Patents

Literature

308results about How to "Improve sewing quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

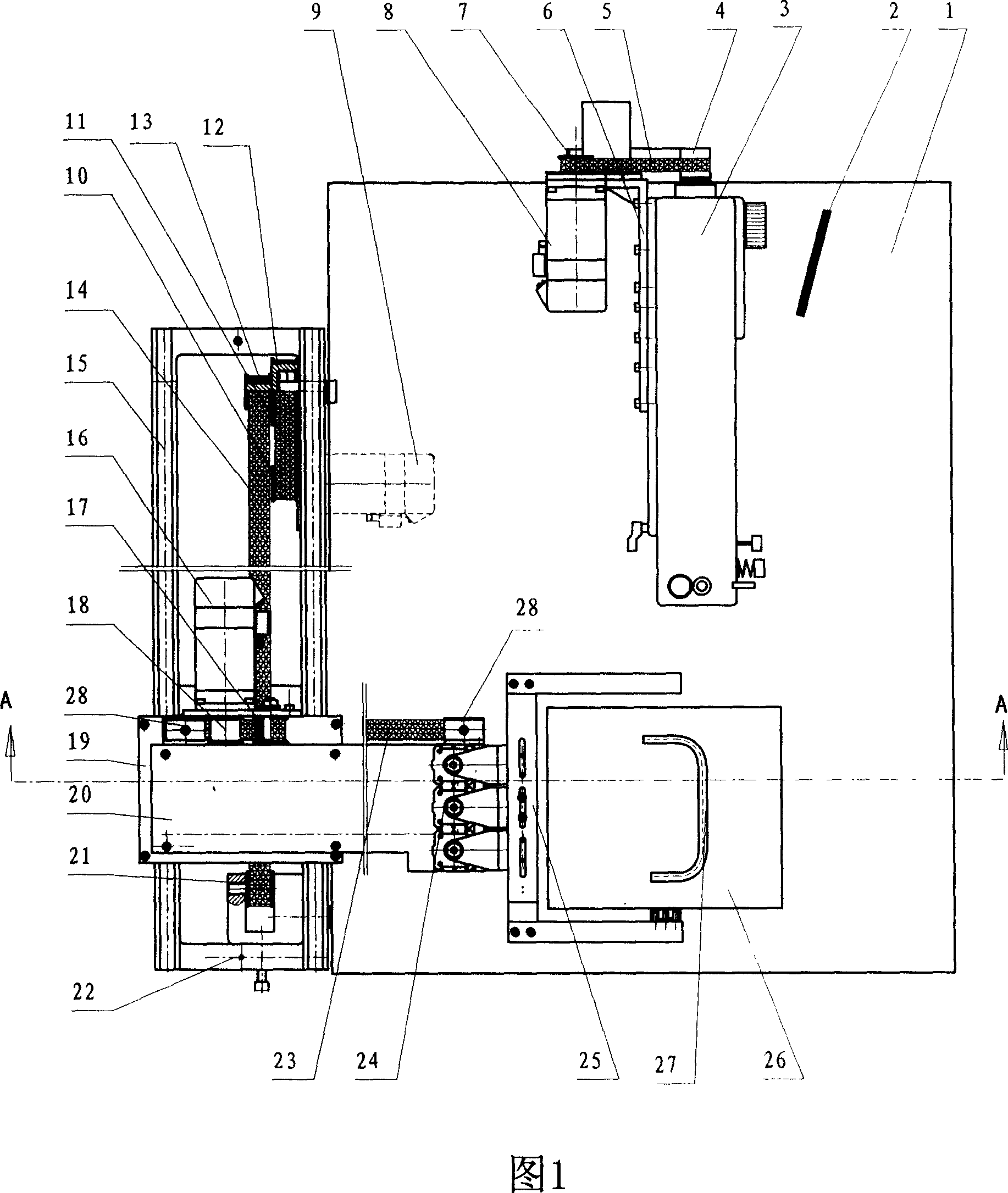

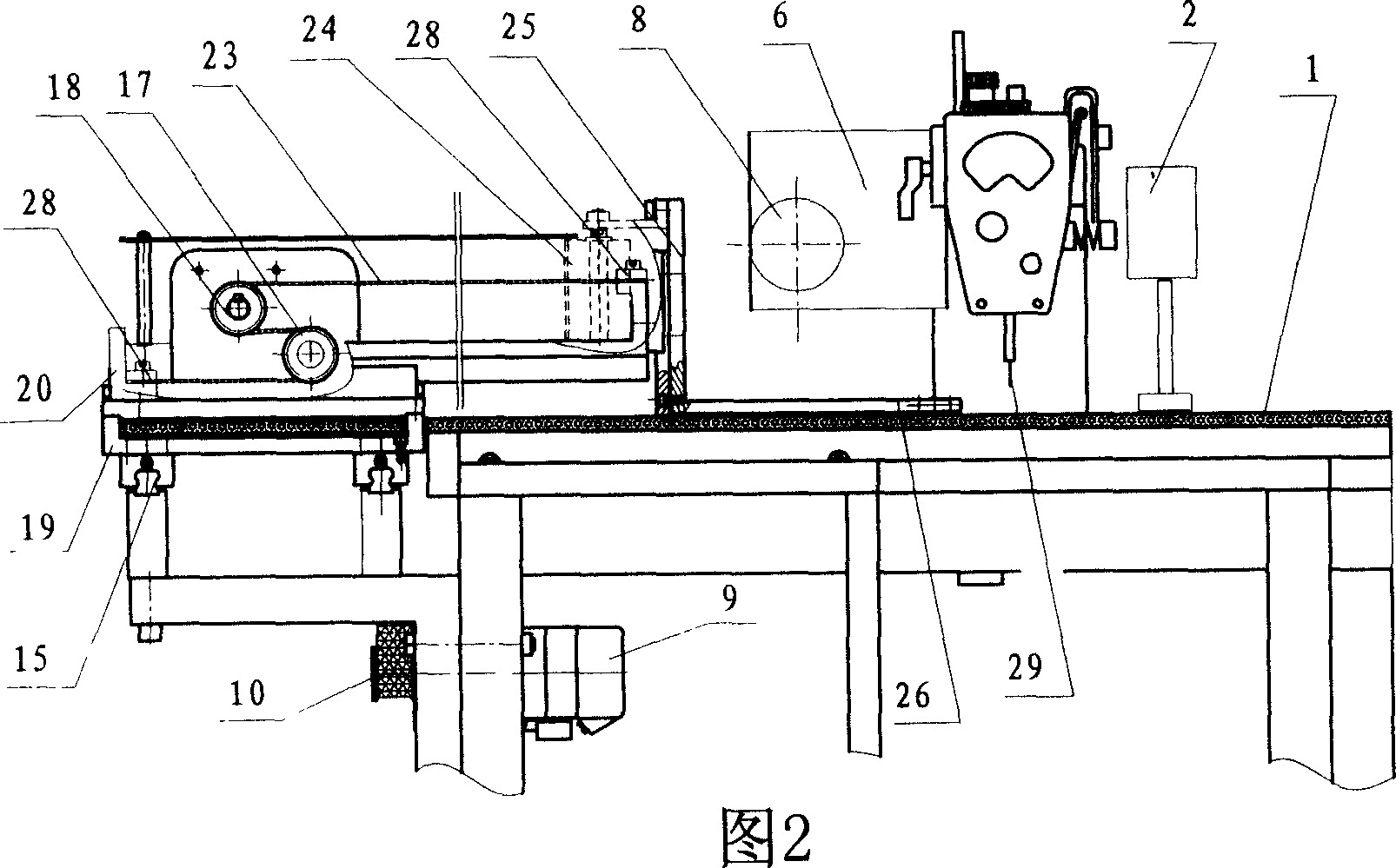

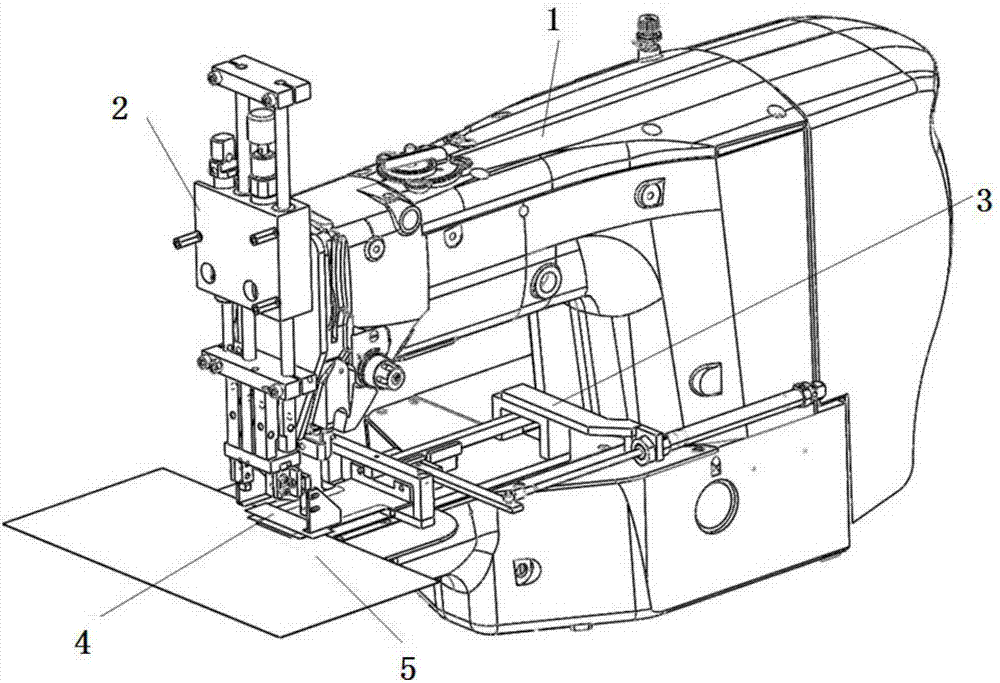

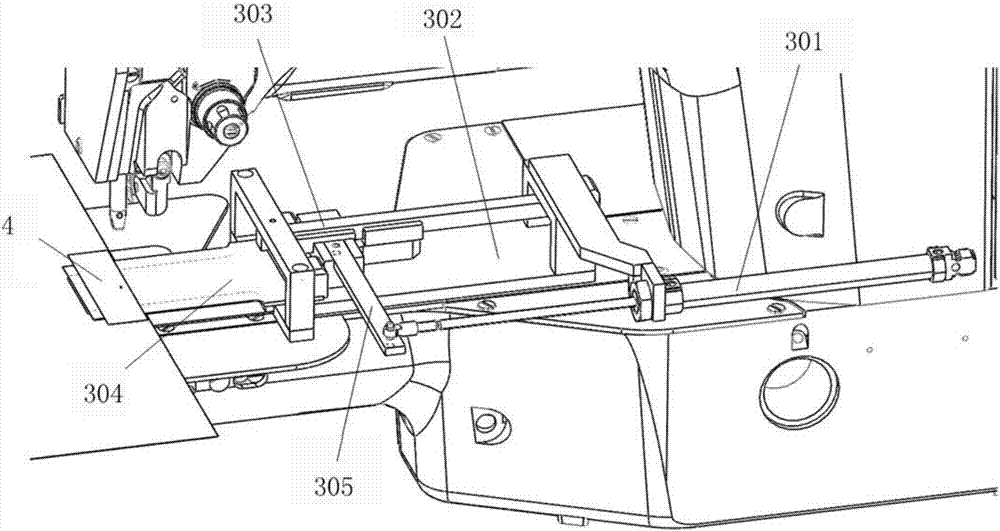

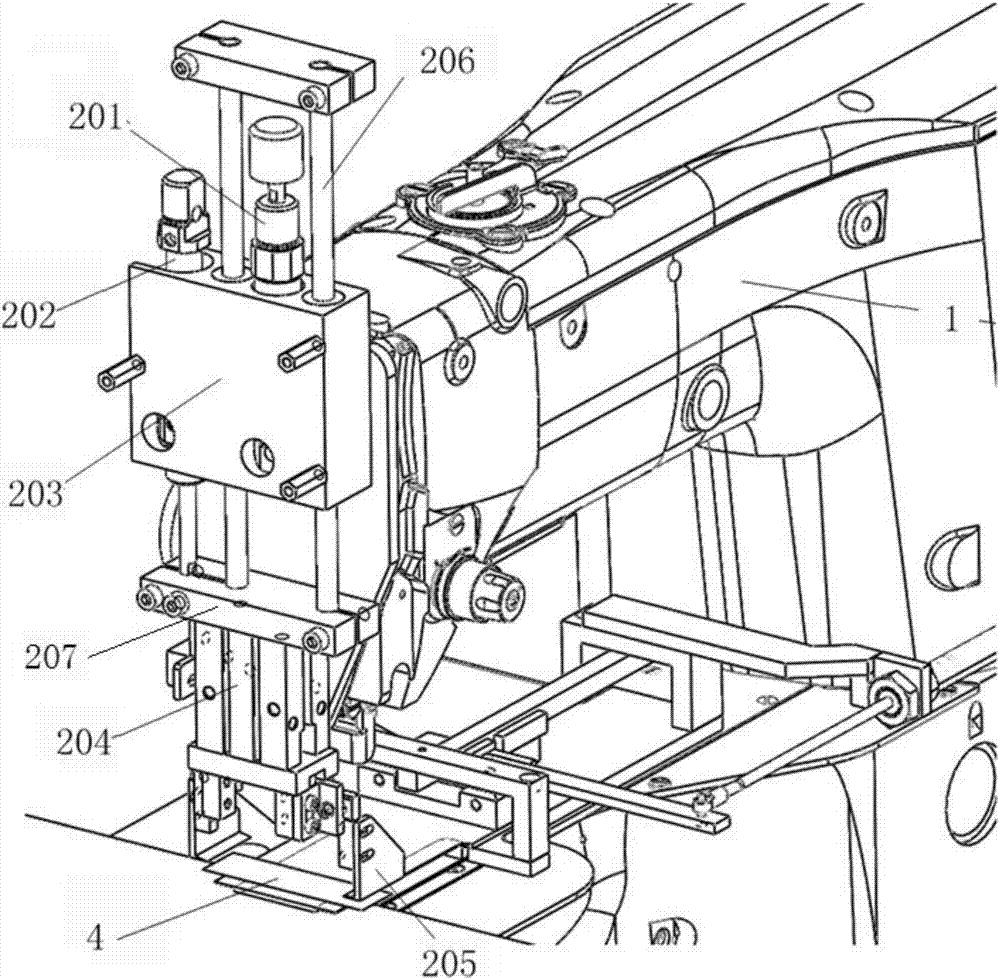

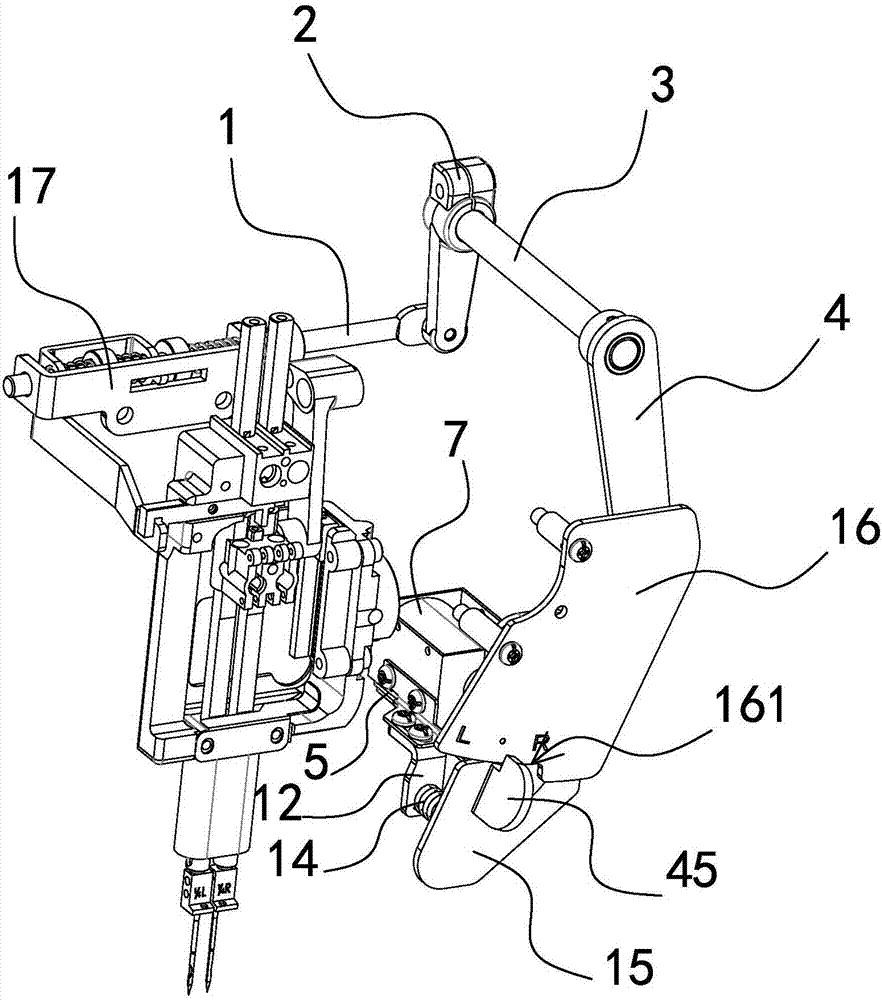

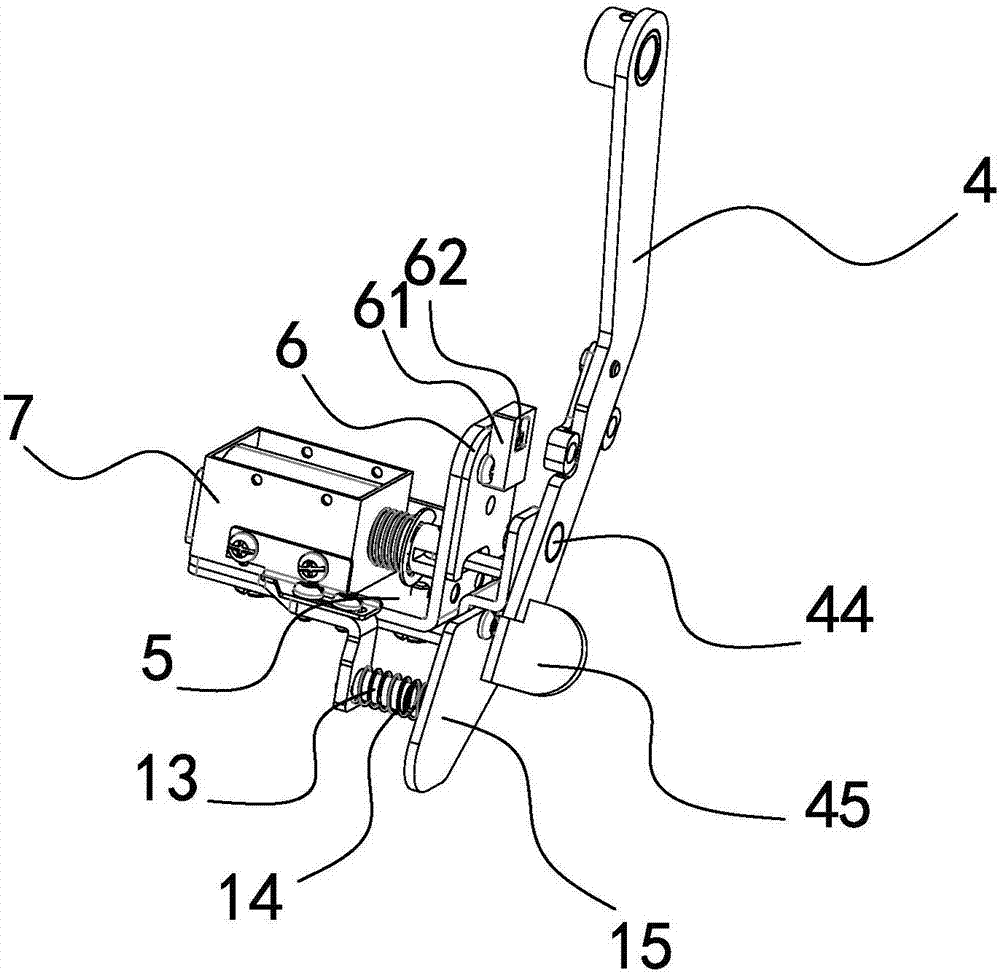

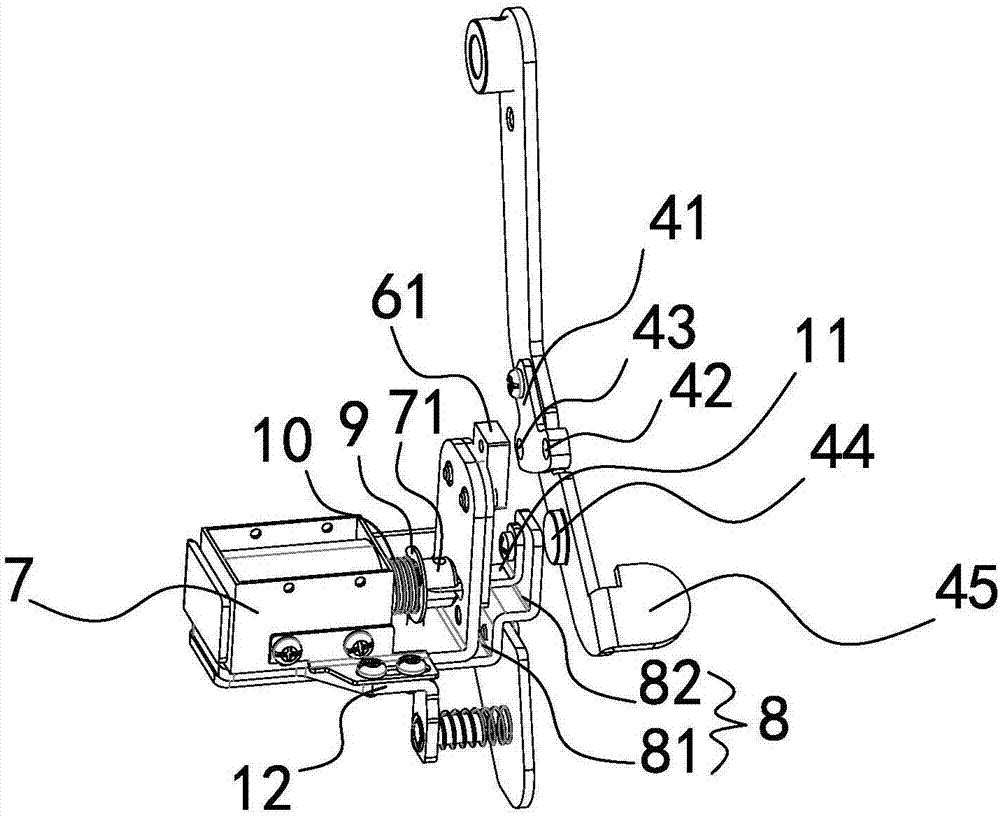

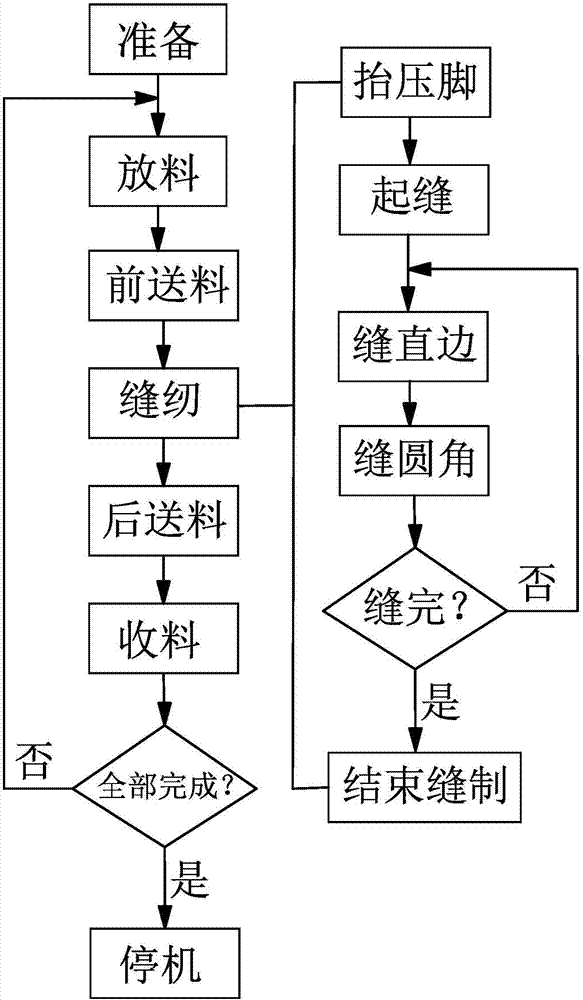

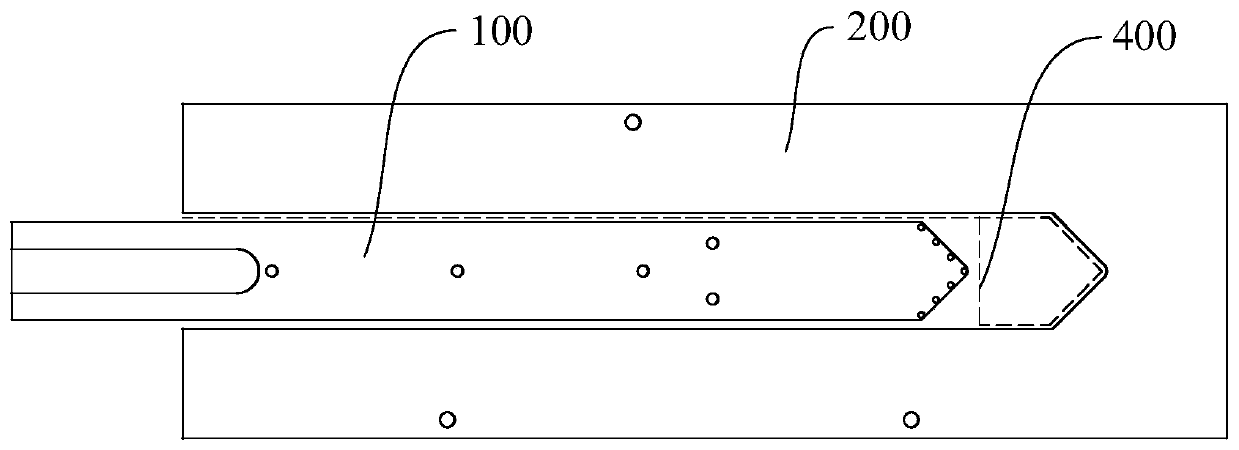

Full-automatic material taking and material feeding sewing machine

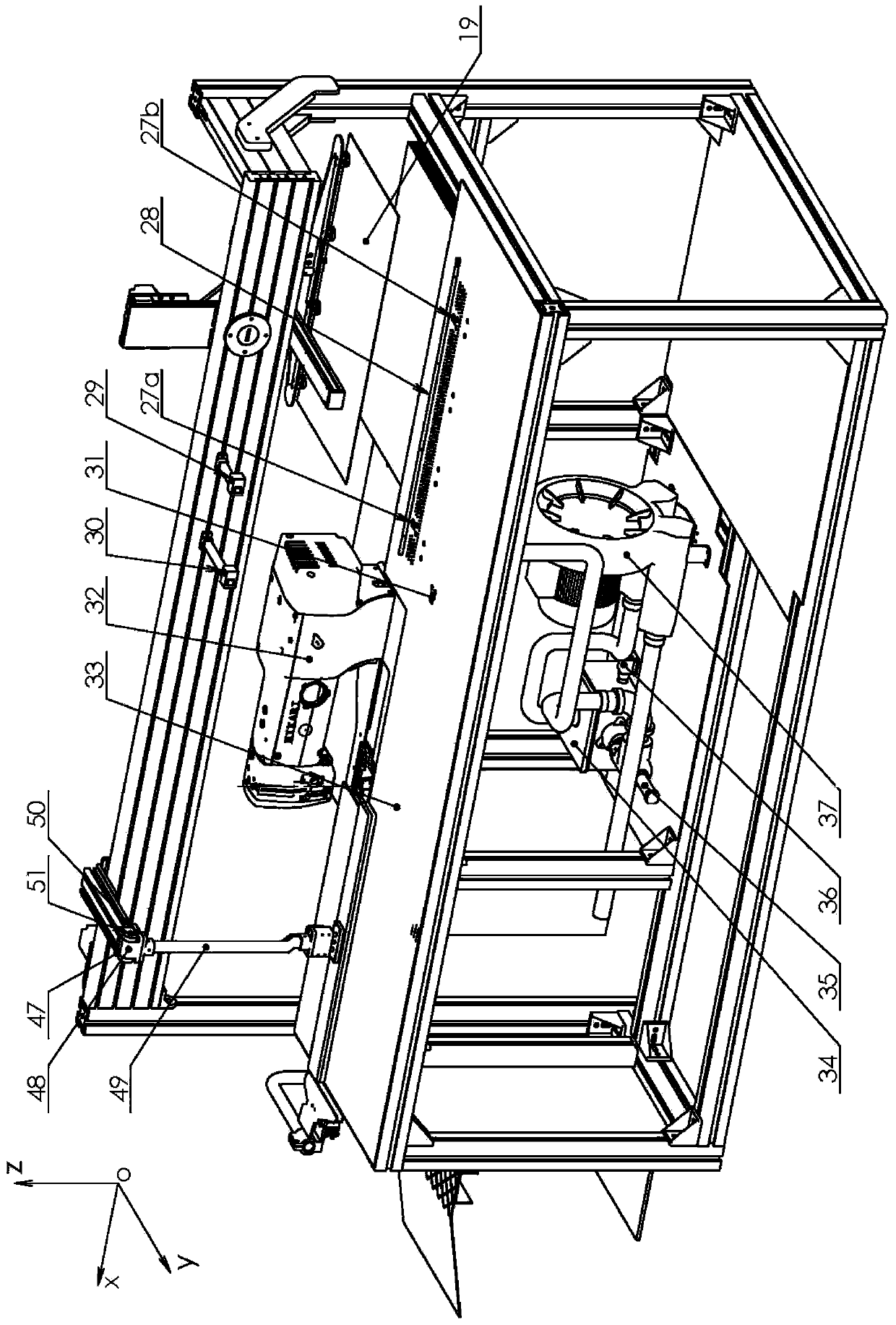

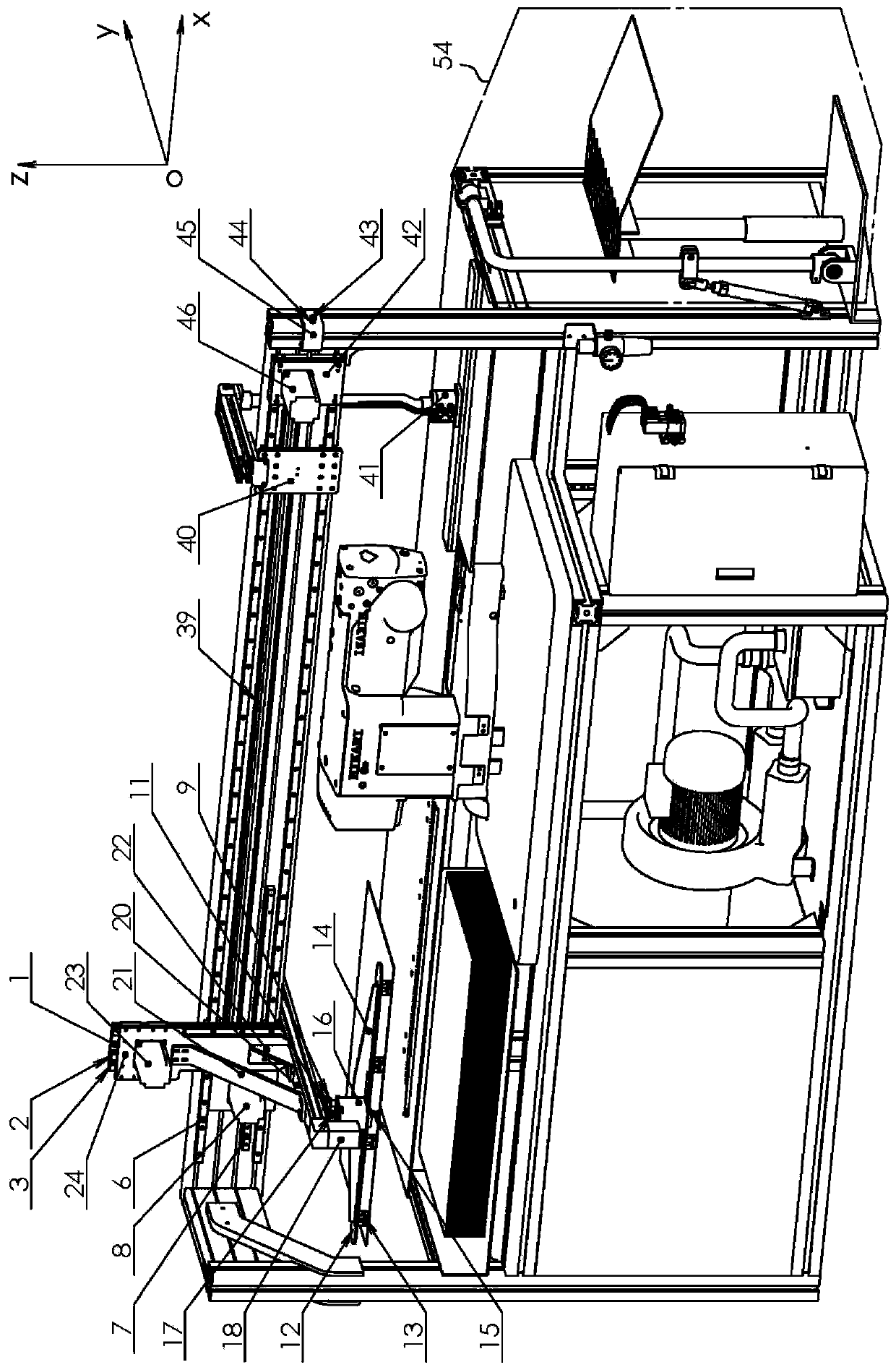

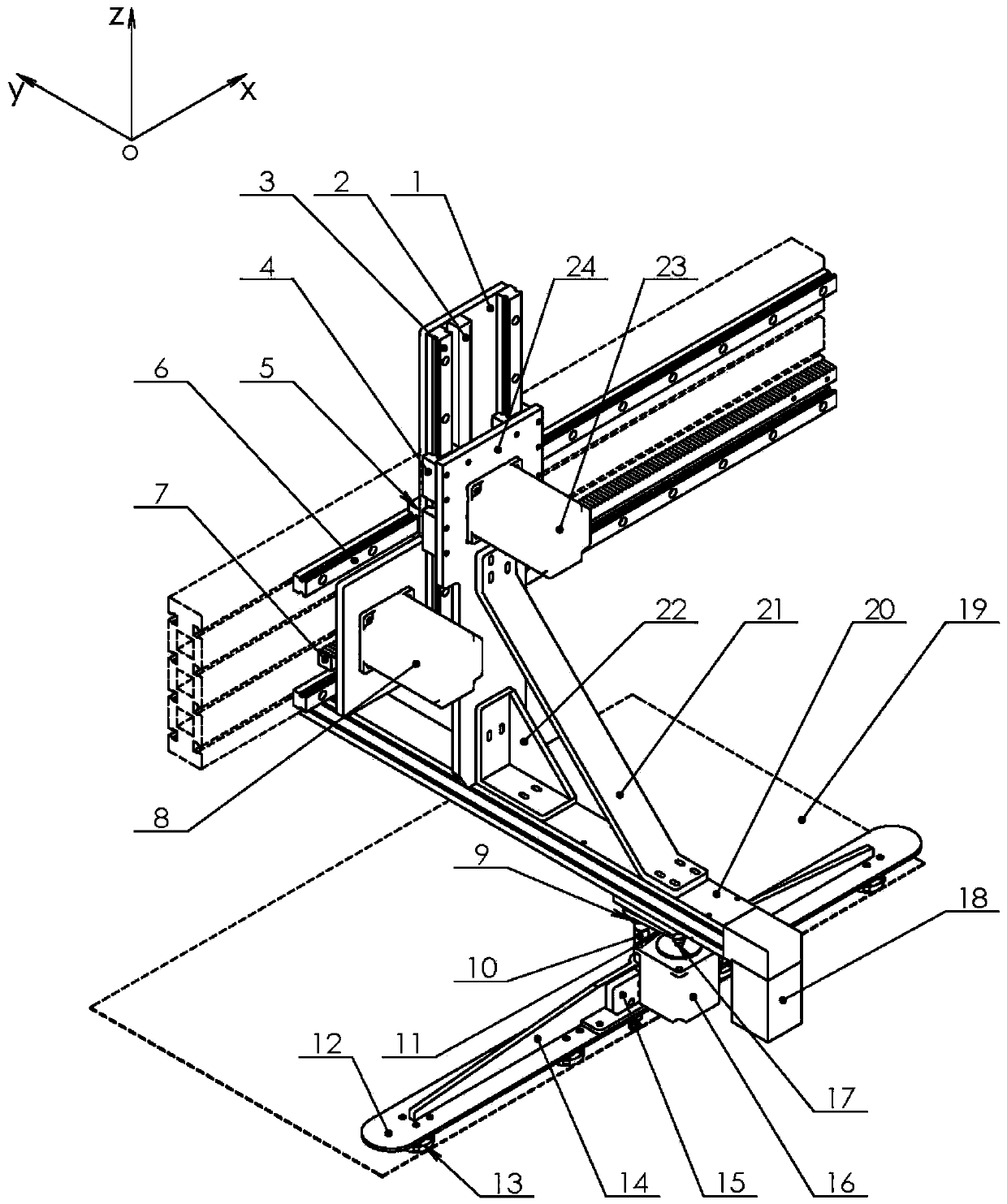

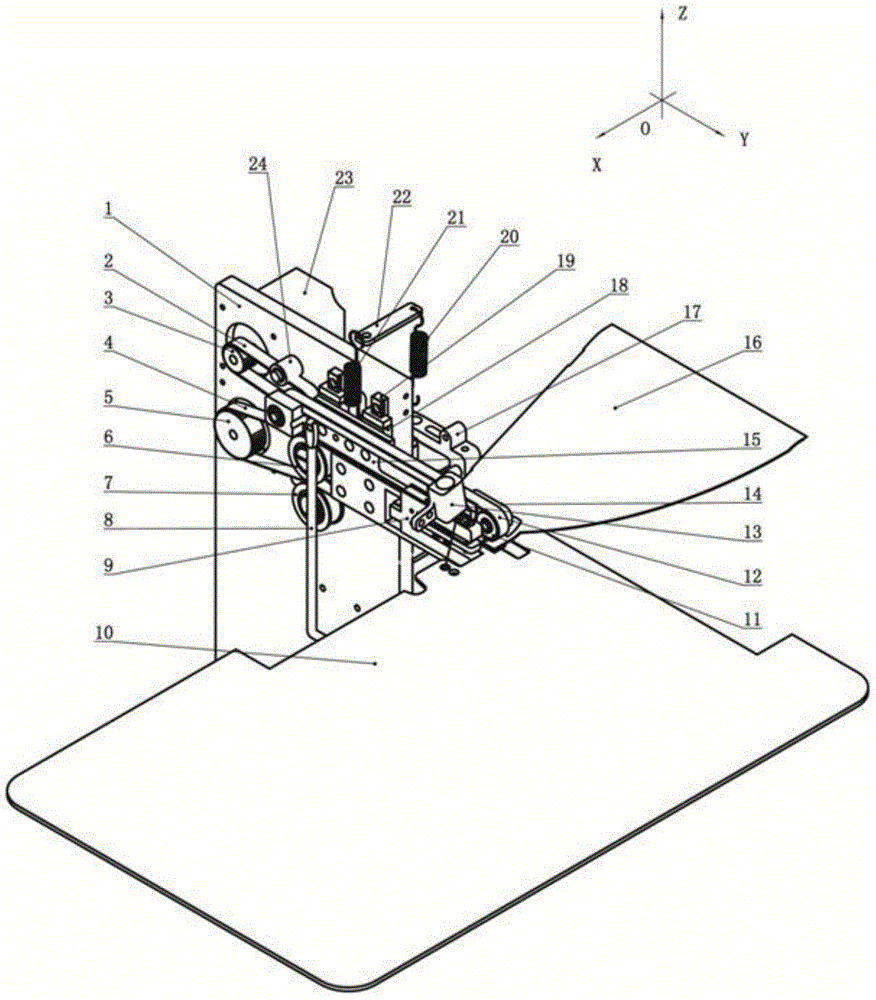

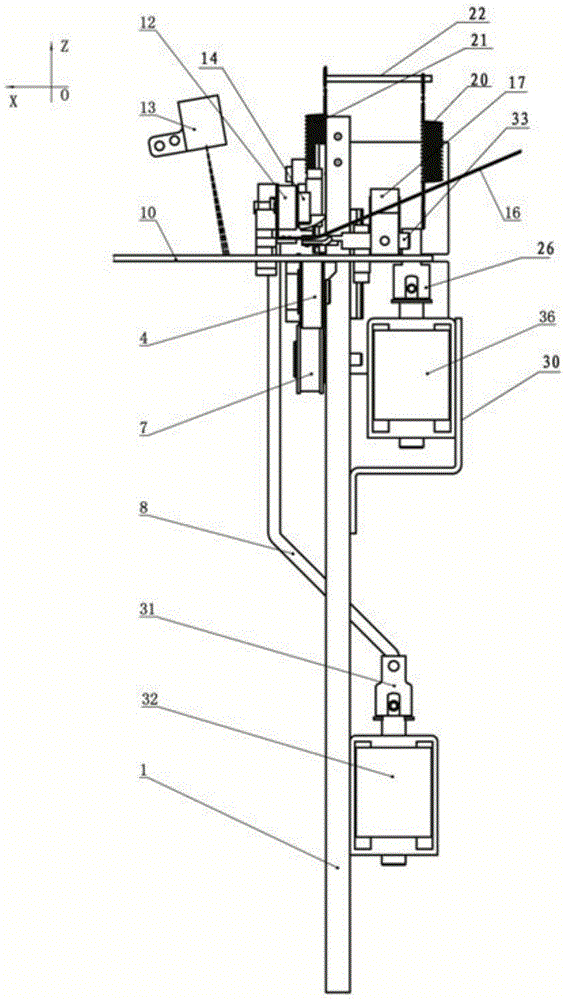

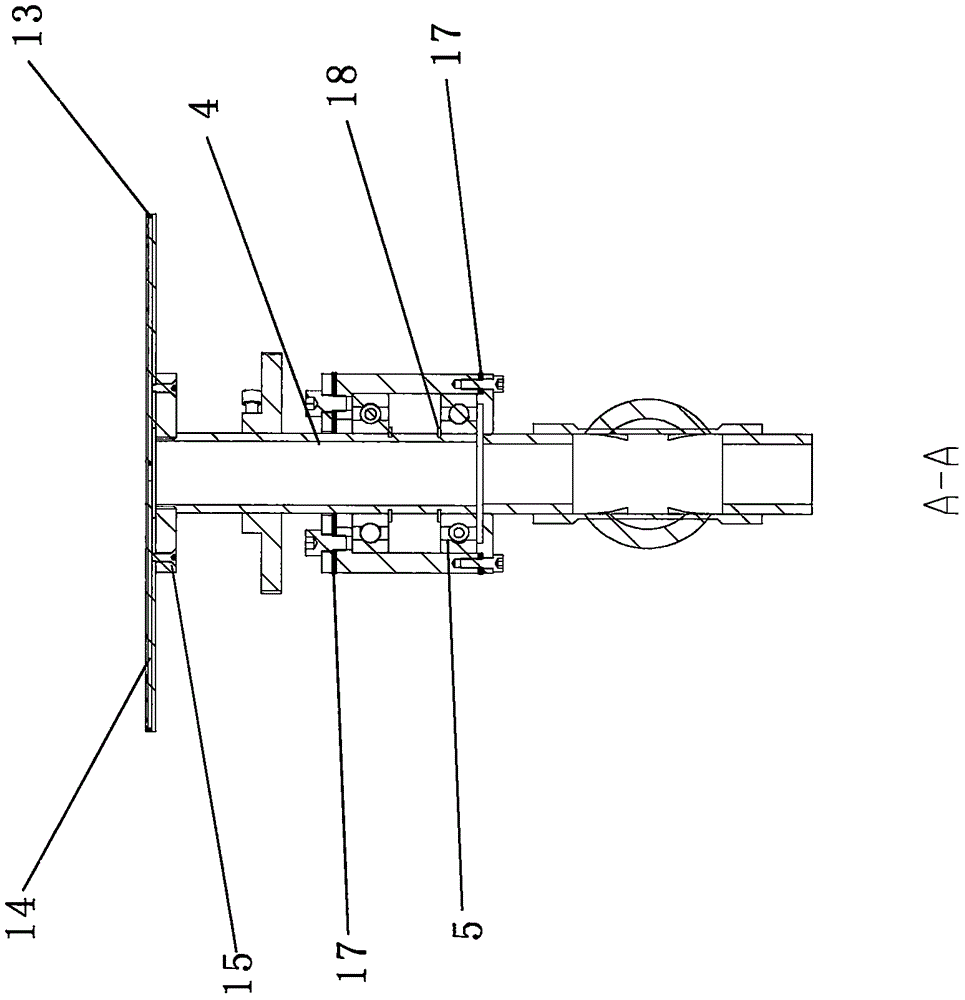

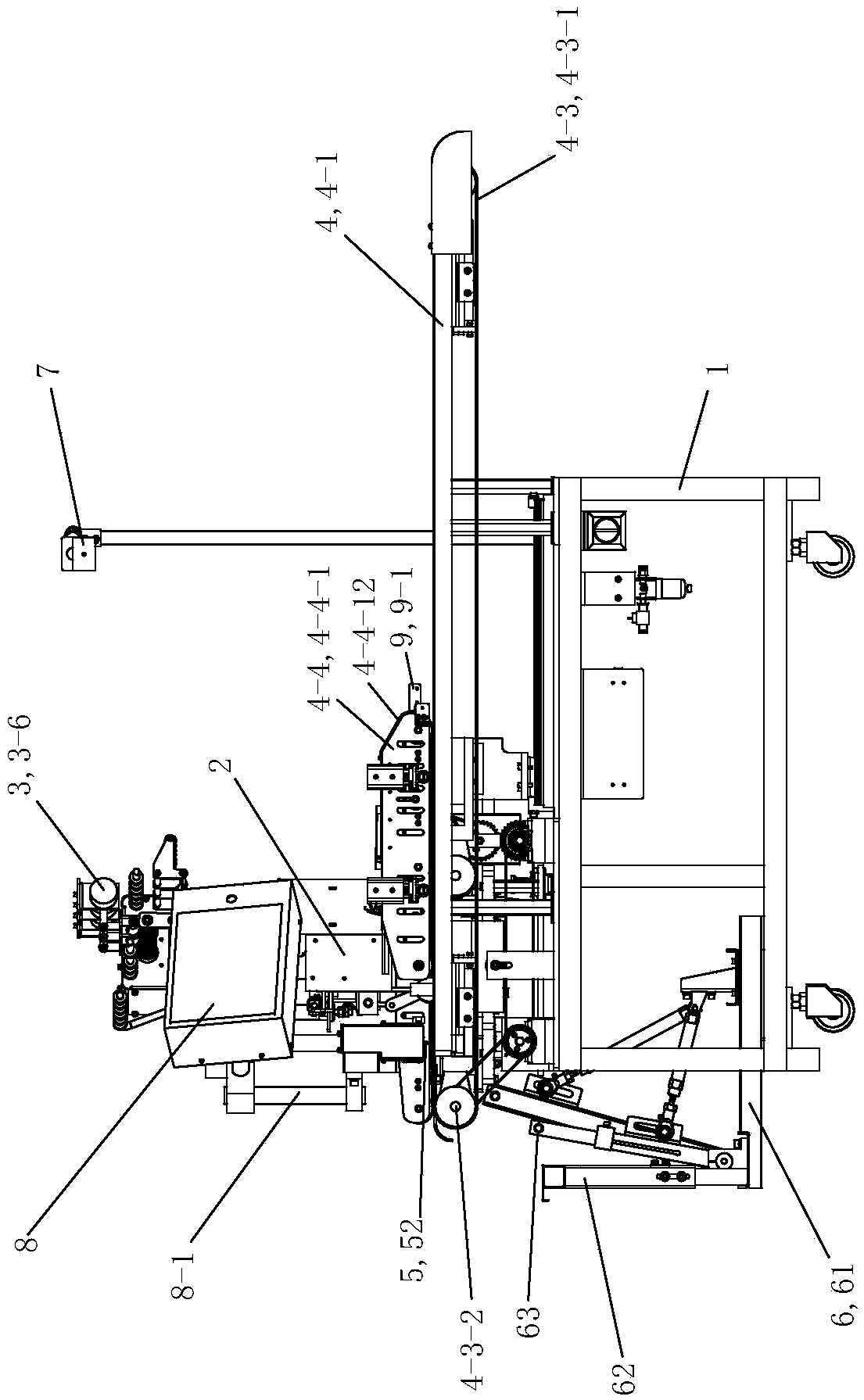

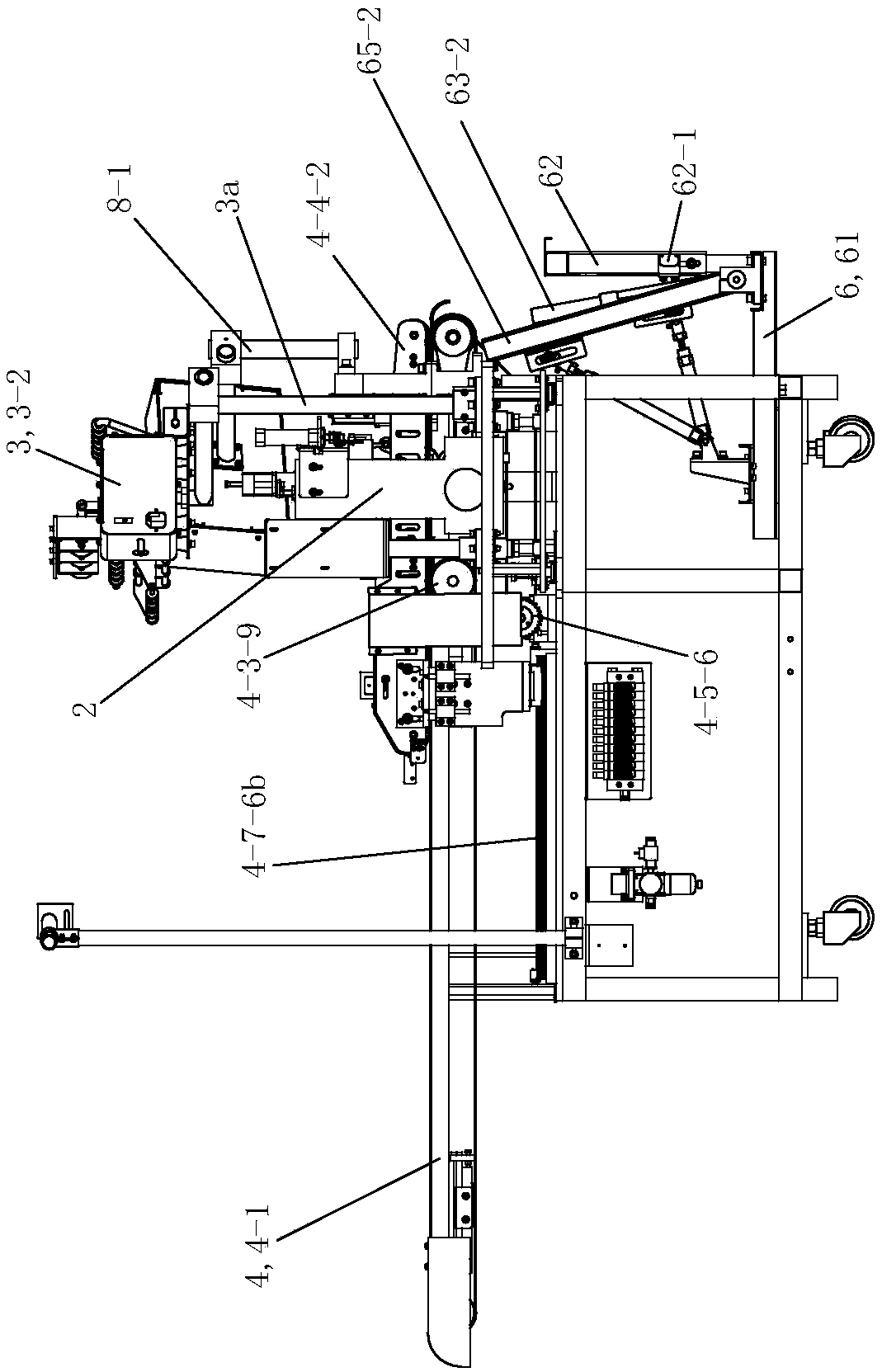

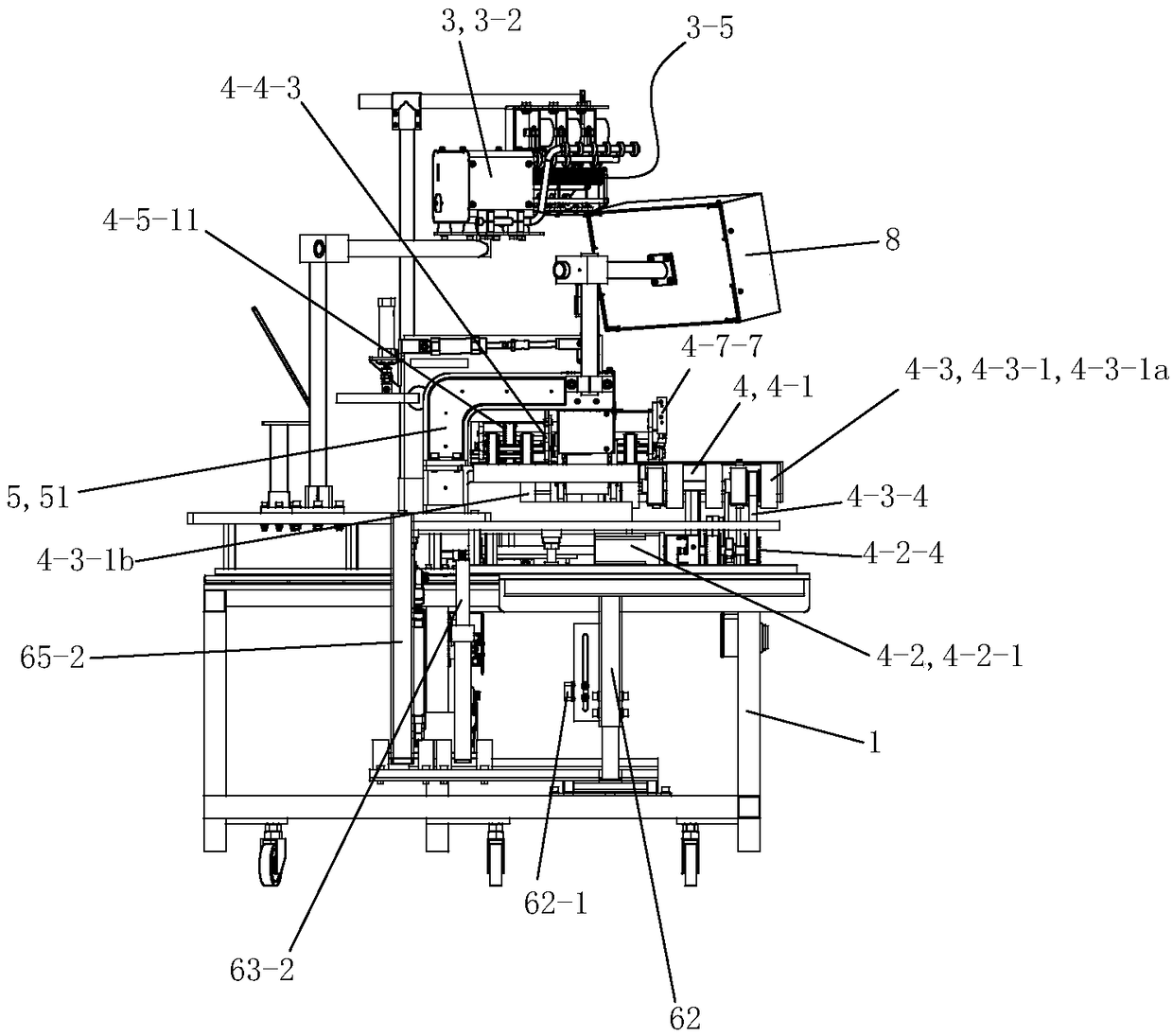

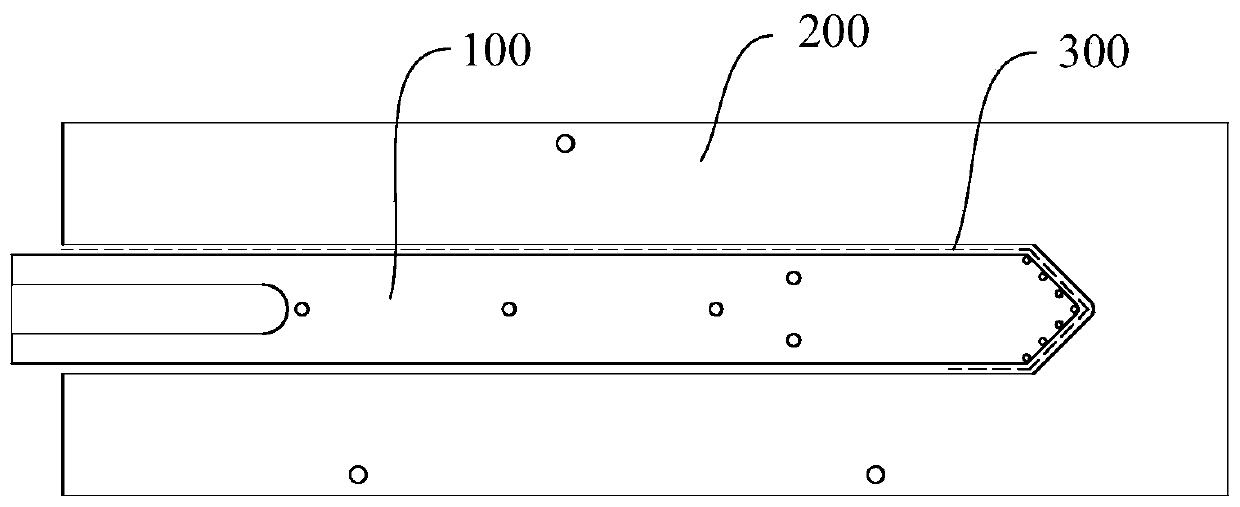

The invention relates to a full-automatic material taking and material feeding sewing machine. The full-automatic material taking and material feeding sewing machine comprises a fabric taking device, a fabric position correction system, an air pump system and a sewing material pressing and feeding device, wherein a horizontal guide rail is arranged in the X direction above a machine frame; the entire fabric taking device can conduct movement in X direction along the horizontal guide rail and can further conduct movement in Z direction on the horizontal guide rail; a linear module in a Y direction is arranged at the lower part of the fabric taking device; a rotating and regulating mechanism is arranged at the lower part of the linear module in the Y direction; a sucking disc fixing plate is arranged at the lower part of the rotating and regulating mechanism; the fabric position correction system comprises a fabric position sensing device; the fabric position sensing device comprises at least three sensors and a driving system that monitors the position of the fabric and transmits the signals of the fabric position deviation to the fabric taking device; the driving system corrects the placing position of the fabric through adjusting the global movement of the fabric taking device in the X direction, the Y-direction movement of the linear module in the Y direction and the rotating angles of the rotating and regulating mechanism.

Owner:上海富山精密机械科技有限公司

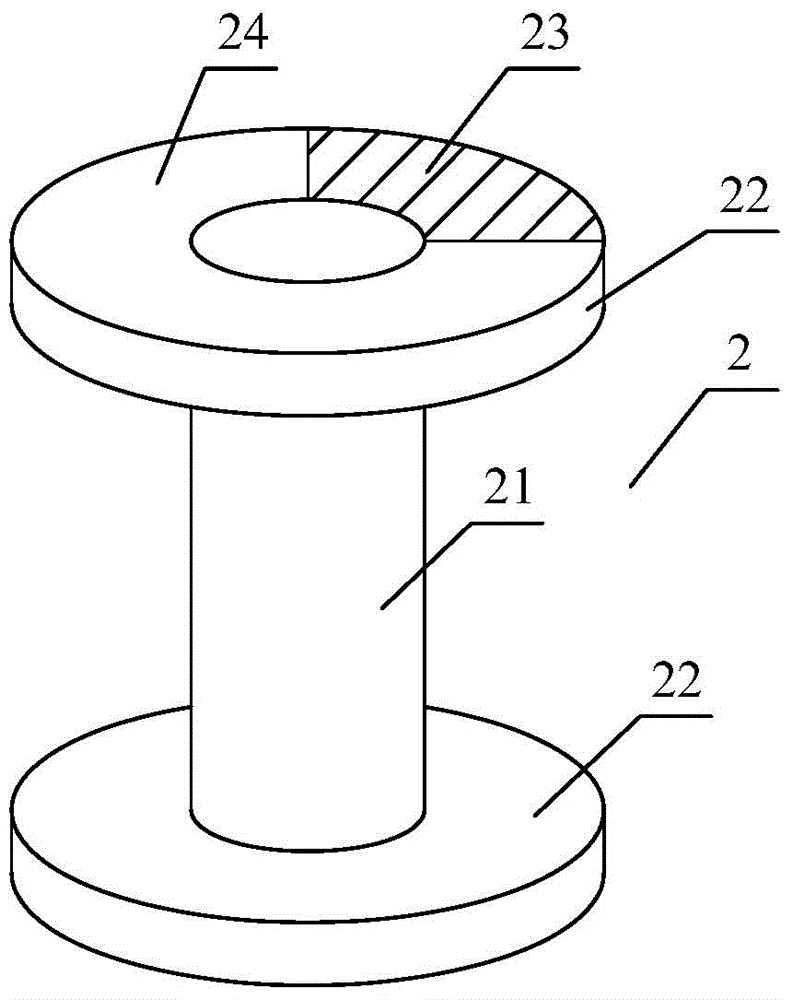

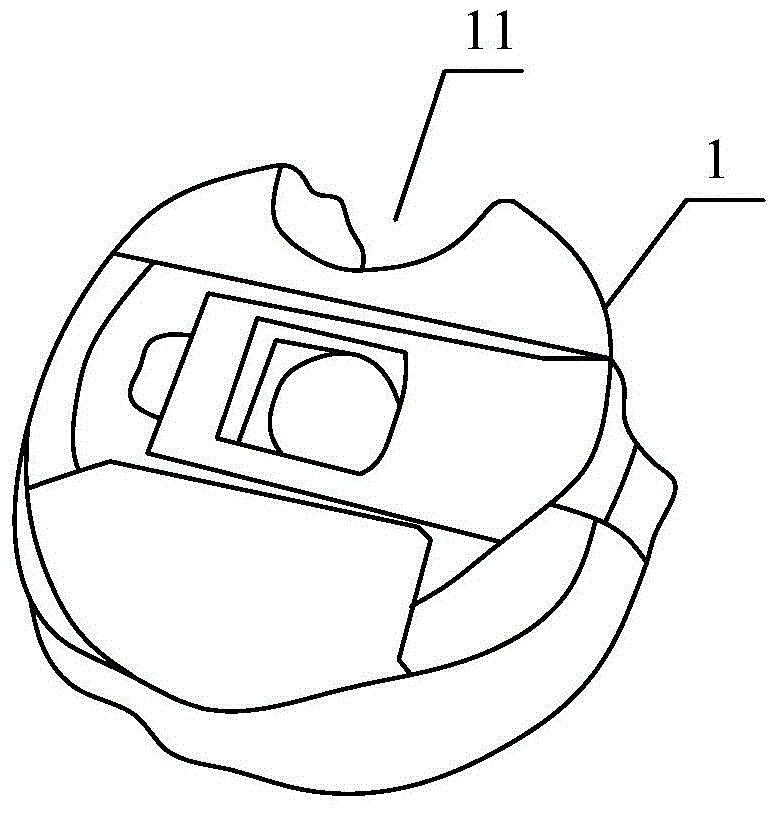

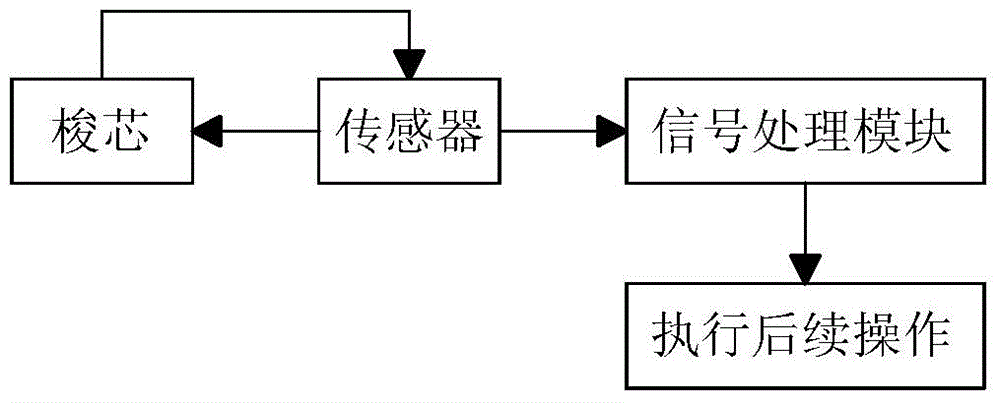

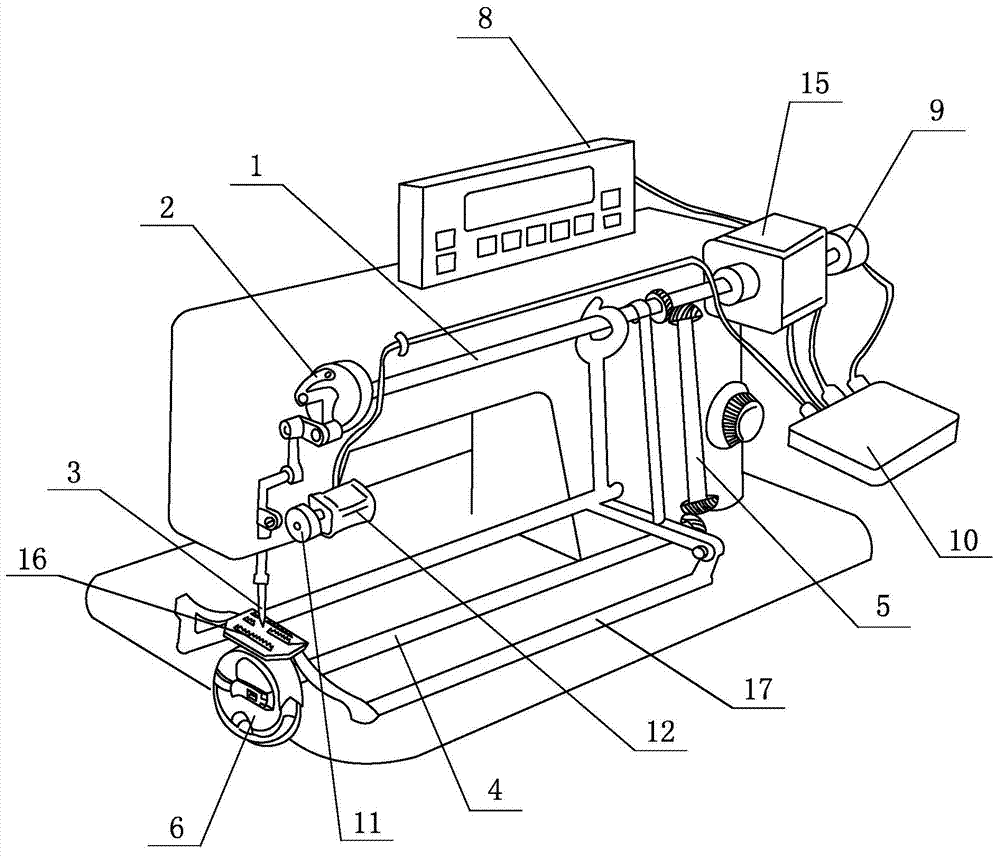

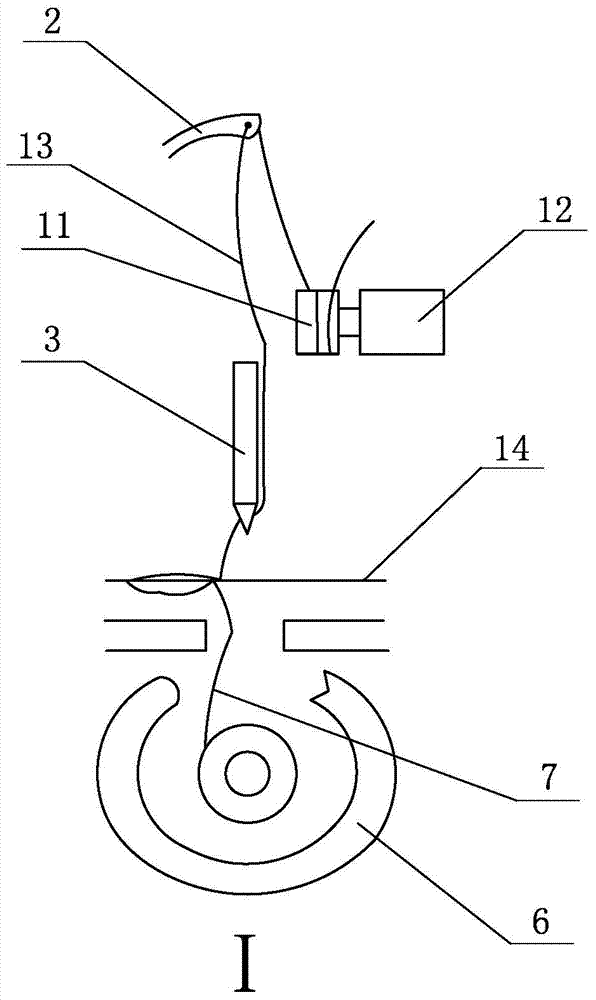

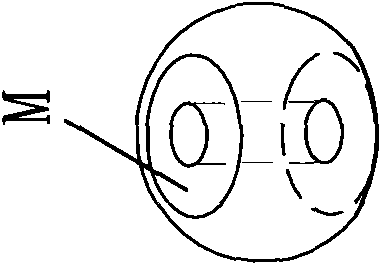

Device and method for detecting amount of bottom thread of sewing machine

The invention provides a device for detecting the amount of bottom thread of a sewing machine. The sewing machine comprises a bottom plate, a rotating shuttle and an electronic control module, wherein the rotating shuttle comprises a shuttle shell and a shuttle core; the shuttle core comprises a winding post and two flanges; at least one flange in the two flanges is provided with a first surface part and a second surface part on the outer surface; a light hole is formed on the outer wall of the shuttle shell; the first surface part or the second surface part is exposed outside from the light hole; the sewing machine also comprises a sensor fixed in the bottom plate; the sensor comprises a transmitter used for transmitting light, and a receiver used for receiving light; the receiver and the transmitter of the sensor just face to the first surface part or the second surface part exposed outside from the light hole, and the light reflection capabilities of the first surface part and the second surface part are different from each other; the sensor is connected with a signal processing module; the signal processing module is connected with the electronic control module. The device for detecting the amount of the bottom thread of the sewing machine is capable of timely detecting whether the bottom thread is used up or not in real time.

Owner:JACK SEWING MASCH CO LTD

Automatic thread feeding system of sewing machine and control method thereof

InactiveCN104120547AConsistent outputConsistent pitchProgramme-controlled sewing machinesSewing-machine control devicesDrive shaftElectric machinery

The invention discloses an automatic thread feeding system of a sewing machine. The automatic thread feeding system comprises an upper shaft, a lower shaft, a control device, a cloth feeding system and a sewing thread tension adjusting device. One end of the upper shaft is connected with a sewing machine driving mechanism, and the other end of the upper shaft is connected with a thread take-up lever and a sewing needle; one end of the lower shaft is connected with the upper shaft through a transmission shaft, and a rotating shuttle is arranged at the other end of the lower shaft and wound with a sewing bottom thread. The automatic thread feeding system is characterized in that the sewing thread tension adjusting device comprises a rotating body and a stepping motor, the rotating body is connected with an output end of the stepping motor, the sewing machine driving mechanism and a control end of the stepping motor are connected with the control device, the rotating body is wound with a sewing upper thread, and the sewing upper thread penetrates through the thread take-up lever and is connected with the sewing needle. The control method includes the steps of parameter setting, sewing needle sewing, rotating body taking up, cloth moving and rotating body paying off. The sewn stitches are in order, and sewing quality is high.

Owner:SUZHOU HAOJIE MACHINERY ELECTRONICS EQUIP

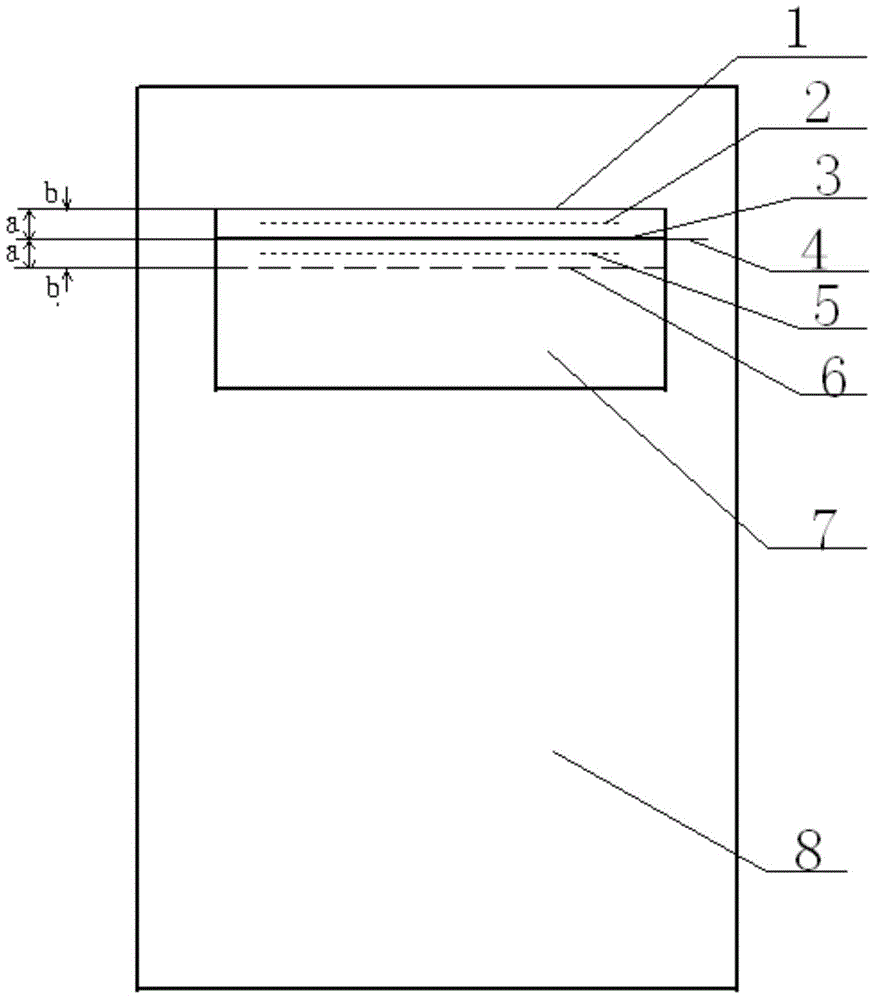

Cloth automatic edge aligning device of sewing machine

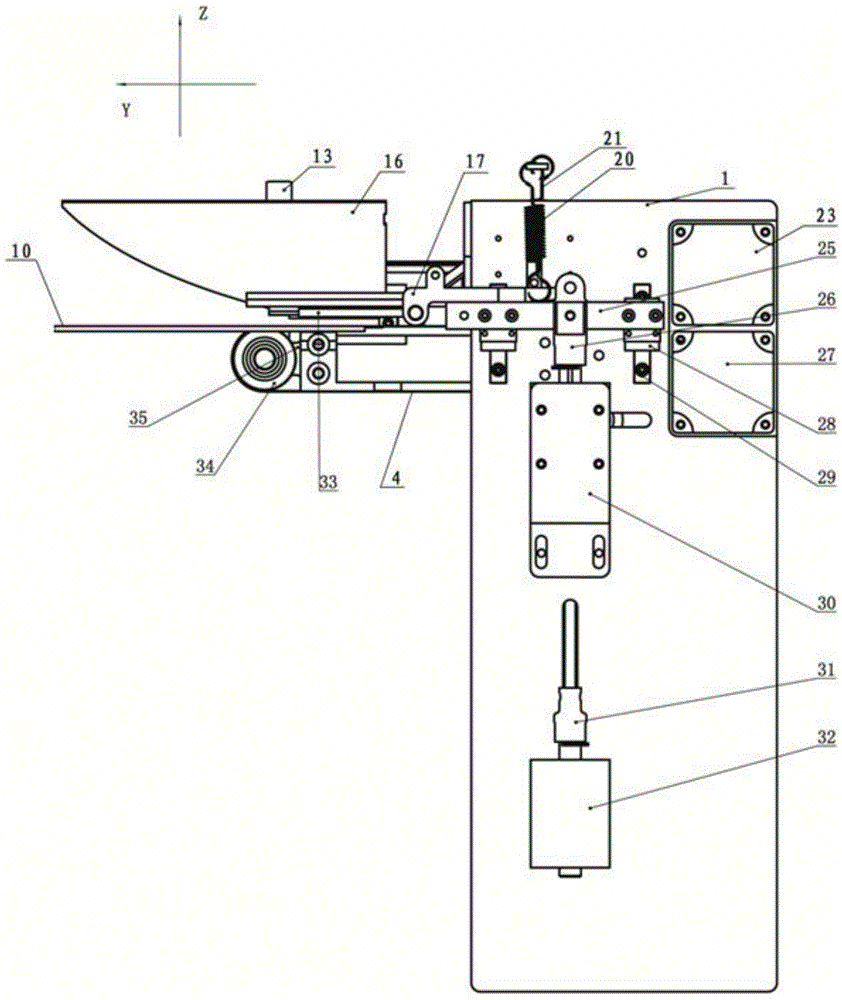

The invention relates to a cloth automatic edge aligning device of a sewing machine. The cloth automatic edge aligning device comprises a detecting mechanism and a regulating mechanism, wherein the detecting mechanism comprises a sensor assembly, a support frame of the sensing assembly is in an E shape and is arranged in a Y direction, three groups of sensors parting vertical arrangement are arranged on a PCB (printed circuit board) arranged at the middle layer, each sensor is a correlation type multipoint sensor, the pair of the upper and lower sensors arranged at the outer side of an E-shaped notch are primary positioning sensors, the two pairs of the upper and lower sensors arranged at the inner side of the E-shaped notch are precise positioning sensors, and the regulating mechanism is divided into an upper layer regulating mechanism and a lower layer regulating mechanism which are respectively used for regulating upper layer cloth and lower layer cloth. The cloth automatic edge aligning device of the sewing machine has the advantages that the edge aligning detection precision is high, the regulation precision is high, the structural design of the sensor assemblies is ingenious, the upper and lower layer cloth detecting efficiency is high, the edge aligning regulation resistance is small, the edge aligning regulating cloth contact area is large, the primary positioning sensors achieve the cloth pre-judgment effect, the cloth edge pressing incapability due to cloth monitoring incapability cannot occur even when the radian of a cloth piece is smaller, and the sewing quality is improved.

Owner:上海富山精密机械科技有限公司

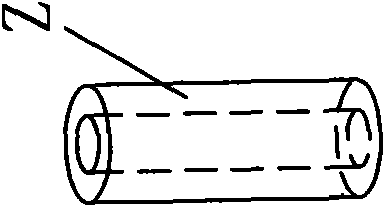

Tube-bead embroidery automatic feeding device

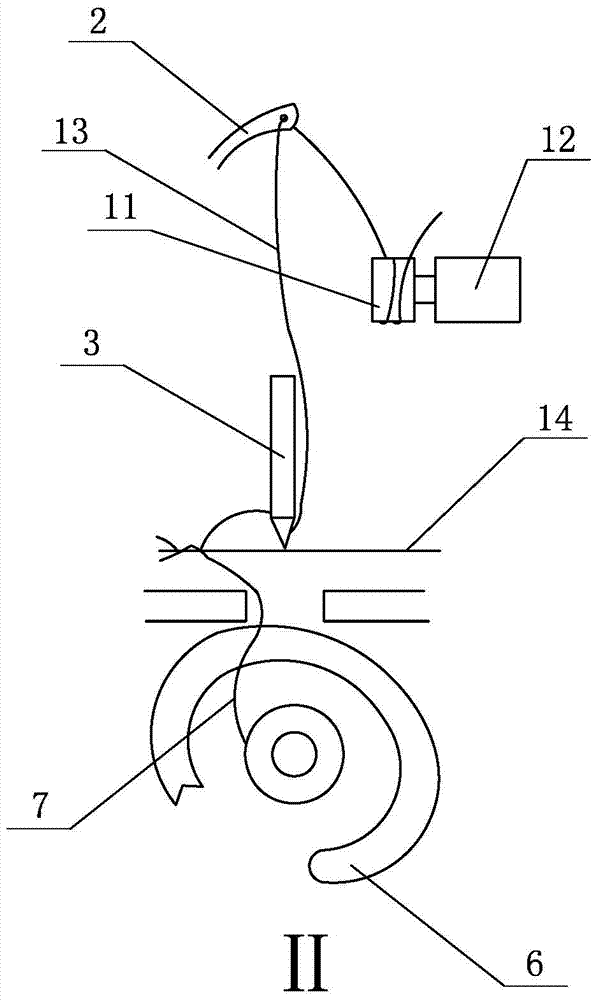

InactiveCN101603254ARealize fully automatic operationImprove sewing qualityAutomatic machinesAuxillary devicesReciprocating motionEngineering

The invention relates to an embroidering machine, and aims to provide a special sewing machine for tubes or beads, which can realize the automatic sewing of tubes or beads, and has the advantages of good sewing quality, high working efficiency and low processing cost. The technical proposal of the invention is characterized in that: the tube-bead embroidery automatic feeding device comprises a feeding device and a pushing device which is matched with the feeding device and is capable of making the straight reciprocating motion, wherein the feeding device is provided with a vibration type feeder, and a bead guide tube of the feeder is an output pipeline of tubes or beads; the pushing device faces the outlet end of the bead guide tube and is provided with a bead guide seat provided with a horizontal track, a bead pushing plate capable of making the reciprocating motion along the track, a swinging mechanism driving the bead pushing plate to move and an air suction device sucking air in a cavity in the bead guide seat through an air suction tube; and the front end of the bead guide seat is provided with a bead guide hole vertically downward, and a space is reserved between the bottom end face of the bead guide hole and the surface of the working table, so that the tubes or beads can be conveniently outputted.

Owner:ZHUJI MAYA ELECTRIC APPLIANCE MACHINERY

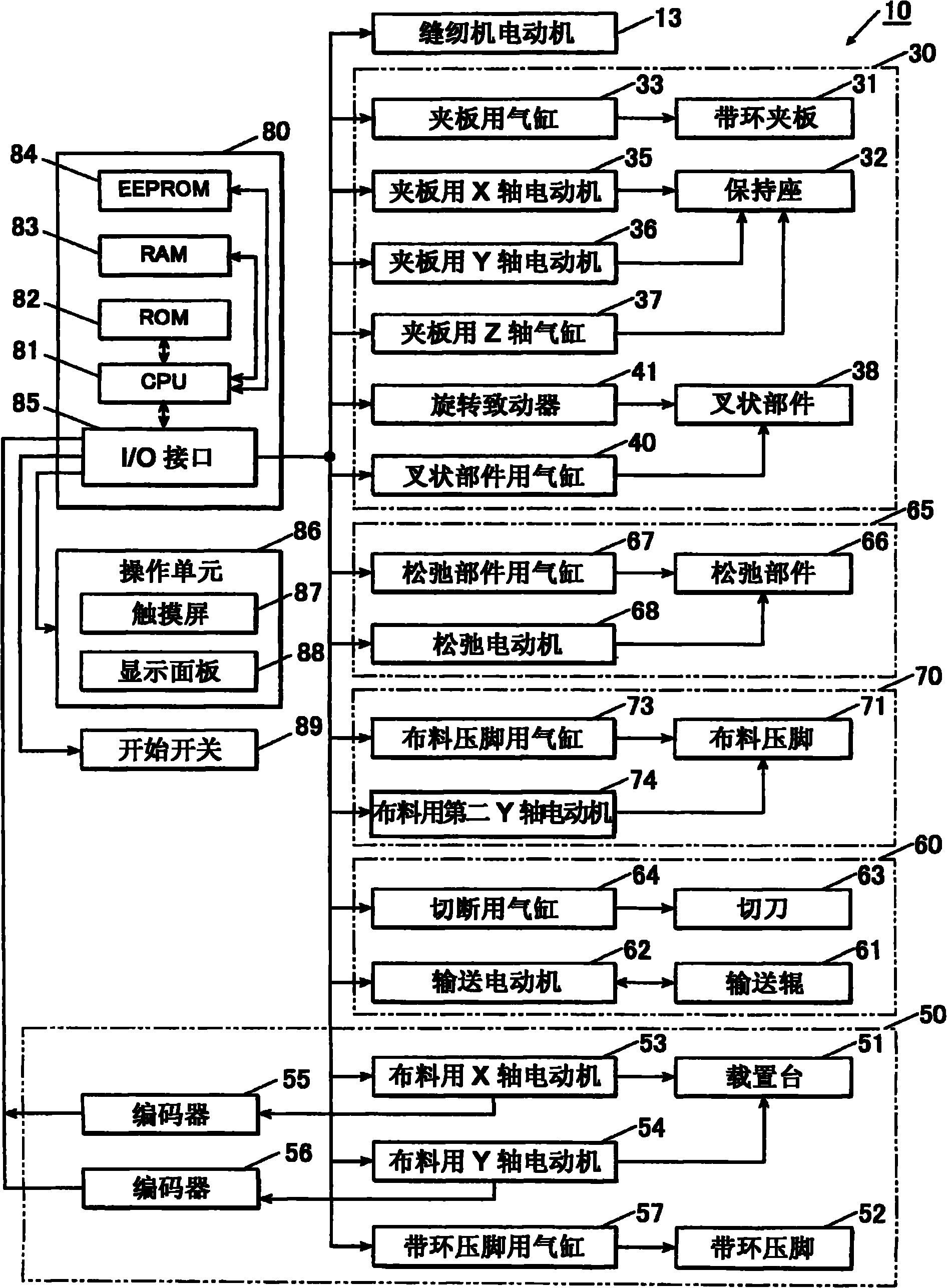

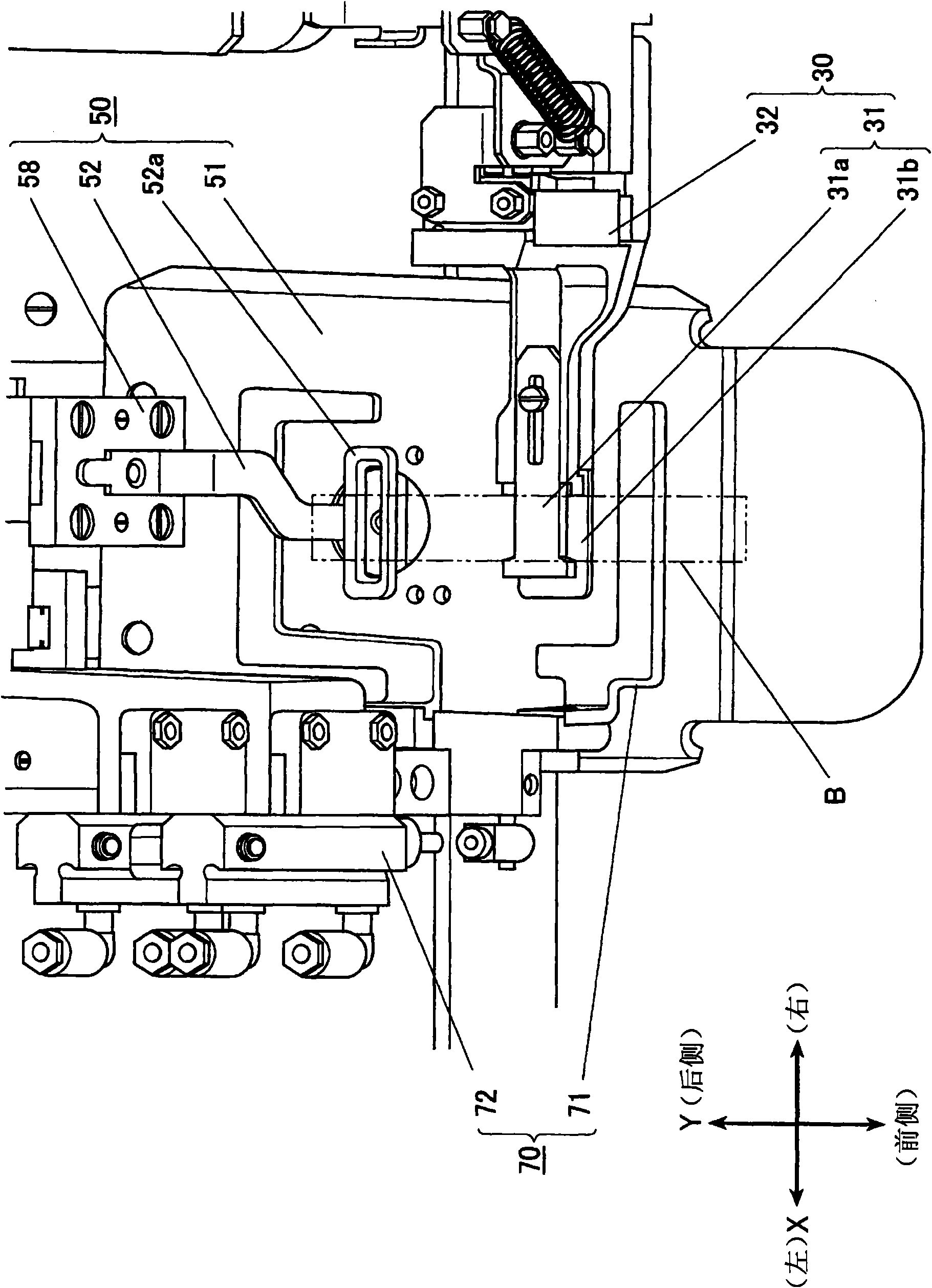

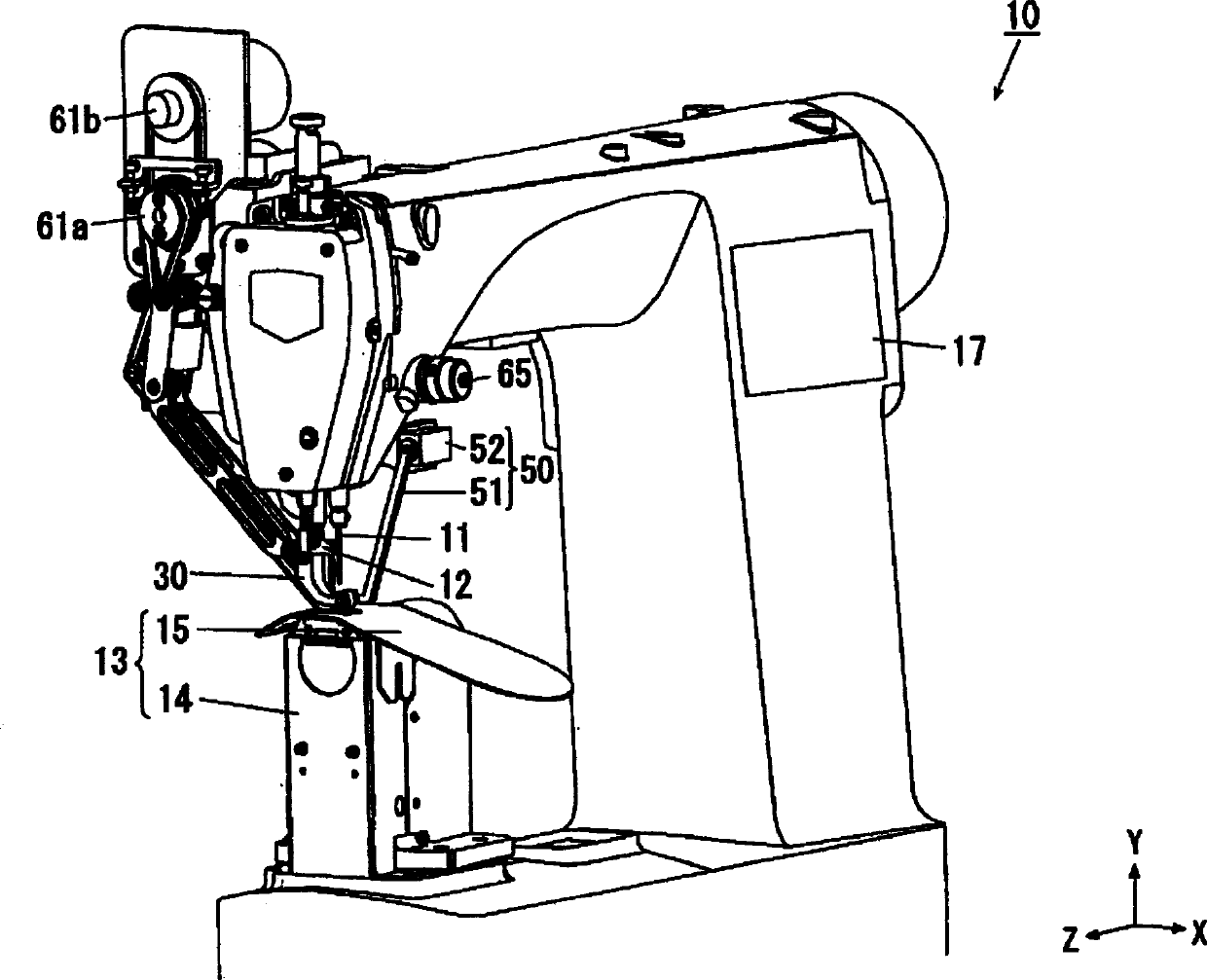

Band tailoring sewing machine

ActiveCN101864643AMeet design requirementsSimple designProgramme-controlled sewing machinesWork-feeding meansControl unitCotton material

The present invention provides a band tailoring sewing machine which performs appropriate band tailoring. The band tailoring sewing machine comprises the following components: a seedling needle vertical moving mechanism; a band splint; band presser feet; a carrying platform; clothes presser feet; a first moving mechanism; a second moving mechanism; a splint moving mechanism; a single fork-shaped component; and a control unit which performs the control described as follows: overlapped stitch forming is controlled; a driving source of the second driving mechanism is used as a feeding motor; crease mark stitches which are used as crease are formed in the width direction of the band held by the band splints; the splint moving mechanism is used for moving the band splint in a direction of turning-back from the crease mark stitch; the overlapped stitch stitches are formed on the crease mark stitches at a state of being shielded by the turned-back band; and the correction of positions of theoverlapped stitches is controlled; the feeding motor of the second moving mechanism is controlled when the overlapped stitches forming control is performed, and the correction control to the forming positions of the overlapped stitches correspondingly to the crease mark stitches is performed.

Owner:JUKI CORP

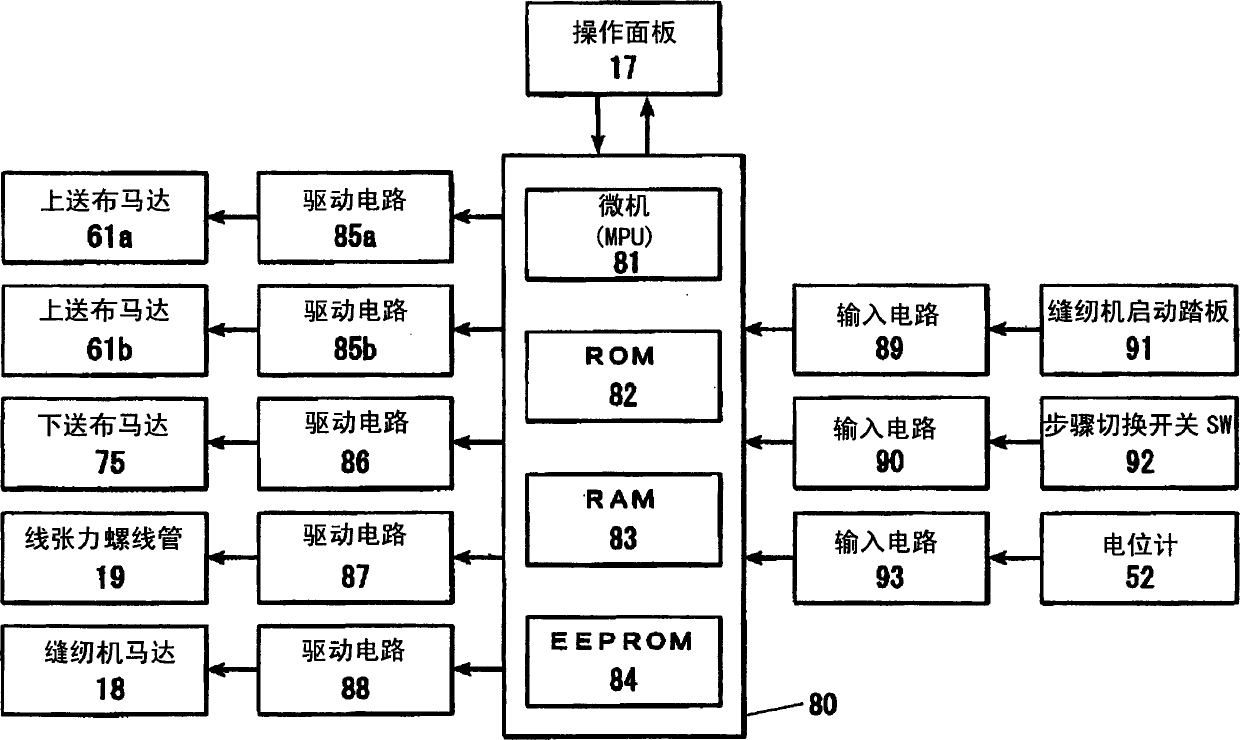

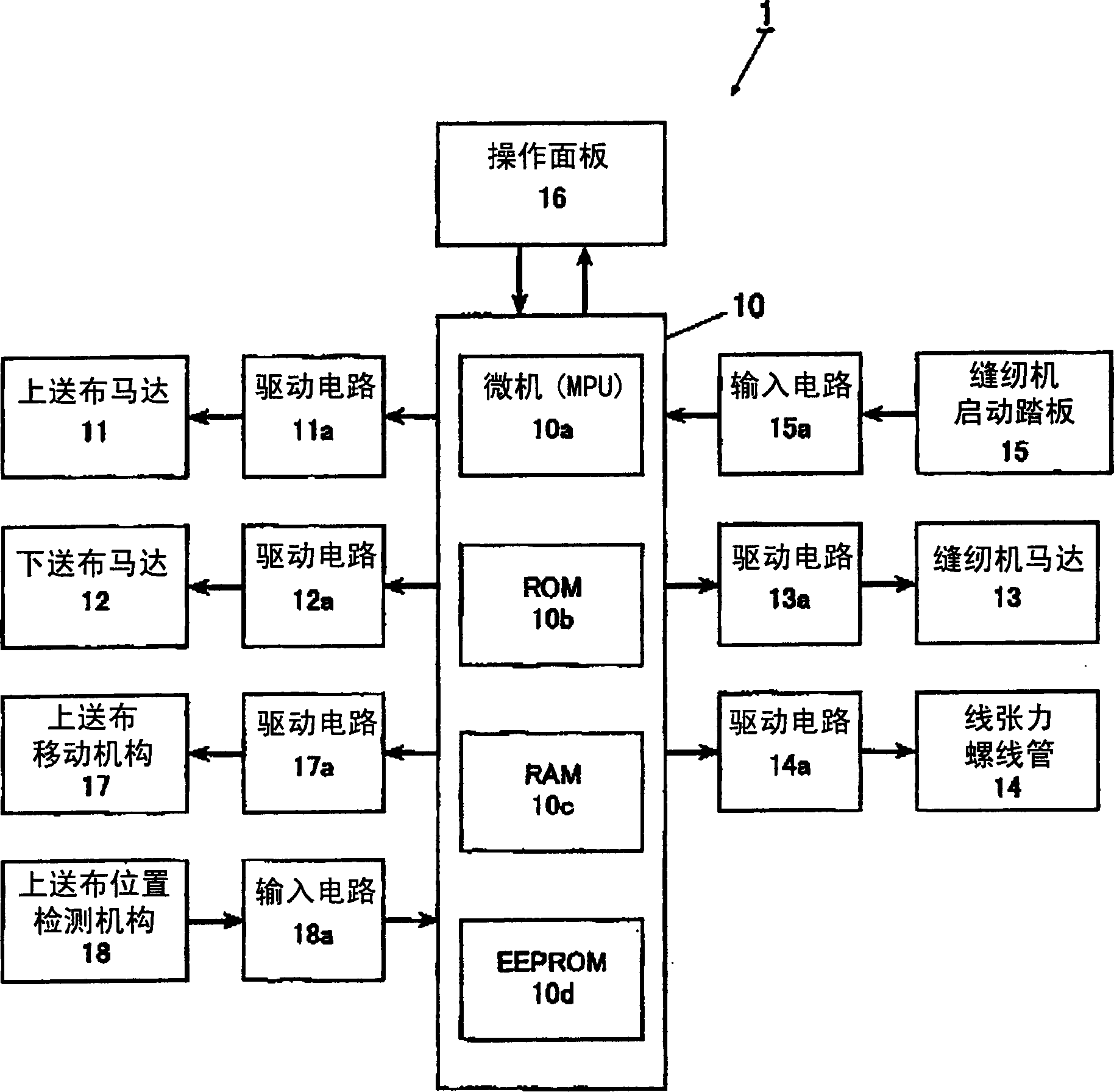

Up and down feeding cloth sewing machine

InactiveCN1782160AImprove sewing qualityThe amount of loose thread is correctProgramme-controlled sewing machinesWork-feeding meansSystem parametersElectrical and Electronics engineering

A sewing machine with top and bottom feeding, comprising: a cloth thickness detection mechanism (50) for detecting the thickness of an object to be sewn; a storage mechanism (84), which stores a plurality of sewing intervals and sewing intervals of each sewing interval; system-related parameters and switch the thickness of the sewing section; and an action control mechanism (80), which, when detecting the thickness of the sewn object in the switching sewing section by the cloth thickness detection mechanism, switches the sewing section, and uses The motion control of the control object is carried out by sewing with the parameters corresponding to each sewing section. This type of top and bottom feed sewing machine can perform sewing corresponding to changes in the thickness of the material.

Owner:JUKI CORP

Digitally controlled multifunctional sewing machine

InactiveCN1932115ASimple mechanical structureEasy to operateSewing-machine control devicesControl systemElectric machinery

The digitally controlled multifunctional sewing machine belongs to the field of automatic sewing apparatus technology. The digitally controlled multifunctional sewing machine includes mainly one sewing machine body with control system on the working platform and motor, one X-Y skid platform mechanism and one presser foot mechanism. The X-Y skid platform mechanism consists of one Y skid platform pedestal with Y guide track, one Y skid platform motor with Y transmission mechanism, one Y skid platform connected to the Y transmission mechanism, one X skid platform motor with X transmission mechanism, one X skid platform connected to the X transmission mechanism, etc. The presser foot mechanism consists of one outer presser foot, presser foot, cylinder and other part. The digitally controlled multifunctional sewing machine can grasp fabric and move fabric automatically for sewing.

Owner:绍兴县奇功数控机械有限公司

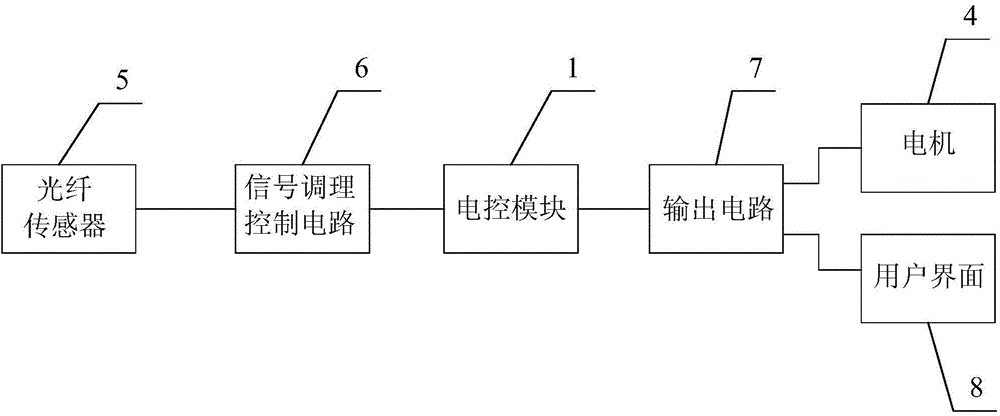

Bottom wire detection control system and method based on optical fiber sensor and applied to industrial sewing machine

ActiveCN104372538AImprove detection accuracyGuaranteed reliabilityBobbin-winding devicesLoop takersBobbinEngineering

The invention provides a bottom wire detection control system based on an optical fiber sensor and applied to an industrial sewing machine. The system comprises an electric control module, a rotating shuttle and a motor. The rotating shuttle comprises a shuttle case and a shuttle core. The shuttle core comprises a winding post and flanges arranged at the two ends of the winding post. A reflective sheet is fixed to the outer circumferential face of the winding post, and bottom wires are wound around the winding post. The optical fiber sensor is fixed to a shuttle support. The shuttle case is provided with an optical fiber emitter inlet and a gap, wherein the optical fiber emitter inlet and the gap are communicated with each other. The optical fiber sensor is connected with the electric control module through a signal conditioning control circuit. The electric control module is also connected with the motor through an output circuit. The bottom wire detection control system applied to the industrial sewing machine can judge whether the shuttle core is not installed in the shuttle case and whether the bottom wires on the shuttle core are enough according to optical signals of reflected light detected by the optical fiber sensor; meanwhile, the optical fiber sensor is adopted as a detection element, so that the system is high in sensitivity, higher and more reliable in detection performance and higher in anti-electromagnetic-interference capability.

Owner:BULLMER ELECTROMECHANICAL TECH

Automatic sewing machine

ActiveCN101100789AAvoid disorderImprove sewing qualityProgramme-controlled sewing machinesSewing-machine control devicesNeedle positionClosed loop

The present invention relates to an automatic sewing sartorius, which implement optimization of sartorius rotary speed and supply time when implementing XY drive to the cloth sewing foot in arbitrary directions through the control of a half closed loop. The sartorius comprises a sewing needle; a orientation unit, which contains a motion quality detecting unit to detect the motion quality of a pulse electromotor which drives a cloth keeping part move to arbitrary positions; a needle position detecting unit, detecting the position of a needle in upper and lower directions; a pattern memory unit, storing sewing pattern data; a motion control unit, to ensure the prescribed difference between the instruction pulse and actual motion, at the same time to output instruction pulses one by one to the pulse electromotor; and a required time memory unit, storing time required for outputting instruction pulse, and time required for motion control unit reference, to begin output the instruction pulse according to the orientation completed by the instruction pulse output when a sewing needle contacts the sewing matter on the needle board.

Owner:JUKI CORP

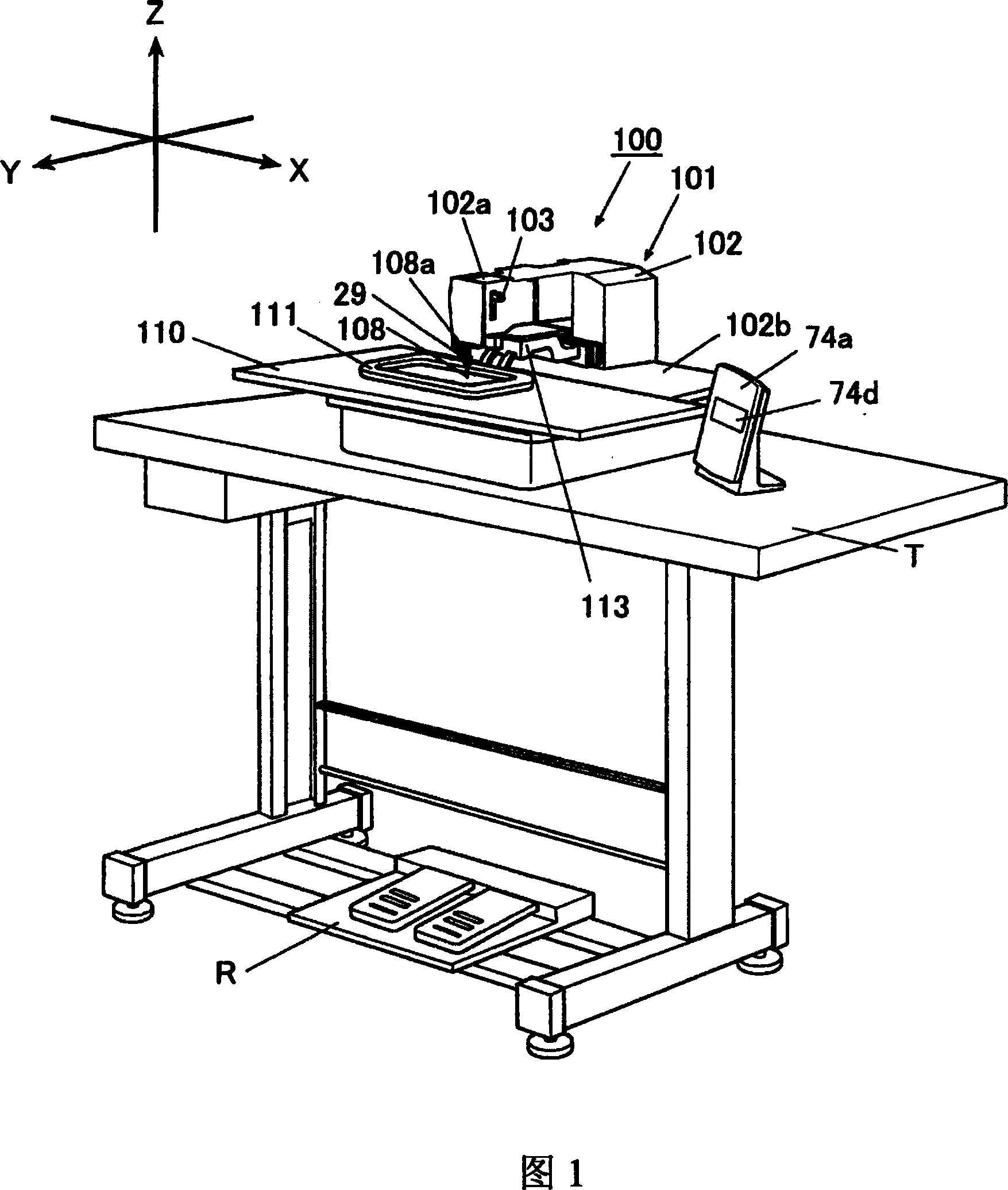

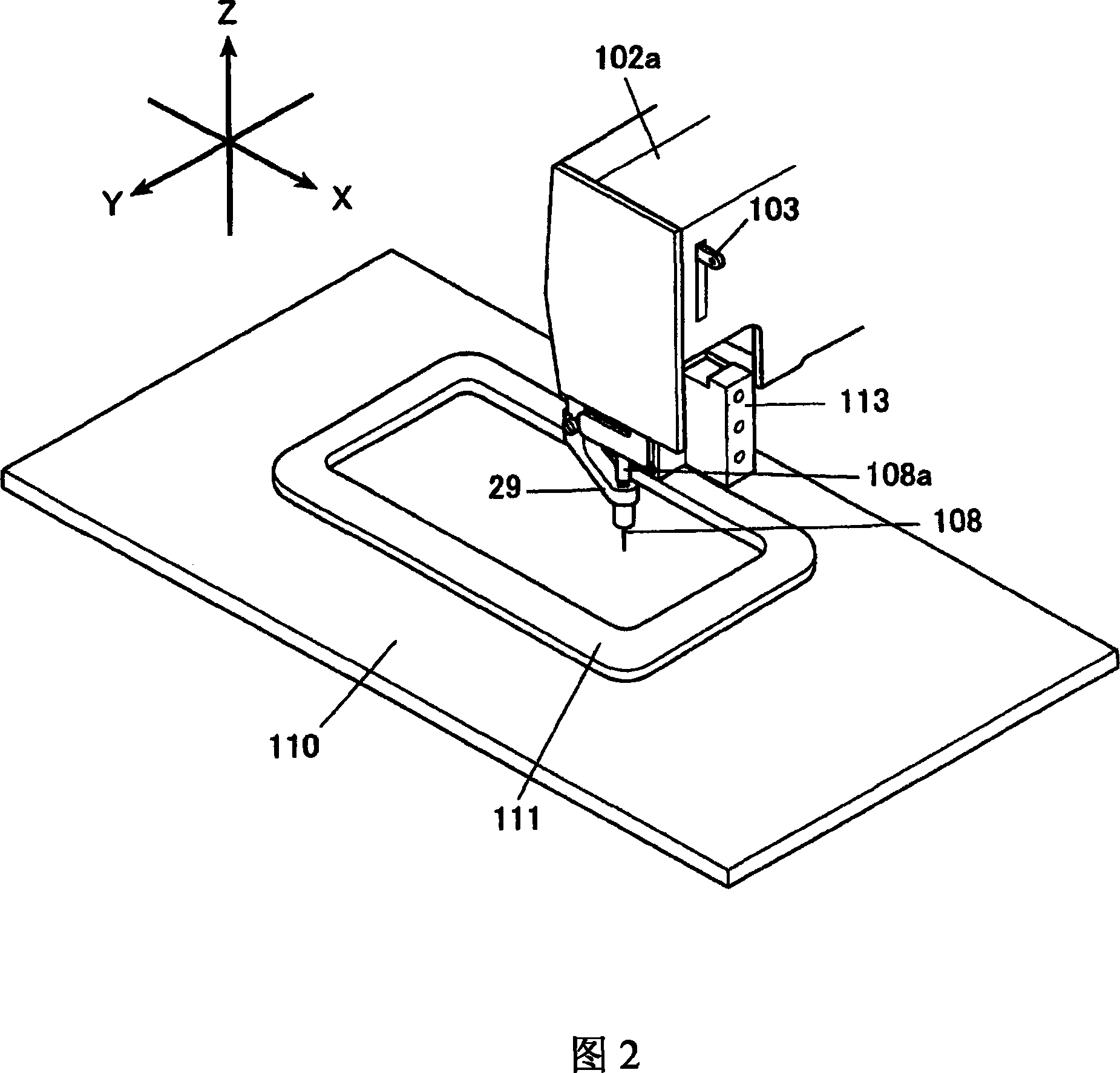

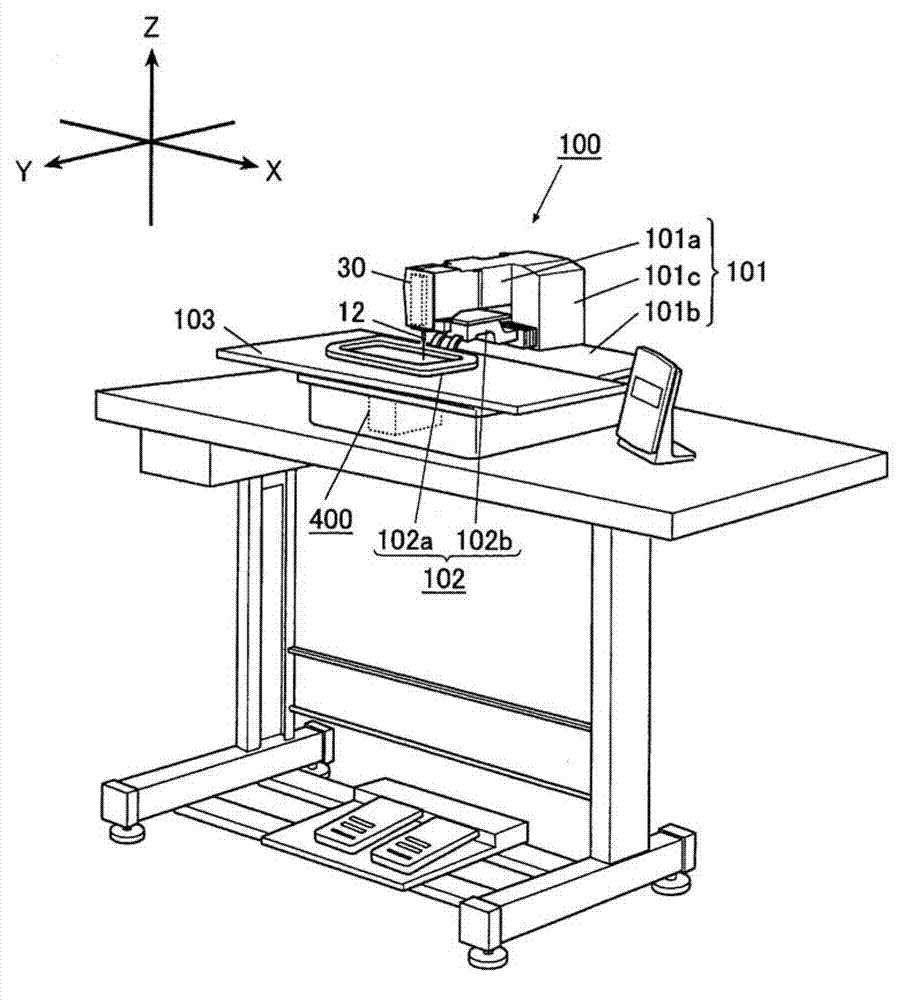

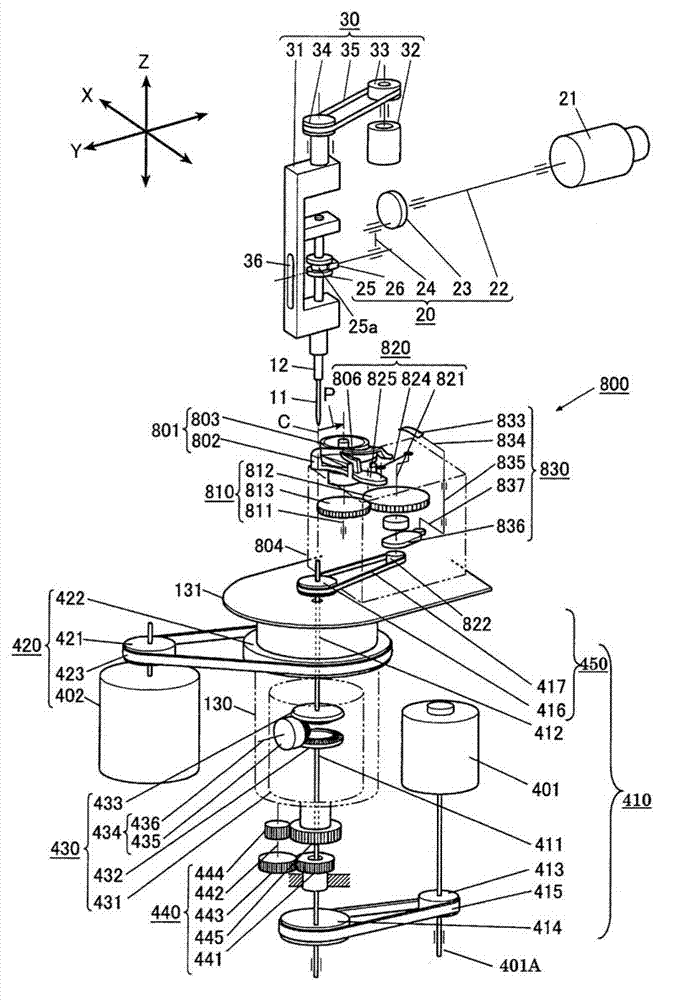

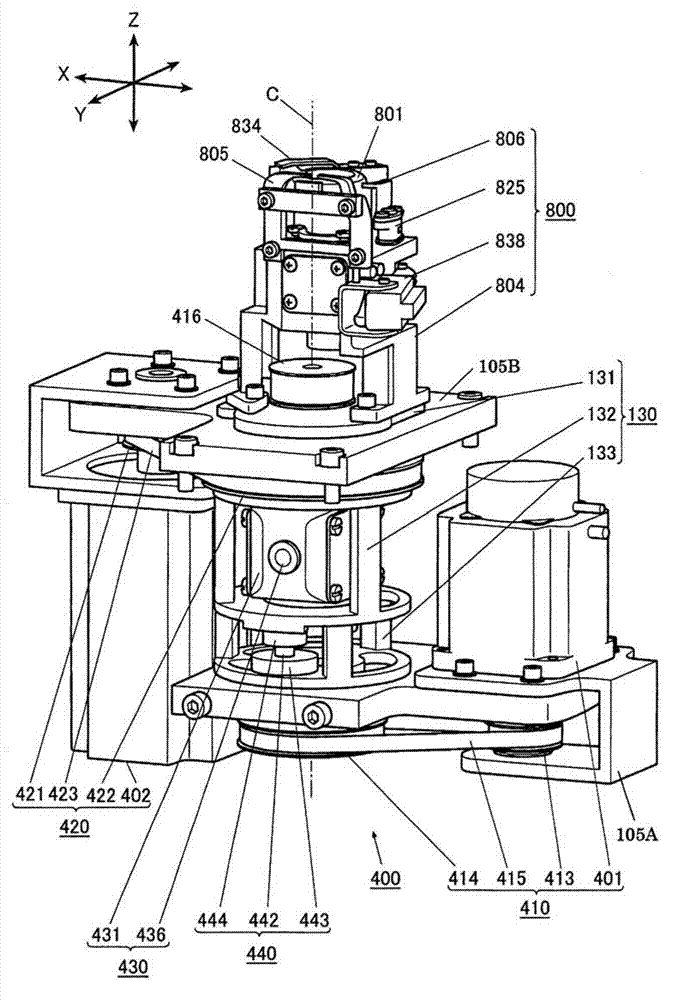

Sewing system

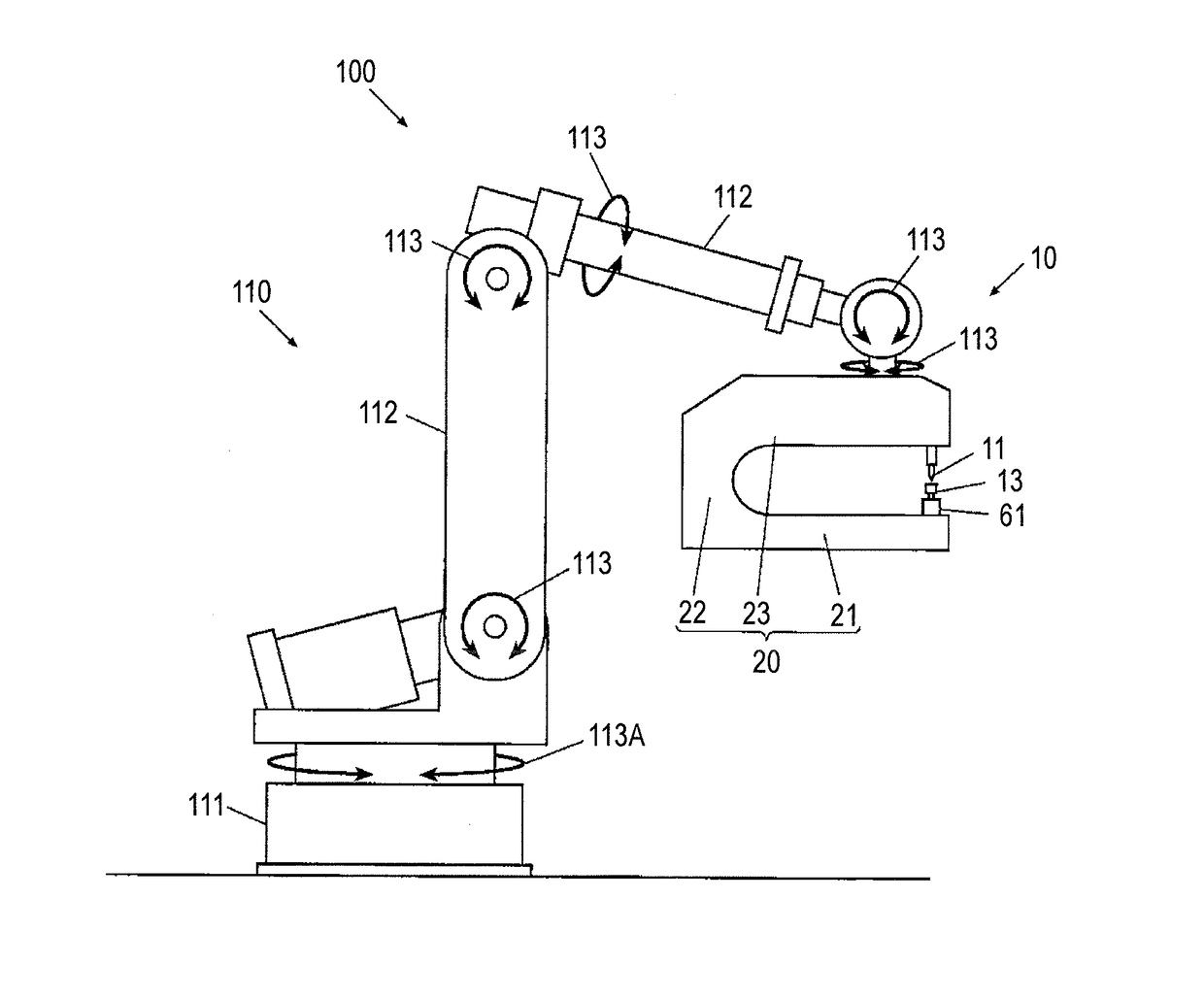

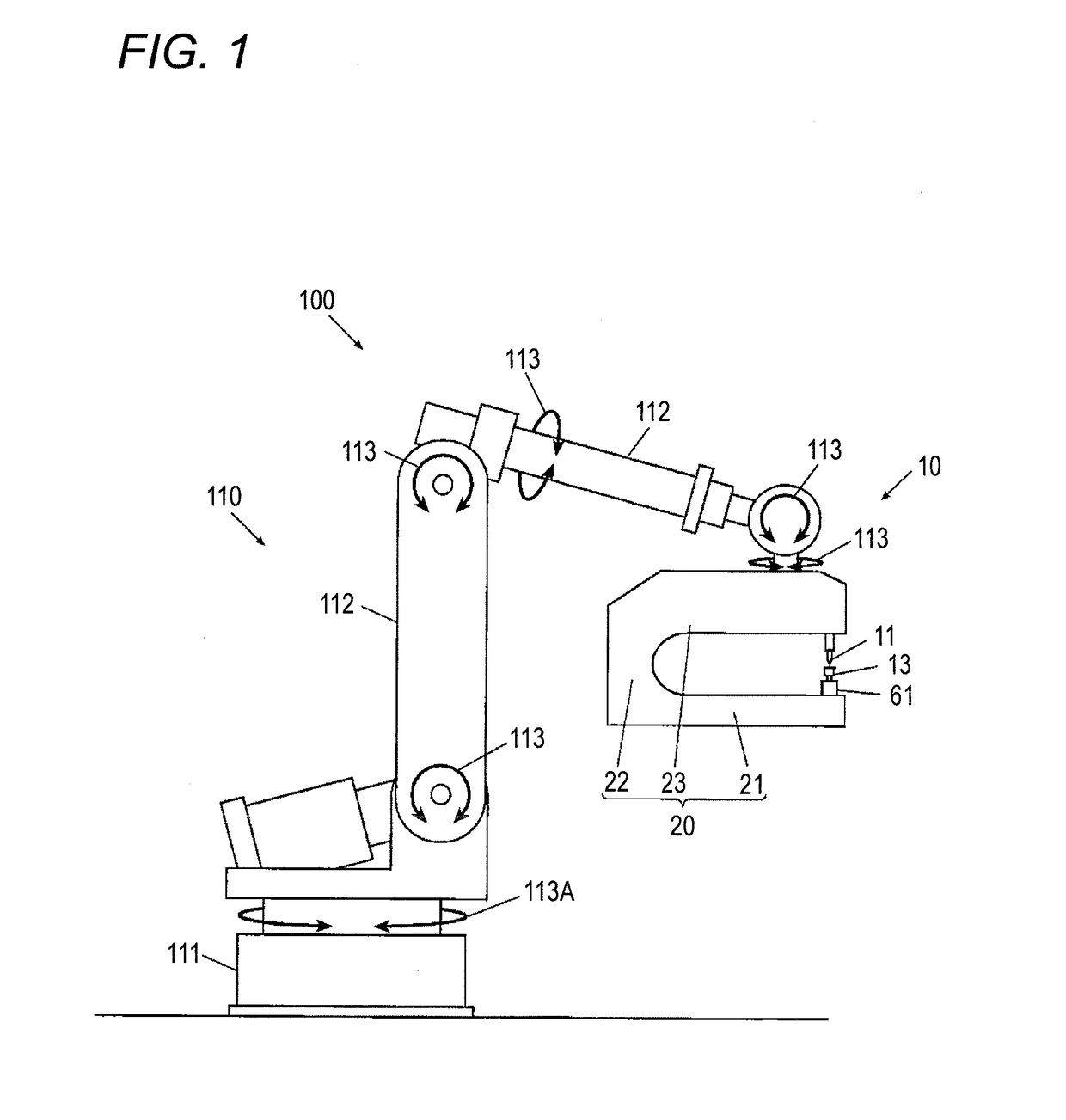

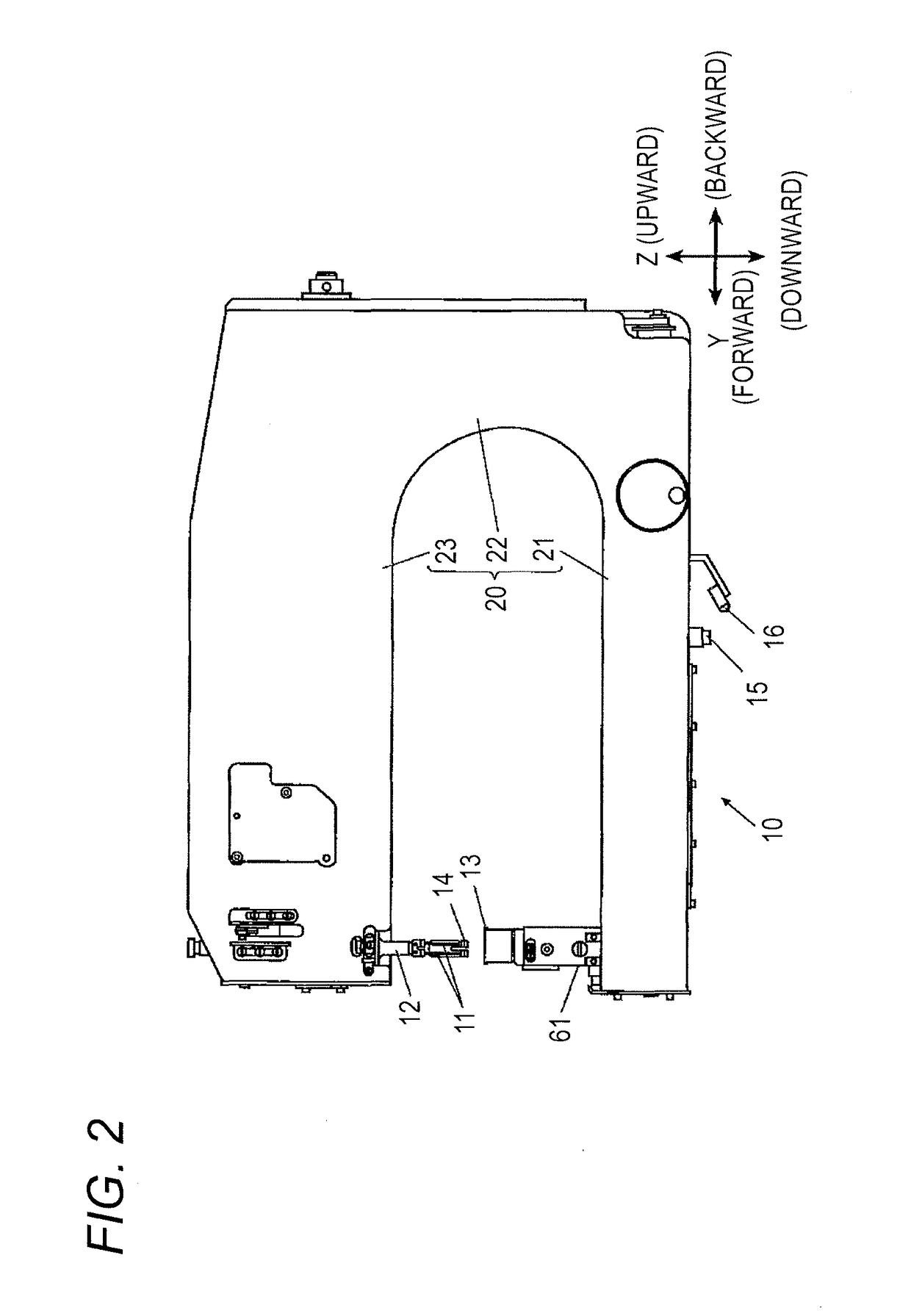

ActiveUS20180080155A1Improve qualityAccurately positionProgramme-controlled sewing machinesSewing-machine control devicesImage captureEngineering

A sewing system comprises a sewing machine, a camera that captures an image of a reference position for sewing, a robot arm that holds the sewing machine and the camera, and a controller. The controller controls operations of forming a first stitch position that results from stitching of the sewing machine, and forming a second stitch position that results from stitching of the sewing machine after rotating the sewing machine at a prescribed angle about a rotation axis that passes through a needle center position stored by the controller. The controller further performs calibration processing that calibrates the needle center position stored by the controller, based on each position of the first stitch position and the second stitch position within image capture ranges of capture images that are obtained by capturing images of the first stitch position and the second stitch position using the camera.

Owner:JUKI CORP

Control device and control method of sewing machine

The present invention provides a control device and a control method of a sewing machine. The control device of the sewing machine easily sets the height data of the sewed object into the sewing pattern data. The control device of the invention comprises the following components: a motor of sewing machine, which causes a sewing needle to move vertically; an intermediate presser foot which prevents the floating of the sewed object in sewing; an intermediate presser foot vertical-moving mechanism which vertically moves the intermediate presser foot synchronously with the sewing needle; a heightadjusting mechanism which adjusts the height of a lower dead point of the intermediate presser foot through the intermediate presser foot motor; an intermediate presser foot control unit which controls the intermediate presser foot motor for stopping the intermediate presser foot through the pressing when the intermediate presser foot descends and contacts; a thickness obtaining unit which computes the thickness of the sewed object according to the height of the intermediate presser foot in the state variation of an output shaft of the intermediate presser foot motor, which is caused by the descending and contacting of the intermediate presser foot; and a thickness recording unit which records the thickness of the sewed object into the sewing pattern data corresponding with the sequence of the needle number.

Owner:JUKI CORP

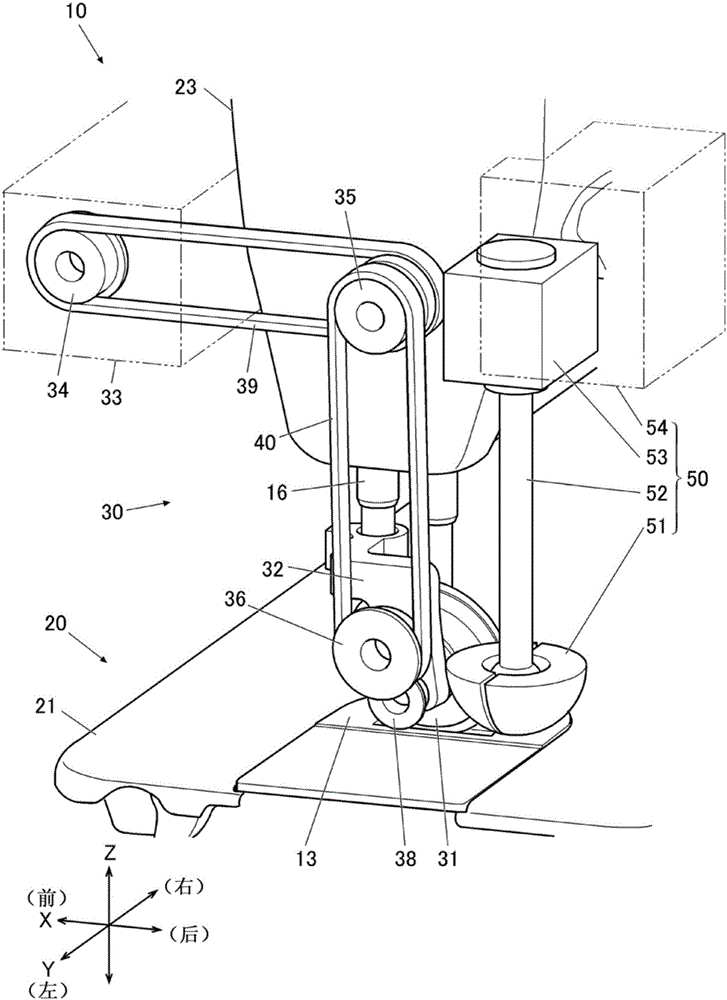

Sewing machine

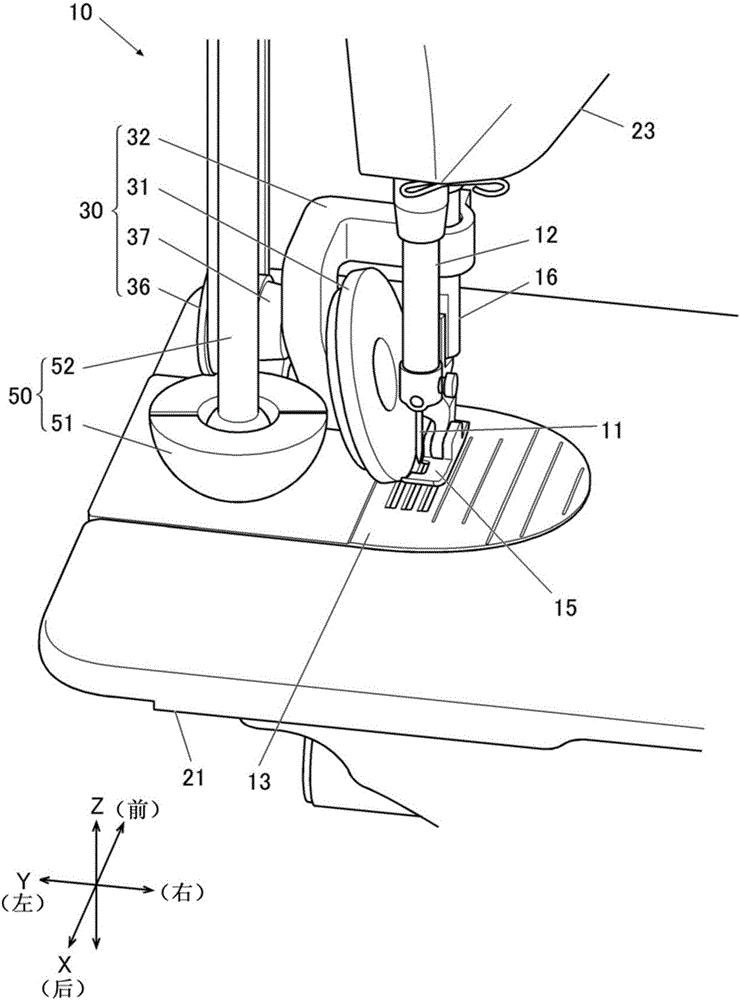

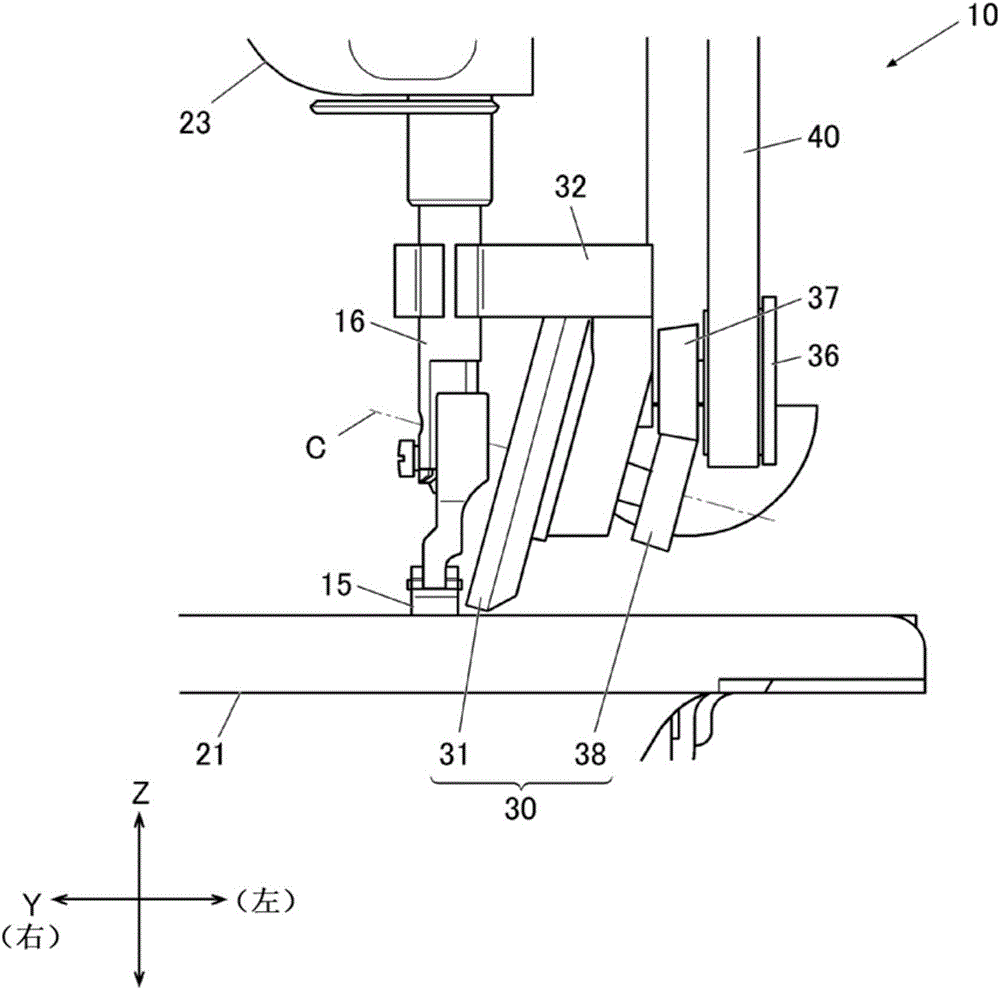

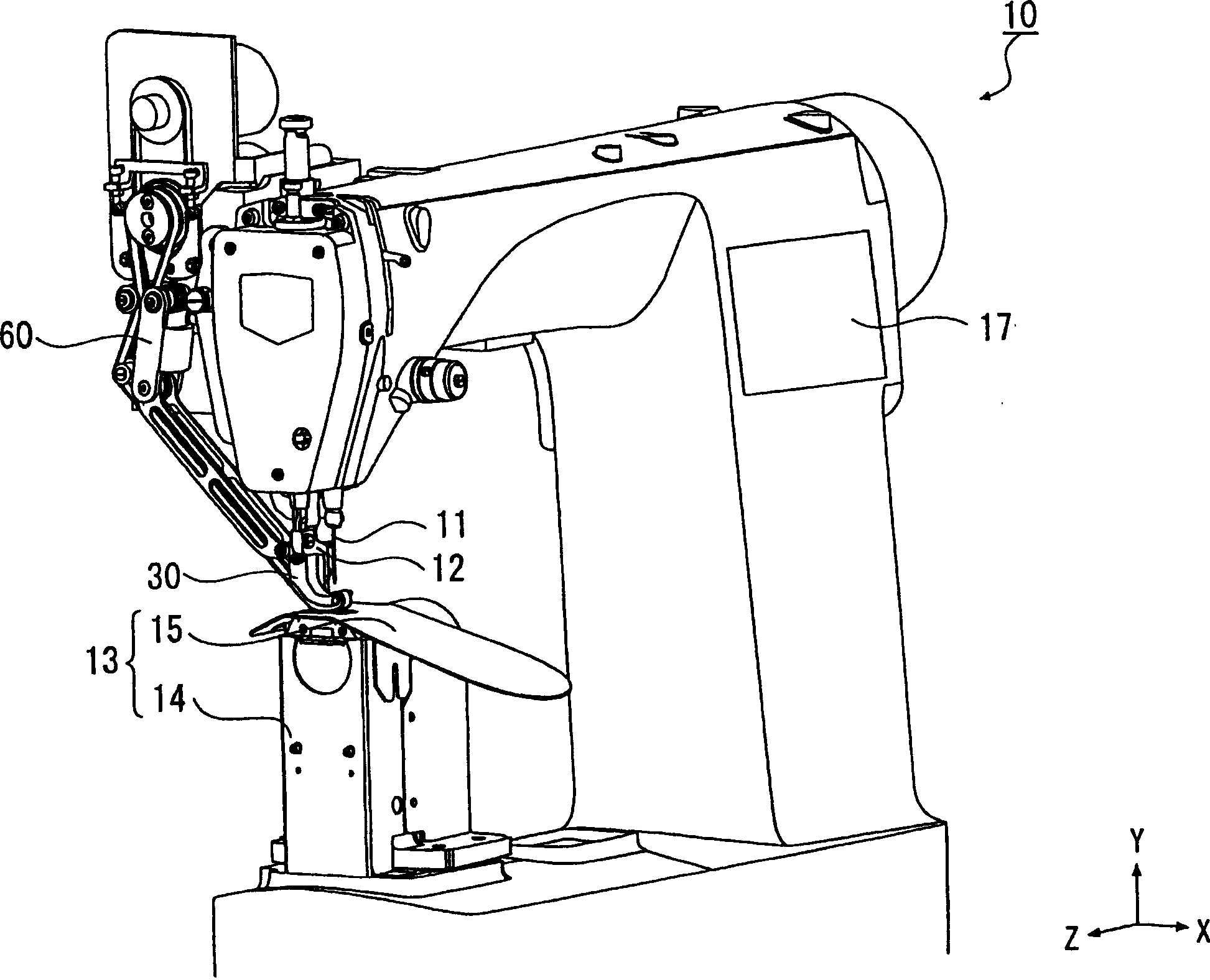

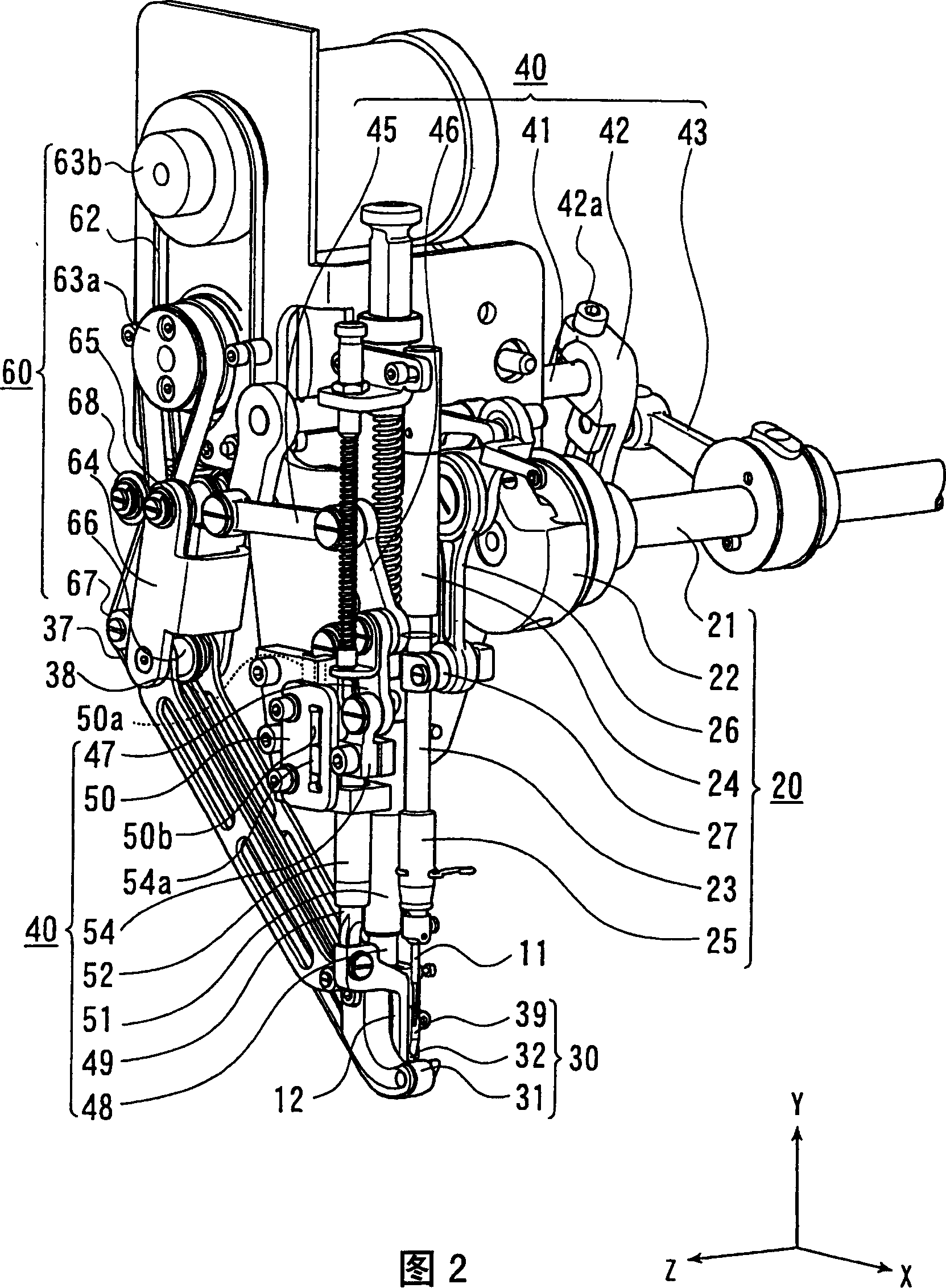

ActiveCN106400326ASteady direction of travelAchieve sewing qualityWork-feeding meansSewing-machine control devicesEngineeringSewing machine

The invention provides a sewing machine which can well perform sewing along a curved line. The sewing machine comprises a first feeding mechanism (30), a second feeding mechanism (50), a control device (90) and a side end detection part (17). The first feeding mechanism is arranged to be adjacent to a sewing position, and feeds to-be-sewn object through a roller which is configured to be in an oblique state. The second feeding mechanism is configured to be on the upstream side in the feeding direction relative to the first feeding mechanism, comprises a feeding body (51) which is in contact with the to-be-sewn object in a position deviating from a rotation center, and feeds the to-be-sewn object along an arc around the rotation center. The control device controls a driving source (33) of the first feeding mechanism and a driving source (53) of the second feeding mechanism. The side end detection part is in the direction intersecting the feeding direction of the to-be-sewn object in the sewing position, and detects the position of the side end part of the to-be-sewn object. The control device and the position, which is detected by the side end detection part, of the side end part of the to-be-sewn object correspondingly control the rotation speed of the driving source of the second feeding mechanism.

Owner:JUKI CORP

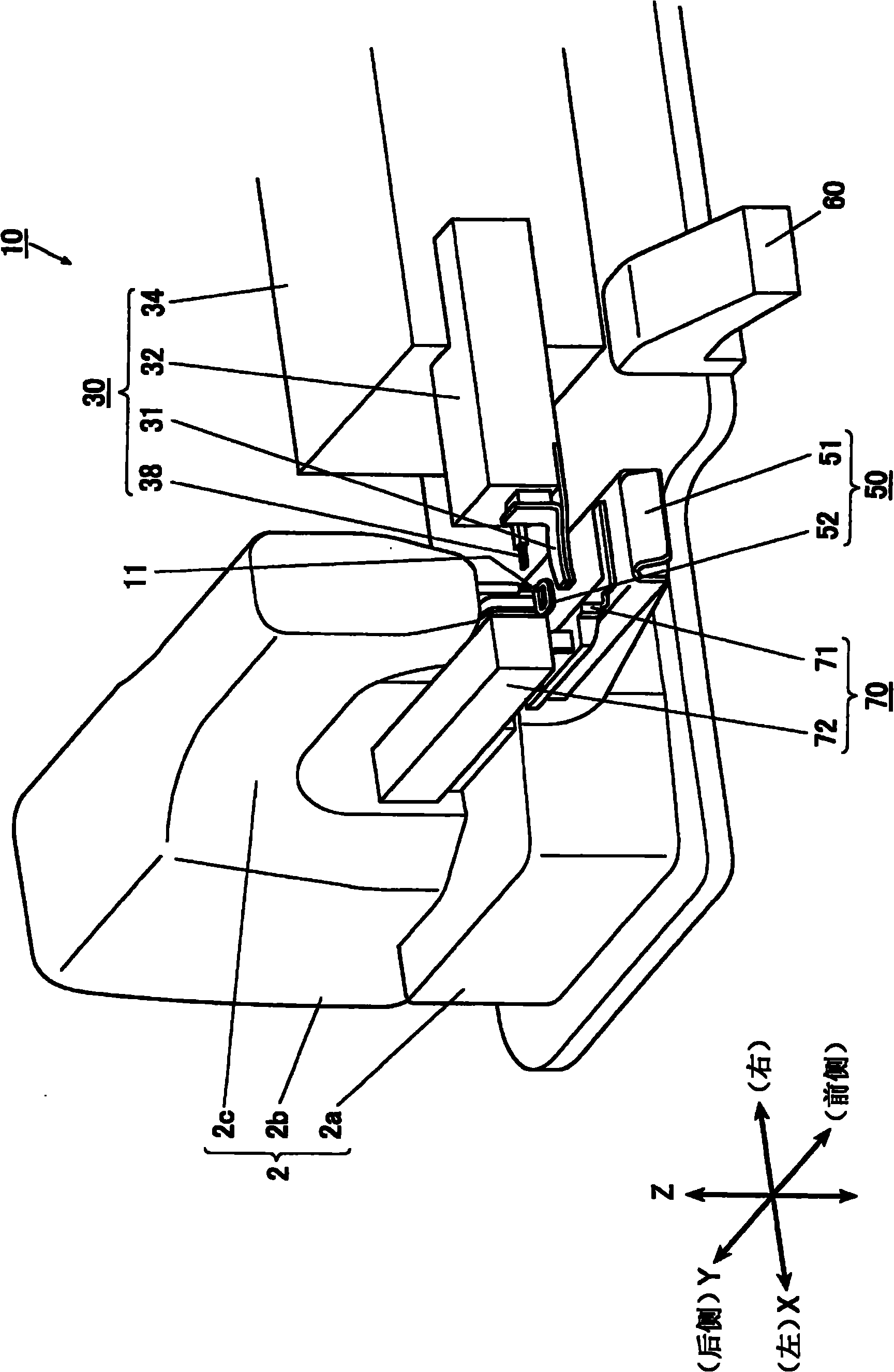

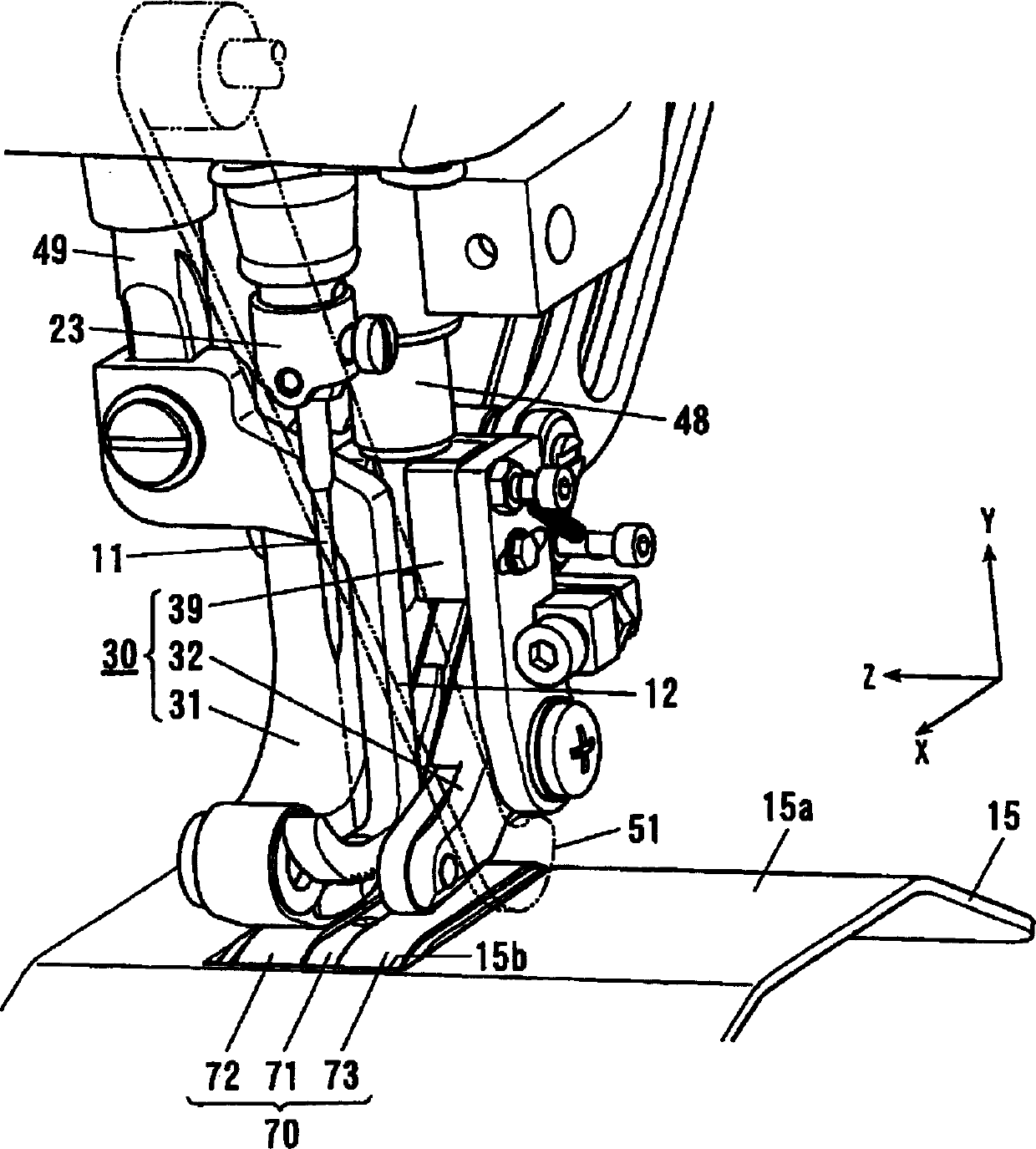

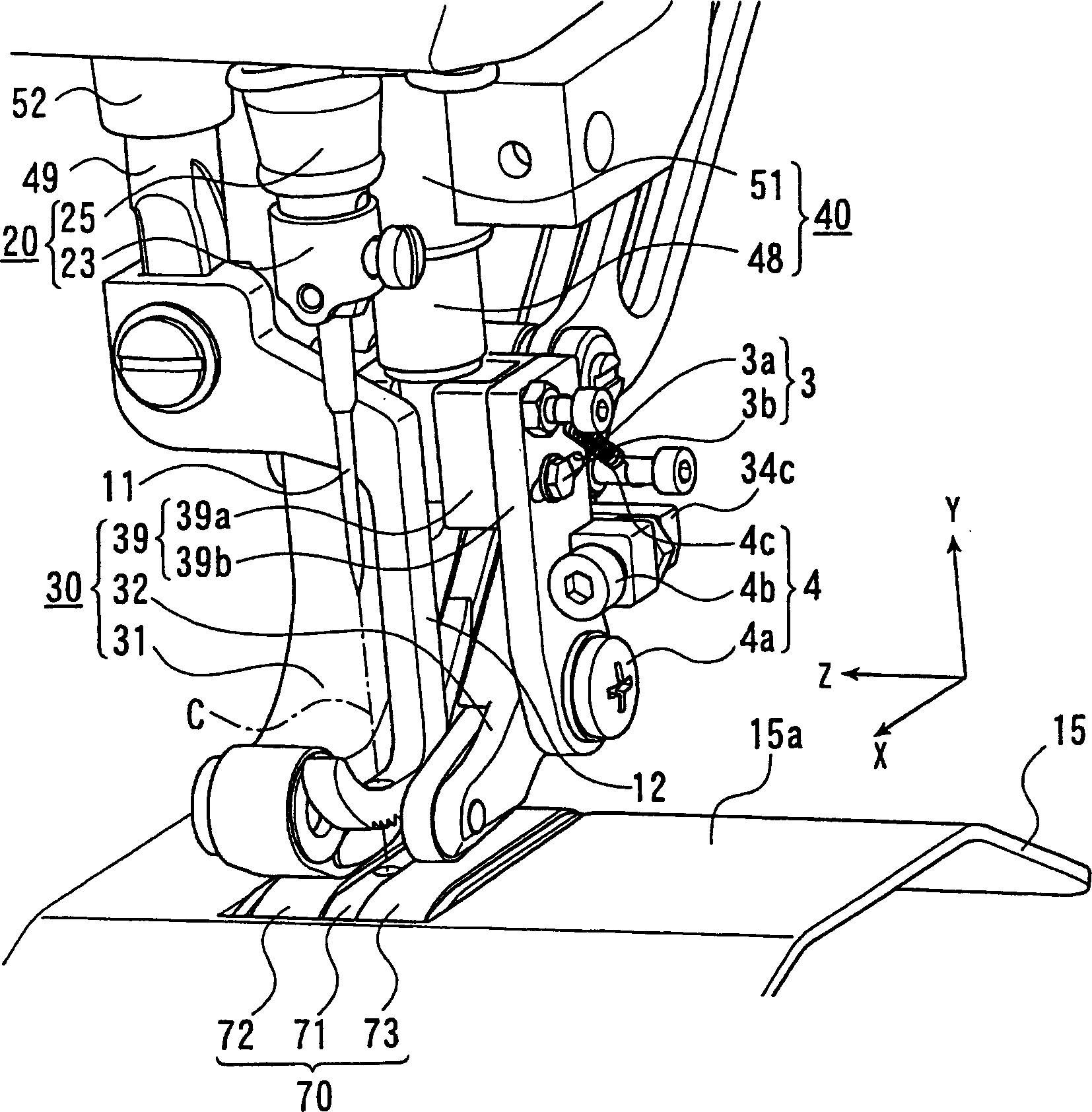

Differential cloth-feed sewing machine

ActiveCN1550604AHigh precision trackingImprove sewing qualityProgramme-controlled sewing machinesWork-feeding meansEngineeringSewing needle

The invention provides a differential feeding sewing machine, the operability of which is improved during sewing. An upper feeder has a first upper feeding section 31 feeding an upper fabric in the vicinity of a sewing needle 11, a second upper feeding section 32 adjoining the first upper feeding section 31 along the direction of intersecting the feeding direction and feeding the upper fabric and a driving means capable of controlling individually the amount of feed. A lower feeder has a lower feeding section 70 feeding a lower fabric and a driving means therefor and has an action control means 80 controlling the action of each driving means on the basis of a setting input to determine the amount of feed of the first upper feeding section and the second upper feeding section and the lower feeding section, respectively for each of a plurality of sewing sections changed during sewing.

Owner:JUKI CORP

Automatic folding and sewing equipment of labels

PendingCN107401001ARealize fully automatic foldingImprove folding efficiencyWork-feeding meansEngineeringIndustrial sewing machine

The invention provides automatic folding and sewing equipment of labels. The automatic folding and sewing equipment of labels comprises an industrial sewing machine, a folding mechanism and a material supporting mechanism, wherein the folding mechanism is arranged on a machine head of the industrial sewing machine; the material supporting mechanism is arranged at the lower part of the industrial sewing machine; the labels are folded by the folding mechanism after being sent below the folding mechanism by the material supporting mechanism, then the folded labels are sewn onto a piece of fabric by the industrial sewing machine; the material supporting mechanism consists of a label supporting plate and a supporting plate driving device; the supporting plate driving device pushes the label supporting plate to a sewing position and retracts the label supporting plate after completion of folding; the folding mechanism consists of a material folding clamping jaw and a clamping jaw driving device; the clamping jaw driving device drives the material folding clamping jaw to move up and down; material folding clamping devices are arranged at both ends of the bottom of the material folding clamping jaw; the material folding clamping devices are driven to retract inward when the material folding clamping jaw is lowered onto the label supporting plate, so that both ends of each label placed on the label supporting plate are folded inward. Through the adoption of the automatic folding and sewing equipment of labels disclosed by the invention, automatic folding of the labels can be achieved, and the sewing efficiency and the sewing quality of the labels are improved.

Owner:JACK SEWING MASCH CO LTD

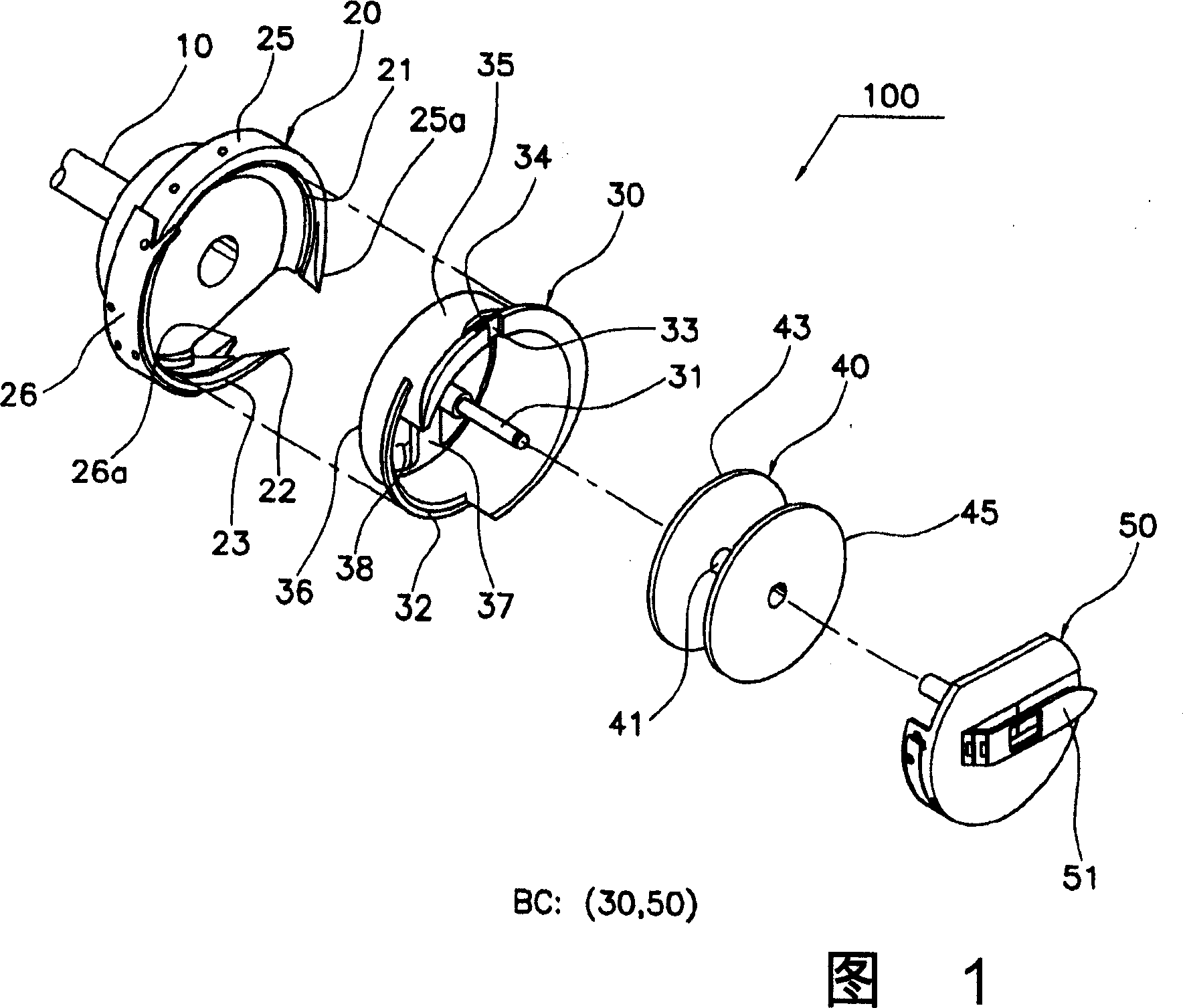

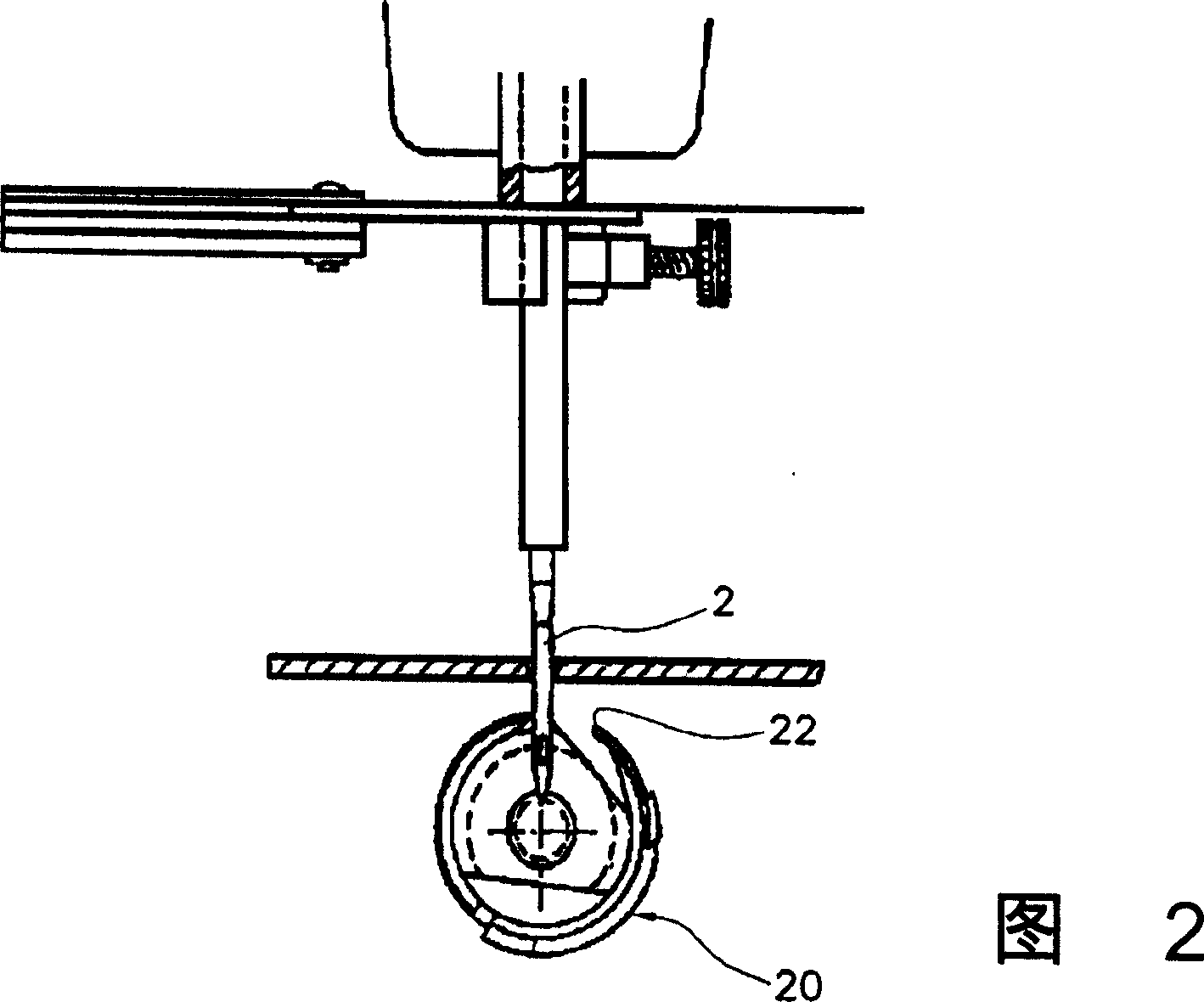

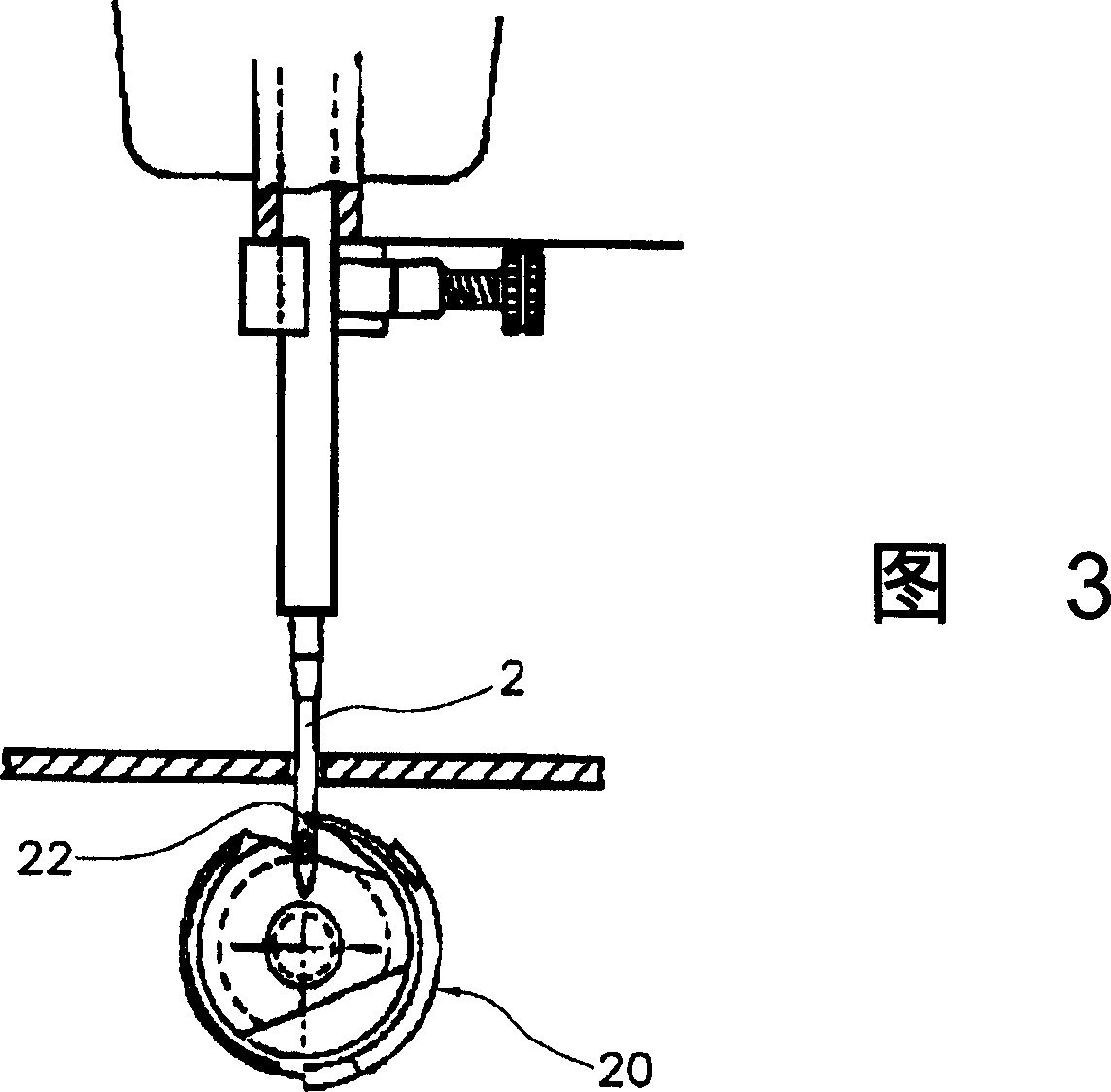

Rotary shuttle device for sewing machine

The present invention relates to a rotary shuttle device for a sewing machine, in which an inclined portion is formed at a first flange of a bobbin so as to allow a significant increase in a winding amount of lower thread and prevent a thread breakage and a thread tangle, and also in which a hook body is adapted to have a single model of gib and a replacement of the hook body is not needed regardless of a sewing speed and a thickness of a sewing material so as to obtain a good sewing quality, thereby remarkably reducing a cost of a component and workforce and labor for replacing the component. The rotary shuttle device for a sewing machine, comprising a hook body disposed at a driving shaft; a bobbin case provided with a bobbin case base having a stud rod and accommodated in the hook body and a bobbin case body for holding a bobbin at an outside; and a bobbin formed with a winding shaft which is disposed in the bobbin case and on which lower thread is wound, a first flange formed at one of the winding shaft so as to be contacted with a bottom surface of the bobbin case base and a second flange formed at the other end of the winding shaft, is characterized in that the bobbin has an inclined portion in which a part of the first flange is inclined toward a winding portion.

Owner:KOBEST

Sewing method of double-embedded-wire pocket

ActiveCN104585947AReduce process difficultyImprove sewing qualityGarmentsClothes making applicancesFlangingEngineering

The invention provides a sewing method of a double-embedded-wire pocket. A pocket center line is drawn in the front side pocket position part of a clothes piece and is used as a positioning line; the rough edge on the top of wire-embedded cloth is downwards flanged for a first distance, the flanged part is subjected to buckling ironing for forming a first flanging line, then, the edge is downwards flanged for a second distance being the twice length of the first distance, and the part which is flanged again is subjected to buckling ironing for forming a second edge flanging line; in the second step, the rough edge, downwards flanged for the first distance, of the wire-embedded cloth is aligned with the center line of the pocket, a press foot with the same width as the first distance is adopted for sewing a first embedded wire in the middle position of the flanged edge with the same width as the first distance, and during the sewing, the lower edge of the press foot is aligned with the positioning line; the press foot is adopted for sewing a second embedded wire in the middle position between the rough edge of the wire-embedded cloth and the second edge flanging line, during the sewing, the press foot is just pressed on a fabric with the same width as the first distance between the rough edge and the second edge flanging line, and the two sides of the press foot are respectively aligned with the rough edge and the second edge flanging line.

Owner:JIANGXI INST OF FASHION TECH

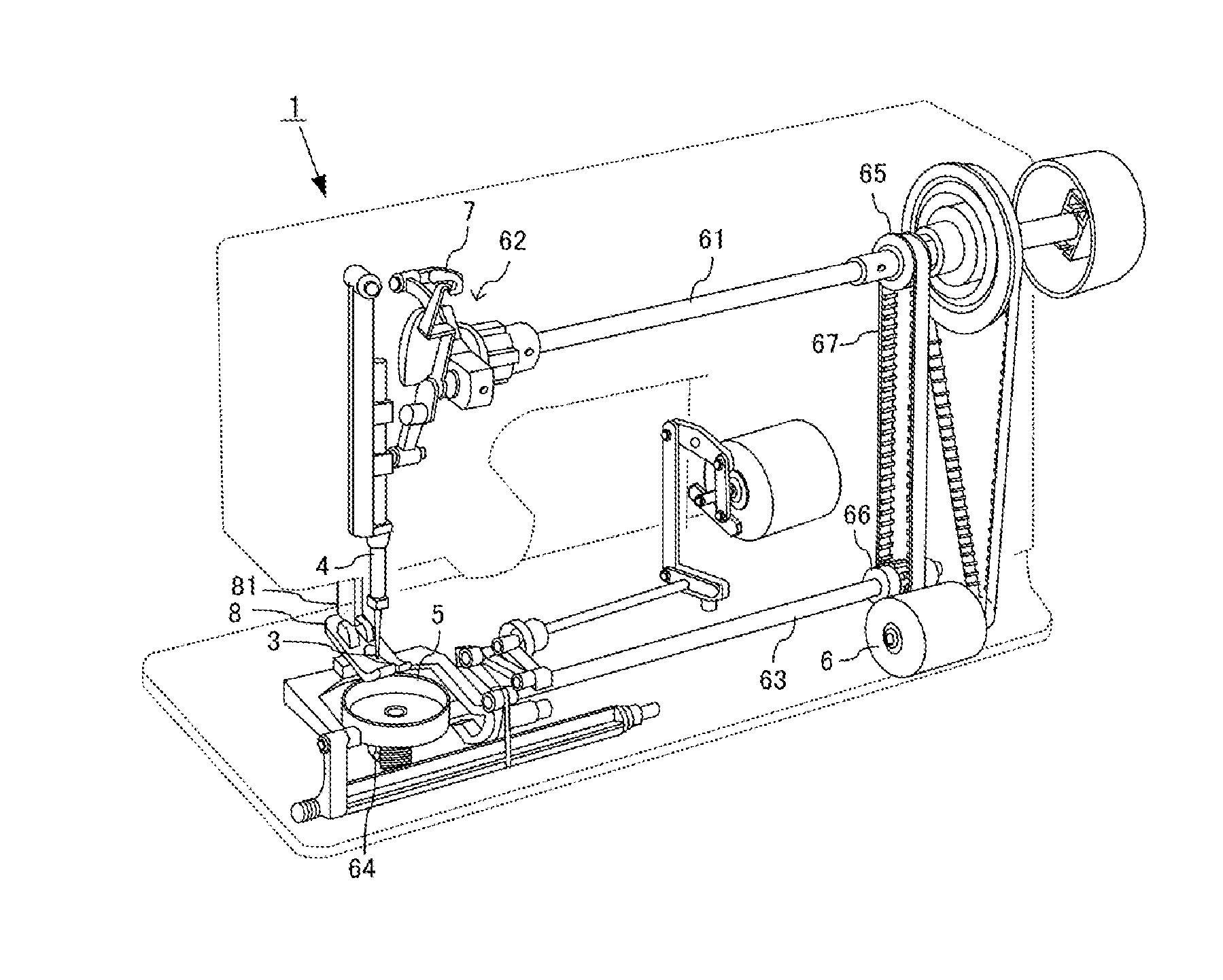

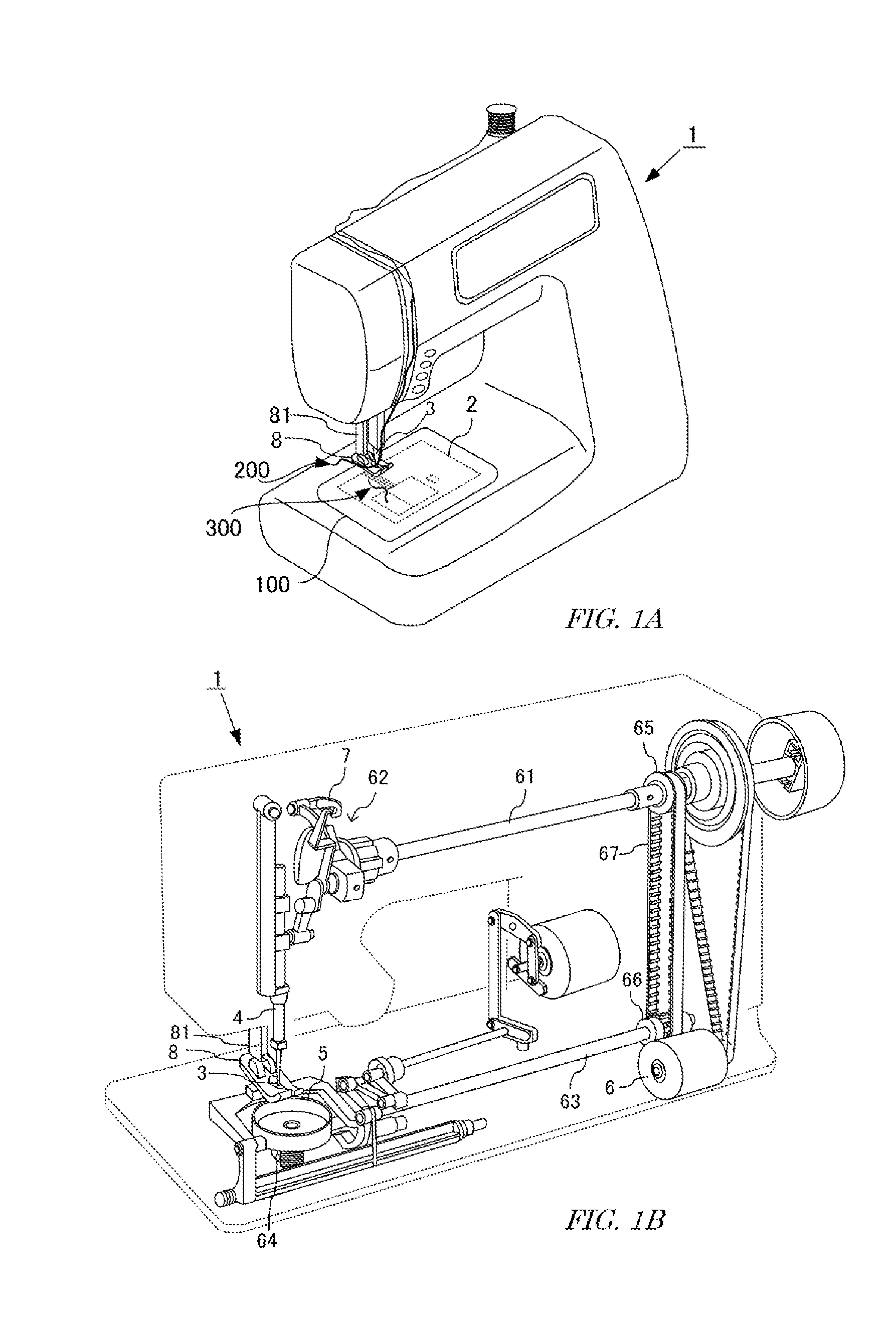

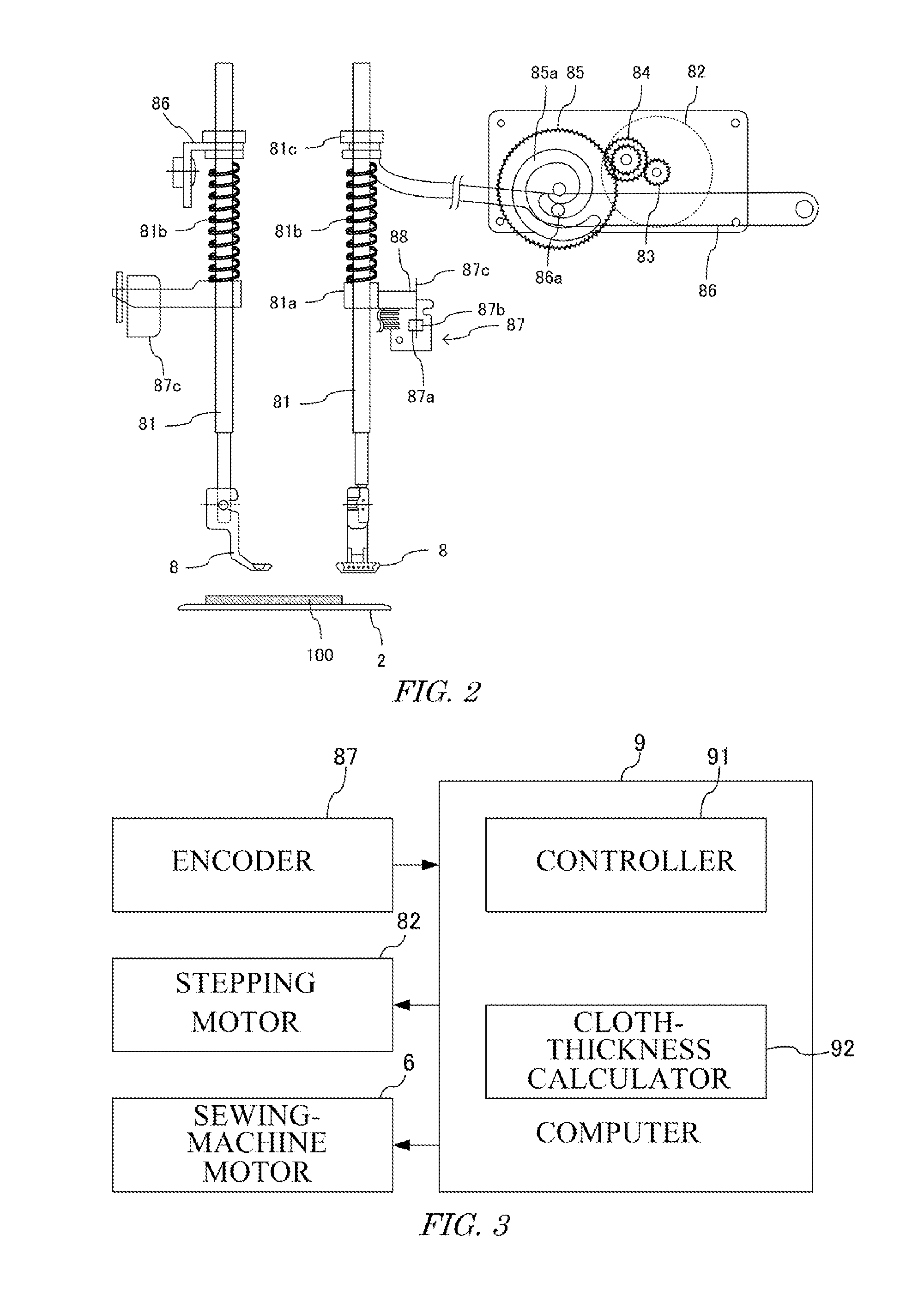

Sewing Machine

ActiveUS20160273144A1Improve qualityImprove sewing qualityProgramme-controlled sewing machinesSewing-machine casingsEngineeringCalculator

A sewing machine moves a presser foot up and down through a presser-bar lifting lever to depress a cloth. The lever is moved down by a stepping motor at a constant move-down amount. A compression spring is present between the stepping motor and the presser foot. The compression spring is compressed by some of the constant move-down amount of the lever, and applies, to the presser foot, pushing force canceling repulsive force from the depressed cloth. The move-down amount of the presser foot is detected by an encoder, and a thickness of the cloth is calculated by a cloth-thickness calculator. The cloth-thickness calculator performs calculation based on the move-down amounts at two timings in a time period at which the presser foot depresses the cloth and attempts to further move down.

Owner:JANOME CORP

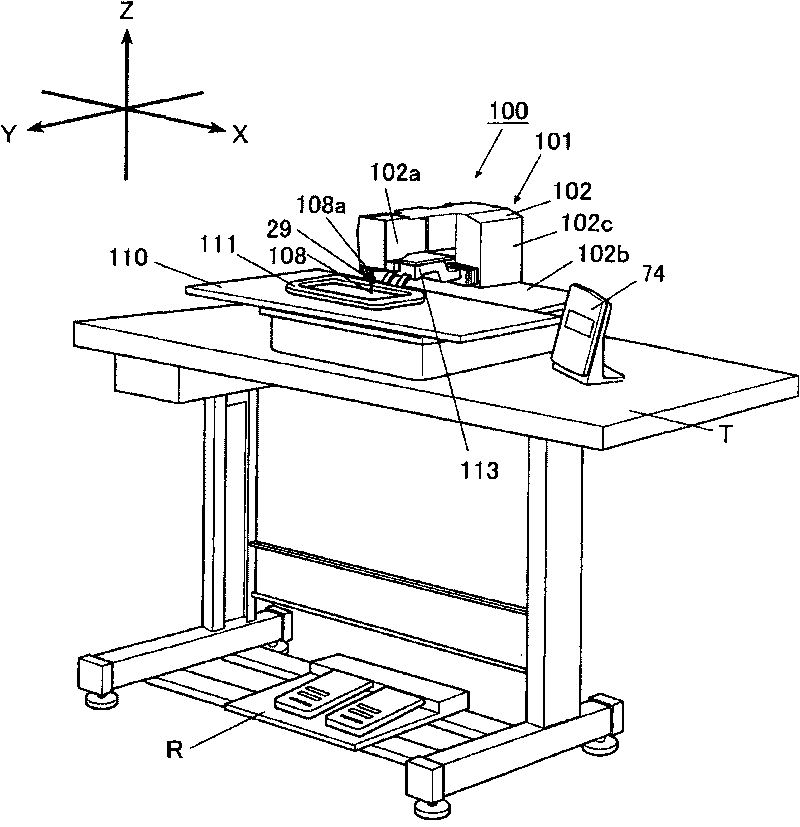

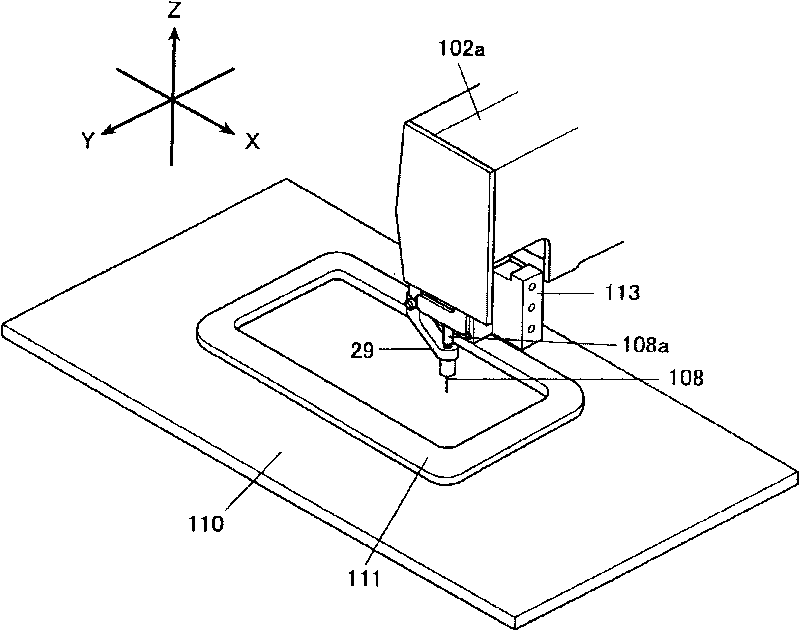

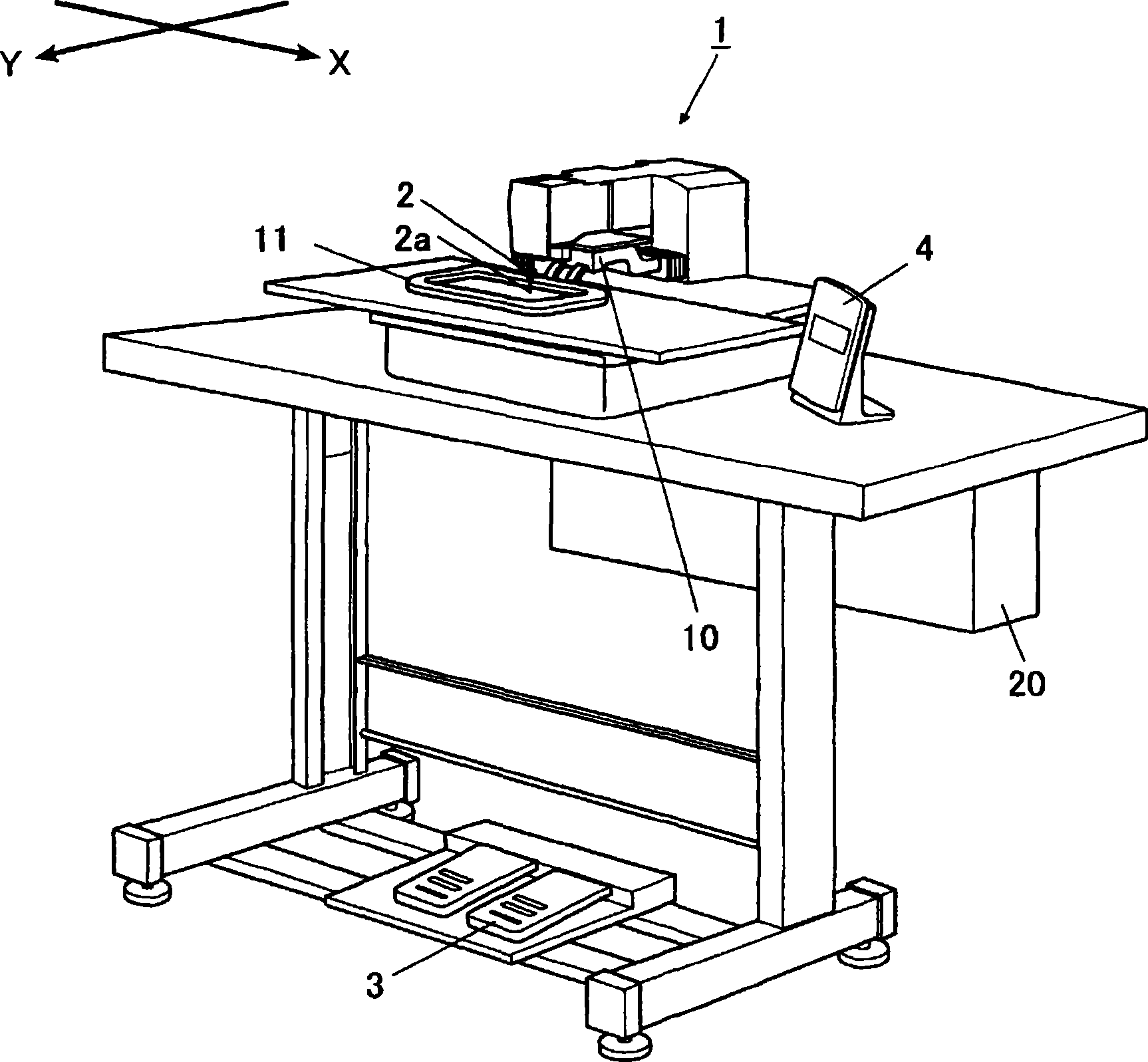

Automatic sewing machine

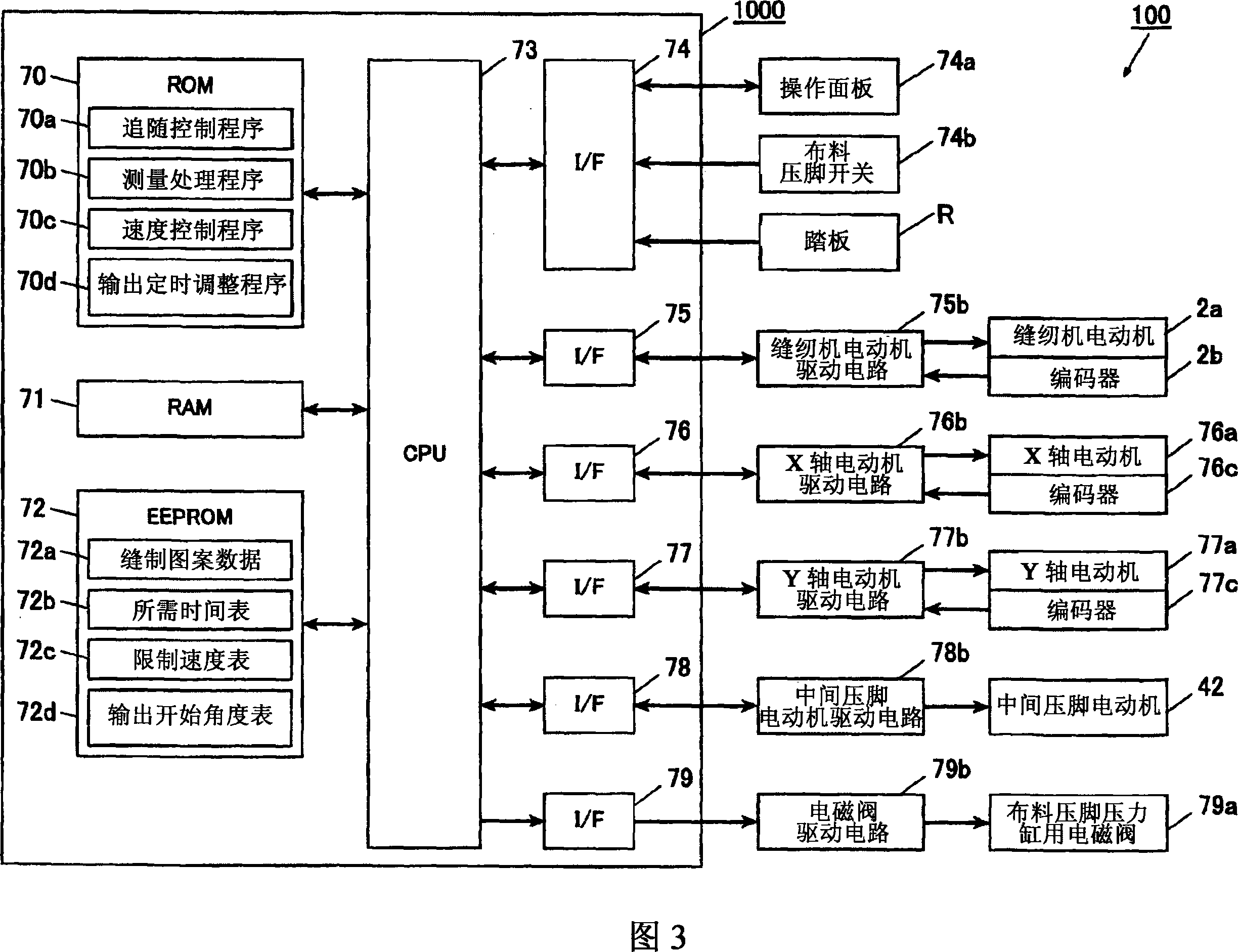

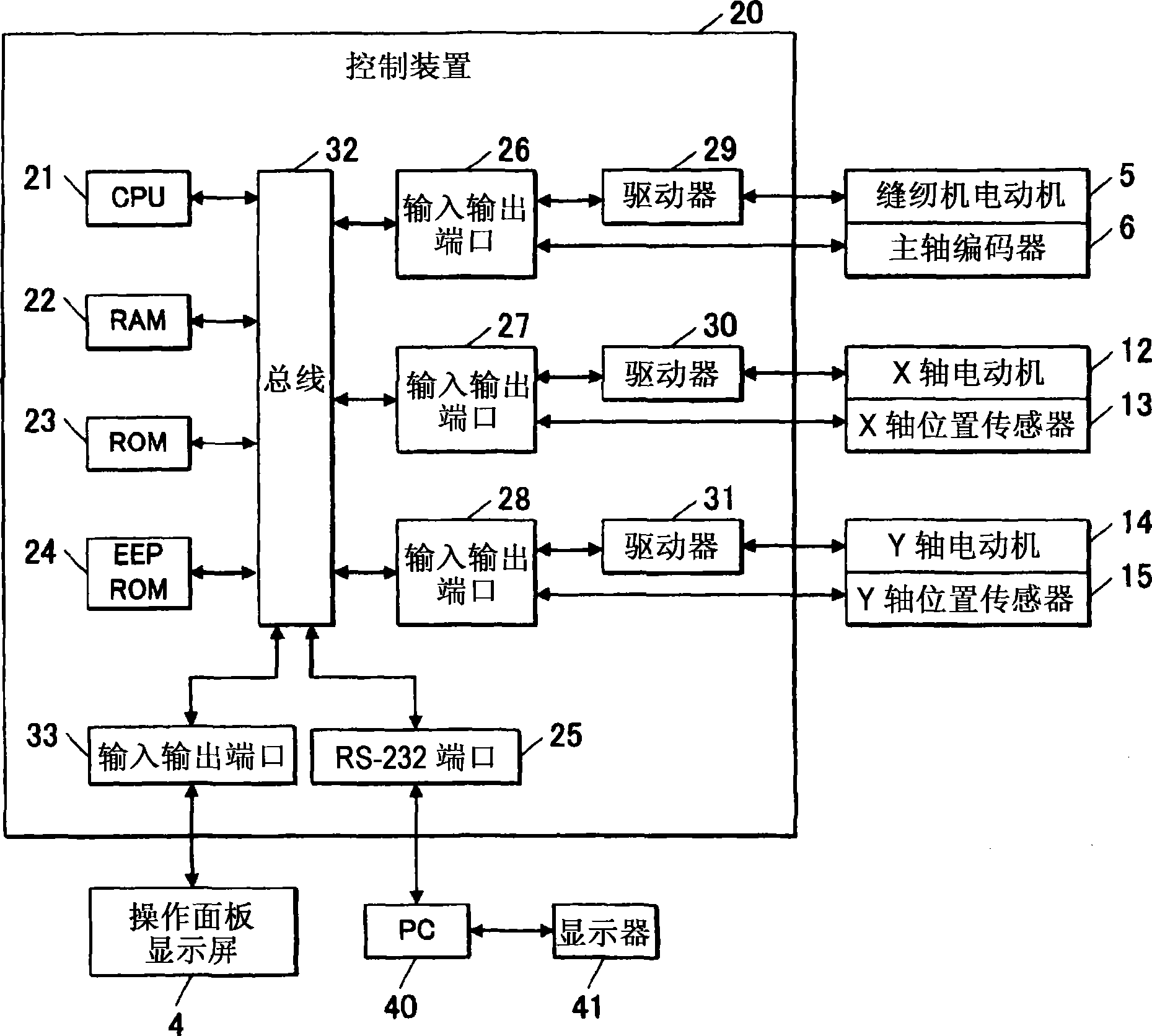

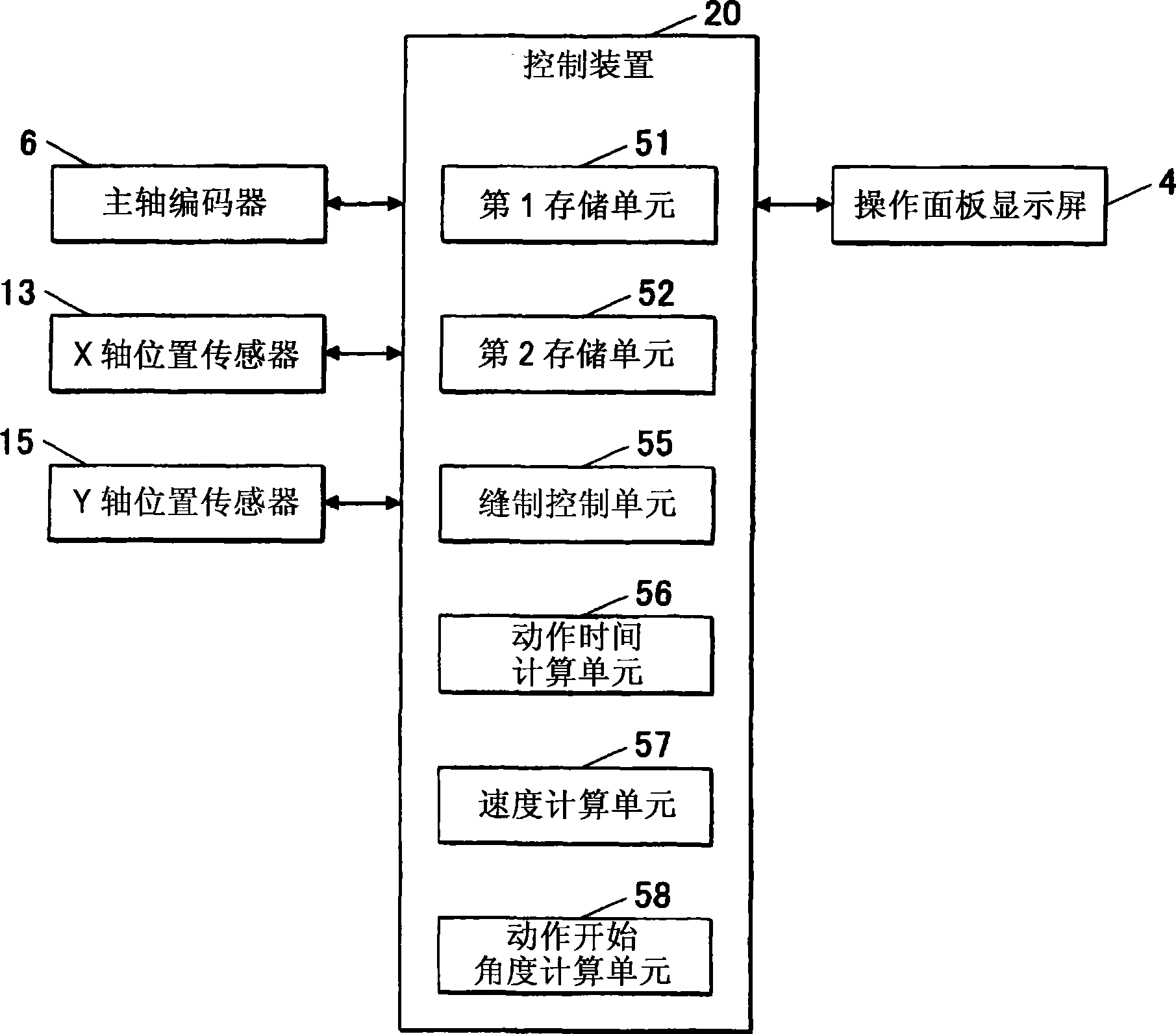

InactiveCN101429708AAvoid pulling pinsSolve the problem of deterioration of sewing qualityProgramme-controlled sewing machinesSewing-machine control devicesRotation velocityEngineering

The invention provides a sewing machine capable of automatic tailoring and easily setting a sewing speed suitable for tailoring. The sewing machine comprises a needle bar with needles for vertical motion; a moving mechanism for moving a sewing; a sewing machine motor; an X axis motor and a Y axis motor for driving the moving mechanism; a control device for controlling the sewing machine motor, the X axis motor and the Y axis motor which enable a spindle rotary; a main encoder for detecting a rotary angle of the spindle; an X axis position sensor and a Y axis position sensor for detecting the position of the moving mechanism; an EEPROM for storing sewing data, the spindle rotary angle and the position of the moving mechanism; a CPU for calculating the stable time of the moving mechanism and the sewing machine motor rotary speed and the moving mechanism action starting angle corresponding to the stable time based on the storage content of the EEPROM.

Owner:JUKI CORP

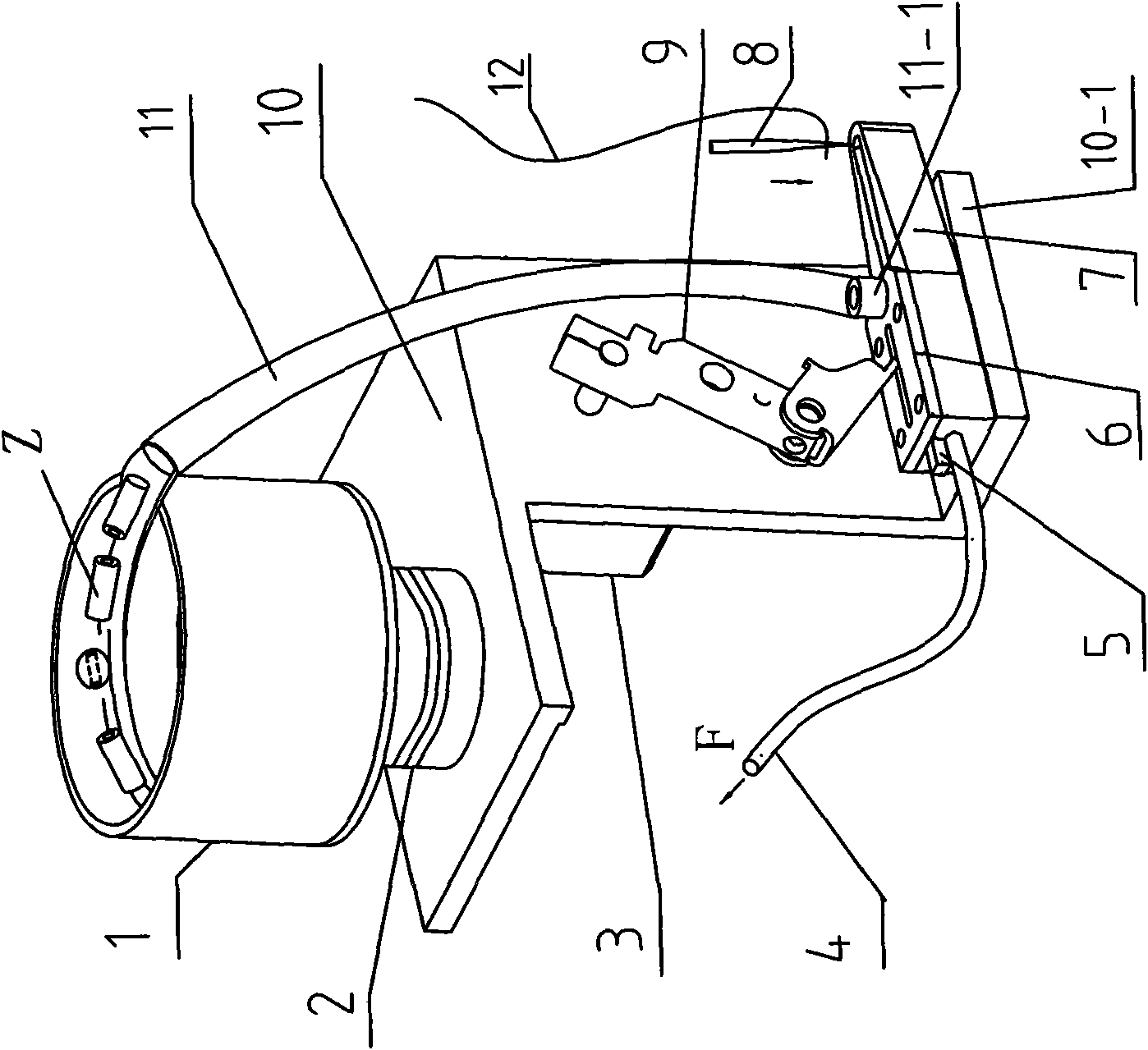

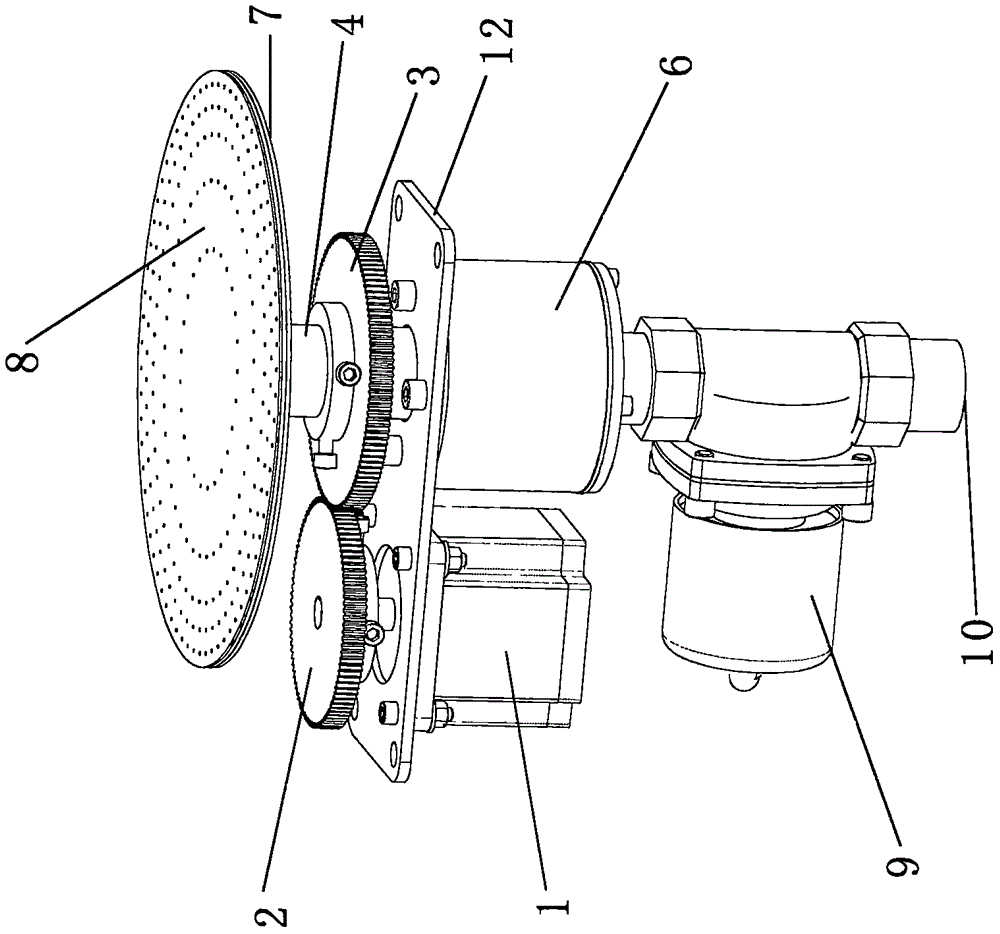

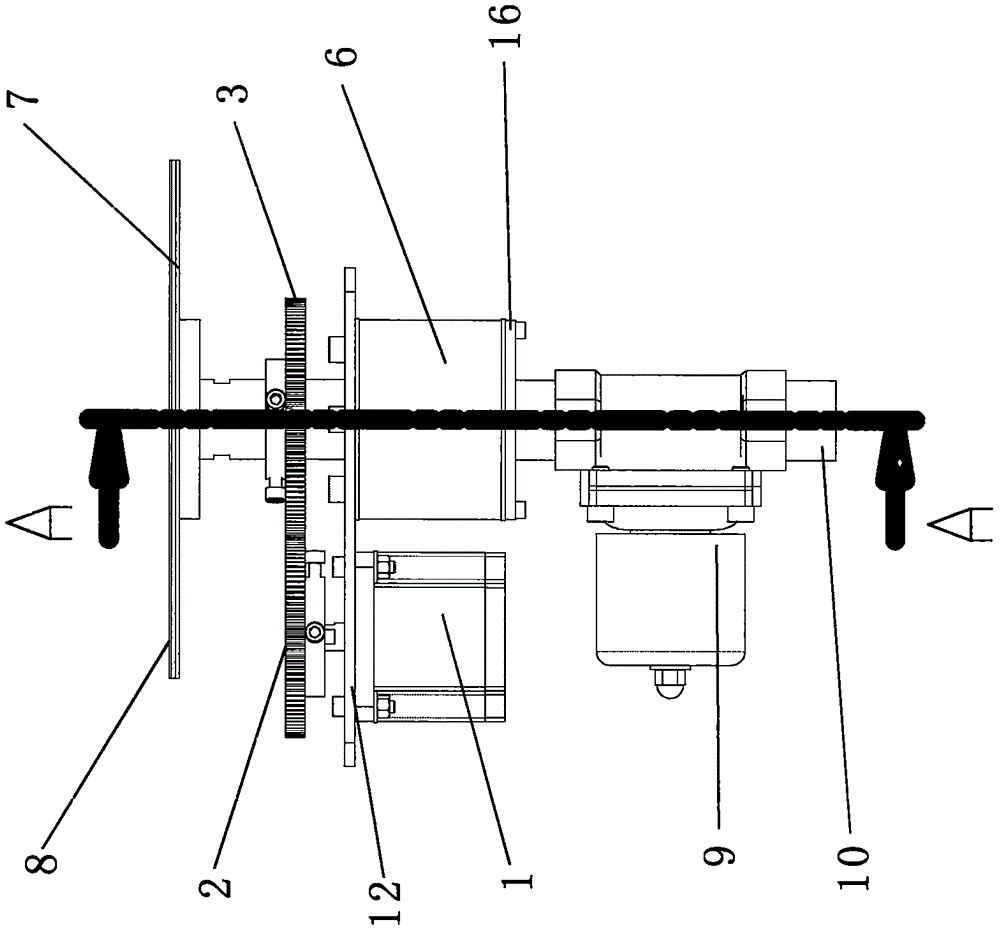

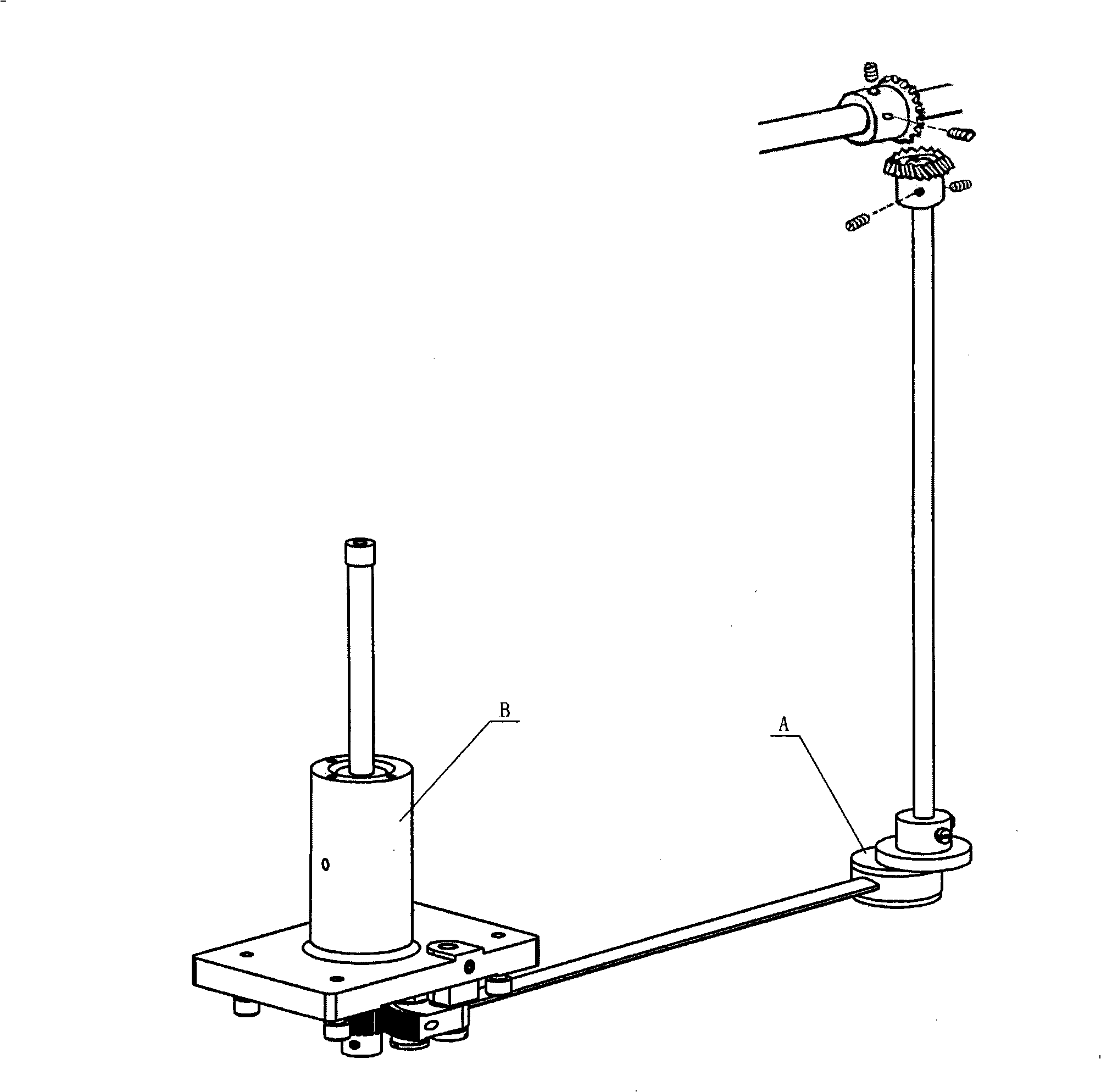

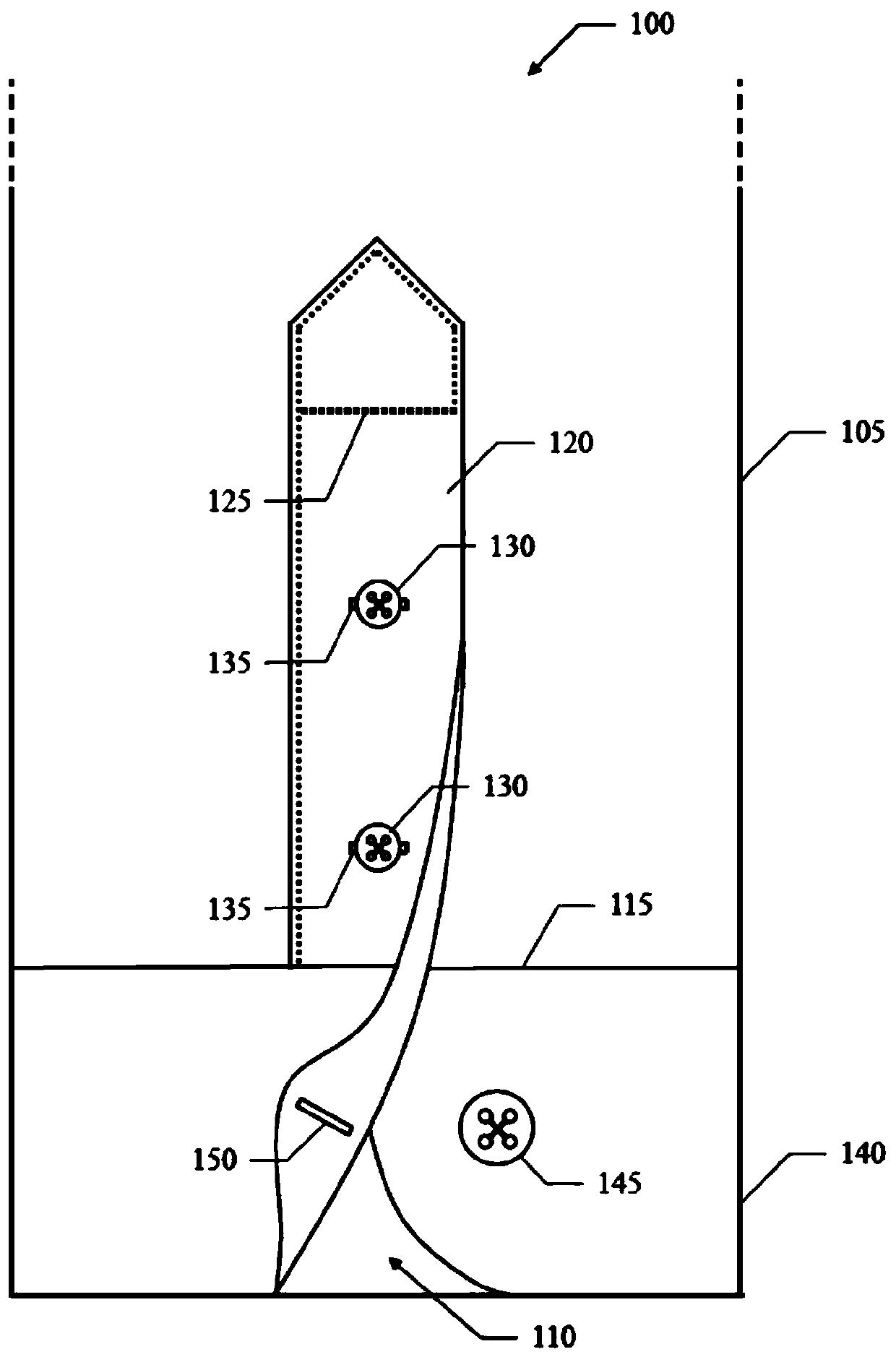

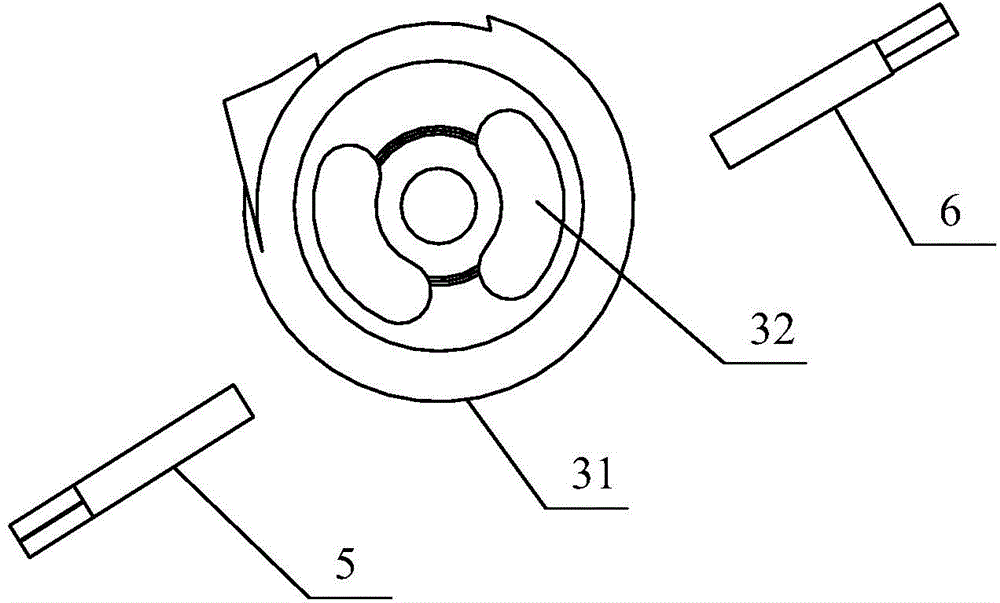

Adsorbing fixed-type synchronous rotating auxiliary device for sewing round cut pieces

ActiveCN105887356AImprove adsorption capacityIncrease the ventilation areaWork-feeding meansControl systemEngineering

The invention discloses an adsorbing fixed-type synchronous rotating auxiliary device for sewing round cut pieces. The auxiliary device comprises a control system, a transmission system and an adsorbing system. The control system is connected with the transmission system, the adsorbing system and a drive system of a sewing machine through a PLC. The transmission system comprises a stepping motor, a gear I, a gear II, a hollow shaft, a bearing, a bearing pedestal, a disc I and a disc II, wherein the gear I and the gear II are connected with the stepping motor, the hollow shaft penetrates through the center of the gear II, the bearing and the bearing pedestal are arranged in the middle of the hollow shaft and are parallel to the stepping motor, and the disc I and the disc II are arranged at the top of the hollow shaft. The round cut pieces manufactured by means of assistance of the auxiliary device are good in sewing quality, efficiency is high, two locating working procedures can be omitted, the total benefits can be increased by ten times or more, product uniformity can be ensured by operation of different personnel, and dependency on the technology of operators is reduced.

Owner:刘玉银

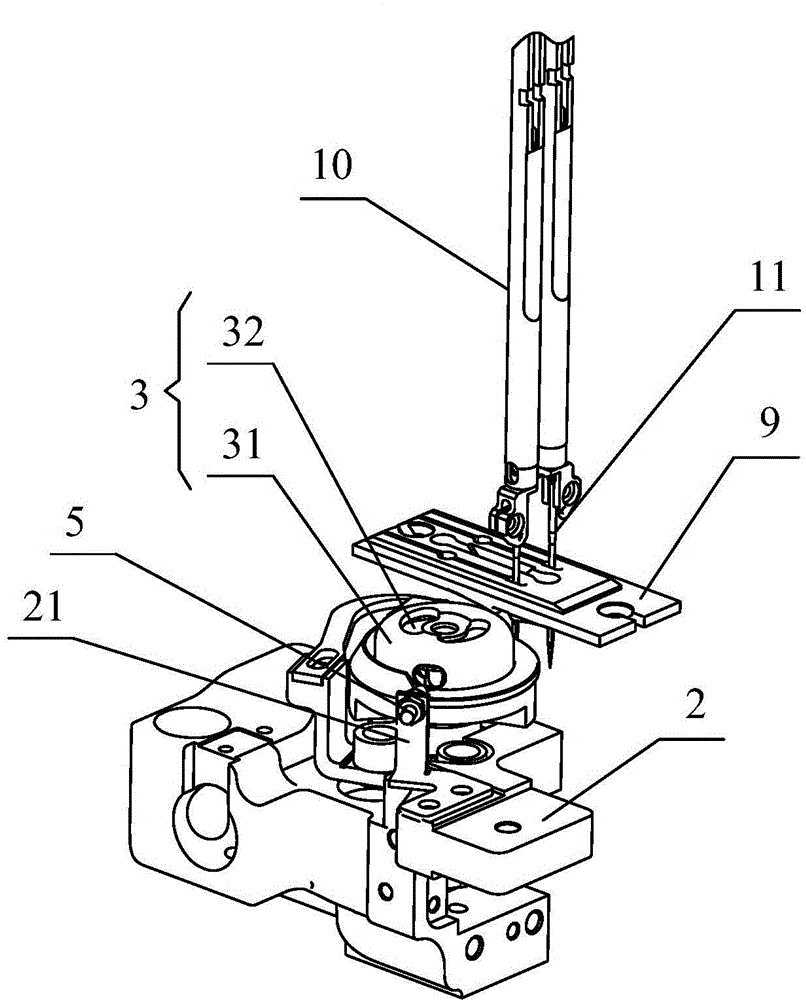

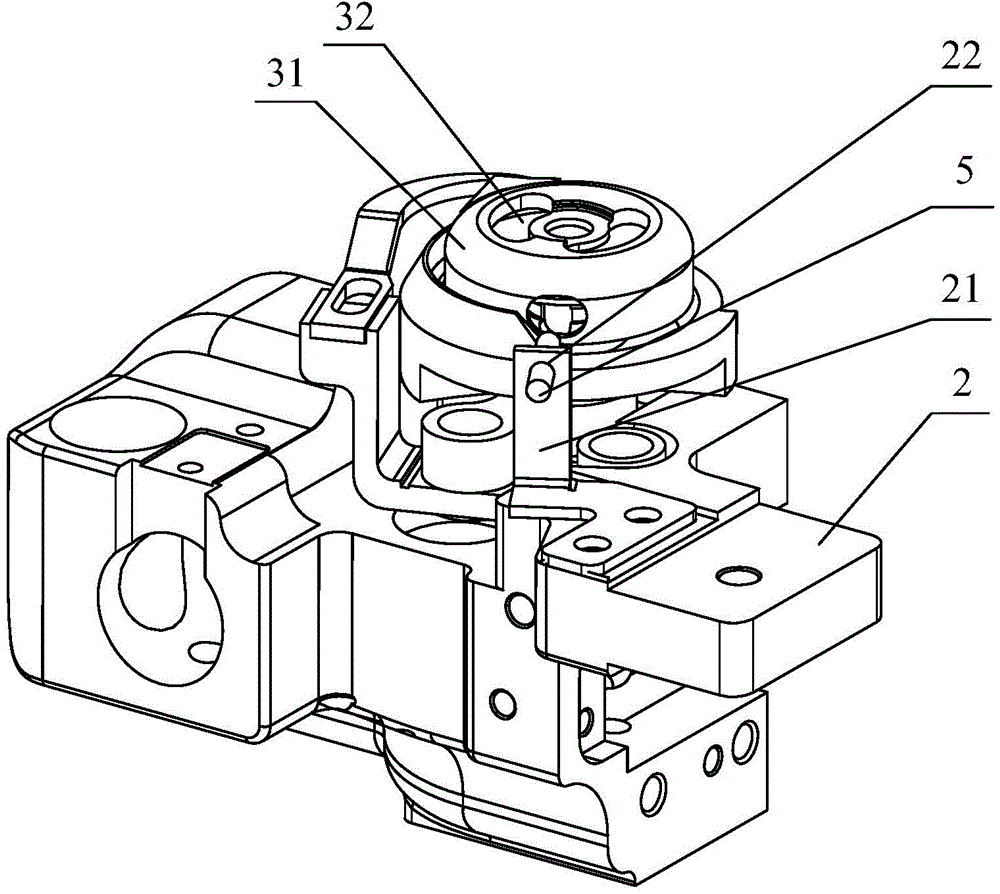

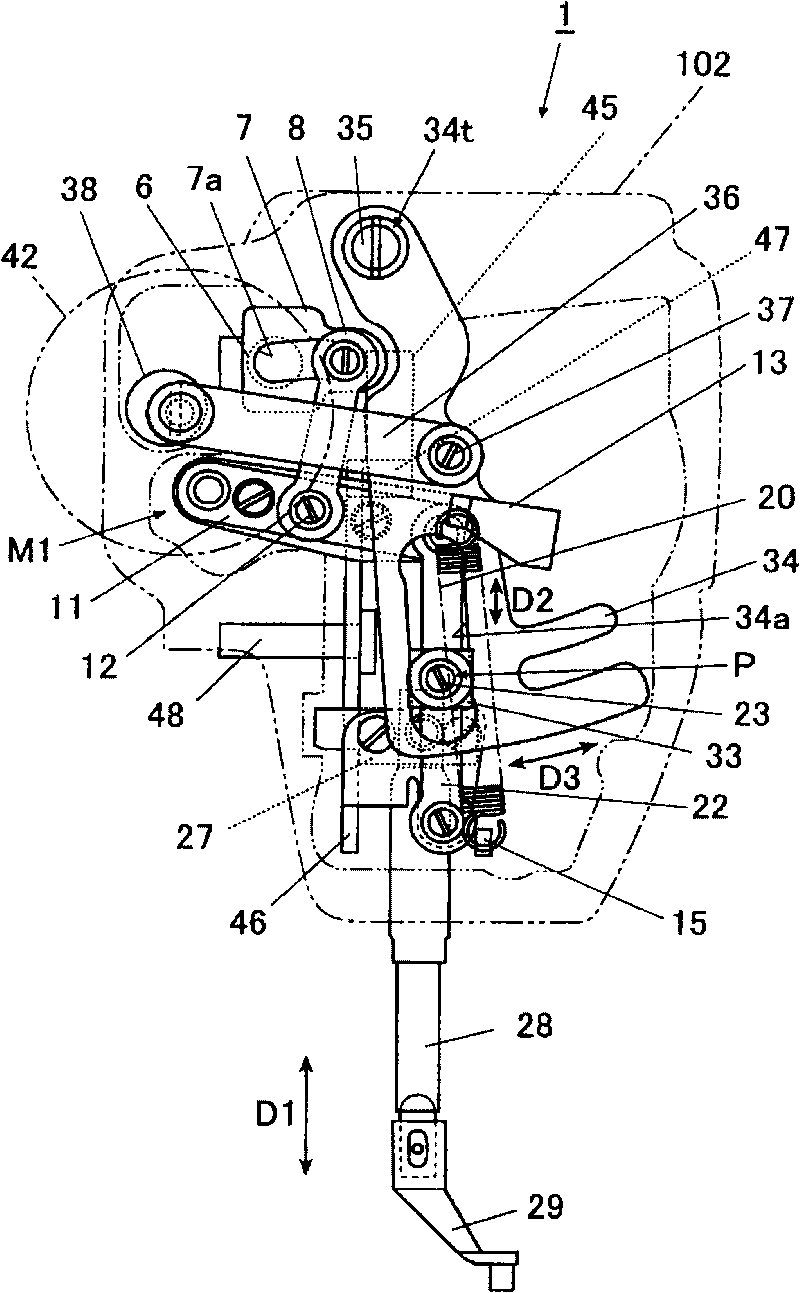

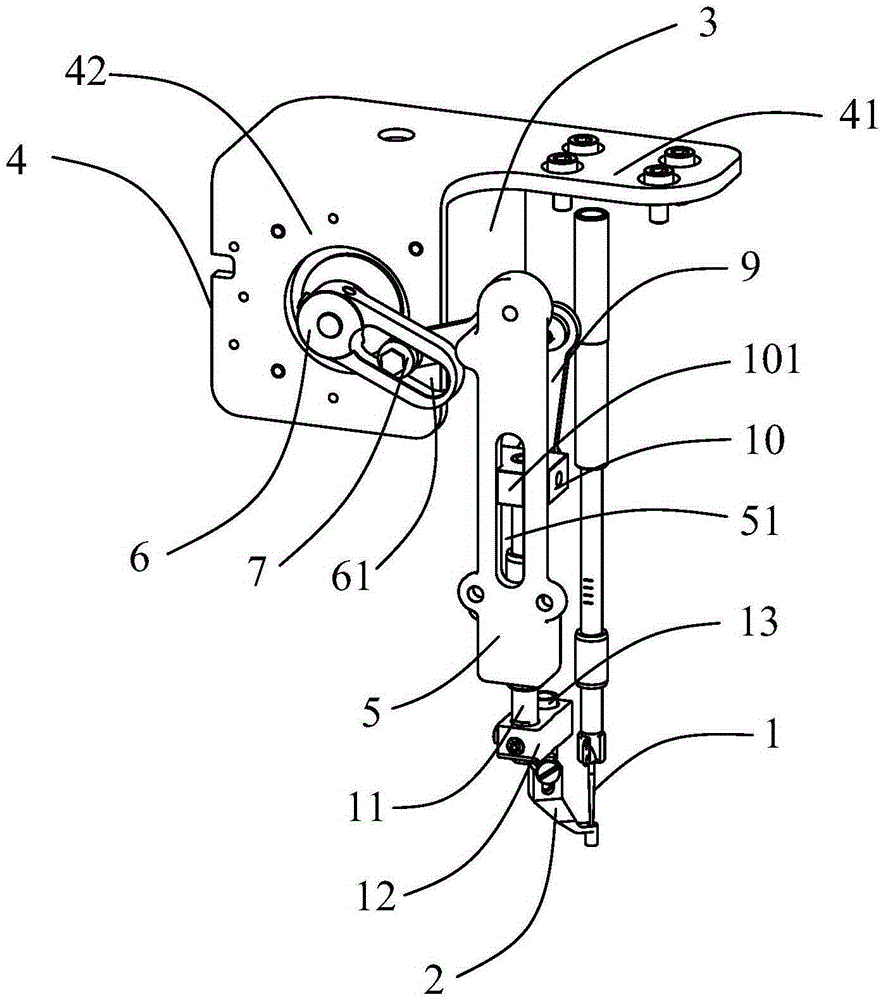

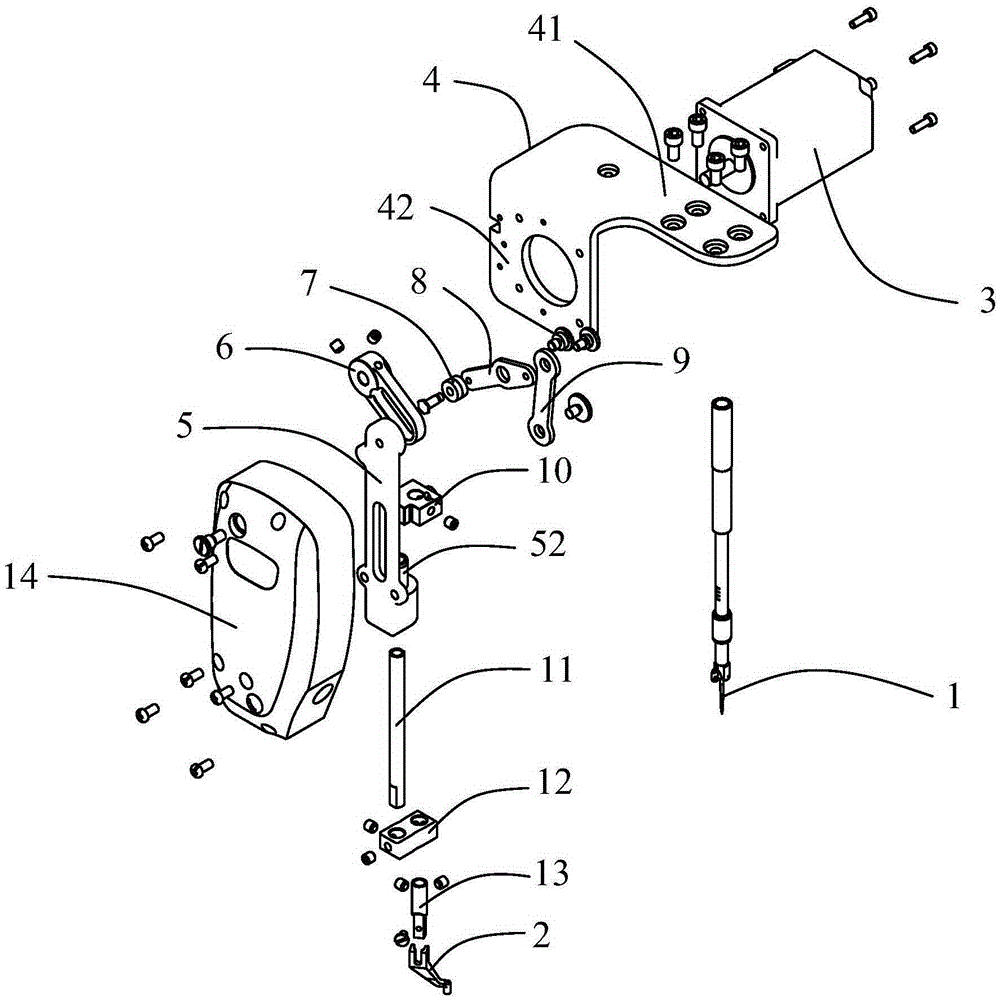

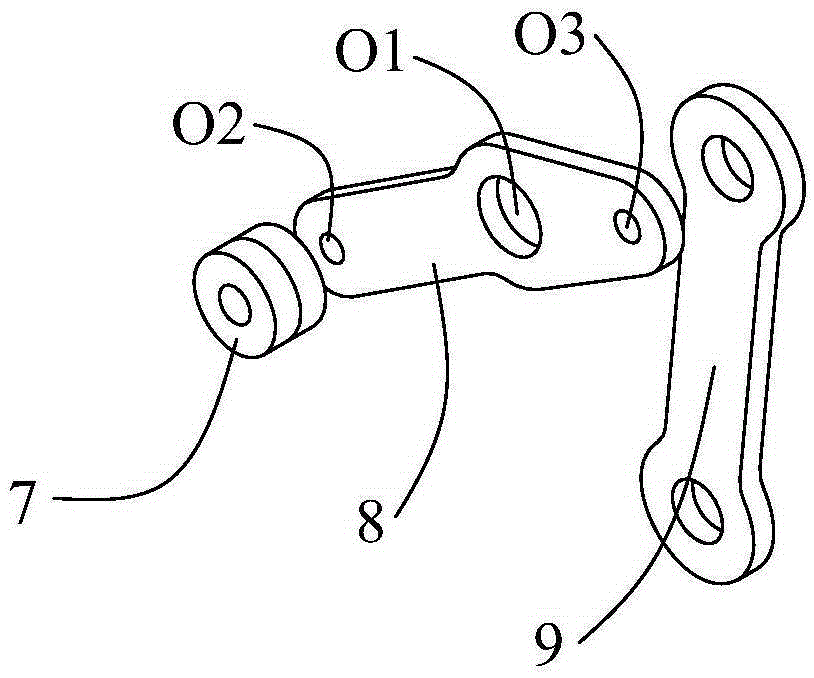

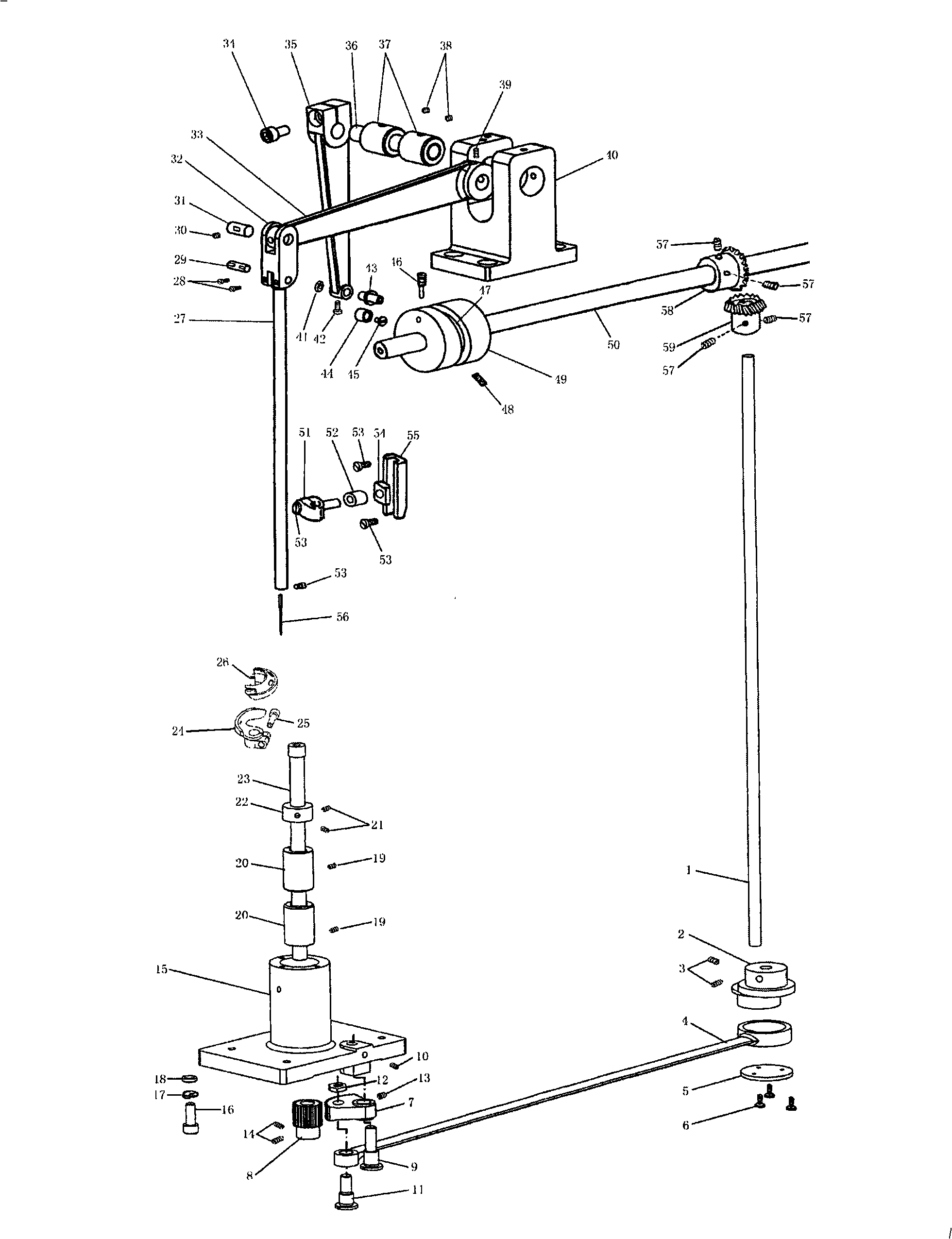

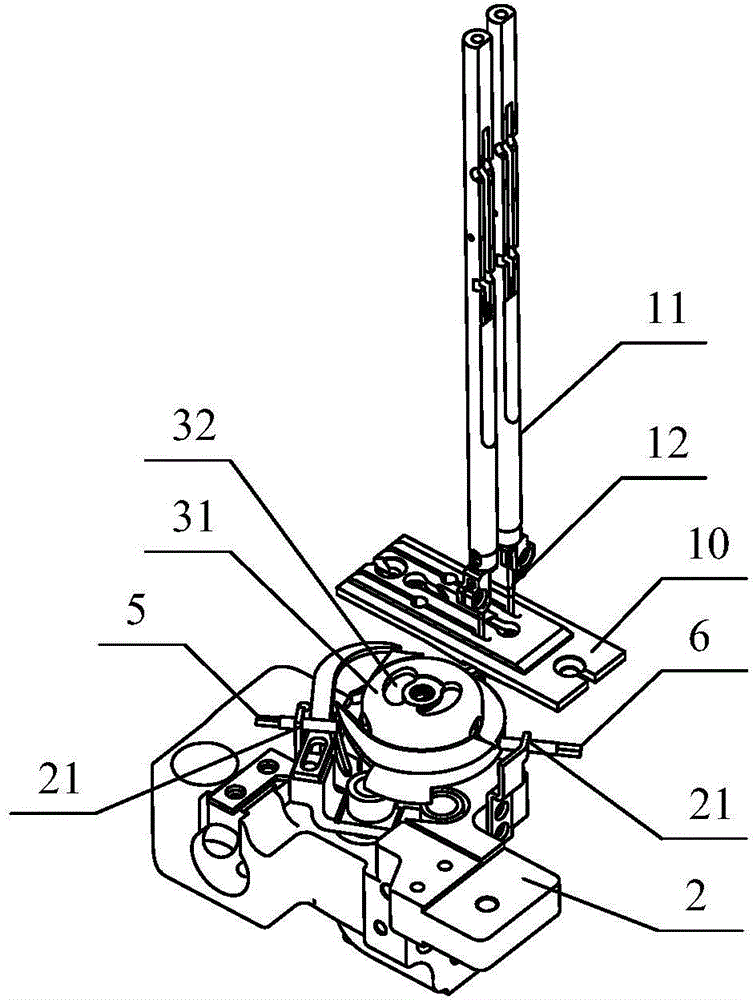

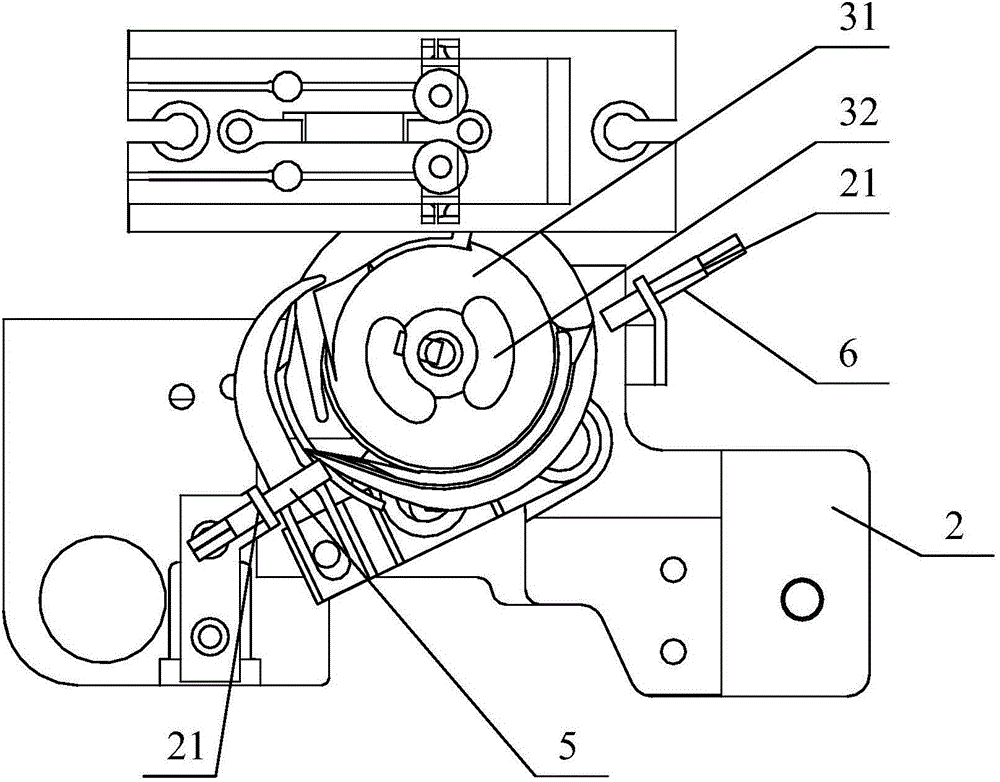

Modular middle presser foot device and sewing machine

The invention provides a modular middle presser foot device and a sewing machine, which comprises a middle presser foot capable of moving up and down along with the up-down movement of a machine needle, a driving motor, a transmission mechanism and a support frame. The driving motor is connected with the middle presser foot via the transmission mechanism so as to drive the middle presser foot to move up and down. The driving motor and the transmission mechanism are arranged on the support frame. The support frame and a housing of the sewing machine are detachably connected. According to the invention, the driving motor, the transmission mechanism, the middle presser foot and the support frame of the middle presser foot device are integrated as an installation disassembly module that can be integrally installed on the sewing machine or integrally removed from the sewing machine. Therefore, the middle presser foot device is modular in structure, and convenient to install and disassemble. At the same time, the middle presser foot device is driven by the independently arranged driving motor. Therefore, the height and the stroke of the middle presser foot device can be freely and conveniently set. As a result, the middle presser foot device can be applied to both the thin material and the thick material at the same time. Meanwhile, the stitch seam of the device is more beautiful.

Owner:BULLMER ELECTROMECHANICAL TECH

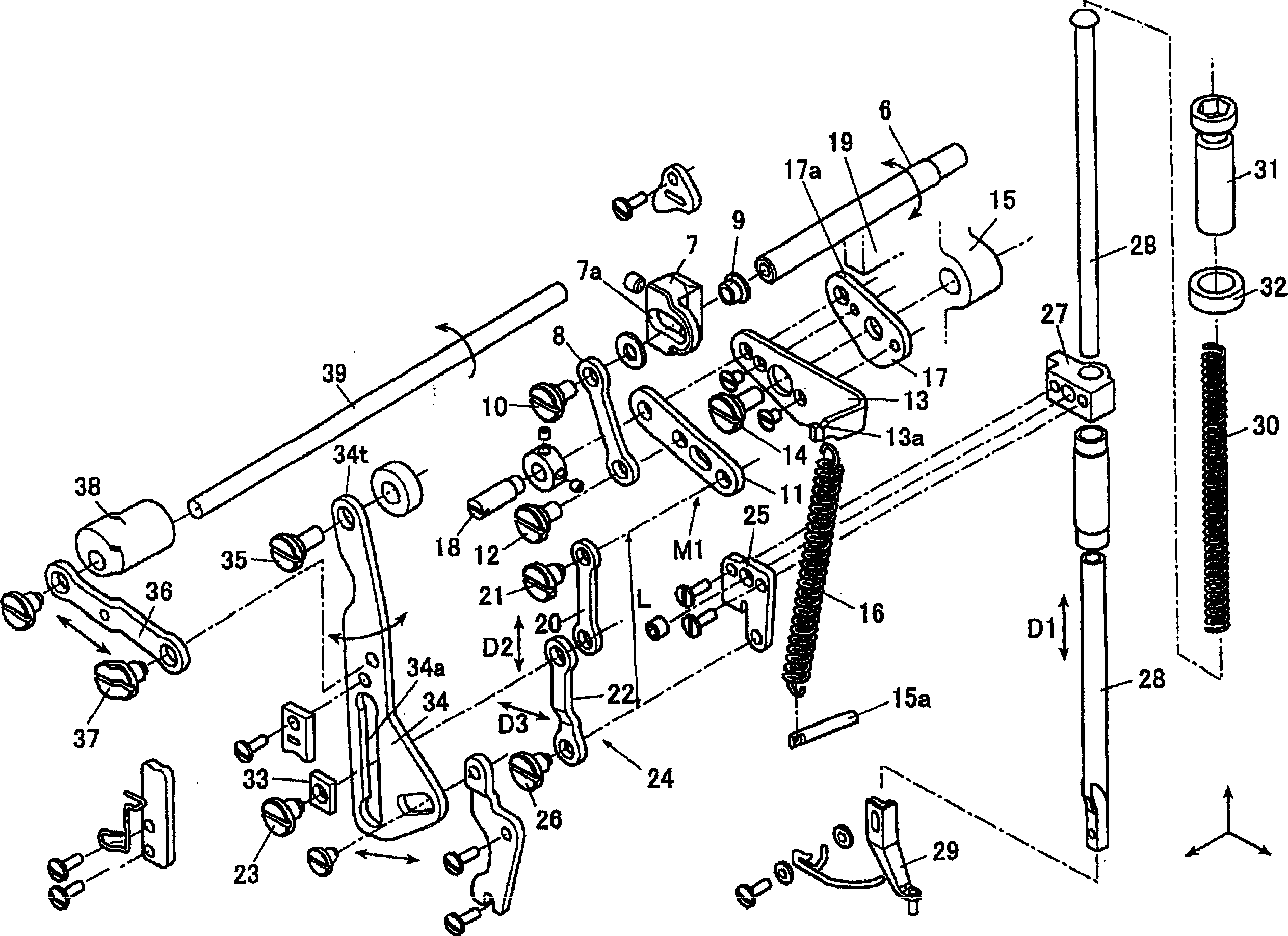

Needle rod clutching mechanism of sewing machine and double-needle machine

ActiveCN106948094ASimple structureEasy to operateProgramme-controlled sewing machinesNeedle barsElectric controlWrench

The invention provides a needle rod clutching mechanism of a sewing machine and a double-needle machine and belongs to the technical field of double-needle machines, aiming at solving the problems of an existing needle rod clutching mechanism of the sewing machine that the separation and resetting stability of a needle rod is poor and the needle rod clutching mechanism easily has faults. The needle rod clutching mechanism of the sewing machine comprises a sliding shaft, wherein one end of the sliding shaft is connected with a separation assembly and the other end of the sliding shaft is connected with a resetting assembly; the separation assembly comprises a rotary shaft, a wrench and a supporting plate assembly mounted on a machine head; the wrench is provided with a pulling sheet and a limiting column; a detection assembly is arranged between the supporting plate assembly and the wrench; the detection assembly is used for detecting leftward and rightward swinging of the wrench, generating left and right separation signals and sending the signals to electric control of the sewing machine; the supporting plate assembly is fixedly provided with a driver which is in electric control connection with the sewing machine. The clutching mechanism has the advantages of simple and beautiful structure, convenience for operation, automatic resetting and good separation and resetting stability.

Owner:JACK SEWING MASCH CO LTD

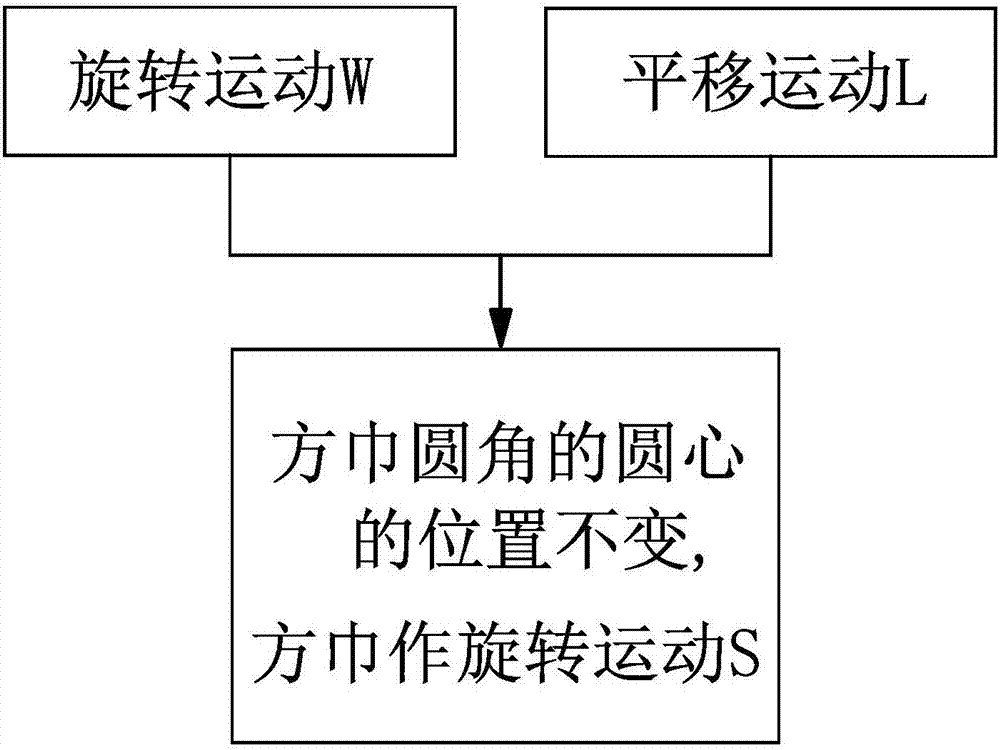

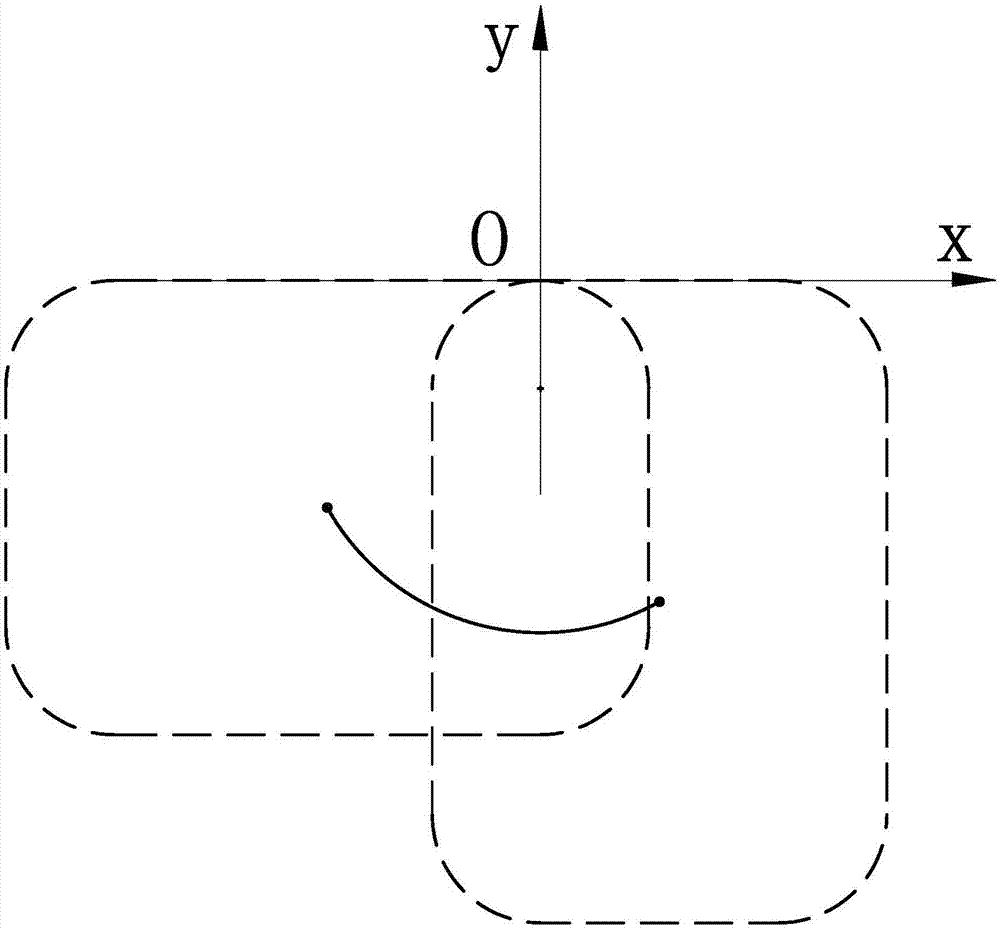

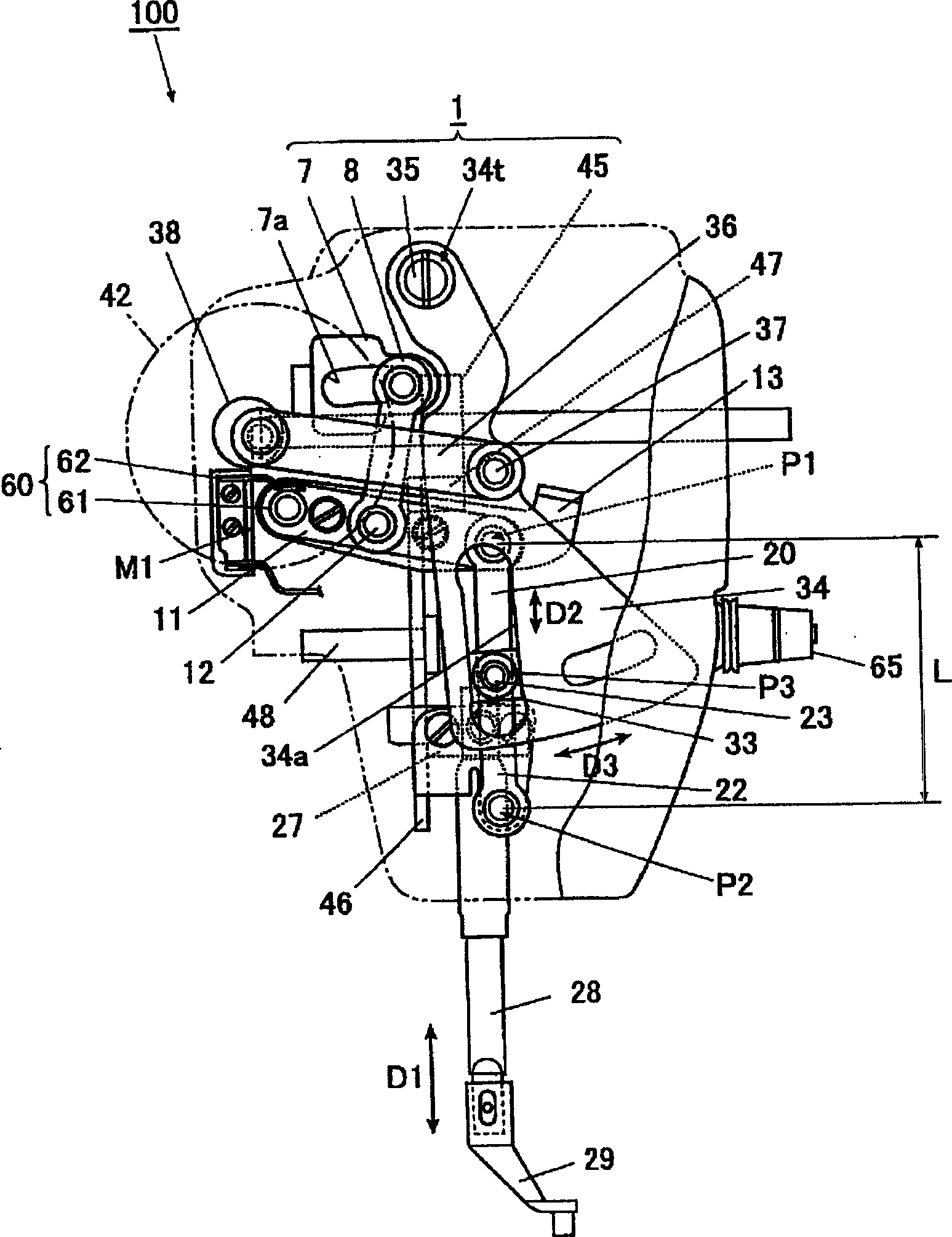

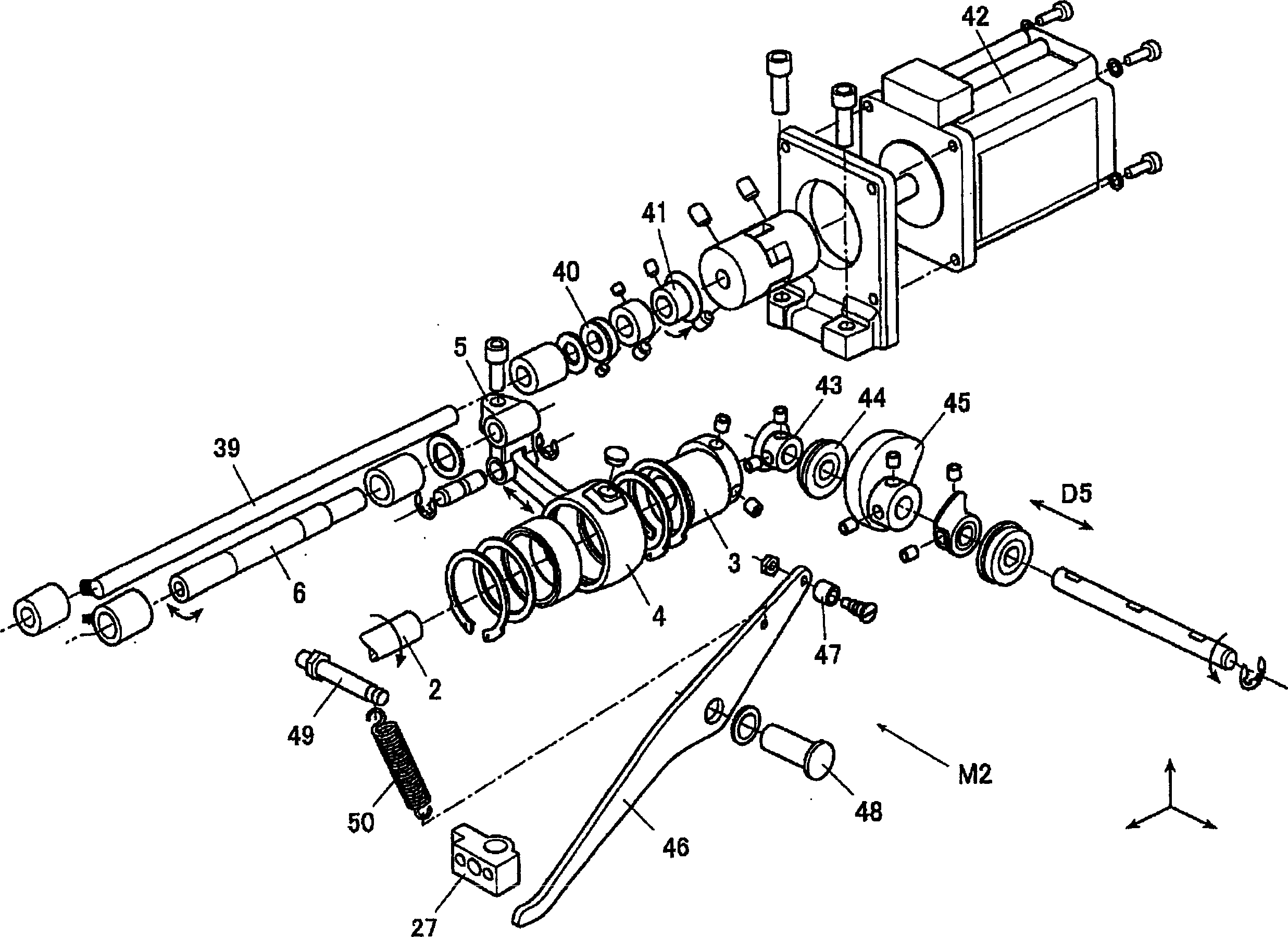

Kerchief circular bead edge sewing method and peripheral edge sewing processing method

The invention provides a kerchief circular bead edge sewing method and a peripheral edge sewing processing method, and belongs to the technical field of sewing. According to the technical scheme, the problems that an existing kerchief circular bead edge sewing method is low in sewing efficiency, and poor in kerchief circular bead edge sewing quality are solved. The kerchief circular bead edge sewing method comprises the steps of a, the original point of a kerchief circular bead is moved to a machine needle falling point; b, a control system controls a sewing body to conduct sewing, besides, the control system controls an auxiliary feeding mechanism to drive a kerchief to conduct rotation movement W on a table board with the center of the kerchief being the rotation center, and synchronously drives the kerchief to conduct translation movement L on the table board, through the combination of the rotation movement W and the translation movement L, the position of the center of a circle of the kerchief circular bead is maintained unchanged, and the kerchief conducts rotation movement S with the center of the circle of the kerchief circular bead being the rotation center; c, after the rotation movement W is conducted and the kerchief rotates by theta degrees, edge sewing of the kerchief is finished. According to the kerchief circular bead edge sewing method and the peripheral edge sewing processing method, the sewing quality of edge sewing of the kerchief circular bead is guaranteed, and meanwhile the sewing efficiency is improved.

Owner:ZHEJIANG ZOJE SEWING MACHINE

Cloth thickness variety supervisory instrument of sewing machine

ActiveCN1800475AMiniaturizationSimplifyProgramme-controlled sewing machinesPressersEngineeringVarying thickness

A device of the sewing machine is to detect a change of the workpiece (fabric) thickness, composing: an inner foot pushing the workpiece to a needle plate side in sewing, an inner foot driving mechanism applying a reciprocating movement along the vertical direction to the inner foot, and a thickness change detecting device detecting the thickness change of the workpiece via the inner foot. The inner foot driving mechanism is provided with an escape member, when receiving a load exceeding a predetermined amount in lowering of the inner foot, implementing an escape operation instead of a lowering operation of the inner foot. The thickness change detecting means detects the thickness change of the workpiece from the escape operation of the escape member.

Owner:JUKI CORP

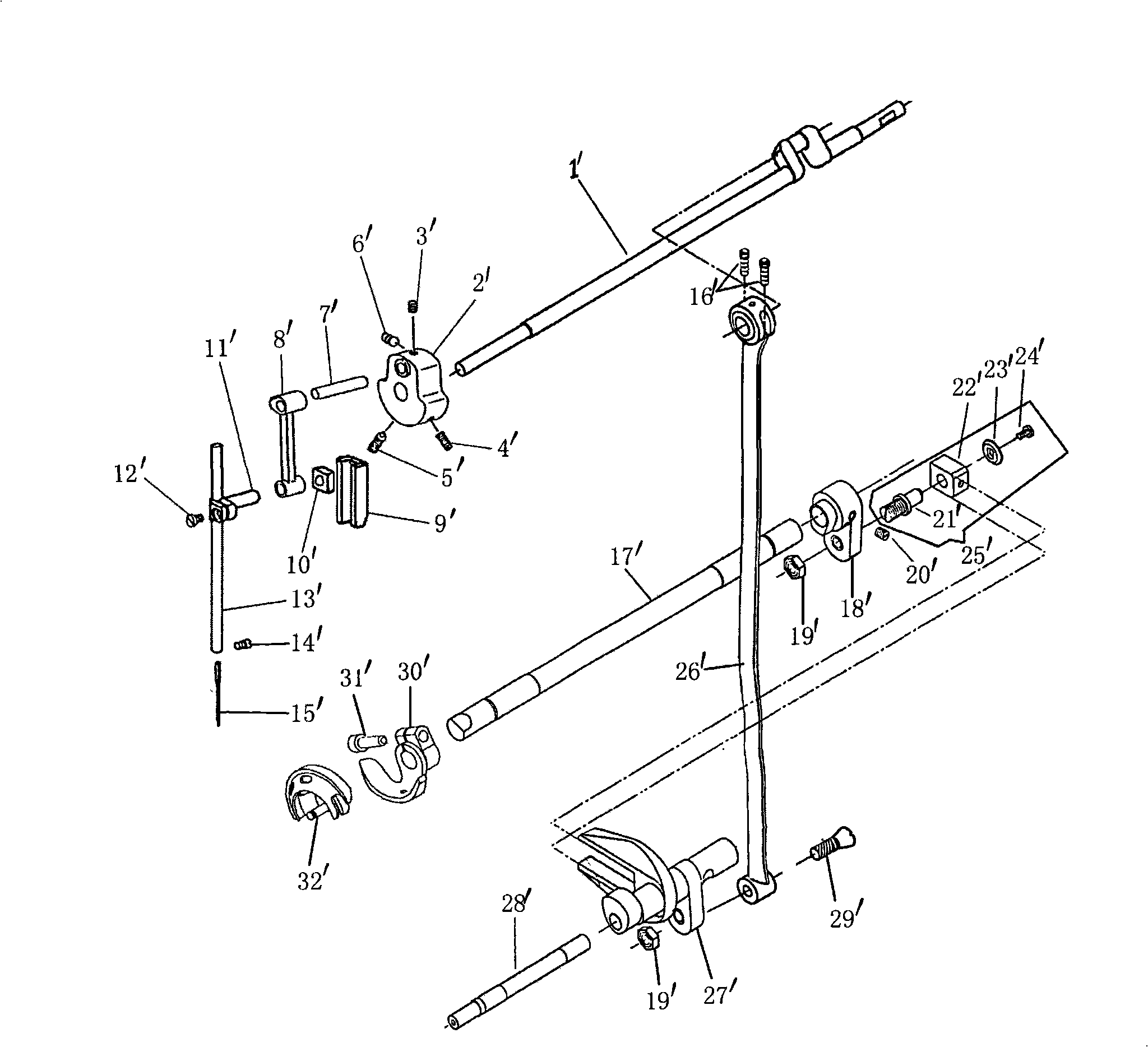

Needle bar and thread hooking assembly of sewing machine

InactiveCN101333735AIncreased complexityImprove sewing qualityNeedle barsLoop takersEngineeringHooking

The invention discloses a needle bar and a thread hooking combination device of the sewing machine, comprising a swing shuttle swinging mechanism and a needle bar mechanism. The swing shuttle swinging mechanism is composed of a thread hooking crank component A and a pendulum shaft component B; the needle bar mechanism is composed of a needle bar cam assembly unit A and a swing rod assembly unit B; wherein, the thread hooking crank component A comprises a vertical shaft, a thread hooking crank, a long connecting rod, a pinion, an upper shaft gear and a vertical shaft gear; the pendulum shaft component B comprises an installing seat and a pendulum shaft strung inside the central seat sleeve of the installing seat; the needle bar cam assembly unit A is composed of an upper shaft connected with a driving device of the host machine of the sewing machine and a needle bar cam nested on the shaft rod; and the swing rod assembly unit B is composed of a needle bar, a swing rod and a fixing pedestal. The swing shuttle swinging mechanism and the cam swing rod slider needle bar mechanism of the sewing machine are matched with each other to move by means of the rotation of the upper shaft, thereby forming a novel thread hooking combination mechanism of the swing shuttle sewing machine needle bar.

Owner:SHANGHAI HUIGONG NO 3 SEWING MACHINE FACTORY CHINA TYPICAL SEWING MACHINE

Full-automatic multi-decoration strip sewing equipment

PendingCN108642733ASimple structureEasy to useWorkpiece carriersWork-feeding meansHuman–computer interactionControl equipment

The invention discloses a full-automatic multi-decoration strip sewing equipment, which comprises a frame, a multi-needle sewing machine and a control panel, wherein the control panel is provided witha man-machine interaction interface for displaying the equipment state and controlling the equipment. The multi-needle sewing machine is fixedly arranged on the left part of the frame. The equipmentis characterized by also comprising a decorative strip feeding device, a feeding device and a shearing device. A pull cylinder is arranged on the multi-needle sewing machine. The decorative strip feeding device is arranged on the frame and above the multi-needle sewing machine. The decorative strip feeding device is used for making the decorative strip to be sewed to be in a relaxed state to enterthe pulling cylinder of the needle sewing machine to roll the edge. The feeding device is arranged on the frame, and the feeding direction of the feeding device is arranged along the left and right direction. The feeding device is used for feeding the cloth to needle sewing machine to be sewed with the decorative strips with rolled edges, and feeding the cloth sewn with the decorative strips outof the multi-needle sewing machine. The shearing device is used for cutting off the corresponding decorative strips after the sewing is finished.

Owner:CHANGZHOU ZHIGU ELECTROMECHANICAL TECH CO LTD

Material moving device and sleeve slit machine

ActiveCN110923966AStable formationThere will be no jumping stitchesWork-feeding meansPressersMechanical engineeringPhysics

The invention provides a material moving device. The material pressing device comprises an outer material pressing plate and an inner material pressing plate which are used for pressing sewing materials. An accommodating cavity is formed in the outer pressing plate; the inner pressing plate is movably arranged in the accommodating cavity and is provided with a first working position and a second working position, a first sewing area is correspondingly formed between the outer edge of the inner pressing plate and the cavity wall of the accommodating cavity, and a second sewing area is correspondingly formed between the top end of the inner pressing plate and the end part of the accommodating cavity; the material moving device further comprises a pressing pad capable of moving in the direction close to or away from the containing cavity. When the inner pressing plate is located at the second working position, the pressing pad is located in the second sewing area and presses the sewing material exposed in the second sewing area, and a third sewing area allowing the sewing material to be exposed is formed between the top end of the inner pressing plate and the pressing pad. By additionally arranging the pressing pad, it is guaranteed that sewing materials in the second sewing area can be firmly pressed, when a machine needle conducts transverse sewing in the third sewing area, a thread ring is formed stably, and the phenomenon of needle jumping is avoided.

Owner:迈卡有限责任公司

Bottom line detection correlation type photoelectric control system for sewing machine and control method

ActiveCN104372539AGuaranteed uniformityGuaranteed aestheticsBobbin-winding devicesElectric machineryInfrared

The invention provides a bottom line detection correlation type photoelectric control system for a sewing machine. The system comprises an electric control module, a rotating shuttle and a motor, wherein the rotating shuttle comprises a shuttle casing and a shuttle core, the system further comprises an infrared transmitting tube and an infrared receiving tube, an infrared inlet and an infrared outlet are formed in the shuttle casing, and a through hole is formed in a wrapping post of the shuttle core; when the shuttle core is not in the casing, the infrared inlet and the infrared outlet are communicated; when the quantity of bottom lines with which the wrapping post of the shuttle core is wounded is not enough, the through hole is exposed, and the infrared inlet and the infrared outlet are communicated through the through hole; the electric control module is connected with the infrared transmitting tube and the infrared receiving tube through a signal conditioning and controlling circuit and connected with the motor through an output circuit. In the control system, the electric control module can judge if the shuttle core is missing or the quantity of the bottom lines on the shuttle core is not enough according to the intensity of a signal output to the signal conditioning and controlling circuit by the infrared receiving tube, and accordingly sewing efficiency and quality are improved.

Owner:BULLMER ELECTROMECHANICAL TECH

Sewing machine

ActiveCN103173942ASmall moment of inertiaReduce mistakesWork-feeding meansSewing-machine control devicesRotary stageDifferential transmission

The invention provides a sewing machine, wherein small lightweight and action accelation surrounding a boiler are achieved. The sewing machine includes the components as following: a needle bar, a boiler, a sewing machine motor, a boiler driven motor, a needle bar rotating mechanism, a boiler rotating platform; a needle rotating motor, which enbles the needle bar to rotate; a boiler rotating motor, which enables the boiler rotating platform to rotate, and a differential transmission mechanism, which is provided with an input shaft and an output shaft for transmitting a boiler rotating force. The differential transmission mechanism comprises the components as following: a support frame, which is arranged surrounding the input shaft and the output shaft on a center line to rotate; a transmitter, which is supported on the support frame, wherein the rotating force is transmitted between the input shaft and the output shaft; a driven part, which is arranged on a boiler rotating platform or the support frame and is rotated through the boiler rotating motor; and a rotation linkage mechanism, wherein the boiler rotating platform and the support frame are driven to rotate at the same direction by the rotating force from the driven part, and the boiler rotating platform is rotated with the rotation amount twice as much as the rotation amount of the support frame.

Owner:JUKI CORP

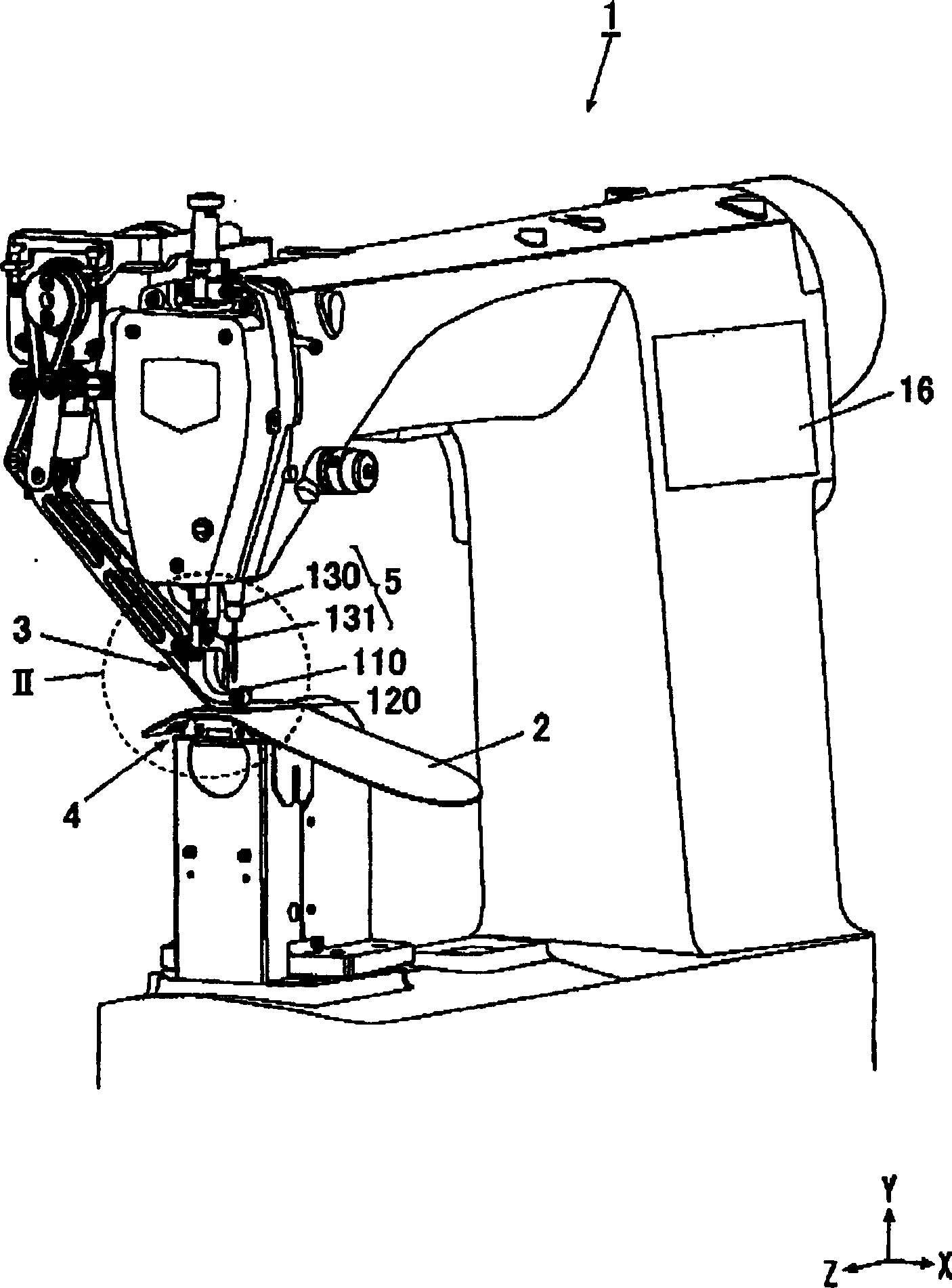

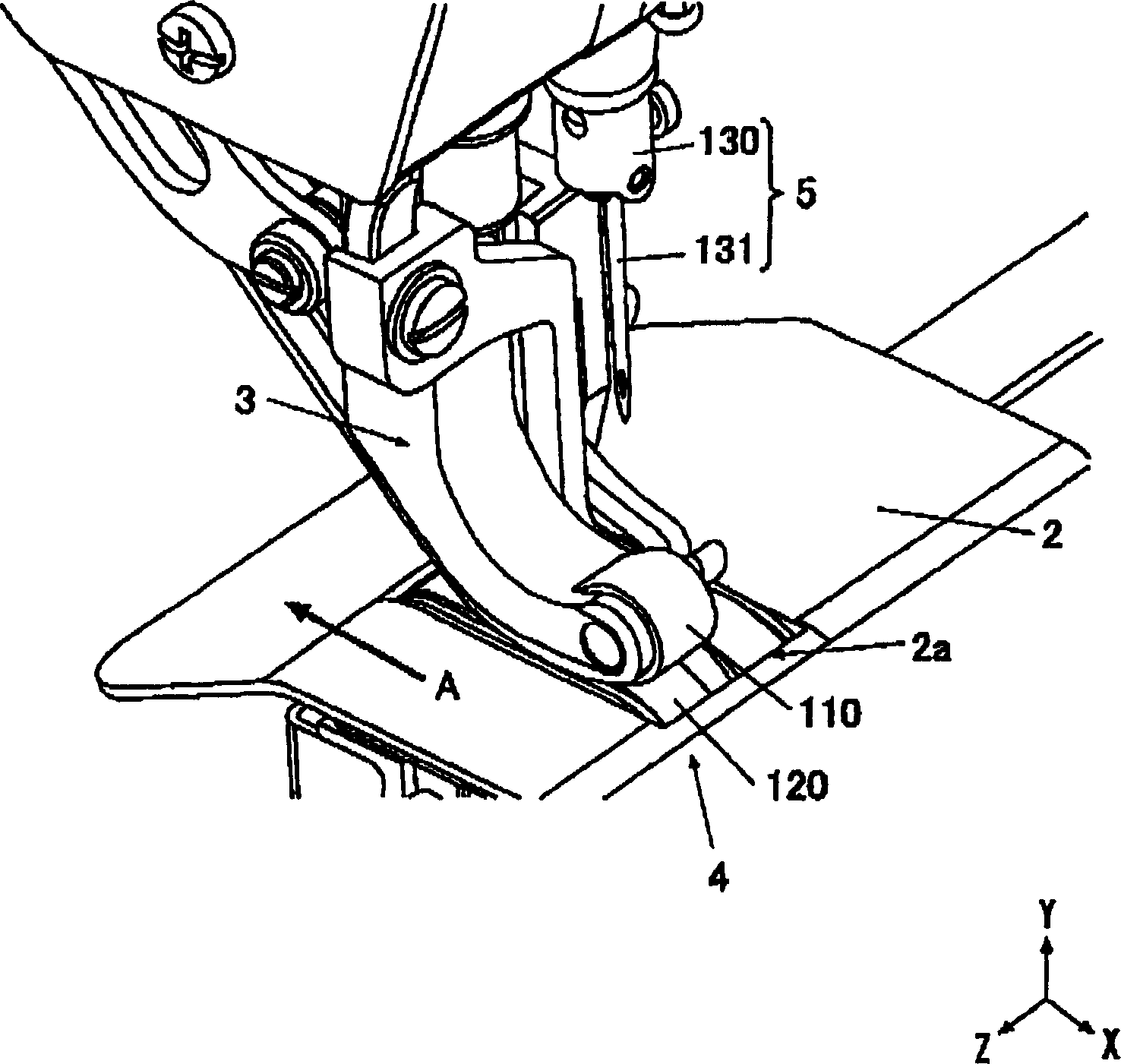

Differential cloth feeding sewing machine

InactiveCN1786313ASewing reductionSewing increaseProgramme-controlled sewing machinesSewing-machine casingsMomentumEngineering

A differential feed sewing machine, a differential feed sewing machine (1), when the top feed mechanism part (3) moved by the top feed moving mechanism (17) is arranged at the first moving position, the upper cloth and The lower cloth is clamped between the upper cloth feeding mechanism part (3) and the lower cloth feeding mechanism part (4) and the upper cloth feeding mechanism part (3) and the lower cloth feeding The upper cloth and the lower cloth are conveyed together. In addition, when the upper cloth feeding mechanism part (3) moved by the upper cloth feeding moving mechanism (17) is arranged at the second moving position, the upper cloth feeding mechanism part (3) is moved from the bottom The cloth feeding mechanism part (4) is slightly separated and the upper cloth feeding mechanism part (3) is activated, so that, according to the set value, the amount of cloth feeding for each stitch of feeding the upper cloth exceeds the amount of the lower cloth feeding as the difference The differential amount only conveys the upper cloth. This differential feed sewing machine is easy to adjust the amount of shirring and can improve the quality of sewn products.

Owner:JUKI CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com