Patents

Literature

5366results about "Work-feeding means" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Ribbon loom

ActiveCN103696153ASimple structureImprove processing efficiencyWorkpiece carriersWork-feeding meansMechanical engineeringEngineering

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

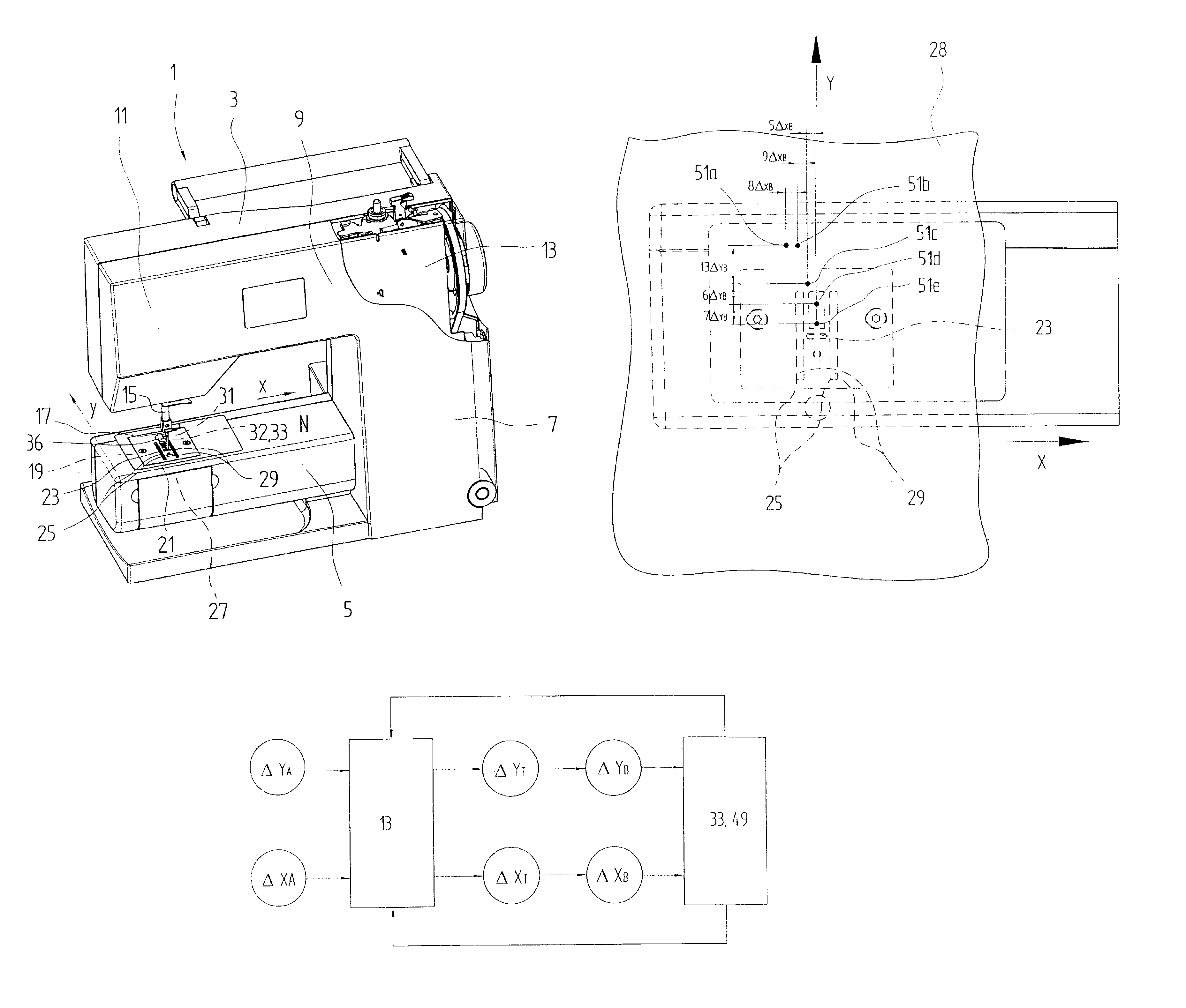

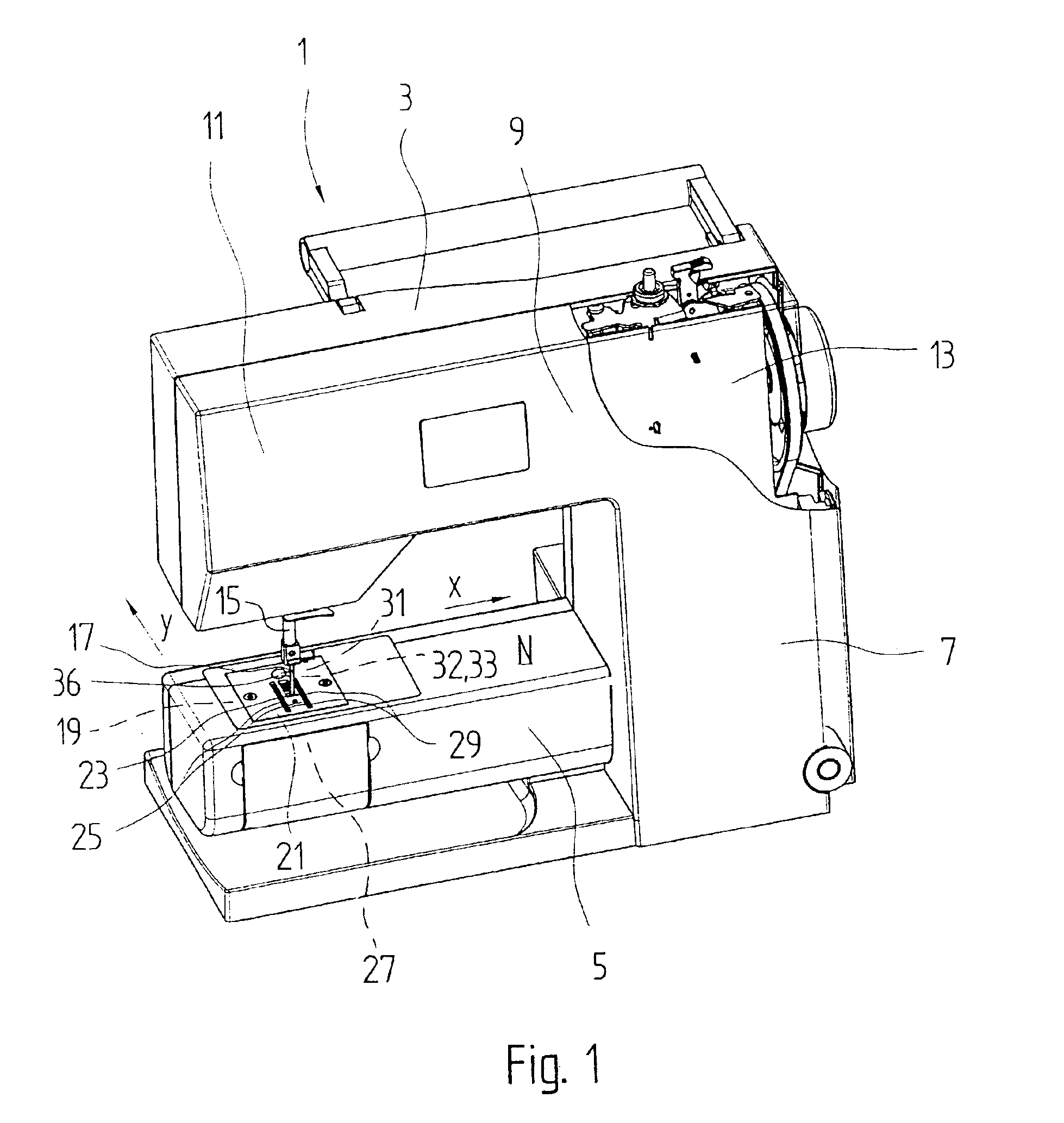

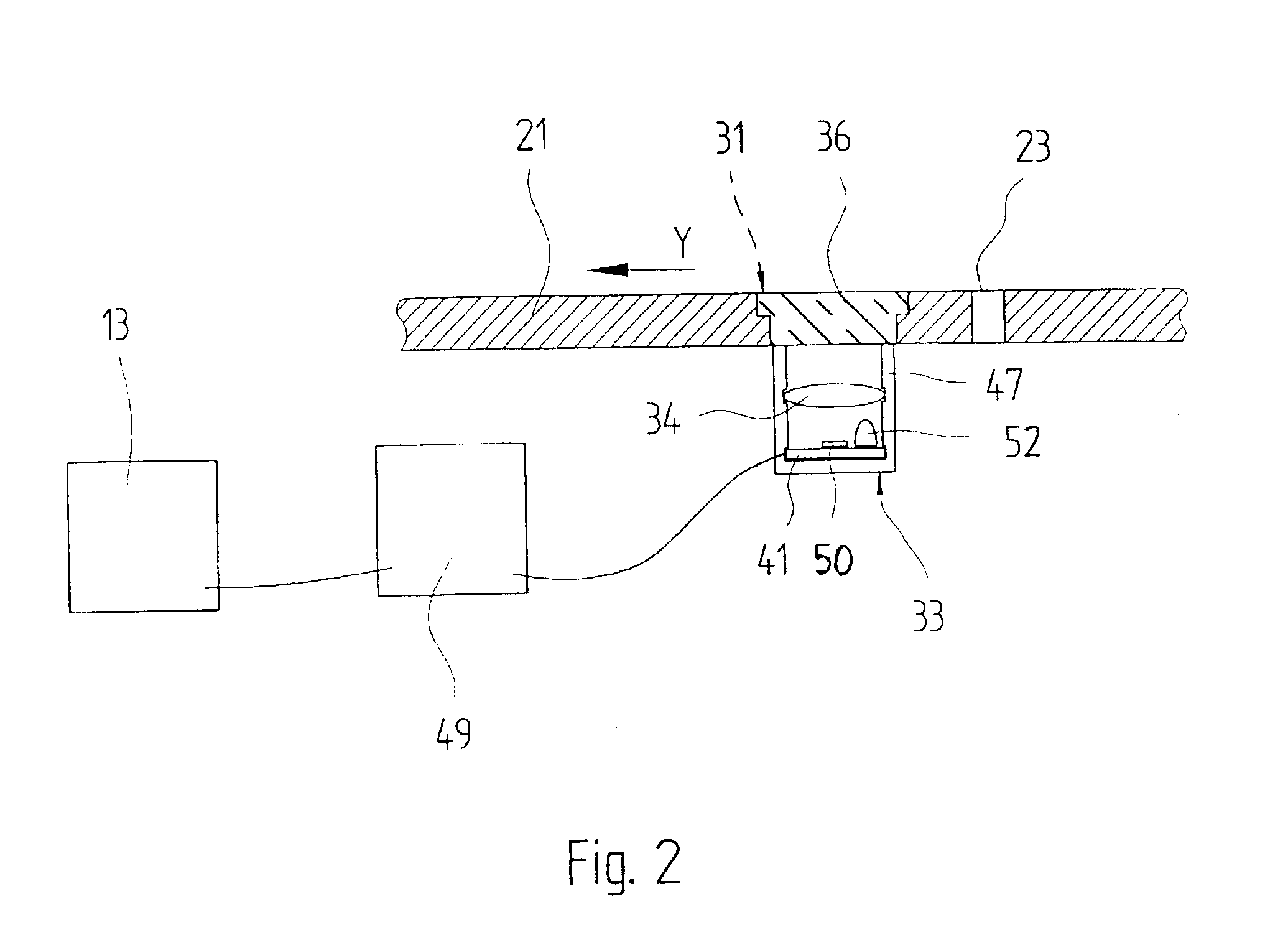

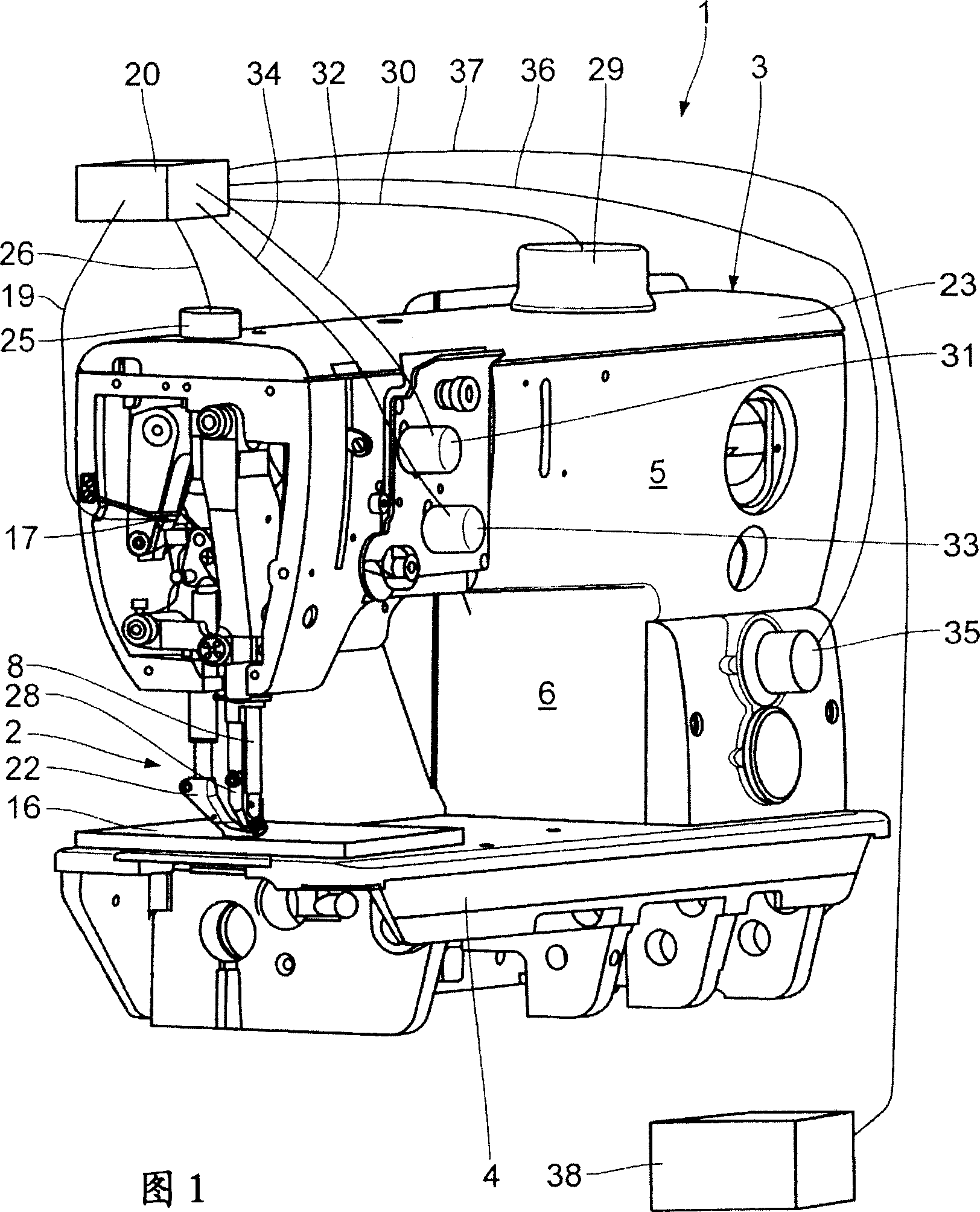

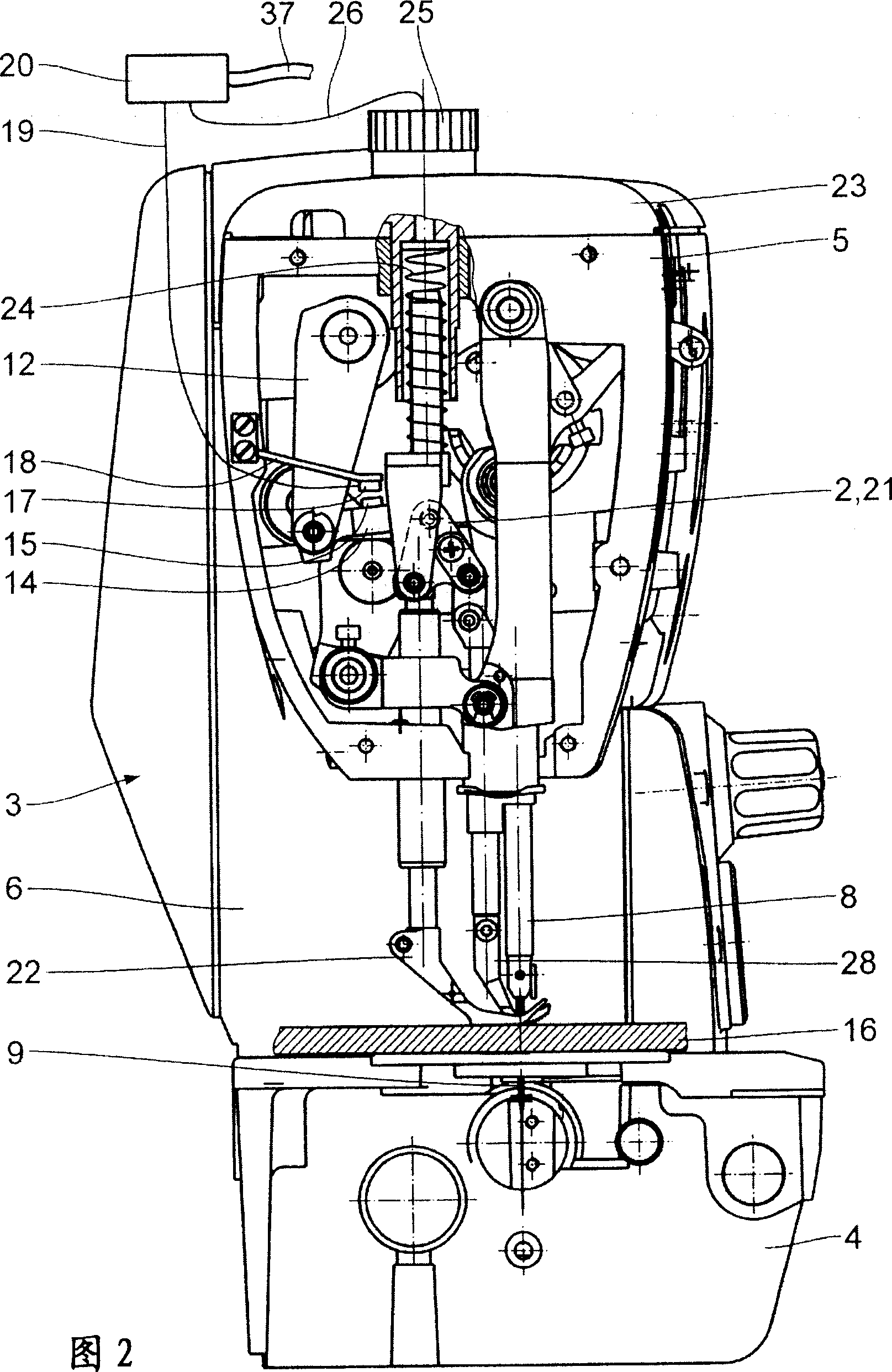

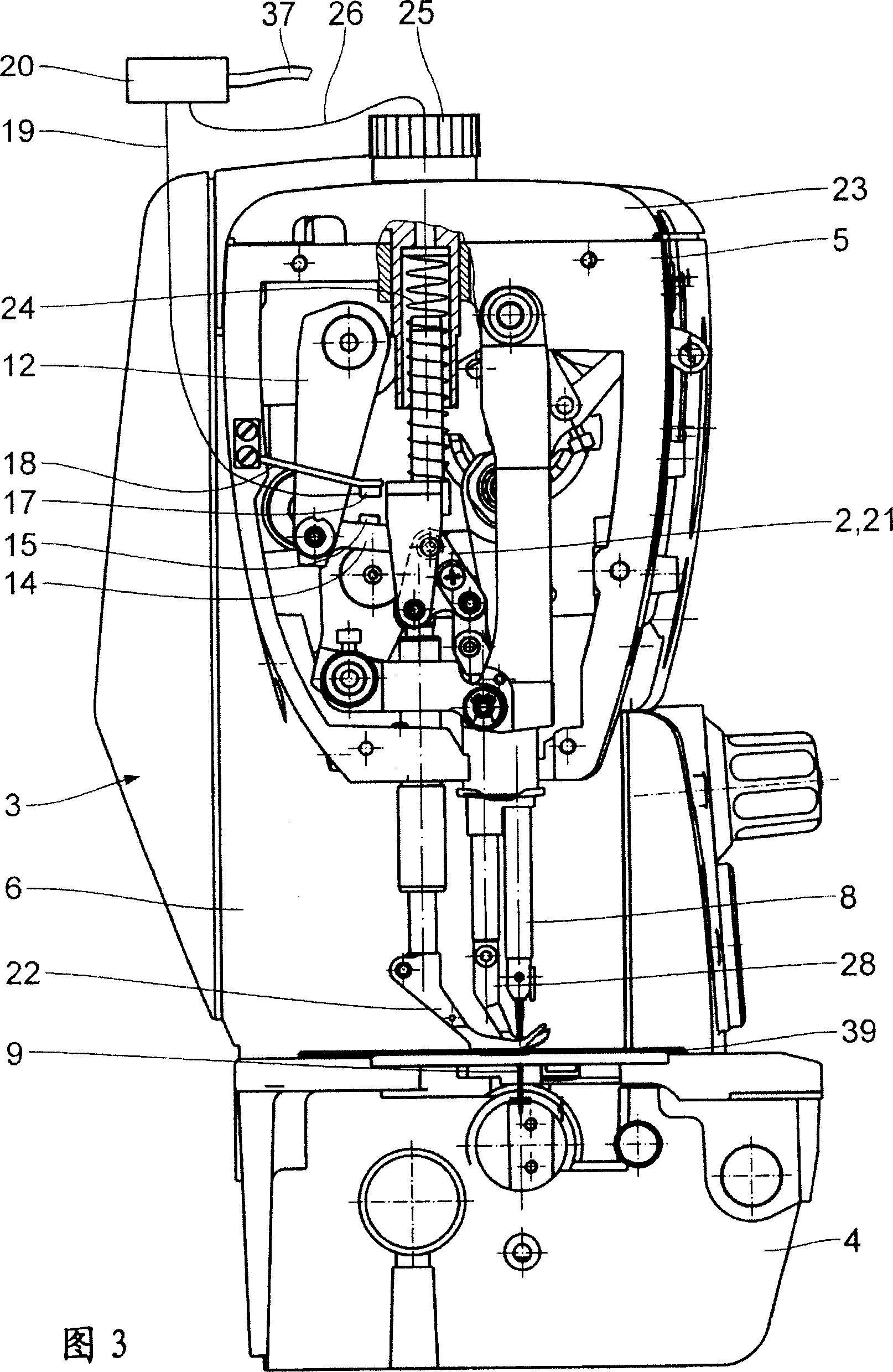

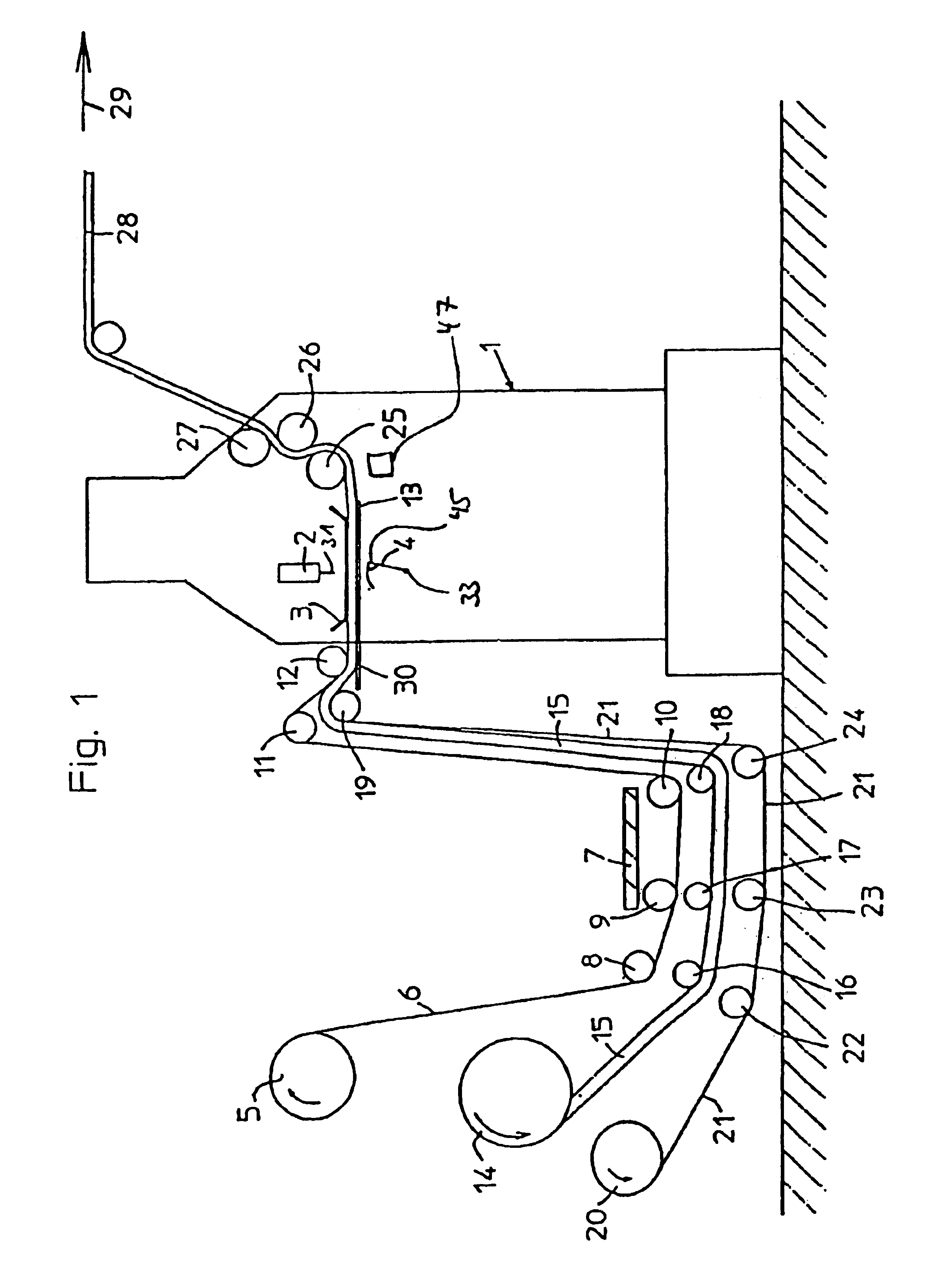

Method and device for regulating material transport in a sewing or embroidery machine

InactiveUS6871606B2Quickly and accurately calculated and compensatedImprove scanning rateProgramme-controlled sewing machinesWork-feeding meansMaterial transportMotion sensors

A method and device for regulating the transport of material in a sewing or embroidery machine (1) that uses information from a position or movement sensor (33) located underneath the throat plate (21). The controls for the sewing machine (1) calculate deviations of the actual feeding increments of the article to be sewn from the corresponding target values from the periodically read sensor signals. With this information, the feeding increments are regulated in such a way that the deviations are cancelled out by averaging.

Owner:FRITZ GEGAUF AKTIENGES BERNINA NAHMASCHFAB

Undergarments having finished edges and methods therefor

ActiveUS7228809B2Improve material yieldDirect contact guaranteeLeather sewingWork-feeding meansFiberEngineering

A method of making a fabric having a finished edge includes providing a fabric having a plurality of fibers with free ends of the fibers at an edge of the fabric, disposing a curable polymer such as silicone over the edge of the fabric so that the curable polymer engages the free ends of the fibers at the edge of the fabric, and, after the disposing step, curing the polymer for finishing the edge of the fabric. The polymer binds the free ends of the fibers to prevent fraying of the fabric. The fabric is cut into a pattern piece for a garment before the step of disposing the curable polymer on the edge of the fabric.

Owner:CUPID FOUND

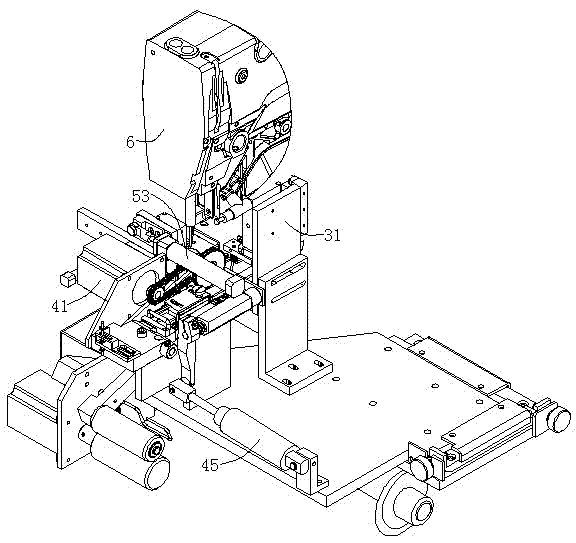

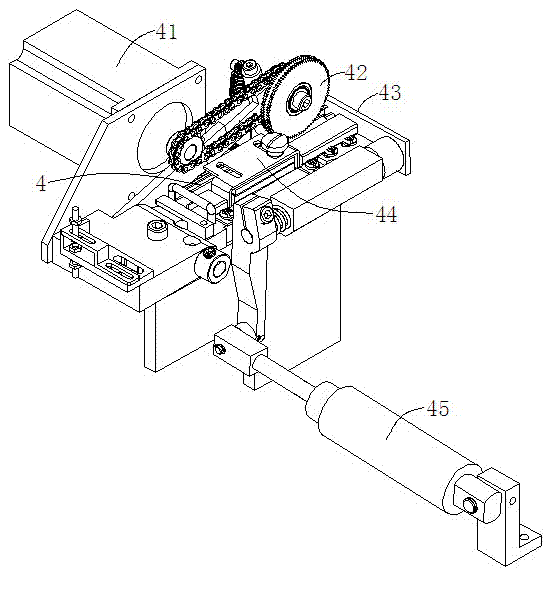

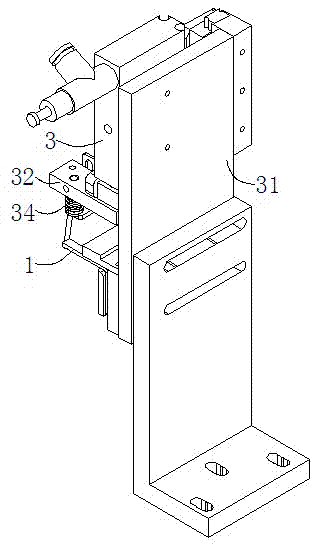

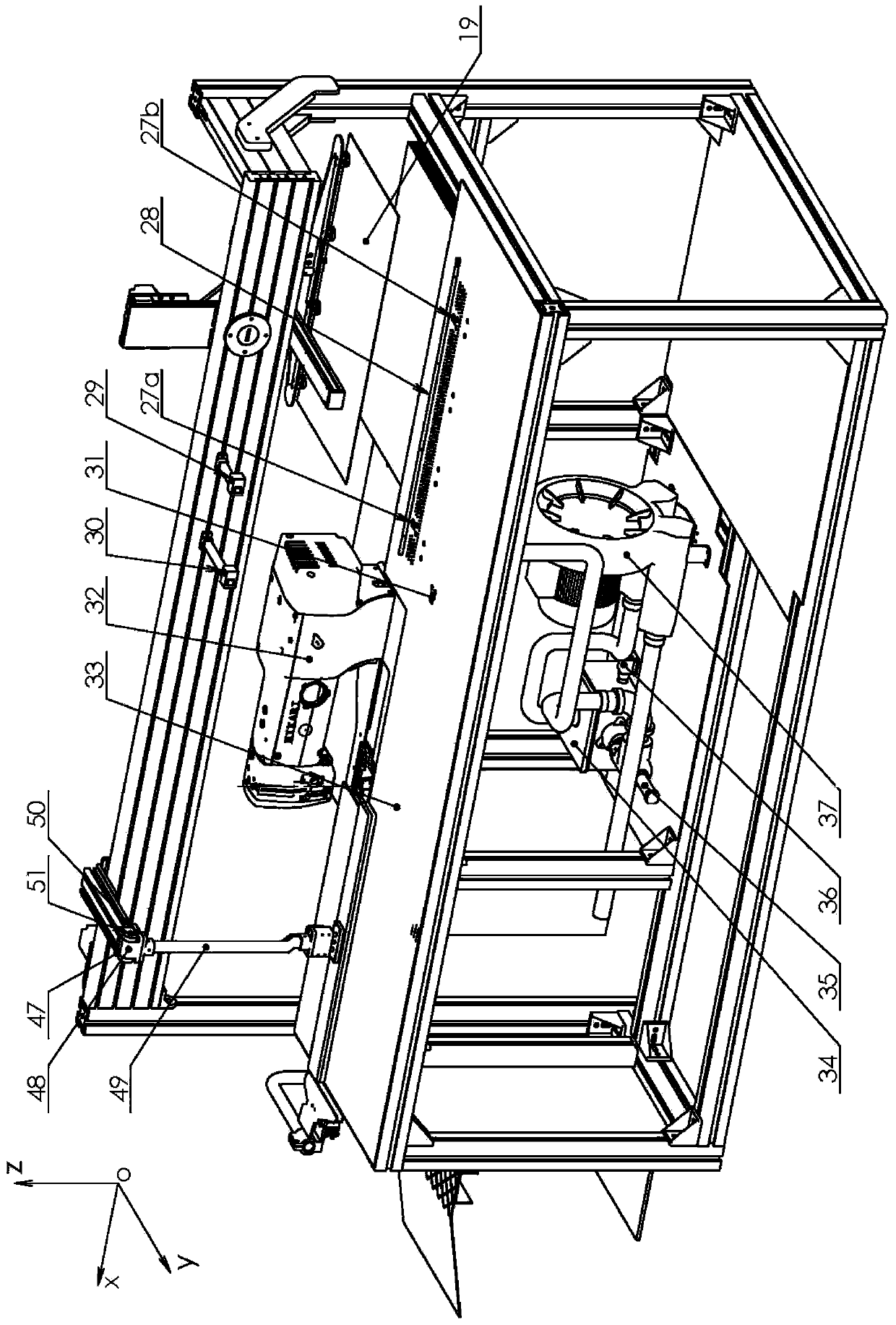

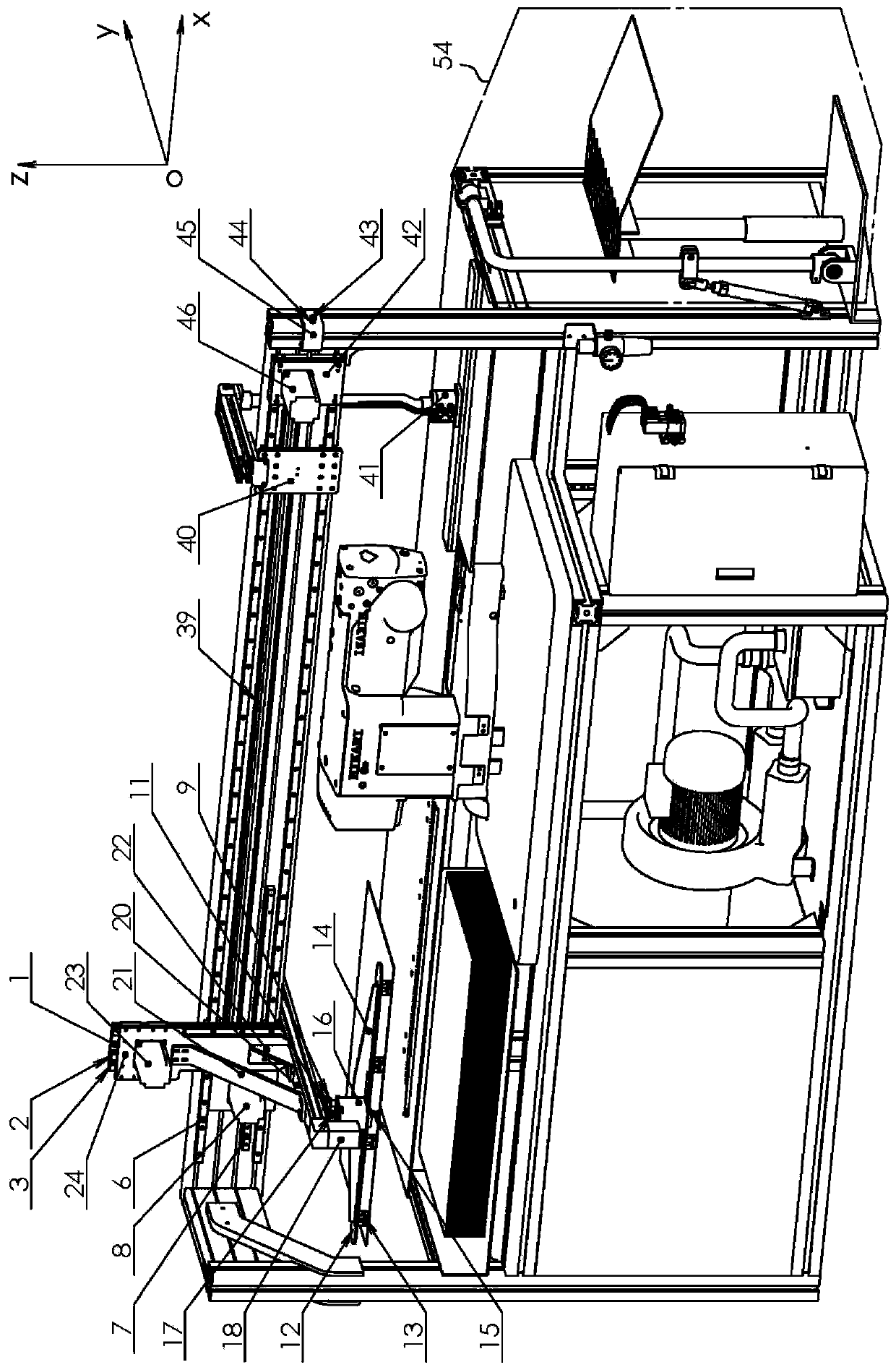

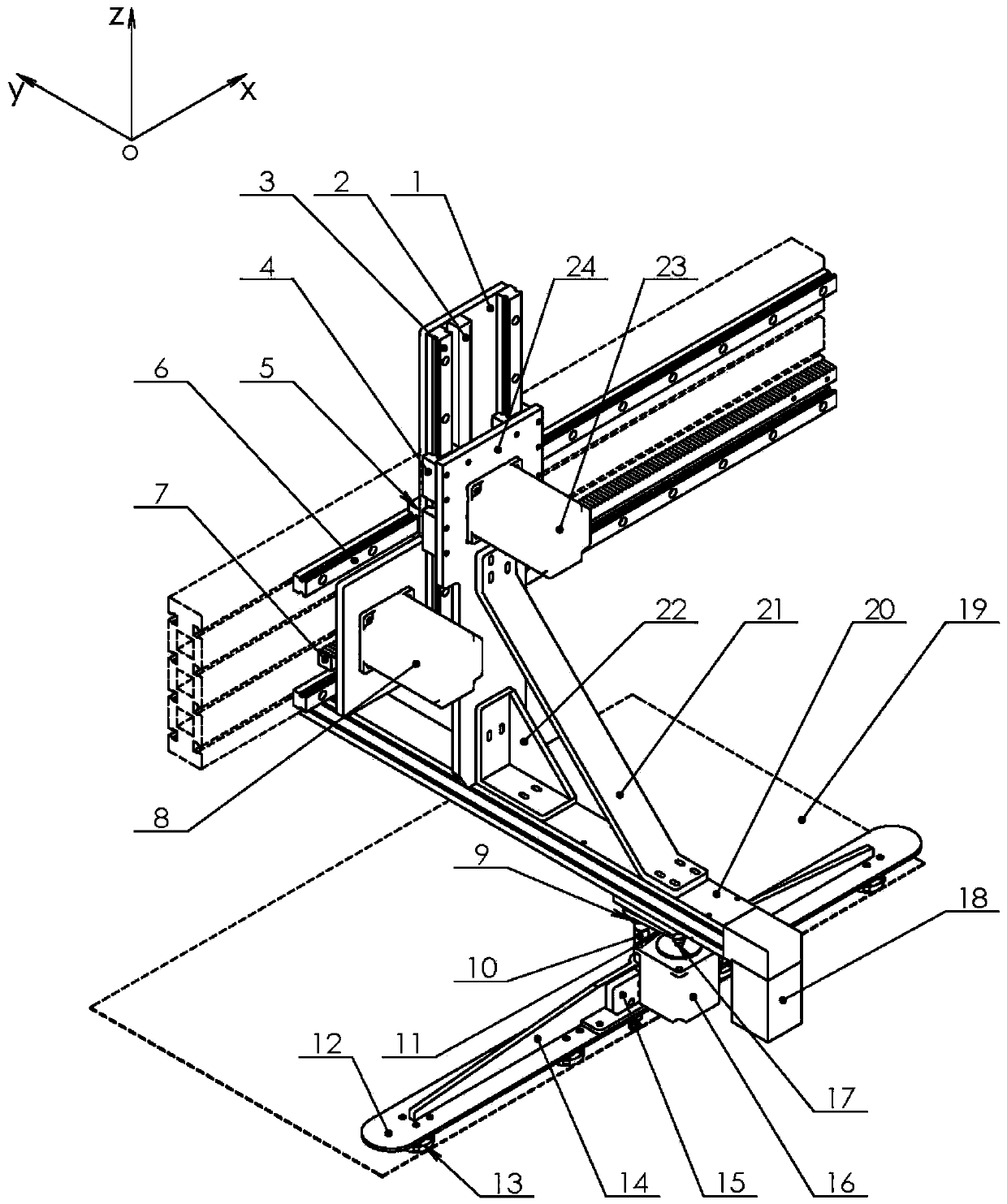

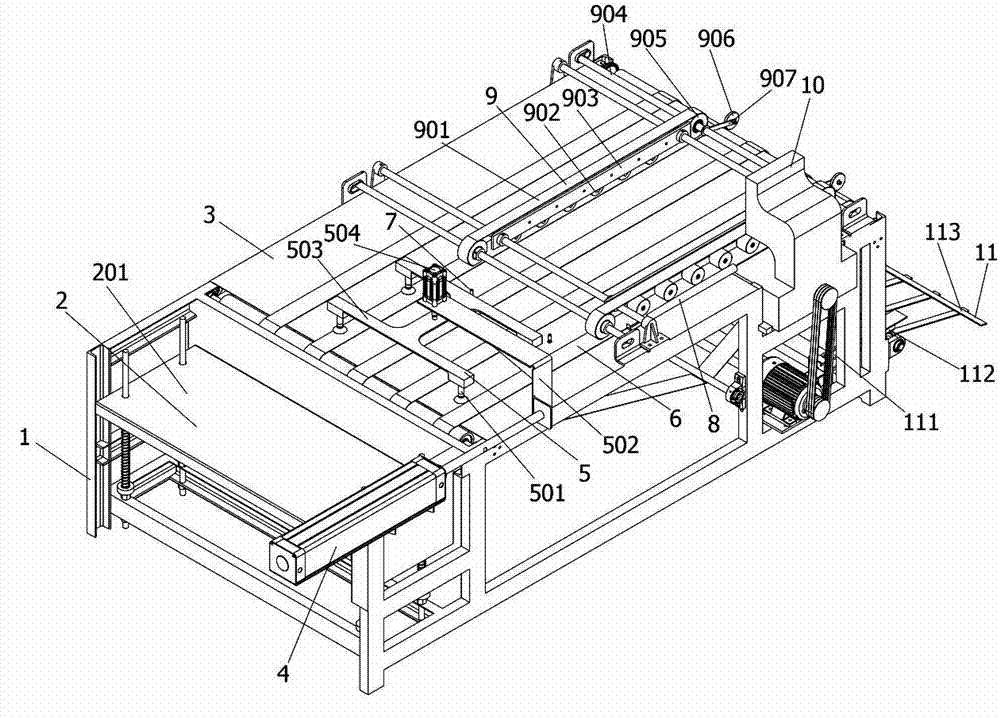

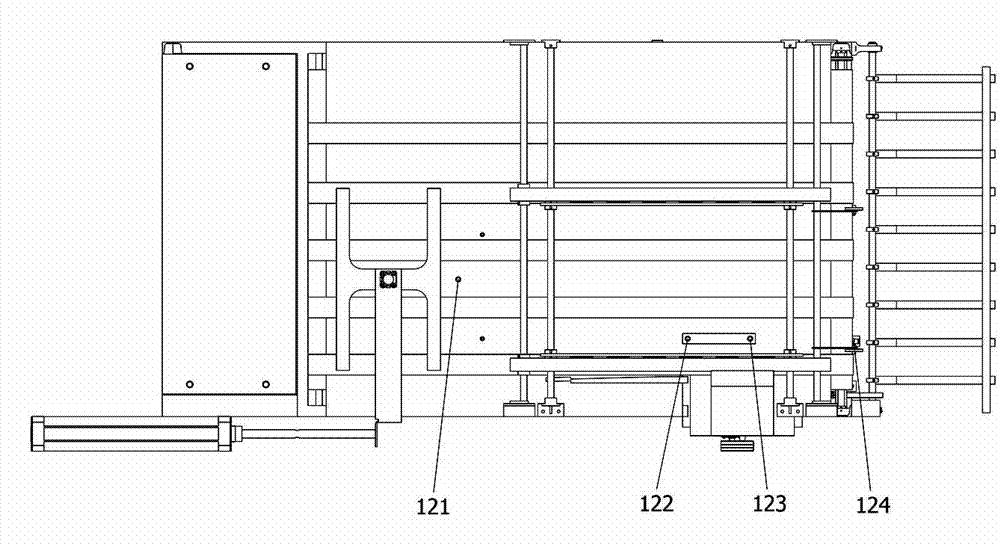

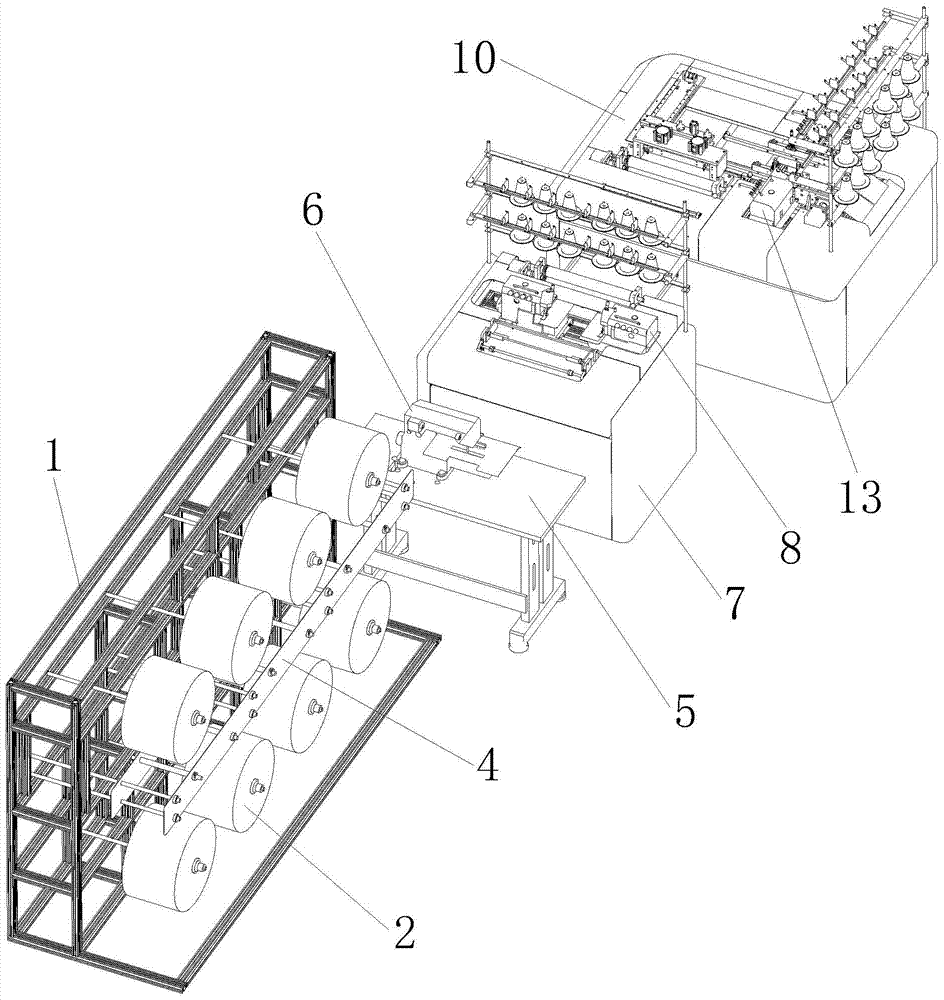

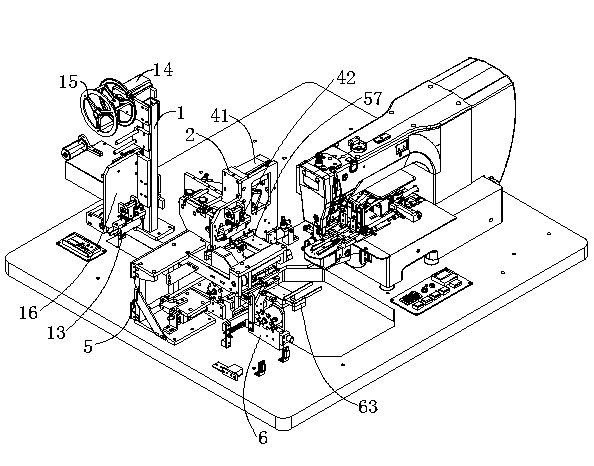

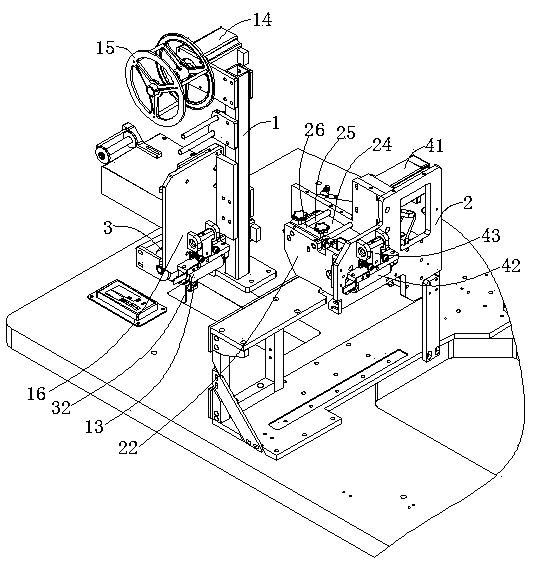

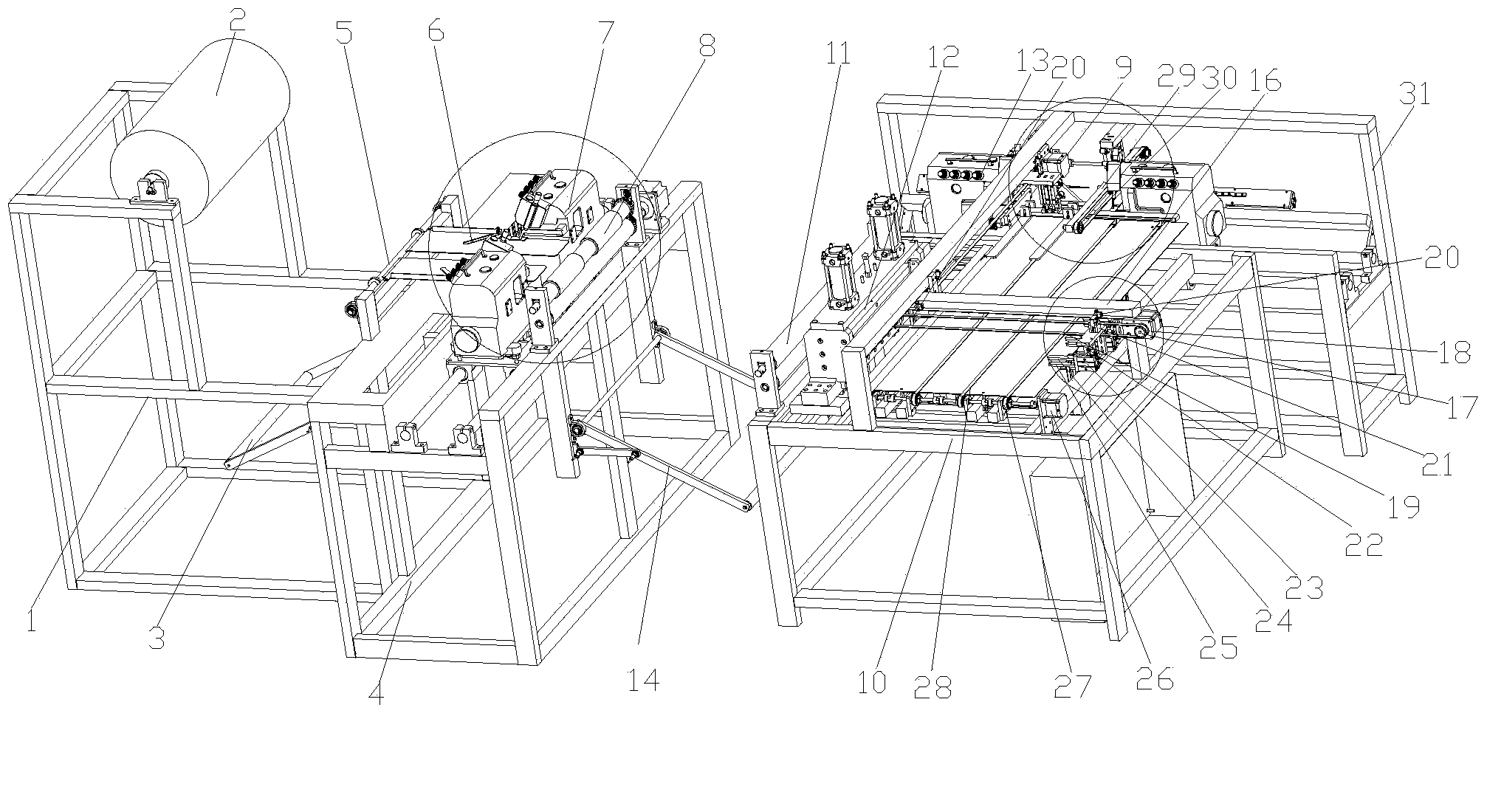

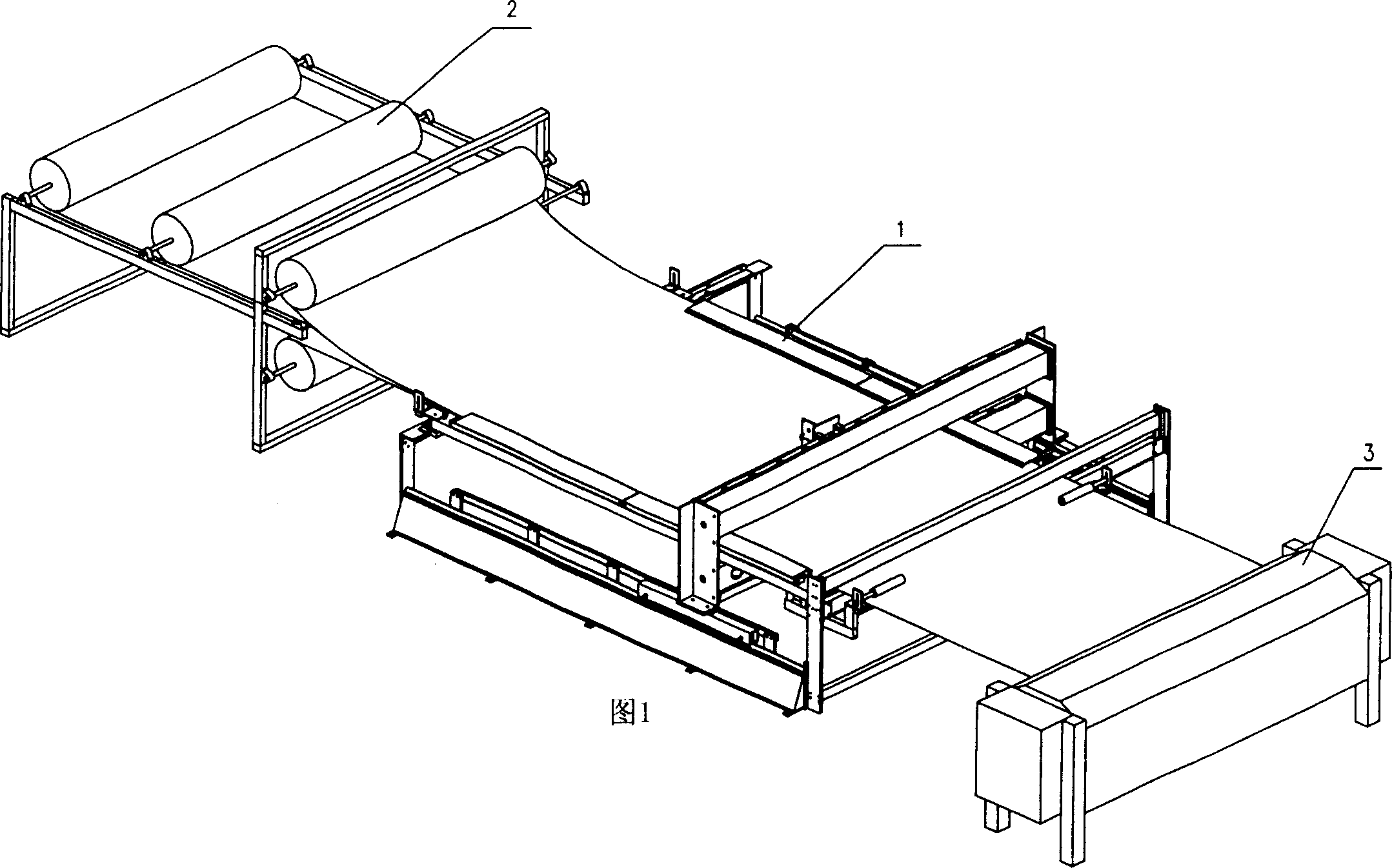

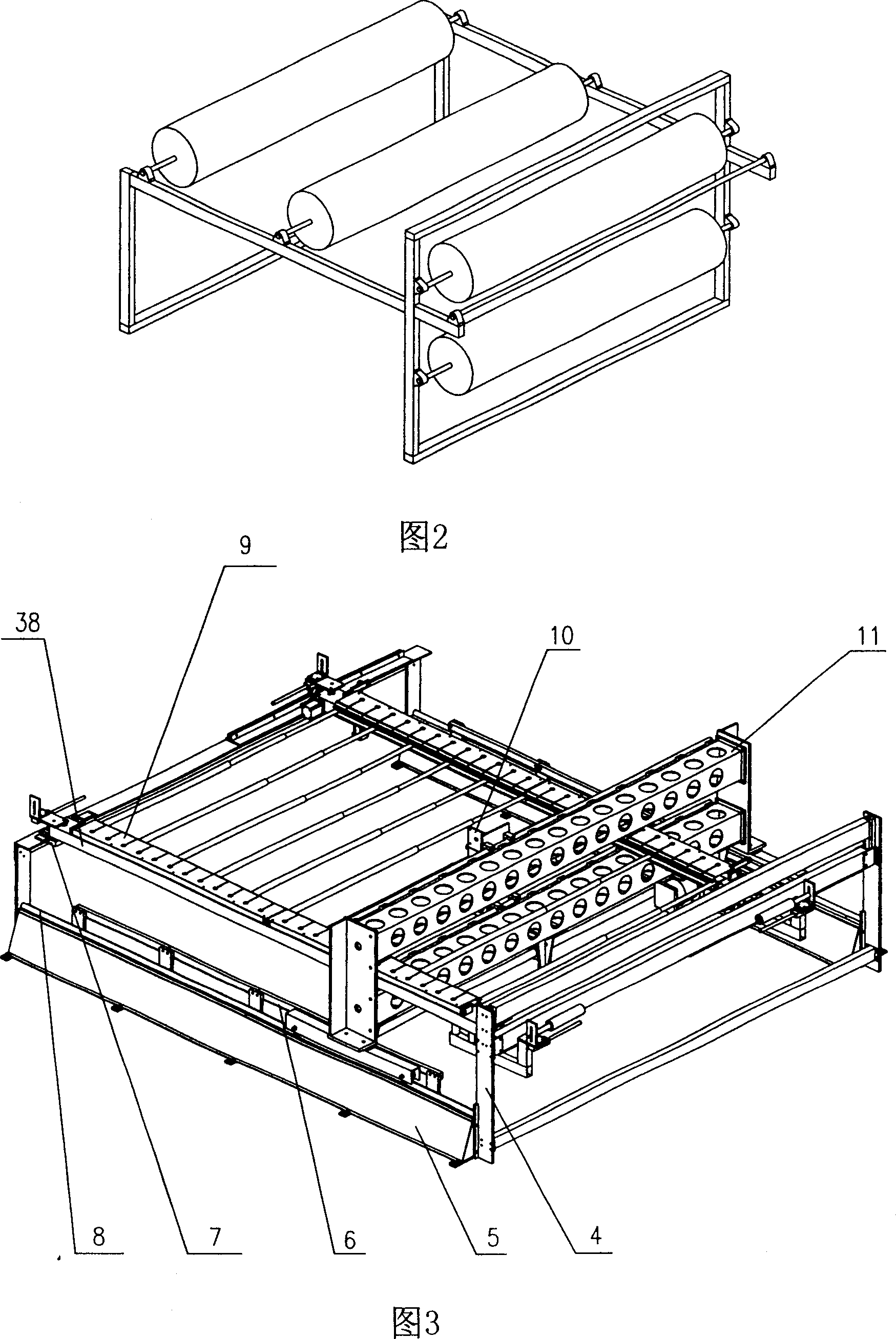

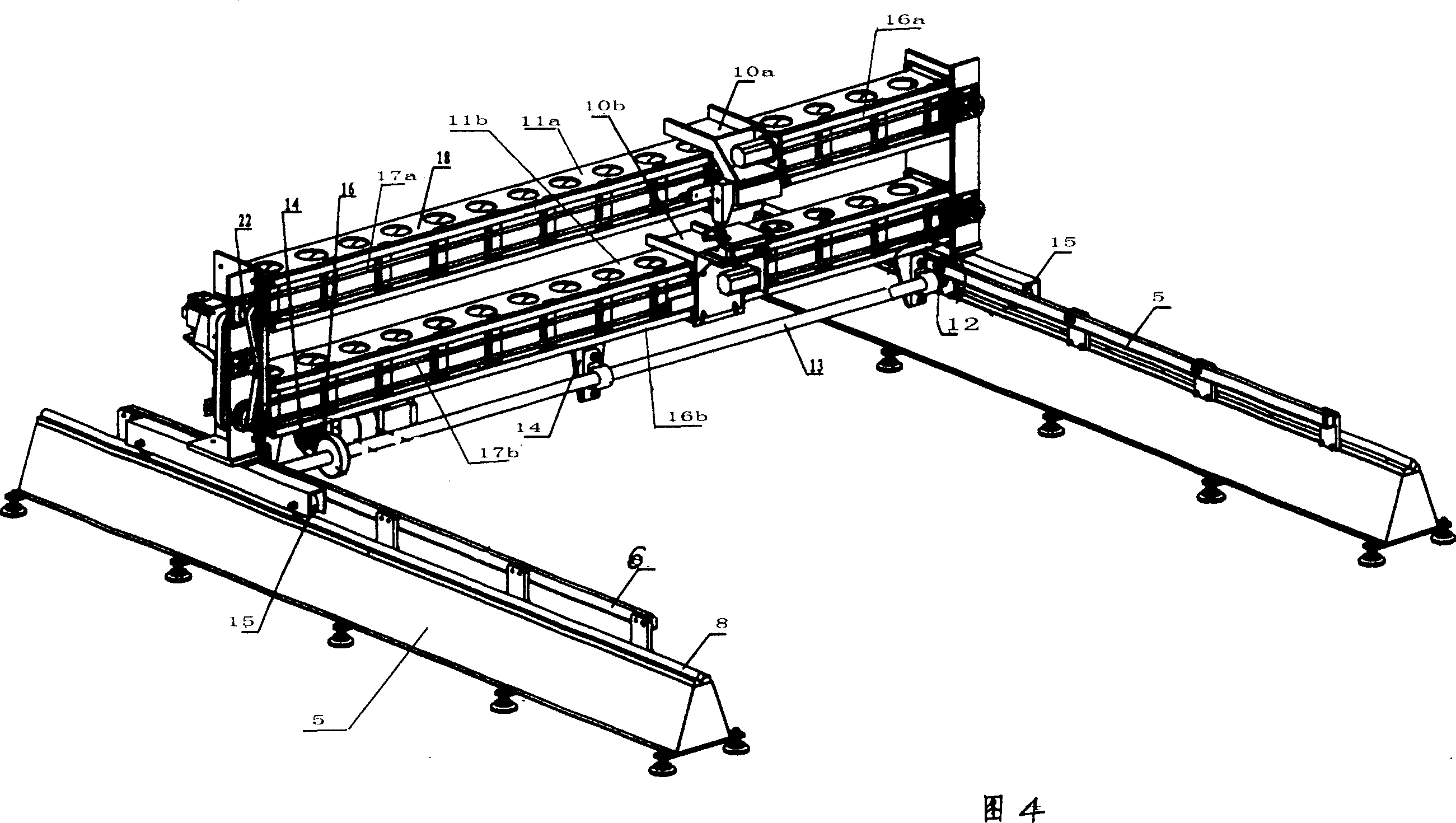

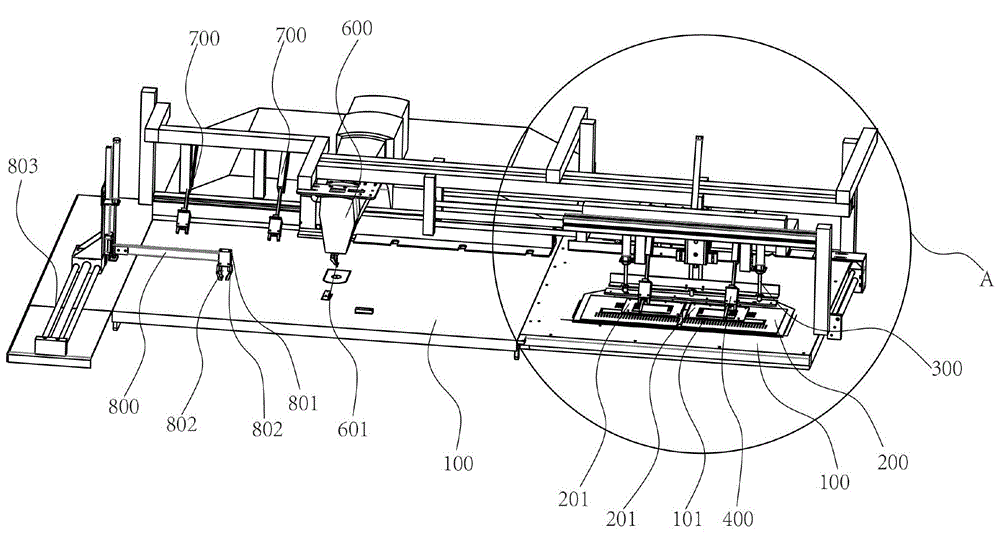

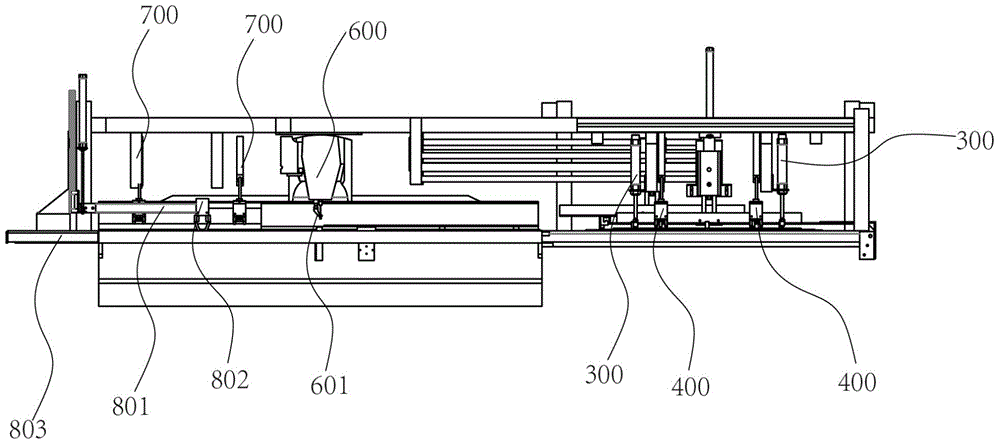

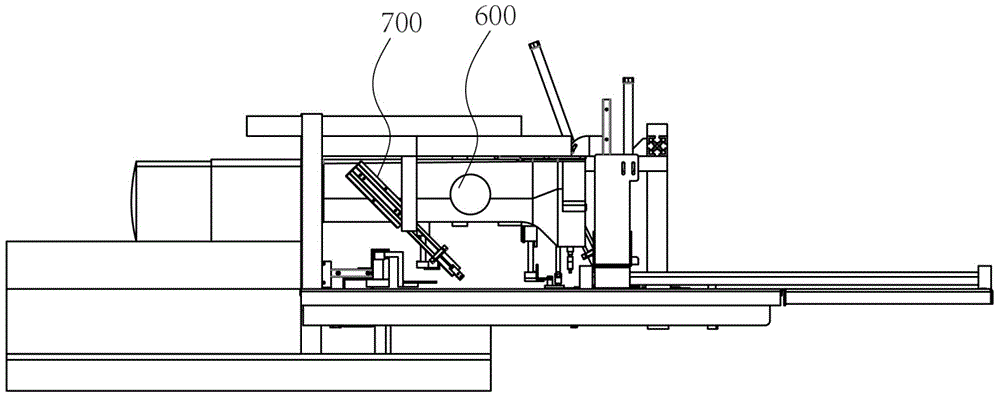

Full-automatic material taking and material feeding sewing machine

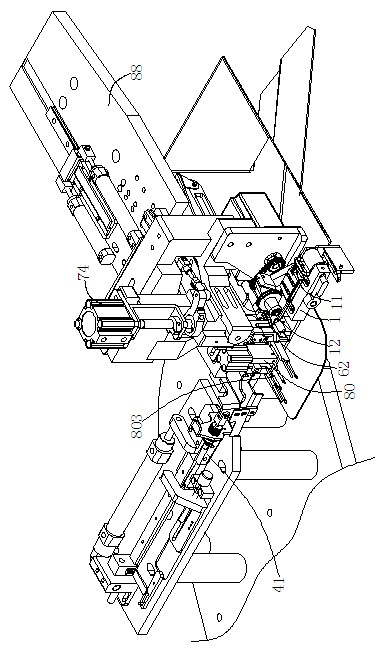

The invention relates to a full-automatic material taking and material feeding sewing machine. The full-automatic material taking and material feeding sewing machine comprises a fabric taking device, a fabric position correction system, an air pump system and a sewing material pressing and feeding device, wherein a horizontal guide rail is arranged in the X direction above a machine frame; the entire fabric taking device can conduct movement in X direction along the horizontal guide rail and can further conduct movement in Z direction on the horizontal guide rail; a linear module in a Y direction is arranged at the lower part of the fabric taking device; a rotating and regulating mechanism is arranged at the lower part of the linear module in the Y direction; a sucking disc fixing plate is arranged at the lower part of the rotating and regulating mechanism; the fabric position correction system comprises a fabric position sensing device; the fabric position sensing device comprises at least three sensors and a driving system that monitors the position of the fabric and transmits the signals of the fabric position deviation to the fabric taking device; the driving system corrects the placing position of the fabric through adjusting the global movement of the fabric taking device in the X direction, the Y-direction movement of the linear module in the Y direction and the rotating angles of the rotating and regulating mechanism.

Owner:上海富山精密机械科技有限公司

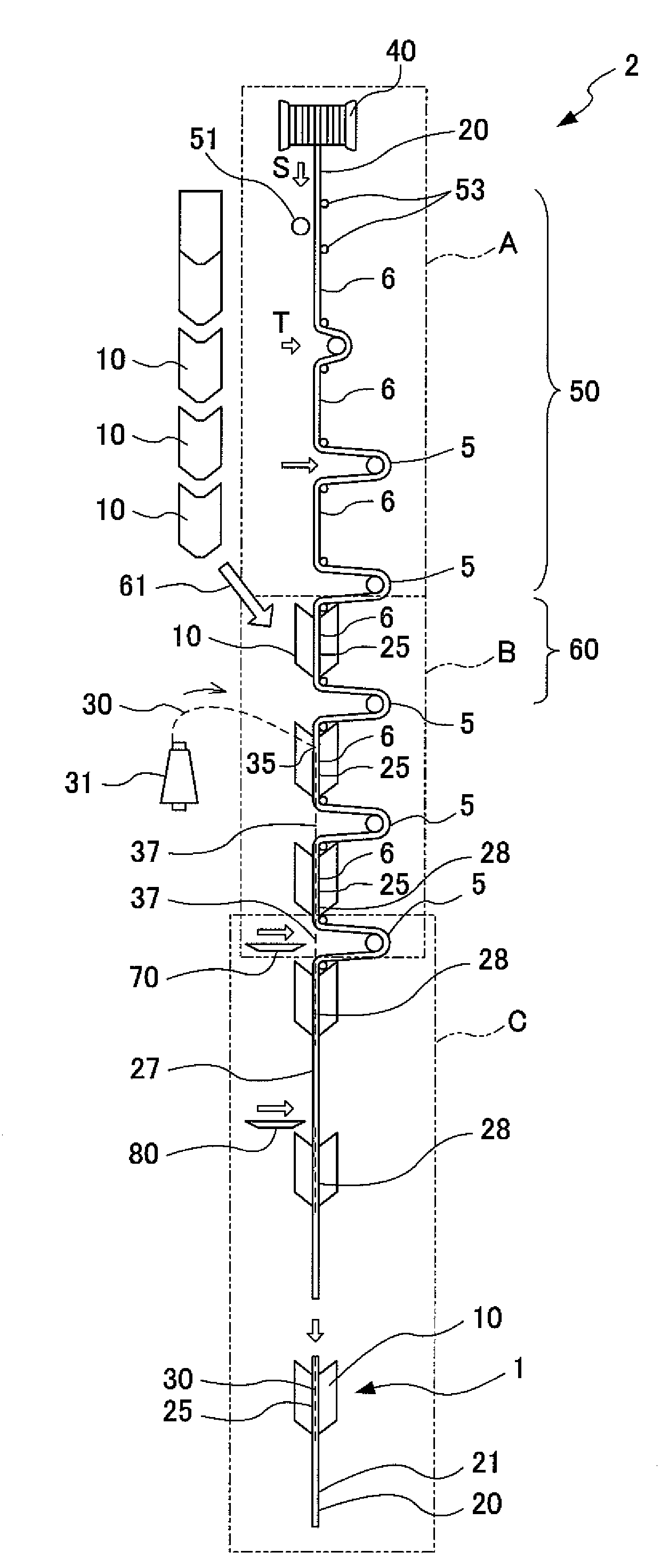

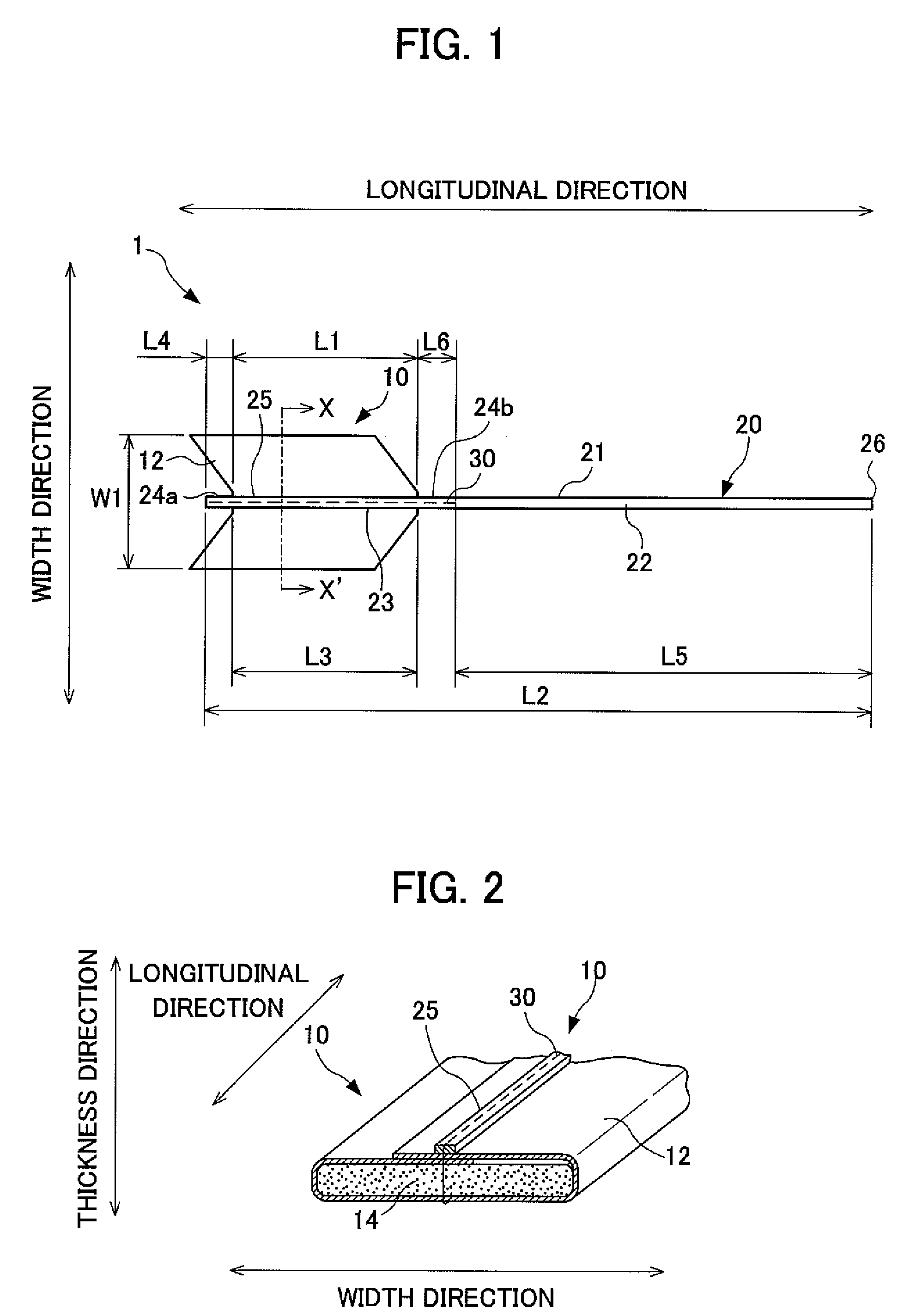

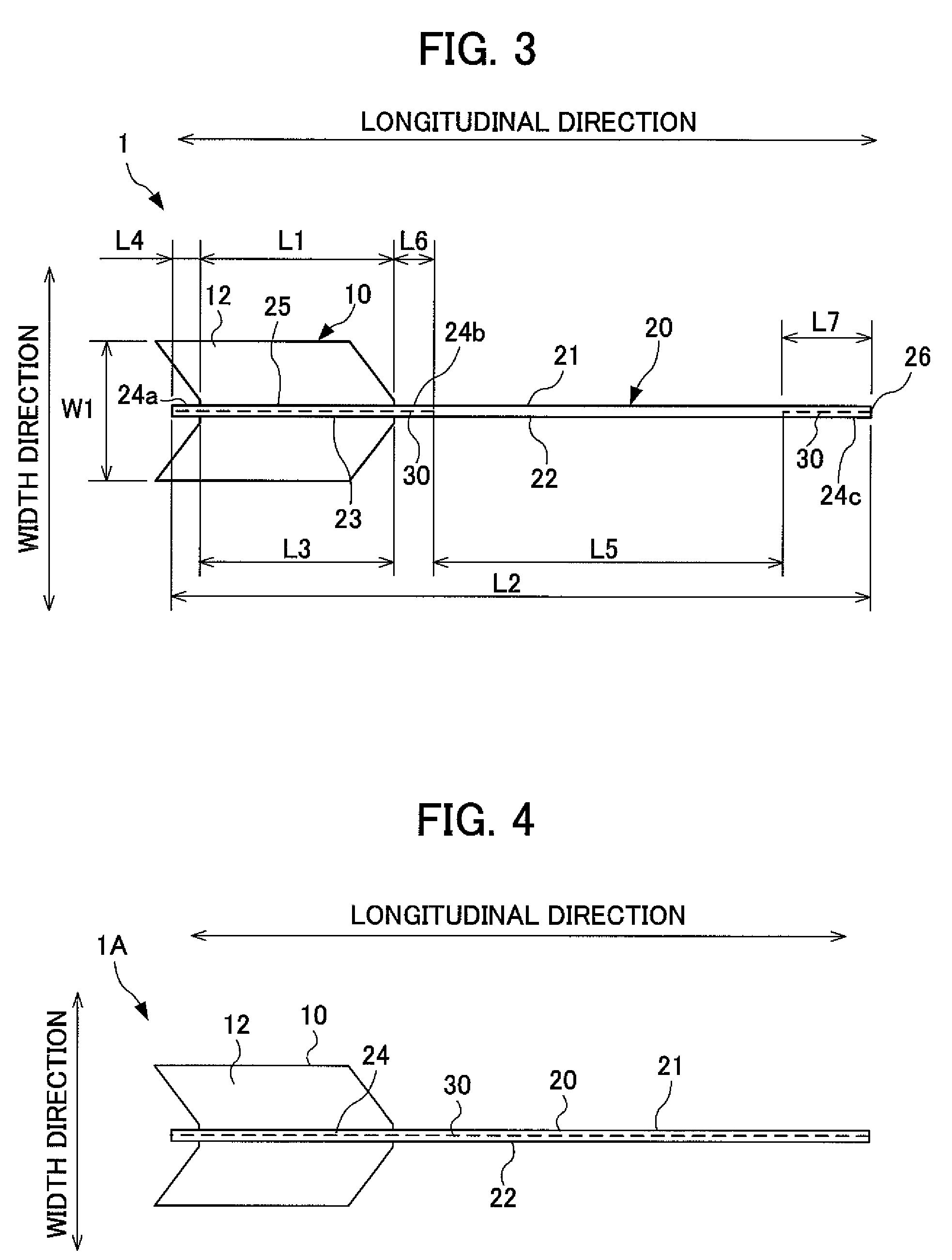

Manufacturing system and manufacturing method for sheet-like structure

An object of the present invention is to provide a manufacturing system and a method for manufacturing sheet-like structures. The manufacturing system of sheet-like structures contains a loosened portion forming apparatus by which plural loosened portions, which are substantially U-shaped, are formed on a cord member, and plural linear portions, which connect each of the plural loosened portions, are formed substantially linearly; and a sewing apparatus by which each of the plural absorbing members and each of the plural linear portions are sewn with a thread member.

Owner:UNI CHARM CORP

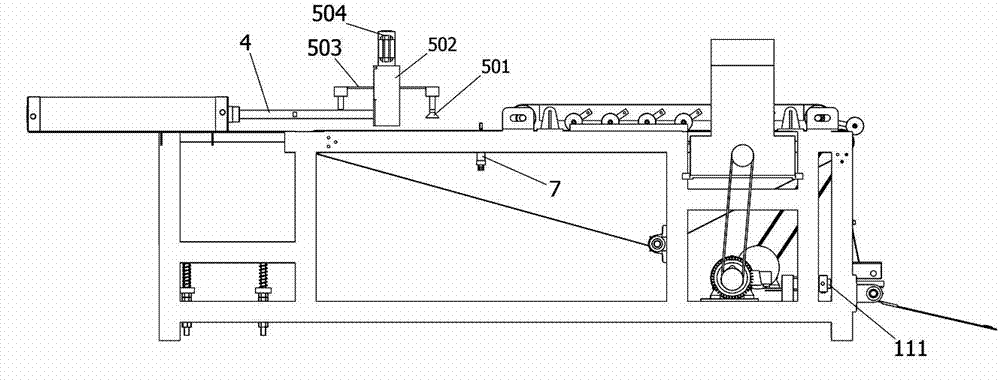

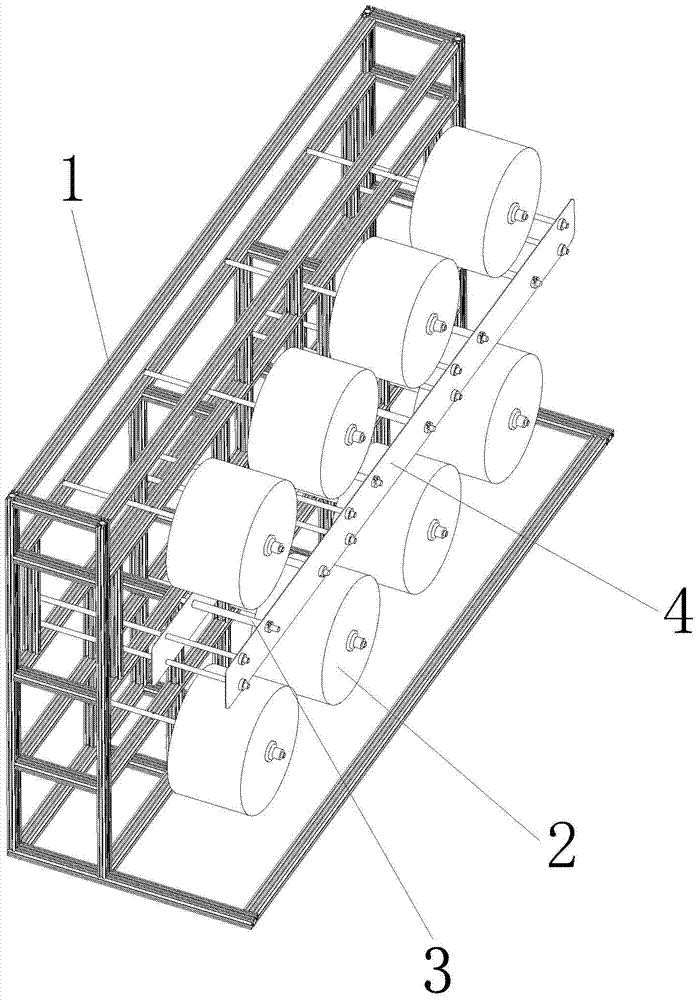

Automatic bag sewing machine

InactiveCN103882629AReduce labor costsShorten the lengthWork-feeding meansWork-collecting devicesReciprocating motionAutomation

The invention discloses an automatic bag sewing machine which comprises a rack assembly, a conveying assembly, a suction cup feeding assembly and a pressing wheel assembly. The rack assembly is located at the feeding end of the conveying assembly, and woven bags to be sewn are placed on the rack assembly. The suction cup feeding assembly is installed above the conveying assembly and the rack assembly and can reciprocate above the conveying assembly and the rack assembly so that the woven bags to be sewn can be moved from the rack assembly onto the conveying assembly. The pressing wheel assembly is installed on the conveying assembly so that the woven bags moving on the conveying assembly can be tightly attached to the conveying assembly to be flattened. A hemmer and a sewing machine body are installed on at least one side of the conveying assembly. The automatic bag sewing machine has the advantages of being simple and compact in structure, high in automation degree, good in consistency of sewn products, capable of reducing the labor cost and the like.

Owner:重庆市巨恒塑料有限公司

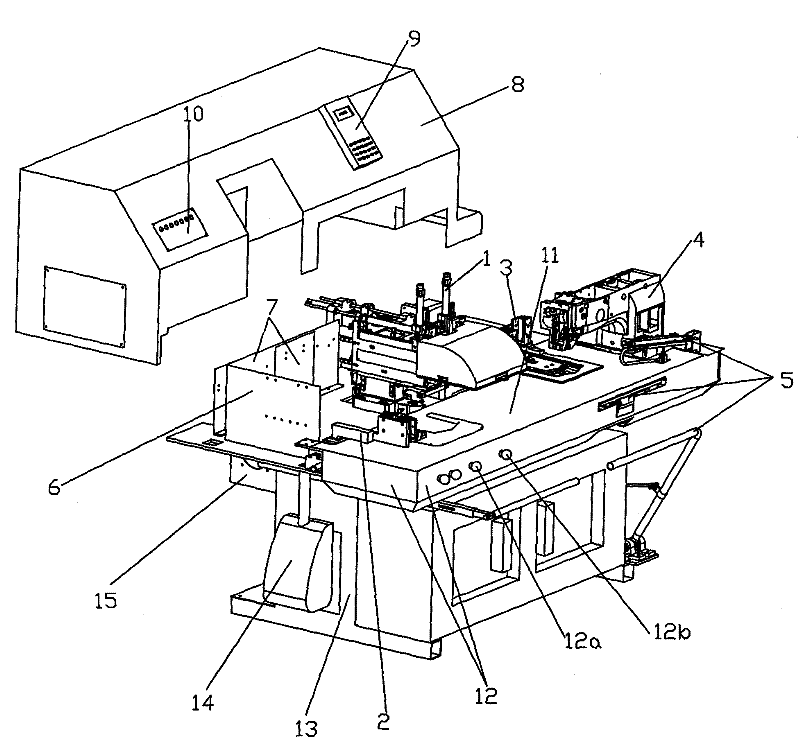

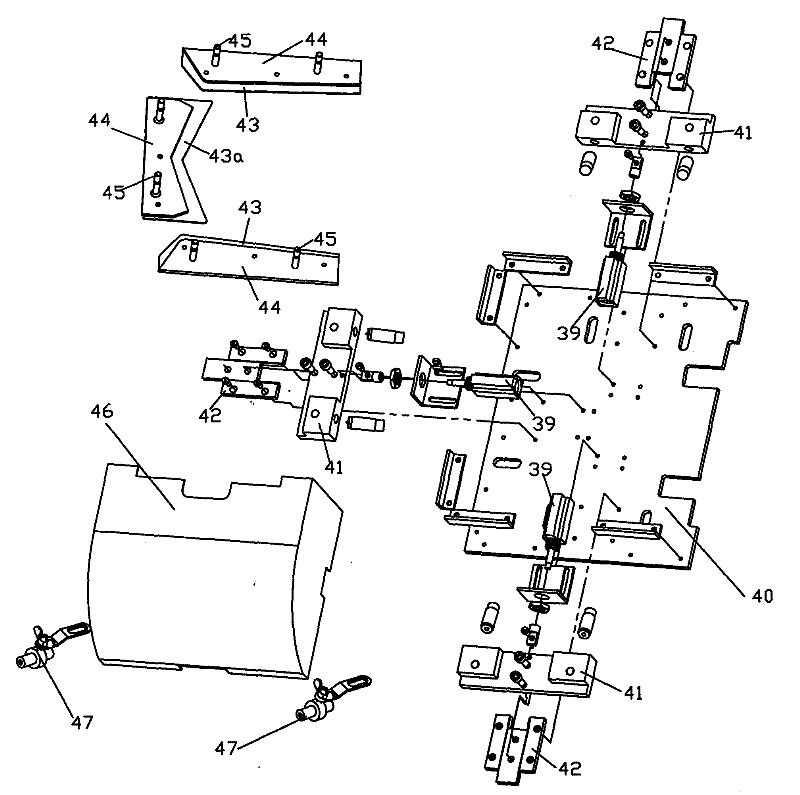

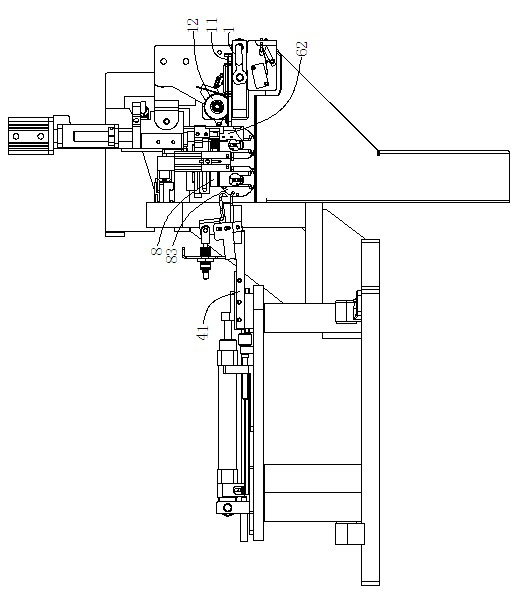

Pneumatic full-automatic pocket patching machine

InactiveCN102191633AReasonable structureEasy to operateWork-feeding meansSewing-machine control devicesManufacturing cost reductionSolenoid valve

The invention discloses a pneumatic full-automatic pocket patching machine. The machine comprises a rack steel plate, a pneumatic automatic non-ironing and folding mechanism and the like, wherein the pneumatic automatic non-ironing and folding mechanism is arranged above the rear part of the rack steel plate; a pneumatic automatic feeding mechanism is transversely arranged in front of the pneumatic automatic non-ironing and folding mechanism; a coordinate pattern transmission mechanism is arranged on the left of the pneumatic automatic non-ironing and folding mechanism; a rotating shuttle type pattern sewing machine sewing head is arranged in front of the rack steel plate on the right and is transversely arranged; an air pressure adjusting mounting plate is arranged at the left rear end of the rack steel plate; solenoid valve mounting plates are arranged on the right of the air pressure adjusting mounting plate; a shield is arranged on the rear half part of the whole rack steel plate; stainless steel coamings are arranged below a stainless steel working table; a first starting switch and a second starting switch are arranged above one stainless steel coaming; a dust collector is arranged on the left of a rack; and an electrical appliance control box is arranged behind the rack and on the lower part of the rack steel plate. The machine has the effects of lowering the manufacturing cost and realizing automatic programs such as non-ironing programs and the like.

Owner:SHANGHAI GUIYI SEWING EQUIP MFG

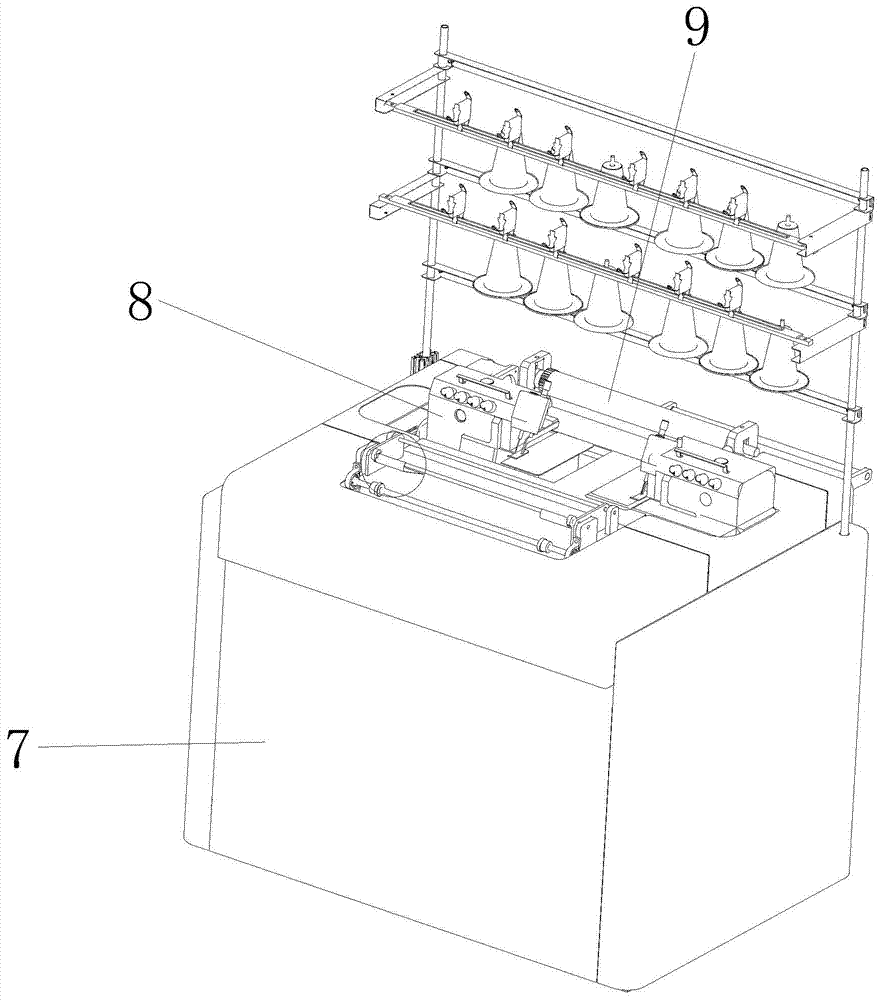

Towel machine

ActiveCN103498291AReduce manufacturing costIncrease productivityWorkpiece carriersWork-feeding meansIndustrial engineering

The invention discloses a towel machine. The towel machine comprises a feeding device, a first processing device and a second processing device. The feeding device, the first processing device and the second processing device are oppositely and fixedly placed in sequence. The feeding device is used for feeding cloth to the first processing device; the first processing device is used for binding off the two edges of the cloth fed by the feeding device for the first time; the second processing device is used for cutting off the cloth fed by the first processing device and then binding off the two edges of the cloth for the second time. According to the towel machine, original manual operation is replaced by mechanical automatic operation for towel production, so that labor intensity is greatly reduced for workers, the production mode that a single worker operates multiple machines can be realized in production, production efficiency of the product is improved, production cost is lowered, effective production management is facilitated, and the production value of the product is maximized.

Owner:SUZHOU TRANSPARENT TECH CO LTD

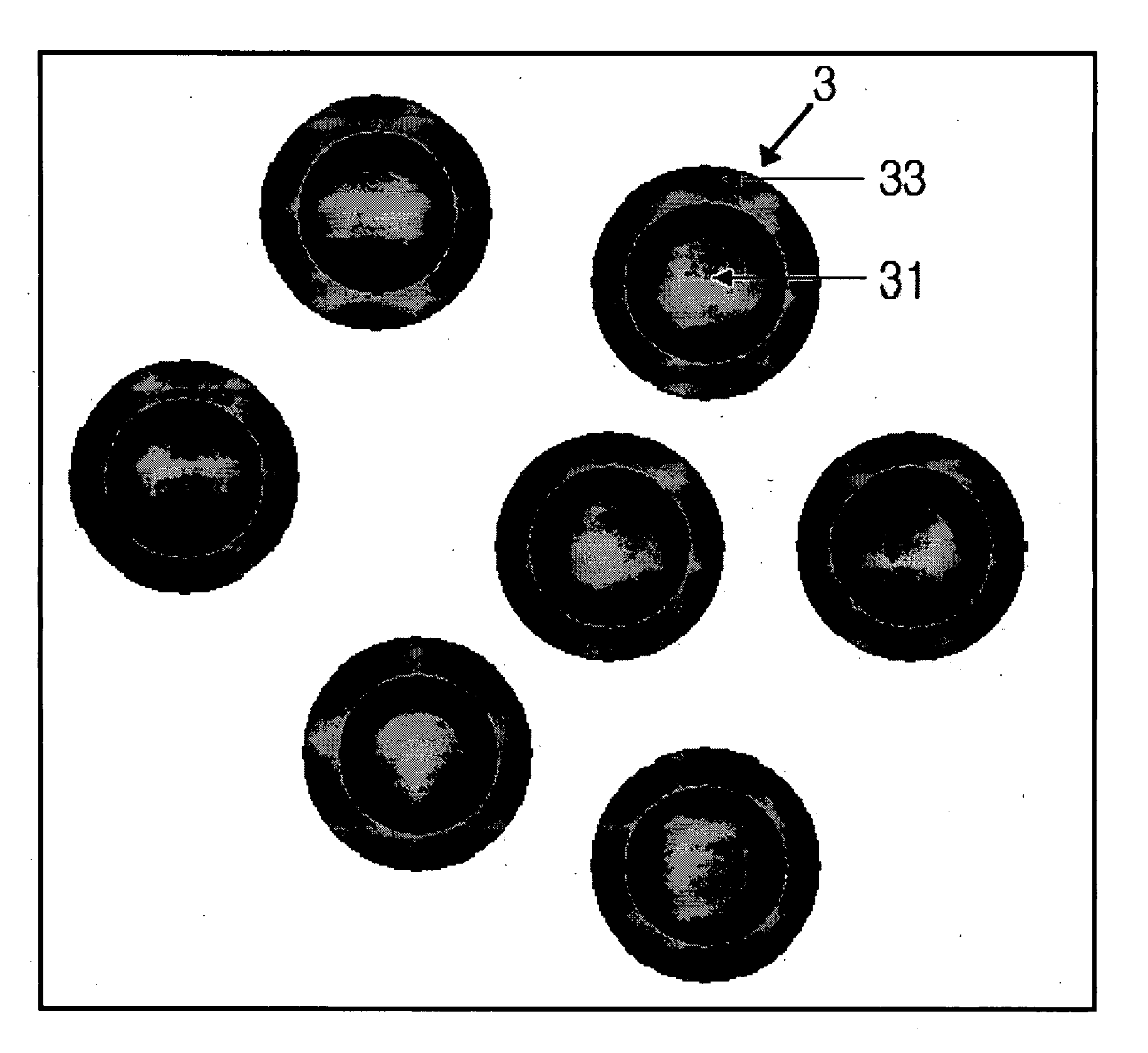

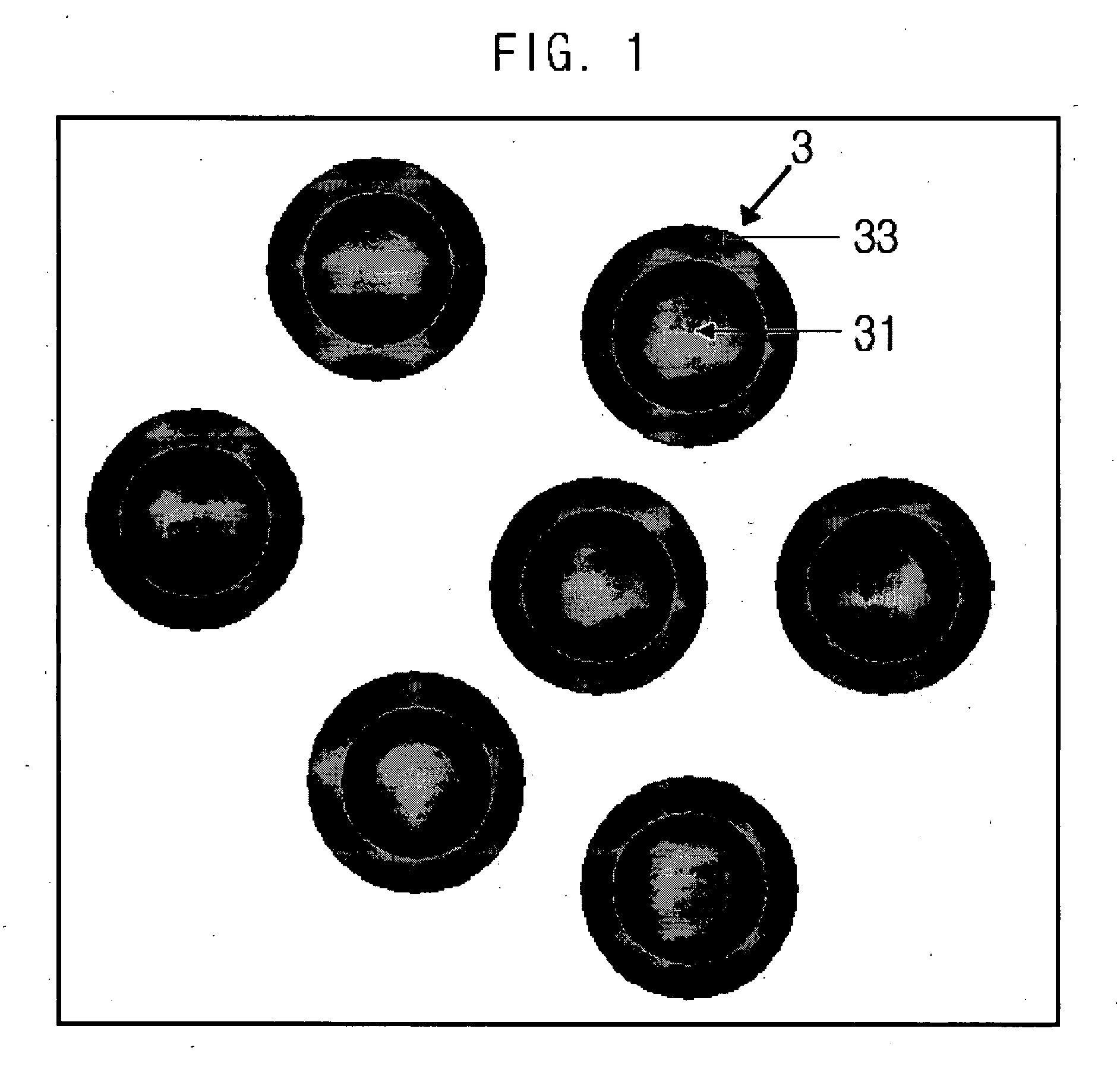

Core-shell structure metal nanoparticles and its manufacturing method

InactiveUS20070212562A1Prevent oxidationEconomical efficiencyMaterial nanotechnologyNon-insulated conductorsThin layerCore shell

The present invention provides metal nanoparticles, containing copper core and thin layer of precious metals enclosing the core to prevent oxidization of copper, in which manufacturing the metal nanoparticles is economical efficiency because of increased copper content and since such metal nanoparticles contain a metal having high electrical conductivity such as silver for a thin layer, they can form a wiring having better conductivity than copper and there is little concern that silver migration may occur.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Elastic ribbon machine

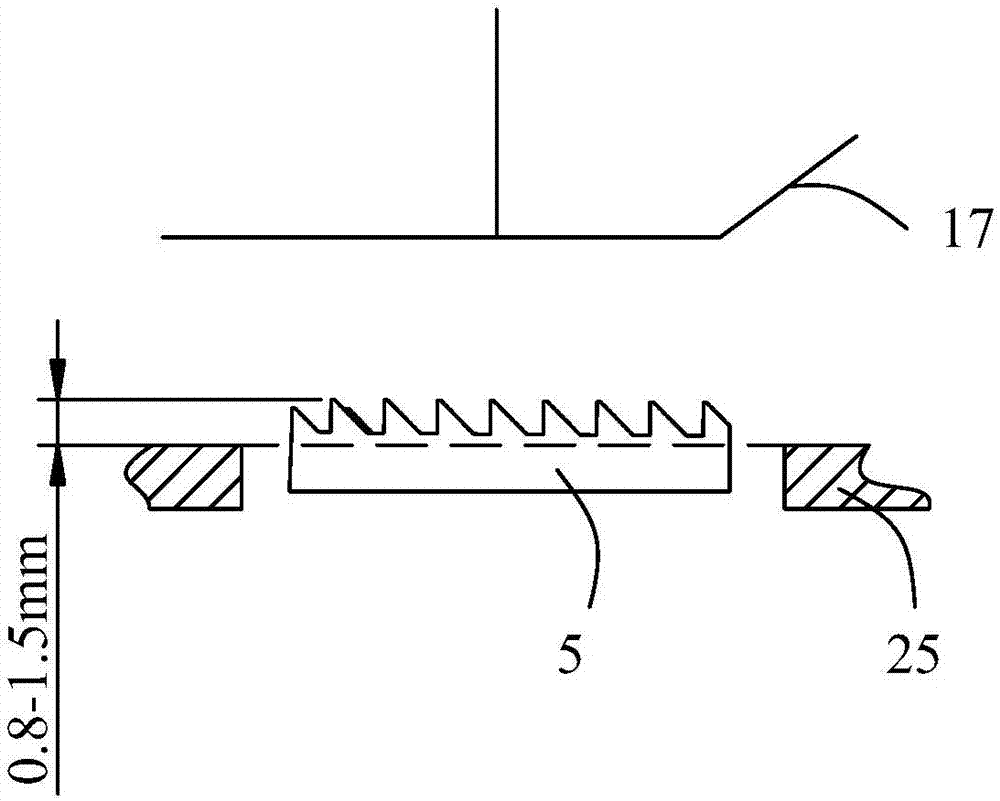

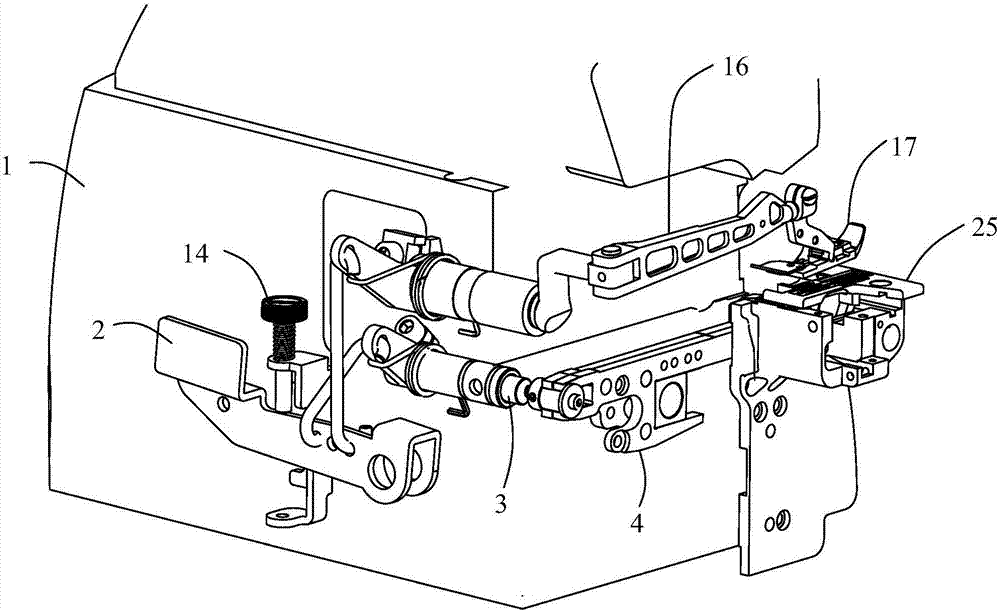

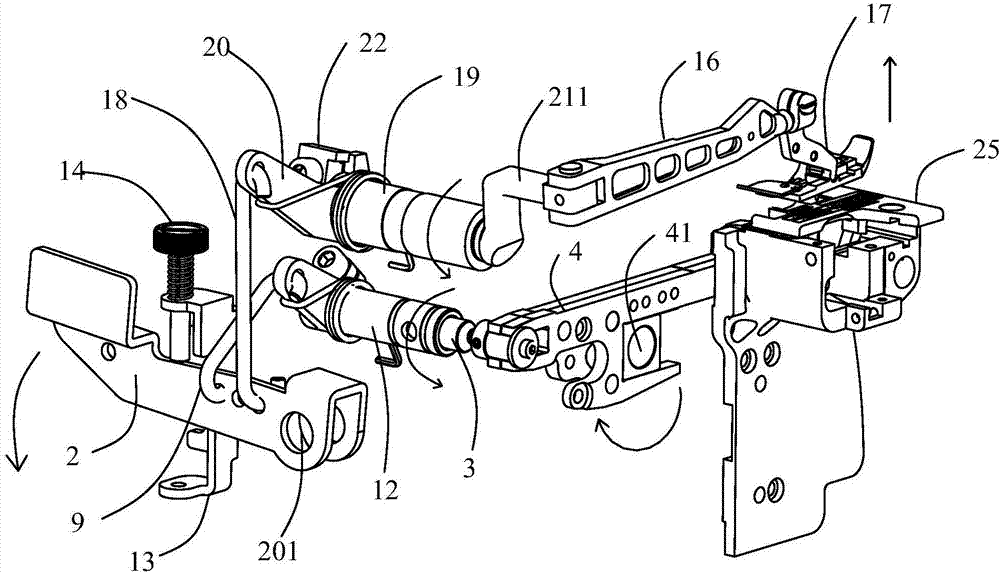

ActiveCN103352330ASimple structureEasy to fix with sewingWorkpiece carriersWork-feeding meansAutomatic controlFeed drive

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

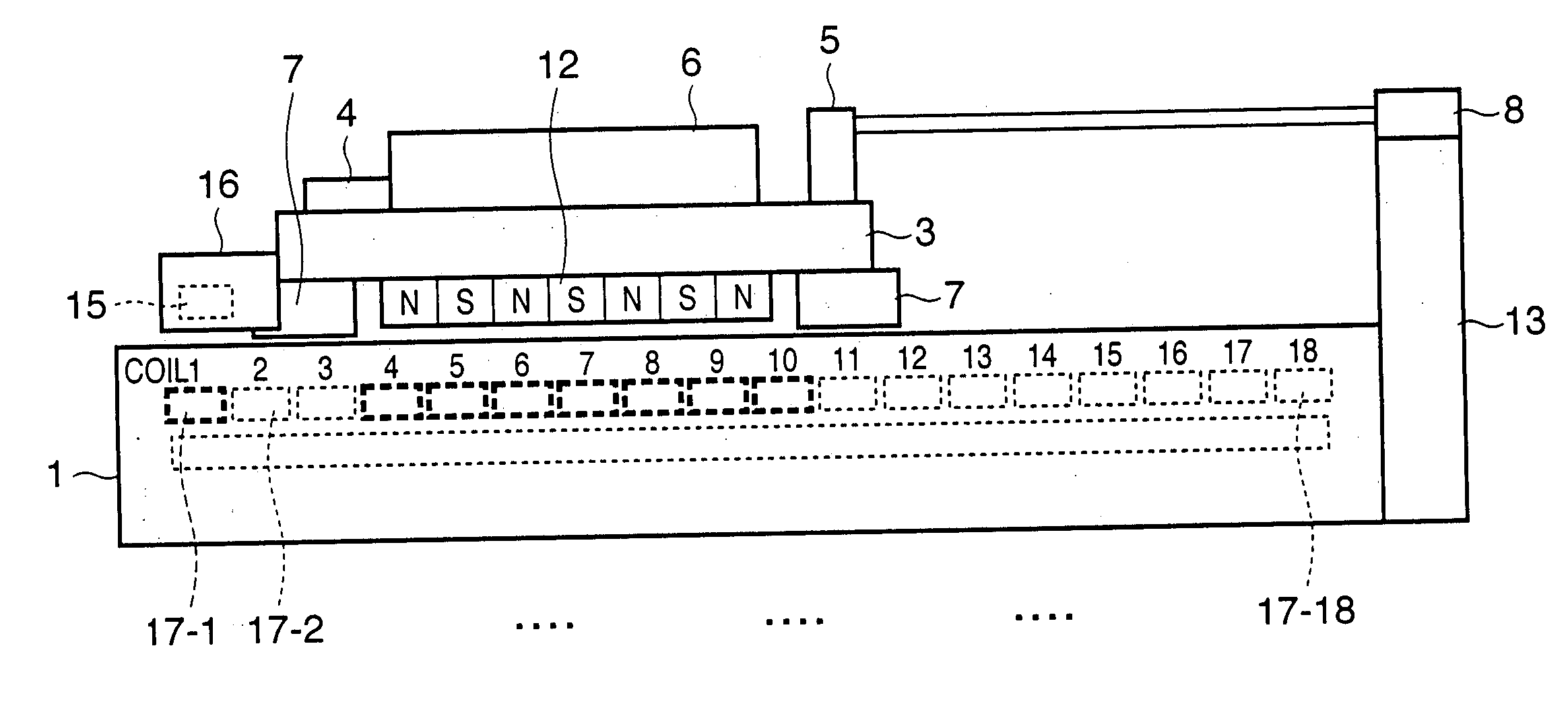

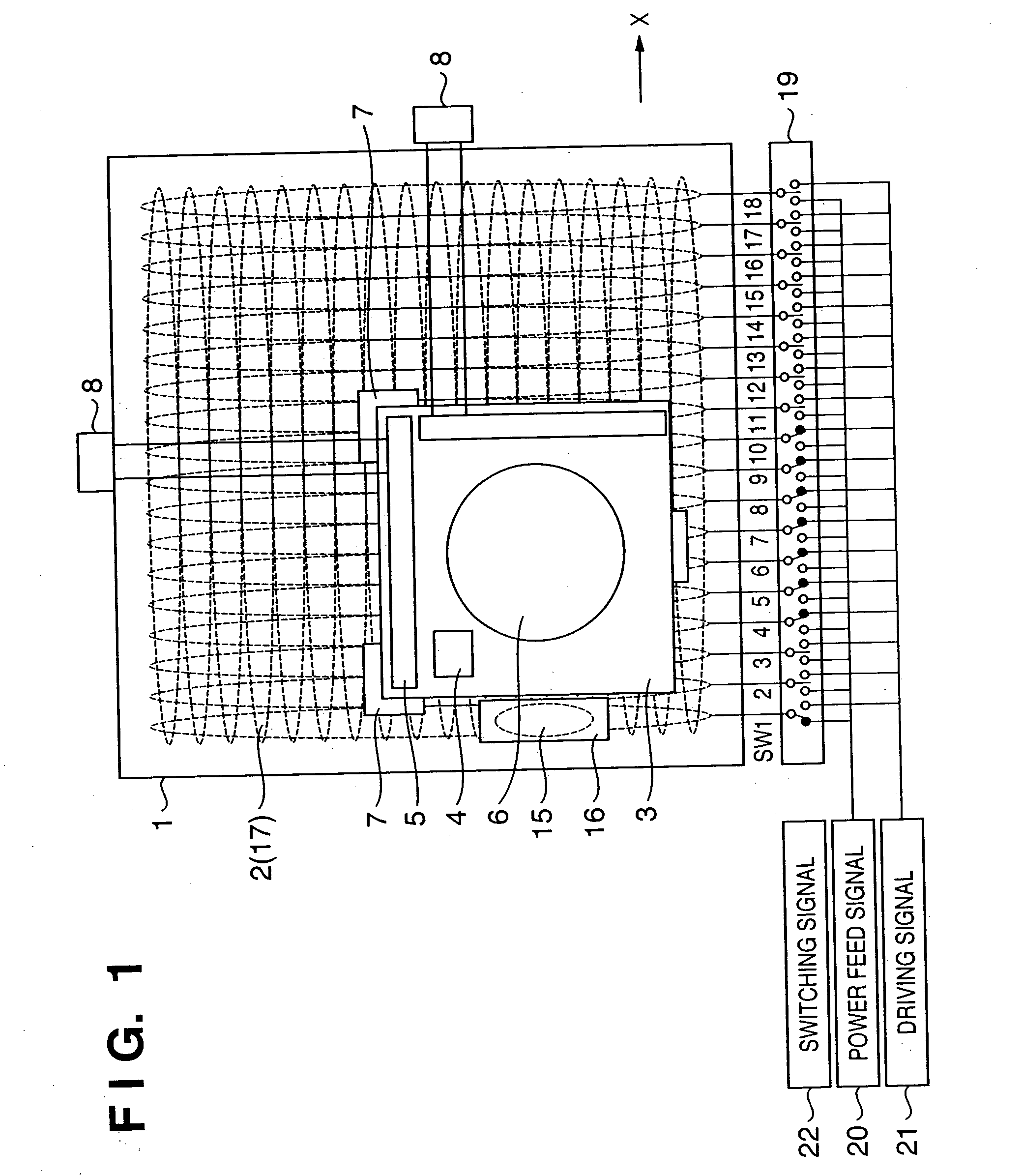

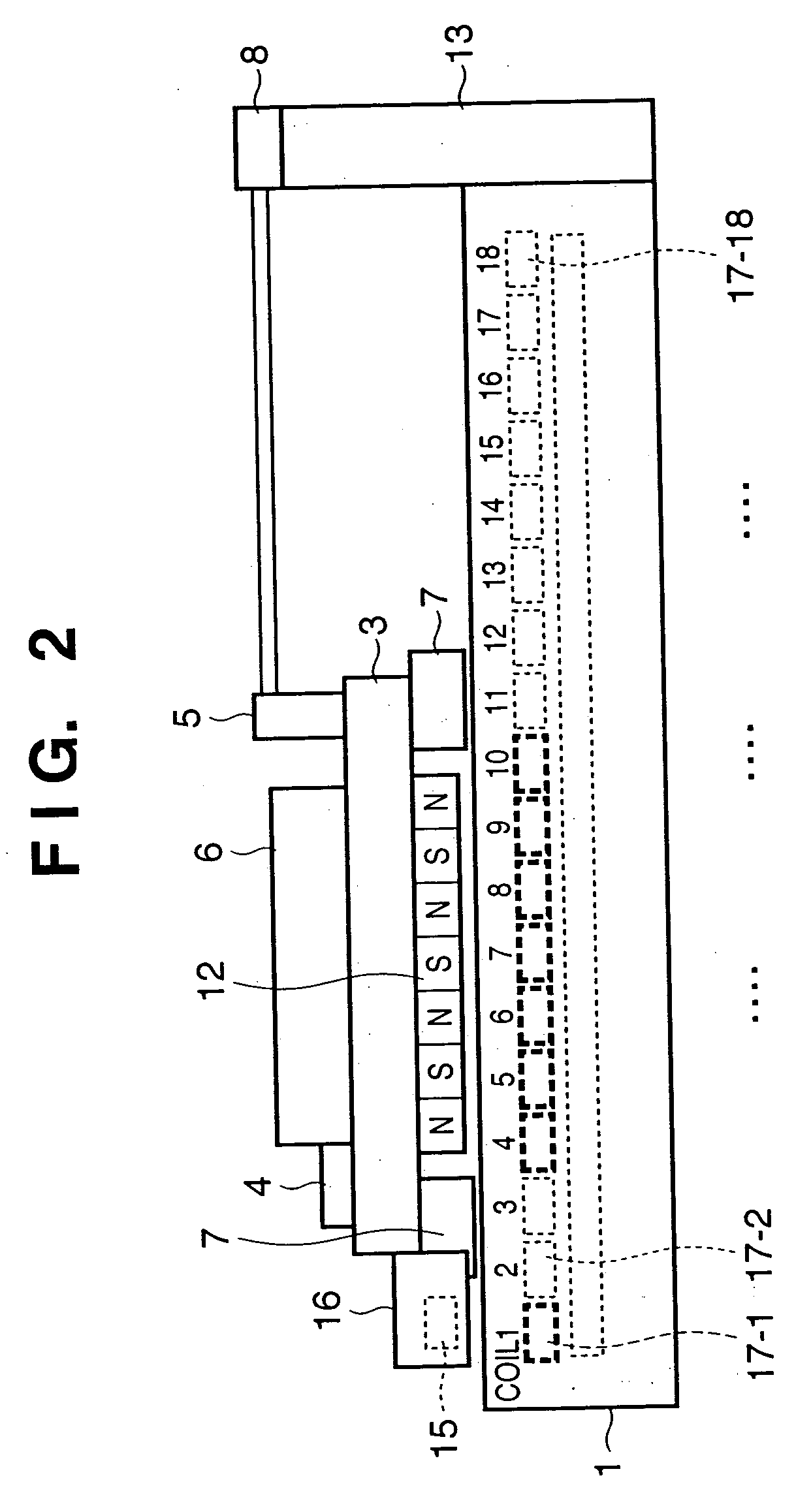

Alignment stage apparatus

InactiveUS20050093378A1Improve throughputIncrease speedDC motor speed/torque controlSemiconductor/solid-state device manufacturingElectric power transmissionElectricity

Power is supplied at an arbitrary position of a movable stage main body or arbitrary timing by downsizing or removing a battery mounted on a movable stage main body, in a non-contact manner without using any electrical cable. In an alignment stage having a power reception coil to which an AC magnetic field is supplied to obtain power in a non-contact manner, a plurality of power transmission coils which supply power are buried in a base structure. An unit for sequentially switching the power transmission coils in accordance with a position of the stage is provided. The power reception coils on the stage include a plurality of power transmission coils arranged to be phase-shifted from the power transmission coils. The frequency of the AC magnetic field is set at a resonance frequency determined by a load and the mutual inductance of the power transmission coils and power reception coils.

Owner:CANON KK

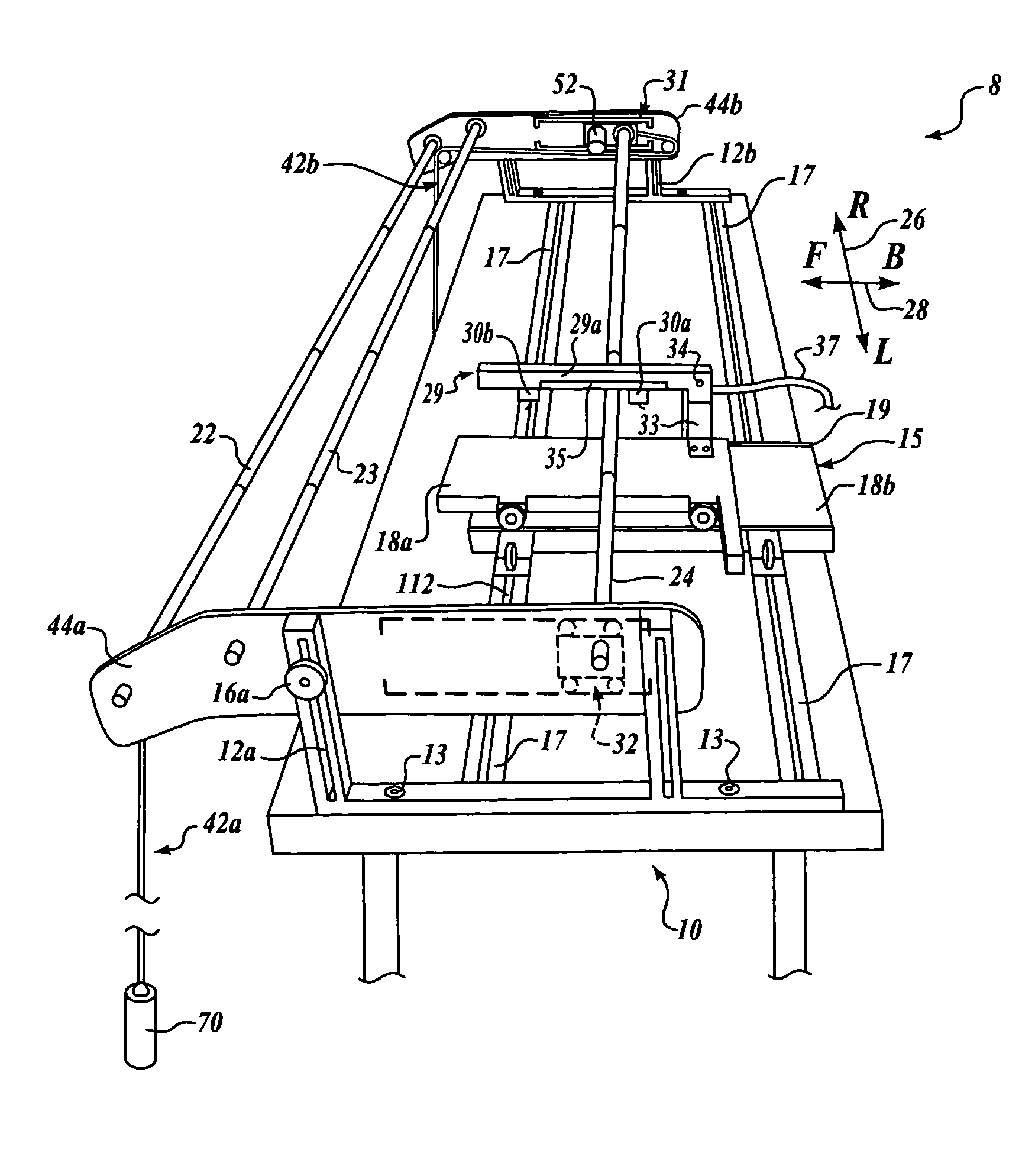

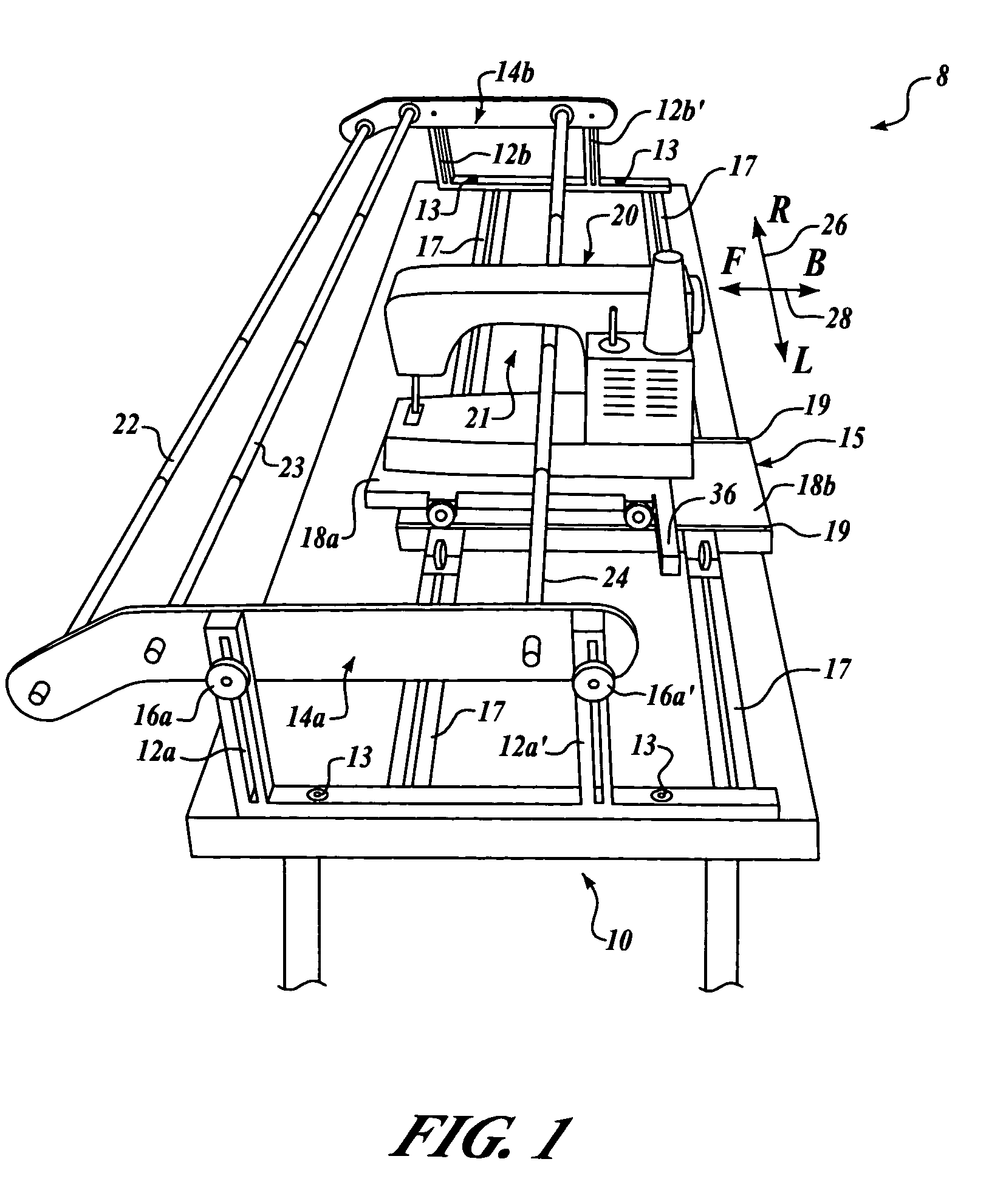

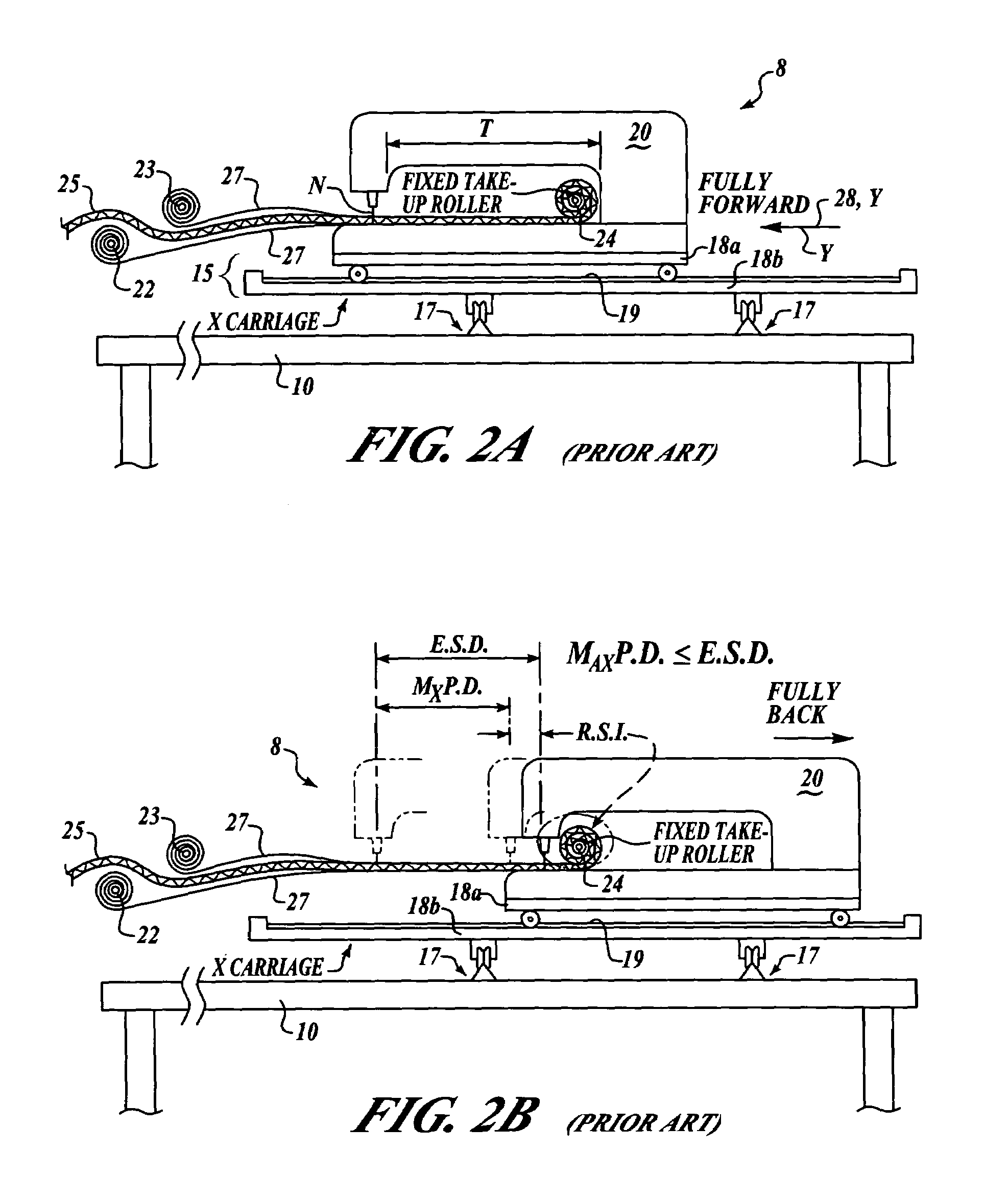

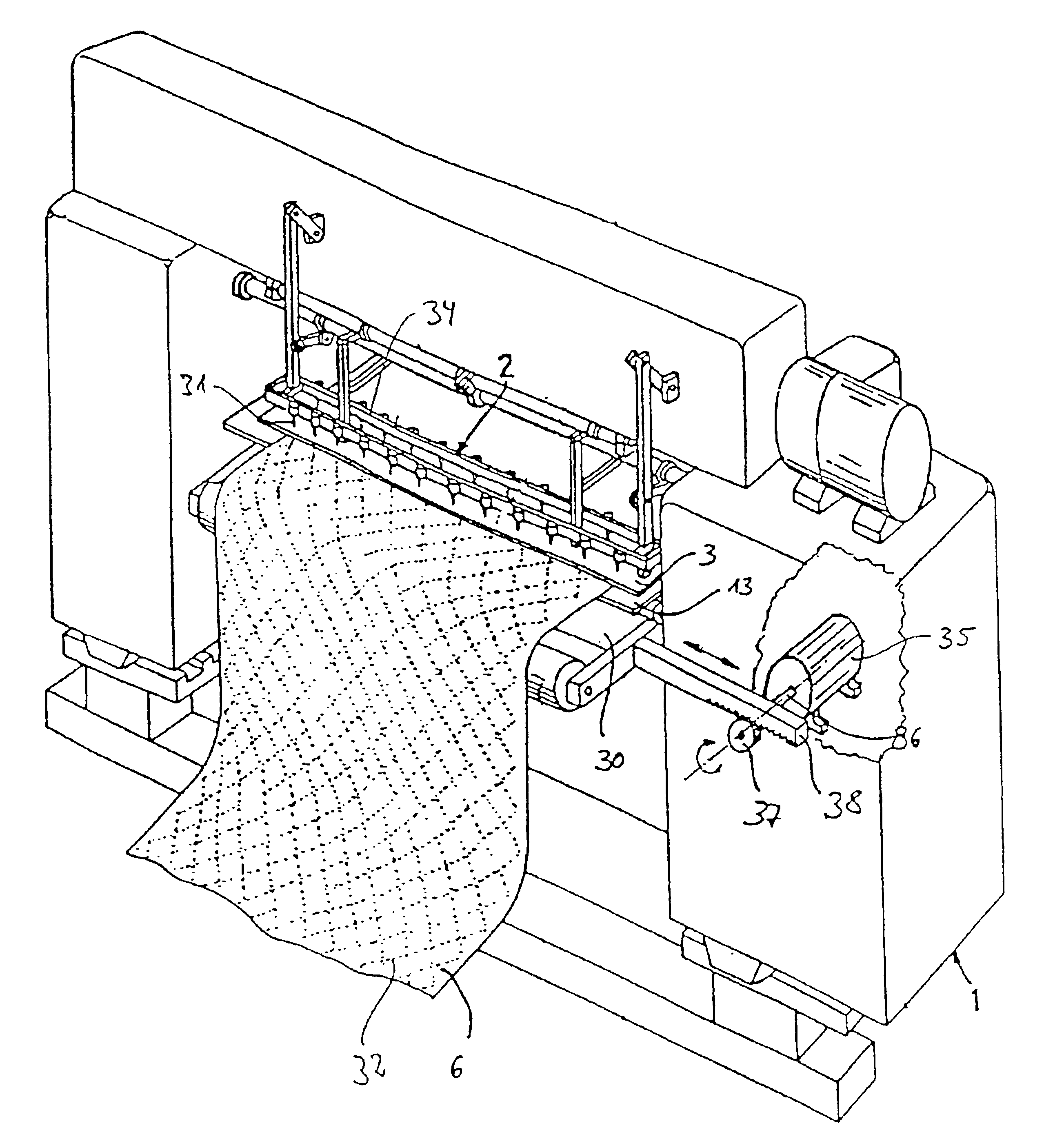

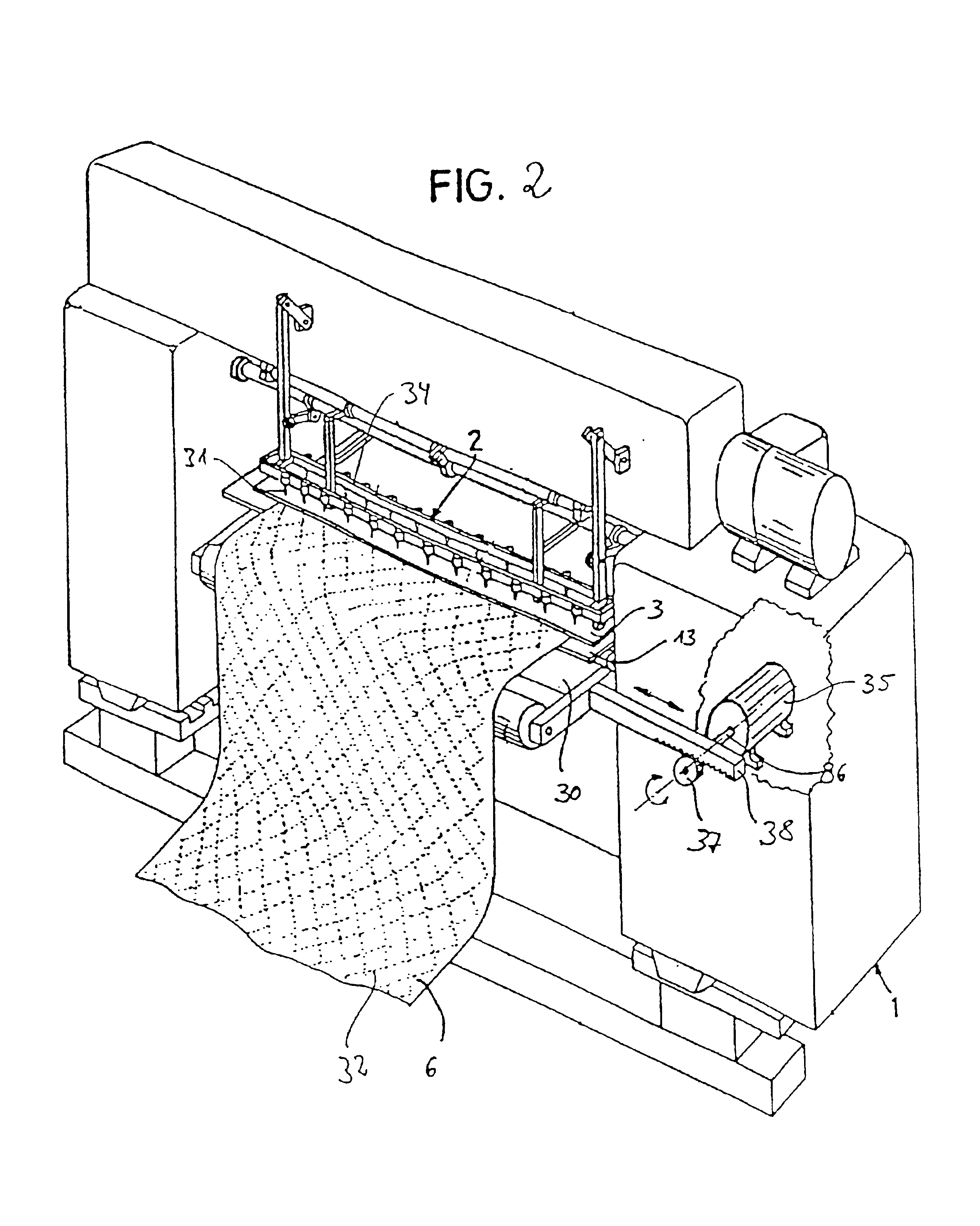

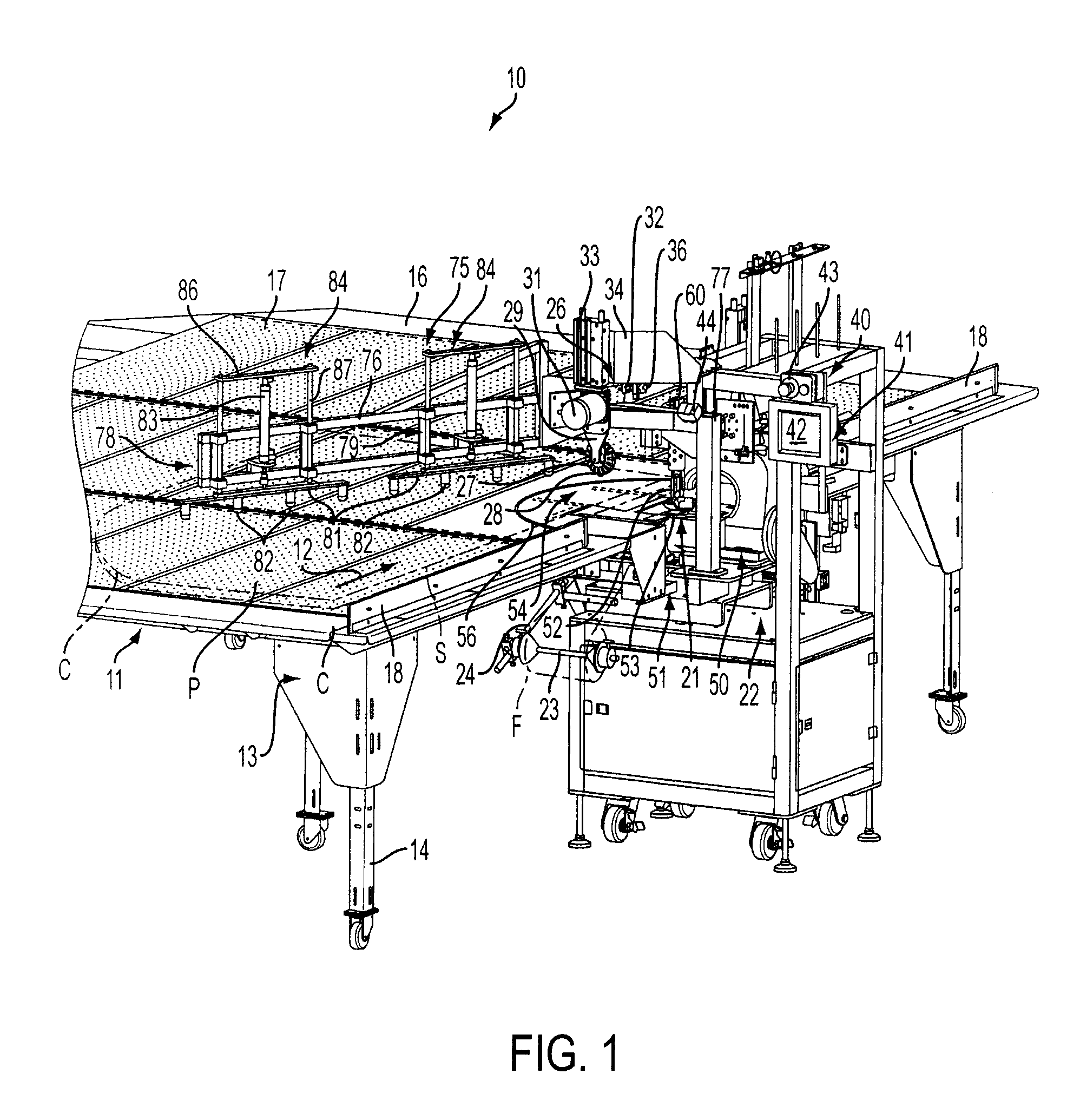

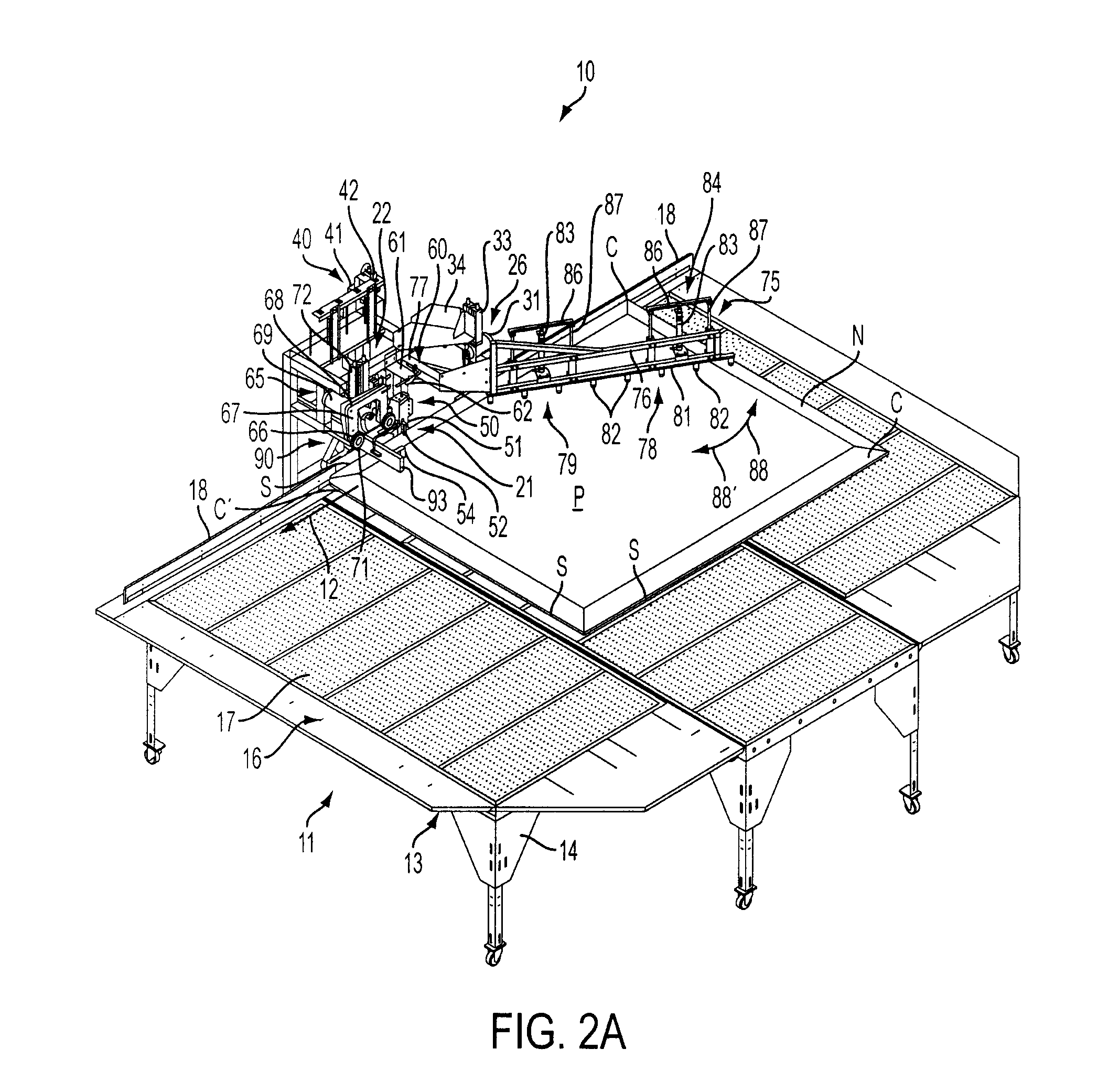

Movable quilting work area system and method

InactiveUS6990914B2Maintain tensionRestrict movementWork-feeding meansMattress sewingEngineeringMicroprocessor

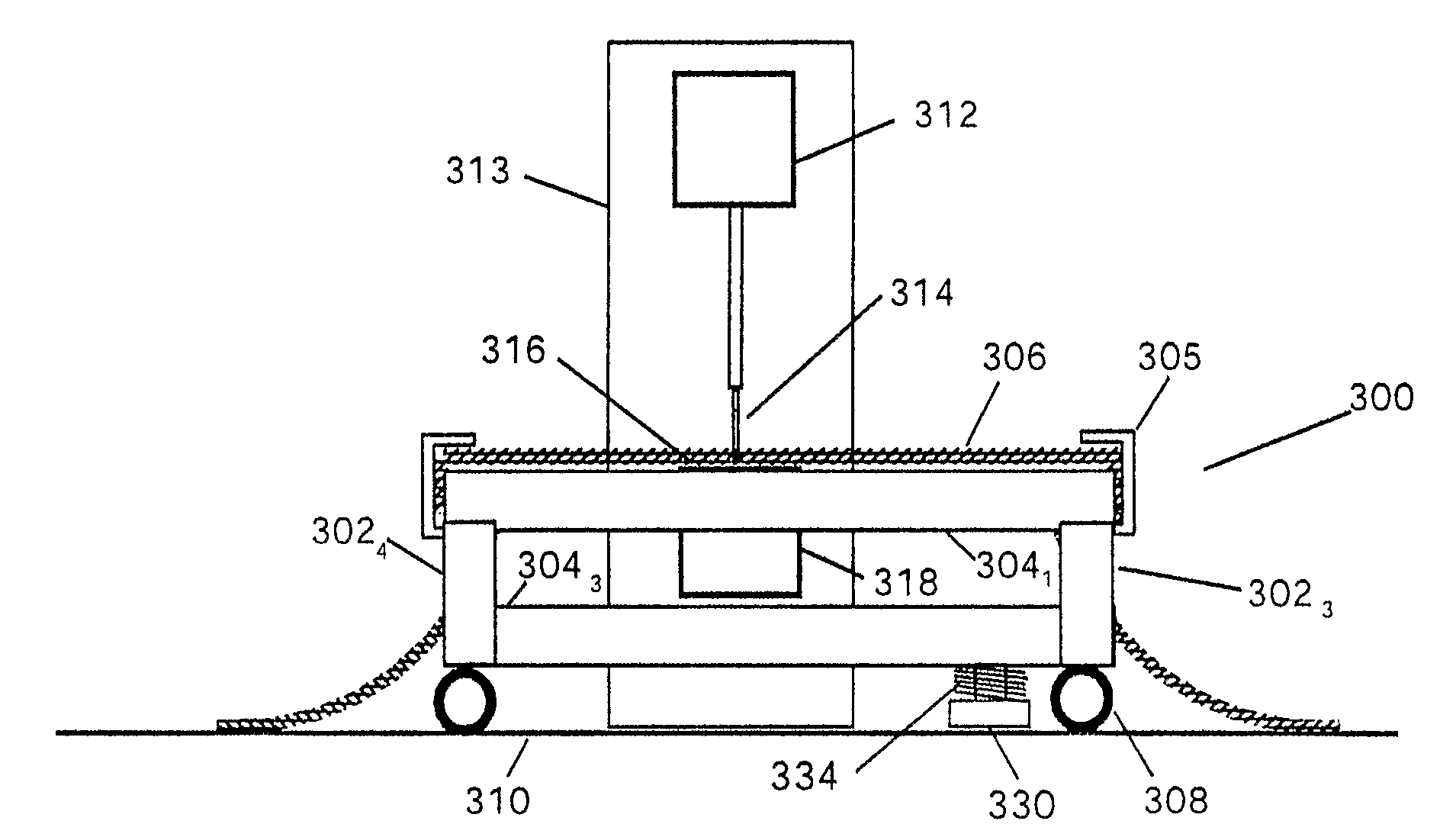

An improved quilting apparatus and method for automatically providing a variable sewing area (VSA) independent of the throat depth of the sewing machine used and X / Y carriages on which the sewing machine is mounted, comprising a rotatably-powered take-up roller mounted on laterally movable carriages, a tension system for continuous tension on fabric and batting, arm-mounted or sewing machine-mounted sensors that detect proximity or engage fabric on the take-up roller and cause rotation of the take-up roller so that it is out of the way of the advancing or returning sewing machine. The inventive VSA system includes a microprocessor-based controller for automatic operation, which controller interfaces with PC operated quilting programs that drive powered X / Y carriage systems to allow sewing of quilting patterns much larger than the throat depth of conventional sewing machines.

Owner:MCMUFFIN & SNUFFLES

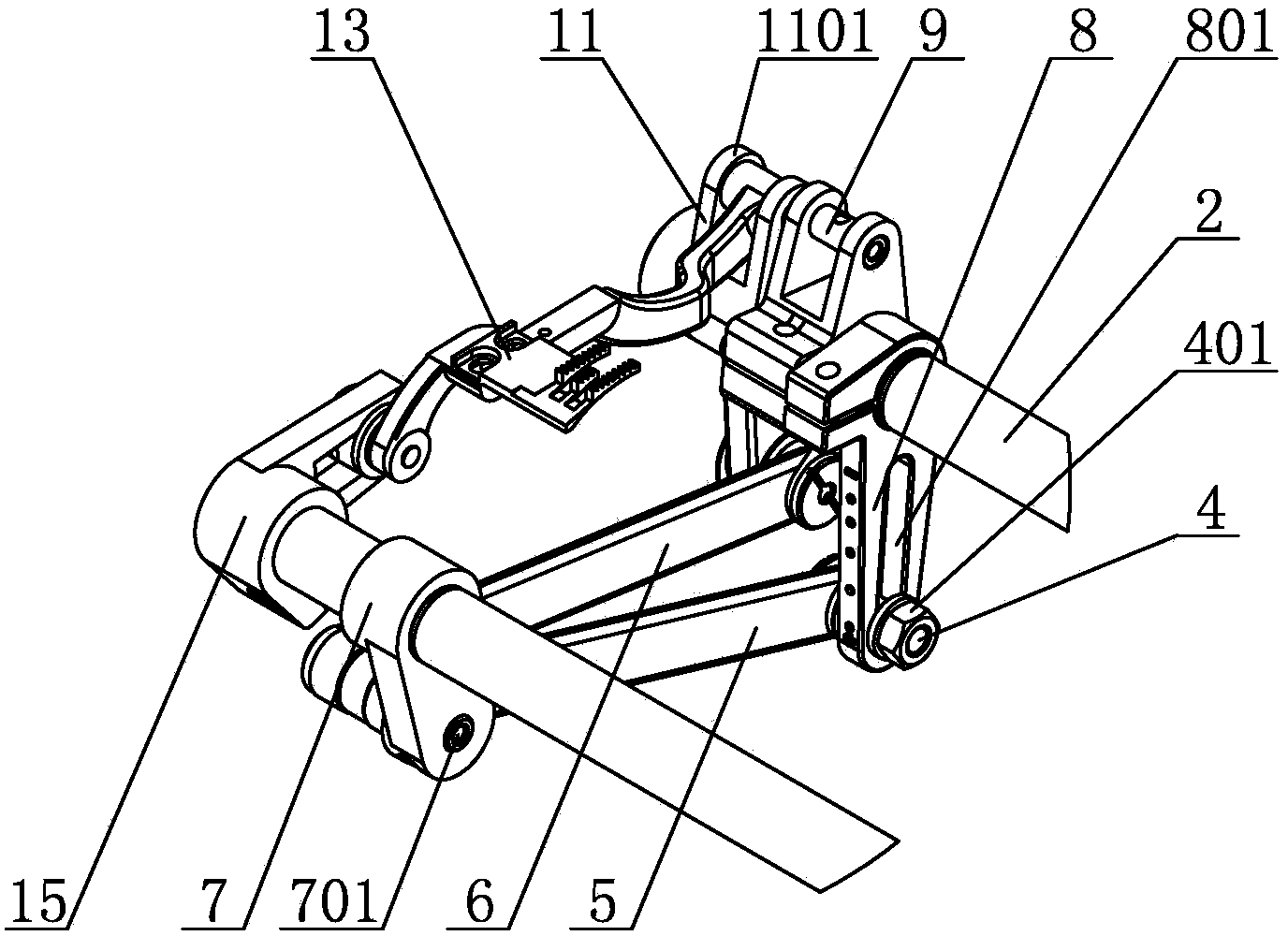

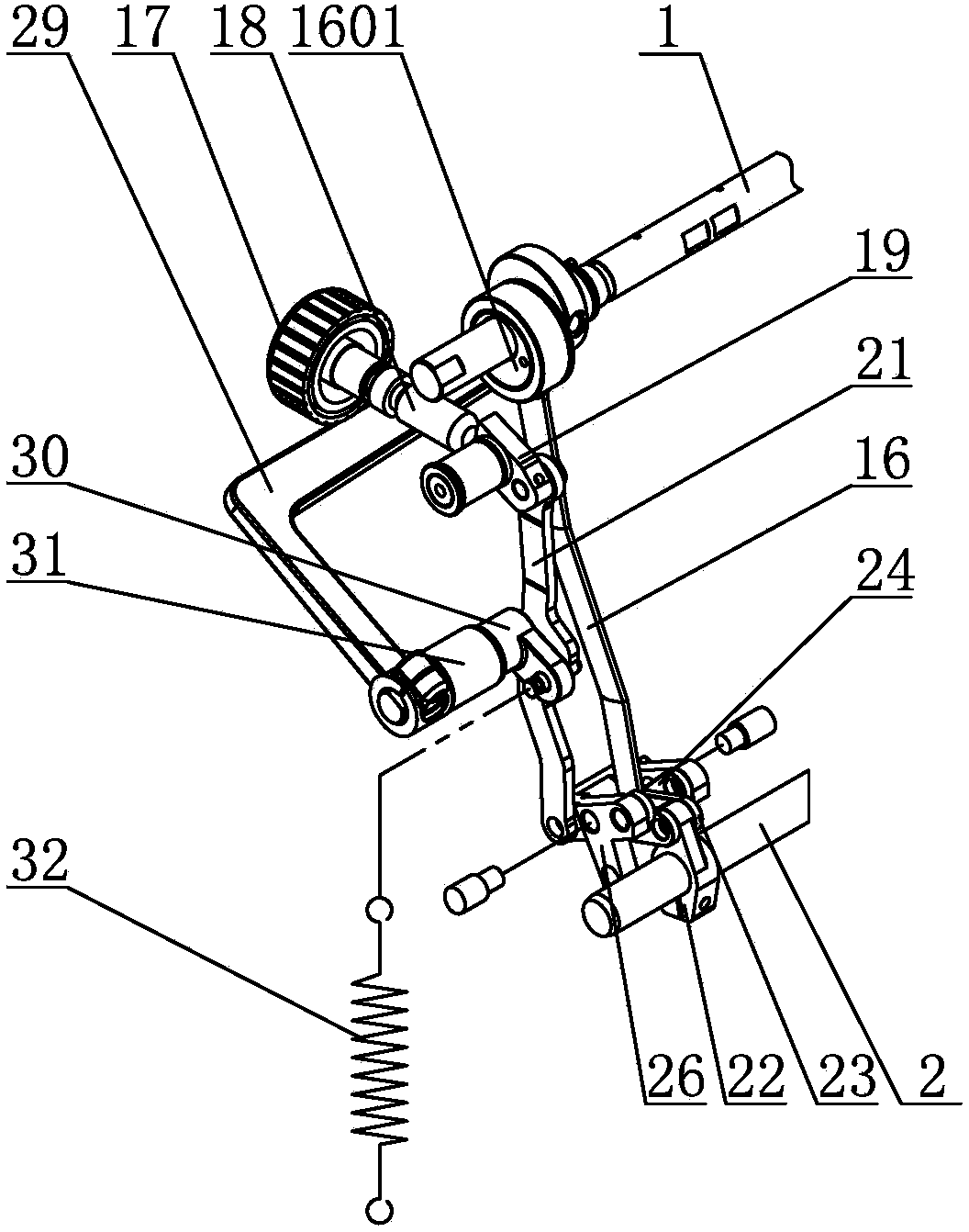

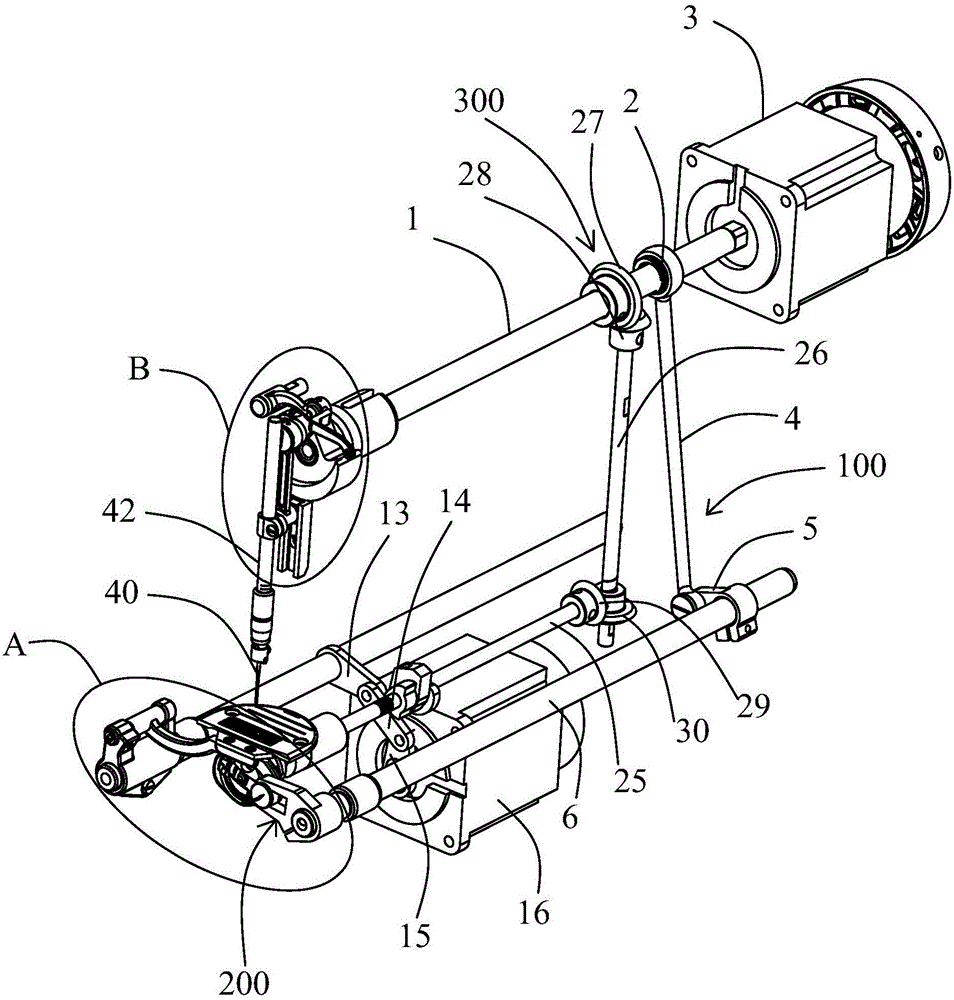

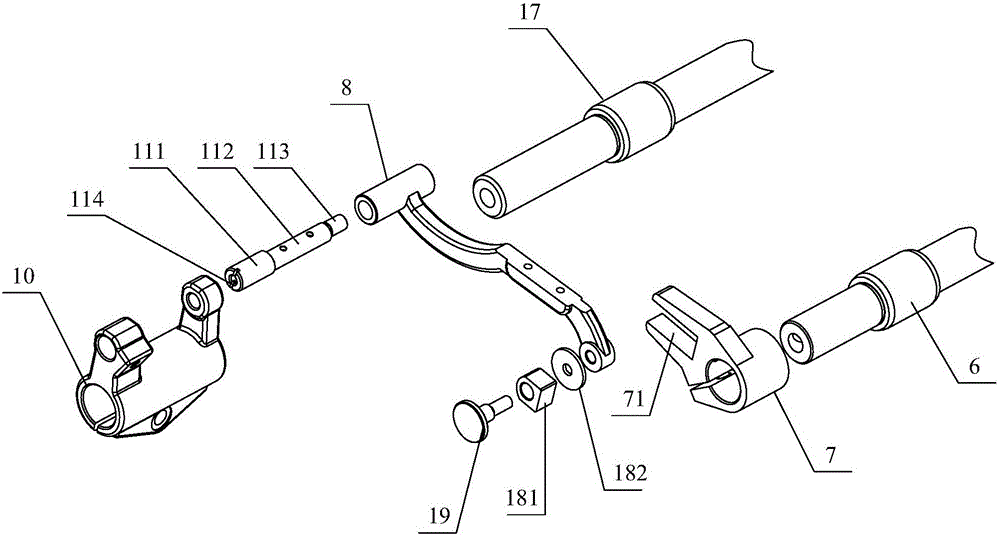

Feeding mechanism downward movement structure controlled by presser foot lifting mechanism and sewing machine

ActiveCN106988030AGuaranteed effective heightEasy to feedWork-feeding meansPressersDental ArticulatorsEffective height

The invention provides a feeding mechanism downward movement structure controlled by a presser foot lifting mechanism and a sewing machine. The feeding mechanism downward movement structure includes a presser foot lifting wrench, an eccentric shaft rotatably installed in a machine housing, a dental articulator having a second swinging supporting point, and a feeding tooth installed at one end of the dental articulator; a sliding groove is formed in the dental articulator, the eccentric shaft has a shaft body part and a shaft eccentric part eccentrically arranged on the shaft body part, the presser foot lifting wrench is connected with the shaft body part of the eccentric shaft through a first transmission mechanism, and the shaft eccentric part of the eccentric shaft can be rotatably installed in the sliding groove of the dental articulator and cooperated with the sliding groove in a sliding mode; when a presser foot is lifted, the presser foot lifting wrench swings around a first swinging supporting point and swings around the second swinging supporting point through a first transmission mechanism and an eccentric shaft driven dental articulator, so that the end, provided with the feeding tooth, of the dental articulator moves downward to the upper surface of a needle plate, the effective height between the presser foot and the needle plate after the presser foot is lifted is ensured, and therefore a to-be-sewed material is easily delivered between the presser foot and the needle plate before sewing is started.

Owner:JACK SEWING MASCH CO LTD

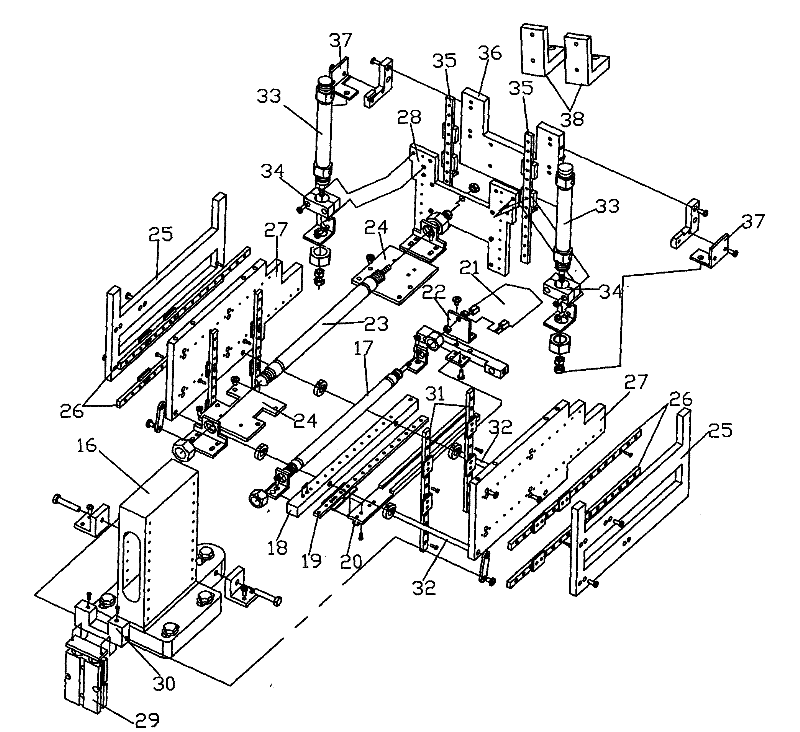

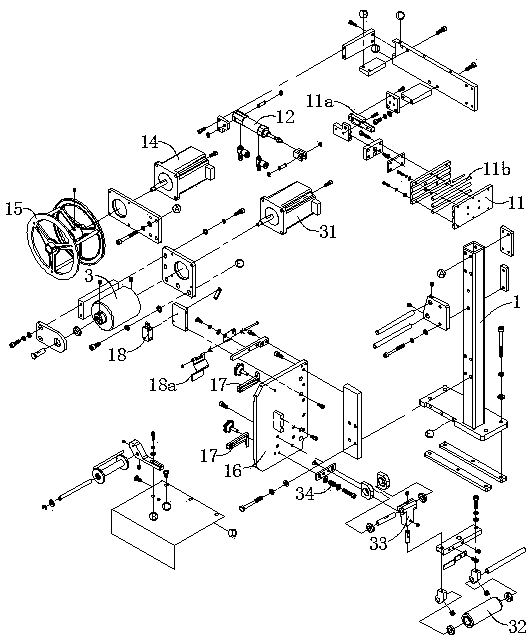

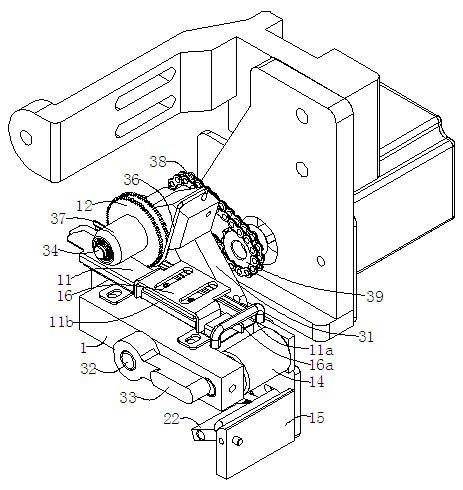

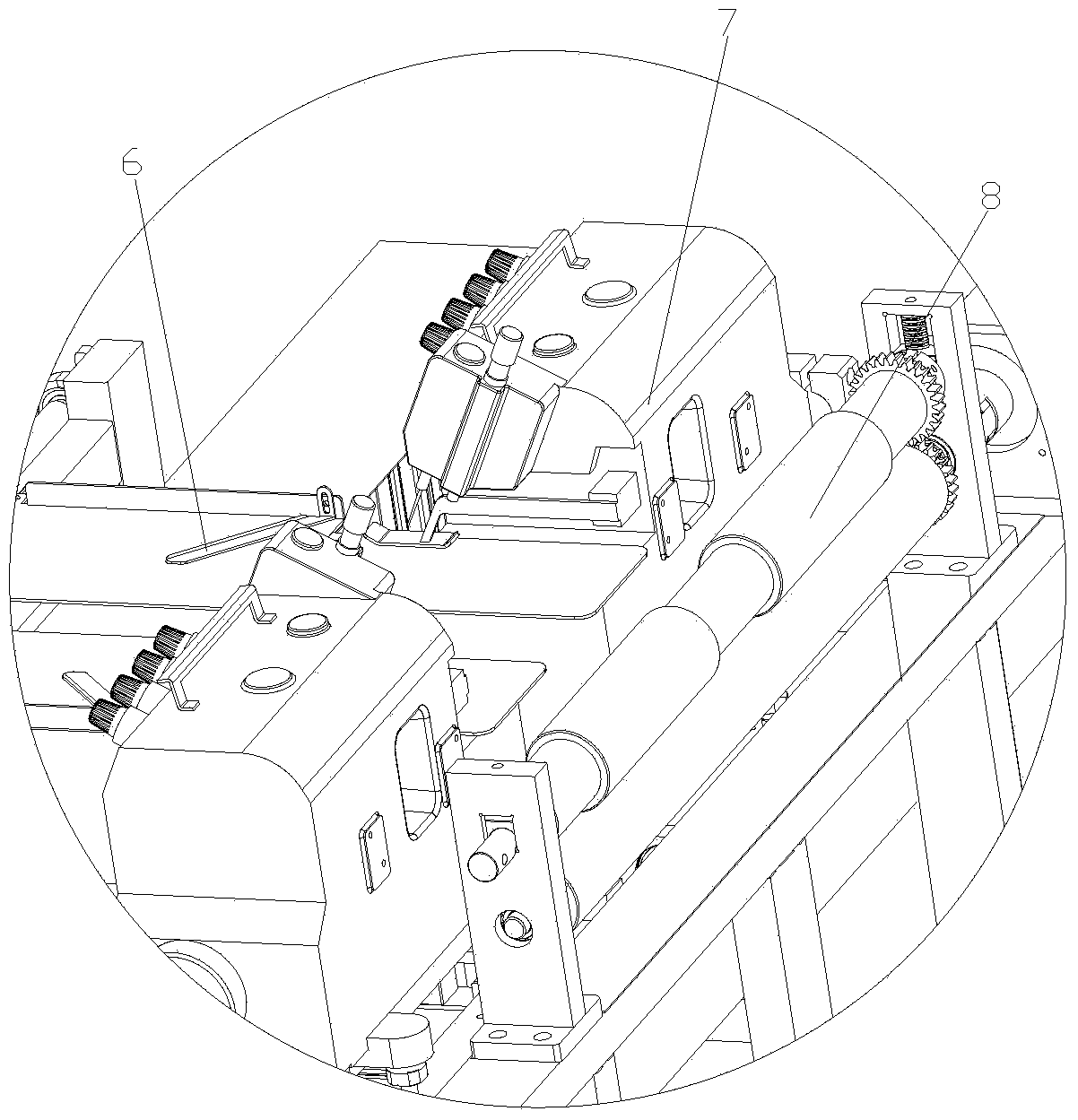

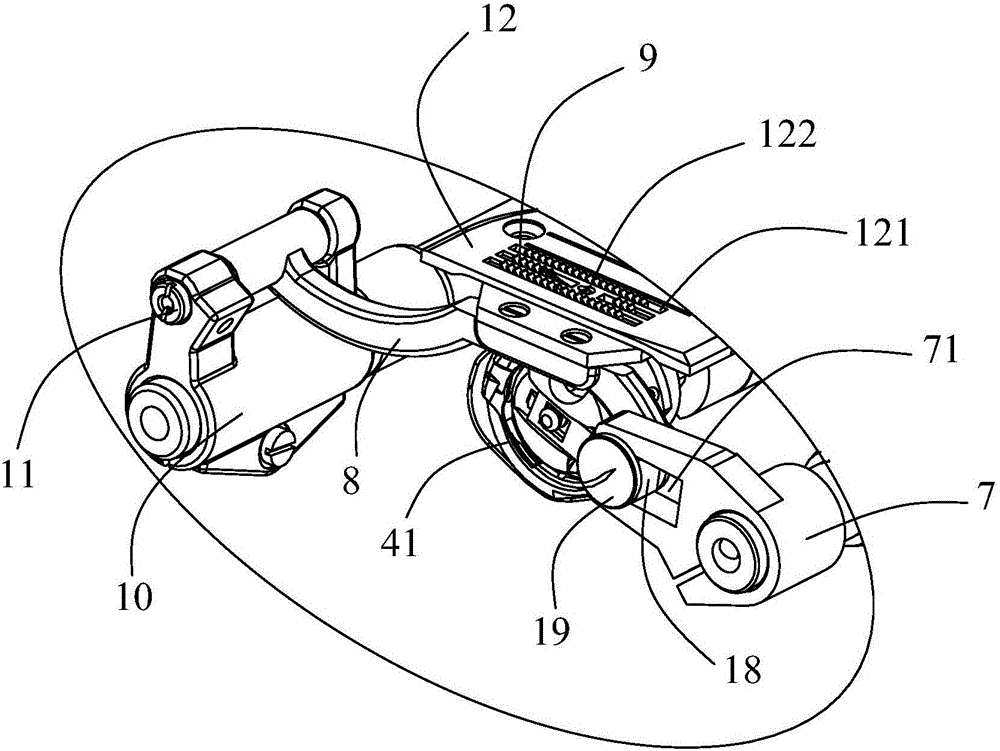

Feeding device for automatic band nailing machine

ActiveCN102493131AEasily adjust the range of motionAdjust the range of motionWorkpiece carriersWork-feeding meansEngineeringFeed tank

The invention discloses a feeding device for an automatic band nailing machine. The feeding device comprises a feeding mechanism for inputting bands, a clamping mechanism used for clamping the heads of the bands in the feeding mechanism and drawing the heads by a set length, a cutter mechanism used for cutting off the bands, and a winding mechanism used for clamping two ends of the bands and winding. The bands are input into a feeding tank through a feeding hole, are conveyed by the feeding tank to pass through a tool rest, a clamping head component can move to the tool rest to clamp the heads of the bands and draw out the bands from the feeding tank by the set length; a telescopic platform of the winding mechanism moves, two winding arms clamp and draw out the two ends of the bands; a cutter cuts off the bands at the outlet of the feeding tank; the two winding arms of the winding mechanism rotate to wind the two ends of the bands; and the telescopic platform continuously moves to feed the wound bands to a sewing area. The feeding device can automatically feed, cut and wind the bands and convey the bands to the sewing area, and has the advantages of convenience for operation, highspeed and high efficiency.

Owner:NINGBO SUPREME ELECTRONIC MASCH INC

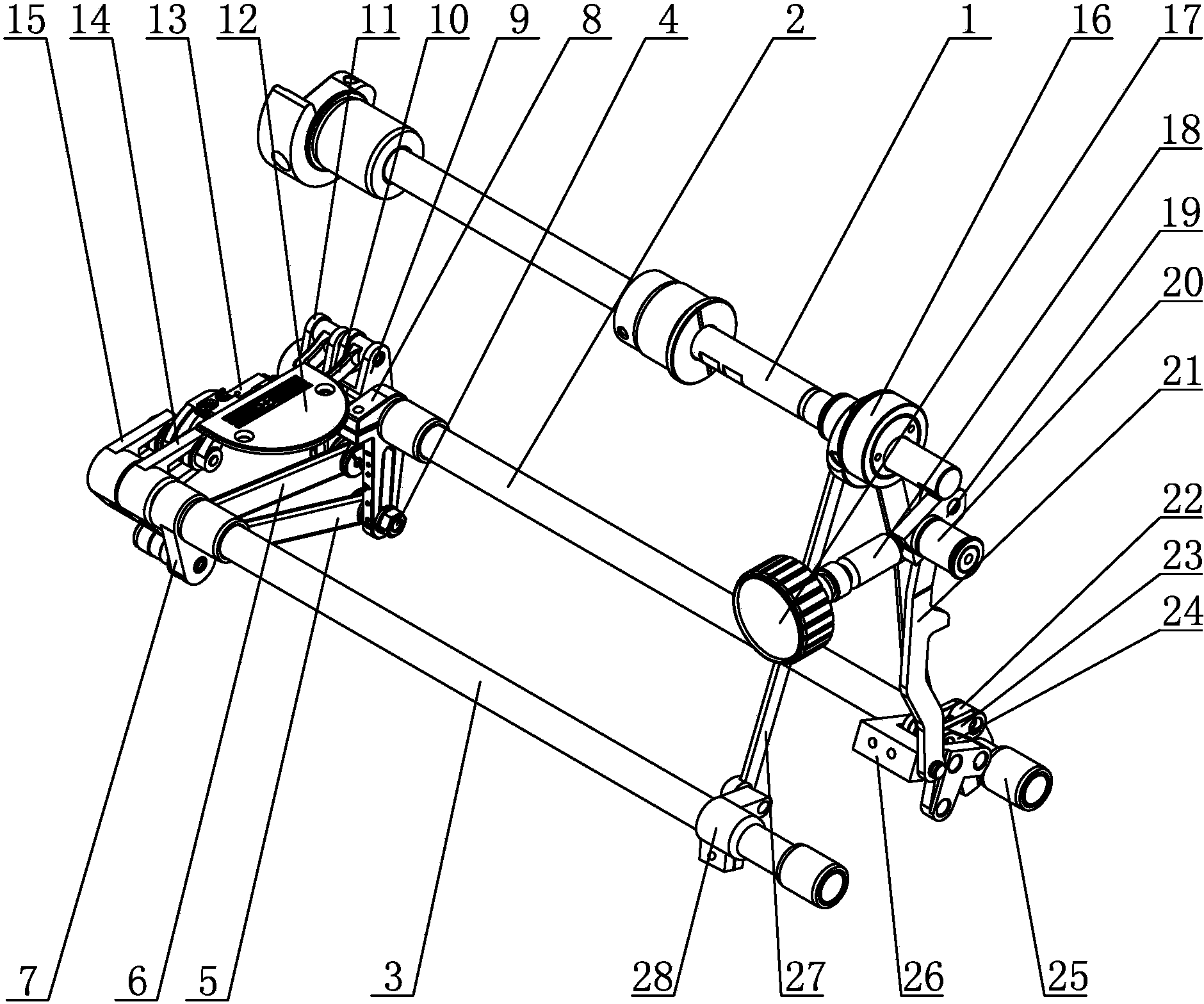

Sewing machine for up-down differential feeding

ActiveCN104233644ASimple structureCombined design is reasonableWork-feeding meansSewing-machine control devicesCrankControl engineering

The invention relates to a sewing machine for up-down differential feeding. The sewing machine comprises a secondary feeding adjusting mechanism, a feeding shaft and a feed lifting rock shaft, wherein the secondary feeding adjusting mechanism comprises a lower differential feeding adjusting crank and a first tooth frame seat which are fixed on the feeding shaft, a lower differential feeding crank which movably sleeves the feeding shaft and a lower differential transmission crank which movably sleeves the feed lifting rock shaft; the first tooth frame seat is connected with a feeding tooth; the lower differential feeding crank is connected with a lower differential feeding tooth; the lower differential feeding adjusting crank, a first lower differential feeding connecting rod, the lower differential transmission crank, a second lower differential feeding connecting rod and the lower differential feeding crank are hinged and linked in sequence; the hinging position between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is adjustable. The hinging position is adjusted so that a force arm relation between the lower differential feeding adjusting crank and the first lower differential feeding connecting rod is changed and a relation of swinging and transferring the feeding shaft to the feeding tooth and the lower differential feeding tooth is changed, namely the lower differential feeding adjustment is realized.

Owner:宁波新三合自动化有限公司

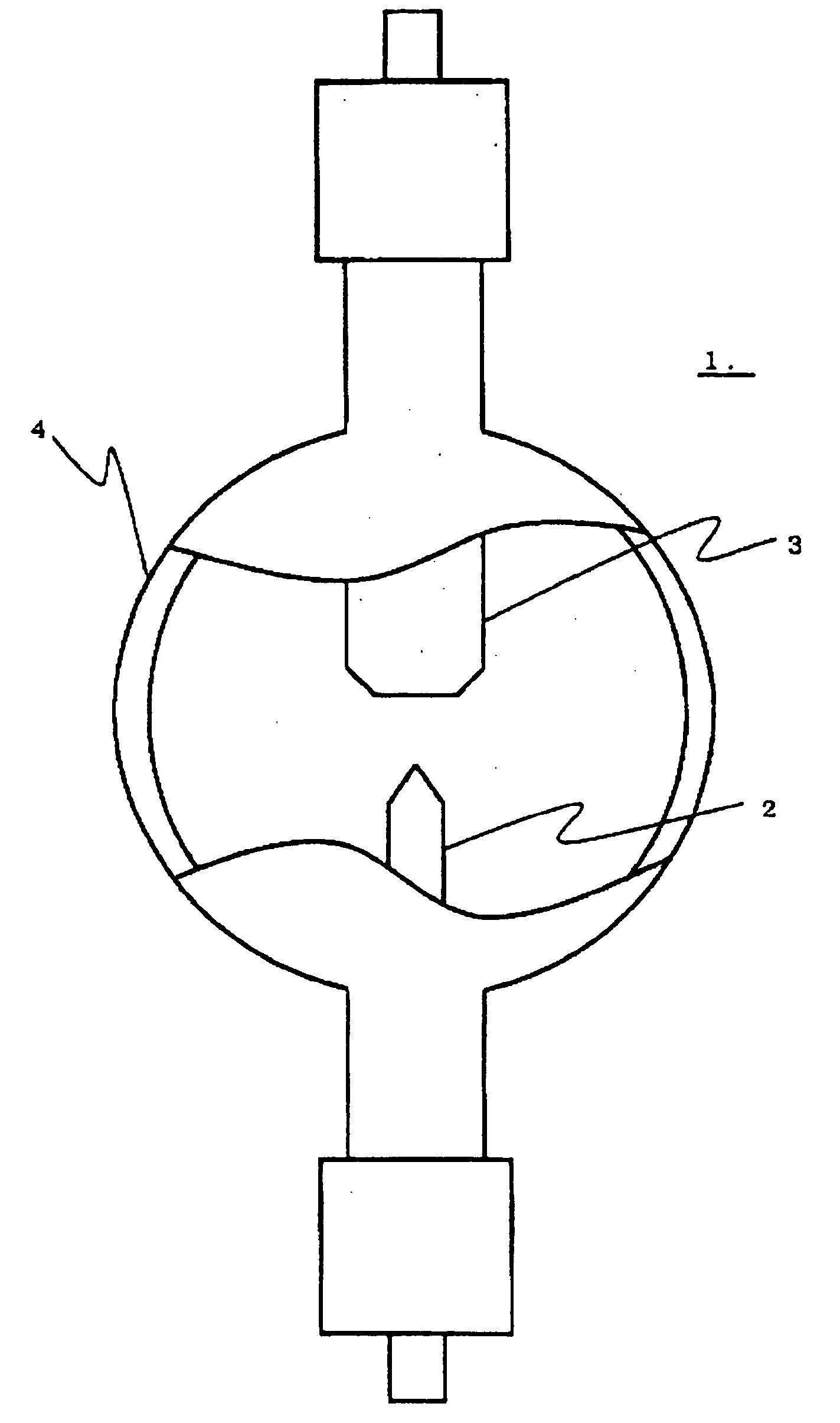

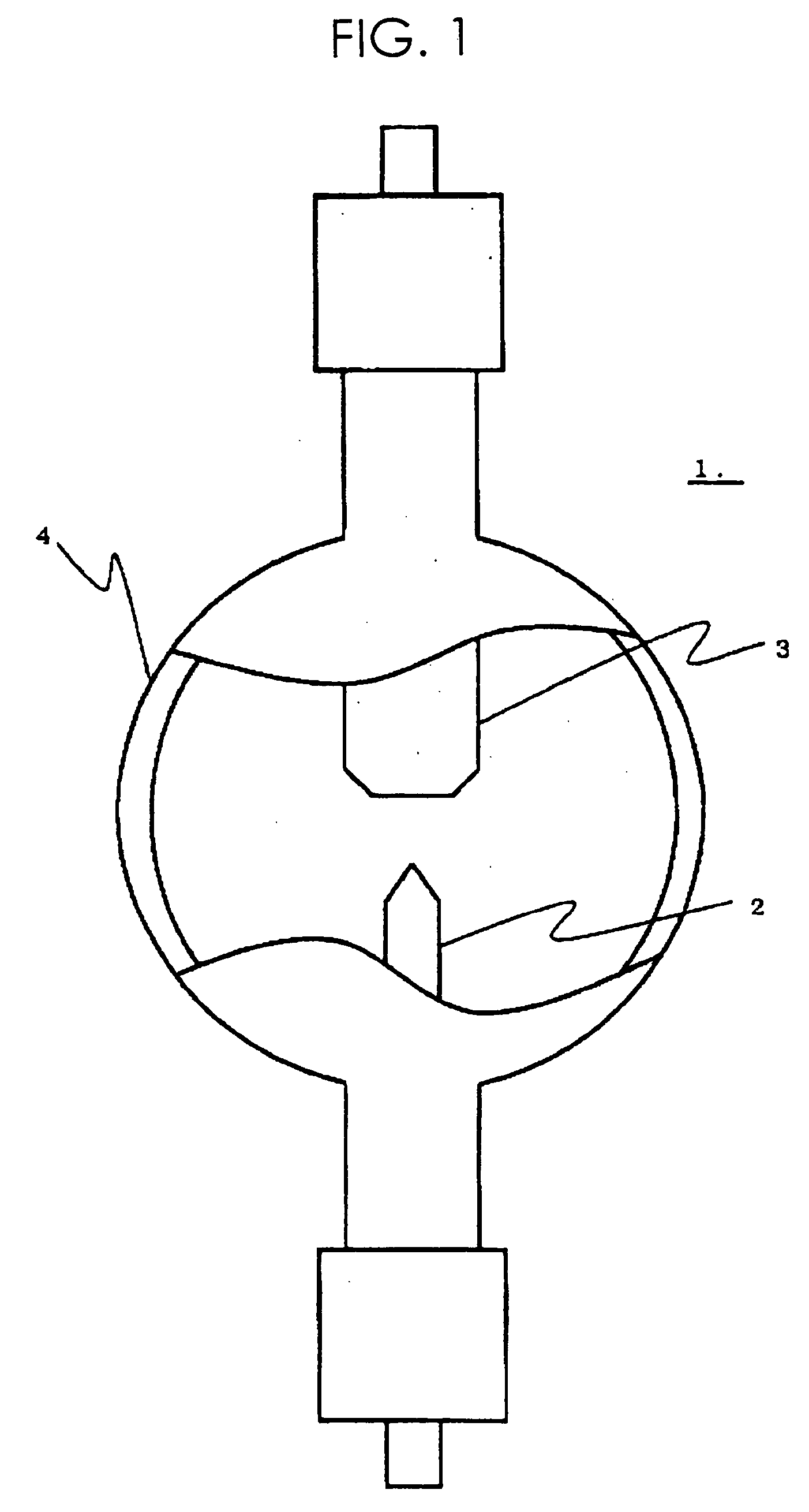

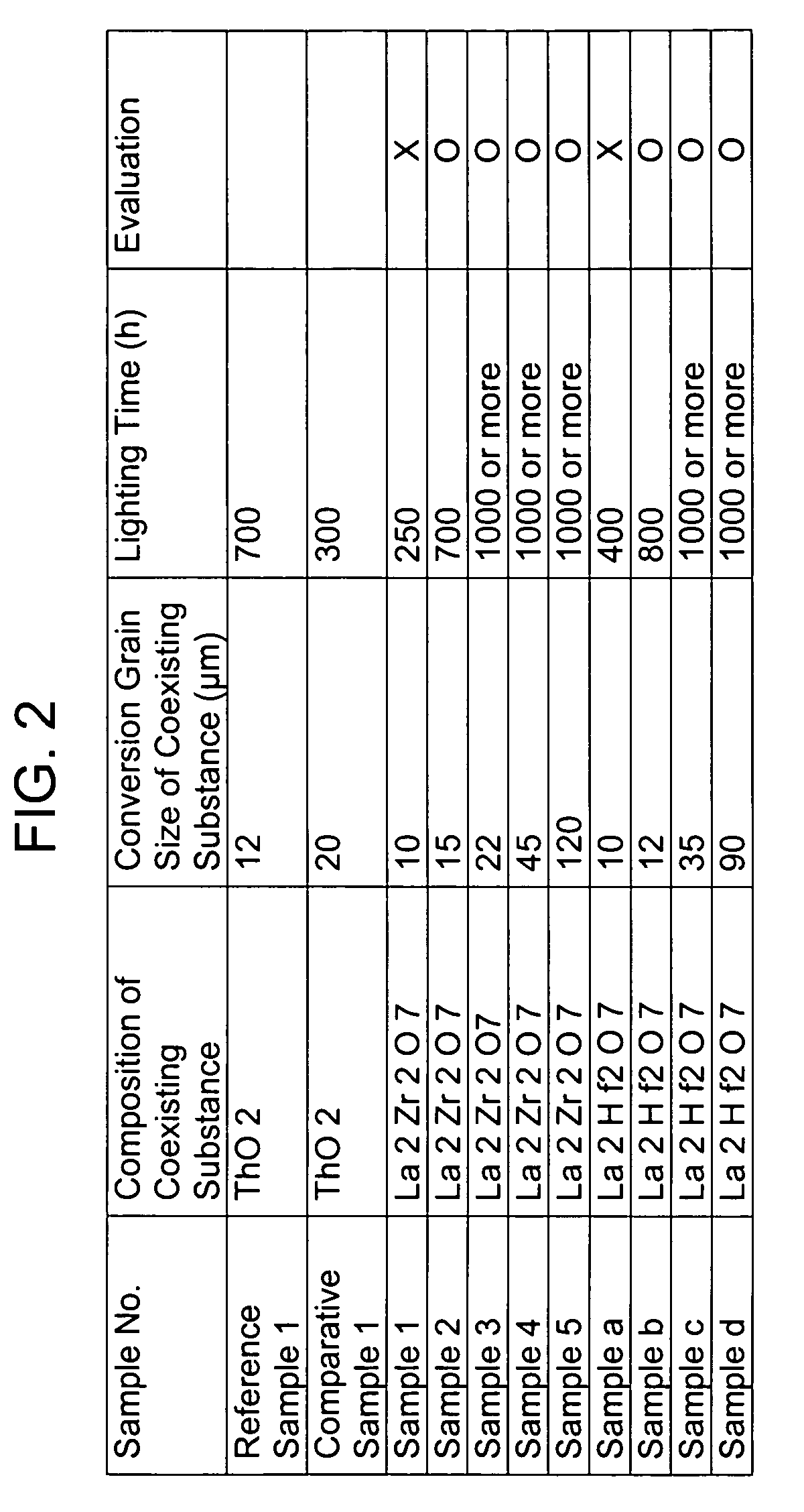

High-load and high-intensity discharge lamp

ActiveUS20060220559A1Long life-timeImprove stabilityWork-feeding meansSolid cathode detailsNiobiumCerium

The present high-load and high-intensity discharge lamp includes a cathode made of a material which does not (substantially) include thorium but can be used as a cathode material of high heat load, so that a long lifetime and high stability corresponding to those of thoriated-tungsten can be realized. Specifically, the cathode is made of a metal base having a high melting point which mainly consists of tungsten and includes a coexisting substance in which an oxide of at least one kind of metal selected from lanthanum, cerium, yttrium, scandium, and gadolinium and an oxide of at least one kind of metal selected from titanium, zirconium, hafnium, niobium, and tantalum are coexistent. The conversion grain size of the coexisting substance is 15 μm or greater, and the plurality of coexisting substances are present in the metal base with a high melting point.

Owner:USHIO DENKI KK

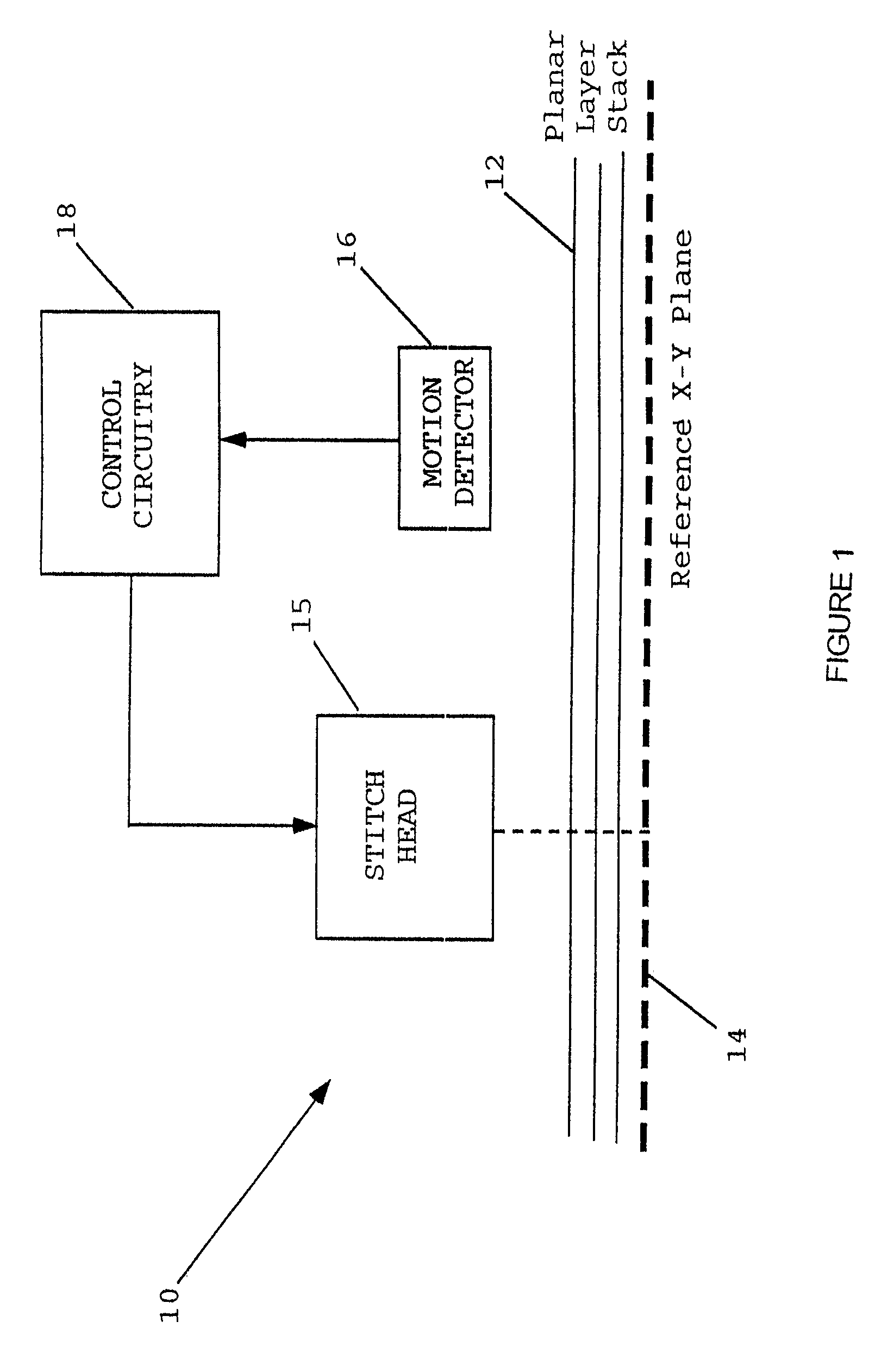

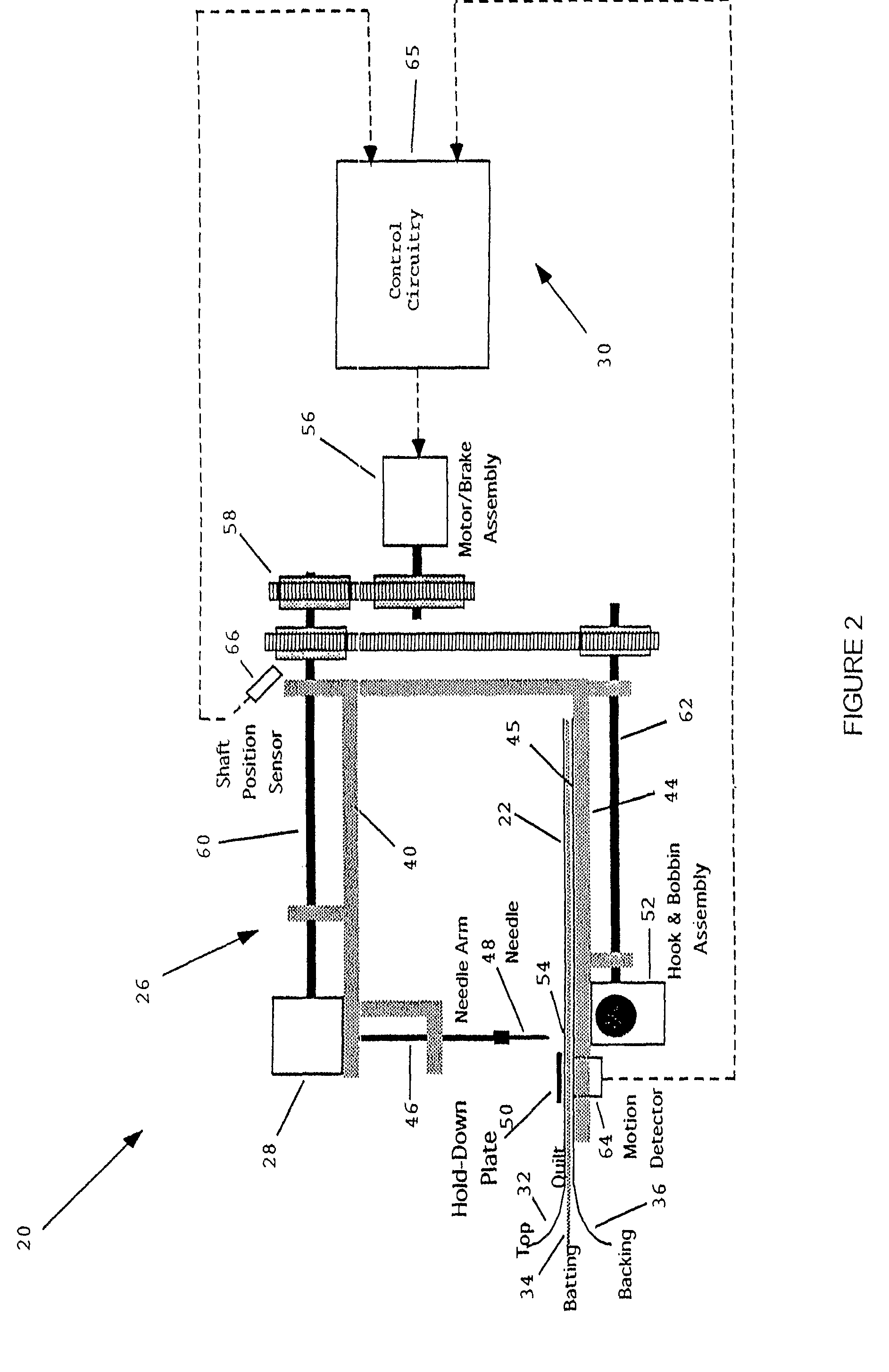

Quilting method and apparatus using frame with motion detector

Owner:KOERNER RALPH J

Sewing machine

InactiveCN1891887AReduce setup timeAvoid misadjustmentProgramme-controlled sewing machinesWork-feeding meansControl systemEngineering

The invention provided a sewing machine, improved to automatically switch the sewing machine to the thickness of cloth. This sewing machine includes: a housing having a base plate; a top arm; and a strut for integrating the base plate with the top arm. A metallic presser presses a cloth piece near a stitch forming position. The metallic presser driven by a movable rod is capable of moving between the lift position for releasing the cloth piece and the pressing position for the cloth piece to be pressed. When the metallic presser moves between these positions, the distance of at least one movable rod part from a reference structure fixed to the housing stably changes. The position sensor detects the position of the metallic presser in the pressing position. A control system makes signal connection thereto. The system sets an adjustment variable for the sewing machine depending upon the output value of the position sensor. As a result, the obtained sewing machine automatically performs switching to the thickness of variable cloth piece.

Owner:DURKOPP ADLER AG

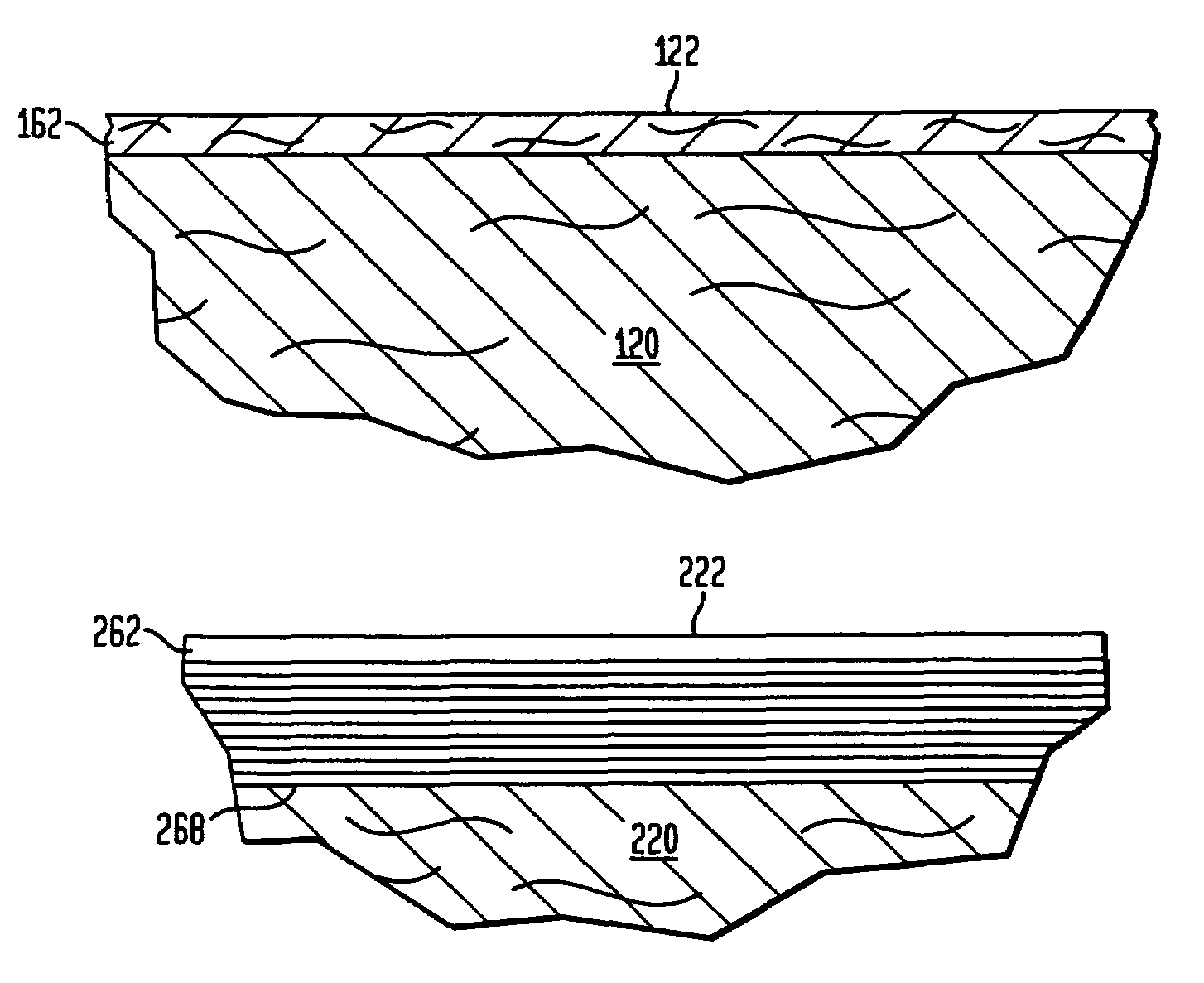

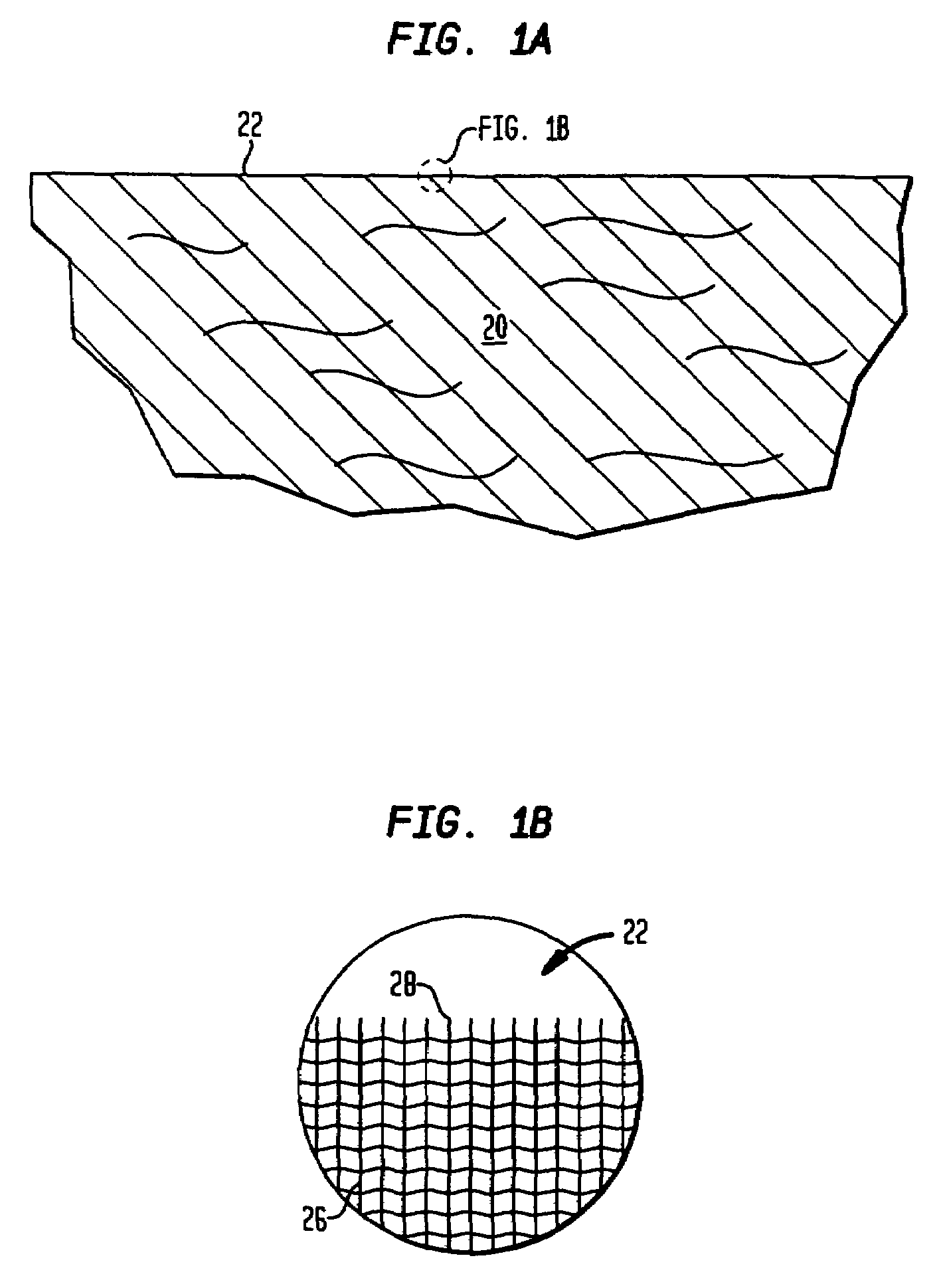

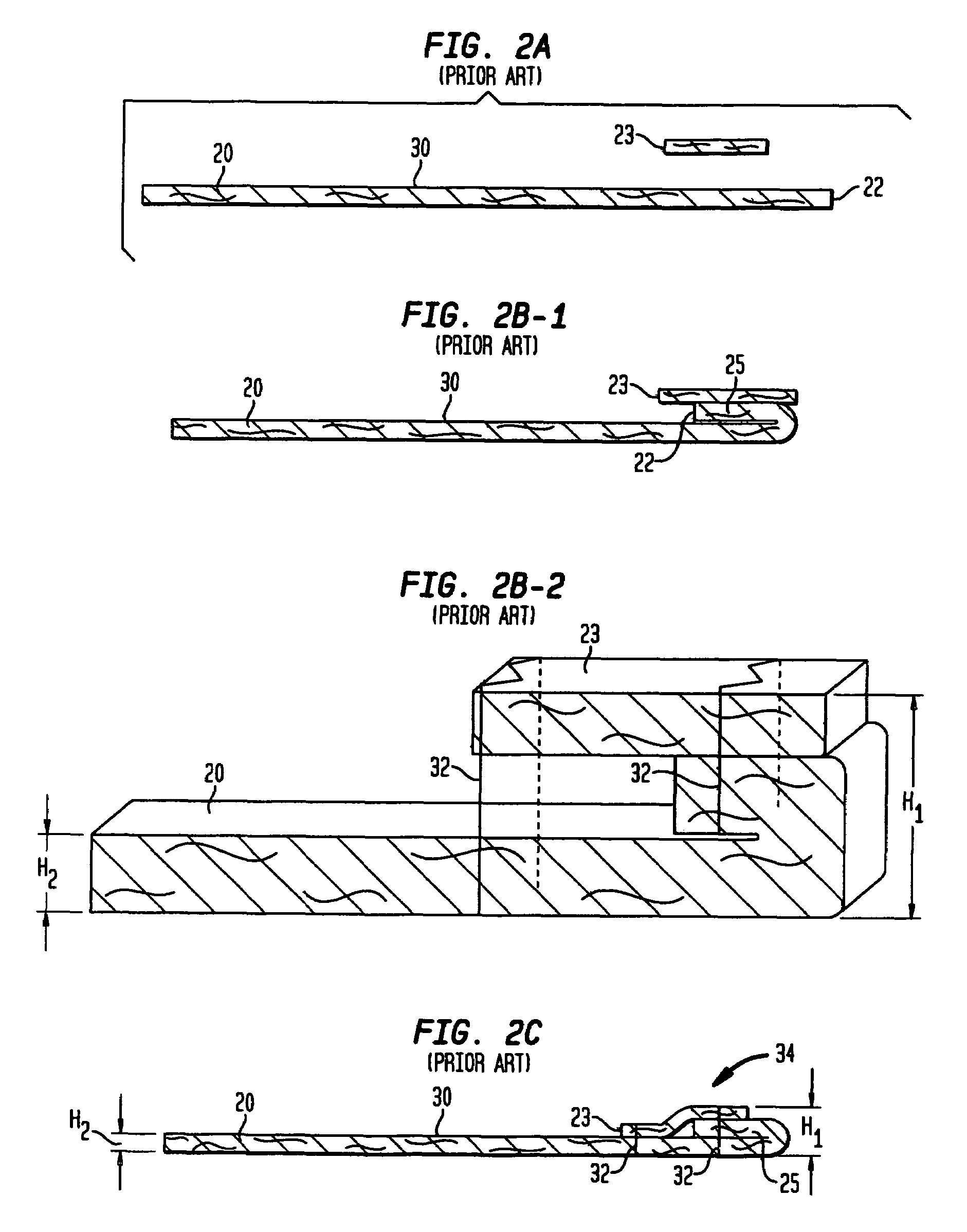

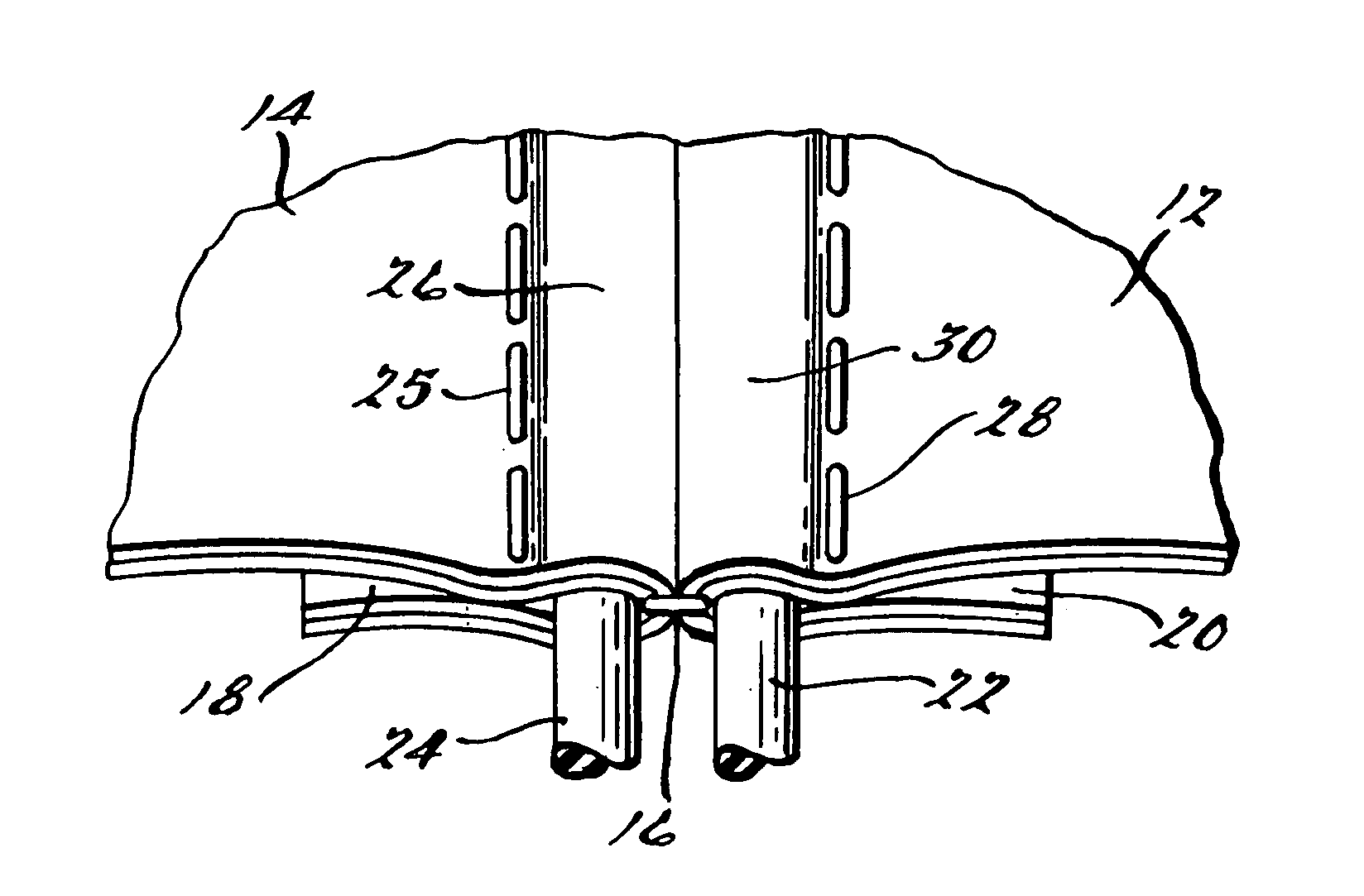

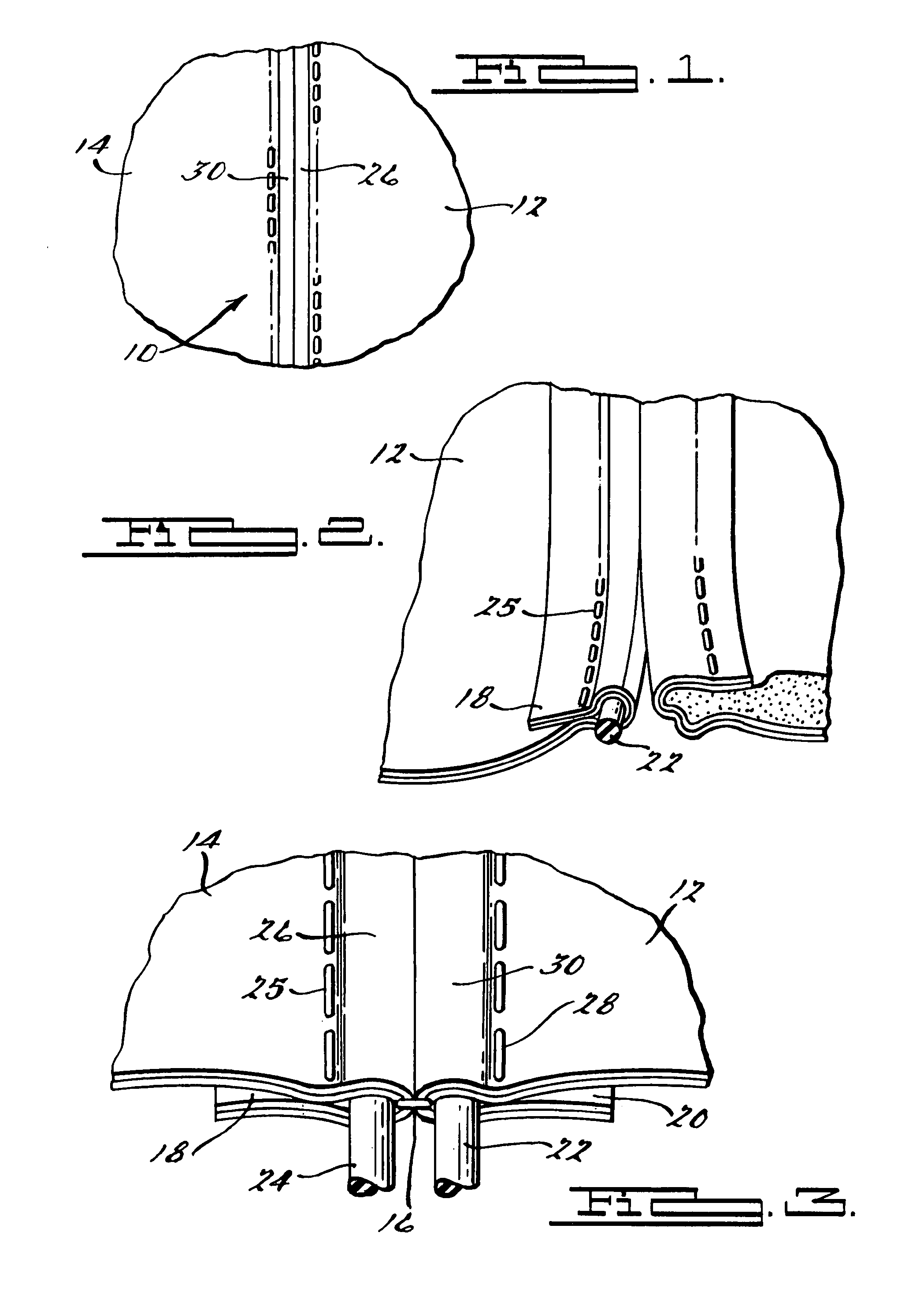

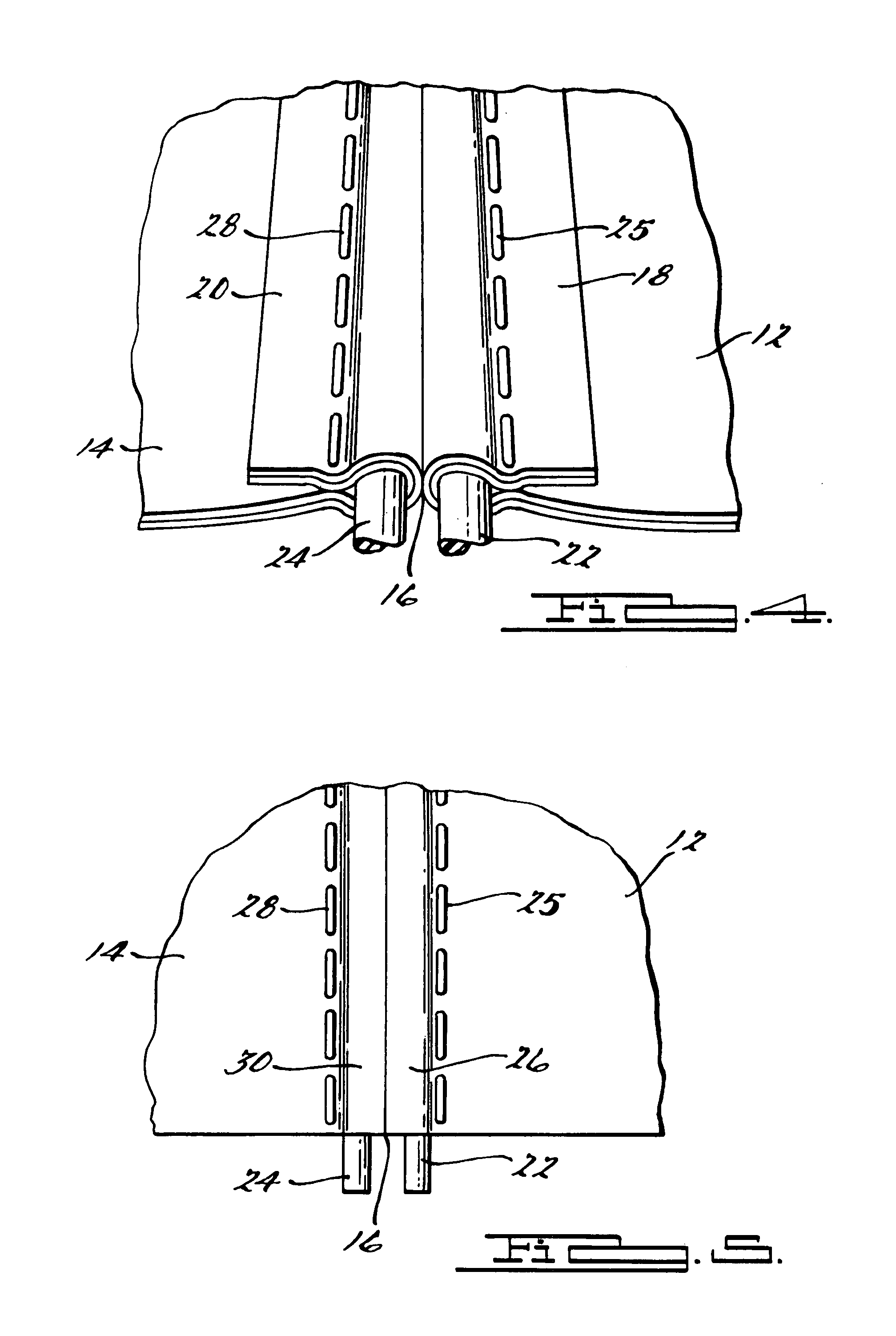

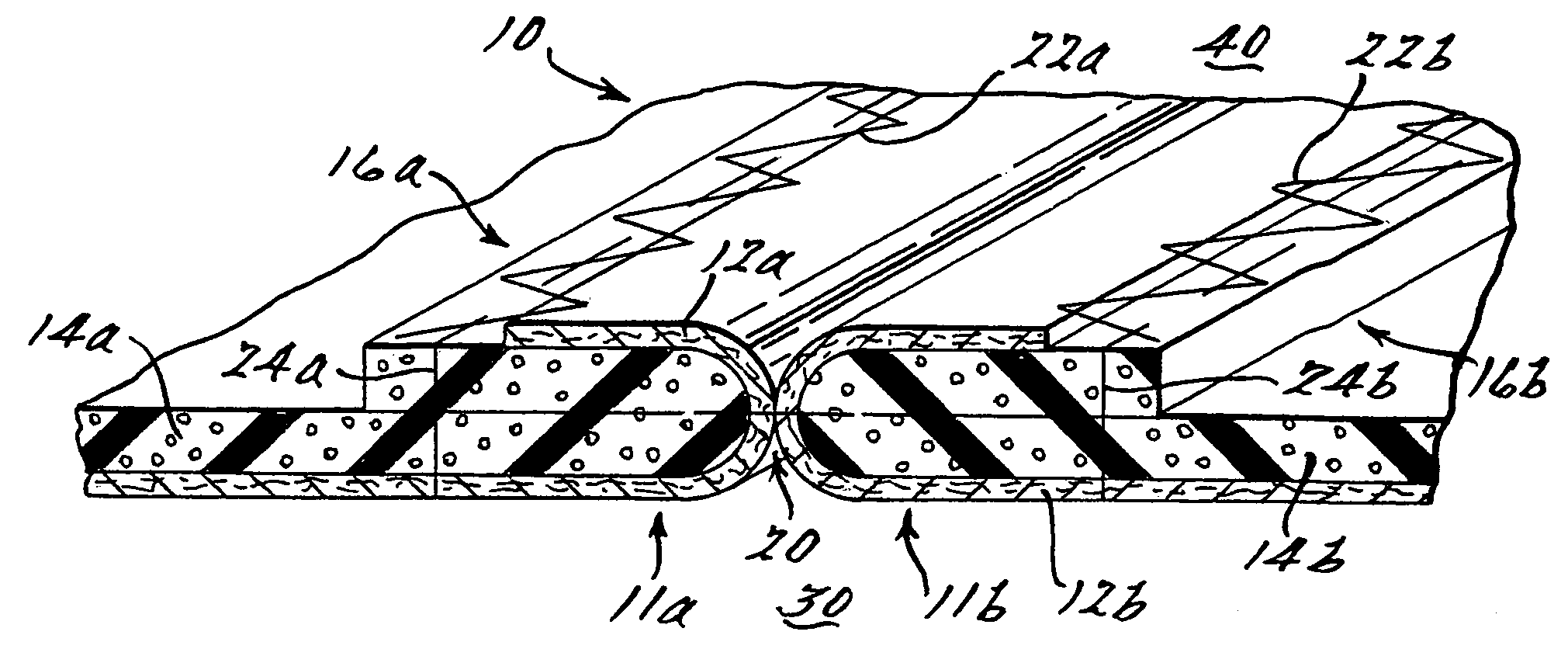

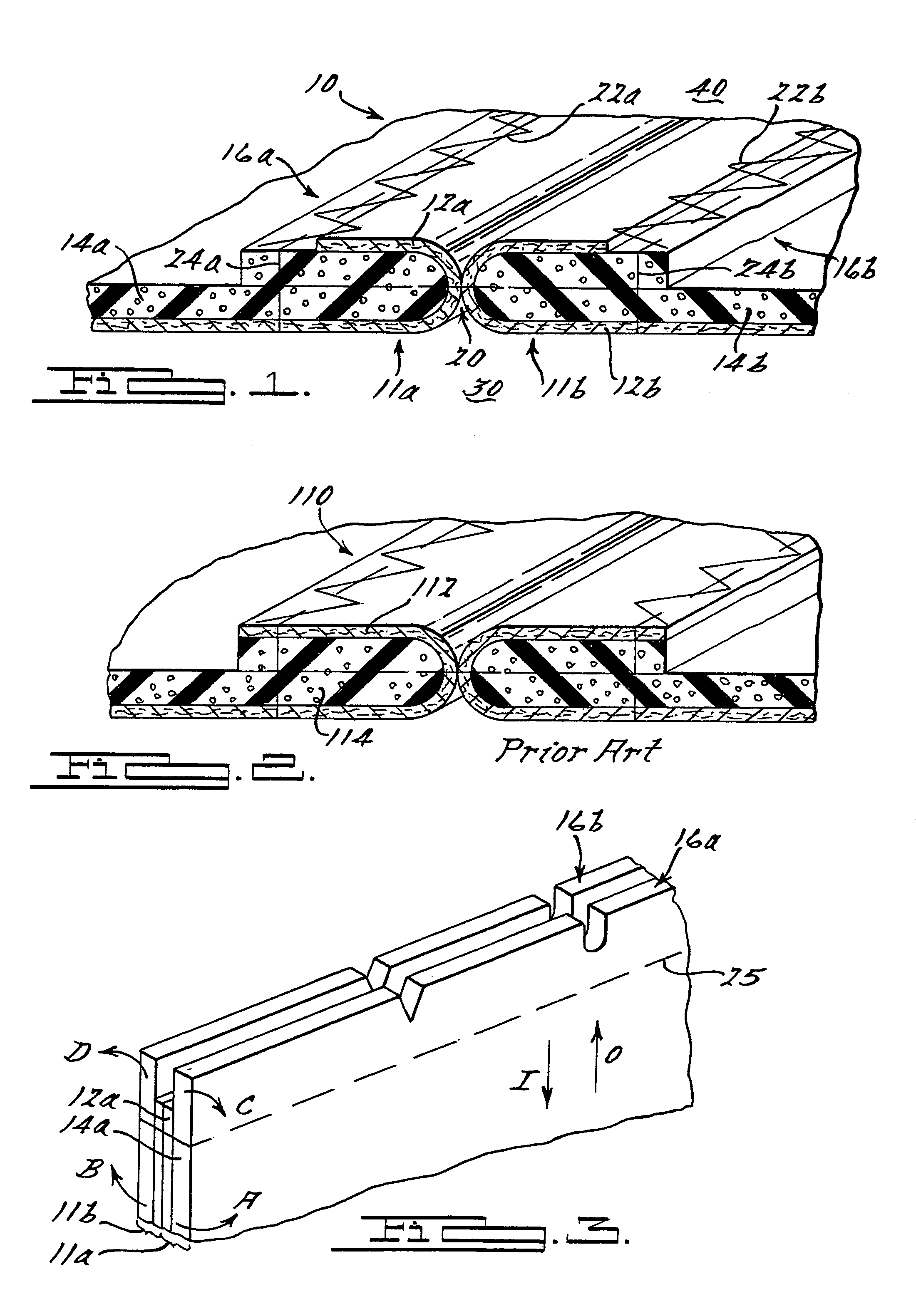

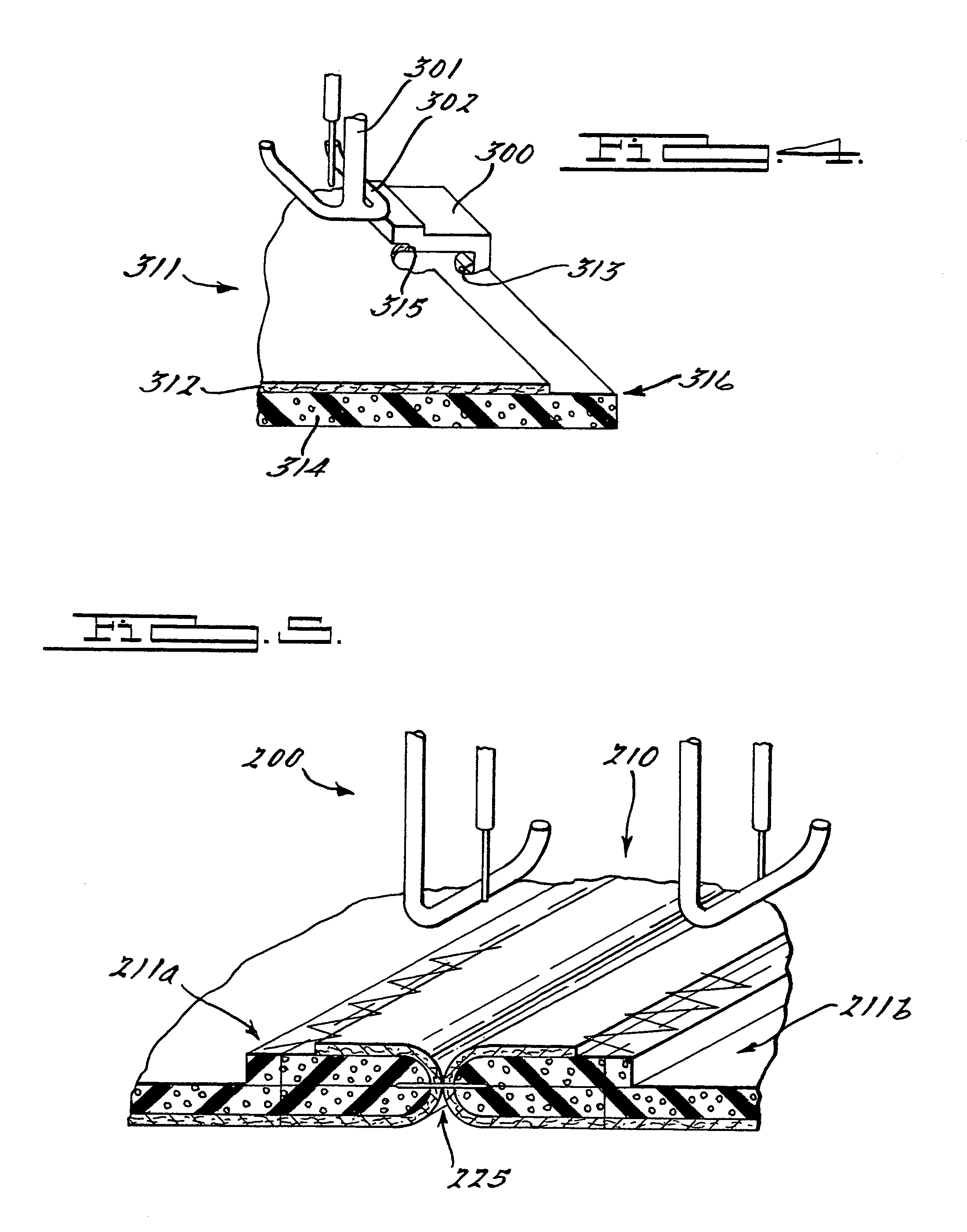

Non-laminate seam

ActiveUS7278363B2Cleaner lookLow costUpholstery manufactureVehicle seatsEngineeringMechanical engineering

Owner:IRVIN AUTOMOTIVE PROD LLC

Towel machine with high product quality

ActiveCN103757827AReduce labor intensityReduce manufacturing costWork-feeding meansPressersUltimate tensile strengthAutomation

The invention discloses a towel machine with high product quality. The towel machine comprises a feeding device, a serging device, a manufacturing device and a hot melting device. The feeding device is fixedly connected with the serging device. The manufacturing device and the serging device are arranged in a relatively fixed mode. The hot melting device is arranged on the side face of the manufacturing device. Cloth is fed into the serging device by the feeding device. Primary double-side serging is carried out on the cloth fed by the feeding device by the serging device. Secondary double-side serging is carried out on the cloth by the manufacturing device after the cloth discharged out of the serging device is cut off. The hot melting device carries out hot melting on the cloth discharged out of the manufacturing device. According to the towel machine with the high product quality, mechanical automation replaces the original manual operation to produce towels, the labor intensity of workers is lowered, product production efficiency is stably improved, production cost is lowered, production can be effectively managed, and practical high production requirements are met.

Owner:SUZHOU TRANSPARENT TECH CO LTD

Offset seam sewing process

InactiveUS6997126B2Good lookingReducing knuckling along upholstery seamsSeat coveringsLeather sewingEngineeringLateral offset

A process for joining adjacent panels of plural layered upholstery, including the steps of adjacently positioning first and second panels, each having an offset backing and exterior layers, and substantially aligning longitudinal peripheries of the first and second panels. Stitching the panels together along a first stitching line positioned inboard of the longitudinal peripheries and substantially parallel thereto, and stitching portions of the first and second panels outboard of the first stitching line to an inboard portion of one or more of the panels along at least a second stitching line. In a preferred embodiment, the exterior layer in the first panel is offset laterally relative to the backing layer in an inboard direction, wherein the lateral offset imparts a substantially regular contour to portions of the exterior layer proximate the first stitching line and inboard thereof.

Owner:IRVIN AUTOMOTIVE PROD LLC

Chain stitch multi-needle quilting machine and method to create a pattern in a quilting material

InactiveUS6895878B2Cut shortAvoid insufficient lengthWork-feeding meansNeedle severing devicesEngineeringBiomedical engineering

The invention relates to a chain stitch multi-needle guilting machine with stitch-forming quilting elements and a method for creating a pattern in a guilting material. The elements of the quilting machine are comprised of at least one needle bar with attached needles and at least one looper shaft with attached loopers. Each of the needles and the loopers have a corresponding needle thread and looper thread associated therewith, form quilting element pairs, and are driven to build chain stitches in a quilting material. At least one of the needles is adjustable between two positions and participates in the quilting procedure in a first position and does not prick into the quilting material in the second position during the quilting procedure. The quilting machine can be made to have a device to knot the needle thread with the looper thread, or a device to cut the looper thread, or both.

Owner:NAHMASCHFAB EMIL STUTZNACKER

Numerically controlled single-needle quilter

InactiveCN1962987AFast quiltingGood quilting stabilityWork-feeding meansSewing-machine control devicesNumerical controlGear wheel

The numerical control single needle quilter of the invention also includes cloth discharge tensioning mechanism with a cross cutter, gantry mobile device of said quilter main is equipped with two parallel chassis and gantries symmetrically. Two chassis are provided with vertical racks respectively, gantries strung between the two chassis, two sides of gantries are supported by the vertical guiding parts equipped on the chassis with sliding and engage with racks of the chassis through the gear wheels of corresponding side, said gear wheels are fixed on the two ends of crosswise transmission shaft, the transmission shaft is fitted on the bearing block on the support of bearing of the immovable gantry floor with sliding, the gears are connected with generator to transmitting motion; the upper and lower body of gantries is equipped with guidance axis respectively, the upper and lower machine nose devices are sleeved on the two guidance axis with sliding respectively and are connected with the machine nose move synchronous belt devices, the devices are connected with the generator; gripper mechanism to adjusting fiber tension is connected with frame horizontally with sliding.

Owner:李德锵

Sewing machine

ActiveCN105113152AChange trajectoryAchieve sewingWork-feeding meansSewing-machine control devicesEngineeringFeed dogs

The invention provides a sewing machine. The sewing machine comprises an upper shaft driven by a first motor, a needle bar take-up mechanism arranged at one end of the upper shaft, a lower shaft parallel to the upper shaft, a thread take-off mechanism arranged at one end of the lower shaft, a feed dog frame and a feed dog fixed to the feed dog frame. The upper shaft is connected with the lower shaft through a drive unit. The upper shaft is connected with one end of the feed dog frame through a feed dog lifting mechanism. The sewing machine further comprises a second motor connected with the other end of the feed dog frame through a cloth feed mechanism. The feed dog lifting mechanism and the cloth feed mechanism which form a feed mechanism are driven by the two motors respectively, and therefore the output amount of the cloth feed mechanism can be regulated by regulating the output amount of the second motor, the movement tracks of the feed dog frame and the feed dog can be conveniently changed, and sewing of various patterns can be achieved.

Owner:JACK SEWING MASCH CO LTD

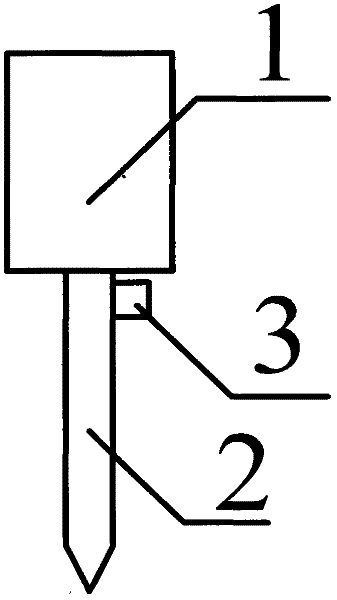

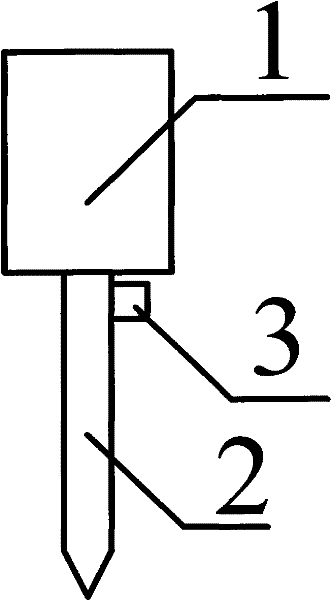

Drilling machine

The invention discloses a drilling machine, which comprises a motor and a machine needle, wherein the machine needle is provided with a point heating device, and is made of stainless steel; and the point heating device gradually heats in a radiation mode. The drilling machine has the advantages that: good marks can be left, and the influence of the loose degree of cloth is avoided.

Owner:SHAANXI LONGHAI ENG CONSTR

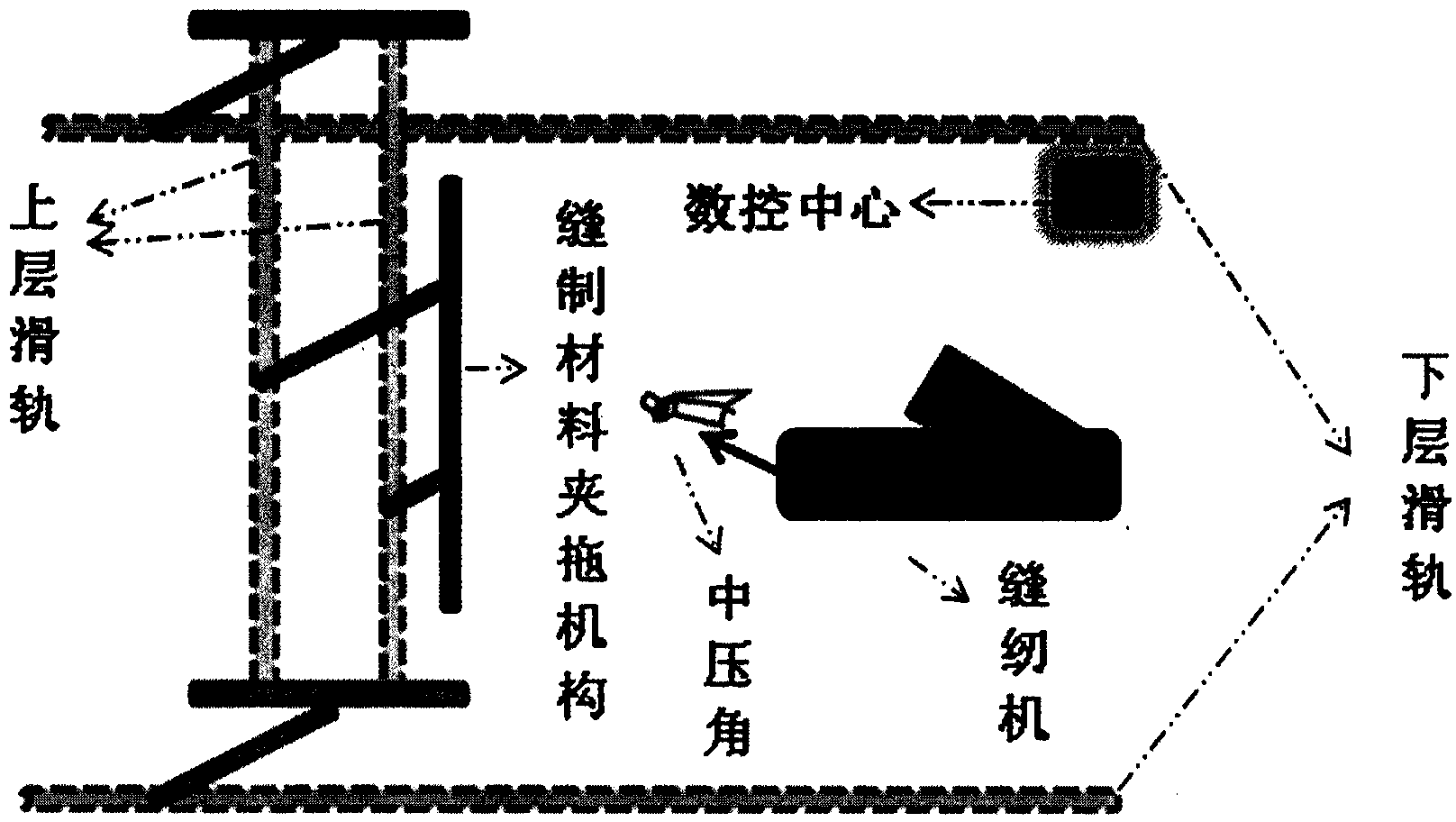

Numerical-control sewing processing equipment

InactiveCN104233647AGuaranteed operational safetyGuaranteed independenceWork-feeding meansSewing-machine control devicesNumerical controlMultiple layer

Owner:王艳玲

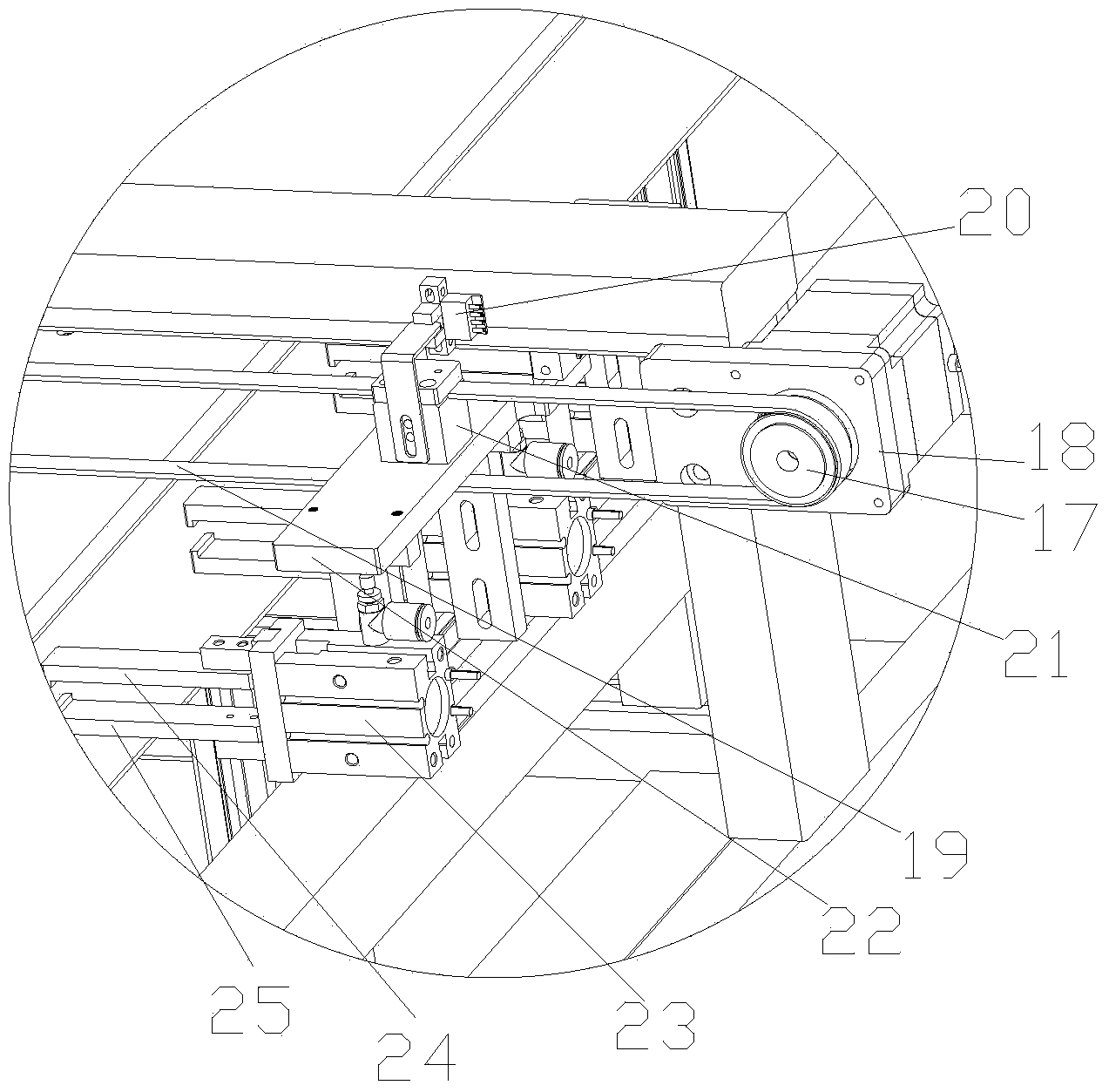

Automatic seam abutting device for cutting pieces and seam abutting method of automatic seam abutting device

ActiveCN104593956AGuaranteed continuous operationLower skill requirementsWork-feeding meansPressersEngineeringMechanical engineering

The invention discloses an automatic seam abutting device for cutting pieces and a seam abutting method of the automatic seam abutting device. The automatic seam abutting device comprises a machine table, a control device, an air sucking device, a stamper device, a positioning device, a feeding device and a sewing device, wherein the air sucking device is provided with a plurality of air sucking holes, and the air sucking holes are formed in a table surface of the machine table; the stamper device is provided with at least one pressing arm and a stamper driving device for driving the pressing arm to move; the positioning device is provided with at least one positioning arm and a positioning driving device for driving the positioning arm to move; the air sucking device, the stamper device, the positioning device, the feeding device and the sewing device are connected to the machine table, and the air sucking device, the stamper driving device, the positioning driving device, the feeding device and the sewing device are electrically connected to the control device. The automatic seam abutting device for the cutting pieces involved by the invention is suitable for the seam abutting technology of most collars, the requirements for the skills of workers are greatly lowered, and the production efficiency is improved.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +1

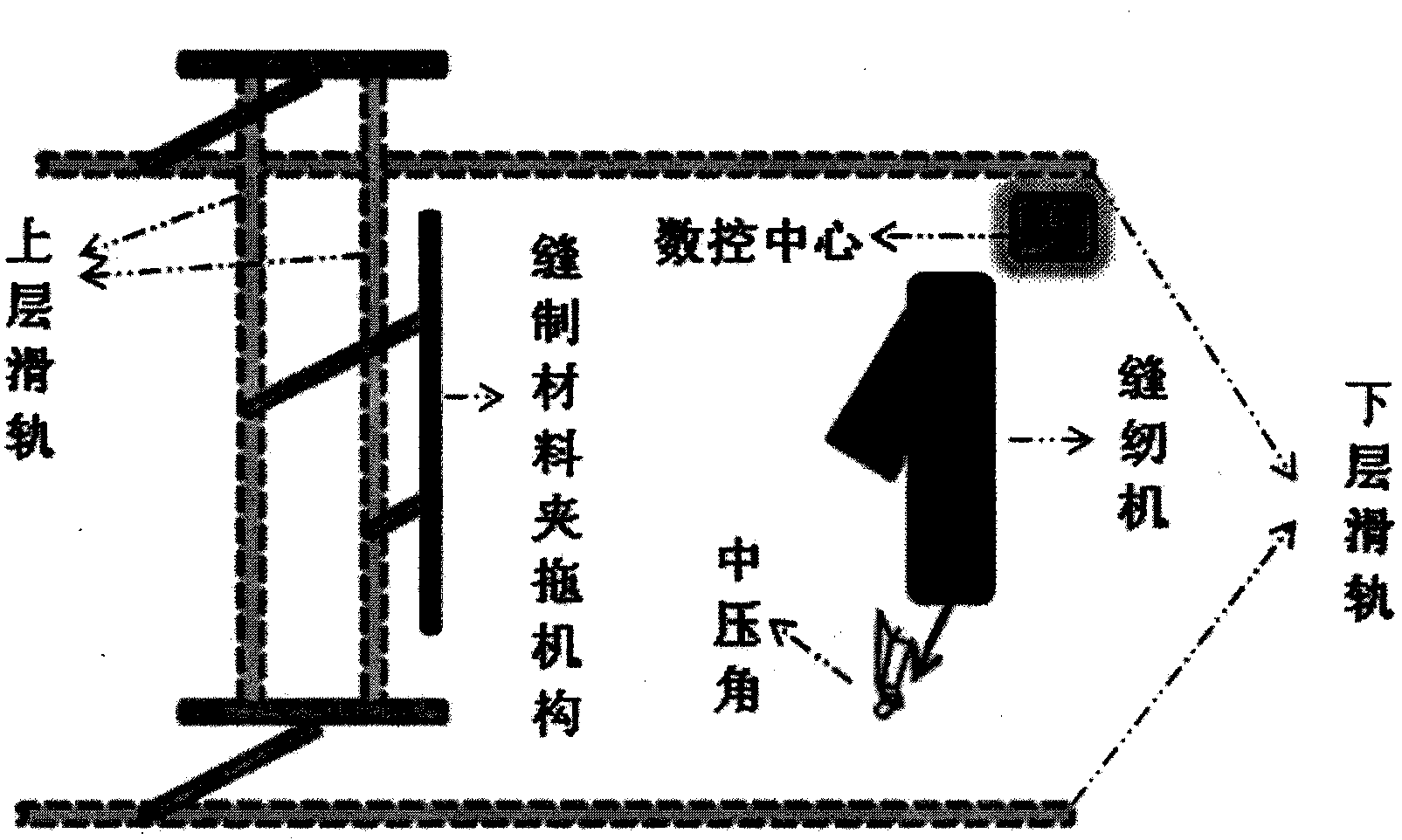

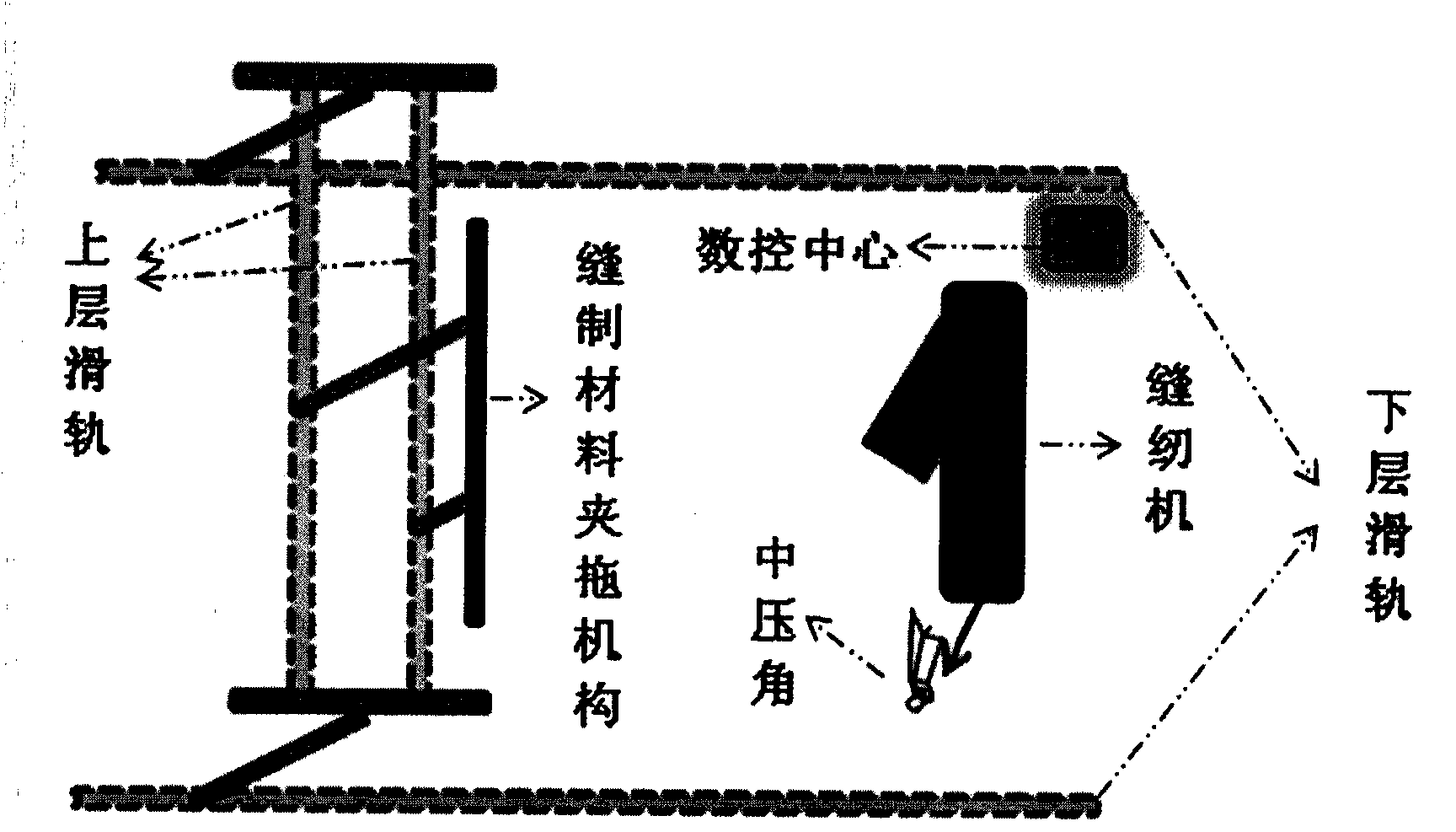

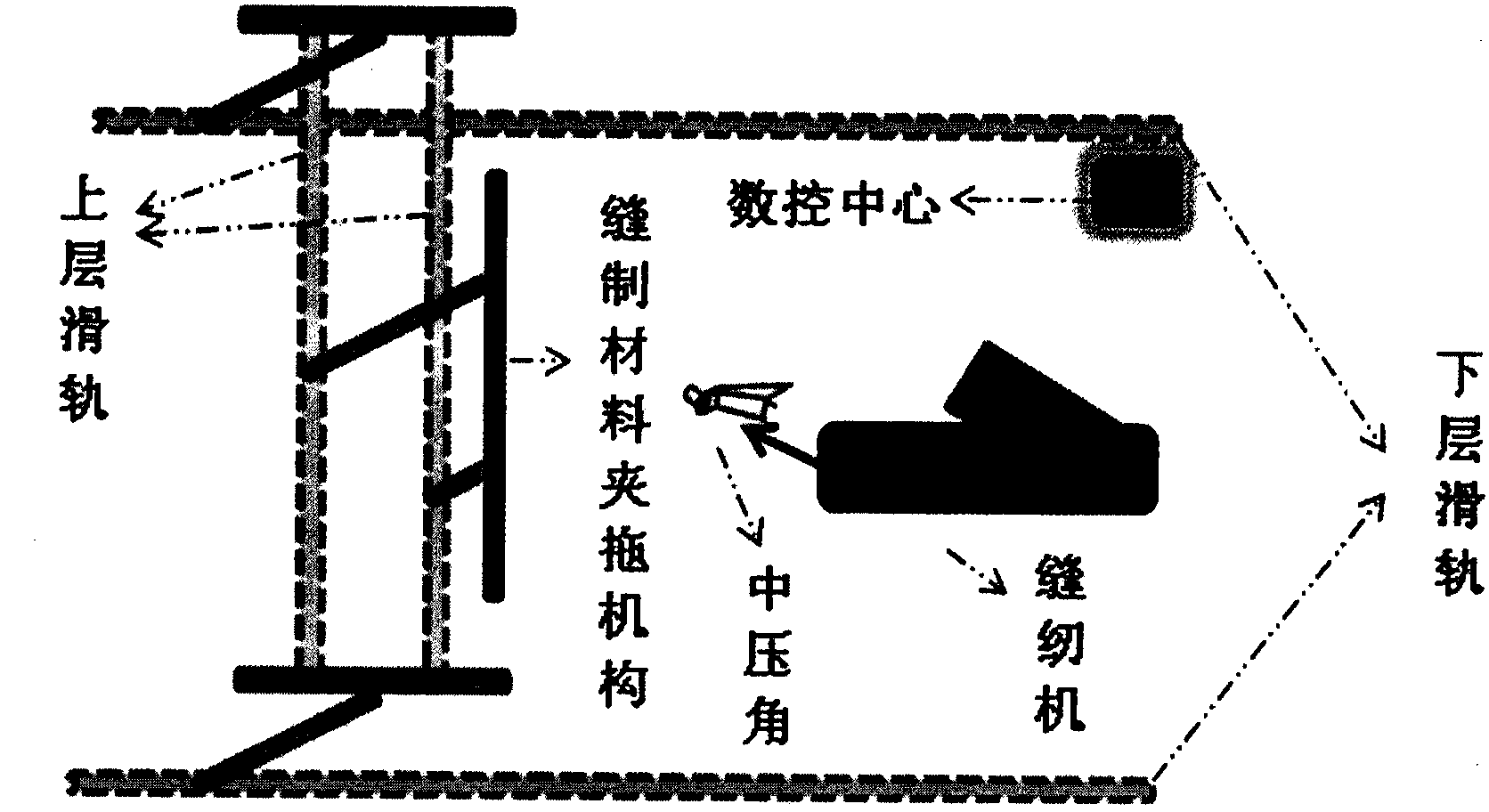

Robustness numerical control sewing processing equipment

InactiveCN104233640AGuaranteed independenceAvoid positioning deviationWork-feeding meansNumerical controlSewing machine

The invention discloses robustness numerical control sewing processing equipment, which comprises a sewing machine, a sewing material clamping and dragging mechanism, two parallel slide rails at an upper layer, two parallel slide rails at a lower layer and a numerical control center. The robustness numerical control sewing processing equipment has the advantages that the sewing of multilayer sewing materials, various stitches and various pattern layer patterns can be realized, the work efficiency is improved, in addition, the production cost is lower, the installation and the debugging are simple, and the repair and the maintenance of the sewing machine are easy.

Owner:王艳玲

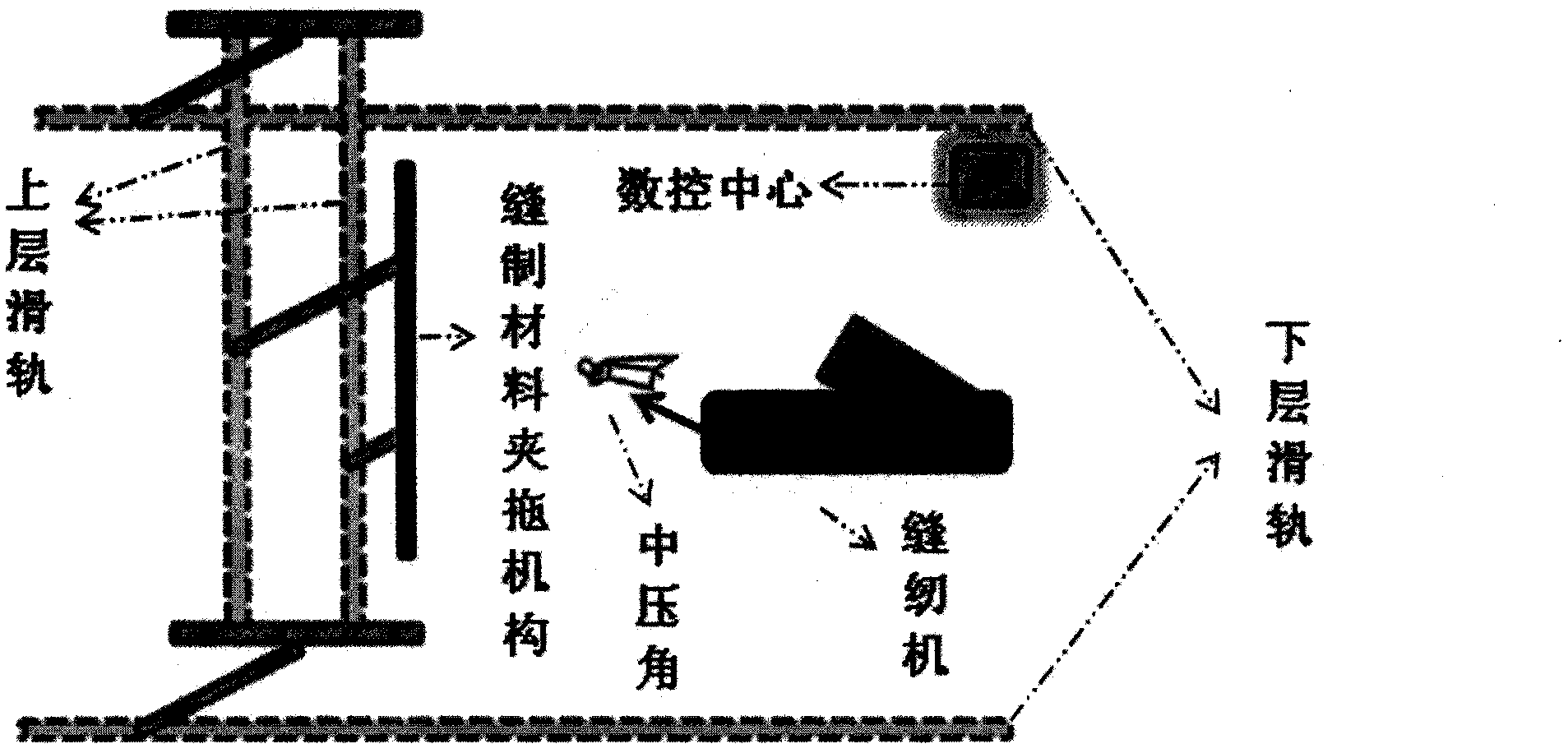

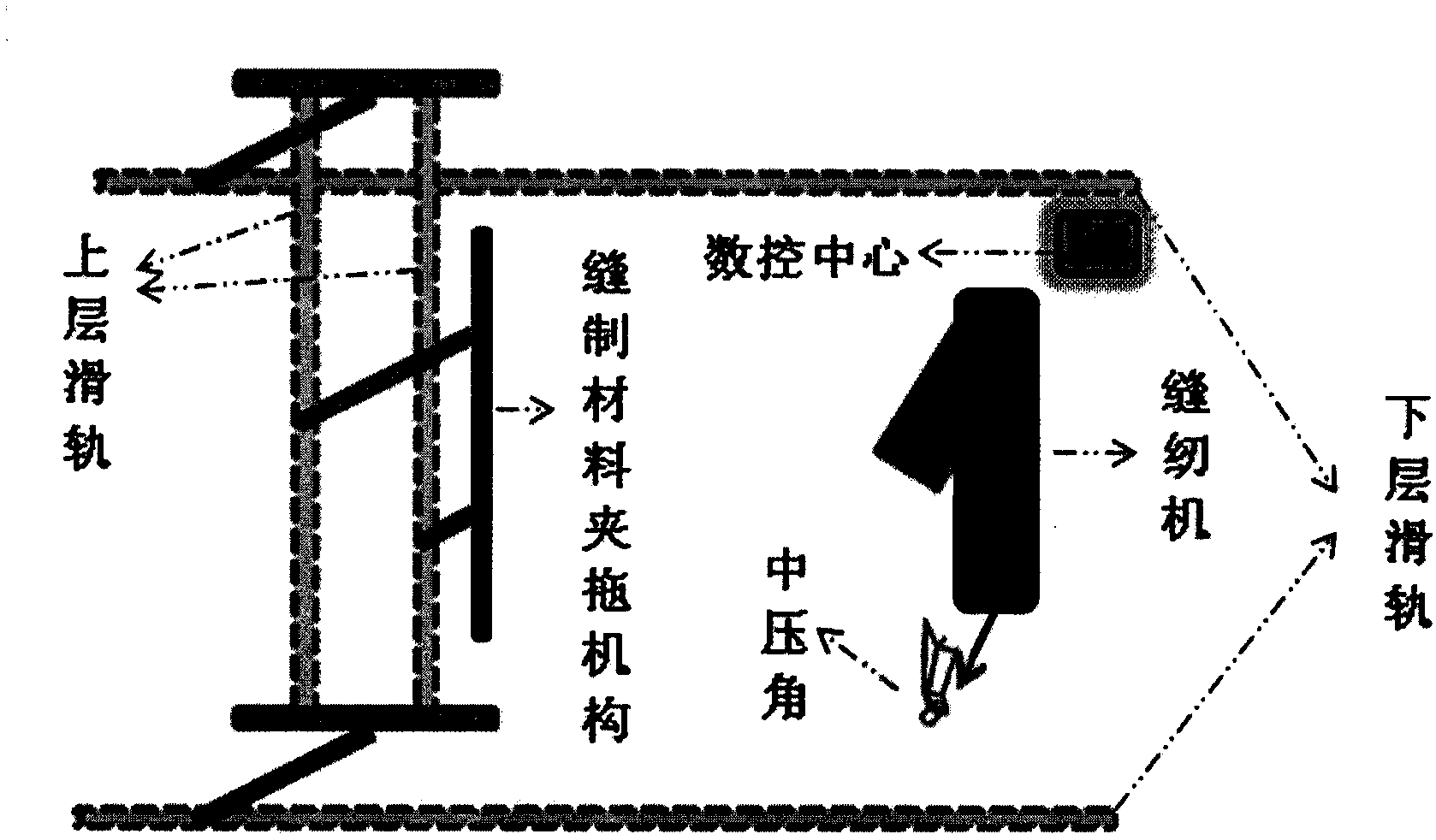

Numerical-control automatic sewing processing equipment

InactiveCN104233641AGuaranteed independenceAvoid the problem of origin positioning deviation easily caused by changing different sewing templatesWork-feeding meansNumerical controlMultiple layer

The invention discloses numerical-control automatic sewing processing equipment. The numerical-control automatic sewing processing equipment comprises a sewing machine, a sewing-material clamping and towing mechanism, two parallel sliding rails at the upper layer, two parallel sliding rails at the lower layer and a numerical-control center. The numerical-control automatic sewing processing equipment disclosed by the invention has the advantages that not only can the sewing of multi-layer sewing materials, multiple stitches and multiple layer patterns be realized, but also the working efficiency is improved; the production cost is lower, the installation and the debugging are simple, and the repair and the maintenance of the sewing machine are easy.

Owner:王艳玲

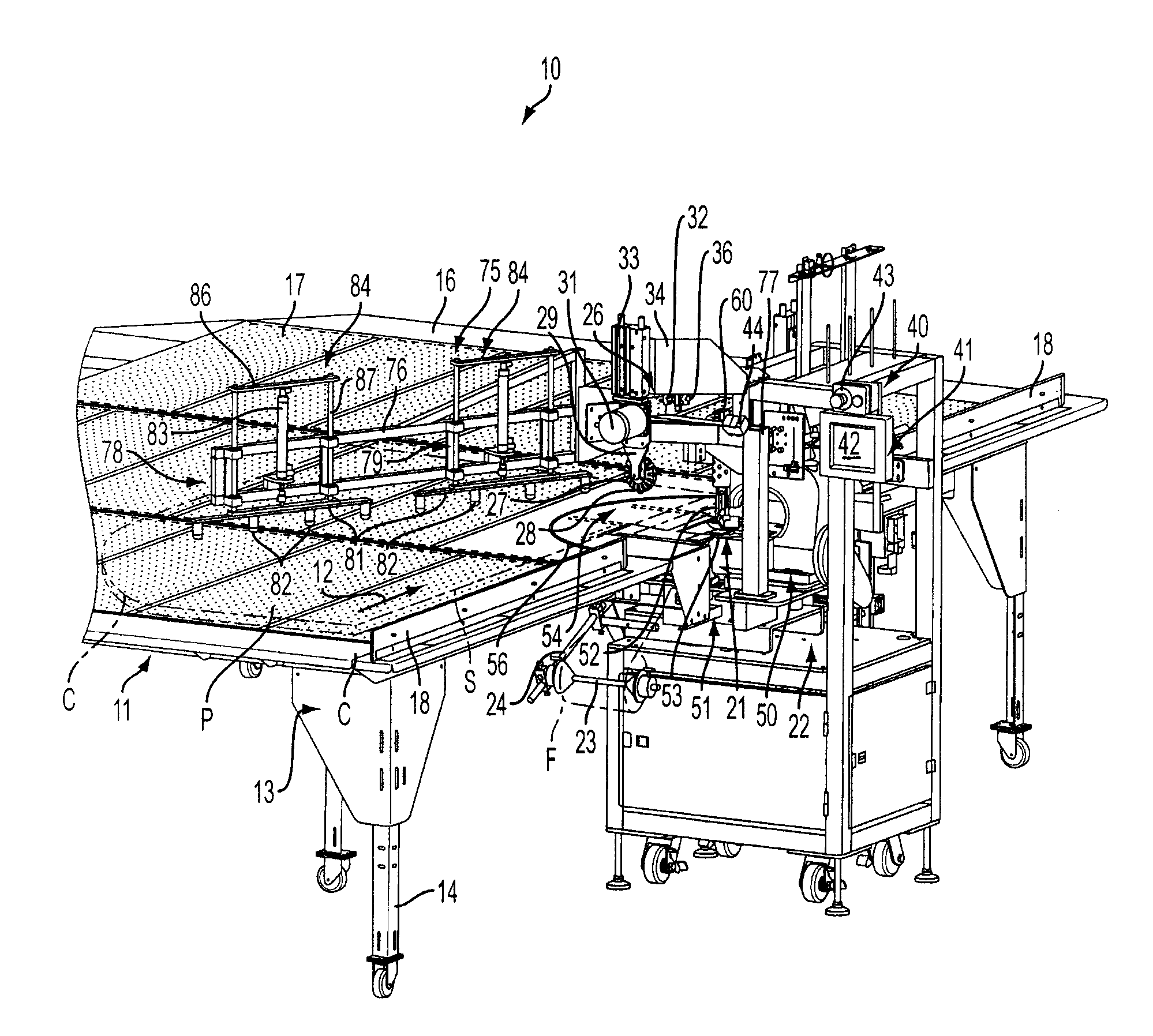

Automatic panel sewing and flanging system

ActiveUS7984681B1Less distortionMore accurate rounded or accurate cornersWork-feeding meansMattress sewingFlangingSewing machine

A system for automatically attaching a flanging material to the edges of a panel such as for a mattress, including a work table on which the panel is supported and a sewing assembly having a sewing machine located along a path of travel of the panel across the work table. The flanging material is fed from a supply of flanging material located adjacent the sewing assembly, and is attached to the side edges and about the corners of the panel by the sewing machine of the sewing assembly. A clamp mechanism engages and holds the panel as the sewing machine of the sewing assembly attaches the flanging material about the corners of the panel.

Owner:ATLANTA ATTACHMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com