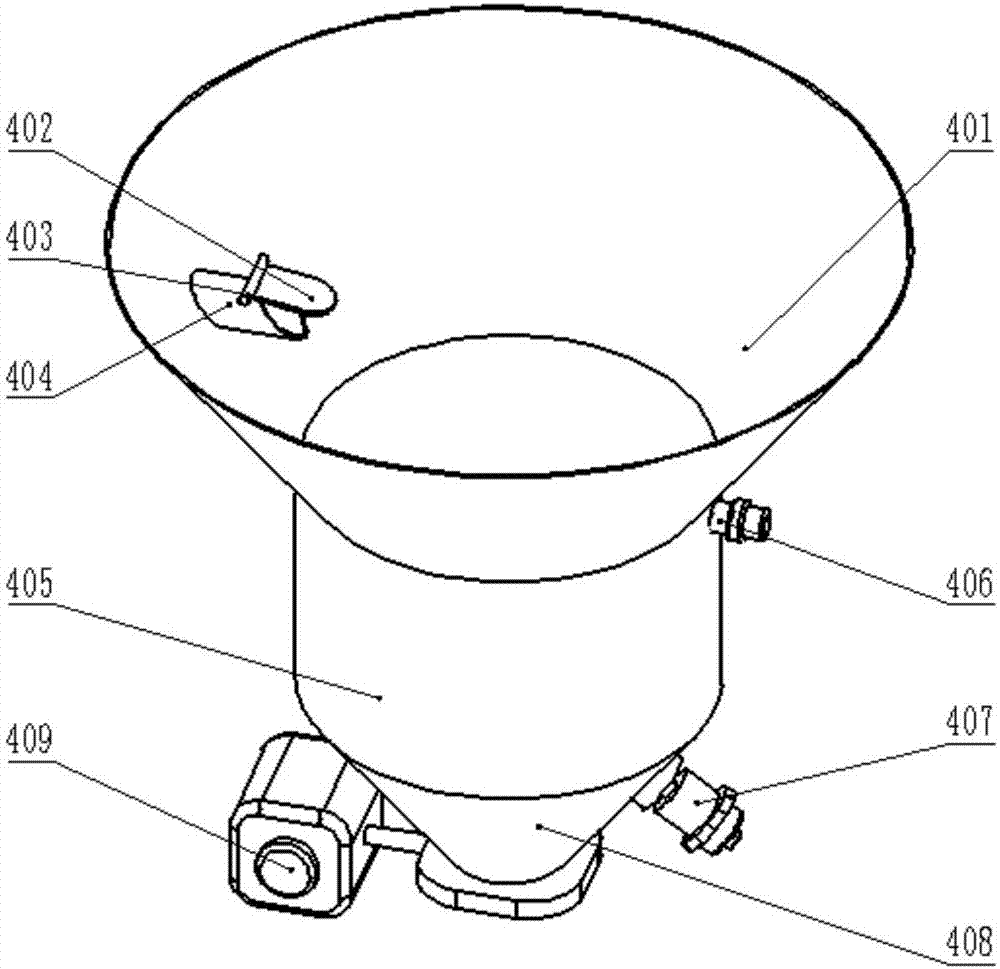

System and method for intermittent negative-pressure pneumatic conveying for powder

The invention provides a system and a method for intermittent negative-pressure pneumatic conveying for a powder. The system comprises a feeding device, a horizontal feeder, a conveying pipeline, a separator, a dust remover, a blowback device, an air source, auxiliary equipment and a control device. According to the system and the method, the possibility of arching in a hopper and adhesion onto the wall of the hopper, of materials, is lowered, through using an air nozzle air-supplementing device and the novel horizontal feeder; the safety of the system is improved through installing a safety valve and a vacuum pressure sensor; the cost is lowered and the floor area is reduced by virtue of the integrated structure of the separator and the dust remover; the filter effect is enhanced and the number of filters is reduced through designing a filter with a novel structure; a pneumatic component and an electromagnetic valve are matched by virtue of the characteristics of high flexibility and high reliability of a PLC; and the need of frequently starting up and turning off a fan in order to realize an intermittent conveying manner at the present stage is avoided through using a ball valve. The system provided by the invention has the advantages of being simple in structure, low in cost, high in automation degree, high in conveying speed and the like, and reduces human labour.

Owner:JIANGSU UNIV

Grinding device for outer edges of automobile fittings

InactiveCN106985026ASimple structureSimple and fast operationEdge grinding machinesGrinding work supportsEngineeringLinear motor

The invention discloses a grinding device for outer edges of automobile fittings. The grinding device comprises a workbench, wherein two slide grooves are formed in one side of the workbench; linear motors which are in sliding connection are arranged inside the slide grooves; one side of each linear motor is connected with an L-shaped bracket through a connecting base; the lower surface of a transverse rod of each L-shaped bracket is connected with a first electric telescopic pole through a bolt; a grinding wheel can be driven by a second motor to rotate for grinding the fittings, so that grinding is more convenient; the fittings are fixed through a fixing disc, so that the fittings are fixed more conveniently; the fittings can be driven by a first motor to rotate, so that the edges of the fittings re grinded, and therefore, the grinding is more convenient; and through the collecting disc, grinded chippings can be collected. The grinding device for outer edges of the automobile fittings is simple in structure, is simple and convenient to operate, can automatically grind the fittings for enabling the grinding to be more convenient, and also can collect the grinded chippings.

Owner:江苏恒丰橡胶制品有限公司

Intelligent unmanned freight vehicle, shared system and business model

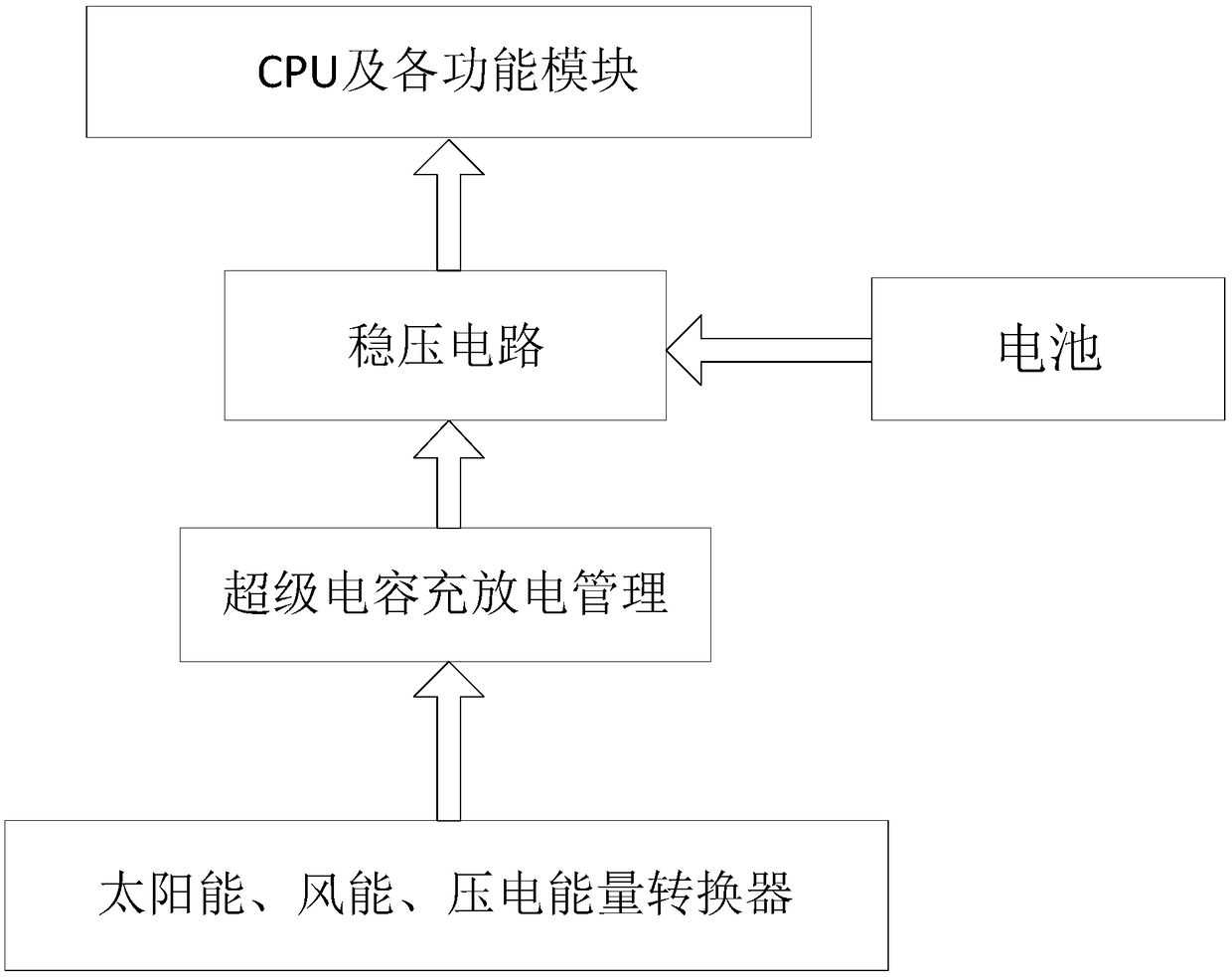

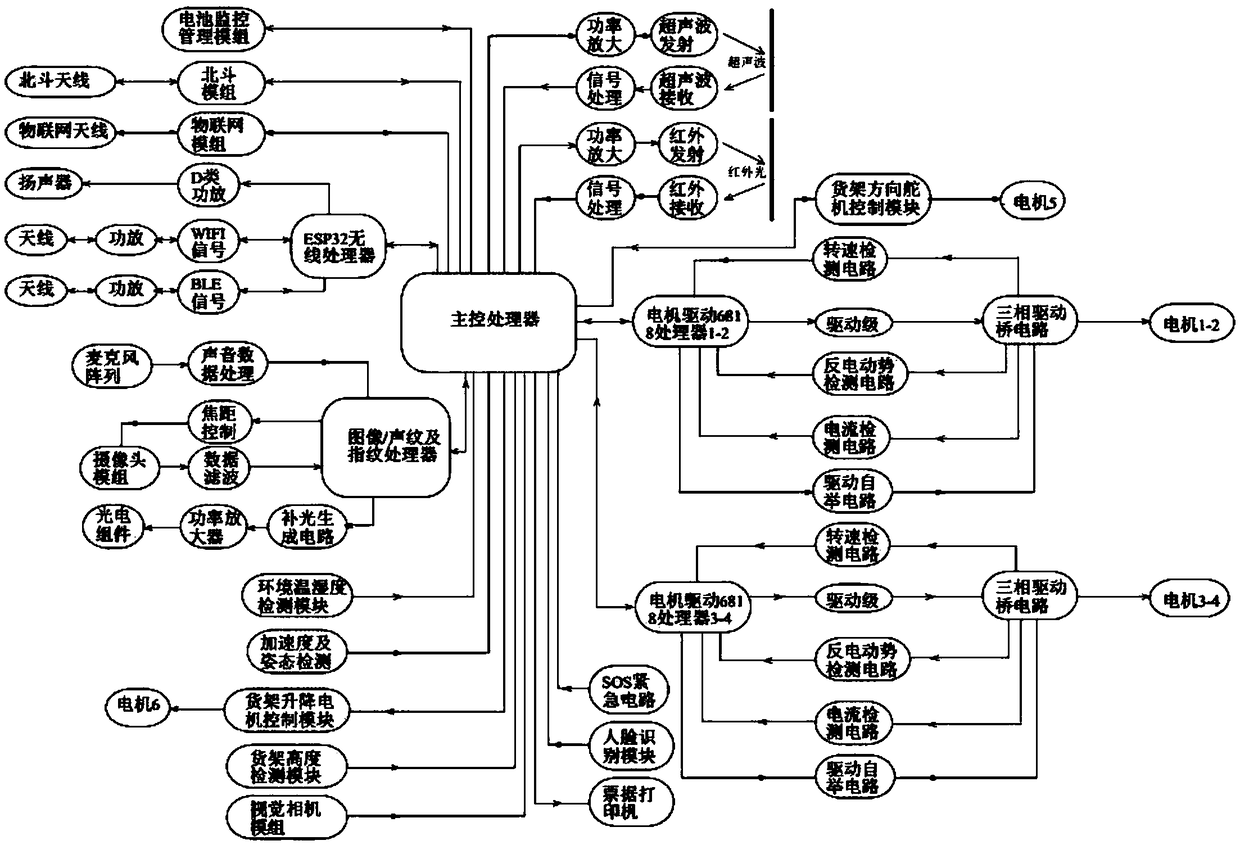

PendingCN109146361AEasy to search onlineSpeed up the flowBuying/selling/leasing transactionsLogisticsBattery chargeMonitoring system

The invention discloses an intelligent unmanned freight vehicle, a shared system and a business mode. The system comprises at least a vehicle chassis and a vehicle body, wherein the vehicle chassis isprovided with an automatic driving system for unmanned driving, a warehouse for loading goods is arranged on the vehicle body, and the automatic driving system for unmanned driving comprises a driving module, a path navigation module, an obstacle avoidance module, a communication module and a data processing module; the system also includes a sensor module, an intelligent identification system, amonitoring and detection system, a monitoring system and a main control processor. The main control processor analyzes and controls the vehicle to take corresponding action according to the collectedinformation to ensure the safety and normal operation of the vehicle. The battery charge management module comprises a battery pack, a charging module, a charging / discharging chip and a battery detection chip. The battery charge management module comprises a battery pack, a charging module, a charging / discharging chip and a battery detection chip. The invention realizes the unmanned transportation of the large truck through the unmanned driving technology, and frames the whole commercial operation mode based on the basis of the unmanned freight vehicle.

Owner:SMART HLDG CO LTD

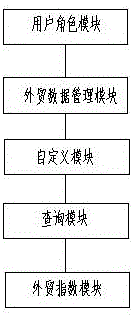

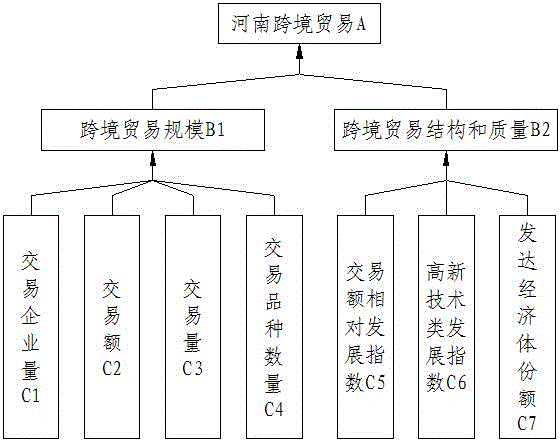

Big data analysis system and method for cross-border trade

InactiveCN105809482AImprove rationalityHighly creativeMarket data gatheringData managementData analysis system

The invention relates to the field of computer, specifically relates to a big data analysis system and a method for cross-border trade, and the system comprises the following modules: a user role module, a foreign trade data management module, a self-defining module, a query module and a foreign trade index module; all in all, the system and method have advantages of creativity, rationality, low time consumption, low cost, wide application range, accurate data and high efficiency and can accurately access present cross-border trade condition.

Owner:ZHENGZHOU NORMAL UNIV

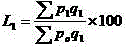

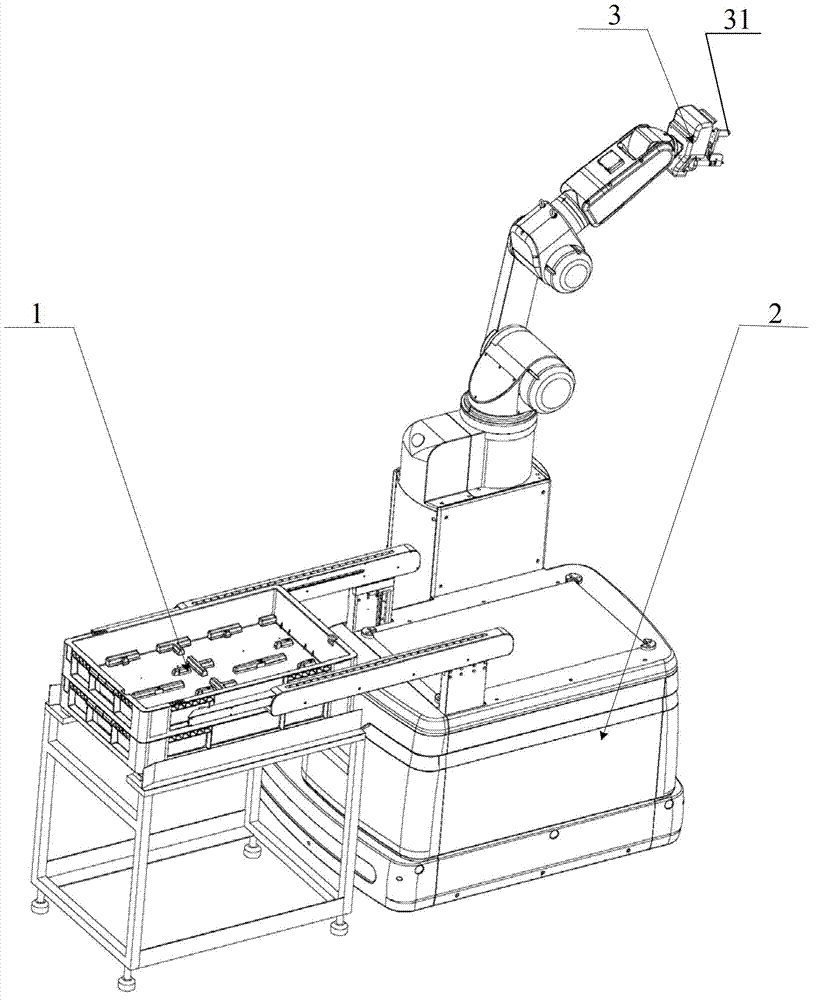

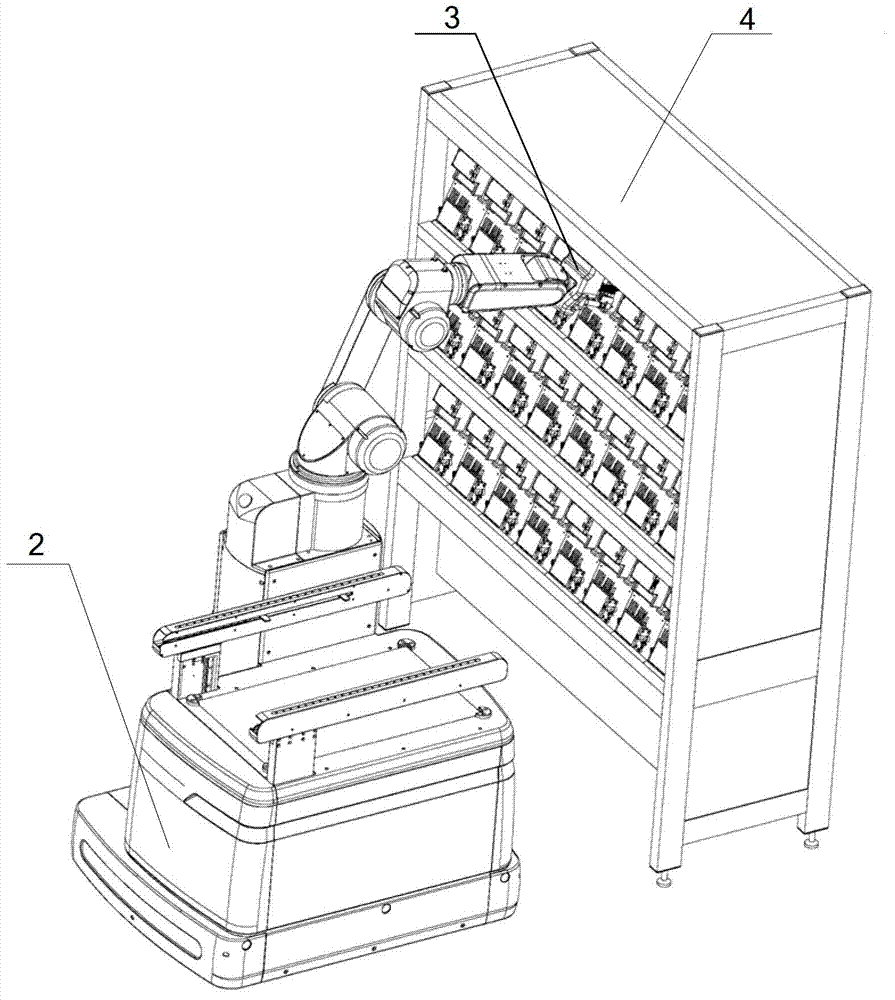

Control method and control system for electric energy meter verification robot

InactiveCN102788966AReduce the amount of manual laborImprove work efficiencyProgramme-controlled manipulatorElectrical measurementsElectricity meterElectric energy

The invention discloses a control system for an electric energy meter verification robot. The control system comprises a base plate, a manipulator, a verification device, a master control computer and a servo system. The base plate is provided with a position for storing an electric energy meter transfer box, and the electric energy meter transfer box with an electric energy meter position is arranged on the base plate. The manipulator is used for taking and putting an electric energy meter and cooperates with the electric energy meter verification device to complete part of electric energy meter detection items, and a video acquisition device used for acquiring image information is arranged on the manipulator. The verification device is provided with an electric energy meter position and used for holding the electric energy meter to be detected. The master control computer is used for receiving the image information acquired by the video acquisition device, comparing the image information with preset standard information, computing positional deviation according to the difference value between the image information and preset standard information, and sending signals. The servo system is used for receiving the signals of the master control computer and controlling operations of the base plate and the manipulator. By the aid of the control system for the electric energy meter verification robot, manual labor for taking, putting and detecting the electric energy meter can be effectively reduced, and working efficiency can be improved. The invention further provides a control method for the electric energy meter verification robot.

Owner:CHONGQING ELECTRIC POWER RES INST +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com